Preparation methods of medical alpha-calcium sulfate hemihydrate powder and calcium sulfate artificial bone material

A technology of calcium sulfate hemihydrate and calcium sulfate, which is applied in the fields of calcium/strontium/barium sulfate, prosthesis, medical science, etc., can solve the problem that does not meet the requirements of mechanical properties of artificial bone repair materials, and is difficult to provide mechanical strength of bone repair parts , poor mechanical strength and other problems, to achieve good application prospects, effectively prolong the degradation time, and improve the compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

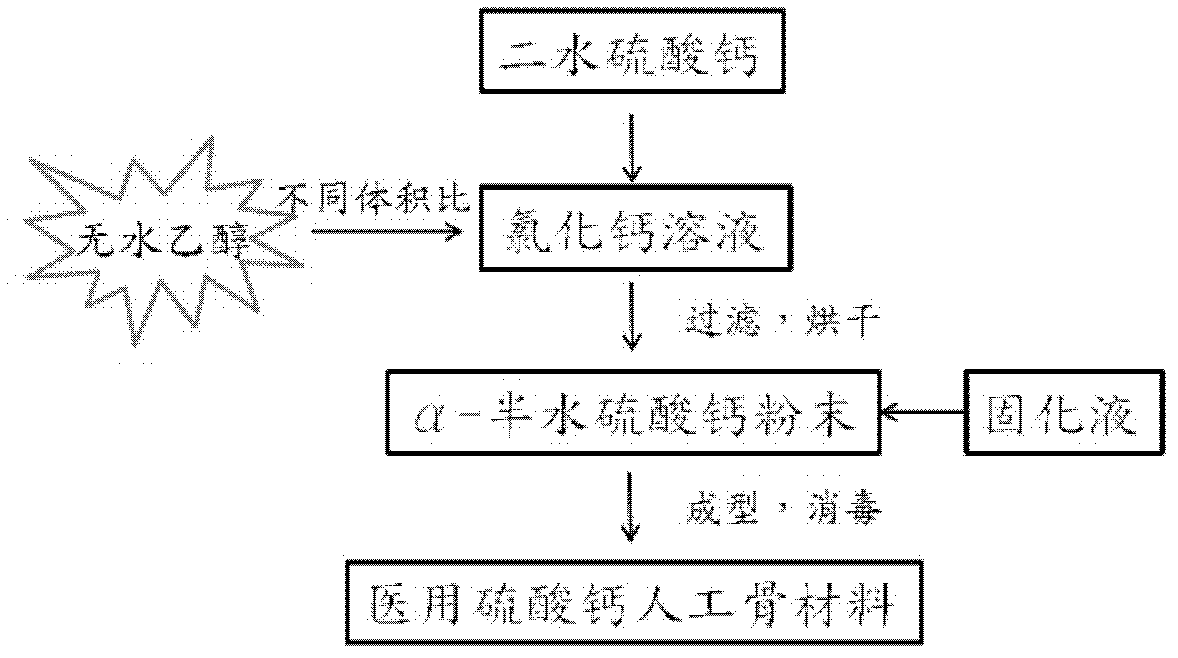

Method used

Image

Examples

Embodiment 1

[0060] In this embodiment, the α-calcium sulfate hemihydrate powder is prepared by reacting calcium sulfate dihydrate in a reaction solution, which is a mixed solution of calcium chloride, absolute ethanol, succinic acid and distilled water. Wherein, the mass ratio of calcium chloride to distilled water is 0.3, the volume ratio of absolute ethanol to distilled water is 0.5, the mass ratio of succinic acid to distilled water is 0.0045, and the mass ratio of calcium sulfate dihydrate to reaction solution is 0.0355.

[0061] The concrete preparation method of this α-calcium sulfate hemihydrate powder comprises the steps:

[0062] (1) At room temperature, add 0.75g of succinic acid into 165ml of distilled water and ultrasonically disperse for 5 minutes, then add 50g of anhydrous calcium chloride and 82.5ml of absolute ethanol one by one, and stir thoroughly for 10 minutes each to obtain a uniform reaction solution.

[0063] (2) Pour the reaction solution obtained in step (1) into ...

Embodiment 2

[0075] In this embodiment, the α-calcium sulfate hemihydrate powder is prepared by reacting calcium sulfate dihydrate in the reaction solution, which is basically the same as the reaction solution in Example 1, except that absolute ethanol and The volume ratio of water is 1:1.

[0076] The specific preparation method of this α-calcium sulfate hemihydrate powder is basically the same as the preparation method in Example 1, except that in step (1), the volume ratio of dehydrated alcohol to water is 1, and the volume ratio of dehydrated alcohol is 1. The addition amount is 165ml, specifically comprises the following steps:

[0077] (1) At room temperature, add 0.75g of succinic acid into 165ml of distilled water and ultrasonically disperse for 5 minutes, then add 50g of anhydrous calcium chloride and 165ml of absolute ethanol one by one, and stir thoroughly for 10 minutes each to obtain a uniform reaction solution.

[0078] (2) is identical with (2) in embodiment 1;

[0079] (3...

Embodiment 3~7

[0090] In the following examples 3 to 7, the α-calcium sulfate hemihydrate powder is prepared by reacting calcium sulfate dihydrate in the reaction solution. The reaction solution is basically the same as in Example 1, except that the concentration of the calcium chloride solution or The volume ratio of absolute ethanol and water (see table 1 below for details).

[0091] Utilize this α-calcium sulfate hemihydrate powder and solidifying liquid to mix evenly, can prepare medical calcium sulfate artificial bone material after solidifying, its concrete steps are basically the same as embodiment 1, difference is the kind of solidifying liquid that adopts (see below for details Table 1). Table 1: Preparation conditions and properties of α-calcium sulfate hemihydrate powder and calcium sulfate artificial bone material in Examples 3-7

[0092]

[0093]

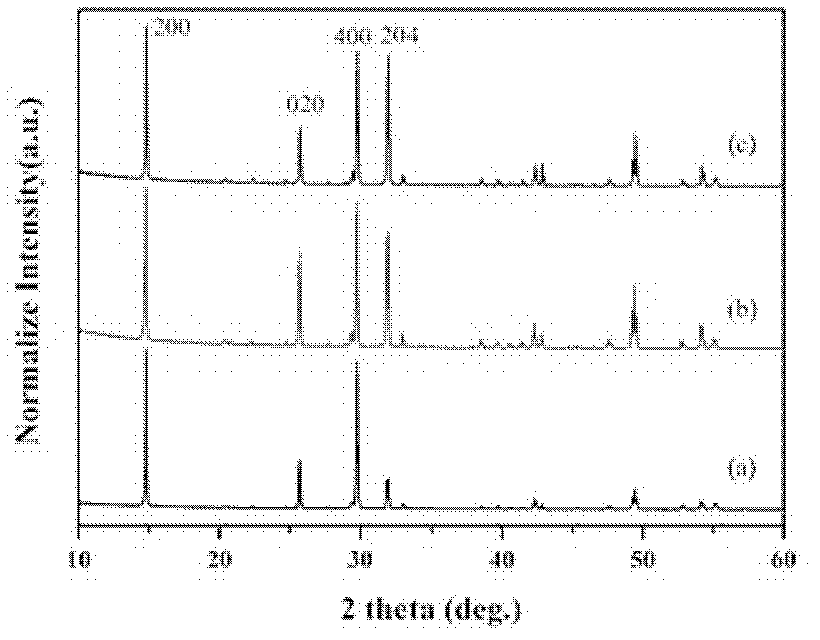

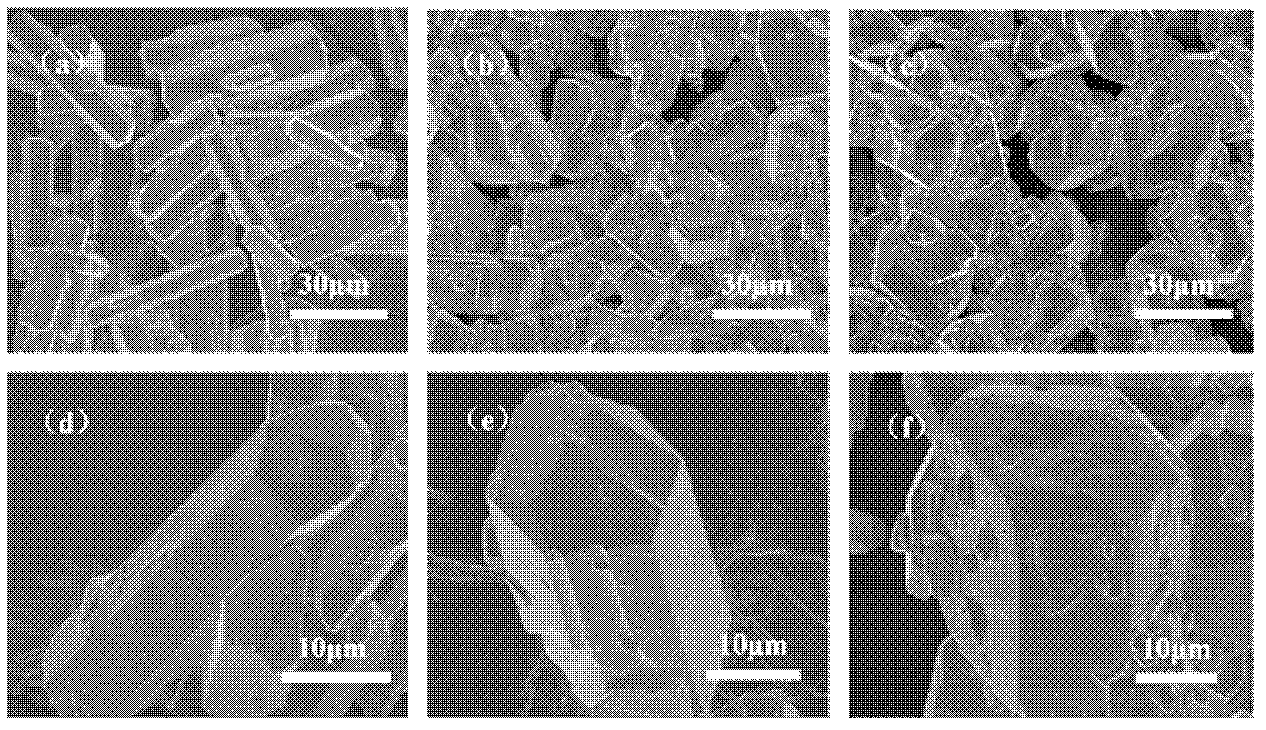

[0094] The phase of the α-calcium sulfate hemihydrate powder that above-mentioned making is analyzed, obtains similar figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial length | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com