High-entropy alloy refiner for refining industrial pure aluminum or aluminum alloy and refining method thereof

A high-entropy alloy, industrial pure aluminum technology, applied in the field of metallurgical materials, can solve the problems of reducing the plasticity, low strength, and easy deformation of aluminum alloys, and achieve the effects of improving the shape, improving the uniformity, and reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

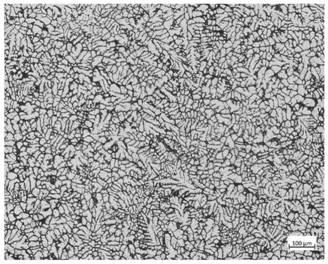

Image

Examples

Embodiment 1

[0037] According to the elemental composition and molar ratio of the high-entropy alloy refiner to be prepared, mix the metal elements with a purity greater than 99.9%, put them into a vacuum electric arc furnace, and melt them with a current of 200A under the protection of high-purity argon. 2.0min to 3.0min until it is completely melted, and repeated smelting for 5 to 6 times to ensure that its composition is uniform, and about 40g of button-shaped high-entropy alloy refiner is obtained. Among them, the relationship between each high-entropy alloy refiner and the metal element ingredients is shown in Table 1 below:

[0038] Table 1

[0039]

[0040]

Embodiment 2

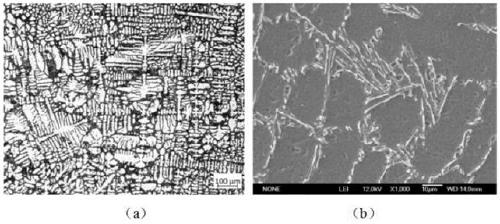

[0042] (1) Heat pure aluminum at 810°C in a Si-C rod crucible furnace until it is completely melted into molten metal, wrap a small piece of high-entropy alloy refiner 1 with aluminum foil, and press it into the molten metal at a temperature of 810°C In the process, the high-entropy alloy refining agent 1 is added in an amount of 0.1% of the total melt mass, kept at 810°C for 1 hour, and mechanically stirred once every 10 minutes during the process;

[0043] (2) Cover the solid hexachloroethane refining agent with aluminum foil and press it into the heat-preserved molten metal. The amount of hexachloroethane refining agent added is 0.8% of the weight of the molten metal. Rapidly stir and refine to remove impurities in the melt and gas, after removing the slag, cast it at about 720°C to obtain a refined pure aluminum casting 1.

Embodiment 3

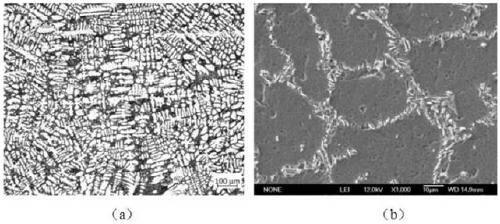

[0045] (1) Heat pure aluminum at 790°C in a Si-C rod crucible furnace until it is completely melted into molten metal, wrap a small piece of high-entropy alloy refiner 1 with aluminum foil, and press it into the molten metal at a temperature of 790°C In the process, the high-entropy alloy refining agent 1 is added in an amount of 0.5% of the total melt mass, kept at 790°C for 1 hour, and mechanically stirred once every 10 minutes during the process;

[0046] (2) Cover the solid hexachloroethane refining agent with aluminum foil and press it into the heat-preserved molten metal. The amount of hexachloroethane refining agent added is 0.8% of the weight of the molten metal. Rapidly stir and refine to remove impurities in the melt and gas, after removing the slag, cast it at about 700°C to obtain a refined pure aluminum casting 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com