Patents

Literature

27703results about "Glass/slag layered products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

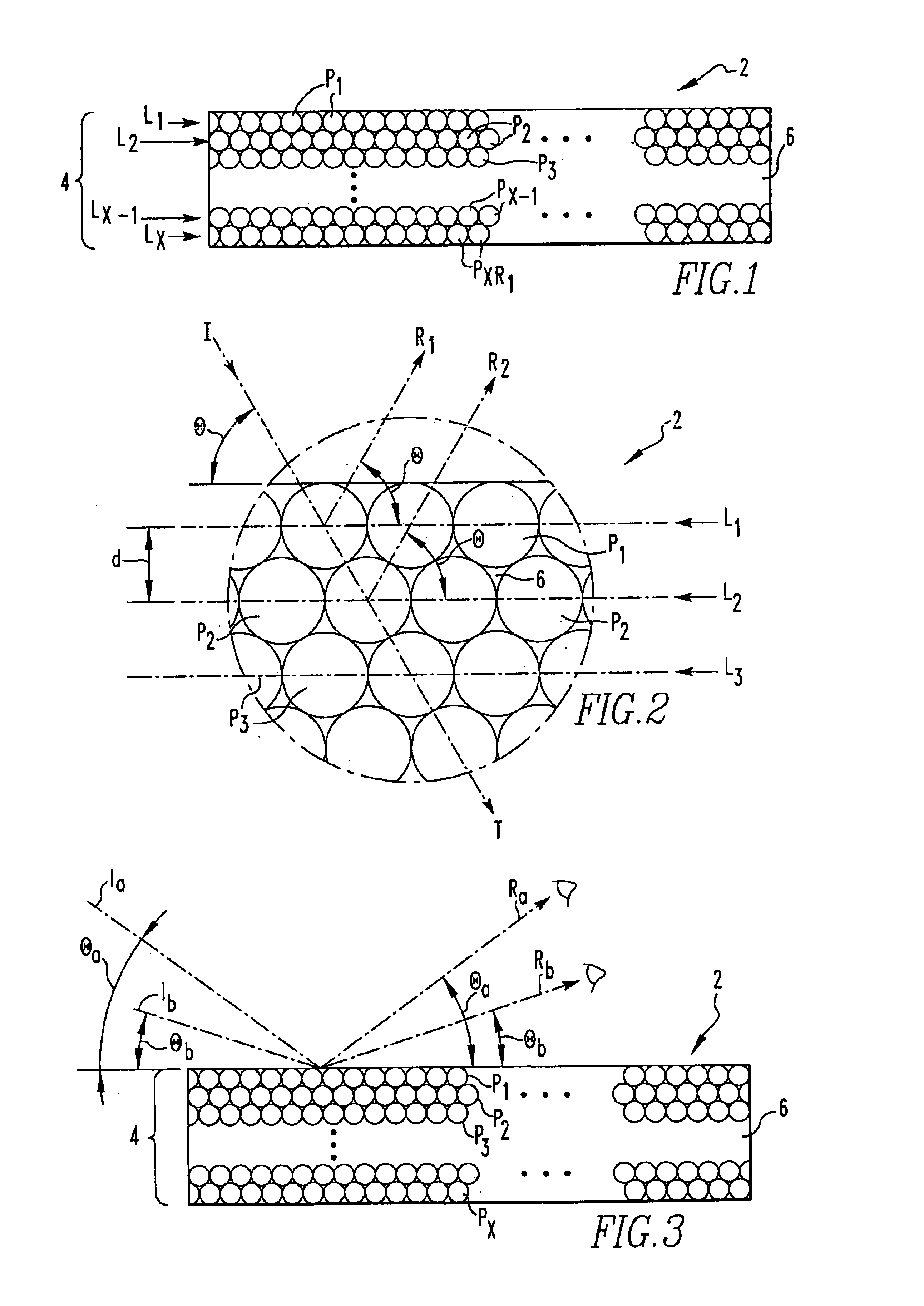

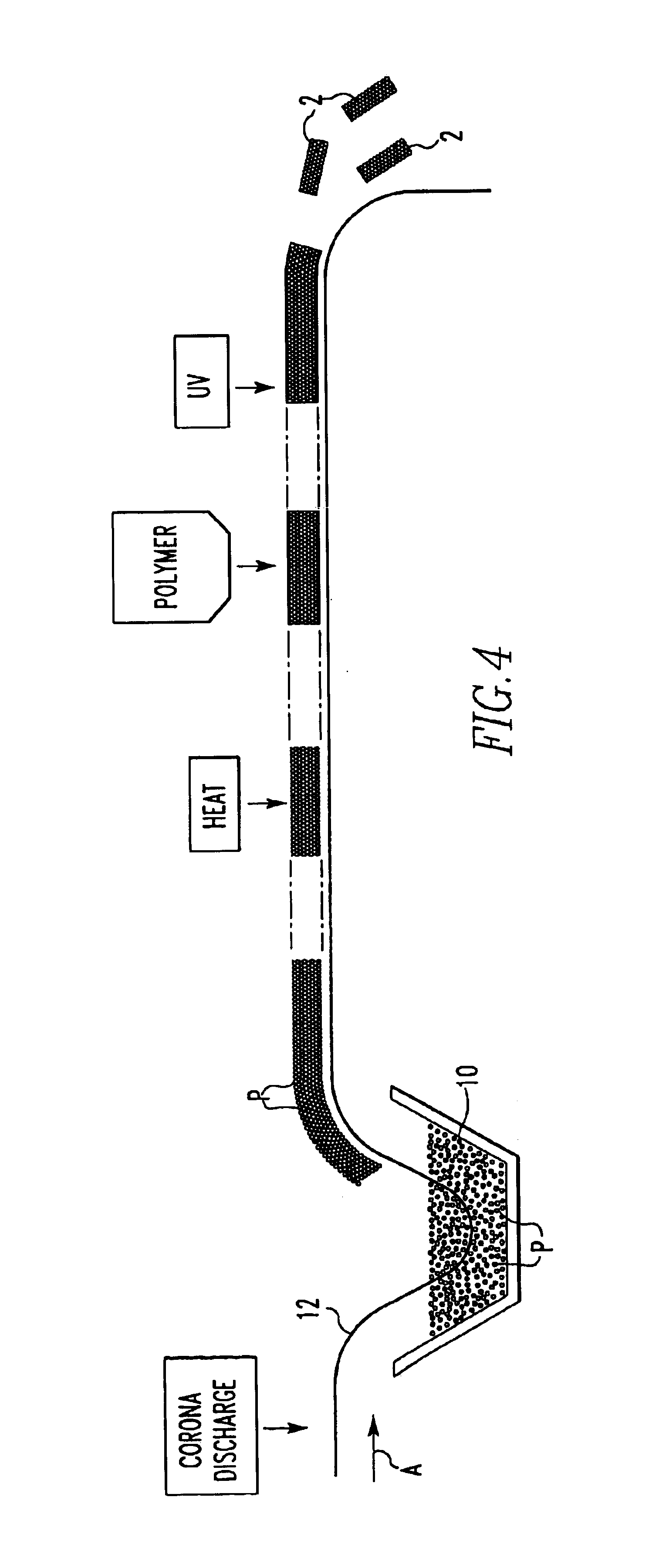

Color effect compositions

A coating composition comprising a resinous binder and a color effect colorant in particulate form. The colorant includes an ordered periodic array of particles held in a polymer wherein a difference in refractive index between the polymer and the particles is at least about 0.01. The colorant reflects visible light according to Bragg's law to yield a goniochromatic effect to the coating composition.

Owner:PPG IND OHIO INC

Support for high performance affinity chromatography and other uses

Multilayered particulate materials are formed by coating a particulate substrate with a metal and adsorbing an organic layer comprising a recognition moiety onto the metal film. The recognition moiety interacts with an analyte of interest allowing for its detection, purification, etc. Suitable recognition moieties can be selected from a range of species including, small molecules, polymers and biomolecules and the like. The novel particulate materials of the invention can be utilized in an array of methods including, ion-exchange, ion-selective ion-exchange, assays, affinity dialysis, size exclusion dialysis, as supports in solid phase synthesis, combinatorial synthesis and screening of compound libraries and the like.

Owner:RGT UNIV OF CALIFORNIA

Organo luminescent semiconductor nanocrystal probes for biological applications and process for making and using such probes

A semiconductor nanocrystal compound is described capable of linking to an affinity molecule. The compound comprises (1) a semiconductor nanocrystal capable of emitting electromagnetic radiation and / or absorbing energy, and / or scattering or diffracting electromagnetic radiation-when excited by an electromagnetic radiation source or a particle beam; and (2) at least one linking agent, having a first portion linked to the semiconductor nanocrystal and a second portion capable of linking to an affity molecule. The compound is linked to an affinity molecule to form a semiconductor nanocrystal probe capable of bonding with a detectable substance. Subsequent exposure to excitation energy will excite the semiconductor nanocrystal in he probe, causing the emission of electromagnetic radiation. Further described are processes for respectively: making the semiconductor nanocrystal compound; making the semiconductor nanocrystal probe; and using the probe to determine the presence of a detectable substance in a material.

Owner:RGT UNIV OF CALIFORNIA

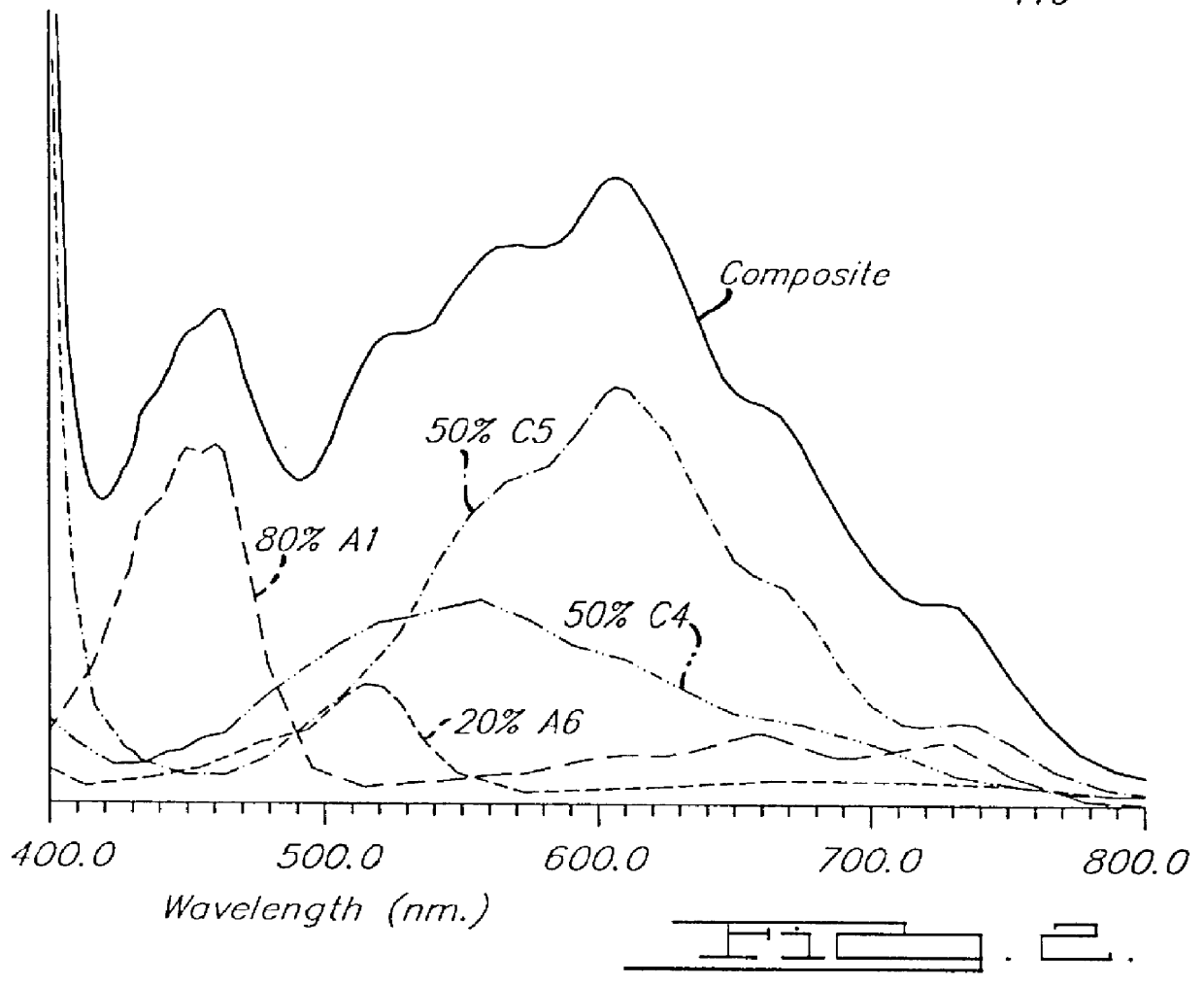

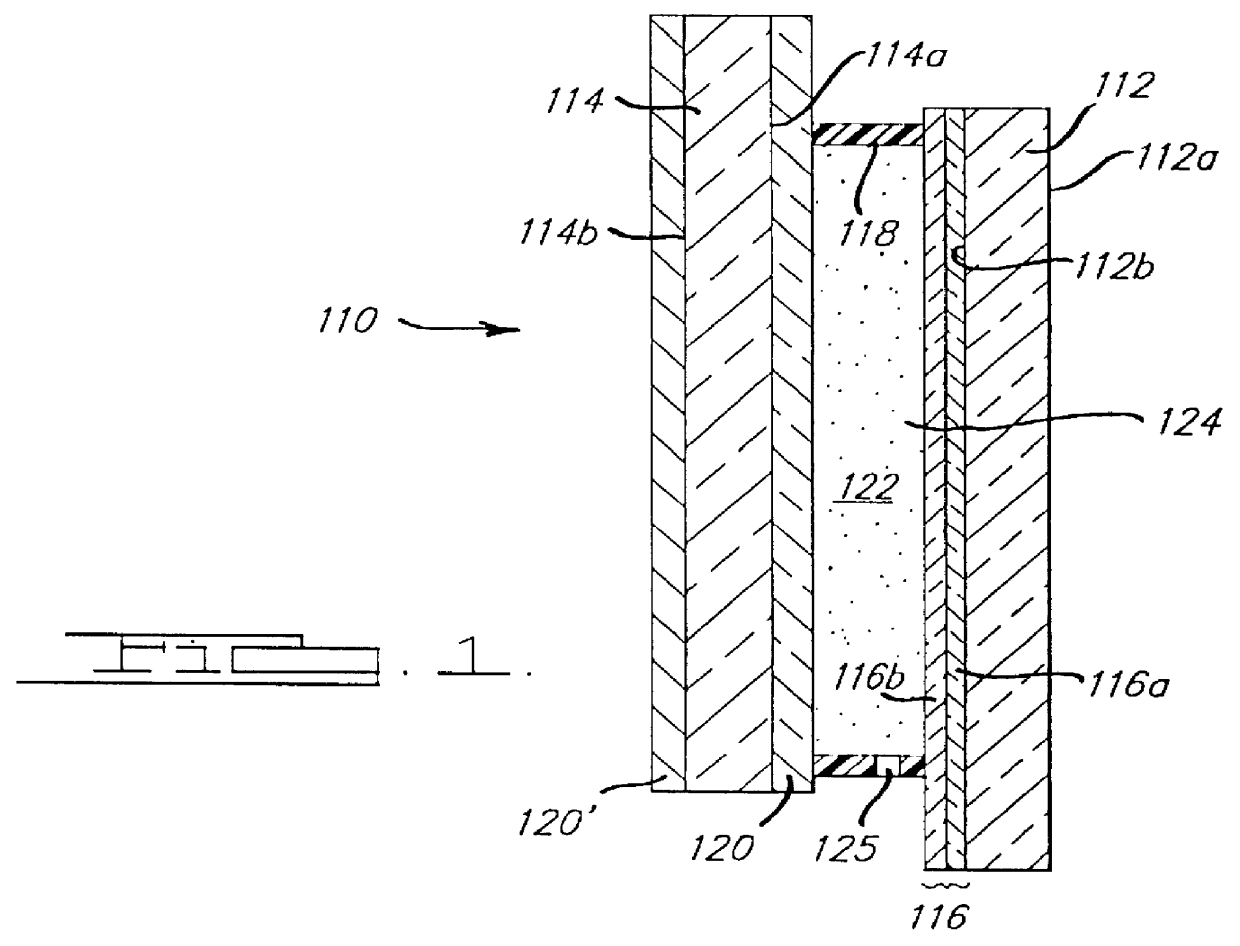

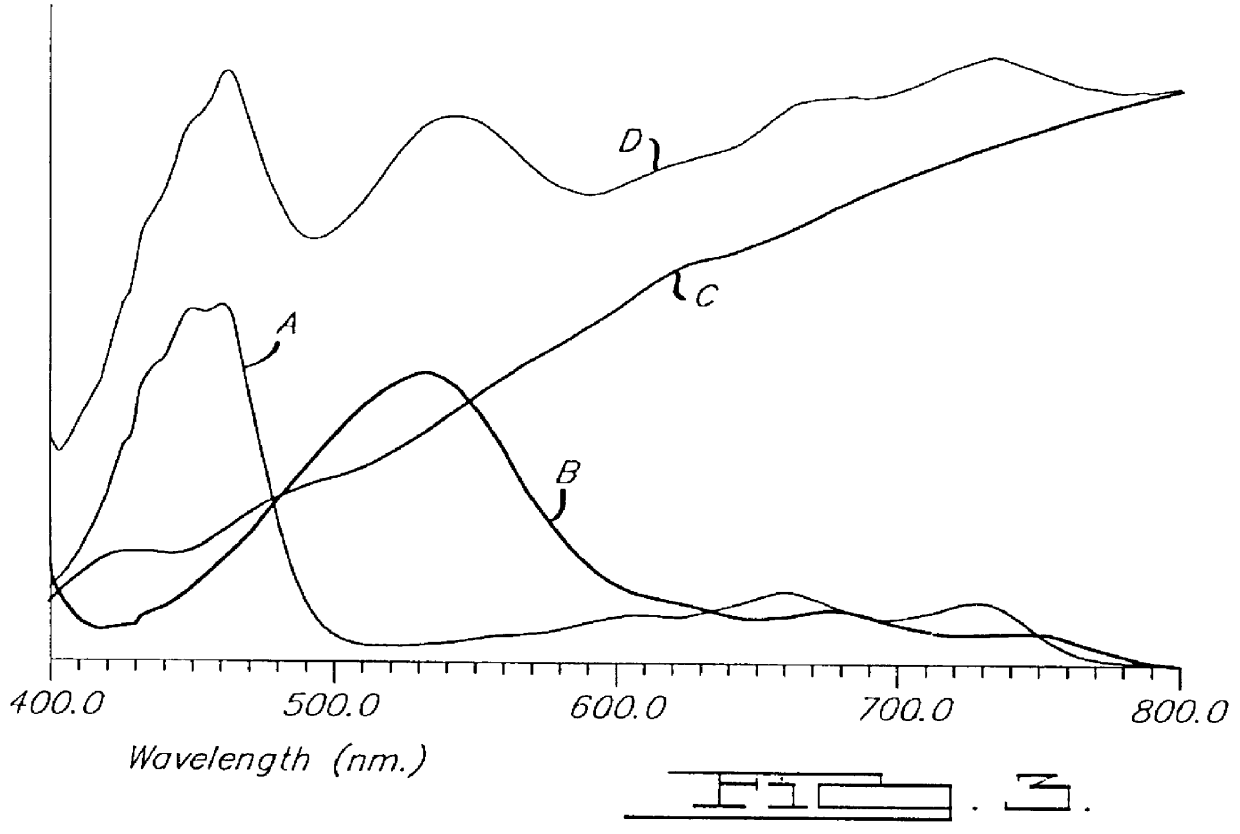

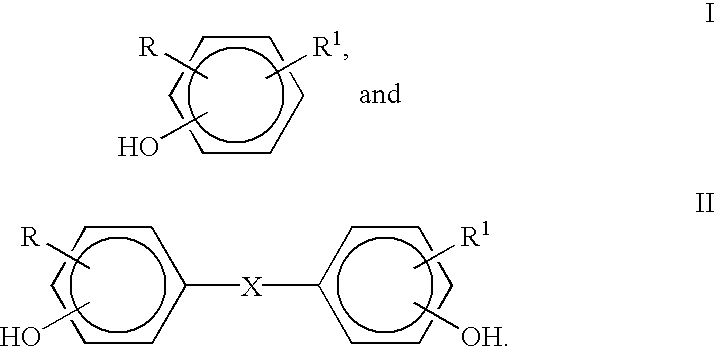

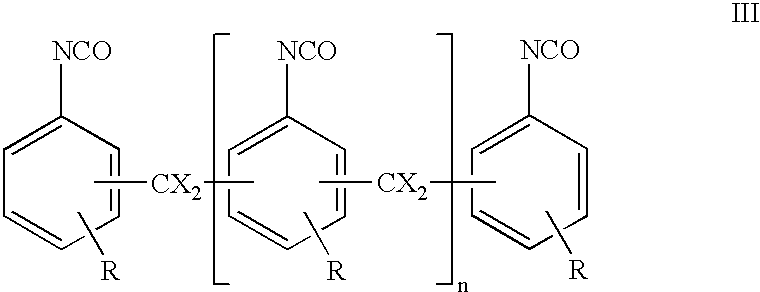

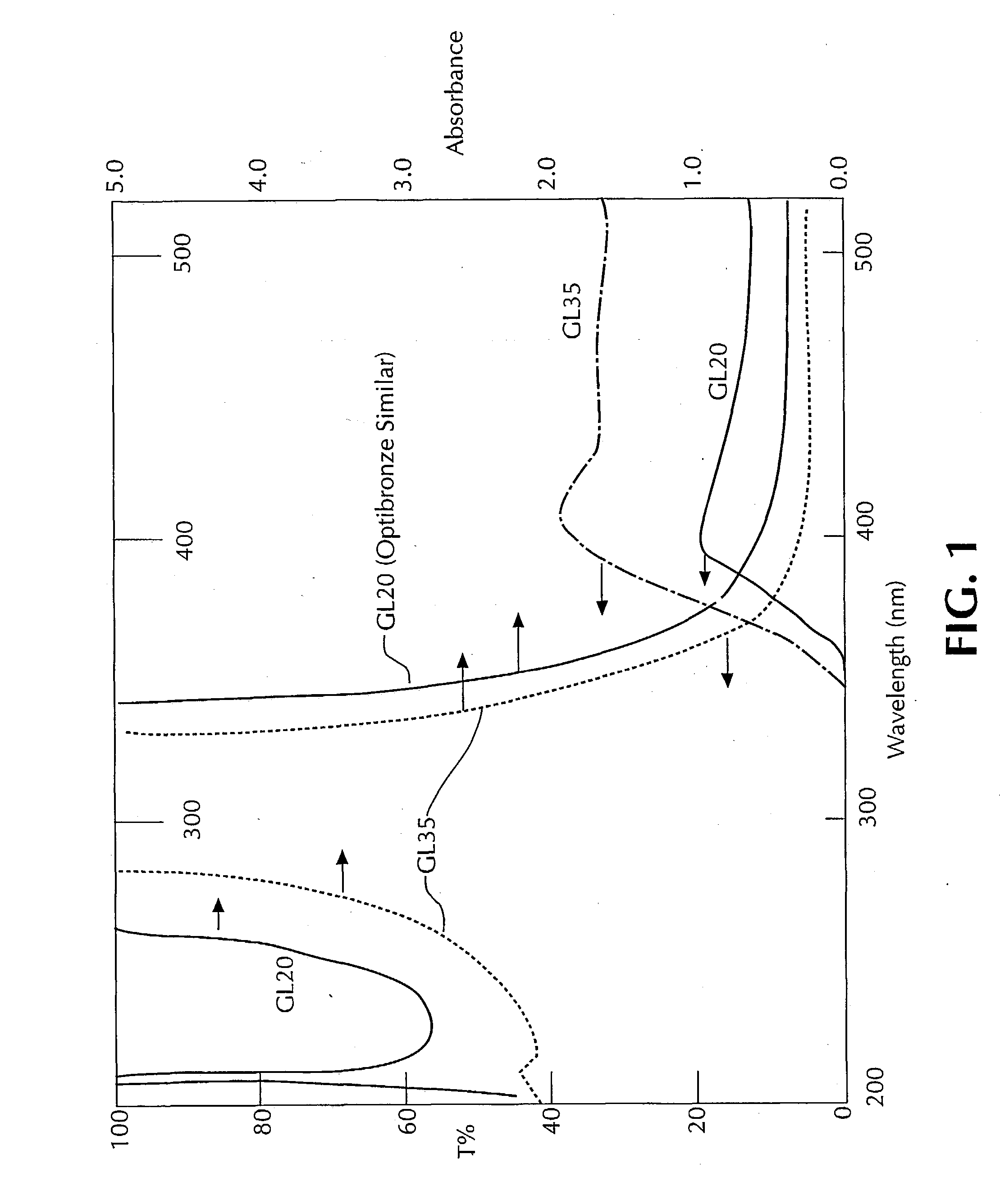

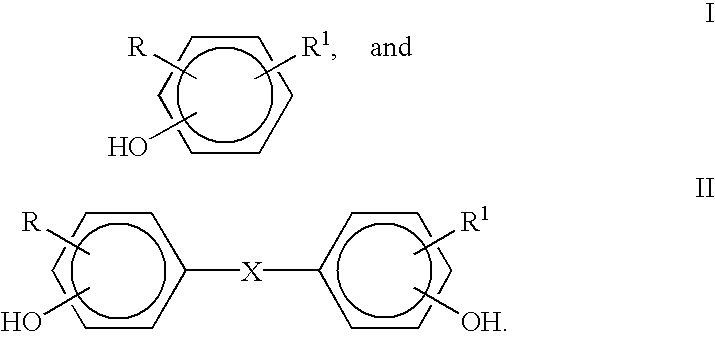

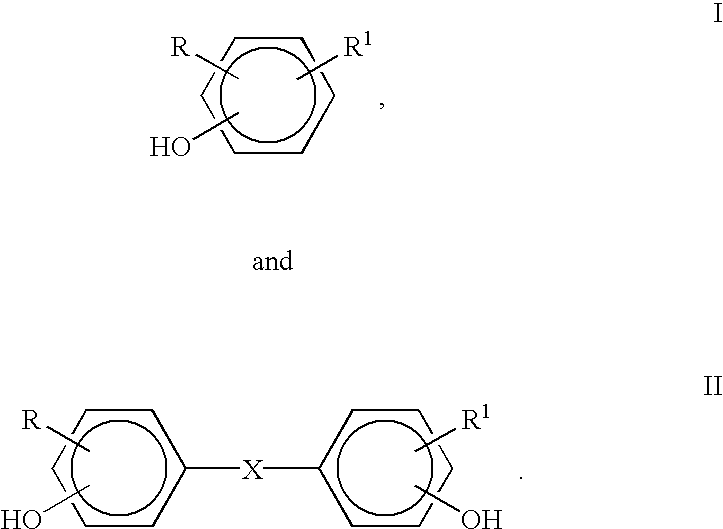

Electrochromic medium capable of producing a pre-selected color

An improved electrochromic device, the device incorporating an electrochromic medium that comprises at least three electroactive materials having absorption spectra that add together such that the color of the electrochromic medium can be pre-selected by individually choosing the concentrations of the at least three electroactive materials. The electrochromic medium generally maintains the pre-selected perceived color throughout its normal range of voltages when used in an electrochromic device. The at least three electroactive materials include at least one electrochemically reducible material (cathodic material), at least one electrochemically oxidizable material (anodic material) and at least one additional electroactive material which may be either an anodic or cathodic material. Thus, there are always three electroactive materials present in the medium, with at least two either being anodic or cathodic materials. The pre-selected color may be chosen from a wide variety of colors and may be, for example, red, orange, yellow, green, blue, purple. For electrochromic mirrors for motor vehicles, a presently preferred color is gray.

Owner:GENTEX CORP

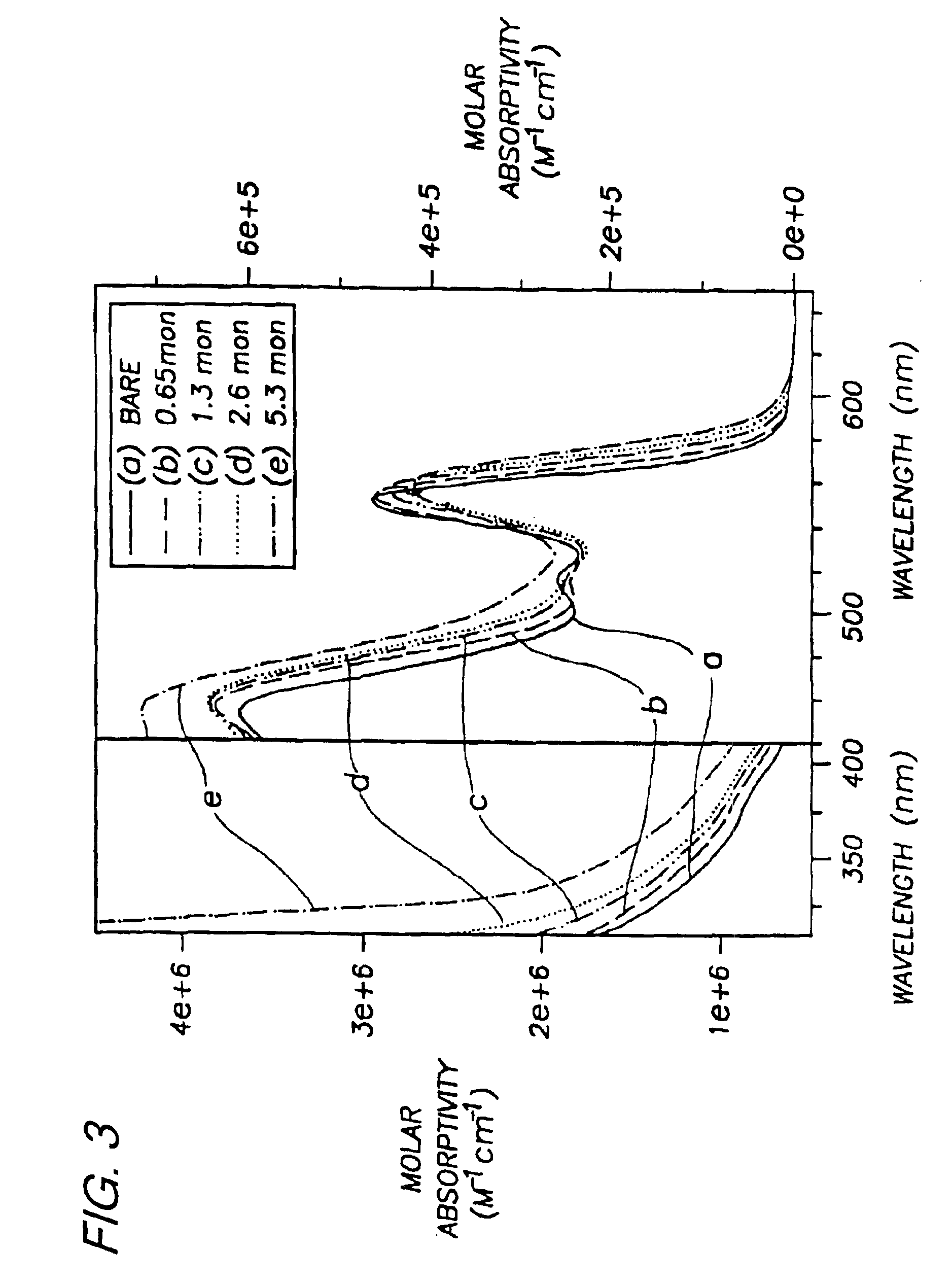

Water-soluble fluorescent nanocrystals

InactiveUS6444143B2High quantum yieldHigh spectral purityMaterial nanotechnologyNanosensorsQuantum yieldOrganic layer

A water soluble semiconductor nanocrystal capable of light emission is provided, including a quantum dot having a selected band gap energy, a layer overcoating the quantum dot, the overcoating layer comprised of a material having a band gap energy greater than that of the quantum dot, and an organic outer layer, the organic layer comprising a compound having a least one linking group for attachment of the compound to the overcoating layer and at least one hydrophilic group space apart from the linking group by a hydrophobic region sufficient to prevent electron charge transfer across the hydrophobic region. The particle size of the nanocrystal core is in the range of about 12.ANG. to about 150.ANG., with a deviation of less than 10% in the core. The coated nanocrystal exhibits photoluminescende having quantum yield of greater than 10% in water.

Owner:MASSACHUSETTS INST OF TECH

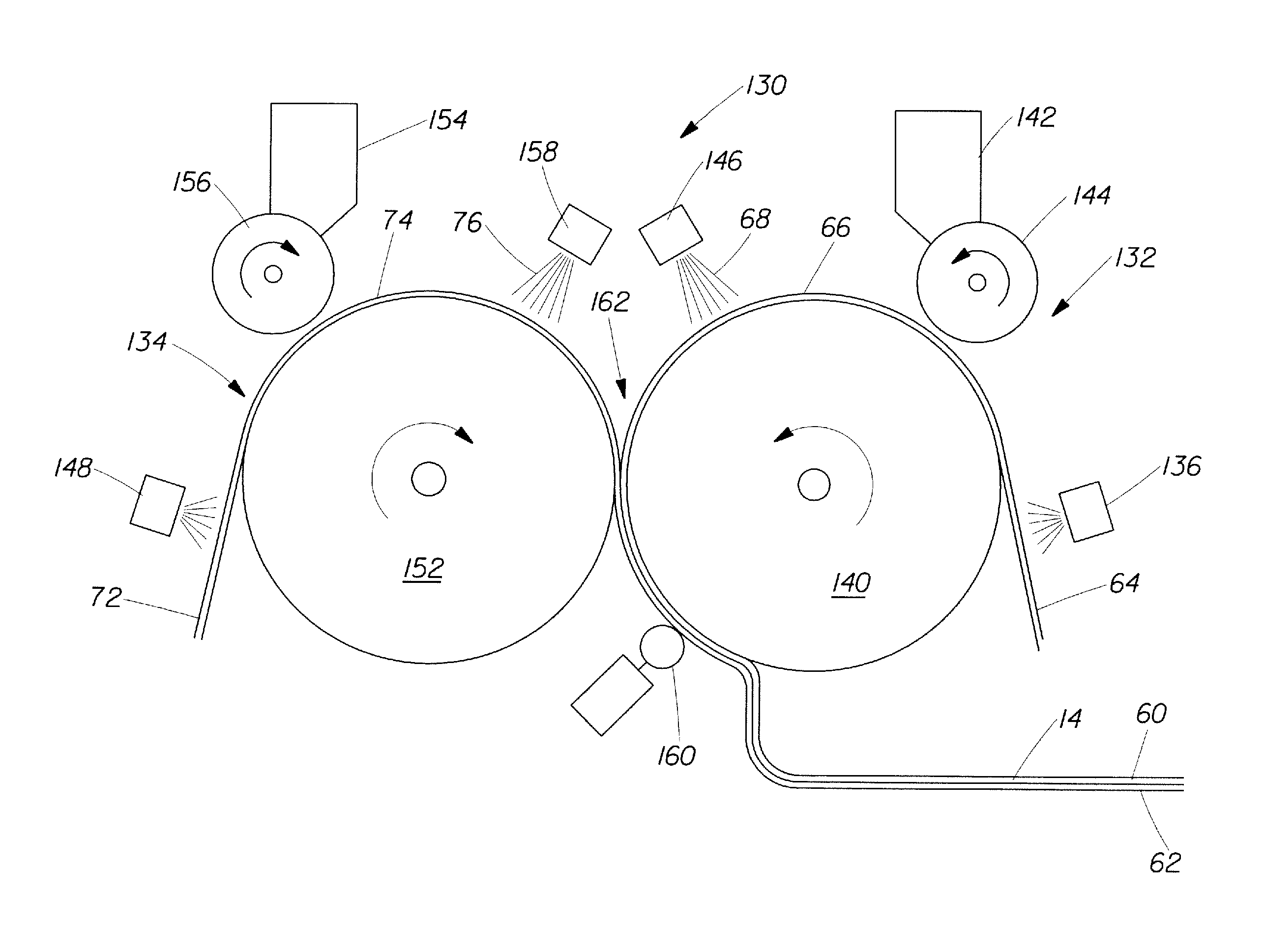

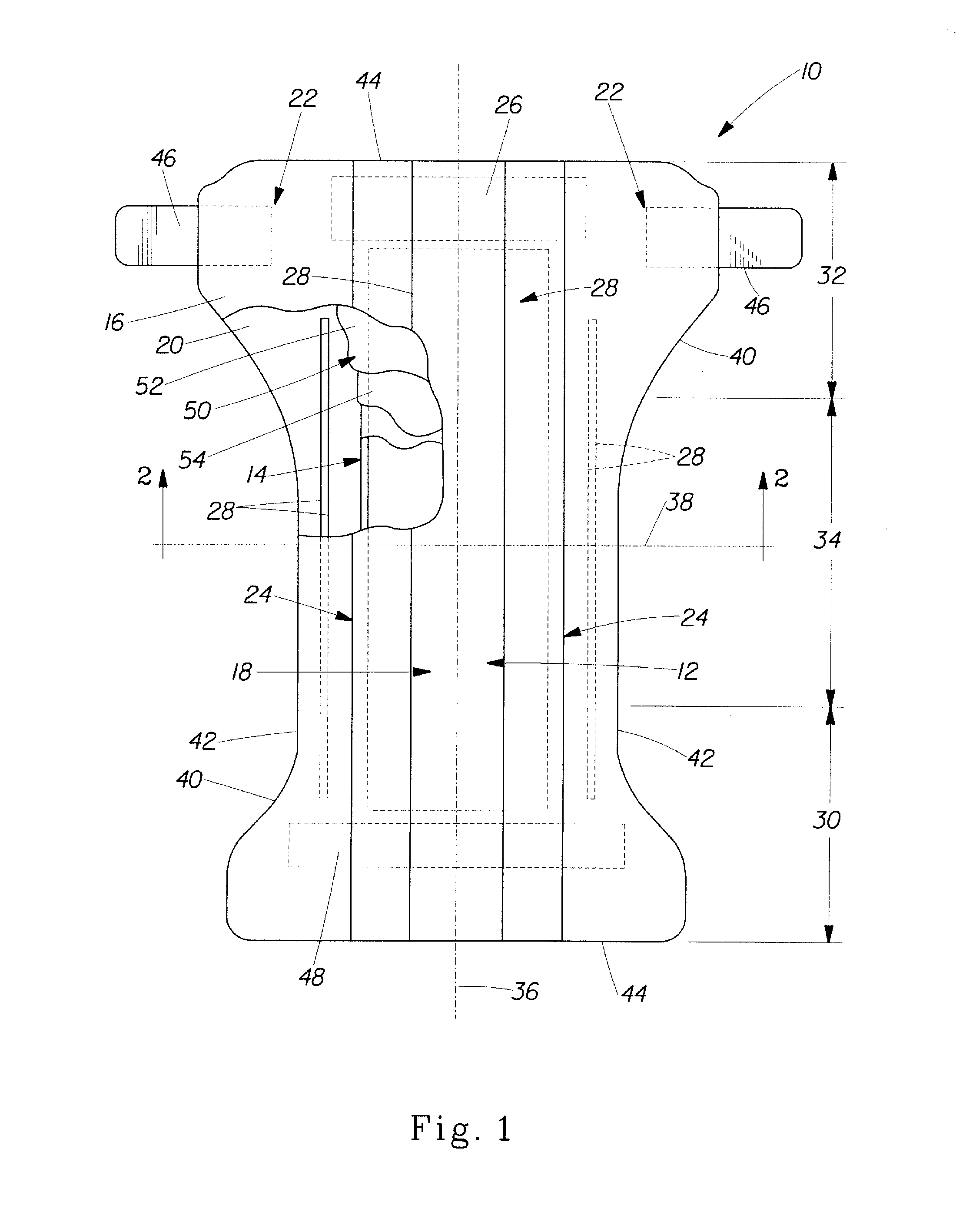

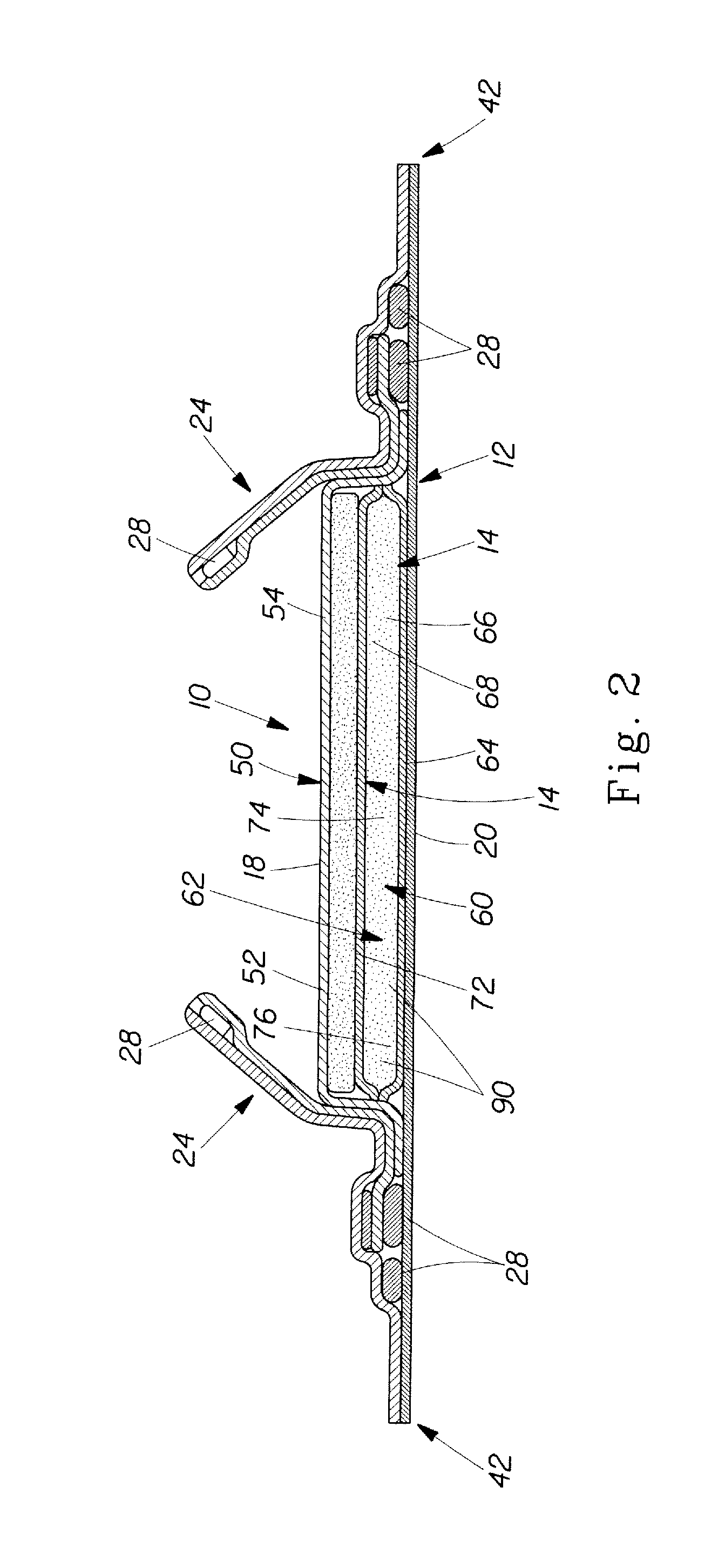

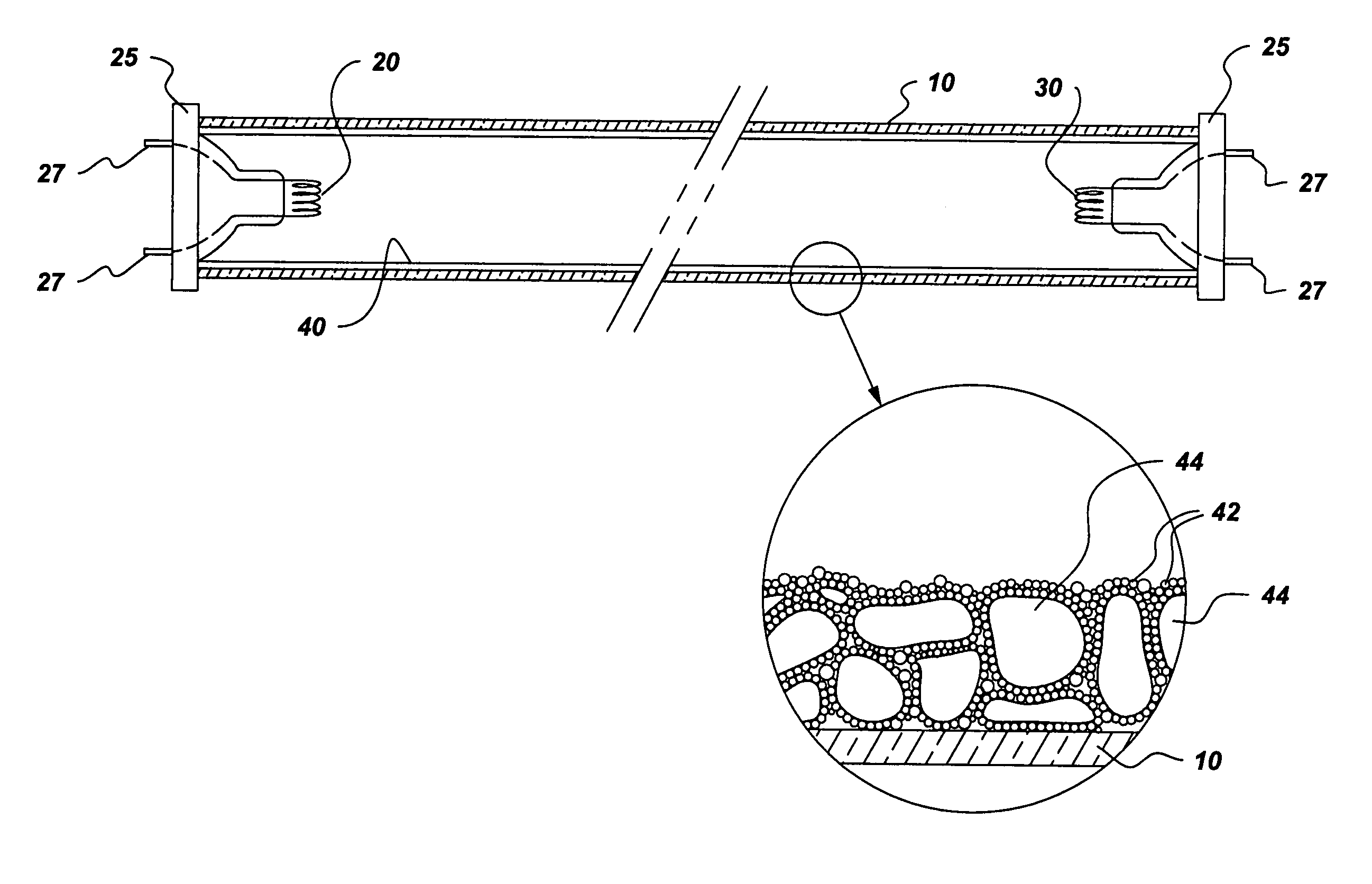

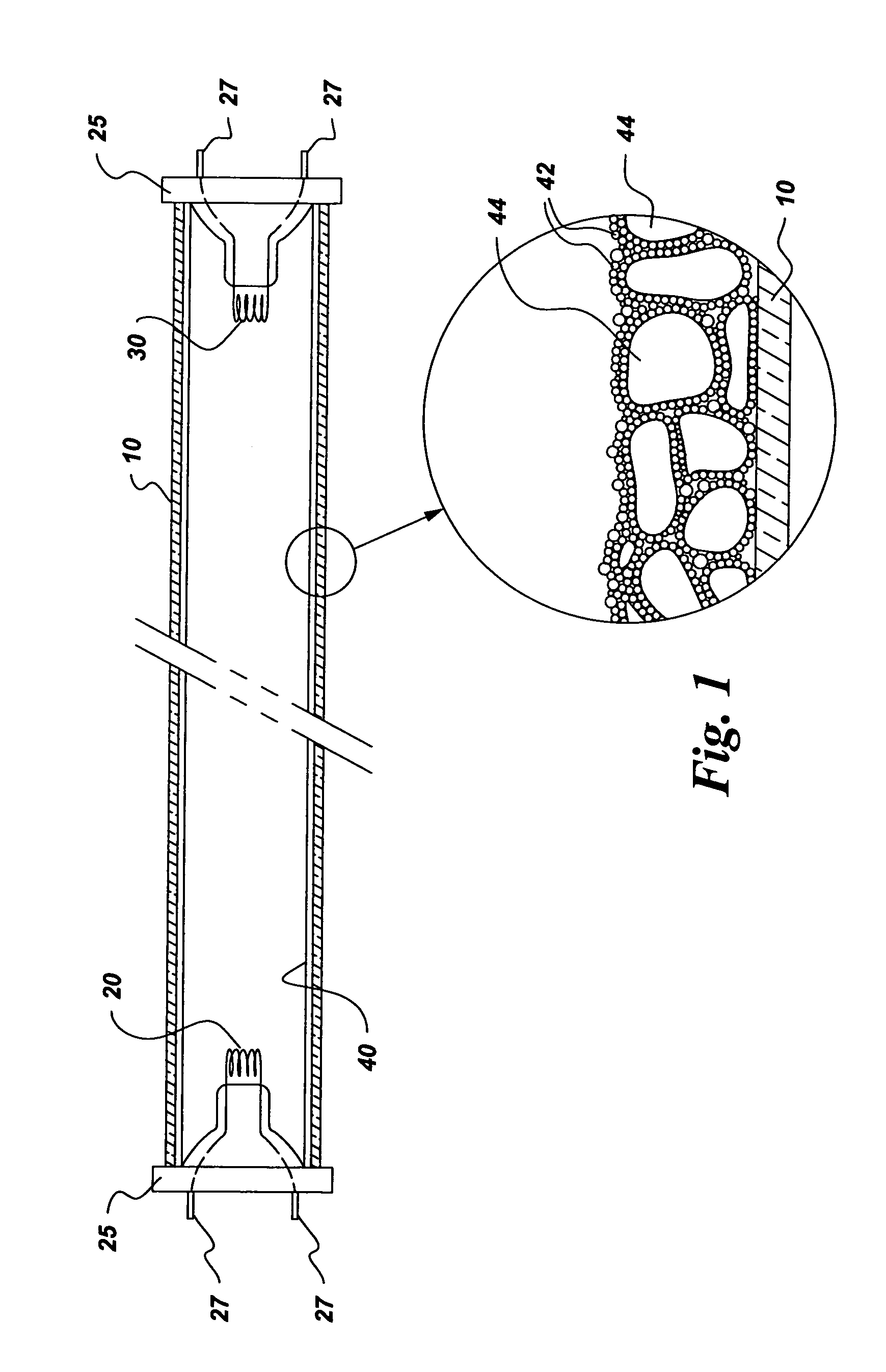

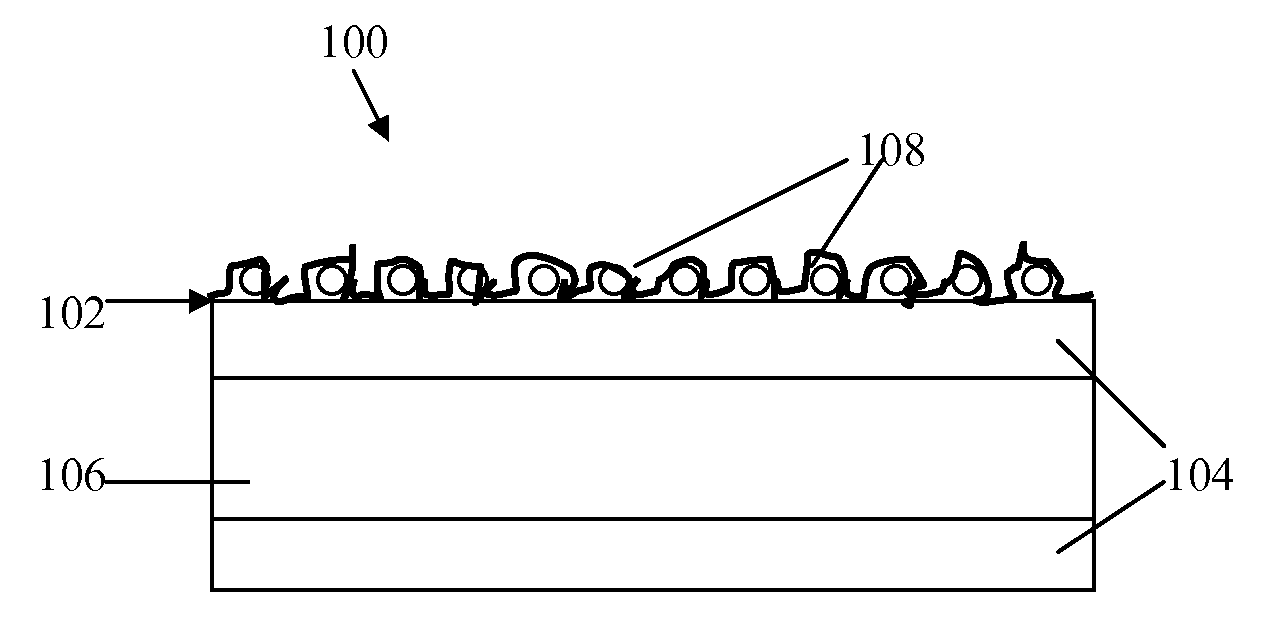

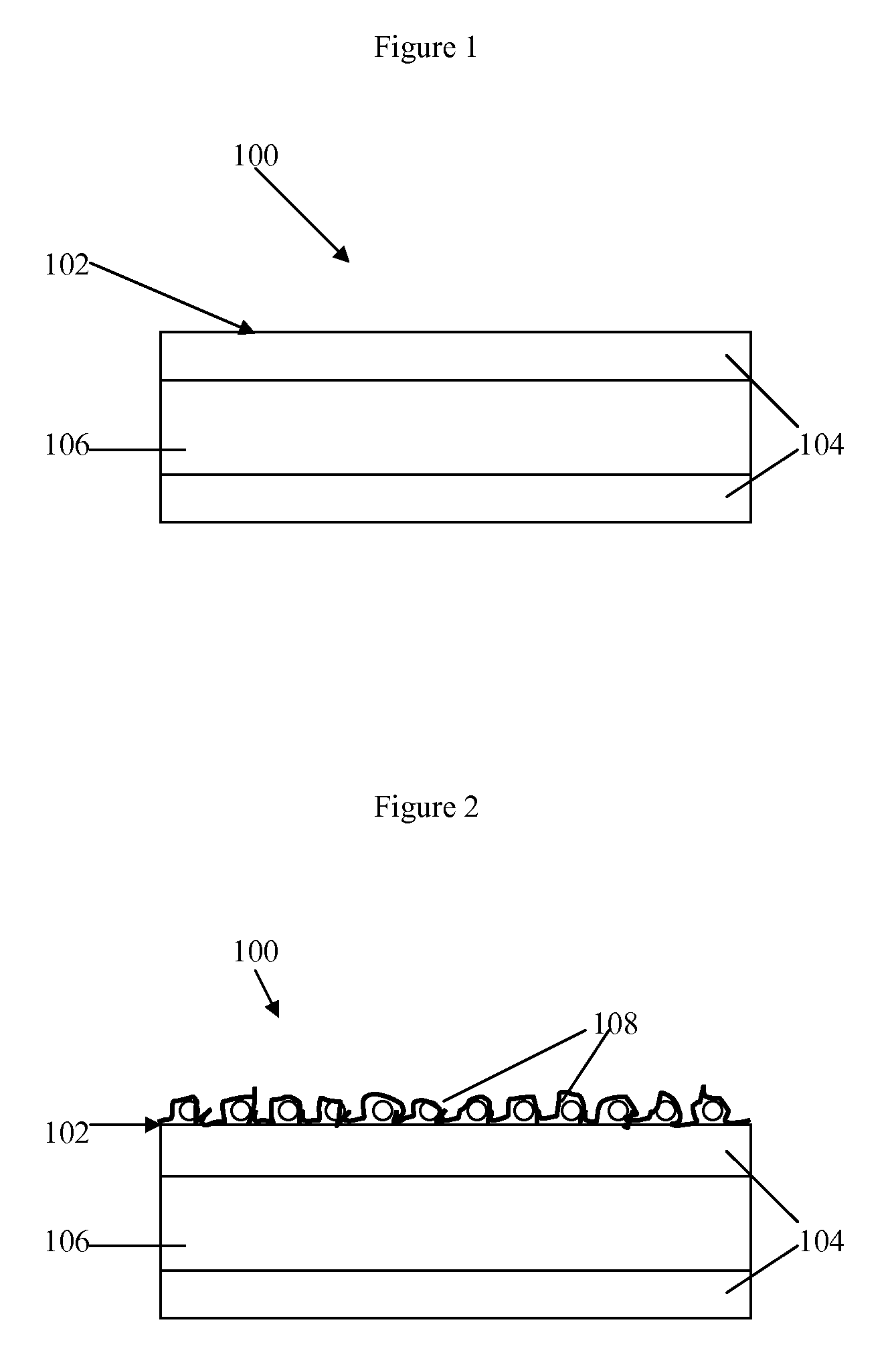

Method And Apparatus For Making Disposable Absorbent Article With Absorbent Particulate Polymer Material And Article Made Therewith

A method for making a disposable absorbent core comprises depositing absorbent particulate polymer material from a plurality of reservoirs in a printing roll onto a substrate disposed on a grid of a support which includes a plurality of cross bars extending substantially parallel to and spaced from one another so as to form channels extending between the plurality of cross bars. The plurality of reservoirs in the first peripheral surface are arranged in an array comprising rows extending substantially parallel to and spaced from one another. The support and printing roll are arranged such that the plurality of cross bars are substantially parallel to the rows of the plurality of reservoirs and the absorbent particulate polymer material is deposited on the substrate in a pattern such that the absorbent particulate polymer material collects in rows on the first substrate formed between the first plurality of cross bars. A thermoplastic adhesive material is deposited on the absorbent particulate polymer material and the substrate to cover the absorbent particulate polymer material on the substrate and form an absorbent layer. A disposable absorbent article and apparatus for making an absorbent article are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

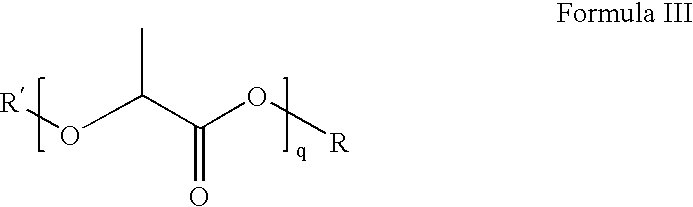

Composite proppant, composite filtration media and methods for making and using same

InactiveUS6632527B1Avoid condensationReduce molecular weightPretreated surfacesGlass/slag layered productsFiberFiltration

Composite particles made of a binder and filler material are provided for use in subterranean formations. The filler is finely divided mineral and optional fiber. The particles are proppants useful to prop open subterranean formation fractures. The particles are also useful for water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.< / PTEXT>

Owner:HEXION INC

Down-drawable, chemically strengthened glass for cover plate

An alkali aluminosilicate glass that is chemically strengthened and has a down-drawable composition. The glass has a melting temperature less than about 1650° C. and a liquidus viscosity of at least 130 kpoise and, in one embodiment, greater than 250 kpoise. The glass undergoes ion exchange at relatively low temperatures to a depth of at least 30 μm.

Owner:CORNING INC

Chromogenic glazing

A transparent chromogenic assembly in which color changes are selectively effectable over predefined areas comprises a pair of facing transparent substrates (15, 21, 28) each covered with a conductive layer divided into individual energizeable areas each provided with a set of busbars (187, 188). A passive layer may be superimposed over one of the substrates, its color being chosen so that the color and the transmissivity of the passive layer accommodates the range of color change and transmissivity of the electrochromic layer to maintain the transmitted color of the panel in a warm or neutral shade. Various other chromogenic windows, devices and systems are also disclosed.

Owner:SCHOTT AG

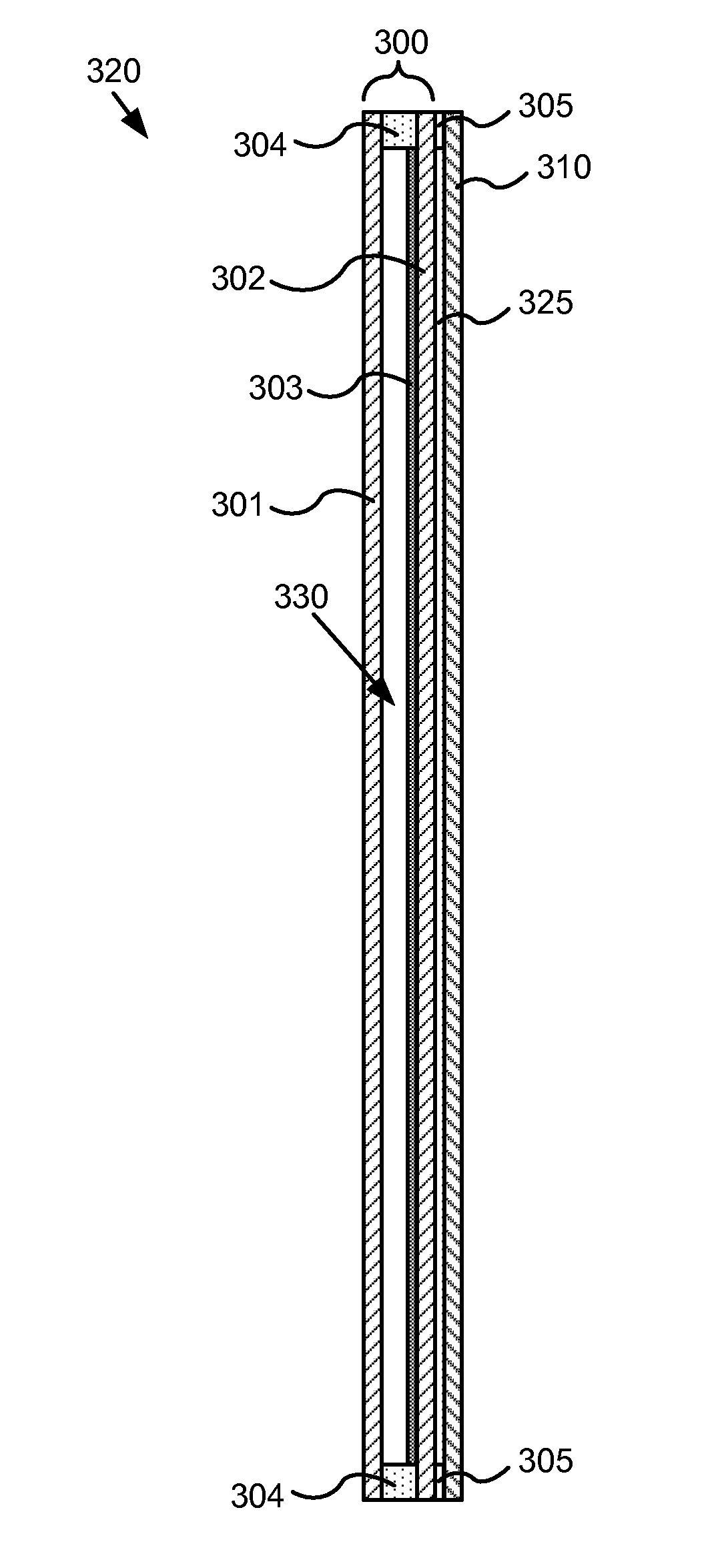

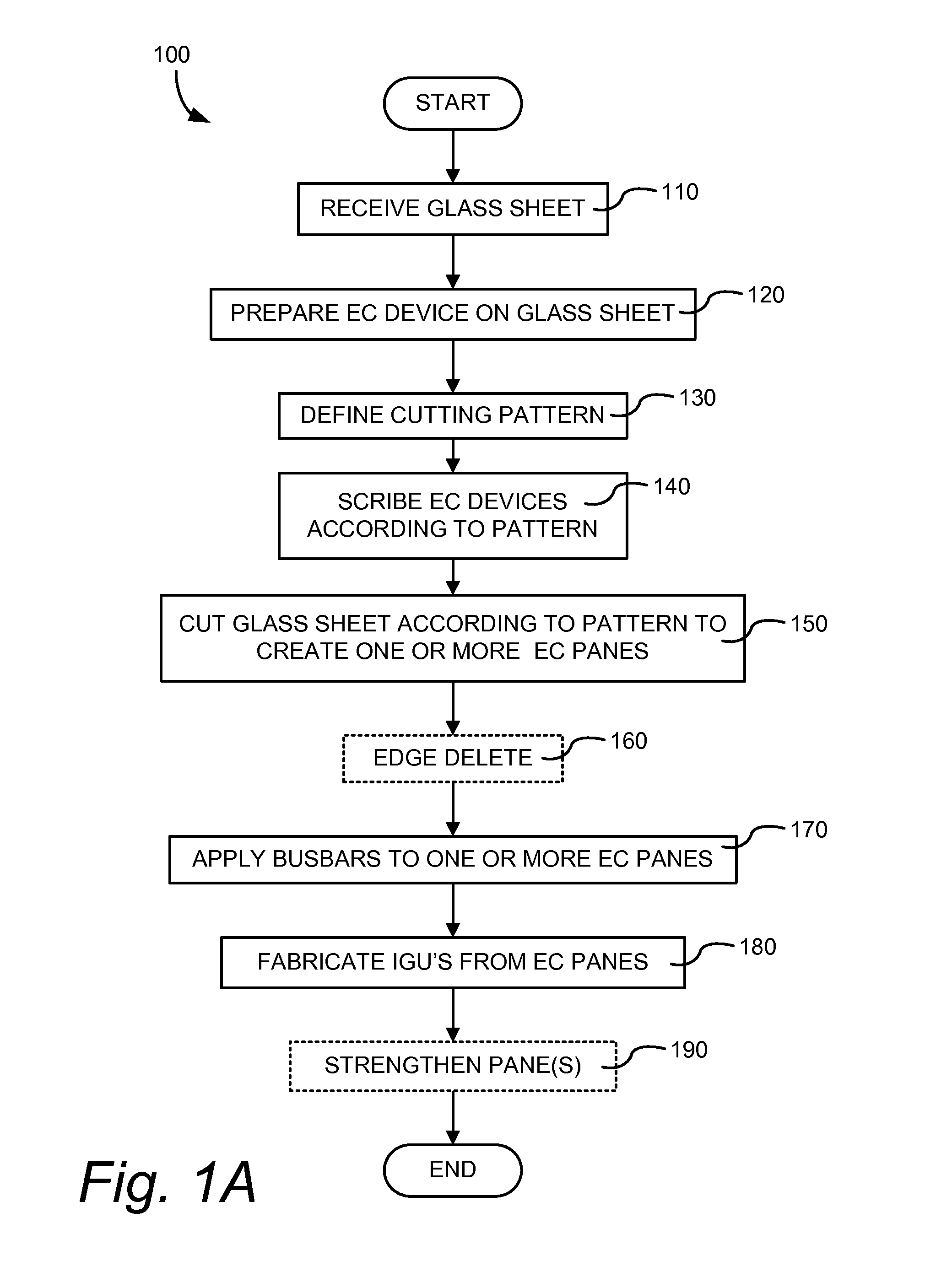

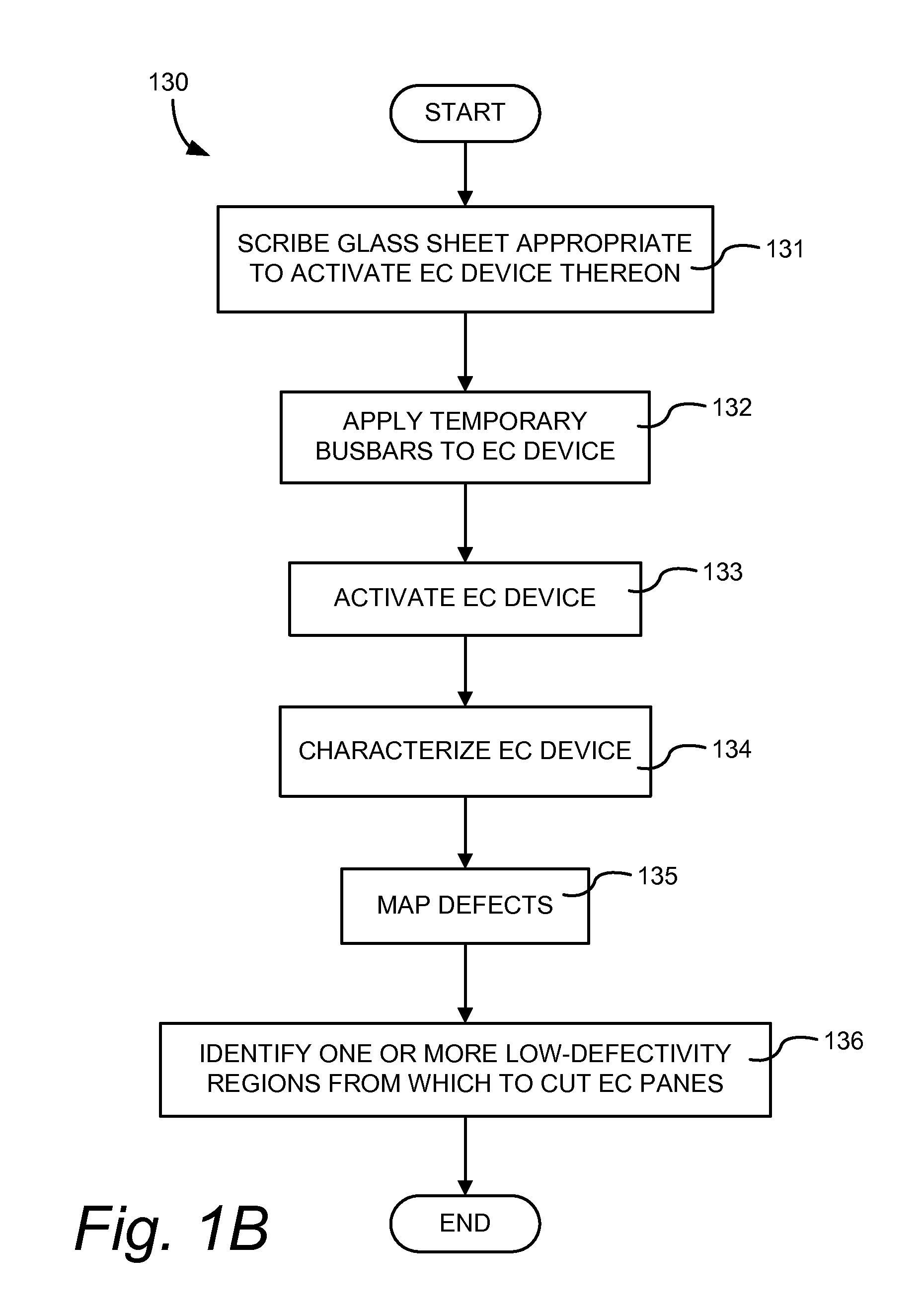

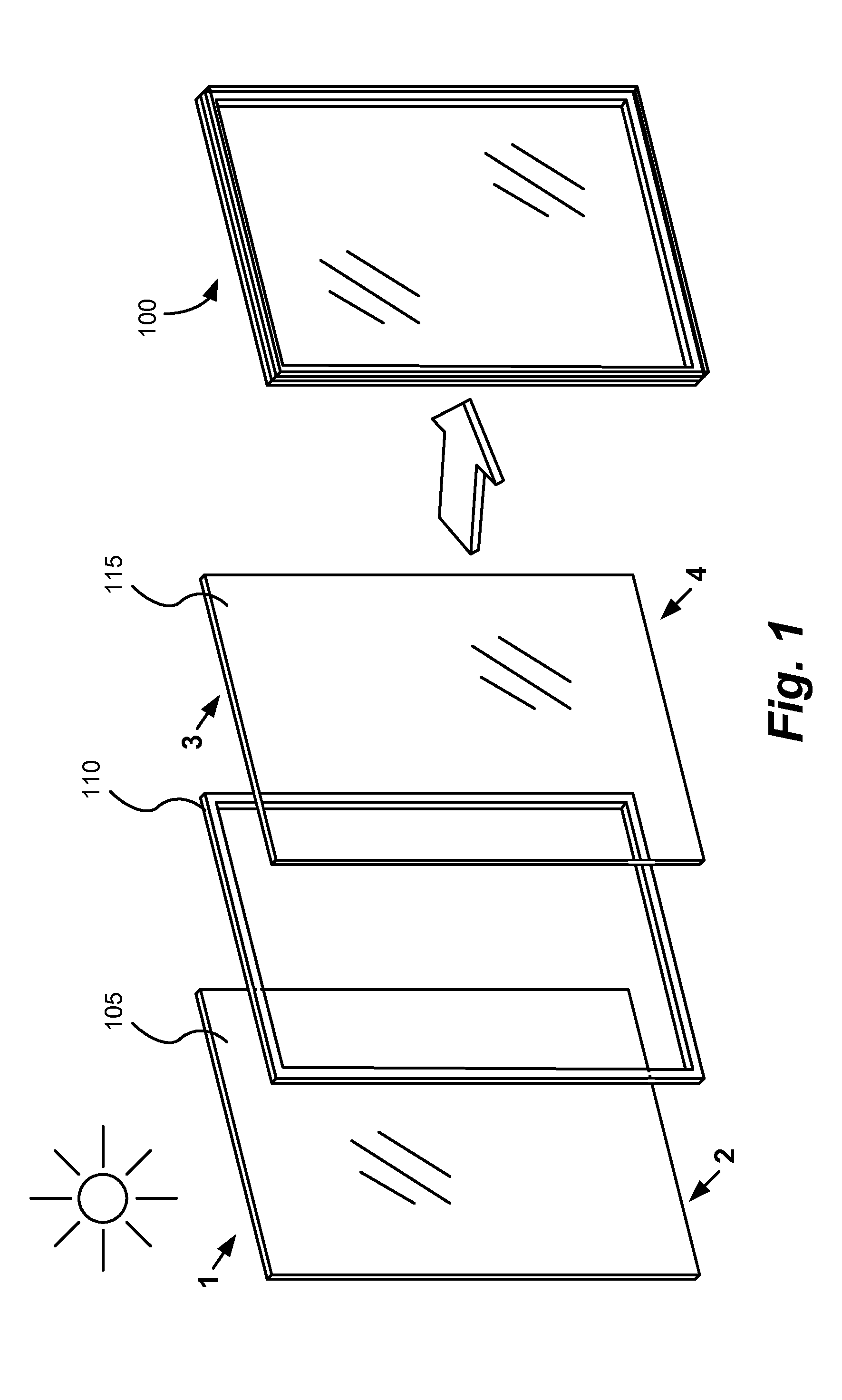

Electrochromic window fabrication methods

ActiveUS20120026573A1Maximize effective useLamination ancillary operationsLaminationEngineeringElectrochromism

Methods of manufacturing electrochromic windows are described. An electrochromic device is fabricated to substantially cover a glass sheet, for example float glass, and a cutting pattern is defined based on one or more low-defectivity areas in the device from which one or more electrochromic panes are cut. Laser scribes and / or bus bars may be added prior to cutting the panes or after. Edge deletion can also be performed prior to or after cutting the electrochromic panes from the glass sheet. Insulated glass units (IGUs) are fabricated from the electrochromic panes and optionally one or more of the panes of the IGU are strengthened.

Owner:VIEW INC

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS6582819B2Low densityEasy to transportGranule coatingPretreated surfacesFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

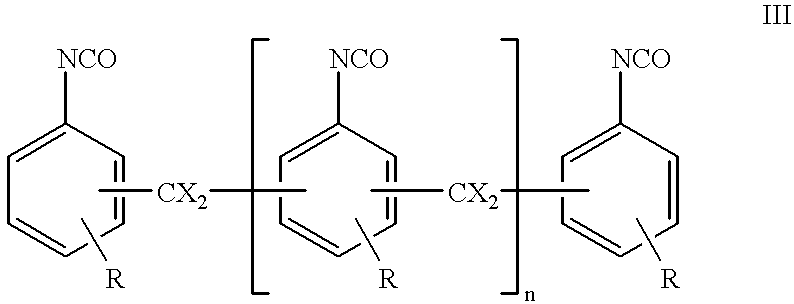

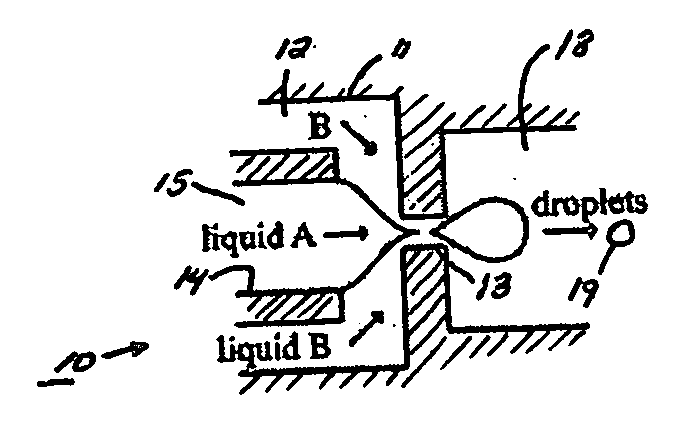

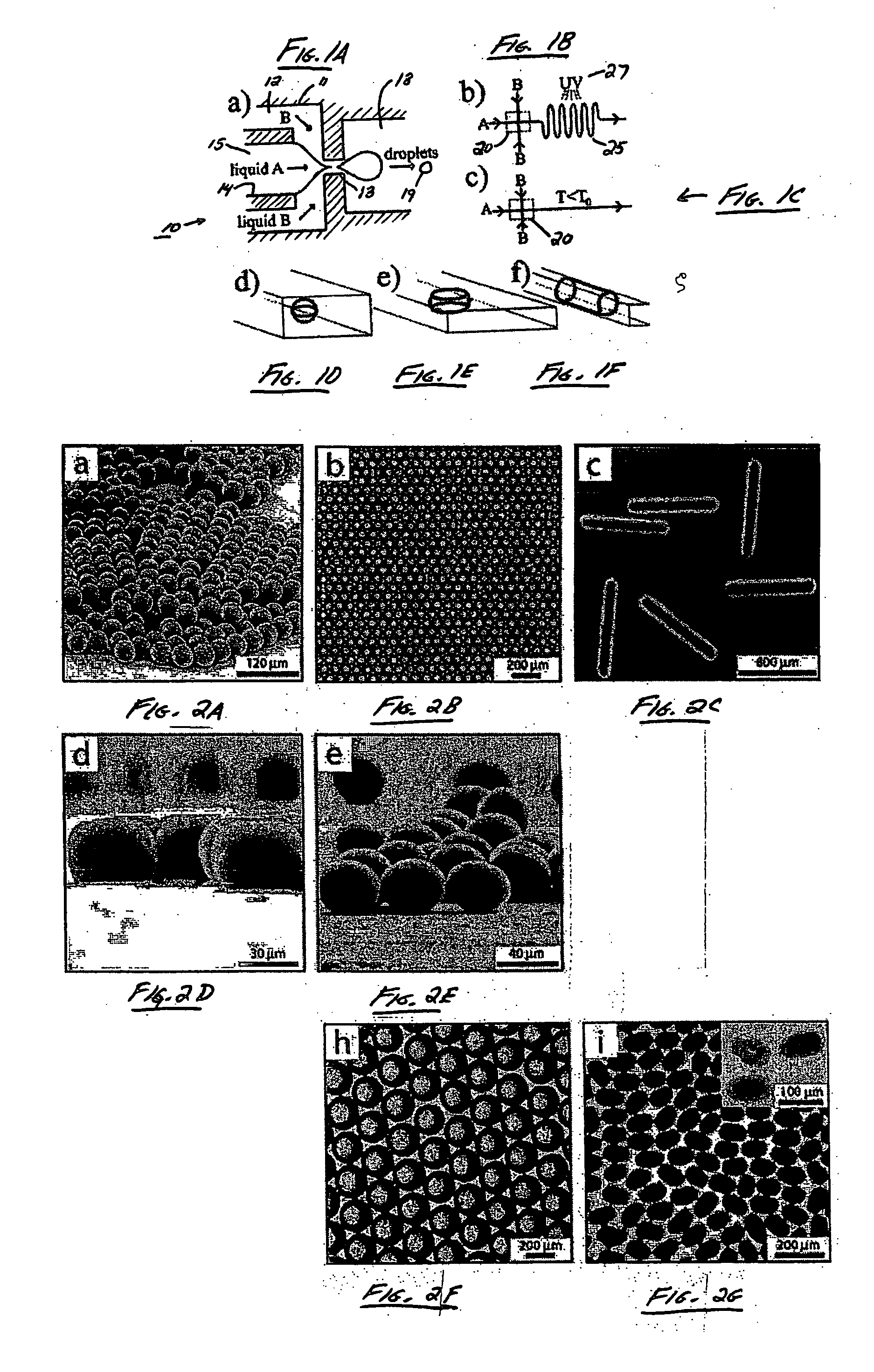

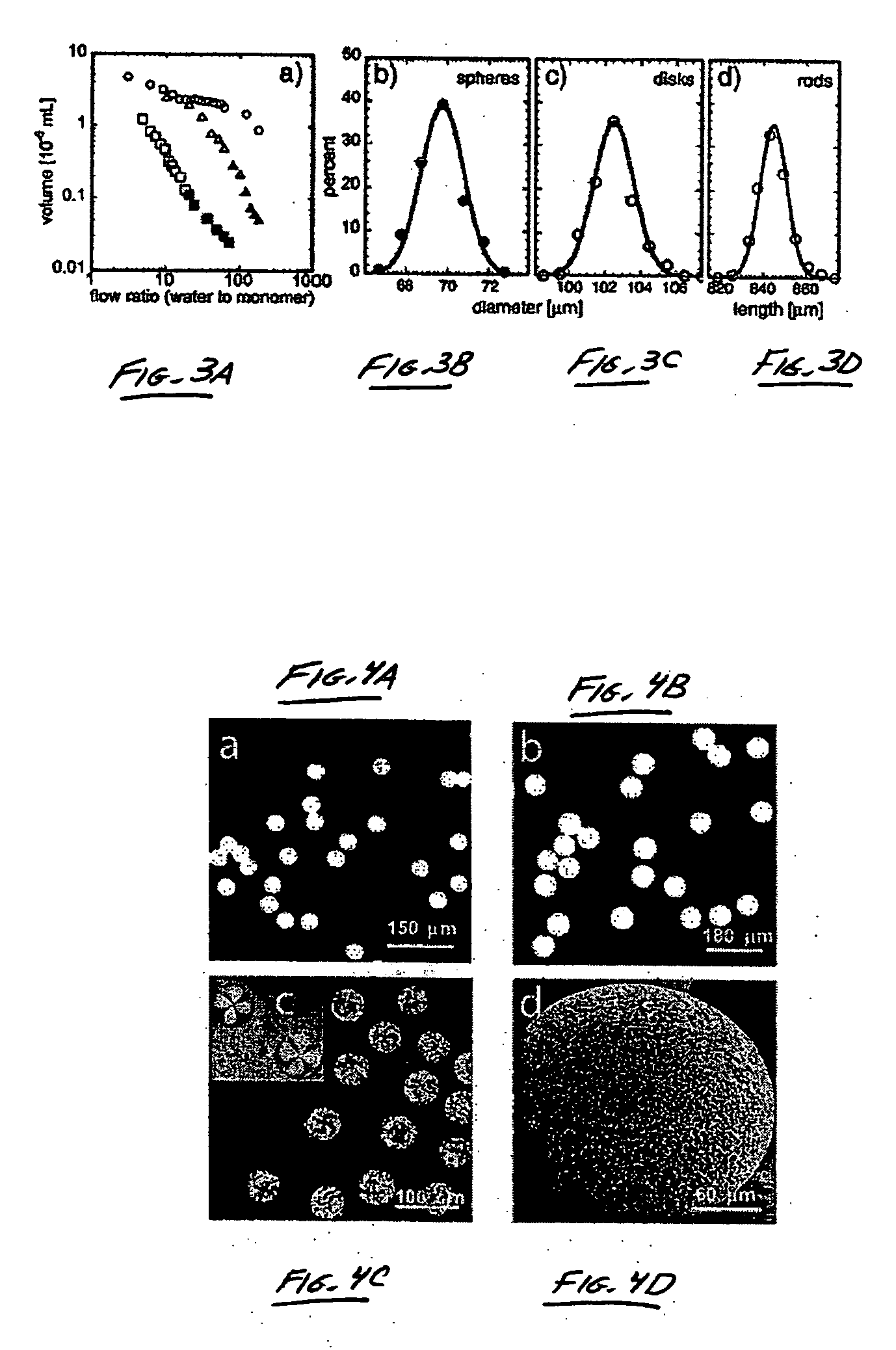

Systems and methods of forming particles

InactiveUS20070054119A1Synthetic resin layered productsChemical/physical/physico-chemical microreactorsChemical reactionMicrometer

The present invention generally relates to systems and methods of forming particles and, in certain aspects, to systems and methods of forming particles that are substantially monodisperse. Microfluidic systems and techniques for forming such particles are provided, for instance, particles may be formed using gellation, solidification, and / or chemical reactions such as cross-linking, polymerization, and / or interfacial polymerization reactions. In one aspect, the present invention is directed to a plurality of particles having an average dimension of less than about 500 micrometers and a distribution of dimensions such that no more than about 5% of the particles have a dimension greater than about 10% of the average dimension, which can be made via microfluidic systems. In one set of embodiments, at least some of the particles may comprise a metal, and in certain embodiments, at least some of the particles may comprise a magnetizable material. In another set of embodiments, at least some of the particles may be porous. In some embodiments, the invention includes non-spherical particles. Non-spherical particles may be formed, for example, by urging a fluidic droplet into a channel having a smallest dimension that is smaller than the diameter of a perfect mathematical sphere having a volume of the droplet, and solidifying the droplet, and / or by exposing at least a portion of a plurality of particles to an agent able to remove at least a portion of the particles.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

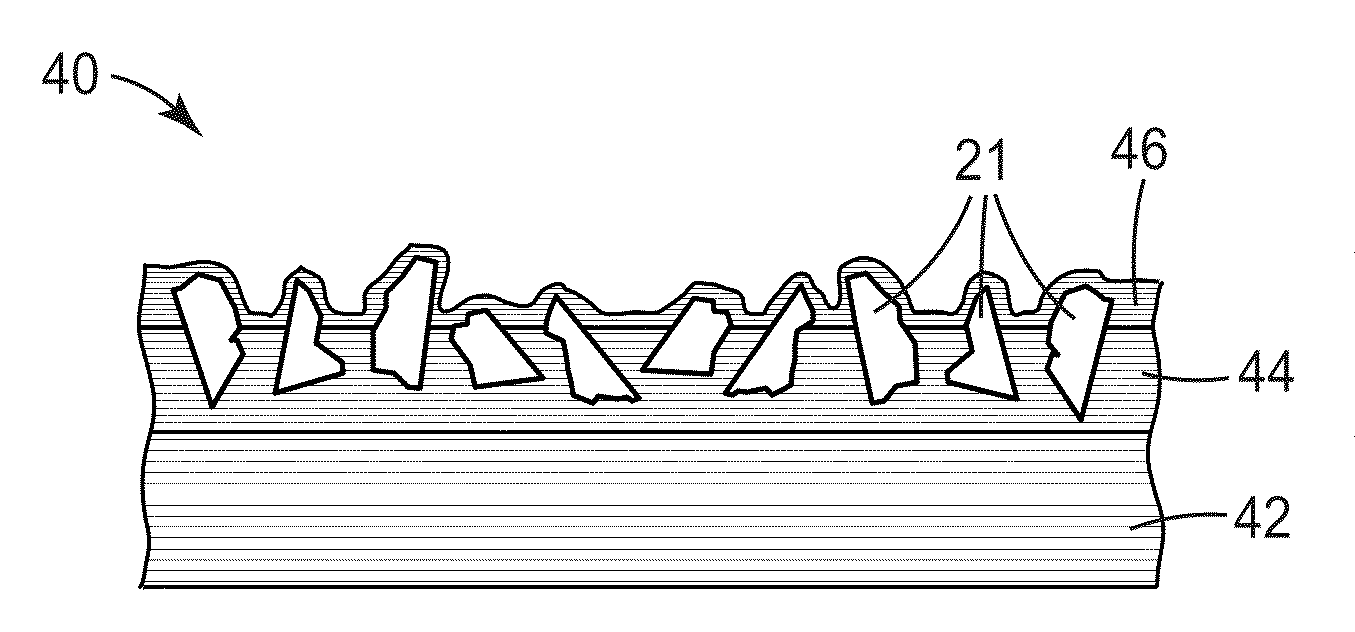

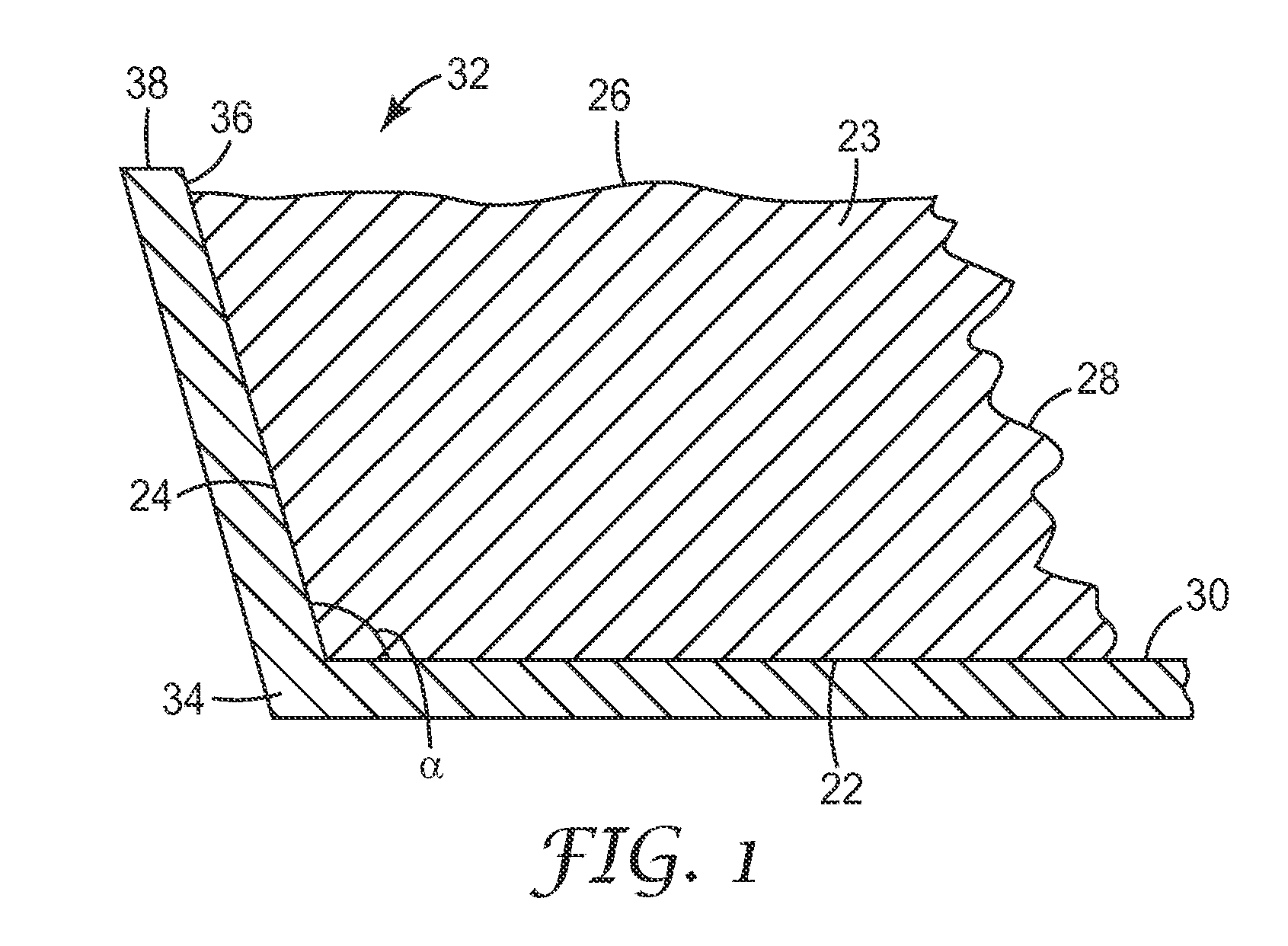

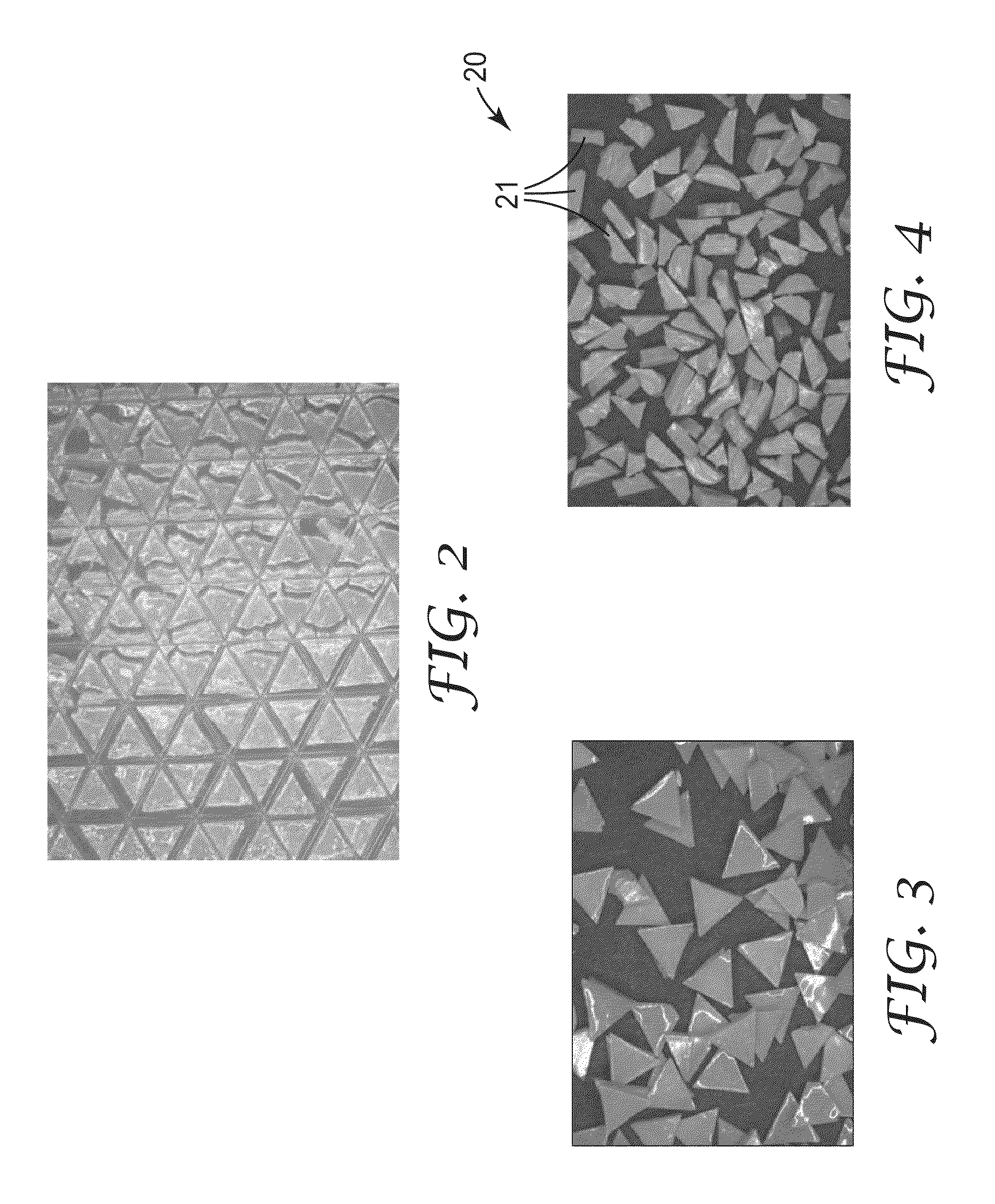

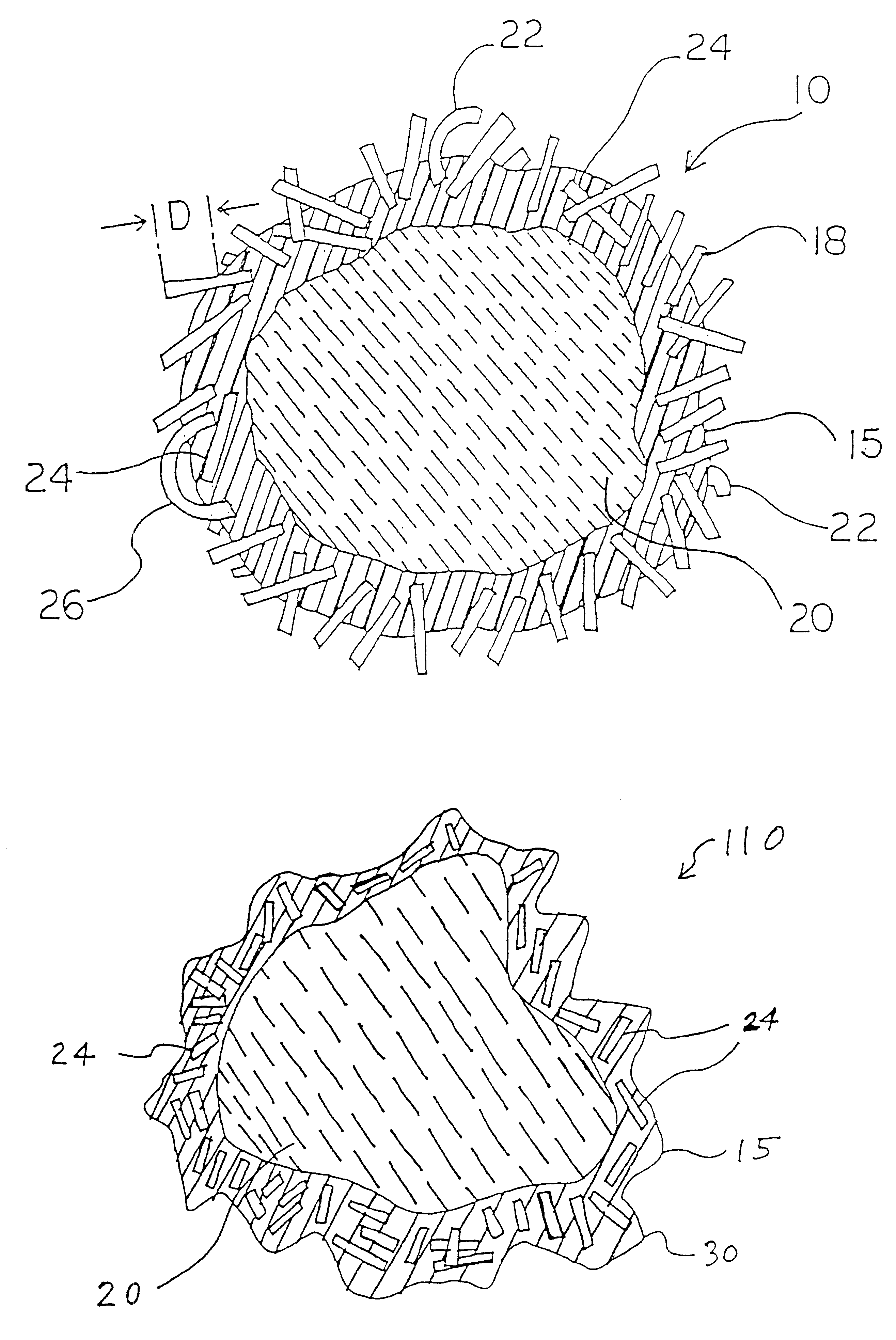

Shaped, fractured abrasive particle, abrasive article using same and method of making

ActiveUS20090169816A1Improve performanceLarge distributionPigmenting treatmentSpecial ornamental structuresPolymer chemistryAbrasive

Precursor alpha alumina abrasive particles in a mold are subjected to a drying process that cracks or fractures at least a majority of the precursor abrasive particles into at least two pieces thereby producing abrasive shards having a smaller size than the mold cavity from which they were made. The smaller abrasive shards, once formed, could be reassembled like jigsaw puzzle pieces to reproduce the original cavity shape of the mold from which they were made. The cracking or fracturing of the precursor abrasive particles is believed to occur by ensuring that the surface tension of the abrasive dispersion to the walls of the mold is greater than the internal attractive forces of the abrasive dispersion as the abrasive dispersion is dried within the mold cavity.

Owner:3M INNOVATIVE PROPERTIES CO

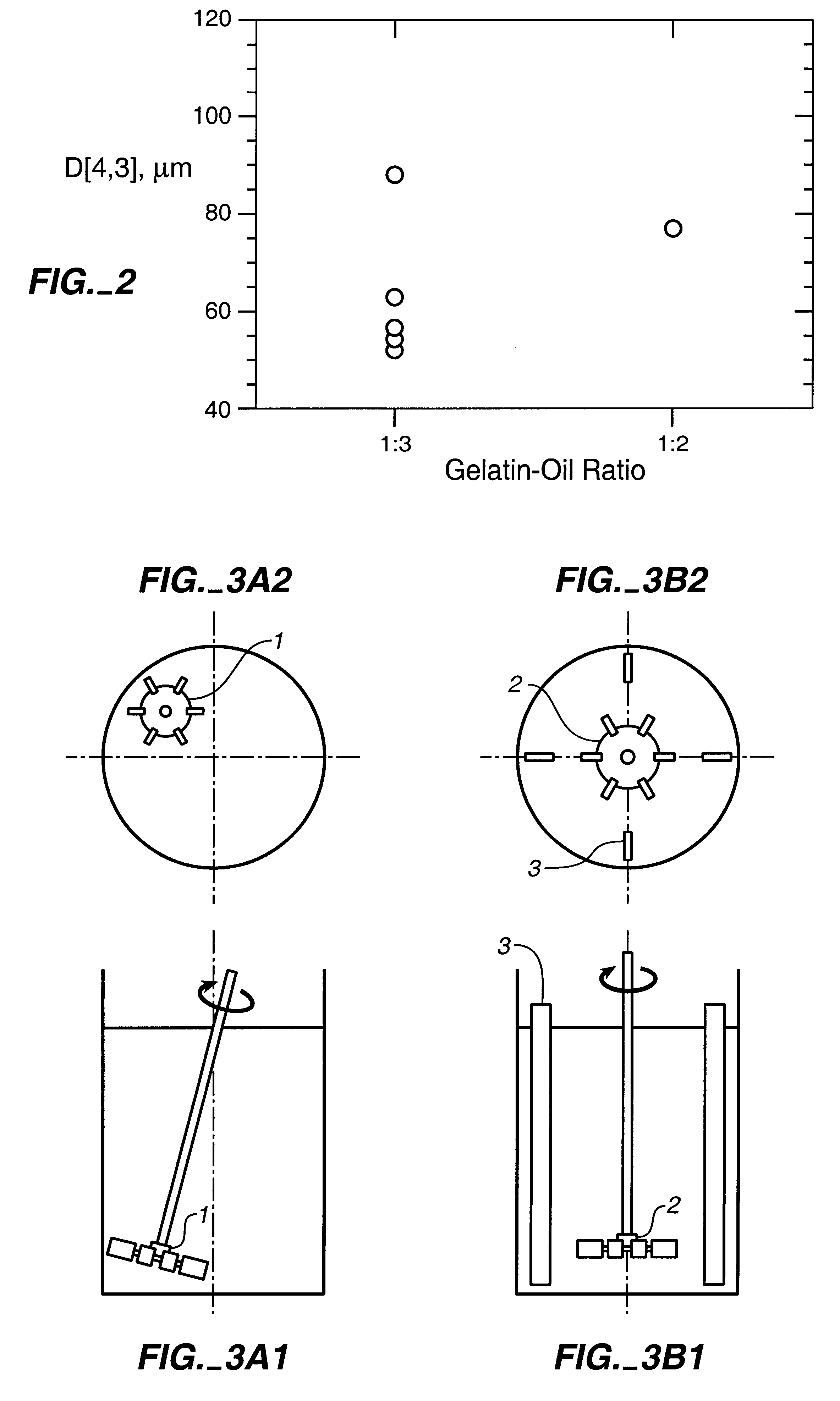

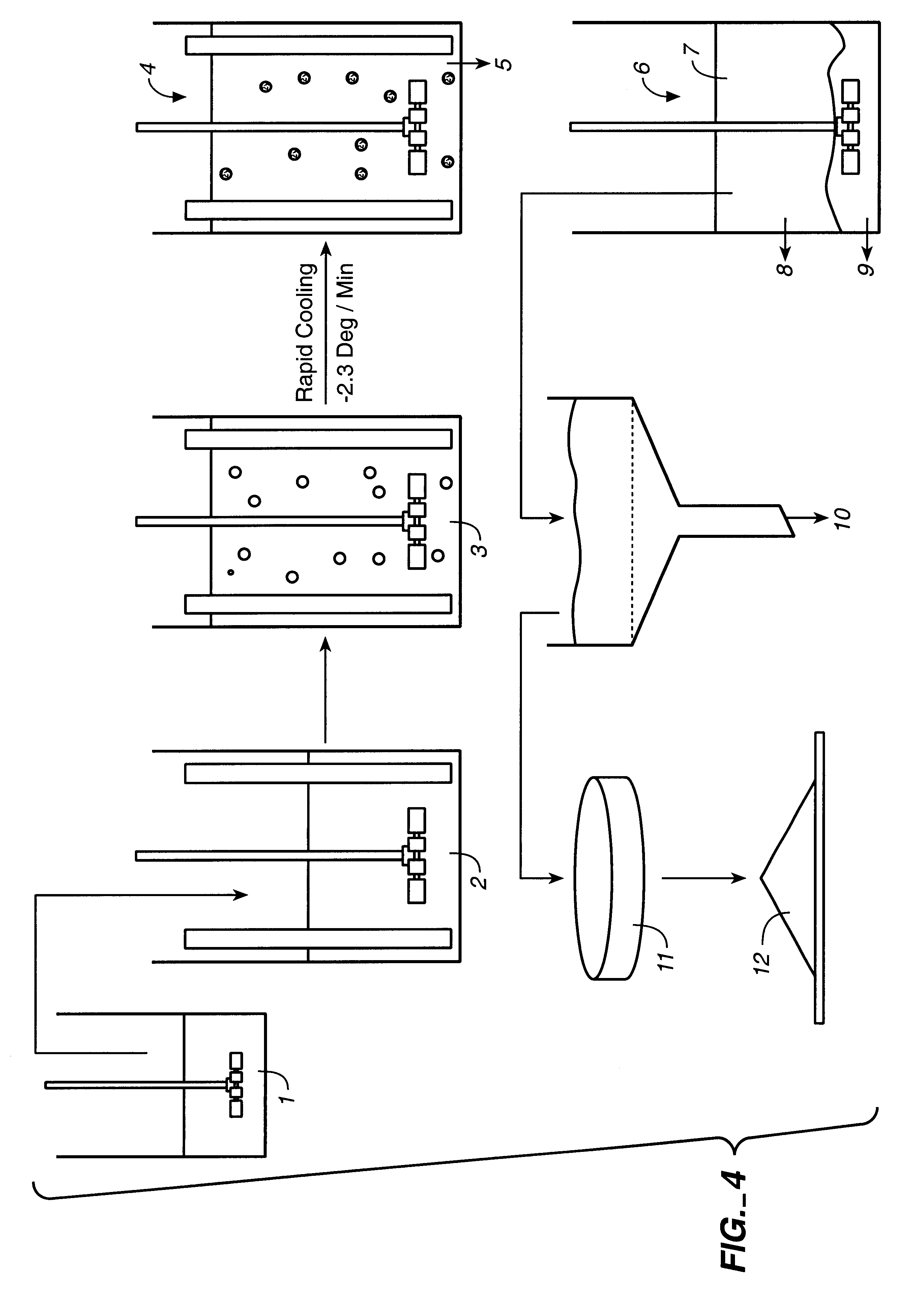

Compositions for nasal drug delivery, methods of making same, and methods of removing residual solvent from pharmaceutical preparations

InactiveUS6391452B1Taller in heightSlow down the mixing speedLiquid surface applicatorsPeptide/protein ingredientsNasal cavityNose

The present invention relates to pharmaceutical compositions for delivery of drugs intended to reside in the nose, compositions for nasal administration of drugs, e.g., antiviral agents, and particularly antiviral agents comprising the human major rhinovirus receptor, also known as intercellular adhesion molecule-1 (ICAM-1); to methods of making said nasal drug compositions, and to an improved process for the removal of residual solvent from pharmaceutical matrices.

Owner:BAYER PHARMA CORP

Light sources with nanometer-sized VUV radiation-absorbing phosphors

A light source comprises: (a) a source of plasma discharge that emits electromagnetic radiation, a portion of which has wavelengths shorter than about 200 nm; and (b) a phosphor composition that comprises particles, each of the particles comprising at least a first phosphor and at least a second phosphor, the phosphor composition is disposed such that the first phosphor absorbs substantially the portion of EM radiation having wavelengths shorter than about 200 nm, and the first phosphor emits EM radiation having wavelengths longer than about 200 nm.

Owner:GENERAL ELECTRIC CO

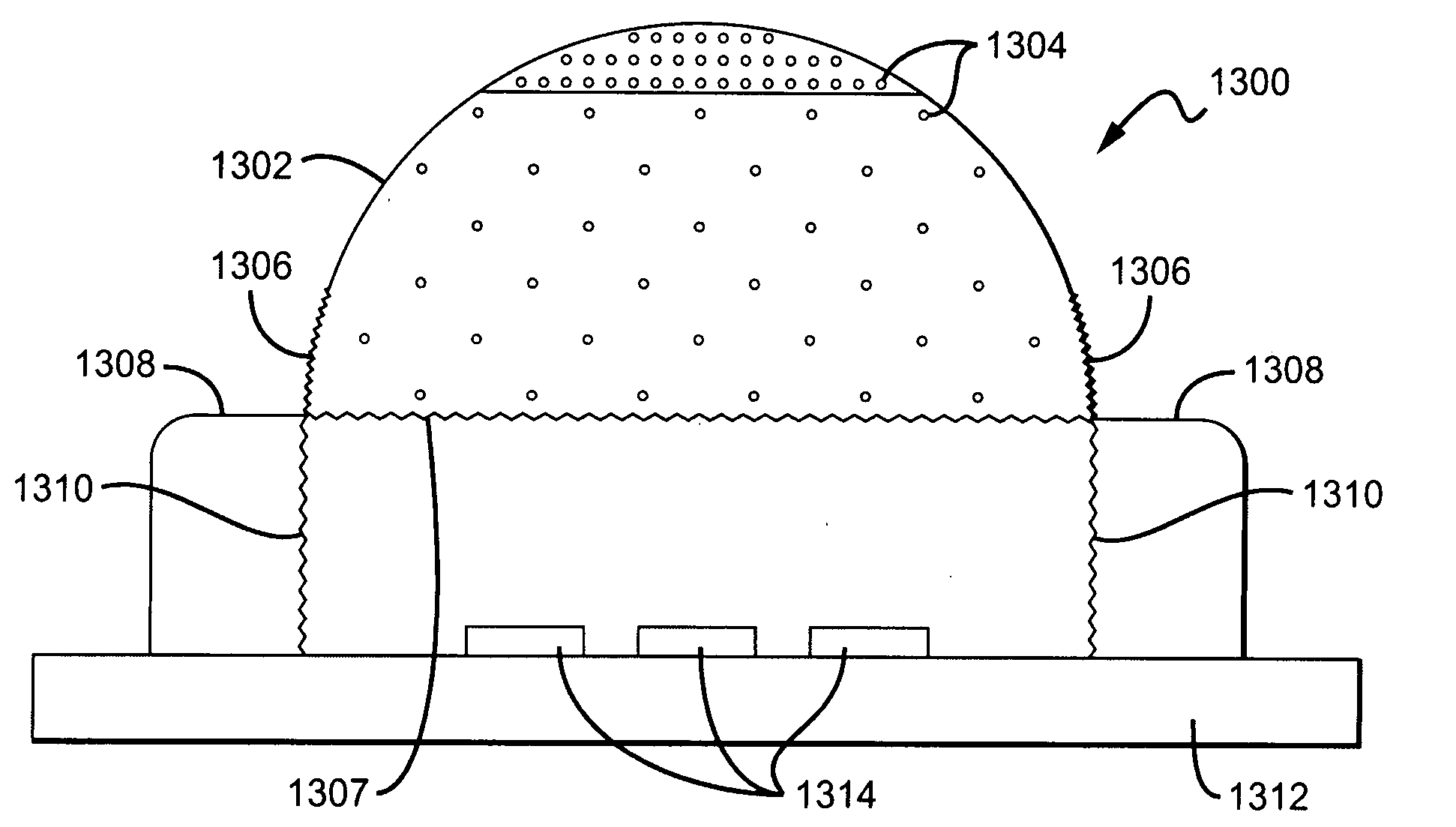

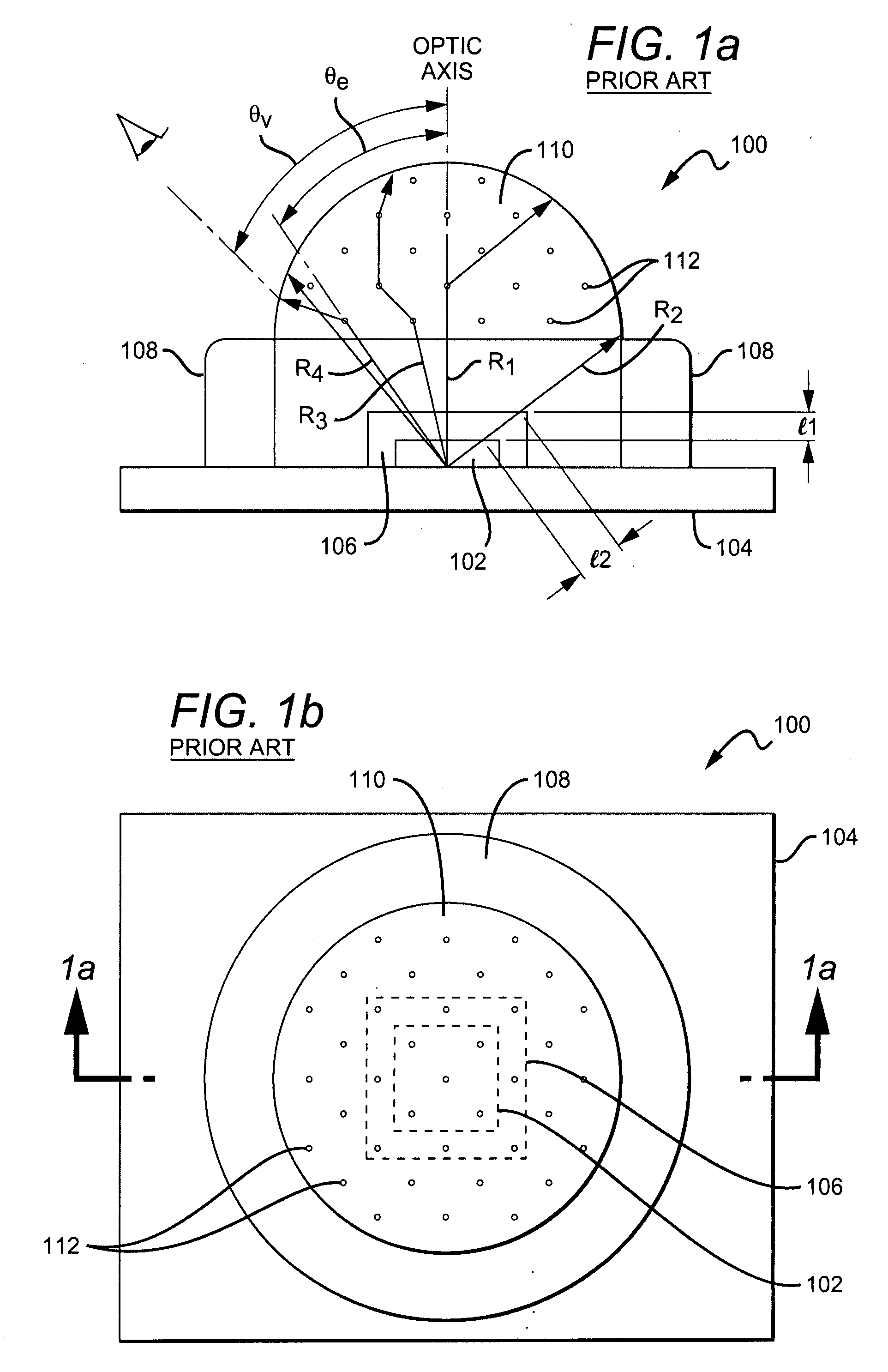

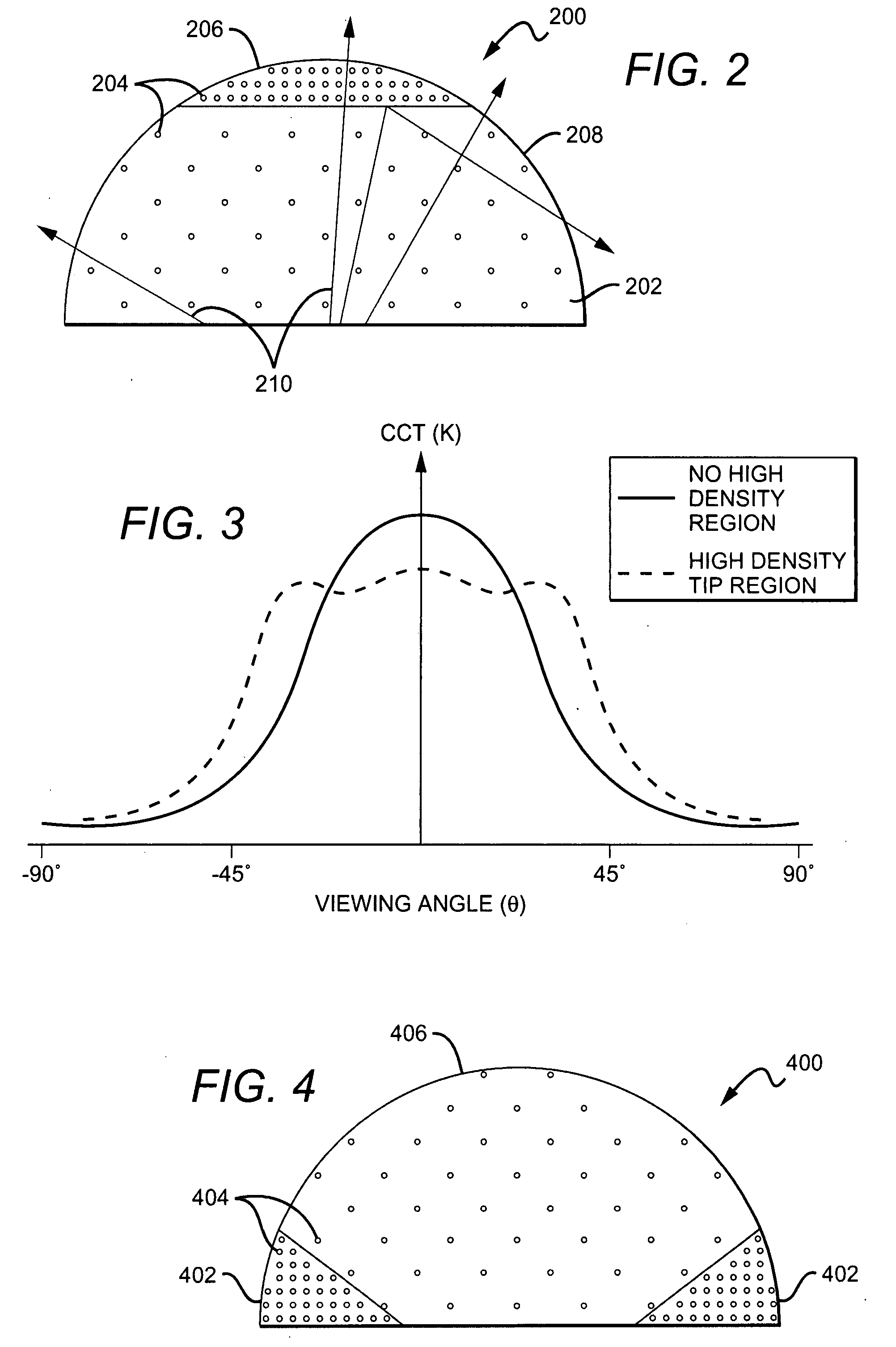

Encapsulant with scatterer to tailor spatial emission pattern and color uniformity in light emitting diodes

ActiveUS20080308825A1Solid-state devicesSemiconductor/solid-state device manufacturingHigh densityLight beam

A light emitting device having an encapsulant with scattering features to tailor the spatial emission pattern and color temperature uniformity of the output profile. The encapsulant is formed with materials having light scattering properties. The concentration of these light scatterers is varied spatially within the encapsulant and / or on the surface of the encapsulant. The regions having a high density of scatterers are arranged in the encapsulant to interact with light entering the encapsulant over a desired range of source emission angles. By increasing the probability that light from a particular range of emission angles will experience at least one scattering event, both the intensity and color temperature profiles of the output light beam can be tuned.

Owner:CREELED INC

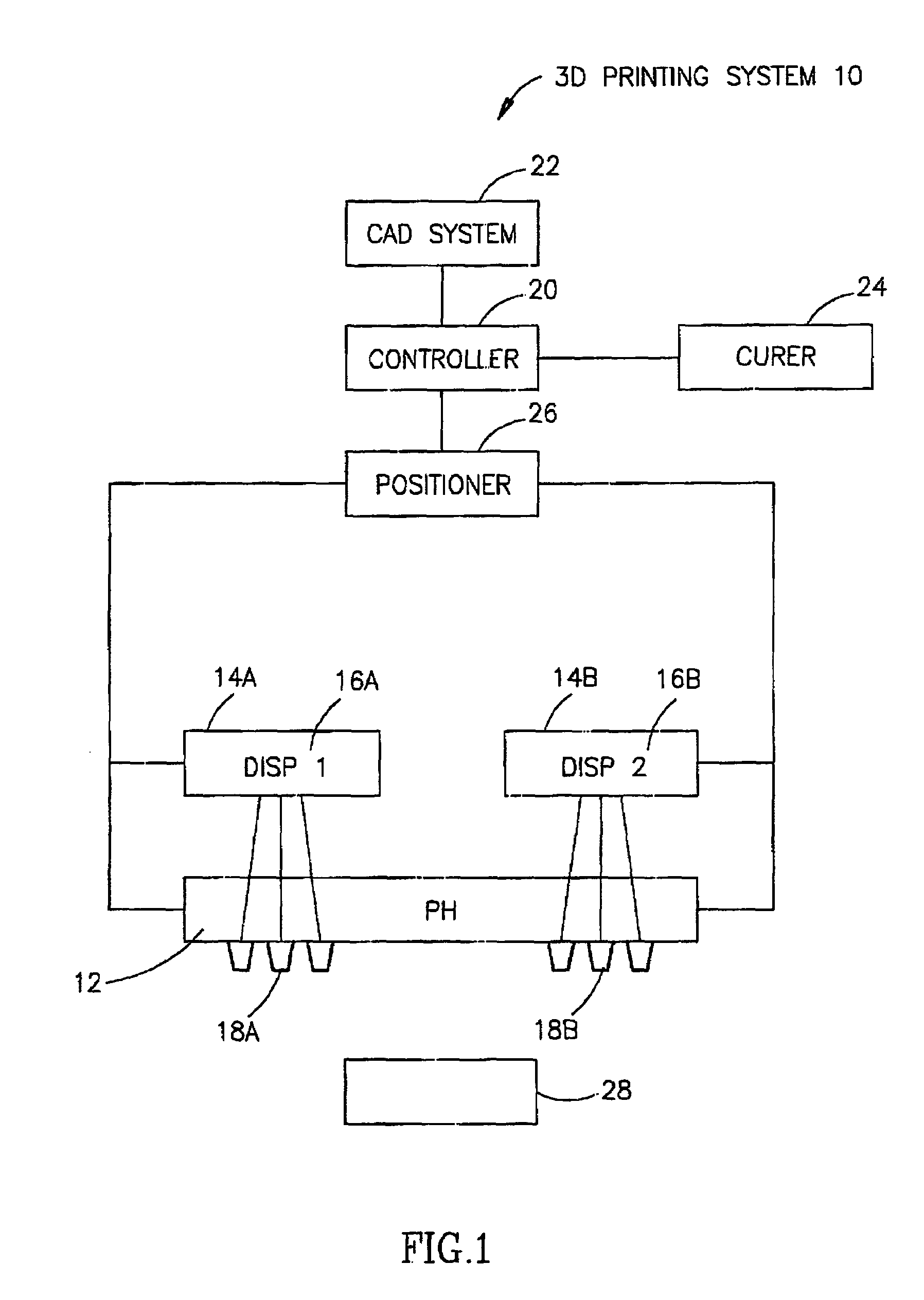

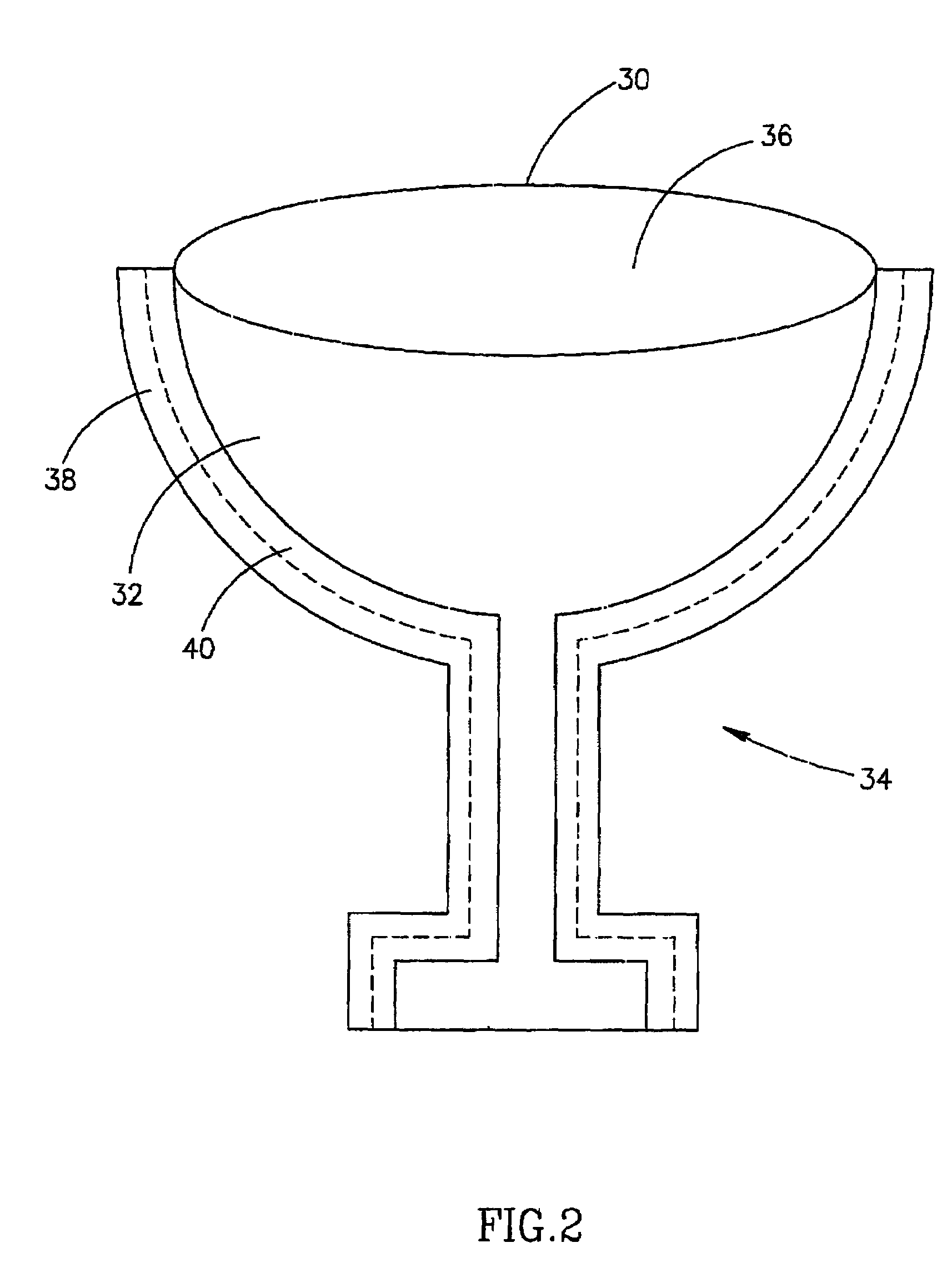

Compositions and methods for use in three dimensional model printing

Compositions for use in the manufacture of three-dimensional objects including compositions for use as a support and / or release material in the manufacture of the three-dimensional objects are provided. There is thus provided, in accordance with an embodiment of the present invention, a composition suitable for building a three-dimensional object. The compositions may include, inter alia, a curable component, having a functional group, wherein if the functional group is a polymerizable reactive functional group, then the functional group is a (meth)acrylic functional group, a photo-initiator, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 50–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after curing, the composition results in a solid form. There is thus provided, in accordance with another embodiment of the present invention, a composition suitable for support in building a three-dimensional object. The compositions may include, inter alia: a non-curable component, a curable component, wherein the non-curable component is not reactive with said curable component, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 20–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after irradiation, the composition results in a solid, a semi-solid or liquid material. A method for the preparation of a three-dimensional object by three-dimensional printing is provided in accordance with embodiments of the present invention. Embodiments of the present invention further provide a three-dimensional object prepared according to the methods of the invention.

Owner:STRATASYS LTD

Damage resistant glass article for use as a cover plate in electronic devices

InactiveUS20090197048A1Minimizing transportEasy to disassembleFilm/foil adhesivesSynthetic resin layered productsAnti-reflective coatingChemical Linkage

An alkali aluminosilicate glass article, said alkali aluminosilicate glass having a surface compressive stress of at least about 200 MPa, a surface compressive layer having a depth of at least about 30 μm, a thickness of at least about 0.3 mm and an amphiphobic fluorine-based surface layer chemically bonded to the surface of the glass. In one embodiment the glass has an anti-reflective coating applied to one surface of the glass between the chemically strengthened surface of the glass and the amphiphobic coating. In another embodiment the surface of the chemically strengthened glass is acid treated using a selected acid (e.g., HCL, H2SO4, HClO4, acetic acid and other acids as described) prior to placement of the amphiphobic coating or the anti-reflective coating.

Owner:CORNING INC

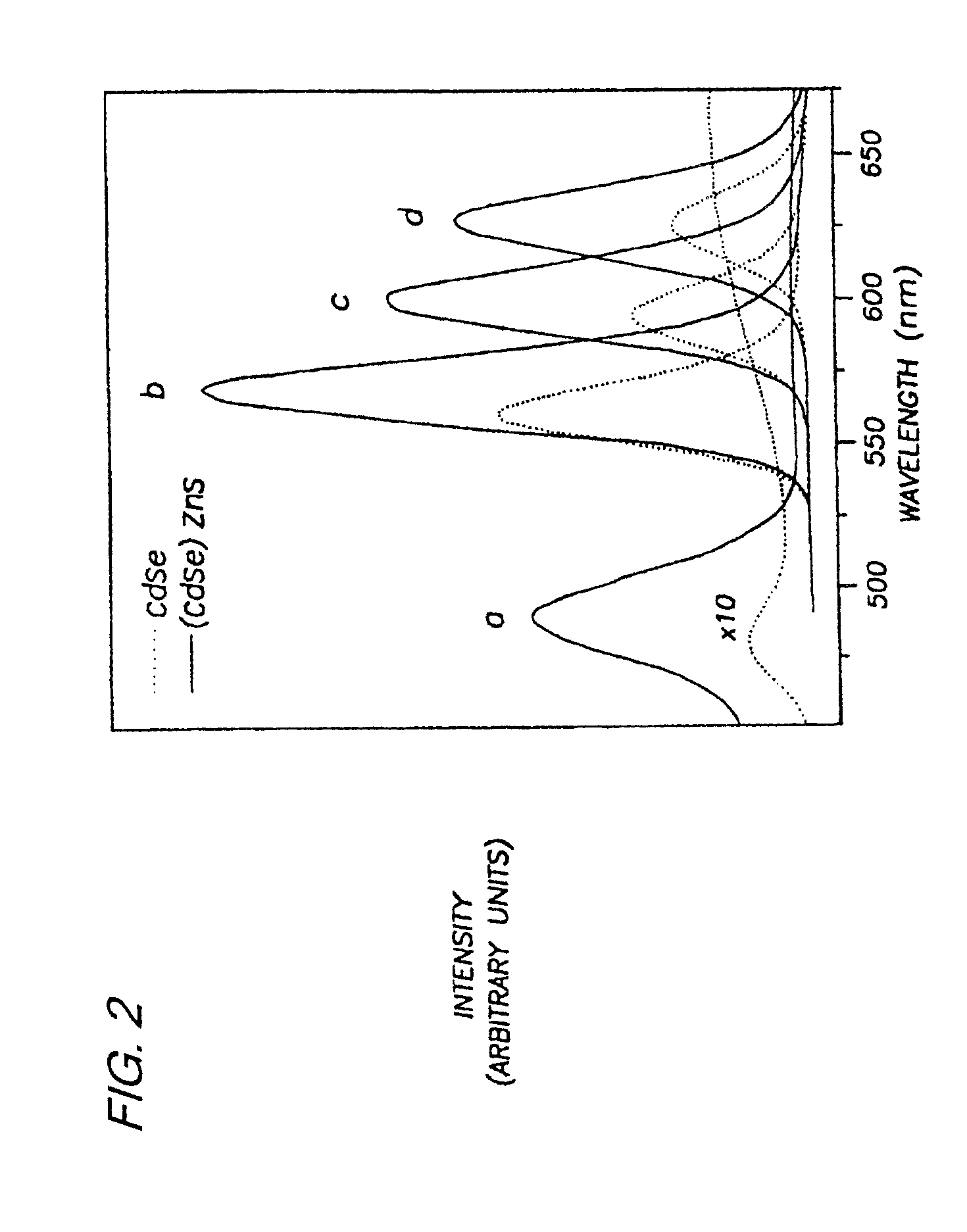

Highly luminescent color selective nanocrystalline materials

InactiveUS6861155B2Improve coordinationMaterial nanotechnologyFrom normal temperature solutionsQuantum yieldPhotoluminescence

A coated nanocrystal capable of light emission includes a substantially monodisperse nanoparticle selected from the group consisting of CdX, where x=S, Se, Te and an overcoating of ZnY, where Y=S, Se, uniformly deposited thereon, said coated nanoparticle characterized in that when irradiated the particles exhibit photoluminescence in a narrow spectral range of no greater than about 60 nm, and most preferably 40 nm, at full width half max (FWHM). The particle size of the nanocrystallite core is in the range of about 20 Å to about 125 Å, with a deviation of less than 10% in the core. The coated nanocrystal exhibits photoluminescence having quantum yields of greater than 30%.

Owner:MASSACHUSETTS INST OF TECH

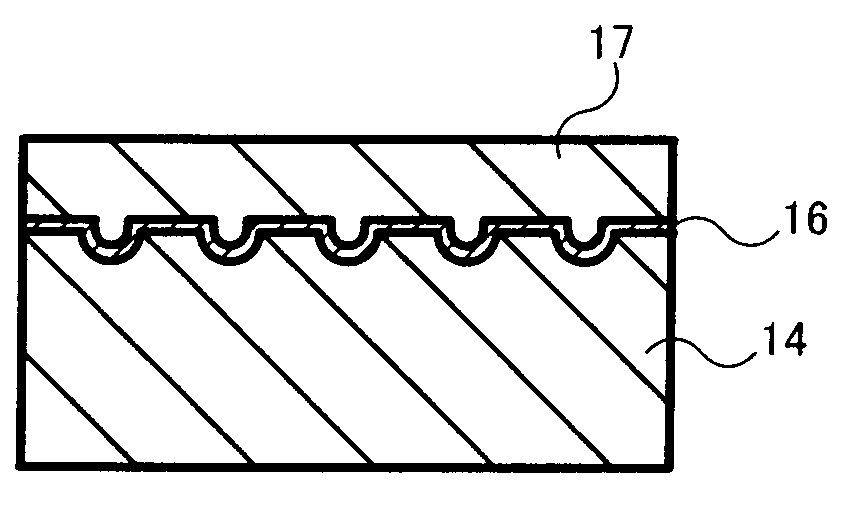

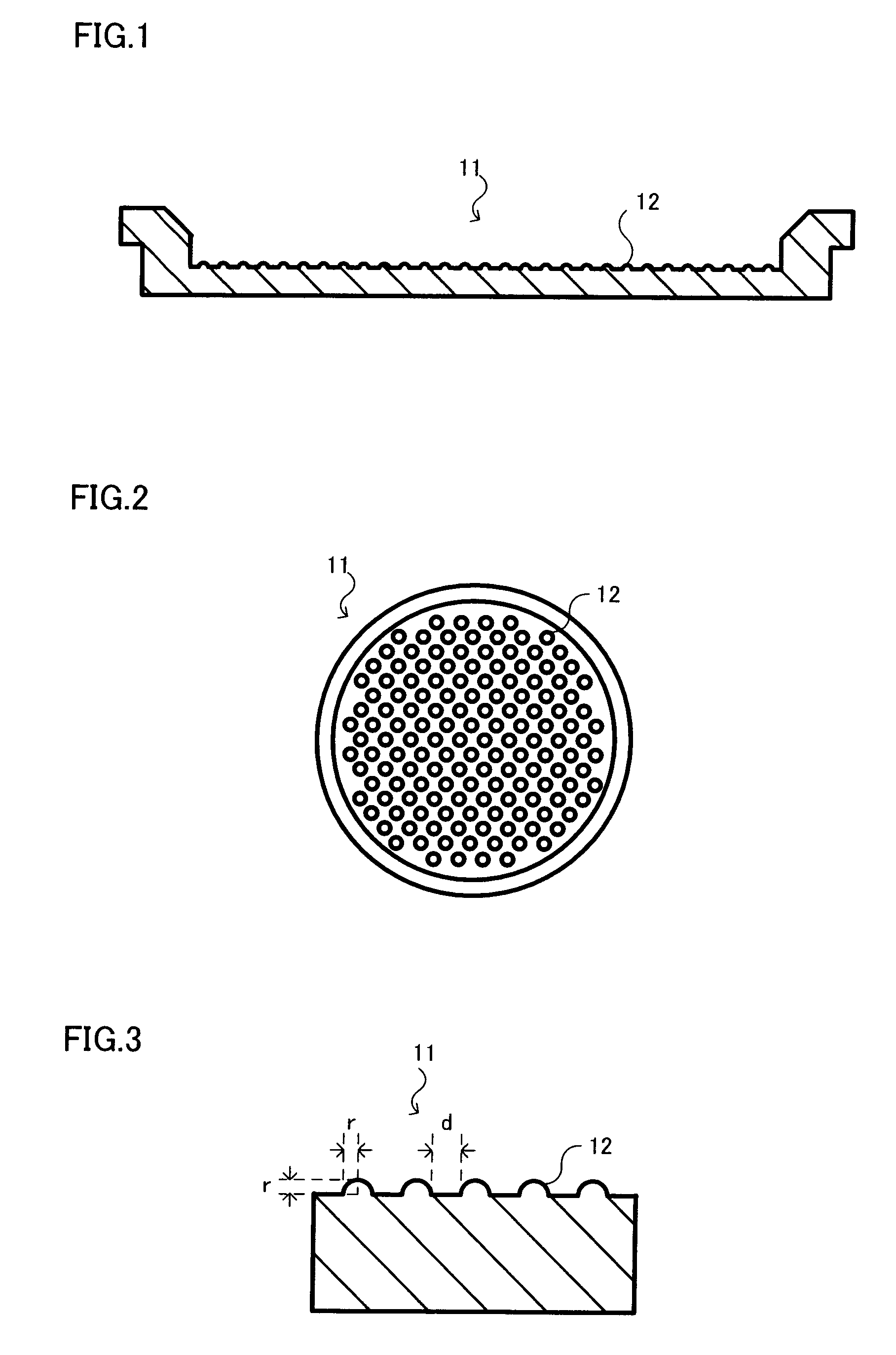

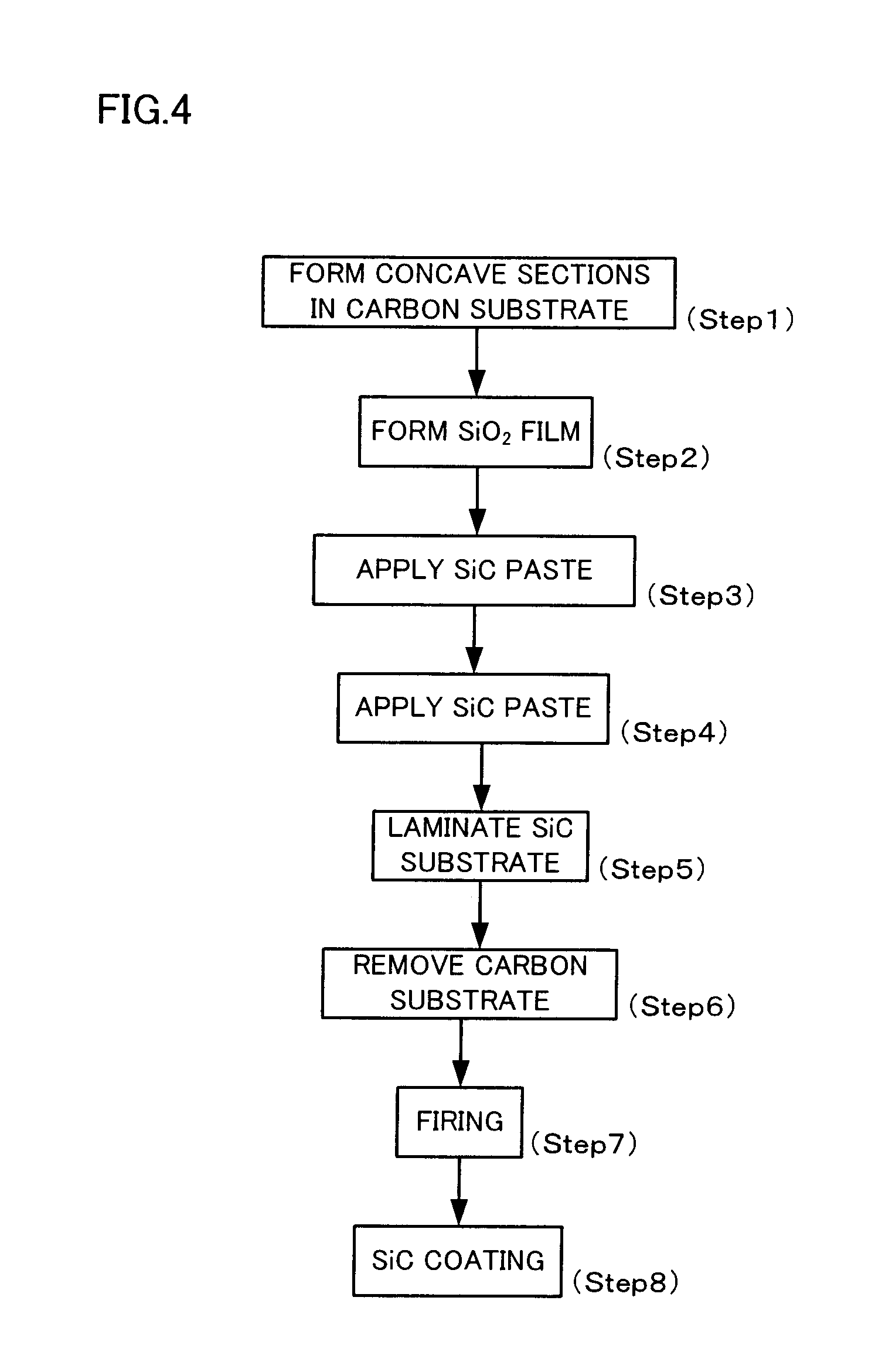

Method for manufacturing susceptor

ActiveUS20100163524A1Decorative surface effectsSemiconductor/solid-state device manufacturingSusceptorMetallurgy

A method for manufacturing a susceptor includes: forming a concave pattern in a surface of a substrate to be processed; applying a SiC paste containing a SiC powder and a sintering agent to the surface of the substrate to be processed to fill the concave pattern to form a SiC coating layer; laminating a SiC substrate on the SiC coating layer; and firing the SiC coating layer to form a SiC layer having at least one convex section on the surface of the SiC substrate.

Owner:NUFLARE TECH INC

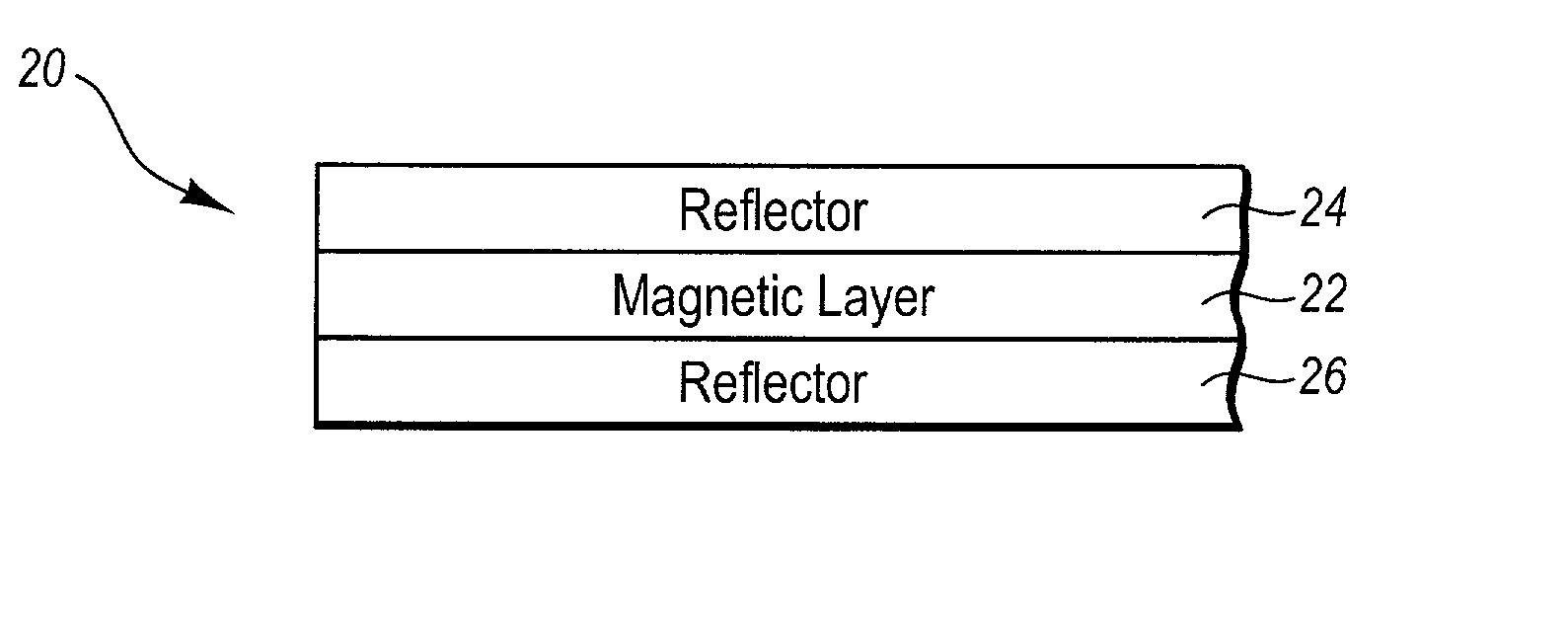

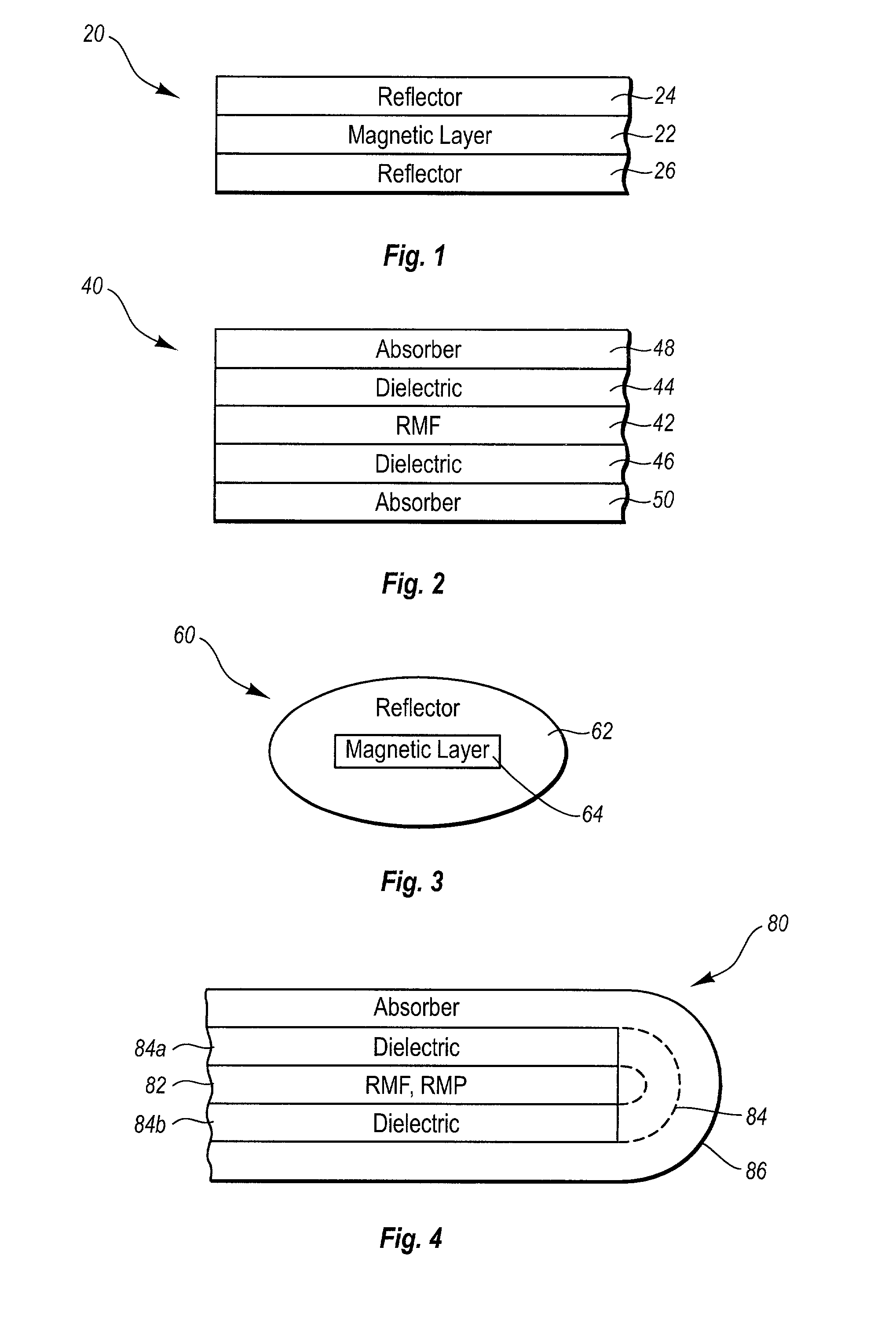

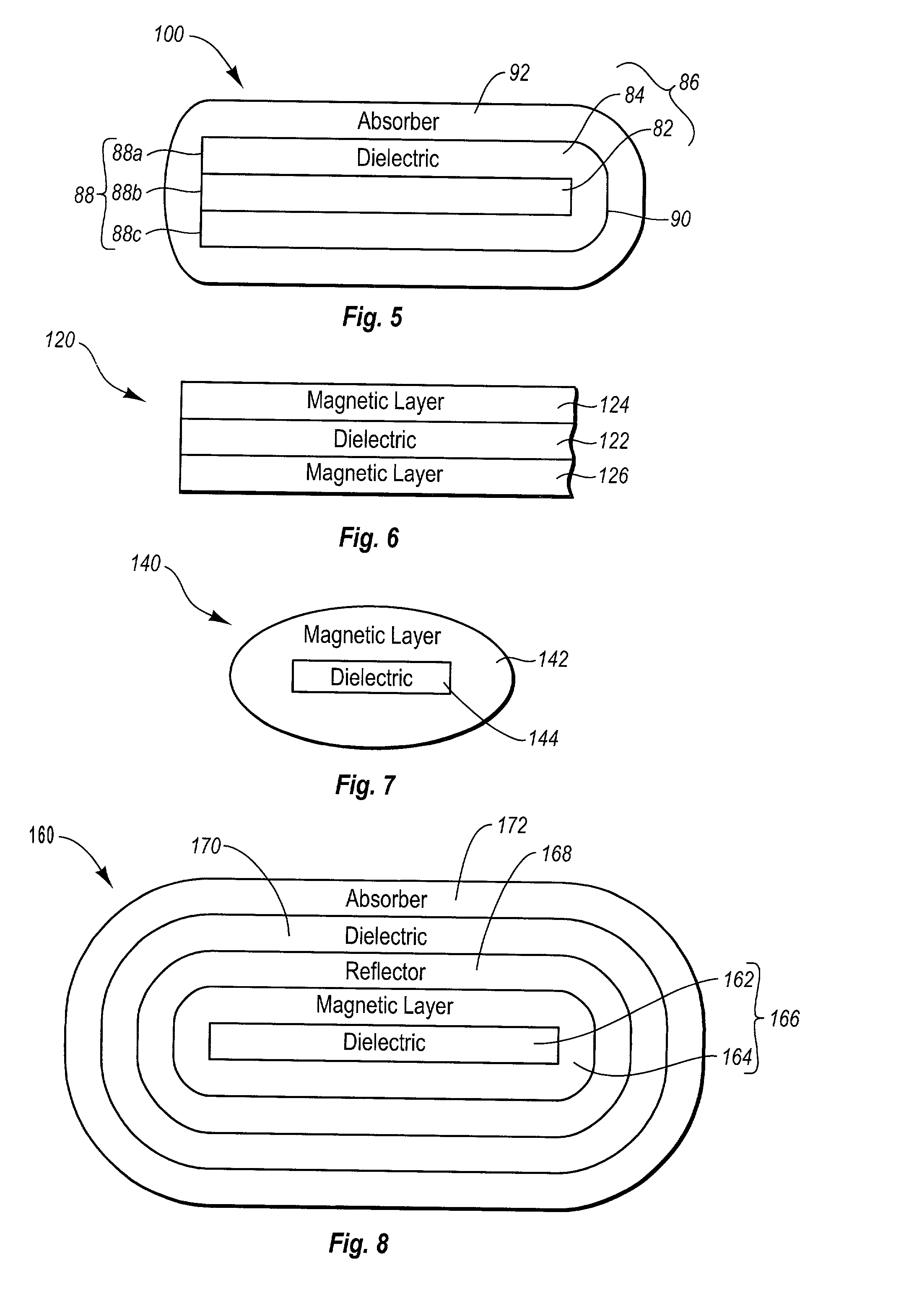

Multi-layered magnetic pigments and foils

InactiveUS20020160194A1High chromaIncreased durabilityPigment preparation by PVD/CVD methodsPattern printingLiquid mediumColor shift

Multilayered magnetic pigment flakes and foils are provided. The pigment flakes can have a symmetrical coating structure on opposing sides of a magnetic core, or can be formed with encapsulating coatings around the magnetic core. The magnetic core can be a magnetic layer between reflector or dielectric layers, a dielectric layer between magnetic layers, or only a magnetic layer. Some embodiments of the pigment flakes and foils exhibit a discrete color shift so as to have distinct colors at differing angles of incident light or viewing. The pigment flakes can be interspersed into liquid media such as paints or inks to produce colorant compositions for subsequent application to objects or papers. The foils can be laminated to various objects or can be formed on a carrier substrate.

Owner:FLEX PRODUCTS INC

Light-emitting nanoparticles and method of making same

InactiveUS6846565B2Reduce aggregationResist formationMaterial nanotechnologyLiquid surface applicatorsParticle compositionHigh pressure

A method for the production of a robust, chemically stable, crystalline, passivated nanoparticle and composition containing the same, that emit light with high efficiencies and size-tunable and excitation energy tunable color. The methods include the thermal degradation of a precursor molecule in the presence of a capping agent at high temperature and elevated pressure. A particular composition prepared by the methods is a passivated silicon nanoparticle composition displaying discrete optical transitions.

Owner:MERCK PATENT GMBH +1

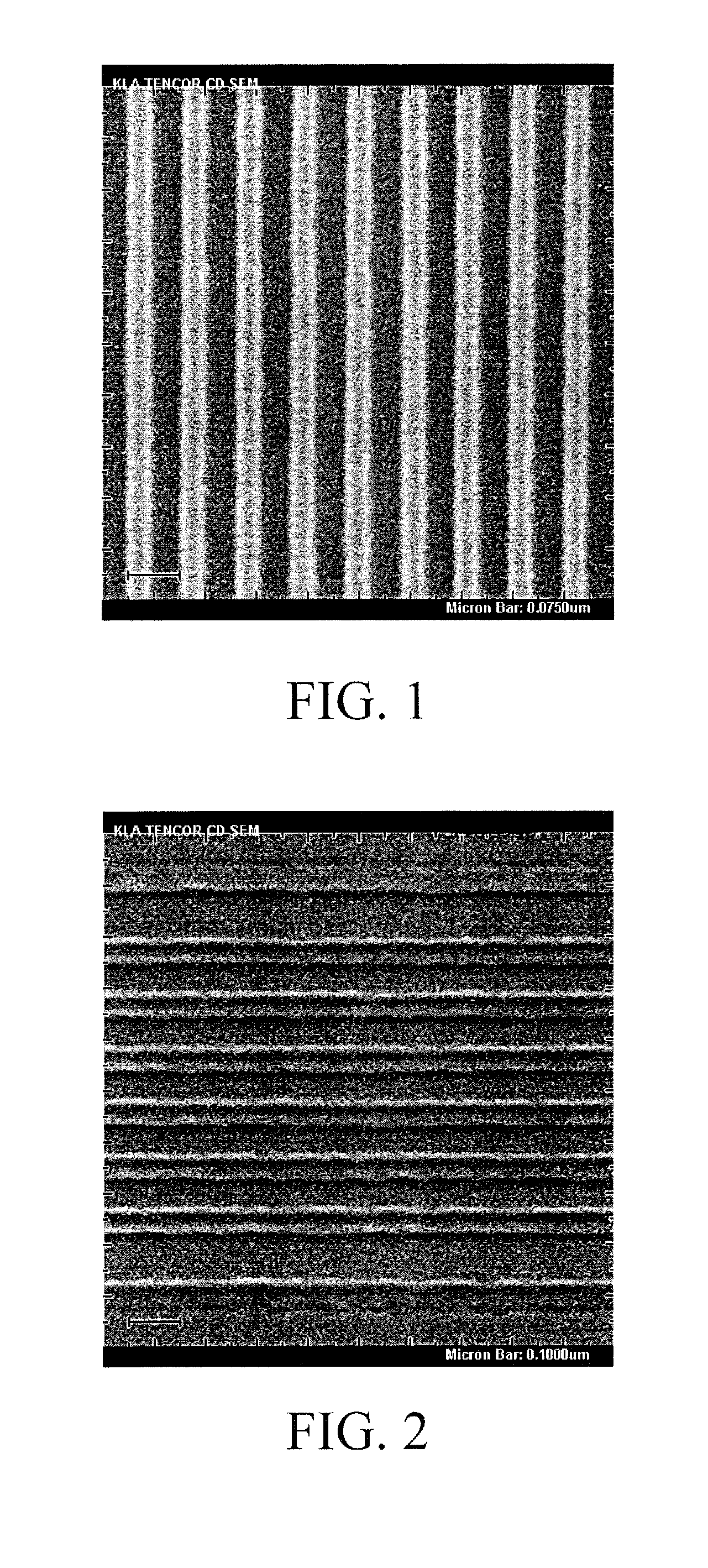

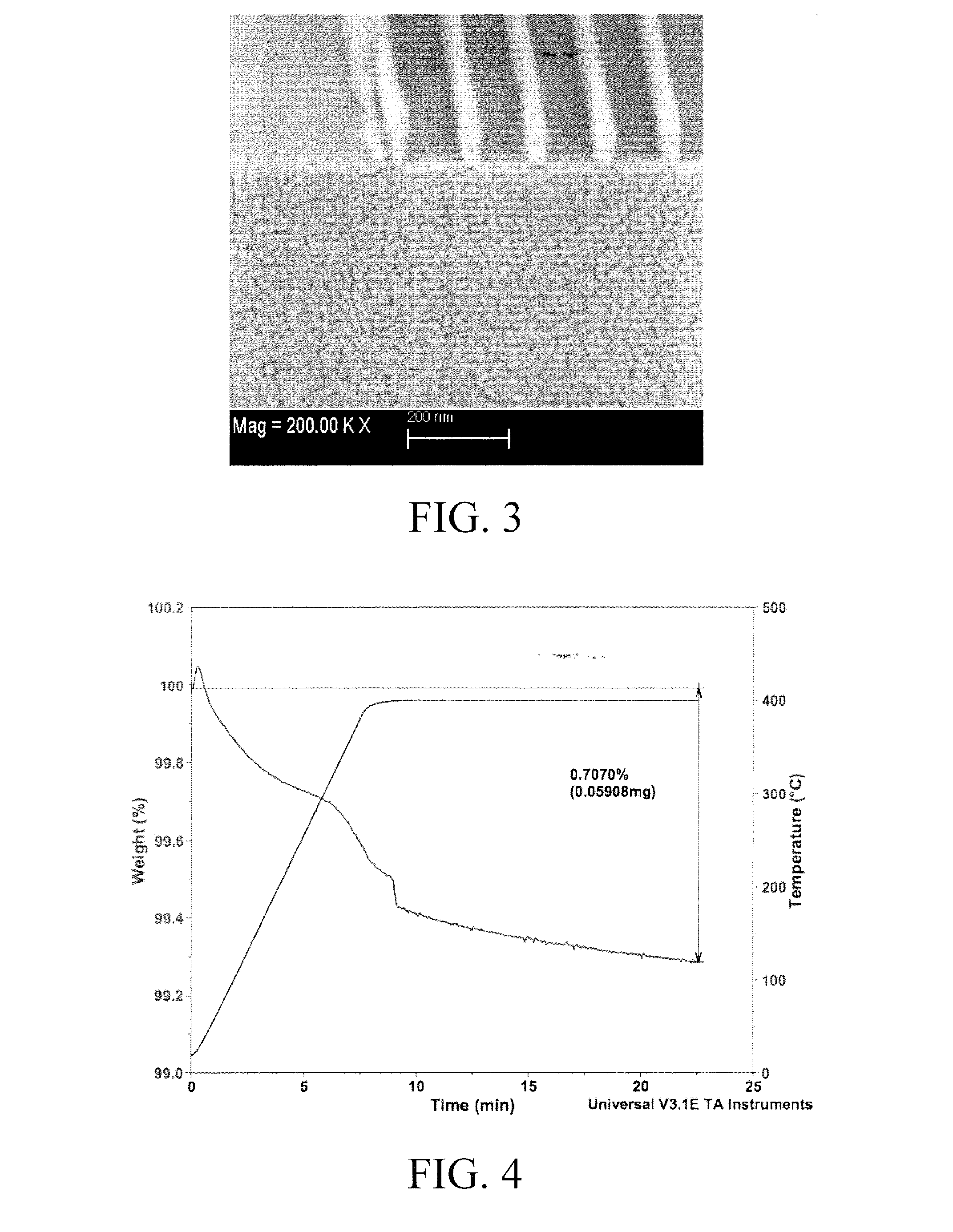

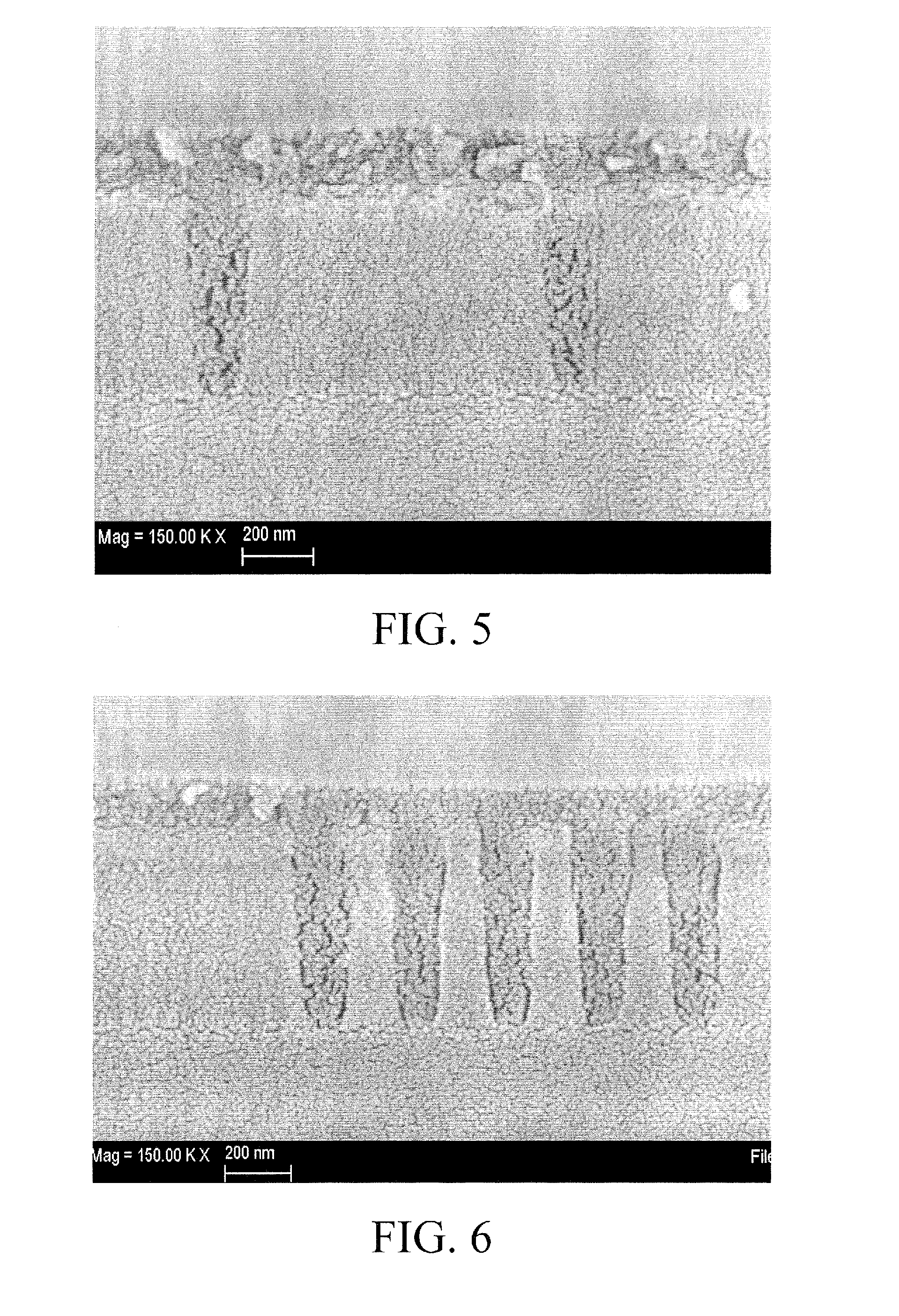

Spin-on carbon compositions for lithographic processing

The invention described herein is directed towards spin-on carbon materials comprising polyamic acid compositions and a crosslinker in a solvent system. The materials are useful in trilayer photolithography processes. Films made with the inventive compositions are not soluble in solvents commonly used in lithographic materials, such as, but not limited to PGME, PGMEA, and cyclohexanone. However, the films can be dissolved in developers commonly used in photolithography. In one embodiment, the films can be heated at high temperatures to improve the thermal stability for high temperature processing. Regardless of the embodiment, the material can be applied to a flat / planar or patterned surface. Advantageously, the material exhibits a wiggling resistance during pattern transfer to silicon substrate using fluorocarbon etch.

Owner:BREWER SCI

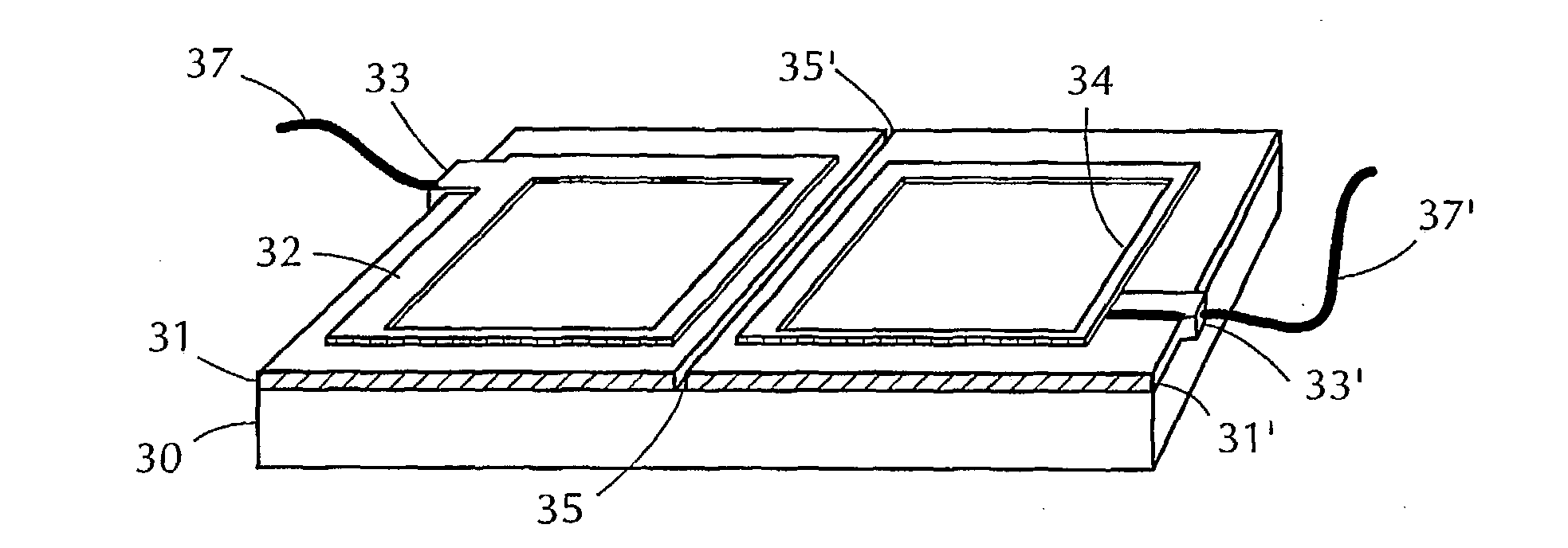

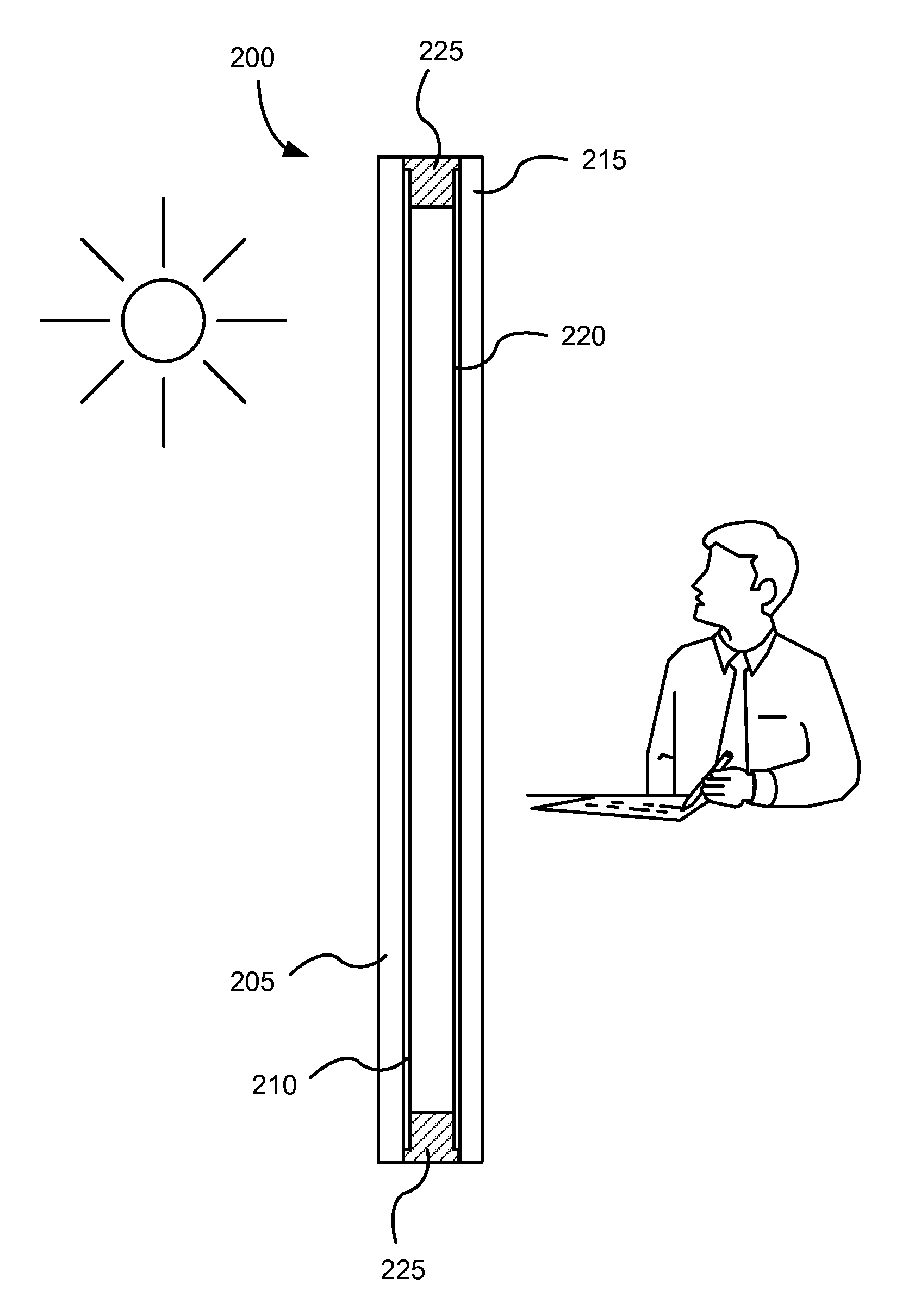

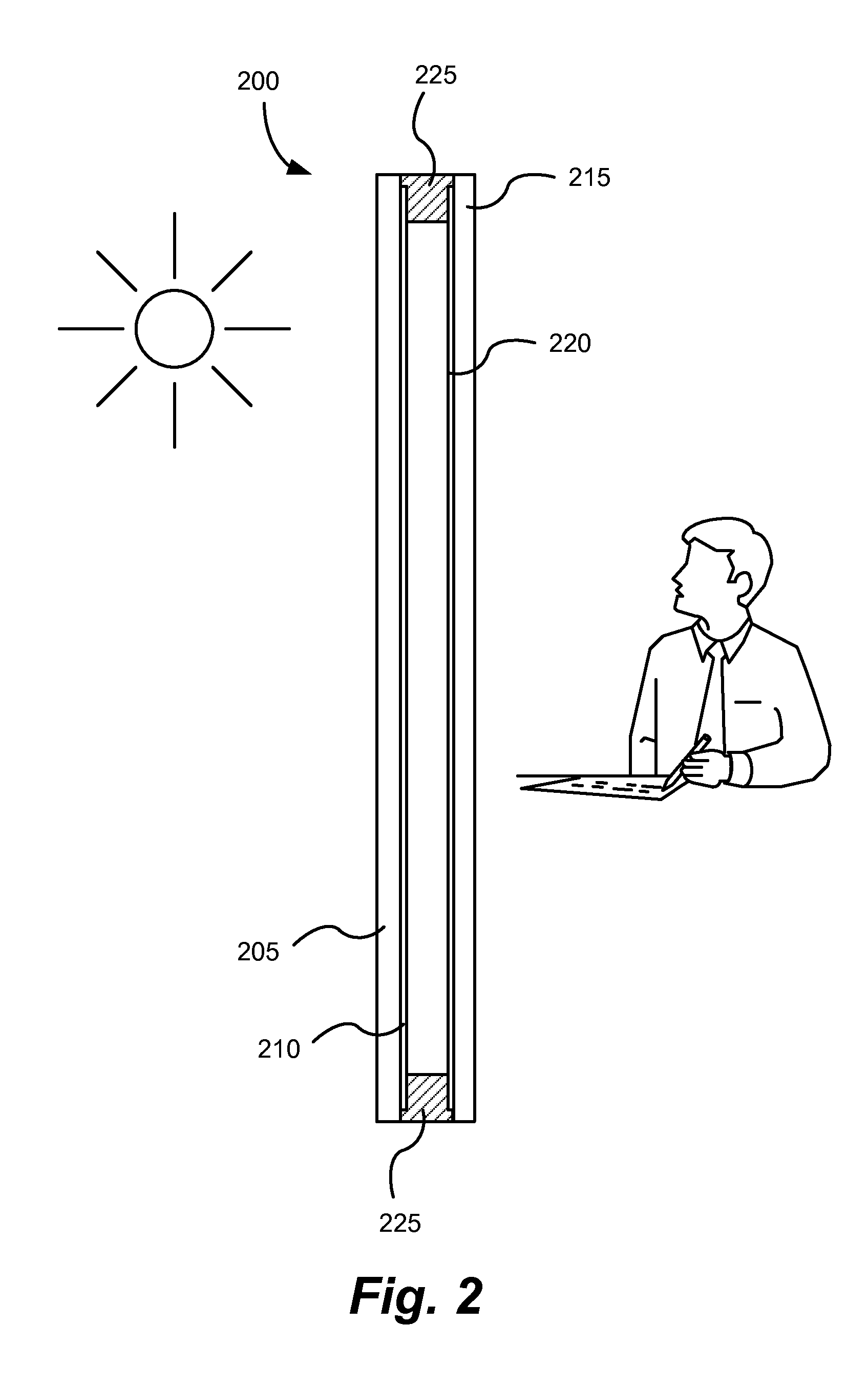

Multi-pane electrochromic windows

ActiveUS20120033287A1Increased defectivityGood choiceTransparent/reflecting heating arrangementsLaminationElectricityElectrochromism

Window units, for example insulating glass units (IGU's), that have at least two panes, each pane having an electrochromic device thereon, are described. Two optical state devices on each pane of a dual-pane window unit provide window units having four optical states. Window units described allow the end user a greater choice of how much light is transmitted through the electrochromic window. Also, by using two or more window panes, each with its own electrochromic device, registered in a window unit, visual defects in any of the individual devices are negated by virtue of the extremely small likelihood that any of the visual defects will align perfectly and thus be observable to the user.

Owner:VIEW INC

Alignable diffractive pigment flakes

Diffractive pigment flakes are selectively aligned to form an image. In one embodiment, flakes having a magnetic layer are shaped to facilitate alignment in a magnetic field. In another embodiment, the flakes include a magnetically discontinuous layer. In a particular embodiment, deposition of nickel on a diffraction grating pattern produces magnetic needles along the grating pattern that allow magnetic alignment of the resulting diffractive pigment flakes. Color scans of test samples of magnetically aligned flakes show high differentiation between illumination parallel and perpendicular to the direction of alignment of the magnetic diffractive pigment flakes.

Owner:VIAVI SOLUTIONS INC

Reduced-density proppants and methods of using reduced-density proppants to enhance their transport in well bores and fractures

InactiveUS20050006095A1Easy to transportImprove conductivitySynthetic resin layered productsCellulosic plastic layered productsParticulatesMaterials science

The present invention provides reduced-density coated particulates and methods for enhancing the transport of such particulates into well bores and fractures, and for enhancing the conductivity and permeability of subterranean formations using such particulates, and for sand control treatments using such particulates. The reduced-density, coated particulates of the present invention generally comprise particulate having a surface and a coating wherein the surface comprises a porous or partially hollow geometry and coating is capable of trapping a fluid between the particulate's surface and the coating.

Owner:HALLIBURTON ENERGY SERVICES INC

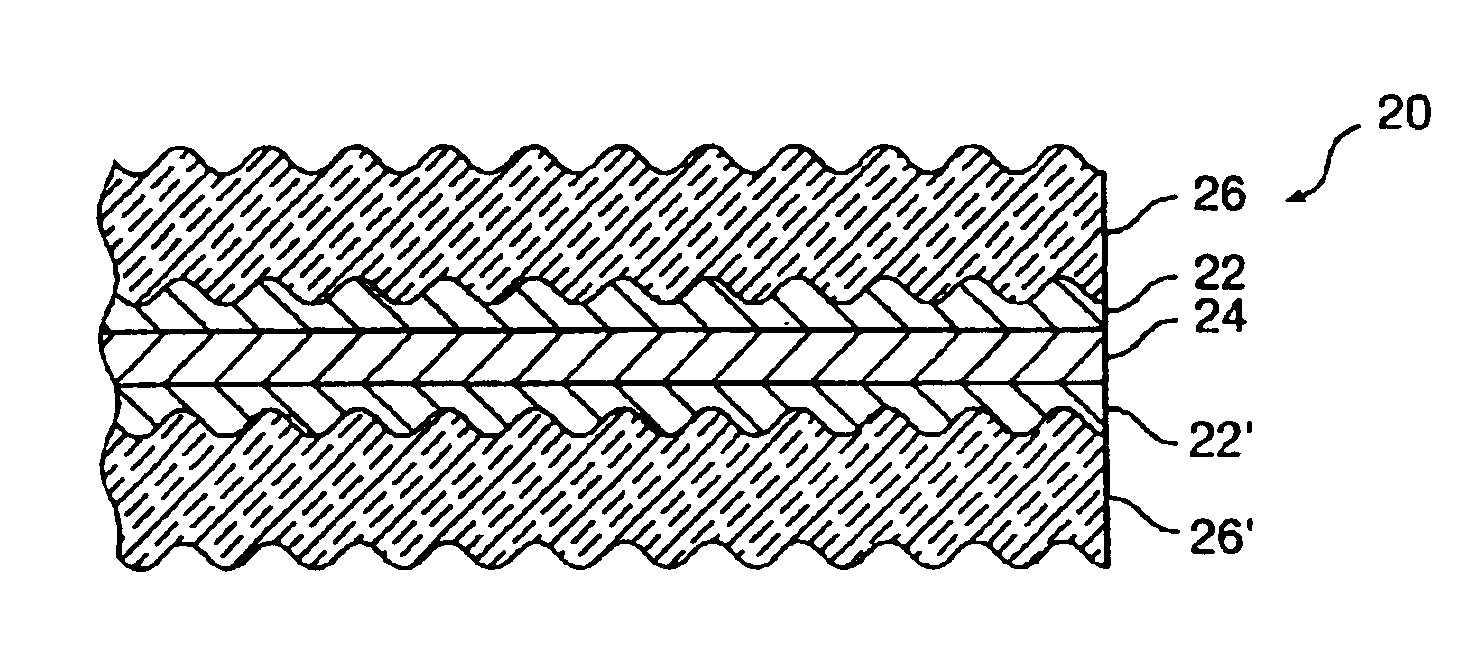

Proppants with fiber reinforced resin coatings

InactiveUS6528157B1High compressive strengthWithstanding stressCeramic layered productsDrilling compositionParticulatesResin coating

Coated particles made of particulate substrates having a coating of resin and fibrous material are provided for use in subterranean formations. The coated substrate particles are proppants useful to prop open subterranean formation fractures. The coated substrate particles are also useful for sand control, that is, acting as a filter or screen to prevent backwards flow of sand, other proppants or subterranean formation particles. Methods of making the coated particles are also disclosed.

Owner:HEXION INC

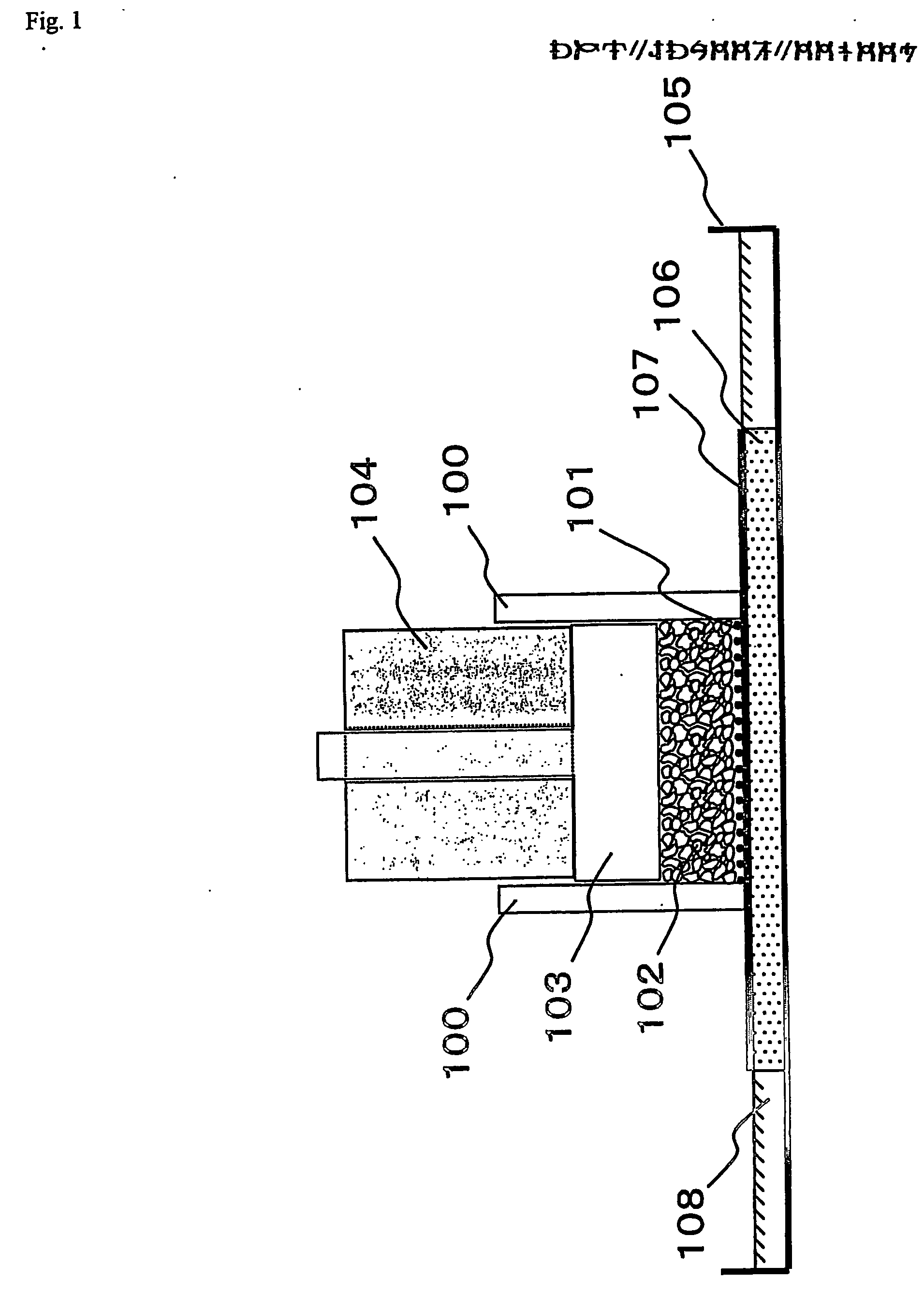

Walter-absorbing agent

There is disclosed a water-absorbing agent which combines both performances of the capillary suction force and the liquid permeability. This water-absorbing agent is a particulate water-absorbing agent comprising water-absorbent resin particles (α) and a liquid-permeability-enhancing agent (β), wherein the water-absorbent resin particles (α) are surface-crosslink-treated particles of a crosslinked polymer of a monomer including acrylic acid and / or its salt; with the water-absorbing agent being characterized in that the particulate water-absorbing agent has: a mass-average particle diameter (D50) in the range of 234 to 394 gm, a logarithmic standard deviation (σξY) of a particle diameter distribution in the range of 0.25 to 0.45, an absorption capacity without load (CRC) of not less than 15 g / g, and a water-extractable component content of not higher than 15 mass %; and further a liquid-permeability-enhancing agent (β) content in the range of 0.01 to 5 mass parts per 100 mass parts of the water-absorbent resin particles (α).

Owner:NIPPON SHOKUBAI CO LTD

Tempered glass substrate and method of producing the same

ActiveUS20090197088A1High ion exchange capacityExcellent devitrification resistanceGlass/slag layered productsThin material handlingToughened glassMaterials science

A tempered glass substrate of the present invention is a tempered glass substrate, which has a compression stress layer on a surface thereof, and has a glass composition comprising, in terms of mass %, 40 to 71% of SiO2, 3 to 21% of Al2O3, 0 to 3.5% of Li2O, to 20% of Na2O, and 0 to 15% of K2O.

Owner:NIPPON ELECTRIC GLASS CO LTD

Organically-functionalized monodisperse nanocrystals of metals

InactiveUS6103868AHigh selectivityAvoid problemsPolycrystalline material growthLiquid surface applicatorsNanocrystalReducing agent

PCT No. PCT / US96 / 20402 Sec. 371 Date Jun. 18, 1998 Sec. 102(e) Date Jun. 18, 1998 PCT Filed Dec. 27, 1996 PCT Pub. No. WO97 / 24224 PCT Pub. Date Jul. 10, 1997Organically functionalized metal nanoparticles are produced by mixing a metal precursor with an organic surface passivant and reacting the resulting mixture with a reducing agent to generate free metal while binding the passivant to the surface of the free metal to produce organically functionalized metal particles.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com