Patents

Literature

966 results about "Liquidus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The liquidus temperature, TL or Tliq, specifies the temperature above which a material is completely liquid, and the maximum temperature at which crystals can co-exist with the melt in thermodynamic equilibrium. It is mostly used for impure substances (mixtures) such as glasses, alloys and rocks.

Down-drawable, chemically strengthened glass for cover plate

An alkali aluminosilicate glass that is chemically strengthened and has a down-drawable composition. The glass has a melting temperature less than about 1650° C. and a liquidus viscosity of at least 130 kpoise and, in one embodiment, greater than 250 kpoise. The glass undergoes ion exchange at relatively low temperatures to a depth of at least 30 μm.

Owner:CORNING INC

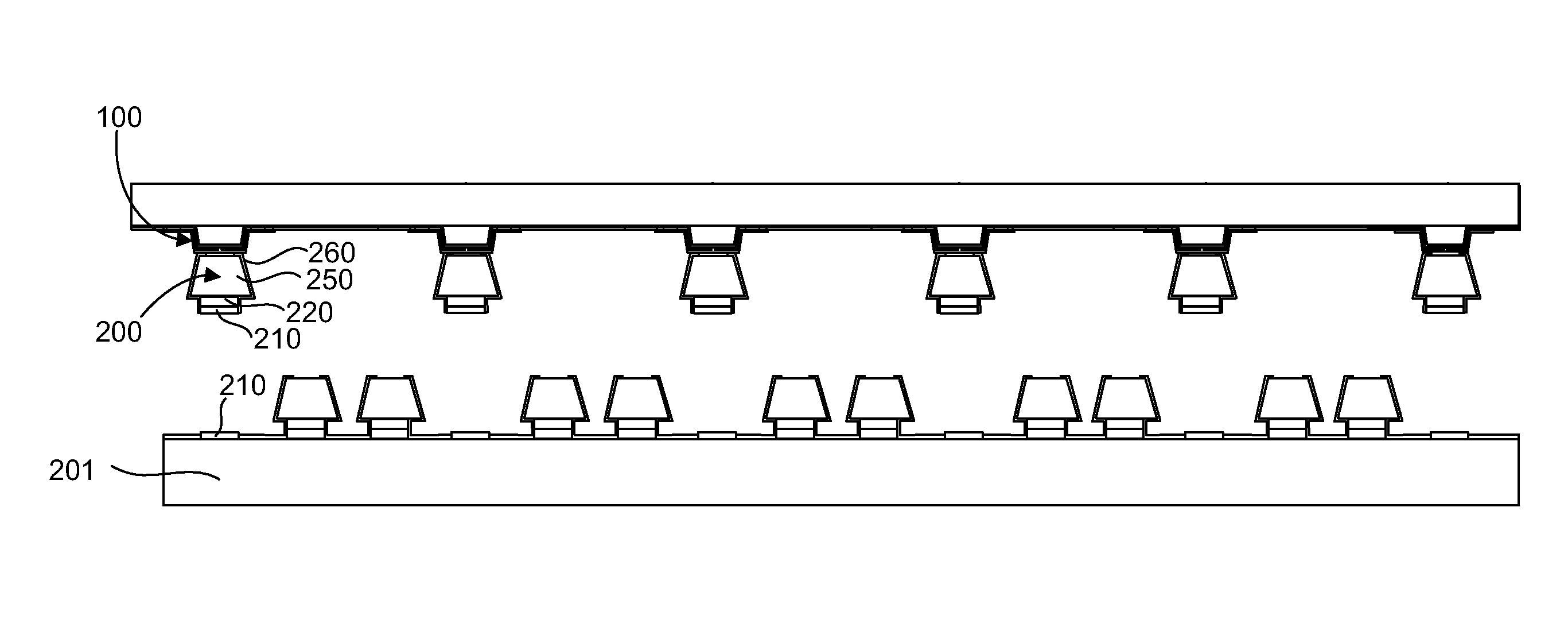

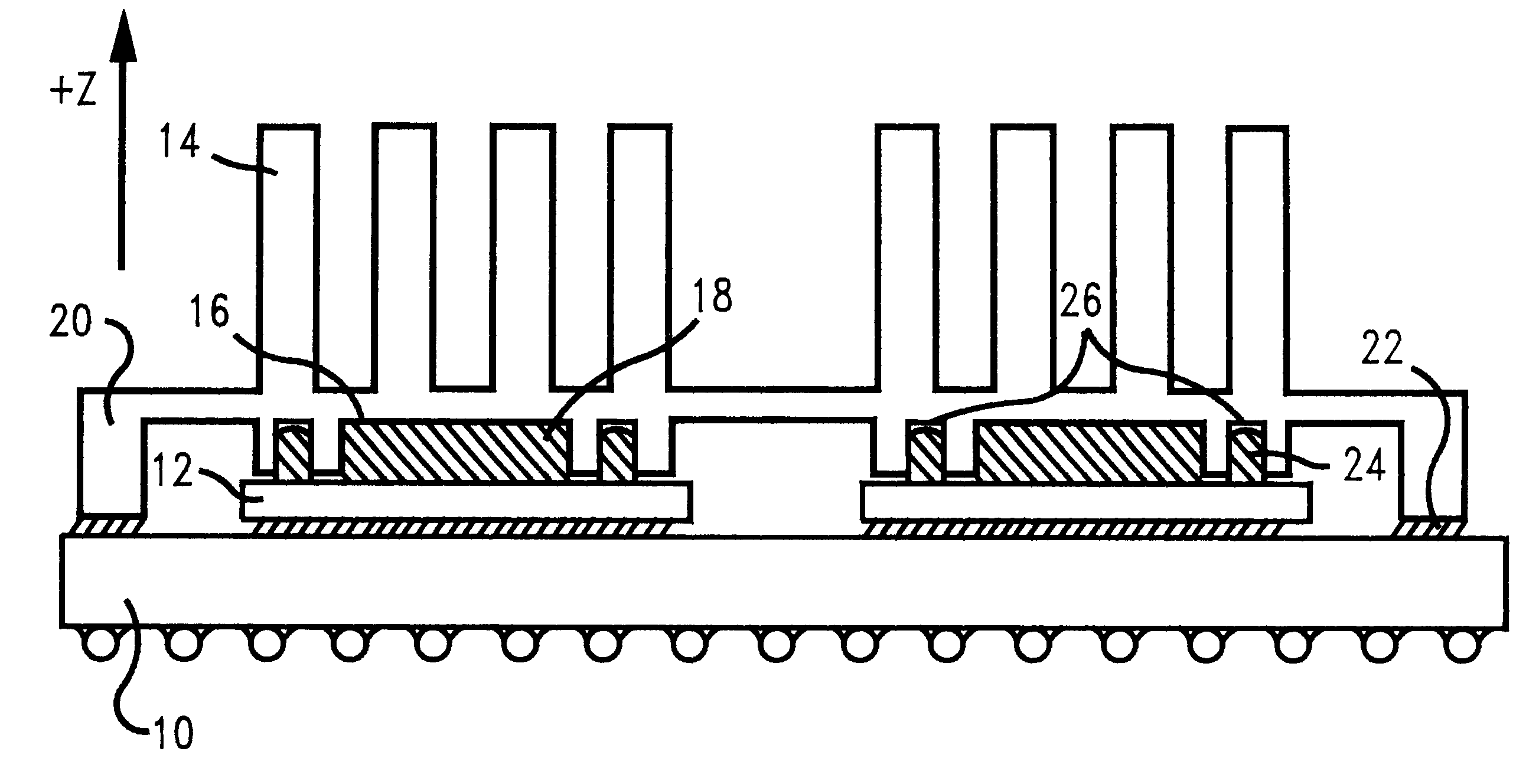

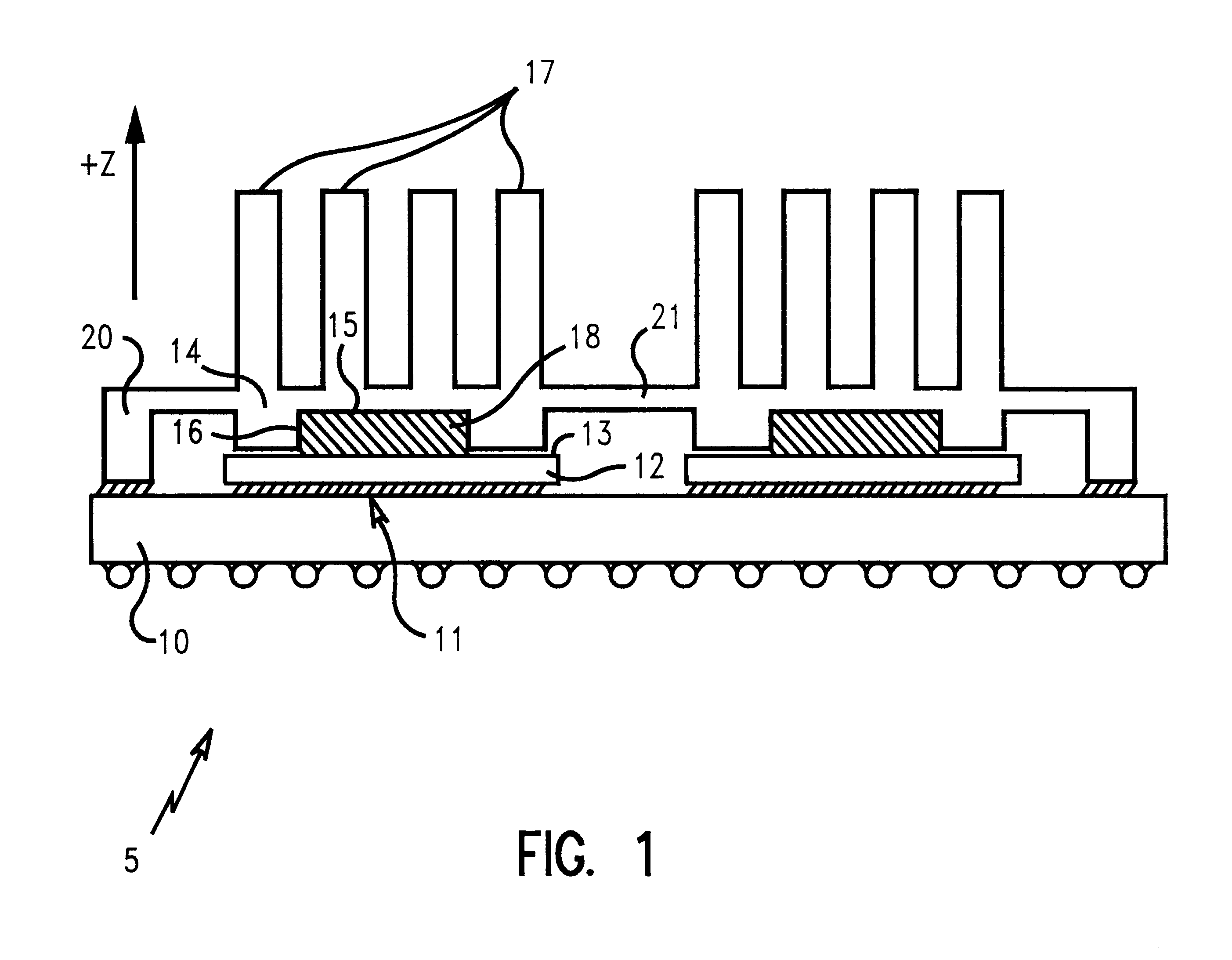

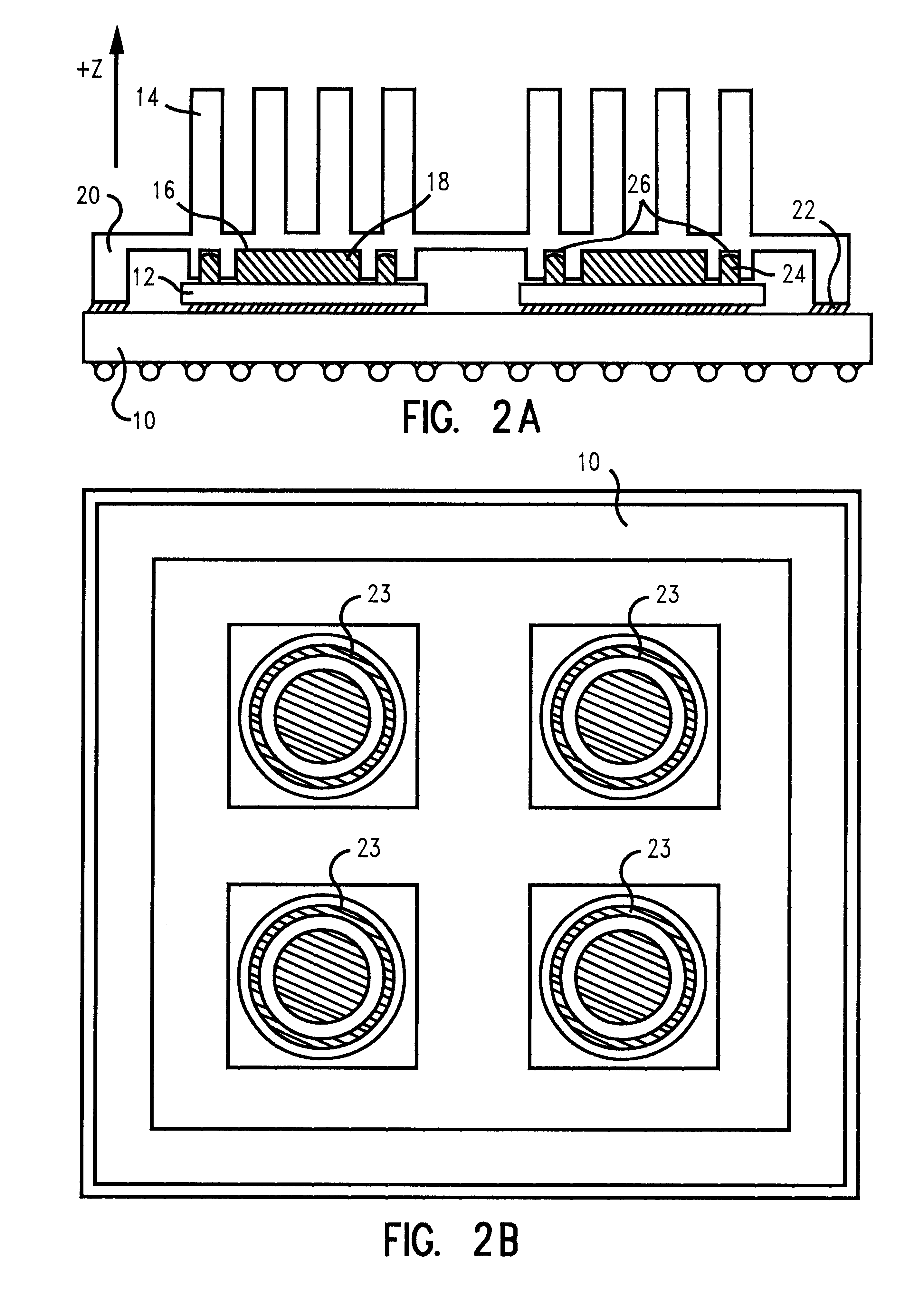

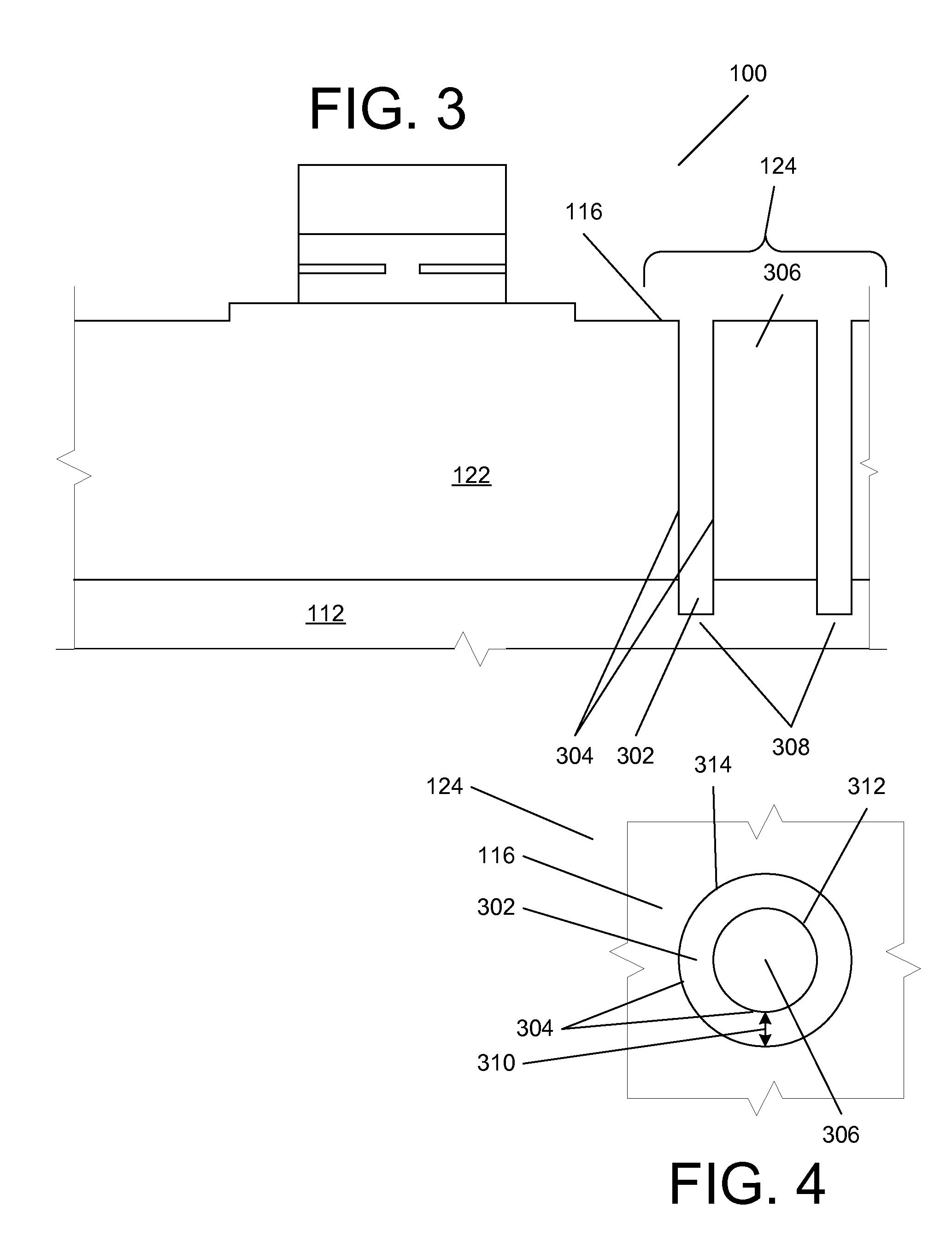

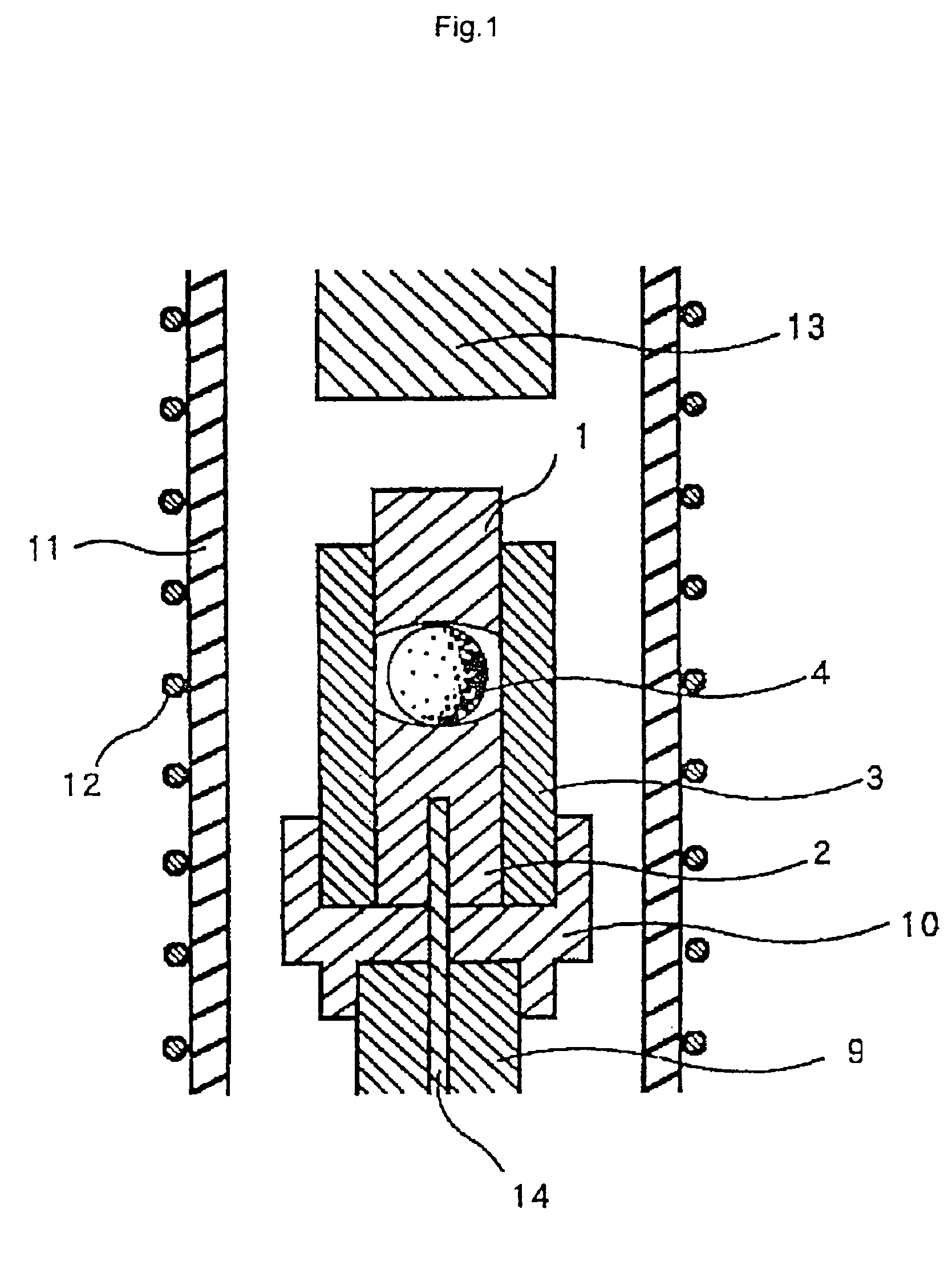

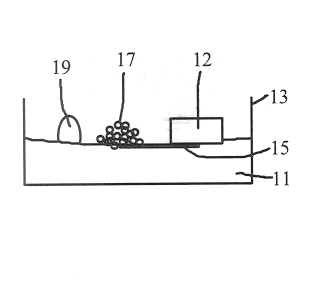

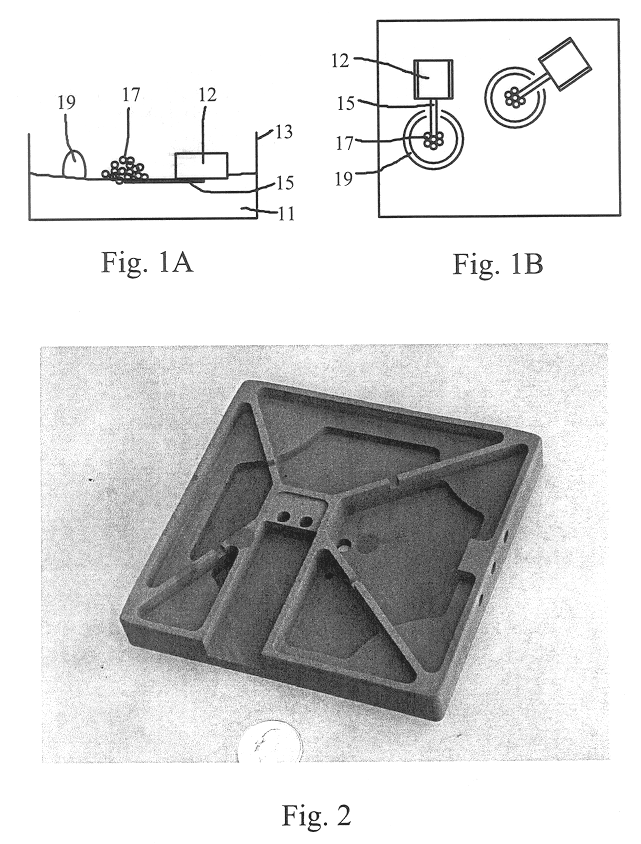

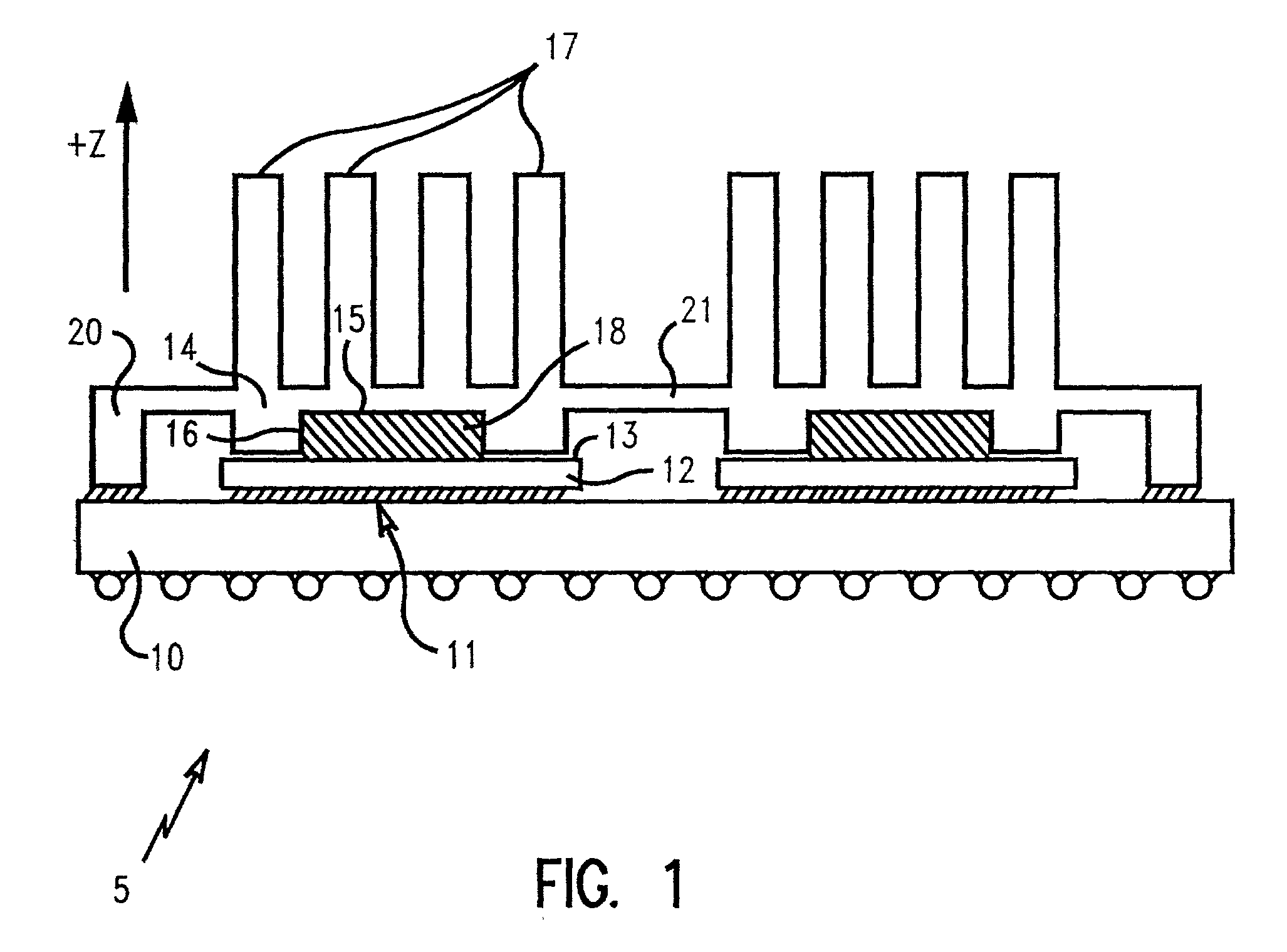

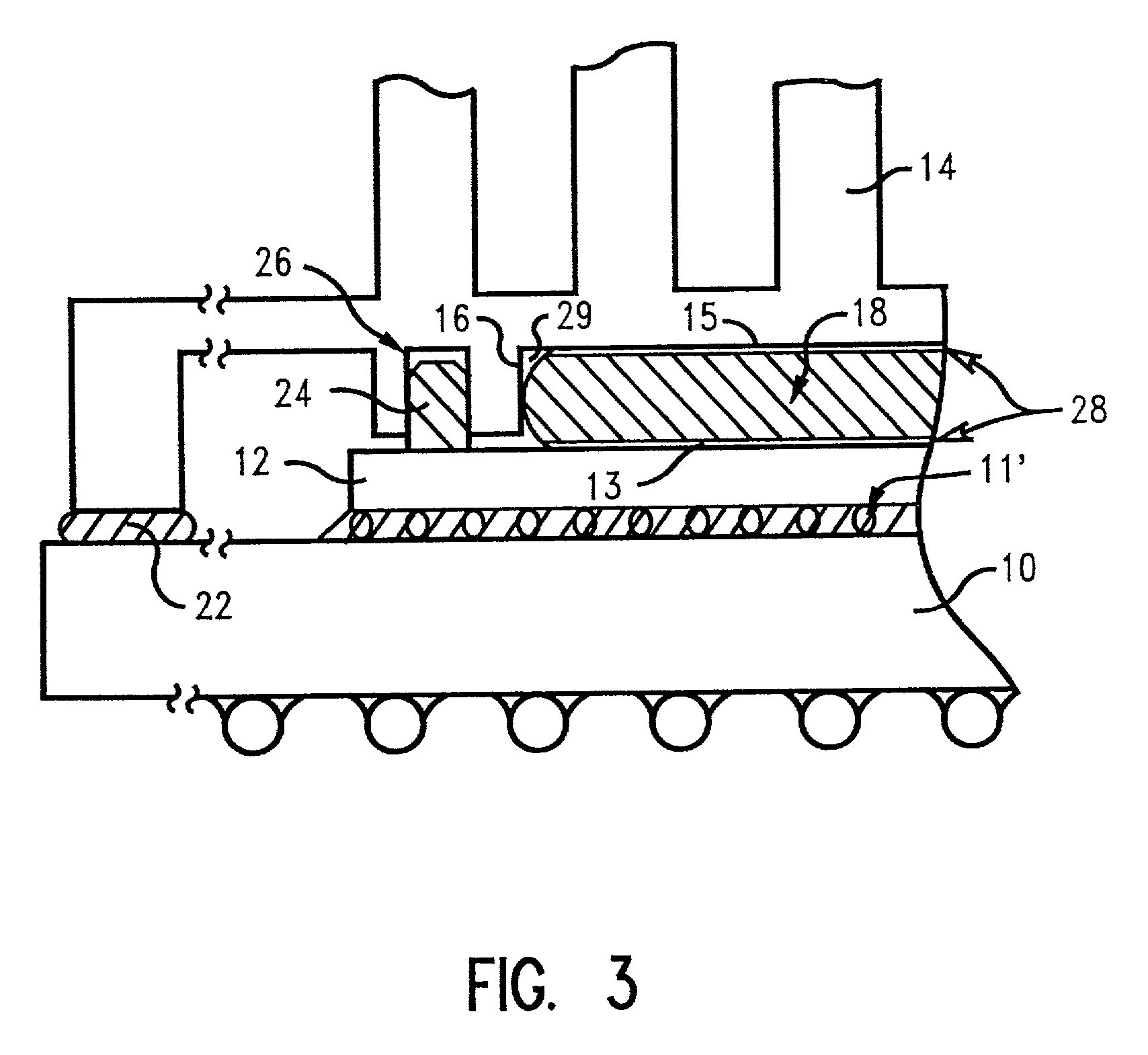

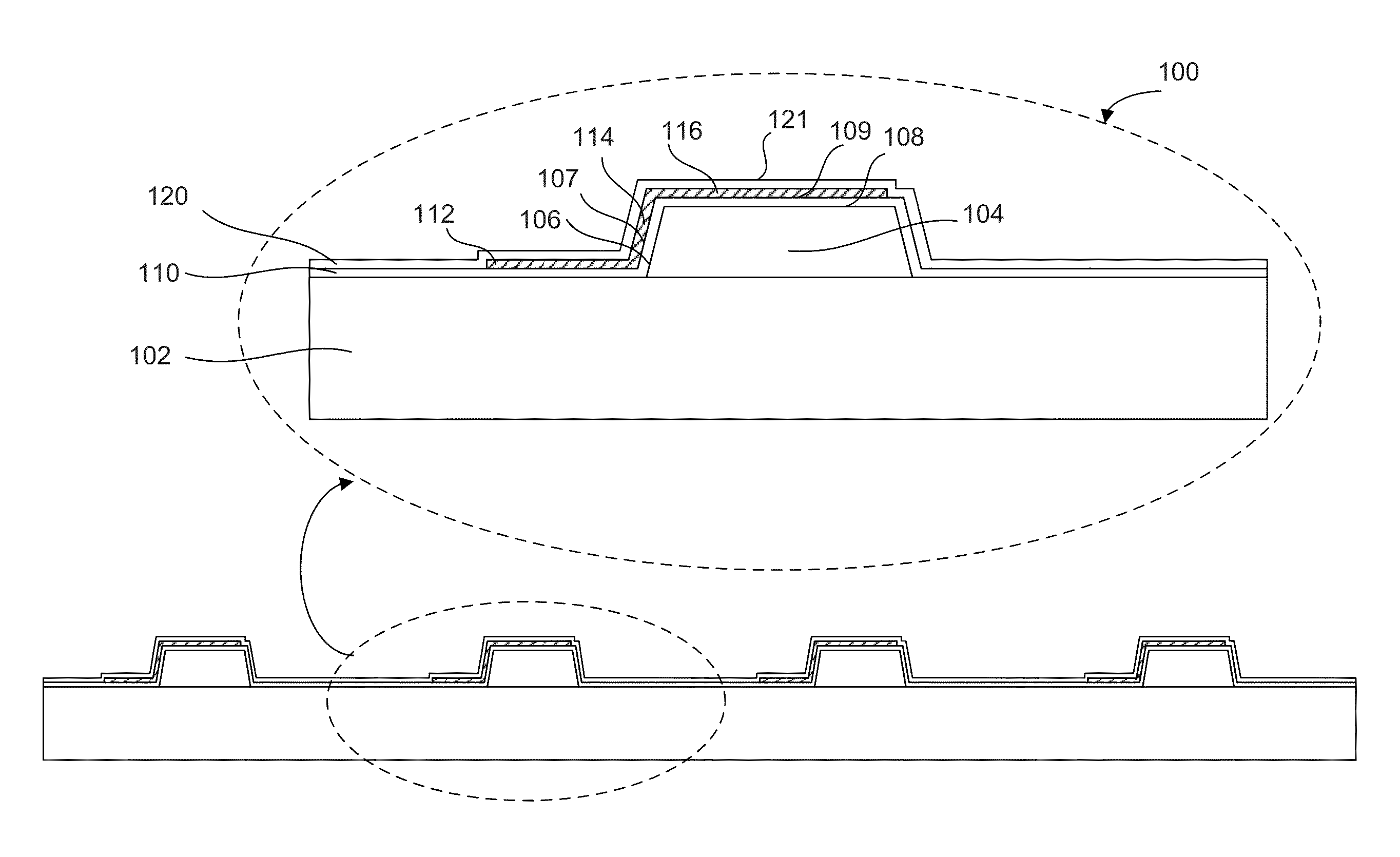

Micro device transfer head heater assembly and method of transferring a micro device

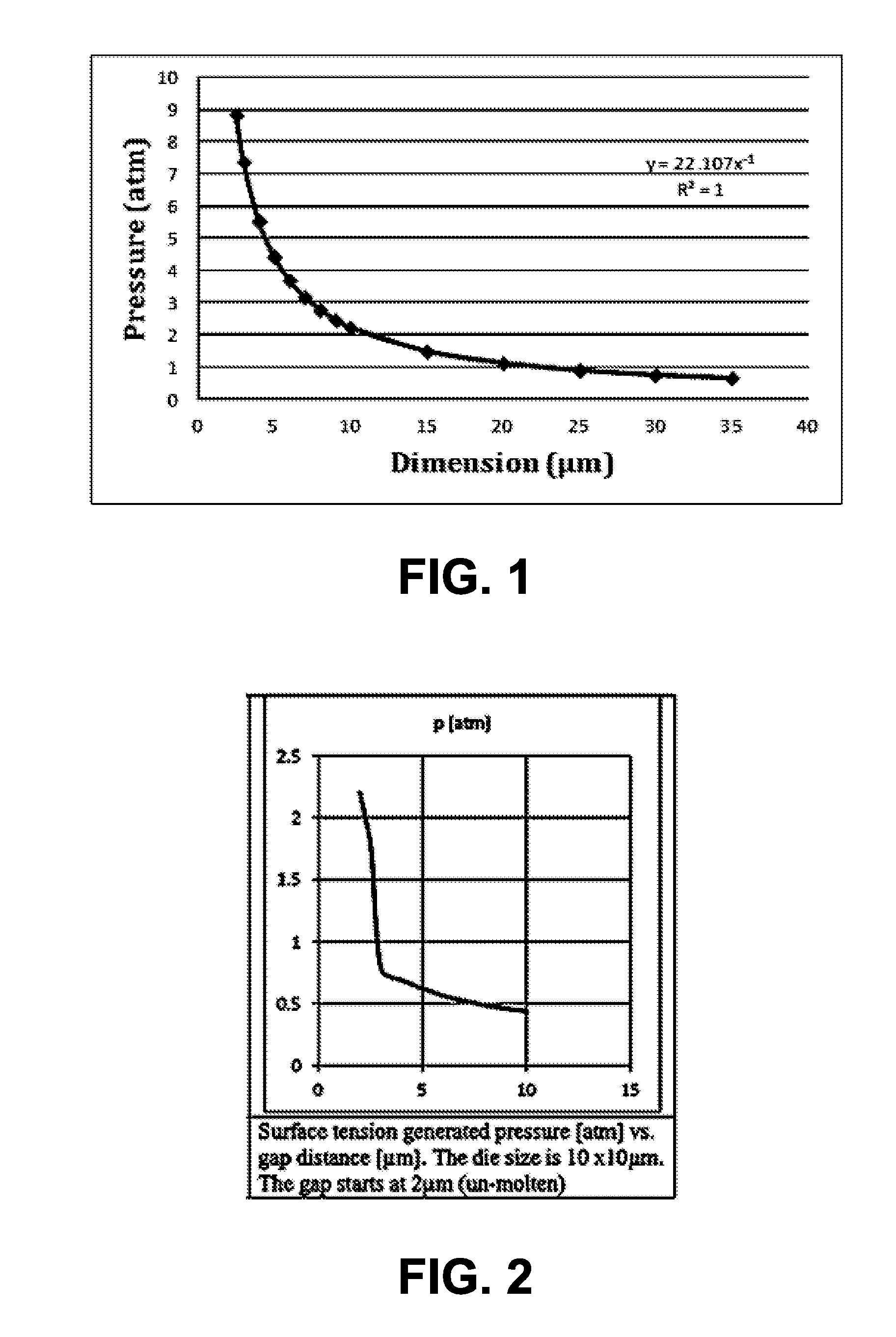

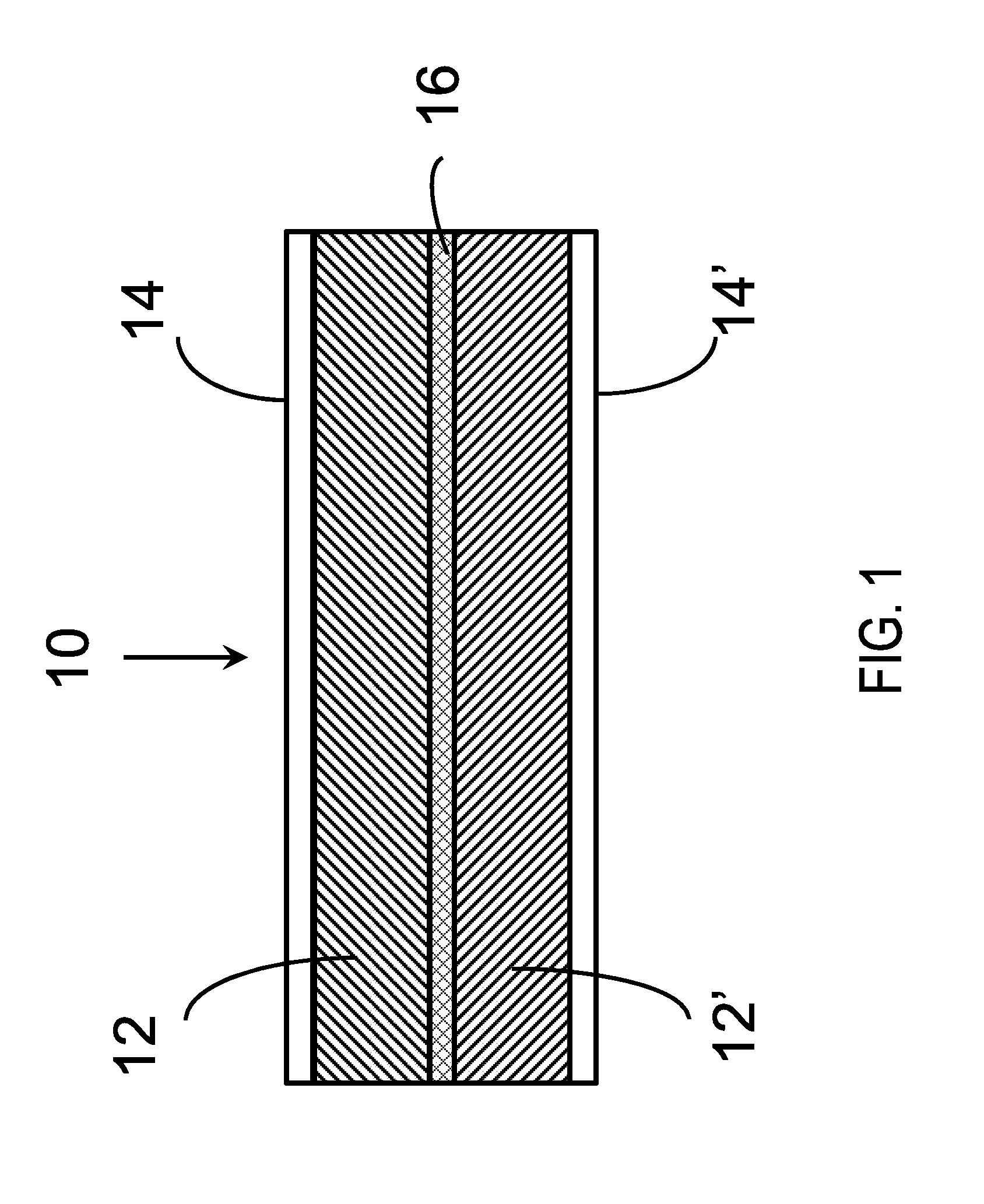

A method of transferring a micro device and an array of micro devices are disclosed. A carrier substrate carrying a micro device connected to a bonding layer is heated to a temperature below a liquidus temperature of the bonding layer, and a transfer head is heated to a temperature above the liquidus temperature of the bonding layer. Upon contacting the micro device with the transfer head, the heat from the transfer head transfers into the bonding layer to at least partially melt the bonding layer. A voltage applied to the transfer head creates a grip force which picks up the micro device from the carrier substrate.

Owner:APPLE INC

Method for casting composite ingot

ActiveUS20050011630A1Easy to controlImprove corrosion resistanceThin material handlingIngotMaterials science

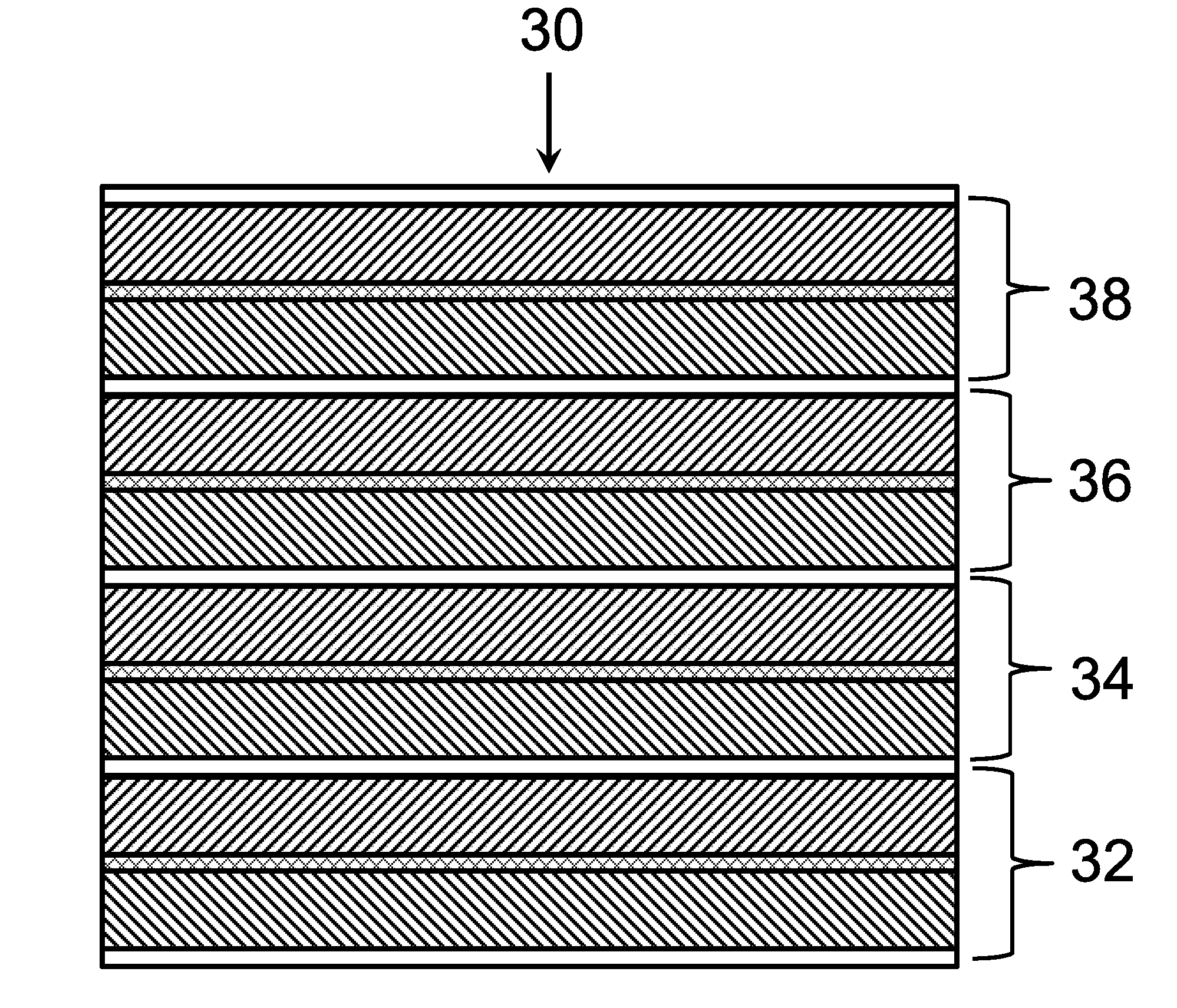

A method and apparatus are described for the casting of a composite metal ingot comprising at least two separately formed layers of one or more alloys. An open ended annular mould has a feed end and an exit end and divider wall for dividing the feed end into at least two separate feed chambers, where each feed chamber is adjacent at least one other feed chamber. For each pair of adjacent feed chambers a first alloy stream is fed through one of the pair of feed chambers into the mould and a second alloy stream is fed through another of the feed chambers. A self-supporting surface is generated on the surface of the first alloy stream and the second alloy stream is contacted with the first stream such that the upper surface of the second alloy stream is maintained at a position such that it first contacts the self-supporting surface where the self-supporting surface temperature is between the liquidus and solidus temperatures of the first alloy or it first contacts the self-supporting surface where the self-supporting surface temperature is below the solidus temperatures of the first alloy but the interface between the two alloys is then reheated to between the liquidus and solidus temperatures, whereby the two alloy streams are joined as two layers. The joined alloy layers are then cooled to form a composite ingot. This composite ingot has a substantially continuous metallurgical bond between alloy layers with dispersed particles of one or more intermetallic compositions of the first alloy in a region of the second alloy adjacent the interface.

Owner:NOVELIS INC

Aluminum/magnesium 3D-Printing rapid prototyping

InactiveUS20060045787A1Additive manufacturing apparatusTransportation and packagingCopperRapid prototyping

A 3D Printing Rapid Prototyping process using Al / Mg particles coated with a metal (i.e. copper, nickel, zinc, or tin) that (1) prevents oxidation of the Al / Mg particles, and (2) either alone, or when alloyed with the aluminum or magnesium core metal, melts below the liquidus temperature of the core.

Owner:GM GLOBAL TECH OPERATIONS LLC

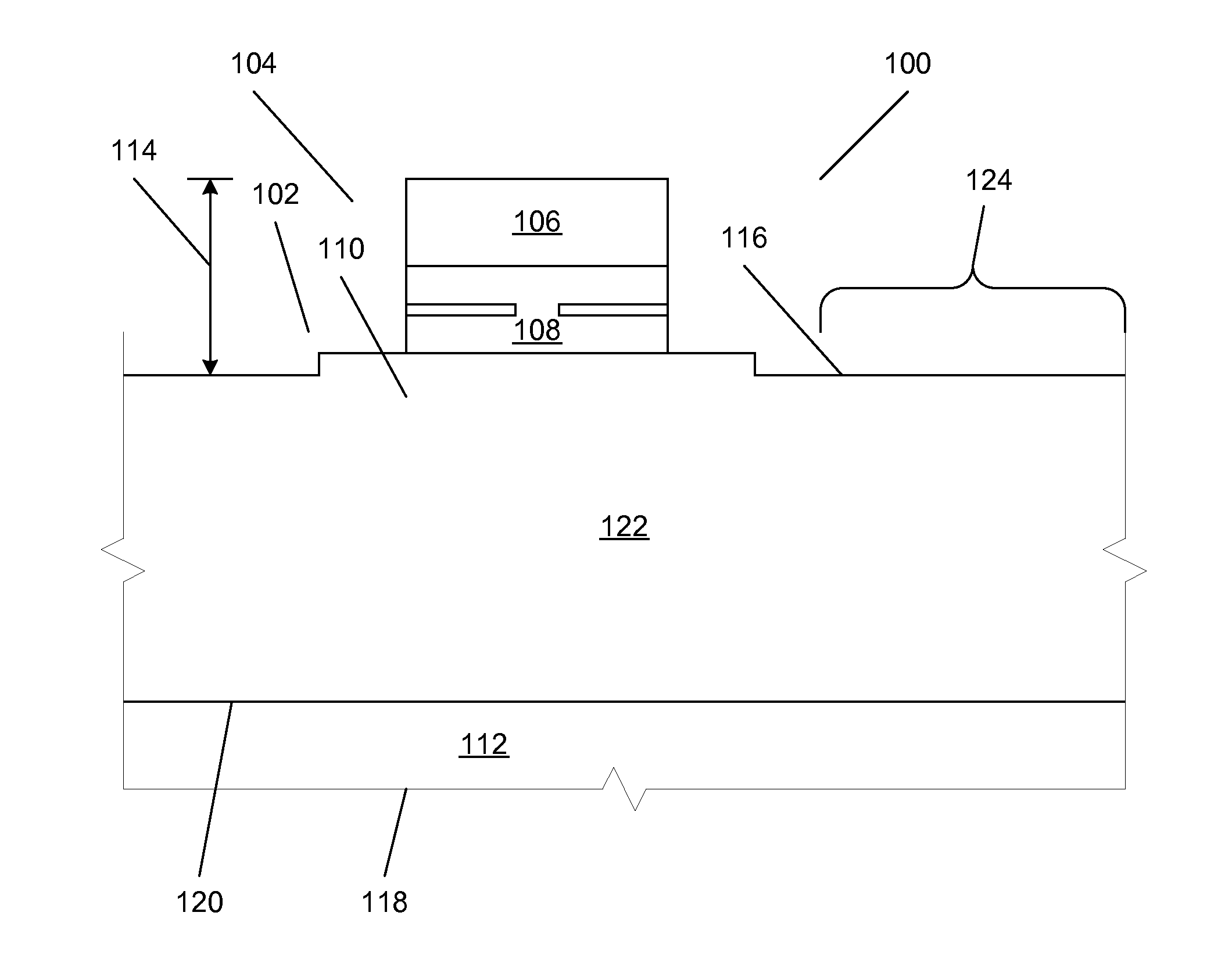

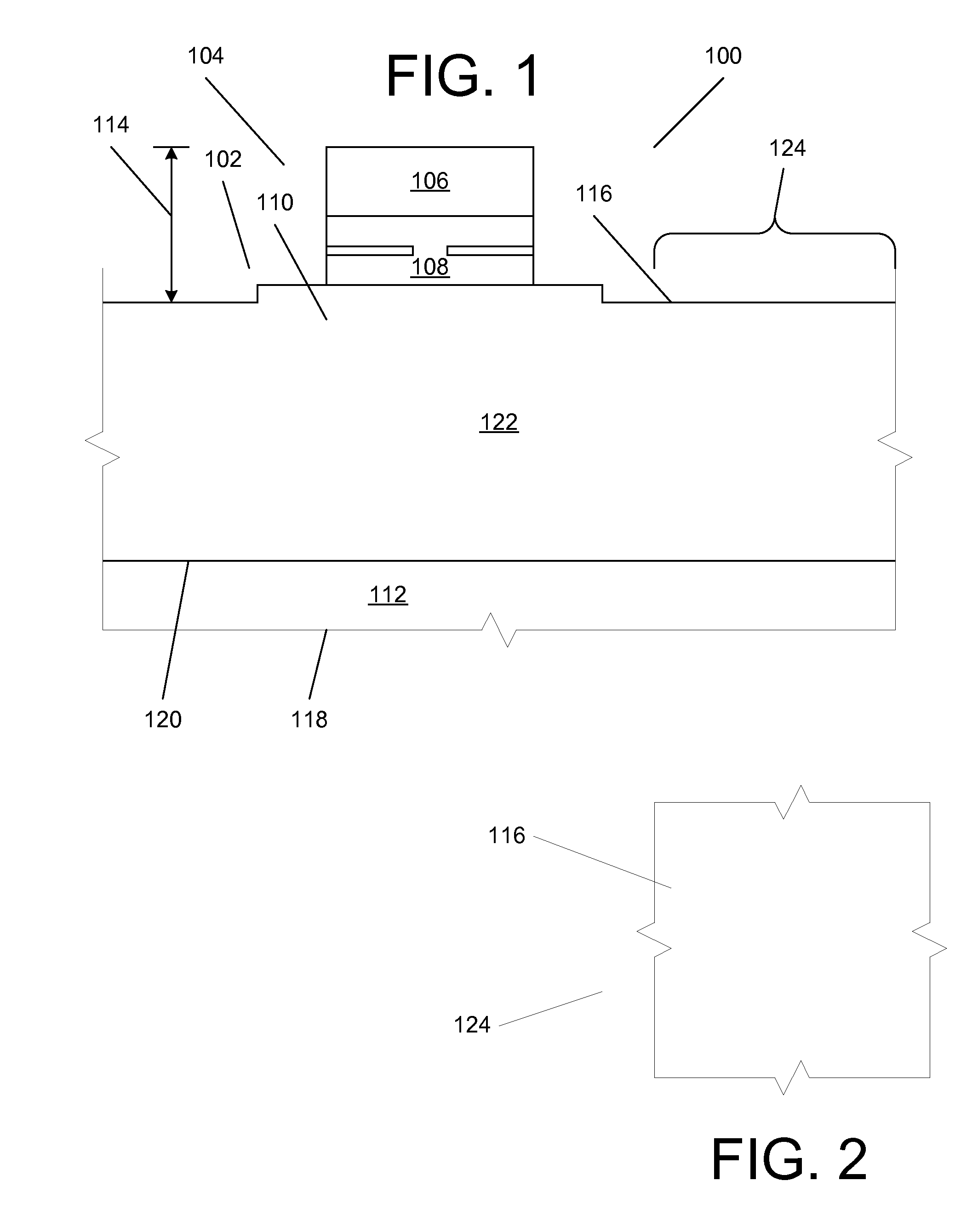

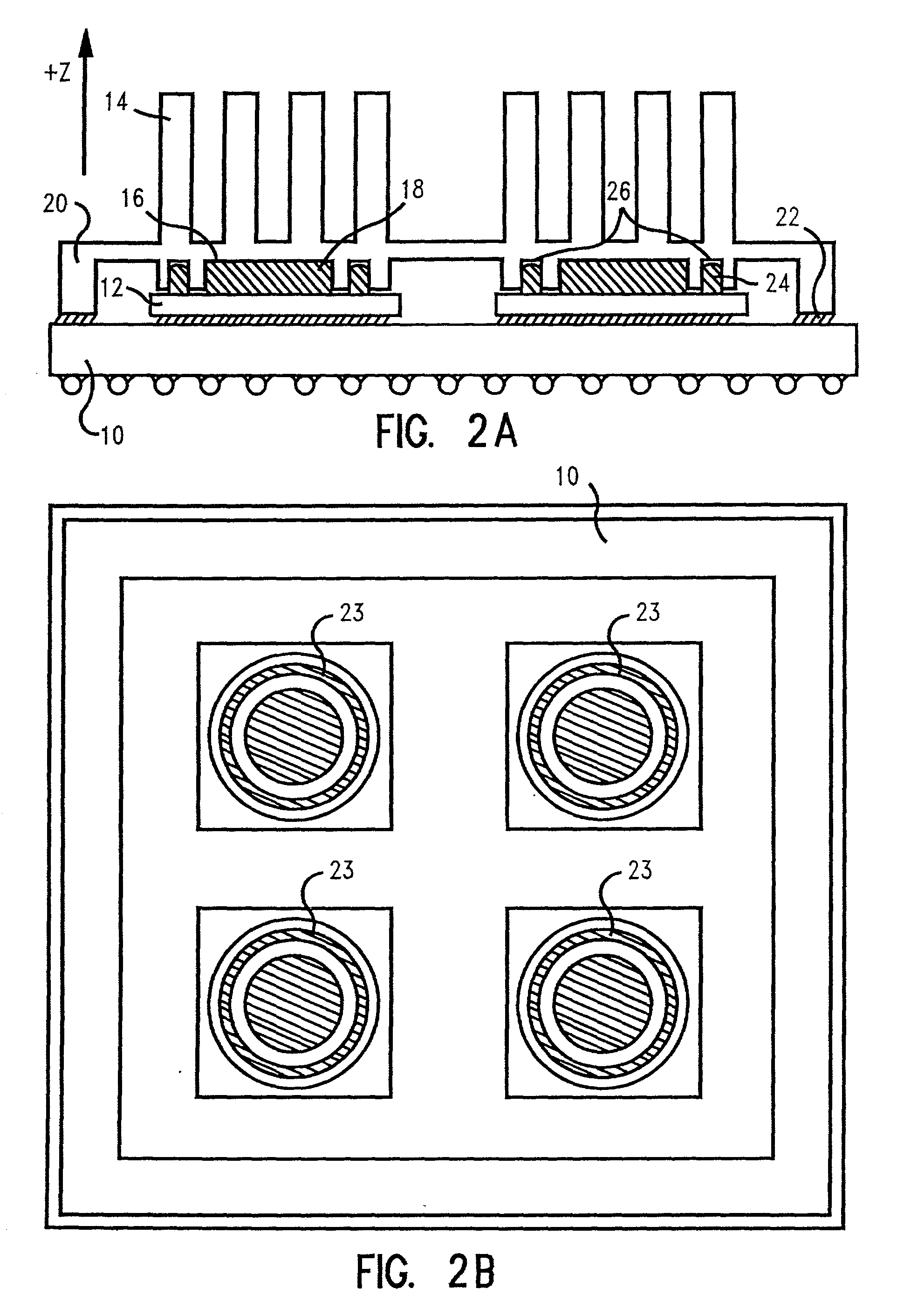

Thermal enhancement approach using solder compositions in the liquid state

InactiveUS6281573B1Lower resistanceThermal mismatchPrinted electric component incorporationSemiconductor/solid-state device detailsThermal energyThermal coefficient

Solder compositions are introduced to interface between an IC chip and its associated heat exchanger cover. The solder compositions have a solidus-liquidus temperature range that encompasses the IC chip operational temperature range. The solder composition has the desired property of absorbing and rejecting heat energy by changing state or phase with each temperature rise and decline that result from temperature fluctuations associated with the thermal cycles of the integrated circuit chips. A path for high thermal conduction (low thermal resistance) from the IC chip to the heat exchanger to the ambient air is provided by an electronic module cover, configured as a cap with a heat exchanger formed or attached as a single construction, and made of the same material as the substrate, or made with materials of compatible thermal coefficients of expansion to mitigate the effects of vertical displacement during thermal cycling. The cap-heat exchanger cover is constructed to be compliant, and to contact both the IC chip and substrate.

Owner:IBM CORP

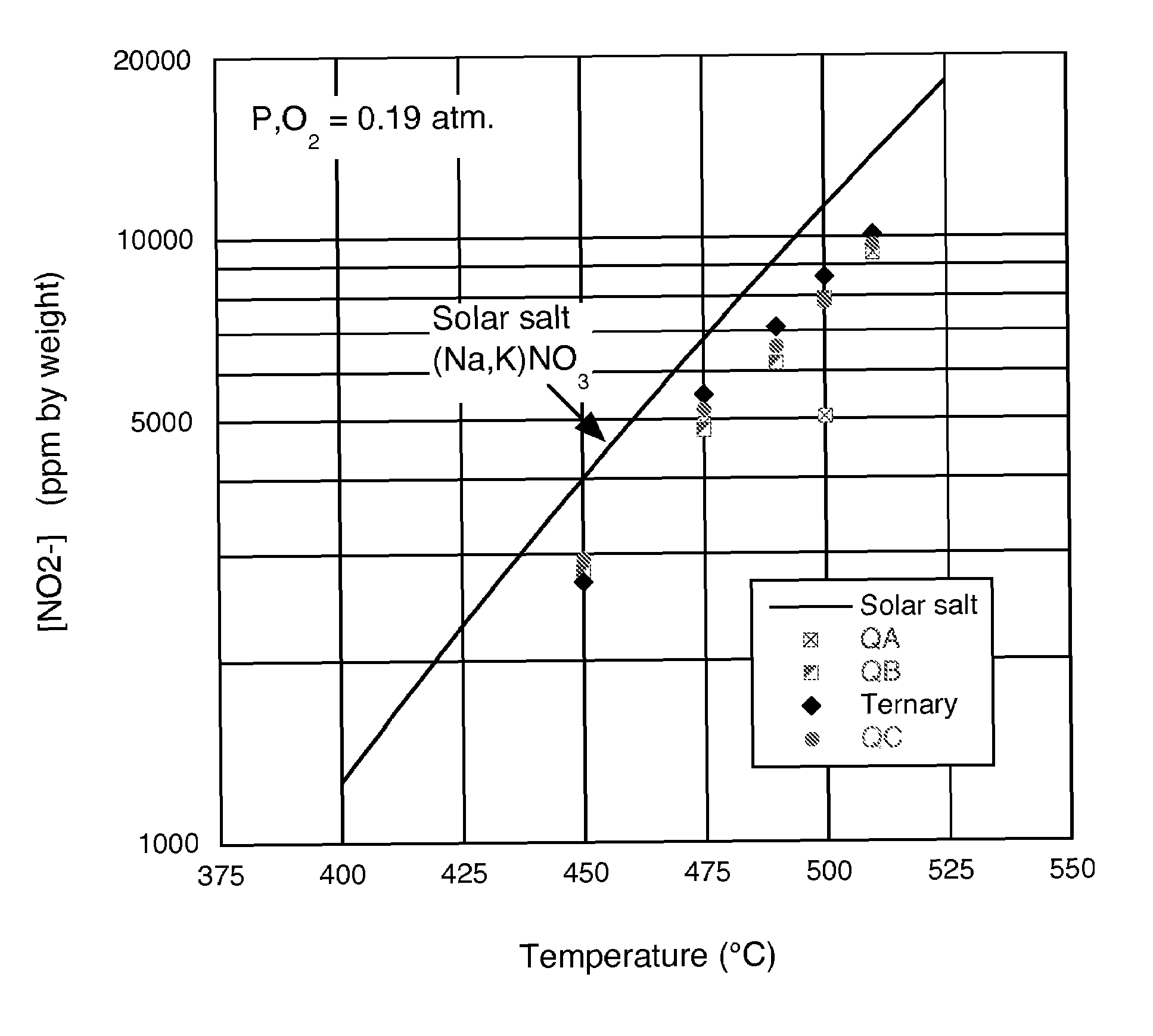

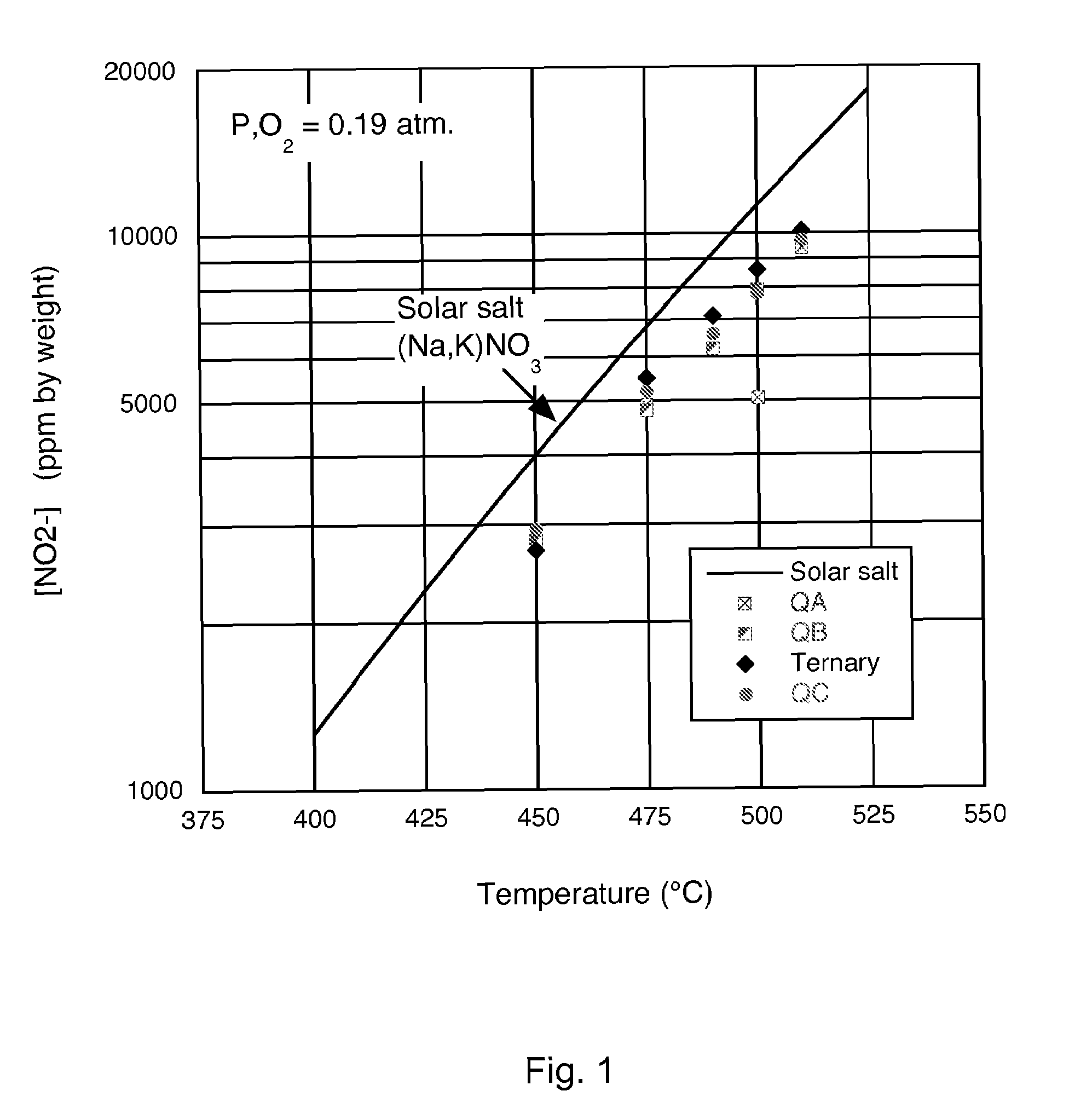

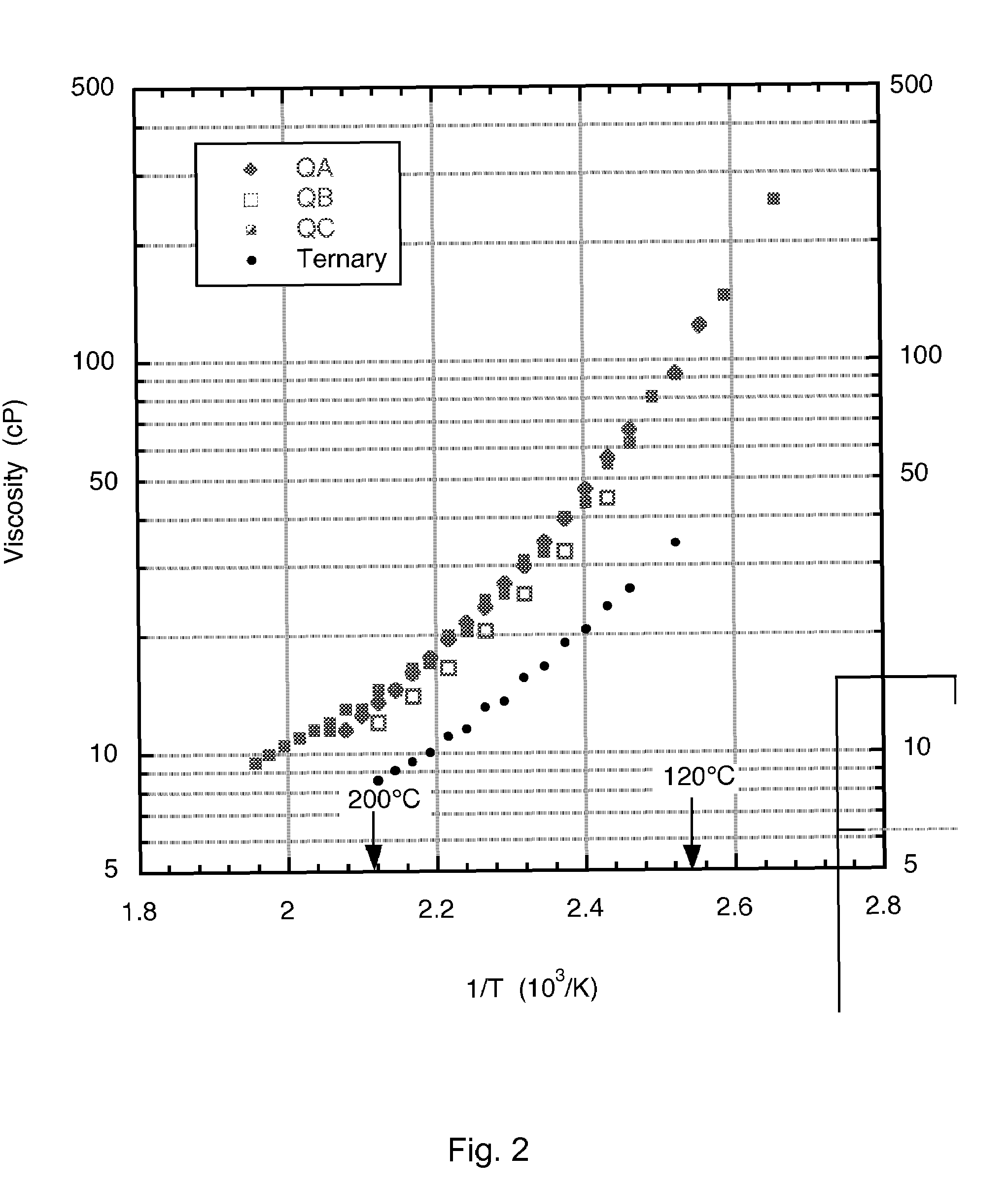

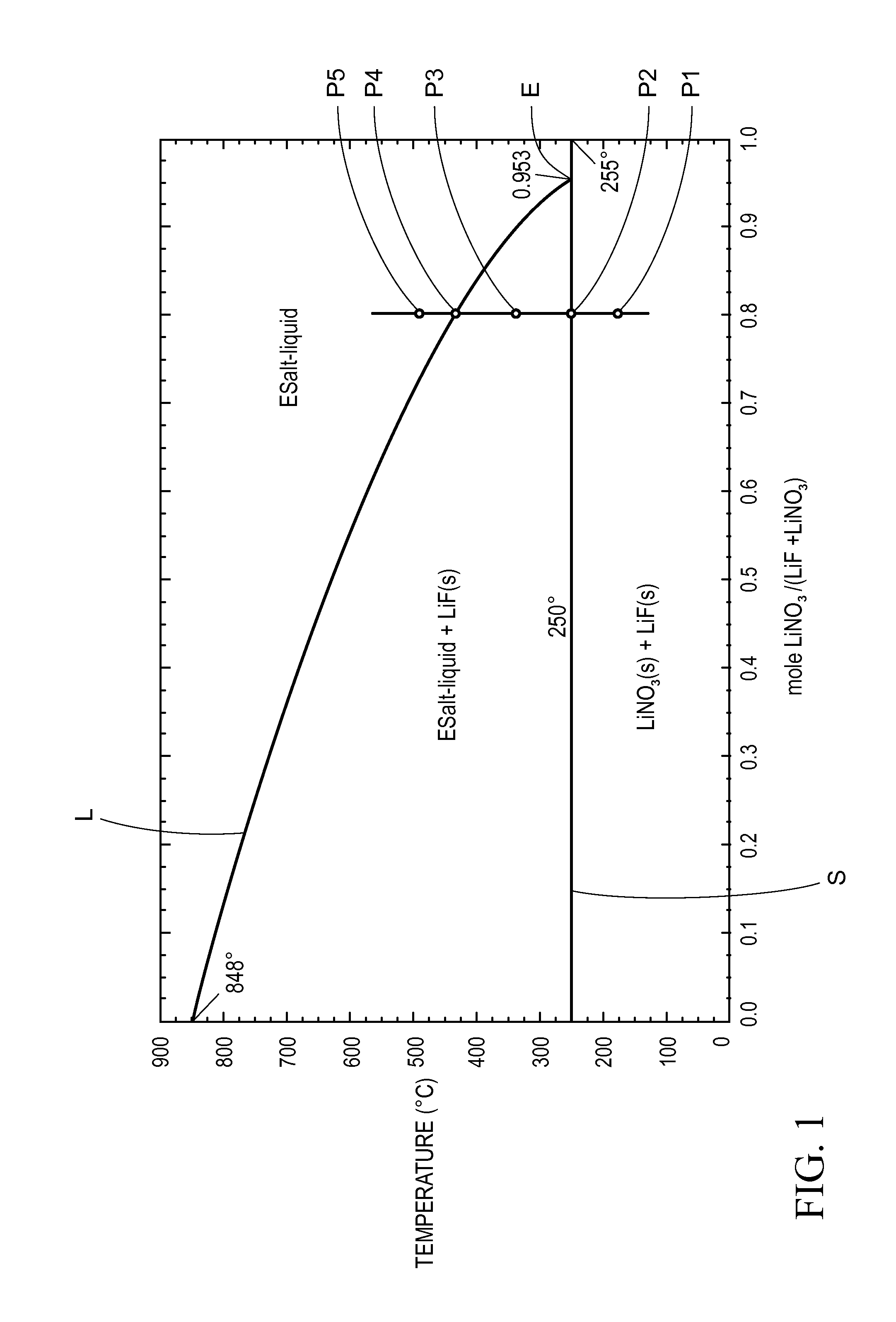

Low-melting point inorganic nitrate salt heat transfer fluid

A low-melting point, heat transfer fluid made of a mixture of four inorganic nitrate salts: 9-18 wt % NaNO3, 40-52 wt % KNO3, 13-21 wt % LiNO3, and 20-27 wt % Ca(NO3)2. These compositions can have liquidus temperatures less than 100 C; thermal stability limits greater than 500 C; and viscosity in the range of 5-6 cP at 300 C; and 2-3 cP at 400 C.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Aluminum/magnesium 3D-Printing rapid prototyping

InactiveUS7141207B2Additive manufacturing apparatusTransportation and packagingRapid prototypingZinc

A 3D Printing Rapid Prototyping process using Al / Mg particles coated with a metal (i.e. copper, nickel, zinc, or tin) that (1) prevents oxidation of the Al / Mg particles, and (2) either alone, or when alloyed with the aluminum or magnesium core metal, melts below the liquidus temperature of the core.

Owner:GM GLOBAL TECH OPERATIONS LLC

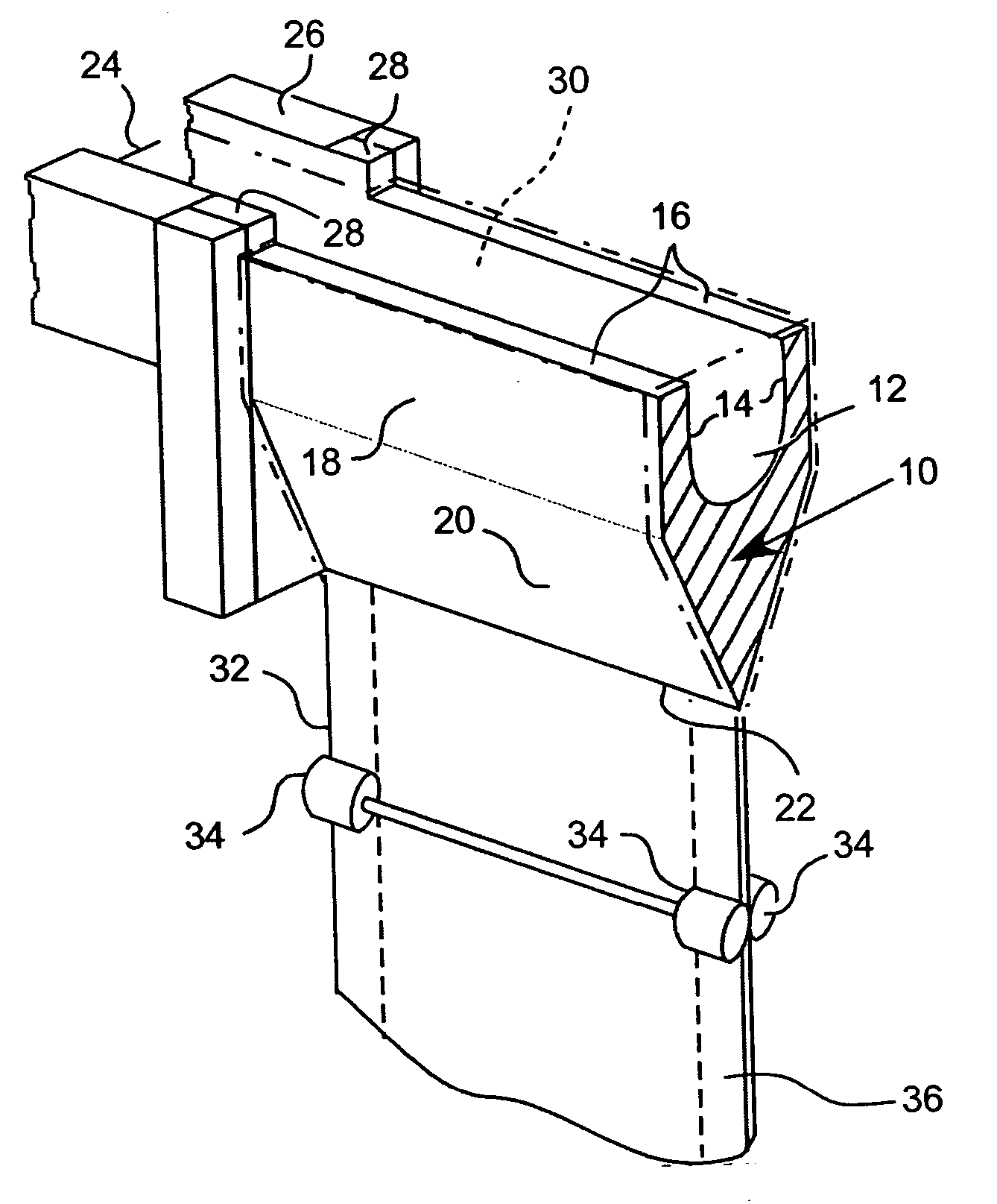

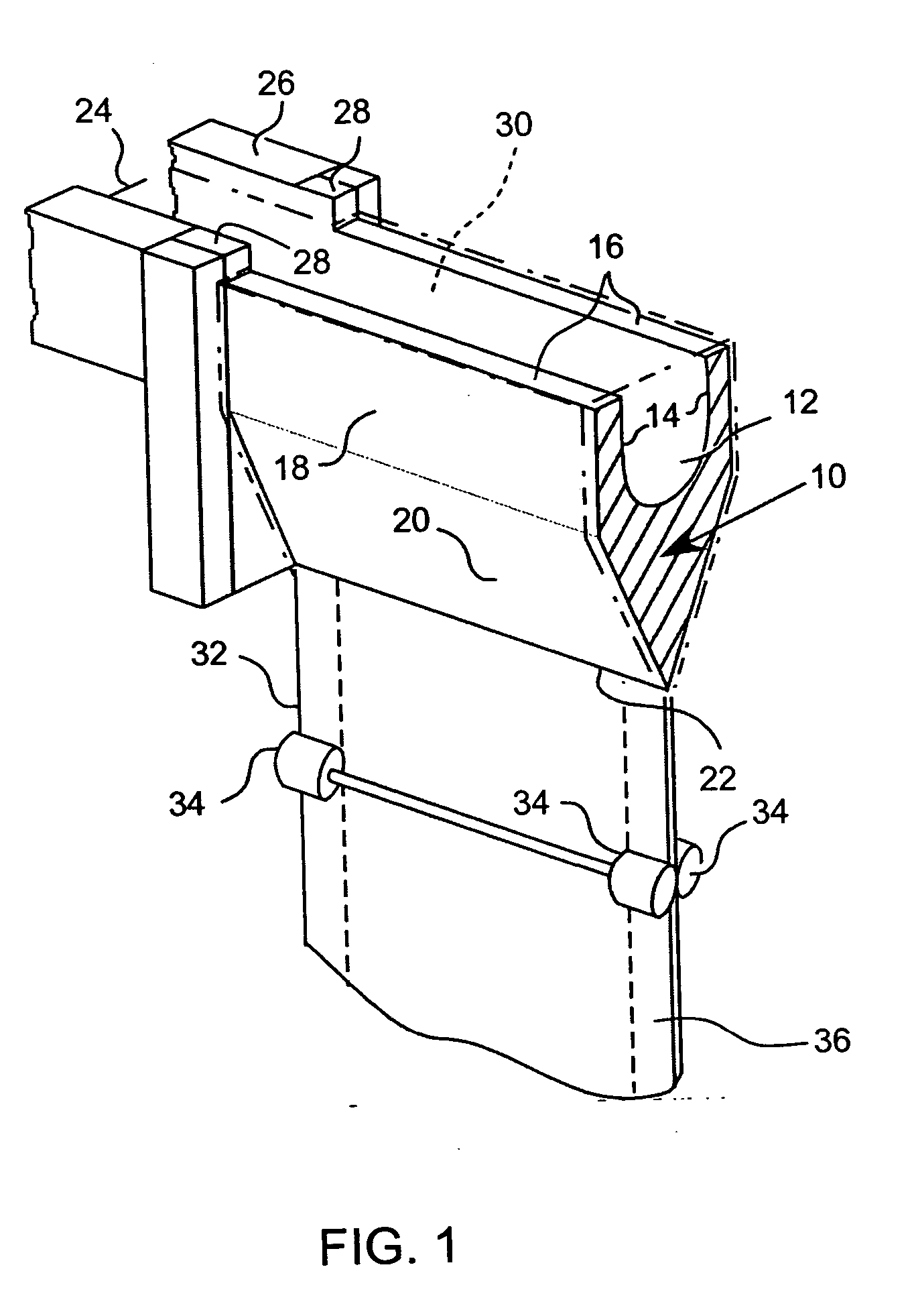

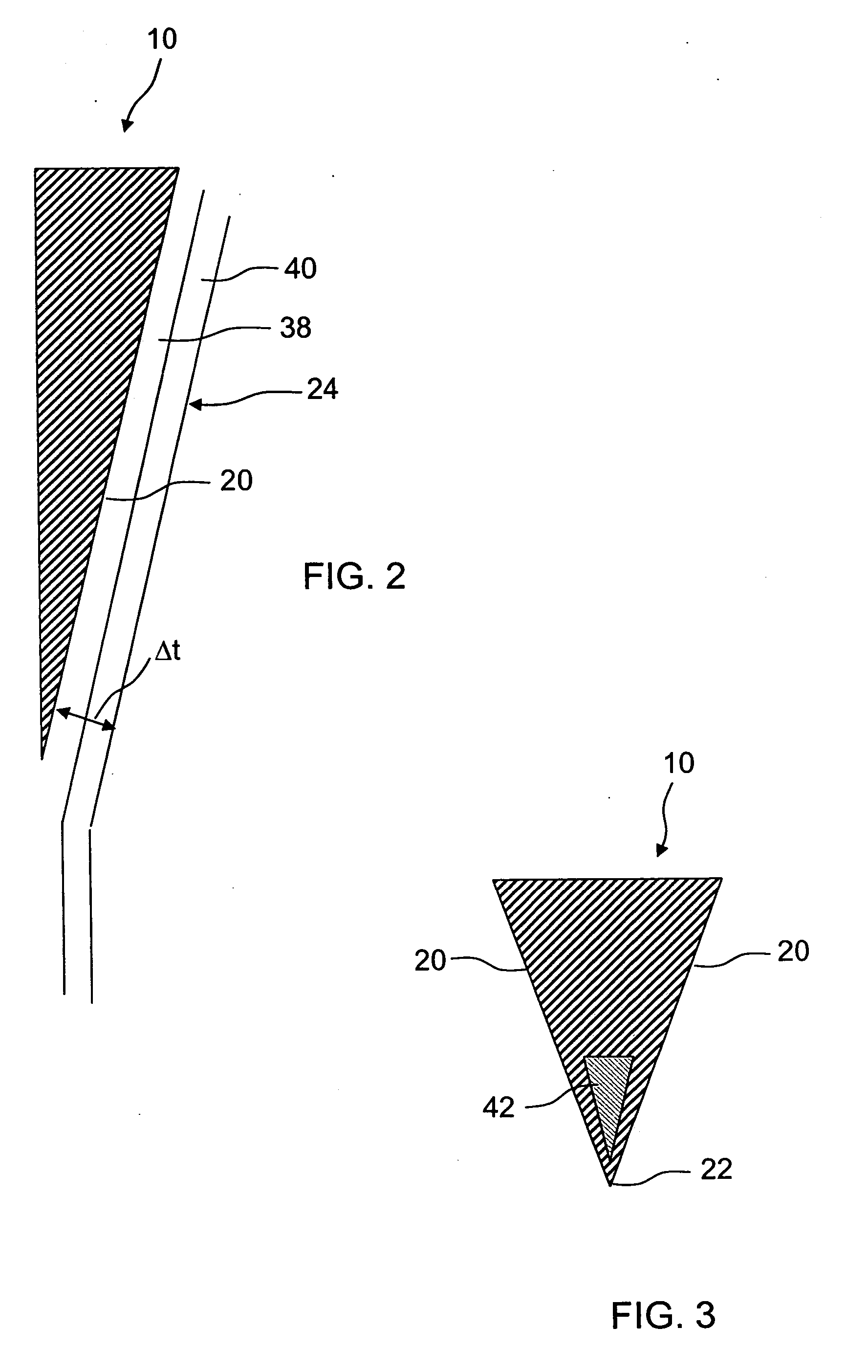

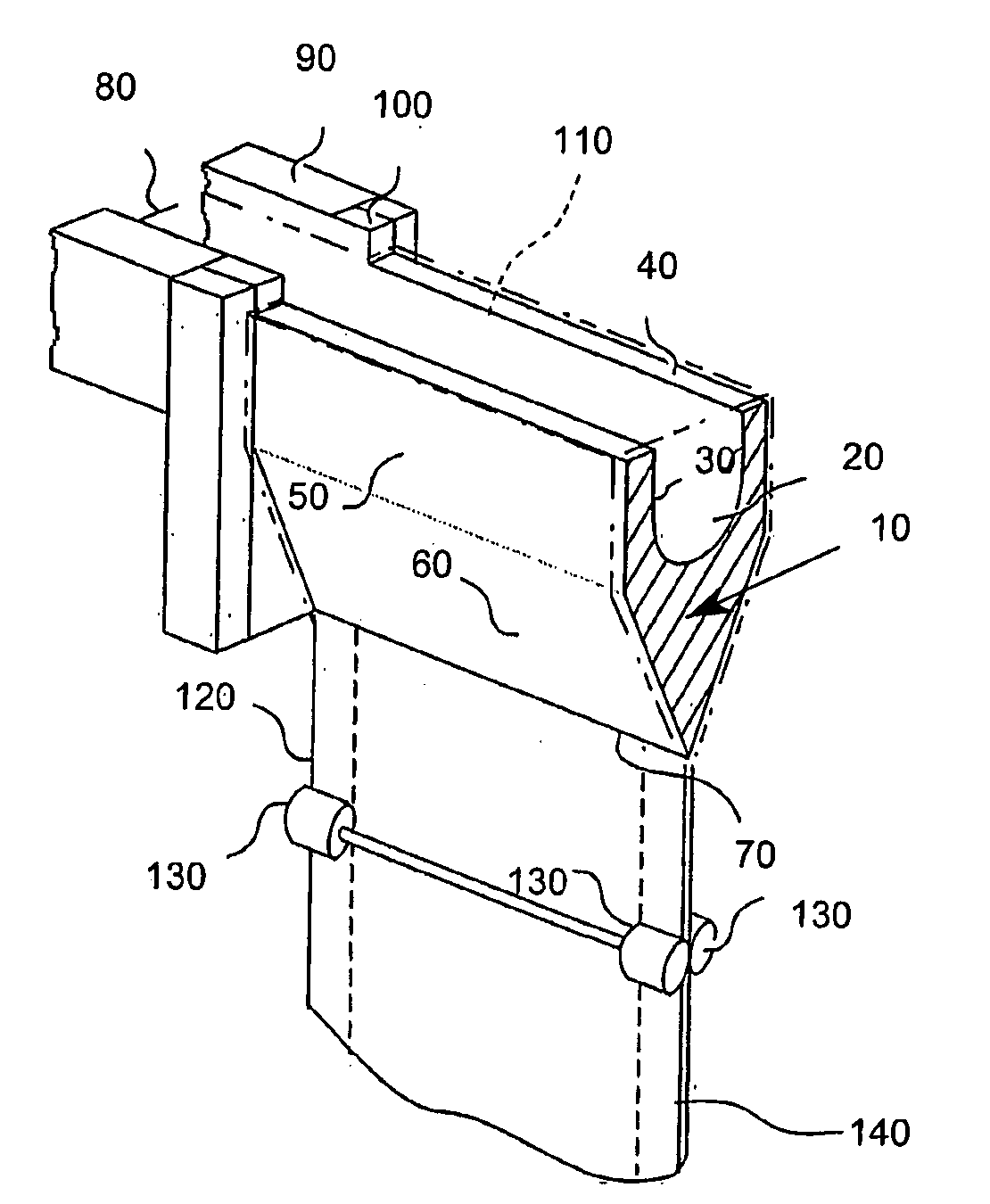

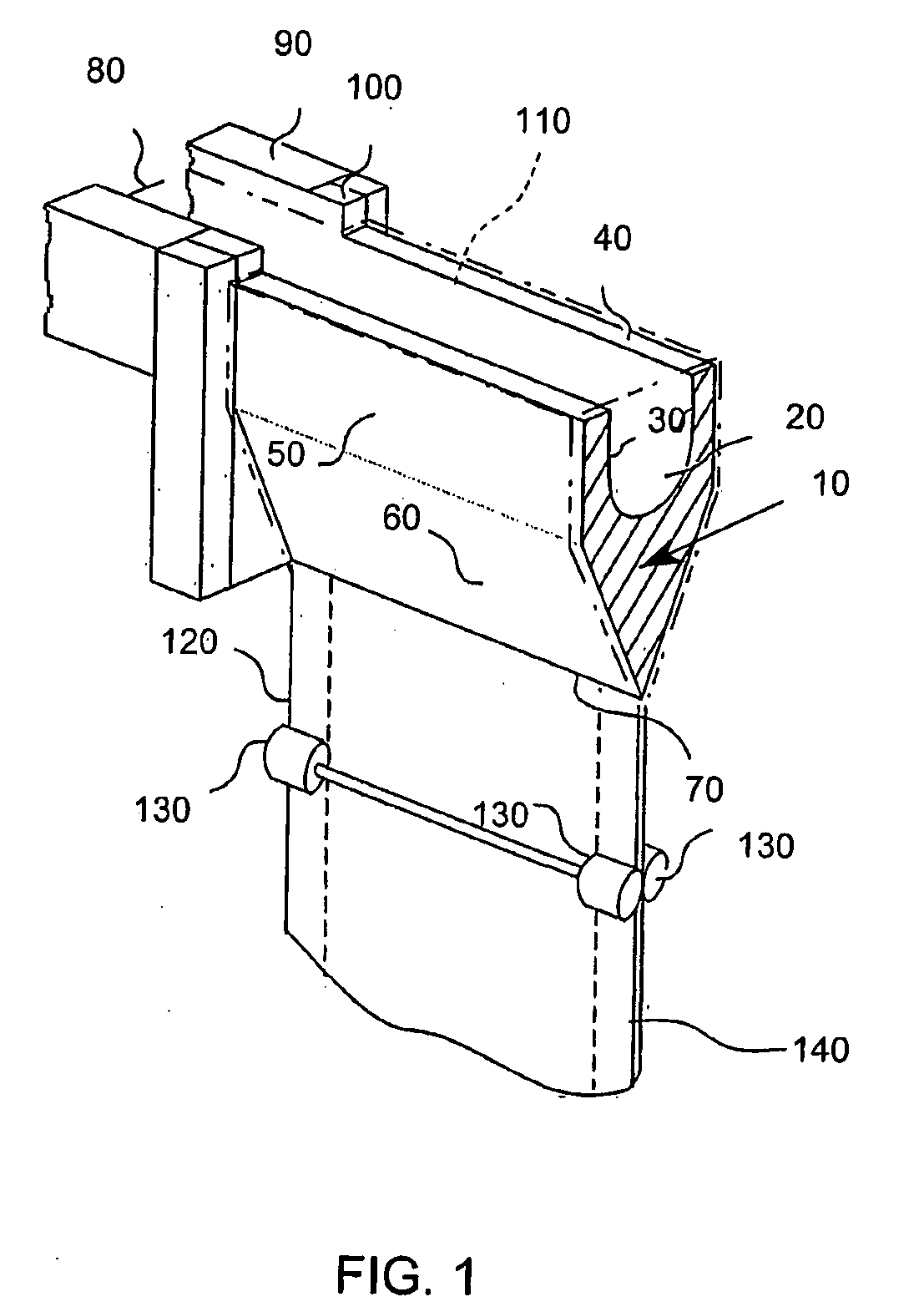

Method and apparatus for drawing a low liquidus viscosity glass

InactiveUS20070130994A1Easy to understandGlass furnace apparatusGlass drawing apparatusViscosityGlass sheet

A method of a drawing a glass ribbon from molten glass sheet via a downdraw process by creating a temperature drop across a thickness of the molten glass flowing over forming surfaces of a forming wedge. The forming wedge includes an electrically conductive material for heating the glass above the root.

Owner:CORNING INC

Fusion formable silica and sodium containing glasses

ActiveUS20110017297A1Point becomes highImprove battery efficiencyPhotovoltaic energy generationSemiconductor devicesSilicate glassThermal expansion

Sodium containing aluminosilicate and boroaluminosilicate glasses are described herein. The glasses can be used as substrates or superstrates for photovoltaic devices, for example, thin film photovoltaic devices such as CIGS photovoltaic devices. These glasses can be characterized as having strain points≧535° C., for example, ≧570° C., thermal expansion coefficients of from 8 to 9 ppm / ° C., as well as liquidus viscosities in excess of 50,000 poise. As such they are ideally suited for being formed into sheet by the fusion process.

Owner:CORSAM TECH

Tack & fuse chip bonding

InactiveUS20060281303A1Easy to shapeSemiconductor/solid-state device detailsSolid-state devicesElectrical contactsLiquidus

A method of joining contacts on two chips, each having multiple contacts, to each other involves maintaining a first of the chips at a first temperature, the first of the chips having a rigid electrical contact thereon, bringing a second chip, having an electrical contact that is malleable with respect to the rigid contact and matingly corresponding thereto, into contact with the first such that the corresponding rigid and malleable contacts are brought together, locally raising the second of the chips to a local temperature that is sufficiently high to cause material of the rigid and malleable contact to interdiffuse, interpenetrate or both, but below both a temperature that would cause the material to become liquidus and a fuse temperature, and allowing the second of the chips to cool to at least the first temperature.

Owner:CUFER ASSET LTD LLC

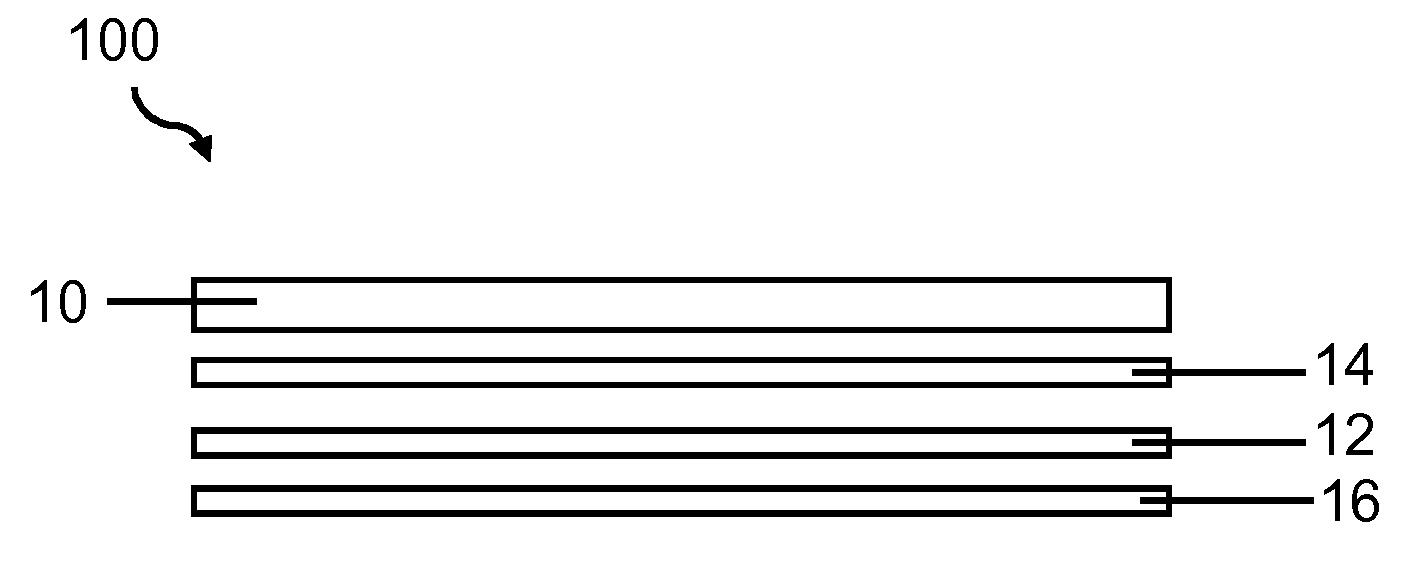

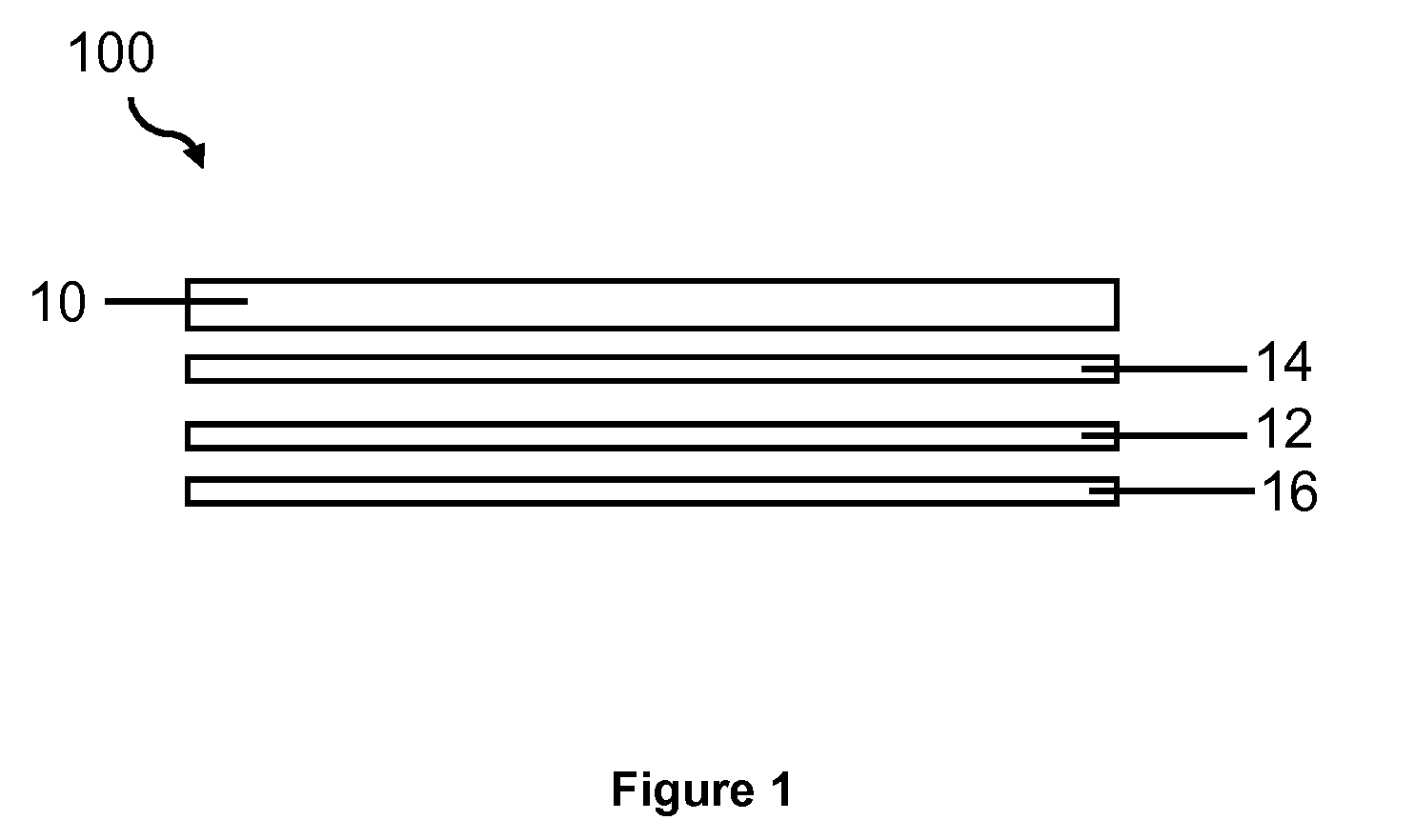

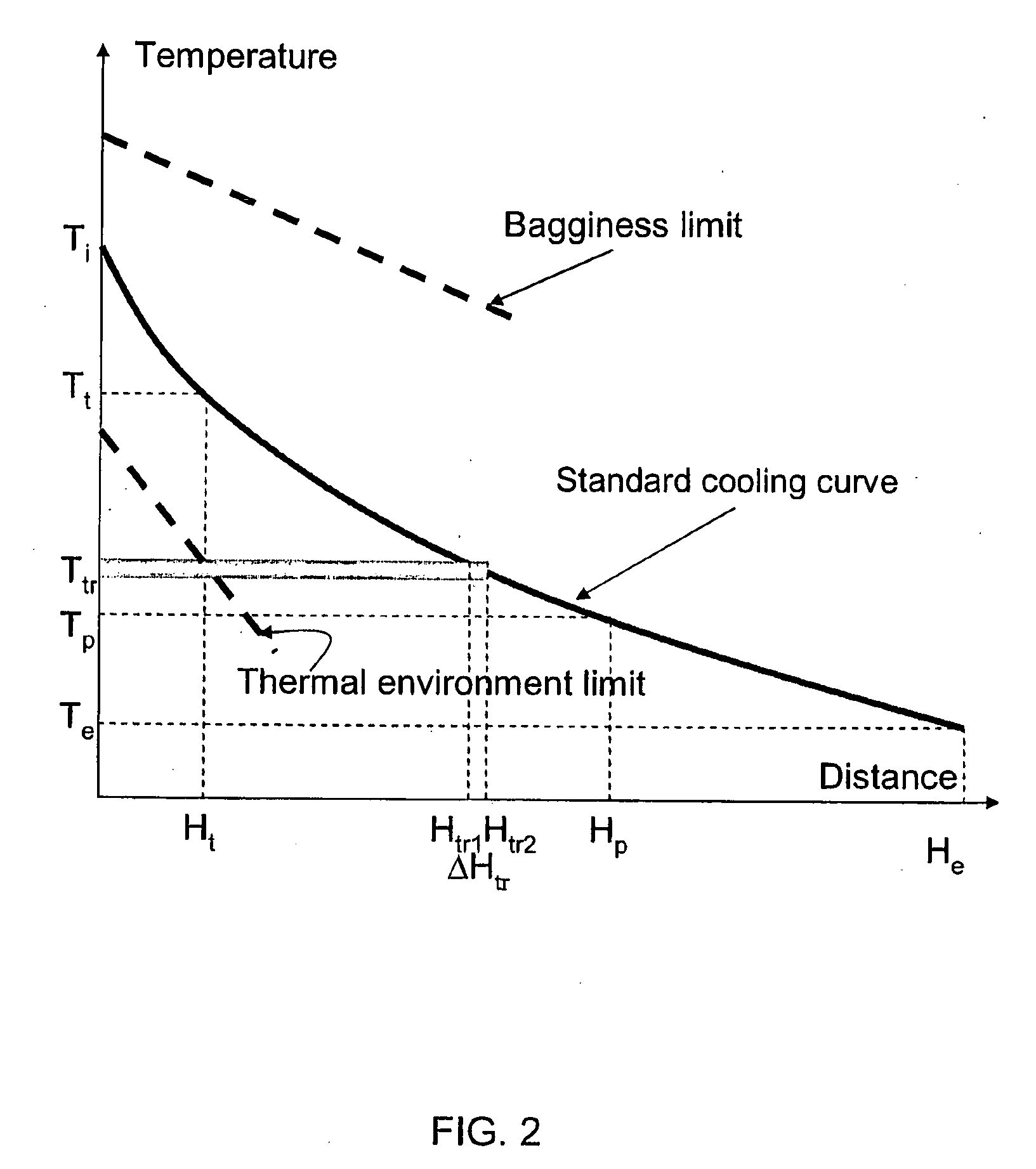

Method of making a glass sheet using controlled cooling

InactiveUS20090100873A1Increase rate increaseHigh trafficGlass drawing apparatusGlass forming apparatusFluid phaseEngineering

Methods of drawing glass sheet via a downdraw process are provided. In certain aspects, the methods utilize rapid cooling below the root (70) of the forming apparatus (10). Such rapid cooling can, for example, facilitate the use of glass having a liquidus viscosity less than about 100,000 poise. In other aspects, the methods utilize slow cooling between the viscosities of 1011 poises and 1014 poises. Such slow cooling can facilitate the production of glass substrates which exhibit low levels of compaction. In further aspects, substrates are removed from the glass sheet at elevated temperatures which can facilitate increases in the production rates of downdraw machines. In still further aspects, rapid cooling below the root, slow cooling between the viscosities of 1011 poises and 1014 poises, and / or substrate removal at elevated temperatures are combined. Such combinations can facilitate economically effective utilization of downdraw equipment.

Owner:CORNING INC

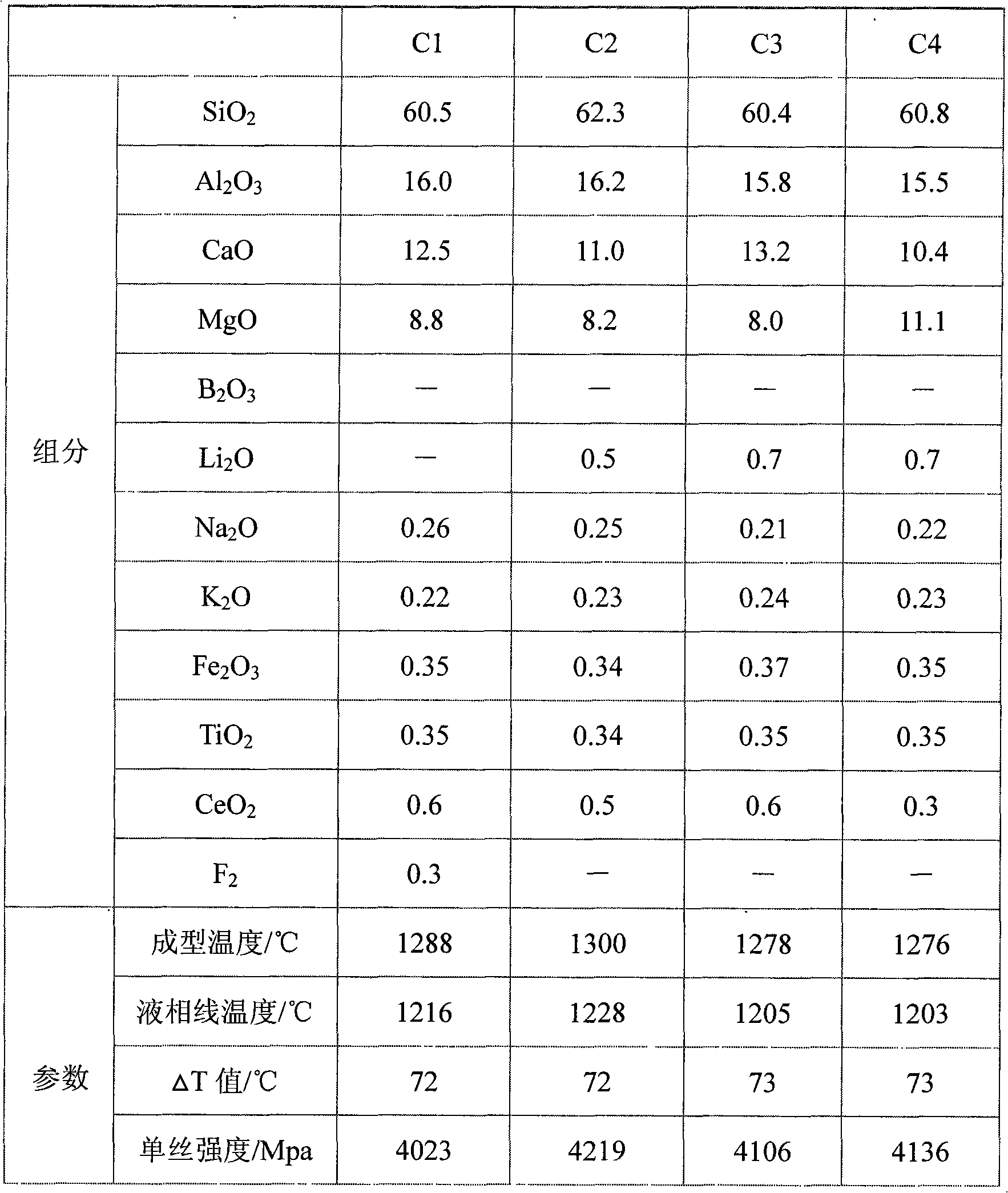

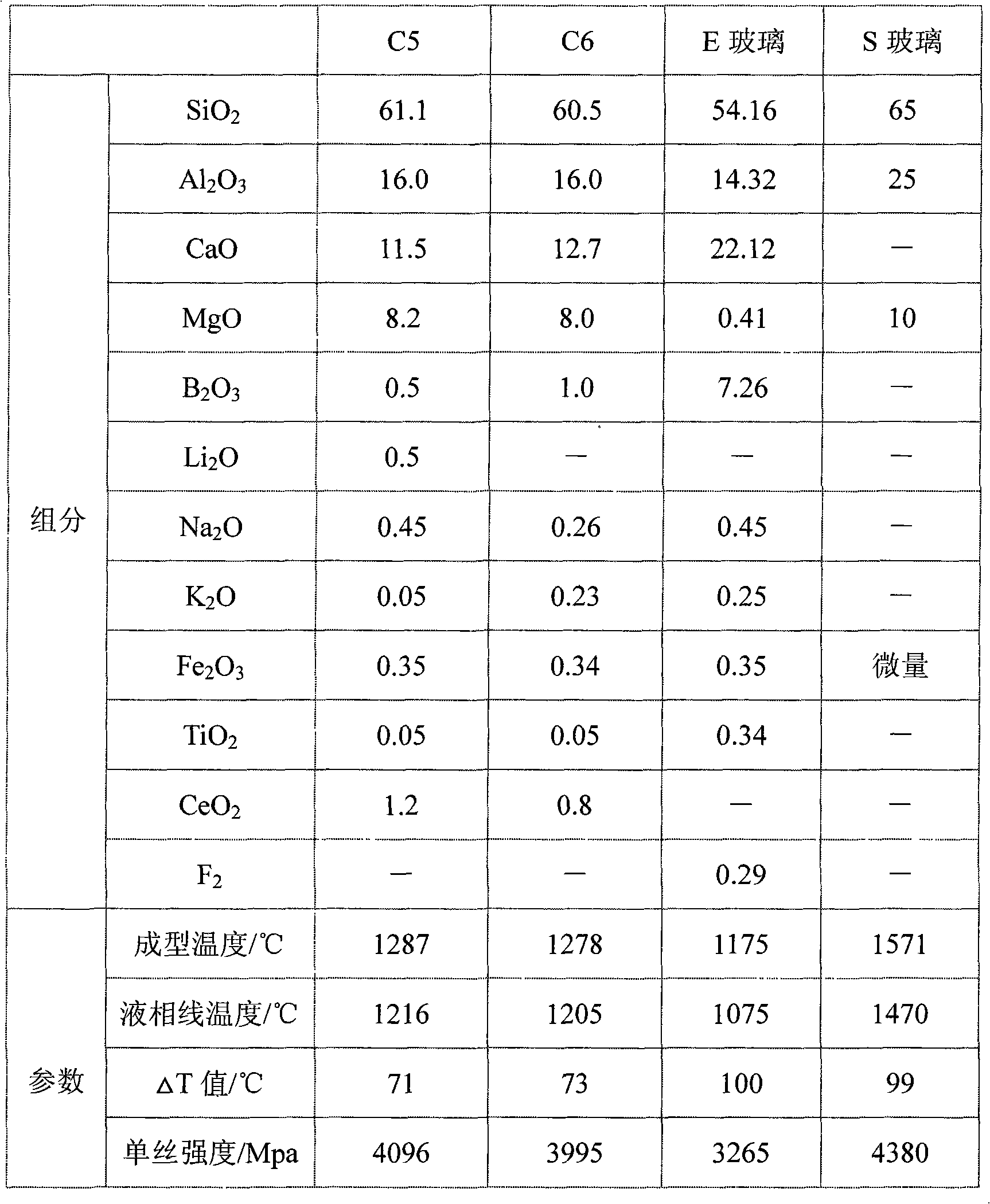

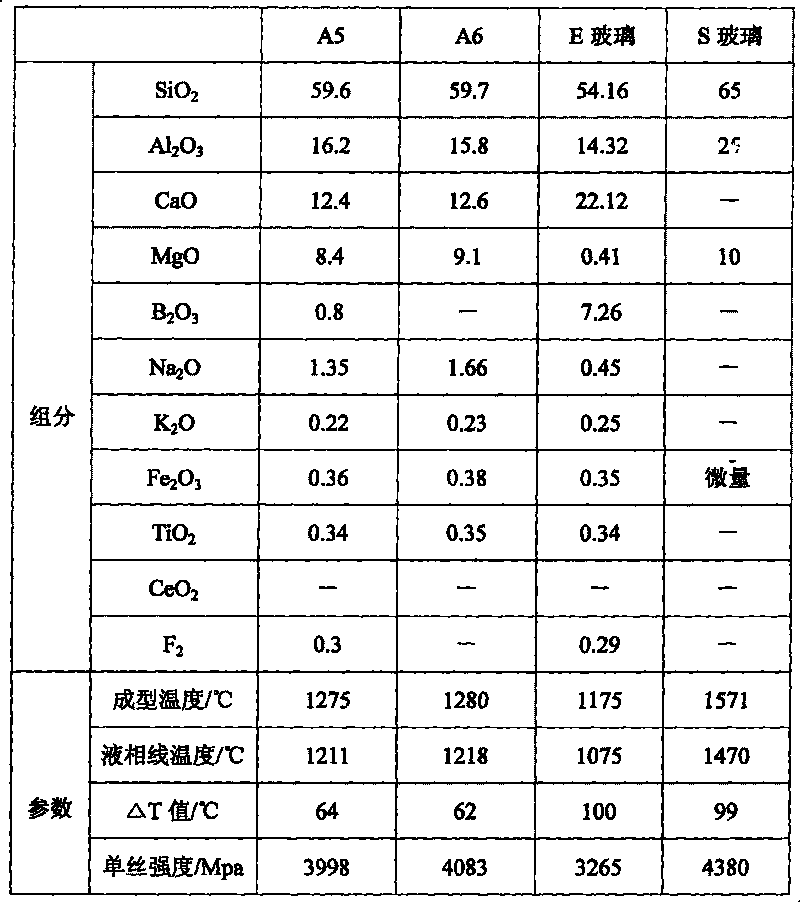

High strength glass fiber composition

The invention discloses a high strength glass fiber composition which comprises the components with the weight percentage: 58-65% of SiO2, 14-20% of Al2O3, 15-25% of CaO+MgO, 0.05-1% of K2O+Na2O, 0.05-1% of Fe2O3 and 0.1-2% of CeO2; wherein, the proportional relation of the components is that CaO / MgO is more than 0.7 and less than 2.2. By preference and combination of the components, the high strength glass fiber composition not only can fully utilize rich raw mineral materials of China, but also can reduce mold temperature, liquidus temperature and clarification temperature and has lower total cost and easy large scale commercial process under the premise of ensuring the high strength of glass fiber.

Owner:JUSHI GRP CO

Copper-based alloy and its manufacturing method

As a rawmaterial of a copper base alloy containing at least one of 0.2 to 12 wt% of tin and 8 to 45 wt% of zinc, at least one of a copper base alloy having a large surface area and containing carbon on the surface thereof, a copper base alloy having a liquidus line temperature of 1050 DEG C or less, a copper base alloy surface-treated with tin, and a copper base alloy containing 20 to 1000 ppm of carbon, is used for obtaining a copper base alloy having an excellent hot workability. If necessary, when the raw material of the copper base alloy is melted, the material of the copper base alloy may be coated with a solid material containing 70 wt% or more of carbon, or 0.005 to 0.5 wt% of a solid deoxidizer having a stronger affinity with O than C with respect to the weight of the molten metal may be added to the molten metal.

Owner:DOWA HLDG CO LTD

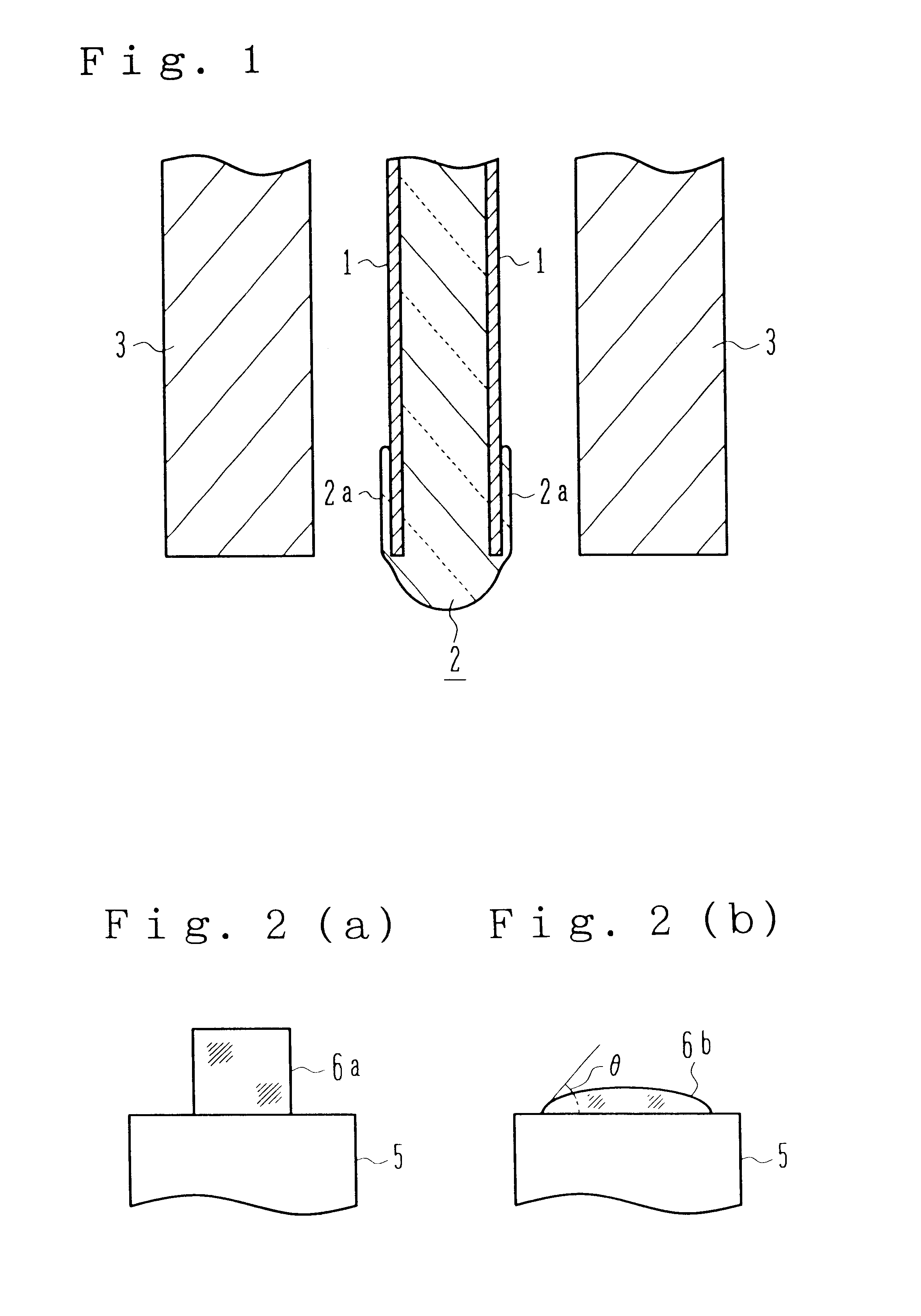

Optical glass, press-molding preform and optical part

InactiveUS6844279B2Improve plasticityGlass pressing apparatusGlass reforming apparatusRefractive indexGlass transition

A high-refractivity low-dispersion optical glass that gives press-molding preforms excellent in high-temperature shapability and suitable for precision press-molding, including an optical glass comprising B2O3, La2O3, Gd2O3 and ZnO as essential components, substantially containing none of lead and fluorine, having a refractive index (nd) of 1.72 to 1.83, an Abbe's number (νd) of 45 to 55 and a glass transition temperature (Tg) of 630° C. or lower and having a viscosity of at least 0.6 Pa·s at its liquidus temperature, and an optical glass comprising, by mol %, 45 to 65% of B2O3, 5 to 22% of La2O3, 1 to 20% of Gd2O3, provided that the total content of La2O3 and Gd2O3 is 14 to 30%, 5 to 30% of ZnO, 0 to 10% of SiO2, 0 to 6.5% of ZrO2 and 0 to 1% of Sb2O3, substantially containing none of lead and fluorine, and having a refractive index (nd) of 1.72 to 1.83 and an Abbe's number (νd) of 45 to 55.

Owner:HOYA CORP

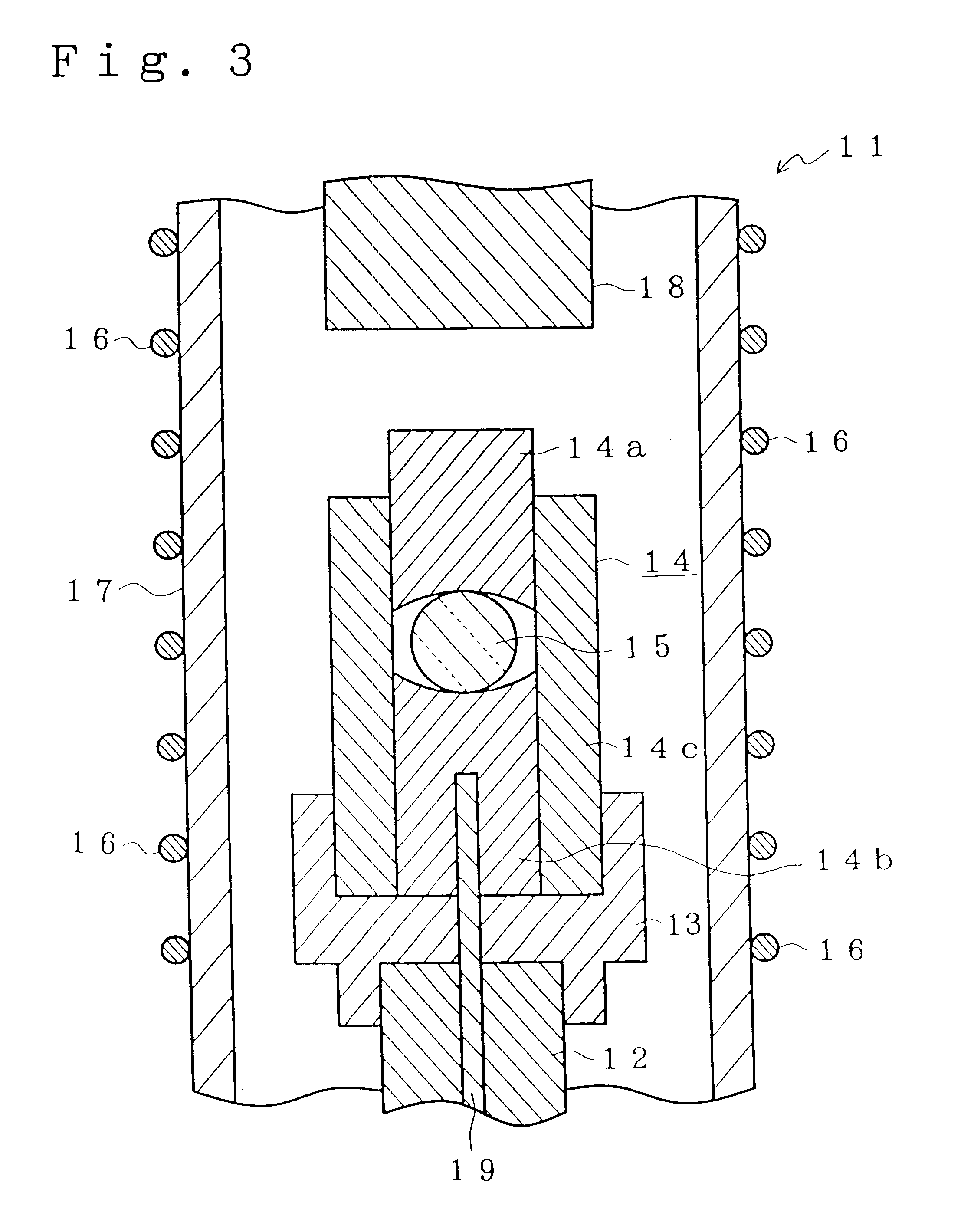

Method of producing glass substrate for information recording medium

InactiveUS6332338B1Avoid deformationIncrease speedGlass drawing apparatusGlass forming apparatusProduction ratePoise

Disclosed is a process for producing a glass substrate for an information recording medium by press-shaping a molten glass which gives a glass containing 0.1 to 30 mol % of TiO2, 1 to 45 mol % of CaO, 5 to 40 mol % of total of MgO and the above CaO, 3 to 30 mol % of total of Na2O and Li2O, 0 to 15 mol % of Al2O3 and 35 to 65 mol % of SiO2 and having properties of a liquidus temperature of 1,360° C. or lower and a viscosity of at least 10 poise in a shaping-allowable temperature range, or by preparing a preform formed of a glass which contains 0.1 to 30 mol % of TiO2, 1 to 45 mol % of CaO, 5 to 40 mol % of total of MgO and the above CaO, 3 to 30 mol % of total of Na2O and Li2O, 0 to 15 mol % of Al2O3 and 35 to 65 mol % of SiO2 and has properties of a liquidus temperature of 1,360° C. or lower and shaping the preform in the form of a disc by a re-heat pressing method. According to the above process, there can be mass-produced, with high productivity, high-quality glass substrates to be used for information recording media such as a magnetic disc, an optical disc, a magneto-optic disc, and the like.

Owner:HOYA CORP

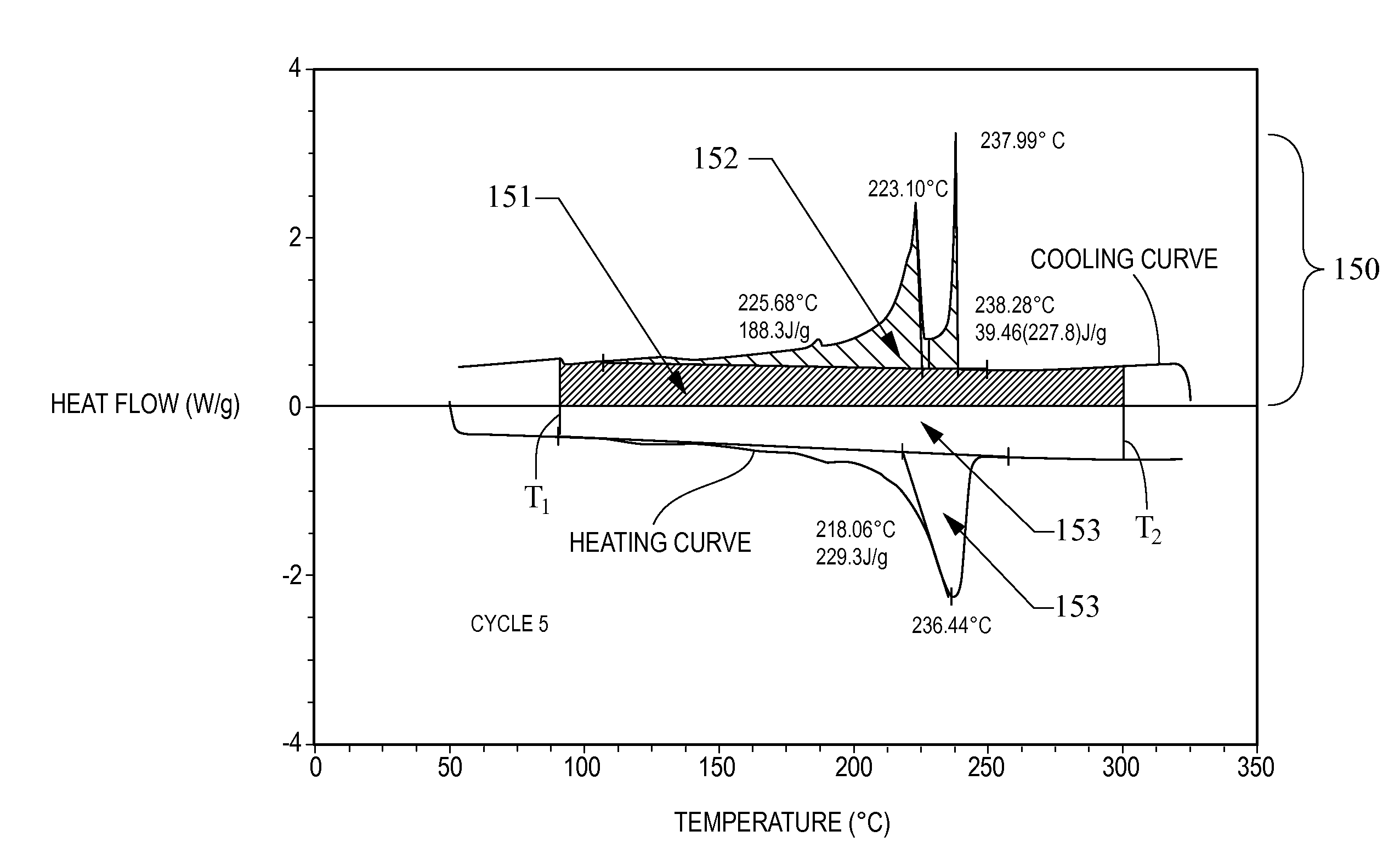

Thermal energy storage materials

A thermal energy storage material (TESM) system (and associated methods) that reproducibly stores and recovers latent heat comprising i) at least one first metal containing material including at least one first metal compound that includes a nitrate ion, a nitrite ion, or both; ii) at least one second metal containing material including at least one second metal compound; and iii) optionally including water, wherein the water concentration if any is present is less than about 10 wt. %; wherein the TESM has a liquidus temperature, TL, from about 100° C. to about 250° C.; and wherein the TESM exhibits a heat storage density from 300° C. to 80° C. of at least about 1 MJ / l; so that upon being used in a system that generates heat, at least a portion of the heat is captured and stored by the TESM and subsequently released for use, and the system is generally resistant to corrosion at temperatures of about 300° C.

Owner:DOW GLOBAL TECH LLC

Lead-free solder alloy

InactiveUS6319461B1Low melting pointImprove wettabilityWelding/cutting media/materialsSoldering mediaCeramicBonding strength

A lead-free solder alloy substantially contains Sn and Ti, and has a temperature of a liquidus line of not greater than 400° C. The lead-free solder alloy contains no toxic lead and has sufficient bonding strength to oxide materials such as glass and ceramics.

Owner:NIPPON SHEET GLASS CO LTD

Silicon carbide composites and methods for making same

InactiveUS6503572B1Improve permeabilityReduce the amount requiredPretreated surfacesCoatingsNet shapeToughness

Improved silicon carbide composites made by an infiltration process feature a metal phase in addition to any residual silicon phase. Not only are properties such as mechanical toughness improved, but the infiltrant can be so engineered as to have much diminished amounts of expansion upon solidification, thereby enhancing net-shape-making capabilities. Further, multi-component infiltrant materials may have a lower liquidus temperature than pure silicon, thereby providing the practitioner greater control over the infiltration process. In particular, the infiltration may be conducted at the lower temperatures, where low-cost but effective bedding or barrier materials can terminate the infiltration process once the infiltrant has migrated through the permeable mass up to the boundary between the mass and the bedding material.

Owner:BUSINESS ALLIANCE CAPITAL +1

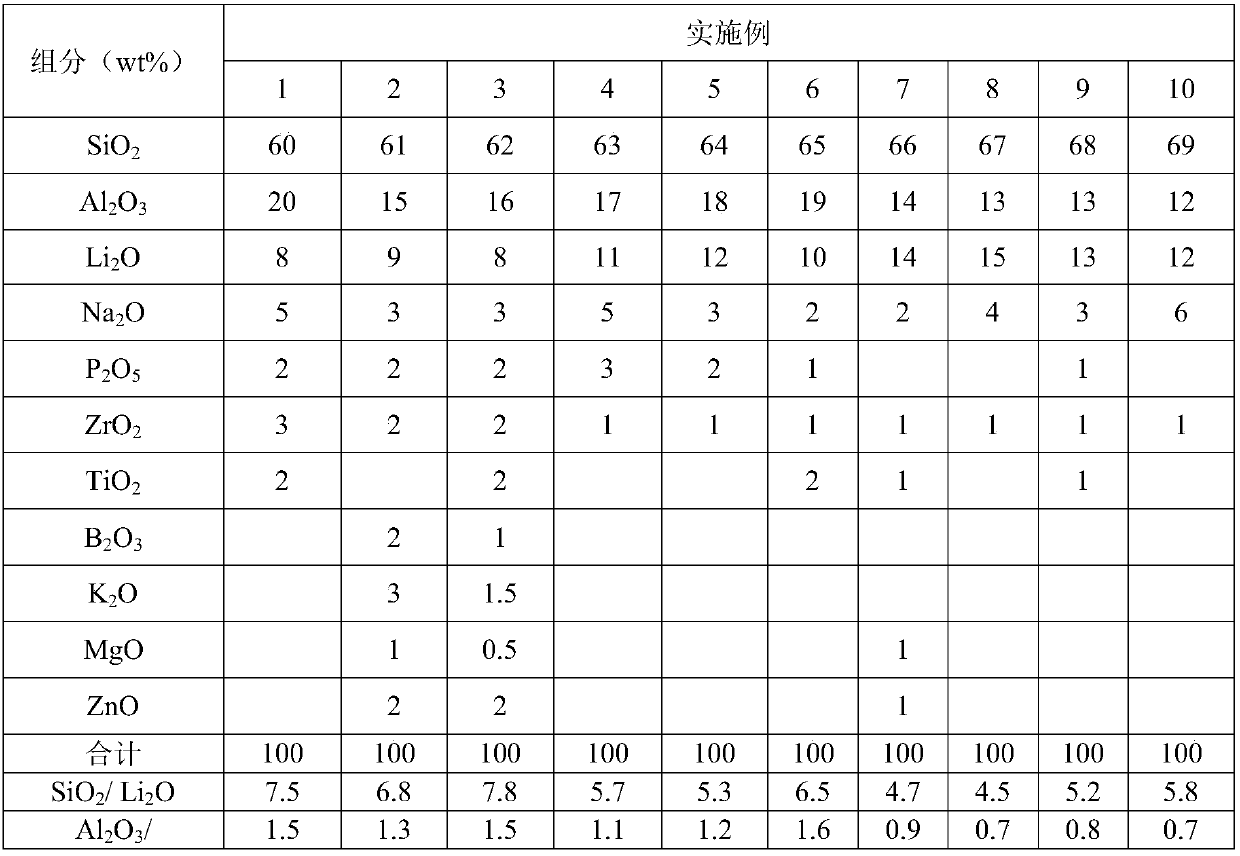

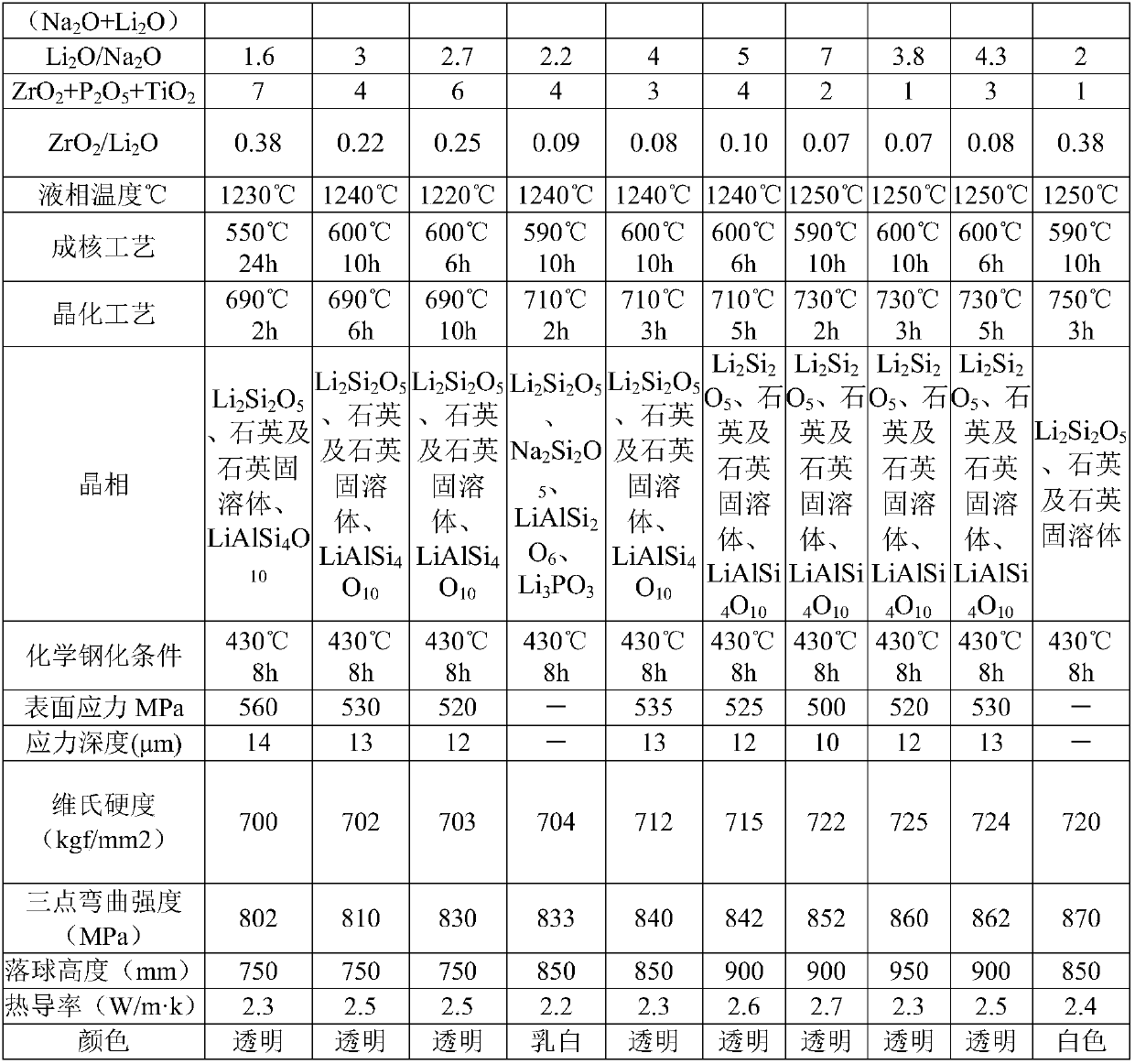

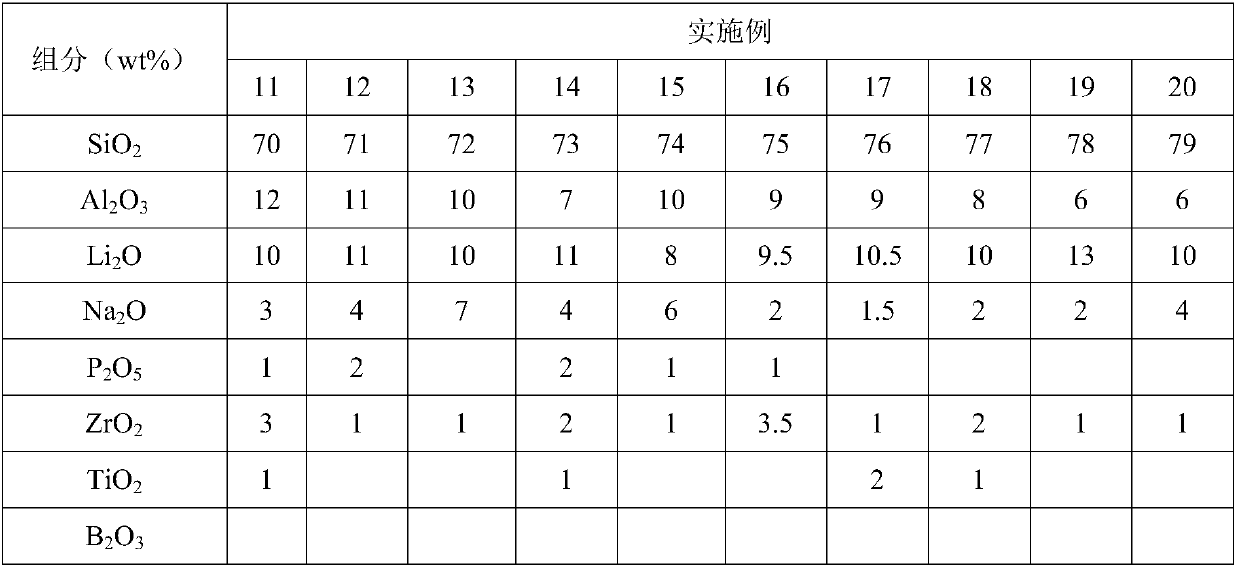

Microcrystalline glass and substrate thereof

The invention provides microcrystalline glass and a substrate thereof. The microcrystalline glass is low in liquidus temperature, and comprises the following components in percentage by weight: 60 to80 percent of SiO2; 4 to 20 percent of Al2O3; 0 to 15 percent of Li2O; greater than 0 and smaller or equal to 12 percent of Na2O; 0 to 5 percent of K2O; greater than 0 and smaller or equal to 5 percent of ZrO2; 0 to 5 percent of P2O5; 0 to 10 percent of TiO2. Crystalline phase contains one or more of R2SiO3, R2Si2O5, R2TiO3, R4Ti5O12, R3PO3, RAlSi2O6, RAlSiO4O10, R2Al2Si2O8, R4Al4Si5O18, quartz and quartz solid solution. The liquidus temperature of the microcrystalline glass is 1450 DEG C or less, the heat conductivity is 2w / m.k or more, the Vickers hardness is 600 kgf / mm<2> or more, and the microcrystalline glass is applicable to portable electronic equipment and optical equipment.

Owner:CDGM OPTICAL GLASS

Low-density glass for flat panel display substrates

Disclosed is a glass material essentially free of BaO and alkali oxide particularly suitable for the glass substrate of LCDs. The glass material consists essentially, expressed in mole percent on an oxide basis, of 70–80%, preferably 72–77% of SiO2, 3–9%, preferably 4–7% of Al2O3, 8–18%, preferably 10–16% B2O3, 3–10%, preferably 3–8% of CaO, 0–4%, preferably 0–3% RO, 0–0.2%, preferably 0–0.1% SnO, 0–1%, preferably 0 to 0.5% of XO, where RO represents, collectively, MgO, SrO and ZnO, XO represents, collectively, TiO2, ZrO2, Y2O3 and La2O3. The glass has a strain point in the range of over about 600° C., a coefficient of thermal expansion (CTE) in the range of about 23–35×10−7 / ° C., a density lower than about 2.35 g / cm3, a liquidus temperature lower than or equal to about 1200° C. and a durability in BHF less than or equal to 0.5 mg / cm2 weight loss.

Owner:CORNING INC

Lead-free alloy solder containing rare-earth and more alloy components

InactiveCN1346728ALower melting temperatureAdjust mechanical propertiesWelding/cutting media/materialsSoldering mediaRare-earth elementChemical composition

A lead-free alloy solder containing rare-earth elements and multiple other elements for electronic package contains Ag (0.1-5 wt.%), Cu (0.1-1 wt.%), Bi (0.1-8 wt.%), In (0.1-7.5 wt.%), Sb (0-8 wt.%), the mixture of La and Ce or the mixture of La, Ce and one or both of Pr and Nd (0.01-2 wt.%) and Sn (the balance). It has liquidus temp less than 210 deg.c (even 190 deg.C or lower), less than 15 deg.c for liquidus and solidus temp difference, at least 60 MPa of yield strength, at least 18% of elongation percentage, excellent wetting ability, and high soldering quality.

Owner:DALIAN UNIV OF TECH

Thermal enhancement approach using solder compositions in the liquid state

InactiveUS20010026957A1Thermal mismatchAvoid environmental degradationSemiconductor/solid-state device detailsSolid-state devicesThermal energyThermal coefficient

Solder compositions are introduced to interface between an IC chip and its associated heat exchanger cover. The solder compositions have a solidus-liquidus temperature range that encompasses the IC chip operational temperature range. The solder composition has the desired property of absorbing and rejecting heat energy by changing state or phase with each temperature rise and decline that result from temperature fluctuations associated with the thermal cycles of the integrated circuit chips. The electronic module cover is a cap with a heat exchanger formed or attached as a single construction, and made of the same material as the substrate, or made with materials of compatible thermal coefficients of expansion to mitigate the effects of vertical displacement during thermal cycling. The cap-heat exchanger cover is constructed to be compliant, and to contact both the IC chip and substrate in order to provide, in conjunction with the solder composition, a path of high thermal conduction (low thermal resistance) from the IC chip to the heat exchanger to the ambient air.

Owner:INT BUSINESS MASCH CORP

Optical glass and optical product

When a glass melt of an optical glass having a refractive index (nd) of at least 1.7 and an Abbe number (νd) of 28 to 41 is flowed down from a flow pipe made of Pt or a Pt alloy to form glass gobs continuously, there is caused a problem that the glass gobs have striae or that the weight variability among the glass gobs is large, and the problem can be overcome by the use of an optical glass comprising silicon oxide and boron oxide, the ratio of a content of the silicon oxide to a content of the boron oxide being greater than 0.78, the optical glass having a contact angle of at least 40° to Pt or a Pt alloy at a predetermined temperature equivalent to, or higher than, its liquidus temperature or in a predetermined temperature range whose lower limit is equivalent to, or higher than, the liquidus temperature and having a sag temperature Ts of 580° C. or lower.

Owner:HOYA CORP

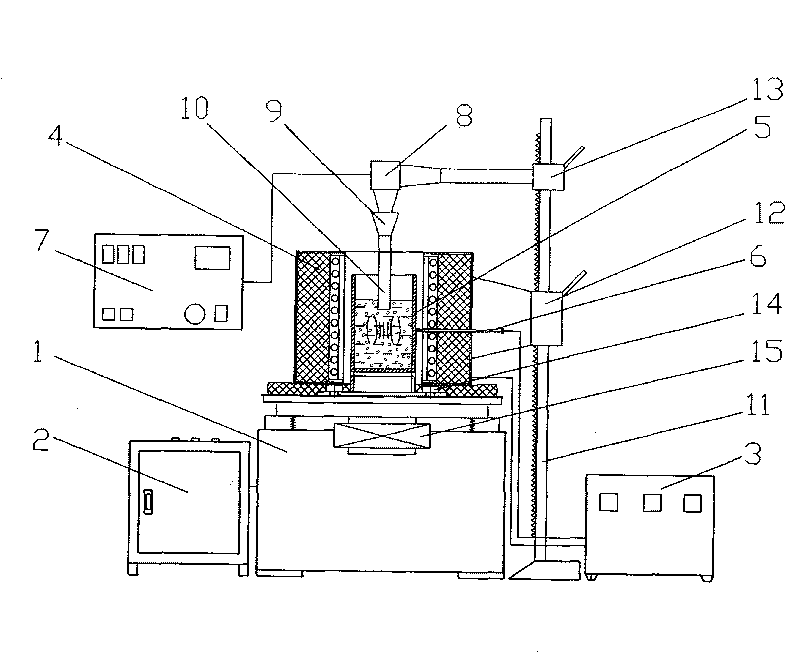

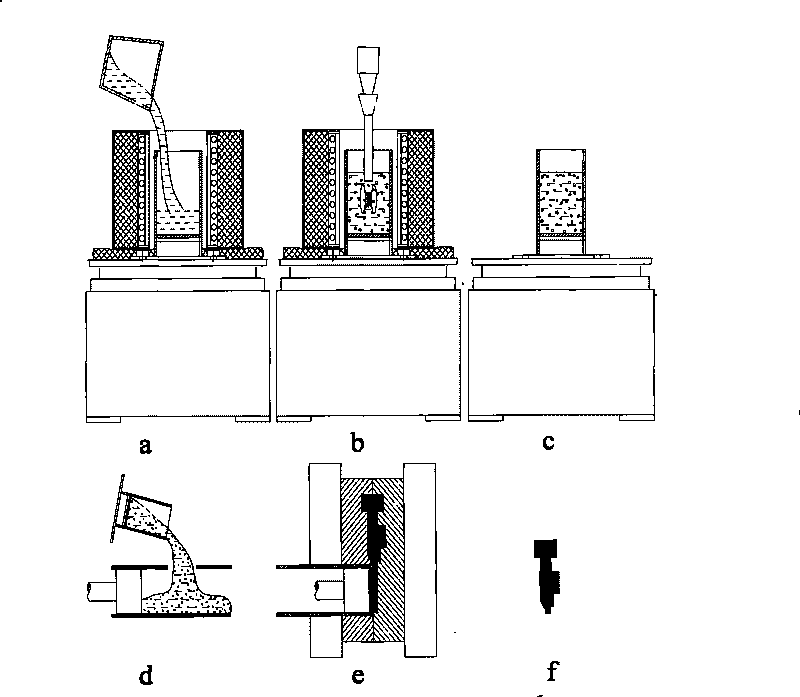

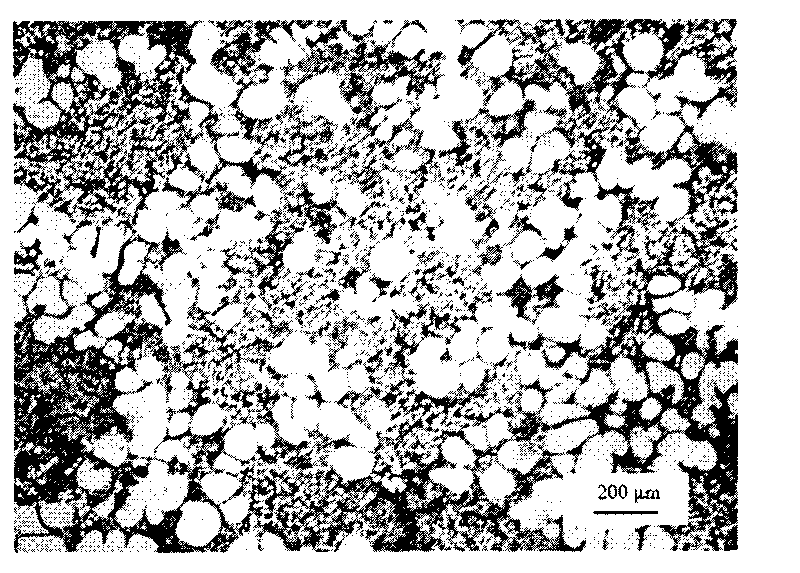

Method and device for preparing semisolid metal slurry by mixing vibration

The invention belongs to the technical field of metal semisolid processing, relating to a method and a device for preparing semisolid metal slurry by mixing vibration. A slurry containing container is tightly fixed on a mechanical vibration table, and superheating molten metal 0-40 DEG C higher than the liquidus is poured into the slurry containing container of which the temperature is lower than molten metal temperature. An ultrasonic vibrator is lowered below the molten metal liquid level for 1-25 mm and simultaneously starts low-frequency mechanical vibration and supersonic vibration; after performing mixing vibration for certain time, the molten metal is controlled to be 5-30 DEG C below the liquidus temperature to obtain the semisolid metal slurry of which the solid phase rate is 5-40%. The semisolid metal slurry prepared with the method has fine primary and round grain and even distribution. The device of the invention comprises a slurry containing container, an attemperation unit, a supersonic generating and controlling unit, a low-frequency mechanical vibration generating and controlling unit and a lifting unit. The invention can be used for preparing semisolid slurry of various alloy parts, such as aluminium, magnesium, stannum, copper, zinc and the like as well as used for forming parts.

Owner:HUAZHONG UNIV OF SCI & TECH

Glass fiber capable of being used as advanced reinforced substrate of composite material

InactiveCN101691278ALow molding temperatureReduce the temperatureGlass fiberUltimate tensile strength

The invention discloses a glass fiber capable of being used as an advanced reinforced substrate of a composite material, comprising the following components in percentage by weight: 57 to 65 percent of SiO2, 14 to 20 percent of Al2O3, 8 to 13 percent of CaO, 7 to 12 percent of MgO, less than 23 percent of CaO and MgO, 0.05 to 2 percent of Na2O and K2O, and 0.05 to 1 percent of Fe2O3. While the mold temperature, the liquidus temperature and the refining temperature of the glass fiber are maintained to be relatively low, through optimization and combination of the components, the mechanical performance of the glass fiber is greatly improved compared with conventional E glass fiber, and the increase range of monofilament strength can be increased up to 26 percent, and the total cost of the glass fiber is possibly close to or lower than the cost of the conventional E glass fiber, thus being easy for implementing large-scale industrial production.

Owner:JUSHI GRP CO

Electrolyte Compositions, Methods Of Making And Battery Devices Formed There From

InactiveUS20130095392A1Reduce volatilityWide rangeHybrid capacitor electrolytesAlkaline accumulatorsElectrolysisPhosphonium

The invention generally encompasses phosphonium ionic liquids, salts, compositions and their use in many applications, including but not limited to: as electrolytes in electronic devices such as memory devices including static, permanent and dynamic random access memory, as electrolytes in energy storage devices such as batteries, electrochemical double layer capacitors (EDLCs) or supercapacitors or ultracapacitors, electrolytic capacitors, as electrolytes in dye-sensitized solar cells (DSSCs), as electrolytes in fuel cells, as a heat transfer medium, among other applications. In particular, the invention generally relates to phosphonium ionic liquids, salts, compositions, wherein the compositions exhibit superior combination of thermodynamic stability, low volatility, wide liquidus range, ionic conductivity, and electrochemical stability. The invention further encompasses methods of making such phosphonium ionic liquids, salts, compositions, operational devices and systems comprising the same.

Owner:ESIONIC

Fusion formable sodium free glass

ActiveUS20100300536A1Improve battery efficiencyImprove film adhesionFinal product manufactureSynthetic resin layered productsSilicate glassThermal expansion

A compositional range of fusion-formable, high strain point sodium free, silicate, aluminosilicate and boroaluminosilicate glasses are described herein. The glasses can be used as substrates for photovoltaic devices, for example, thin film photovoltaic devices such as CIGS photovoltaic devices. These glasses can be characterized as having strain points≧540° C., thermal expansion coefficient of from 6.5 to 10.5 ppm / ° C., as well as liquidus viscosities in excess of 50,000 poise. As such they are ideally suited for being formed into sheet by the fusion process.

Owner:CORSAM TECH

Glasses for flat panel displays

Glasses are disclosed which are used to produce substrates in flat panel display devices. The glasses exhibit a density less than about 2.45 gm / cm3 and a liquidus viscosity greater than about 200,000 poises, the glass consisting essentially of the following composition, expressed in terms of mol percent on an oxide basis: 65-75 SiO2, 7-13 Al2O3, 5-15 B2O3, 0-3 MgO, 5-15 CaO, 0-5 SrO, and essentially free of BaO. The glasses also exhibit a strain point exceeding 650° C.

Owner:CORNING INC

Glass article and glass substrate for information recording media using the same

InactiveUS20020193233A1Easy to useEasy to produceBase layers for recording layersLight beam reproducingHydrofluoric acidWorking temperature

A glass article of the present invention has a rate of dissolution in an acidic liquid of from 10 to 100 nm / min in terms of etching rate in immersing in a 0.1% by weight 50° C. aqueous solution of hydrofluoric acid and an average linear thermal expansion coefficient of 70x10-7 / ° C. or higher as measured in the range of from -50° C. to 70° C., and the working temperature T4 (° C.) and the liquidus temperature TL (° C.) thereof satisfy the relationship: T4-TL>=-100° C.

Owner:HOYA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com