Method and device for preparing semisolid metal slurry by mixing vibration

A semi-solid metal and slurry technology, which is applied in the field of semi-solid processing and casting of metals, can solve the problem of inappropriate preparation of semi-solid metal slurry, high cost of semi-solid slurry and billet, and difficulty in preparing solid fraction slurry, etc. problem, to achieve the effect of efficient preparation, reduced preparation cost and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

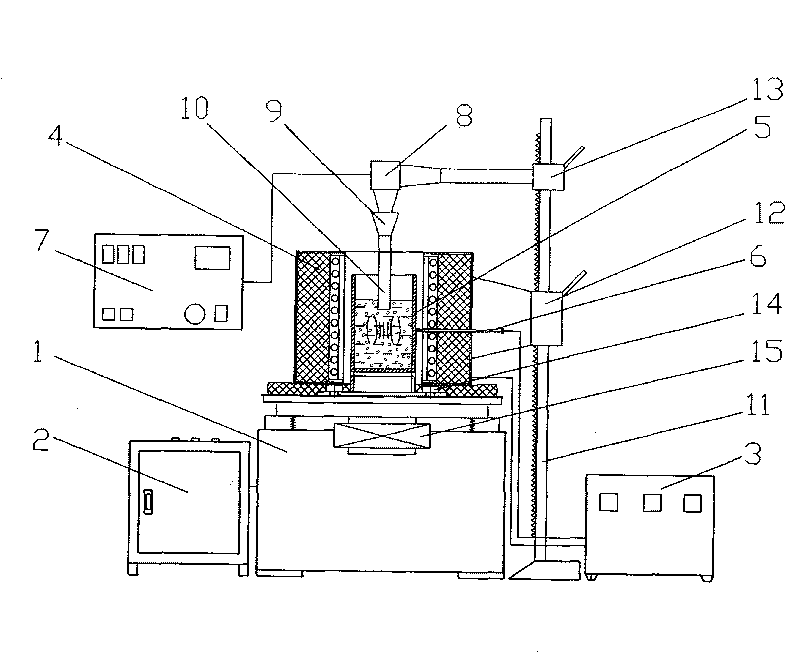

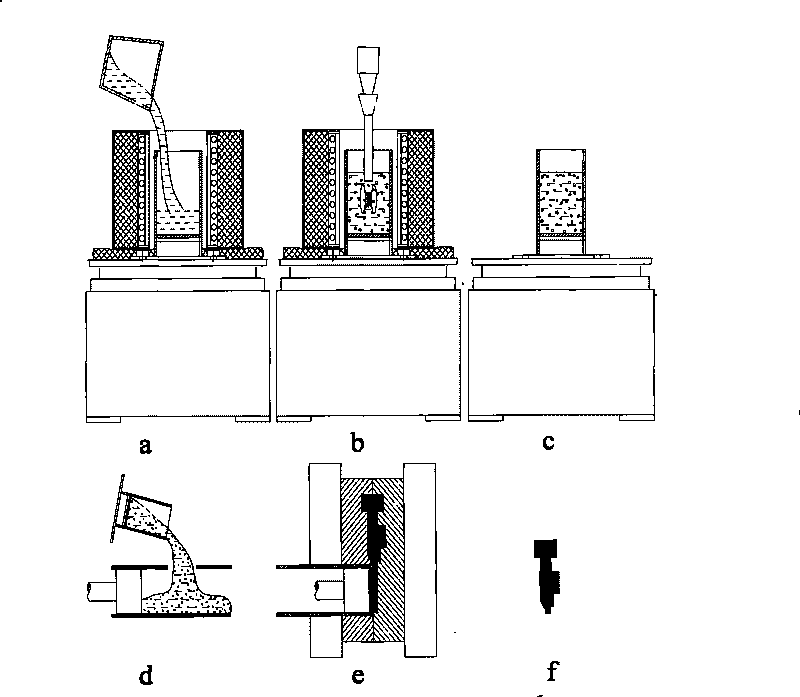

[0045] Preparation of semi-solid parts by using ZL101 aluminum alloy for mixed vibration. The liquidus temperature of ZL101 aluminum alloy is 616°C and the solidus temperature is 567°C. The alloy is melted in a heating furnace and heated to 740°C, refined and degassed for later use. The temperature of the alloy liquid is maintained at about 660°C by means of a temperature control device. Take an appropriate amount of alloy liquid, import it into the slurry container, use the temperature control system (heating furnace 4, thermocouple 6 and temperature controller 3) to control the temperature of the melt at 610°C, and the cooling rate of the melt is 0.1-3°C / s .

[0046] Insert the ultrasonic vibration head 10 into the place 15mm below the liquid level of the aluminum alloy in the slurry container ( figure 1 ), simultaneously turn on ultrasonic vibration and low-frequency mechanical vibration, and perform mixed vibration on the molten metal. Ultrasonic vibration frequency is...

example 2

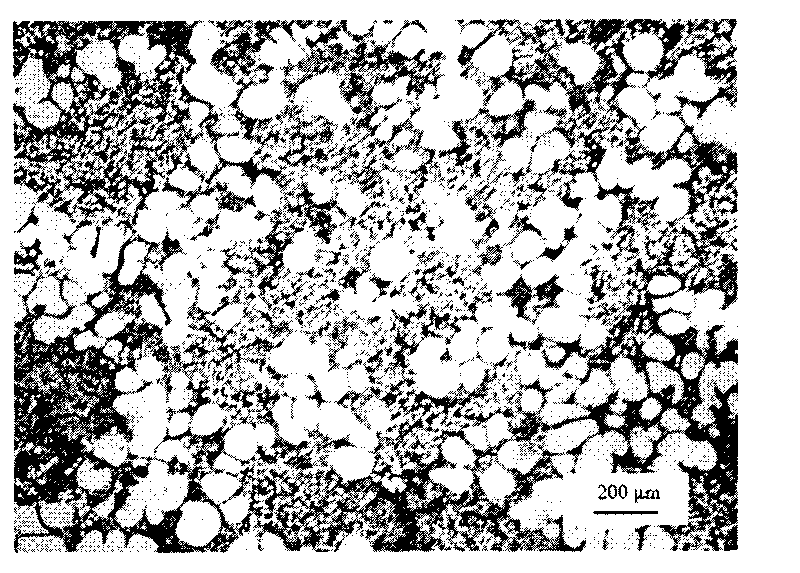

[0048] The semi-solid slurry was prepared by mixing and vibrating Al-20Si-2.0Cu-0.4Mg-1.0Ni high-silicon aluminum alloy. Al-20Si-2.0Cu-0.4Mg-1.0Ni high-silicon aluminum alloy has a liquidus temperature of 700°C and a solidus temperature of 535°C. The alloy is melted in a heating furnace and heated to 850°C, refined and degassed for later use. The temperature of the alloy liquid is kept at about 740°C by means of a temperature control device. Take an appropriate amount of alloy liquid and pour it into a slurry crucible ( figure 1 ), using a temperature control device to control the temperature of the alloy liquid at 720°C, and the melt cooling rate at 0.1-3°C / s.

[0049] Lower the ultrasonic vibration head 10 to 15 mm below the liquid level of the high-silicon aluminum alloy in the slurry container 5, and simultaneously turn on the ultrasonic vibration and low-frequency mechanical vibration to perform mixed vibration on the molten metal. Ultrasonic vibration frequency is 25k...

example 3

[0051] Preparation of semi-solid parts by using ZL104 aluminum alloy for mixed vibration. The liquidus temperature of ZL104 aluminum alloy is 610°C and the solidus temperature is 565°C. The alloy is melted in a heating furnace and heated to 740°C, refined and degassed for later use. The temperature of the alloy liquid is maintained at about 660°C by means of a temperature control device. Take an appropriate amount of alloy liquid, import it into the slurry container, use the temperature control system (heating furnace 4, thermocouple 6 and temperature controller 3) to control the temperature of the melt at 600°C, and the cooling rate of the melt is 0.1-3°C / s .

[0052] Insert the ultrasonic vibrating head 10 into the place 10mm below the liquid level of the aluminum alloy in the slurry container ( figure 1 ), simultaneously turn on ultrasonic vibration and low-frequency mechanical vibration, and perform mixed vibration on the molten metal. Ultrasonic vibration frequency is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com