Patents

Literature

67results about How to "Improve pulping quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

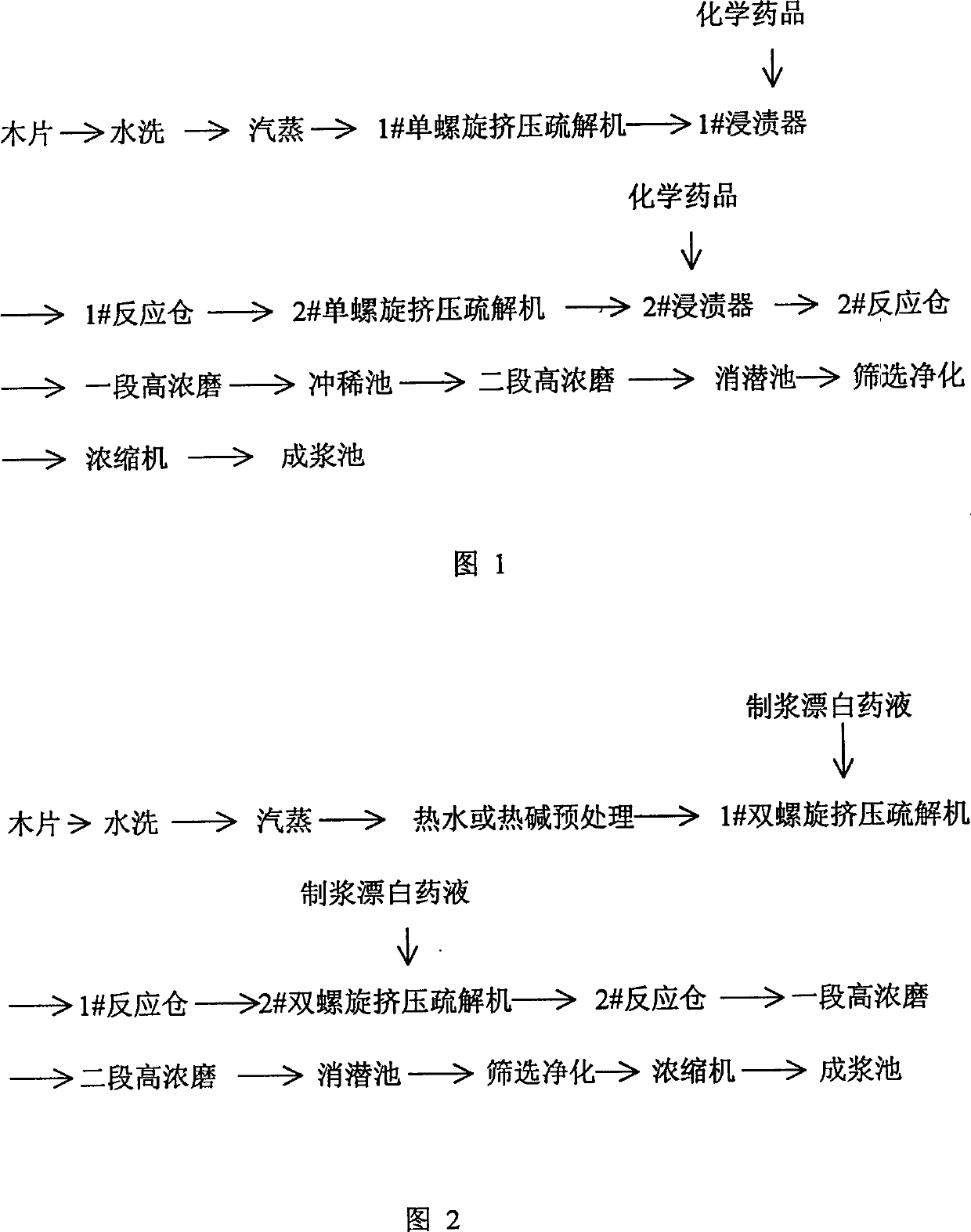

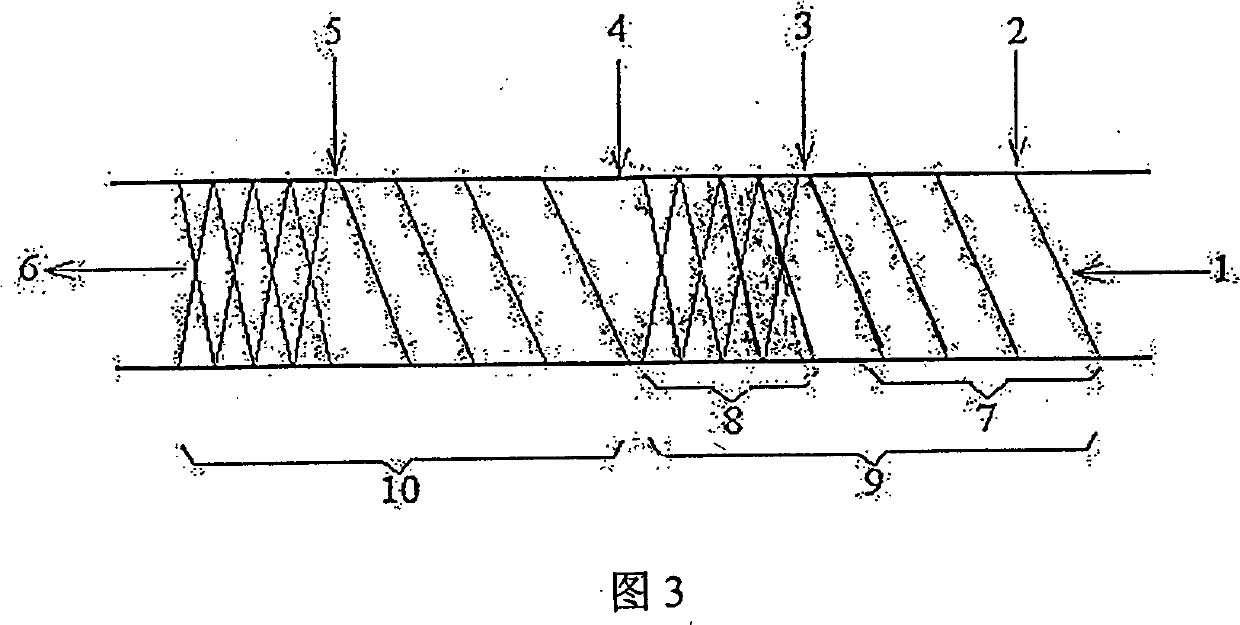

New process for producing alkaline hydrogen peroxide mechanical pulp by double scrwe extruding method

InactiveCN1587502AImprove extrusion tear effectImprove pulping qualityPulp bleachingPulp beating/refining methodsHigh concentrationFiber

The present invention is improved double screw extruding pulp producing process of alkali hydrogen peroxide mechanical pulp (APMP). The technological process includes water washing spill, steam digestion, hot water or hot alkali pre-treatment, treating in the first screw extruding breaker beater, reaction in the first reaction compartment, treating in the second screw extruding breaker beater, reaction in the second reaction compartment, milling in the first high concentration mill, milling in the second high concentration mill, sieving and purification, concentration, pulping pond treatment and other steps. Compared with traditional APMP, the present invention has similar quality and the advantages of simplified technological process, saving in investment and power consumption, less water consumption and lower waste water treating load. The present invention is suitable for producing APMP with different timber material, bagasse, etc.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

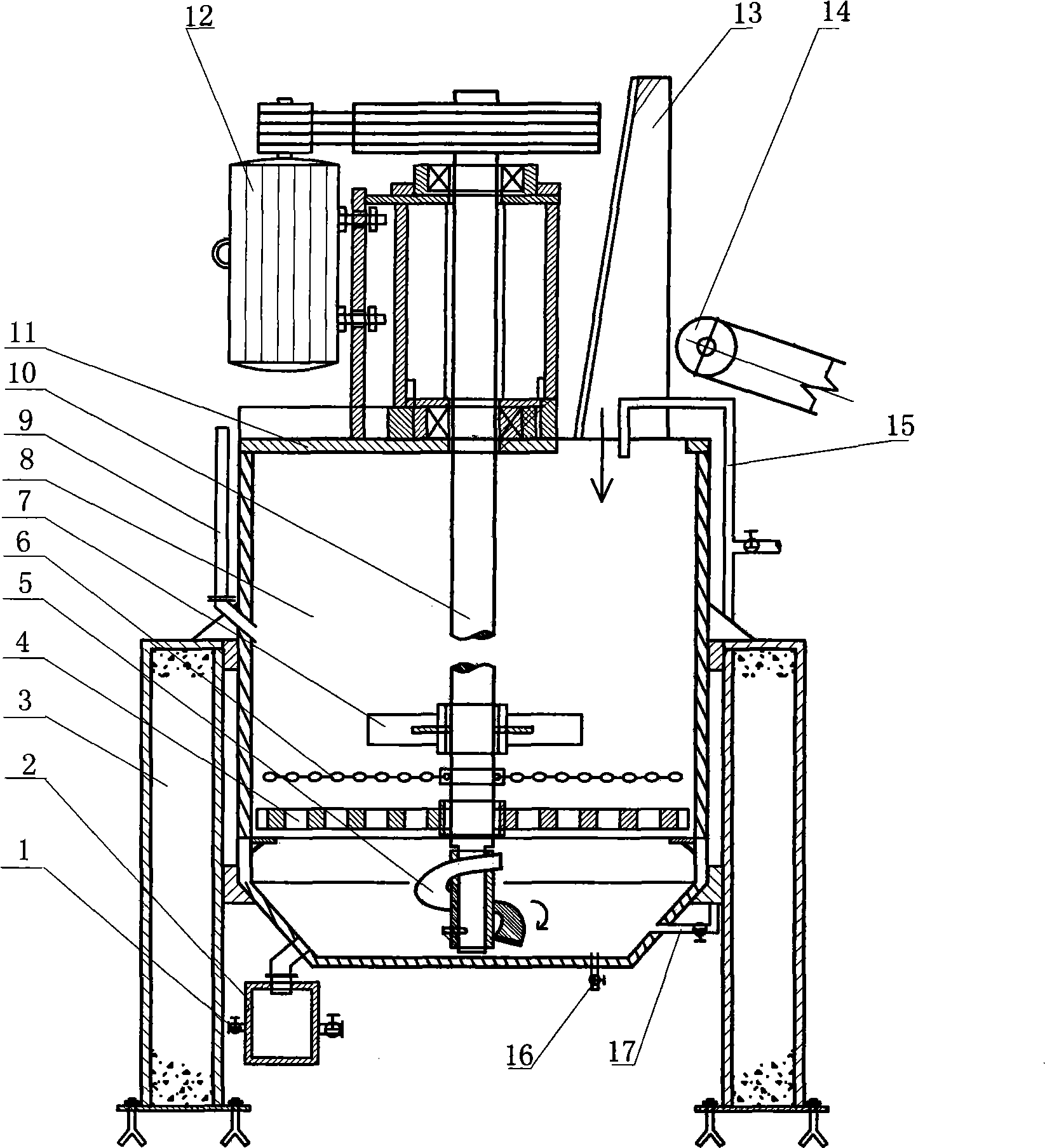

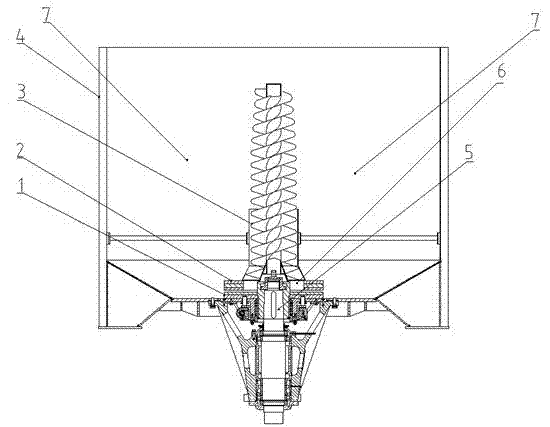

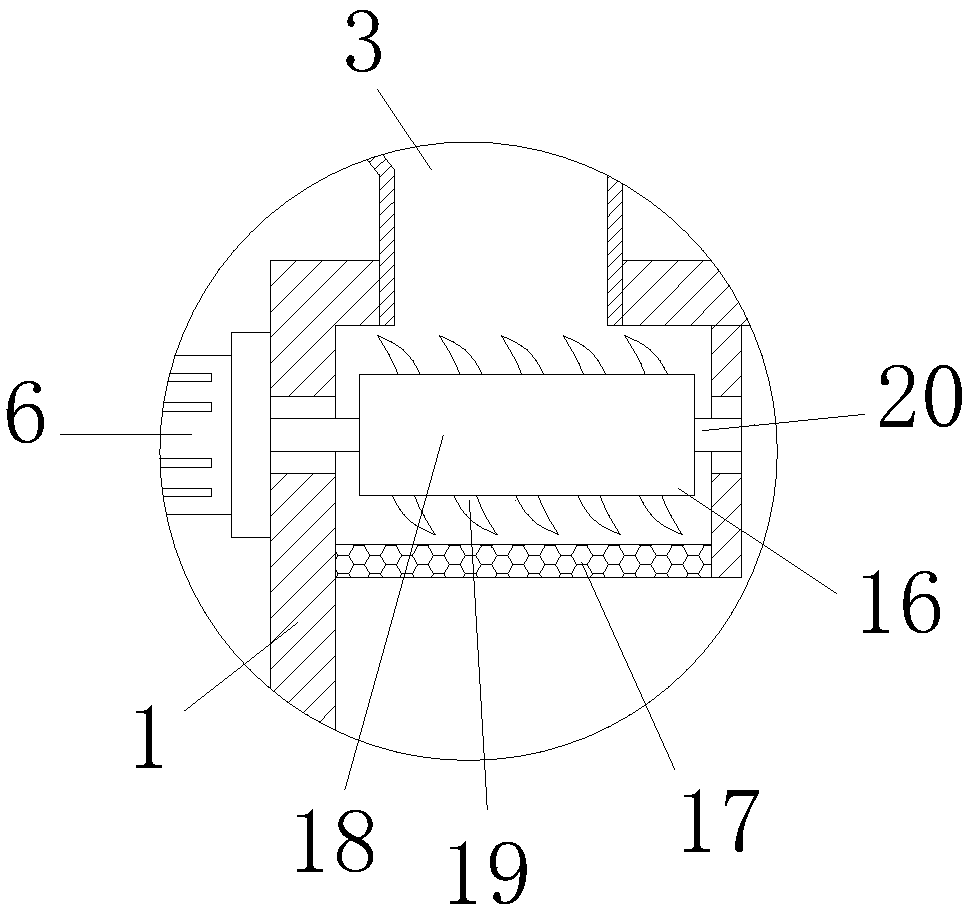

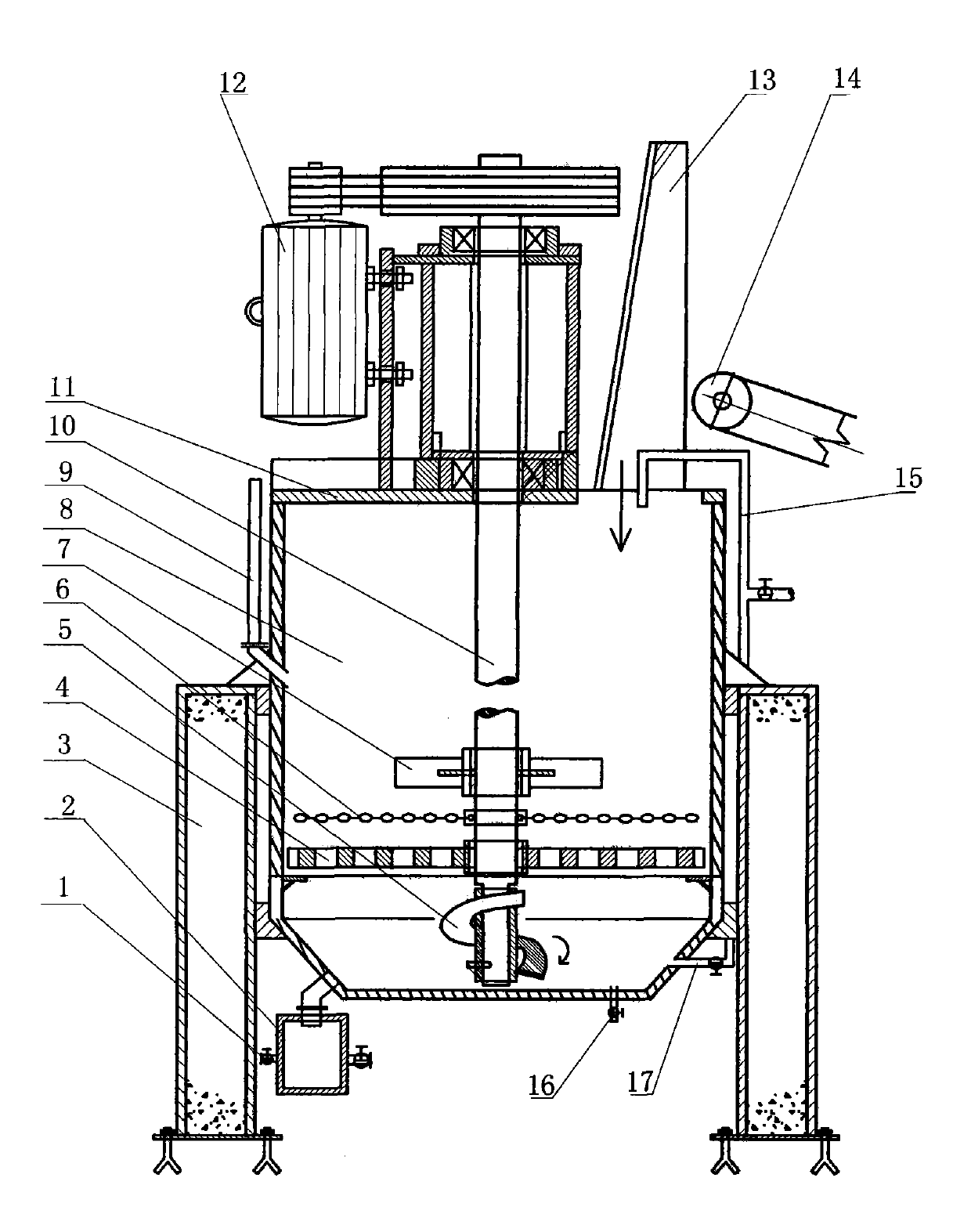

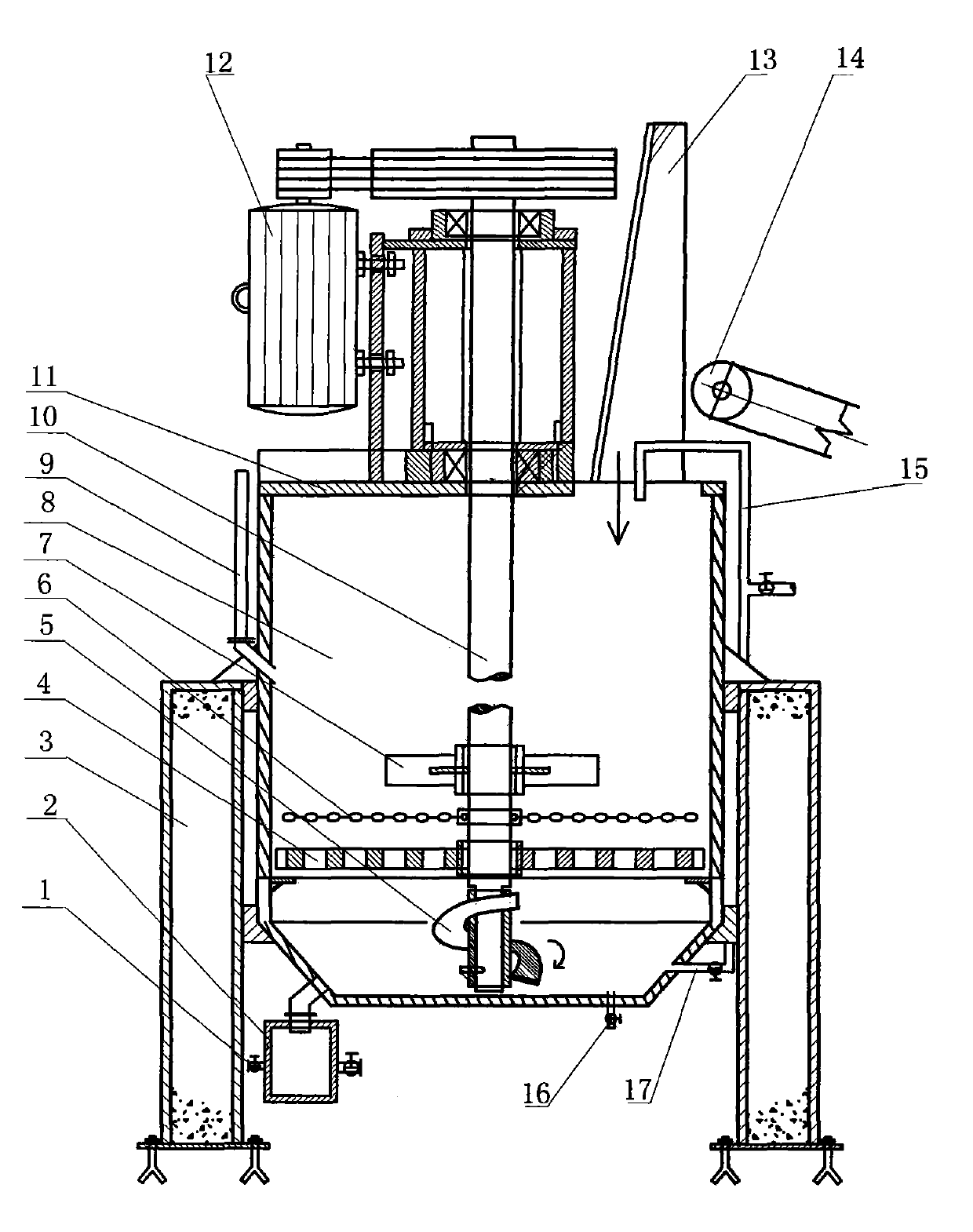

Mortar mixer

InactiveCN101508146AIncrease volumeLong hydrophilic timeDischarging apparatusMixing operation control apparatusEngineeringMechanical engineering

The invention relates to a mortar mixer, which comprises a mixer barrel body and a transmission device. A mixing main shaft in the mixer barrel body is connected with a mixing vane, the mixer barrel body has a vertical structure, a motor is arranged on the top of the mixer barrel body, the mixing main shaft penetrates into the mixer barrel body vertically, a sandy material feeding baffle plate is arranged between a charging opening and the transmission device, a sand feeding belt is arranged above a feed inlet, the end part of a water inlet pipe is positioned in the feed inlet, and a mixing chain is connected below the mixing vane of the mixing main shaft. The mortar mixer combines the functions of mixing and crashing, and has high slurrying efficiency, large volume of a mixing drum, and large slurrying capacity.

Owner:刘兴才

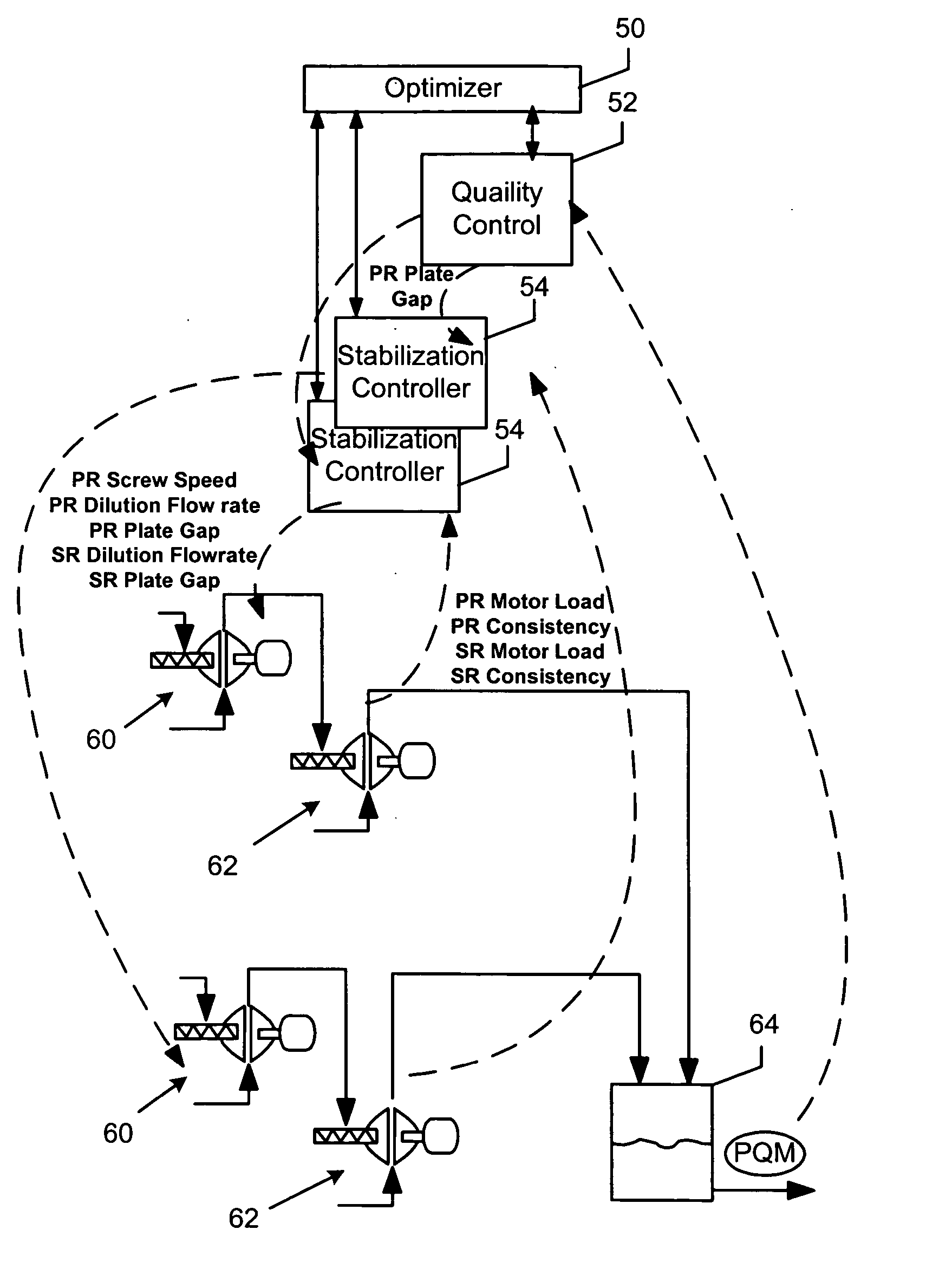

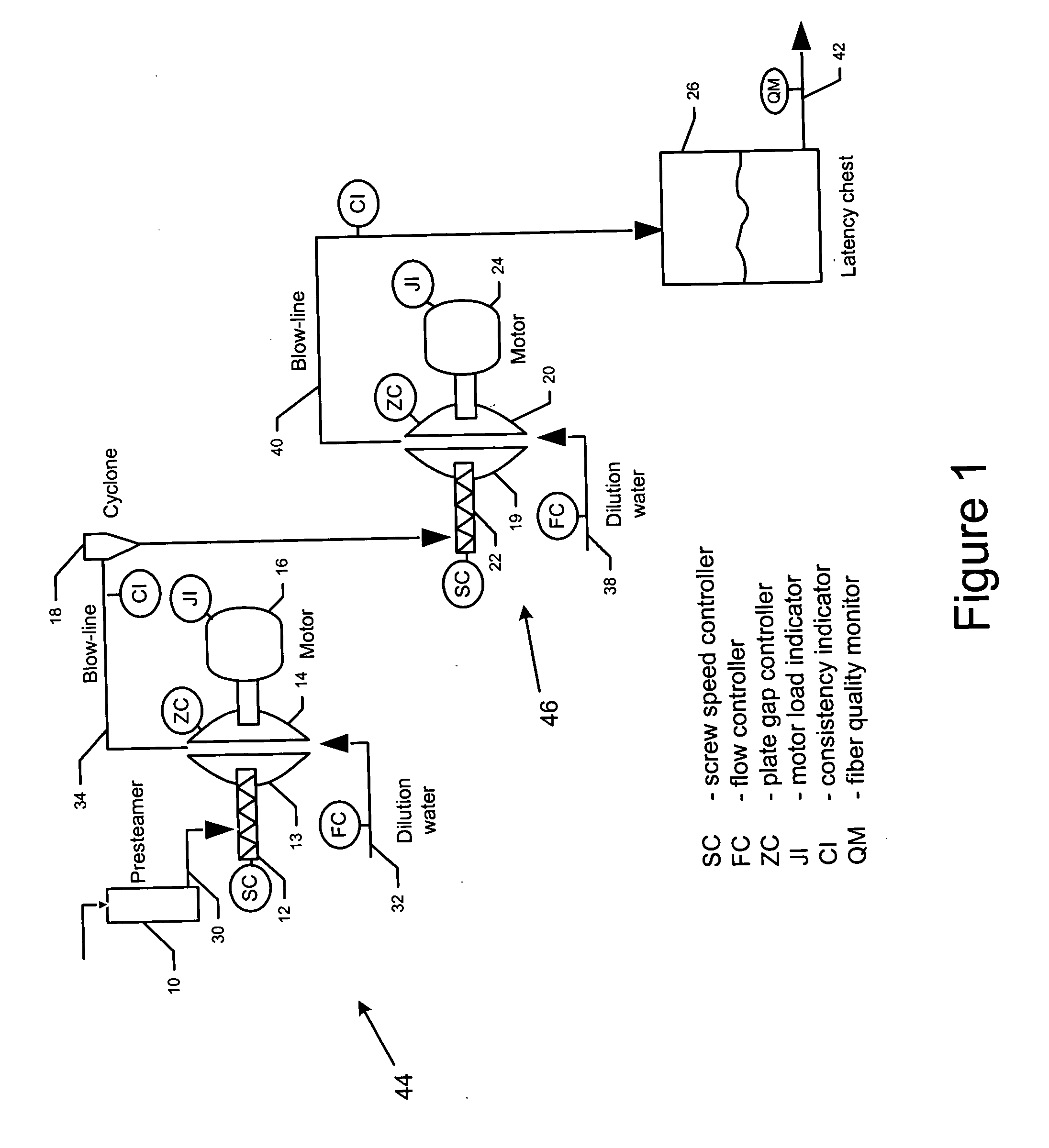

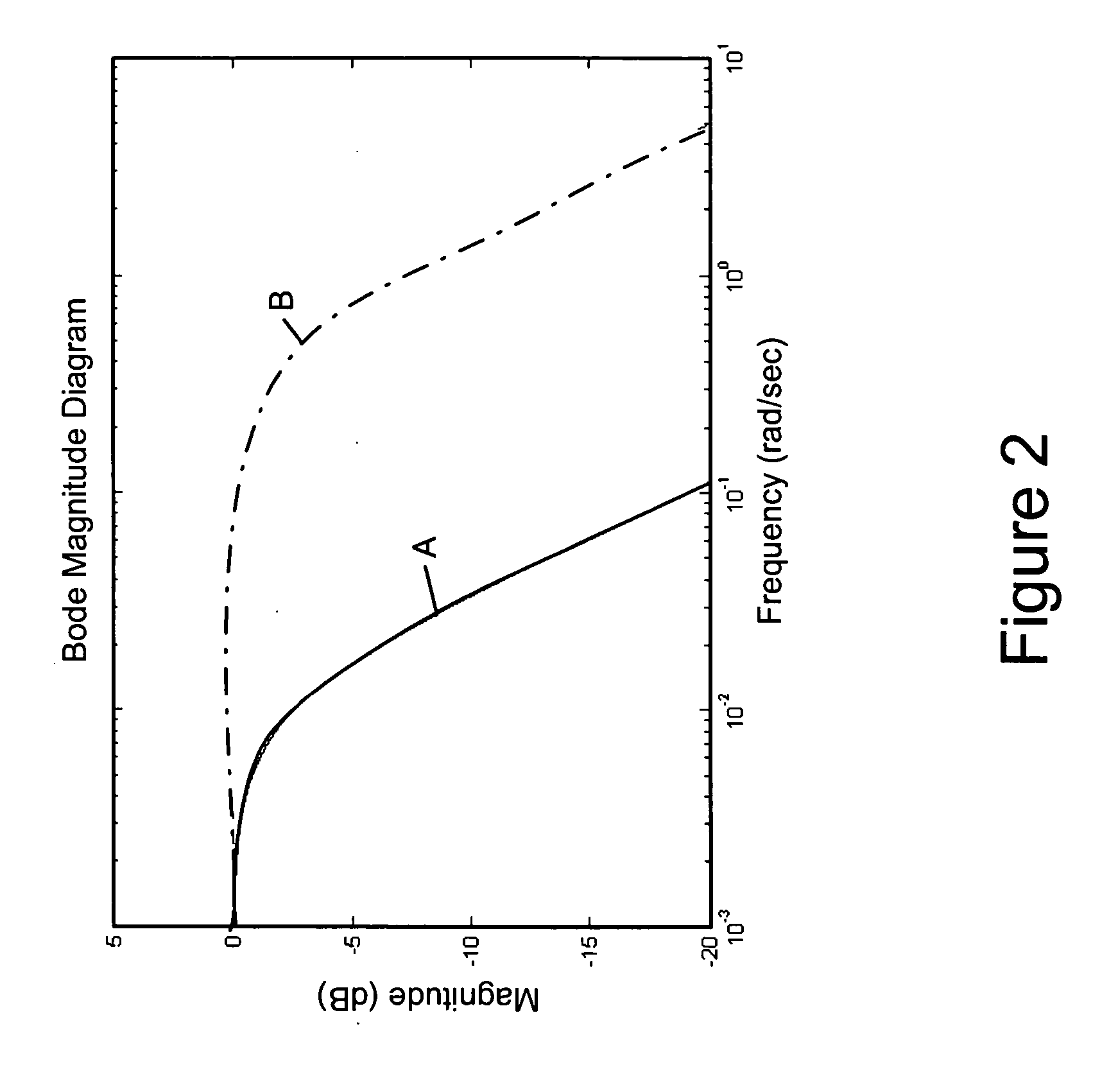

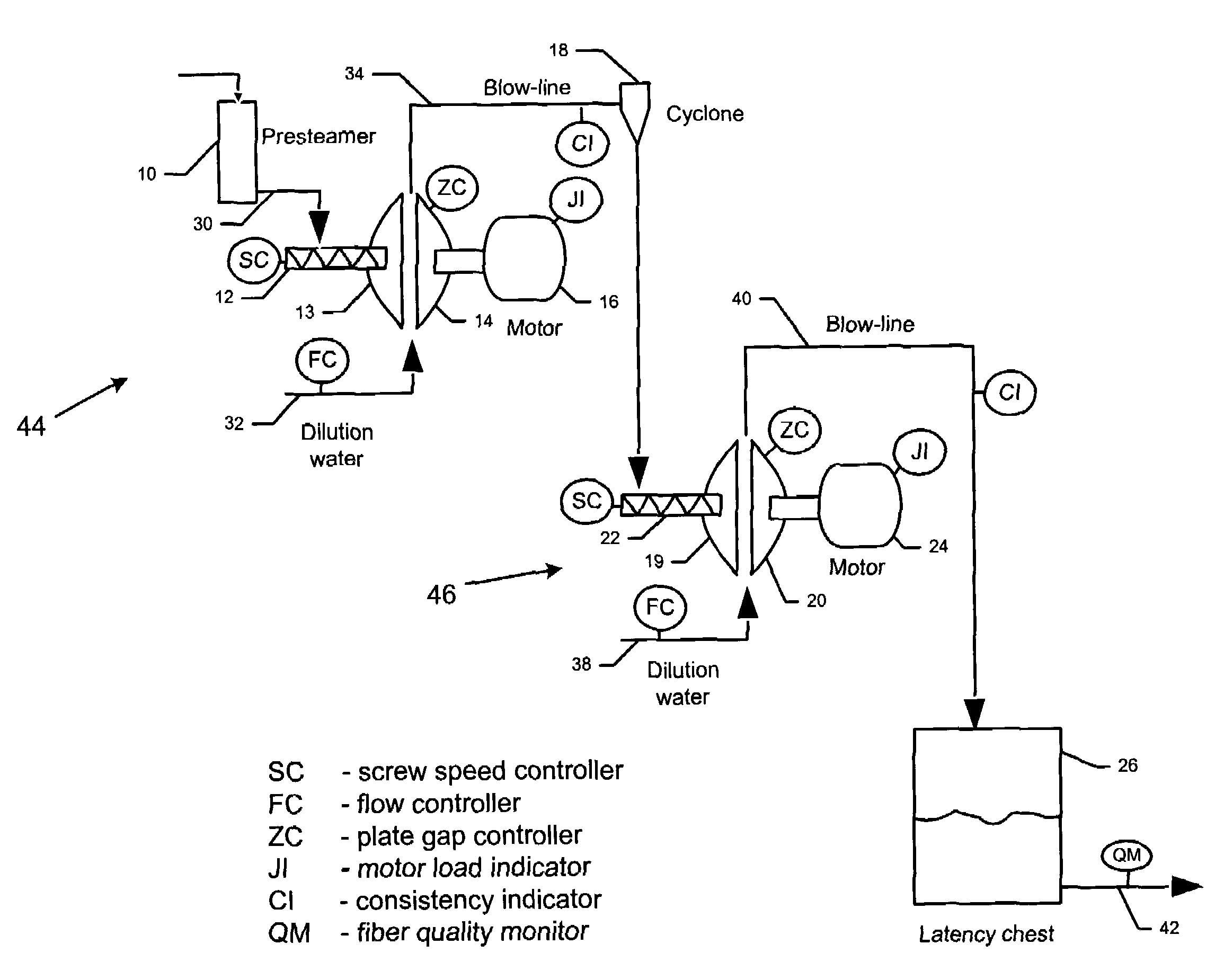

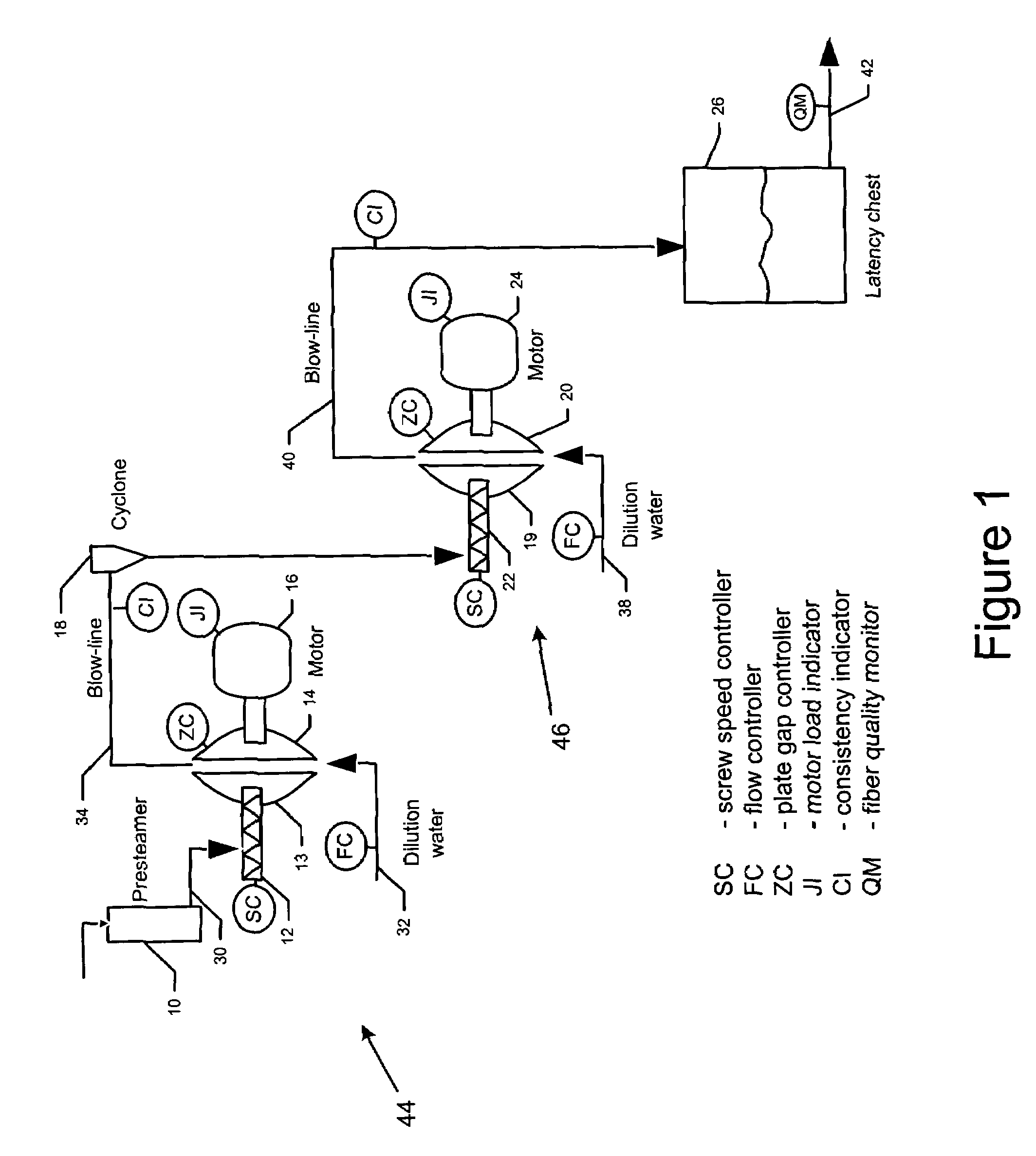

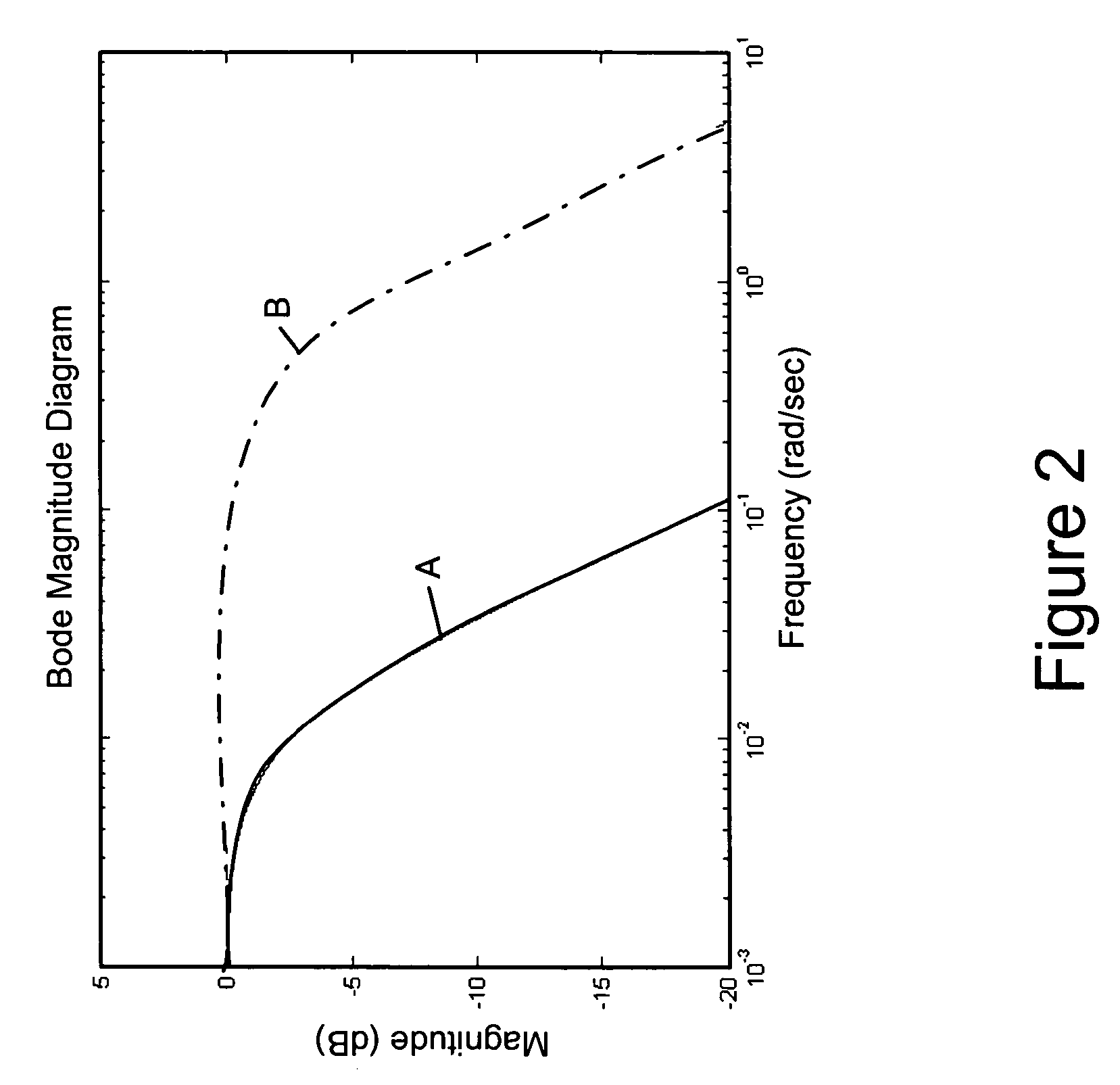

System and method for controlling a thermo-mechanical wood pulp refiner

ActiveUS20050263259A1Improve throughputReduce energy useBeating/refining control devicesComputer controlFiberQuality optimization

Thermomechanical pulp is an important process for producing fibrous mass used in papermaking. A two-level control strategy that stabilizes and optimizes the refining process has been developed. The Stabilization layer consists of a multivariable model predicative range controller that regulates the refiner line operations. The Quality Optimization layer provides the pulp quality control as measured by an online pulp quality (freeness, fibre length) sensor. This control startegy leverages the natural decoupling in the process. The modular design technique is able to handle multiple refiner lines that empty into a common latency chest. A global optimizer is also used to integrate and coordinate the two layers for enhanced constraint handling.

Owner:HONEYWELL INT INC

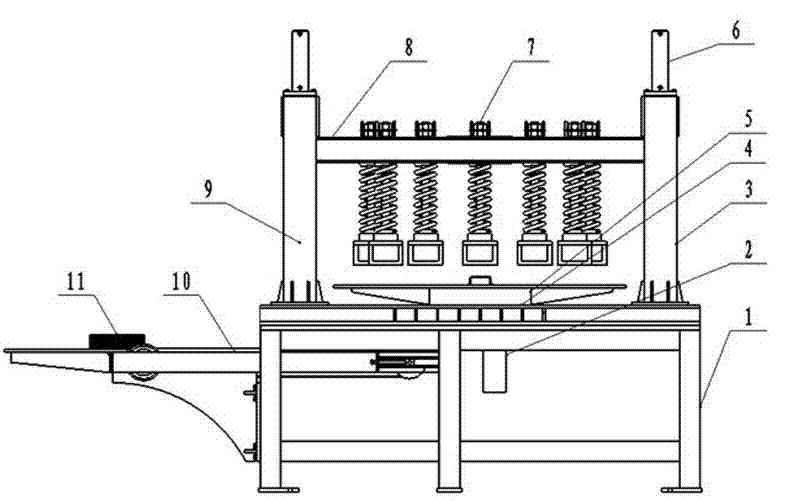

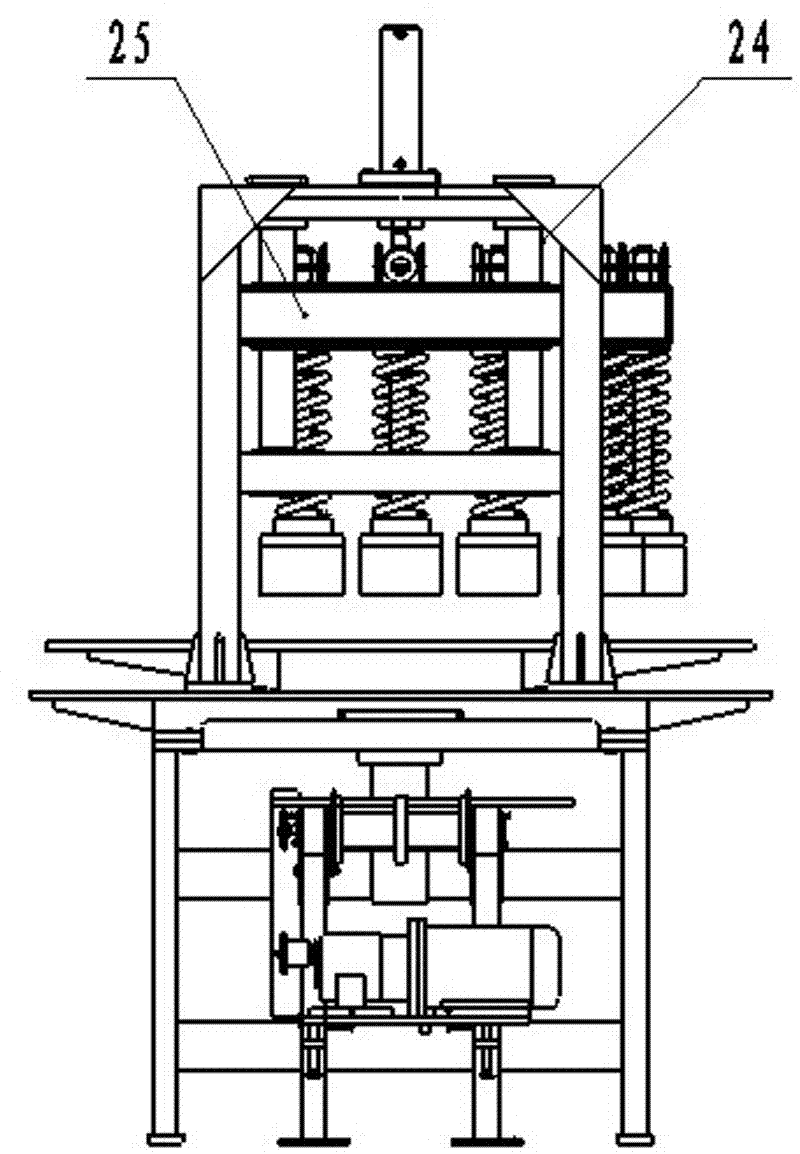

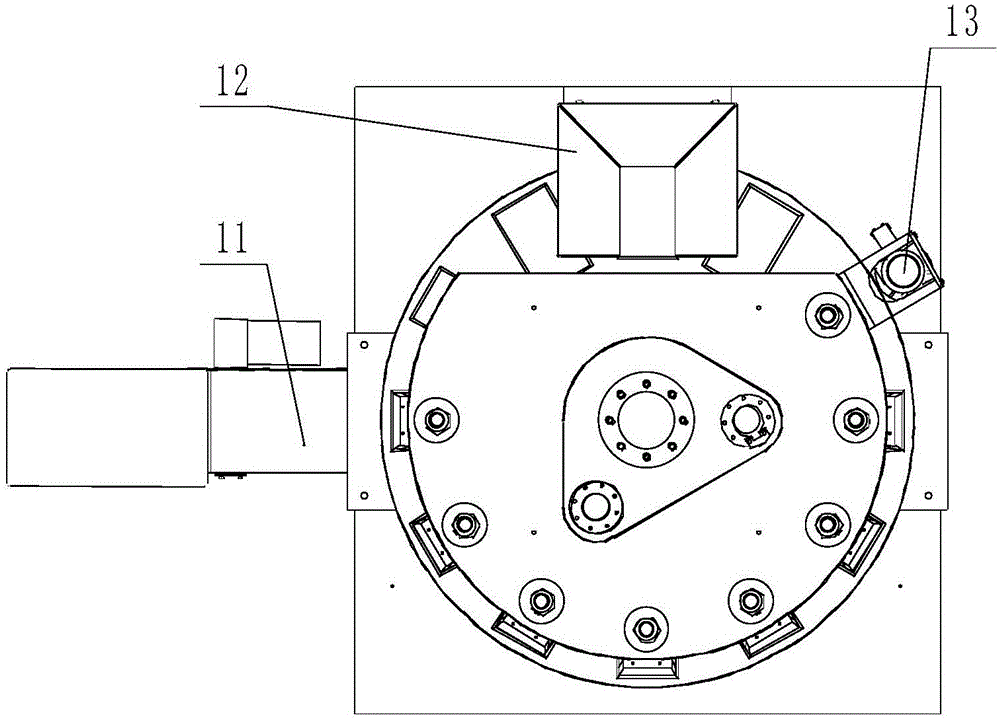

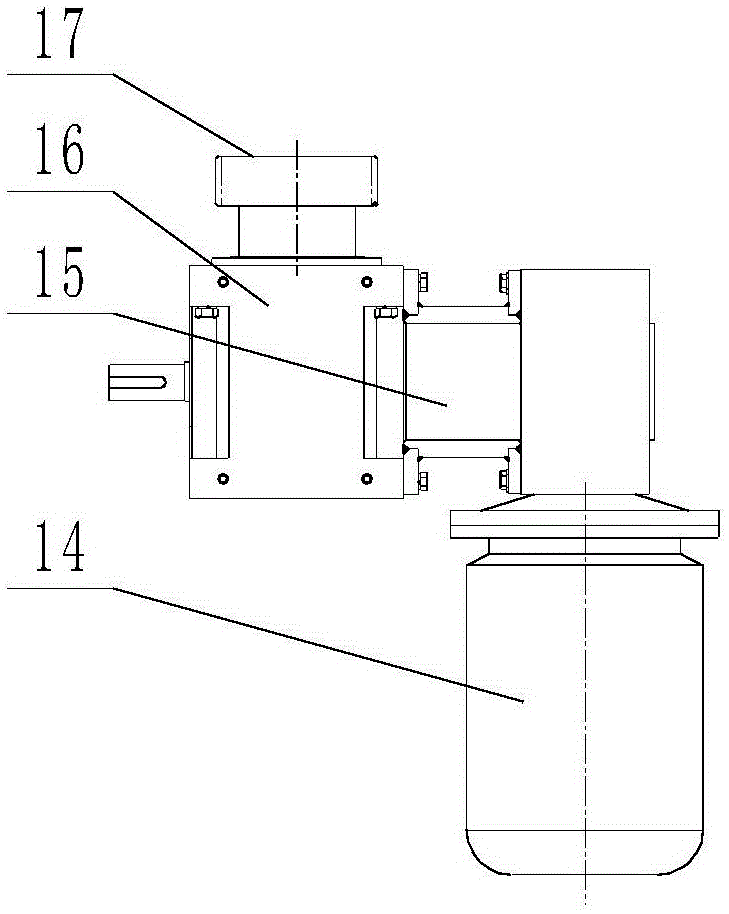

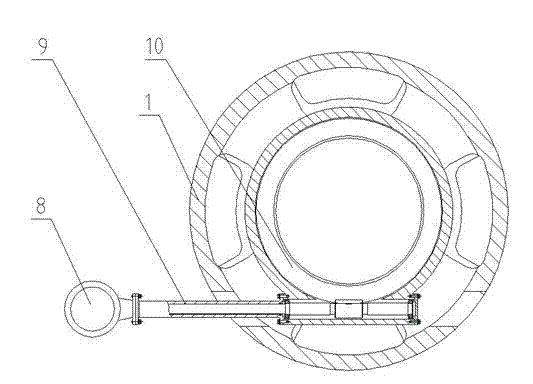

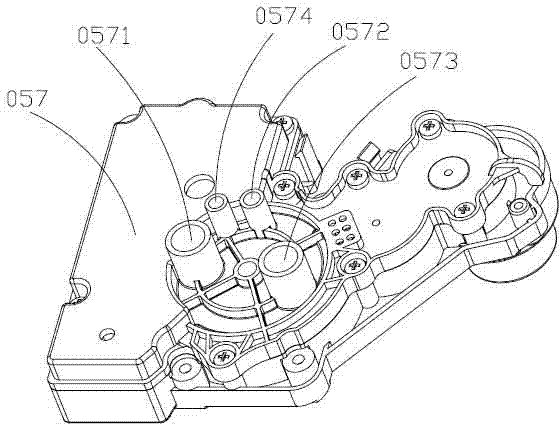

Hydraulic rotary koji pressing machine and pressing method thereof

InactiveCN102206564AUniform qualityQuality improvementAlcoholic beverage preparationEngineeringMechanical engineering

The invention relates to a hydraulic rotary koji pressing machine and a pressing method thereof. The hydraulic rotary koji pressing machine comprises a hydraulic motor, a frame, a rotary assembly, a pressure assembly and a runout table for starter materials. The hydraulic motor drives the rotary assembly into rotation, a hydrocylinder provides impetus for a pressuring hammer assembly to perform vertical reciprocating motion. The pressuring hammer crushes the koji material in a koji mould box located on a turntable, and the koji material is then output by the runout table for koji material. After prepressing and multiple crushing of the koji material, water and powder within the koji material have been mixed uniformly. The generated koji piece has appropriate tightness, so that the phenomena of tight koji piece surface, loose center and poor slurry extraction are completely avoided. The hydraulic rotary the koji pressing machine provided in the invention is characterized by simple structure, convenient operation, low energy consumption and high efficiency, thus being suitable for brewing and koji making.

Owner:TAIYUAN UNIV OF TECH

Method for preparing pulp for making natural-color packaging paperboards by using corn straw raw material

InactiveCN109629282AReduce consumptionEfficient removalPretreatment with water/steamPretreatment with alkaline reacting compoundsCardboardFiber

The invention relates to a method for preparing pulp for making natural-color packaging paperboards by using a corn straw raw material. The corn straw raw material is pretreated to separate most leaves and piths of corn straw and then is pulped by adopting a chemical mechanical method, and prepared paper pulp can replace waste paper pulp to be used for making corrugated raw paper or cardboard paper and other natural-color packaging paperboards. The method is characterized in that the structural characteristics of different components such as leaves, piths and straw skin in the corn straw raw material are fully utilized, the leaves and piths with smaller fiber contents are turned into powder or granules and the straw with higher fiber content is turned into dense sheets in the pretreatmentprocess, and then the extruded powder or granular leaves and piths are separated through screening for preparation of fodders or bio-organic fertilizers; the straw skin raw material without leaves andpiths is pulped by adopting the chemical mechanical method, and the organic waste generated in the preparation and pulping process can be used for preparing the fodders or bio-organic fertilizers.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Pulping digestion agent production method

InactiveCN1508357AWide adaptabilityHigh degree of polymerizationCellulose material pulpingAlcoholSodium bisulfate

The invention is a producing method of paper pulp boiling agent, its raw materials comprising penetrating agent BS 4-10 weight shares, sodium bisulfate 4-10 weight shares, sodium chloride 4-10 weight shares, pleregal 0 15-25 weight shares, polyoxyethylenated alcohol 15-25 weight shares, alkyl sulphonate 40-55 weight shares, and water 60-80 weight shares. The producing process: adding the pleregal 0 and polyoxyethylenated alcohol in the 55-65 deg.C water, heating to 70-75deg.C, blending, and adding in alkyl sulphonate, blending and adding in BS, sodium bisulfate, sodium chloride, blending, cooling to 30-40deg.C, and blending to make the finished product.

Owner:湖南美莱精化有限公司

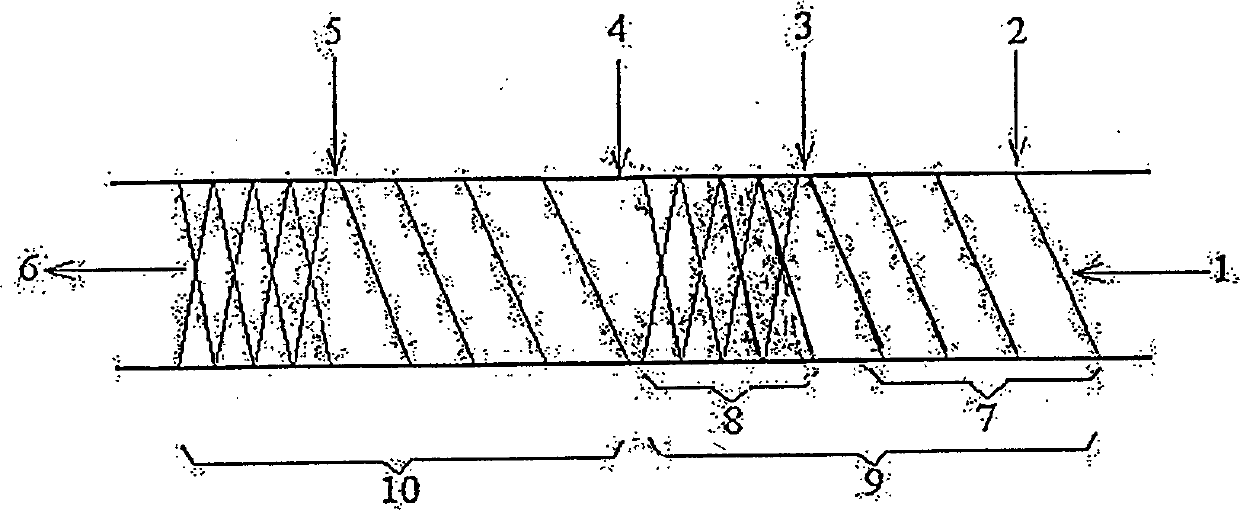

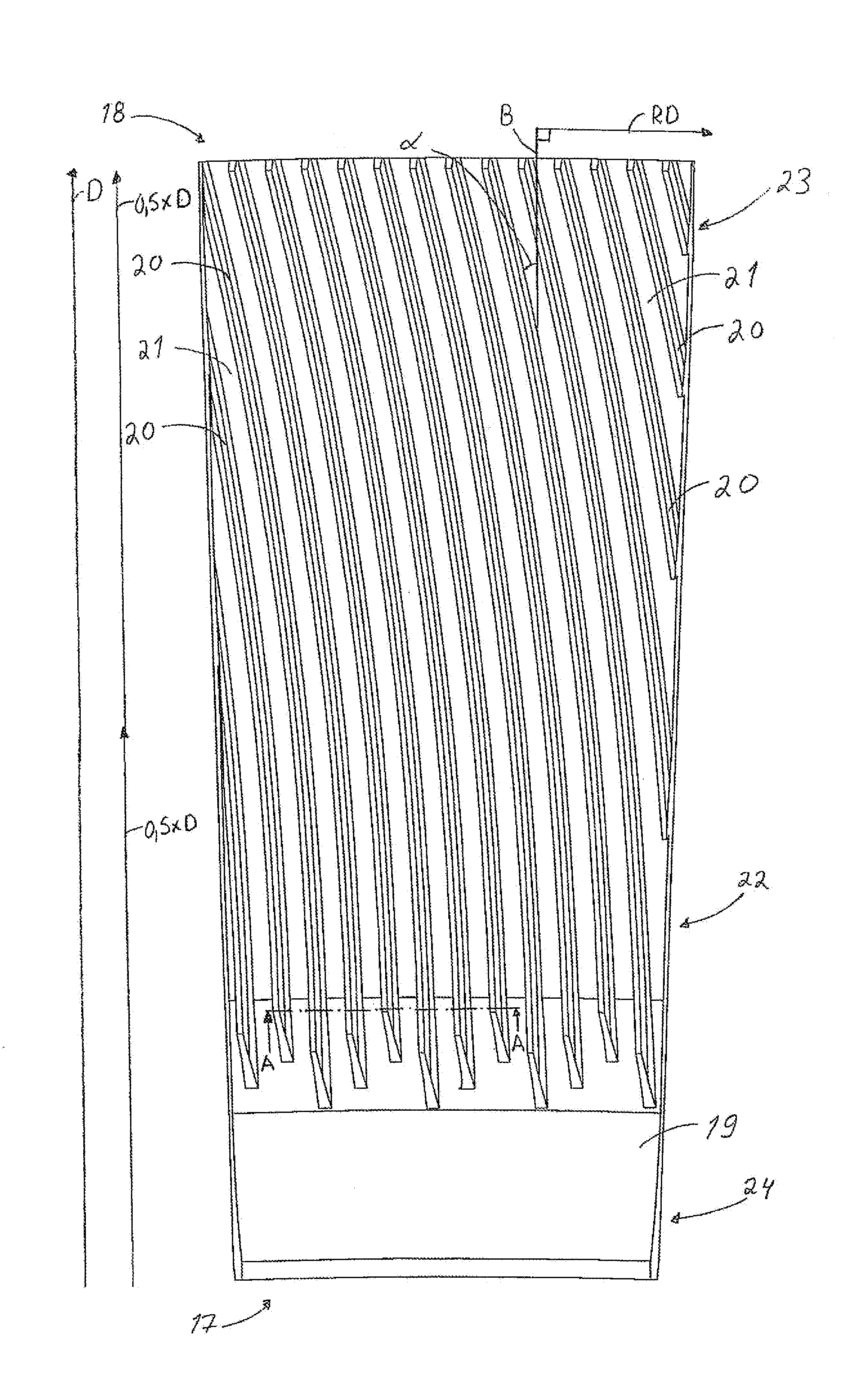

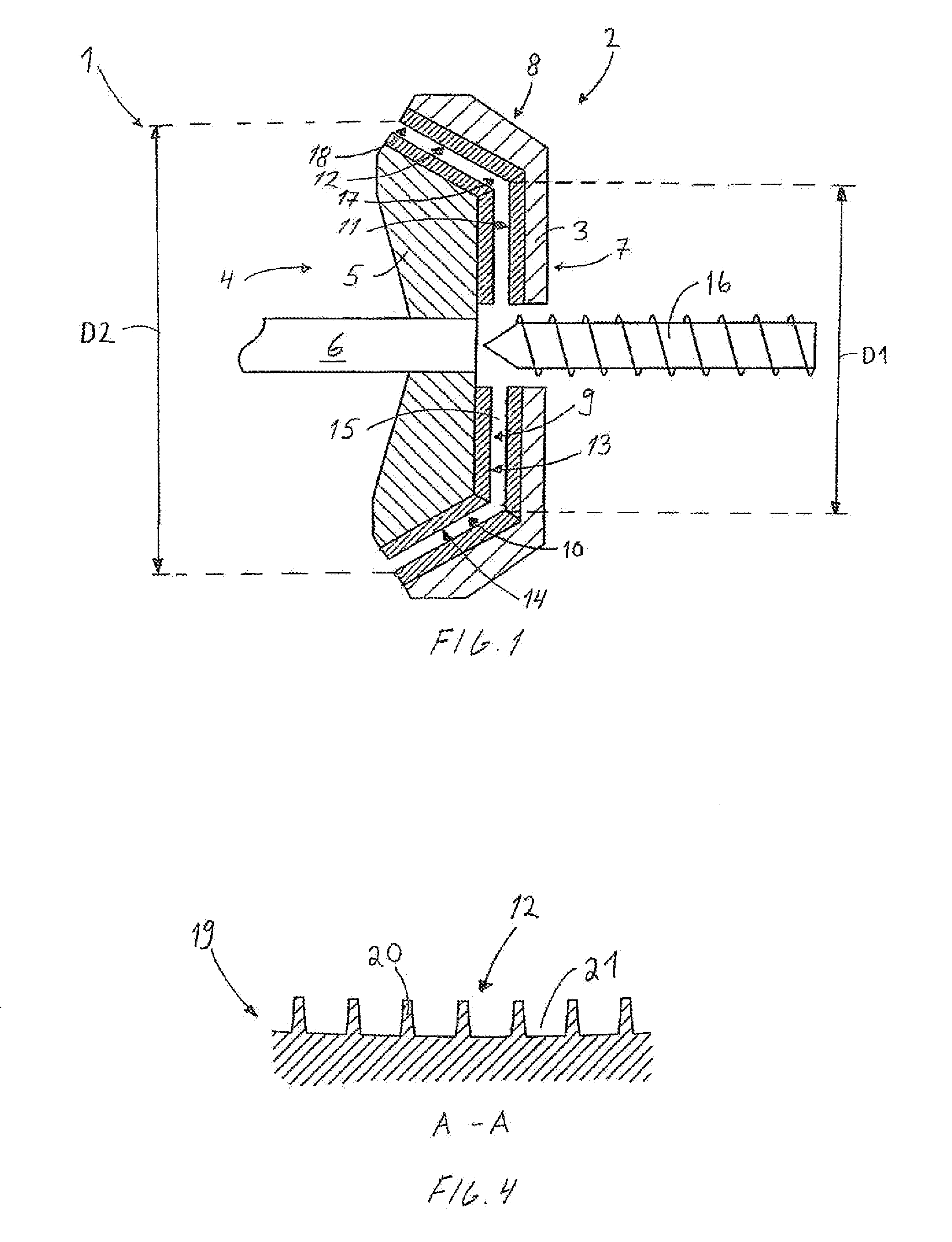

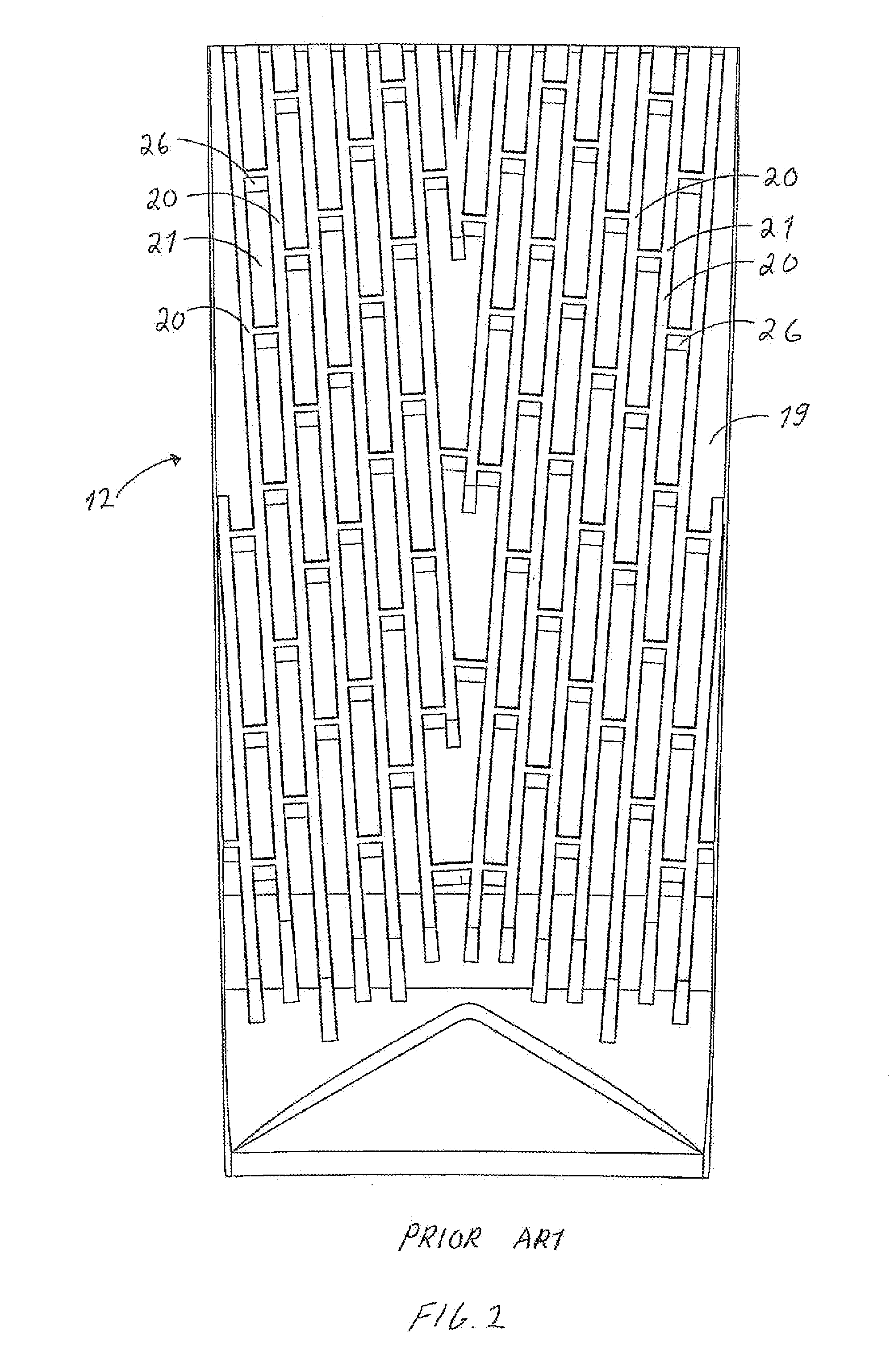

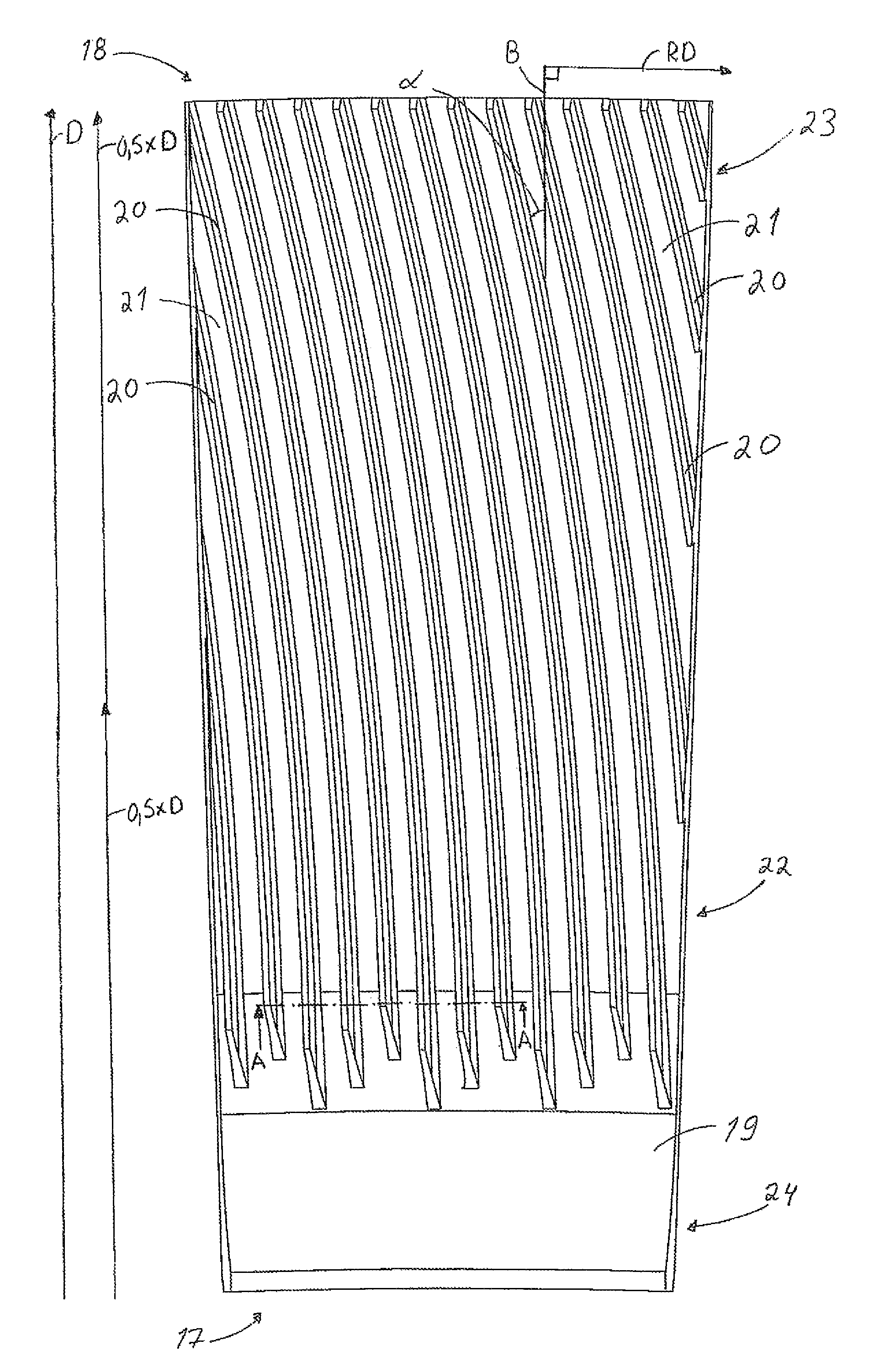

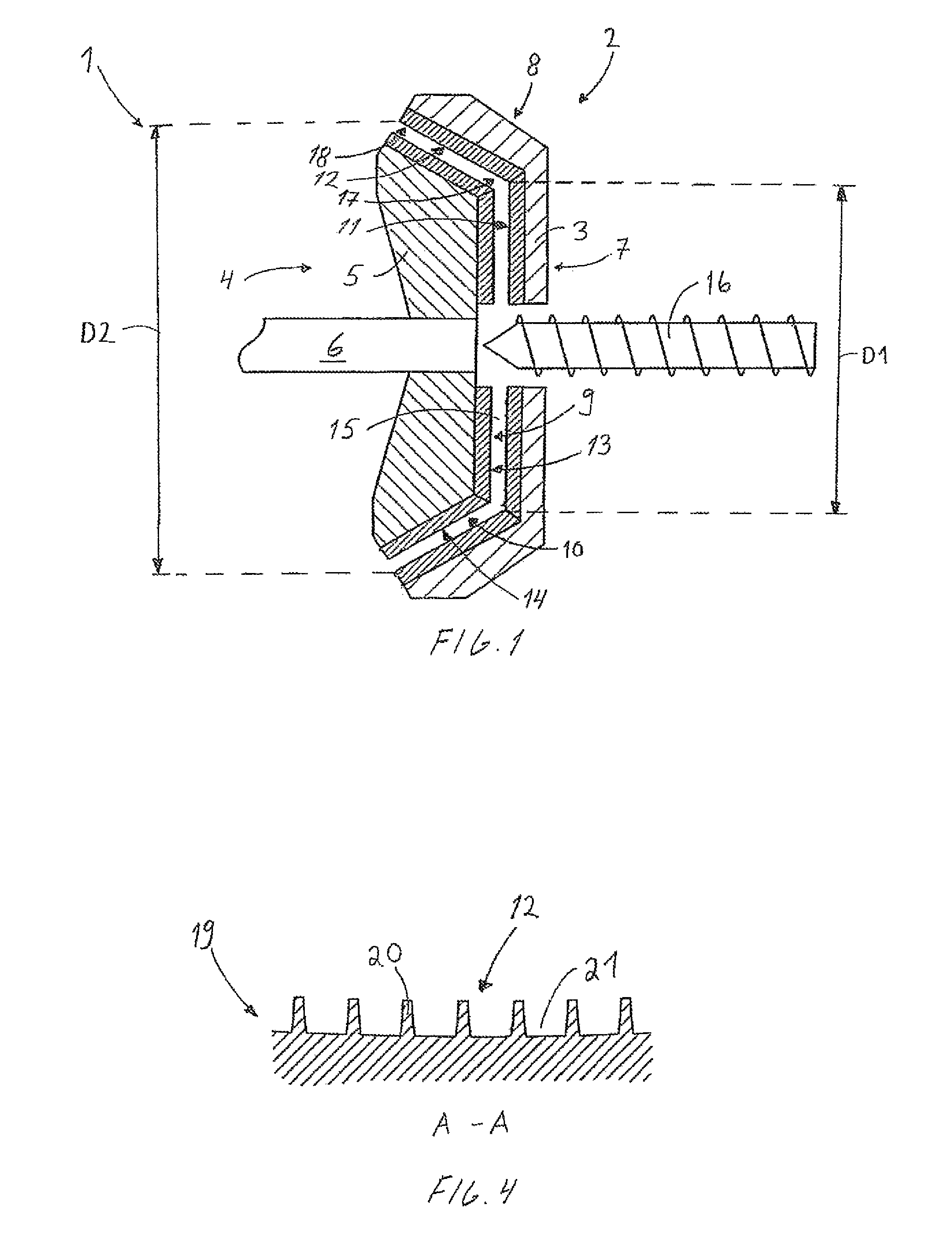

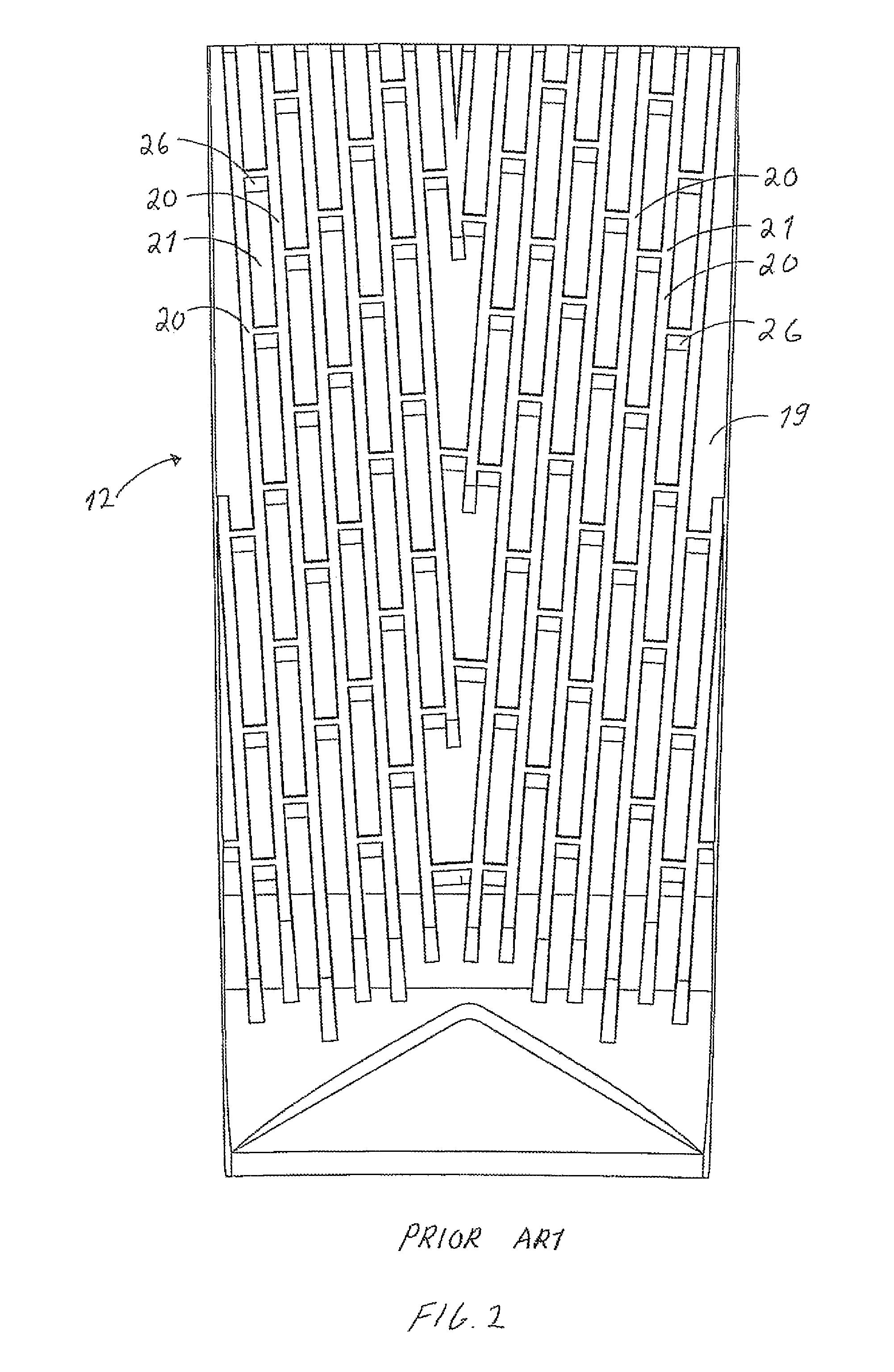

Refiner

ActiveUS20100270411A1Promote resultsImprove pulping qualityCocoaGrain treatmentsEngineeringMechanical engineering

A refiner (1) comprising a stator (2) and a rotor (4). The stator (2) and the rotor (4) comprise a flat portion (7, 9) and a conical portion (8, 10). The conical portion has a first end (17) of smaller diameter (D1) and a second end (18) of greater diameter (D2) such that the first end is directed towards the flat portion and the second end is directed away from the flat portion. The refining surface (12) of the conical portion of the stator comprises at least an outer zone (23) arranged at the second end of the conical portion and an inner zone (22) arranged relative to the outer zone on the side of the first end of the conical portion. A portion of the length of the blade bars (20) in the outer zone are arranged relative to the rotation direction (RD) of the rotor such that they have a retentive effect on the material to be refined. Also a blade segment (19) for a conical portion of a stator of a refiner.

Owner:VALMET TECH INC

System and method for controlling a thermo-mechanical wood pulp refiner

ActiveUS7381303B2Improves overall constraint handling of control strategyImprove throughputBeating/refining control devicesComputer controlFiberProduction line

Thermomechanical pulp is an important process for producing fibrous mass used in papermaking. A two-level control strategy that stabilizes and optimizes the refining process has been developed. The Stabilization layer consists of a multivariable model predicative range controller that regulates the refiner line operations. The Quality Optimization layer provides the pulp quality control as measured by an online pulp quality (freeness, fibre length) sensor. This control startegy leverages the natural decoupling in the process. The modular design technique is able to handle multiple refiner lines that empty into a common latency chest. A global optimizer is also used to integrate and coordinate the two layers for enhanced constraint handling.

Owner:HONEYWELL INT INC

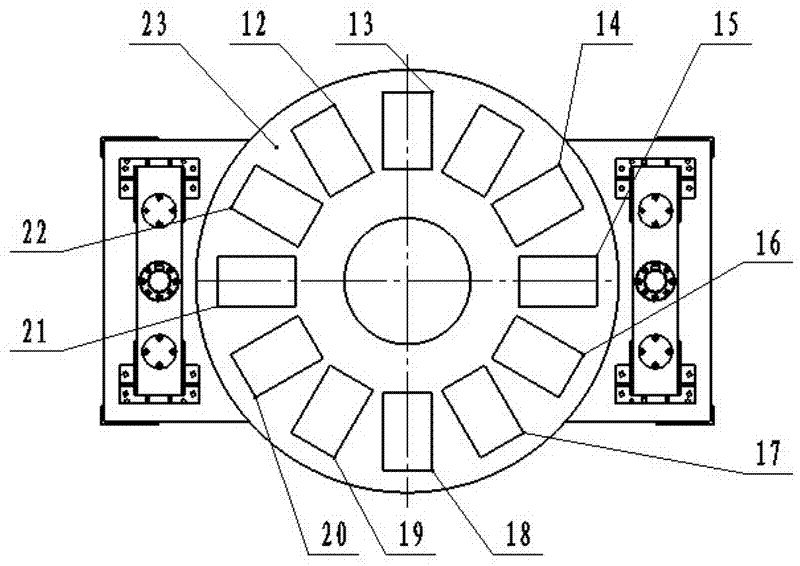

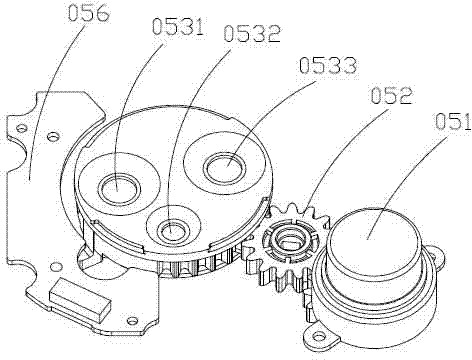

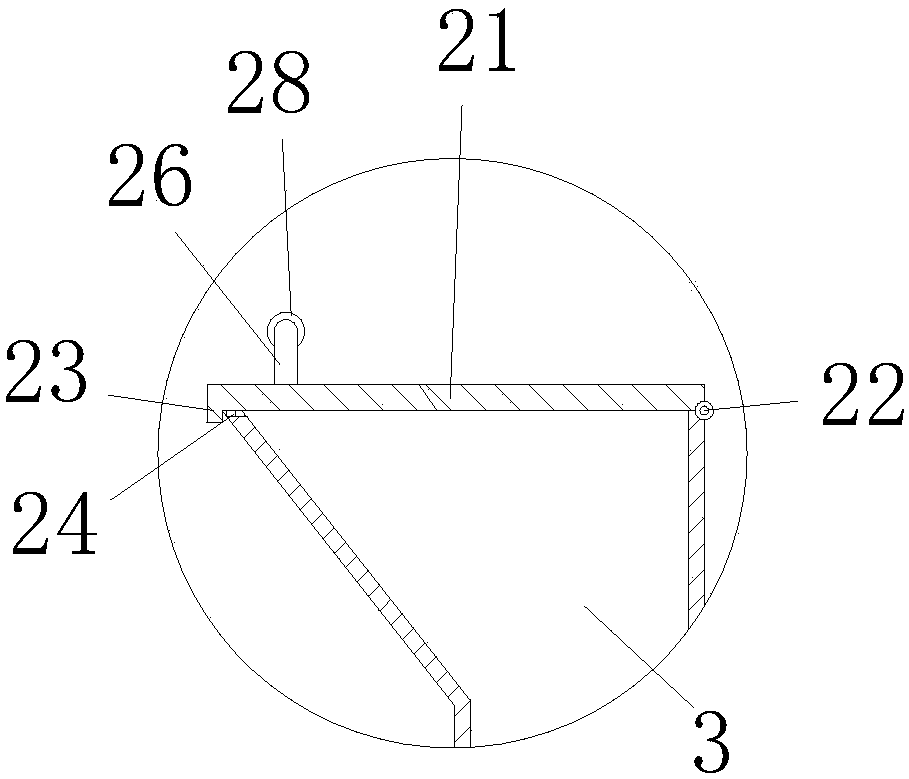

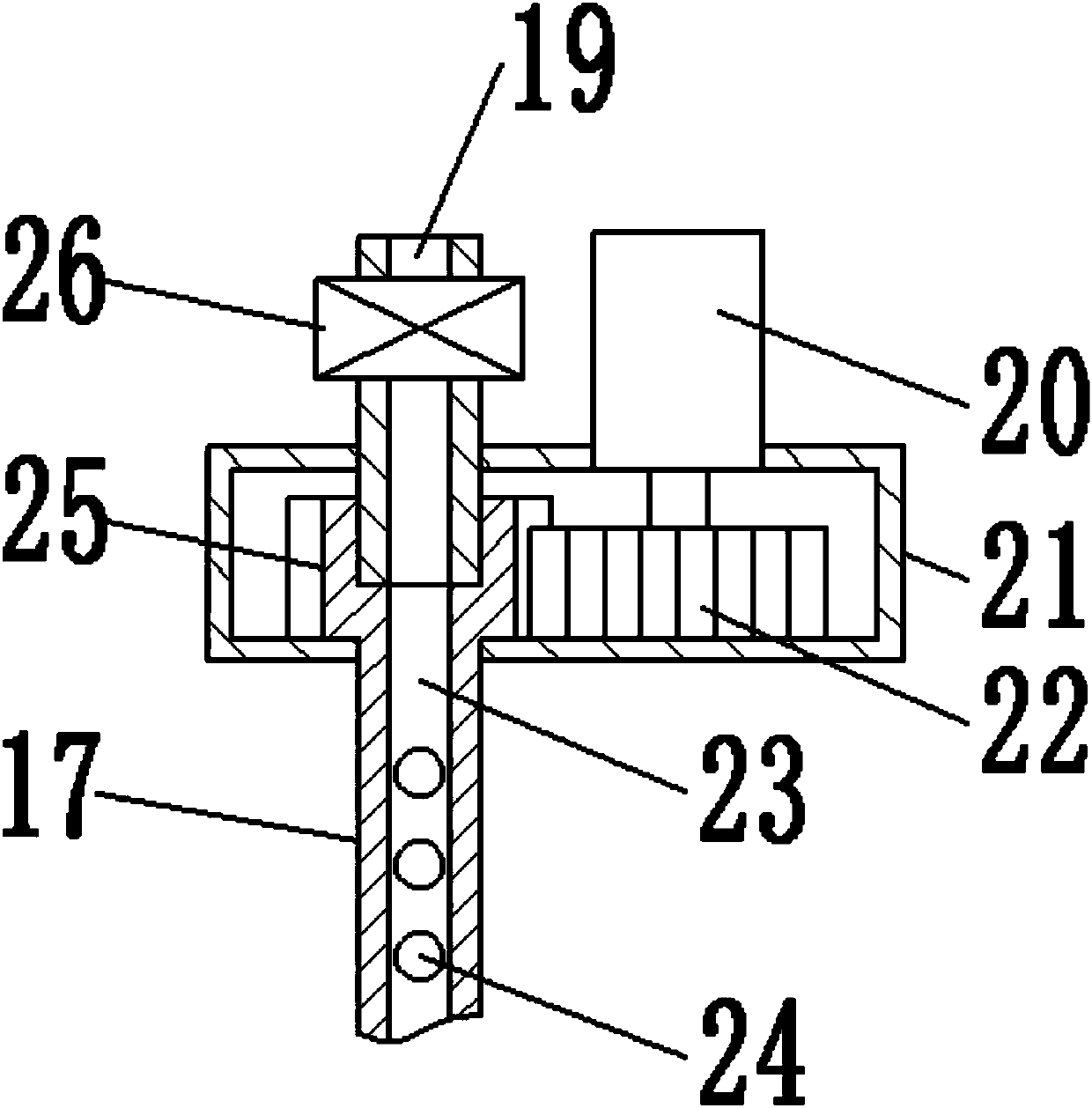

Motor driving and positioning rotary koji pressing machine, and koji pressing method thereof

The invention relates to a motor driving and positioning rotary koji pressing machine, and a koji pressing method thereof. According to the motor driving and positioning rotary koji pressing machine, the motor driving structure of a driving and positioning system is arranged under a rack platform and is fixedly connected with a rotary assembly, a pressure assembly is positioned above the rotary assembly and is arranged on a rack through a center shaft, the pressure assembly and an auxiliary guide column form a matching structure in a vertical direction, and a koji material enters a mold box through a material feeding hopper, then is subjected to pre-pressing, kneading and treading molding, and then is output through a koji output table. According to the present invention, after the pre-pressing and the multiple treading, the water and the powder are uniformly mixed, the koji block compactness is moderate, and the phenomena that the koji block surface is compact, the center portion is loose and the slurry extracting are completely avoided; and the motor driving and positioning rotary koji pressing machine has characteristics of simple structure, easy operation, low consumption and high efficiency, and is suitable for wine brewing and koji production.

Owner:TAIYUAN UNIV OF TECH

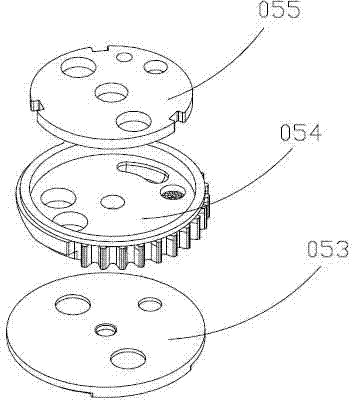

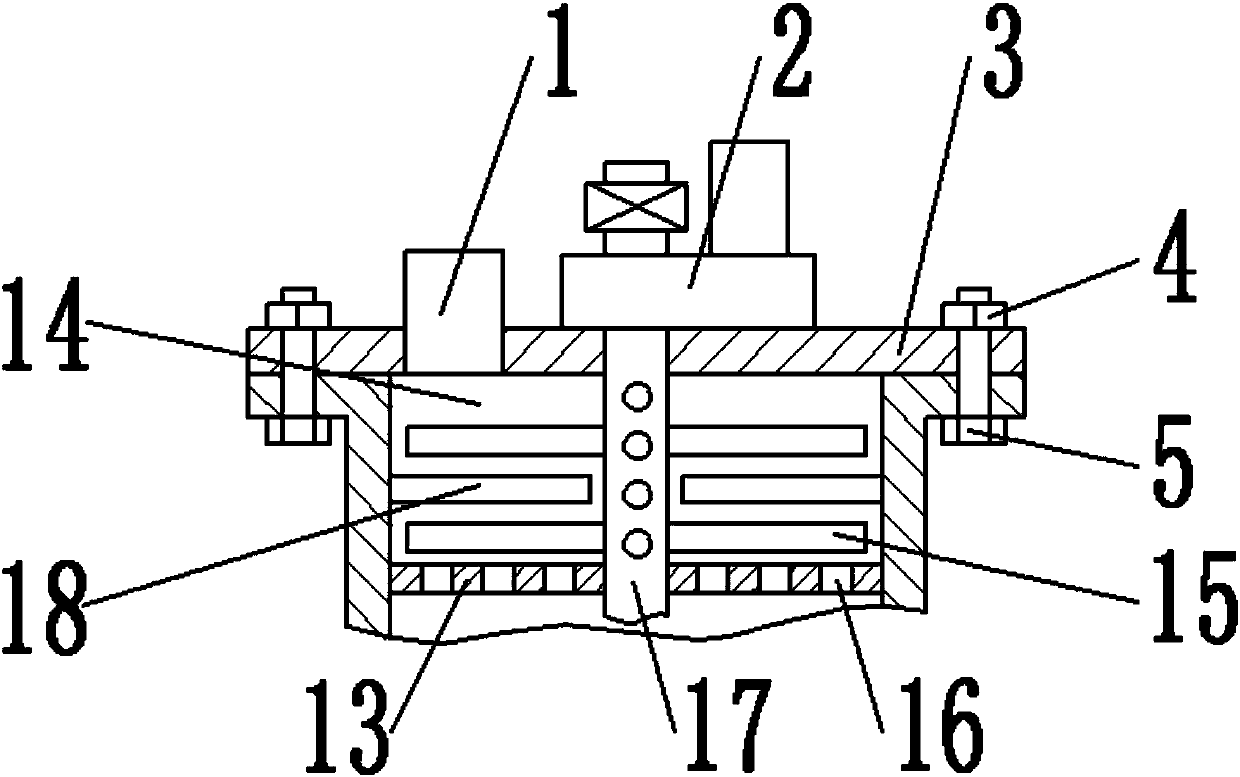

Batch refiner and refining process thereof

ActiveCN102828432AFlexible operationAchieve regulationPulp beating/refining methodsProcess engineeringIndustrial engineering

The invention provides a batch refiner which comprises a shell, a moving refining plate, a fixed refining plate, a transmission shaft and a gap adjusting mechanism, wherein the moving refining plate and the fixed refining plate are coaxially arranged, and the transmission shaft is coaxially connected with the moving refining plate. The batch refiner is further provided with a fluid pushing device, a fluid inlet channel is arranged on the moving refining plate or the fixed refining plate and penetrates through two bottom surfaces of the moving refining plate or the fixed refining plate, a discharge end face of the fluid pushing device faces the fluid inlet channel, and communicated backflow gaps are reserved between the fluid pushing device and the shell as well as between each refining plate and the shell respectively. Multiple refining can be achieved by circulating pulp between the refining plates when the batch refiner is operated, and times of refining are not limited by the batch refiner; and gaps between the refining plates can be adjusted by the gap adjusting mechanism so as to adapt to changes of the pulp. The batch refiner is simple and flexible in operation.

Owner:山东惠祥专利造纸机械有限公司

Two-step isolation type full non-chlorine full cotton stalk bleaching pulp cleaning production process

ActiveCN101435165AControl concentrationAccurate measurementPulp bleachingCellulose material pulpingMaterials preparationPulp and paper industry

The invention discloses a clean production technology of two-step isolation type totally chlorine-free and whole cotton stalk bleaching pulp, which has the advantages of simplifying the process, saving cost, reducing pollution, saving energy and the like. The clean production technology comprises the following steps of: 1) material preparation: the whole cotton stalk plant material is treated with cotton-shell removal, leave removal and cutting-off; 2) steaming and water washing; 3) discongesting: the whole cotton stalk material is sent to a compressing and discongesting machine for compression and discongesting; 4) first-step dipping: a one-step bleaching solution is used for dipping the whole cotton stalk material released from the compressing and discongesting machine, and the dipping is maintained; 5) first-step bleaching: the dipped whole cotton stalk material is heated and bleached; 6) jordaning of a first stage: the bleached whole cotton stalk material is ground into unscreened stock by a pulping machine; 7) second-step dipping: the unscreened stock ground by the pulping machine is dipped by using a second-step bleaching solution; 8) second-step bleaching: the unscreened stock treated with second-step dipping is heated and bleached; 9) jordaning of a second stage: the unscreened stock treated with second-step bleaching is ground and dissolved into water pulp; 10) pulp washing and pulp shoving; and 11) stock screening and pulp forming.

Owner:山东凯隆材料科技有限公司

Refiner

ActiveUS8226023B2Improve pulping qualityCocoaPulp beating/refining methodsEngineeringMechanical engineering

A refiner (1) comprising a stator (2) and a rotor (4). The stator (2) and the rotor (4) comprise a flat portion (7, 9) and a conical portion (8, 10). The conical portion has a first end (17) of smaller diameter (D1) and a second end (18) of greater diameter (D2) such that the first end is directed towards the flat portion and the second end is directed away from the flat portion. The refining surface (12) of the conical portion of the stator comprises at least an outer zone (23) arranged at the second end of the conical portion and an inner zone (22) arranged relative to the outer zone on the side of the first end of the conical portion. A portion of the length of the blade bars (20) in the outer zone are arranged relative to the rotation direction (RD) of the rotor such that they have a retentive effect on the material to be refined. Also a blade segment (19) for a conical portion of a stator of a refiner.

Owner:VALMET TECH INC

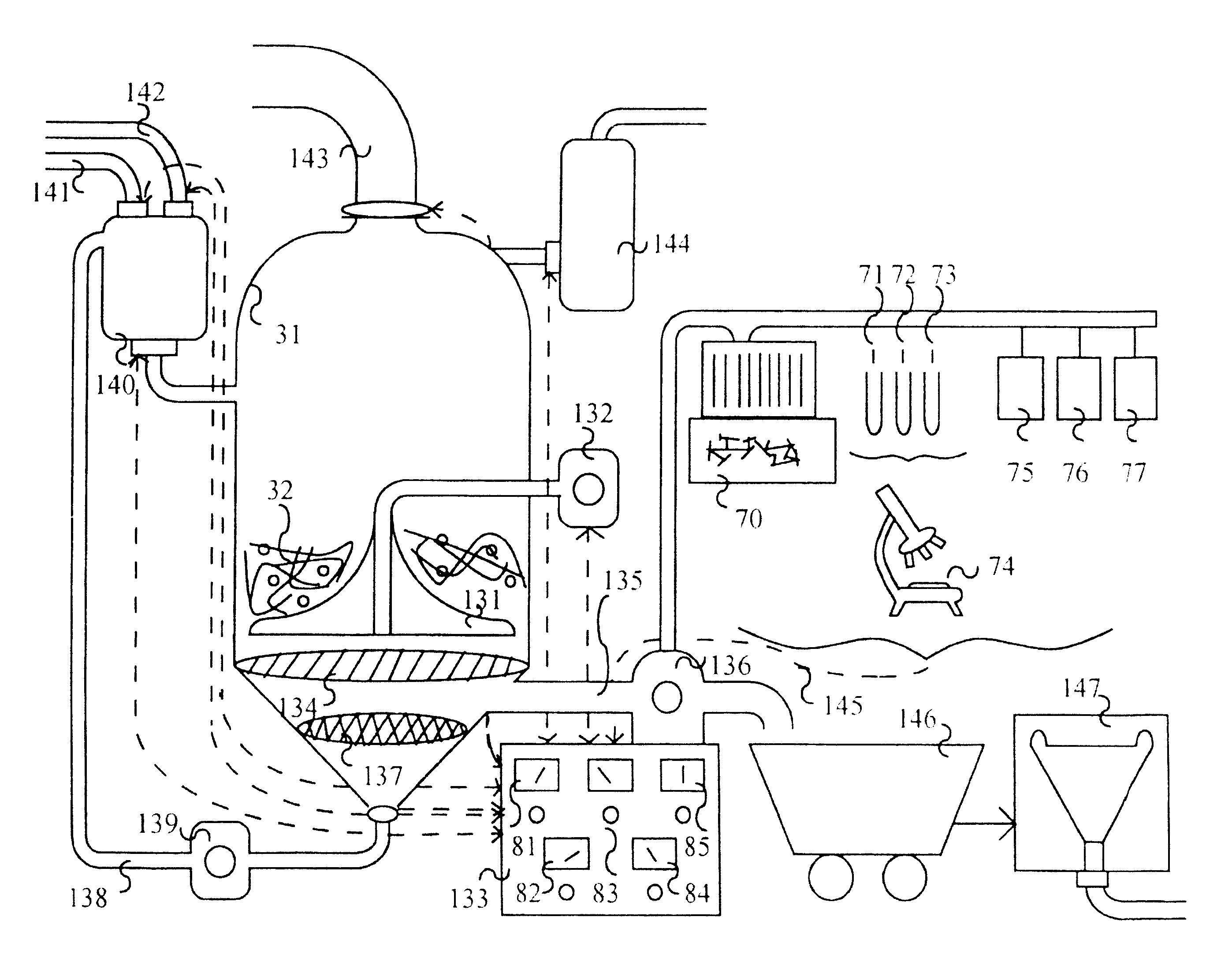

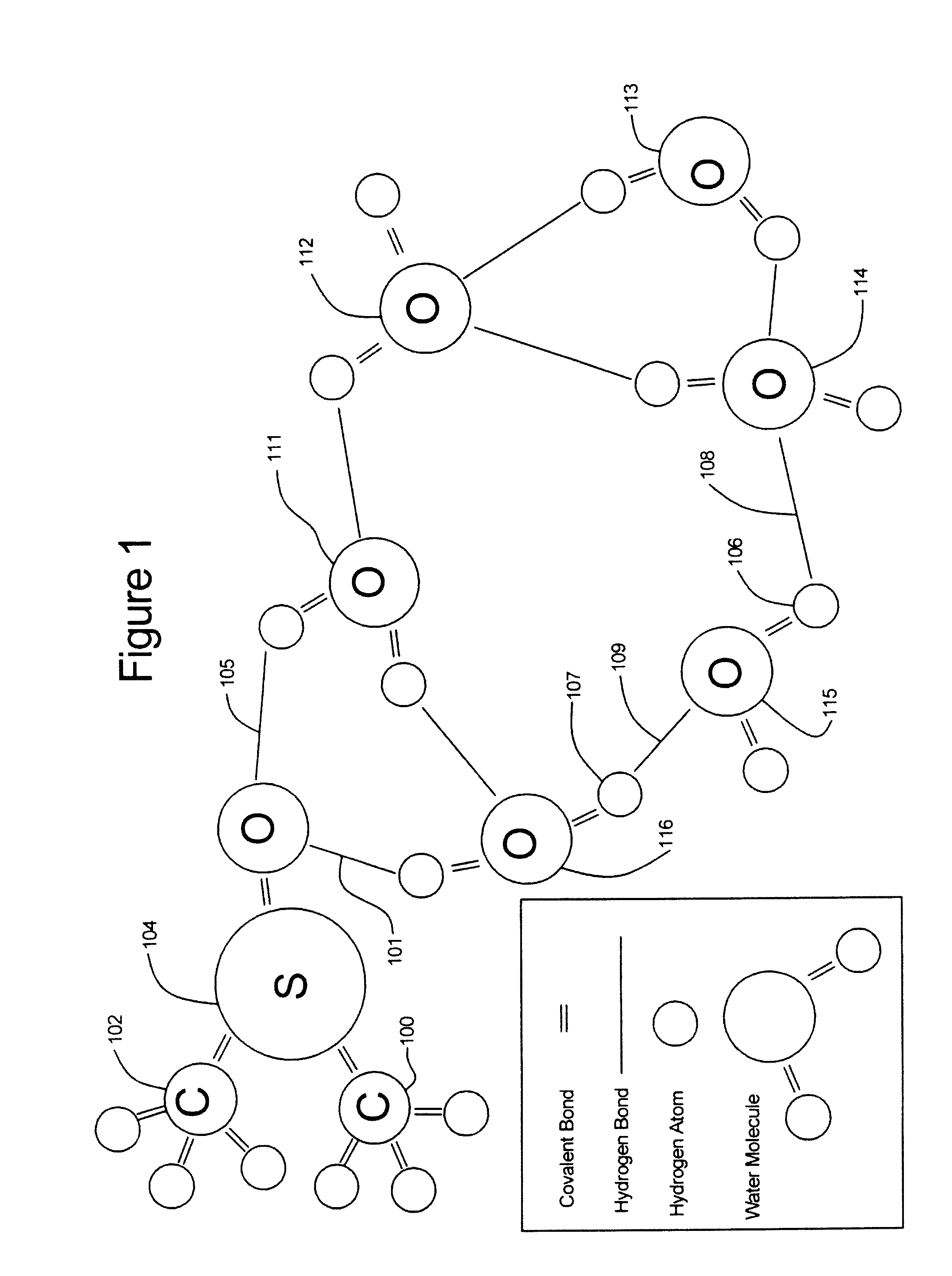

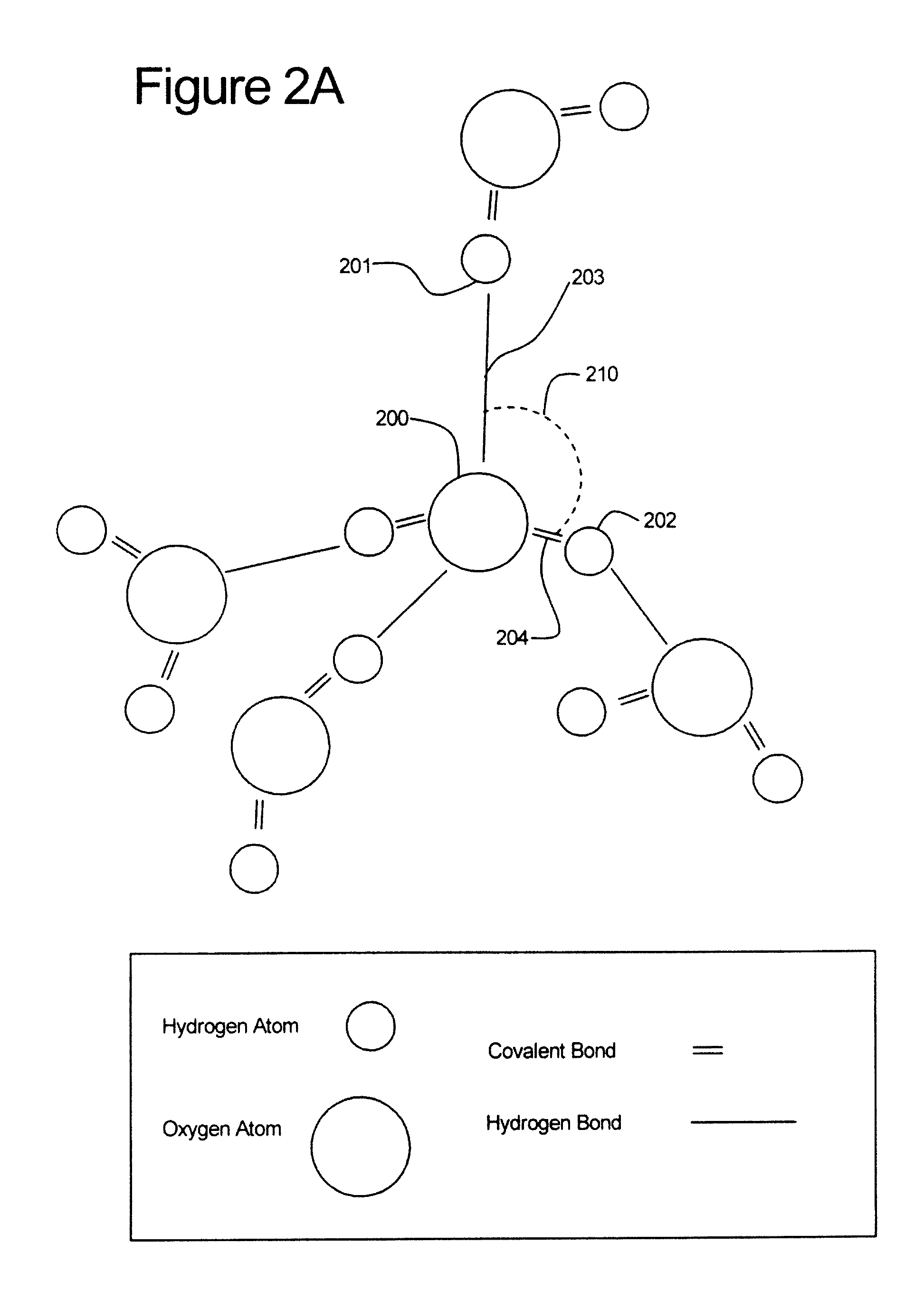

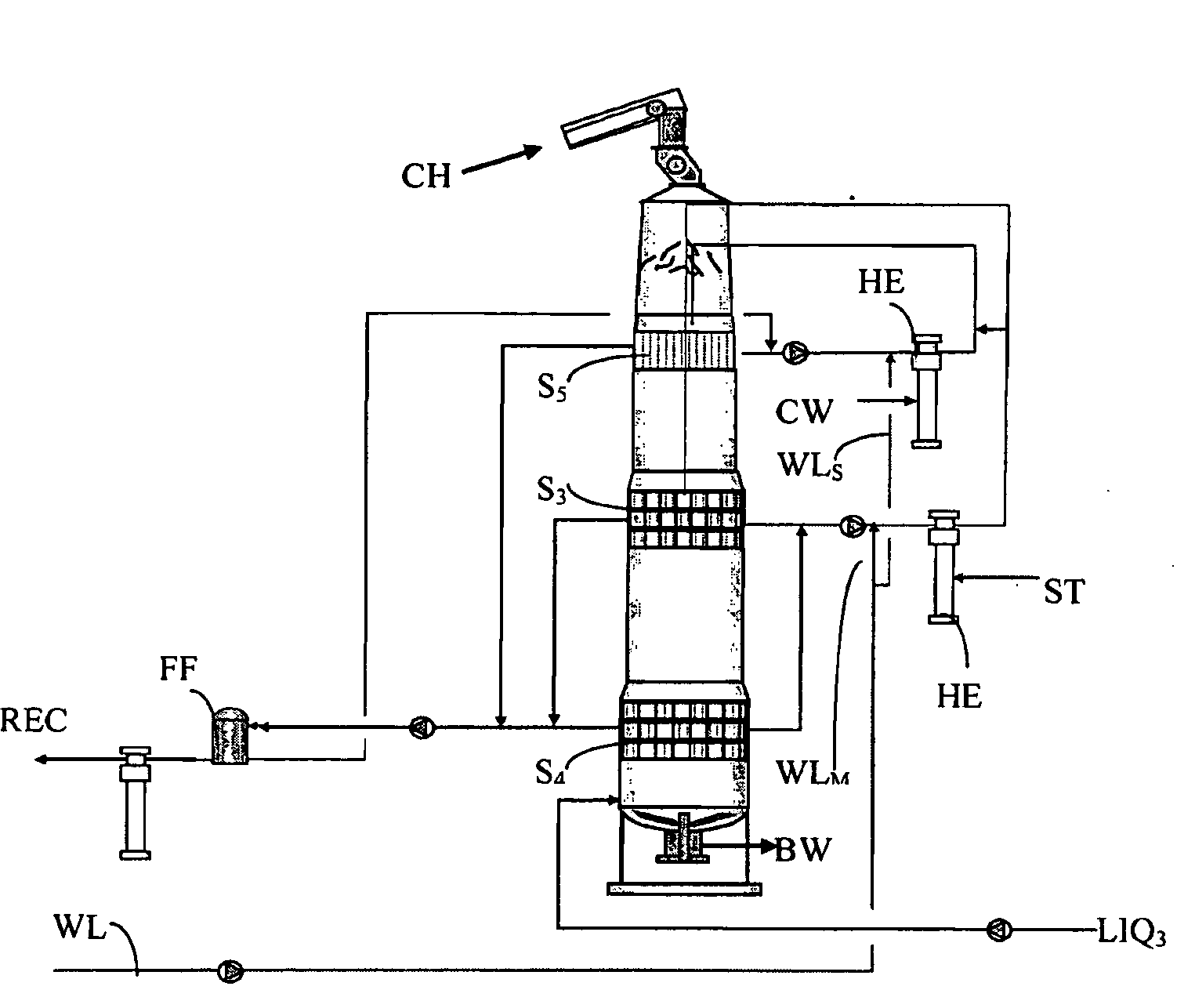

System and method for repulping of paper products and improvement of water quality with dipolar solvents and recovery

InactiveUS20100263812A1Quality improvementFibre mixing performanceDigestersPaper recyclingFiberHydrogen

An enhanced method of repulping paper and improving water quality by placing used paper product material in an aqueous solution of dipolar aprotic protophylic solvent, processing it, and recovering recycled pulp based on two physical reactions of the dipolar solvent: first with water from one part of the solvent, and second with cellulosic material from the other part of the solvent. The water reaction involves a rearrangement of hydrogen bonds within the water, improving its reactivity and solvent capacity, and the cellulosic reaction involves dissolution of hemicellulose in a manner which results in reduced fibre loss and improved pulp quality. The net result is more efficient pulping and reduced environmental impact.

Owner:SANATA TECH

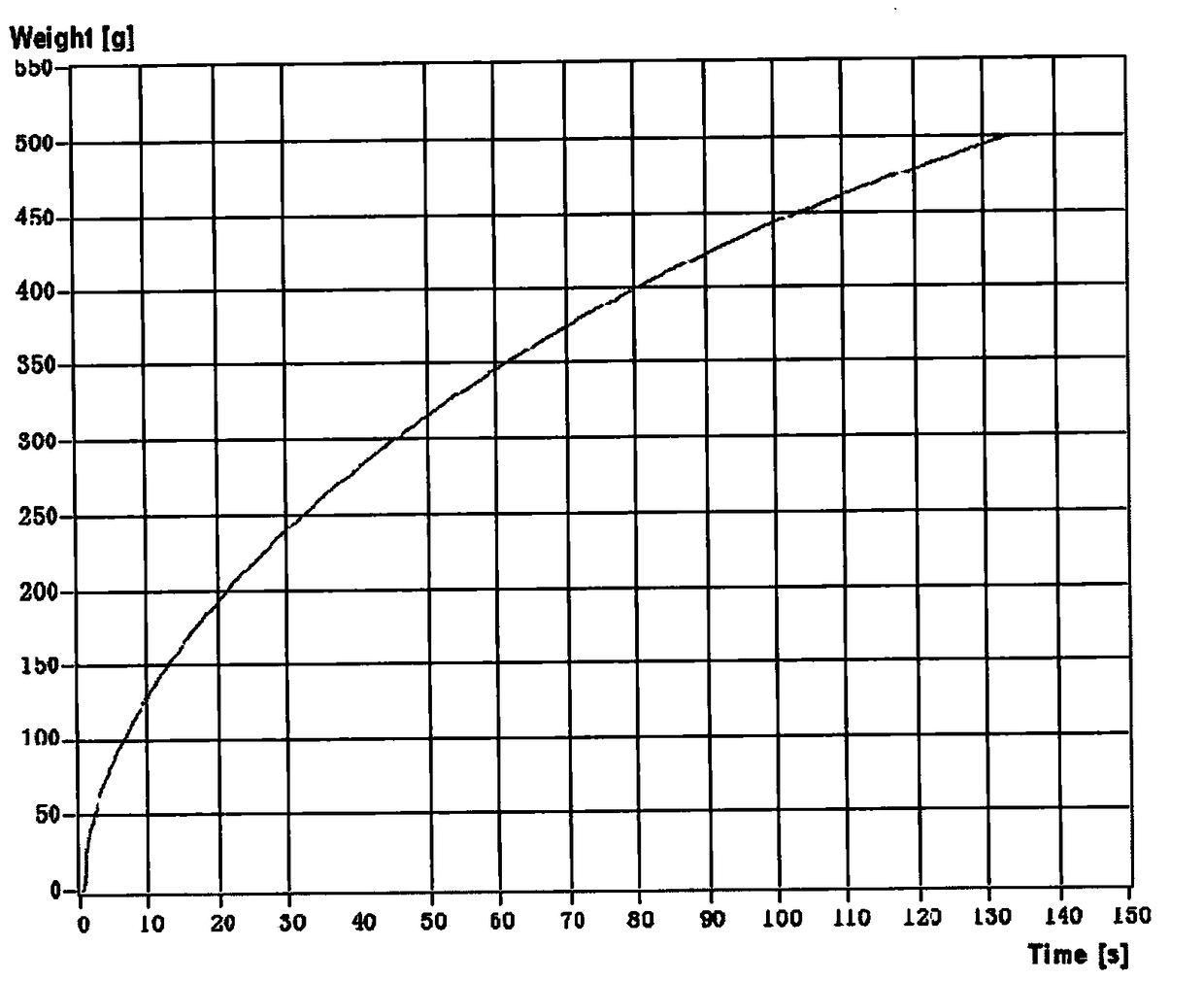

Rapid soybean milk making method of soybean milk machine

The invention provides a rapid soybean milk making method of a soybean milk machine. Before a soybean milk discharging stage is performed, water corresponding to soybean milk to be made in amount is filled into a soybean milk receiving cup; soybean milk liquid / paste generated in the dense soybean milk making stage is made to be mixed with the water in the soybean milk receiving cup, and therefore problem that time is wasted due to the facts that soybean milk discharging is performed firstly and then blending is performed is solved. During soybean milk discharging, when the water of the soybean milk receiving cup fluctuates upwards and downwards, the soybean milk liquid / paste and the water can be fully mixed in the soybean milk receiving cup, and therefore the quality of the made soybean milk is improved.

Owner:JOYOUNG CO LTD

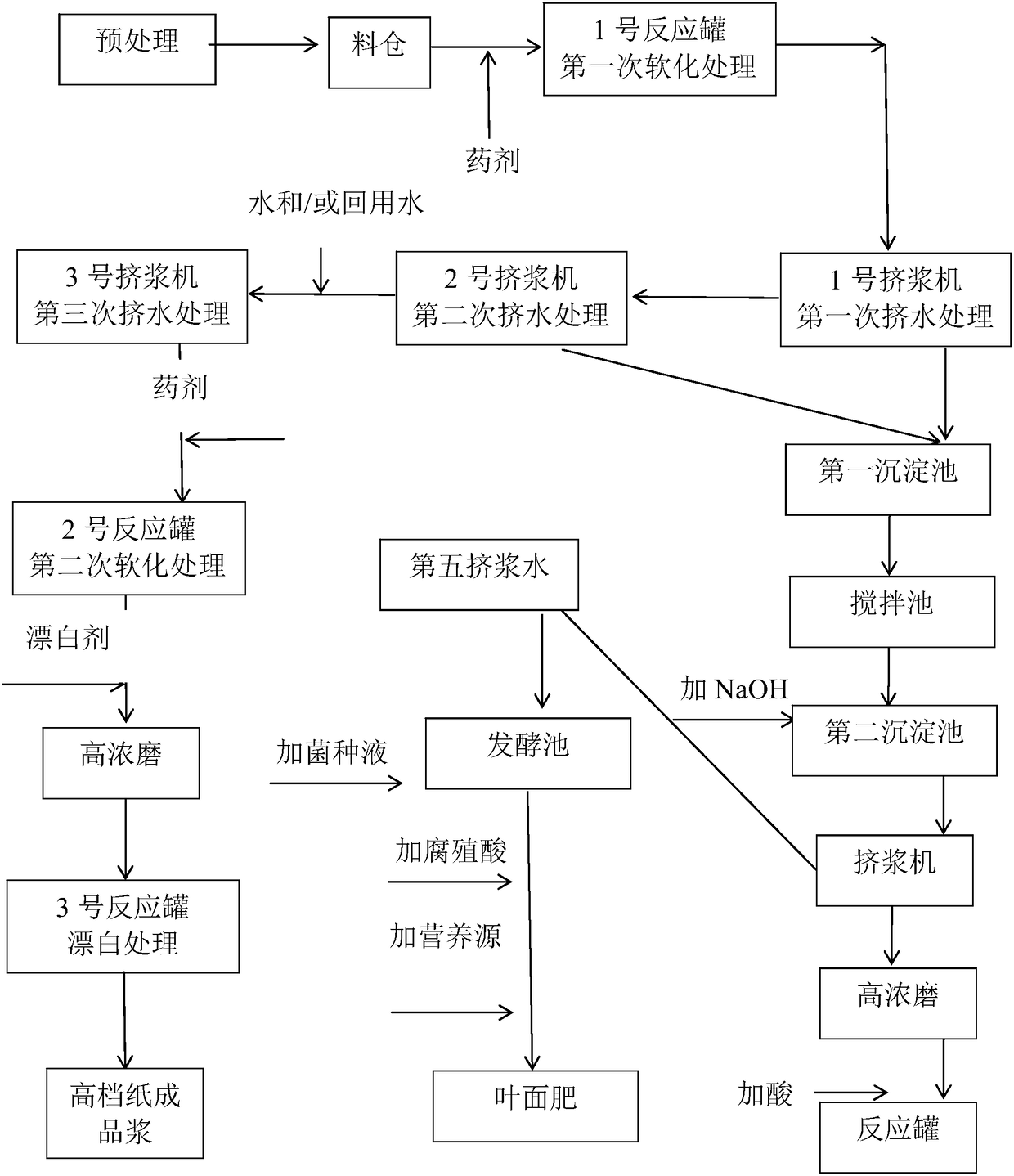

Combined process using grasses as raw materials

The invention discloses a combined process using grasses as raw materials. The combined process is a whole-process reaction process comprising a preparation process of a high-grade paper slurry, a preparation process of a pulp for packaging paper, and a preparation process of a foliar fertilizer. The preparation process of the high-grade paper slurry mainly includes the process steps of: three reactions in three reaction tanks, four times of extrusion and pulping by a high concentration pulping machine; and the slurry with high yield is prepared. Pulp squeezing water obtained by first alkali addition softening, first pulp squeezing and / or first two times of pulp squeezing in the preparation process of the high-grade paper slurry is used as a raw material for the preparation process of thepulp for packaging paper; the pulp squeezing water containing a part of cellulose and unreacted agents is subjected to softening and grinding treatment to obtain the slurry for packaging paper. Squeezing water produced in the preparation process of the pulp for packaging paper is recovered and treated as a raw material for preparation of the foliar fertilizer. The combined process has the advantages of no black liquor discharge, water recycling, and energy conservation; therefore, the combined process is a green pulping process.

Owner:黑龙江如柏科技有限公司

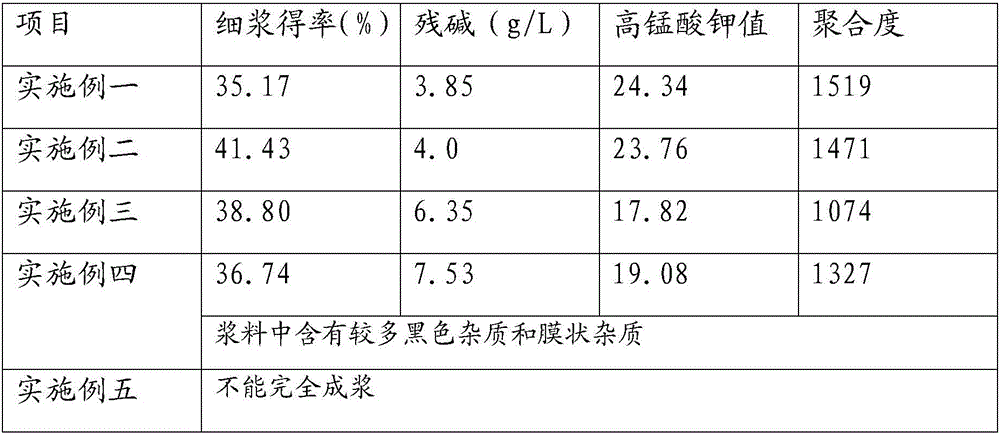

Method for preparing unbleached pulp from sunflower seed shells

ActiveCN105862494AIncrease varietyAlleviate the raw material pressure of the pulp and paper industryPretreatment with water/steamWashing/displacing pulp-treating liquorsSunflower seedElectric heating

The invention relates to the technical field of unbleached paper making, in particular to a method for preparing unbleached pulp from sunflower seed shells. The method includes the steps that 1, raw sunflower seed shells are soaked in clean water, kneaded, rinsed, filtered and aired; 2, pretreated material slices are put in a small digesting tank layer by layer, digesting chemical liquid is sprinkled between the layers, and after sealing and shaking up, the small digesting tank is put in a warm water pool to be softened; 3, the small tank is directly put in a rotary electric heating digester and is subjected to sealing, temperature rise, heat preservation, deflation and blowing; 4, pulp and concentrated black liquid are separated, the pulp is put in a filter screen and washed to be neutral with clean water; 5, slag pulp of the washed pulp is screened out, extruding dewatering is conducted, fibers are dispersed through a pulp scattering device, and the sunflower seed shell unbleached chemical pulp is obtained. The unbleached chemical pulp prepared through the pulp preparation method is low in screened pulp yield, small in chemical dosage, high in polymerization and good in strength, and can be independently made into unbleached paper or / and blended with other fibers to be made into unbleached paper or bleached in the following process to produce paper with the requirement for whiteness.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

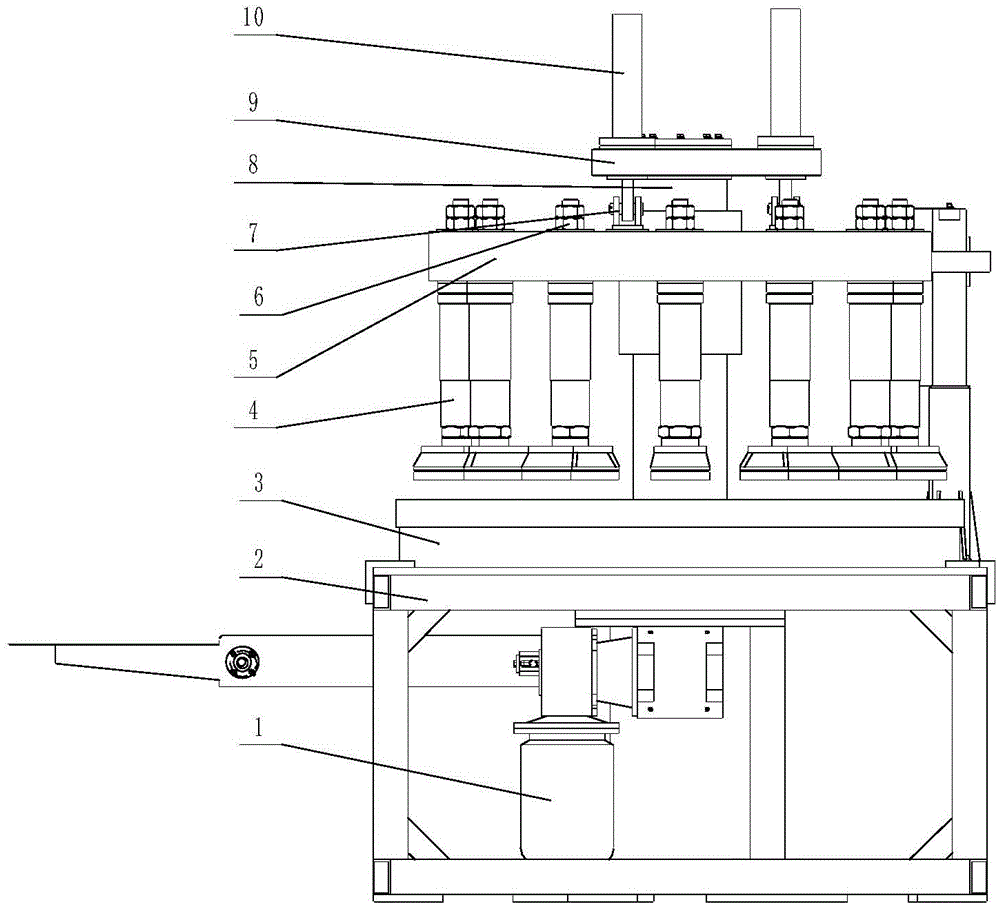

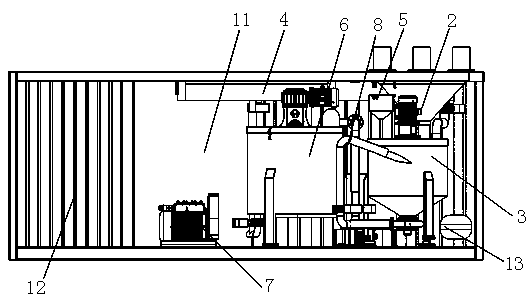

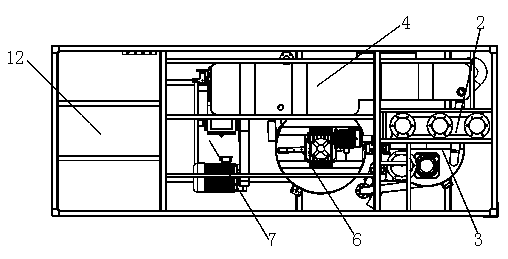

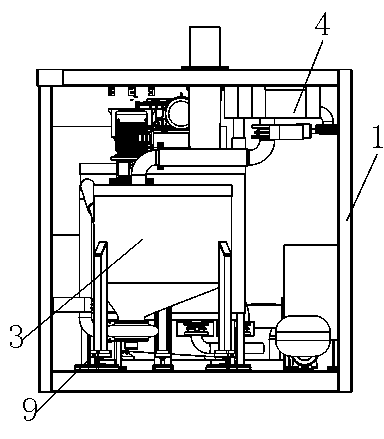

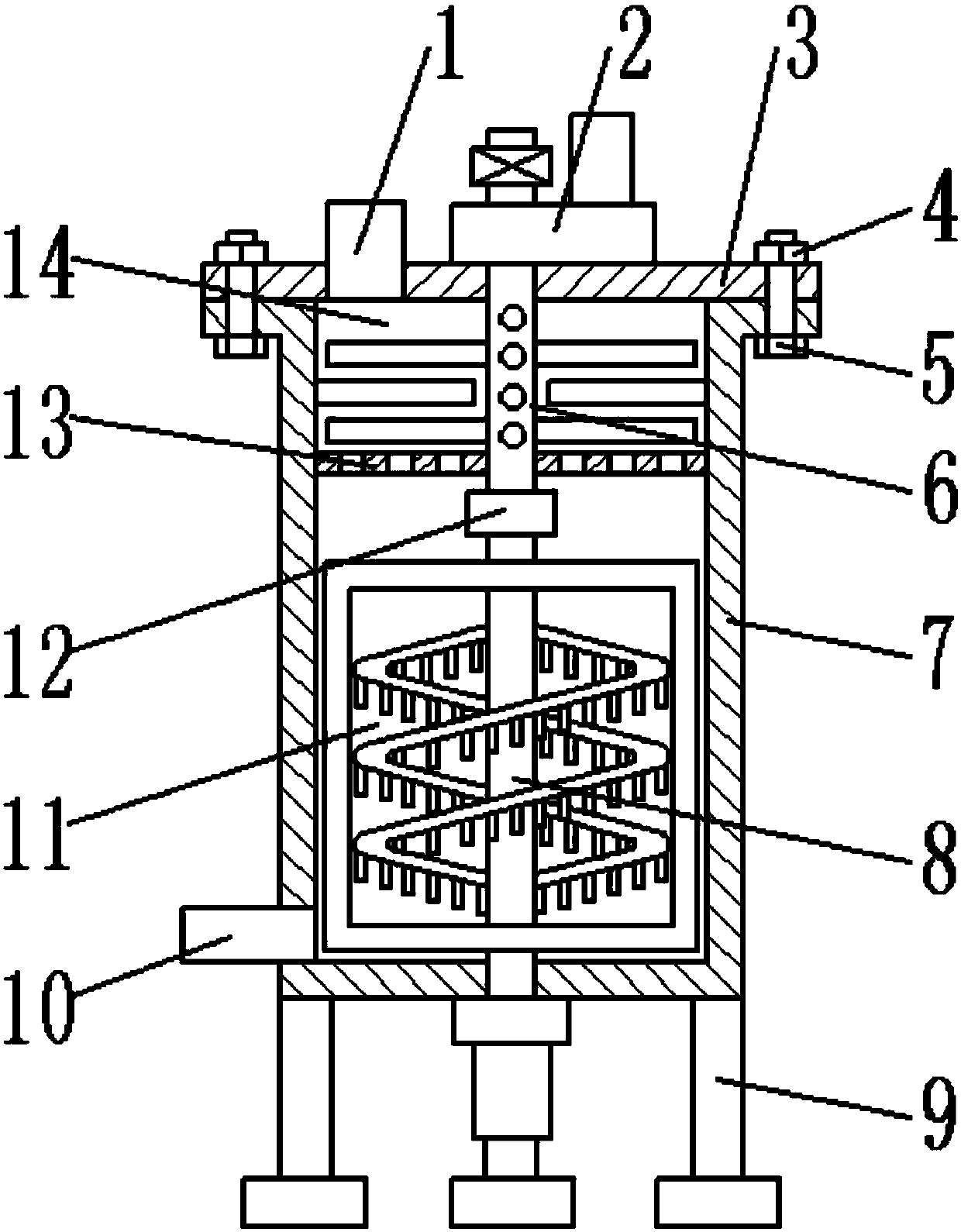

Integrated pulping system

ActiveCN103538151ASmall footprintReduce labor intensityMixing operation plantControl systemPulp and paper industry

The invention discloses an integrated pulping system. The integrated pulping system mainly solves the problems of large floor area, waste of labor and time in disassembly and assembly, loss and damage of components in transportation, easiness in environmental pollution in work, low degree of automation and low effect in the conventional pulping station. The pulping system comprises an openable and closable container, a centralized feed hopper, a pulping tank, a water tank, an additive supply device, a pulp storage tank, a pulp delivery device, a power system and a control system, wherein the centralized feed hopper is arranged on the upper part in the container; the pulping tank is positioned below a discharge port of the centralized feed hopper; the water tank and the additive supply device are communicated with the upper part of the pulping tank through pipelines respectively; the pulp storage tank is communicated with the lower part of the pulping tank through a pipeline; the pulp delivery device is connected with the pulp storage tank; the power system is used for providing power for the operation of the integrated pulping system; the control system is used for controlling the operation of the integrated pulping system; the centralized feed hopper, the pulping tank, the water tank, the additive supply device, the pulp storage tank and the pulp delivery device are all arranged in the container. According to the integrated pulping system, the pulping system is highly integrated, the floor area of the pulping system is reduced, and the degree of automation of the equipment is improved.

Owner:SINOHYDRO FOUND ENG

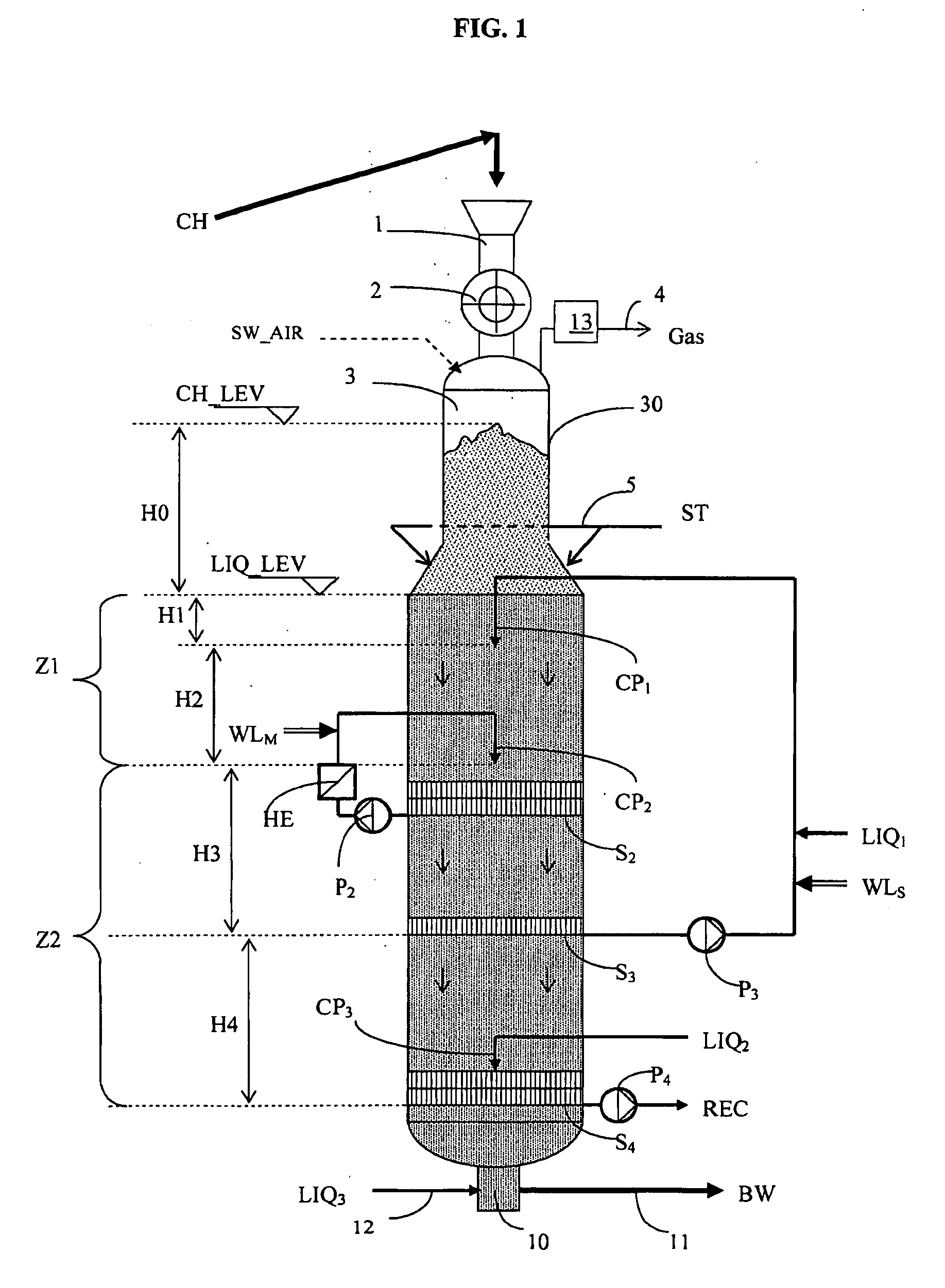

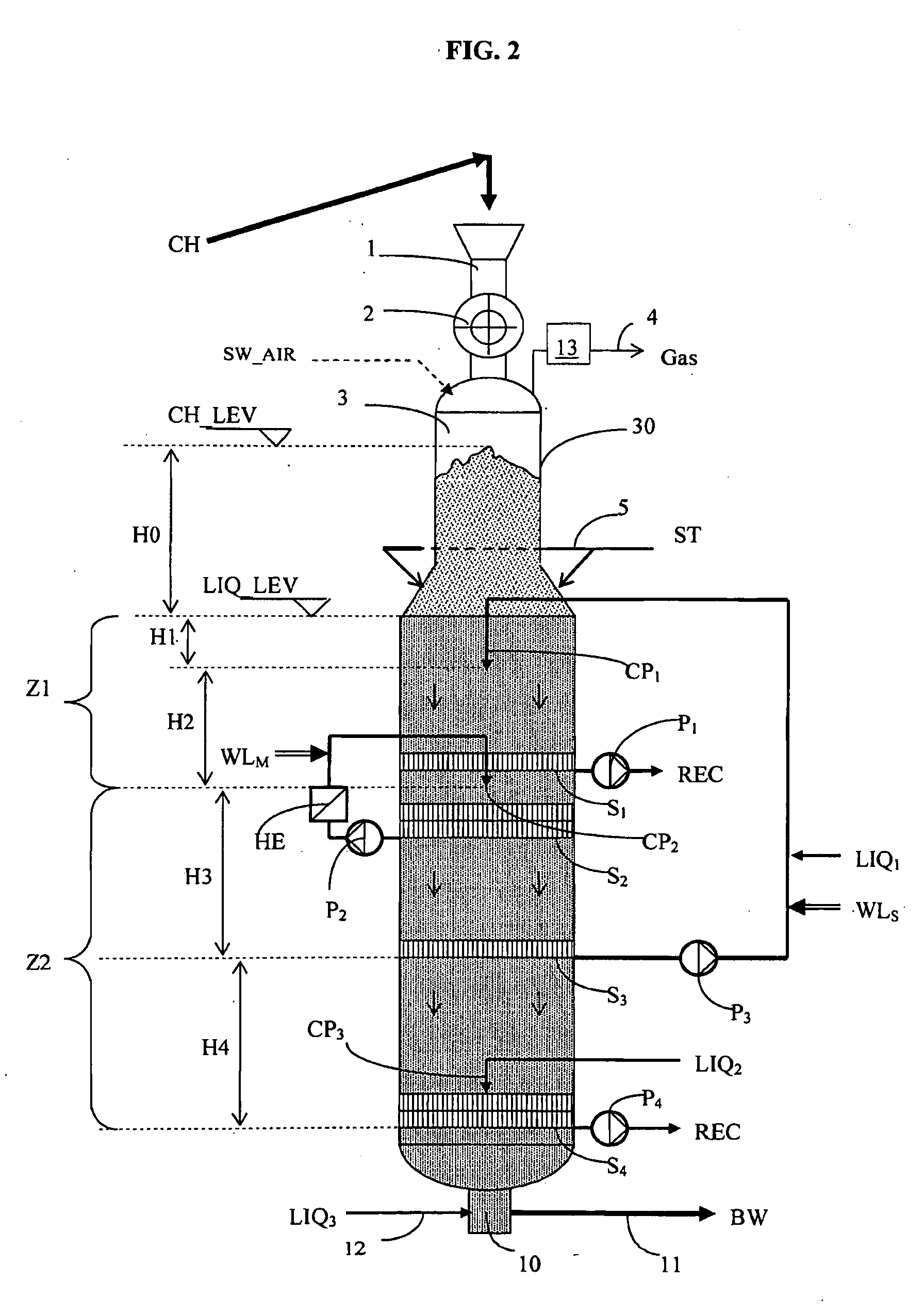

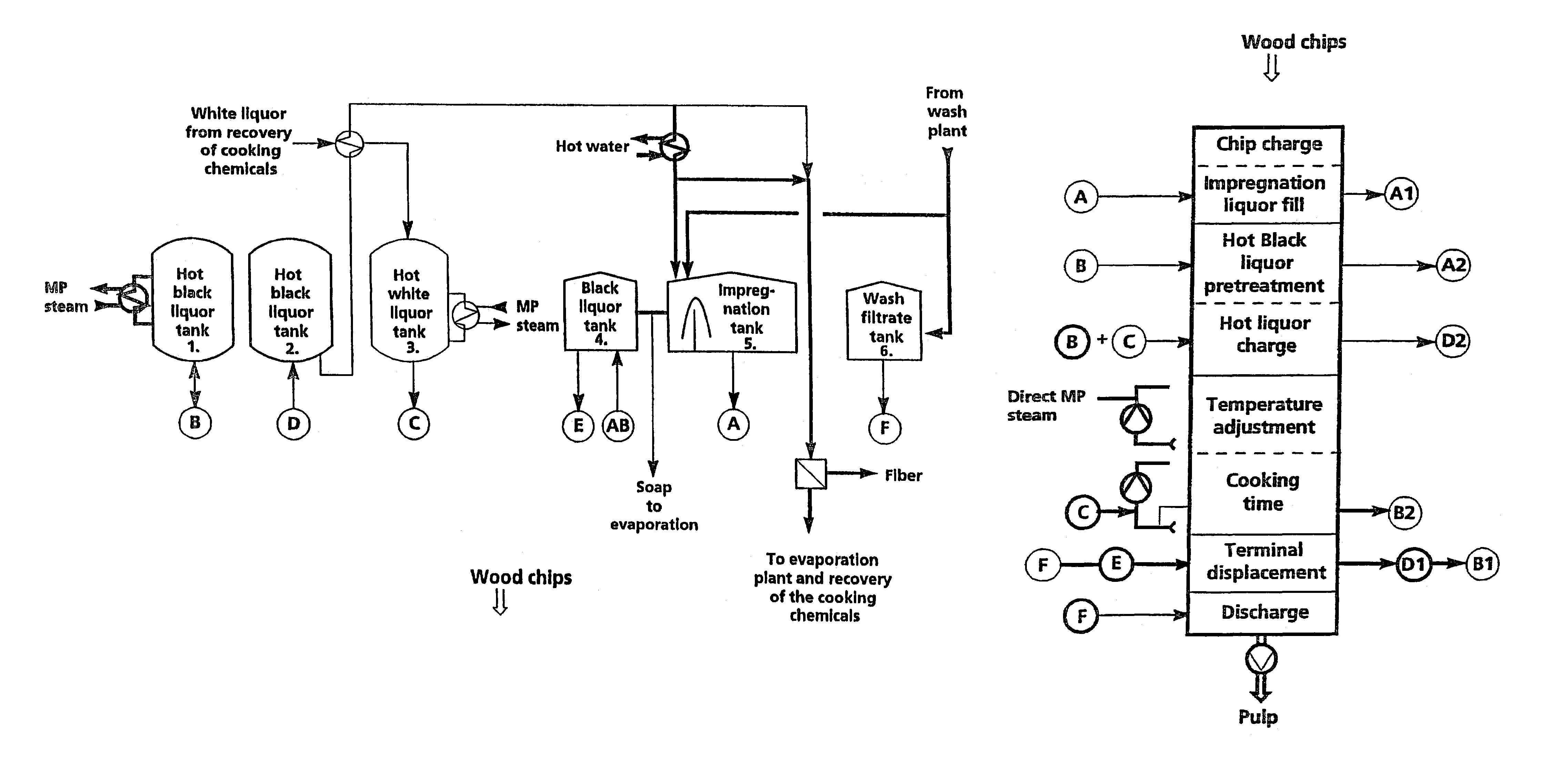

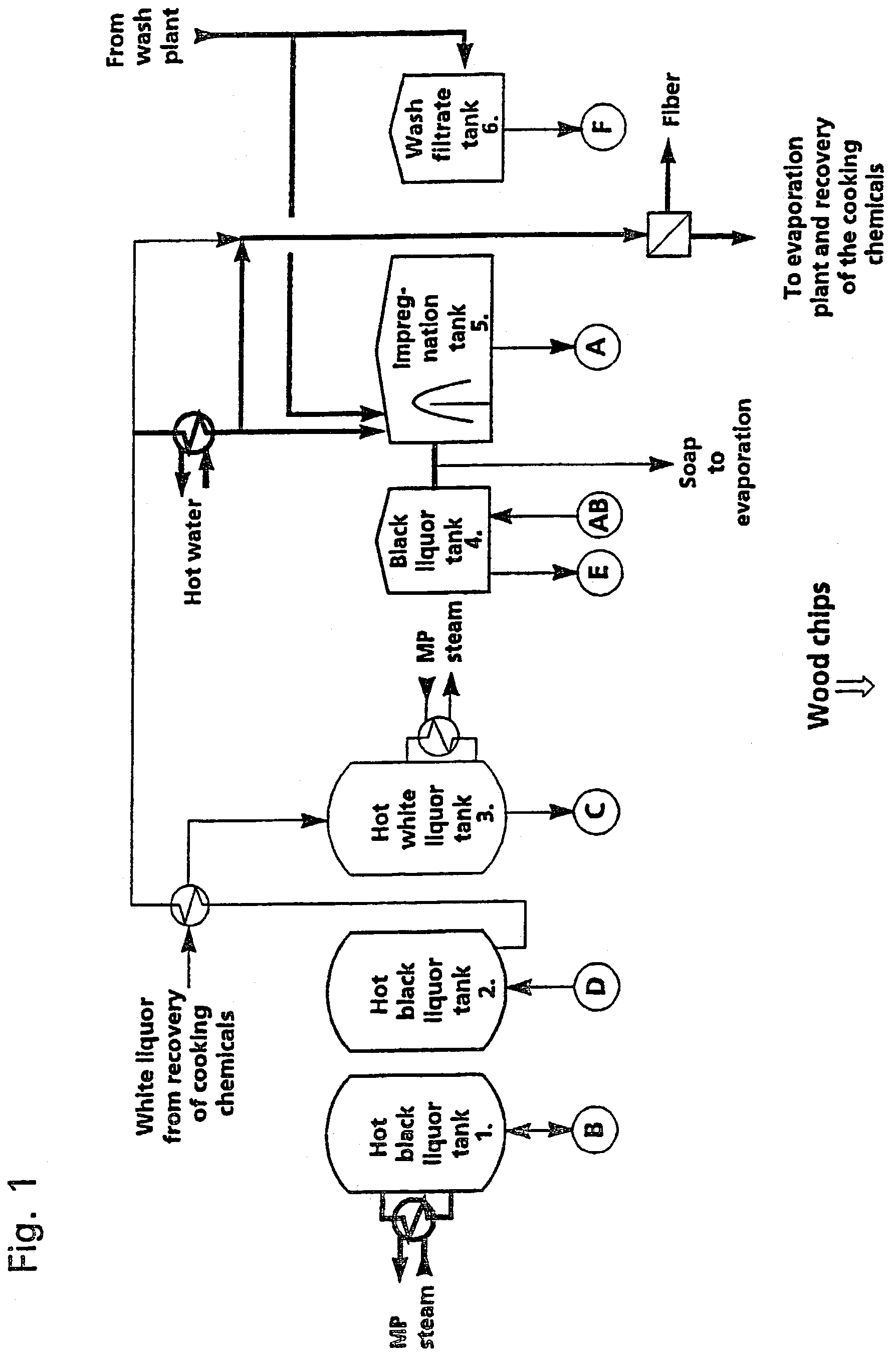

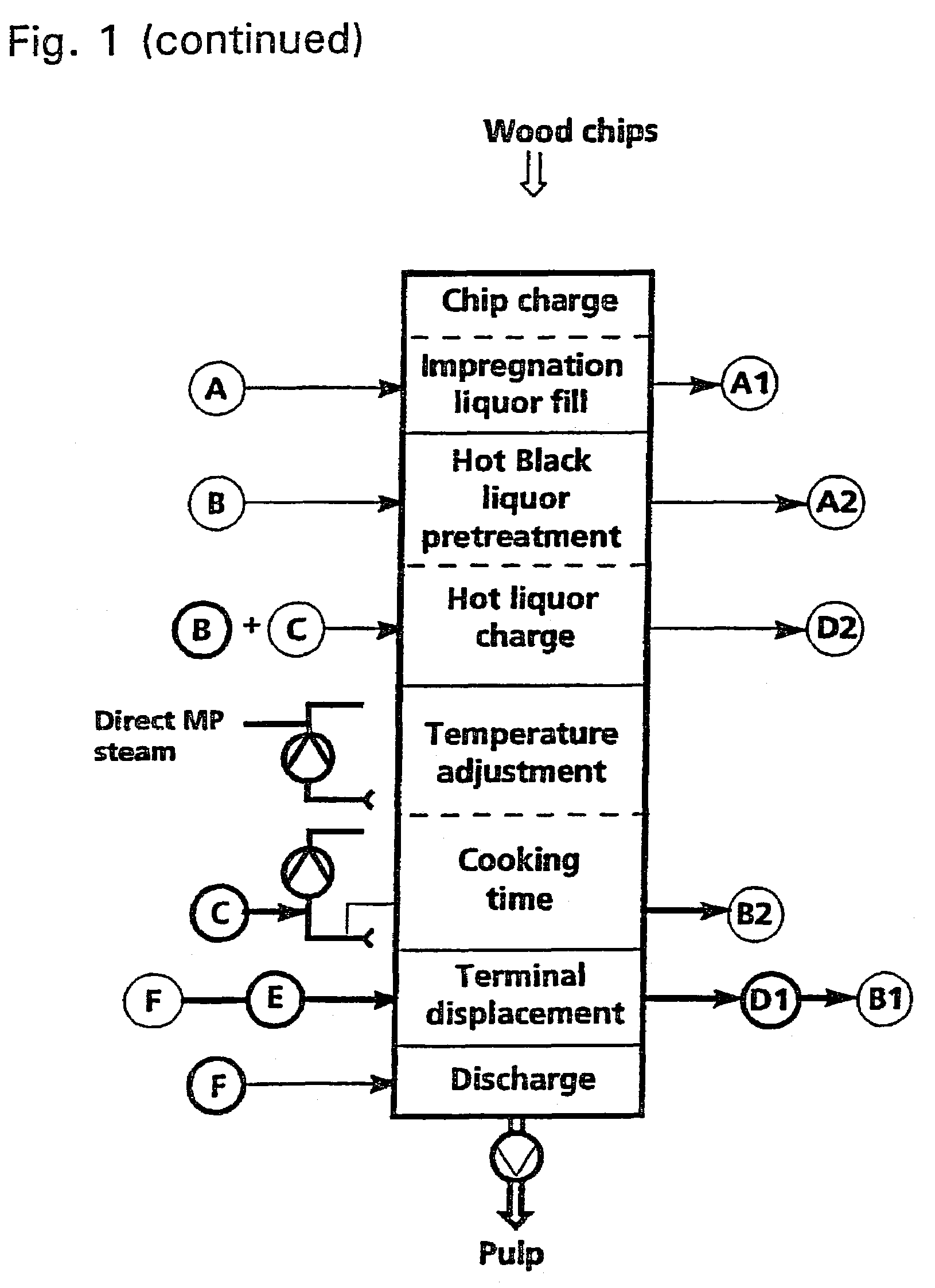

Continuous digester system

InactiveUS20100051222A1High sulfidity levelSufficient acidityDigestersContinuous pulping processSluiceHigh pressure

Owner:METABO PAPER SWEDEN

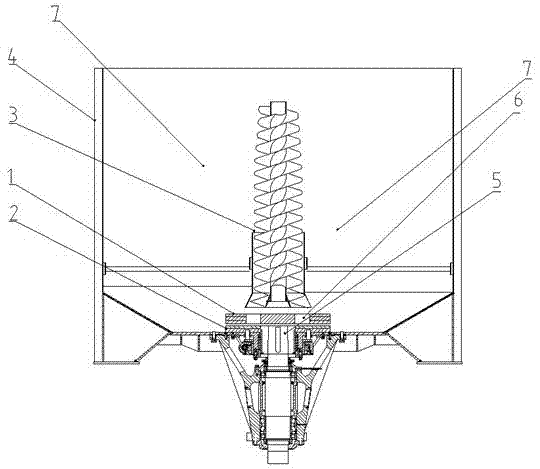

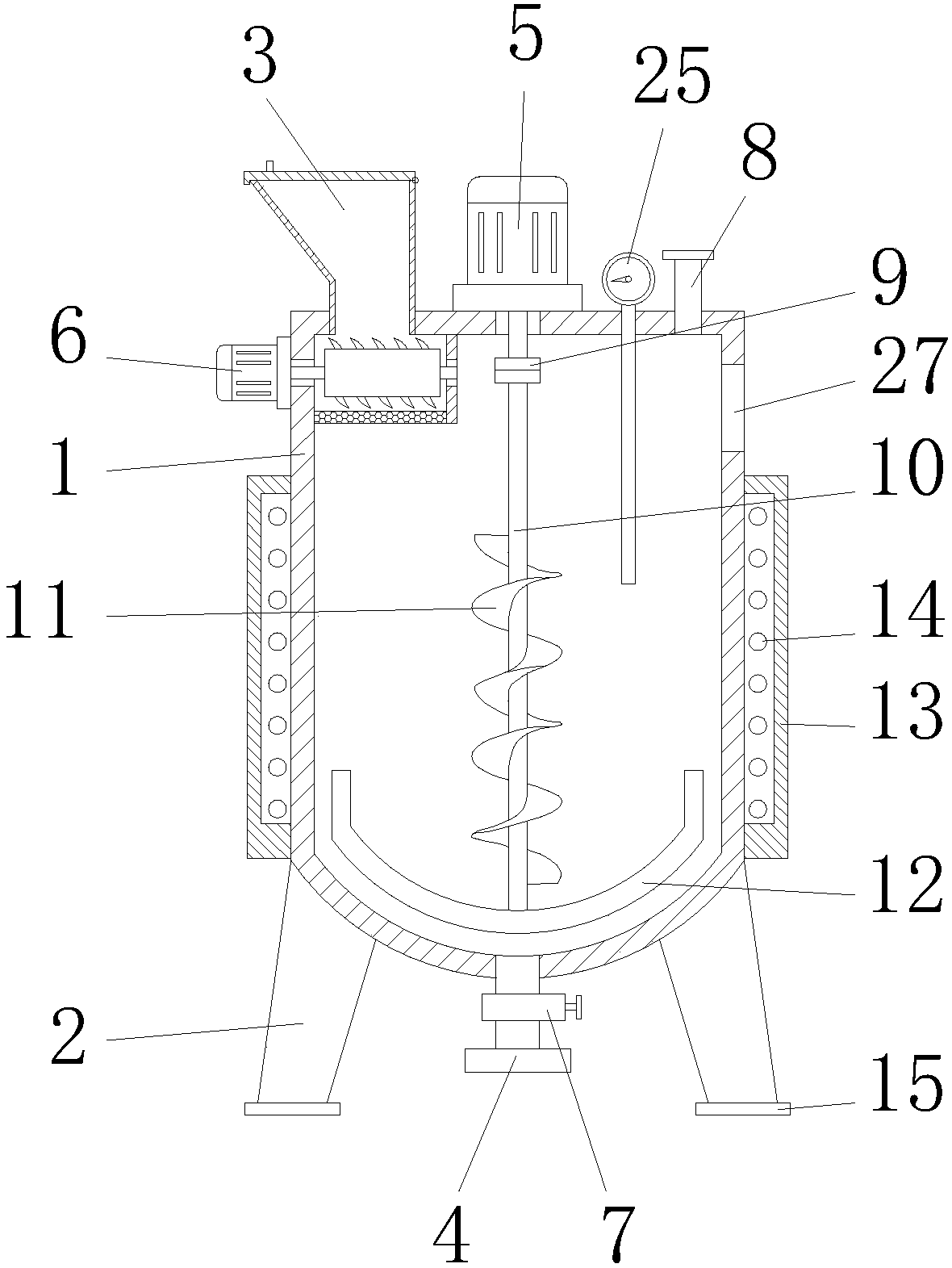

Vertical plant fiber reactor

InactiveCN107551981AWell mixedMeet the needs of useChemical/physical/physico-chemical stationary reactorsGrain treatmentsFiberSpiral blade

The invention discloses a vertical plant fiber reactor. The vertical plant fiber reactor comprises a tank body, wherein a crushing box is mounted at the top of the left side in the tank body; a screenmesh is mounted at the bottom end of the crushing box; blades are mounted on an outer wall of a cutter roller; a stirring shaft is mounted at the center in the tank body; a spiral blade is mounted onthe outer wall of the stirring shaft. According to the vertical plant fiber reactor disclosed by the invention, the blades, the screen mesh and the spiral blade are matched; the blades are rotated tocrush plant fiber, and the crushed plant fibers fall off from mesh holes of the screen mesh, fall into the bottom end in the tank body and are stirred to react; the plant fibers can be overturned upand down through the rotation of the spiral blade, so that the plant fibers and reaction medicines are uniformly mixed and react better; a valve is switched on and the plant fibers, which are preparedinto pulp after reaction is finished, are discharged out from a discharging hole; the plant fibers are crushed and then are subjected to stirring and reaction; the plant fibers are uniformly stirredand react sufficiently; the pulping quality is good and the utilization requirements of users can be met.

Owner:WUHU LINGMENG E COMMERCE CO LTD

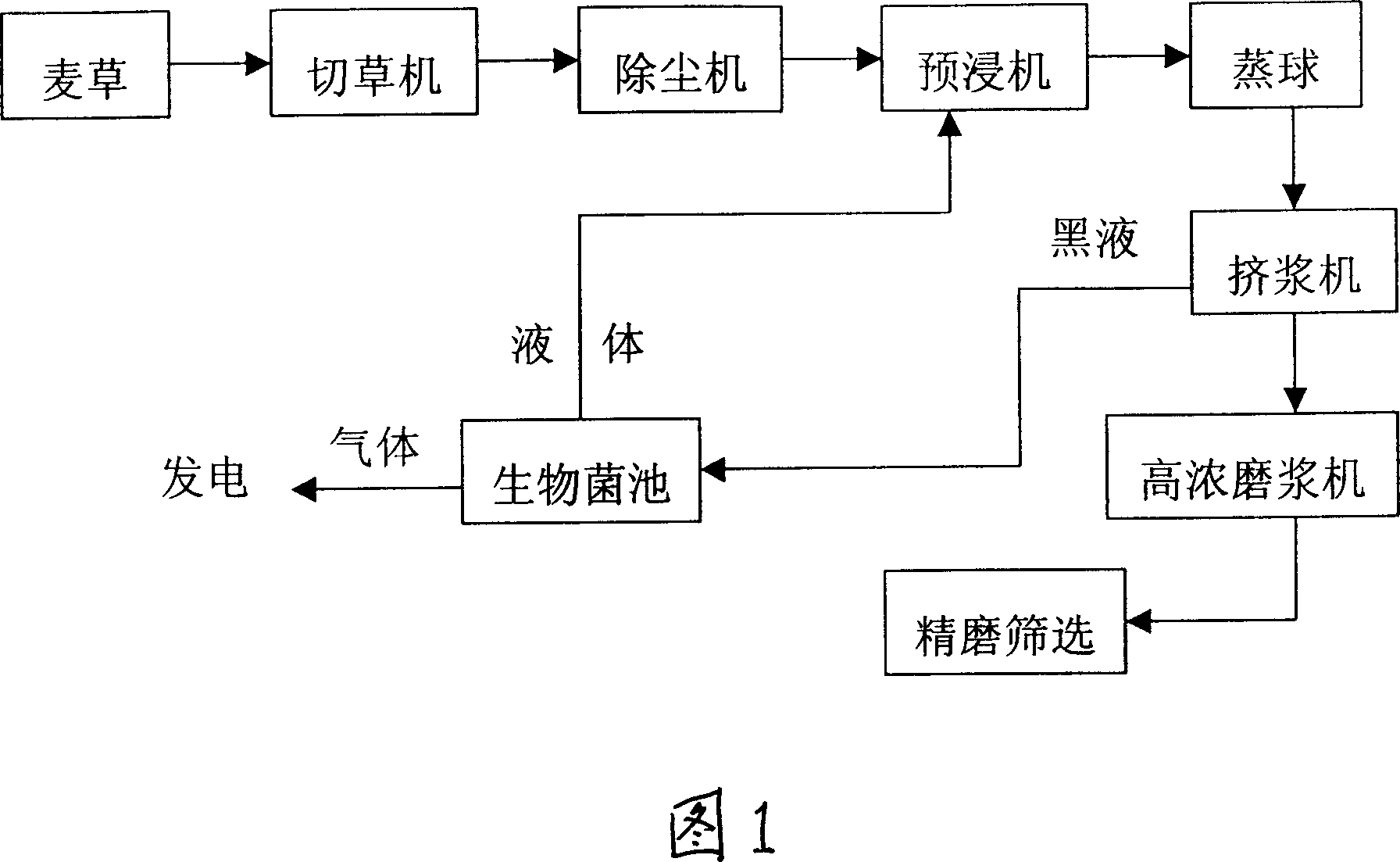

Wheat-straw biological clean pulping technology by black liquor bacterizing treatment

InactiveCN1932145AImprove pulping qualityGuaranteed closed recyclingCellulose material pulpingBlack liquorSlurry

The present invention relates to a wheat straw cleaner biopulping process. Its main technique is characterized by that firstly, the wheat straw raw material is cooked by using original bacterial liquor as cooking liquor, then the cooked stock can be passed through a pulp-extruding machine to make pulp liquor separation and the obtained black liquor can be fed into a biological bacterial pool and mixed with the described original bacterial liquor so as to form a biological liquor which can be used as cooking liquor of wheat straw raw material and form closed circulation. Said invention also provides the concrete preparation method of original biological bacterial liquor by using methanogen, saccharomycetes and white rottera as original biological bacterial seed.

Owner:山东贵和显星纸业有限公司

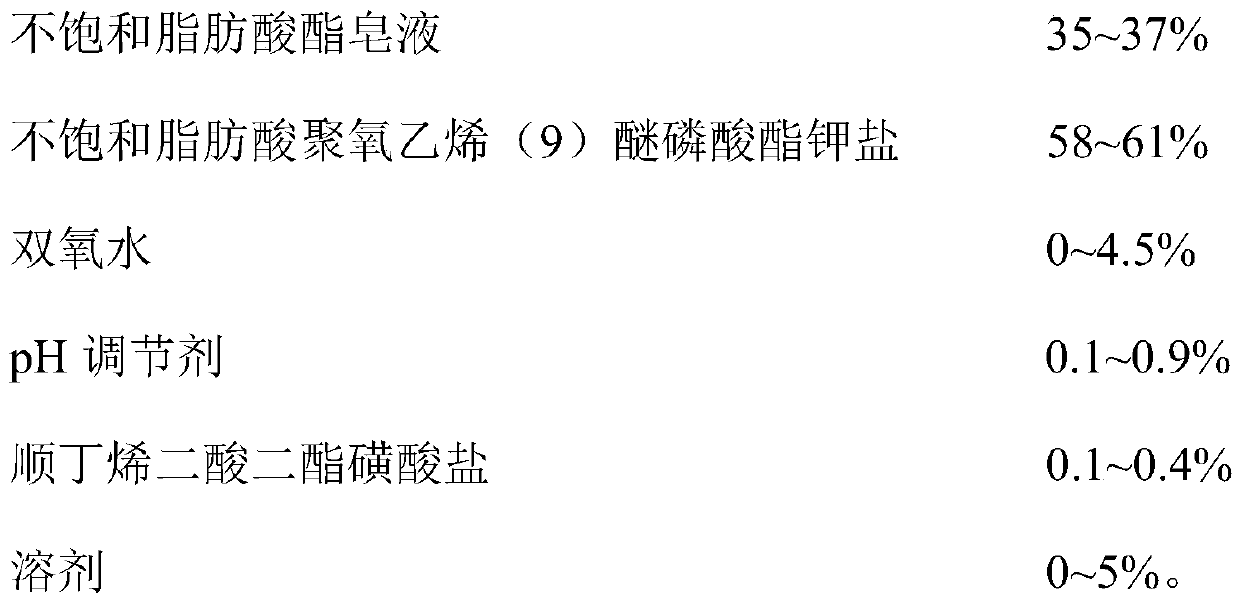

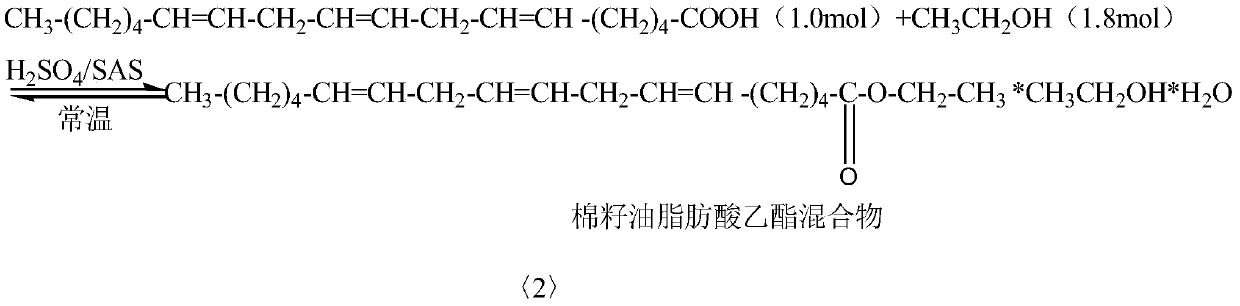

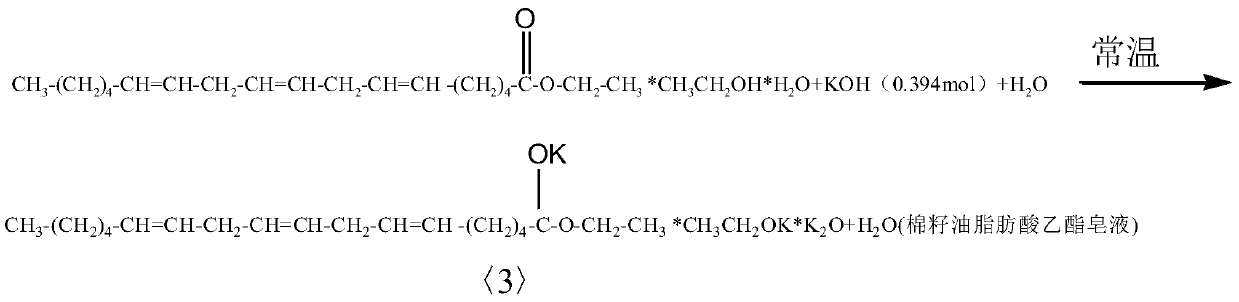

Quick-acting dissolving osmotic active matter, and preparation method and application thereof

ActiveCN111576073AStrong permeabilityExcellent antistatic and dispersion propertiesPulping with organic compoundsPaper recyclingUnsaturated fatty acidEthyl ester

The invention provides a quick-acting dissolving osmotic active matter, and a preparation method and application thereof. The quick-acting dissolving osmotic active matter comprises compound unsaturated fatty acid ethyl ester soap liquid and compound unsaturated fatty acid polyoxyethylene (9) ether phosphate potassium salt, wherein composite unsaturated fatty acids in the compound unsaturated fatty acid ethyl ester soap liquid and the compound unsaturated fatty acid polyoxyethylene (9) ether phosphate potassium salt are respectively and independently selected from at least one of C12-C18 unsaturated fatty acids. A composition of the quick-acting dissolved osmotic active matter has high permeability, compatibility, antistatic property and saponification value, and can effectively reduce oravoid the use amount of chemical raw materials and cooking aids in the paper pulp preparation or waste paper treatment process.

Owner:广州腾龙材料科技有限公司

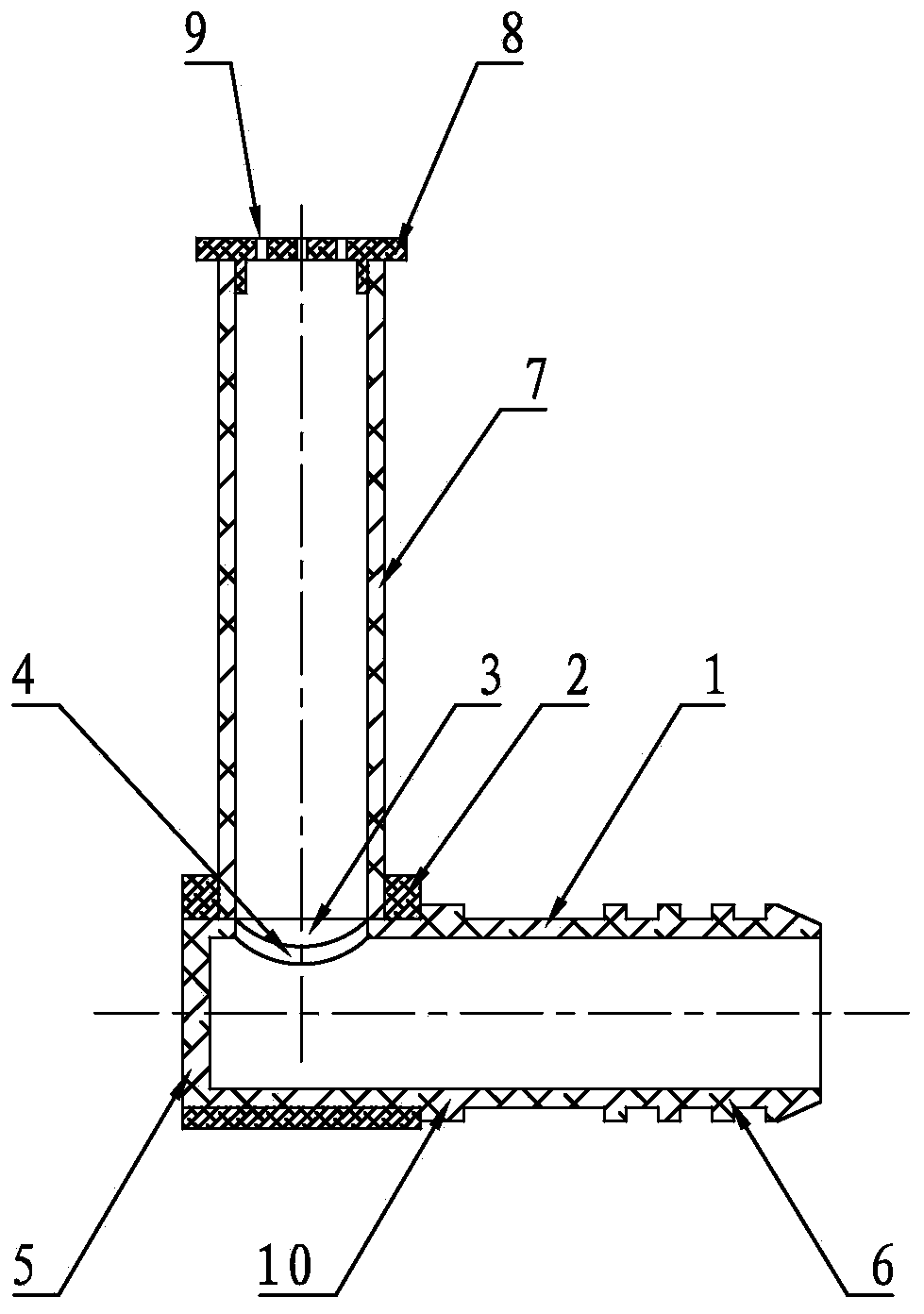

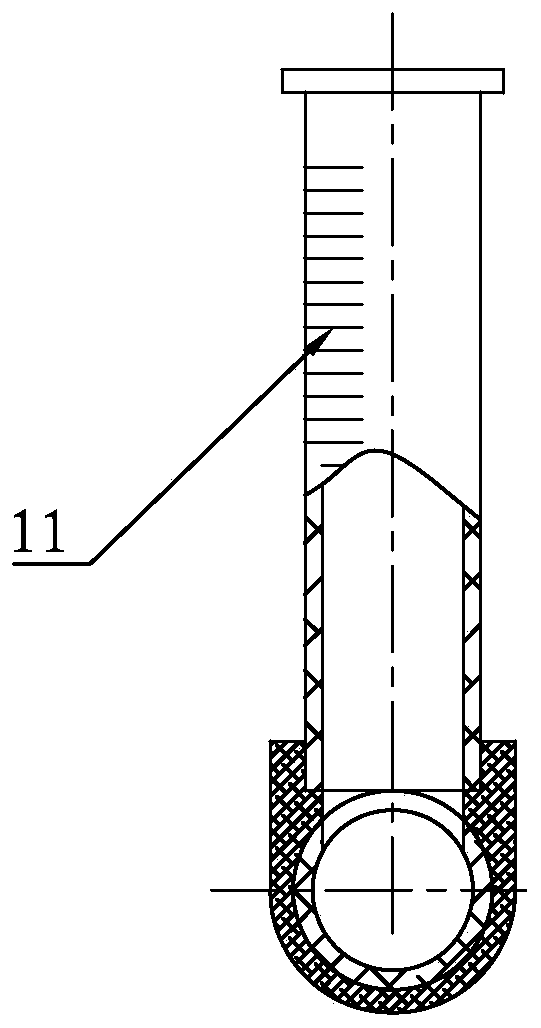

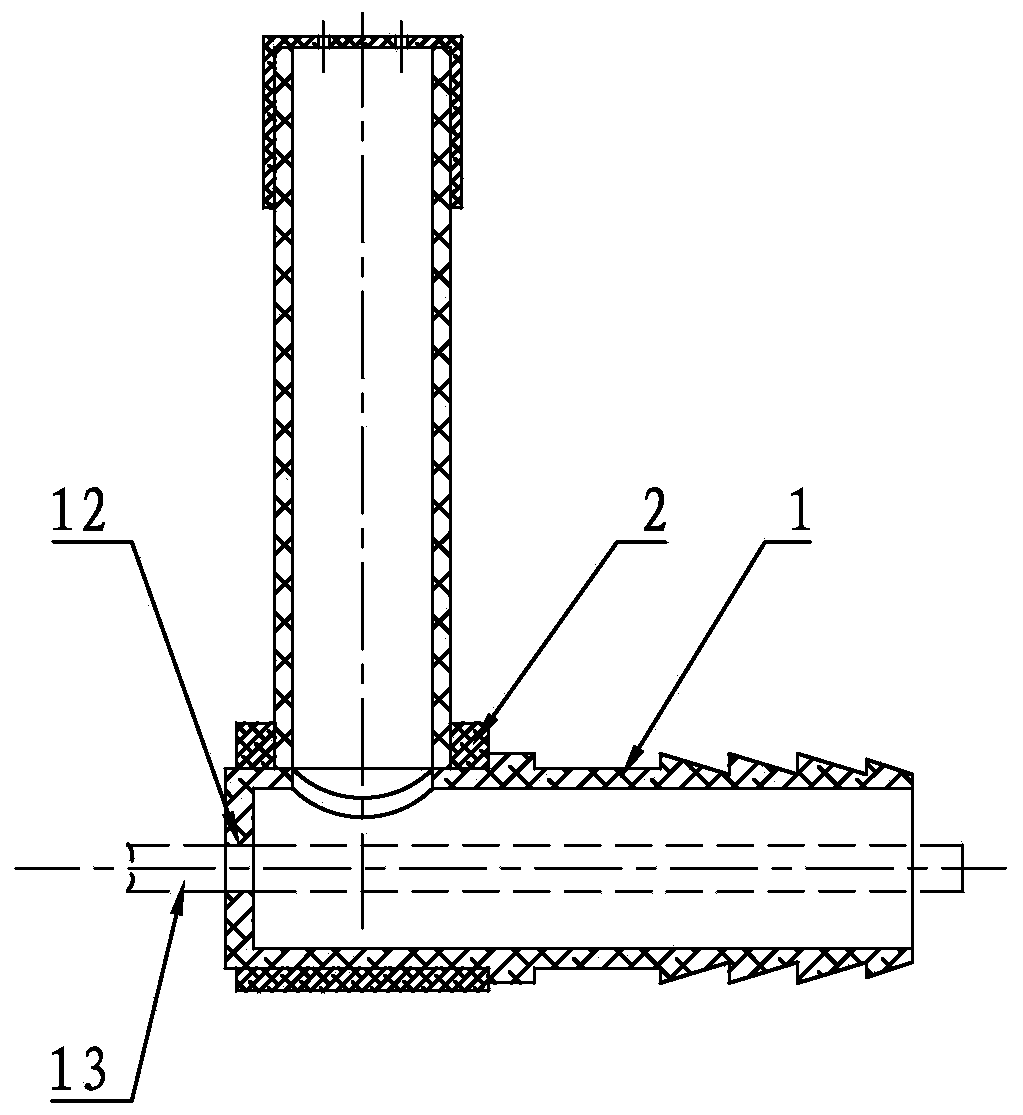

Plugging and monitoring device for grouting material insteel bar grouting joint

PendingCN110499917AImprove the quality of groutingIncrease frictionMachines/enginesLevel indicatorsArchitectural engineeringEngineering

The invention provides plugging and monitoring device fora grouting materialin a steel bar grouting joint. The plugging and monitoring device comprises a plugging pipe, a sealing ring, a monitoring pipe and a ventilation cover,the sealing end of the plugging pipe is provided with a transparent bottom surface, the opening end is connected to a grout outlet hole of the steel bar grouting joint, andthe plugging pipe is provided with a first grout through hole; the sealing ring sleeve outside the plugging pipe, and the annular outer wall of the sealing ring is provided with a second grout throughhole;the monitoring pipe can be vertically inserted into the second through hole to form a detachable fixed connection; and the ventilation cover forms a detachable fixed connection with the upper end of the monitoring pipe, and at least one ventilation hole is formed in the ventilation cover. According to the plugging and monitoring device, installation is conducted before grouting, an operatorcan visually observe a position of a grouting material slurry surface in the monitoring pipe, slurry supplying can be conducted in time when grouting material slurry backflow occurs, construction difficulty is reduced, the grouting quality and construction efficiency are improved, the cost is low and waste of the grouting material can be avoided.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Pulping digestion agent production method

InactiveCN1219938CWide adaptabilityHigh degree of polymerizationCellulose material pulpingAlcoholSodium bisulfate

Owner:湖南美莱精化有限公司

Graded pulp crushing equipment used for papermaking and capable of facilitating cleaning

ActiveCN108043796AQuality improvementQuality assurancePaper recyclingCleaning using liquidsPulp and paper industryEquipment use

The invention provides graded pulp crushing equipment used for papermaking and capable of facilitating cleaning. The graded pulp crushing equipment comprises a tank body and an upper cover. The interior of the tank body is divided into a breaking cavity and a pulp crushing cavity through a partition plate. The upper cover is provided with a feeding pipe and a cleaning and driving device. The cleaning and driving device consists of a transmission box, a rotating motor and a water inlet pipe. A breaking device is arranged in the breaking cavity. The breaking device is composed of a breaking rotating shaft, a rotating cutter blade and a fixed cutter blade. A pulp crushing device is arranged in the pulp crushing cavity. The pulp crushing device is composed of a pulp crushing motor, a pulp crushing rotating shaft, a first helical stirring belt, a second helical stirring belt and a material scraping plate. According to the graded pulp crushing equipment used for papermaking and capable of facilitating cleaning, through relative rotation of the rotating cutter blade and the fixed cutter blade, breaking treatment is conducted on large block of paper pulp, and the pulp crushing quality of anext step is improved advantageously; the cleaning quality and the cleaning speed are improved advantageously through the cleaning and driving device, and the working efficiency is improved; and through a mode of two level treatment, the quality of pulp materials is ensured.

Owner:博兴战新产业发展有限公司

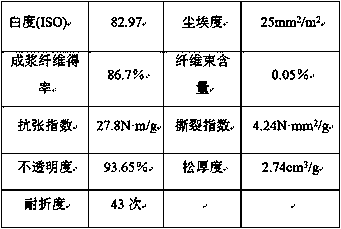

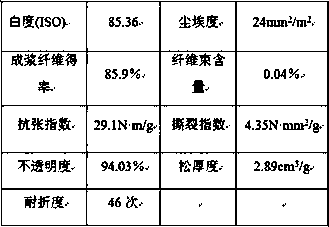

Production method for preparing chemimechanical pulp by synergy of biological enzyme and alkali

InactiveCN110656525AImprove pulping qualityImprove bindingPulp bleachingPulping with inorganic basesPulp and paper industryPre treatment

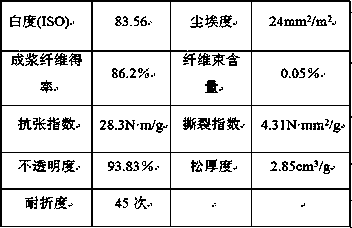

The invention provides a production method for preparing chemimechanical pulp through synergy of a biological enzyme and an alkali. The production method specifically comprises the steps of raw material pretreatment, biological enzyme treatment, primary extrusion defibering, secondary extrusion defibering, liquid medicine dipping, and bleaching. Wastewater generated by the process is adopted for pretreatment of wood chips, biological enzyme treatment is combined, so that residual chemicals are fully utilized, the wastewater discharge is reduced, the consumption of sodium hydroxide and peroxides in the subsequent bleaching process is greatly reduced, and the method has dual significance of environmental protection and reality. The chemimechanical pulp prepared by the production process is good in pulping quality, pulp ISO whiteness reaches 82.97-85.36, pulp tearing index reaches 4.24-4.35 N.mm < 2 > / g, tensile strength reaches 27.8-29.1 N.m / g, and pulp fibers are firmly combined.

Owner:山东晨鸣纸业集团股份有限公司

Method for preparing pulp using fresh palm empty fruit bunch and equipment thereof

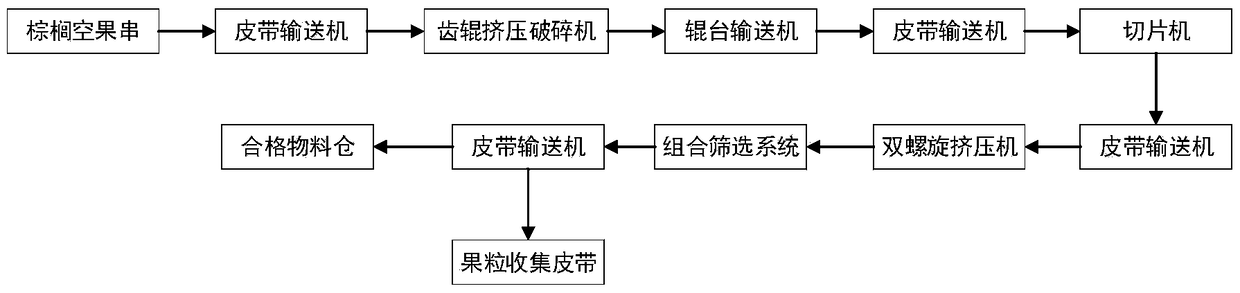

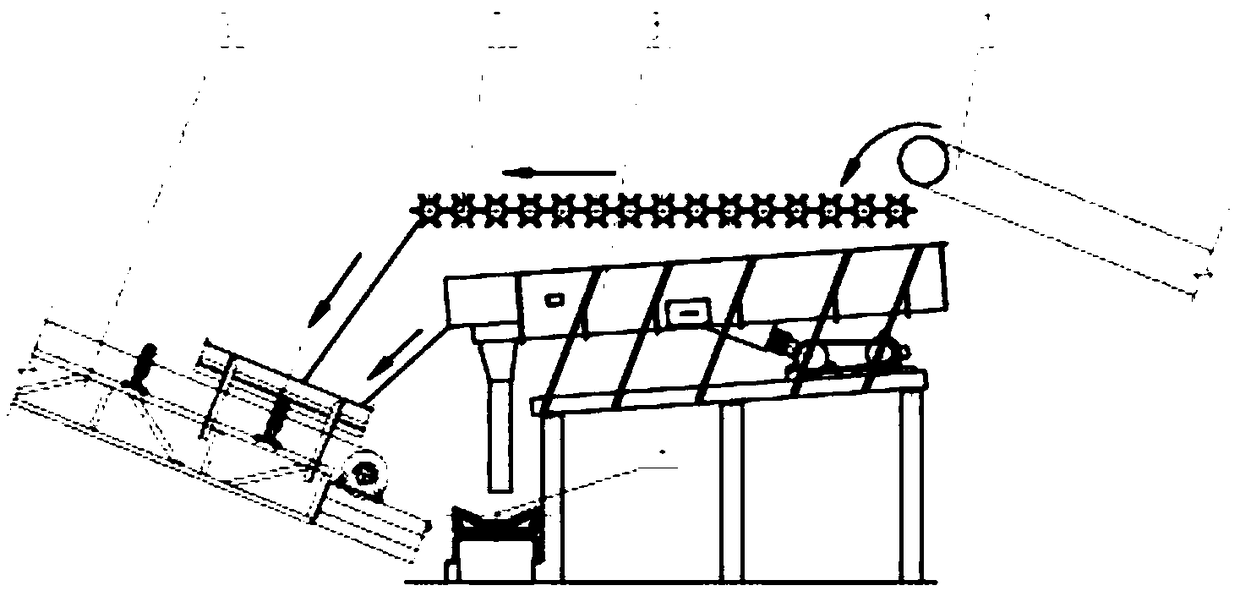

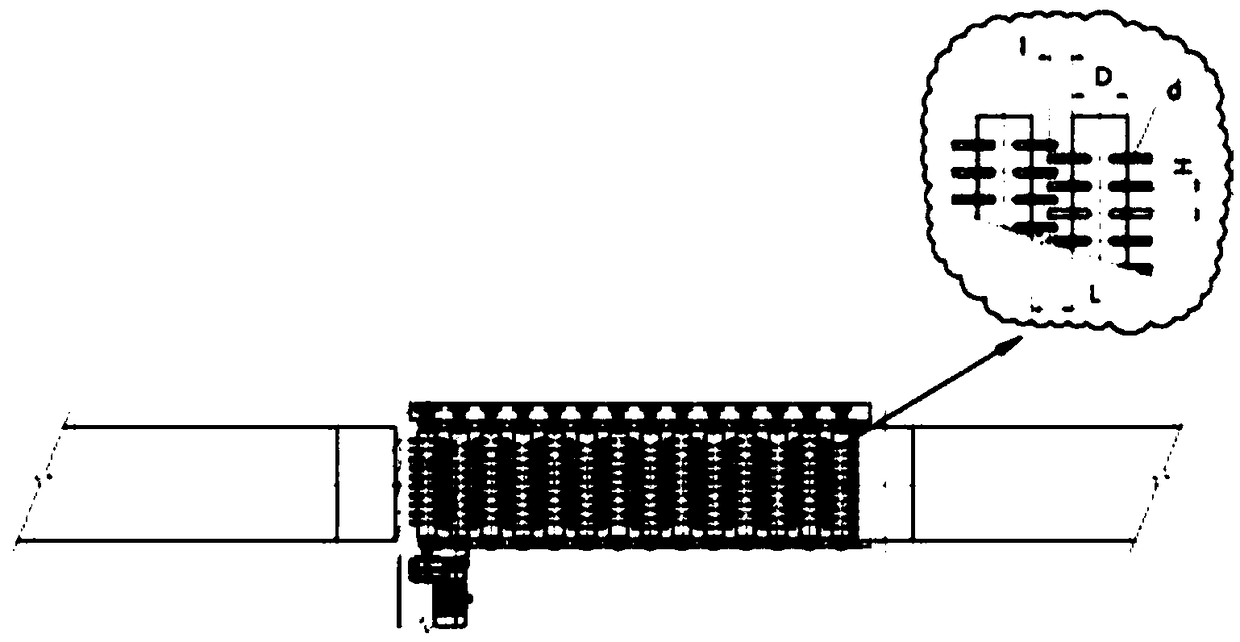

InactiveCN108824048AThe material preparation process is compactIncrease productivityRaw material divisionPalm fiberChemical products

The invention relates to a method for preparing pulp using fresh palm empty fruit bunches and equipment thereof. The method is characterized in that procedures of squeezing tearing, threshing, cutting, double screw extrusion, finishing sorting and the like are conducted on the fresh palm empty fruit bunches to effectively remove non-fiber components of free water, non-fiber peels, residual fat, fruit grains and the like in the palm fruit bunches, and adverse influences of the non-fiber components on pulp preparation in subsequent pulp preparation process can be significantly reduced. By meansof the method, the quality of palm fiber raw materials can be greatly improved to achieve the purposes of the reduction of ineffective consumption on chemical products of non-fiber components of the raw materials in the pulp preparation process and the improvement of the quality of paper pulp.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

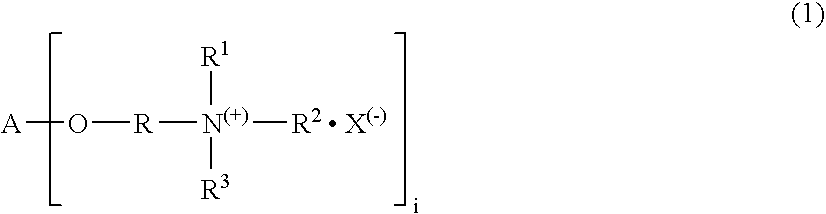

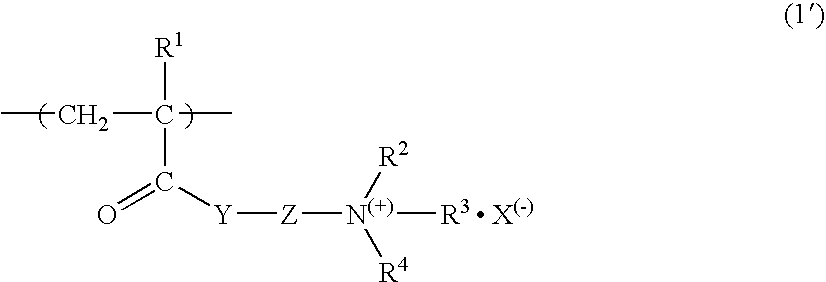

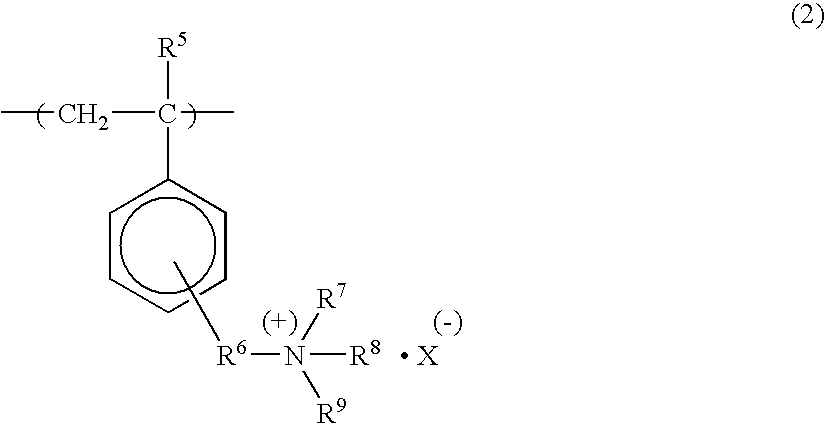

Paper quality improver

InactiveUS20060106137A1Overcome the small stiffnessStiffness improverNatural cellulose pulp/paperSpecial paperPolymer scienceIonic polymerization

The invention provides an additive for internal addition, which improves the paper qualities of a pulp sheet, such as stiffness and bulk. The invention relates to a paper quality improver for internal addition, which comprises a polymeric emulsion containing a natural cationic polymer (A) or synthetic cationic polymer (A′) and polymer particles (B) containing vinyl monomer-derived structural units.

Owner:KAO CORP

Method for improved turpentine recovery from modern cooking plants

InactiveUS7384501B2Reduce solubilityQuality improvementDrying using combination processesOrganic compound preparationTurpentinePulp and paper industry

A method for the preparation of pulp by means of alkaline cooking, in which method spent liquor is transferred to pressurized tanks, and at least one liquor is expanded corresponding to a temperature difference of 1 to 5° C. The generated steam is led to turpentine recovery. Thus, the removal of turpentine and gases dissolved in said liquor is effective, the amount of recovered turpentine increases, and pulp of better washability and higher quality is obtained.

Owner:METSO PAPER PORI OY

Mortar mixer

InactiveCN101508146BIncrease volumeLong hydrophilic timeDischarging apparatusMixing operation control apparatusEngineeringLeather belt

The invention relates to a mortar mixer, which comprises a mixer barrel body and a transmission device. A mixing main shaft in the mixer barrel body is connected with a mixing vane, the mixer barrel body has a vertical structure, a motor is arranged on the top of the mixer barrel body, the mixing main shaft penetrates into the mixer barrel body vertically, a sandy material feeding baffle plate isarranged between a charging opening and the transmission device, a sand feeding belt is arranged above a feed inlet, the end part of a water inlet pipe is positioned in the feed inlet, and a mixing chain is connected below the mixing vane of the mixing main shaft. The mortar mixer combines the functions of mixing and crashing, and has high slurrying efficiency, large volume of a mixing drum, and large slurrying capacity.

Owner:刘兴才

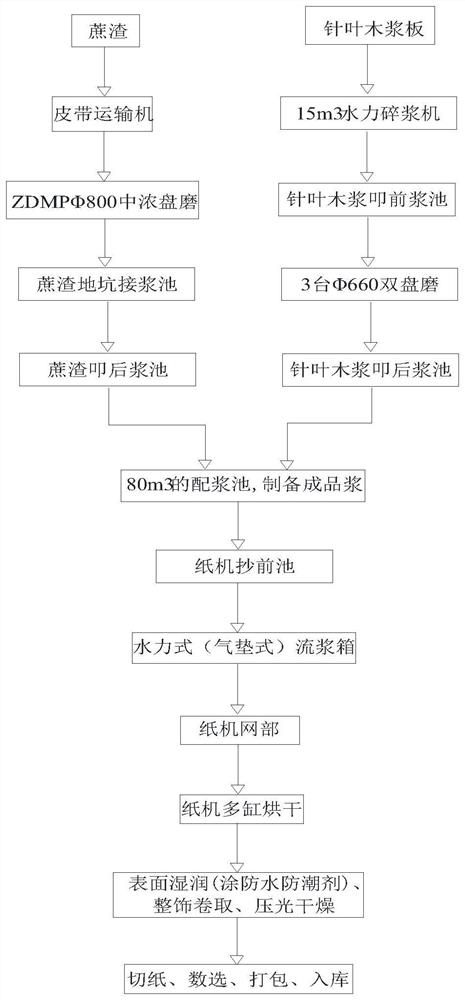

Method for producing food packaging paper by using bagasse pulp

The invention discloses a method for producing food packaging paper by using bagasse pulp. According to the method, mainly bagasse is used as a raw material and is matched with a small amount of imported softwood pulp board; and the method comprises the following steps: S1, separately pulping bagasse and softwood pulp board to prepare bagasse pulp and softwood pulp; S2, conveying the bagasse pulpand the softwood pulp prepared in the step S1 into a pulp preparation pool, and uniformly mixing to prepare finished pulp; S3, conveying the finished pulp prepared in the step S2 into a pre-papermaking pool of a paper machine, and making the finished pulp into paper so as to finish papermaking; and S4, wetting the surface of the paper prepared in the step S3, carrying out finishing coiling and calendaring drying, and finally slitting by adopting a slitting machine to obtain finished paper. According to the invention, bagasse is adopted as a raw material and matched with a small amount of imported softwood pulp boards, the proportion of expensive long fibers in paper can be reduced, the proportion of bagasse pulp is increased, the production cost is reduced, resources are saved, environmental protection is facilitated, and the produced product is high in quality, stable and reliable.

Owner:GUILIN QIFENG PAPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com