Graded pulp crushing equipment used for papermaking and capable of facilitating cleaning

A technology of pulping and equipment, applied in papermaking, textiles and papermaking, cleaning methods and appliances, etc., can solve the problems of poor crushing effect of pulping blades, reduced working efficiency of pulper, and waste residues that cannot be cleaned up in time, etc., to achieve Improve cleaning quality and cleaning speed, speed up work efficiency and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

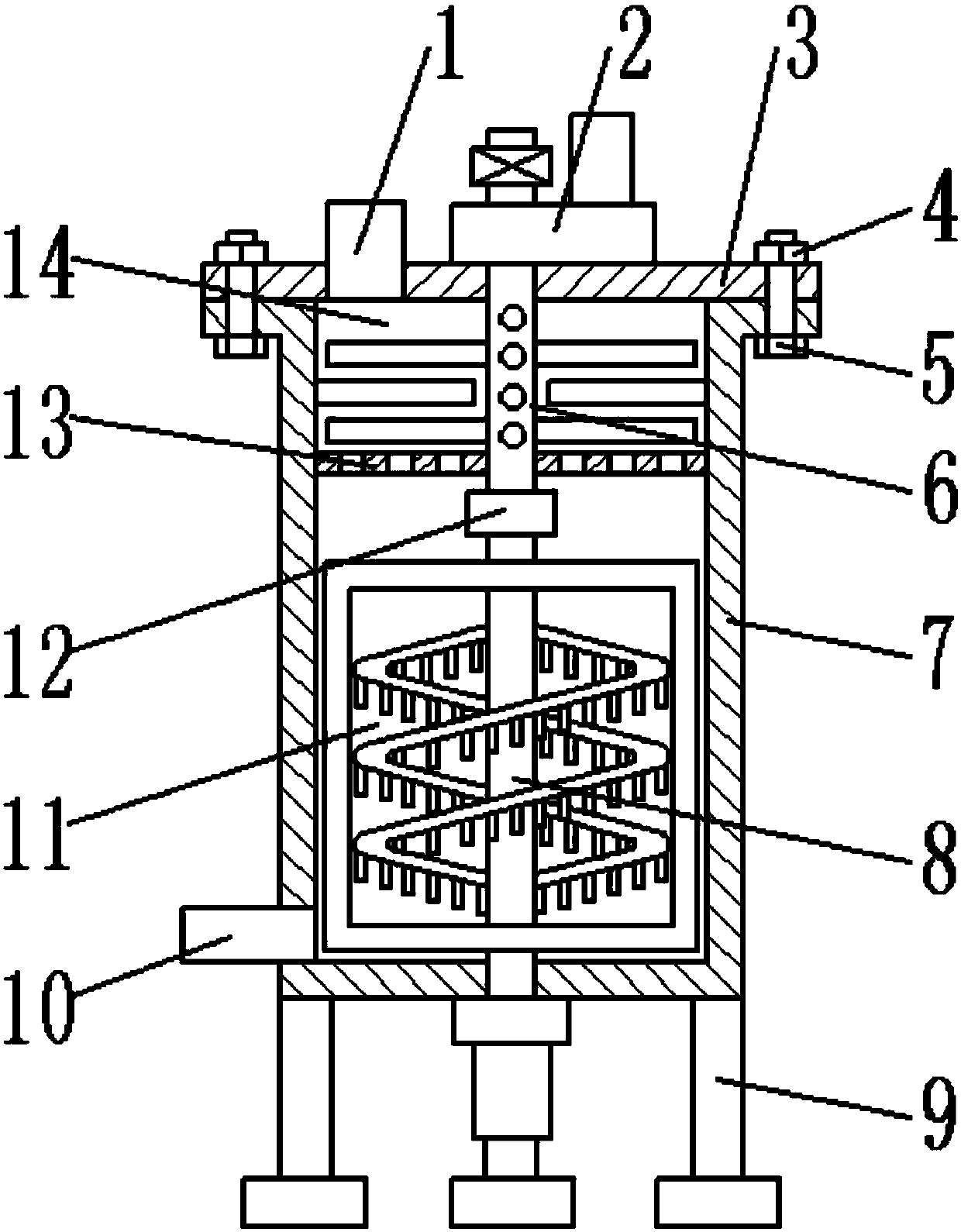

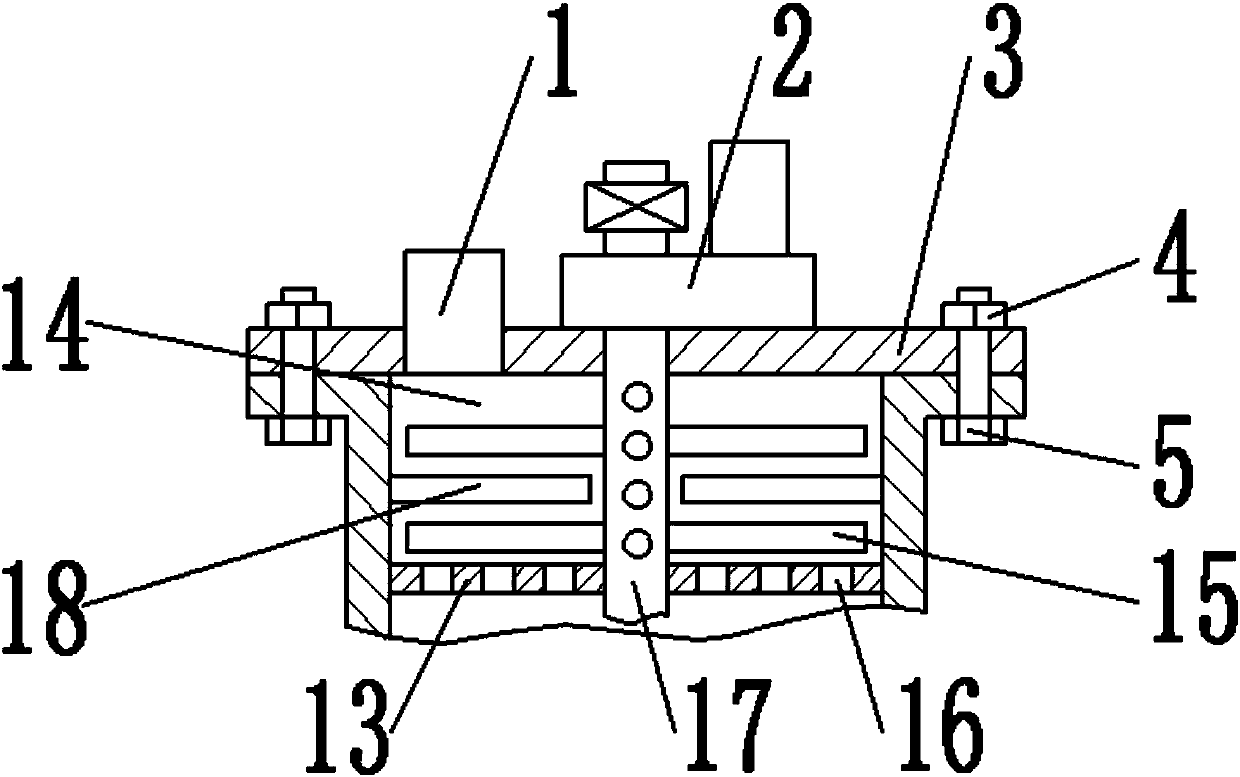

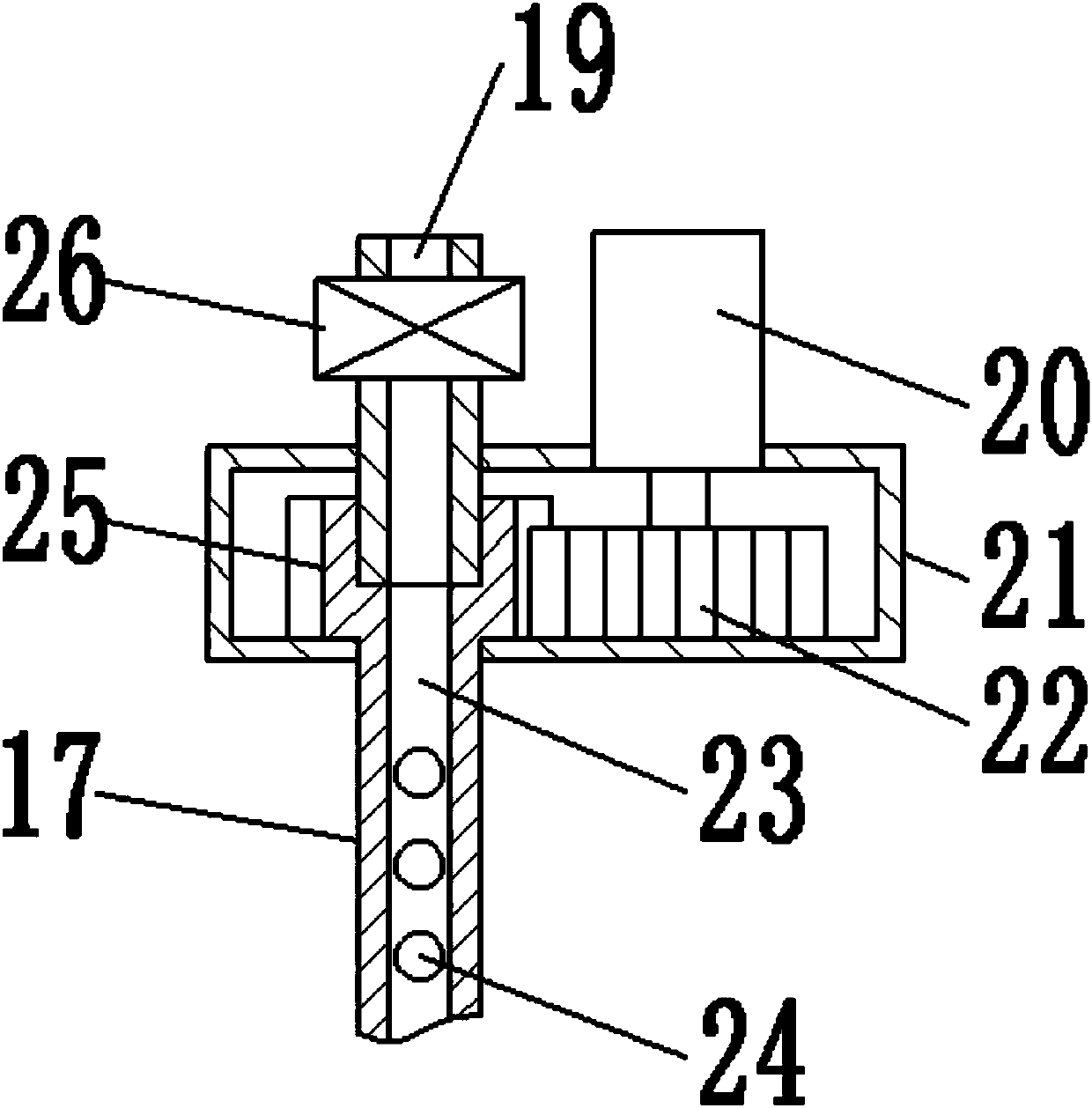

[0018] see Figure 1-4 , a graded pulping equipment for papermaking that is easy to clean, includes a tank body 7 and an upper cover 3; the tank body 7 is set as a hollow cylinder, and the inside is separated into a breaking chamber 14 and a pulping chamber 11 by a partition 13, A loam cake 3 is provided at the top opening; a number of blanking holes 16 are evenly distributed on the partition plate 13; and the tank body 7 are all made of stainless steel; the upper cover 3 is provided with a feed pipe 1 and a cleaning and driving device 2; the feed pipe 1 is arranged on the left side of the upper cover 3 for adding materials to be processed; The cleaning and driving device 2 is arranged in the middle of the upper cover 3, and the cleaning and driving device 2 is composed of a transmission box 21, a rotating motor 20 and a water inlet pipe 19; Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com