Patents

Literature

169results about How to "Increase the degree of crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

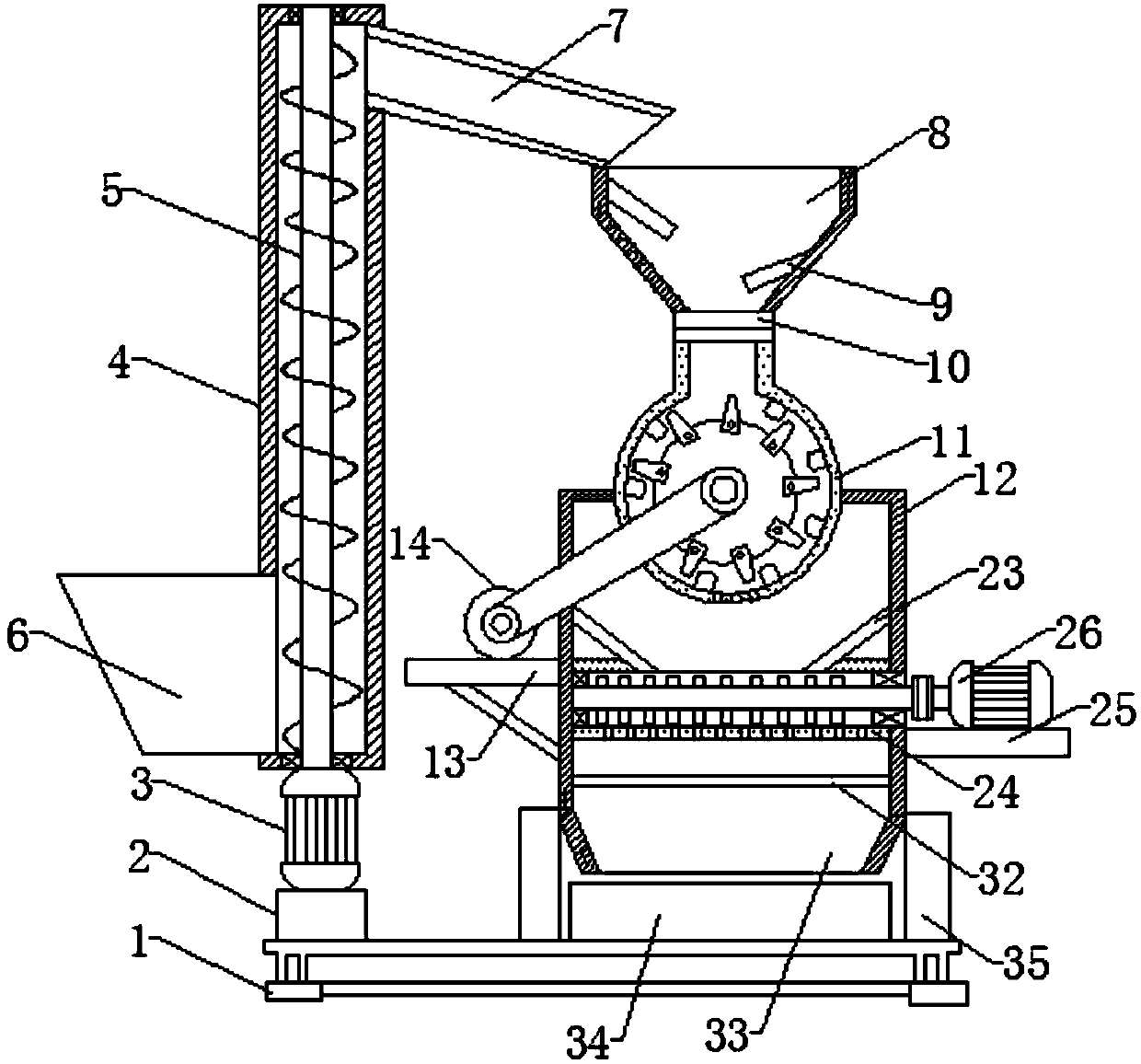

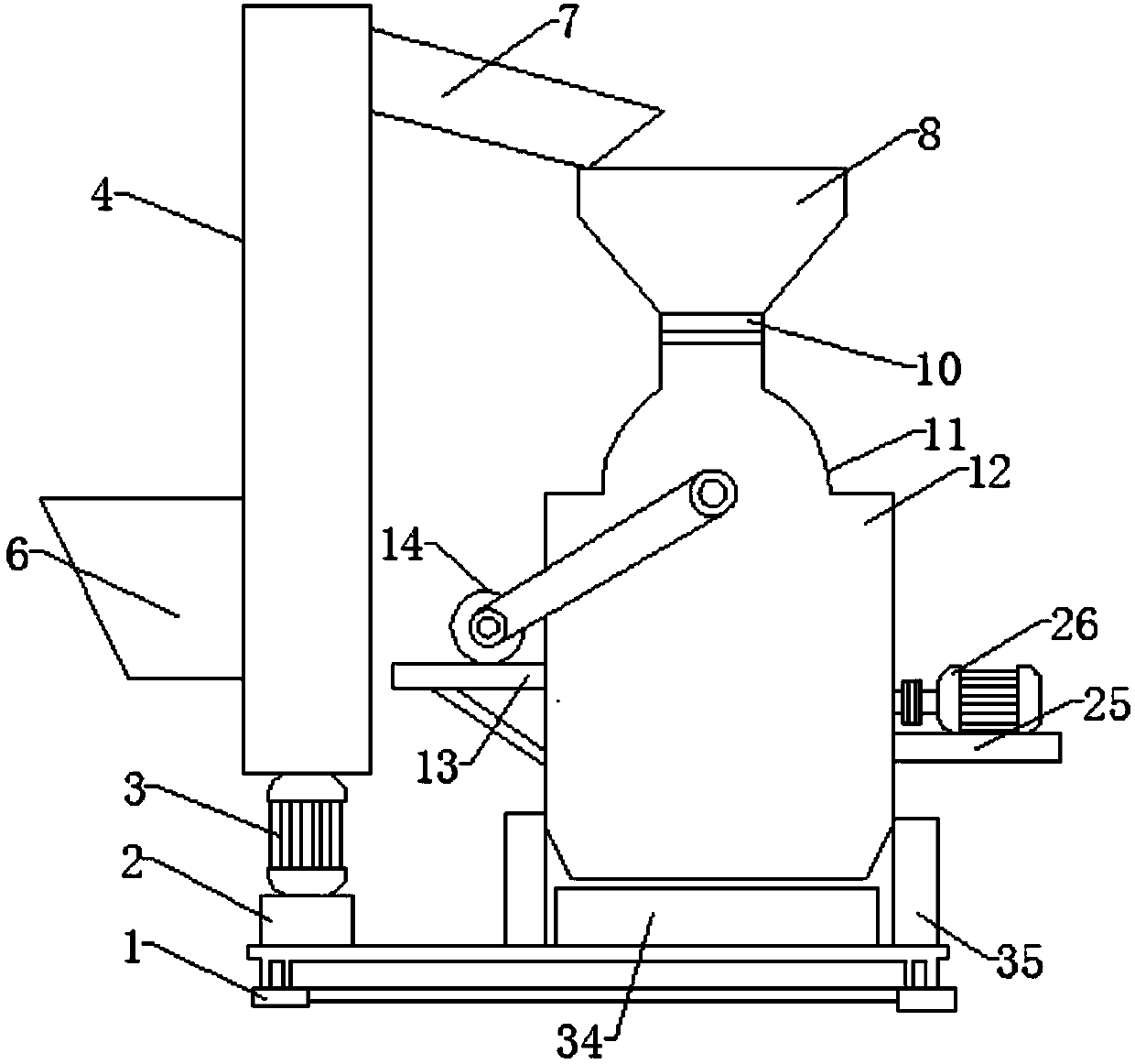

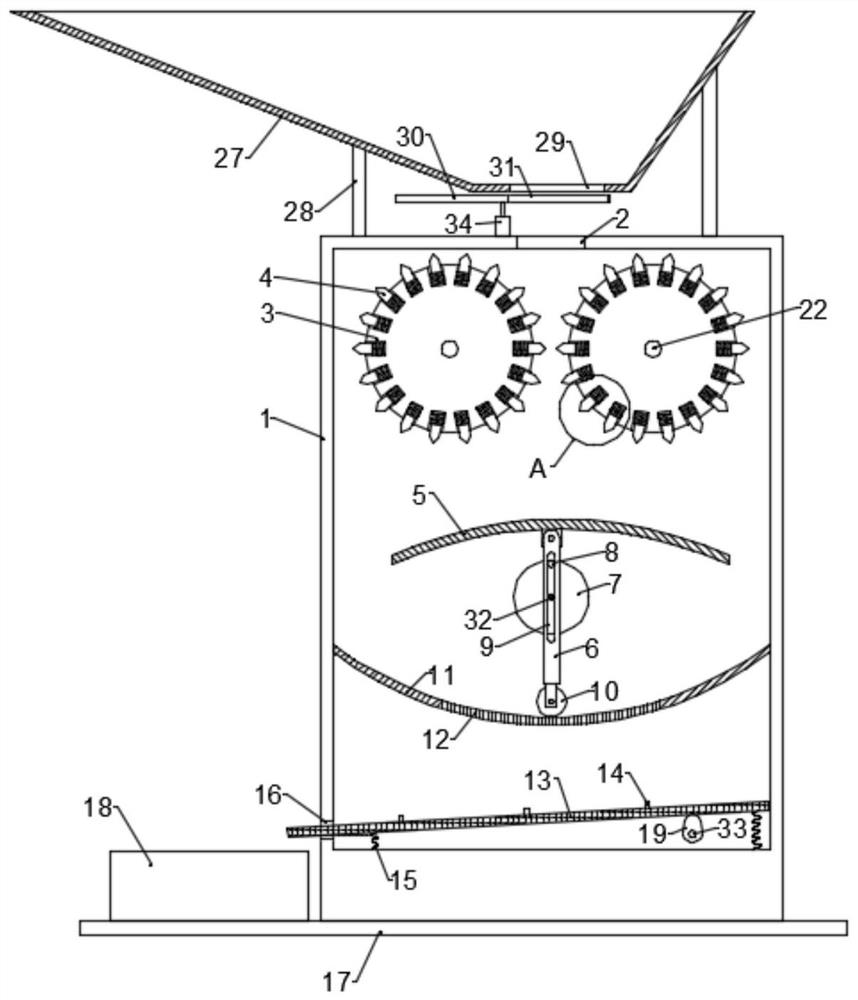

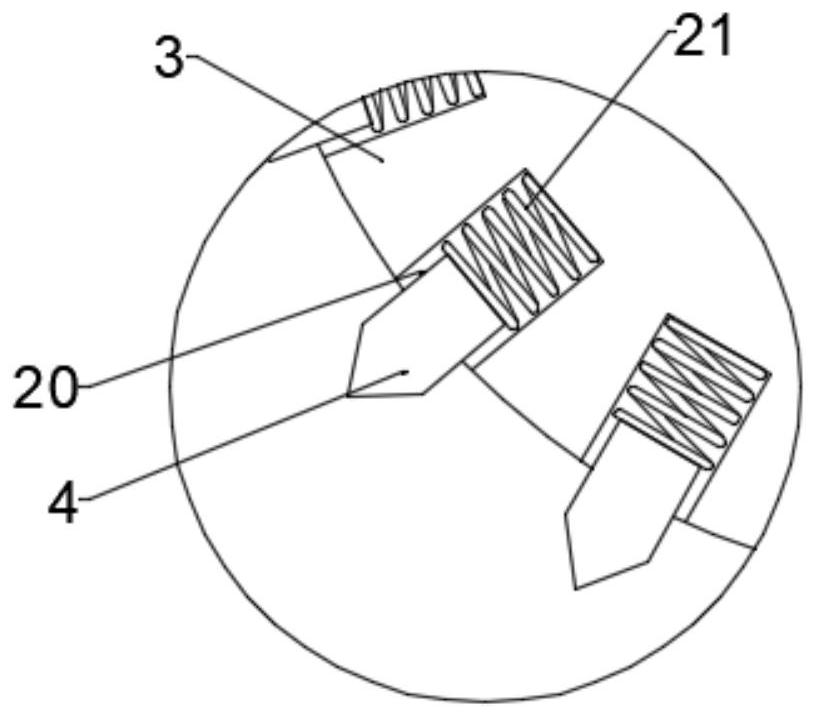

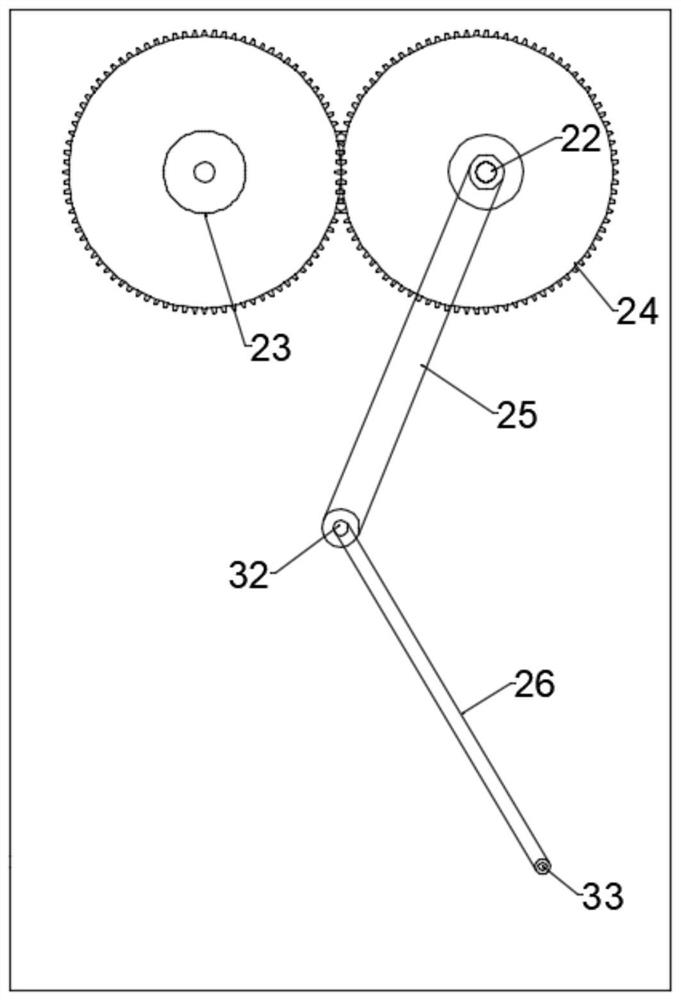

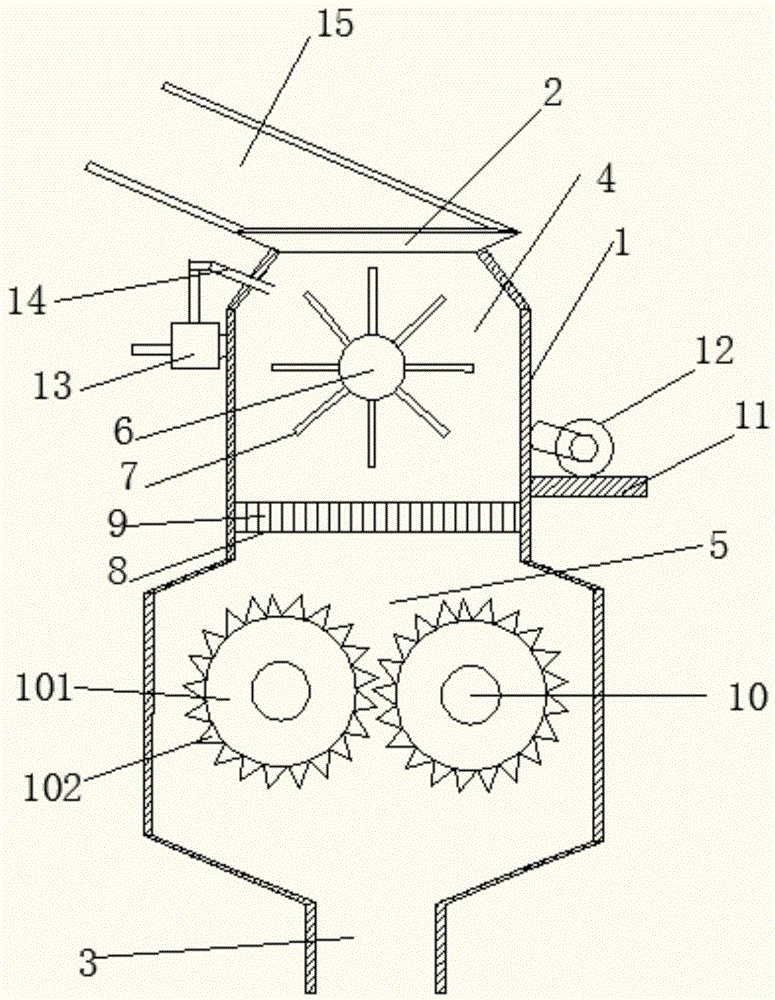

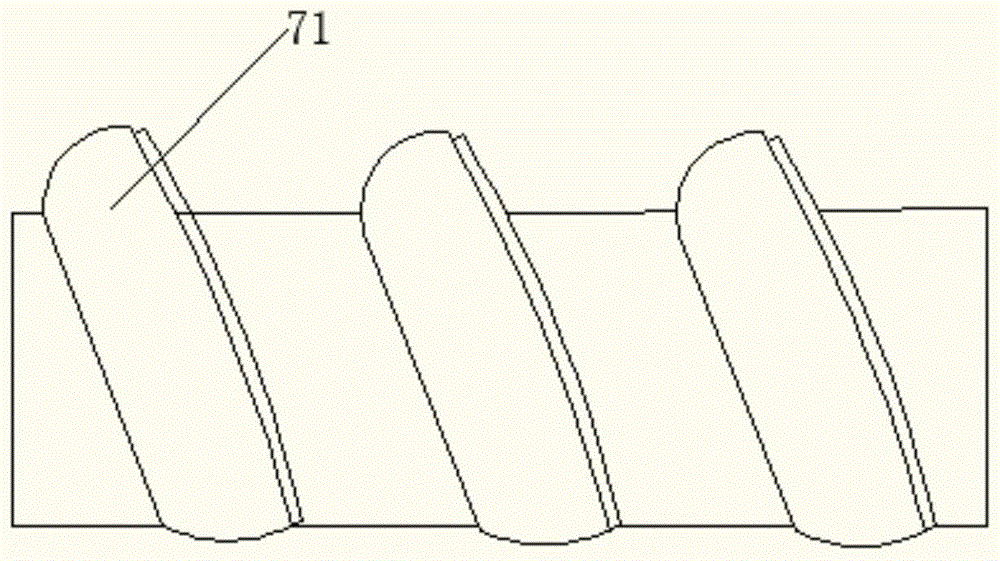

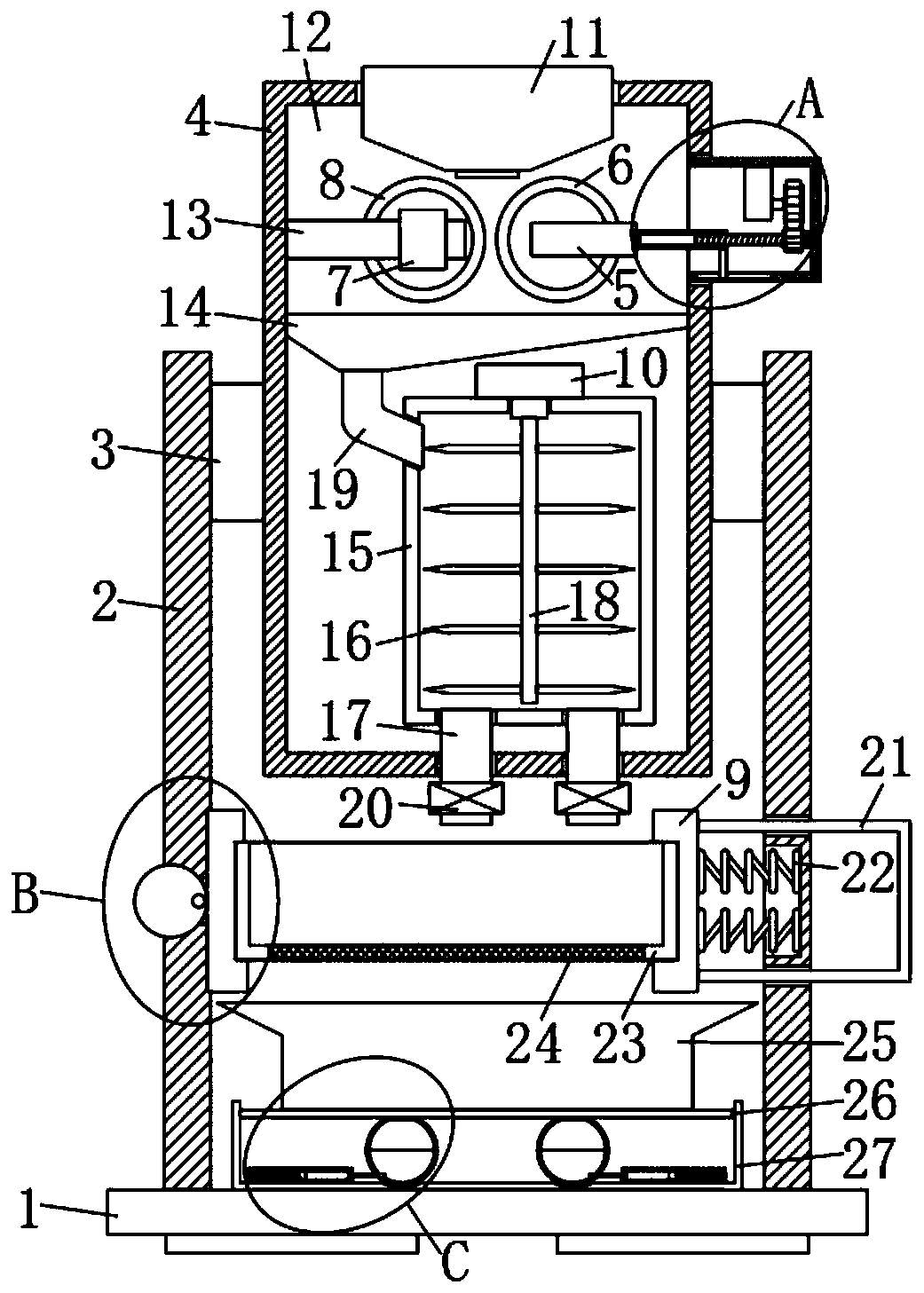

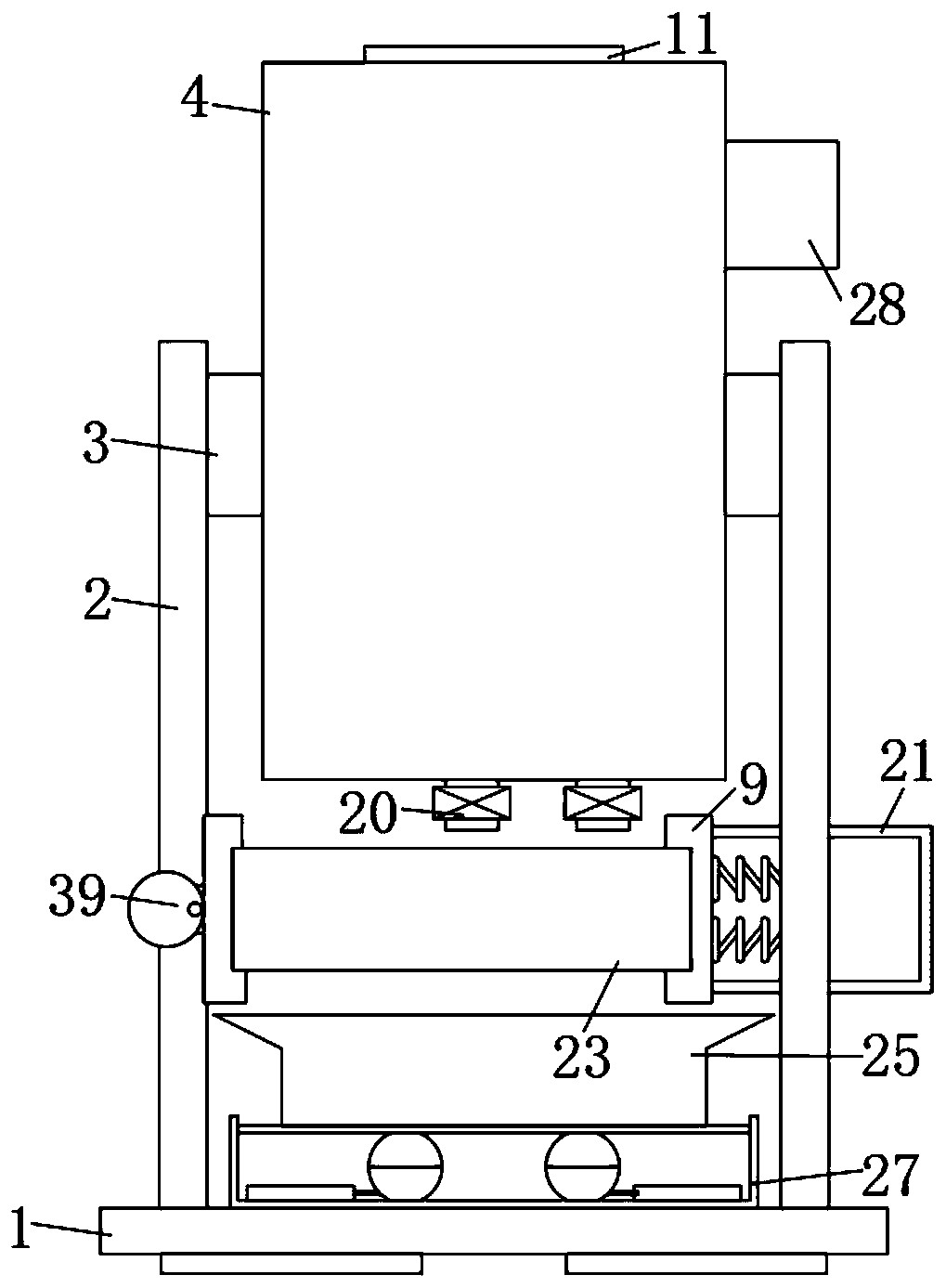

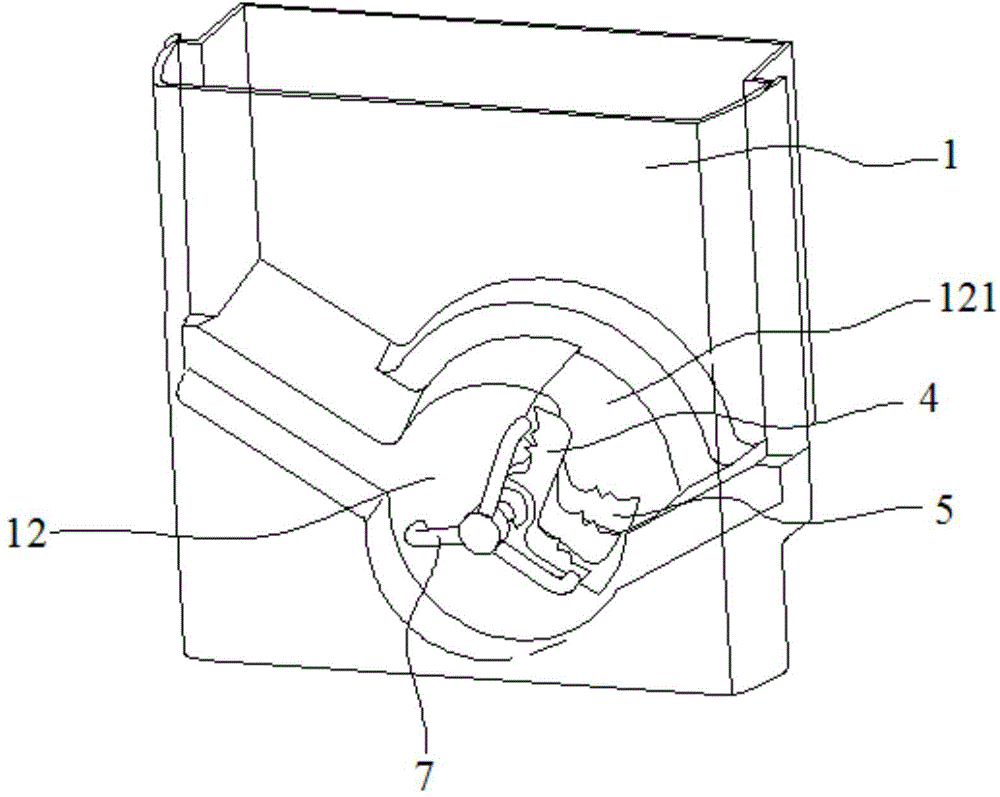

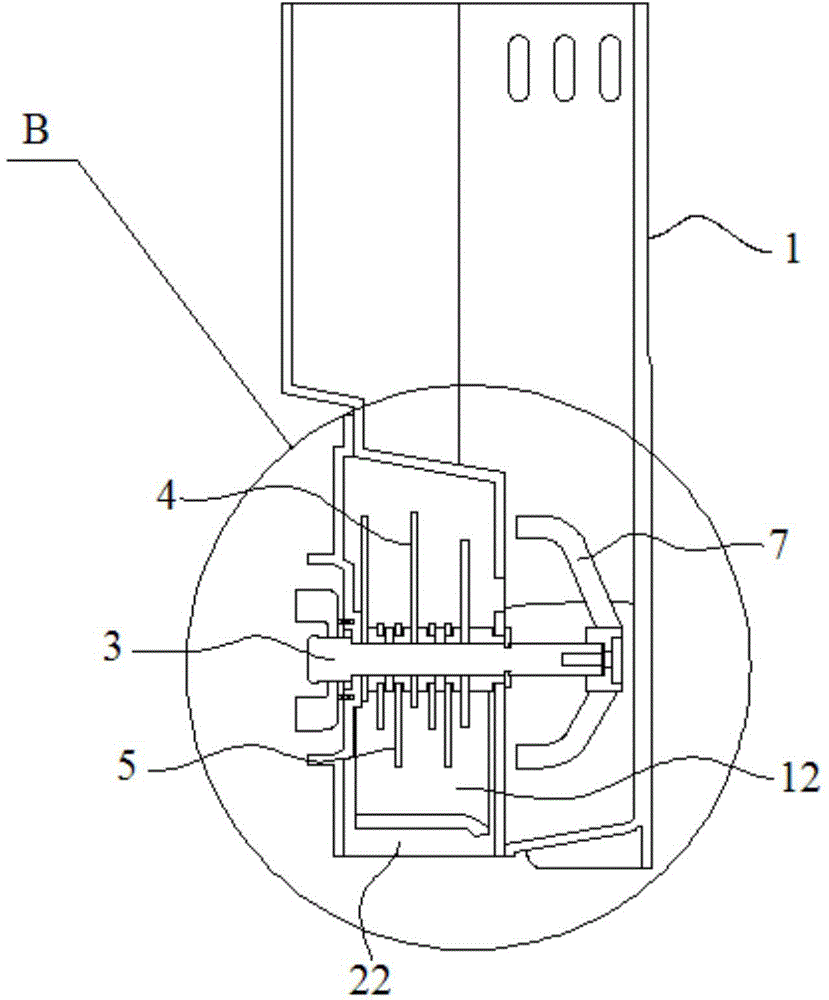

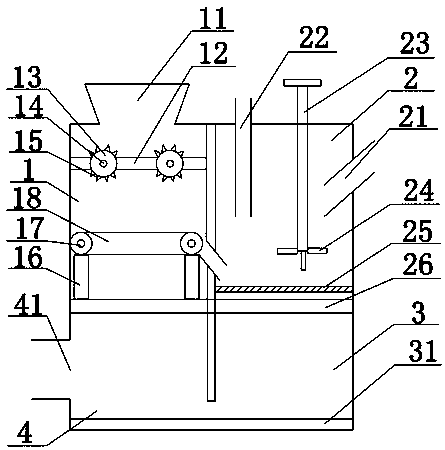

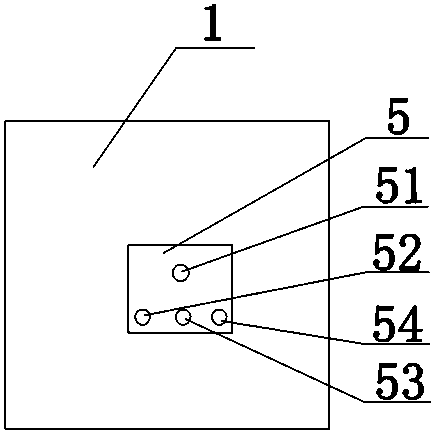

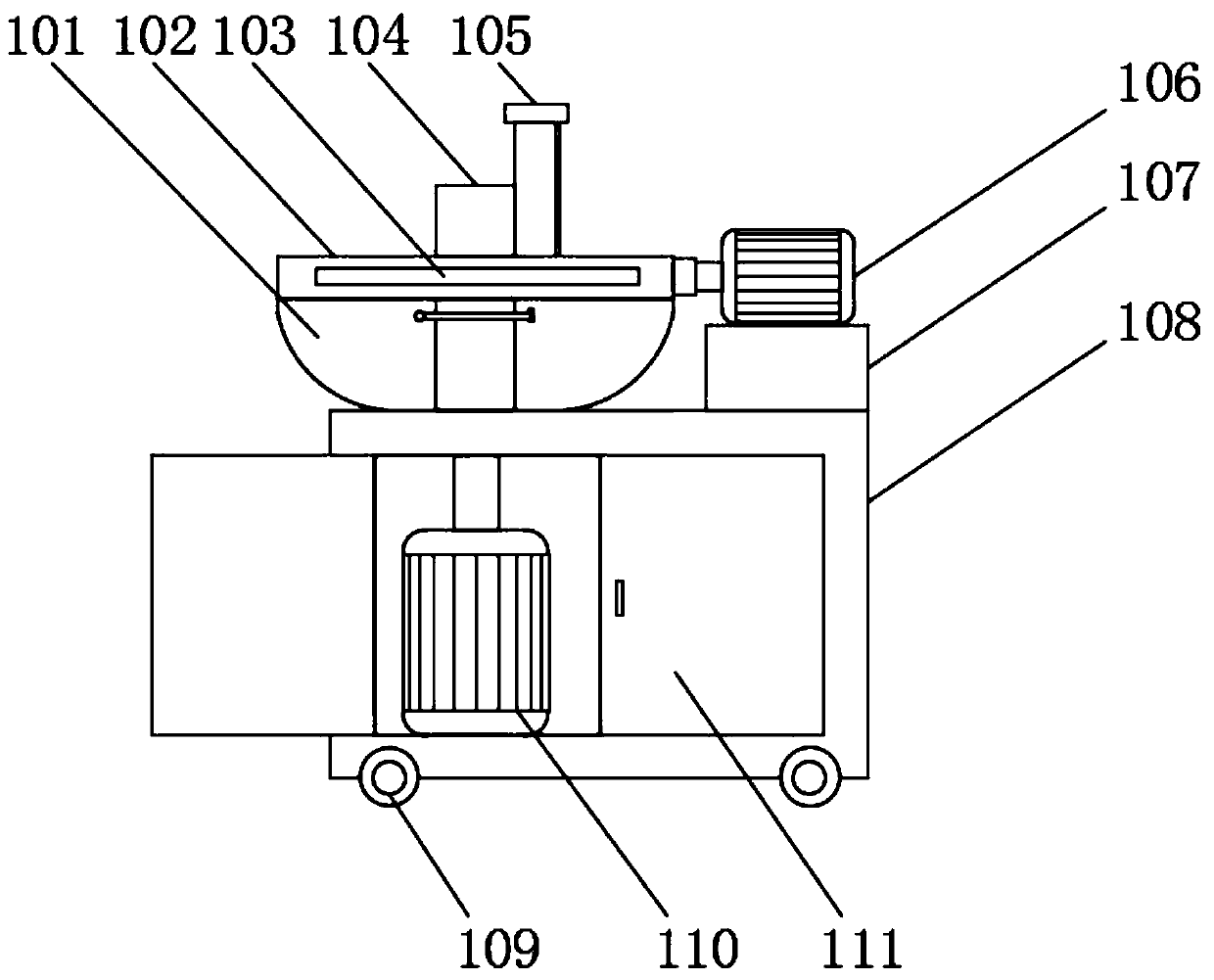

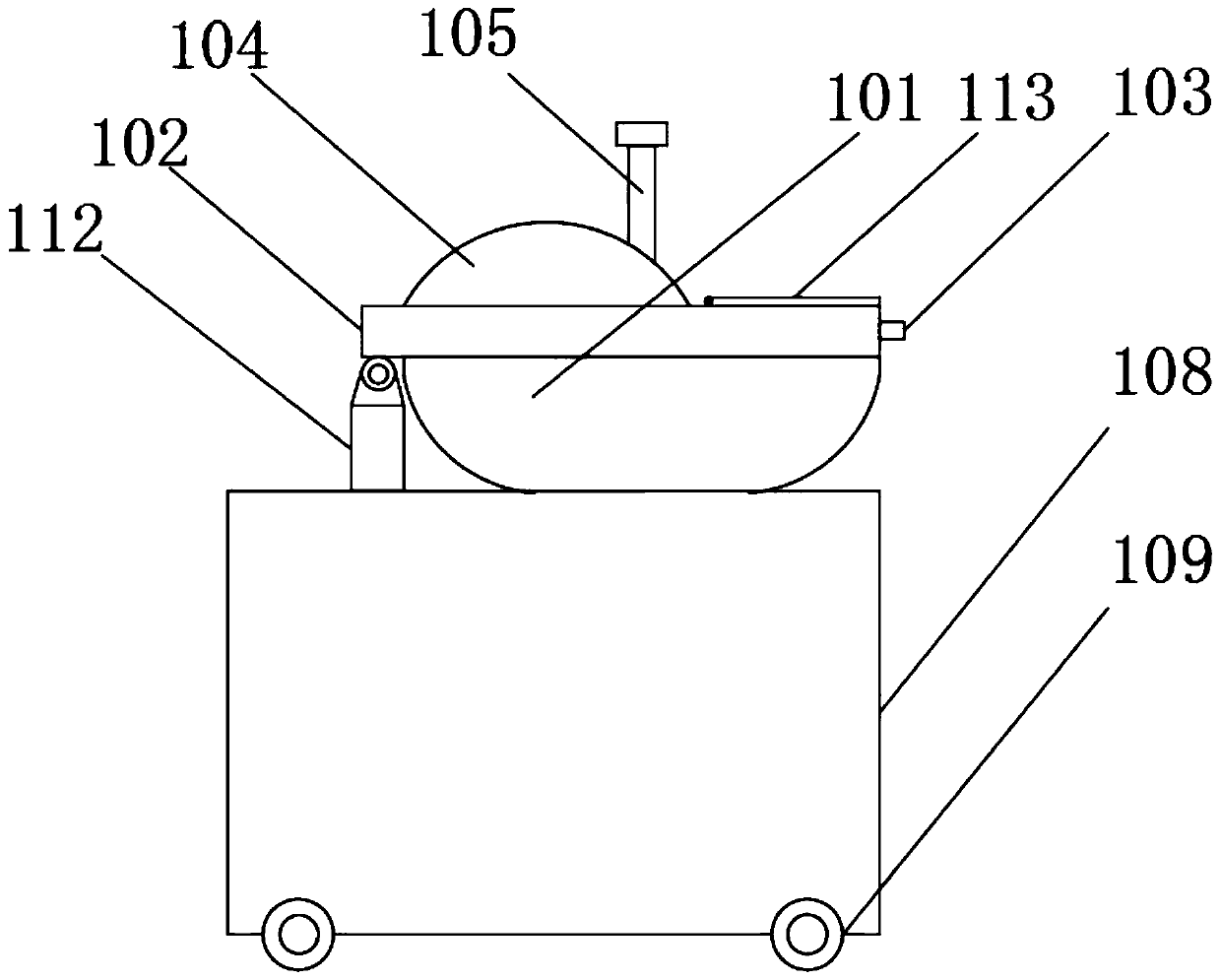

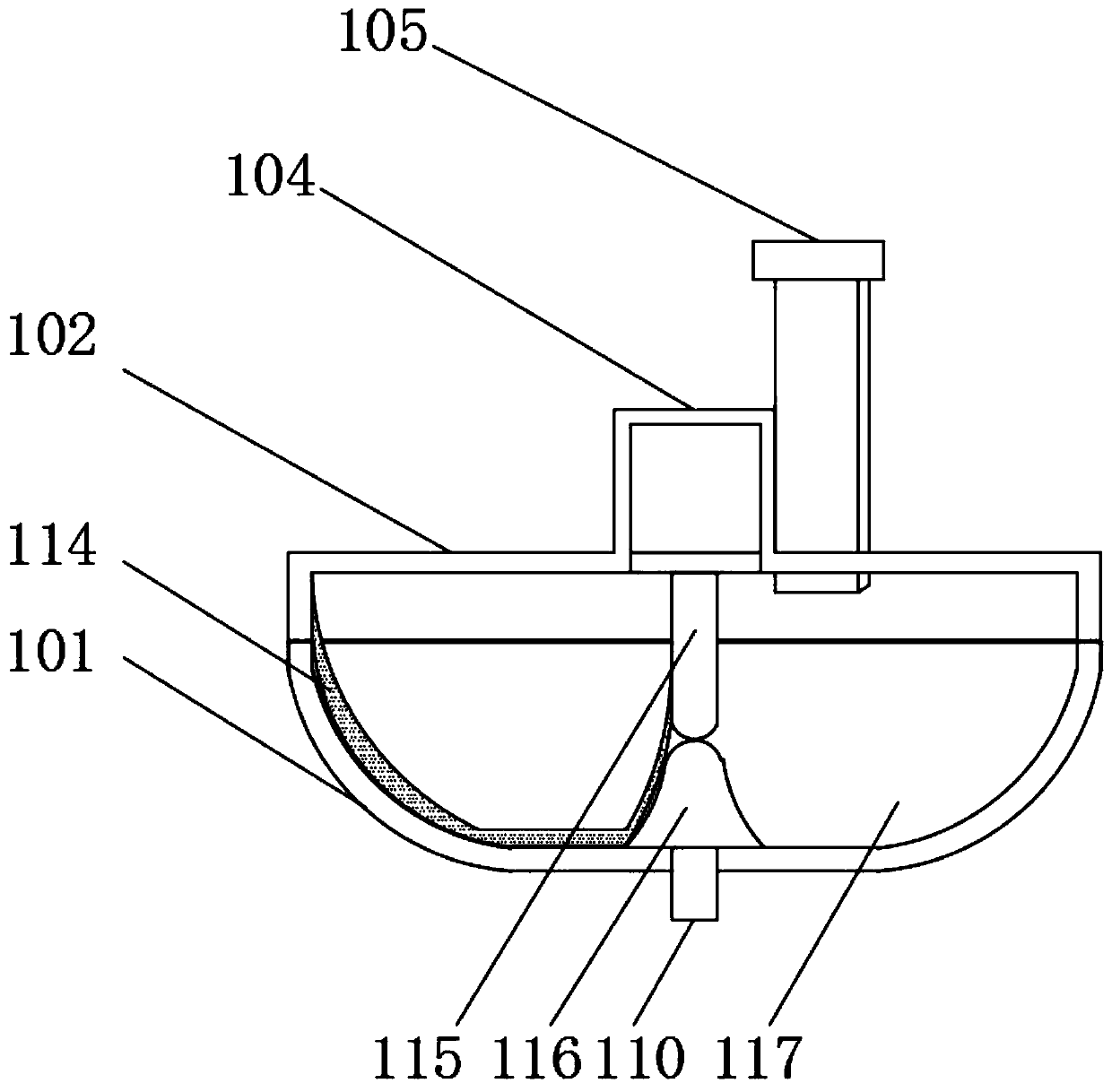

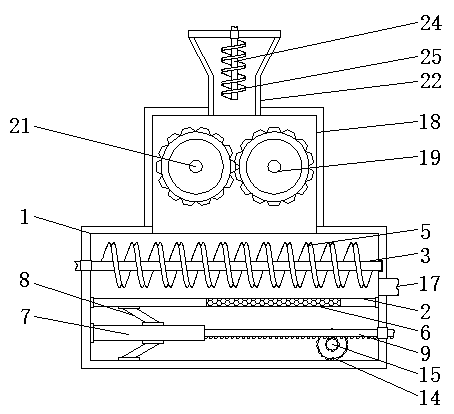

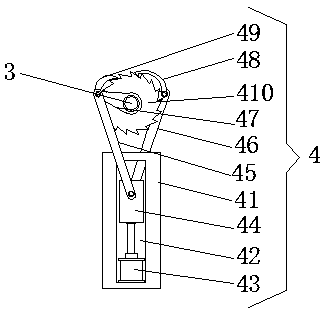

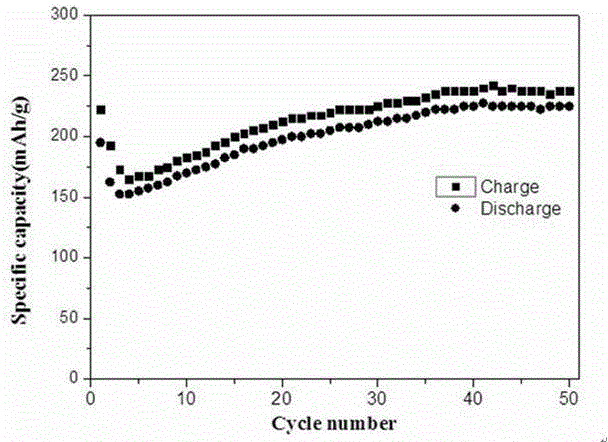

Circulation solid poultry feed smashing device

InactiveCN107377086AImprove crushing effectIncrease the degree of crushingFeeding-stuffGrain treatmentsDrive shaftAgricultural engineering

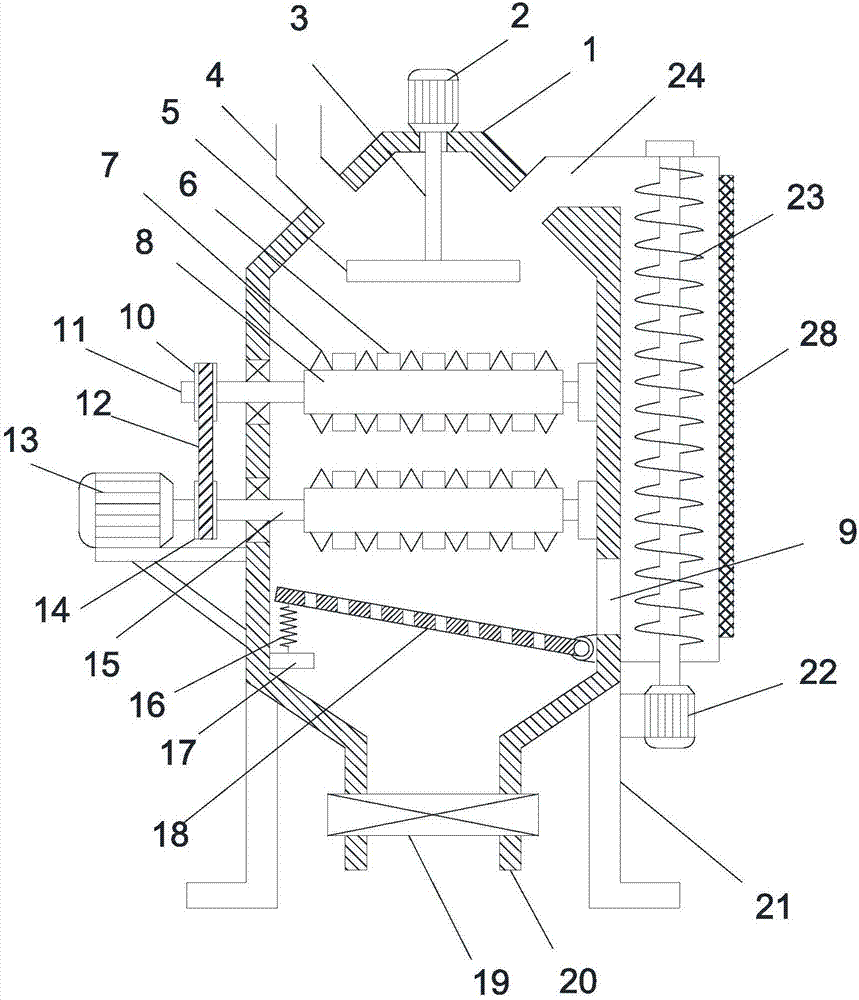

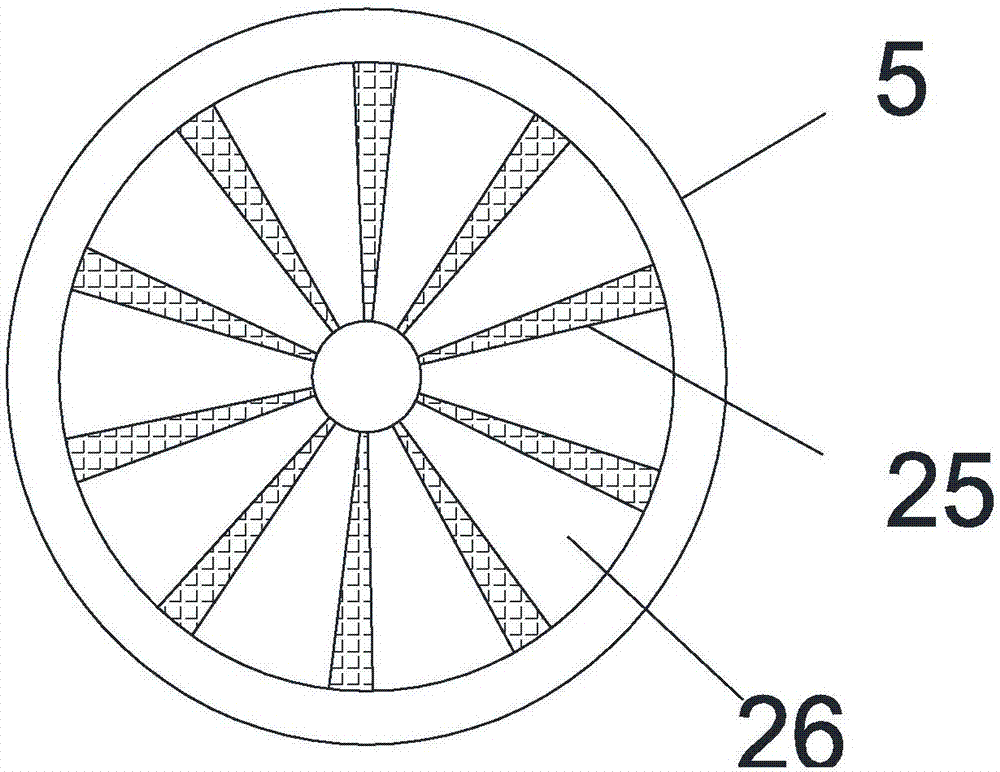

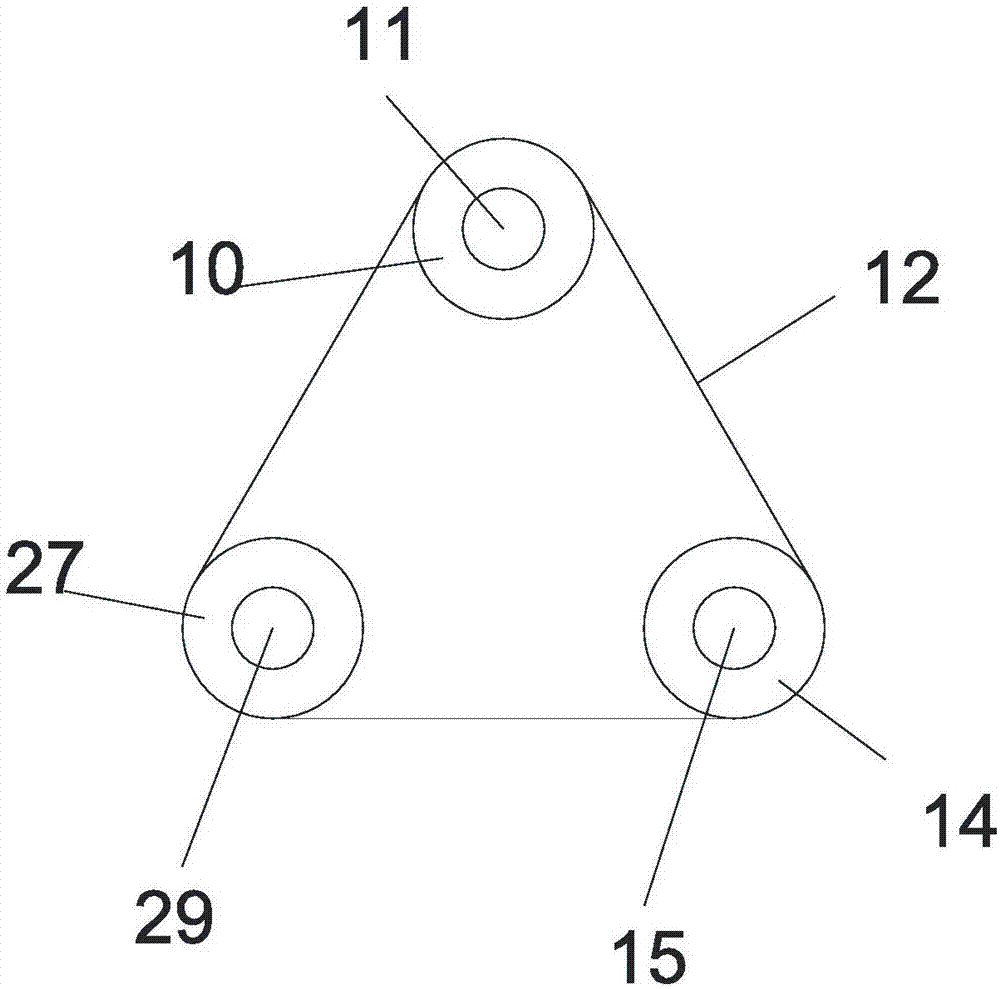

The invention discloses a circulation solid poultry feed smashing device. The device comprises a smashing box, a material inlet tube is arranged on the upper portion of the smashing box, and a first motor is arranged on the top of the smashing box; a first driven shaft is located above a drive shaft and a second driven shaft, and the central axes of the second driven shaft and the drive shaft are located on the same horizontal plane; a drive belt wheel, a first driven belt wheel and a second driven belt wheel are connected to and sleeved with a transmission belt; a screening plate is arranged in the smashing box, the right end of the screening plate is hinged to the inner wall of the right side of the smashing box, a spiral lifter is arranged on the right side of the smashing box, and a third motor is arranged on the bottom of the spiral lifter. The smashing device is ingenious in structure and reasonable in design, smashing rollers drive stirring plates to rotate and stir falling fertilizer, so that the fertilizer is cut and smashed multiple times by smashing blades between the smashing rollers, and the smashing effect of the fertilizer is greatly improved; the spiral lifter can convey the fertilizer to the smashing box, so that the fertilizer is smashed repeatedly, and the smashing degree of the fertilizer is improved.

Owner:武晓丹

Waste paper recovery device with high recovery efficiency

ActiveCN109482303ASolve the problem of low recycling efficiencyFully processedGrain treatmentsStationary filtering element filtersDrive wheelPulp and paper industry

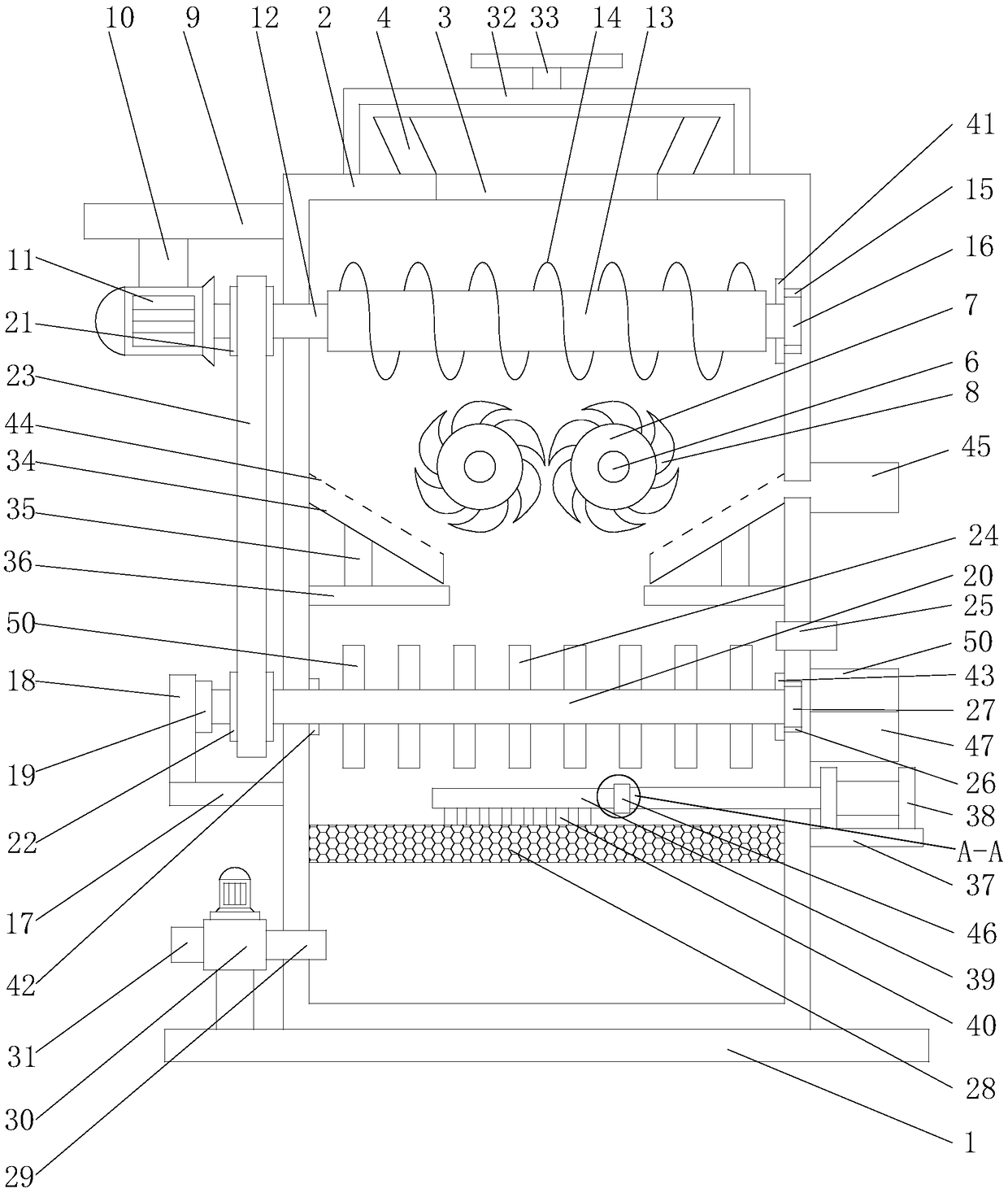

The invention discloses a waste paper recovery device with high recovery efficiency. The device comprises a base plate; the top of the base plate is fixedly connected with a machine shell; a materialpassing port is formed in the top of the inner wall of the machine shell; the top of the machine shell is fixedly connected with a material passing hopper matched with the material passing port; and two crushing motors are fixedly connected to the back surface of the machine shell. Through cooperation of the crushing motors, crushing rotating shafts, crushing wheels, crushing blades, breaking motors, breaking rotating shafts, breaking wheels, breaking blades, a first bearing, a second bearing, a stirring rotating shaft, a driving wheel, a driven wheel, a belt, stirring blades, a third bearing,a filter screen and a discharge pump, the device solves the problem of lower recovery efficiency in a common waste paper recovery device, fully treats waste papers in the waste paper treatment process, enables paper pulp to become fine and smooth through stirring, filters the paper pulp by the filter screen to improve the uniformity, and achieves more convenience for the waste paper recovery work.

Owner:SUZHOU BATAO INFORMATION TECH CO LTD

Garbage crushing device for garbage power generation

InactiveCN107597396AEasy to GrindAvoid clogging the feed hopperGrain treatmentsEngineeringUltimate tensile strength

The invention discloses a garbage crushing device for garbage power generation. The garbage crushing device comprises a base, and one end of the upper part of the base is connected to a cushion blockwhich is provided with a first motor; the output end of the first motor is connected to a screw rod which is provided with a lifting box in a run-through manner; the bottom of one side of the liftingbox communicates with a feed port, and the upper part of the other side of the lifting box communicates with a feed delivery pipe of which the bottom is provided with a feed hopper; and the inner wallof the feed hopper is provided with material guide plates. According to the garbage crushing device, through arranging the screw rod in the lifting box, garbage put from the feed port is easy to convey to the feed hopper from the feed delivery pipe, so that the labor intensity of workers is reduced, and the labor time is saved; the labor efficiency is improved; materials can be fed into a first crushing cavity slowly through the material guide plates arranged in the feed hopper crosswise, and the garbage is prevented from blocking the feed hopper, so that the garbage is crushed in order.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

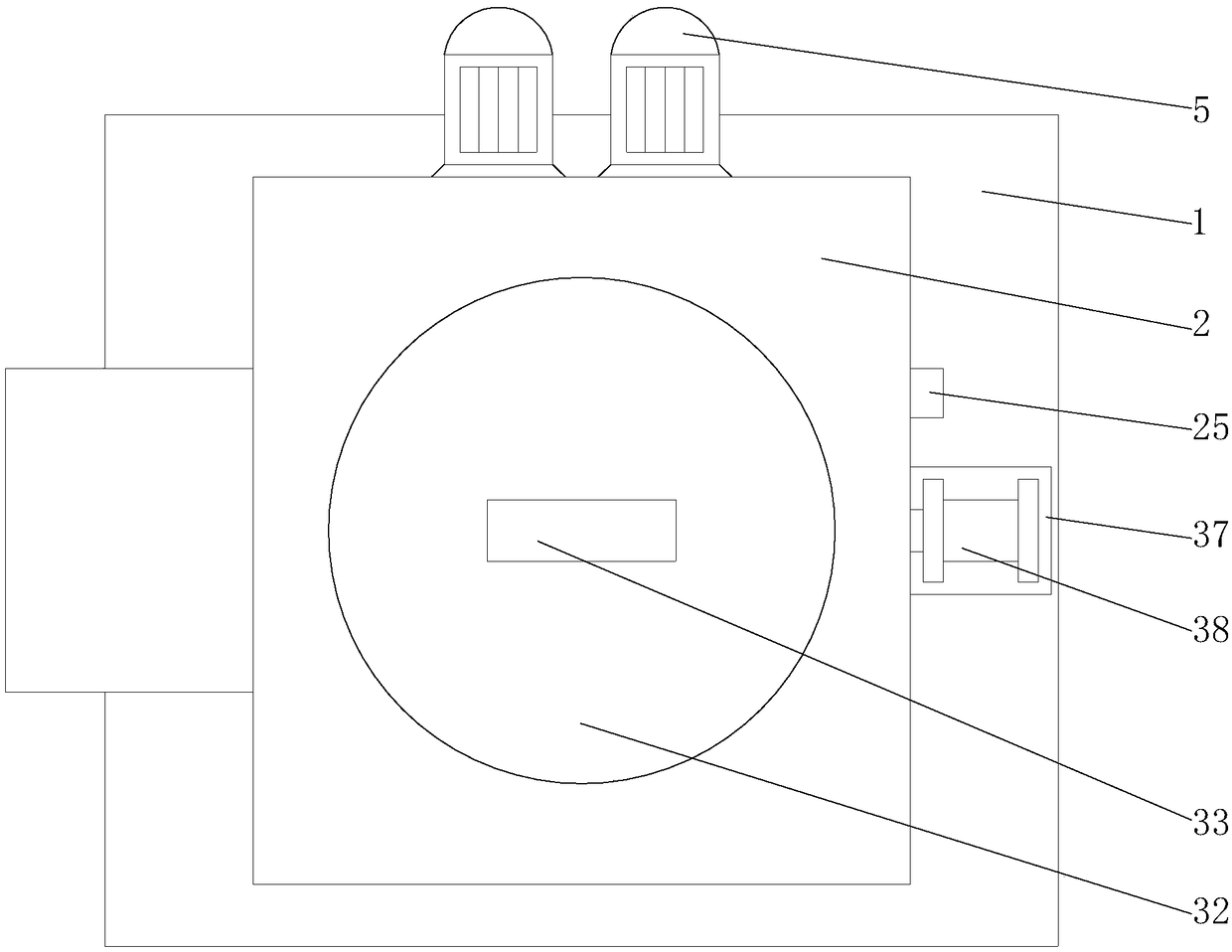

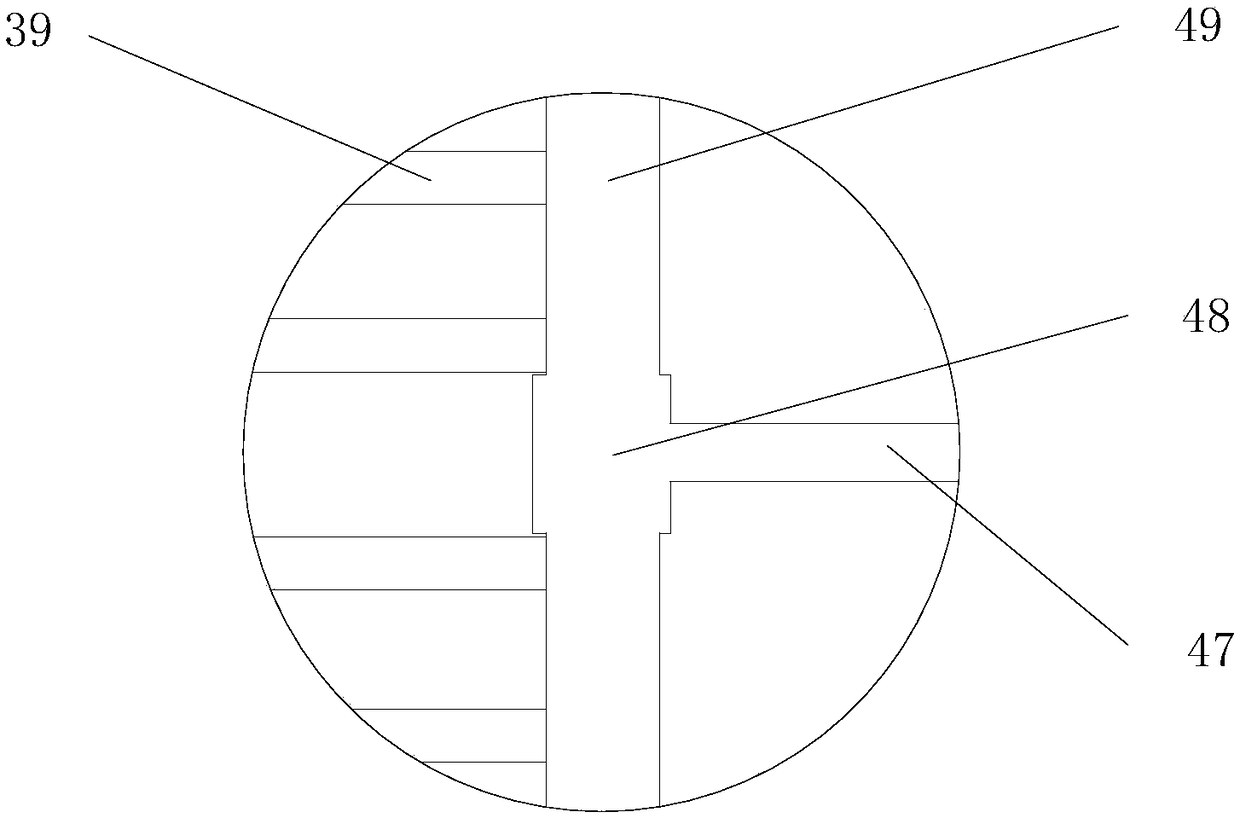

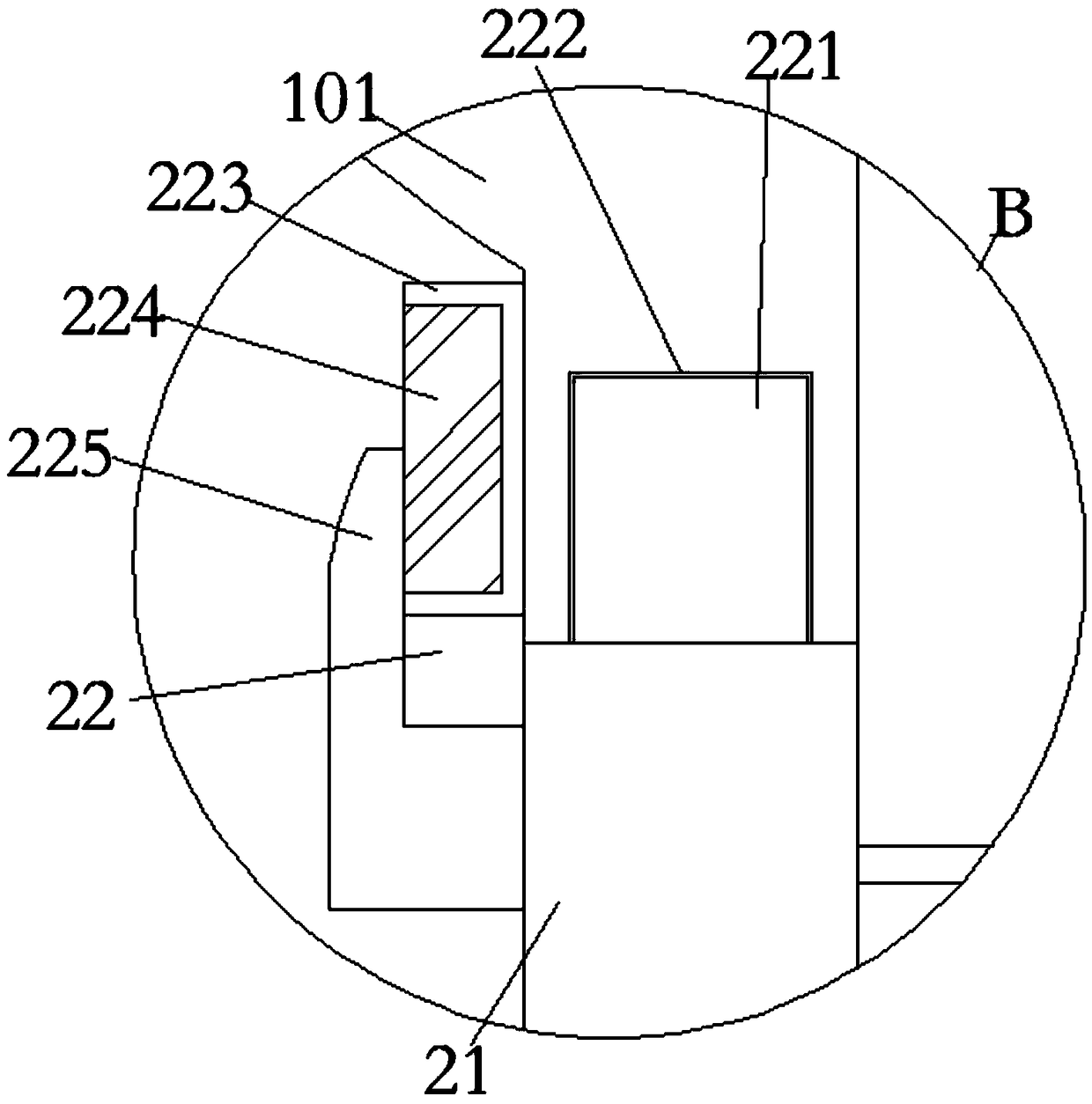

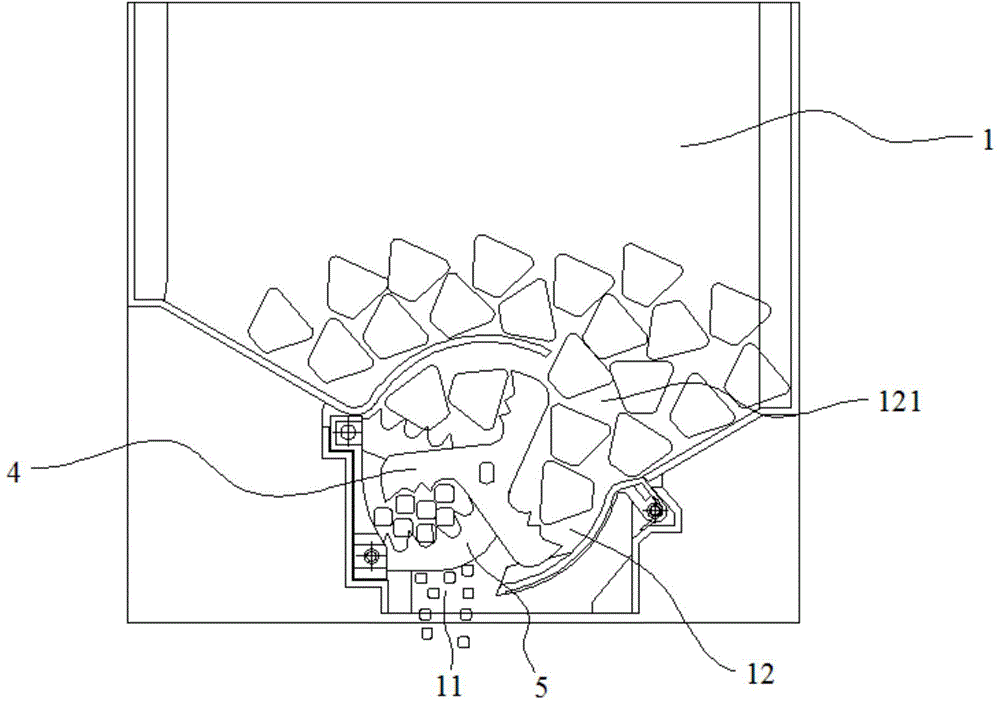

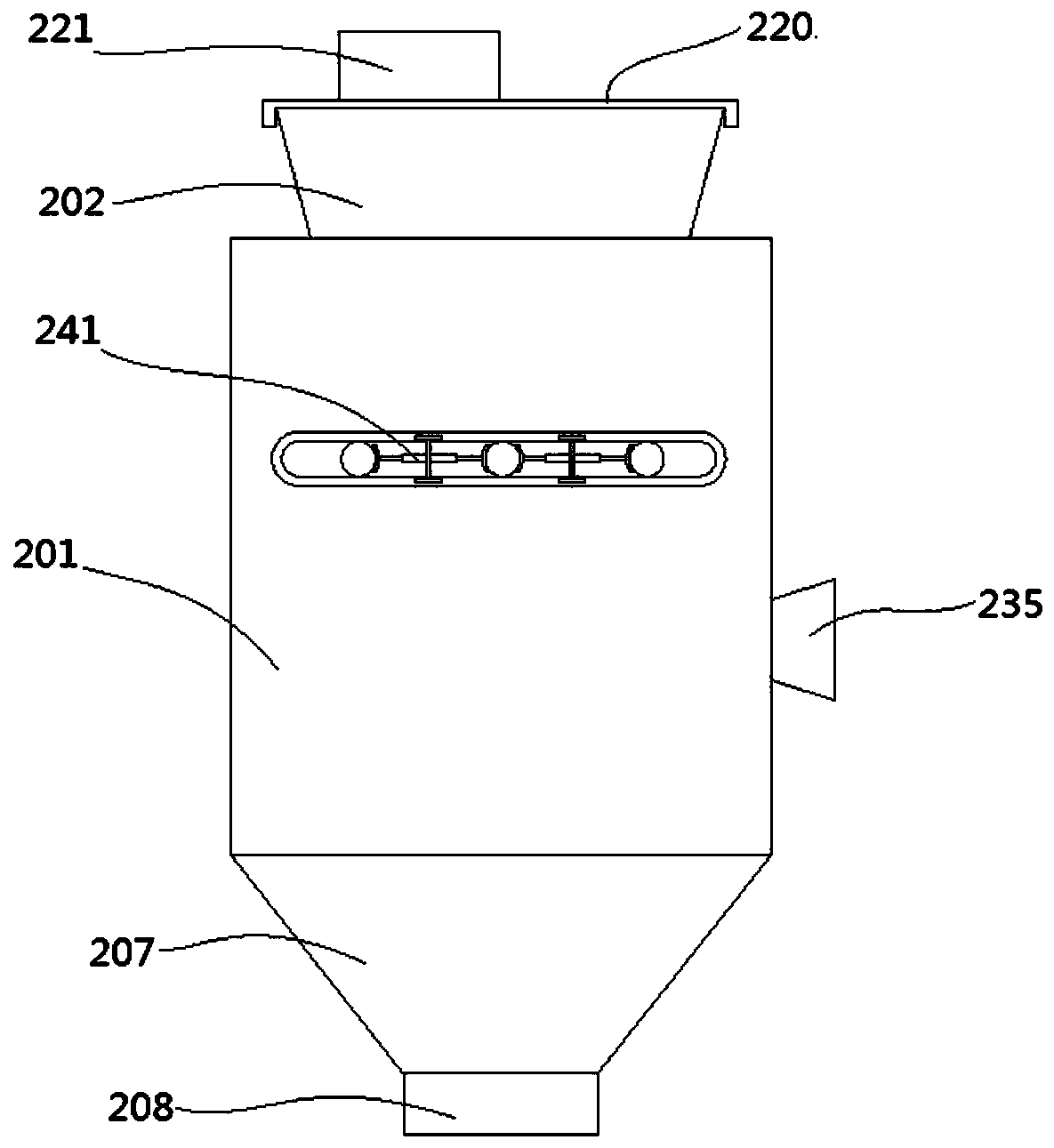

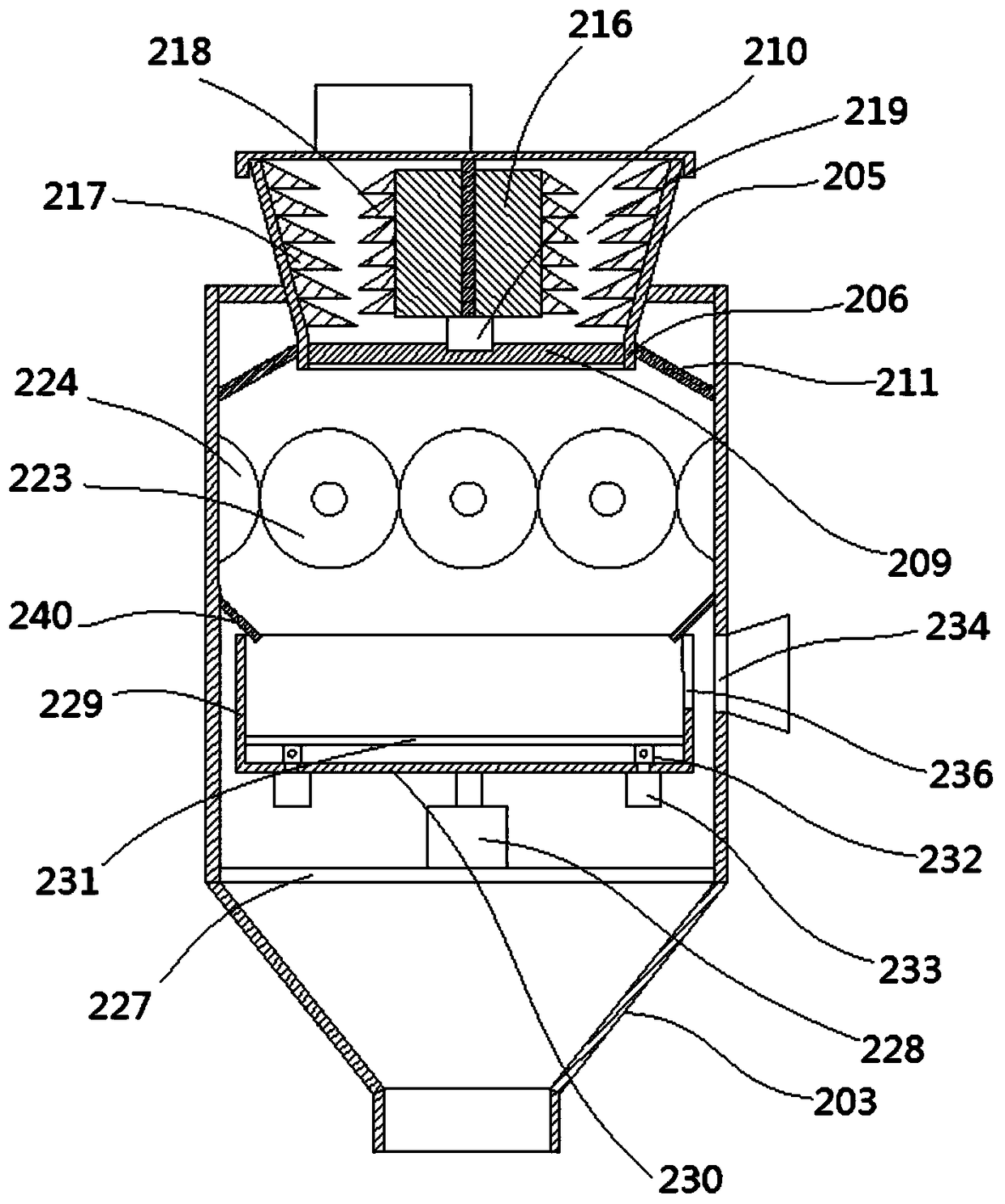

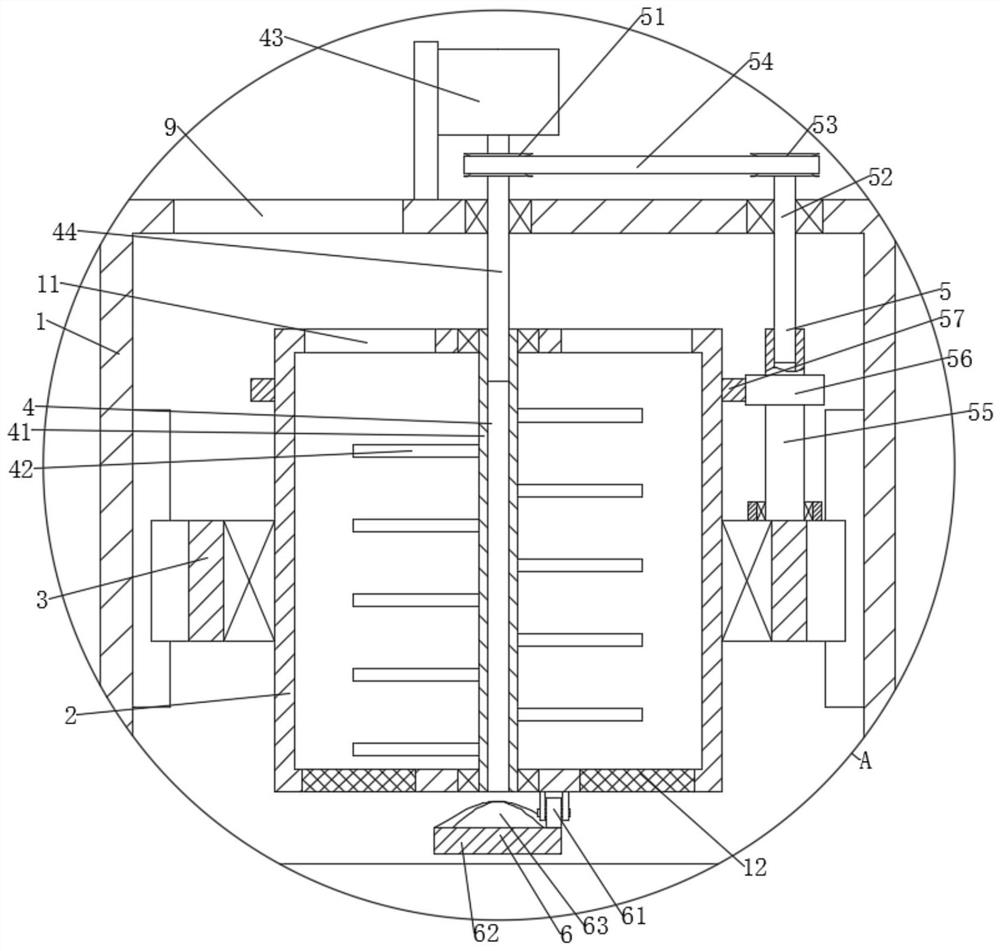

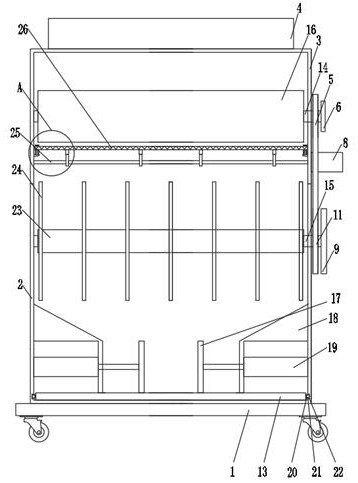

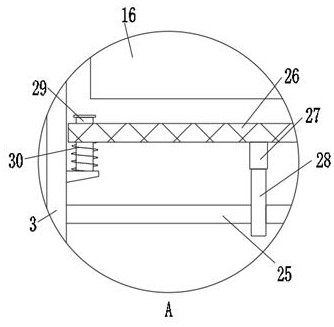

Solid building waste crushing and recycling device

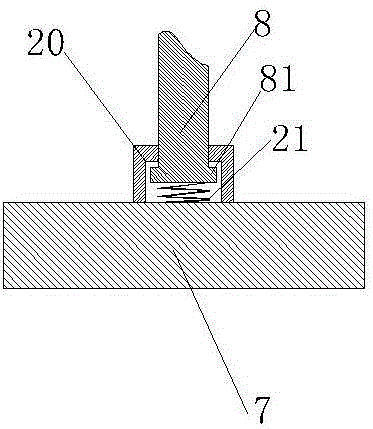

InactiveCN111921605AReduce the chance of jammingIncrease the degree of crushingSievingConstruction waste recoveryConstruction engineeringStructural engineering

The invention discloses a solid building waste crushing and recycling device. The solid building waste crushing and recycling device comprises a base and a main box body fixed to the base. A feeding port is formed in the shell wall of the top of the main box body, two symmetrically-arranged crushing rollers are arranged at the upper part of an inner cavity of the main box body, and the crushing rollers are rotationally connected with the main box body through first rotating shafts. Crushing teeth are evenly distributed on the crushing rollers, a gap between the two crushing rollers directly faces the feeding port, and a flow guide plate is fixed to the middle of the inner cavity of the main box body. An arc-shaped pressing plate is arranged below the flow guide plate in a spaced mode, anda material falling hole is formed in the pressing plate. A swing frame is rotationally connected to the center of the bottom of the flow guide plate, a pressing roller is installed at the bottom of the swing frame, and the rotating radius of the pressing roller is the same as the radius of the pressing plate. A strip-shaped hole is formed in the swing frame in the length direction of the swing frame, and a rotary disc is arranged on the rear side of the swing frame. The crushing degree of waste is improved, and the crushing effect can be effectively guaranteed when the pressing rollers crush the waste.

Owner:深圳市汇利德邦环保科技有限公司

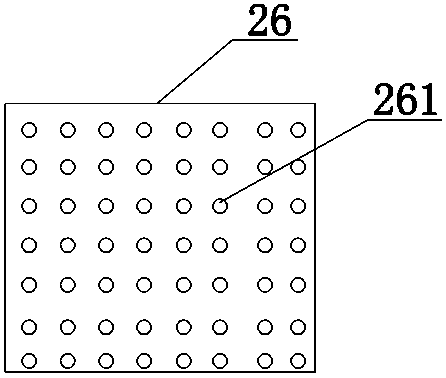

Coal mine crushing device

InactiveCN106391247AGuaranteed uptimeReduce work intensityGrain treatmentsCleaning processes and apparatusEngineeringCoal

The invention relates to mine machinery, in particular to a coal mine crushing device. The technical problem to be solved by the invention is to provide the coal mine crushing device capable of thoroughly crushing coal mines. The coal mine crushing device comprises a main body; a feed port is formed above the main body; a discharge port is formed below the main body; the main body includes a crushing bin and a grinding bin; the crushing bin is arranged above the main body; the grinding bin is arranged at the lower part of the crushing bin; a rotating shaft is arranged in the crushing bin; a crushing roller is mounted on the rotating shaft; a broken tile crushing cutter is mounted on the crushing roller; a screen plate is arranged between the crushing bin and the grinding bin; and through holes are formed in the screen plate. The coal mine crushing device further comprises tooth roller grinding devices symmetrically arranged in the grinding bin. In the coal mine crushing device, the coal mines are primarily crushed by the effect of the crushing roller in the crushing bin, and are grinded again by the effect of the tooth roller grinding devices in the grinding bin, so that the coal mine crushing effect is greatly improved, the coal mine crushing degree is higher, and the coal mine crushing is more thorough.

Owner:PANZHIHUA COAL IND GRP CO LTD

Powder breaking mechanism for secondary utilization of waste glass

The invention relates to the technical field of environmental protection equipment, in particular to a powder breaking mechanism for secondary utilization of waste glass. The powder breaking mechanismfor the secondary utilization of the waste glass solves the technical problems that the waste glass is not broken completely and the broken effect is not high. The powder breaking mechanism for the secondary utilization of the waste glass comprises a block breaking mechanism, a crushing cylinder mechanism is movably connected to the bottom of the block breaking mechanism, the bottom of the crushing cylinder mechanism is movably connected with an feed inlet of the top of a power stirring box, a power stirring mechanism is arranged in the power stirring box, support legs are separately and fixedly connected to four right angle positions of the bottom of the power stirring mechanism, and a discharge sleeve is connected to the interior of an opening of the bottom of the power stirring box ina sleeving mode. According to the powder breaking mechanism for the secondary utilization of the waste glass, when pushing rods push crushing heads to move, because the crushing heads on the two sidesare arranged in an inclined mode, when the glass enters a block breaking sleeve, the glass can be crushed into small pieces from large pieces by squeezing, and the farther down, the distance betweenthe two crushing heads is smaller, so that glass with large pieces is gradually broken.

Owner:安徽强钢钢化玻璃股份有限公司

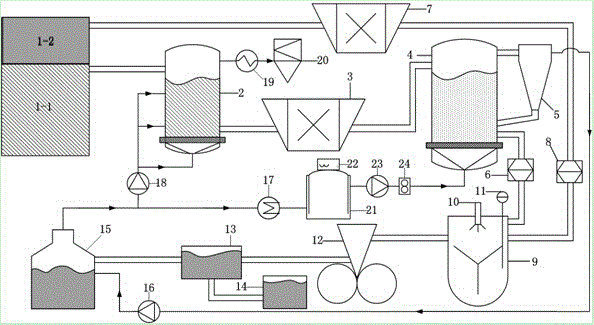

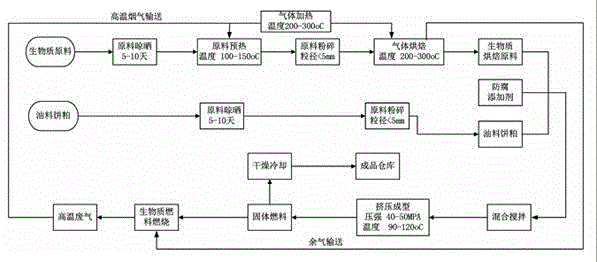

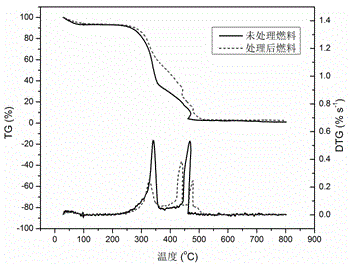

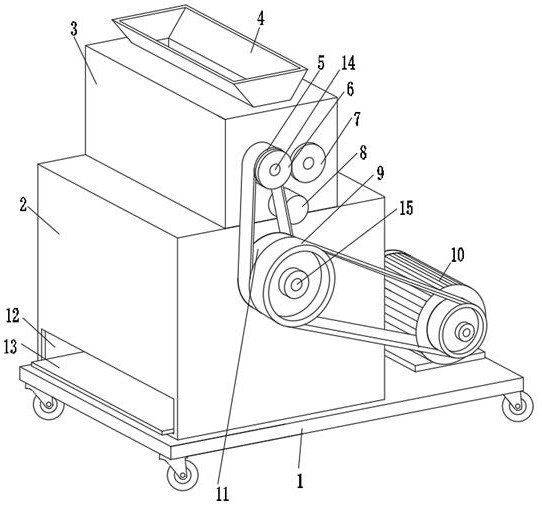

Method and system for preparing solid fuel through biomass fluidized bed roasting

The invention discloses a method and system for preparing solid fuel through biomass fluidized bed roasting. The preparation system comprises a biomass crushing system, a fluidized bed roasting system, a biomass mixing and molding system and a biomass combustion system, wherein the biomass crushing system comprises an airing chamber, a dryer used for preheating biomass raw materials, and a crusher used for crushing the biomass raw materials; the fluidized bed roasting system comprises a gas heating device, a fluidized bed reactor and a cyclone separator; the biomass mixing and molding system comprises a mixer for mixing materials and additives, an annular mould forming machine used for performing extrusion forming on the mixed raw materials, and a cooling device for cooling granules; and the biomass combustion system comprises a biomass boiler. By the system for preparing the solid fuel by using the biomass, which stably runs and is capable of saving the energy and easy and convenient to operate, a process method through which the biomass can be fully and rapidly roasted and the problems such as high molding energy consumption and low particle strength can be effectively solved is realized.

Owner:HUNAN ACAD OF FORESTRY

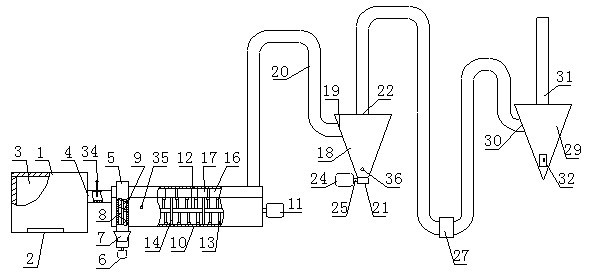

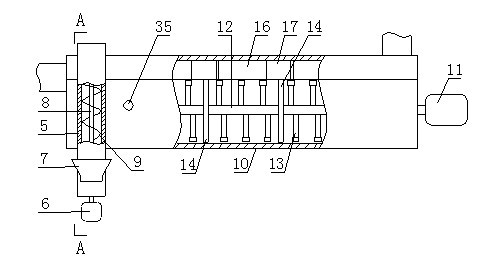

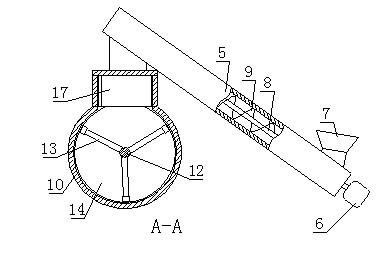

Poultry excrement drying device

ActiveCN101900479AModerate moisture contentSuitable for productionDrying solid materials with heatDrying machines with non-progressive movementsEngineeringFodder

The invention discloses a poultry excrement drying device. The device comprises a hot-blast stove, a feeding mechanism, a stirring and grinding device, a separating column, a discharging mechanism, a fan and a dust recovery device, wherein the hot-blast stove is used to provide hot blast; the feeding mechanism is used to feed poultry excrement; the stirring and grinding device can scatter and grind the poultry excrement entering the shell of the device; the separating column is used to separate the poultry excrement from air flow; the discharging mechanism is arranged at a discharge hole on the lower end of the separating column and used for discharging; the fan is arranged in a pipe between the separating column and the dust recovery device and used to generate air flow along the hot-blast stove, the stirring and grinding device, the separating column and the dust recovery device; and the dust recovery device is used for air-out and dust recovery. The poultry excrement drying device has the advantages of fast processing speed, good dewatering effect and deodorizing effect, high nutrient retention capacity, good sterilizing effect, high degree of grinding, uniform fineness, no environmental pollution and the like. The technology is especially suitable for the pretreatment of poultry excrement feed preparation and is especially suitable to be used in the poultry farm.

Owner:重庆福纳斯生物技术有限公司

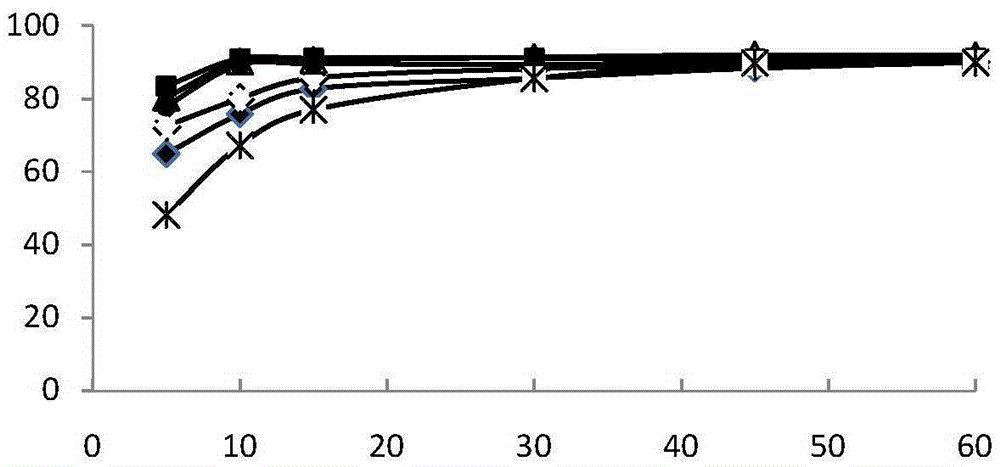

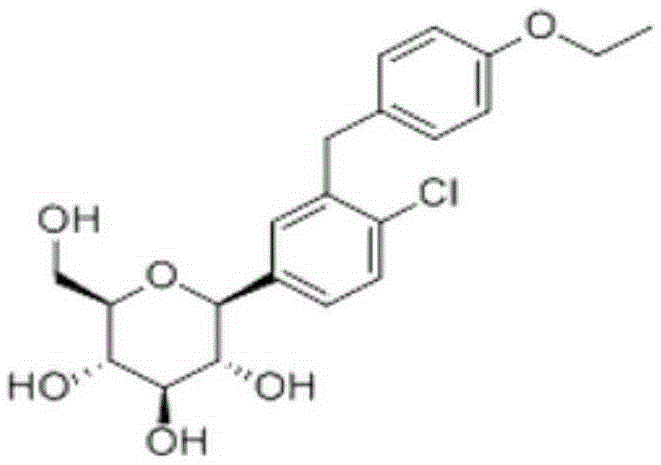

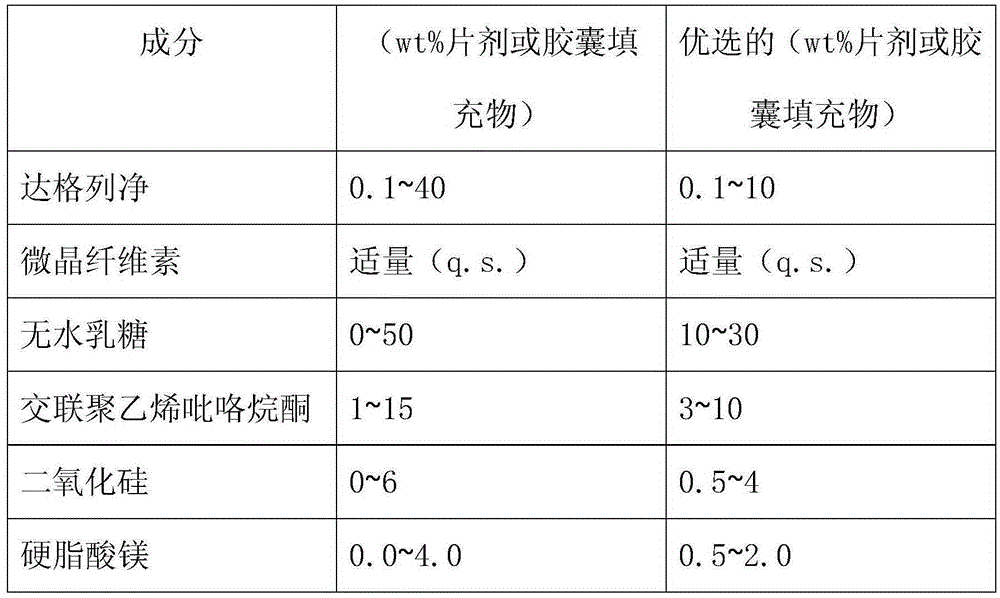

Dapagliflozin medicinal composition and preparation method thereof

InactiveCN106727368ANon-fibrousLiquidityOrganic active ingredientsMetabolism disorderMedicineAdhesive

The invention provides a dapagliflozin medicinal composition. The dapagliflozin medicinal composition is characterized by consisting of the following components in percentage by mass: 1 to 95 percent of a dapagliflozin and microcrystalline cellulose composition, 0 to 95 percent of a filling agent / an adhesive, 0 to 20 percent of a disintegrant, 0.1 to 5 percent of a lubricating agent and 0 to 10 percent of a flow aid. According to the dapagliflozin medicinal composition, microcrystalline cellulose serves as a carrier material; according to a method provided by the invention, the dapagliflozin and microcrystalline cellulose are mixed and heated so that the dapagliflozin is molten; the dapagliflozin covers the surface of the microcrystalline cellulose in a liquid form; after the dapagliflozin is cooled, the dapagliflozin is solidified on the surface of the microcrystalline cellulose to form a dapagliflozin and microcrystalline cellulose compound; the specific surface area of the dapagliflozin is increased, so that the medicine dissolving speed can be improved and the quality is stable; the preparation method provided by the invention is simple and feasible, and is suitable for industrial production.

Owner:SHANGHAI SUNTECH PHARMA

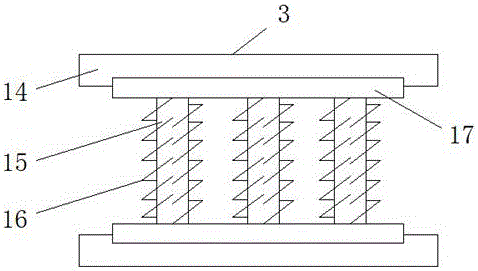

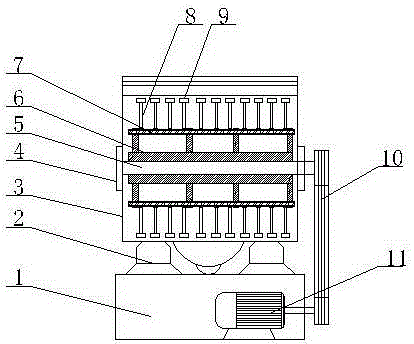

Flour grinding and screening equipment for coarse grains

InactiveCN109909003AAdjust the degree of primary crushing by yourselfIncrease the degree of crushingSievingScreeningElectric machineryEngineering

The invention discloses flour grinding and screening equipment for coarse grains. The flour grinding and screening equipment comprises a base, wherein two support plates are symmetrically arranged atthe upper end of the base; the opposite side walls of the two support plates are fixedly connected with fixed blocks; the opposite side walls of the two fixed blocks are commonly and fixedly connectedwith a first shell; a first hollow cavity is formed in the first shell; a feeding hopper which mutually communicate with the first hollow cavity is arranged at the upper end of the first shell in a penetrating manner; the inner side wall of the first hollow cavity is fixedly connected with a first fixed plate; the side wall of the first fixed plate is fixedly connected with a first motor; an output shaft of the first motor passes through the side wall of the first fixed plate and is fixedly connected with a first press roller; and a mounting plate is arranged on the side wall of the first shell in a penetrating manner. The flour grinding and screening equipment disclosed by the invention is reasonable in structural design, the pulverization degree can be automatically adjusted according to actual demands, and a dedicated material receiving measure is provided while the pulverized rice raw materials are screened at the same time, so that the processing efficiency is further improved.

Owner:李正梅

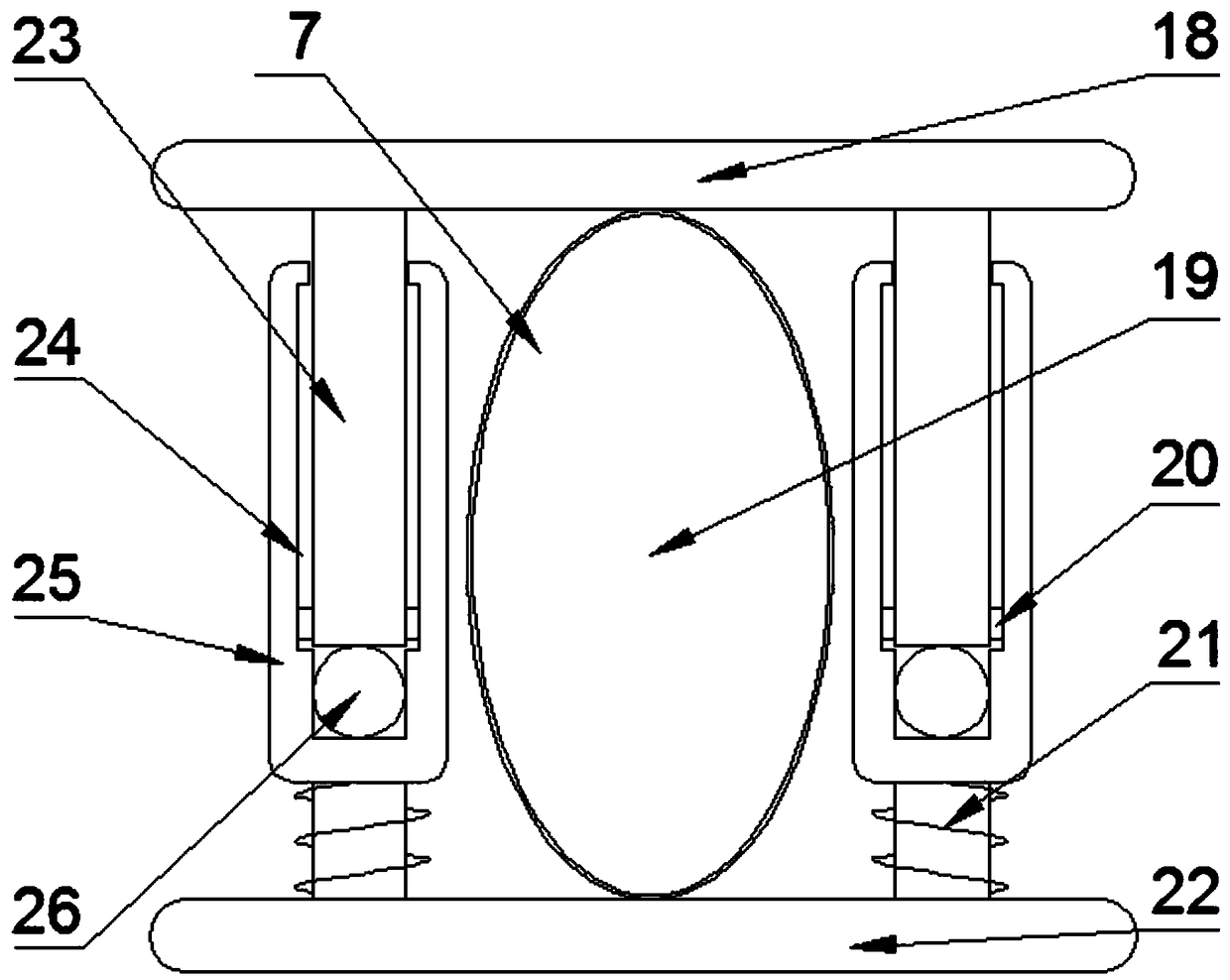

Refrigerator ice crushing device and refrigerator

ActiveCN104390402AIncrease the degree of crushingReduce power consumptionDomestic cooling apparatusLighting and heating apparatusRefrigerator carEngineering

The embodiment of the invention provides a refrigerator ice crushing device and a refrigerator, and relates to the technical field of refrigerators. The crushing degree of ice blocks can be improved without increasing the power consumption. The refrigerator ice crushing device comprises a shell and a driving device, wherein a rotary shaft is arranged in the shell, the driving device can drive the rotary shaft to rotate, and multiple movable blades are fixed on the rotary shaft; at least two fixed blades are arranged between at least two adjacent movable blades, and are arranged along the circumference of the rotary shaft by taking the rotary shaft as the center; when the movable blades rotate along the rotary shaft, the movable blades can drive the ice blocks to sequentially pass through the at least two fixed blades and are matched with the at least two fixed blades to crush the ice blocks. The refrigerator ice crushing device provided by the embodiment of the invention is applied to a refrigerator.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

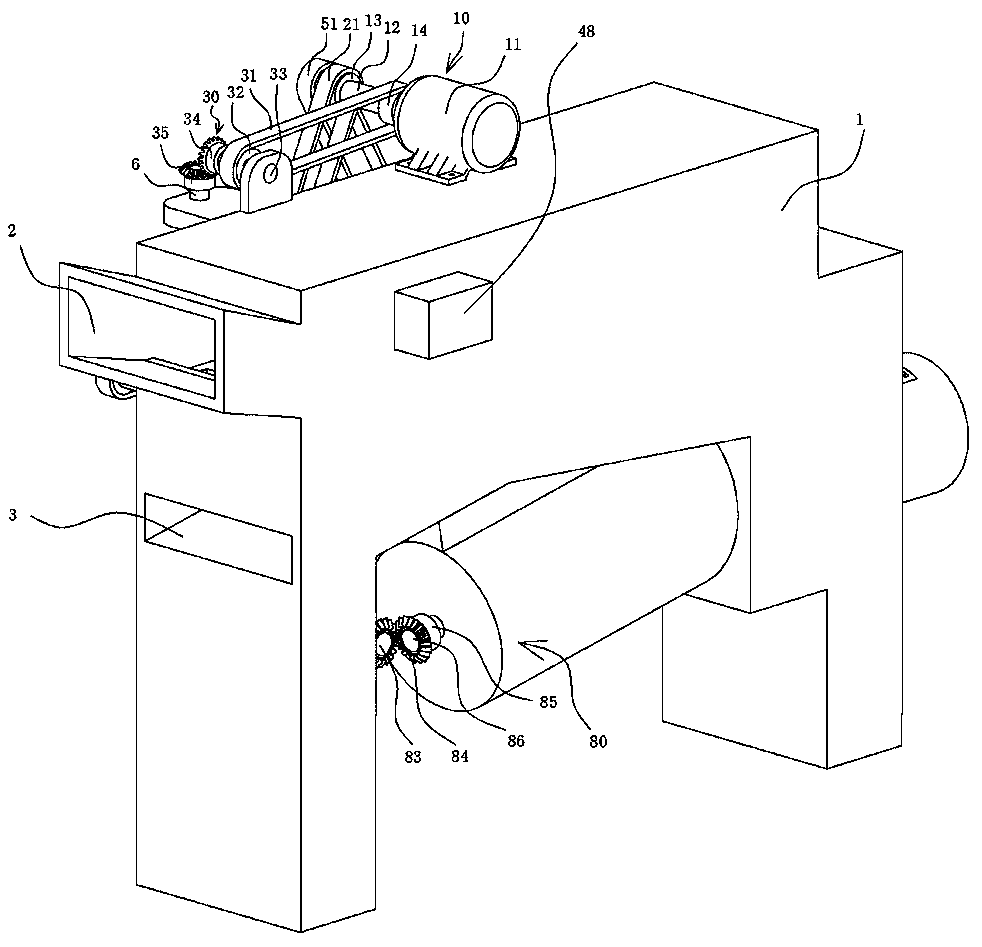

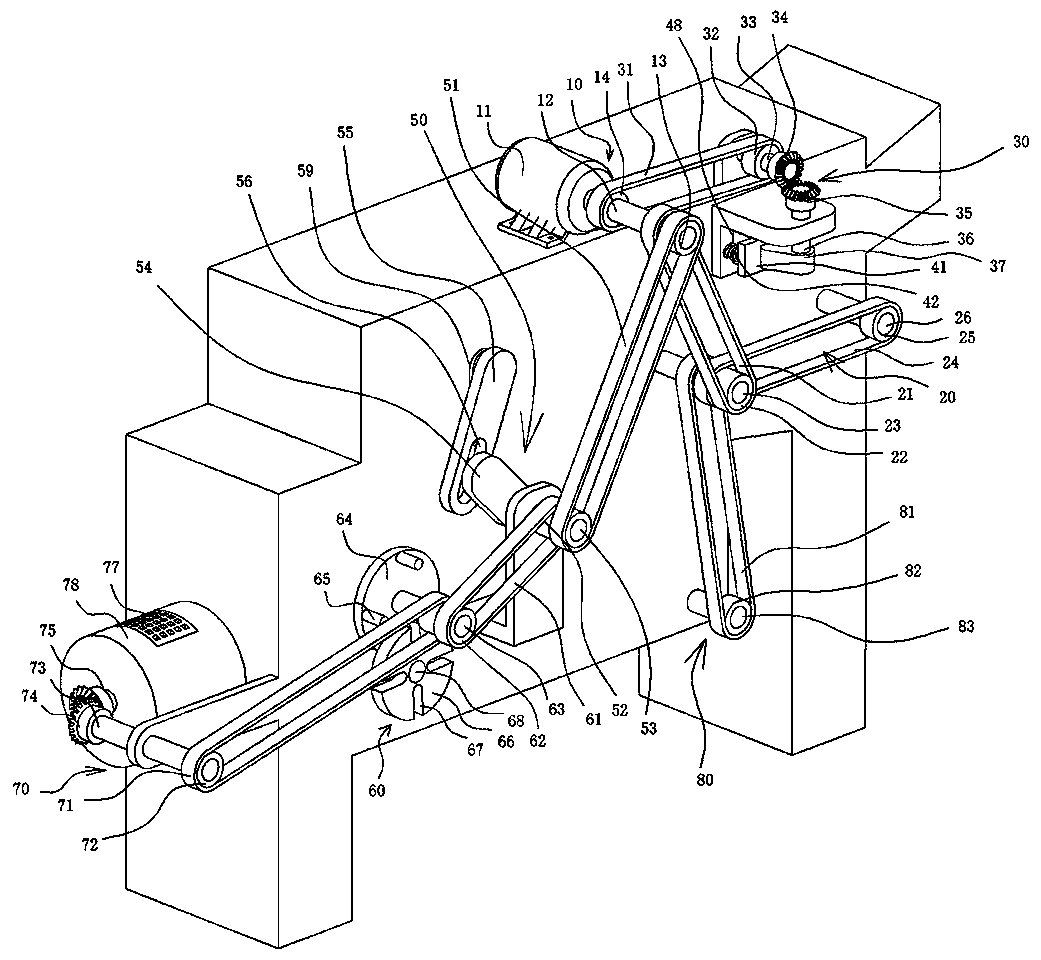

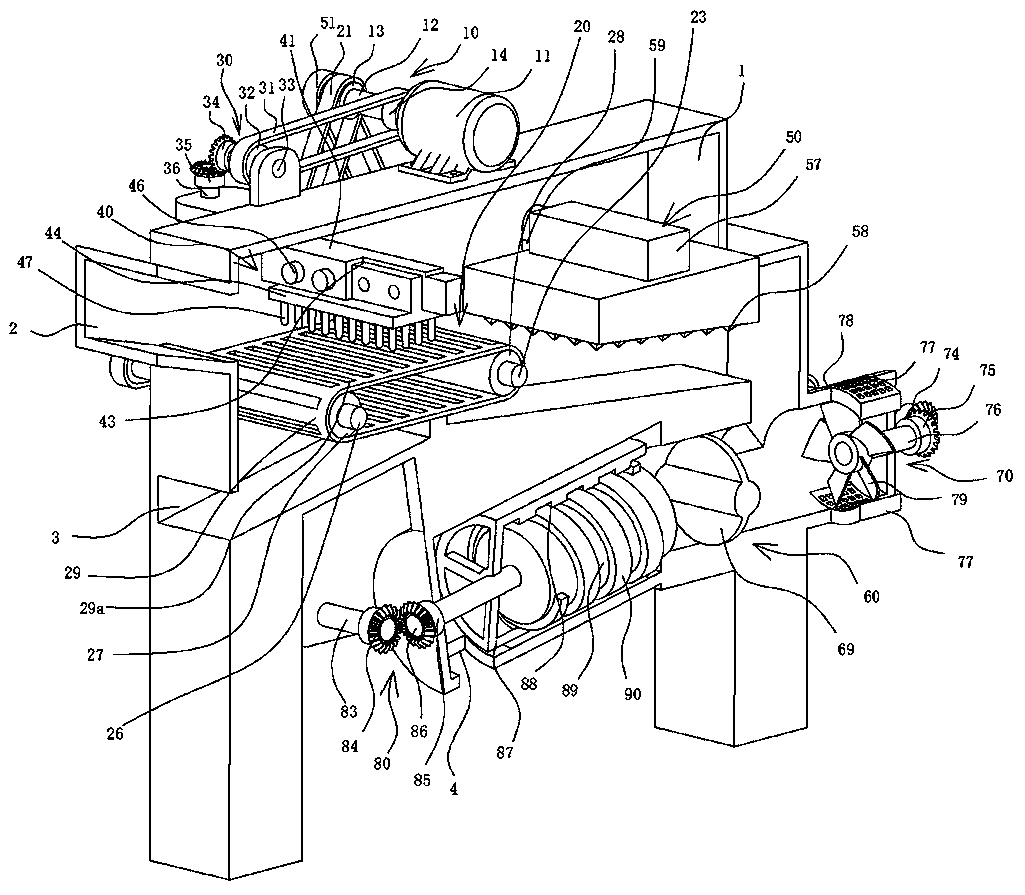

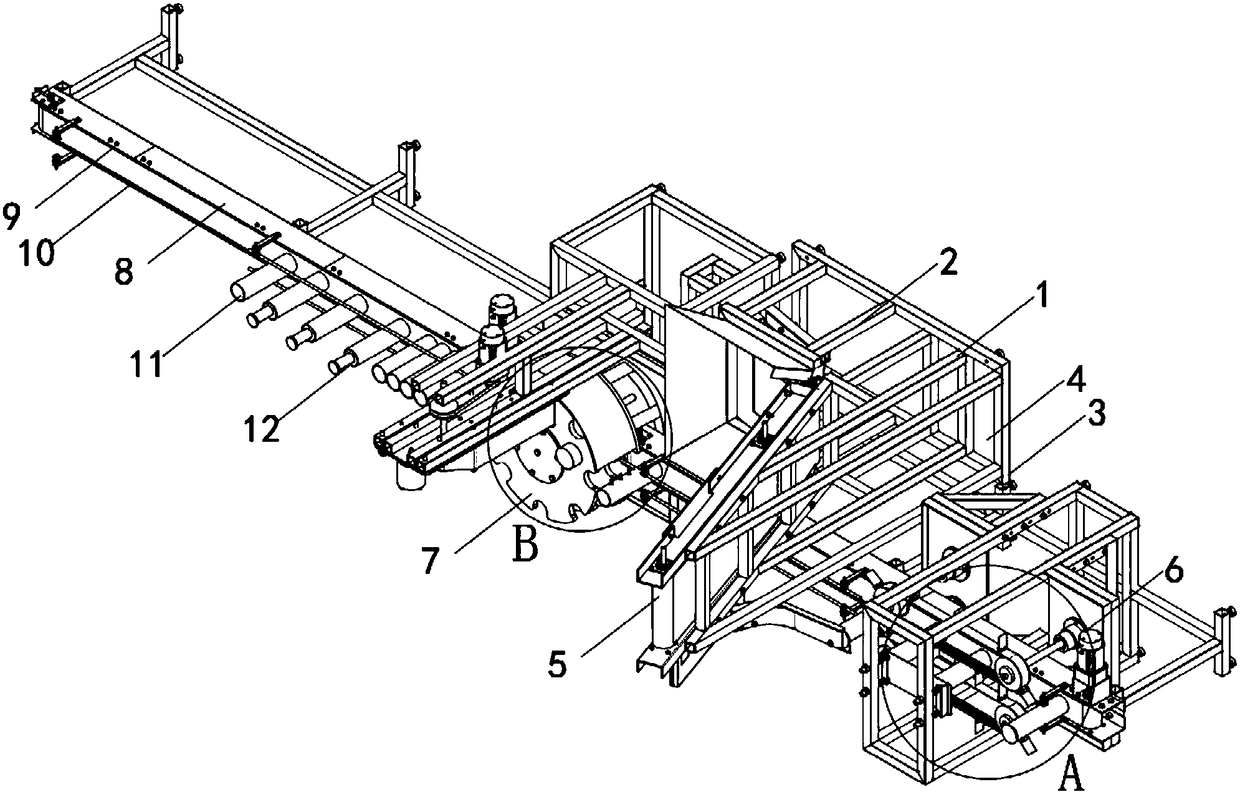

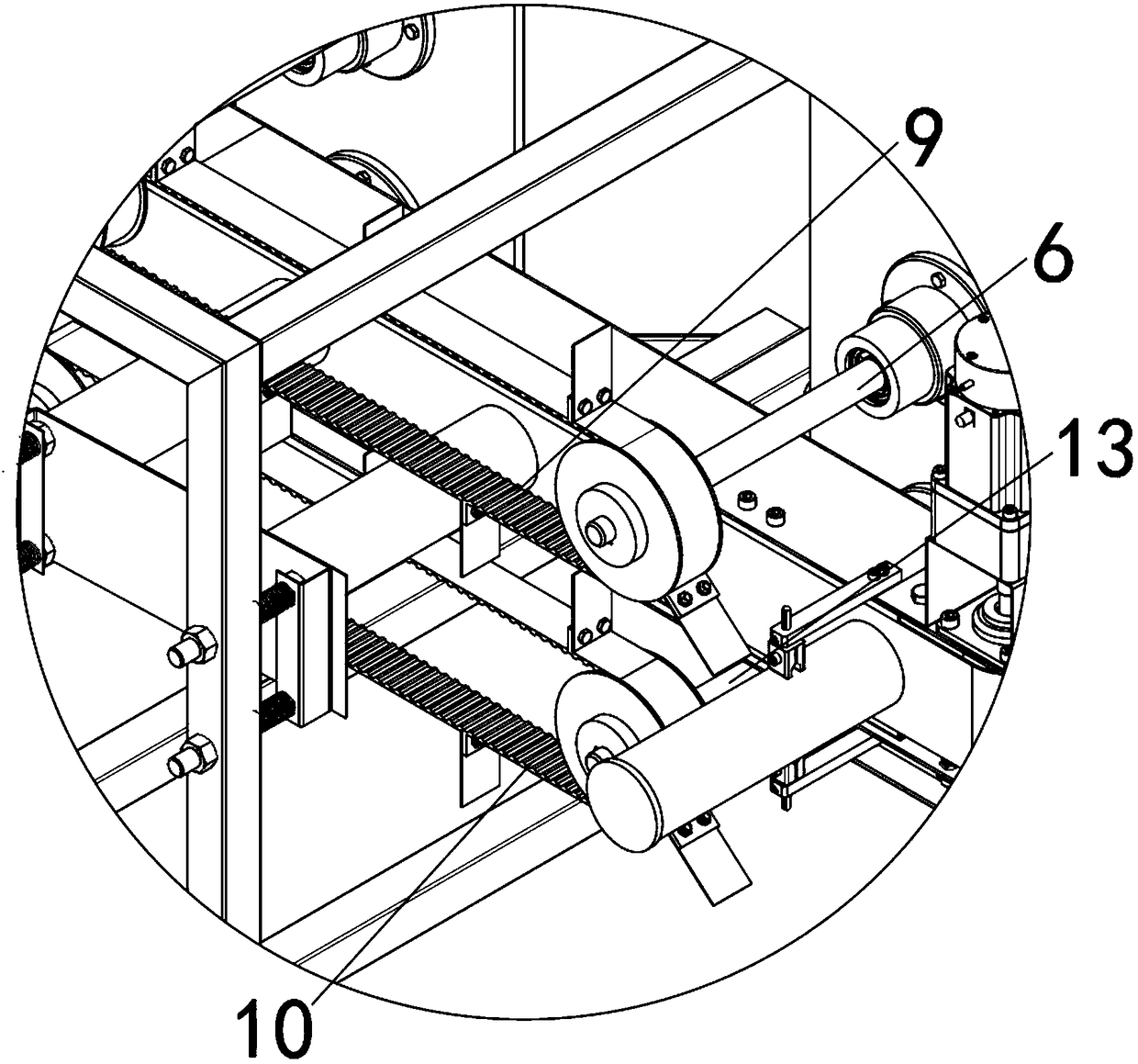

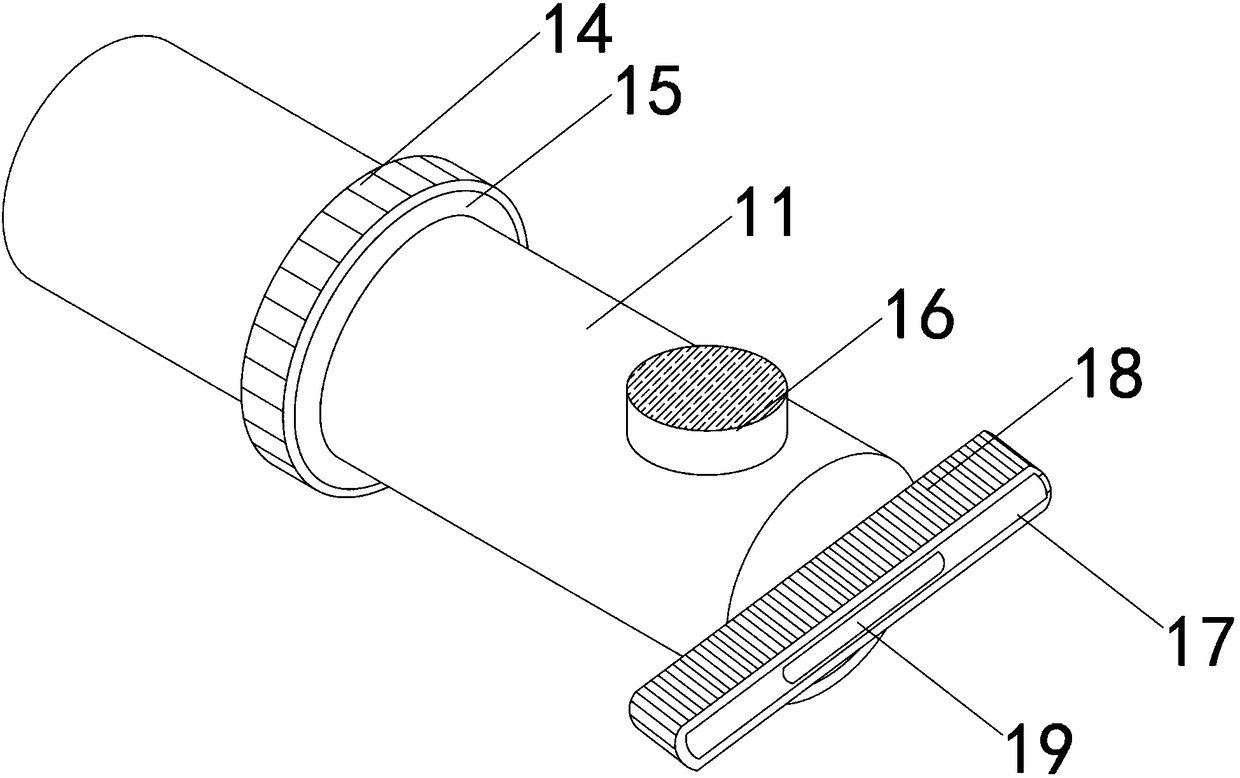

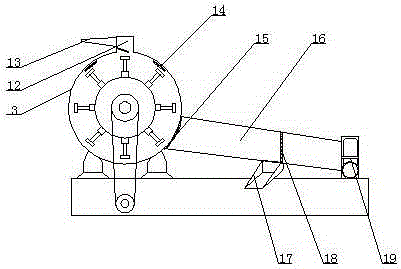

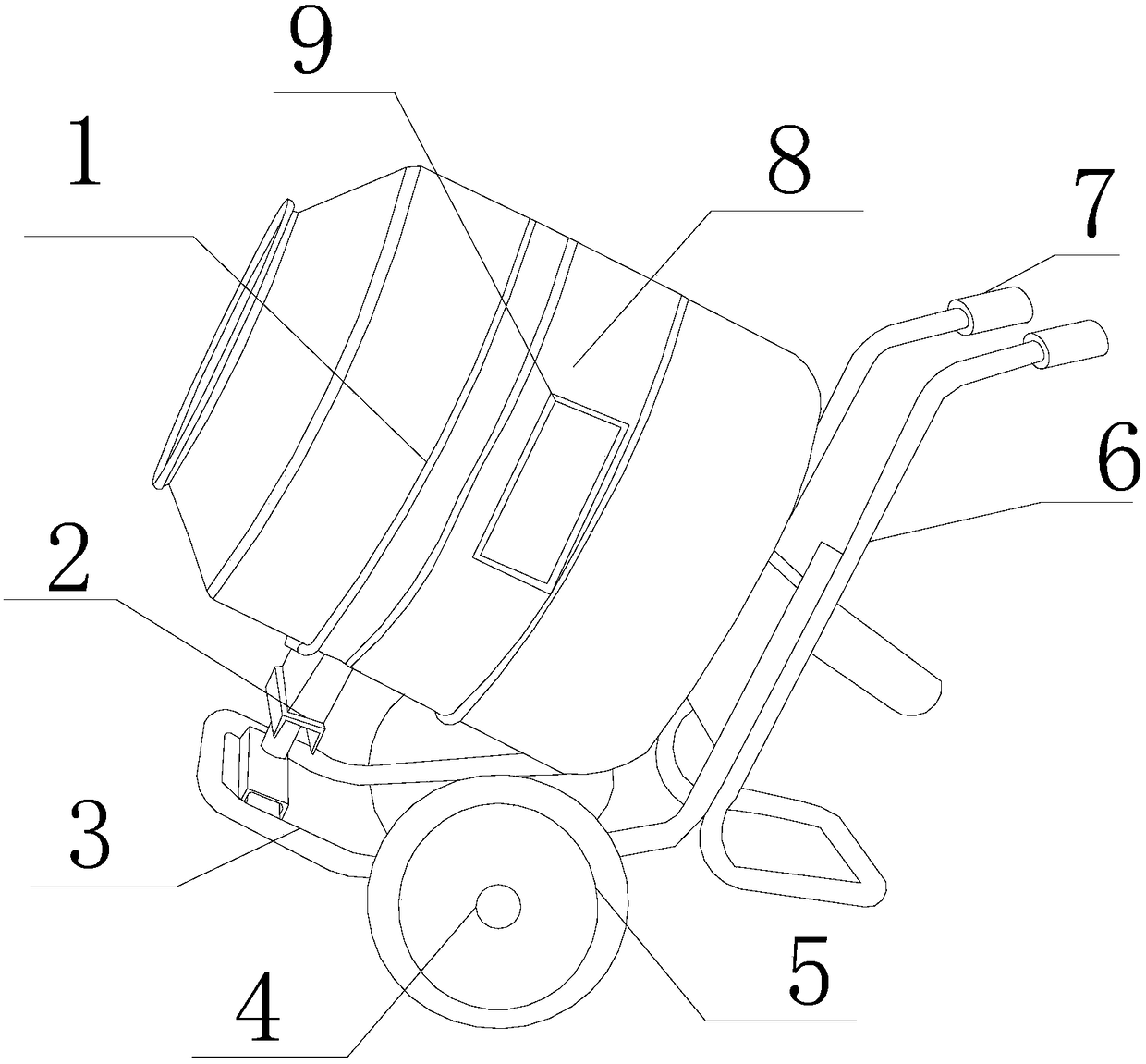

Corncob pulverizer

InactiveCN110773270AEasy to cleanEasy to replaceCleaning using toolsGrain treatmentsProcess engineeringMechanical engineering

The invention discloses a corncob pulverizer. The corncob pulverizer comprises a rack, wherein one end of the rack is provided with a feeding port, one side of the feeding port is provided with an impurity discharging port, and the corncob pulverizer is characterized in that one end of the rack is provided with a power mechanism, a conveying mechanism is arranged on one side of the power mechanism, a transmission mechanism is arranged on one side of the power mechanism, one end of the transmission mechanism is provided with an impurity removing mechanism capable of removing impurities such asstones mixed among corncobs, the impurity removing mechanism is arranged on one side of the conveying mechanism, one end of the power mechanism is provided with a pulverizing mechanism capable of crushing the corncobs, one side of the pulverizing mechanism is provided with a material shifting mechanism, one side of the material shifting mechanism is provided with a drying mechanism, and the otherside of the conveying mechanism is provided with a grinding mechanism. The corncob pulverizer has the beneficial effects that the corncobs can be efficiently crushed, corncob fragments are dried and ground to obtain fine corncob powder, meanwhile, the labor intensity of operators can be reduced, and the production efficiency is improved.

Owner:杭州和源园艺有限公司

Feeding device for production of non-woven fabric

ActiveCN108642586AAutomatically control the amount of inputImprove rationalityFilament forming substance formingSpinning head liquid feederAutomatic controlCombustion

The invention relates to a feeding device for production of a non-woven fabric. The feeding device comprises a body and a combustion flue. A pulling port is formed in the middle of the body. By meansof a feeding port, a rotating shaft, a connecting plate, a rotating handle and a cylinder, the rotating angle of the connecting plate can be automatically controlled to control the openness of a feeding port, so that the feeding amount of a raw material for producing the non-woven fabric can be controlled, the feeding rationality and high efficiency are improved. At the same time, the raw materialprocessing efficiency is improved, and the waste is avoided. At the same time, the area of the connecting plate is larger than that of the feeding port, the inside of a feeding pipe in the idle statecan be protected from dust and moisture, the raw material is protected from pollution in the conveying process, and the processing quality of the non-woven fabric is ensured. By means of a crushing plate in a tip net structure, the raw material entering the body can be crushed, the contact area between the raw material and the bottom of the body is increased, so that the melting rate of the raw material is increased, and the working efficiency is improved by means of an elastic plate.

Owner:翰诠特种纺织品(平湖)有限公司

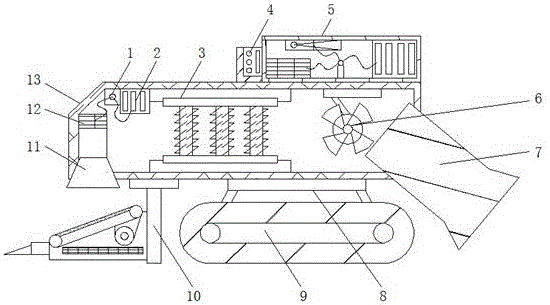

Crushing and returning machine

ActiveCN106211934AQuick cutIncrease the degree of crushingCrop conditionersMowersElectricityNumerical control

The invention discloses a crushing and returning machine. the crushing and returning machine includes a straw crushing machine, a working main body and a power device; the straw crushing machine is arranged in the center of the inner part of the working main body; fixing supports are arranged at the upper side and the lower side of the straw crushing machine, respectively; a power extraction device is arranged over the left side of the straw crushing machine; an attraction channel is arranged the left lower part of the power extraction device; an attraction fan is arranged at the right side of the straw crushing machine; a working case is arranged at the right side over an external part of the working main body; the power device is arranged in the upper part of the inner part of the working case; a numerical control execution element is arranged on the left lower part of the power device; an electricity energy storage device is arranged at the right side of the power device; a rolling track is arranged under the external part of the working main body; and a straw cutting device is arranged under the attraction channel. The crushing and returning machine is easy and simple to use, can quickly crush straw and pave the crushed straw in a farmland, and is improved in working efficiency.

Owner:HENAN HAOFENG AGRI EQUIP CO LTD

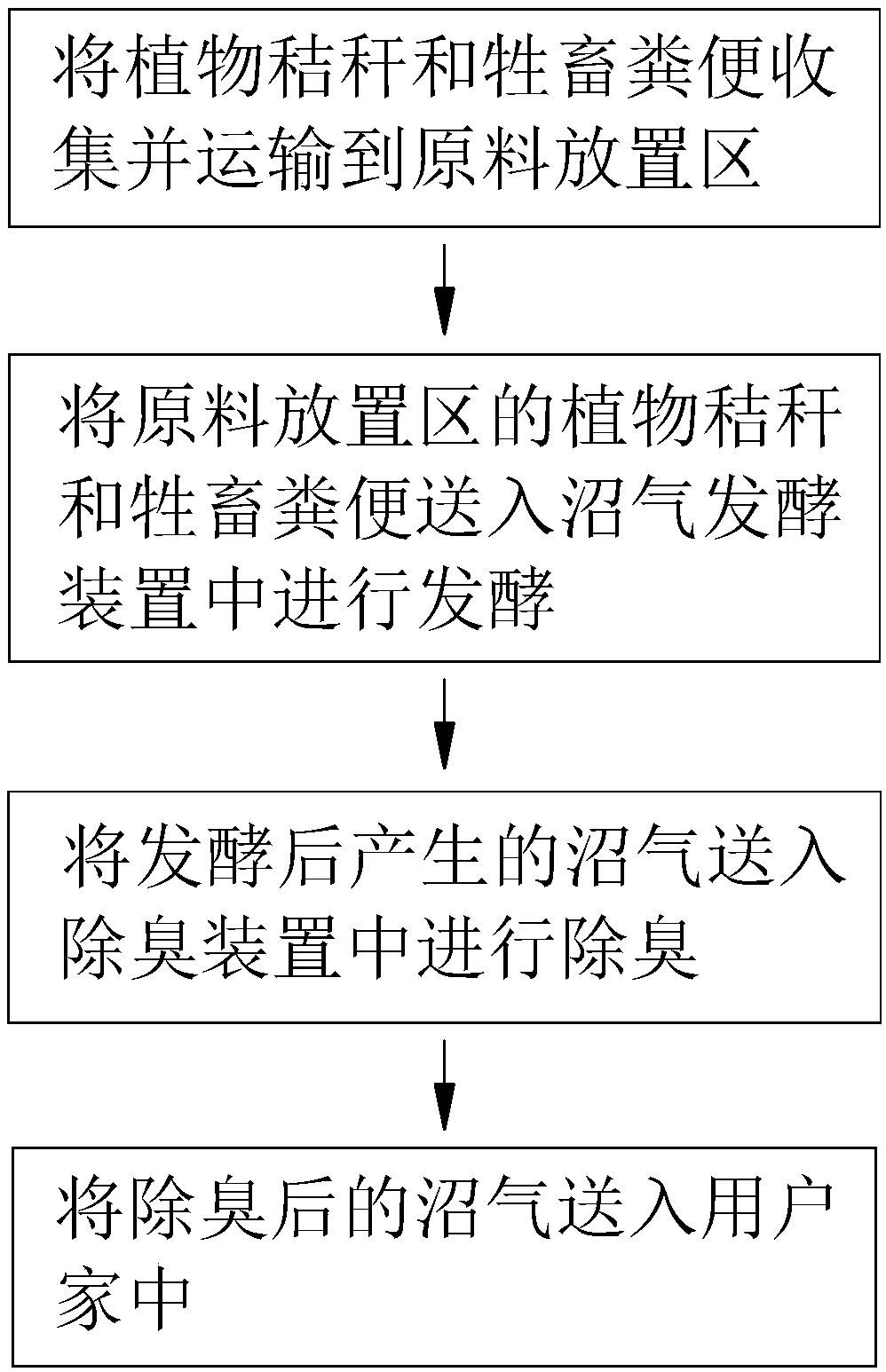

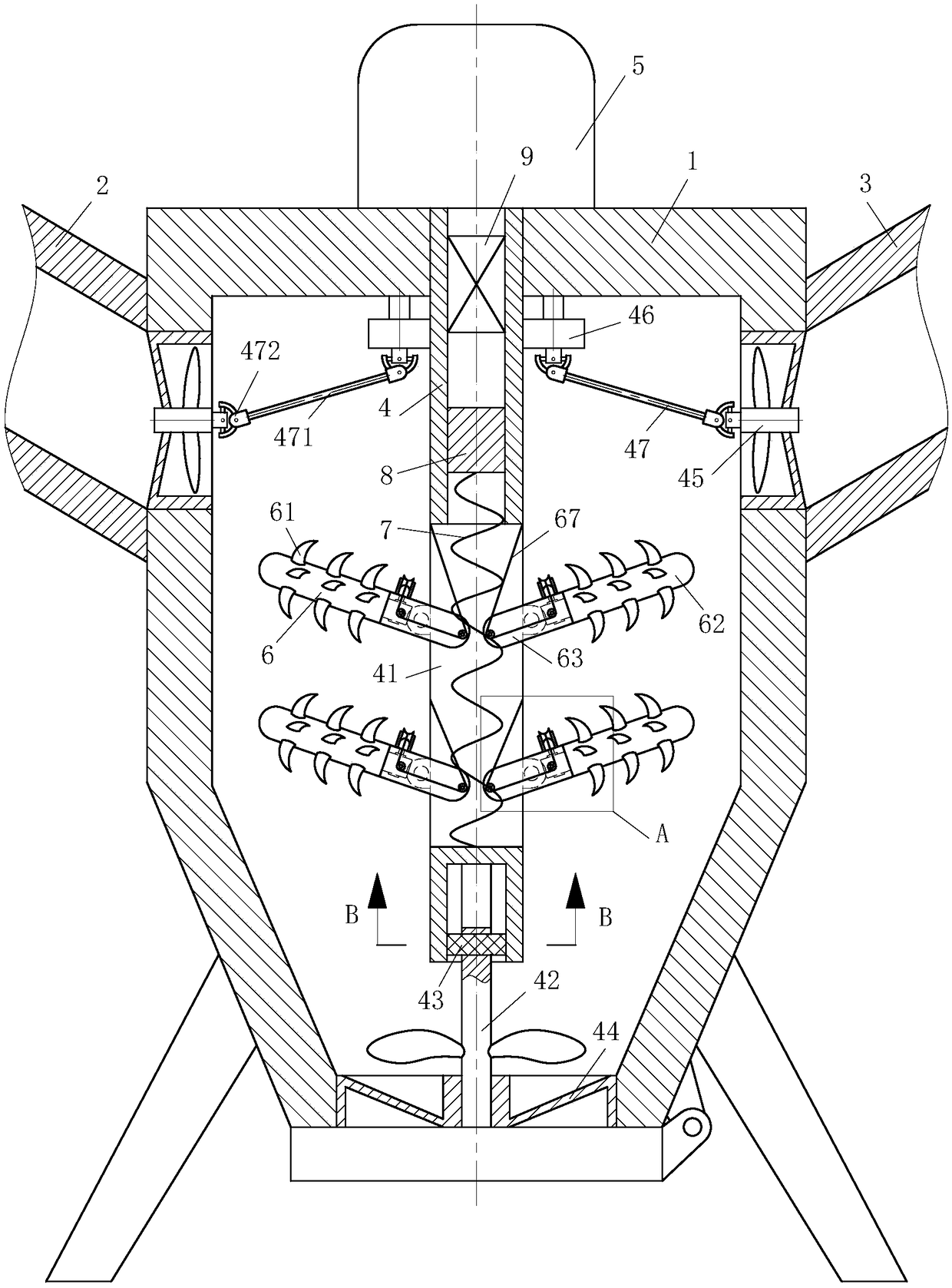

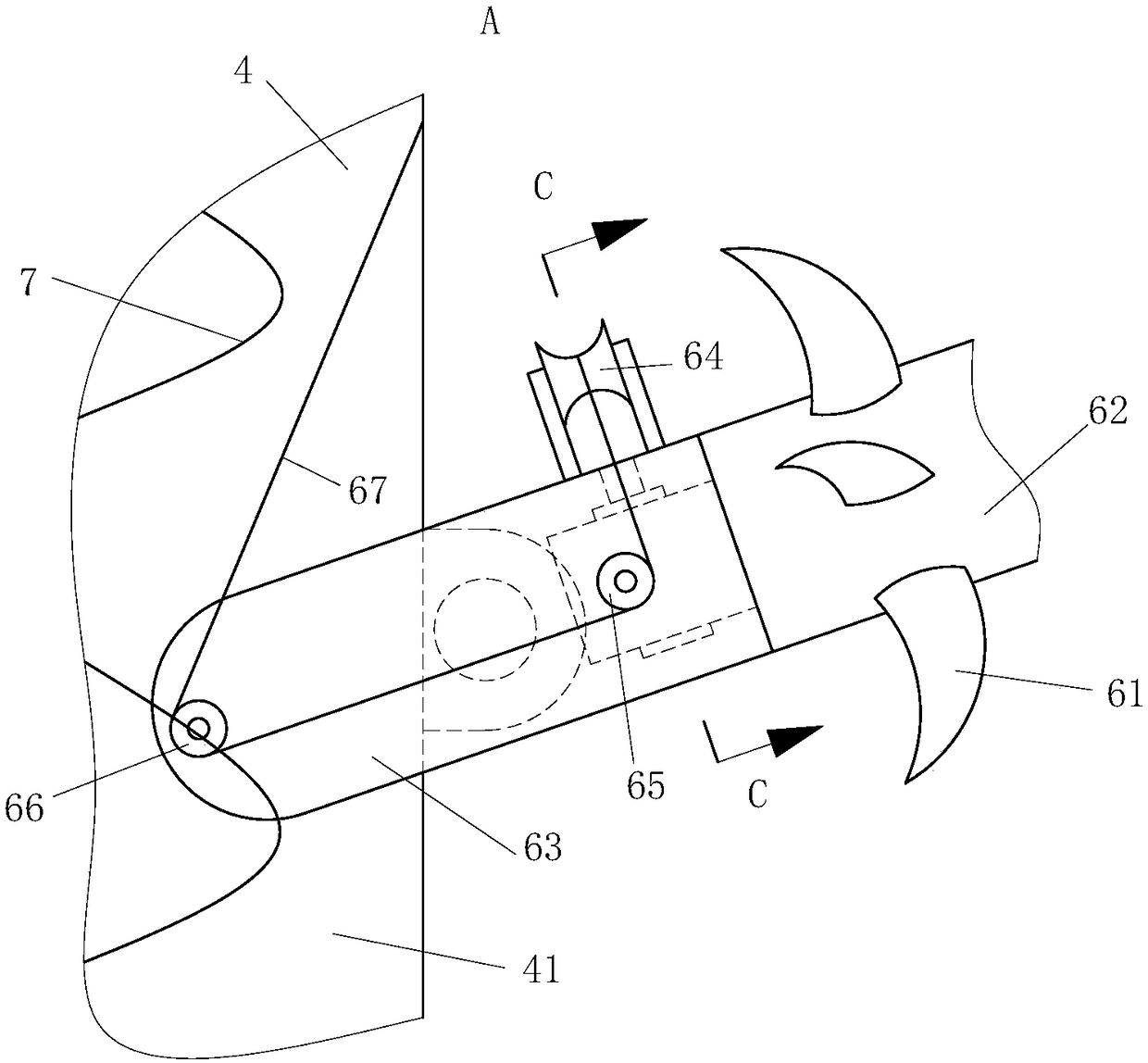

Method for efficiently utilizing plant straw

InactiveCN108949836AUniform fermentationWell mixedBioreactor/fermenter combinationsBiological substance pretreatmentsAnimal fecesEngineering

The invention belongs to the technical field of straw treatment and particularly relates to a method for efficiently utilizing plant straw. A biogas fermenting device in the method comprises a fermenting tank body, a first feeding pipeline, a second feeding pipeline, a stirring shaft, a driving motor, swinging rods, a first spring, a sliding block and an electromagnet, wherein two groups of swinging rods are symmetrically arranged in a rectangular through groove of the stirring shaft; and middle parts of the swinging rods are hinged on the stirring shaft. According to the method disclosed by the invention, the first spring is arranged in the rectangular through groove of the stirring shaft passes; the lower end of the first spring is fixedly connected with the bottom surface of the rectangular through groove; the upper end of the first spring is fixedly connected with the sliding block; the electromagnet is arranged above the sliding block; through intermittently energizing and de-energizing the electromagnet, the swinging rod can swing up and down and further swings up and down while rotating around the stirring shaft; and therefore, feces and the straw in the fermenting tank bodyare fully mixed and uniformly fermented and finally the fermentation efficiency reaches the highest state.

Owner:张振洋

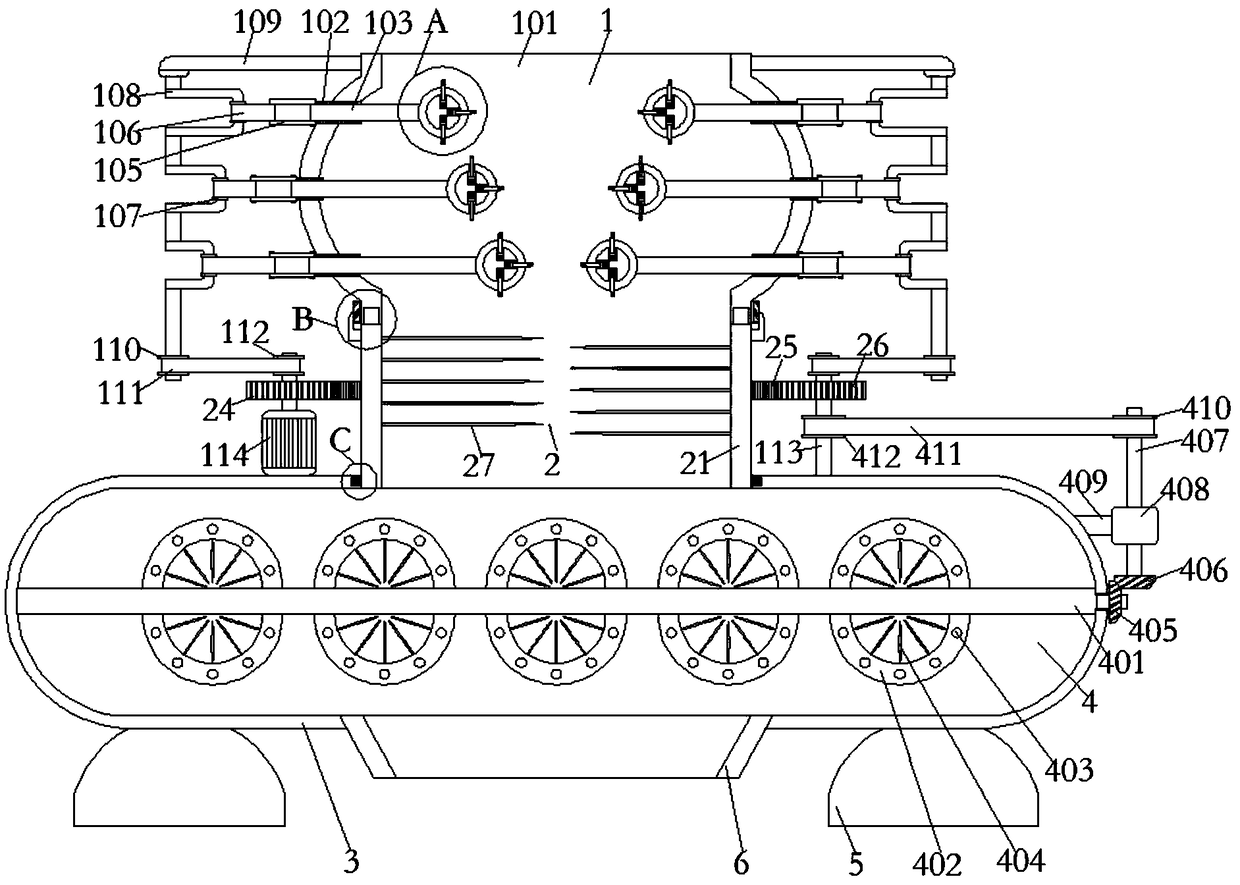

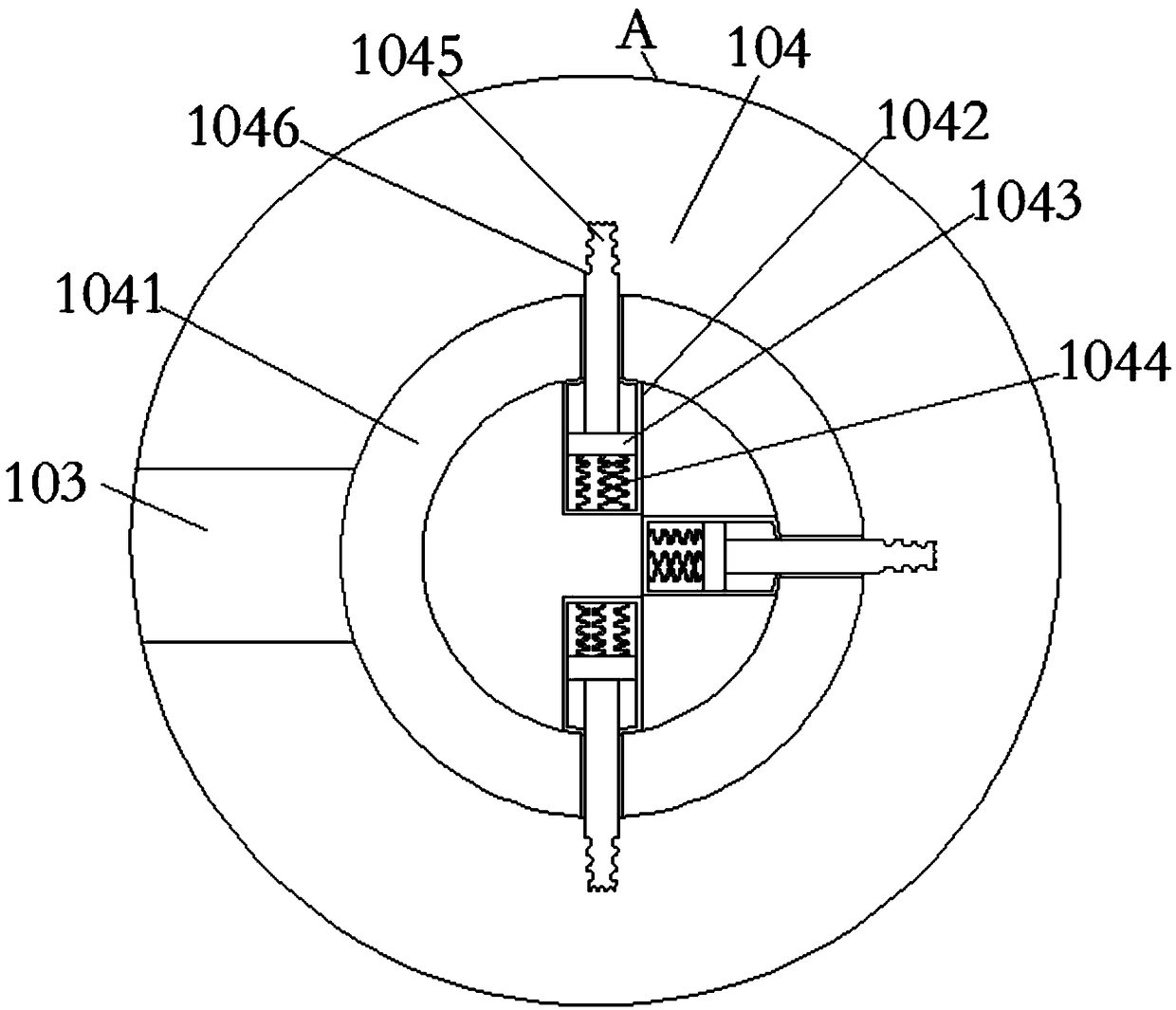

Biomass fuel energy-saving supply system for thermal power plant boiler and supply method thereof

InactiveCN109237507ACrushed fullyCrushed completelyFuel feeding arrangementsSolid fuel pretreatmentThermal energyCombustion

The invention discloses a biomass fuel energy-saving supply system for a thermal power plant boiler. The system comprises an assembling and connecting frame, an aggregate crushing box, a conveying bin, a supply cylinder and a first hydraulic pump. A plurality of transverse partition plates are arranged in the middle of the assembling and connecting frame in parallel, and one ends of the transversepartition plates are each perpendicularly provided with a longitudinal partition. The system has the advantages that fuel is scraped and cut through cutter edges, the fuel and a scraper are oppositein rotating direction, the collision probability of the fuel and the scraper is increased, the fuel crushing efficiency and crushing degree of the scraper are improved, the fuel is crushed more thoroughly, fuel combustion is more sufficient and more thorough, the fuel thermal energy conversion rate is increased, when the boiler generates the equivalent electric quantity, less biomass fuel is adopted, and working energy conservation of the supply system is ensured; a pressing plate moves up and down to extrude the biomass fuel, the density is larger when the fuel is put into the boiler, the fuel containing amount in the boiler is increased, and the phenomenon that the boiler is blocked by the fuel is avoided.

Owner:王幼林

Construction waste recycling and brick making equipment

InactiveCN111331722ASimple processEasy to addCeramic shaping plantsAuxillary shaping apparatusBrickMolding machine

The invention provides construction waste recycling and brick making equipment, and relates to the technical field of construction waste brick making, in particular to the construction waste recyclingand brick making equipment. The construction waste recycling and brick making equipment comprises a crushing bin, a feed port, a fixed rod, crushing devices, a rotating shaft, crushing hammer pieces,supporting rods, rotating wheels, a conveying belt, a stirring bin, a feed inlet, a water inlet (22), a rocking handle, stirring rollers, a screen net, a separation plate, circular holes, a brick forming machine, a conveyer belt, a brick stacking machine, a discharge port and a control panel. The feed port is formed in the upper portion of the crushing bin, and the fixed rod is arranged in the crushing bin. After the technical scheme is adopted, the construction waste recycling and brick making equipment has the beneficial effects that the structure is simple, the brick making processes are simple and practical, the crushing degree is high, construction waste can be crushed to the maximum extent, raw materials needed to make bricks can be added conveniently and easily, the processes of bricking forming and brick stacking are carried out, the labor force is saved, and the steps are simple.

Owner:徐州鼎足再生资源有限公司

Fish meal processing crushing device

InactiveCN105170241AQuality assuranceIncrease the degree of crushingGrain treatmentsDrive motorEngineering

The invention discloses a fish meal processing crushing device. The fish meal processing crushing device comprises a base, a crushing chamber, a rotating shaft, a hammer head, a driving motor, a discharge channel and a blower; the crushing chamber is arranged on the base; an elastic supporting leg is fixed at the joint of the crushing chamber and the base; a rotating shaft is arranged inside the crushing chamber; one end of the rotating shaft is connected with the driving motor inside the base through a belt pulley mechanism; a rotor is fixed on the rotating shaft; a rotating pin shaft is mounted on the rotor; a hammer rod is fixed on the rotating pin shaft; a hammer head is fixed at one end of the outer side of the hammer rod; a crushing plate is arranged at the internal upper end of the crushing chamber; the discharge channel is connected with the lower end of one side of the crushing chamber, and a first screen mesh is arranged at the joint of the discharge channel and the crushing chamber; the other end of the discharge channel is communicated with the blower; a discharge hole is formed in the bottom of the discharge channel. The fish meal processing crushing device is not only capable of guaranteeing the quality of the fish meal, but also high in crushing efficiency and good in crushing effect.

Owner:荣成海达鱼粉有限公司

Preparation method for oyster powder

The invention provides a preparation method for oyster powder. The preparation method for the oyster powder comprises the following steps: step 1, taking out oyster meat from oyster shells, and cleaning the oyster meat; step 2, adding 1-3% of trehalose according to the weight of the oyster meat and uniformly stirring, and then slurrying to obtain an oyster meat slurry; step 3, carrying out vacuum freeze drying on the oyster meat slurry, and then crushing and passing through a 100-mesh sieve to obtain the oyster powder. According to the preparation method for the oyster powder provided by the invention, the trehalose is added during the slurrying process for the oyster meat as a cryoprotectant, thus preventing the nutritional ingredients of the oyster meat slurry from being lost under low-temperature freezing.

Owner:北海市银海区蓝海牧场贝类养殖农民专业合作社

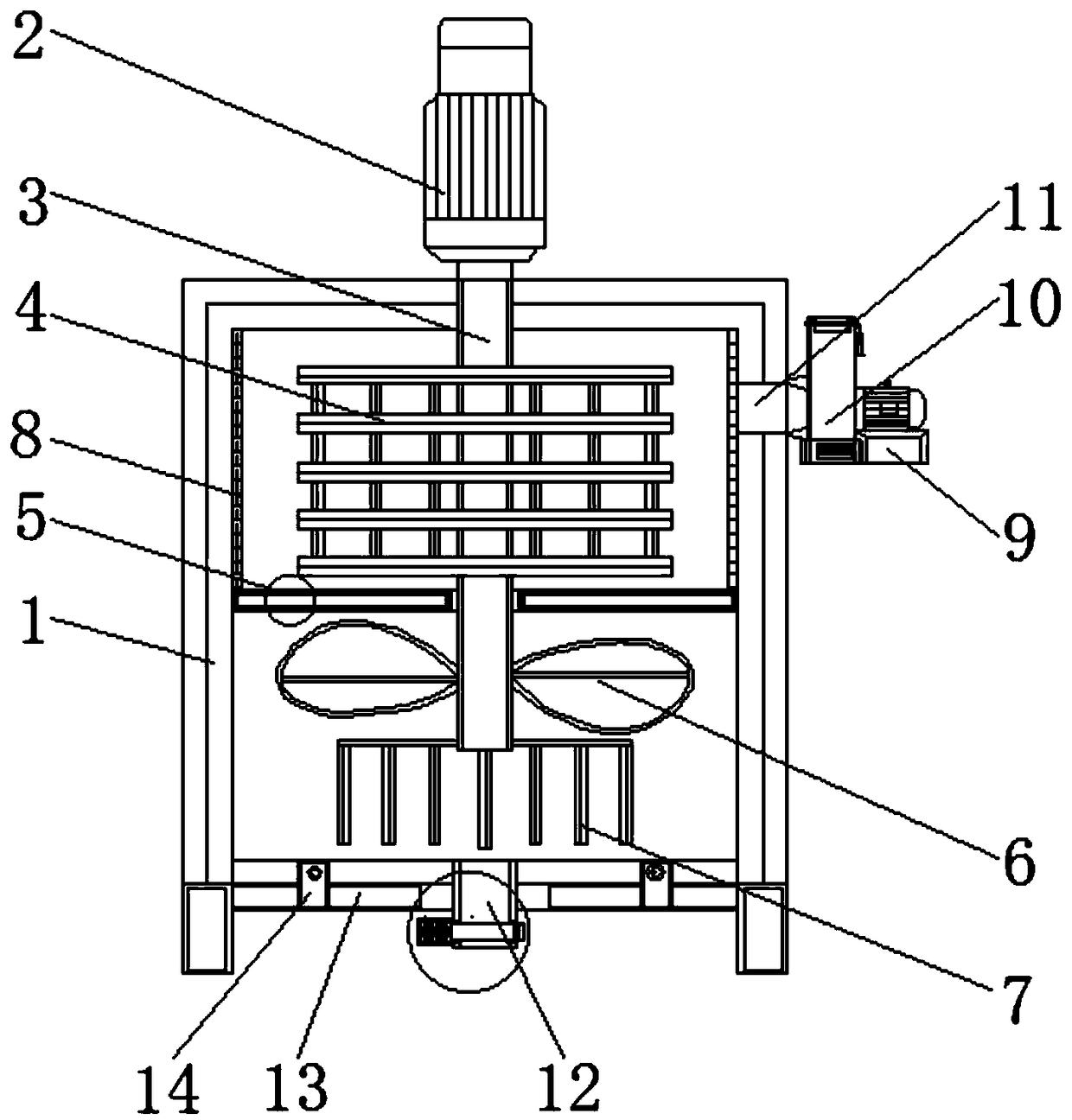

Stirring and smashing integration device used for baijiu manufacture

InactiveCN108148704AQuality improvementQuick breathAlcoholic beverage preparationBiochemical engineeringAir exchange

The invention discloses a stirring and smashing integration device used for baijiu manufacture. The stirring and smashing integration device structurally comprises a stirring and smashing integrationdevice, a connecting frame, an L-shaped bottom fixing frame, a connecting rod, movement wheels, a hand pushing frame, a rubber sleeve, a machine body and tempered glass, wherein the stirring and smashing integration device is installed in the machine body; the side surface of the tempered glass is inlaid on the front side of the machine body; the top of the connecting frame is welded with the bottom of the machine body; the bottom of the connecting frame is fixedly connected with the top of the left end of the L-shaped bottom fixing frame. According to the stirring and smashing integration device used for baijiu manufacture, articles required for baijiu manufacture can be smashed and grinded and are finally evenly distributed, so that the balance of a fermentation effect when the baijiu ismanufactured can be improved, baijiu brewing quality is improved, meanwhile, quick air exchange can be quickly carried out in the device, the internal temperature of the equipment is quickly lowered,meanwhile, moisture in the equipment can be lowered, and the use value of the equipment is improved.

Owner:福建聚云科技股份有限公司

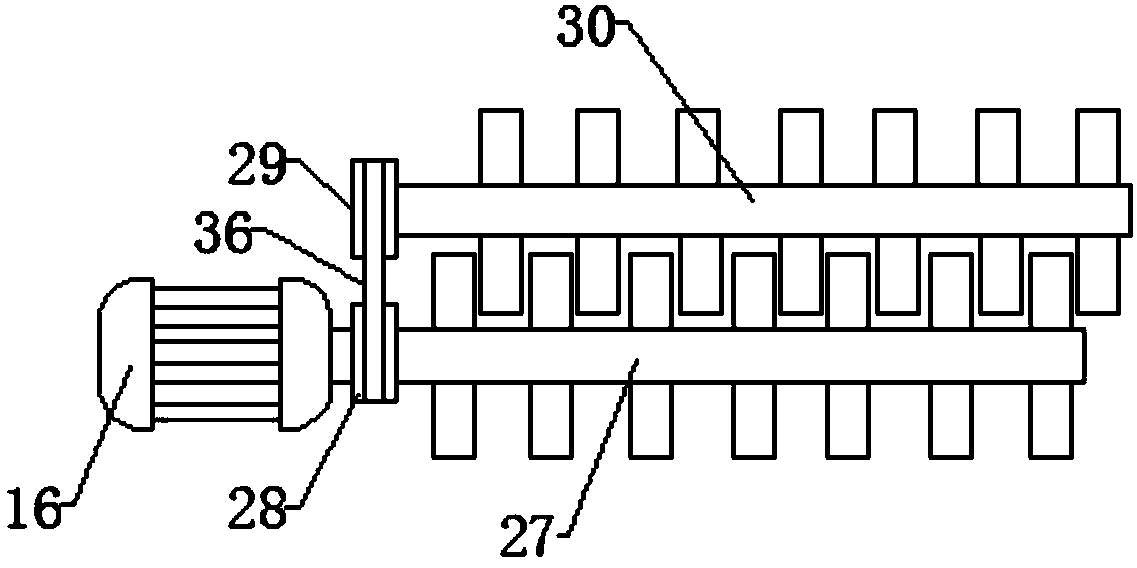

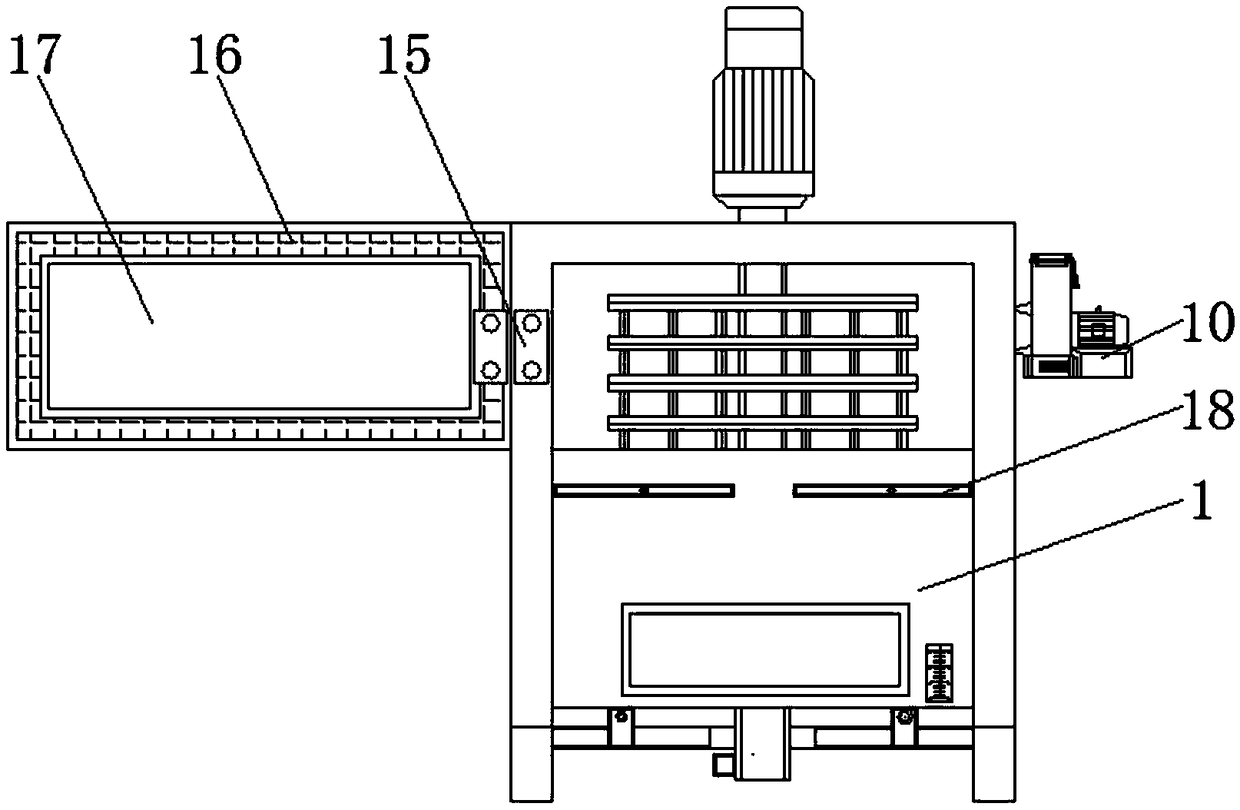

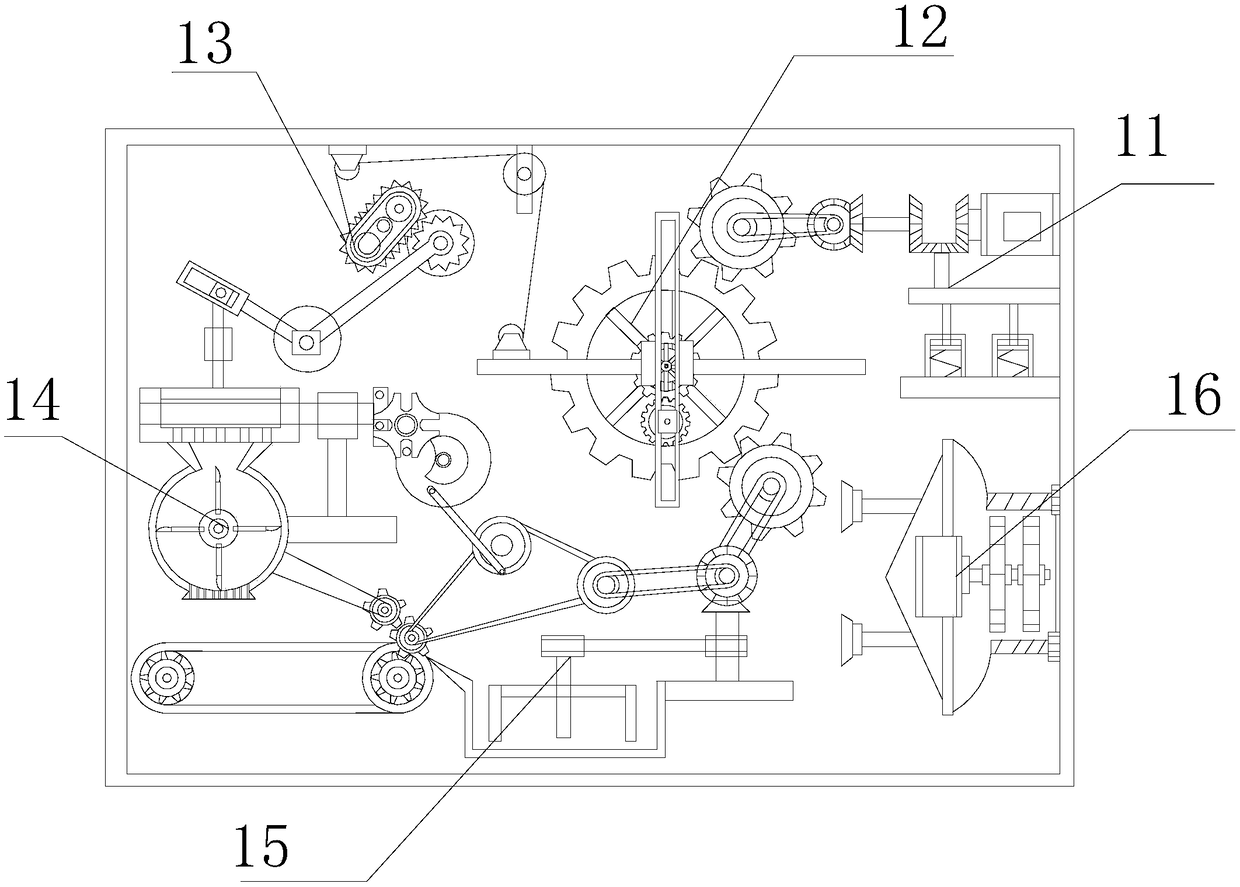

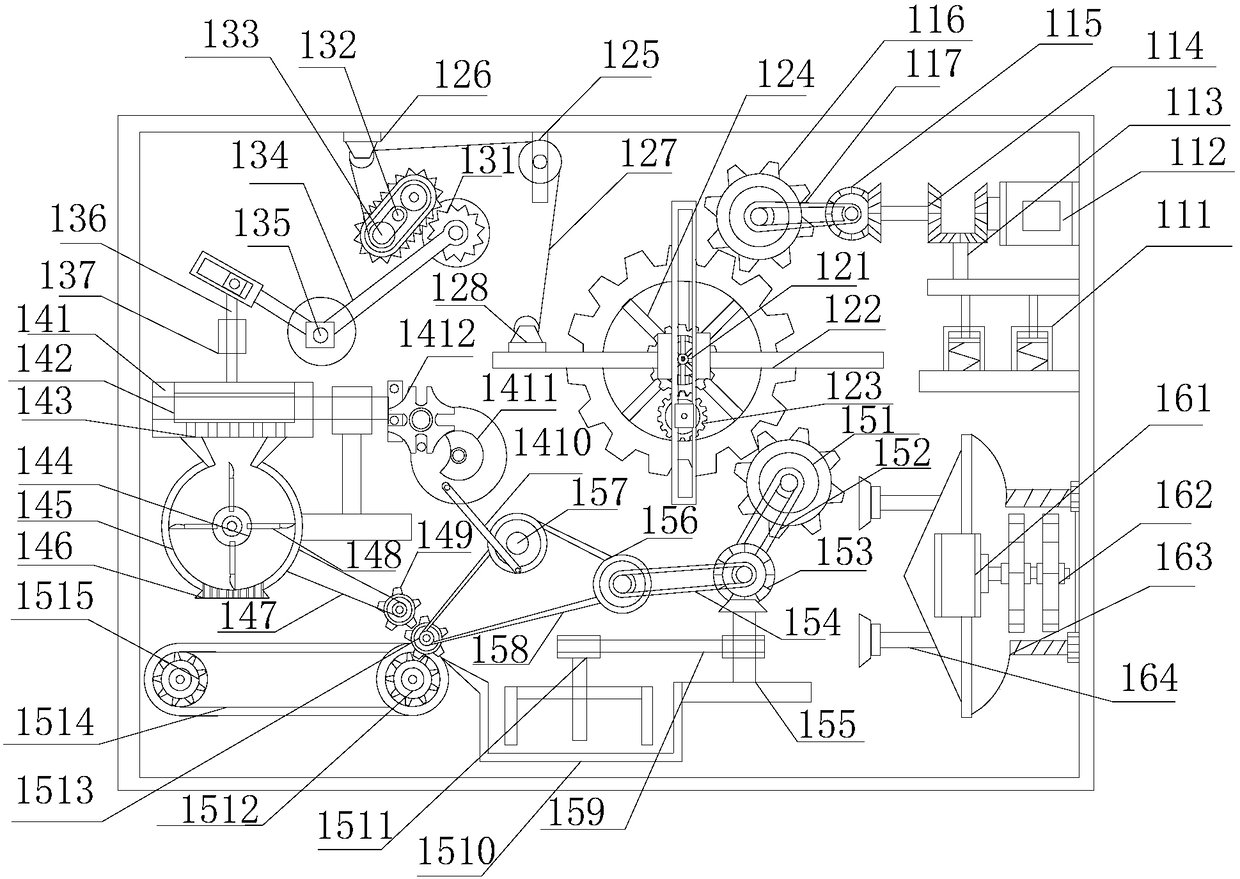

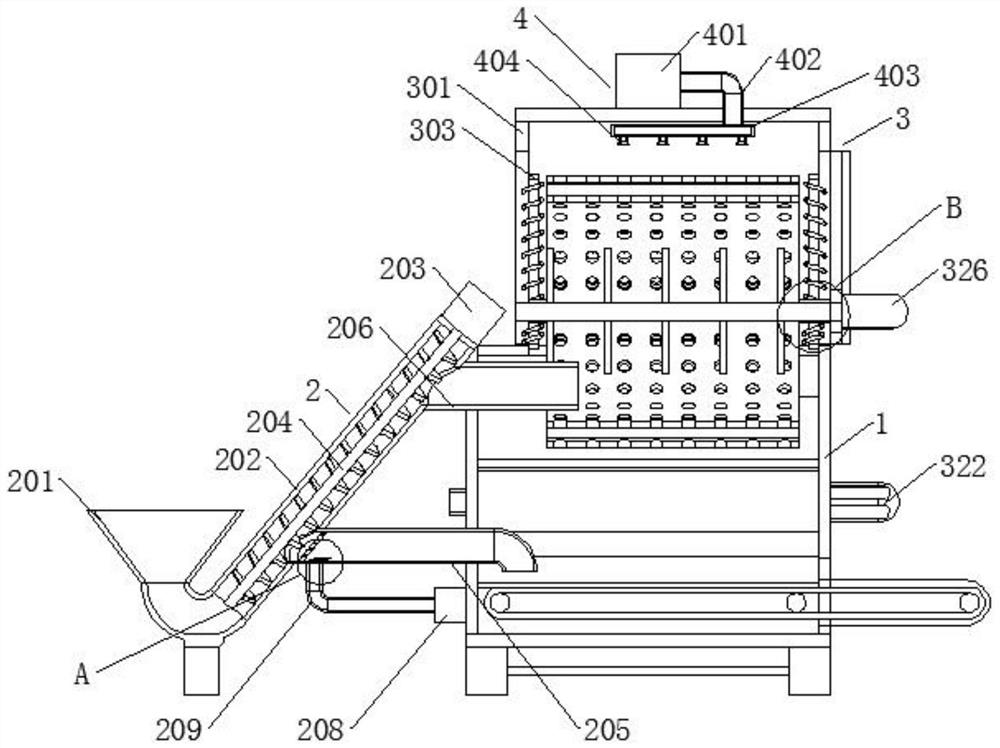

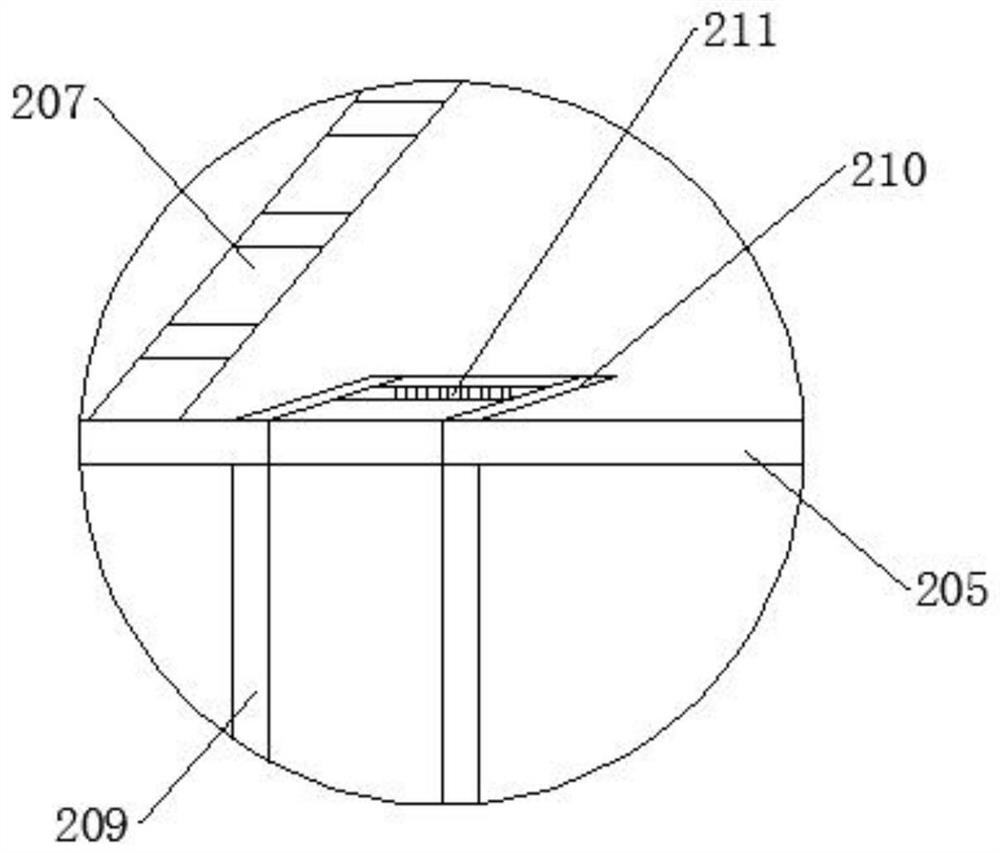

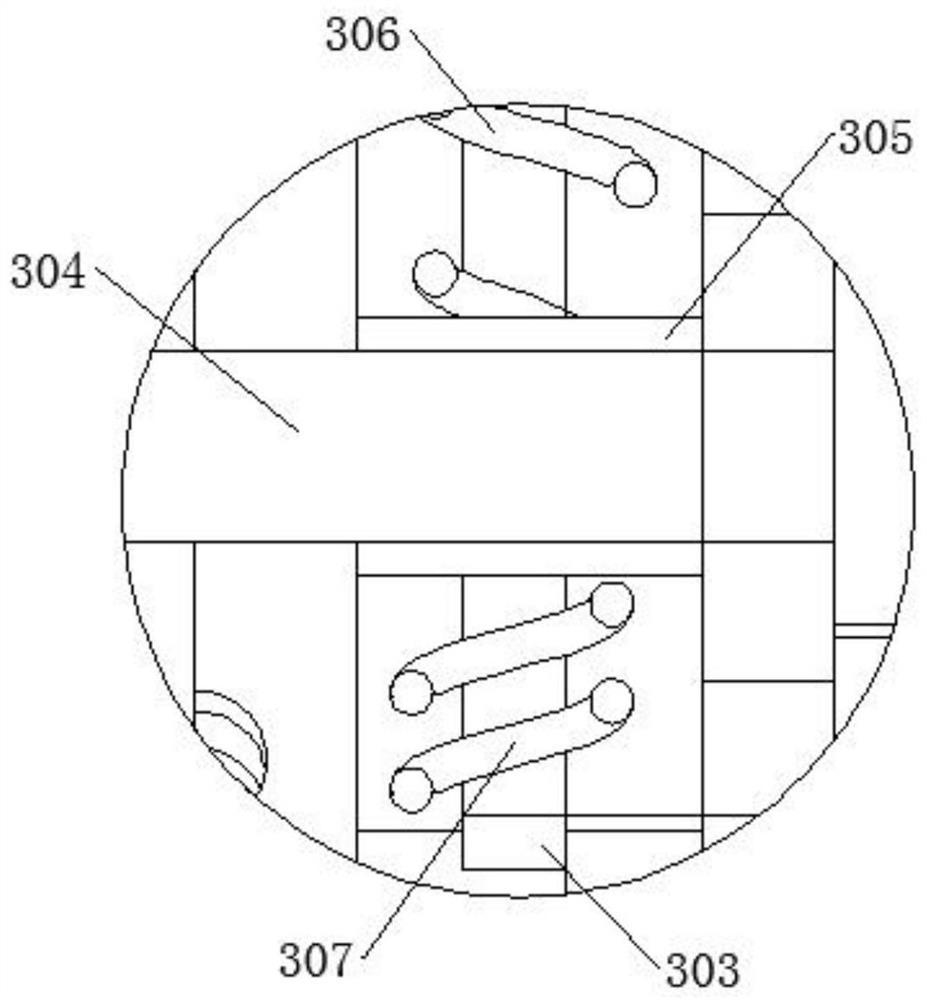

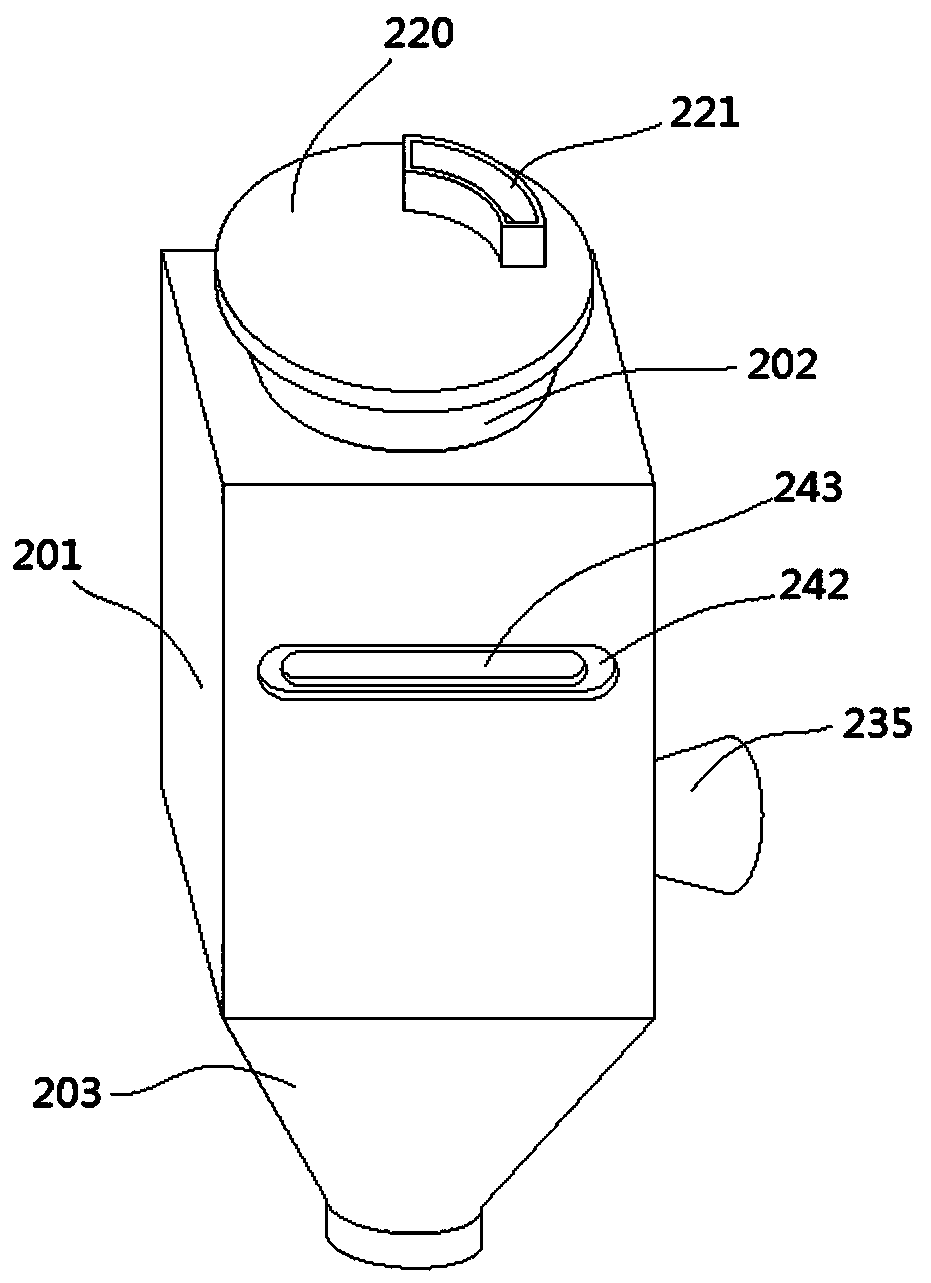

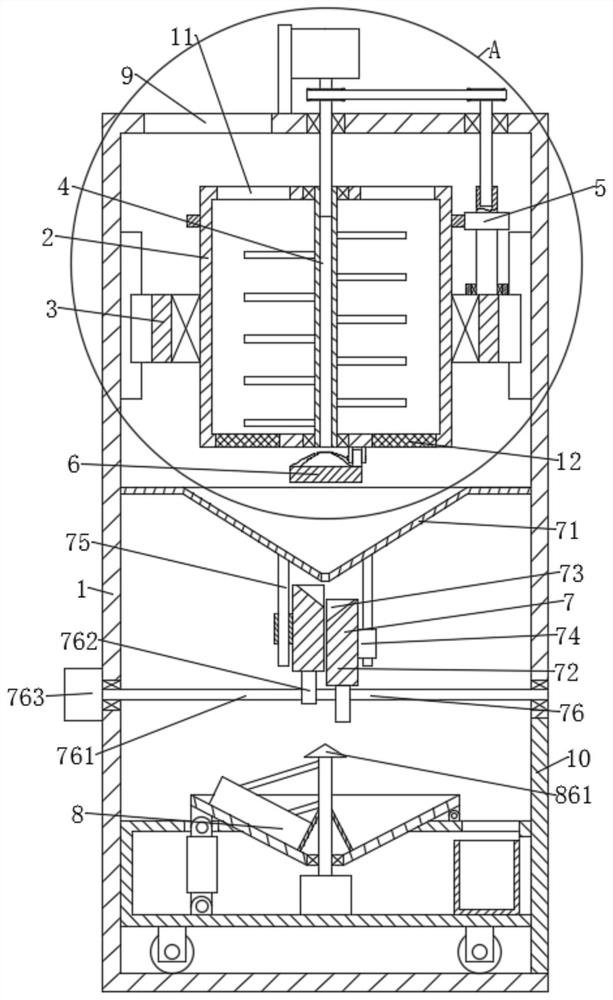

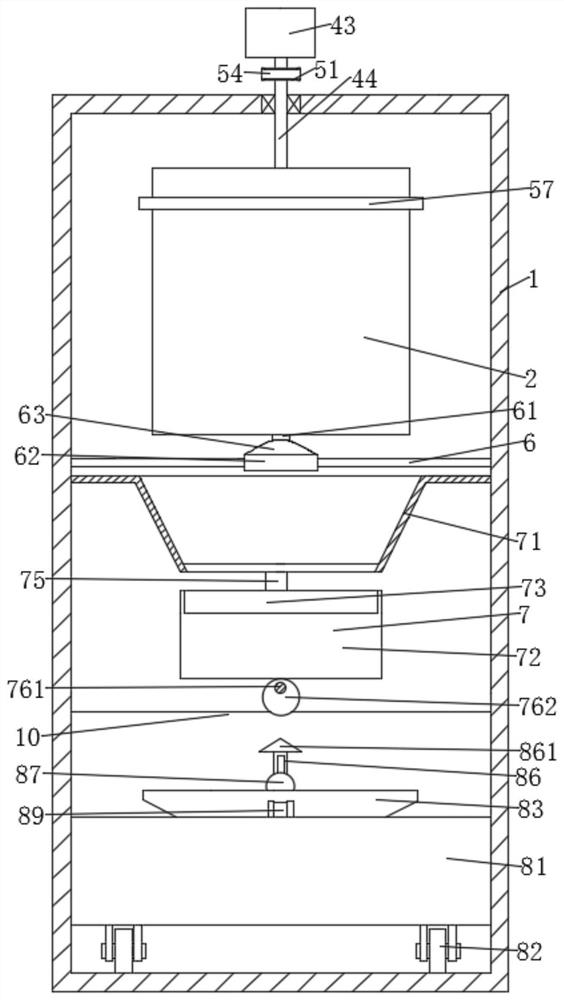

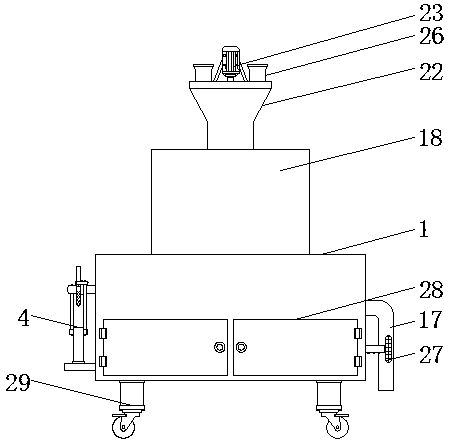

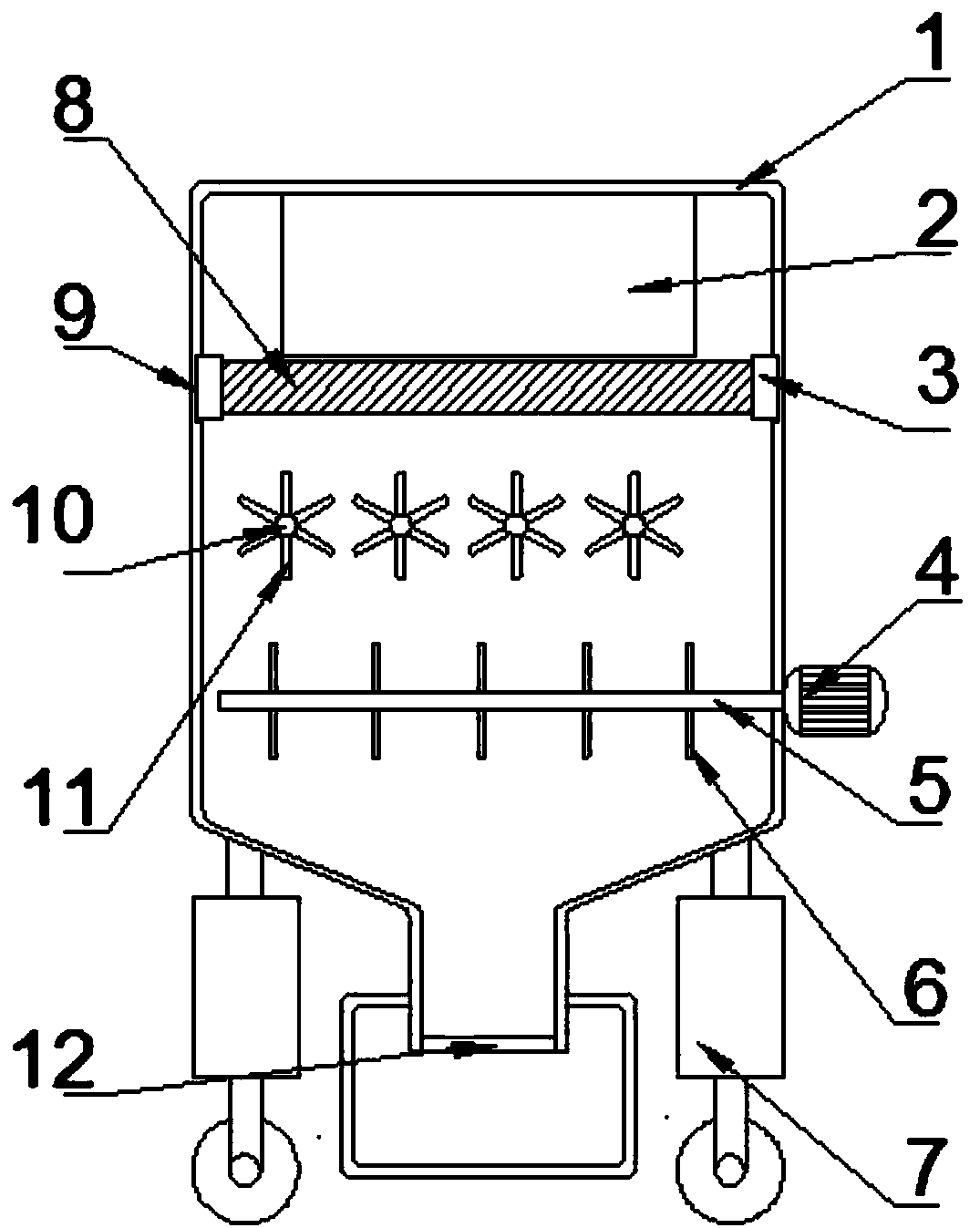

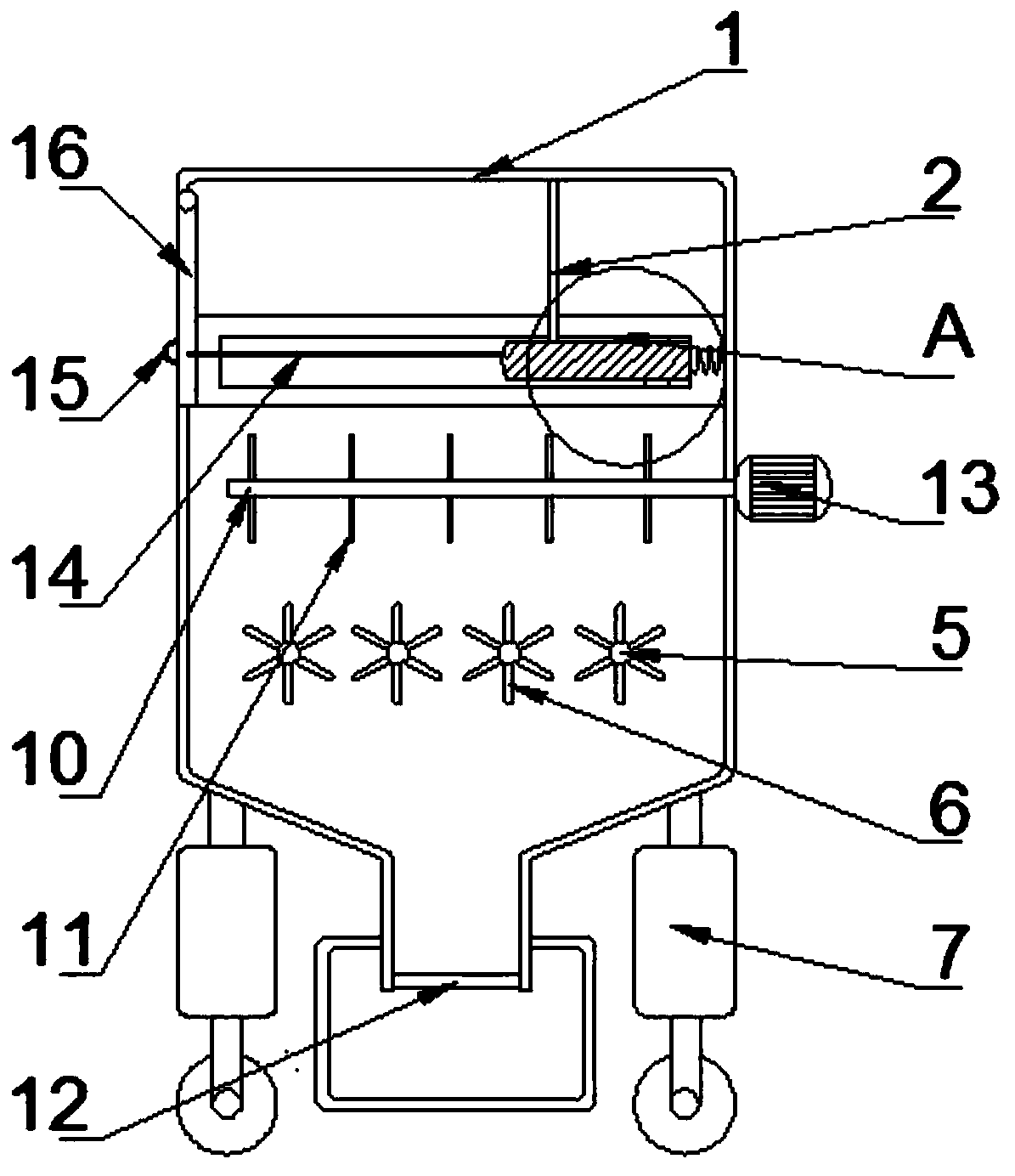

Crushing and drying integrated processing equipment for pig feed

ActiveCN113399078AImprove absorptionIncrease the degree of crushingSievingFeeding-stuffAnimal scienceElectric machinery

The invention discloses crushing and drying integrated processing equipment for pig feed. The crushing and drying integrated processing equipment comprises a crushing equipment body, a pre-screening mechanism is connected to the crushing equipment body and comprises a feeding hopper, a conveying pipe is connected between the feeding hopper and the crushing equipment body, and an auger motor is connected to the end, away from the feeding hopper, of the conveying pipe; the auger motor is connected with a feeding auger, the feeding auger is arranged in the conveying pipe, and a first discharging pipe and a second discharging pipe are connected between the conveying pipe and the crushing equipment body. According to the crushing and drying integrated processing equipment, through arrangement of corresponding mechanisms on the feed crushing equipment, feed fed into the crushing equipment can be screened, large feed particles and small feed particles are distinguished, the crushing degree of the large feed particles is greatly improved, meanwhile, the situation that the crushing time of the small feed particles is too long is avoided, the absorption degree of the animal cubs to the feed is greatly increased, and the growth of the animal cubs is facilitated.

Owner:豪汇(广东)农业科技有限公司

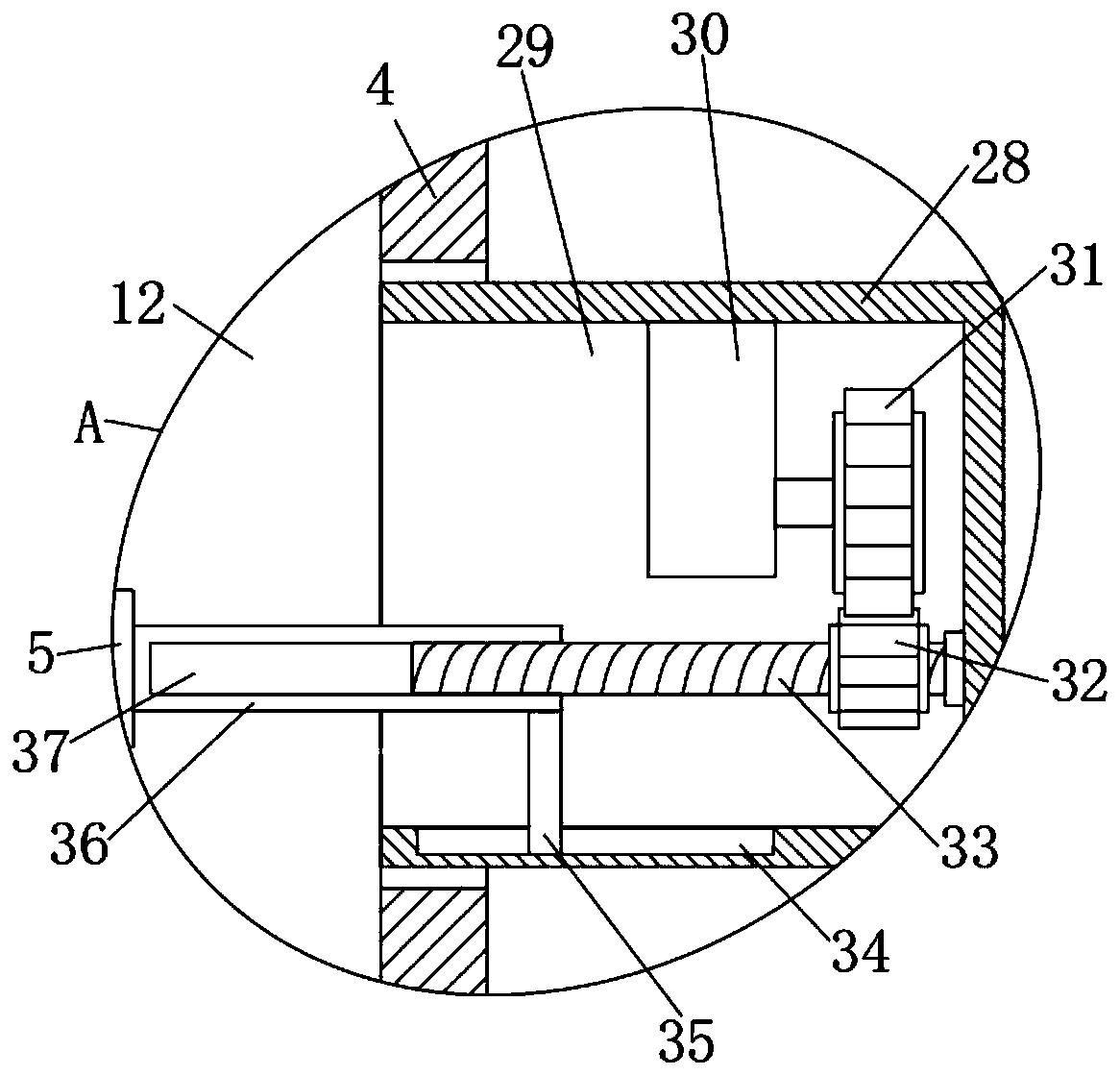

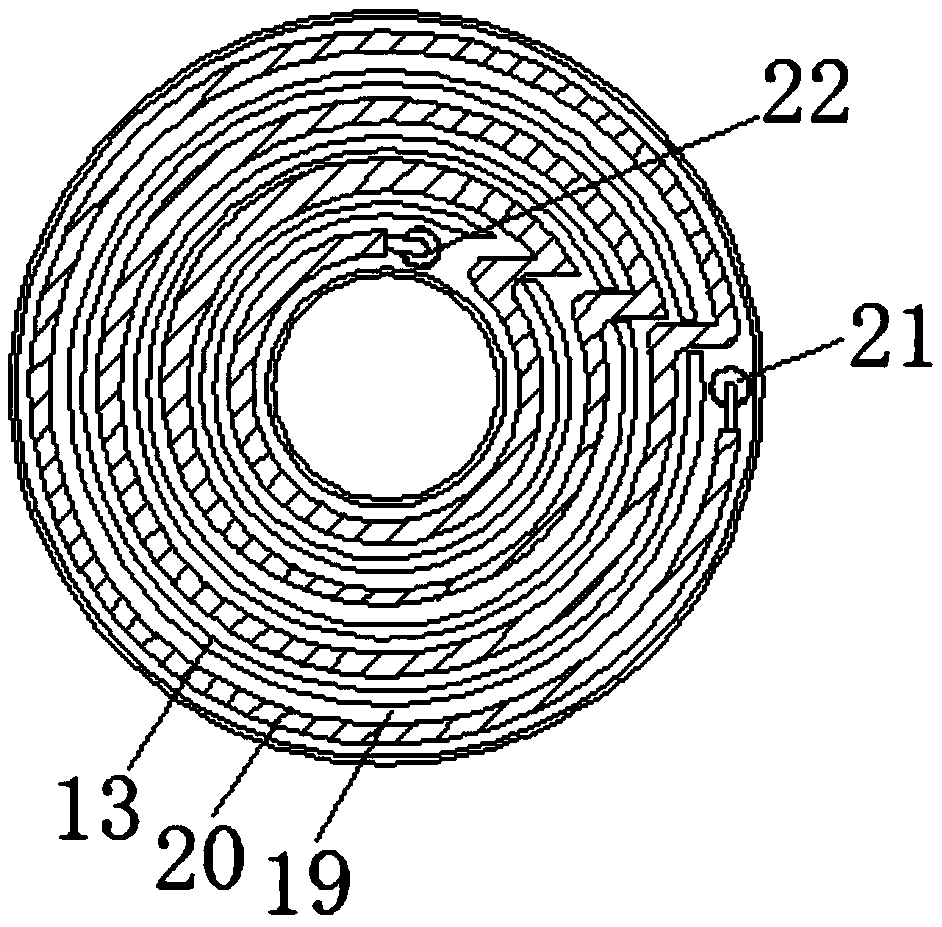

Composite organic fertilizer dust-proof smashing device and control method thereof

ActiveCN109201257AGuaranteed to completeGuaranteed to be completely crushedGrain treatmentsEngineeringOrganic fertilizer

The invention relates to a smashing mechanism, and discloses a composite organic fertilizer dust-proof smashing device and a control method thereof. The composite organic fertilizer dust-proof smashing device comprises a smashing shell, a feeding section and a discharging section are arranged at the upper end and the lower end of the smashing shell correspondingly, and a mashing mechanism is arranged in the feeding section; the mashing mechanism comprises a mashing motor, a roller is mounted on a motor shaft of the mashing motor, first mashing teeth are fixed to the outer side wall of the roller, and second mashing teeth matched with the first mashing teeth are arranged on the inner side wall of a mashing section; an annular feeding cavity is formed between the first mashing teeth and thesecond mashing teeth, and the width of the annular feeding cavity is gradually decreased from the upper end of the feeding section to the lower end of the feeding section; and a dust-proof cover plateis arranged at the upper end of the mashing section in a covering mode, and a feeding pipe communicating with the annular feeding cavity is fixed to the upper surface of the dust-proof cover plate. According to the composite organic fertilizer dust-proof smashing device, organic fertilizer is broken through the mashing mechanism, by adopting a step-by-step progressing mode, the organic fertilizeris mashed more finely step by step along with the time entering the annular feeding cavity, and the smashing effect is effectively improved.

Owner:白银丰宝农化科技有限公司

Grinding device for sesame paste processing

InactiveCN113751149AIncrease the degree of crushingShorten the timeCocoaGrain treatmentsEngineeringMechanical engineering

The invention discloses a grinding device for sesame paste processing. According to the grinding device for the sesame paste processing, a smashing assembly, a vibration assembly and a rotating assembly are arranged, sesame can be smashed preliminarily, the subsequent grinding time is shortened, and the grinding device is high in smashing degree and good in smashing effect; a first grinding assembly is arranged, the sesame can be preliminarily ground, and the sesame is finer through preliminary grinding; a second grinding assembly is arranged, the size of crushed sesame particles can be reduced again, grinding is more sufficient, after grinding is finished, the second grinding assembly is pulled out of an inner cavity of a box body, the telescopic end of an electric telescopic rod is made to extend, and then crushed sesame in a grinding disc falls into a material receiving box through a material inlet, and the material receiving box is taken away from a material taking opening; and when the sesame does not need to be ground for the second time, the second grinding assembly is moved out, and a collecting container is placed below grinding blocks, so that switching between coarse grinding and fine grinding can be realized.

Owner:安徽省福运食品有限公司

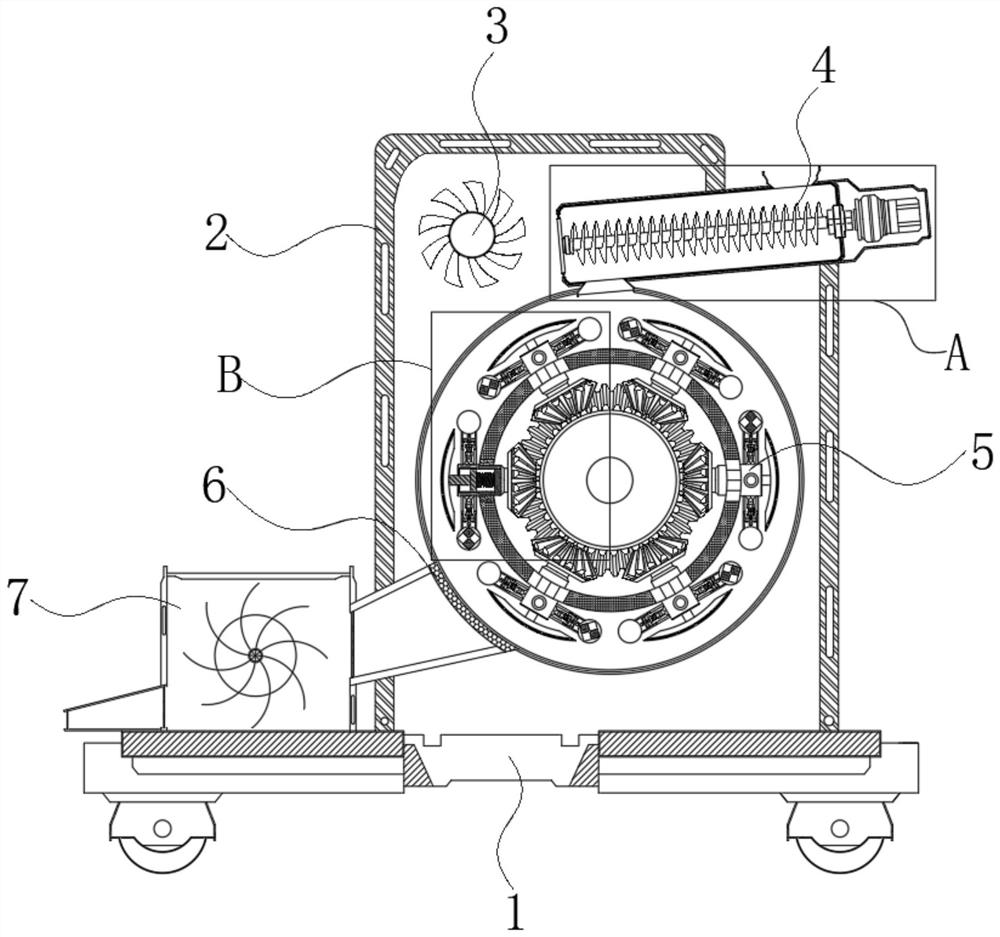

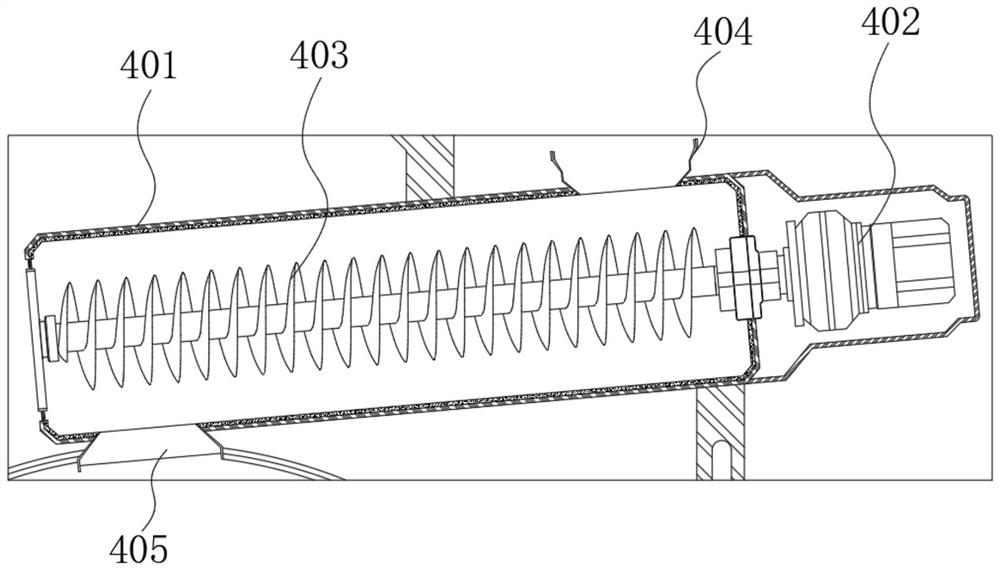

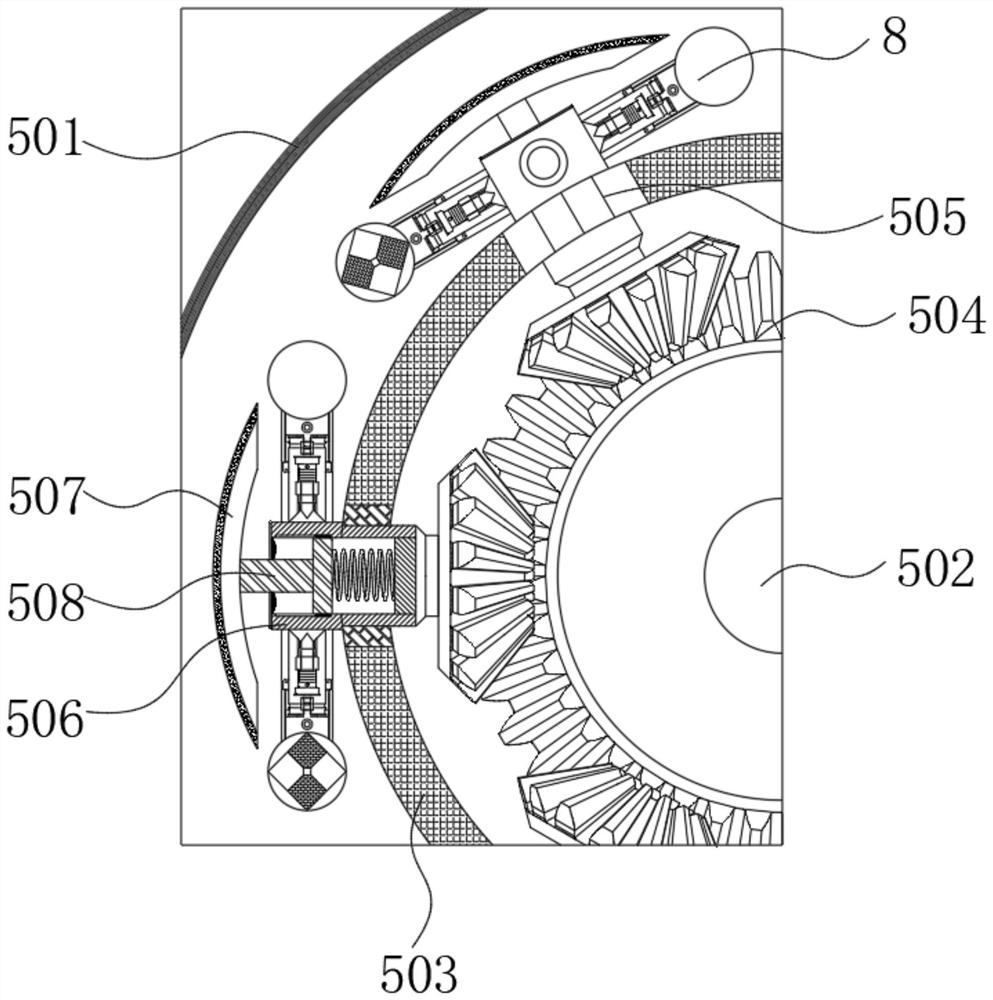

Carbide slag crushing device

ActiveCN112295712AImprove drying effectImprove liquidityDrying machines with local agitationDrying machines with materials at restDrive wheelSlag

The invention discloses a carbide slag crushing device. The carbide slag crushing device comprises a base, a pre-drying assembly, a crushing assembly and a drying chamber, wherein a plurality of driving wheels are symmetrically arranged at four corners of the lower end surface of the base, an outer box shell is fixed on one side of the upper end surface of the base, a heat dissipation fan is arranged on one side of the interior of the outer box shell so that heat in the outer box shell can be discharged, the pre-drying assembly is further arranged in the outer box shell in a penetrating mode,the pre-drying assembly can carry out primary drying treatment on carbide slag placed in the pre-drying assembly, the discharging end of the pre-drying assembly communicates with the crushing assembly, a discharging port of the crushing assembly penetrates through the outer box shell and is connected with the drying chamber fixed on the upper end surface of the base, the drying chamber can carry out secondary drying on the crushed carbide slag, so that the fluidity of the carbide slag is improved, and the carbide slag is not easy to be compacted during stacking.

Owner:陕西煤业化工集团神木电化发展有限公司

Beef processing chopper mixer and use method thereof

ActiveCN111227015AFineness is easy to controlWell mixedMeat mixing apparatusMeat processing devicesMeat pasteElectric machinery

The invention discloses a beef processing chopper mixer and a use method thereof. The beef processing chopper mixer comprises a chopping mixing pot, a chopping mixing cover body and a bearing tank, wherein the chopping mixing pot is mounted at the top of the bearing tank; the chopping mixing cover body is arranged at the top of the chopping mixing pot; a cushion block is mounted at the top of thebearing tank; a first driving motor is mounted at the top of the cushion block; a second driving motor is mounted in the inner cavity of the bearing tank; and the output shaft of the second driving motor is connected with the chopping mixing pot. With the combination of the rotating chopping mixing pot and a chopping mixing cutter, beat can be cut for multiple times within a short time, and the quality of the obtained product can be high; when the chopper mixer is operated, other auxiliary materials can be added at any time, so that the working efficiency can be improved, fineness of various auxiliary materials can be easily controlled, and convenience in use and easiness in operation are achieved; and the chopper mixer adopts a pressing transferring plate to accumulate and mix chopped meat, and the mixed meat can be discharged after a moveable plate is opened, so that the chopper mixer is convenient and rapid in discharge process and convenient to use.

Owner:FUYANG FUMENG FOOD CO LTD

Waste battery smashing and sieving apparatus

ActiveCN108281728ASimple procedureImprove efficiencyWaste accumulators reclaimingBattery recyclingSlide plateEngineering

The invention discloses a waste battery smashing and sieving apparatus. The waste battery smashing and sieving apparatus comprises a box body; a partition plate is fixedly connected between the two sides of the inner walls of the box body; a movable rod runs through one side of the box body; one end, which extends to the interior of the box body, of the movable rod is movably connected with one side of the inner wall of the box body; one end, which extends to the exterior of the box body, of the movable rod is fixedly connected with a rotary apparatus; and the rotary apparatus comprises a sliding plate. The invention relates to the technical field of battery recycling. According to the waste battery smashing and sieving apparatus, the partition plate is fixedly connected between the two sides of the inner walls of the box body, so that higher convenience is provided for operation of the next step, system smashing with relatively more time is not needed, a complex program is simplified,and efficiency is greatly improved; the top of the box body is connected with a smashing box, so that a better smashing effect can be achieved; and an externally wrapped copper sheet and internal graphite can be separated, so that the operation is very simple, convenient and efficient, and the waste battery smashing and sieving apparatus is also very convenient to use.

Owner:吕慧峰

Papermaking solid waste disposal device

ActiveCN108636549AImprove buffer protection effectImprove stabilityGrain treatmentsRotational axisPulp and paper industry

The invention discloses a papermaking solid waste disposal device which comprises a box, a baffle, a first sliding block, first motors, first rotating shafts, first smashing blades, a buffer device, aseparating plate, a first sliding groove, second rotating shafts, second smashing blades, a filtering net, second motors, a digging rope, a pull ring, a box door and a stretchable spring; the box door is connected to one side of the box through a hinge, the pull ring is fixed to one side of the box door in a welding manner, the filtering net is connected to the center position of the bottom of the box through a snap joint, the buffer device is correspondingly installed at the bottom of the box, the first motors are evenly distributed on one side of the box, the first rotating shafts are movably connected to one sides of the first motors through the bearings, the first smashing blades are evenly distributed on one sides of the first rotating shafts, and the second motors are movably connected to one sides of the first motors through the bearings. The papermaking solid waste disposal device has the beneficial effects that the stability is good, the practicability is high, and the working efficiency is high.

Owner:浙江迅科精密机械有限公司

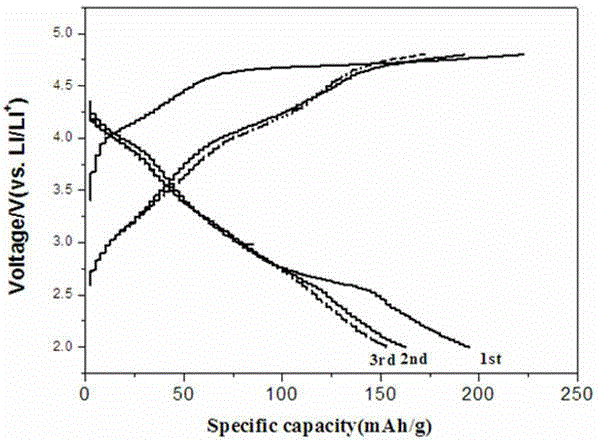

Niobium-based manganese-lithium-rich cathode material and preparation method thereof

InactiveCN104577073AIncrease capacityImproved magnification performanceCell electrodesSecondary cellsNiobiumManganese

The invention provides a niobium-based manganese-lithium-rich cathode material and a preparation method thereof. The niobium-based manganese-lithium-rich cathode material is xLi3NbO4.(1-x)LiMnO2, wherein x is smaller than 0.8 and greater than 0. The preparation method comprises the following steps: a, charging a manganese source, a lithium source and a niobium source into a ball-milling tank at the ratio of manganese to lithium to niobium, and carrying out ball-milling at the speed of 200-400r / min for 1-8 hours to obtain a mixed precursor; b, putting the precursor into a heating furnace, heating to 450-700 DEG C at the rate of 2-5 DEG C / min, and carrying out heat preservation for 1-10 hours to obtain a sintering precursor; and c, grinding the sintering precursor, tabletting, and putting into the heating furnace again, heating to 800-1100 DEG C at the rate of 2-5 DEG C / min, carrying out heat preservation and then cooling to a room temperature, so as to obtain the niobium-based manganese-lithium-rich cathode material. The niobium-based manganese-lithium-rich cathode material prepared by the method has high capacity and rate capability, relatively good cycle performance and low cost.

Owner:MCNAIR TECH +1

Industrial solid waste treatment equipment and using method thereof

InactiveCN112517212AIncrease the degree of crushingSmall particle sizeSievingScreeningProcess engineeringEnvironmental engineering

The invention discloses industrial solid waste treatment equipment and a using method thereof, and relates to the field of waste treatment. The treatment equipment comprises a primary crushing mechanism used for primarily crushing solid waste, a secondary crushing mechanism used for secondarily crushing the solid waste treated by the primary crushing mechanism, and an extruding mechanism used forbriquetting the solid waste crushed by the secondary crushing mechanism. According to the equipment, by means of the primary crushing mechanism and the secondary crushing mechanism, the industrial solid waste can be crushed for two times, the crushed degree of the solid waste is improved, and the particle size of the crushed solid waste is small, so that prerequisite conditions are provided for recycling, and the actual practical effect of the treatment equipment is improved; and by means of a power output mechanism, power can be provided for driving the primary crushing mechanism and the secondary crushing mechanism at the same time so that electric power resources can be saved to a certain extent, and an energy-saving effect is achieved.

Owner:毛建军

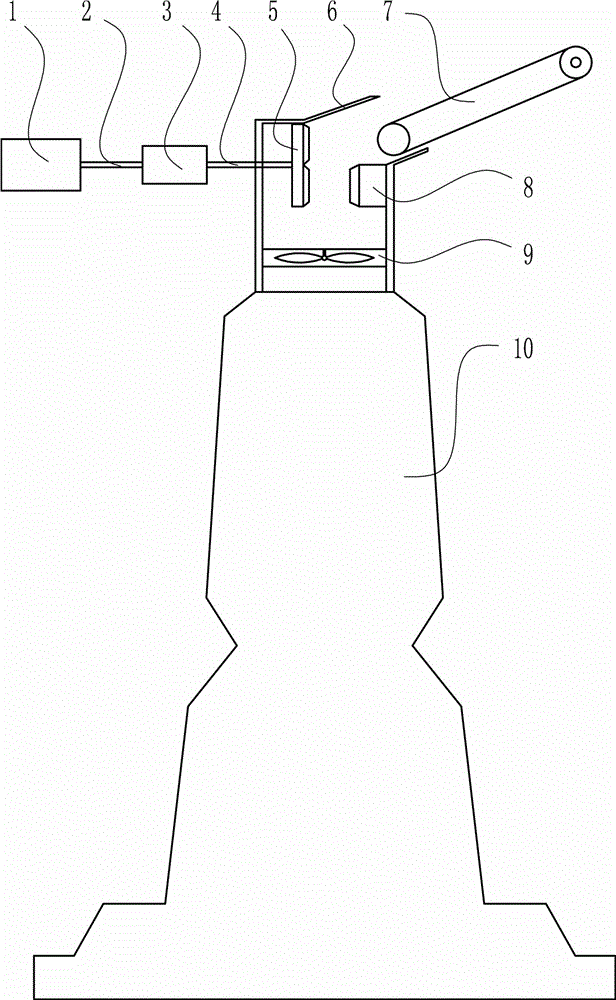

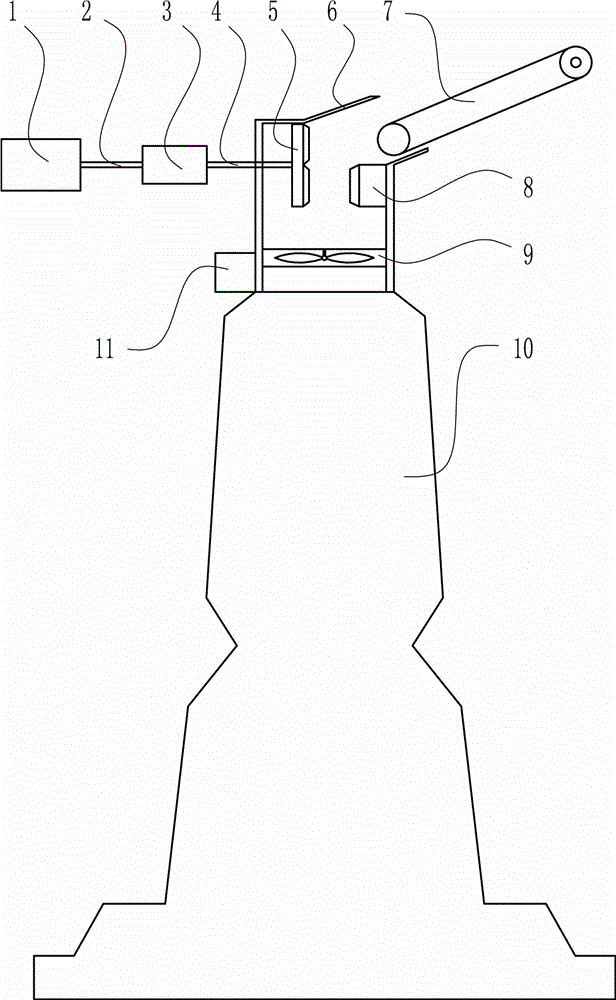

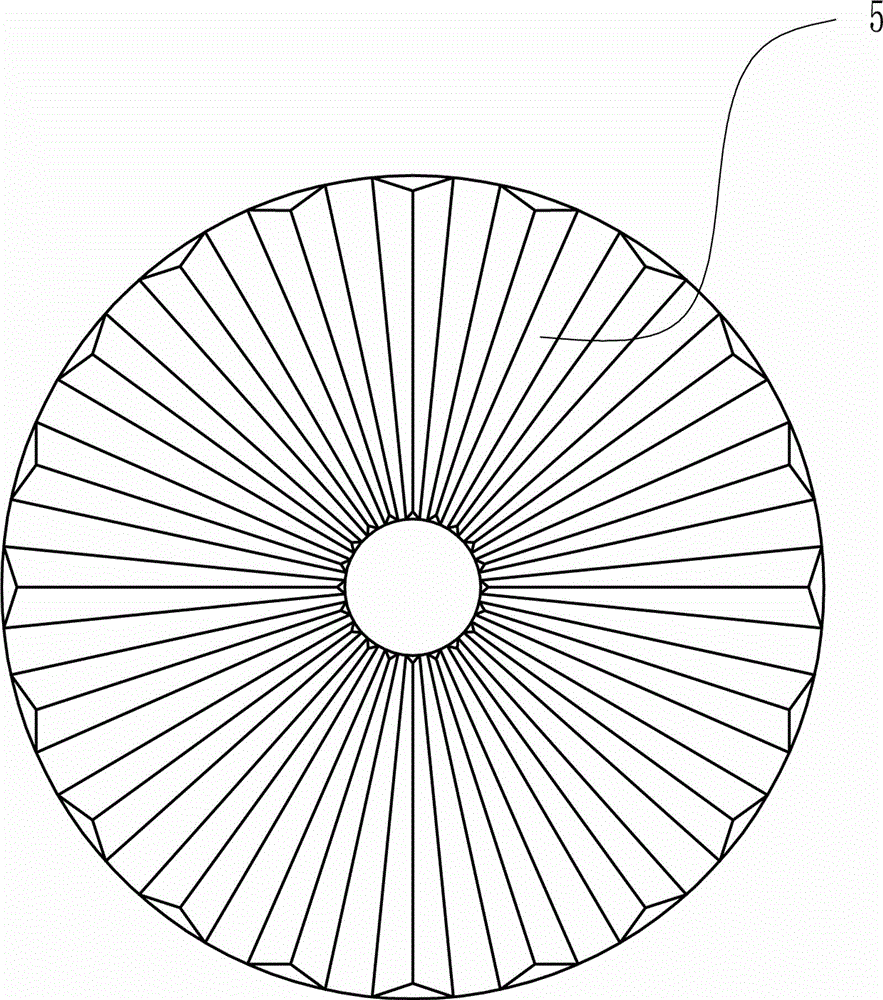

Uniform spreading device for blast furnace smelting

InactiveCN105400919AIncrease the degree of crushingQuality improvementBell-and-hopper arrangementRotational axisCircular disc

The invention relates to a blast furnace spreading device, in particular to an uniform spreading device for blast furnace smelting. The technical problem to be solved by the invention is to provide the uniform spreading device for blast furnace smelting. In order to solve the technical problem, the invention provides the uniform spreading device for blast furnace smelting; the uniform spreading device for blast furnace smelting comprises left and right cylinders, left and right extension rods, motors, rotating shafts, a left disc-shaped grinding disc, a hopper, a belt conveying device, a right disc-shaped grinding disc and a fan; the left and right extension rods are arranged at the right sides of the left and right cylinders; the left and right cylinders are connected with the left and right extension rods; the motors are arranged at the right sides of the left and right extension rods; the left and right extension rods are connected with the motors; and the rotating shafts are arranged at the right sides of the motors. The uniform spreading device for blast furnace smelting, provided by the invention, rubs and crushes such raw materials as iron ores through grinding teeth of the grinding disc, improves the crushing degree of such raw materials as iron ores, and realizes uniform spreading.

Owner:CHONGQING YUXI STEEL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com