Patents

Literature

394results about "Meat mixing apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preservation of intermediate moisture foods by controlling humidity and inhibition of mold growth

InactiveUS20030203081A1Reduce the growth of moldMaintain oxygen levelsDrying solid materials with heatTobacco devicesWater vaporFood packaging

A humidity control device for use in maintaining a desired humidity in packages of food, the device including a protective case, a water vapor permeable pouch and a thickened saturated solution, the solution having a suitable humidity control point for use within a food container. The device further employs a combination of an oxygen scavenger system to stop mold growth with anaerobic conditions and / or a mold inhibitor in the filling of the pouch or preferentially printed on the outside of the pouch.

Owner:BOVEDA INC

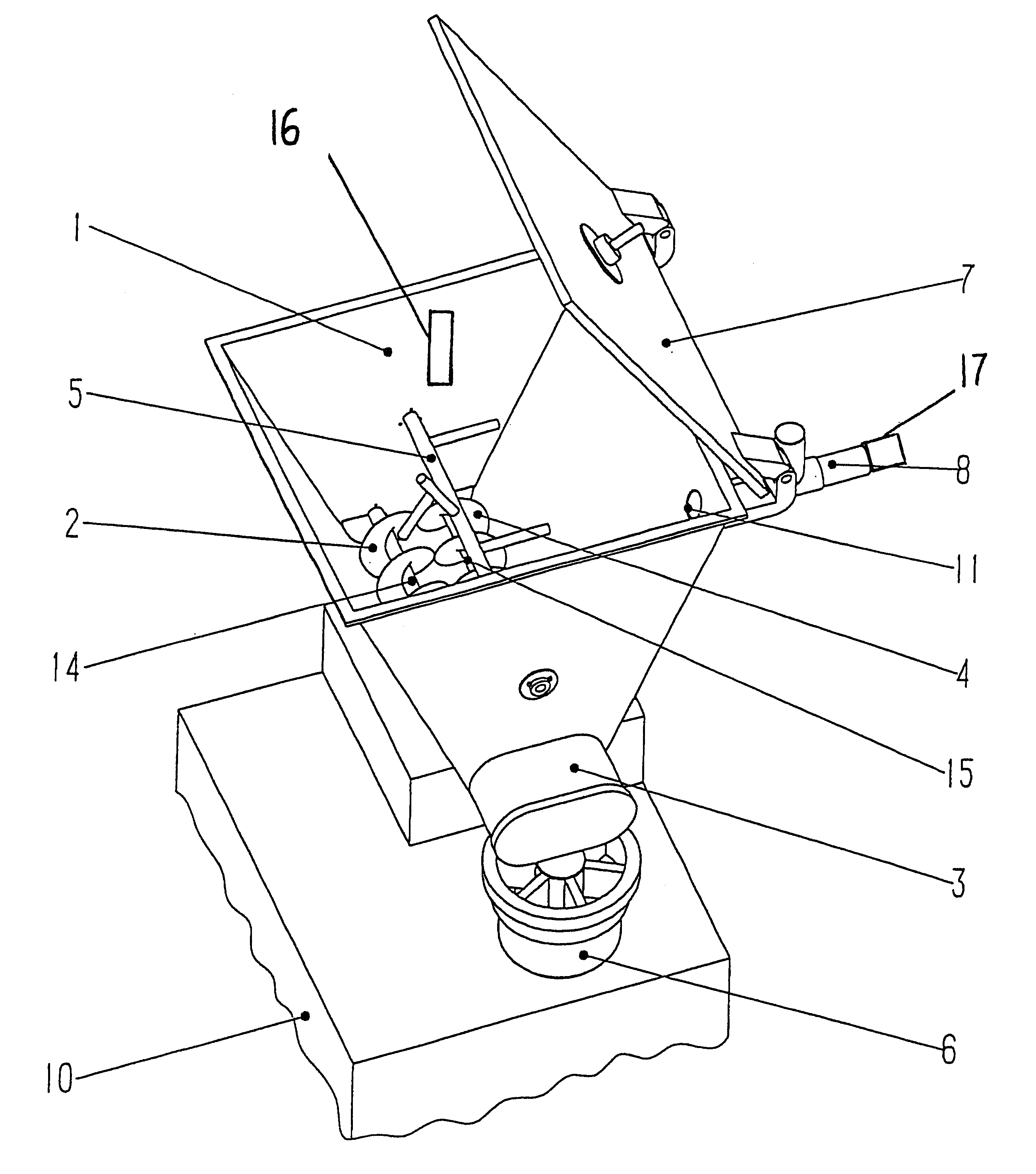

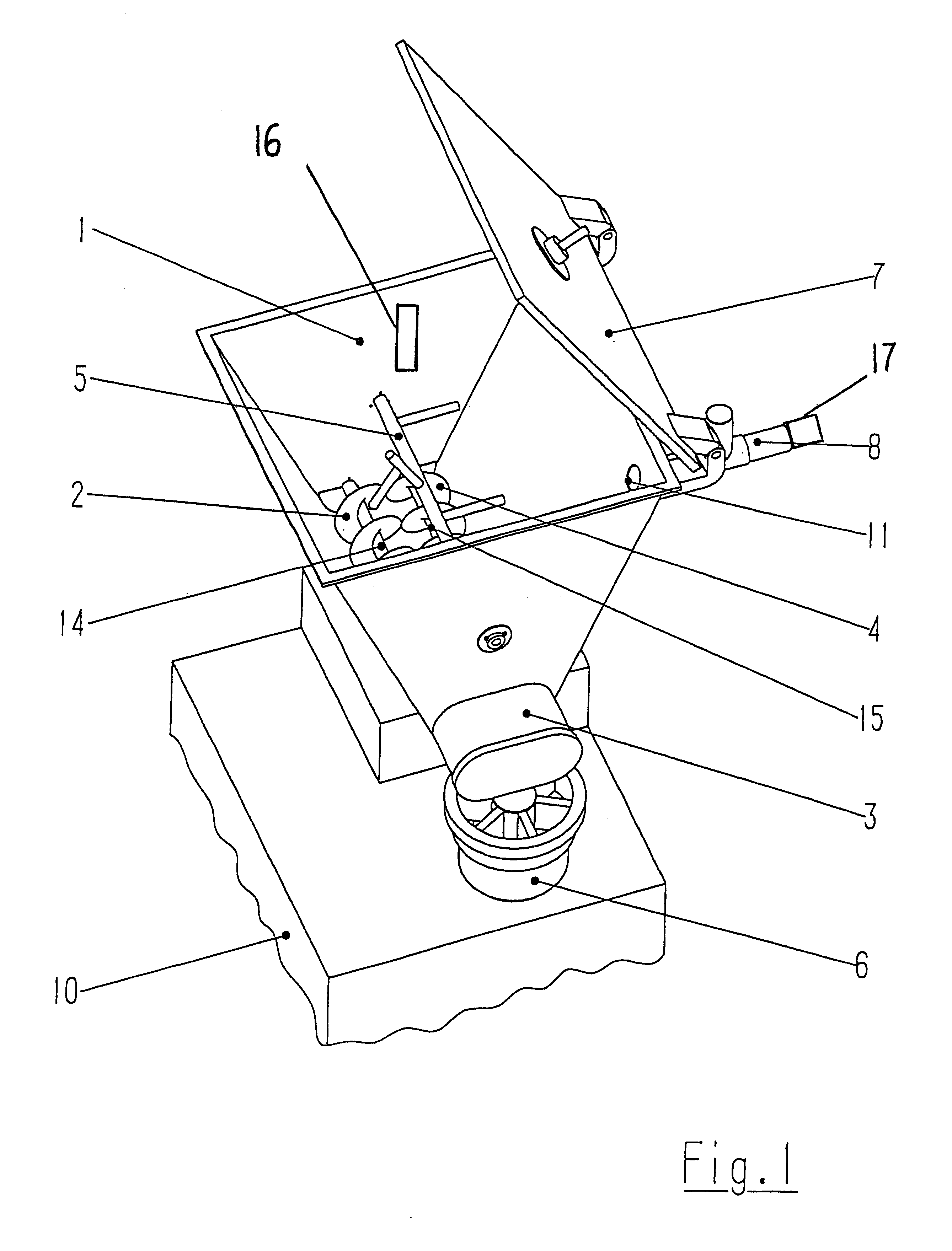

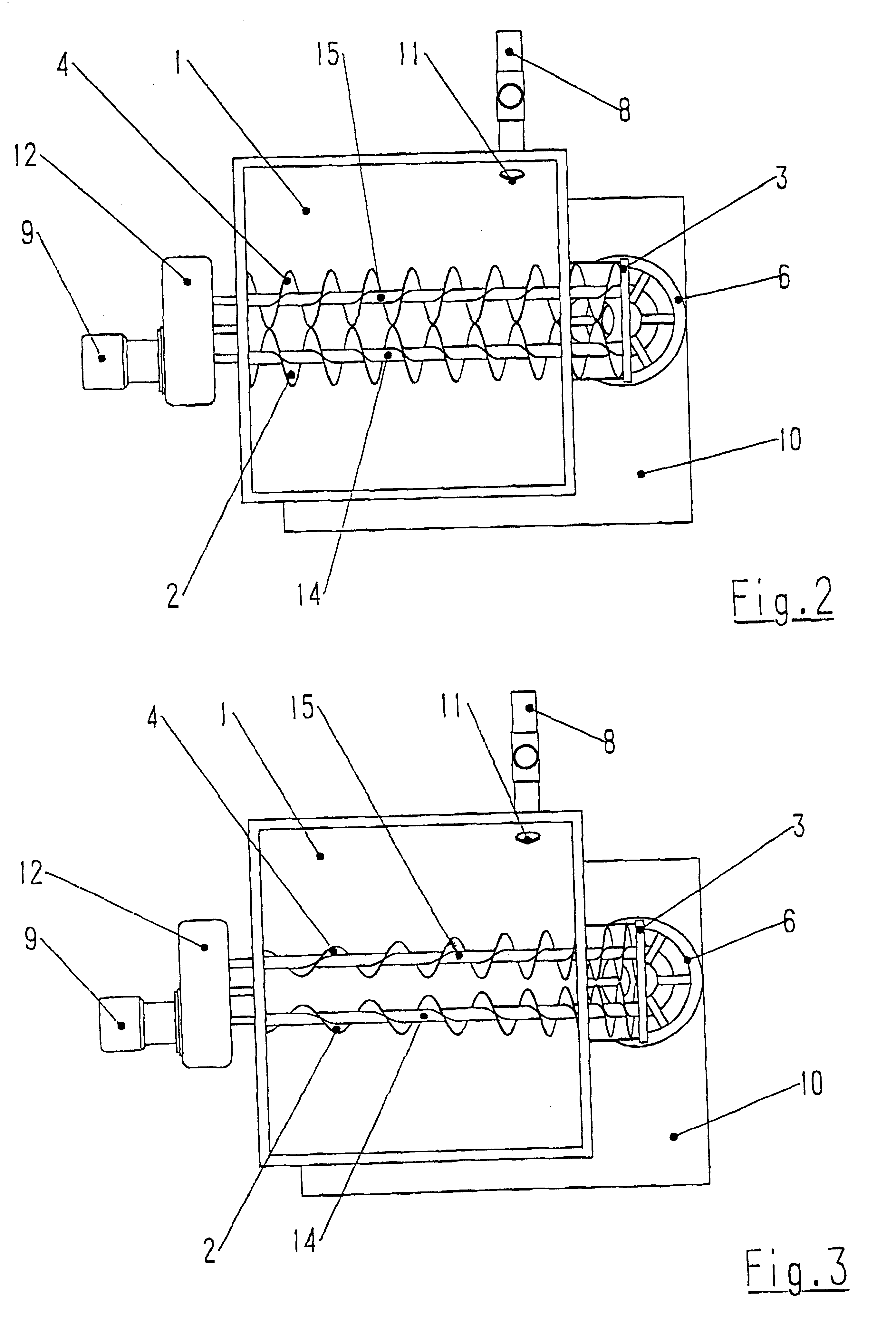

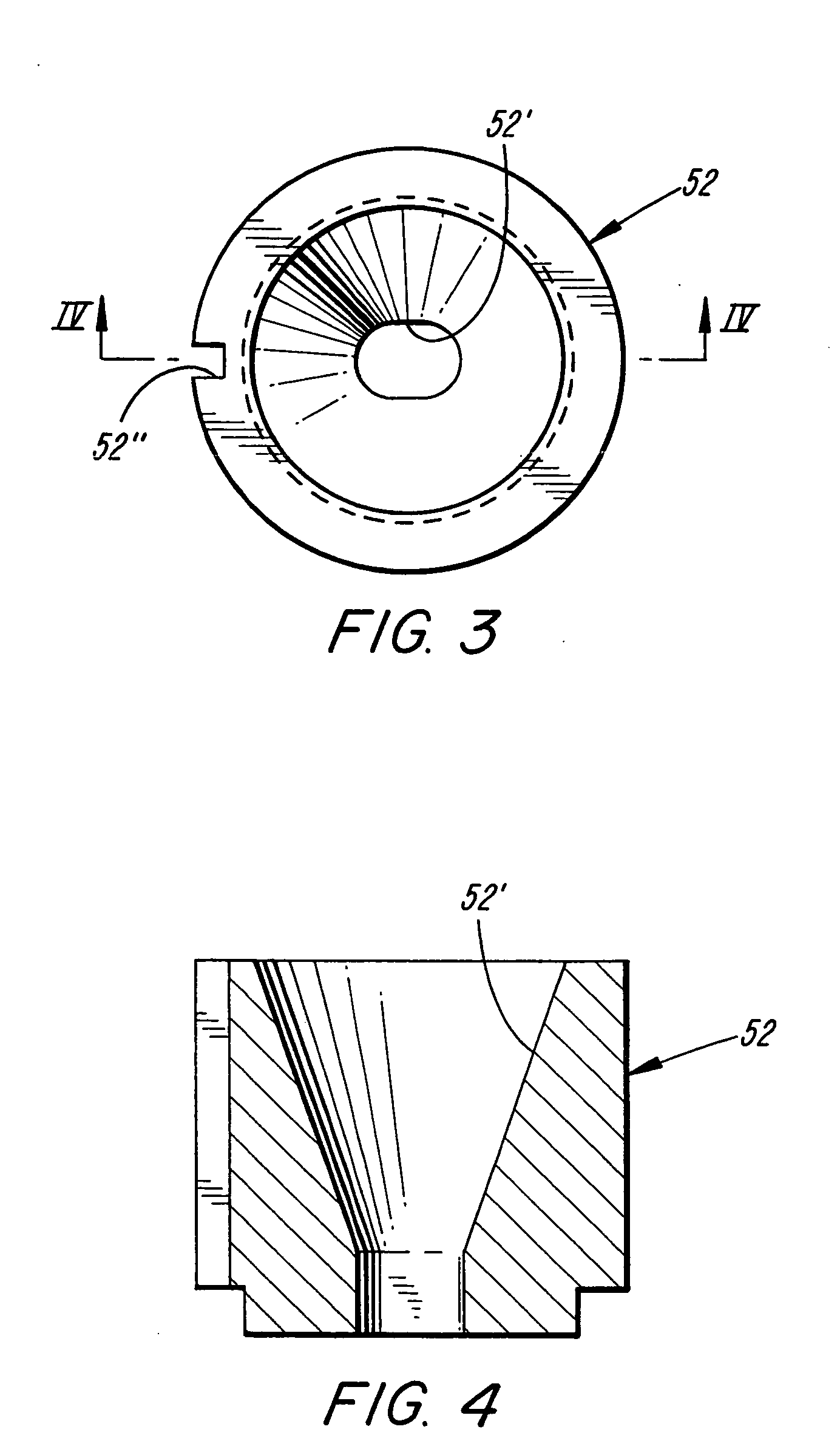

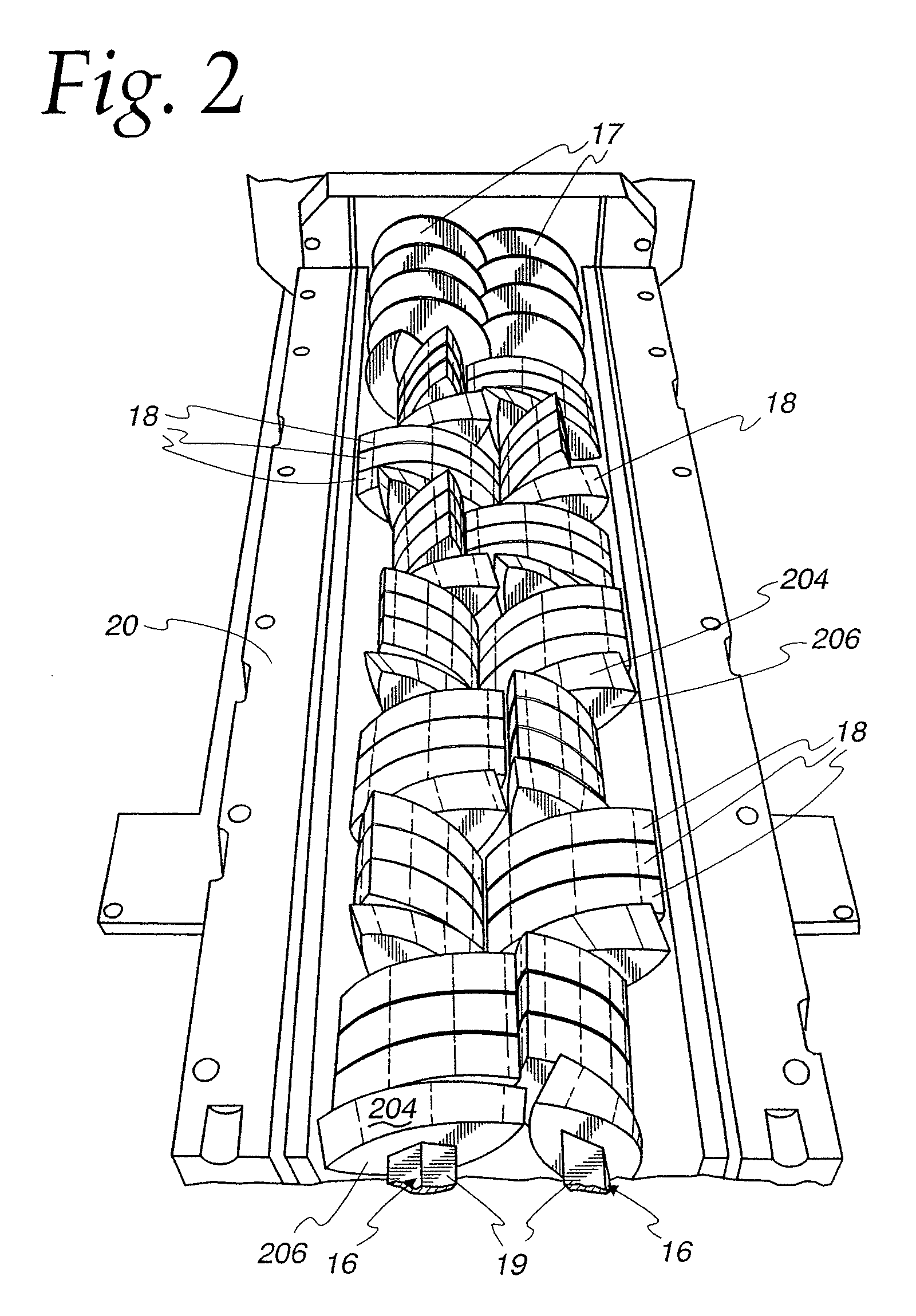

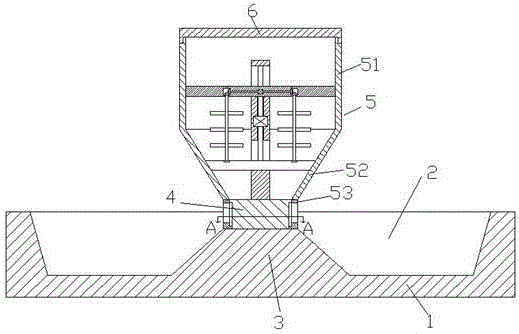

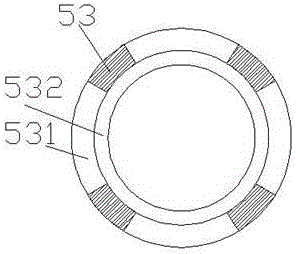

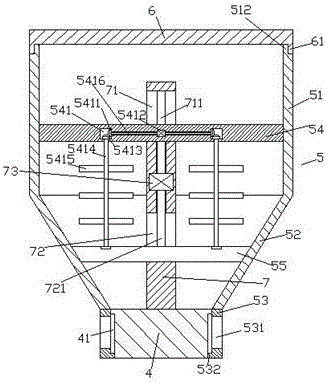

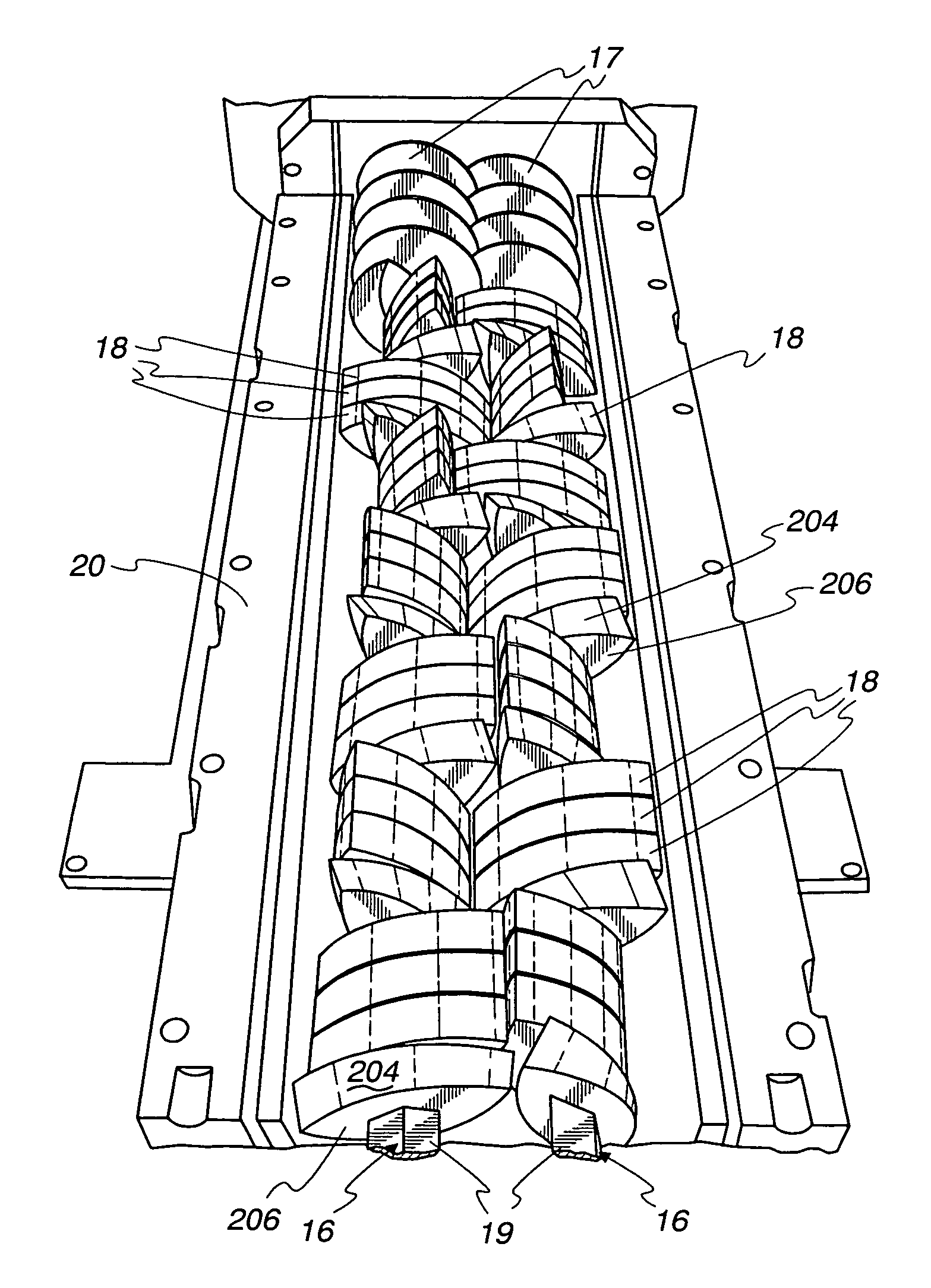

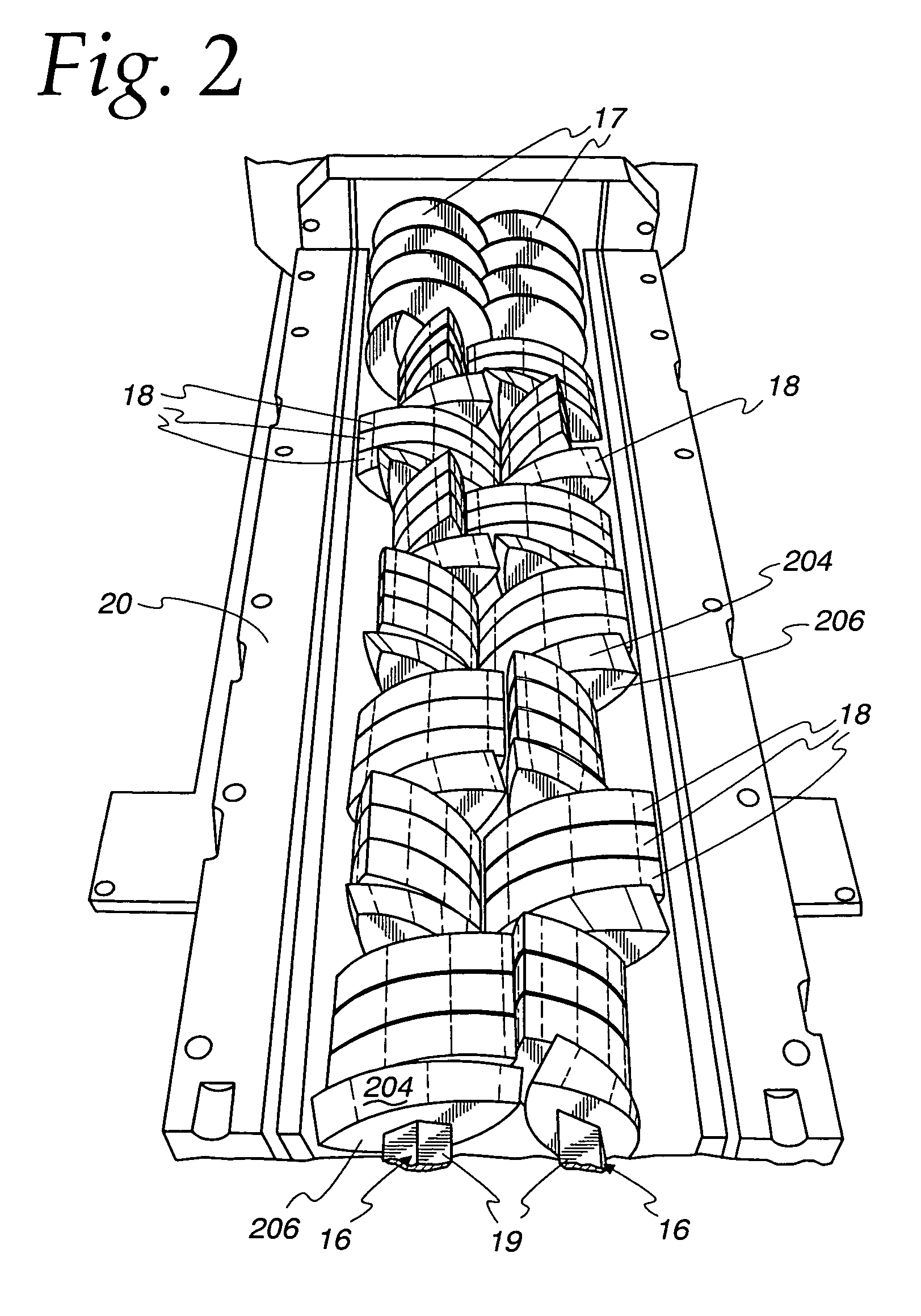

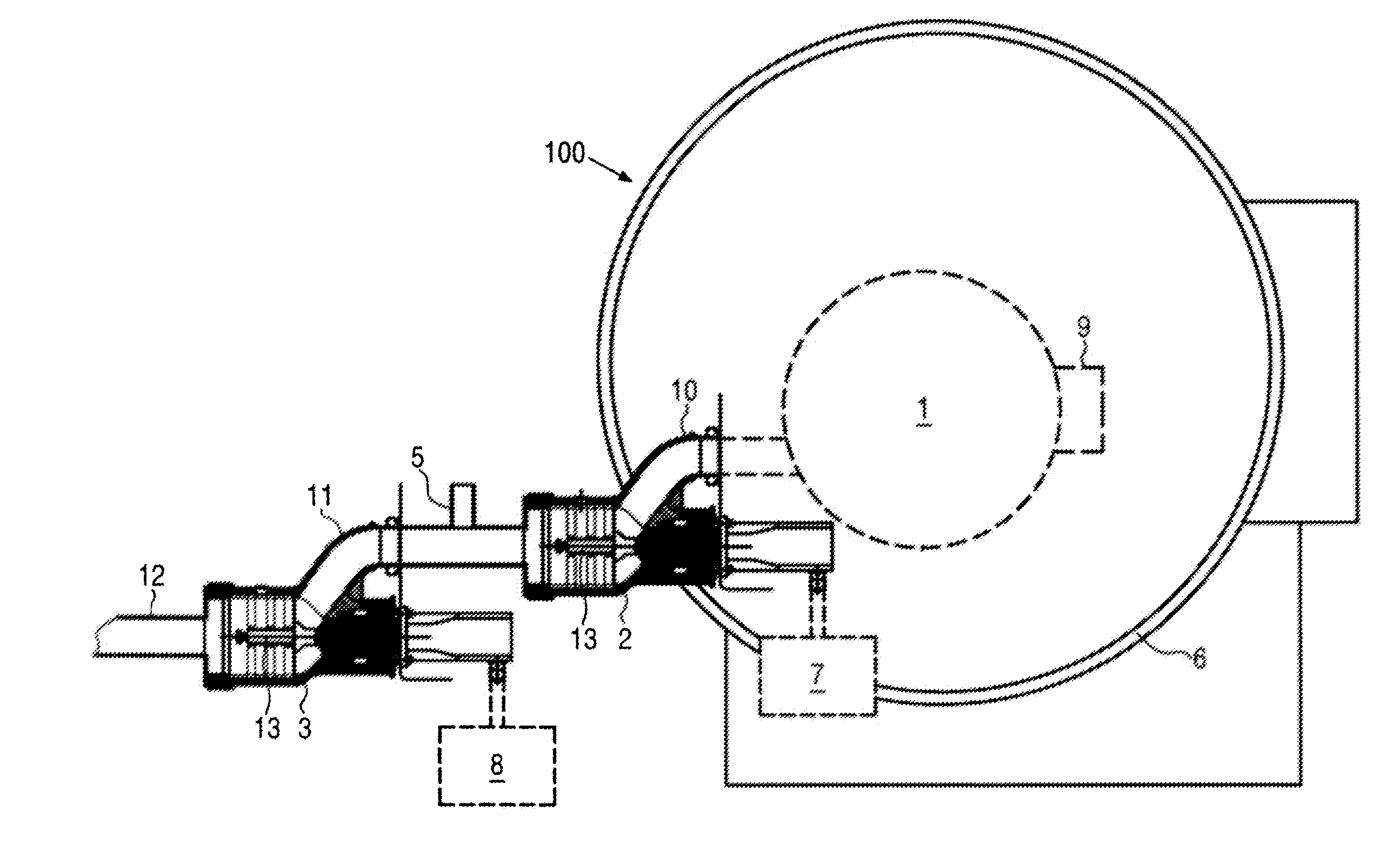

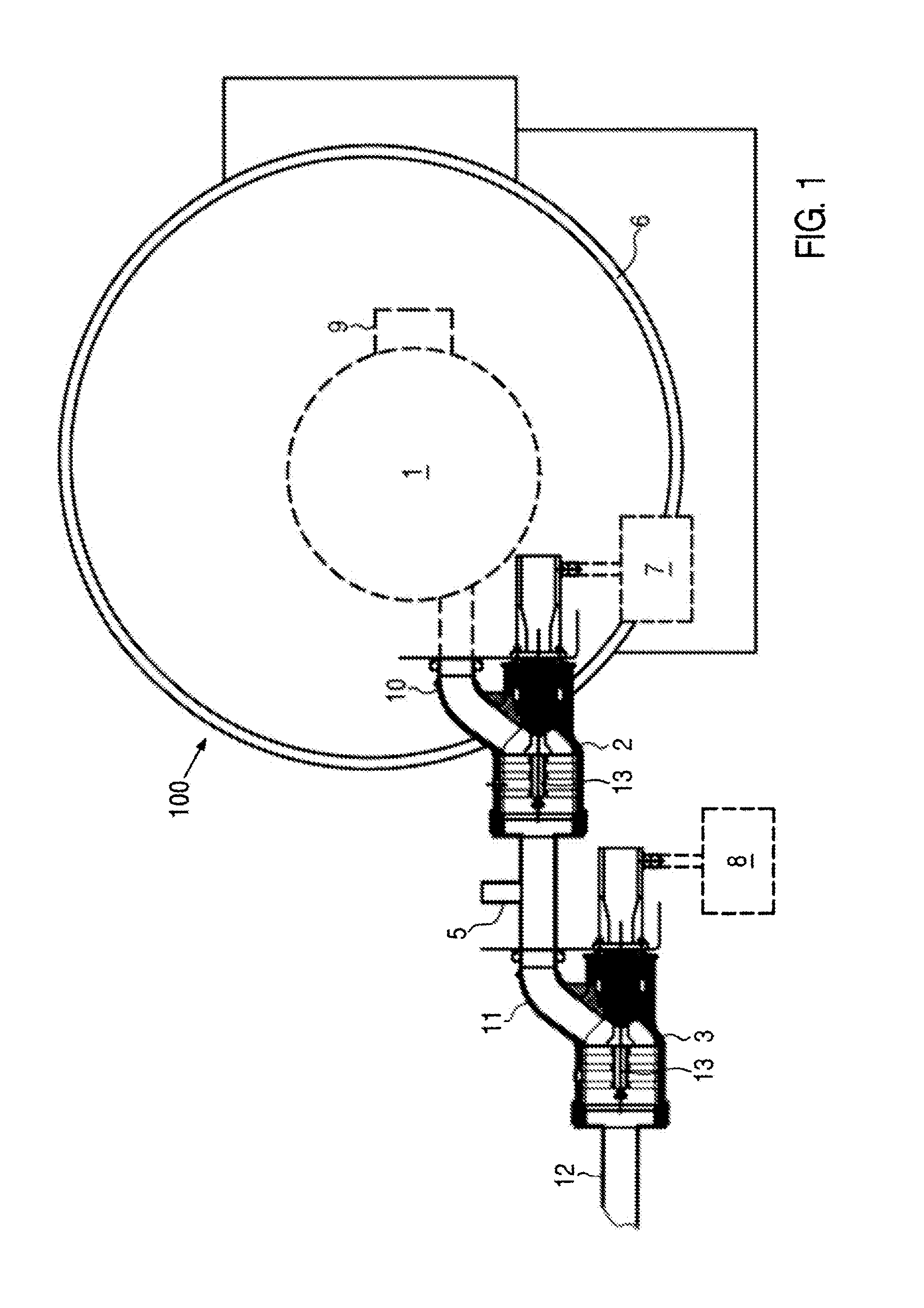

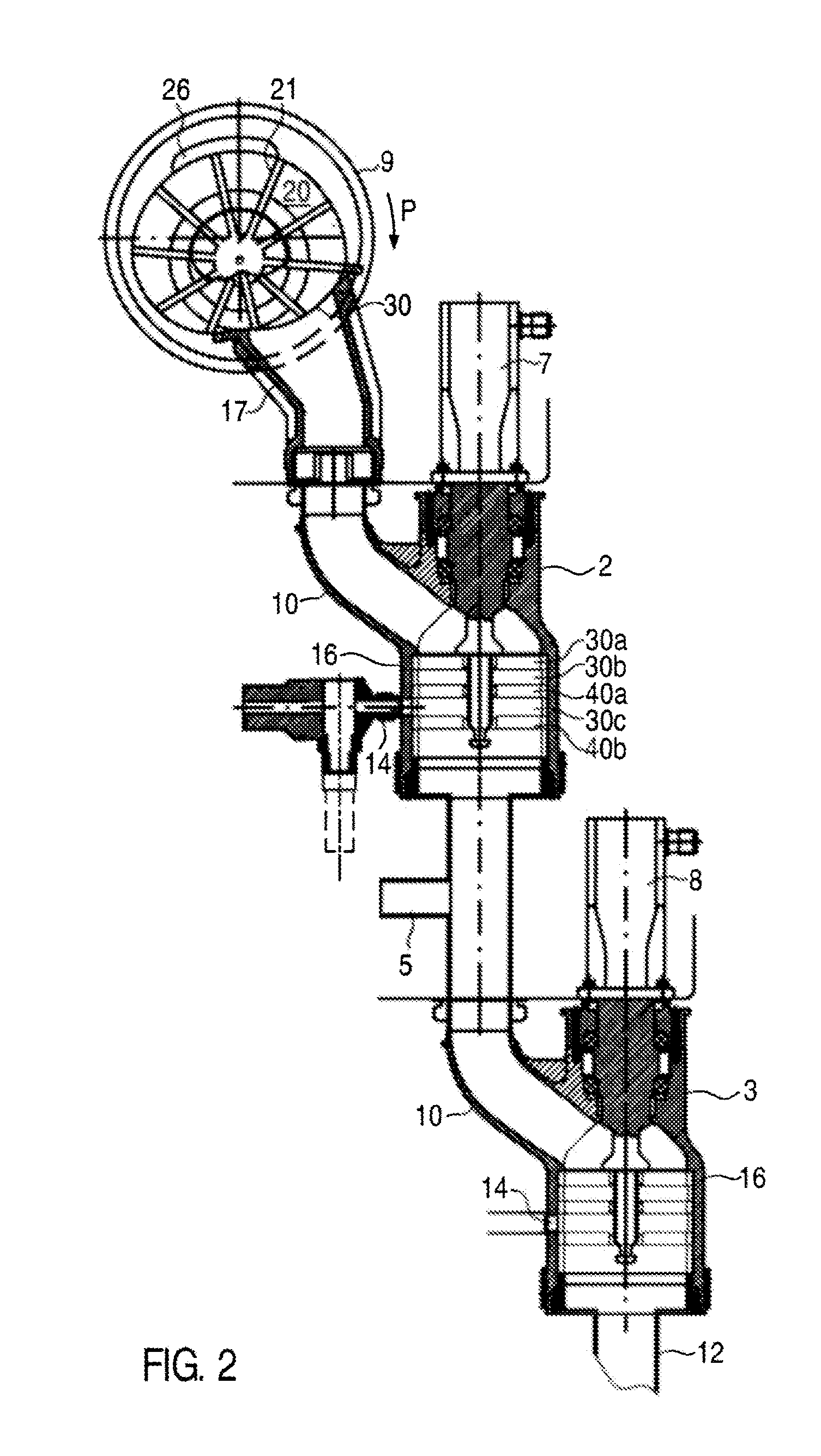

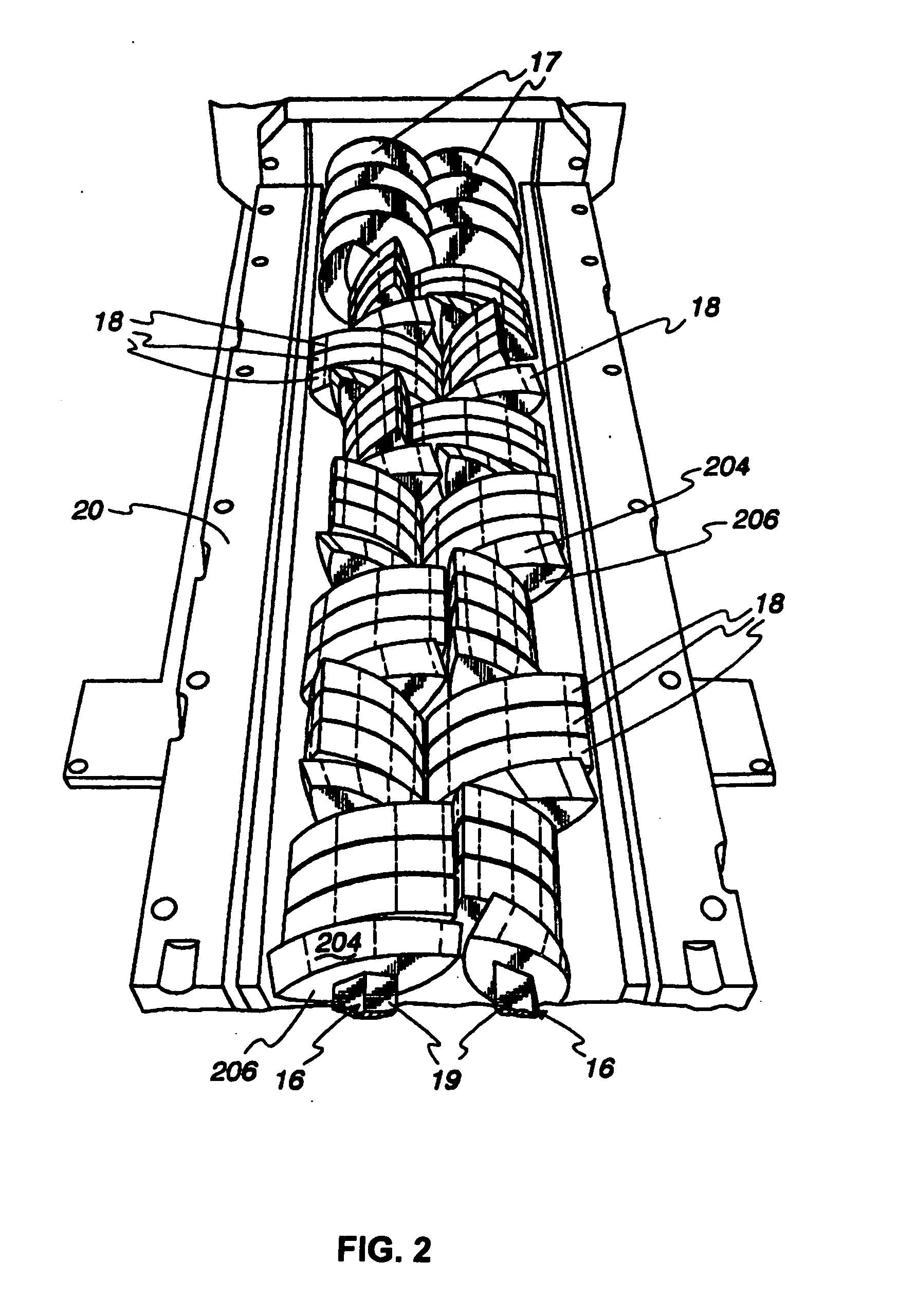

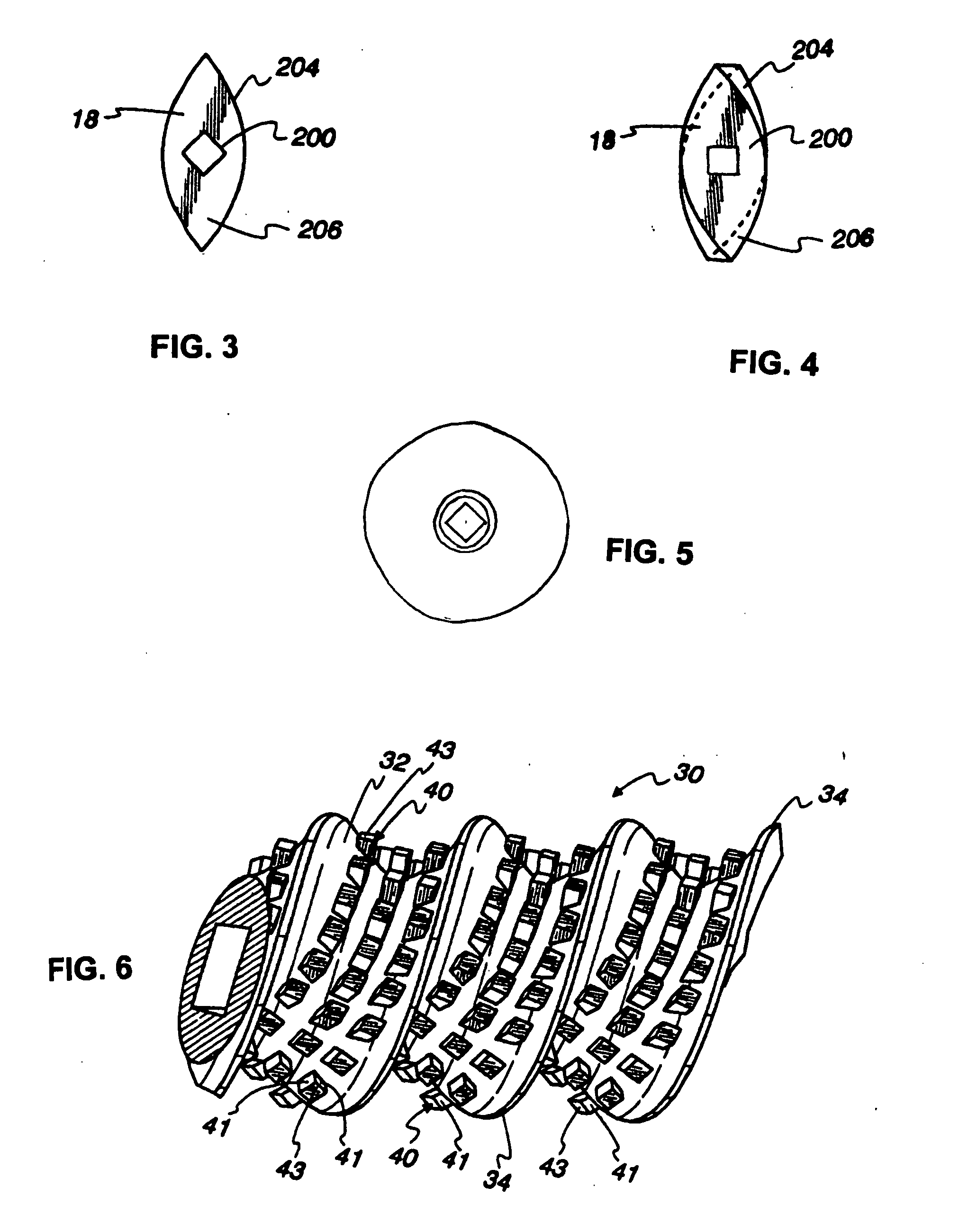

Feeding device of a stuffing machine; in particular for ground meats or the like

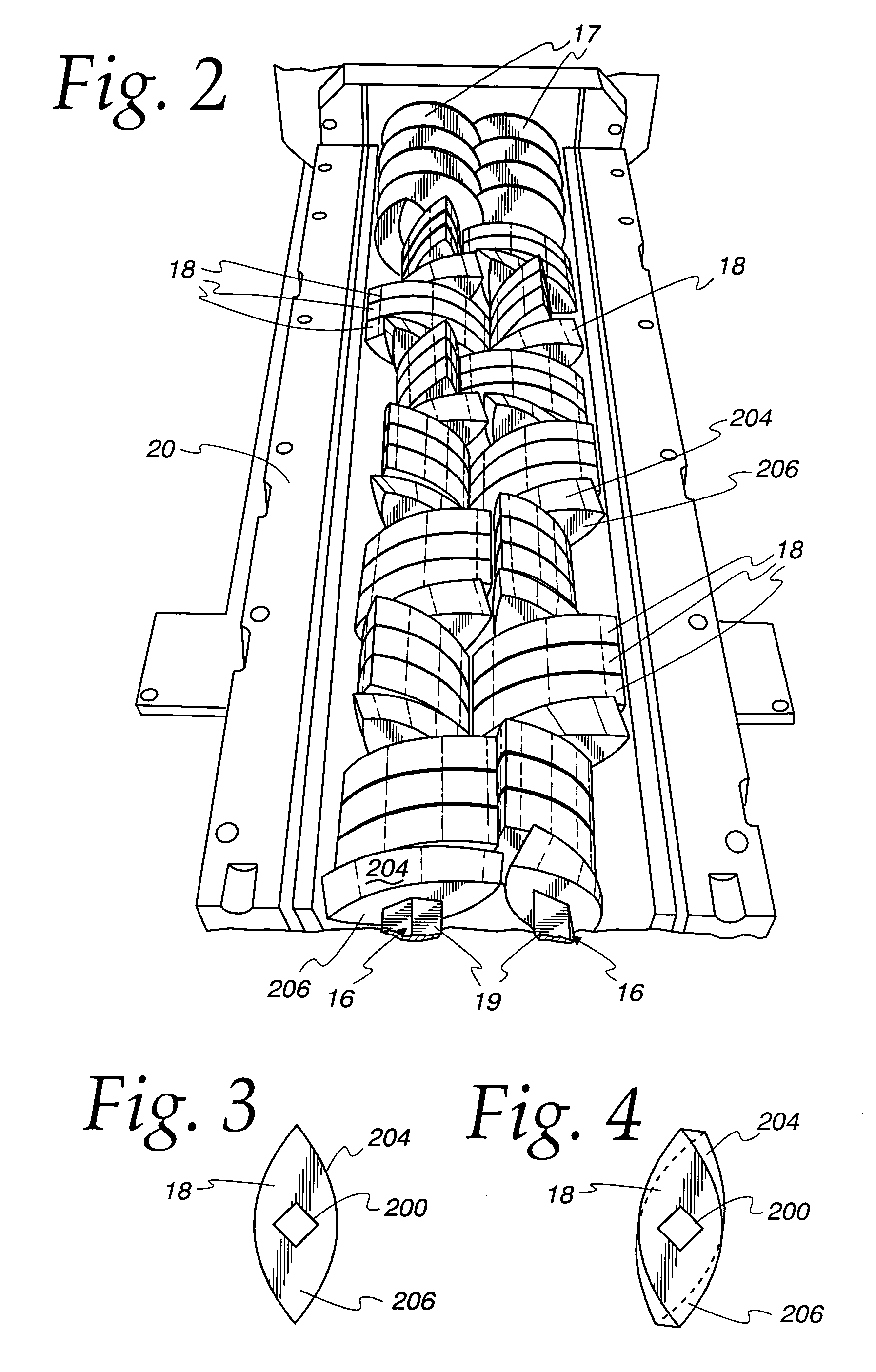

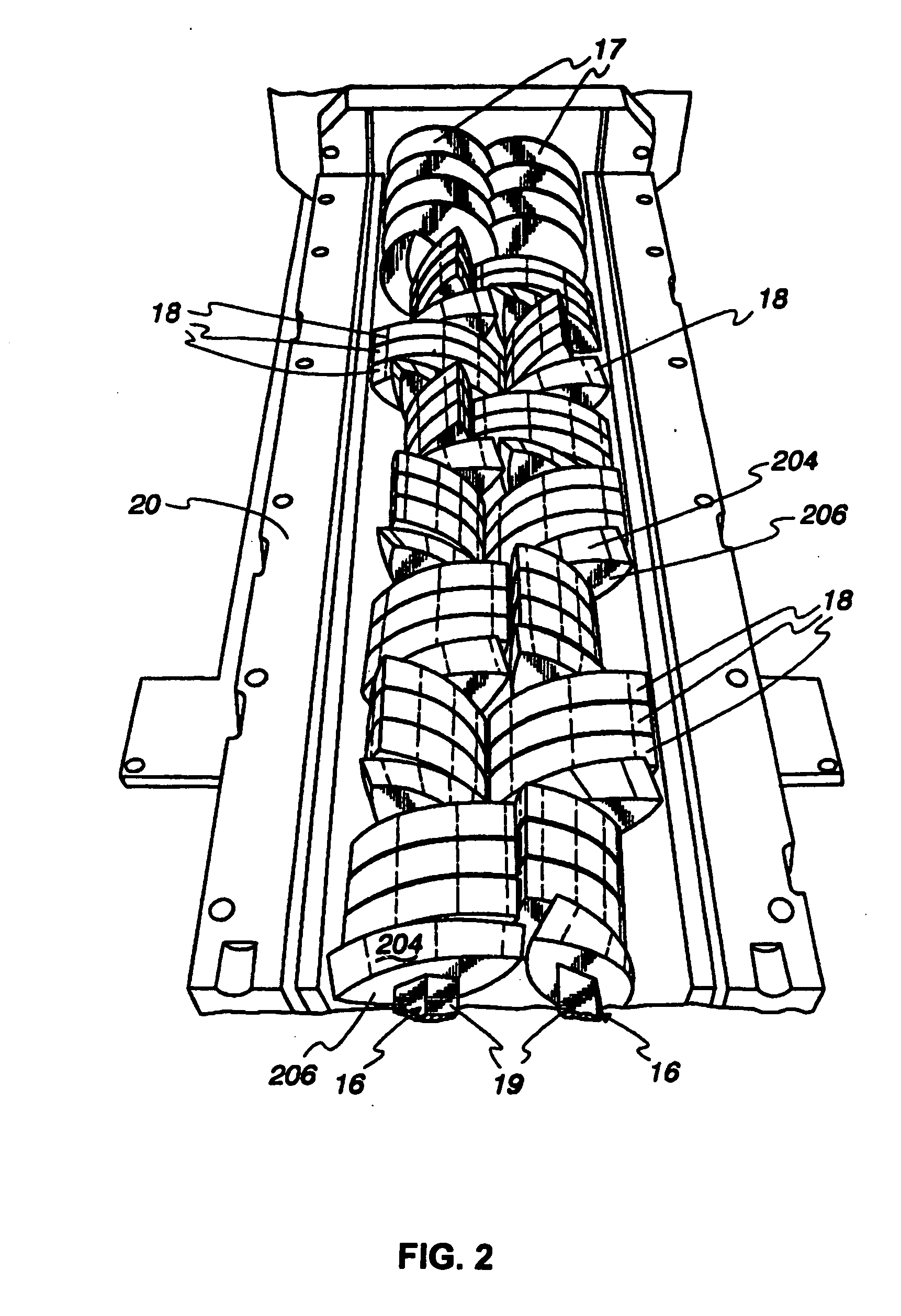

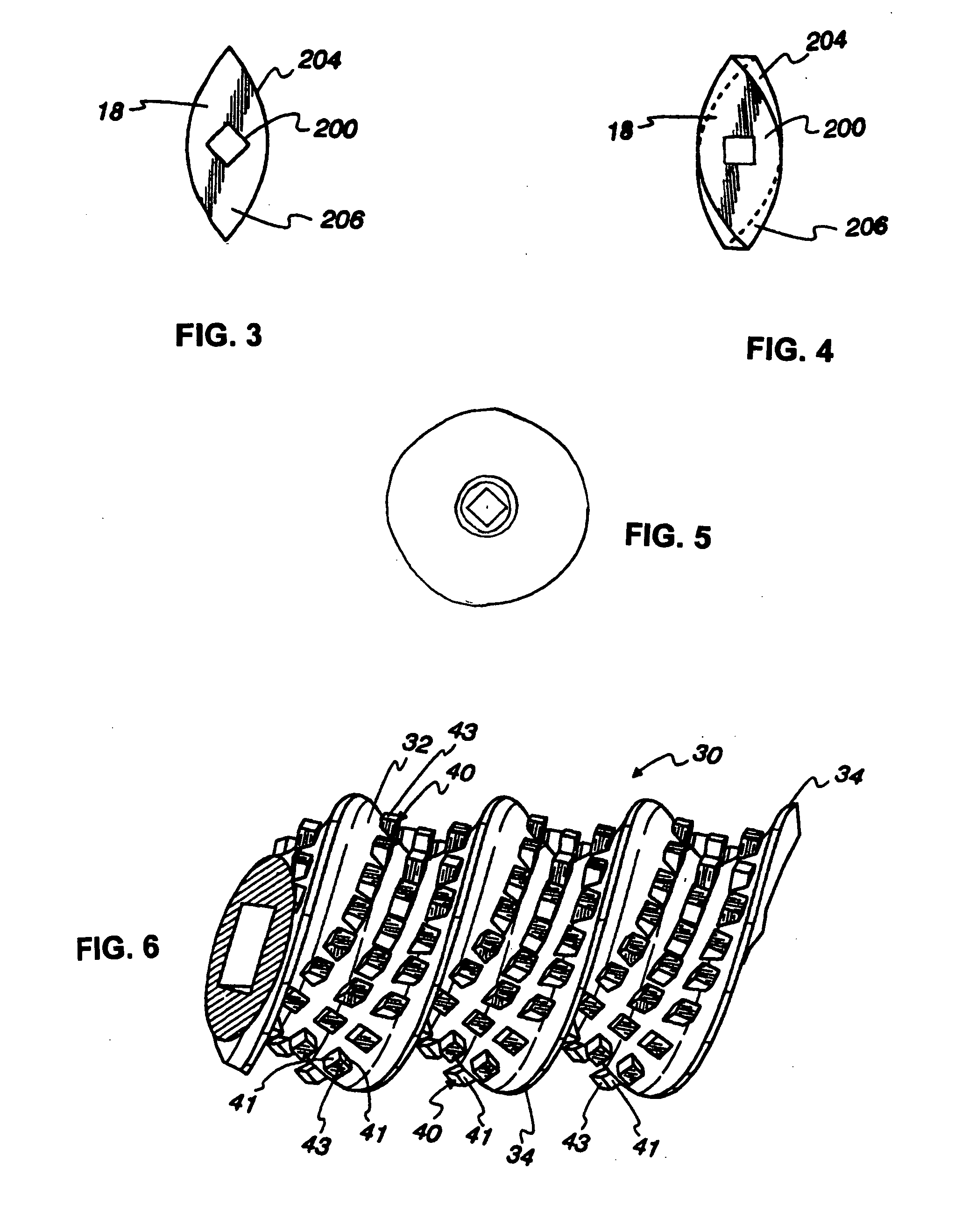

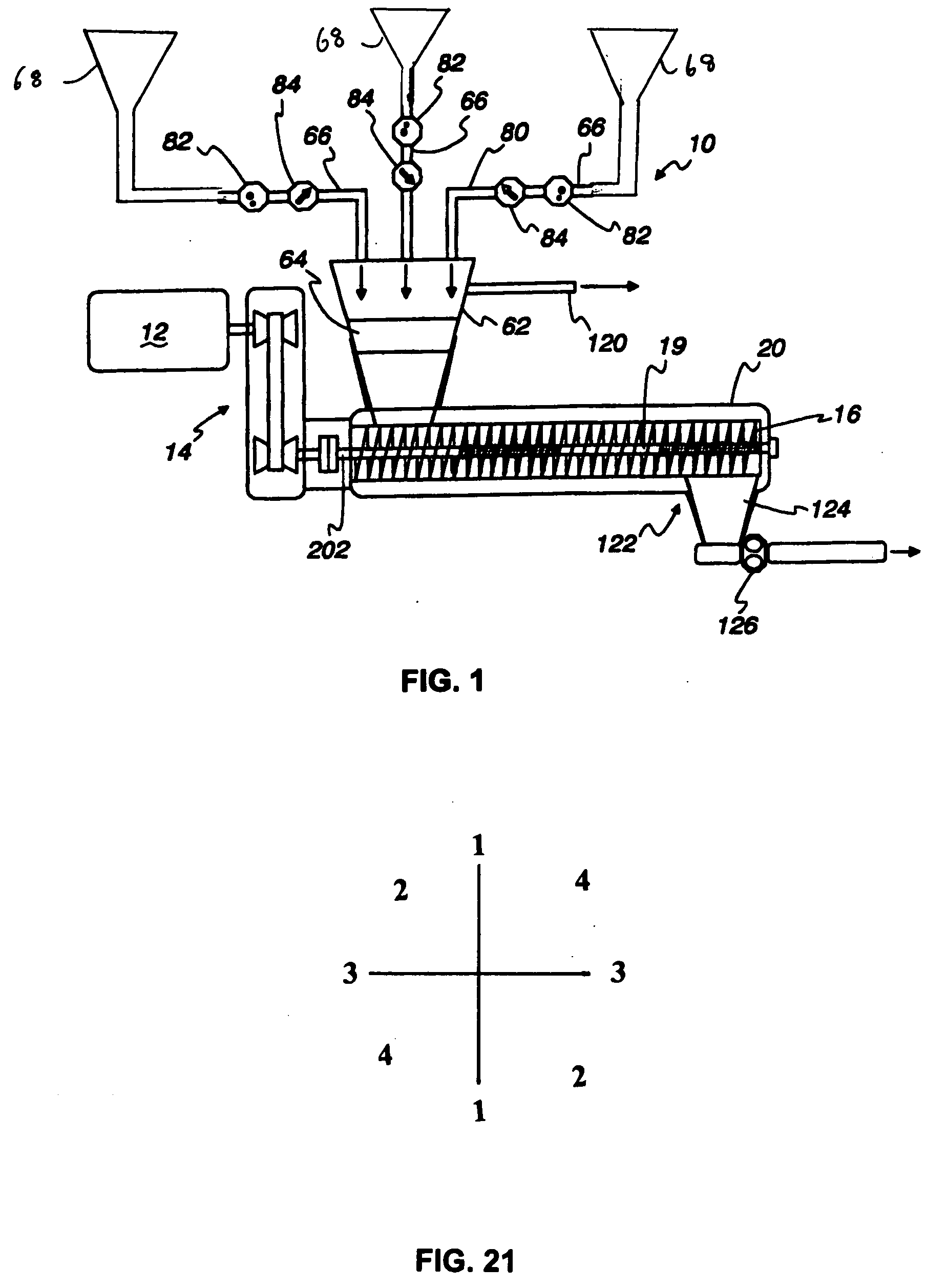

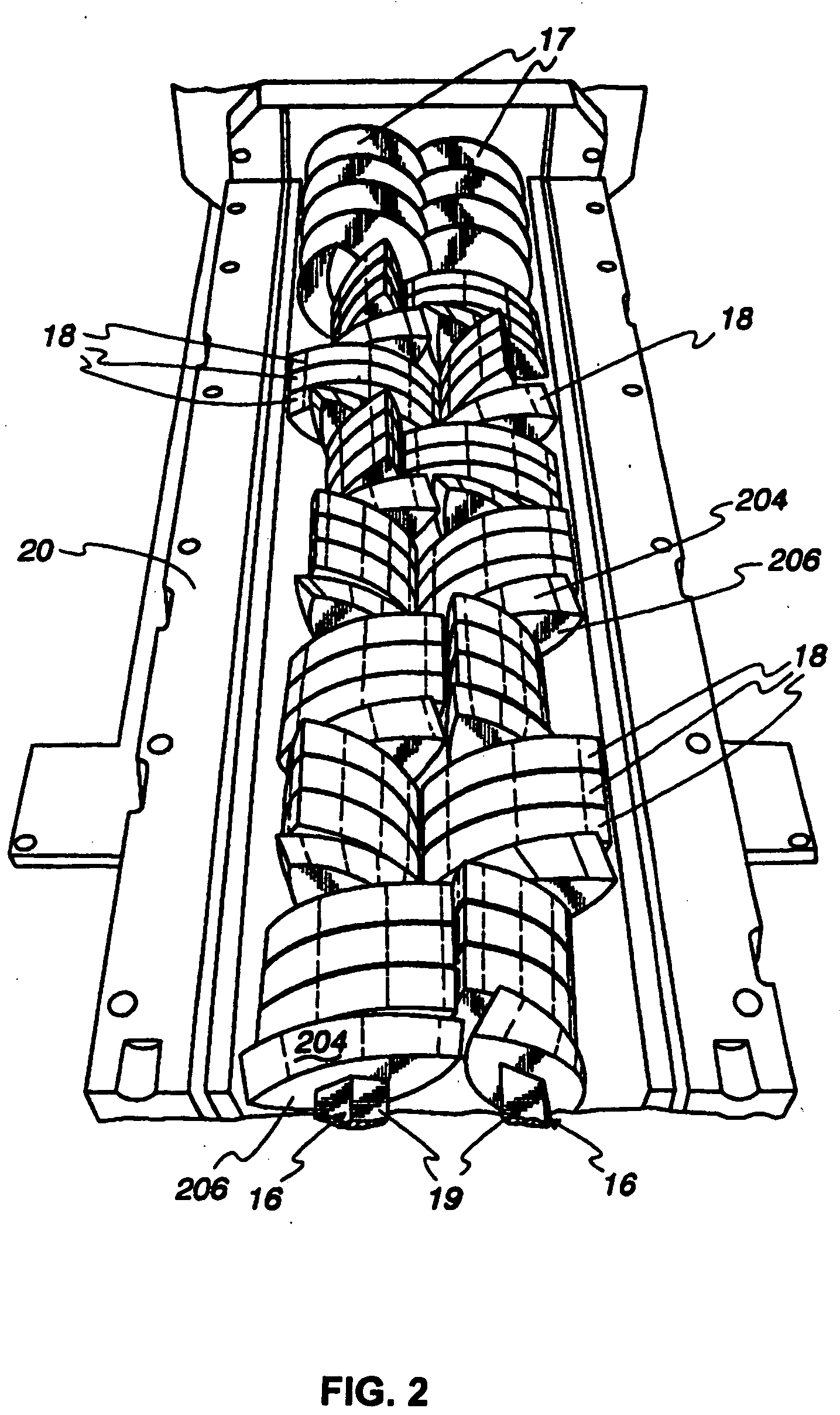

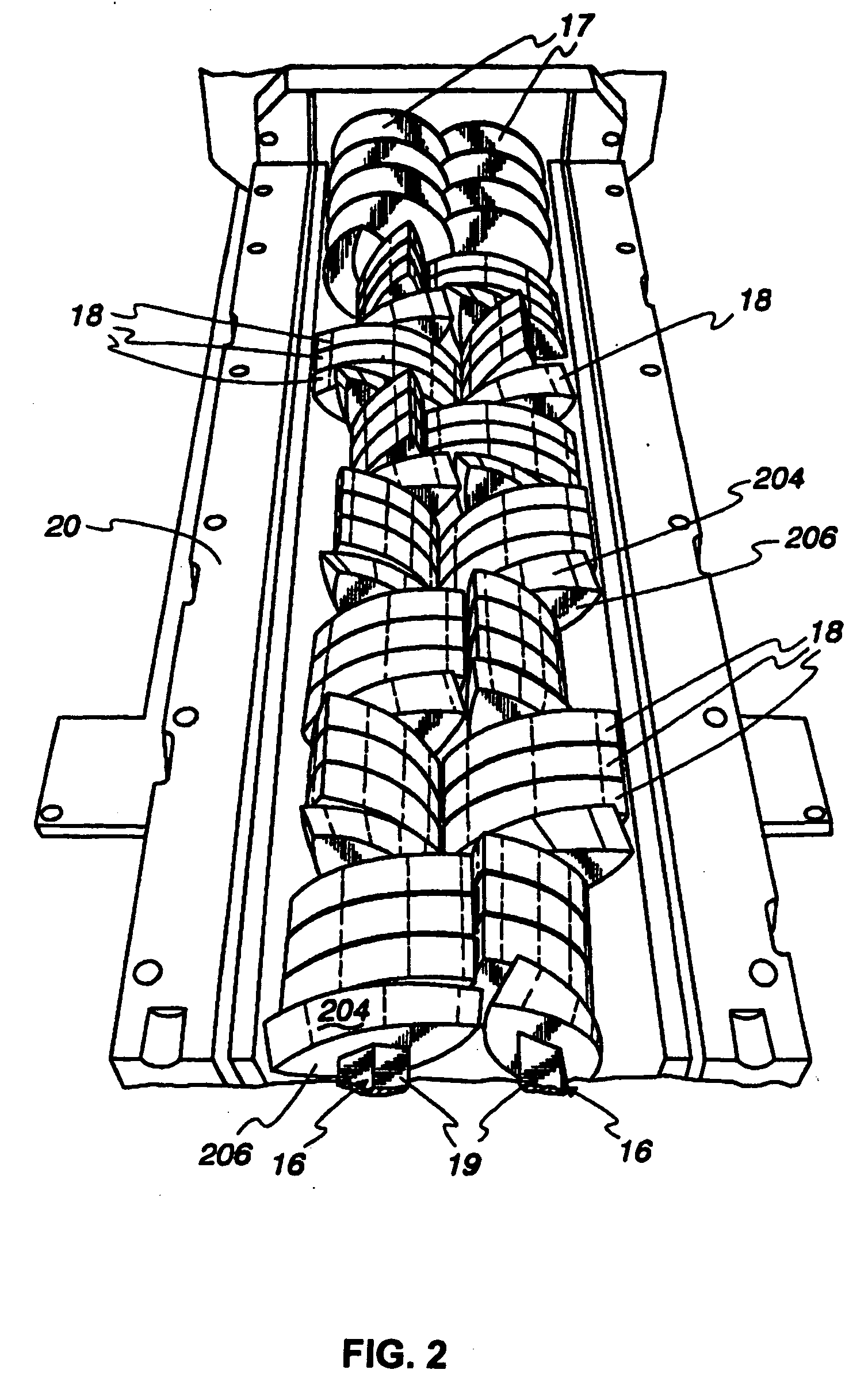

InactiveUS6287188B1Pleasant lookQuality improvementSausage filling/stuffing machinesMeat mixing apparatusEngineeringMechanical engineering

The invention relates to a feeding device for a stuffing and dosing pump of a vacuum stuffing machine for alimentary paste products, preferably ground or extruded meats.More specifically, the feeding device provides two elical scroll thrusting elements, facing each other and placed in the space under the hopper in order to operate continuously on the meat paste, thrusting and compacting it in the direction and toward the inlet of the stuffing pump.

Owner:REFIN

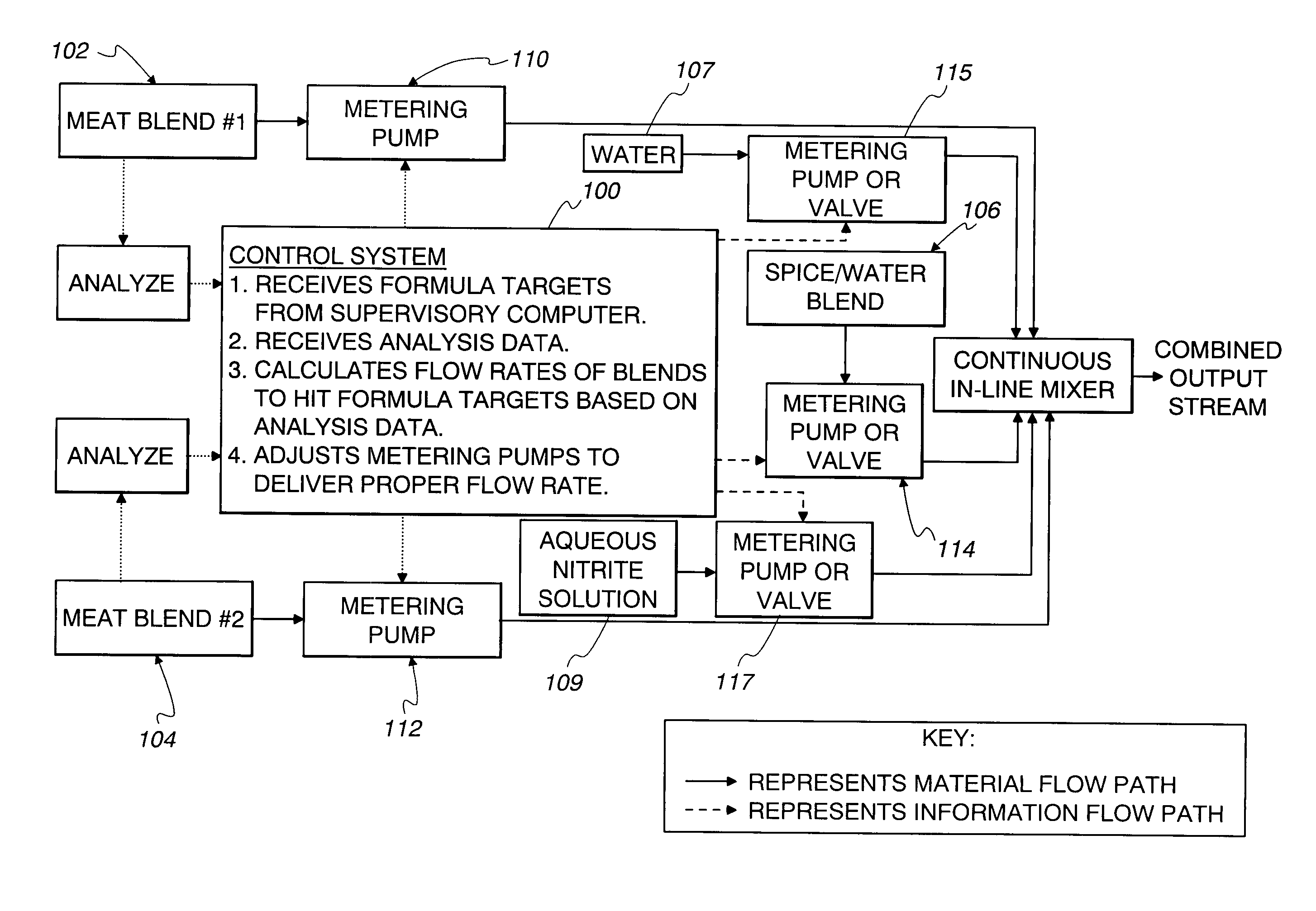

Method of making processed meat products

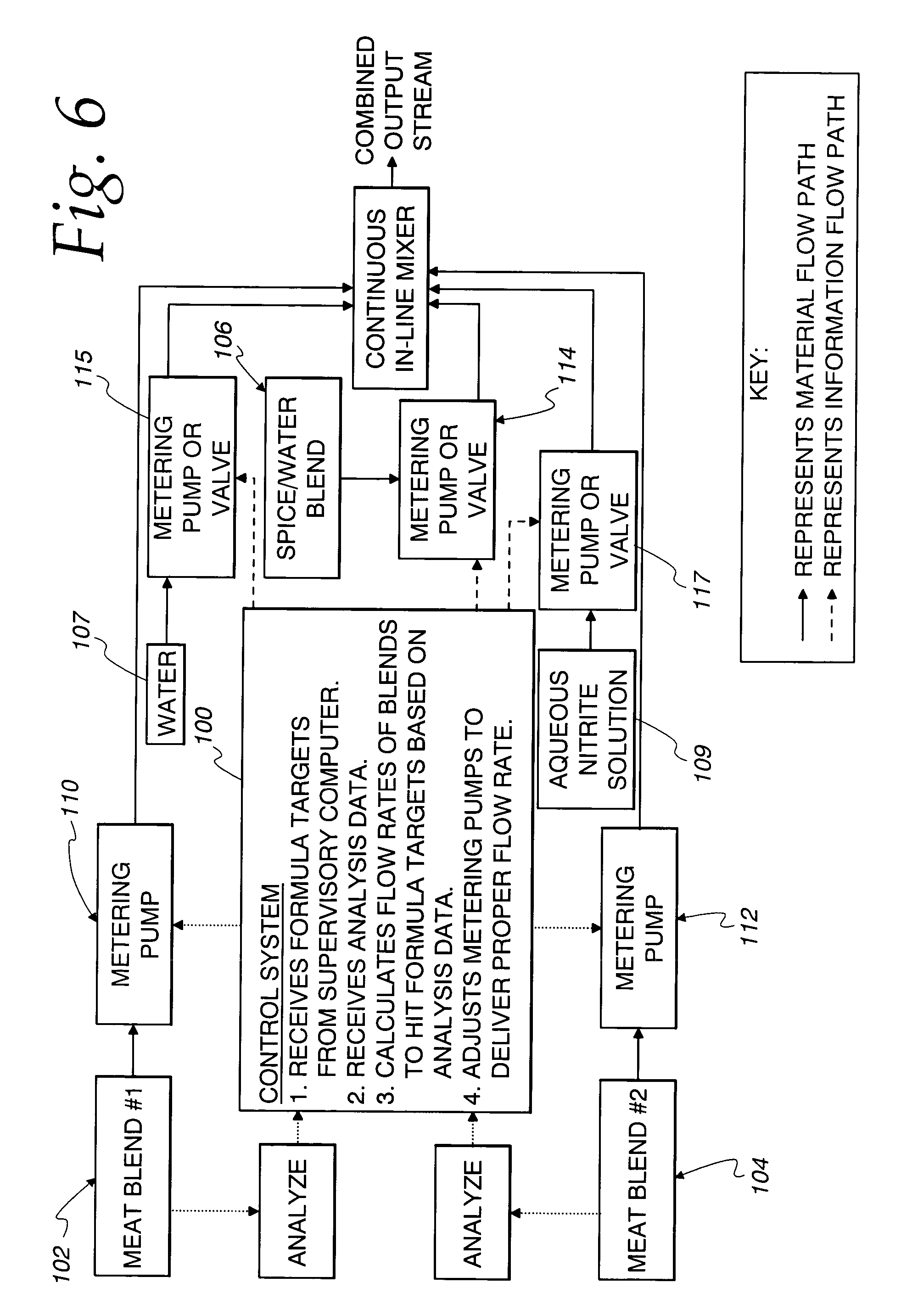

ActiveUS7169421B2Small sizeRapid adjustment of flow rateMeat/fish preservationRotary stirring mixersEngineeringProcessed meat

Owner:KRAFT FOODS GRP BRANDS LLC

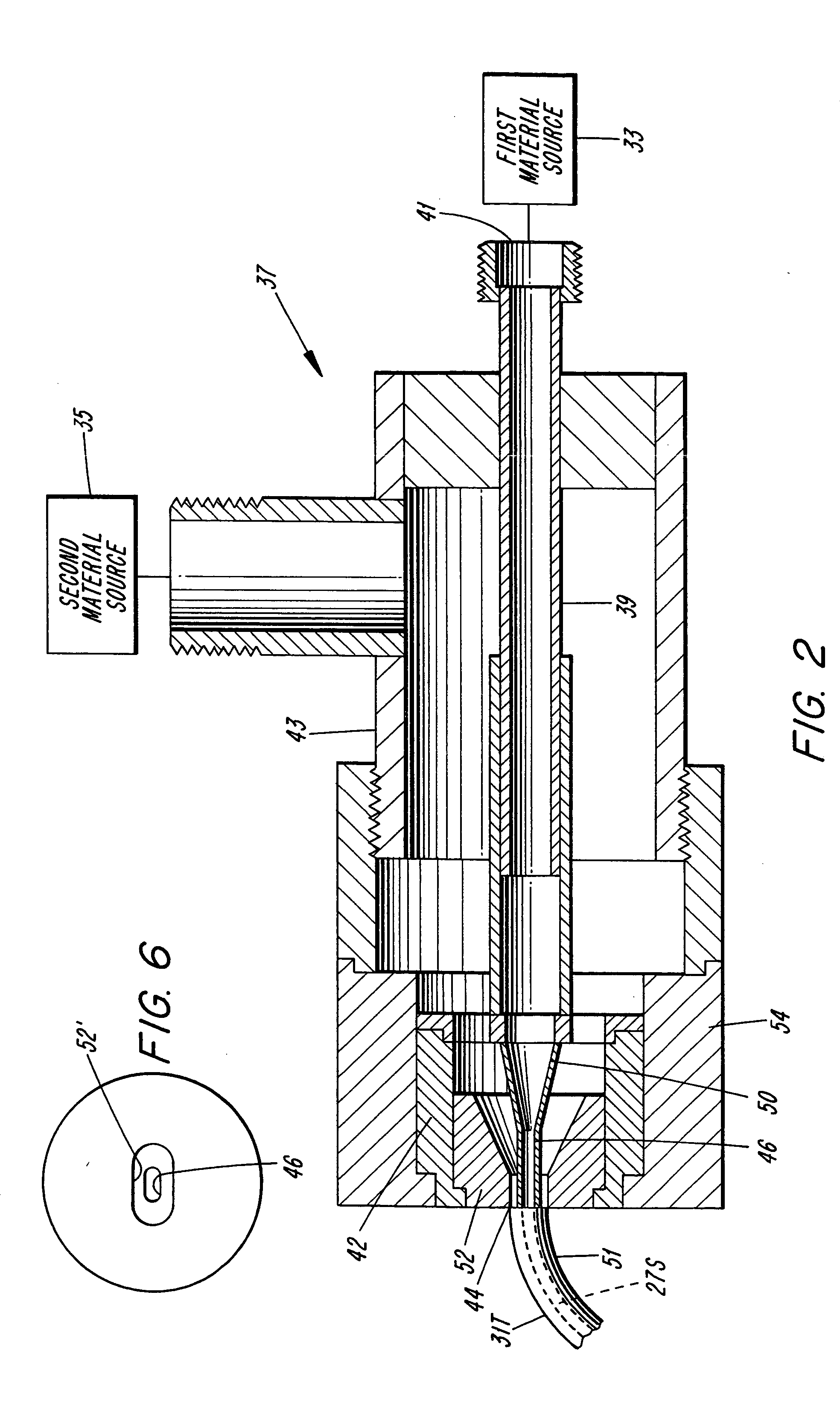

Filled edible product, and system and method for production of a filled edible product

An edible product includes an edible outer cover component in which is located an inner edible component. A system for producing the edible product includes an arrangement for delivering the edible product in the form of an elongated rope-type product to a crimping apparatus. The crimping apparatus receives the longitudinal rope-like product for crimping the longitudinal rope to separate the longitudinal rope into individual edible products.

Owner:BIG HEART PET INC

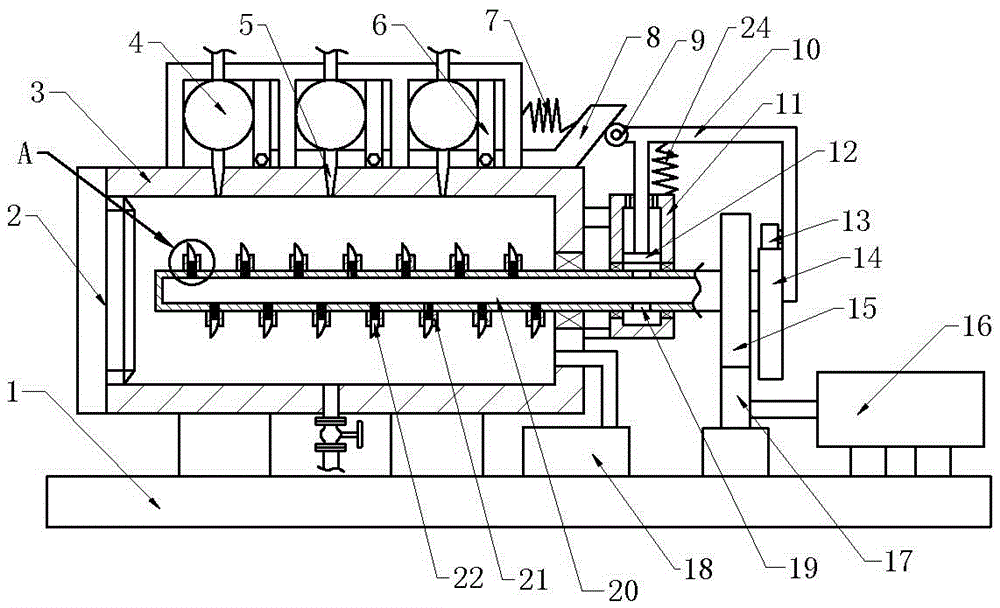

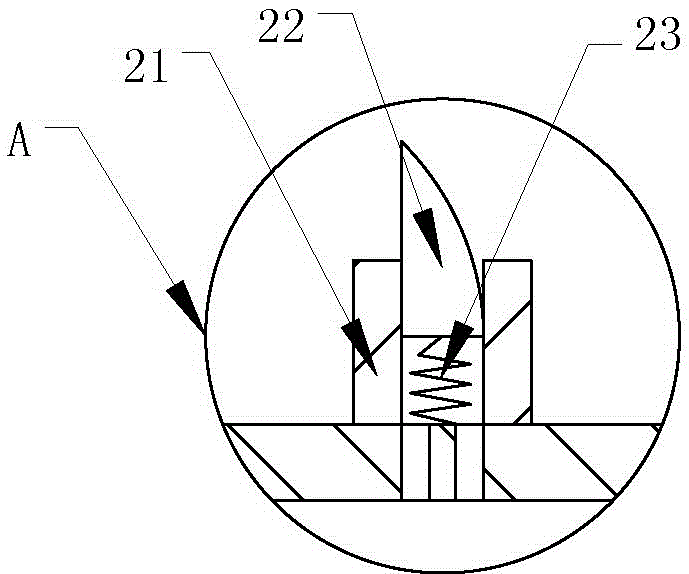

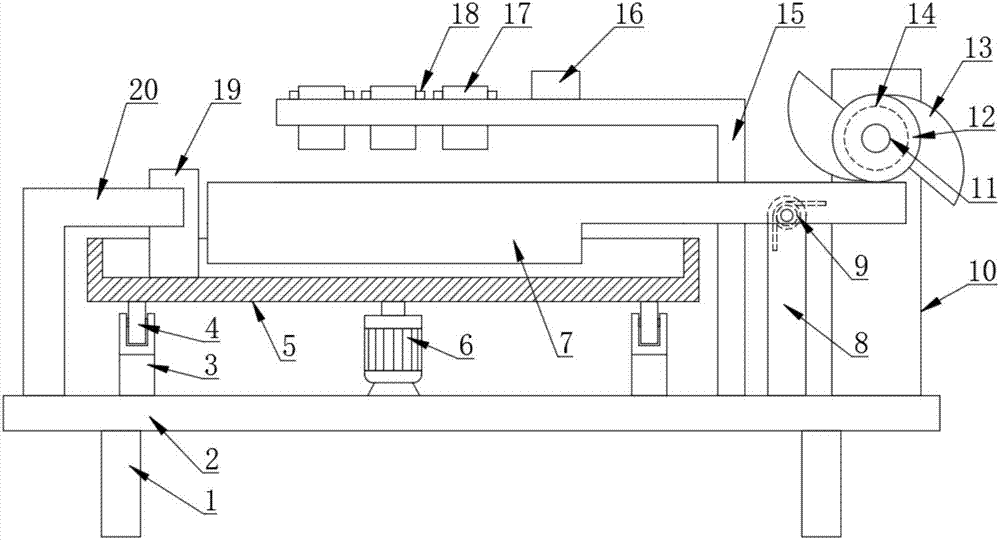

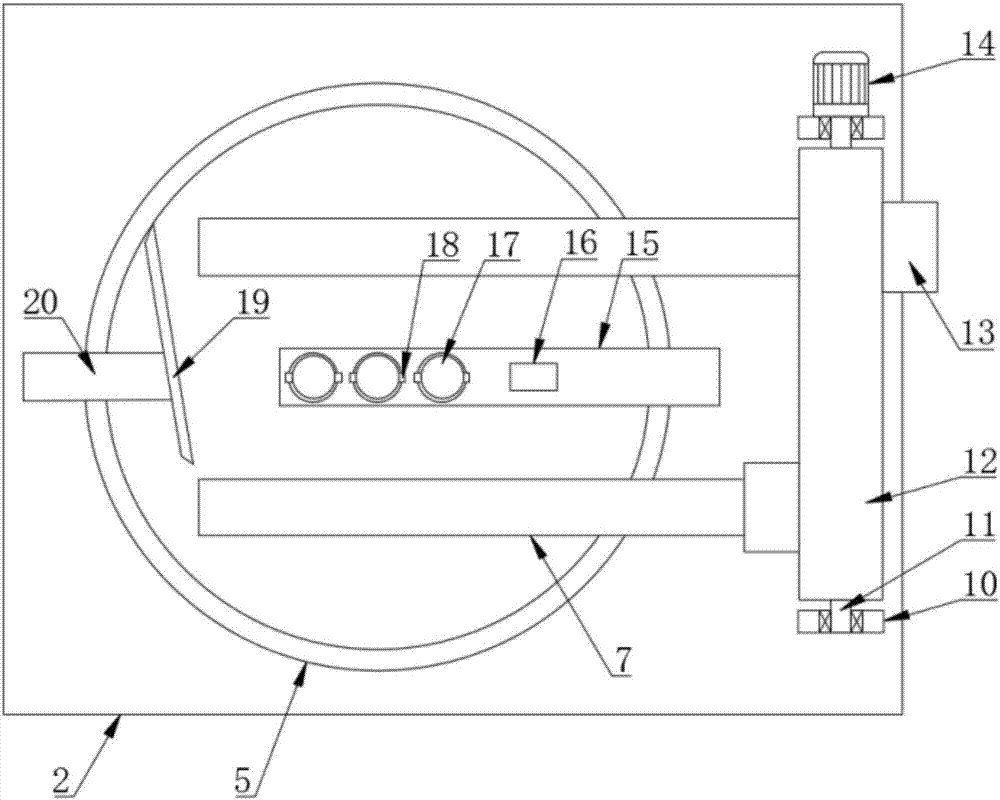

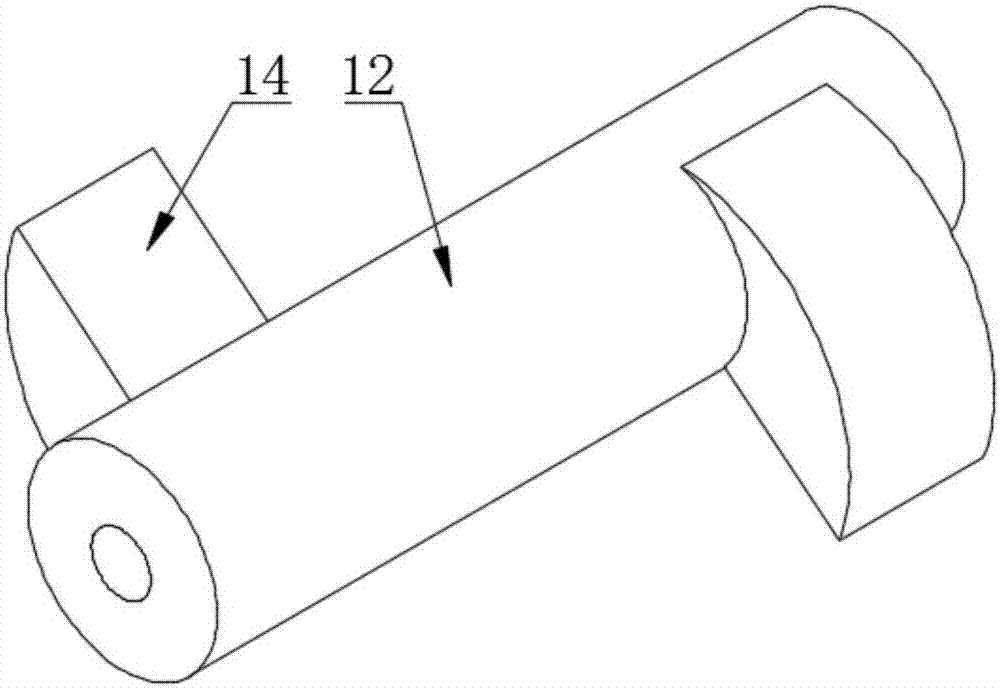

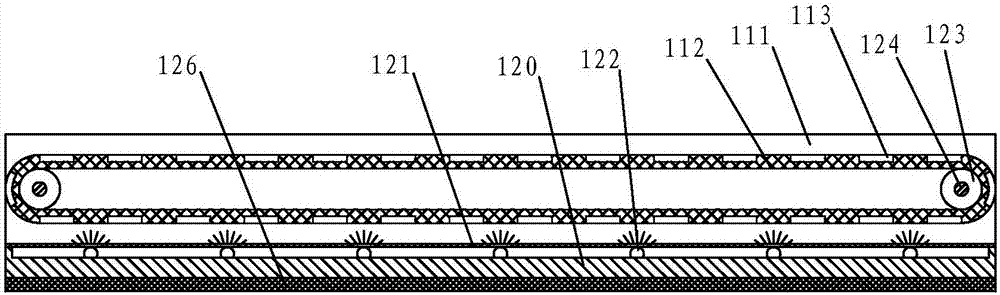

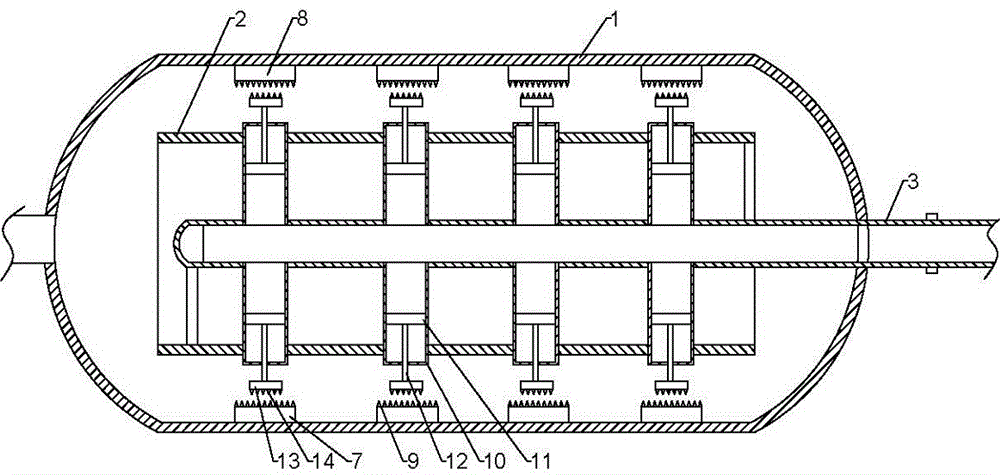

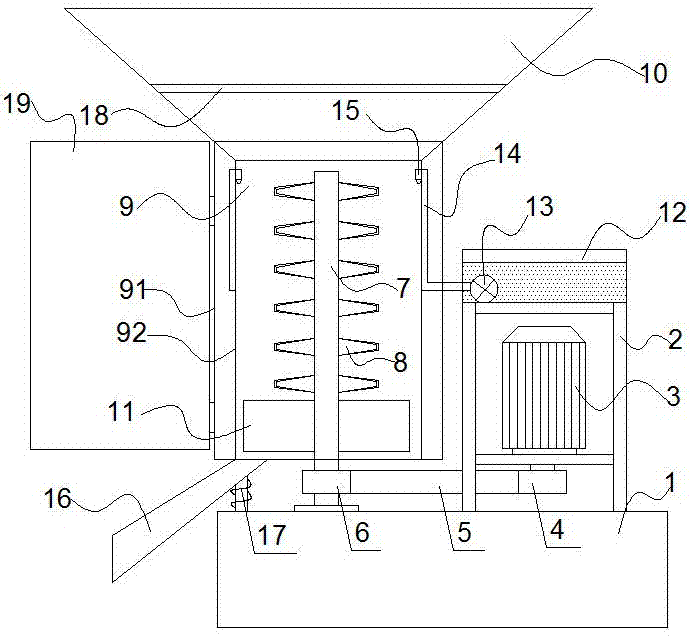

Vacuum roll kneading machine for food processing

ActiveCN106665780AImprove tumbling effectRoll quicklyMeat mixing apparatusMeat tenderisingEngineeringVacuum pump

The invention discloses a vacuum roll kneading machine for food processing. The vacuum roll kneading machine comprises a frame, a vacuum pump and a roll kneading drum. The vacuum pump is communicated with the roll kneading drum, a rotating shaft in a hollow structure is rotatably connected in the roll kneading drum, a plurality of slide barrels are arranged on the rotating shaft in the roll kneading drum, each roll kneading knife is provided with a plurality of through holes, the slide barrels are communicated with the through holes, and each roll kneading knife is slidably connected in the corresponding slide barrel. The rotating shaft outside the roll kneading drum is provided with a vent hole, an air cylinder is fixed to the rotating shaft and communicated with the vent hole, and a piston is arranged in the air cylinder and fixedly connected with a piston rod. A motor is arranged on the frame, a first gear meshed with a second gear is fixedly connected with an output shaft of the motor, the rotating shaft is fixedly connected to the second gear, and an eccentric gear is fixedly connected to the rotating shaft and abutted against the piston rod. Due to the hollow structure of the rotating shaft, the roll kneading knives continuously reciprocate to slide in the slide barrels in a continuous rotation process of the rotating shaft, a meat roll kneading effect is enhanced, and roll kneading efficiency is improved.

Owner:重庆汤嫂食品有限公司

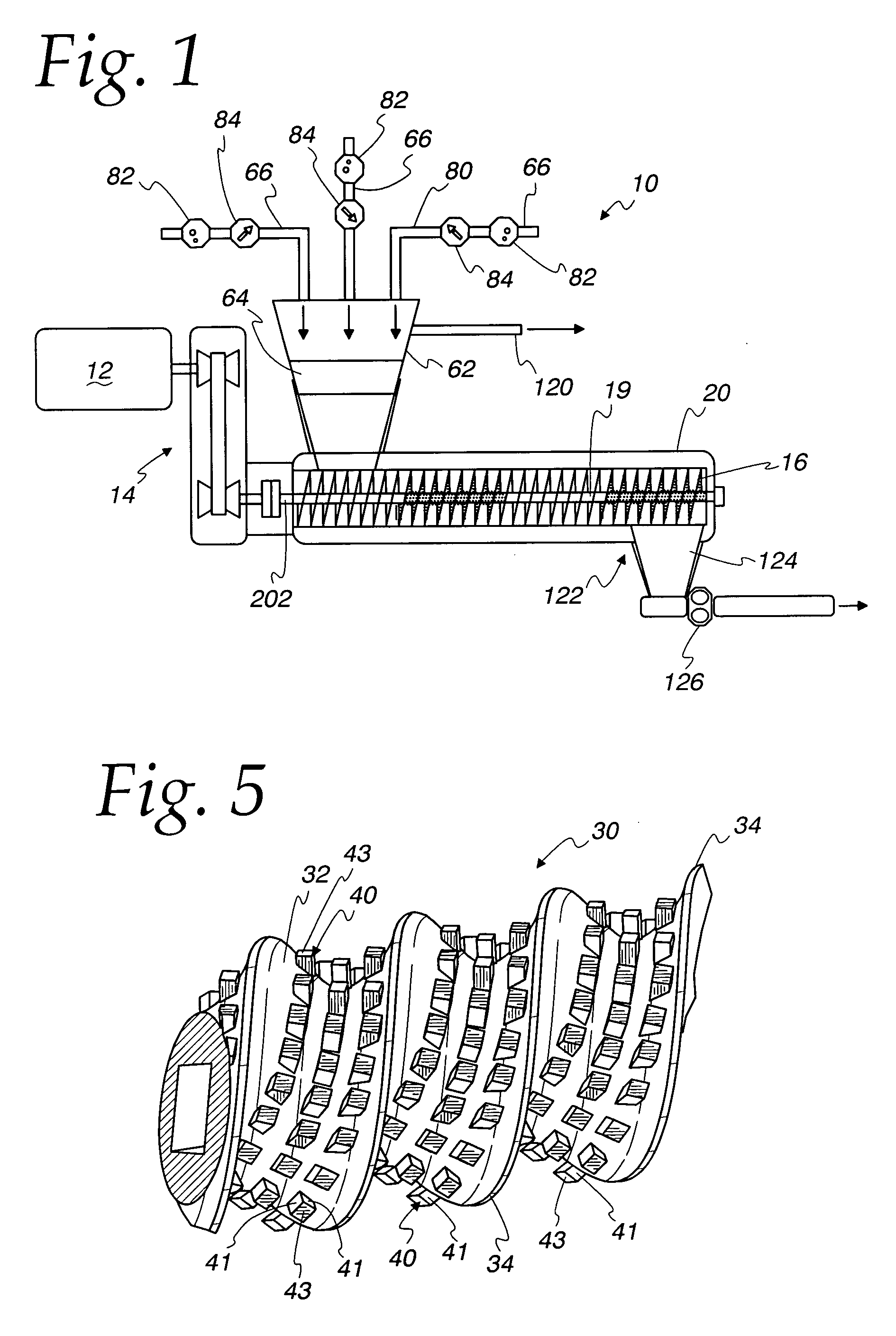

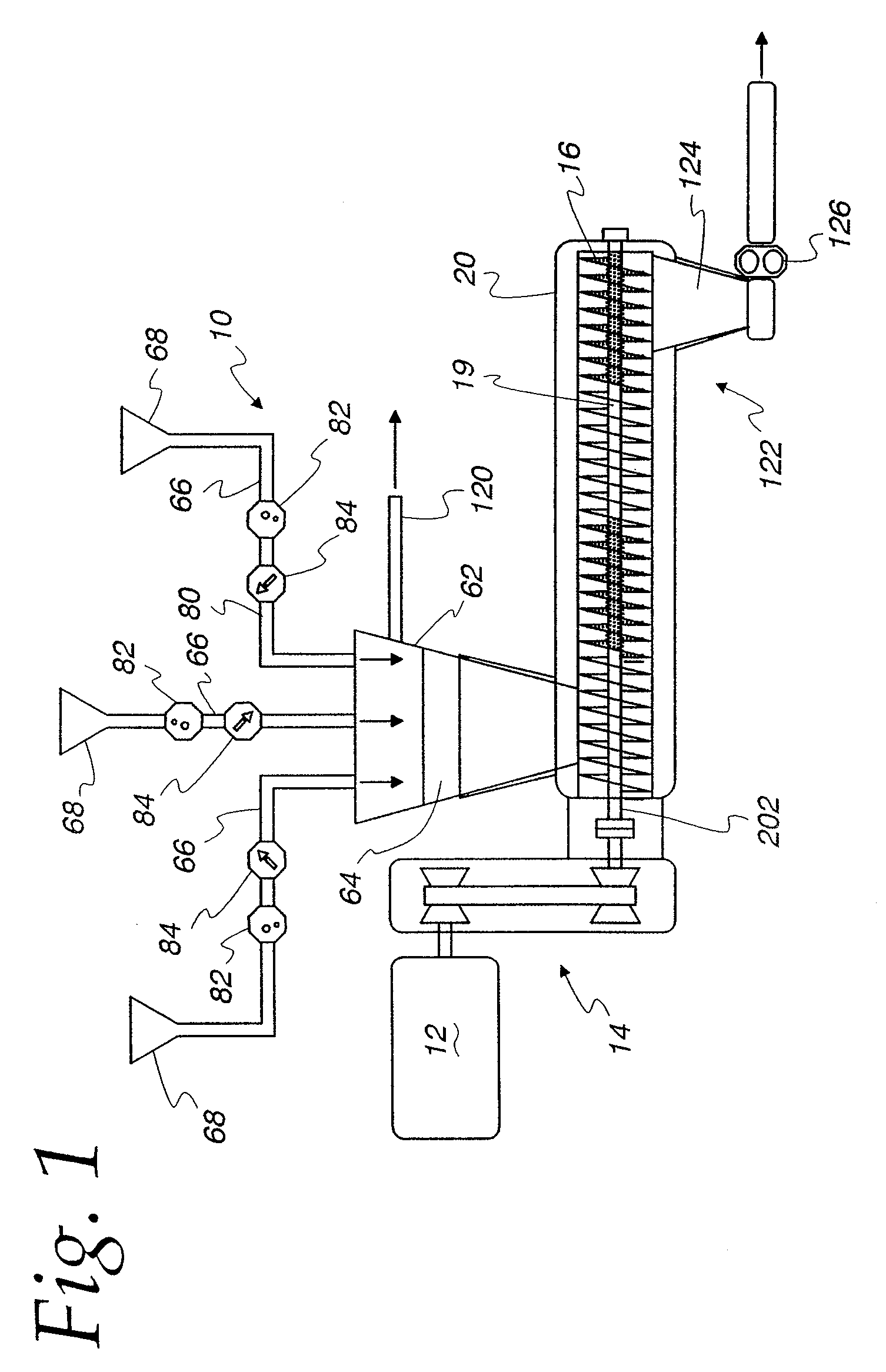

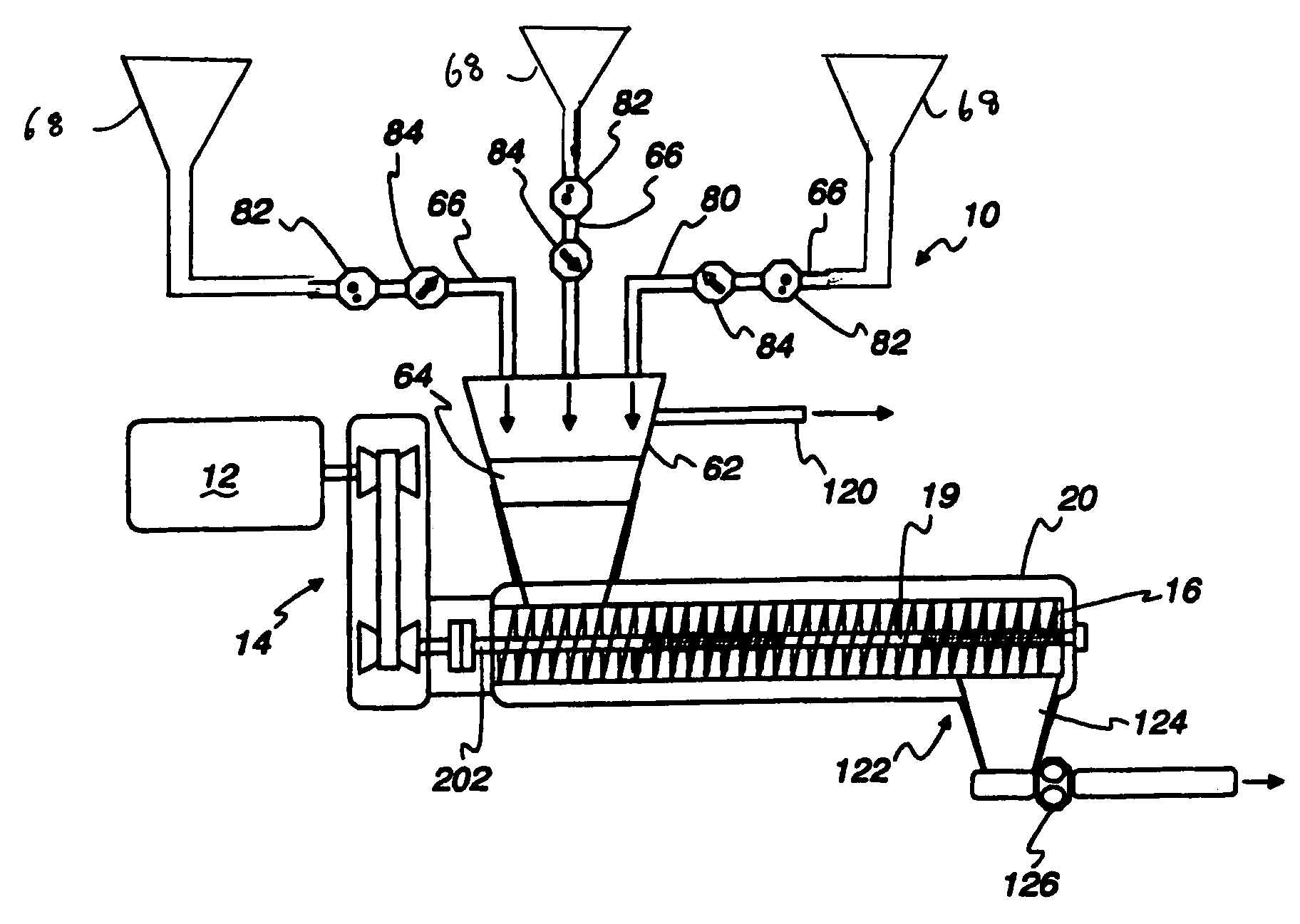

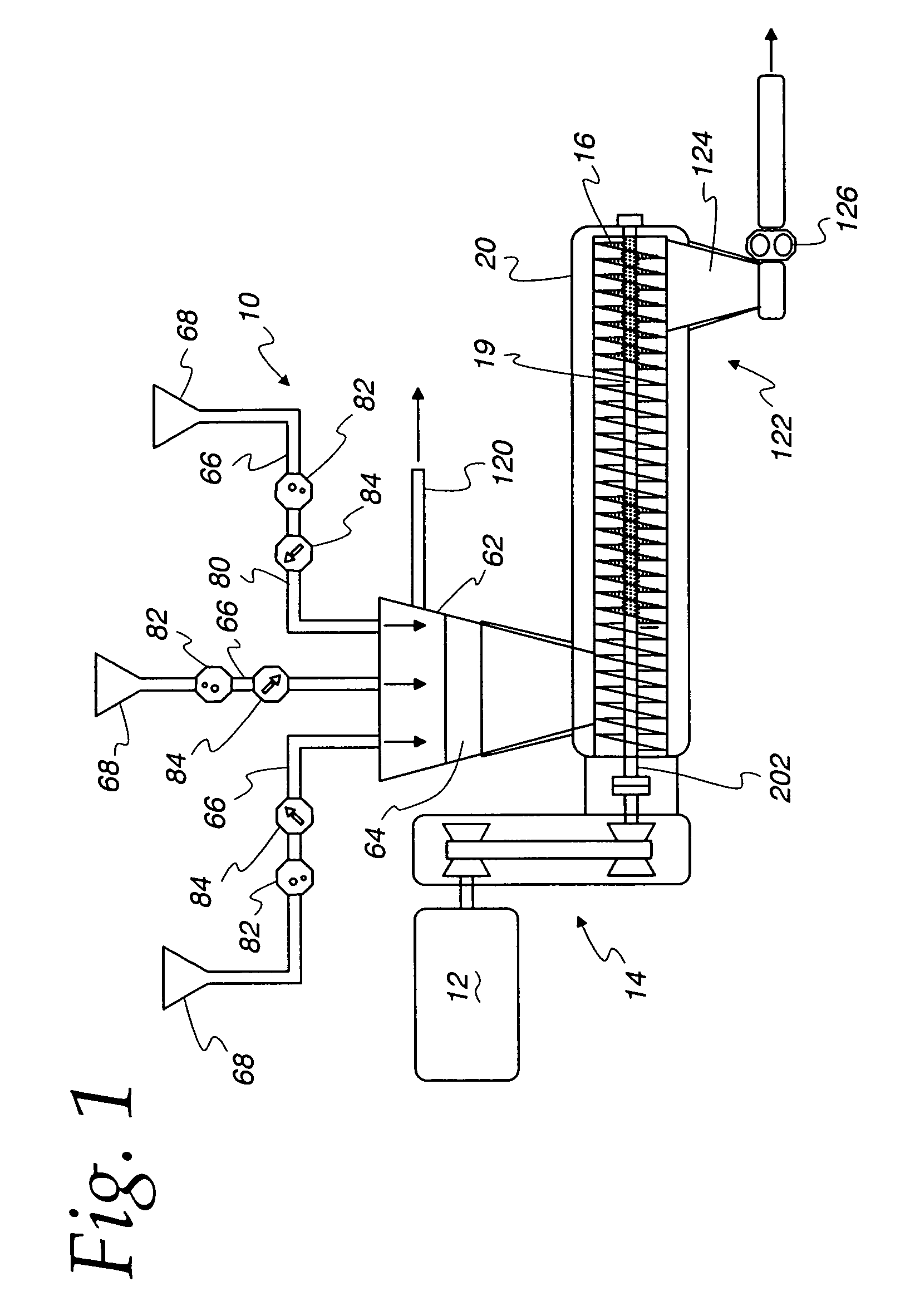

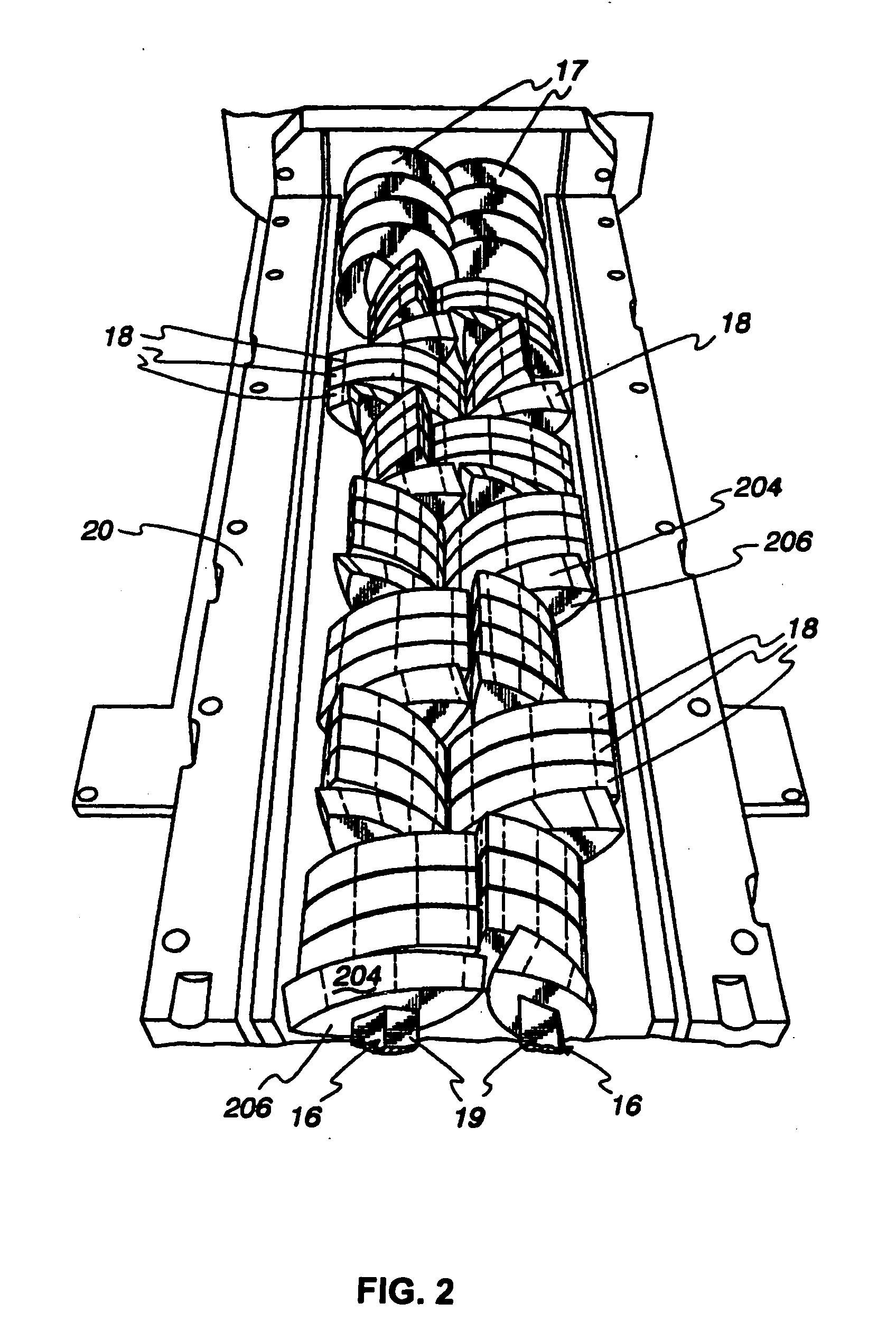

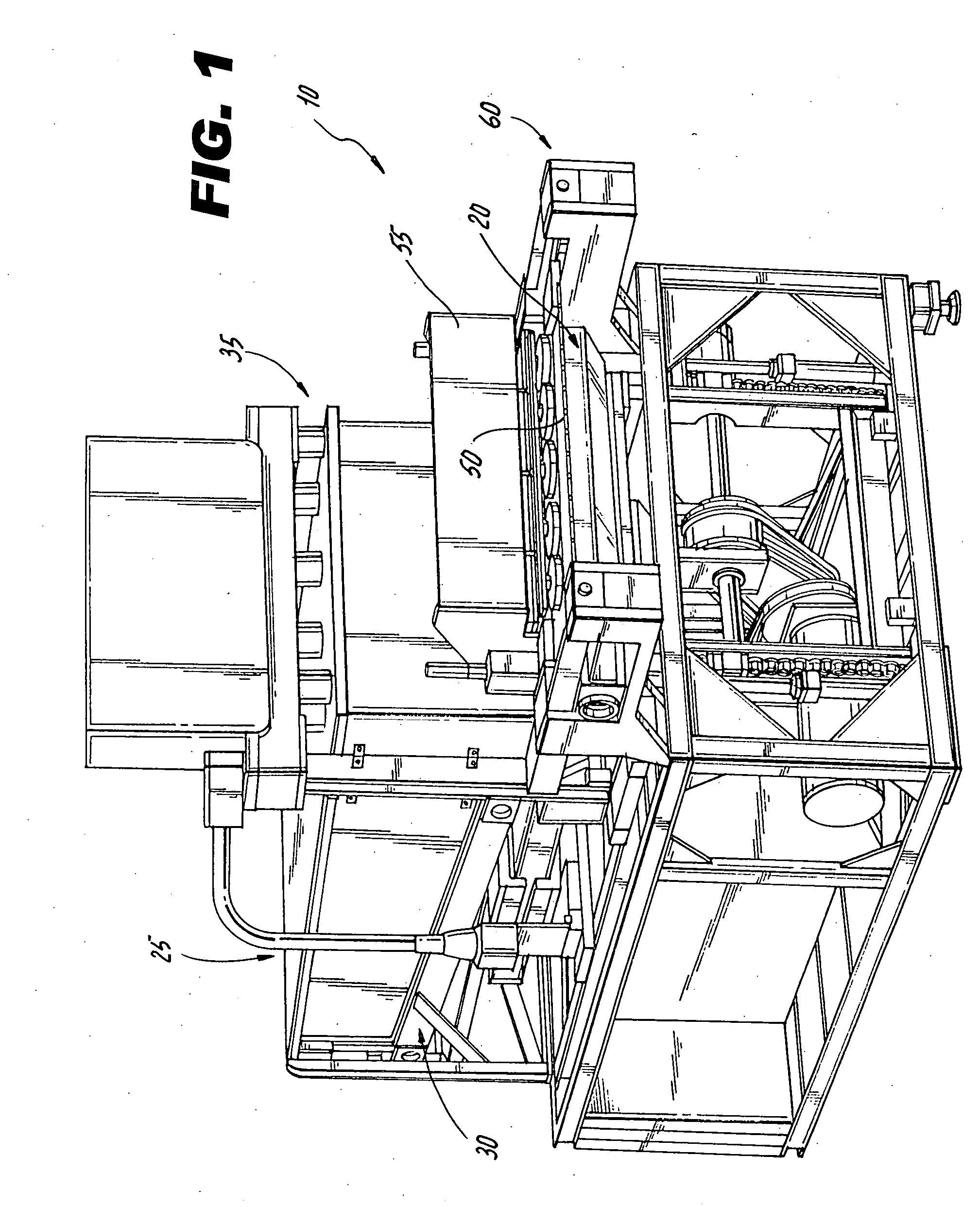

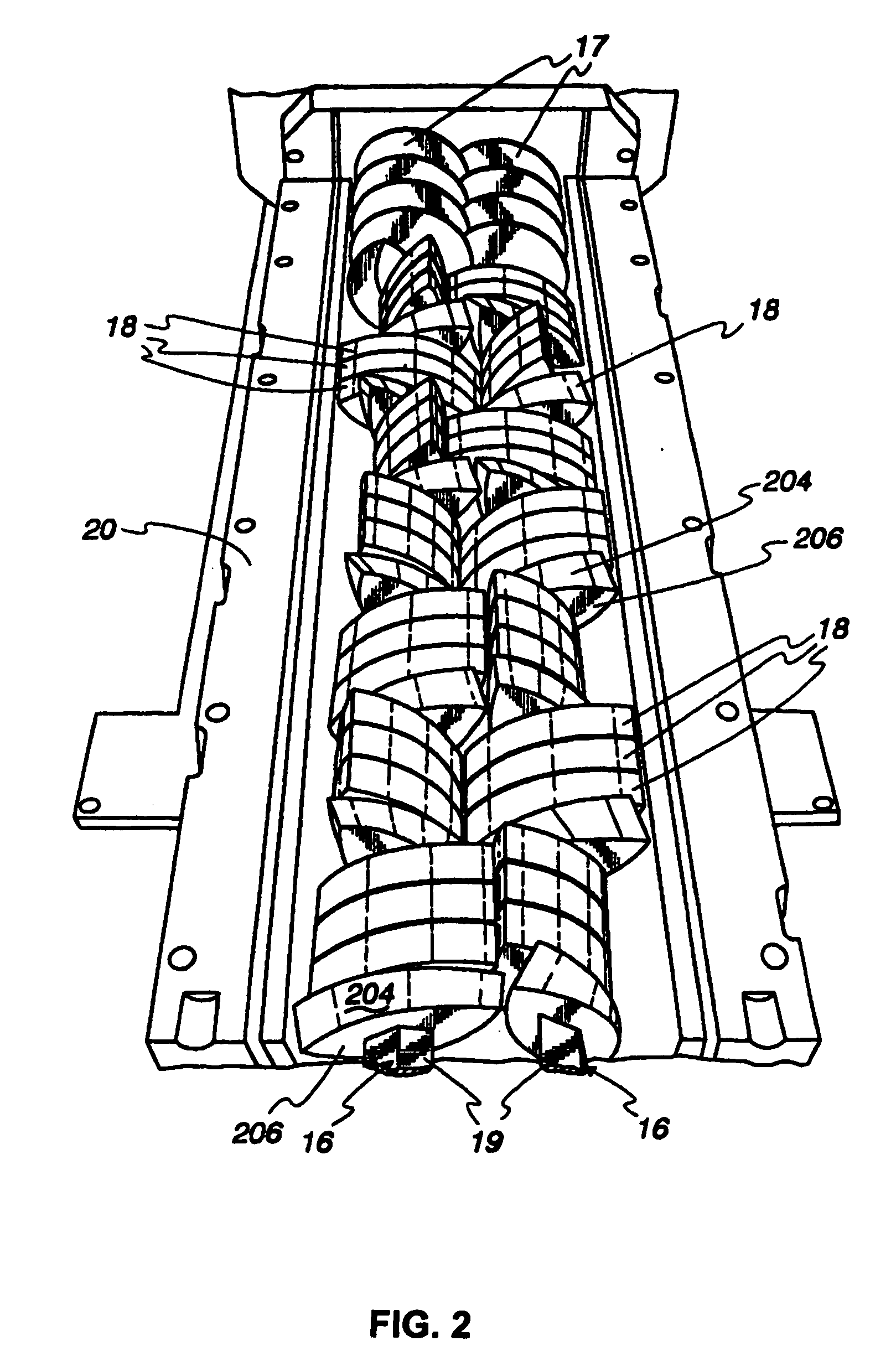

Meat processing system

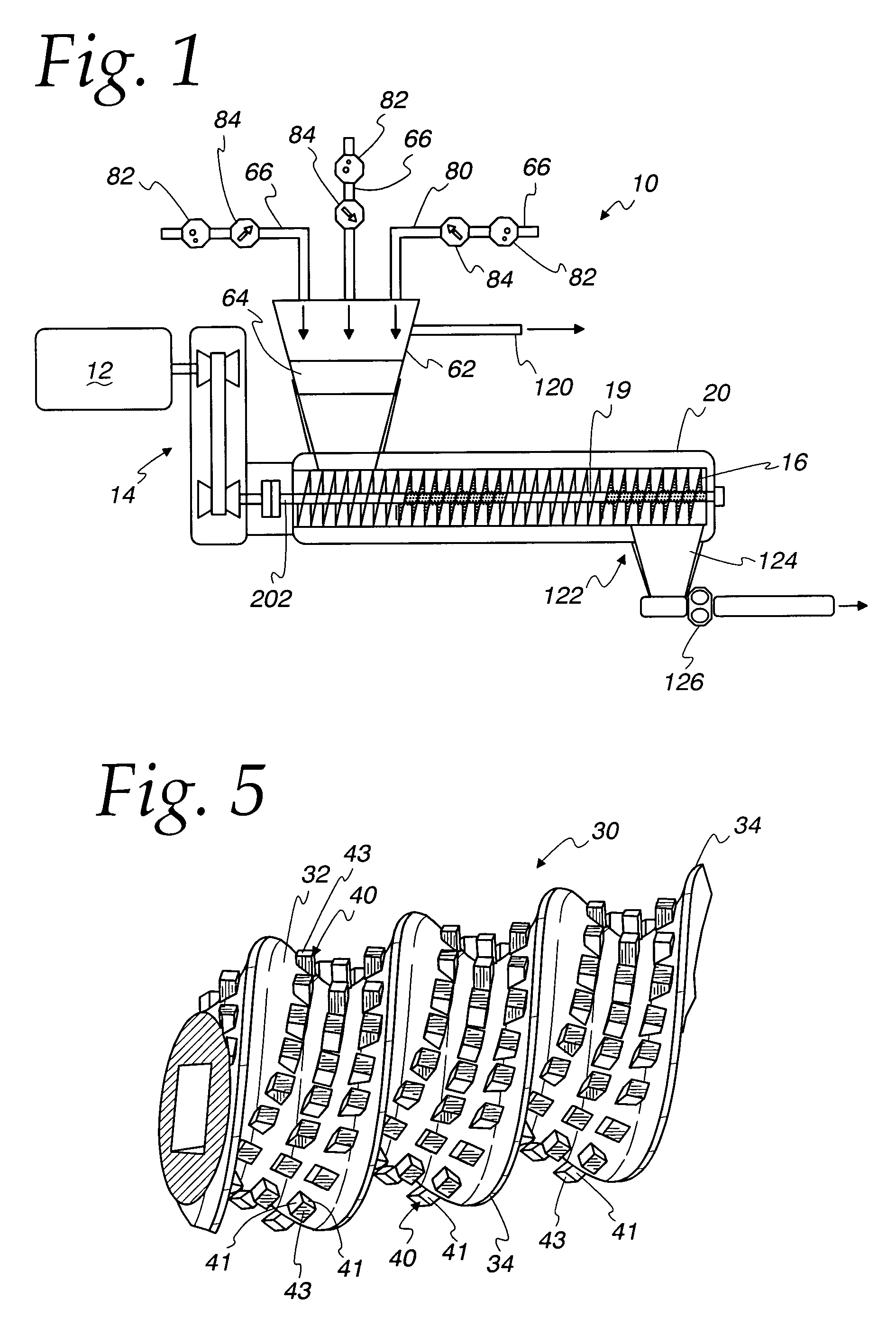

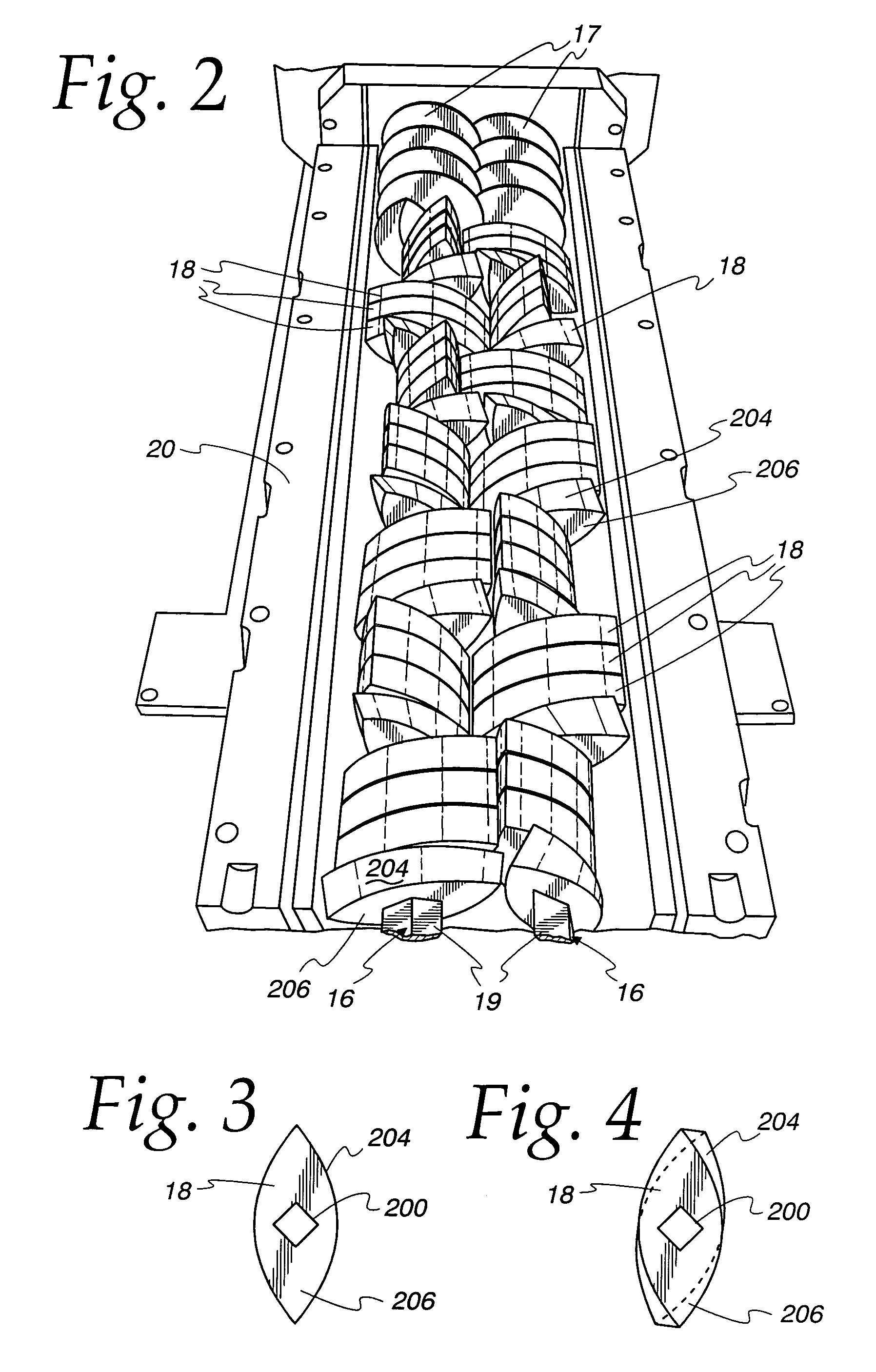

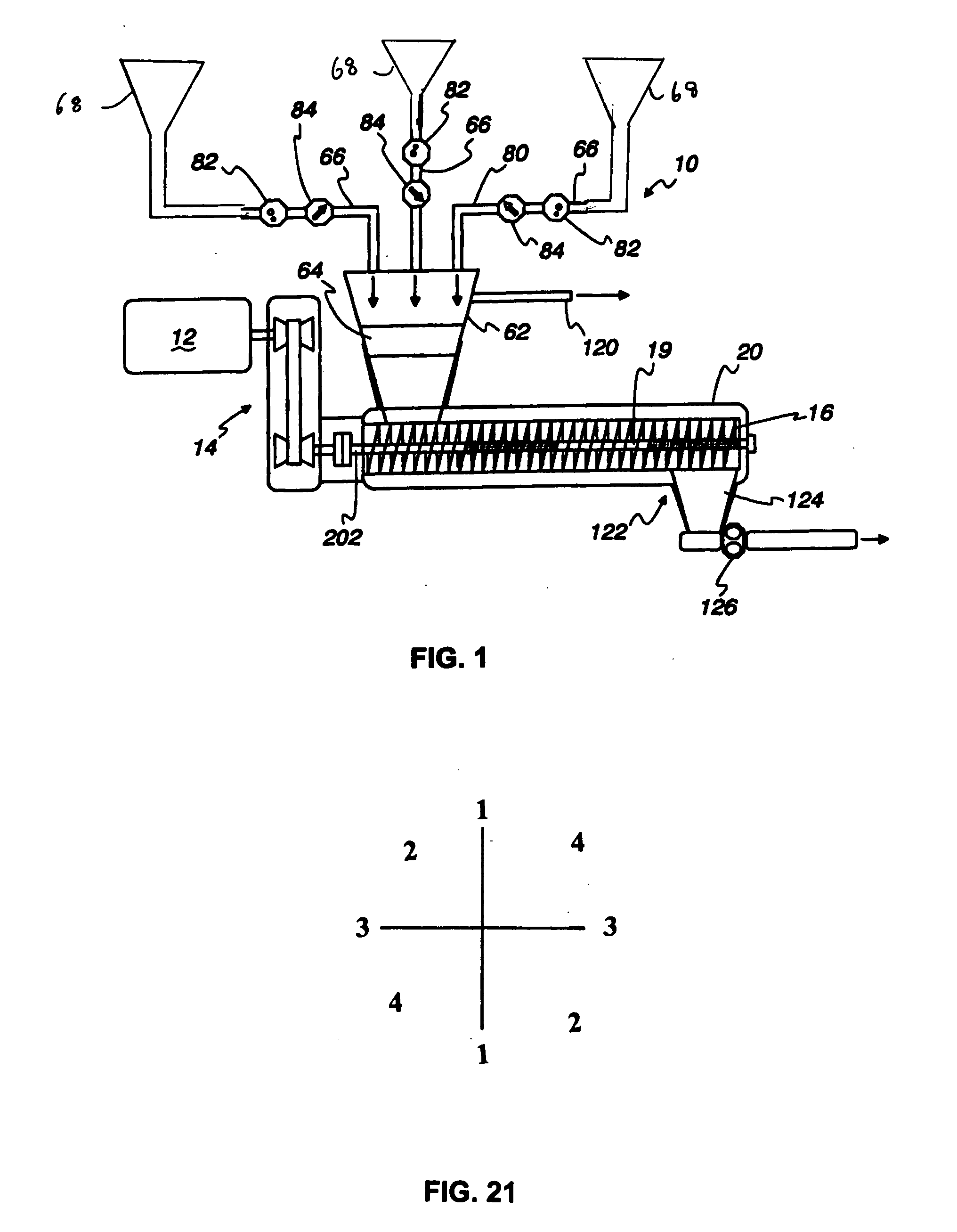

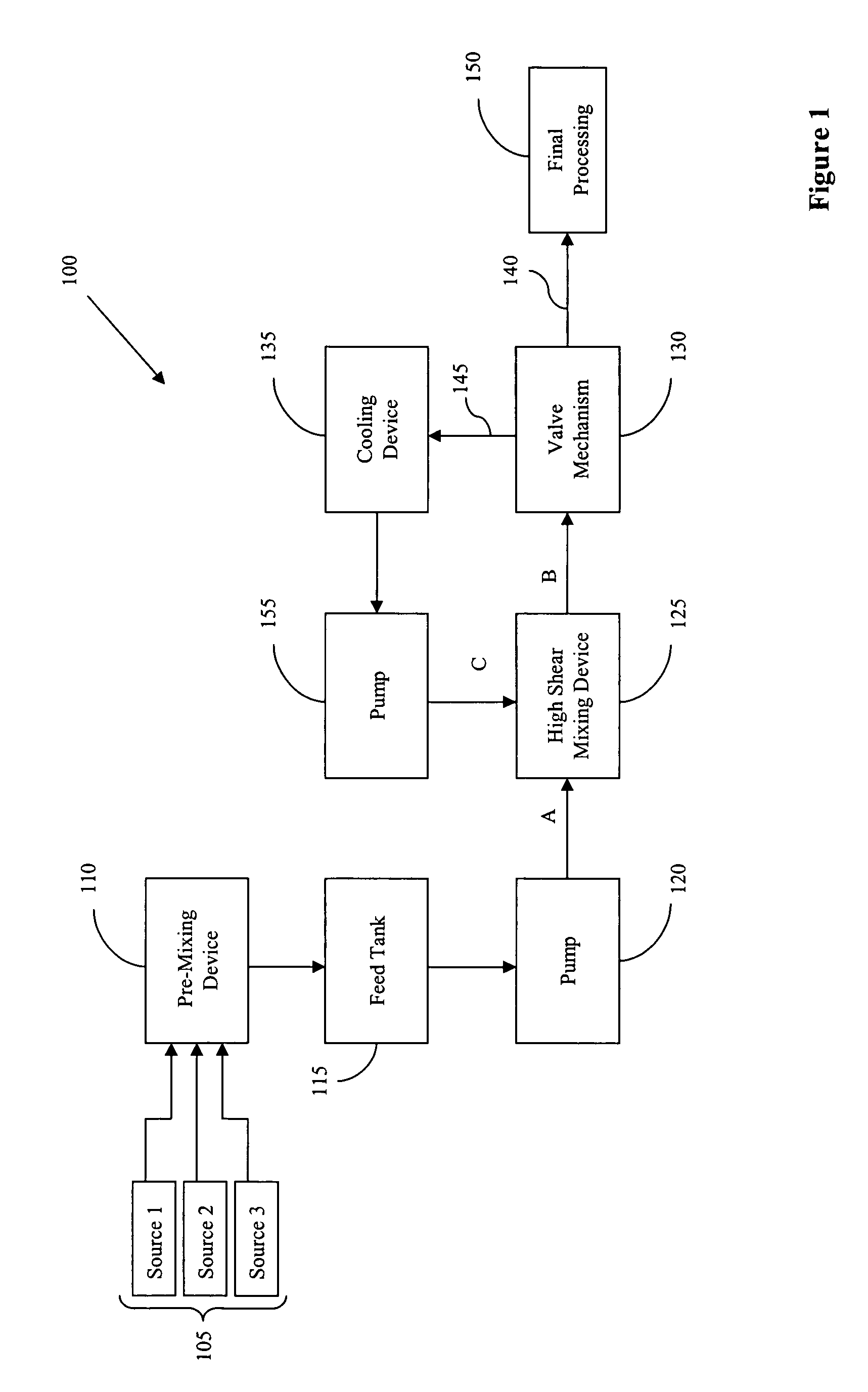

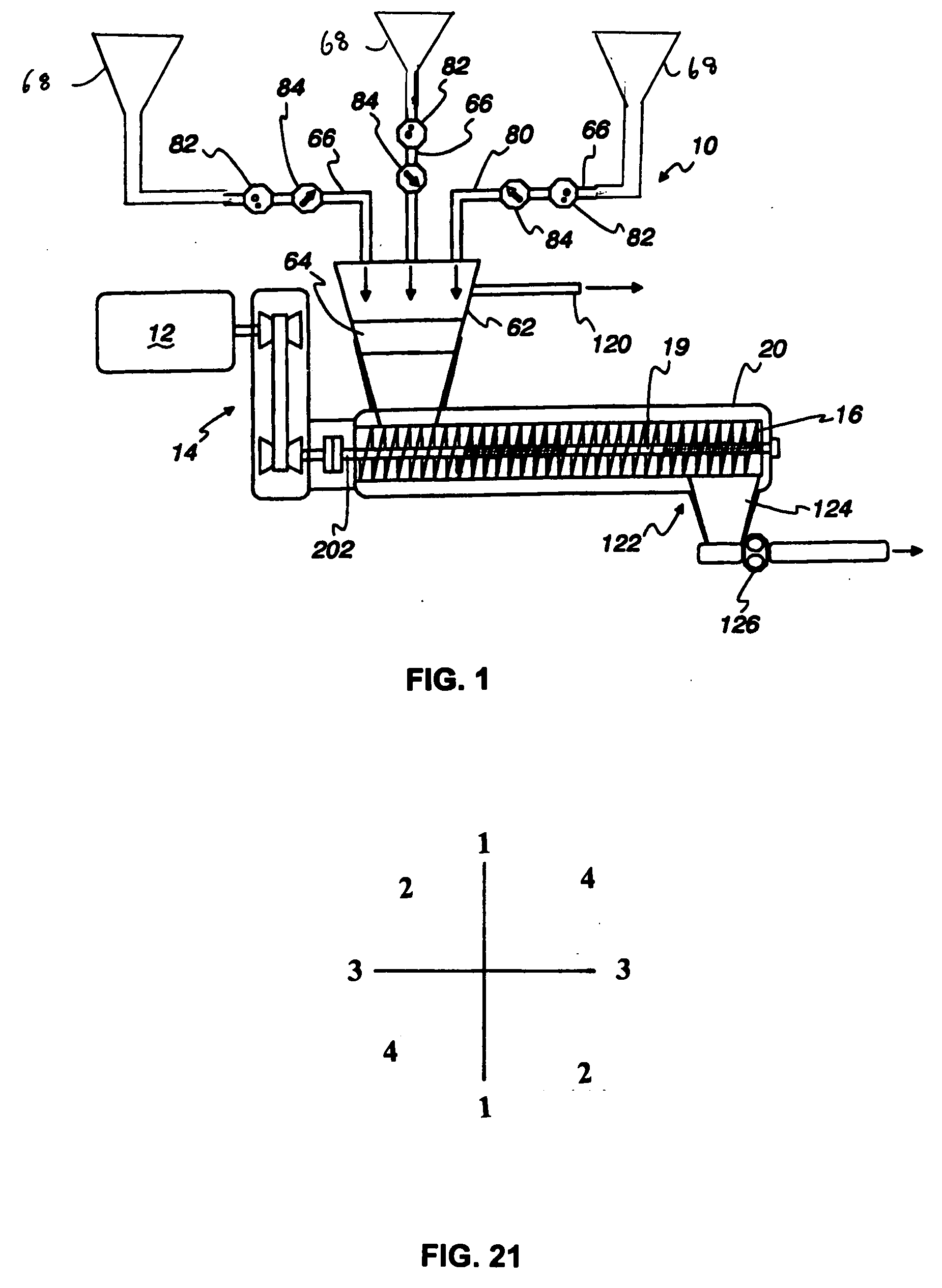

ActiveUS20050042361A1Small sizeRapid adjustment of flow rateMeat/fish preservationRotary stirring mixersMechanical engineeringProcessed meat

A system for making processed meat products employing a feed-forward analysis wherein input streams are analyzed and their flow rates are controlled relative to each other. The system incorporates mixing devices in a housing through which the input streams are forced. The mixing devices provide high shear mixing and blending, and in some cases maceration and salt infusion for rapid protein extraction.

Owner:KRAFT FOODS GRP BRANDS LLC

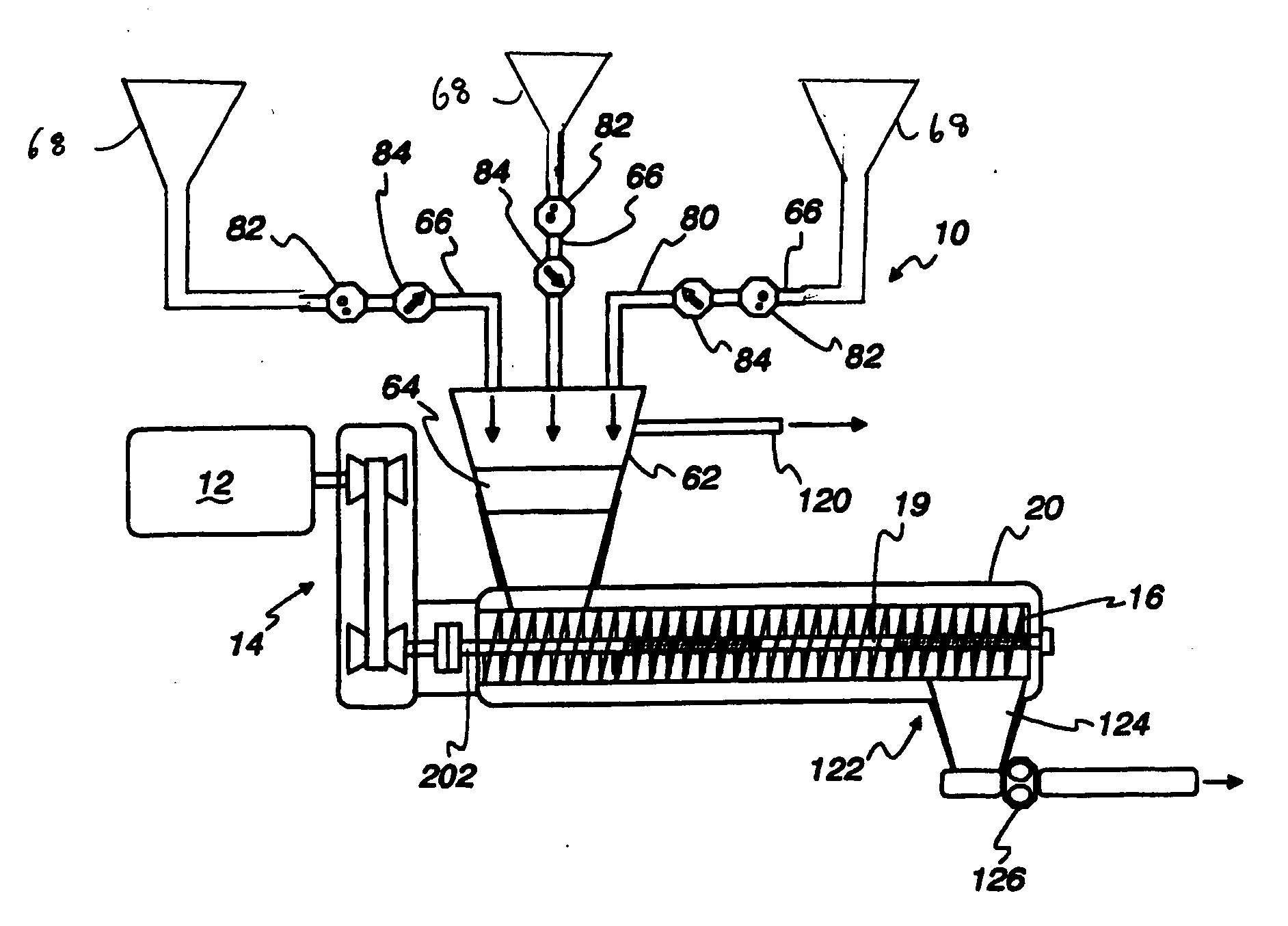

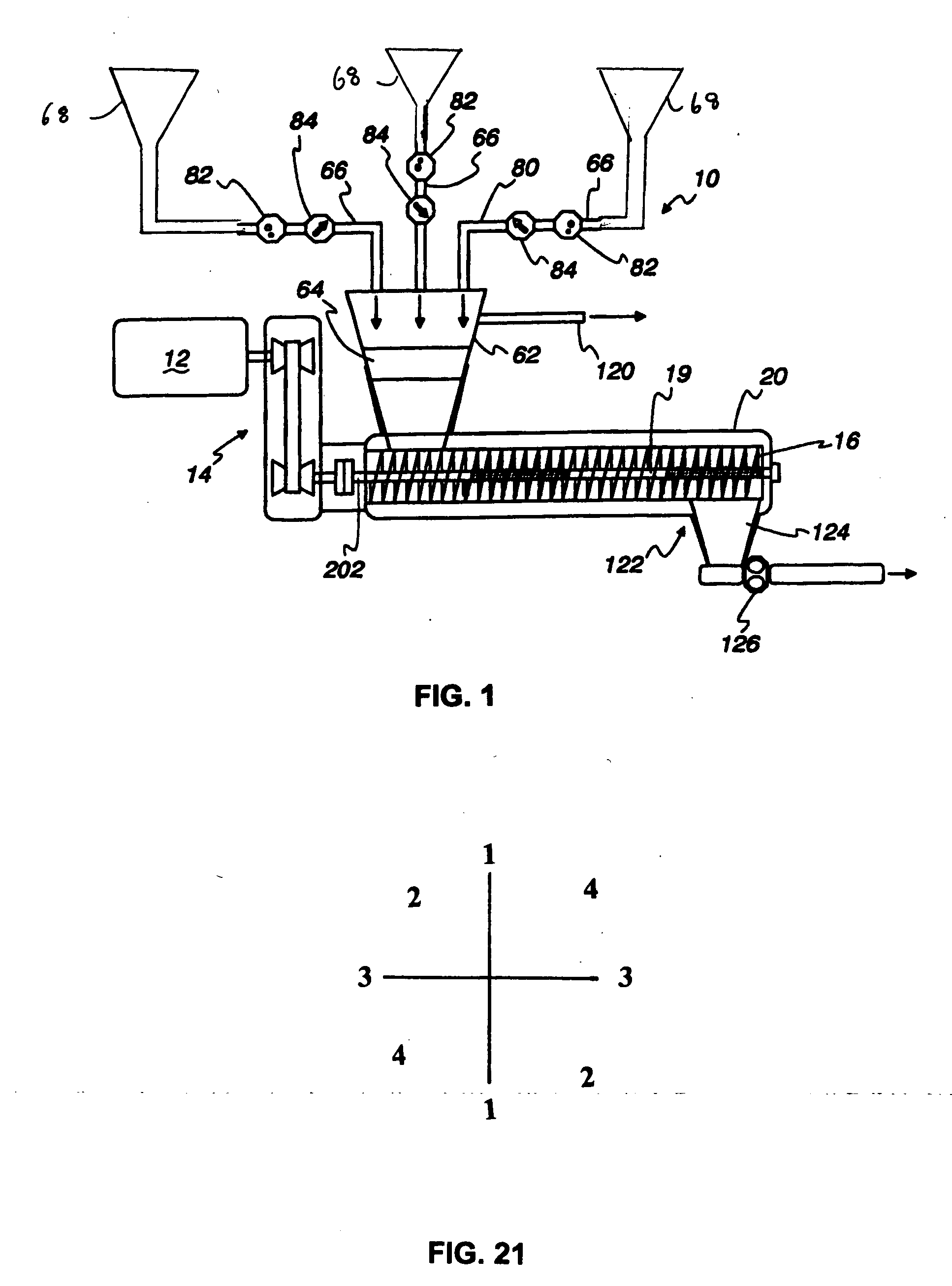

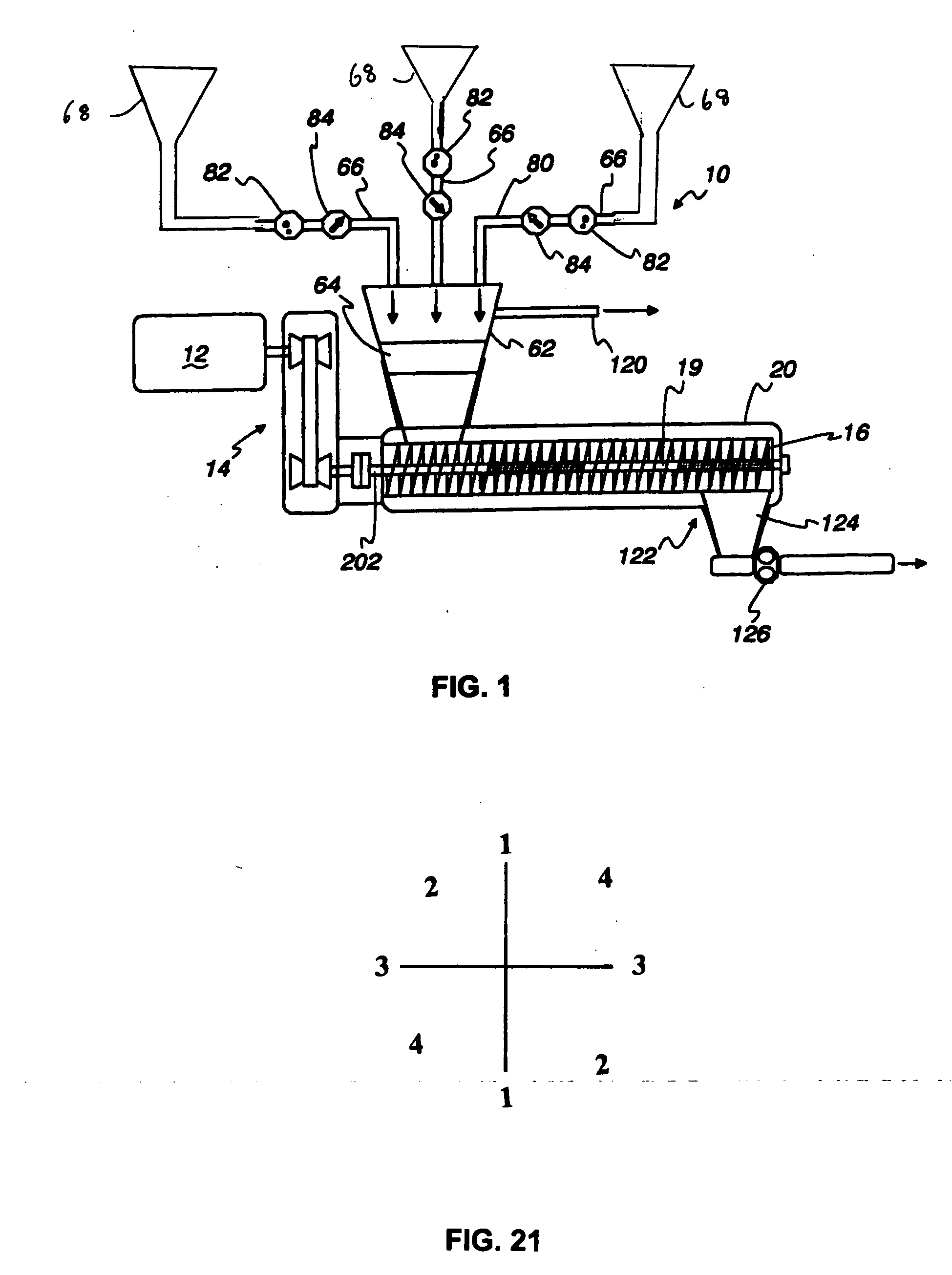

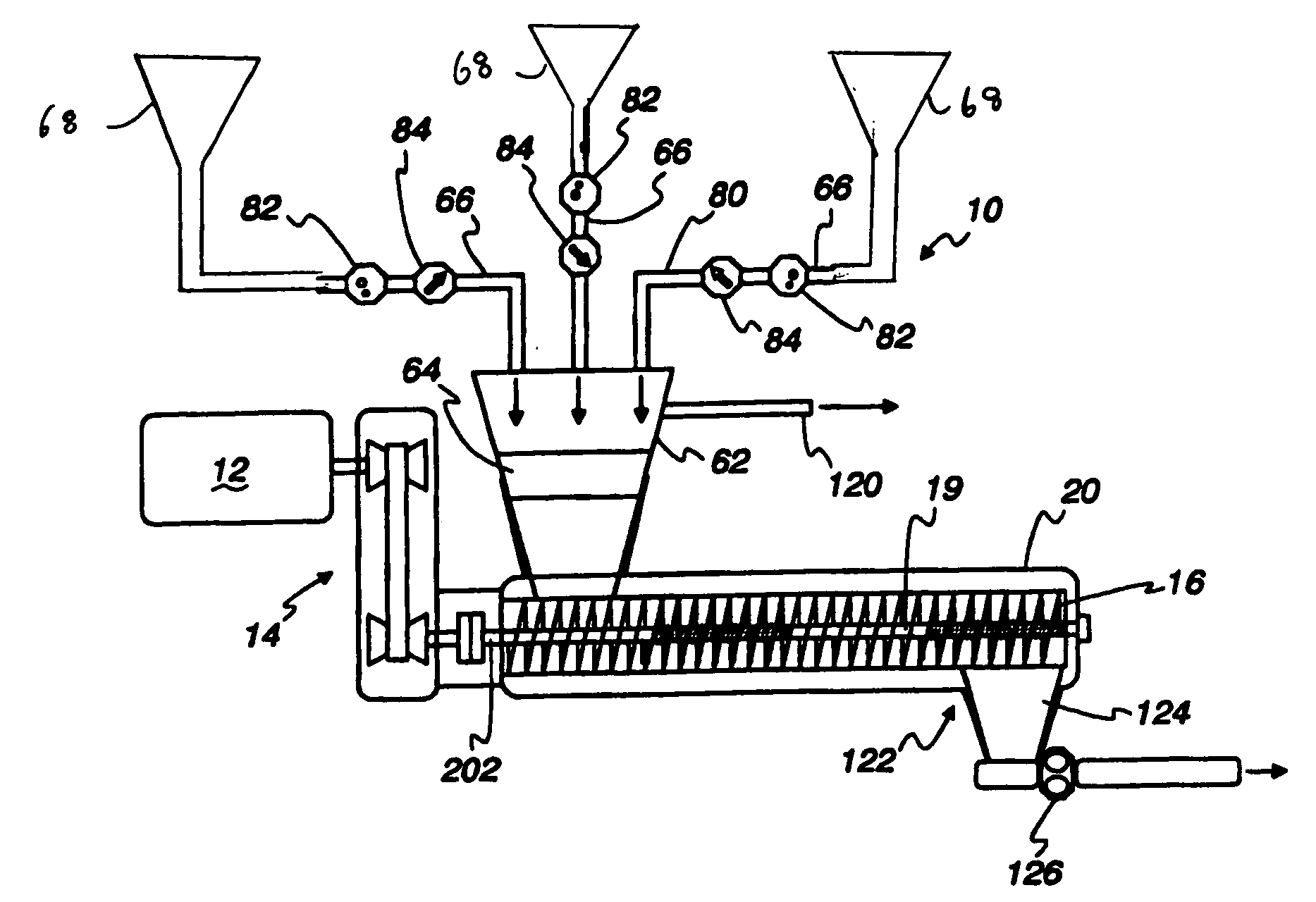

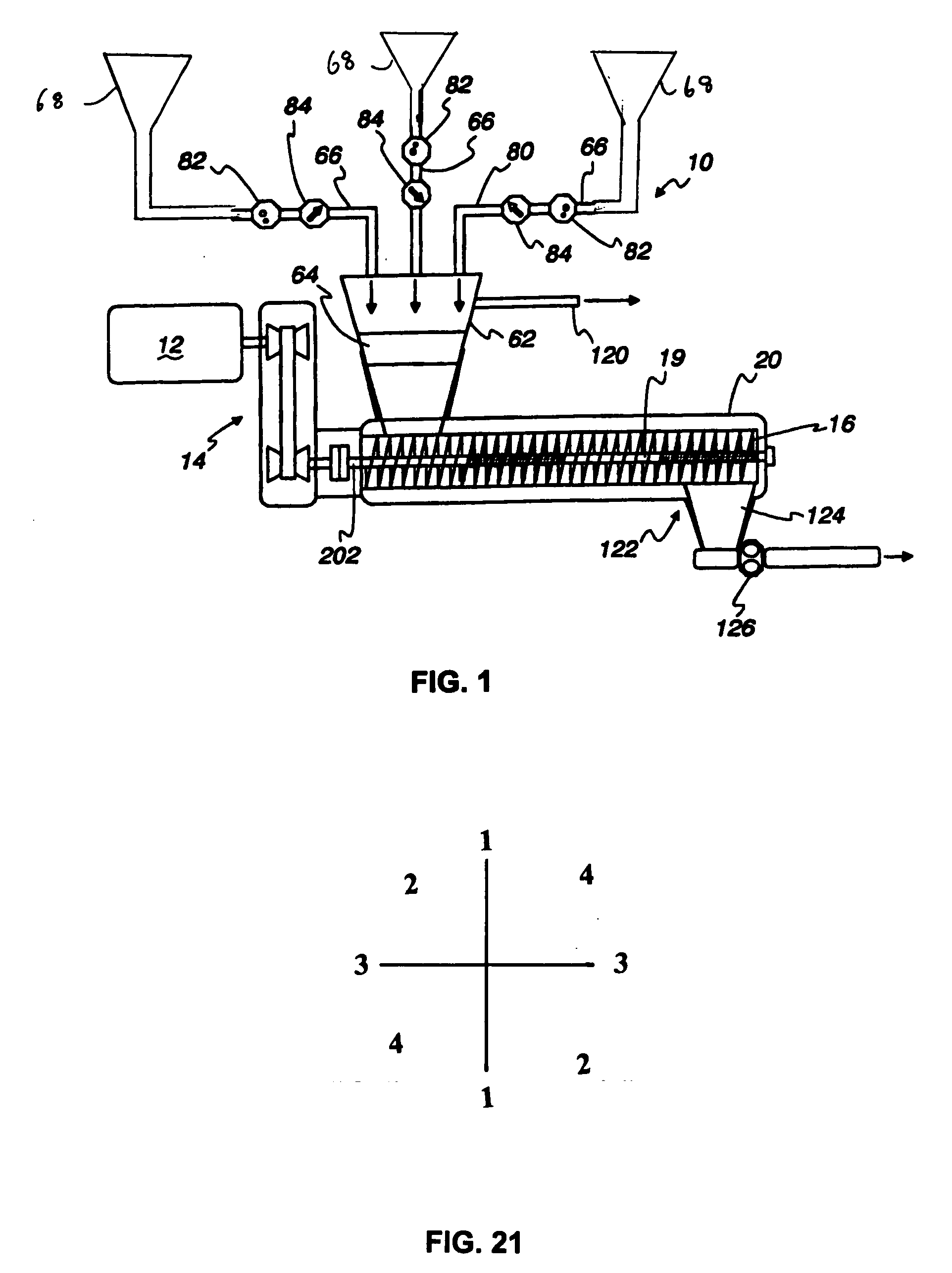

Meat processing system

InactiveUS20050249863A1Small sizeIncreased formationRotary stirring mixersTransportation and packagingAdditive ingredientSize reduction

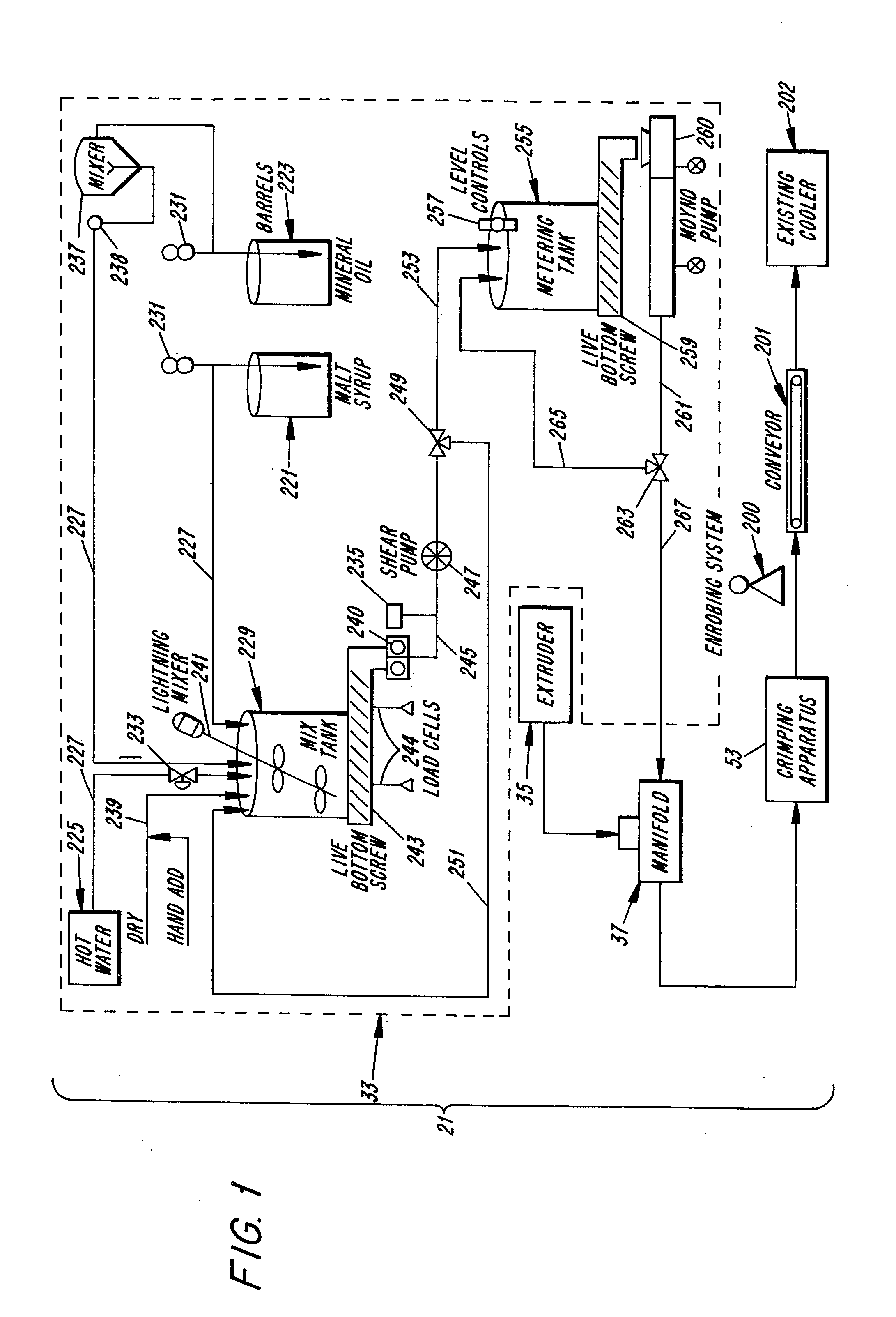

A system and method for continuous processing of meat product constituents is disclosed. Selected meats are loaded into hoppers, and inputs lines direct the meats and other meat product constituents into a mixer. The mixer provides initial size reduction of the meats, grinds the meat, infuses and mixes the meats and other ingredients, forces protein extraction for forming a stable meat mixture, finely comminutes the mixture, and outputs the mixture.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Method of making processed meat products

InactiveUS7488502B2Small sizeIncreased formationMeat/fish preservationRotary stirring mixersEngineeringProcessed meat

A method and system for making processed meat products employing a feed-forward analysis wherein input streams are analyzed and their flow rates are controlled relative to each other. The system incorporates mixing devices in a housing through which the input streams are forced. The mixing devices provide high shear mixing and blending, and in some cases maceration and salt infusion for rapid protein extraction.

Owner:KRAFT FOODS GRP BRANDS LLC

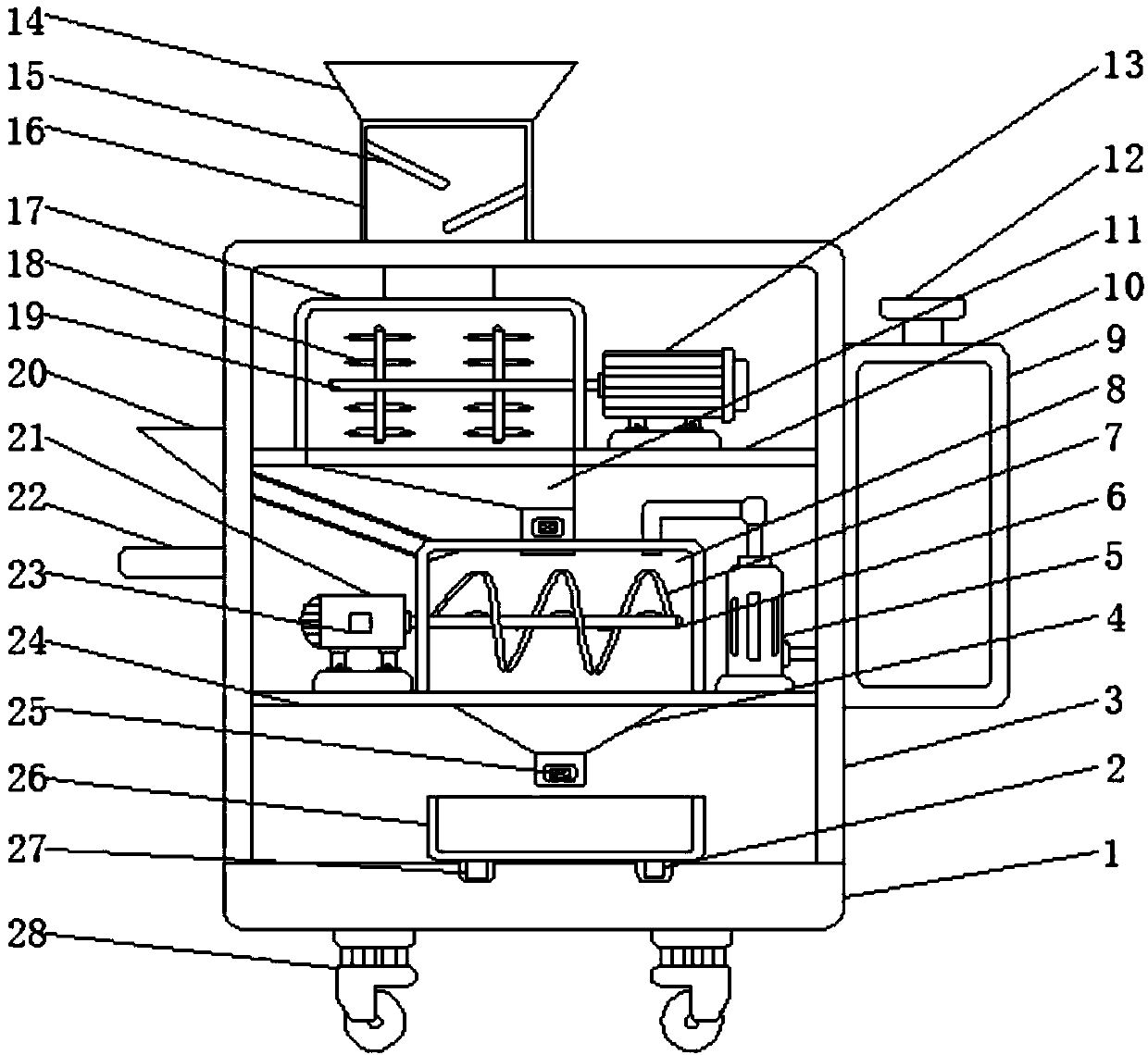

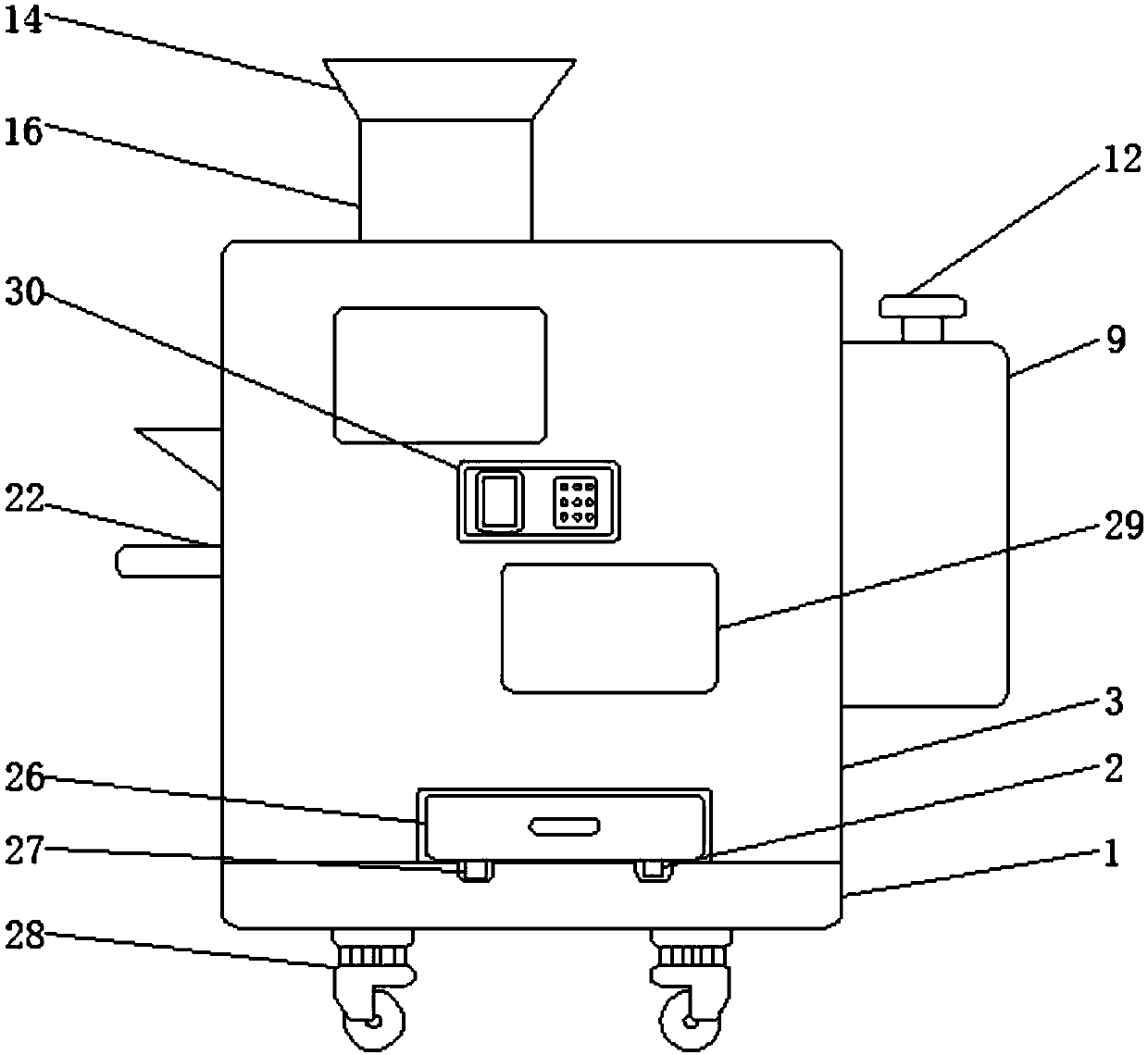

Pork processing device used for production of meat products

InactiveCN107593859AEasy to processEnter at a constant speedMeat mixing apparatusMeat processing devicesBiochemical engineering

The present invention discloses a pork processing device used for a production of meat products. The pork processing device comprises a base seat, a box body, a stirring chamber and a crushing chamber. Walking wheels are arranged on a bottom part of the base seat, the box body is arranged on the base seat, a sliding chute is arranged on the base seat in the box body, a material taking groove is arranged on the sliding chute via sliding blocks, a second supporting plate is arranged in the box body at an upper side of the material taking groove, the stirring chamber is arranged on the second supporting plate, a first material discharge funnel extending to the material taking groove is arranged on a bottom part of the second supporting plate of an output end of the stirring chamber, and a servo motor is mounted on the second supporting plate at one side of the stirring chamber. The processing device is more comprehensive in a processing of pork. During a stirring in the stirring chamber,working staff can conduct a throwing of seasoning materials at the same time according to an amount of the pork and an amount of water in the stirring chamber. The processing device realizes the stirring and at the same time conducts a blending of the pork, avoids the blending by the working staff in a material discharge of the pork, and is strong in practicality and worthy of promotion and use.

Owner:江苏裕邦食品有限公司

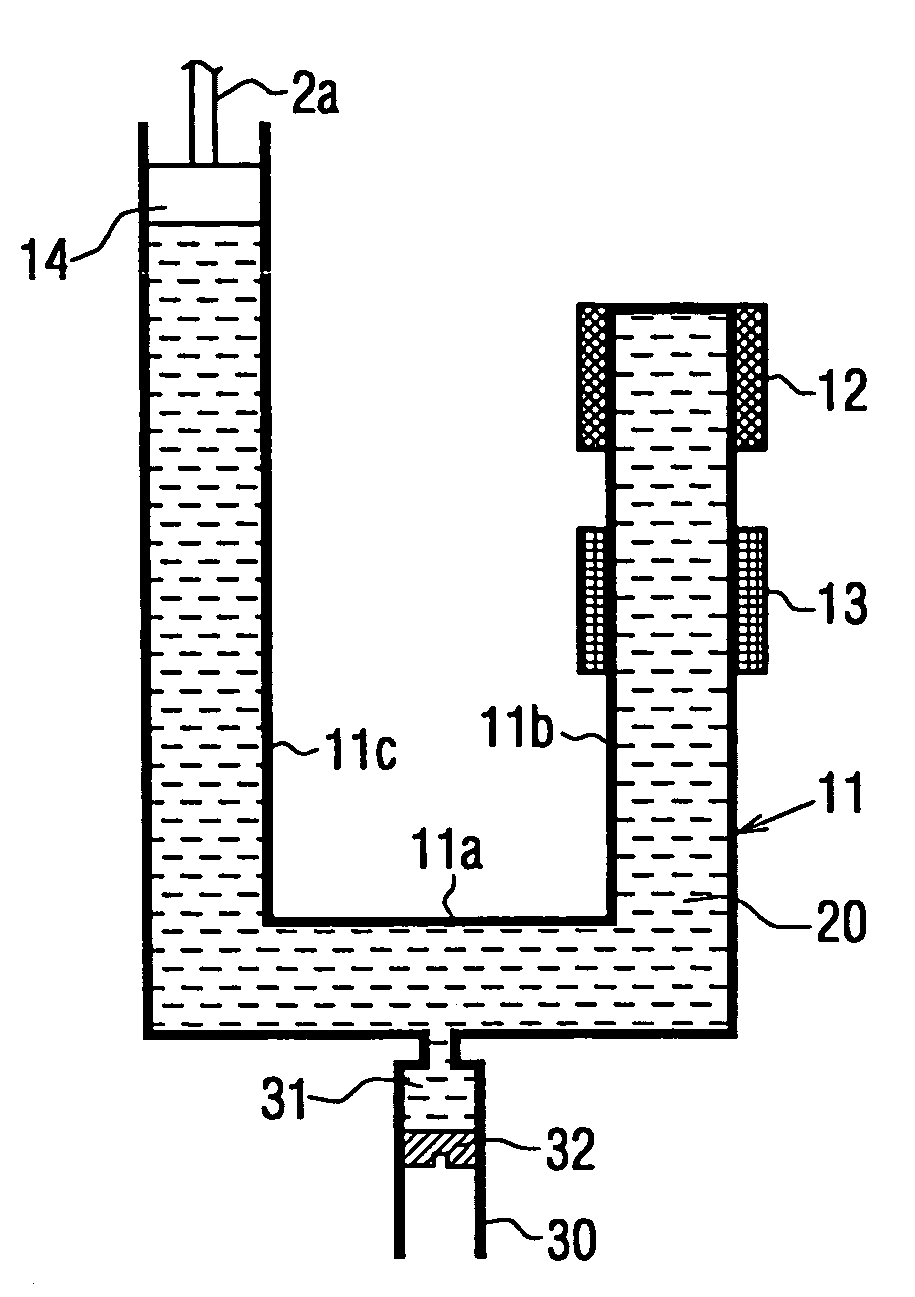

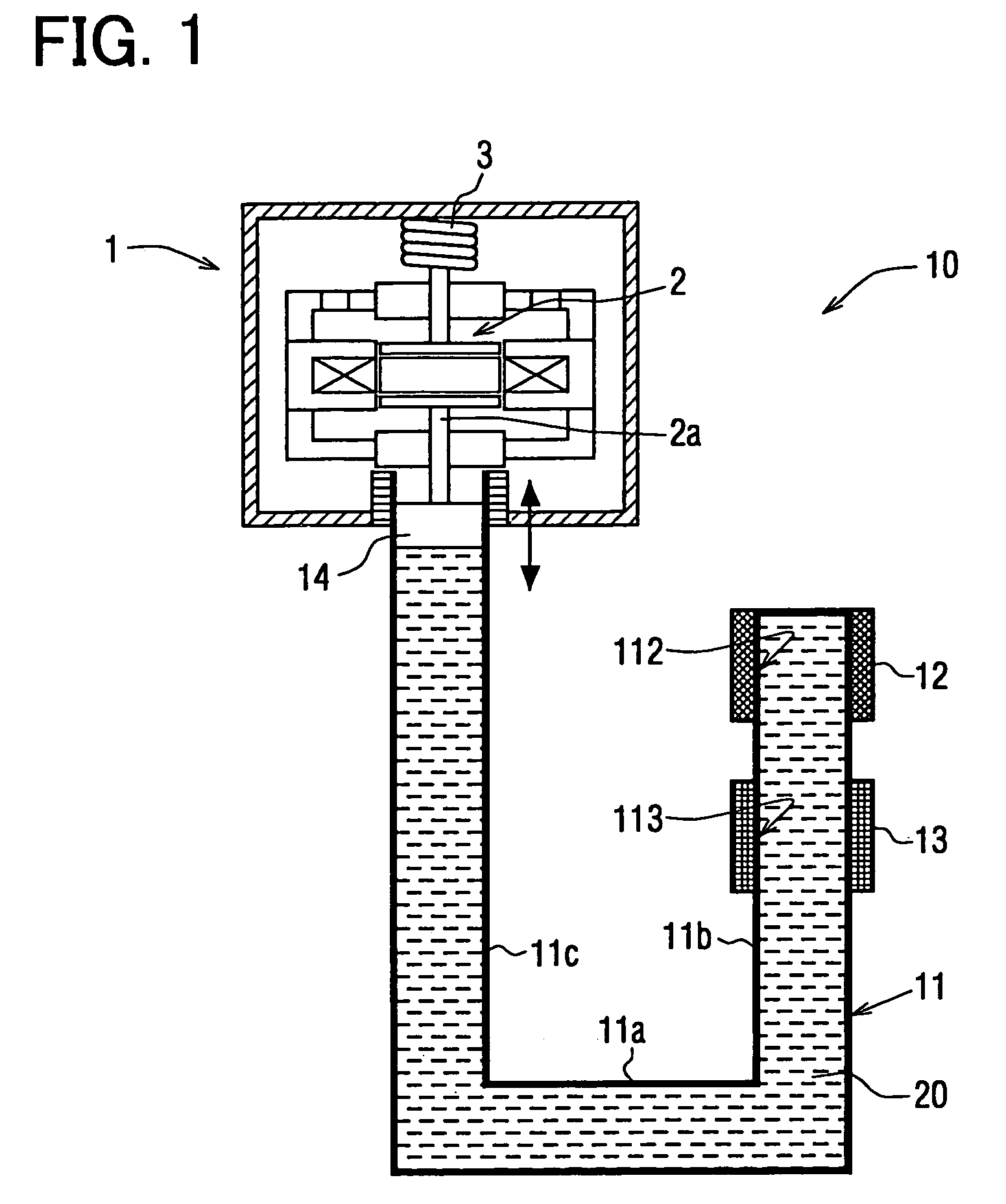

Steam engine

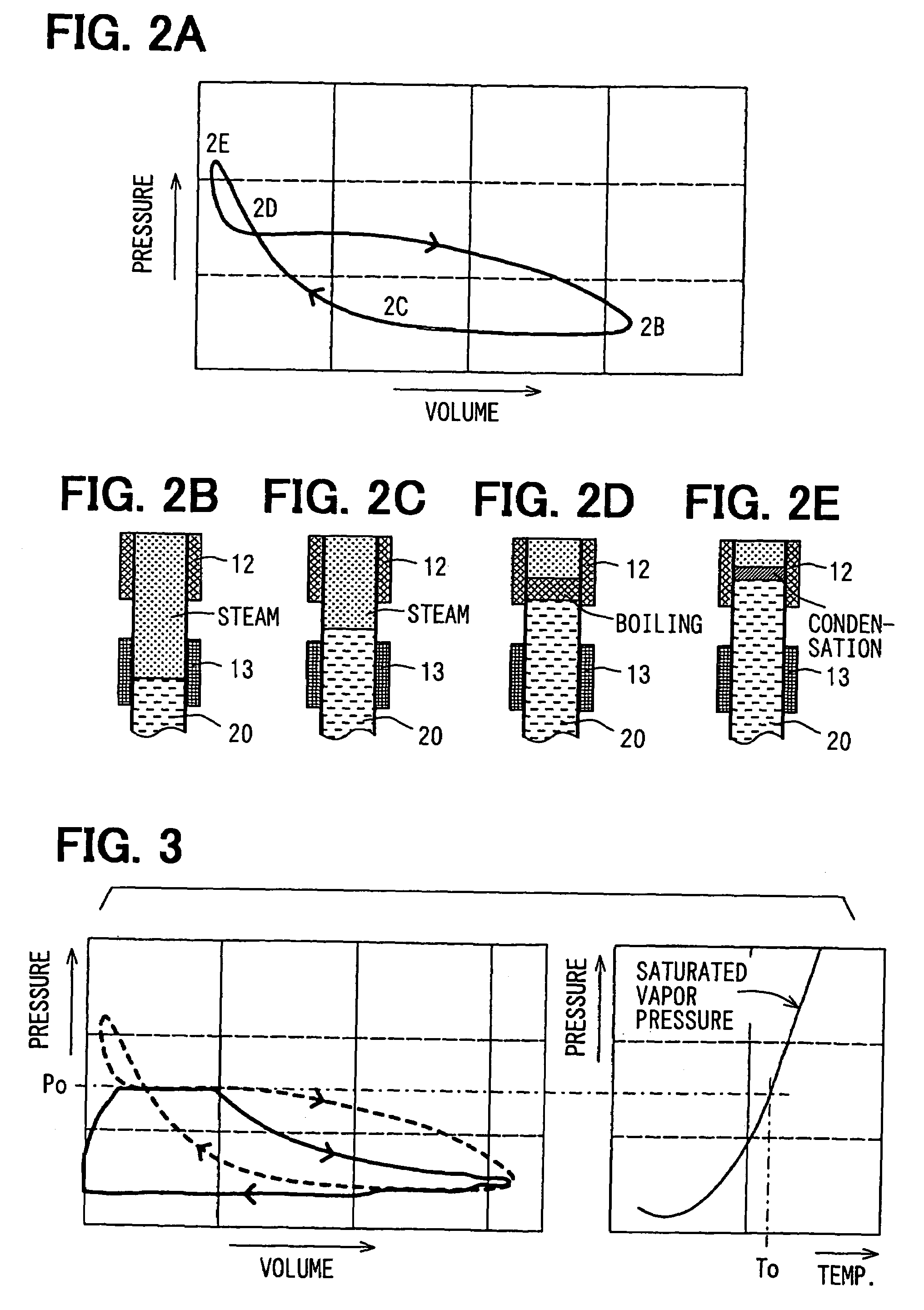

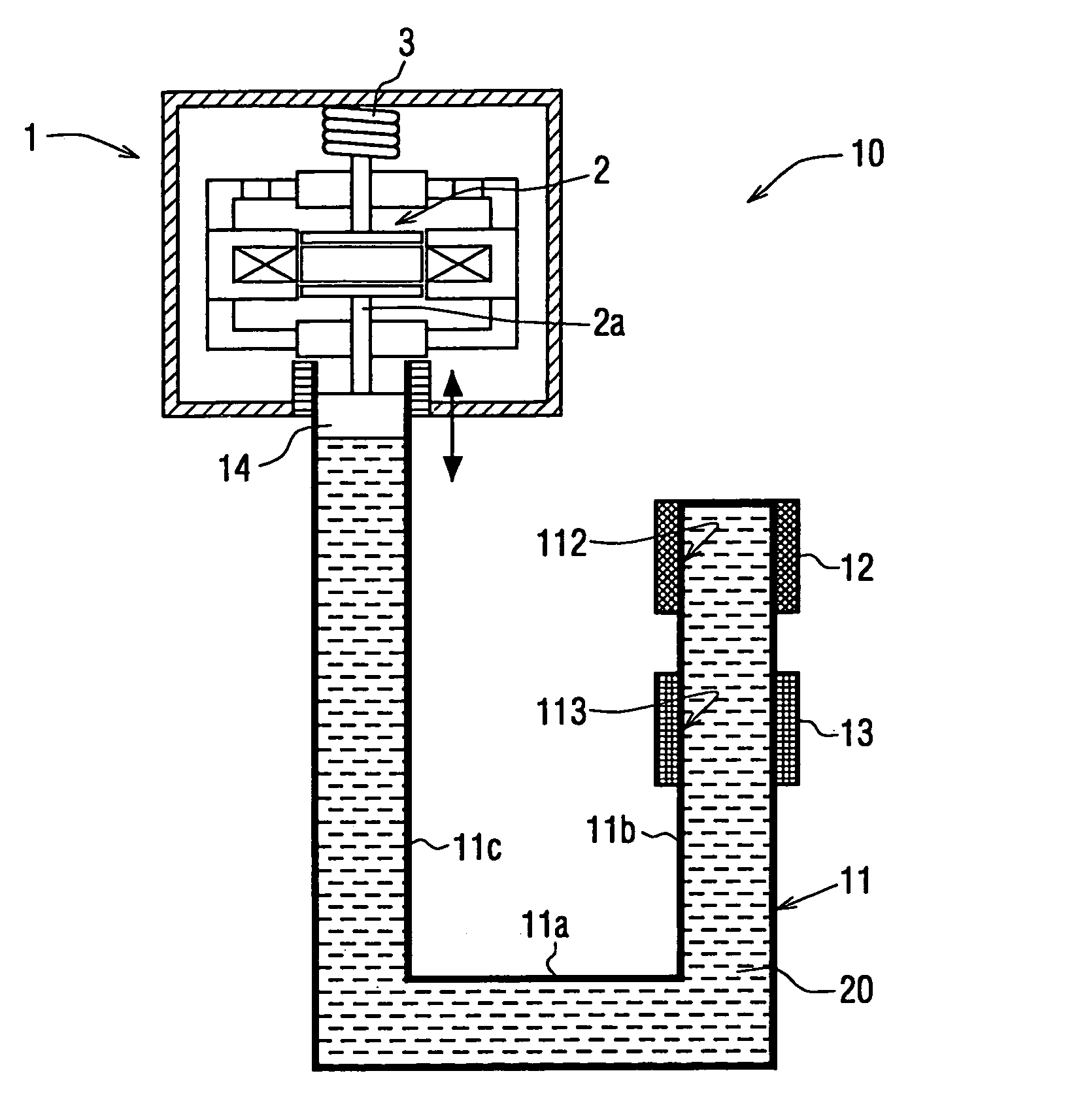

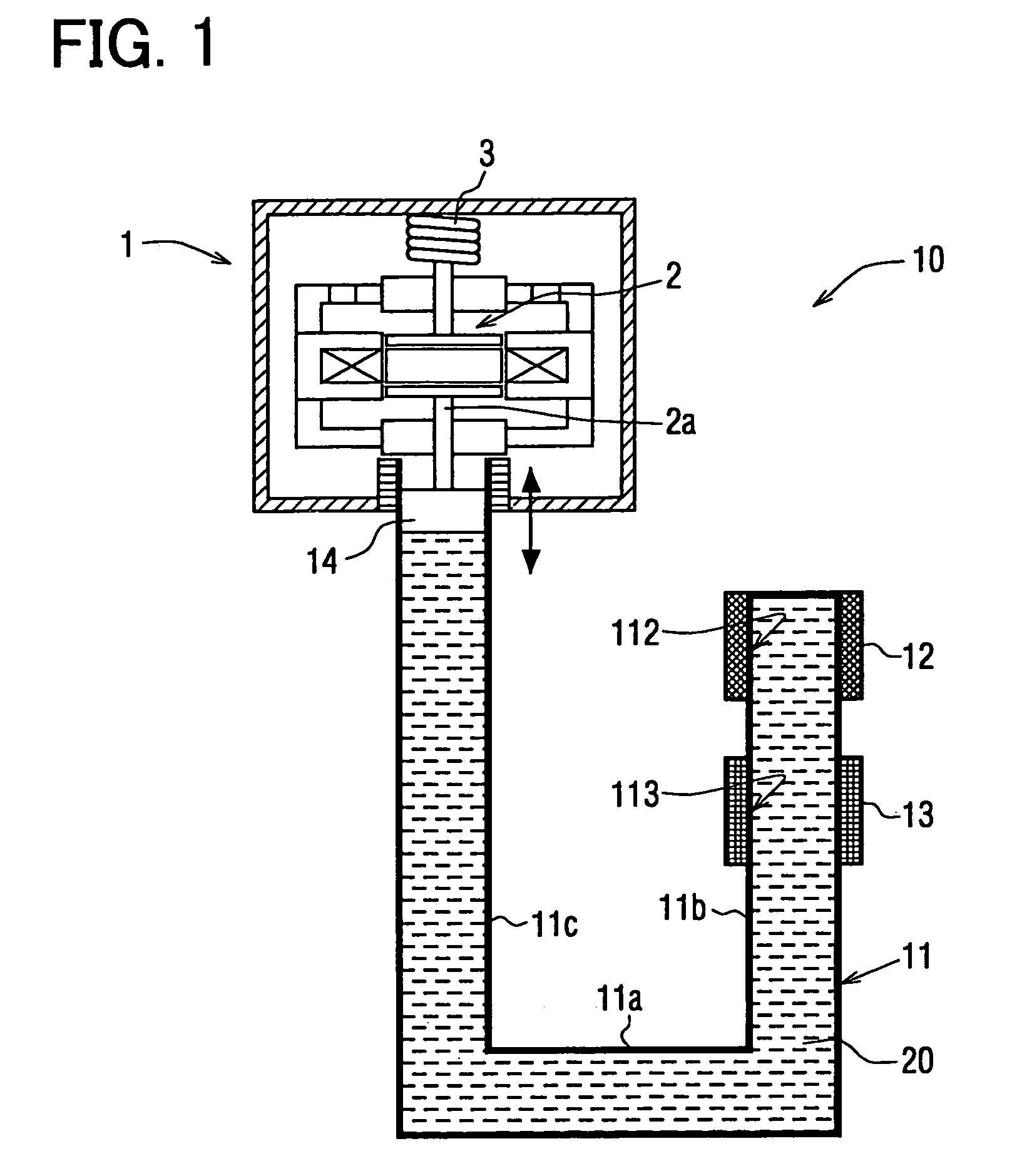

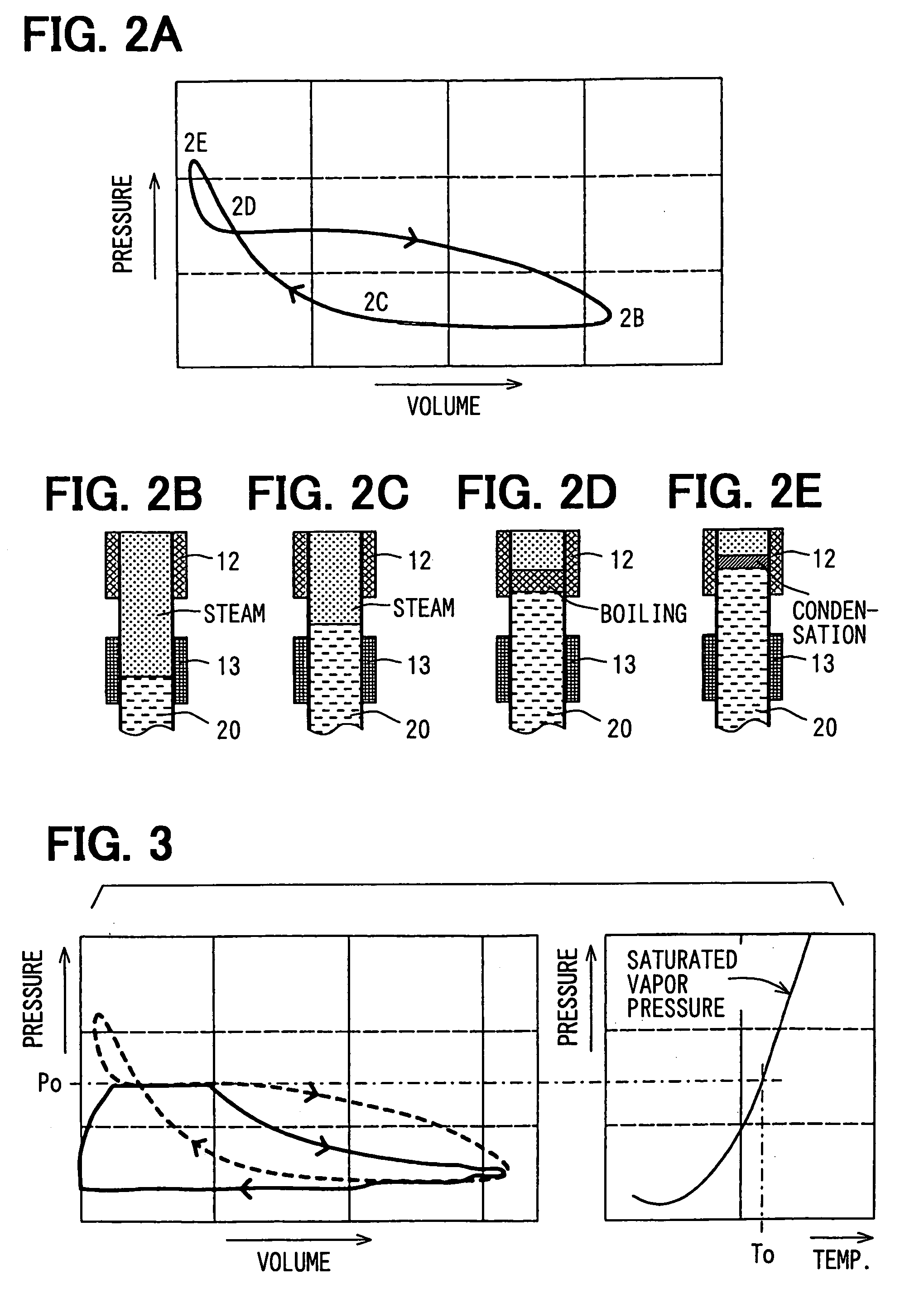

InactiveUS7415824B2Increase productionImprove efficiencySteam accumulatorsSteam engine plantsEngineeringOutput device

A steam engine has a pipe shaped fluid container, a heating and cooling devices respectively provided at a heating and cooling portions of the fluid container, and an output device connected to the fluid container, so that the output device is operated by the fluid pressure change in the fluid container, to generate an electric power. In such a steam engine, the fluid pressure in the fluid container is adjusted such that the fluid pressure does not exceed a saturated vapor pressure at the operating temperature. As a result, unnecessary condensation and liquefaction of the steam due to the increased pressure higher than the saturated vapor pressure can be prevented, to improve performance of the steam engine.

Owner:DENSO CORP

Steam engine

InactiveUS20050257525A1Increase productionImprove efficiencySteam accumulatorsSteam engine plantsSteam pressureEngineering

A steam engine has a pipe shaped fluid container, a heating and cooling devices respectively provided at a heating and cooling portions of the fluid container, and an output device connected to the fluid container, so that the output device is operated by the fluid pressure change in the fluid container, to generate an electric power. In such a steam engine, the fluid pressure in the fluid container is adjusted such that the fluid pressure does not exceed a saturated vapor pressure at the operating temperature. As a result, unnecessary condensation and liquefaction of the steam due to the increased pressure higher than the saturated vapor pressure can be prevented, to improve performance of the steam engine.

Owner:DENSO CORP

Minced meat processing device

ActiveCN106614984ARealize automatic openingAchieve closureMeat mixing apparatusAutomatic controlFood safety

The invention discloses a minced meat processing device. The minced meat processing device comprises a basin and a storage tank above the basin, the basin is internally provided with an arc groove, a top stage is arranged in the inner middle of the arc groove, a base is arranged at the top of the top stage, and the storage tank is formed by assembly of a first storage chamber, a second storage chamber and a third storage chamber. The base is externally provided with slide grooves, the third storage chamber externally sleeves the base, convex rings entering the slide grooves to realize slide fit connection are arranged on the inner bottom side of the third storage chamber, and four outer walls of the third storage chamber are provided with slots respectively. A supporting column extending upwards is arranged on the end face of the top of the base, a top extending section of the supporting column passes through the second storage chamber to enter the first storage chamber, the supporting column in the first storage chamber and the supporting column in the second storage chamber are provided with a first motion guide groove and a second motion guide groove respectively, and a first motor is arranged in the supporting column between the first motion guide groove and the second motion guide groove. The minced meat processing device is simple in structure, convenient to operate, reasonable in design and capable of automatically controlling stirring and discharging and improving food safety and operation efficiency and has a reminding function to meet current requirements.

Owner:JIAXING YUZHUANGYUAN FOOD

Rectal plug and method of introducing same into a slaughtered animal

InactiveUSRE36994E1Easy to useNot lose viscosityAnimal stomach clearanceSurgeryFood gradePolymixiiformes

Fecal leakage and contamination from the vent opening of an animal carcass during slaughtering and processing is eliminated by injecting a highly viscous material comprising a mixture of food grade constituents through the vent opening so as to create a self-adhering plug in the lower colon and rectum of the animal. The plug material preferably comprises a blended mixture of water, gum, modified food starch and a preservative whose viscosity is in the range of from about 220,000 centipoise to 480,000 centipoise. Being formed from food grade constituents, the offal can safely be harvested and used in animal feed as a by-product of the meat processing operation.

Owner:STARCHTECH

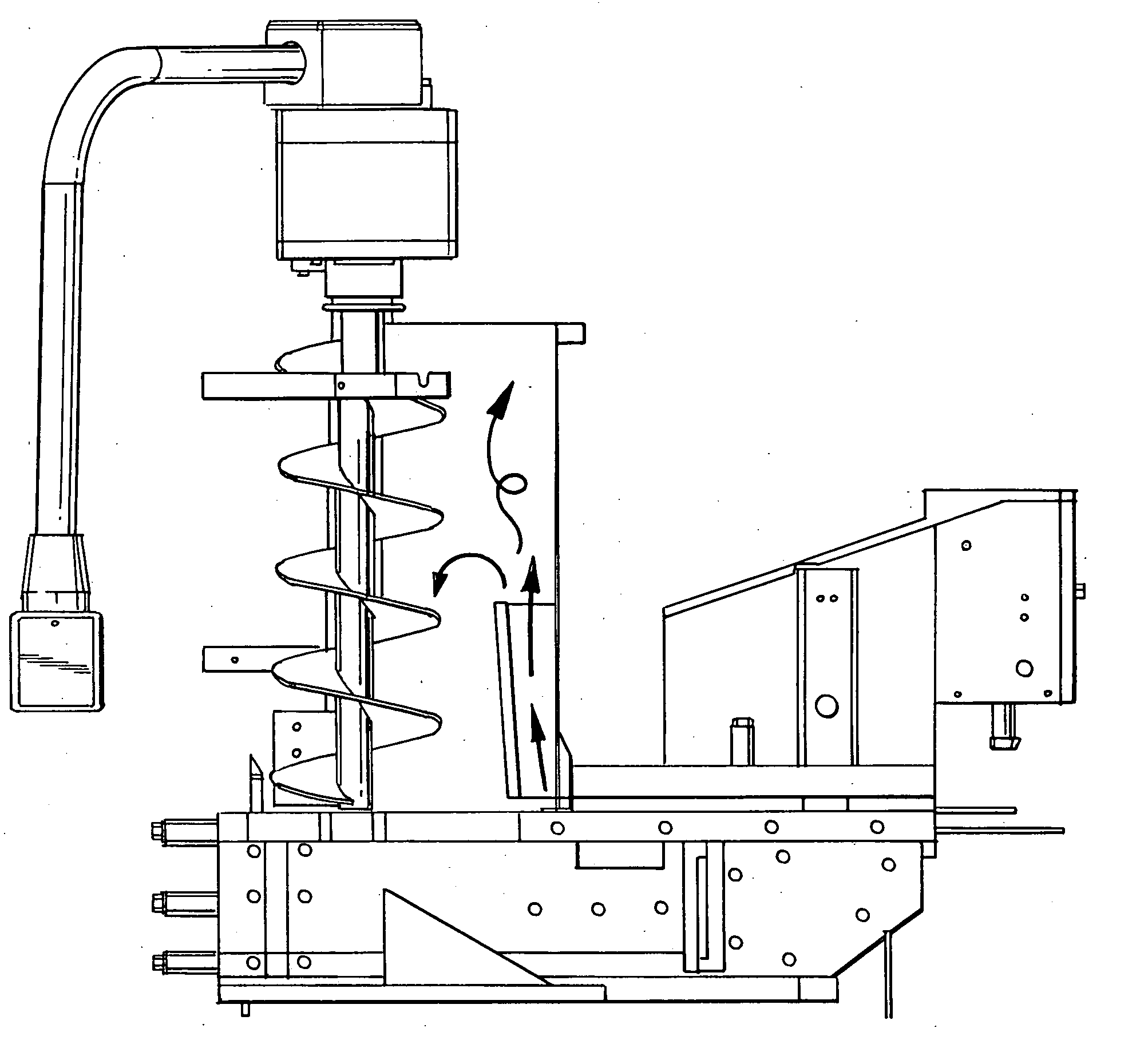

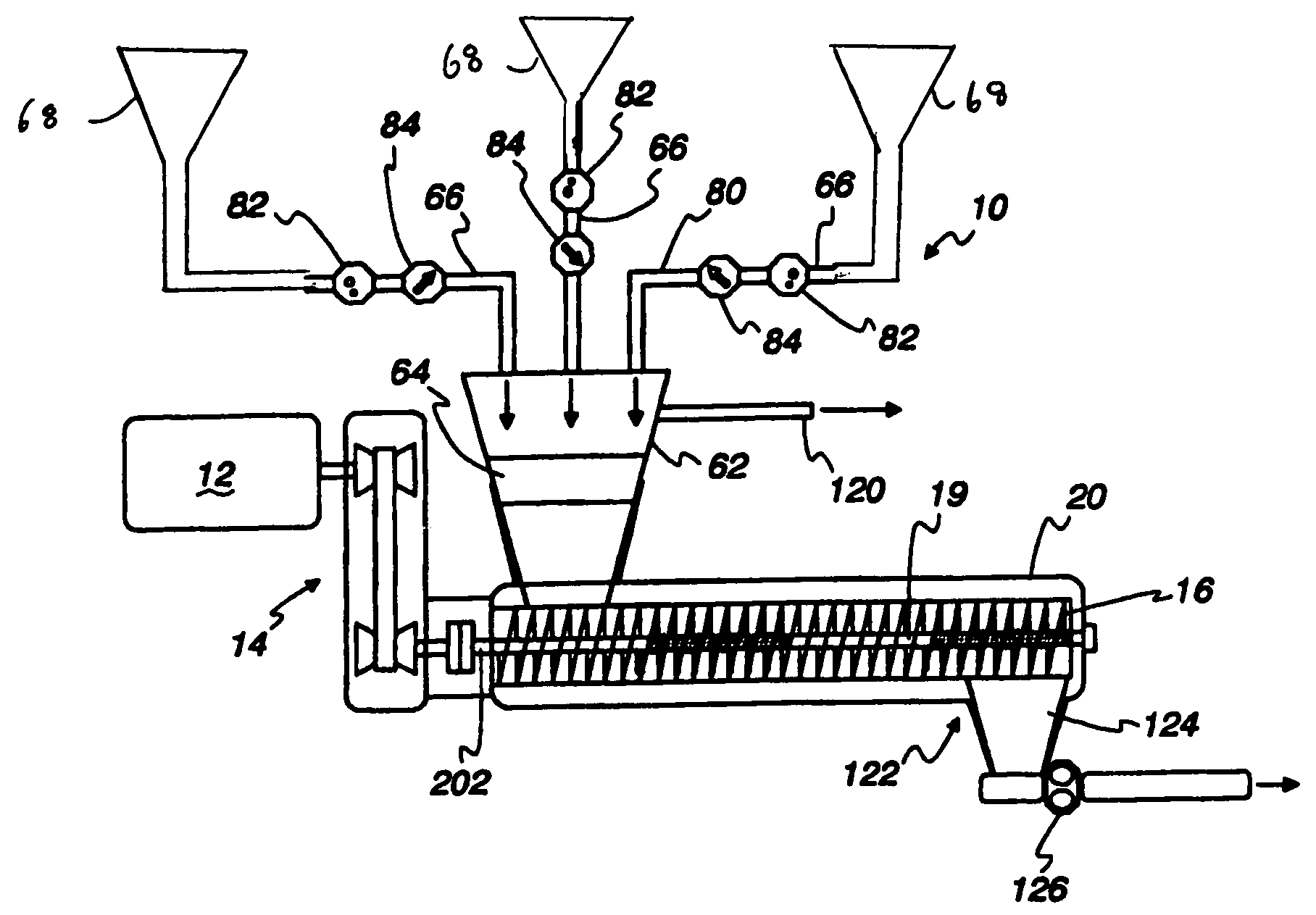

Integrated continuous meat processing system

InactiveUS20050255224A1Extended processing timeEliminate delaysRotary stirring mixersTransportation and packagingProcess engineeringContinuous mixing

An integrated system for continuous production of processed meat products utilizing a continuous mixing system is disclosed. The system includes storage and pre-input hoppers, input lines for pumping streams of meat product constituents into a continuous grinder and mixer, rotating elements within the mixer for mixing the constituents, a surge hopper, equipment for further processing such as stuffing equipment, and transport to and utilization of a continuous thermal process.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

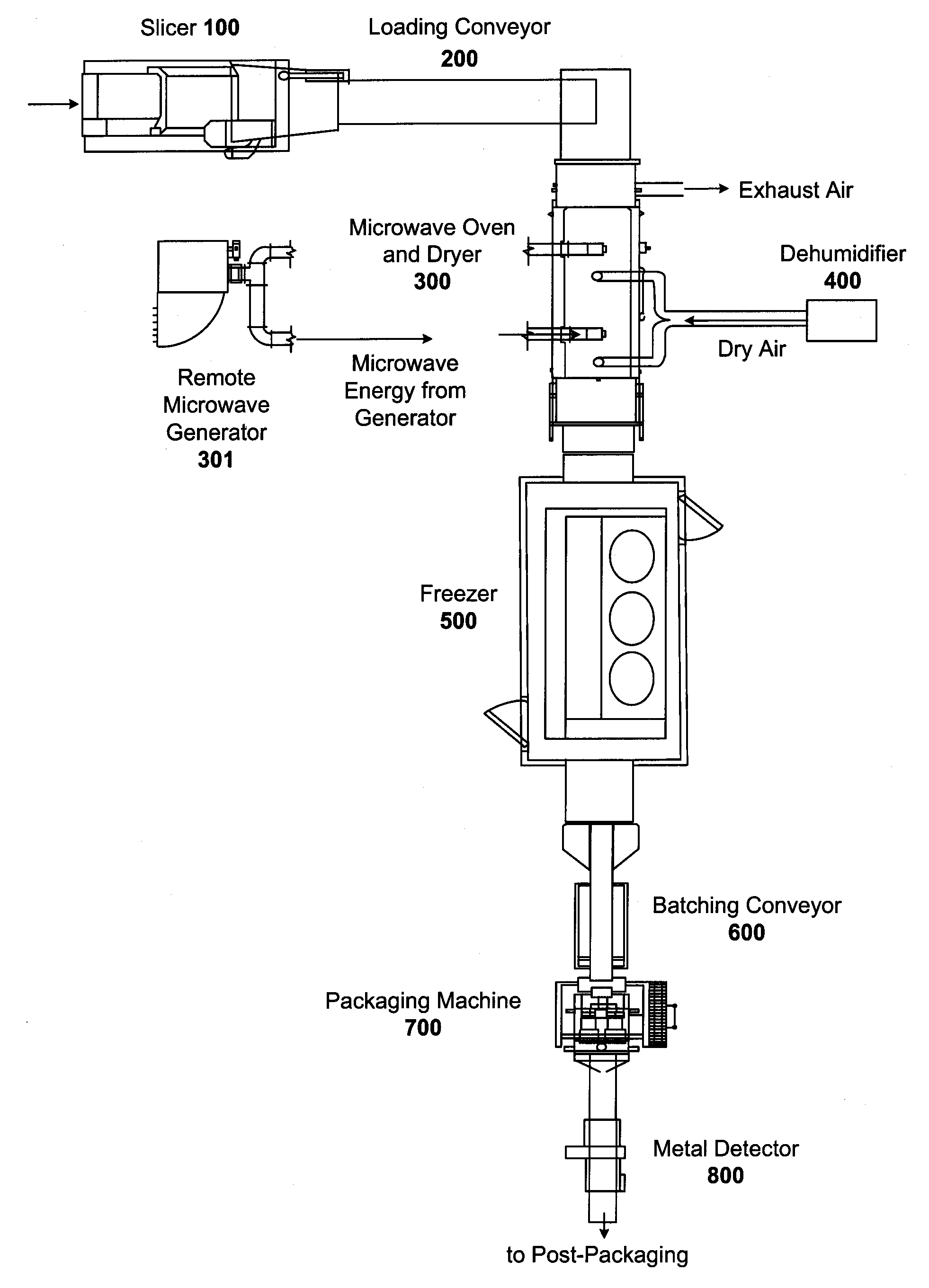

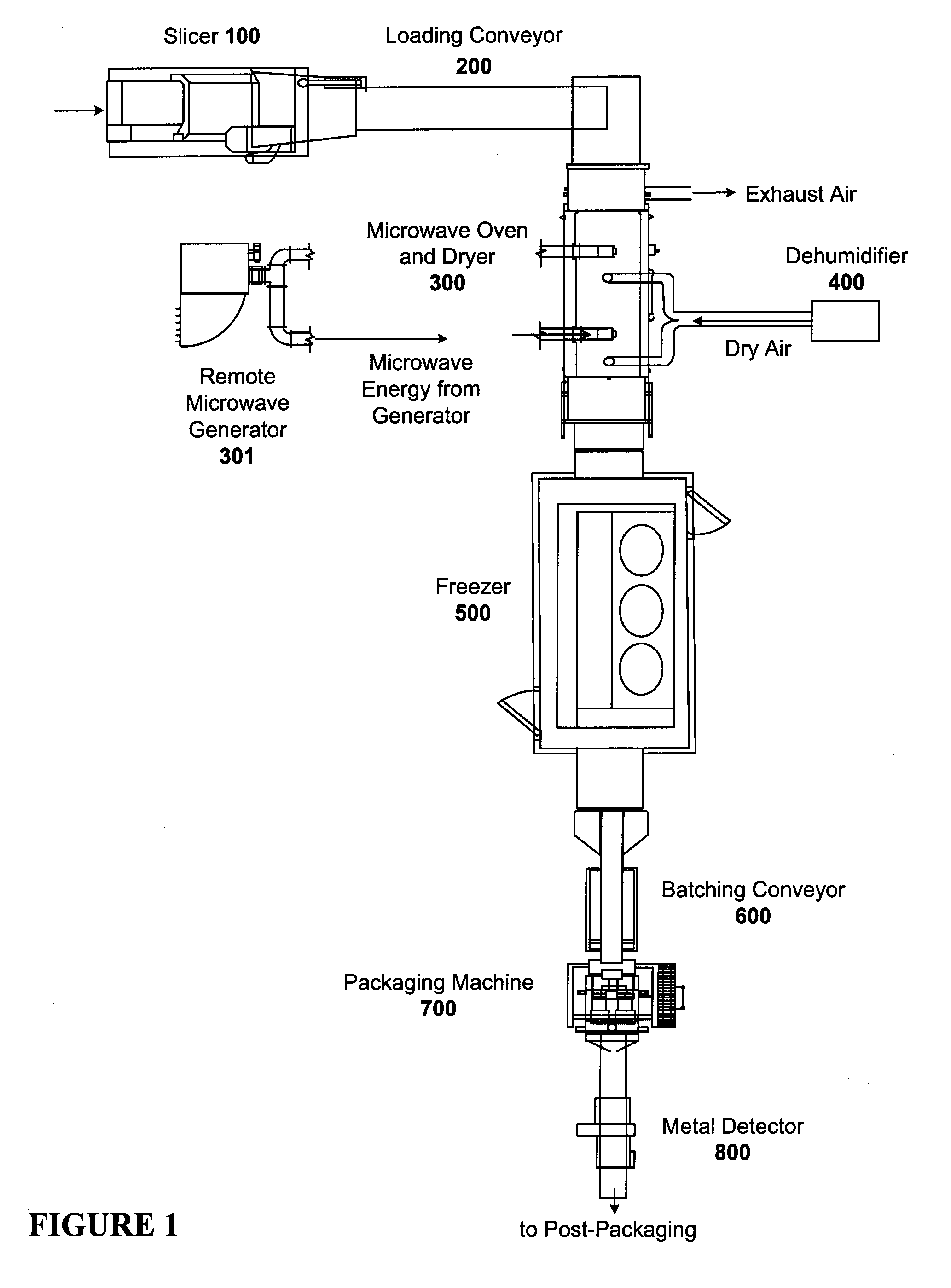

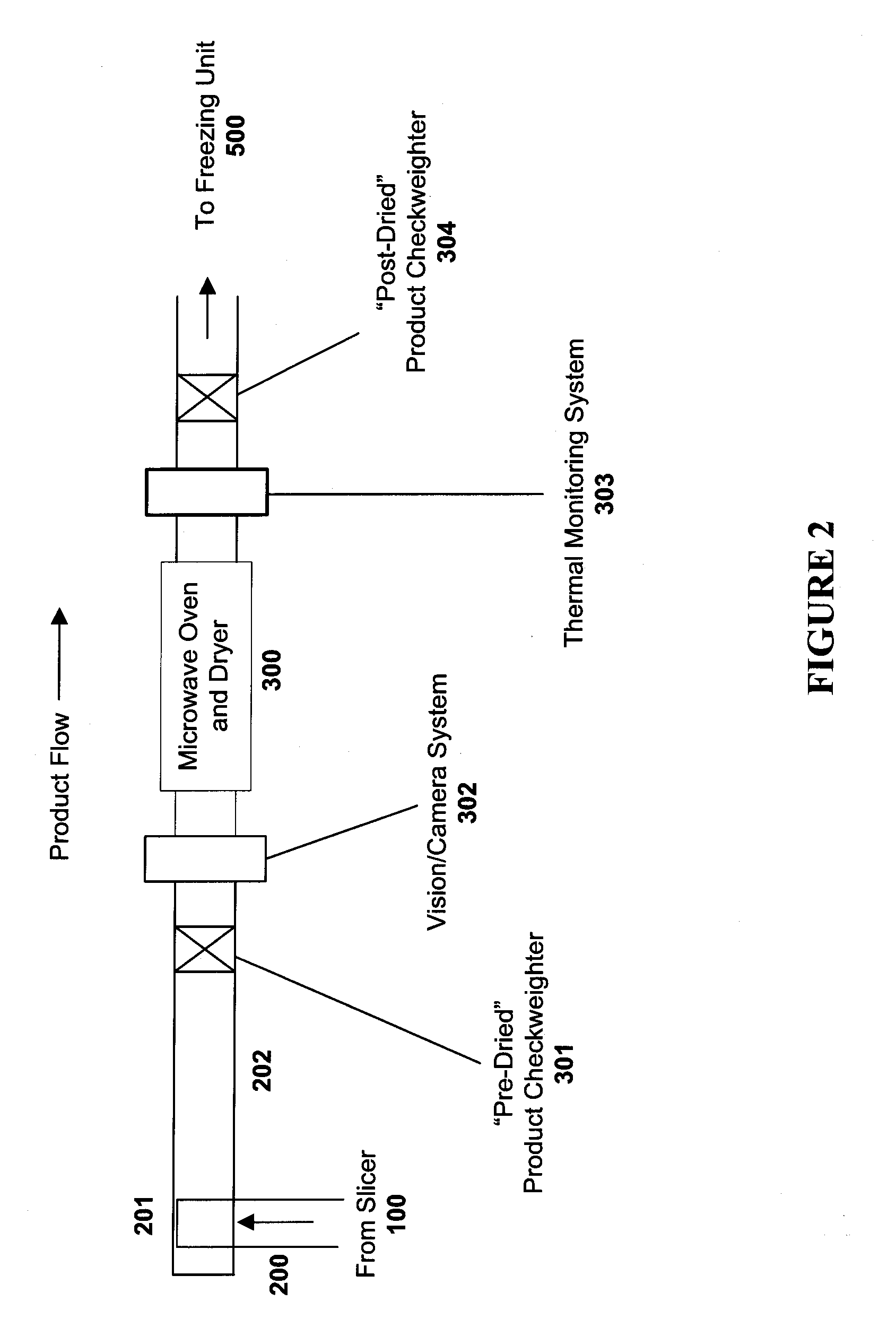

Process and Apparatus for Rapid Preparation of Dry Sausage

ActiveUS20120282372A1Meat/fish preservation by heatingHorizontally conveying sausagesMicrowaveEngineering

A process for manufacturing dry sausage. The process includes preparing a dry sausage meat mixture, stuffing the mixture into a casing or mould, fermenting the mixture, heat treating the mixture, cooling the mixture to a temperature sufficiently low to permit slicing, slicing the sausage, placing the sausage onto a conveyor, and passing the conveyor and sausage through a chamber. The process also includes introducing a supply of conditioned air into the chamber, the air having a relative humidity below about 60% and a temperature in the range of at least about 40° F. to 130° F., and introducing a supply of microwaves into the chamber. The air supply and microwaves are selected to reduce the moisture content of the meat to a predetermined moisture to protein ratio.

Owner:SMITHFIELD FOODS

Method for reducing protein exudate on meat product

InactiveUS7731998B2Small sizeIncreased formationMeat/fish preservationRotary stirring mixersVisible surfaceChemistry

A system and method for reducing protein exudate on meat product. The system utilizes input hoppers and eliminates standing time for the meats. The elimination of a standing time for curing or protein extraction eliminates the ability for visible surface protein exudate to form.

Owner:KRAFT FOODS GRP BRANDS LLC

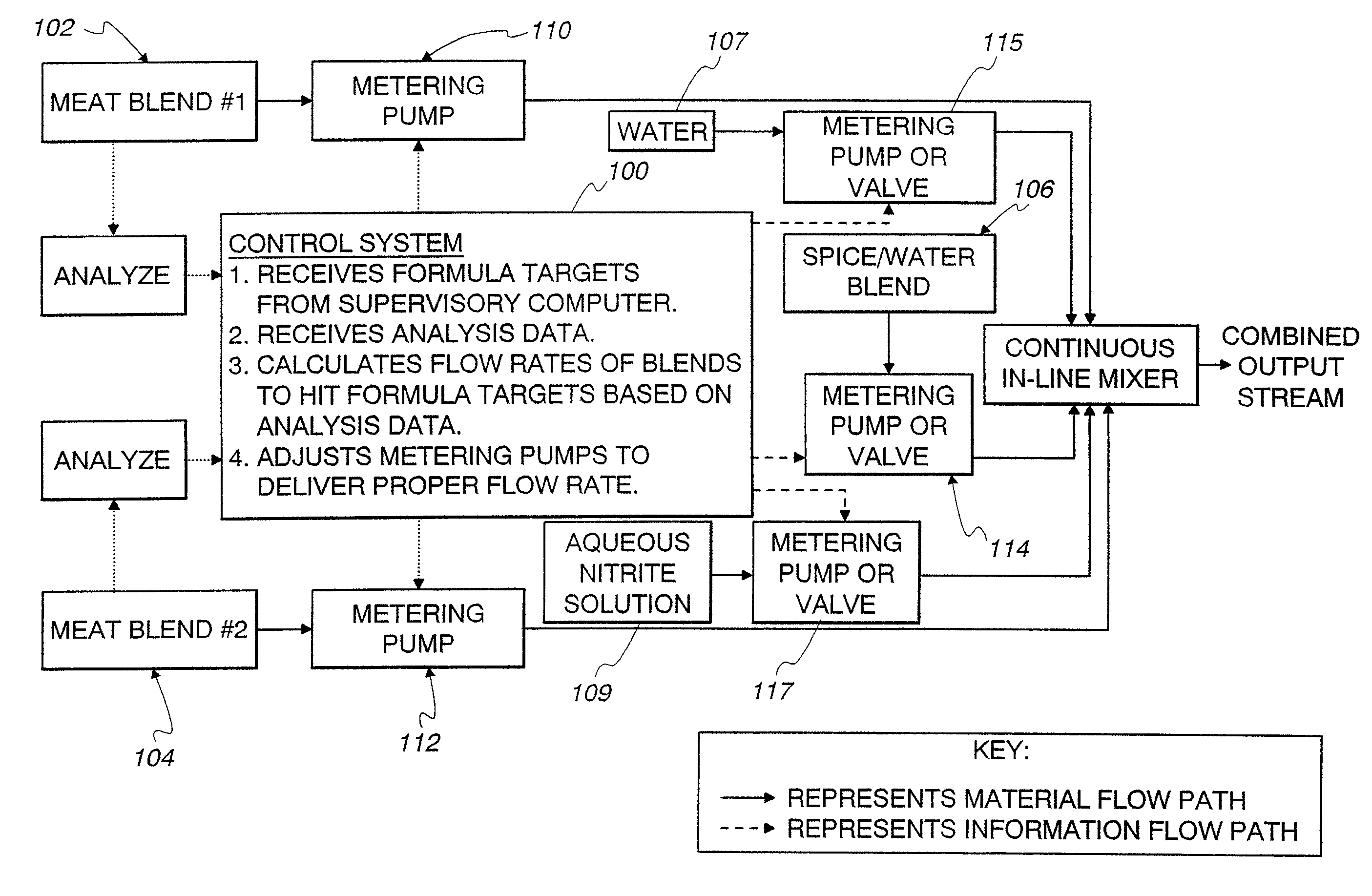

Method and apparatus for meat product manufacturing

InactiveUS20050276903A1Extended processing timeEliminate delaysRotary stirring mixersTransportation and packagingInformation analysisBiochemical engineering

A system and method for providing information to a control system for regulating the formulation of a meat product is disclosed. The control system may receive information prescribing the formulation of the meat product, analyze characteristics of incoming constituent streams, and adjust the flows based on the final product formulation. The control system may further provide feedback regarding the final product formulation relative to the incoming constituent streams.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Device and method of manufacturing and filling up fine sausage meat, in particular an emulsion

ActiveUS20110248105A1Continuous operationShorten the timeCocoaSausage filling/stuffing machinesEmulsionEngineering

A device and a method of manufacturing and filling up product in the form of fine sausage meat, in particular an emulsion, with a feed means for the product, a feed pump for transporting the product, at least one downstream fine mincer as well as a filling and / or portioning means arranged downstream of the fine mincer for filling up the produced fine sausage meat or the emulsion, respectively.

Owner:ALBERT HANDTMANN MASCHFABRICK

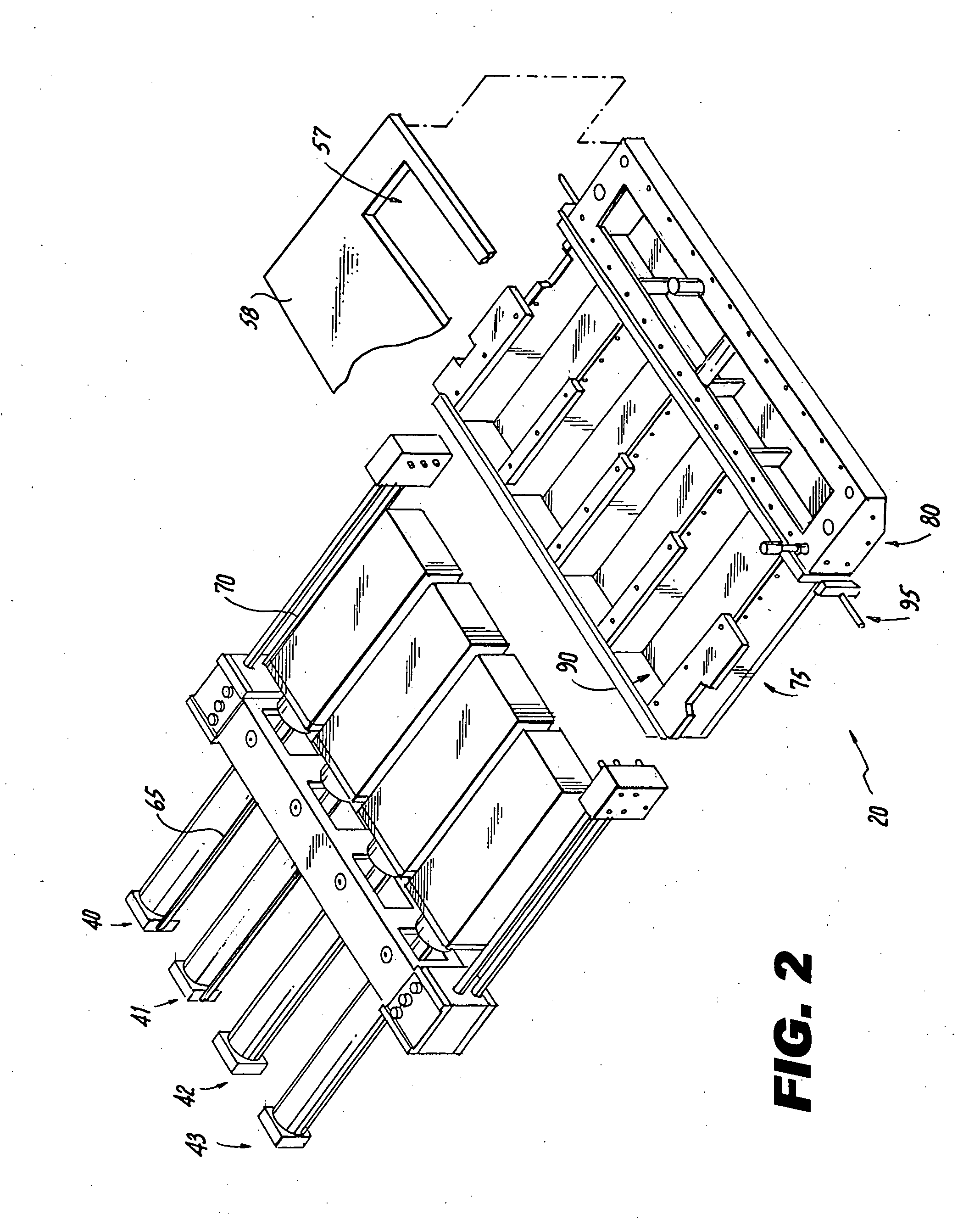

Method and system for controlling product flow on a food product molding machine

A manifold for a food product molding machine, which balances the flow and pressure of the food product over a wide fill area. The invention further relates to a feed system for a food product molding machine which has a multiple plunger configuration which increases the capacity of the food product molding machine. The invention further provides a valve for controlling the flow of food product molding machine. A breather vent assembly and auger cover is configured to return exhaust air and excess food product to the food product supply.

Owner:PATRIOT UNIVERSAL HLDG

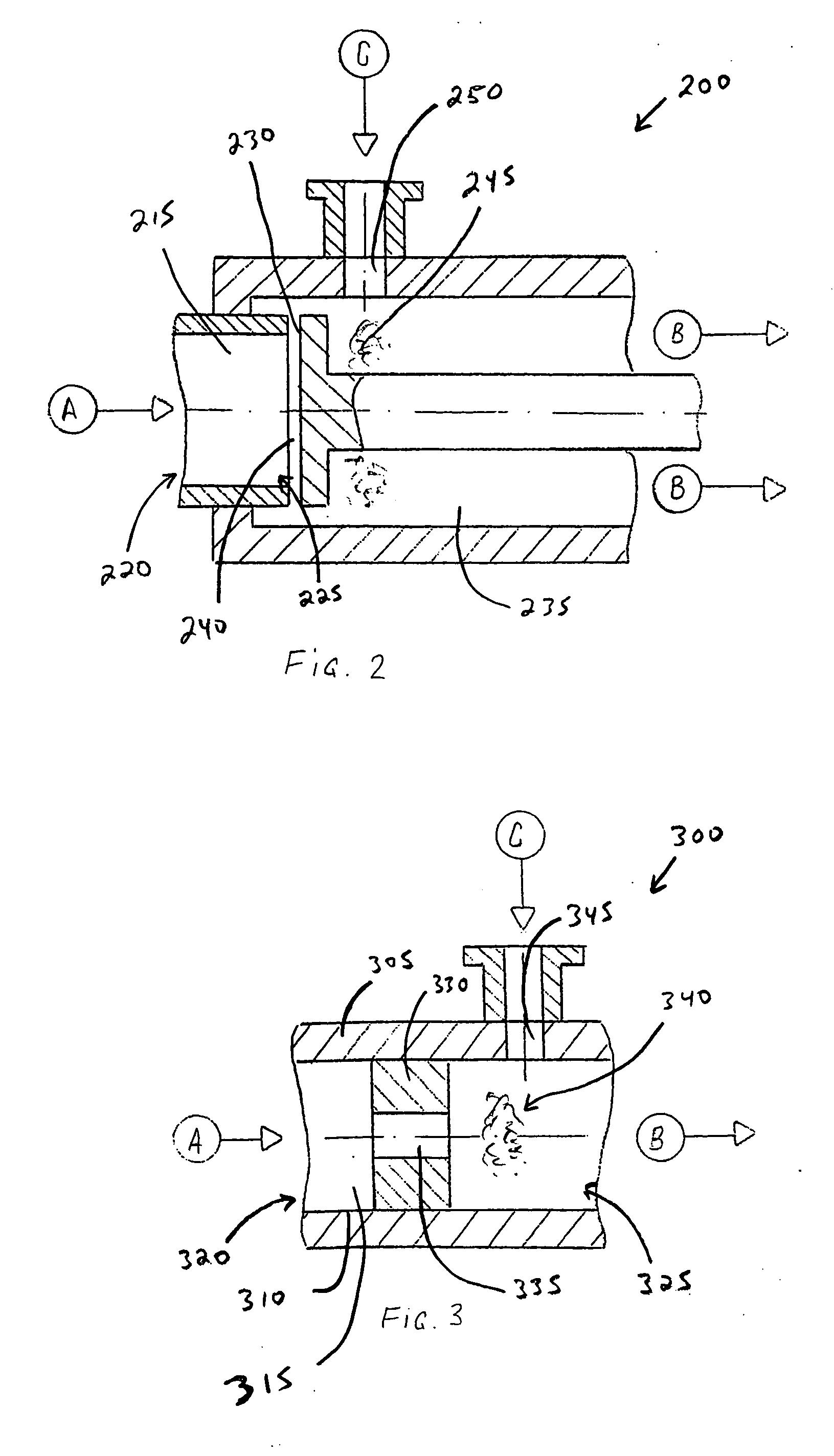

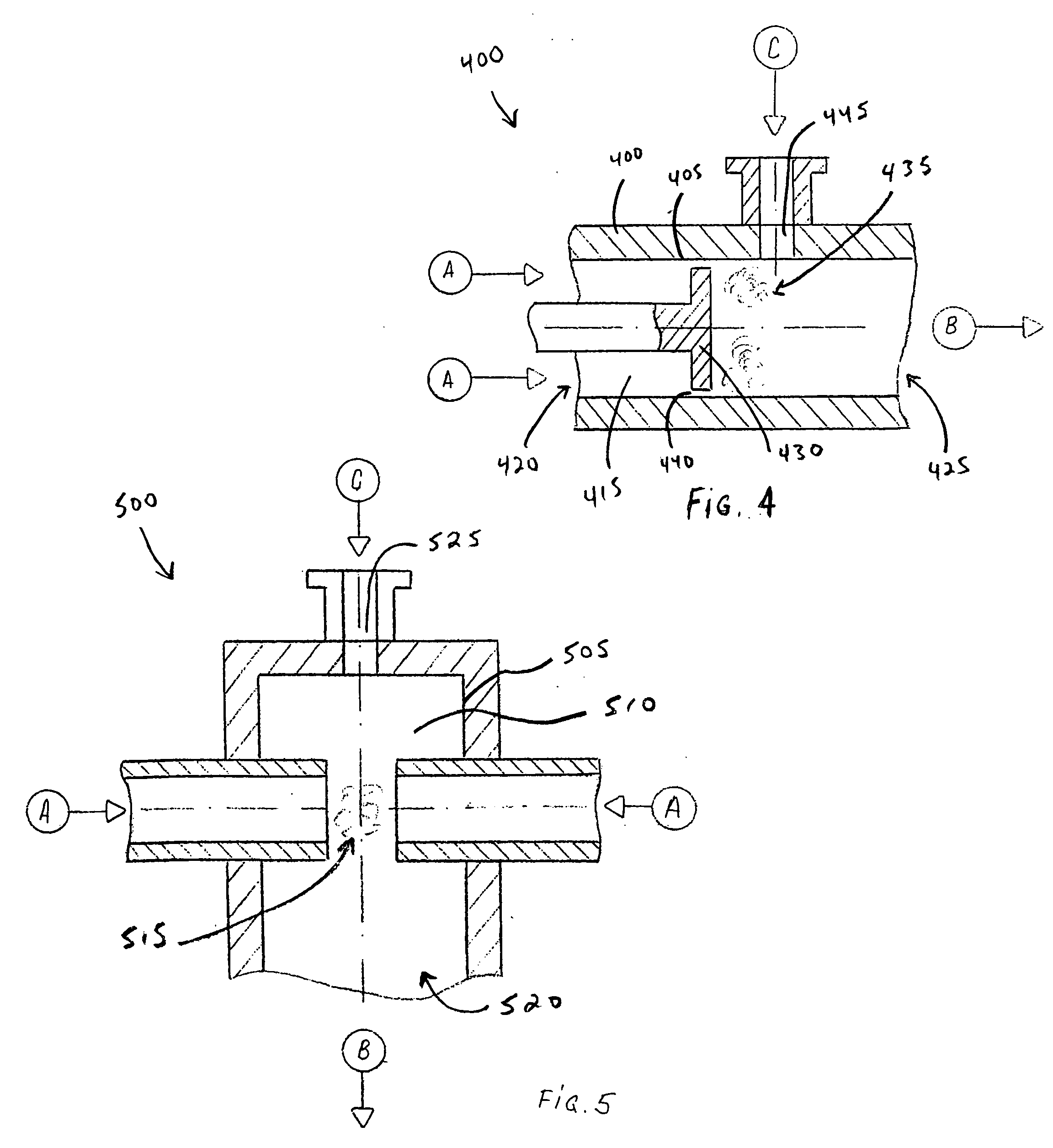

System and method for heat treating a homogenized fluid product

InactiveUS20050136123A1Food preservationMammal material medical ingredientsAdditive ingredientProcess engineering

A system and method for heat treating a homogenized fluid product, the method comprising the steps of feeding a stream of fluid product ingredients through a local constriction of flow to effectuate high shear mixing of the fluid product ingredients in a high shear mixing zone downstream from the local constriction of flow and thereby form a homogenized fluid product at a first temperature and introducing a sufficient amount of the homogenized fluid product at a second temperature, which is less than the first temperature, into the high shear mixing zone to effectuate mixing of the homogenized fluid product at the first temperature with the homogenized fluid product at the second temperature to thereby heat treat the homogenized fluid product fluid product.

Owner:CAVITECH HLDG

Beef beating device for beef ball preparation

InactiveCN107960441ABeat evenly and fullyBeating without interruptionBeating-based meat tenderisingMeat mixing apparatusEngineeringBlock match

The invention discloses a beef beating device for making beef balls, which comprises a bottom plate, the bottom of the bottom plate is provided with outriggers; the top of the bottom plate is fixedly provided with a first deceleration motor, and the motor shaft at the top of the first deceleration motor is fixedly connected with a beating plate; the top right side of the bottom plate Two second support rods, front and rear, are fixedly installed, and the tops of the second support rods are respectively hinged with square hammer rods; two front and rear support plates are fixedly installed on the right side of the top of the legs, and there is a rotating shaft connected between the front and rear support plates. A rotating roller is fixedly installed, and the left front side and the right rear side of the side wall of the rotating roller are respectively fixedly connected with arc-shaped blocks matching with the front and rear square hammer bars; the left side of the top of the bottom plate is also fixedly equipped with a third pole, and the right end of the third pole top is Fixed connection with scraper. The invention automatically beats the beef through the up and down swing of the square hammering rod, and the beating speed is fast and the efficiency is high; during the beating process, the beating plate rotates, and at the same time cooperates with the scraper to scrape the beef to the middle of the beating plate to ensure that the beef is beaten evenly and fully.

Owner:顾志裕

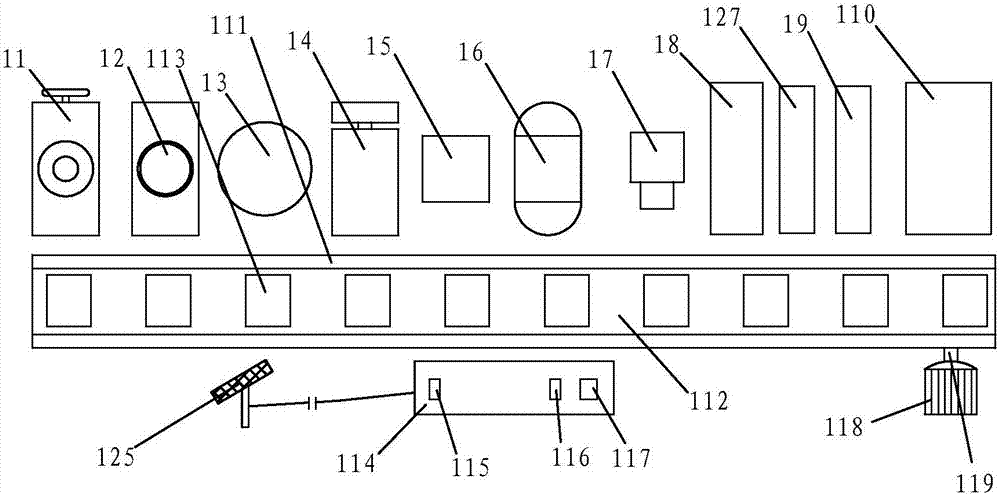

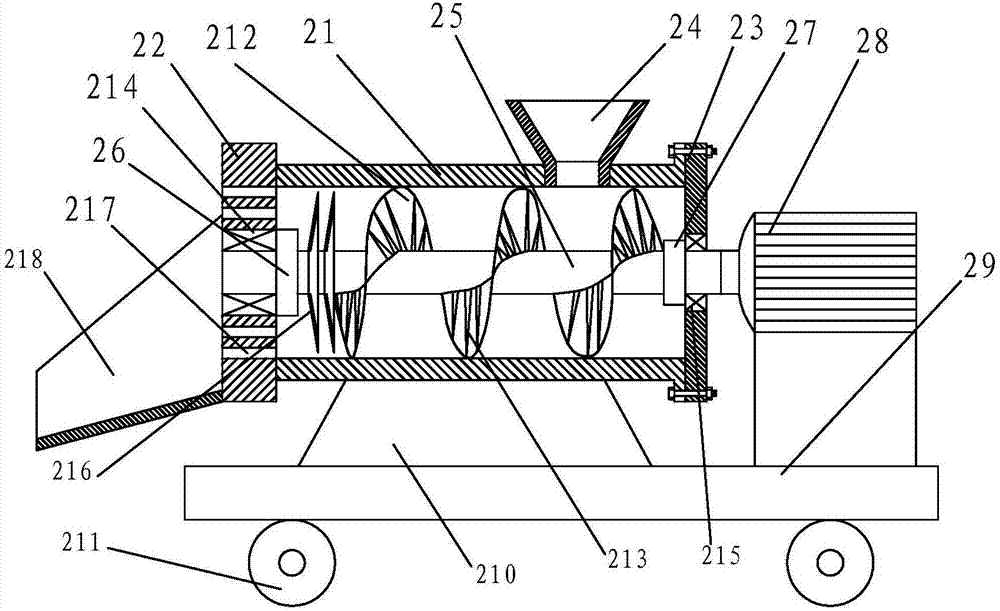

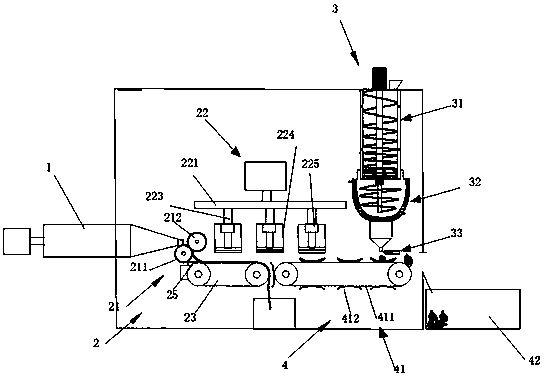

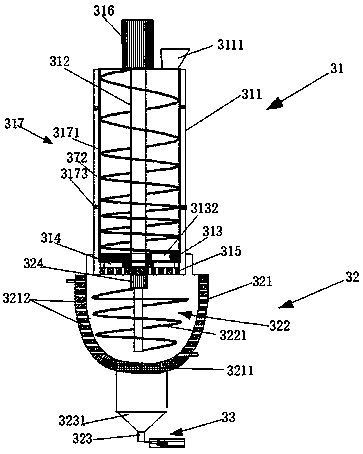

Energy-saving, environmentally-protective and high-quality production technology and production device of qinqin sausage (short and juicy sausage)

ActiveCN107996668AThe production process is simple and applicableSteady improvement in qualityLinked sausage separationSausage filling/stuffing machinesEngineeringControl table

The present invention provides an energy-saving, environmentally-protective and high-quality production technology and production device of a qinqin sausage (a short and juicy sausage). The processingdevice comprises a base seat. A control table is arranged at one side of the base seat, a meat grinder system is arranged at a left end of the other side of the base seat, a right side of the meat grinder system is successively provided with a stuffing blending system, a pickling tank, a rolling system, a weighing system, a sausage filling system, a steaming and smoking system, a cooling room, acutting system, a secondary sterilization system and a cold storage. Each system transfers the sausage via a conveyor belt, transportation labor is reduced, important devices are improved, automationdegrees of production processes are further improved, more mechanized operations are used, labor costs are reduced, and at the same time, the production device can improve production efficiency, is lower in error rate and steadily improves quality of the qinqin sausage.

Owner:福建舜洋食品有限公司

Dumpling making device

PendingCN107637620AConducive to the process of making dumplingsPrevent compactionDough-sheeters/rolling-machines/rolling-pinsMeat mixing apparatusLeft halfEngineering

The invention relates to a dumpling making device, which comprises an extrusion device, a dumpling wrapper forming device and a kneading device which are connected sequentially. A dumpling filling forming device is arranged at the upper part of the kneading device; the dumpling wrapper forming device comprises a pressing device for pressing a paste into a wrapper and a fixed die device; an extrusion nozzle of the extrusion device is arranged at one side of the pressing device; a wrapper conveying mechanism is arranged under the dumpling wrapper forming device; the fixed die device comprises arotary plate; the rotary plate is driven by a stepping motor; the lower part of the rotary plate is connected with multiple hollow cylinders arranged annularly and vertically through hydraulic rods ofa hydraulic device; absorbing machines for absorbing dumpling wrappers are arranged in the hollow cylinders; the kneading device is located under the fixed die device, and comprises a dumpling wrapper conveying mechanism; a dumpling wrapper fitting mechanism is arranged on a conveying belt of the dumpling wrapper conveying mechanism, and comprises a left half die and a right half die hinged together; an upper edge of the left half die is matched with an upper edge of the right half die.

Owner:肖仕清

Method and apparatus for vacuum-less meat processing

InactiveUS20050249864A1Small sizeIncreased formationTransportation and packagingRotary stirring mixersEngineeringShear force

A system and method for making processed meat products without the need for a vacuum system is disclosed. Meats and other meat product constituents are forced into a mixer having rotating elements for directing the constituents through a housing. The system limits the amount of air that is in contact with the constituents while resident within the housing, and provides high shear force to reduce the necessary mixing time.

Owner:KRAFT FOODS GRP BRANDS LLC

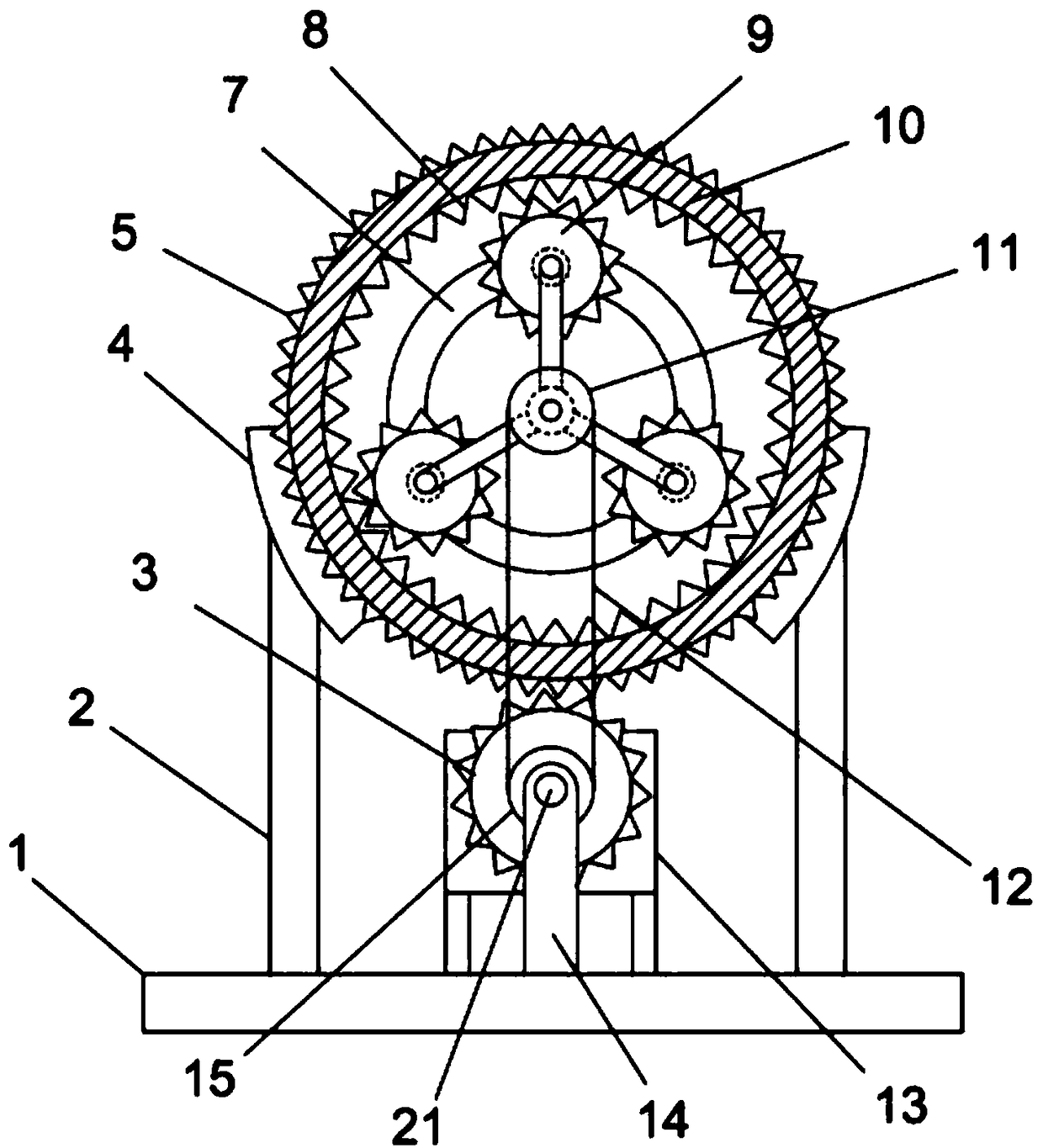

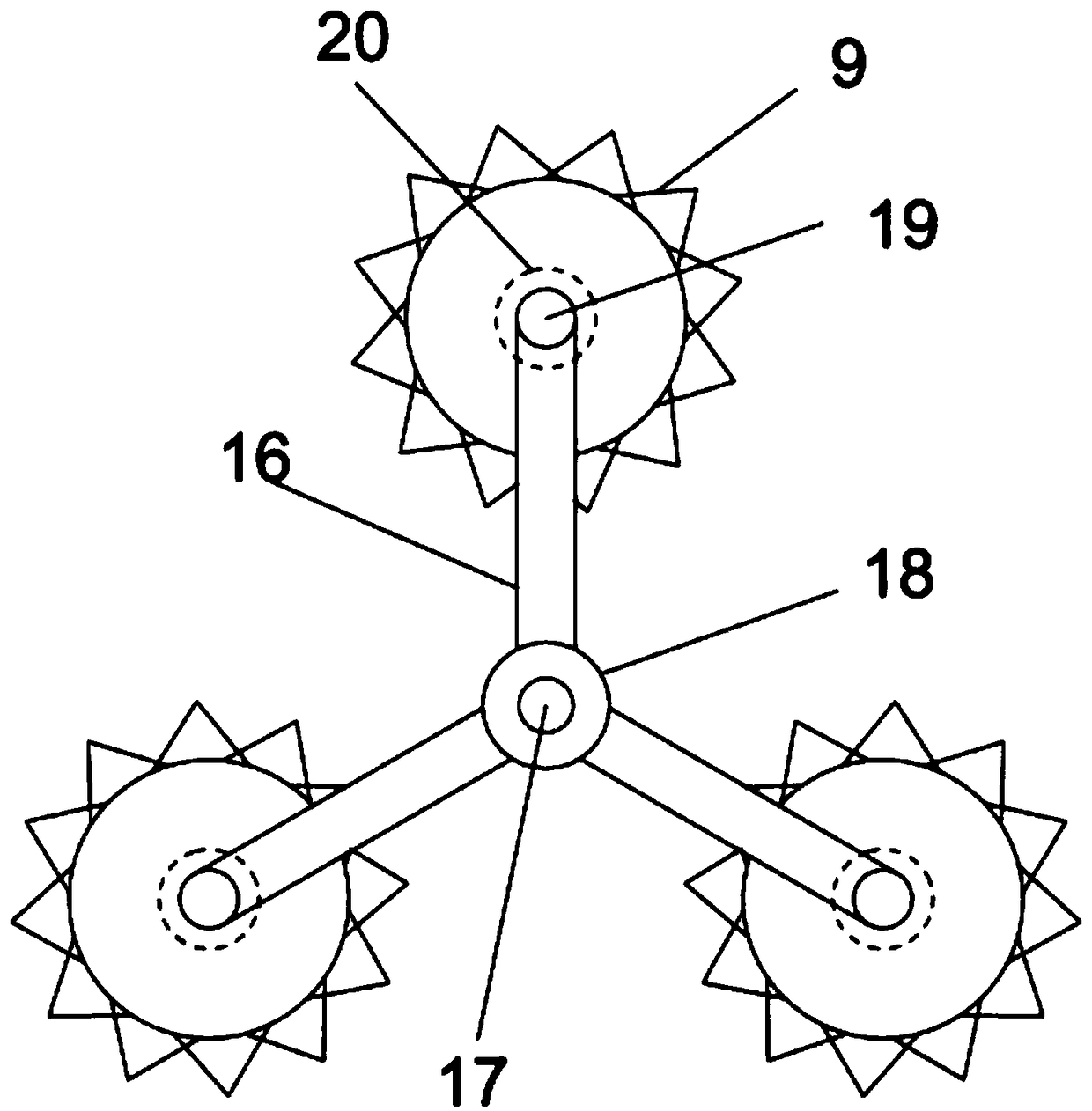

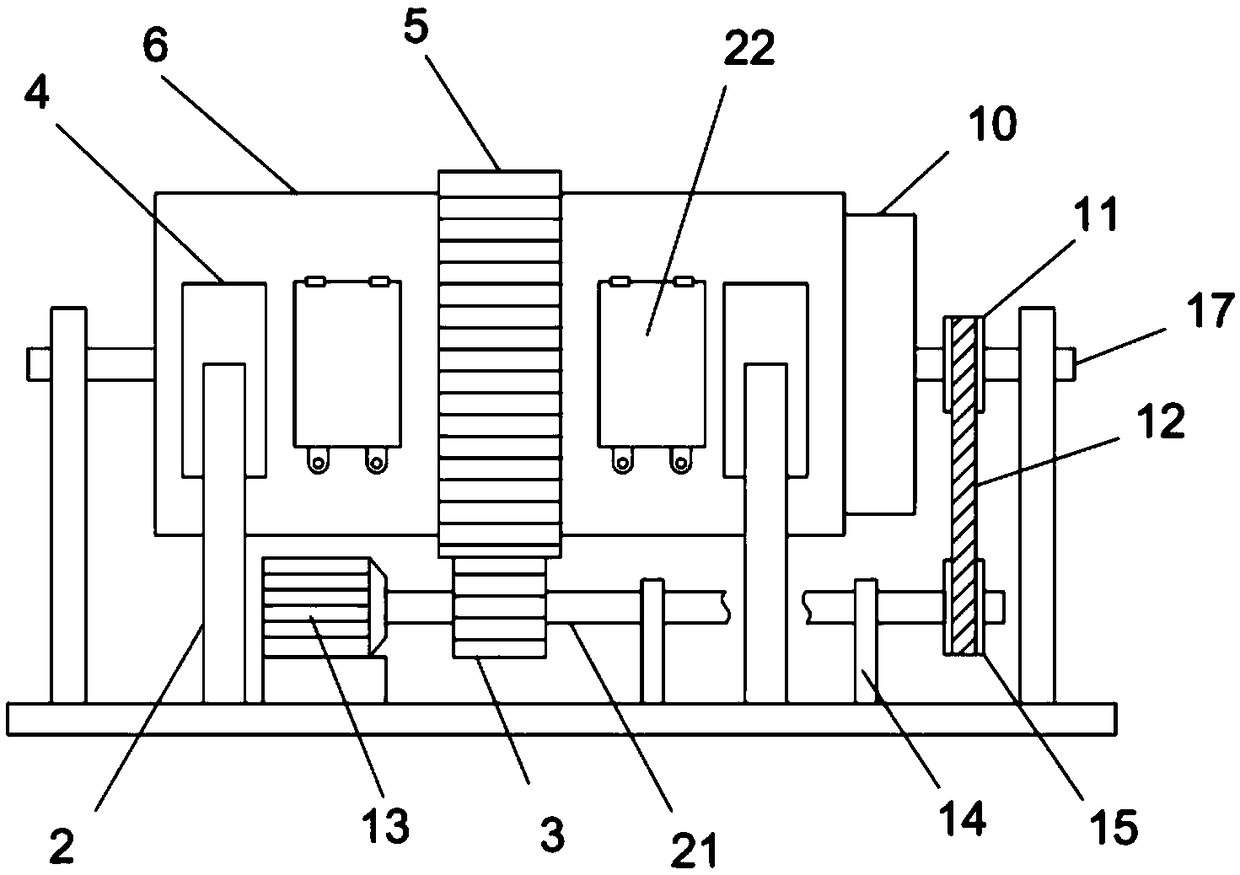

Meat piece rolling and mixing device for processing meat

ActiveCN108887357APickling processing efficiency increasedMeat mixing apparatusDrive shaftGear wheel

The invention discloses a meat piece rolling and mixing device for processing meat. The meat piece rolling and mixing device comprises a mixing drum. Support plates are vertically fixedly mounted on abearing bottom plate, limit supporting plates are fixedly mounted at the upper ends of the support plates, the mixing drum is rotationally connected onto the limit supporting plates, the outer side wall of the mixing drum slidably clings to the limit supporting plates, and a roller chain sleeves a driven chain wheel and a driving chain wheel in a transmission manner; a mixing mechanism is connected onto a driven shaft in a rotationally sleeving manner; an extension annular plate which is concentric with the horizontal axis of the mixing drum is fixedly mounted on the right side wall of the mixing drum. The meat piece rolling and mixing device has the advantages that the mixing drum can rotate, and accordingly meat pieces and condiments inside the mixing drum can be rolled; the mixing drumcan be driven by the mixing mechanism to reversely rotate, and accordingly meat and the condiments can be sufficiently turned over and mixed with one another; driven gears and an inner gear ring canfittingly rotate, accordingly, turning straight plates and turning arc plates can be driven by mixing rods of the mixing mechanism to carry out rotary scraping and turning actions on the meat and thecondiments, the condiments can sufficiently cover the surfaces of the meat pieces, and the meat piece pickling and processing efficiency can be greatly improved.

Owner:广东无尽食品有限公司

Method for reducing protein exudate on meat product

InactiveUS20050255207A1Extended processing timeEliminate delaysMeat/fish preservationRotary stirring mixersVisible surfaceChemistry

A system and method for reducing protein exudate on meat product. The system utilizes input hoppers and eliminates standing time for the meats. The elimination of a standing time for curing or protein extraction eliminates the ability for visible surface protein exudate to form.

Owner:KRAFT FOODS GRP BRANDS LLC

Method for processing animal minced meat

The invention discloses a method for processing animal minced meat, which comprises the steps of: adding auxiliary materials such as protein, meat adhesives, compound phosphate, seasoning and the like into the minced meat, performing processes of vacuum tumbling, salting, stirring and the like for forming through finishing, and applying a certain pressure to form a structure similar to one-piece meat through refrigeration. After being cutting into slices, meat products produced by the processing method are good in flakiness and elastic, can be kept perfect integrity after being cooked, are tender and smooth in mouthfeel through long-term cooking, can be used for cooking of instant boiling, roasting, stir-frying and the like and production of other meat products, and improves the utilization factor and additional value of the minced meat.

Owner:青岛康大食品有限公司

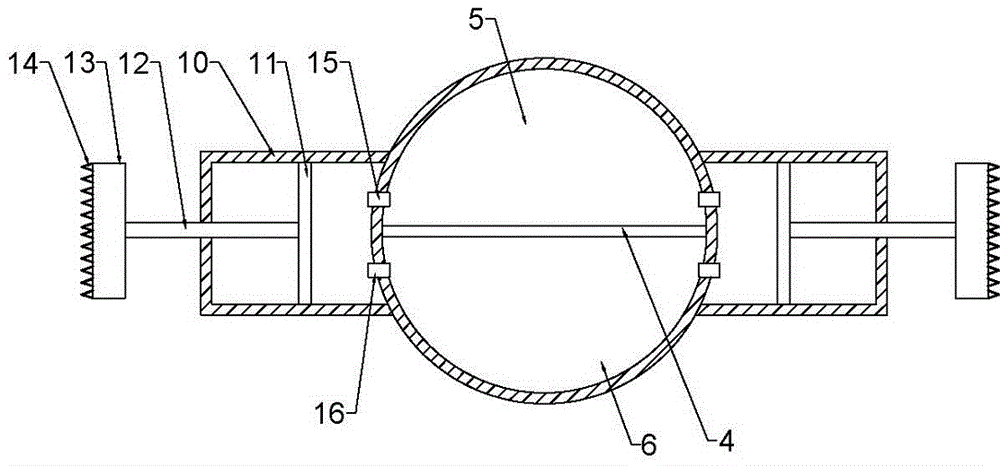

Vacuum refrigeration rolling machine

ActiveCN106819037AMarinate Tumble FastImprove tumbling efficiencyBeating-based meat tenderisingMeat mixing apparatusWater dischargeMagnetic poles

The invention relates to the field of food processing and discloses a vacuum refrigeration rolling machine. The vacuum refrigeration rolling machine comprises a rolling barrel and a hollow rotating shaft, wherein a separating plate is arranged in the rotating shaft; the rotating shaft is separated into a water feeding chamber and a water discharging chamber; the rolling barrel comprises an outer barrel and an inner barrel; a first magnet set and a second magnet set are arranged on the inner wall of the outer barrel; the first magnet set and the second magnet set are both faced to the rotating shaft; the magnetic poles at the ends of the first magnet set and the second magnet set faced to the rotating shaft are opposite to each other; a plurality of striking mechanisms are arranged on the rotating shaft; each striking mechanism comprises a piston barrel; the piston barrel is fixedly connected with the rotating shaft and is communicated with the water feeding chamber and the water discharging chamber; a piston plate is arranged in the piston barrel in a sliding form; a connecting rod is fixedly connected with one end of the piston plate away from the rotating shaft; a third magnet is connected with one end of the connecting rod away from the piston plate; a one-way feeding valve is connected between the piston barrel and the water feeding chamber; and a one-way discharging valve is connected between the piston barrel and the water discharging chamber. Compared with the prior art, the vacuum refrigeration rolling machine has higher rolling efficiency.

Owner:重庆汤嫂食品有限公司

Easy-to-clean chopper mixer

The invention discloses an easy-to-clean cutting and mixing machine. A welded and assembled channel steel bracket is fixedly installed on the base, a driving motor is fixedly installed on the channel steel bracket, and an output shaft end of the driving motor is fixedly connected to a driving pulley. , the driving pulley is connected to the driven pulley through a transmission belt, the driven pulley is fixedly arranged on the chopping shaft, the upper shaft section in the vertical direction of the chopping shaft is arranged in the chopping chamber, and is connected with the chopping chamber The bottom surface of the chopping shaft forms a rotational connection, and the left and right ends of the outer circumferential shaft wall of the chopping shaft are welded to connect several knives arranged in the axial direction. A scraper is arranged below the knives, and A cleaning water tank is provided, and a water pump is arranged in the cleaning water tank, and the water pump is connected to a high-pressure nozzle through a pipeline. By adopting the technical scheme, the chopping and mixing chamber is sprayed and washed with high pressure by the high-pressure spray head, and the cleaning is thorough, the application range is wide, and the practicability is good.

Owner:张辉

Method and apparatus for accelerating formation of functional meat mixtures

InactiveUS20050255221A1Extended processing timeEliminate delaysMeat/fish preservationRotary stirring mixersAdditive ingredientShear force

A system and method wherein meat product constituents are mixed under a high shear force to combine the constituents into a mixture having a stable protein matrix is disclosed. The system incorporates mixing devices in a housing into which the input streams are directed. The system then applies a high shear force over a small volume to mix the constituents together, thereby rapidly combining the meat constituents and other ingredients to rapidly form a stable protein matrix and eliminate the need for a curing stage for protein extraction.

Owner:KRAFT FOODS GRP BRANDS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com