Vacuum refrigeration rolling machine

A vacuum refrigeration and tumbler technology, which is used in slaughtering, meat mixing equipment, meat tenderization, etc., can solve the problem of low tumbler efficiency, and achieve the effect of fast pickling and tumbler speed and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

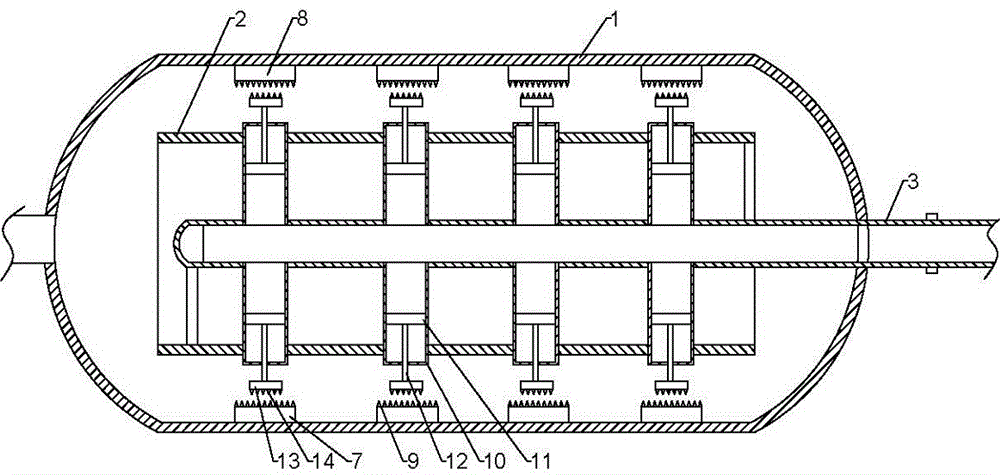

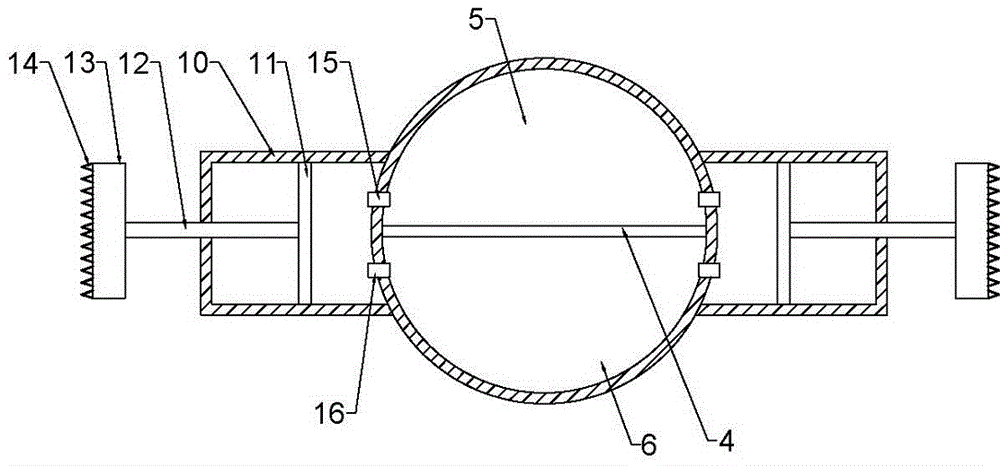

[0017] The reference signs in the drawings of the specification include: outer cylinder 1, inner cylinder 2, rotating shaft 3, partition 4, water inlet chamber 5, water outlet chamber 6, first magnet 7, second magnet 8, second conical teeth 9 , Piston barrel 10, piston plate 11, connecting rod 12, third magnet 13, first conical tooth 14, one-way liquid inlet valve 15, one-way liquid outlet valve 16.

[0018] Example basic reference figure 1 and figure 2 Shown: a vacuum refrigeration tumbler, including a tumbler, the tumbler includes an outer cylinder 1 and an inner cylinder 2, the outer wall of the inner cylinder 2 is provided with external threads, the inner wall of the inner cylinder 2 is provided with internal threads, and the outer thread Contrary to the direction of rotation of the internal thread, the inner cylinder 2 is provided with a rotating shaft 3, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com