Patents

Literature

55results about How to "Tumble evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

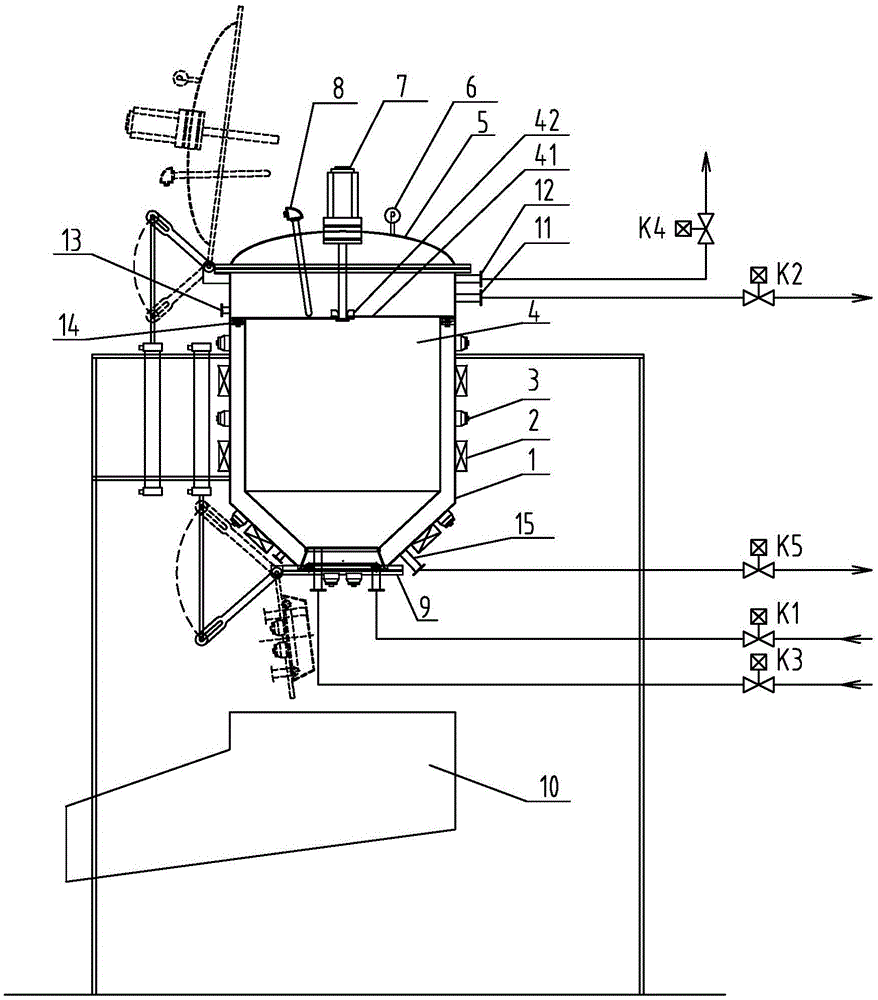

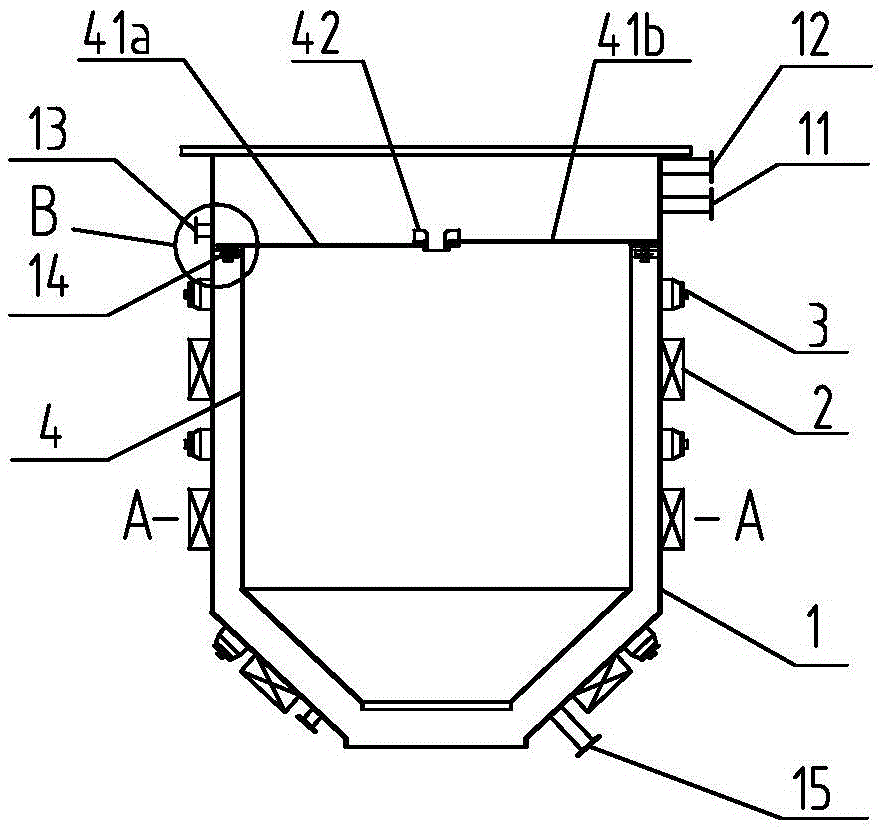

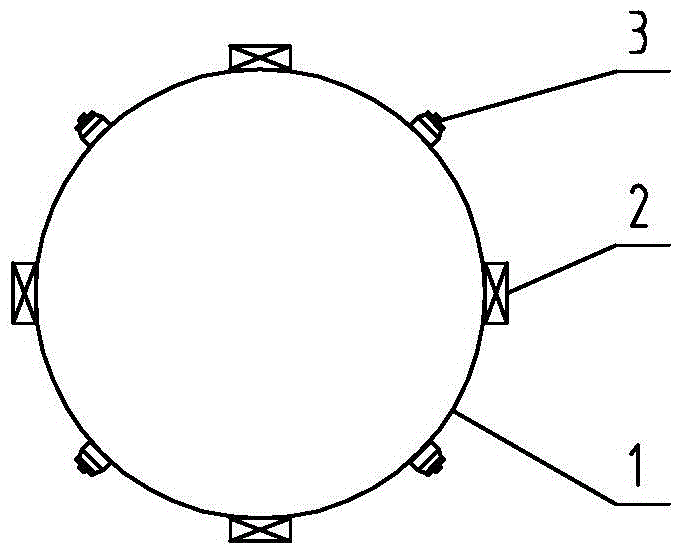

Microwave and ultrasonic wave assisted cocoon cooking device and method for cooking cocoons

ActiveCN105648542ASolve for uniformitySolve heatingSilk filament obtainingUltrasonic assistedCoupling

A microwave and ultrasonic wave assisted cocoon cooking device comprises a cocoon cooking barrel outer drum, a microwave generator, an ultrasonic wave generator, a cocoon cooking barrel inner drum, an upper cover of the cocoon cooking barrel outer drum, a lower cover of a cocoon cooking barrel discharge opening, and a cocoon cooking barrel; a plurality of microwave generators and ultrasonic wave generators are distributed on the outer side of the cocoon cooking barrel outer drum; the cocoon cooking barrel inner drum is made of punching hole meshes or mesh materials, and a cover of the cocoon cooking barrel inner drum consists of two semi-circular sector cover plates made of punching hole meshes or mesh materials and connected through a coupling at the circle center; the cover of the cocoon cooking barrel inner drum can be opened or closed in a rotational manner; a pressure gage and a temperature measurer are mounted on the upper cover of the cocoon cooking barrel outer drum; the lower cover of the cocoon cooking barrel discharge opening is connected with a hot water inlet pipe and is equipped with a porous steam coil and the ultrasonic wave generator; the filature cocoon cooking device has a compact and reasonable structure and is high in integration, and a cocoon cooking of the device adopts a microwave assisted direct-streaming technology and an ultrasonic wave assisted cocoon cooking technology at the same time, so that inner, middle and outer layers of cocoons are heated uniformly, the energy is saved, the consumption is reduced, and the cocoon cooking is shortened.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

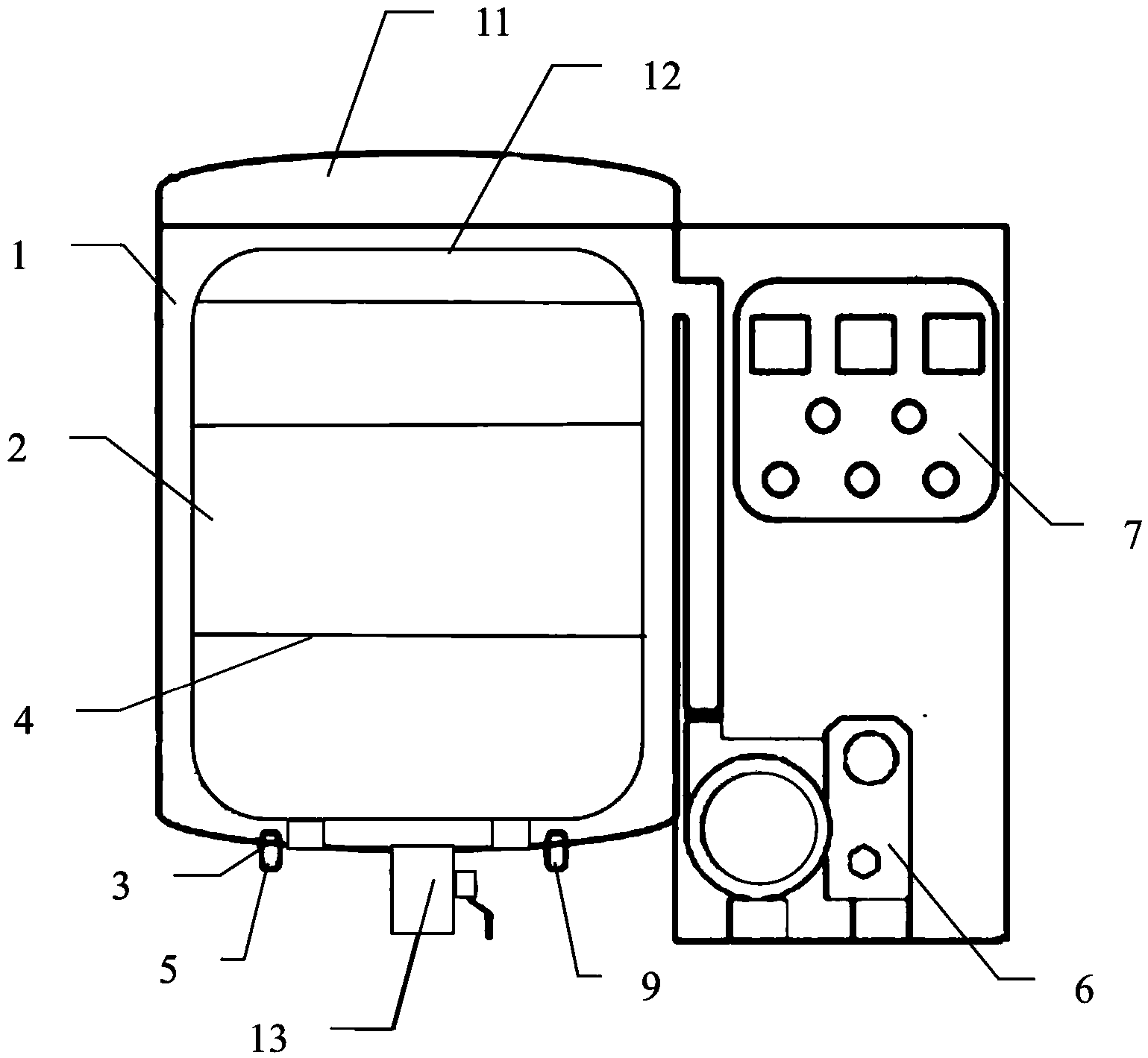

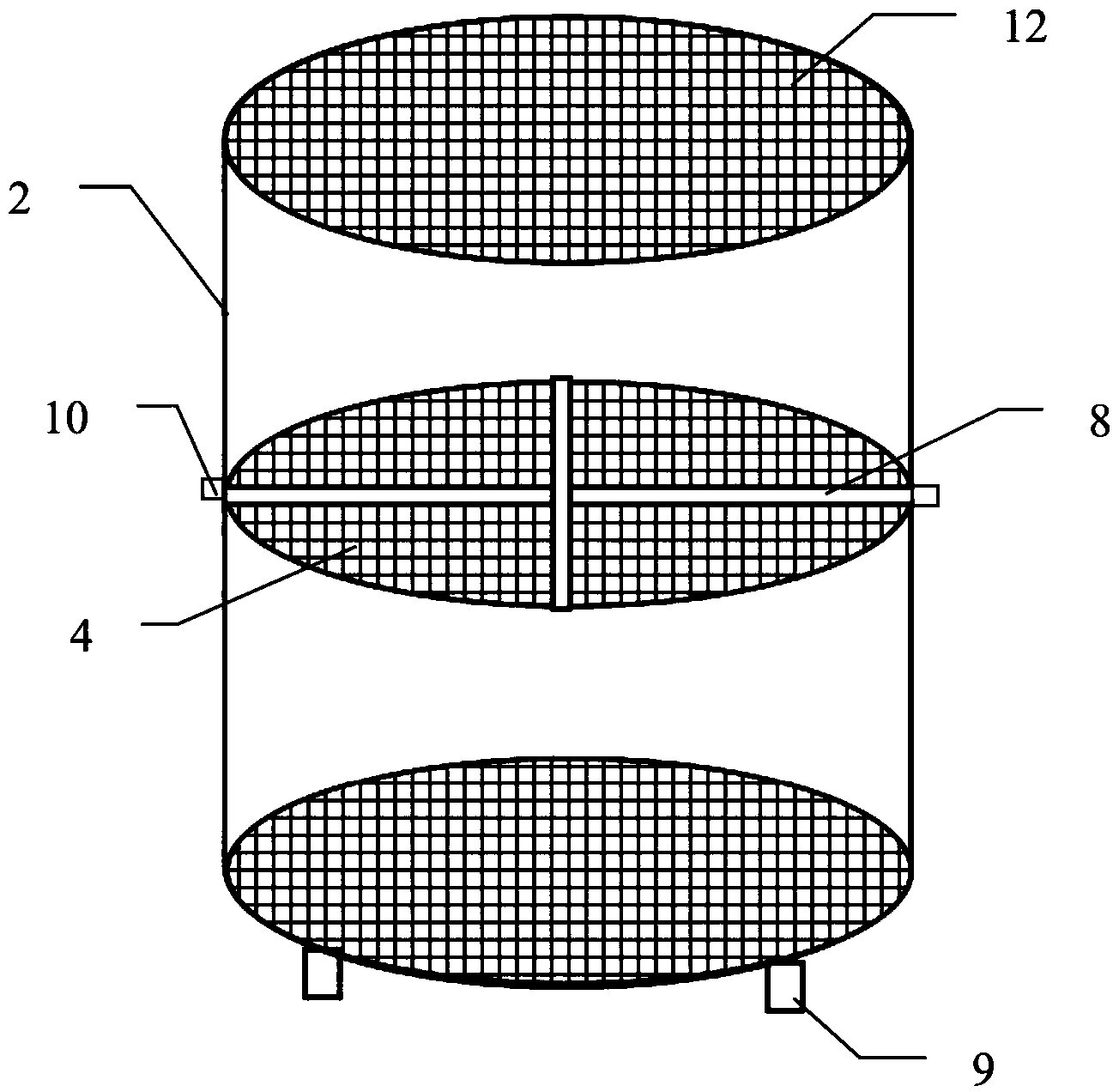

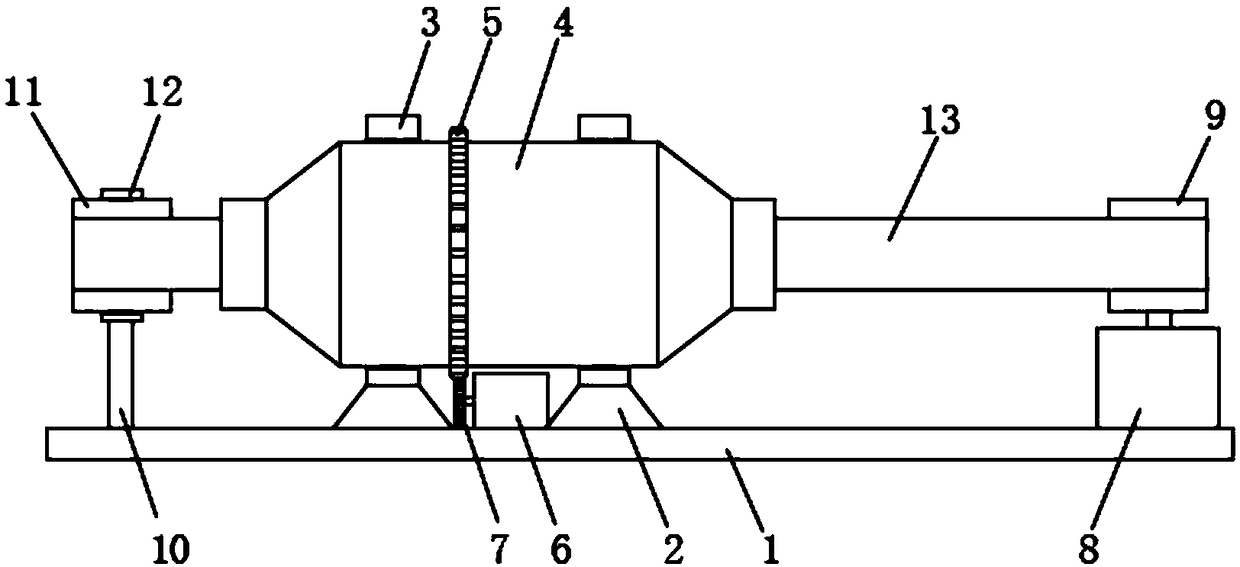

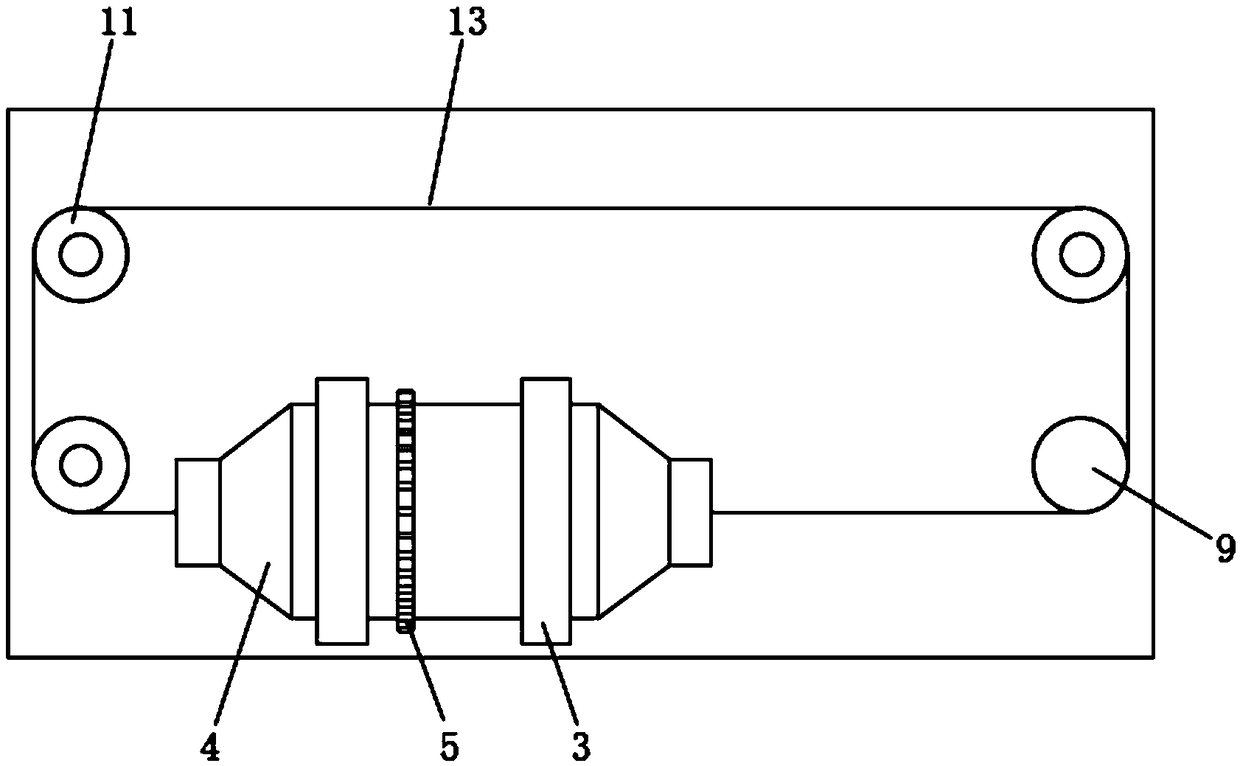

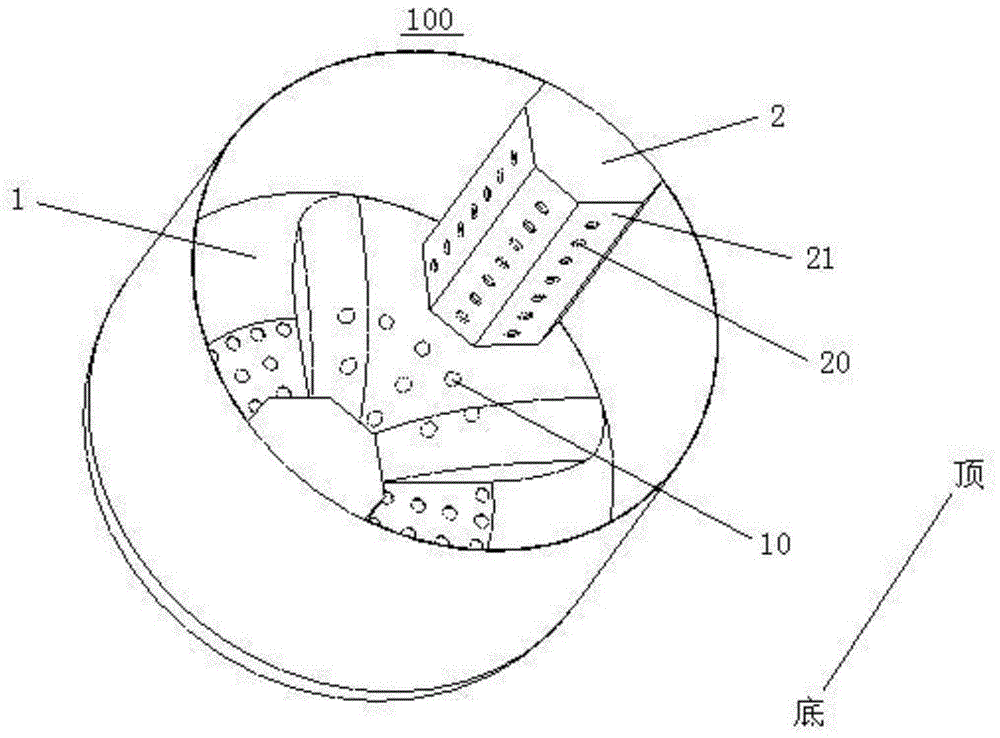

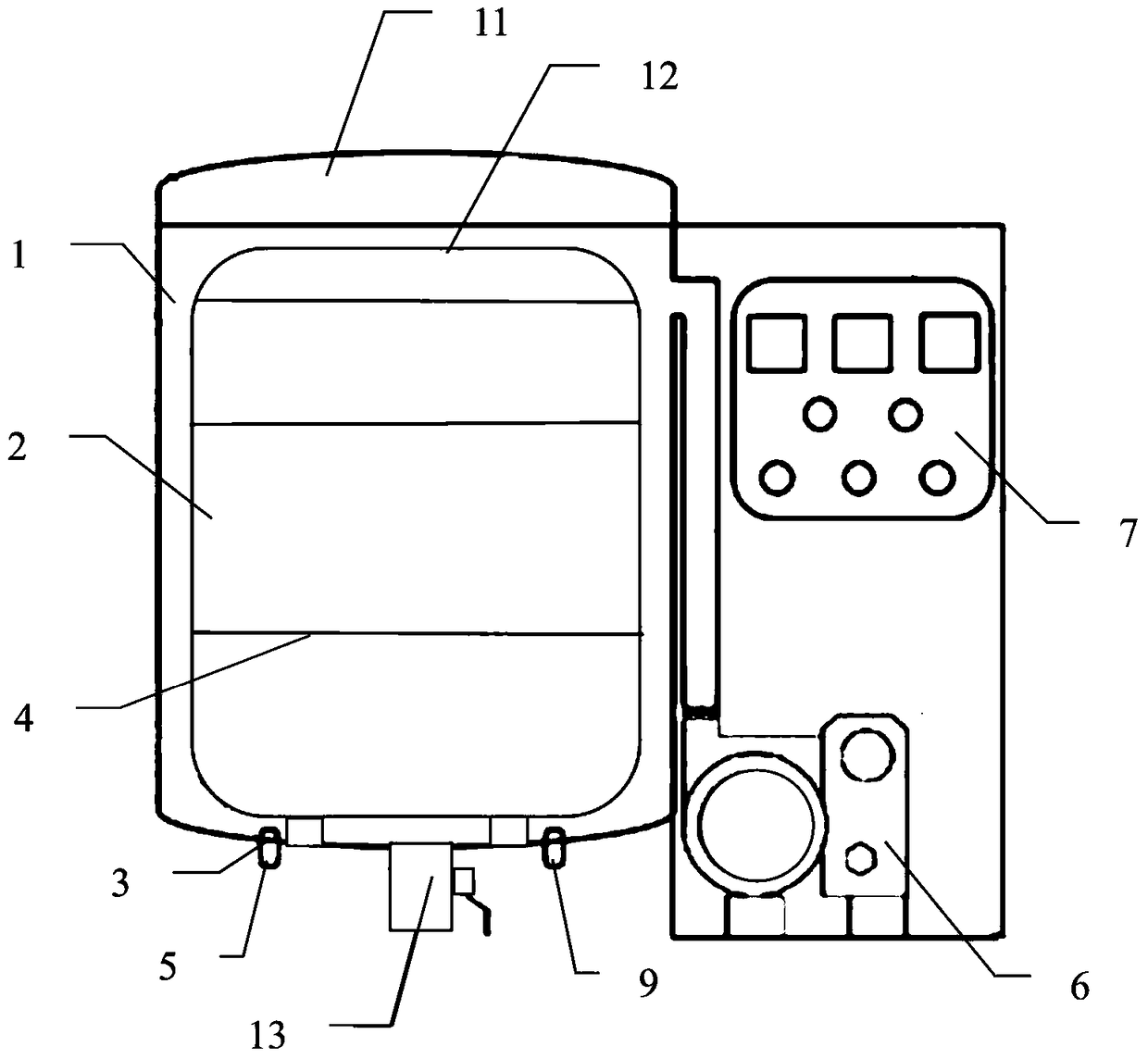

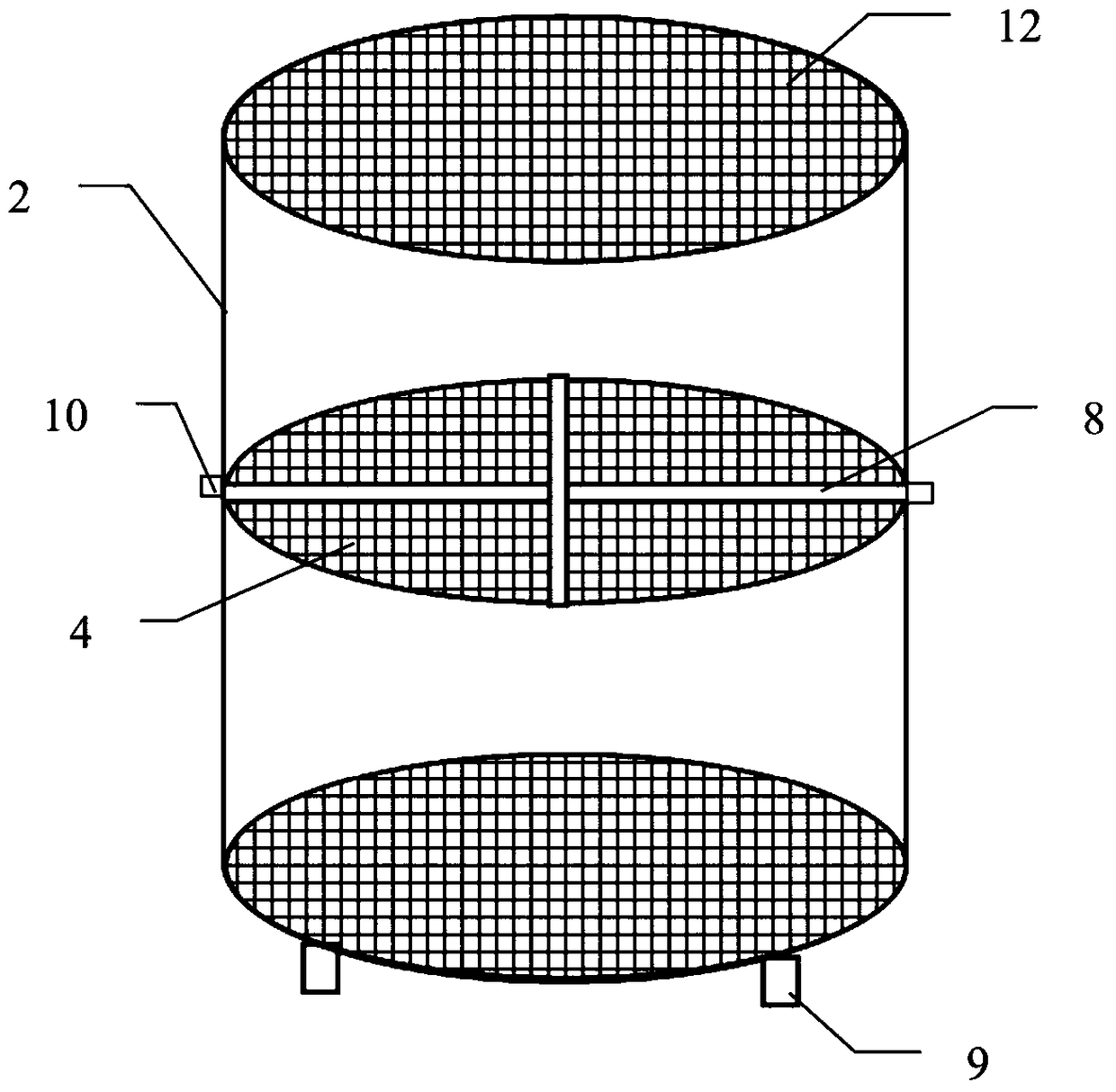

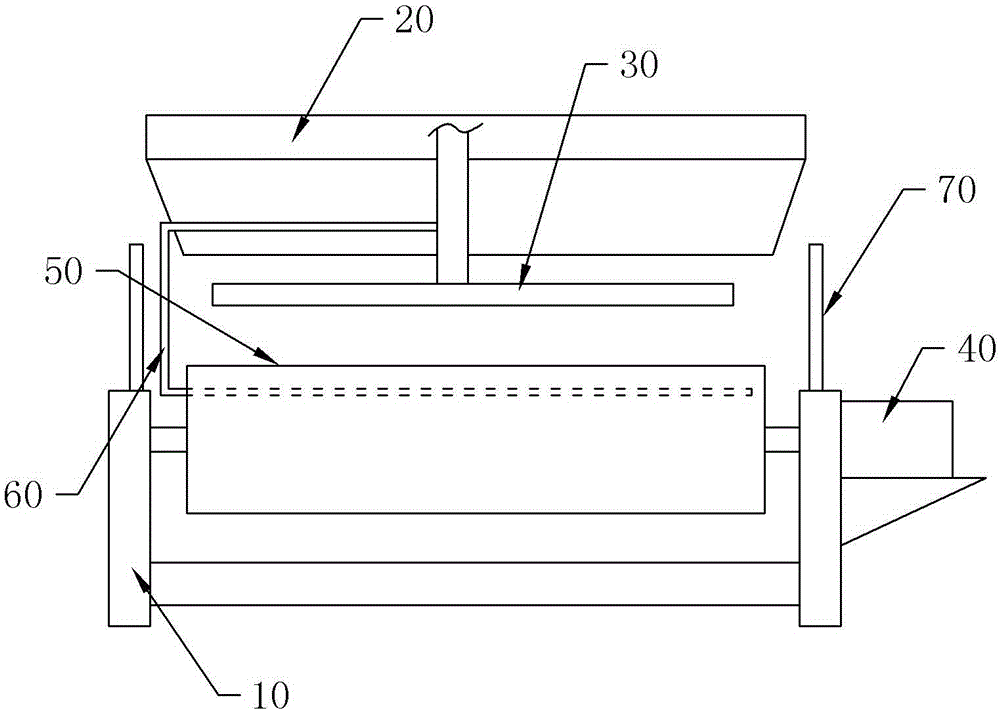

Transformation static curing equipment for foods and curing method thereof

ActiveCN104256848AIncrease impactAccelerate the speed of penetration into the tissue of the material to be marinatedFood preservationPositive pressureEngineering

The invention discloses transformation static curing equipment for foods and a curing method thereof. A pressure regulation device which is capable of increasing or decreasing pressure in a curing pot is connected onto the curing pot; by utilizing pressure change in the curing pot, the materials to be cured are cured; particularly, when the curing pressure in the curing pot changes from negative pressure to positive pressure, the impact of the curing liquid entering into the materials to be cured is enlarged, so that the speed of the curing liquid permeating into the tissues of the materials to be cured is accelerated, the curing efficiency is improved and the requirements of the production process are satisfied. Moreover, the curing pot is designed into a double-layer structure of a latticed inner cylinder, and latticed separation plates are added in the inner cylinder to divide the inner cylinder into a plurality of communicated curing units, so that the structural strength of the curing pot is effectively improved, the extrusion between the materials to be cured can be decreased and the integrity of the cured materials is kept.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

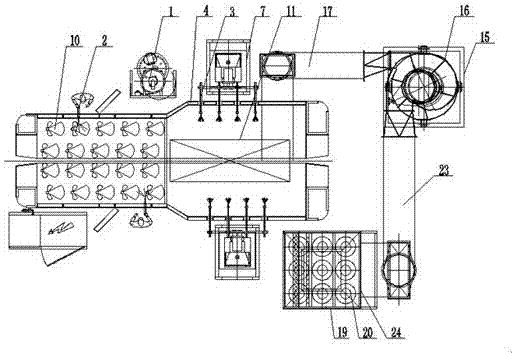

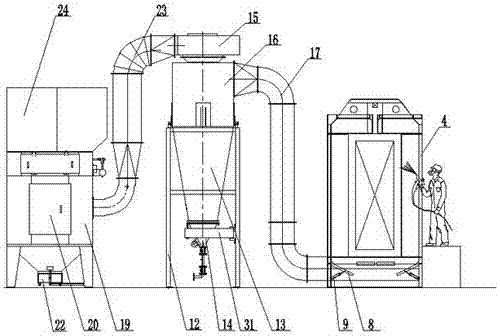

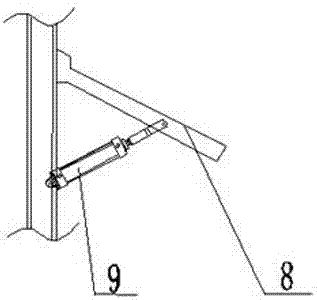

Plastic powder spraying room with a cyclone recycling and filtering function for coating

PendingCN107042183AIncrease profitImprove sealingLiquid surface applicatorsSpraying apparatusCycloneMetallurgy

The invention discloses a plastic powder spraying room with a cyclone recycling and filtering function for coating. The plastic powder spraying room comprises a plastic powder spraying system and a large cyclone recycling system, wherein the plastic powder spraying system comprises a powder spraying device and a powder room body; the powder spraying device comprises a powder spraying cylinder and spray gun mechanisms connected with the powder spraying cylinder; the powder room body is of a plastic structure and is opened on the left side and the right side, and a side plate is arranged on each of the front side and the rear side of the powder room body; each of the spray gun mechanisms is arranged on the outer side of the corresponding side plate; a plurality of vertical through holes allowing spray guns to be embedded in are formed in each of the side plates; a left stopping block and a right stopping block which are clung to each other are arranged in each of the through holes; a plurality of horizontal bottom plates are arranged at the bottom in the powder room body; the bottom plates arranged on the two sides are turnover bottom plates; a collecting barrel is arranged below the bottom plates; the large cyclone recycling system comprises a large cyclone collecting device and a filtering device. The plastic powder spraying room with the cyclone recycling and filtering function for coating has the advantages that the design is reasonable, the powder recycling rate is greatly improved, the cost is reduced, and the degree of contamination caused by powder to the air and operators is reduced.

Owner:JIANGSU XINTU MACHINERY CO LTD

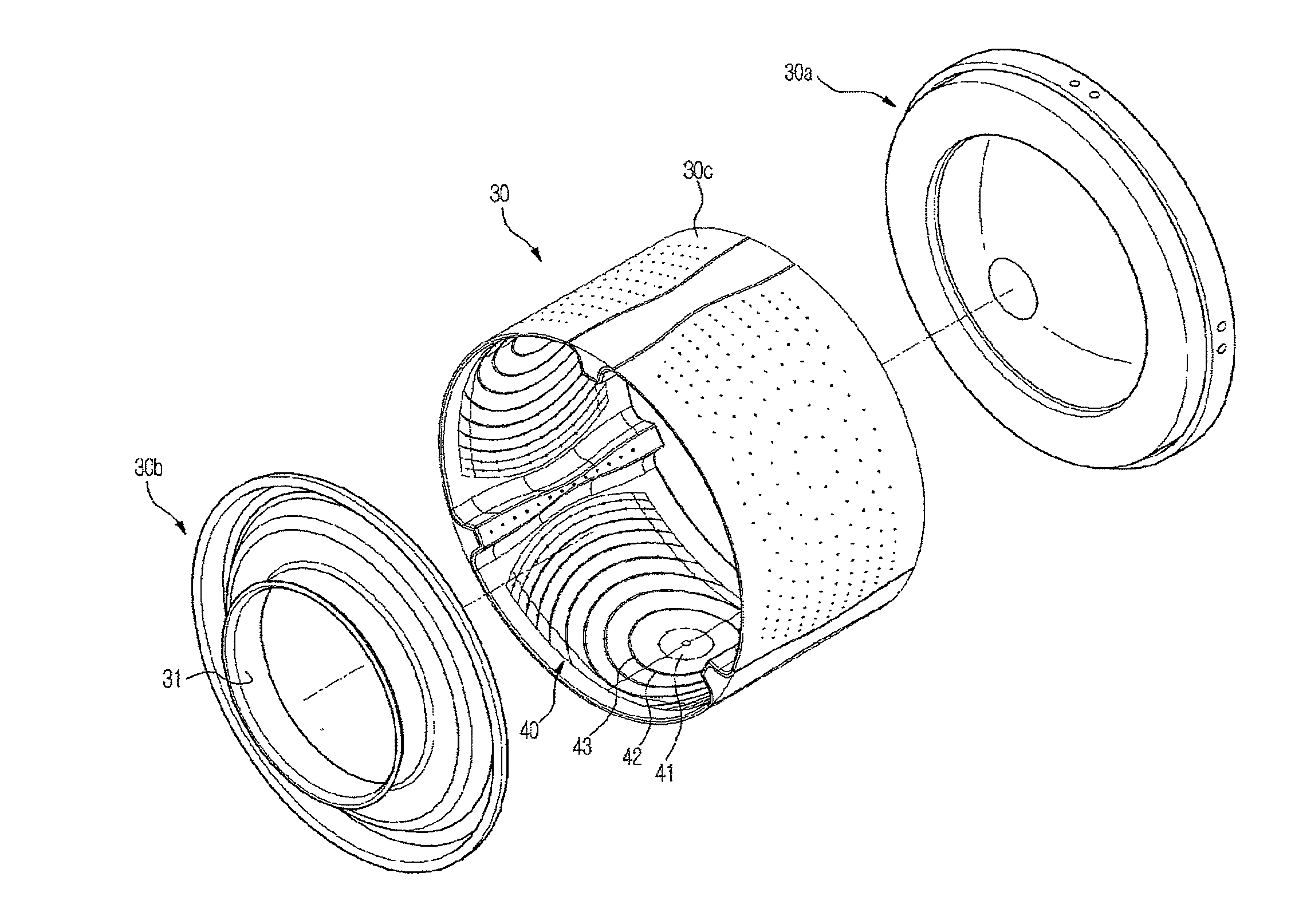

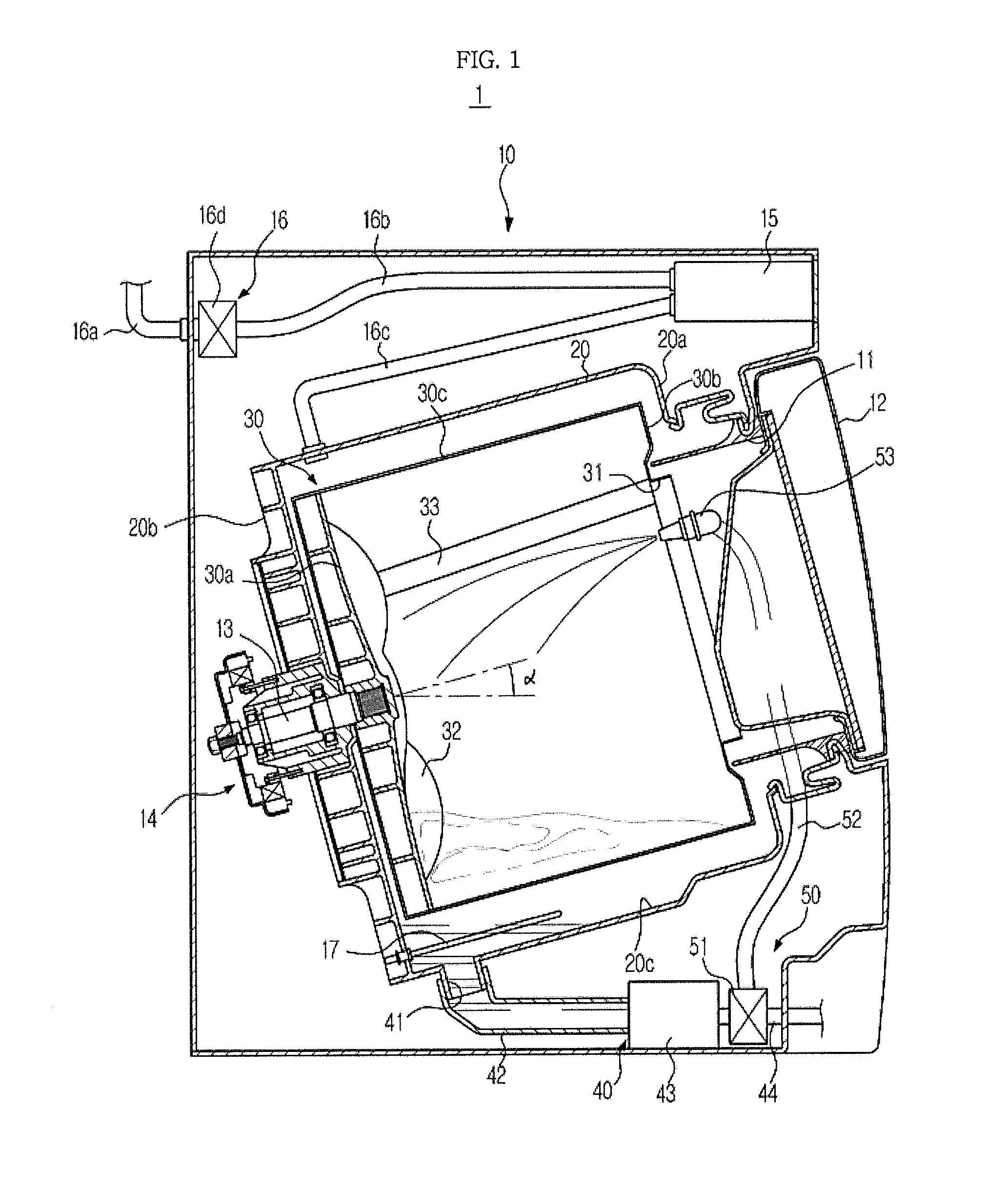

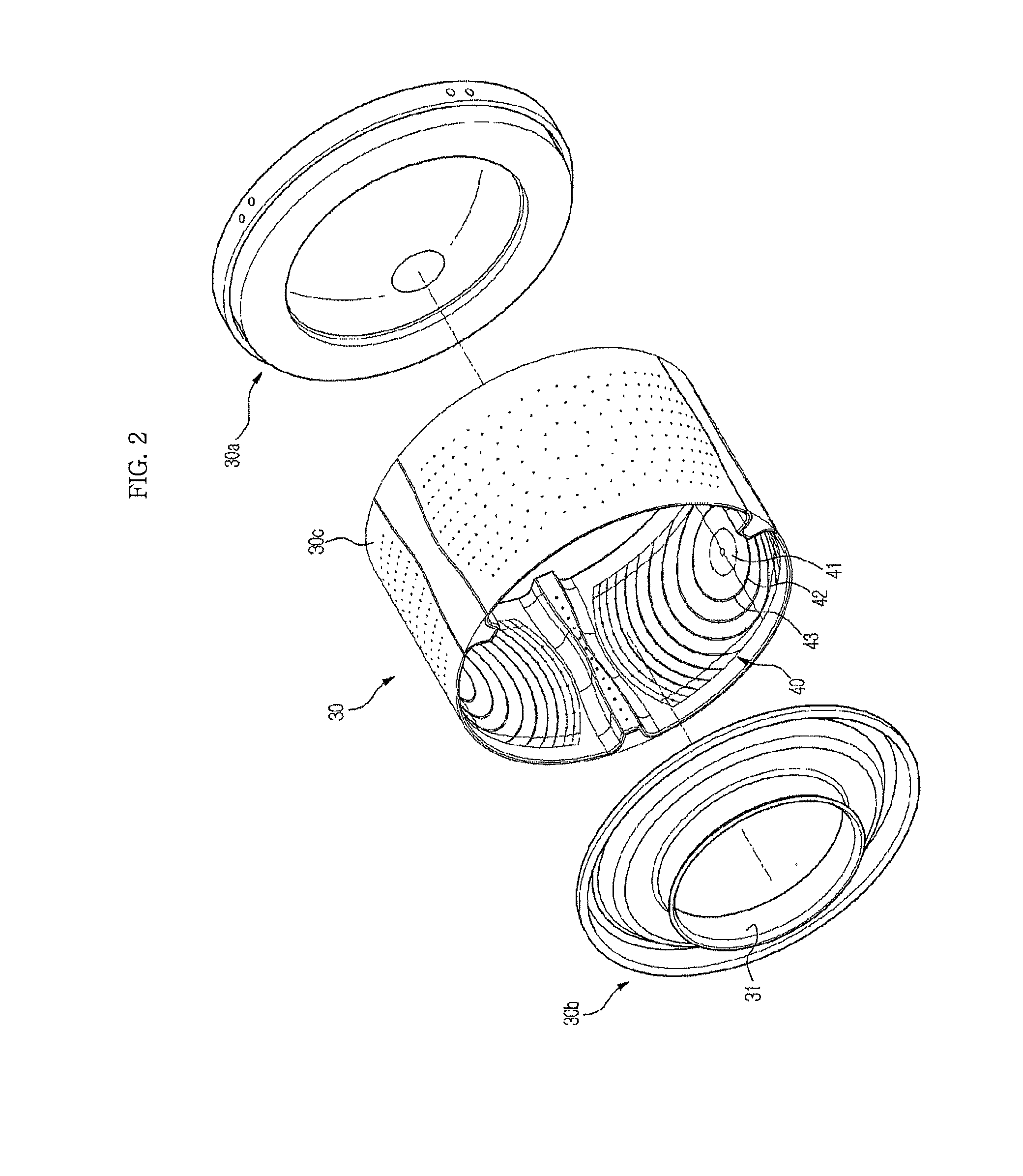

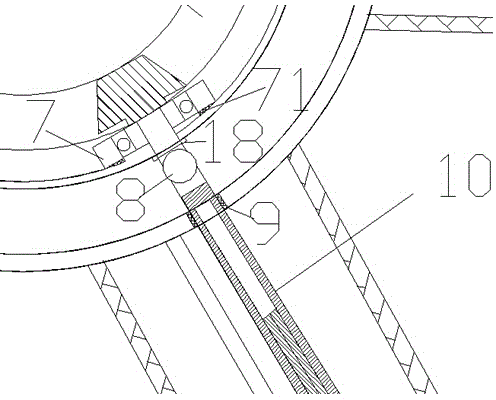

Washing machine

ActiveUS20140096571A1Enhance wash efficiencyImprove structureWashing receptaclesOther washing machinesLaundryConvex structure

A washing machine including a washing tub to allow enhancement in washing efficiency. A washing tub of the washing machine includes a pattern having a protrusion portion to generate friction force between laundry and the washing tub and to thereby increase washing efficiency. The pattern has a concave-convex structure and performs action similar to a lifter, washing efficiency may be enhanced using tumbling generated by the pattern. A plurality of drain holes are arranged in a certain pattern in the washing tub to prevent a dehydration bottleneck phenomenon in which dehydration is concentrated at a particular drain hole and to increase a dehydration rate. The pattern is provided such that protrusion portions and recessed portions continue on the surface of the washing tub to enhance stiffness of the washing tub.

Owner:SAMSUNG ELECTRONICS CO LTD

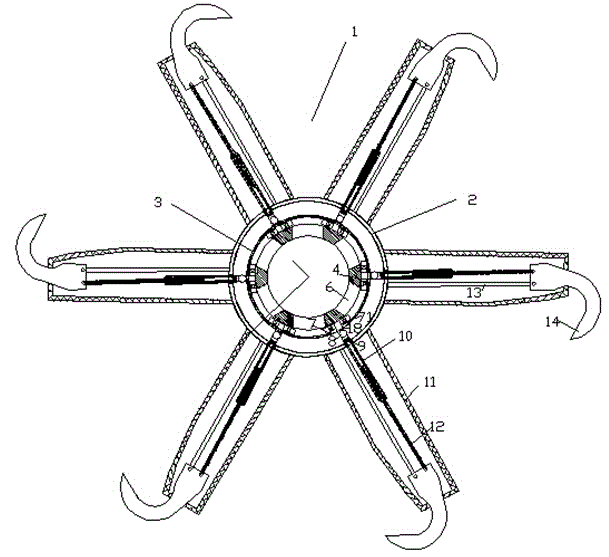

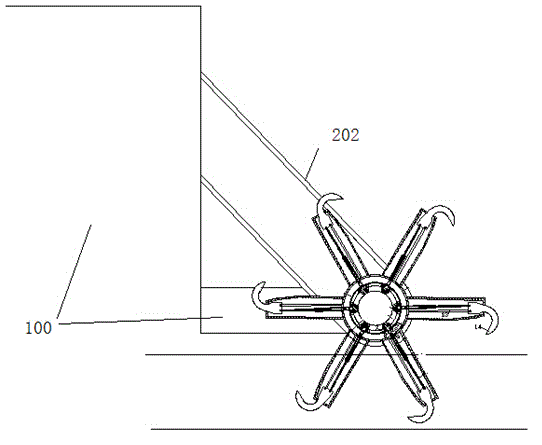

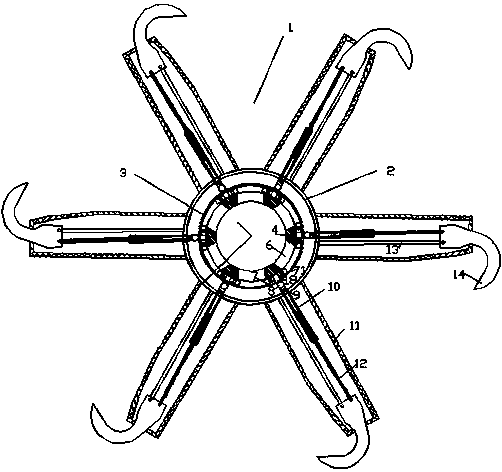

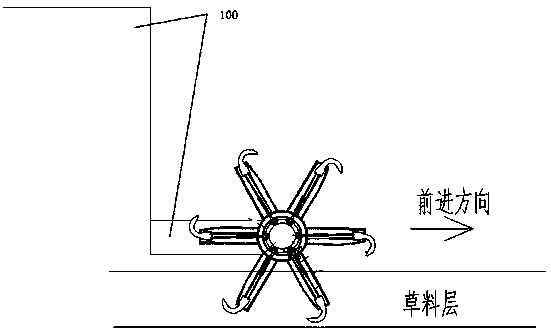

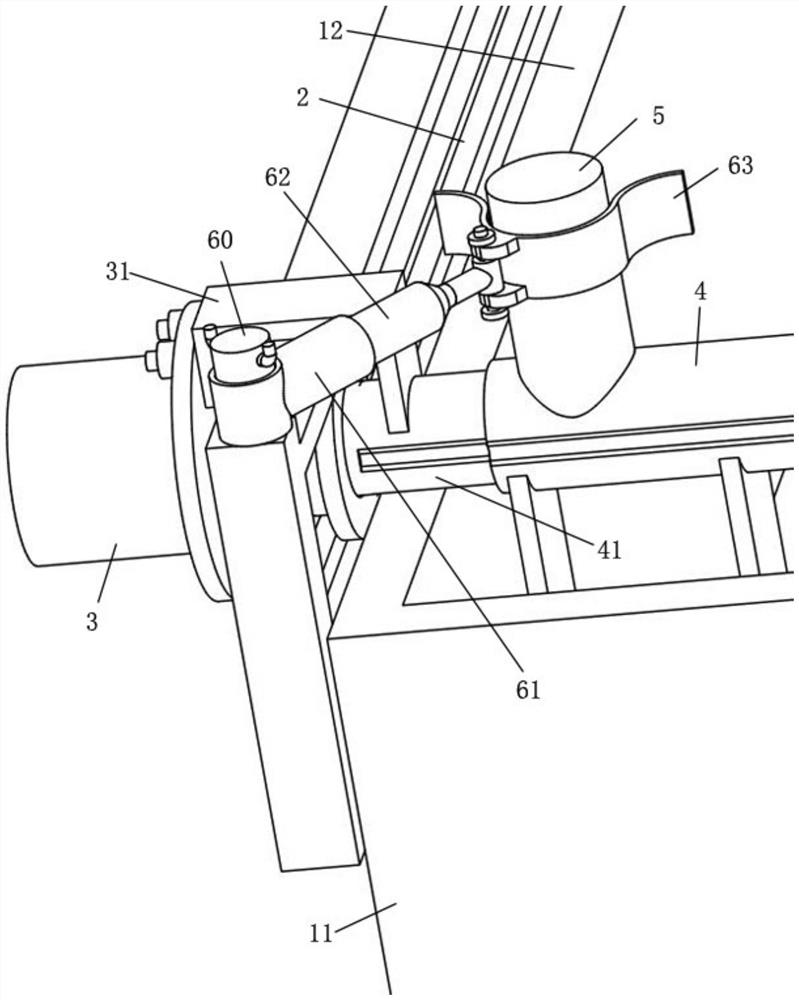

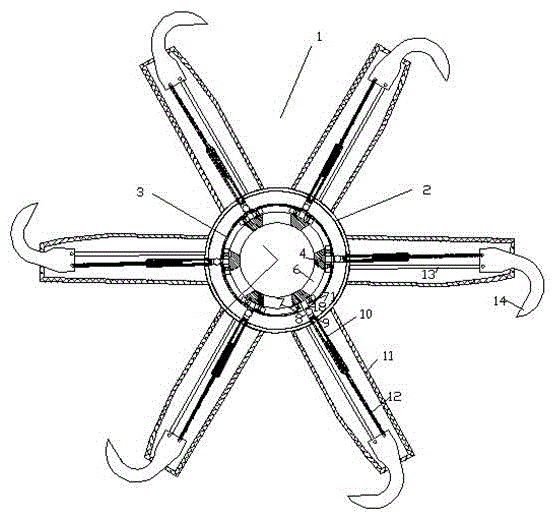

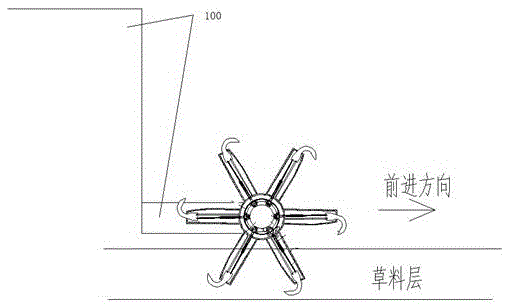

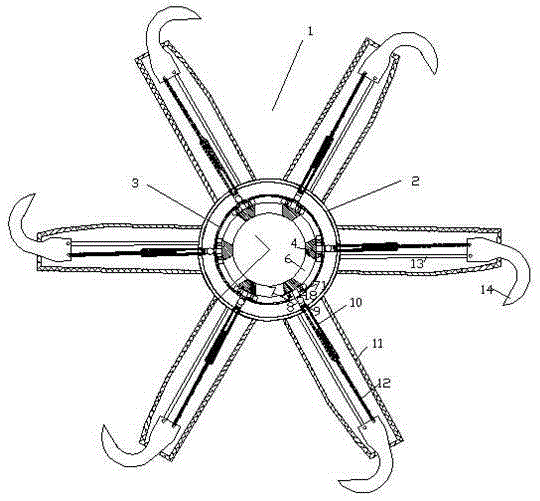

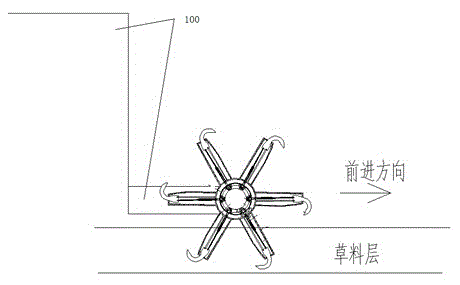

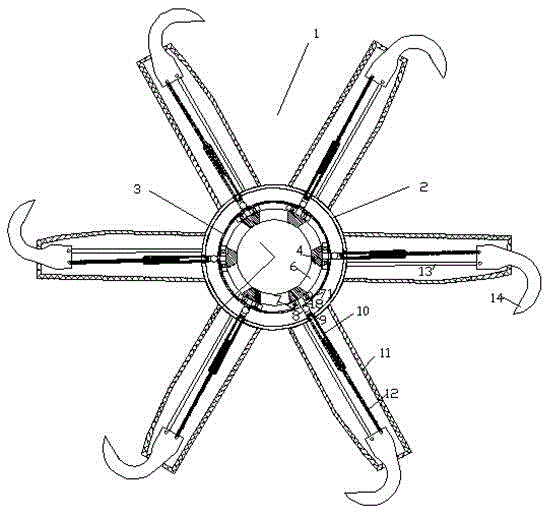

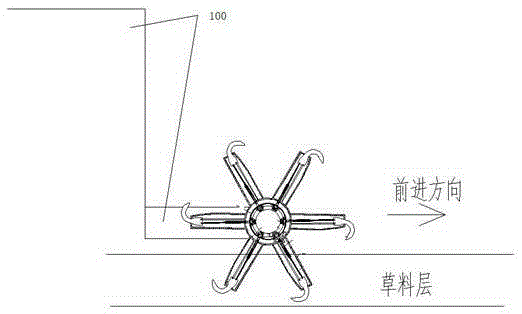

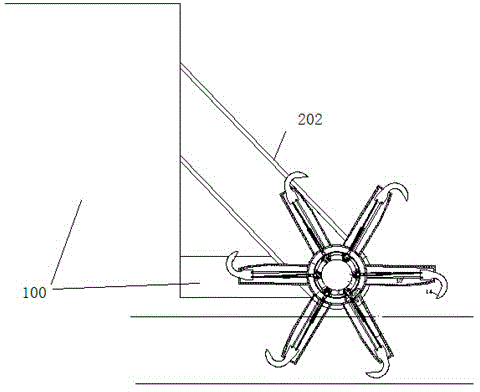

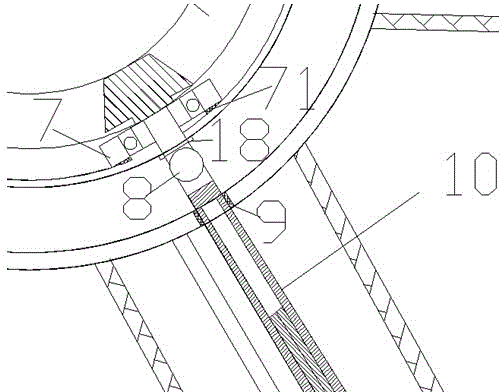

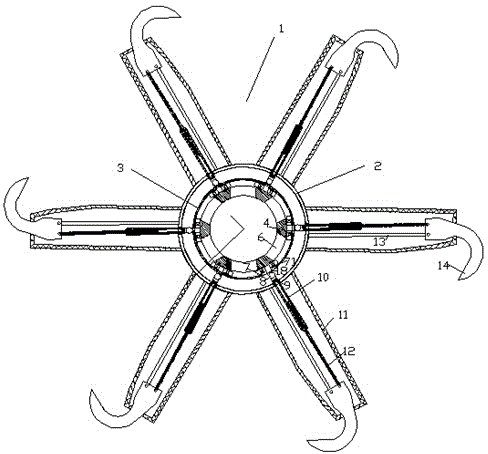

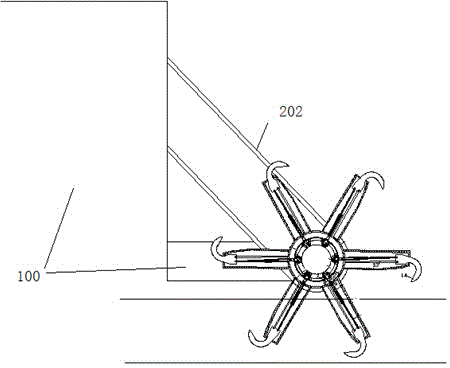

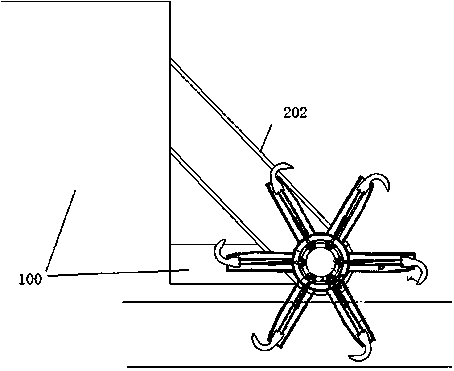

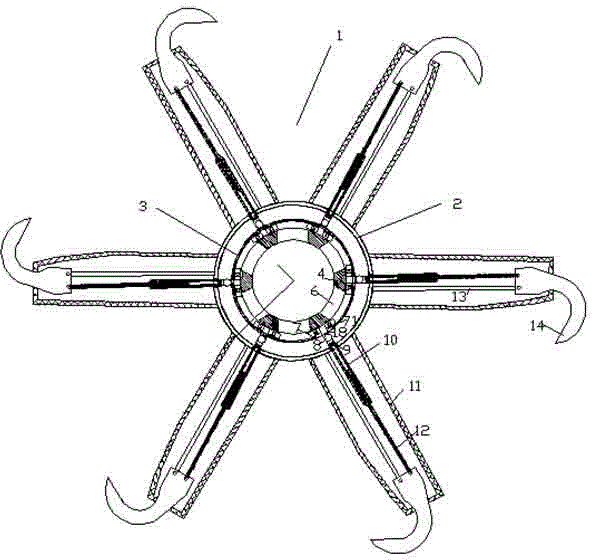

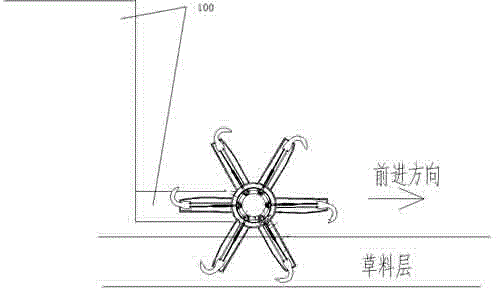

Liftable fodder tedding device driven by belt

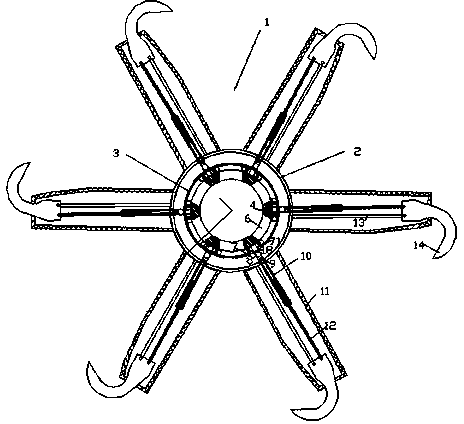

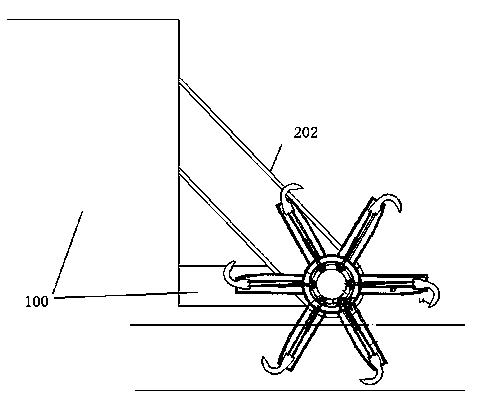

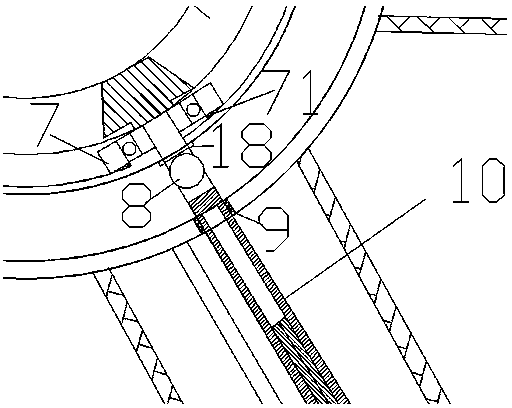

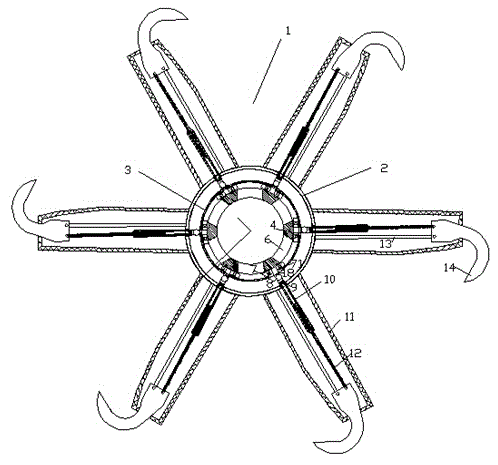

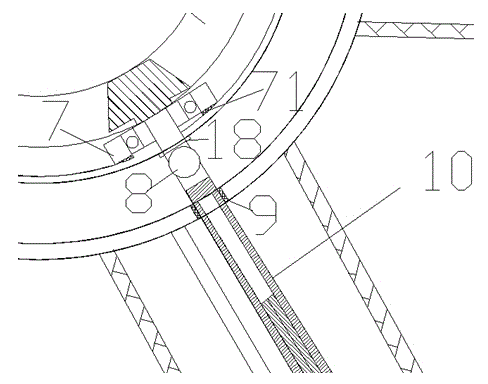

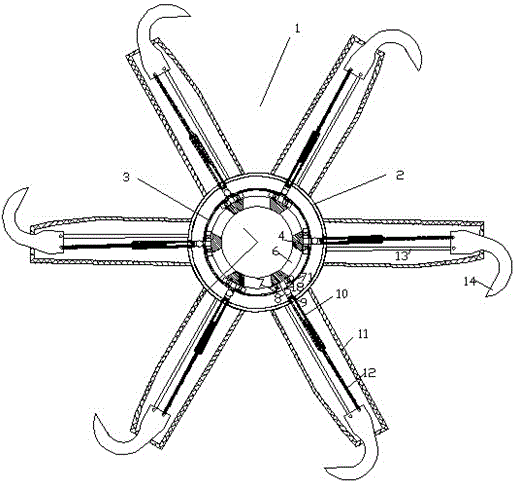

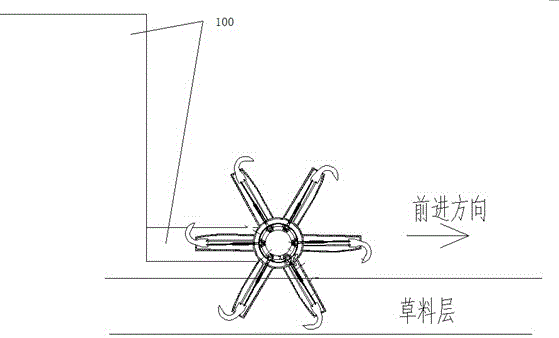

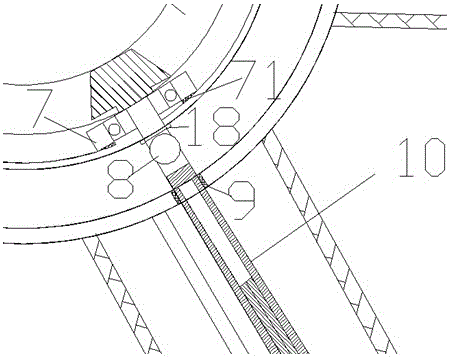

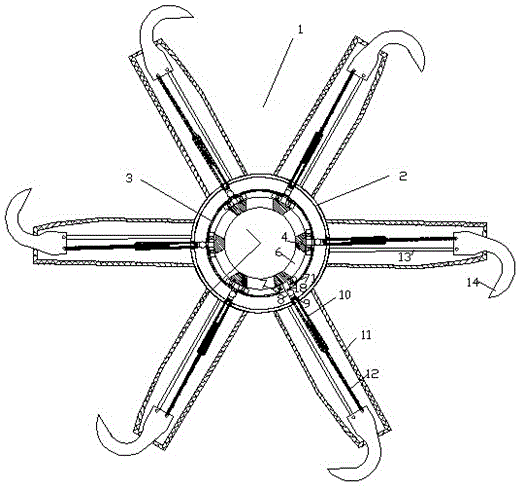

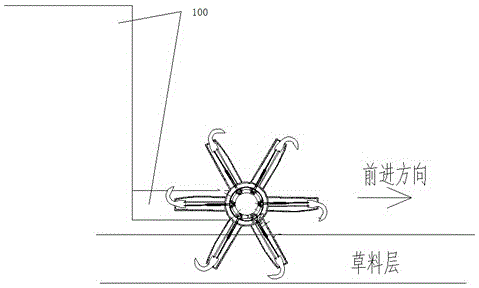

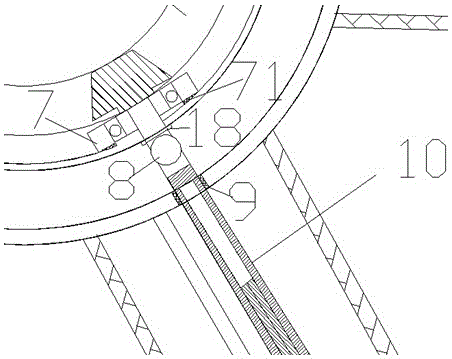

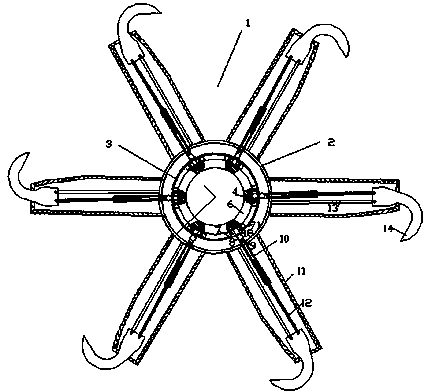

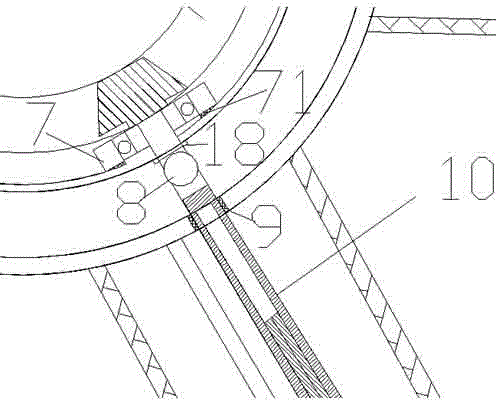

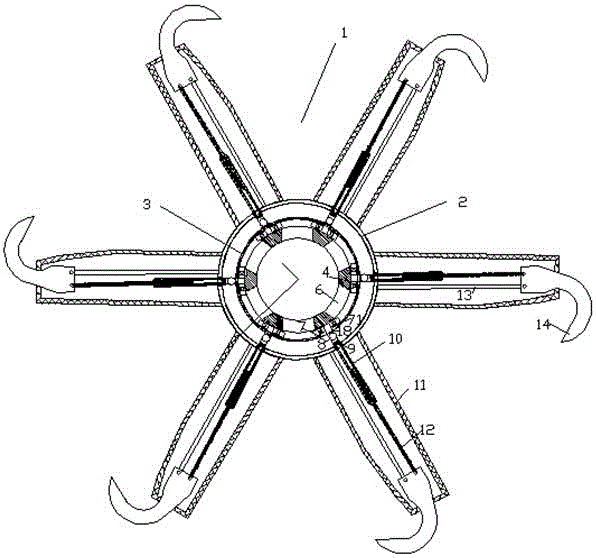

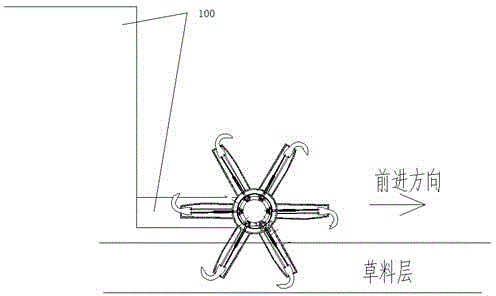

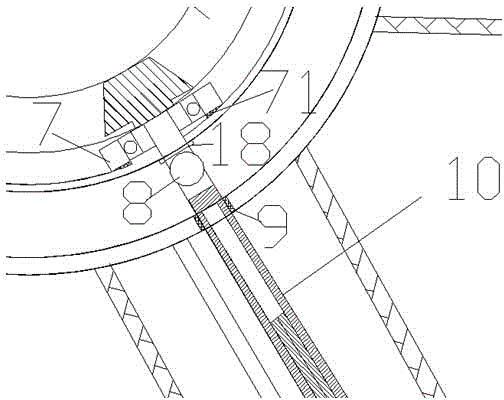

A liftable fodder tedding device driven by a belt comprises an operative part and a connection part; the operative part is used for carrying out tedding operations, and comprises an outer supporting barrel (2), an inner supporting barrel (3) and six tedding hook components (1); moreover, each tedding hook component (1) is uniformly fixed on the cylindrical surface of the outer supporting barrel (2) in the circumferential direction; every two adjacent tedding hook components (1) in the six tedding hook components (1) are uniformly distributed on the cylindrical surface of the outer supporting barrel (2) in the circumferential direction at spacing of 60 degrees; thus, the six tedding hook components (1) are uniformly distributed on the cylindrical surface of the outer supporting barrel (2) in the circumferential direction.

Owner:张春雨

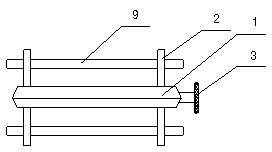

Novel coal magnetic separation device

The invention discloses a novel coal magnetic separation device. The novel coal magnetic separation device comprises a base; two pedestals are installed on the top wall of the base; fixing rings are installed on the two pedestals; a drum is installed on the two fixing rings together, and is located in the fixing rings; a feeding port and a discharge port are correspondingly formed in the two endsof the drum; an annular rack is fixedly installed on the outer side wall of the drum; a first driving motor is installed on the top wall of the base; a circular gear is installed at the driving end ofthe first driving motor and is mutually engaged with the annular rack; and a magnetic separation belt is arranged in the drum in a penetrating manner. The belt having the magnetic property is inserted into coal to cyclically adsorb broken iron mixed into the coal out in a reciprocating manner, so that automatic operation of the whole magnetic separation process is achieved, the novel coal magnetic separation device is time-saving, labor-saving, efficient, convenient and rapid, the coal is subjected to magnetic separation and is uniformly rolled by utilizing the drum, the efficiency of the magnetic separation is improved, the sufficient degree of the magnetic separation is raised, and the novel coal magnetic separation device is easy to achieve, stable and efficient.

Owner:福州宇卓科技有限公司

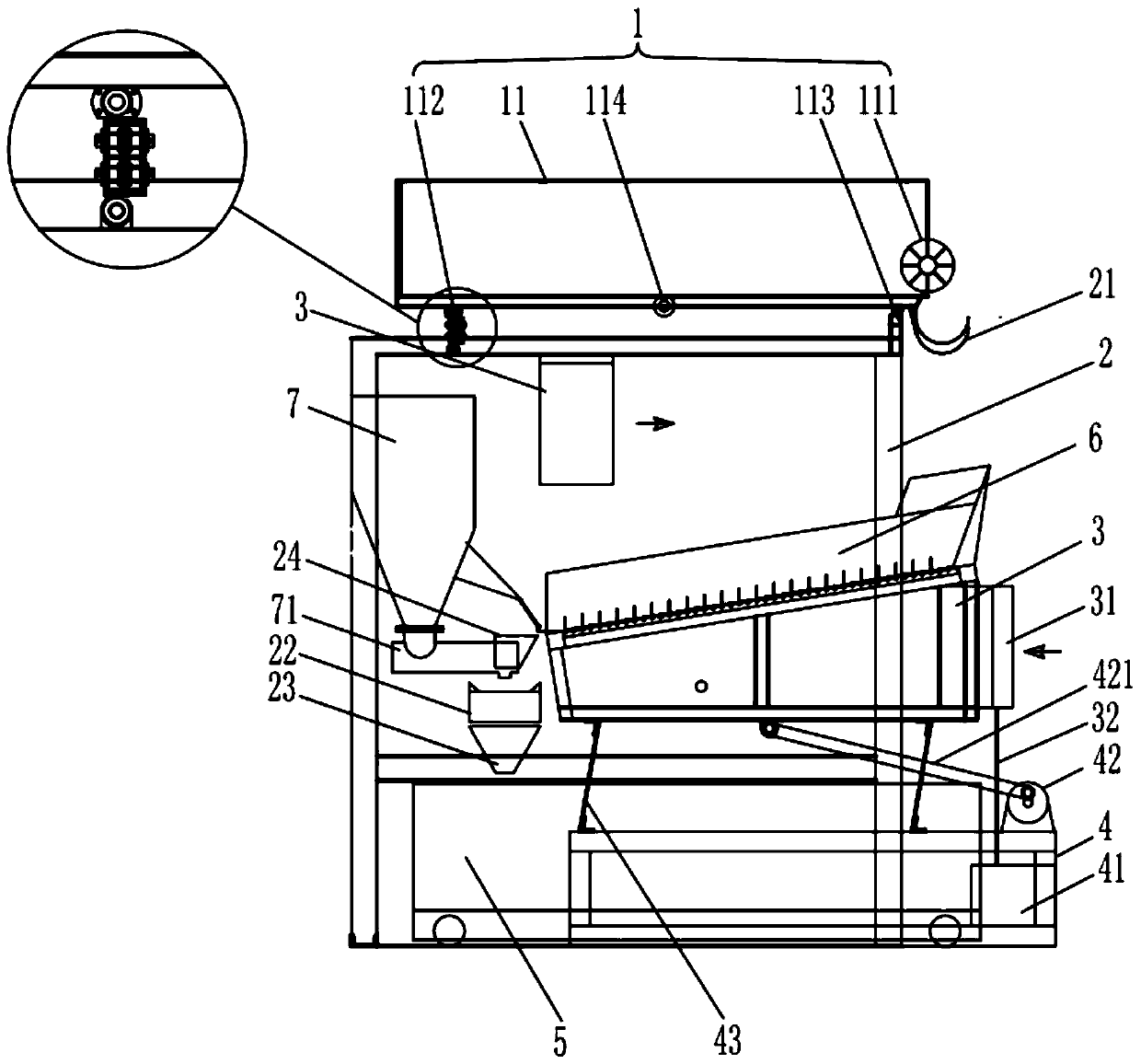

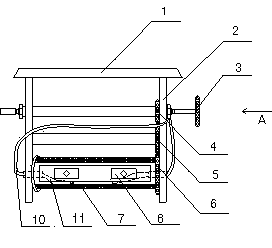

Wine-making grain dross spreading airing and yeast adding integrated machine

PendingCN110540907AAvoid breedingAvoid easy cloggingAlcoholic beverage preparationYeastMaterial supply

The invention discloses a wine-making grain dross spreading airing and yeast adding integrated machine, and relates to the technical field of wine-making grain dross spreading equipment. The wine-making grain dross spreading airing and yeast adding integrated machine is mainly used for solving the problems that grain dross blocks ventilation holes, and yeast needs to be manually added. According to the main structure, the wine-making grain dross spreading airing and yeast adding integrated machine comprises a rack and a material supplying mechanism; a scattering roller and a spreading airing bed are sequentially arranged on the position, below the material discharging end of the material supplying mechanism, of the rack, the spreading airing bed comprises a plurality of bed boards which are sequentially arrayed and partially overlapped, and fans blowing air towards the spreading airing bed are arranged on the upper part and the lower part of the spreading airing bed correspondingly; ayeast box is further arranged on the rack, and the material discharging end of the yeast box is connected with a spiral material conveying device; and a material conveying belt, a material mixing hopper and a transferring material box are sequentially arranged below the spreading airing bed and the material discharging end of the spiral material conveying device. The wine-making grain dross spreading airing and yeast adding integrated machine provided by the invention can effectively prevent the grain dross from blocking an air channel and being caked, and meanwhile can further automatically complete spreading airing and yeast adding of the grain dross, and thus manpower is saved.

Owner:许兴萍

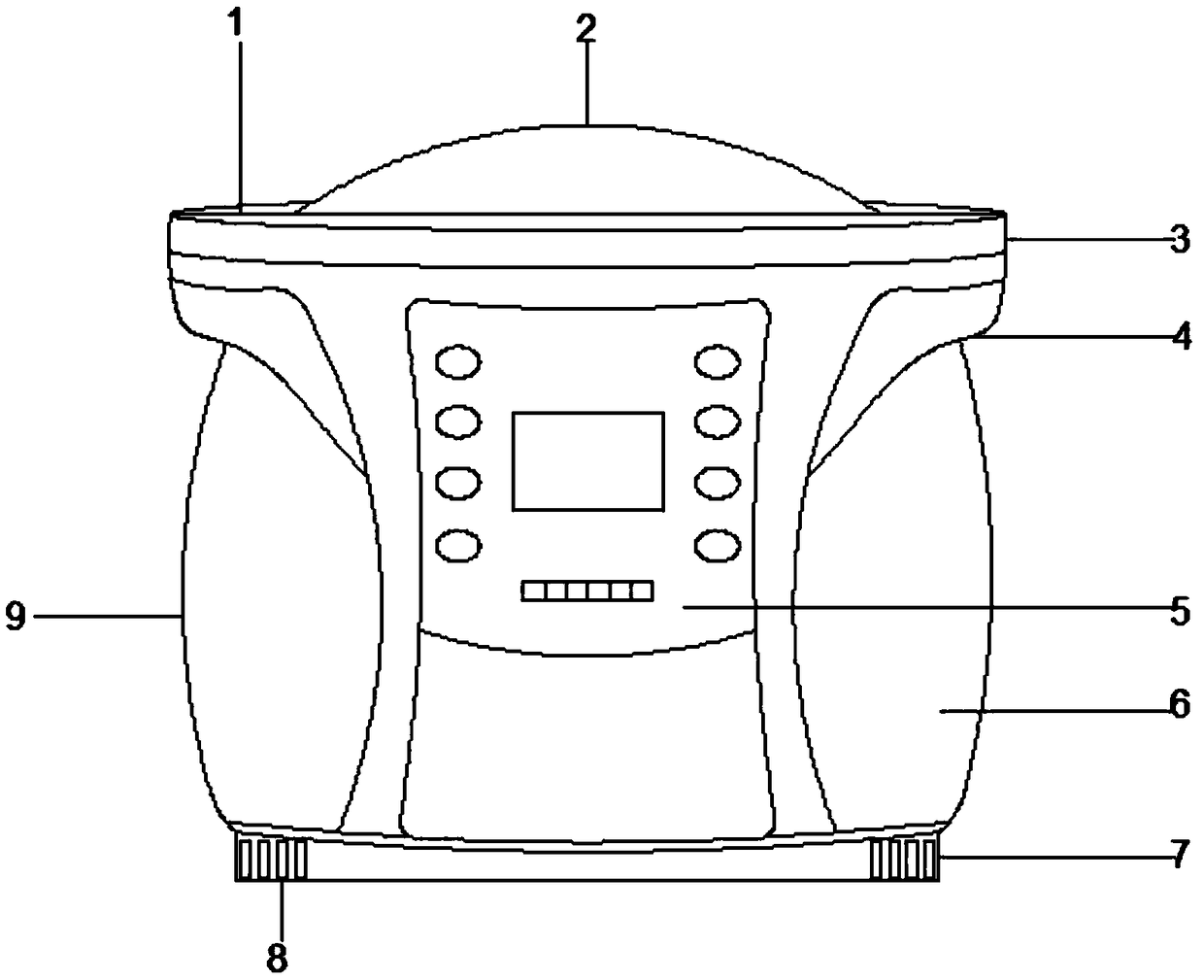

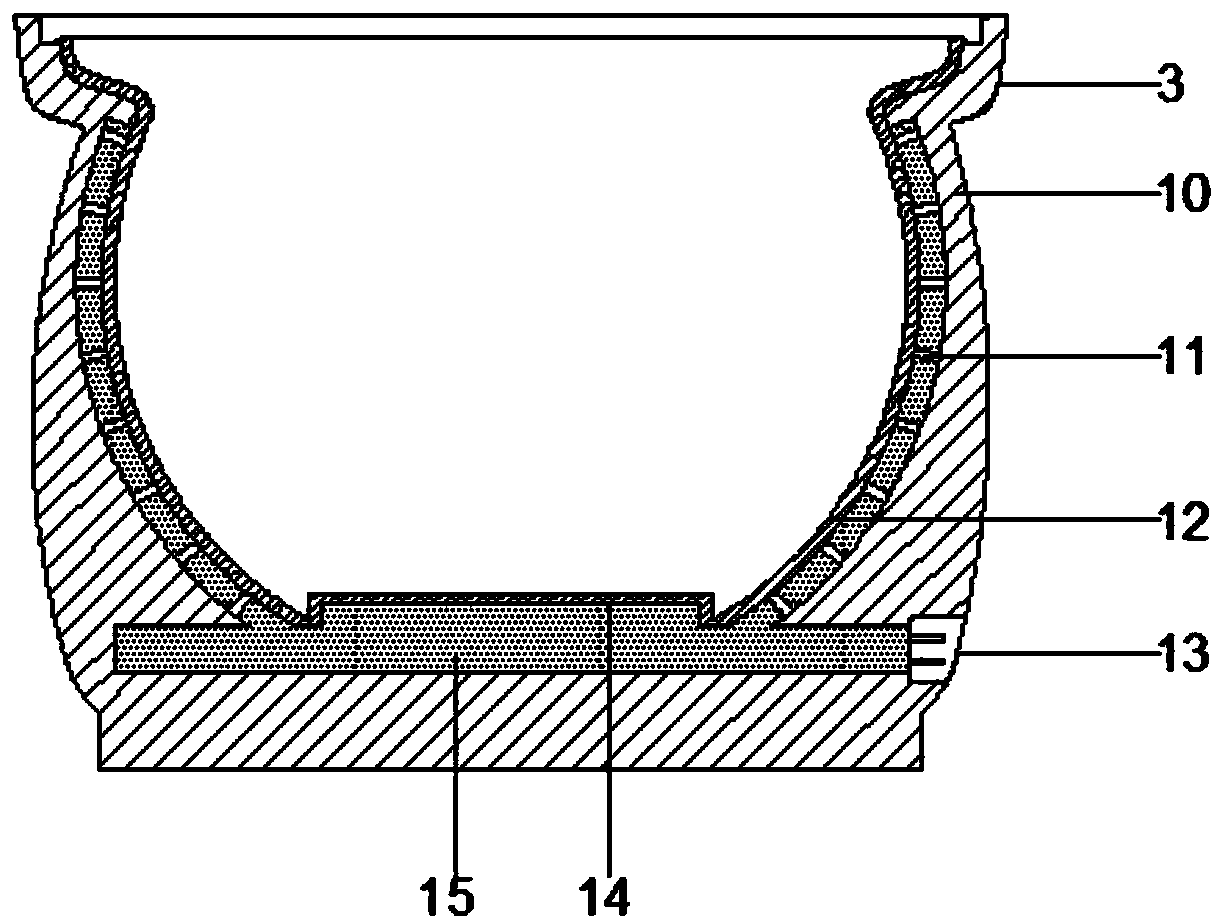

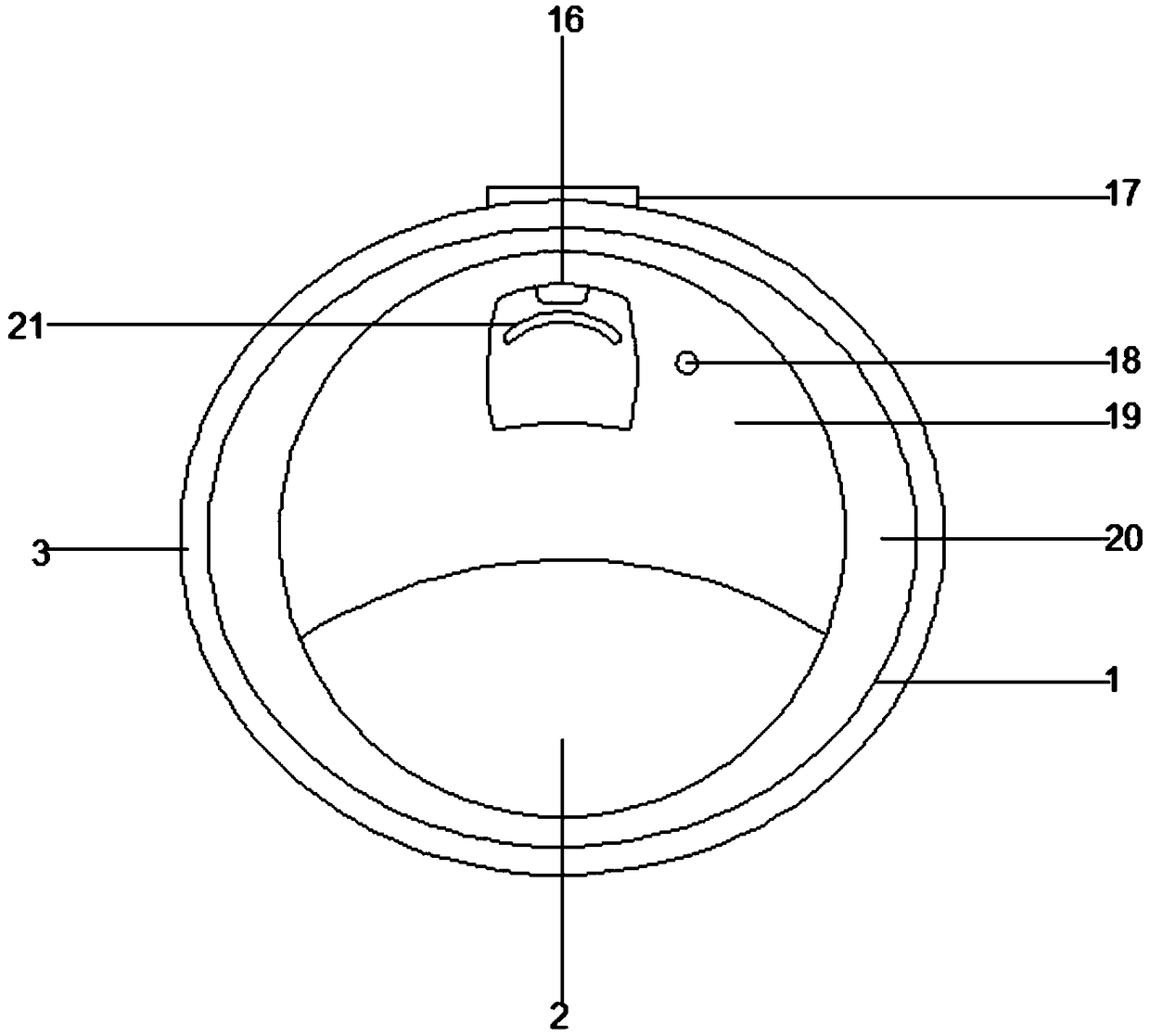

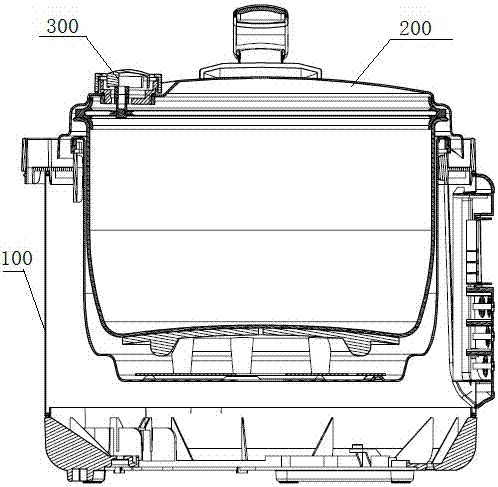

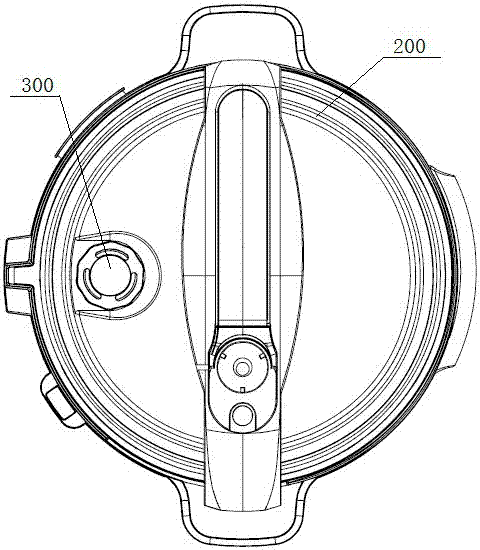

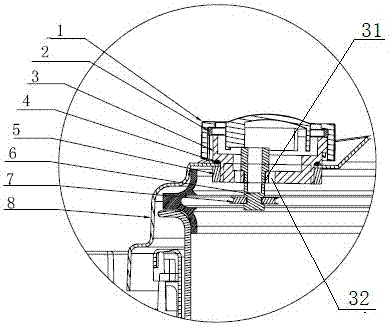

Anti-corrosion and anti-rust electric pressure cooker

InactiveCN108433528AIncrease the usable areaEasy to useCooking-vessel materialsPressure-cookersExhaust valveEngineering

The invention relates to an anti-corrosion and anti-rust electric pressure cooker which comprises a cooker lid, a grip, a cooker edge, a cooker ear, a cooker shell, a cooker body, a magnetic coil, a liner, a lug boss, a heating plate, steam boxes, an inner cover, an outer cover, a protective cover, a bottom cover, ventilation holes, a cutting ferrule, upper clamping blocks, a clamping column and an exhaust valve. The cooker body is spherical laterally. The cooker body comprises the cooker lid, the cooker shell and the base from top to bottom in sequence. The hemispheric cooker shell is arranged at the top end of the base. The cooker shell and the base adopt an integrated structure. The cooker shell comprises a housing, the heating plate and the liner from outside to inside in sequence. Thecircular lug boss is arranged at the bottom end of the heating plate. Through the modification, the anti-corrosion and anti-rust electric pressure cooker has the advantages of being free of coatings,anti-corrosion, anti-rust, easy to clean, balanced in heating, efficient in heat conduction, and multiple-purpose, and occupying less space, and solves the problem and overcomes the defects in the prior art.

Owner:SUZHOU XINJINGYI TITANIUM PROD

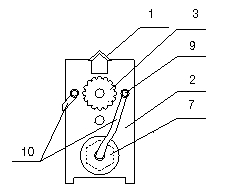

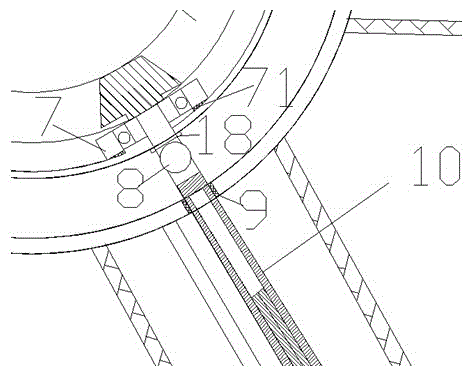

Method for preparing electroplating roller

InactiveCN103668413ASimple structureIncrease loading capacityElectrolysis componentsProduction linePulp and paper industry

The invention discloses a method for preparing an electroplating roller, relating to a method for preparing a roller used in an electroplating production line. The designed roller comprises a hanger rod with a triangular section and two support rods, and also comprises two side plates, wherein the hanger rod is arranged at the tops of the side plates, the roller is arranged between the two side plates, and a roller gear is arranged at one end of the roller, is sequentially connected with a secondary gear and a main gear and then is connected with a power gear outside the side plates. The method has the beneficial effect that the roller prepared by the method has a simple structure, large loading capacity and high production efficiency, and can well roll; due to the rotation of the roller, the parts are turned over uniformly, and the product is fully electroplated.

Owner:天津祥和兴金属制品有限公司

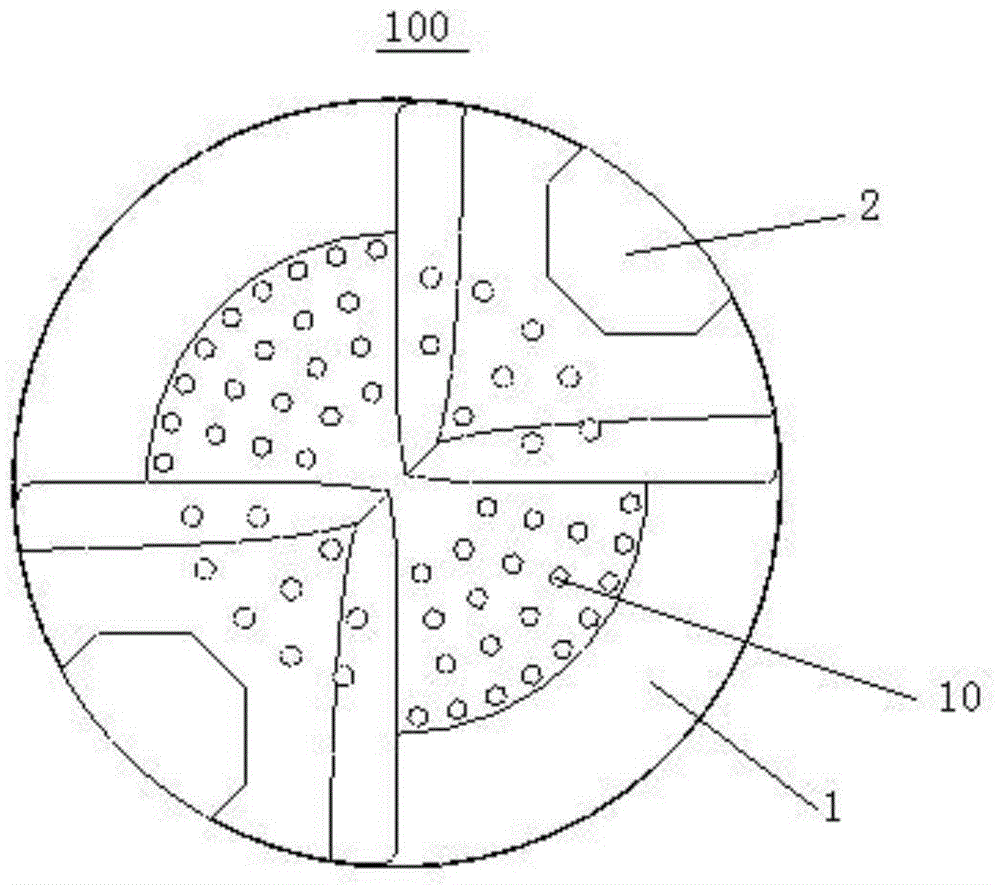

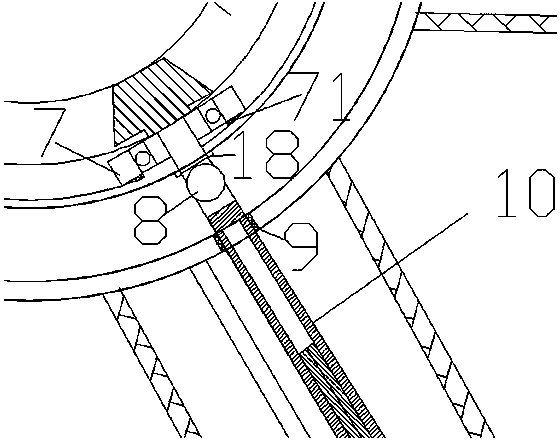

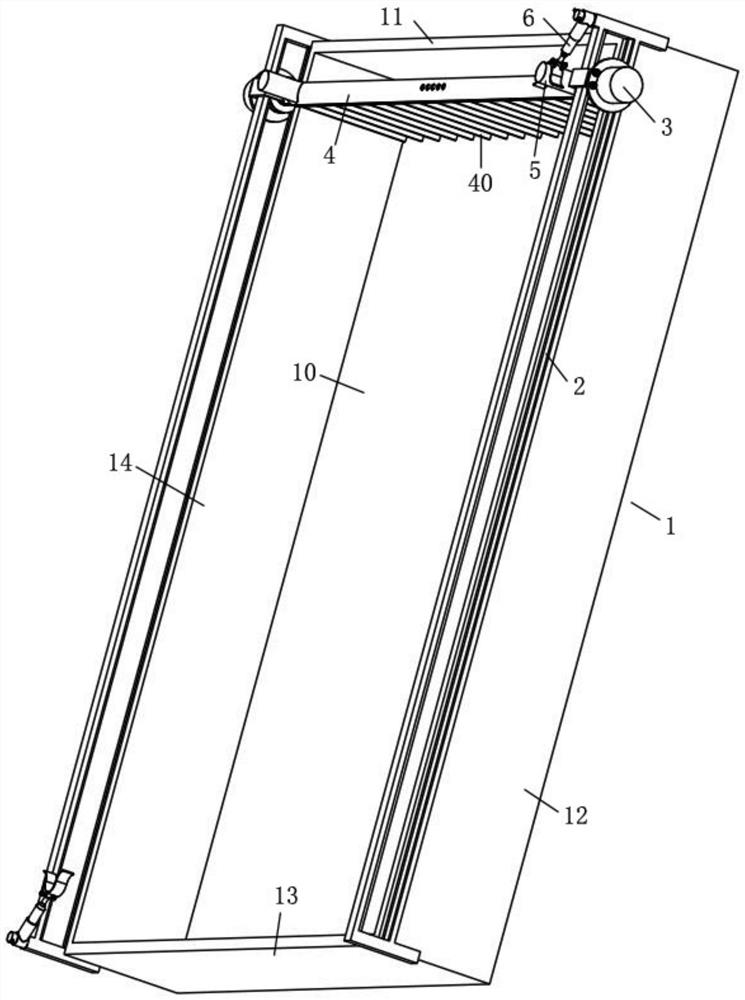

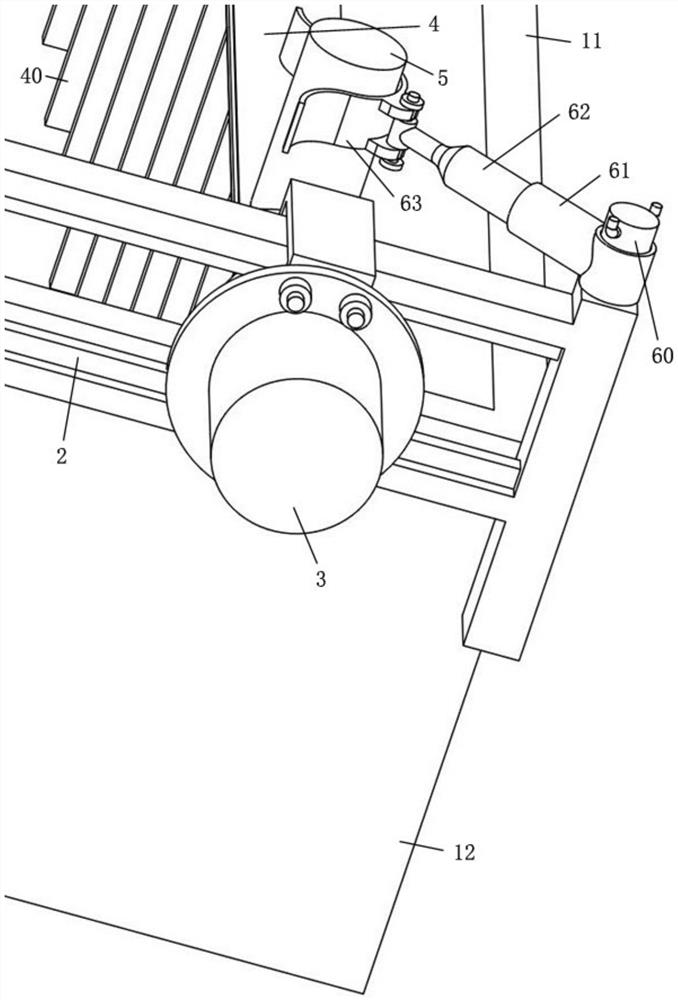

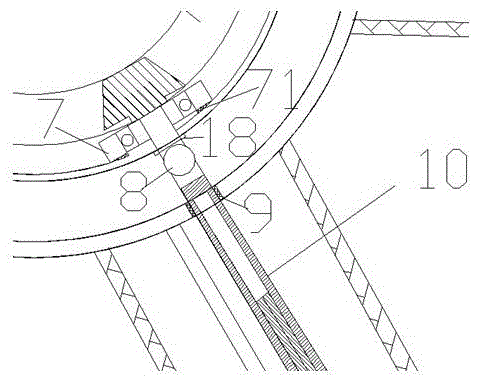

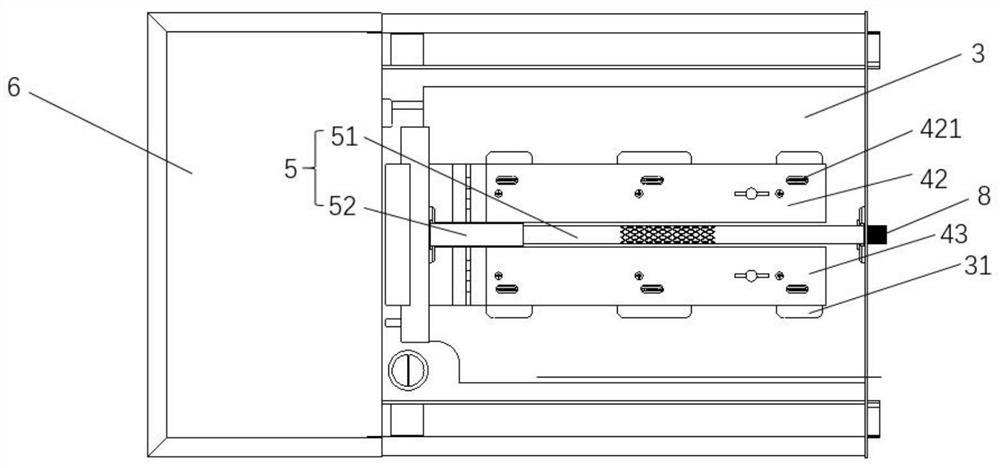

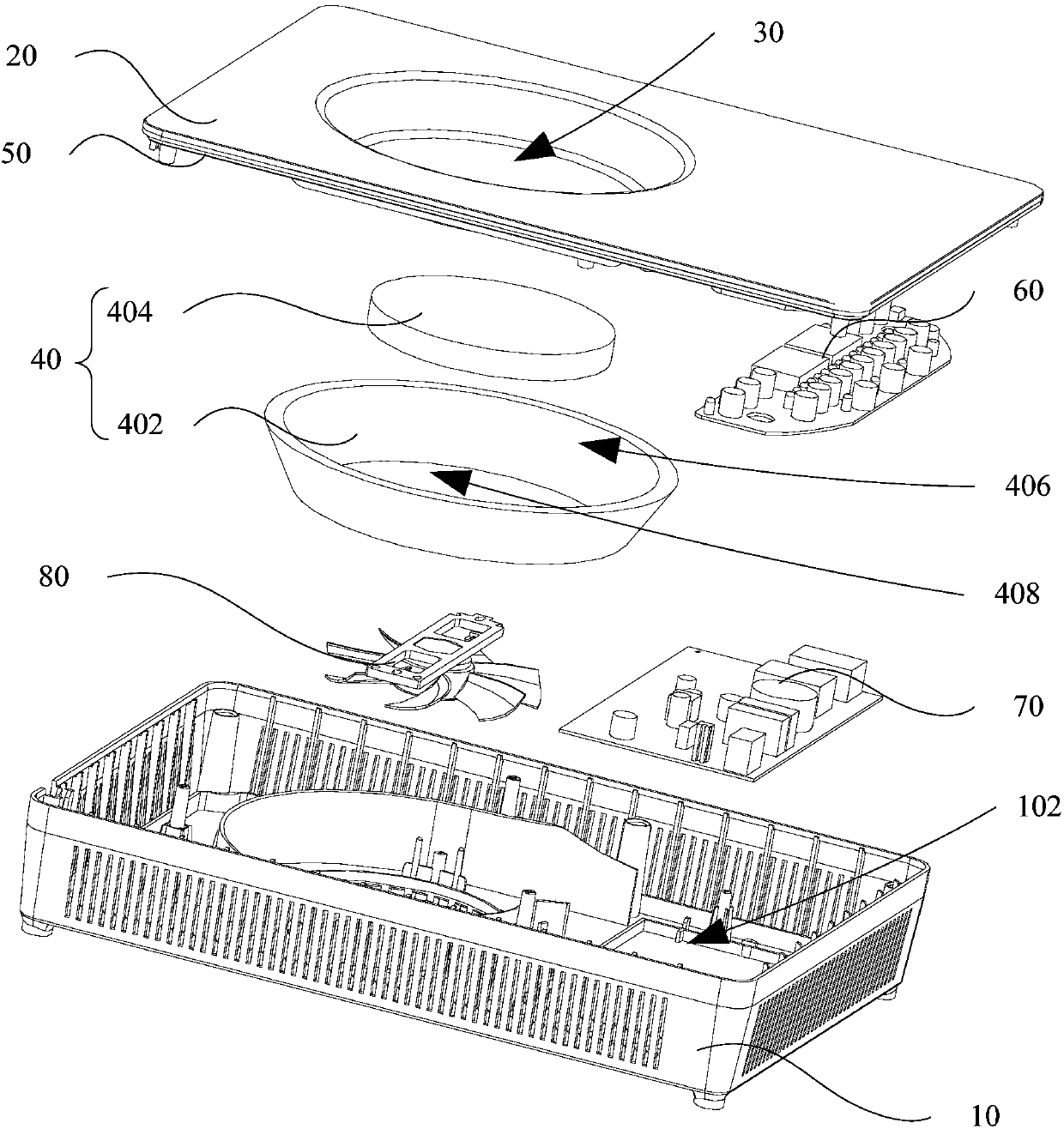

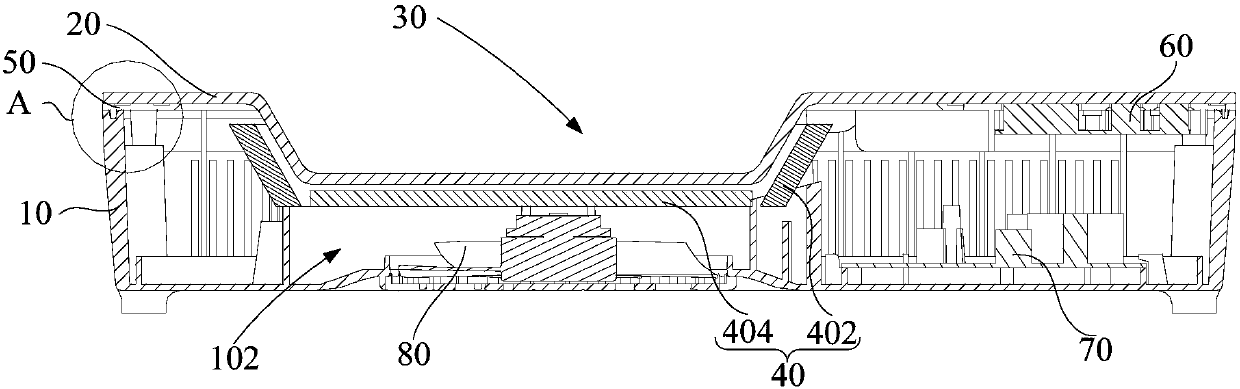

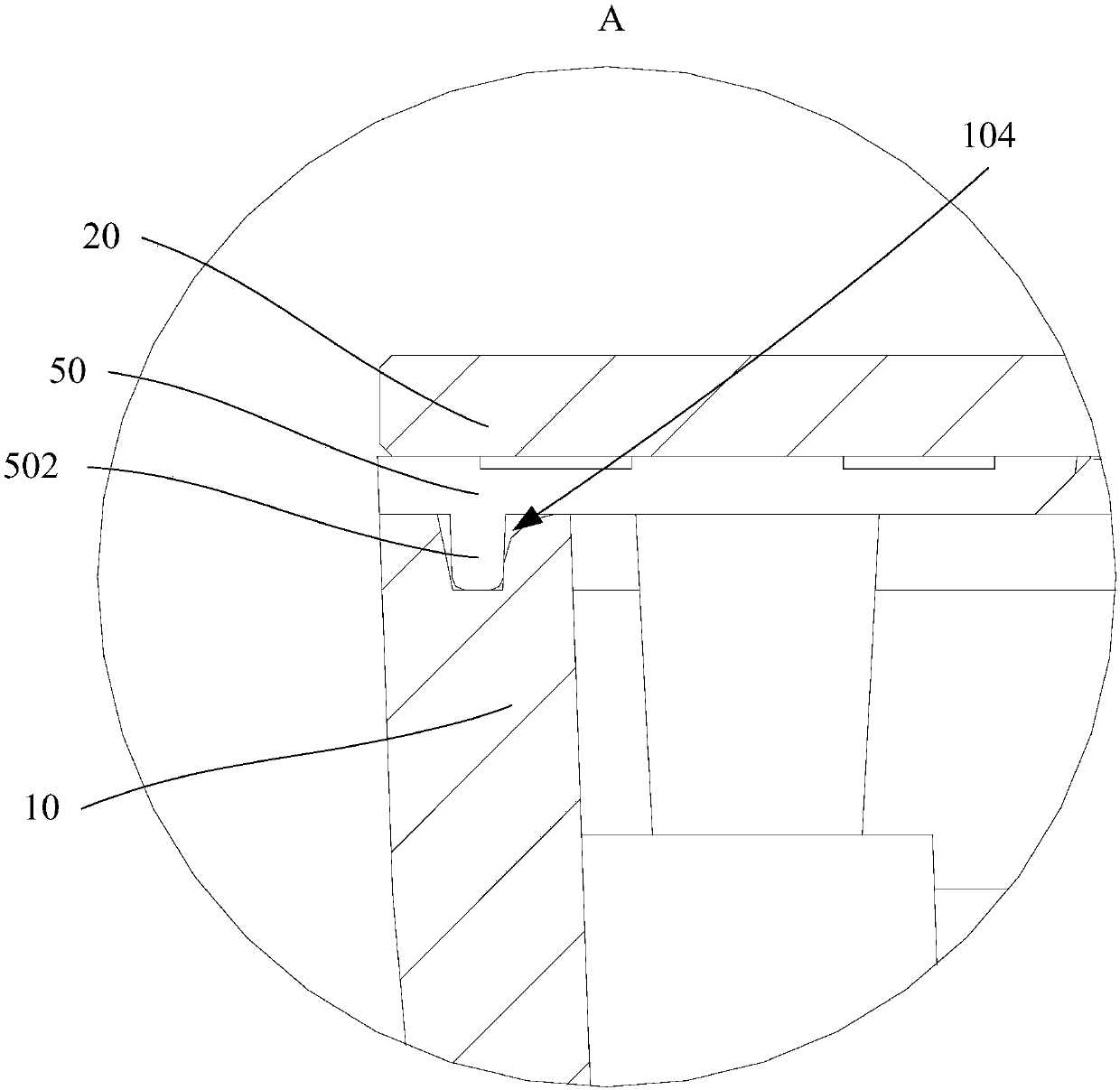

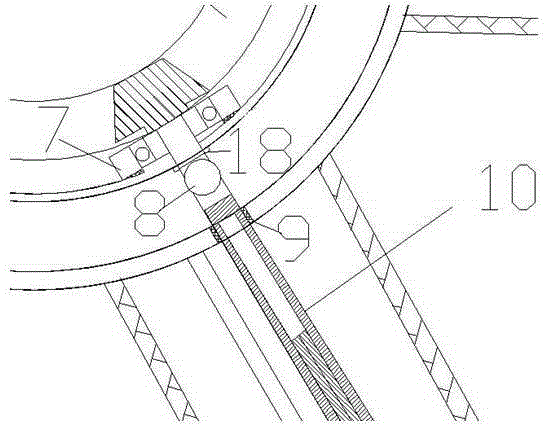

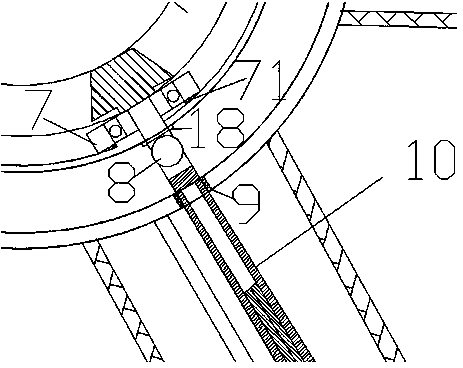

Inner cylinder for clothes dryer and clothes dryer with same

InactiveCN105648719ASolve the entanglementTumble evenlyTextiles and paperLaundry driersEngineeringAir channel

The invention discloses an inner cylinder for a clothes dryer and the clothes dryer with the same. The inner cylinder includes a body and air ribs; the top wall of the body is open, and the bottom wall of the body is provided with a plurality of first air holes; the air ribs are arranged on the inner wall of the body and extends to the bottom wall of the body; air channel joints are formed between the air ribs and the bottom wall of the body and the side wall of the body; and the air ribs are provided with second air holes. According to the inner cylinder, the air ribs are provided to form the air channel joints, and different side walls of the air ribs are provided with the second air holes, and in this way, air can blew clothes from different directions, the clothes in the inner cylinder are scattered, and winding of the clothes in the inner cylinder can be avoided.

Owner:WUXI LITTLE SWAN CO LTD

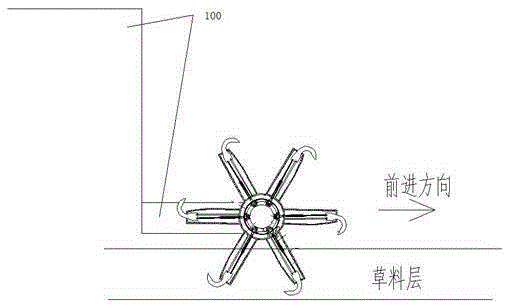

Forage tedding device with air blowing device and allowing lifting

A forage tedding device with an air blowing device and allowing lifting comprises an executing portion and a connecting portion; the executing portion which is used for executing the tedding operation comprises an outer supporting cylinder (2), an inner supporting cylinder and six turning hook components (1); every turning hook component (1) is uniformly fixed on the cylindrical surface of the outer supporting cylinder (2) in the peripheral direction; the six turning hook components (1) are arranged in the cylindrical peripheral direction of the outer supporting cylinder (2) in a mode of being mutually spaced by 60 degrees, so that the six turning hook components (1) are uniformly distributed in the cylindrical peripheral direction of the outer supporting cylinder (2).

Owner:夏良海

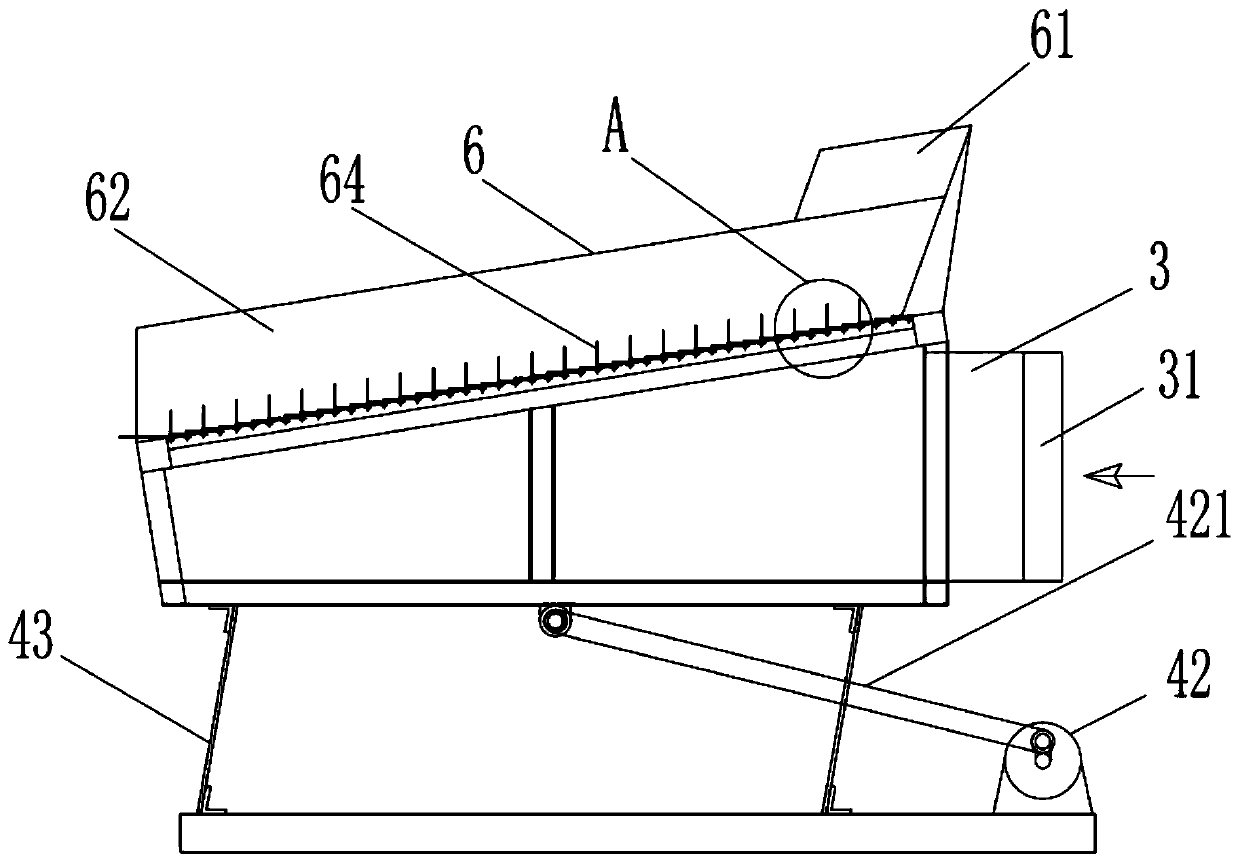

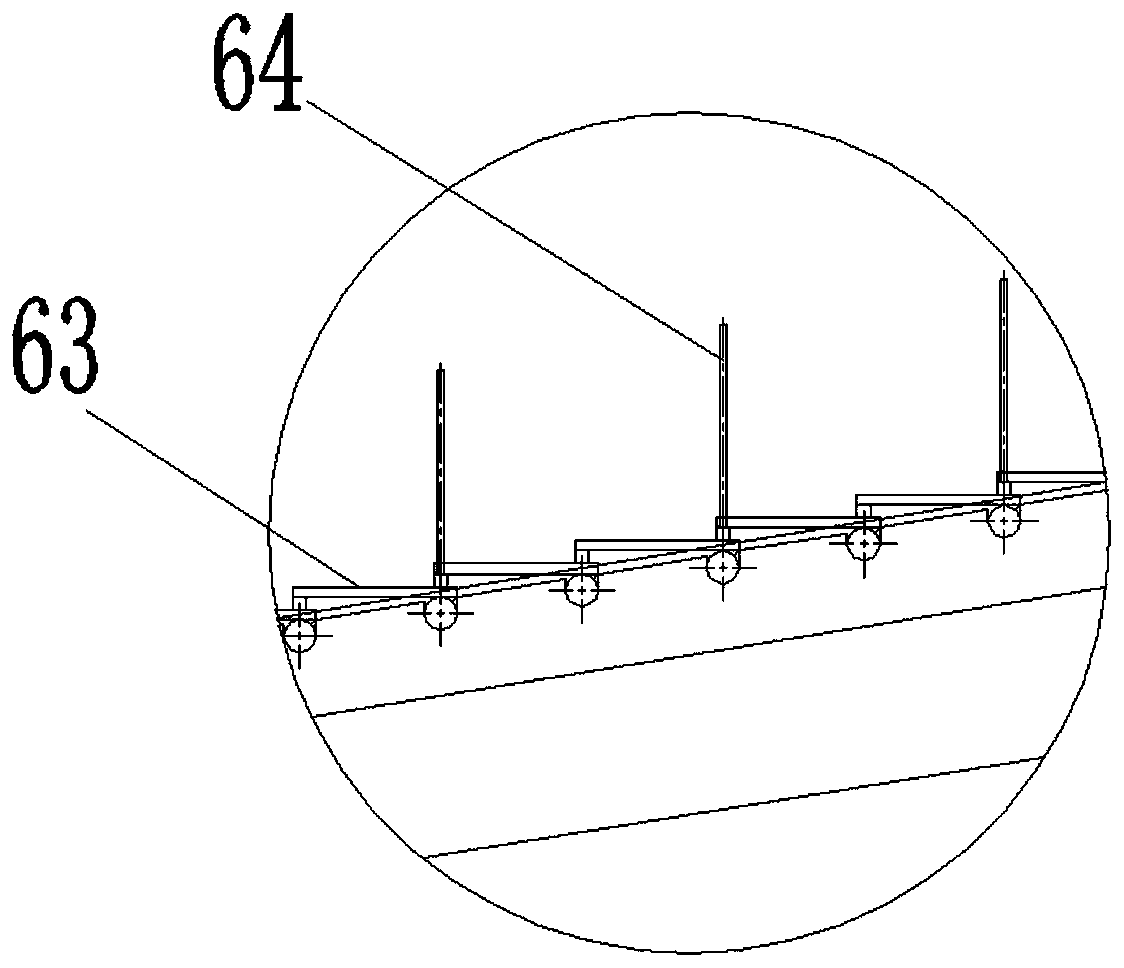

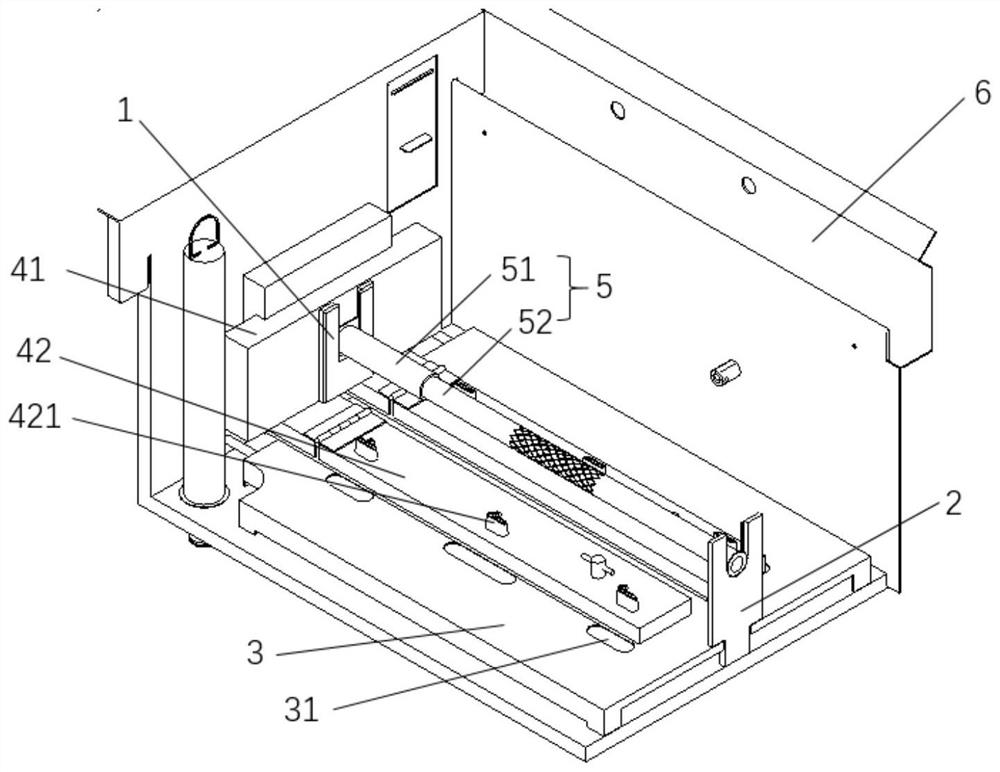

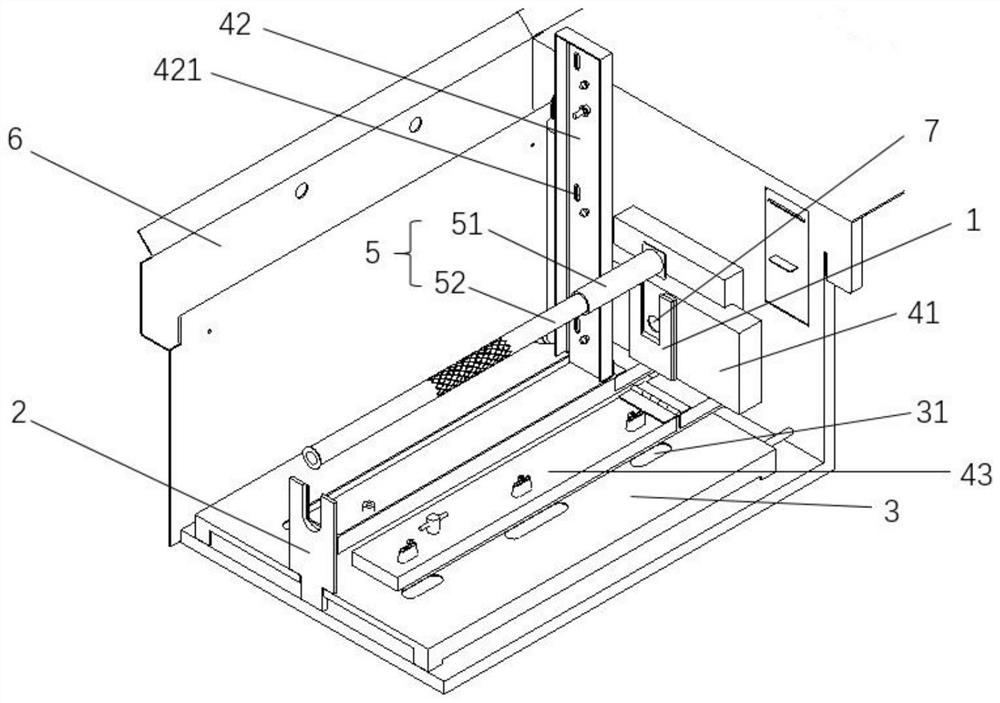

Ganoderma lucidum spore powder drying device and method

InactiveCN112503896AGuaranteed qualityTumble evenlyDrying solid materialsDrying machines with non-progressive movementsBiotechnologySpore

The invention discloses a ganoderma lucidum spore powder drying device, and belongs to the harvesting and drying technology. The ganoderma lucidum spore powder drying device comprises an airing groove, a driving mechanism and a tedding mechanism. The tedding mechanism comprises a tedding rake assembly and lane changing assemblies, and the tedding rake assembly transversely extends along the airinggroove and stretches across the airing groove. The driving mechanism can drive the tedding rake assembly to move back and forth in the airing groove in the longitudinal direction of the airing grooveso as to rake spore powder. The lane changing assemblies are arranged at the two longitudinal ends of the airing groove correspondingly, and one lane changing assembly pushes the tedding rake assembly to move leftwards by a certain distance L in the transverse direction when the tedding rake assembly moves to the end portion of the end I of the airing groove. And the other lane changing assemblypushes the tedding rake assembly to move rightwards by a certain distance L in the transverse direction when the tedding rake assembly moves to the end portion of the end II of the airing groove. Under the action of the driving mechanism, the tedding rake assembly moves back and forth at the two ends of the airing groove, the lane changing assemblies can force the tedding rake assembly to move leftwards or rightwards in the transverse direction, and the problem that mildewing is likely to be caused due to uneven manual tedding is solved.

Owner:MICROBIOLOGY RES INST GUANGXI ZHUANG AUTONOMOUS REGION ACADEMY OF AGRI SCI

A kind of variable pressure static pickling equipment and pickling method for food

ActiveCN104256848BIncrease impactAccelerate the speed of penetration into the tissue of the material to be marinatedFood preservationKitchen equipmentPositive pressureUltimate tensile strength

The invention discloses transformation static curing equipment for foods and a curing method thereof. A pressure regulation device which is capable of increasing or decreasing pressure in a curing pot is connected onto the curing pot; by utilizing pressure change in the curing pot, the materials to be cured are cured; particularly, when the curing pressure in the curing pot changes from negative pressure to positive pressure, the impact of the curing liquid entering into the materials to be cured is enlarged, so that the speed of the curing liquid permeating into the tissues of the materials to be cured is accelerated, the curing efficiency is improved and the requirements of the production process are satisfied. Moreover, the curing pot is designed into a double-layer structure of a latticed inner cylinder, and latticed separation plates are added in the inner cylinder to divide the inner cylinder into a plurality of communicated curing units, so that the structural strength of the curing pot is effectively improved, the extrusion between the materials to be cured can be decreased and the integrity of the cured materials is kept.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Forage tumbling device capable of shaking off forage and sweeping off forage

The invention provides a forage tedding device capable of shaking off forage and sweeping off forage. The forage tedding device comprises an executing part and a connecting part, wherein the executing part is used for executing the tedding operation, and comprises an outer supporting barrel (2), an inner supporting barrel (3) and six overturning hook parts (1), the overturning hook parts (1) are uniformly fixed on the cylindrical surface of the outer supporting barrel (2) along the circumferential direction, and the six overturning hook parts (1) are arranged on the cylindrical surface of the outer supporting barrel (2) along the circumferential direction in a manner that every two overturning hook parts are spaced from a 60-degree angle, so that the six overturning hook parts (1) are uniformly distributed on the cylindrical surface of the outer supporting barrel (2) along the circumferential direction.

Owner:江苏叠石桥家纺产业集团有限公司

A noodle cooker with an adjusting rod

ActiveCN112294083BLengthen or shortenExtended service lifeBoiling over preventionTime-controlled ignitorsTemperature controlWater leak

Owner:安庆诚旺厨具科技有限公司

Grass tumbling device capable of sweeping down grass and controlling speed

A fodder tedding device capable of sweeping fodder and performing speed control comprises an execution part and a connecting part. The execution part is used for executing tedding operations and comprises an outer supporting drum (2), an inner supporting drum (3) and six overturning hook components (1). Each overturning hook component (1) is evenly fixed on the cylindrical surface of the outer supporting drum (2) in the circumferential direction, the six overturning hook components (1) are arranged at an interval of 60 degrees with one another in the cylindrical circumferential direction of the outer supporting drum (2), and accordingly the six overturning hook components (1) are evenly distributed in the cylindrical circumferential direction of the outer supporting drum (2).

Owner:巫山县新牧草业科技有限公司

Grass tumbling device driven by belt and capable of speed control

Provided is a hay turning and drying device adopting belt driving and allowing the speed to be controlled. The hay turning and drying device comprises an execution part and a connection part. The execution part is used for executing turning and drying operation and comprises an outer supporting cylinder (2), an inner supporting cylinder (3) and six turning hook components (1). The turning hook components (1) are uniformly fixed to the cylindrical surface of the outer supporting cylinder (2) in the peripheral direction. Every two of the six turning hook components (1) are arranged in the cylindrical peripheral direction of the outer supporting cylinder (2) at a 60-degree interval, and therefore the six turning hook components (1) are uniformly arranged in the cylindrical peripheral direction of the outer supporting cylinder (2).

Owner:巫山县新牧草业科技有限公司

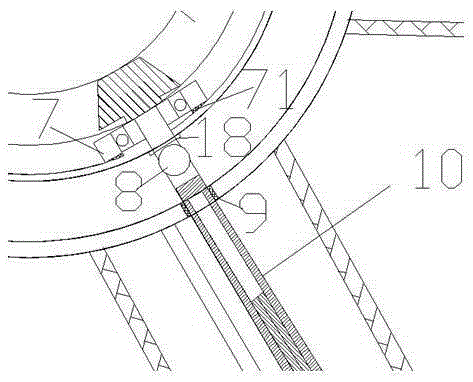

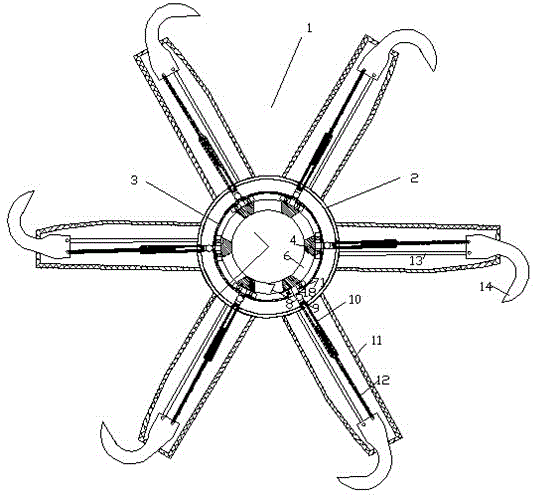

Forage tumbling device that shakes off forage and has separate hooks

ActiveCN103975708BQuick flipEnsure consistencyAgriculture tools and machinesHarvested fruit hanging devicesAnimal ForagingEngineering

The invention discloses a forage tedding device capable shaking off forage and provided with separated hooks. The forage tedding device comprises an executing part and a connecting part, wherein the executing part is used for executing the tedding operation, and comprises an outer supporting barrel (2), an inner supporting barrel (3) and six overturning hook parts (1), the overturning hook parts (1) are uniformly fixed on the cylindrical surface of the outer supporting barrel (2) along the circumferential direction, and the six overturning hook parts (1) are arranged on the cylindrical surface of the outer supporting barrel (2) along the circumferential direction in a manner that every two overturning hook parts are spaced from a 60-degree angle, so that the six overturning hook parts (1) are uniformly distributed on the cylindrical surface of the outer supporting barrel (2) along the circumferential direction.

Owner:浙江嘉佑农业发展有限公司

Heating stove

ActiveCN109931634AIncrease the heating areaEvenly distributedDomestic stoves or rangesLighting and heating apparatusBoiling processHeat distribution

The invention provides a heating stove. The heating stove comprises a base, a panel, a groove and a heating device. A mounting cavity is formed in the base. The panel is located above the base. The groove is formed in the panel, the side wall of the groove inclines to the center of the groove, the groove gradually expands towards the panel to become larger, and the side wall and the bottom wall ofthe groove are both located in the mounting cavity. The heating device is arranged in the mounting cavity, and the heating device is arranged on the outer side of the side wall of the groove and theouter side of the bottom wall of the groove. The heating stove can heat a cooking utensil from the side wall and the bottom wall of the cooking utensil, heat distribution is more uniform, food in thecooking utensil roll more uniformly in the boiling process, and the situation that food are pasted on the pot as heat is concentrated on the bottom wall of the cooking utensil is avoided. Meanwhile, the cooking utensil is heated from the side wall of the cooking utensil and the bottom wall of the cooking utensil, the heating area of the cooking utensil is also increased, and therefore the heatingefficiency of the heating stove is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Forage tedder with drop curtain and with air blowing device

The invention discloses a forage tedding device with a hanging curtain and a blowing device. The forage tedding device comprises an executing part and a connecting part. The executing part is used for executing the tedding operation and comprises an outer supporting barrel (2), an inner supporting barrel (3) and six overturning hook components (1). The six overturning hook components (1) are evenly fixed to the cylindrical surface of the outer supporting barrel (2) in the circumferential direction, the six overturning hook components (1) are arranged on the outer supporting barrel (2) in the cylinder circumferential direction every 60 degrees, and therefore the six overturning hook components (1) can be evenly distributed on the outer supporting barrel (2) in the cylinder circumferential direction.

Owner:临沂金盛机械配套有限公司

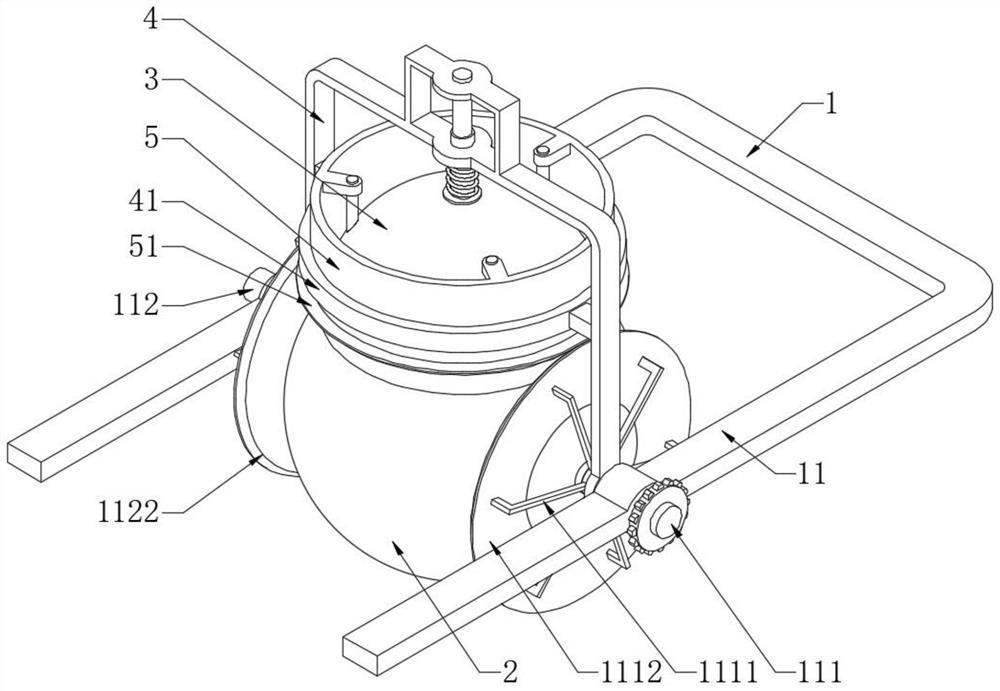

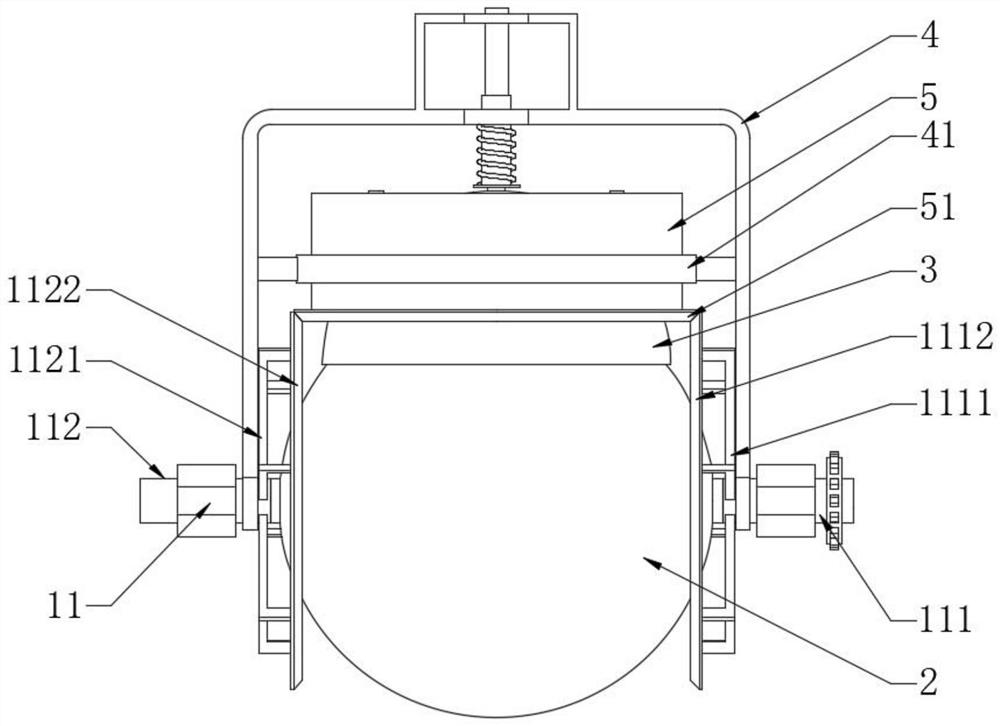

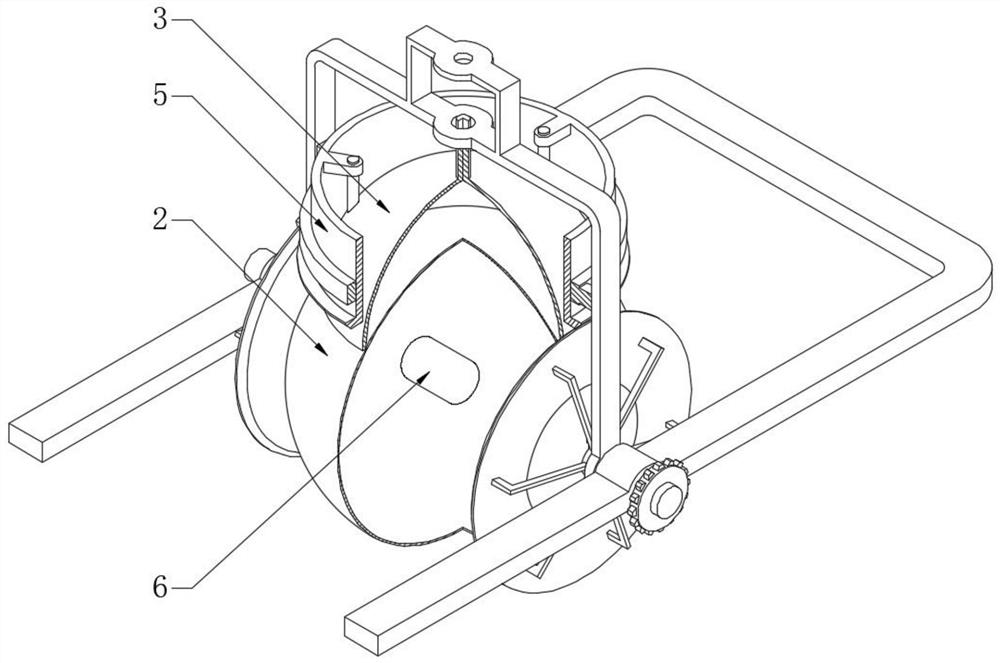

Transposition type constant-temperature thawing device for aquatic products

InactiveCN112841293ATumble evenlyWon't hurtMeat/fish preservation by freezing/coolingEngineeringEnvironmental geology

The invention discloses a transposition type constant-temperature thawing device for aquatic products. The device comprises a supporting frame, a heating ball, a hemispherical shell, a door-shaped frame and a power sleeve, two supporting plates distributed in parallel are arranged on the supporting frame, a right supporting shaft and a left supporting shaft which are coaxially distributed are arranged on the two supporting plates correspondingly, the heating ball is located between the two supporting plates, the outer surface wall of the heating ball is fixedly connected with one end of the left supporting shaft, and the interior of the heating ball is of a hollow structure. According to the device, the heating ball and the hemispherical shell are arranged, the opening part of the hemispherical shell is buckled on the outer surface wall of the heating ball, an aquatic product in the hemispherical shell is unfrozen after the surface wall of the heating ball is heated, and the hemispherical shell can rotate and move around the heating ball at the same time, so that the aquatic product can be uniformly rolled without damaging the unfrozen aquatic product. Meanwhile, as the aquatic products continuously move and are in contact with different outer surface walls of the heating balls, the heating is uniform, and the unfreezing efficiency is greatly improved.

Owner:陈首君

Belt-driven forage tumbling unit with separate hooks

A forage tedding device provided with separated hooks and driven by a belt comprises an executing part and a connecting part. The executing part is used for executing the tedding operation and comprises an outer supporting barrel (2), an inner supporting barrel (3) and six overturning hook components (1). The six overturning hook components (1) are evenly fixed to the cylindrical surface of the outer supporting barrel (2) in the circumferential direction, the six overturning hook components (1) are arranged on the outer supporting barrel (2) in the cylinder circumferential direction every 60 degrees, and therefore the six overturning hook components (1) can be evenly distributed on the outer supporting barrel (2) in the cylinder circumferential direction.

Owner:临沂高新物业管理有限公司

Forage tedding device capable of sweeping off forage and driven by belt

The invention provides a forage tedding device capable of sweeping off forage and driven by a belt. The forage tedding device comprises an executing part and a connecting part, wherein the executing part is used for executing the tedding operation, and comprises an outer supporting barrel (2), an inner supporting barrel (3) and six overturning hook parts (1), the overturning hook parts (1) are uniformly fixed on the cylindrical surface of the outer supporting barrel (2) along the circumferential direction, and the six overturning hook parts (1) are arranged on the cylindrical surface of the outer supporting barrel (2) along the circumferential direction in a manner that every two overturning hook parts are spaced from a 60-degree angle, so that the six overturning hook parts (1) are uniformly distributed on the cylindrical surface of the outer supporting barrel (2) along the circumferential direction.

Owner:巫山县新牧草业科技有限公司

Forage tedder with speed control and separate hooks

Provided is a hay turning and drying device allowing speed to be controlled and provided with separate hooks. The hay turning and drying device comprises an execution part and a connection part. The execution part is used for executing turning and drying operation and comprises an outer supporting cylinder (2), an inner supporting cylinder (3) and six turning hook components (1). The turning hook components (1) are uniformly fixed to the cylindrical surface of the outer supporting cylinder (2) in the peripheral direction. Every two of the six turning hook components (1) are arranged in the cylindrical peripheral direction of the outer supporting cylinder (2) at a 60-degree interval, and therefore the six turning hook components (1) are uniformly arranged in the cylindrical peripheral direction of the outer supporting cylinder (2).

Owner:巫山县新牧草业科技有限公司

Forage taddling device with separate hooks and can be raised and lowered

The invention relates to a forage tedding device provided with a separate hook and capable of lifting. The forage tedding device comprises an execution part and a connecting part, wherein the execution part is used for performing tedding operation, and comprises an outer support cylinder body (2), an inner support cylinder body (3) and six tedding hook parts (1); each tedding hook part (1) is uniformly fixed to the cylindrical surface of the outer support cylinder body (2) in the circumferential direction, the six tedding hook parts (1) are arranged on the cylindrical surface of the outer support cylinder body (2) in the circumferential direction, and the angle formed by every two tedding hook parts (1) is 60 degrees, so that the six tedding hook parts (1) can be uniformly distributed on the cylindrical surface of the outer support cylinder body (2) in the circumferential direction.

Owner:JIASHAN TIANHUI OPTOELECTRONICS TECH

Forage tedding device provided with separated hooks and driven by belt

A forage tedding device provided with separated hooks and driven by a belt comprises an executing part and a connecting part. The executing part is used for executing the tedding operation and comprises an outer supporting barrel (2), an inner supporting barrel (3) and six overturning hook components (1). The six overturning hook components (1) are evenly fixed to the cylindrical surface of the outer supporting barrel (2) in the circumferential direction, the six overturning hook components (1) are arranged on the outer supporting barrel (2) in the cylinder circumferential direction every 60 degrees, and therefore the six overturning hook components (1) can be evenly distributed on the outer supporting barrel (2) in the cylinder circumferential direction.

Owner:临沂高新物业管理有限公司

Cleaning device used for rubber plug

The invention discloses a cleaning device used for a rubber plug. The cleaning device comprises a rack, a feeding hopper and a water ejector mounted on the rack, a conveying mesh belt and a power source for driving the conveying mesh belt to move, wherein the water ejector is positioned above the conveying mesh belt; the ejecting direction of the water ejector faces towards the upper surface of the conveying mesh belt; a distributing tube is further arranged; one end of the distributing tube is connected with the water ejector; the other end of the distributing tube extends to a position below the conveying mesh belt; the extending direction of the distributing tube is perpendicular to the moving direction of the conveyor belt; the part, below the conveying mesh belt, of the distributing tube is provided with a plurality of spray openings which are upwards formed. According to the scheme, the cleaning device is relatively simple in structure and relatively low in cost.

Owner:CHONGQING WEIXING RUBBER

A control valve and an electric pressure cooker equipped with the valve

ActiveCN105310492BEasy to achieve boilingRealize the function of holding pressurePressure-cookersEngineeringControl valves

Owner:FOSHAN SHUNDE QINGNENG ELECTRIC APPLIANCES CO LTD

Fodder tedding device capable of sweeping fodder and performing speed control

A fodder tedding device capable of sweeping fodder and performing speed control comprises an execution part and a connecting part. The execution part is used for executing tedding operations and comprises an outer supporting drum (2), an inner supporting drum (3) and six overturning hook components (1). Each overturning hook component (1) is evenly fixed on the cylindrical surface of the outer supporting drum (2) in the circumferential direction, the six overturning hook components (1) are arranged at an interval of 60 degrees with one another in the cylindrical circumferential direction of the outer supporting drum (2), and accordingly the six overturning hook components (1) are evenly distributed in the cylindrical circumferential direction of the outer supporting drum (2).

Owner:巫山县新牧草业科技有限公司

Forage tedding device capable shaking off forage and provided with separated hooks

ActiveCN103975708AQuick flipEnsure consistencyAgriculture tools and machinesHarvested fruit hanging devicesEngineeringForage

The invention discloses a forage tedding device capable shaking off forage and provided with separated hooks. The forage tedding device comprises an executing part and a connecting part, wherein the executing part is used for executing the tedding operation, and comprises an outer supporting barrel (2), an inner supporting barrel (3) and six overturning hook parts (1), the overturning hook parts (1) are uniformly fixed on the cylindrical surface of the outer supporting barrel (2) along the circumferential direction, and the six overturning hook parts (1) are arranged on the cylindrical surface of the outer supporting barrel (2) along the circumferential direction in a manner that every two overturning hook parts are spaced from a 60-degree angle, so that the six overturning hook parts (1) are uniformly distributed on the cylindrical surface of the outer supporting barrel (2) along the circumferential direction.

Owner:浙江嘉佑农业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com