Ganoderma lucidum spore powder drying device and method

A technology of Ganoderma lucidum spore powder and spore powder, which is applied in drying, drying machine, drying solid materials and other directions, can solve the problems of raising spore powder at the speed of drying, consuming a lot of time and energy, and avoiding excessive moving distance, The effect of ensuring quality and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

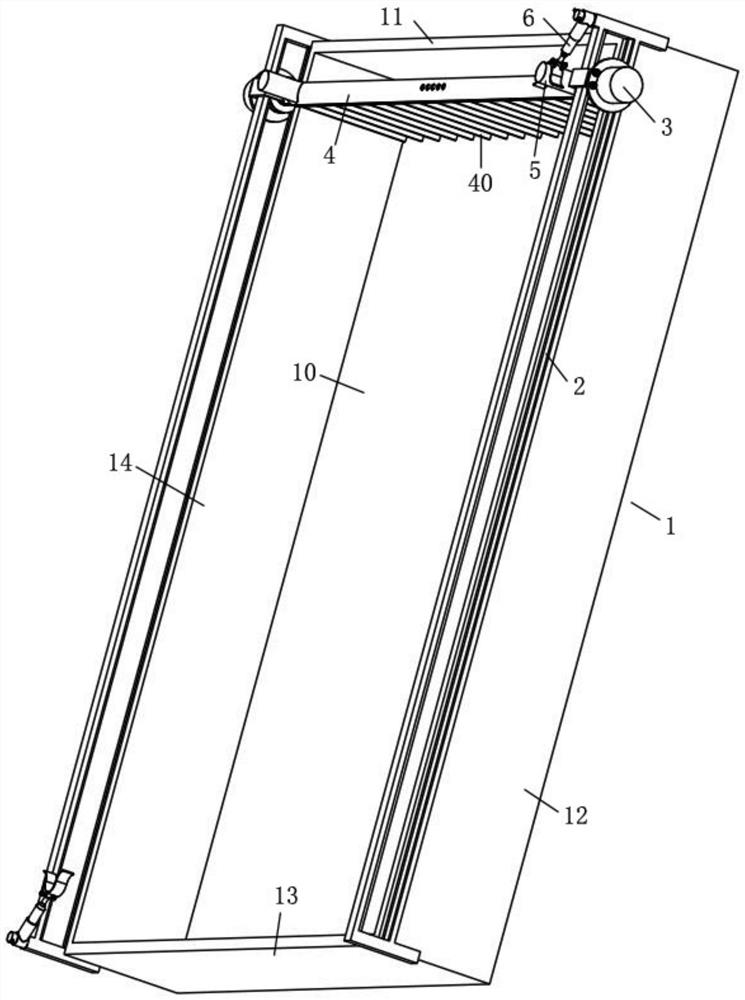

[0055] The drive mechanism includes a drive assembly and a slide rail, the slide rail extends longitudinally along the drying trough, the drive assembly is arranged in the slide rail, and, under the action of the drive assembly, the tumbling rake assembly moves back and forth along the slide rail in the drying trough, thereby achieving The purpose of driving the movement of the tumbling rake assembly in the longitudinal direction. Specific examples are as follows:

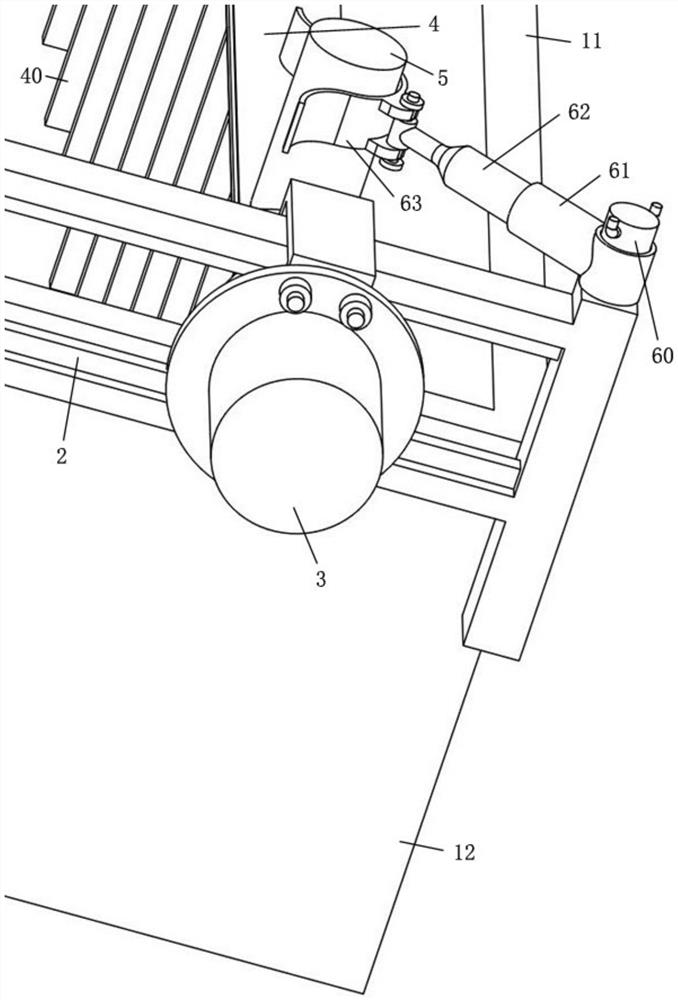

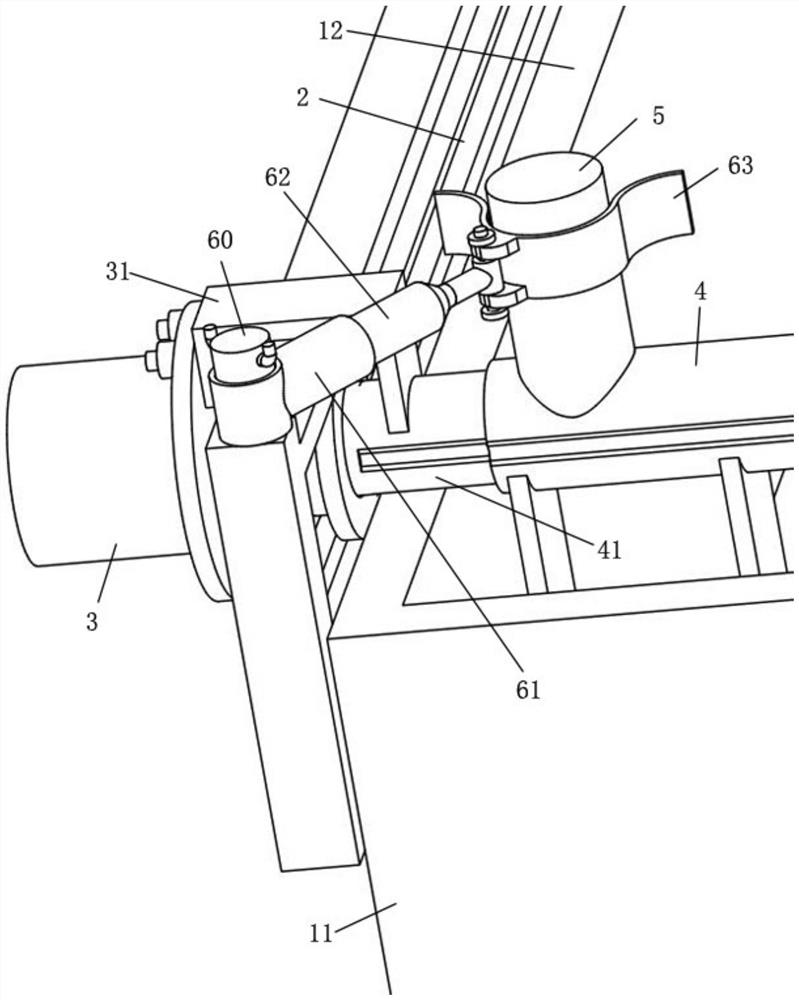

[0056] see Figure 1-Figure 11 , the drive assembly includes two sets of drive motors 3 and two sets of pulleys 32, the slide rails are two sets of tracks, the two sets of tracks are respectively arranged on the lateral sides of the drying tank, the two sets of pulleys are paired with the two sets of tracks and each pulley is configured with One drive motor, two sets of drive motors are respectively fixed on the two ends of the rake assembly horizontally through brackets, the drive motor drives the pulley to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com