Cleaning device used for rubber plug

A technology for cleaning devices and rubber stoppers, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of increased production costs, complex structures, etc., and achieve the effect of uniform beating and tumbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

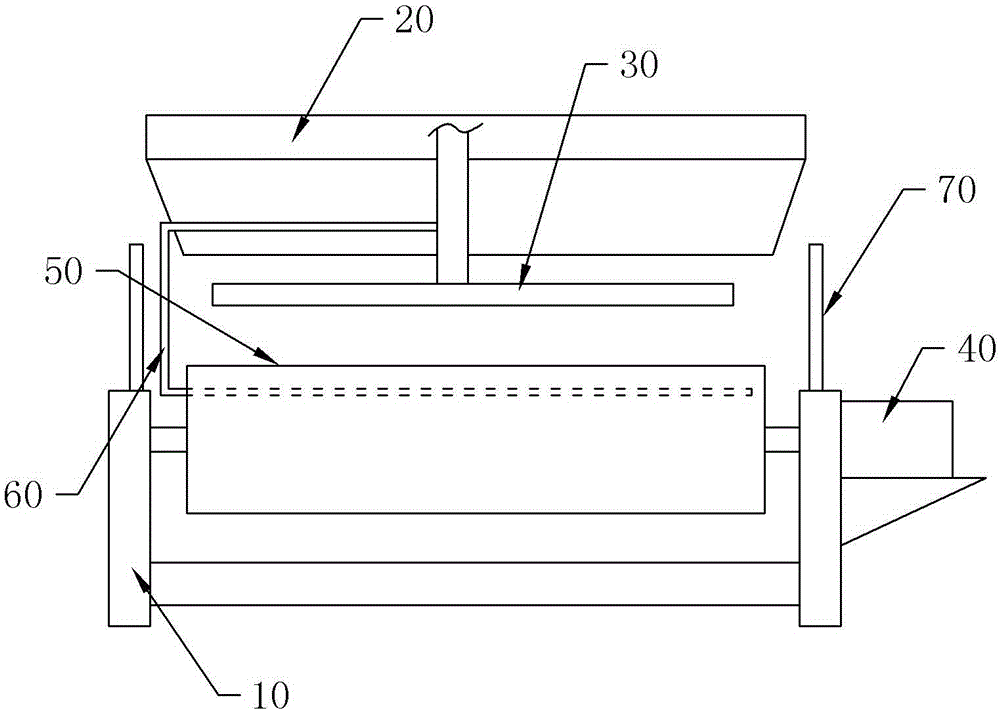

[0014] The reference numerals in the drawings of the description include: frame 10 , feed hopper 20 , water jet 30 , servo motor 40 , conveying mesh belt 50 , distribution pipe 60 , and baffle 70 .

[0015] The embodiment is basically as attached figure 1 Shown: a cleaning device for rubber stoppers, including a frame 10, a feed hopper 20 installed on the frame 10, a water jet 30, a conveyor belt 50 and a power source for driving the conveyor belt 50 to move, The specific connection structure between the power source and the conveying mesh belt 50 can adopt existing common connection methods, and will not be repeated here. The power source of this embodiment adopts the servo motor 40, and the servo motor 40 can be used to rotate forward and reverse, so that the rubber plug on the conveying mesh belt 50 can be controlled to be cleaned multiple times. The water injector 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com