Patents

Literature

5199 results about "Water jet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

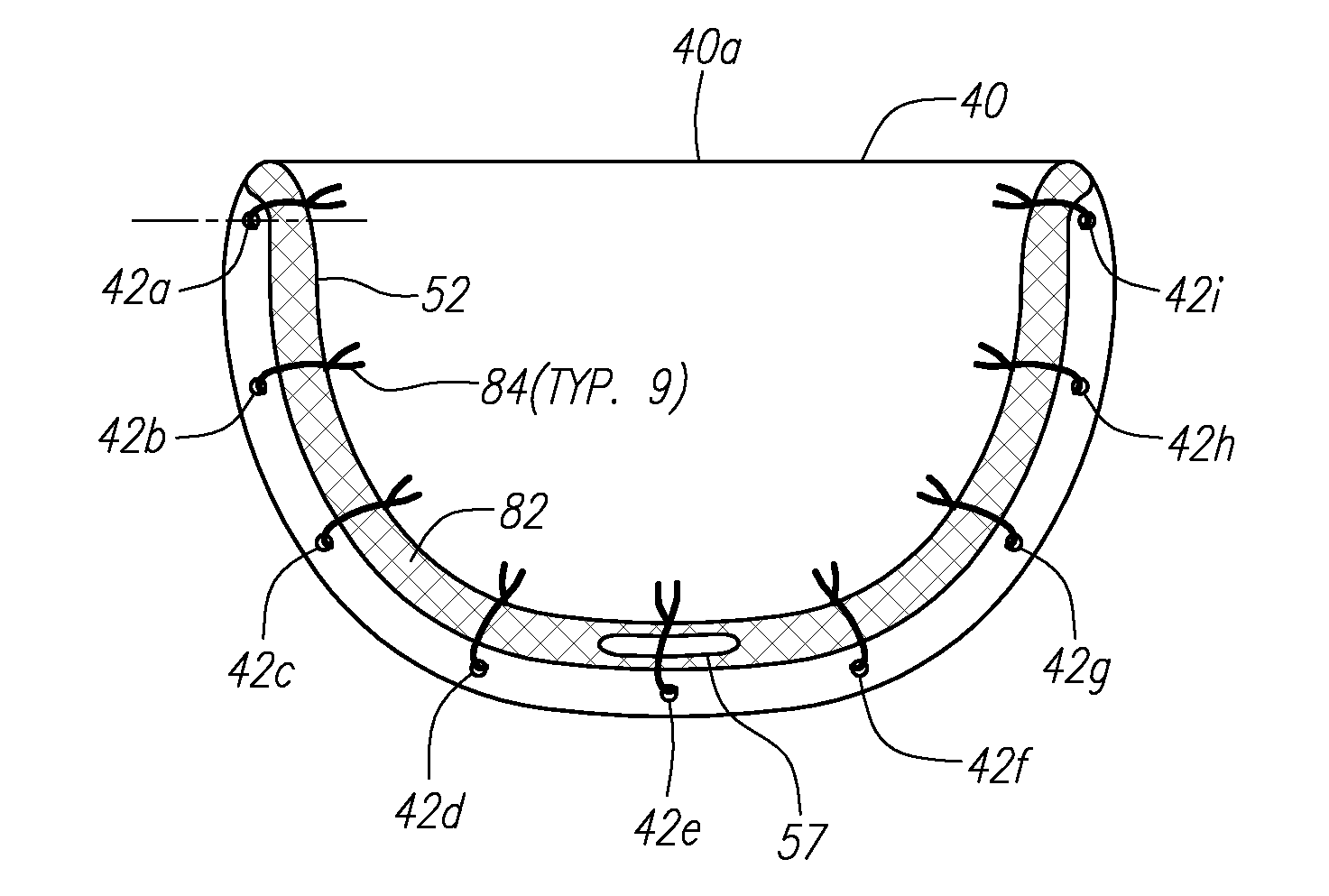

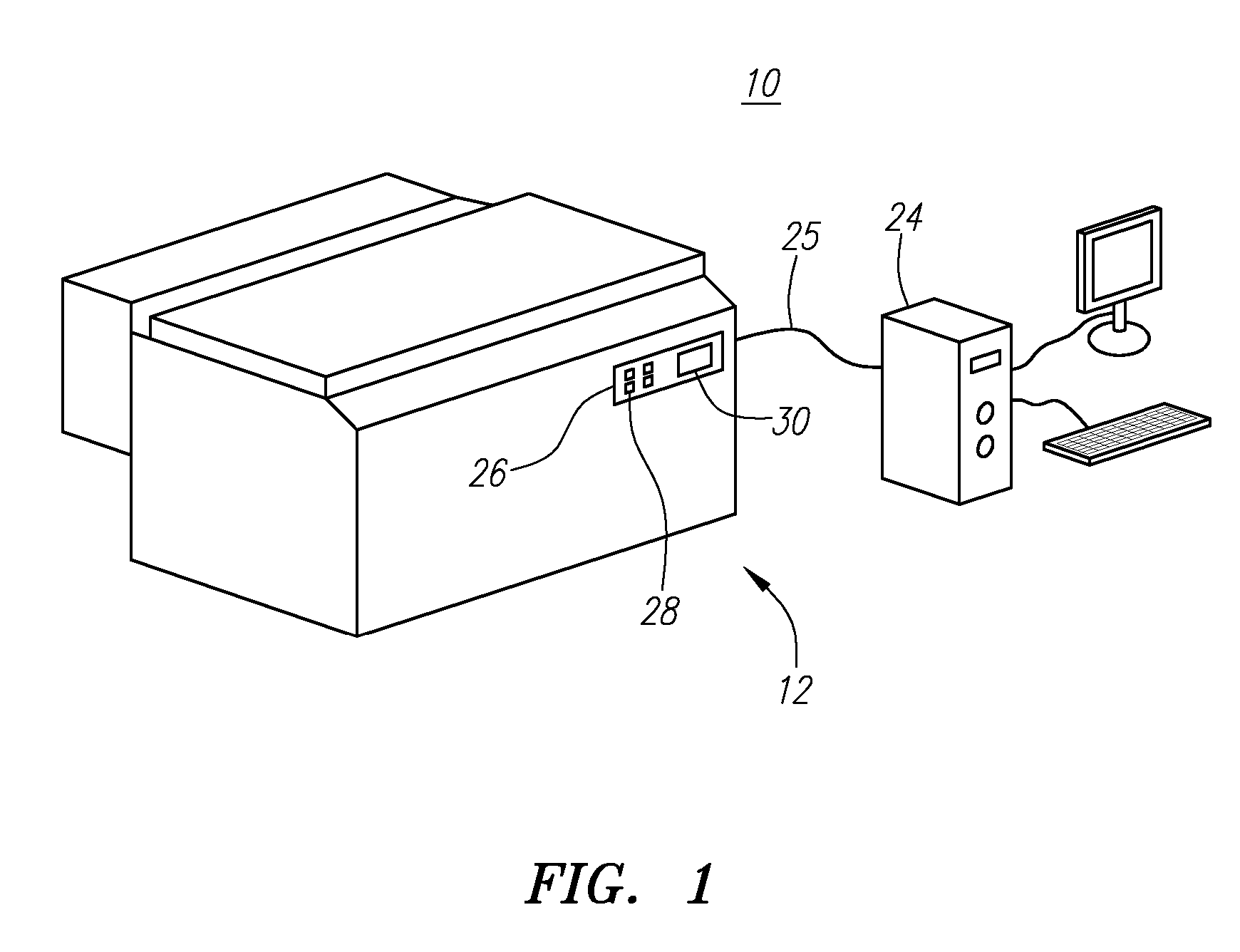

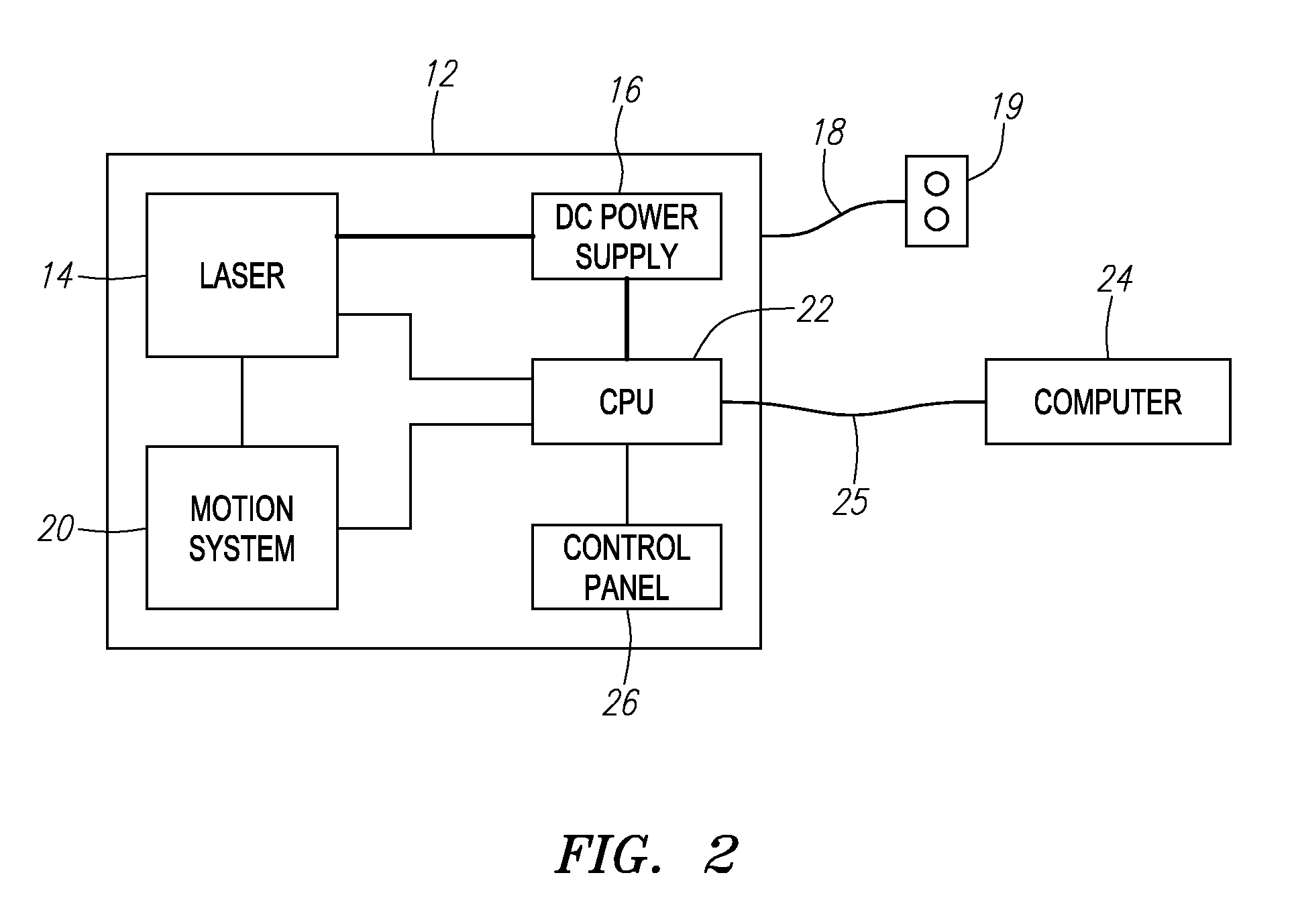

Apparatus and methods for making leaflets and valve prostheses including such leaflets

A method for making a bioprosthetic heart valve includes providing a non-contact cutting apparatus and a layer of tissue. The non-contact cutting apparatus may include a laser cutting system or high pressure water jet system. A leaflet is cut from the layer of tissue using a predefined template, and a plurality of alignment holes in the leaflet are created in the leaflet, e.g., along a peripheral edge. A support structure is provided having a plurality of alignment holes corresponding to alignment holes in the leaflet. The leaflet is secured to the support structure by securing one or more sutures through corresponding alignment holes in the leaflet and the support structure to provide a leaflet subassembly. A bioprosthetic heart valve is made by securing a set of leaflet subassemblies to a frame.

Owner:MEDTRONIC INC

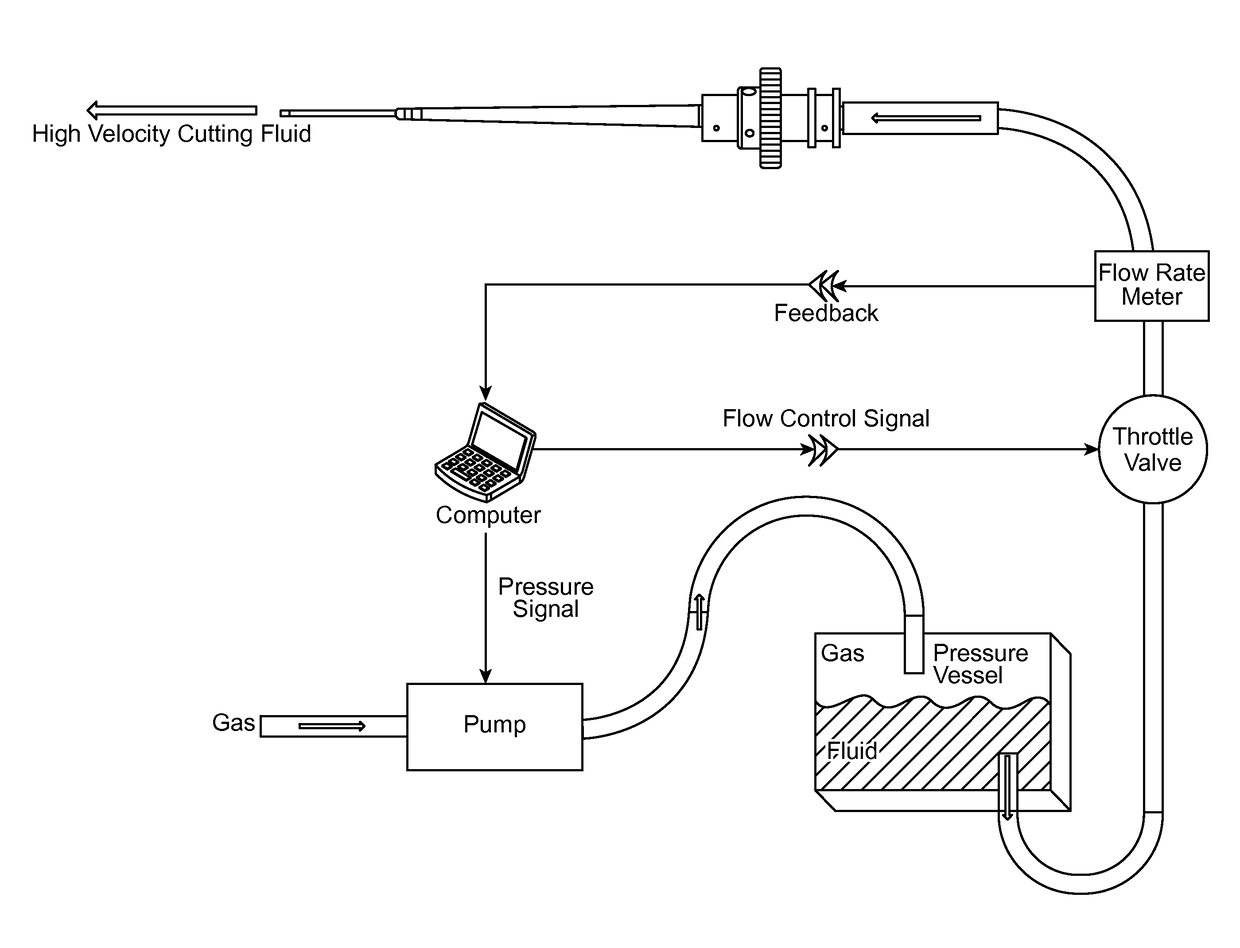

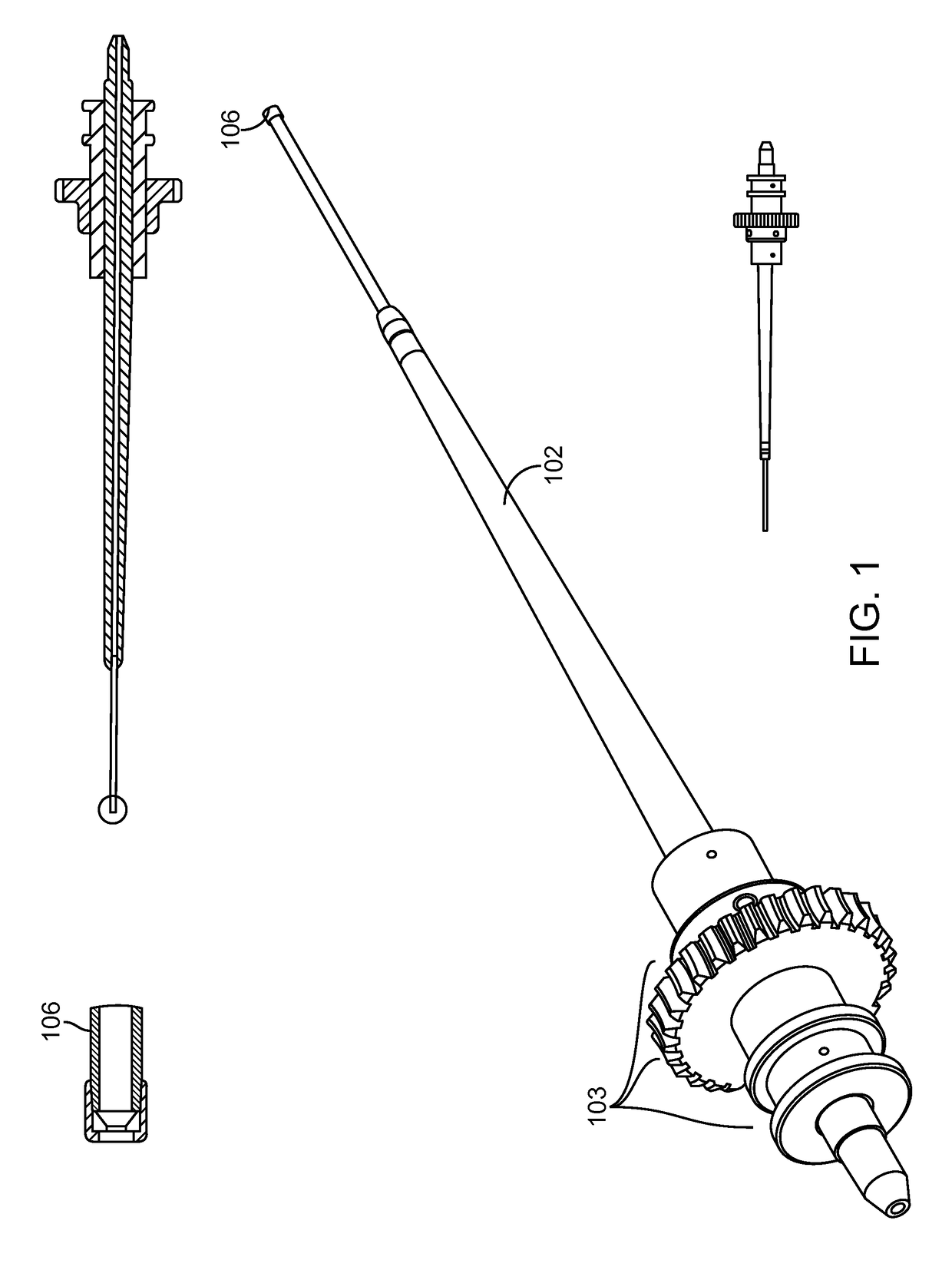

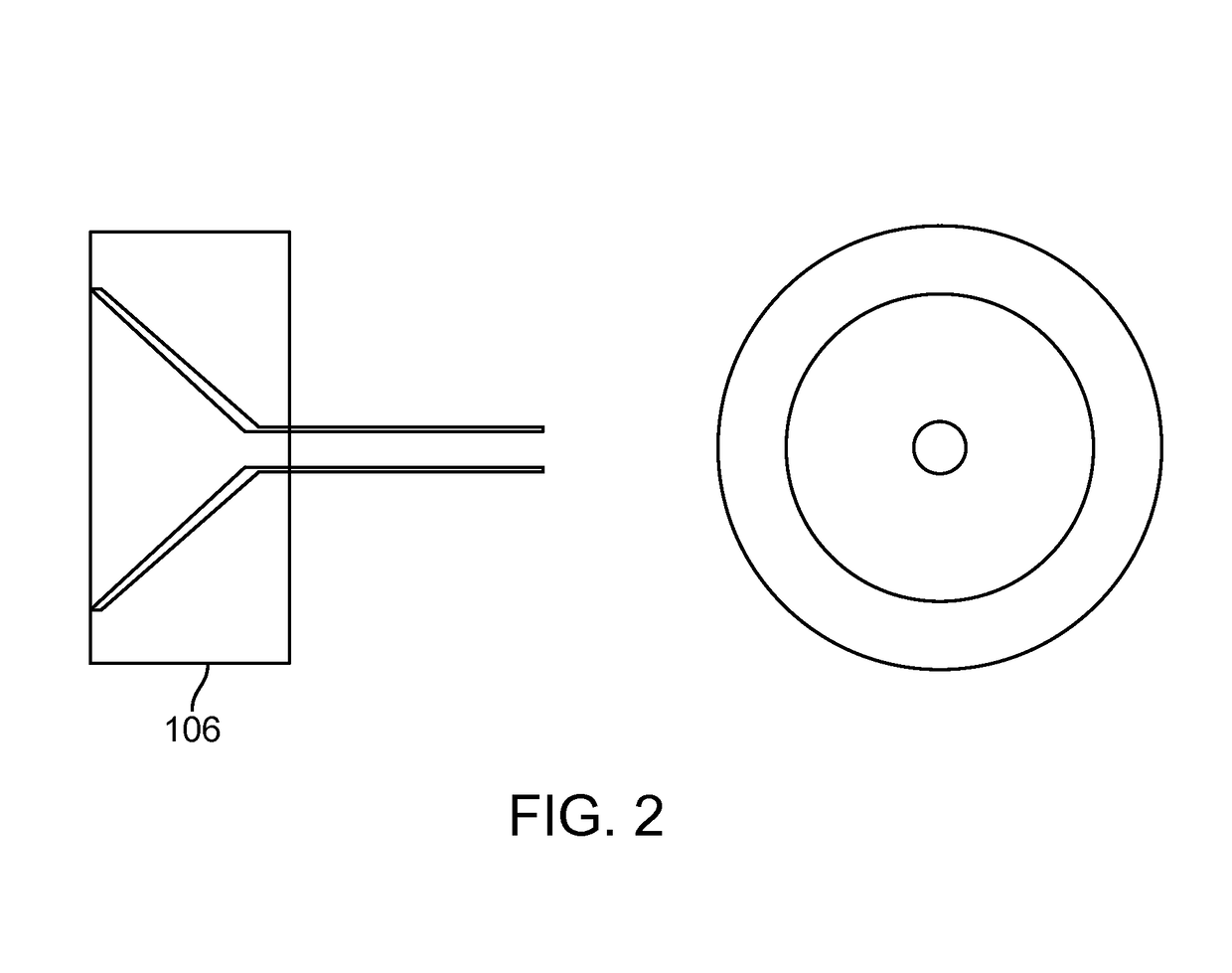

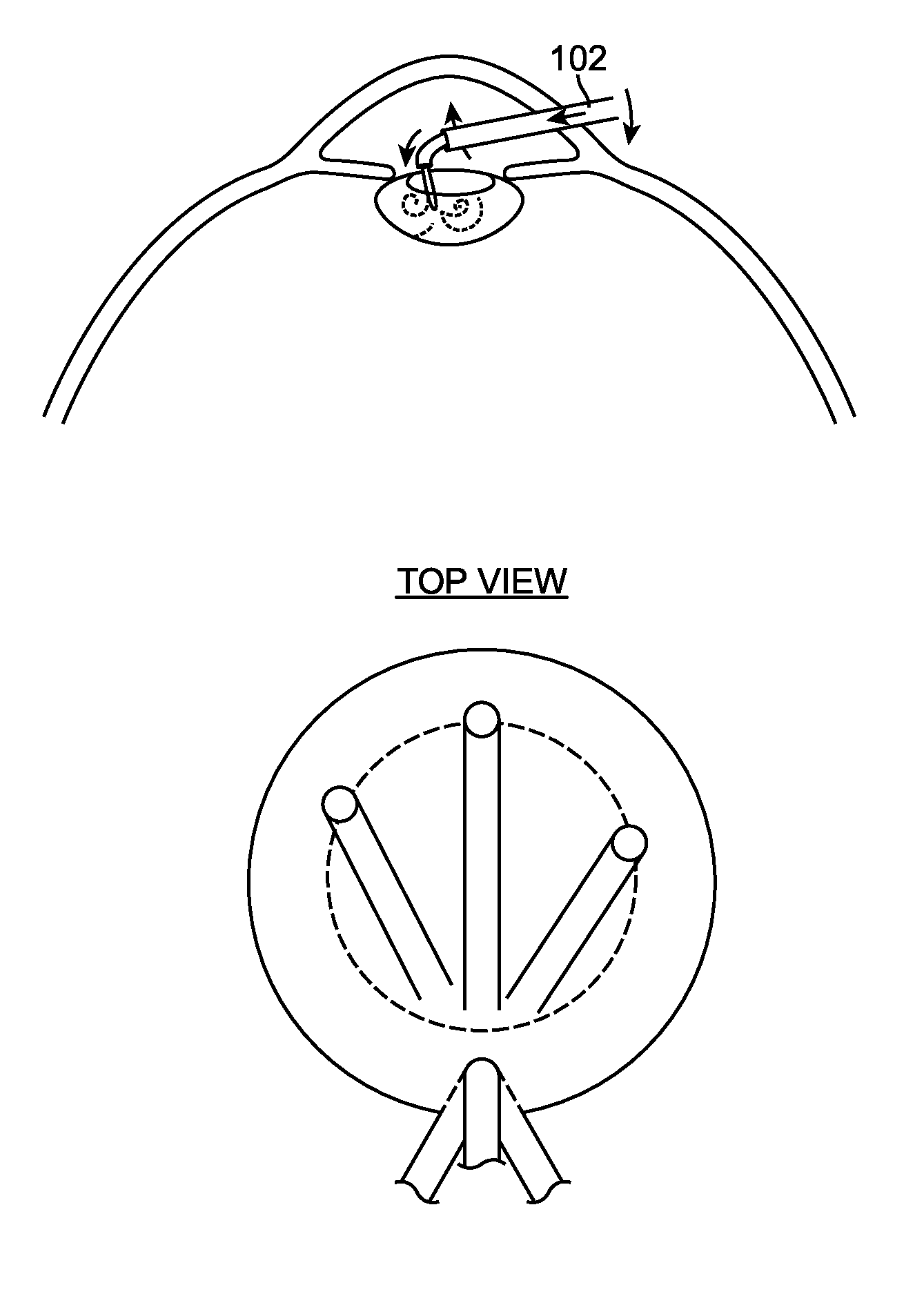

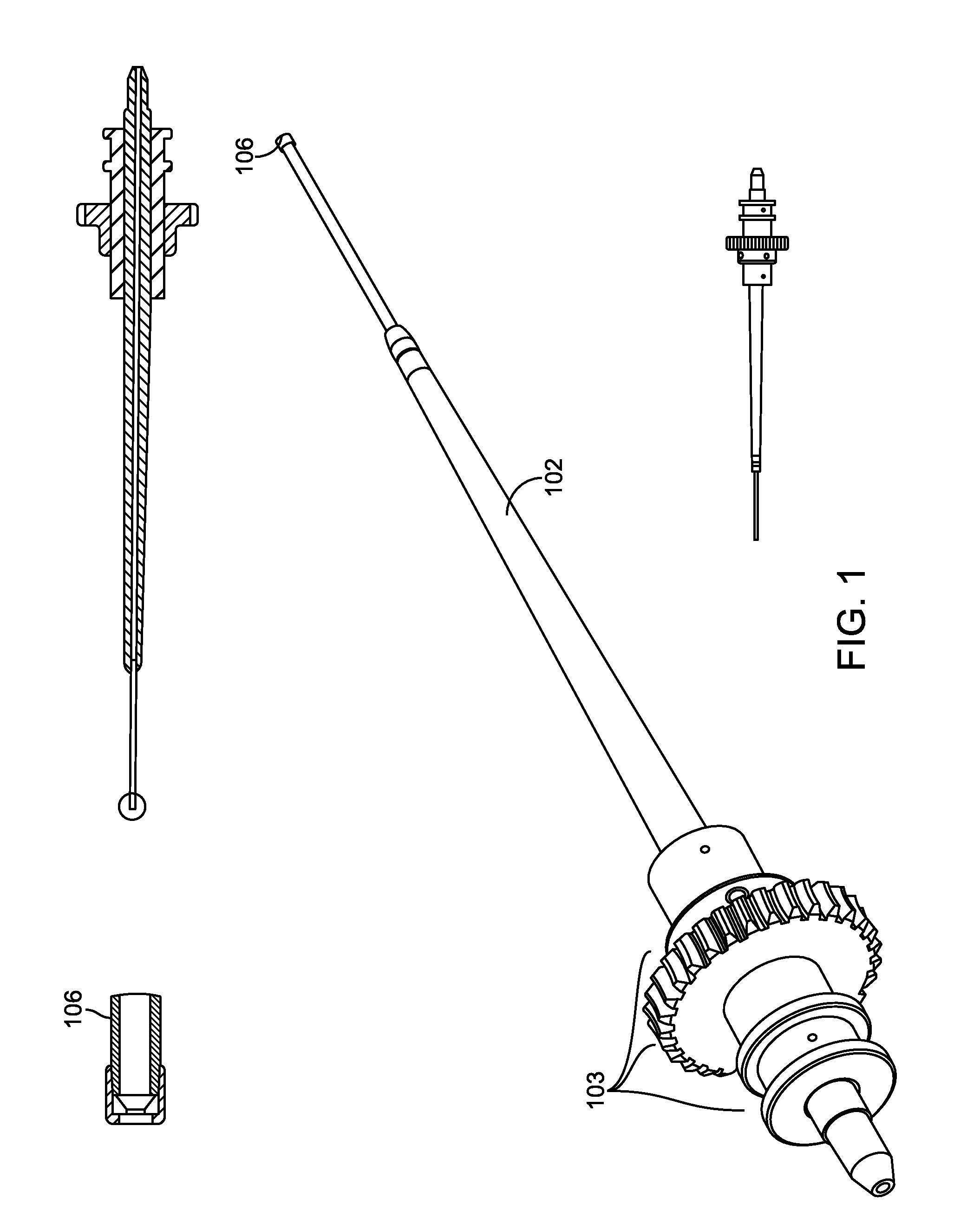

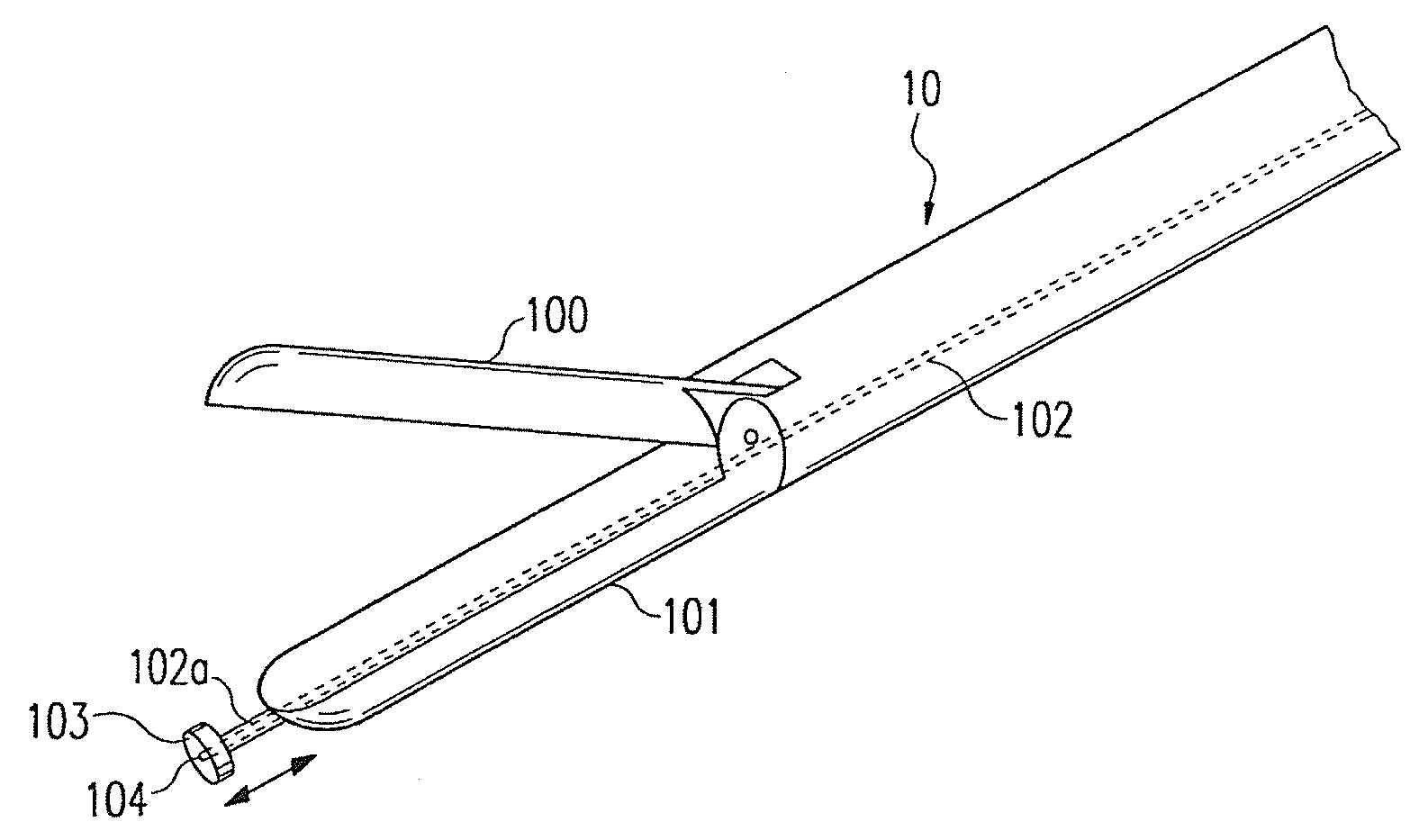

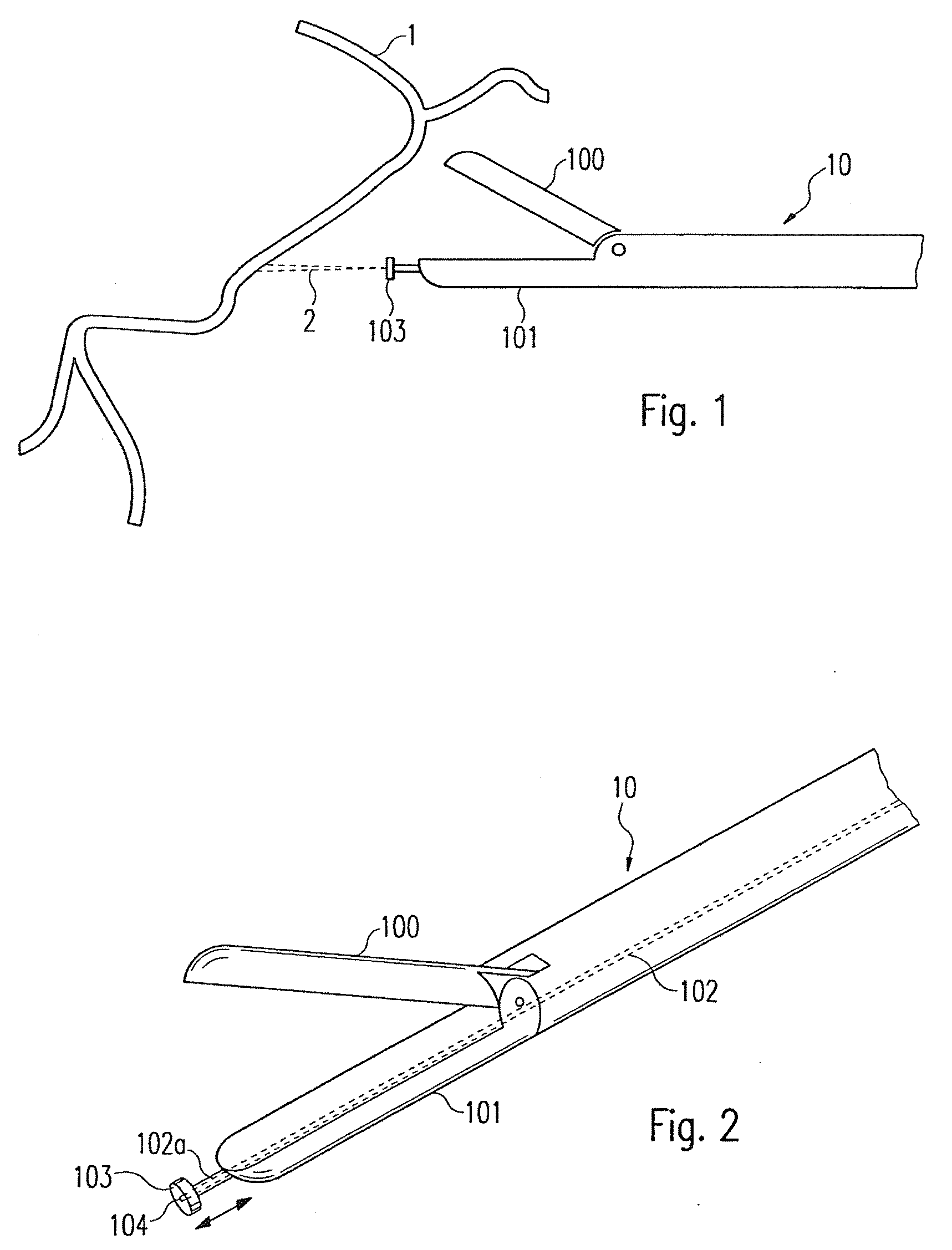

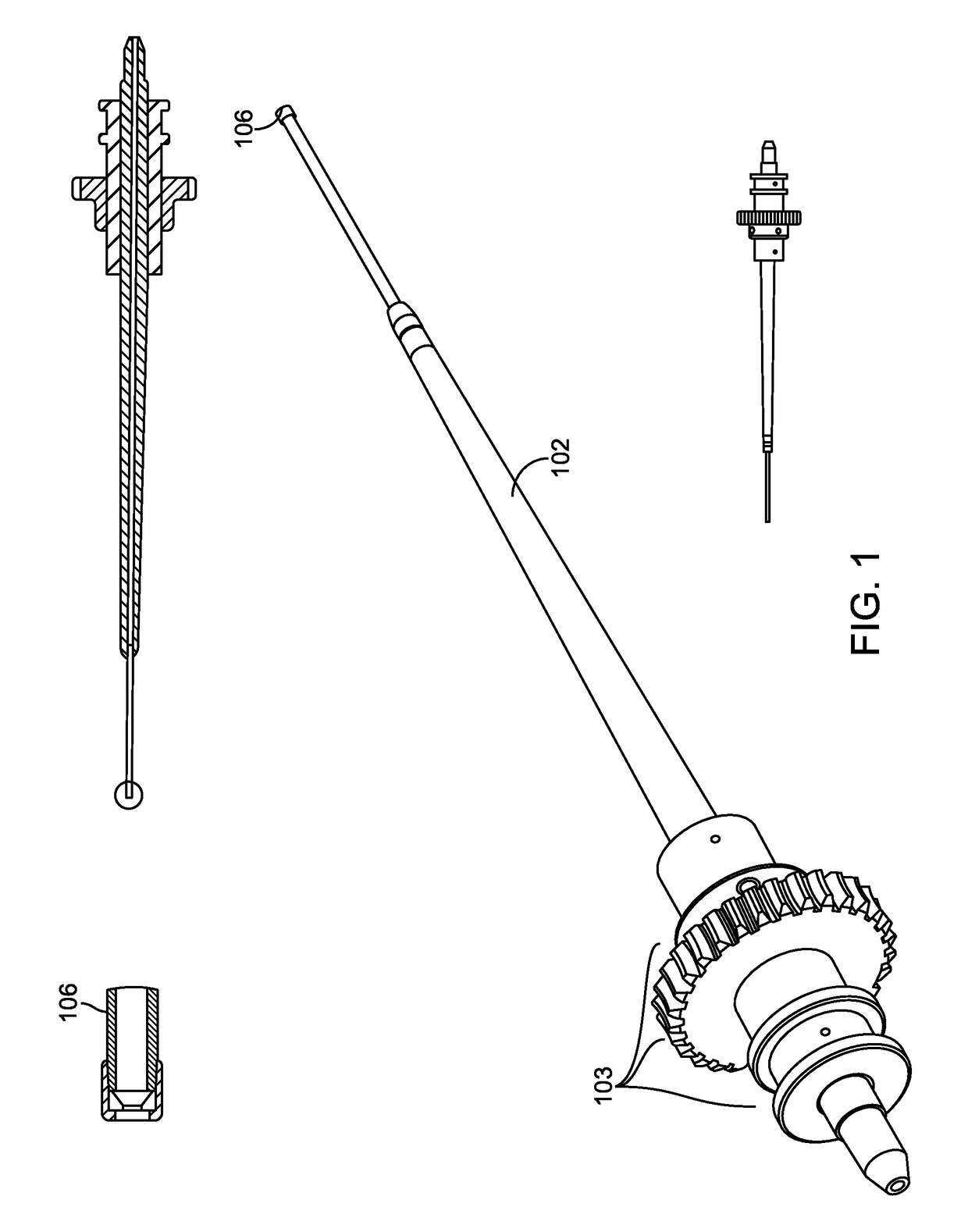

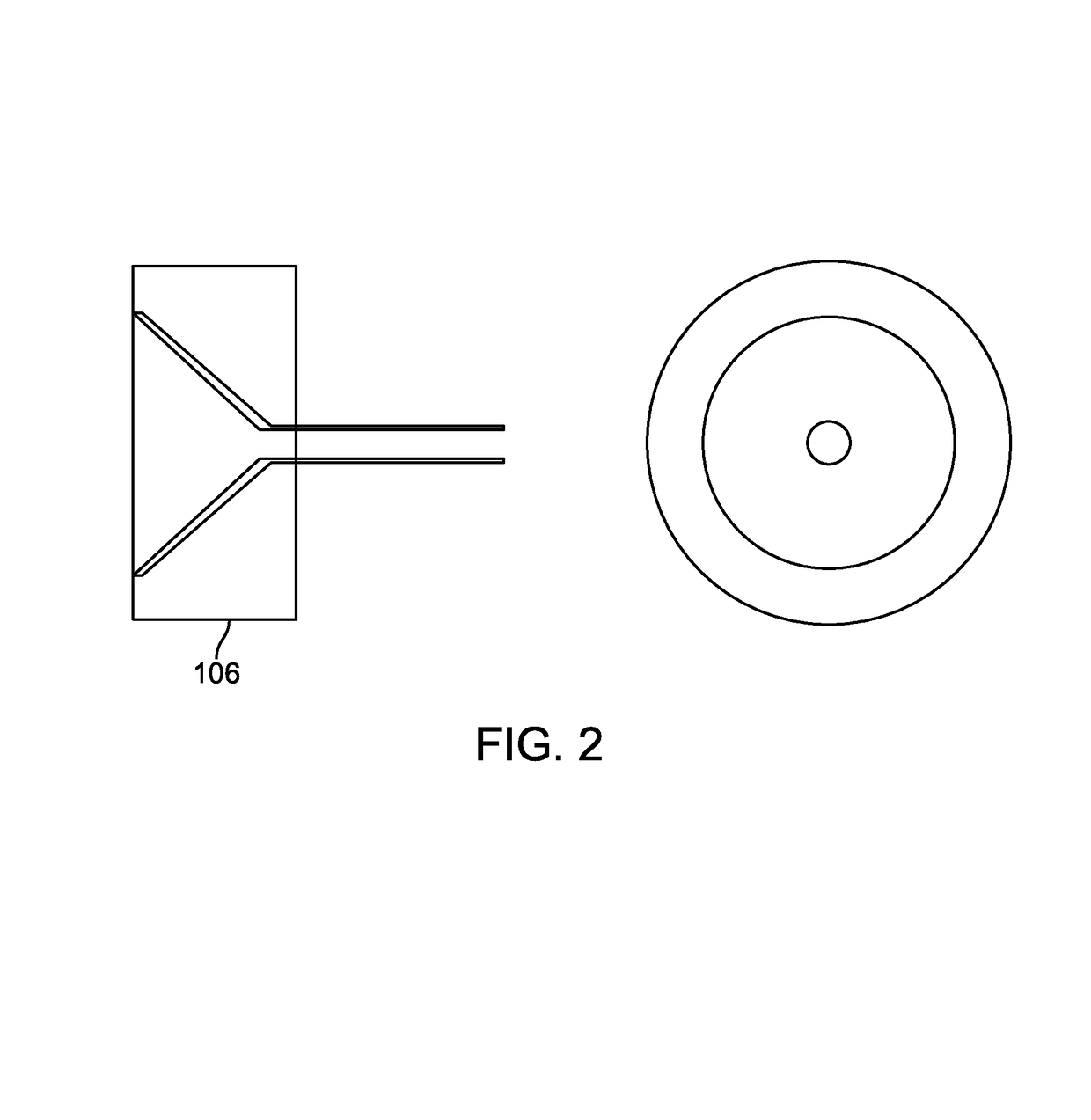

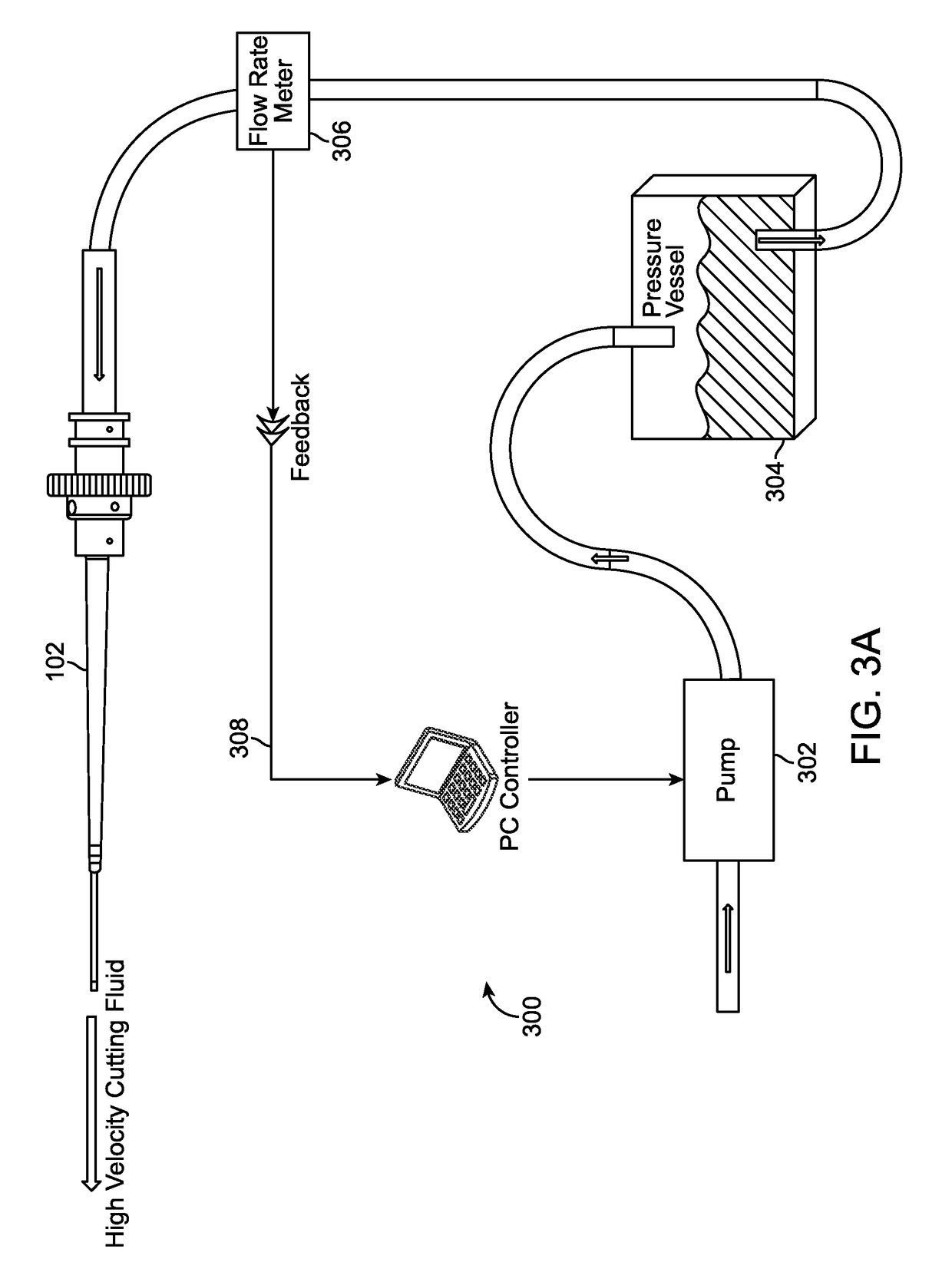

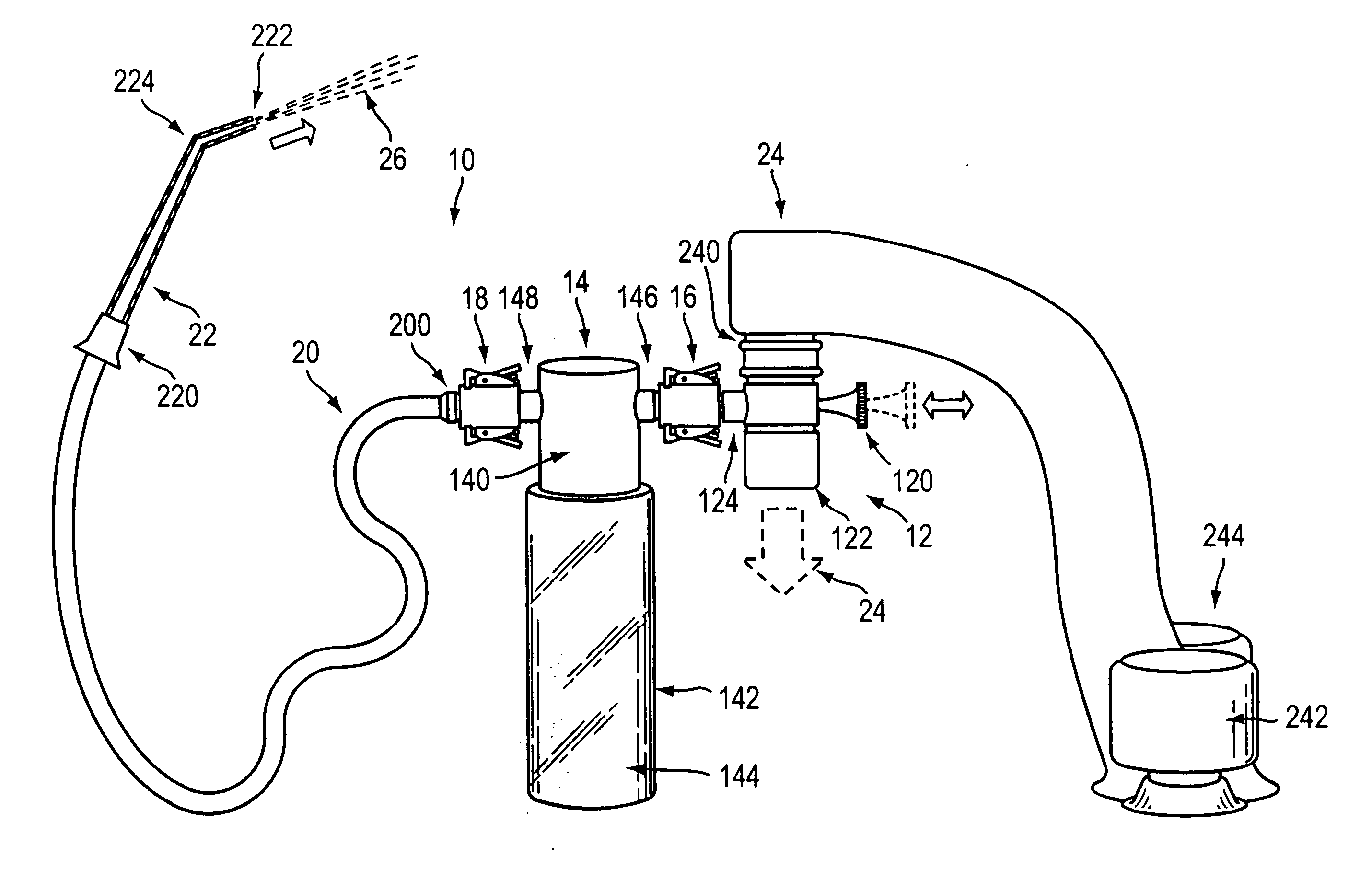

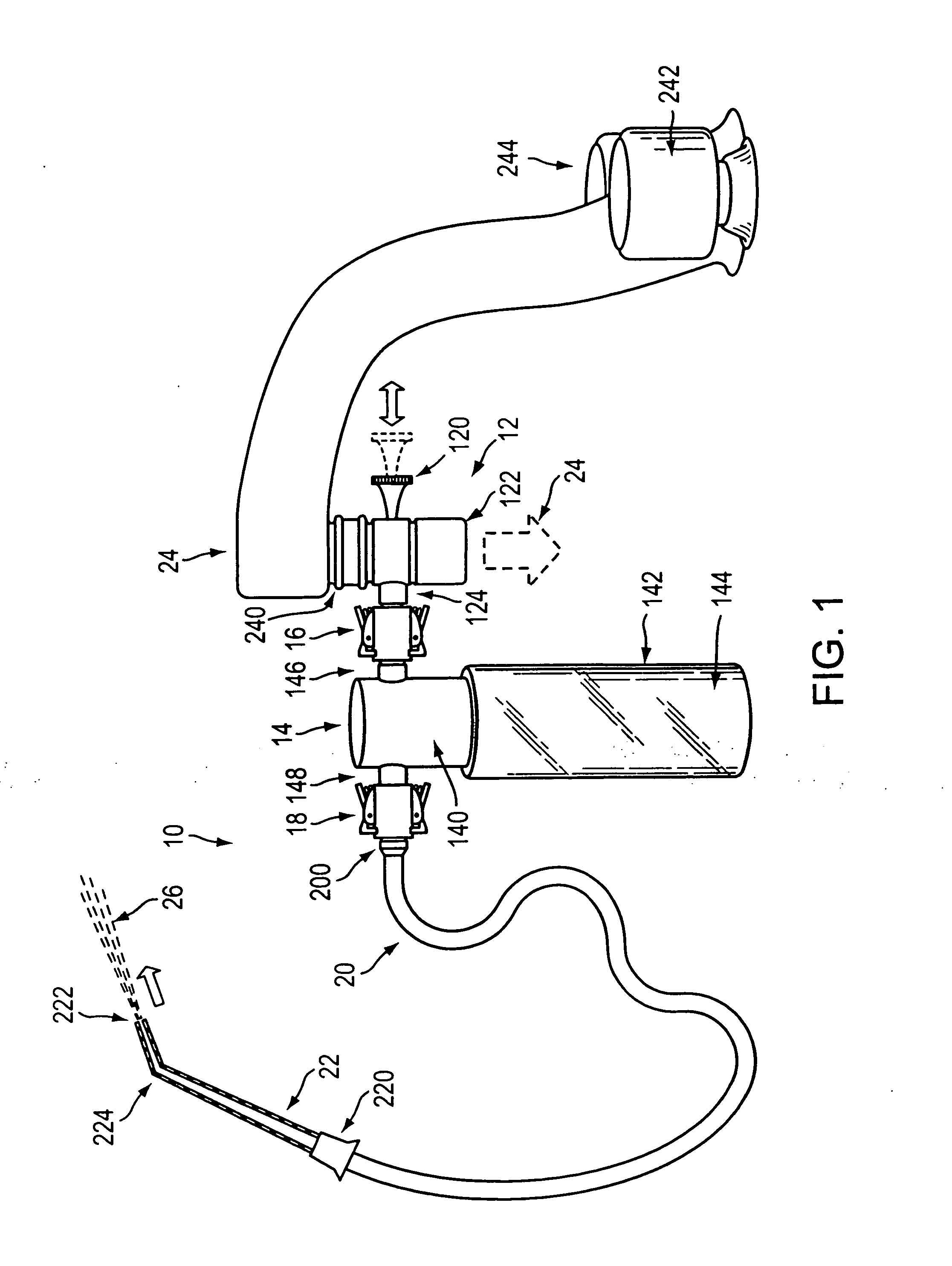

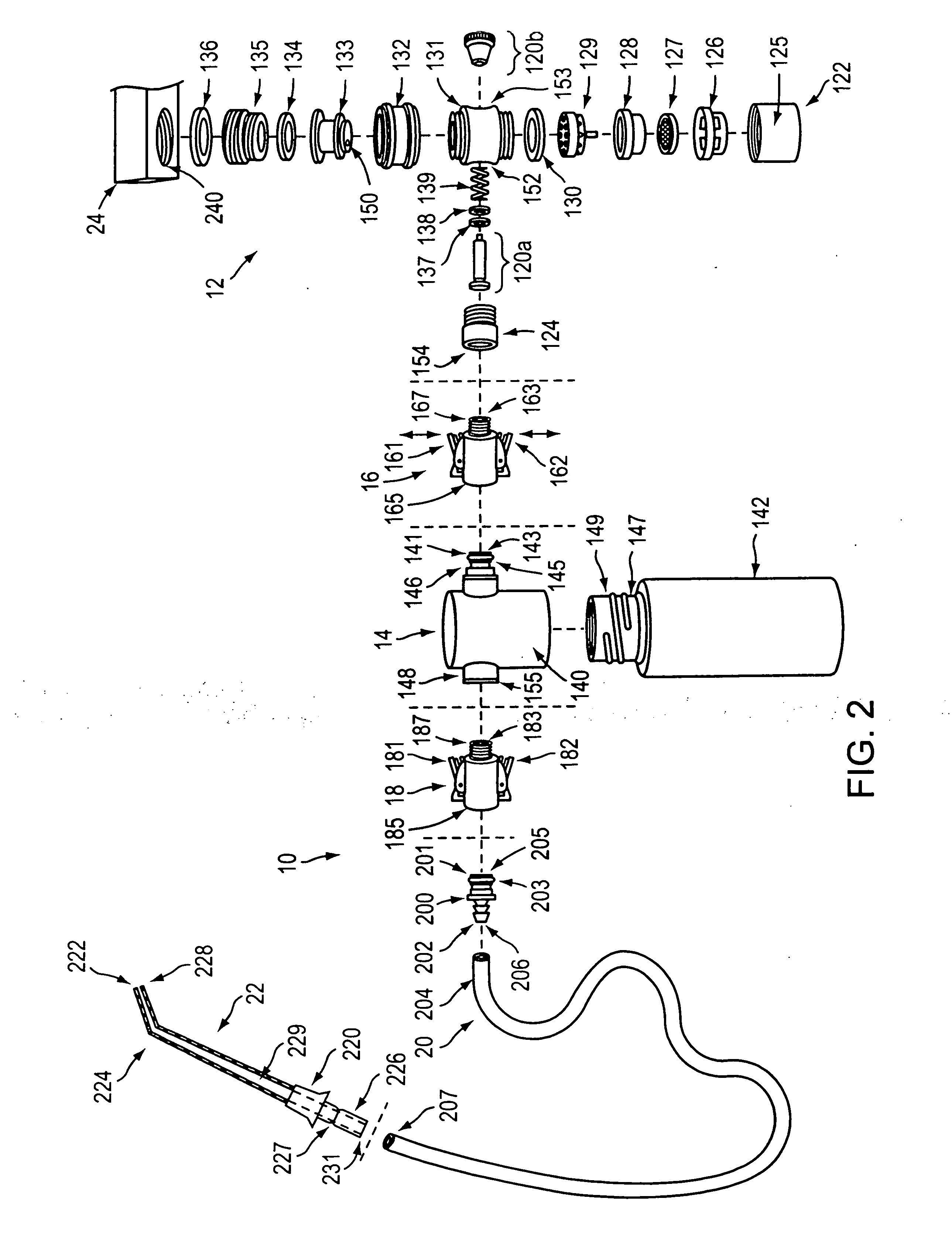

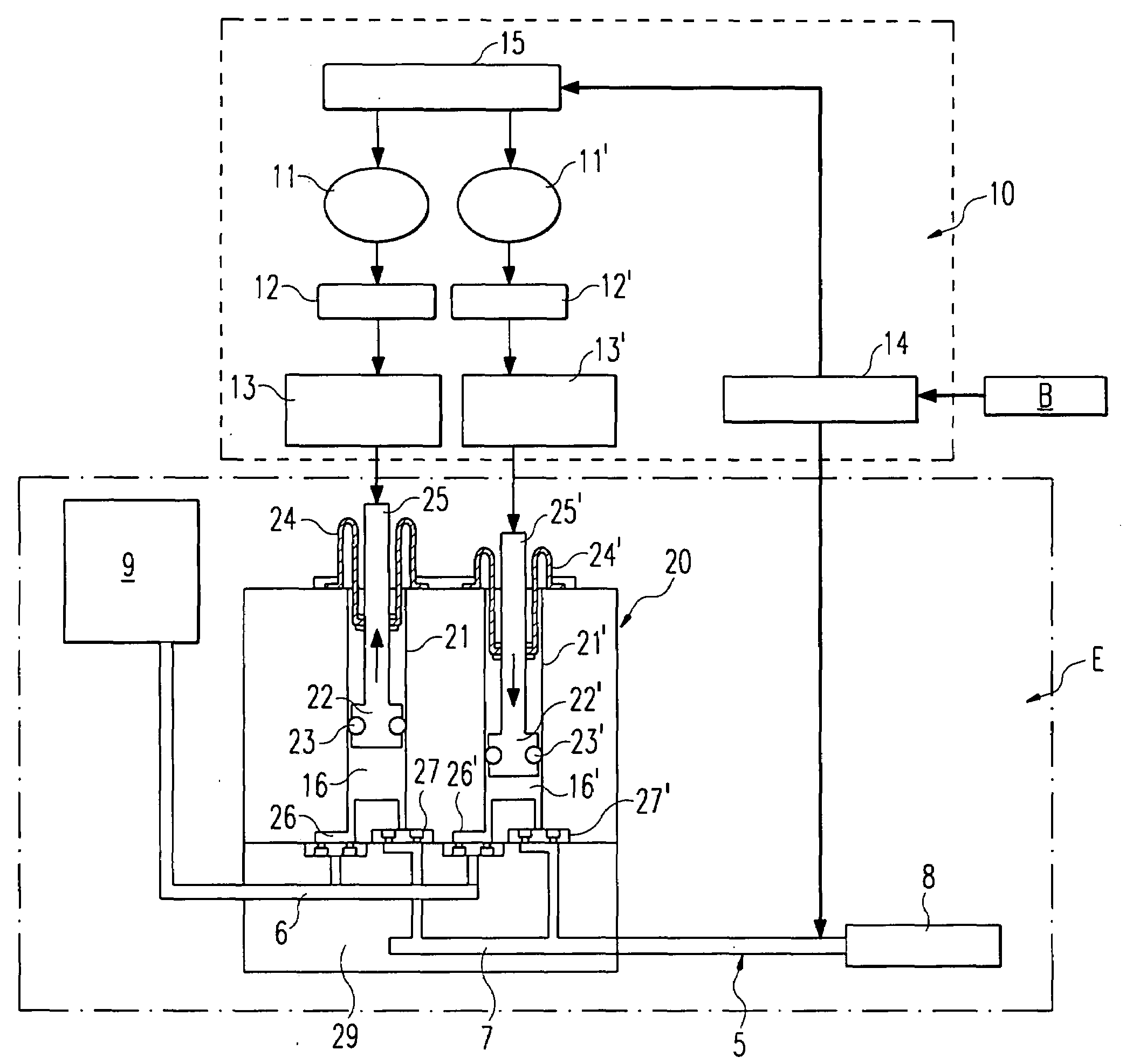

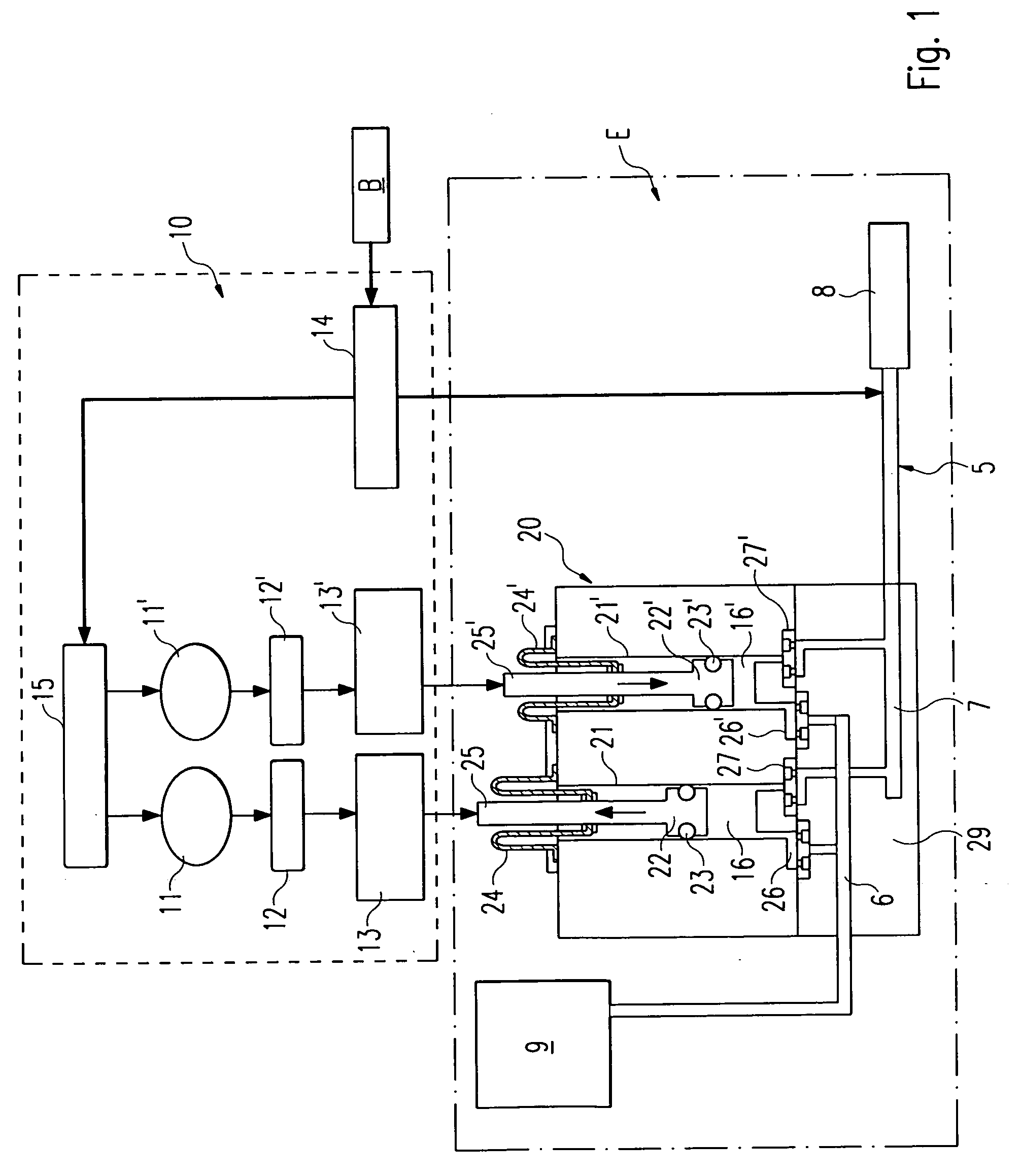

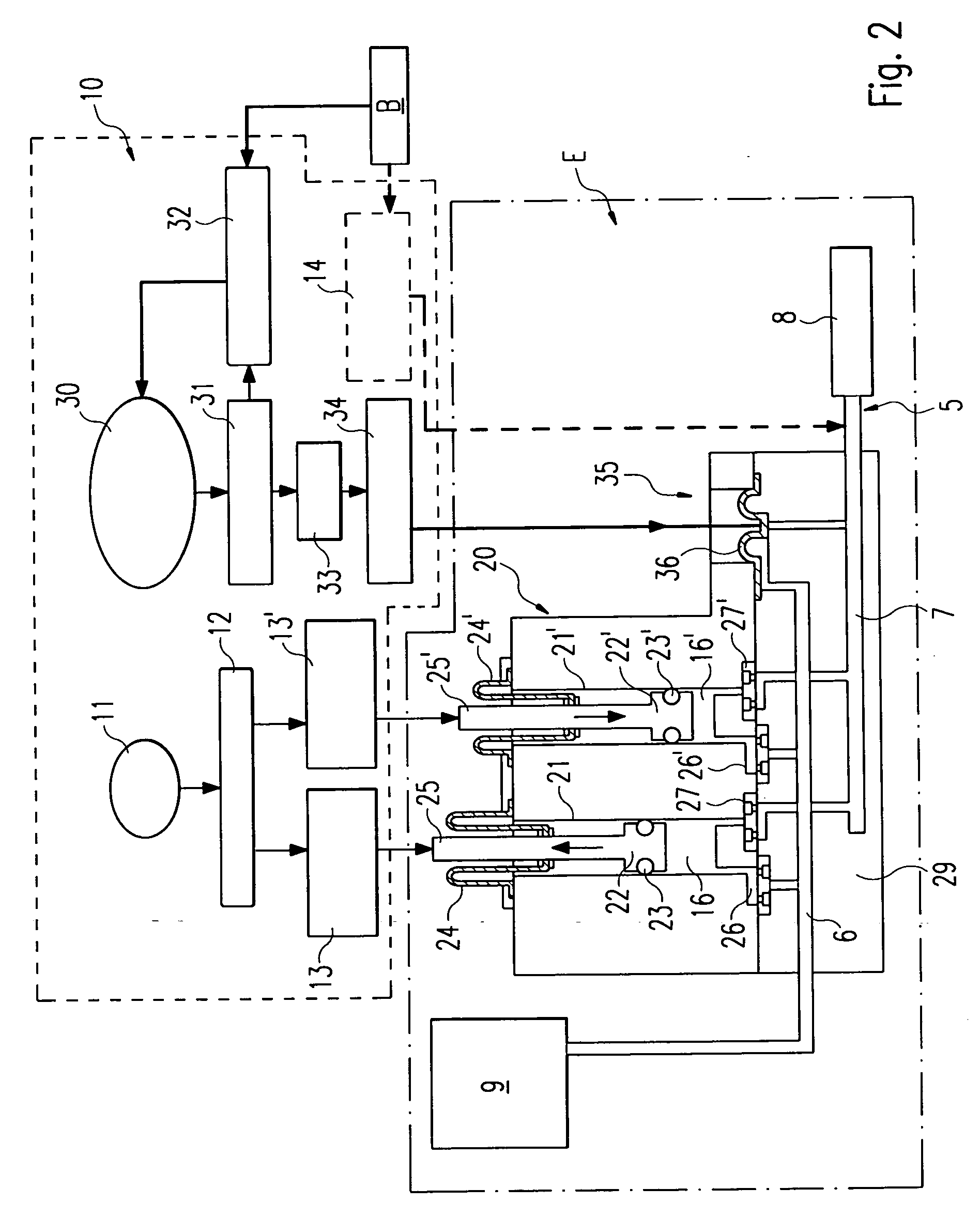

Method, apparatus and system for a water jet

A water jet instrument may be used for manually performing eye surgery such as, cataract, or perform micro-surgery (remove cartilage), or any emulsification technique. The water jet instrument may be manually controlled or controlled by a system with a robotic control. The water jet apparatus defines a jet cutting area that is based at least in part on a flow rate meter and a feedback loop.

Owner:AURIS HEALTH INC

Electret filter media and filtering masks that contain electret filter media

InactiveUS6783574B1Reduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersFilter mediaRespiratory mask

Electret filter media comprising a nonwoven web of thermoplastic nonconductive microfibers having trapped charge, said charge provided by (1) subjecting the nonwoven web to a corona treatment, followed by (2) impingement of jets of water or a stream of water droplets on the web at a pressure sufficient to provide the web with filtration enhancing electret charge and (3) drying the web. This electret filter media may be used in a respiratory mask to provide extraordinarily good filtration properties.

Owner:3M CO

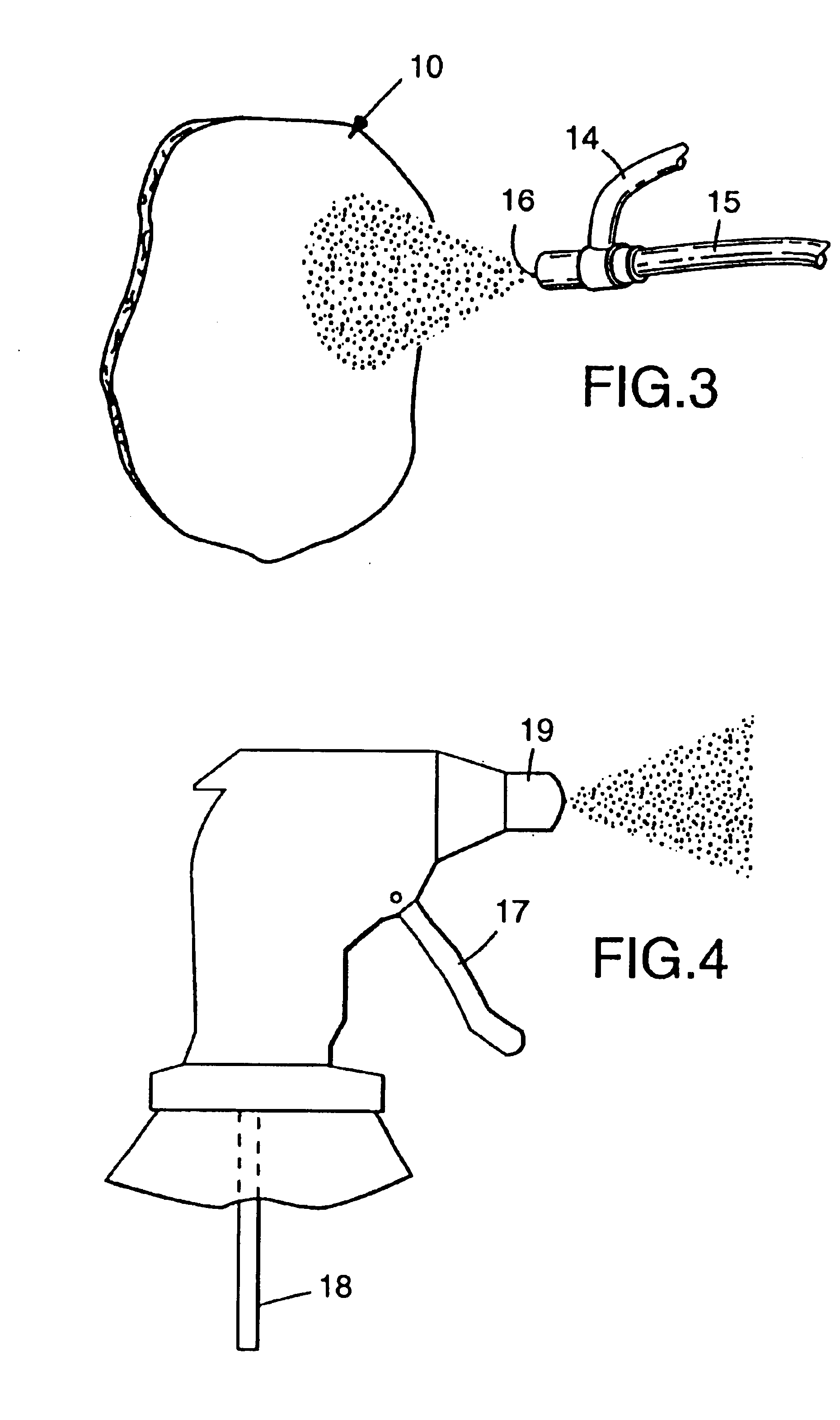

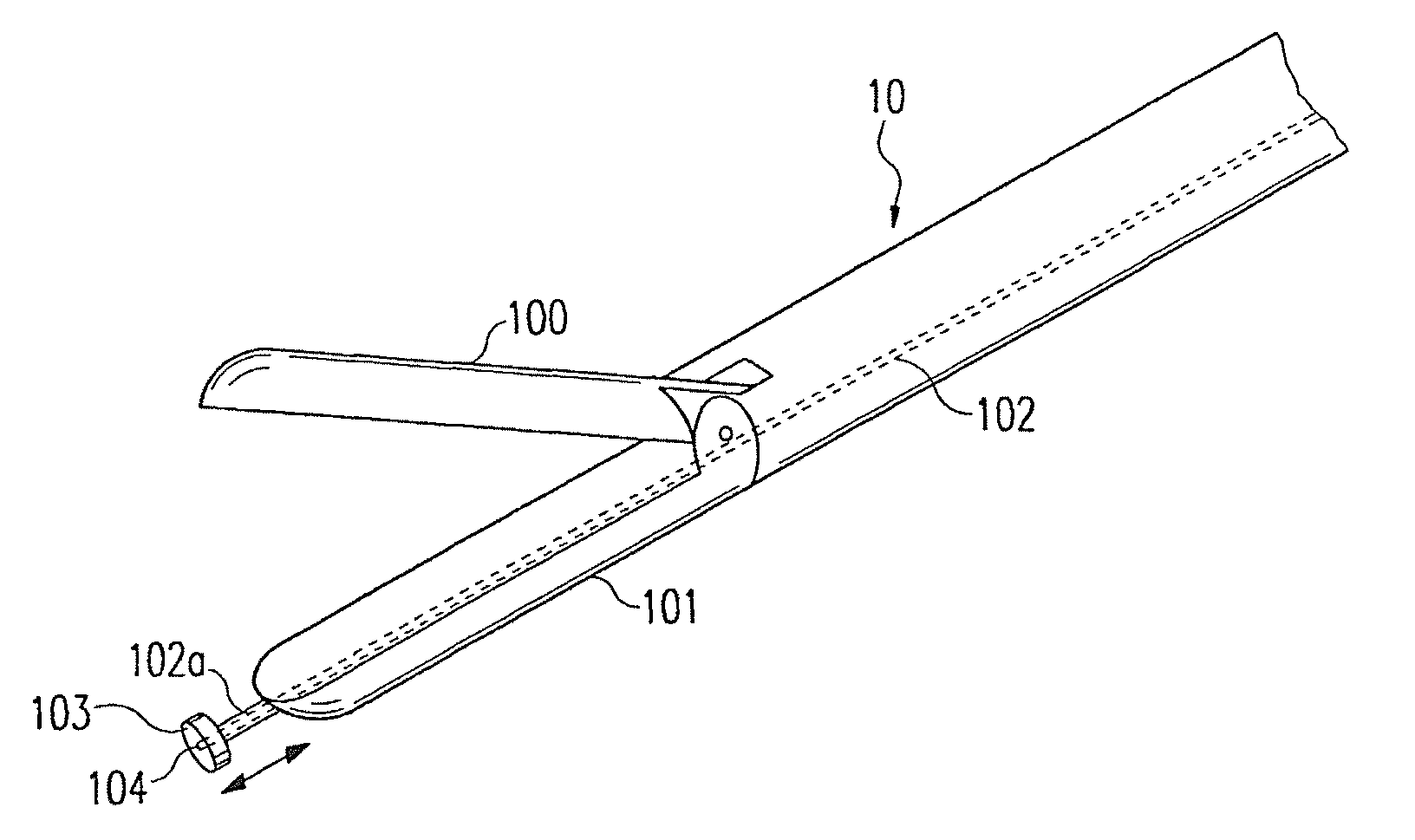

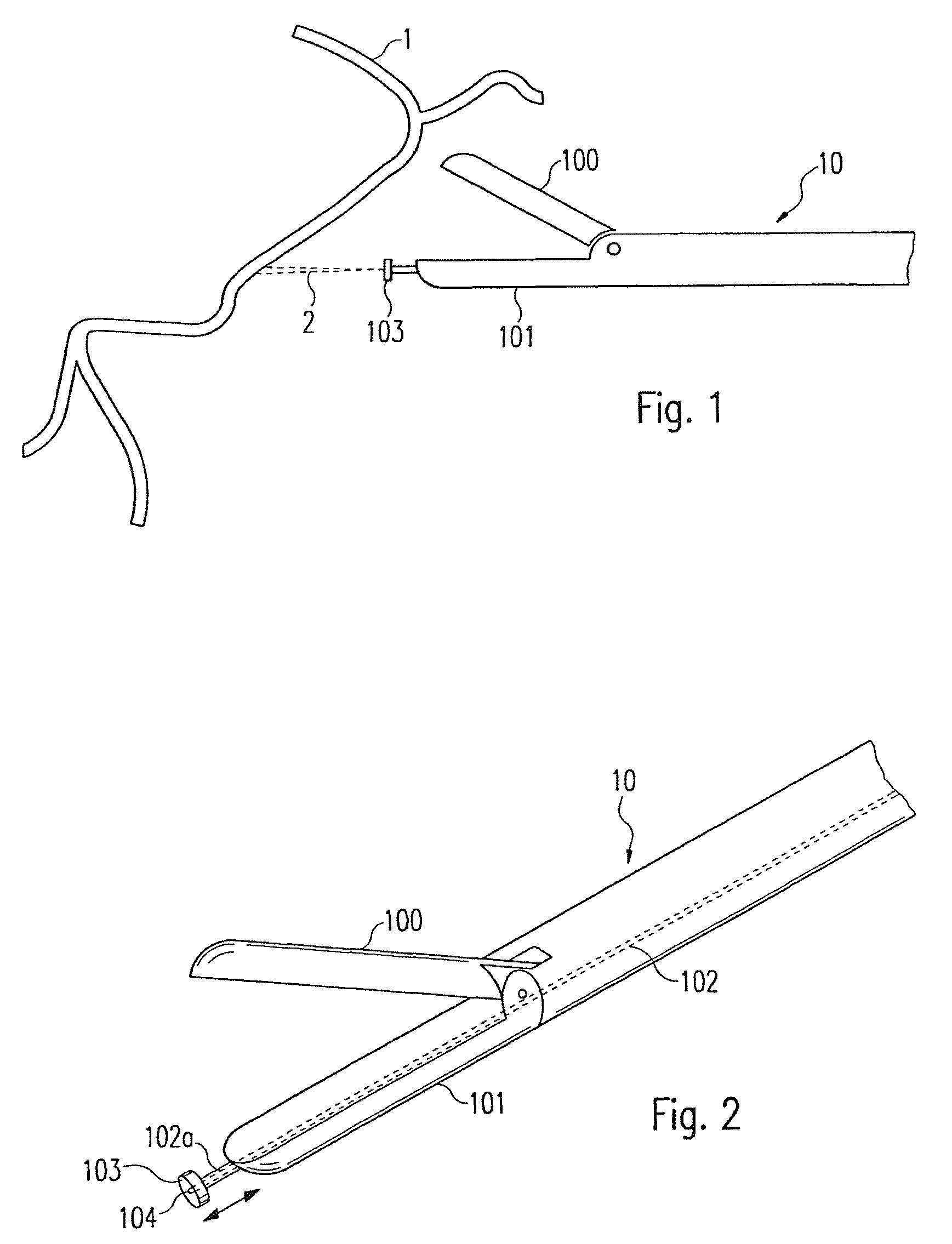

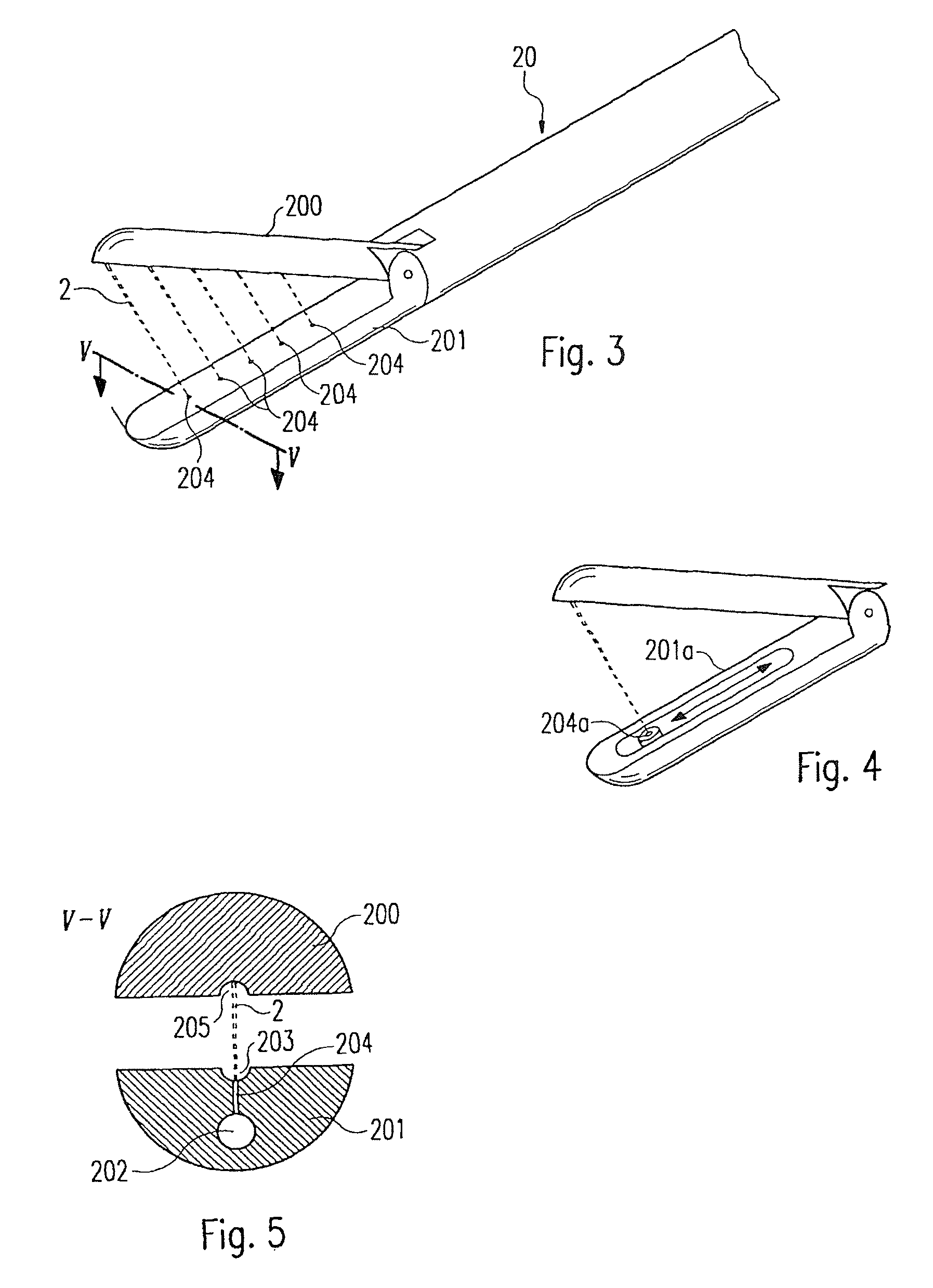

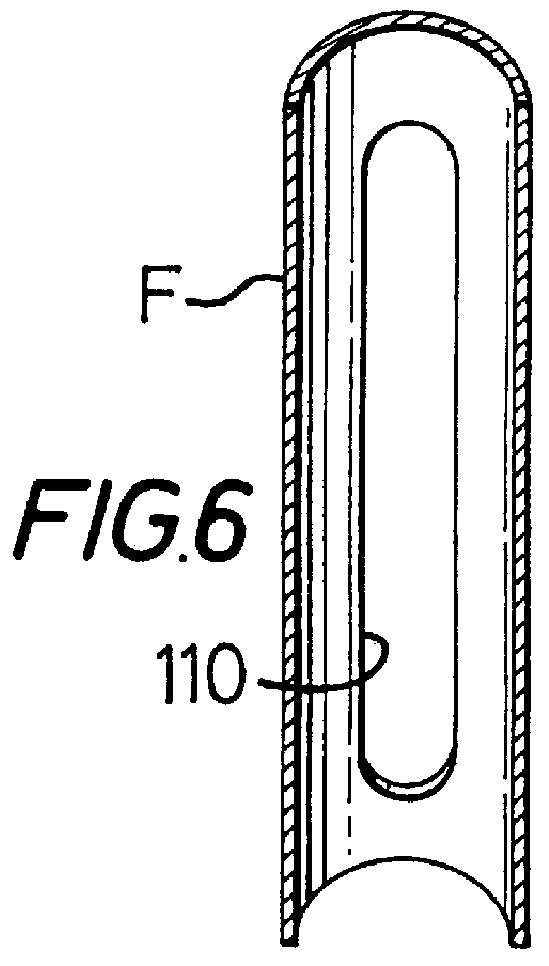

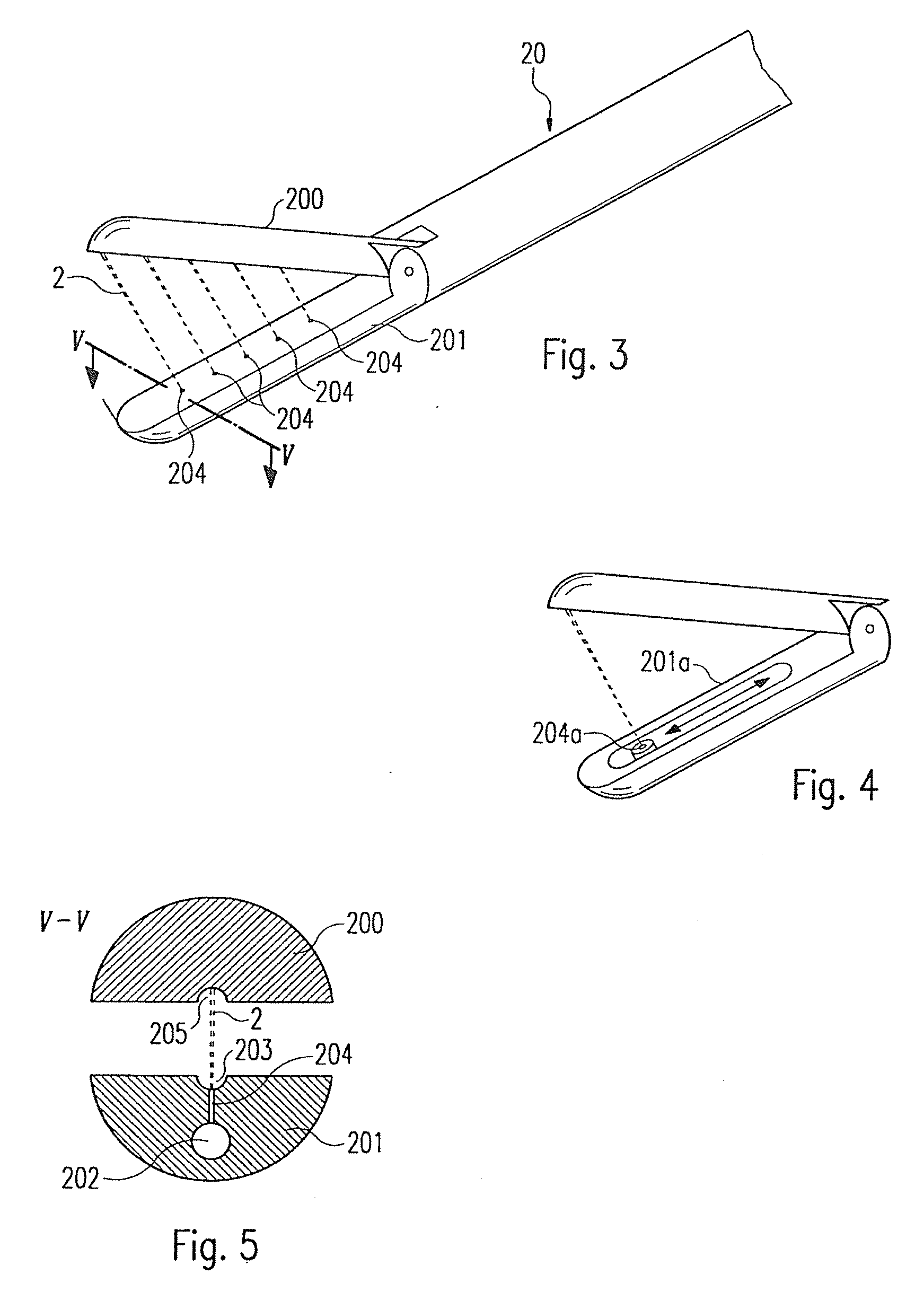

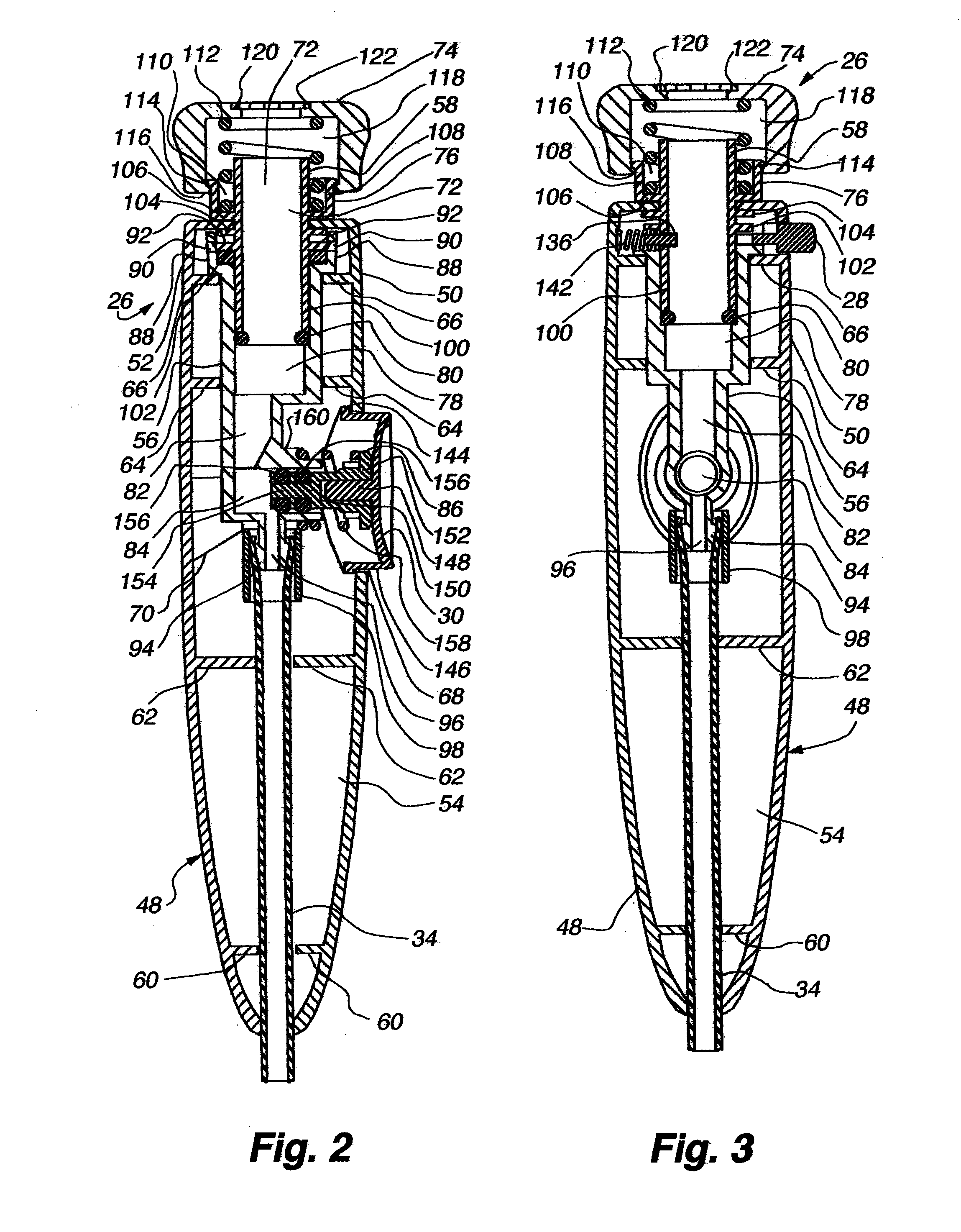

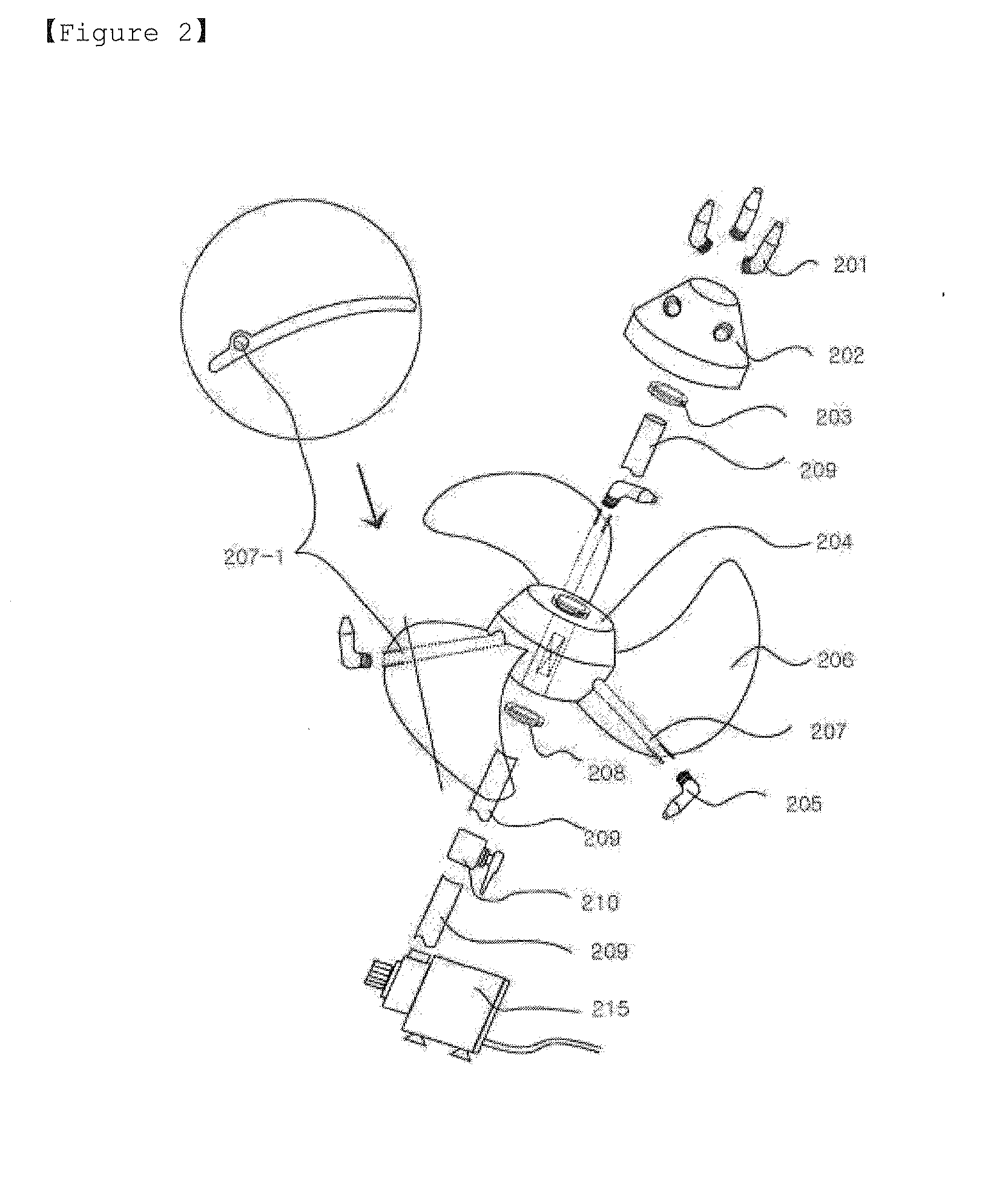

Multifunction device for endoscopic surgery

ActiveUS9308014B2Coagulation facilitatedFacilitate functioningVaccination/ovulation diagnosticsFluid jet surgical cuttersForcepsEndoscopic surgery

A multifunction device for endoscopic surgery including a supply means for the supply of at least one fluid and forceps or a clamp which comprise forceps-shaped electrodes with jaw parts for high-frequency surgery. The supply means is formed to dissect tissue by means of a fluid jet at or in a jaw part of the forceps or clamp. The multifunction device is one for both water jet surgery and high-frequency coagulation and / or cutting that occupies no more space than a conventional high-frequency instrument or conventional forceps or clamps.

Owner:ERBE ELEKTROMEDIZIN GMBH

Method, apparatus and system for a water jet

A water jet instrument may be used for manually performing eye surgery such as, cataract, or perform micro-surgery (remove cartilage), or any emulsification technique. The water jet instrument may be manually controlled or controlled by a system with a robotic control. The water jet apparatus defines a jet cutting area that is based at least in part on a flow rate meter and a feedback loop.

Owner:AURIS HEALTH INC

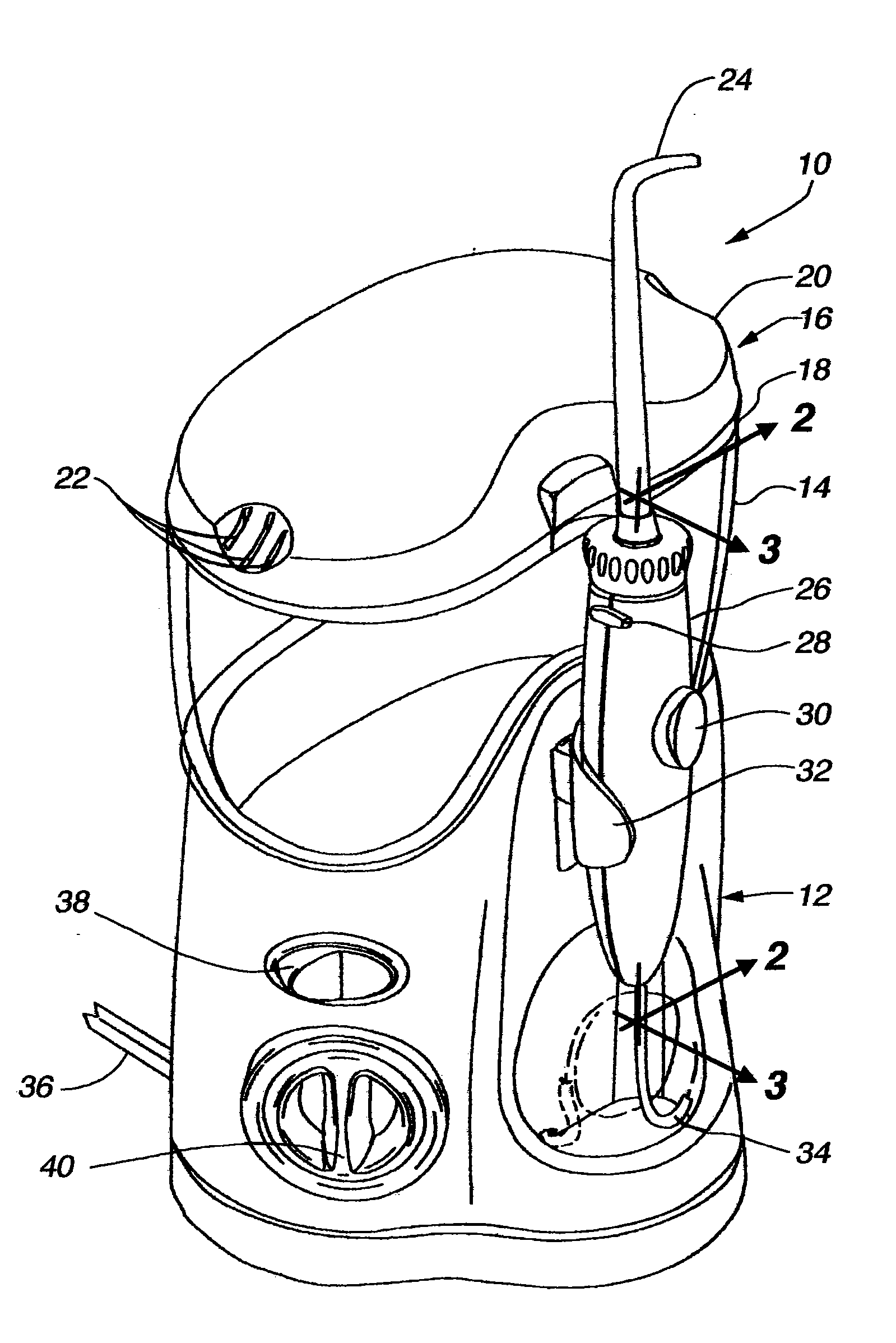

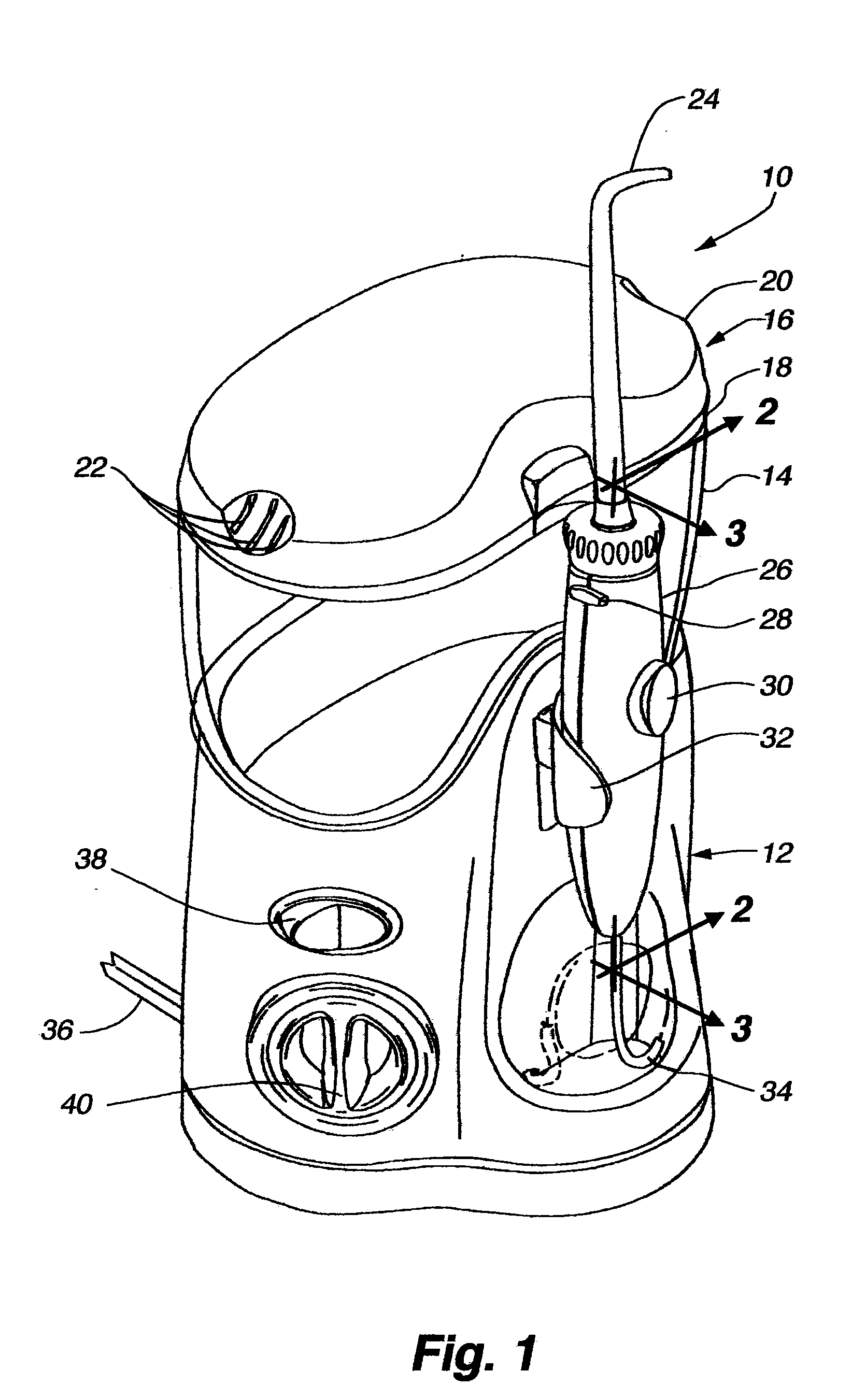

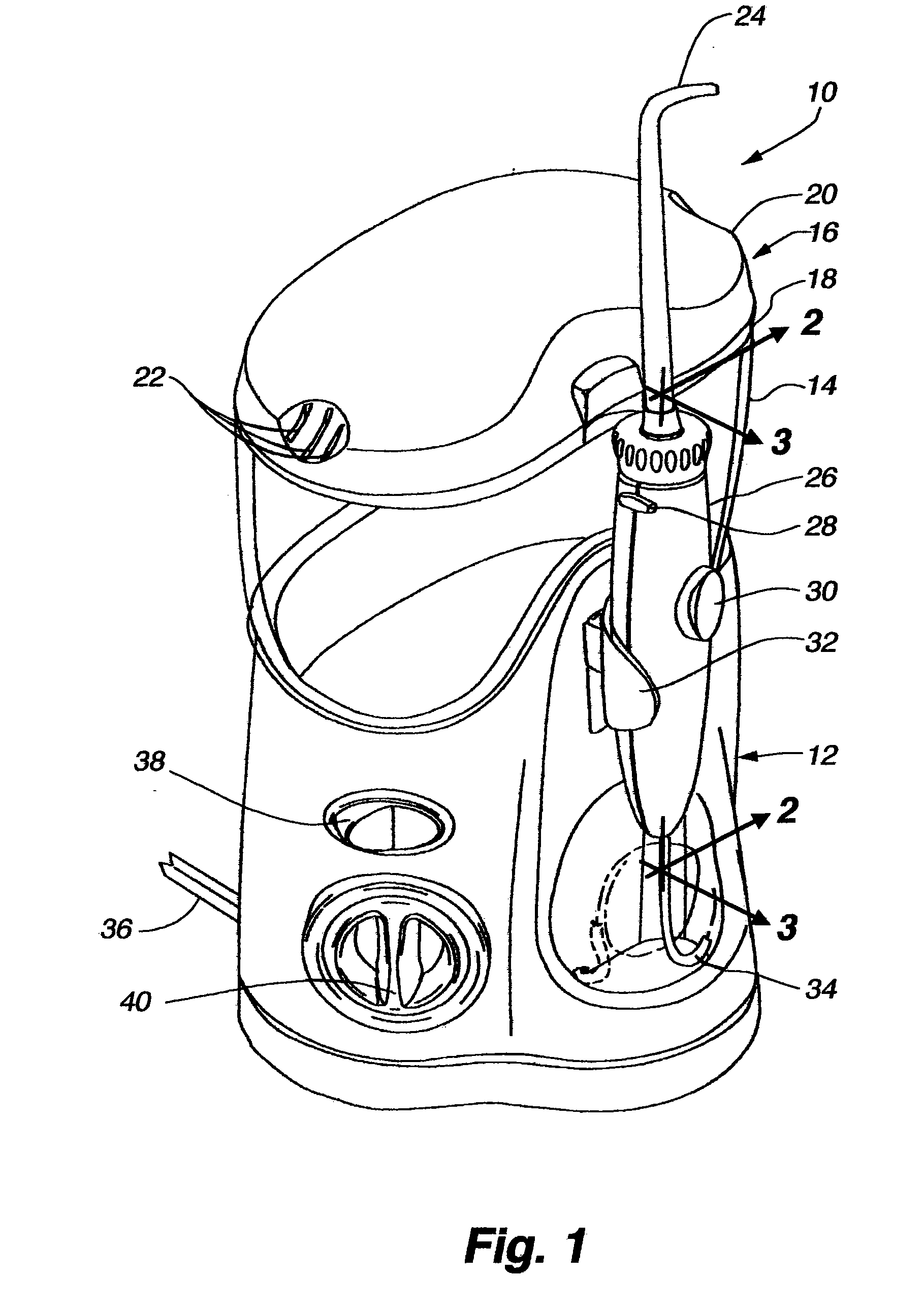

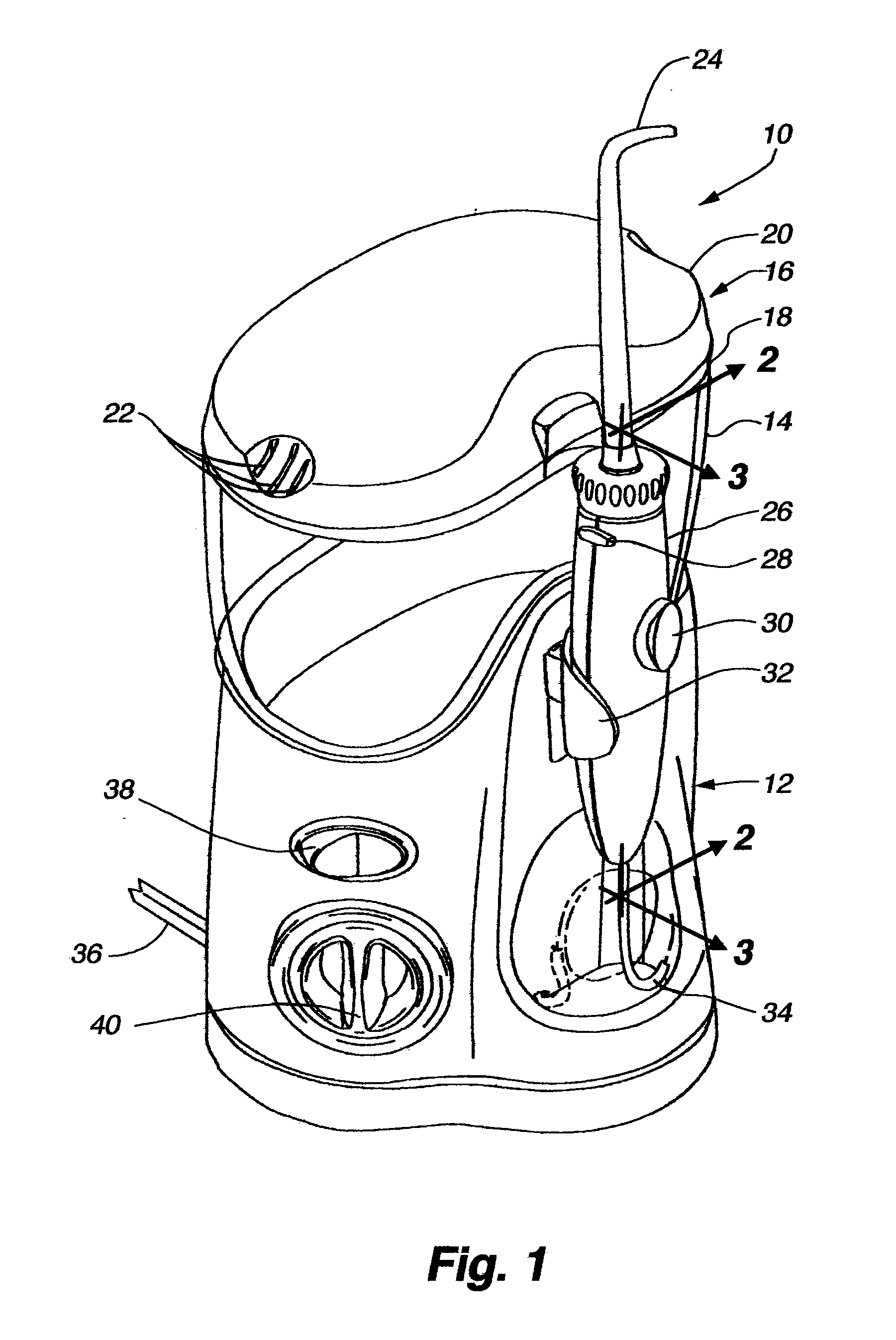

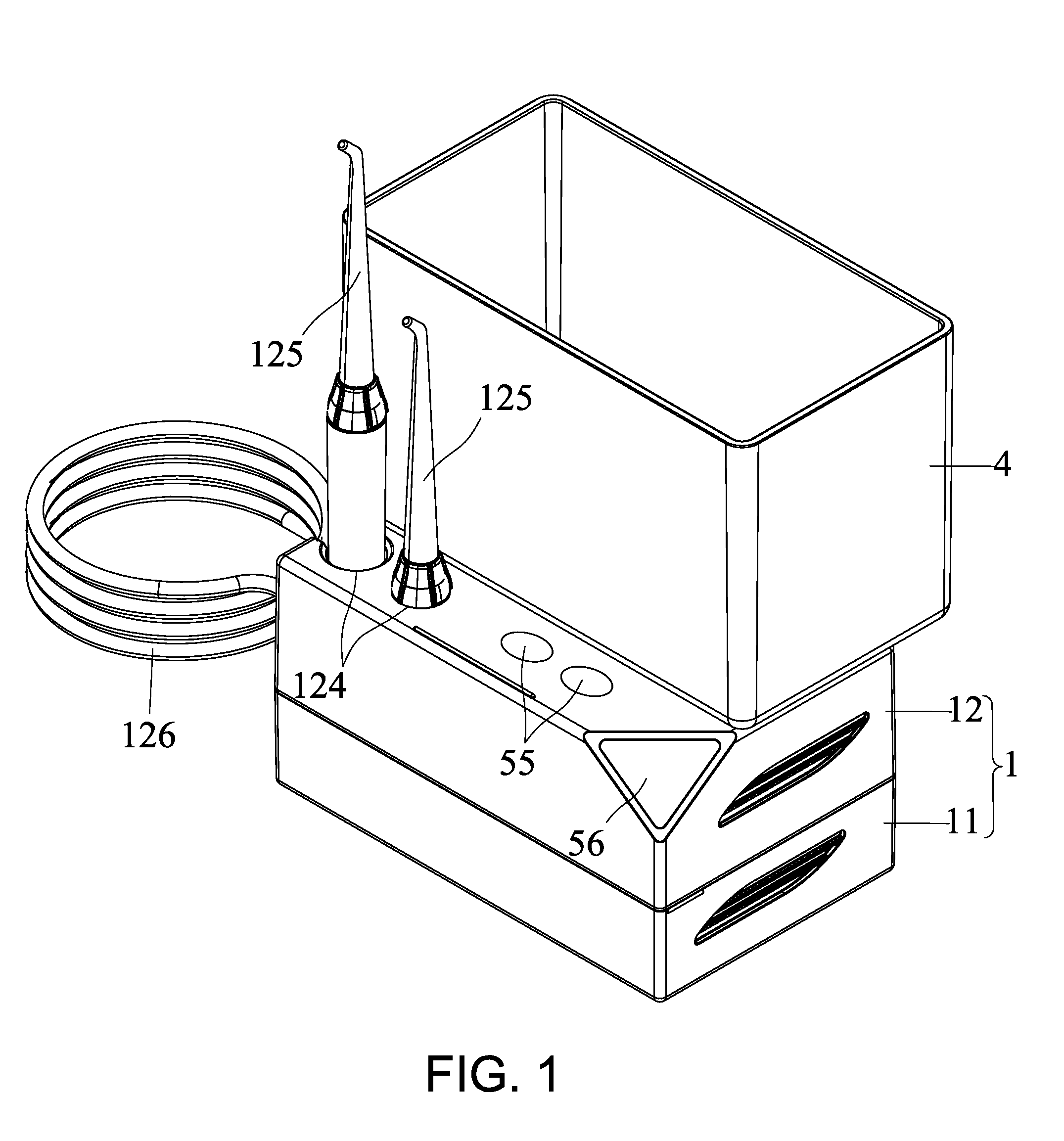

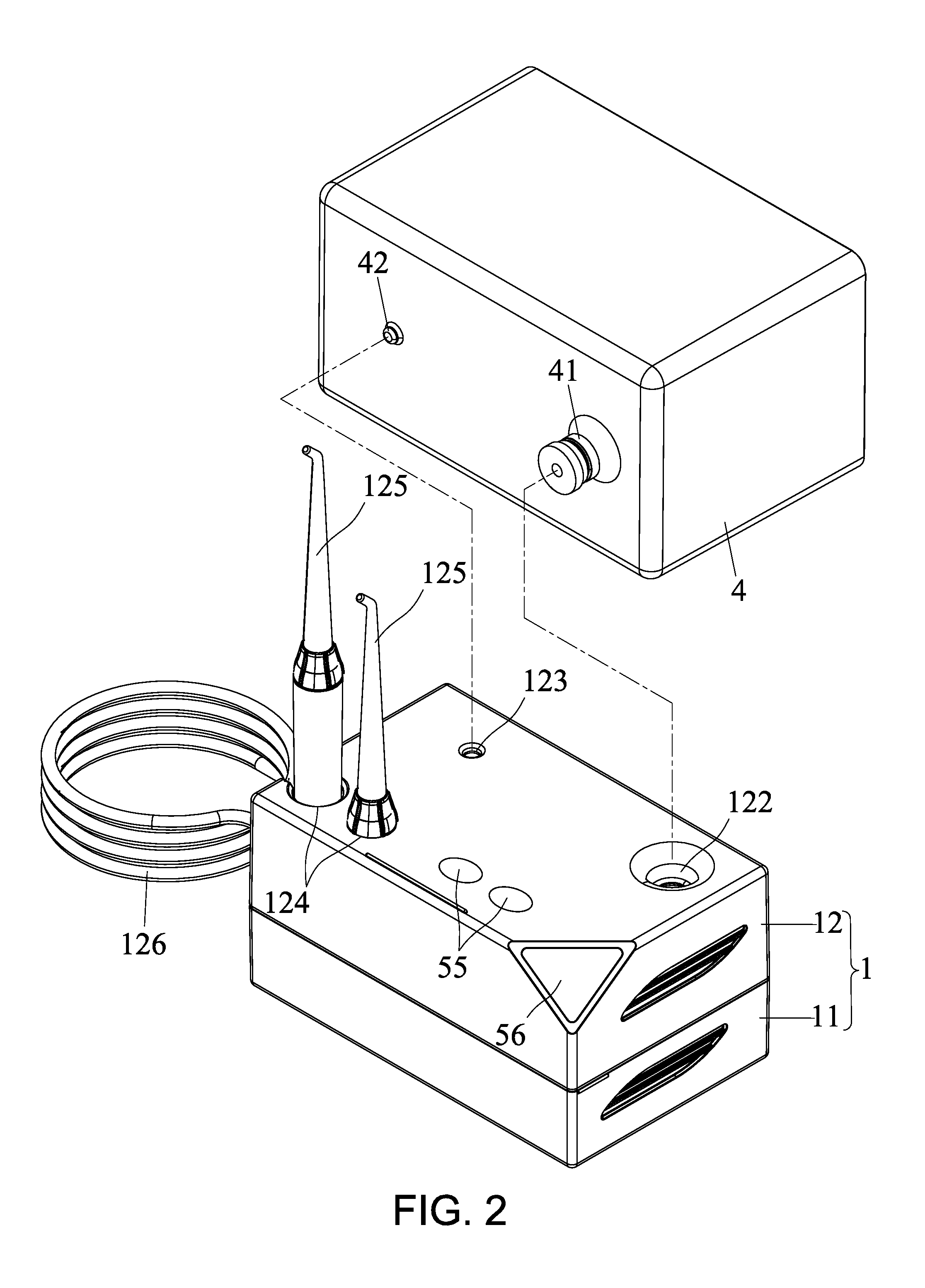

Water jet unit and handle

An apparatus for providing a pressurized water stream for cleaning gums and teeth. The embodiment includes a base unit defining a cavity. The cavity contains a pump, which may move pressurized water from a reservoir to a tip in fluid communication with the pump. A flow control knob may be turned to selectively adjust the water pressure supplied by the tip between a minimum and a maximum value. The reservoir may be removed from the base unit so that it may be filled with the fluid. The reservoir may support a container for storing tips or other items. Fluid may flow from the reservoir and ultimately into the tip to provide oral irrigation and / or cleaning of the teeth, gums, and tongue.

Owner:WATER PIK INC

Method for window formation in wellbore tubulars

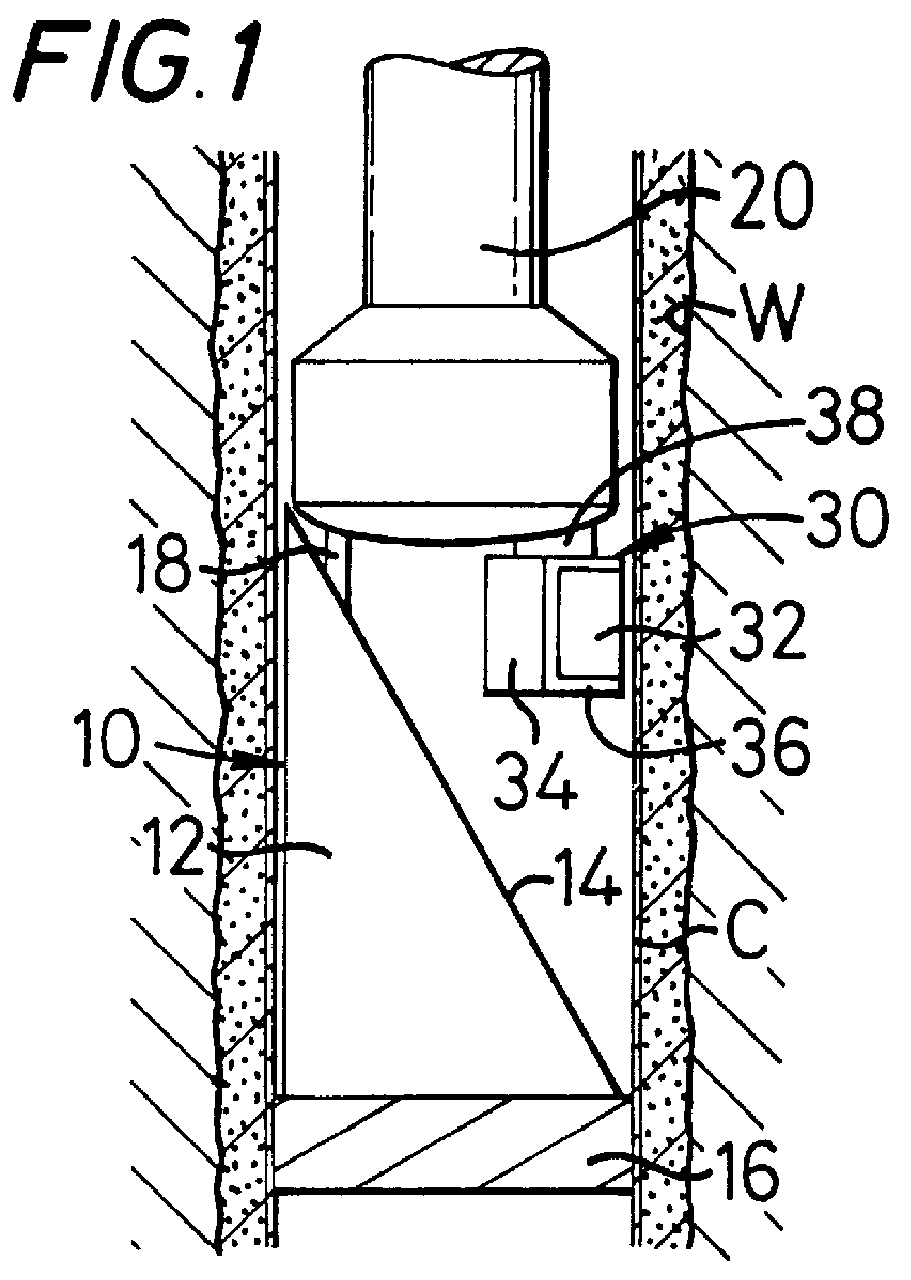

InactiveUS6024169APreventing coringEasy millingFluid removalDirectional drillingStream flowEngineering

New systems and methods have been invented for explosively forming openings, ledges, windows, holes, and lateral bores through tubulars such as casing, which openings may, in cerain aspects, extend beyond the casing into a formation through which a wellbore extends. In certain aspects openings (e.g. ledges, initial, or completed windows) in wellbore tubulars (e.g. tubing or casing) are made using metal oxidizing systems, water jet systems, or mills with abrasive and / or erosive streams flowing therethrough and / or therefrom.

Owner:WEATHERFORD TECH HLDG LLC

Multifunction device for endoscopic surgery

ActiveUS20090125027A1Coagulation facilitatedFacilitate functioningVaccination/ovulation diagnosticsFluid jet surgical cuttersEndoscopic sinus surgeryForceps

A multifunction device for endoscopic surgery including a supply means for the supply of at least one fluid and forceps or a clamp which comprise forceps-shaped electrodes with jaw parts for high-frequency surgery. The supply means is formed to dissect tissue by means of a fluid jet at or in a jaw part of the forceps or clamp. The multifunction device is one for both water jet surgery and high-frequency coagulation and / or cutting that occupies no more space than a conventional high-frequency instrument or conventional forceps or clamps.

Owner:ERBE ELEKTROMEDIZIN GMBH

Method, apparatus and system for a water jet

Owner:AURIS HEALTH INC

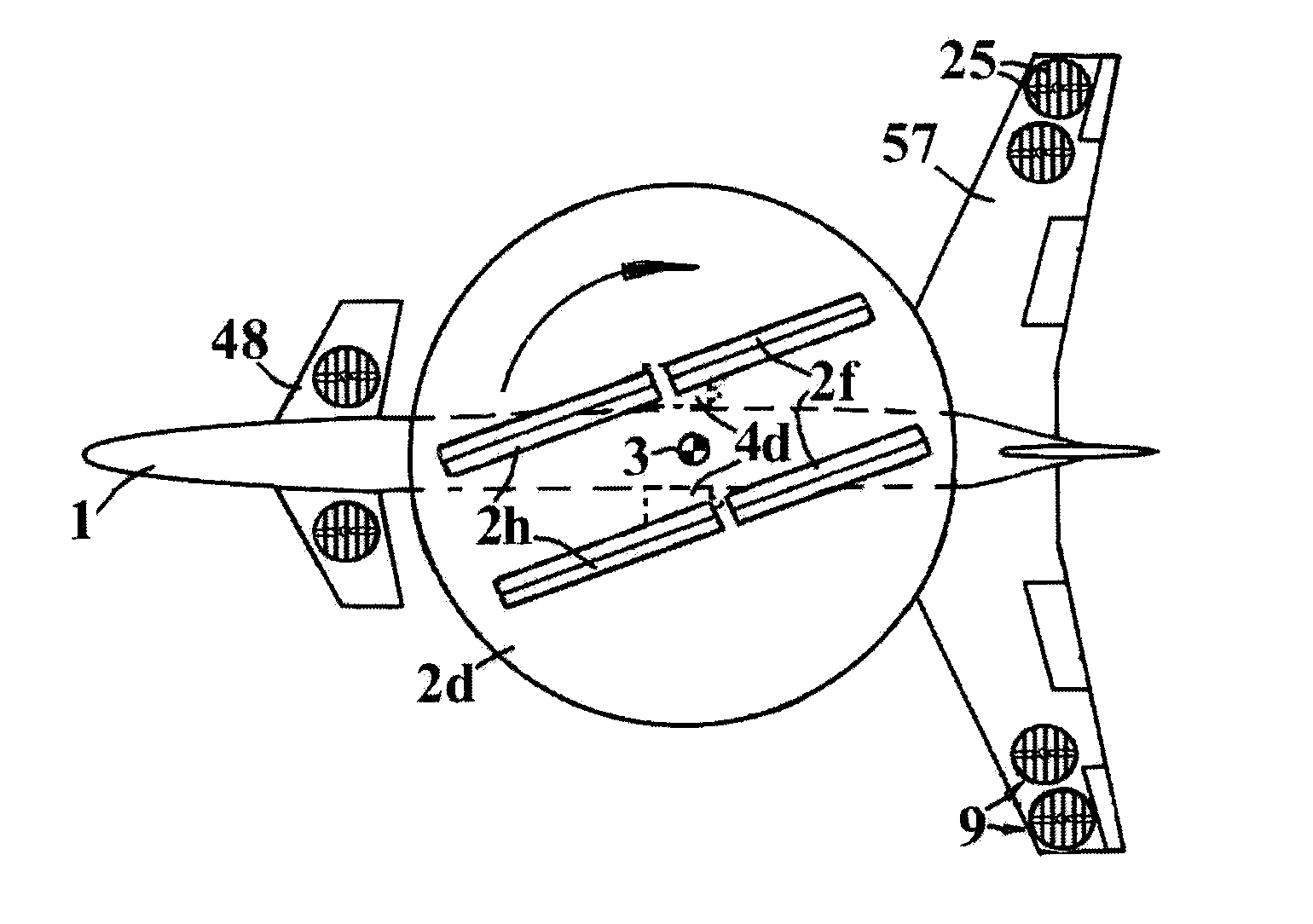

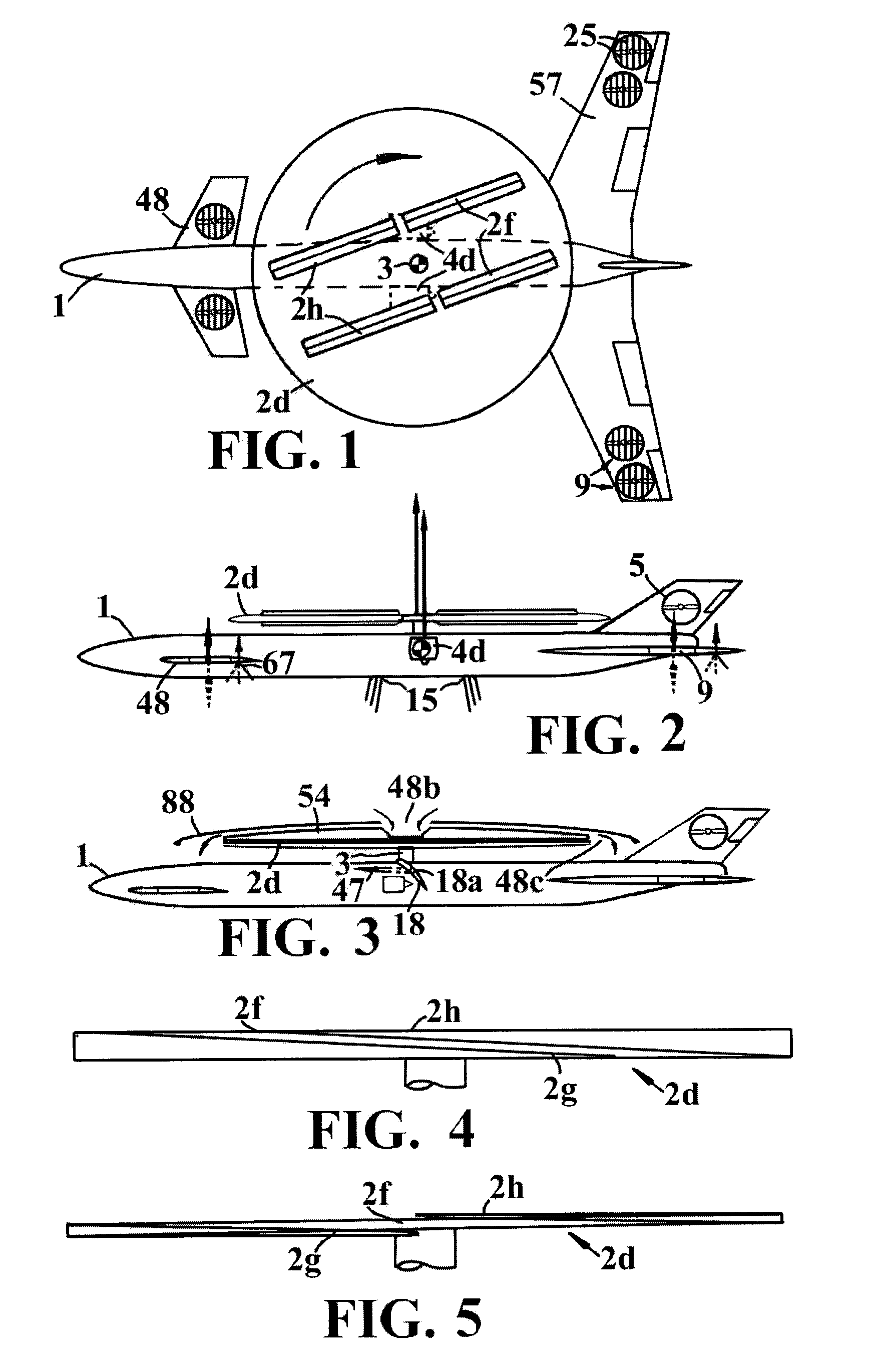

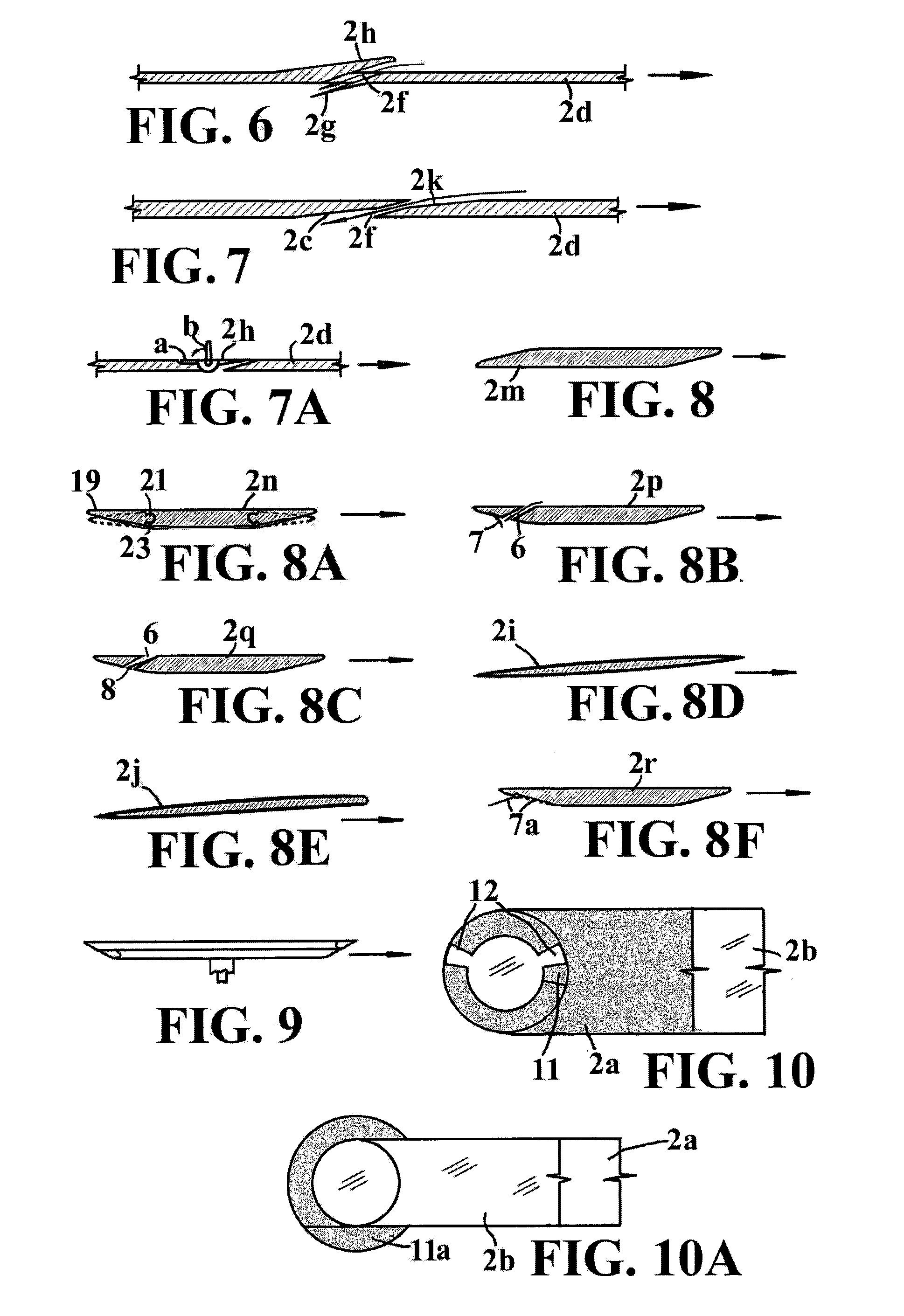

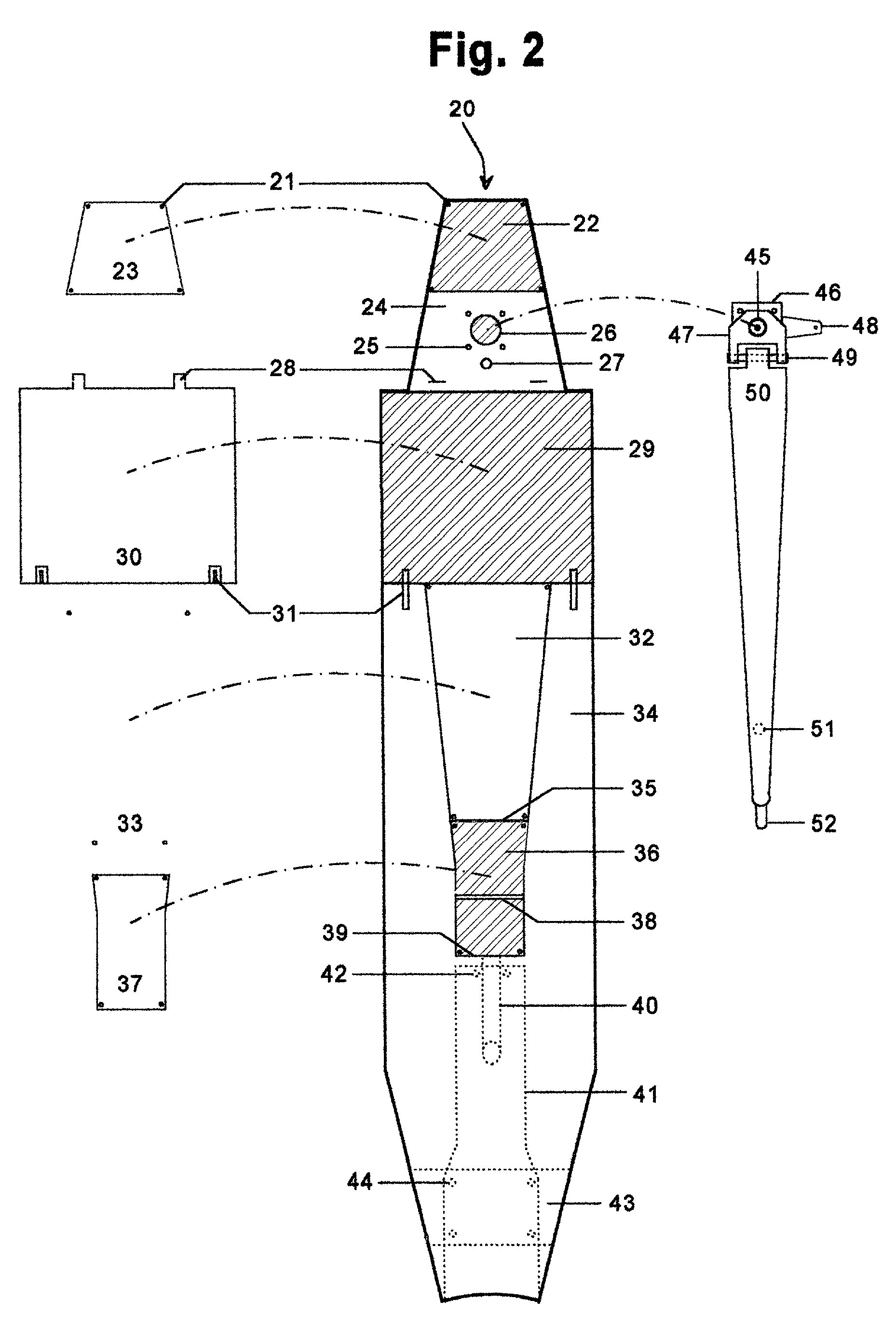

Lift Propulsion and Stabilizing System and Procedure For Vertical Take-Off and Landing Aircraft

InactiveUS20130251525A1Inhibition effectLow costElectric power distributionPropellersLeading edgeTurbine

Lift propulsion and stabilizing system and procedure for vertical takeoff and landing aircraft that consists in applying simultaneously and combined as lifters during the initial portion of the climb and at the end of the descent of: a) some fans or electric turbines, EDF, and b) at least one rotor with external blades and / or rotary and / or c) the engine flow directed downwards and / or d) pressure air jets injected on leading edges control fins, and / or e) water jets and / or f) supplemented with aerodynamic lift produced during frontal advance of the aircraft, the stabilization is achieved by the gyroscopic stiffness of the rotor and two or more lifting fans oscillating fins and / or air jets located on two or stabilizers more peripheral points in a plane perpendicular to the vertical axis of the aircraft.

Owner:SAIZ MANUEL M

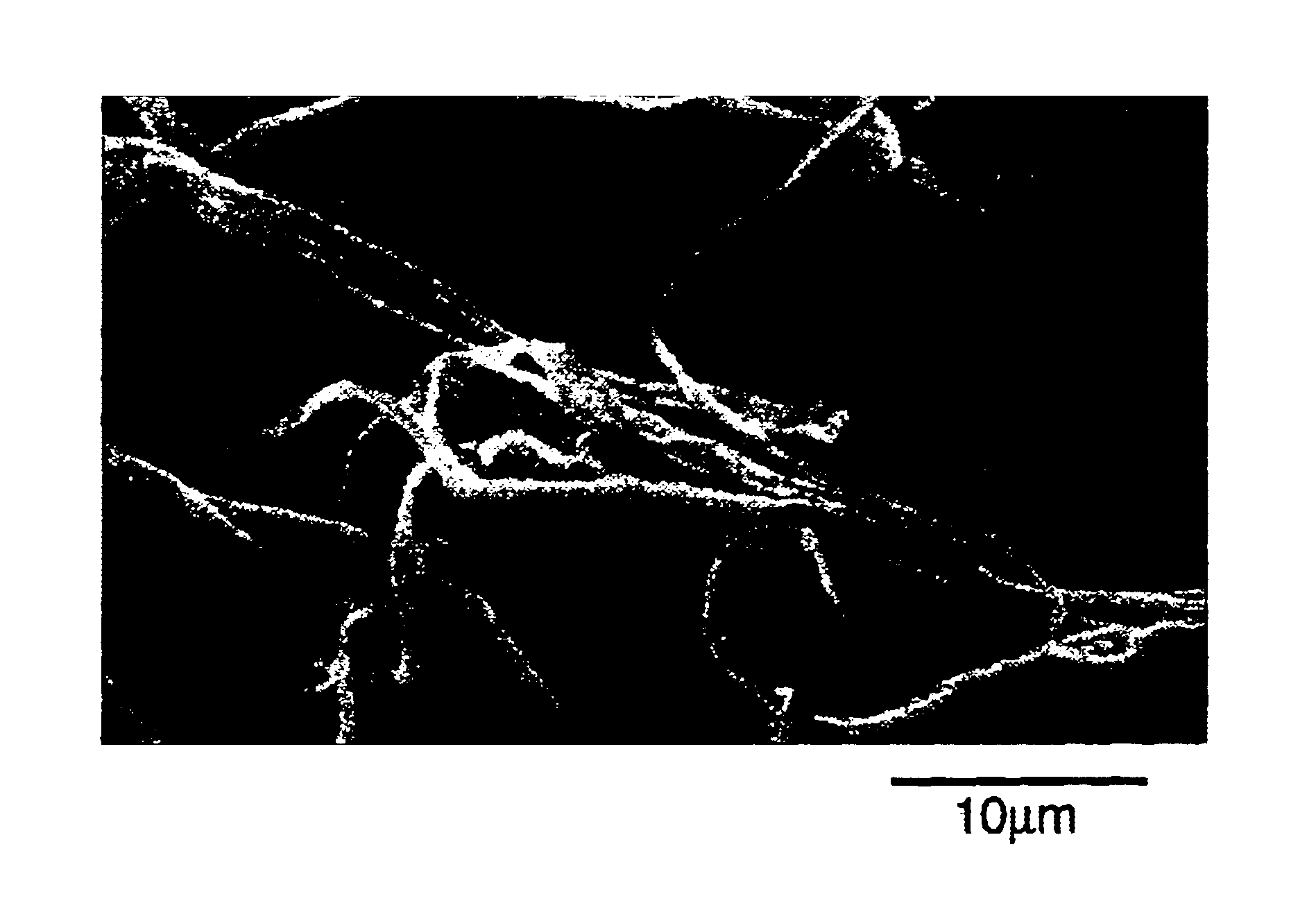

Aliphatic polyester microfibers, microfibrillated articles and use thereof

InactiveUS6890649B2Increase surface areaUseful applicationEngine sealsFilament/thread formingPolyesterParticulates

The present invention relates to aliphatic polyester microfibers, films having a microfibrillated surface, and methods of making the same. Microfibers of the invention can be prepared by imparting fluid energy, typically in the form of high-pressure water jets, to a highly oriented, highly crystalline, aliphatic polyester film to liberate microfibers therefrom. Microfibrillated films of the invention find use as tape backings, filters for particulate contaminants, such as face masks and water or air filters, fibrous mats, such as those used for removal of oil from water and those used as wipes, and thermal and acoustical insulation. Microfibers of the invention, when removed from the film matrix may be used in the preparation of woven or nonwoven articles and used as wipes for the removal of debris or dust from a surface. The microfibers and microfibrillated articles of the invention may be biodegradable, rendering them useful for geotextiles.

Owner:3M INNOVATIVE PROPERTIES CO

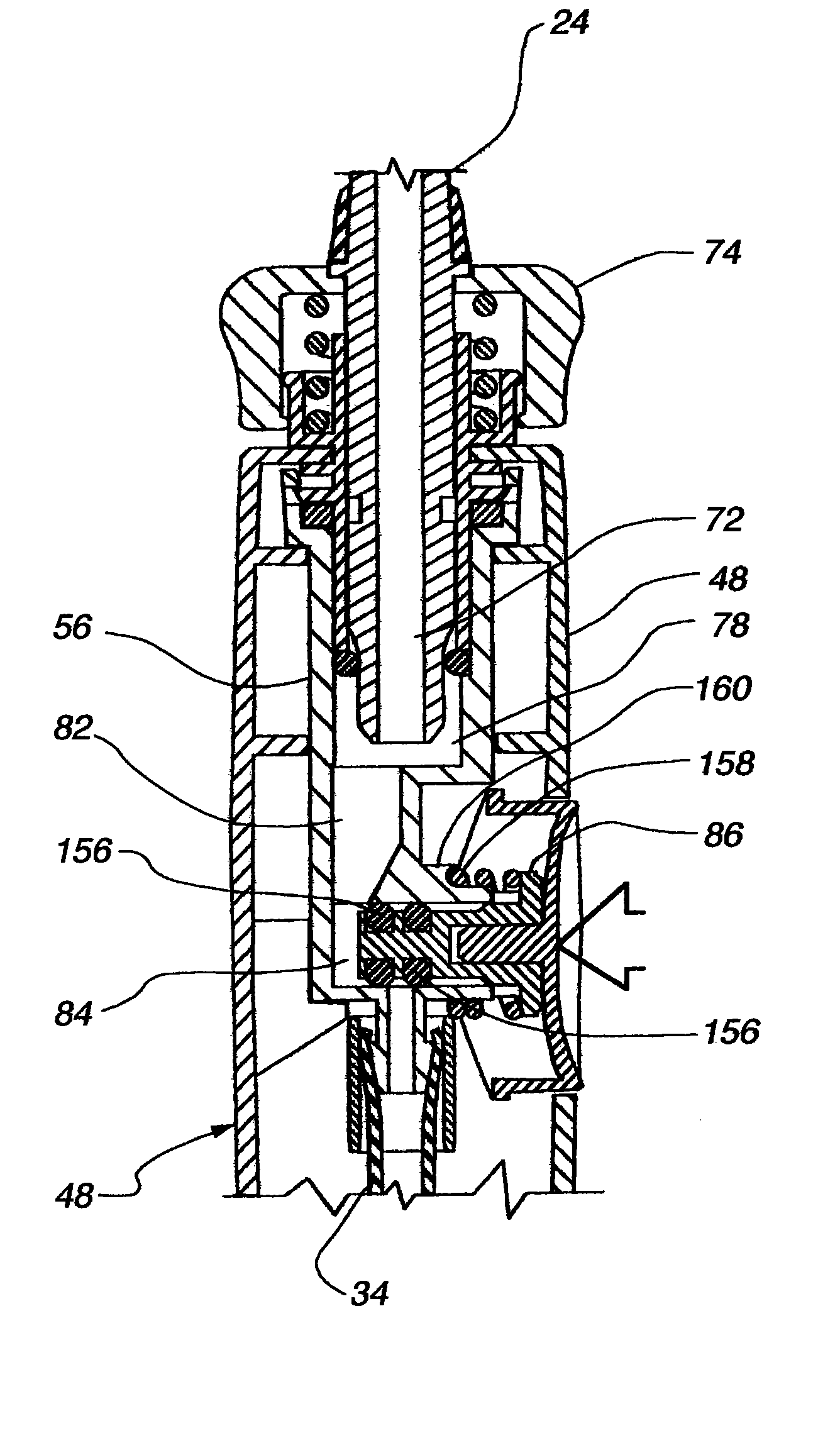

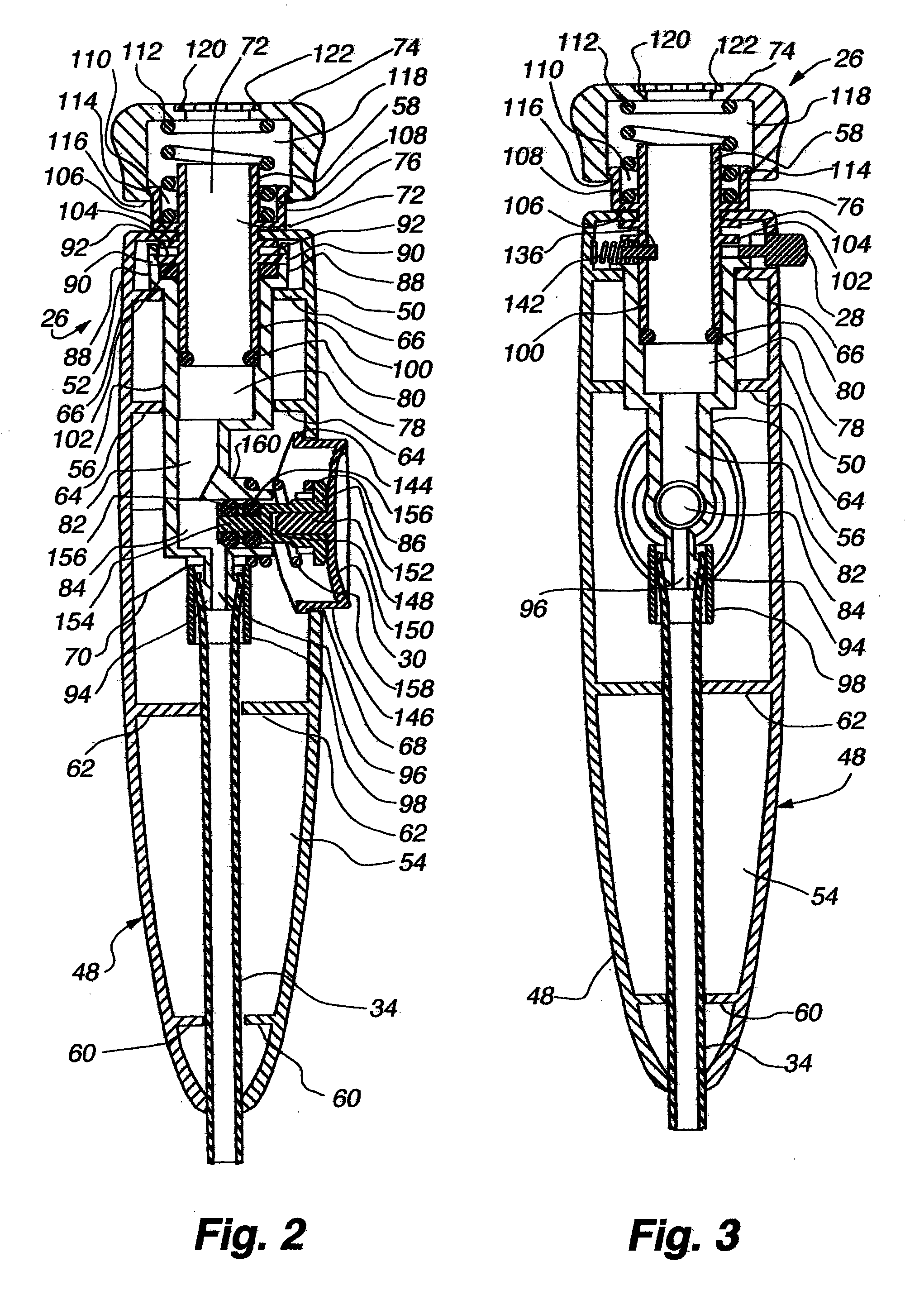

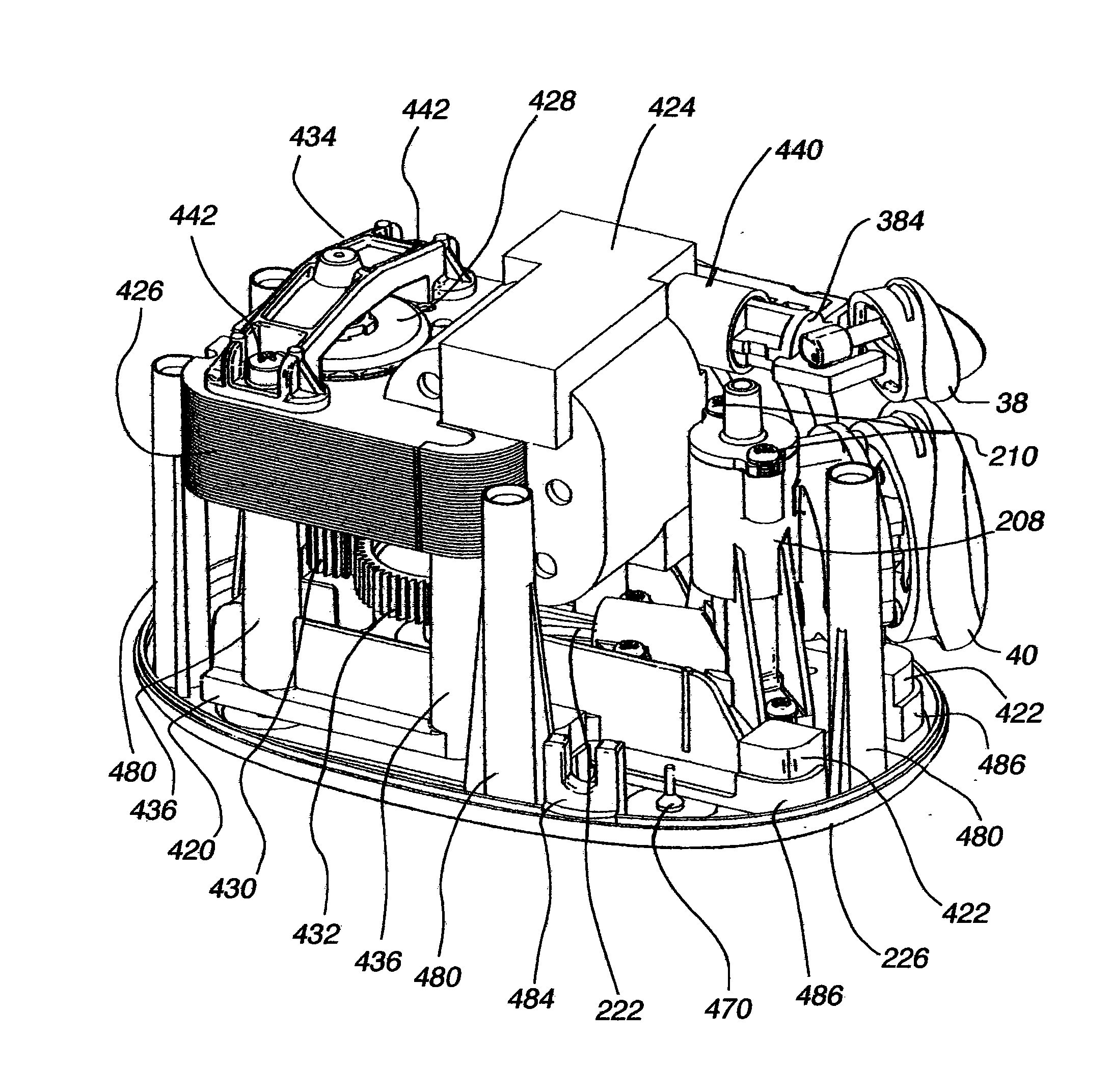

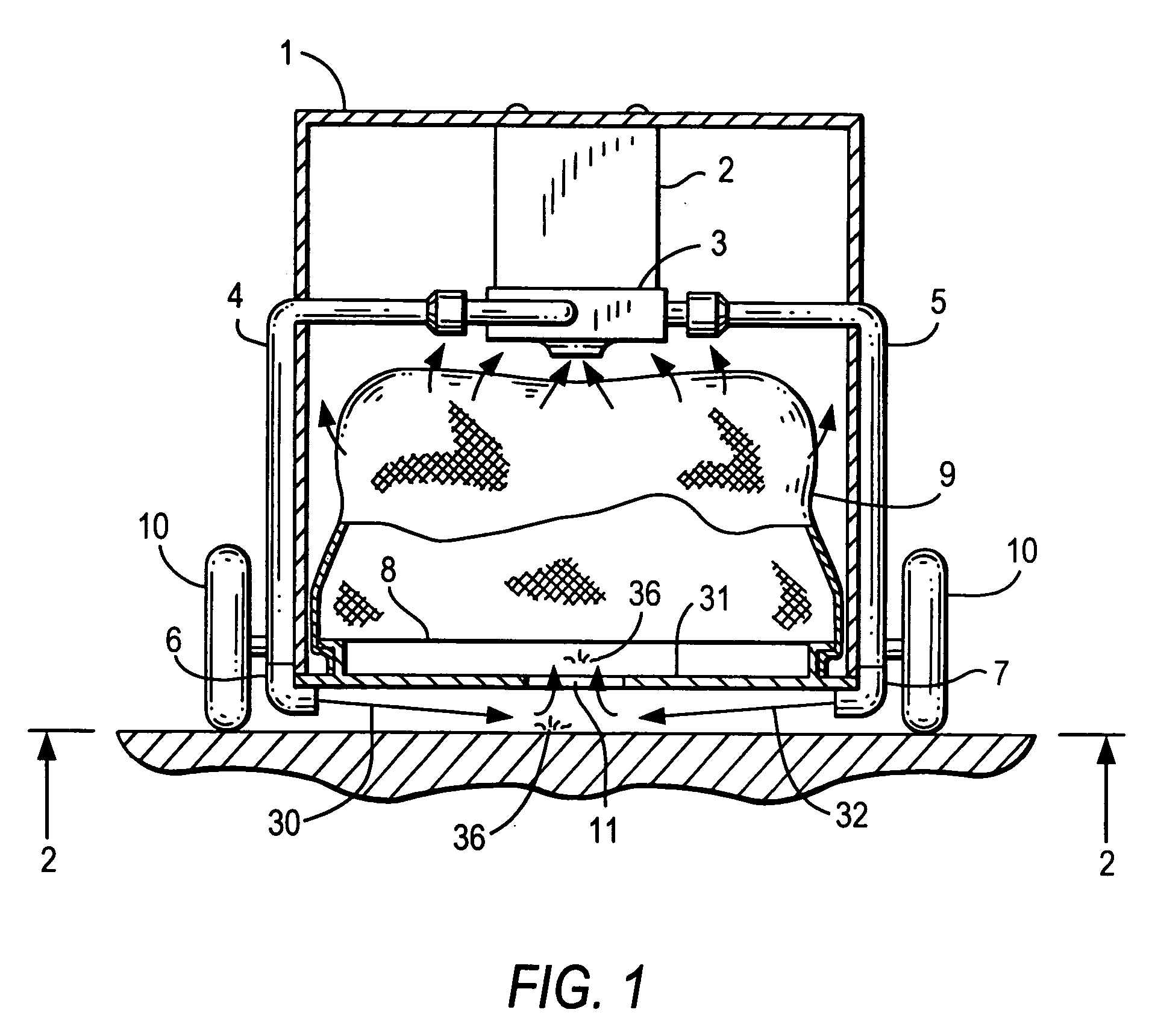

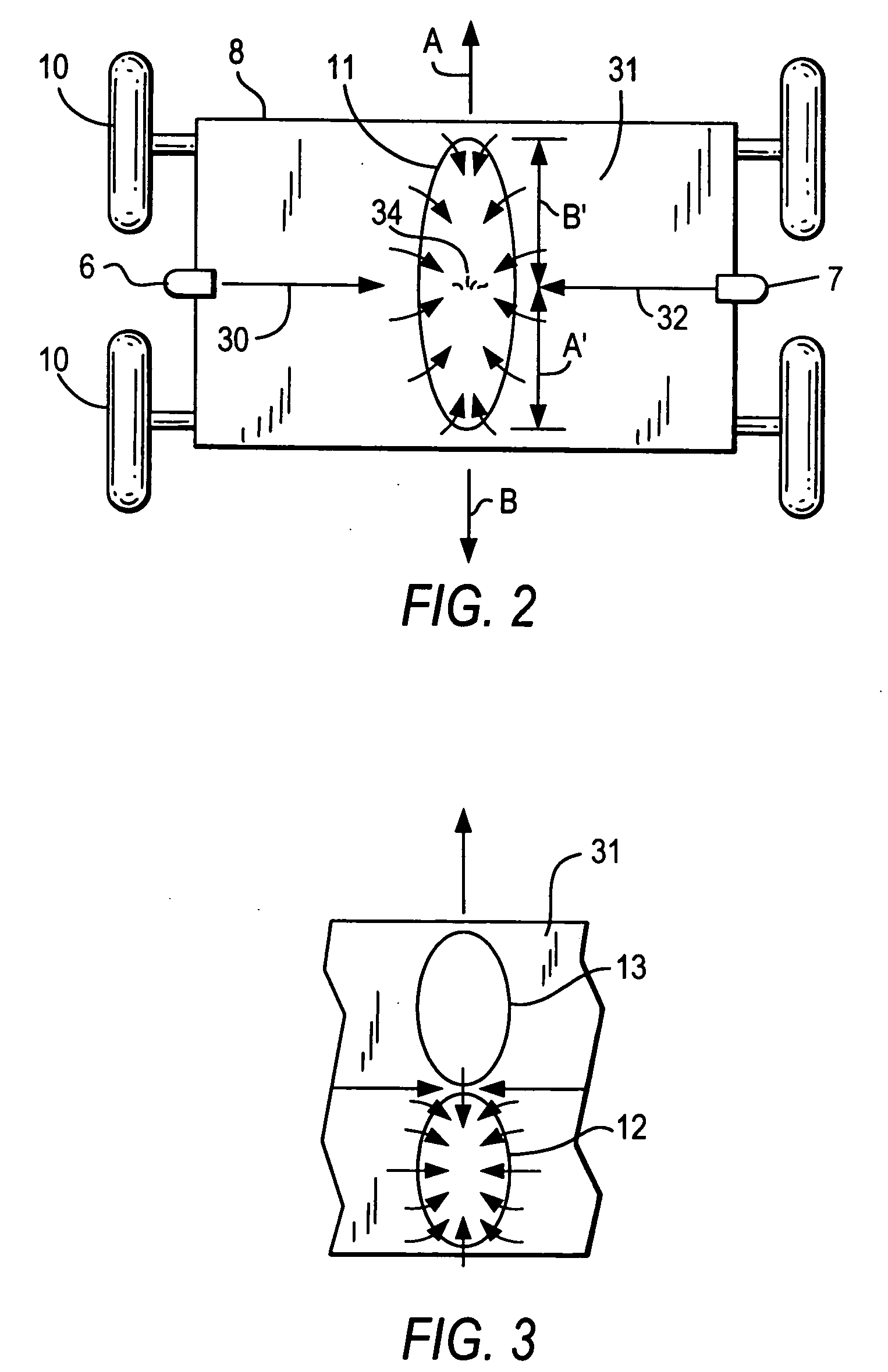

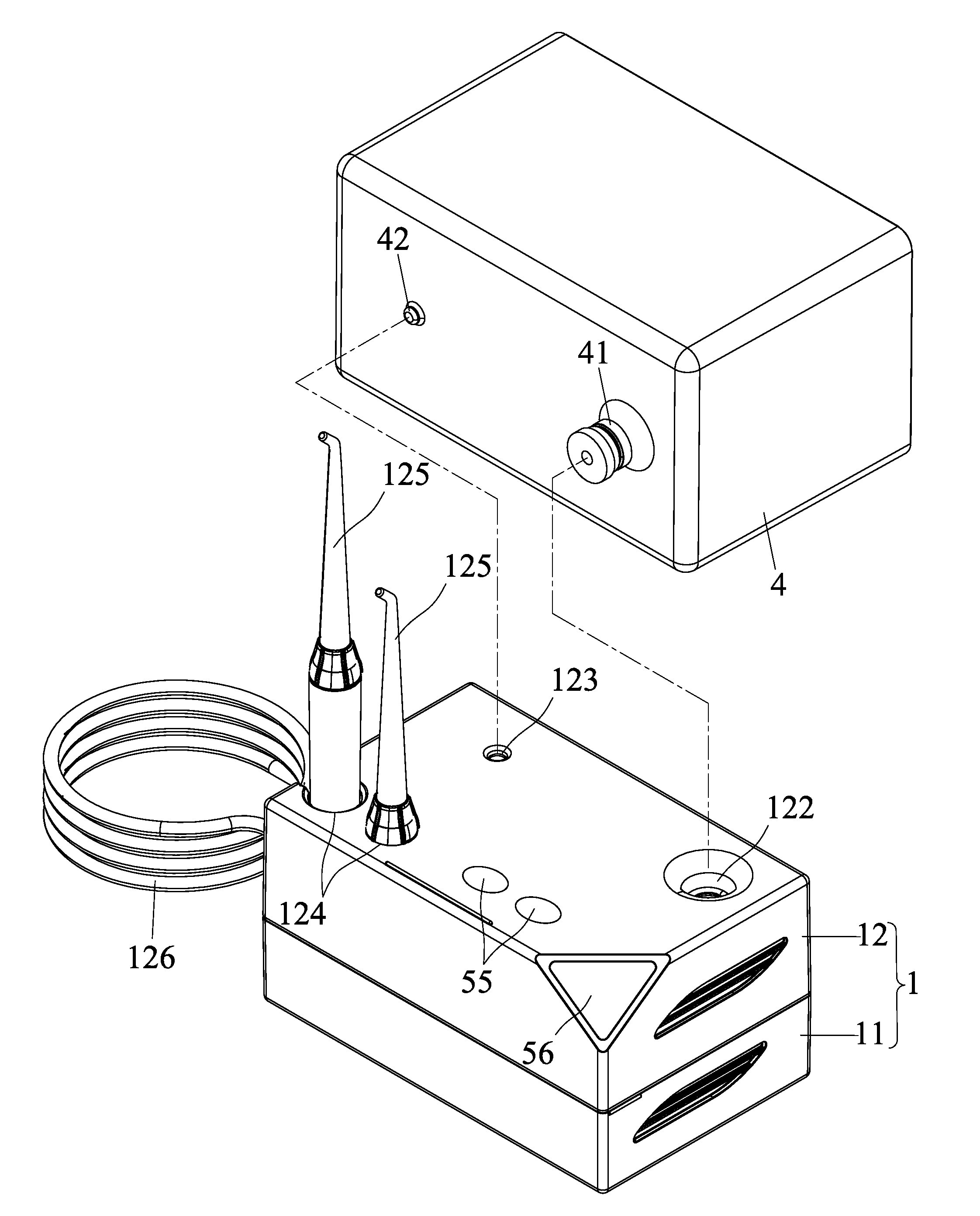

Vibration damping for dental water jet

An apparatus for providing a pressurized water stream for cleaning gums and teeth includes a base unit defining a cavity. The cavity contains a pump, which may move pressurized water from a reservoir to a tip in fluid communication with the pump. The pump may be secured within the cavity by at least one vibration reduction mount. Fluid may flow from the reservoir and ultimately into the tip to provide oral irrigation and / or cleaning of the teeth, gums, and tongue. The base may include a plurality of footings that elevate the base unit above a surface supporting the base unit. Also, the base may include a basin for receiving a reservoir. The basin may include a reservoir valve initially biased to a closed position and operationally attached to the reservoir, and a tube projection connected to the base unit and opening the valve when the reservoir is received within the basin. The basin and the reservoir are configured to guide the reservoir valve adjacent to the tube projection.

Owner:WATER PIK INC

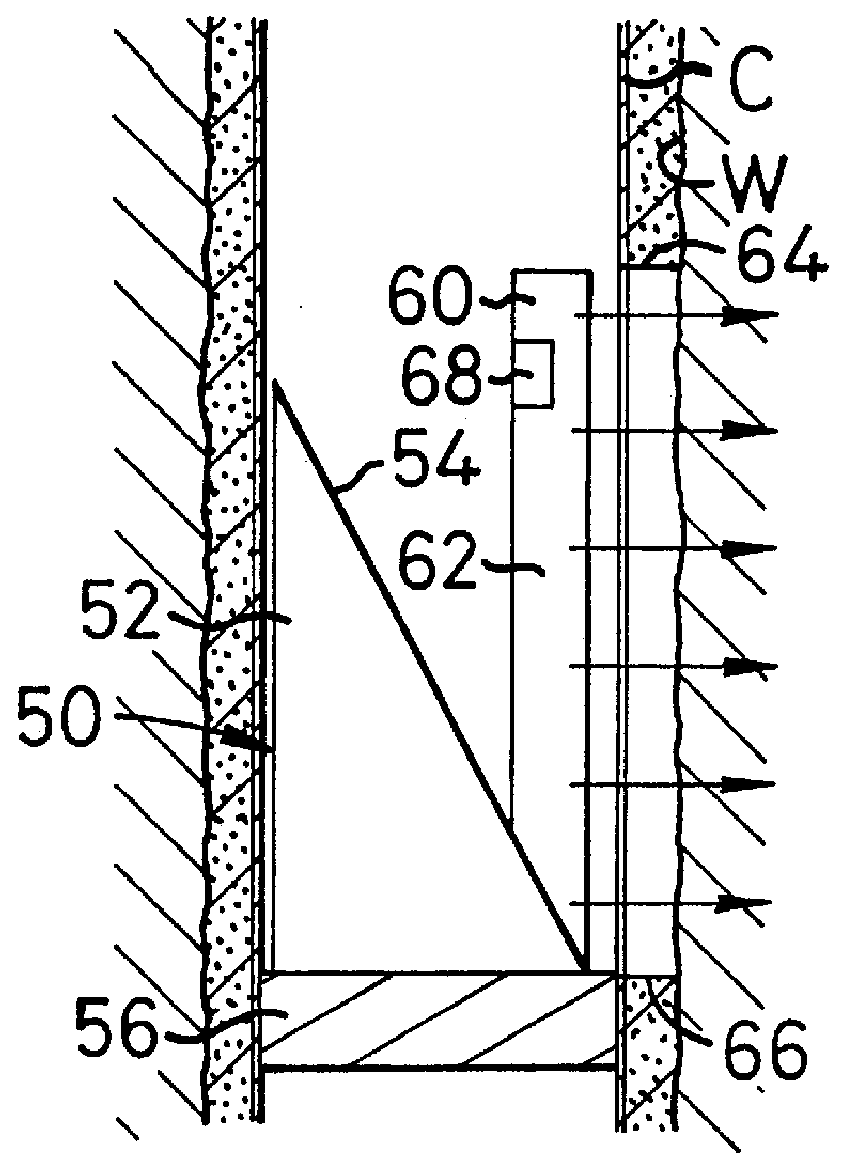

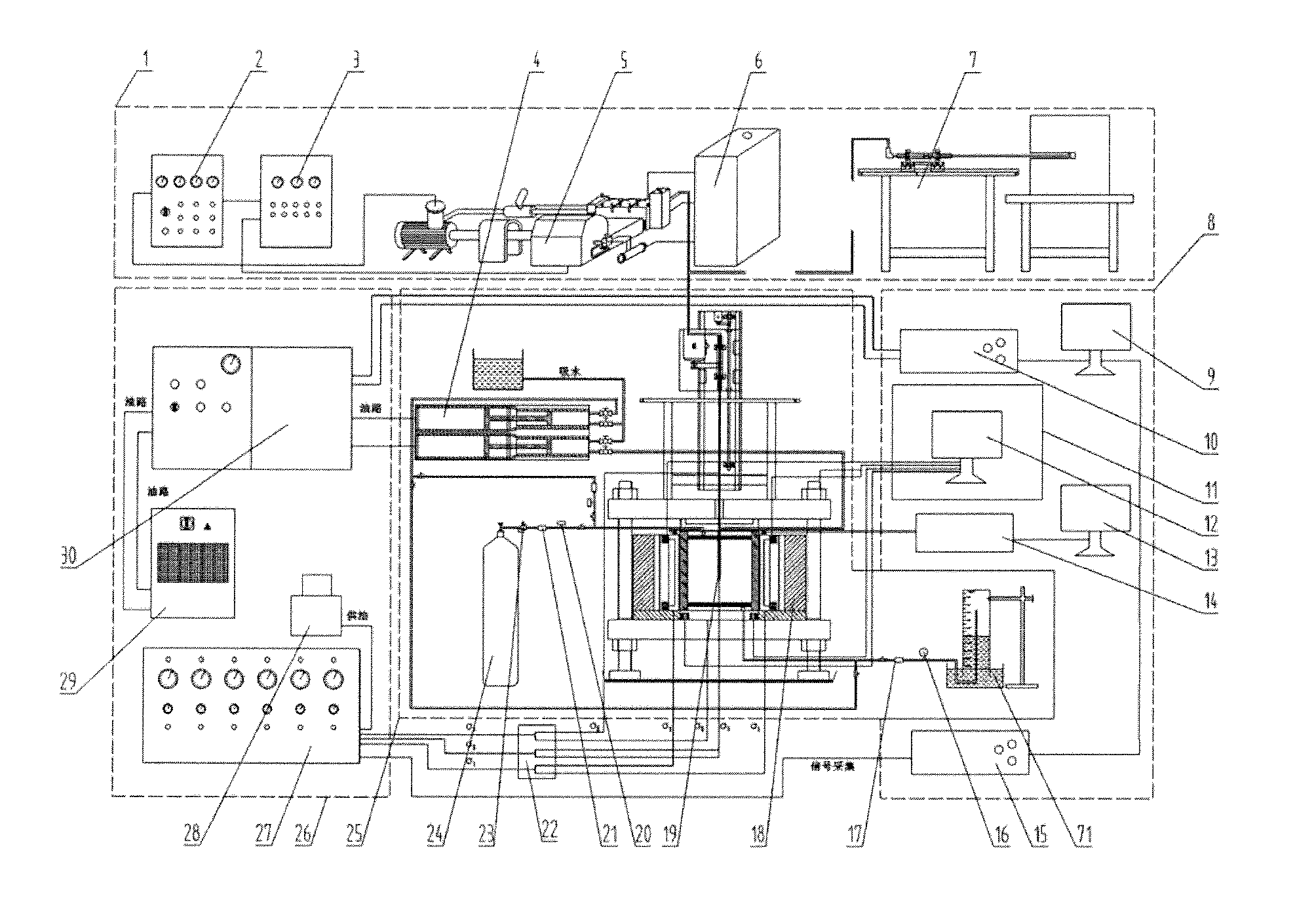

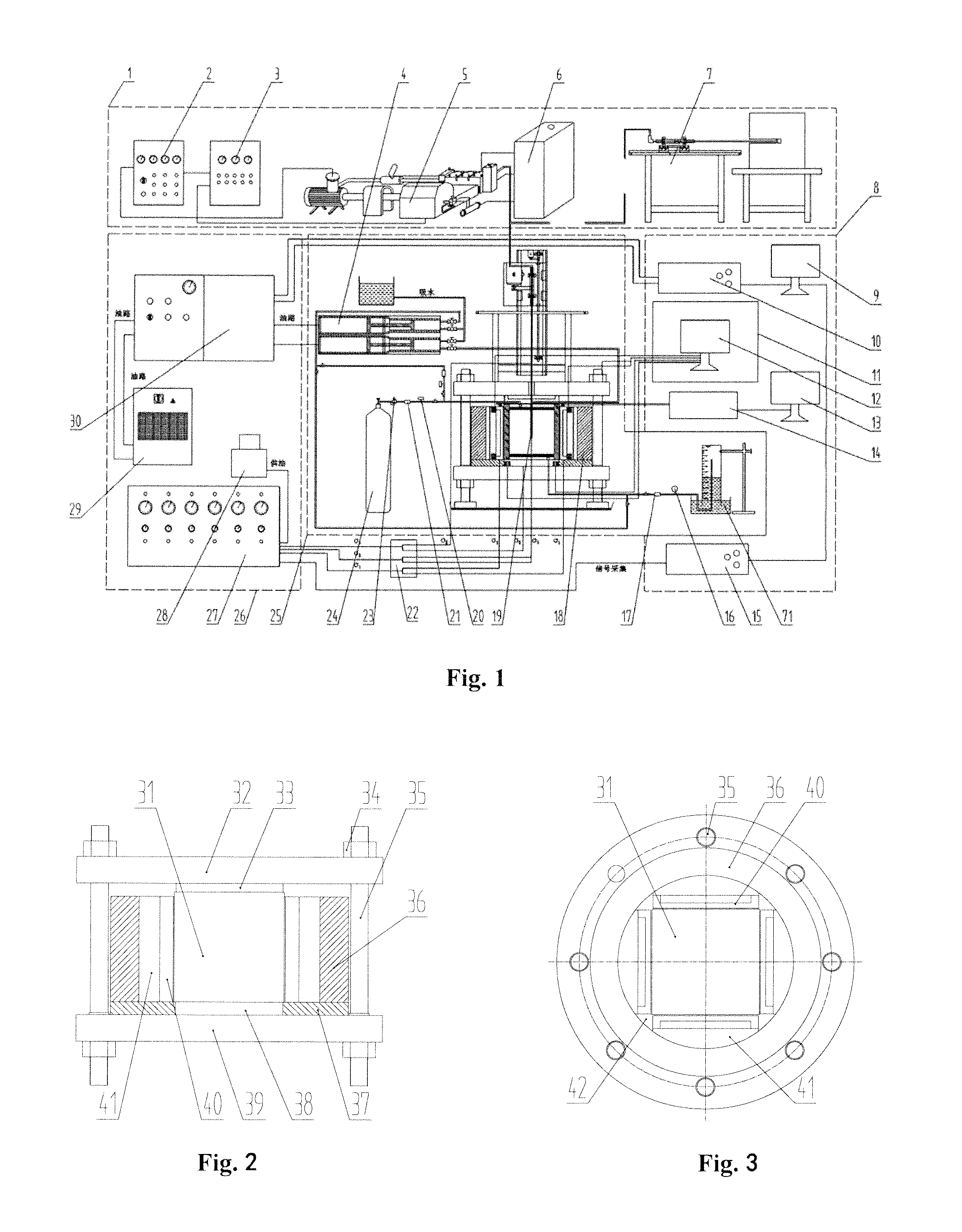

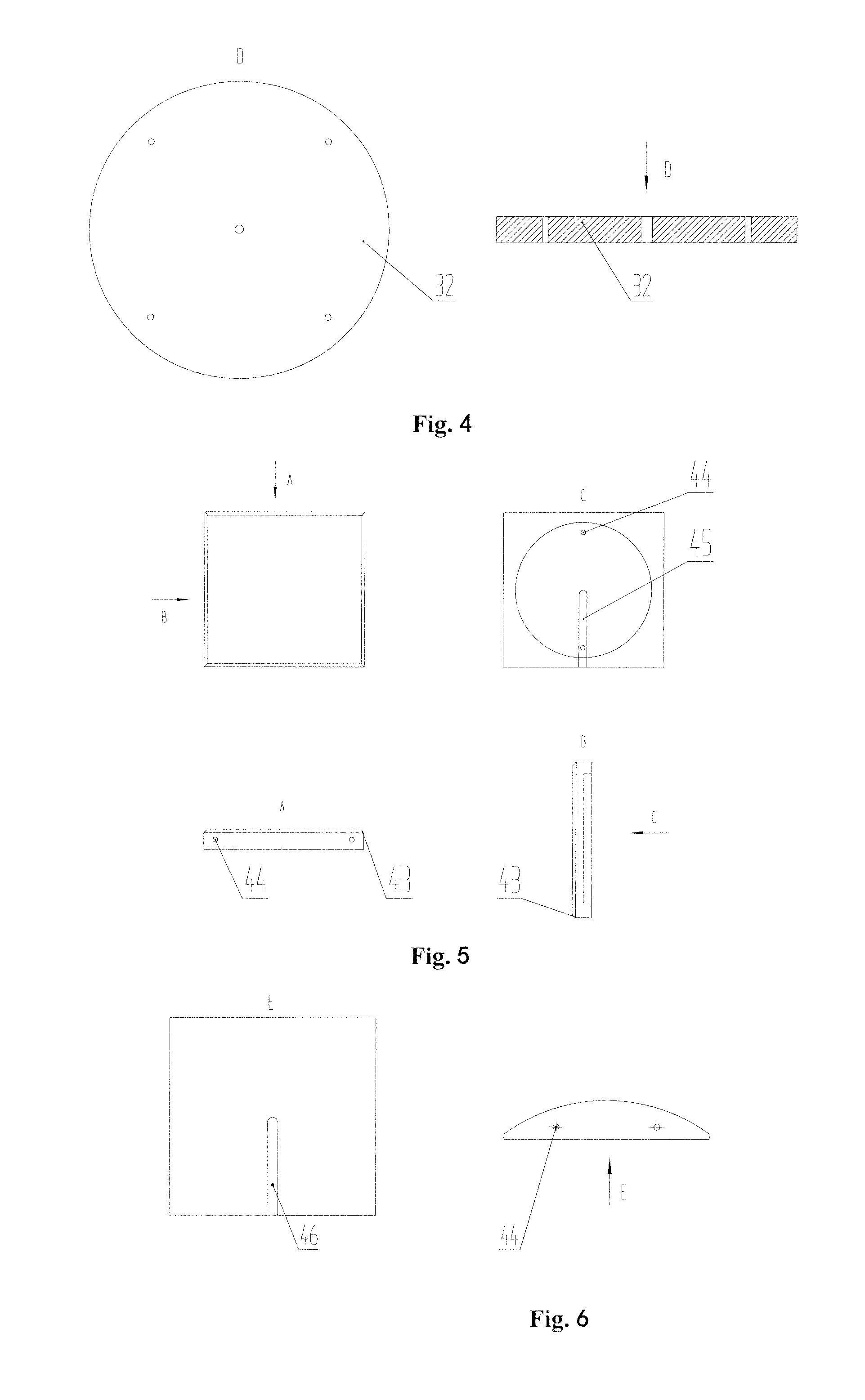

Integrated experimental system of hydrofracturing, water jet slotting, seepage and gas displacement under true triaxial stress

ActiveUS20170003263A1Good effectImprove securityEarth material testingMultiple fluid pressure valves simultaneous measurementMonitoring systemHydraulic fracturing

This invention relates to the coal mining field, specifically, to an integrated experimental system of hydrofracturing, water jet slotting, seepage and gas displacement under true triaxial stress. This invention consists of true triaxial stress loading experimental framework, a loading system and a monitoring system. Under true triaxial stress, experiments can be conducted with sample size as large as of 500 mm×500 mm×500 mm. The hydrofracturing experiment can be controlled by as many as 5 independent boreholes at the same time. The borehole water pressure in hydraulic fracturing can reach 63 MPa. Experiments of seepage and fluid-structure interaction with high seepage pressure can be achieved with sample dimension as large as 400 mm×400 mm×400 mm. Mine-used experimental bench of high pressure pump with rated flow of 70 L / min and maximum water pressure of 70 MPa can be used to drill borehole and the like.

Owner:CHINA UNIV OF MINING & TECH

Coupling device for security coupling first and second elements

The present invention relates generally to coupling devices for securely coupling first and second elements. The disclosed device can be used, for example, to connect different components of oral hygiene apparatuses that produce a relatively high-velocity water jet to clean a person's teeth.

Owner:HIPPENSTEEL JOSEPH B

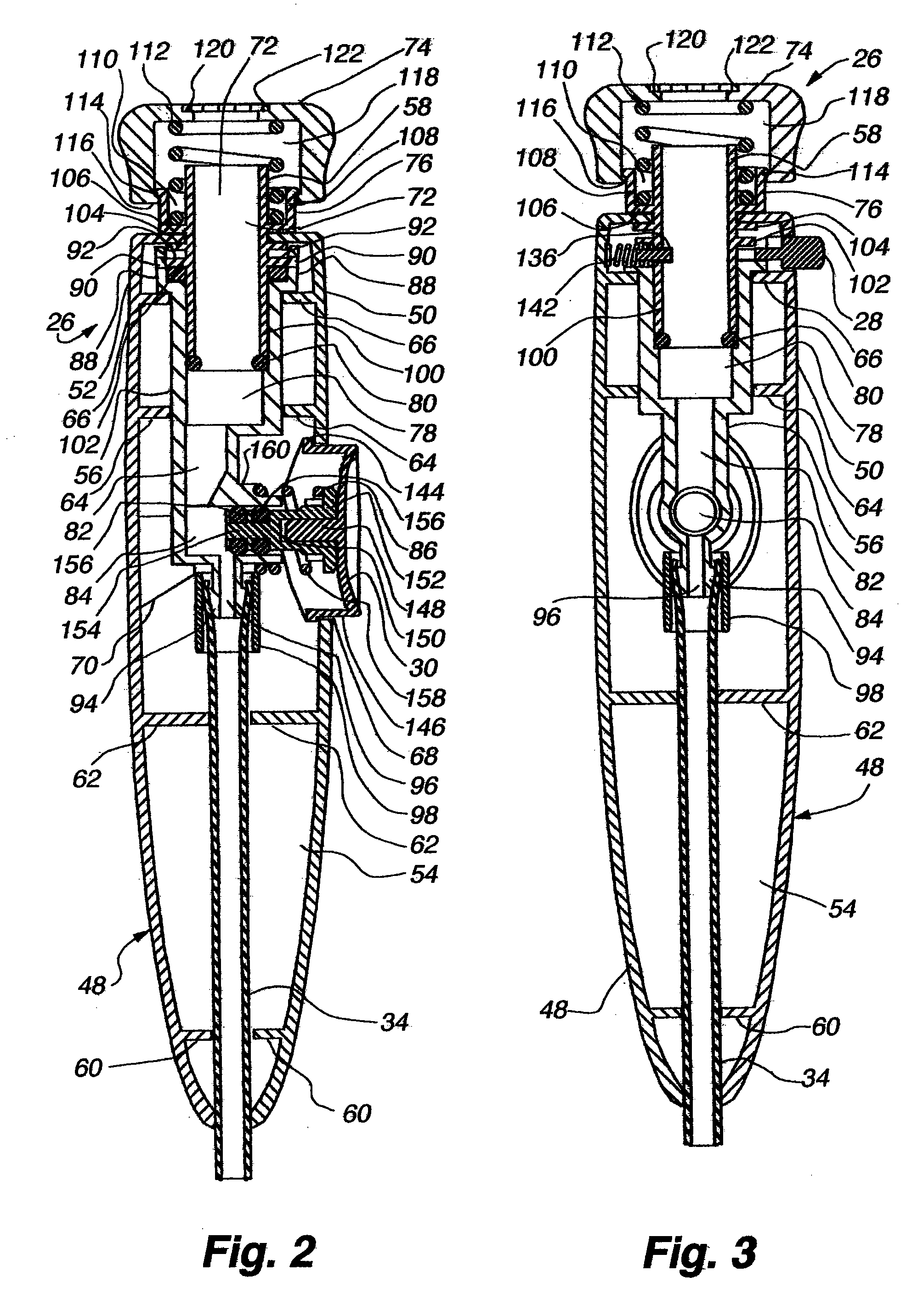

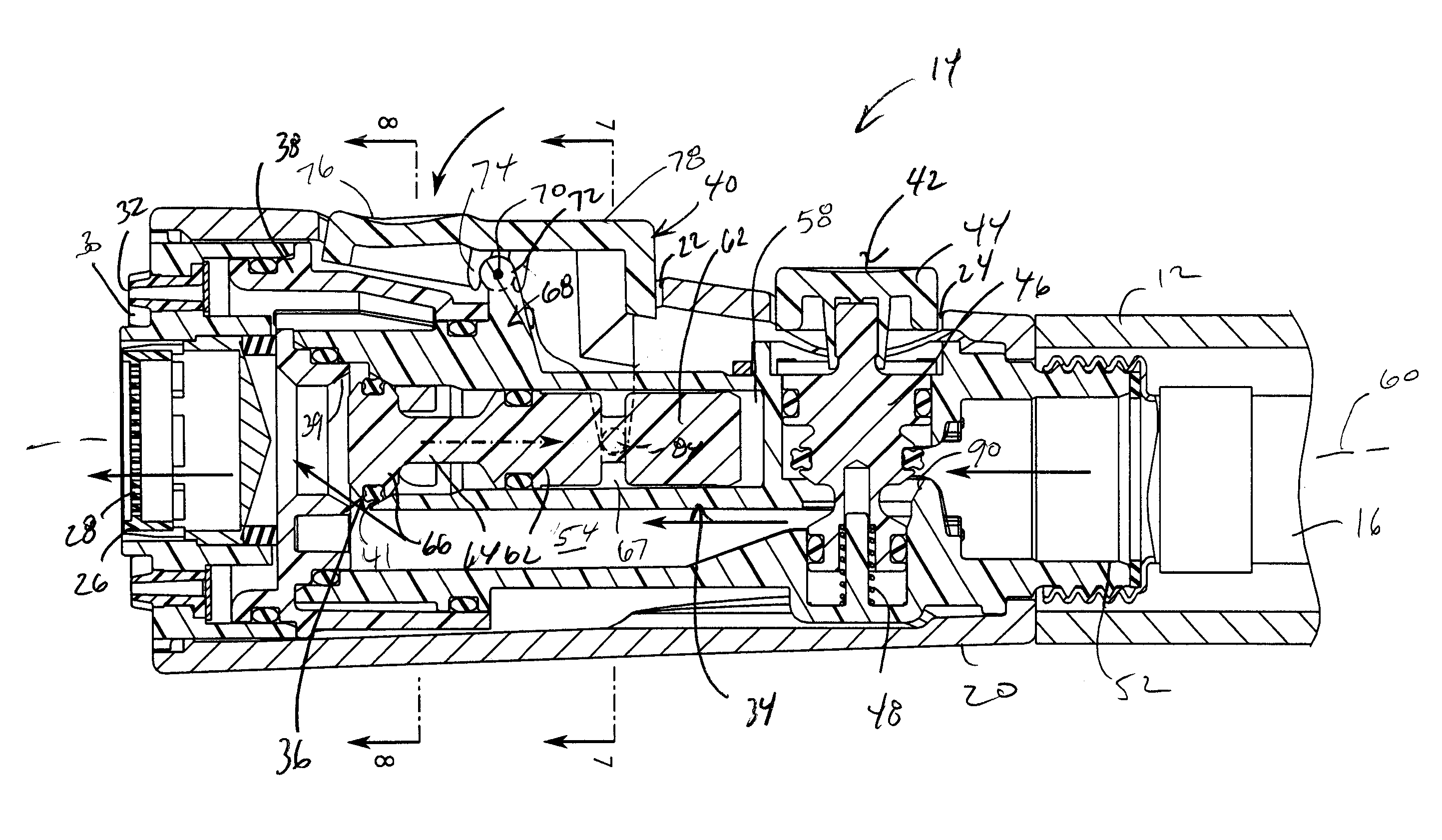

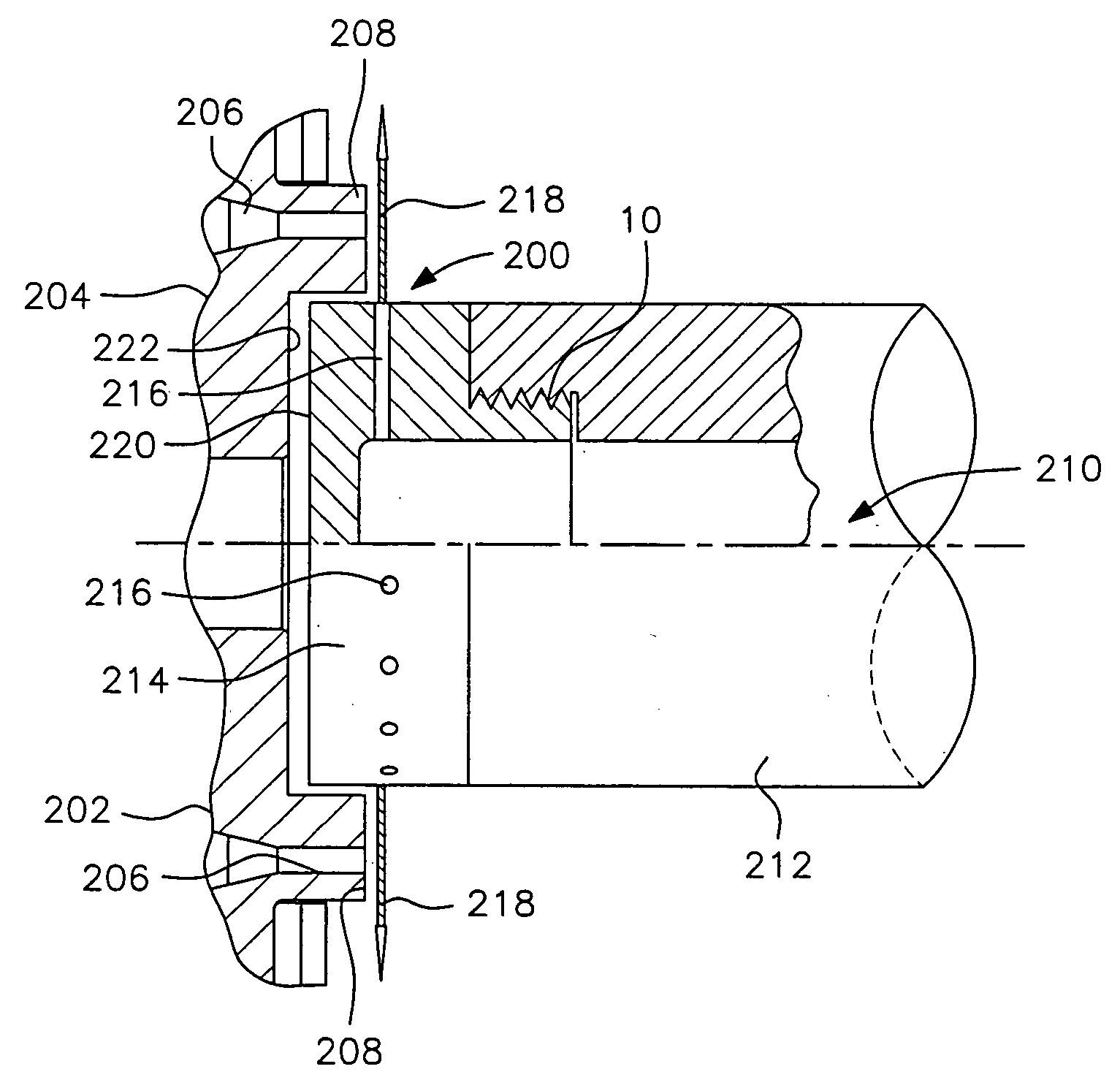

Pump for dental water jet

A pump for an oral irrigator includes a pump chassis, an eccentric end plate movably connected to the pump chassis, a first alignment shaft connected to the pump chassis, a second alignment shaft connected to the eccentric end plate, a first gear rotating around a longitudinal axis of the first alignment shaft, and a second gear engaging the first gear and rotating around a longitudinal axis of the second alignment shaft. By selectively moving the eccentric end plate relative to the pump chassis selectively moves the second gear relative to the first gear.

Owner:WATER PIK INC

Method of manufacturing a water disintegratable non-woven fabric and the water disintegratable non-woven fabric

InactiveUS6451718B1Improve wiping effectNon-fibrous pulp additionSynthetic resin layered productsFiberCarboxymethyl cellulose

A water disintegratable non-woven fabric having excellent water disintegratability and high wet strength can be obtained by a step of forming a fiber web from fibers having a fiber length of 10 mm or less, a step of applying a water jet treatment to the fiber web to obtain a fiber sheet having wet strength of less than 100 g / 25 mm in MD and CD, the wet strength being defined by tensile strength at break of the fiber sheet, as measured by using a tensilon tester with a chuck distance of 100 mm, at a tensile speed of 100 mm / min to the fiber sheet which is cut into 25 mm width and 150 mm length and impregnated with water in an amount 2.5 times the weight of the fiber sheet, and a step of adding at least one binder selected from the group consisting of carboxymethyl cellulose, alkylcellulose, polyvinyl alcohol and modified polyvinyl alcohol to the fiber sheet. The water disintegratable non-woven fabric is sufficiently bulky and has an excellent wiping effect.

Owner:UNI CHARM CORP

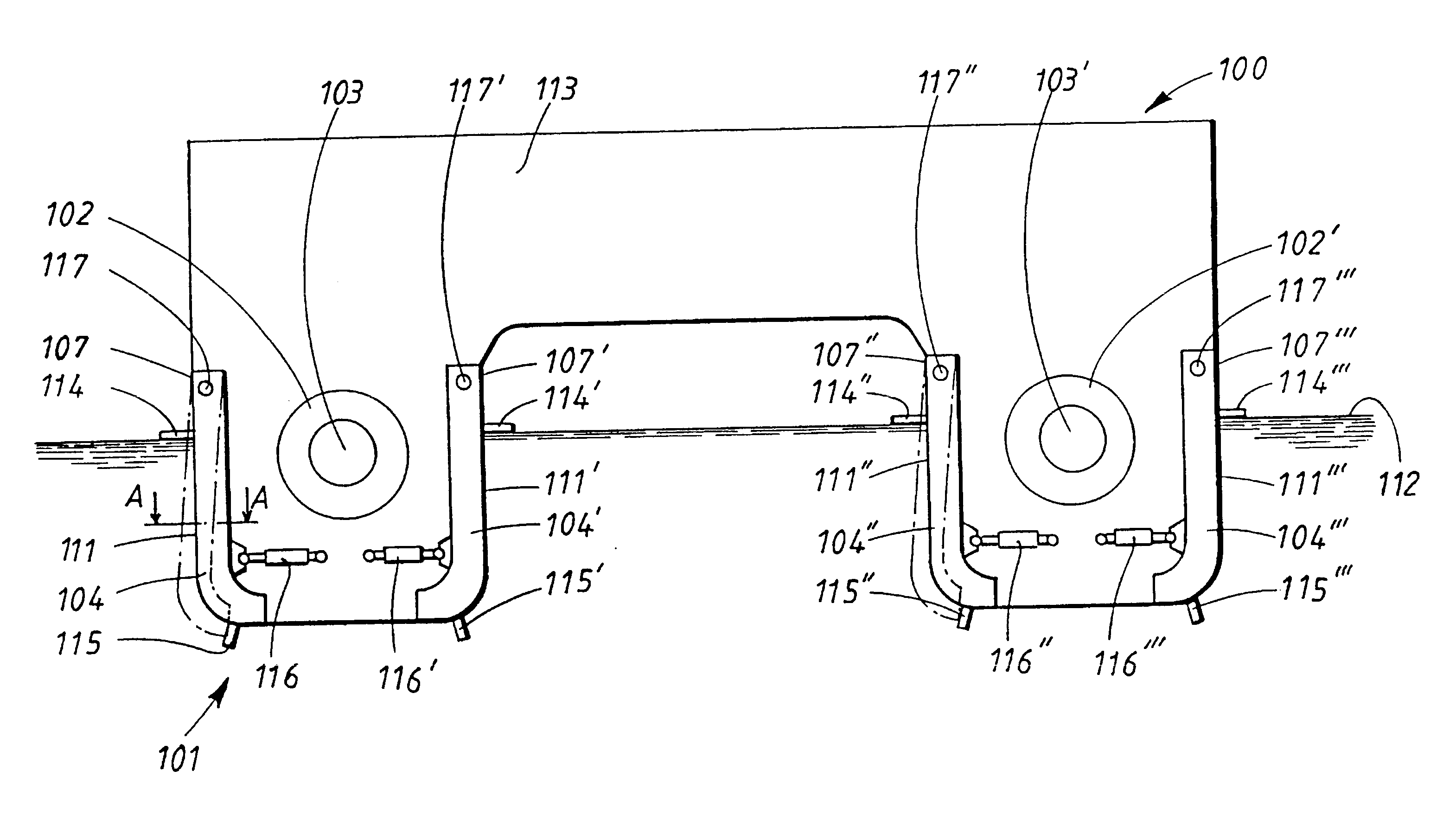

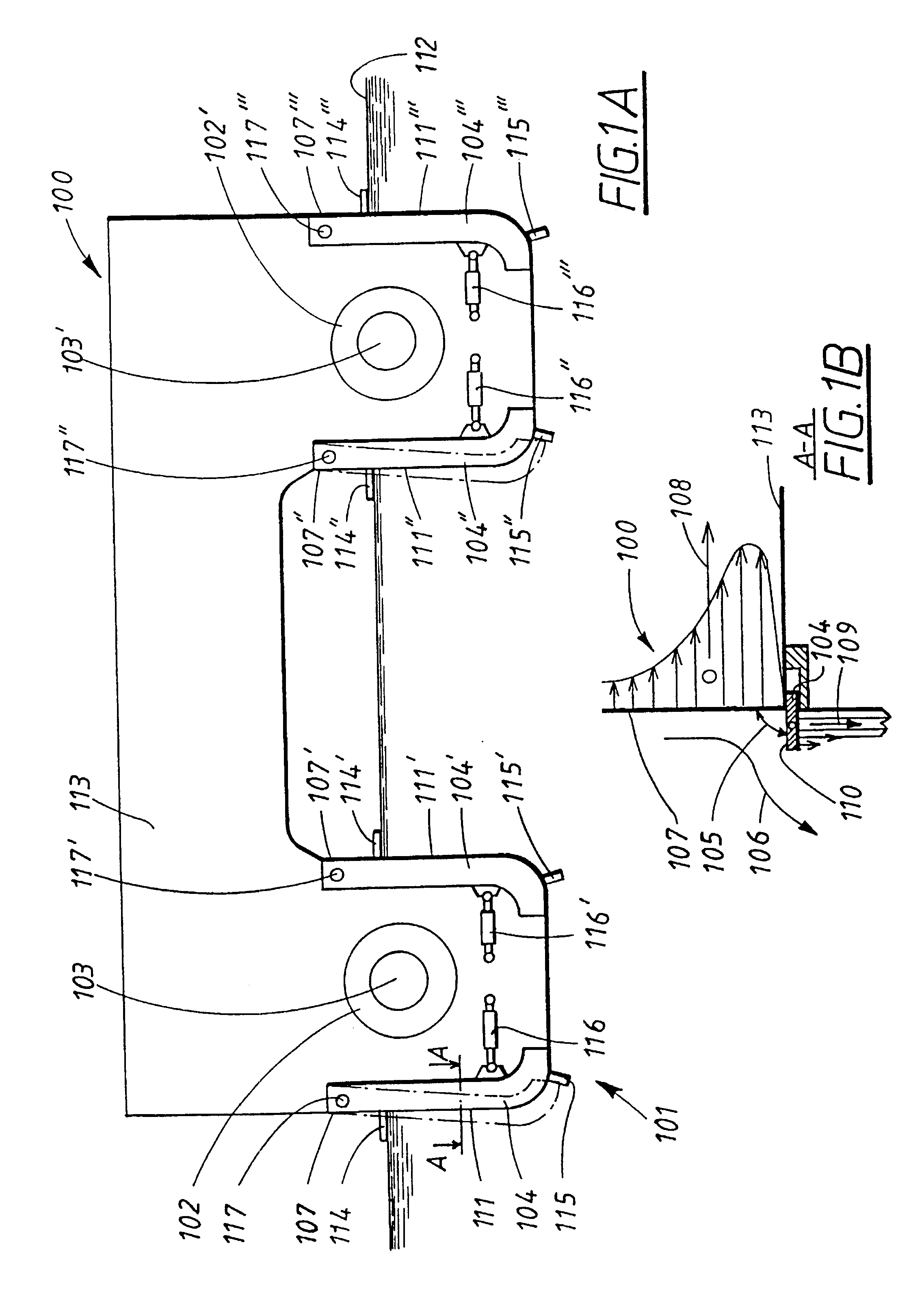

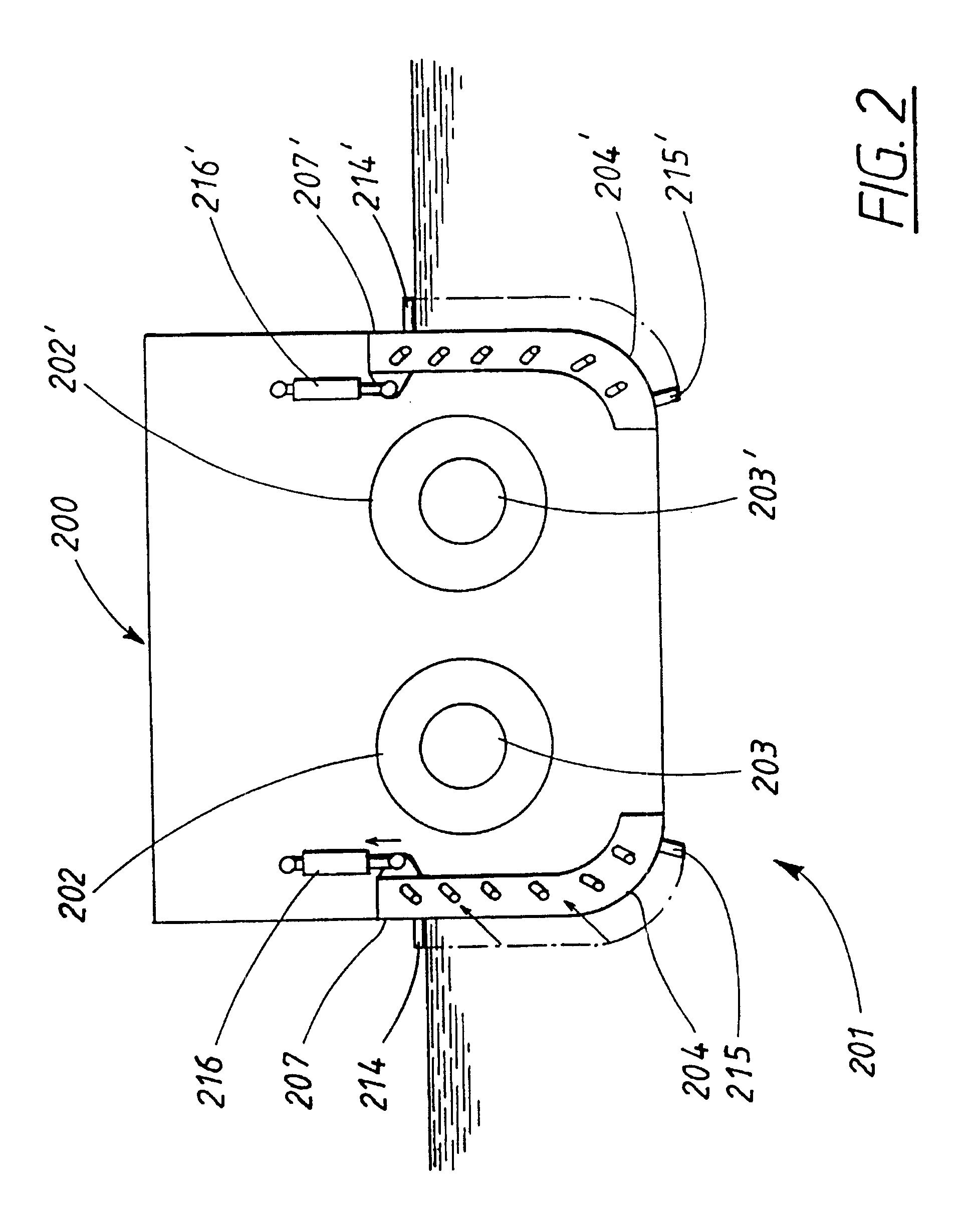

Arrangement and method for dynamic control of the movements and course of a high-speed ship hull

InactiveUS6520104B1Increase pressureReduce energy lossSteering ruddersWatercraft hull designMarine engineeringWater flow

The invention relates to an arrangement and a method for dynamic control of the movements and course of a high-speed vessel hull (100). The arrangement (101) comprises propulsion members (102, 102') and at least one flap member (104, 104', 104'', 104'''). In this connection, the flap member is arranged so as to be capable of being brought adjustably at an angle (105) in relation to a water flow (106) relative to an aft side surface (107) of the vessel hull (100) in order in this connection to generate force components (108, 109) which act on said vessel hull (100) and on a front side (110) of the flap member (104), the flap member (104) being arranged so that the force components (108, 109) generated are directed on the one hand towards the aft side surface (107) of the vessel hull and on the other hand towards the front side (110) of the flap member (104) in the water flow (106) relative to the aft side surface (107) so as in this way to be capable of bringing about a change in the movements and / or course of the vessel hull (100). The invention is particular intended for manoeuvring vessel hulls of high-speed vessels of the type which are provided with water-jet drive, that is to say vessels with a water-free stem while in motion, but can also be applied to other types of high-speed vessels.

Owner:LA ME

Pool cleaner with high pressure cleaning jets

InactiveUS20080236628A1Easy to cleanKeep for a long timeGymnasiumCleaning using gasesHigh pressureJet stream

A pool cleaning apparatus includes a housing and a pump for drawing water and debris through an intake port into a filter. A jet-valve housing having a jet valve flap is mounted over the pump to direct a propulsion jet stream from the pump to move the cleaner in a forward direction. A cleaning nozzle is mounted over each of the front and rear portions of the housing, and a pressurized water jet stream is directed at a first pool surface beneath the cleaner through the front end nozzle while moving in a forward direction. When the cleaner engages a second pool surface substantially perpendicular to the first surface, propulsion outlets of the jet valve housing are partially closed to redirect a portion of the propulsion jet stream to the front-end nozzle to lift the front end of the cleaner off the first surface. When the front end of the cleaner disengages from contact with the second surface, the propulsion outlets open to permit the propulsion jet stream to propel the cleaner along the second surface.

Owner:AQUA PRODS

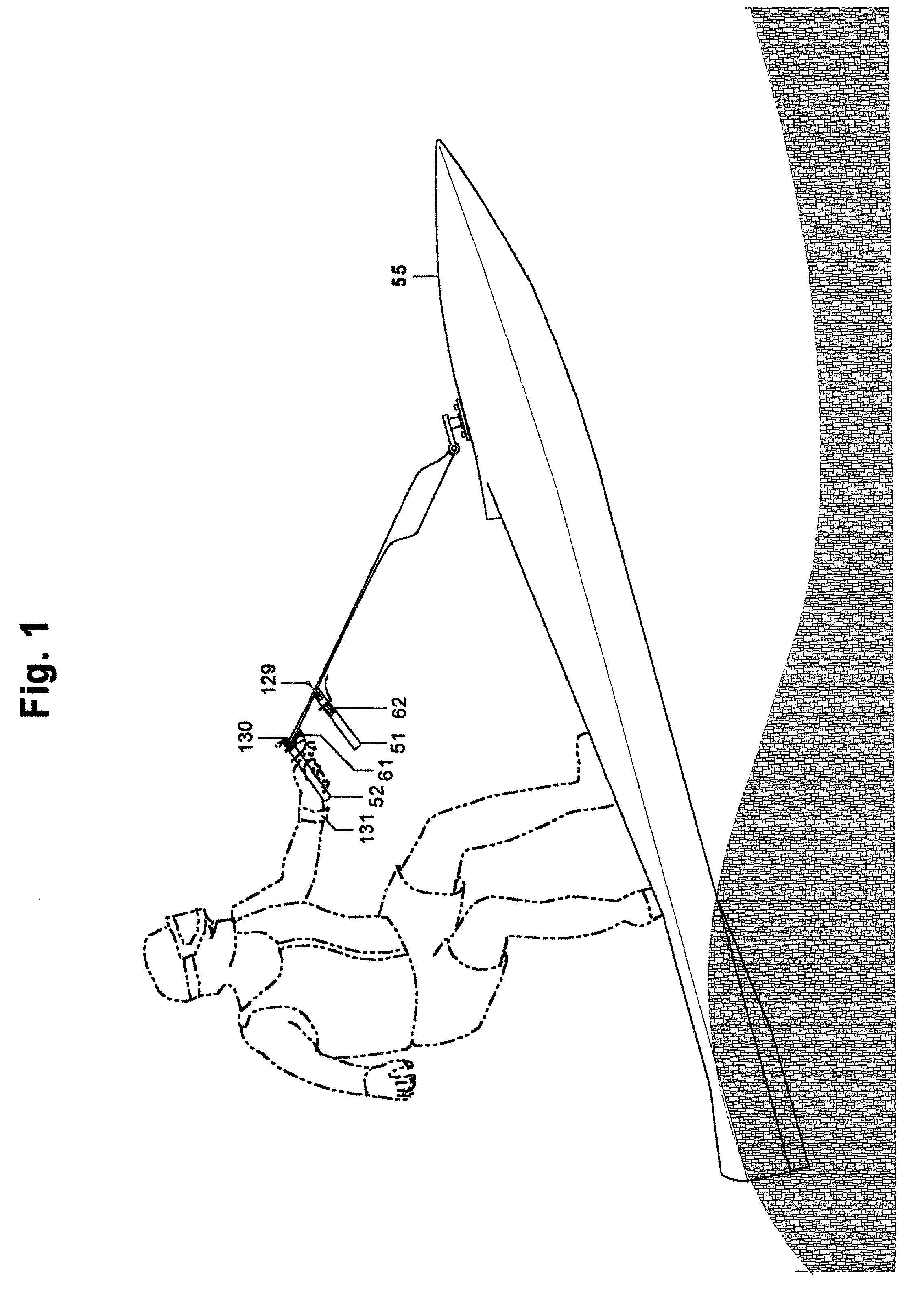

Drive and control system for watercraft

InactiveUS20010042498A1High possible performance and overall efficiency and overall utilityLeast possible vehicle emissionWaterborne vesselsWater sport boardsPower stationFlight vehicle

A surfboard-based powered water craft is propelled by gas or electric power plant. A water jet pump supplies water under pressure, which is exhausted through a steering nozzle. A steering shaft, carried by the surfboard-based body, pivots in response to movement of a steering arm. The steering arm pivots about a vertical axis and a horizontal axis. The weight of the power plant is carried forward the center, whereby a rider on top of the surfboard based body tends to balance the weight of the power plant.

Owner:BURNHAM DANIEL J

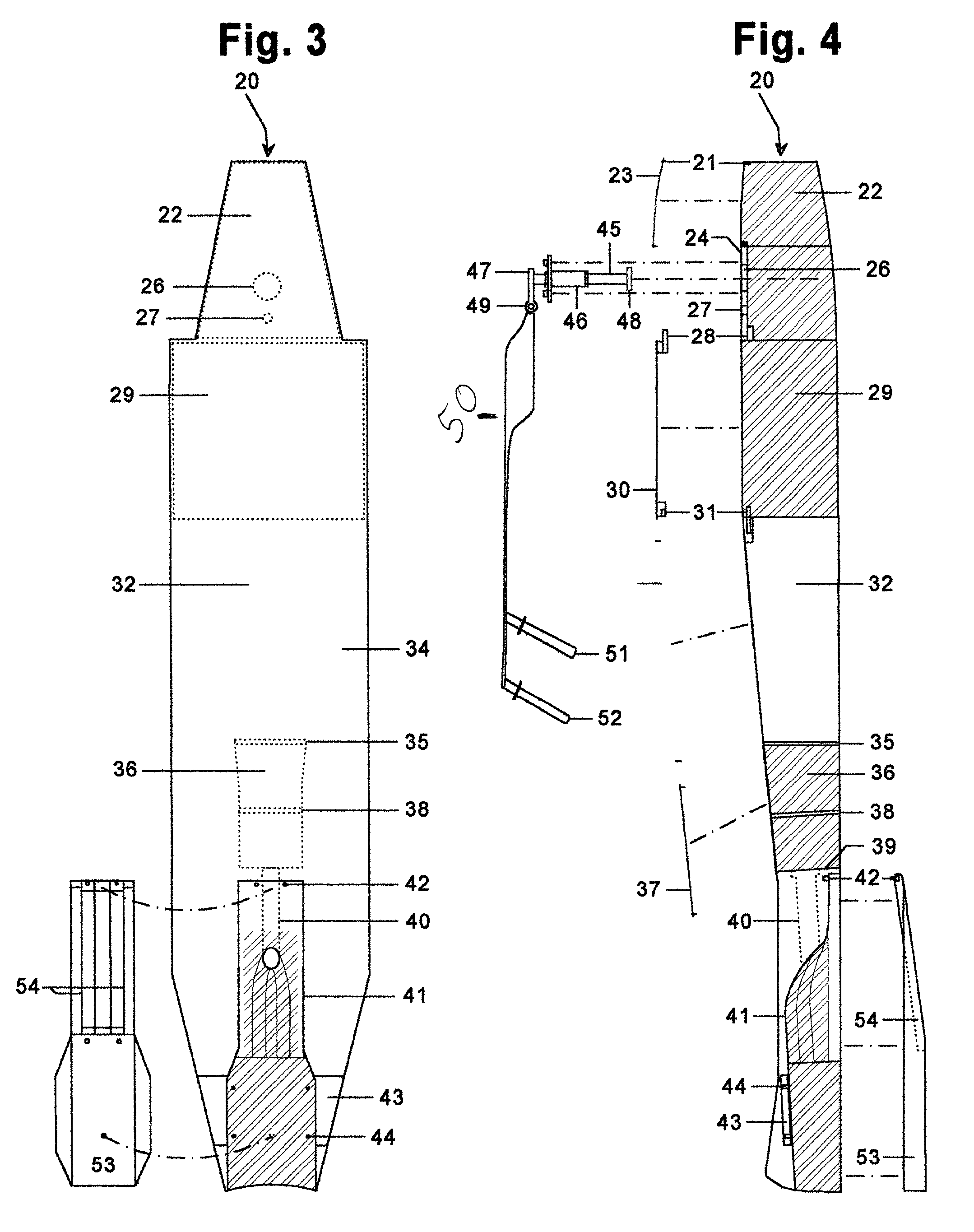

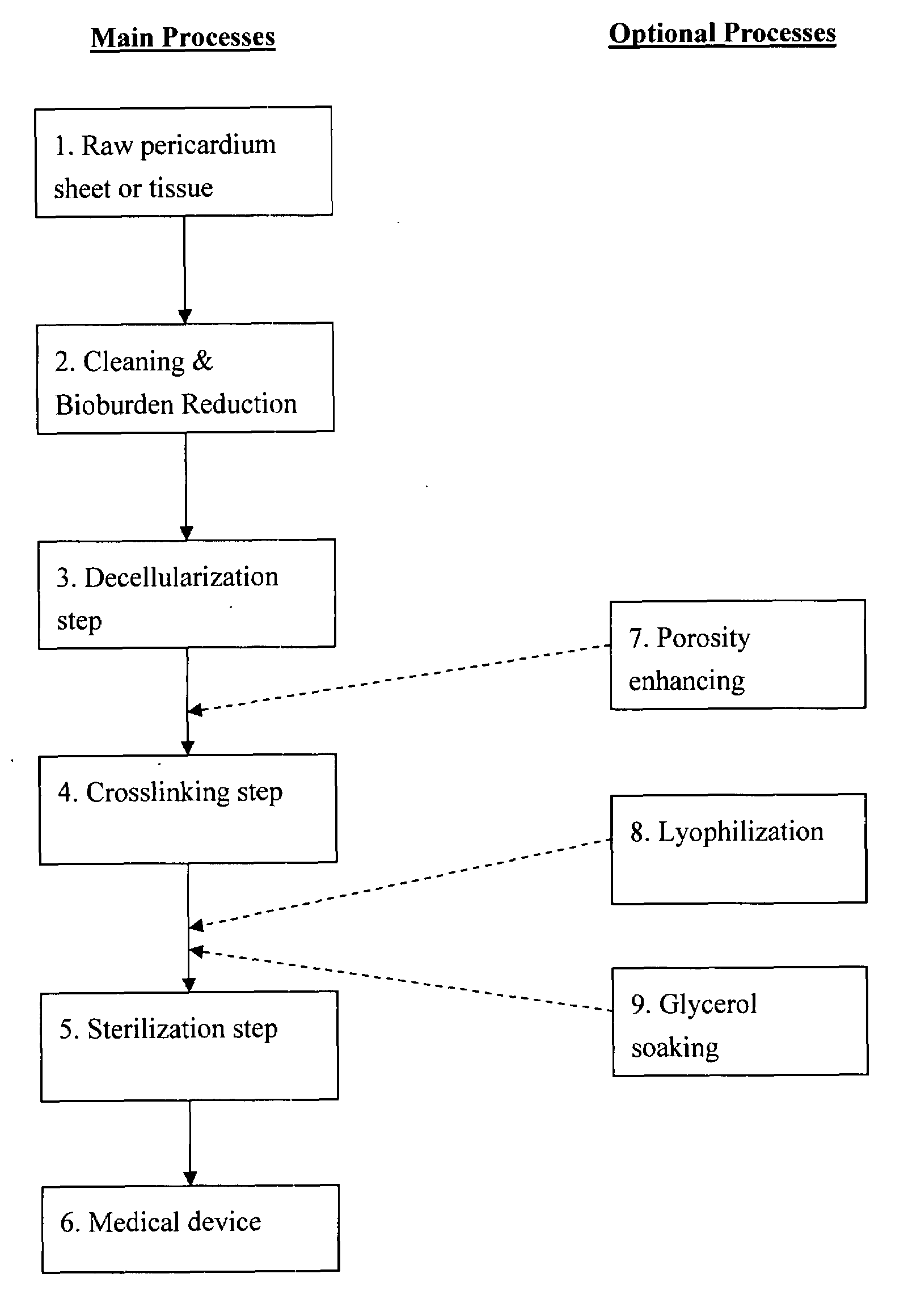

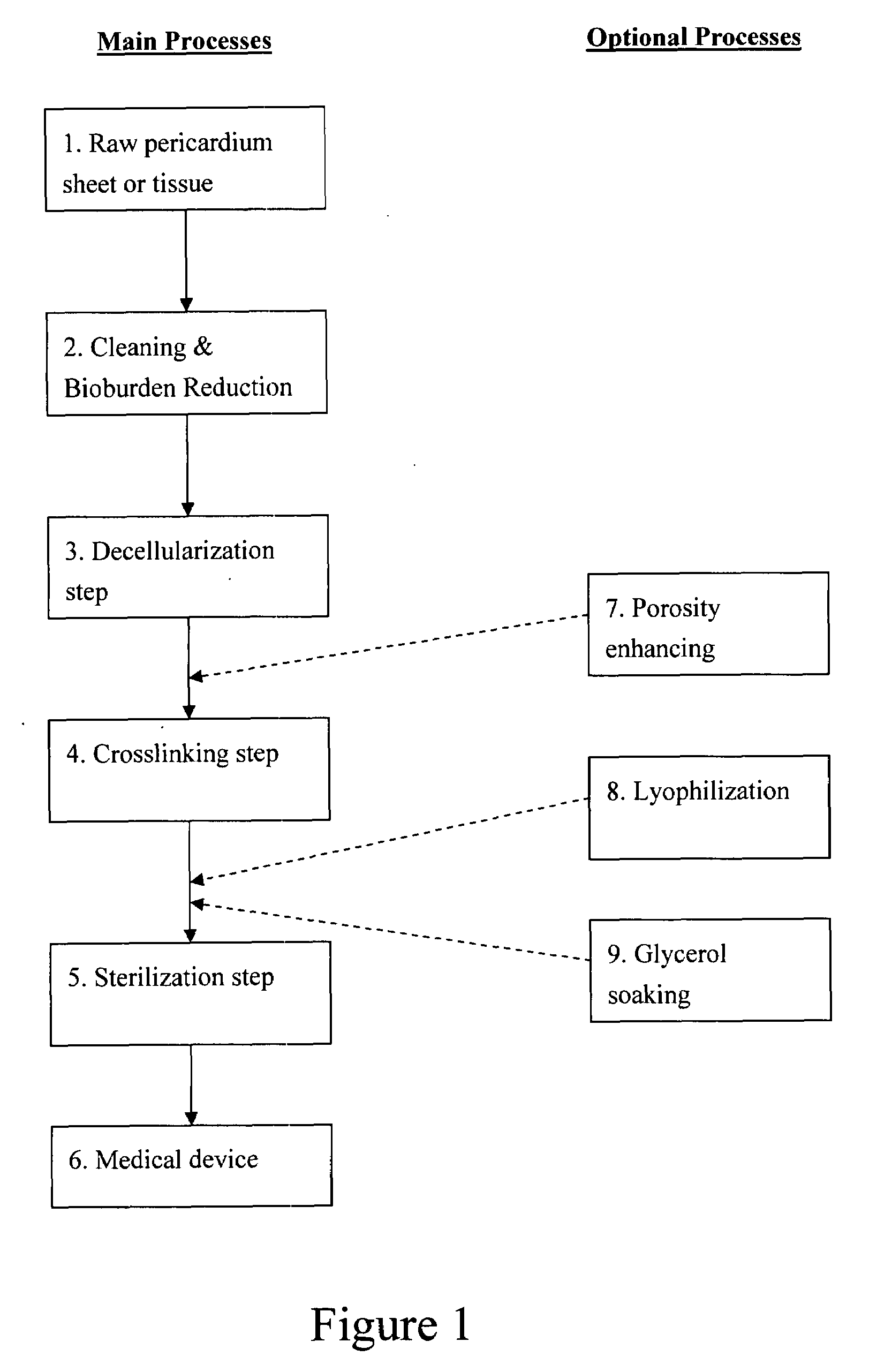

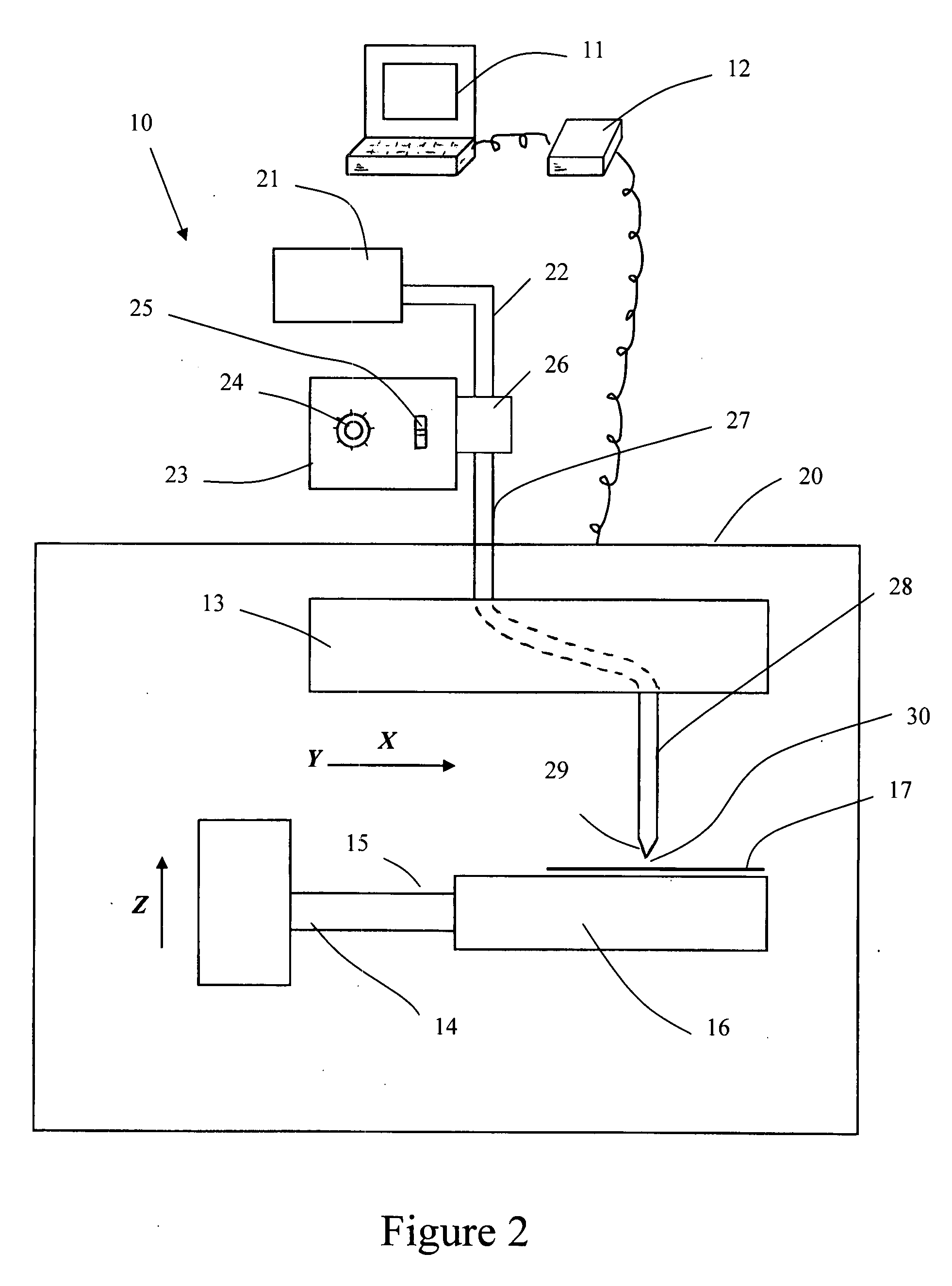

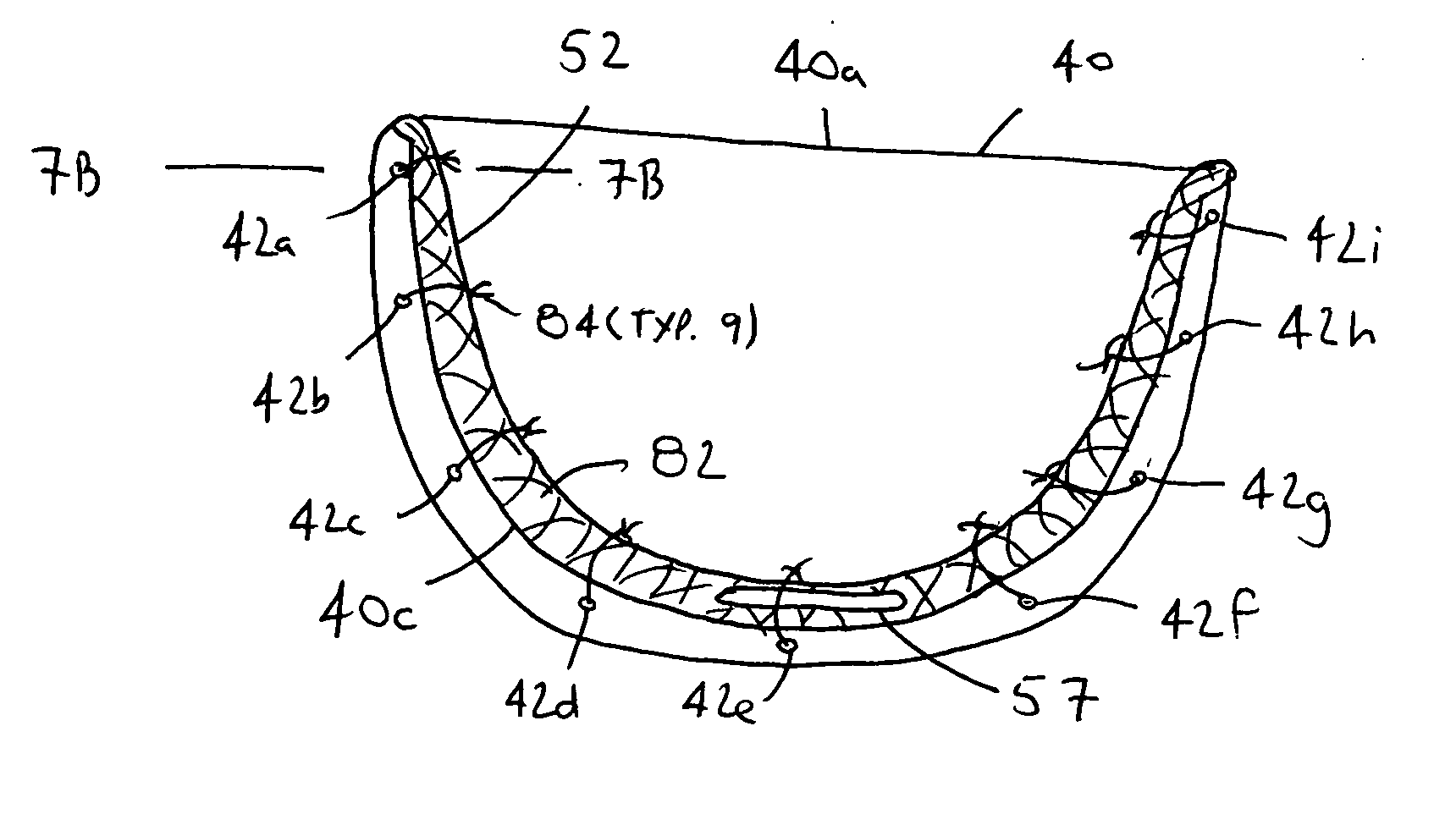

Pericardial tissue sheet

InactiveUS20080195230A1Low antigenicityLow immunogenicityFluid jet surgical cuttersSurgical instruments for heatingThermal energyTissue material

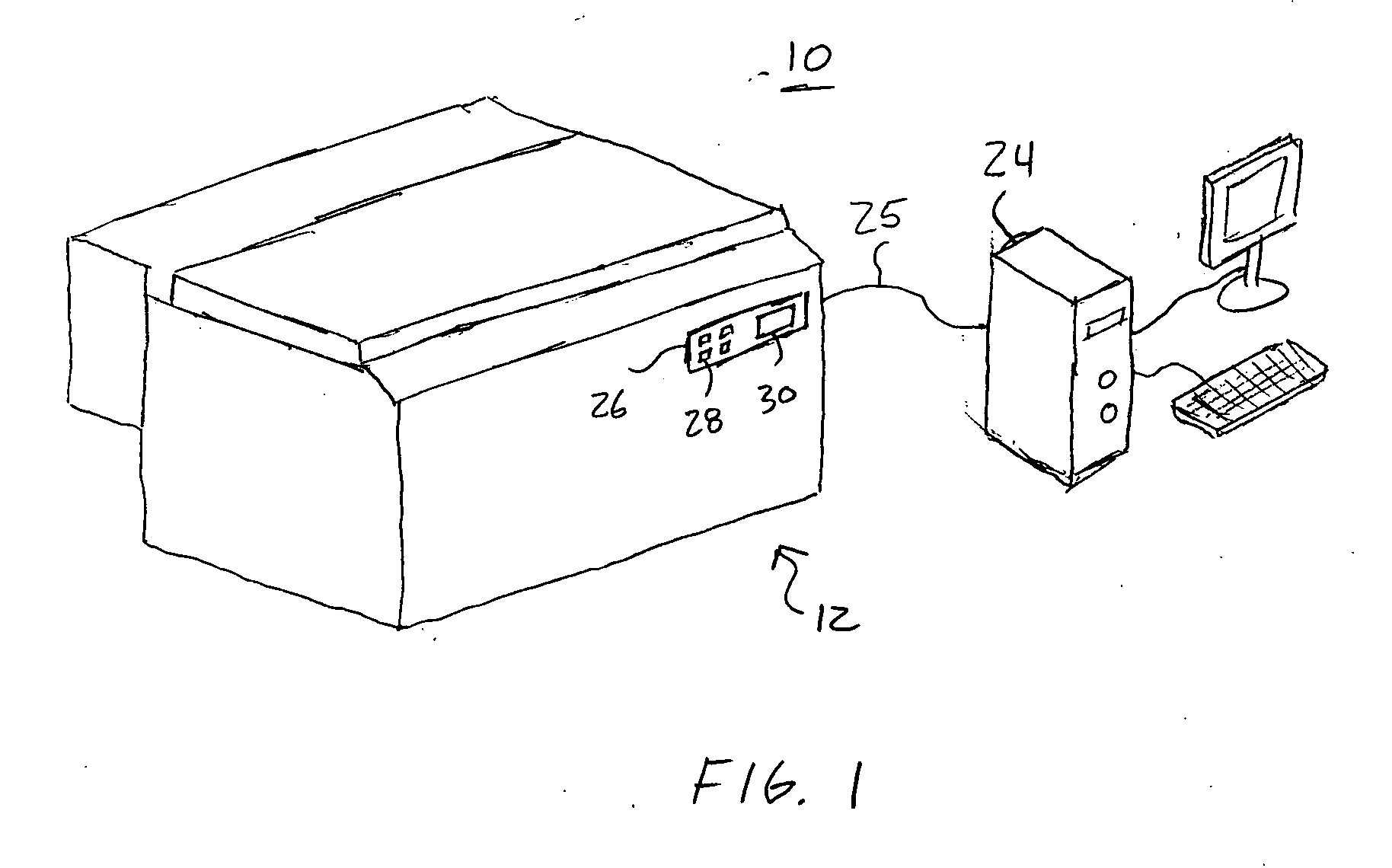

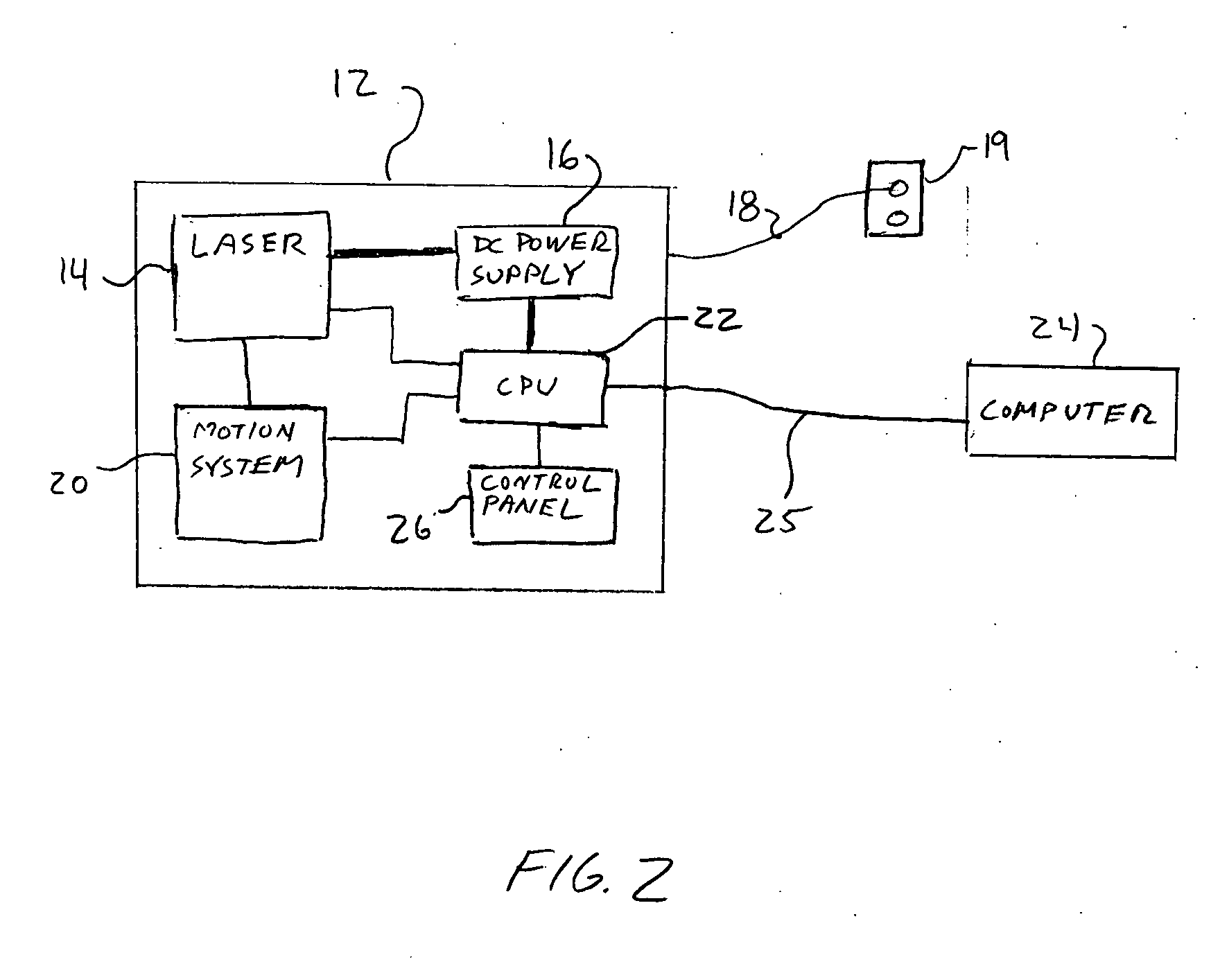

A method of cutting tissue material of biology origin employs a plotted water-jet or RF cutting system. The cutting system is computer controlled and includes a water-jet or RF cutting means combined with a motion system. The cutting energy is selected so that communication of thermal energy into the segment beyond the edge is minimized to avoid damaging the segment adjacent the edge.

Owner:QUIJANO RODOLFO C +1

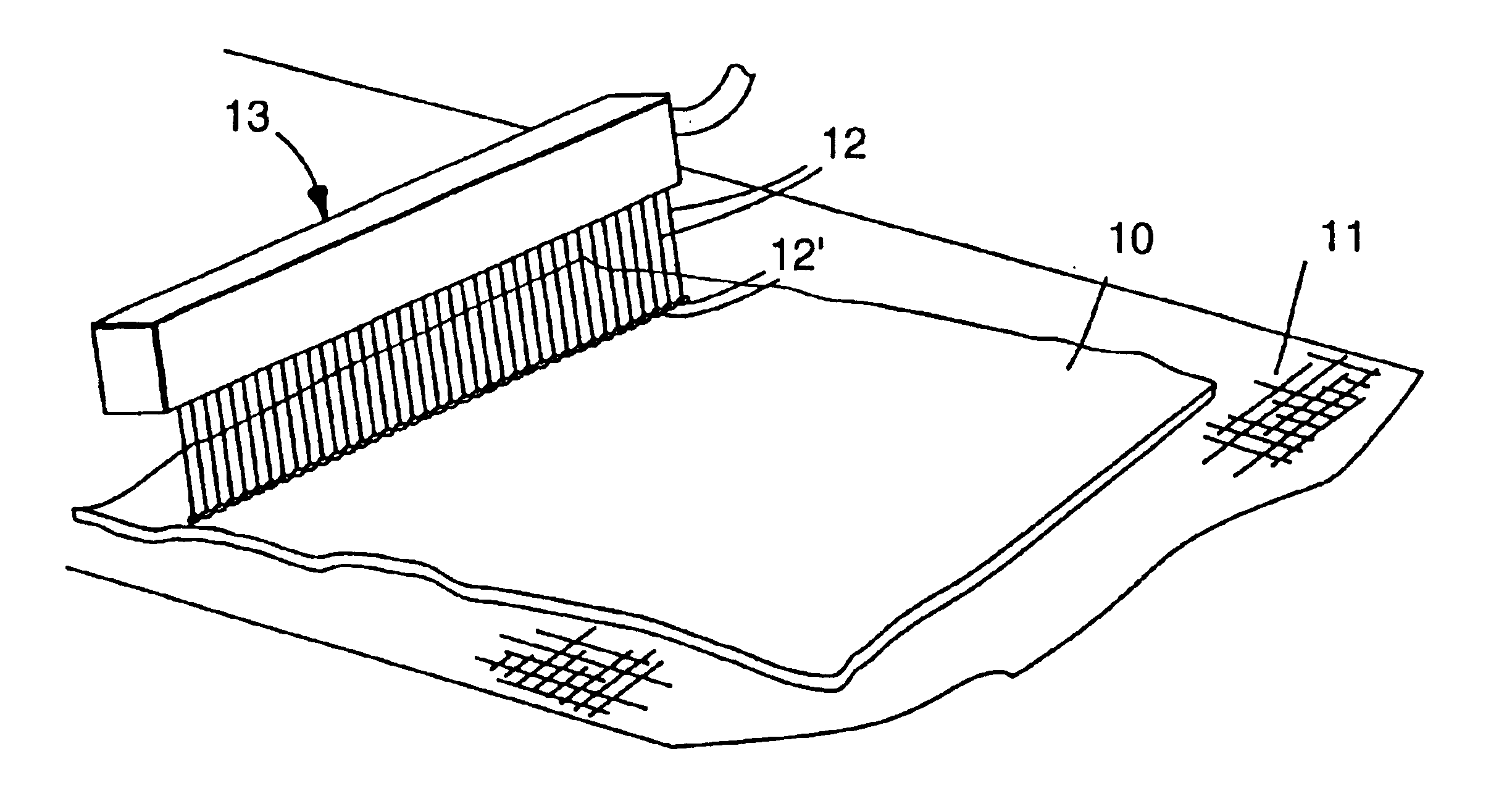

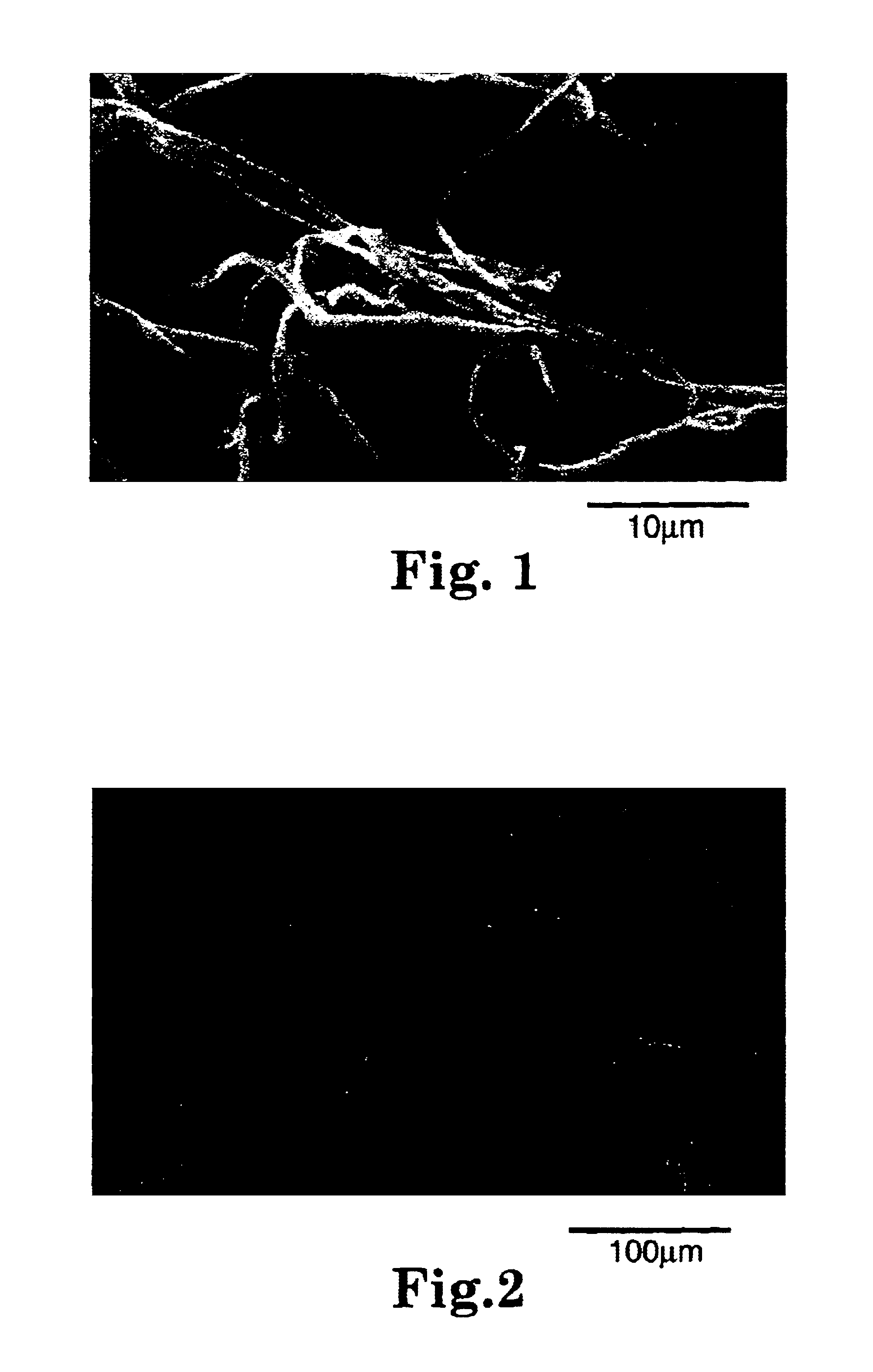

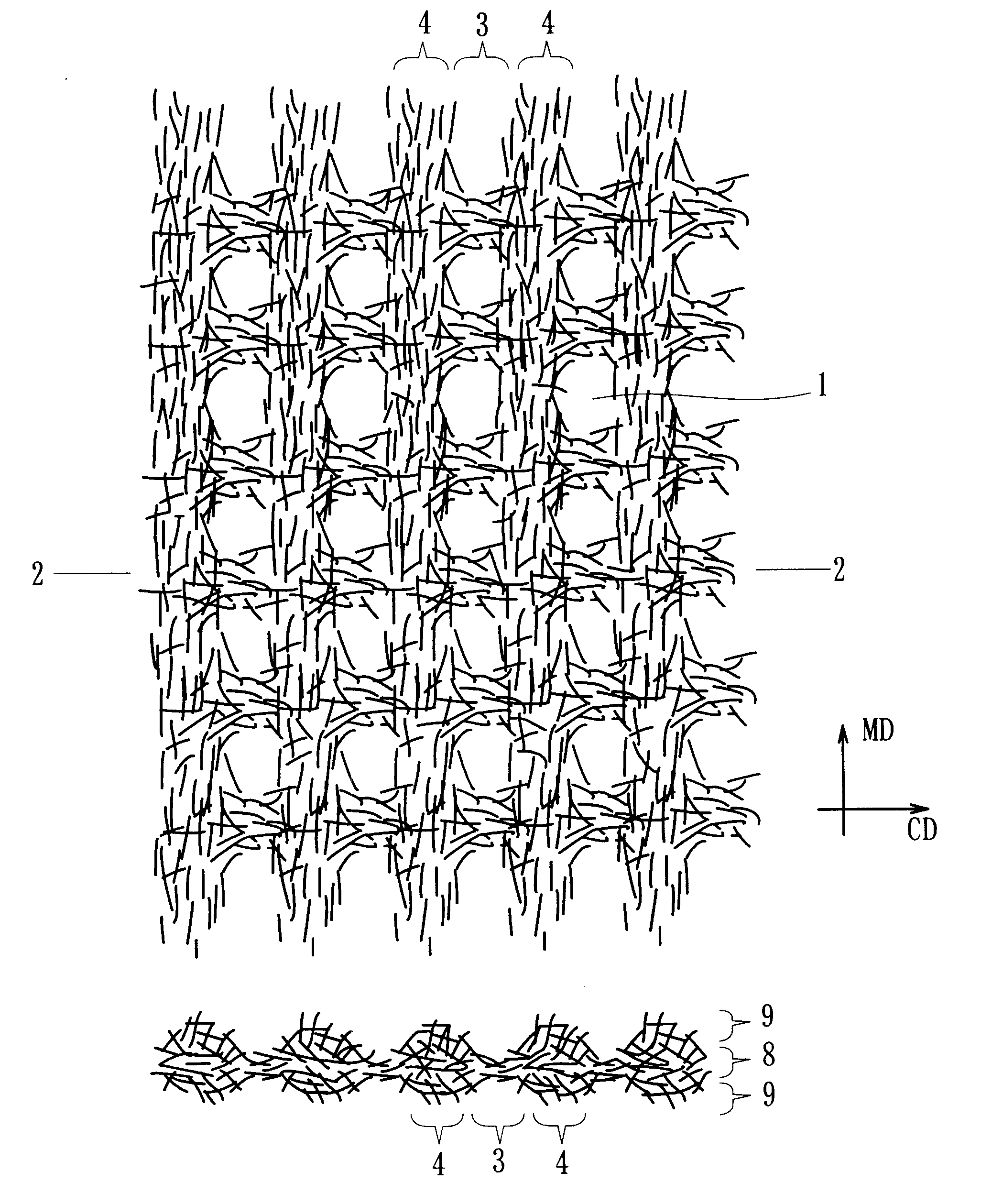

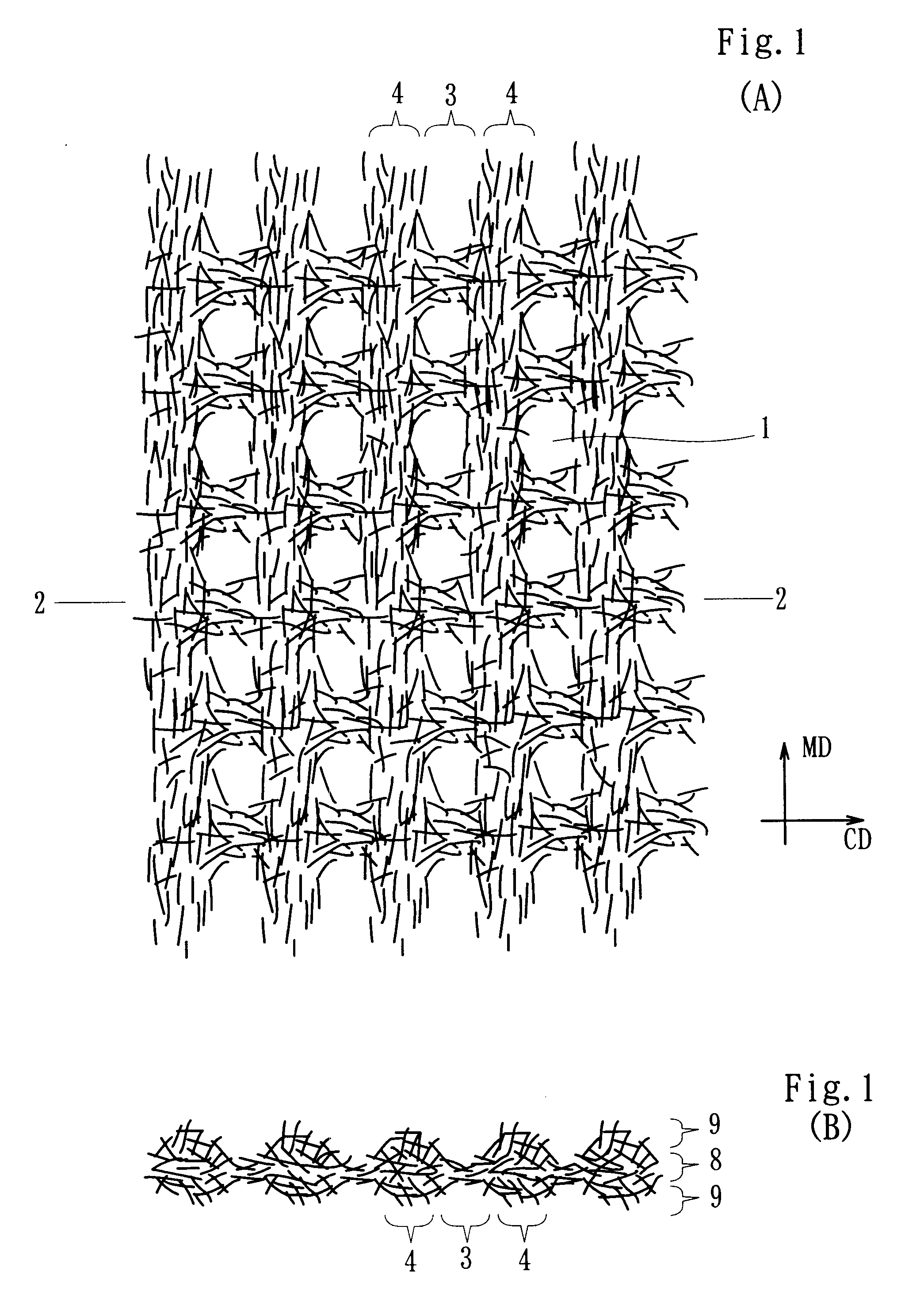

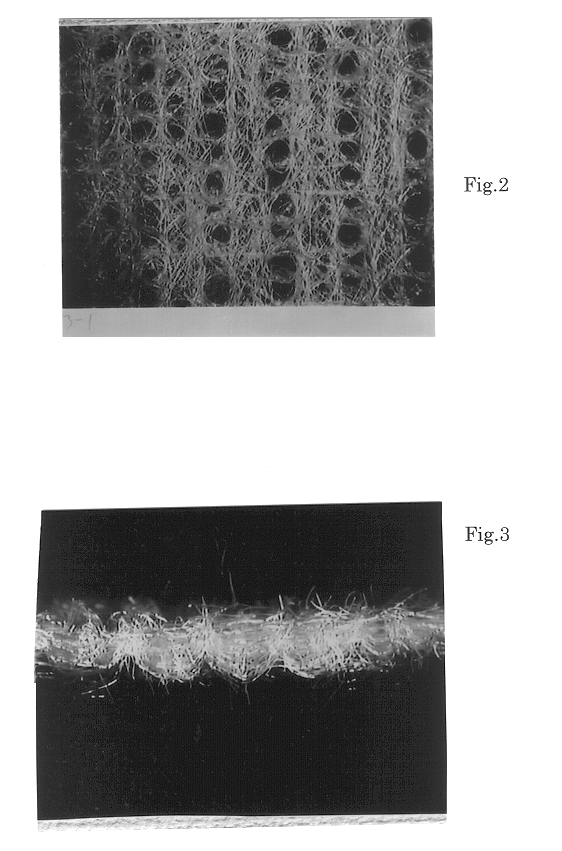

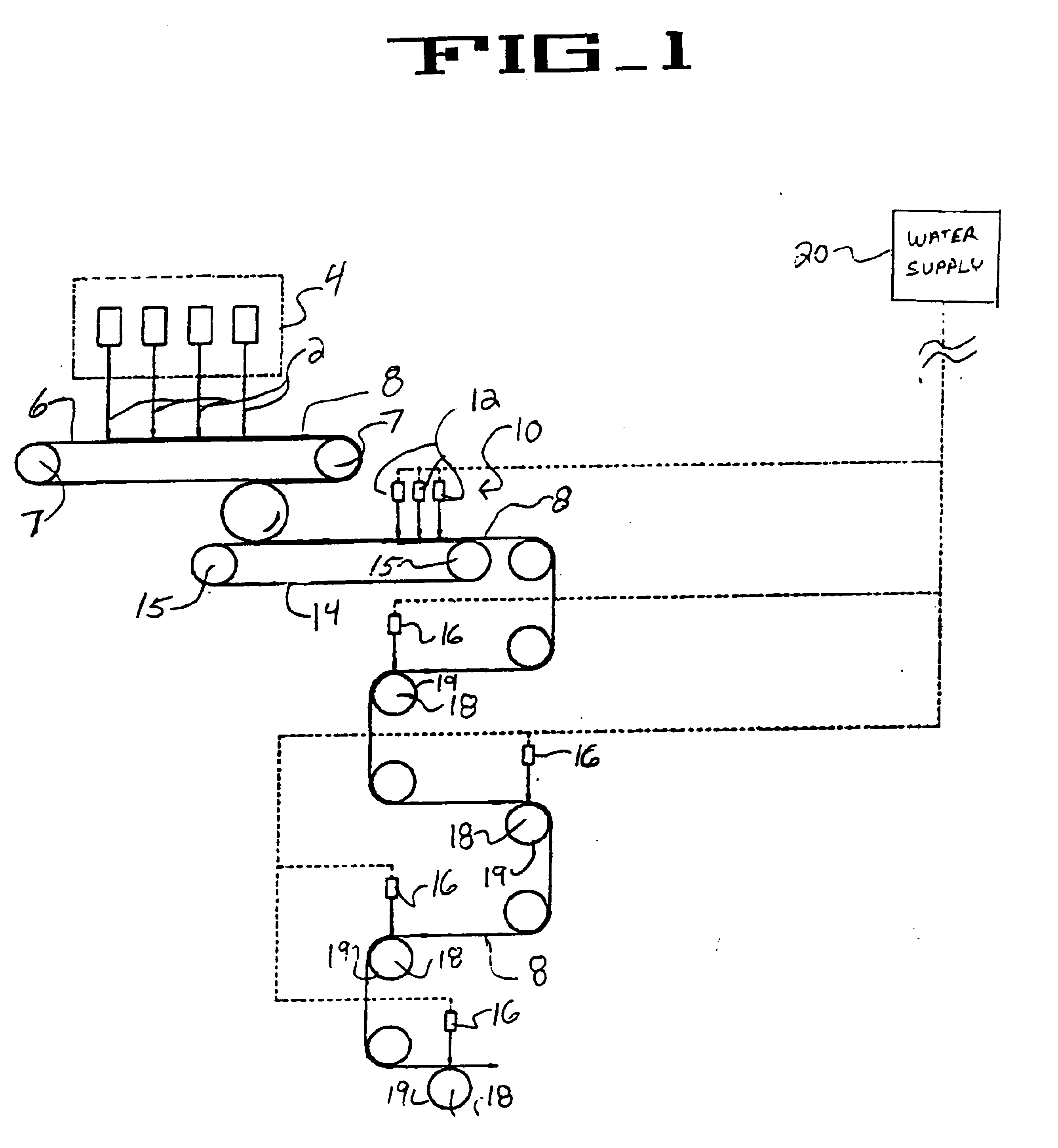

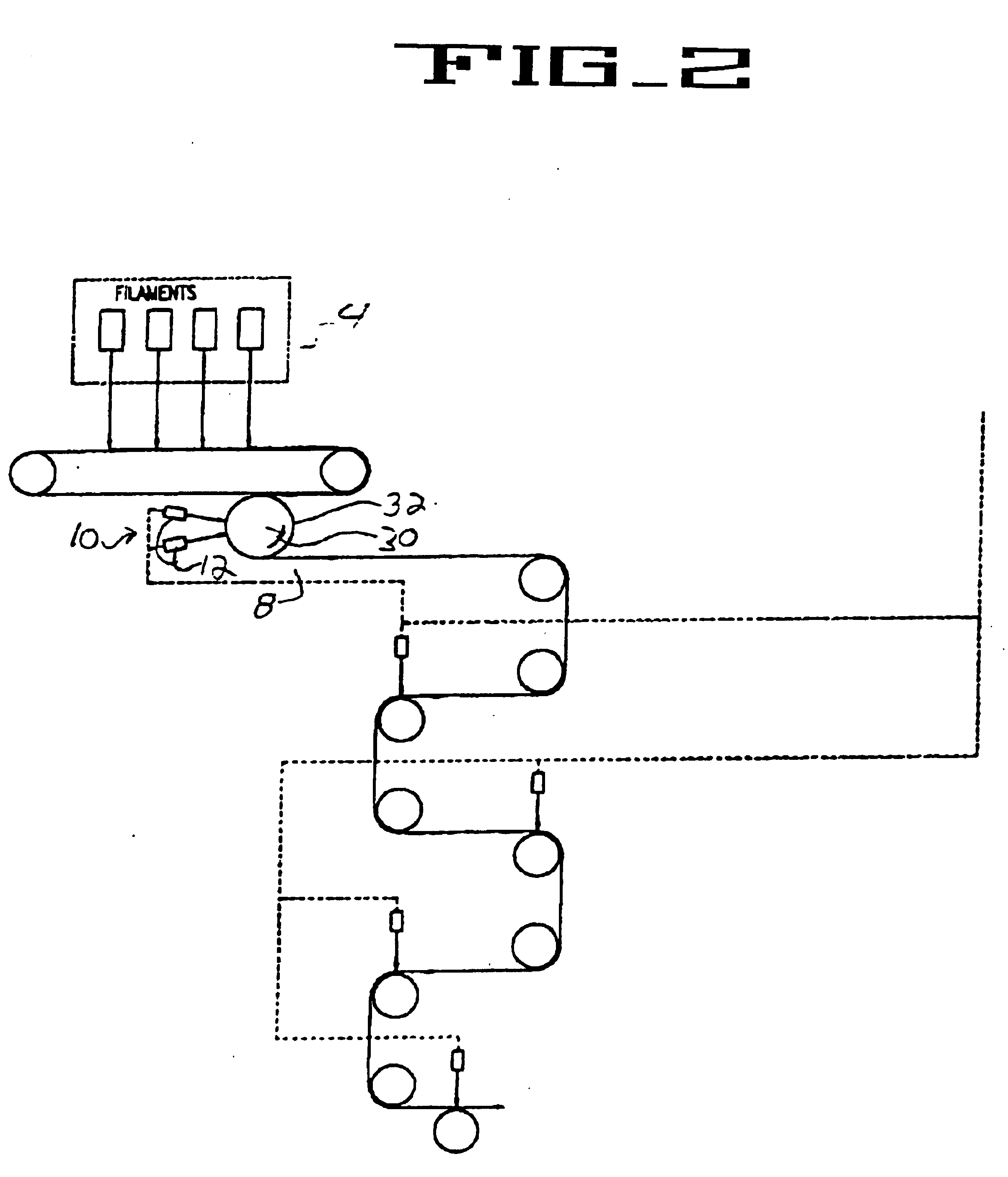

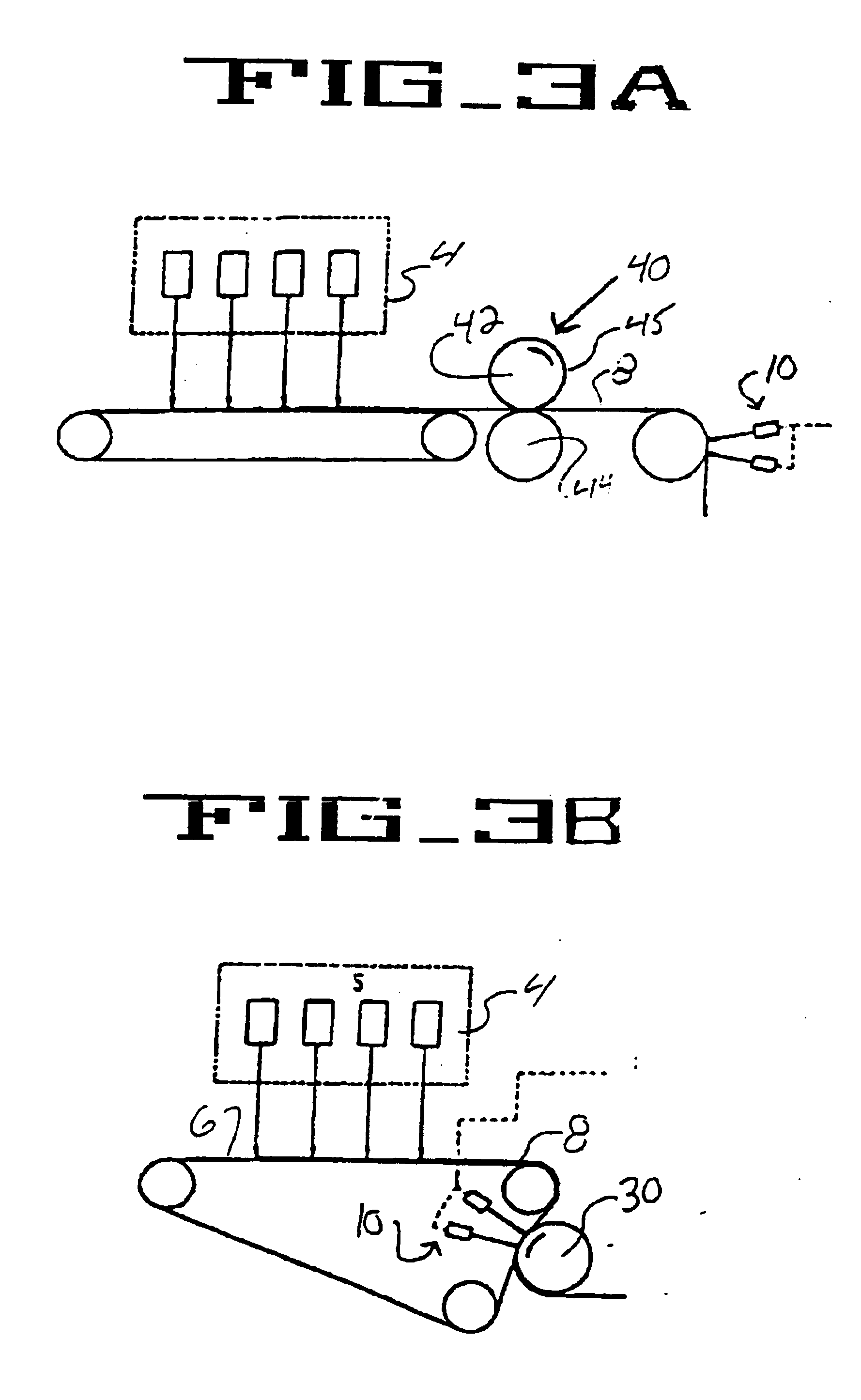

Hydroentanglement of continuous polymer filaments

InactiveUS6903034B1Differing bonding temperatureEasy to produceSynthetic resin layered productsWoven fabricsImage transferEngineering

A nonwoven fabric comprises continuous polymer filaments of 0.5 to 3 denier that have been hydroentangled in a complex matrix for interconnecting filament loops, and that is otherwise substantially free of knotting, or of otherwise wrapping about one another. A process for making a nonwoven fabric comprises continuously extruding polymer filaments of 0.5 to 3 denier onto a moving support, pre-entangling the filaments with water jets, and entangling the filaments with a second set of water jets on a three-dimensional image transfer device. An apparatus for making a nonwoven fabric comprises means for continuously extruding substantially endless polymer filaments of 0.5 to 3 denier onto a moving support to form an unbonded web, a pre-entangling station for entangling the web with a plurality of water jets, and a plurality of water jets for final entanglement of the filament web on a three-dimensional image transfer device. In another aspect of the present invention, plural precursor webs, each comprising polymeric filaments, can be employed to form a laminated nonwoven fabric.

Owner:AVINTIV SPECIALTY MATERIALS INC

Full-voltage dental water jet

InactiveUS20130295520A1Easy to useImprove securityTeeth fillingTooth rinsingElectricityControl system

A full-voltage dental water jet of the invention includes a base, a pump, a suspension stand, a reservoir and a microcomputer control system. The base has a lower case and an upper case. The pump disposed in the lower case has an inlet and an outlet. The suspension stand having at least three engaging portions, a heat dissipating aluminum plate, a first standing portion and a second standing portion is disposed between the pump and the lower case. The reservoir is disposed above the base. The microcomputer control system is disposed in the upper case. The microcomputer control system has the function of adapting the dental water jet to the universal input voltage. In addition, the suspension stand made of the silica gel material reduces the operation noise and the vibration of the pump.

Owner:MEGAHOME

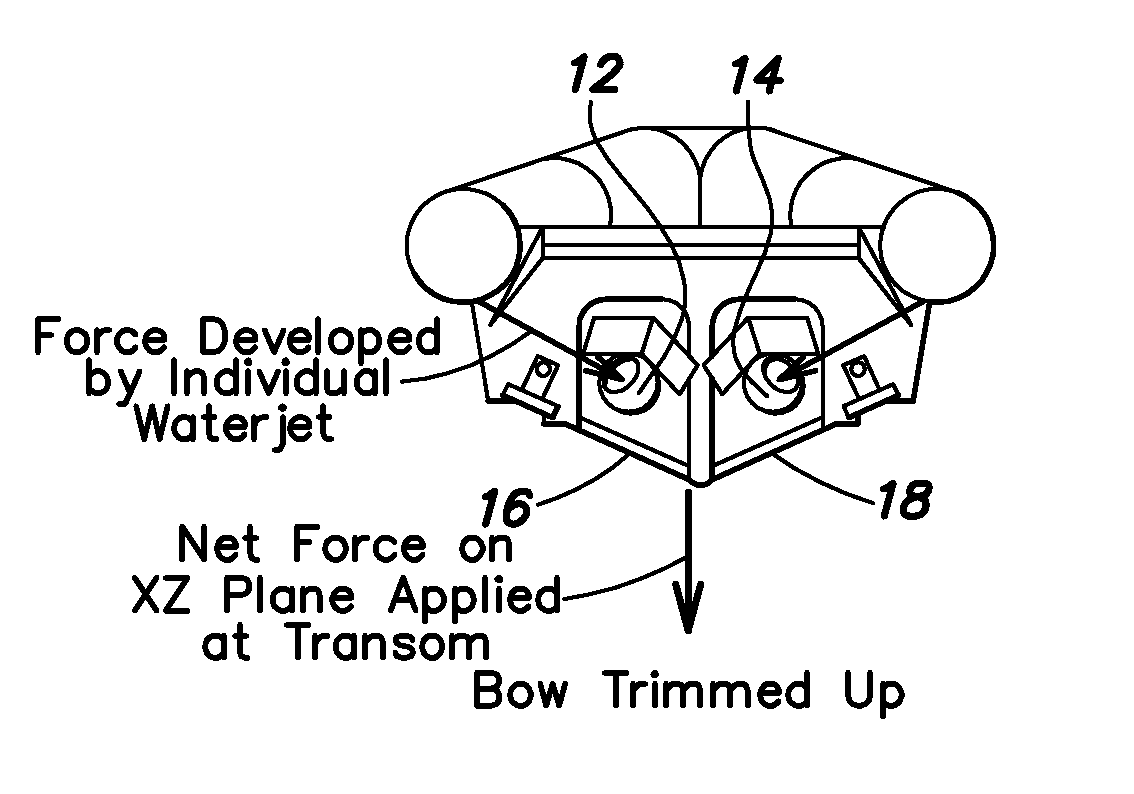

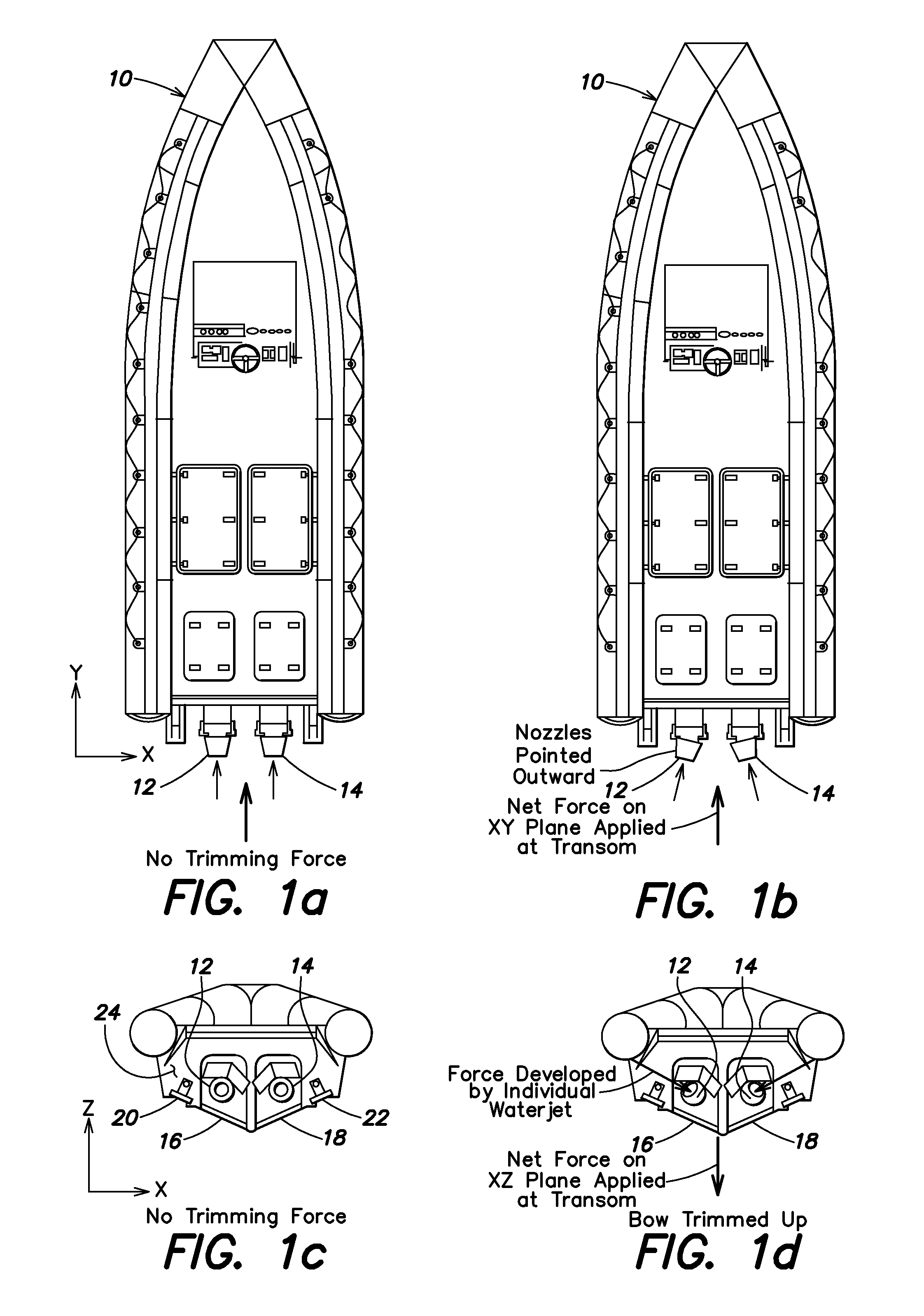

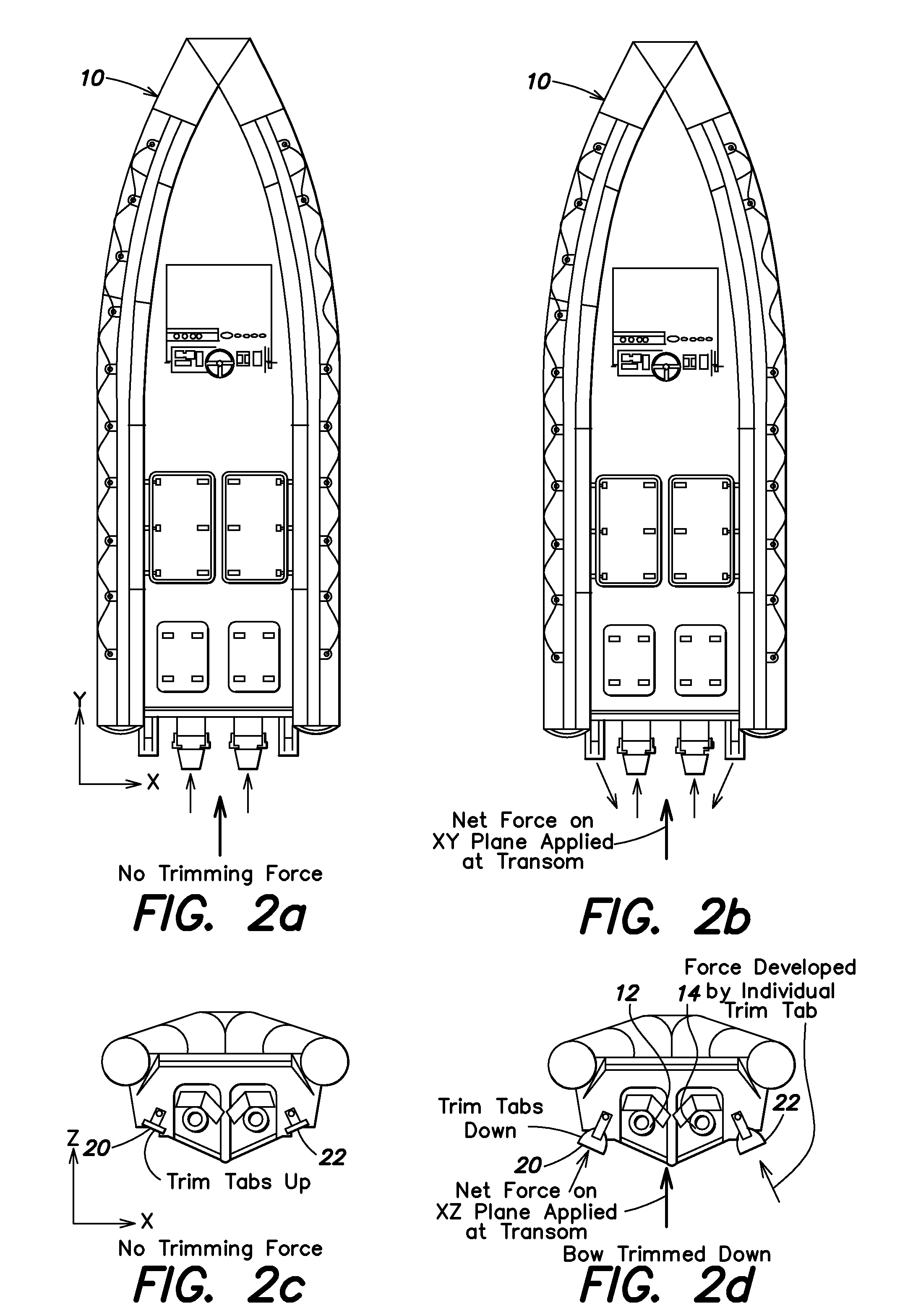

System and method for controlling a waterjet driven vessel

A method for controlling a marine vessel having first and second steering nozzles and first and second trim deflectors comprises generating at least a first set of actuator control signals and a second set of actuator control signals. The first set of actuator control signals is coupled to and controls the first and second steering nozzles, and the second set of actuator control signals is coupled to and controls the first and second trim deflectors. The acts of generating and coupling the first set of actuator control signals and the second set of actuator control signals result in inducing any of a net yawing force, a net rolling force, and a net trimming force to the marine vessel without inducing any other substantial forces to the marine vessel by controlling the first and second steering nozzles and the first and second trim deflectors. Also disclosed is a system for controlling a marine vessel.

Owner:MORVILLO ROBERT A

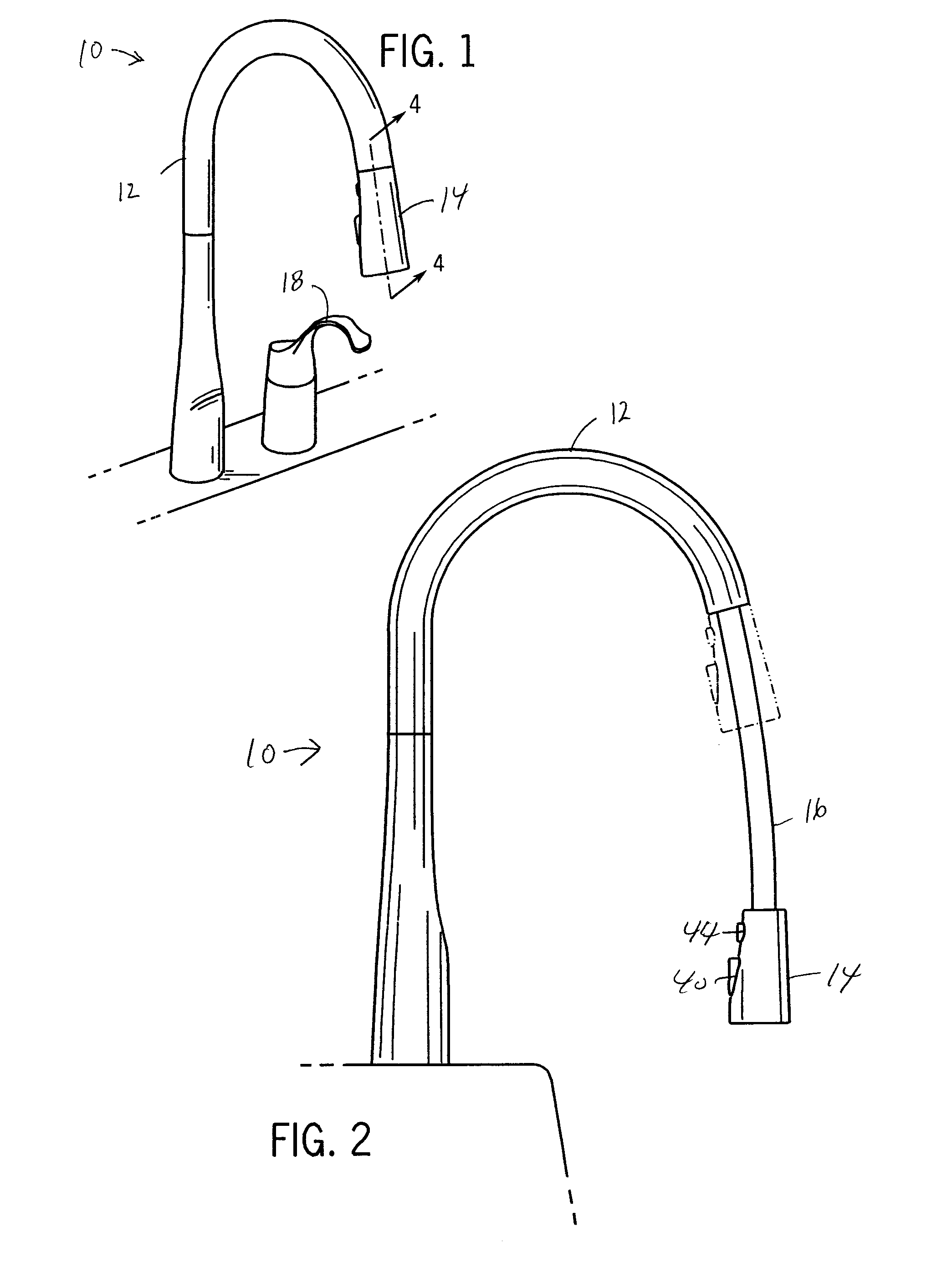

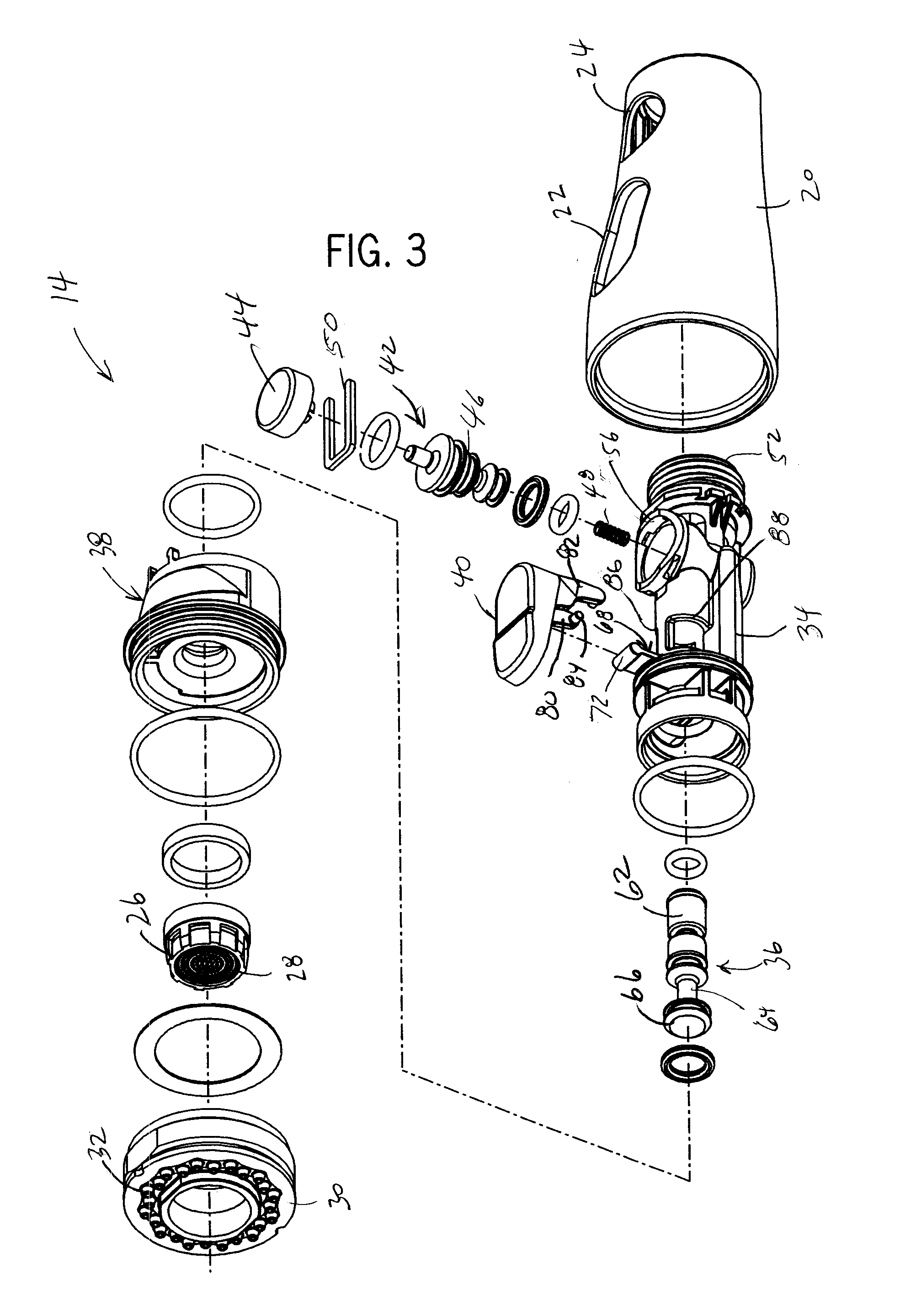

Faucet Spray Control Assembly

A pull-out faucet has a spray head with spray selection and pause control. A spring-loaded push button interrupts outlet spray entirely as long as it is being depressed. A rocker button controls spray through inner and outer sets of outlet orifices, for example, giving the user the option of an aerated water jet or an unaerated shower. The rocker button mounts on an integral pivot post of a valve body that houses a diverter valve that is controlled by the rocker button. The rocker button has a pair of legs that extend through openings in the valve body to engage a groove in the diverter valve. Pivoting the rocker button about a pivot axis by depressing either its forward or aft portion, moves the diverter valve along a valve axis to route flow to either the inner or outer orifices.

Owner:KOHLER CO

Medical Pump

InactiveUS20090060764A1Easy constructionPositive displacement pump componentsFluid jet surgical cuttersCylinder headEngineering

Medical pumps for water jet surgery are known. The invention relates to a pump comprising at least two pistons provided with piston rods for displacing the pistons in cylinders and for coupling to a pump actuation device, a cylinder head for closing the cylinders, and valve means for respectively connecting a pressure chamber in the cylinder to at least one fluid inlet and at least one fluid outlet. Said fluid outlet is connected to the fluid inlet in a communicating manner by means of an adjustable pressure regulating valve, in such a way that the pressure in the fluid outlet can be limited to a predetermined maximum value so that operation of the pump can be.

Owner:ERBE ELEKTROMEDIZIN GMBH

Apparatus and methods for making leaflets and valve prostheses including such leaflets

A method for making a bioprosthetic heart valve includes providing a non-contact cutting apparatus and a layer of tissue. The non-contact cutting apparatus may include a laser cutting system or high pressure water jet system. A leaflet is cut from the layer of tissue using a predefined template, and a plurality of alignment holes in the leaflet are created in the leaflet, e.g., along a peripheral edge. A support structure is provided having a plurality of alignment holes corresponding to alignment holes in the leaflet. The leaflet is secured to the support structure by securing one or more sutures through corresponding alignment holes in the leaflet and the support structure to provide a leaflet subassembly. A bioprosthetic heart valve is made by securing a set of leaflet subassemblies to a frame.

Owner:MEDTRONIC INC

Method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing, and permeability increasing

InactiveCN101644166AImprove flow statusEasy to extractUnderground miningSurface miningHigh pressure waterHigh pressure

The invention discloses a method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing and permeability increasing, comprising the following steps: whena drill is drilled into a predetermined position of the coal seam, coal bodies at both sides of a drill hole are cut in the drill hole by high pressure water jet with a certain pressure and flow; a flat slot is formed at both sides of the drill hole; the cut coal bodies is led out the hole by the high pressure water jet. The exposed area of the coal body at the slotted part in the drill hole aregreatly increased, namely that an extremely thin protective layer is exploited with local scope of the flat slot, which enlarges effective influential range of pressure releasing, permeability increasing and gas discharging of the coal bodies in the drill hole, thus the air permeability of the coal bodies is increased about 200-300 times, the average amount of single-hole gas extraction reaches 0.3m<3> / min, the concentration of the gas extraction is 30-60%, gas drainage rate of working face of coal extraction is more than 50%, the number of drill holes for gas drainage is reduced by 10-20% after slotting, pressure releasing and permeability increasing. The method realizes the safety, high efficiency and uniform extraction of the gas from the high gas low permeability outburst coal seam, and changes high gas coal seam with outburst danger into low gas coal seam without outburst danger.

Owner:CHINA UNIV OF MINING & TECH

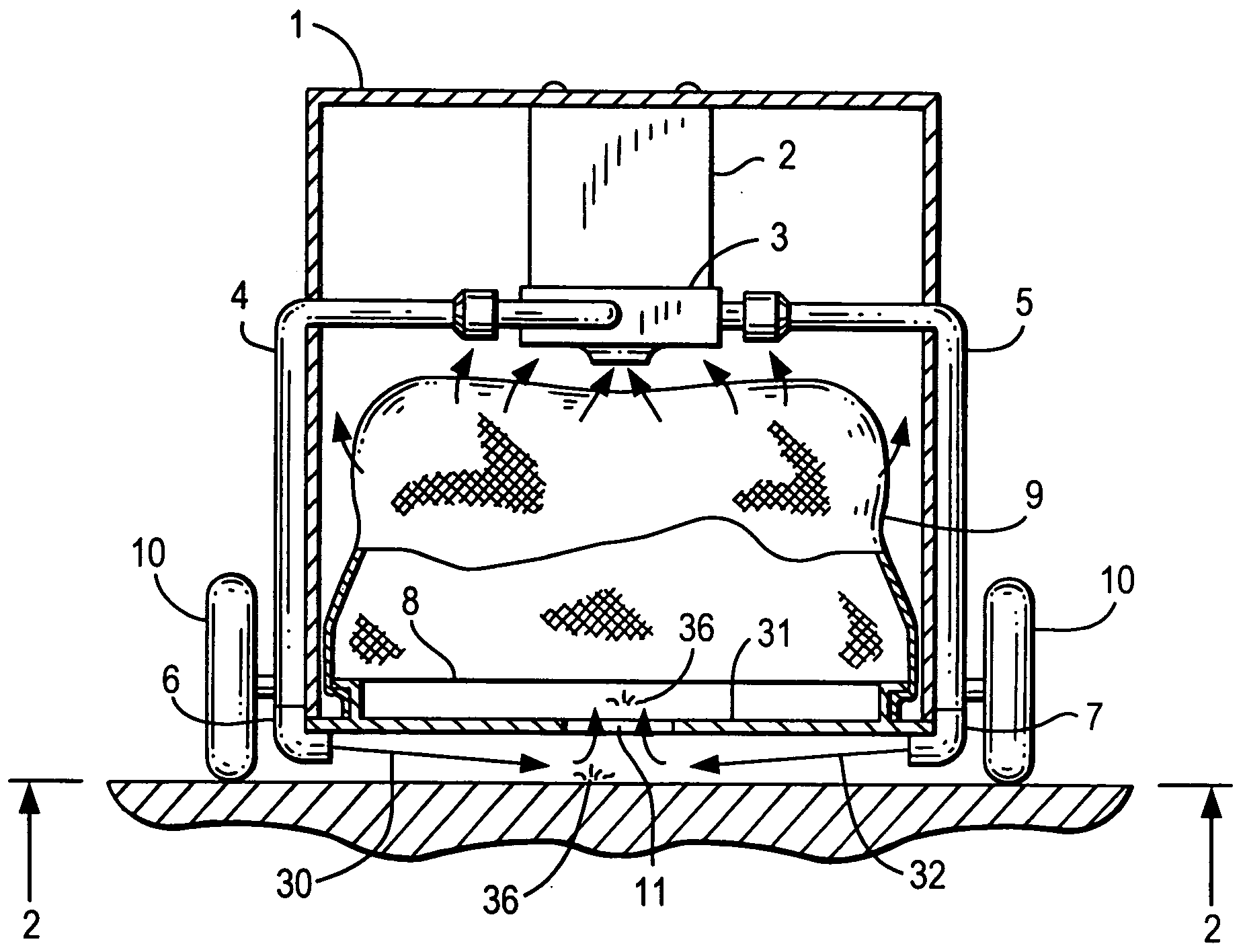

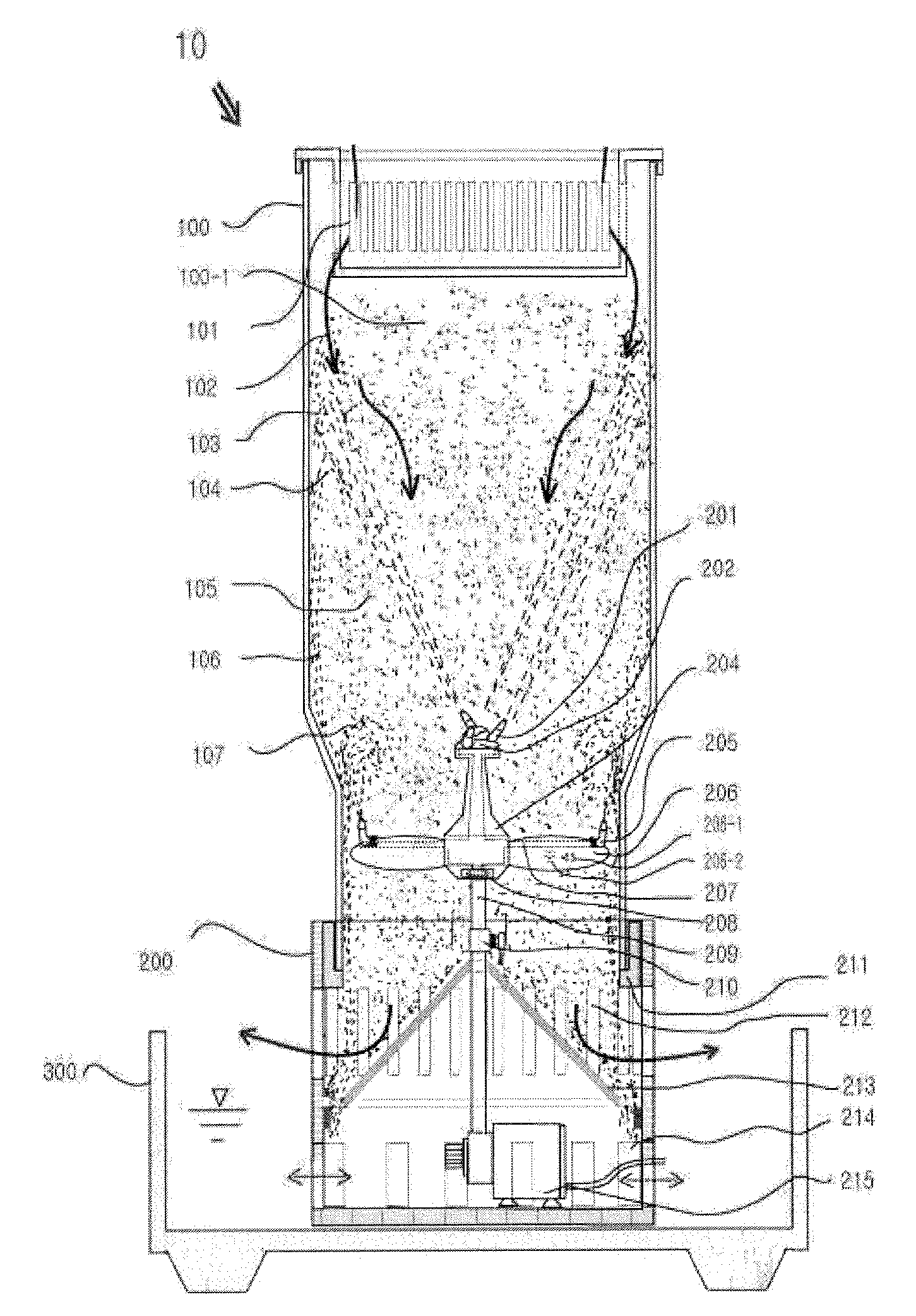

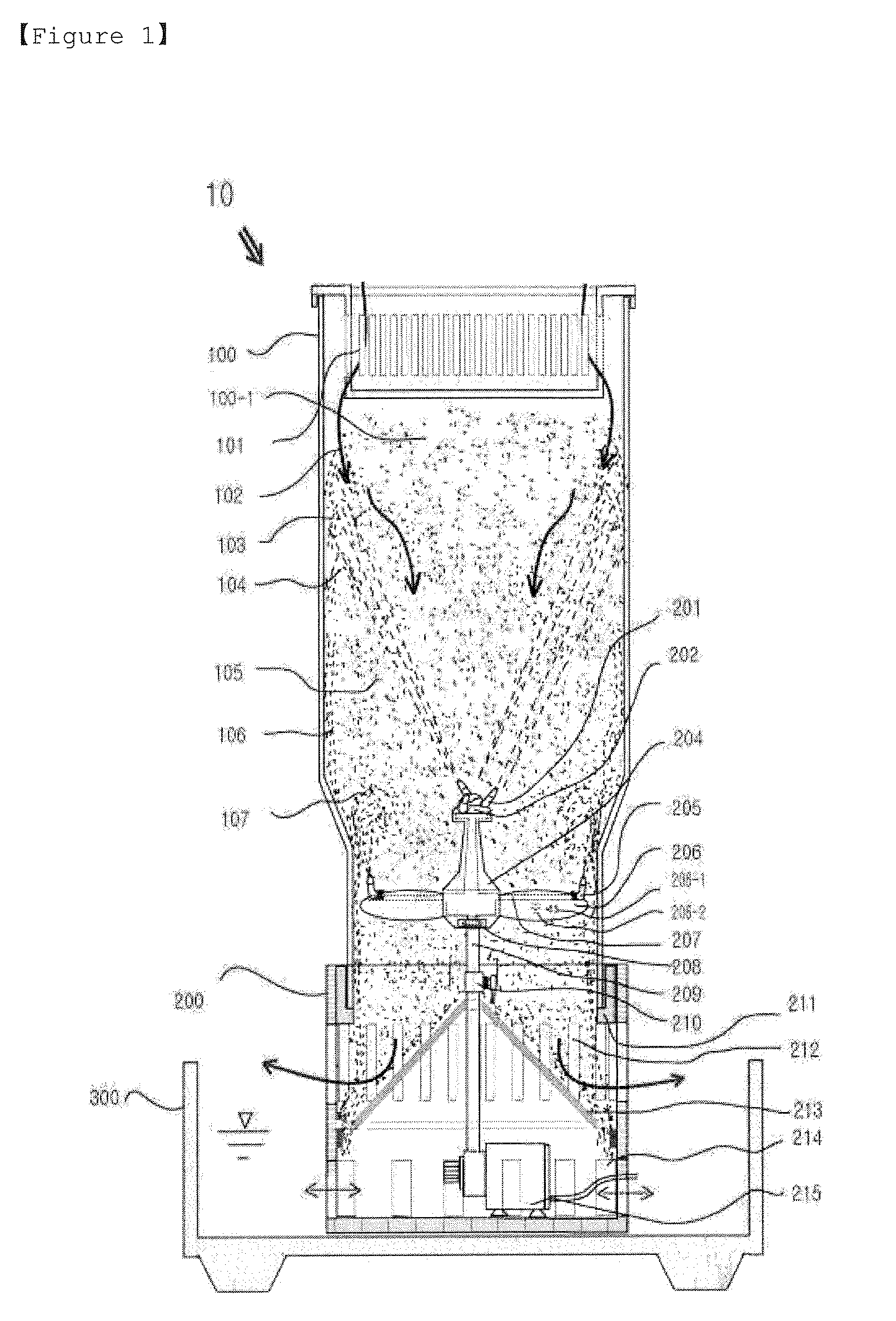

Air Purifier Employing A Water Jet-Type Fan System, and Purification Method Thereof

InactiveUS20110139005A1Reduce manufacturing costSolve the real problemDispersed particle filtrationLighting and heating apparatusAir cyclePurification methods

The present invention relates to an air purifier employing a water jet-type fan system having a simple structure, in which water is pumped by a water pump and sprayed and scattered by the water jet-type fan system in which a plurality of spray nozzles are mounted on a fan having a flow channel, in order to purify contaminants. The fan system rotates by the principle of action and reaction using the spraying force of water. The air purifier of the present invention performs an air purification process and an air circulation function at the same time by spraying and scattering water so as to use the adsorption power of water, instead of using a motor fan for circulating air. The present invention also relates to a purification method of the air purifier.

Owner:KWON YONG JOON

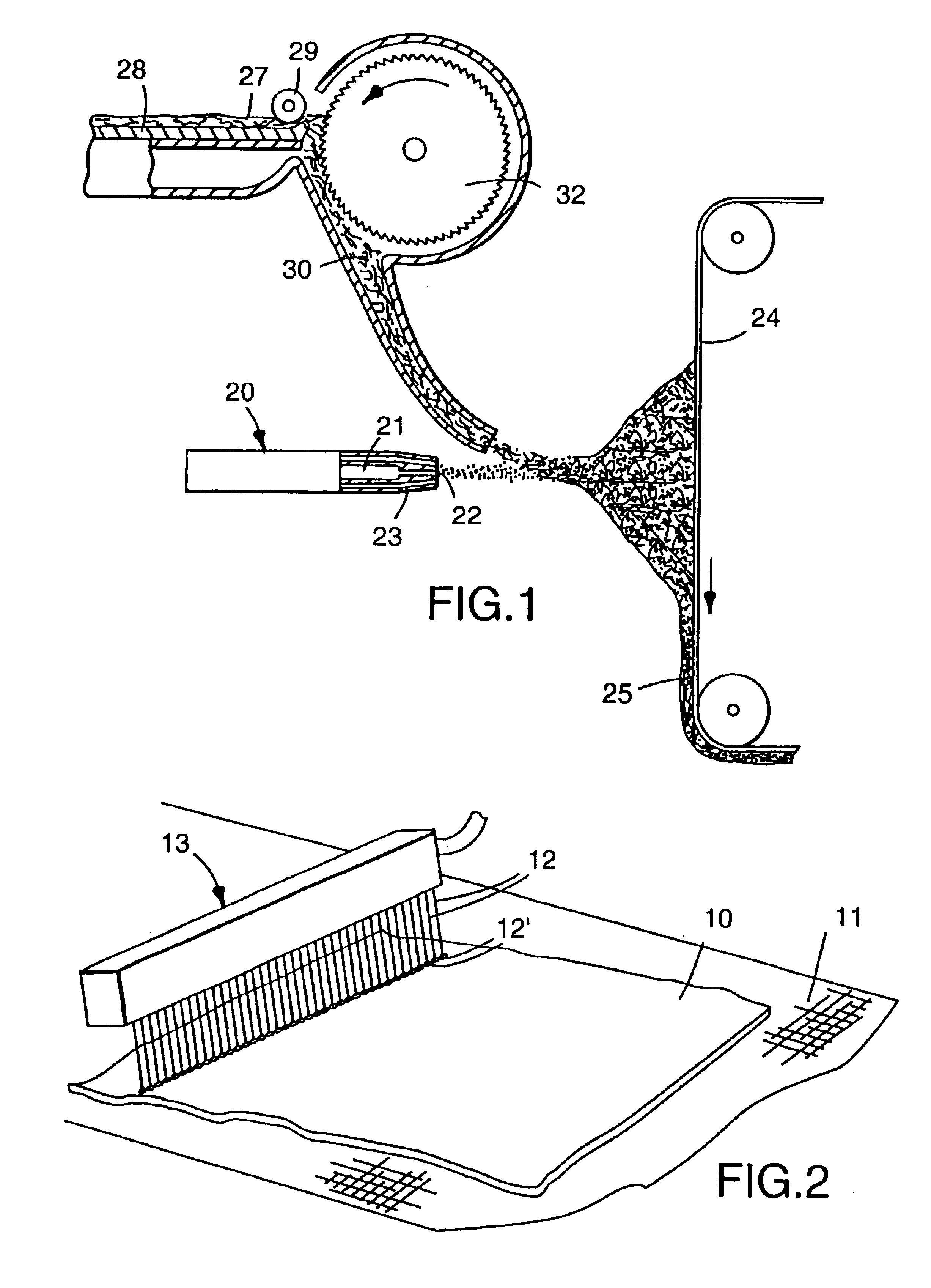

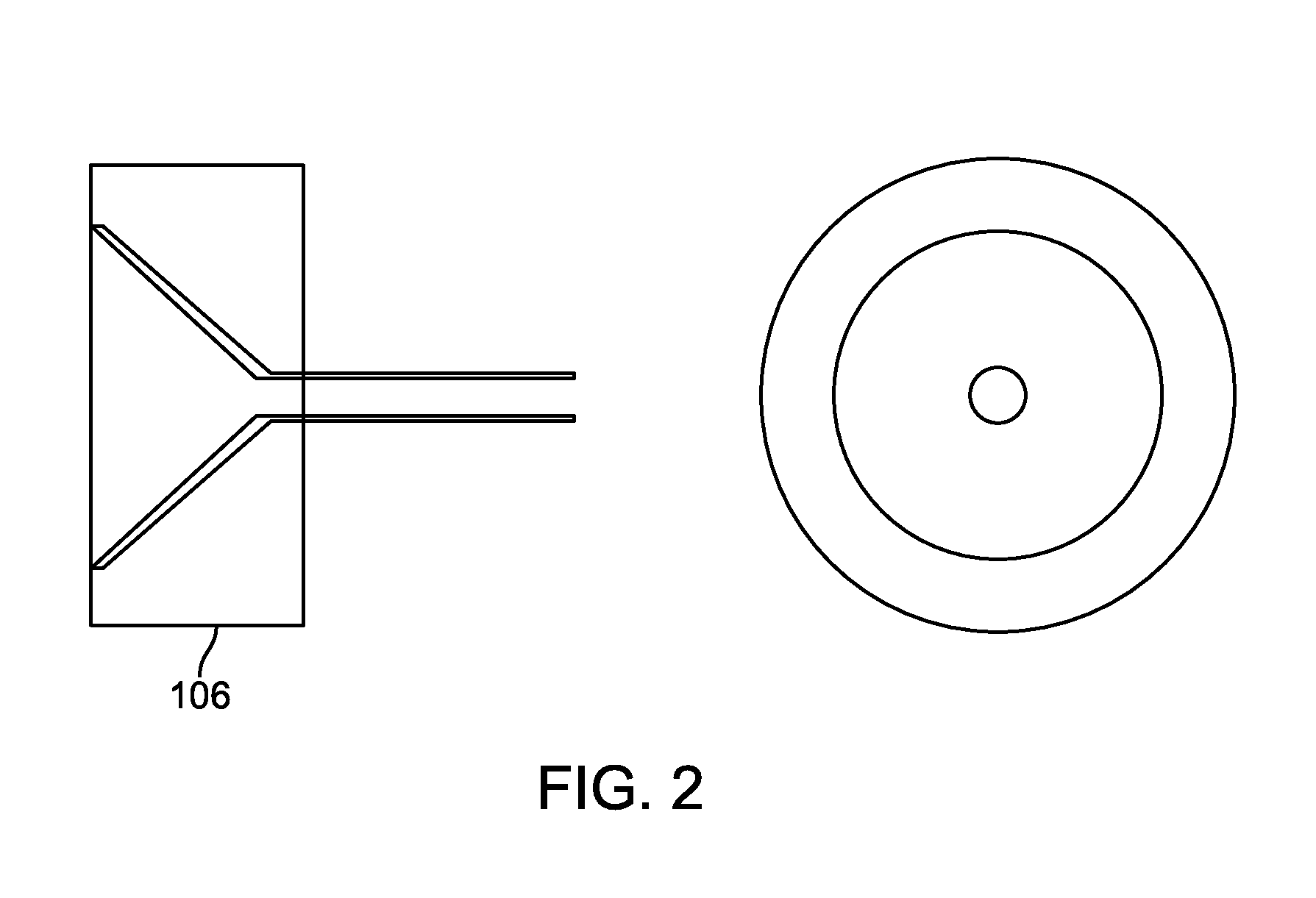

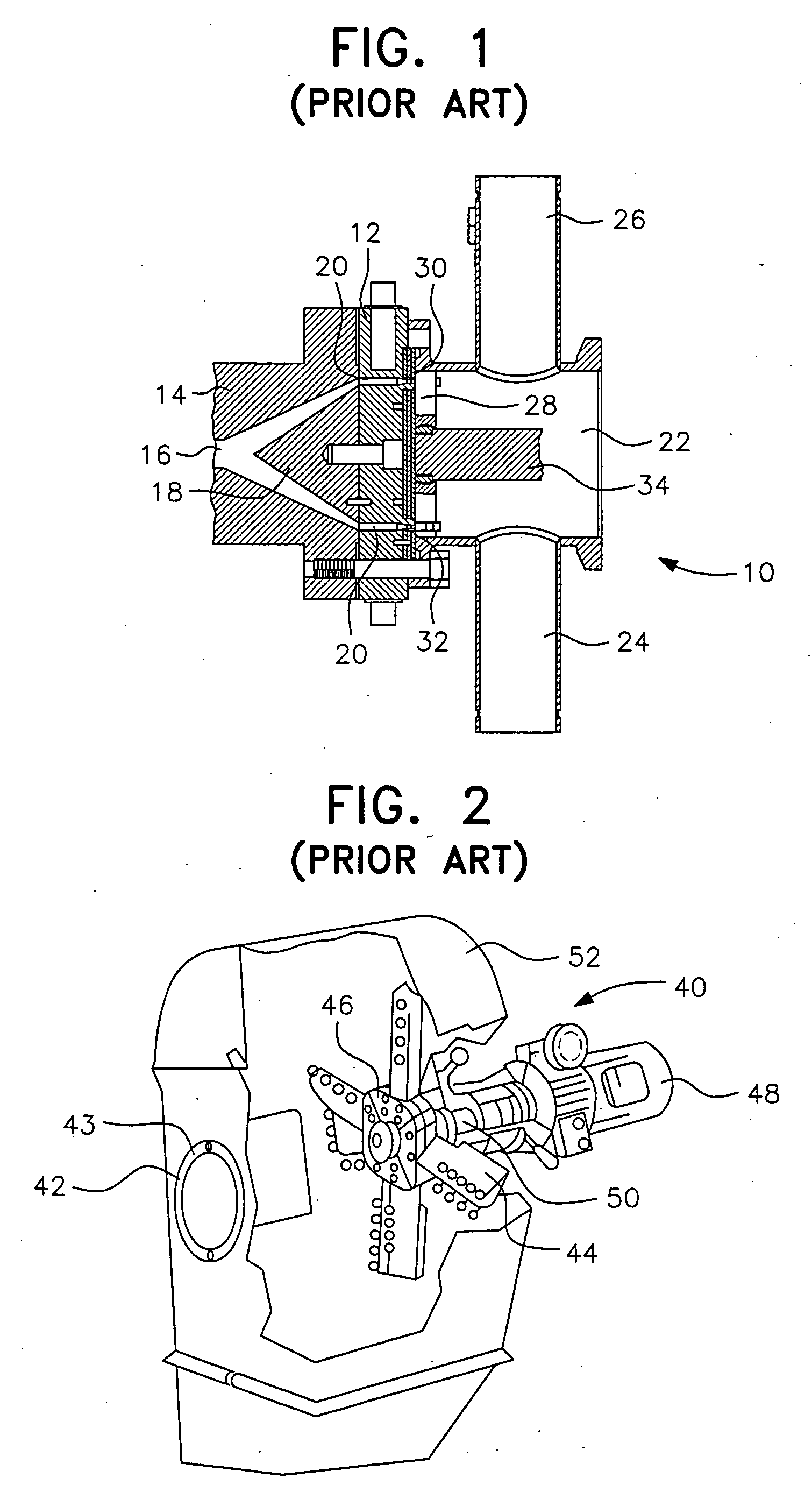

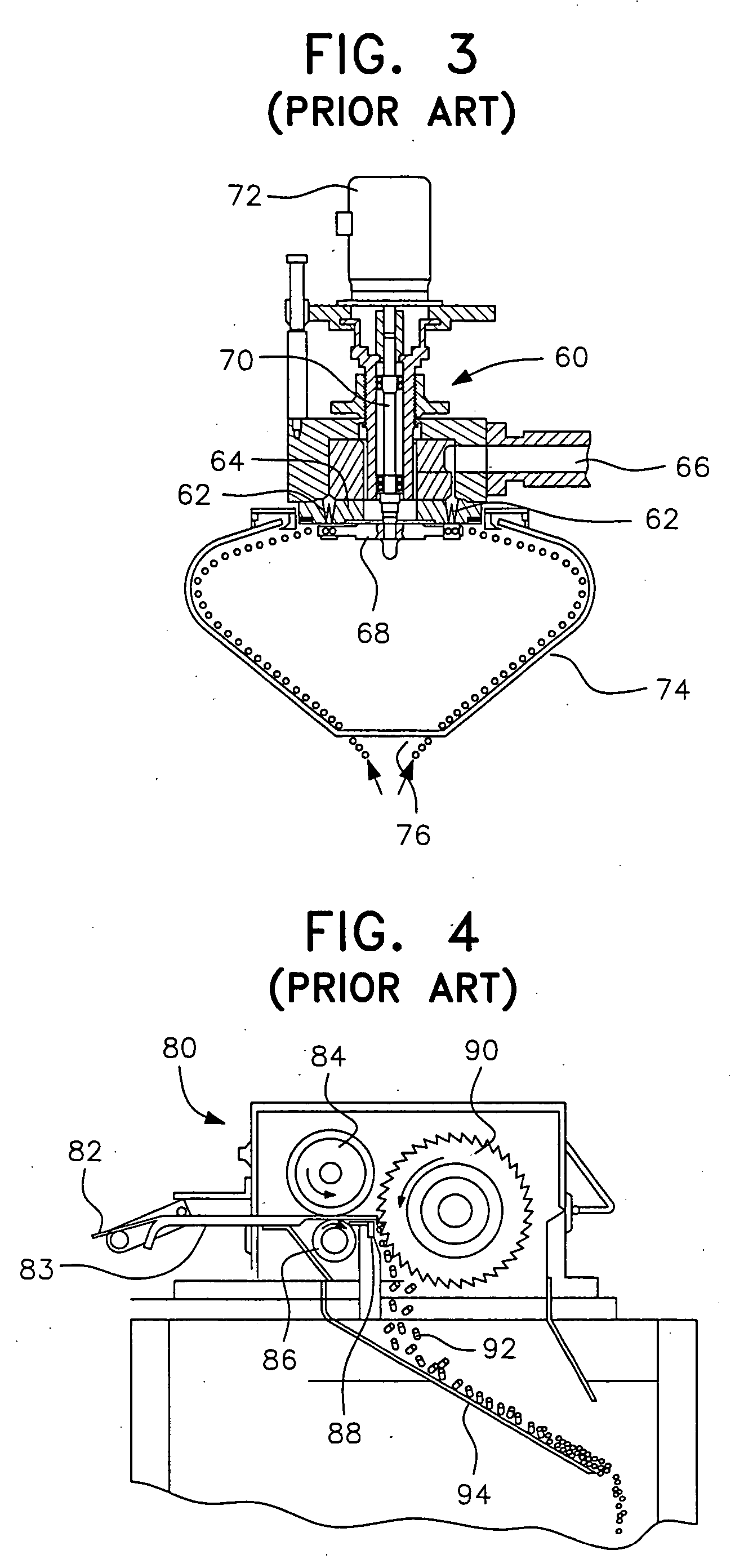

High pressure liquid jet cutting system and method for forming polymer pellets

InactiveUS20050077644A1Without unnecessary down timeContinuous operationMouldsConfectioneryWater basedLiquid jet

A system and method for pelletizing extruded materials, such as thermoplastic polymers in various pelletizing applications, including underwater, hot face, and strand pelletizing applications, utilizes a high pressure liquid delivered to one or more nozzles which direct a high pressure liquid jet cutting stream at the extruded polymer strand to cut the strand into pellets. The system and method are particularly applicable to underwater pelletizers utilizing water or water-based solutions. In a preferred underwater pelletizing embodiment, a plurality of nozzles are mounted on a rotating nozzle hub which is fed high pressure water through sealed hollow pelletizer and hollow motor shafts. The high pressure water jet cutting streams exiting the rotating nozzles are preferably in the form of a flat V-shaped spray with a spread angle of about 15° to about 45° and an approach angle between 0° and 60°, depending upon the pelletizing application.

Owner:GALA INDUSTRIES INC

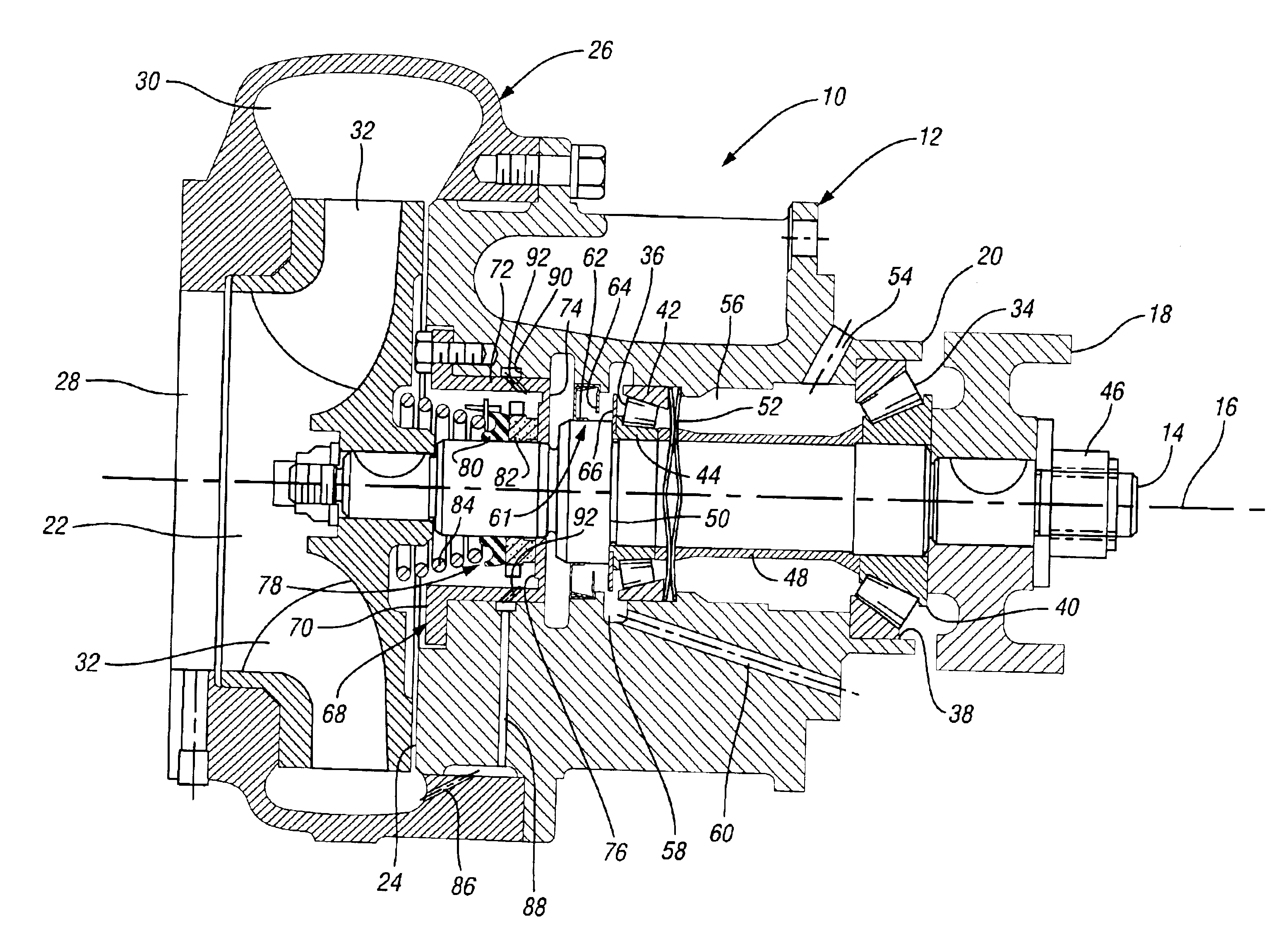

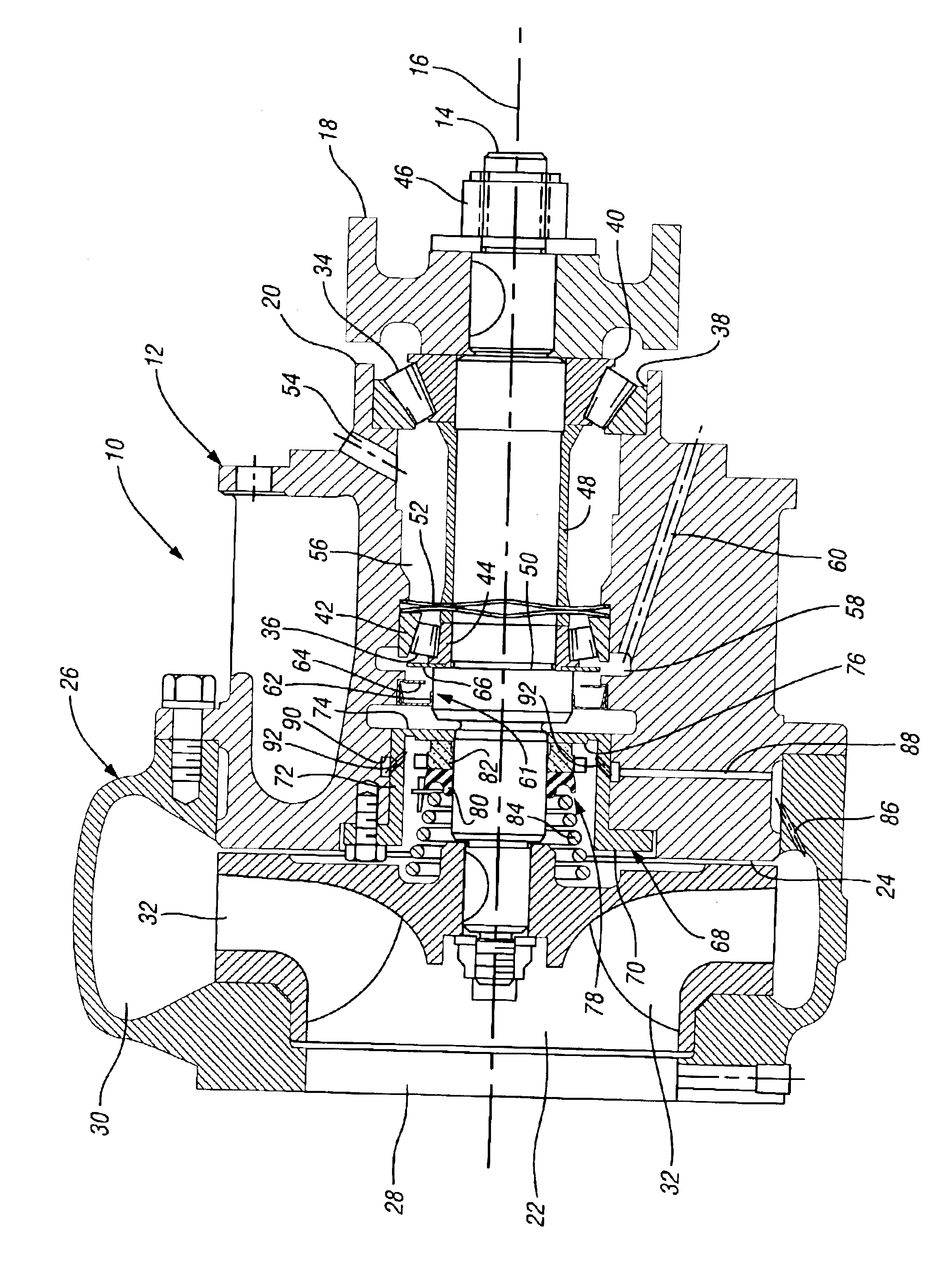

Diesel engine water pump with improved water seal

ActiveUS6884022B2Extended service lifeEasy constructionRotary bearingsEngine sealsImpellerWear particle

An improved diesel engine water pump includes three main features that aid in extending the maintenance-free life of the pump. The impeller shaft is carried by tapered roller shaft support bearings of which the impeller bearing has a floating outer race that is urged axially by a preload spring to provide a prescribed axial preload that maintains concentricity of the shaft with the axis and prolongs bearing life. An improved oil seal combines an oil slinger, a stationary deflector and a lip oil seal with a return passage to the engine to more effectively limit oil leakage from the pump. An improved water seal includes pressurized water jets fed from the pump volute that flush wear particles from the water seal surface and increase water seal life. Further details of these features are also disclosed.

Owner:ELECTRO-MOTIVE DIESEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com