Patents

Literature

571results about How to "Improve wiping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

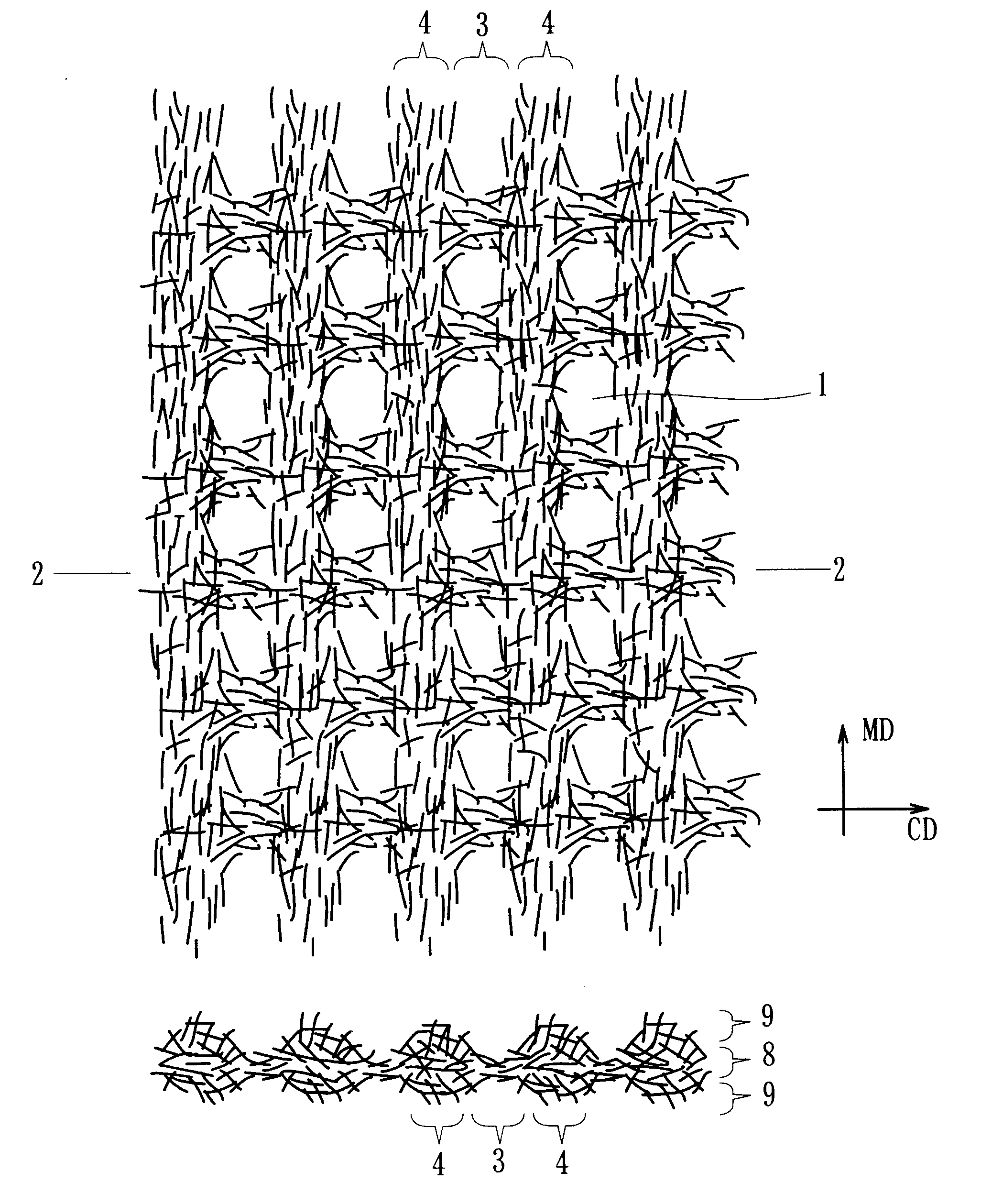

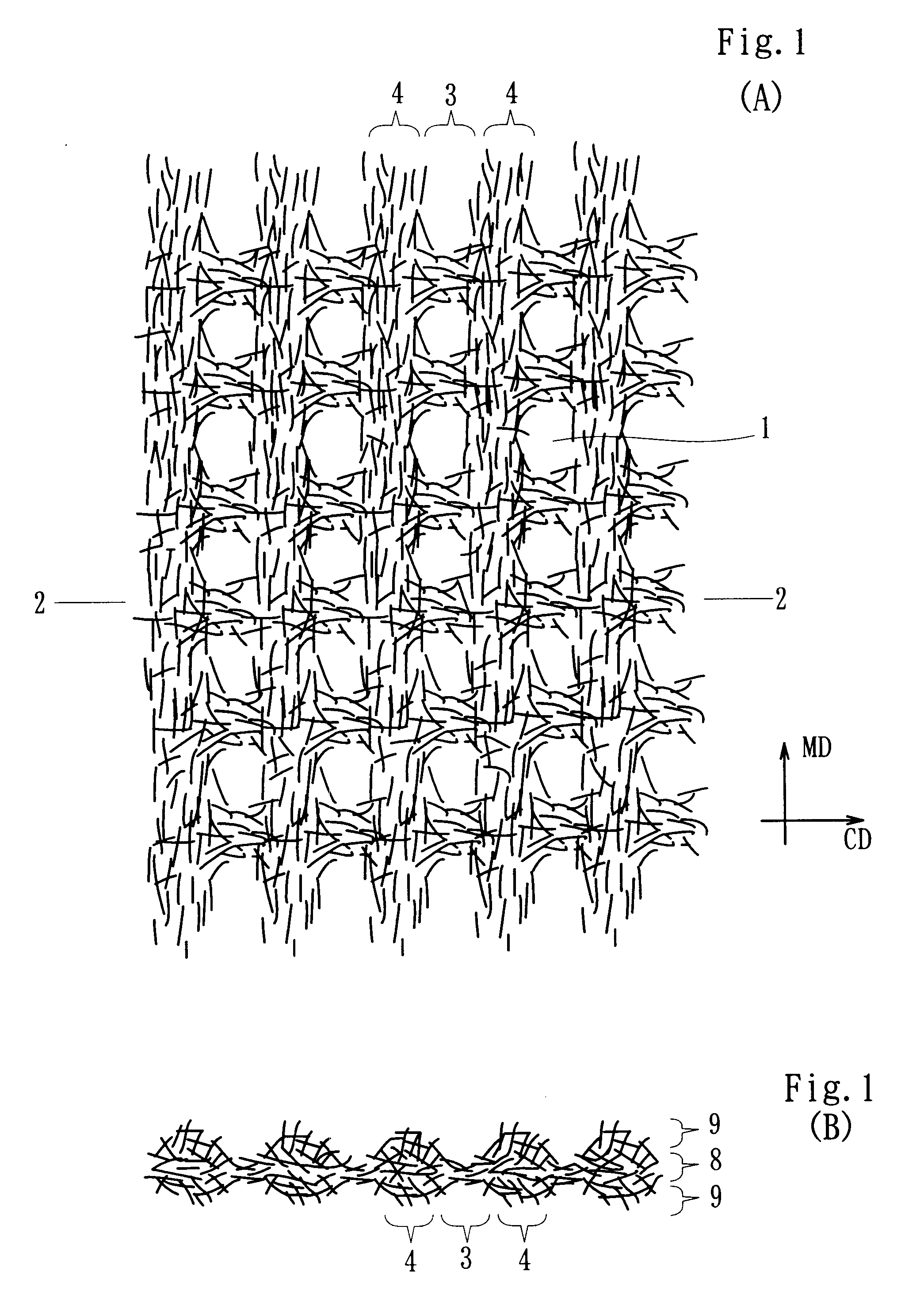

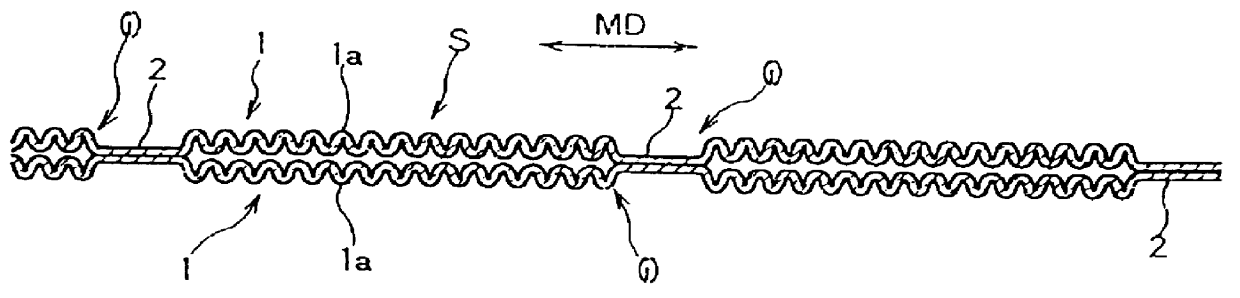

Method of manufacturing a water disintegratable non-woven fabric and the water disintegratable non-woven fabric

InactiveUS6451718B1Improve wiping effectNon-fibrous pulp additionSynthetic resin layered productsFiberCarboxymethyl cellulose

A water disintegratable non-woven fabric having excellent water disintegratability and high wet strength can be obtained by a step of forming a fiber web from fibers having a fiber length of 10 mm or less, a step of applying a water jet treatment to the fiber web to obtain a fiber sheet having wet strength of less than 100 g / 25 mm in MD and CD, the wet strength being defined by tensile strength at break of the fiber sheet, as measured by using a tensilon tester with a chuck distance of 100 mm, at a tensile speed of 100 mm / min to the fiber sheet which is cut into 25 mm width and 150 mm length and impregnated with water in an amount 2.5 times the weight of the fiber sheet, and a step of adding at least one binder selected from the group consisting of carboxymethyl cellulose, alkylcellulose, polyvinyl alcohol and modified polyvinyl alcohol to the fiber sheet. The water disintegratable non-woven fabric is sufficiently bulky and has an excellent wiping effect.

Owner:UNI CHARM CORP

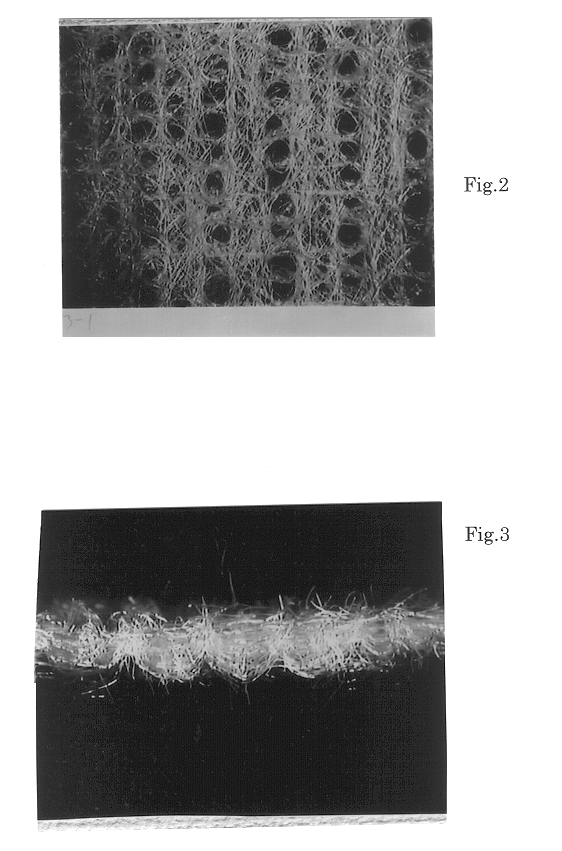

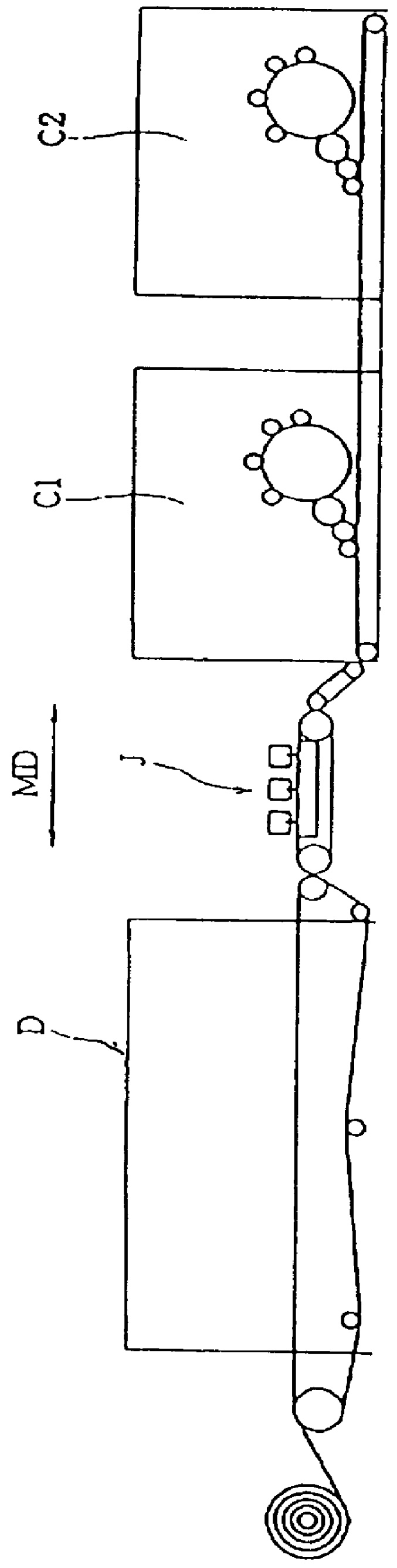

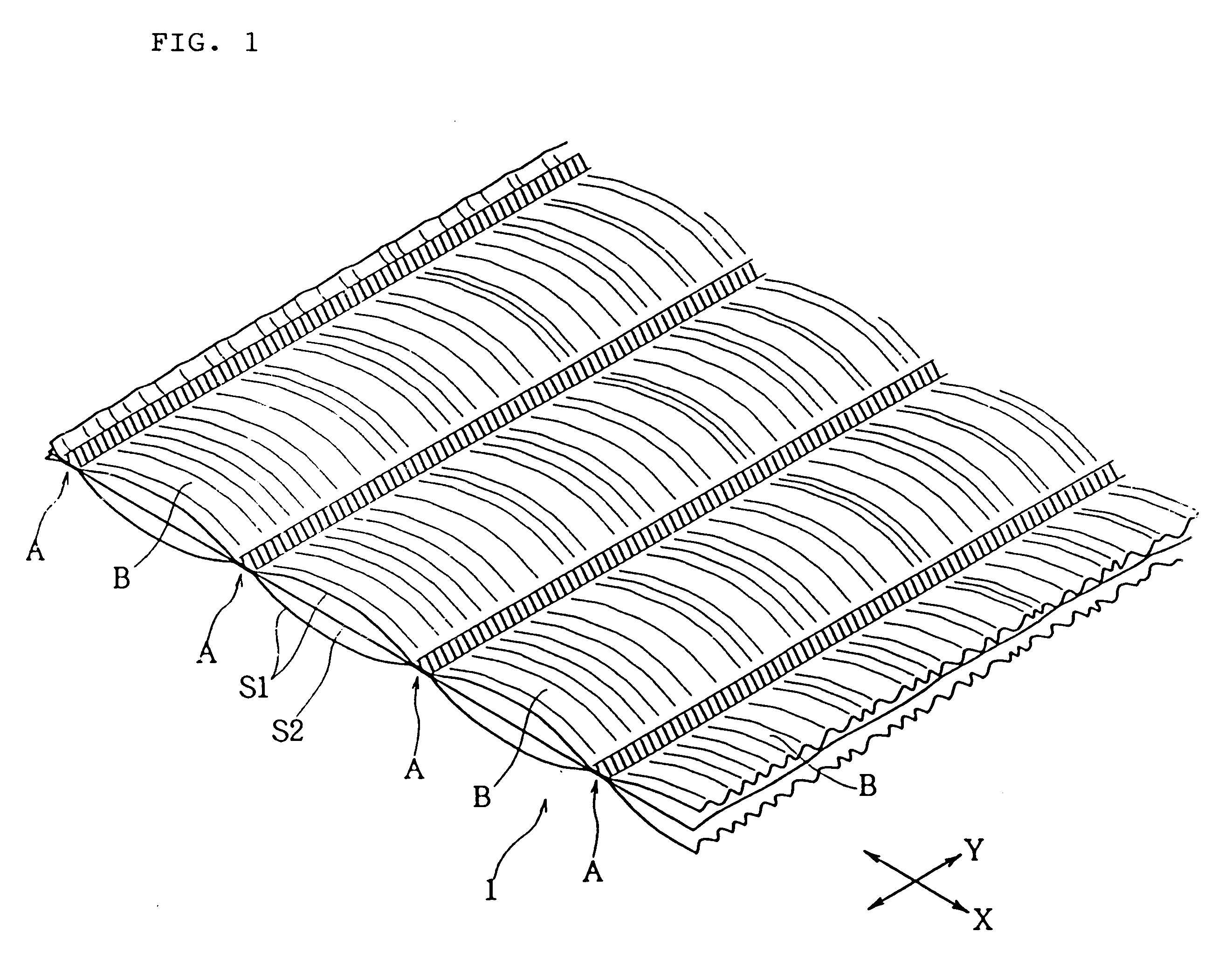

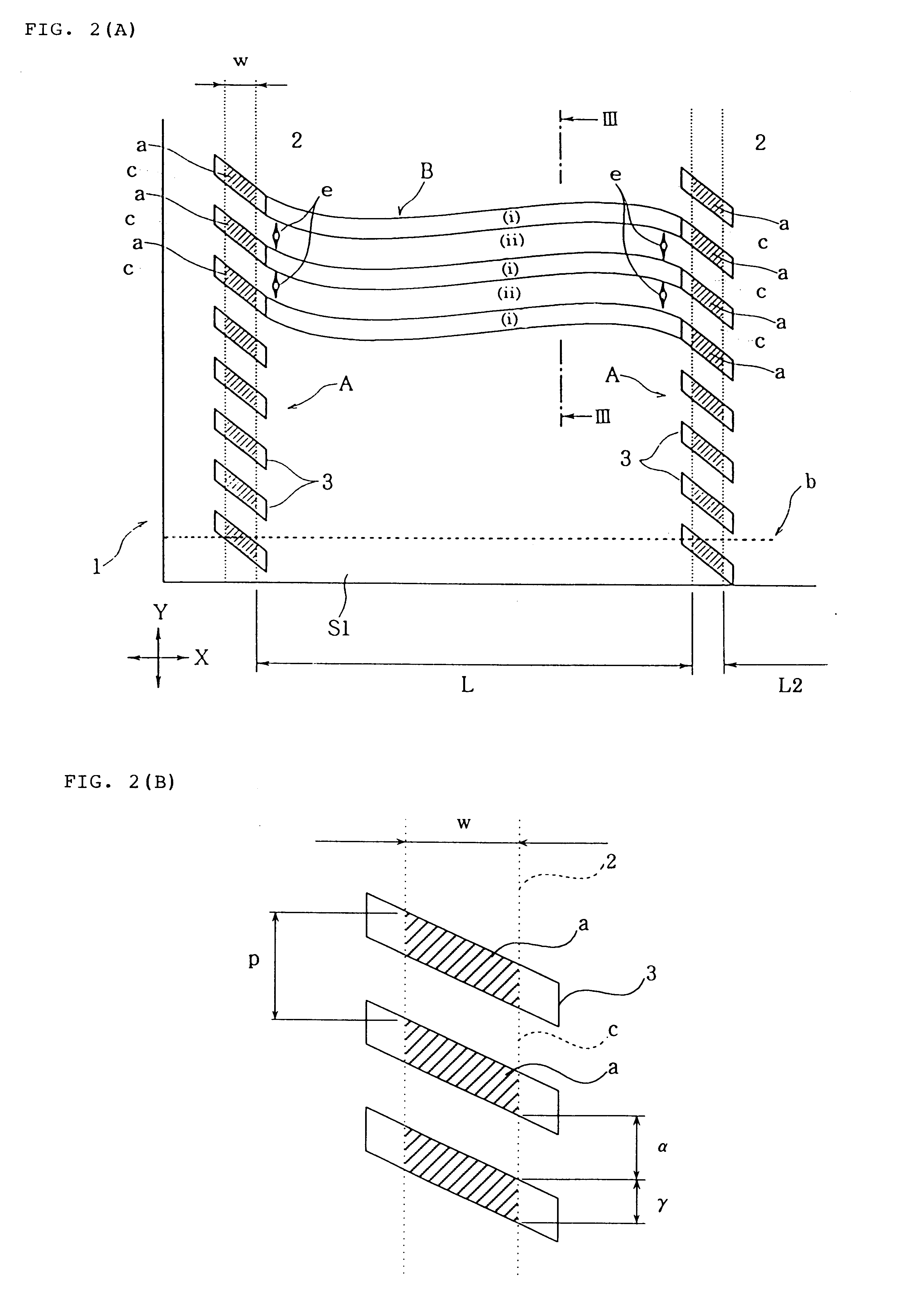

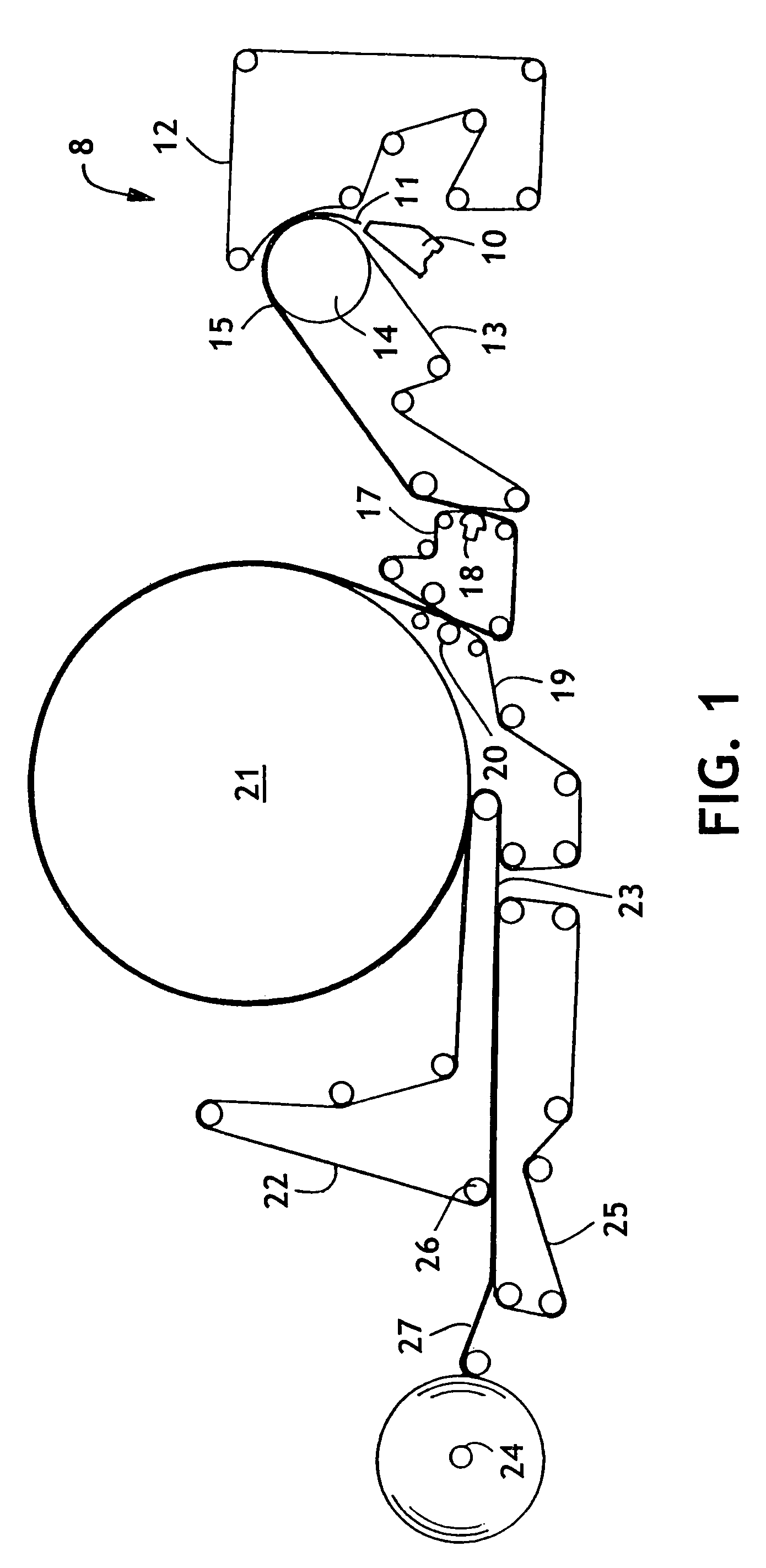

Wiping sheet and production thereof

InactiveUS6054202AHigh tensile strengthImproving surface frictional strengthCarpet cleanersFloor cleanersSingle fiberEngineering

Disclosed herein is a wiping sheet composed of two pieces of spunlace nonwoven fabrics containing heat-shrinkable fiber which are fusion-bonded together with fusion-bonding lines which extend in the cross direction perpendicular to the machine direction. The fusion-bonding lines are formed such that their pitch in the machine direction is shorter than one half of the fiber length so that each fusion-bonding line intersects a single fiber at 3 or more points. This structure prevents surface fluffing and imparts a high surface frictional strength and a high bending resistance for comfortable wiping work.

Owner:UNI CHARM CORP

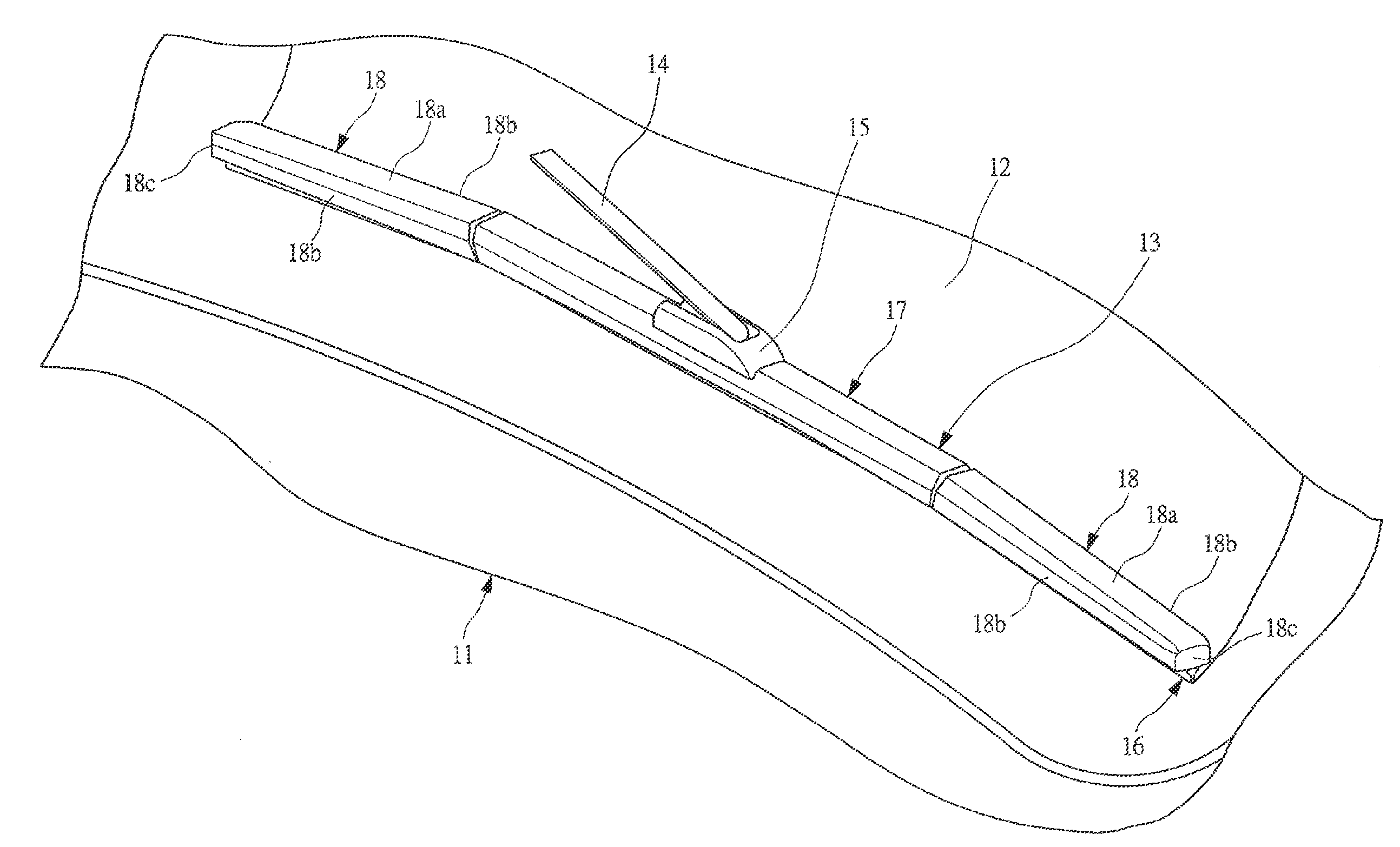

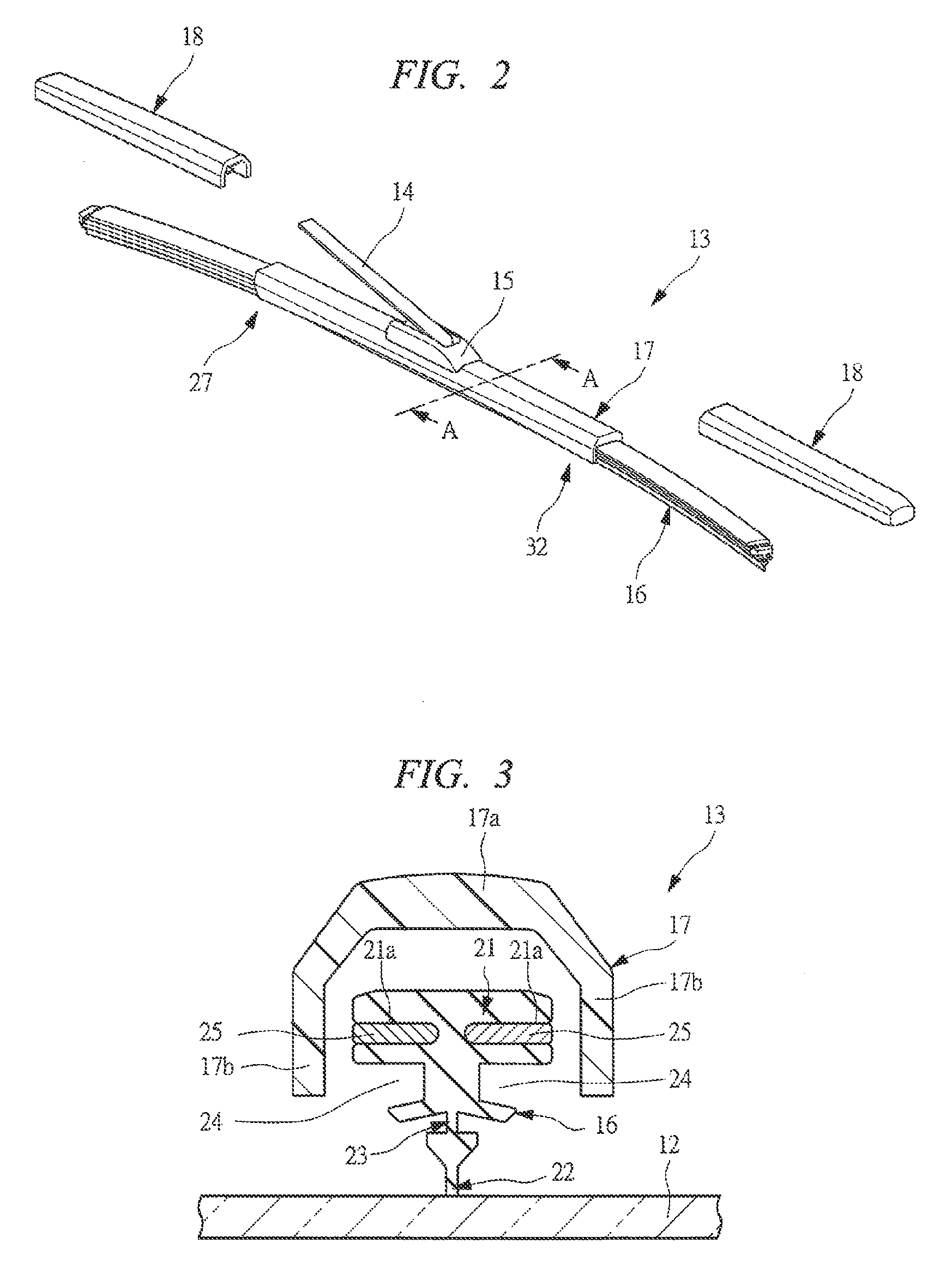

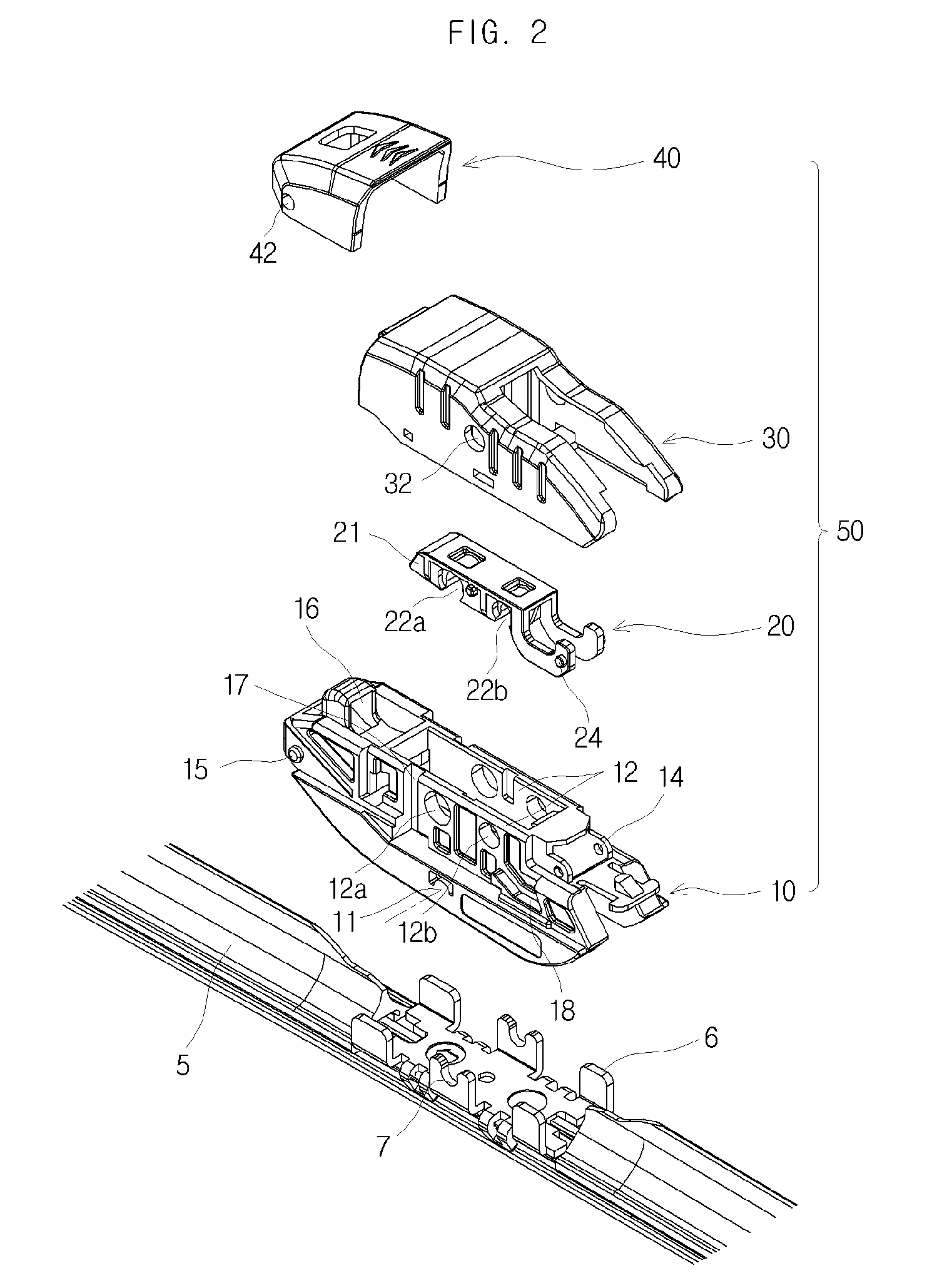

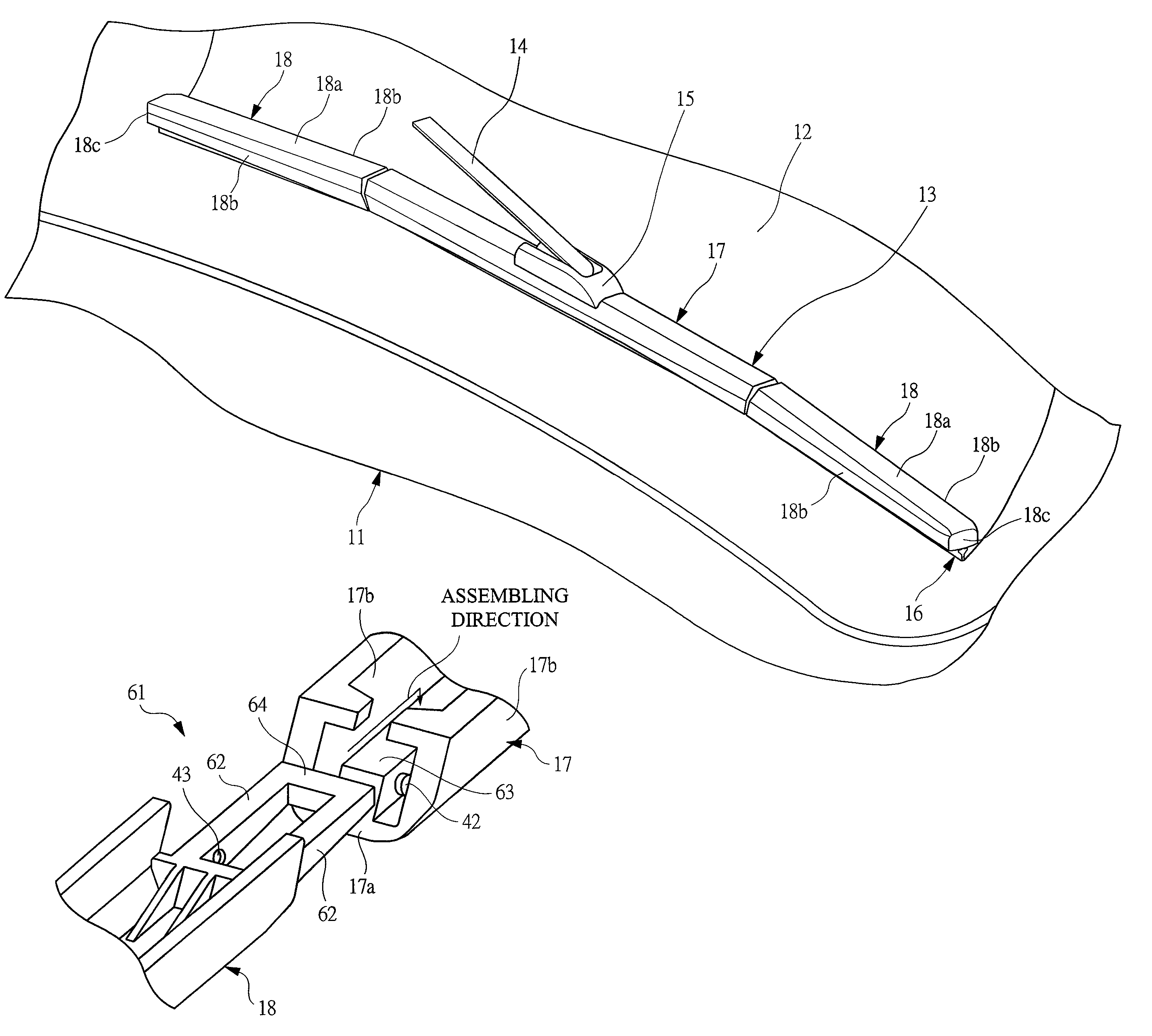

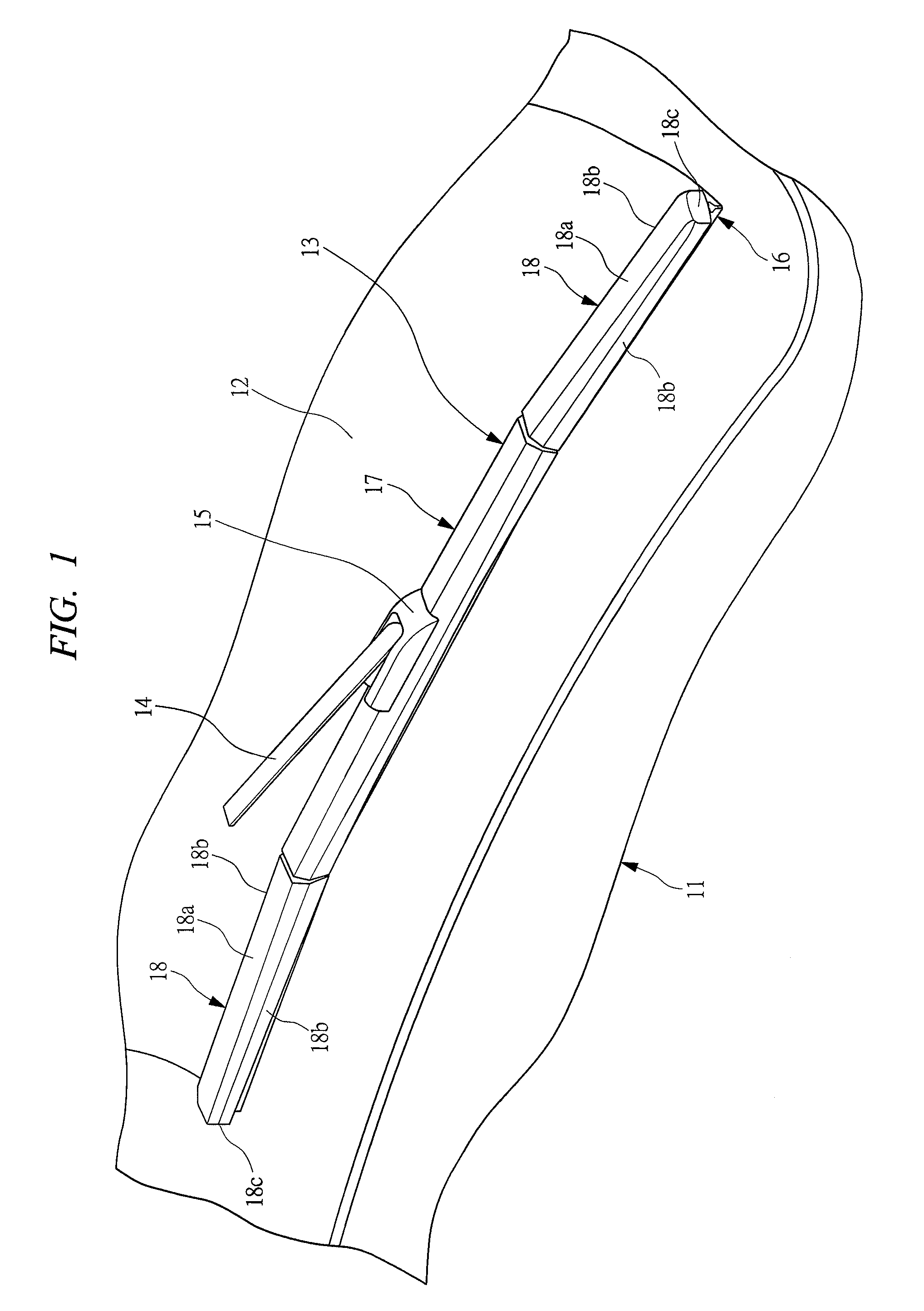

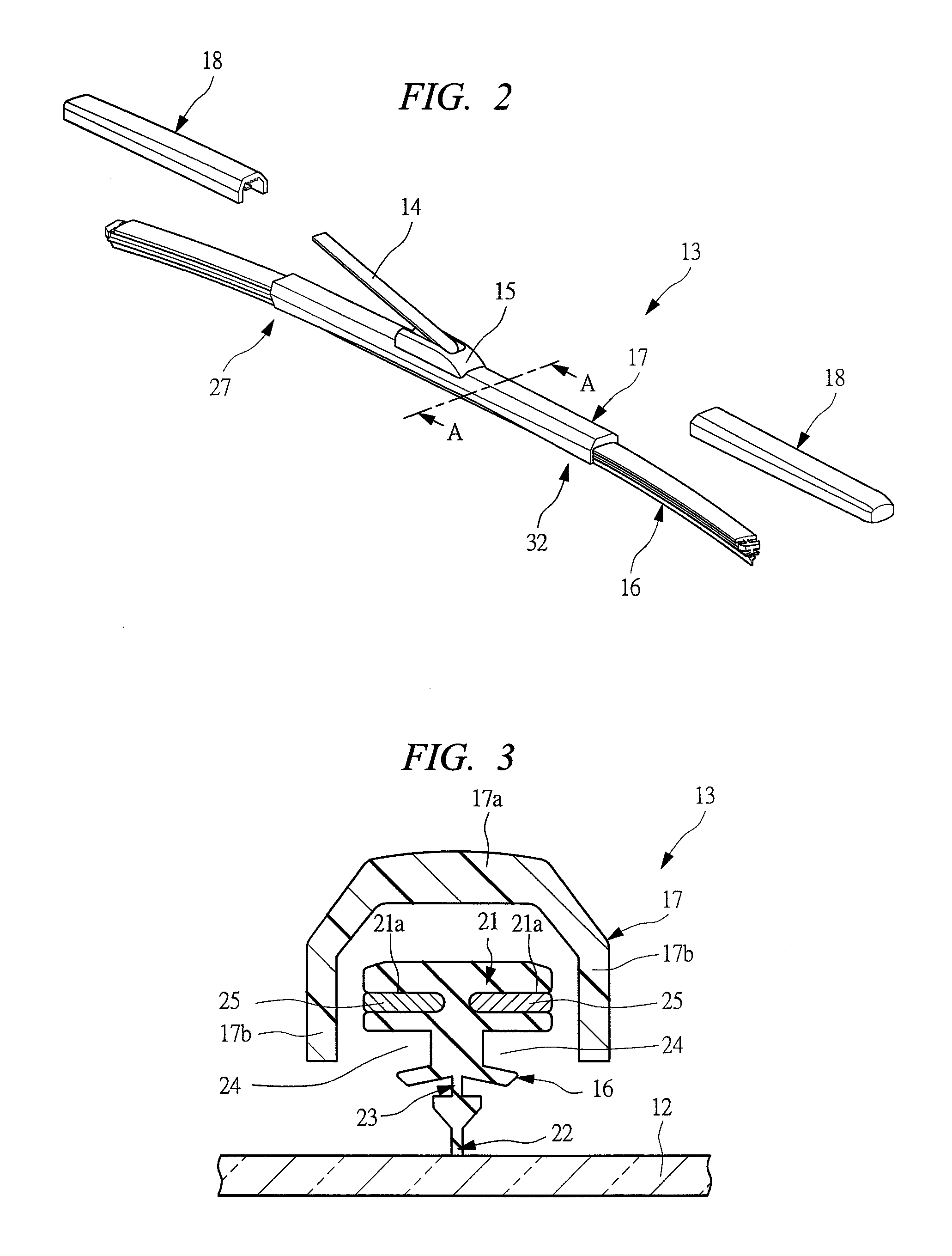

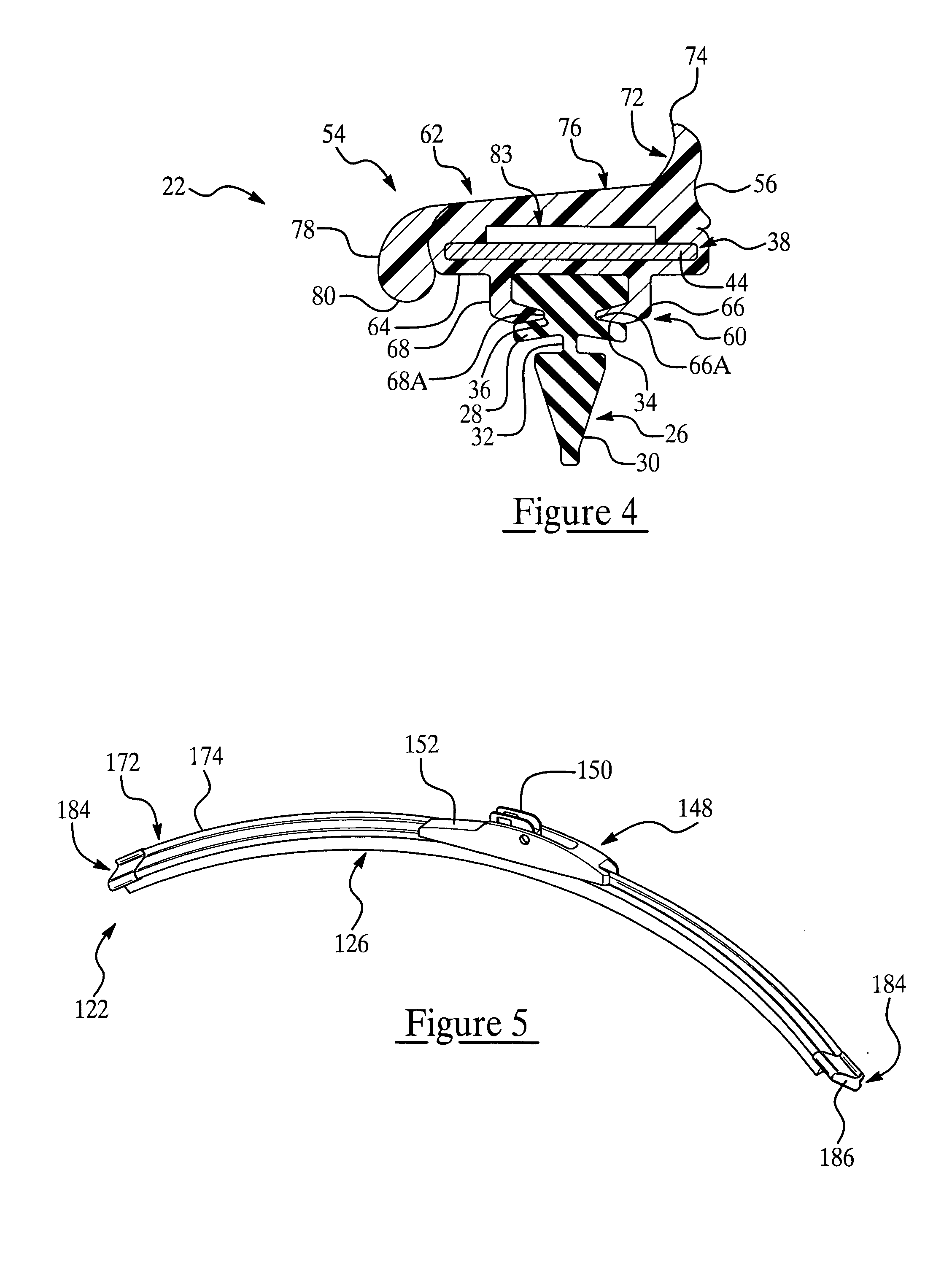

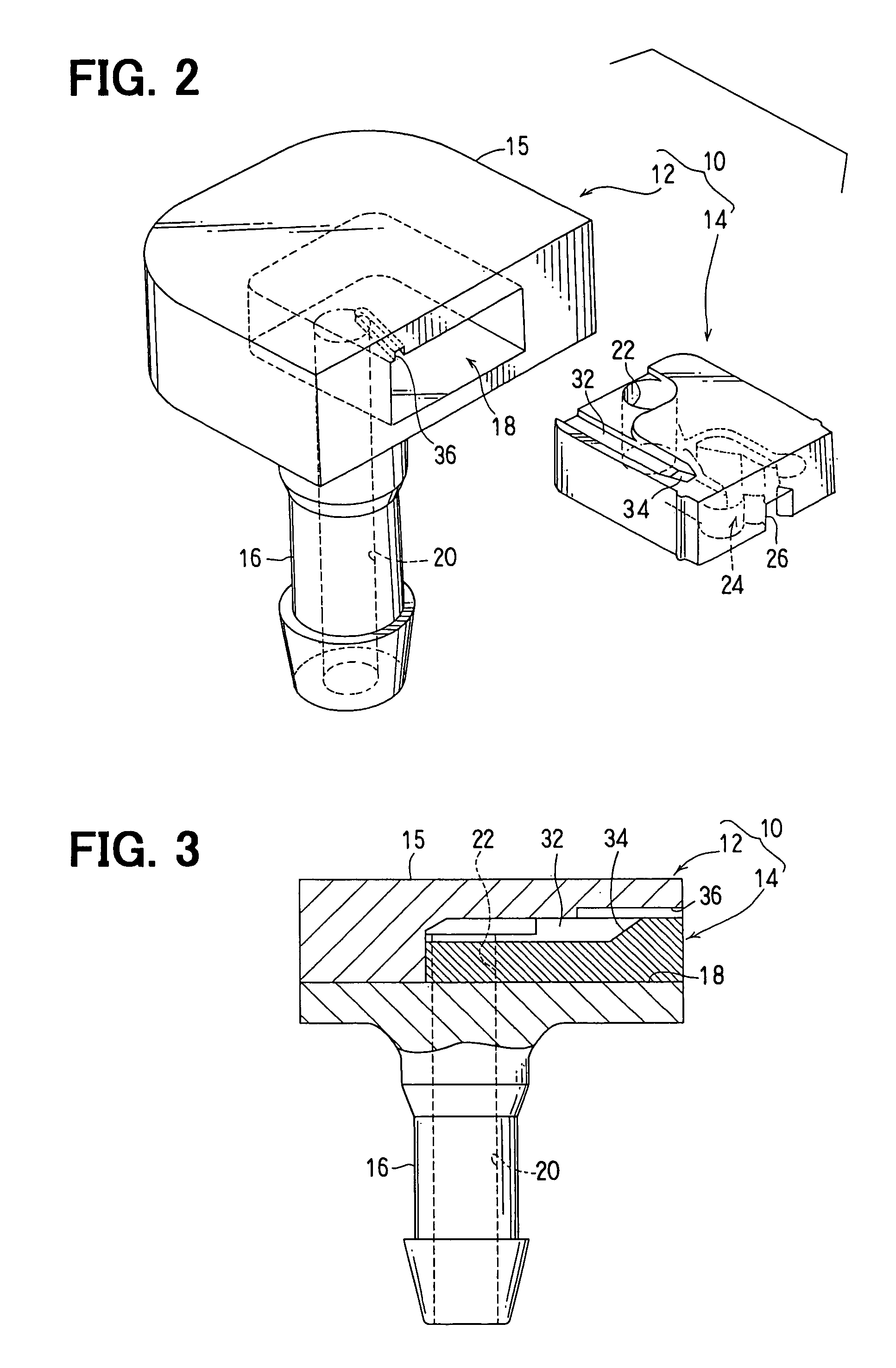

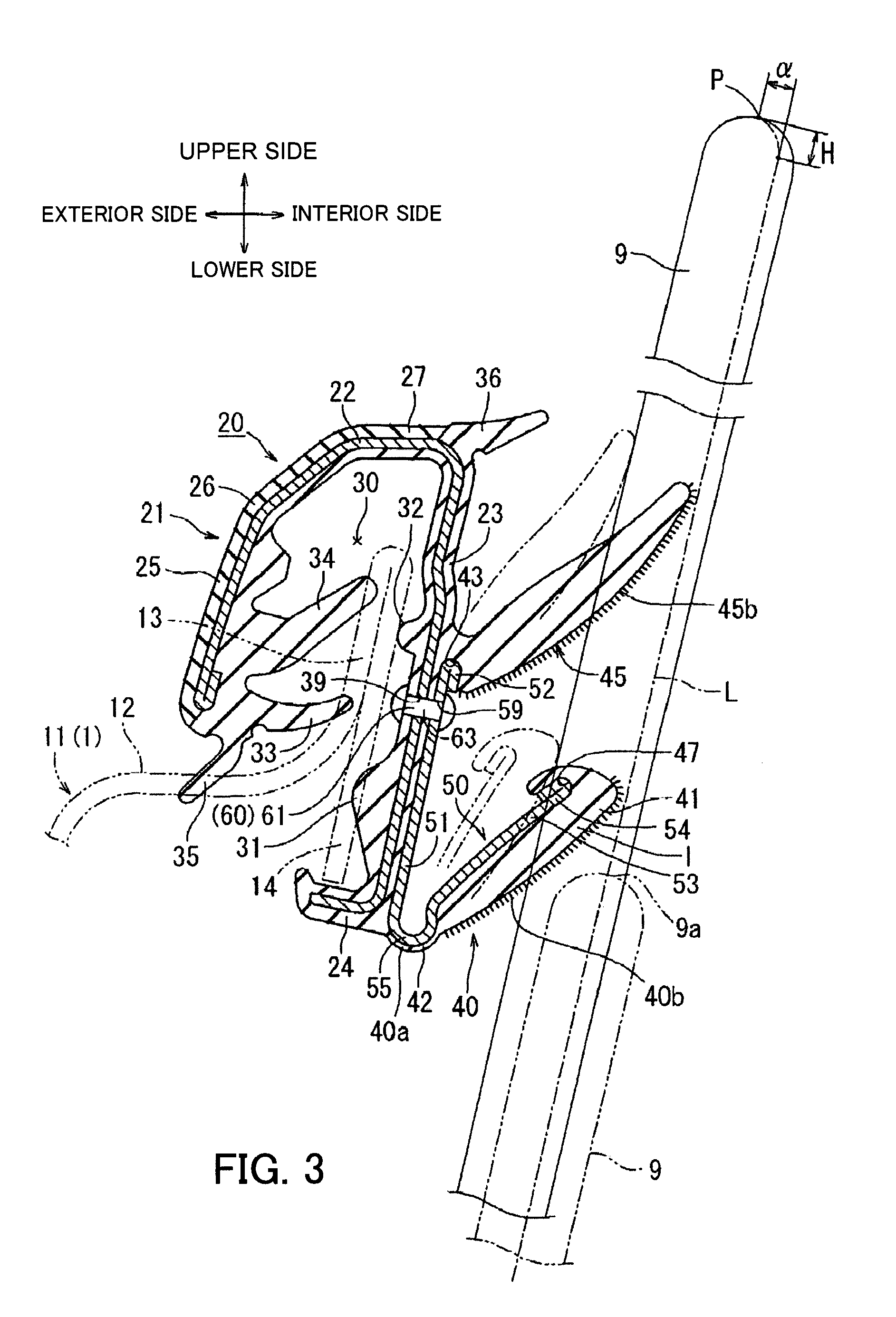

Wiper Blade

ActiveUS20080098559A1Fine appearance be improveEnhance versatilityWindow cleanersVehicle cleaningEngineeringWindshield

A wiper blade 13 comprises a rubber holder 17 attached to a tip of a wiper arm 14 and a blade rubber 16 supported by the rubber holder 17. The rubber holder 17 is formed into a U-shaped cross section, and an intermediate portion of the blade rubber 16 is covered with the rubber holder 17. Also, both sides of the rubber holder 17 are provided with covers 18 in a longitudinal direction in series. Each of the cover 18 becomes rotatable to the rubber holder 17 in a direction perpendicular to a front windshield glass 12, and exposed portions from the rubber holder 17 of the blade rubber 16 are covered with these covers 18 in an elastically deformable state.

Owner:MITSUBA CORP

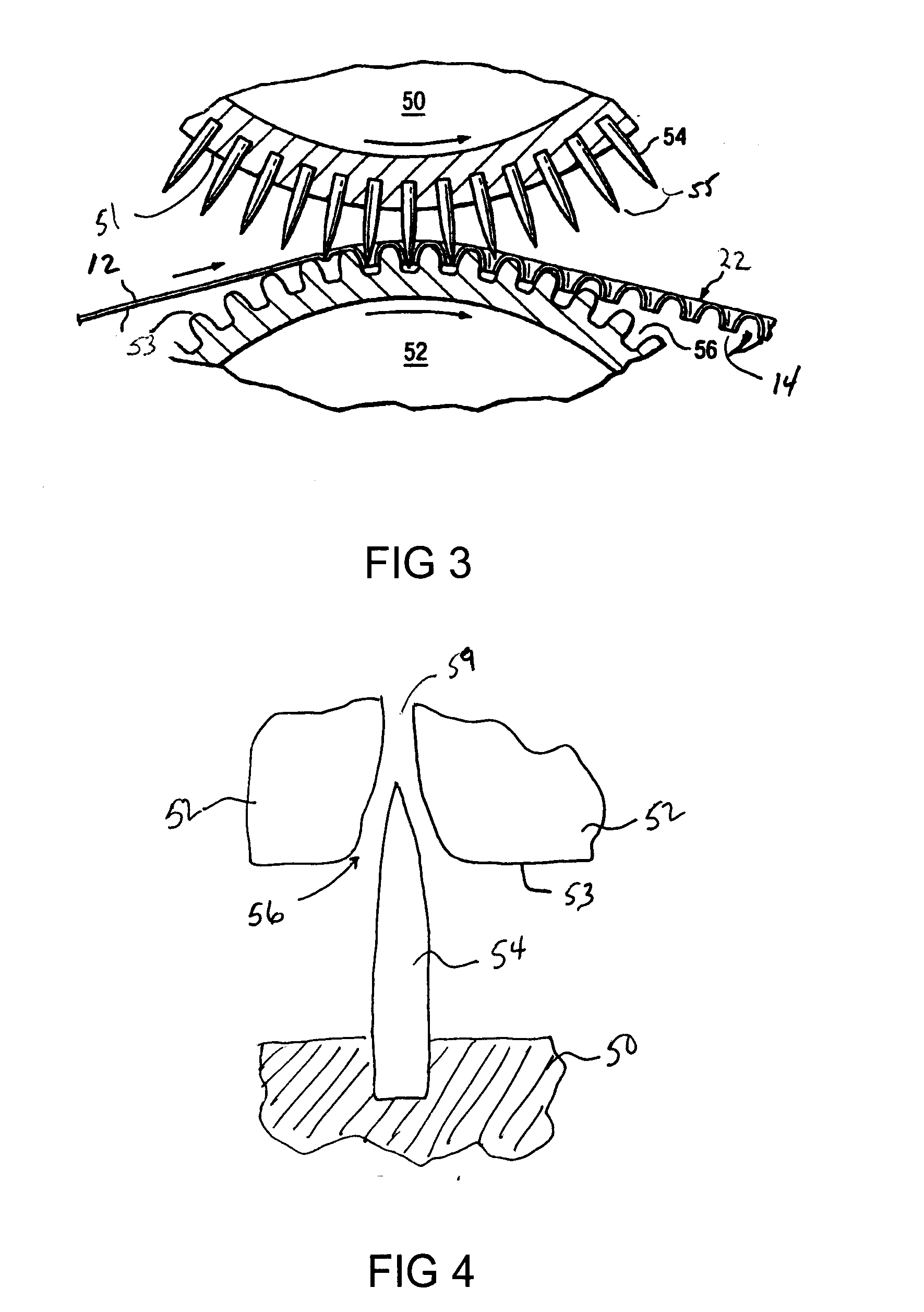

Wiping sheet

InactiveUS20060009106A1Improve wiping effectPromote stratificationCarpet cleanersFloor cleanersNonwoven fabricFiber structure

A wiping sheet is provided, which presents excellent in handling during wiping, high wiping ability for greasy dirt, and less liquid remains on an object after wiping. A wiping sheet having a fiber structure (such as a woven fabric, a knitted fabric and a nonwoven) is obtained, which includes an ultrafine fiber layer containing ultrafine fibers having a fineness of at most 0.9 dtex which result from at least two types of ultrafine fiber-generating conjugate fibers, at least one conjugate fiber giving ultrafine fibers containing a modified vinyl alcohol resin, and the other conjugate fibers giving ultrafine fibers containing another resin(s). The ultrafine fibers can be obtained by a first splittable conjugate fiber including a component containing the modified vinyl alcohol resin and a second splittable conjugate fiber composed of components of other resins. In the ultrafine fiber layer, the fibers are preferably bonded by thermoadhesive resin-containing ultrafine fibers.

Owner:DAIWABO HLDG +1

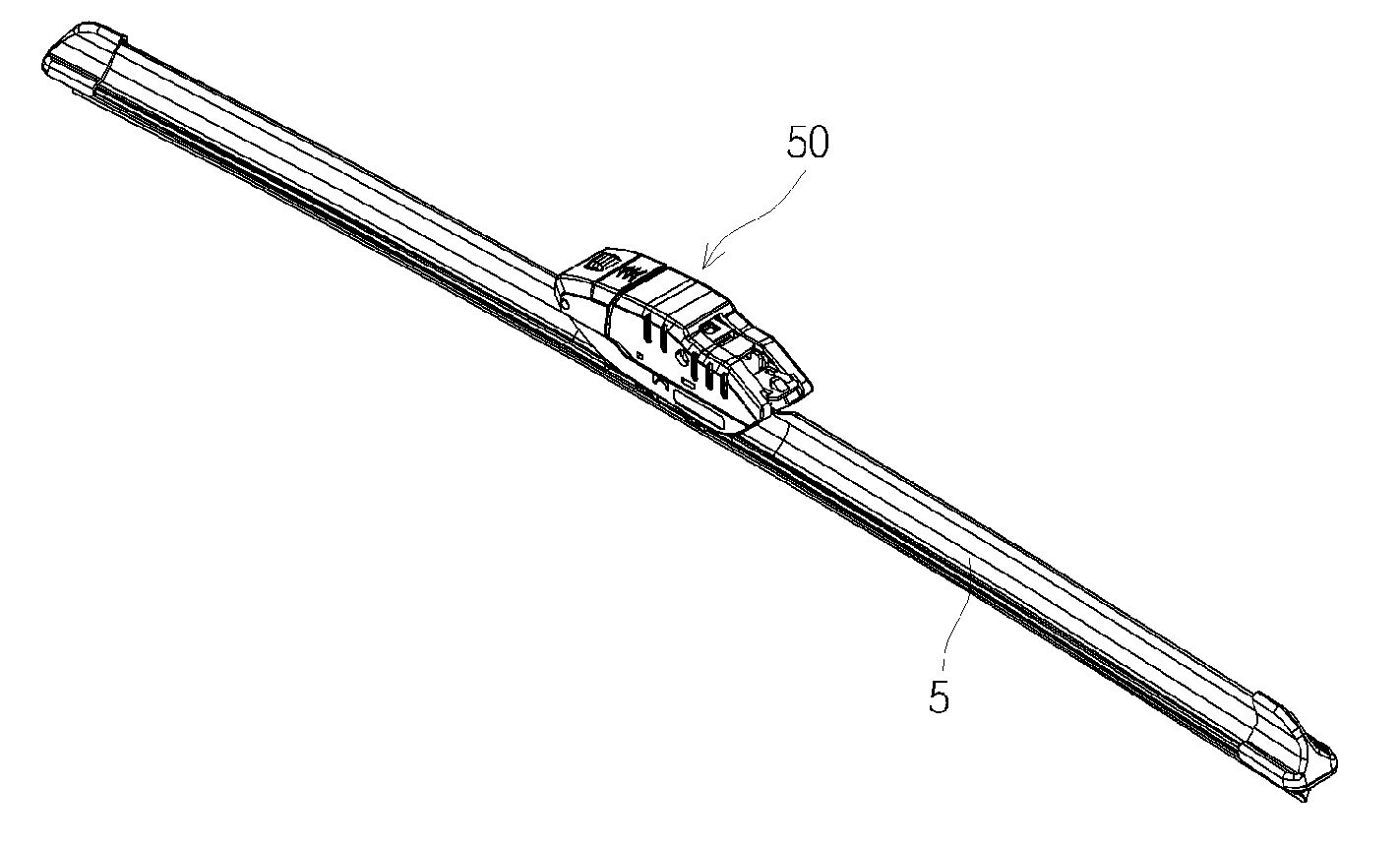

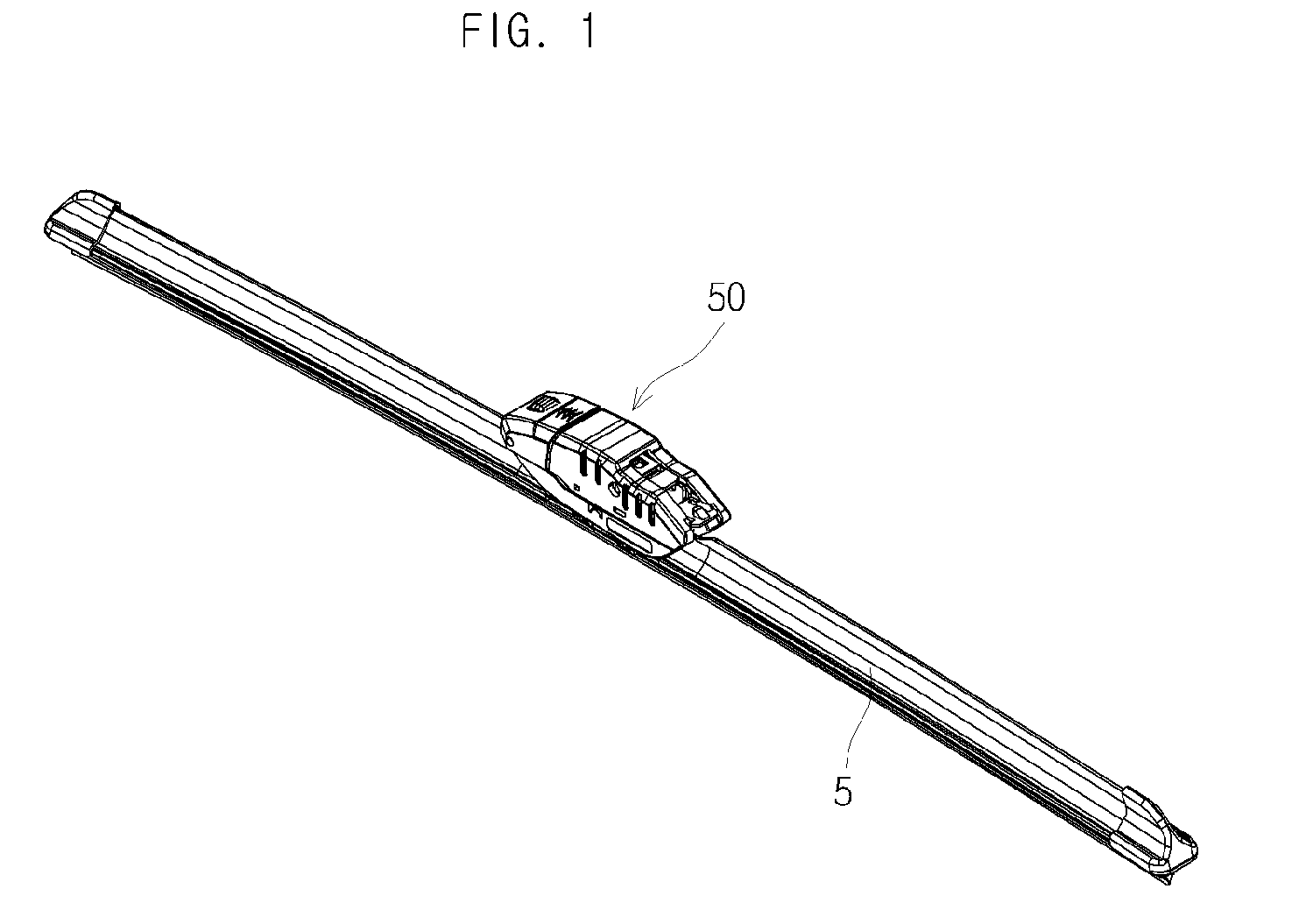

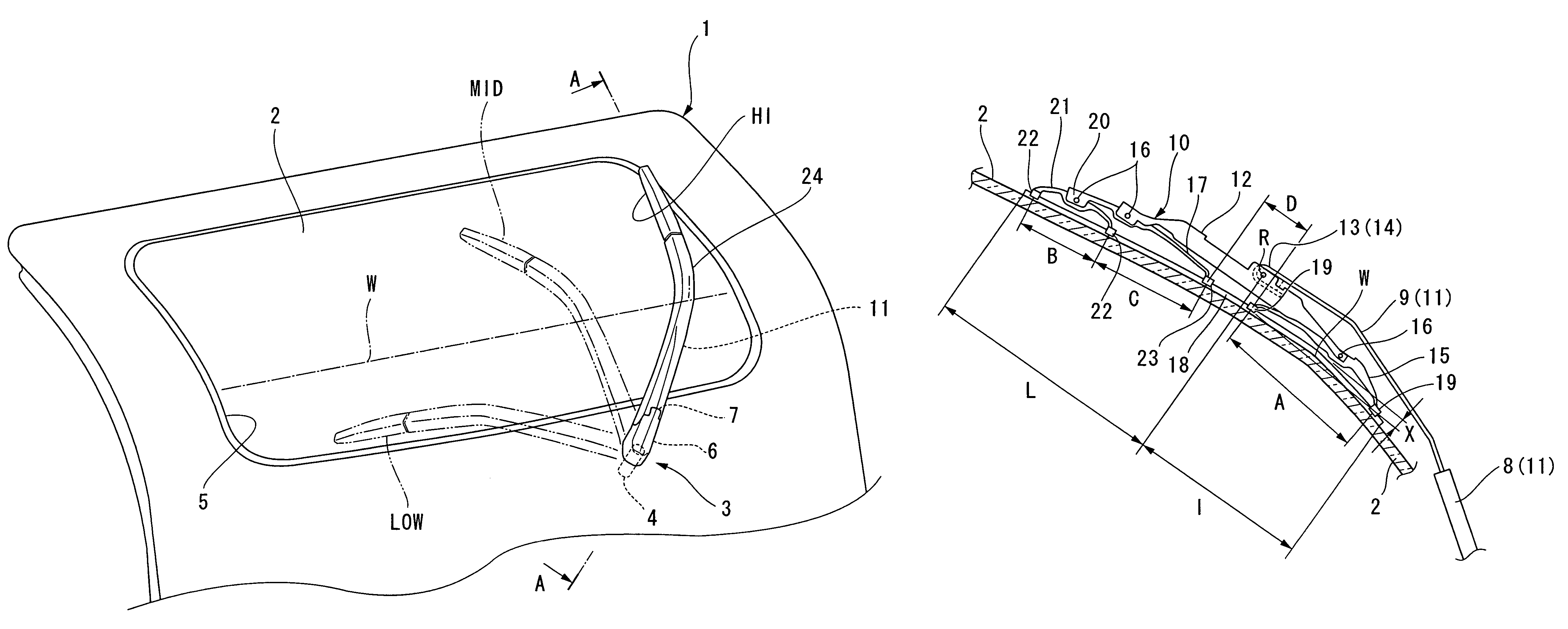

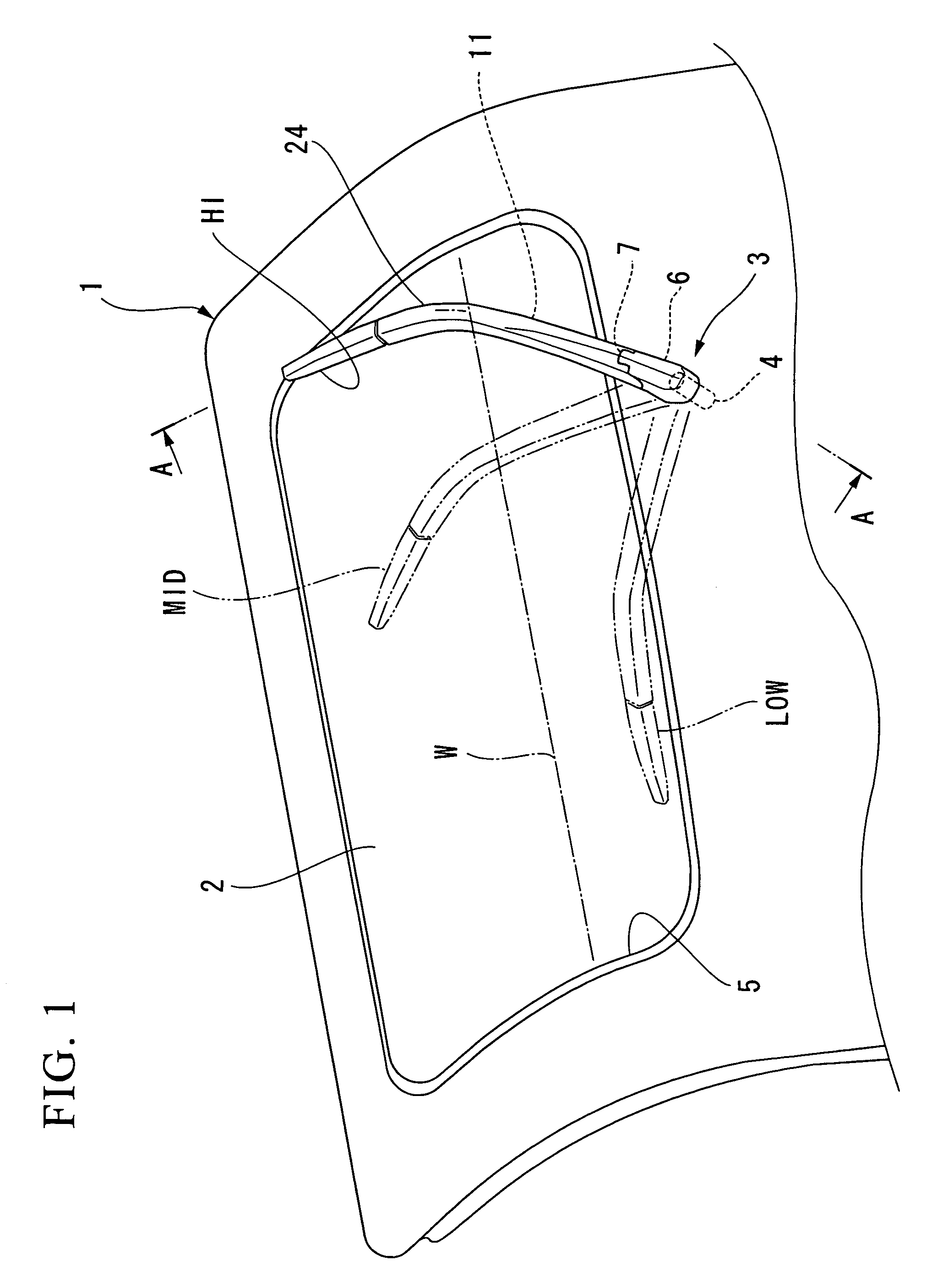

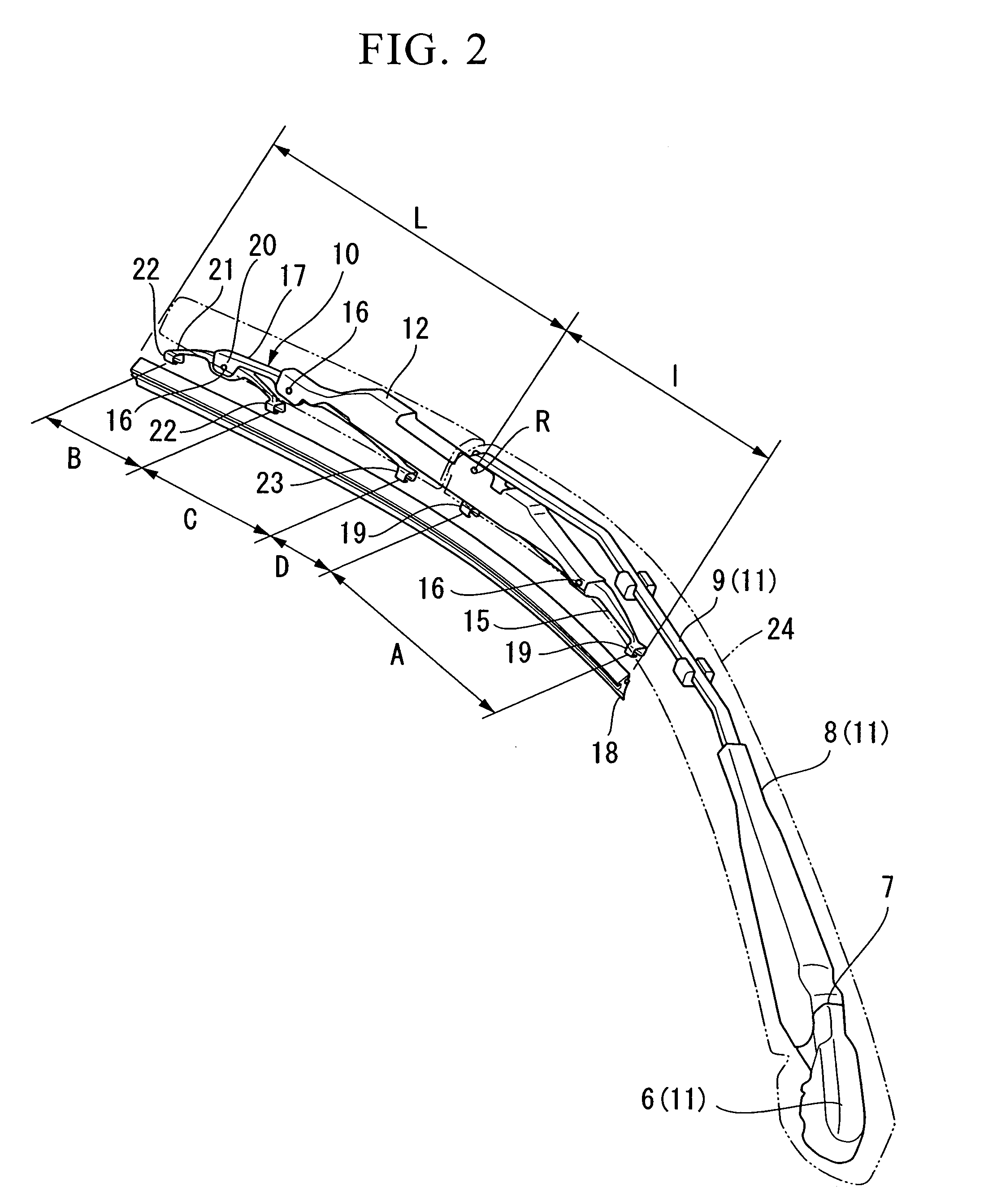

Wiper device

ActiveUS20120144615A1Good wiping performanceImprove wiping effectWindow cleanersVehicle cleaningForeign substanceWindshield

Wiper device is disclosed. a wiper device includes a wiper blade tightly contacted to a windshield and configured to wipe a foreign substance and an adaptor connecting the wiper blade to a wiper arm, wherein the adaptor includes a body rotatably connected to the wiper blade about an axle formed in a traverse direction of the wiper blade, and a connector extended in a lengthwise direction of the wiper blade and having one end that is connected to the wiper arm and the other end that is hinge-connected to the body. Since it is possible to adjust the wiper arm and the wiper blade in various angles, the wiper blade can be tightly contacted to the windshield and thus have a superior wiping performance.

Owner:CAP CORP

Wiper structure

Owner:HONDA MOTOR CO LTD

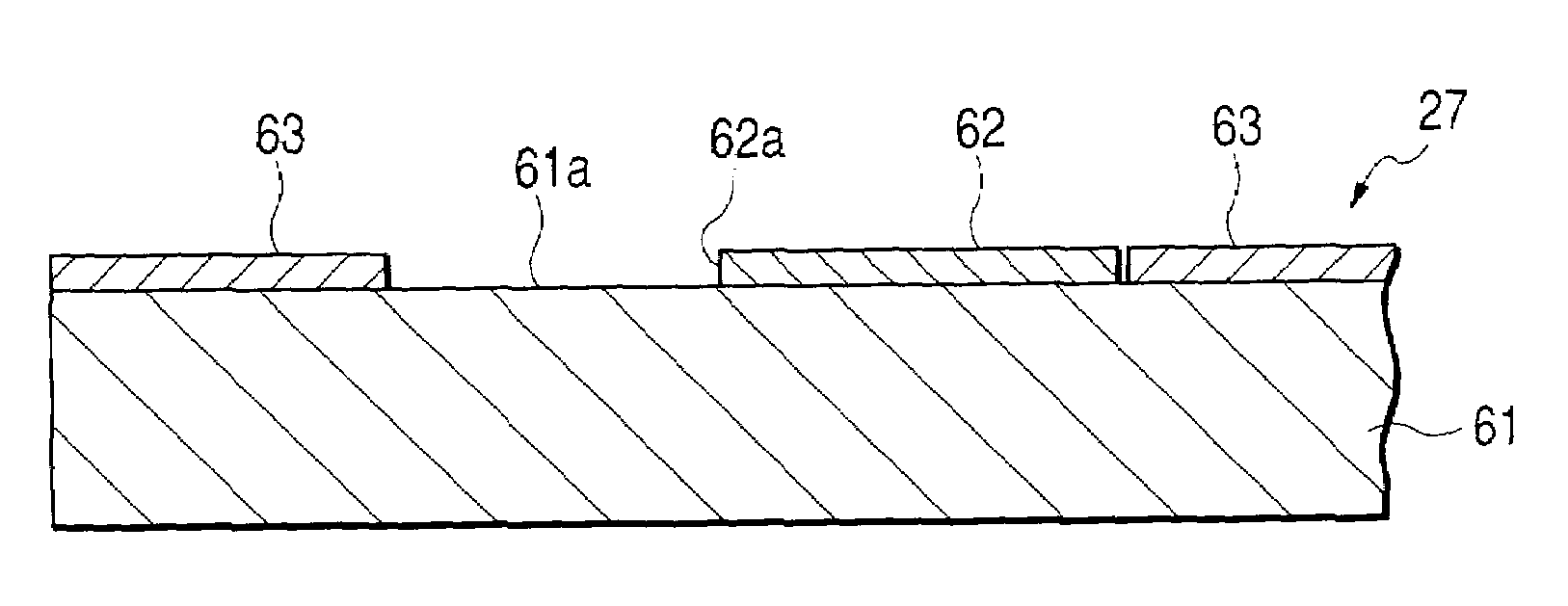

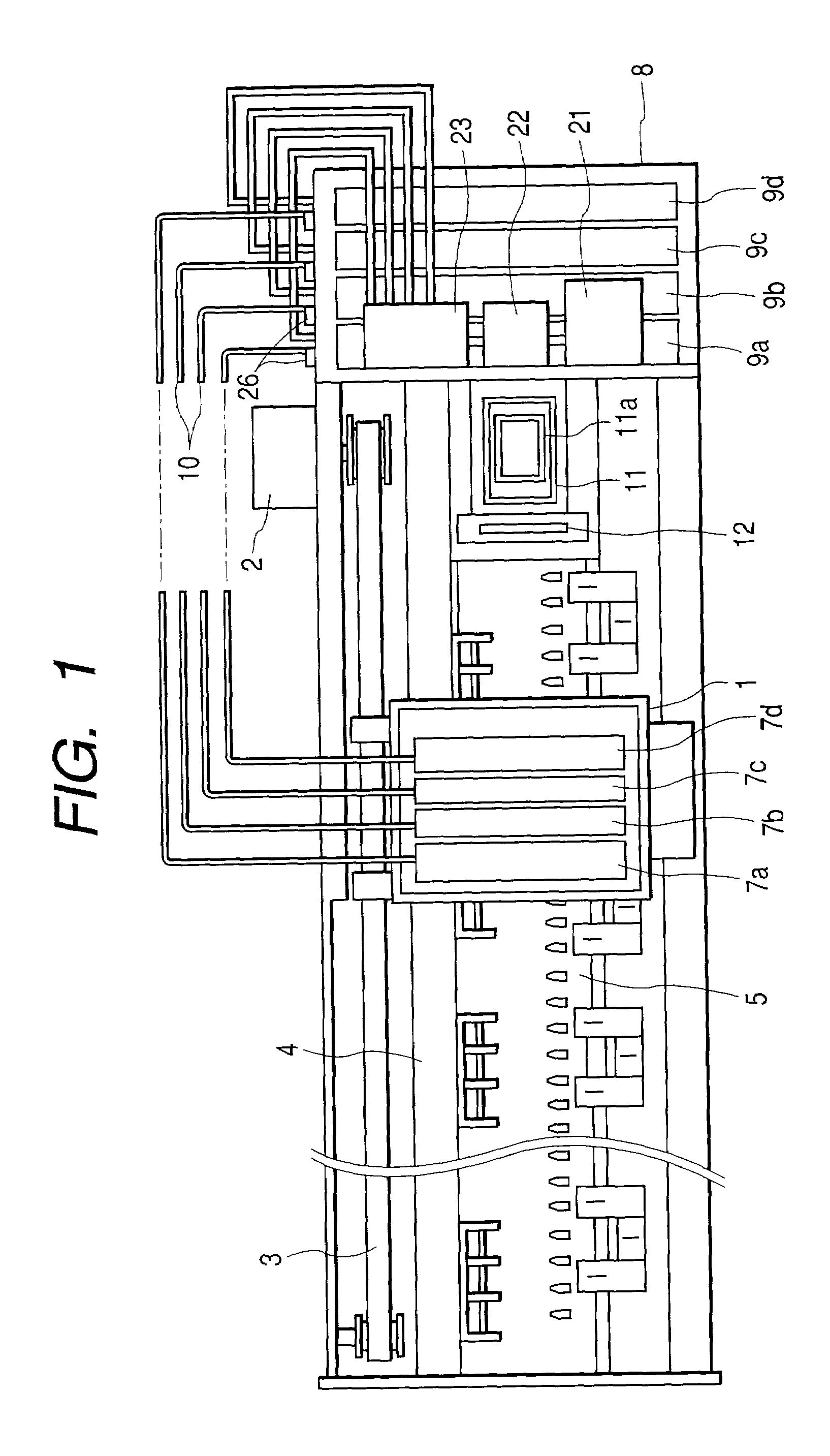

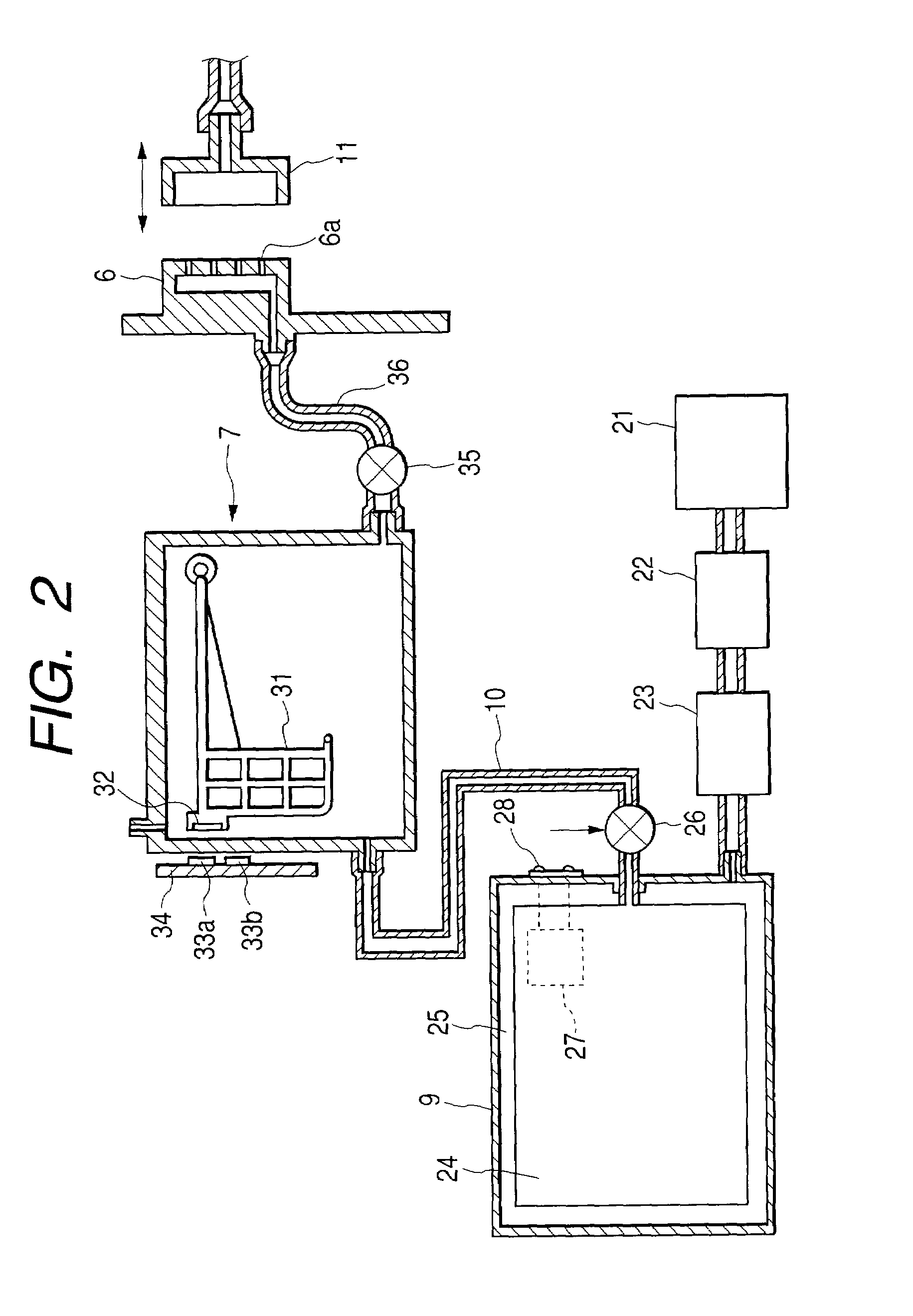

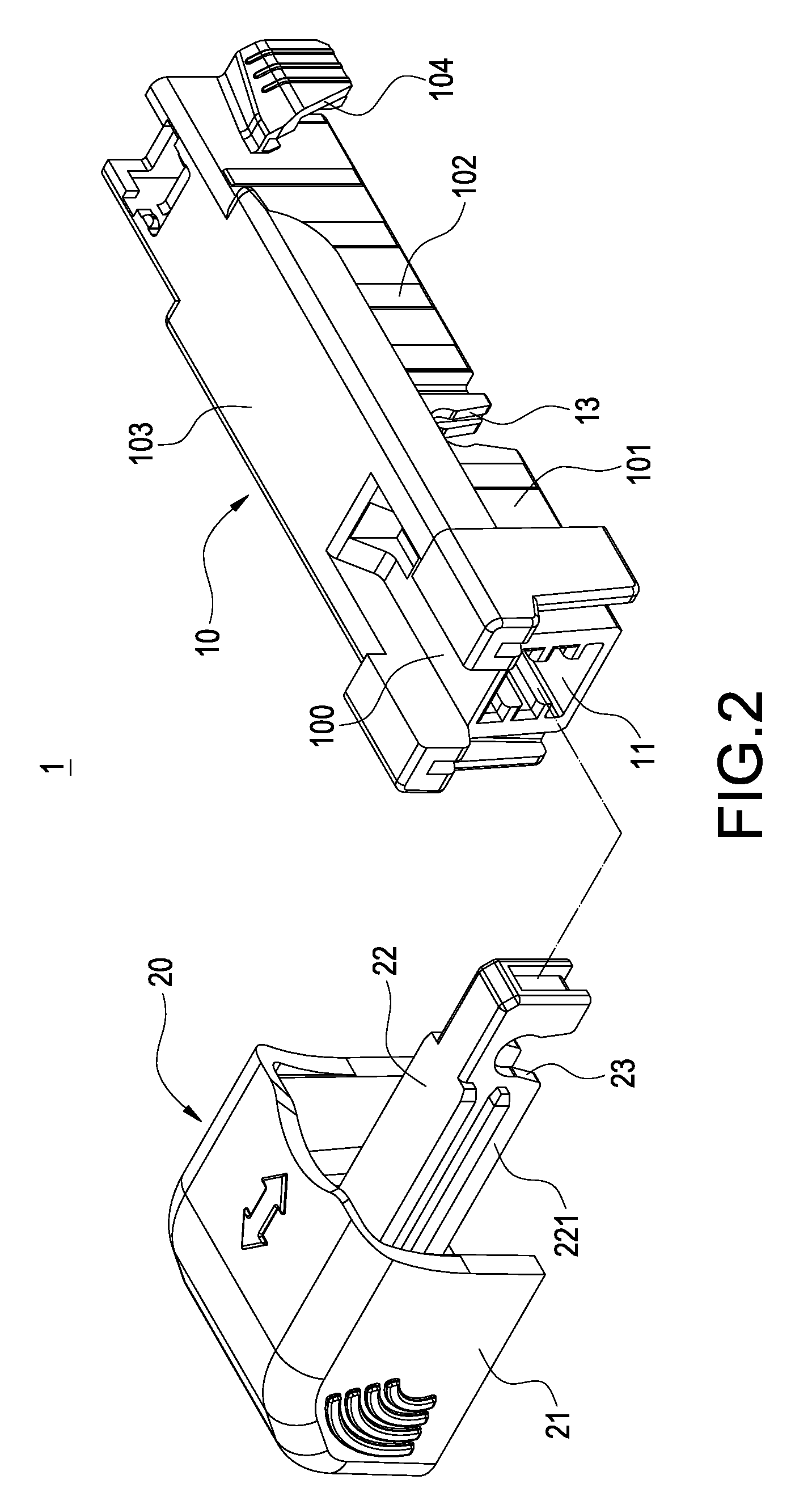

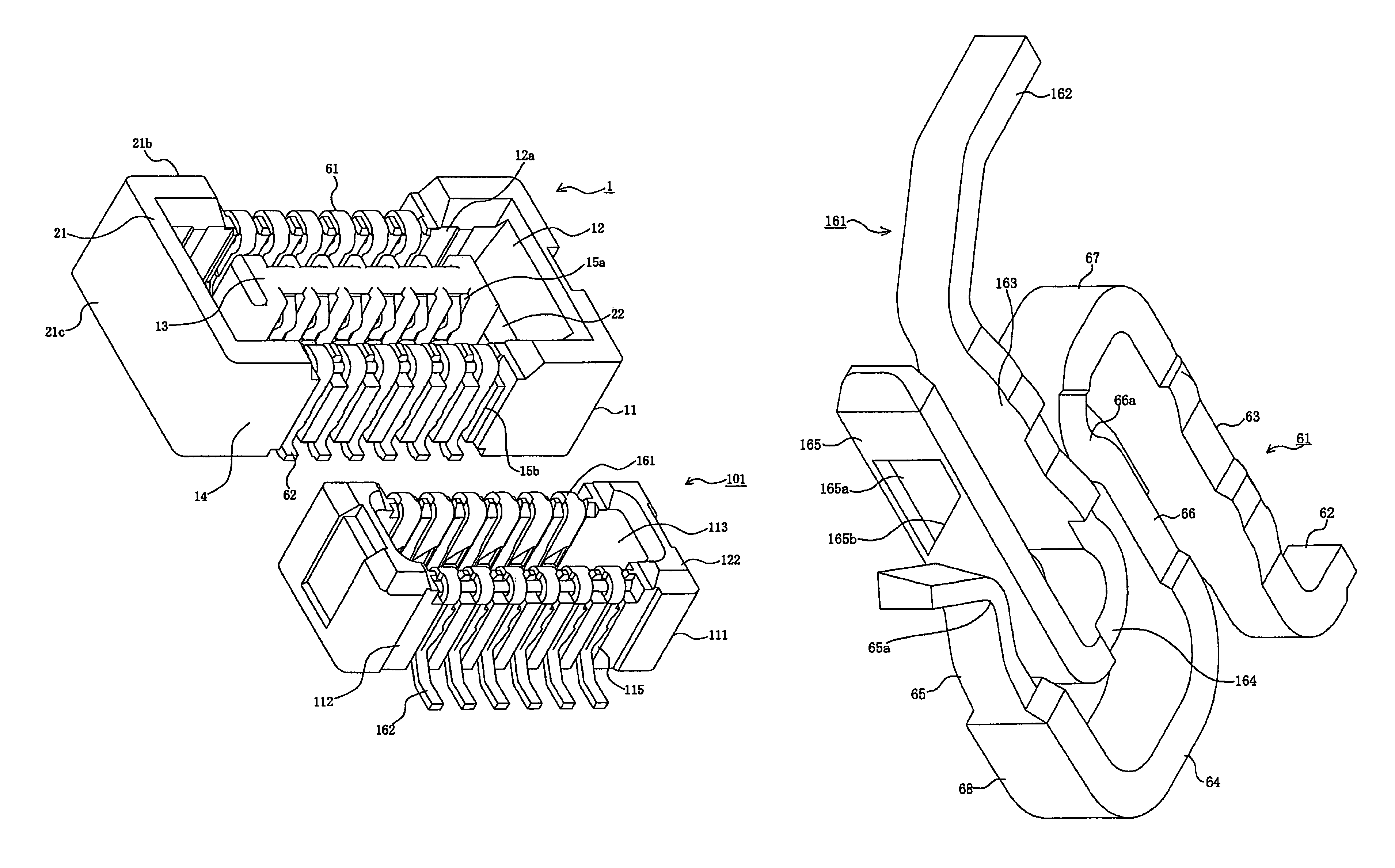

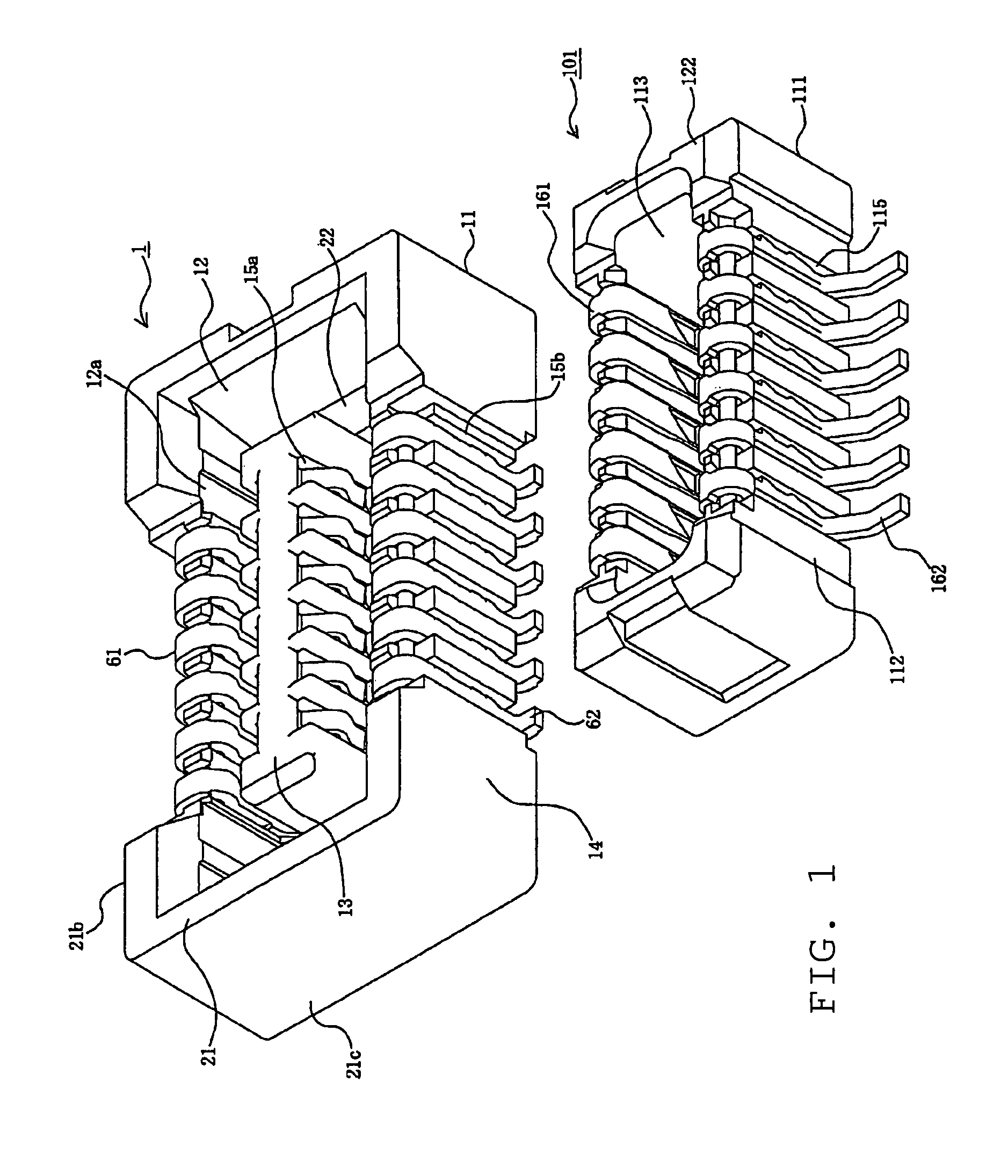

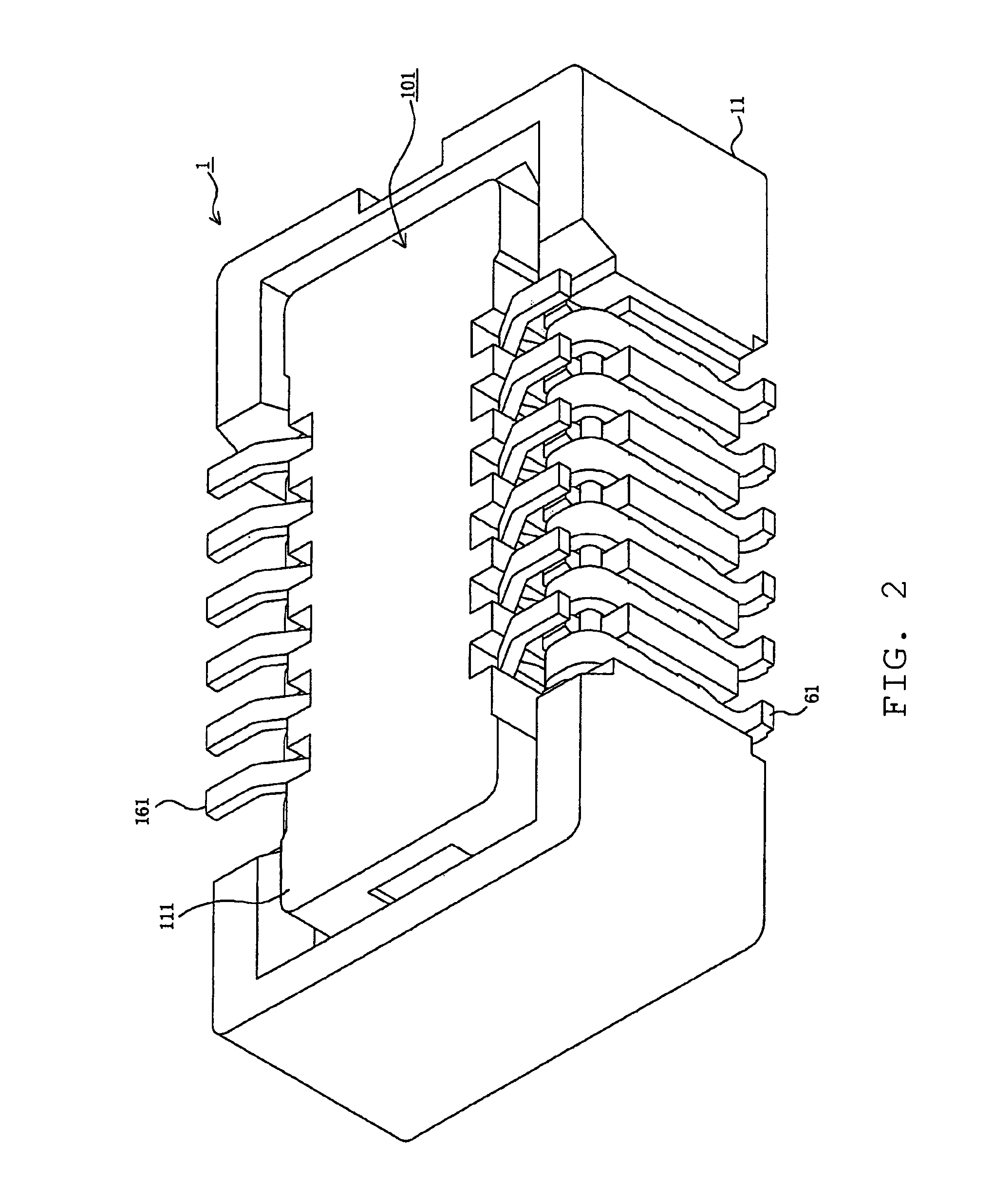

Connection apparatus for circuit board, ink jet type recording apparatus using the same, IC chip and ink cartridge having IC chip

InactiveUS7101021B2Avoid it happening againAccurate operationPrinted circuit assemblingPrinted circuit aspectsResistContact pad

A circuit board on an ink cartridge has contact pads which are electrically conducted to a semiconductor storage element mounted on the circuit board. Connector terminals on an ink jet recording apparatus are brought into relative slide contact with a surface of this circuit board, and electrically connected to the contact pads. When the connector terminals come in contact with the contact pads, the dust adhering to the connector terminals is wiped and removed by step portions that are constituted by no-resist-film formation parts and that are adjacent to the contact pads. Consequently, the reliability of the electrical contact between the connector terminals and the contact pads is ensured.

Owner:SEIKO EPSON CORP

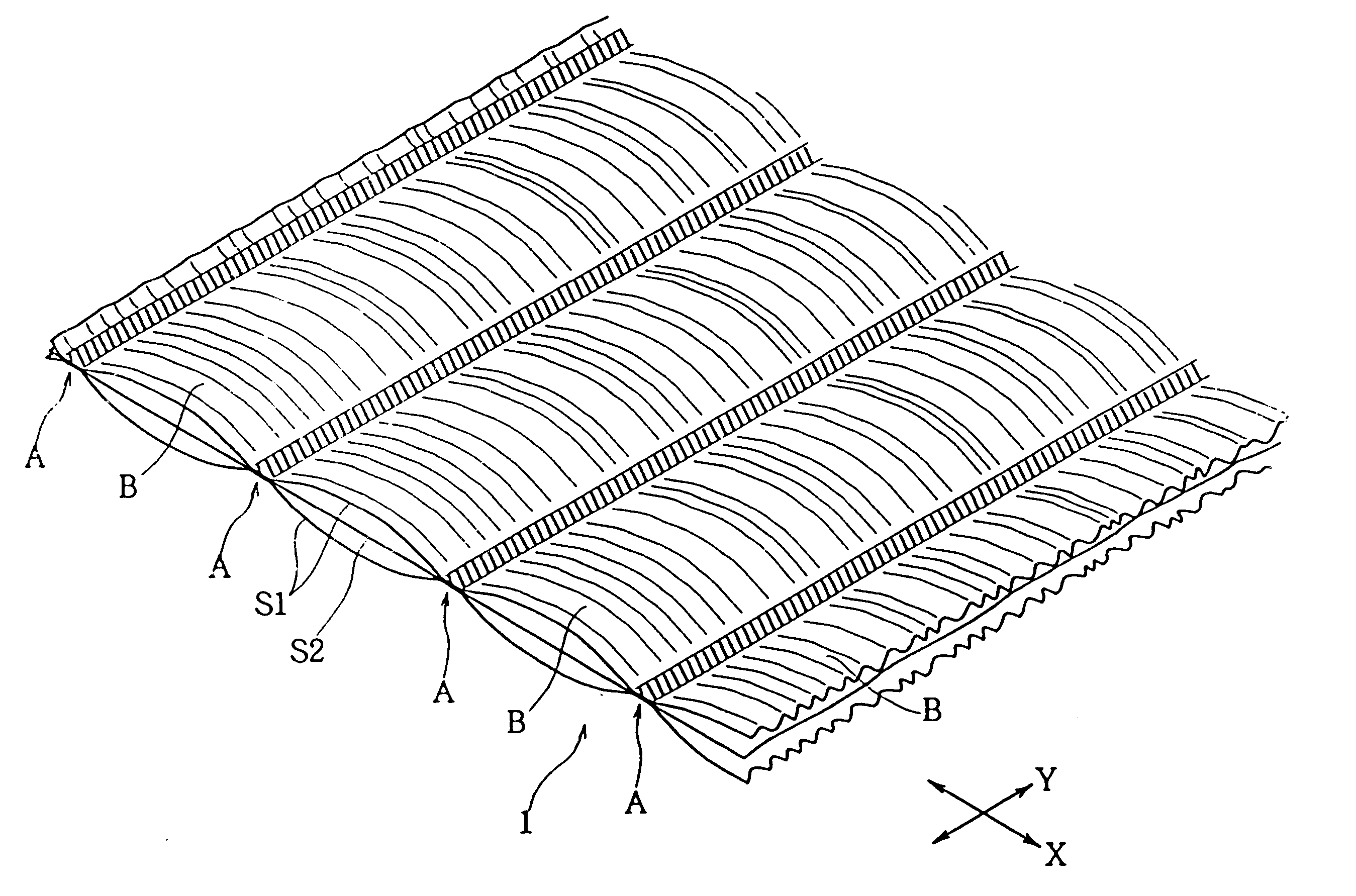

Wiping sheet

InactiveUS6309731B1Improve wiping effectHigh strengthMechanical working/deformationSpecial paperWrinkle skinEngineering

After laminating together the first sheets crepe-processed at a high crepe ratio and the second sheet crepe-processed at a crepe ratio lower than that of the first sheet or not crepe-processed, the sheets are bonded together at bonding parts at a given pitch in rows. When the resulting bonded sheets are impregnated with a liquid, expansions are generated between the rows of bonding parts due to the difference in ratios of the elongation of the two sheets. The expansions take on the shape of large wrinkle according to the pitch of the bonding parts. At the production process of the sheet, the sheet is crepe-processed containing water at a preset ratio, whereby small wrinkles as residual crepe wrinkles are formed on the sheet surface. The large wrinkles and the small wrinkles can enhance the wiping effect.

Owner:UNI CHARM CORP

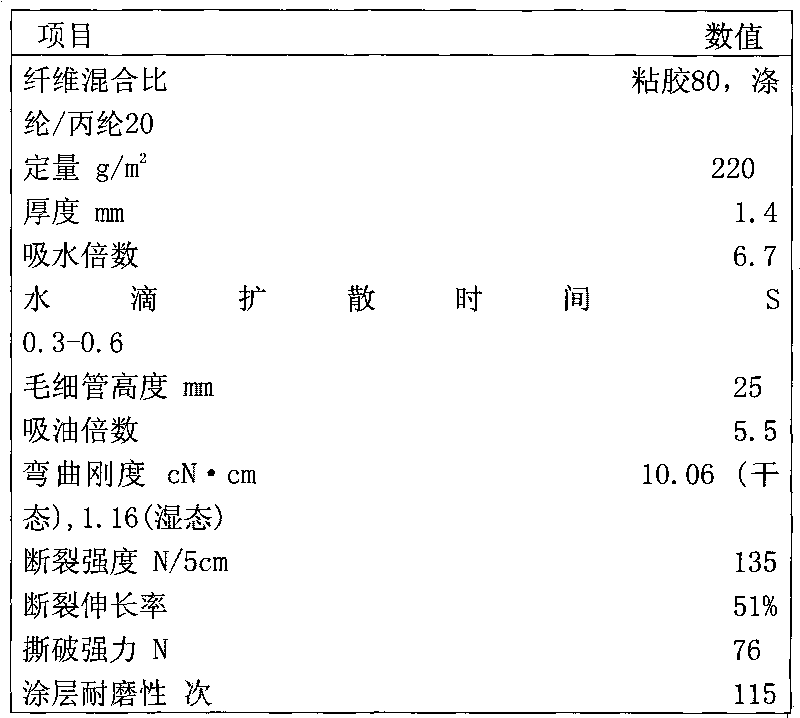

Method for preparing non-woven wiping cloth

InactiveCN101713147AGood water and oil absorptionGood flexibilityCarpet cleanersFloor cleanersCross-linkFoaming agent

The invention belongs to daily necessities, and in particular relates to a method for preparing a non-woven wiping cloth. The method is characterized by comprising the following steps: performing coating finishing on a non-woven base fabric with an acrylate coating agent, wherein 1 liter of coating agent mainly comprises 100 to 800 milliliter of acrylate adhesive, 0.5 to 50 grams of foaming agent, 1 to 30 grams of stabilizer, 0.5 to 40 grams of tackifier, 5 to 80 grams of water absorbent, 1 to 50 grams of cross-linking finishing agent, 10 to 80 milliliter of softener and 200 to 900 milliliter of water; and coating with a scraper is adopted, and the thickness of the coating is 0.05 to 1.5mm; and after the amount of the adhesive is controlled to be between 20 and 250g / m2, performing baking and tapping finishing on the coated material. The vehicle wiping cloth prepared by the process of the invention has good water and oil absorption and relatively good softness, solves the problems of dropping chips, scraping the surface of a vehicle and leaving water marks after wiping which usually appear in a wiping process of an ordinary wiping cloth, and the coating surface and a base fabric have good adhesion.

Owner:张金六

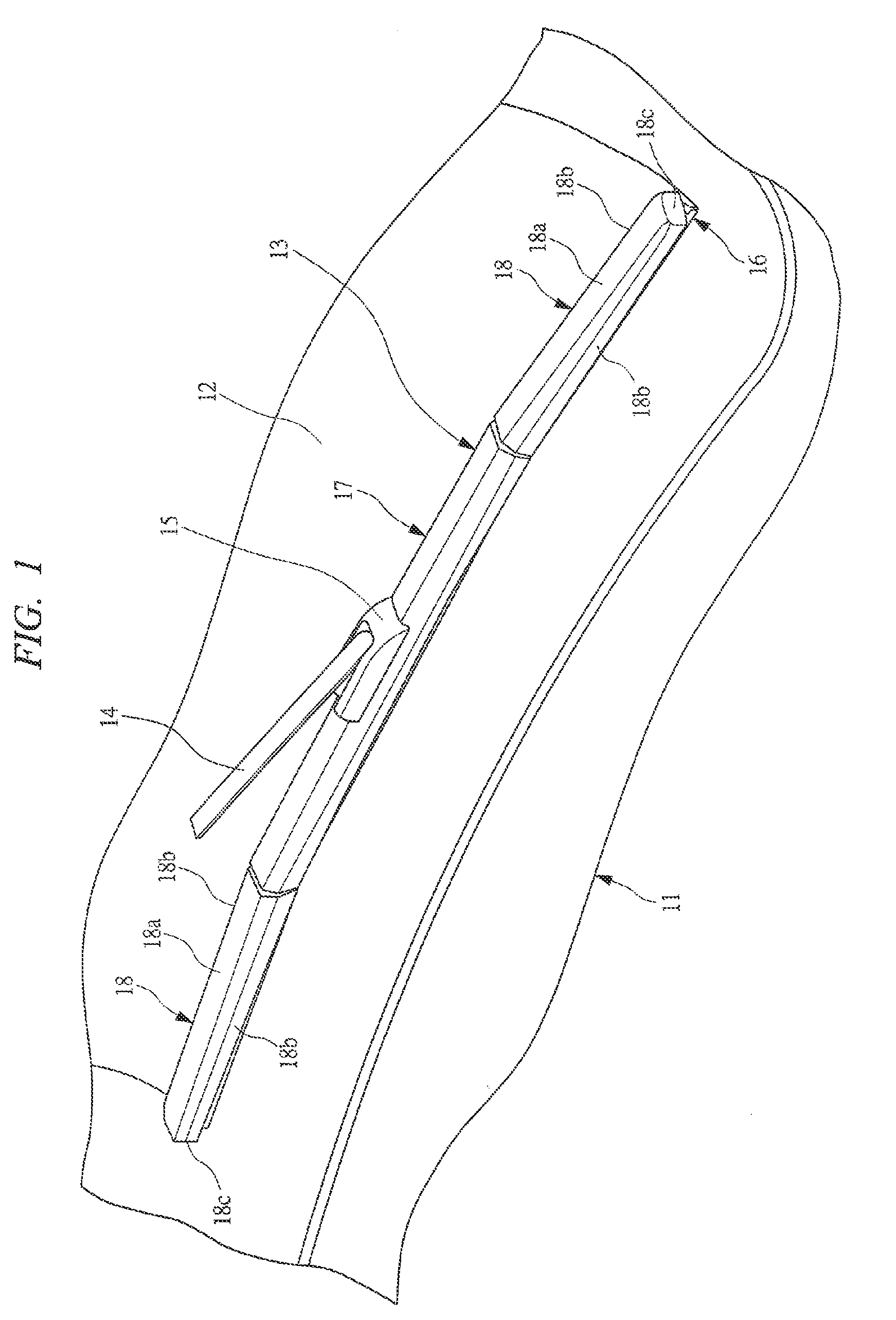

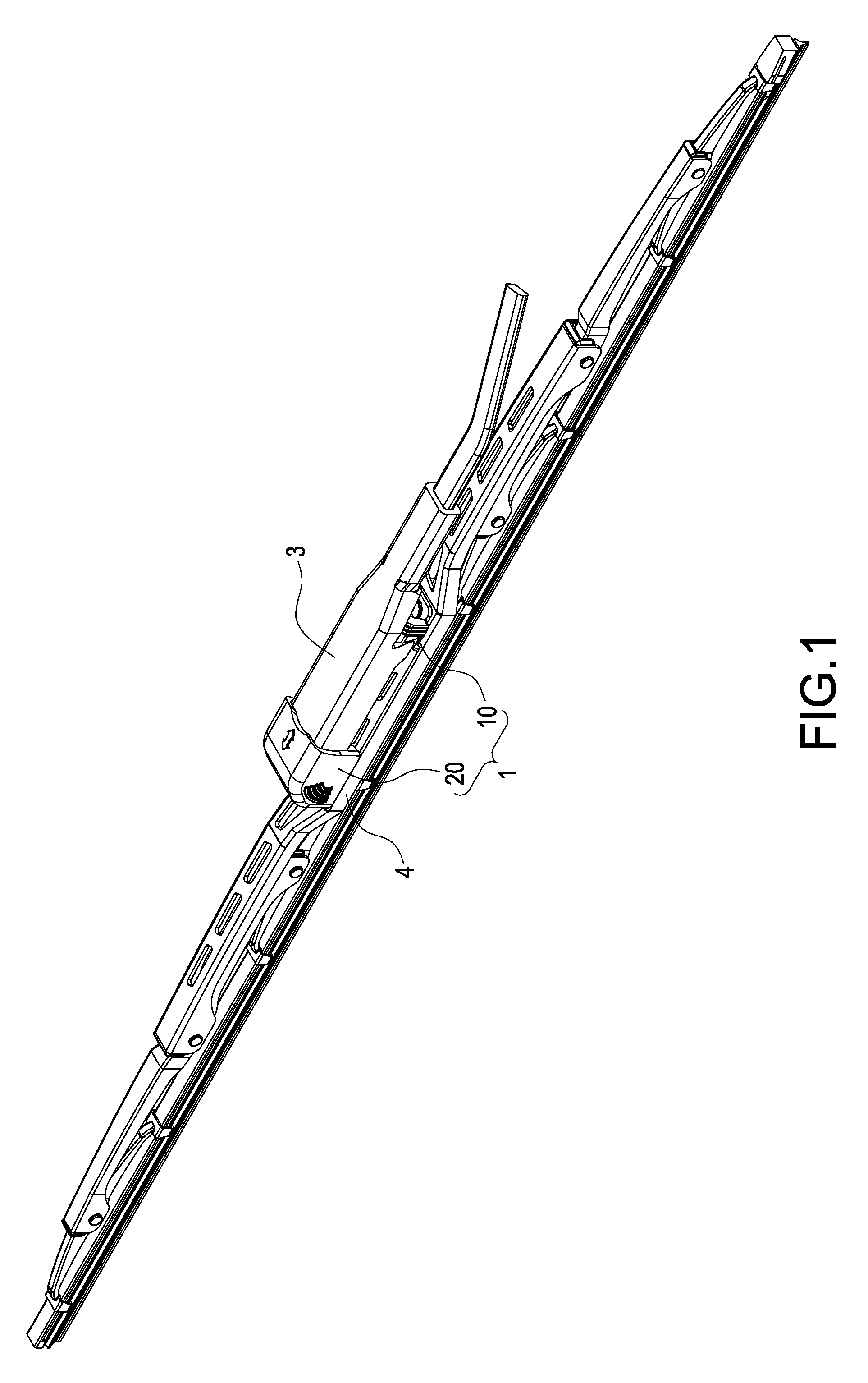

Wiper blade

ActiveUS8151406B2Good lookingImprove versatilityWindow cleanersVehicle cleaningEngineeringWindshield

A wiper blade 13 comprises a rubber holder 17 attached to a tip of a wiper arm 14 and a blade rubber 16 supported by the rubber holder 17. The rubber holder 17 is formed into a U-shaped cross section, and an intermediate portion of the blade rubber 16 is covered with the rubber holder 17. Also, both sides of the rubber holder 17 are provided with covers 18 in a longitudinal direction in series. Each of the cover 18 becomes rotatable to the rubber holder 17 in a direction perpendicular to a front windshield glass 12, and exposed portions from the rubber holder 17 of the blade rubber 16 are covered with these covers 18 in an elastically deformable state.

Owner:MITSUBA CORP

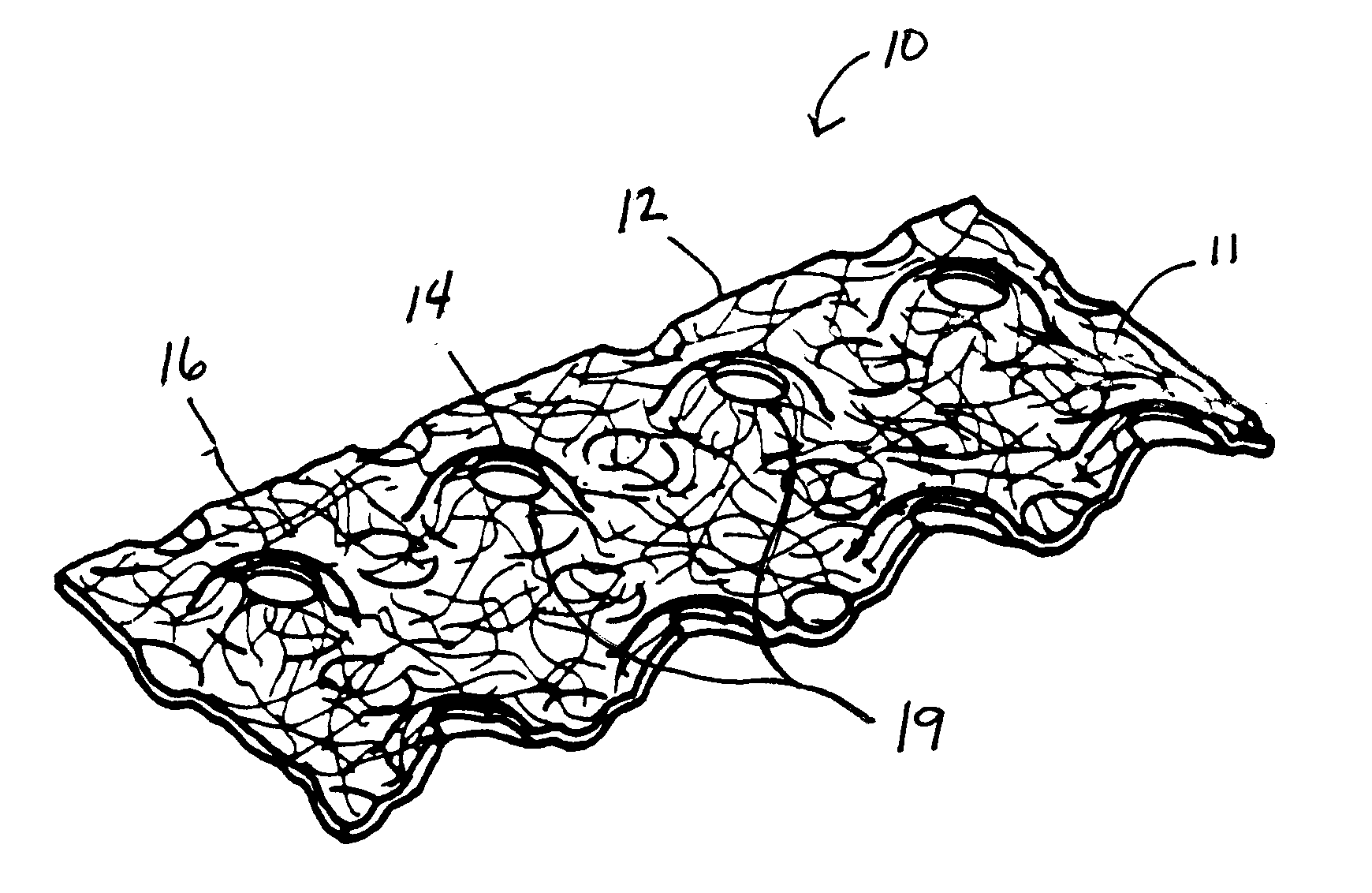

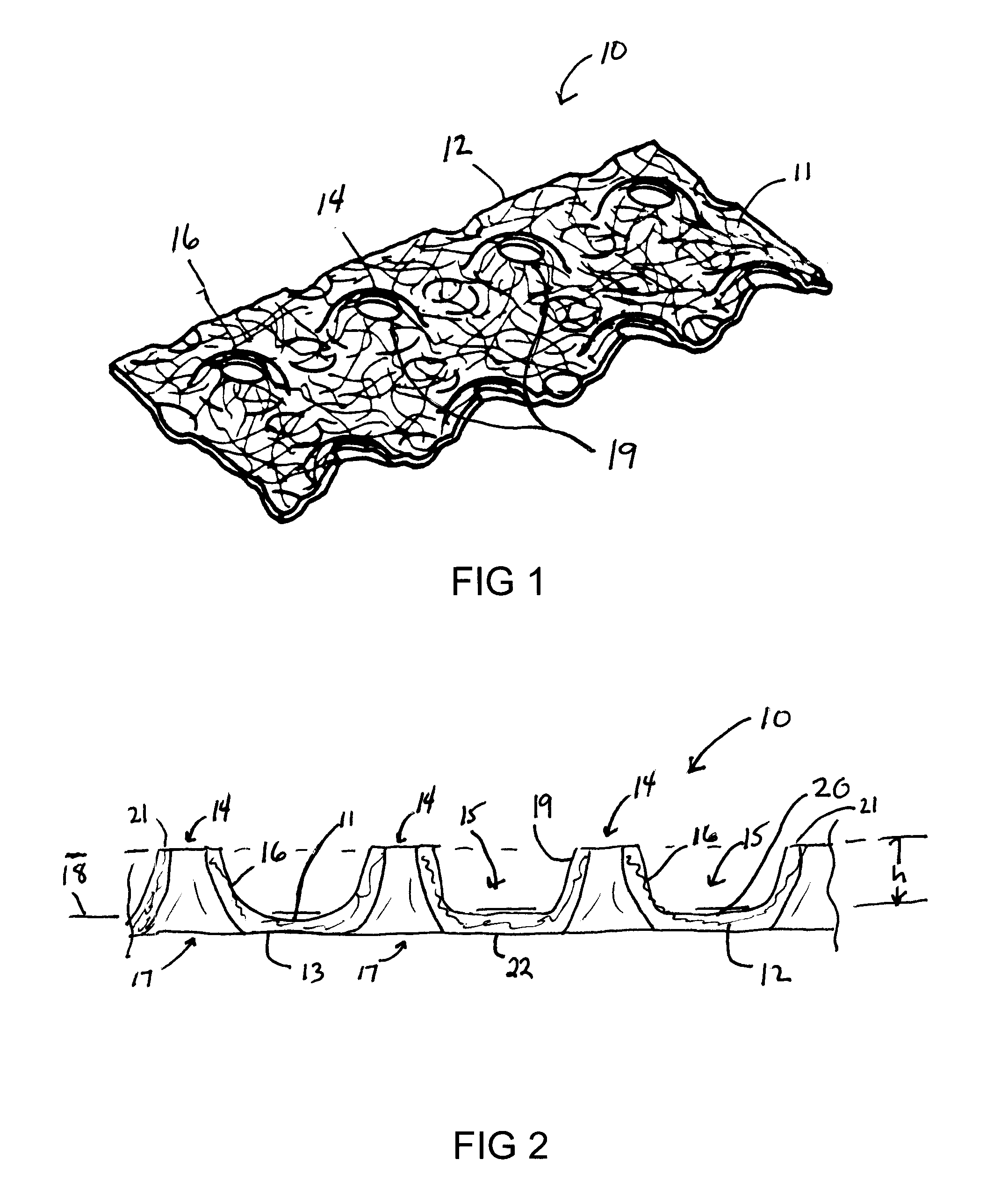

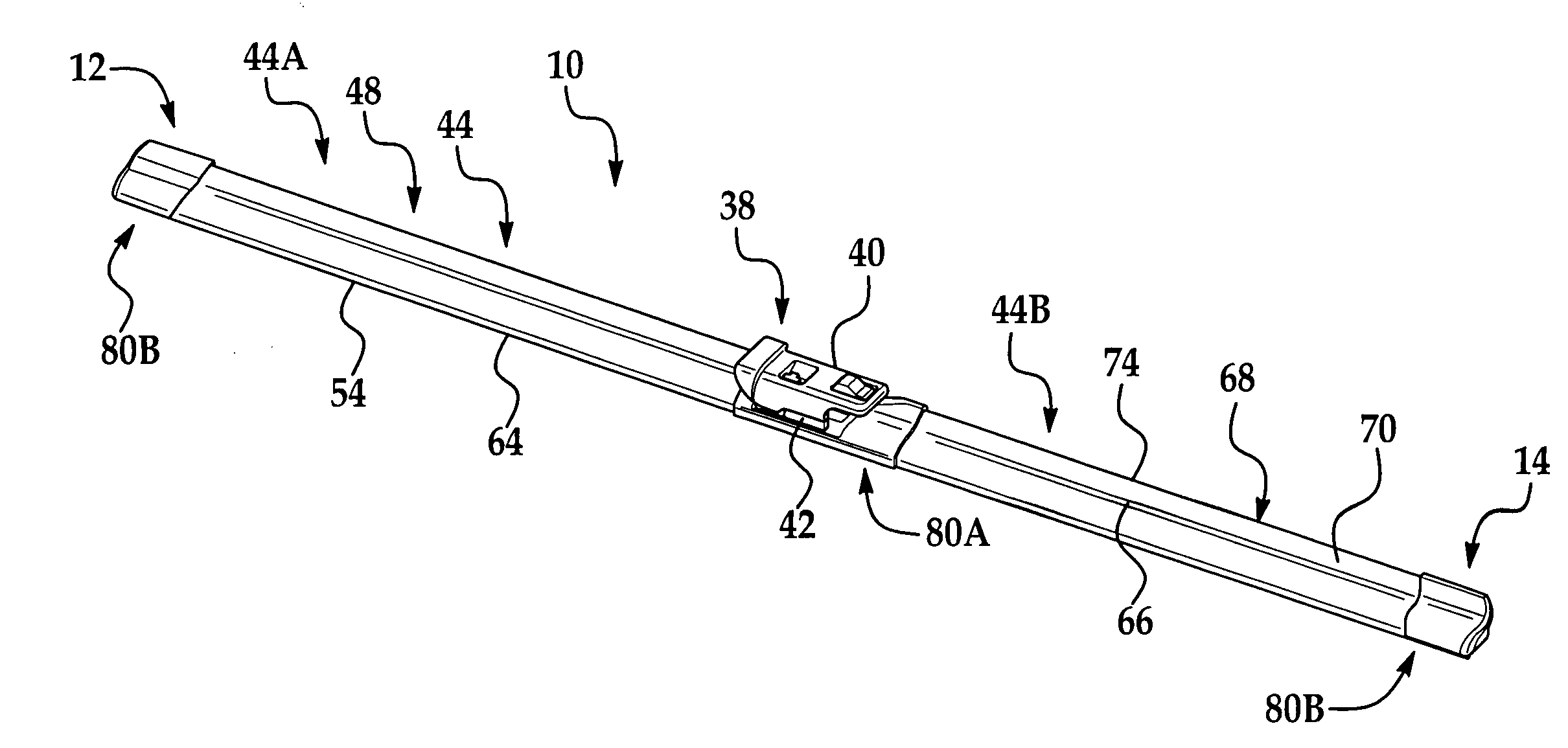

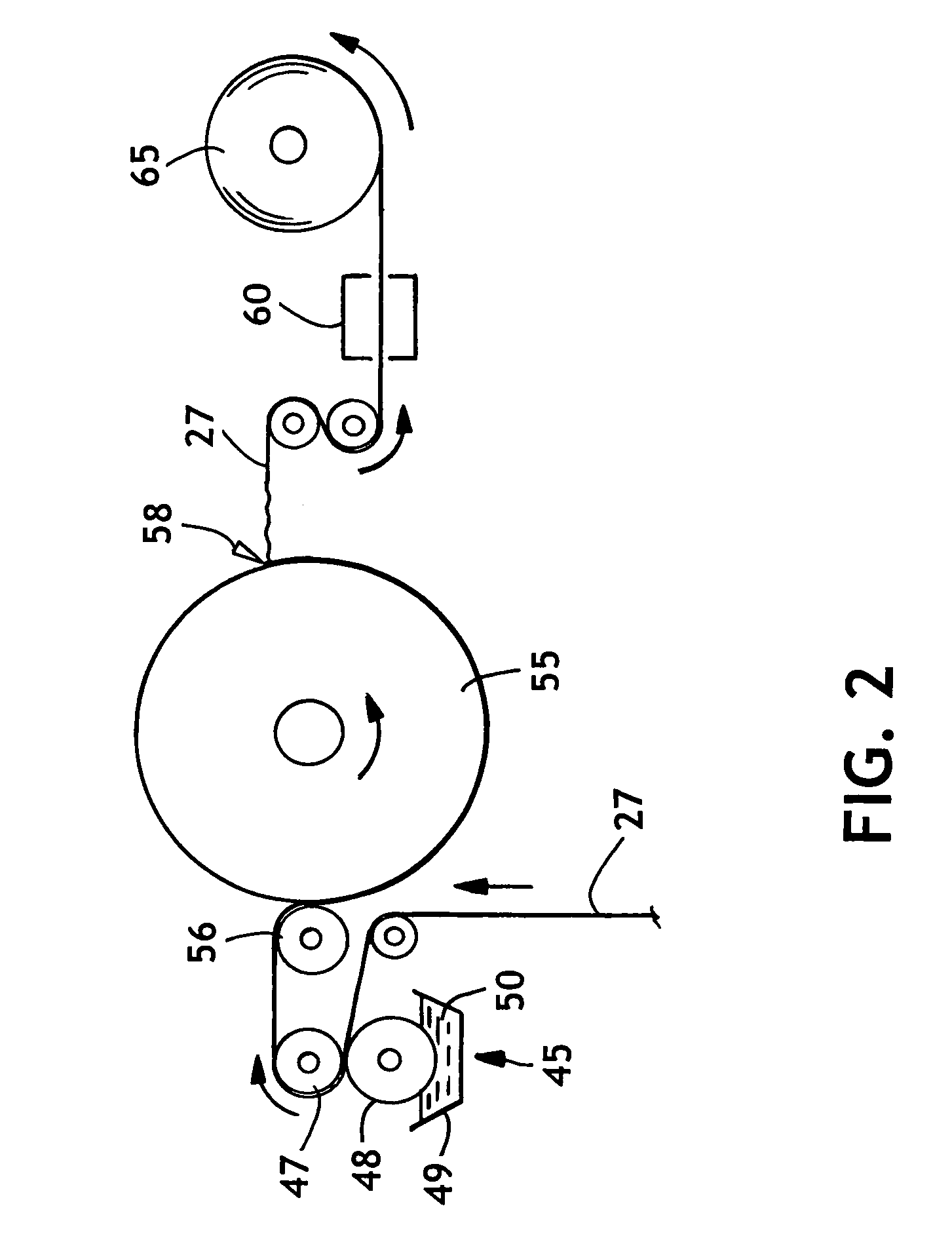

Apertured Wiping Cloth

InactiveUS20110119850A1Unique surface and tactile propertyImprove wiping performanceBoard cleaning devicesCarpet cleanersEngineeringThermoplastic polymer

The present invention provides a wiping cloth which has unique surface properties, tactile feel and enhanced wiping performance for wiping both wet and dry surfaces. The wiping cloth has a series of three-dimensional projections which encircles apertures. The wiping cloth is made from a substrate which contains a thermoplastic polymer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

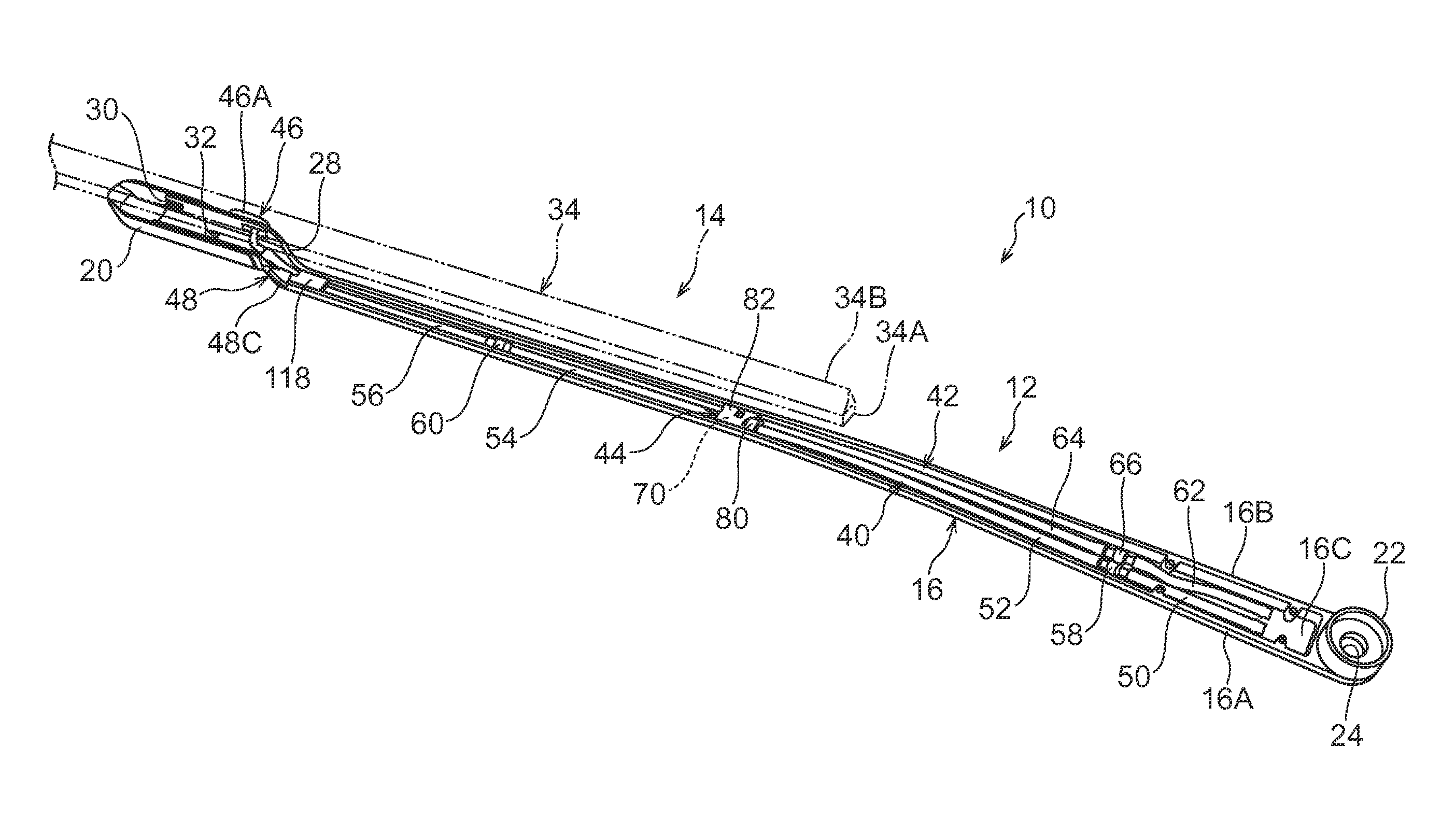

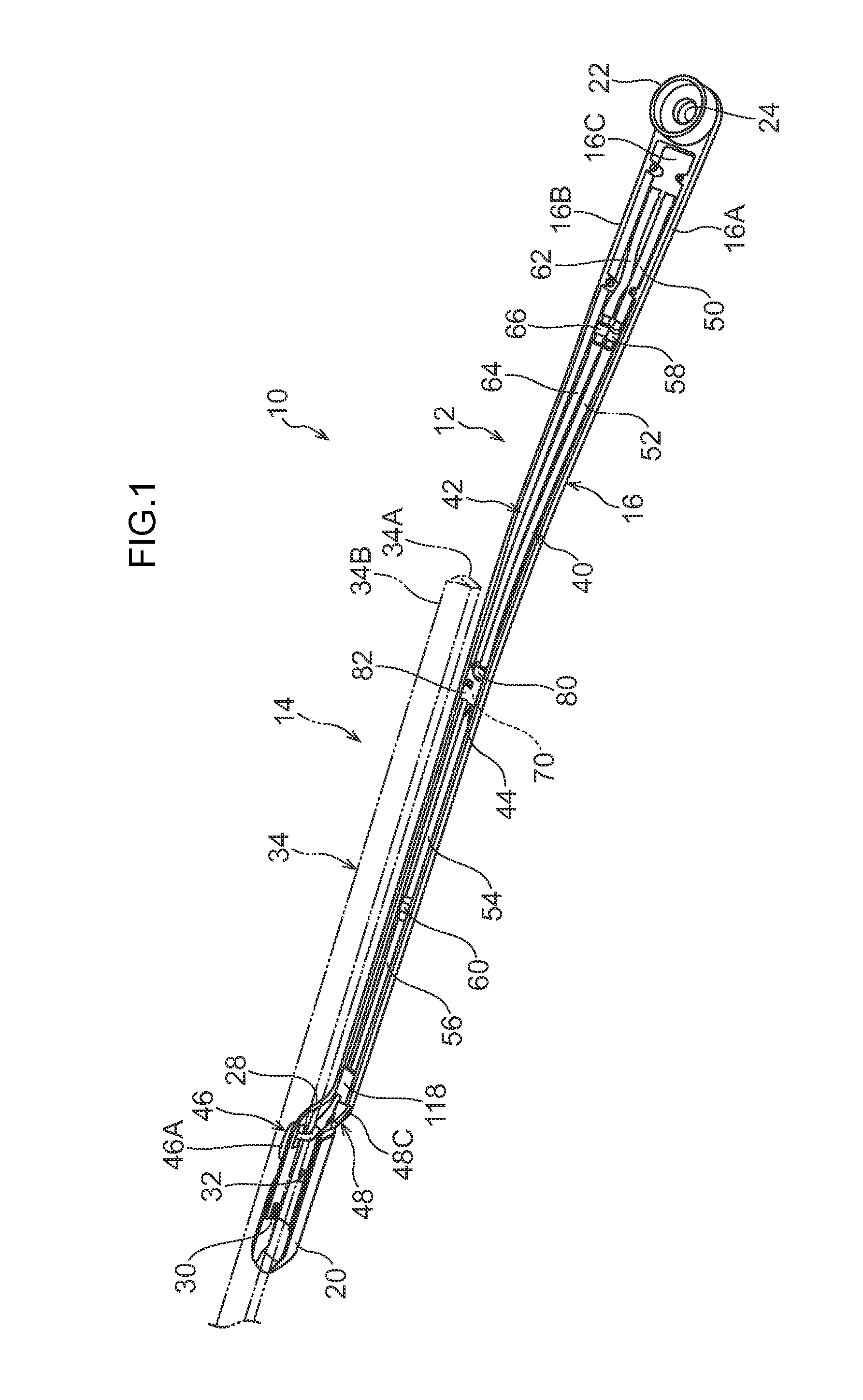

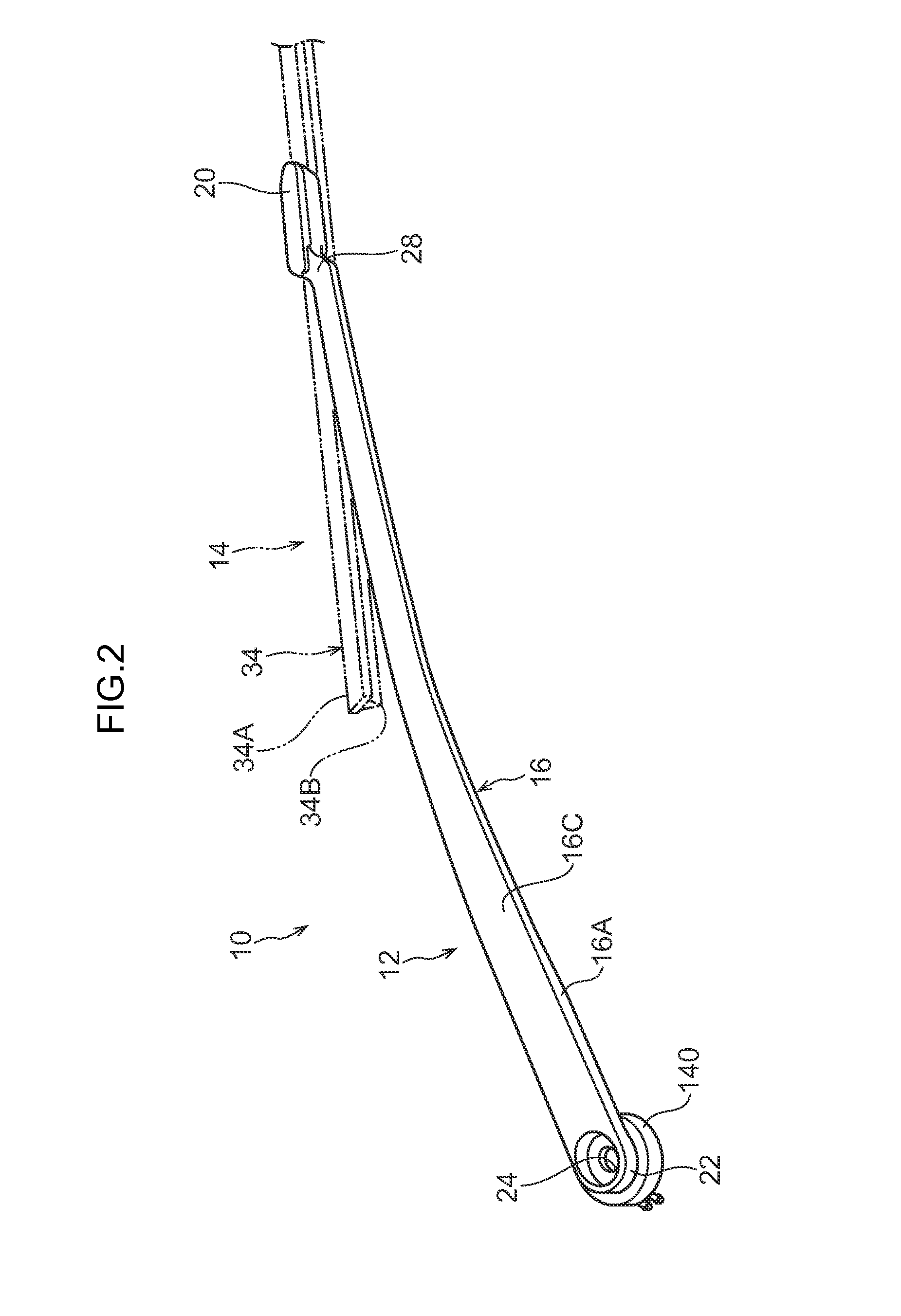

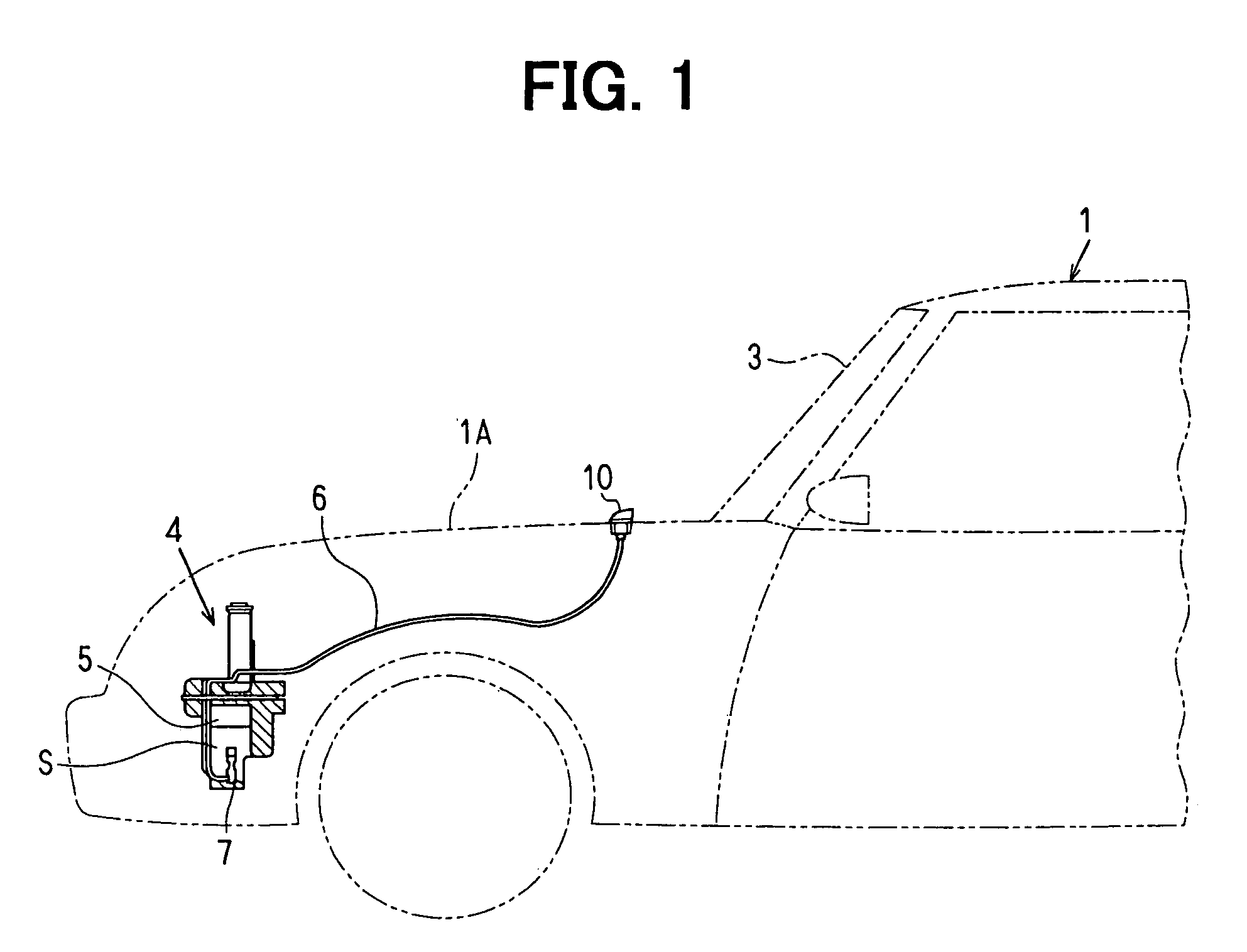

Wiper arm and vehicle wiper apparatus equipped therewith

ActiveUS20150113754A1Improve wiping effectStable state of arrangementWindow cleanersVehicle cleaningLine tubingEngineering

A wiper arm comprising an arm main body; a first nozzle portion disposed at a first predetermined position in a length direction of the arm main body; a second nozzle portion disposed at a second predetermined position in the length direction of the arm main body, and jets washing fluid toward a position that is different from an impact point of the washing fluid jetted from the first nozzle portion; a first line hose accommodated in the arm main body and connected to the first nozzle portion; a second line hose accommodated in the arm main body side-by-side with the first line hose and connected to the second nozzle portion; and a hose retention unit attached to the arm main body and that comprises: a first hose retention portion retaining the first line hose; and a second hose retention portion provided integrally with the first hose retention portion and retaining the second line hose.

Owner:DENSO CORP

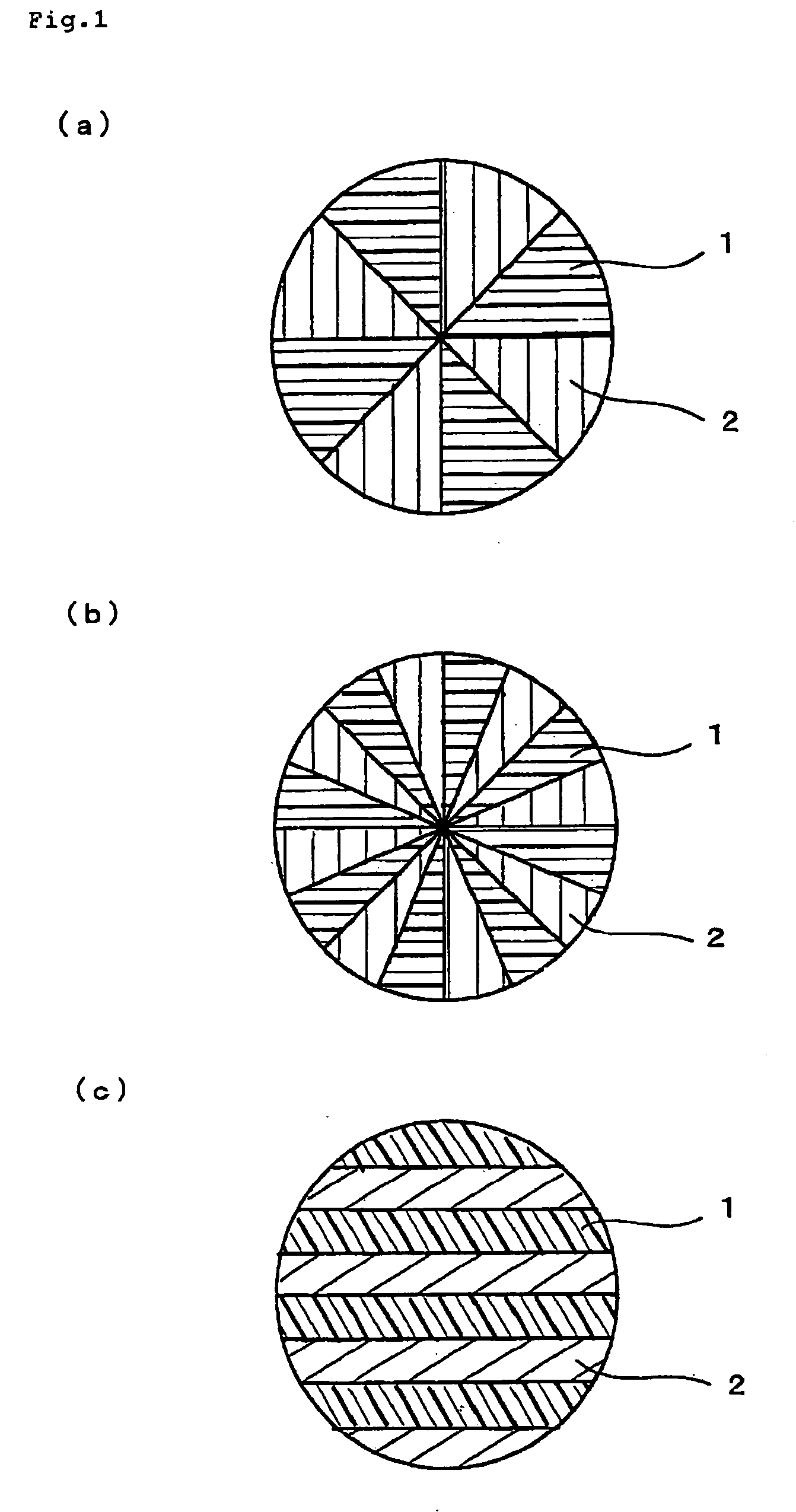

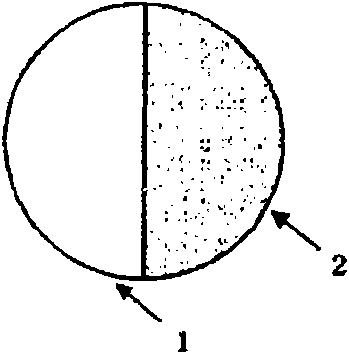

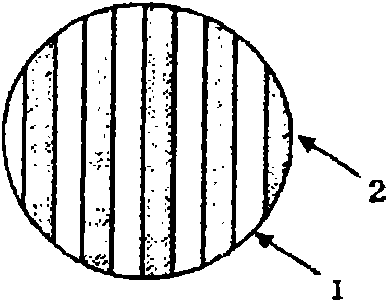

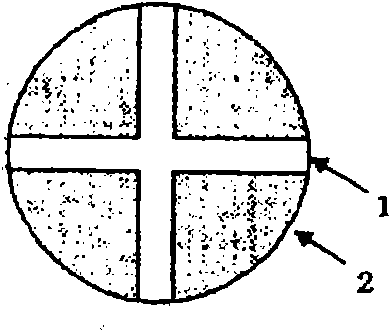

Splittable conjugate fiber, fiber structure using the same, and wiping cloth

A dividual conjugate fiber for obtaining a fiber structure excelling in denseness and bulkiness. The dividual conjugate fiber is one having a polyamide resin composition and a fiber forming polymer with no compatibility with the polyamide resin composition bonded together in the direction of fiber length, characterized in that the polyamide resin composition is composed of an aromatic polyamide and an aliphatic polyamide. Preferably, the aromatic polyamide is a nylon MXD6 polymer, and the aliphatic polyamide is a nylon 6 polymer.

Owner:SEIREN CO LTD

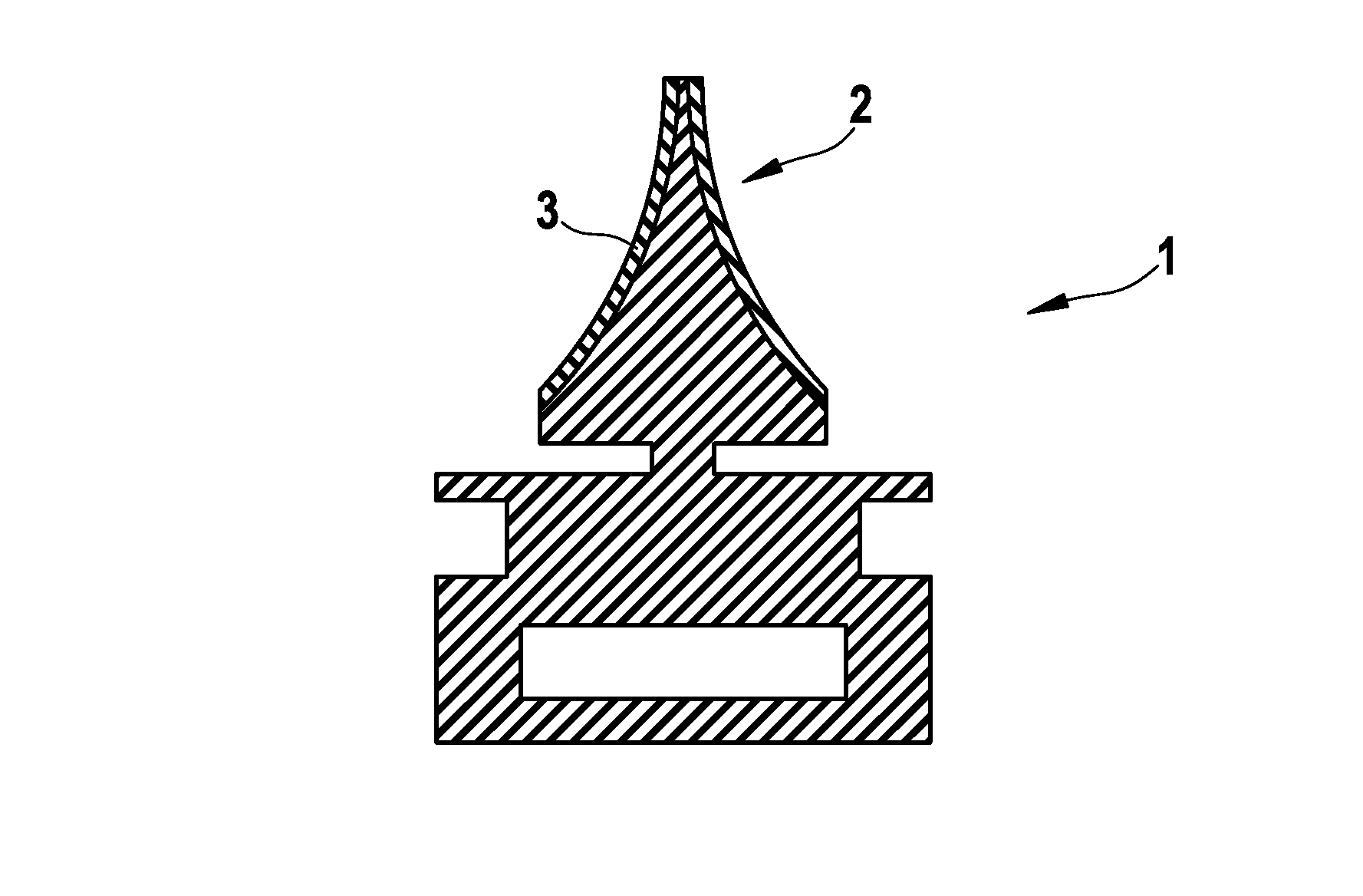

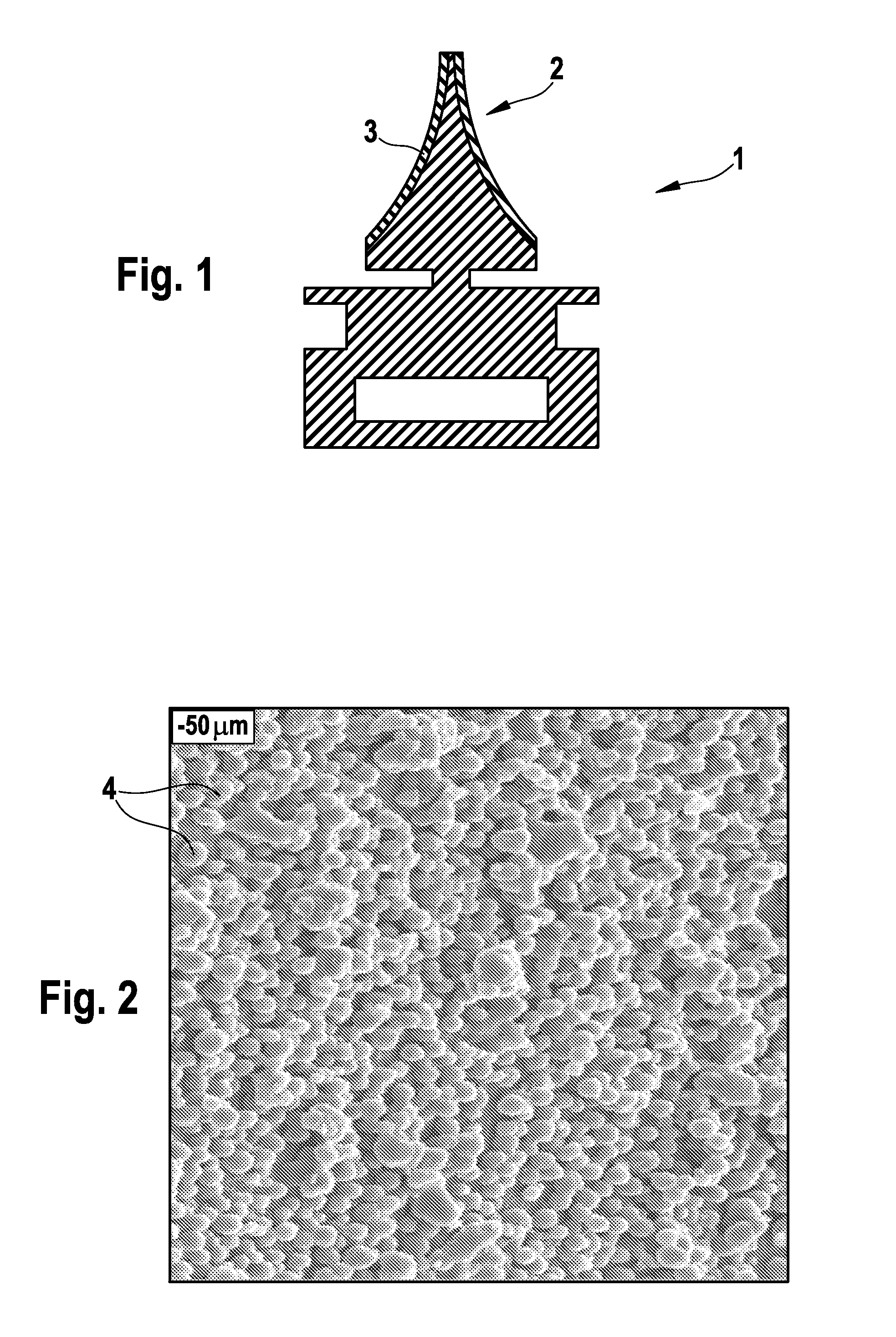

Wiper blade rubber and method for the production thereof

ActiveUS8361595B2Improve wipe qualityImprove wiping effectDecorative surface effectsRecord information storageElastomerSurface layer

The invention relates to a wiper blade rubber and a method for the production thereof, in particular for a rail wiper of a motor vehicle, made from a formed, vulcanizable elastomer material the surface of which comprises a surface layer which is hydrophobic, with a contact angle with respect to water greater than 90°, preferably greater than 120°, and a surface structure with raised regions and / or recesses in the micrometer range.

Owner:ROBERT BOSCH GMBH

Windshield wiper assembling structure for preventing loose attachment of driven wiper arm

ActiveUS8413292B2Loose attachmentImprove wiping effectWindow cleanersVehicle cleaningEngineeringWindshield

Owner:SCAN TOP ENTERPRISE

Rubber material of a wiper blade for windshield wipers and process for production thereof

ActiveUS8552113B2Avoid disadvantagesGood compatibilityWindow cleanersVehicle cleaningRubber materialPolymer science

A rubber material of a wiper blade for windshield wipers is described, which comprises a first rubber component of a first polarity and a second rubber component of a second greater polarity. To equalize the first and second polarities, the first rubber component is at least partially replaced by a chemically functionalized derivative.

Owner:ROBERT BOSCH GMBH

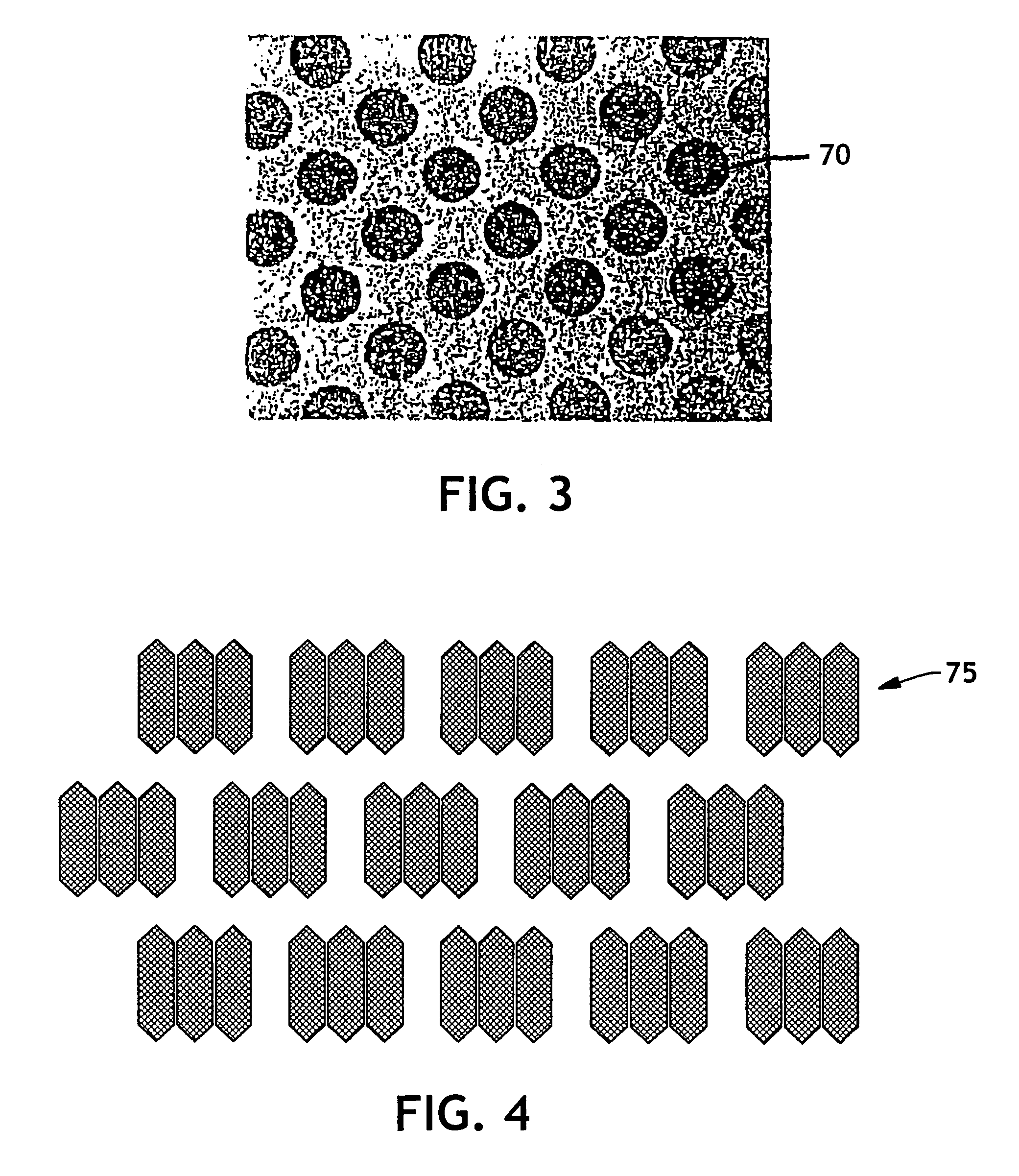

Paper towel with superior wiping properties

ActiveUS20070000629A1Dry wellSuperior liquid wiping propertyNatural cellulose pulp/paperMechanical working/deformationPaper towelMaterials science

Owner:KIMBERLY-CLARK WORLDWIDE INC

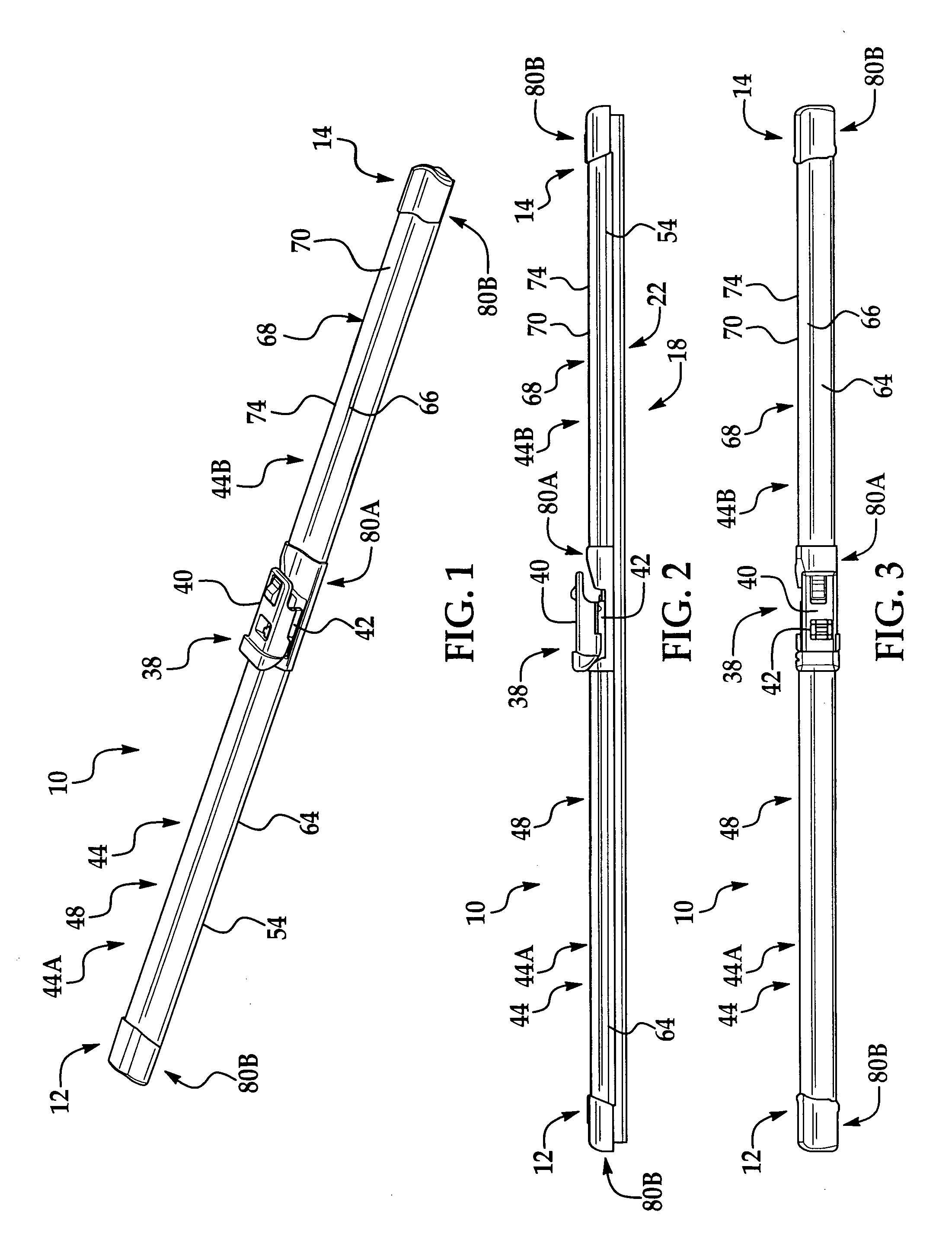

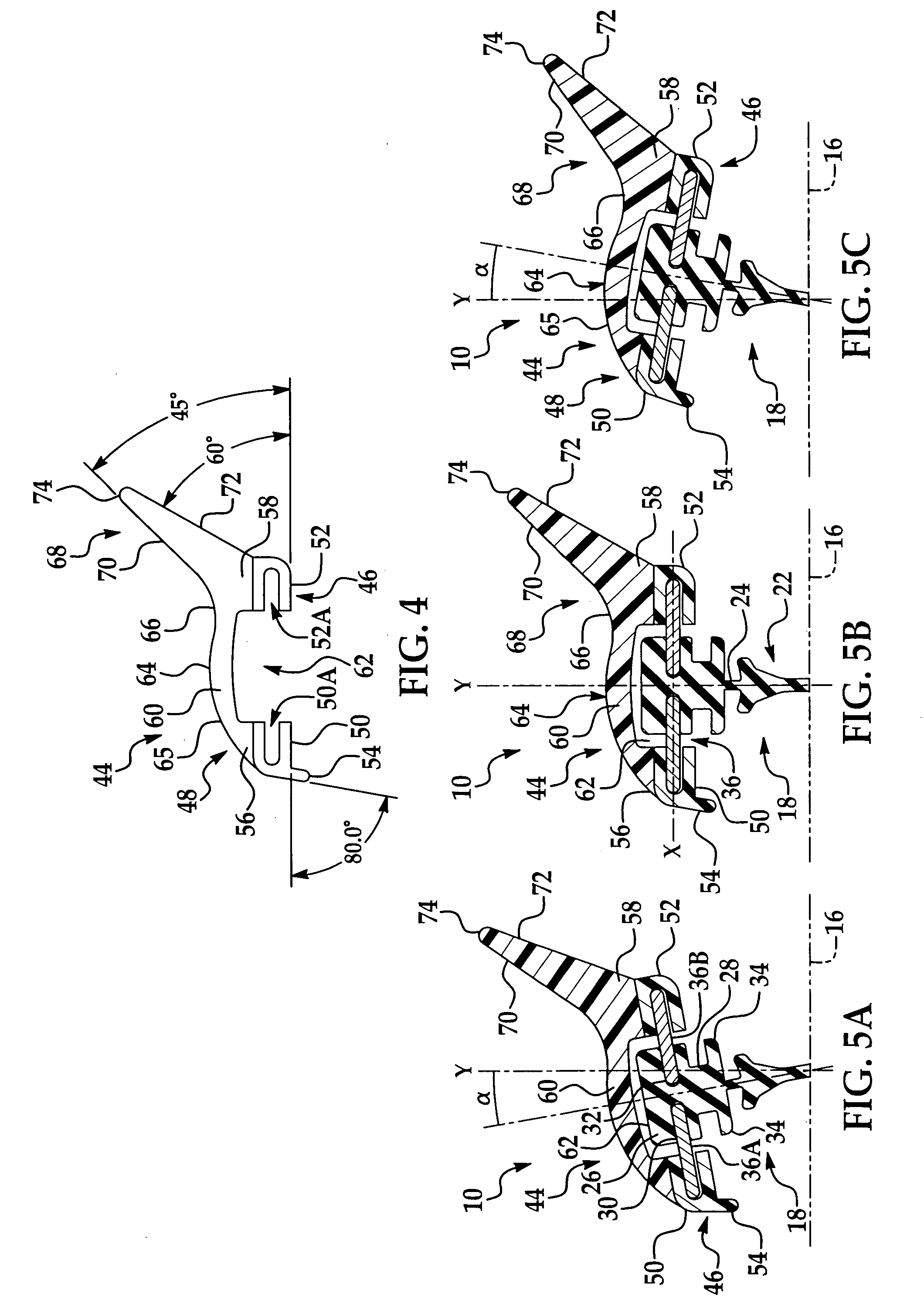

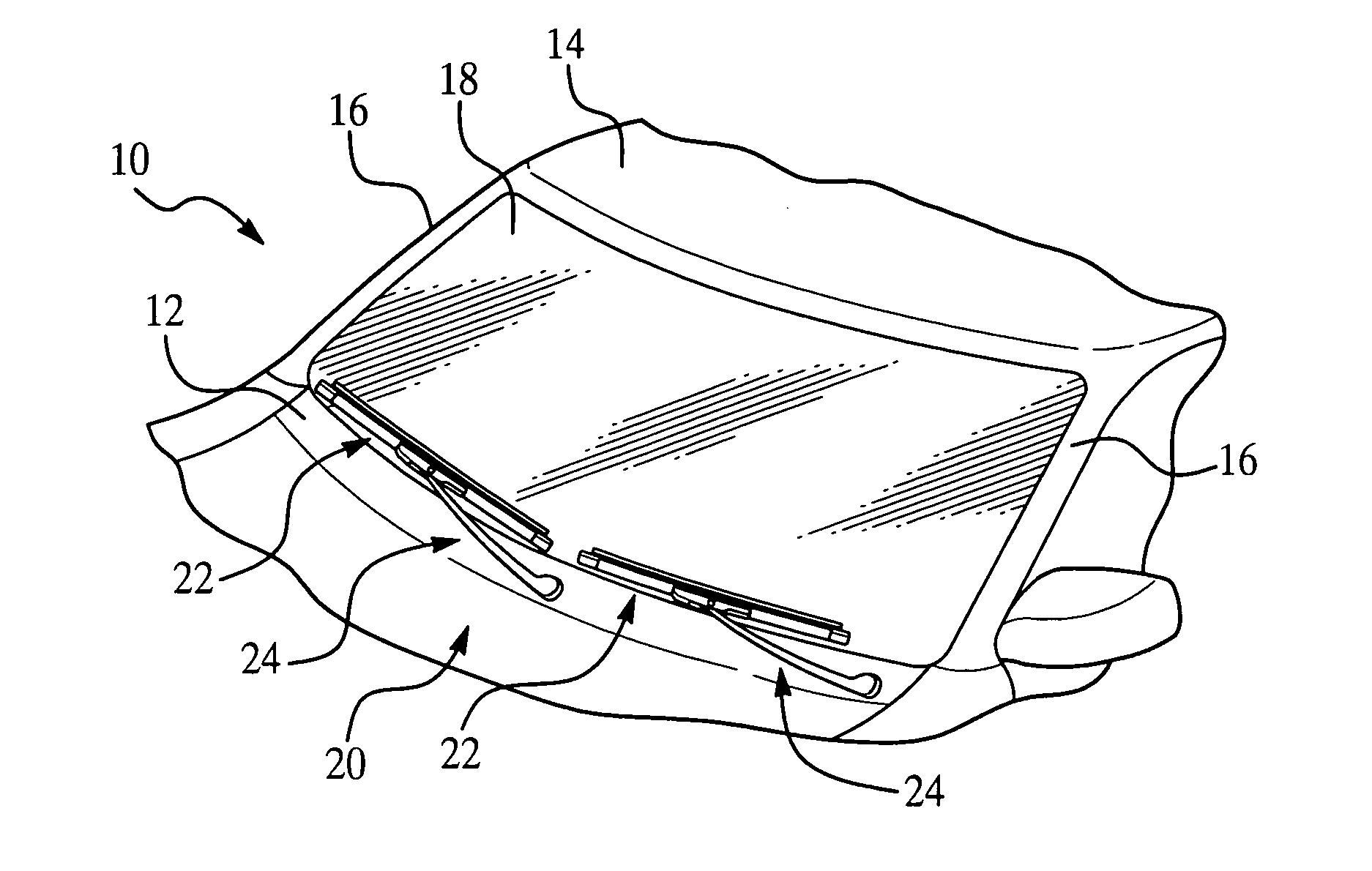

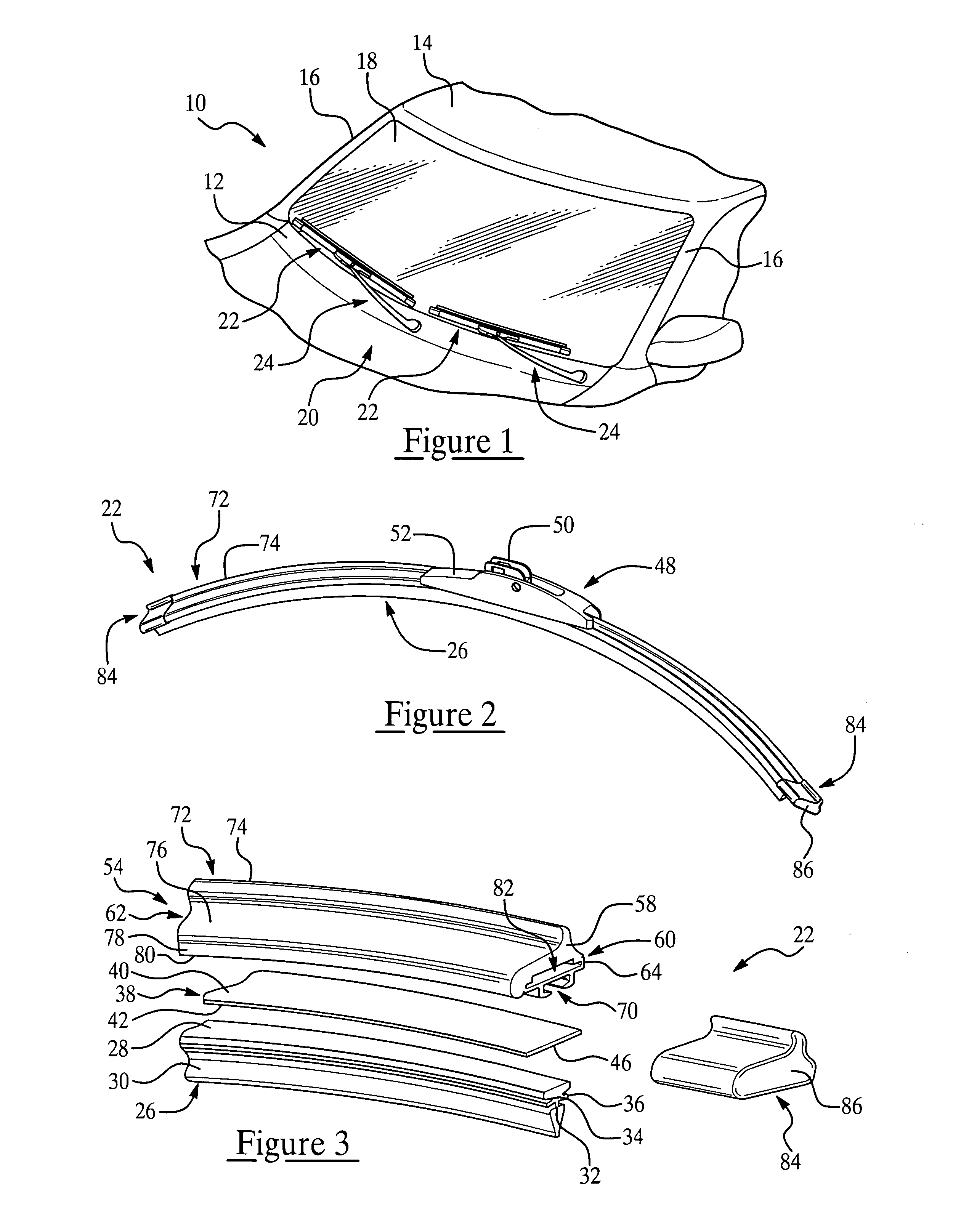

Windshield wiper assembly having an optimized airfoil

ActiveUS20100218332A1Reduces wind liftImprove wiping effectWindow cleanersVehicle cleaningEngineeringWindshield

A wiper assembly having a wiping element for contact with a windshield within a predetermined attack angle range of ±10° perpendicular relative to the surface to be wiped. The wiper assembly further includes two elongated beams that are engaged to the wiping element and apply a downward force thereto. The wiper assembly also includes a connecting member mounted to the elongated beams. The wiper assembly also includes an airfoil that has an attachment portion attached to the elongated beams and an upper portion that is attached to the attachment portion. The upper portion includes a wing having a facing surface and a trailing surface that extend outwardly from the upper portion at converging angles to improve wind lift resistance and reduce drag.

Owner:TRICO PROD CORP

Beam blade windshield wiper assembly having an airfoil

ActiveUS20100037417A1Reduces wind liftImprove wiping effectWindow cleanersVehicle cleaningLeading edgeEngineering

A beam blade wiper assembly including a rubber wiping element and an elongated beam having first and second longitudinal ends. The wiper assembly also includes an airfoil having an attachment portion and an upper portion extending between first and second distal ends. The attachment portion includes a flat rib and a pair of legs adapted to operatively engage the rubber wiping element. The upper portion includes a solid base having a leading edge that extends from the base toward the wiping element. The base and the rib define a space that receives the elongated beam. The base and the elongated beam define a cavity that provides flexibility between the upper portion and the attachment portion during wiper operation. The upper portion further includes a spoiler that extends from the base in a manner opposite to the leading edge.

Owner:TRICO PROD CORP

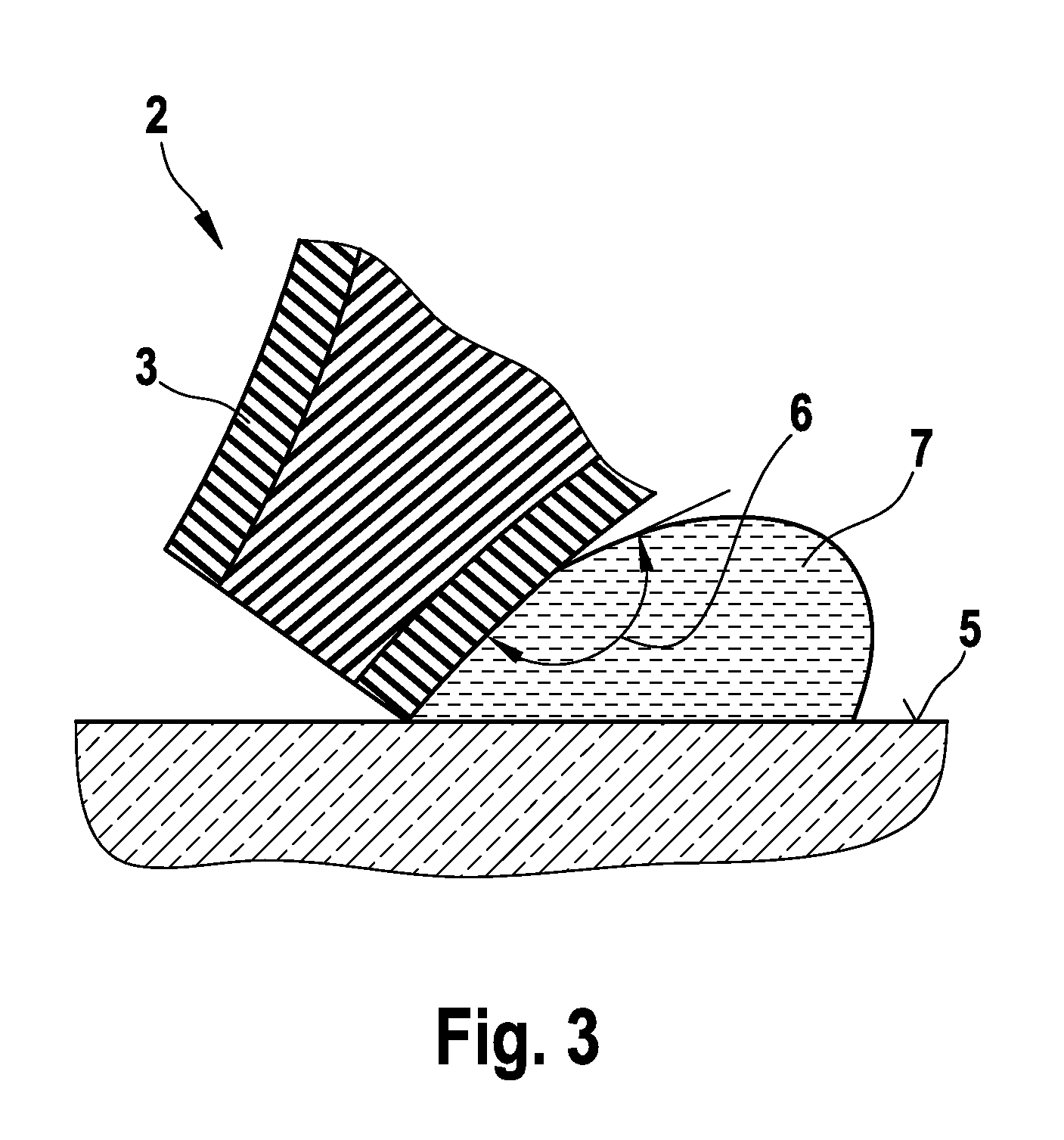

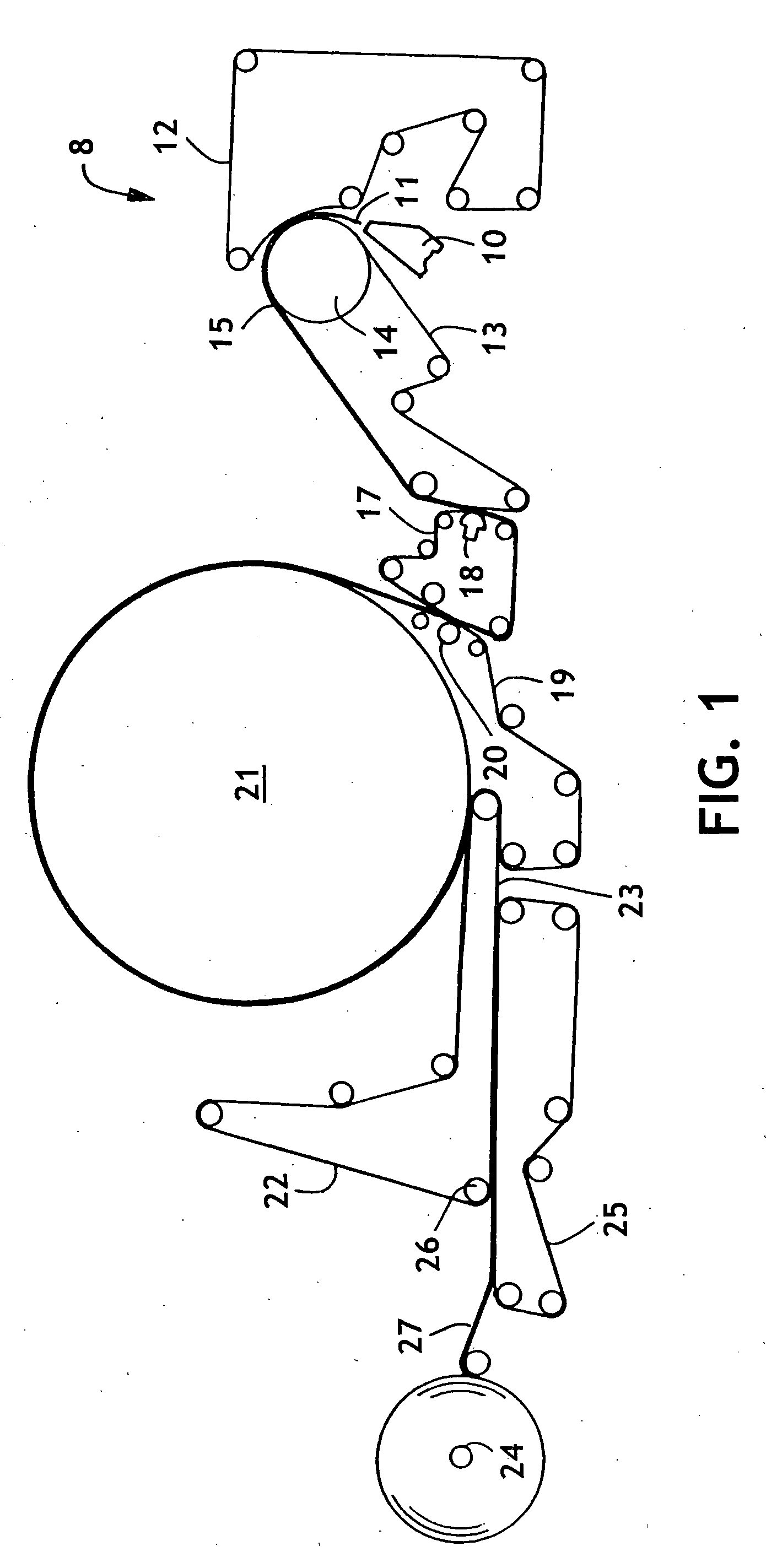

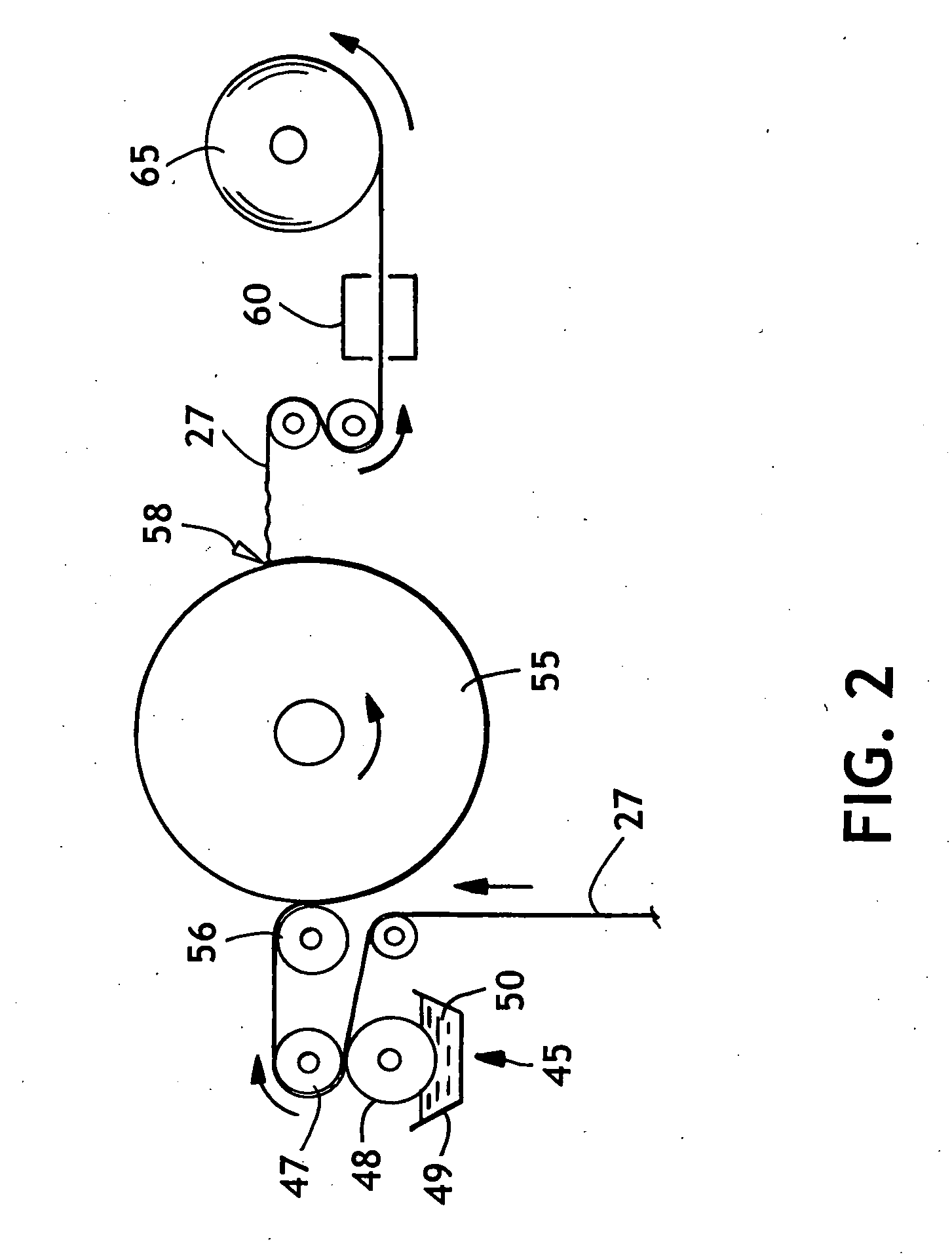

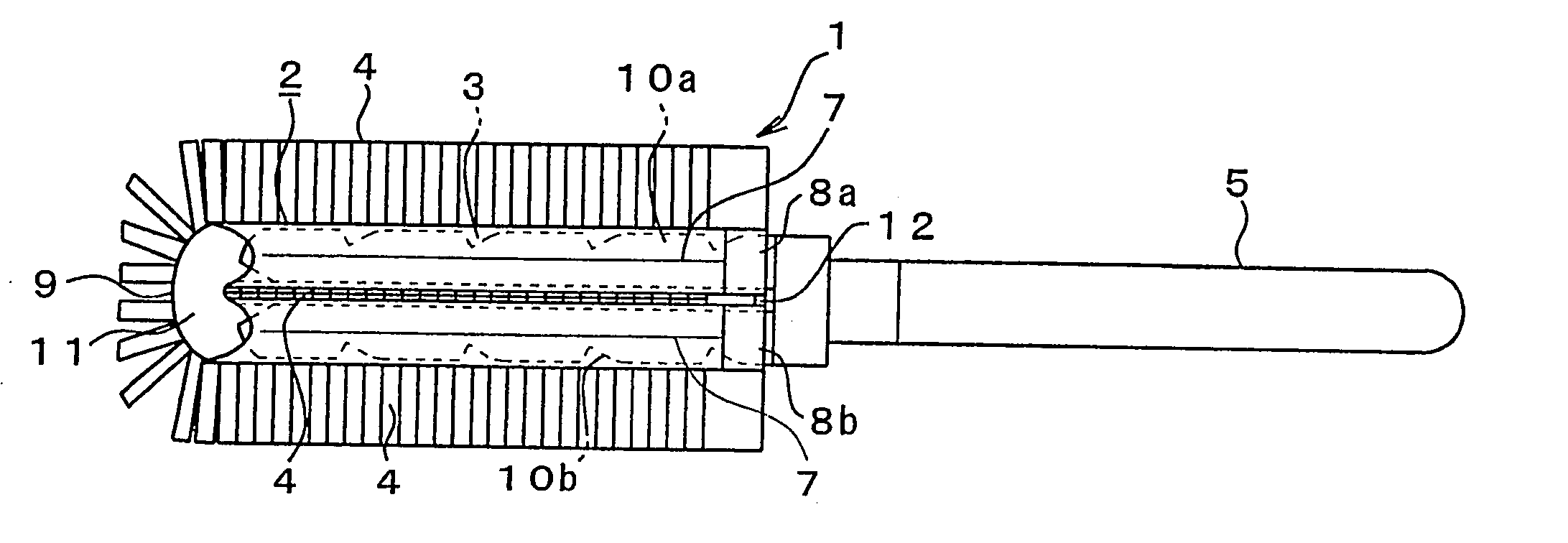

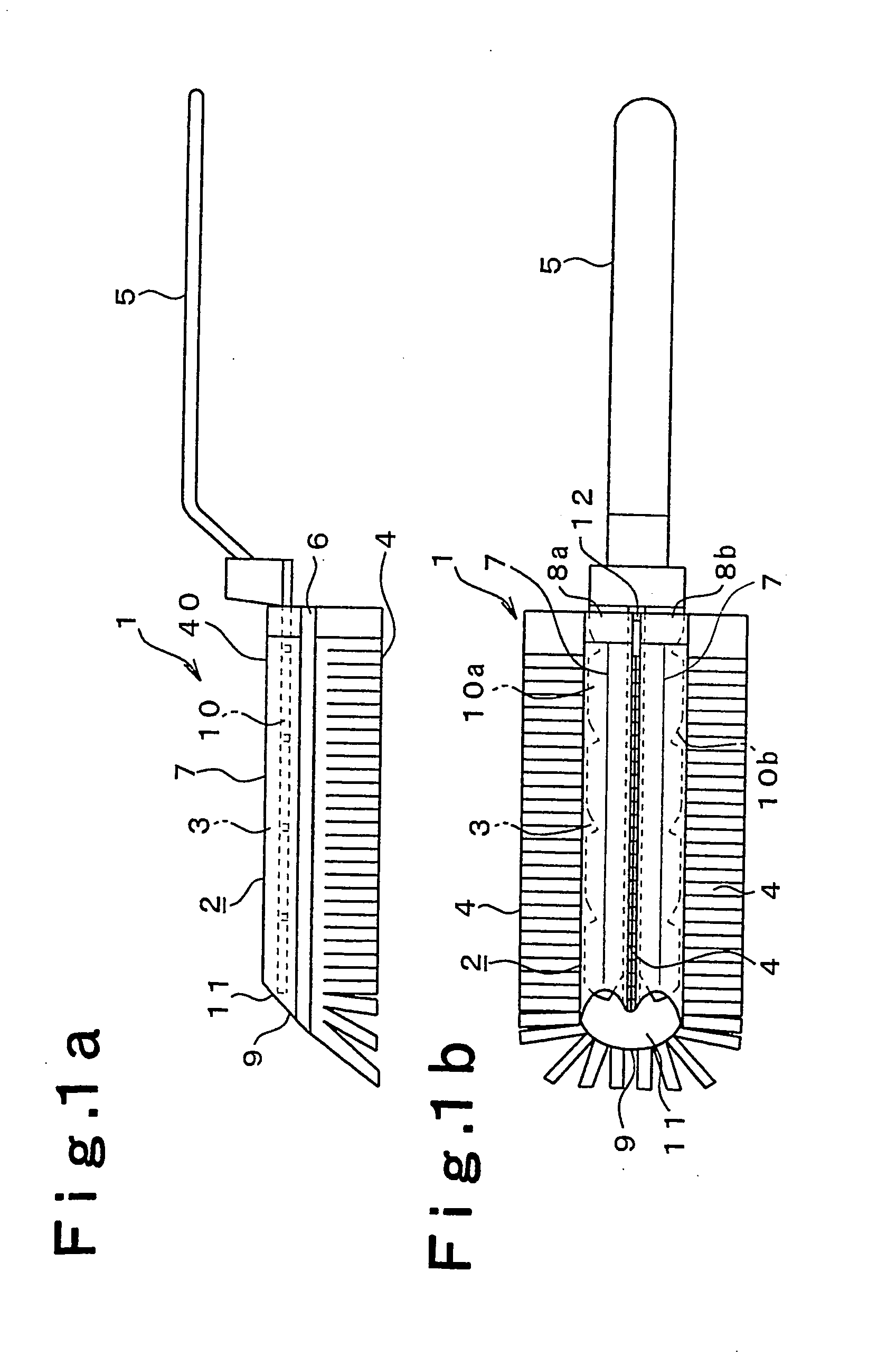

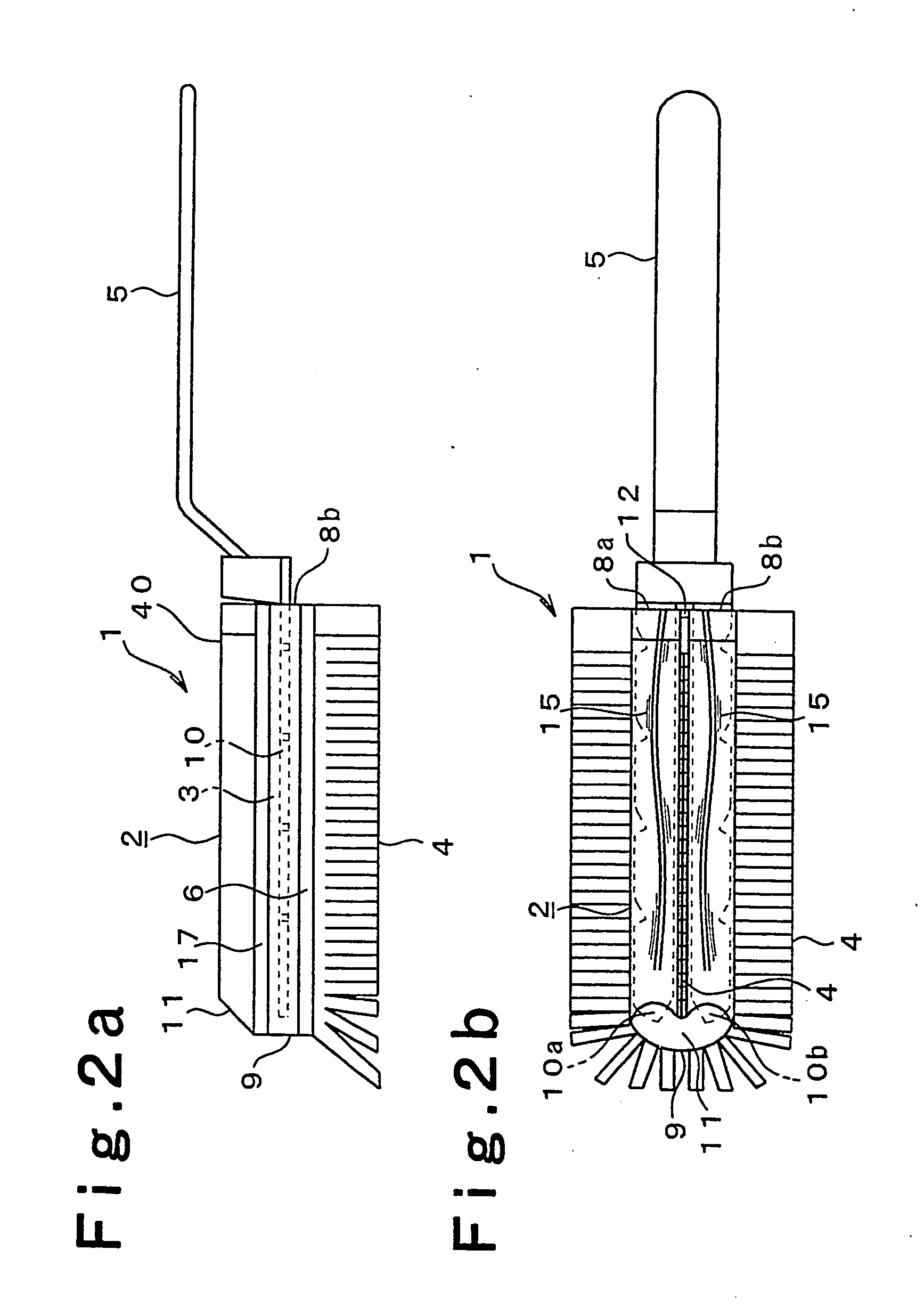

Cleaning tool and method for manufacturing cleaning portion constituting the cleaning tool

InactiveUS20050144749A1Convenient spacingEasy to cleanBoard cleaning devicesCarpet cleanersBiomedical engineering

The present invention is a cleaning tool used to clean furniture, electrical products, interior walls, and so forth. It is an object of the present invention to provide a cleaning tool that traps dust very well and is excellent at removing dirt. The cleaning tool of the present invention comprises a cleaning component (2) and a handle component (5), with the cleaning component (2) being removably attached to the handle component (5). The cleaning component (2) comprises a bulging component (40) bent in a U-shape, a handle insertion component (3) formed inside said bulging component (40), and a pleated component (4) formed along and underneath the bulging component (40). A support component (10) of the handle component (5) is inserted in the handle insertion component (3) of the bulging component (40), and the cleaning component (2) is supported at the distal end of the handle component (5).

Owner:YAMADA CHIYOE

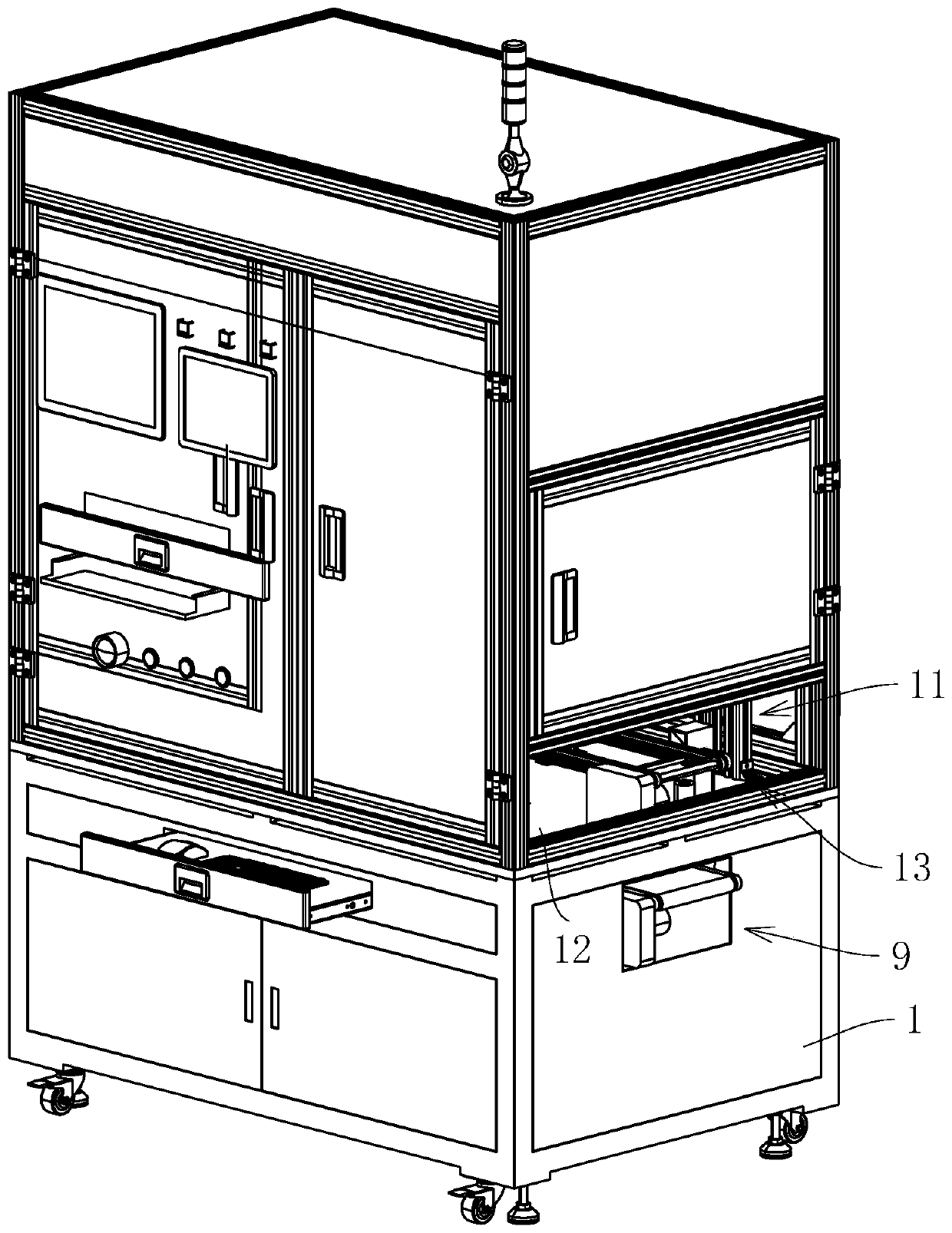

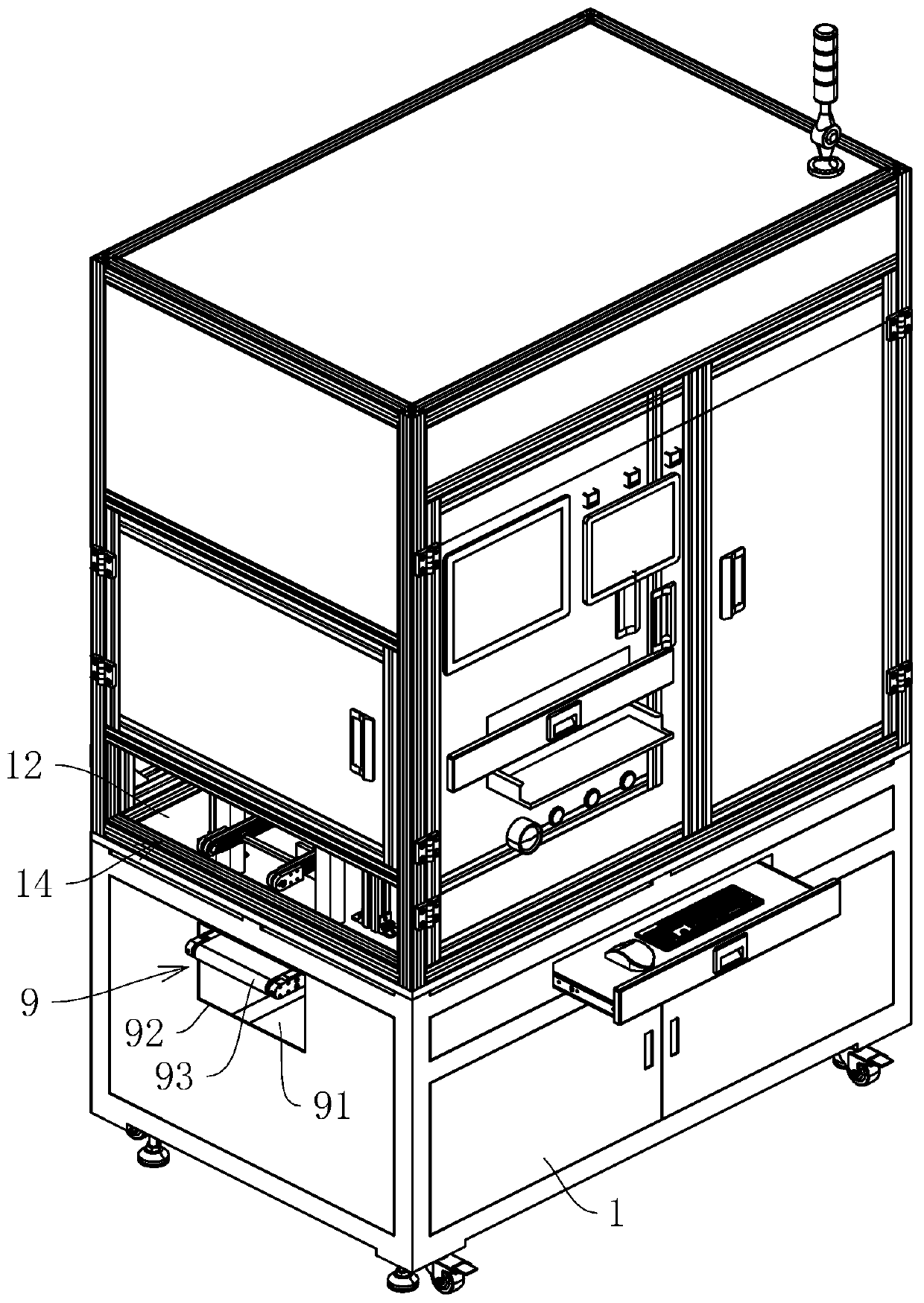

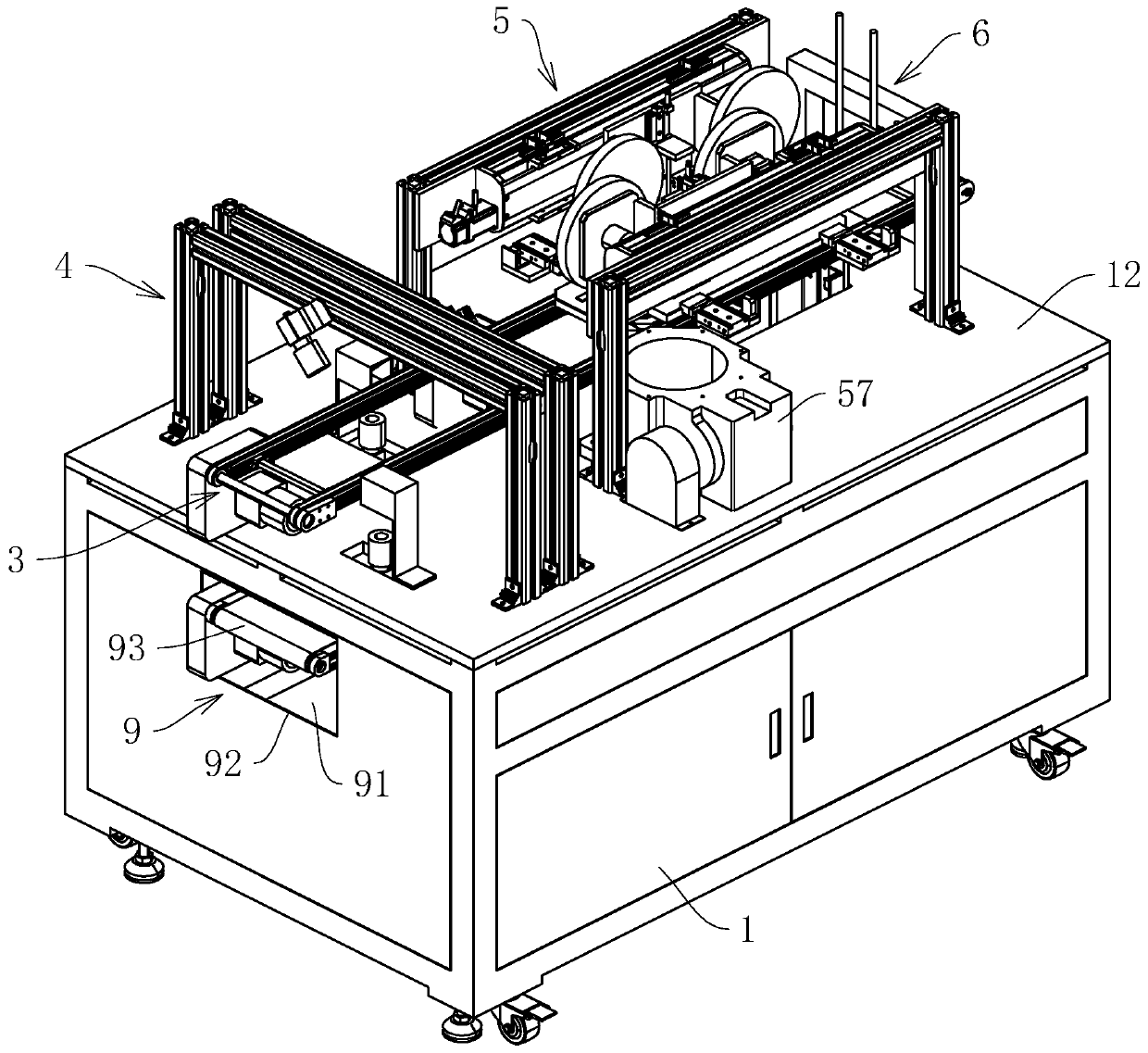

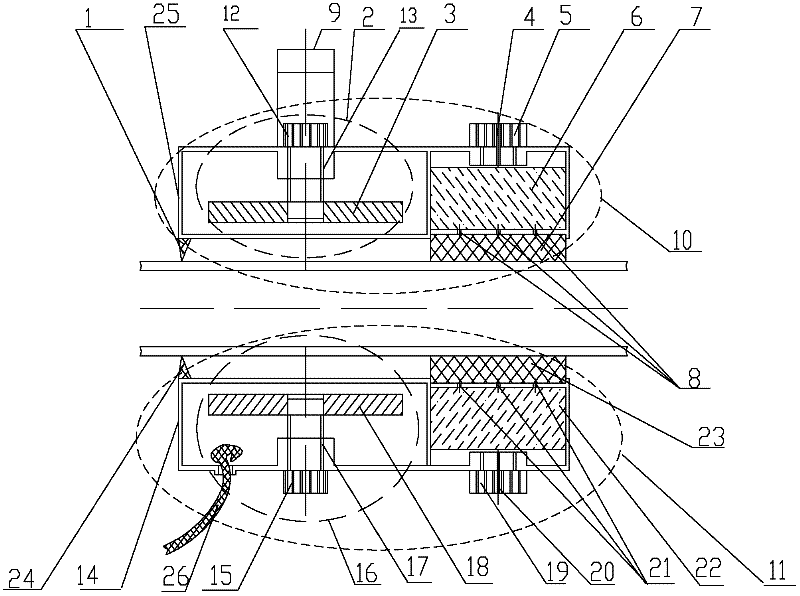

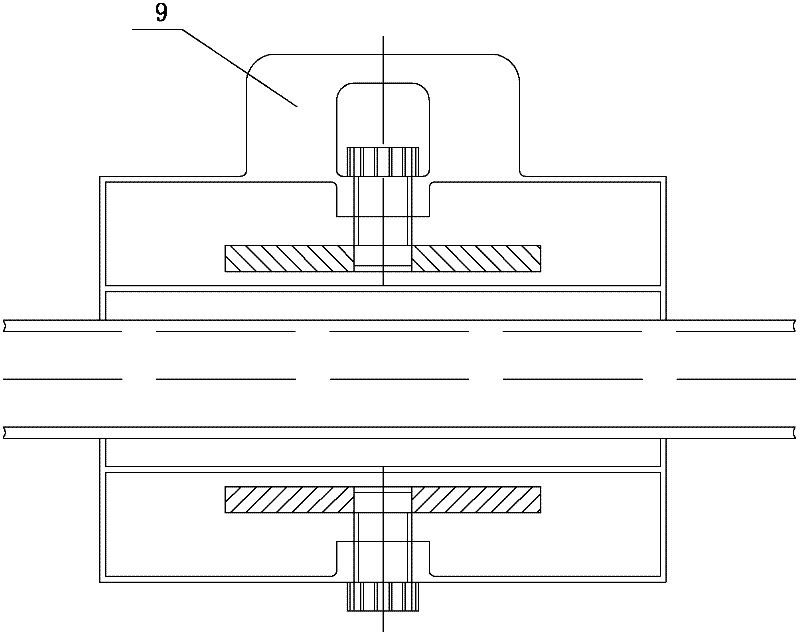

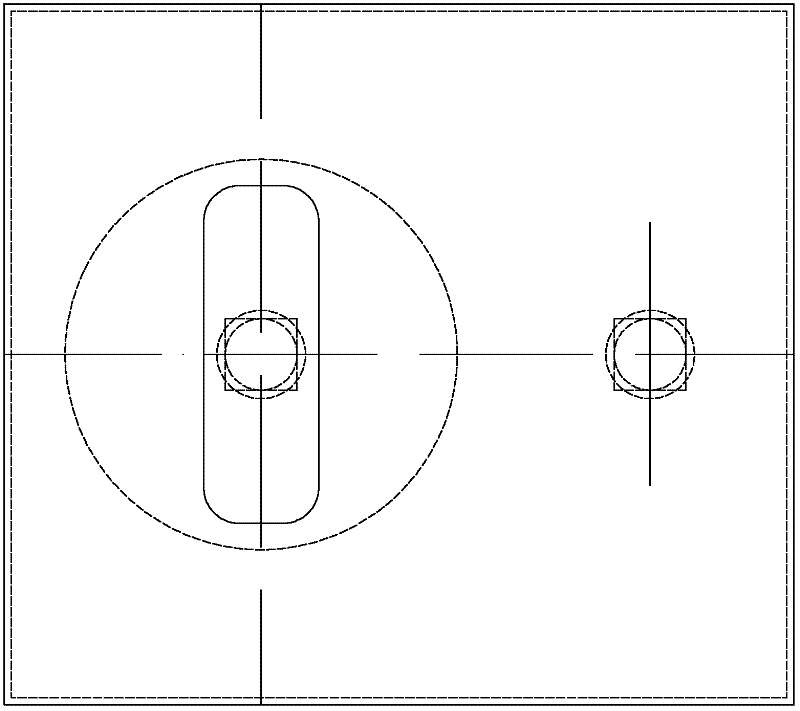

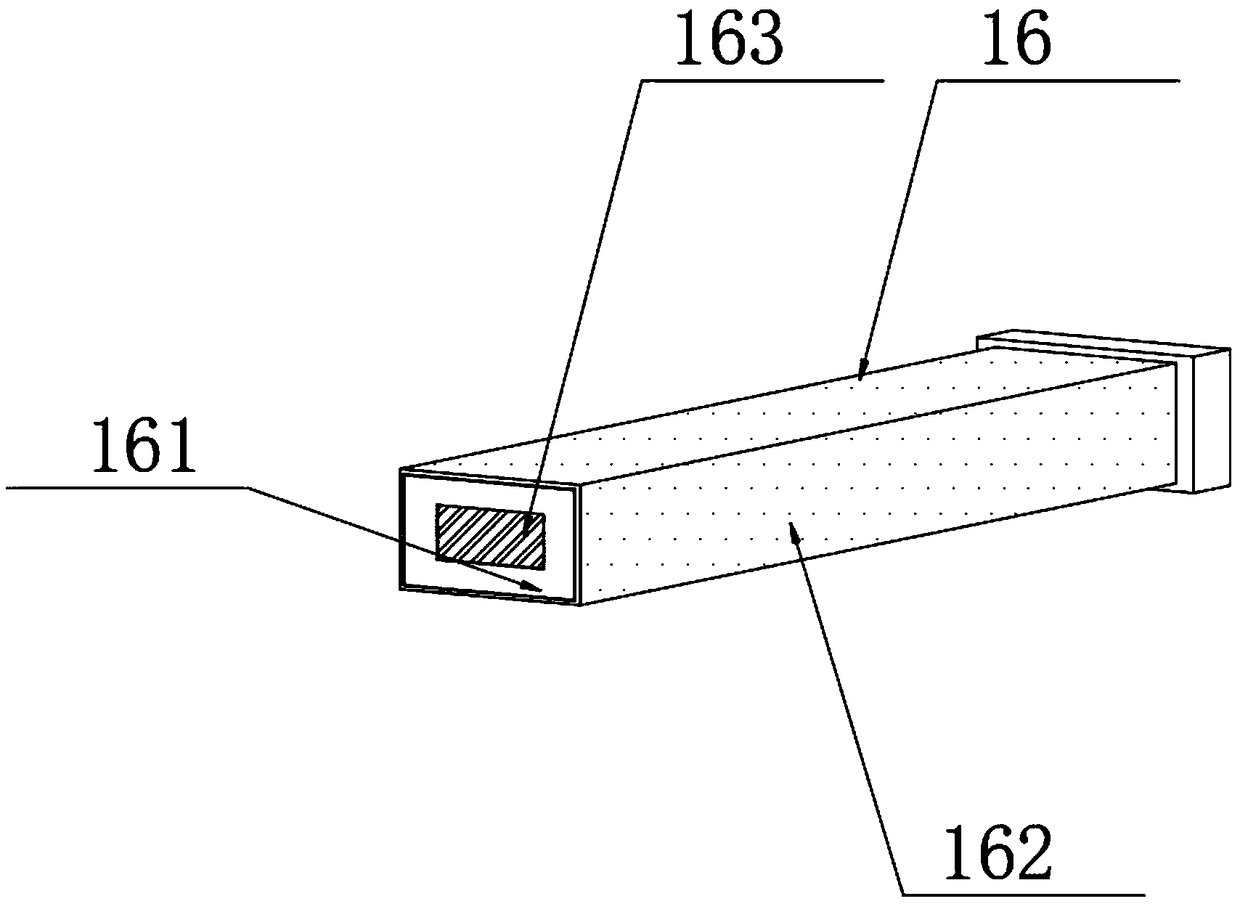

PCB detection and wiping integrated machine

ActiveCN110756465AReduce manufacturing costIncrease productivityDrying gas arrangementsMaterial analysis by optical meansProcess engineeringElectrical and Electronics engineering

The invention discloses a PCB detection and wiping integrated machine, relates to the technical field of PCB cleaning, and aims to solve the problems that an existing PCB gold finger cleaning machineis low in efficiency and unsafe. The key points of the technical scheme are that the PCB detection and wiping integrated machine comprises a workbench, a conveying mechanism, a detection component, awiping mechanism, and a blowing device, wherein the workbench is horizontally arranged in a shell, one end of a machine body is provided with a feeding port, and the other end of the machine body is provided with a discharging port; the conveying mechanism is supported by the workbench and used for conveying a PCB from the feeding port to the discharging port; the detection component is arranged at the end, close to the feeding port, of the workbench and used for detecting gold fingers of the PCB; the wiping mechanism is supported by the workbench and used for wiping the gold fingers of the PCB; and the blowing device is arranged at the end, close to the discharging port, of the workbench and used for blowing and drying the gold fingers of the PCB. The wiping mechanism operates in responseto a detection signal output by the detection component, the blowing device operates in response to an action signal output by the wiping mechanism, and the PCB detection and wiping integrated machine has the effects of being safe, efficient and beneficial to reducing the production cost.

Owner:SUZHOU CHOUCE ELECTRONICS TECH

Glass wiper with adjustable suction force and user method thereof

InactiveCN102512117AAvoiding Poor Wipe ProblemsAchieve dustproofWindow cleanersMagnetic tension forceSuction force

The invention discloses a glass wiper with adjustable suction force and a use method thereof. A driving wiper body and a driven wiper body are provided with a shell I and a shell II respectively; the shell I and the shell II are provided with a magnetic-force adjusting mechanism I and a magnetic-force adjusting mechanism II respectively; the driving wiper body and the driven wiper body are provided with a water storage device I and a wiping part I as well as a water storage device II and a wiping part II respectively; at least one capillary pore I is connected between the water storage device I and the wiping part I; and at least one capillary pore II is connected between the water storage device II and the wiping part II. The invention has the advantages that: the action spacing of magnets on the driving wiper body and the driven wiper body can be adjusted in the glass wiping process according to different glass thickness or cleanness degree, thus the poor glass wiping effect resulted from too tight or loose clamp of the glass by the glass wiper is avoided effectively.

Owner:马睿先

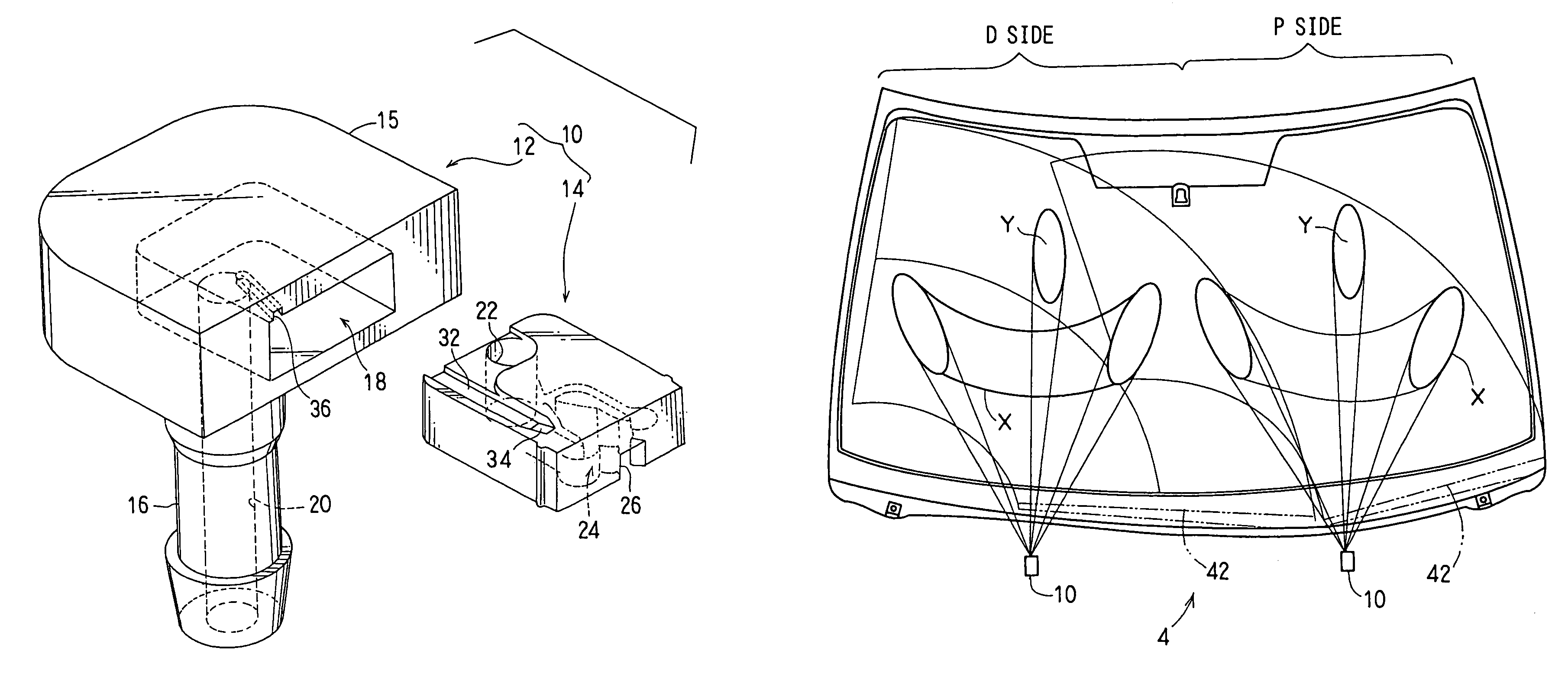

Washer nozzle and washer apparatus

InactiveUS7111793B2Quickly and stably securedDrawback can be obviatedSpray nozzlesFire rescueJet flowAirflow

A washer nozzle includes a spread jet opening for basically jetting washer fluid in a predetermined direction of a vehicle; and a jet opening for accessorily and intensively jetting part of the washer fluid as a directional jet flow which is different from the spread flow basically jetted from the spread jet opening. The washer fluid is jetted and sprayed over a large area in a fan-shaped spread flow from the spread jet opening. Further, the washer fluid is intensively sprayed as the directional jet flow from the jet opening. Thus, sweeping performance of the washer nozzle and a washer apparatus is improved such that the directional jet flow is not substantially affected by airflow during high-speed driving so that the washer fluid is effectively utilized so as to be sprayed and supplied to areas that are prone to be left unwashed.

Owner:DENSO CORP

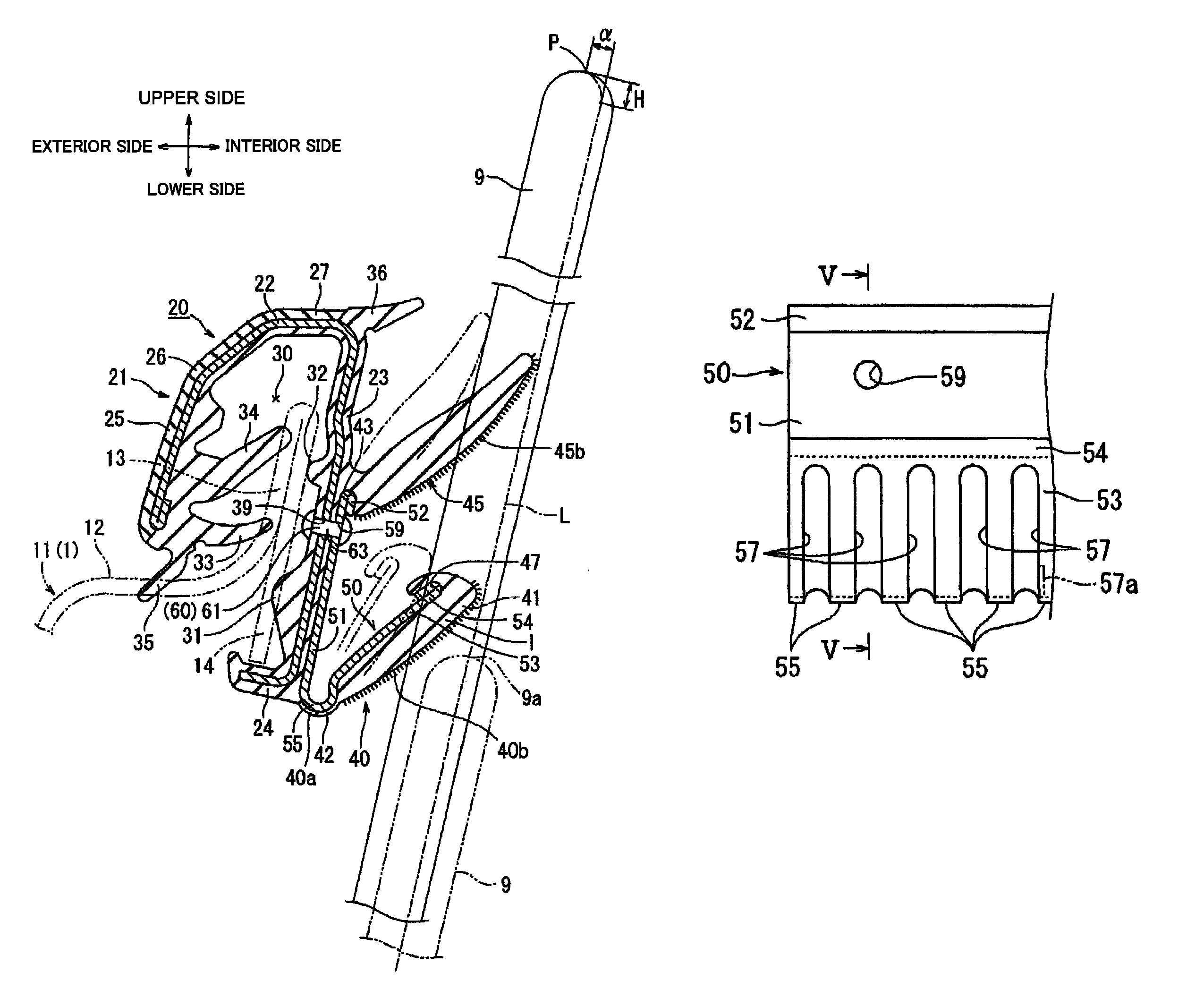

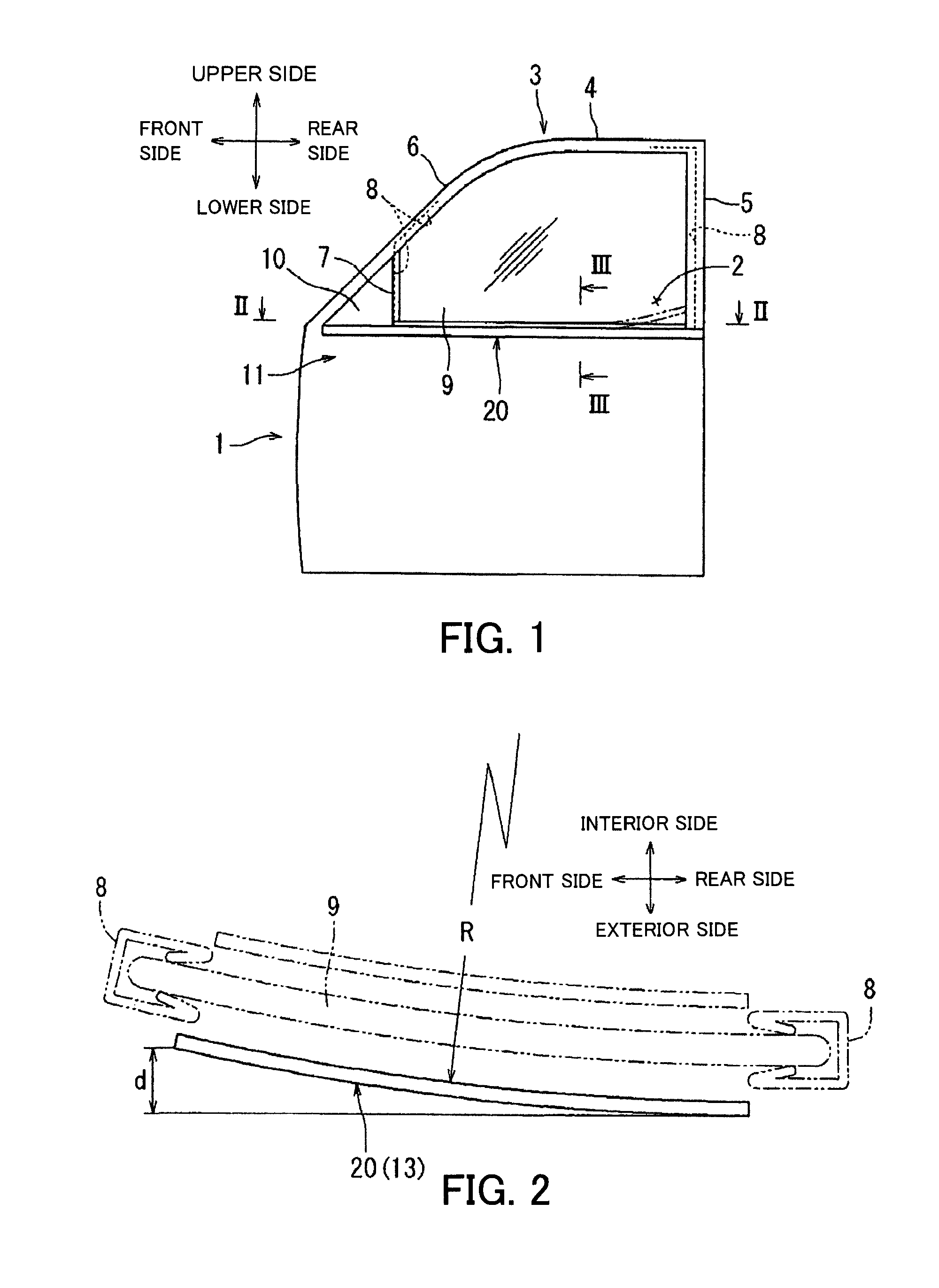

Belt molding for vehicles

ActiveUS8104227B2Improve wiping effectNo longer be sealedWindowsWindscreensEngineeringRestoring force

A vehicle belt molding includes an attaching member and a seal lip. An elastic repulsive member is disposed between the engage wall portion and the seal lip and integrally provided with a fixed piece portion, a shifting piece portion, and a connecting piece portion. The seal lip is always urged toward the window pane by an elastic restoring force of the connecting piece portion itself or by a cooperative function of the elastic restoring force and an elastic restoring force of the elastic polymer material. When the attaching member is mounted to the mounting member, the seal lip causes the contacting portion to be elastically restored by the elastic restoring force toward a thickness direction of the window pane at a speed exceeding a restoring speed obtained only by the elastic polymer material.

Owner:TOKAI KOGYO CO LTD

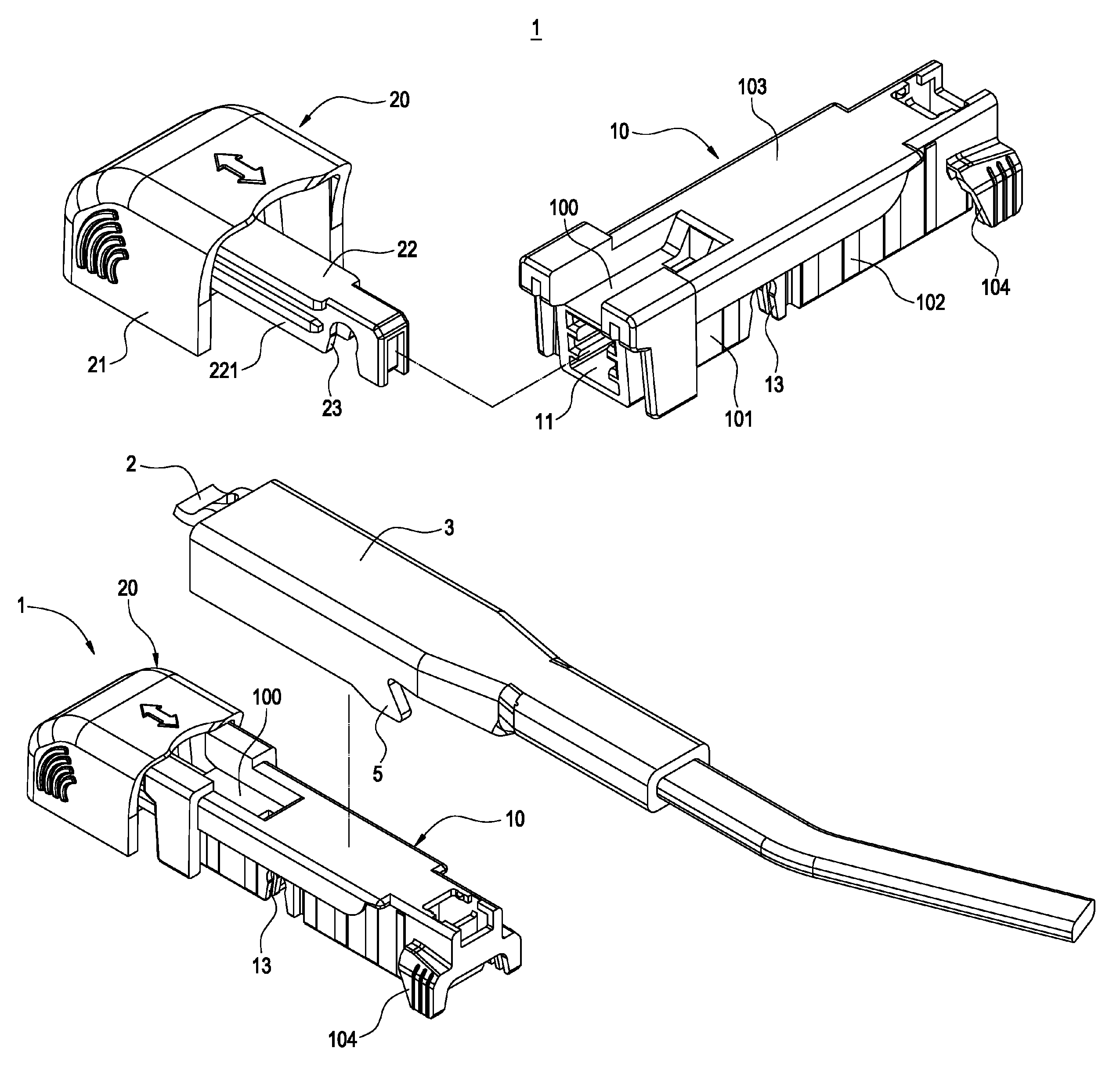

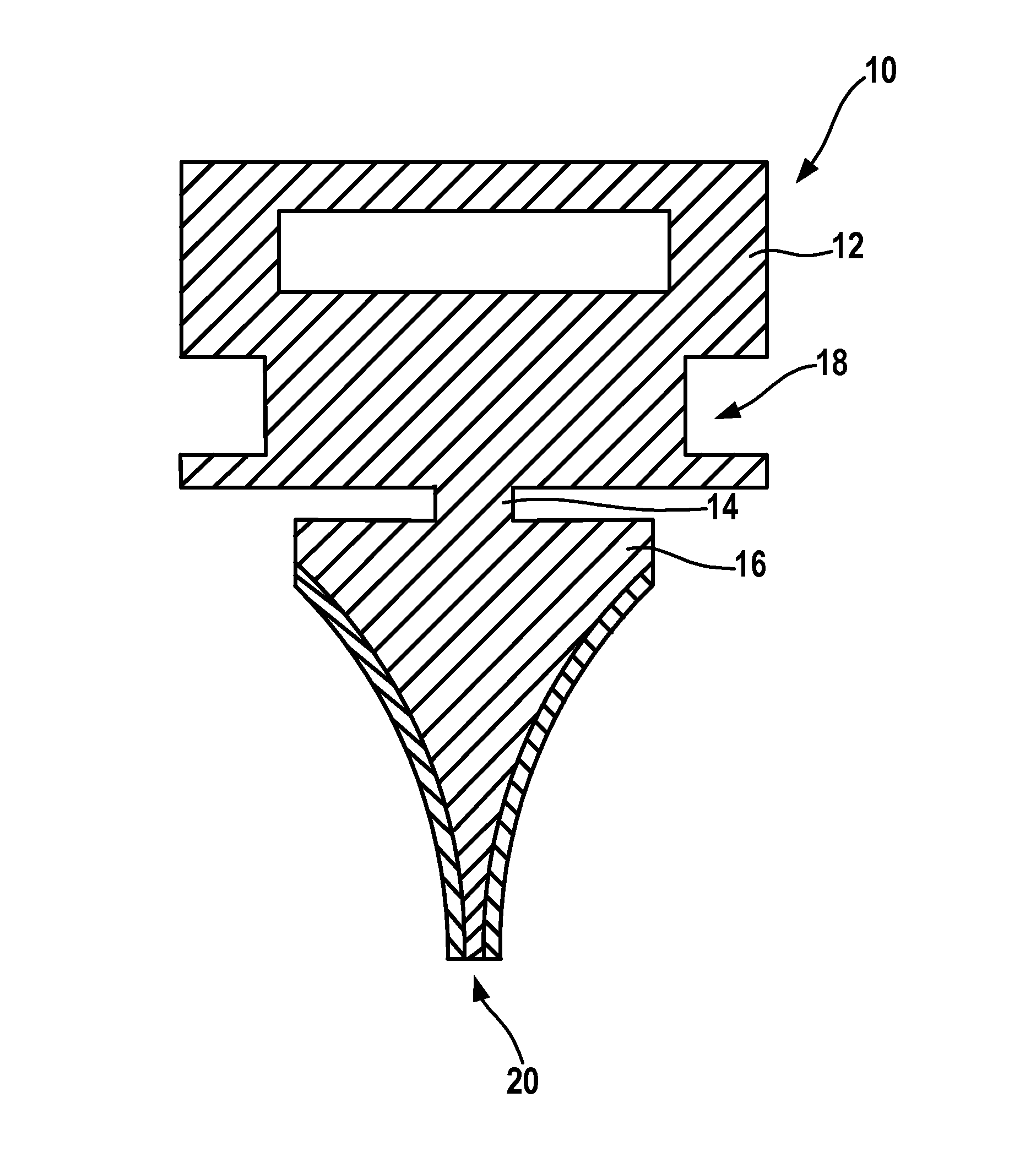

Terminals

InactiveUS8840406B2Improve wiping effectLower resistanceElectrically conductive connectionsCoupling contact membersEngineeringElectrical and Electronics engineering

Owner:MOLEX INC

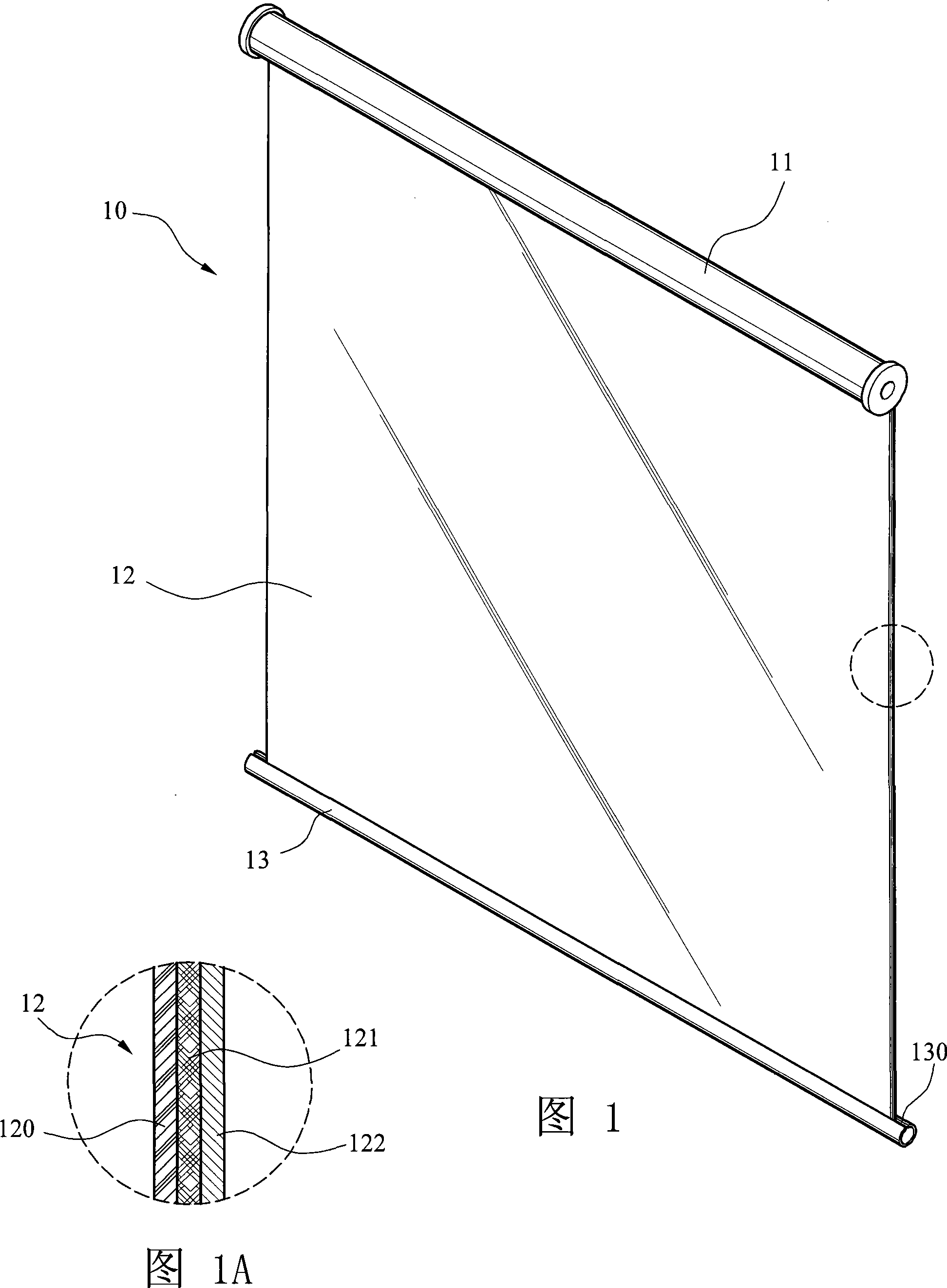

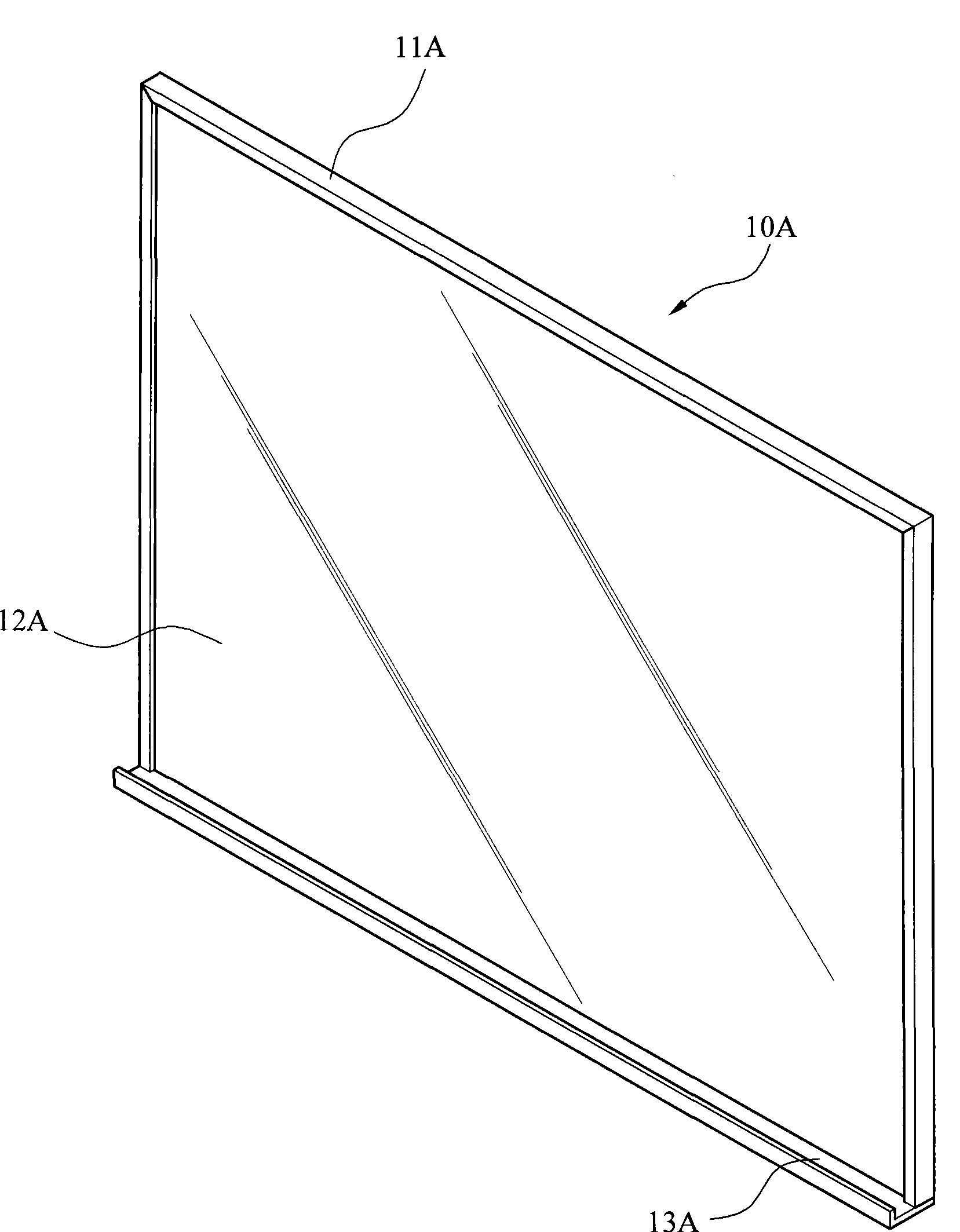

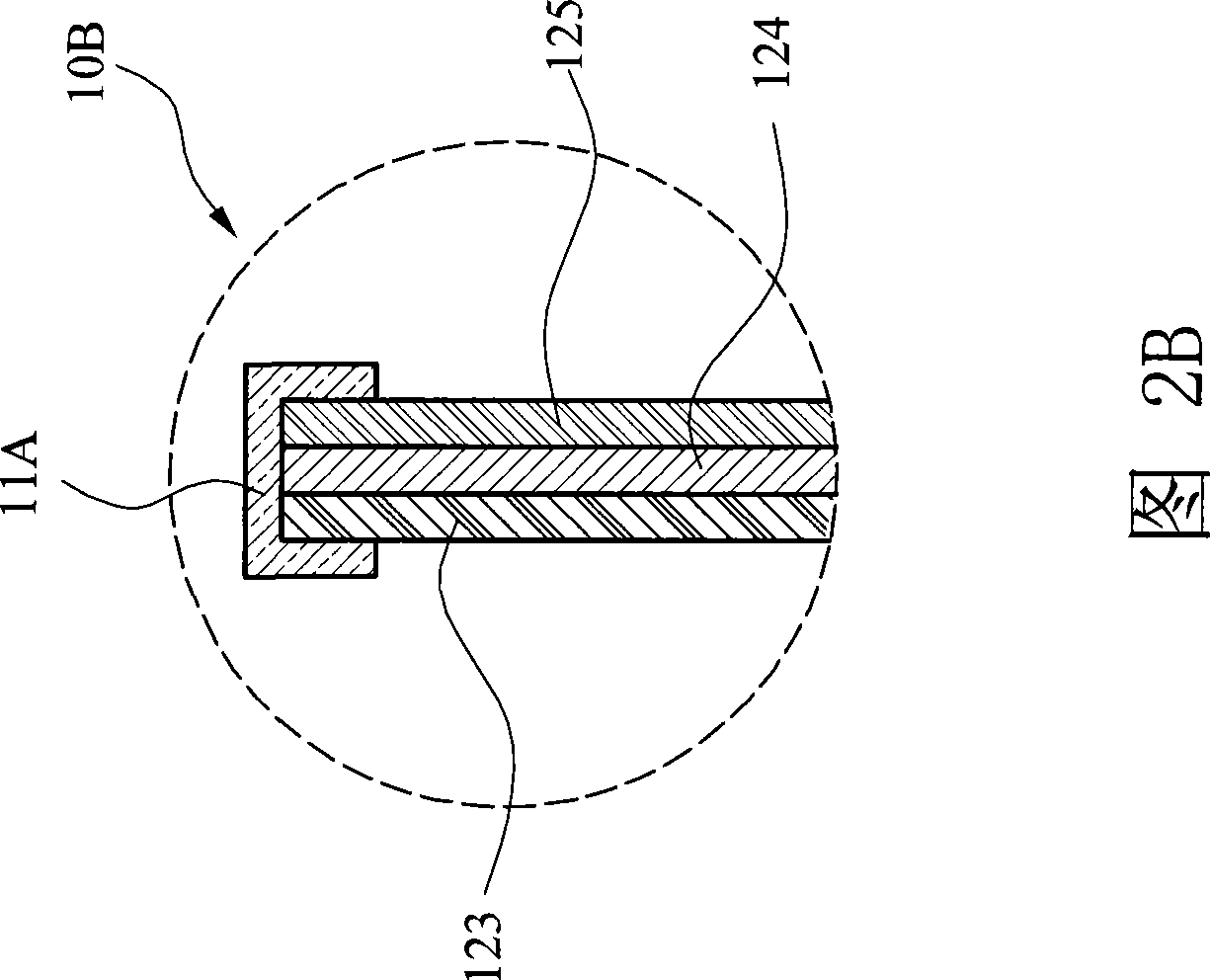

Projection screen structure

The invention provides a projection curtain structure which comprises a projection curtain and a word mopping board wiper. The projection curtain comprises a projection writing layer with a rough face; and an absorption layer which is adhered to and is connected with the projection writing layer. The word mopping board wiper comprises a board casing and a wiping body, wherein the wiping body is made of hydroscopic synthesized sponge. Therefore, the projection curtain can have the projection without light spot reflection; and the words on the projection curtain can be simply and conveniently mopped off through the hydroscopic synthesized sponge. In addition, the projection curtain structure has high economical efficiency and consequently can be universally generalized and industrially utilized.

Owner:蔡炳辉

Mixed continuous fiber non-woven fabric and method for producing the same

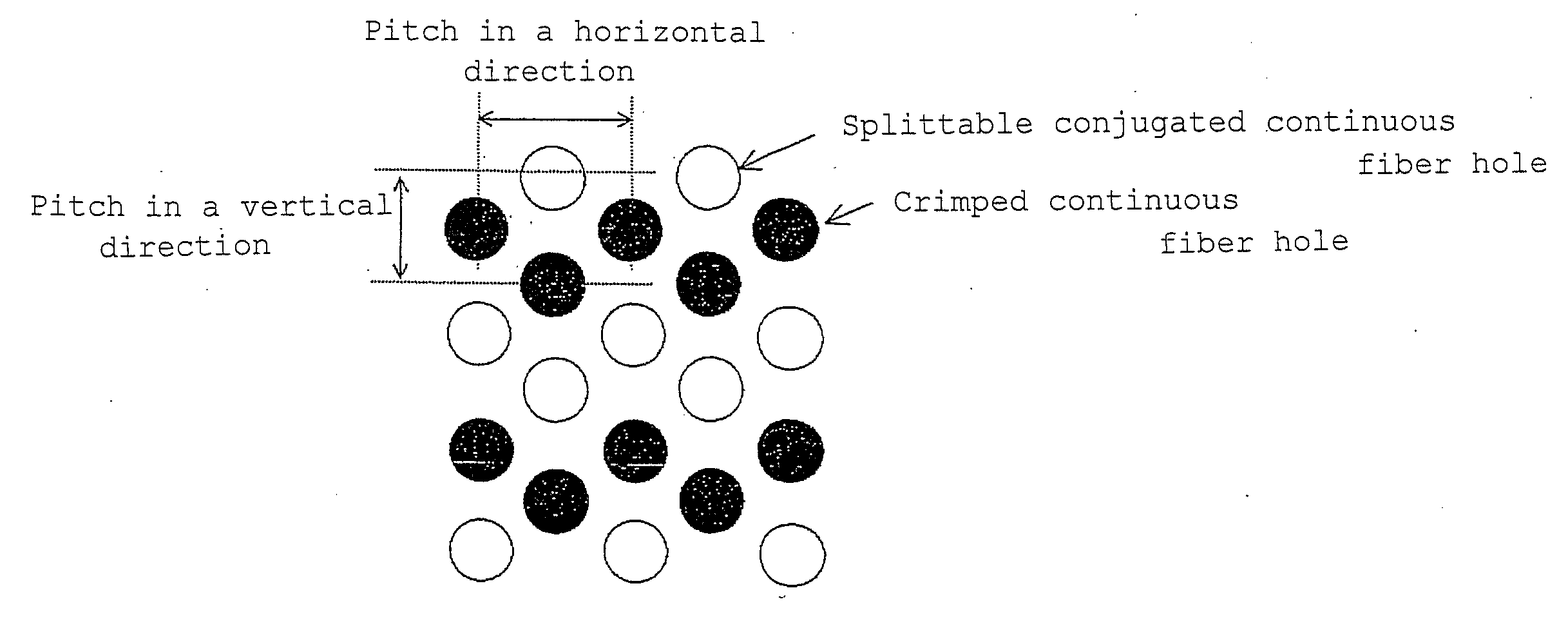

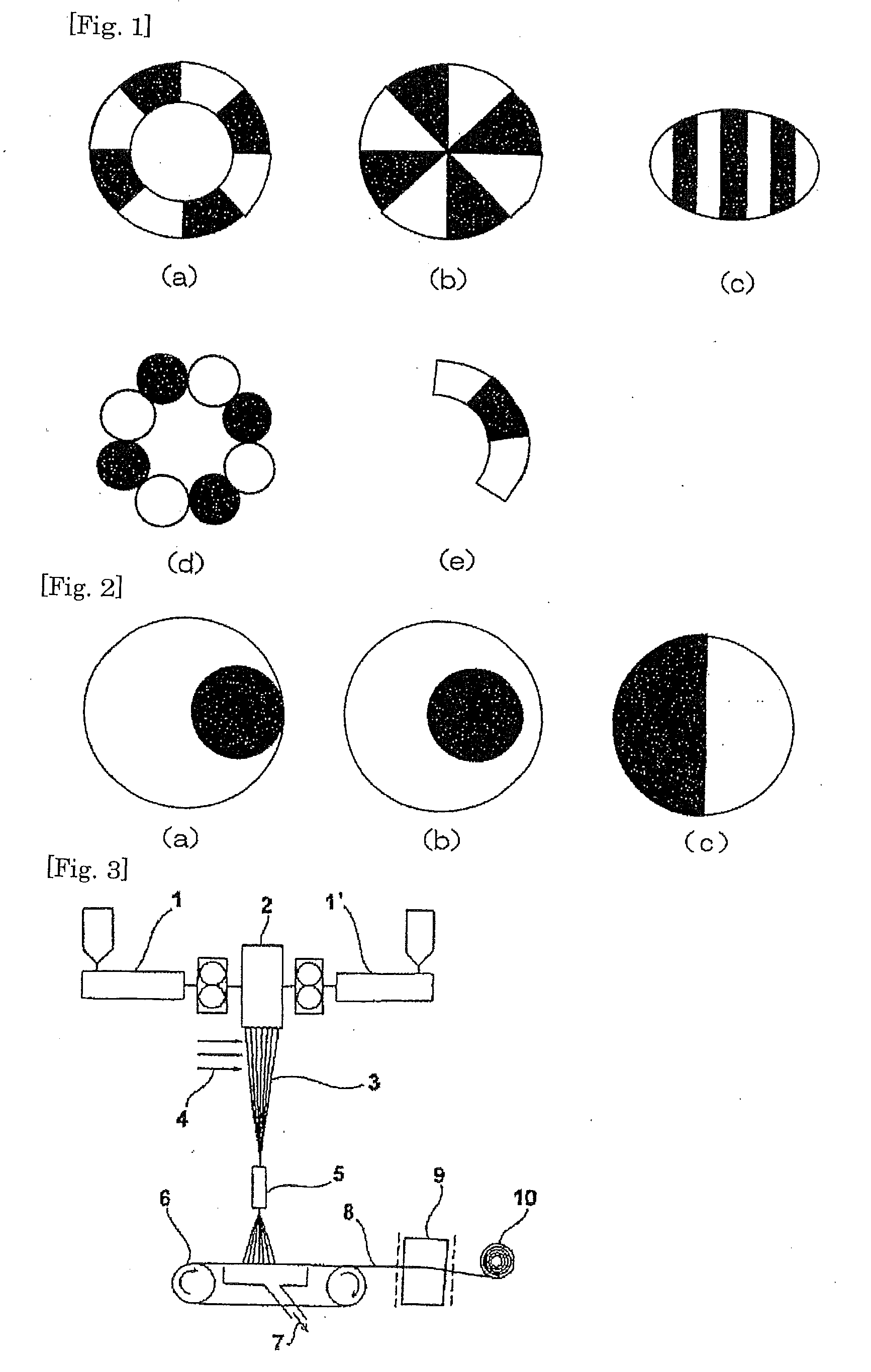

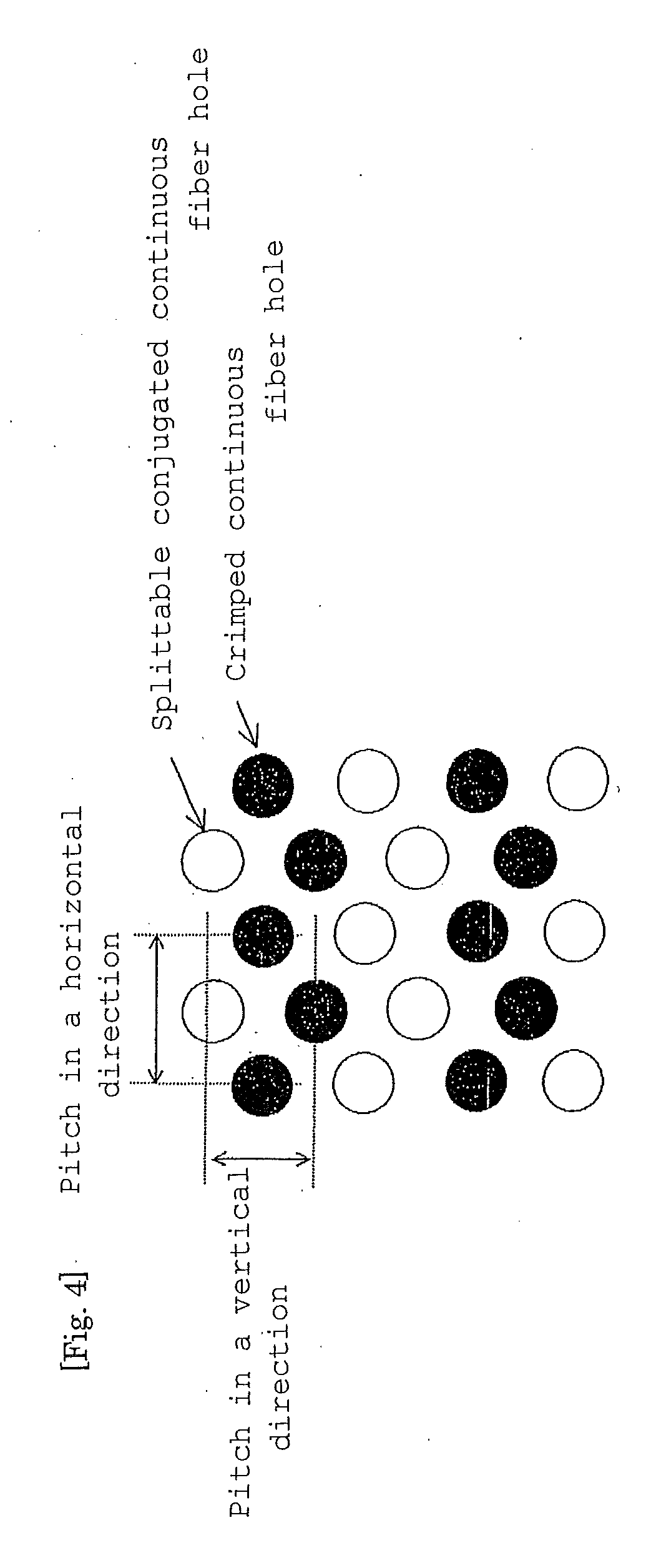

InactiveUS20100130084A1Good bulkinessIncrease flexibilityPersonal careCarpet cleanersPliabilityEngineering

According to the present invention, it is possible to obtain a non-woven fabric that is excellent in bulkiness, flexibility, and feeling, in which less fibers drop out even in the case wherein the non-woven fabric is used for an application such as clothing items and a wiping cloth in which a surface of a non-woven fabric is rubbed, that is, excellent in a lint-free property.A mixed continuous fiber non-woven fabric in accordance with the present invention is characterized by comprising a split continuous fiber and a crimped continuous fiber, and is preferably characterized in that a total amount of the crimped continuous fiber is in the range of 10 to 90% by weight (where a total weight of a split continuous fiber and a crimped continuous fiber is 100% by weight).

Owner:MITSUI CHEM INC

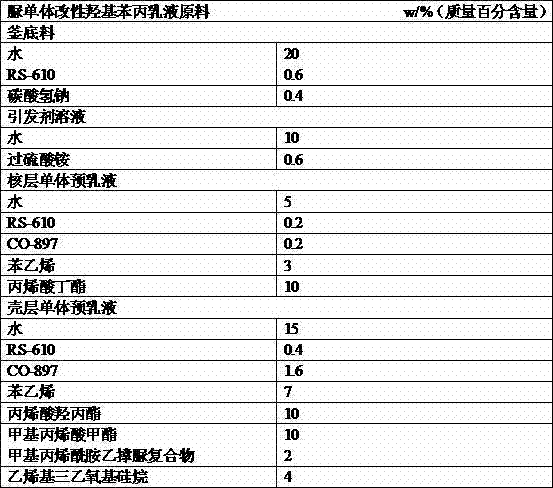

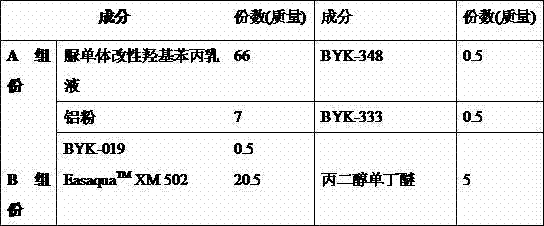

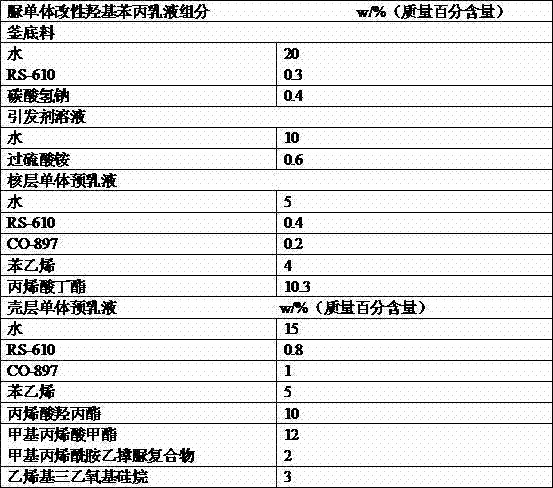

Synthetic method and application of urea monomer modified hydroxyl acrylic emulsion

InactiveCN102516447AThe method is simple and easyGood repeat stabilityCoatingsIsocyanateComposite material

The invention discloses a synthetic method and application of a urea monomer modified hydroxyl acrylic emulsion. The urea monomer modified hydroxyl acrylic emulsion is synthesized by a pre-emulsification semi-continuous seed emulsion polymerization method and applied to double-component aqueous plastic paint. According to performance test, functional groups of urea monomer interact with surface of polar plastic to enhance dry and wet adhesive force; meanwhile, hydroxy reacts with isocyanate to form a stereoscopic net structure to increase compactness of a film, water resistance and ethanol wiping resistance performances. The urea monomer modified hydroxyl acrylic emulsion prepared by the invention can carry out solidification reaction with aqueous isocyanate to gain good adhesive force and ethanol wiping resistance, so as to satisfy application requirements of low temperature solidified polar plastic paint.

Owner:GUANGDONG UNIV OF TECH

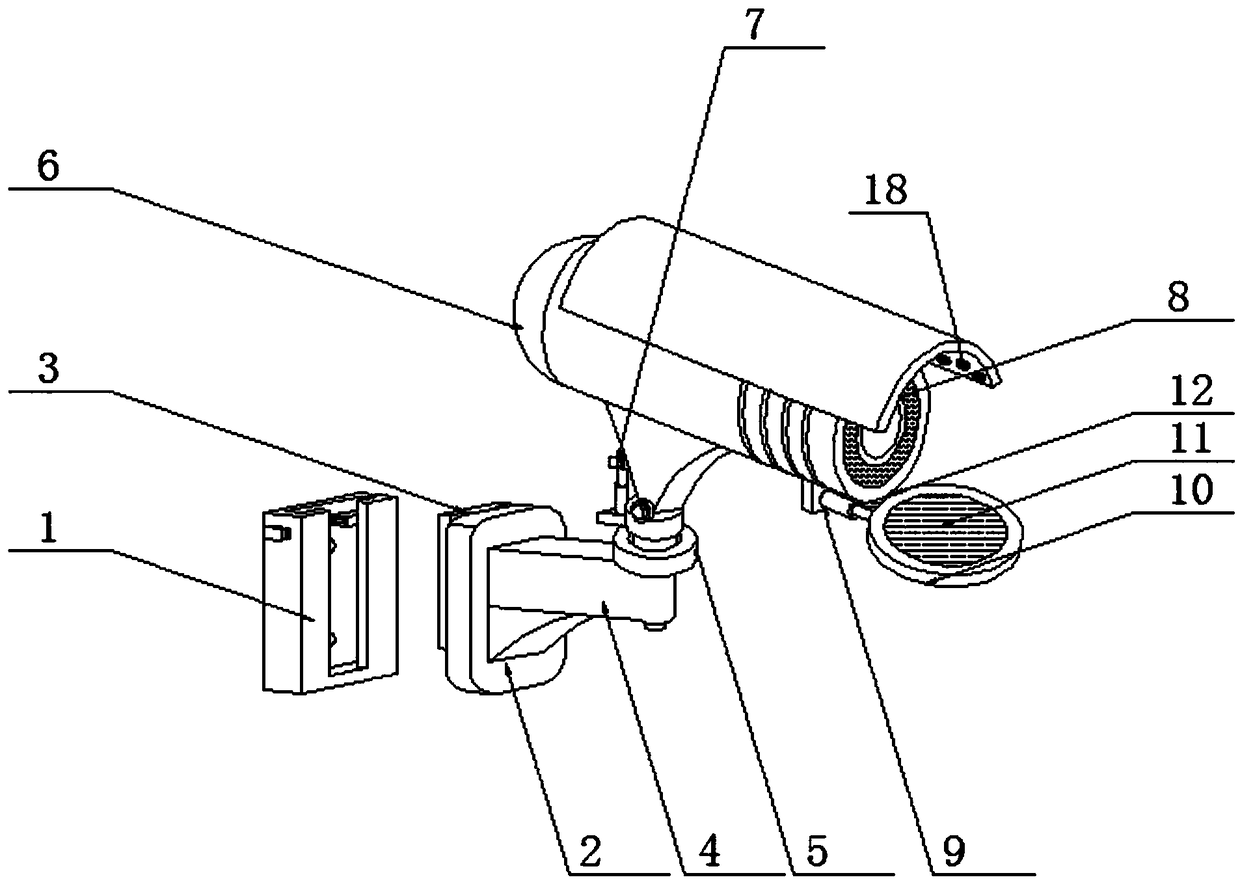

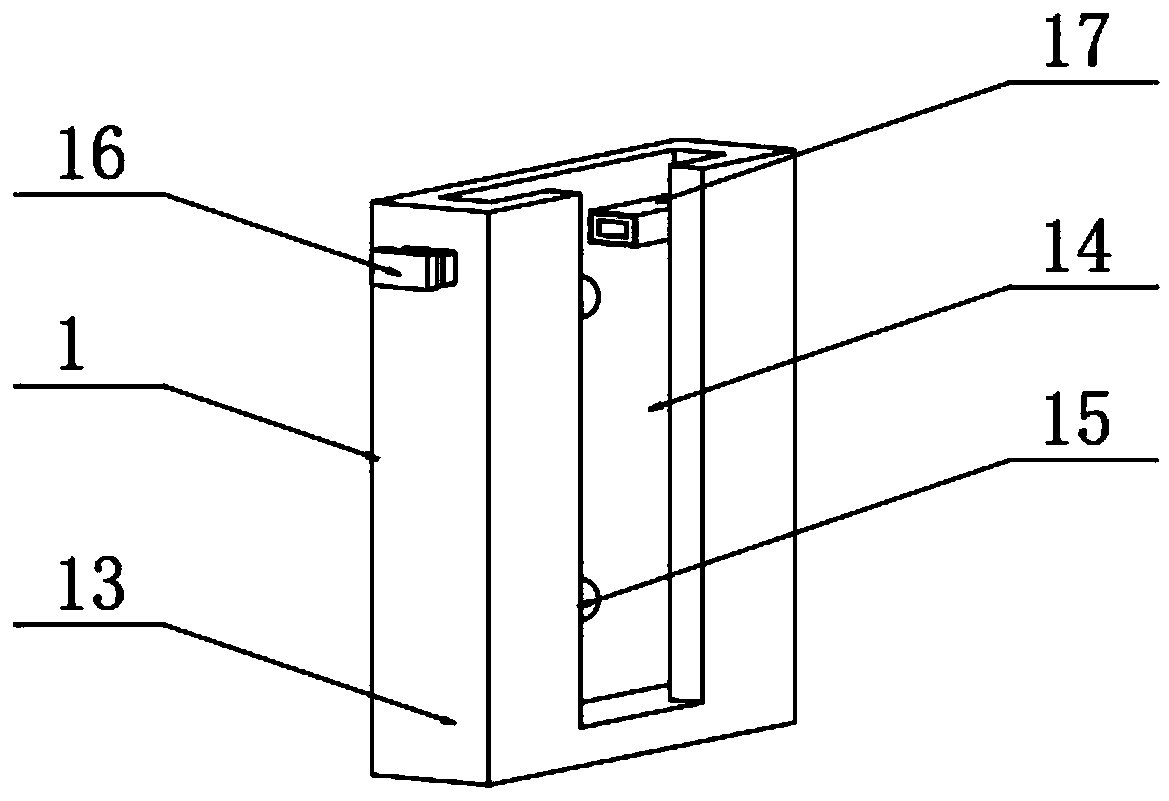

Intelligent remote electronic monitoring device

ActiveCN109277370AReduce the accumulation of dustGood wiping effectClosed circuit television systemsCleaning using toolsSurveillance cameraEngineering

The invention discloses an intelligent remote electronic monitoring device. The intelligent remote electronic monitoring device comprises a mounting assembly, an angle adjusting assembly, a monitoringcamera body, an upper cover shell, a dust-blowing assembly and a wiping assembly; the lower end of the monitoring camera body is provided with the wiping assembly in a connected mode, wherein the wiping assembly is rotatably arranged so as to be buckled on a lens of the monitoring camera body; during cleaning, the dust-blowing assembly conducts air blowing and dust removing on the lens for a period of time firstly, then the wiping assembly is rotatably buckled on the lens of the monitoring camera body for wiping; the wiping assembly is provided with a wiping liquid jetting assembly for automatically jetting wiping liquid and a suction assembly for sucking-dry the wiping liquid. According to the intelligent remote electronic monitoring device, mounting and fixing of the monitoring camera body are facilitated, the mounting structure is simple, replacing and maintaining of the monitoring camera body are facilitated, tools are not needed to be used during mounting and dismounting, the convenience of mounting and dismounting of the monitoring camera body is improved, the replacing and maintaining efficiency of the monitoring camera body is improved, and using and promoting of the monitoring camera body are facilitated.

Owner:HUZHOU TEACHERS COLLEGE

Paper towel with superior wiping properties

ActiveUS7462258B2Keep dryImprove wiping effectNatural cellulose pulp/paperMechanical working/deformationPaper towelFacial tissue

Owner:KIMBERLY-CLARK WORLDWIDE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com