Patents

Literature

1057results about How to "Prevent surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrosurgical system

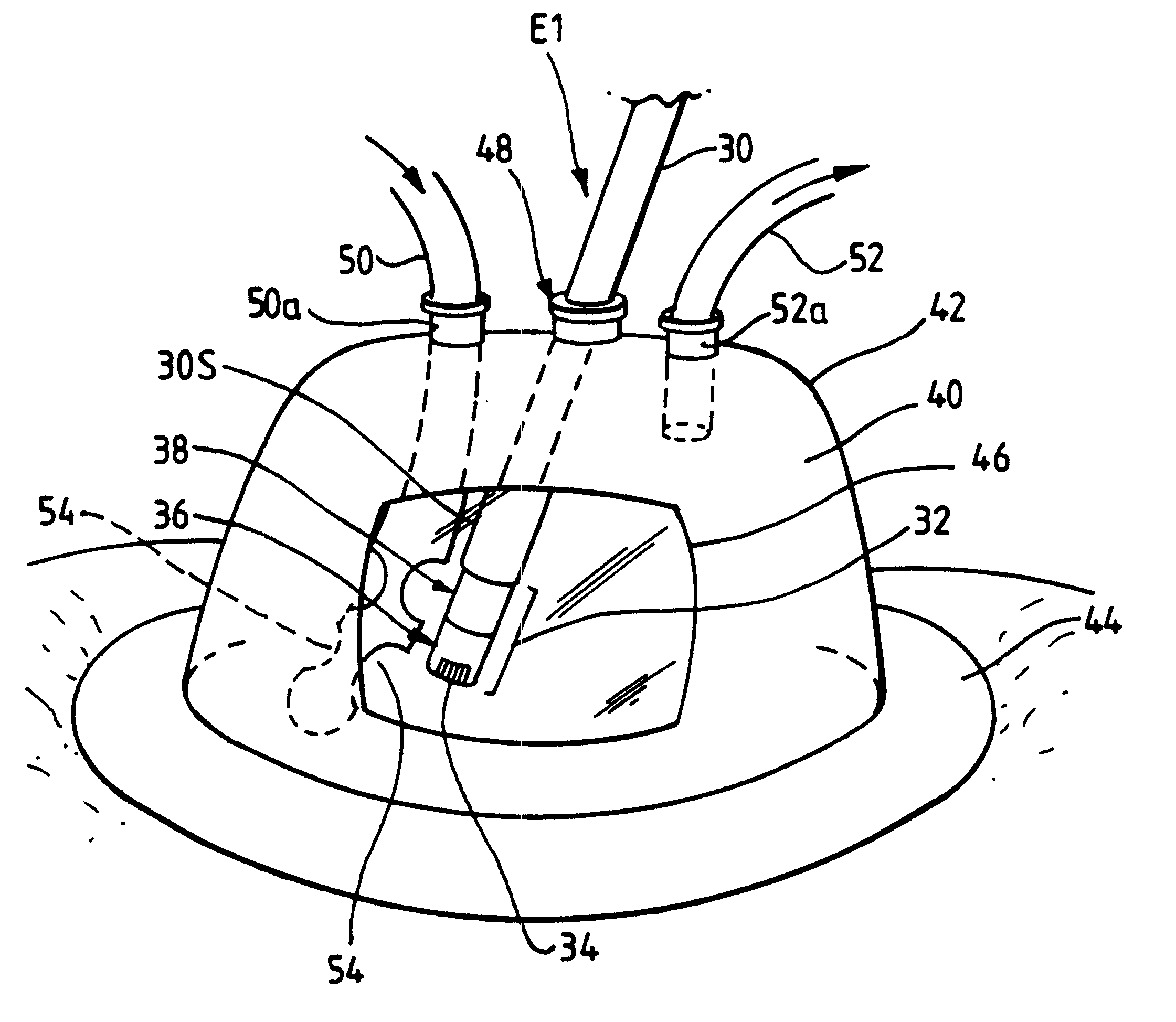

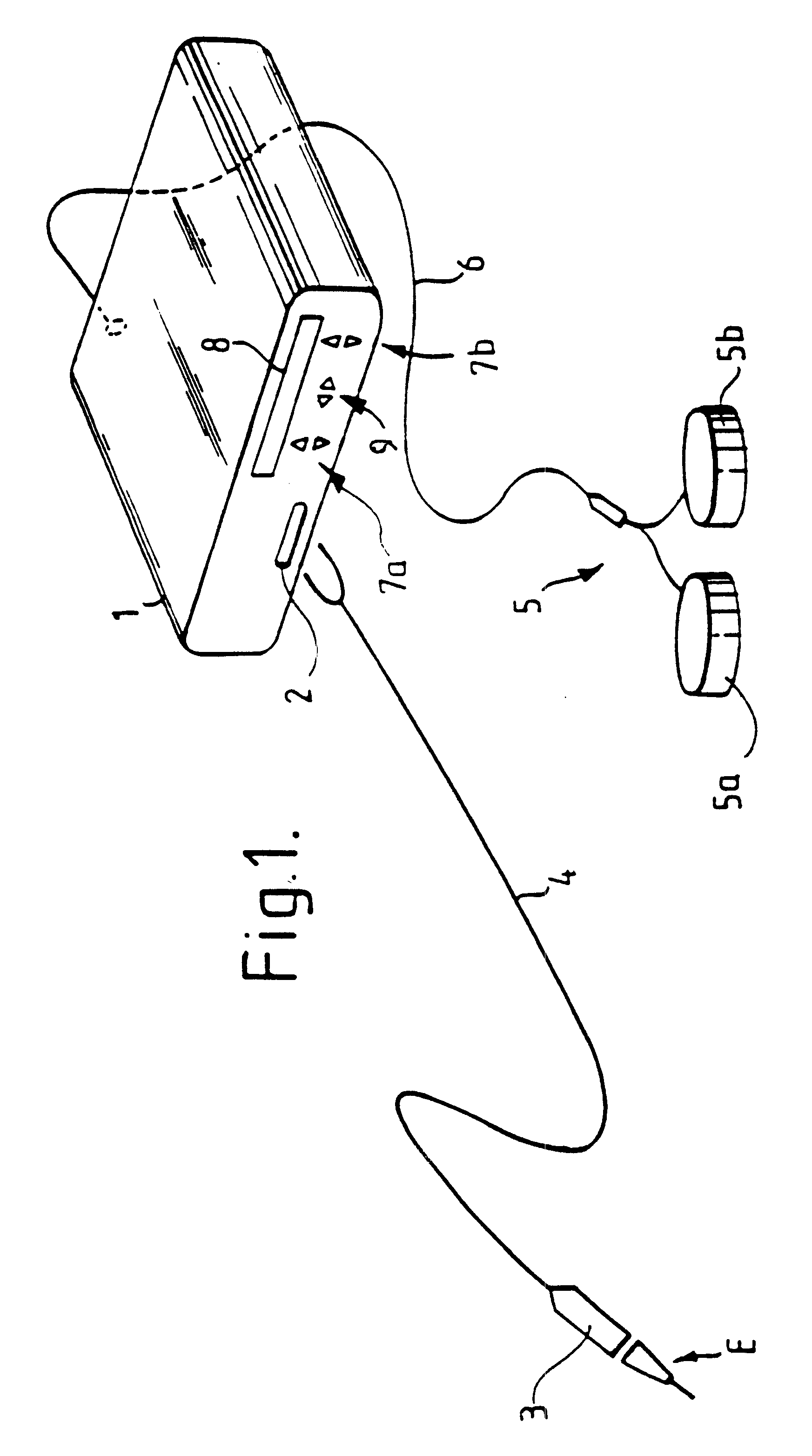

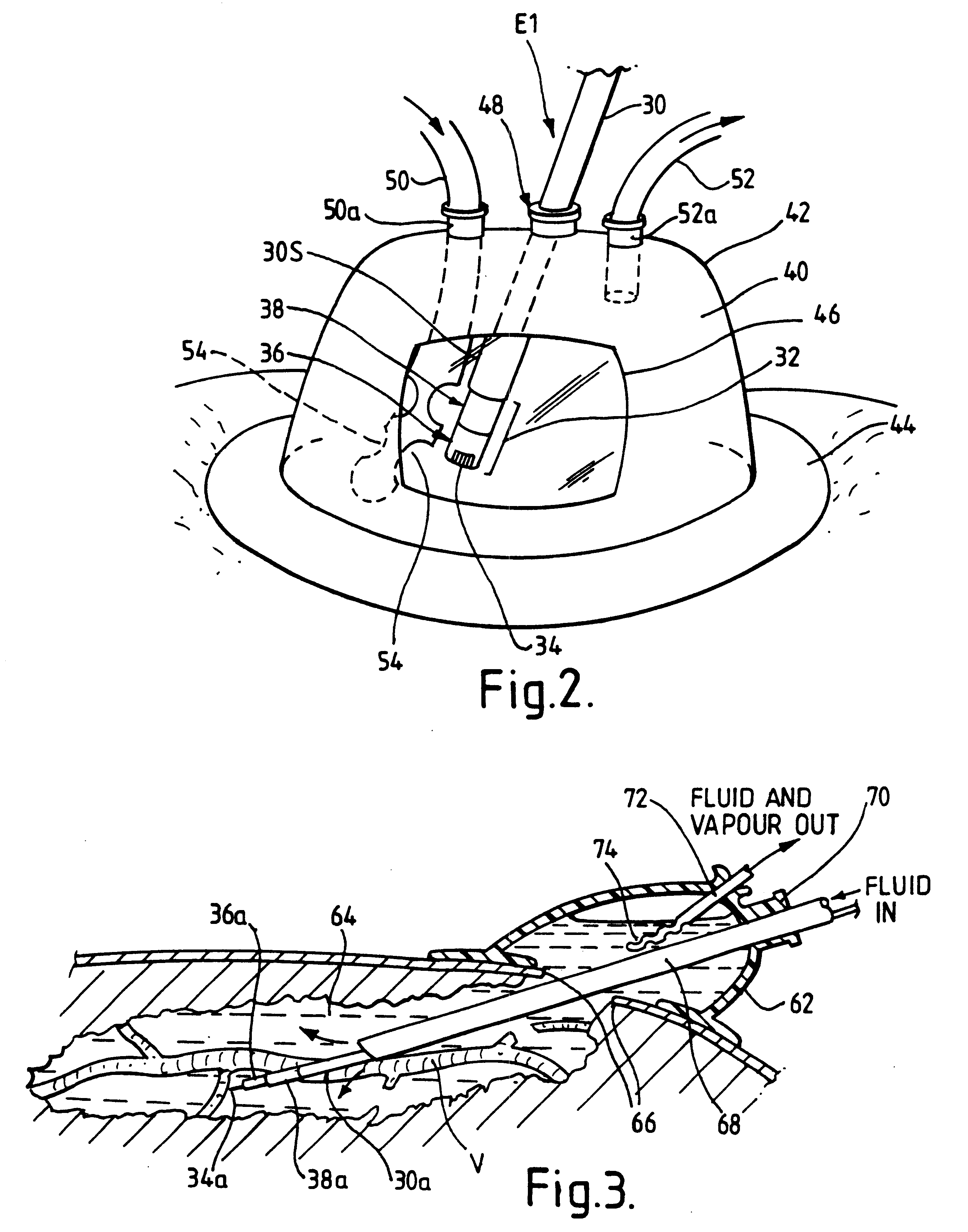

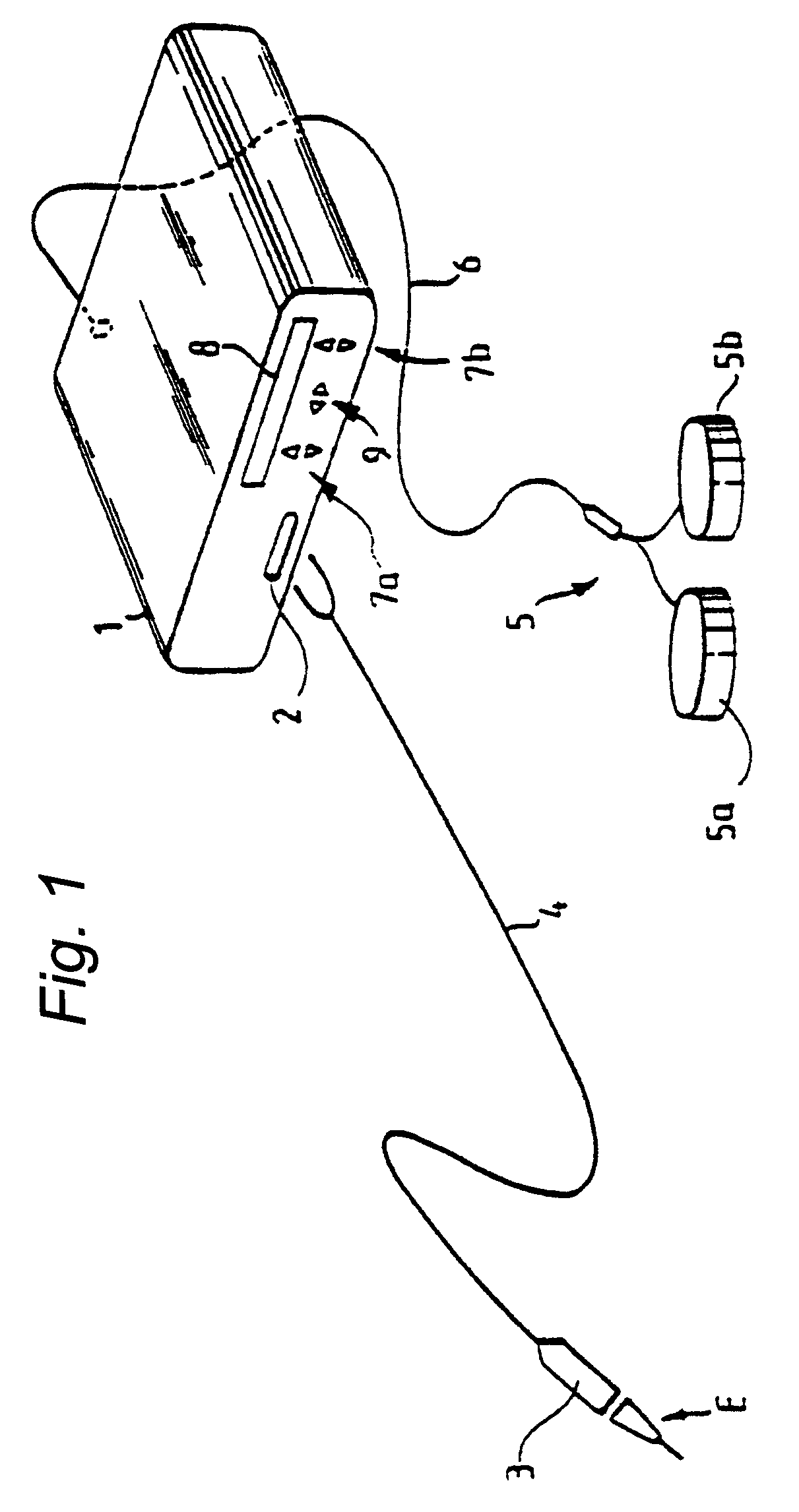

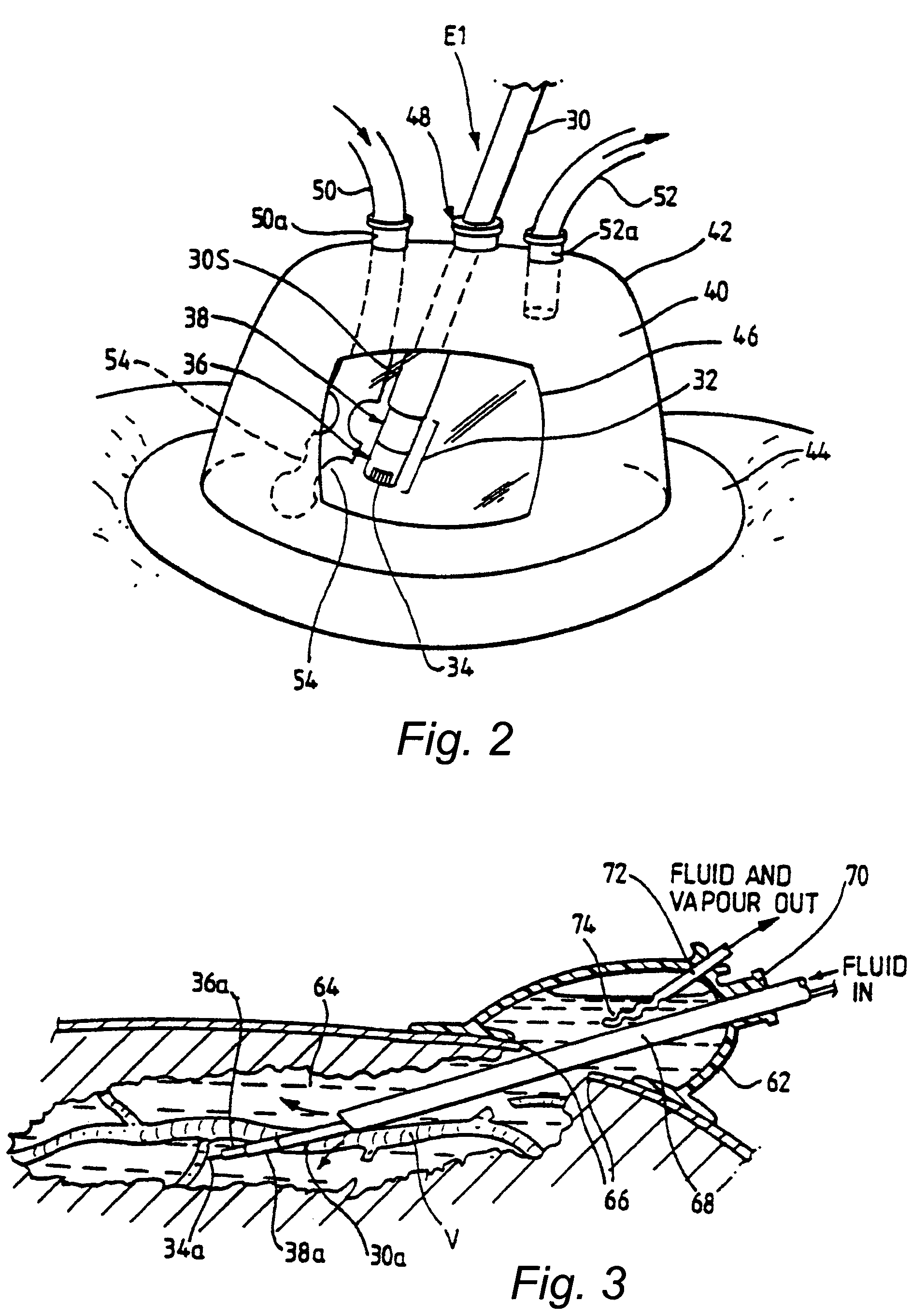

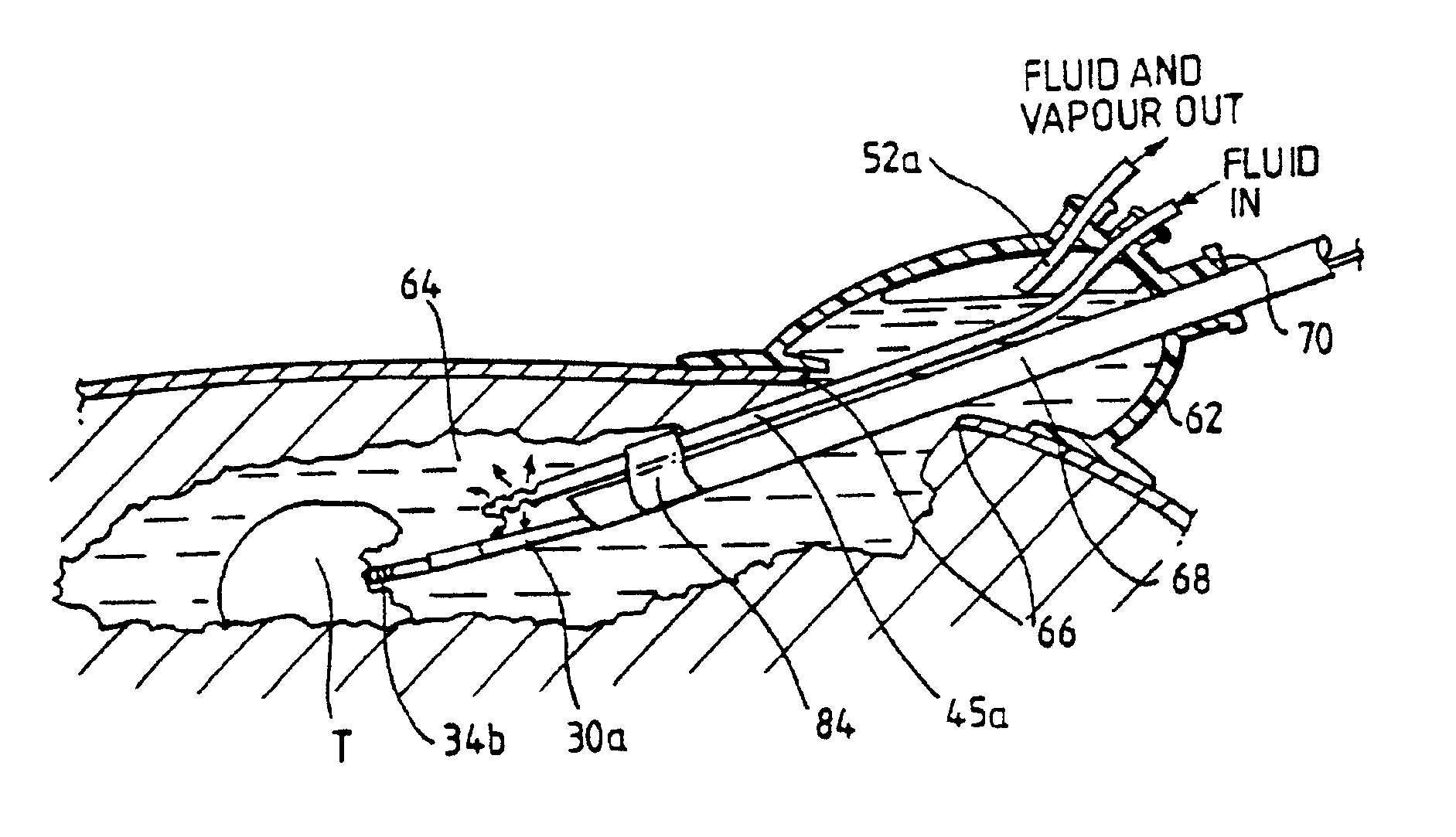

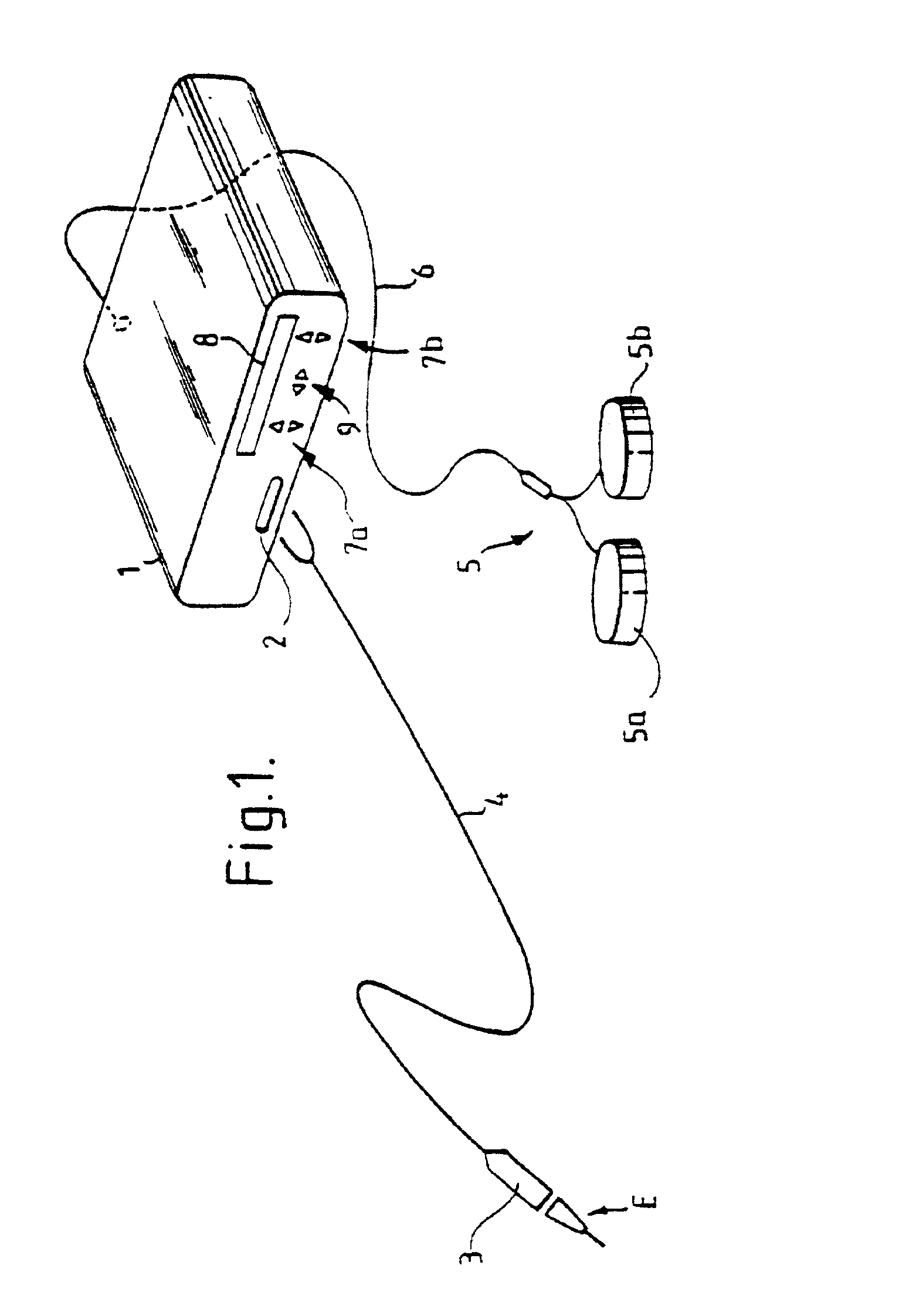

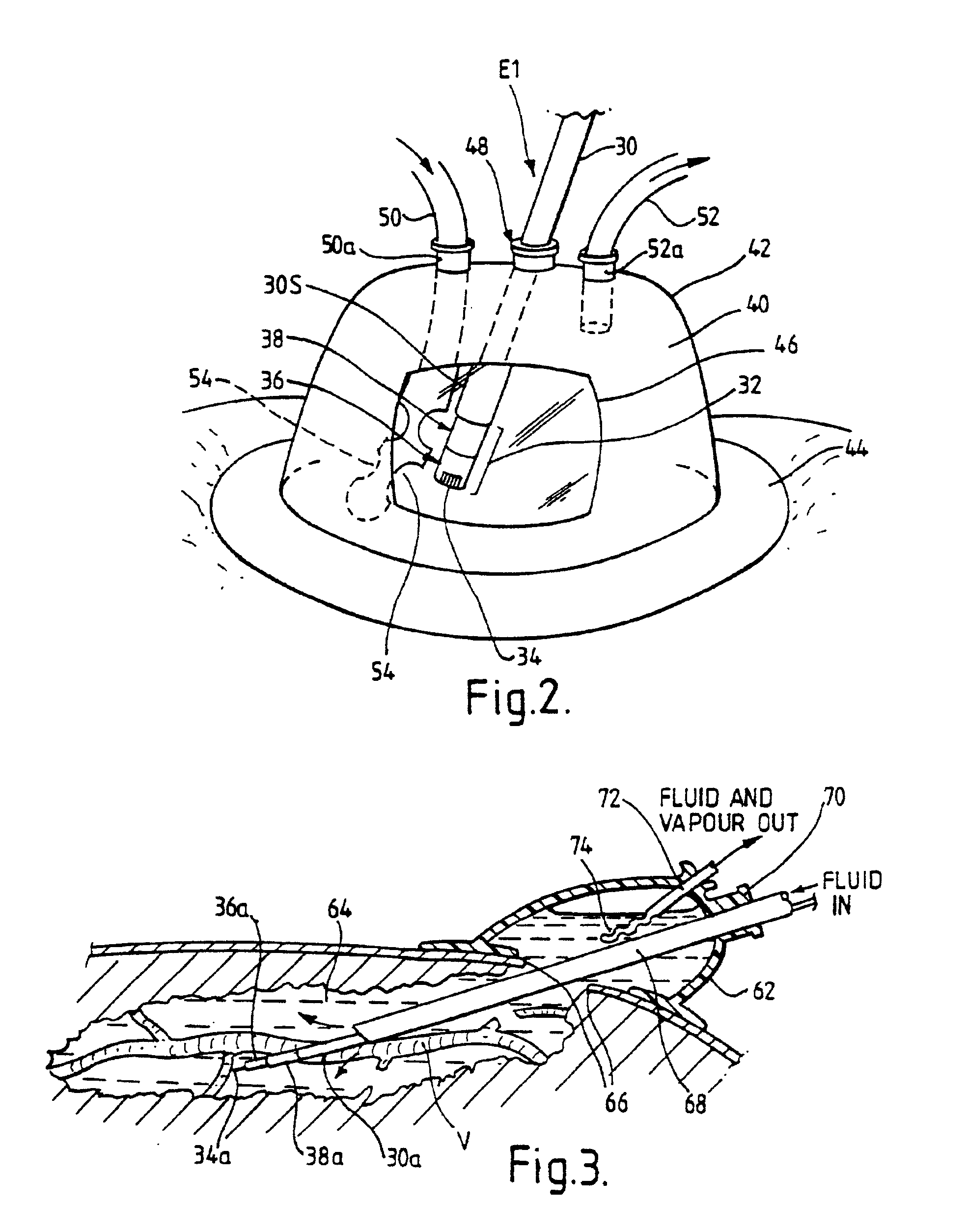

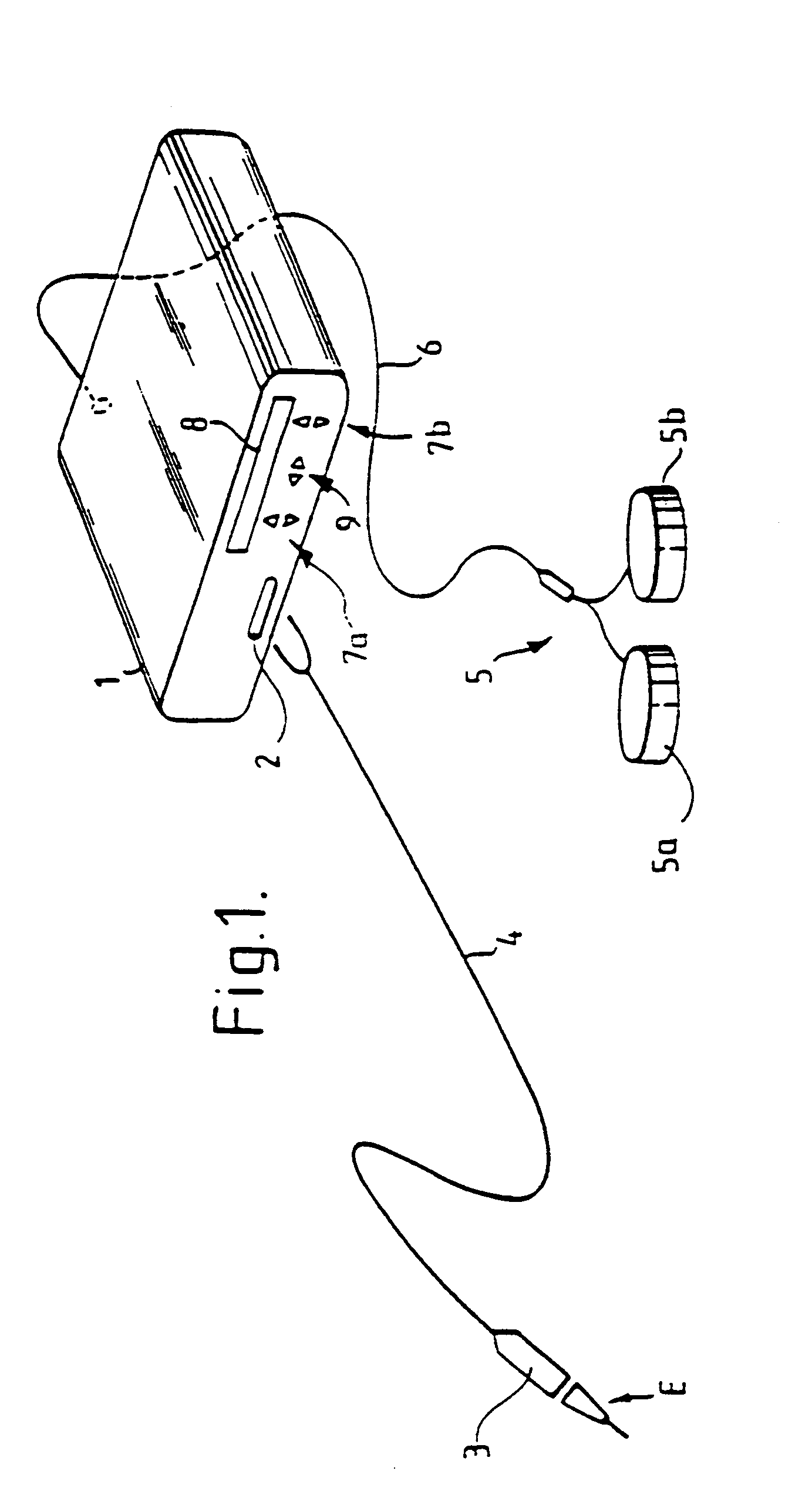

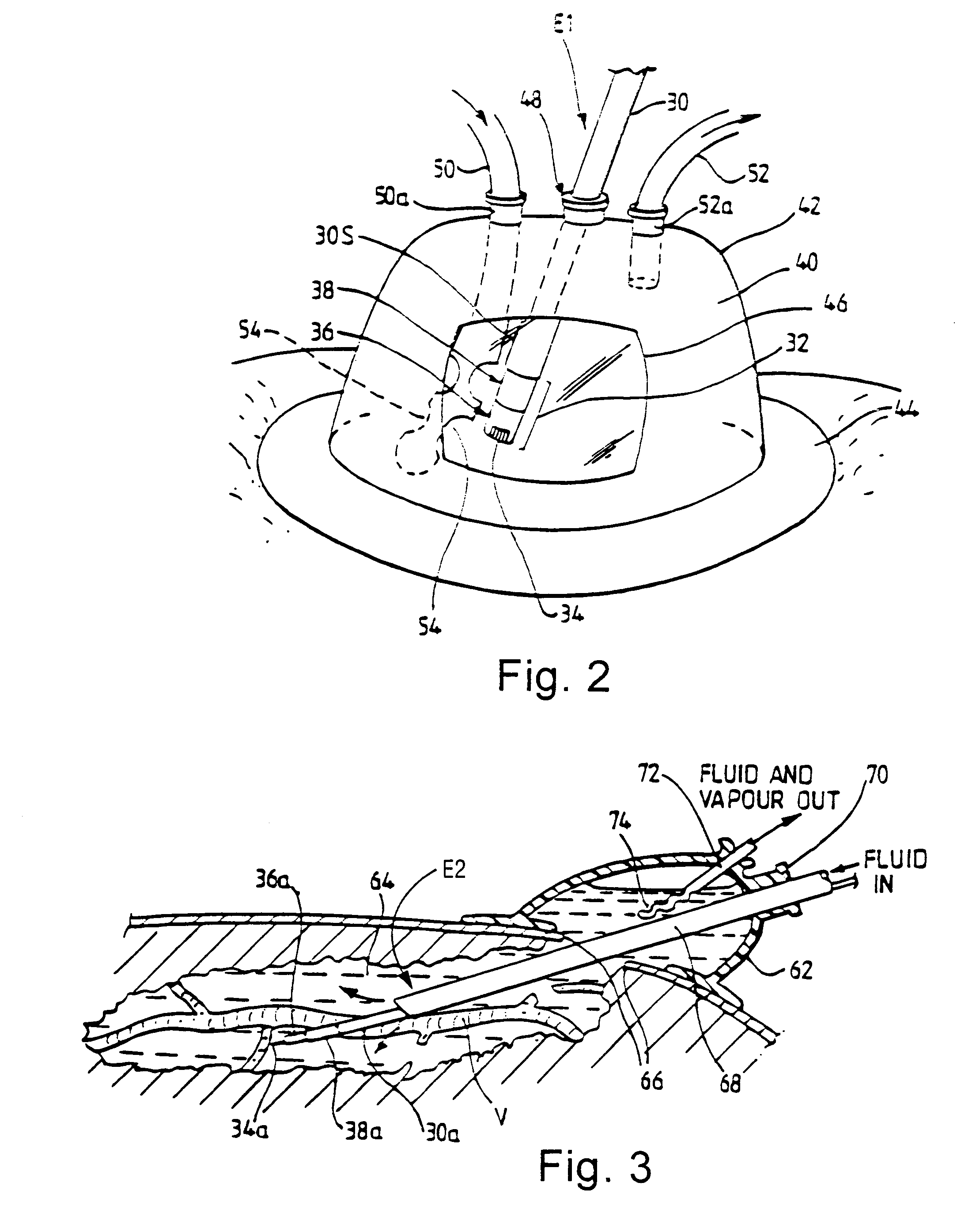

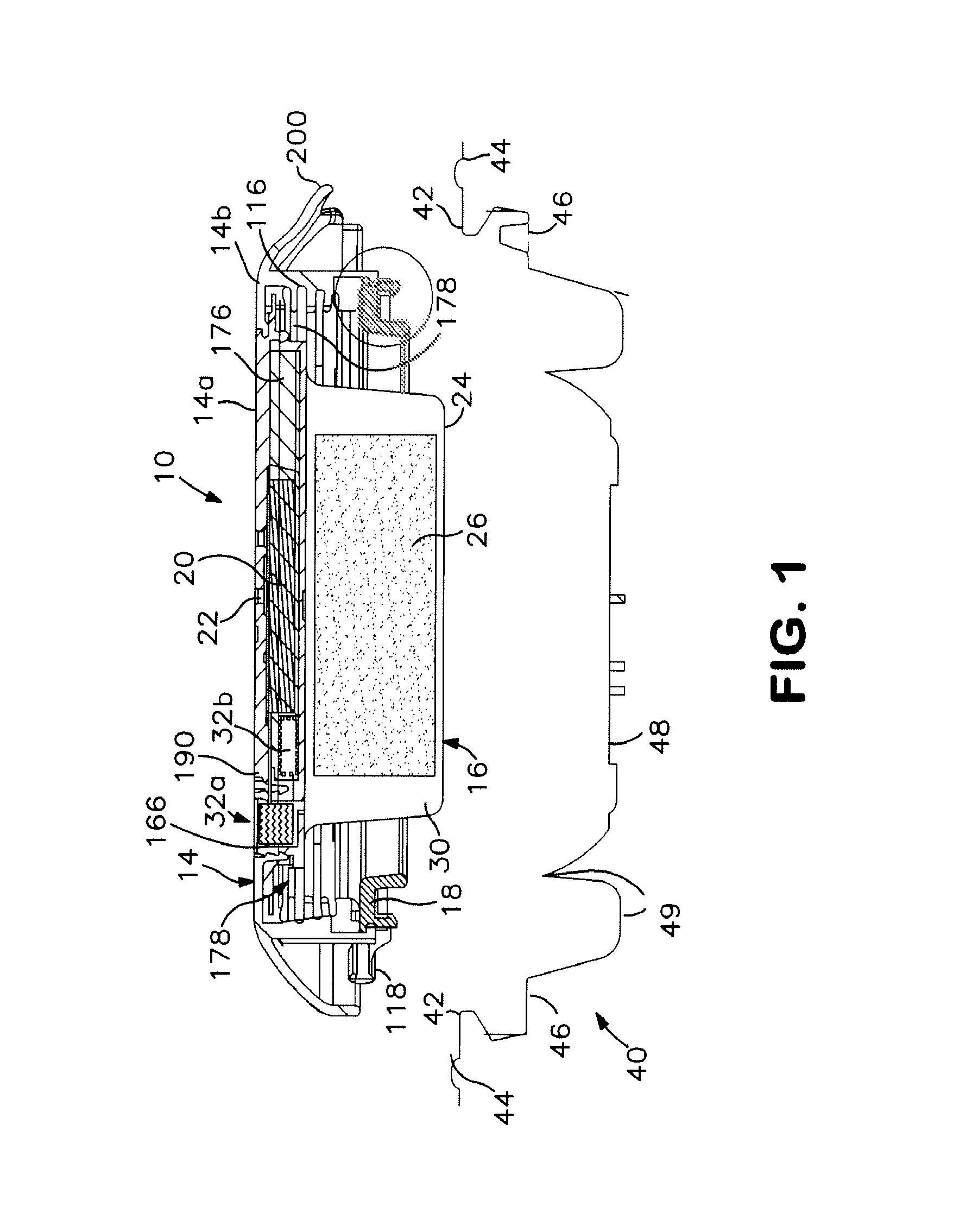

An electrosurgical system comprises a radio frequency generator (1), an electrosurgical instrument (E1), and a fluid enclosure (42). The generator (1) has a radio frequency output for delivery of power to the electrosurgical instrument (E1) when immersed in an electrically-conductive fluid. The electrosurgical instrument (E1) has an electrode assembly (32) at the distal end thereof, the electrode assembly comprising a tissue treatment electrode (34), and a return electrode (38) axially spaced therefrom in such a manner as to define, in use, a conductive fluid path that completes an electrical circuit between the tissue treatment electrode and the return electrode. The fluid enclosure (42) is adapted to surround an operation site on the skin of a patient or an incision leading to a cavity surgically created within the patient's body. The fluid enclosure (42) includes sealing means (44) for sealing against the patient's tissue, and the fluid enclosure includes at least one port (50a, 52a) through which the electrosurgical (E1) is insertable, and through which the electrically-conductive fluid can enter and / or leave the enclosure.

Owner:GYRUS MEDICAL LTD

Electrosurgical instrument

InactiveUS7278994B2Lower impedanceReduced effectivenessCannulasDiagnosticsGynecologyPeritoneal cavity

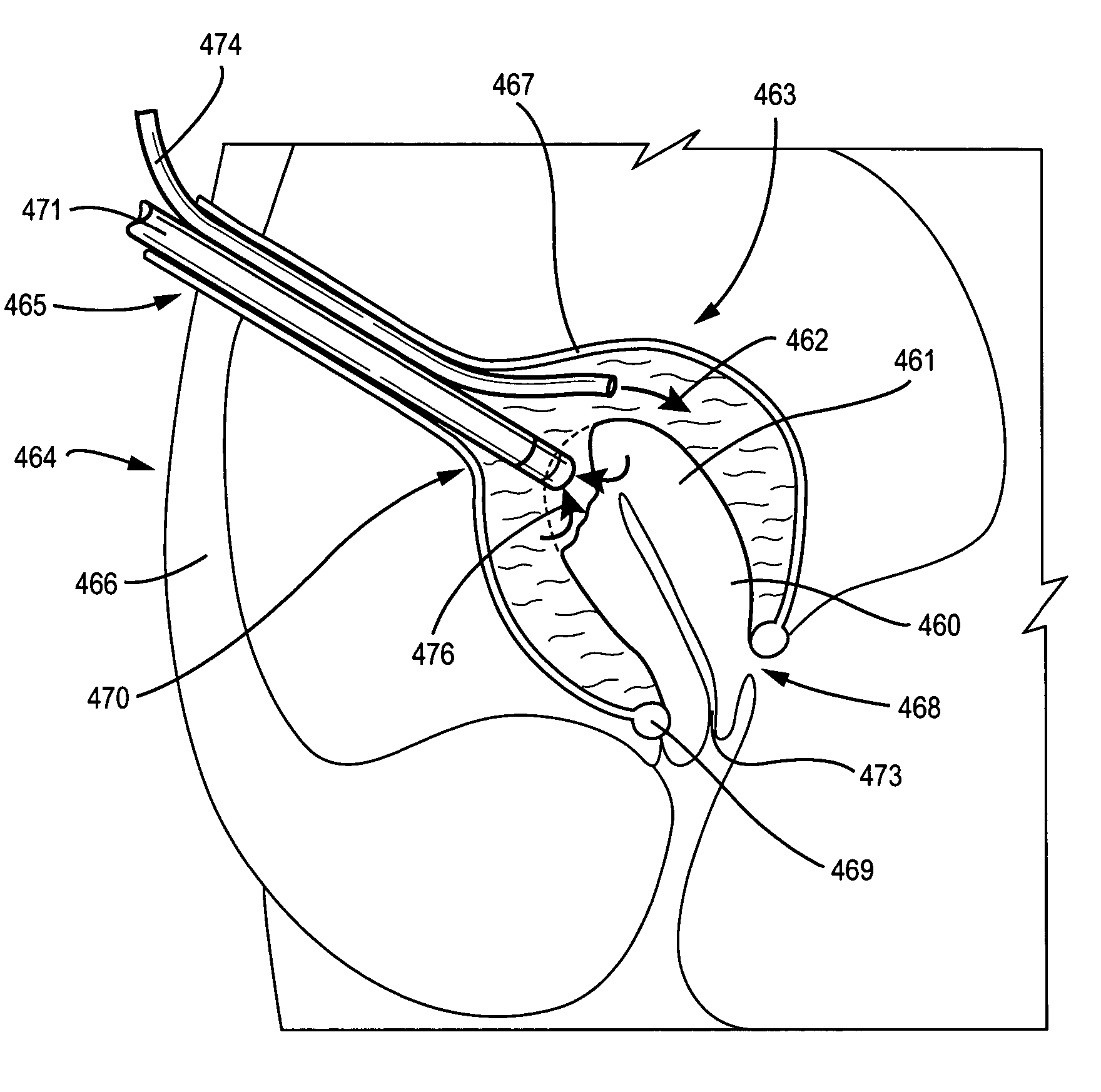

A system and method are disclosed for removing a uterus using a fluid enclosure inserted in the peritoneal cavity of a patient so as to enclose the uterus. The fluid enclosure includes a distal open end surrounded by an adjustable loop, that can be tightened, a first proximal opening for inserting an electrosurgical instrument into the fluid enclosure, and a second proximal opening for inserting an endoscope. The loop is either a resilient band extending around the edge of the distal open end or a drawstring type of arrangement that can be tightened and released. The fluid enclosure is partially inserted into the peritoneal cavity of a patient in a deflated condition and then manipulated within the peritoneal cavity over the body and fundus of the uterus to the level of the uterocervical junction. The loop is tightened around the uterocervical junction, after which the enclosure is inflated using a conductive fluid. The loop forms a pressure seal against the uterocervical junction to contain the conductive fluid used to fill the fluid enclosure. Endoscopically inserted into the fluid enclosure is an electrosurgical instrument that is manipulated to vaporize and morcellate the fundus and body of the uterus. The fundus and body tissue that is vaporized and morcellated is then removed from the fluid enclosure through the shaft of the instrument, which includes a hollow interior that is connected to a suction pump The fundus and body are removed after the uterus has been disconnected from the tissue surrounding uterus.

Owner:GYRUS MEDICAL LTD

Electrosurgical system and method

An electrosurgical system comprises a radio frequency generator (1), an electrosurgical instrument (E1), and a fluid enclosure (42). The generator (1) has a radio frequency output for delivery of power to the electrosurgical instrument (E1) when immersed in an electrically-conductive fluid. The electrosurgical instrument (E1) has an electrode assembly (32) at the distal end thereof, the electrode assembly comprising a tissue treatment electrode (34), and a return electrode (38) axially spaced therefrom in such a manner as to define, in use, a conductive fluid path that completes an electrical circuit between the tissue treatment electrode and the return electrode. The fluid enclosure (42) is adapted to surround an operation site on the skin of a patient or an incision leading to a cavity surgically created within the patient's body. The fluid enclosure (42) includes sealing means (44) for sealing against the patient's tissue, and the fluid enclosure includes at least one port (50a, 52a) through which the electrosurgical (E1) is insertable, and through which the electrically-conductive fluid can enter and / or leave the enclosure. The fluid enclosure device of the present invention can also be used to treat tumours within the colon. The enclosure, which includes a proximal and a distal bung, is inserted into the colon in a deflated condition and then inflated with a conductive fluid or gas. The colon can be supported against the pressure of the fluid or gas with a pressure sleeve that has been inserted to surround the region of the colon being treated. An electrosurgical instrument is then inserted into the colon and manipulated to vaporize the tumor.

Owner:GYRUS MEDICAL LTD

Electrosurgical system and method

InactiveUS7001380B2Lower impedanceMinimizing char formationCannulasDiagnosticsBenign conditionEnlarged tonsils

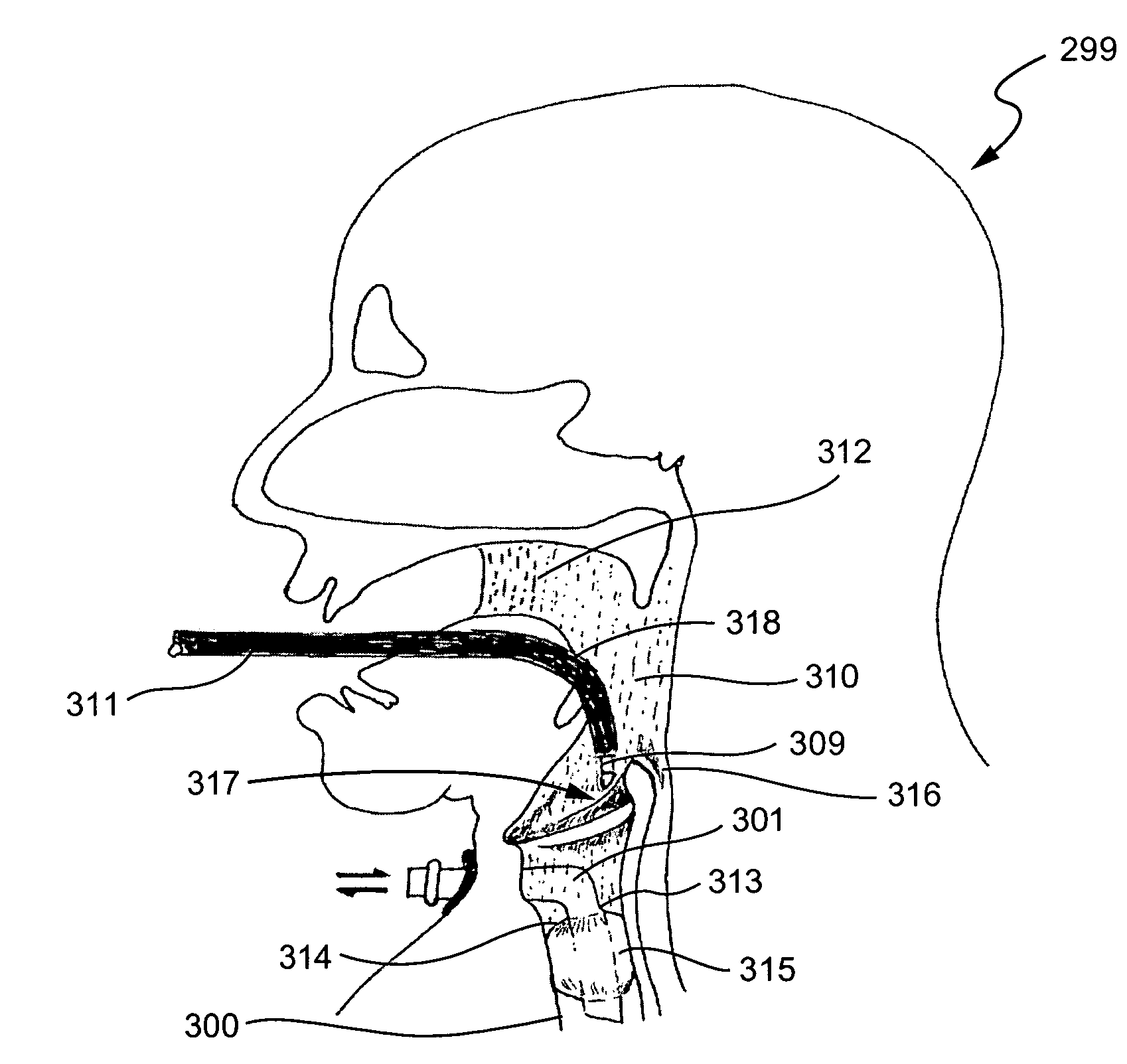

A method is disclosed for treating benign conditions, such as enlarged tonsils and / or adenoids located in a patient's throat or nasopharynx, or soft tissue lesions located in a patient's oropharynx or larynx. According to the method, a space containing the patient's nasopharynx, oropharynx or pharynx and larynx is isolated from the patient's trachea and lungs using an inflatable cuff tracheostomy tube or nasotracheal tube inserted in the patient's trachea. The cuff is inflated to occlude the trachea. The patient is placed in a supine position, whereupon at least a portion of the space containing the nasopharynx and / or oropharynx and larynx is filled with saline. An endoscope is then inserted into the space to view the operative site in which the tonsils or tissue lesion are to be treated. An electrosurgical instrument having an active tissue treatment electrode and a return electrode connected to an electrosurgical generator is then inserted into the space, either along side the endoscope or through the endoscope's working channel. The generator is then operated to apply a radio frequency voltage between the active and return electrodes of the electrosurgical instrument, whereby a conduction path is formed between the active and return electrodes, at least partially through the saline, whereupon the active electrode is manipulated to debulk or otherwise treat the soft tissue lesion or enlarged tonsils and / or adenoids.

Owner:GYRUS MEDICAL LTD

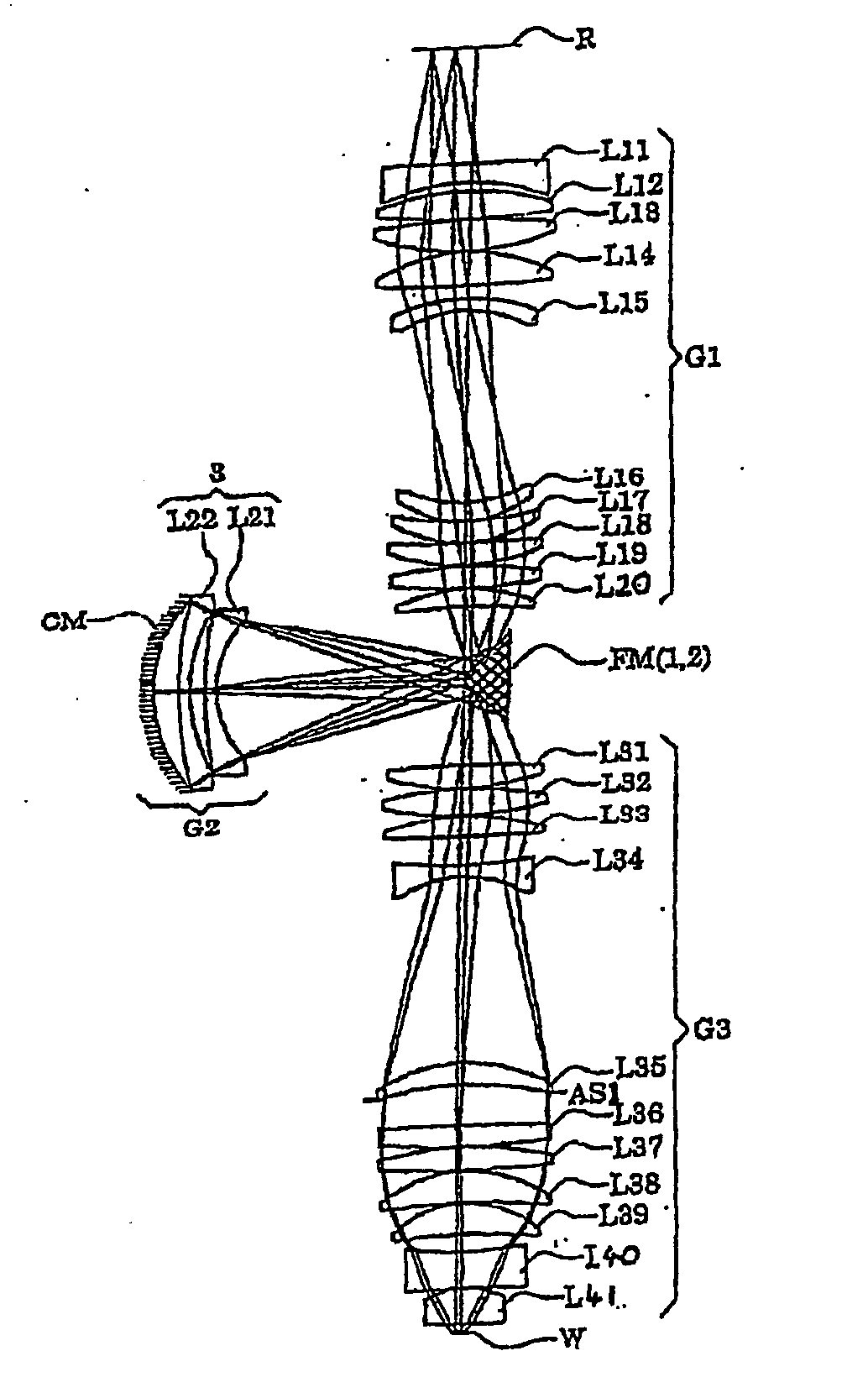

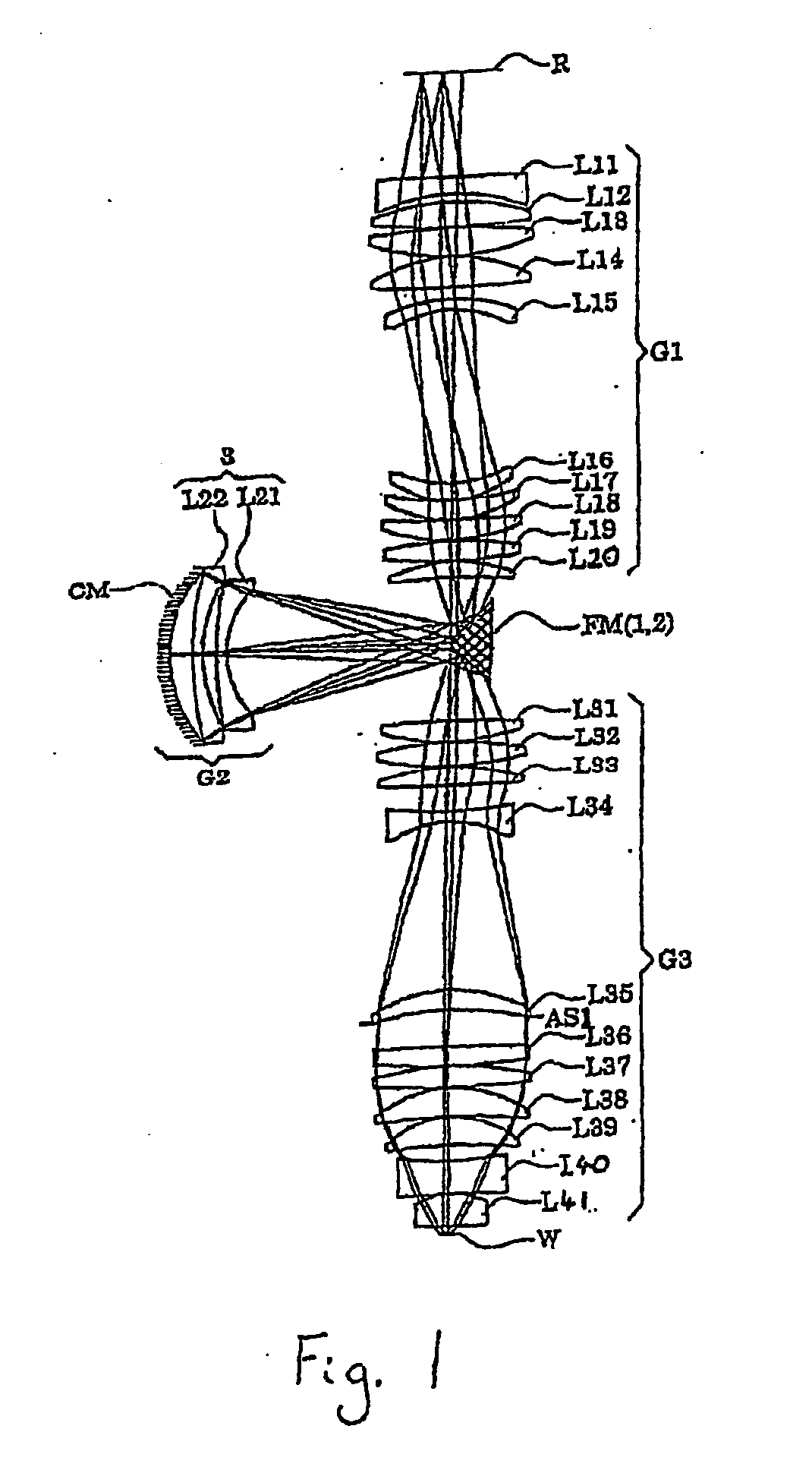

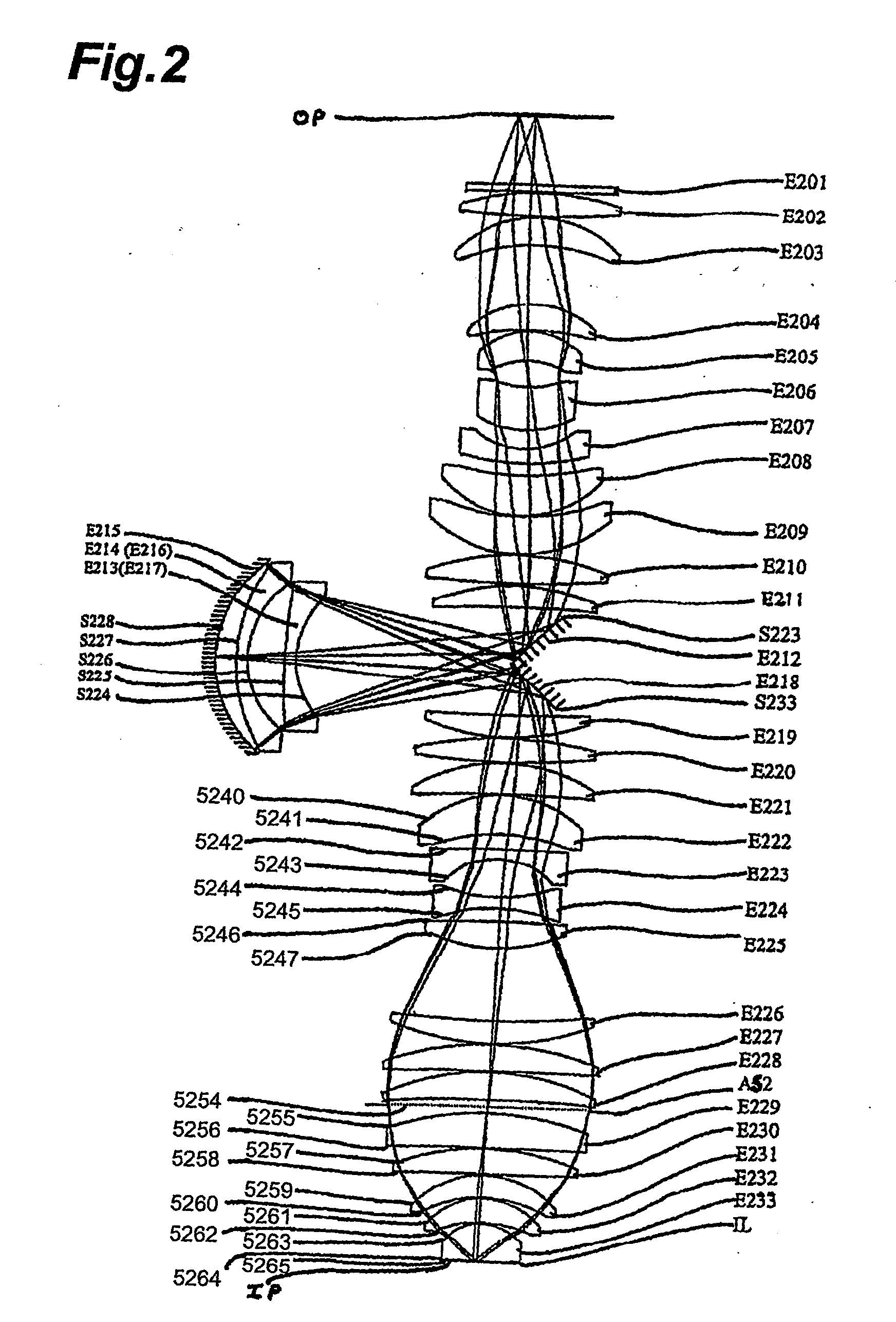

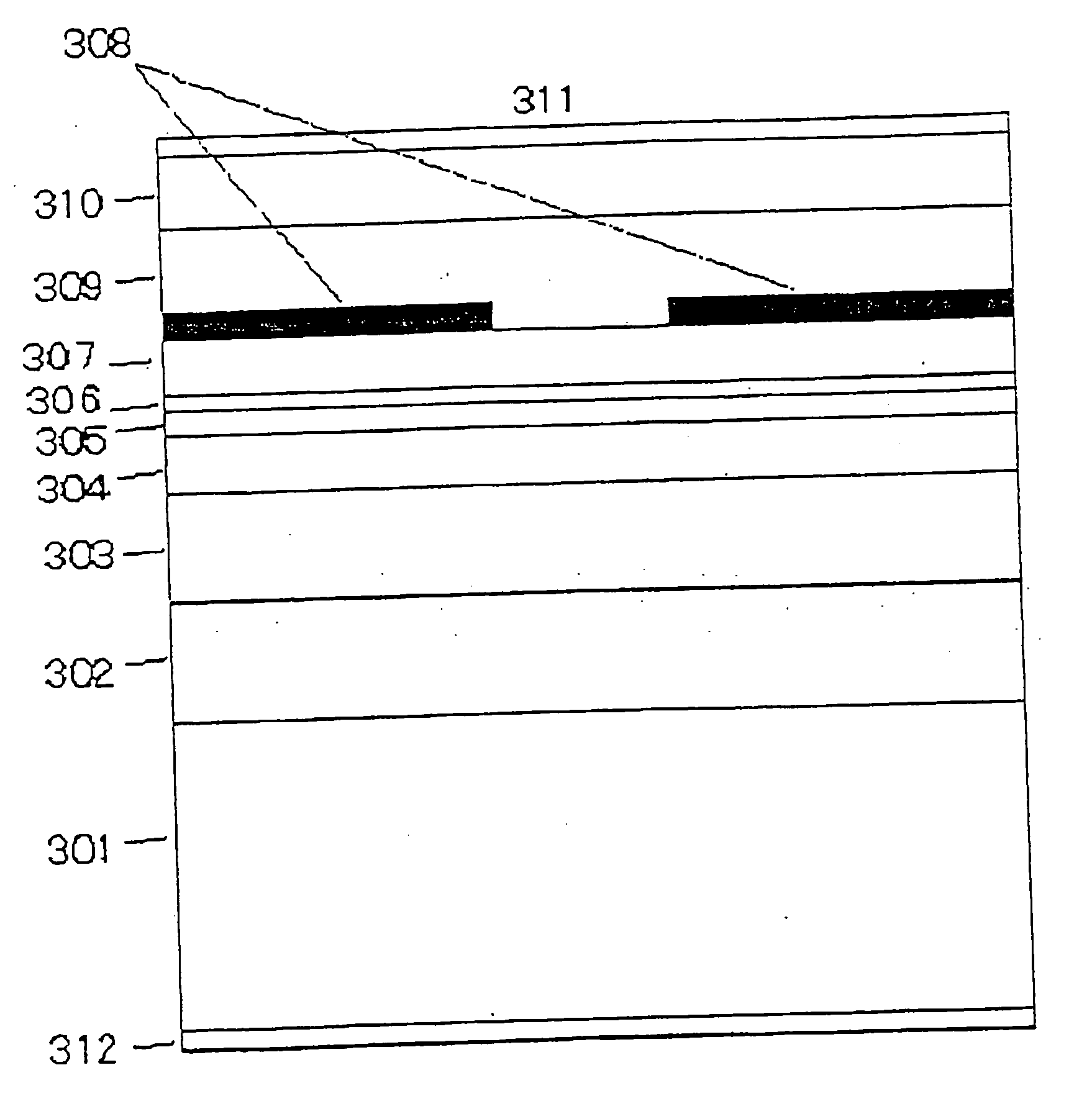

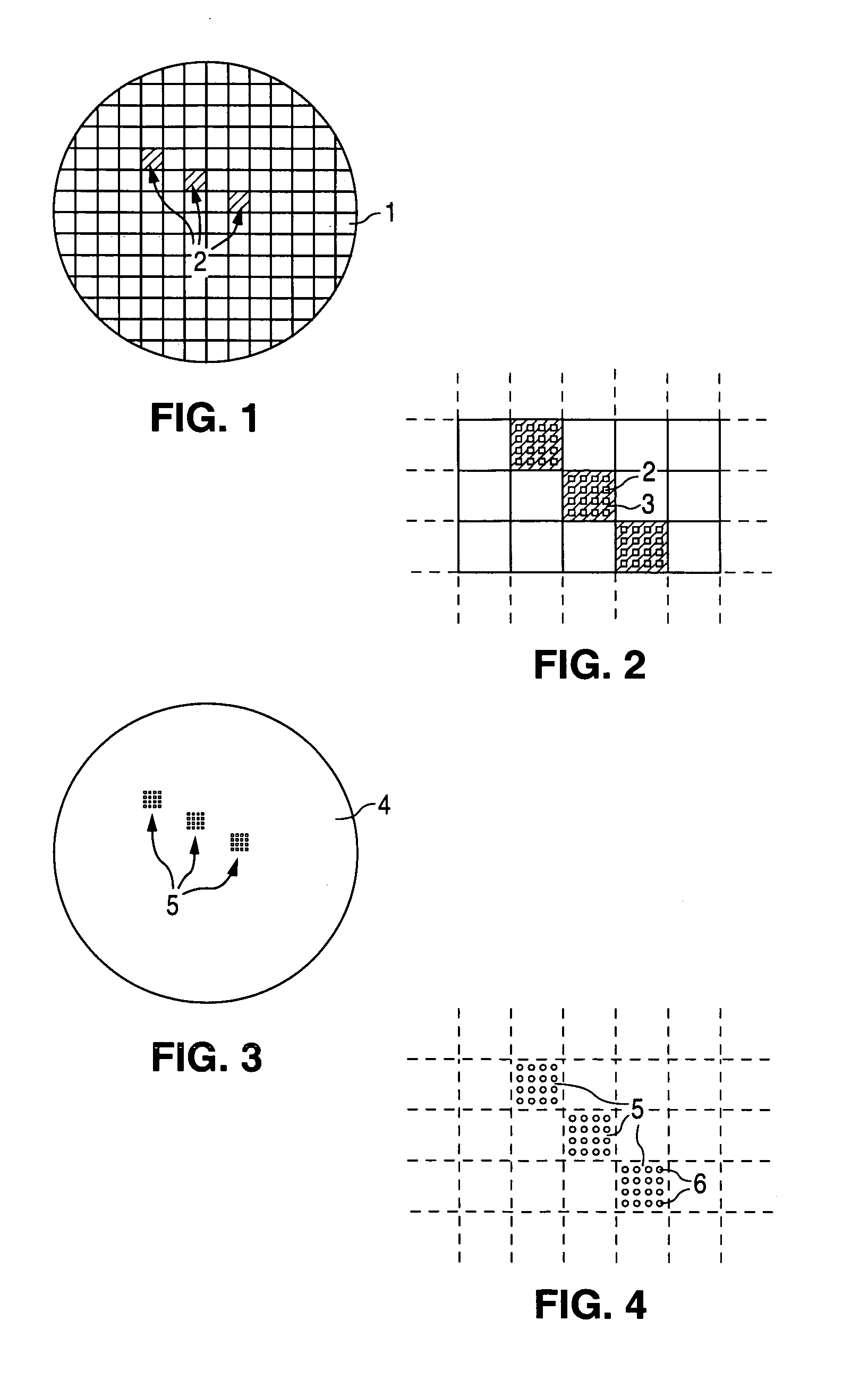

Projection optical system and method for photolithography and exposure apparatus and method using same

InactiveUS20050248856A1Large image-sideWide effective image forming areaSemiconductor/solid-state device manufacturingMicroscopesWide fieldProjection system

Optical Projection System and Method for Photolithography. A lithographic immersion projection system and method for projecting an image at high resolution over a wide field of view. The projection system and method include a final lens which decreases the marginal ray angle of the optical path before light passes into the immersion liquid to impinge on the image plane.

Owner:NIKON CORP

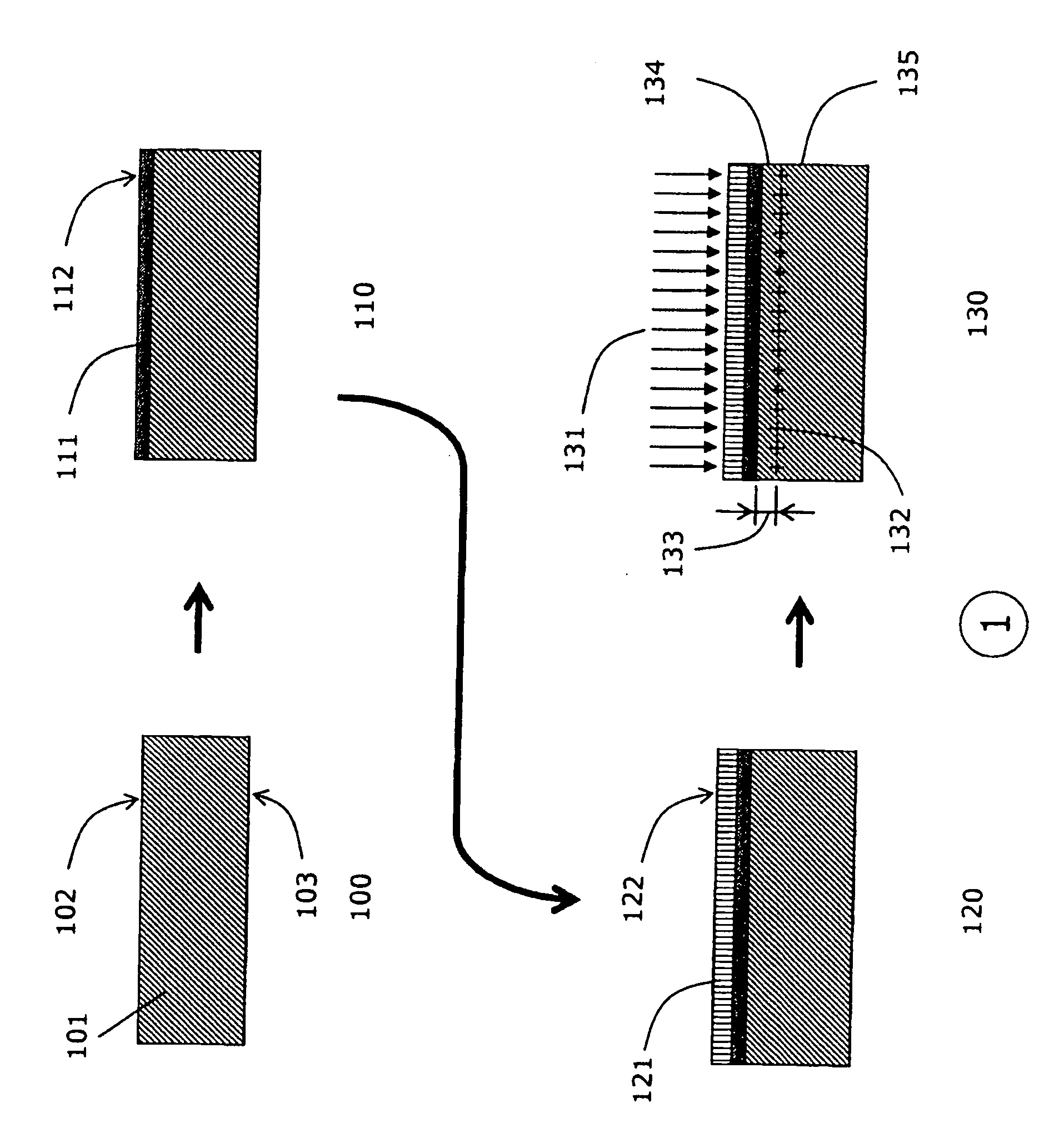

Group-III nitride semiconductor device

InactiveUS20050072986A1Suppress an undesired mass-transportPrevent surfaceOptical wave guidanceLaser detailsNitride semiconductorsCompound semiconductor

A method of forming a partially etched nitride-based compound semiconductor crystal layer includes the following steps. A non-crystal layer of a nitride-based compound semiconductor is formed. At least a part of the non-crystal layer is then etched to form a partially etched non-crystal layer before the partially etched non-crystal layer is crystallized to form a partially etched nitride-based compound semiconductor crystal layer.

Owner:RENESAS ELECTRONICS CORP

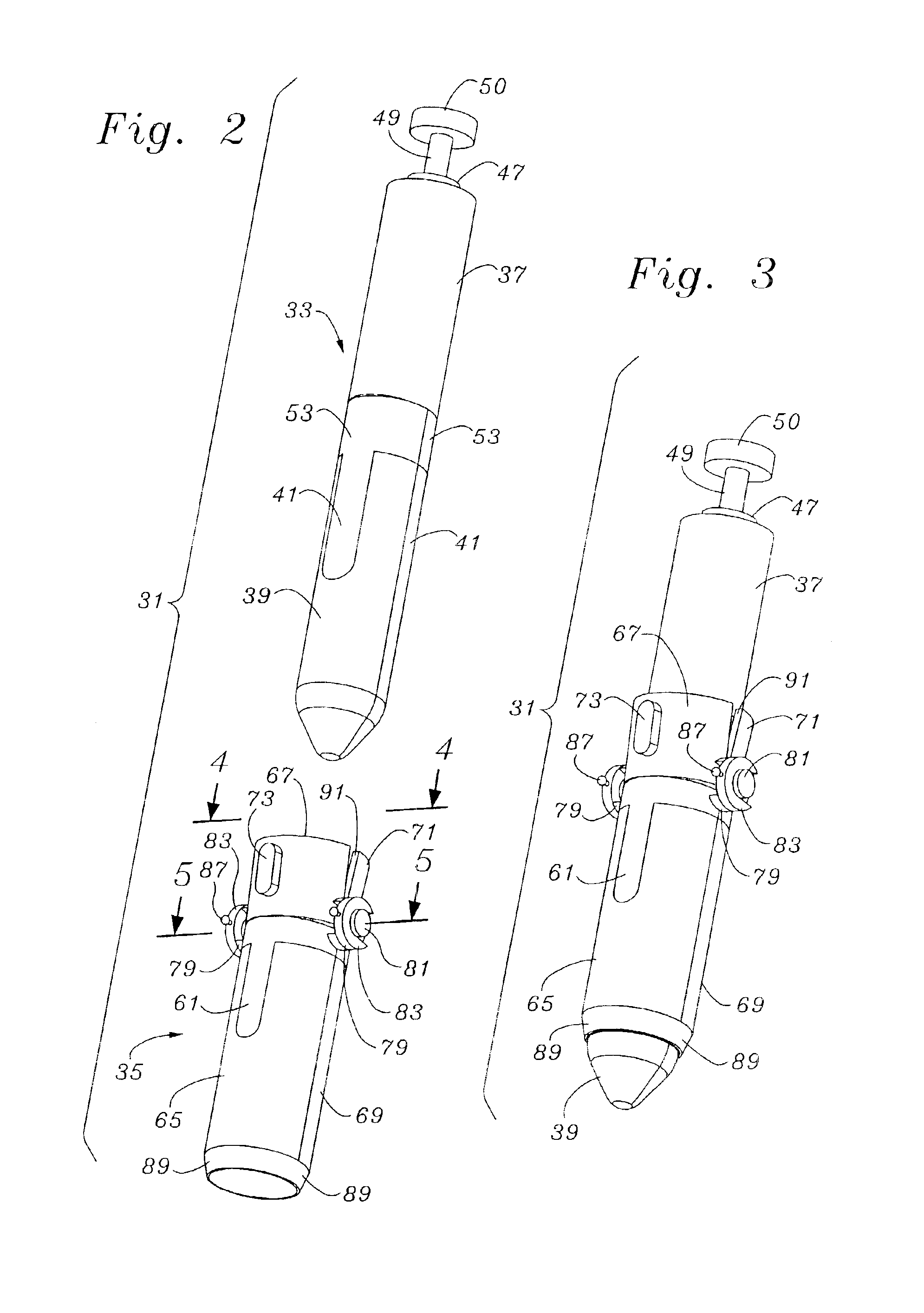

Minimal access lumbar diskectomy instrumentation and method

InactiveUS6849064B2Prevent surfaceEasy to separateCannulasInfusion syringesMuscle tissueSkin surface

A minimal incision maximal access system allows for maximum desirable exposure along with maximum access to the operative field utilizing a minimum incision as small as the METRx and Endius systems. Instead of multiple insertions of dilating tubes the design is is a streamlined single entry device to avoid repetitive skin surface entry. The system offers the capability to expand to optimum exposure size for the surgery utilizing hinged bi-hemispherical or oval working tubes applied over an introducer obturator which is controllably dilated to slowly separate muscle tissue. Deeper end working and visualization areas with maximum proximal access and work dimensions are provided to makes the operative procedure safer in application and shorten the surgeons's learning curve because it most closely approximates the ability to use open microdiskectomy techniques.

Owner:K2M

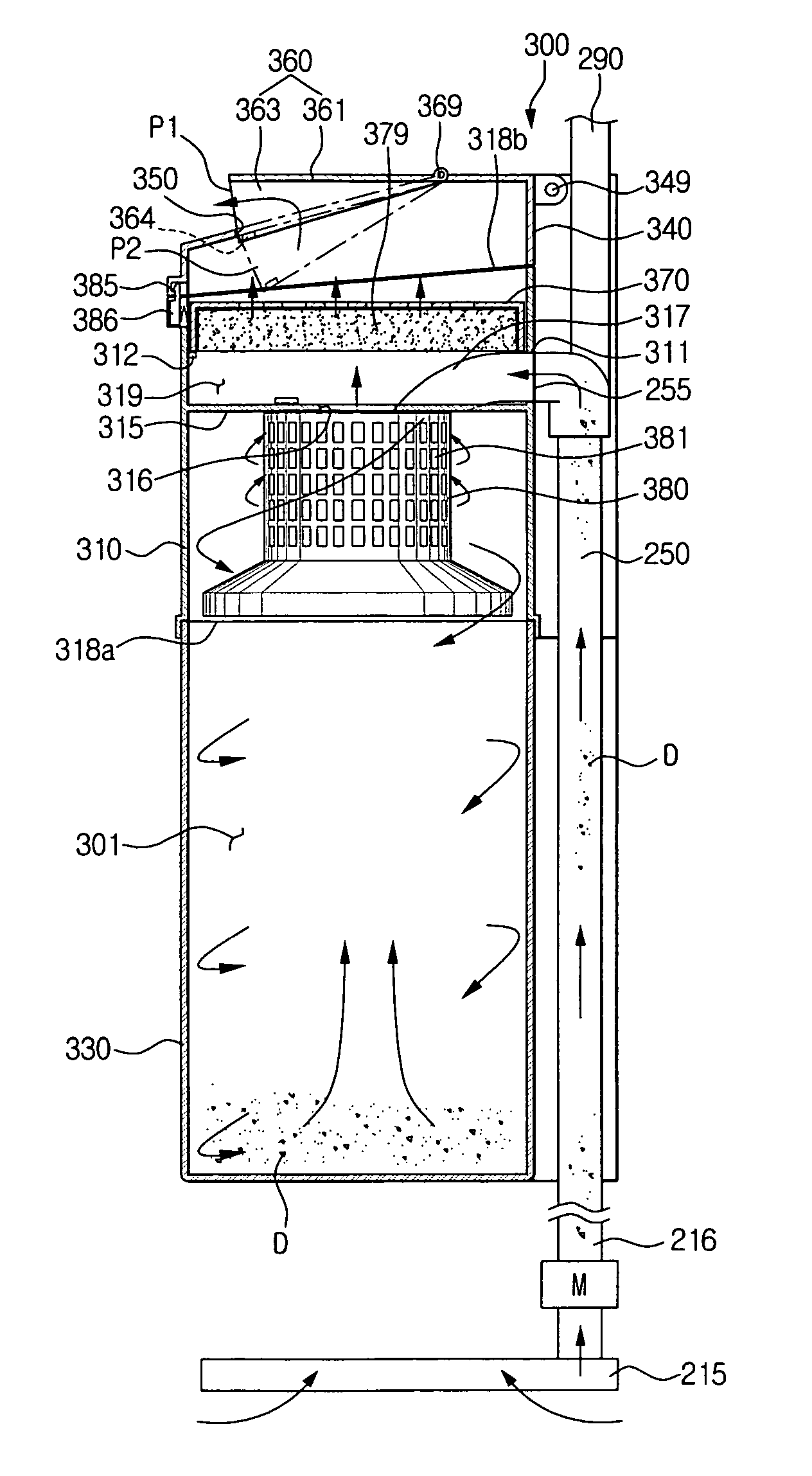

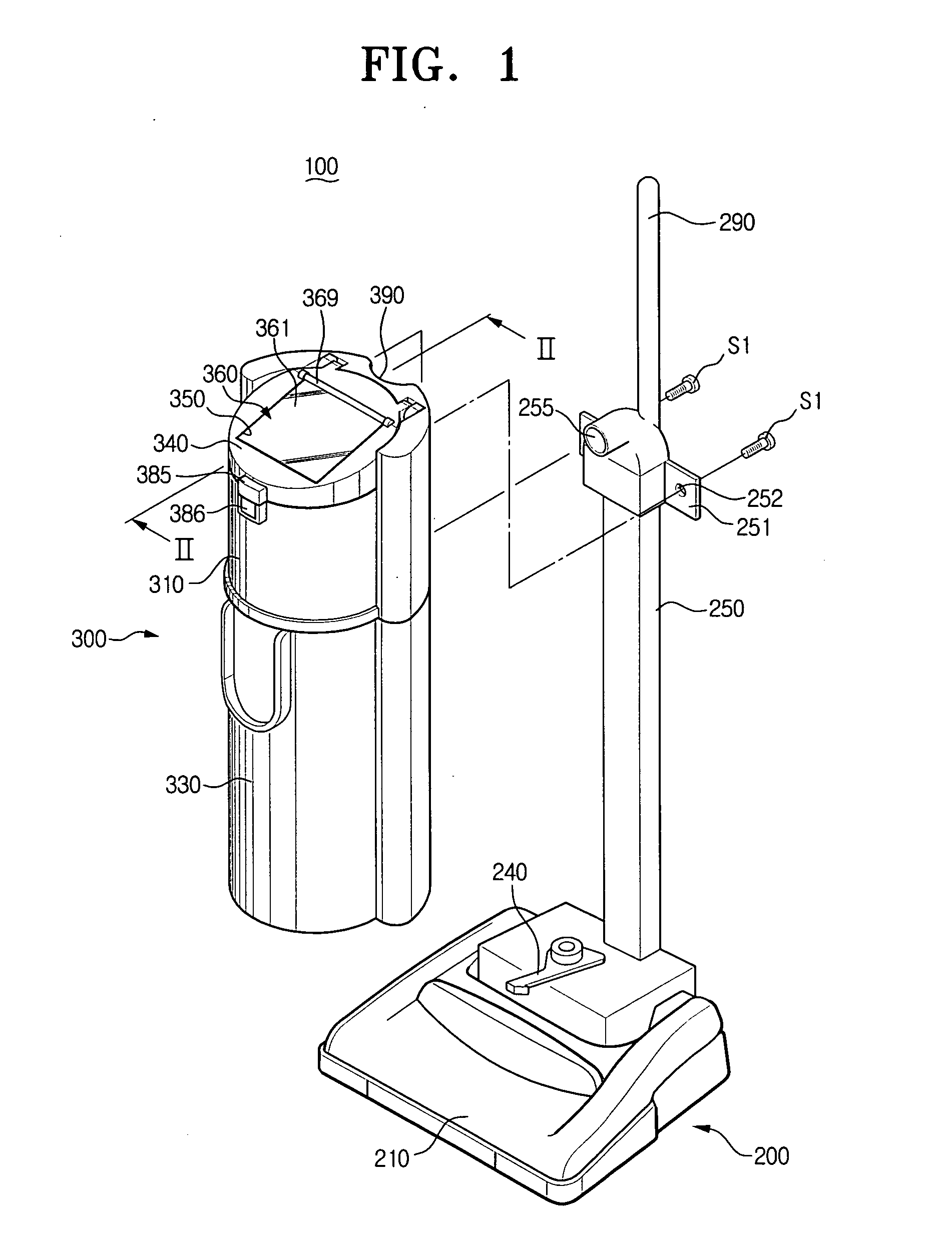

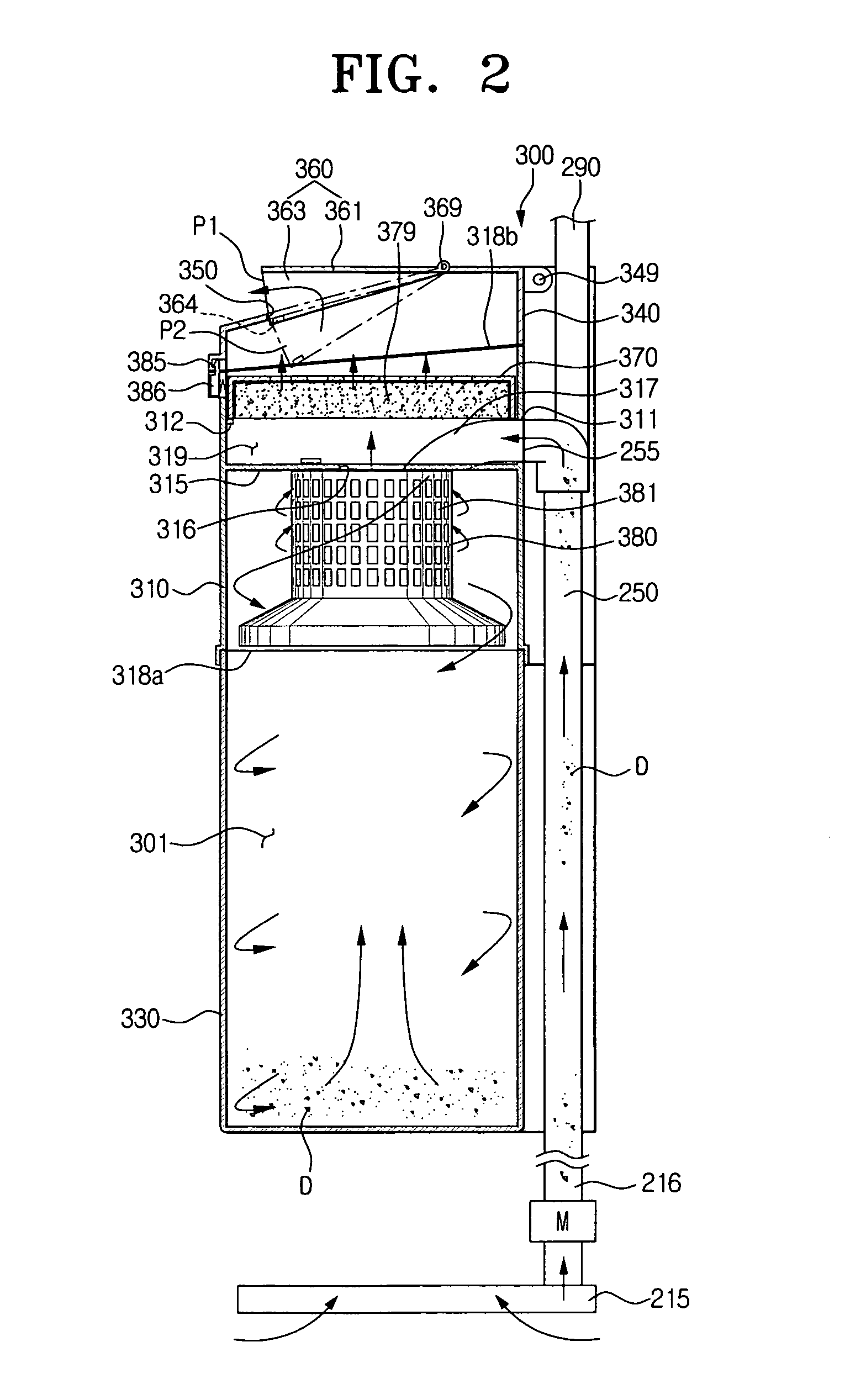

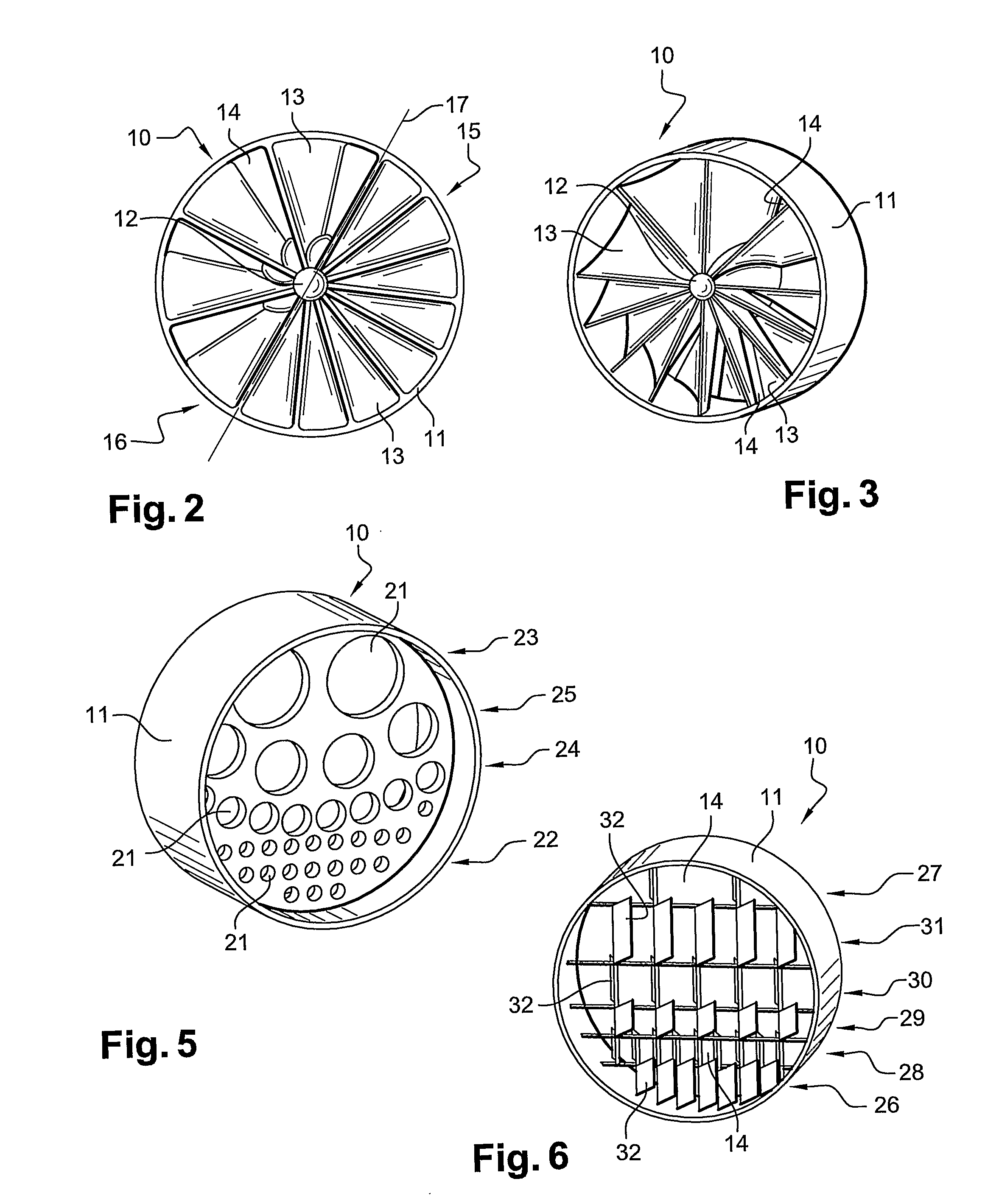

Cyclone dust-collecting device and vacuum cleaner having the same

InactiveUS20060230715A1Clean surface is preventedEffective maintenanceCombination devicesReversed direction vortexEngineeringElectrical and Electronics engineering

A vacuum cleaner includes a suction port assembly, a motor generating a suction force at the suction port assembly, and a cyclone dust collecting device for centrifugally separating air drawn in through the suction port assembly and the motor in sequence. The cyclone dust-collecting device includes an air discharge port penetratingly formed on an outer circumference of the cyclone dust-collecting device and exposed to an outside of the cleaner body, for guiding the air discharged to the outside. Accordingly, since the air discharge port is disposed in the cyclone dust collecting device, not in the cleaner body, a discharge channel for connecting the cyclone dust collecting device and cleaner body is omitted and thus a structure of the vacuum cleaner becomes simplified.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

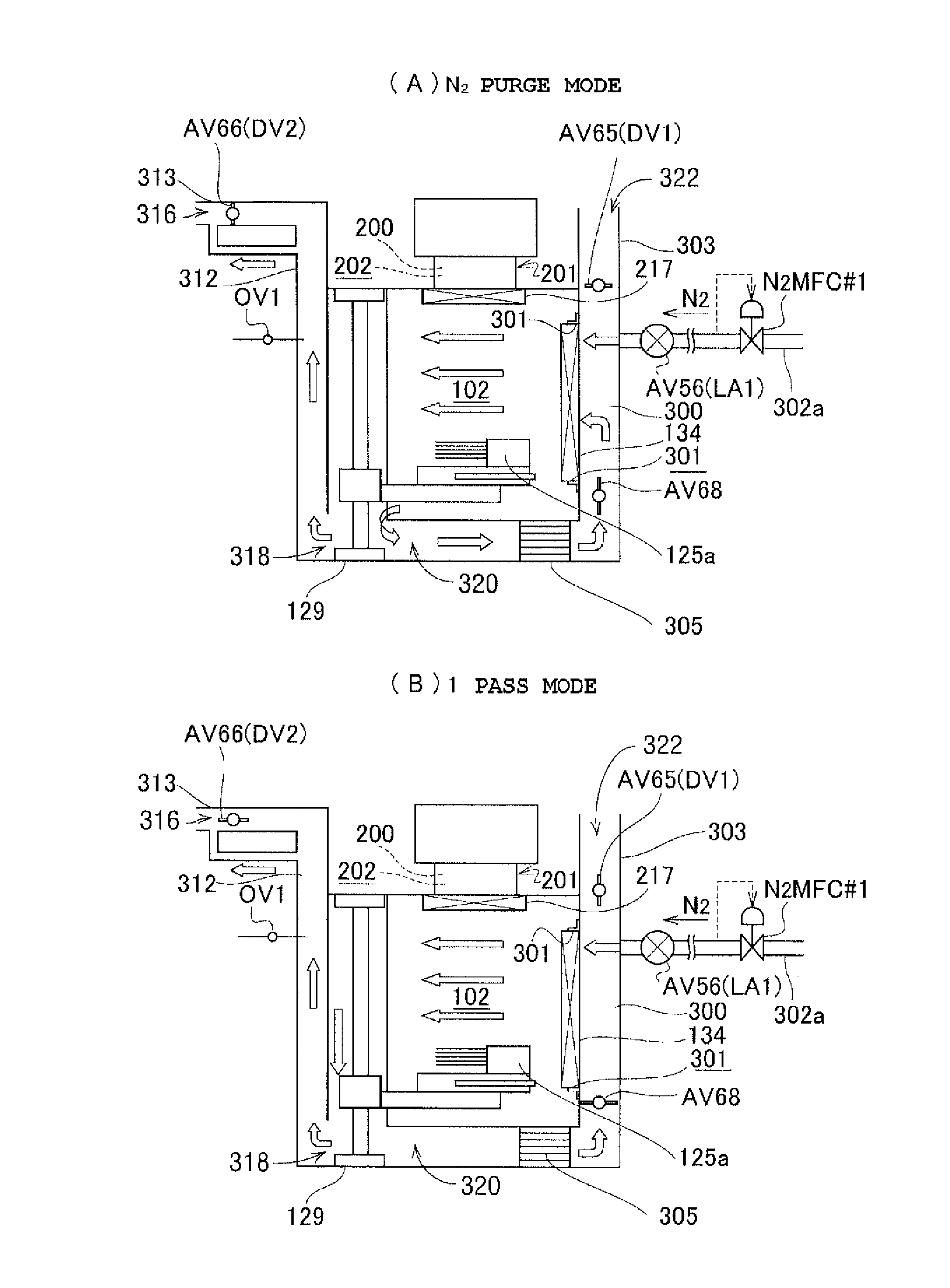

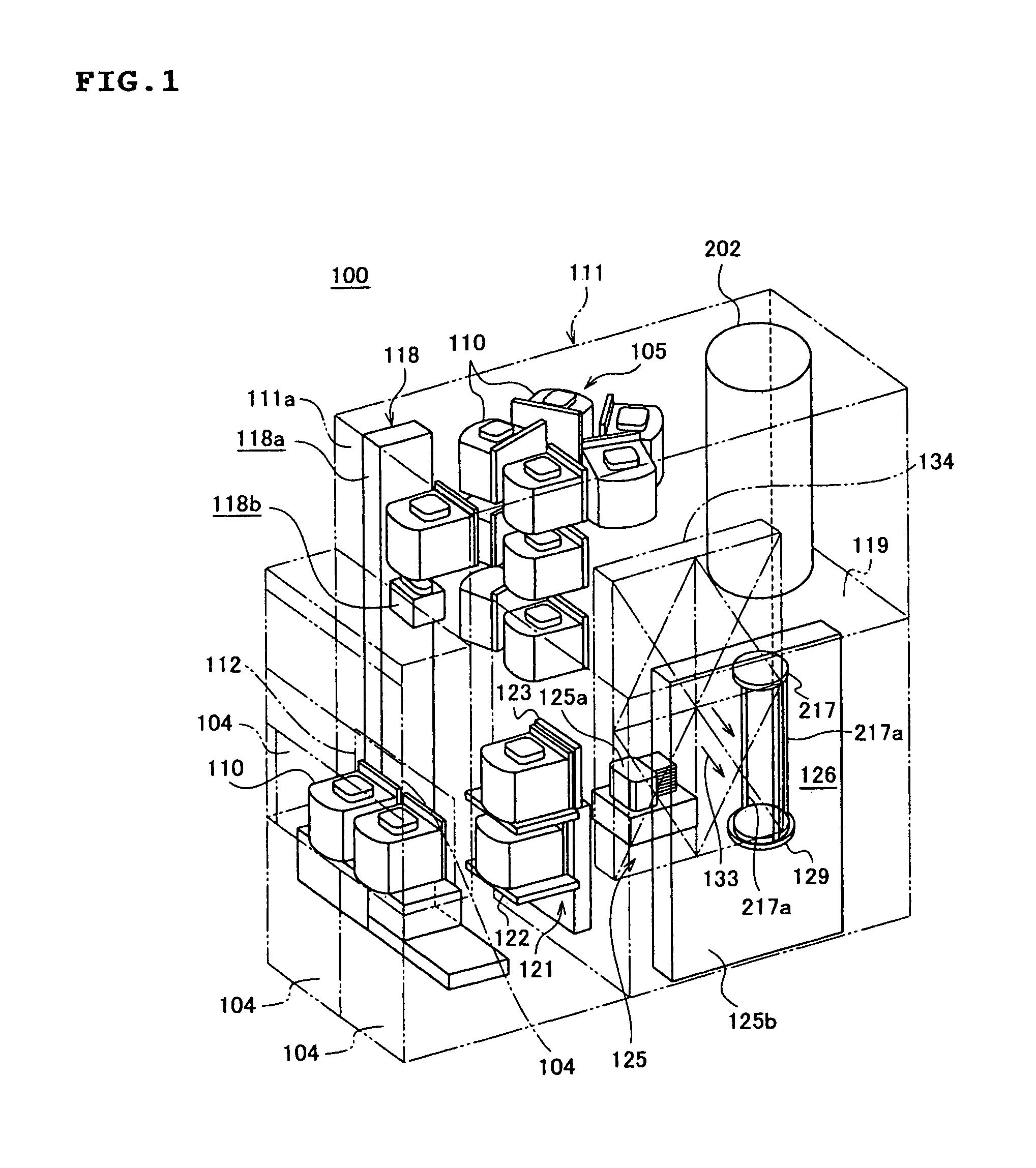

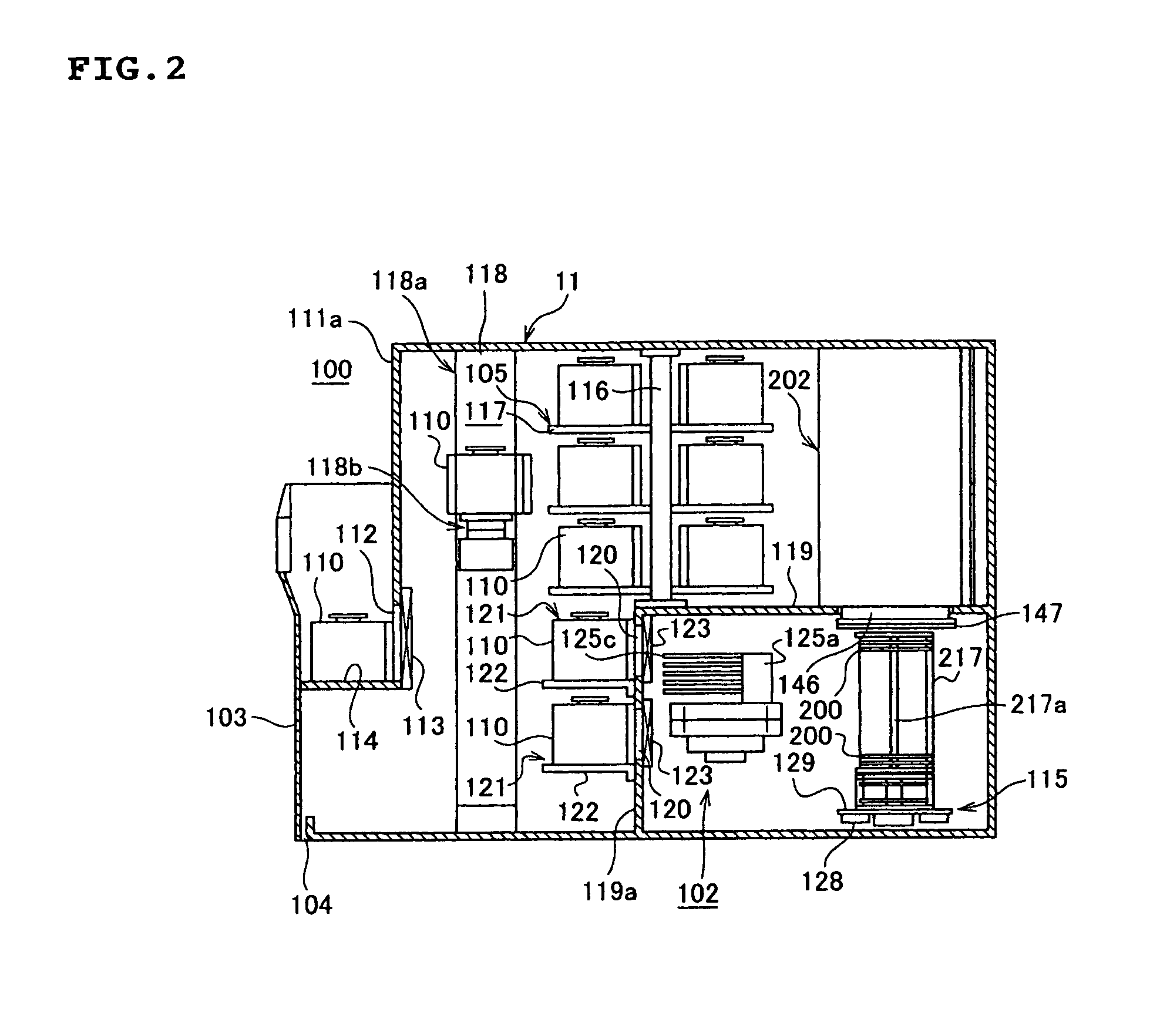

Substrate processing apparatus

ActiveUS8443484B2Avoid stickingPrevent surfaceMechanical cleaningPressure cleaningProcess engineeringIndustrial engineering

To automatically purge a transfer chamber by means of inert gas. There is provided a substrate processing apparatus including a controller that performs control so that a transfer chamber 102 connected to a processing chamber 202 for processing a substrate is purged by gas, the controller having a switching unit that switches a function of exhausting the gas in the transfer chamber 102 in a set direction, and a function of circulating the gas through the transfer chamber 102 in an inert gas atmosphere.

Owner:KOKUSA ELECTRIC CO LTD

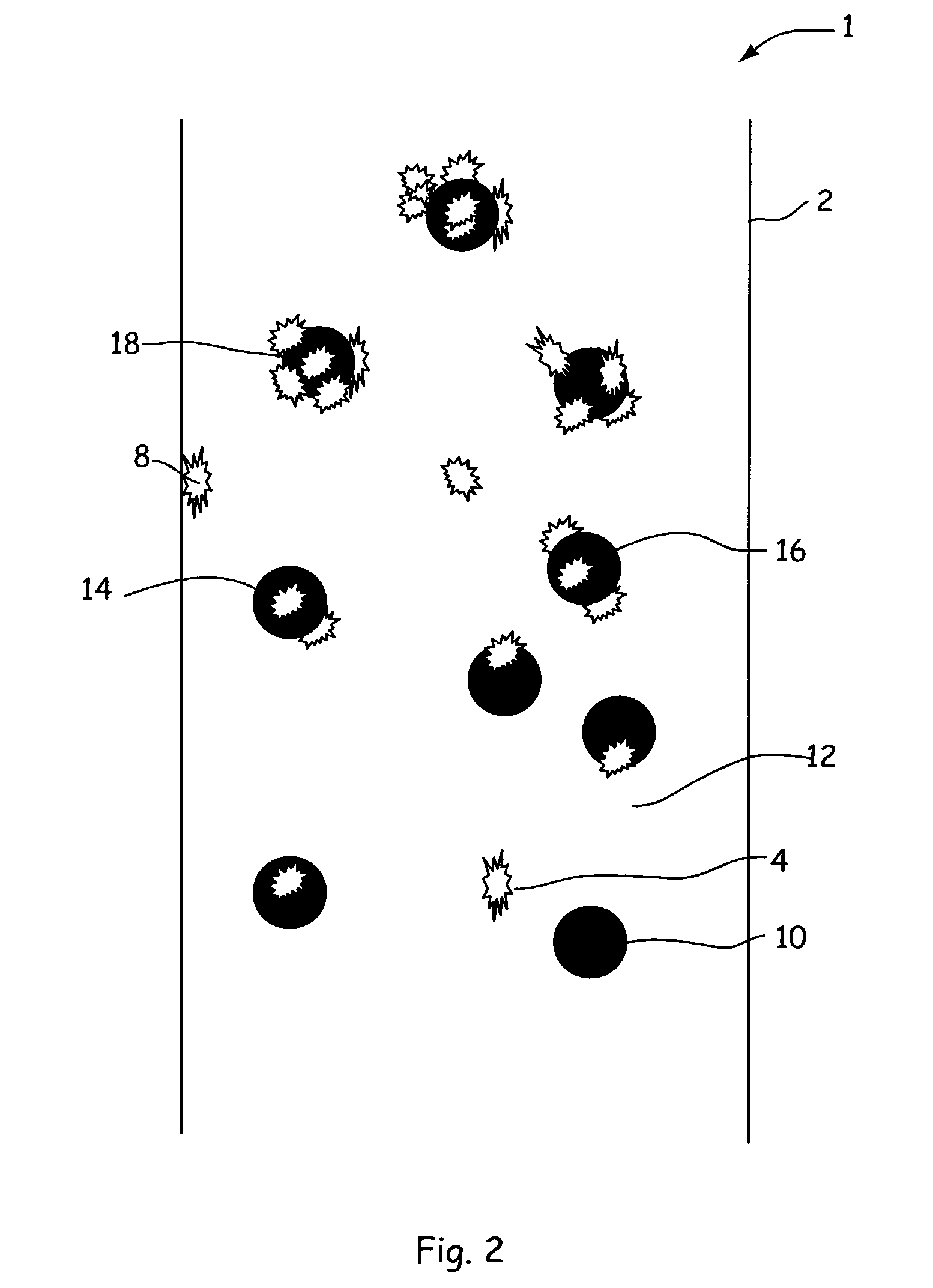

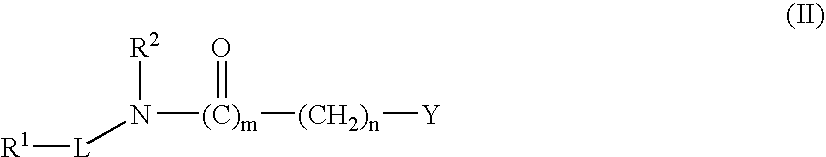

Methods for prevention of surface adsorption of biological materials to capillary walls in microchannels

InactiveUS7252928B1Inhibit bindingPrevent and reduce adsorptionNanotechElectrolysis componentsSilica particleLipid formation

Methods for reducing surface adsorption of biological materials to the walls of microfluidic conduits in microscale devices are provided. In an example of the methods, one or more colloidal-size particles, such as colloidal silica particles, are flowed in a fluid within the microfluidic conduit in the presence of one or more adherent biological materials (such as one or more proteins, cells, carbohydrates, nucleic acids, lipids and the like) to adsorb to the materials and prevent them from binding to the capillary walls of the microfluidic conduit. Other adsorption inhibition agents such as detergents and nonaqueous solvents can be used alone or in combination with colloidal particles to reduce surface adsorption in microfluidic conduits.

Owner:CAPLIPER LIFE SCI INC

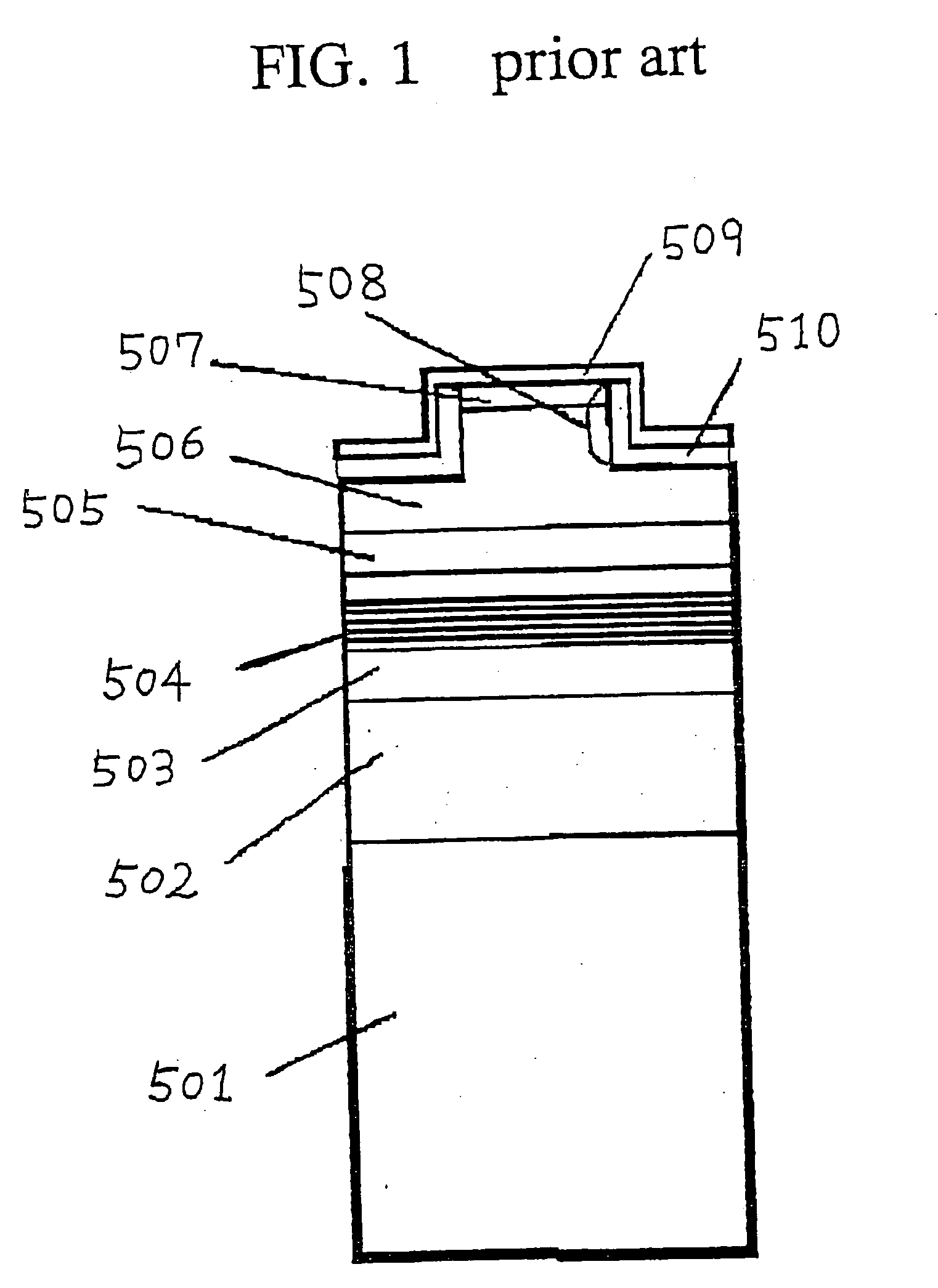

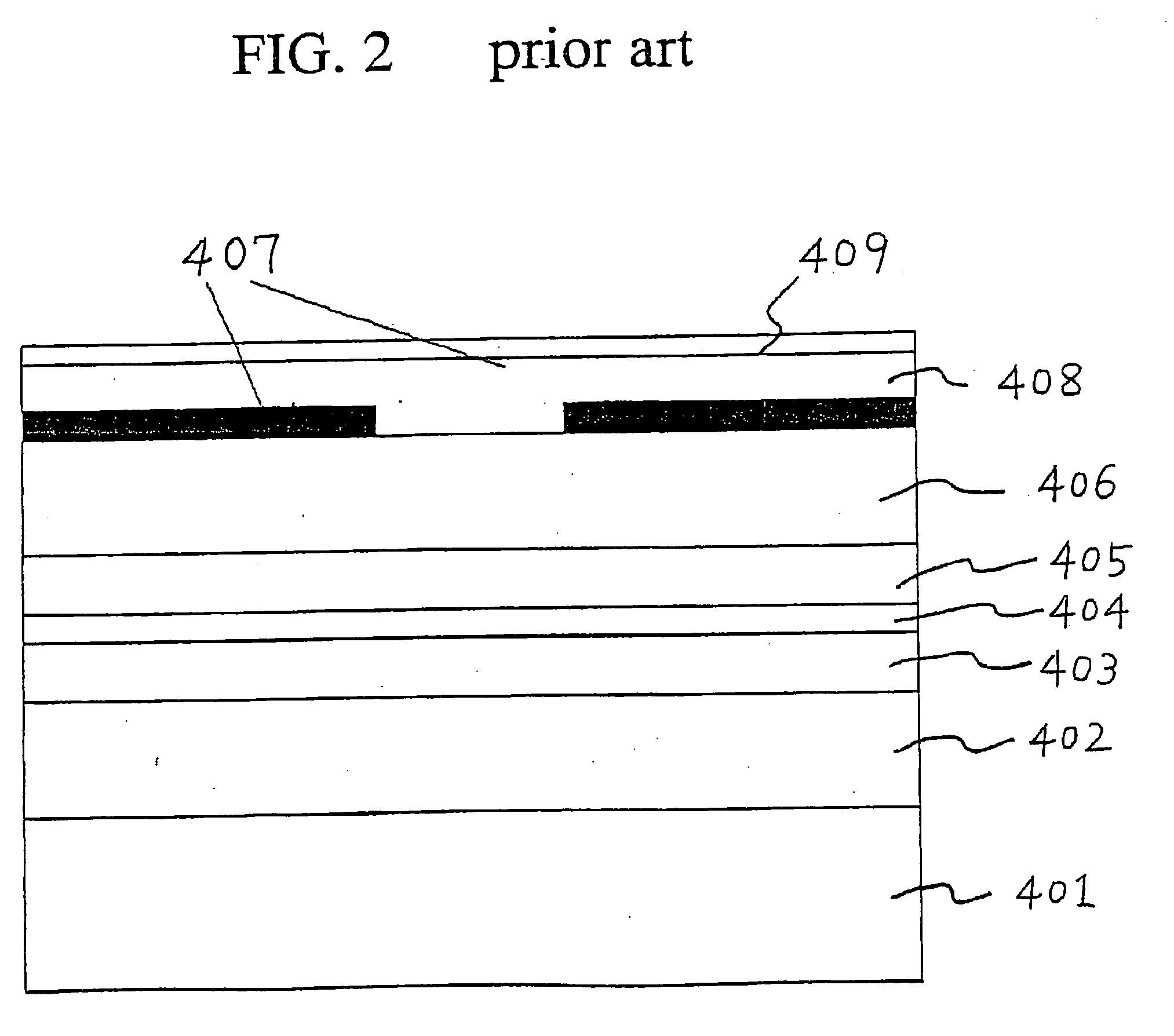

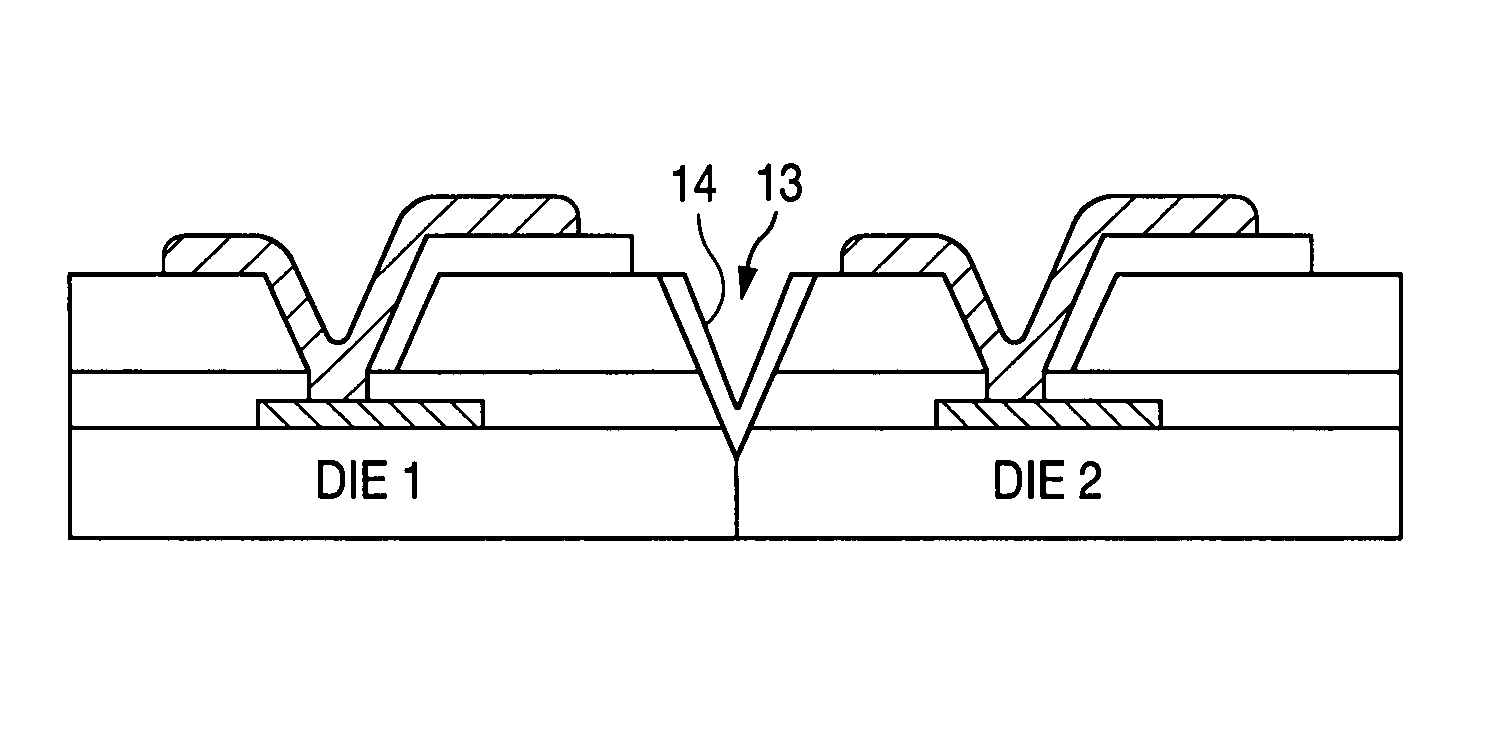

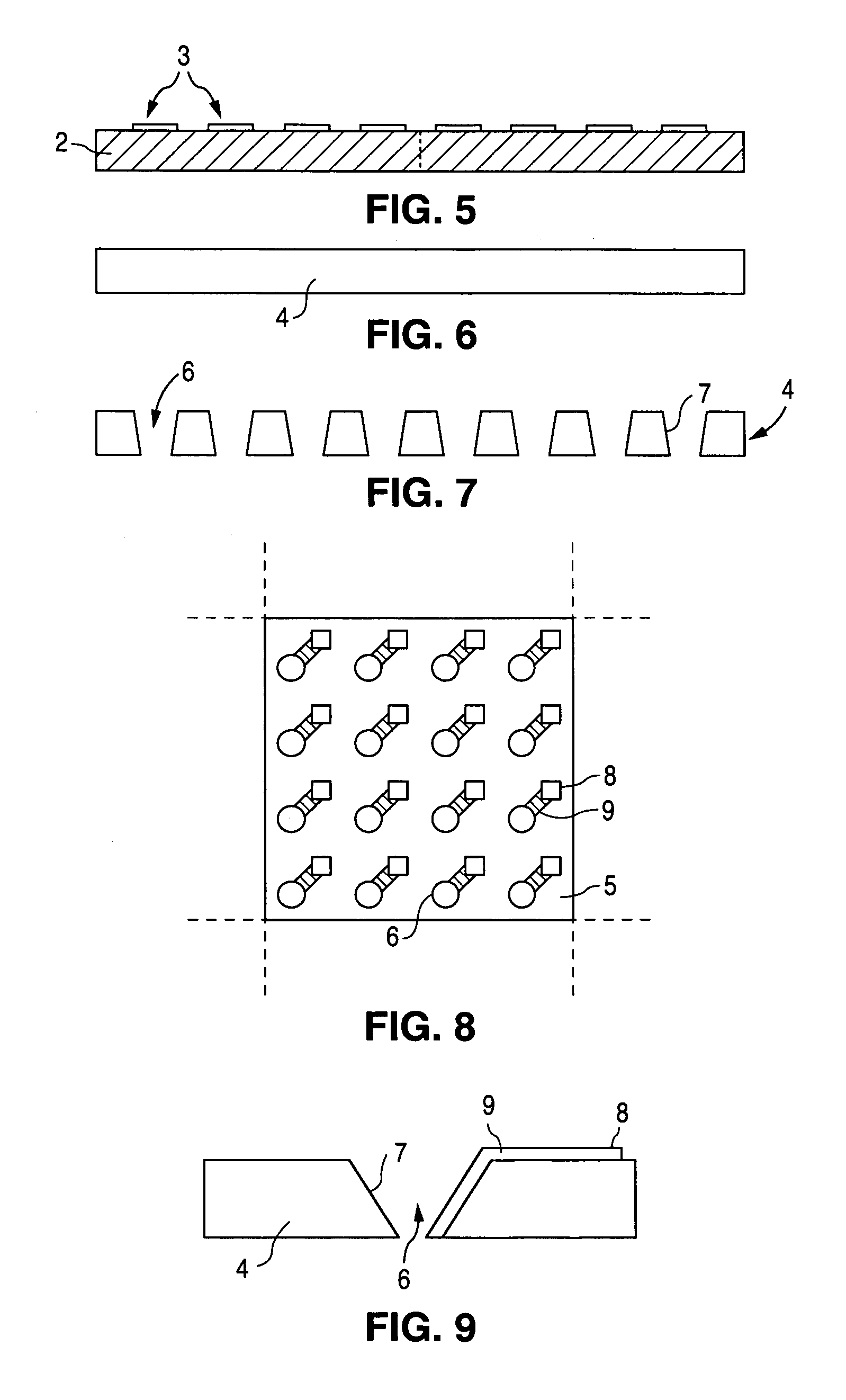

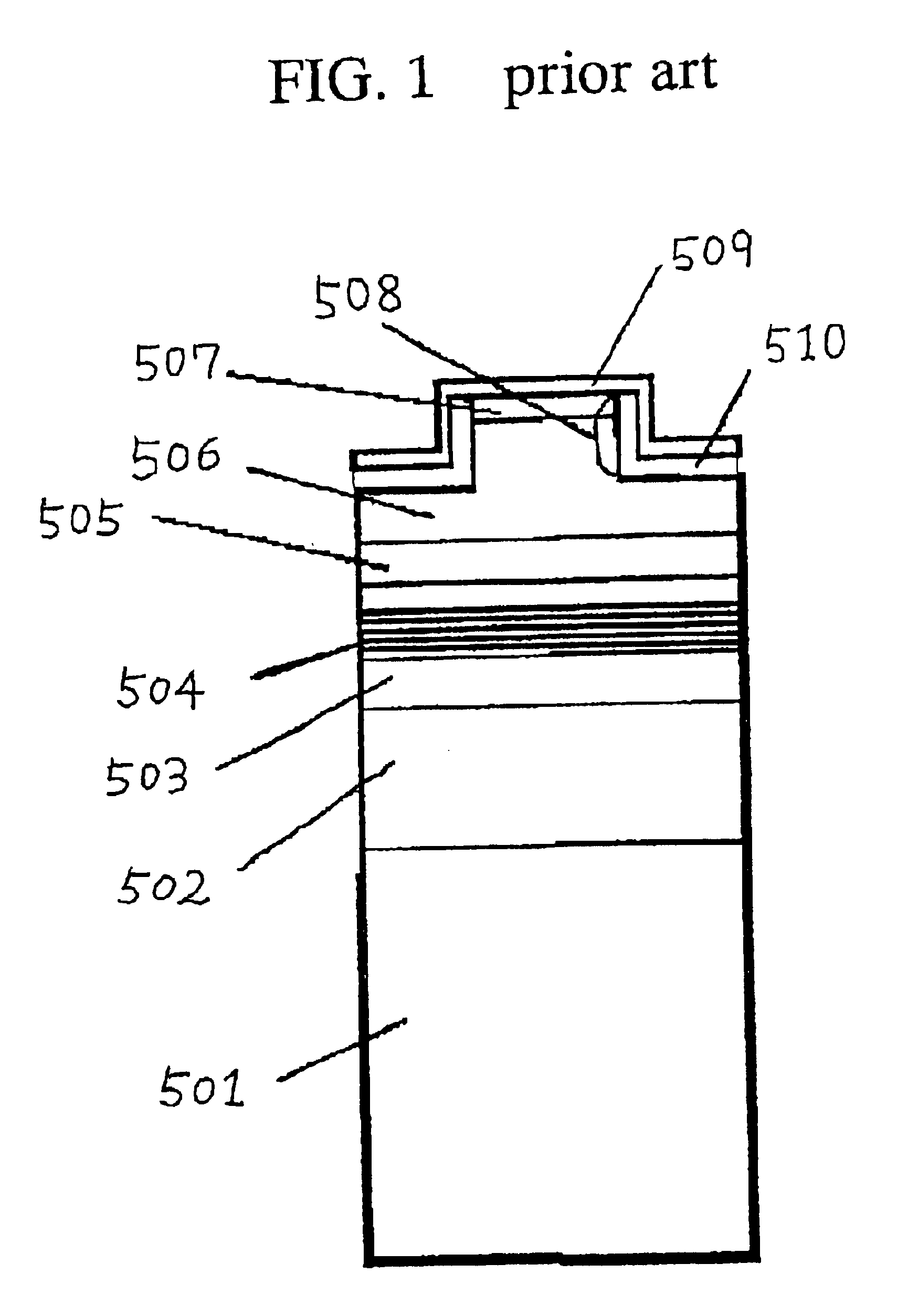

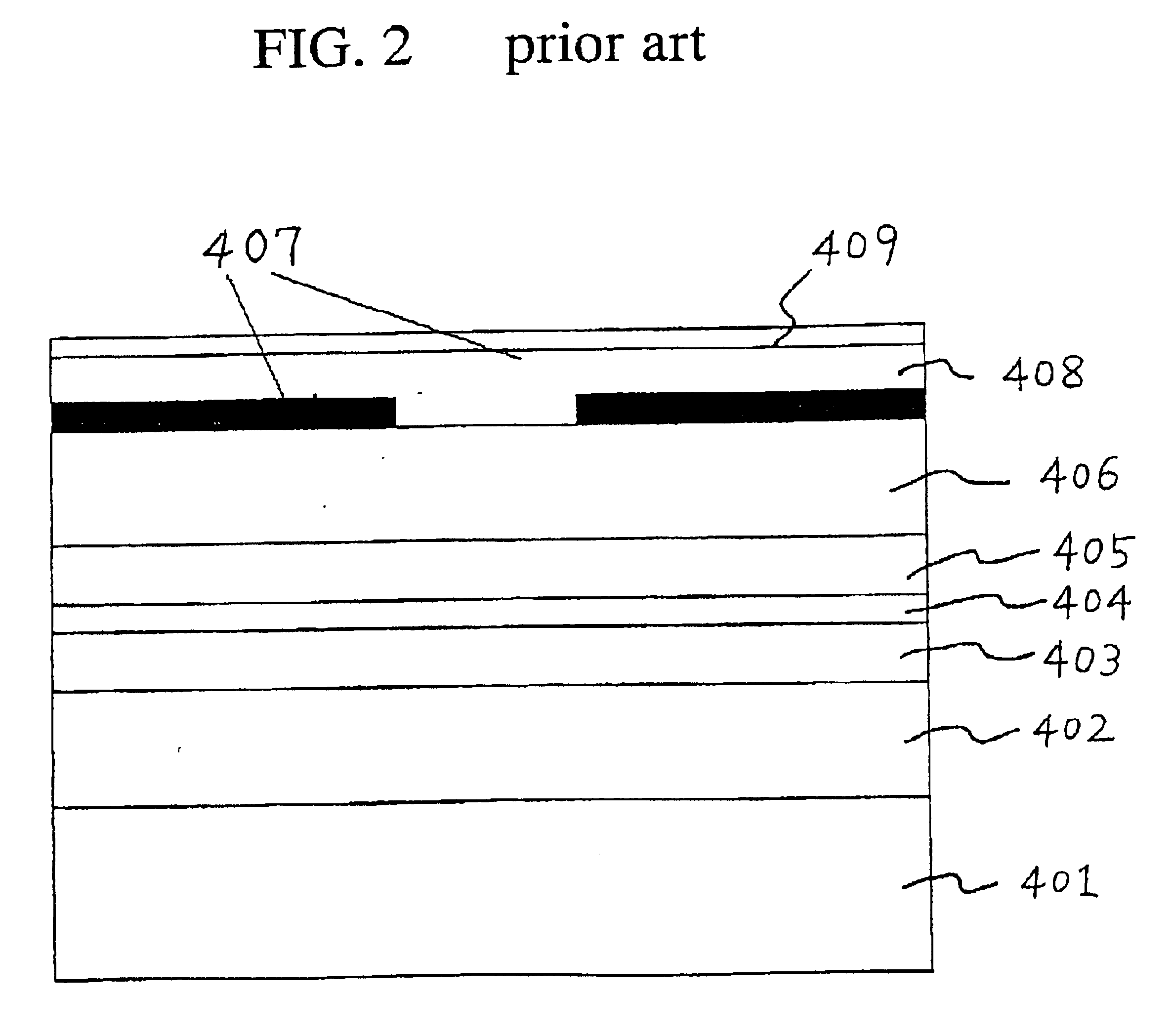

Hermetic wafer scale integrated circuit structure

InactiveUS6982475B1Prevent surfaceDamaged and destroyedSemiconductor/solid-state device detailsSolid-state devicesScale structureHermetic seal

A wafer scale semiconductor integrated circuit packaging technique provides a hermetic seal for the individual integrated circuit die formed as part of the wafer scale structure. A semiconductor wafer is manufactured to include a number of individual semiconductor die. Each individual die formed on the wafer includes a number of bond pads that are exposed on the die surface in various locations to provide electrical connections to the circuitry created on the die. The wafer further includes a planar glass sheet that is substantially the same size as the wafer, the glass sheet being adhered to the wafer using a suitable adhesive. The glass sheet has a number of pre-formed holes in it, the arrangement of the pre-formed holes corresponding to the location of the bond pads at each of the individual semiconductor die formed as part of the wafer structure. Following adherence of the glass sheet to the semiconductor wafer utilizing the intermediate adhesive material, metal connections are made between pads formed on the glass sheet and the bond pads formed on the integrated circuit die. Solder balls are then attached to the pads on the glass sheet to provide a conductive flow between the solder balls and the bond pads. After the solder balls are attached, trenches are cut around each of the individual die on the wafer. The trenches are cut at an angle and extend through the glass sheet and the intermediate adhesive material and into the semiconductor substrate in which the integrated circuits are formed. After the trenches are cut around each individual semiconductor die, a noble metal is deposited on the sidewalls of the trench to extend over the interface between the glass sheet, the adhesive material and the semiconductor die. The wafer is then cut along the noble metal lined trenches to provide individual, hermetically sealed packaged integrated circuit die.

Owner:MICRO CHIP SCALE PACKAGING

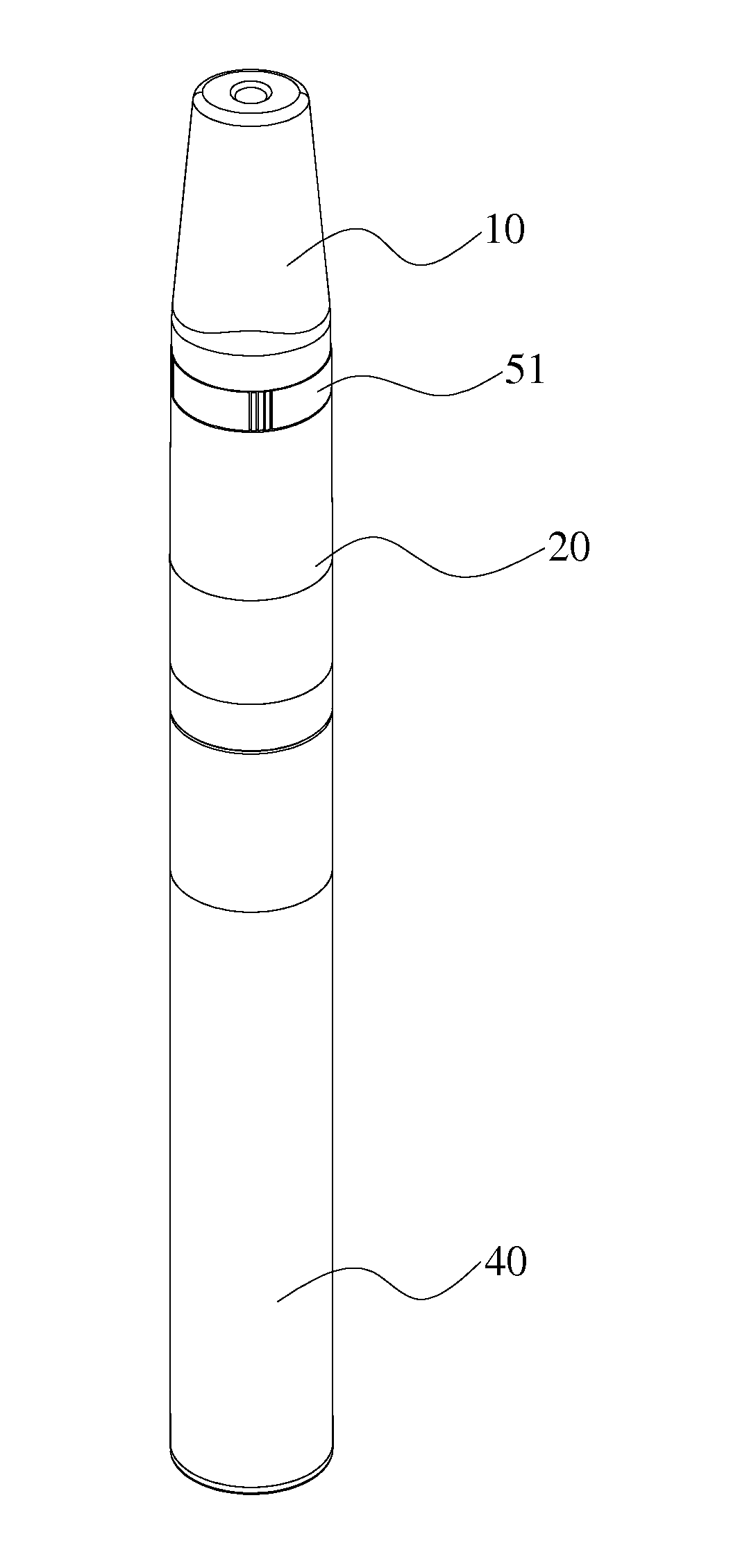

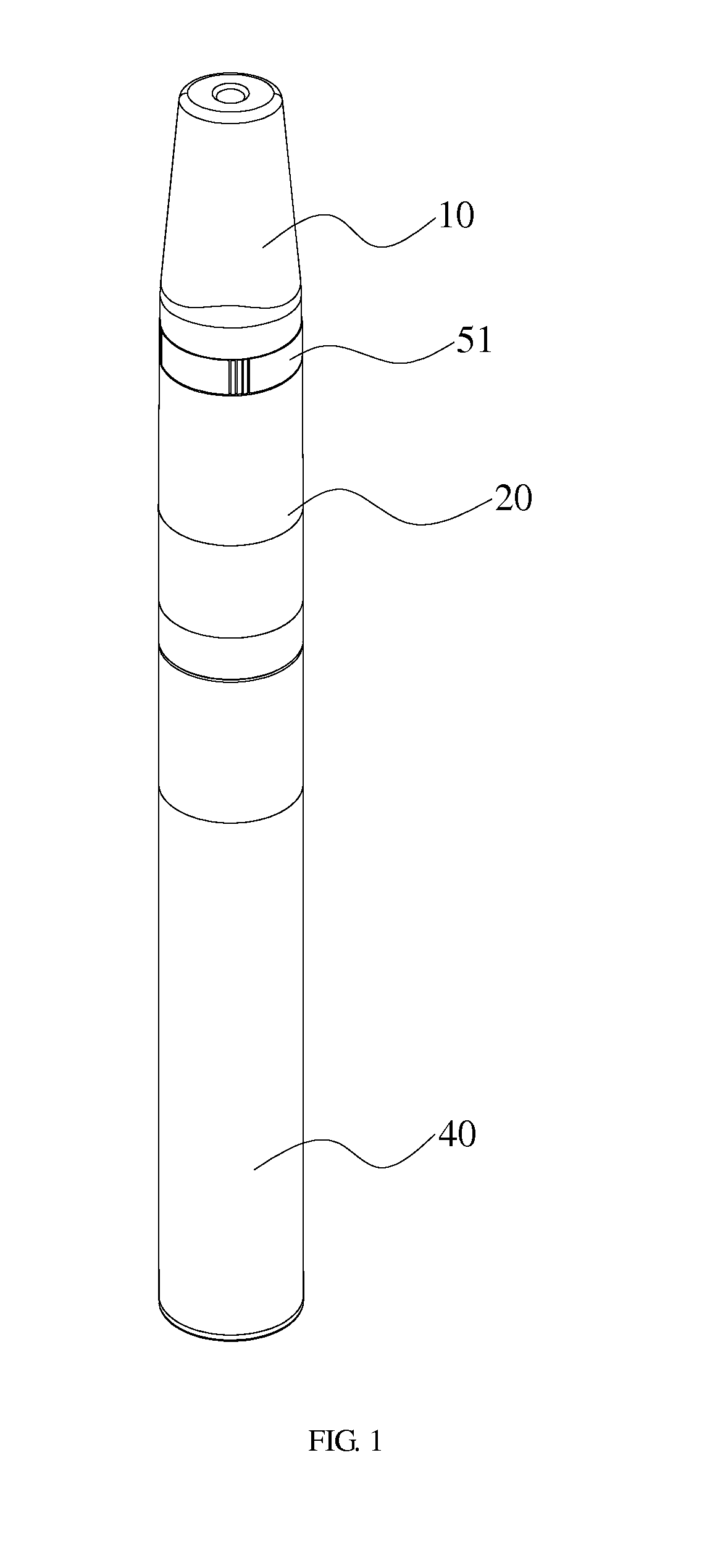

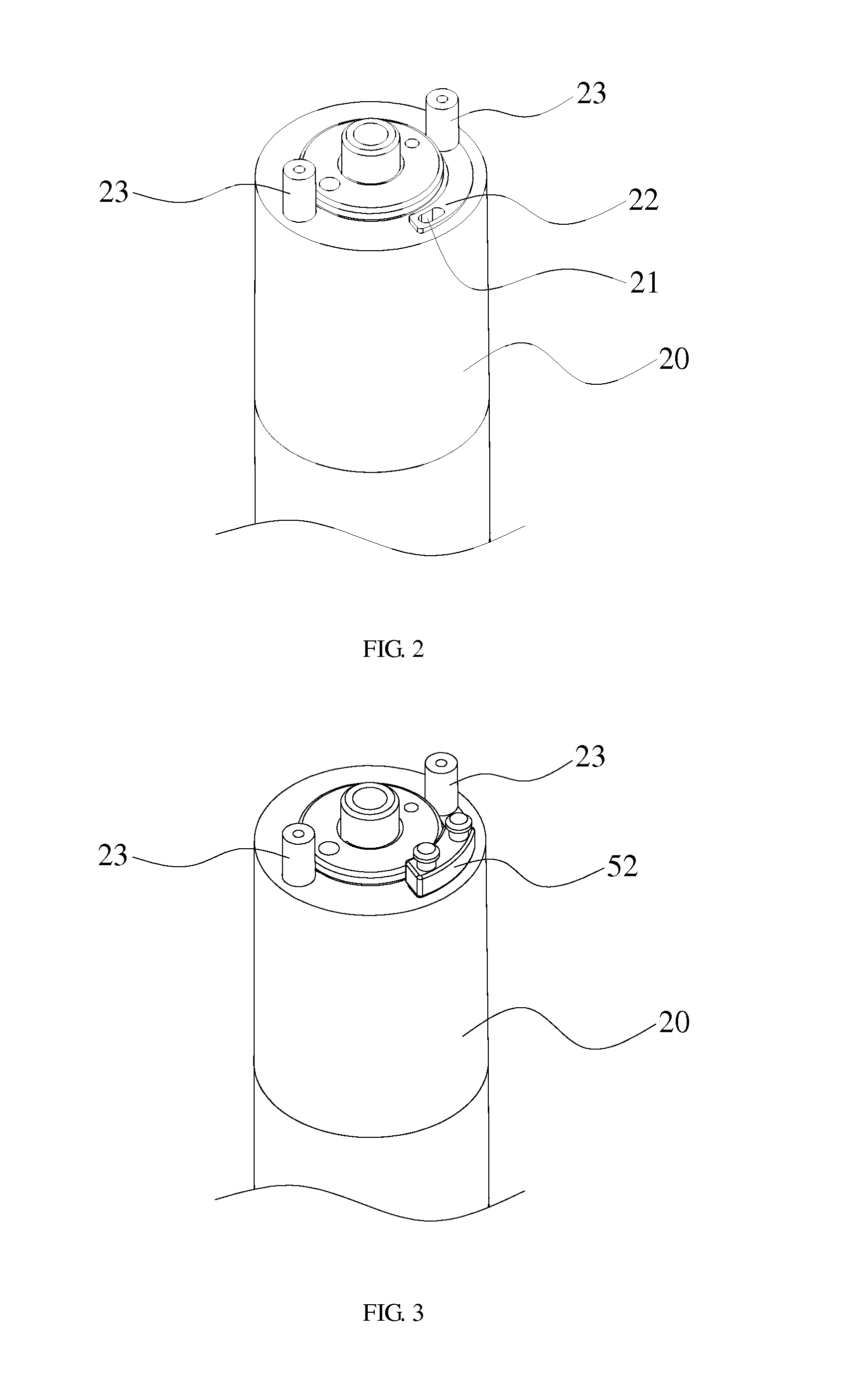

Electronic atomization device with adjustable air inlet

InactiveUS20150342255A1Reduce the possibilityReduce harmRespiratorsMedical devicesEngineeringFood flavor

Disclosed is an electronic atomization device with an adjustable air inlet, which includes a cigarette holder, an atomizer connected to the cigarette holder and a battery assembly for supplying power to the atomizer. An air inlet is disposed at an upper portion of the atomizer for connecting the atomizer to outside world and a switch assembly is disposed between the atomizer and the cigarette holder for opening or closing the air inlet. As disclosed in the present invention, the air inlet can be closed completely by means of the switch assembly thereby preventing the condensate and liquid flavor from flowing to the outside world, avoiding the outsider surface of the electronic atomization device getting dirty and reducing the possibility of the damage of the battery assembly.

Owner:SHENZHEN JIESHIBO TECH

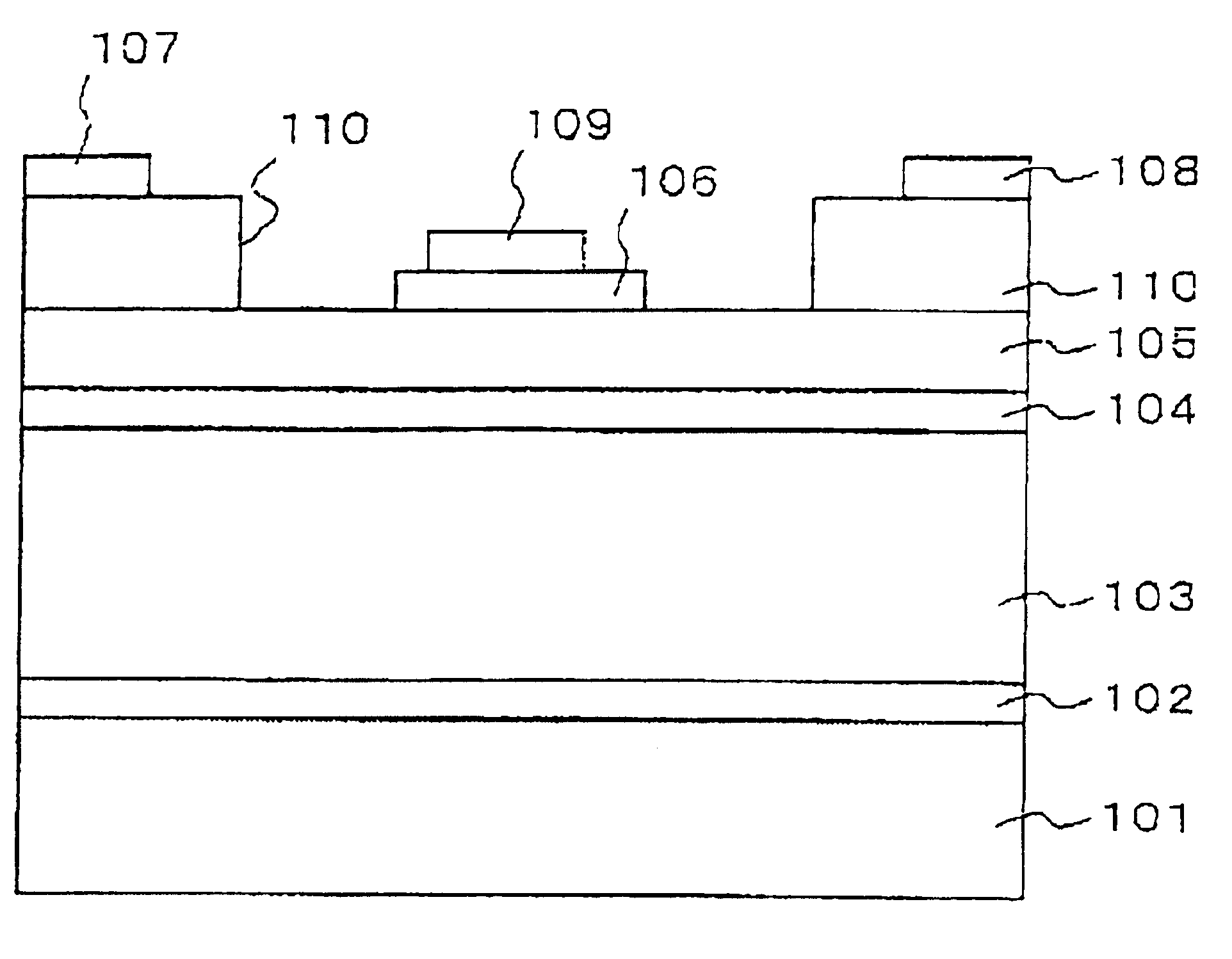

Method for forming group-III nitride semiconductor layer and group-III nitride semiconductor device

InactiveUS6841410B2Suppress an undesired mass-transportPrevent surfaceOptical wave guidanceLaser detailsNitride semiconductorsSemiconductor device

A method of forming a partially etched nitride-based compound semiconductor crystal layer includes the following steps. A non-crystal layer of a nitride-based compound semiconductor is formed. At least a part of the non-crystal layer is then etched to form a partially etched non-crystal layer before the partially etched non-crystal layer is crystallized to form a partially etched nitride-based compound semiconductor crystal layer.

Owner:RENESAS ELECTRONICS CORP

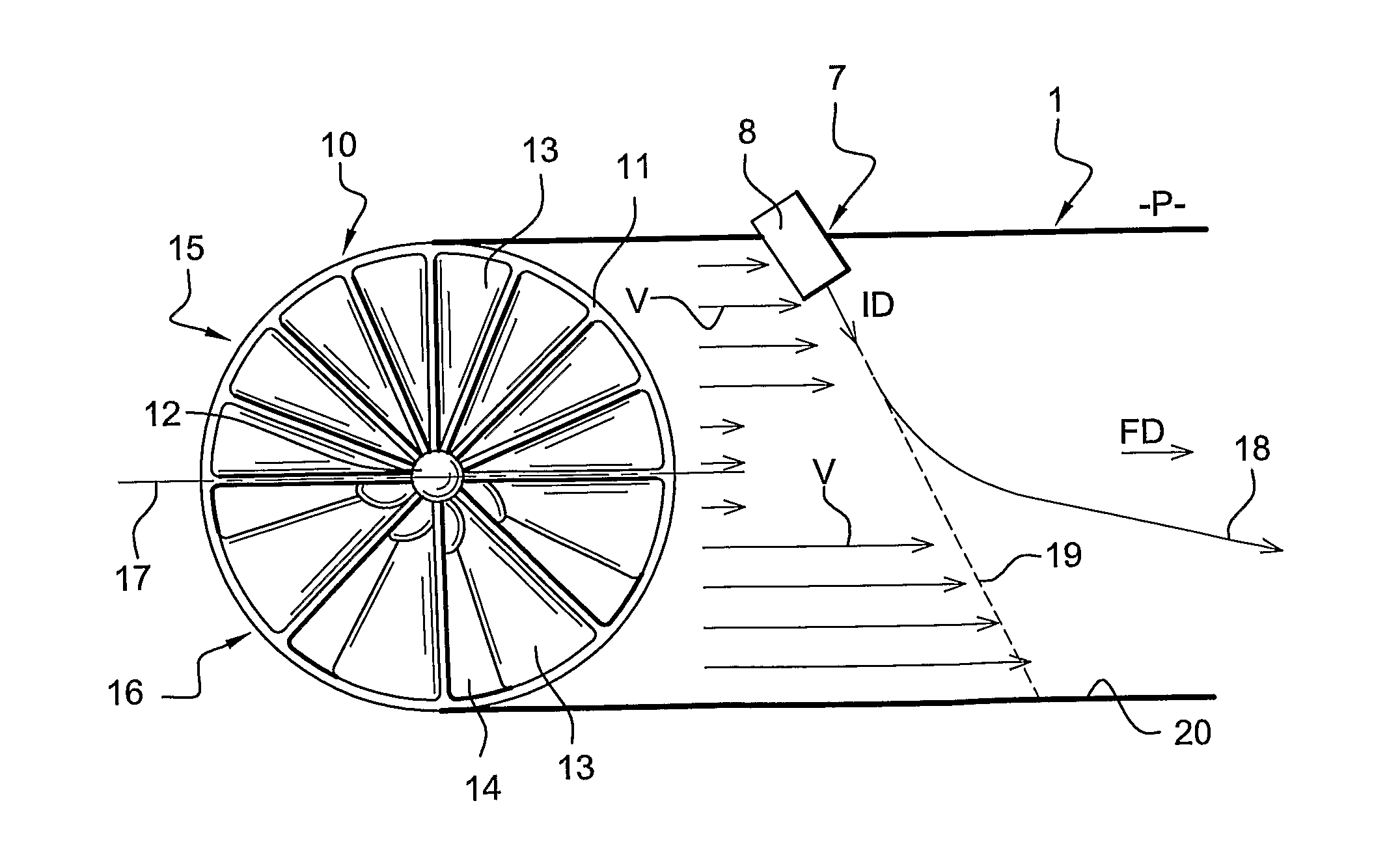

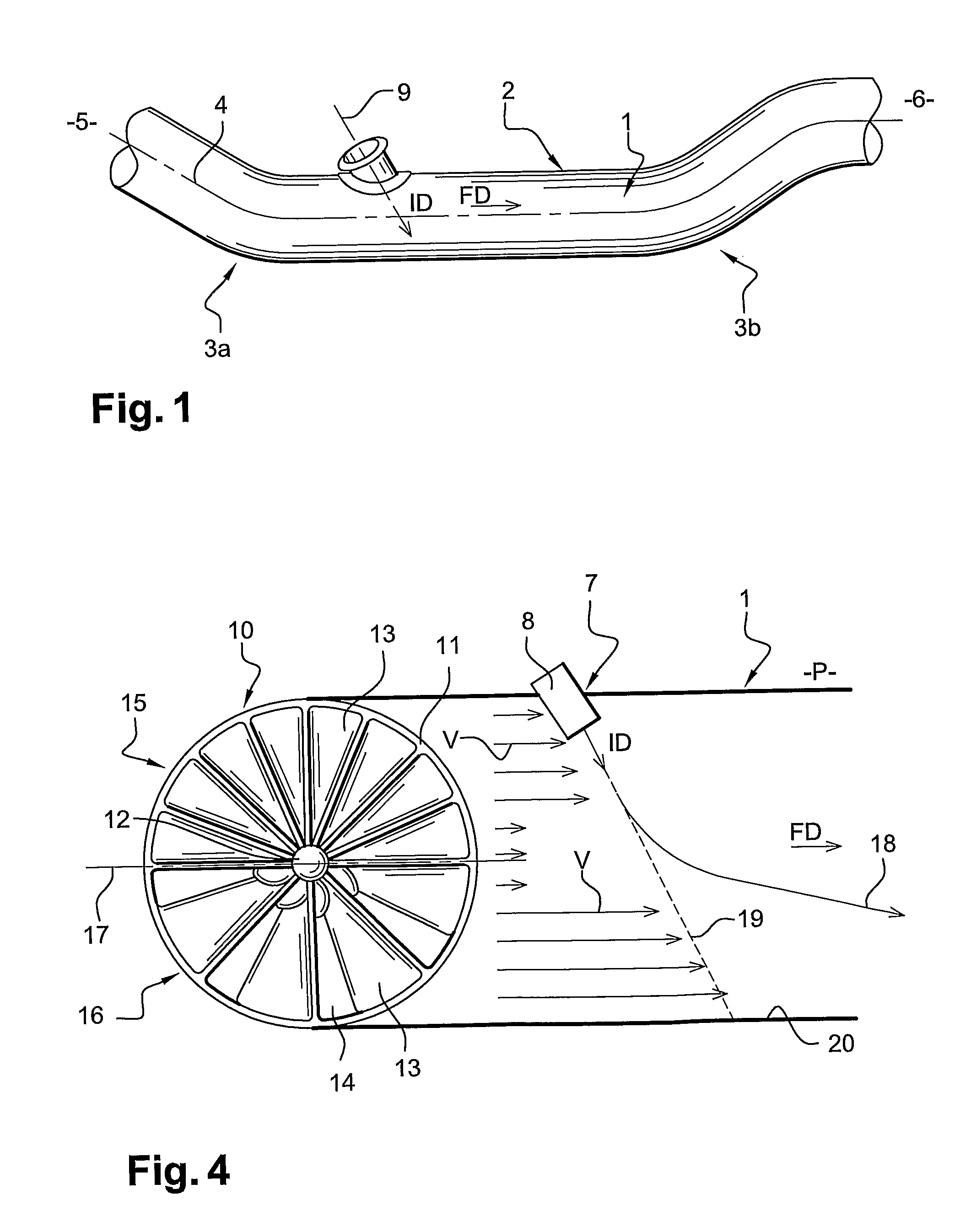

Mixing device in an exhaust gas pipe

ActiveUS20110162353A1Flow fastBetter mixing of fluidGas treatmentInternal combustion piston enginesExhaust fumesEngineering

In an exhaust gas pipe, a first fluid flows in a flow direction in the pipe, and a second fluid is injected inside the pipe by a nozzle, from an injection inlet arranged in the pipe wall, according to an injection direction. A mixing device fastened inside the pipe upstream from the injection inlet creates turbulence that helps the mixing of the fluids. The mixing device has a first portion located on the injection inlet side of the pipe and a second portion located opposite the injection inlet side of the pipe, the portions being designed so that the fluid velocity is higher downstream from the mixing device second portion than downstream from the mixing device first portion. An aqueous solution of urea can be injected inside an exhaust pipe of a diesel engine.

Owner:VOLVO LASTVAGNAR AB

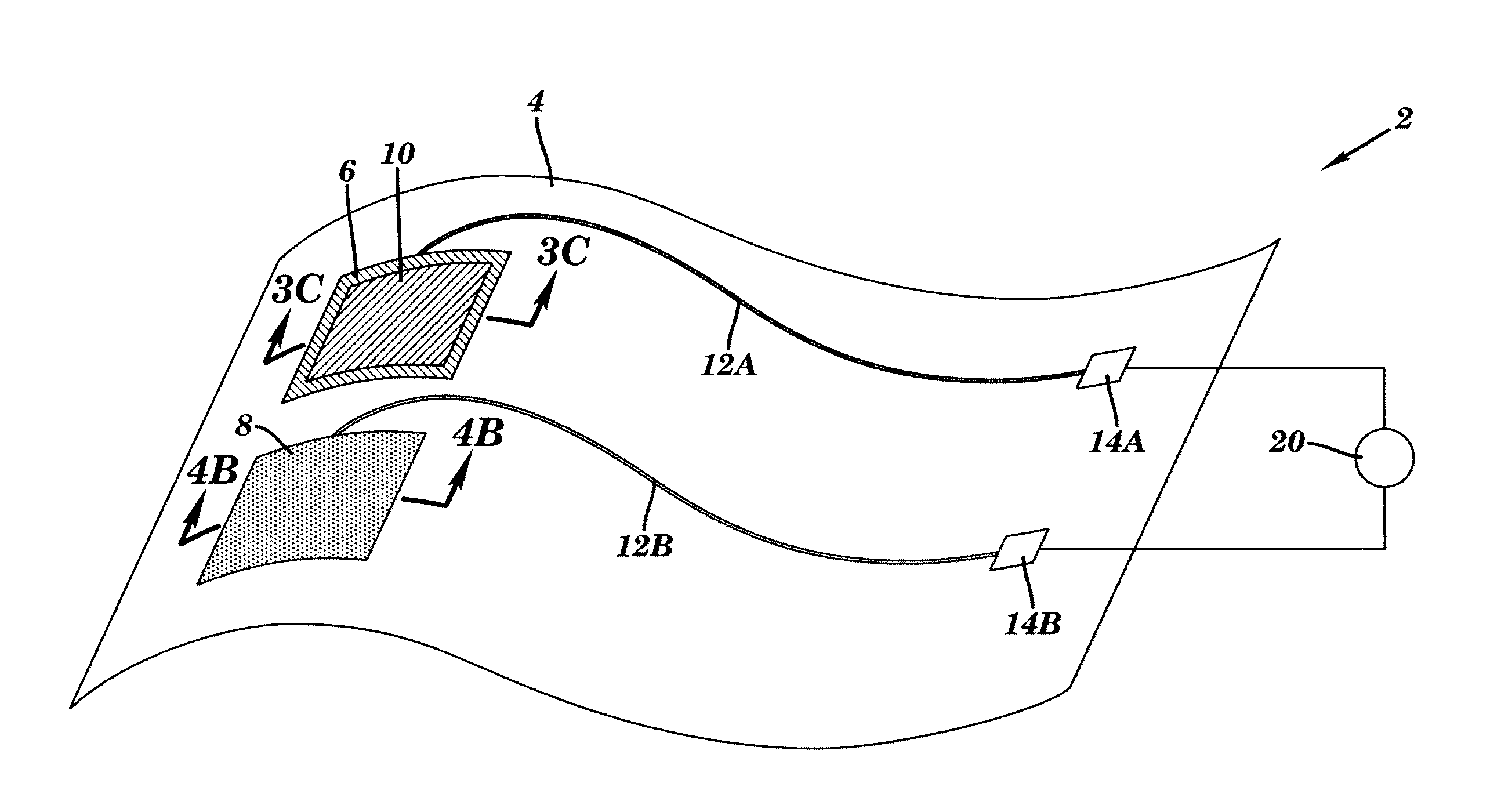

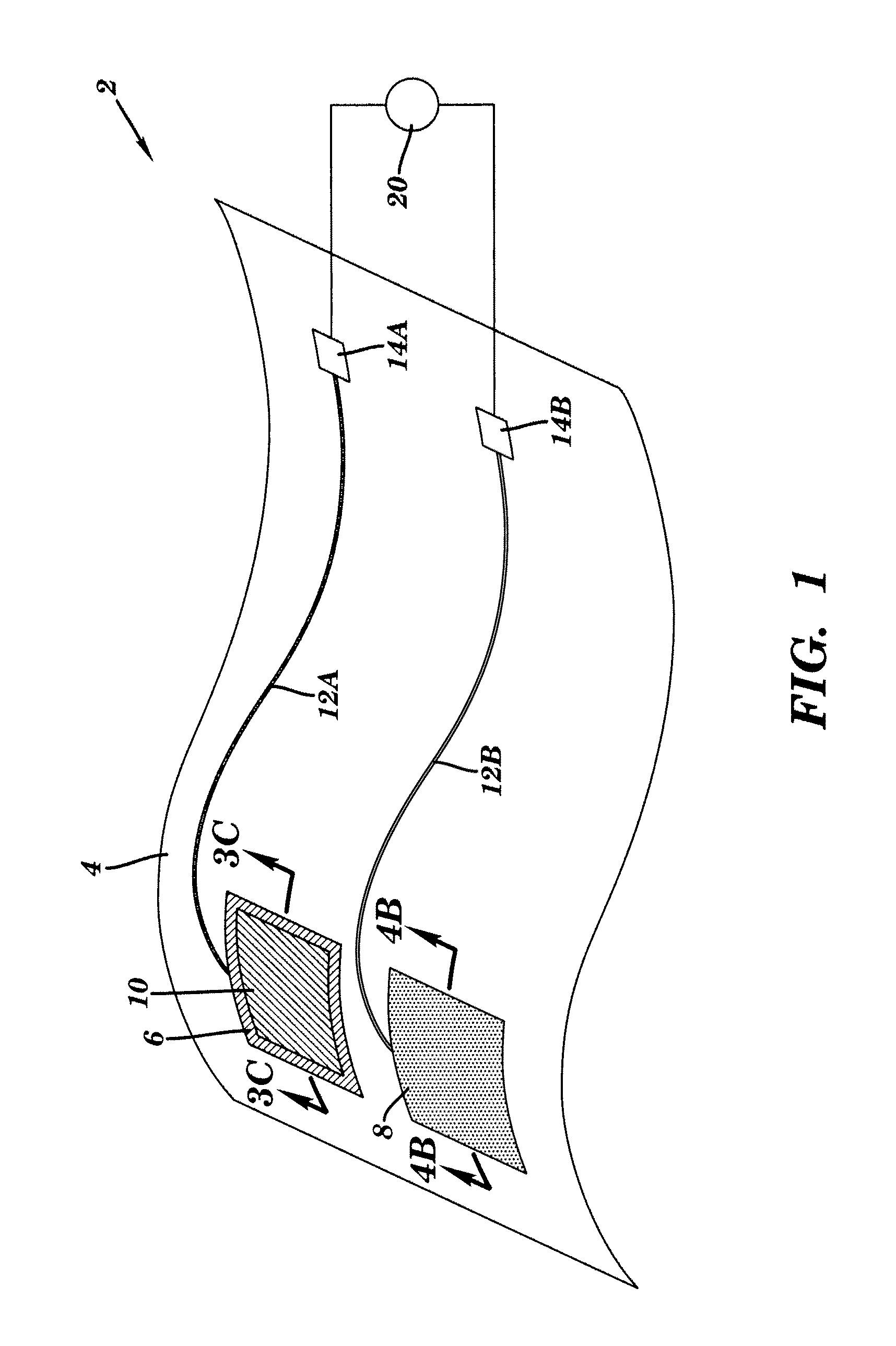

Device for sensing a target chemical and method of its making

InactiveUS20130150689A1Prevent adhesionInhibition of attachmentImmobilised enzymesBioreactor/fermenter combinationsElectricityPlanar substrate

The present invention relates to a device for sensing a target chemical. The device includes a flexible, non-planar substrate; a printed, solid-state sensing element comprising a chemical sensing material which produces an electrical signal upon interaction with the target chemical; a first printed electrode comprising a first conductive composition; and a second electrode comprising a second conductive composition. The first and second electrodes are electrically isolated from one another, and one or both of the first and second electrodes is in electrical contact with said sensing element. The first and second electrodes and the sensing element collectively form an electrochemical sensor which is coupled to the flexible, non-planar substrate. Medical devices comprising the device of the present invention and methods of making a device for sensing a target chemical are also disclosed.

Owner:MICROPEN TECH CORP

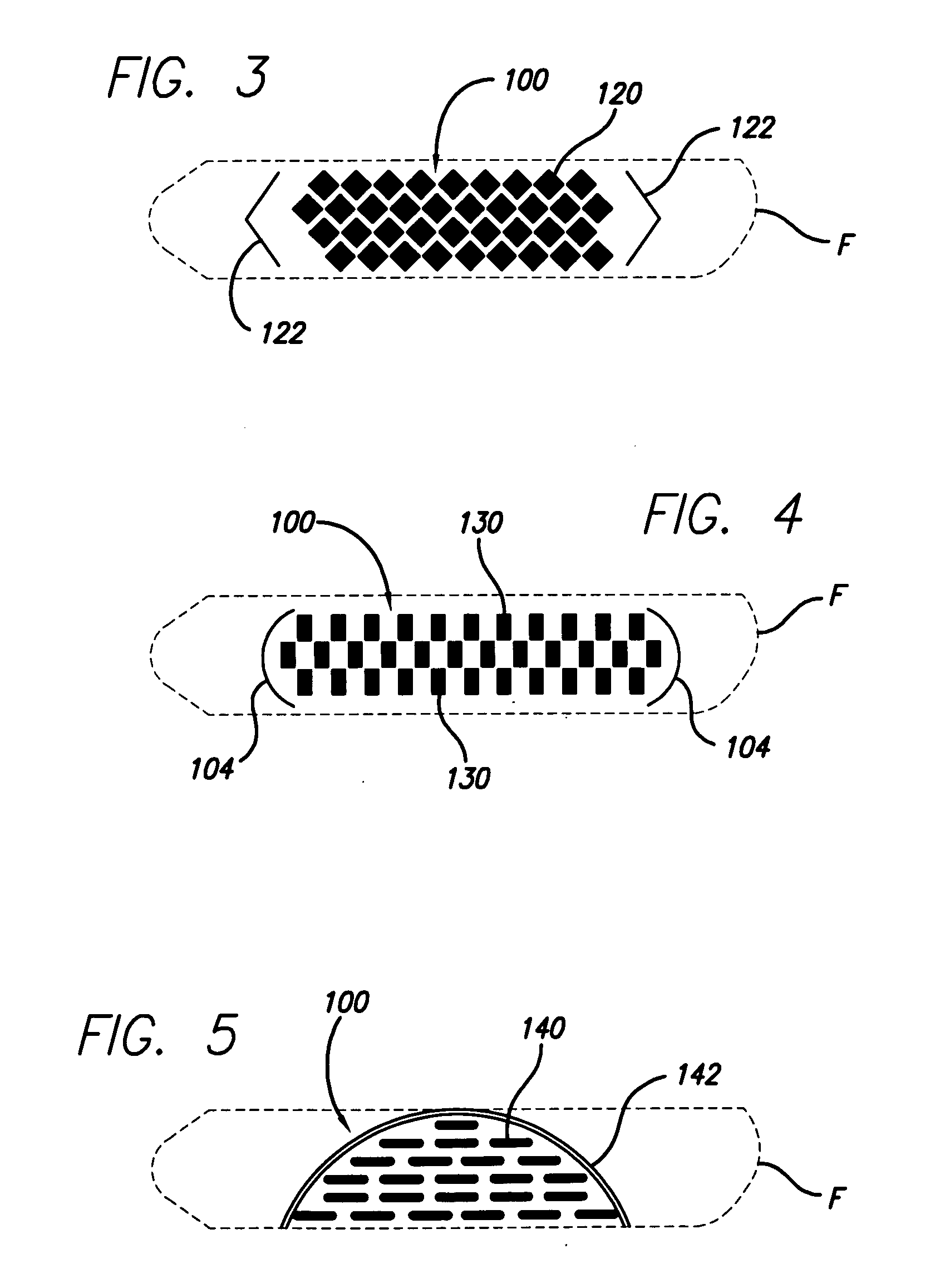

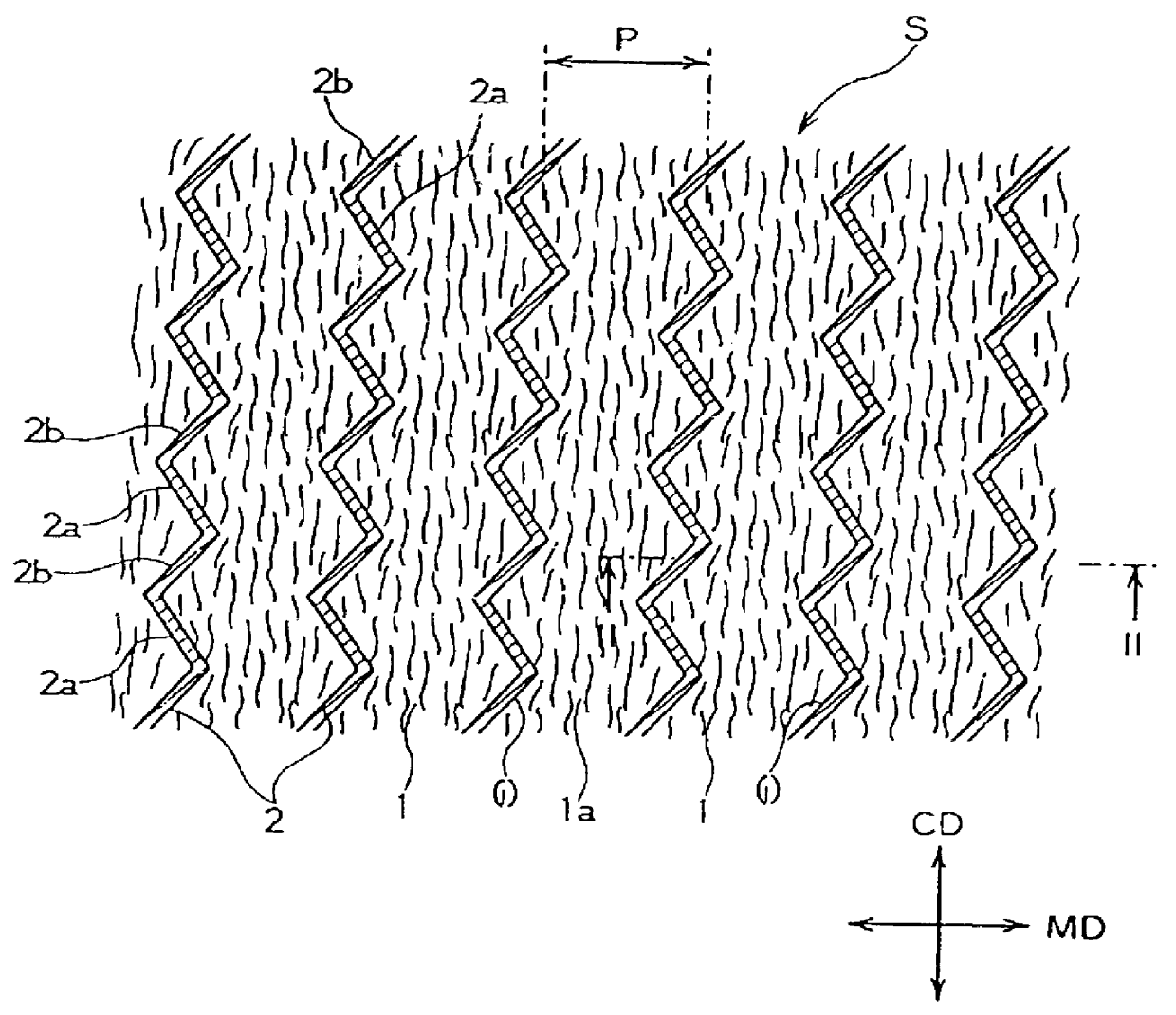

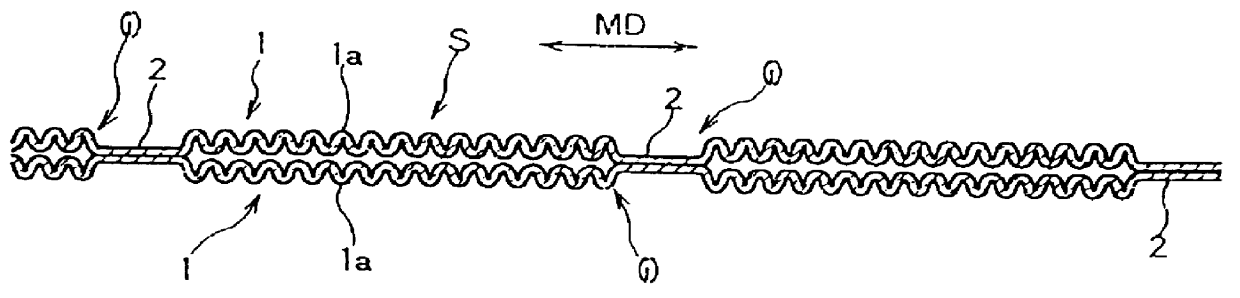

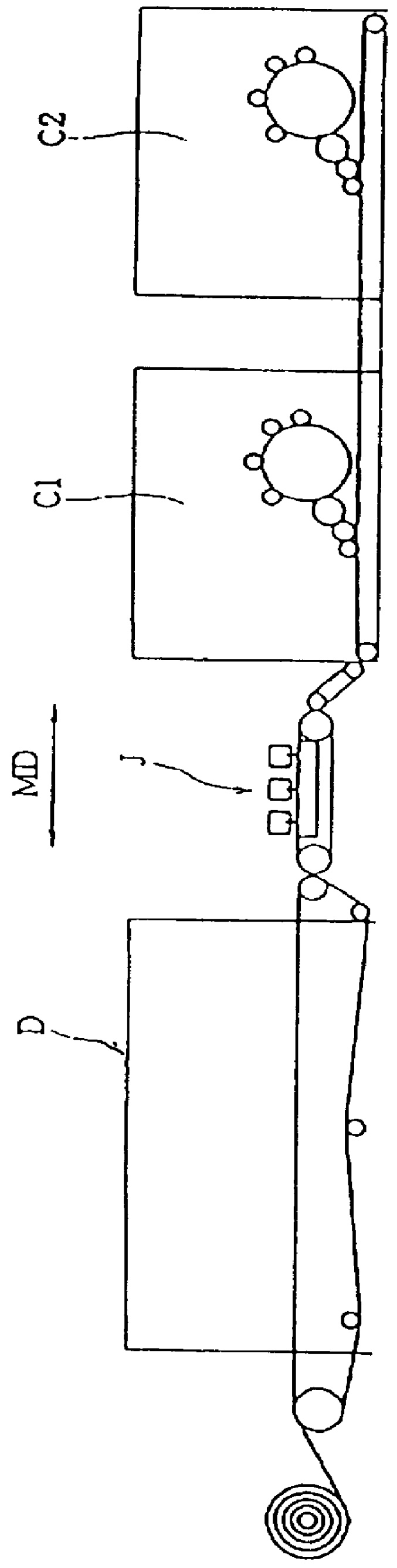

Wiping sheet and production thereof

InactiveUS6054202AHigh tensile strengthImproving surface frictional strengthCarpet cleanersFloor cleanersSingle fiberEngineering

Disclosed herein is a wiping sheet composed of two pieces of spunlace nonwoven fabrics containing heat-shrinkable fiber which are fusion-bonded together with fusion-bonding lines which extend in the cross direction perpendicular to the machine direction. The fusion-bonding lines are formed such that their pitch in the machine direction is shorter than one half of the fiber length so that each fusion-bonding line intersects a single fiber at 3 or more points. This structure prevents surface fluffing and imparts a high surface frictional strength and a high bending resistance for comfortable wiping work.

Owner:UNI CHARM CORP

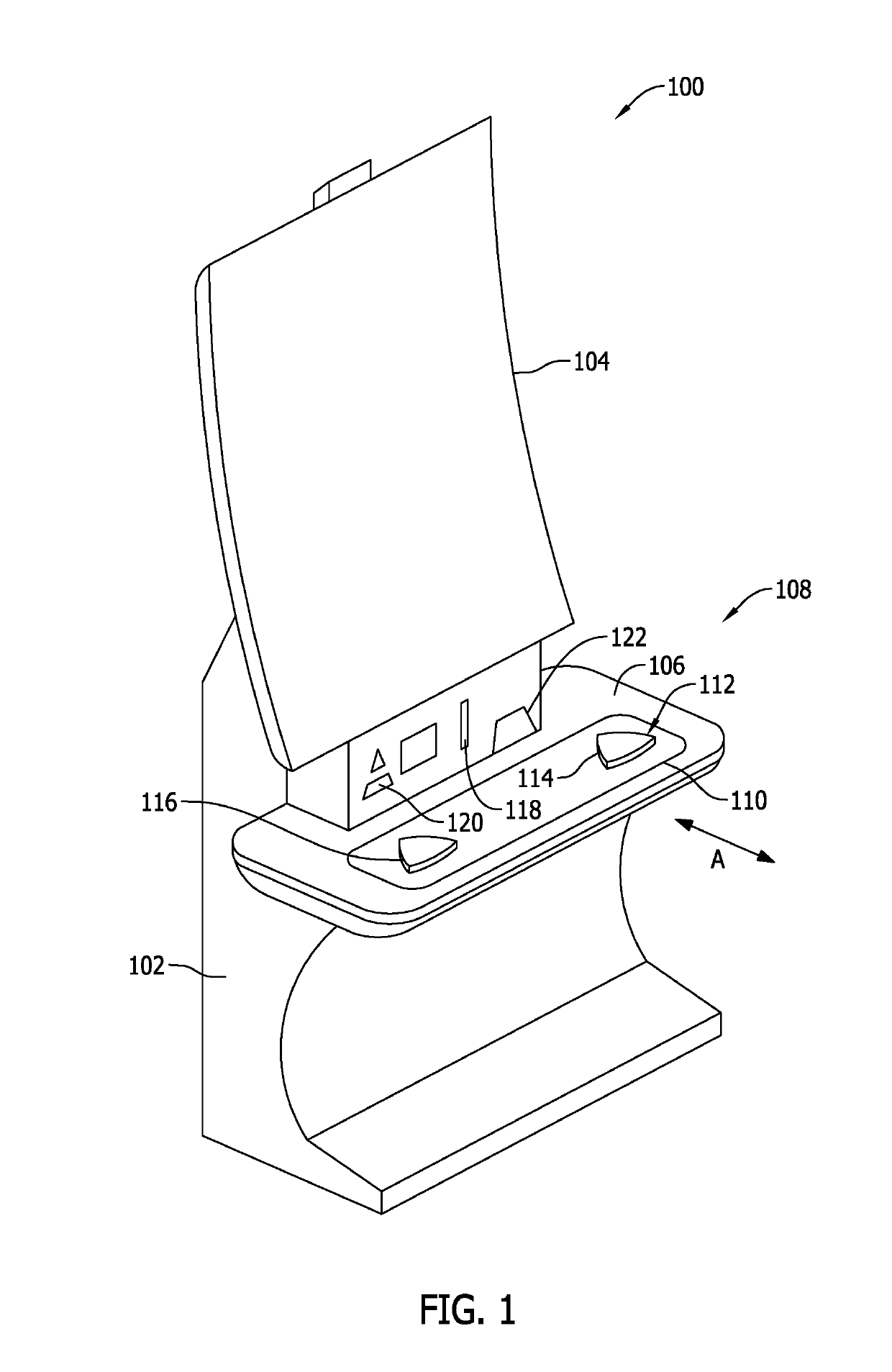

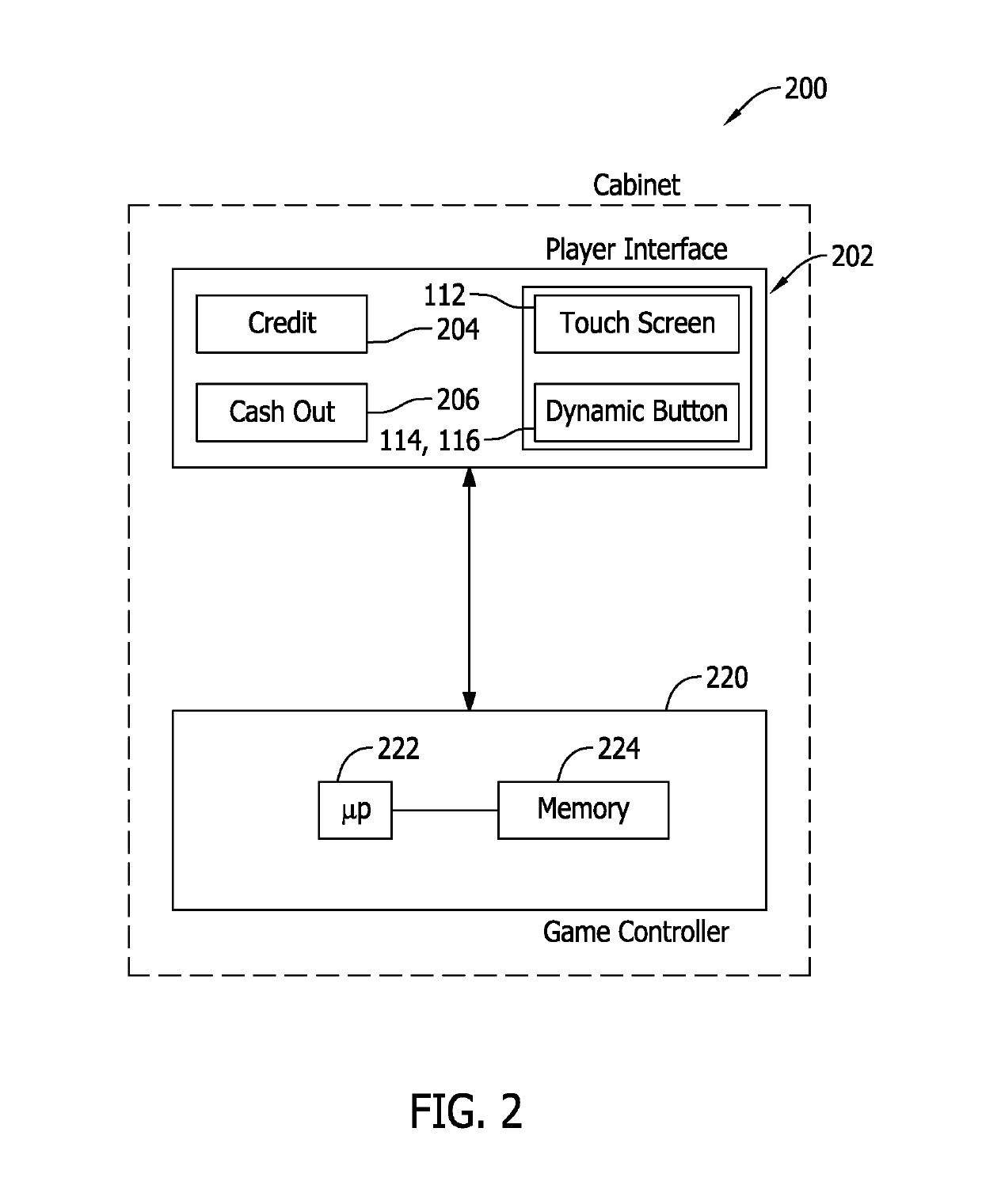

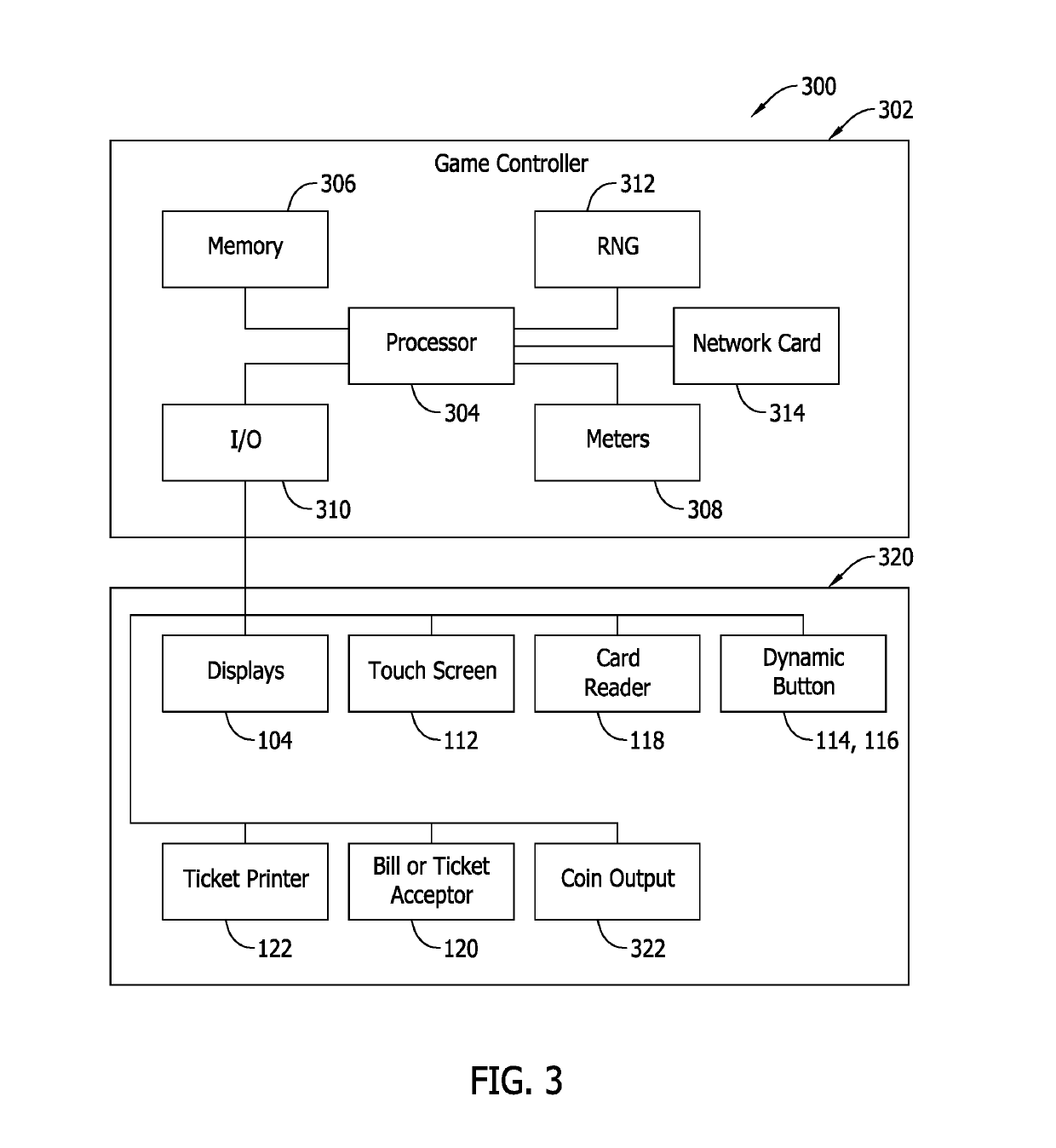

Gaming machine with slide-out button deck assembly and manually operable push-to-release latch mechanism

PendingUS20190096161A1Prevent surfaceApparatus for meter-controlled dispensingEngineeringDisplay device

Owner:ARISTOCRAT TECH AUSTRALIA PTY LTD

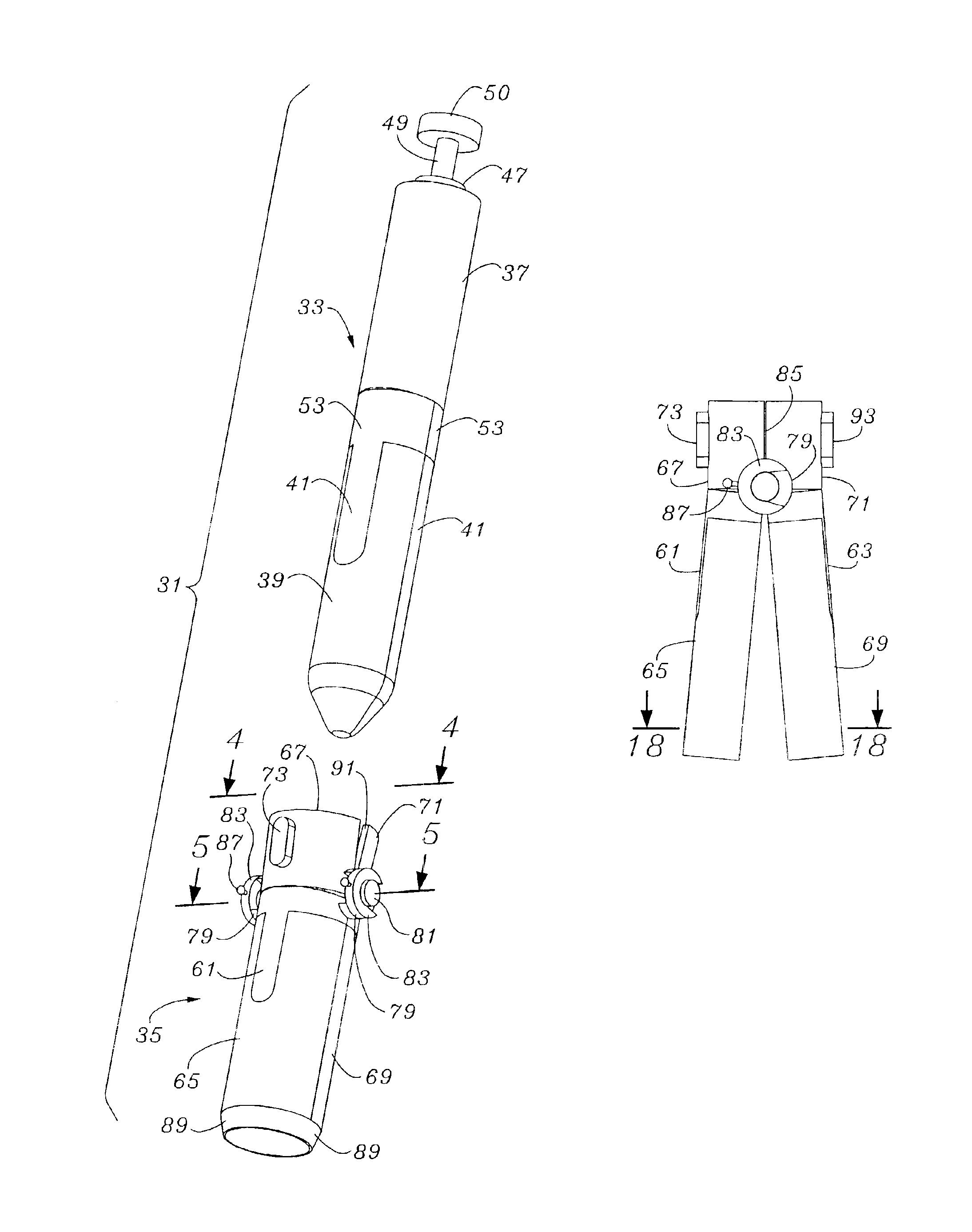

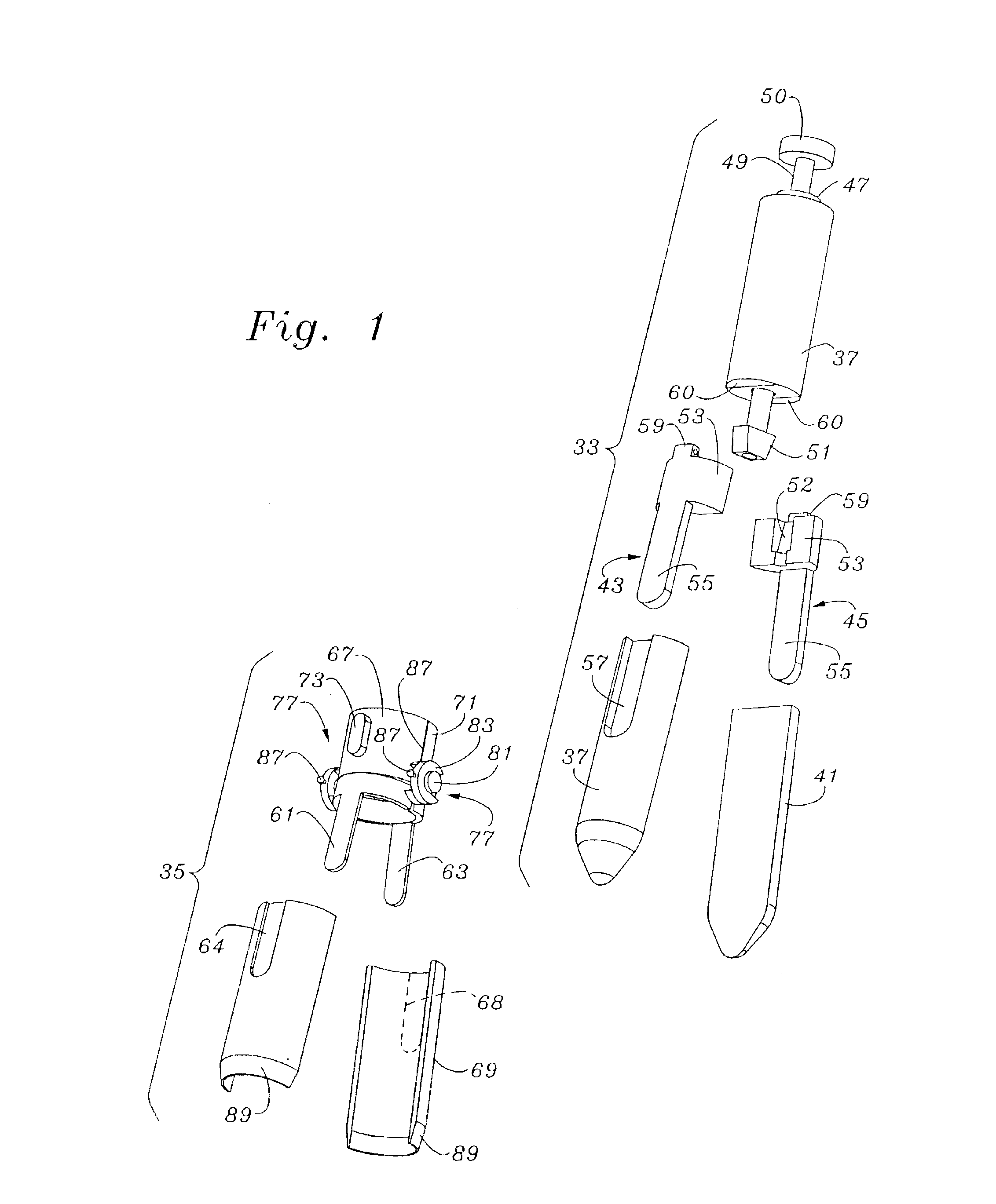

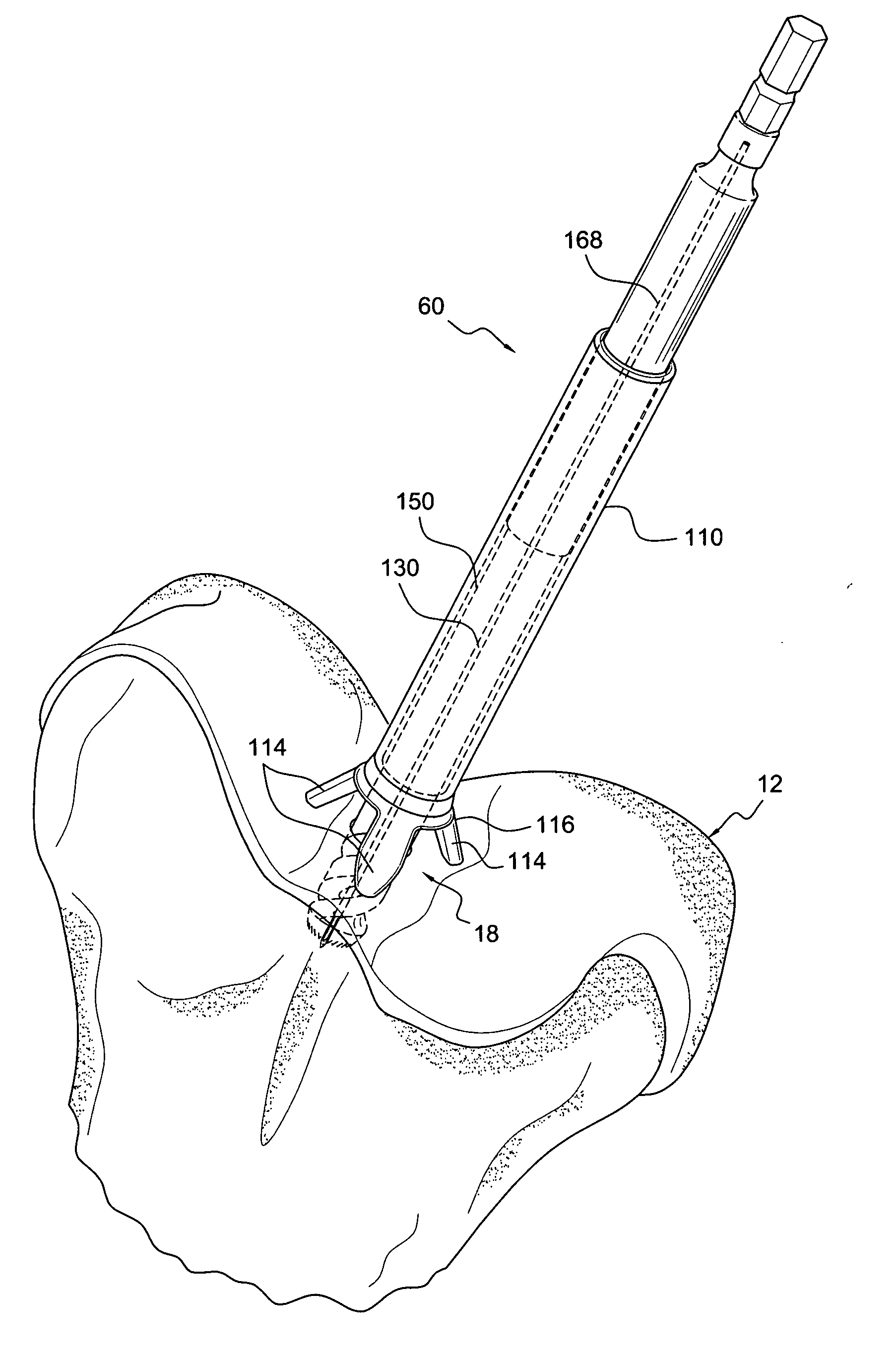

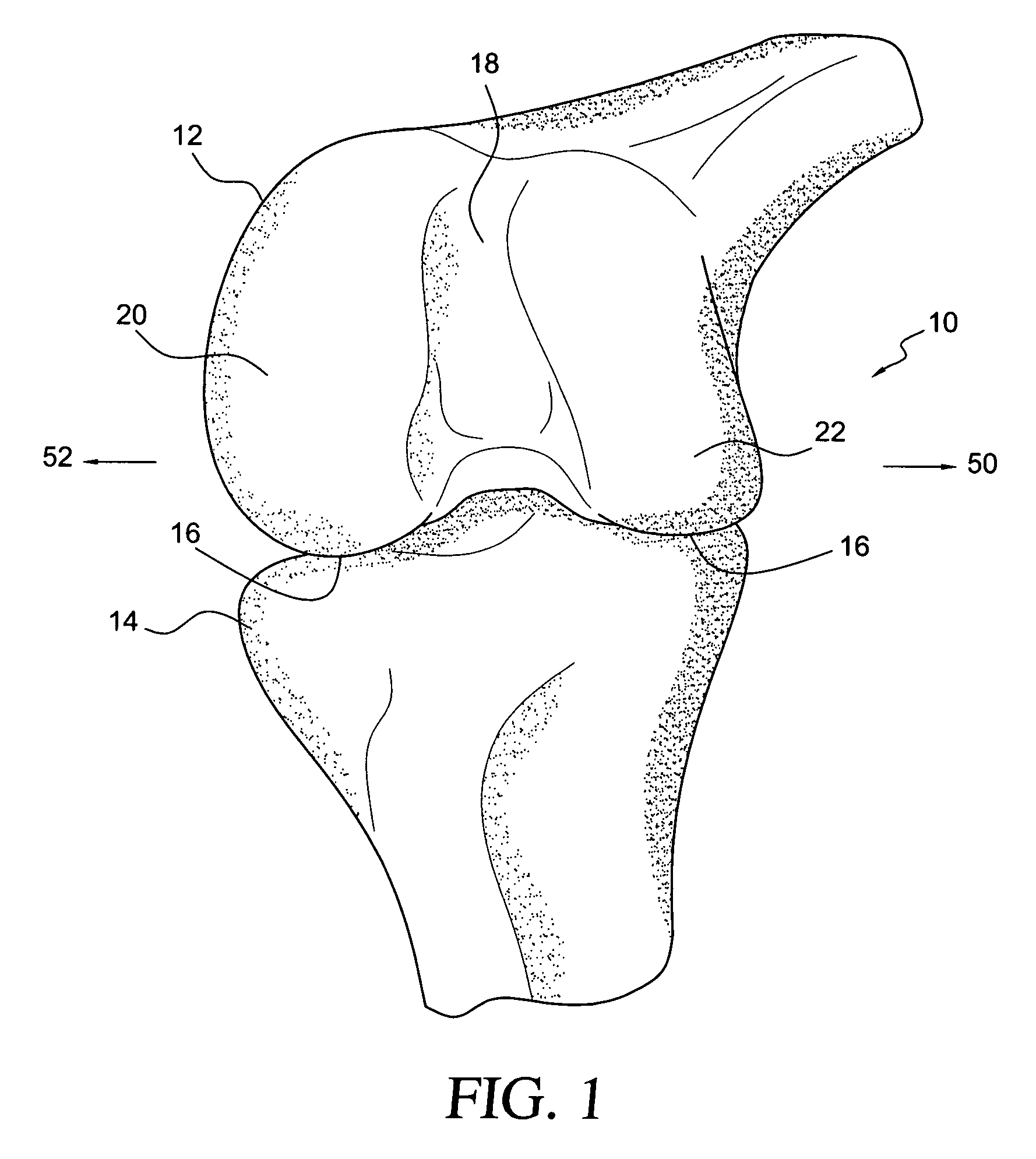

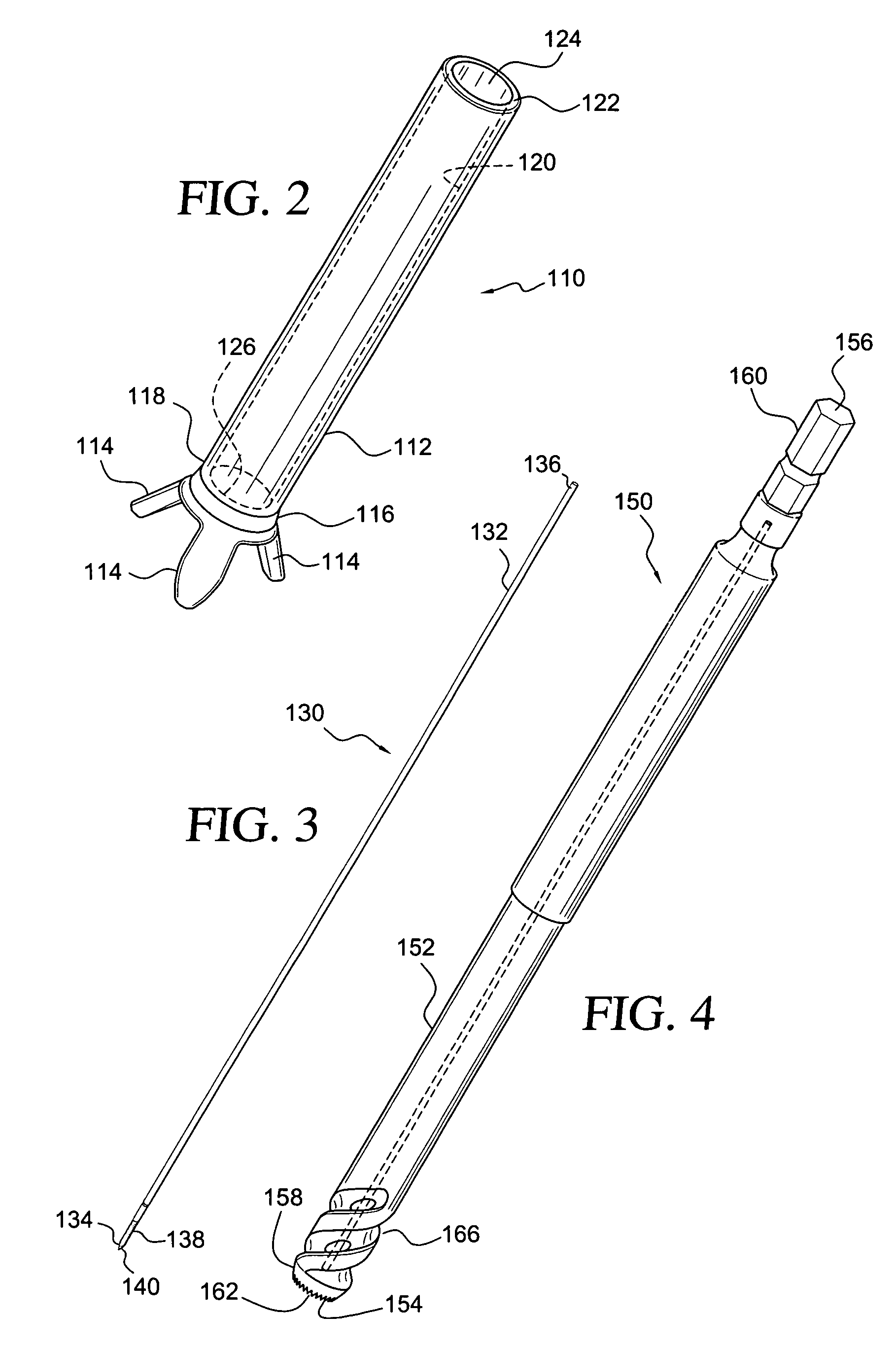

Osteochondral plug graft harvesting instrument, kit and method

ActiveUS20070270711A1Prevent integrationPrevent surfaceVaccination/ovulation diagnosticsNon-surgical orthopedic devicesScrew threadGuide wires

An instrument for harvesting an osteochondral plug graft in an implantable configuration, comprises a support pod comprising an elongated tubular member distally terminating in at least three splayed legs; a drill bit encompassed within a longitudinal axis of the tubular member; and a guide wire encompassed within a longitudinal axis of passageway of the drill bit and terminating at a threaded distal end for removably fixing a distal end of the instrument in a position oriented normal to an osteochondral surface for harvesting an osteochondral plug graft in an implantable normal configuration.

Owner:WARSAW ORTHOPEDIC INC

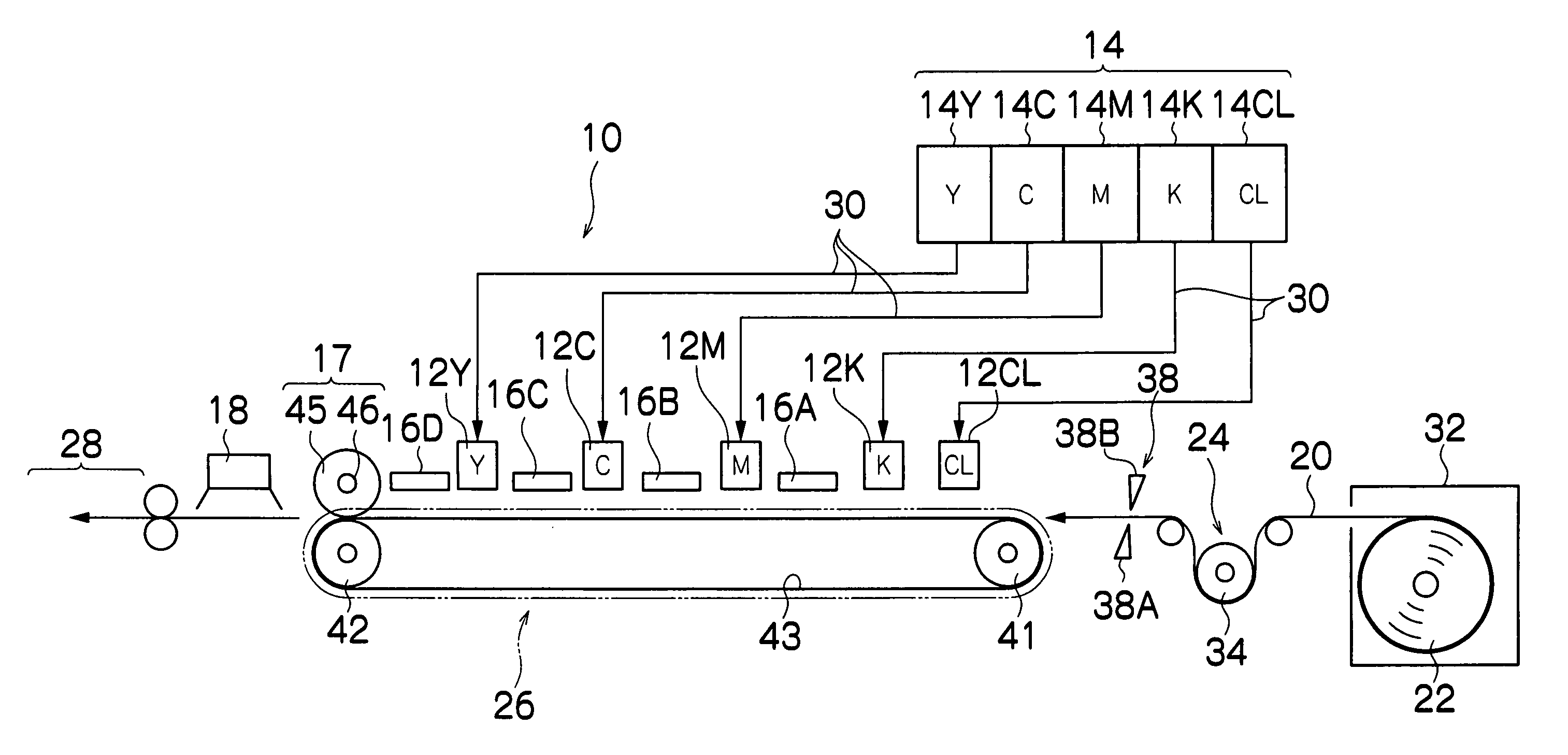

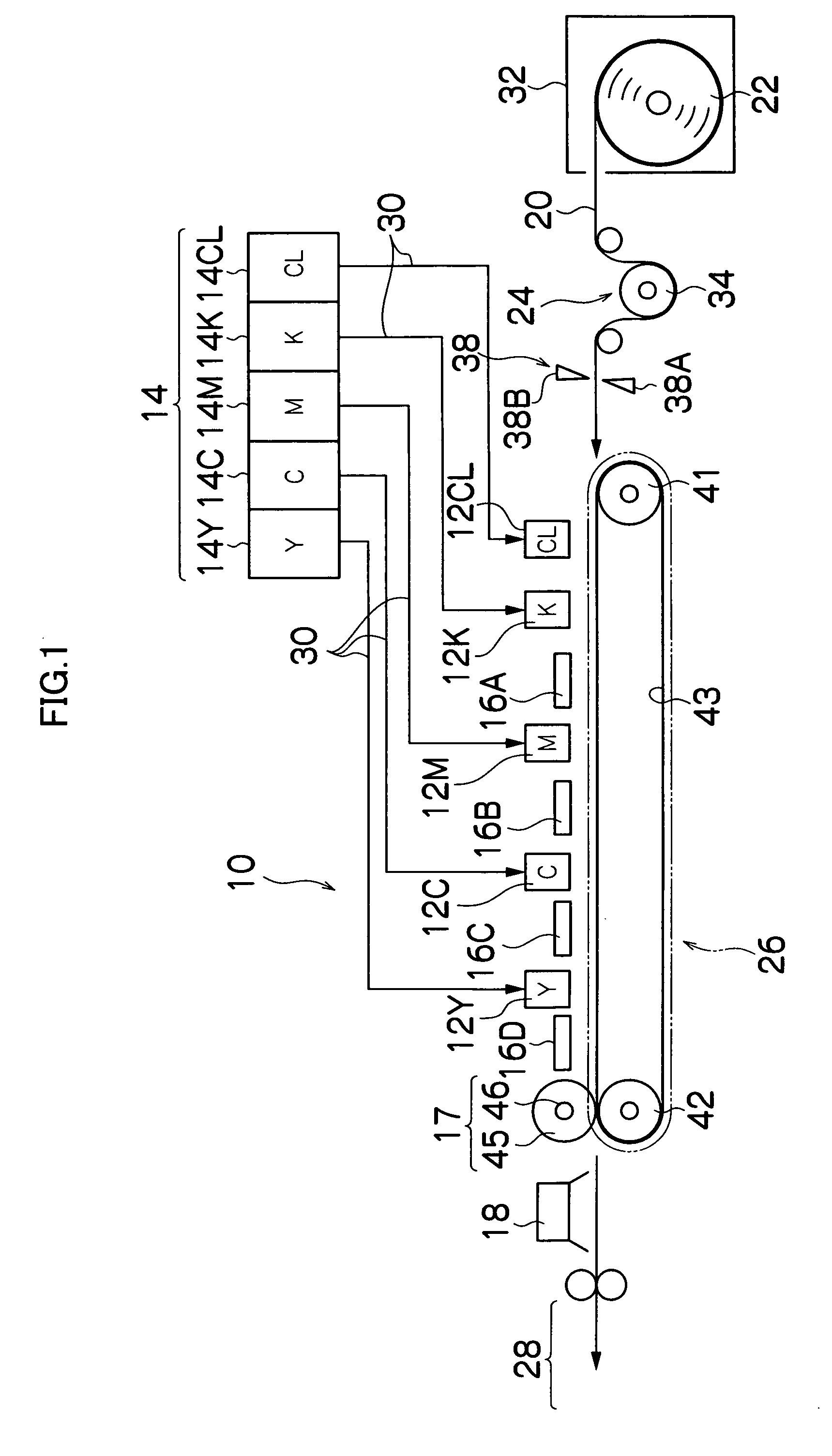

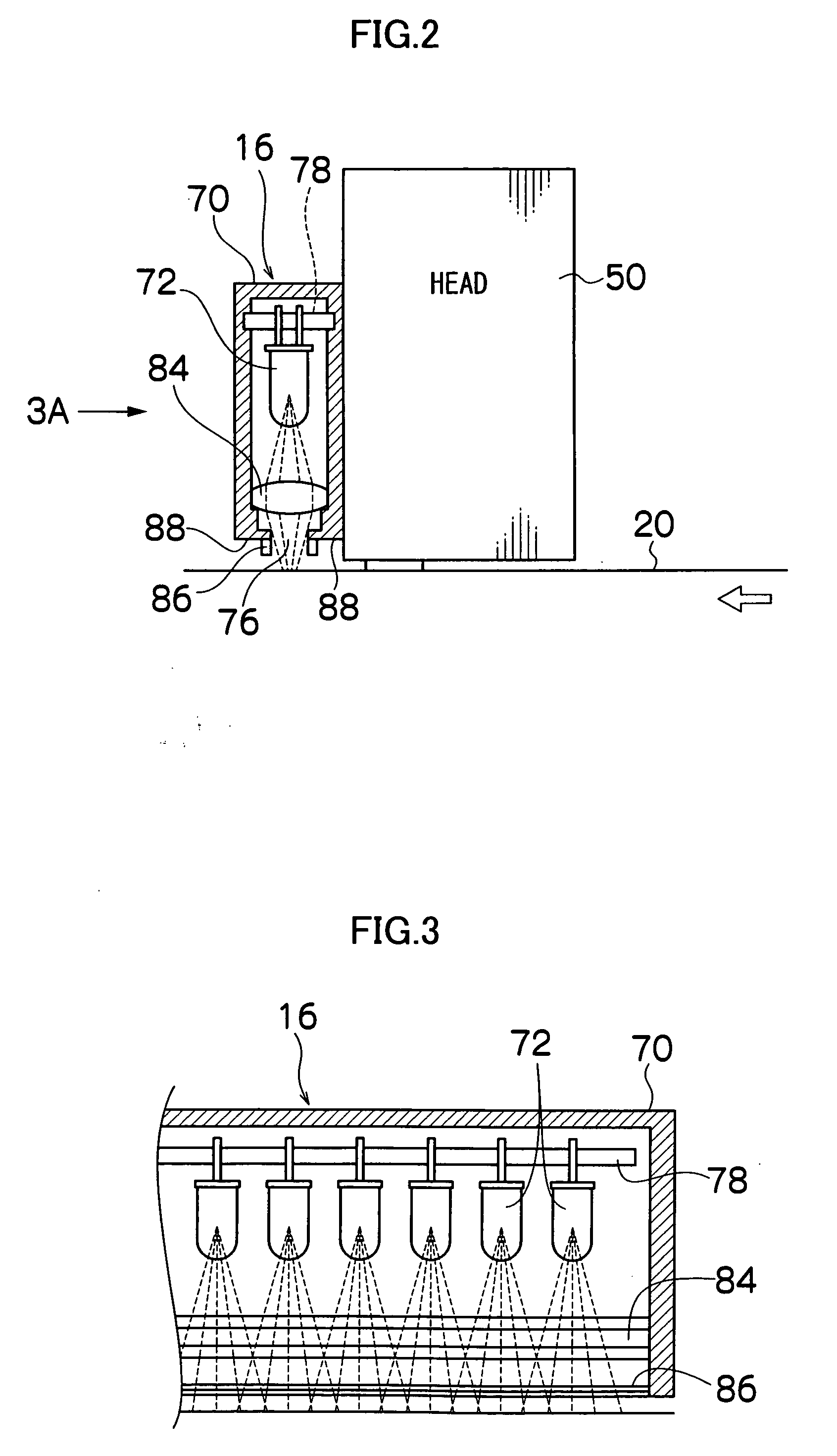

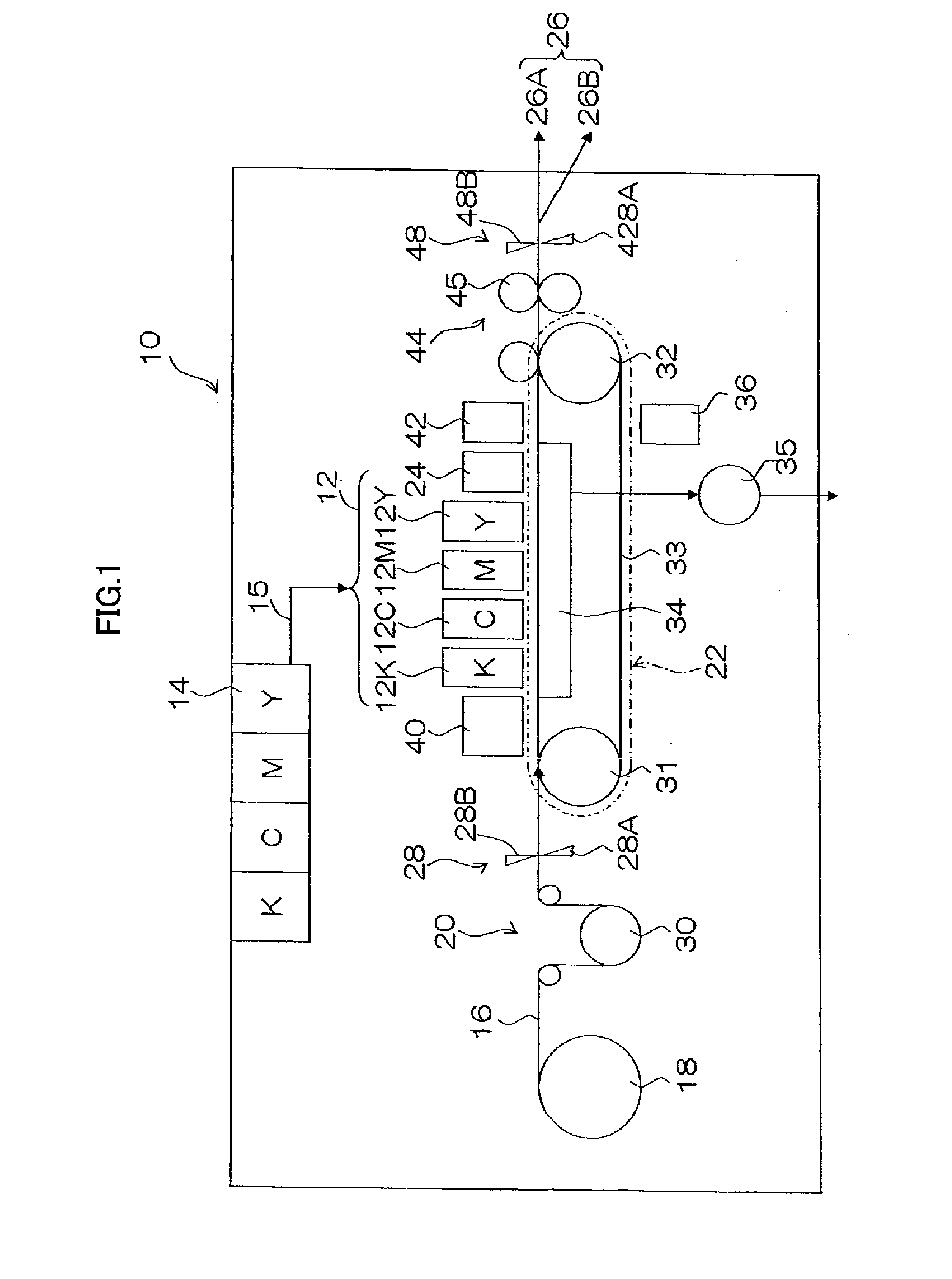

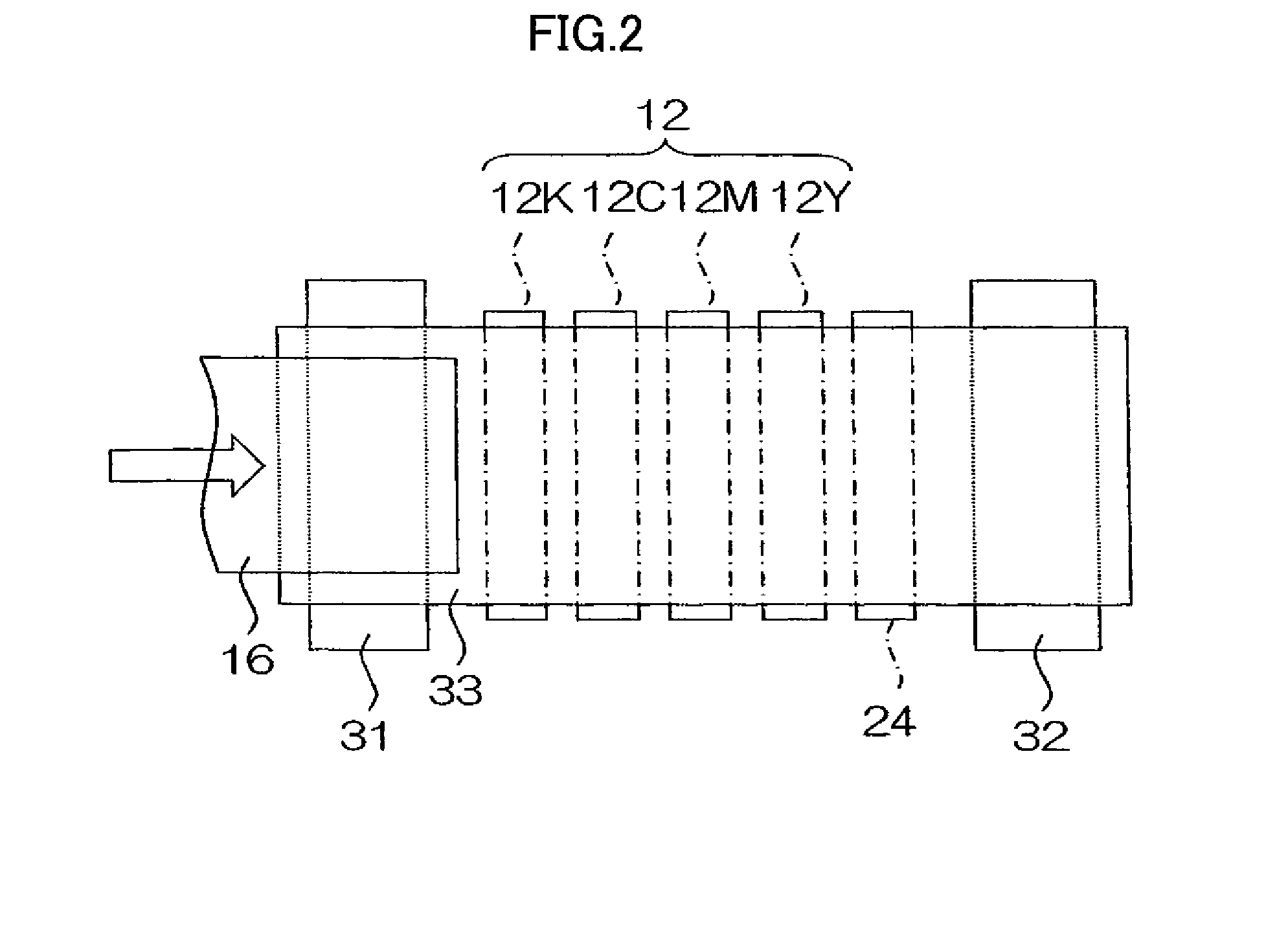

Image forming apparatus and image forming method

InactiveUS20070040885A1Prevent image deteriorationReliable image fixingOther printing apparatusUltraviolet lightsImage formation

The image forming apparatus, comprises: a plurality of ejection heads which eject liquid containing, a first ultraviolet curing initiator having spectral absorption characteristics at least in a first wavelength range, a second ultraviolet curing initiator which has spectral absorption characteristics at least in a second wavelength range being on a shorter wavelength side from the first wavelength range and has no spectral absorption characteristics in the first wavelength range, an ultraviolet-polymerizable compound, and a coloring material, onto a medium; a semi-curing device which radiates, at least once, ultraviolet light having at least a wavelength which is in the first wavelength range and which is on a longer wavelength side from the second wavelength range, onto dots formed by the liquid ejected from the ejection heads onto the medium; an intermediate processing device which performs intermediate processing of an image formed on the medium by the dots; and a main curing device which radiates ultraviolet light having at least a wavelength in the second wavelength range, onto the image which has undergone intermediate processing by the intermediate processing device.

Owner:FUJIFILM CORP

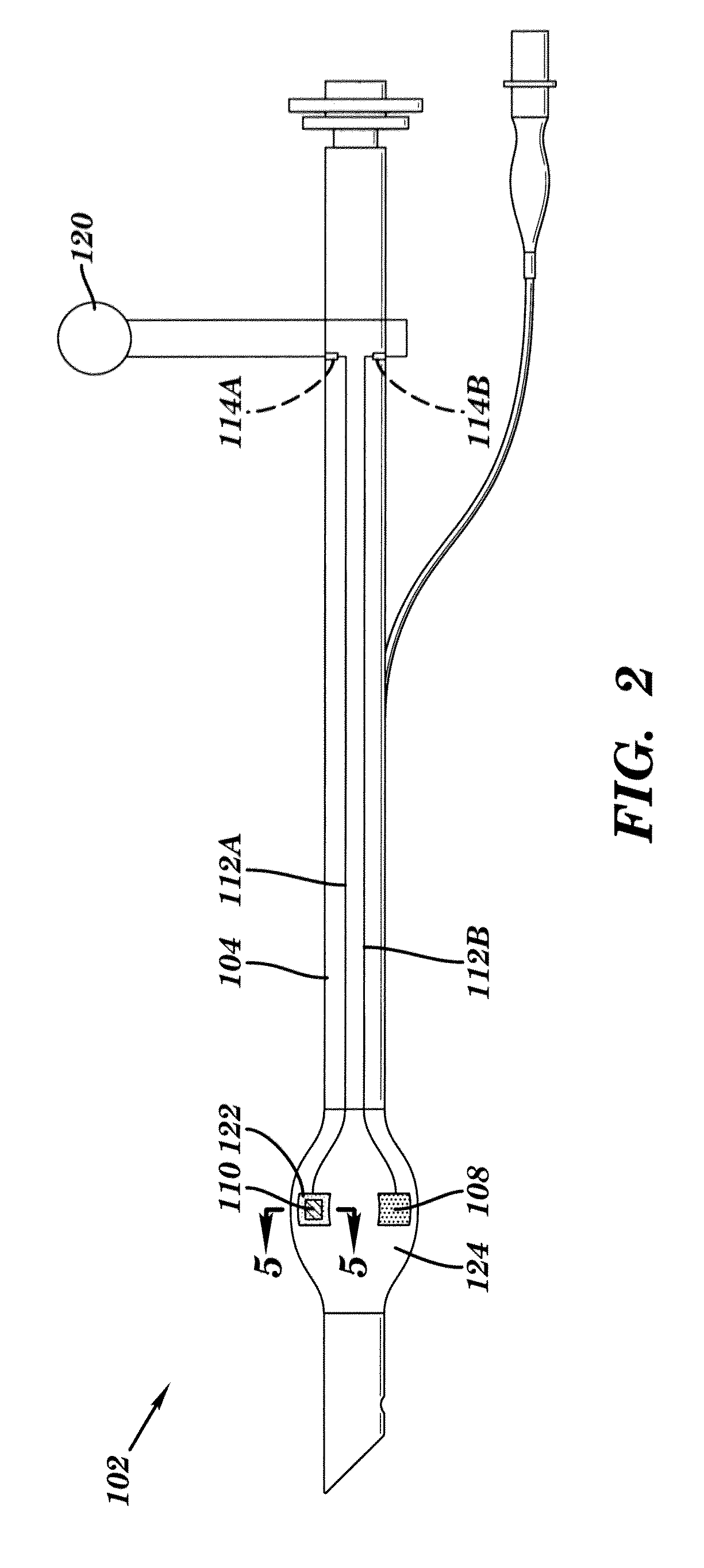

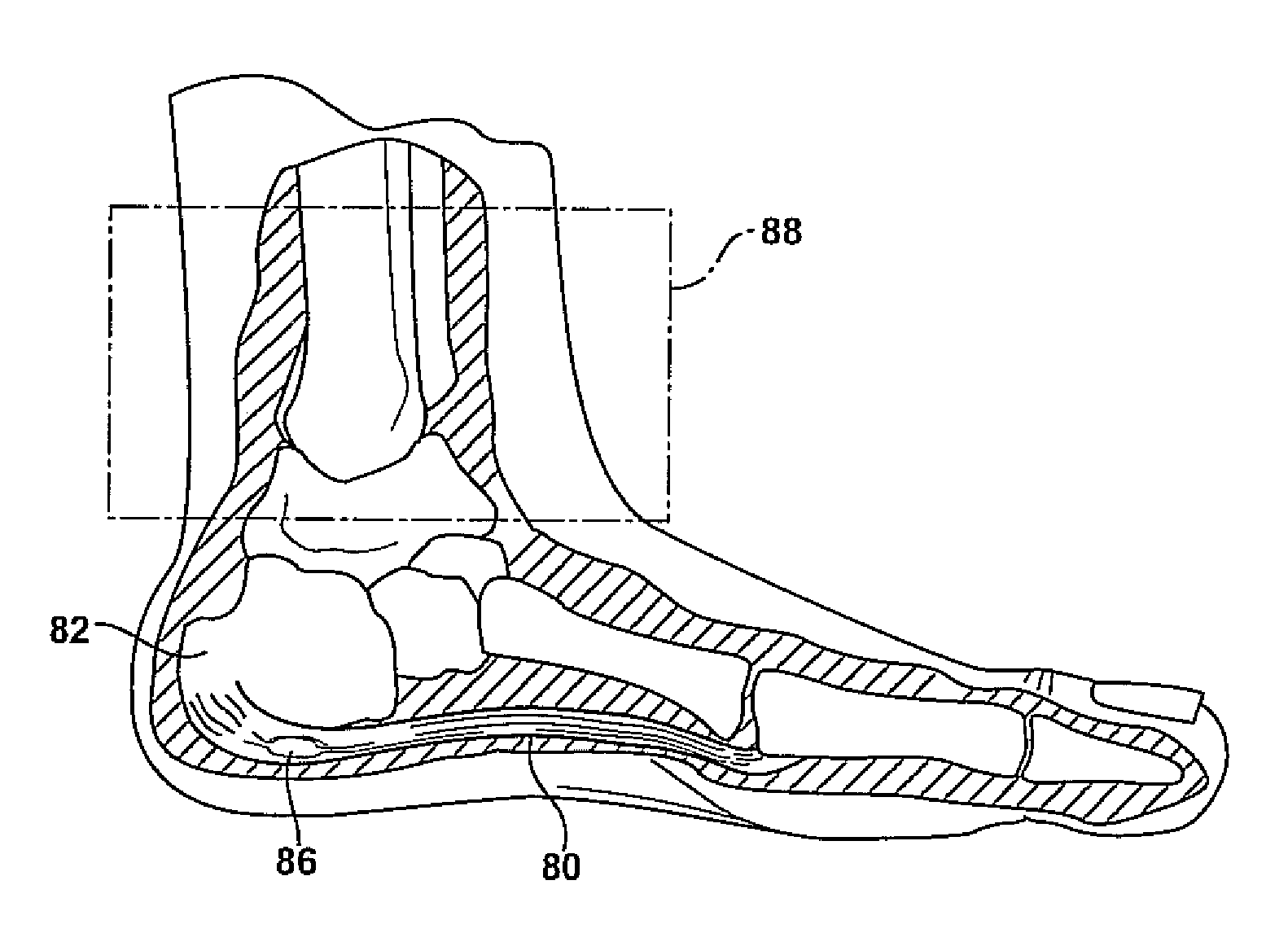

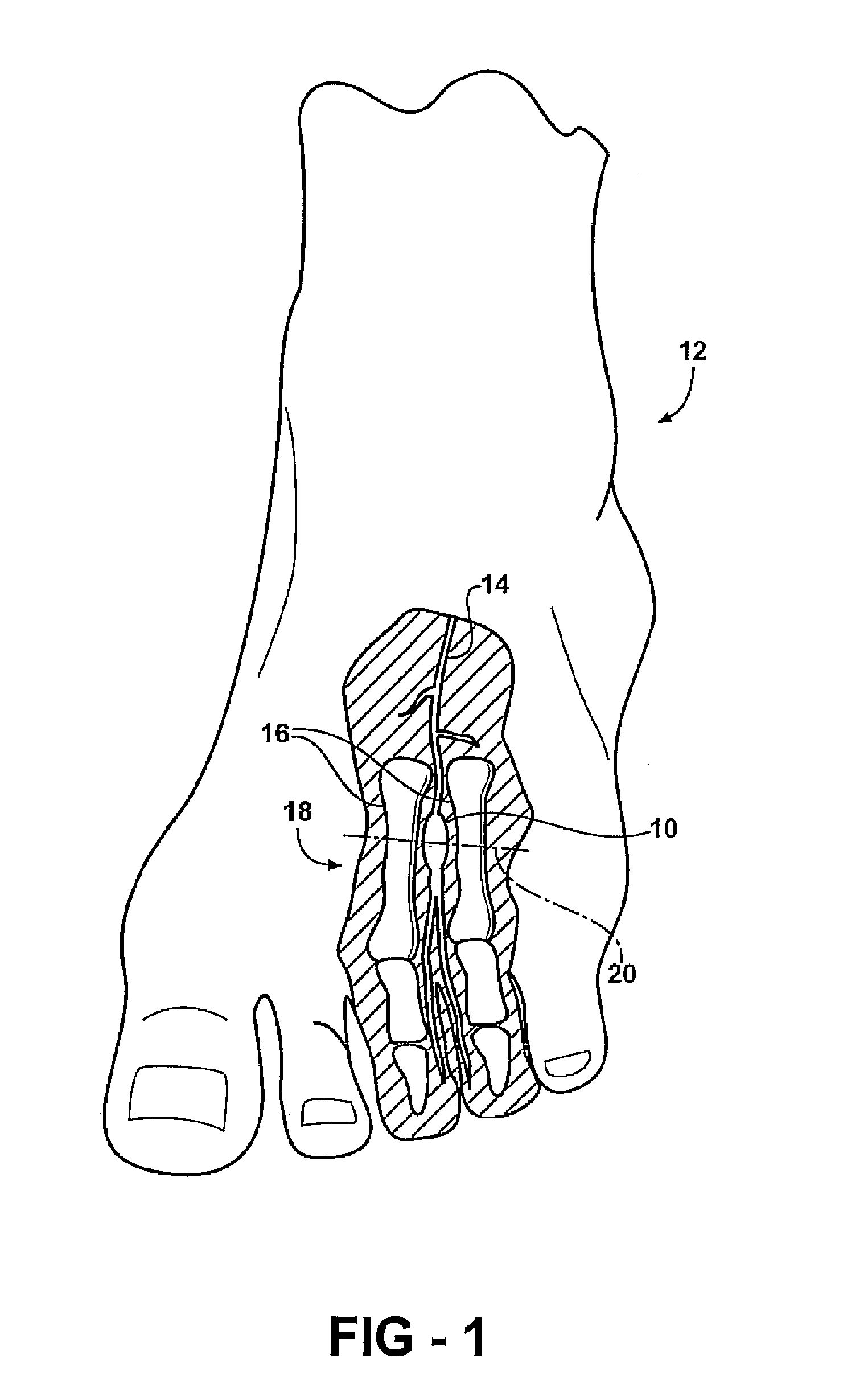

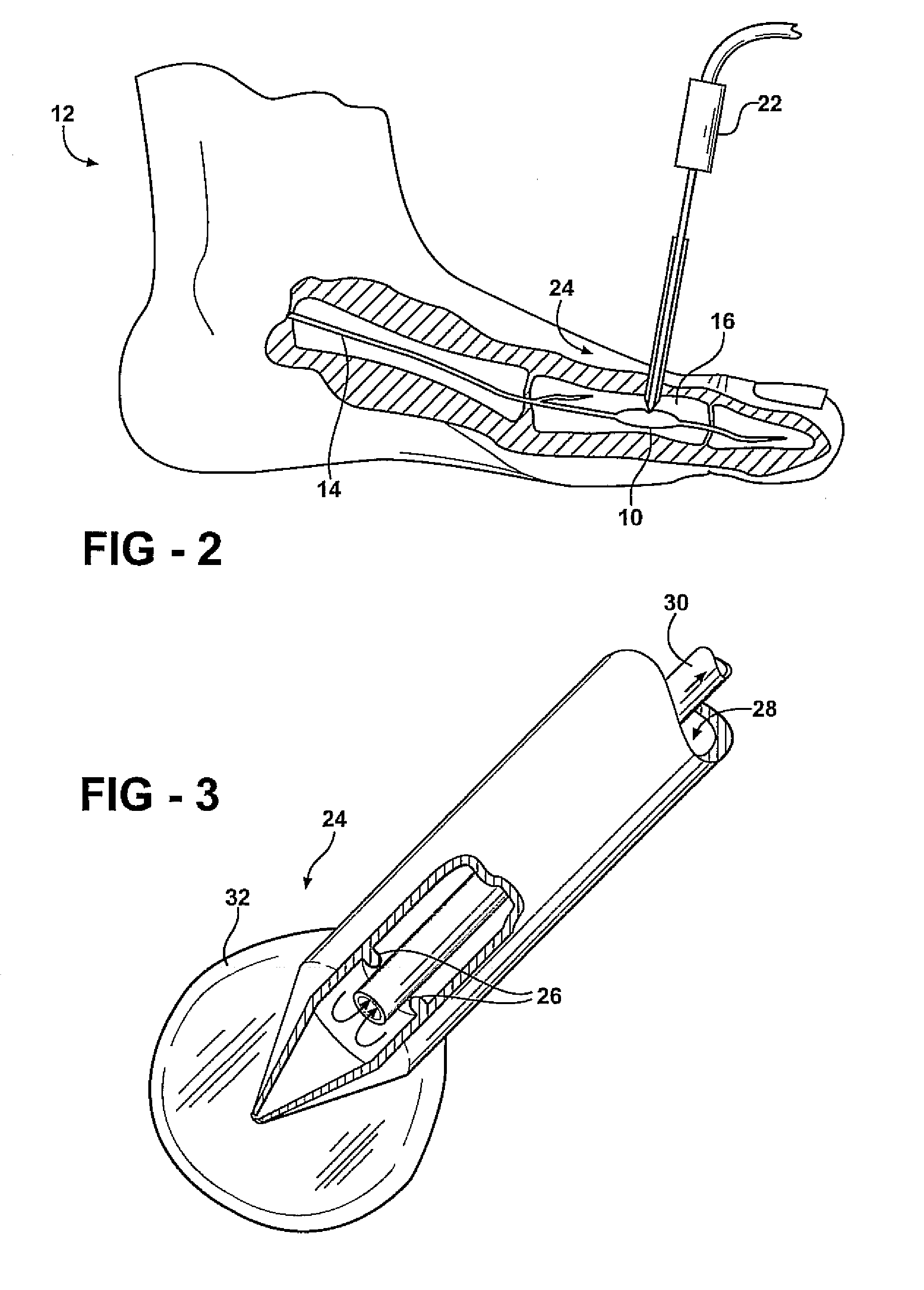

Treatment of lower extremity pain

InactiveUS7250046B1Reduce the possibilityAvoid expensesDiagnosticsSurgical instruments for coolingBody painsSkin surfaces

A method of treatment of lower extremity body pain is described comprising freezing a portion of the lower extremity, for example, for cryoanalgesia. In one form, a method of treating a Morton's neuroma comprises freezing the neuroma in the foot. In another preferred form, a method of treating plantar fasciitis comprises freezing a tissue portion in or adjacent to the foot. The methods include inserting a cryogenic probe through a skin surface for percutaneous access to a region for cryoanalgesia, and operating the probe to provide one or more successive freeze cycles.

Owner:FALLAT LAWRENCE M

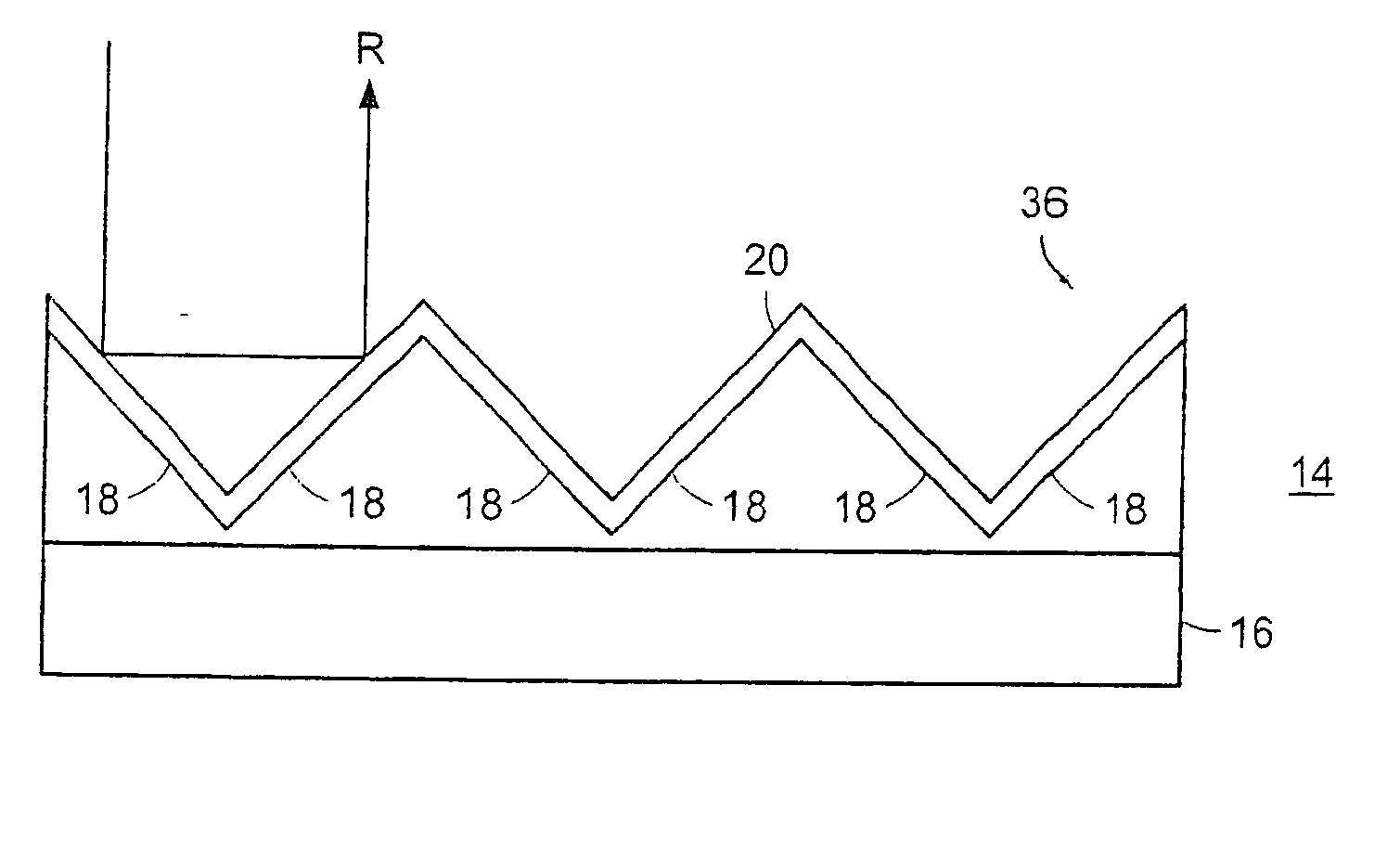

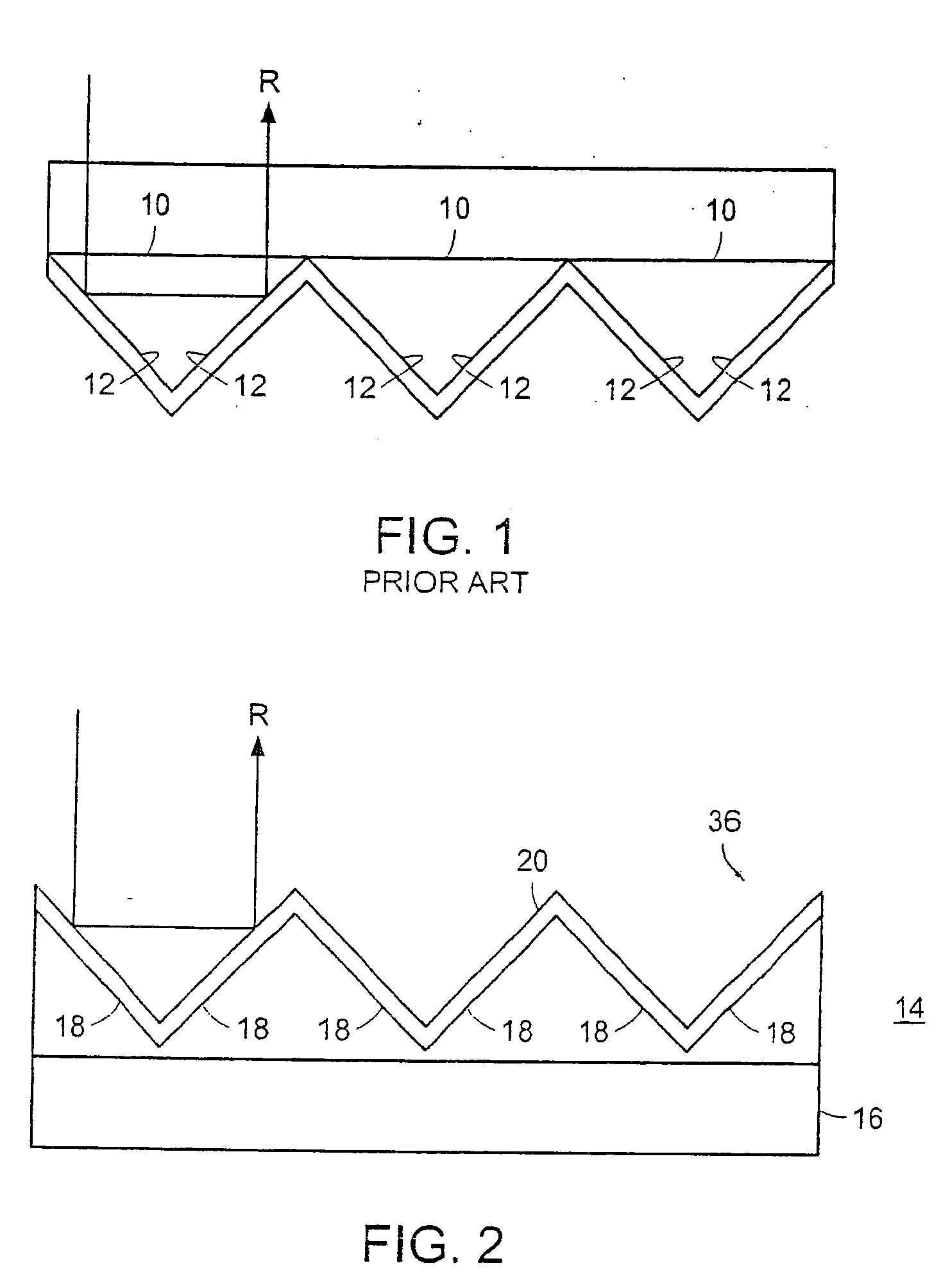

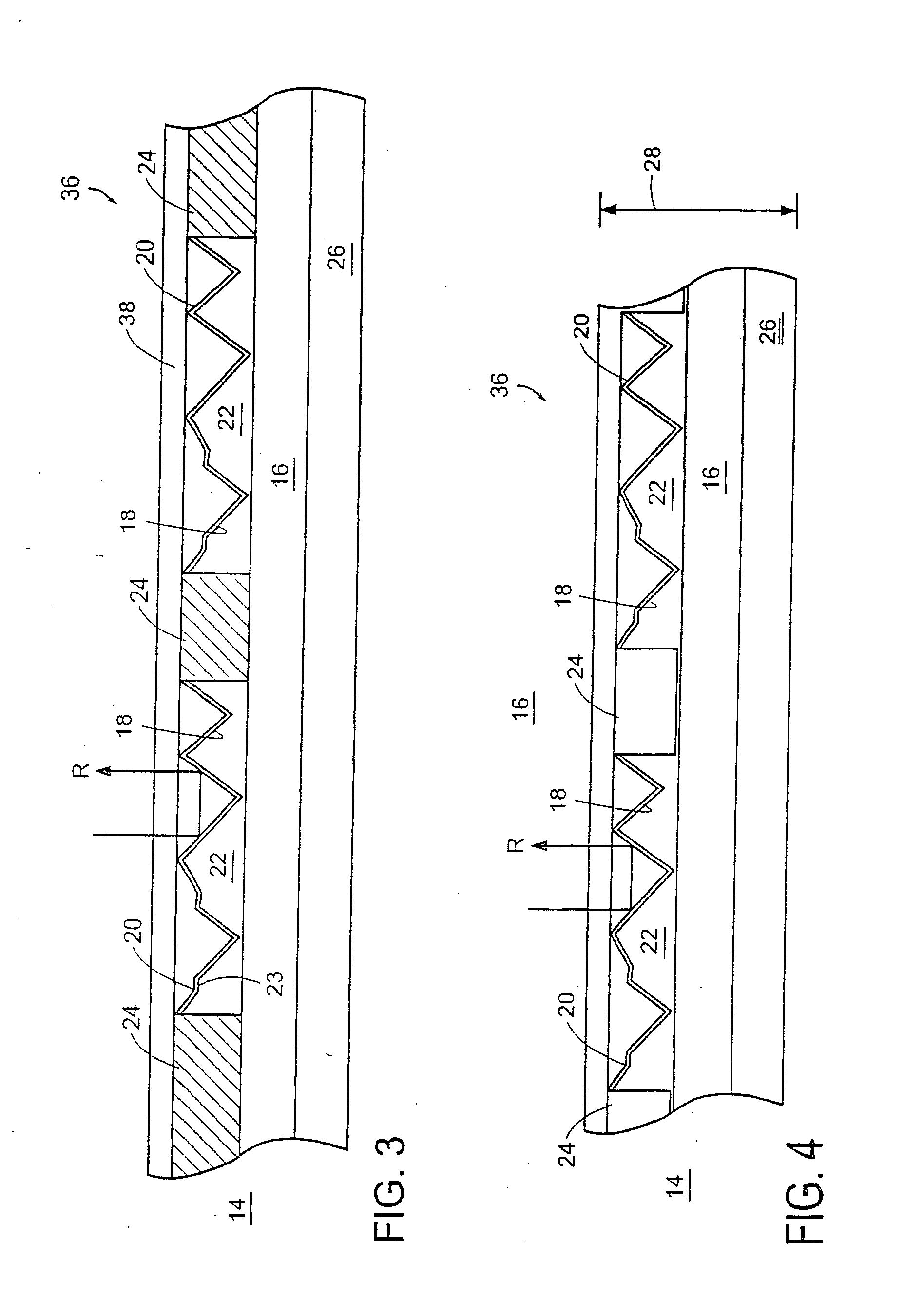

Durable, open-faced retroreflective prismatic construction

InactiveUS20050185279A1Improve adhesionImprove the entrance angleOptical elementsOptical coatingEngineering

Retroreflective sheeting and a method for making the same includes a plurality of open-faced cube-corner surfaces formed from a substantially rigid material to keep the cube-corner surfaces from flexing. A second plurality of open-faced cube-corner surfaces is formed from the substantially rigid material to keep the second plurality of open-faced cube-corner surfaces from flexing. The first and second open-faced cube-corner surfaces are configured to retroreflect light in opposite directions, that is, formed back-to-back in a particular embodiment. An optical coating can be formed on the surfaces. A plurality of voids forms the open-faced cube-corner surfaces. The retroreflective sheeting can be perforated in a particular embodiment.

Owner:REFLEXITE

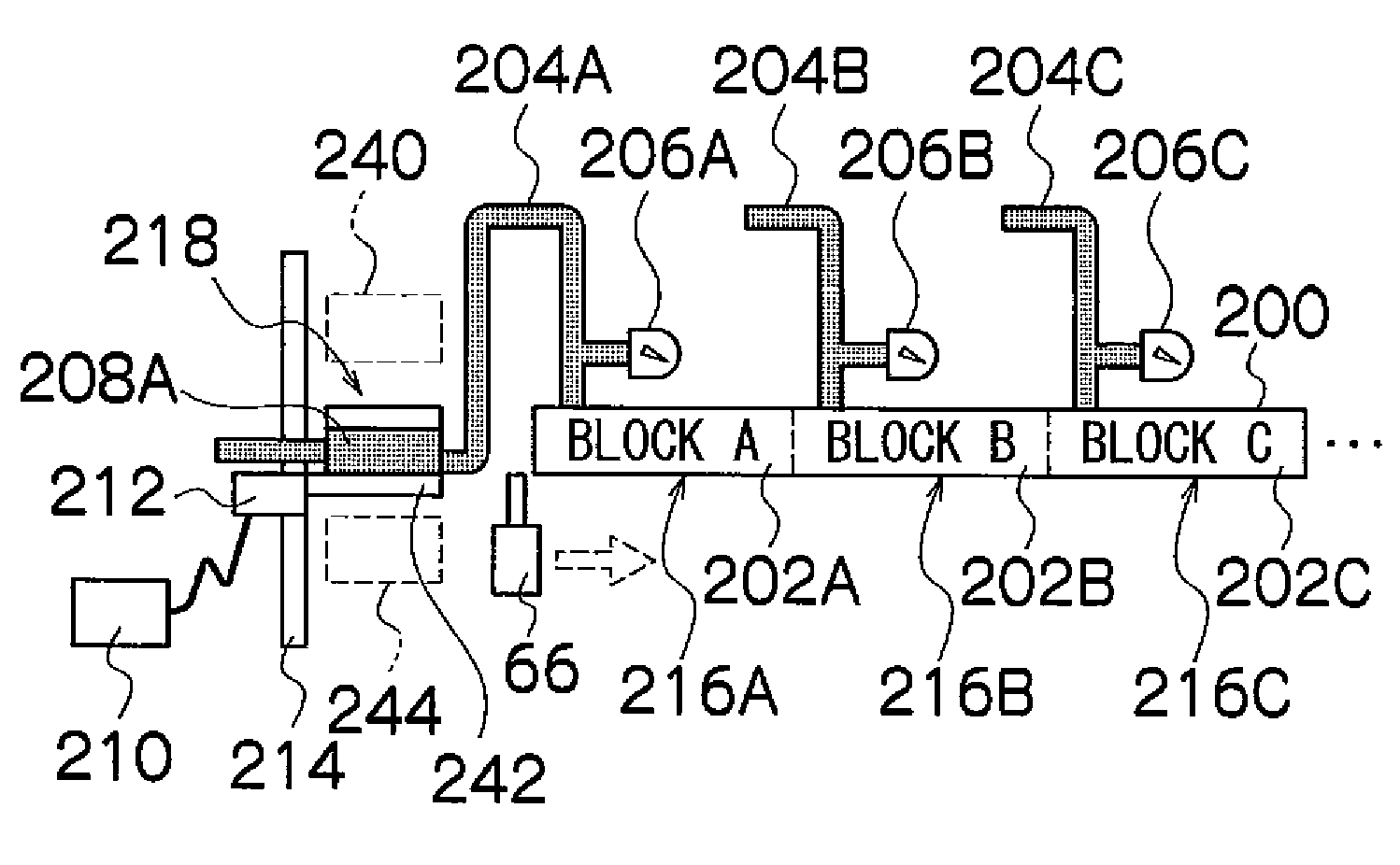

Liquid ejection apparatus and liquid ejection surface maintenance method

InactiveUS20080218554A1Prevent surfaceEfficient and reliable removalOther printing apparatusInternal pressureEngineering

A liquid ejection apparatus includes: a liquid ejection head which includes a nozzle ejecting liquid, a pressure chamber connected to the nozzle and arranged in a liquid ejection surface of the liquid ejection head, and a pressure application device applying pressure to the liquid inside the pressure chamber; an internal pressure adjustment device which adjusts an internal pressure of the liquid ejection head; and a pressure control device which controls the internal pressure adjustment device and the pressure application device so as to spread the liquid over the liquid ejection surface of the liquid ejection head. The internal pressure adjustment device adjusts the internal pressure of the liquid ejection head to a positive pressure so as to still hold the liquid on the nozzle while protruding the liquid from the liquid ejection surface. The pressure application device then applies the pressure to the liquid inside the pressure chamber for a pressure application duration so as not to cause the liquid to be ejected from the nozzle but to flow out the liquid from the nozzle onto the liquid ejection surface, while the internal pressure adjustment device is adjusting the internal pressure to the positive pressure. The pressure application device then stops applying the pressure to the liquid inside the pressure chamber after the pressure application duration, while the internal pressure adjustment device is adjusting the internal pressure to the positive pressure.

Owner:FUJIFILM CORP

Extended release tablet formulations of flibanserin and method for manufacturing the same

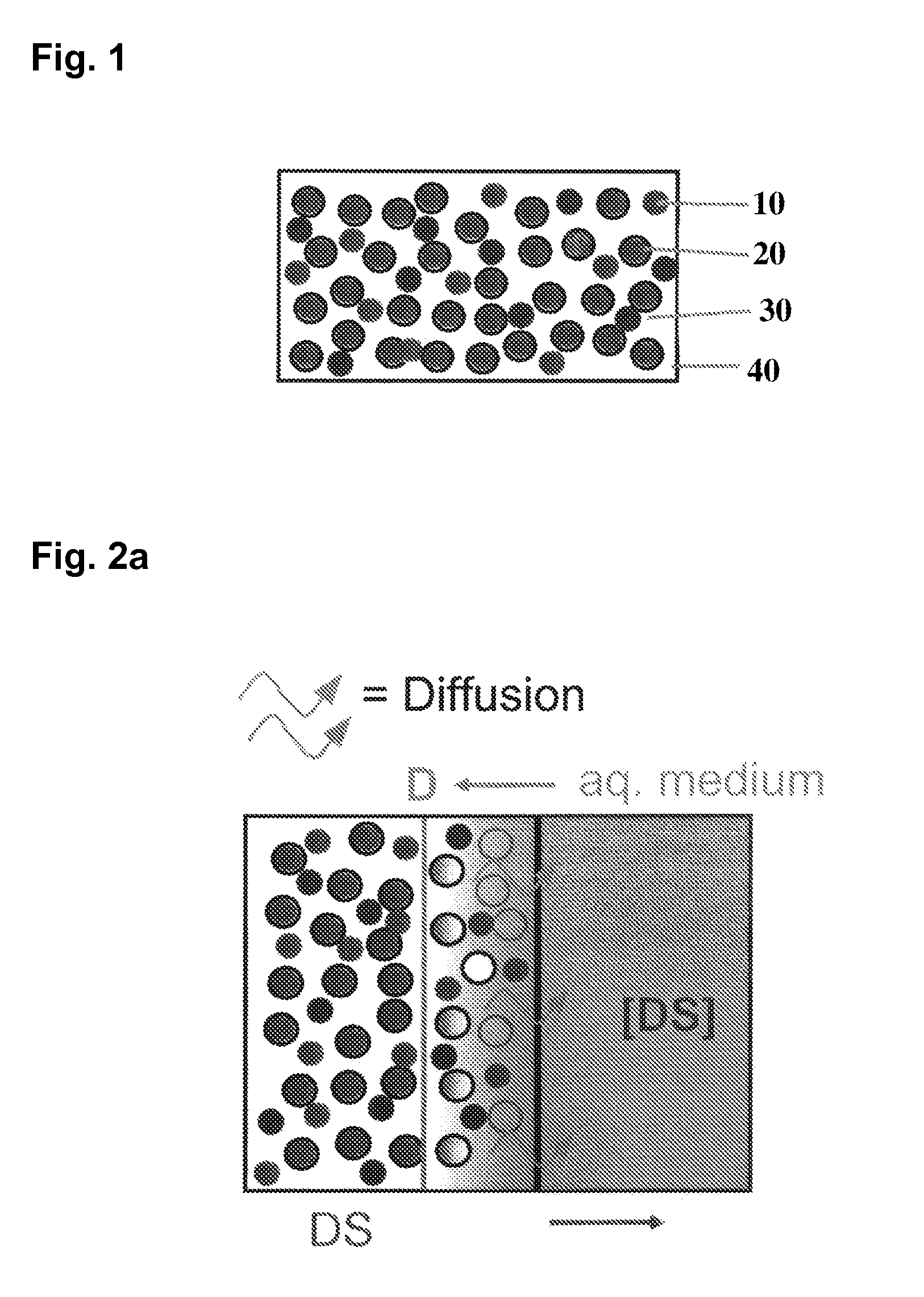

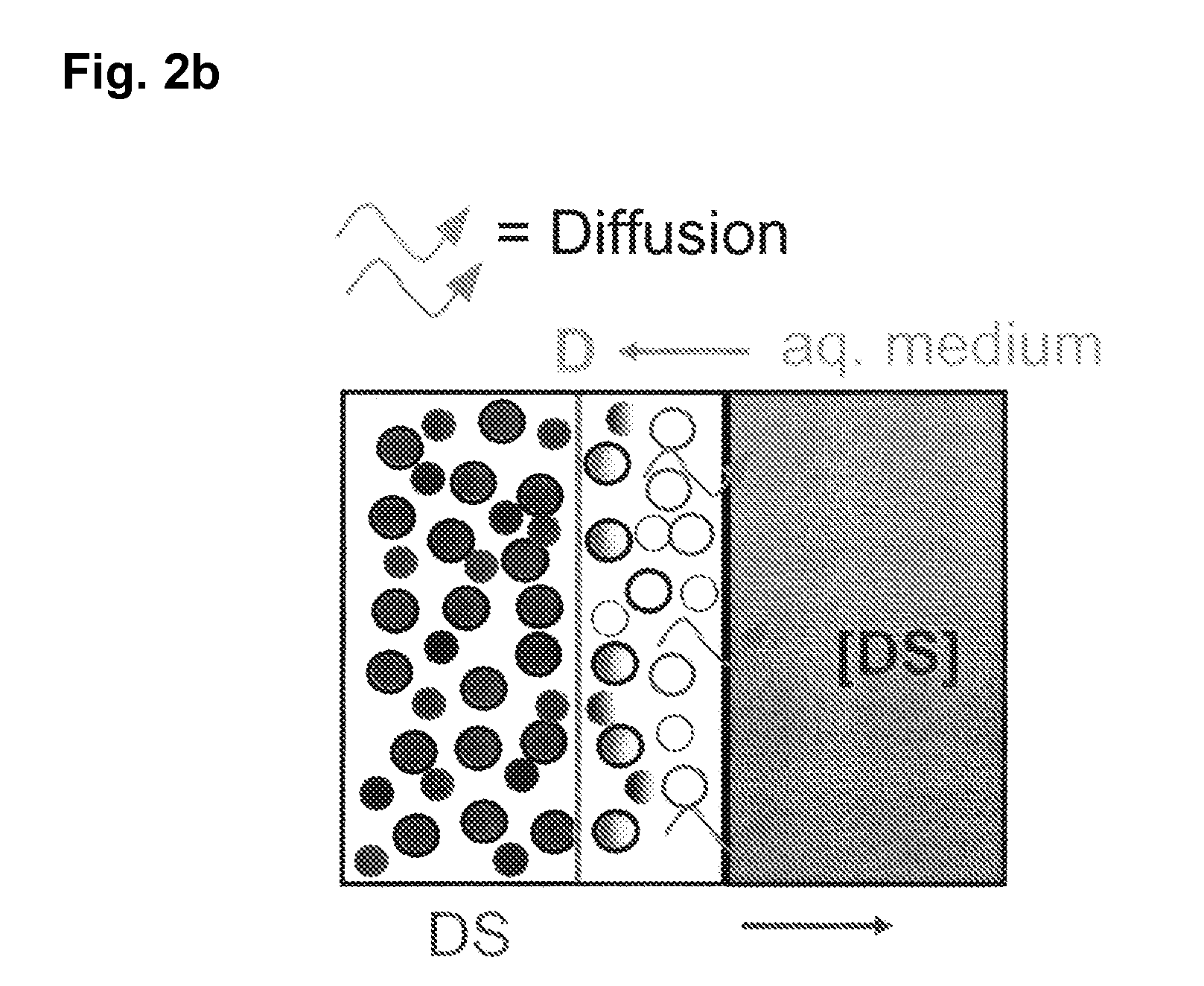

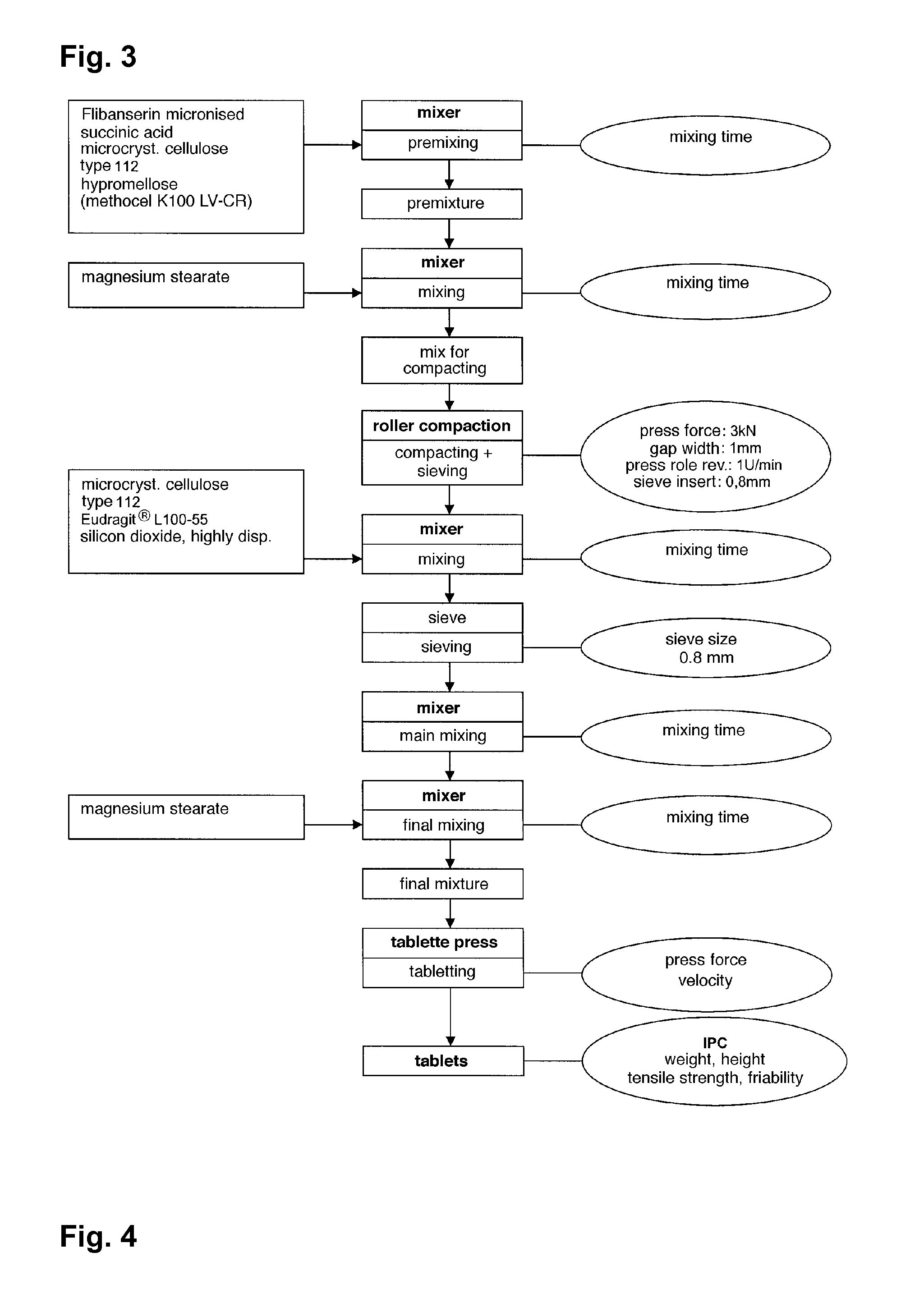

ActiveUS20080038346A1Reduce solubilitySufficiently slow releasePowder deliveryOrganic active ingredientsOral medicationExtended release tablets

The invention is directed to a Pharmaceutical extended release system, particularly for oral administration, of a pH-dependent water-soluble active substance, comprising or essentially consisting of a) flibanserin or a pharmaceutically acceptable derivative thereof as active substance; b) one or more pharmaceutically acceptable pH-dependent polymers; c) one or more pharmaceutically acceptable pH-independent polymers; d) one or more pharmaceutically acceptable acids; and e) optionally one or more additives. The present invention provides a release profile of flibanserin which is independent on the pH in the gastrointestinal tract when administered orally resulting in a significantly improved bioavailability.

Owner:BOEHRINGER INGELHEIM INT GMBH

Textured decorative plating on plastic components

InactiveUS20060086620A1Prevent surfaceOrganic detergent compounding agentsDecorative surface effectsElectroplatingMetal

A relatively inexpensive process for making plastic components having textured chrome finishes that may have fine, crisp, clean lines and intricate details includes steps of electroplating a layer of etchable metal on a surface of a plastic article, typically preserving the surface of the etchable metal, etching a desired relief pattern on the layer of etchable metal, typically cleaning and activating the surface of the relief patterned etched metal layer, and electroplating a layer of decorative metal on the relief patterned etched metal layer.

Owner:LACKS ENTERPRISES

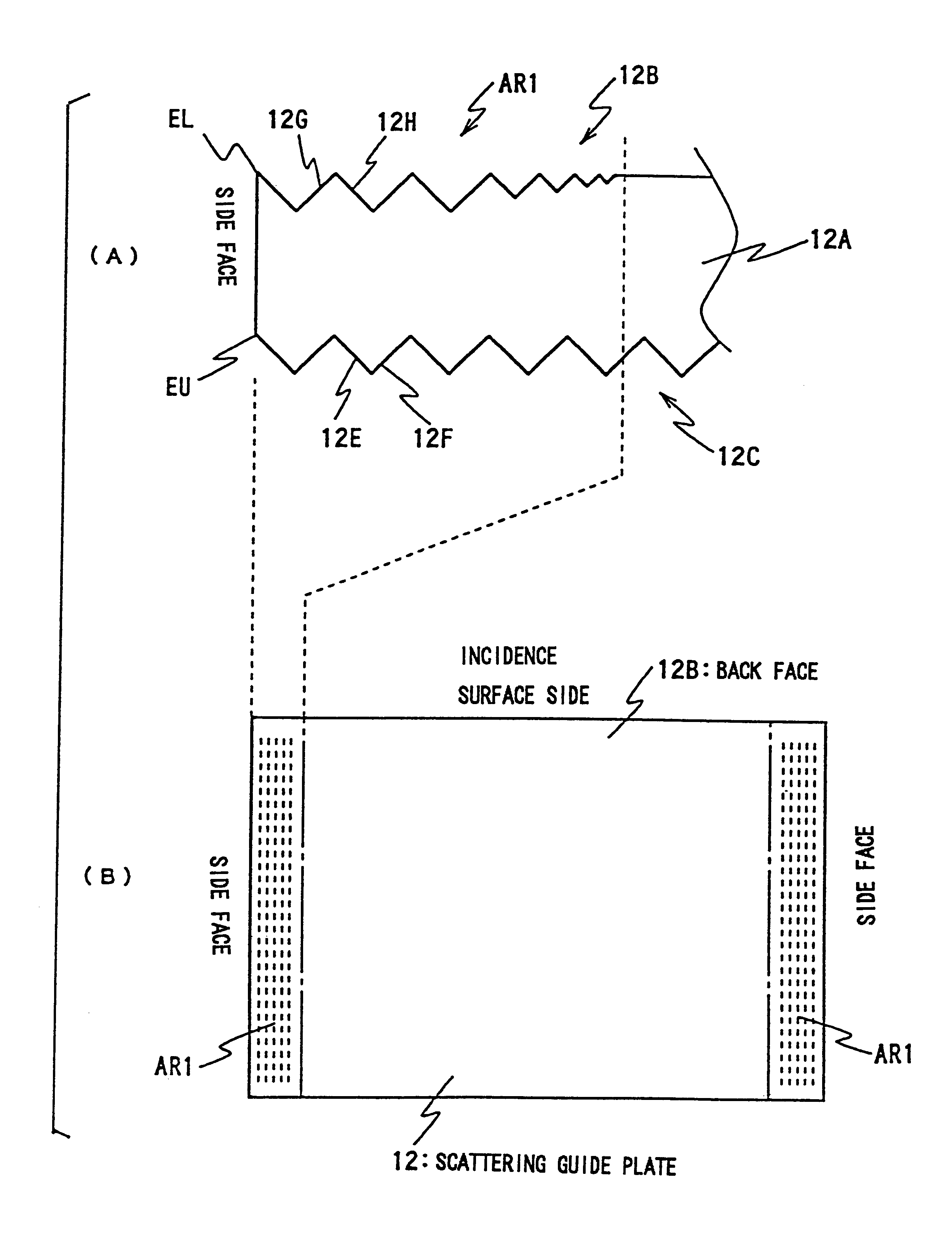

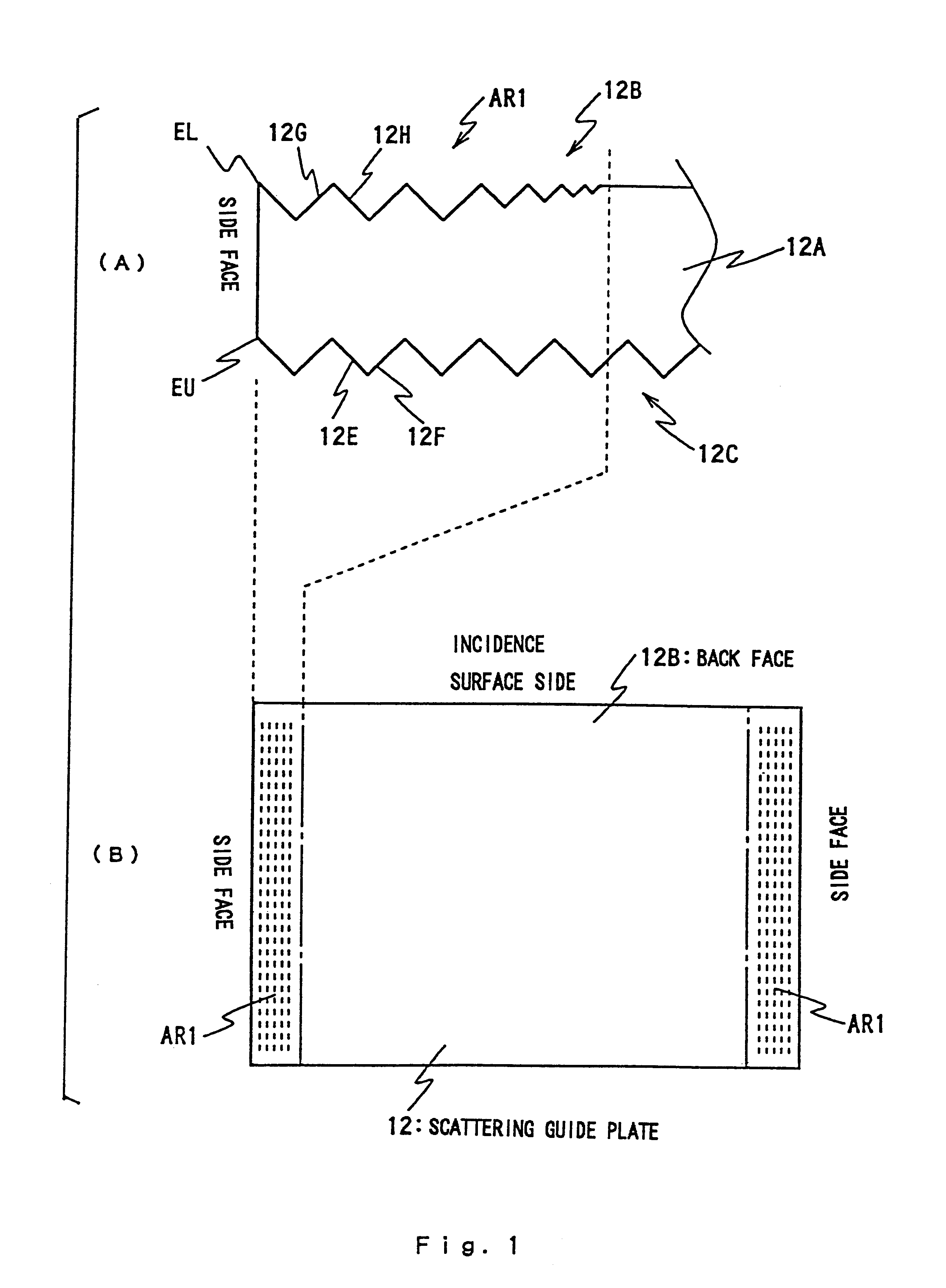

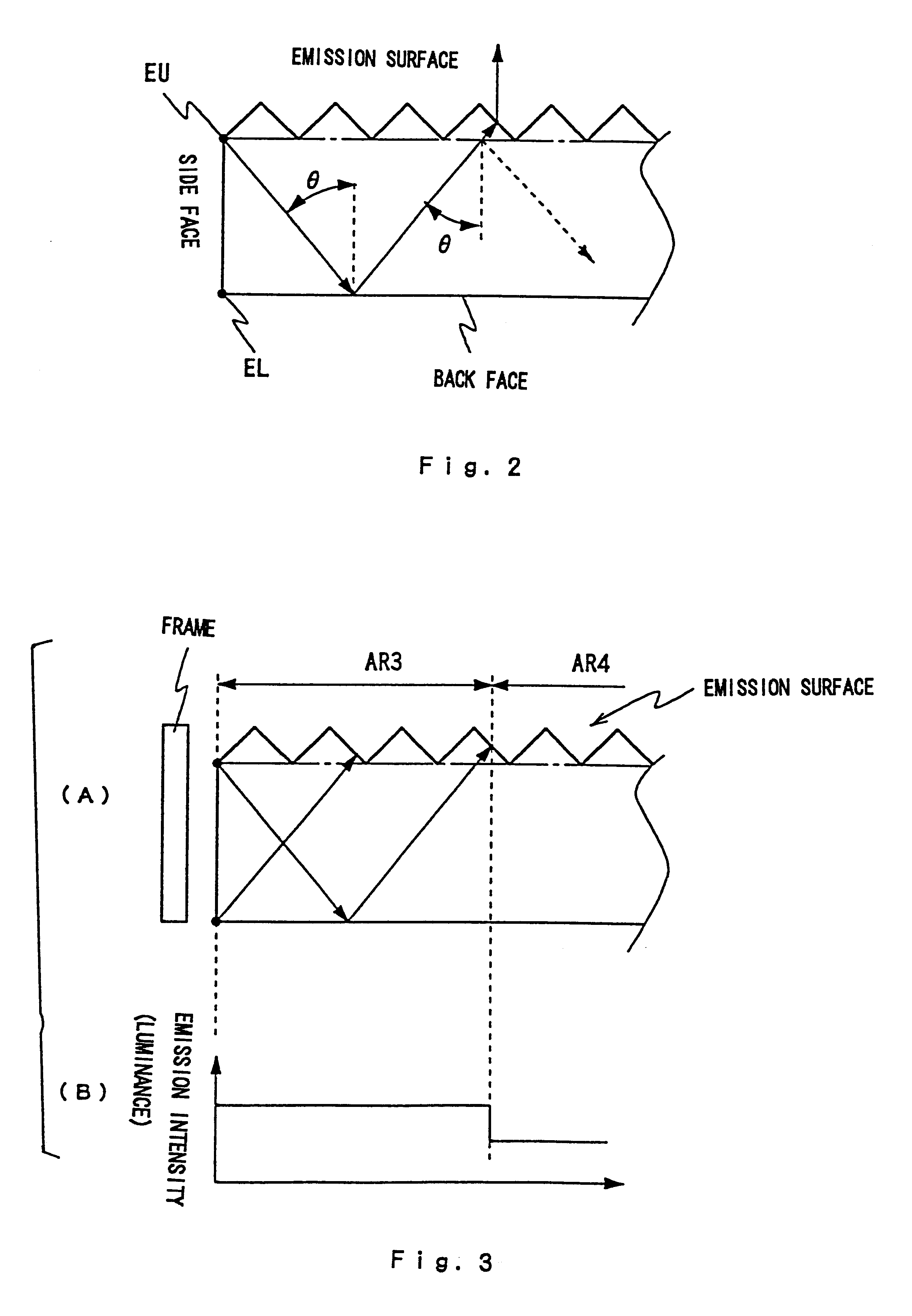

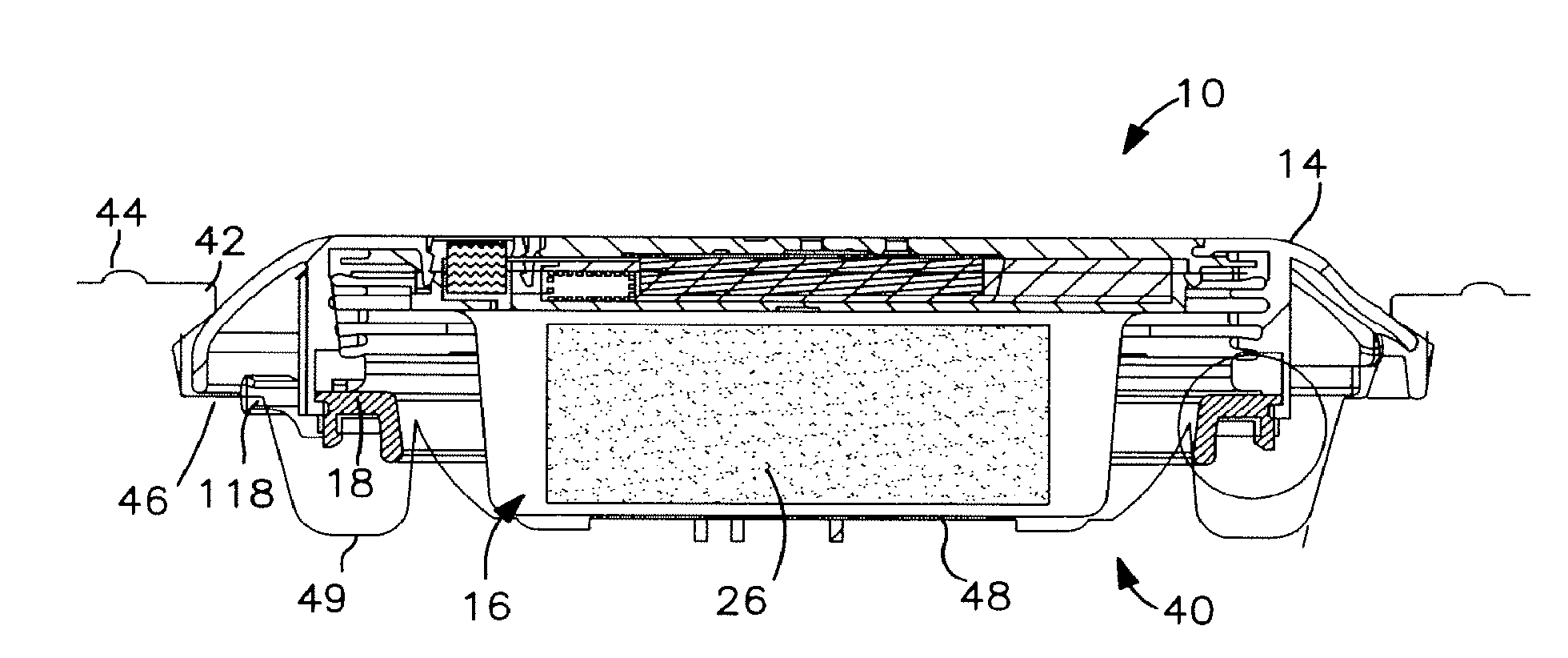

Surface light source device of side light type

InactiveUS6406158B1Avoid it happening againPrevent surfaceMeasurement apparatus componentsMachines/enginesPrismBright line

Illuminating light, supplied from a primary light source of a surface light source device of side light type, passes through an incidence surface (12A) and enters a wedge-shaped scattering guide plate (12). Inside the guide plate (12), the illuminating light propagates toward the end while being repeatedly reflected between a back face (12B) and an emission surface (12C). During this process, the illuminating light receives scattering action of particles or the like in the guide plate (12). The emission surface (12C) provides a prism surface. The back face (12B) comprises a plurality of projections in a belt region (AR1) along an edge (EL). The projections run generally parallel to the edge (EL) and each has a pair of slopes (12G and 12H). The height of the projections (that is, depth of the troughs) or the inclination of the slopes (12G and 12H) preferably decrease according to distance from the edge (EL). The projections diffuse light propagation direction, thereby preventing generation of bright lines around the edge (EU) of the emission surface.

Owner:ENPLAS CORP +1

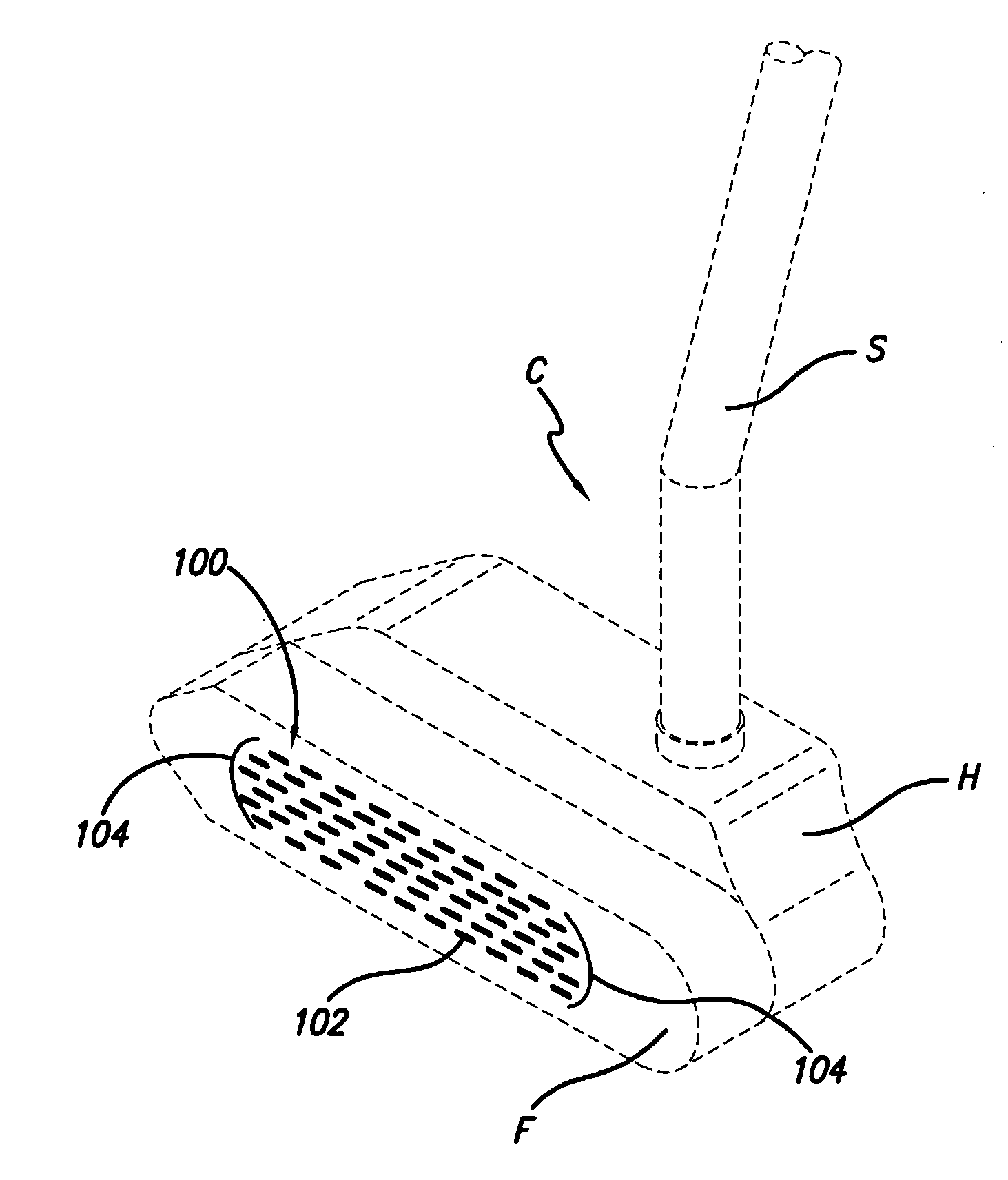

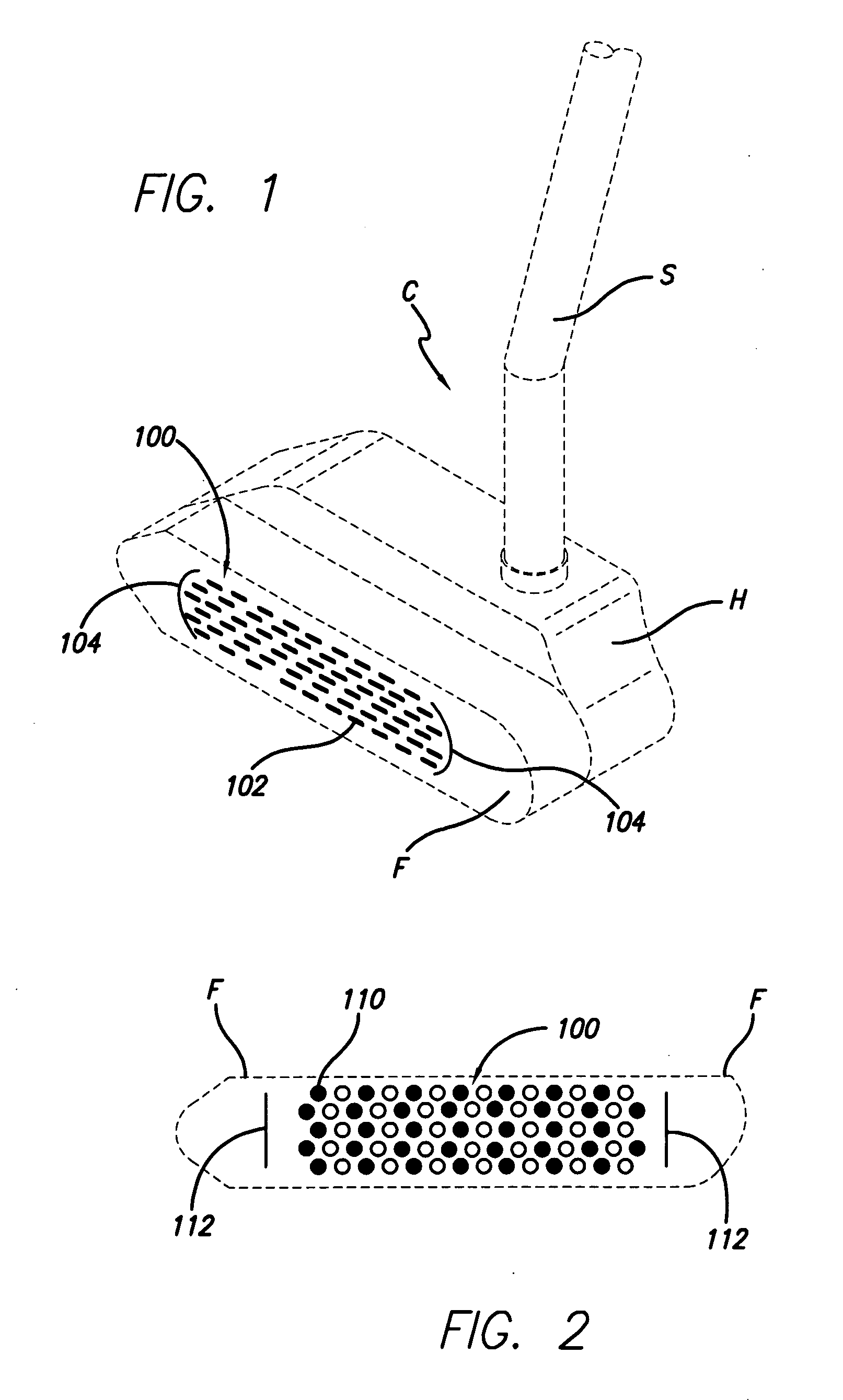

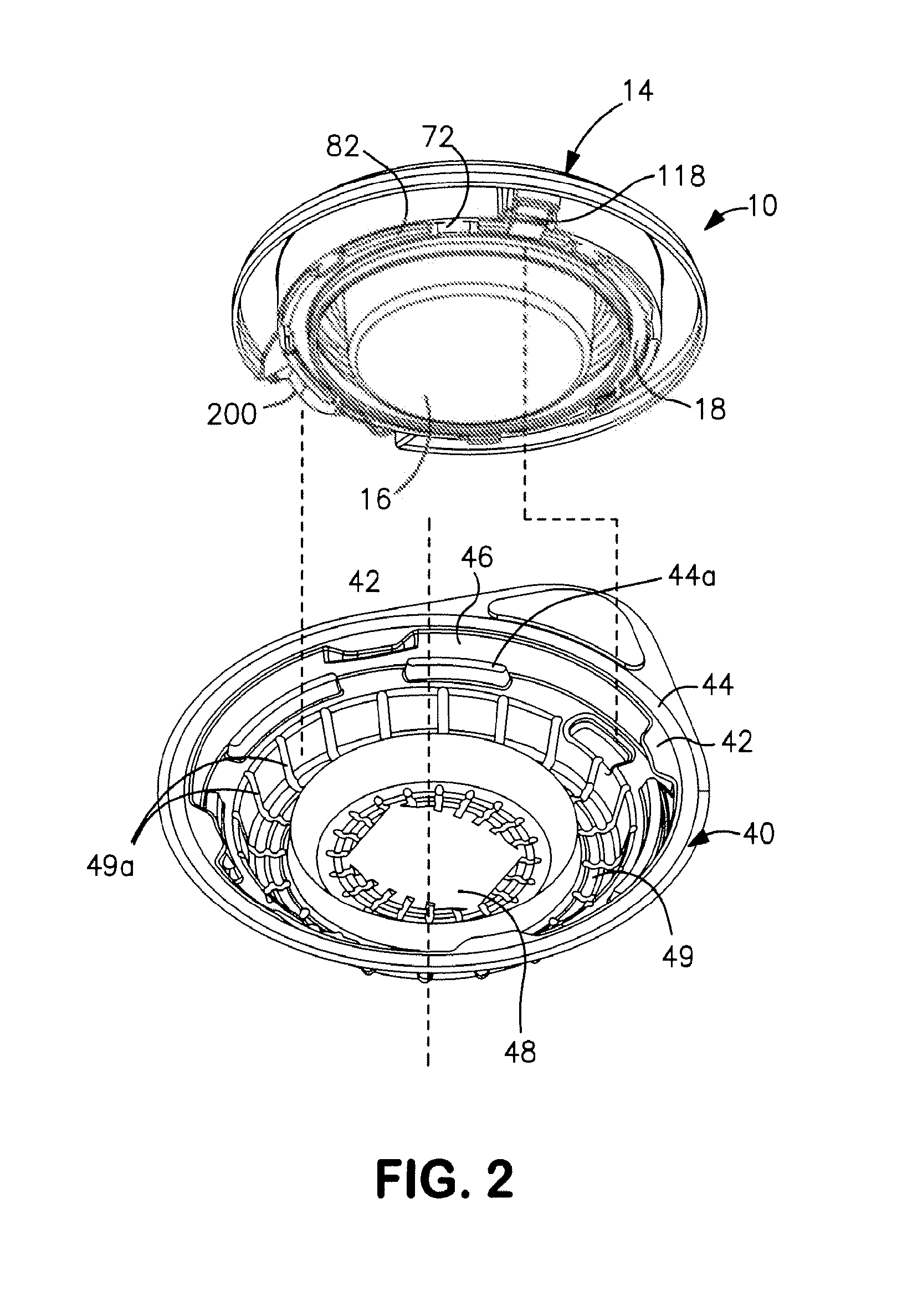

Controlled discharge ostomy appliance and shield therefor

ActiveUS20120179124A1Low efficacyFitting shapeNon-surgical orthopedic devicesColostomyEngineeringMechanical engineering

A controlled discharge ostomy appliance assembly comprises (i) a stoma seal that is self-urging with a dynamic damping characteristic that resists changes of seal volume, (ii) a press-fit coupling member displaceable from an unlocked position to a locked position as part of a press-fit process, and (iii) a single-use frangible portion. The assembly further includes a protector shield removably fastened to the appliance forming a combined assembly therewith. The protector shield comprises (i) a seal displacer manipulable for displacing the stoma seal to a non-operative position ready for fitting, (ii) a substantially rigid coupling member guard portion for protecting the state of the coupling member, and (iii) a bracing portion for bracing the single-use frangible portion.

Owner:CONVATEC TECH INC

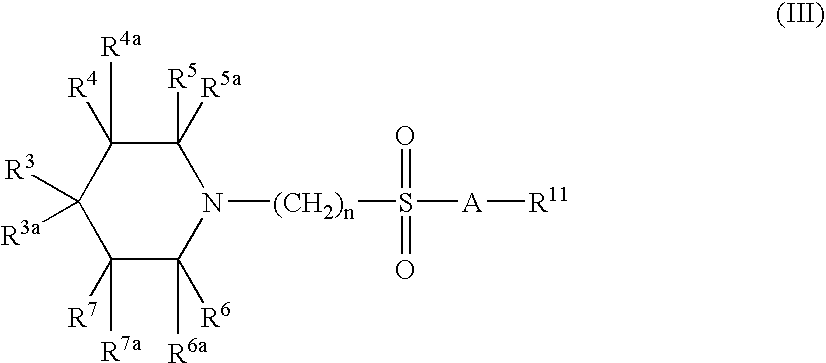

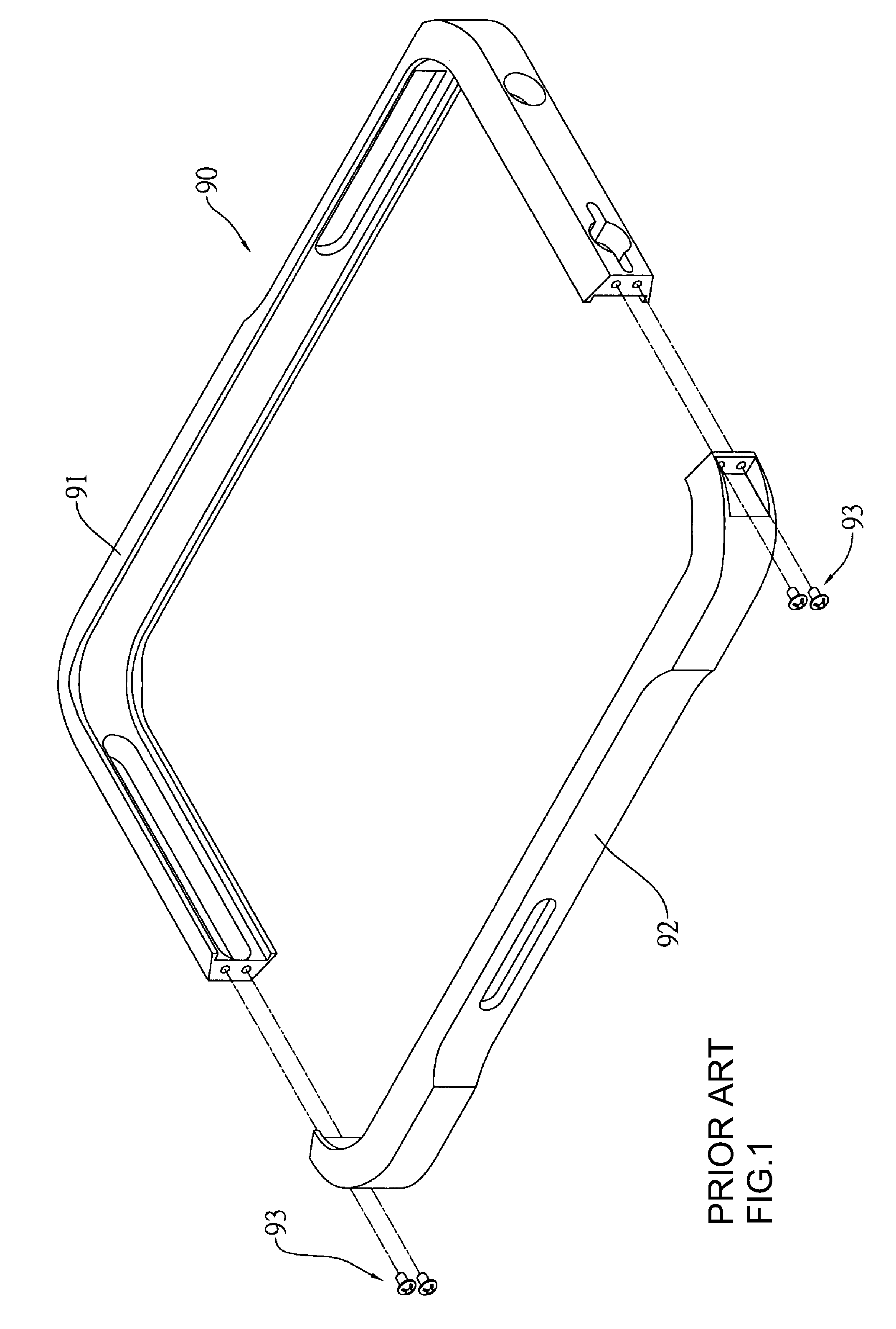

Composite wafers having bulk-quality semiconductor layers and method of manufacturing thereof

InactiveUS20080296586A1High wafer costReduced availabilityLayered productsSolid-state devicesWaferingSemiconductor

Method for producing composite wafers with thin high-quality semiconductor films atomically attached to synthetic diamond wafers is disclosed. Synthetic diamond substrates are created by depositing synthetic diamond onto a nucleating layer deposited on bulk semiconductor wafer which has been prepared to allow separation of the thin semiconductor film from the remaining bulk semiconductor wafer. The remaining semiconductor wafer is available for reuse. The synthetic diamond substrate serves as heat spreader and a mechanical substrate.

Owner:GROUP4 LABS +1

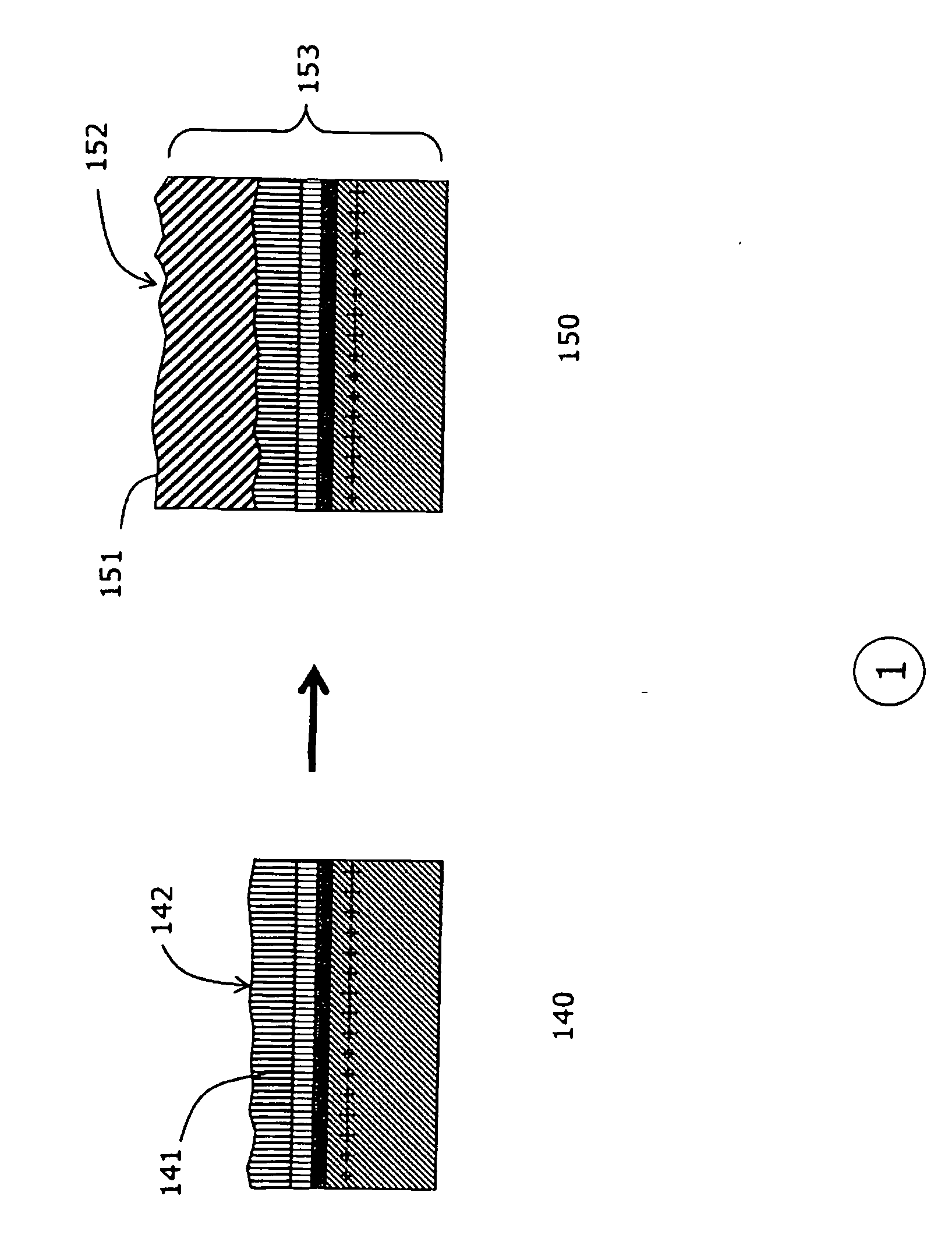

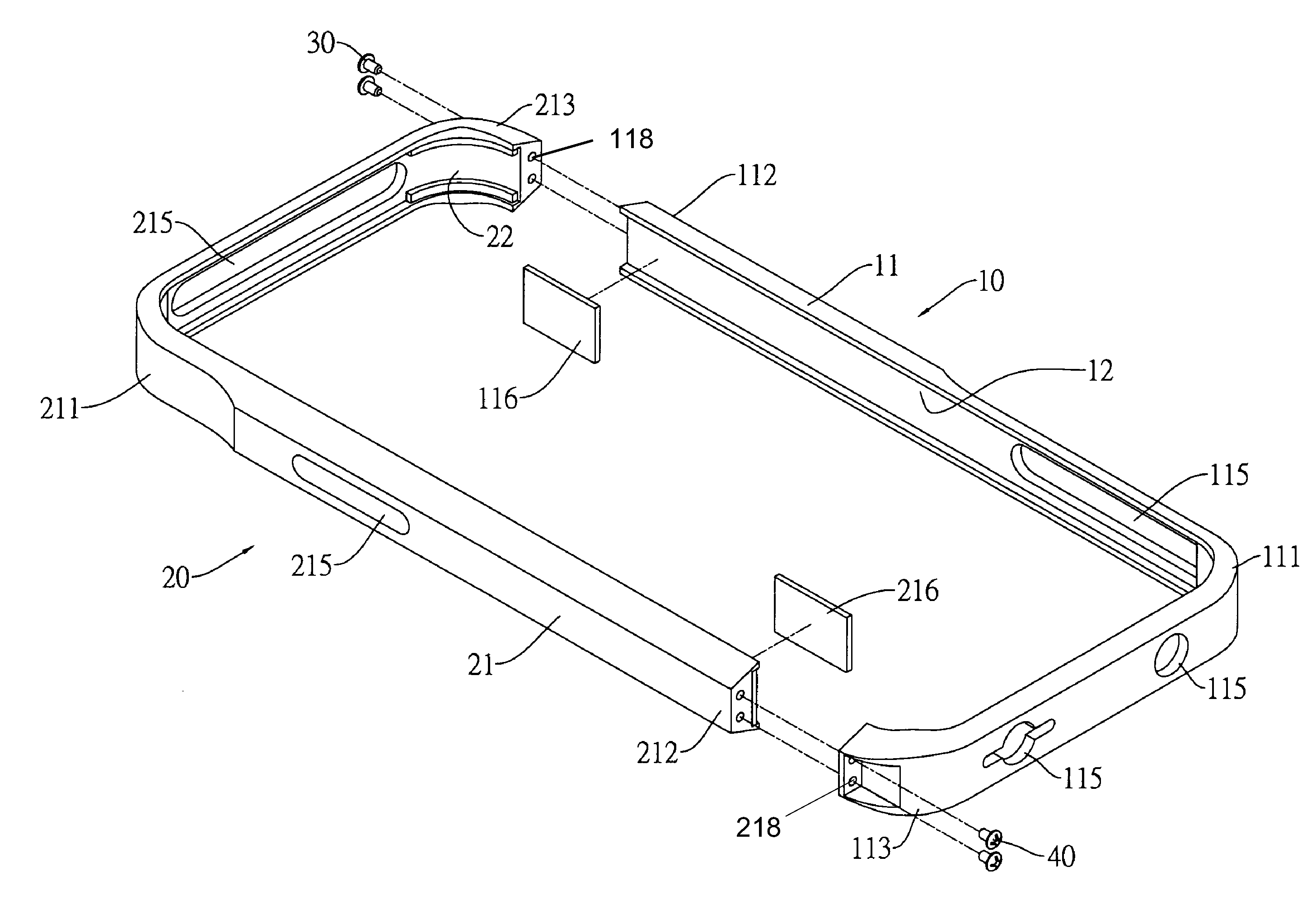

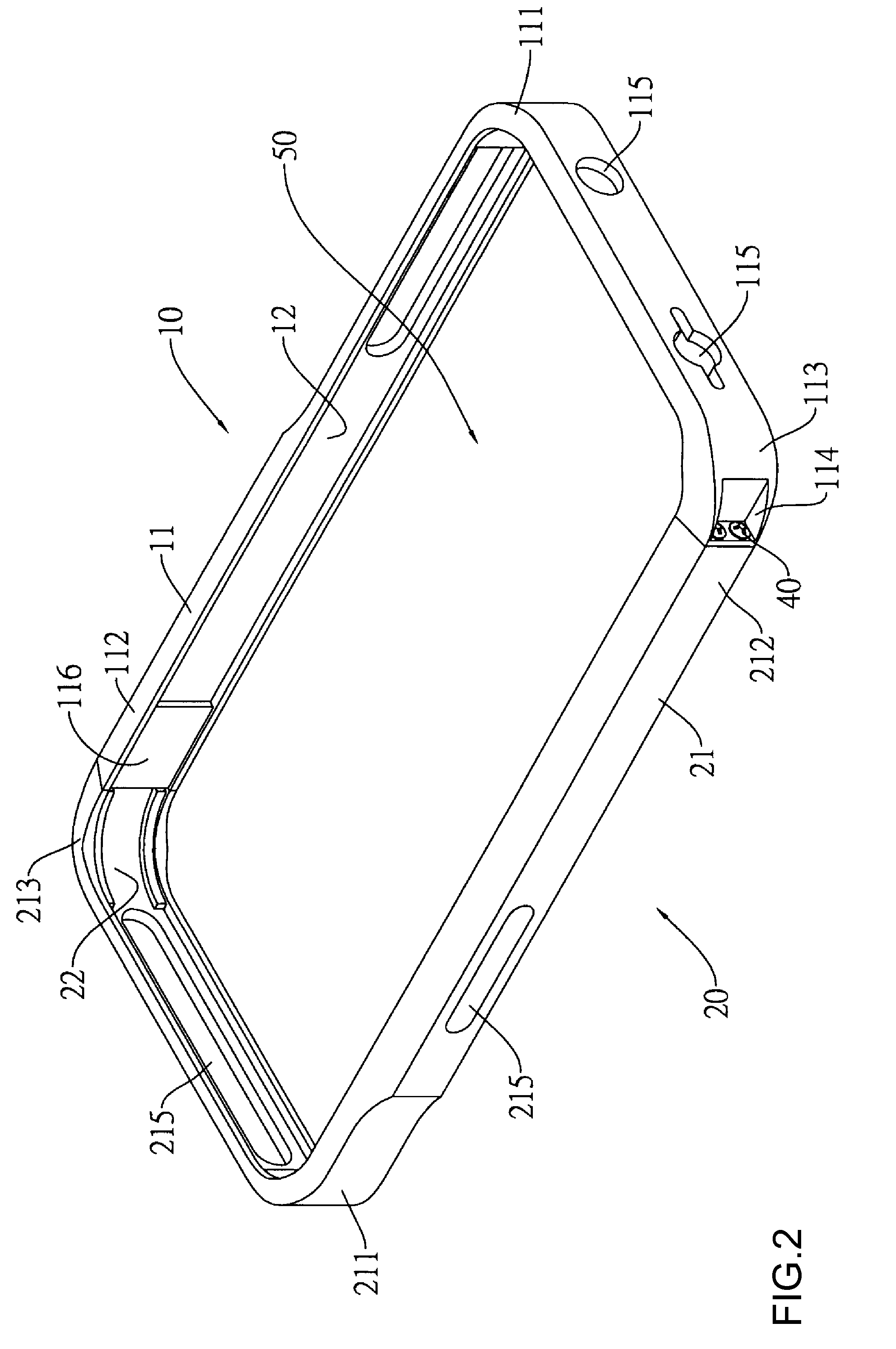

Protective case for electronic devices

InactiveUS20120182678A1Reduce the burden onPrevent surfaceTravelling carriersHoldersCommunication deviceElectronic equipment

The present invention provides a protective case for electronic mobile communication devices in which nips an electronic device in position through an accommodation space formed by combining a first frame with a second frame. When combining the electronic mobile communication device with the protective case according to the invention, the electronic mobile communication device is only required to lean against the first frame and the second frame, and no scratches occur during the combination. Meanwhile, when the device in combination with the invention is placed on a desktop, the electronic mobile communication device can be kept at a distance from the desktop, thereby protecting the surface of the electronic device from being abraded by the desktop.

Owner:ESOTERISM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com