Patents

Literature

2668results about How to "Reduce deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

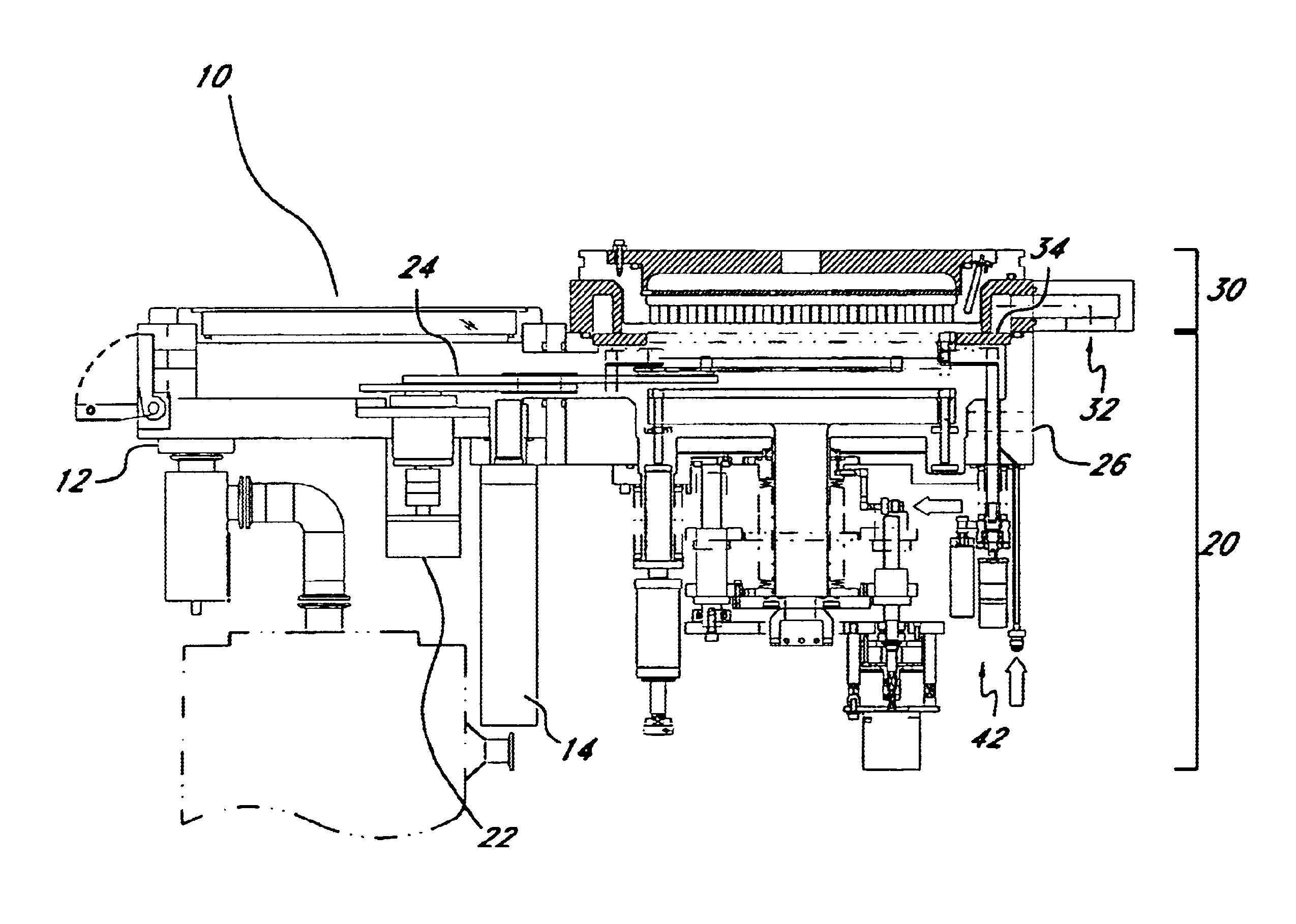

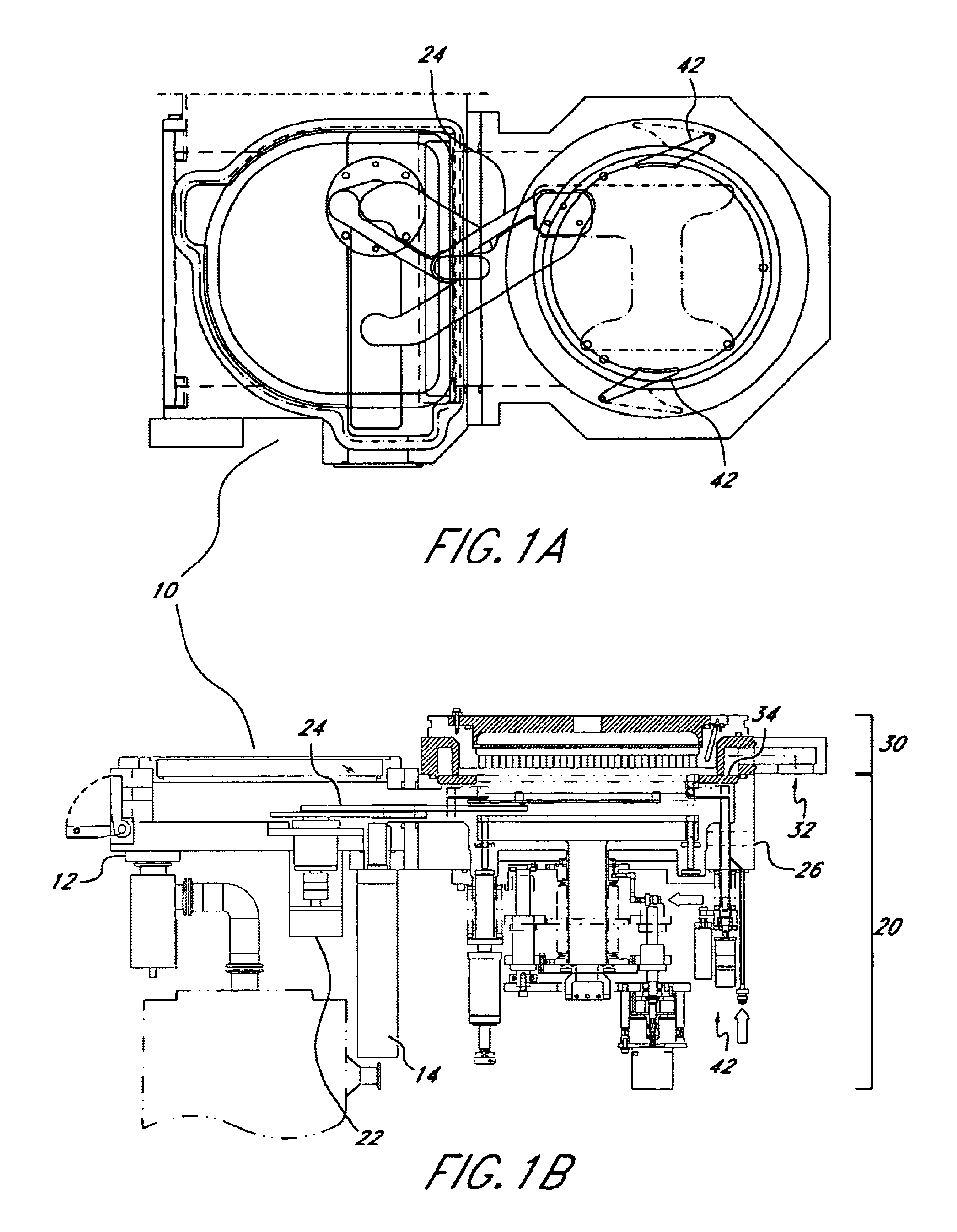

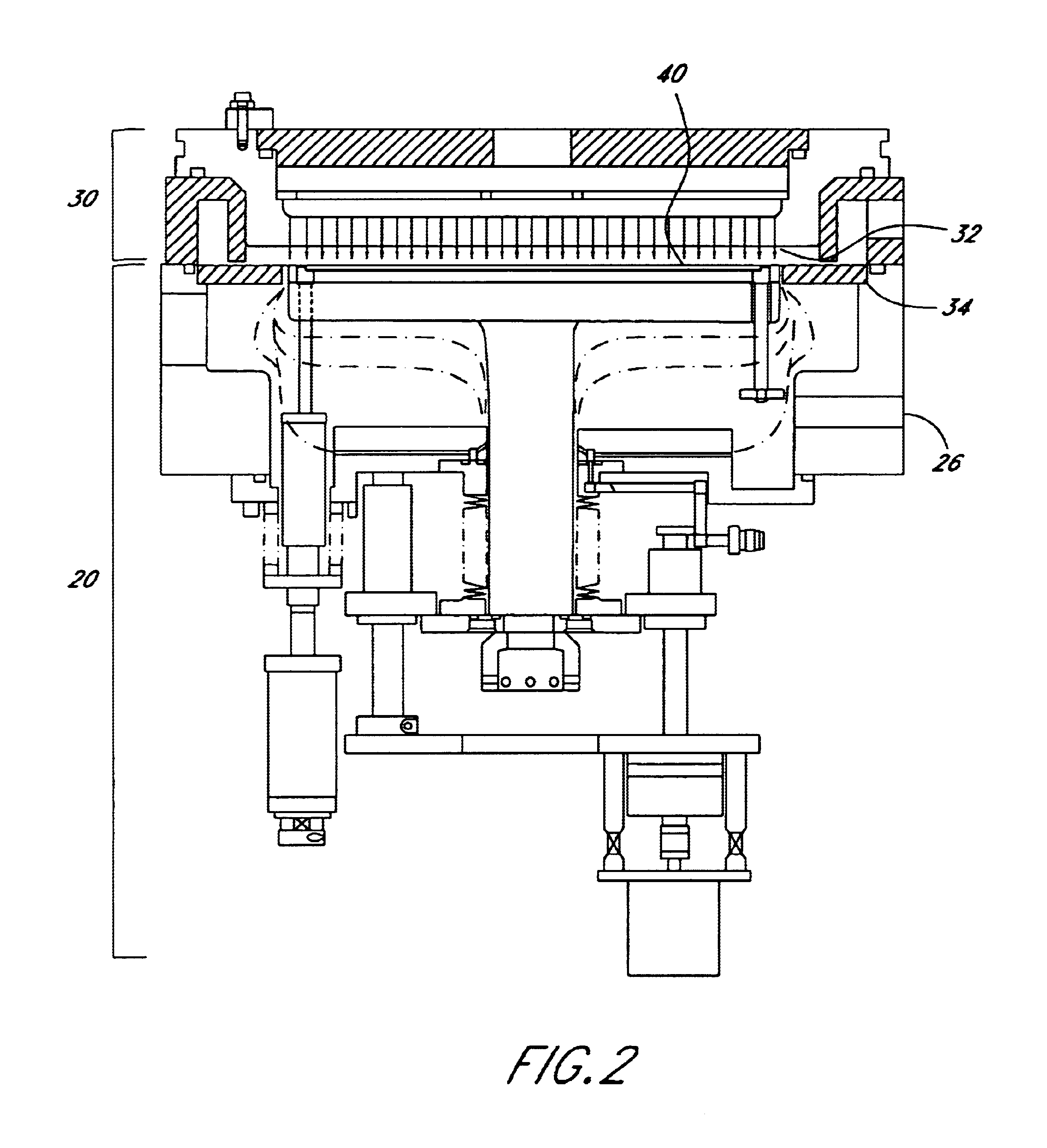

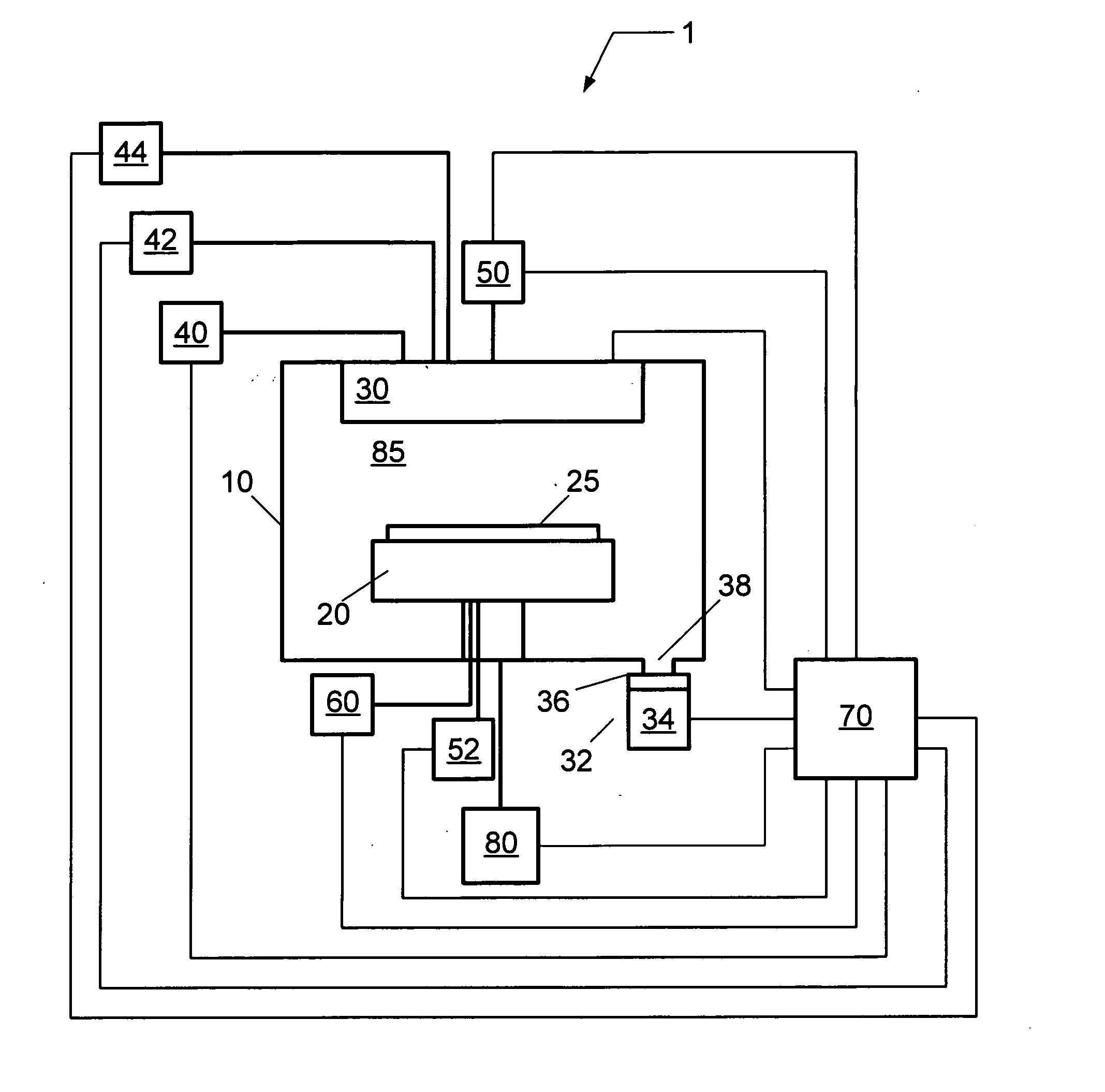

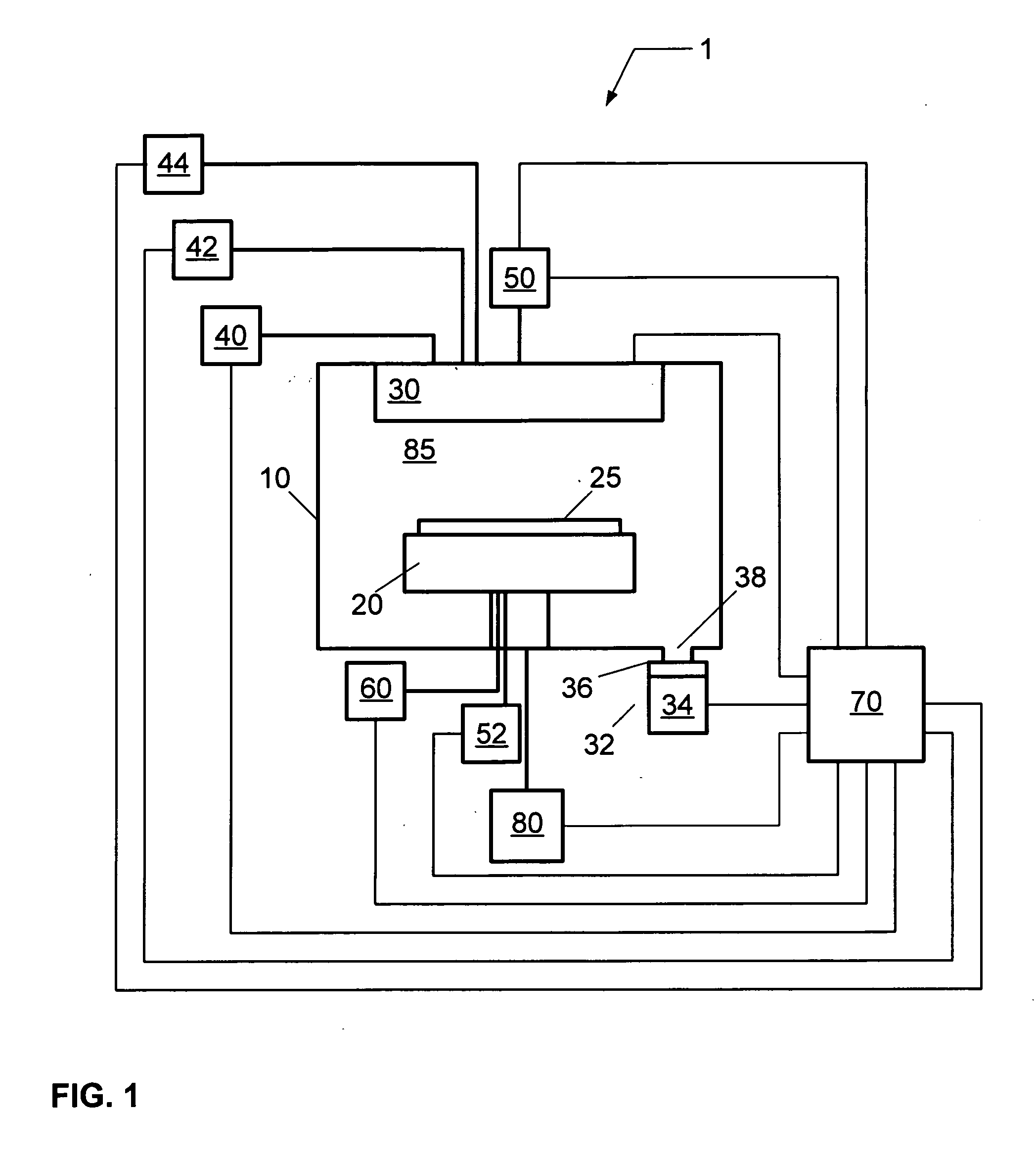

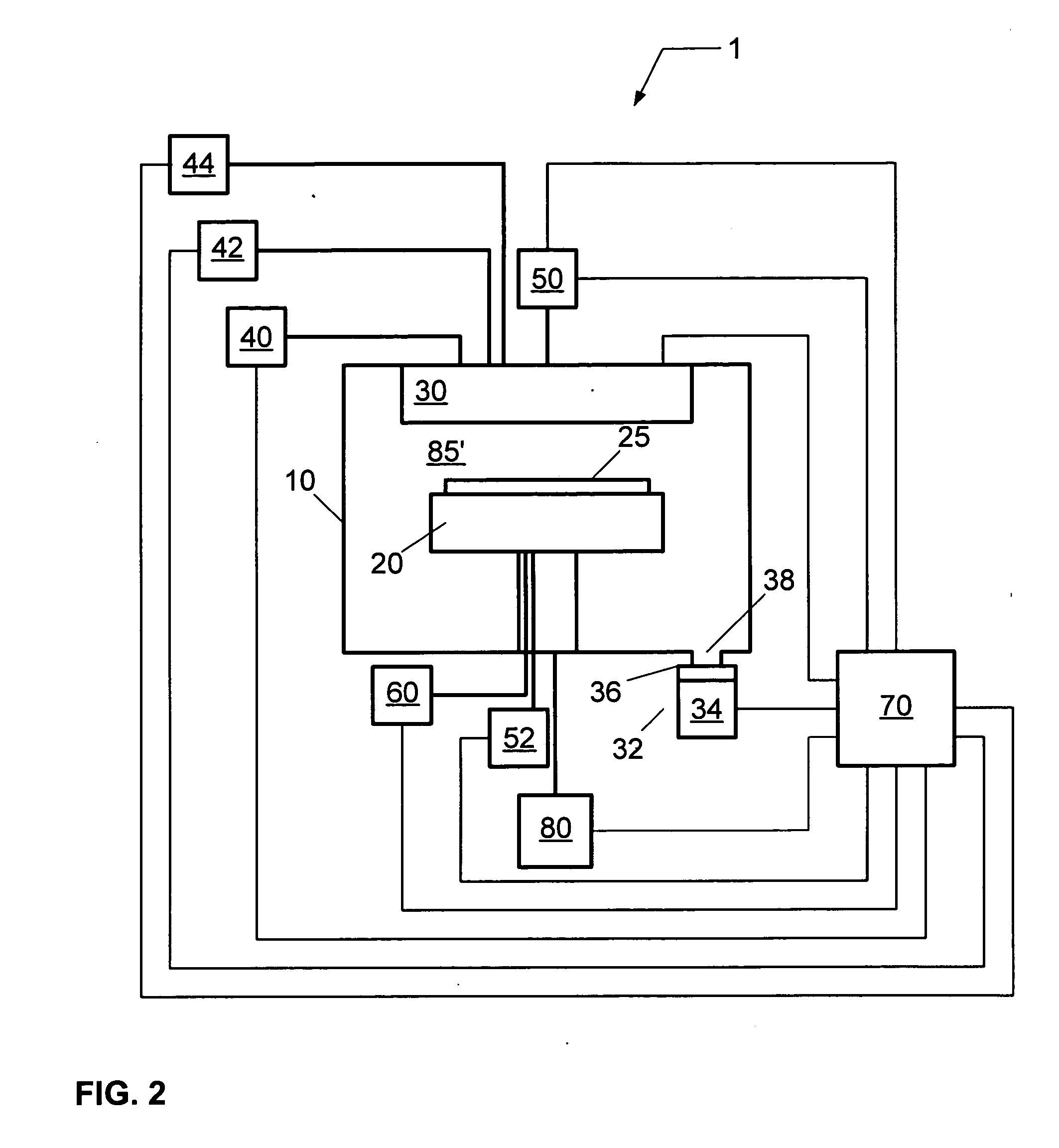

Semiconductor processing apparatus comprising chamber partitioned into reaction and transfer sections

InactiveUS6899507B2Reduce adhesionImprove efficiencySemiconductor/solid-state device manufacturingCharge manipulationEngineeringSemiconductor

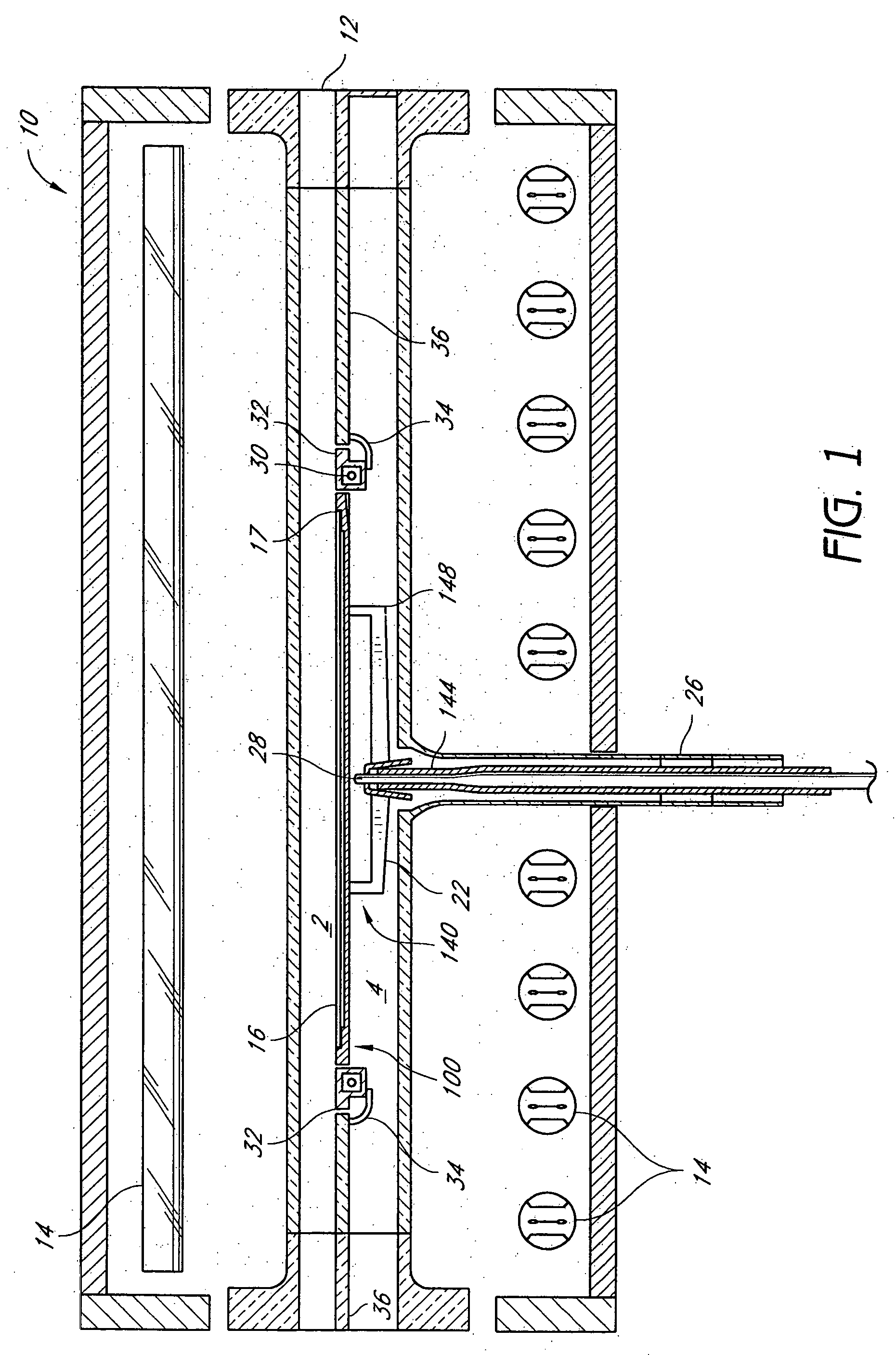

Semiconductor processing equipment that has increased efficiency, throughput, and stability, as well as reduced operating cost, footprint, and faceprint is provided. Other than during deposition, the atmosphere of both the reaction chamber and the transfer chamber are evacuated using the transfer chamber exhaust port, which is located below the surface of the semiconductor wafer. This configuration prevents particles generated during wafer transfer or during deposition from adhering to the surface of the semiconductor wafer. Additionally, by introducing a purge gas into the transfer chamber during deposition, and by using an insulation separating plate 34, the atmospheres of the transfer and reaction chambers can be effectively isolated from each other, thereby preventing deposition on the walls and components of the transfer chamber. Finally, the configuration described herein permits a wafer buffer mechanism to be used with the semiconductor processing equipment, thereby further increasing throughput and efficiency.

Owner:ASM JAPAN

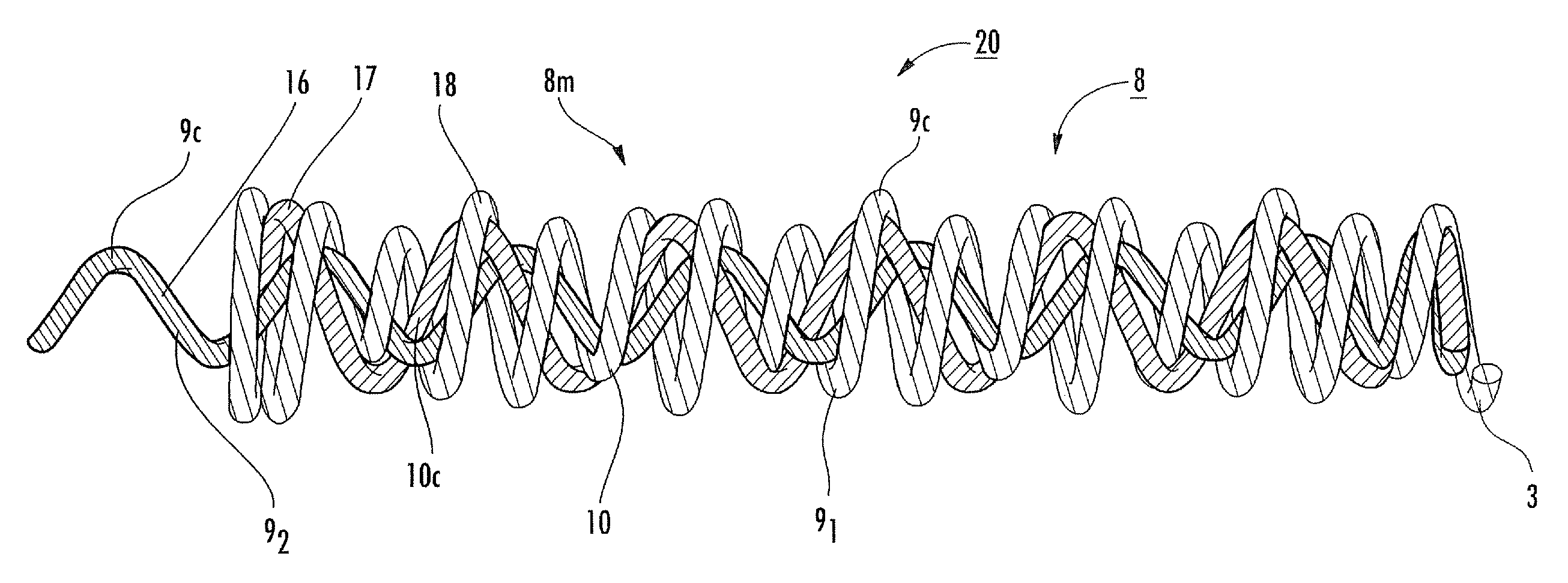

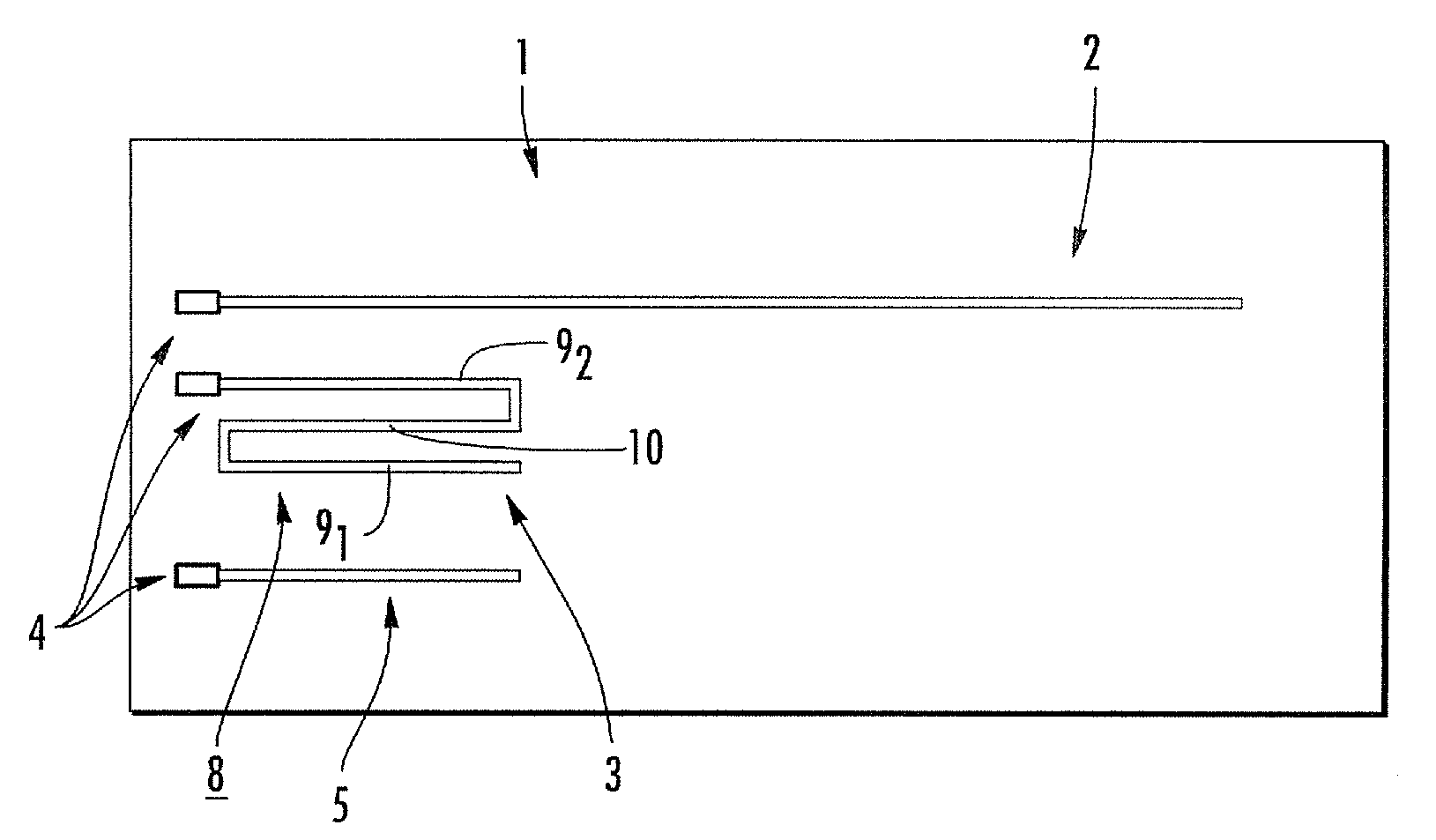

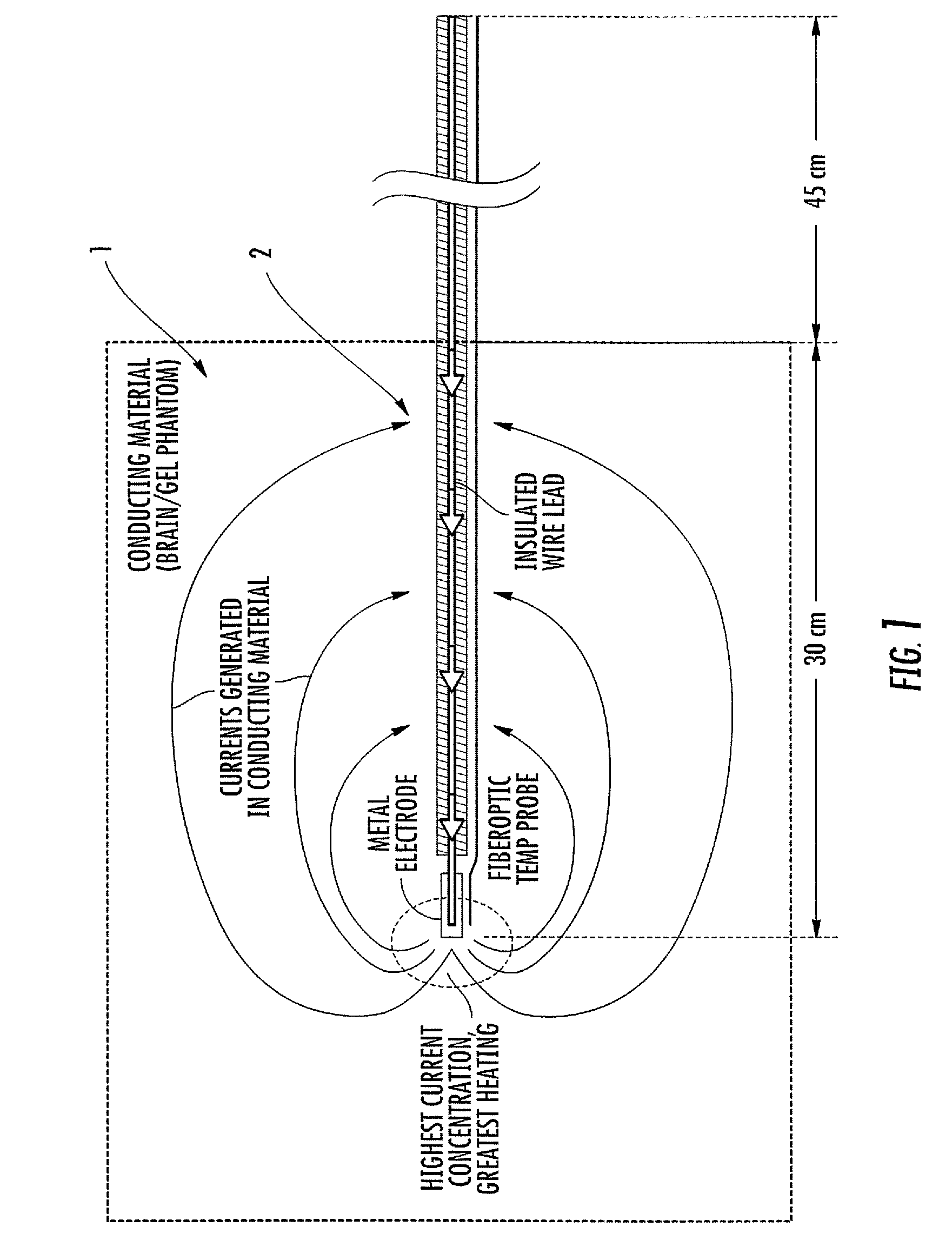

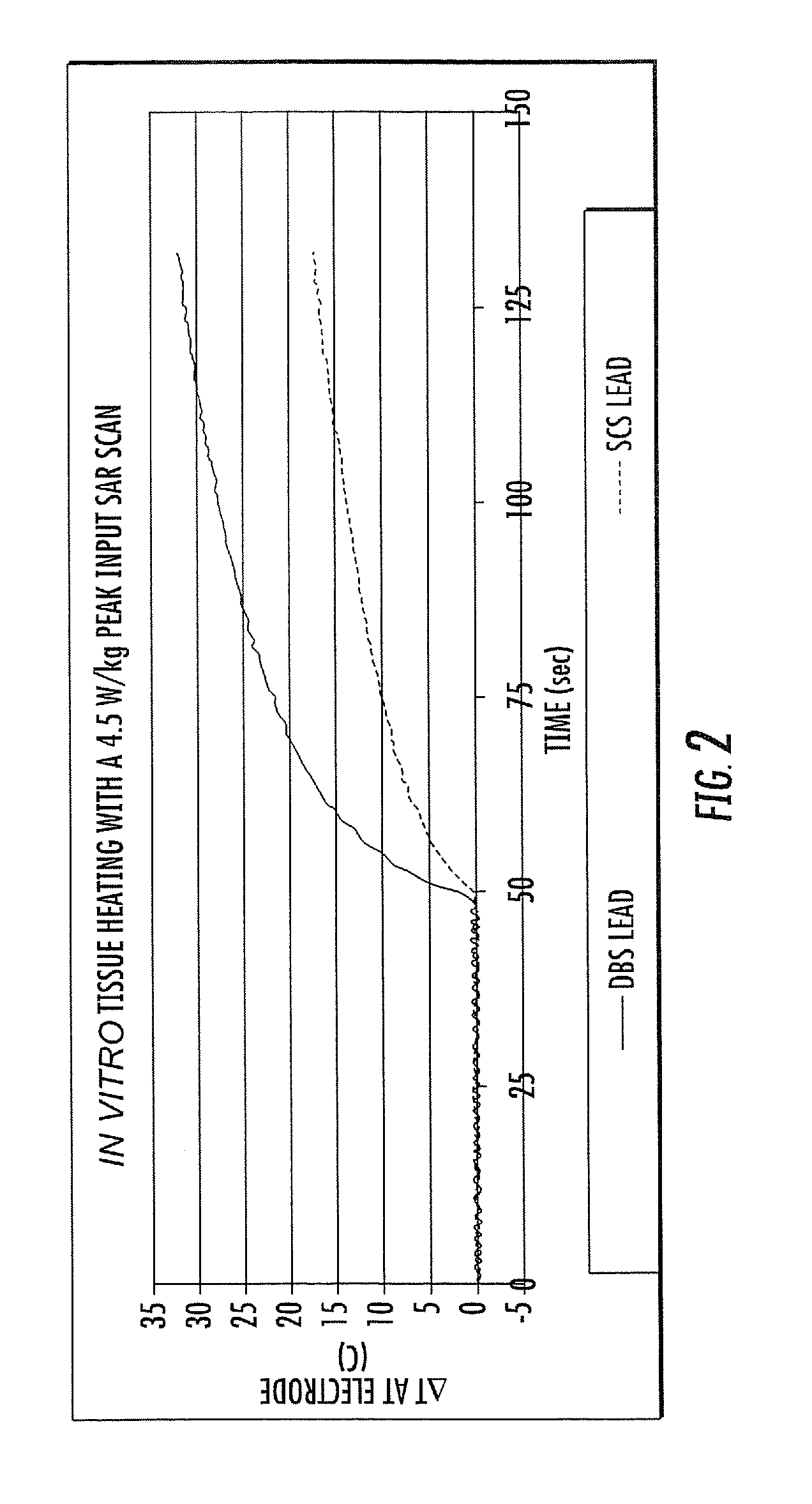

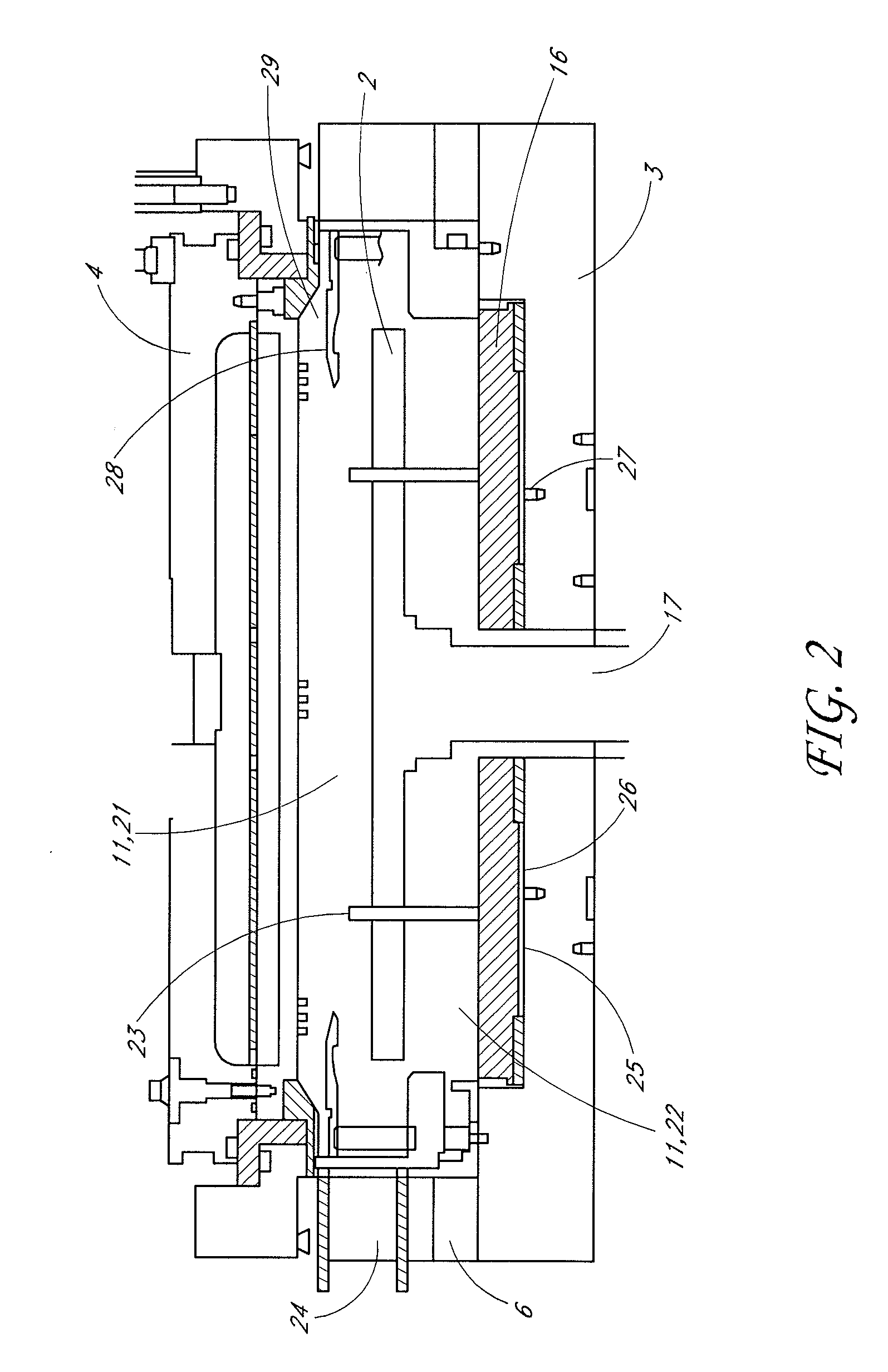

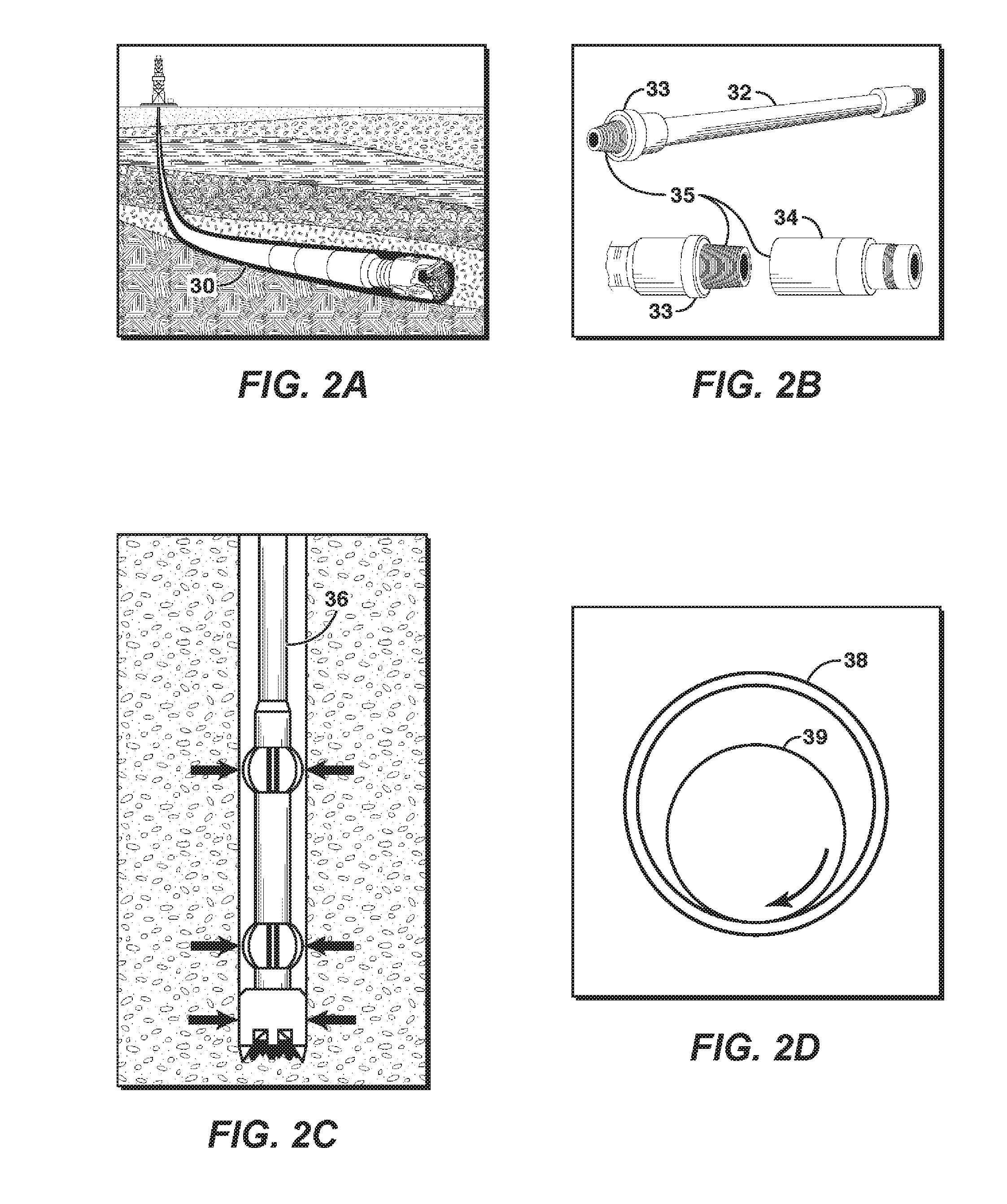

Methods and apparatus for fabricating leads with conductors and related flexible lead configurations

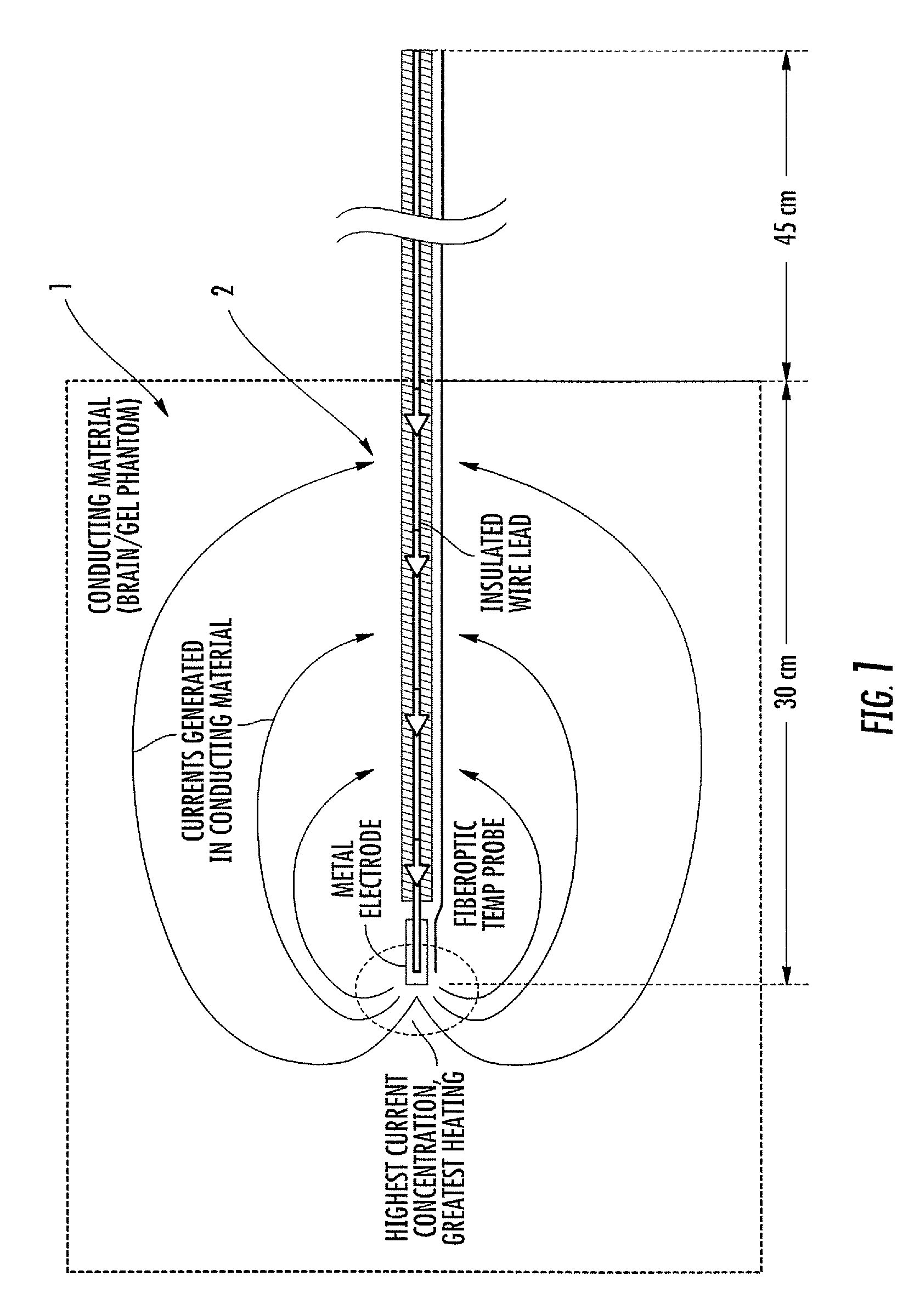

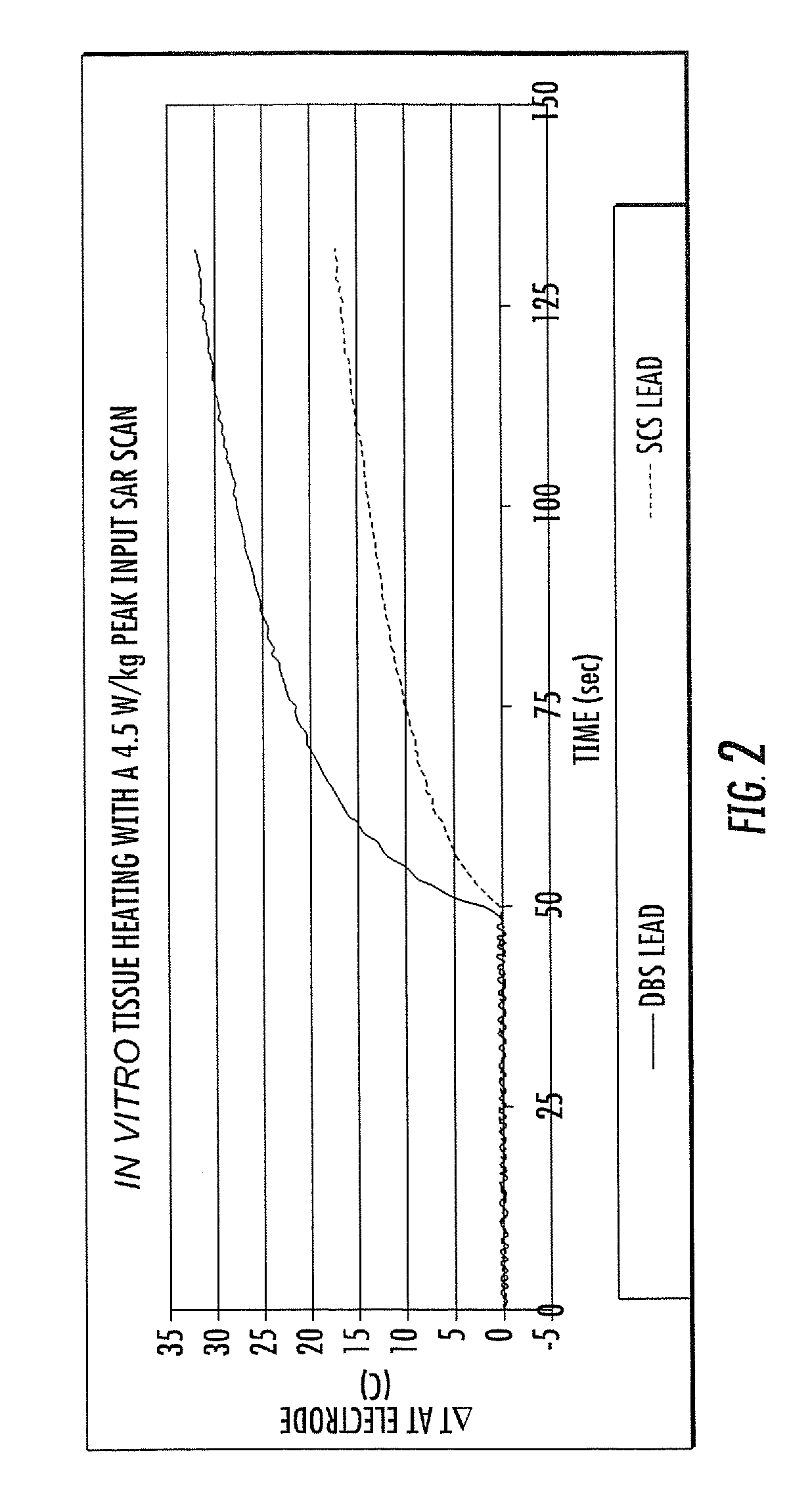

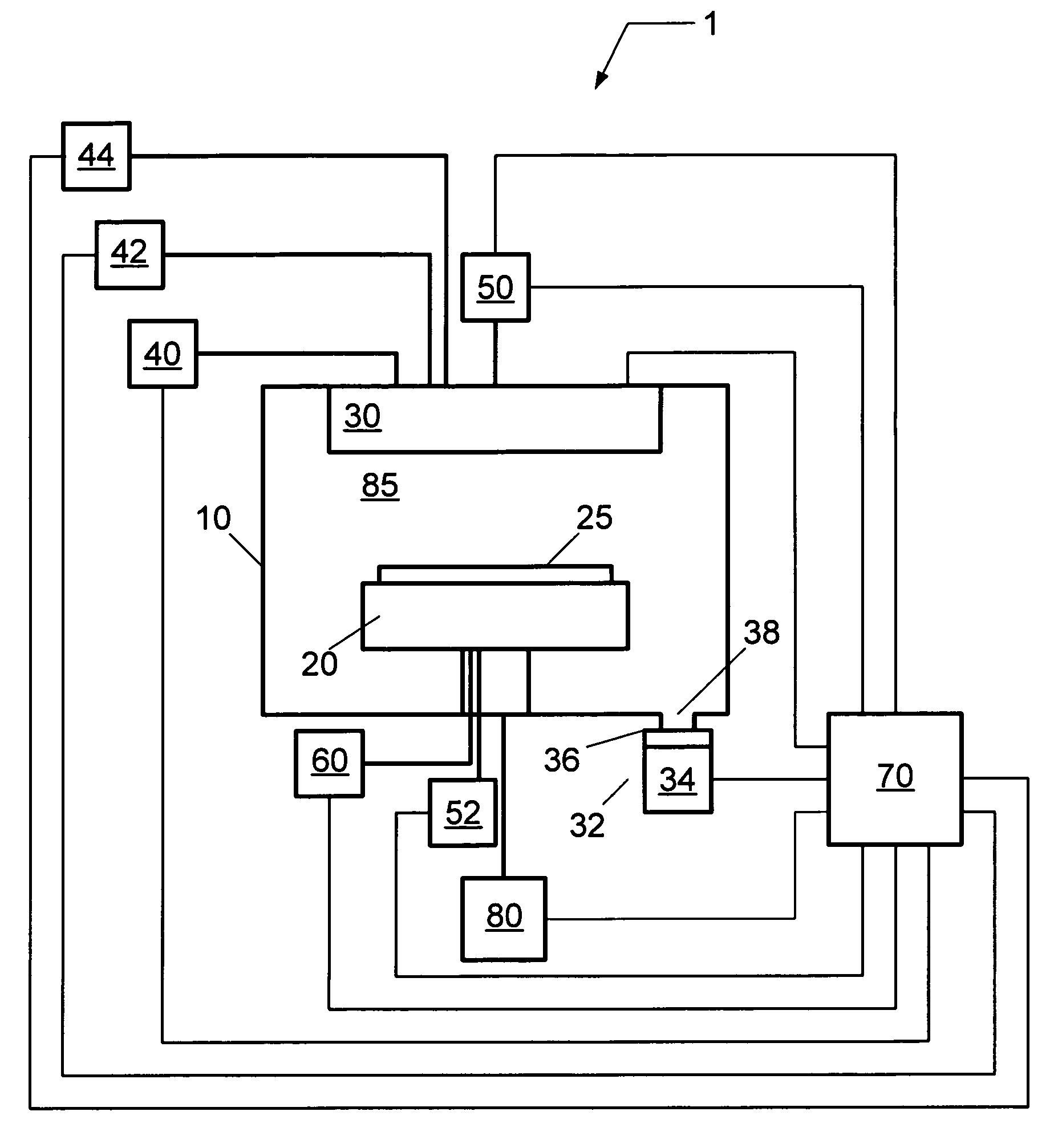

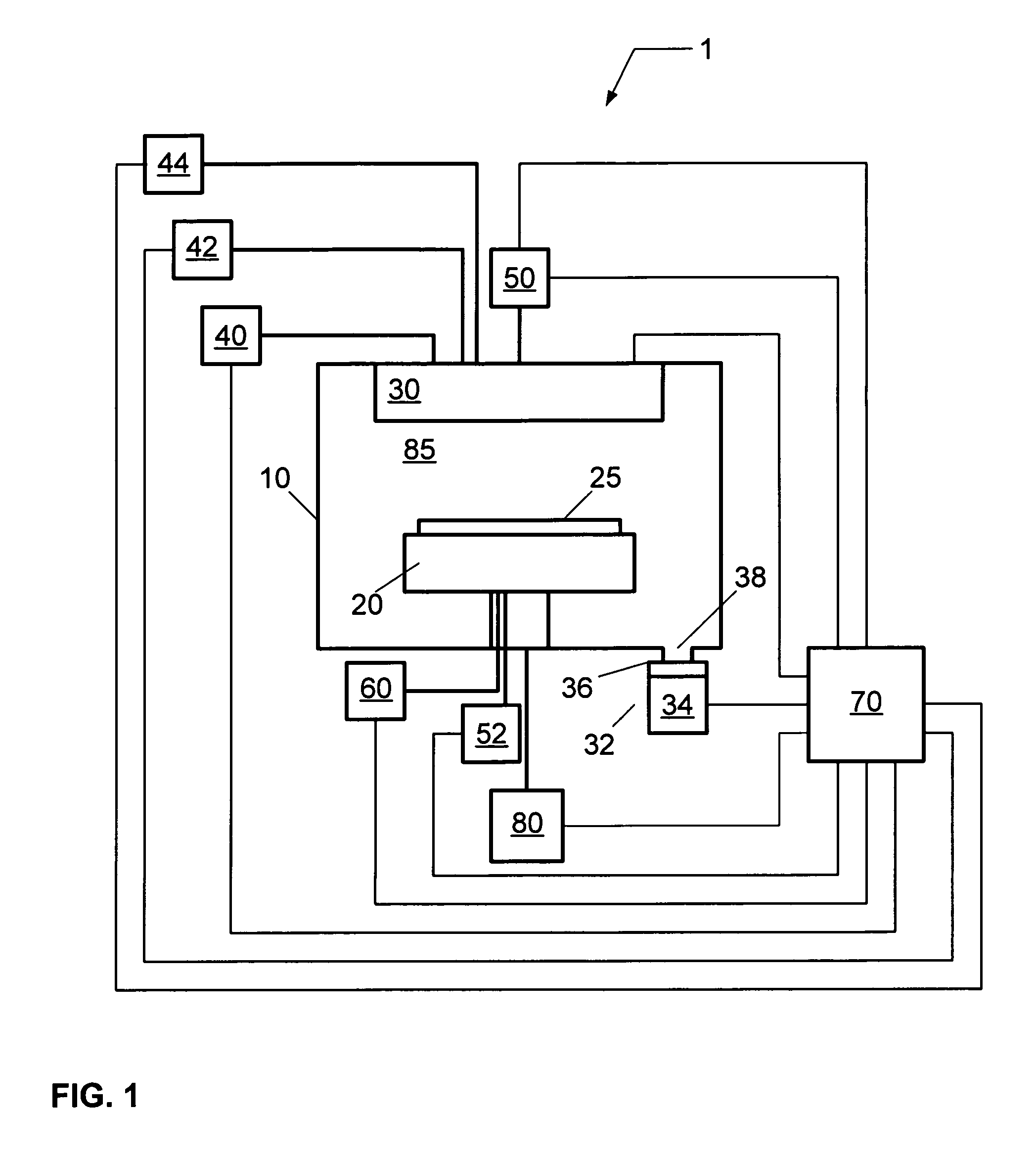

ActiveUS20080262584A1Prevent undesired heatingEasy to useInternal electrodesMaterial strength using steady bending forcesElectrical conductorDegree Celsius

MRI / RF compatible leads include at least one conductor, a respective conductor having at least one segment with a multi-layer stacked coil configuration. The lead can be configured so that the lead heats local tissue less than about 10 degrees Celsius (typically about 5 degrees Celsius or less) or does not heat local tissue when a patient is exposed to target RF frequencies at a peak input SAR of at least about 4 W / kg and / or a whole body average SAR of at least about 2 W / kg. Related leads and methods of fabricating leads are also described.

Owner:MRI INTERVENTIONS INC +1

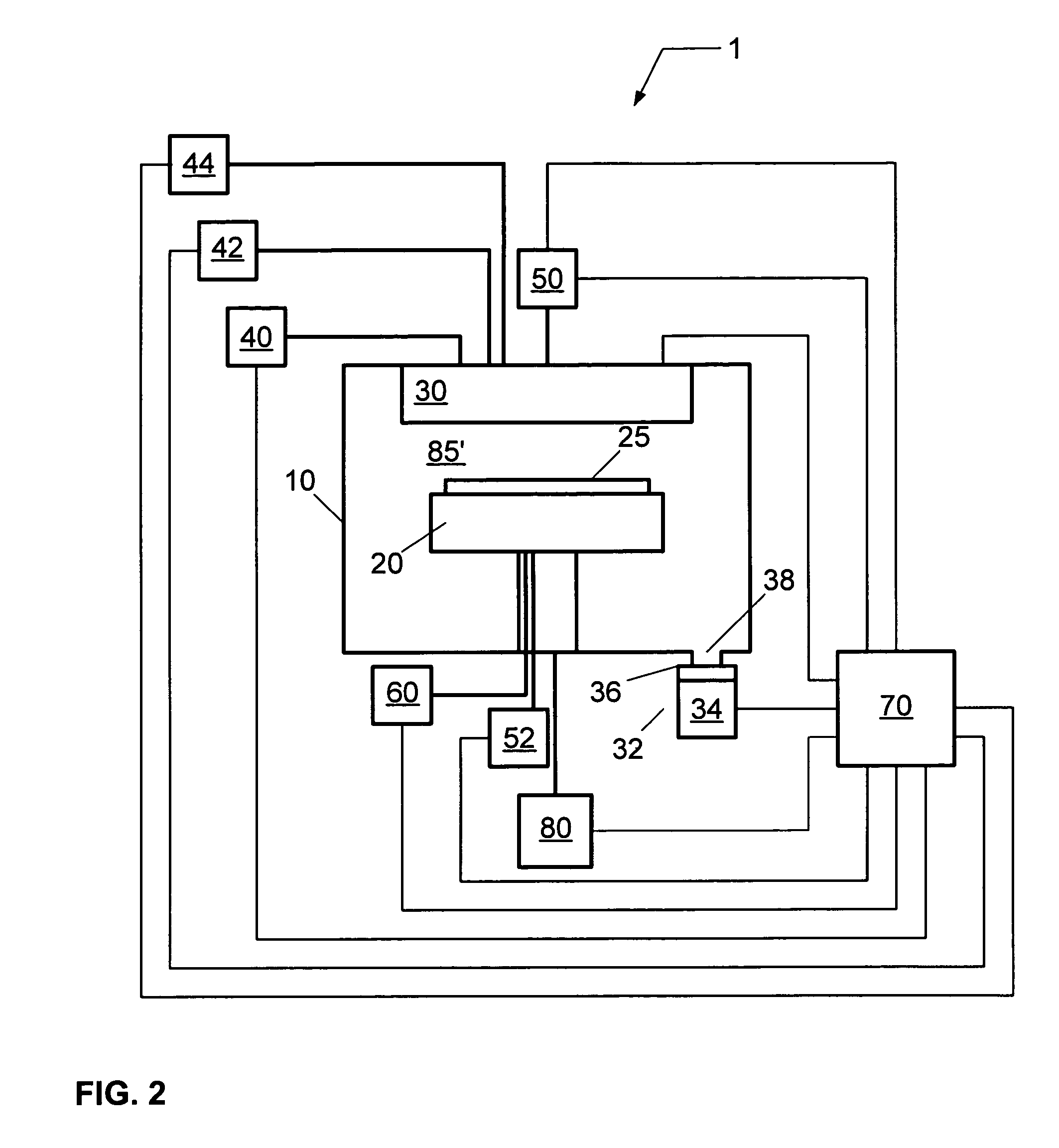

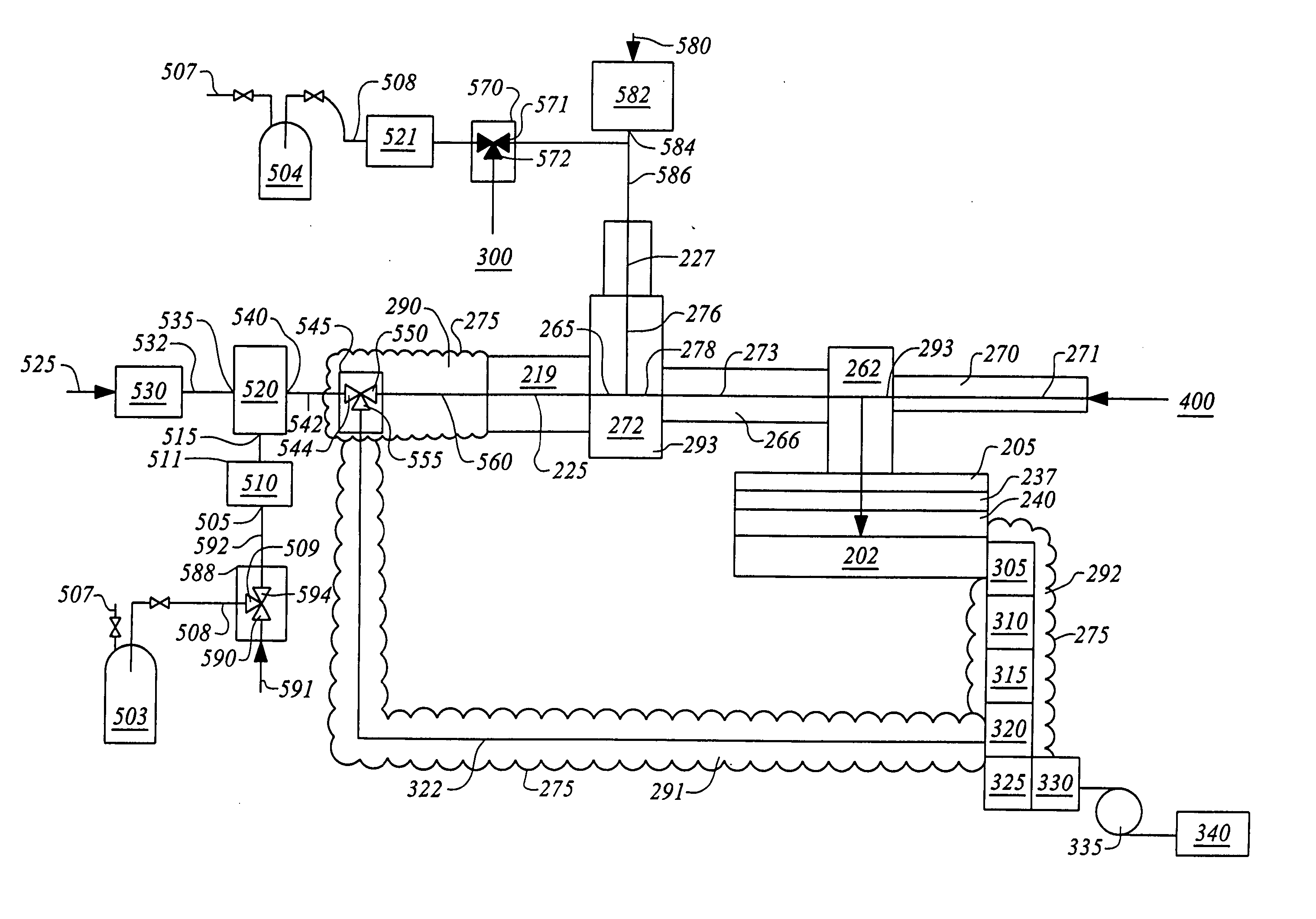

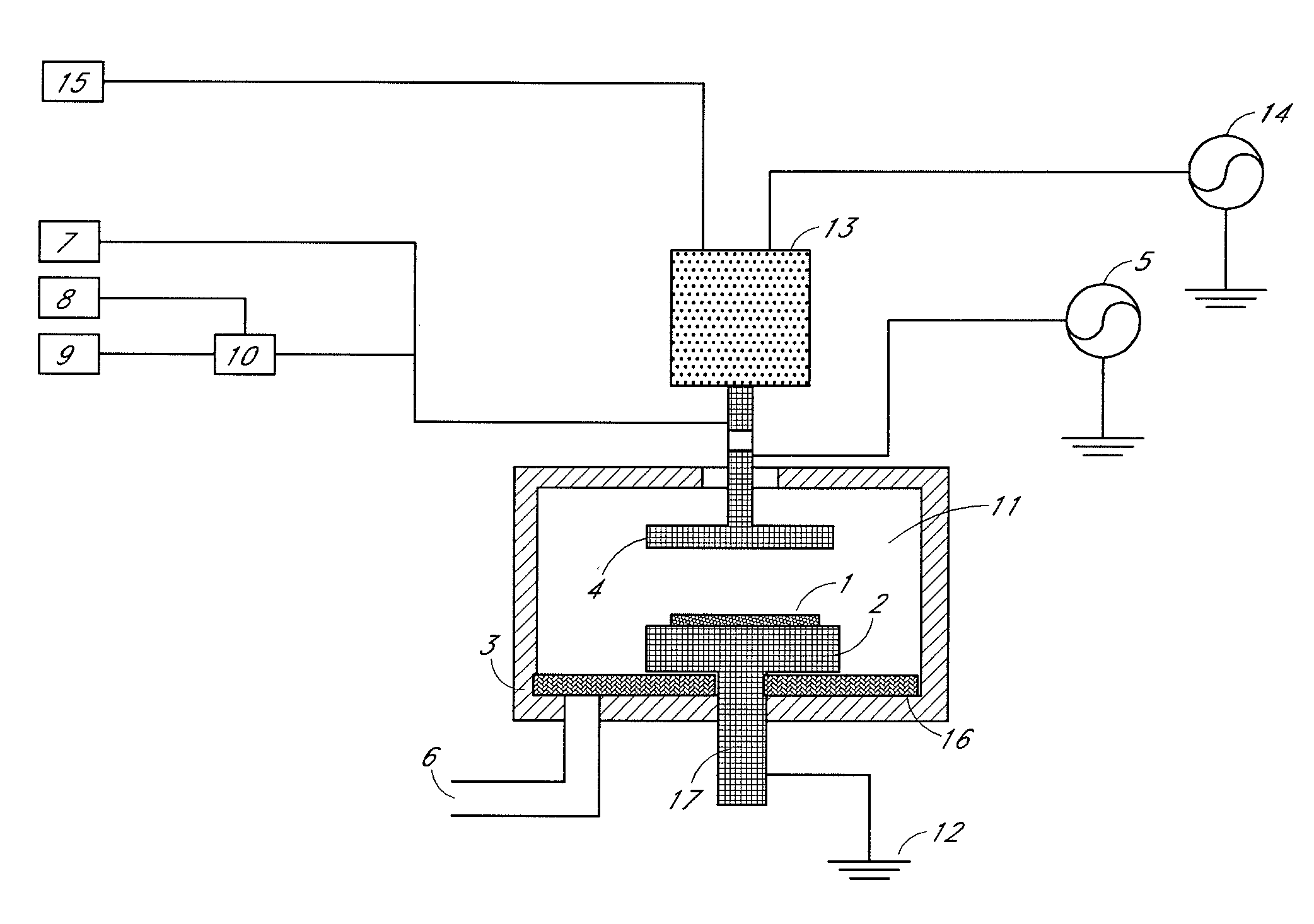

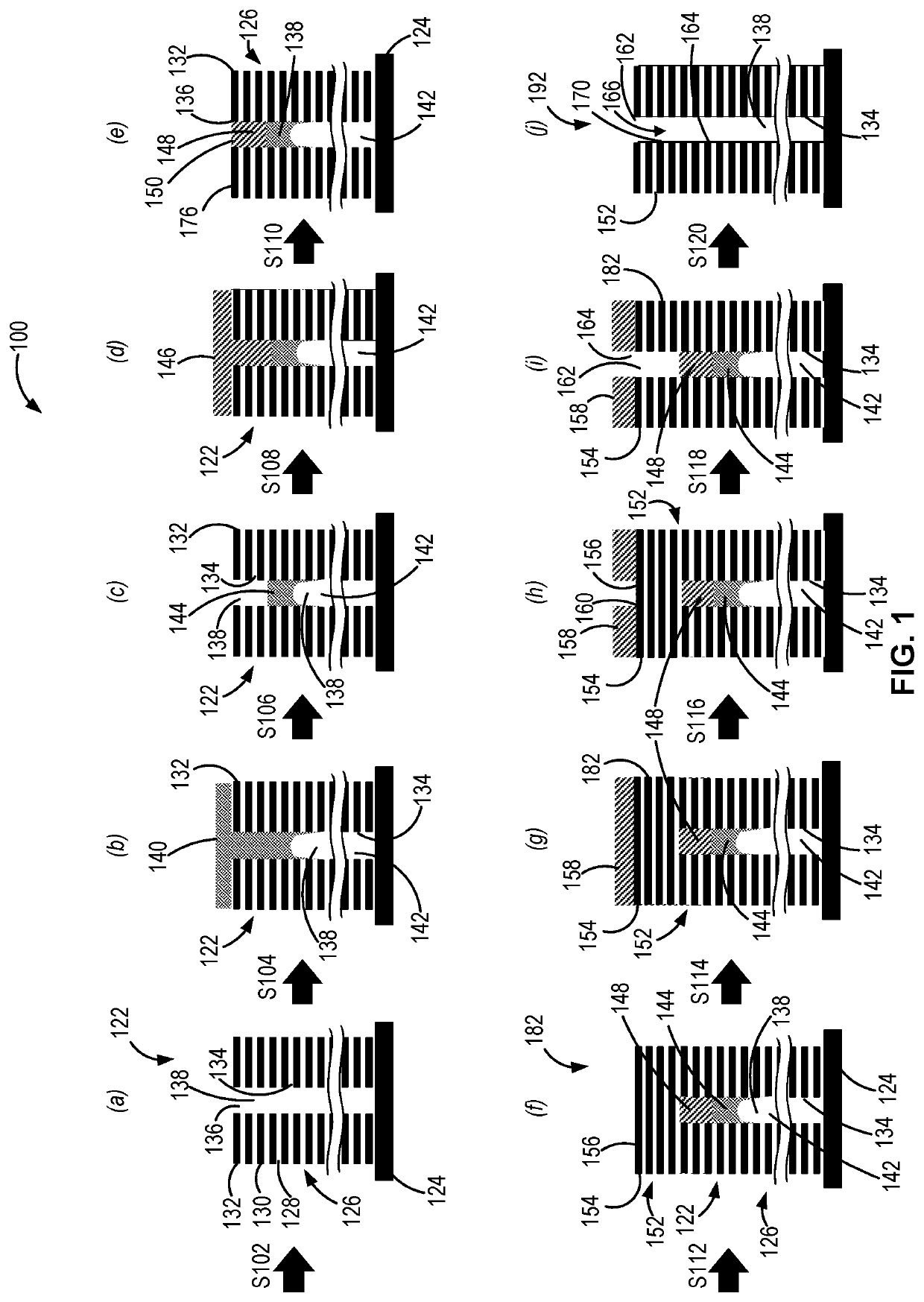

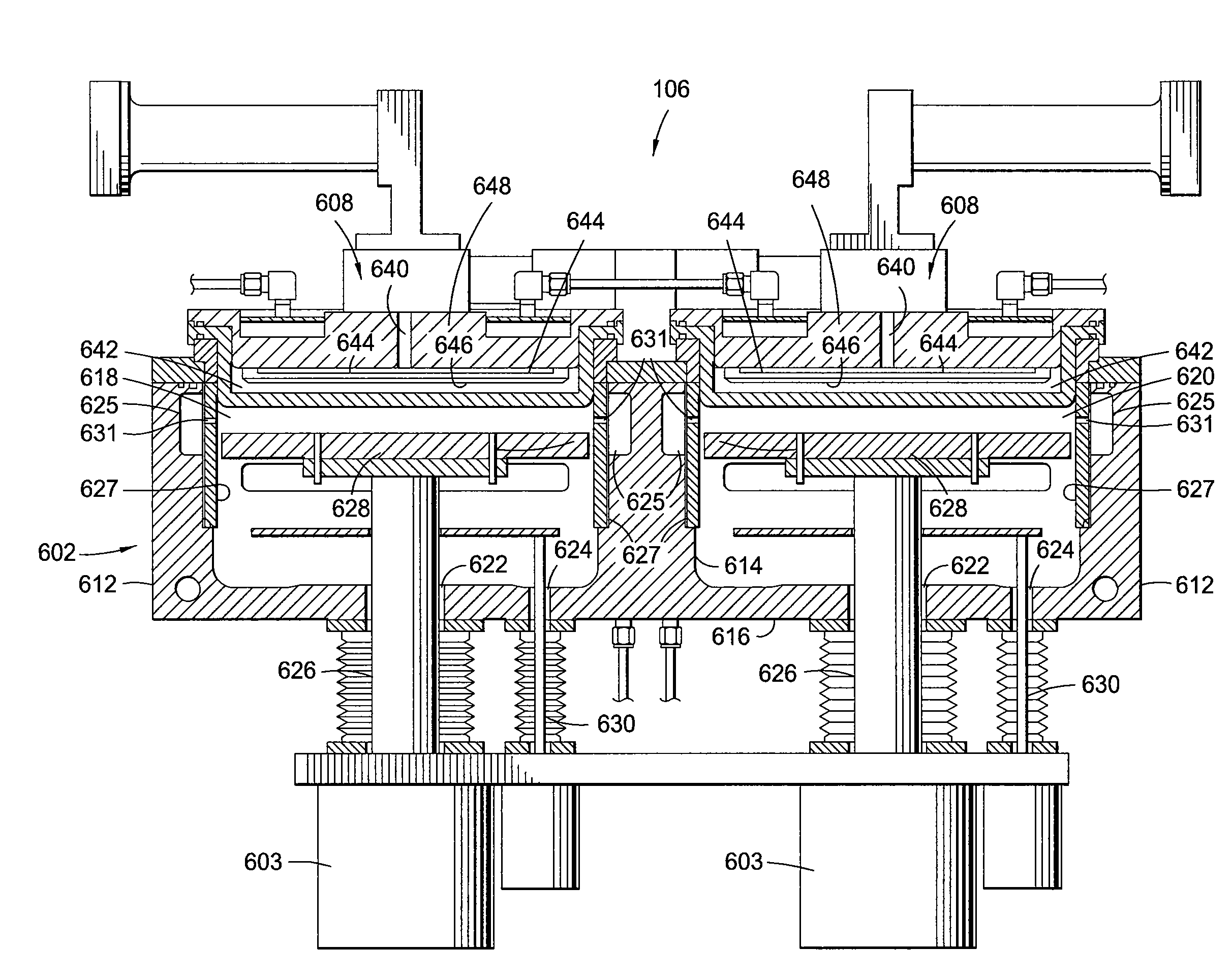

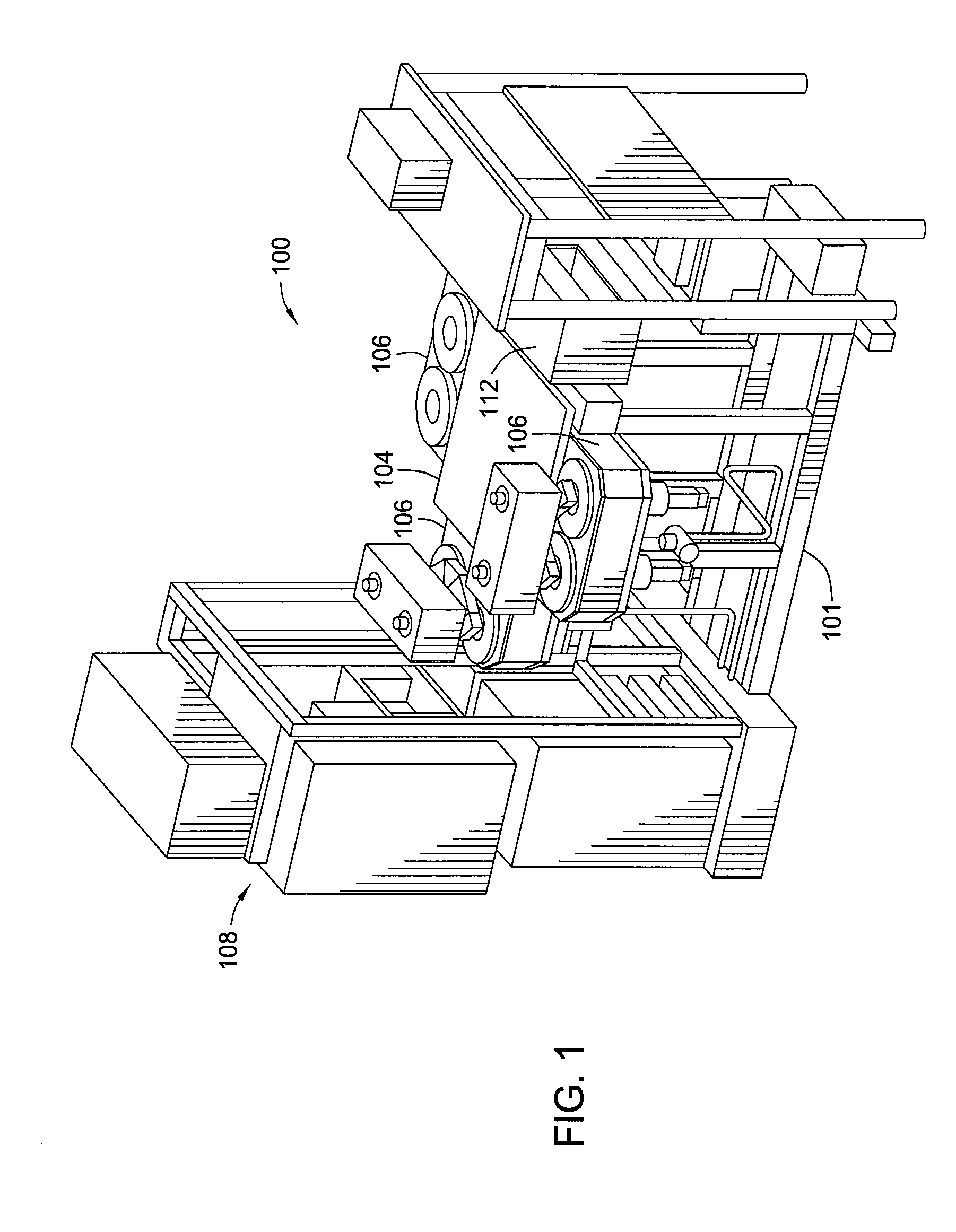

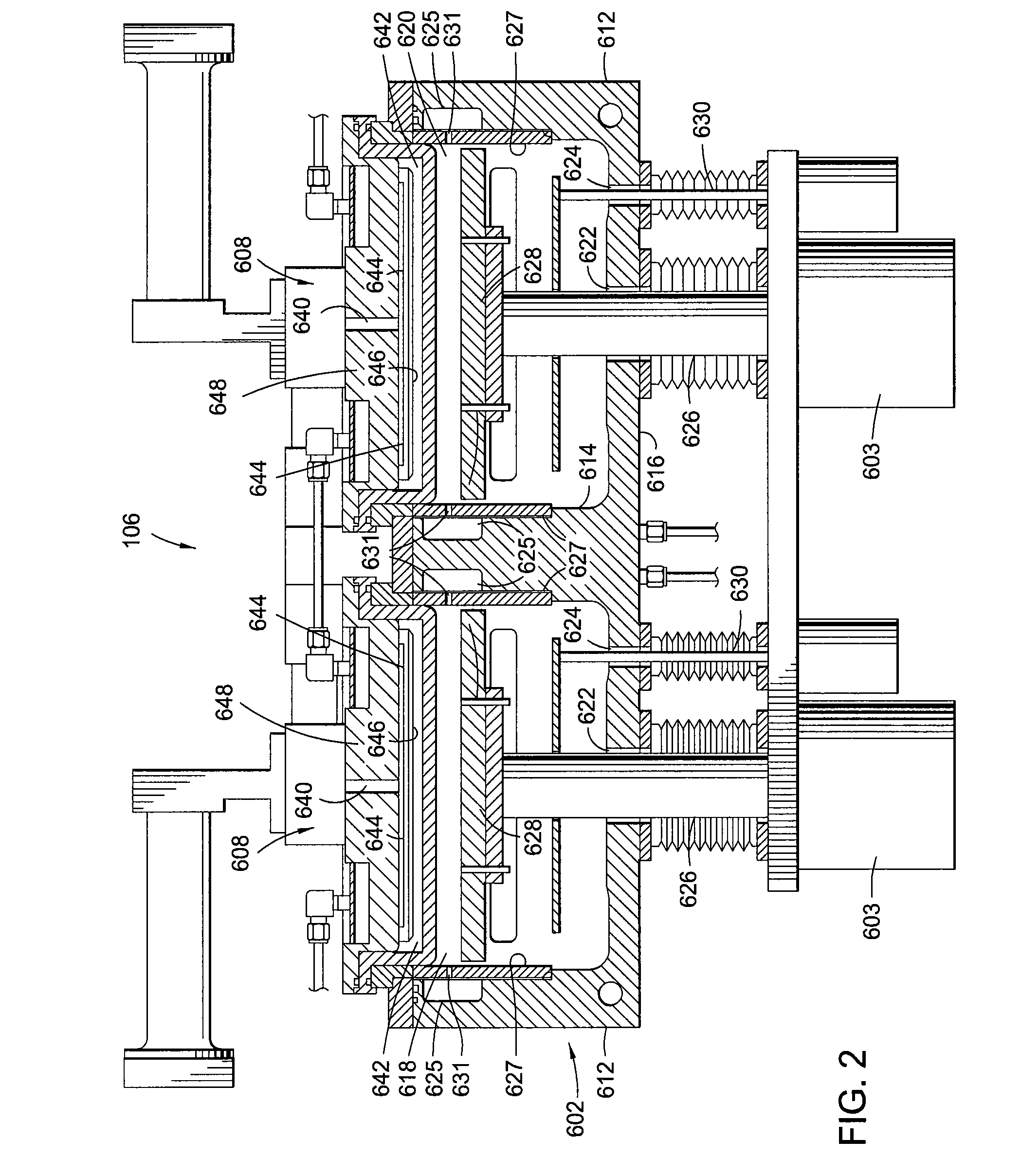

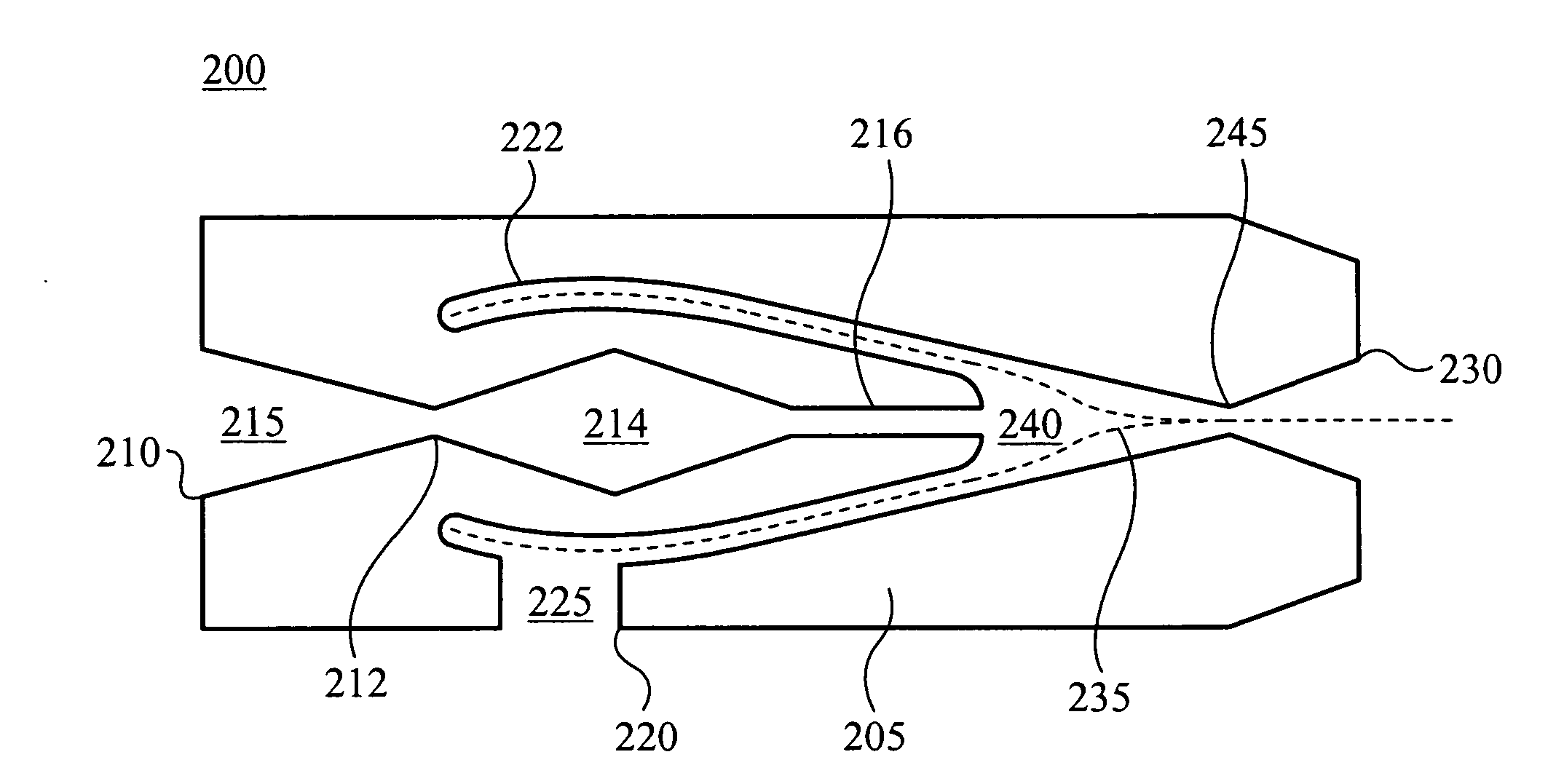

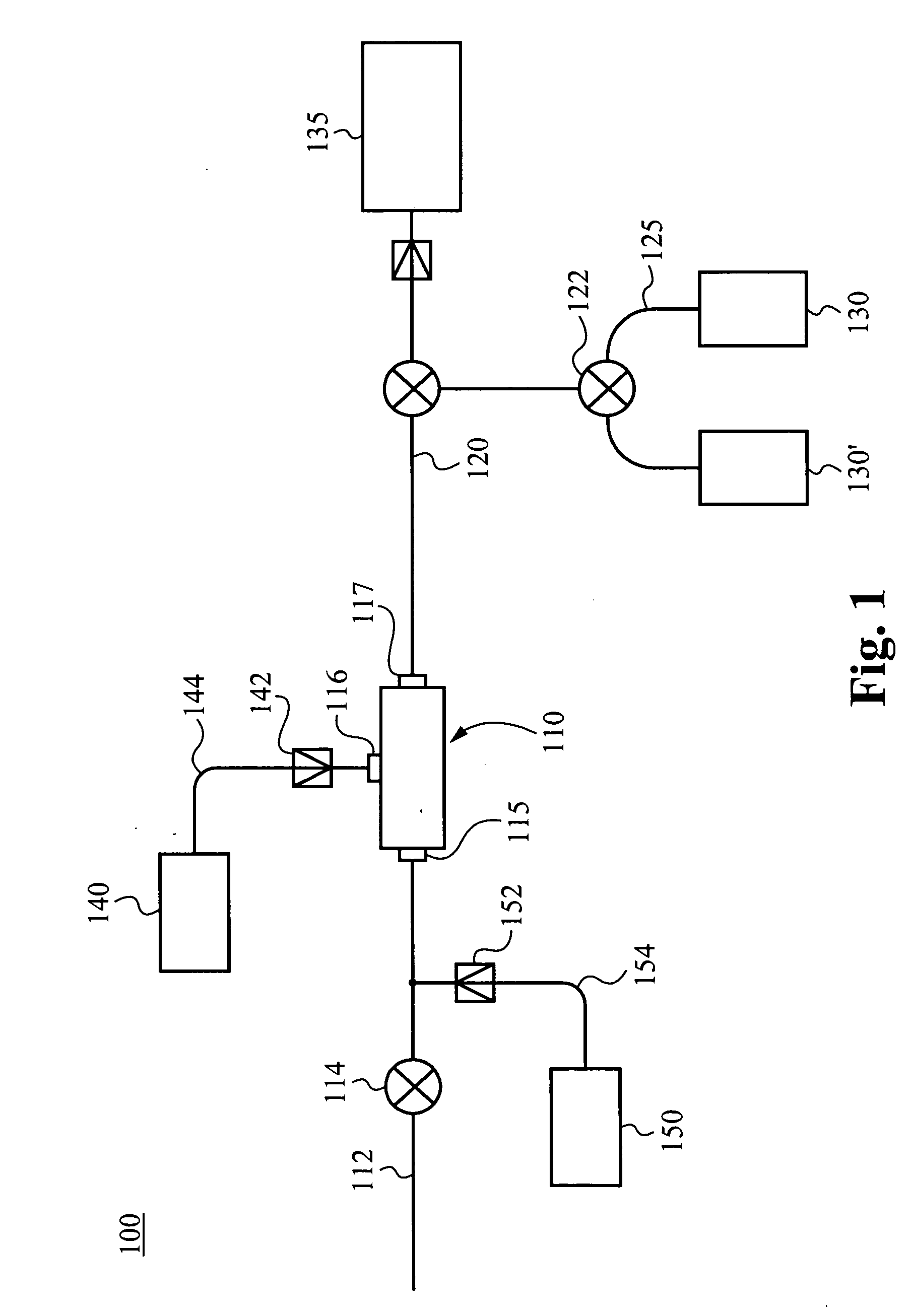

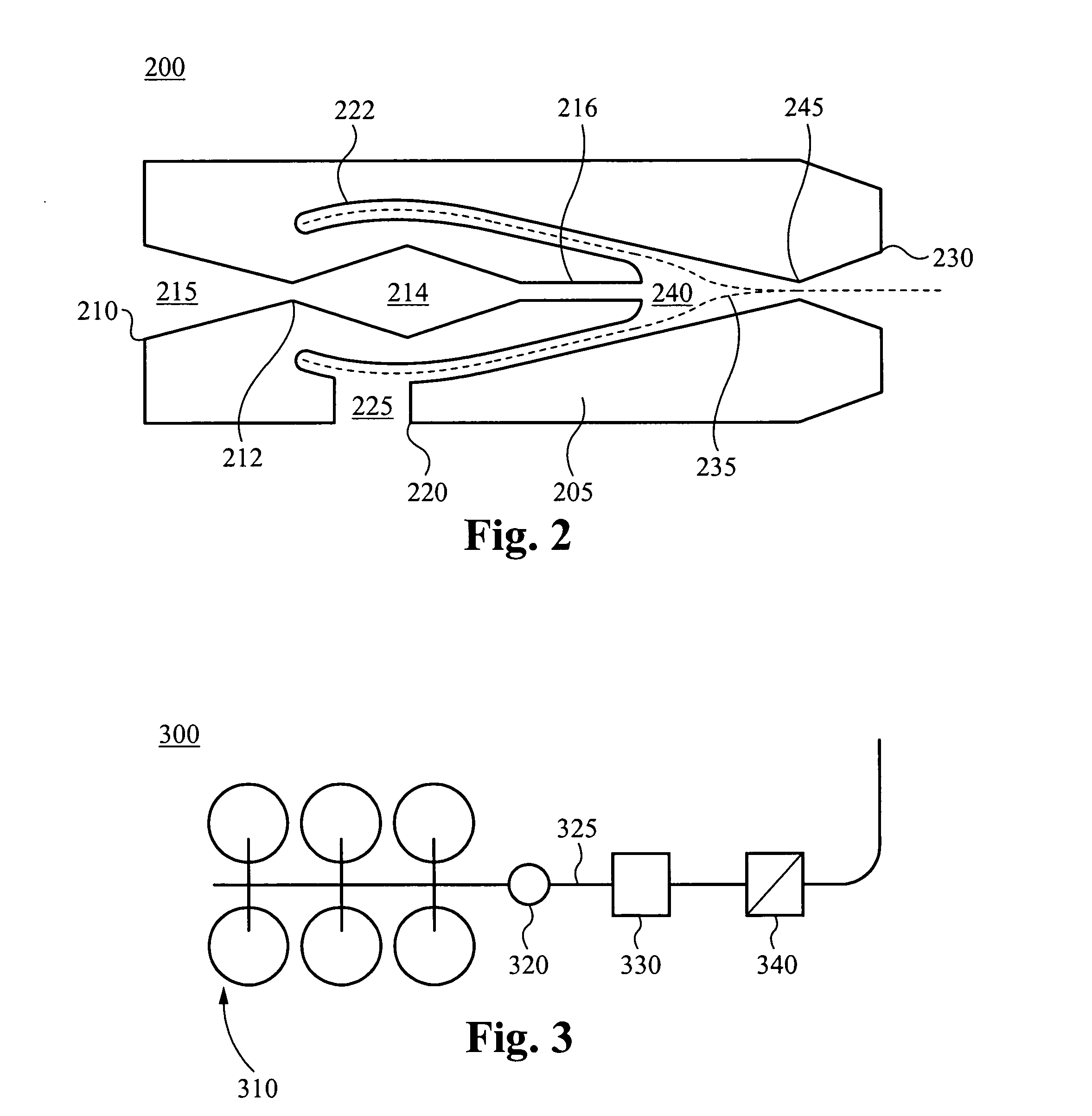

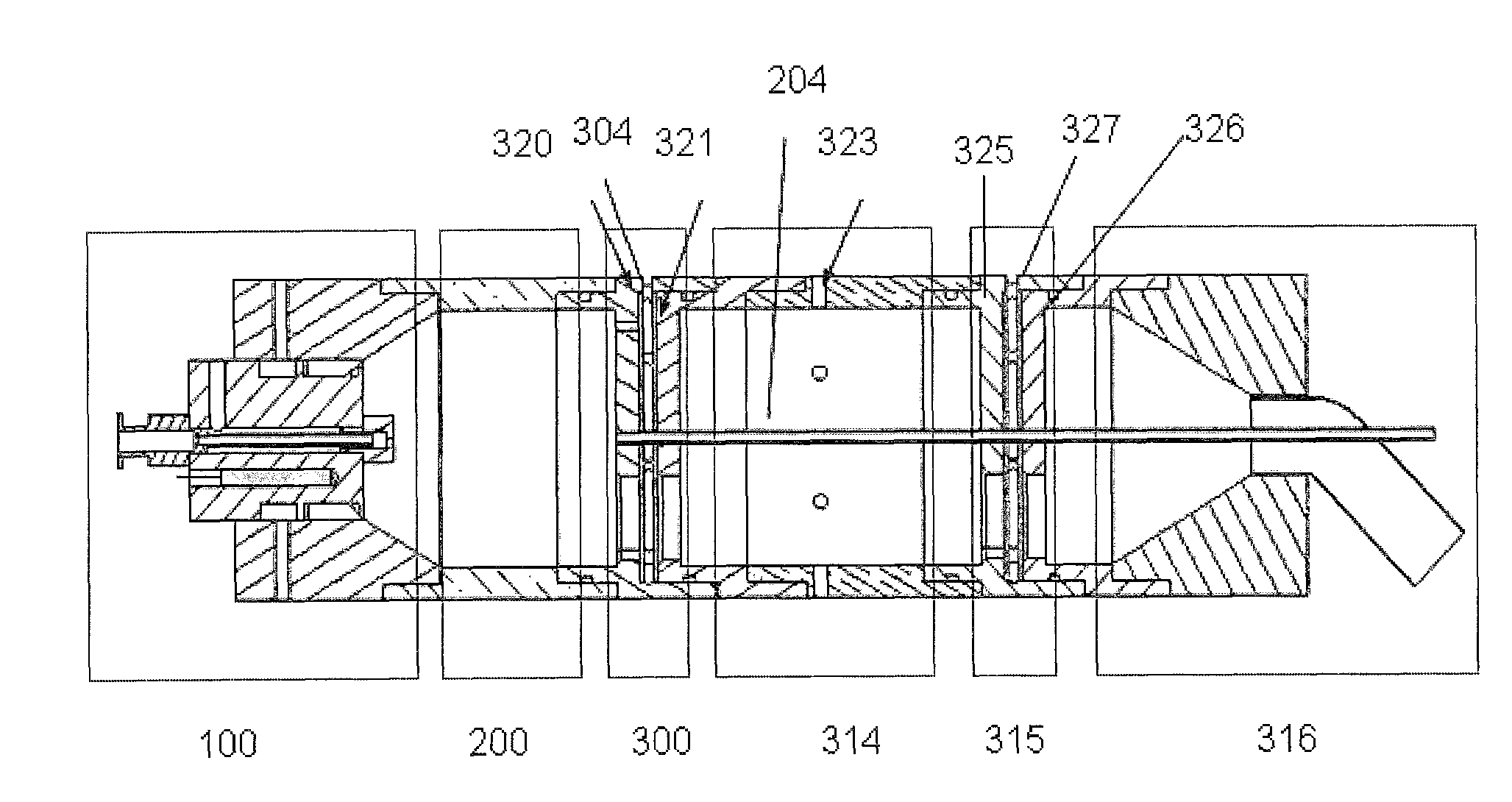

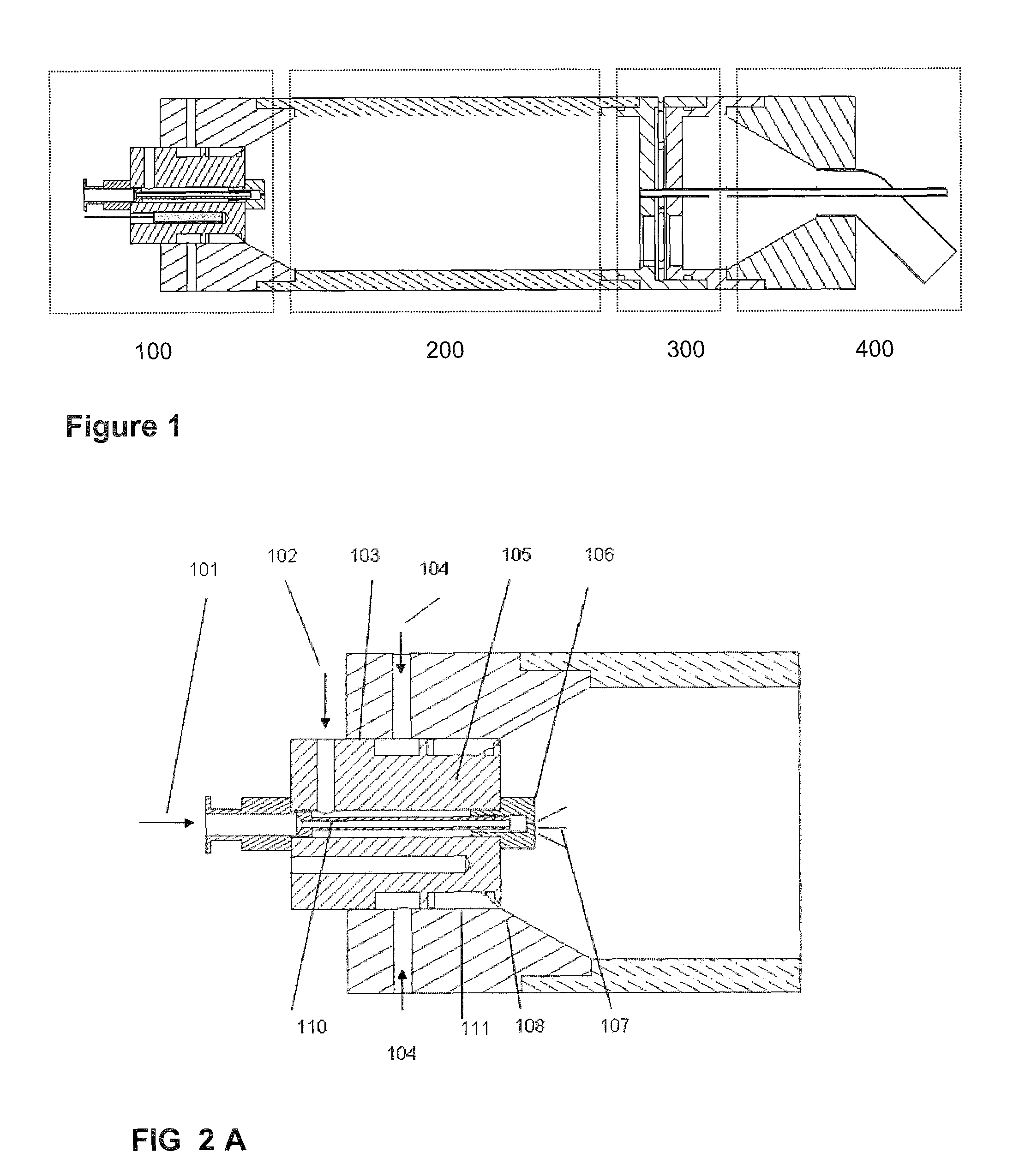

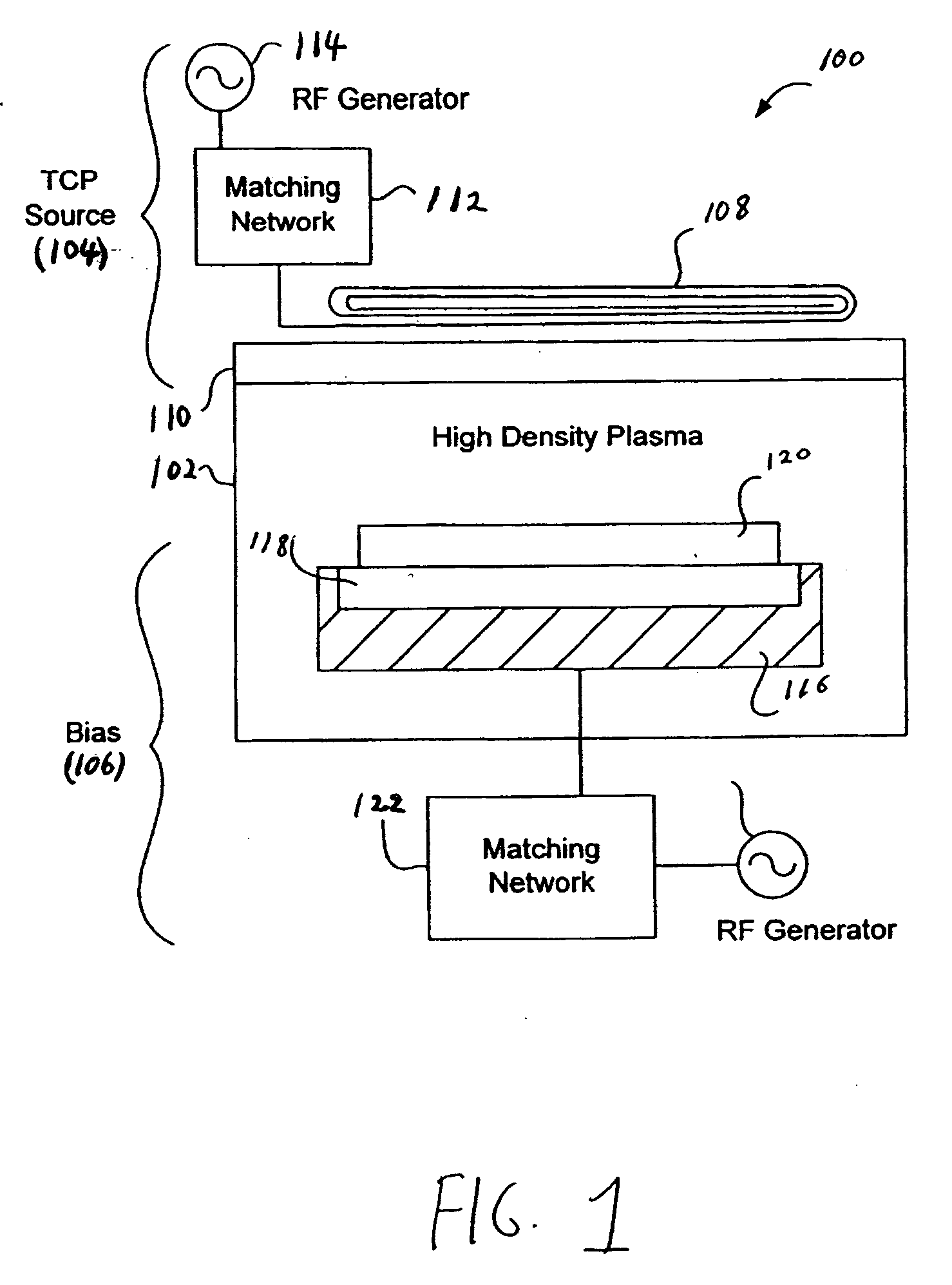

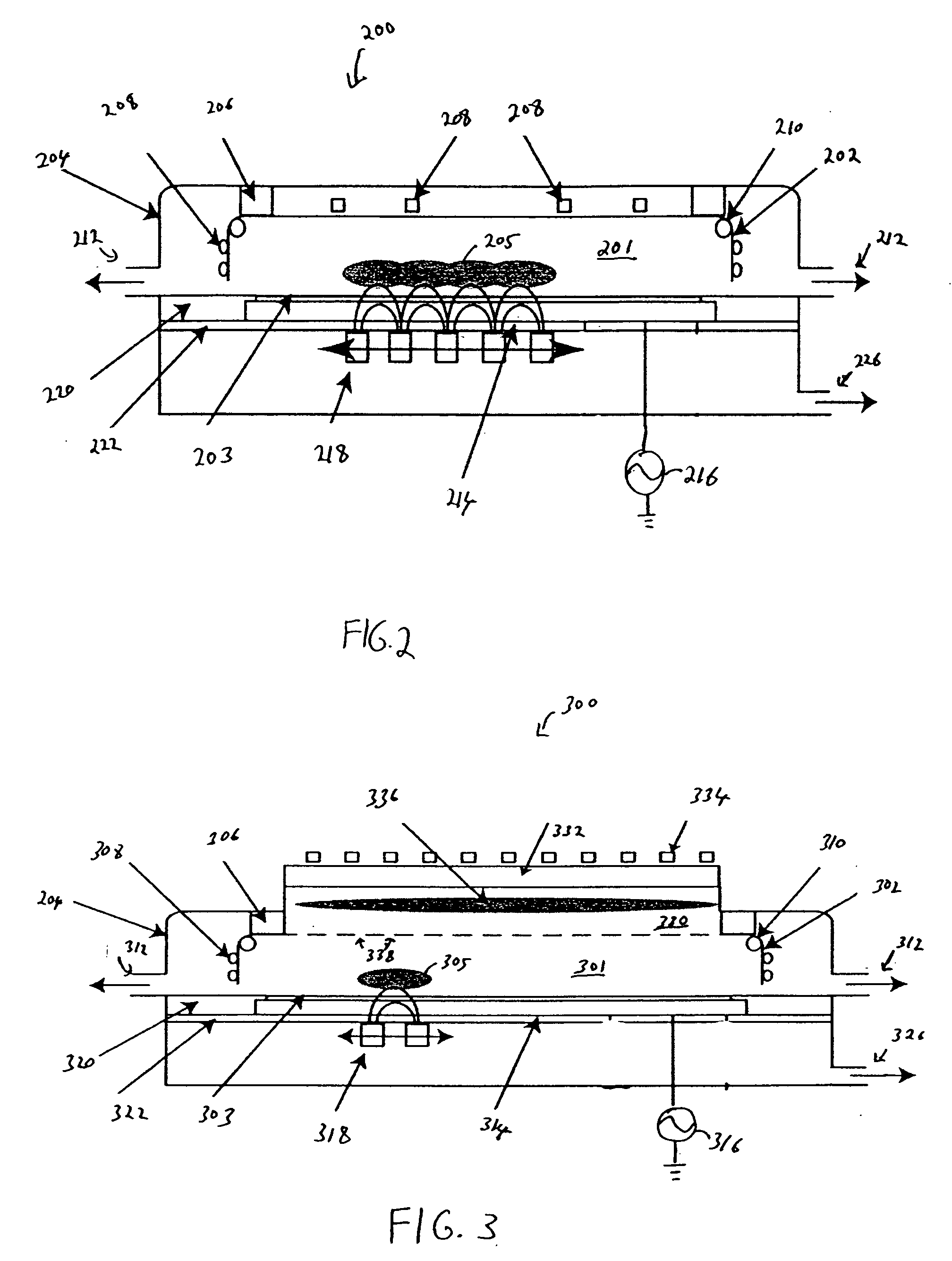

Method and system for performing plasma enhanced atomic layer deposition

InactiveUS7897217B2Reduce pollutionEnhanced reduction within the same systemElectric discharge tubesChemical vapor deposition coatingGas phaseProcess engineering

A method, computer readable medium, and system for vapor deposition on a substrate that introduce a gaseous film precursor to a process space, increase the volume of the process space from a first size to a second size to form an enlarged process space, introduce a reduction gas to the enlarged process space, and form a reduction plasma from the reduction gas. The system for vapor deposition includes a process chamber including a first process space and further including a second process space that includes the first process space and that has a second volume that exceeds the first volume. The first process space is configured for atomic layer deposition, and the second process space is configured for plasma reduction of a layer deposited in the first process space.

Owner:TOKYO ELECTRON LTD

MRI and RF compatible leads and related methods of operating and fabricating leads

ActiveUS20080243218A1Prevent undesired heatingEasy to useLine/current collector detailsInternal electrodesElectricityCelsius Degree

RF / MRI compatible leads include at least one conductor that turns back on itself at least twice in a lengthwise direction, and can turn back on itself at least twice at multiple locations along its length. The at least one electrical lead can be configured so that the lead heats local tissue less than about 10 degrees Celsius (typically about 5 degrees Celsius or less) or does not heat local tissue when a patient is exposed to target RF frequencies at a peak input SAR of at least about 4 W / kg and / or a whole body average SAR of at least about 2 W / kg. Related devices and methods of fabricating leads are also described.

Owner:MRI INTERVENTIONS INC +1

Method and system for performing plasma enhanced atomic layer deposition

InactiveUS20070116887A1Reduce pollutionReduce depositionElectric discharge tubesChemical vapor deposition coatingGas phaseProcess engineering

A method, computer readable medium, and system for vapor deposition on a substrate that introduce a gaseous film precursor to a process space, increase the volume of the process space from a first size to a second size to form an enlarged process space, introduce a reduction gas to the enlarged process space, and form a reduction plasma from the reduction gas. The system for vapor deposition includes a process chamber including a first process space and further including a second process space that includes the first process space and that has a second volume that exceeds the first volume. The first process space is configured for atomic layer deposition, and the second process space is configured for plasma reduction of a layer deposited in the first process space.

Owner:TOKYO ELECTRON LTD

Apparatus for the deposition of high dielectric constant films

InactiveUS20060196421A1Precise temperature controlEasy temperature controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricElectricity

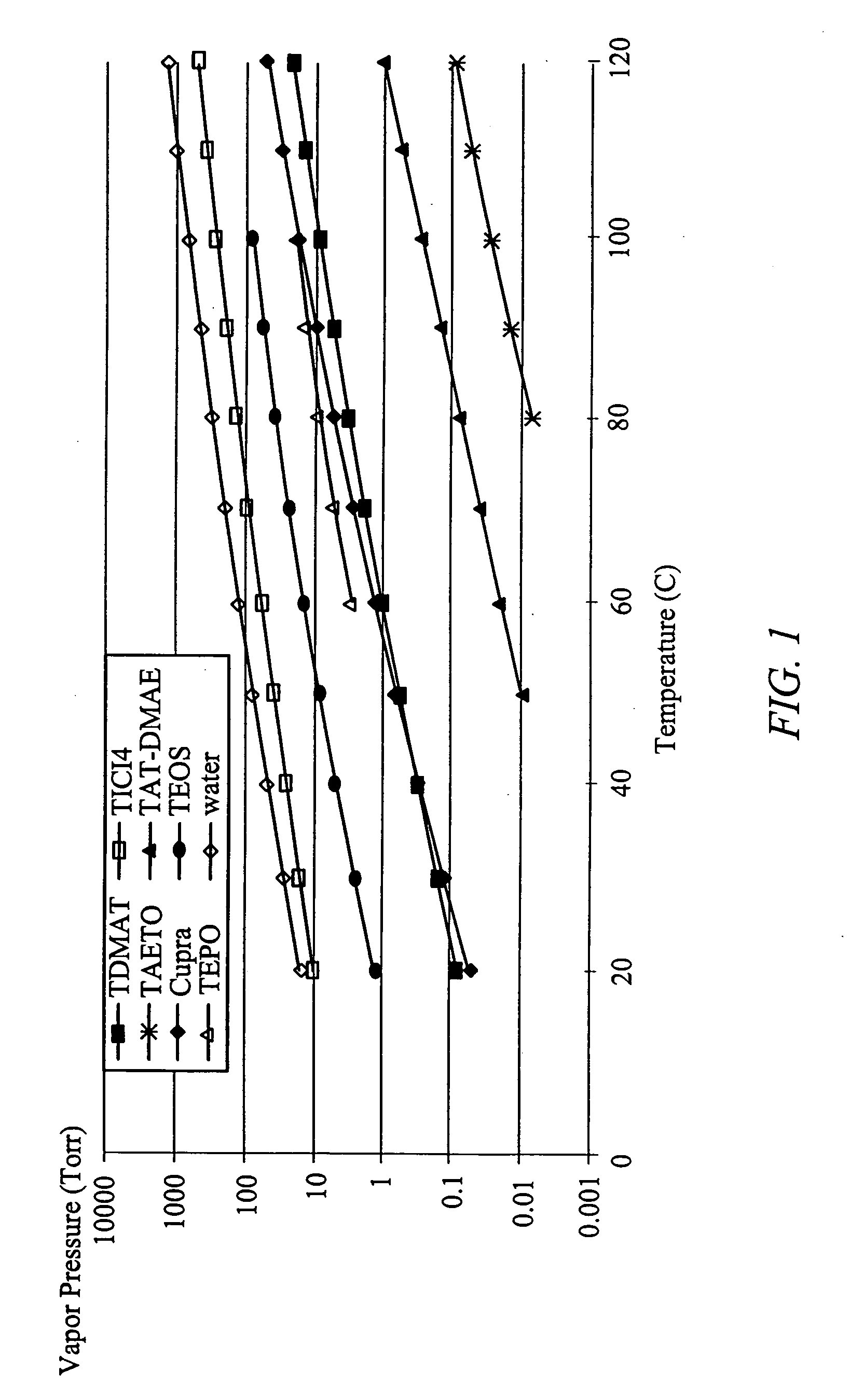

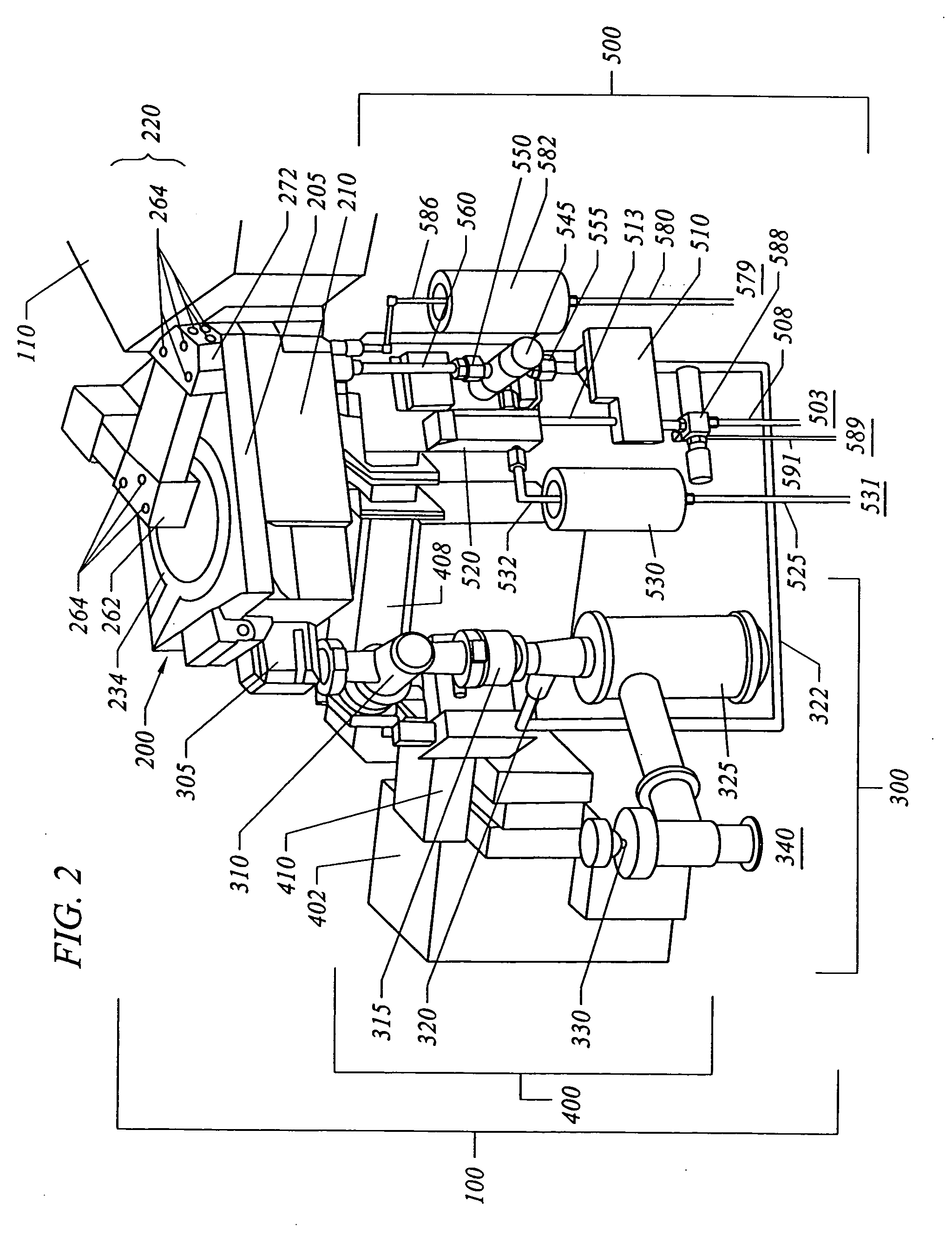

An integrated deposition system is described that is capable of vaporizing low vapor pressure liquid precursors and conveying the vapor to a processing region to fabricate advanced integrated circuits. The integrated deposition system includes a heated exhaust system, a remote plasma generator, a processing chamber, a liquid delivery system, and a computer control module that together create a commercially viable and production worthy system for depositing high capacity dielectric materials from low vapor pressure precursors.

Owner:APPLIED MATERIALS INC

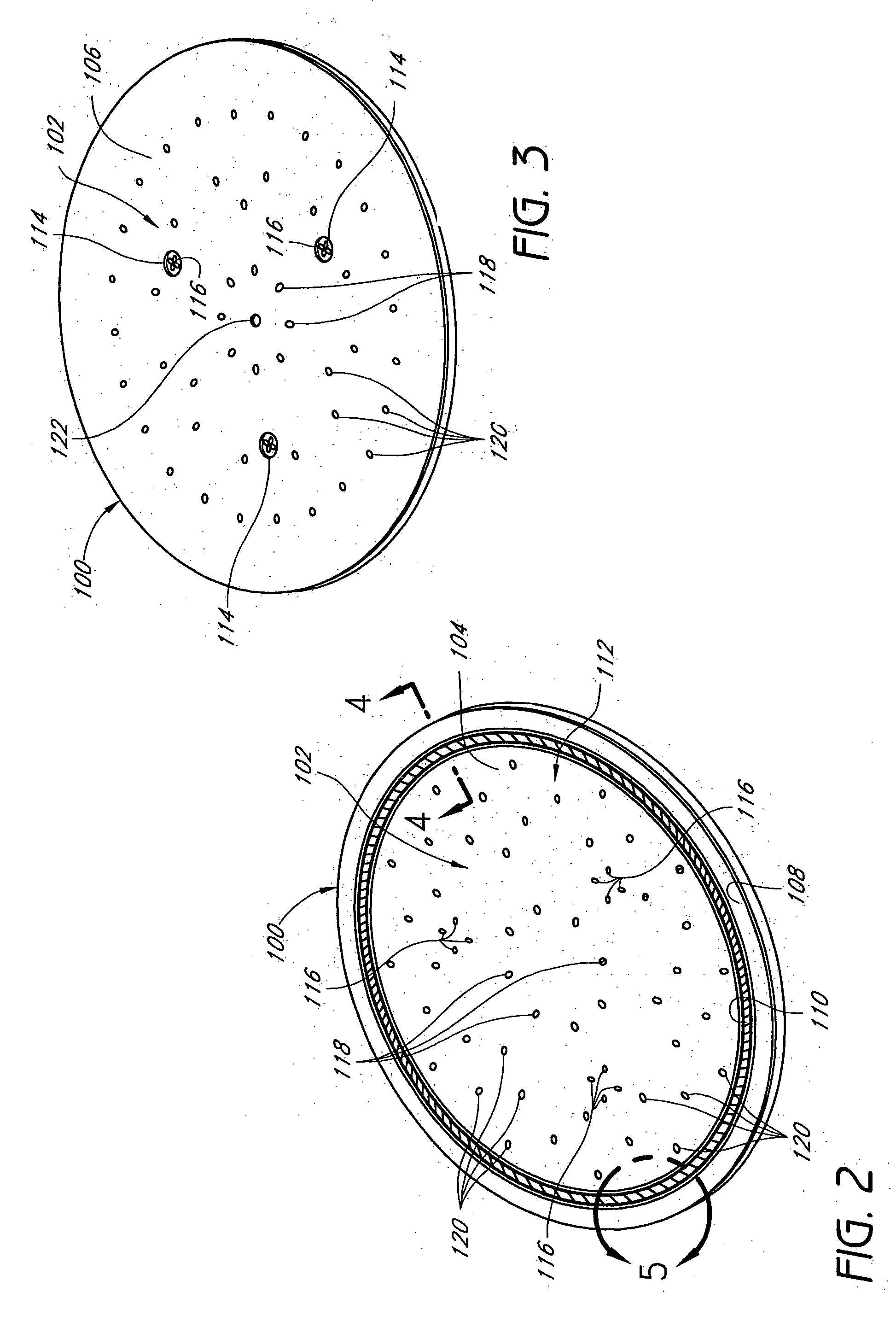

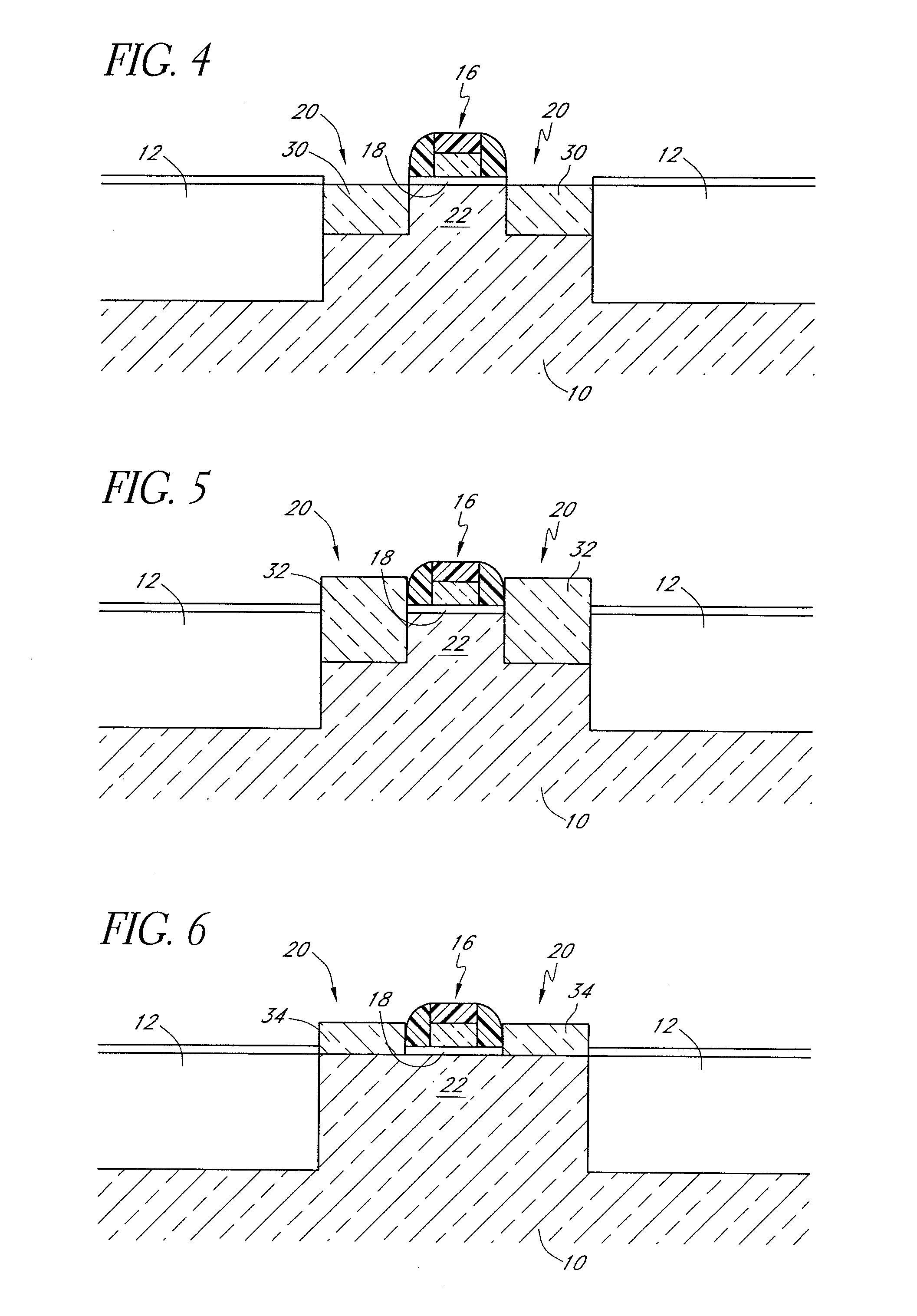

Substrate support system for reduced autodoping and backside deposition

ActiveUS20050193952A1Speed up gas flowAvoid flowLiquid surface applicatorsElectric discharge tubesSupporting systemEngineering

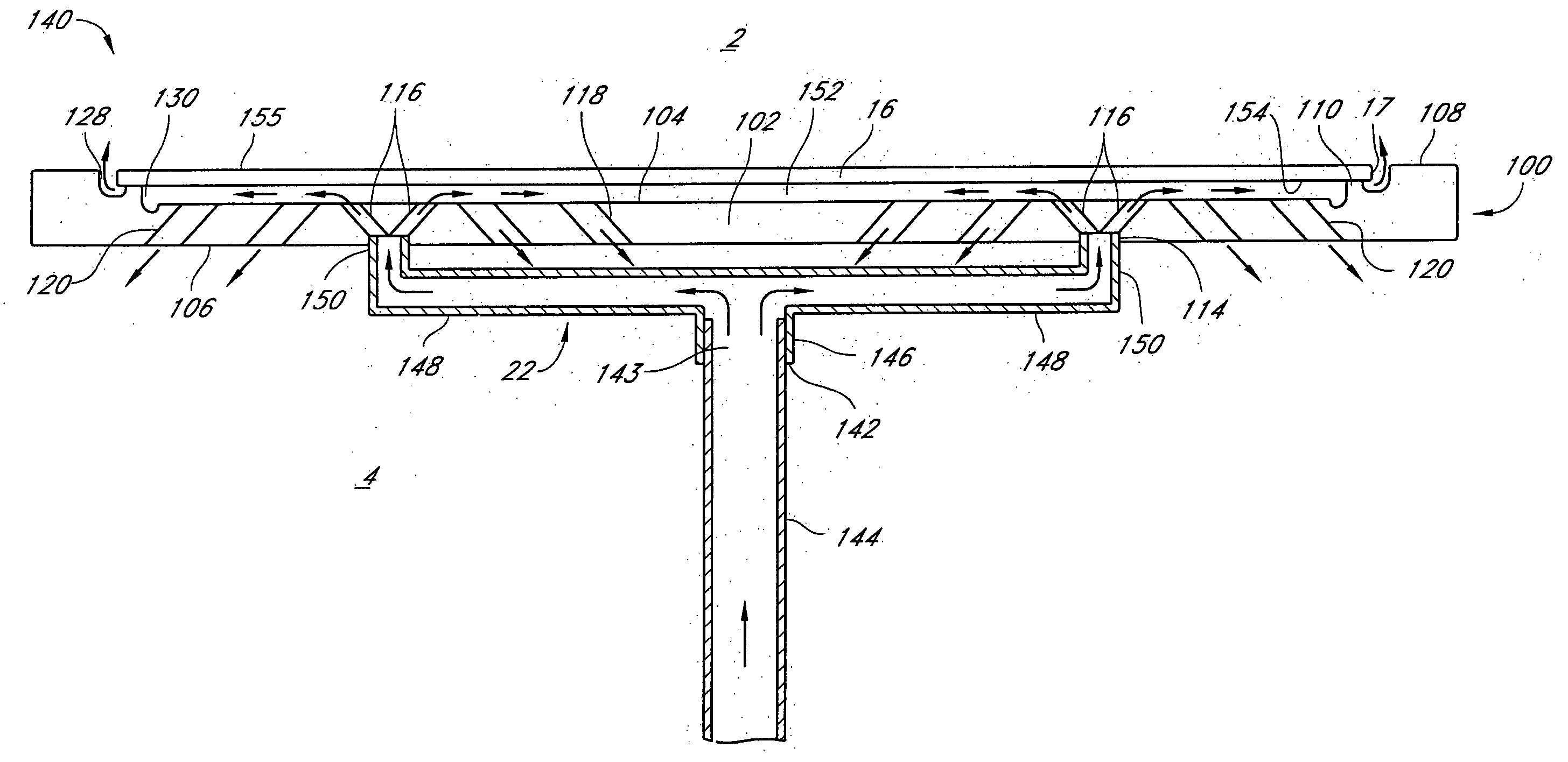

A substrate support system comprises a relatively thin circular substrate holder having a plurality of passages extending between top and bottom surfaces thereof. The substrate holder includes a single substrate support ledge or a plurality of substrate support spacer vanes configured to support a peripheral portion of the substrate backside so that a thin gap is formed between the substrate and the substrate holder. The vanes can be angled to resist backside deposition of reactant gases as the substrate holder is rotated. A hollow support member provides support to an underside of the substrate holder. The hollow support member is configured to convey gas (e.g., inert gas or cleaning gas) upward into one or more of the passages of the substrate holder. The upwardly conveyed gas flows into the gap between the substrate and the substrate holder. Depending upon the embodiment of the invention, the gas in the gap can then flow either (1) outward and upward around the substrate edge or (2) downward through passages of the substrate holder, if any, that do not lead back into the hollow support member. The gas that flows outward and upward around the substrate edge inhibits backside deposition of reactant gases above the substrate. The gas that flows downward through the passages that do not lead back to the support member advantageously inhibits autodoping by sweeping out-diffused dopant atoms away from the substrate front side. In one embodiment, the support member comprises a hollow multi-armed support spider that conveys gas into selected ones of the passages. In another embodiment, the support member comprises a bowl- or cup-shaped structure that conveys gas upward into all of the passages. In yet another embodiment, the support member comprises a bowl- or cup-shaped structure that conveys gas upward into all but one or more of the passages.

Owner:ASM IP HLDG BV

Apparatus and method for improving production throughput in CVD chamber

InactiveUS20090297731A1Prevent penetrationIncrease deposition rateElectric discharge tubesChemical vapor deposition coatingCapacitanceCapacitive coupling

A plasma CVD apparatus for forming a film on a substrate includes: an evacuatable reaction chamber; capacitively-coupled upper and lower electrodes disposed inside the reaction chamber; and an insulator for inhibiting penetration of a magnetic field of radio frequency generated during substrate processing. The insulator is placed on the bottom surface of the reaction chamber under the lower electrode.

Owner:ASM JAPAN

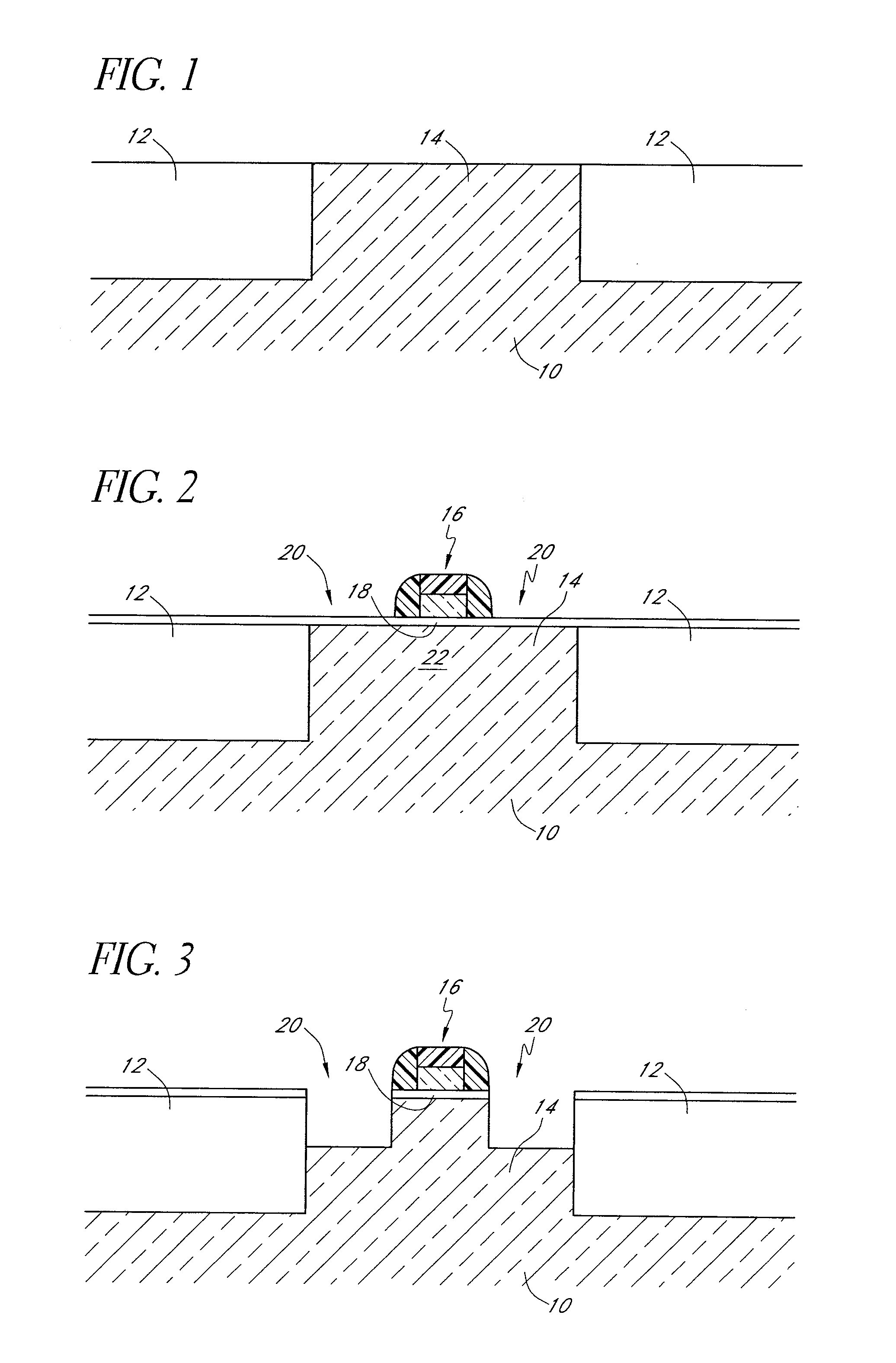

Method of forming high aspect ratio features

PendingUS20210225642A1Prevent and mitigate bowingReduce carbon depositionSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingCarbon layerEngineering

Methods and systems for forming high aspect ratio features on a substrate are disclosed. Exemplary methods include forming a first carbon layer within a recess, etching a portion of the first carbon layer within the recess, and forming a second carbon layer within the recess. Structures formed using the methods or systems are also disclosed.

Owner:ASM IP HLDG BV

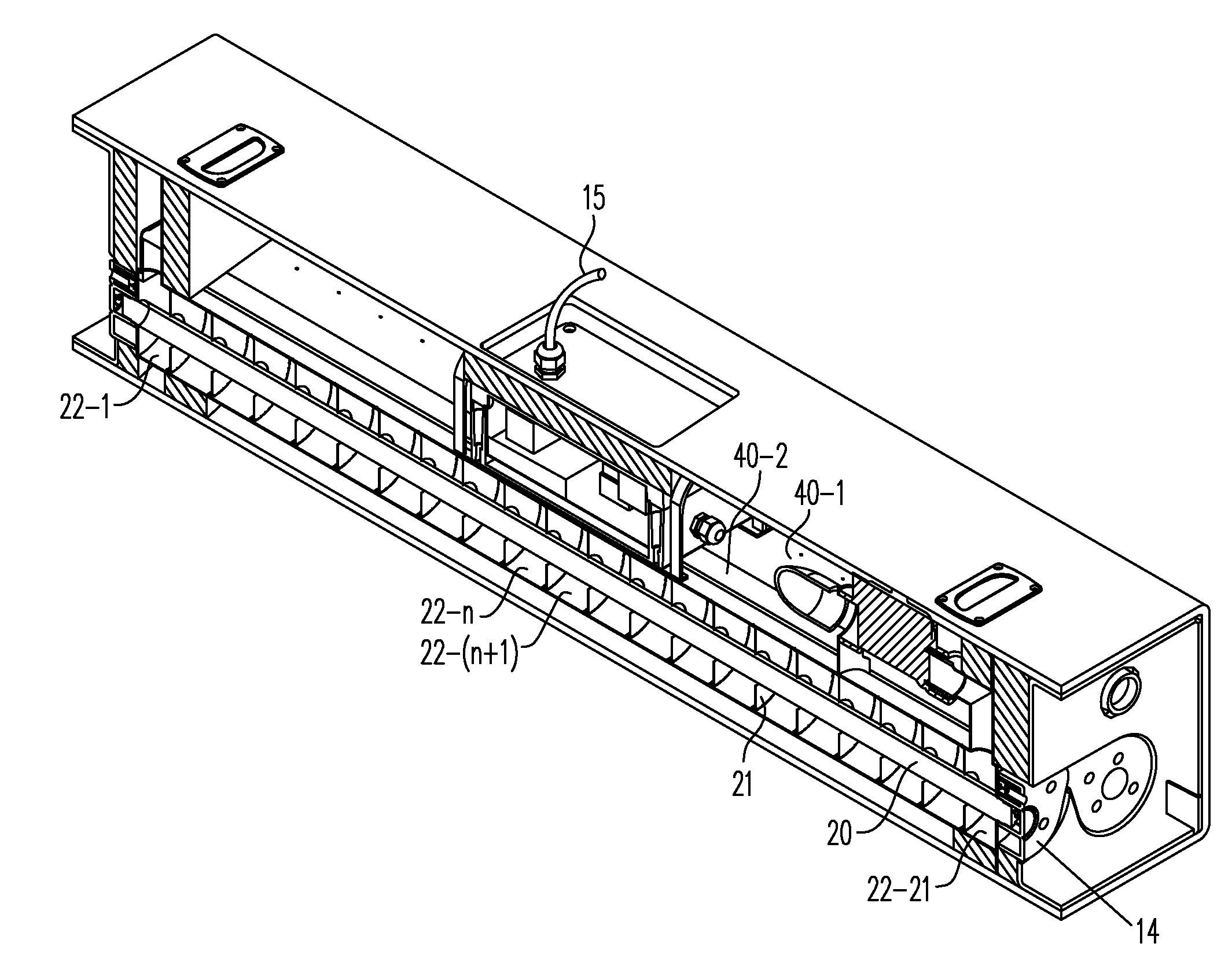

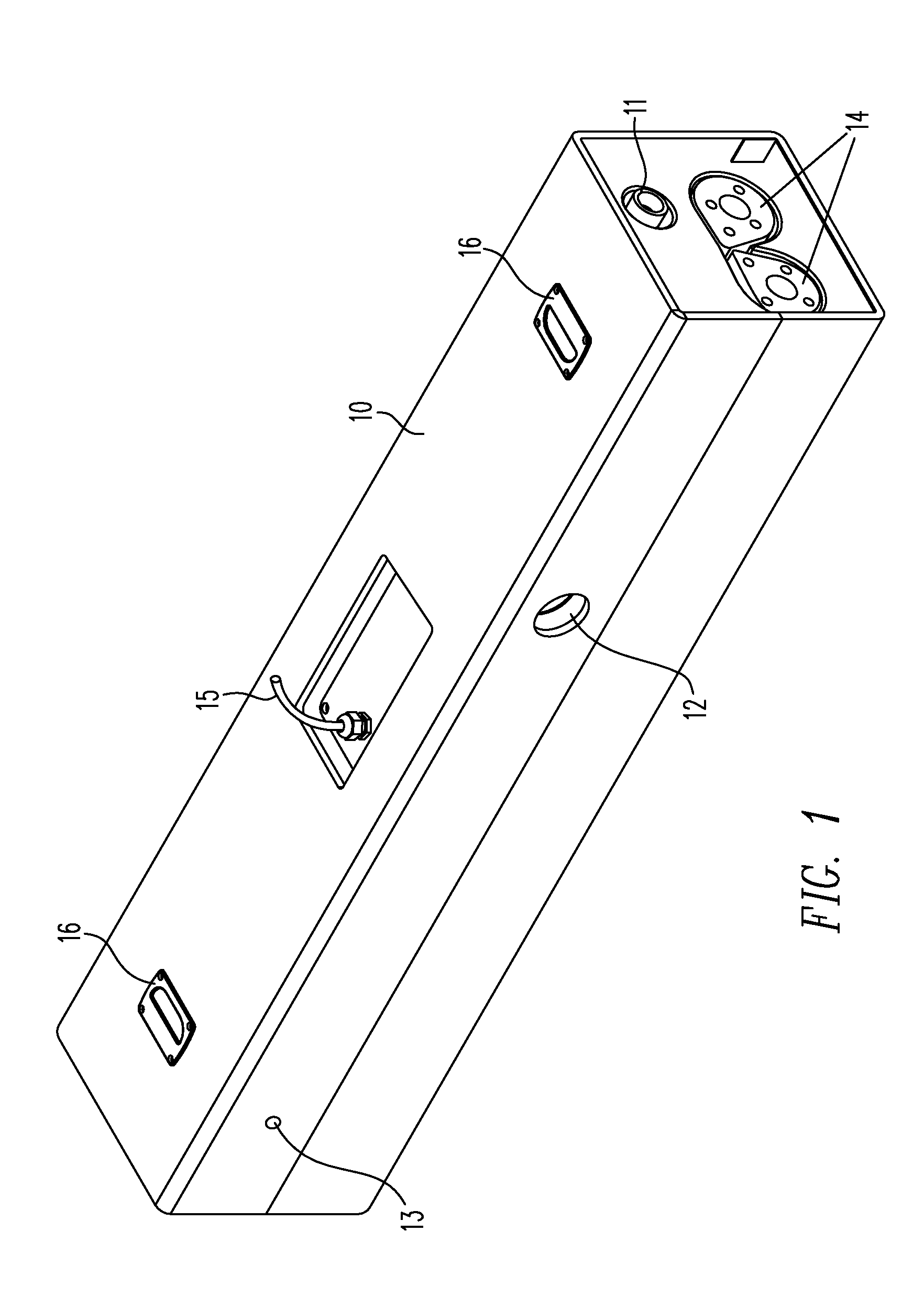

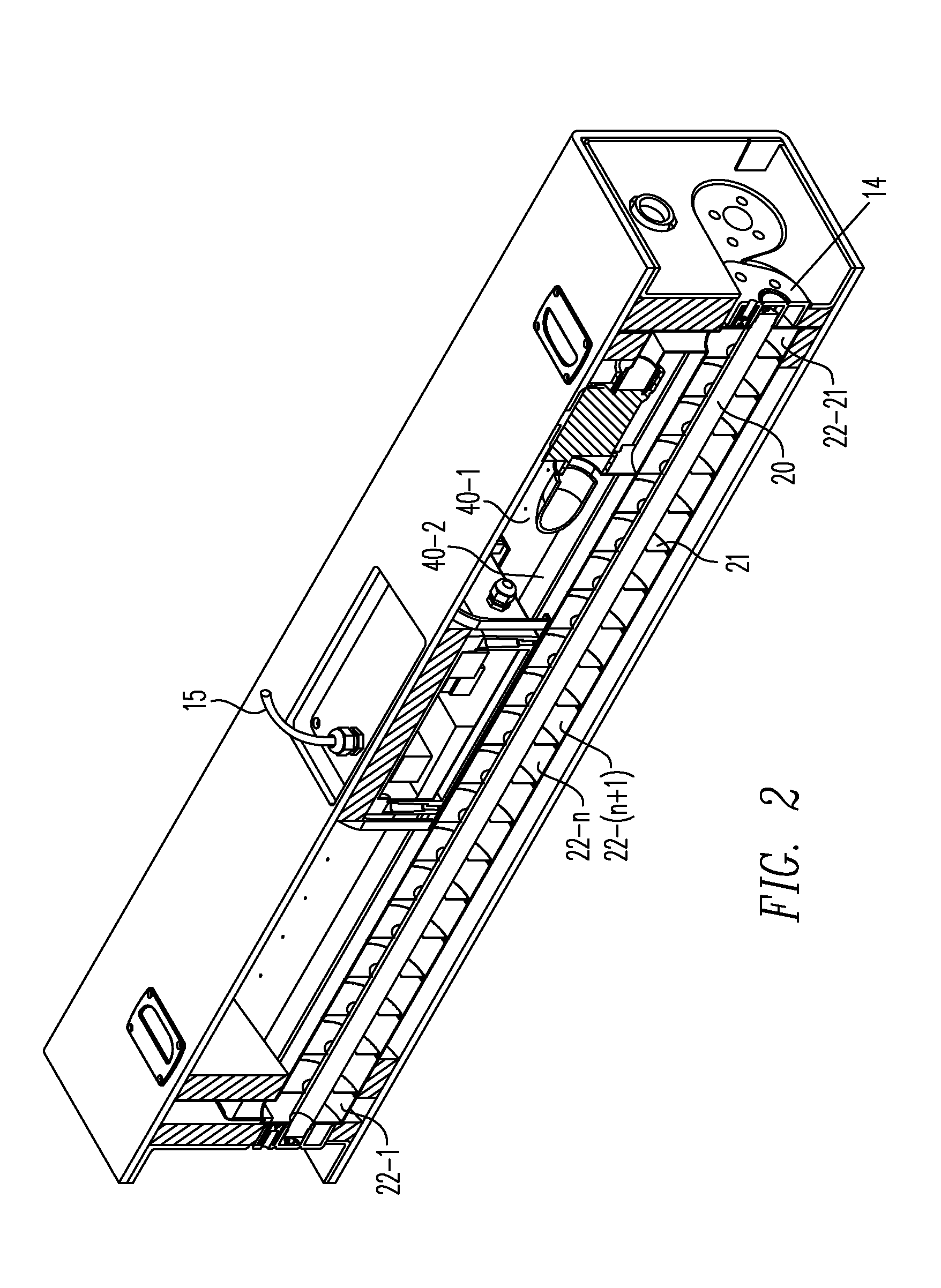

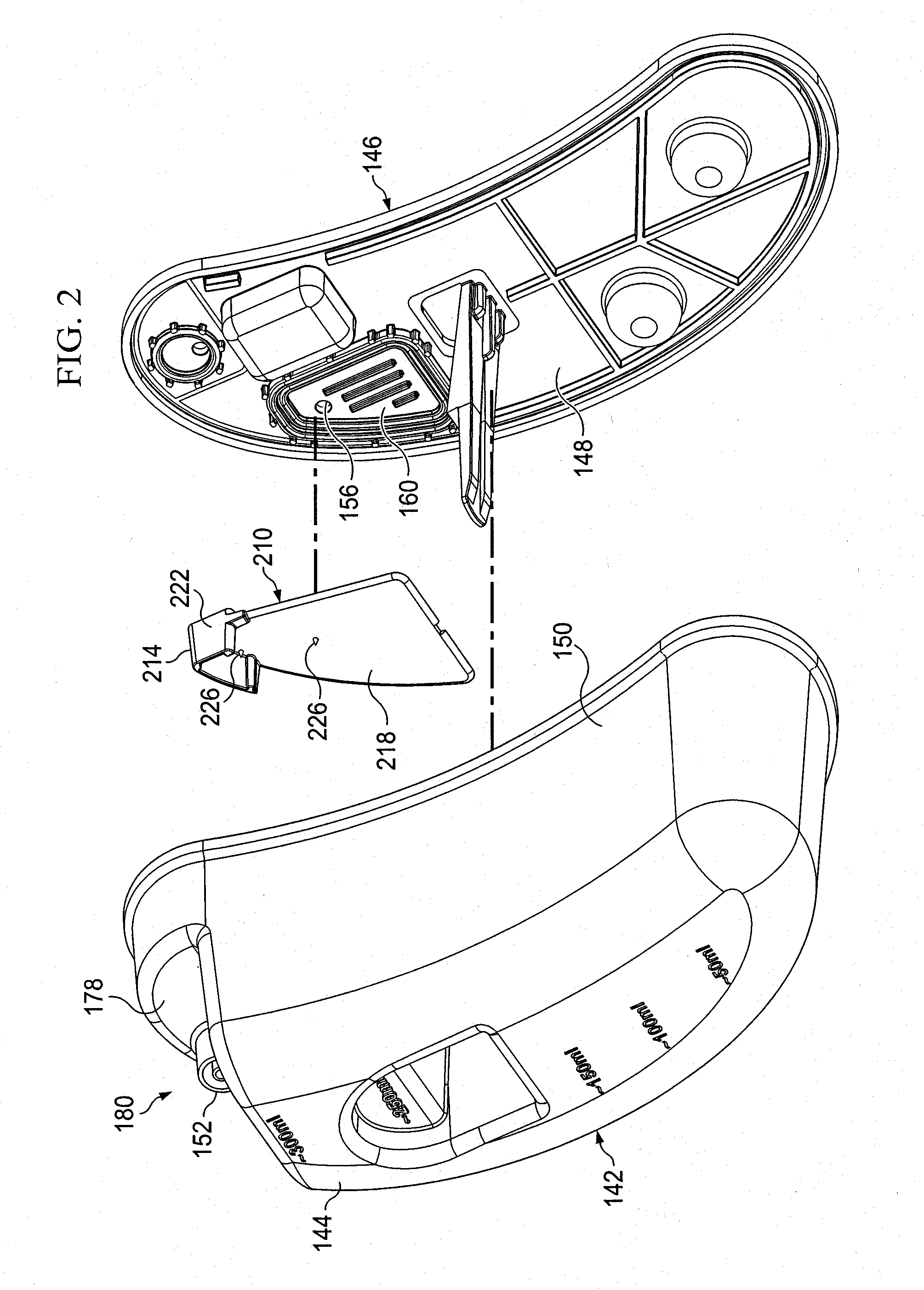

Ultraviolet water purification system

ActiveUS20090084734A1Inhibits ultraviolet disinfectionImprove efficiencySamplingExhaust apparatusWireless mesh networkClosed loop feedback

An Ultraviolet-C (UVC) based portable water purification system employing a novel array of baffles increases the efficiency per unit energy of irradiating UVC light in the eradication of pathogens in the water. Closed loop feedback allows monitoring the application of UVC light power to ensure high levels of pathogen eradication. This system is capable of eradicating a wide range of waterborne bacteria, viruses, protozoa, helminthes, yeast, and mold found in natural freshwater sources worldwide. By adding pre- or post-filters, the system can remove harmful organic compounds, pesticides, inorganic compounds and heavy metals from the water. The system can also be used to eradicate pathogens in fluids other than water. As a feature of this invention, a communications systems that can reach geographically dispersed populations at low cost without the need to install costly wired communications infrastructure is combined with and powered by the water purification system. In one embodiment, a packet radio system is provided to create nodes in a wireless mesh communications system to provide voice, data, video and internet communications using an array of the water purifiers to create a wireless mesh network.

Owner:WATER OF LIFE

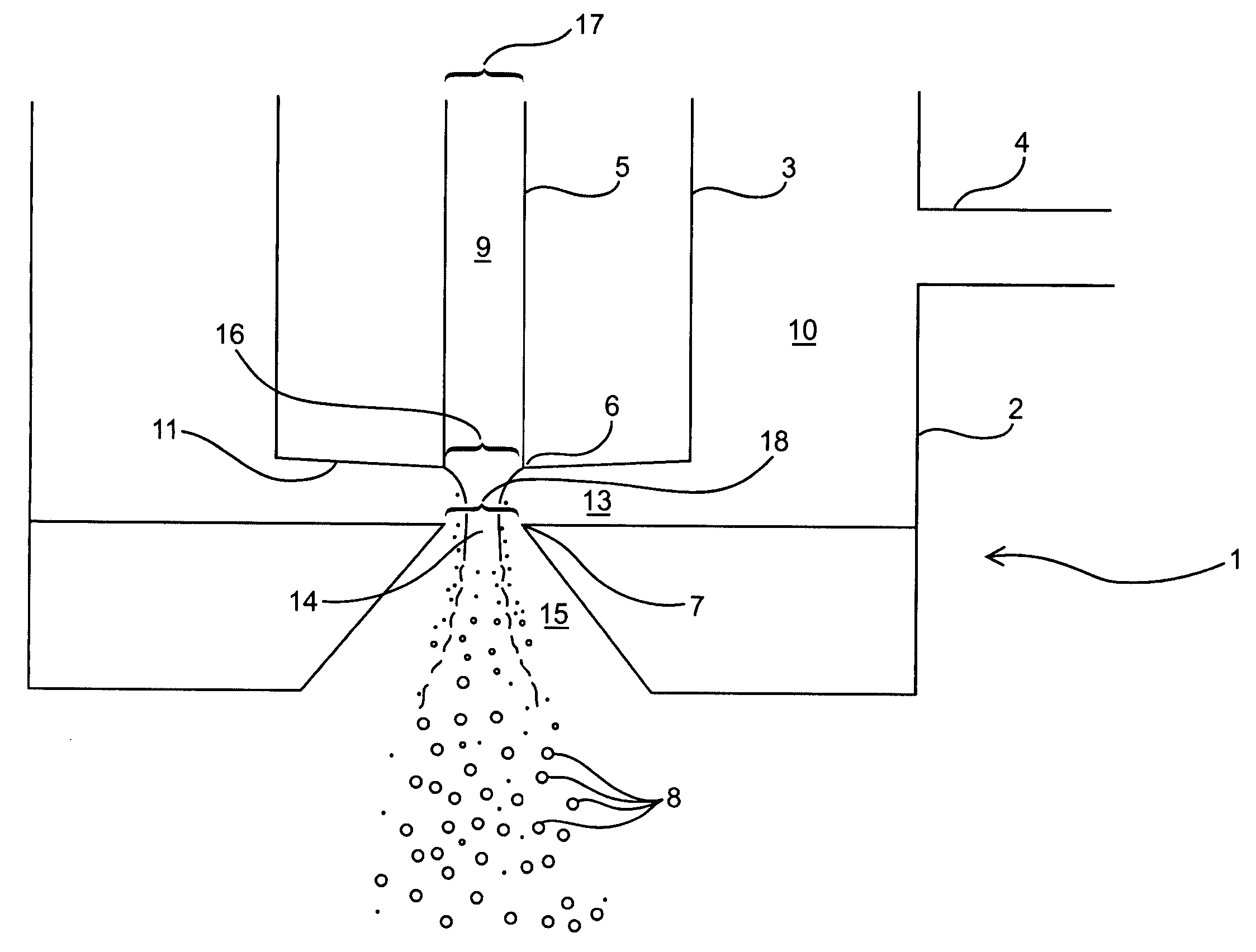

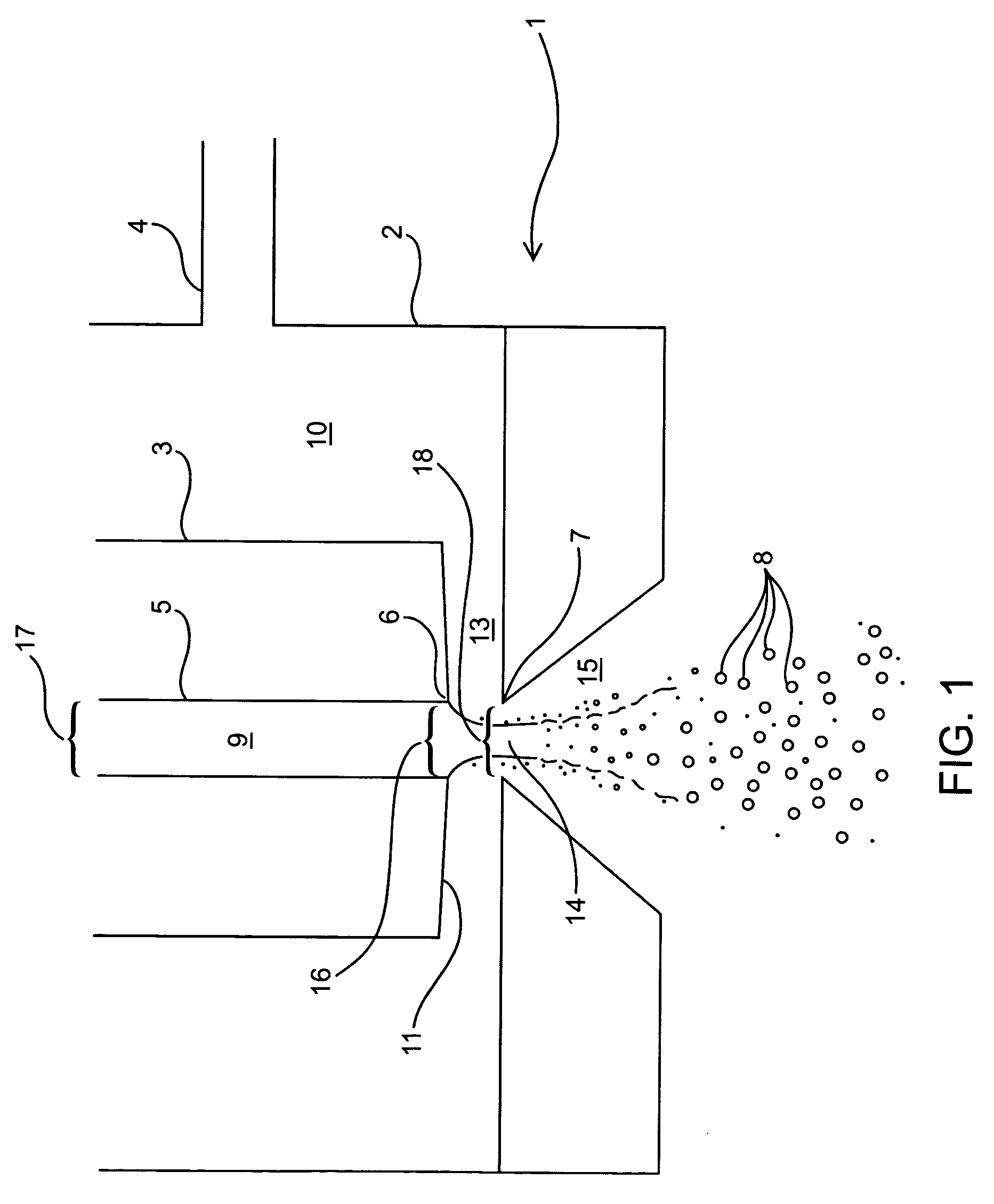

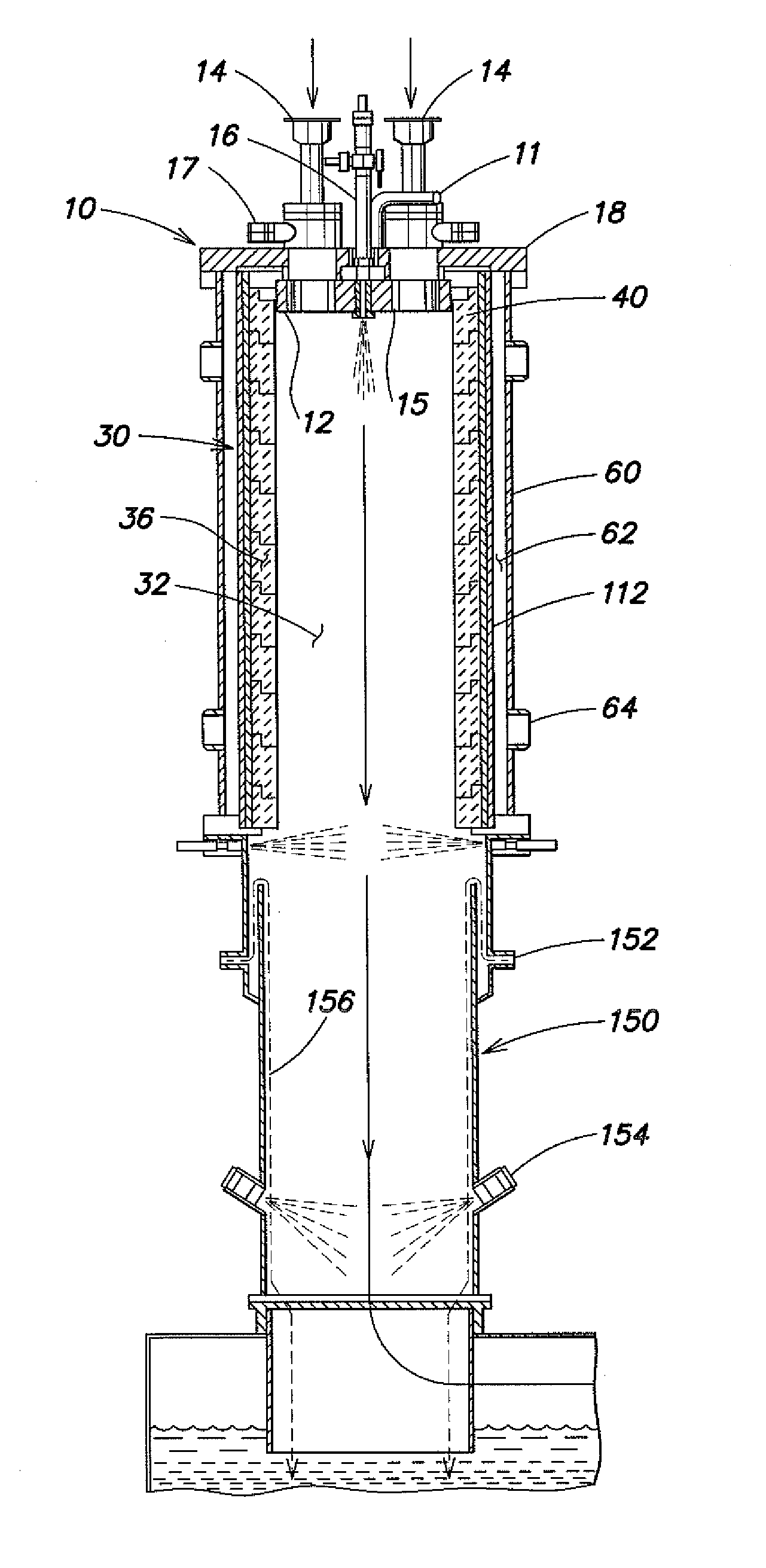

Aerosol created by directed flow of fluids and devices and methods for producing same

InactiveUS20060169800A1Efficient deliveryEasy to manufactureSpray nozzlesLiquid spraying apparatusEngineeringSmall particle

A method of creating small particles by a technology referred to here as “violent focusing” is disclosed, along with devices for generating such violent focusing. In general, the method comprises the steps of forcing a first fluid out of an exit opening of the feeding channel to create a fluid stream. The exit opening is positioned such that the fluid flowing out of the channel flows toward and out of an exit orifice of a pressure chamber which surrounds the exit opening of the feeding channel, and is filled with an atomizing fluid. An atomizing fluid such as a gas is directed towards the first fluid stream in approximately orthogonal directions and surrounding the circumference of the first fluid stream from all sides. The first fluid flow is broken into particles which have dimensions which are smaller than the dimensions of this fluid stream.

Owner:ARADIGM +1

Pecvd multi-step processing with continuous plasma

InactiveUS20110151142A1Reduce defectsReduce depositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingAtomic layer depositionMaterials science

Embodiments of the present invention provide methods for reducing defects during multi-layer deposition. In one embodiment, the method includes exposing the substrate to a first gas mixture and an inert gas in the presence of a plasma to deposit a first material layer on the substrate, terminating the first gas mixture when a desired thickness of the first material is achieved while still maintaining the plasma and flowing the inert gas, and exposing the substrate to the inert gas and a second gas mixture that are compatible with the first gas mixture in the presence of the plasma to deposit a second material layer over the first material layer in the same processing chamber, wherein the first material layer and the second material layer are different from each other.

Owner:APPLIED MATERIALS INC

Apparatus for and method of sampling and collecting powders flowing in a gas stream

InactiveUS20060096393A1High purity samplingEnough timeCombination devicesSequential/parallel process reactionsEngineeringAirflow

A device for sampling of a mixture of ultrafine particles within a moving gas stream includes a suction generator, at least one sample collection element, and a conduit structure coupling the sample collection element with the suction generator. In some embodiments, the suction generator is configurable to separate by suction a portion of a gas stream containing a plurality of ultrafine particles, and to entrain with a motive fluid forming an output mixture. In some embodiments, a conduit is configured to accept a gas stream containing ultrafine particles and to channel it to the collection element.

Owner:UMICORE AG & CO KG +1

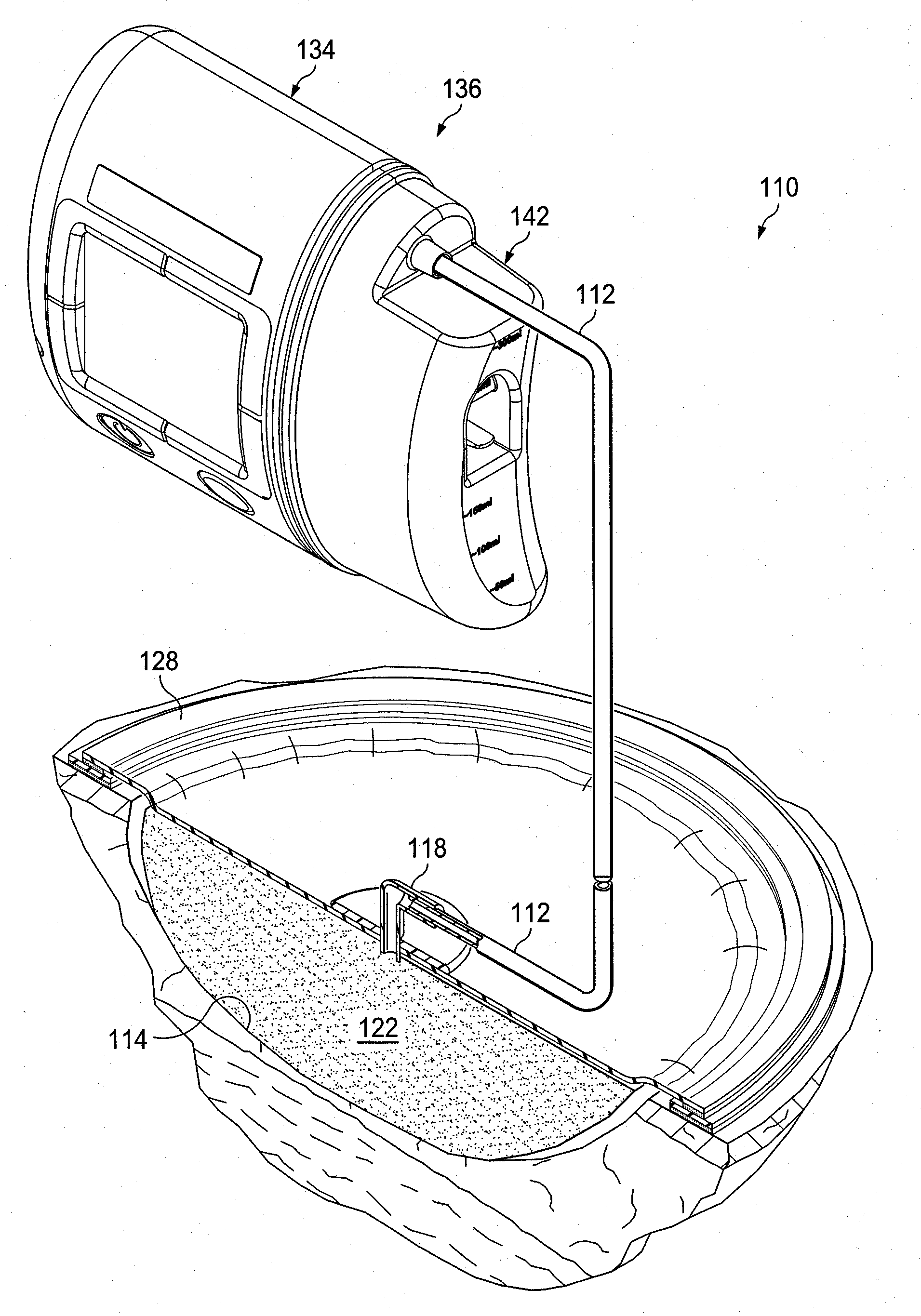

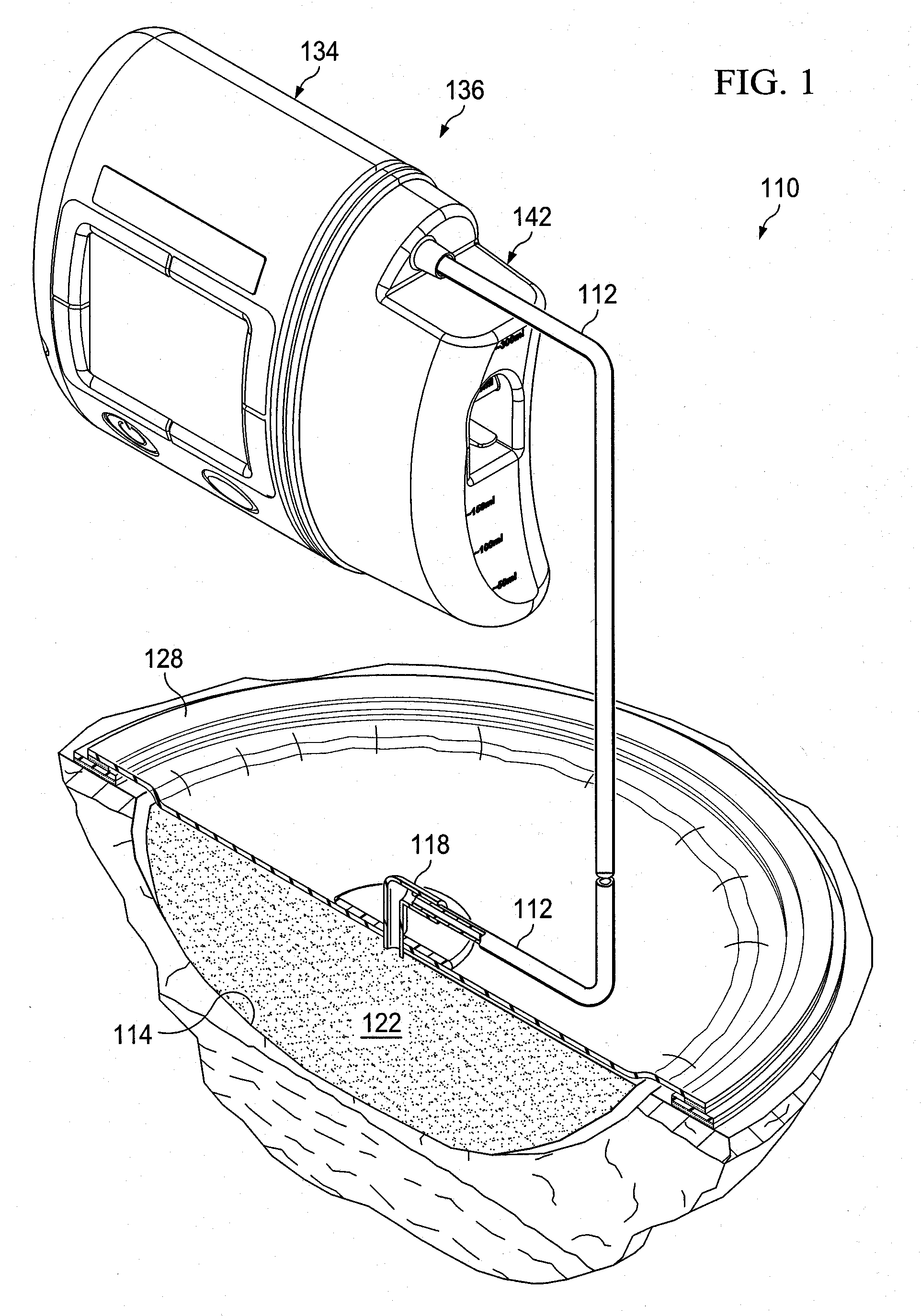

System and method for collecting exudates

A reduced pressure treatment system includes a porous pad positioned at a tissue site and a canister having a collection chamber, an inlet, and an outlet. The inlet is fluidly connected to the porous pad. A reduced pressure source is fluidly connected to the outlet of the canister to such that fluid from the tissue site may be drawn into the collection chamber. A hydrophobic filter is positioned adjacent the outlet to prevent liquid from exiting the collection chamber through the outlet. A baffle is positioned within the canister to create a tortuous path between the inlet and the outlet to prevent premature blocking of the hydrophobic filter.

Owner:3M INNOVATIVE PROPERTIES CO

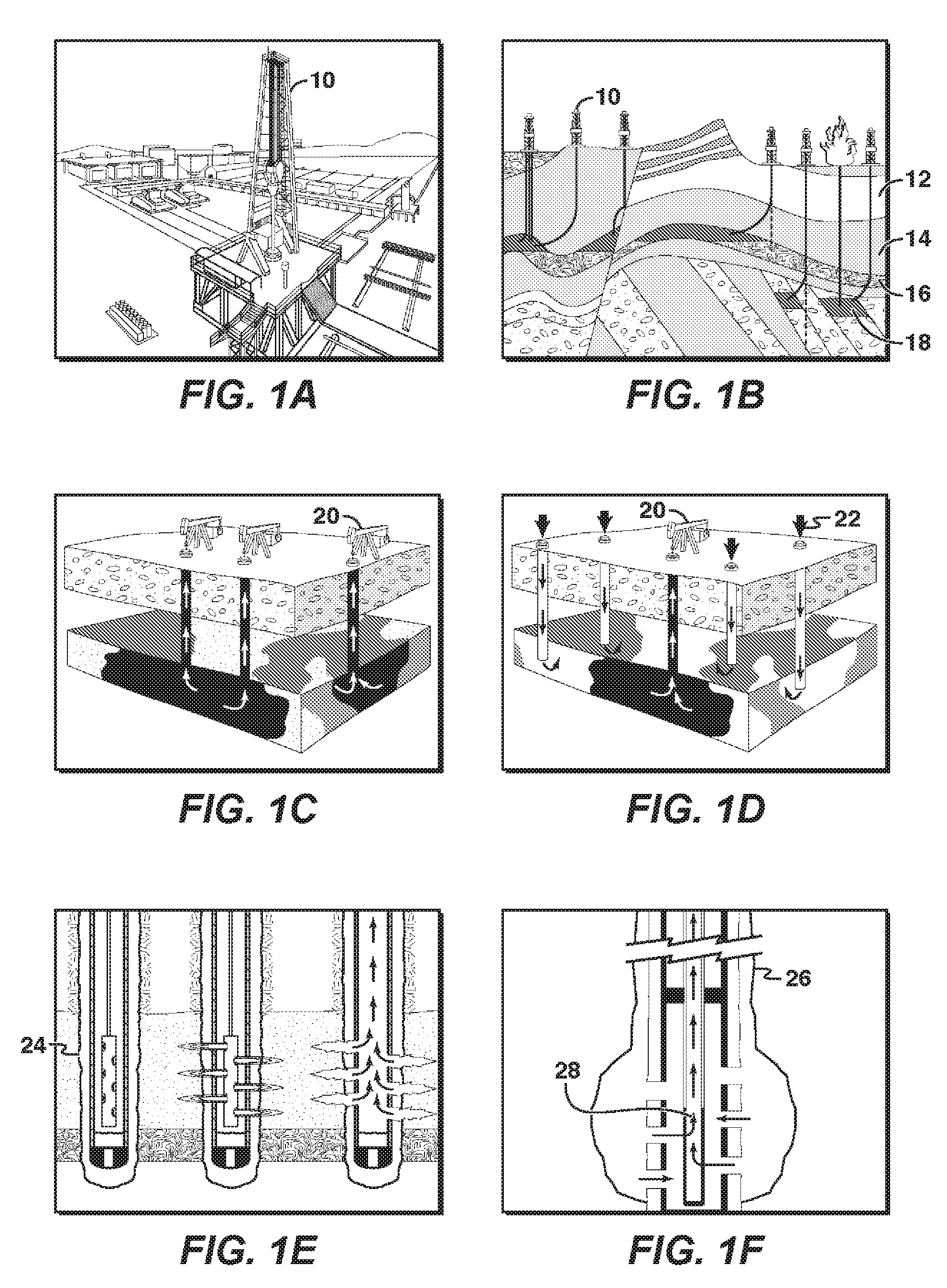

Coated sleeved oil and gas well production devices

ActiveUS20110203791A1Reduce frictionReduce wearDrilling rodsFluid removalLow frictionPetroleum engineering

Provided are coated sleeved oil and gas well production devices and methods of making and using such coated sleeved devices. In one form, the coated sleeved oil and gas well production device includes one or more cylindrical bodies, one or more sleeves proximal to the outer diameter or inner diameter of the one or more cylindrical bodies, hardbanding on at least a portion of the exposed outer surface, exposed inner surface, or a combination of both exposed outer or inner surface of the one or more sleeves, and a coating on at least a portion of the inner sleeve surface, the outer sleeve surface, or a combination thereof of the one or more sleeves. The coating includes one or more ultra-low friction layers, and one or more buttering layers interposed between the hardbanding and the ultra-low friction coating. The coated sleeved oil and gas well production devices may provide for reduced friction, wear, erosion, corrosion, and deposits for well construction, completion and production of oil and gas.

Owner:EXXONMOBIL UPSTREAM RES CO

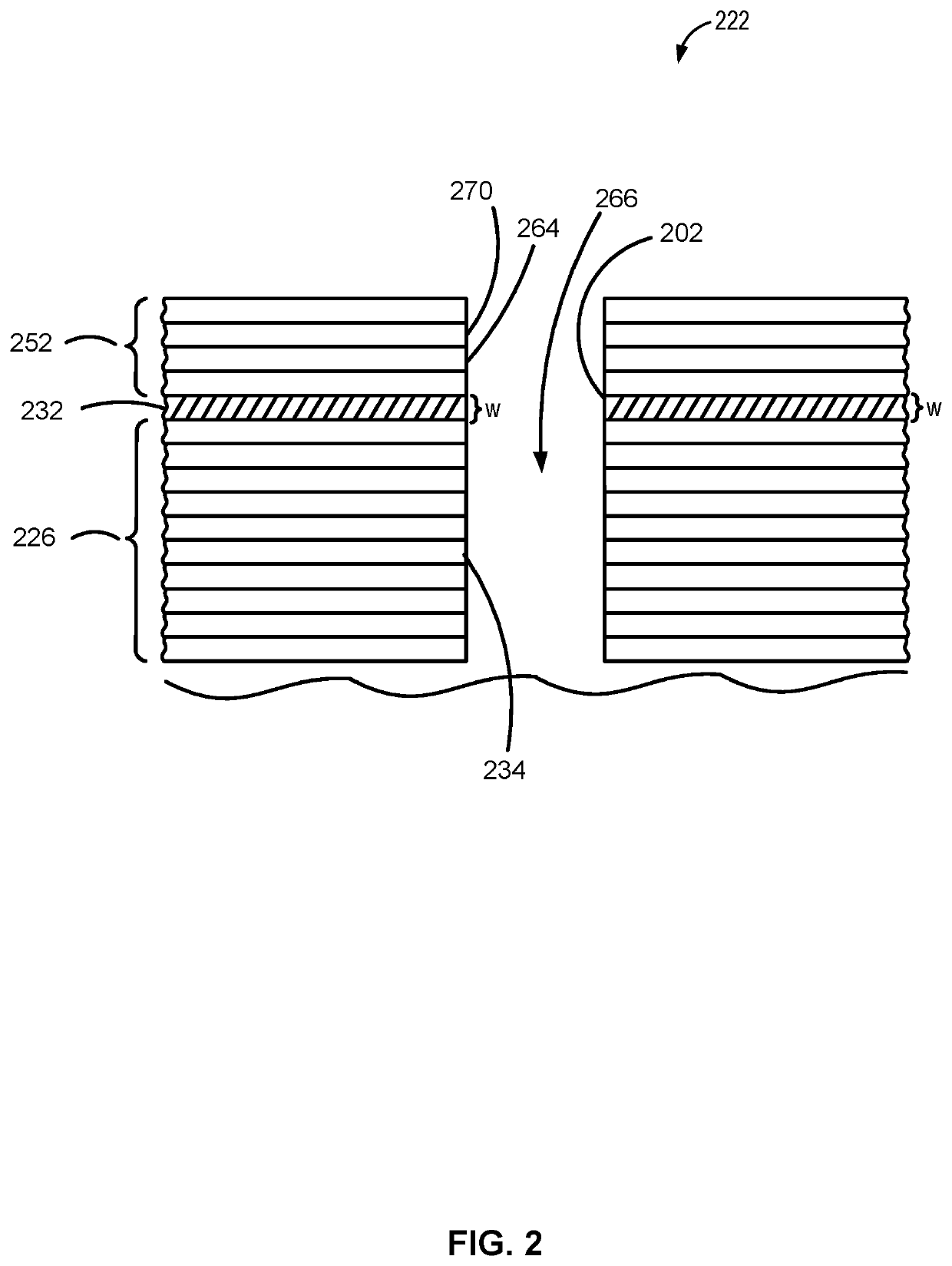

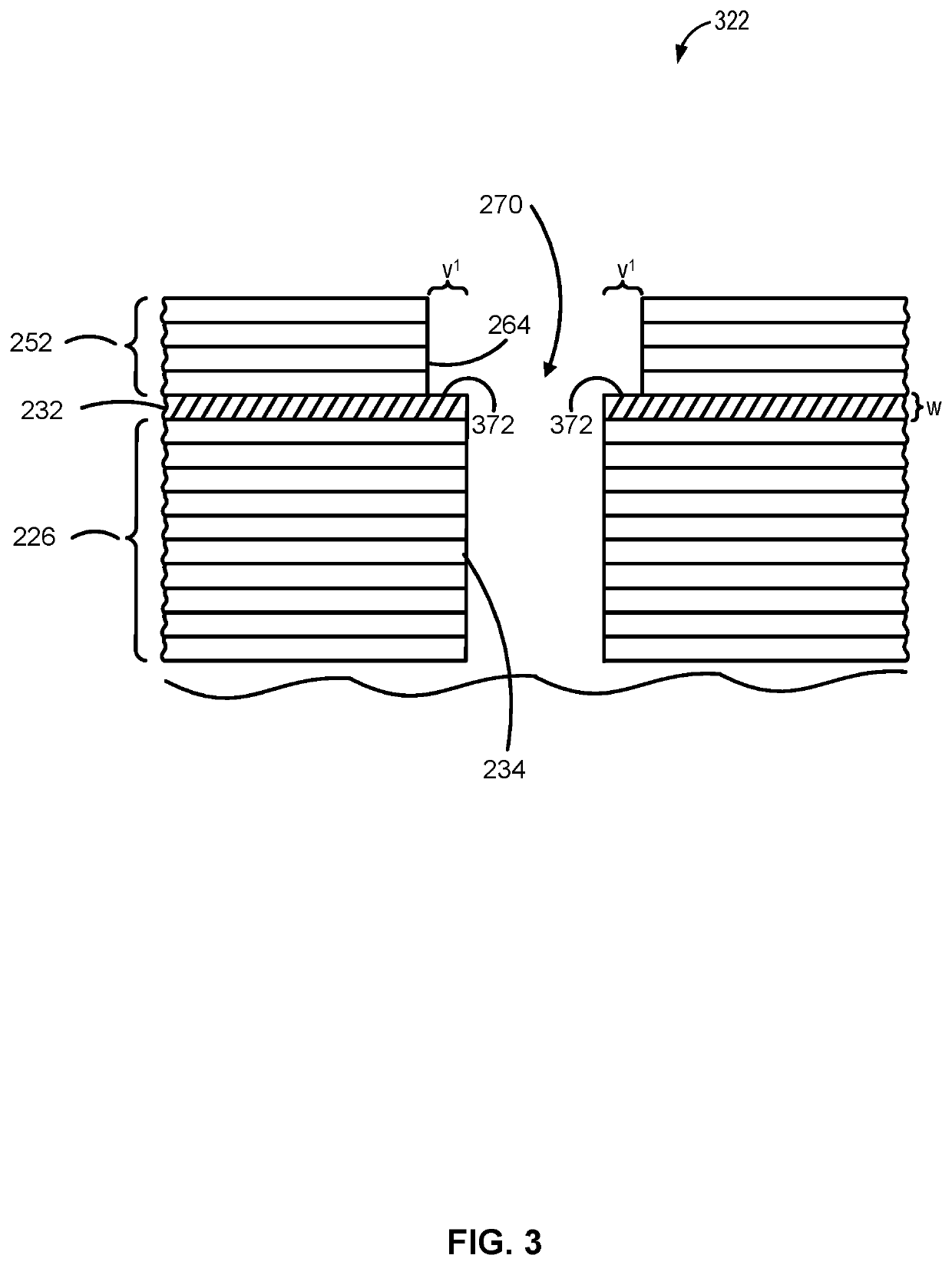

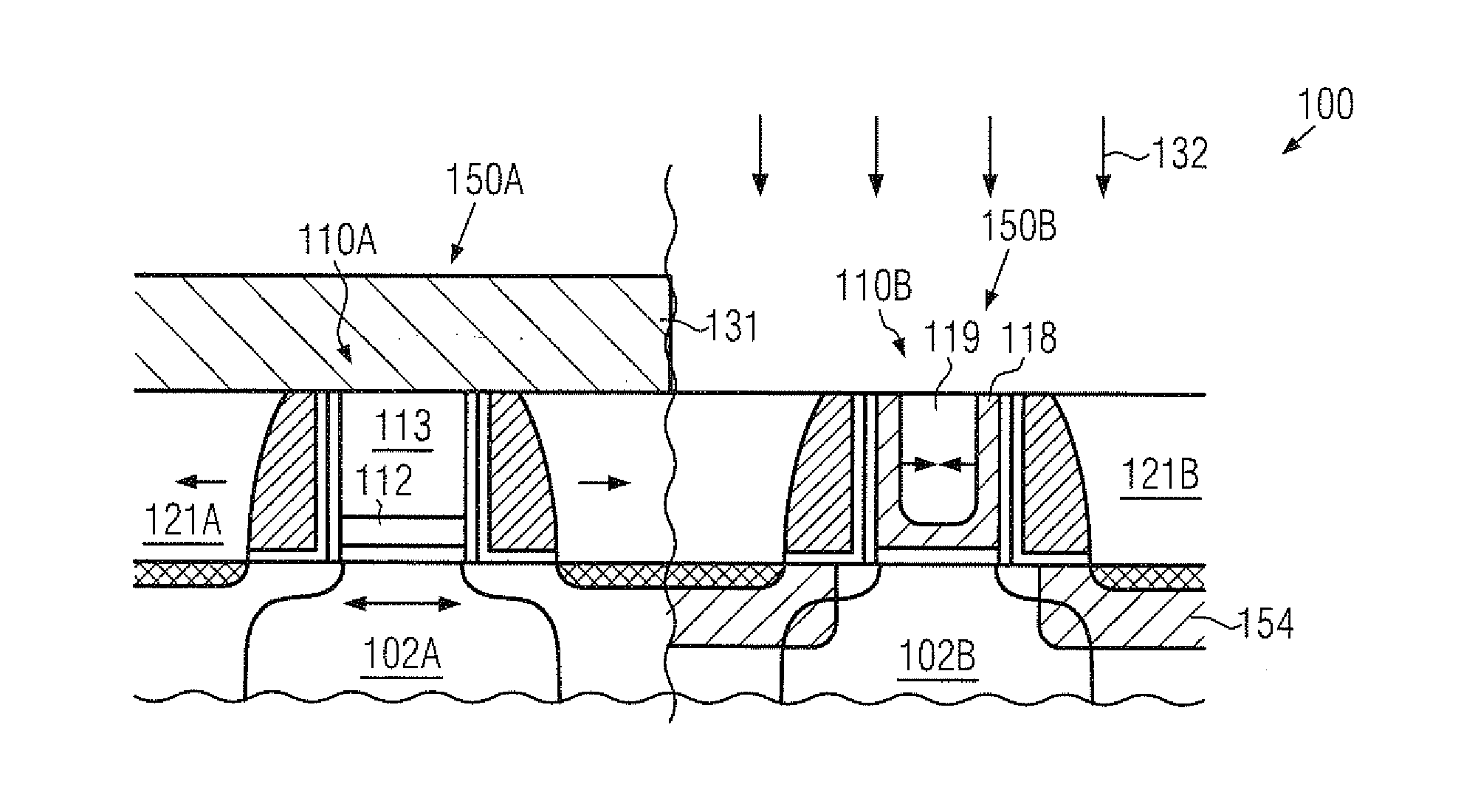

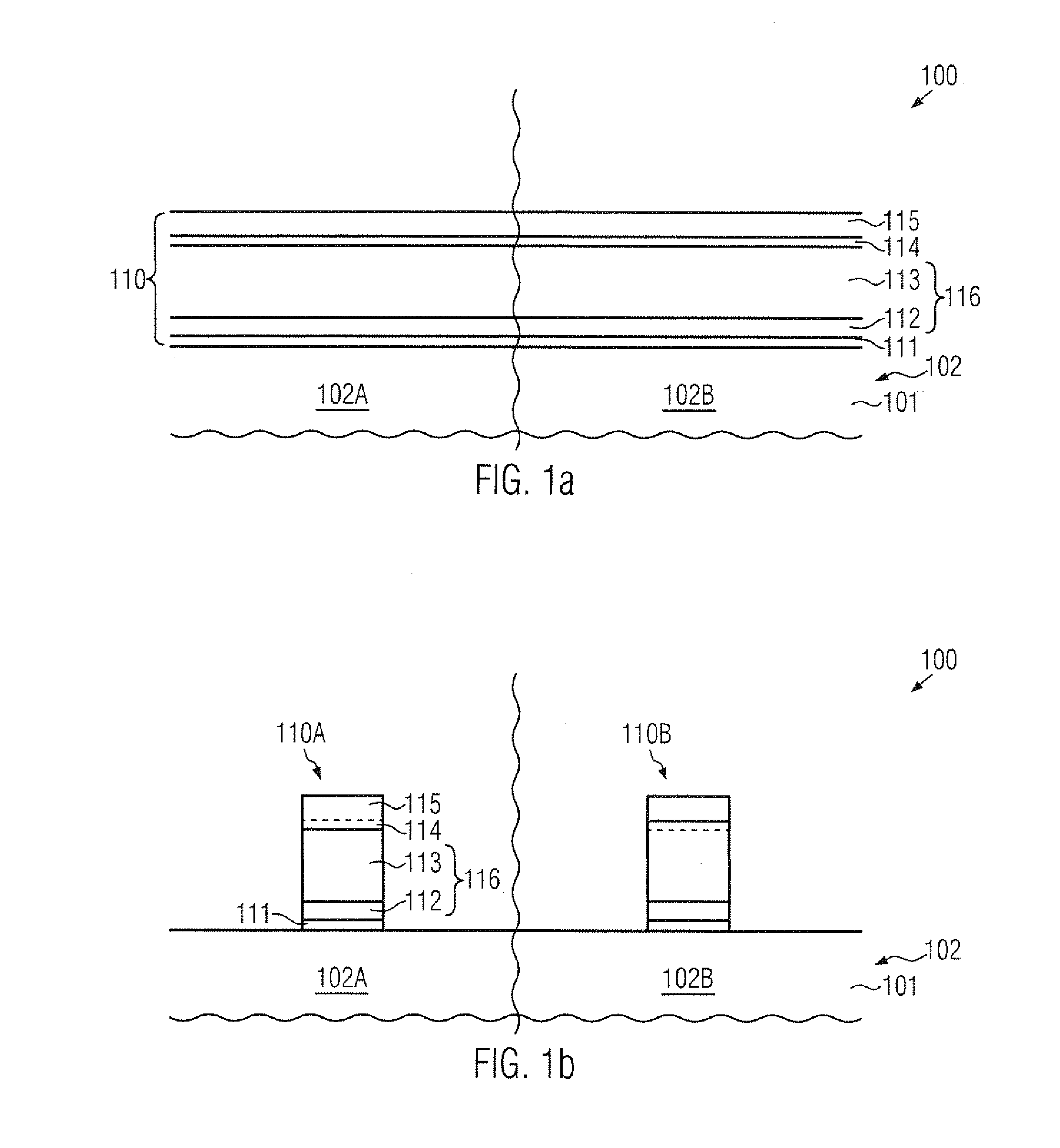

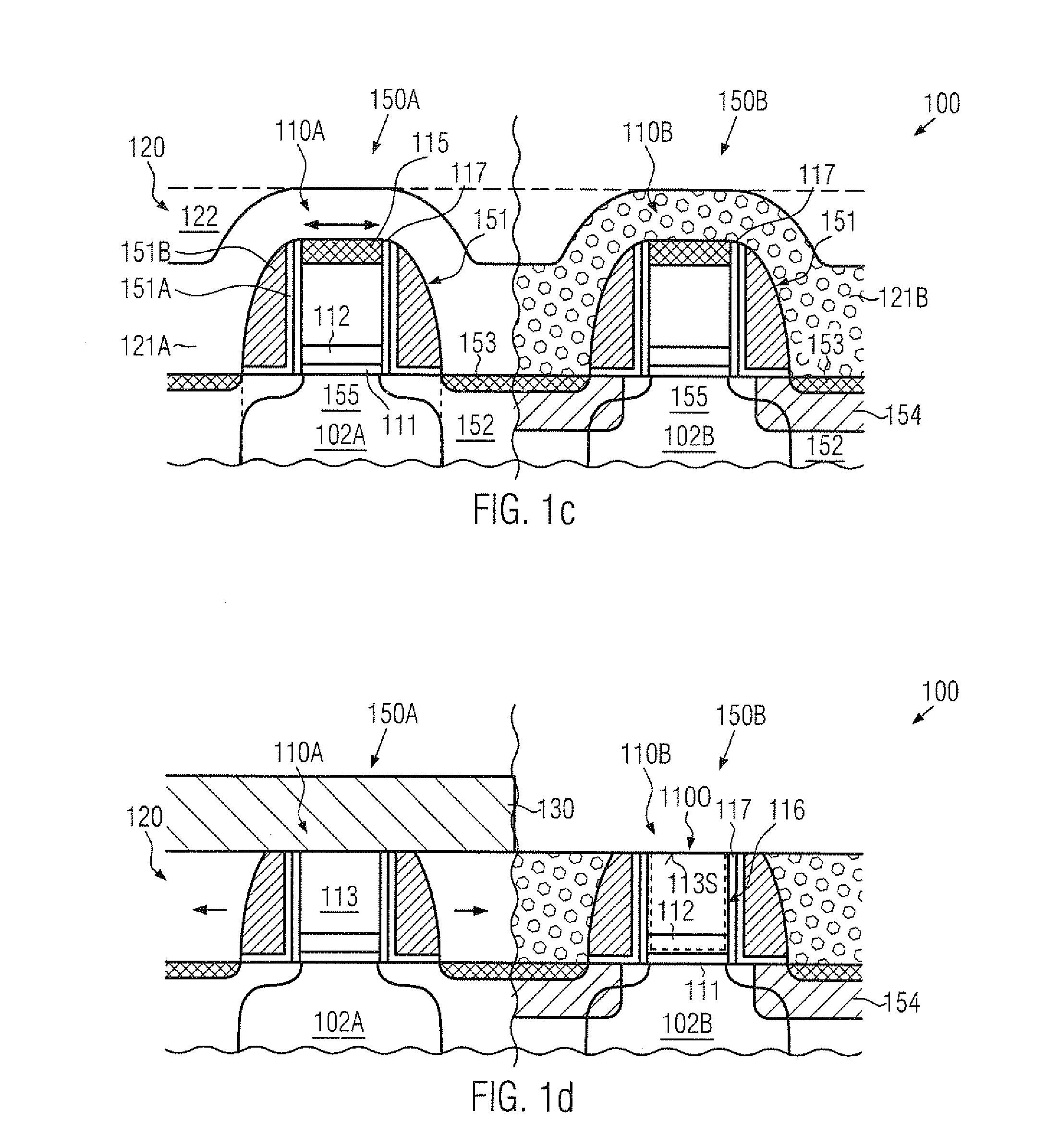

High-k metal gate electrode structures formed at different process stages of a semiconductor device

ActiveUS20110156154A1Improve device performanceEffective regulationTransistorSemiconductor/solid-state device manufacturingWork functionGate stack

Sophisticated high-k metal gate electrode structures are provided on the basis of a hybrid process strategy in which the work function of certain gate electrode structures is adjusted in an early manufacturing stage, while, in other gate electrode structures, the initial gate stack is used as a dummy material and is replaced in a very advanced manufacturing stage. In this manner, superior overall process robustness in combination with enhanced device performance may be achieved.

Owner:GLOBALFOUNDRIES US INC

Artificial tear replacement solution

InactiveUS7001607B1Reduce wearGood film formingHalogenated hydrocarbon active ingredientsSenses disorderConjunctivaConjunctival sac

A tear replacement solution that contains at least one water-soluble fluorosurfactant, water and a non-polar component, preferably in gel form, and a method for the external treatment for the eye of an mammal by applying the tear replacement solution to the eye, preferably by placing in the conjunctival sac.

Owner:PHARMPUR

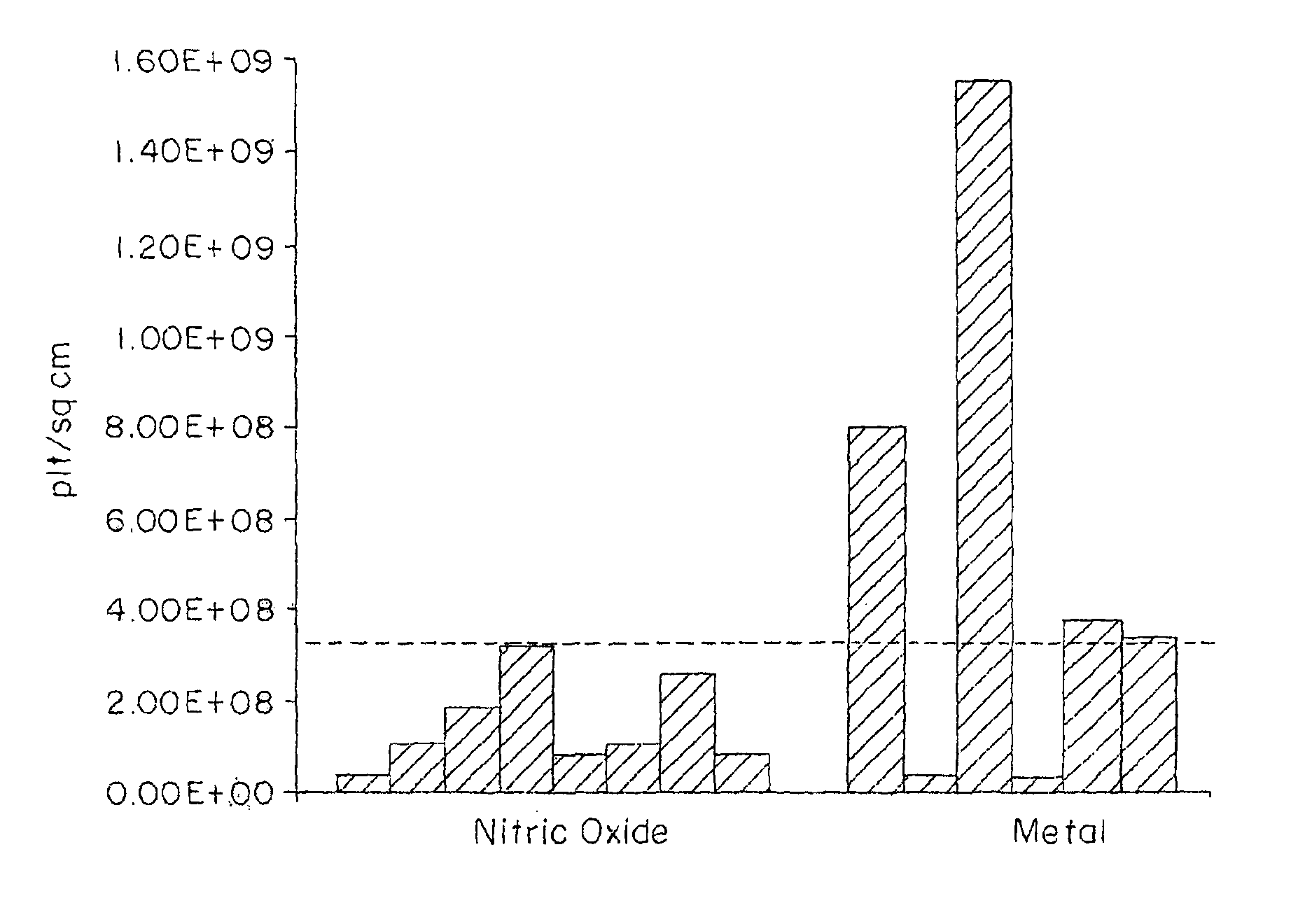

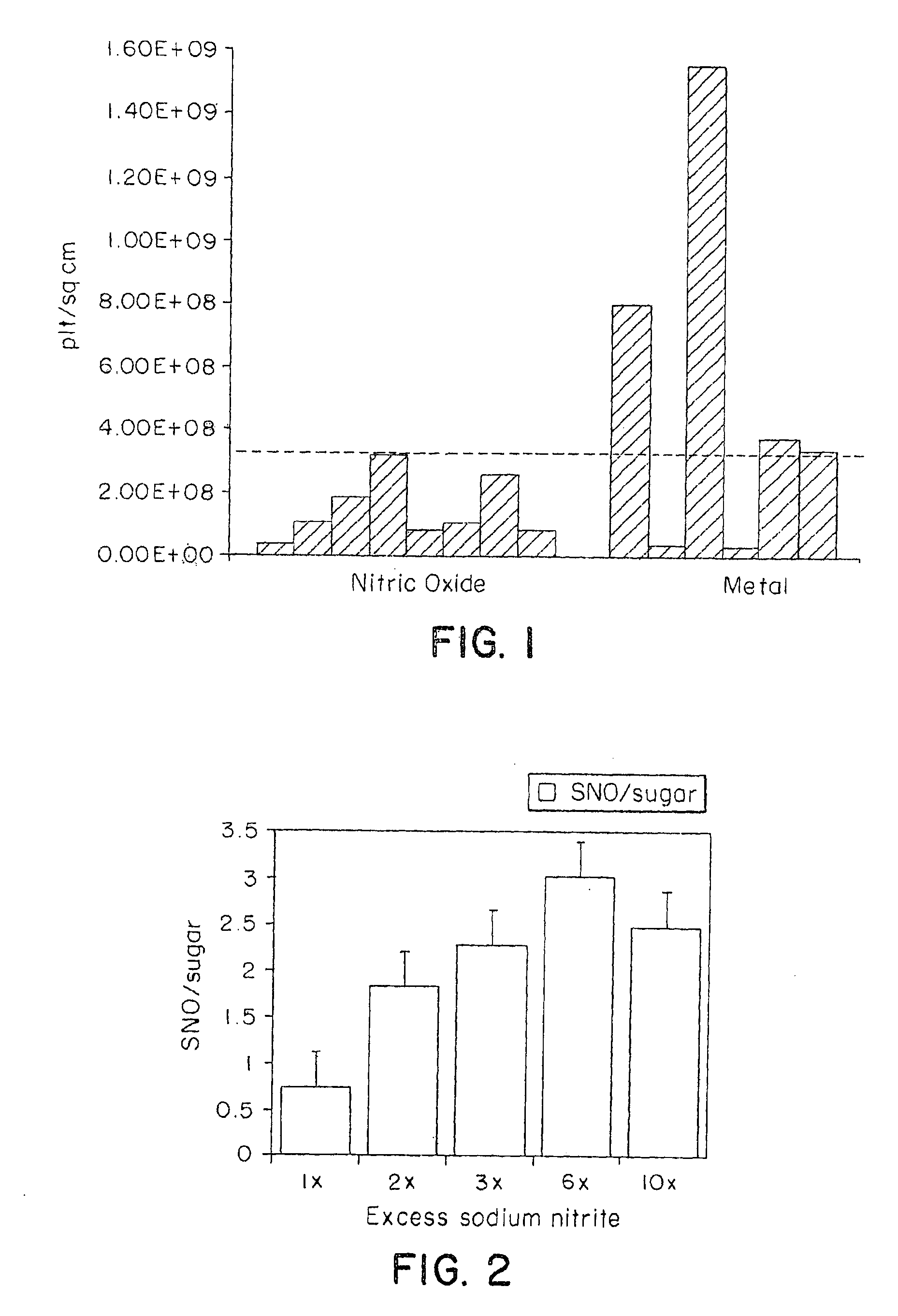

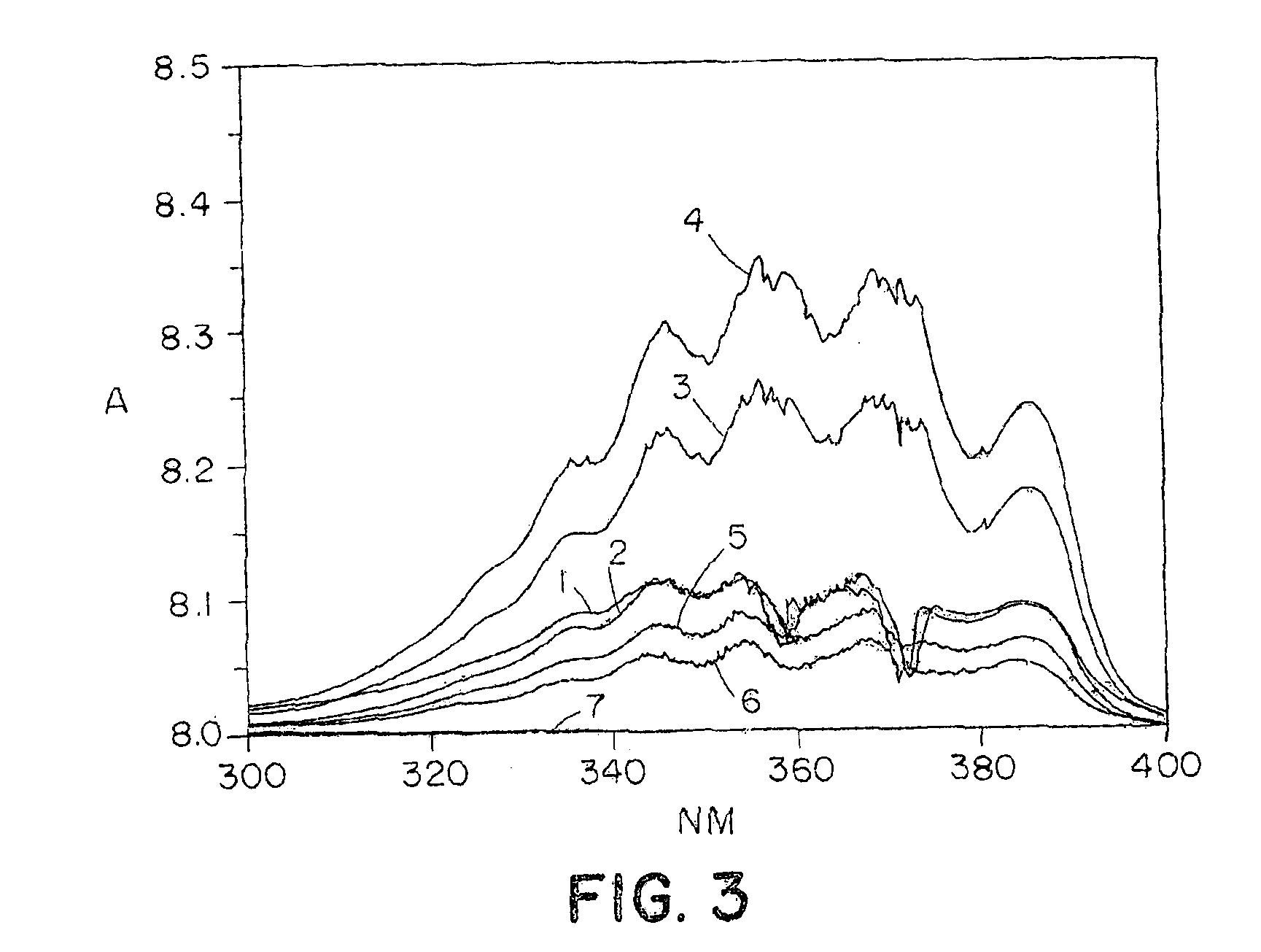

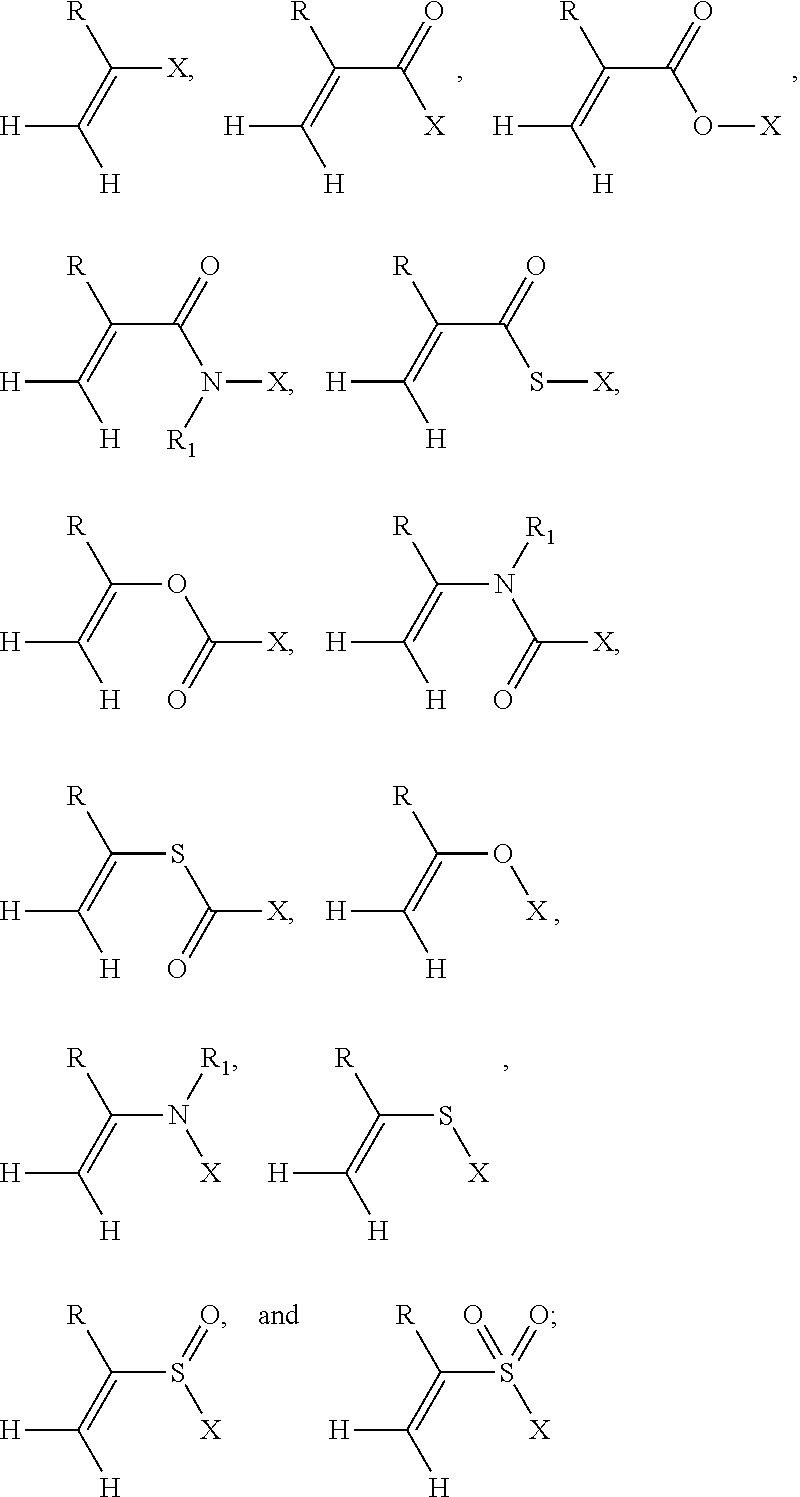

Polymers for delivering nitric oxide in vivo

InactiveUS6875840B2Reducing platelet depositionReduce restenosisOrganic active ingredientsBiocideS-NitrosylationIn vivo

Disclosed are novel polymers derivatized with at least one —NOx group per 1200 atomic mass unit of the polymer. X is one or two. In one embodiment, the polymer is an S-nitrosylated polymer and is prepared by reacting a polythiolated polymer with a nitrosylating agent under conditions suitable for nitrosylating free thiol groups. The polymers of the present invention can be used to coat medical devices to deliver nitric oxide in vivo to treatment sites.

Owner:DUKE UNIV

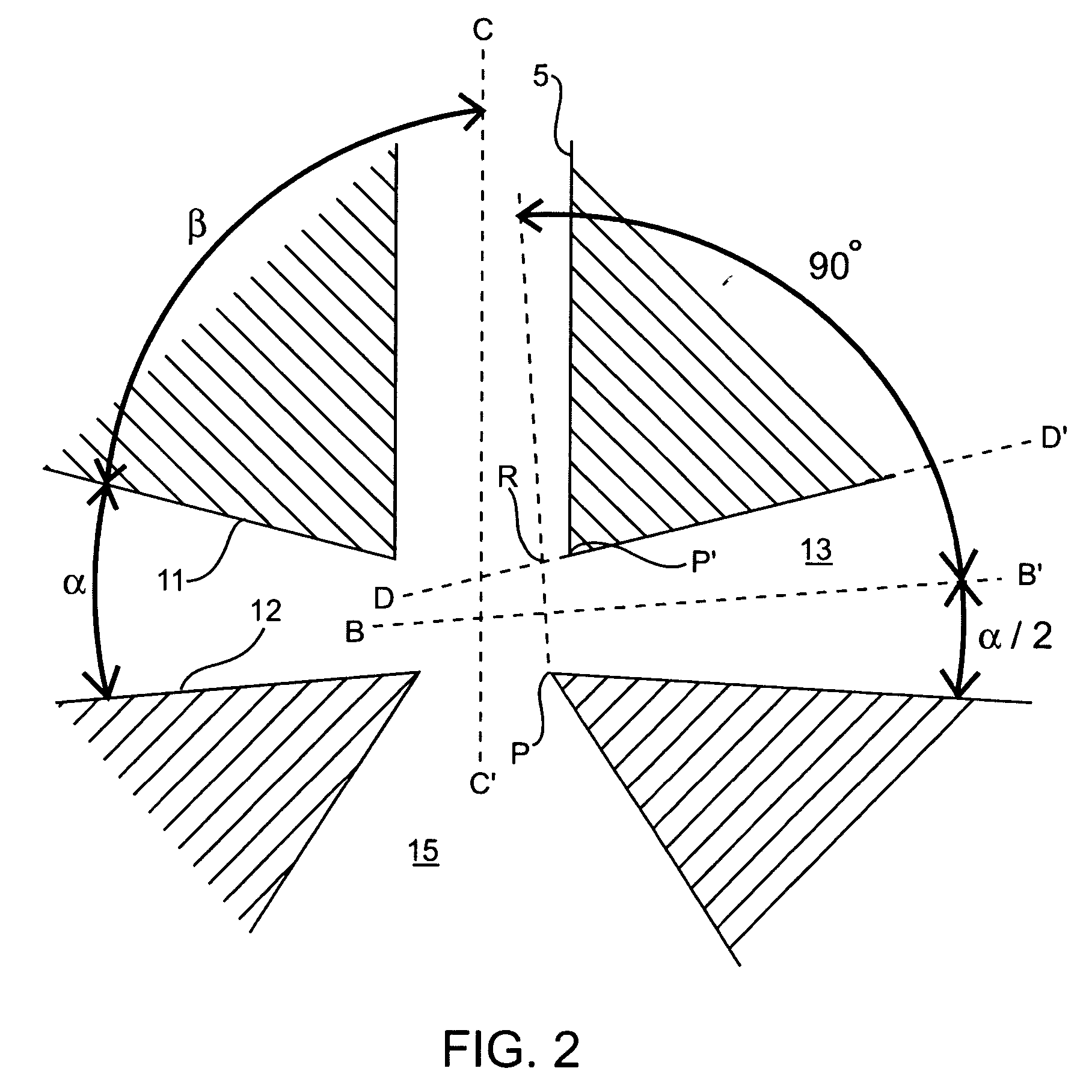

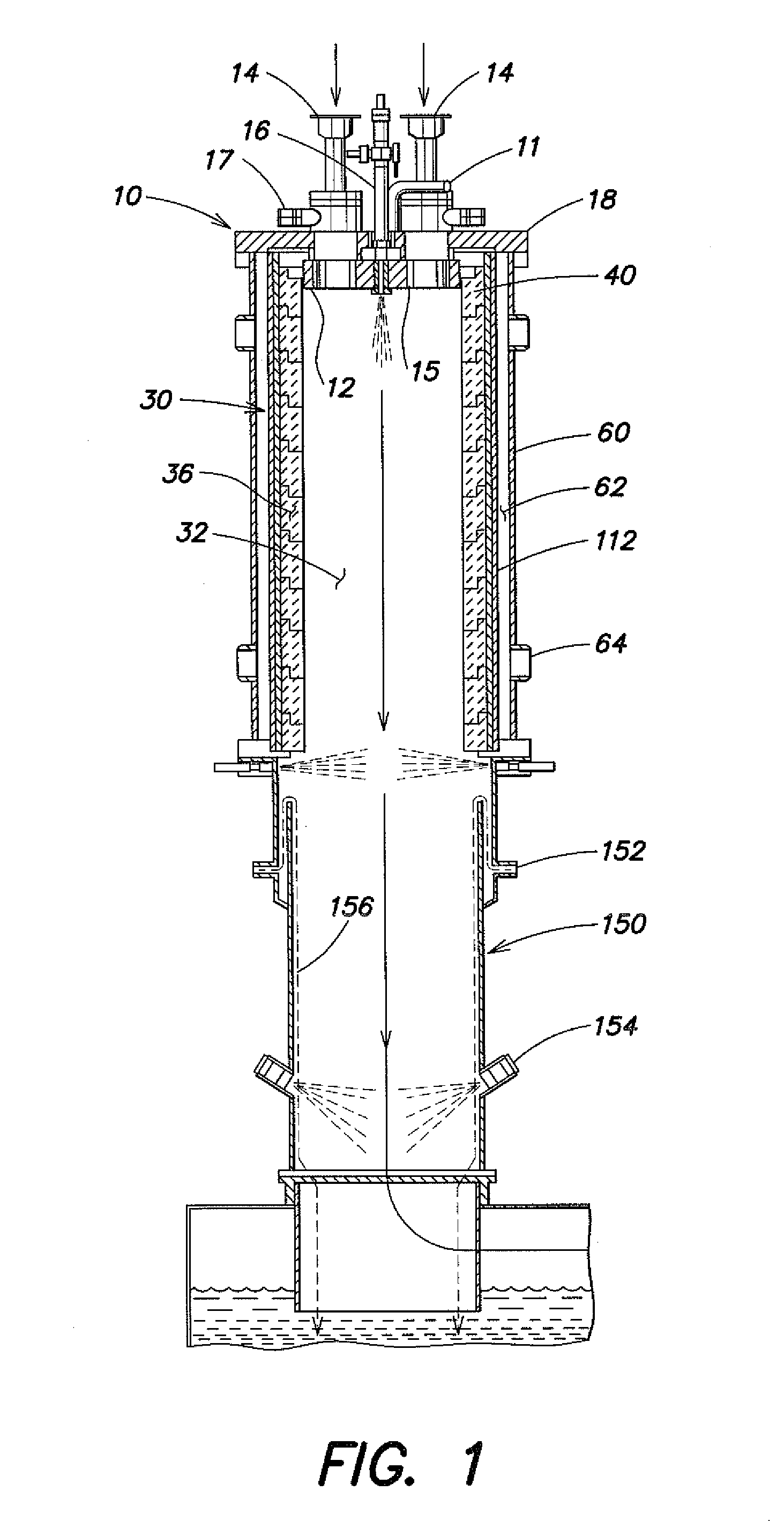

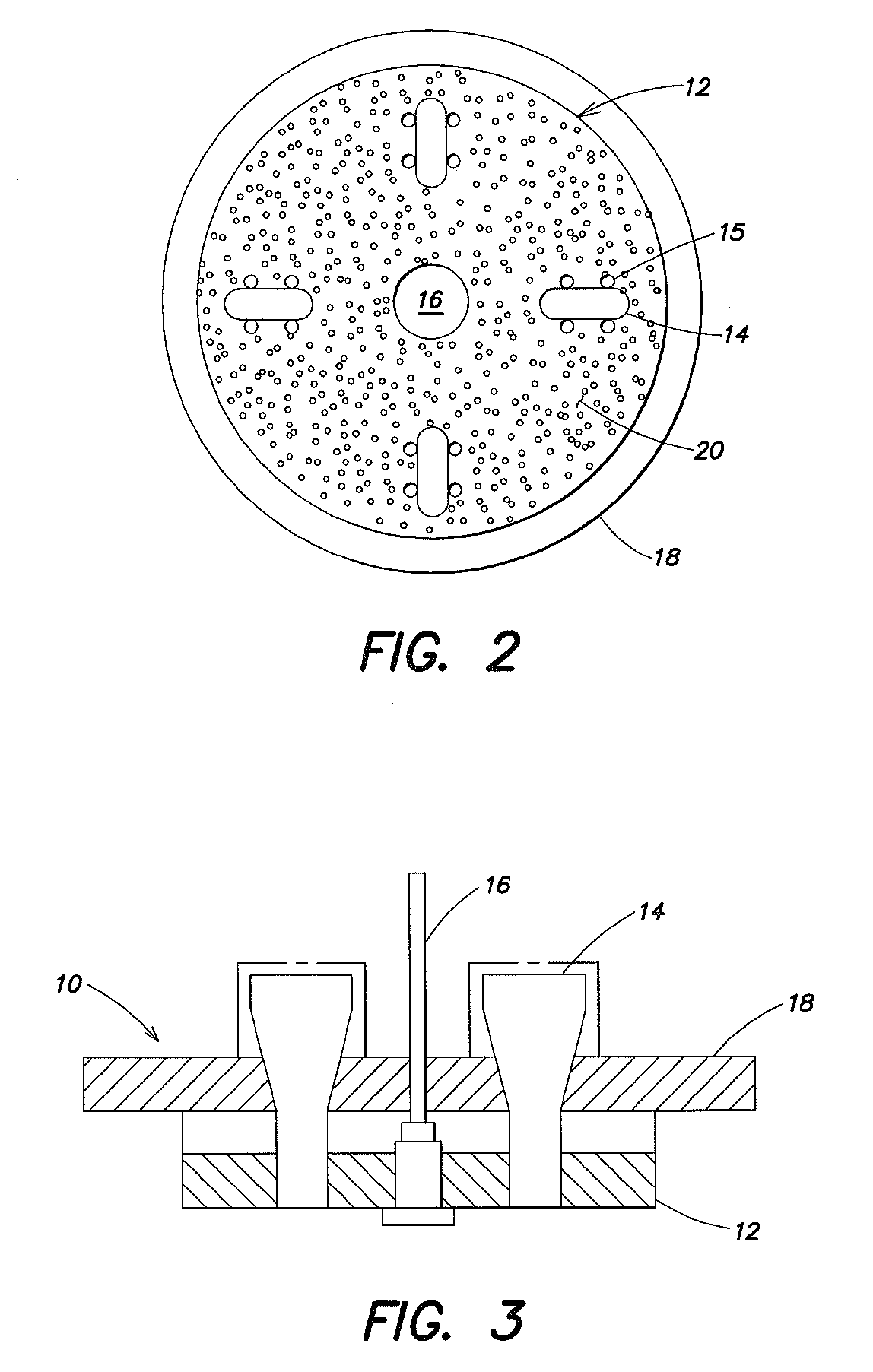

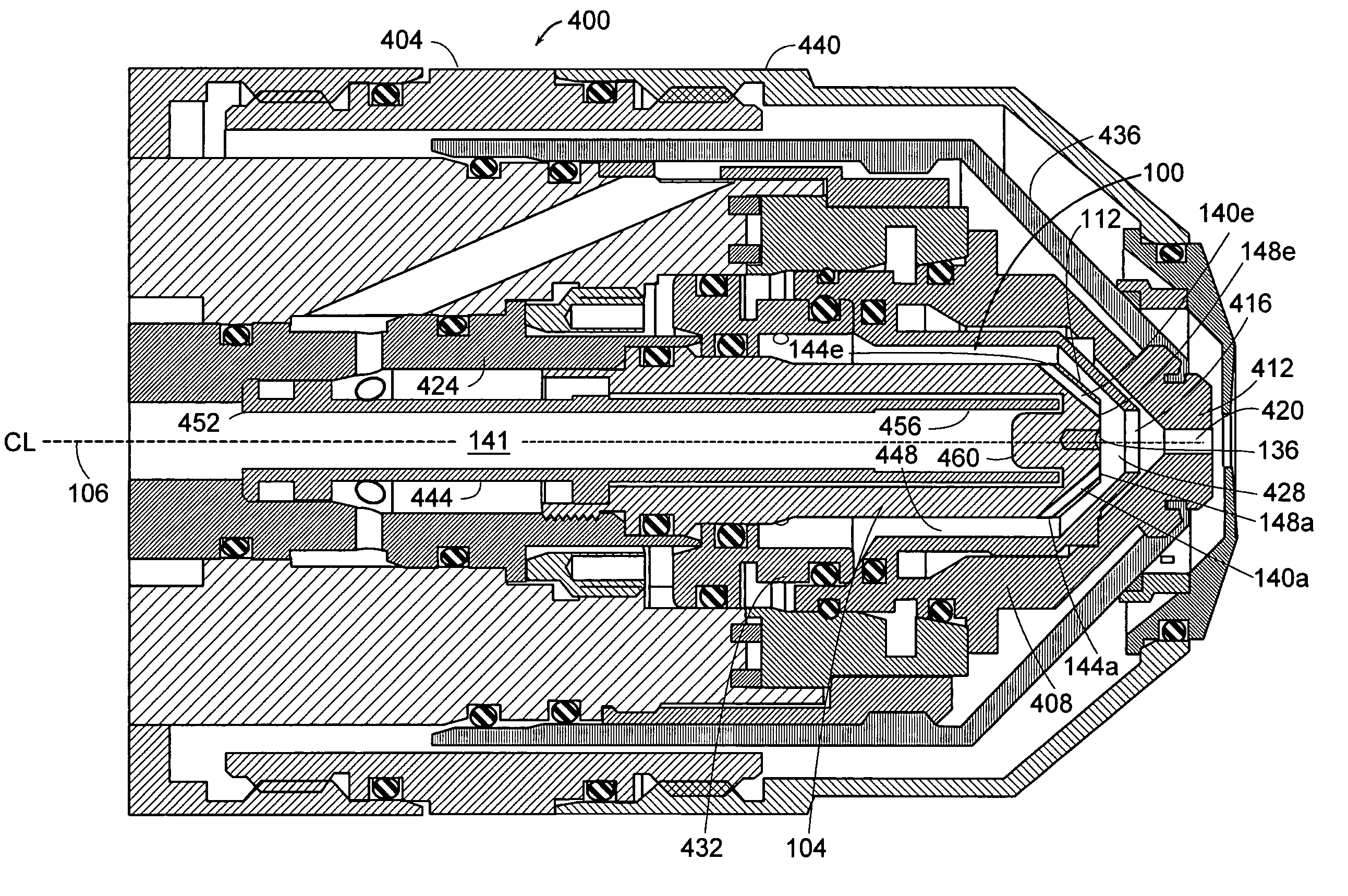

Reactor design to reduce particle deposition during process abatement

InactiveUS20070274876A1Reduce accumulationReduce crackingCombination devicesBurnersCombustionDecomposition

The present invention relates to systems and methods for controlled combustion and decomposition of gaseous pollutants while reducing deposition of unwanted reaction products from within the treatment systems. The systems include a novel thermal reaction chamber design having stacked reticulated ceramic rings through which fluid, e.g., gases, may be directed to form a boundary layer along the interior wall of the thermal reaction chamber, thereby reducing particulate matter buildup thereon. The systems further include the introduction of fluids from the center pilot jet to alter the aerodynamics of the interior of the thermal reaction chamber.

Owner:APPLIED MATERIALS INC

Aerosol processing and inhalation method and system for high dose rate aerosol drug delivery

ActiveUS7802569B2Risk minimizationIncrease dose rateRespiratorsDispersed particle separationCounter flowSolvent vapor

Owner:KAER BIOTHERAPEUTICS CORP

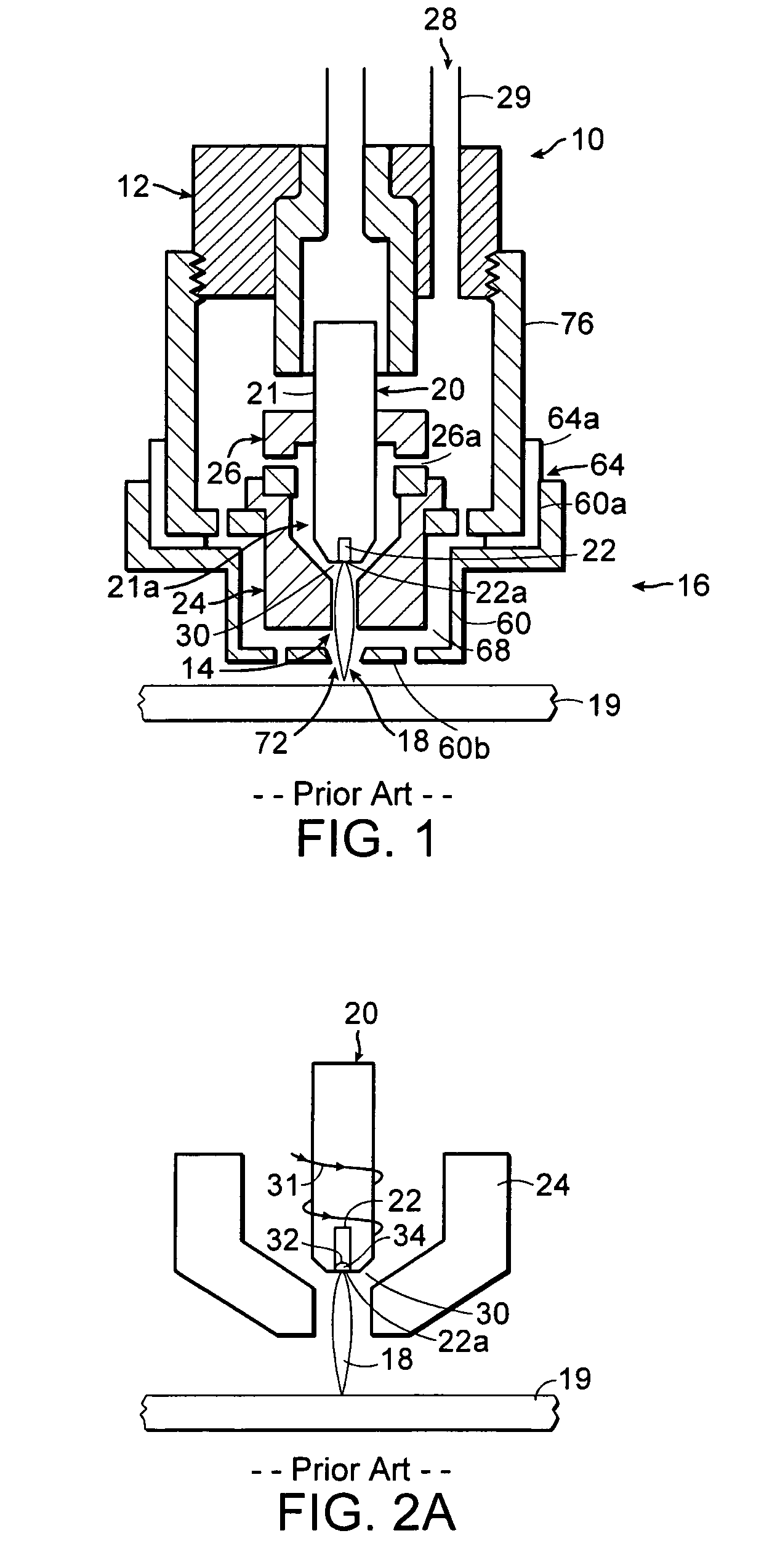

Plasma arc torch having an electrode with internal passages

InactiveUS7375302B2Reduce wearHigh emissivityArc welding apparatusPlasma welding apparatusEmissivityTorch

An electrode for a plasma arc cutting torch which minimizes the deposition of high emissivity material on the nozzle, reduces electrode wear, and improves cut quality. The electrode has a body having a first end, a second end in a spaced relationship relative to the first end, and an outer surface extending from the first end to the second end. The body has an end face disposed at the second end. The electrode also includes at least one passage extending from a first opening in the body to a second opening in the end face.

Owner:HYPERTHERM INC

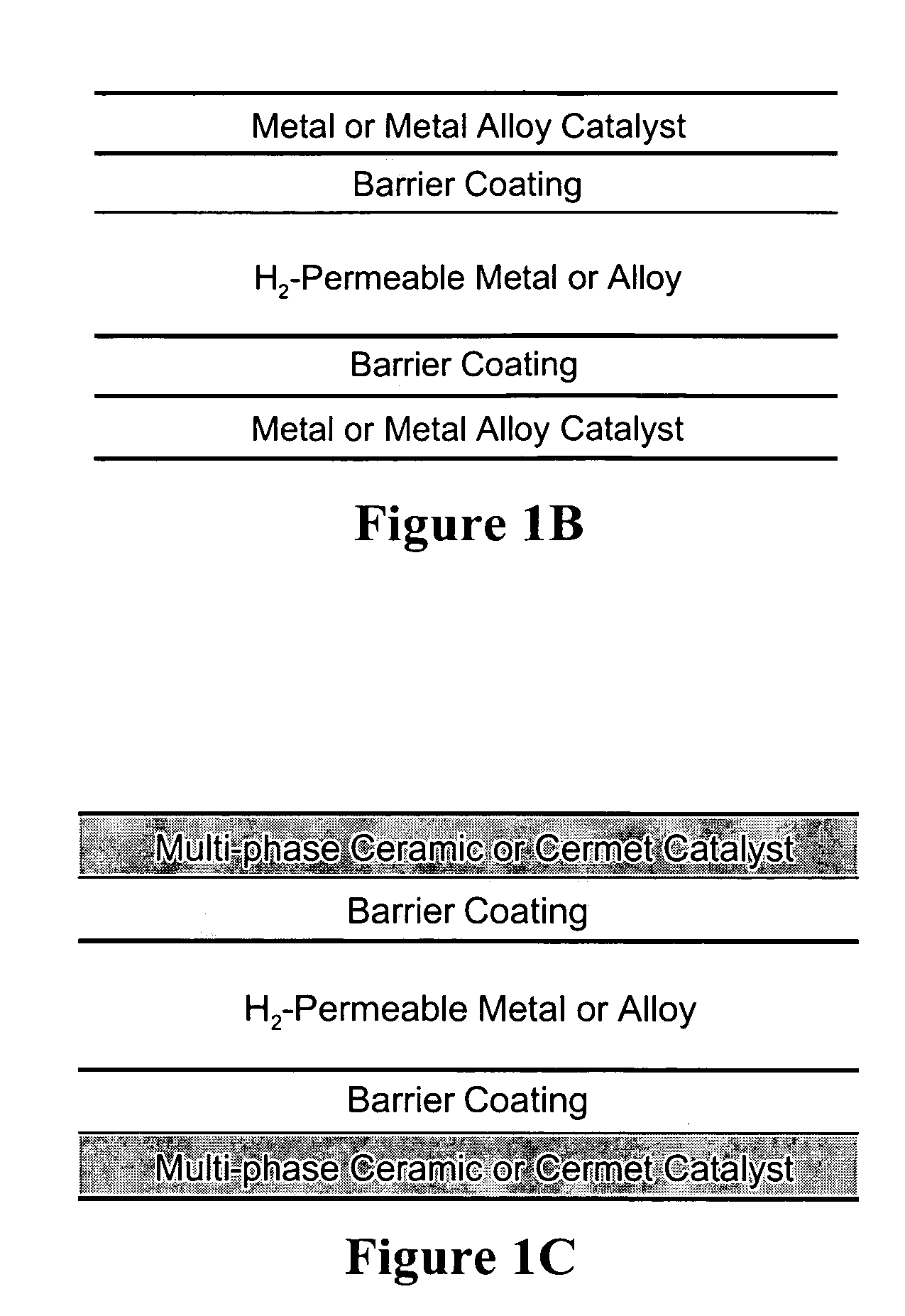

Dense, layered membranes for hydrogen separation

InactiveUS7001446B2Detrimental interdiffusionMinimize interdiffusionMembranesSemi-permeable membranesReactor systemProduct gas

This invention provides hydrogen-permeable membranes for separation of hydrogen from hydrogen-containing gases. The membranes are multi-layer having a central hydrogen-permeable layer with one or more catalyst layers, barrier layers, and / or protective layers. The invention also relates to membrane reactors employing the hydrogen-permeable membranes of the invention and to methods for separation of hydrogen from a hydrogen-containing gas using the membranes and reactors. The reactors of this invention can be combined with additional reactor systems for direct use of the separated hydrogen.

Owner:ELTRON RES

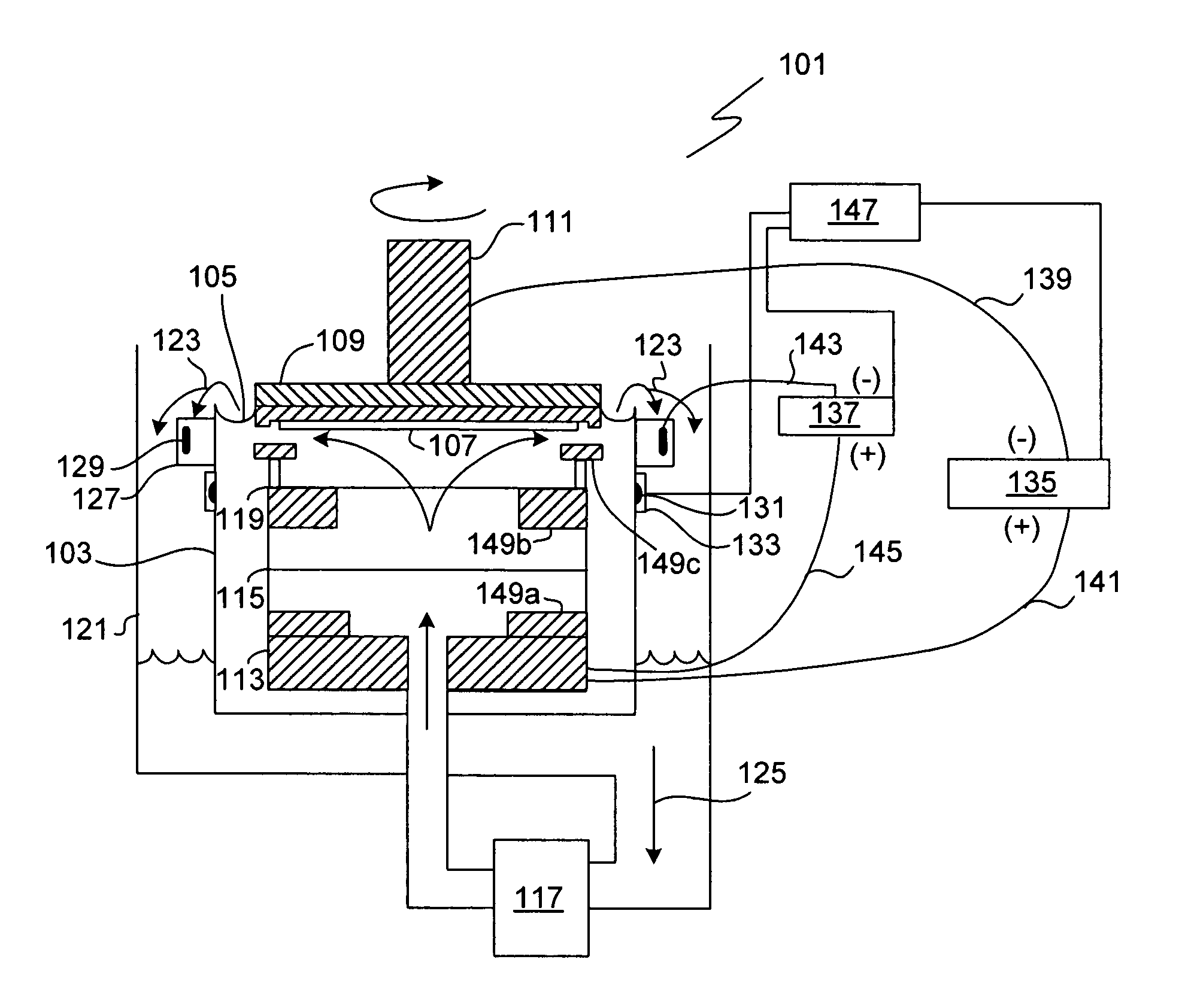

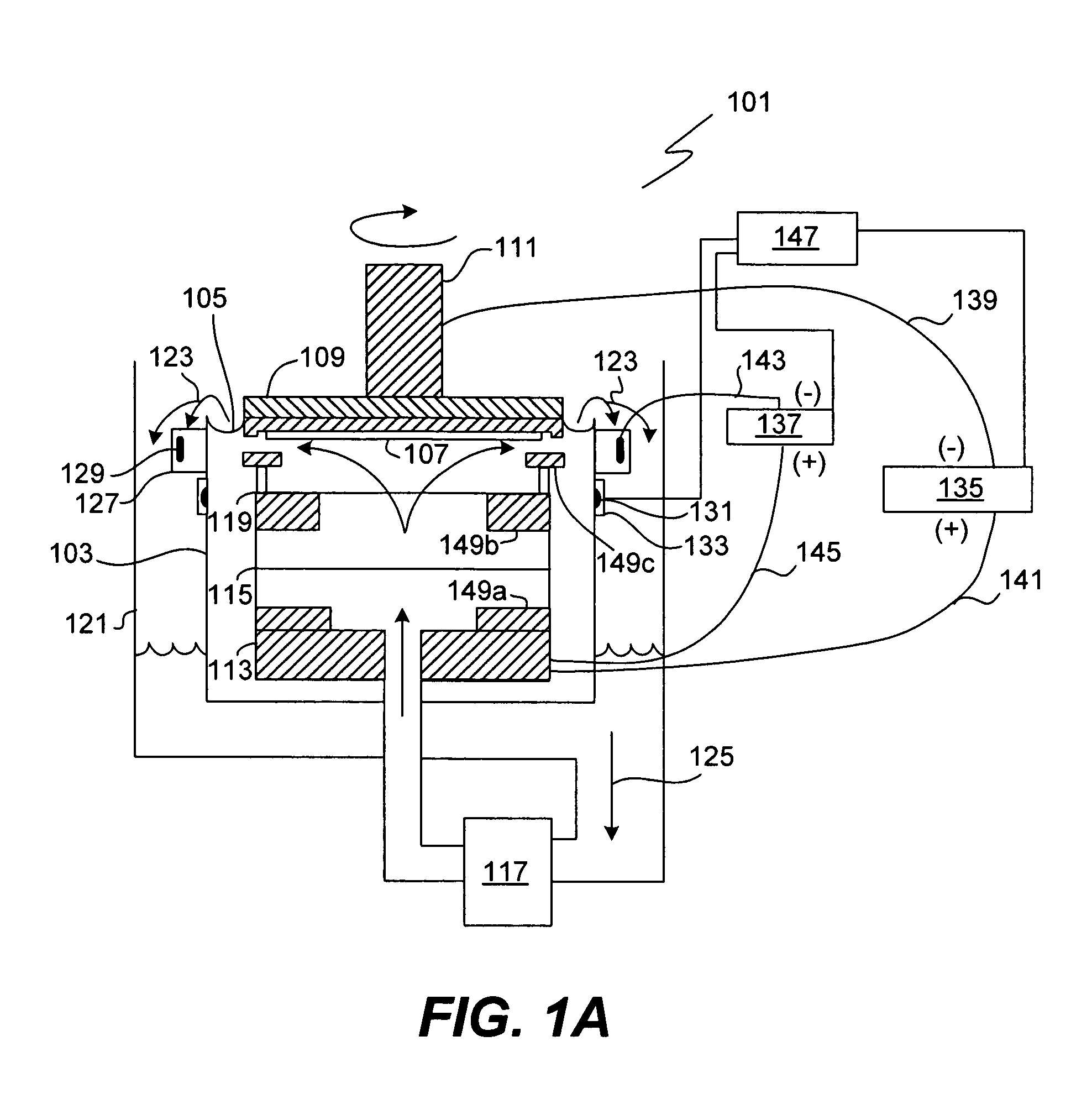

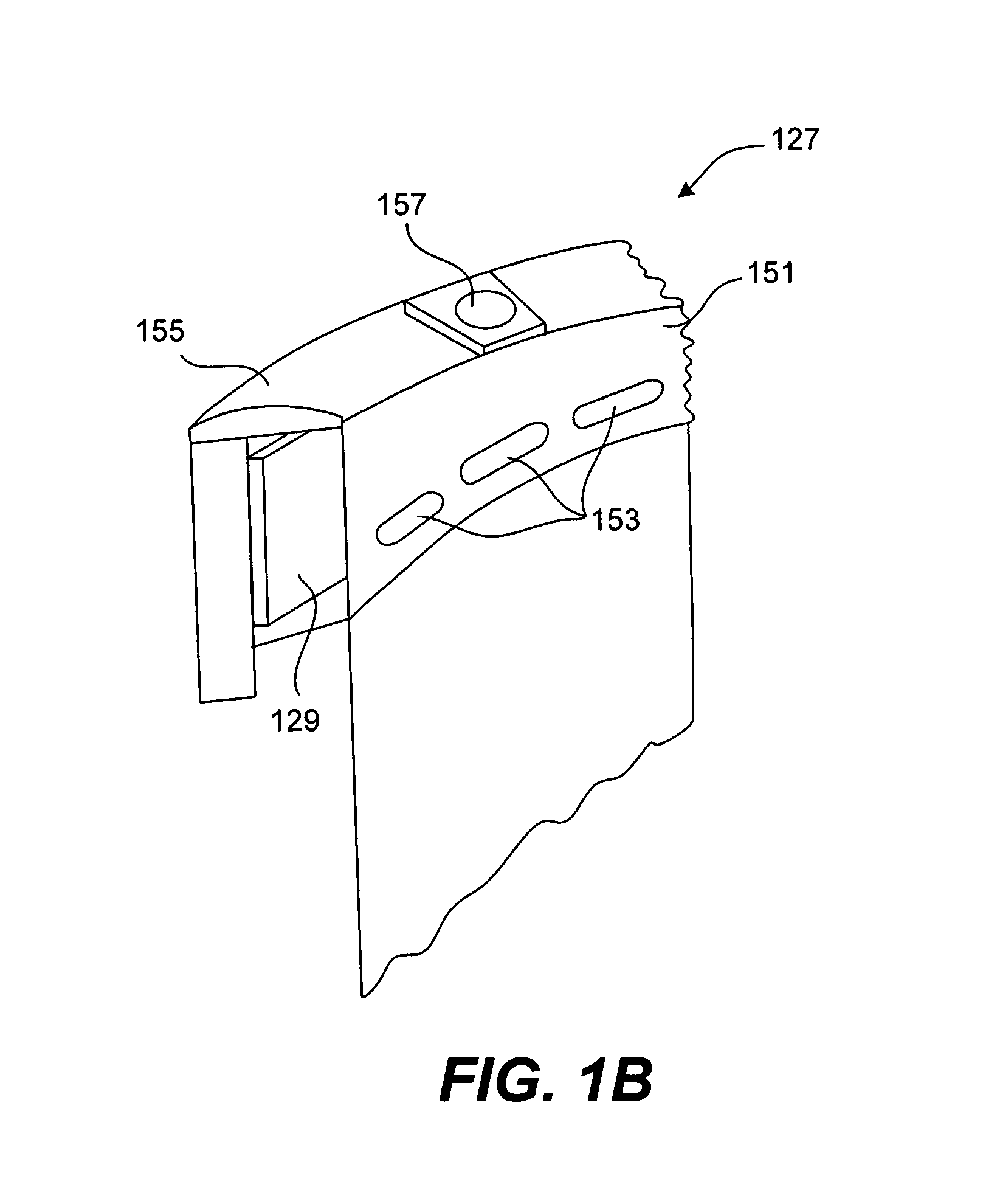

Method and apparatus for electroplating including remotely positioned second cathode

An apparatus for electroplating a layer of metal on the surface of a wafer includes a second cathode located remotely with respect to the wafer. The remotely positioned second cathode allows modulation of current density at the wafer surface during an entire electroplating process. The second cathode diverts a portion of current flow from the near-edge region of the wafer and improves the uniformity of plated layers. The remote position of second cathode allows the insulating shields disposed in the plating bath to shape the current profile experienced by the wafer, and therefore act as a “virtual second cathode”. The second cathode may be positioned outside of the plating vessel and separated from it by a membrane.

Owner:NOVELLUS SYSTEMS

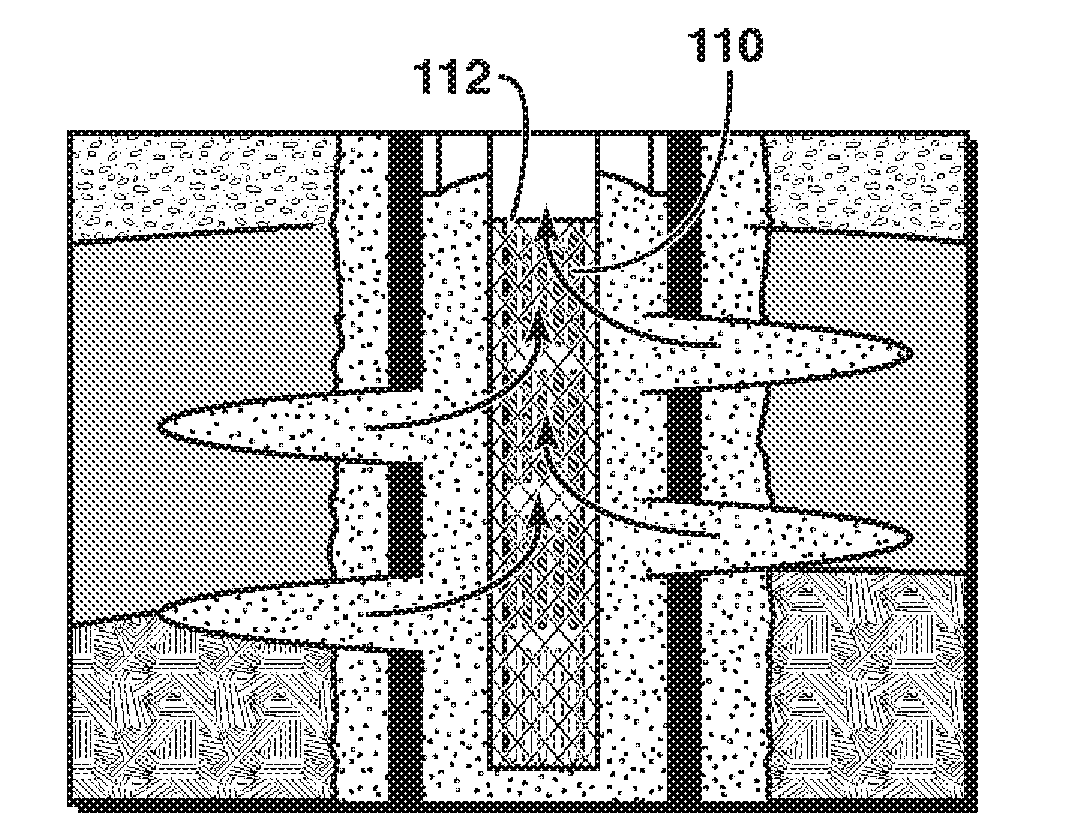

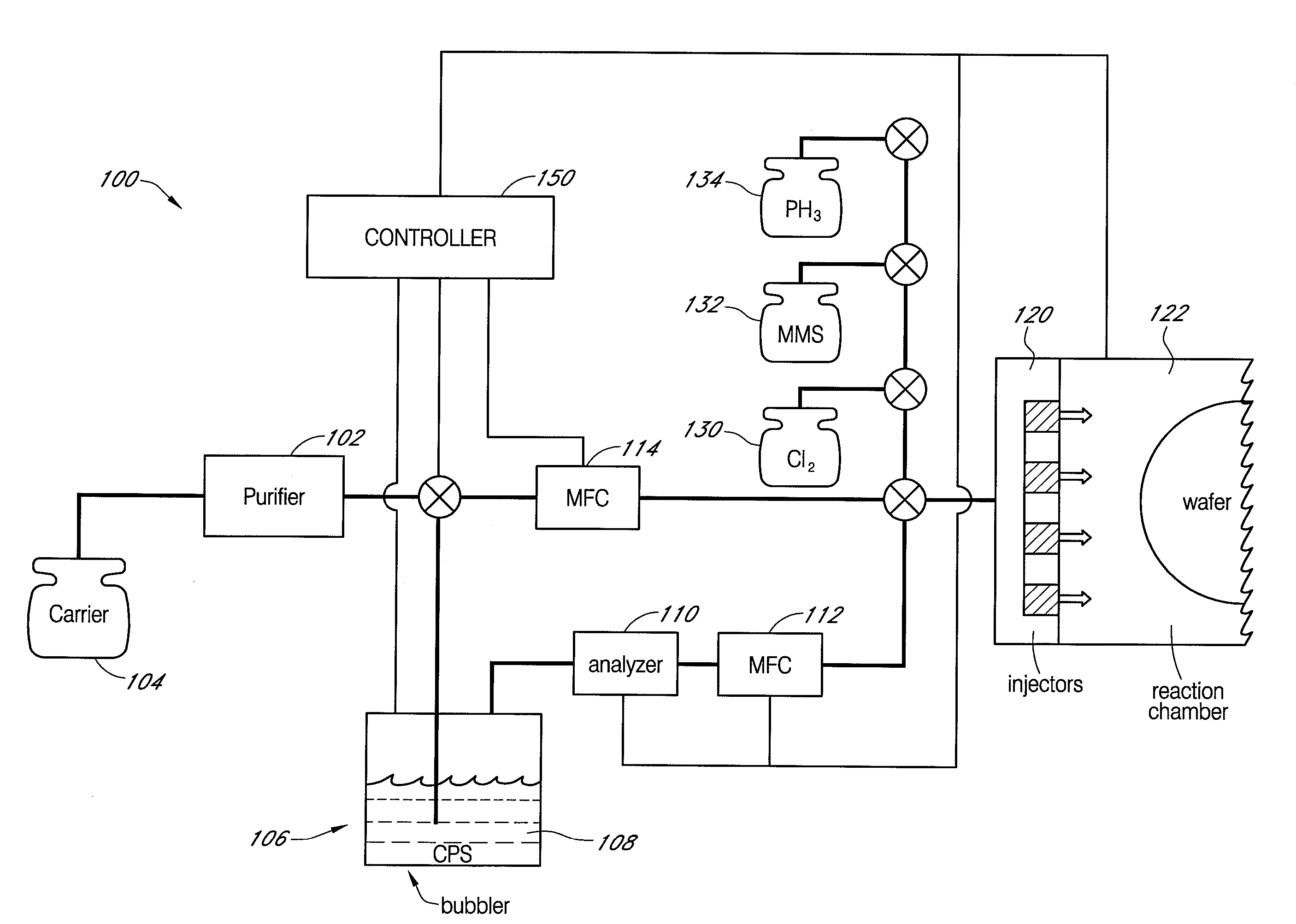

Methods and systems for selectively depositing si-containing films using chloropolysilanes

InactiveUS20080026149A1Less sensitiveReduce depositionPolycrystalline material growthLiquid surface applicatorsMicroelectromechanical systemsEngineering

Chloropolysilanes are utilized in methods and systems for selectively depositing thin films useful for the fabrication of various devices such as microelectronic and / or microelectromechanical systems (MEMS).

Owner:ASM AMERICA INC

Coatings for Electrowetting and Electrofluidic Devices

ActiveUS20130171546A1Low surface energy polymersHigh dielectric strengthElectrostatic separatorsSludge treatmentGas phaseUltimate tensile strength

Electrowetting devices coated with one or more polymeric layers and methods of making and using thereof are described herein. The coatings may be formed in a single layer or as multiple layers. In one embodiment the first layer deposited serves as an insulating layer of high dielectric strength while the second layer deposited serves as a hydrophobic layer of low surface energy. These materials may themselves be deposited as multiple layers to eliminate pinhole defects and maximize device yield. In one embodiment the insulating layer would be a vapor deposited silicone polymeric material including, but not limited to, polytrivinyltrimethylcyclotrisiloxane or polyHVDS. In another embodiment the insulating layer may be a vapor deposited ceramic such as SiO2 with very little carbon content. In a further embodiment the insulating layer may be composed of alternating layers of a siloxane material and a ceramic material.

Owner:GVD CORP

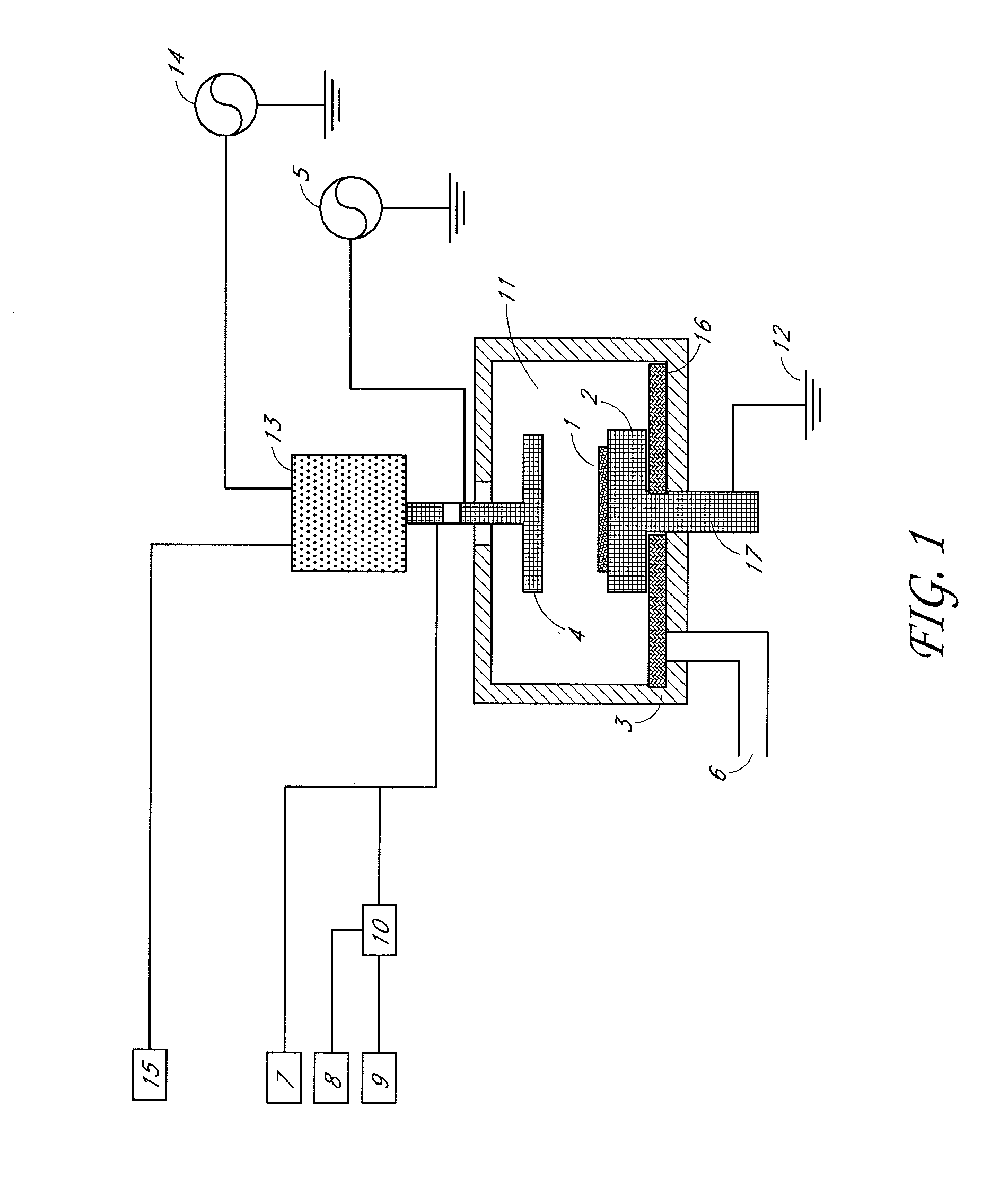

Large surface area dry etcher

InactiveUS20060042755A1Reduce depositionReduce plasma/wall interaction and heatingElectric discharge tubesDecorative surface effectsHigh densityEngineering

A dry etcher includes a process chamber configured to process a substrate therein using plasma; a substrate supporter to support the substrate; an inner chamber wall maintained at a high temperature and at least one magnetron provided in close proximity to the substrate to generate a local uniform high density plasma. The outer chamber wall provides vacuum integrity and is kept at low enough temperature to maintain vacuum integrity and to ensure safe operation of the machine. The dry etcher further includes a radio-frequency (RF) power source coupled to the substrate supporter, wherein the plasma is generated by the RF power applied to the substrate supporter and a magnetic field generated by the magnetron.

Owner:PLASMAMED

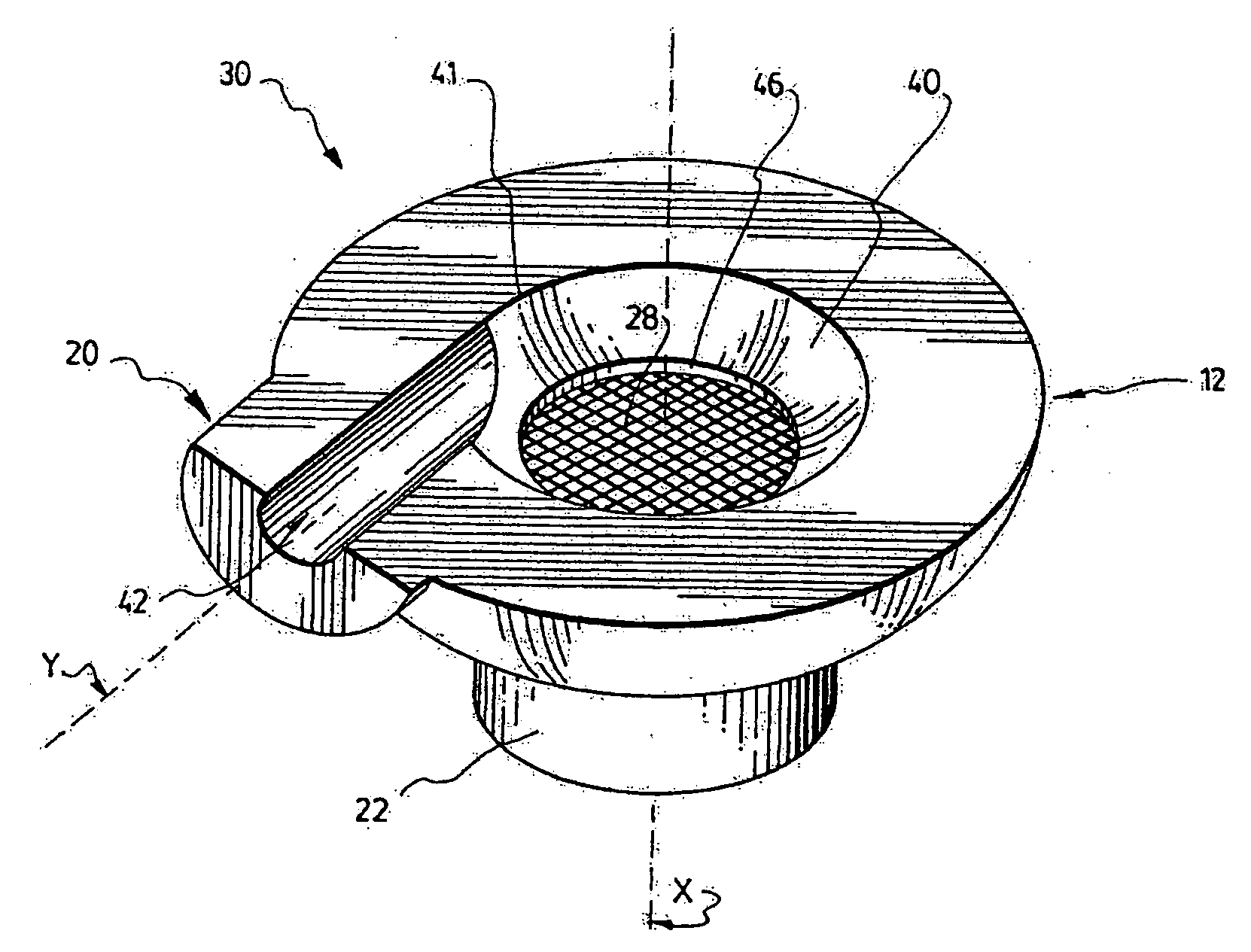

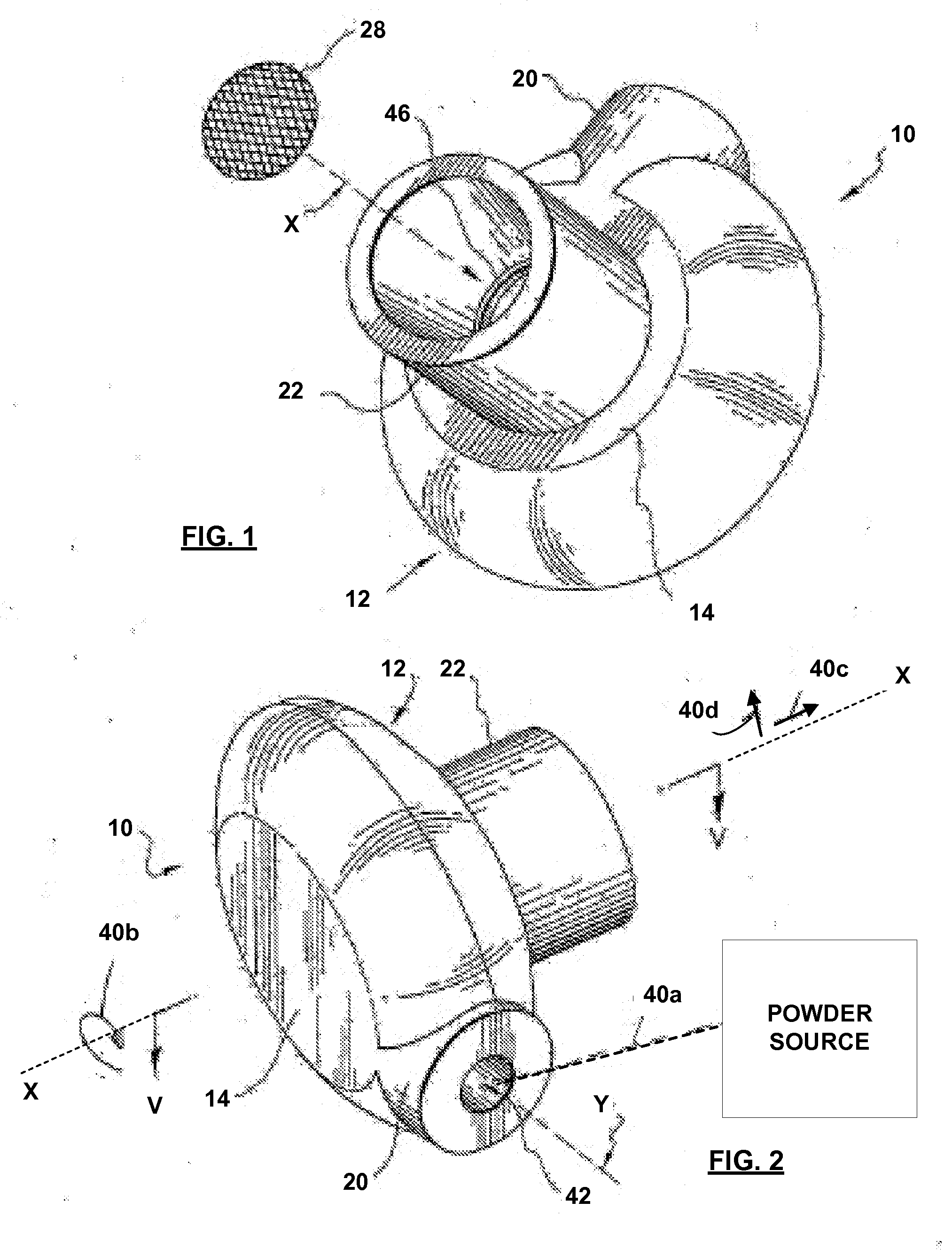

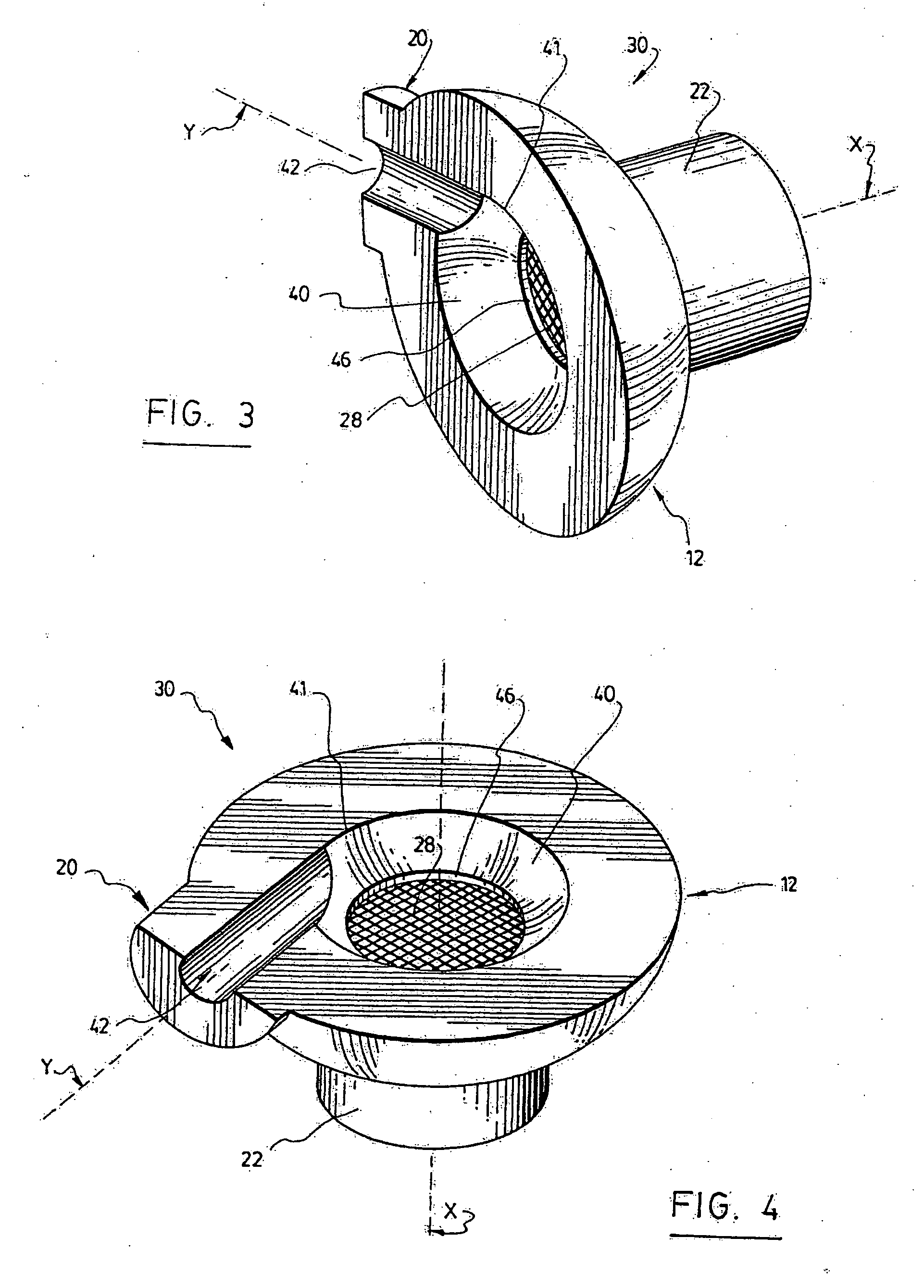

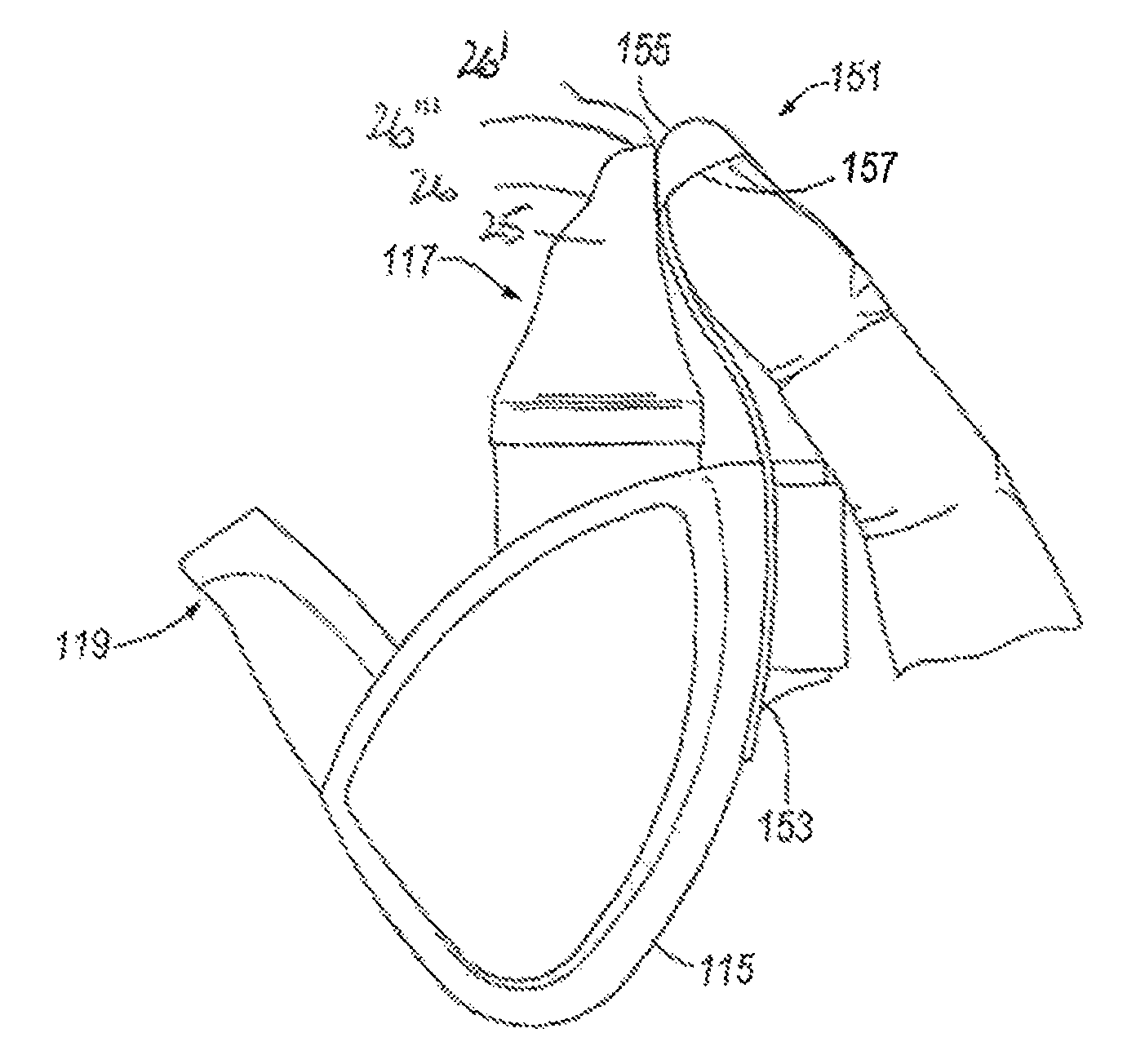

Device and method for deagglomeration of powder for inhalation

InactiveUS20070125375A1Reduce depositionReduce flow of fluidRespiratorsLiquid surface applicatorsInhalationEngineering

A device and method for deagglomerating powder agglomerates for inhalation. The device includes an inlet connected to a chamber and to a powder source for supplying the chamber with powder agglomerates and a flow of gas that define a swirling fluid flow inside the chamber. The device also includes an outlet connected to the chamber for inhalation such that the swirling fluid flow in the chamber can exit from the chamber as a longitudinal fluid flow that is directed along a longitudinal axis of the outlet, and a secondary fluid flow that is directed away from the longitudinal axis of the outlet. A mesh in the outlet prevents powder agglomerates above a predetermined size from traversing the mesh, and reduces the secondary fluid flow relative to the longitudinal fluid flow exiting from the chamber to thereby reduce powder deposition in a mouth and throat of a user.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

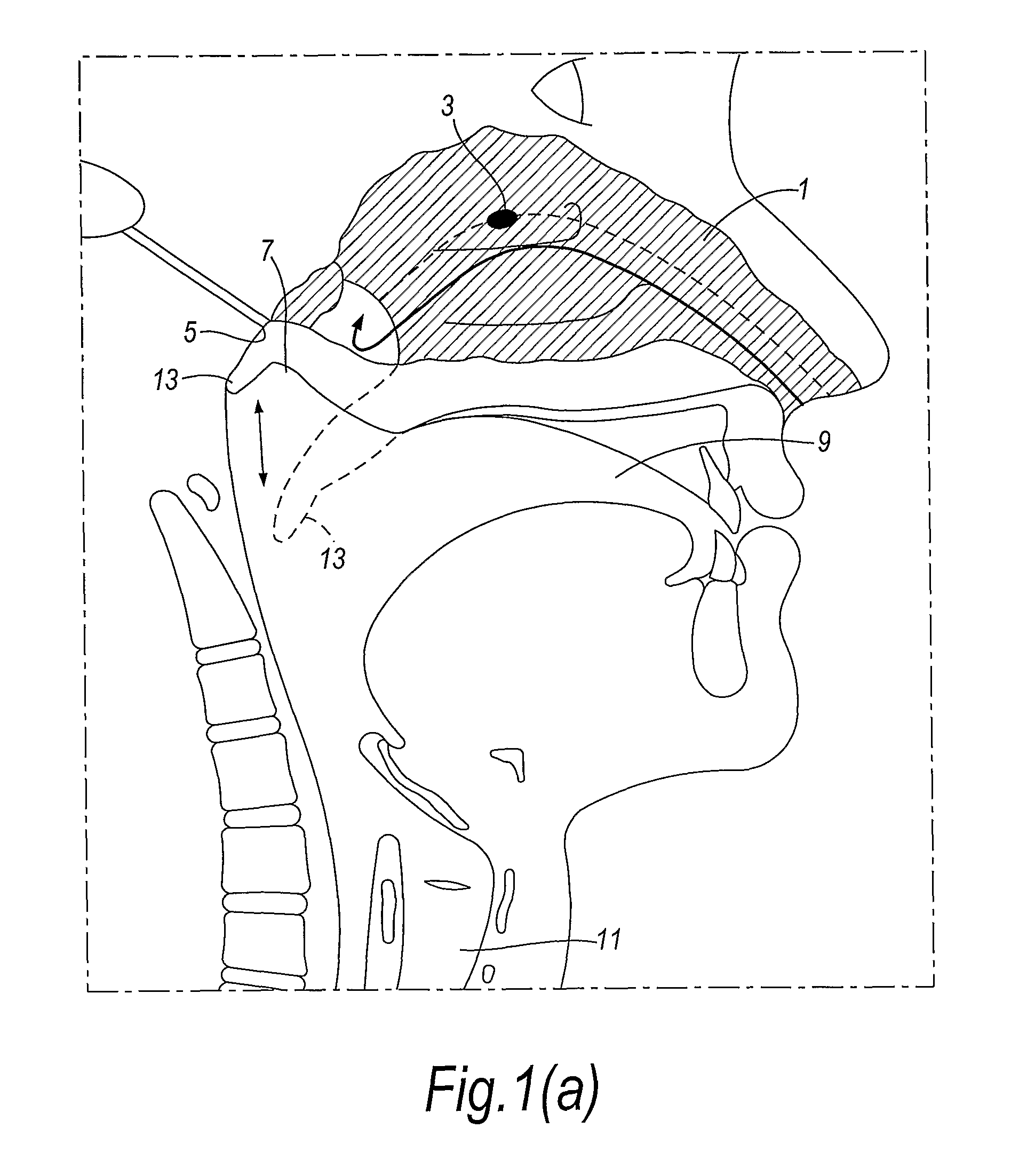

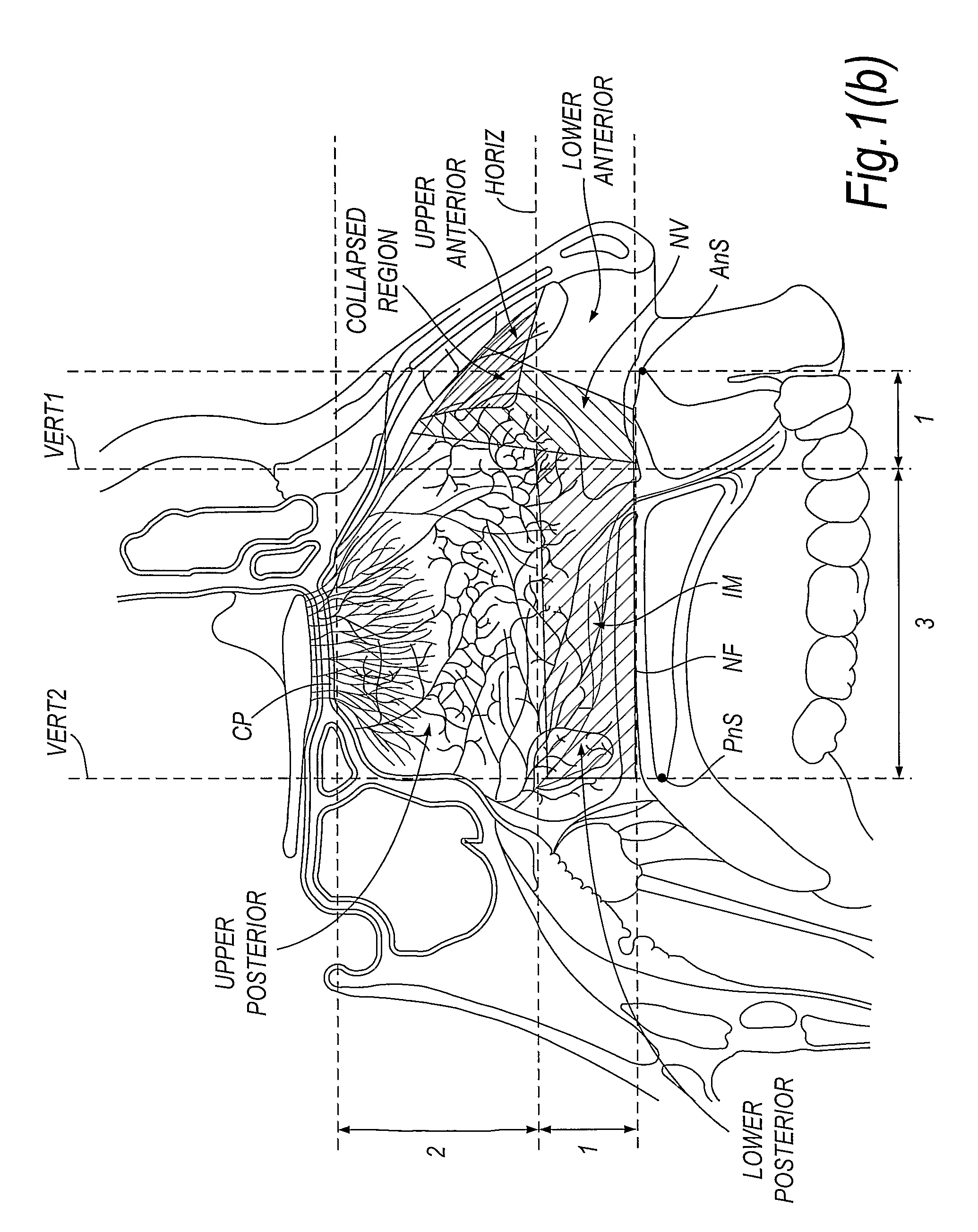

Nasal delivery

A nasal delivery device for and method of delivering substance to a nasal cavity of a subject, the delivery device comprising: a nosepiece for fitting to a nostril of a subject, wherein the nosepiece comprises a tip element which includes a delivery aperture from which substance is in use delivered into the nasal cavity, and the tip element is at least in part tapered such as to be inclined to a longitudinal axis of the nosepiece, with the delivery aperture extending both laterally across the tip element and along a longitudinal extent of the tip element; a nozzle through which substance is in use delivered, preferably substantially axially to a longitudinal axis of the nosepiece, to the respective nasal cavity; and a delivery unit for delivering substance through the nozzle of the nosepiece.

Owner:OPTINOSE INC

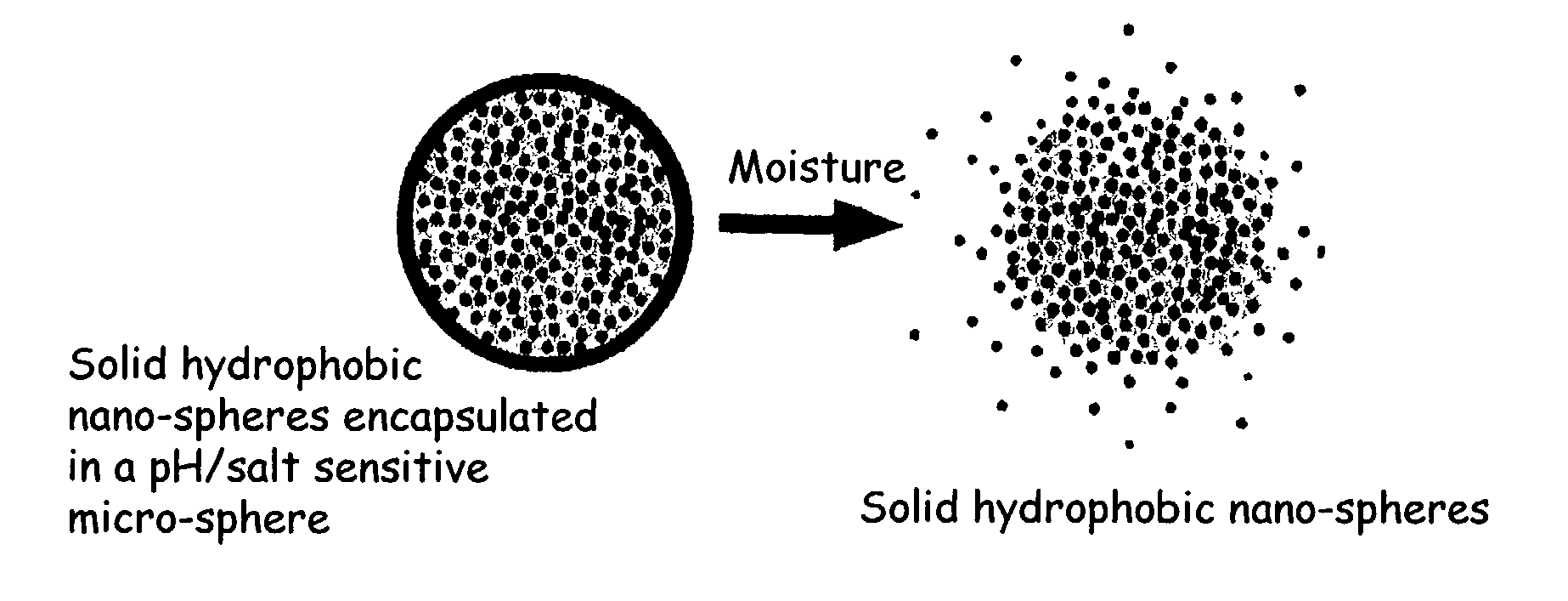

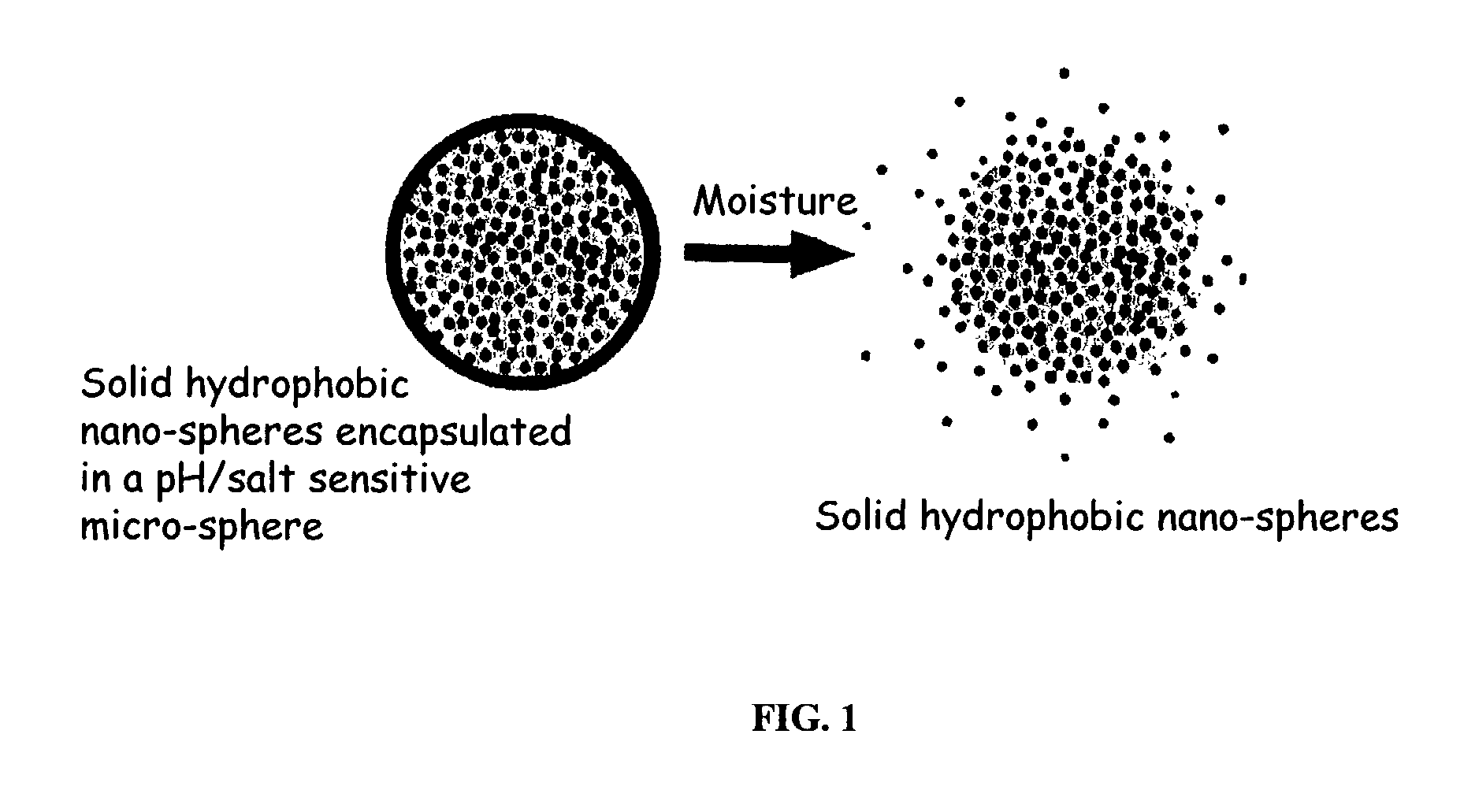

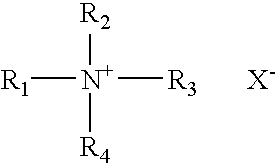

Targeted controlled delivery compositions activated by changes in pH or salt concentration

InactiveUS7053034B2Improve impact performanceFacilitated releaseCosmetic preparationsOrganic detergent compounding agentsCarrier systemProlonged release

The present invention relates to a novel controlled release carrier system for pH or salt triggered release and targeted delivery of fragrances and other active ingredients onto fabric, hair, skin, and other biological surfaces and which provides prolonged release of fragrances and other active ingredients over an extended period of time, or yields a high impact fragrance “burst” upon treating the target surface with heat (blow drying the hair, ironing the fabric). The controlled delivery system of the present invention is substantially a free-flowing powder formed of solid hydrophobic nano-spheres comprising the fragrance and other active ingredients that are encapsulated in a pH or salt sensitive micro-spheres. Also described are processes for preparing such compositions and processes for using same. Furthermore, certain components of the aforementioned compositions in combination with one another are novel, and other components have novel uses in increasing fragrance substantivity, particularly in fabric, hair, and skin care preparations. The invention further pertains to consumer and diversified products comprising the controlled release system of the present invention.

Owner:SALVONA

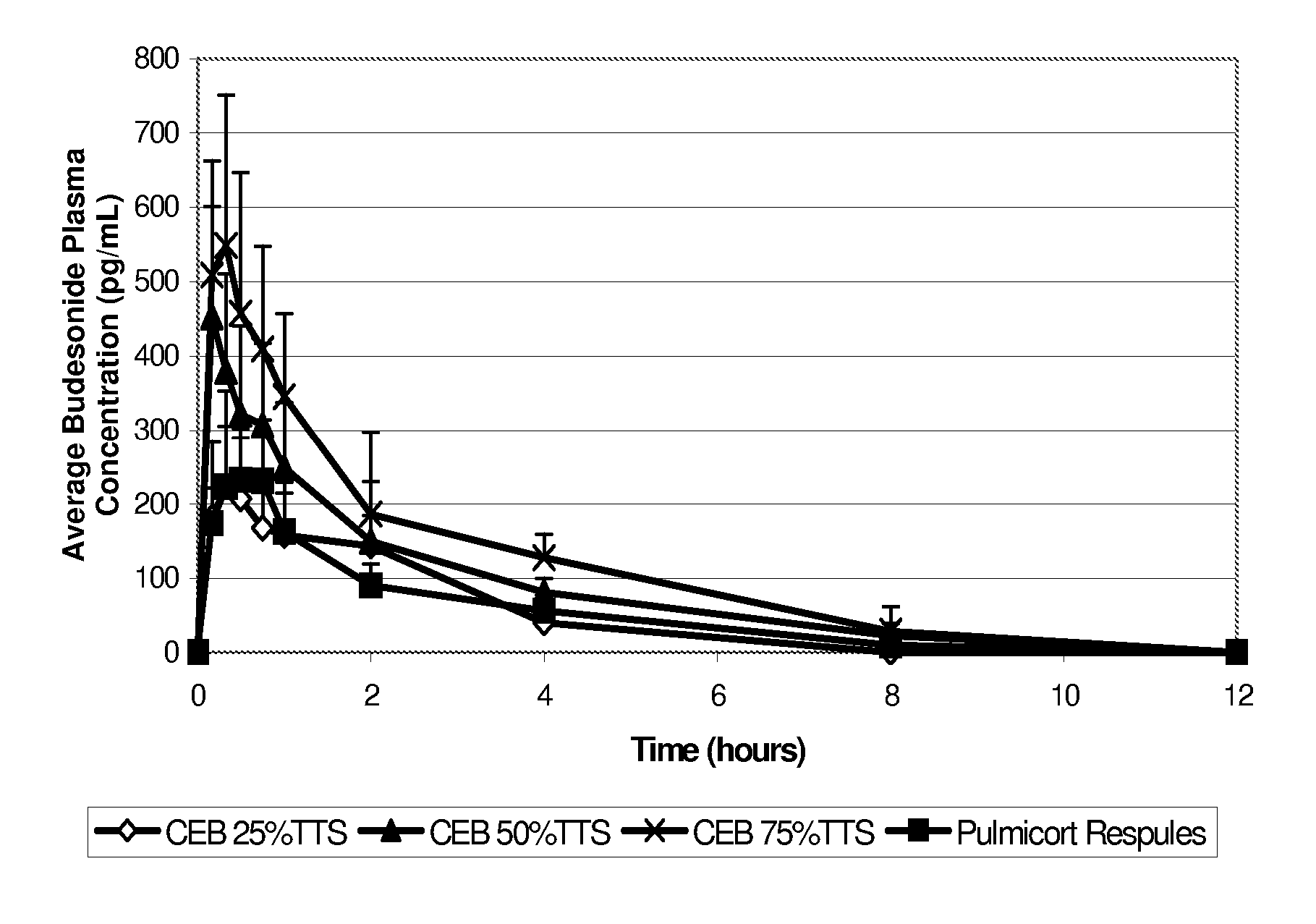

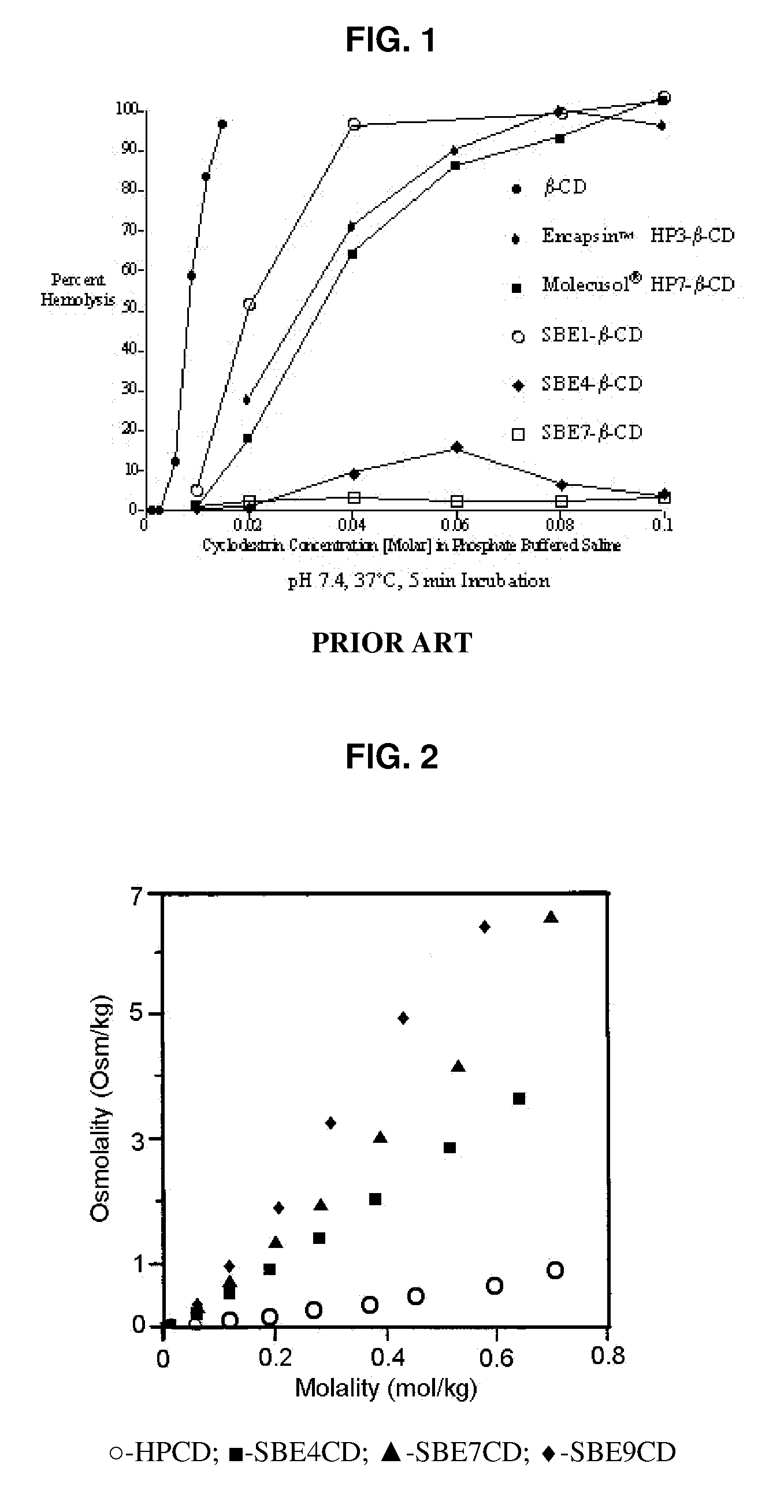

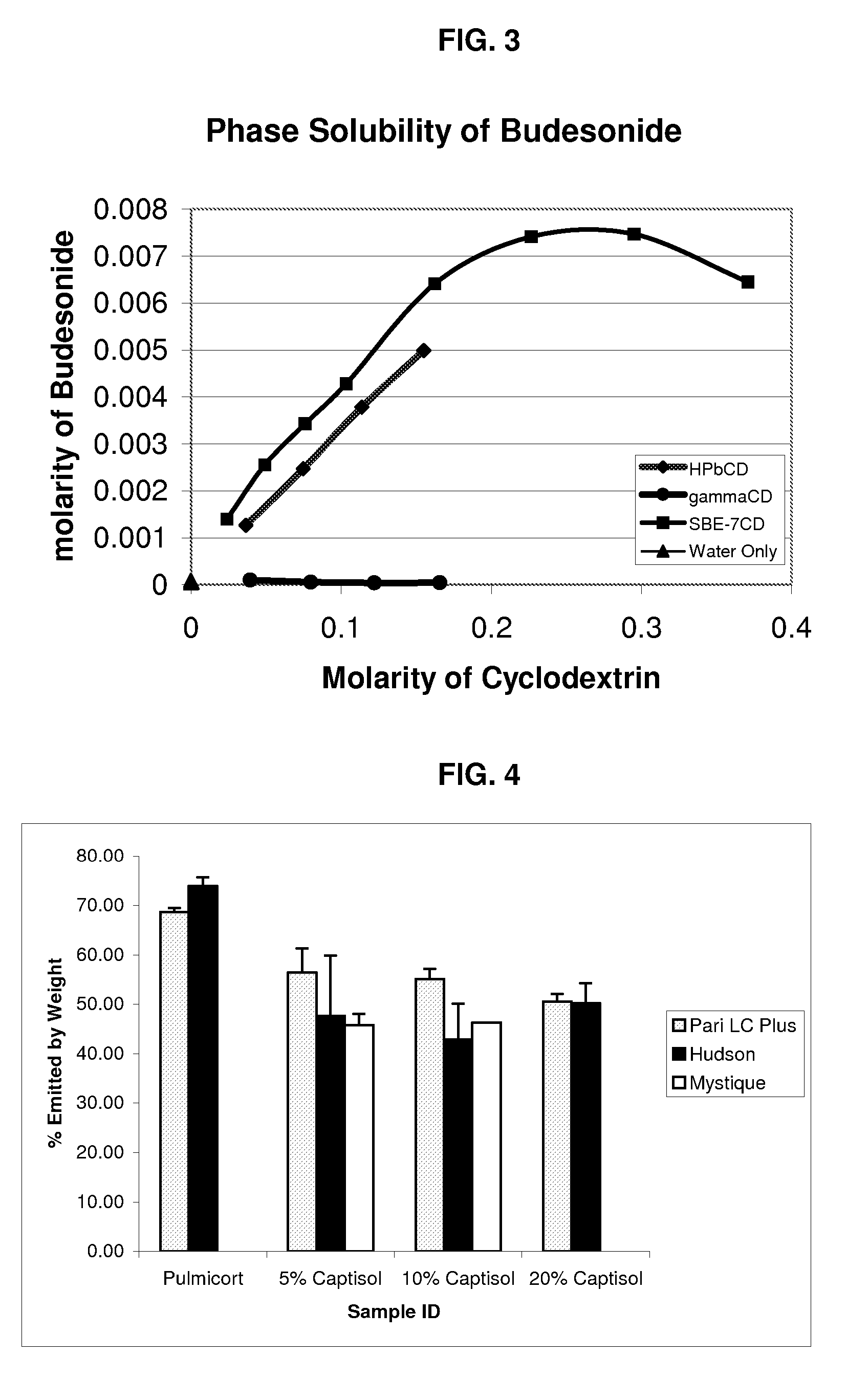

Inhalant Formulation Containing Sulfoalkyl Ether Cyclodextrin and Corticosteroid

InactiveUS20070202054A1Improve solubilityImprove stabilityBiocidePowder deliveryNebulizerCyclodextrin

An inhalable formulation containing SAE-CD and corticosteroid is provided. The formulation is adapted for administration to a subject by nebulization with any known nebulizer. The formulation can be included in a kit. The formulation is administered as an aqueous solution, however, it can be stored as a dry powder, ready-to-use solution, or concentrated composition. The formulation is employed in an improved nebulization system for administering corticosteroid by inhalation. SAE-CD present in the formulation significantly enhances the chemical stability of budesonide. A method of administering the formulation by inhalation is provided. The formulation can also be administered by conventional nasal delivery apparatus.

Owner:CYDEX PHARMA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com