Patents

Literature

3866results about "Plasma welding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

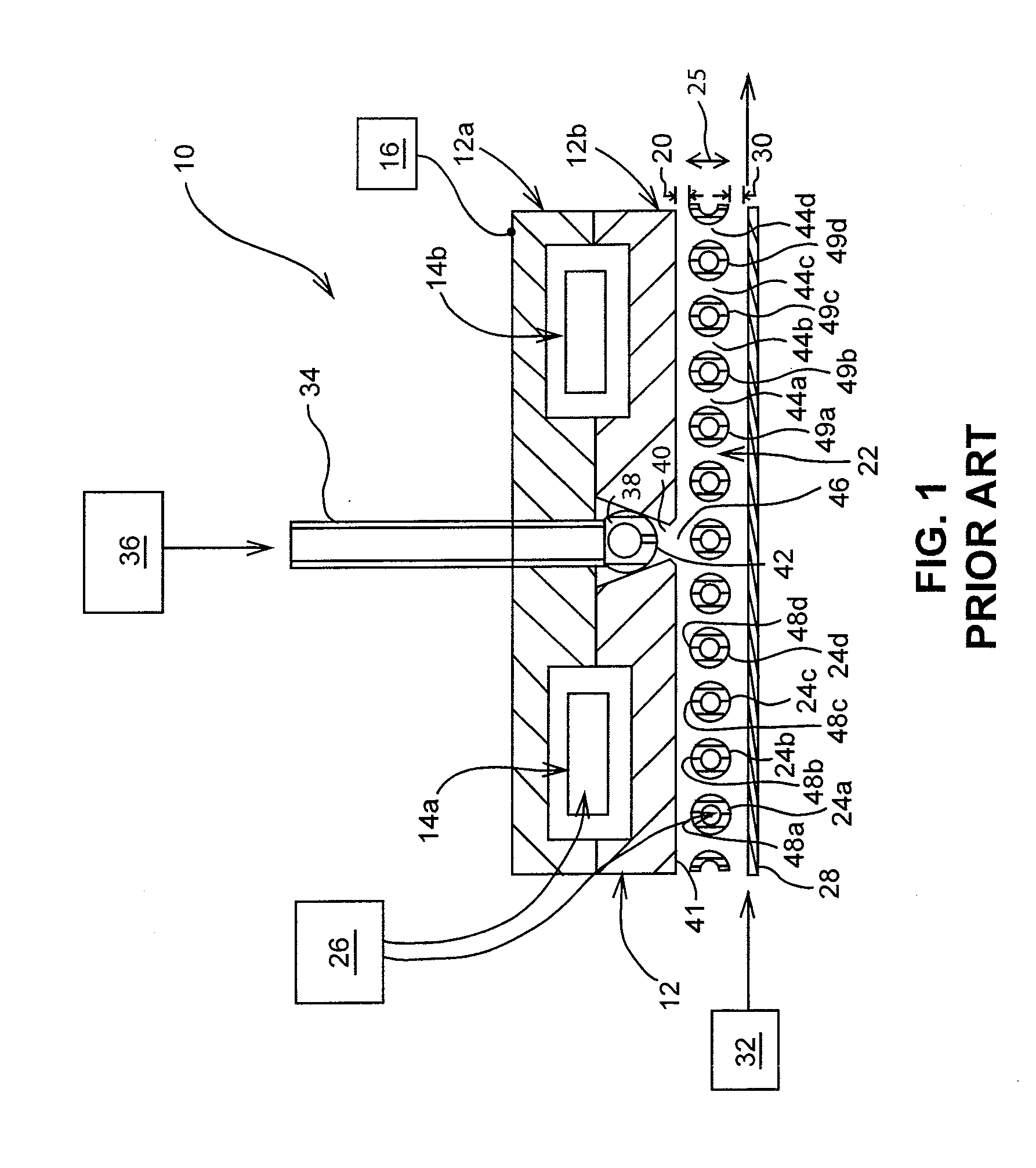

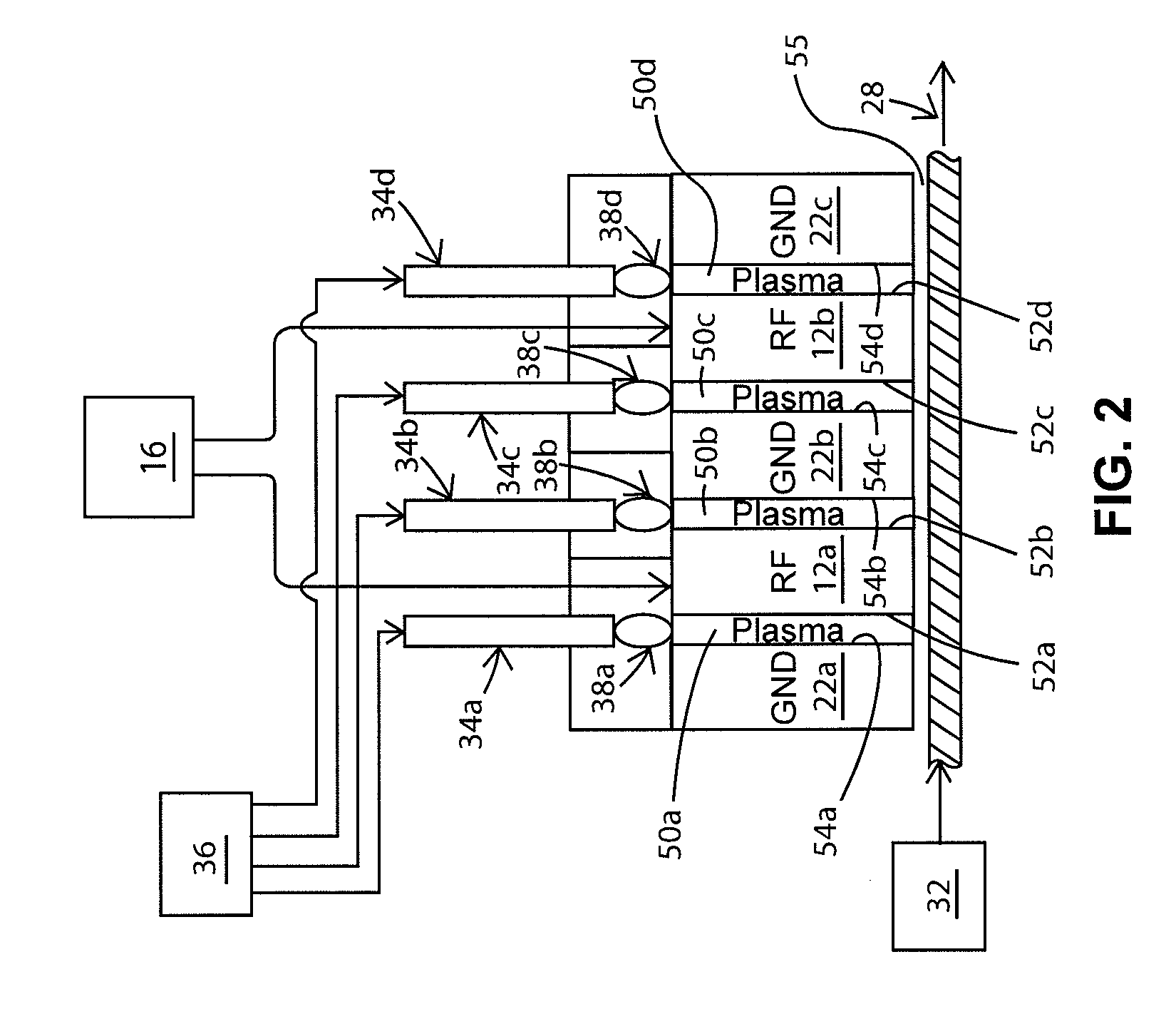

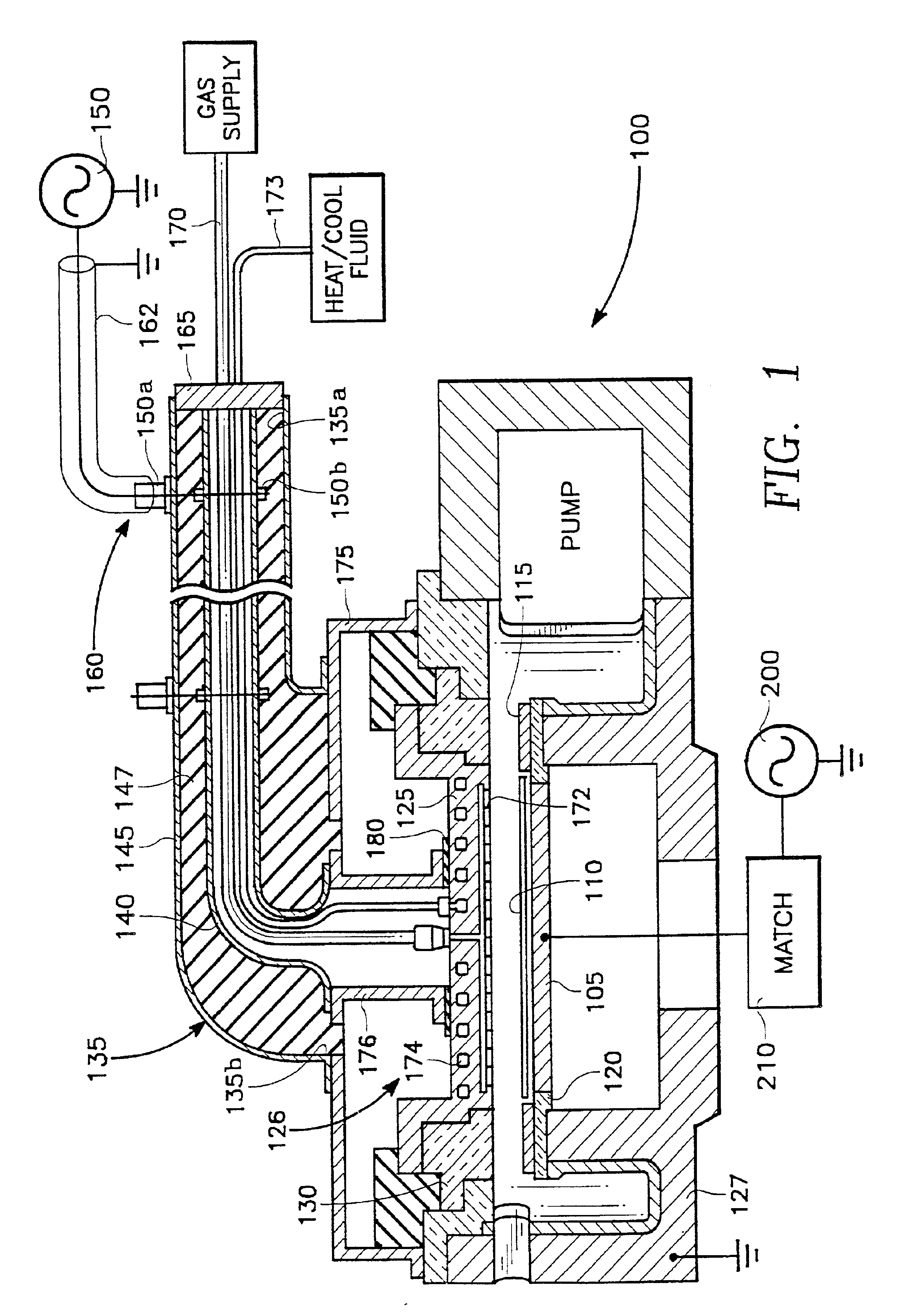

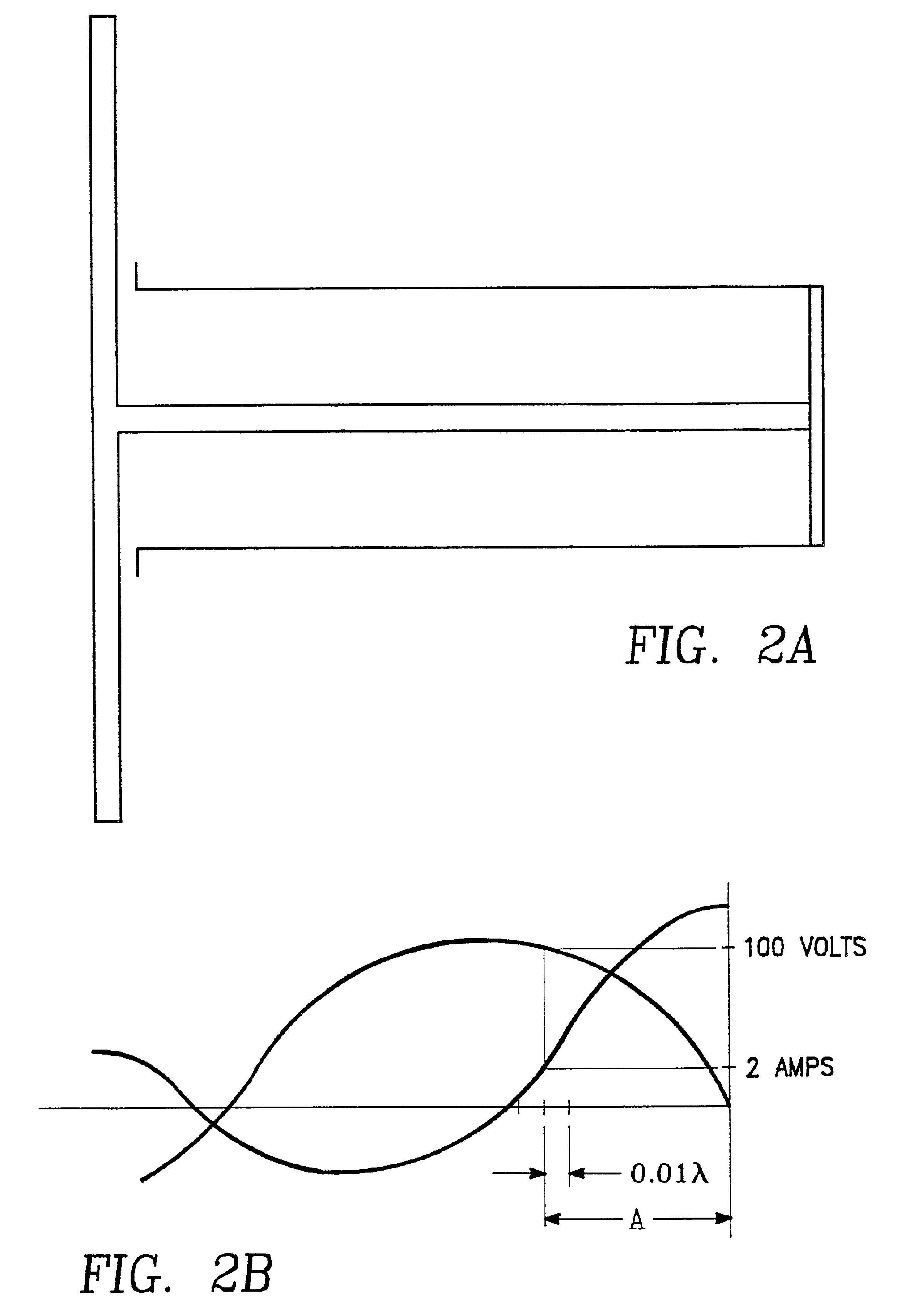

Atmospheric-pressure plasma processing apparatus and method

ActiveUS20140076861A1Faster plasma processing speedMinimum distanceChemical fixing of textilesArc welding apparatusEngineeringAtmospheric pressure

A plasma processing apparatus including powered electrodes having elongated planar surfaces; grounded electrodes having elongated planar surfaces parallel to and coextensive with the elongated surfaces of the powered electrodes, and spaced-apart a chosen distance therefrom, forming plasma regions, is described. RF power is provided to the at least one powered electrode, both powered and grounded electrodes may be cooled, and a plasma gas is flowed through the plasma regions at atmospheric pressure; whereby a plasma is formed in the plasma regions. The material to be processed may be moved into close proximity to the exit of the plasma gas from the plasma regions perpendicular to the gas flow, and perpendicular to the elongated electrode dimensions, whereby excited species generated in the plasma exit the plasma regions and impinge unimpeded onto the material.

Owner:APJET INC

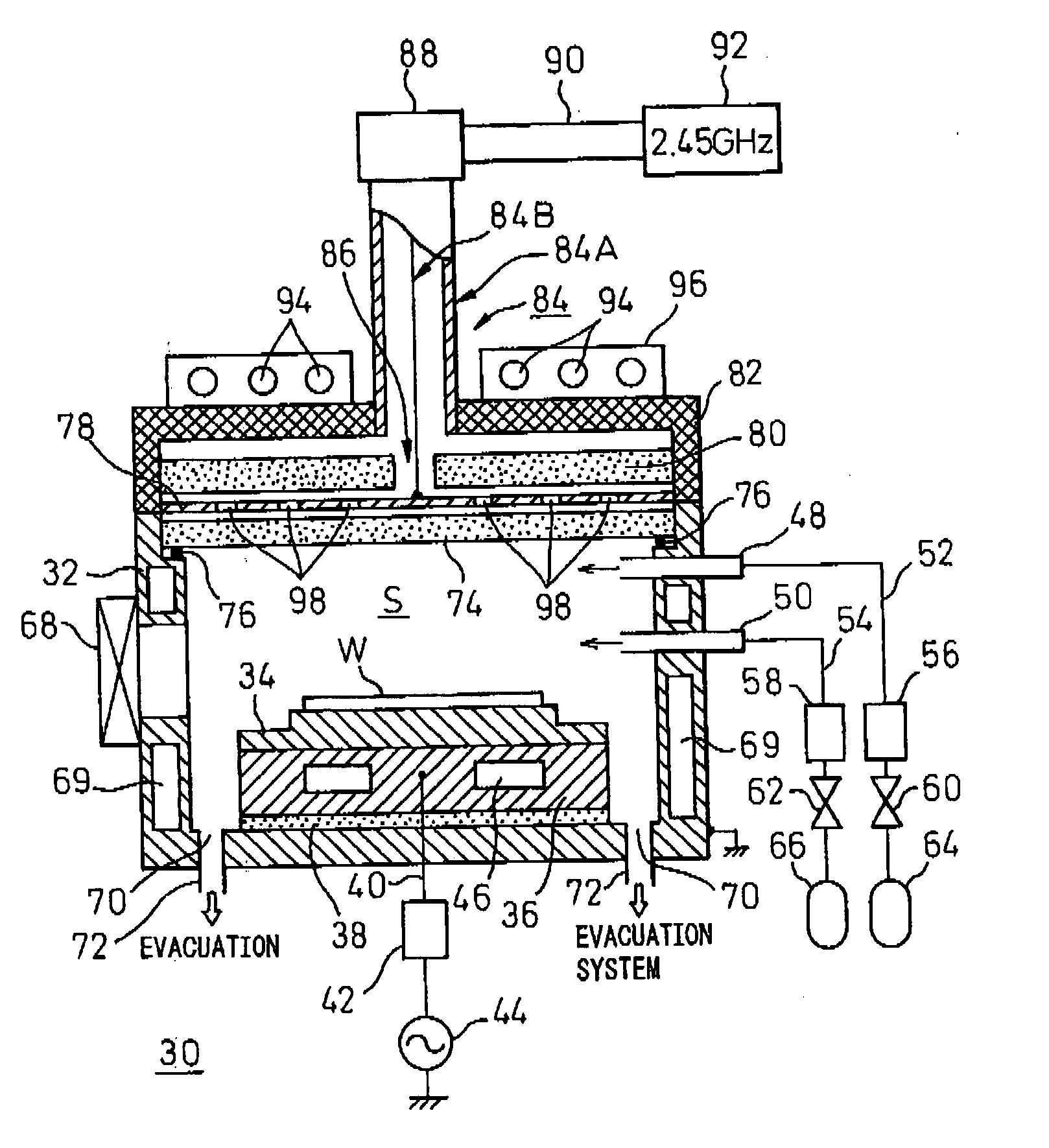

Plasma processing apparatus and plasma processing method

InactiveUS20060108331A1Reduce defectsPollution suppressionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingPre treatment

A plasma processing apparatus comprising at least a plasma processing chamber for plasma-processing an object; object-holding means for disposing the object in the plasma processing chamber; and plasma-generating means for generating a plasma in the plasma processing chamber. The inner wall of the plasma processing chamber is at least partially covered with an oxide film based on a pre-treating plasma. A plasma processing apparatus and a plasma processing method effectively prevent the spluttering and the etching of the inner wall of the plasma processing chamber while suppressing contamination to the object.

Owner:TOKYO ELECTRON LTD

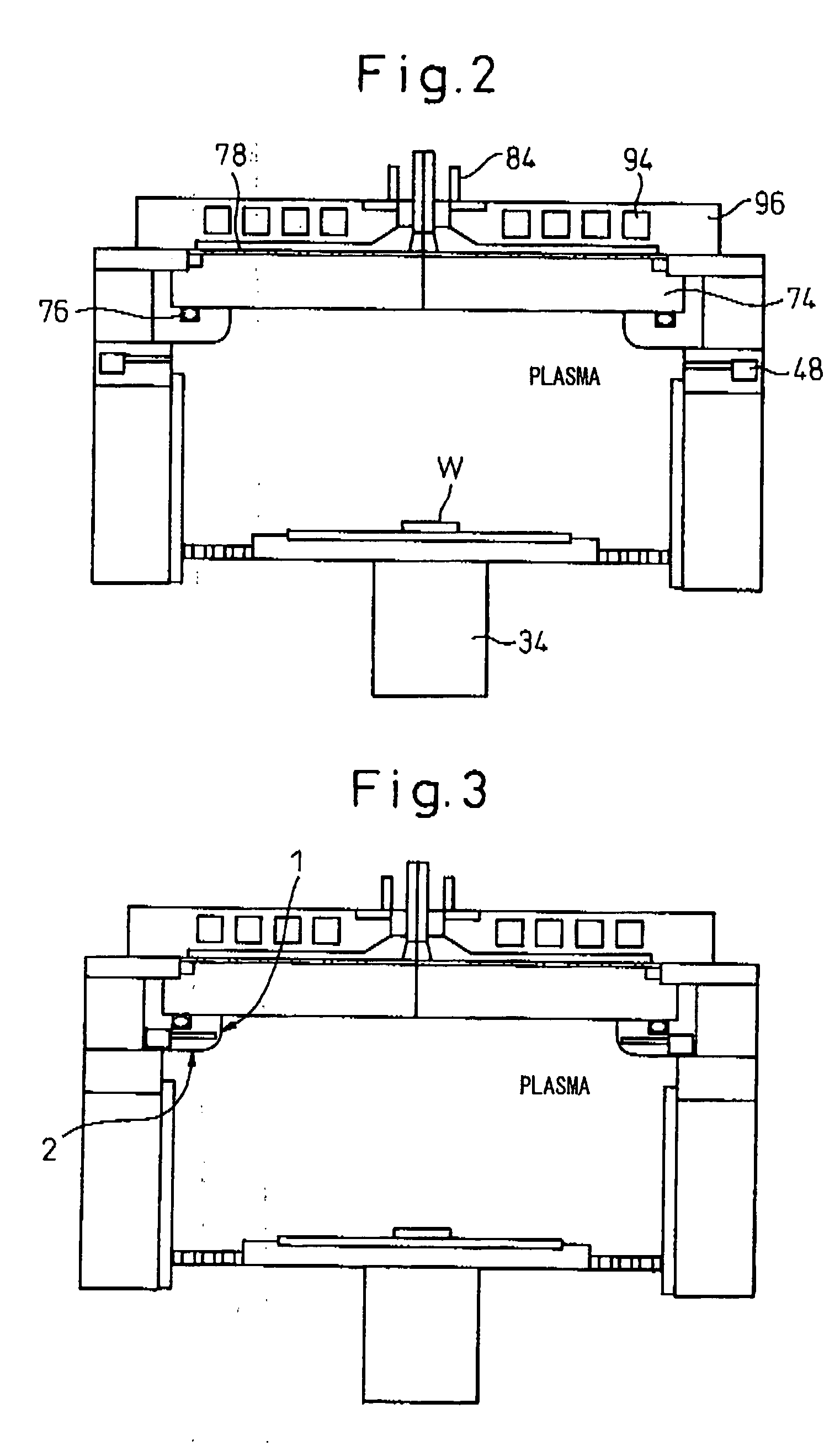

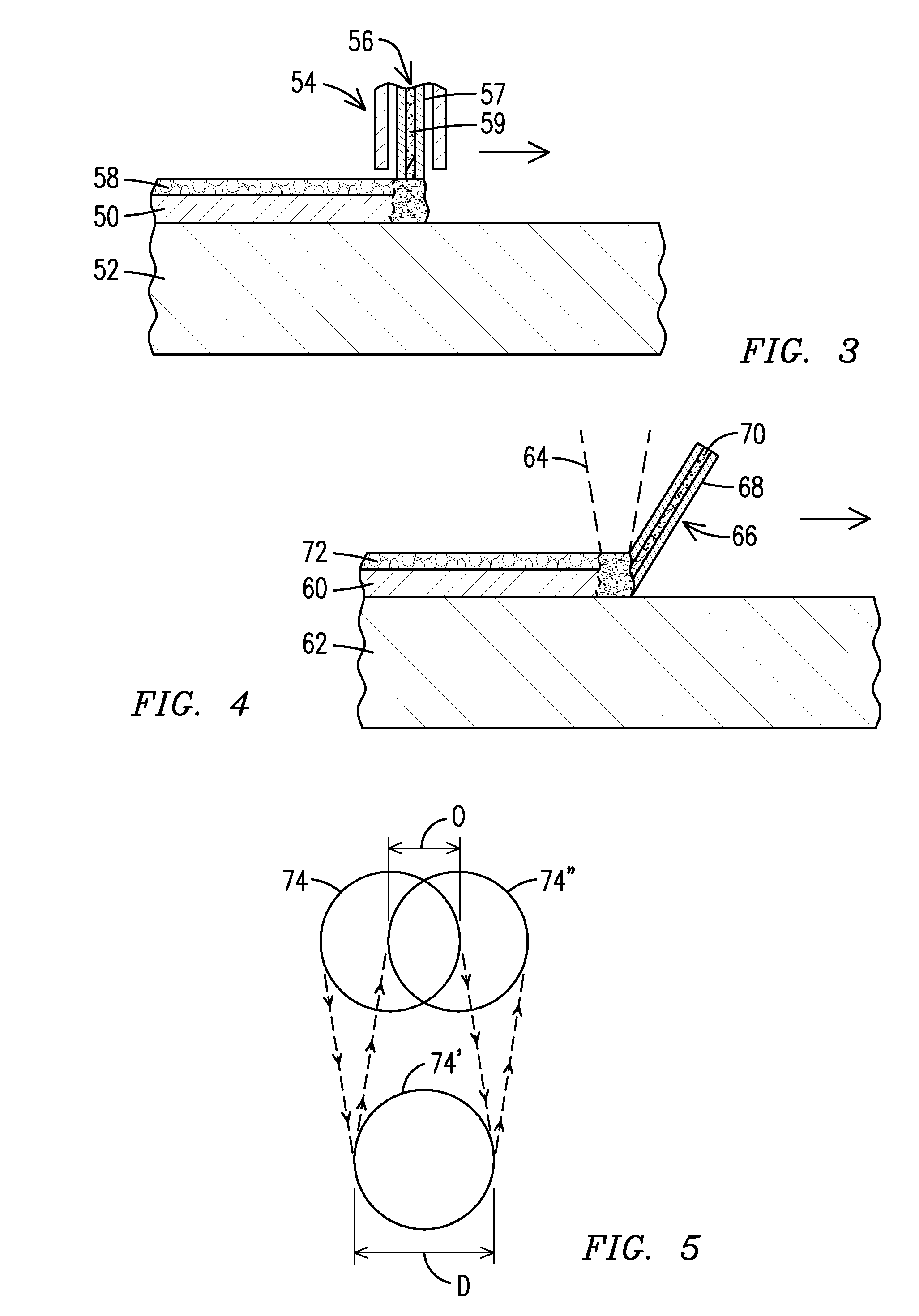

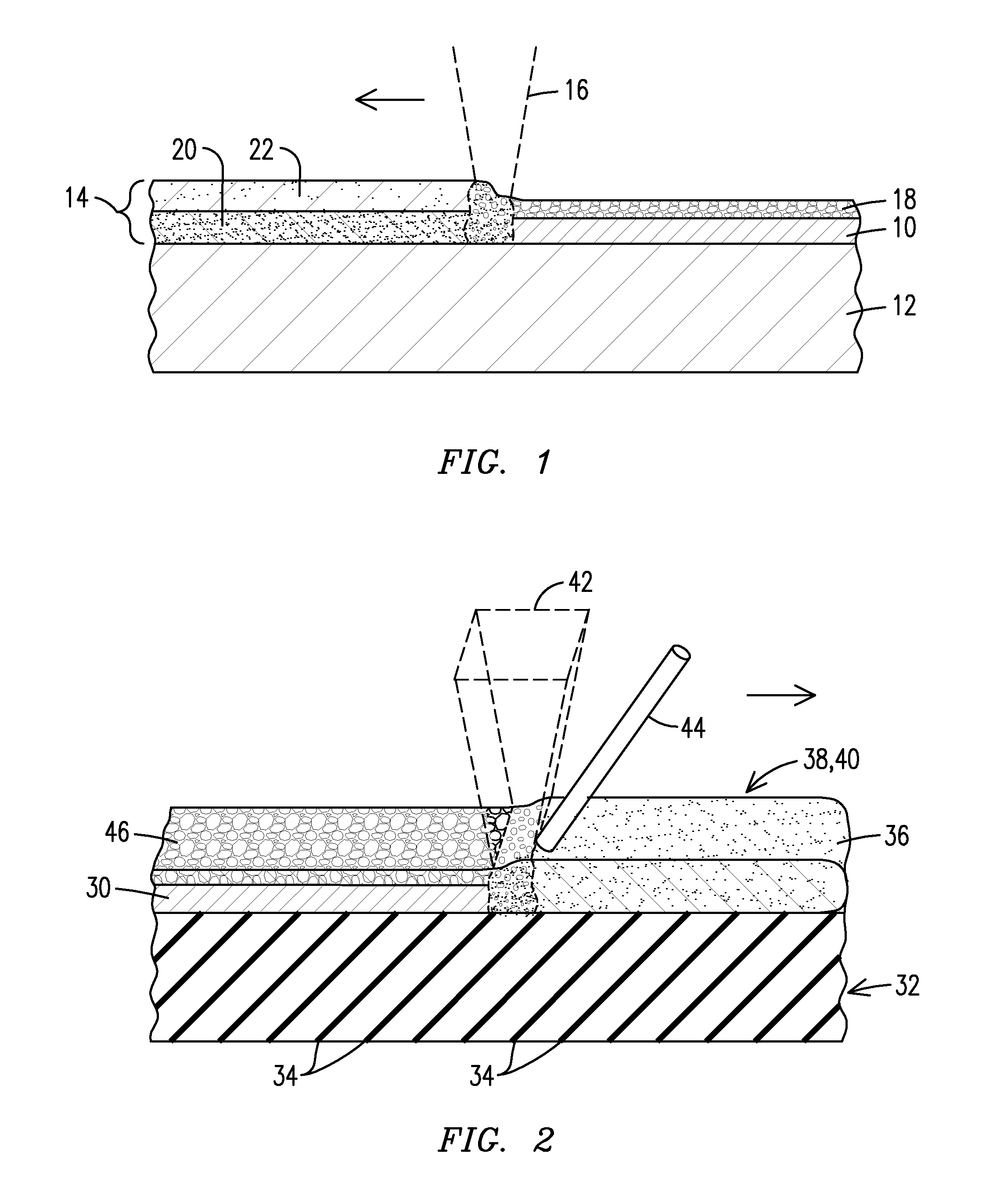

Selective laser melting / sintering using powdered flux

InactiveUS20130136868A1TurbinesRadiation applicationsSelective laser meltingSelective laser sintering

An additive manufacturing process (110) wherein a powder (116) including a superalloy material and flux is selectively melted in layers with a laser beam (124) to form a superalloy component (126). The flux performs a cleaning function to react with contaminants to float them to the surface of the melt to form a slag. The flux also provides a shielding function, thereby eliminating the need for an inert cover gas. The powder may be a mixture of alloy and flux particles, or it may be formed of composite alloy / flux particles.

Owner:SIEMENS ENERGY INC

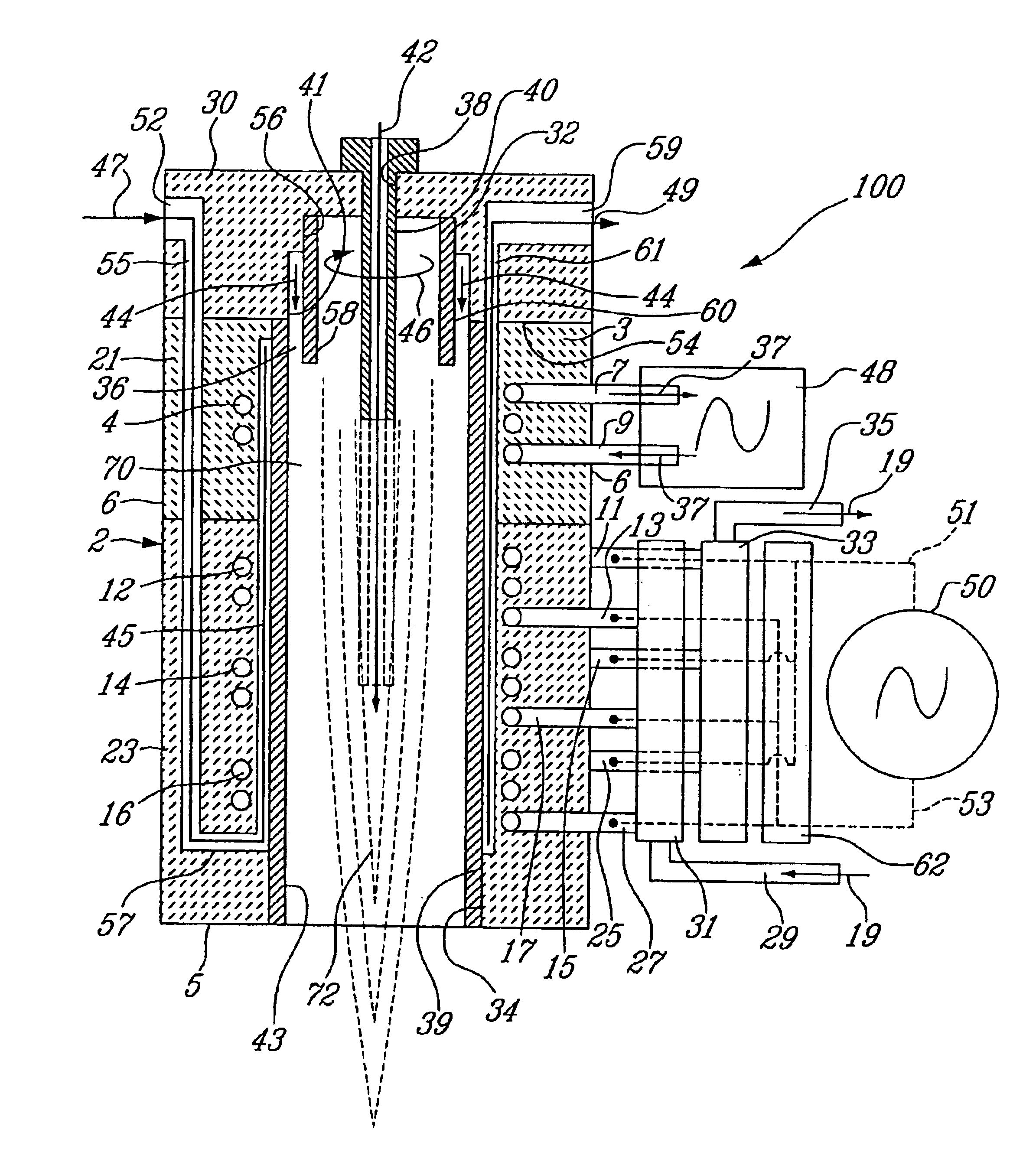

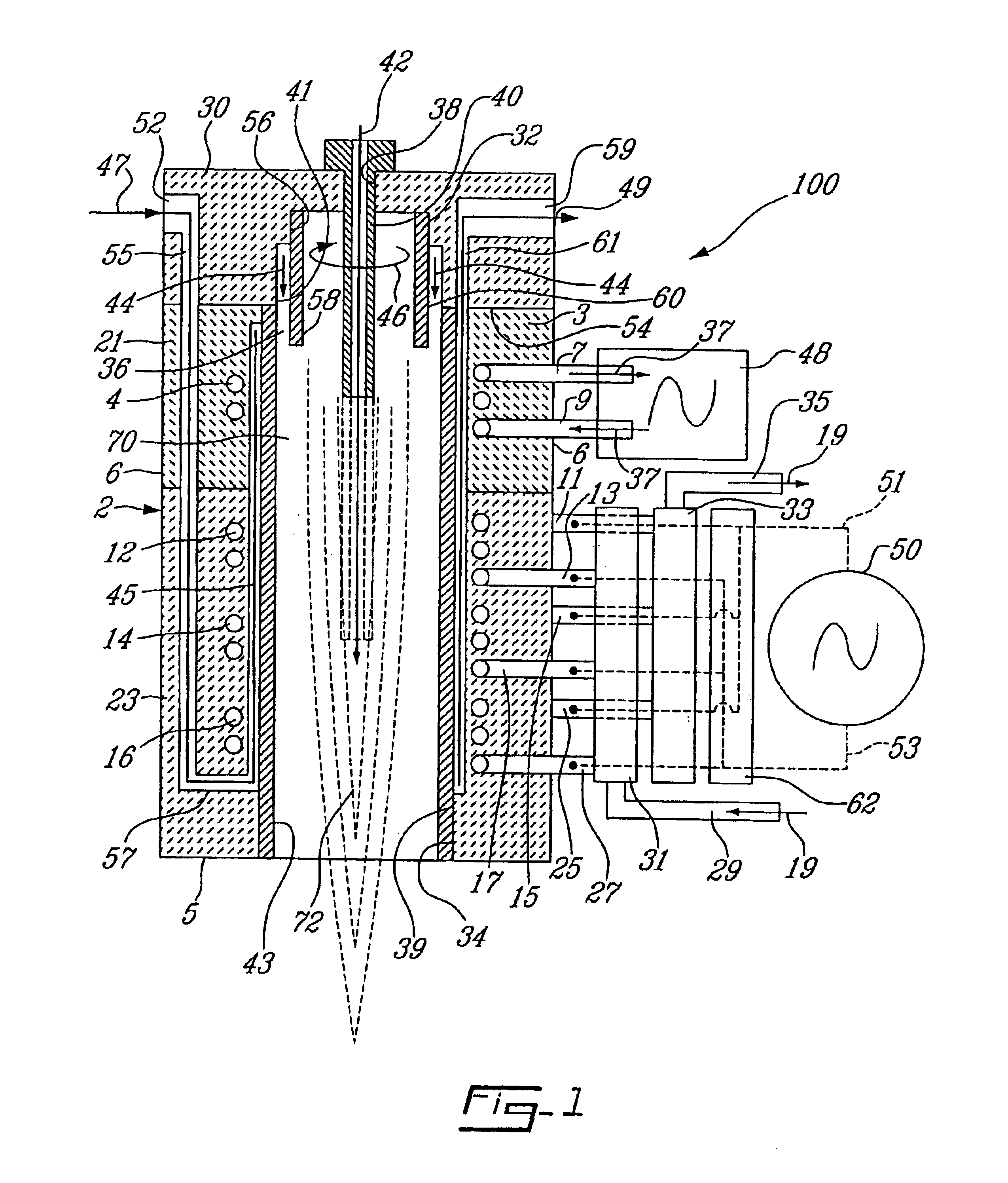

Multi-coil induction plasma torch for solid state power supply

InactiveUS6919527B2Efficient heatingImprove thermal conductivityElectric discharge tubesElectric arc lampsHigh frequency powerInduction plasma technology

Owner:TEKNA PLASMA SYST INC

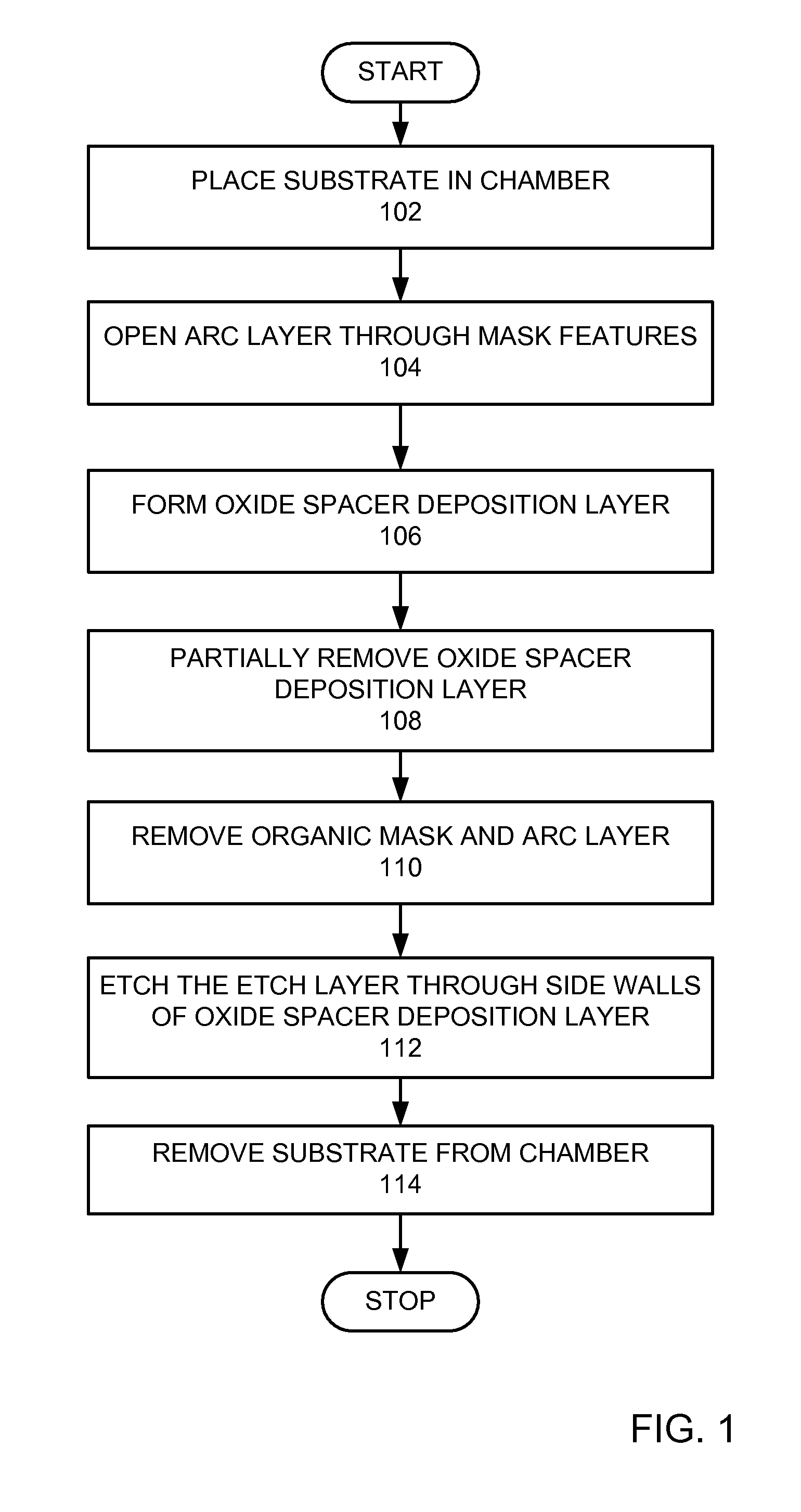

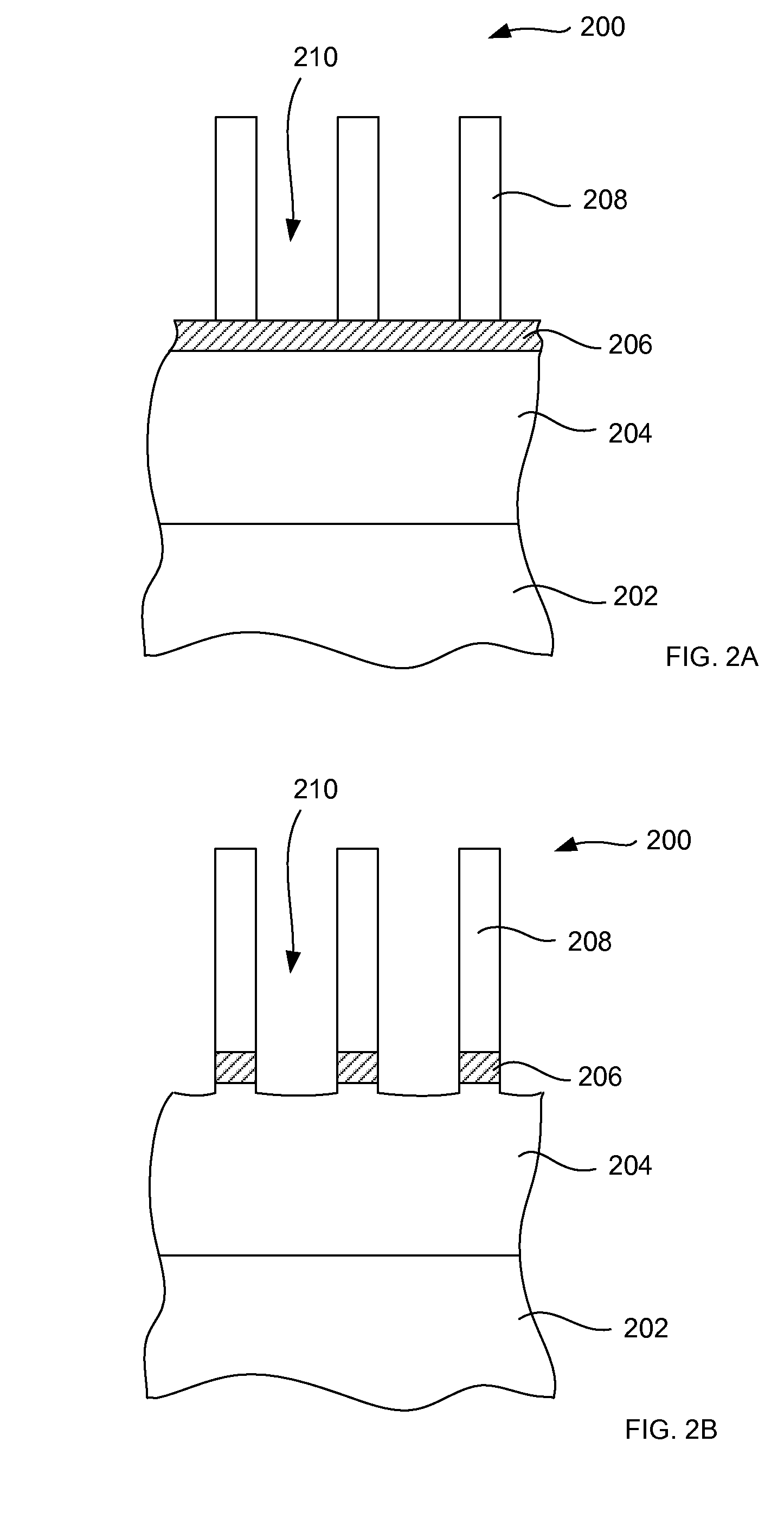

Pitch reduction using oxide spacer

InactiveUS20120052683A1Decorative surface effectsSemiconductor/solid-state device manufacturingOptoelectronicsCoating

A method for etching an etch layer disposed over a substrate and below an antireflective coating (ARC) layer and a patterned organic mask with mask features is provided. The substrate is placed in a process chamber. The ARC layer is opened. An oxide spacer deposition layer is formed. The oxide spacer deposition layer on the organic mask is partially removed, where at least the top portion of the oxide spacer deposition layer is removed. The organic mask and the ARC layer are removed by etching. The etch layer is etched through the sidewalls of the oxide spacer deposition layer. The substrate is removed from the process chamber.

Owner:LAM RES CORP

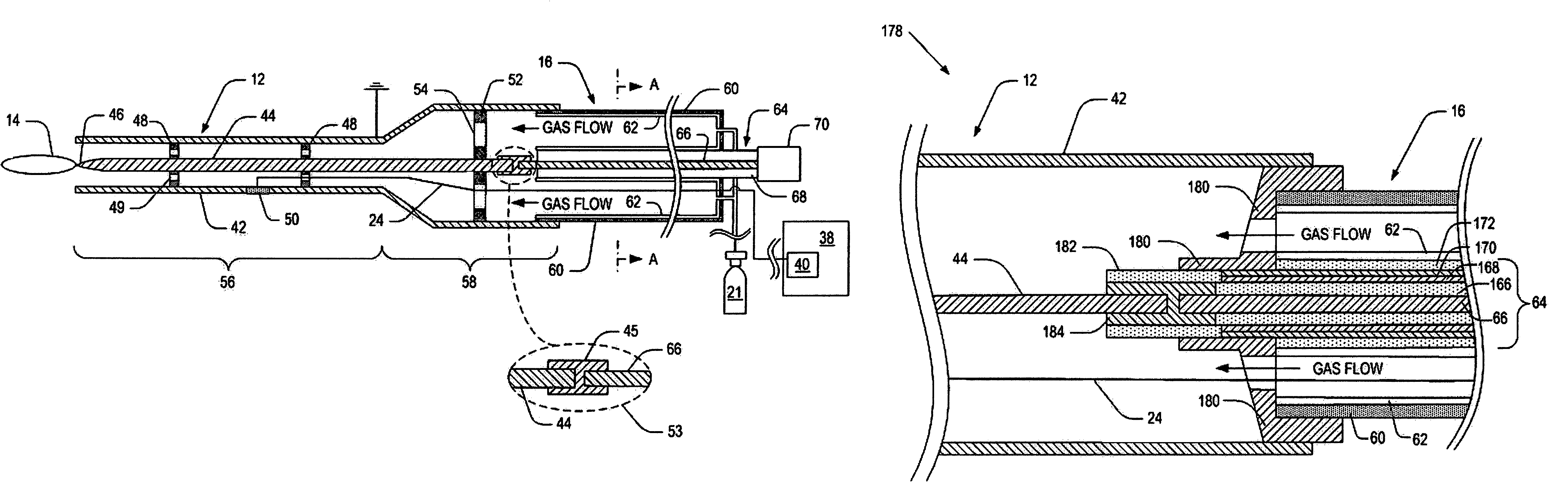

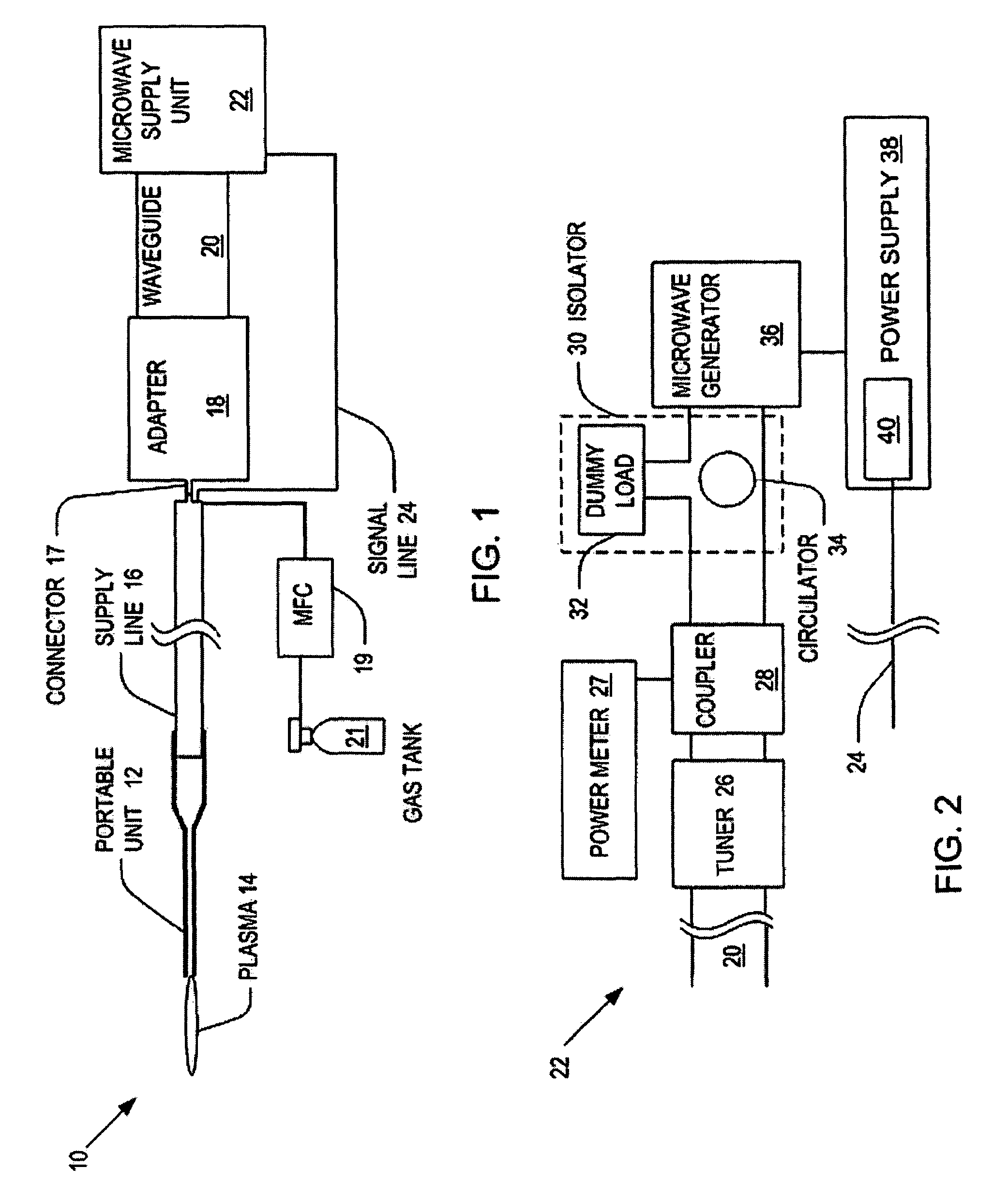

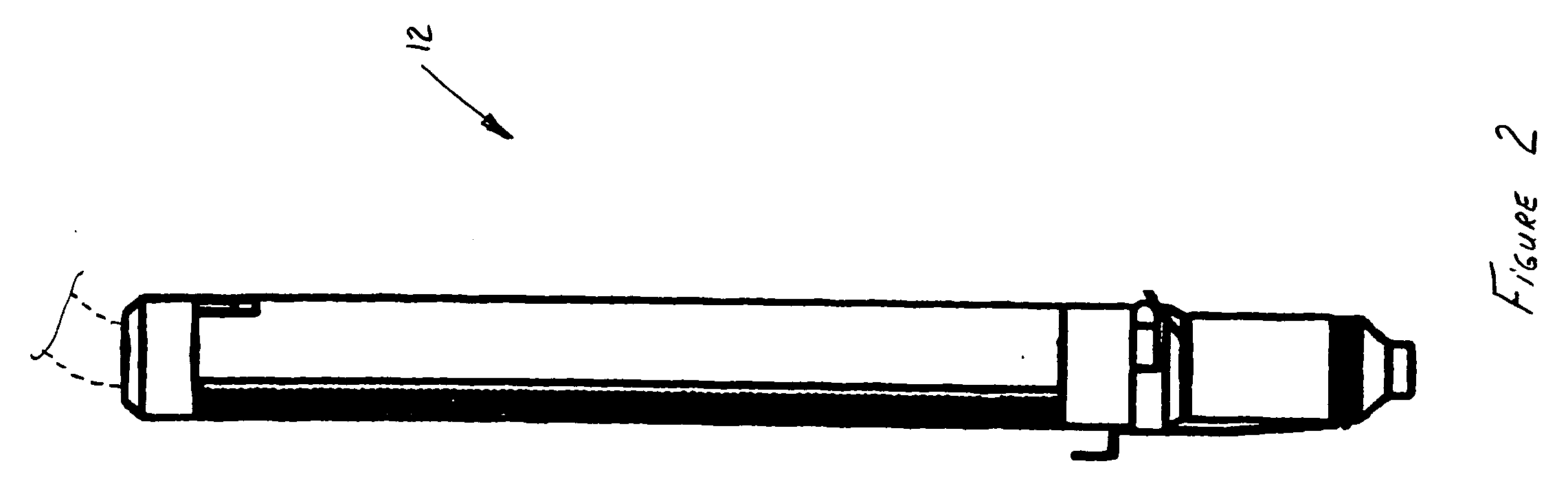

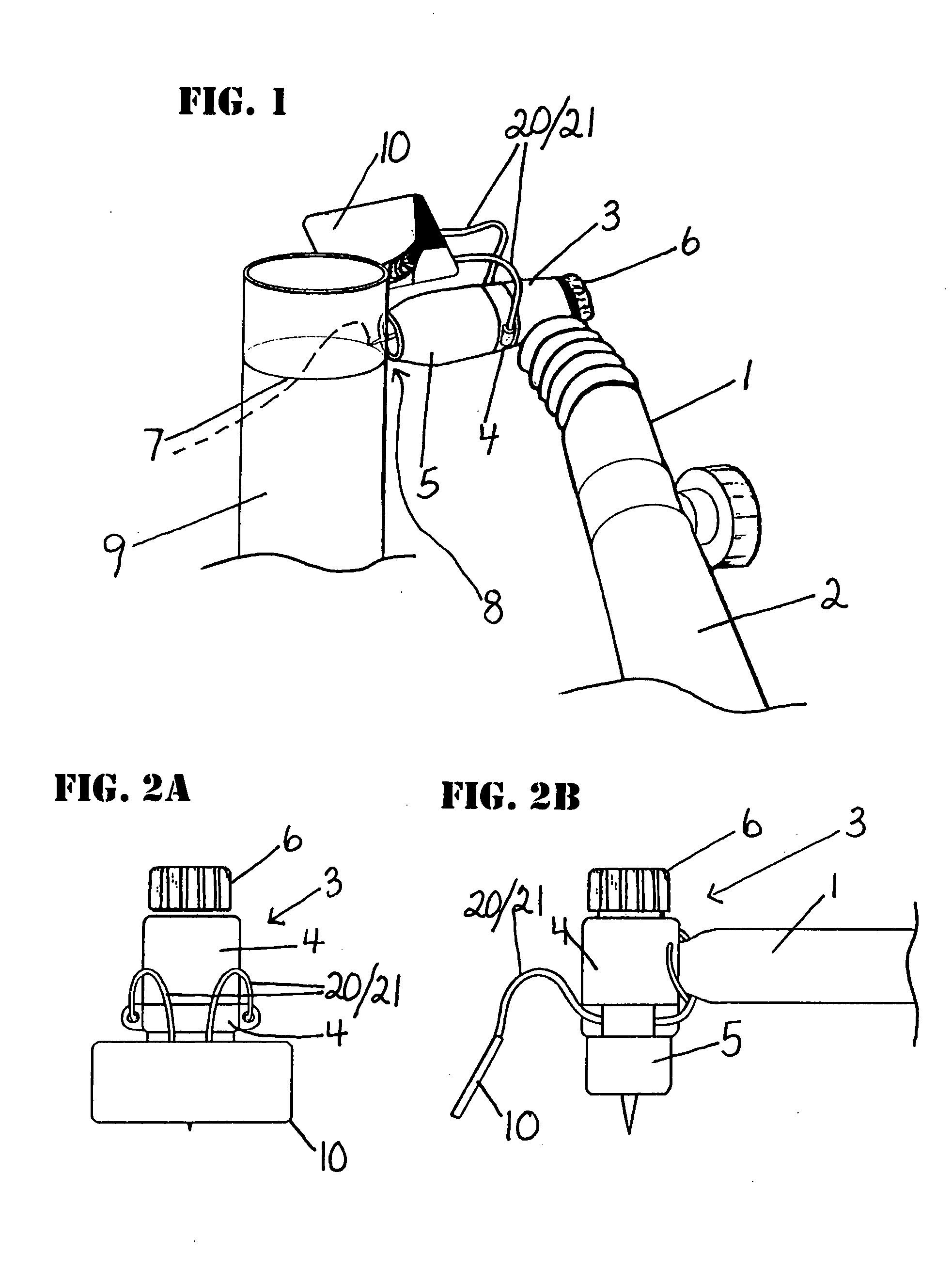

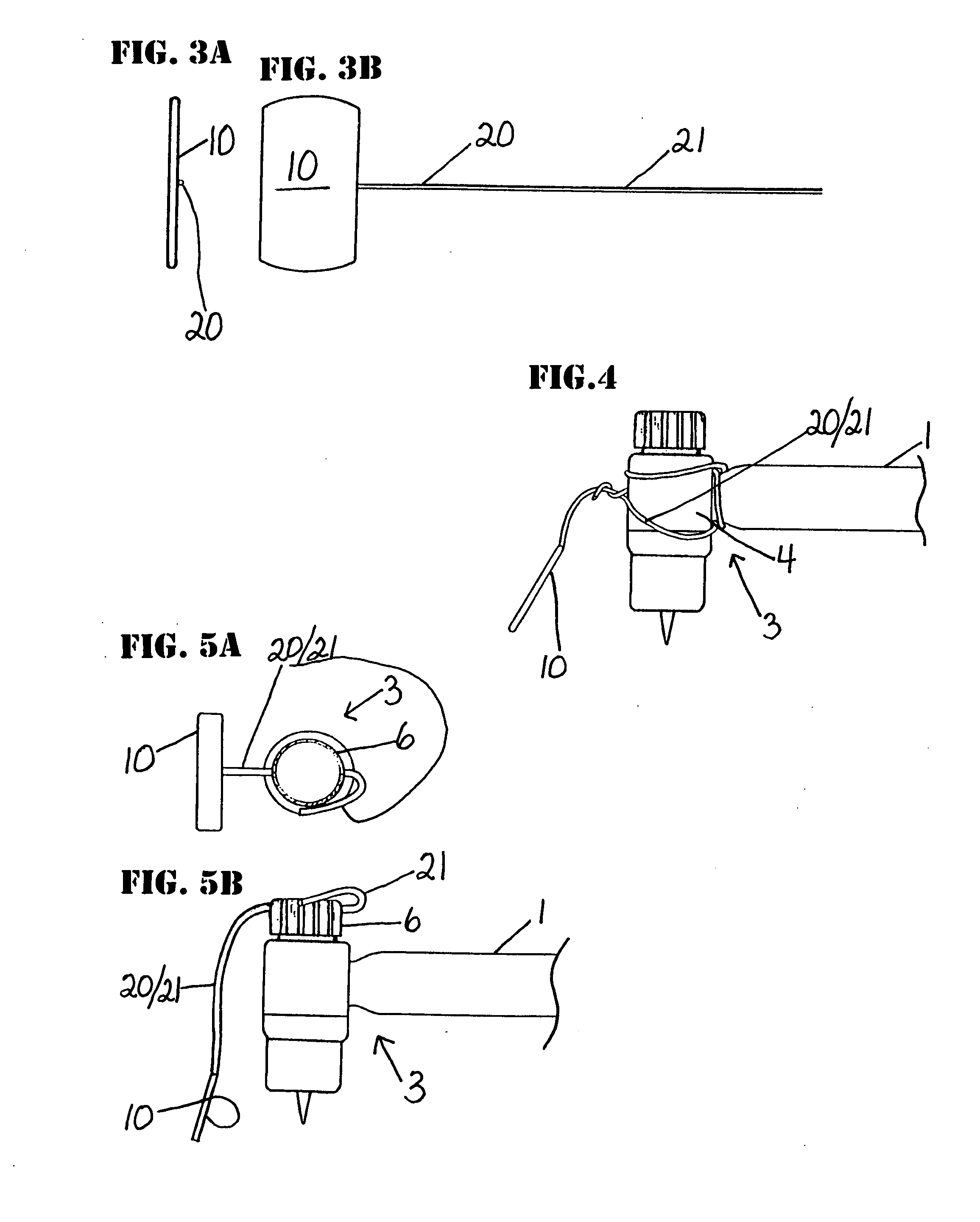

Portable microwave plasma systems including a supply line for gas and microwaves

ActiveUS7271363B2Increase energy densityWeaken energyElectric discharge tubesElectric arc lampsElectrical conductorCoaxial cable

Portable microwave plasma systems including supply lines for providing microwaves and gas flow are disclosed. The supply line includes at least one gas line or conduit and a microwave coaxial cable. A portable microwave plasma system includes a microwave source, a waveguide-to-coax adapter and a waveguide that interconnects the microwave source with the waveguide-to-coax adapter, a portable discharge unit and the supply line. The portable discharge unit includes a gas flow tube coupled to the supply line to receive gas flow and a rod-shaped conductor that is axially disposed in the gas flow tube and has an end configured to receive microwaves from the microwave coaxial cable and a tapered tip positioned adjacent the outlet portion of the gas flow tube. The tapered tip is configured to focus microwave traveling through the rod-shaped conductor and generate plasma from the gas flow.

Owner:RECARBON INC

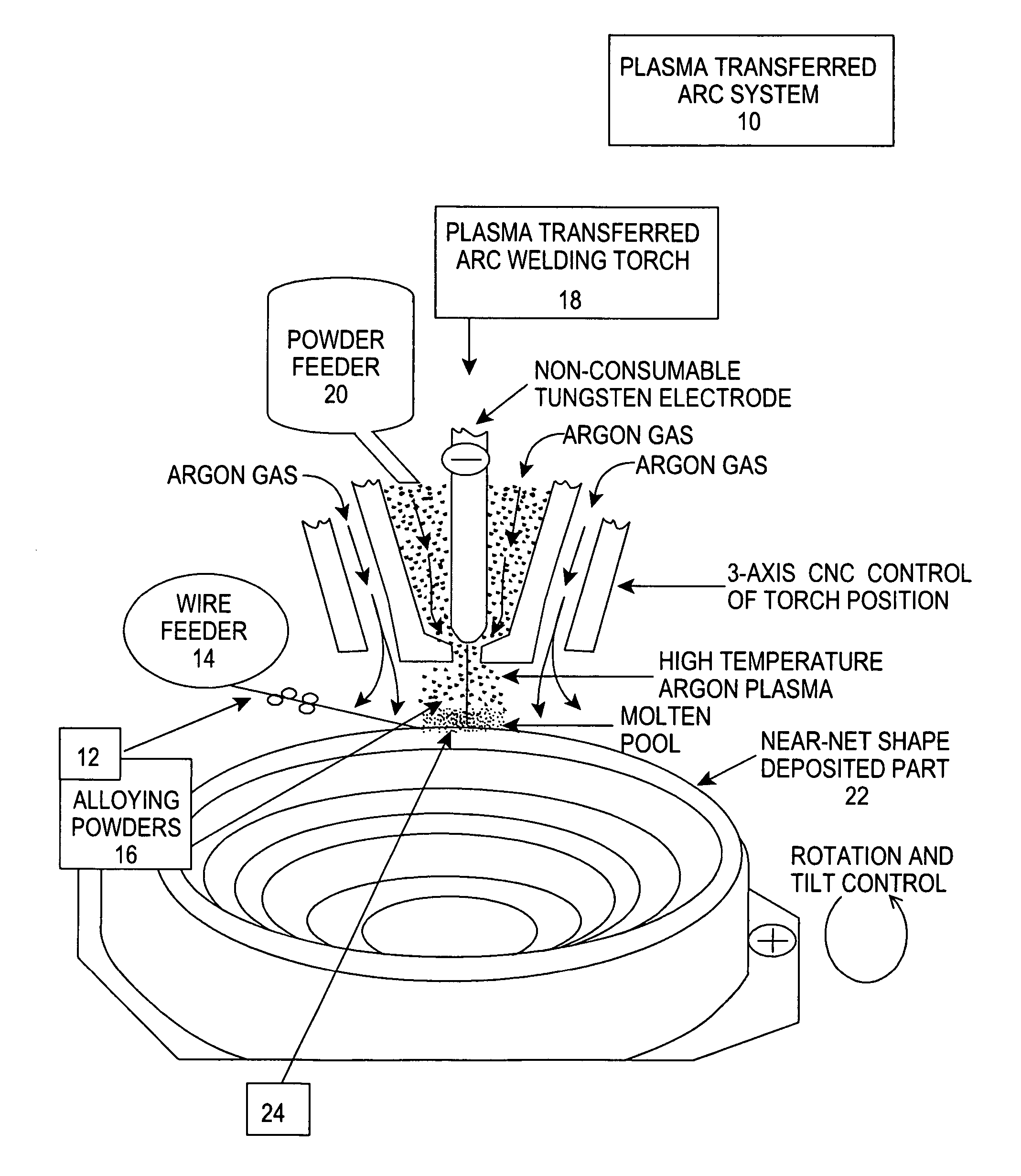

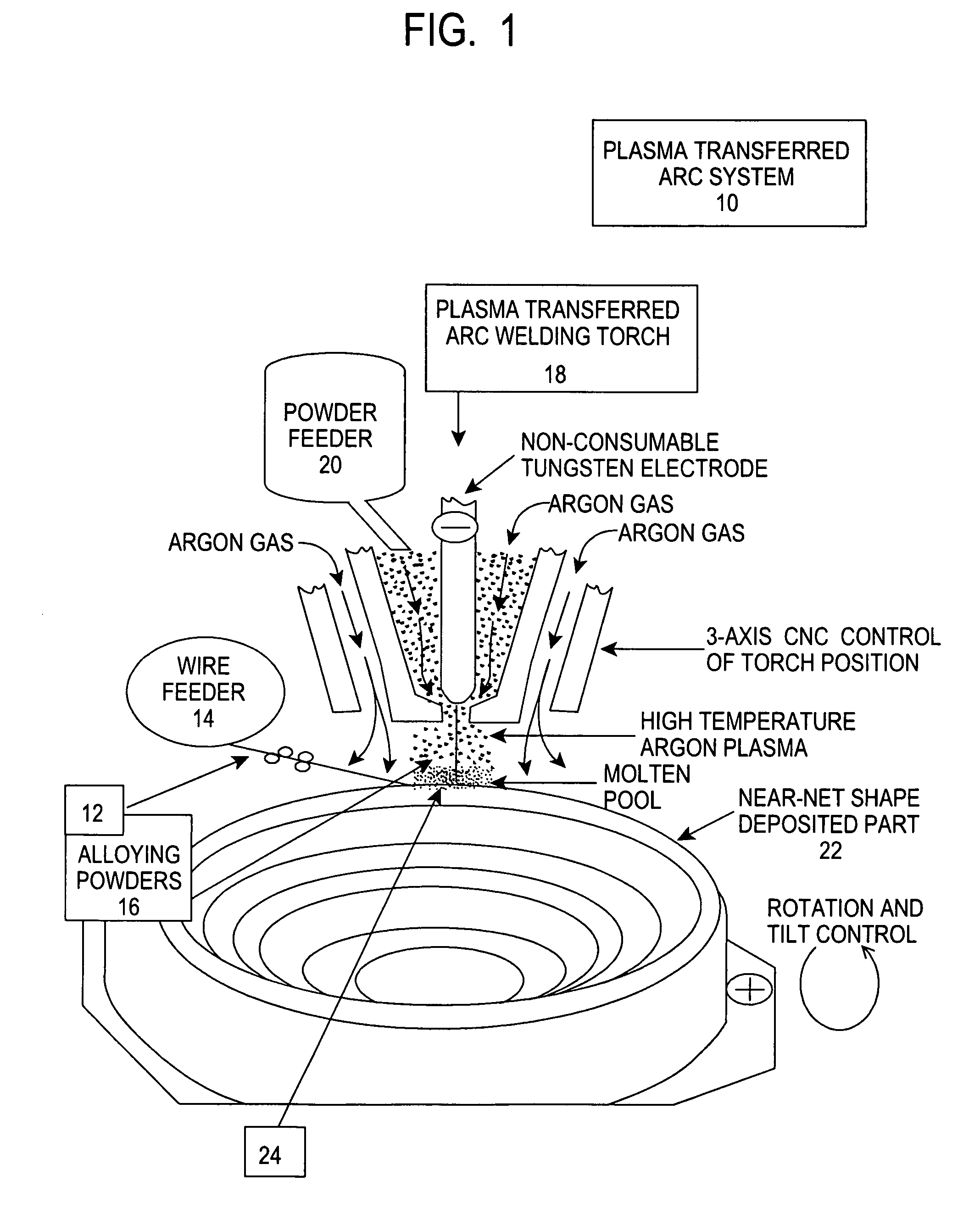

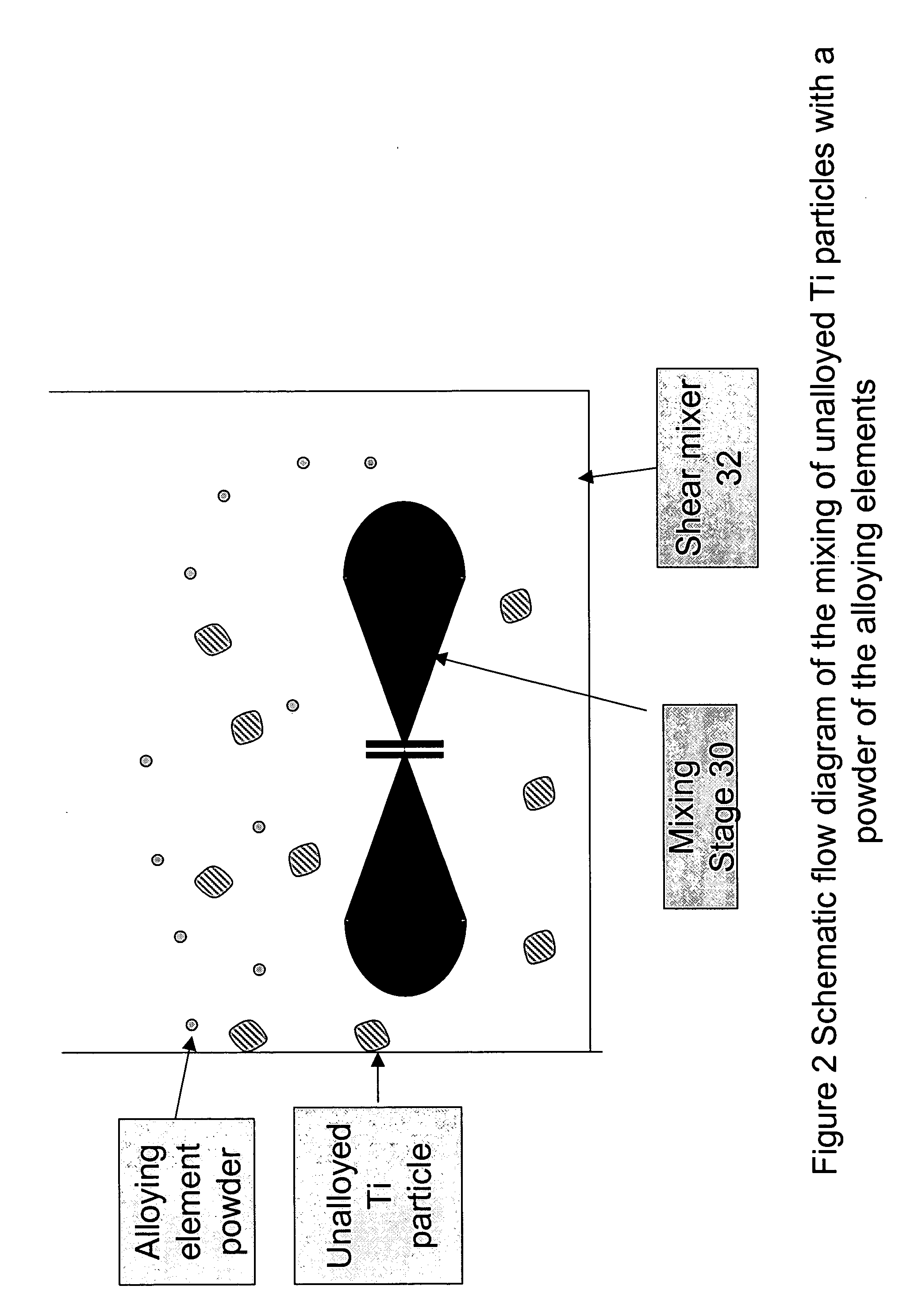

Low cost process for the manufacture of near net shape titanium bodies

InactiveUS20060185473A1Low costAdditive manufacturing apparatusArc welding apparatusHigh energyTitanium

Owner:ATS MER LLC

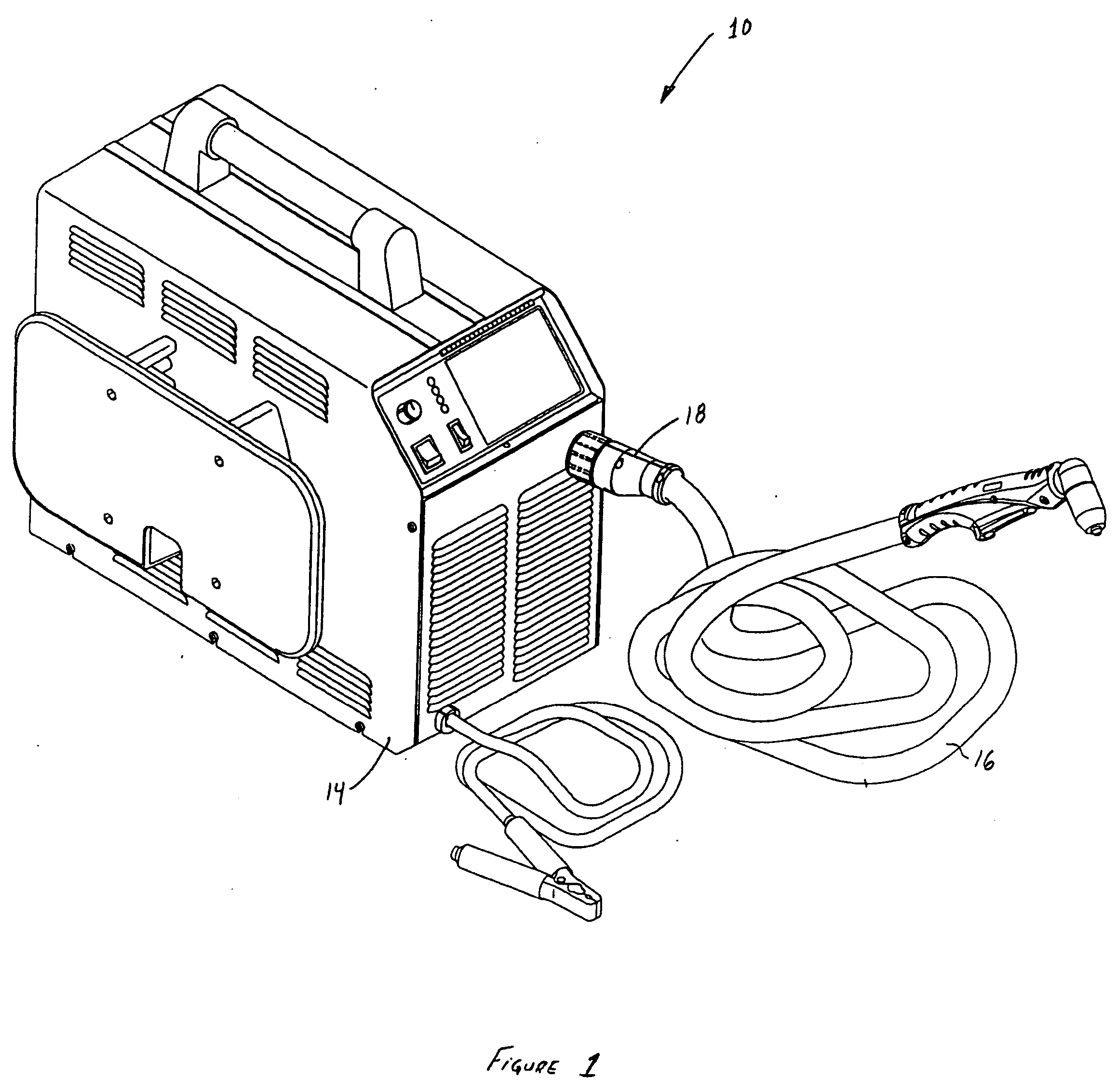

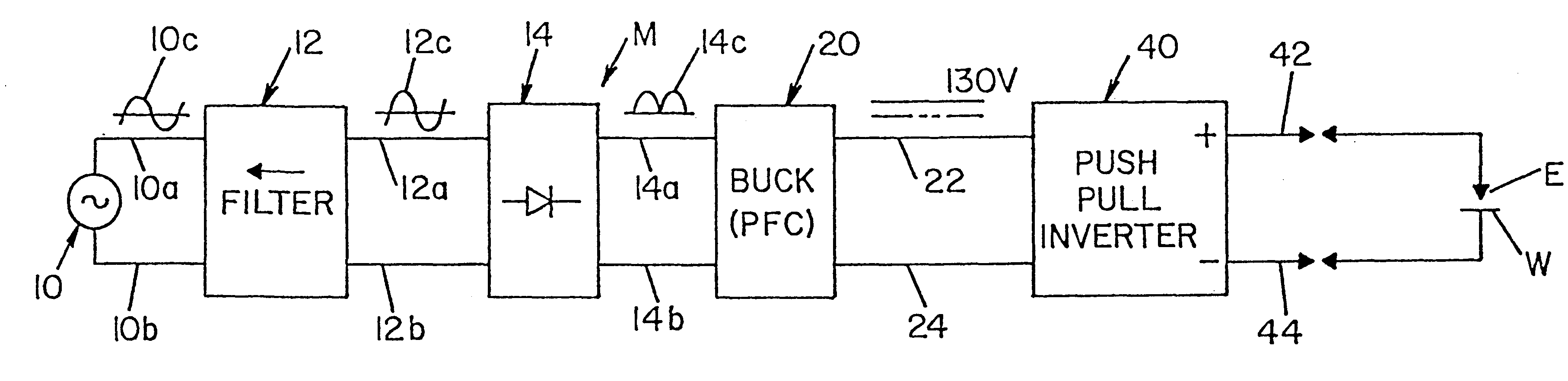

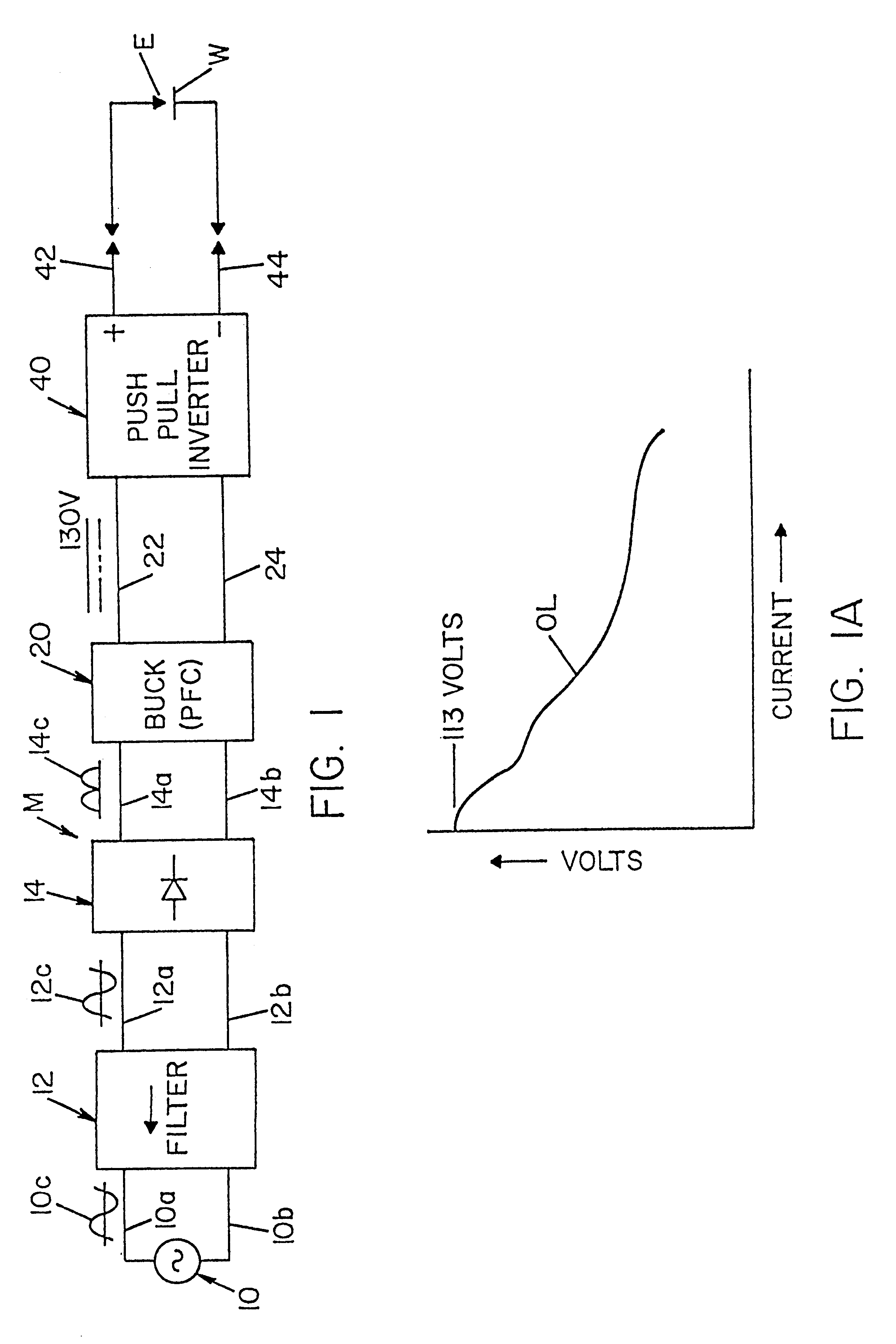

Electric ARC welder and plasma cutter

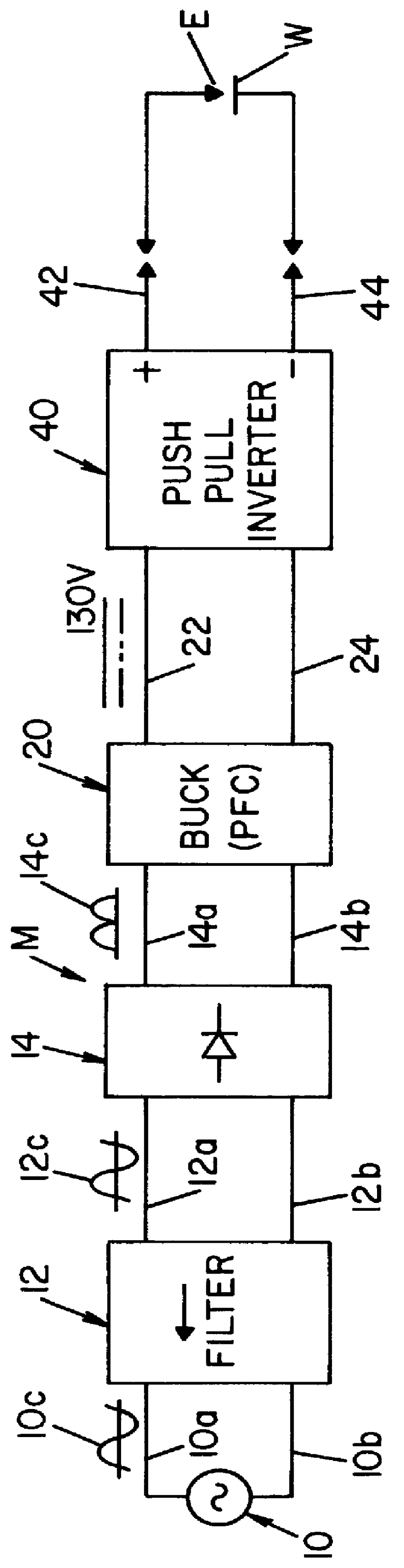

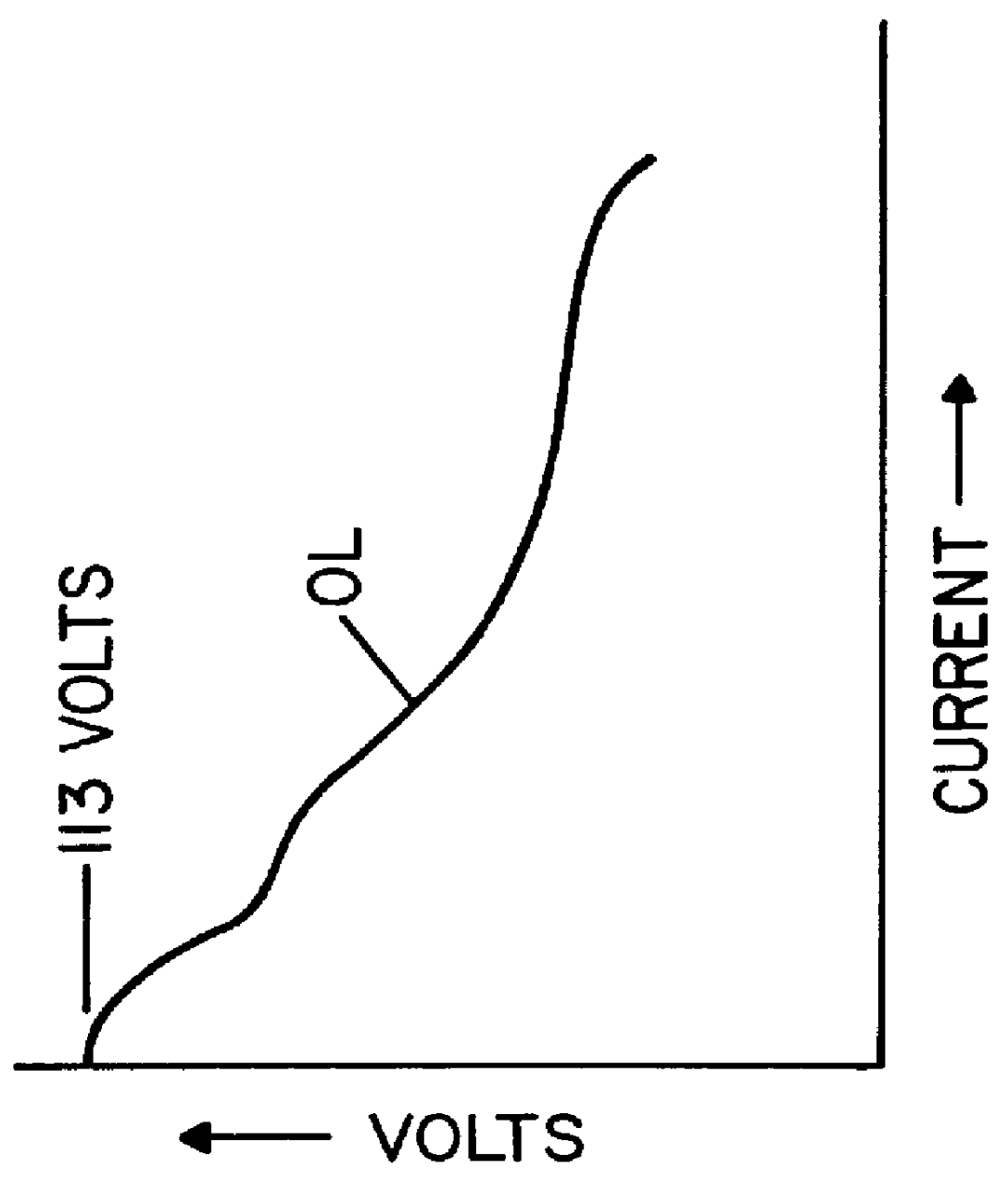

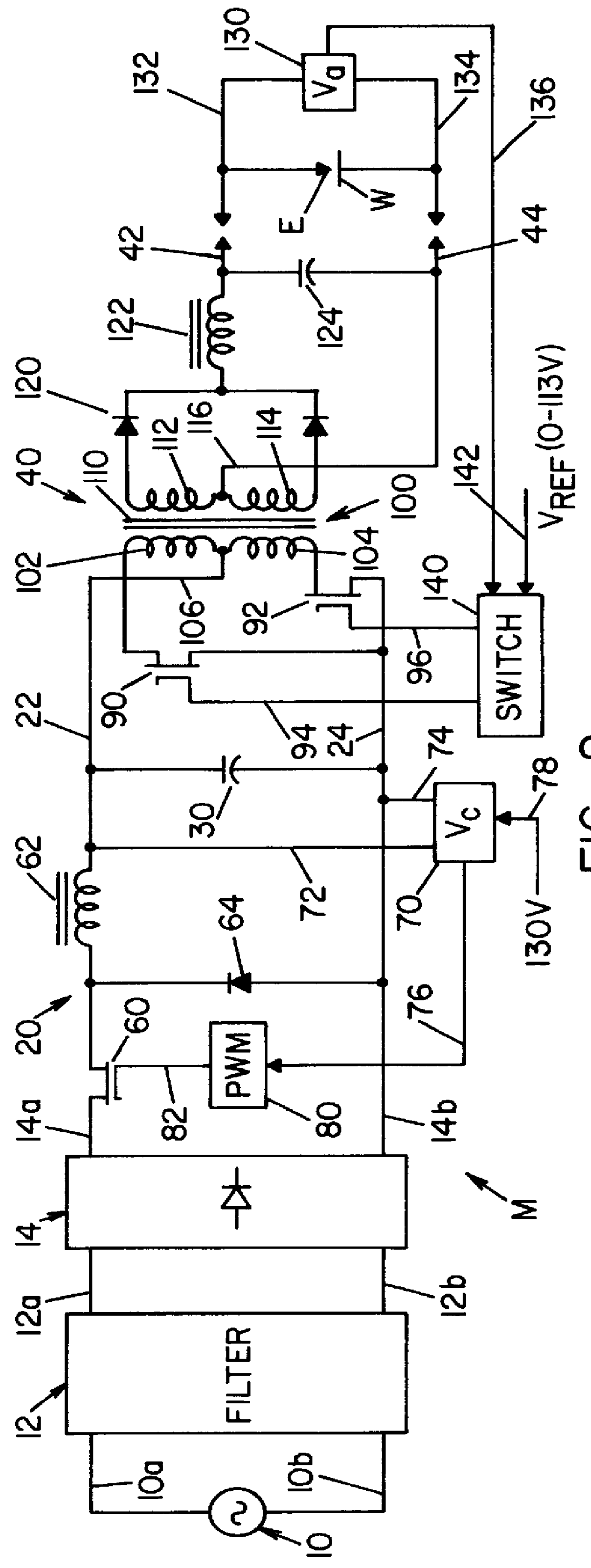

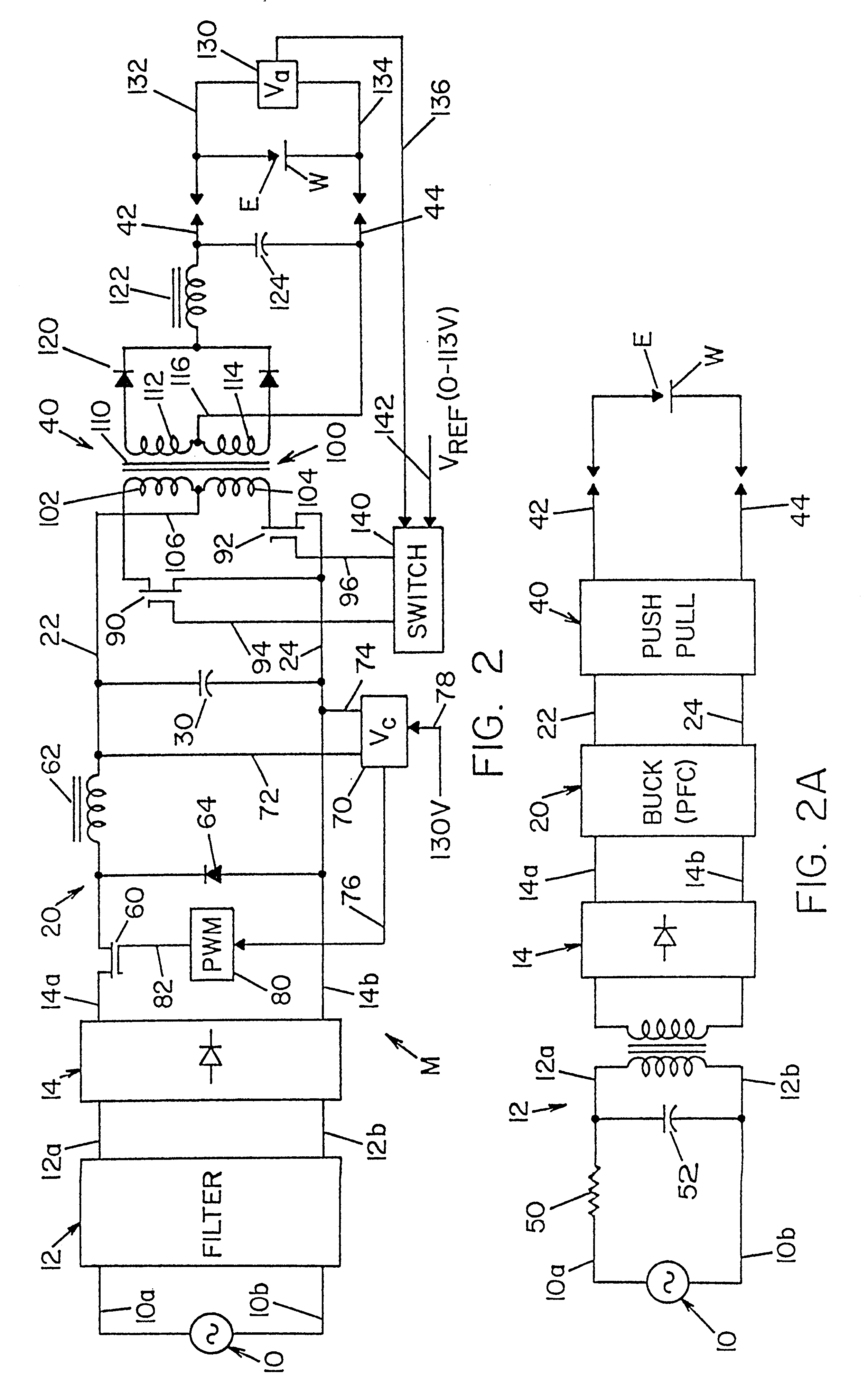

InactiveUS6023037AReduce Harmonic DistortionImprove power factorAc-dc conversion without reversalConversion with intermediate conversion to dcFull waveTransformer coupling

A single phase power supply module for electric arc welders and plasma arc cutters comprising: a single phase input stage; positive and negative output terminals; a full wave rectifier connected to the input stage for rectifying the single phase voltage at the input stage; a buck converter type power factor correcting circuit for controlling current flow from the input stage to the rectifier, which buck converter has an output capacitor regulated to an intermediate voltage in the range of 100-150 volts; and, a high speed DC to DC converter having an internal transformer coupling applying voltage across the output terminals and means for regulating the applied voltage to an output voltage in the range of 0-113 volts. The module is universal and several can be connected in parallel, in series or to switch networks to construct several welders or cutters.

Owner:LINCOLN GLOBAL INC

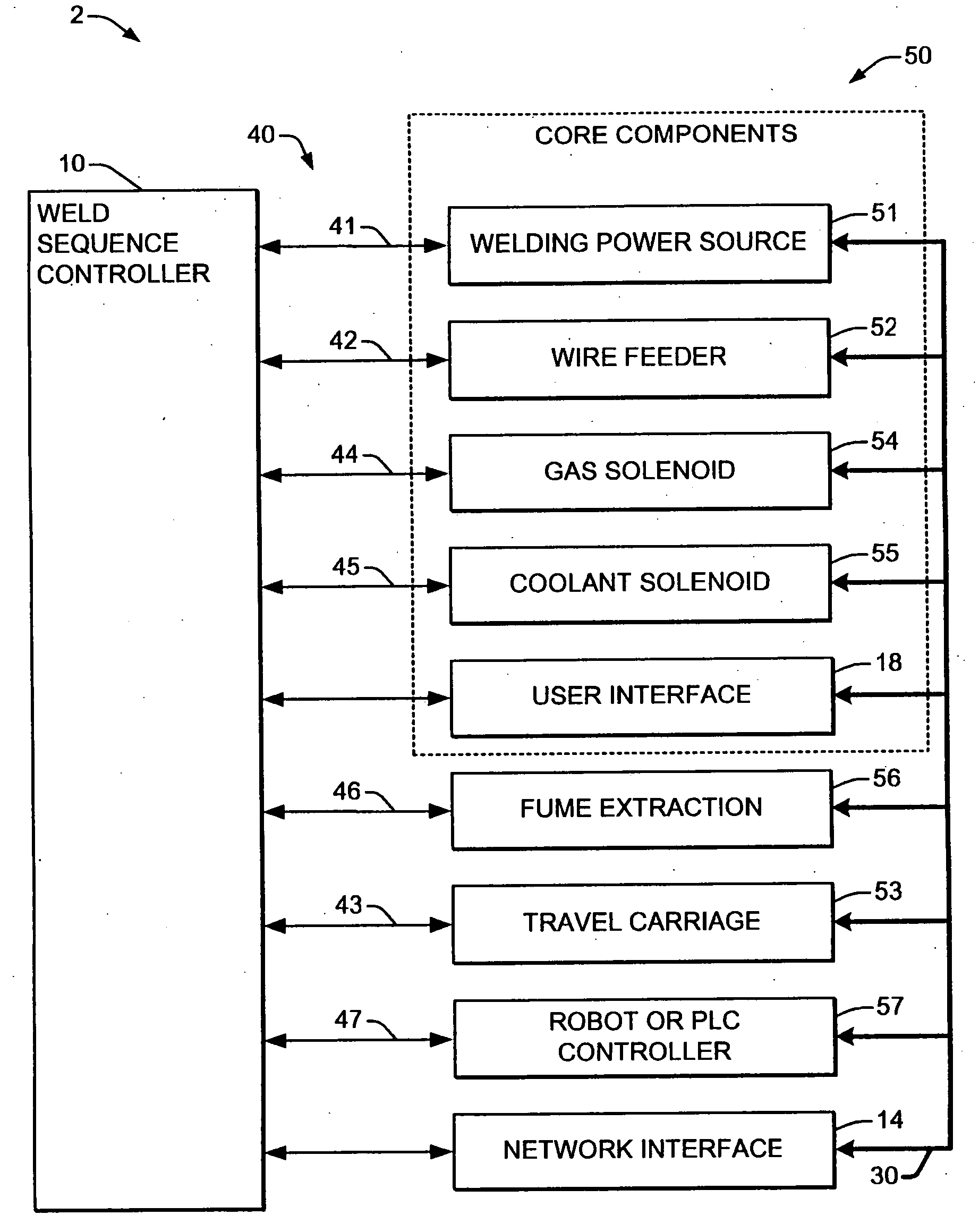

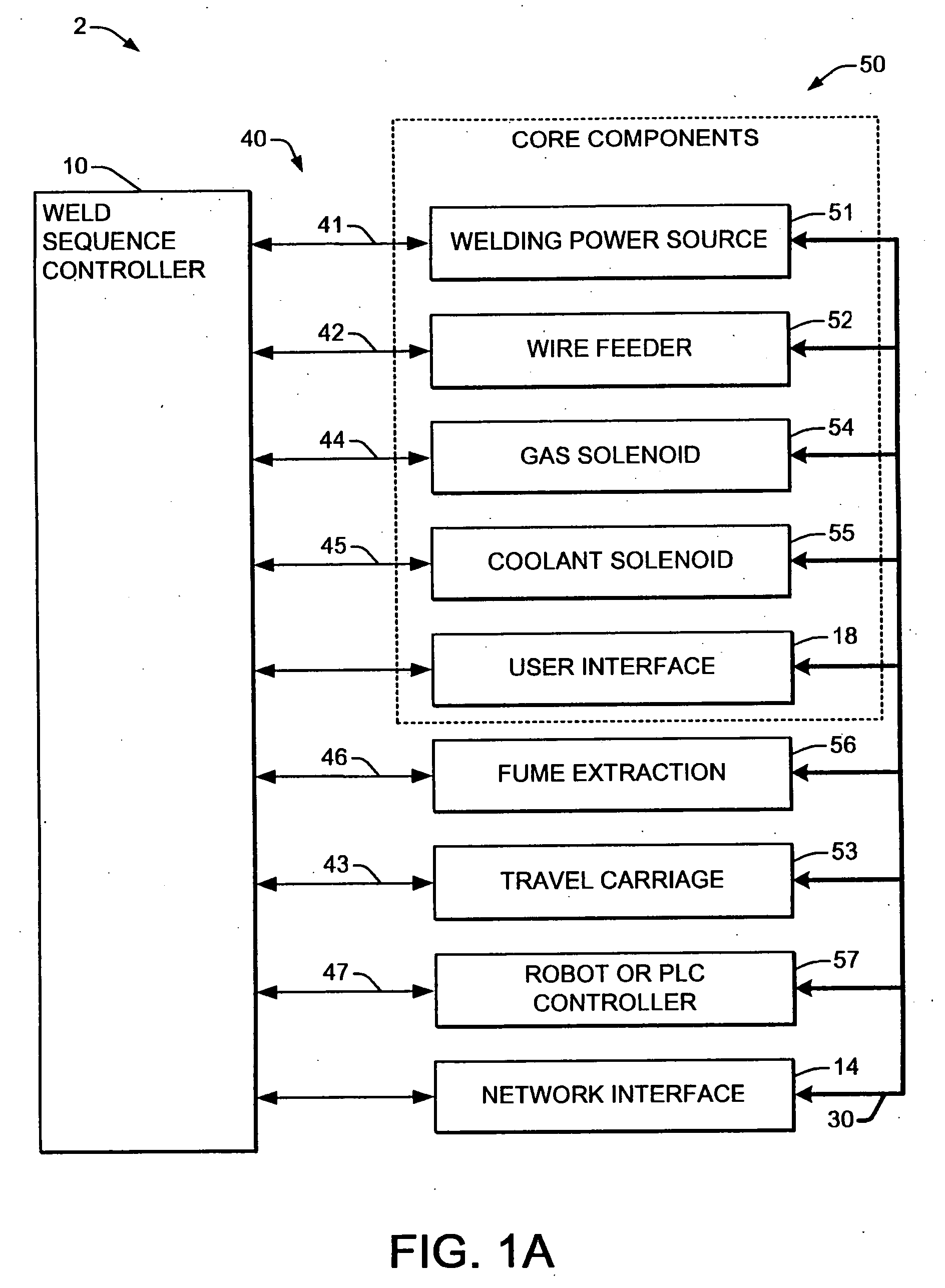

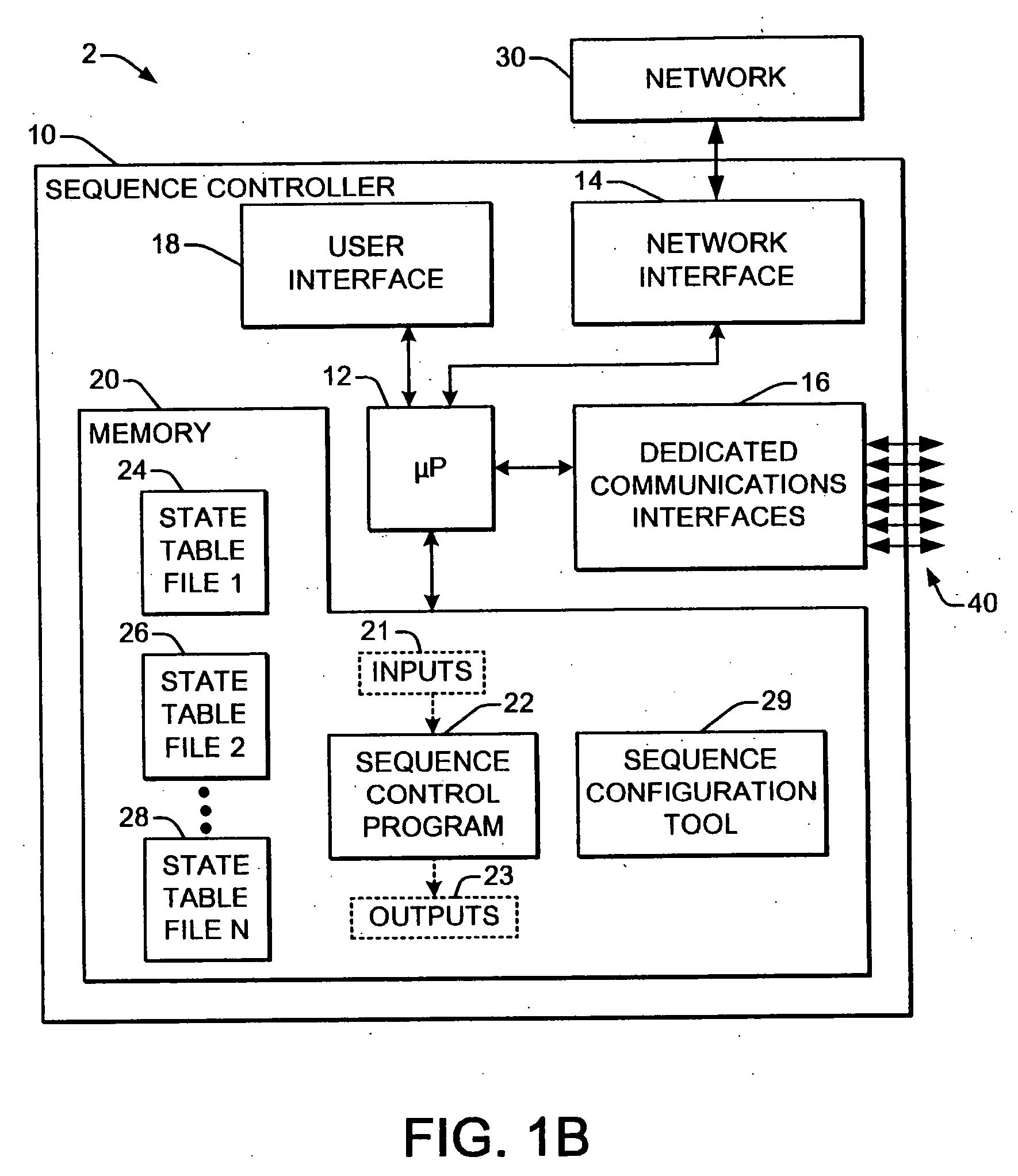

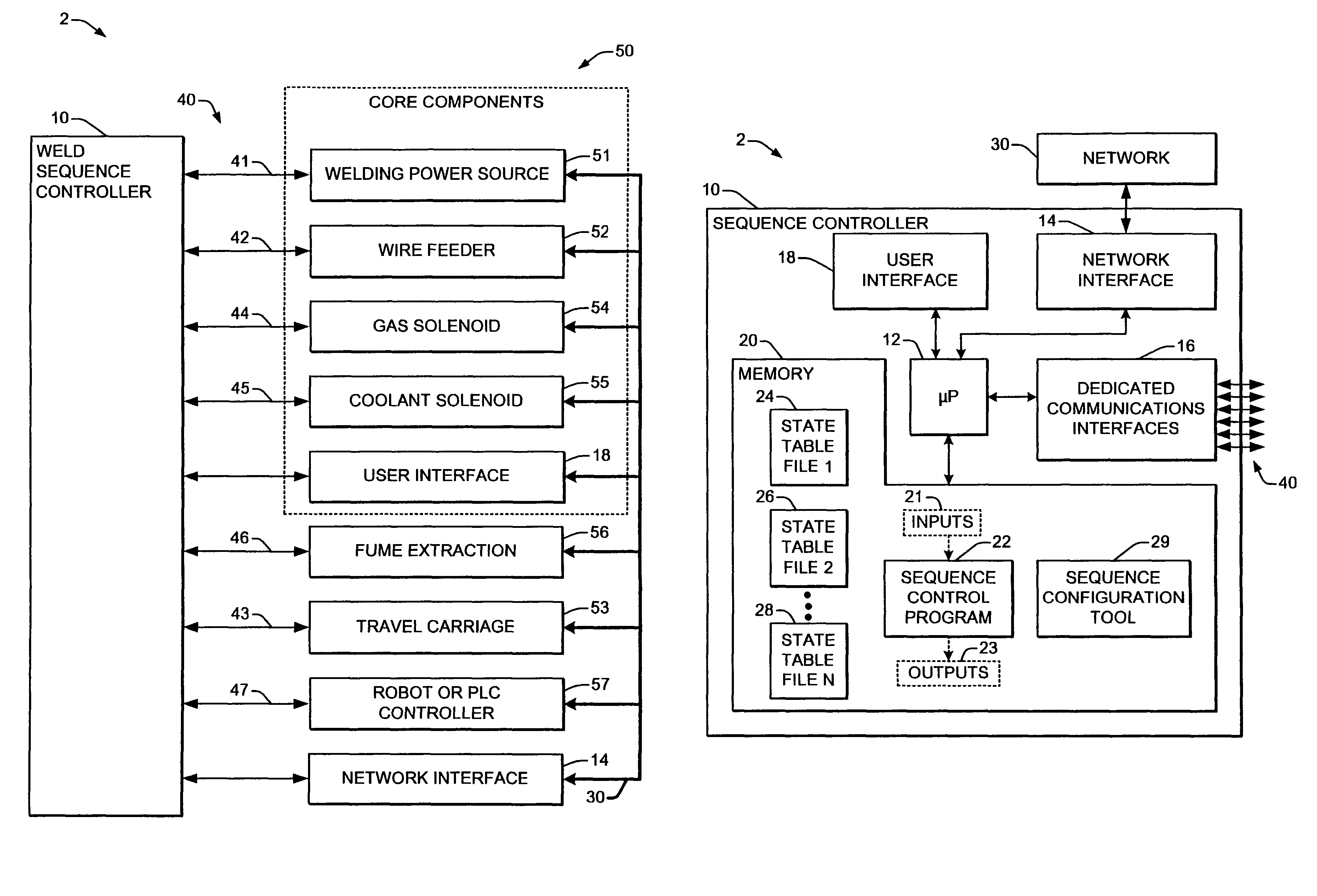

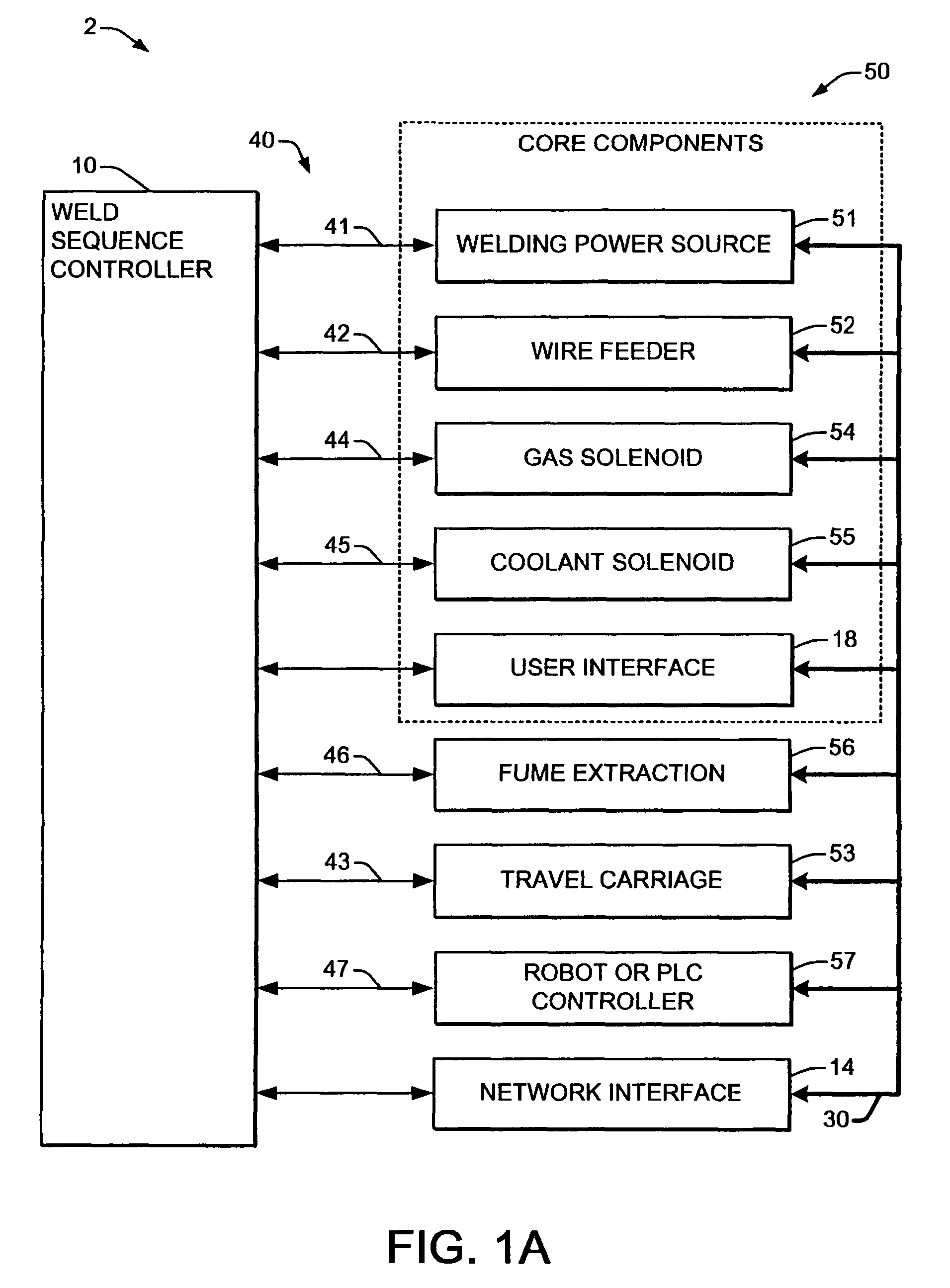

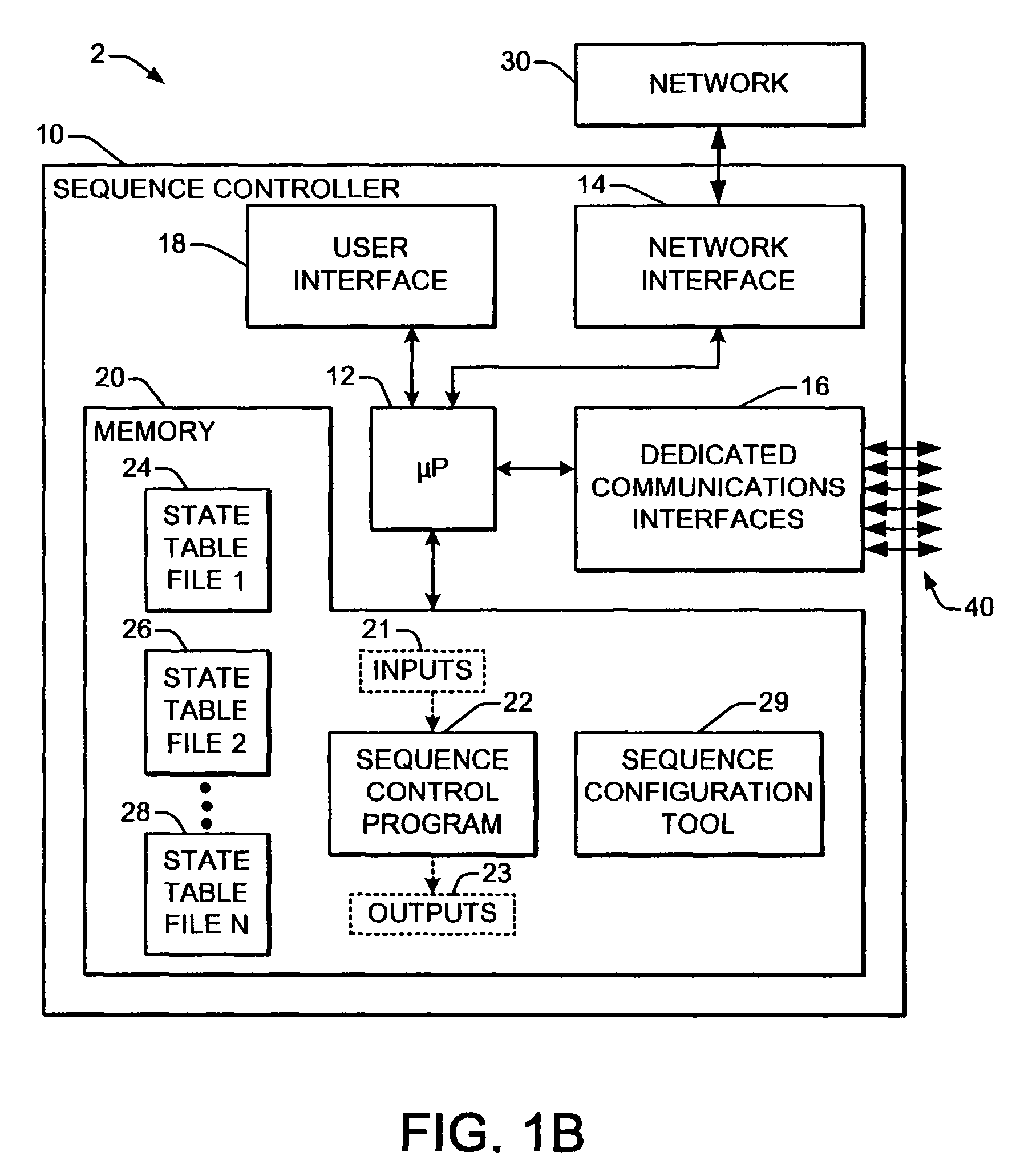

Welding system sequence control apparatus

ActiveUS20070056942A1Reprogram operationEfficient representationArc welding apparatusPlasma welding apparatusSequence controlEngineering

Welding systems and sequence controllers therefor are presented for controlling components of a welding system during a welding operation. The sequence controller receives system inputs and provides control outputs to the system components, and includes a processing component, an executable sequence control program, and a state table file. The sequence control state table file includes a number of entries corresponding to welding operation states, where the individual entries comprise one or more instruction identifiers, instruction parameters, exit condition identifiers and corresponding next state identifiers. The sequence control program is executed according to the sequence controller inputs and according to the state table file to provide the sequence controller outputs, where the state table file can be easily modified or new state table files can be created and downloaded to the sequence controller to facilitate easy reconfiguration of a welding system.

Owner:LINCOLN GLOBAL INC

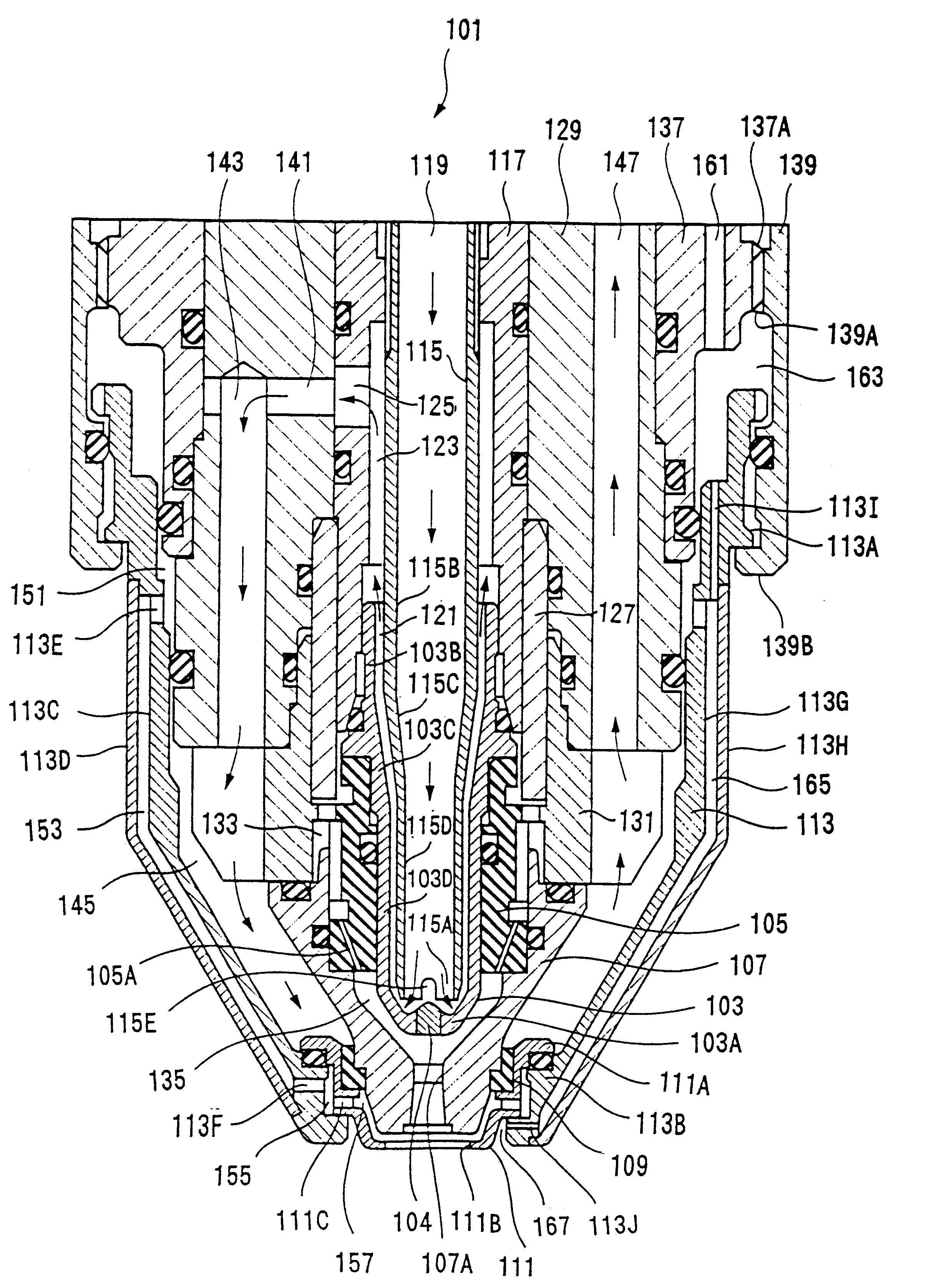

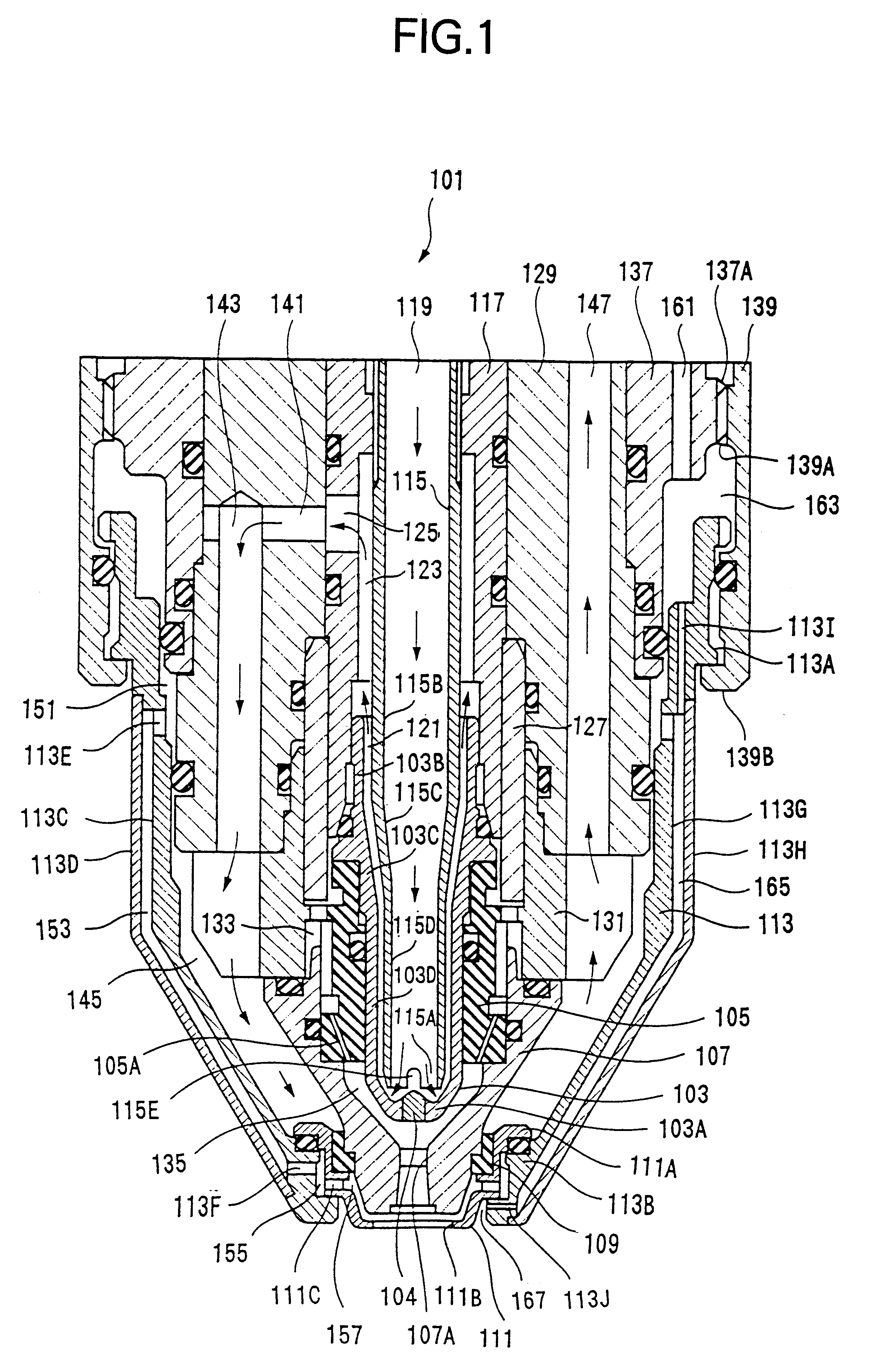

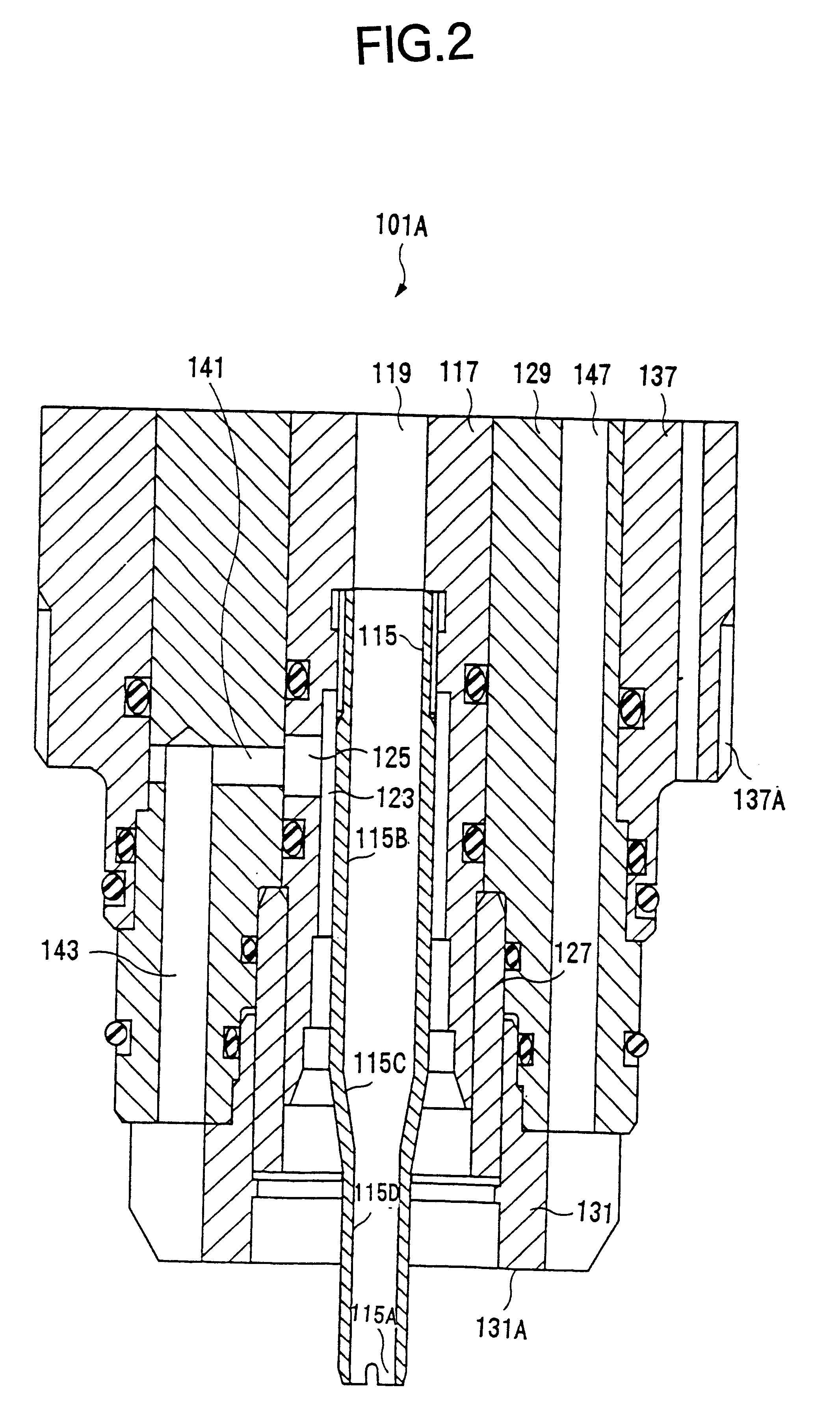

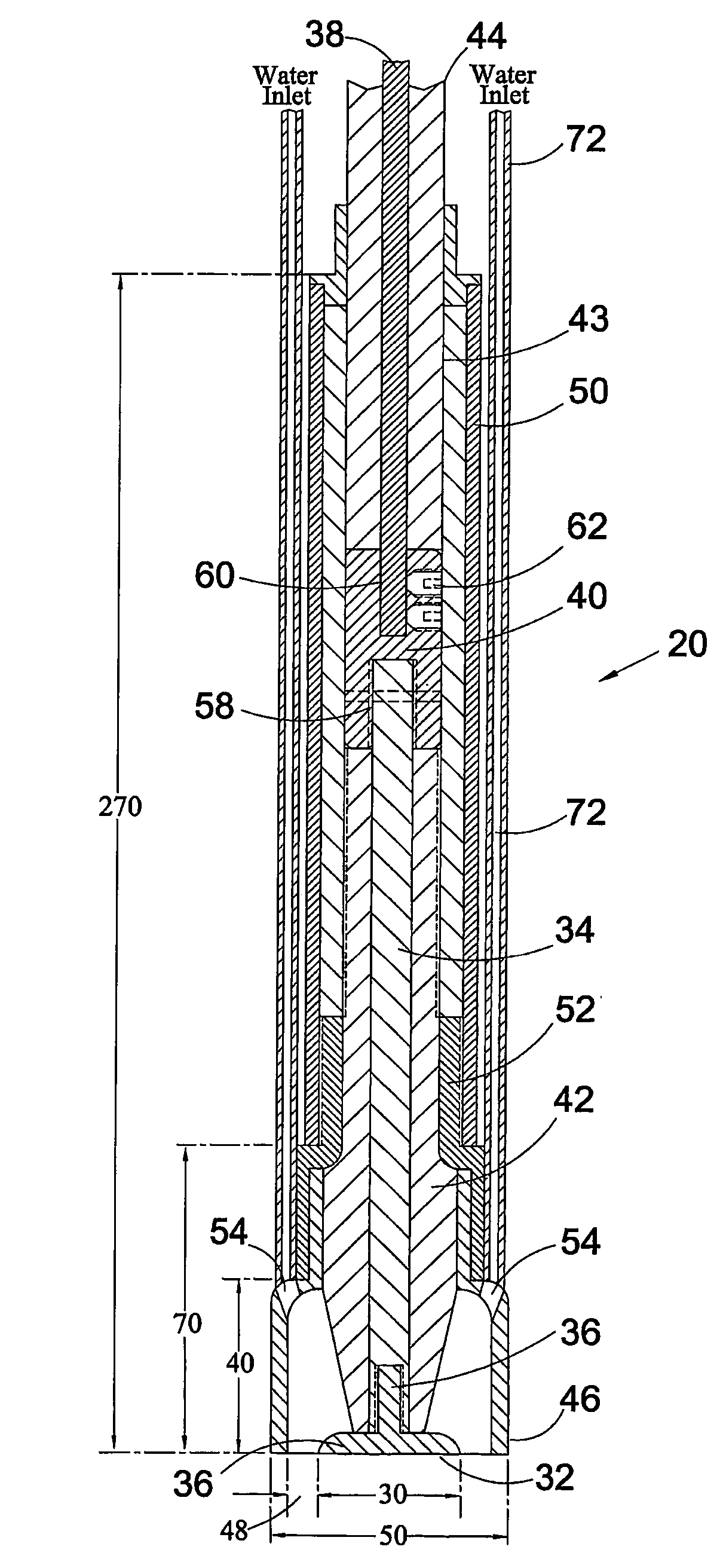

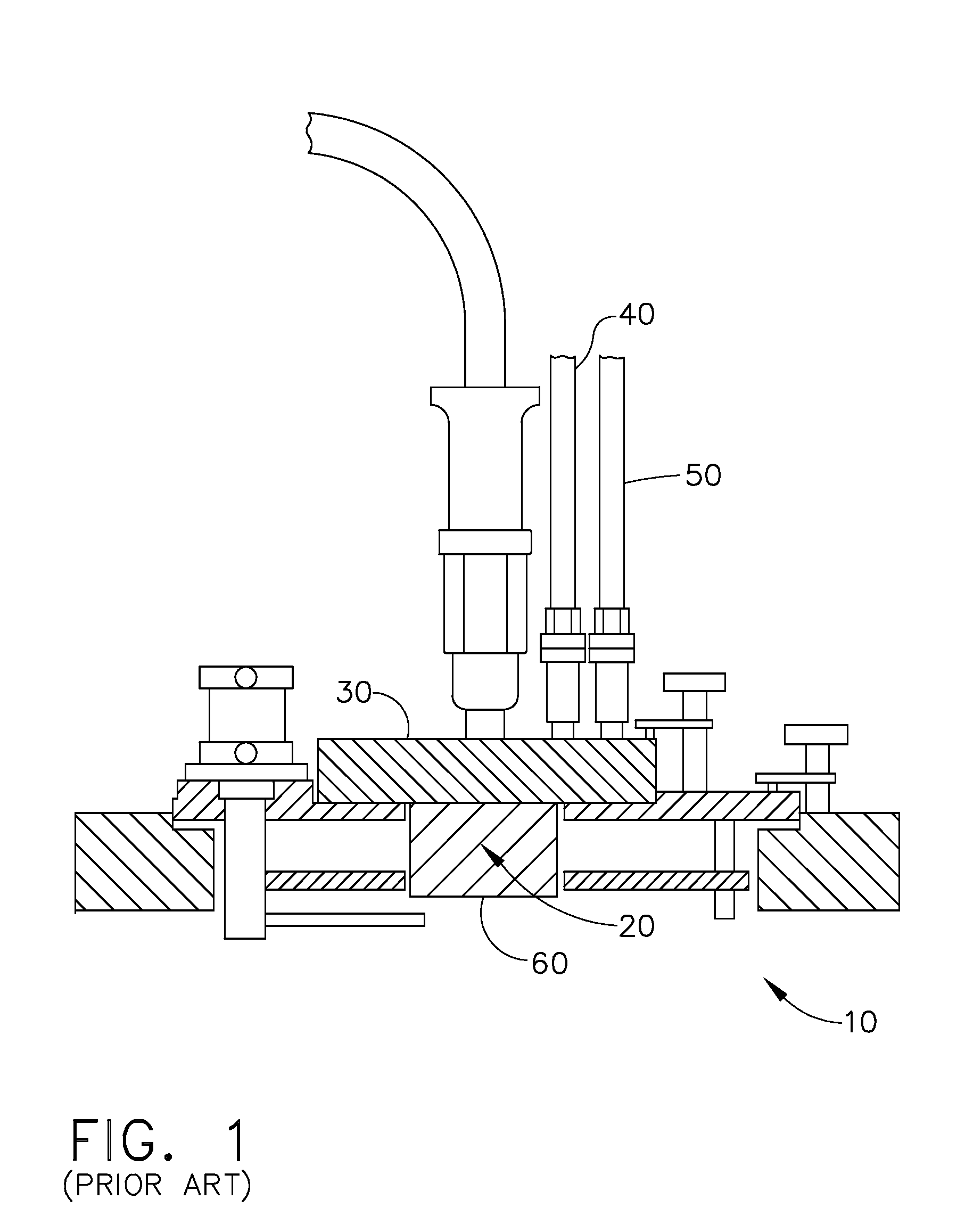

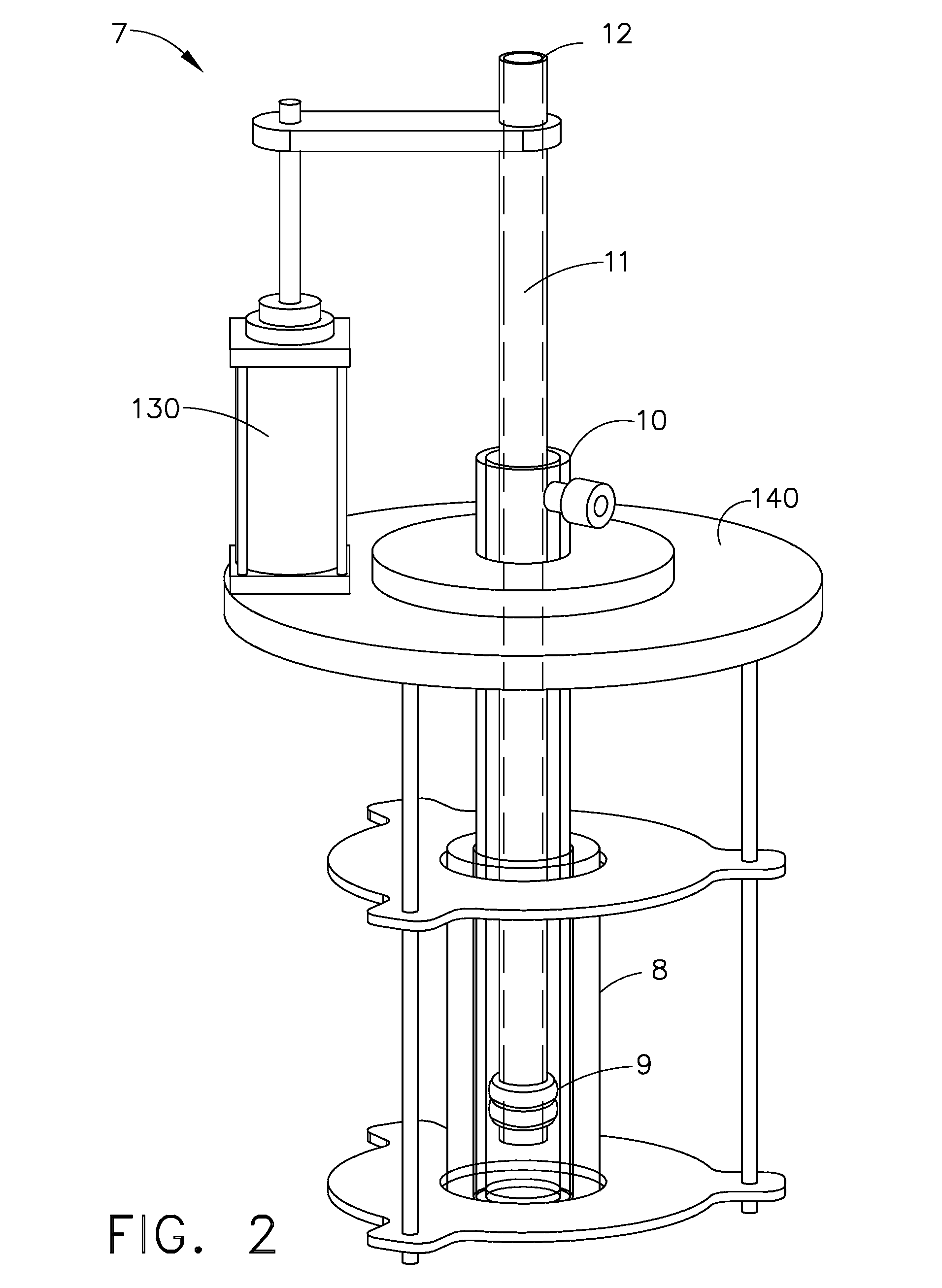

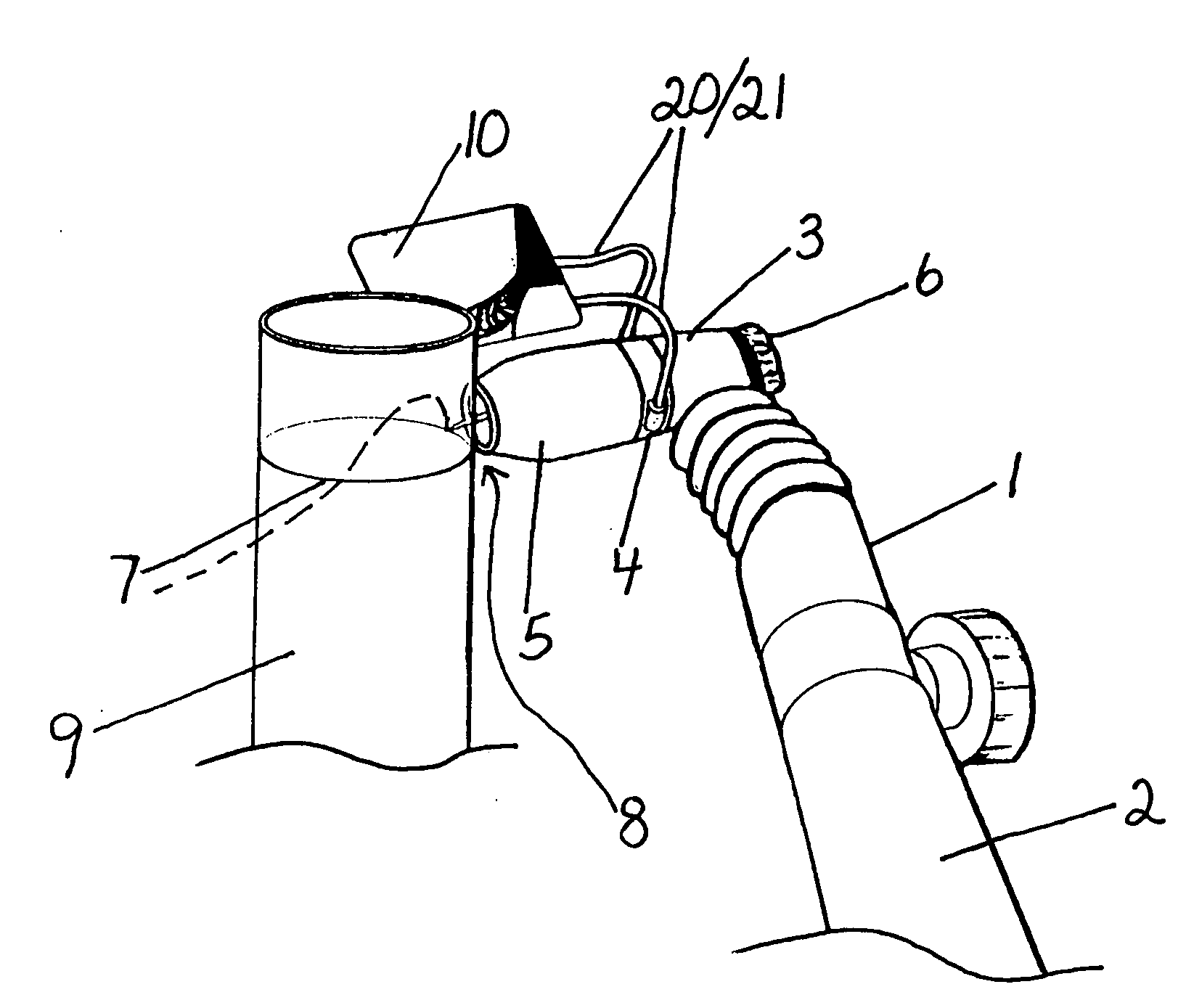

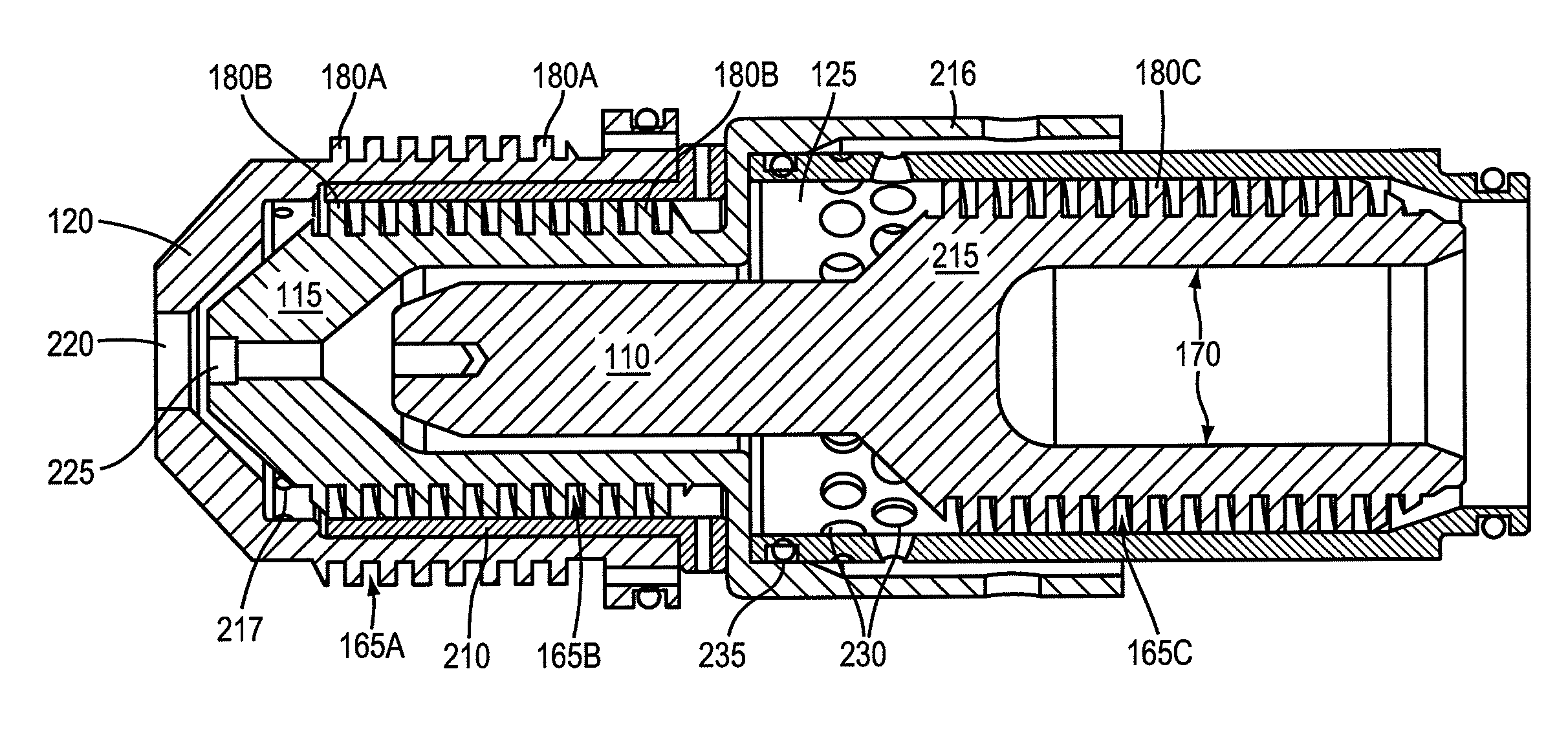

Plasma processing device, plasma torch and method for replacing components of same

InactiveUS6320156B1Simplifies taskAvoid connection failurePlasma welding apparatusWelding/cutting media/materialsCouplingTorch

The object is to facilitate replacement of consumable parts, such as the electrode, nozzle, or the like, in a plasma torch, whilst suppressing any increase in structural complexity or cost. An electrode 103, insulating guide 105 and nozzle 107 are fit together installed in a retainer cap 113. By means of O-rings 193, 195, 197, the electrode 103, insulating guide 105, nozzle 107 and retainer cap 113 are coupled together by a coupling force which allows the components to be pulled apart and separated manually. By attaching the retainer cap 113 to the torch main unit and detaching the retainer cap 113 from same, the electrode 103, insulating guide 105 and nozzle 107 can be attached and detached to and from the torch main unit, simultaneously.

Owner:KOMATSU LTD

Welding system sequence control apparatus

ActiveUS8692157B2Reprogram operationEfficient representationArc welding apparatusPlasma welding apparatusSequence controlEngineering

Welding systems and sequence controllers therefor are presented for controlling components of a welding system during a welding operation. The sequence controller receives system inputs and provides control outputs to the system components, and includes a processing component, an executable sequence control program, and a state table file. The sequence control state table file includes a number of entries corresponding to welding operation states, where the individual entries comprise one or more instruction identifiers, instruction parameters, exit condition identifiers and corresponding next state identifiers. The sequence control program is executed according to the sequence controller inputs and according to the state table file to provide the sequence controller outputs, where the state table file can be easily modified or new state table files can be created and downloaded to the sequence controller to facilitate easy reconfiguration of a welding system.

Owner:LINCOLN GLOBAL INC

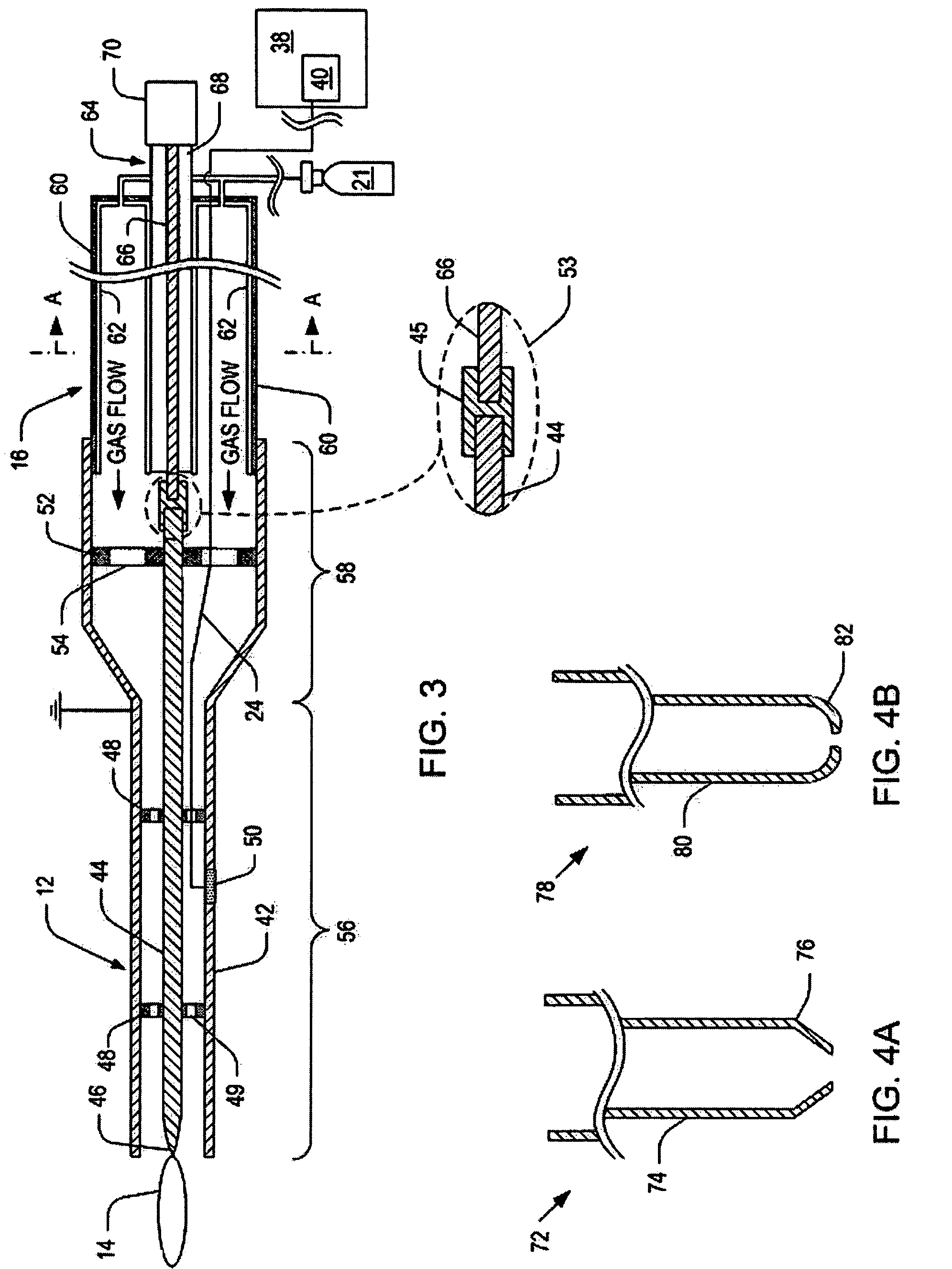

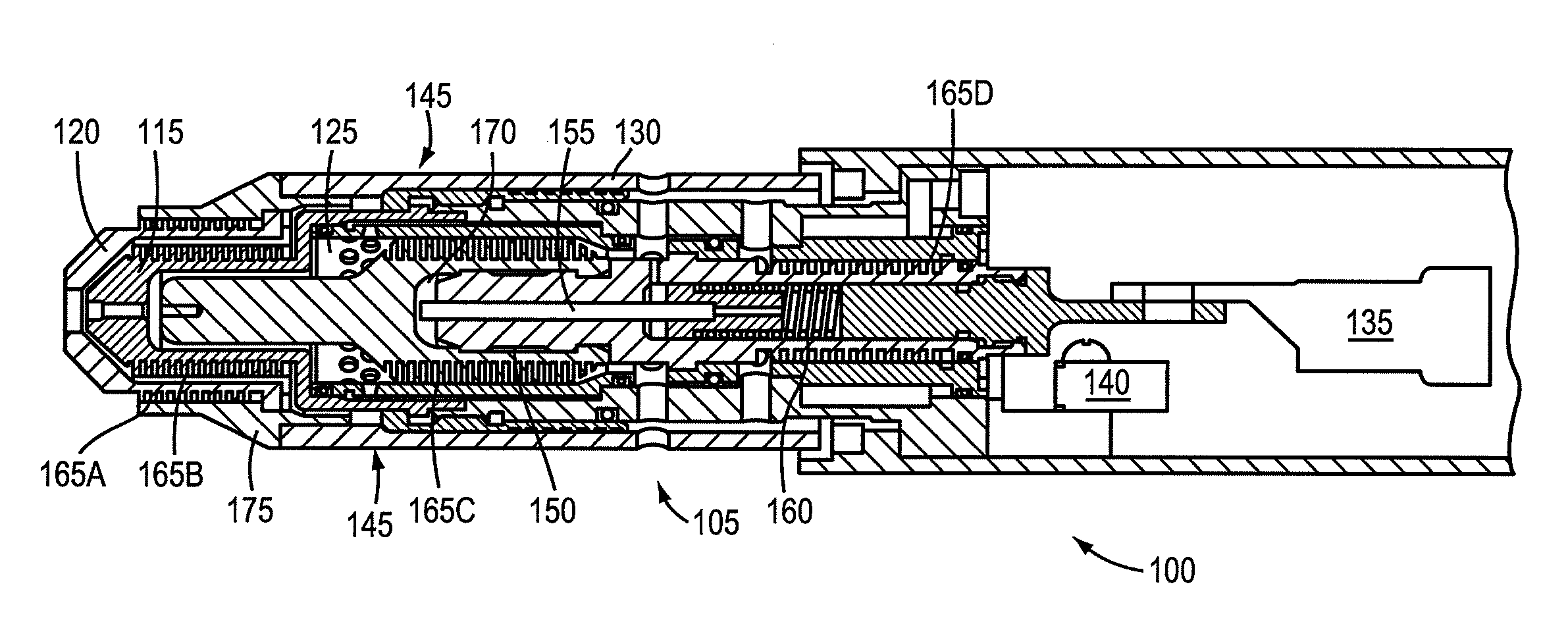

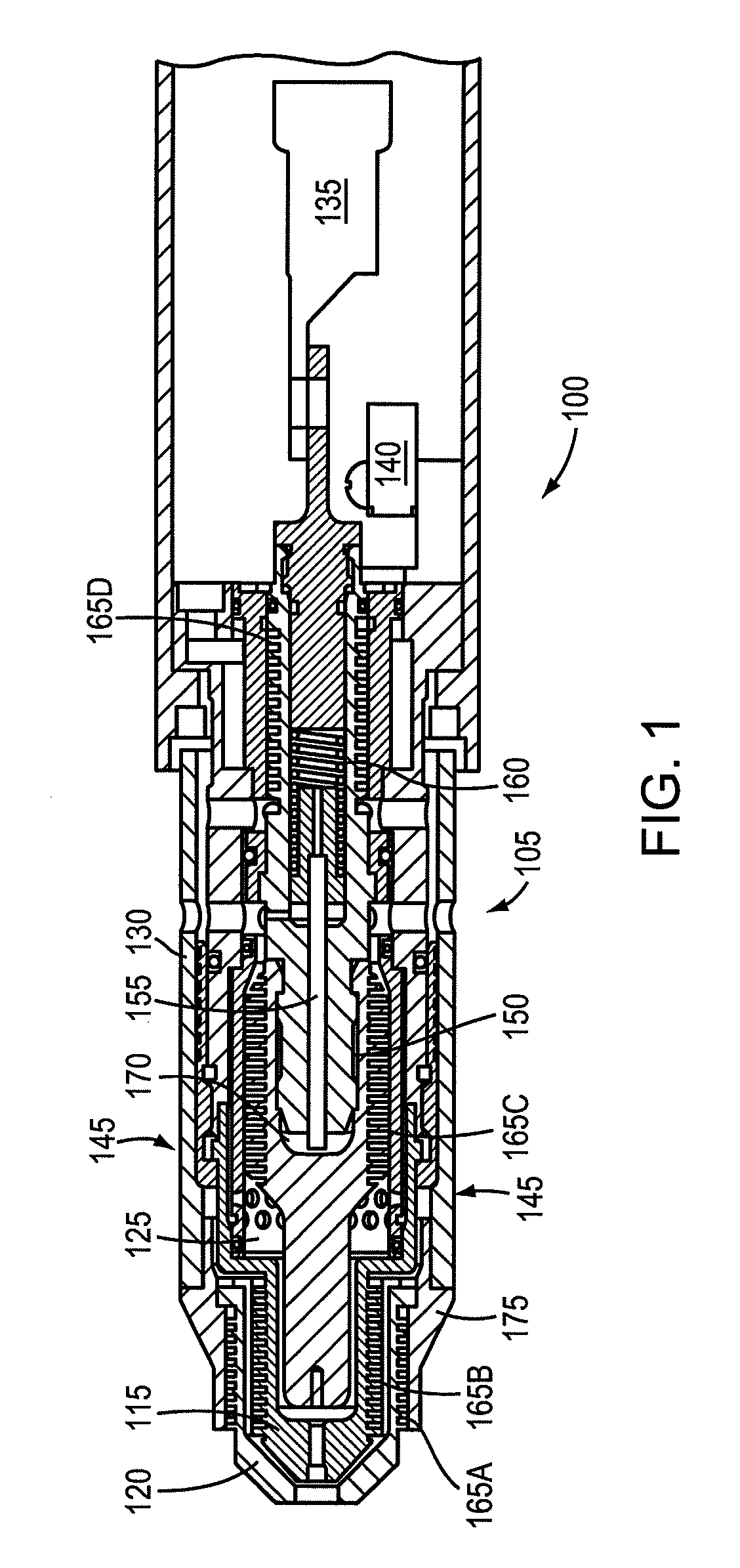

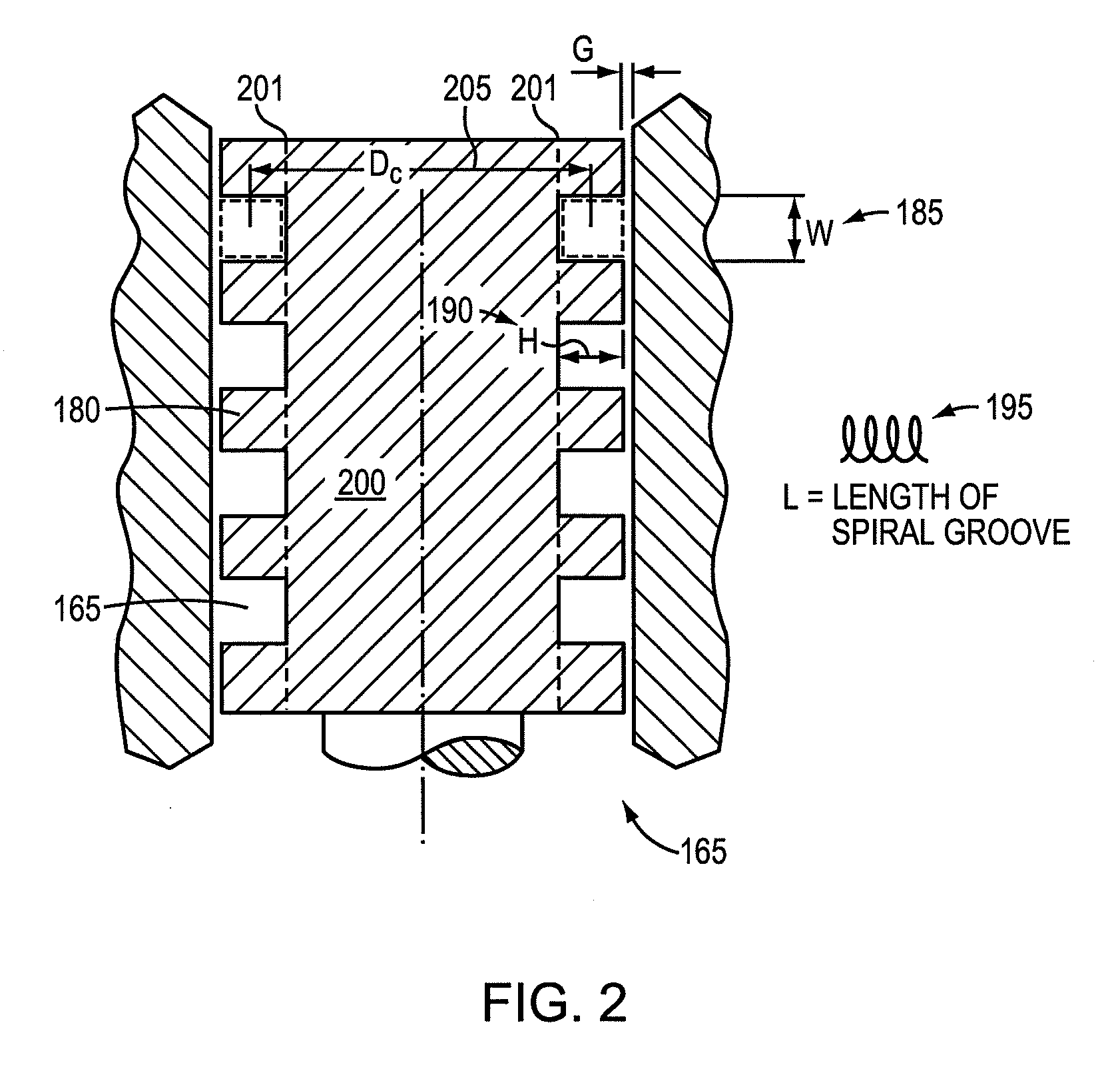

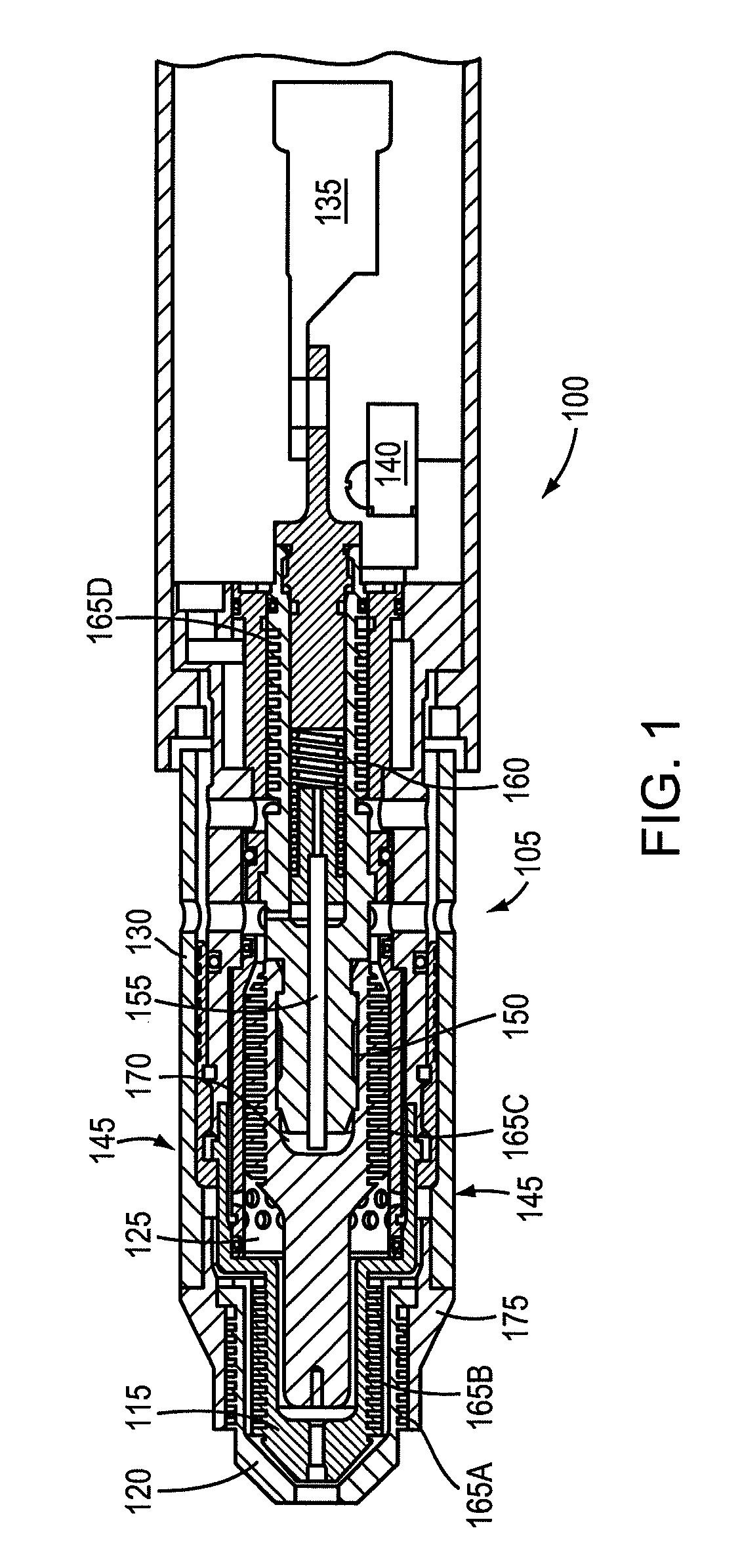

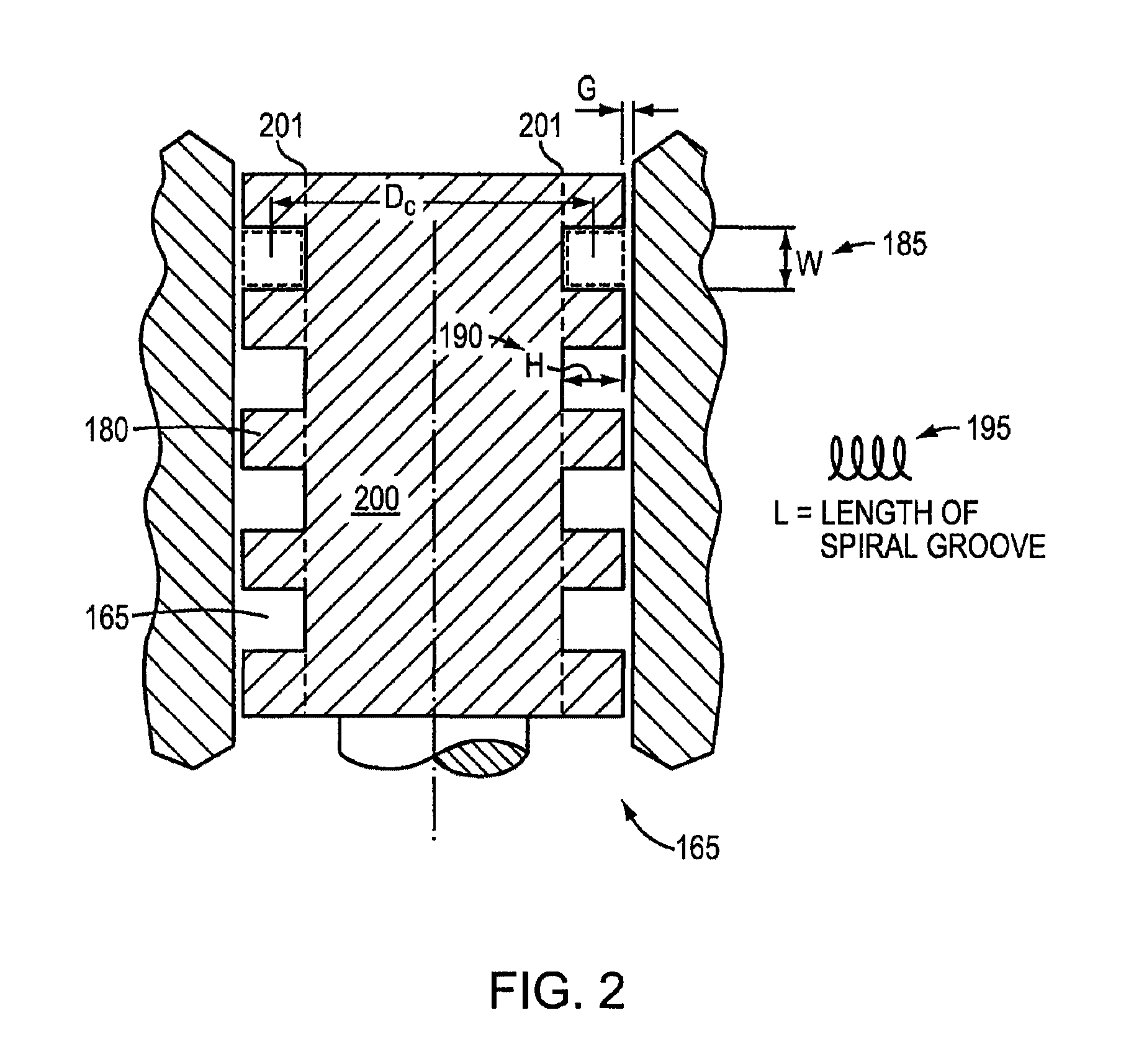

Gas-Cooled Plasma Arc Cutting Torch

ActiveUS20080217305A1Dampening motionPlasma welding apparatusWelding/cutting media/materialsTorchEngineering

A method and apparatus for a gas-cooled plasma arc torch. Components of the torch can include an electrode, nozzle and a shield, each of which can be gas-cooled. The nozzle can be disposed relative to the electrode and can include a generally hollow conductive body and a cooling gas flow channel defined by at least one fin disposed about an exterior surface of the body, the body providing a thermal conductive path that transfers heat between the nozzle to the cooling gas flow channel during operation of the torch. The shield can be disposed relative to the nozzle and can include a generally hollow conductive body and a cooling gas flow channel defined by at least one fin disposed about an exterior surface of the body, the body providing a thermal conductive path that transfers heat between the shield to the cooling gas flow channel during operation of the torch.

Owner:HYPERTHERM INC

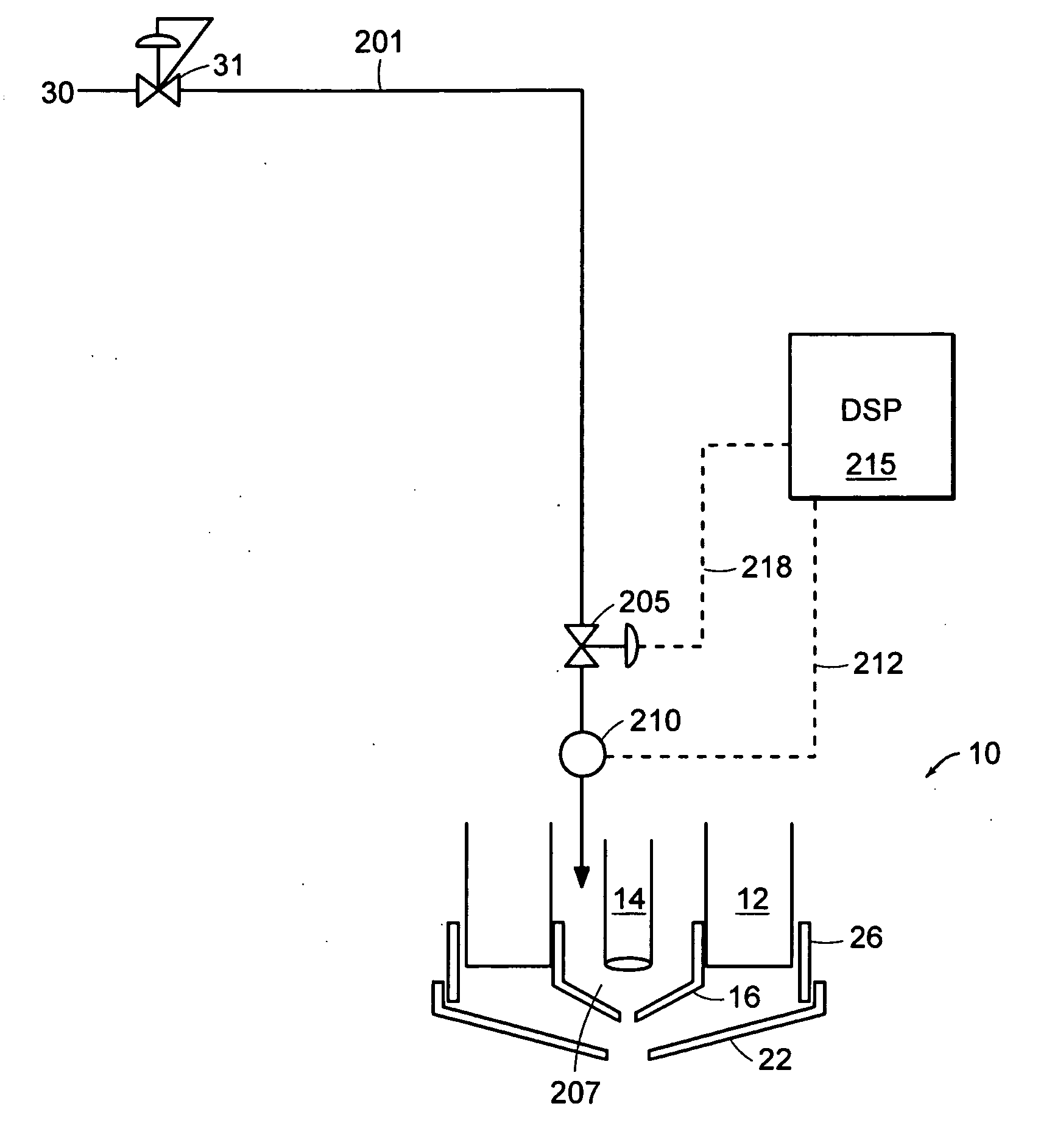

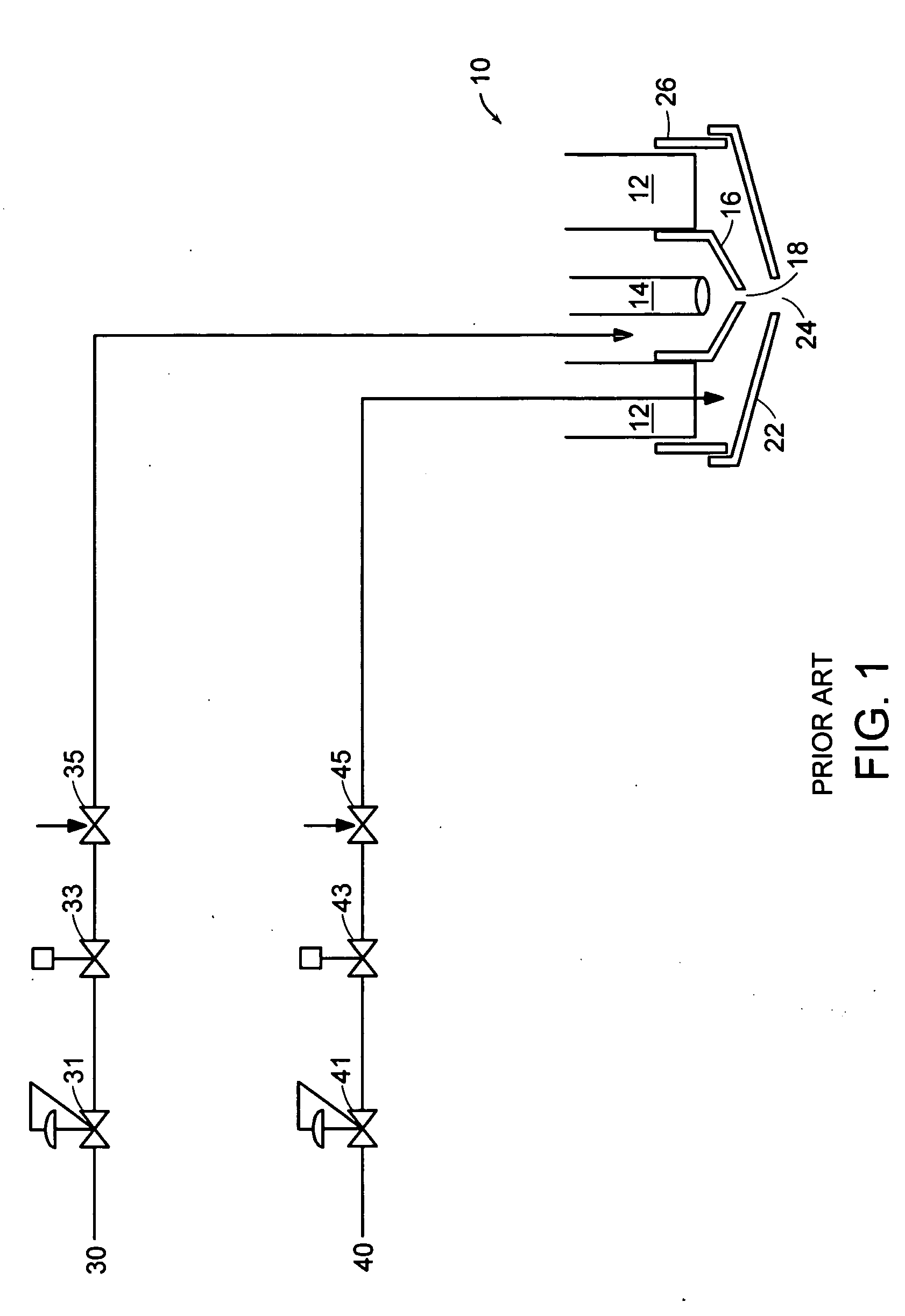

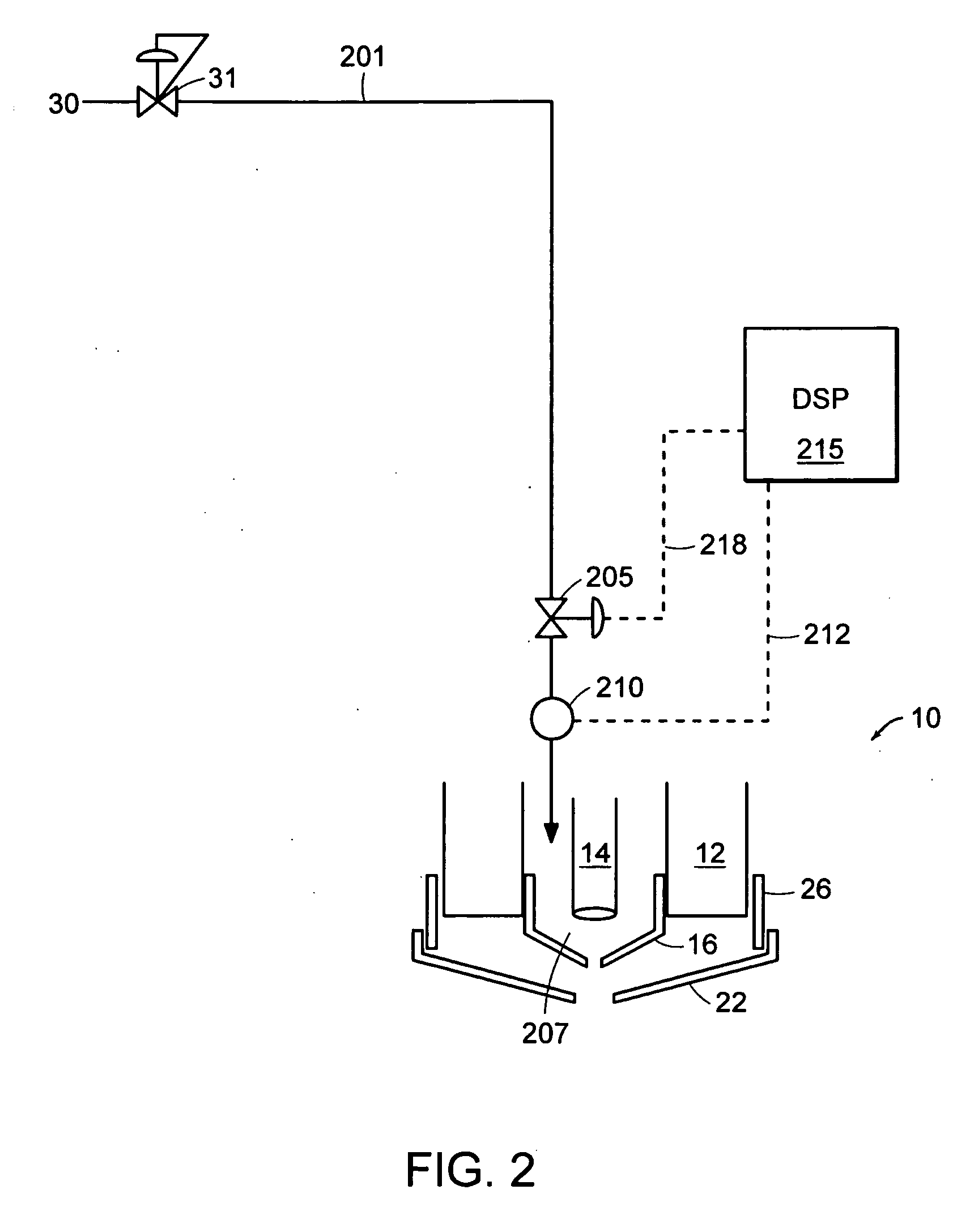

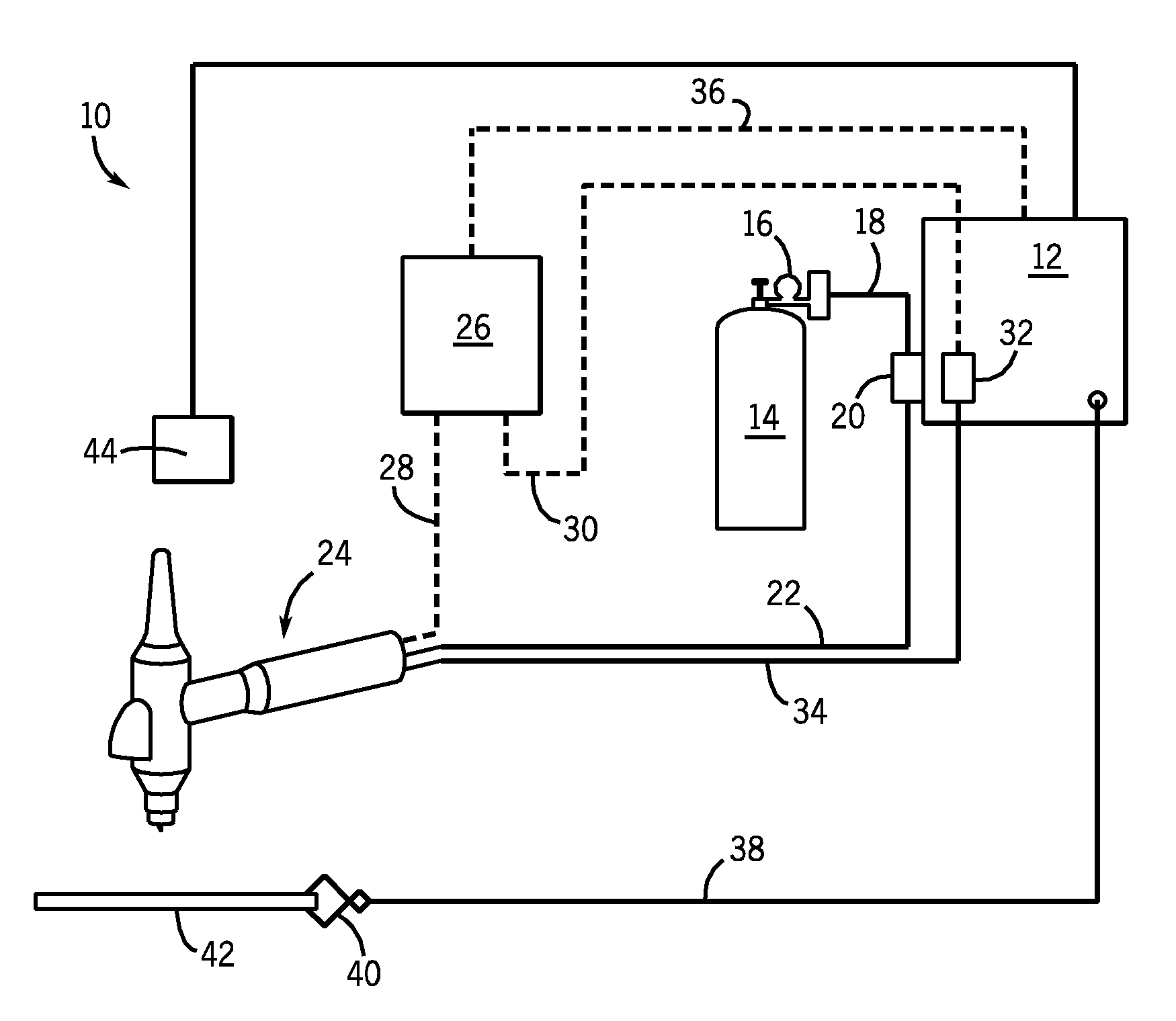

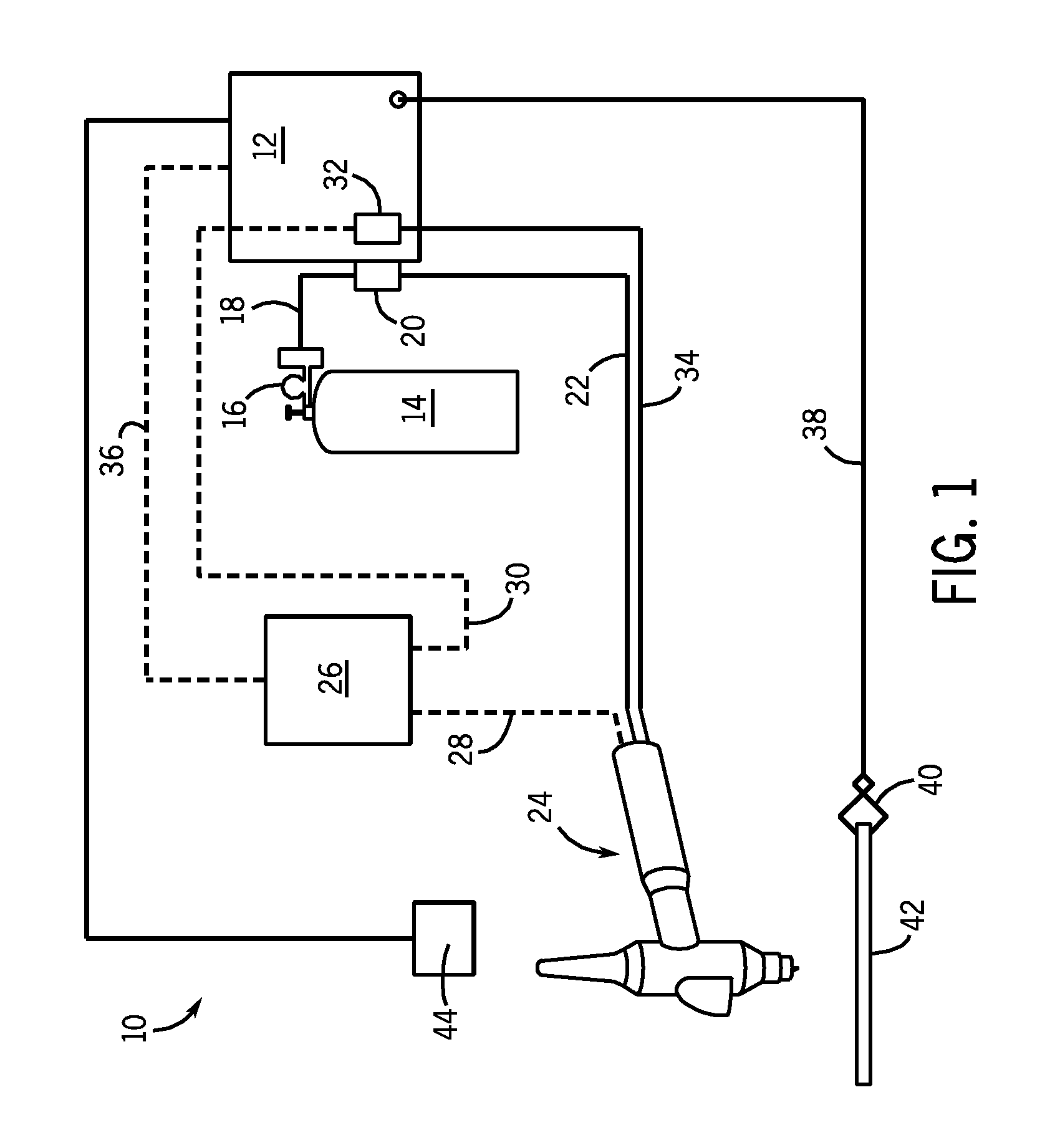

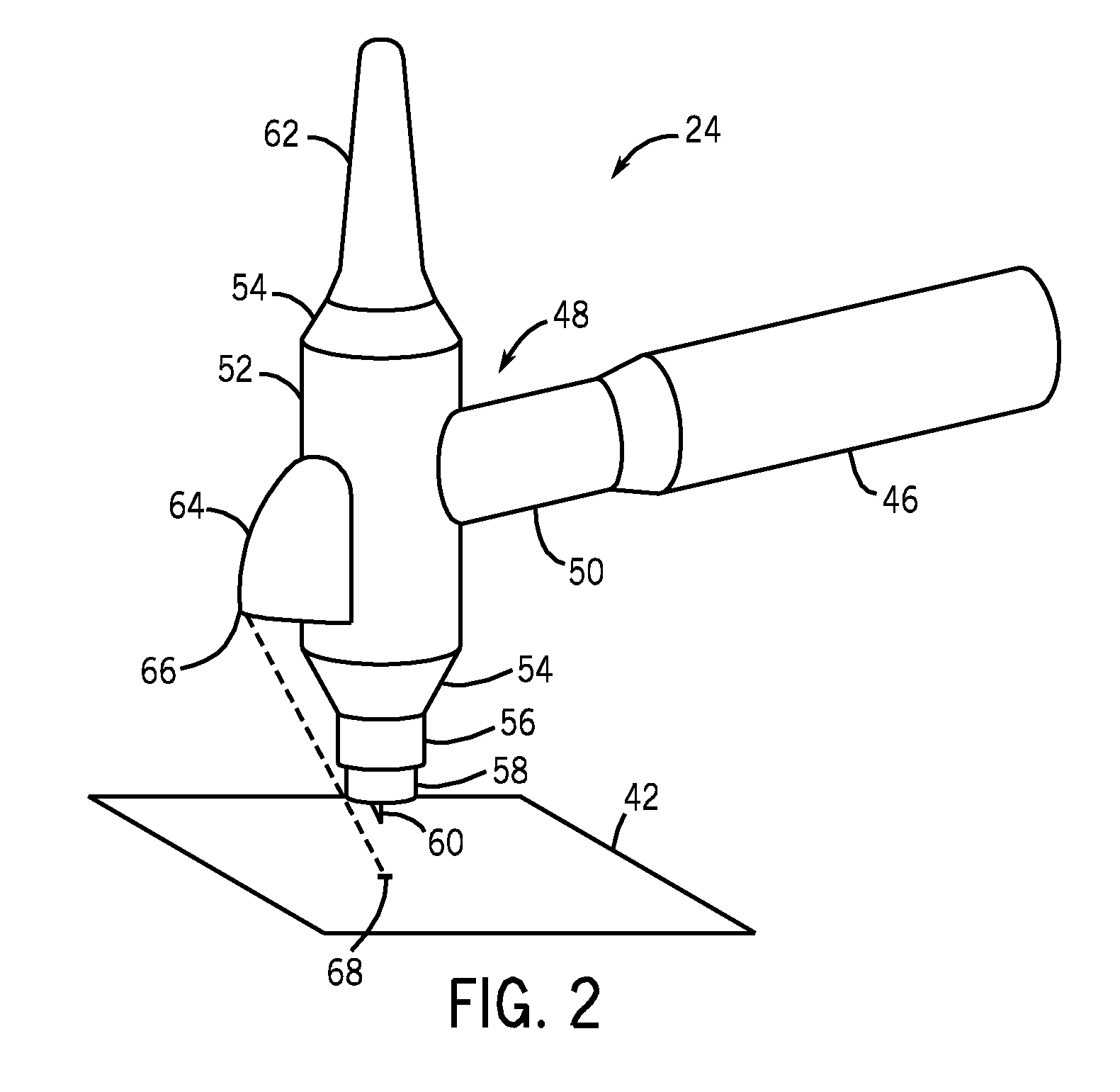

Automatic gas control for a plasma arc torch

InactiveUS20060163216A1Prolong lifeHigh operating current levelArc welding apparatusPlasma welding apparatusProportional controlSolenoid valve

A method and apparatus for controlling a gas supply to a plasma arc torch uses a proportional control solenoid valve positioned adjacent the torch to manipulate the gas flow to the torch, thereby extending electrode life during arc transfer and shutdown. Swirl ring design can be simplified and gas supply and distribution systems become less complicated. The invention also allows manipulation of shield gas flow to reduce divot formation when making interior cuts. The system can be controlled with a digital signal processor utilizing a feedback loop from a sensor.

Owner:HYPERTHERM INC

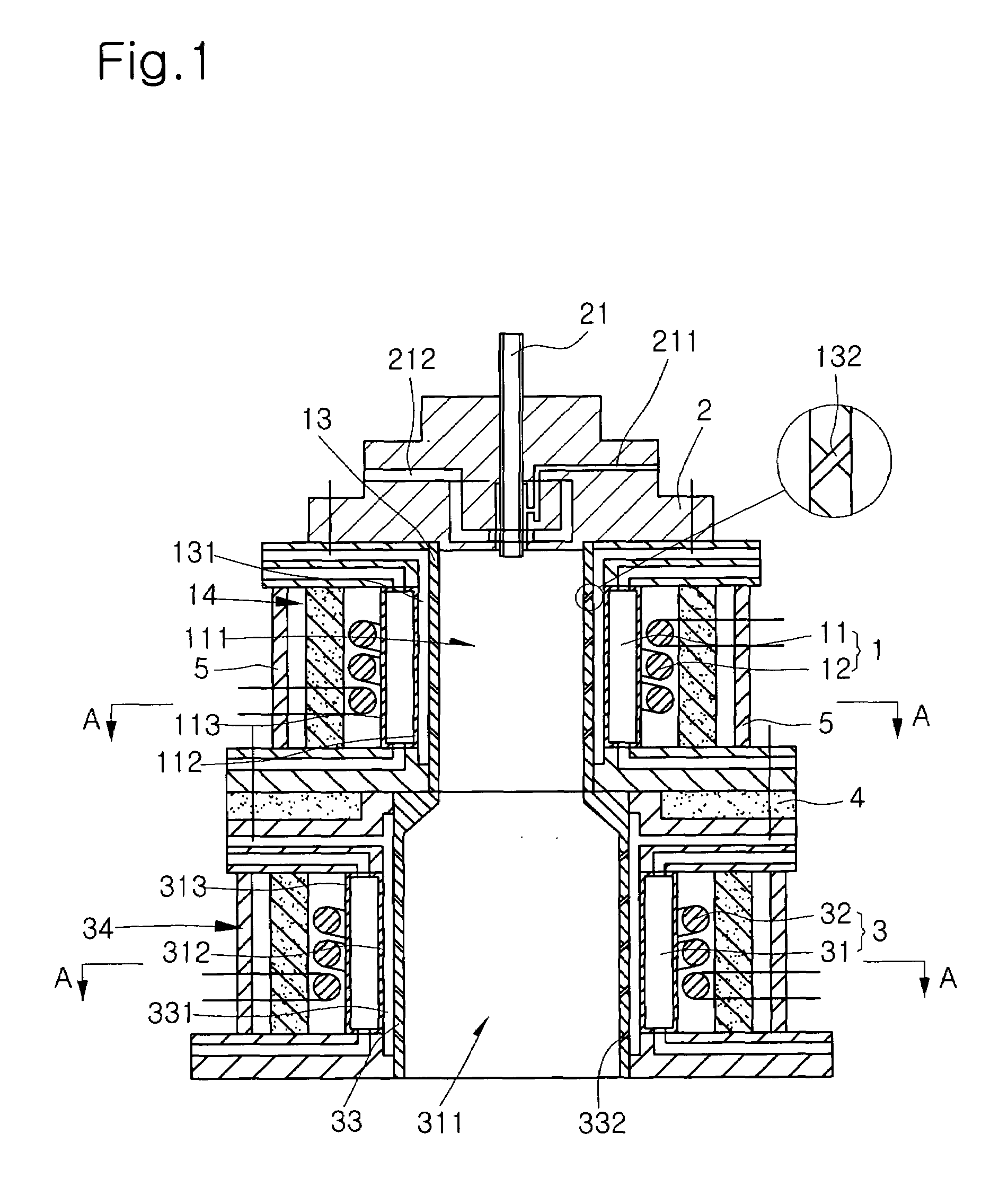

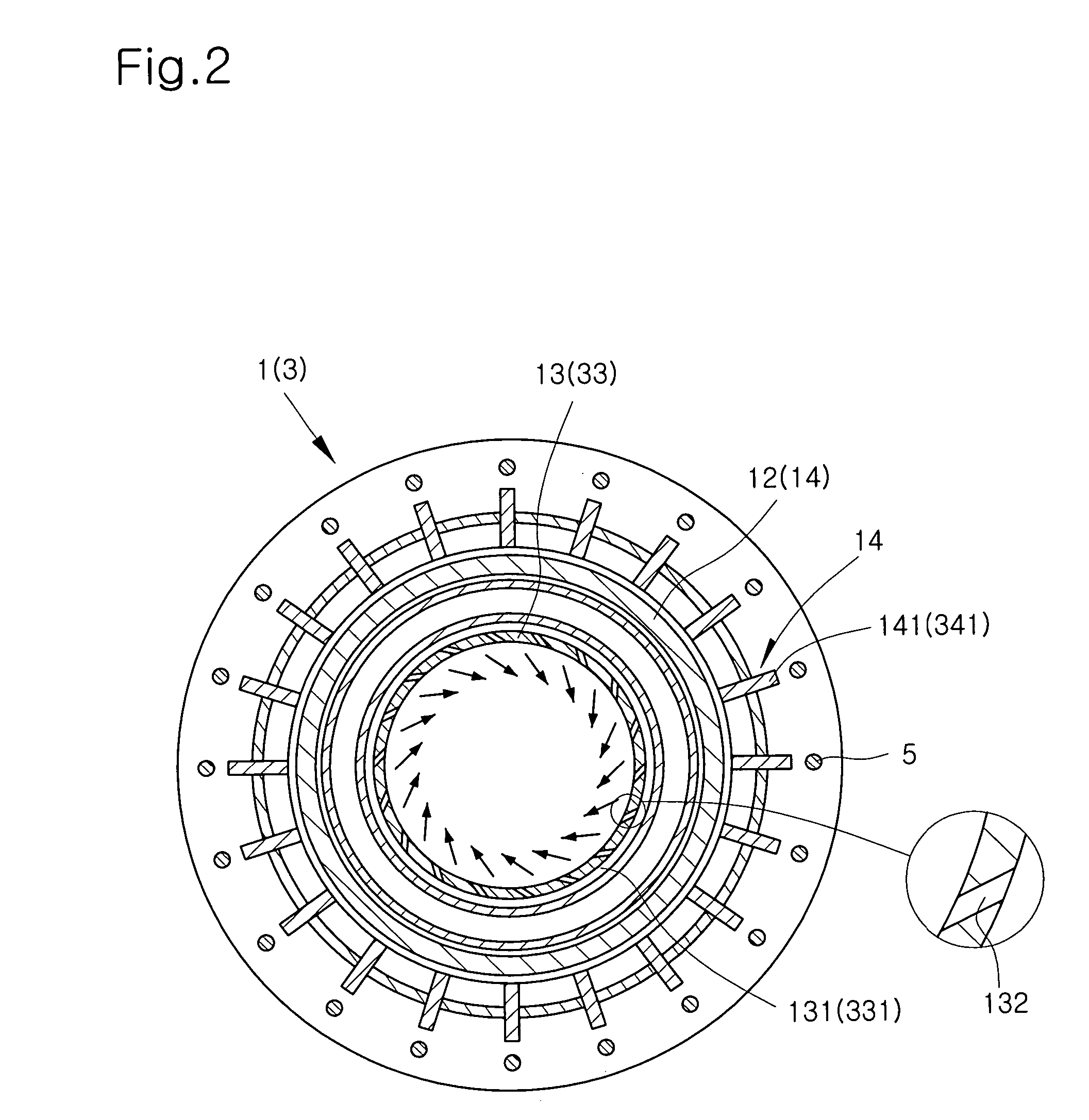

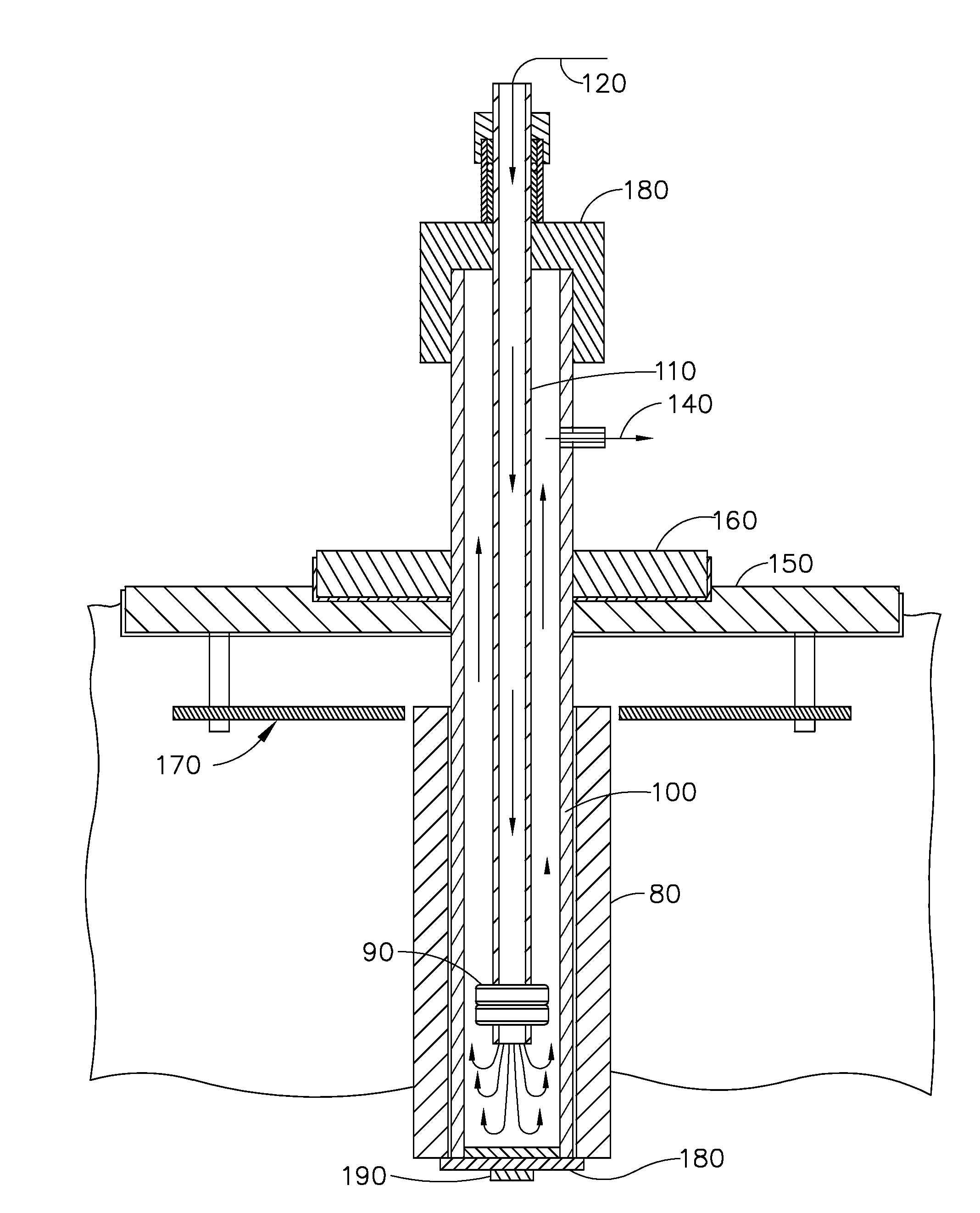

Inductively coupled plasma reactor for producing nano-powder

InactiveUS7323655B2Growth inhibitionGuaranteed to move normallyNanostructure manufactureElectric discharge tubesGas passingInduction plasma technology

Disclosed herein is a high-frequency induction plasma reactor apparatus for producing nano-powder, which is configured to continuously manufacture nano-powder in large quantities using solid-phase powder as a starting raw material and to manufacture high-purity nano-powder by completely vaporizing the material powder. The high-frequency induction plasma reactor apparatus comprises an upper body and a cover. The upper body is provided with a reaction pipe receiving a reactor extending vertically inside thereof, a high-frequency coil surrounding the outer periphery of the reaction pipe and a ceramic inner wall provided inside the reaction pipe. The ceramic inner wall is formed with a plurality of gas passing bores and defines a gas movement passage with the inner side wall of the reaction pipe therebetween for allowing the inflow of argon gas from the outside into the reactor. The cover is mounted to the upper end of the reactor and adapted to seal the reactor. The cover is provided with a powder injection tube communicating with the reactor.

Owner:NPC CO LTD

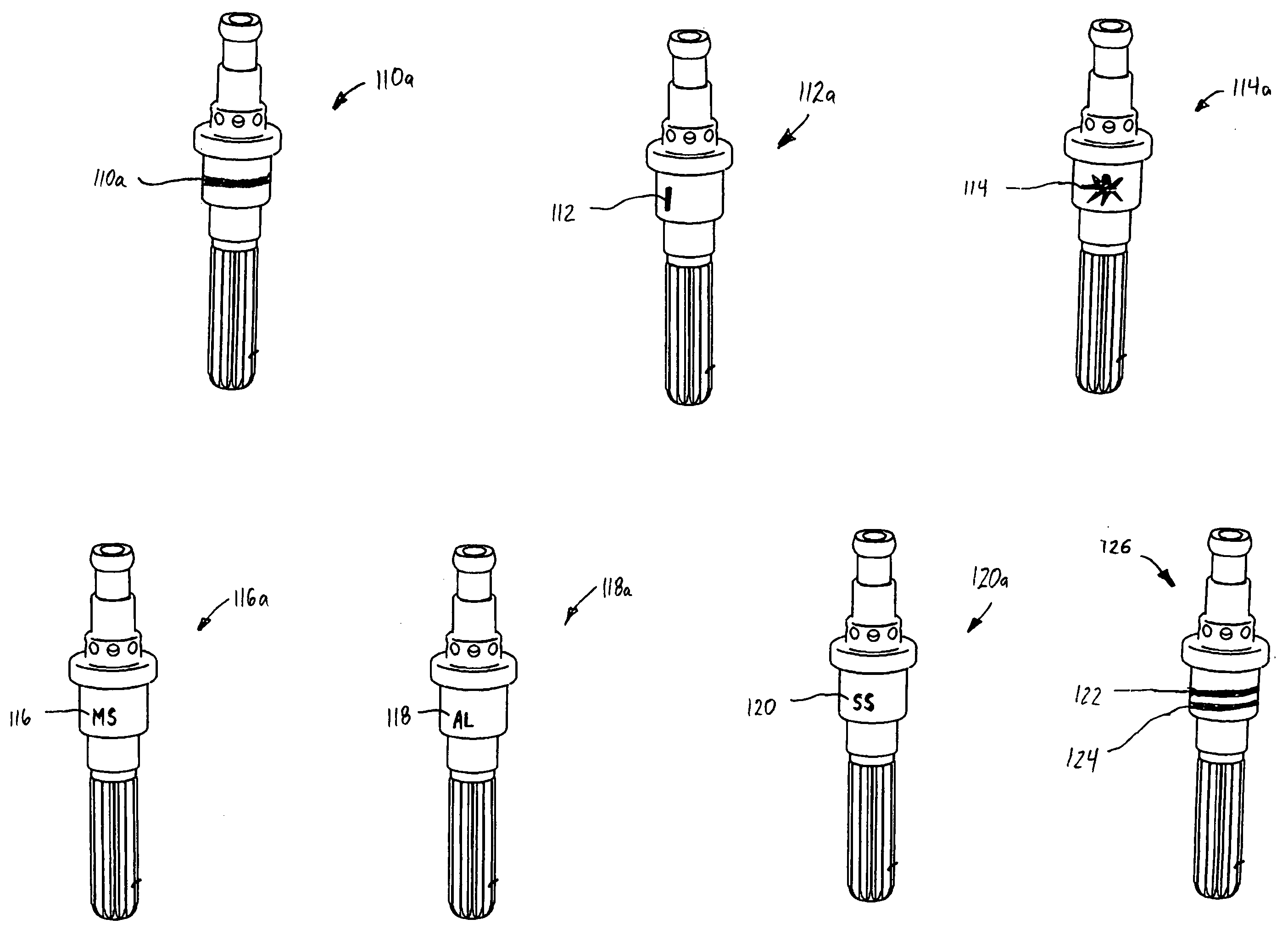

Color coding of plasma arc torch parts and part sets

A series of replacement parts for use in a plasma arc torch is provided, wherein the parts have a color indicia and are adapted for use at different operating parameter values. Each part in the series has a color indicia formed on the part with a different color identifying the particular value of the operating parameter at which the part is adapted to operate. In another form, each part in the series is packaged in a package with a different color indicia identifying the particular value of the operating parameter at which the part is adapted to operate. Additionally, methods of packaging, applying the color indicia, selecting a package or part, and specifying a package or part are provided by the present invention.

Owner:THERMAL DYNAMICS

Lighted welding torch

Provided is system for aiding a welding operator in positioning a welding device. The system includes a welding device and a light source coupled to the welding device, wherein the light source is configured to generate a focused beam of light that is configured to illuminate a weld location. The configuration of the light source's illumination may provide for aligning and positioning of the welding device relative to a work piece or other surface.

Owner:ILLINOIS TOOL WORKS INC

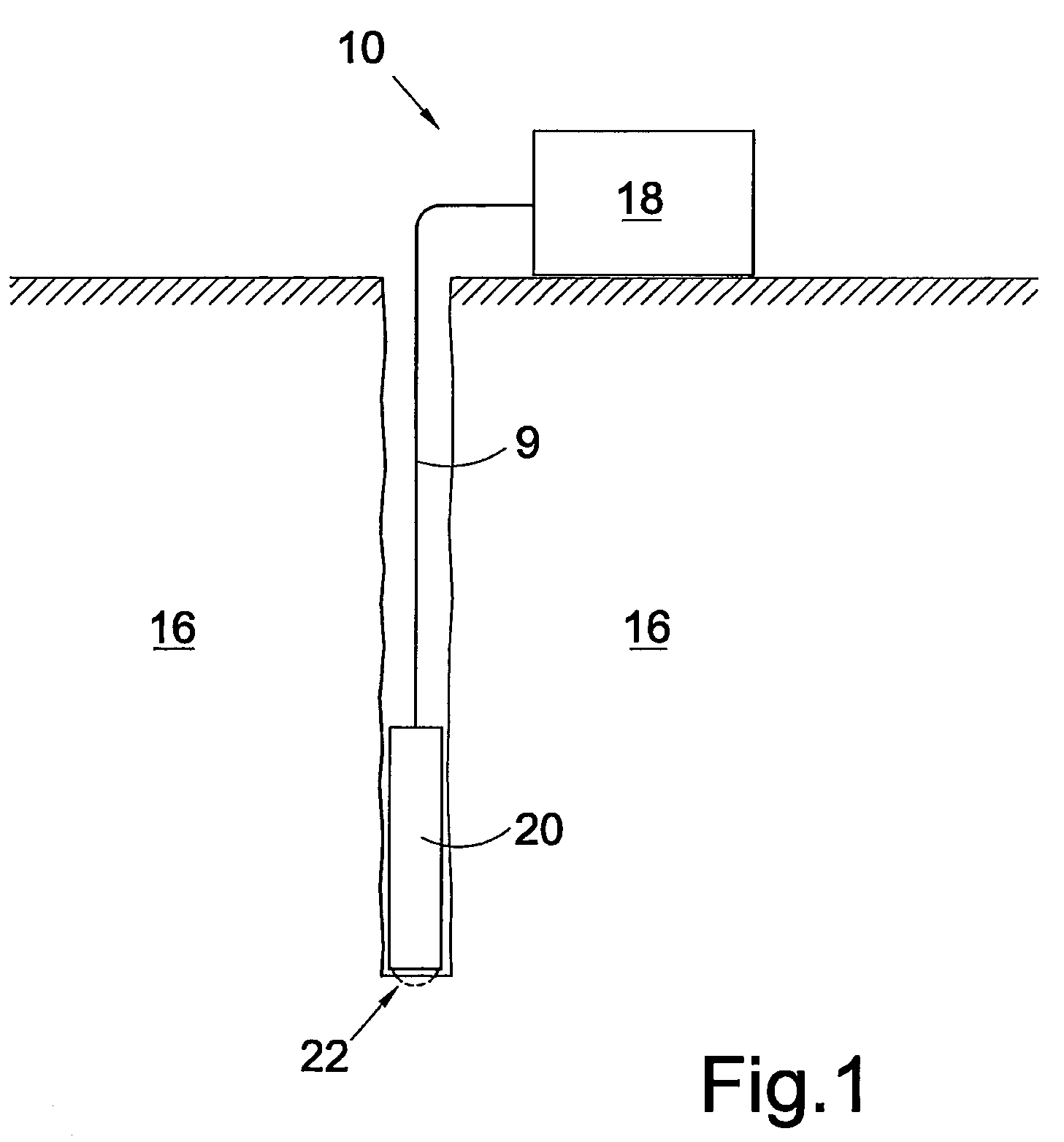

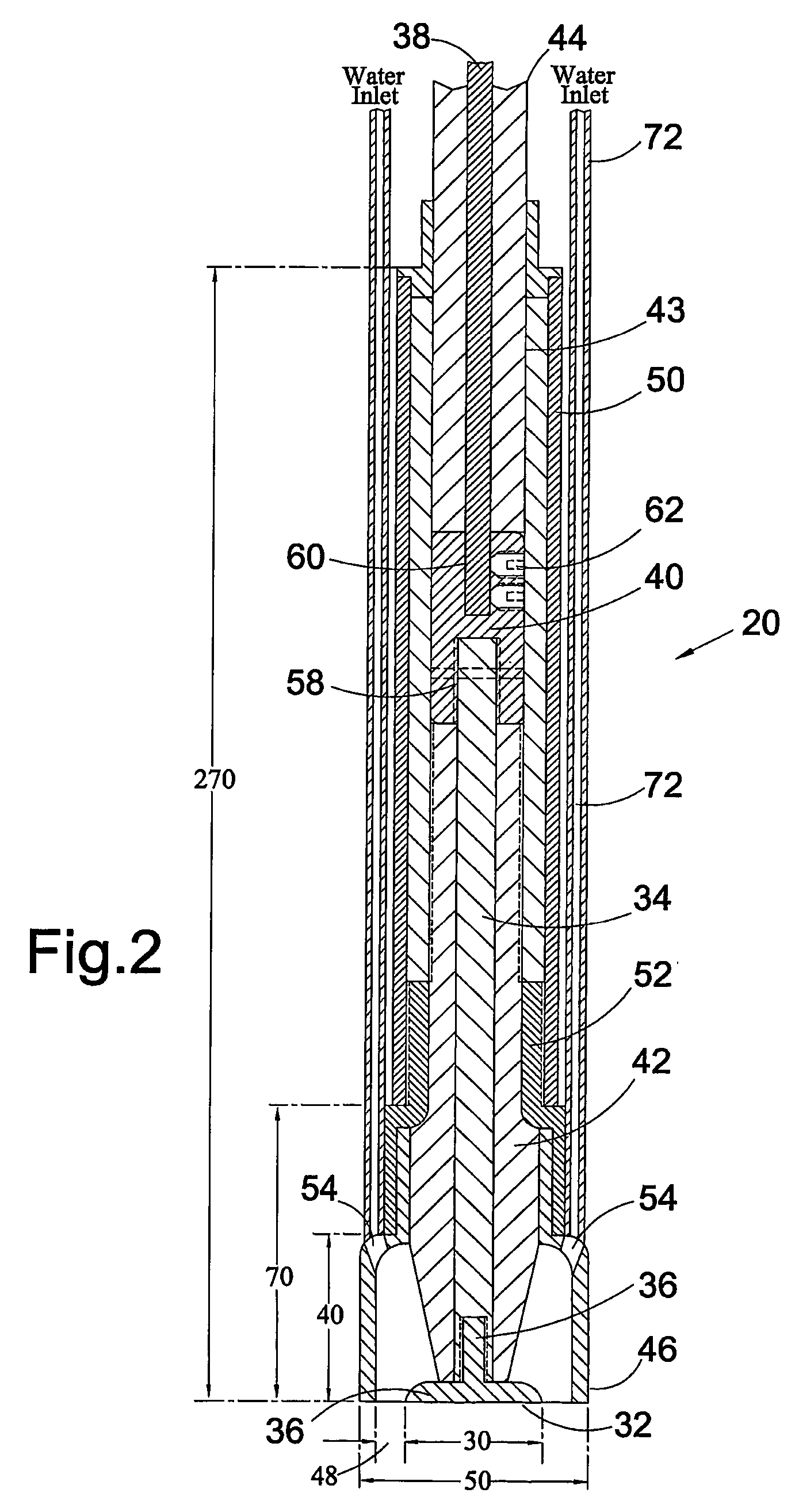

Plasma channel drilling process

Material is removed from a body of material, e.g. to create a bore hole, by plasma channel drilling. High voltage, high energy, rapid rise time electrical pulses are delivered many times per second to an electrode assembly in contact with the material body to generate therein elongate plasma channels which expand rapidly following electrical breakdown of the material causing the material to fracture and fragment.

Owner:STRATHCLYDE UNIV OF

Electric arc welder and plasma cutter

InactiveUS6177645B1Reduce Harmonic DistortionImprove power factorAc-dc conversion without reversalConversion with intermediate conversion to dcFull waveEngineering

A single phase power supply module for electric arc welders and plasma arc cutters comprising: a single phase input stage; positive and negative output terminals; a full wave rectifier connected to the input stage for rectifying the single phase voltage at the input stage; a buck converter type power factor correcting circuit for controlling current flow from the input stage to the rectifier, which buck converter has an output capacitor regulated to an intermediate voltage in the range of 100-150 volts; and, a high speed DC to DC converter having an internal transformer coupling applying voltage across the output terminals and means for regulating the applied voltage to an output voltage in the range of 0-113 volts. The module is universal and several can be connected in parallel, in series or to switch networks to construct several welders or cutters.

Owner:LINCOLN GLOBAL INC

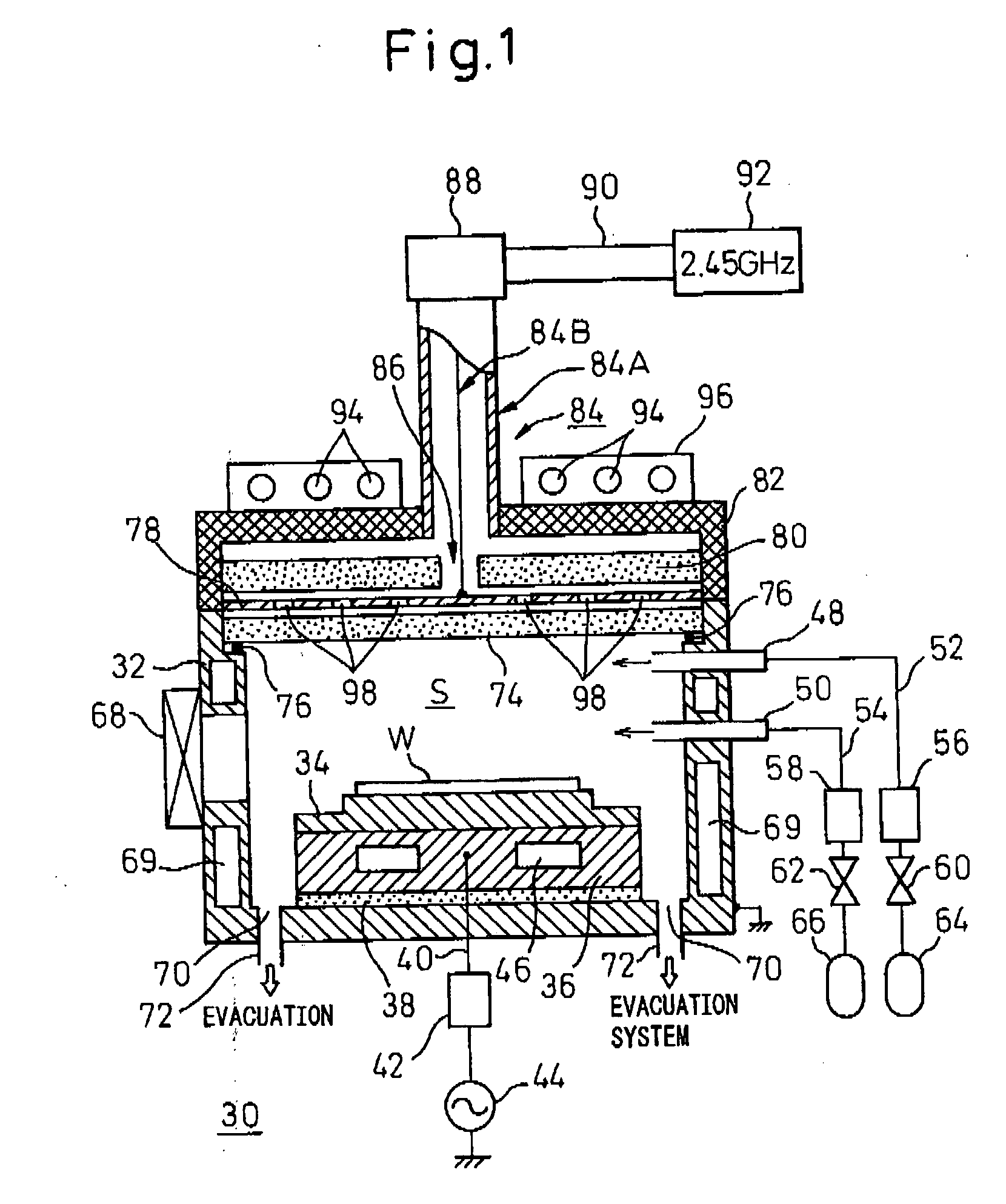

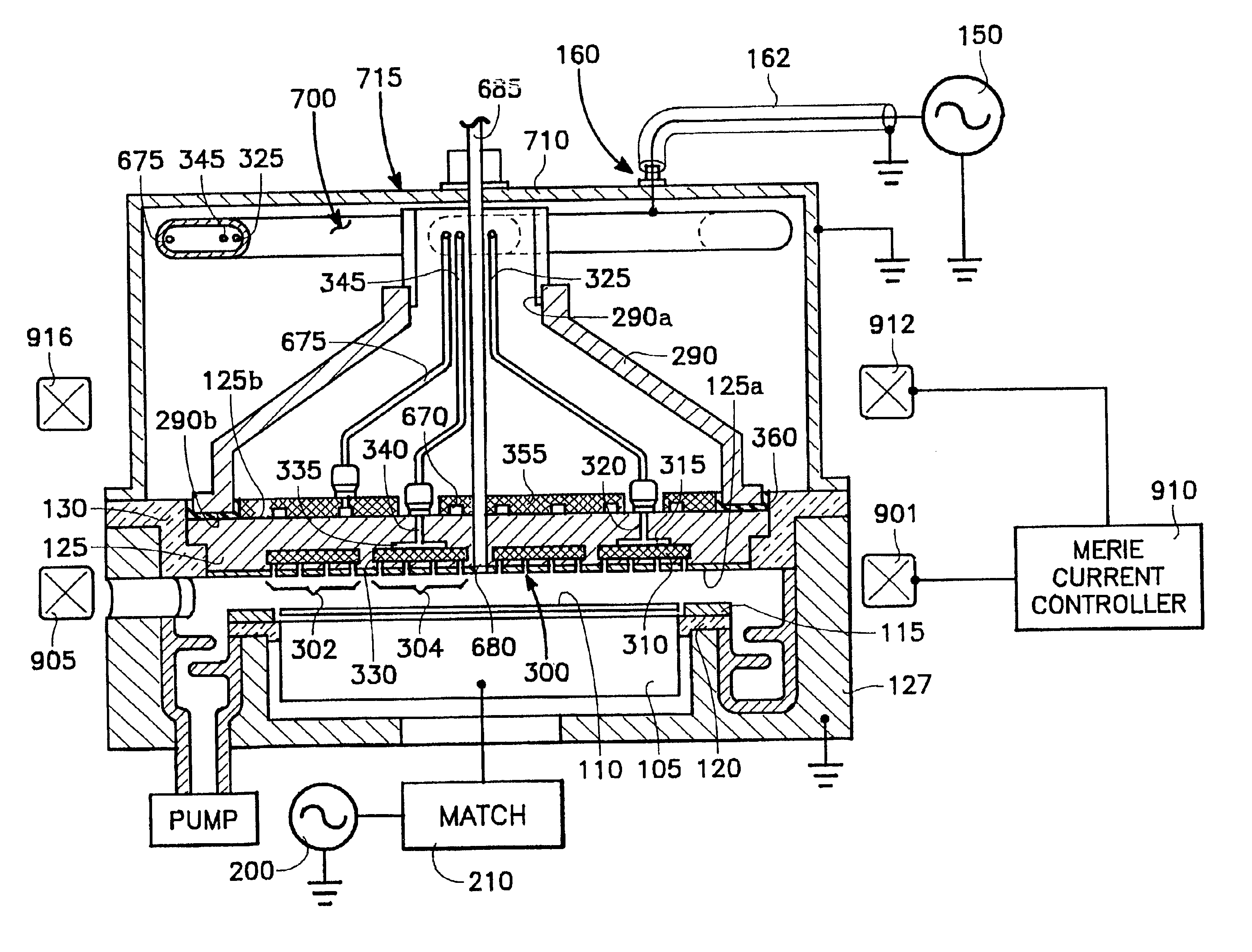

Merie plasma reactor with overhead RF electrode tuned to the plasma with arcing suppression

InactiveUS6894245B2Improve plasma ion density distribution uniformitySufficient capacitanceElectric discharge tubesElectric arc lampsCapacitanceIon density

A plasma reactor for processing a semiconductor workpiece, includes a reactor chamber having a chamber wall and containing a workpiece support for holding the semiconductor support, the electrode comprising a portion of the chamber wall, an RF power generator for supplying power at a frequency of the generator to the overhead electrode and capable of maintaining a plasma within the chamber at a desired plasma ion density level. The overhead electrode has a capacitance such that the overhead electrode and the plasma formed in the chamber at the desired plasma ion density resonate together at an electrode-plasma resonant frequency, the frequency of the generator being at least near the electrode-plasma resonant frequency. The reactor further includes a set of MERIE magnets surrounding the plasma process area overlying the wafer surface that produce a slowly circulating magnetic field which stirs the plasma to improve plasma ion density distribution uniformity.

Owner:APPLIED MATERIALS INC

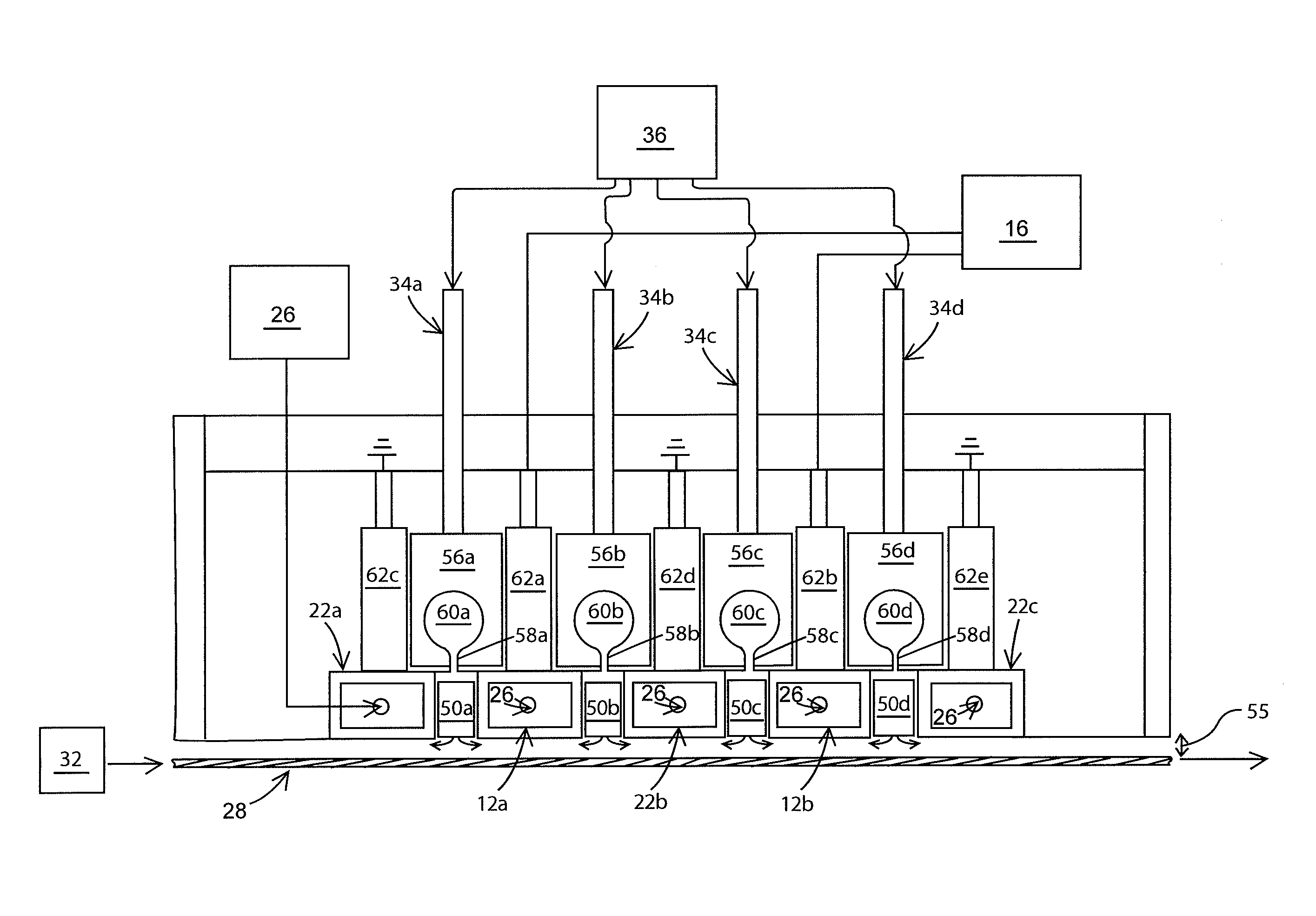

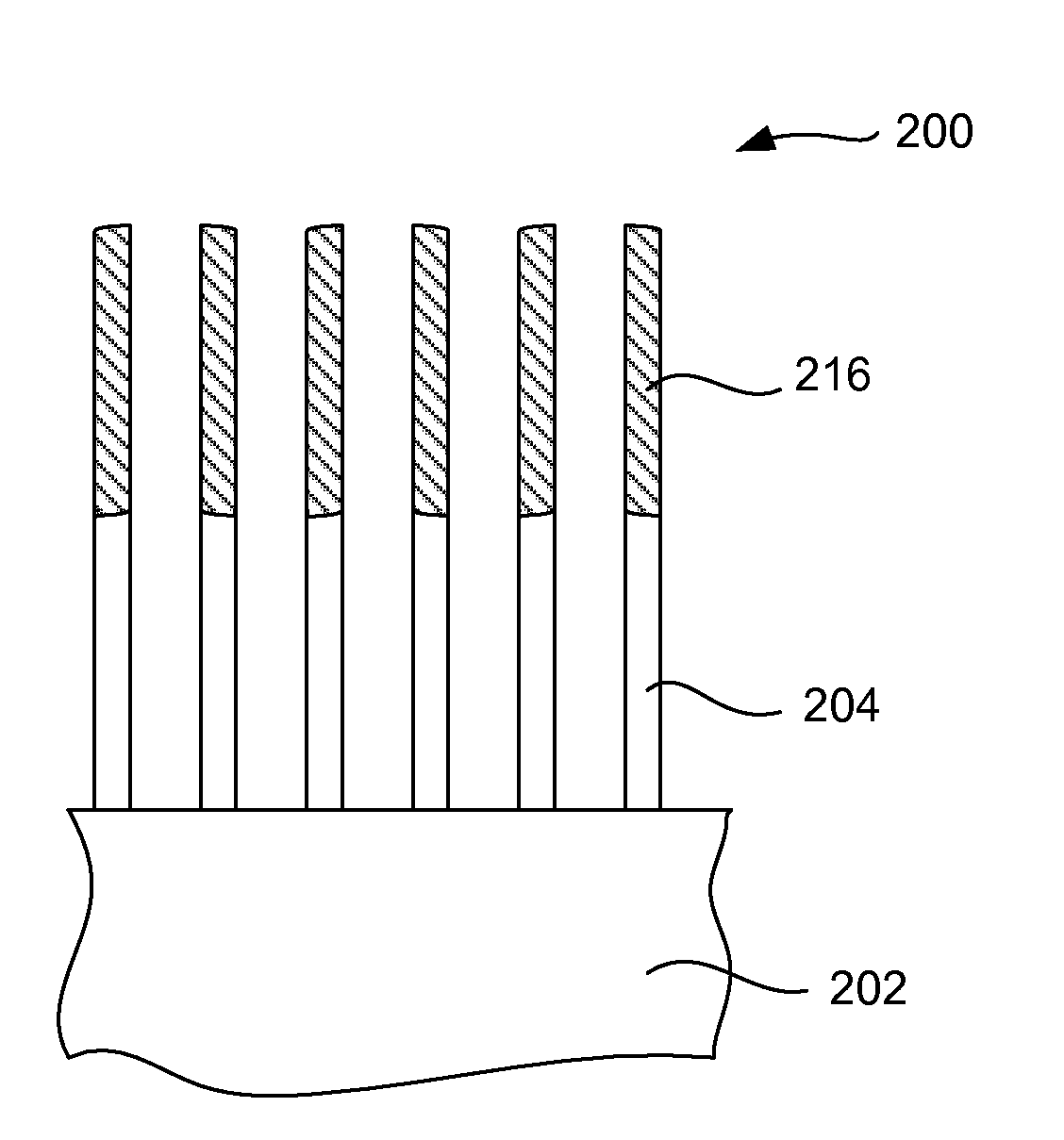

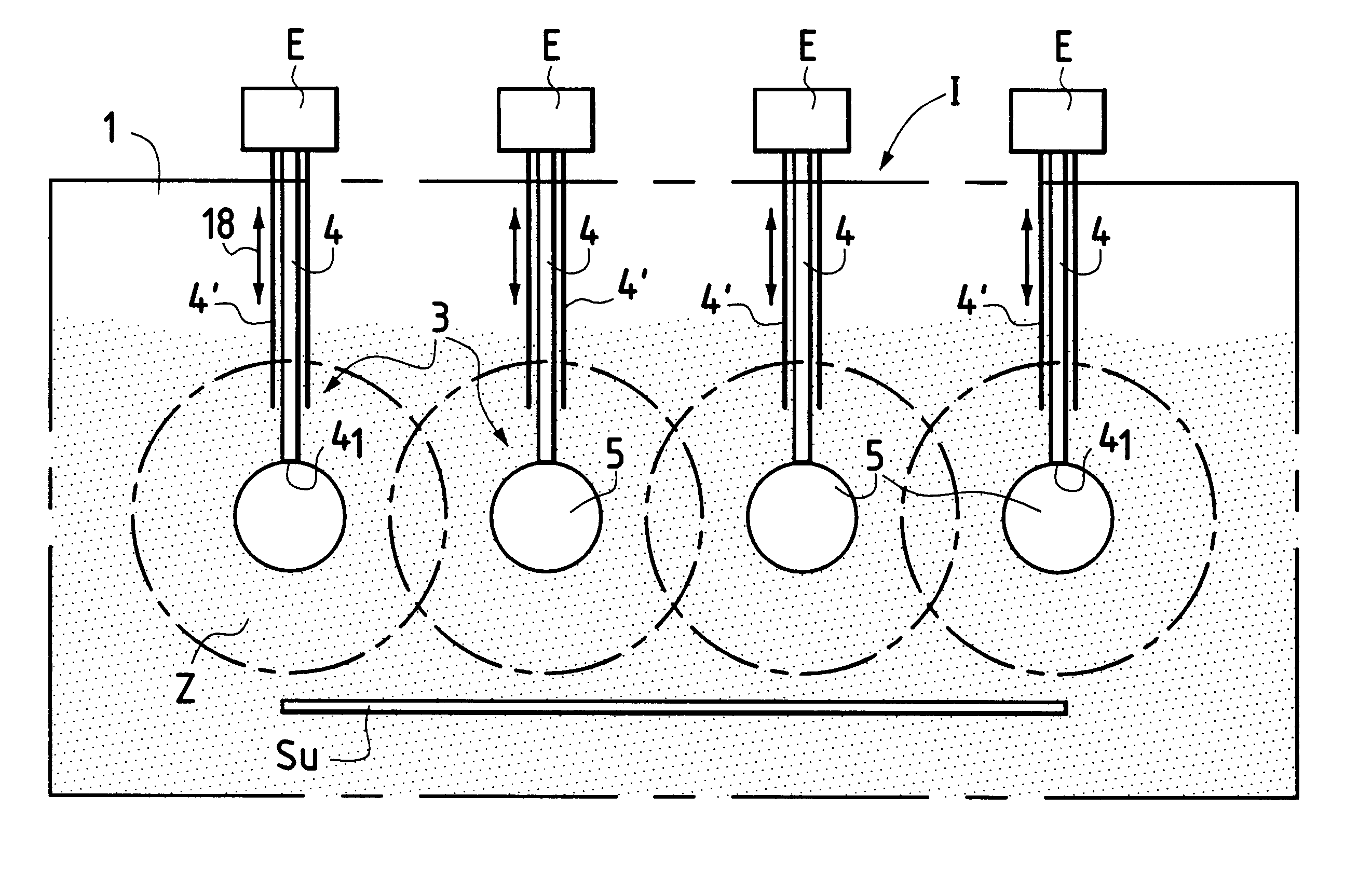

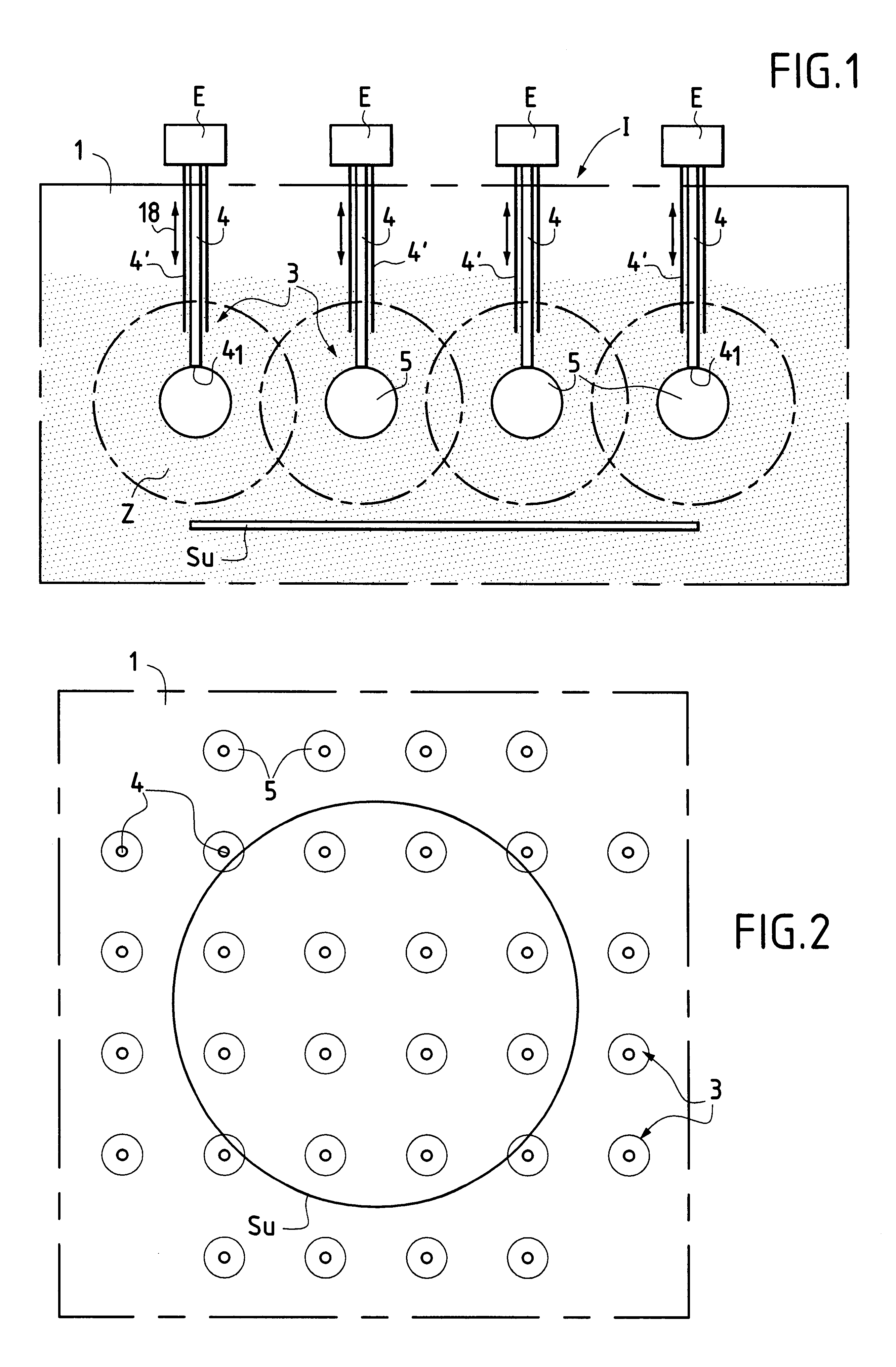

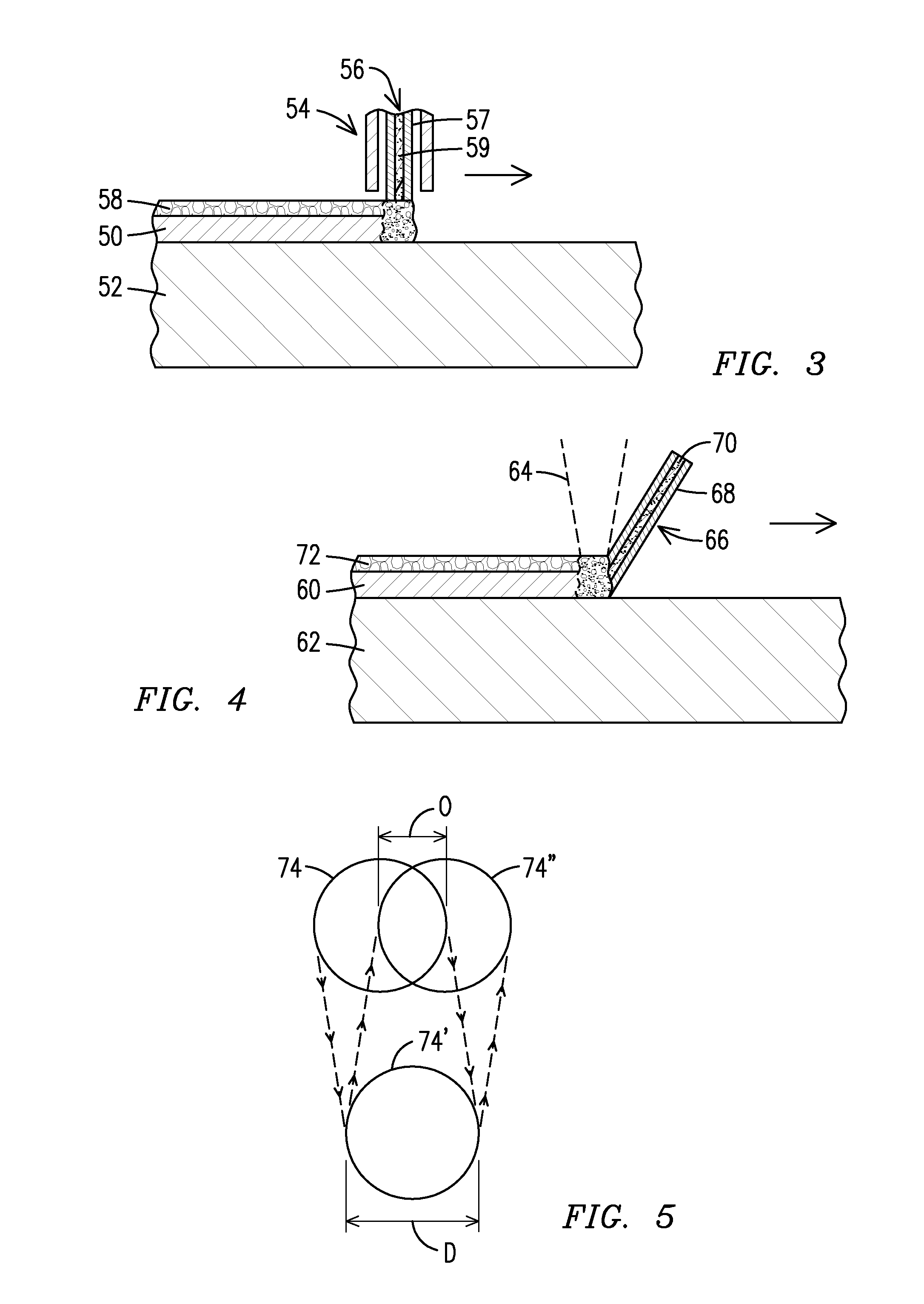

Method of producing individual plasmas in order to create a uniform plasma for a work surface, and apparatus for producing such a plasma

InactiveUS6407359B1Electric discharge tubesElectric arc lampsPlasma diffusionElectron cyclotron resonance

The invention provides apparatus having a series of individual plasma excitation devices each constituted by a wire applicator of microwave energy, having one end connected to a source for producing microwave energy and having an opposite end fitted with at least one magnetic dipole for creating at least one surface having a magnetic field that is constant and of intensity corresponding to electron cyclotron resonance, the dipole being mounted at the end of the microwave applicator in such a manner as to ensure that electrons accelerated to electron cyclotron resonance oscillate between the poles so as to create a plasma diffusion zone situated on the side of the dipole that is remote from the end of the applicator, the individual excitation devices being distributed relative to one another and in proximity with the work surface so as to create together a plasma that is uniform for the work surface.

Owner:H E F

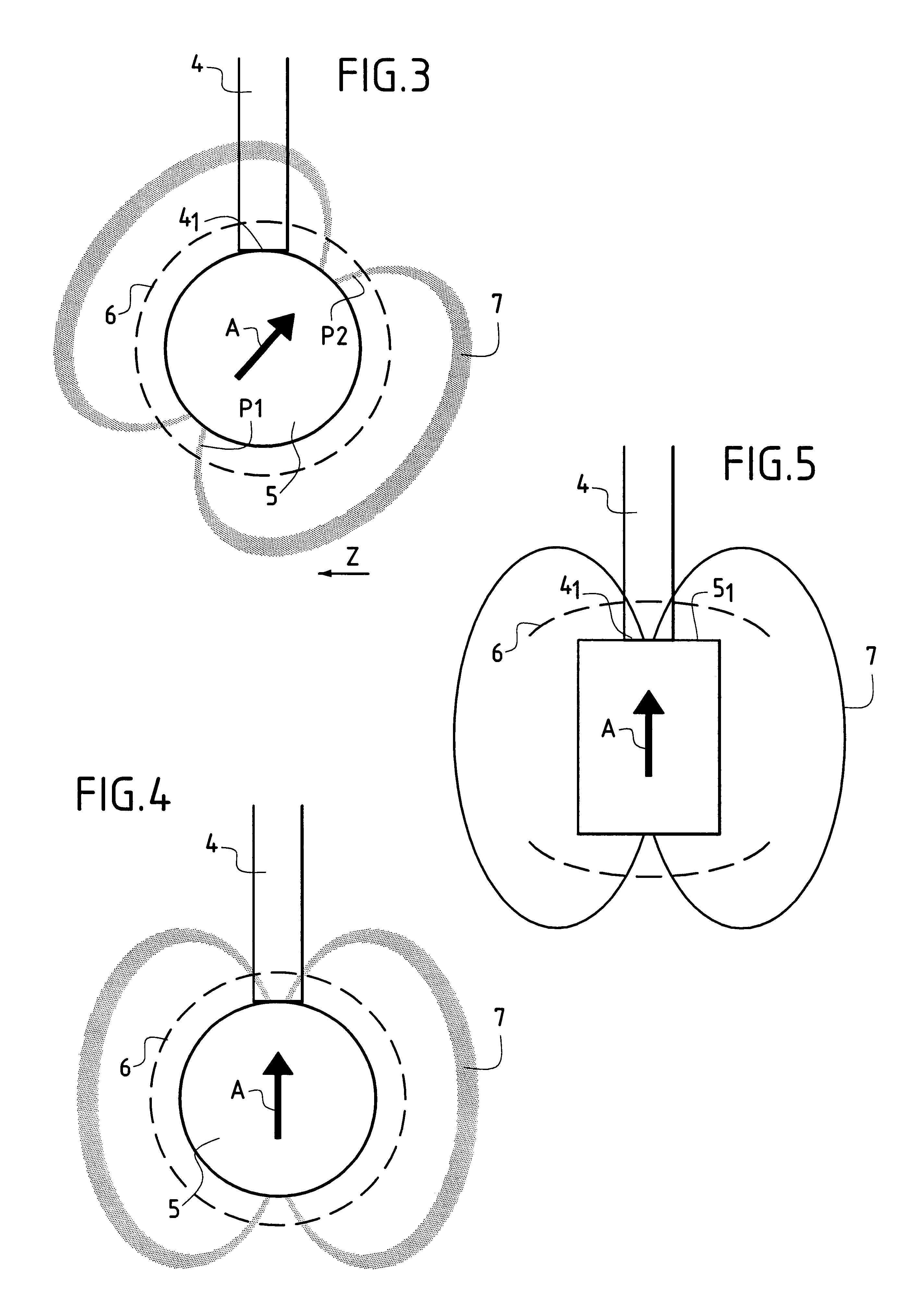

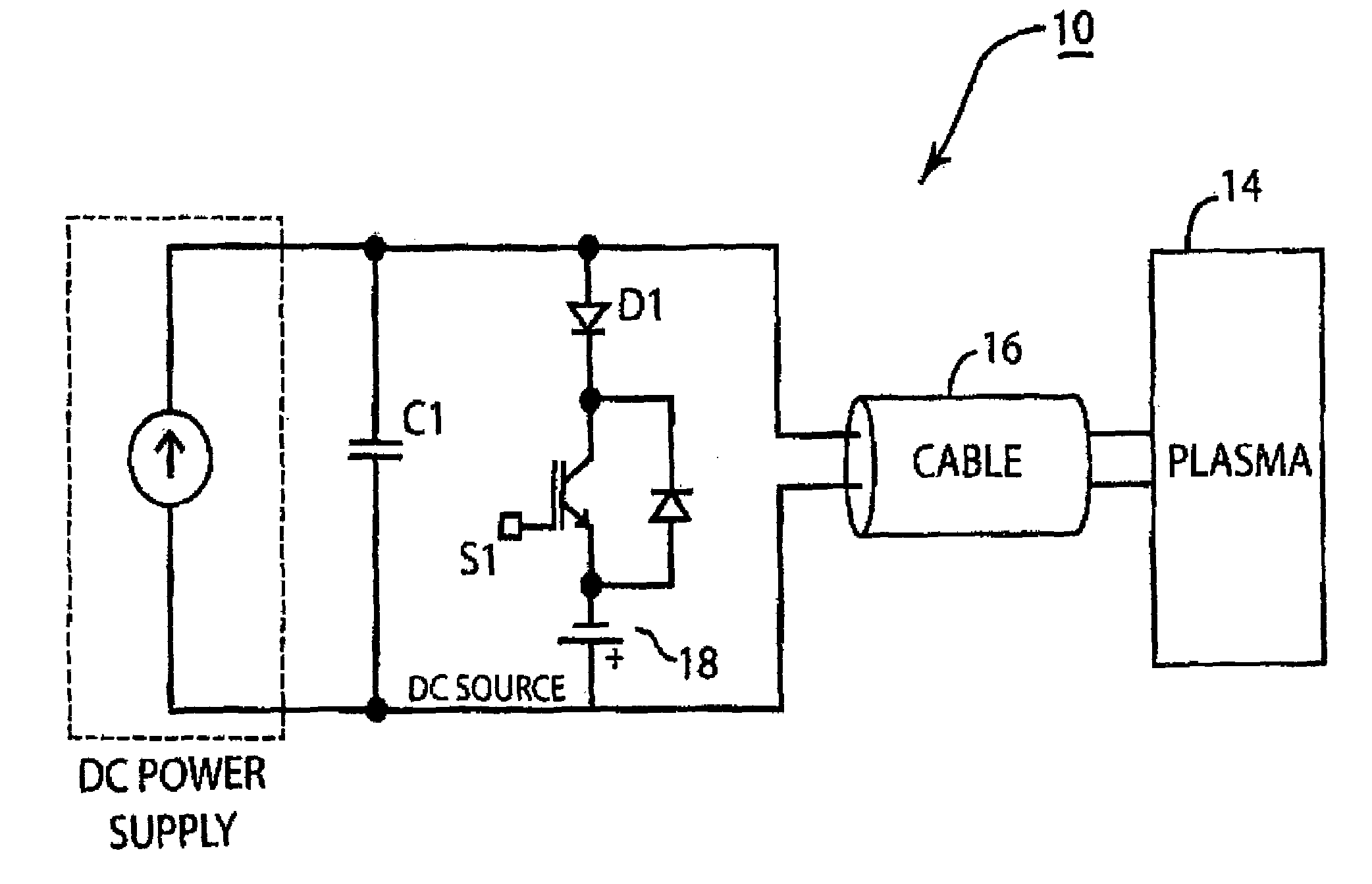

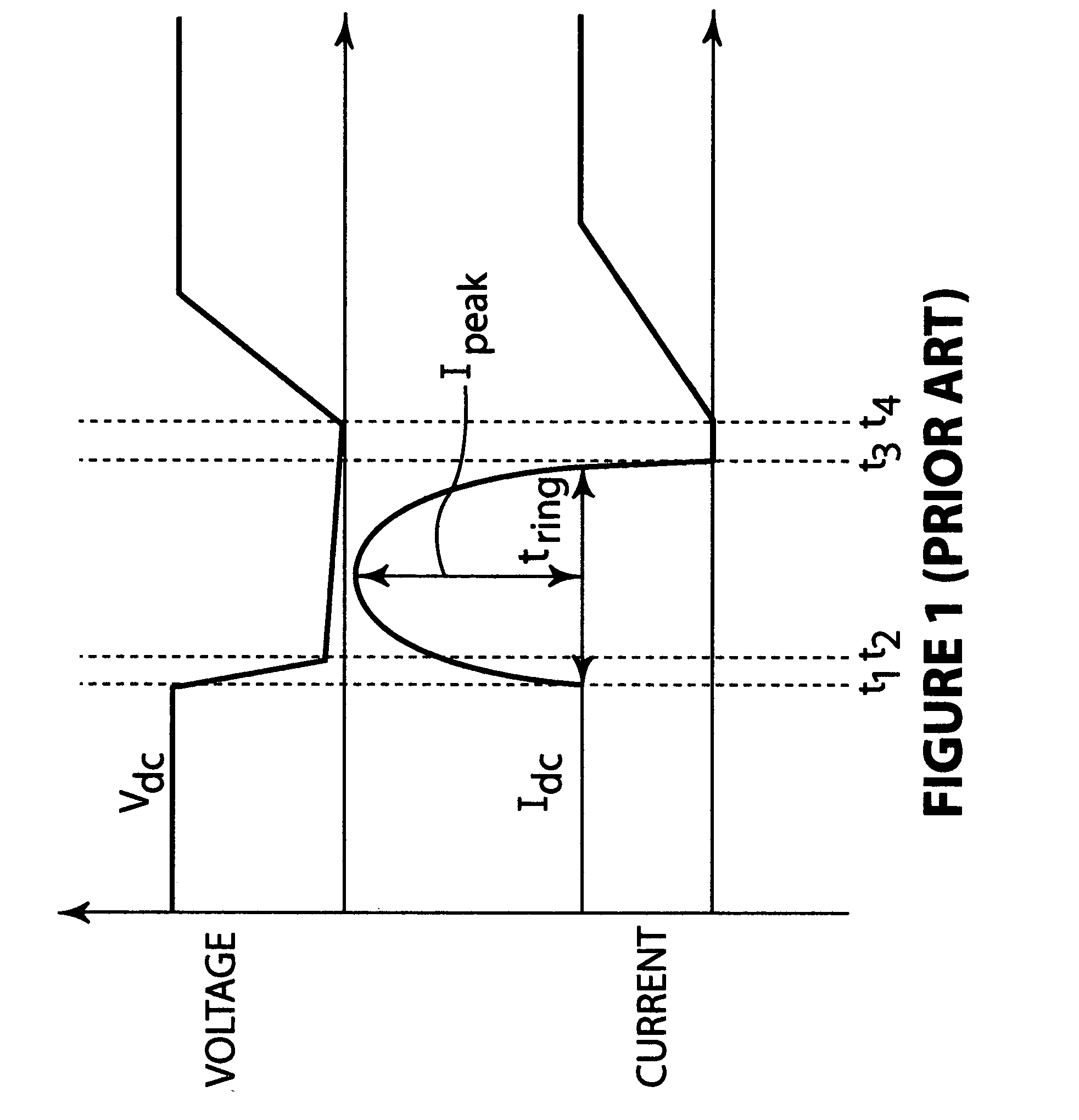

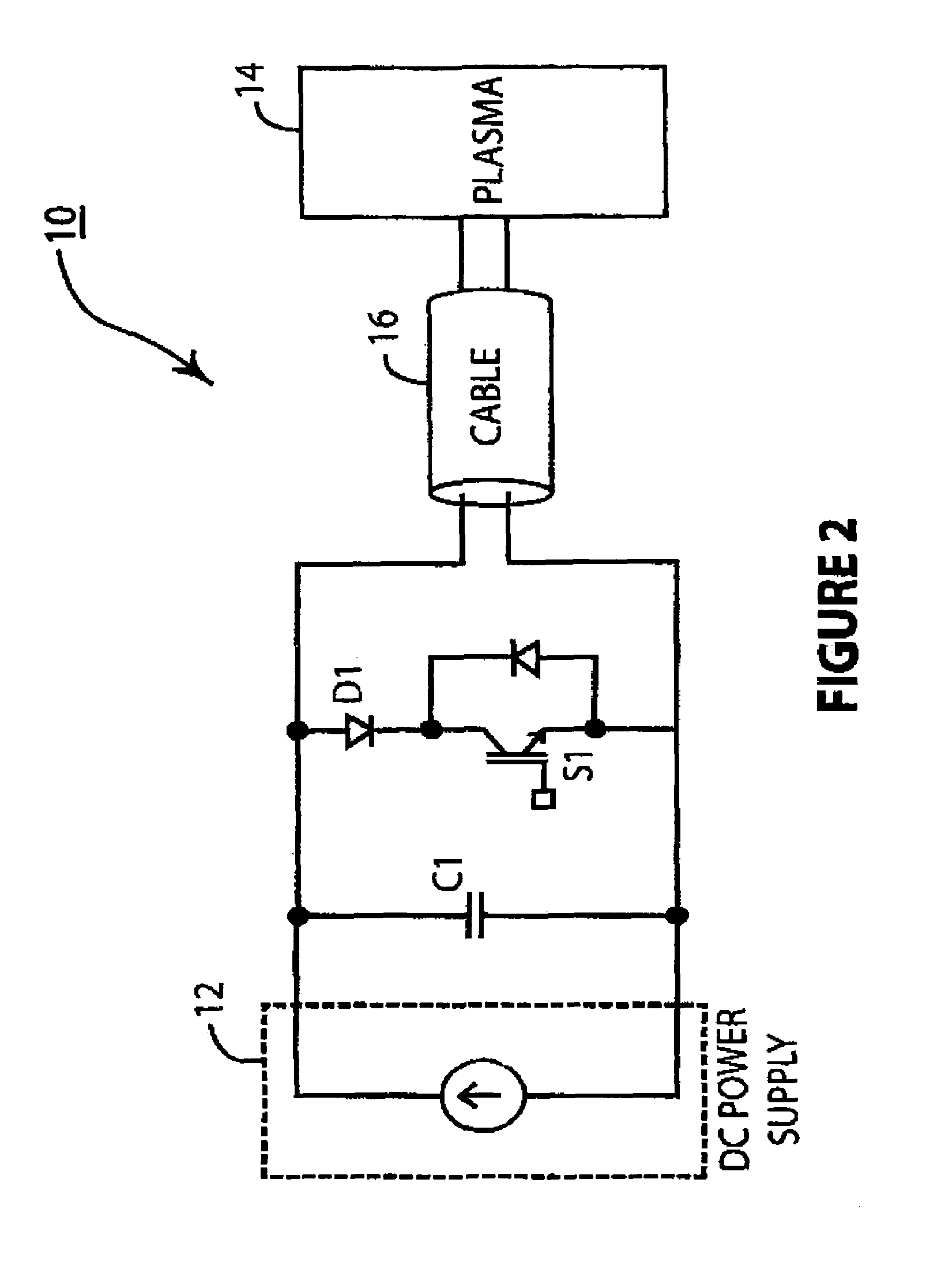

Apparatus and method for fast arc extinction with early shunting of arc current in plasma

InactiveUS6943317B1Reduces effect of arcingReduce probabilityElectric discharge tubesArc welding apparatusPower flowEngineering

There is provided by this invention a novel apparatus and method of operating a dc plasma process that diverts the power supply current from the plasma at the initiation of an arc, thereby inhibiting energy from flowing from the power supply to the plasma, and then to allow energy to flow again when the power supply re-enables energy flow to the plasma. The diverting means is connected to the output of the power supply to divert current away from the plasma at the initiation of an arc wherein the diverting means is actuated when the arc is detected on the output and diverts the current for a first pre-determined time. The diverting means is released at the end of the first pre-determined time before the current reaches zero wherein current is redirected to the plasma and the diverting means is reactivated at the end of a second pre-determined time in the event the arc is not extinguished.

Owner:ADVANCED ENERGY IND INC

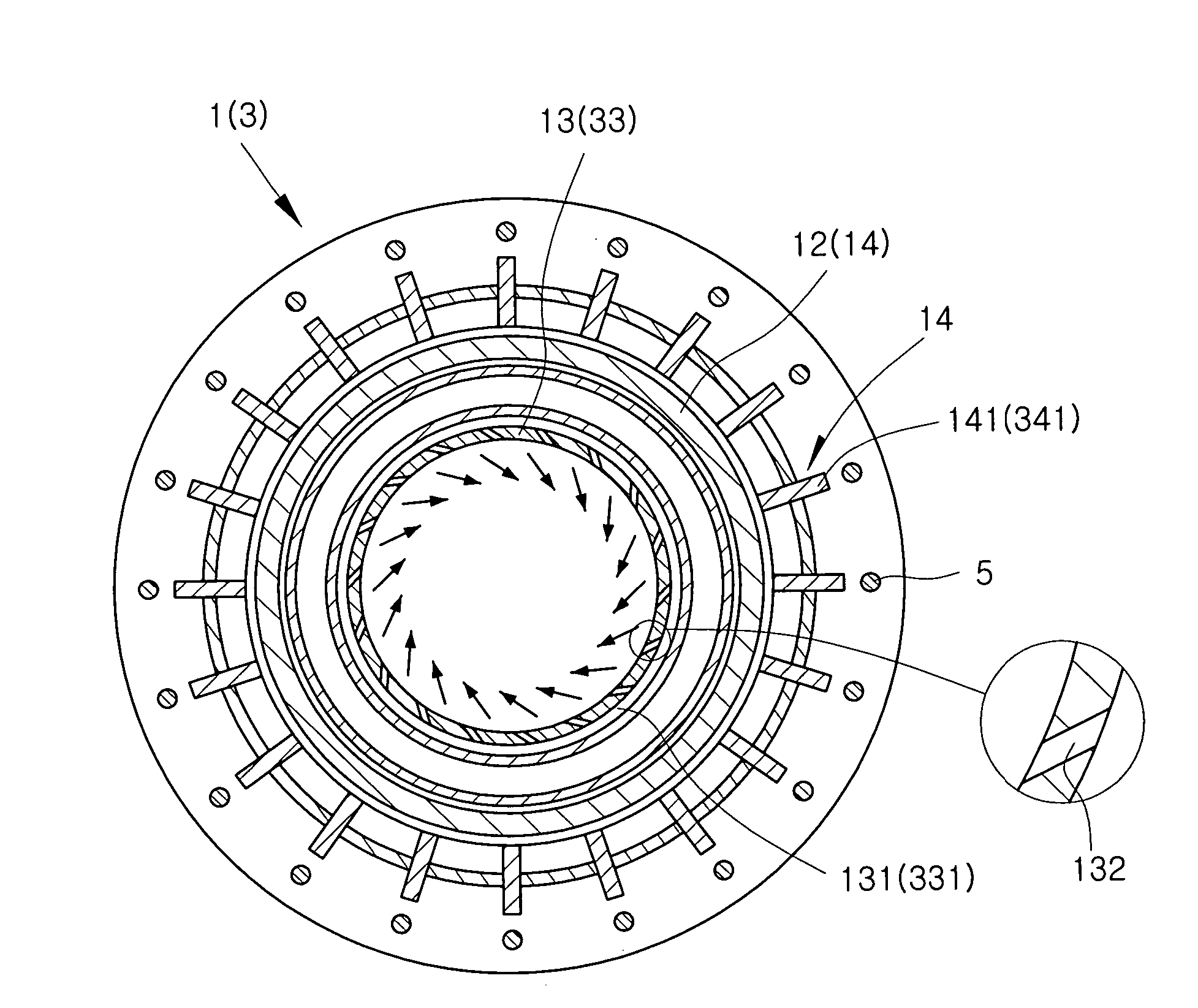

Method and apparatus for cathodic arc ion plasma deposition

InactiveUS20080138529A1Easy to operateConvenient lengthMolten spray coatingVacuum evaporation coatingPlasma depositionDeposition process

A method and apparatus for depositing a coating material on a surface of a substrate by an ion plasma deposition process using a hollow cathode is disclosed. The cathode may be a substantially cylindrical hollow cathode. A plasma arc is formed on the outer circumference of the cathode to remove coating material from the cathode, which is then deposited on a surface of a substrate. An internal arc drive magnet is contained within the hollow bore of the cathode and cooling is provided to the magnet during operation.

Owner:GENERAL ELECTRIC CO

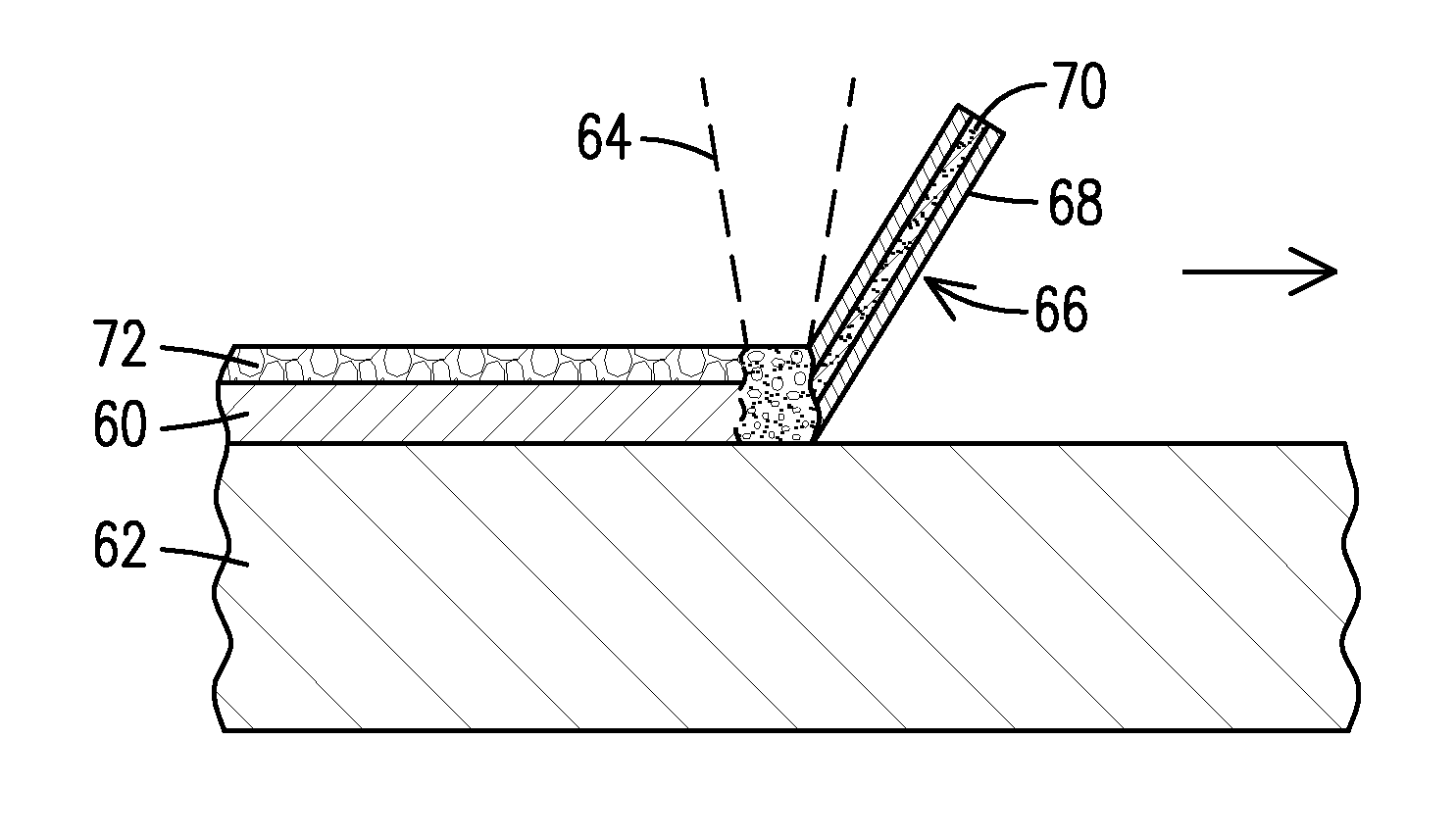

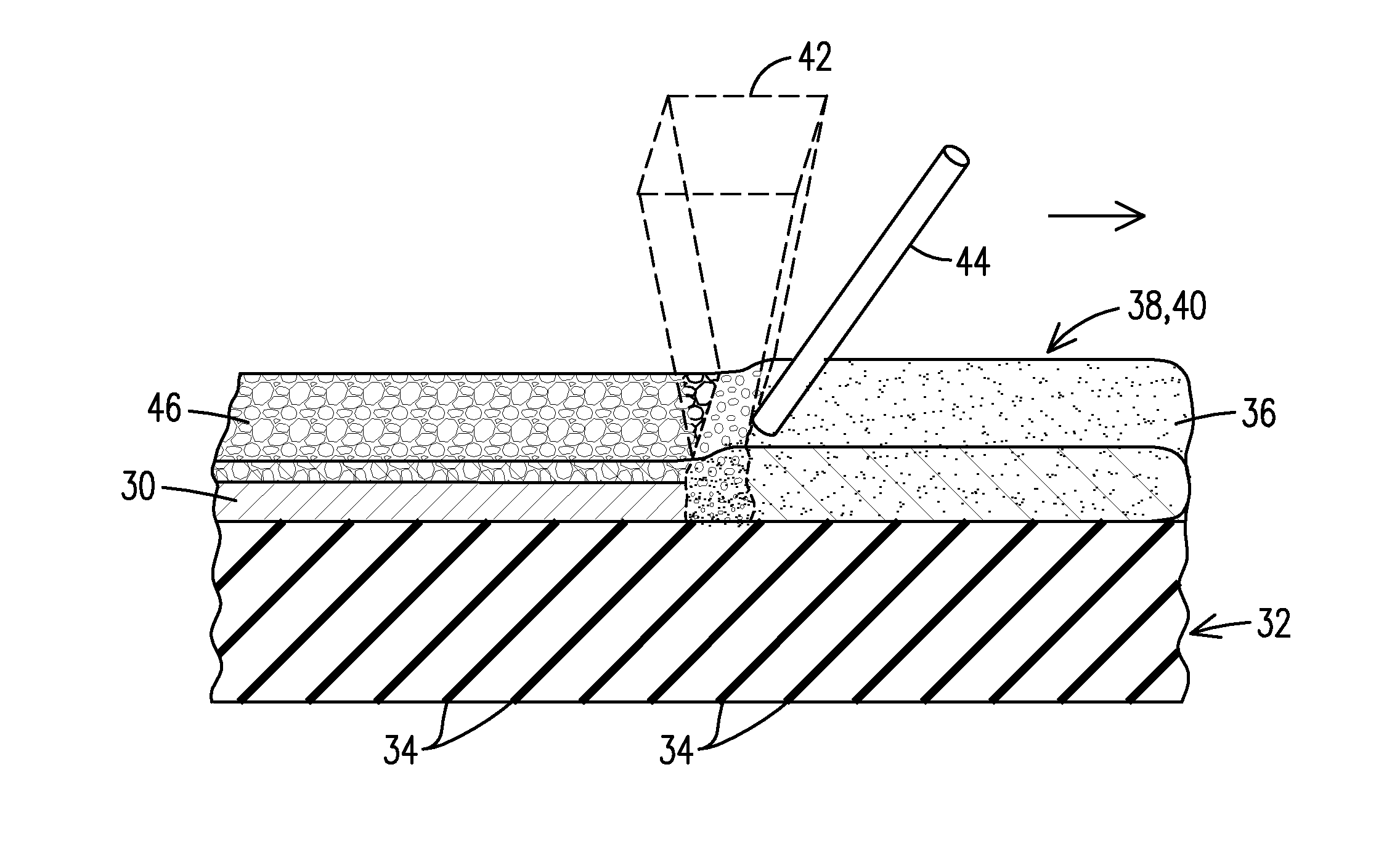

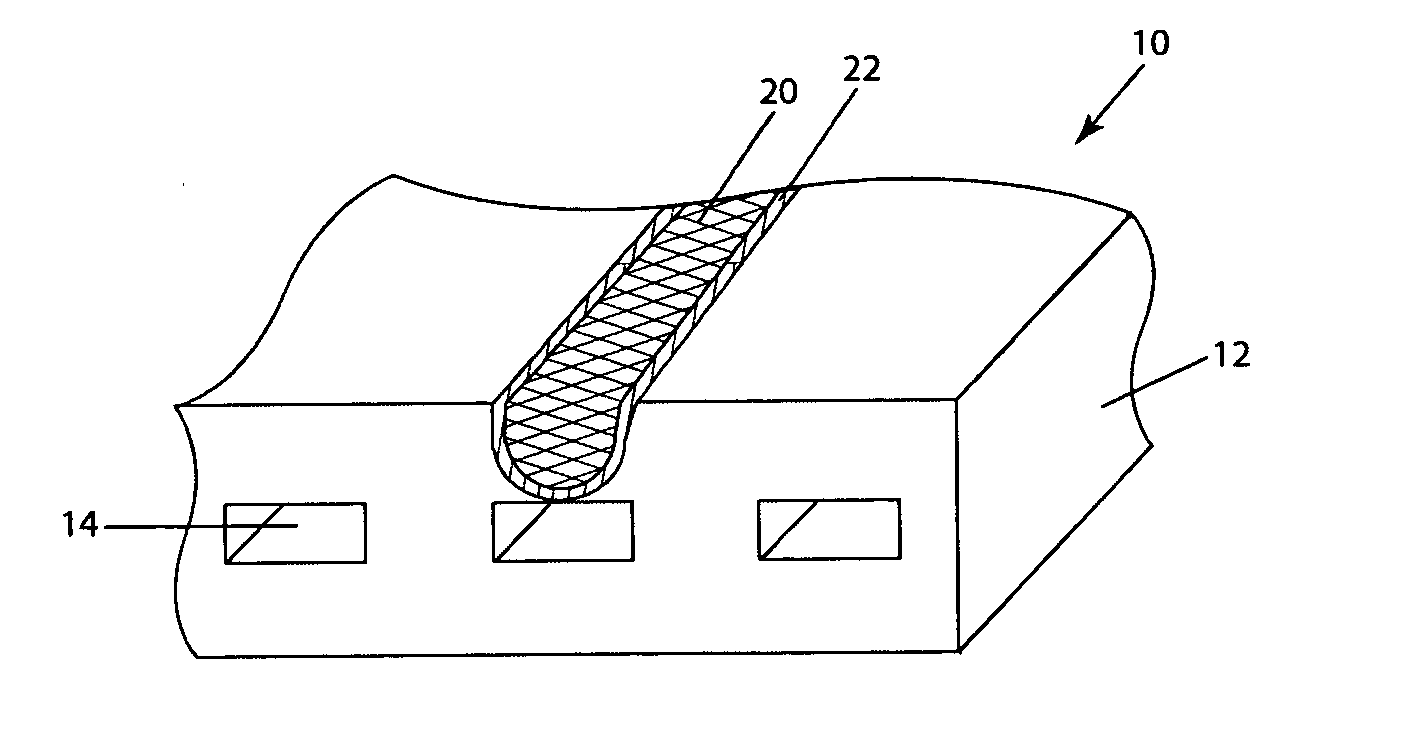

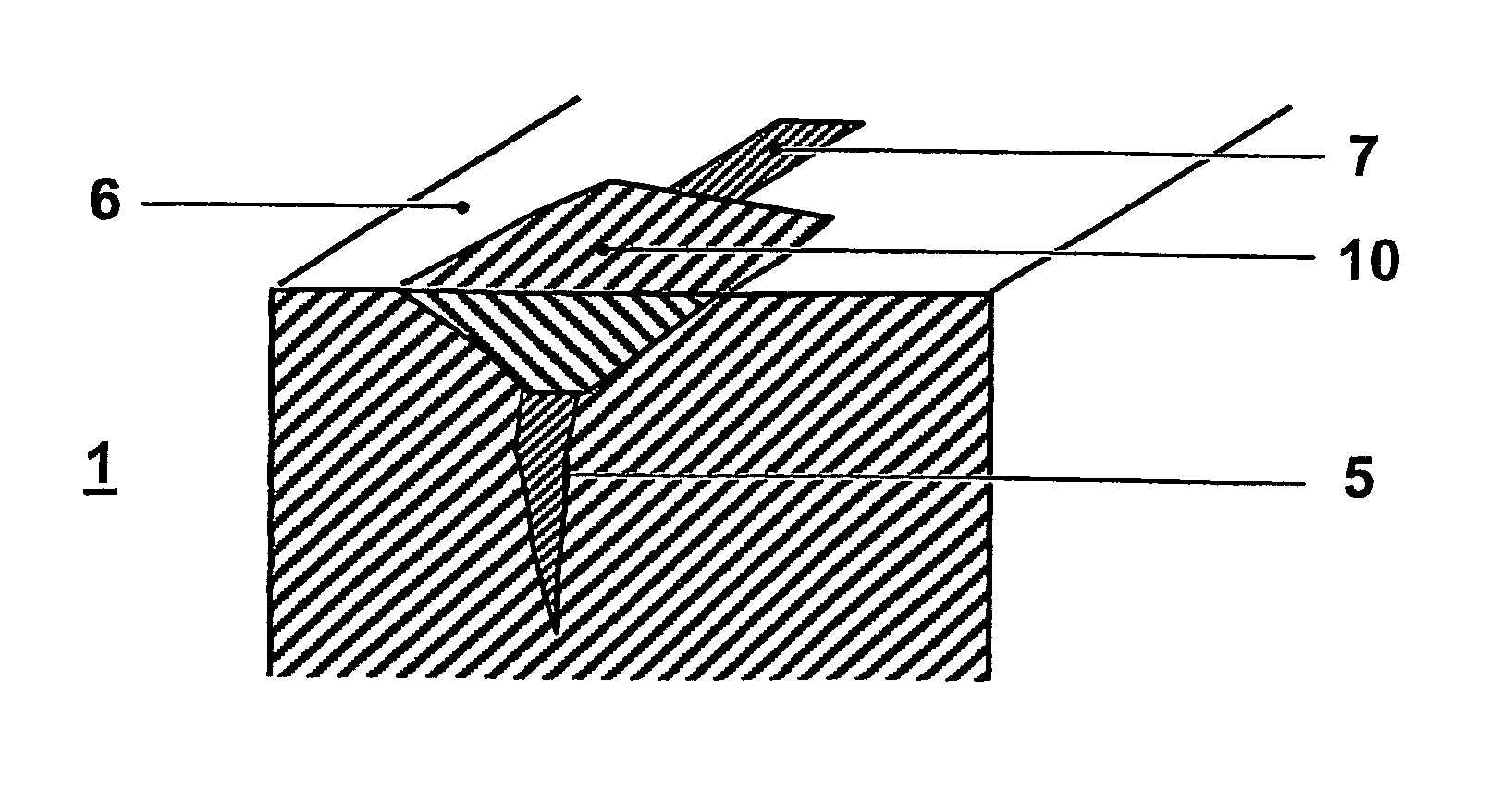

Deposition of superalloys using powdered flux and metal

A method for depositing superalloy materials. A layer of powder (14) disposed over a superalloy substrate (12) is heated with an energy beam (16) to form a layer of superalloy cladding (10) and a layer of slag (18). The layer of powder includes flux material and alloy material, formed either as separate powders or as a hybrid particle powder. A layer of powdered flux material (22) may be placed over a layer of powdered metal (20), or the flux and metal powders may be mixed together (36). An extrudable filler material (44) such as nickel, nickel-chromium or nickel-chromium-cobalt wire or strip may be added to the melt pool to combine with the melted powder to give the superalloy cladding the composition of a desired superalloy material.

Owner:SIEMENS ENERGY INC

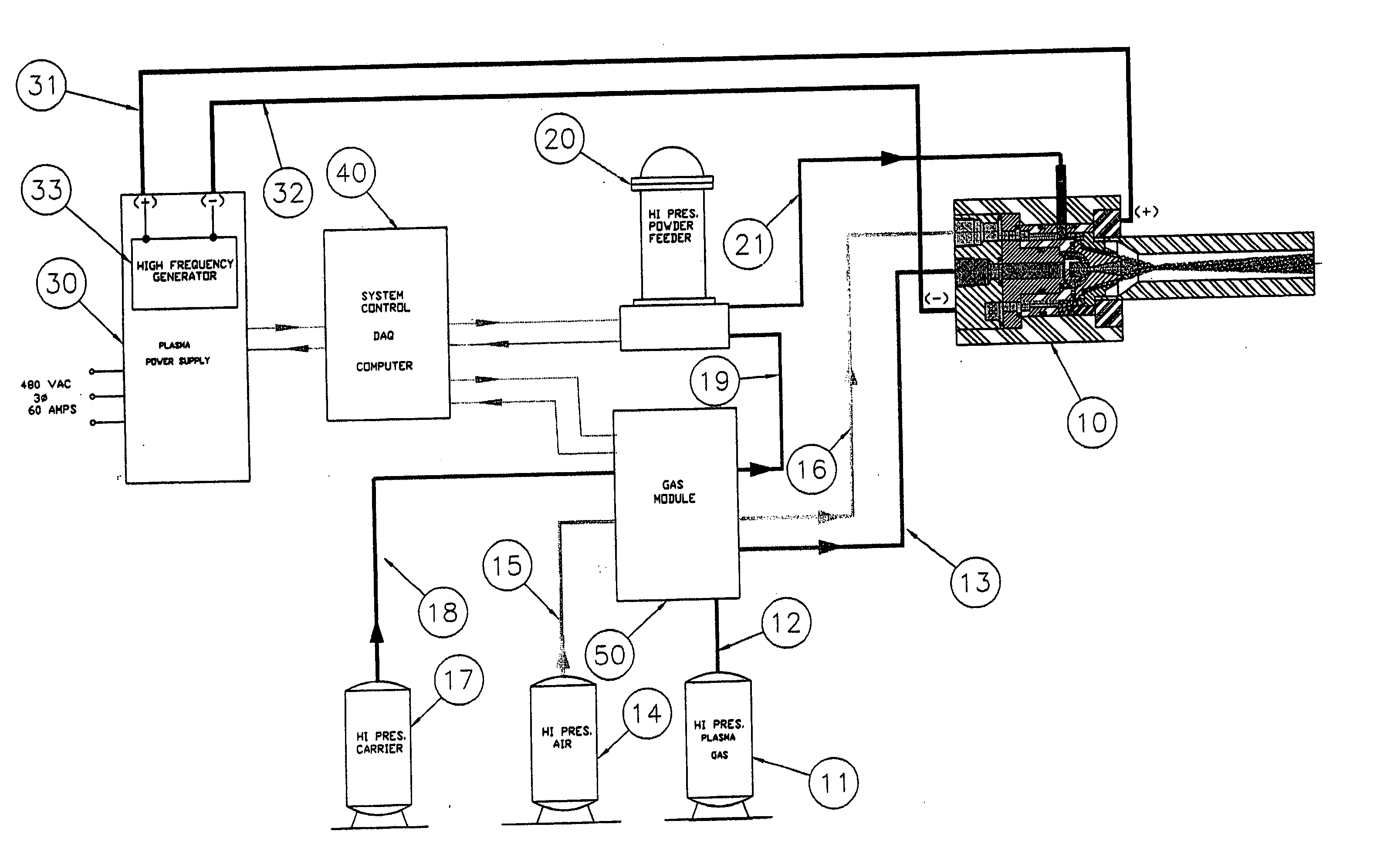

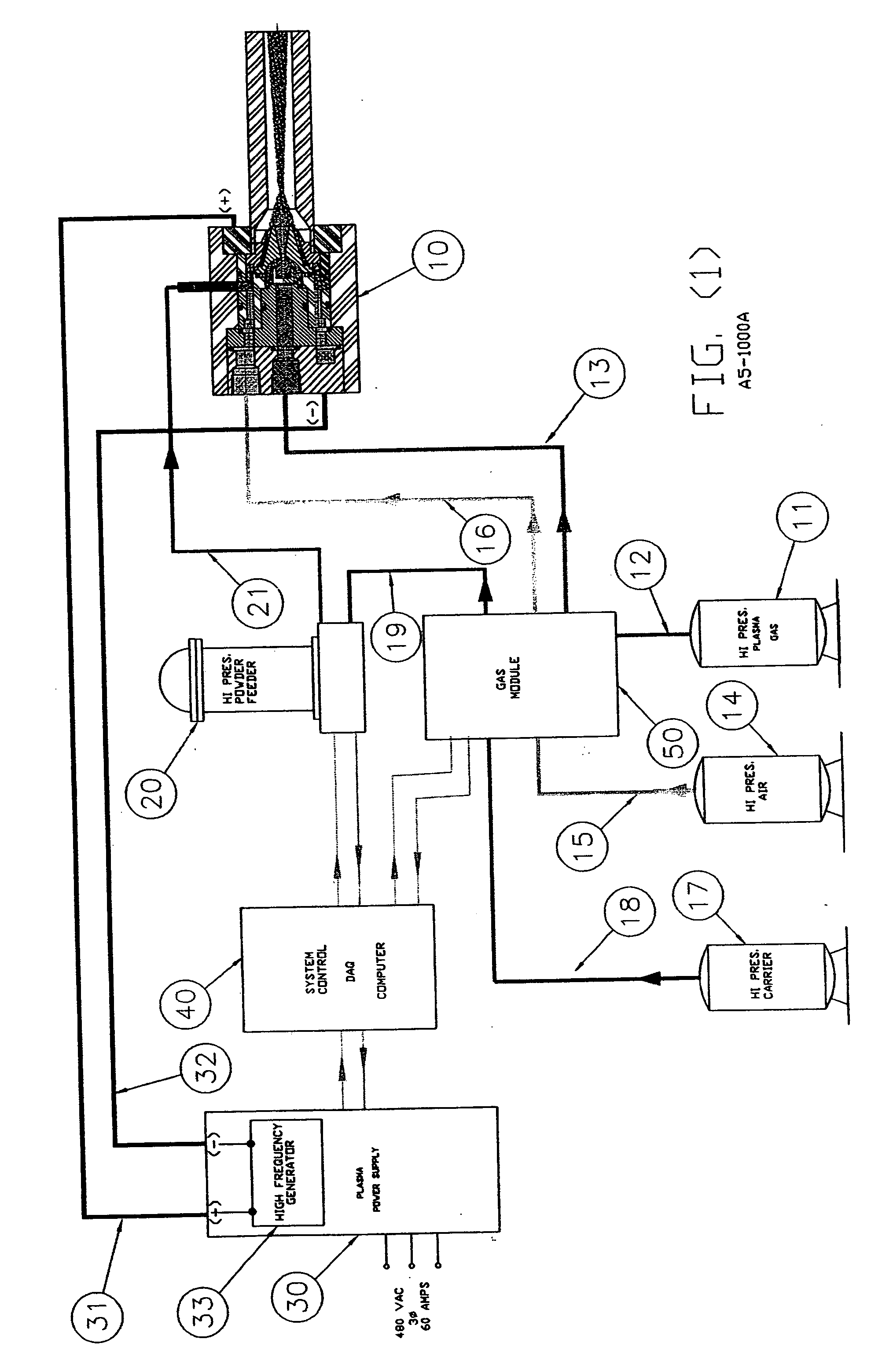

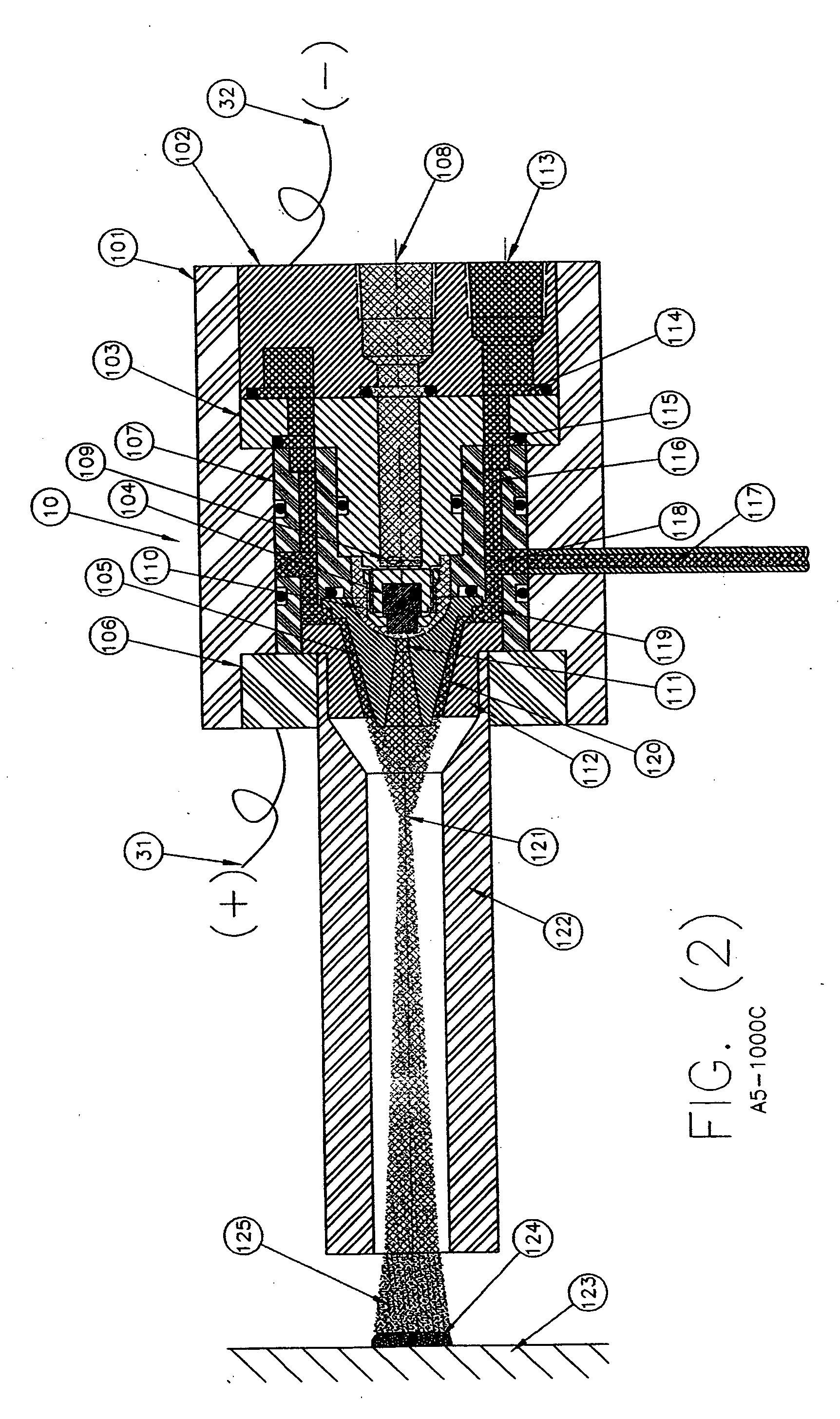

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050120957A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns.

Owner:FLAME SPRAY IND

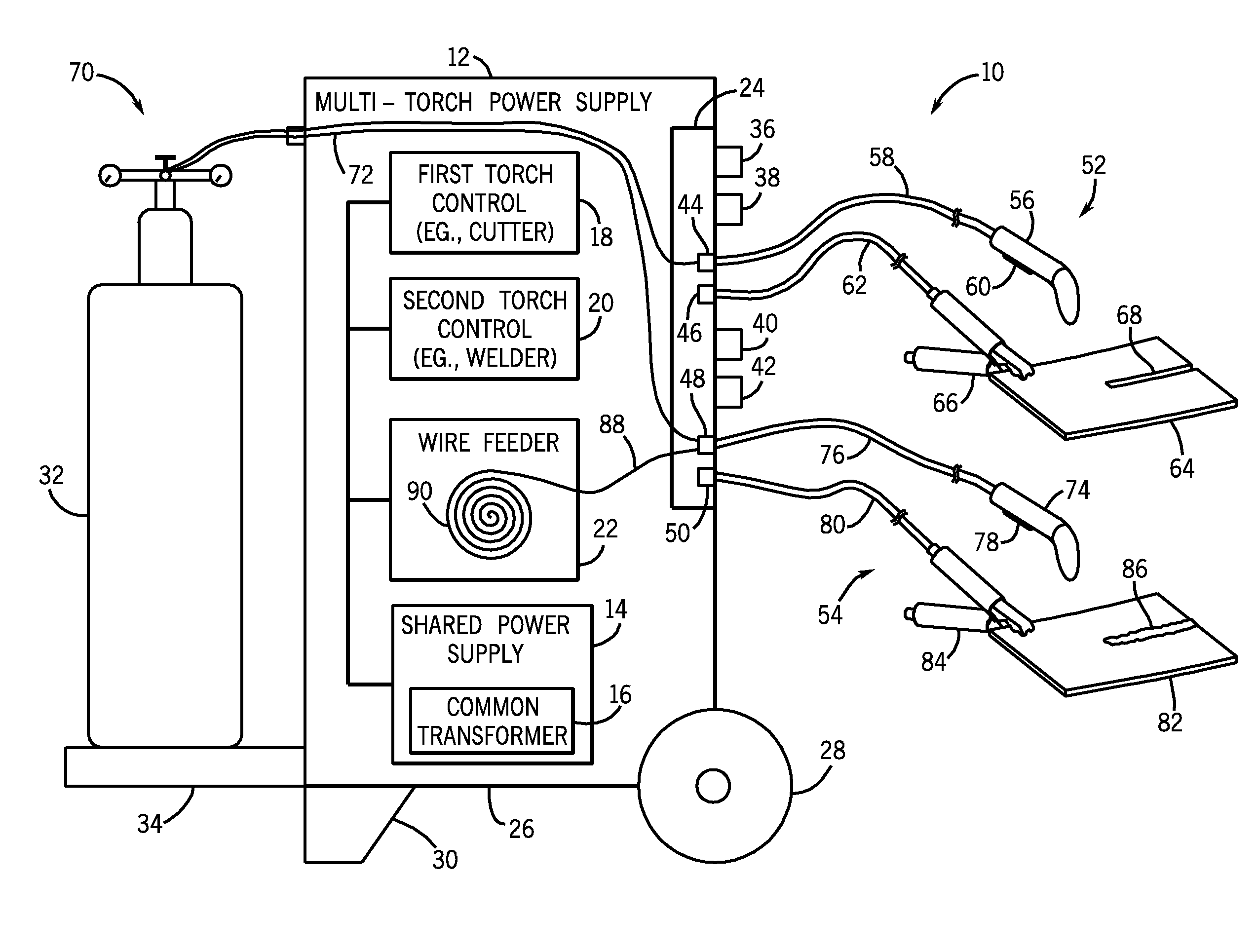

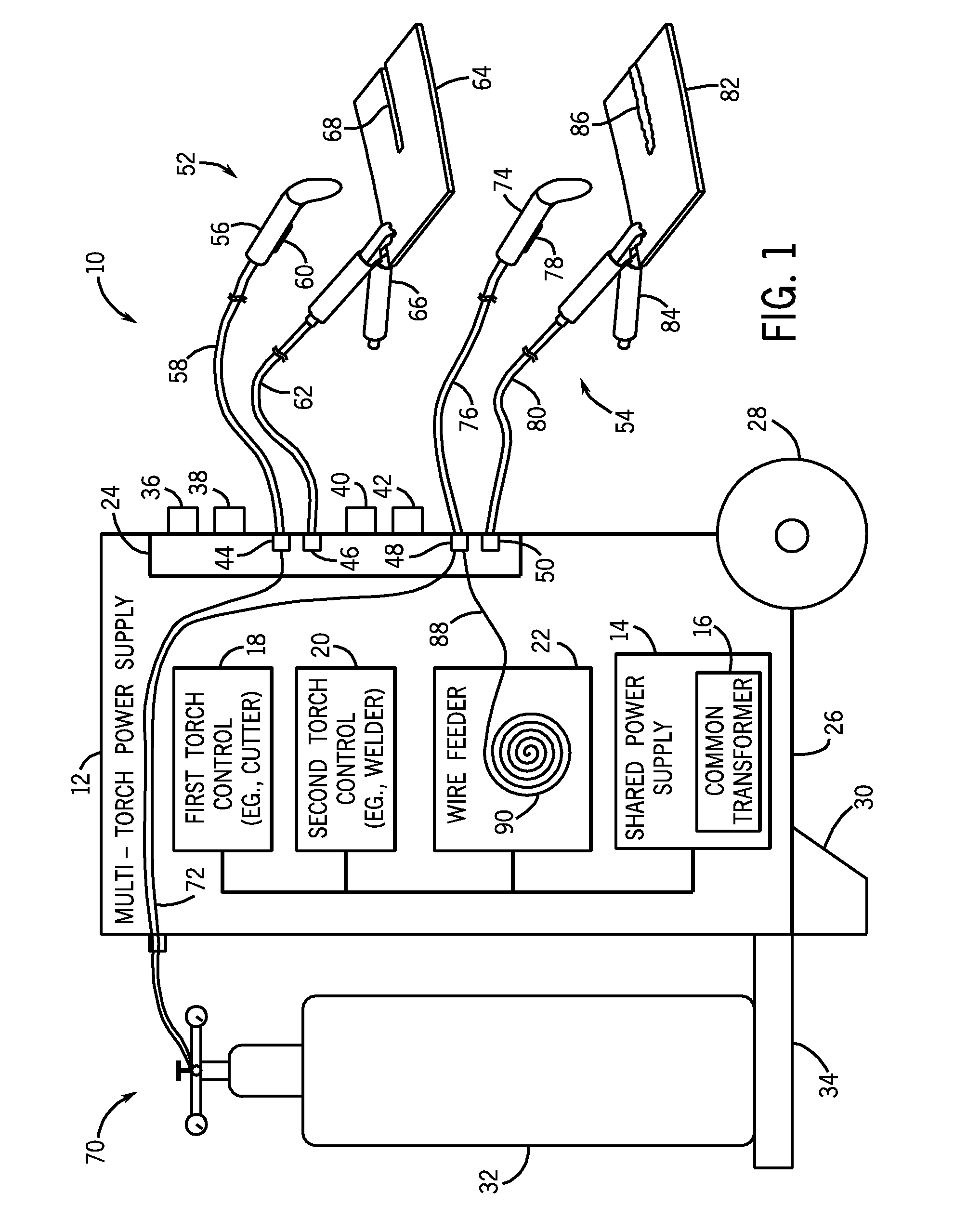

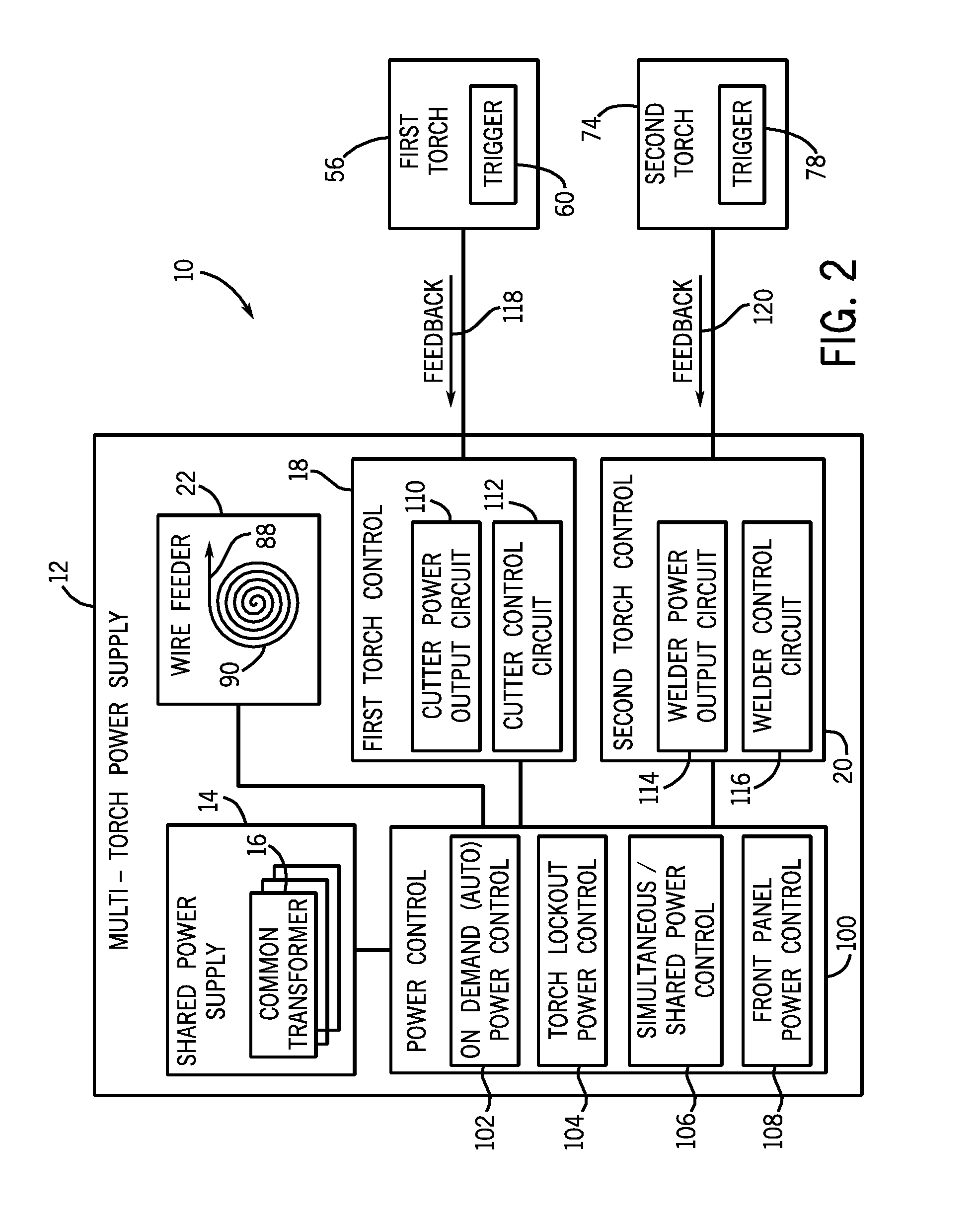

Welding and plasma cutting method and system

A system, in some embodiments, includes a multi-torch power supply. The power supply has a first circuit configured to control output to a first electrical torch, and a second circuit configured to control output to a second electrical torch. The power supply also has a power source configured to supply power to the first and second circuits to enable both independent and simultaneous operation of the first and second electrical torches.

Owner:ILLINOIS TOOL WORKS INC

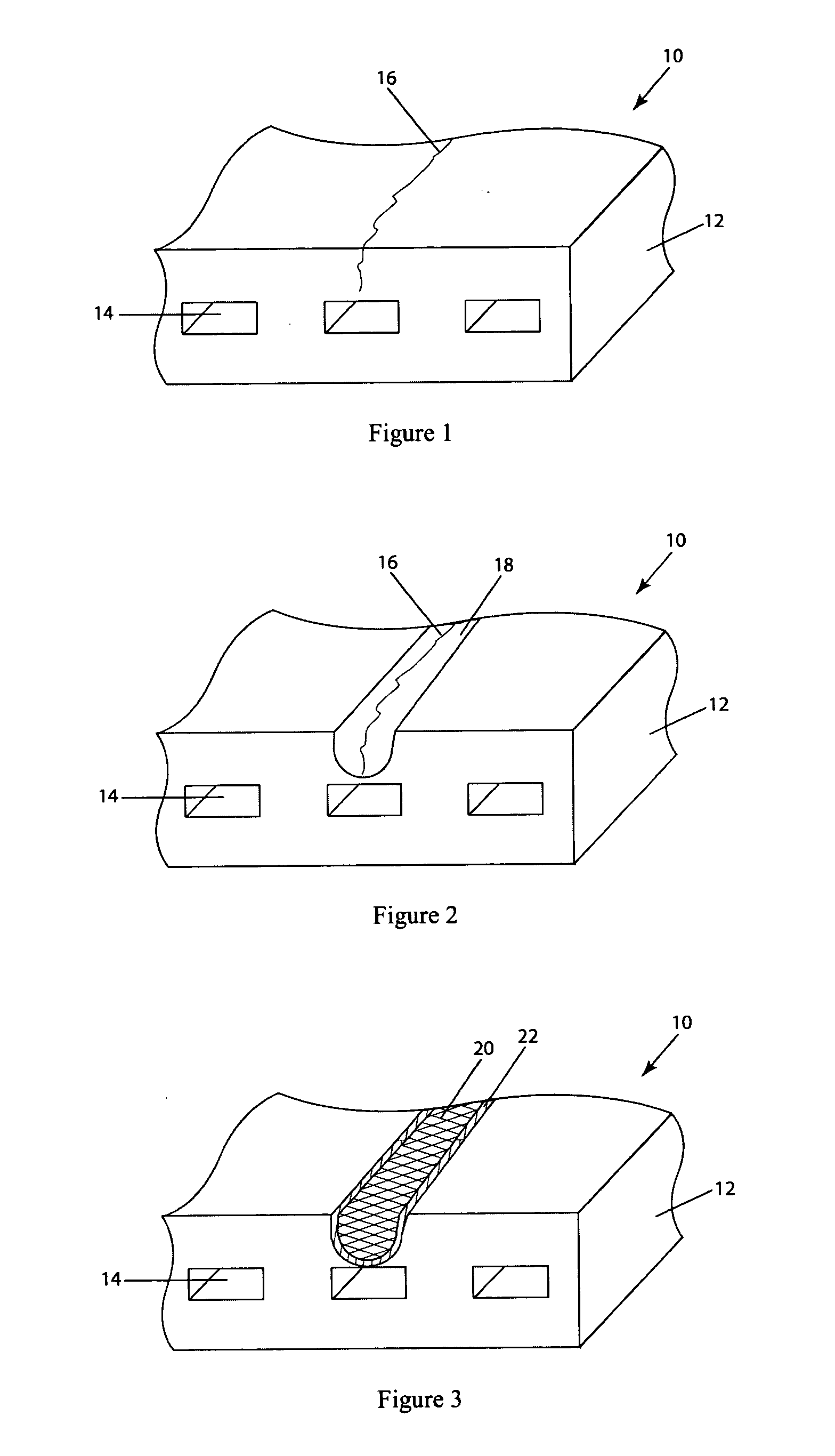

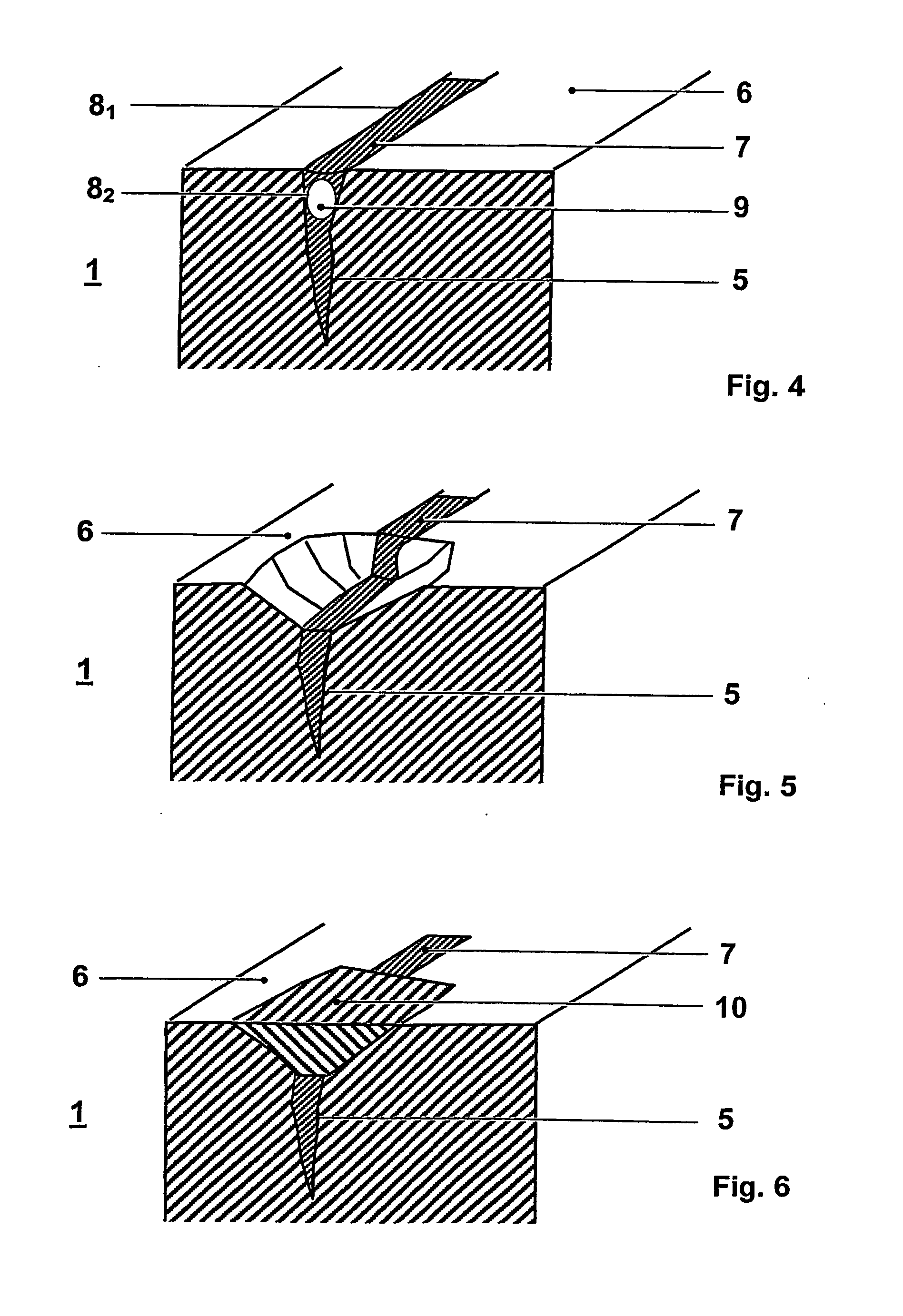

Repair of combustion turbine components

A method of repairing a combustion turbine component having damage located at or near a cooling hole or hollow or geometrically complex portion of the component is provided. The method comprises forming a preparatory groove that extends from a surface of the component to the damaged area but does not extend to the cooling hole or hollow or geometrically complex portion of the component, the groove extending 40-90% the distance from the component to the damaged area; spraying a filler material into the groove with a micro-plasma torch at a current of less than 50 amperes; and filling the groove with the filler material such that the heated filler material substantially extends from the cooling hole or hollow or geometrically complex portion of the component to a surface of the component.

Owner:SIEMENS ENERGY INC

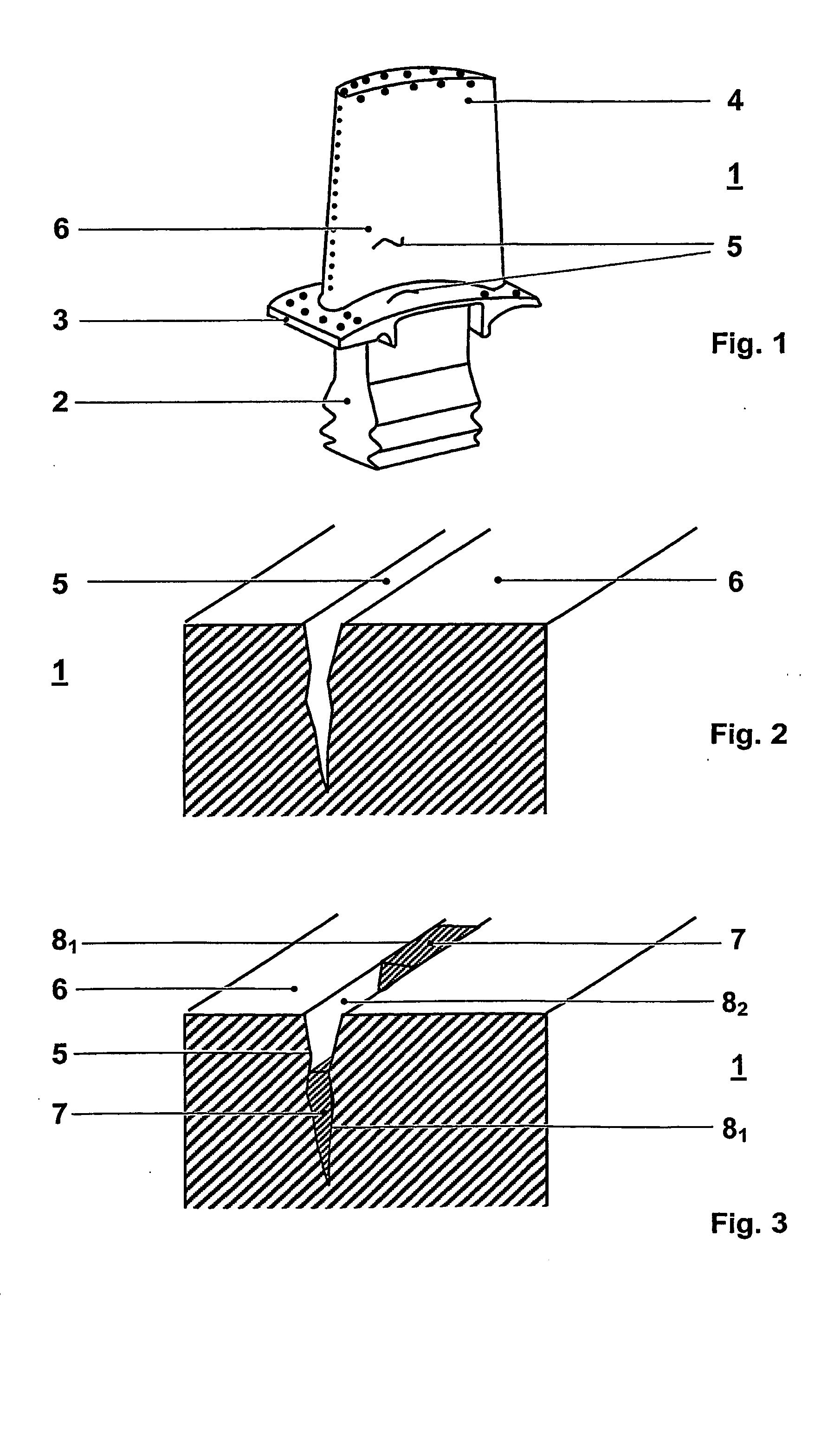

Crack repair method

InactiveUS20050067466A1Rapid and inexpensive mannerMinimize cracksTurbinesArc welding apparatusCrazingGas turbines

A method of repairing cracks on a surface of a component such as gas turbine components includes the steps of repairing the cracks of the component by brazing, detecting remaining cracks on the surface or below the surface, which were not properly filled with braze material during the repair brazing operation, and repairing the crack zones with a focussed low-heat input welding method using an appropriate weld filler materials.

Owner:ALSTOM TECH LTD

Weld viewing

InactiveUS20090161212A1View effectivelyEconomical and compact and transportable solutionMirrorsPlasma welding apparatusComputer scienceWelding torch

A mirror may have hole(s) in or passing through its viewing surface. A video remote may be associated with the mirror, especially as configured with the hole(s). A gas, typically an inert gas, may be passed about or through the mirror system, for example, through one or more of the hole(s) through the viewing surface. The mirror may be part of a mirror system, which can be combined with a welding torch. Obscured sites may be inspected and / or welded therewith.

Owner:GOUGH YUMA E

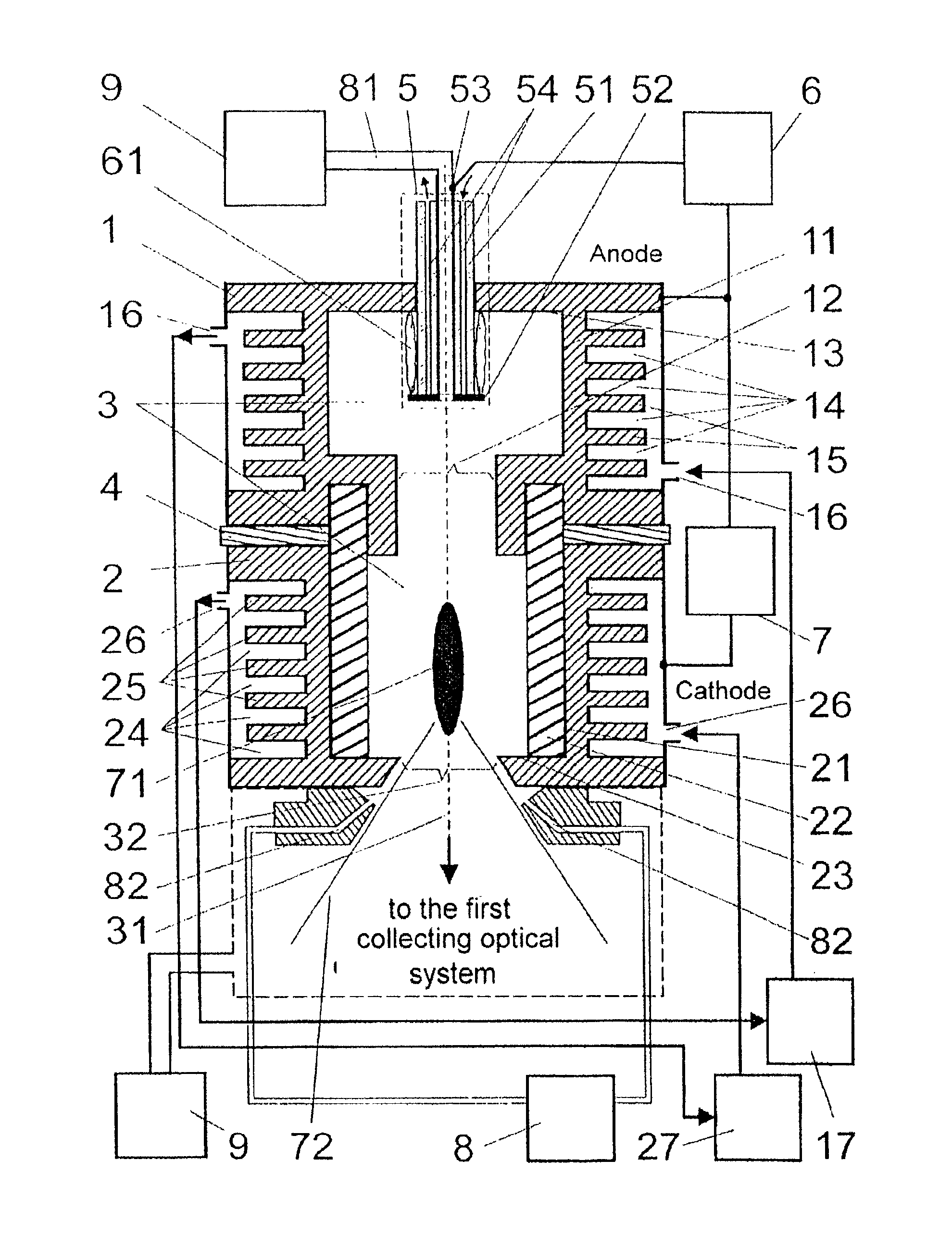

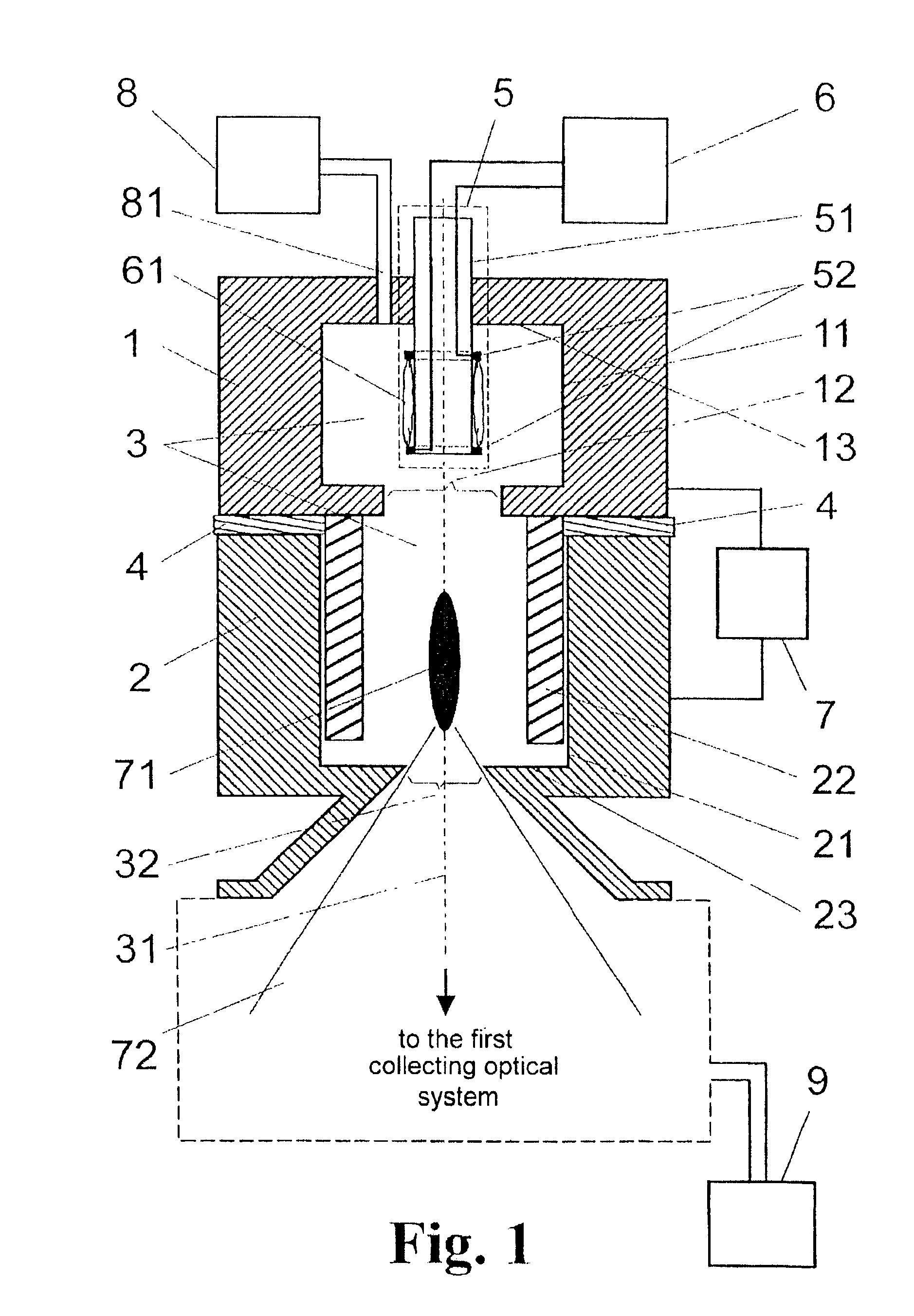

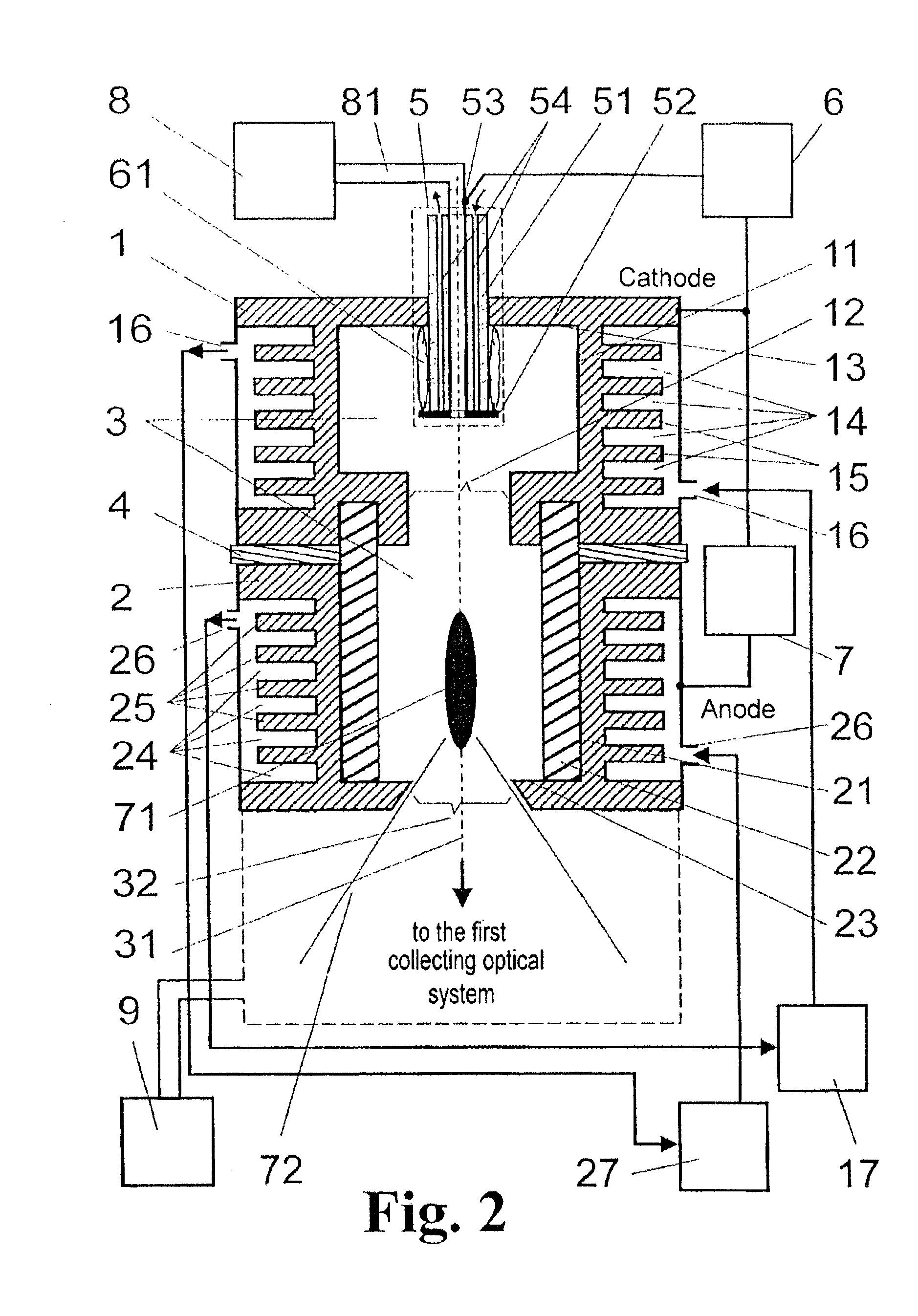

Arrangement for generating extreme ultraviolet (EUV) radiation based on a gas discharge

InactiveUS6894298B2Stable generationProlong lifeOptical radiation measurementElectric lighting sourcesHigh energyPulsed DC

The invention is directed to a method and an arrangement for generating extreme ultraviolet (EUV) radiation, i.e., radiation of high-energy photons in the wavelength range from 11 to 14 nm, based on a gas discharge. The object of the invention, to find a novel possibility for generating EUV radiation in which an extended life of the system is achieved with stable generation of a dense, hot plasma column, is met according to the invention in that a preionization discharge is ignited between two parallel disk-shaped flat electrodes prior to the main discharge by a surface discharge along the superficies surface of a cylindrical insulator with a plasma column generated through the gas discharge with pulsed direct voltage, which preionization discharge carries out an ionization of the working gas in the discharge chamber by means of fast charged particles. The preionization discharge is triggered within a first electrode housing and the main discharge takes place between a narrowed output of the first electrode housing and a part of the second electrode housing close to the outlet opening of the discharge chamber. The plasma develops in a part of the second electrode housing covered by a tubular insulator and, as a result of the current-induced magnetic field, contracts to form a dense, hot plasma column, one end of which is located in the vicinity of the outlet opening of the second electrode housing.

Owner:USHIO DENKI KK

Gas-cooled plasma arc cutting torch

ActiveUS8089025B2Dampening motionPlasma welding apparatusWelding/cutting media/materialsSpray nozzleTorch

A method and apparatus for a gas-cooled plasma arc torch. Components of the torch can include an electrode, nozzle and a shield, each of which can be gas-cooled. The nozzle can be disposed relative to the electrode and can include a generally hollow conductive body and a cooling gas flow channel defined by at least one fin disposed about an exterior surface of the body, the body providing a thermal conductive path that transfers heat between the nozzle to the cooling gas flow channel during operation of the torch. The shield can be disposed relative to the nozzle and can include a generally hollow conductive body and a cooling gas flow channel defined by at least one fin disposed about an exterior surface of the body, the body providing a thermal conductive path that transfers heat between the shield to the cooling gas flow channel during operation of the torch.

Owner:HYPERTHERM INC

Popular searches

Textile treatment by spraying/projecting Plasma technique Solid state diffusion coating Chemical vapor deposition coating Pretreated surfaces Vehicle route interaction devices Route devices for controlling vehicles Increasing energy efficiency Metallic material coating processes Electron beam welding apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com