Patents

Literature

1299results about How to "Guaranteed to move normally" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

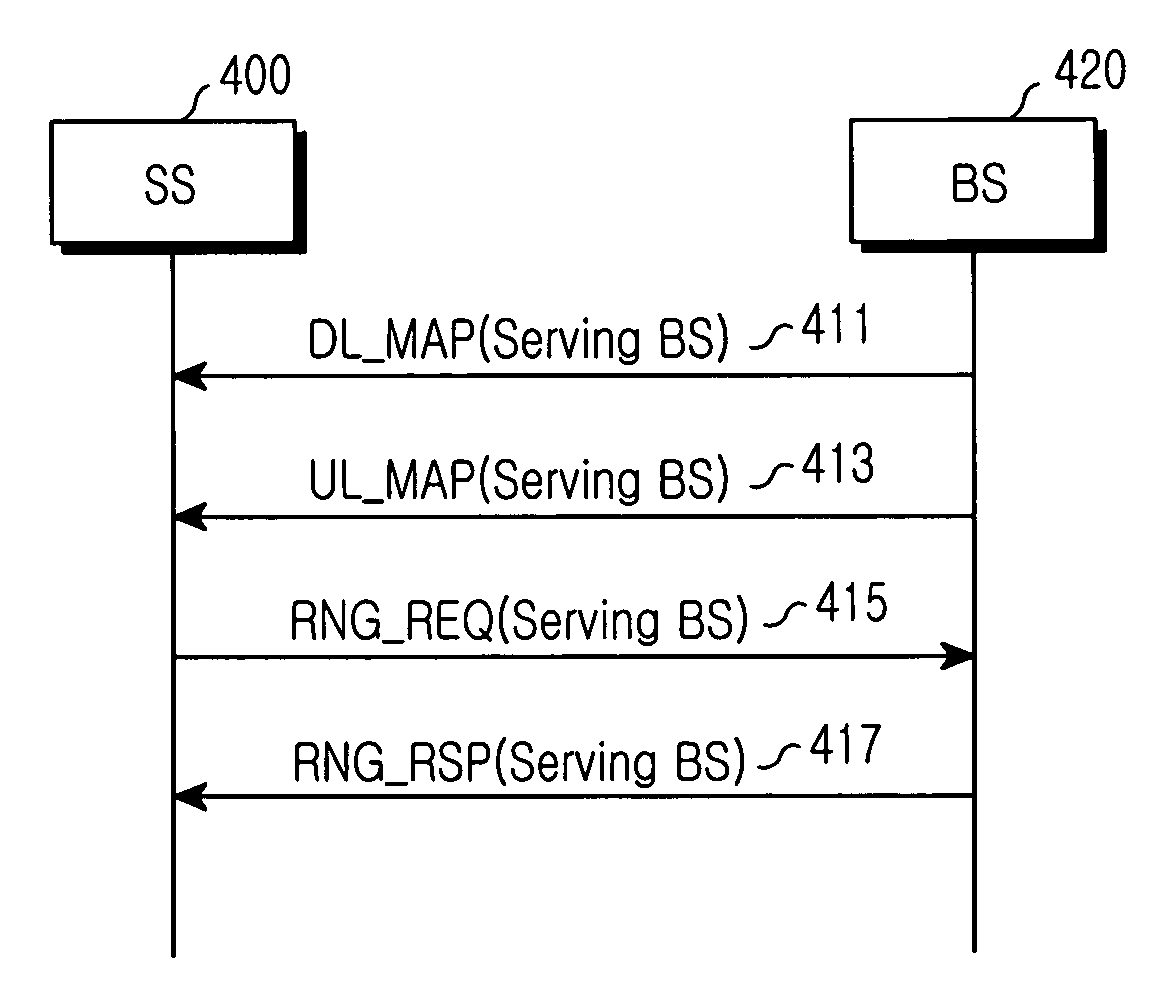

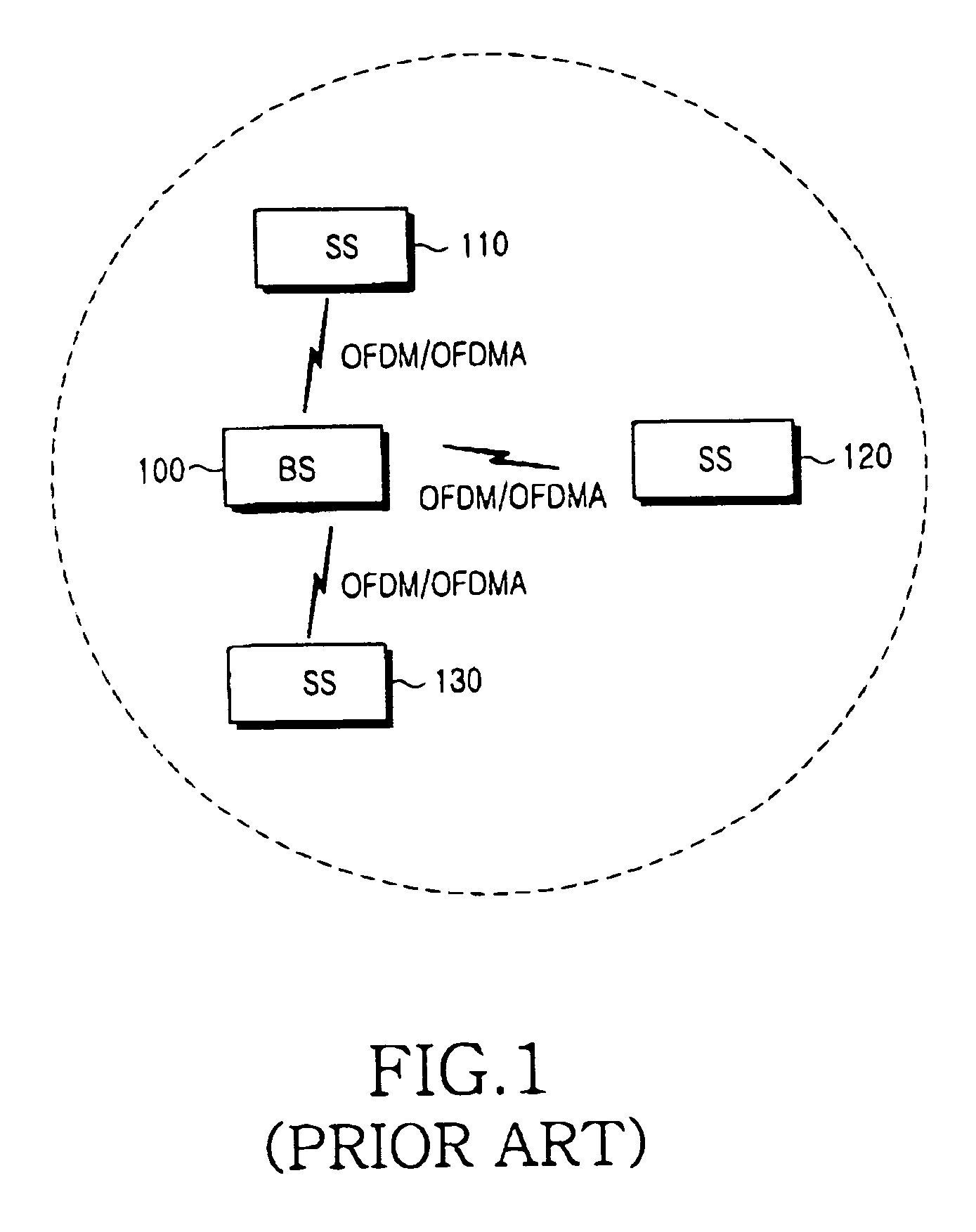

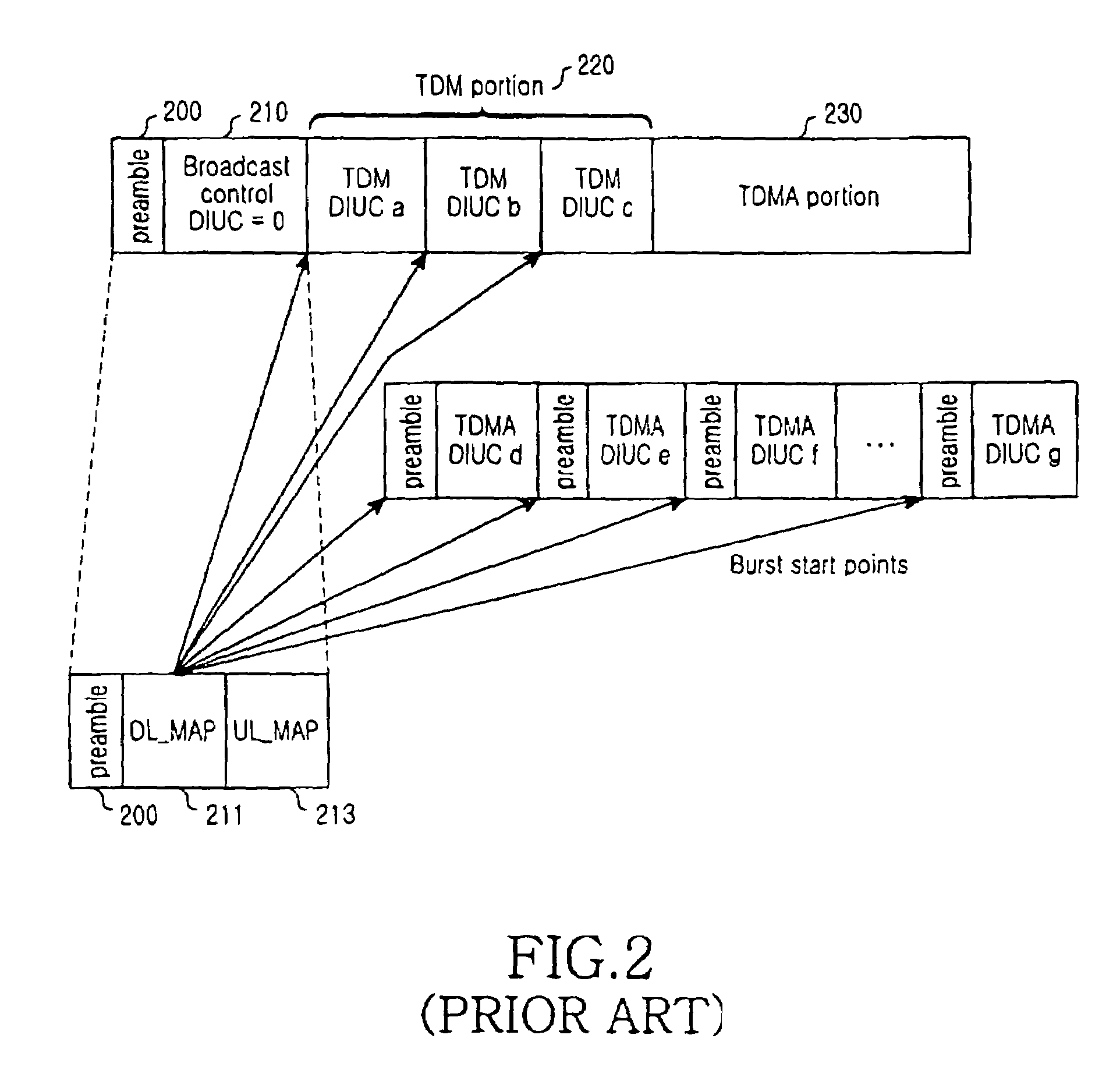

System and method for determining handover at a base station request in a broadband wireless access communication system

ActiveUS7336953B2Efficient data communicationMobility be guaranteeRadio/inductive link selection arrangementsRadio transmission for post communicationBroadbandHandover

A broadband wireless access communication system in which a subscriber station (SS) sends a serving base station (SBS) a handover request to neighbor base stations (NBSs) having a CINR satisfying a handover condition, in response to a handover scan request message, and performs the handover to a particular NBS that transmits a handover response. The SBS transmits the handover scan request message to the SS, sends a handover connection request to NBSs in an order determined by CINRs reported from the SS, and sends, to the SS, information on a particular NBS upon receiving a handover connection response with ACK information from the particular NBS. The particular NBS determines whether it can support handover of the SS, in response to the handover connection request, and sends the handover connection response with the ACK information to the SBS, if it can support handover of the SS.

Owner:SAMSUNG ELECTRONICS CO LTD

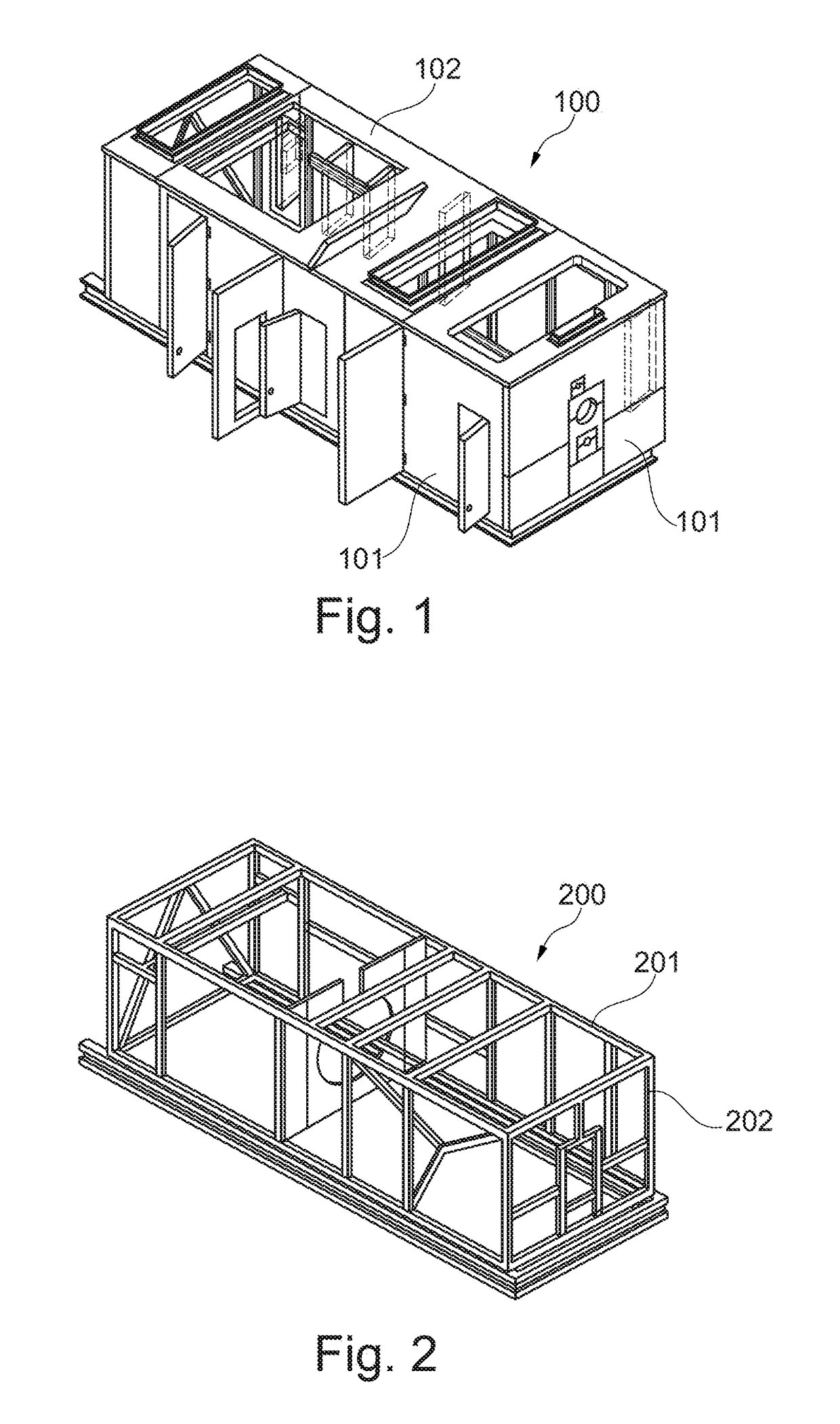

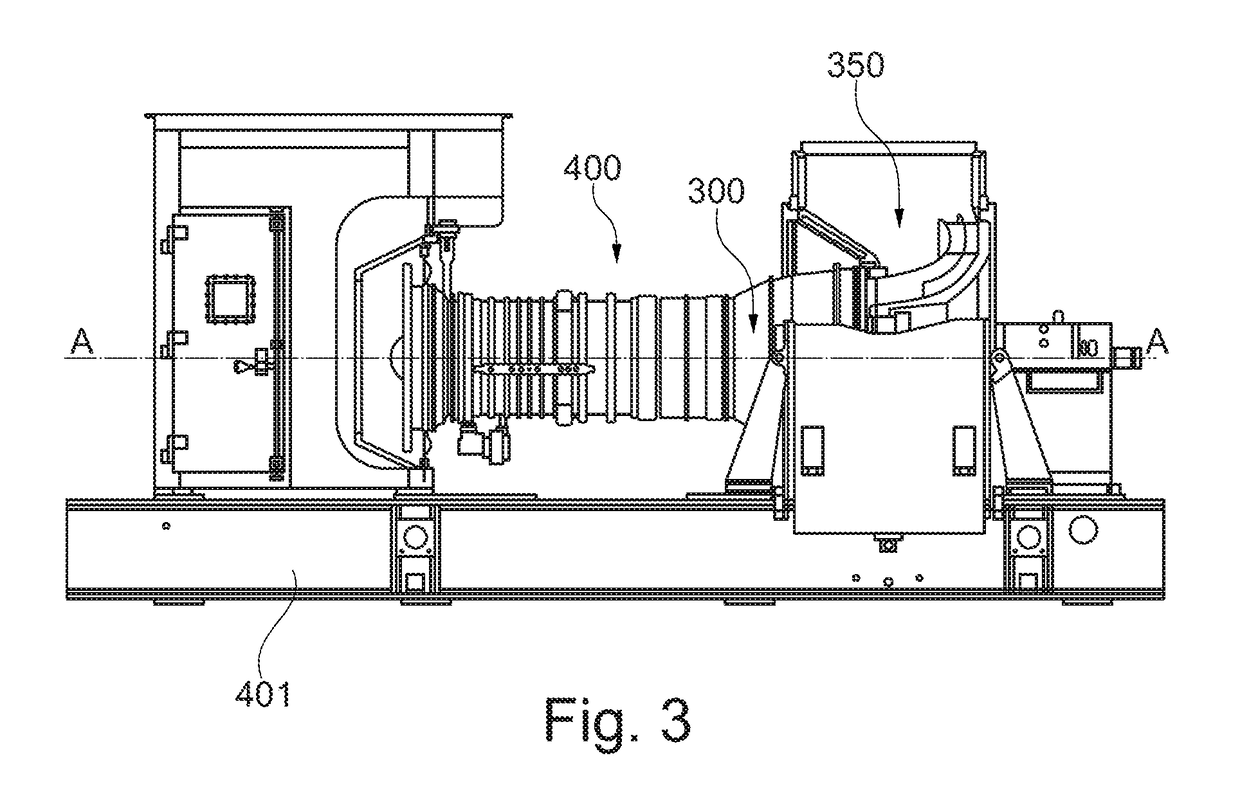

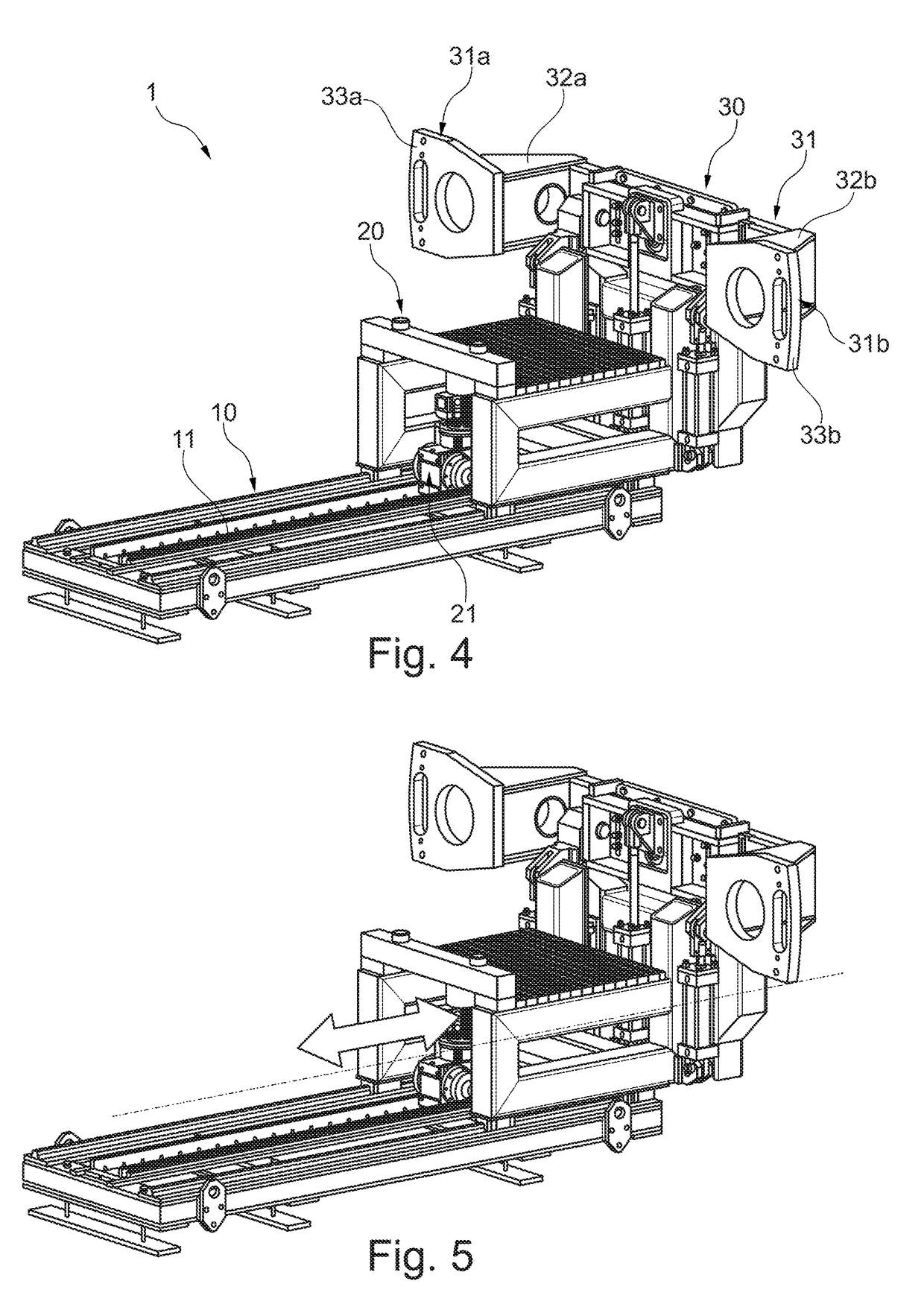

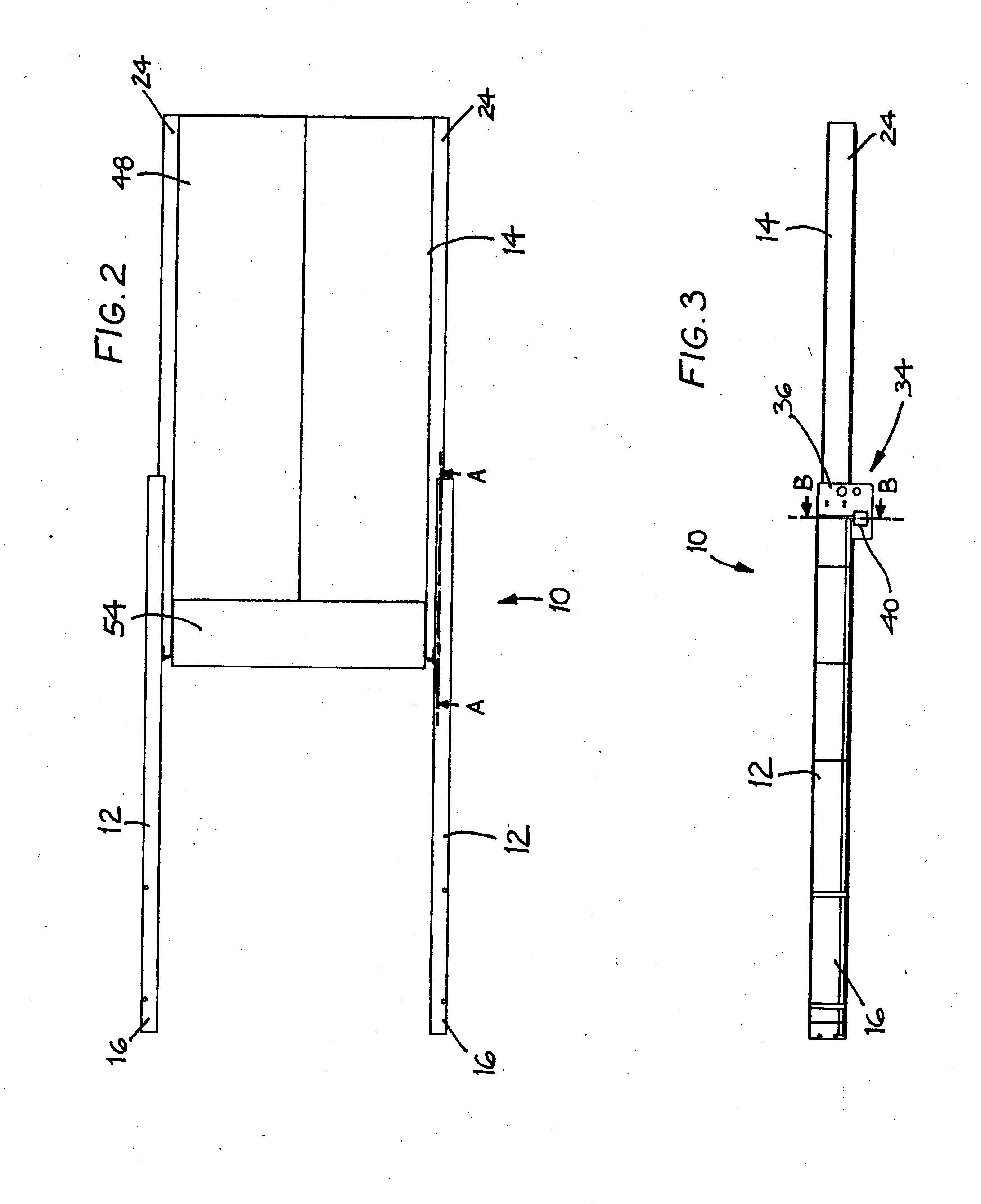

Apparatus for handling a turbomachine part

ActiveUS20190078471A1Reduction of machine downtimeEasy to disassembleEngine manufactureEngine fuctionsEngineeringGas turbines

An apparatus for handling a turbomachine part, particularly during disassembling and reassembling operations. More specifically, an apparatus for handling the stator cone of a gas turbine suitable to completely manipulate the stator cone during disassembling and reassembling operations. The apparatus allows to disassemble and reassemble the stator cone of a gas turbine without the need to dismount the turbomachine enclosure and without the necessity to have personnel inside the turbomachine package during the operations.

Owner:NUOVO PIGNONE TECH SRL

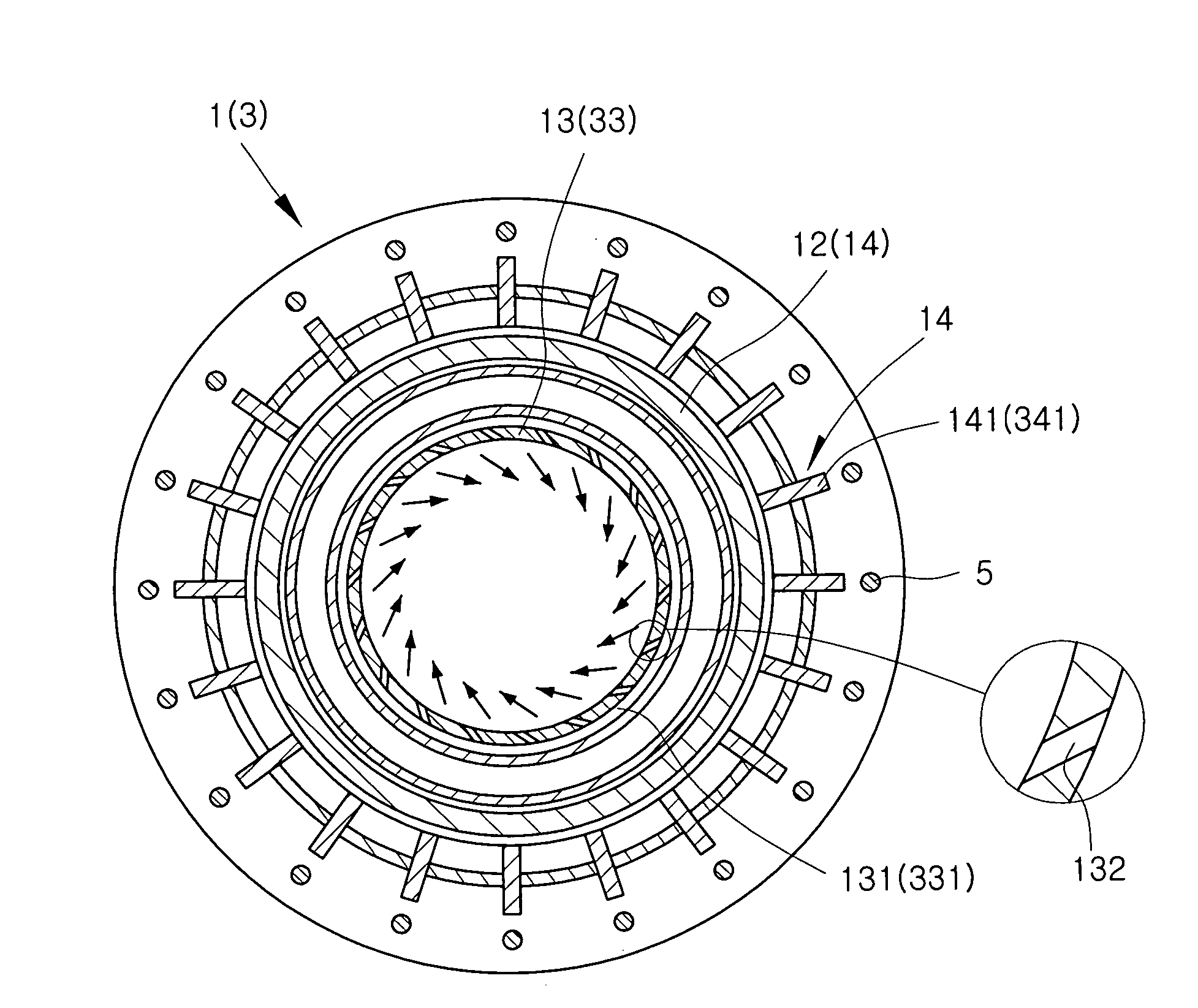

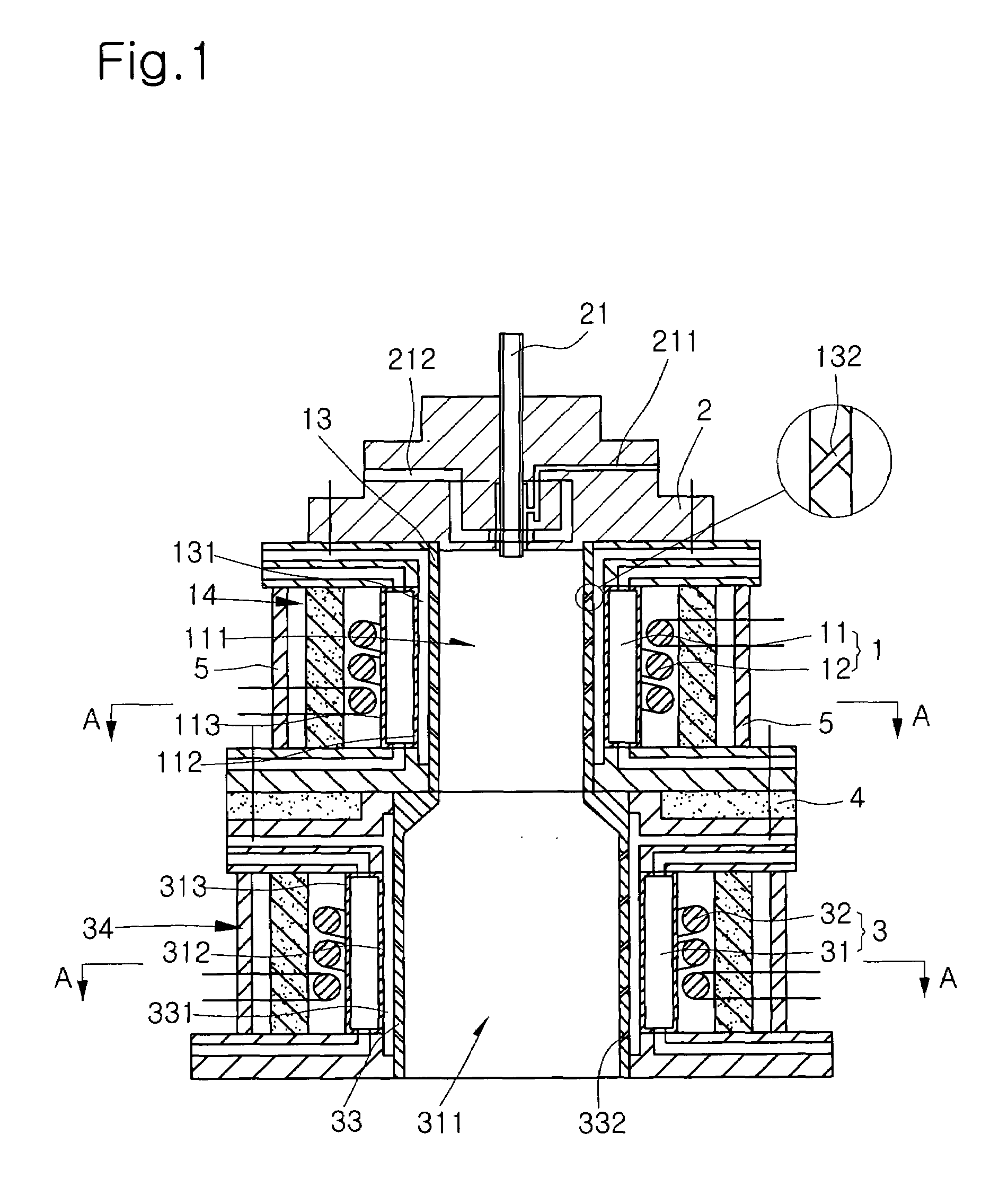

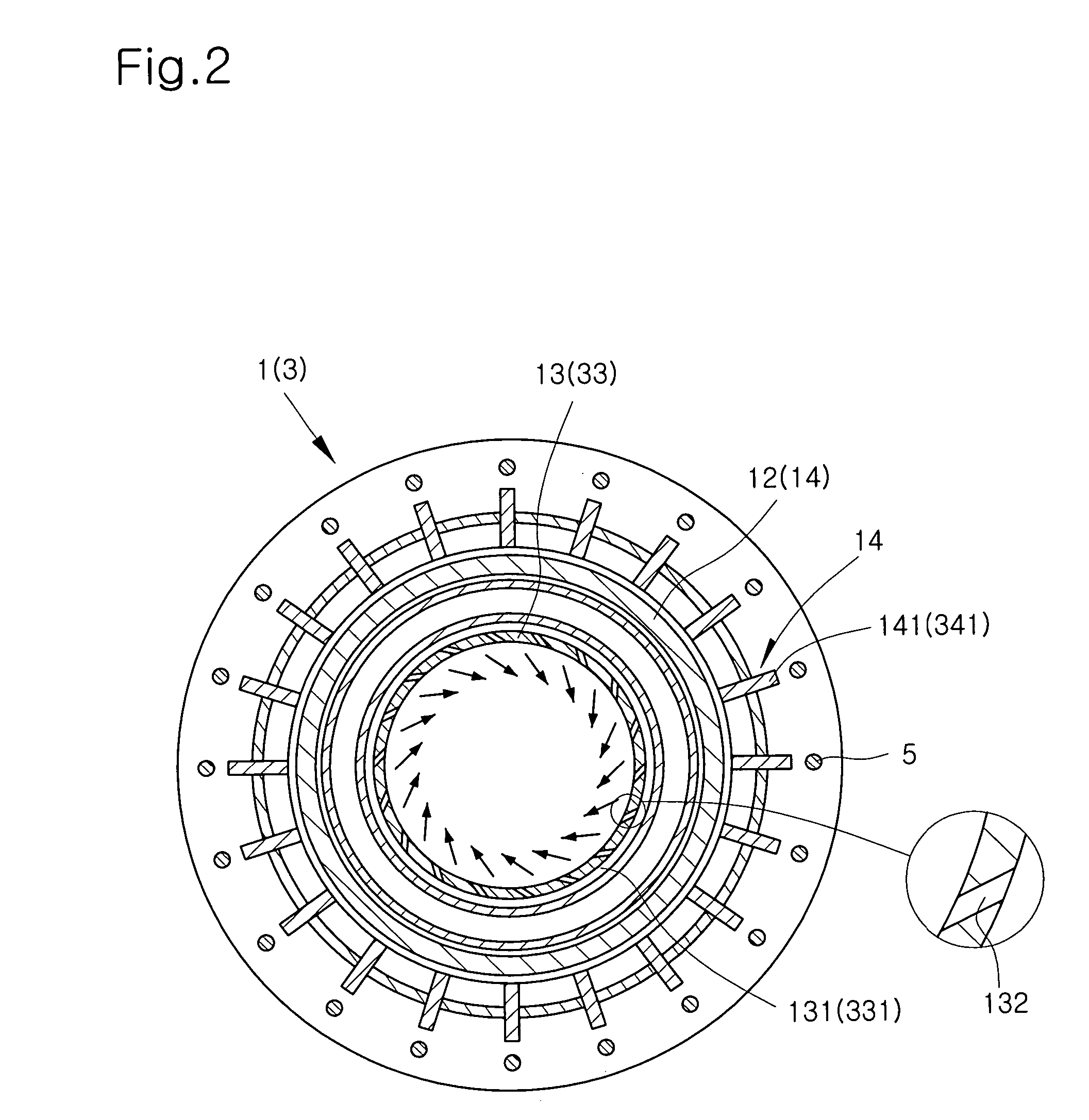

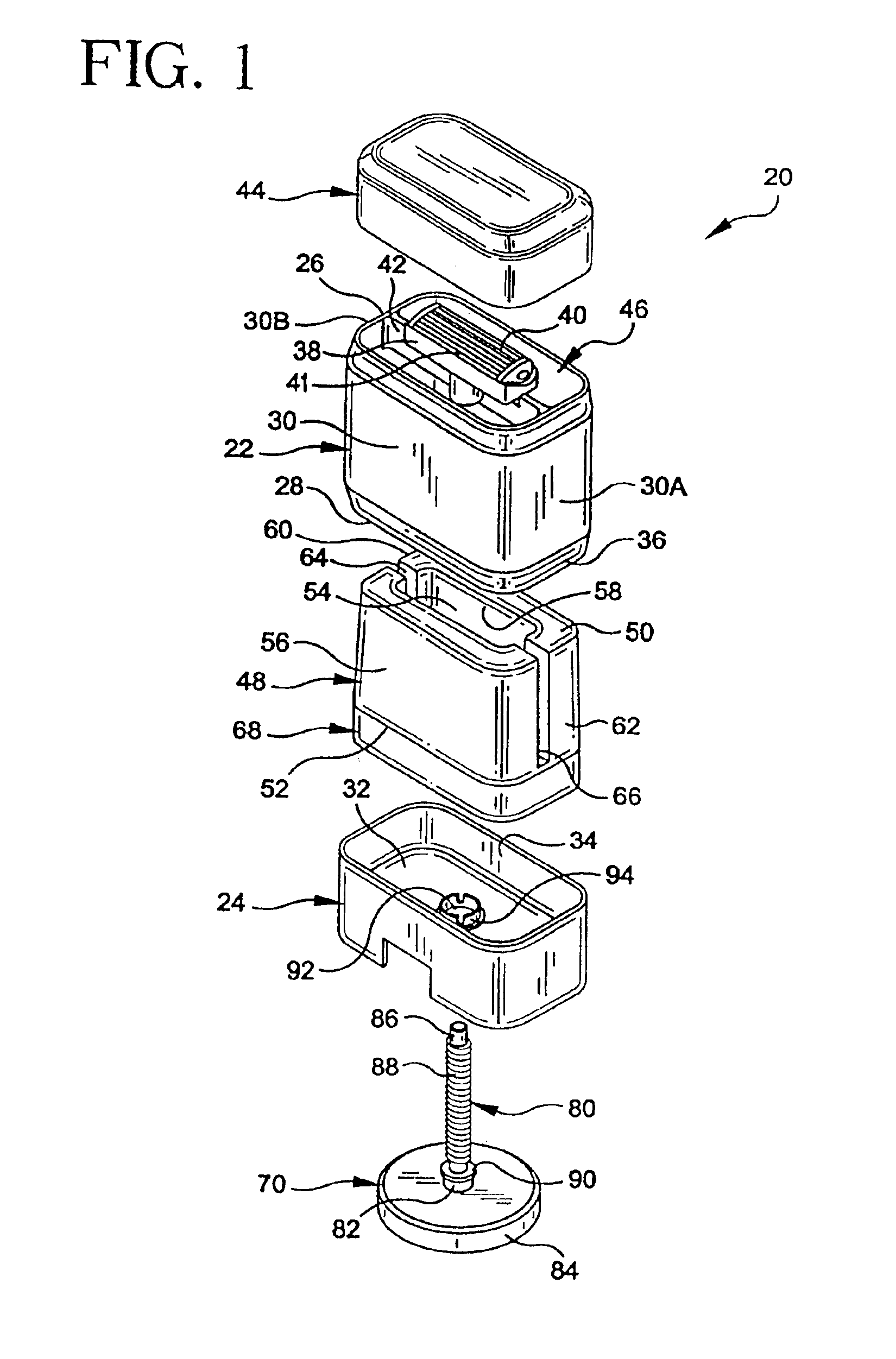

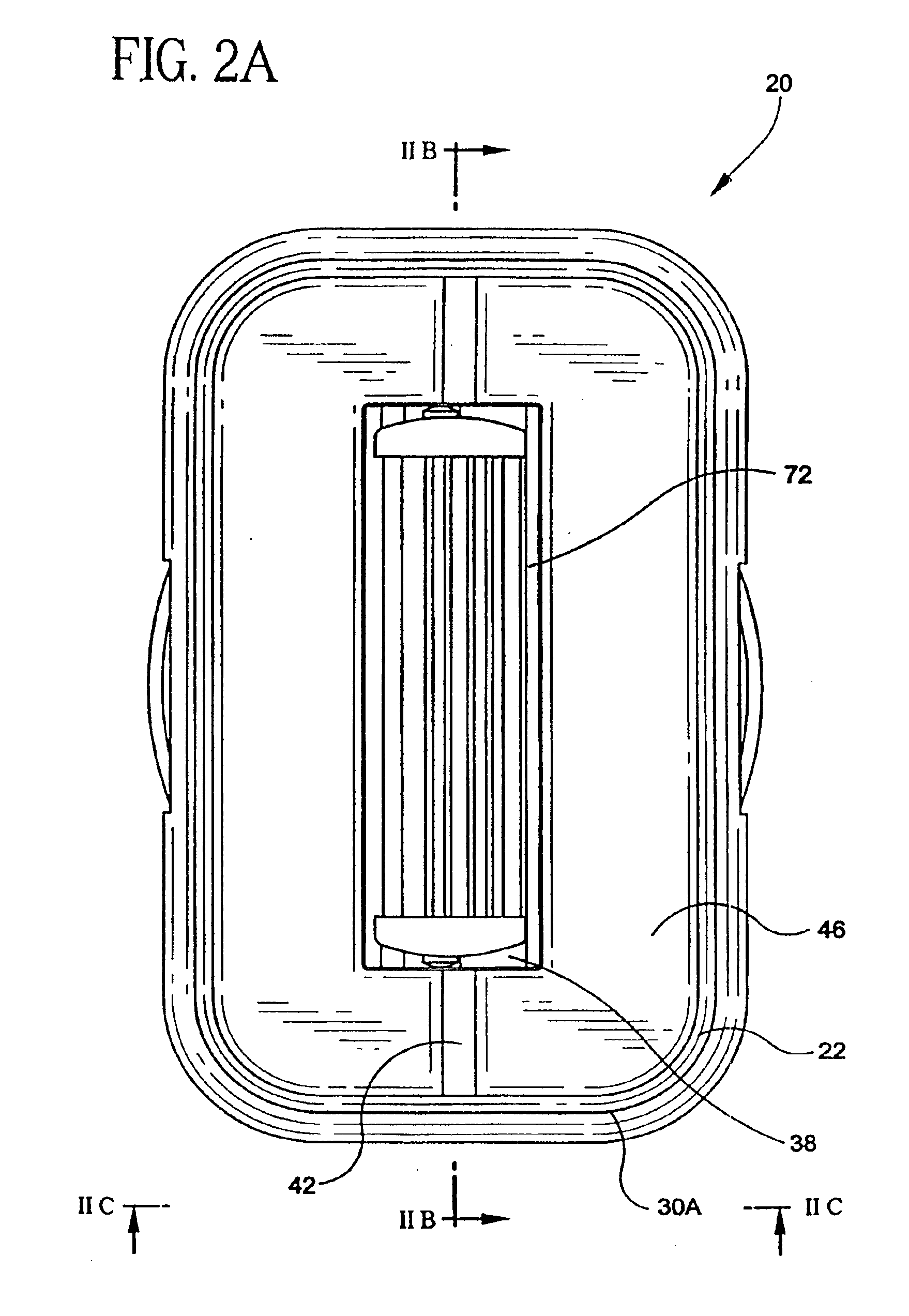

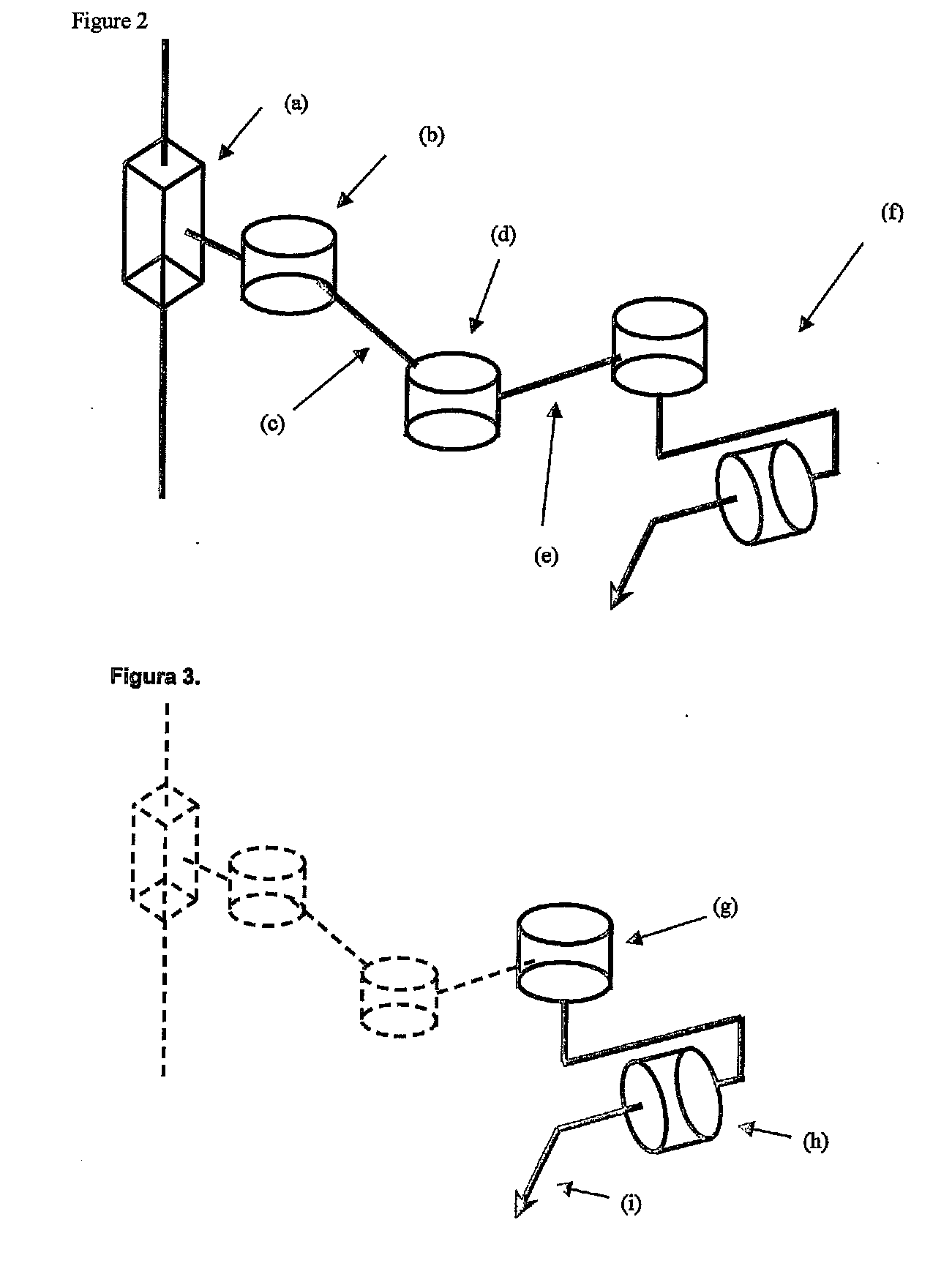

Inductively coupled plasma reactor for producing nano-powder

InactiveUS7323655B2Growth inhibitionGuaranteed to move normallyNanostructure manufactureElectric discharge tubesGas passingInduction plasma technology

Disclosed herein is a high-frequency induction plasma reactor apparatus for producing nano-powder, which is configured to continuously manufacture nano-powder in large quantities using solid-phase powder as a starting raw material and to manufacture high-purity nano-powder by completely vaporizing the material powder. The high-frequency induction plasma reactor apparatus comprises an upper body and a cover. The upper body is provided with a reaction pipe receiving a reactor extending vertically inside thereof, a high-frequency coil surrounding the outer periphery of the reaction pipe and a ceramic inner wall provided inside the reaction pipe. The ceramic inner wall is formed with a plurality of gas passing bores and defines a gas movement passage with the inner side wall of the reaction pipe therebetween for allowing the inflow of argon gas from the outside into the reactor. The cover is mounted to the upper end of the reactor and adapted to seal the reactor. The cover is provided with a powder injection tube communicating with the reactor.

Owner:NPC CO LTD

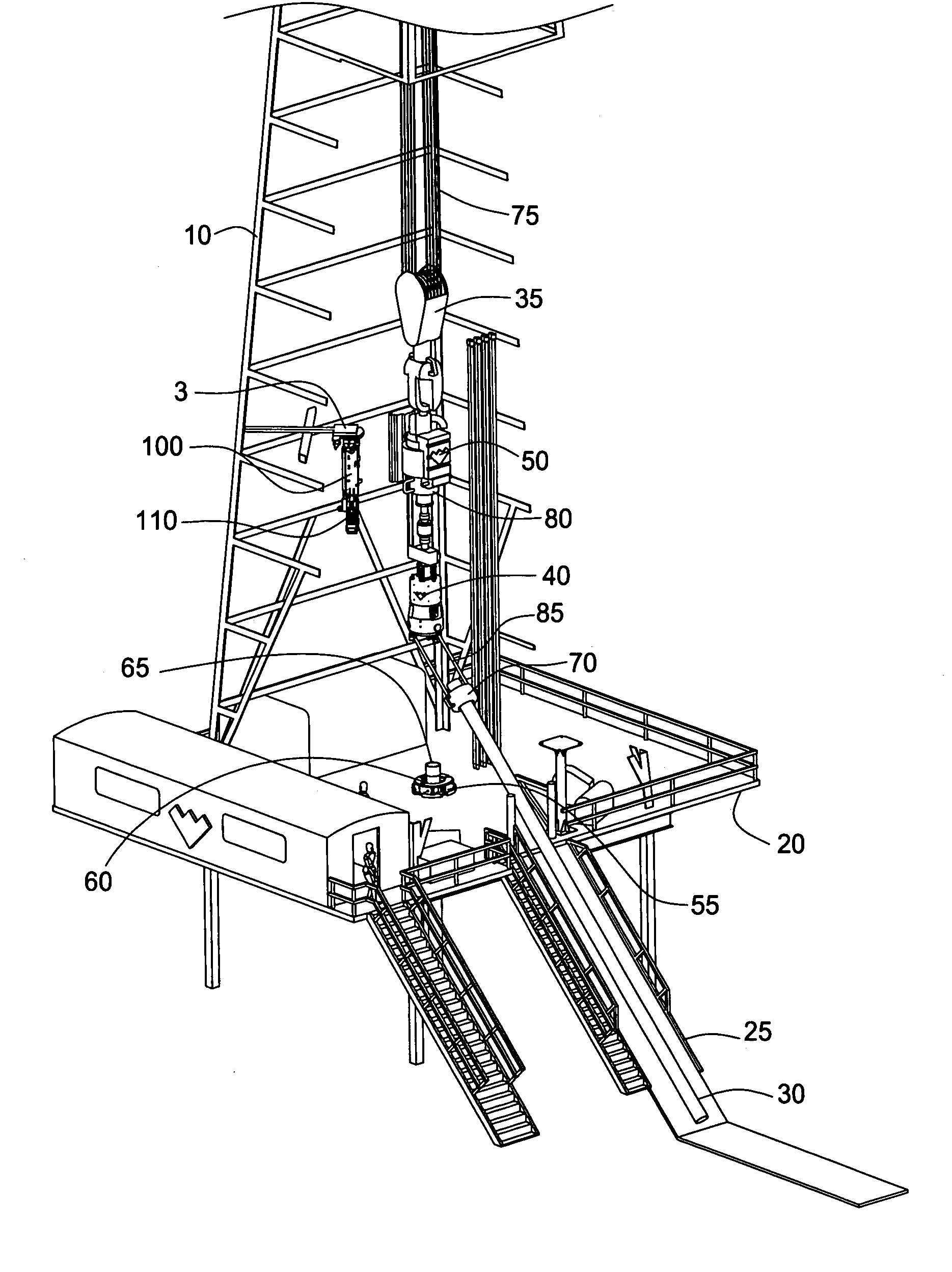

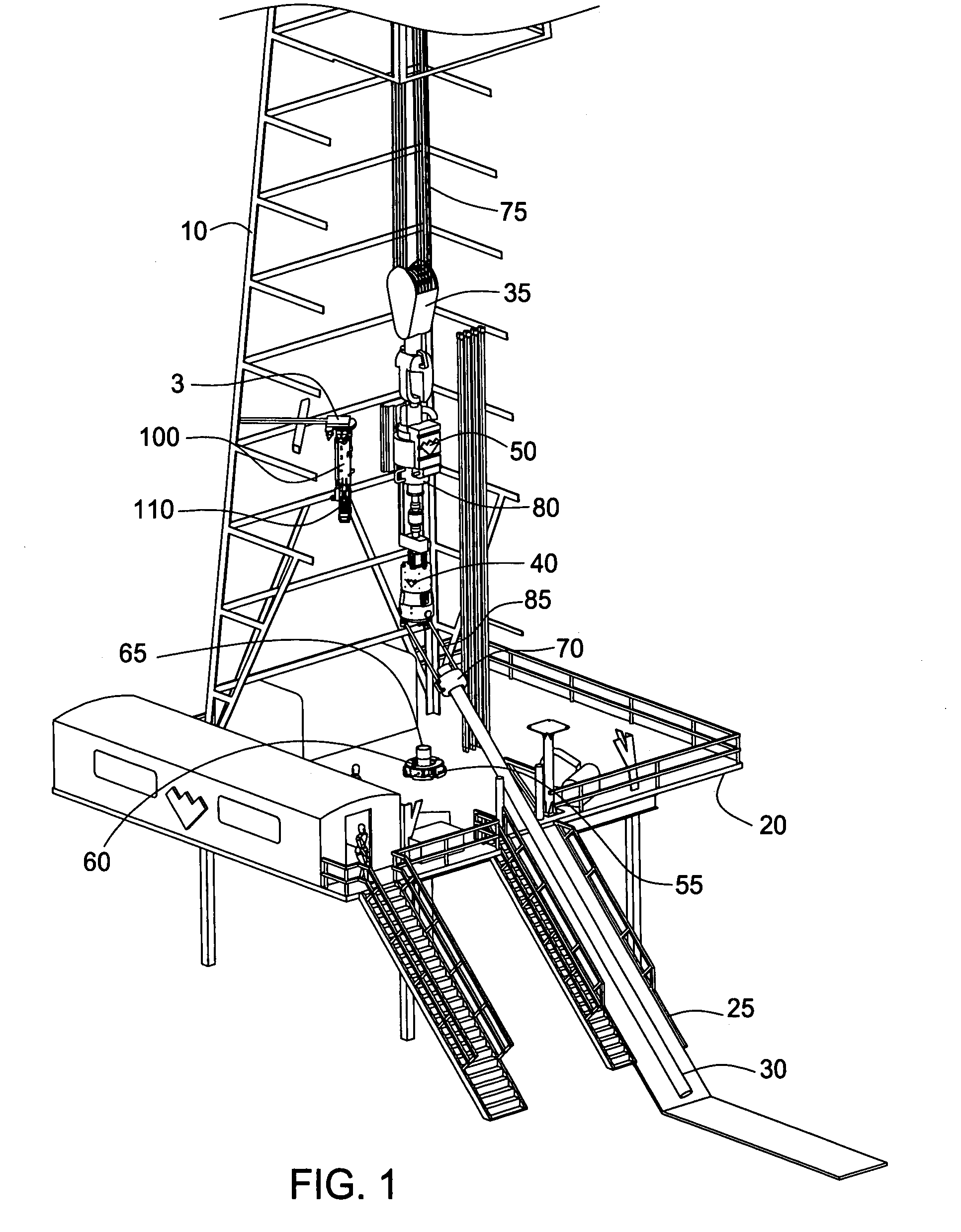

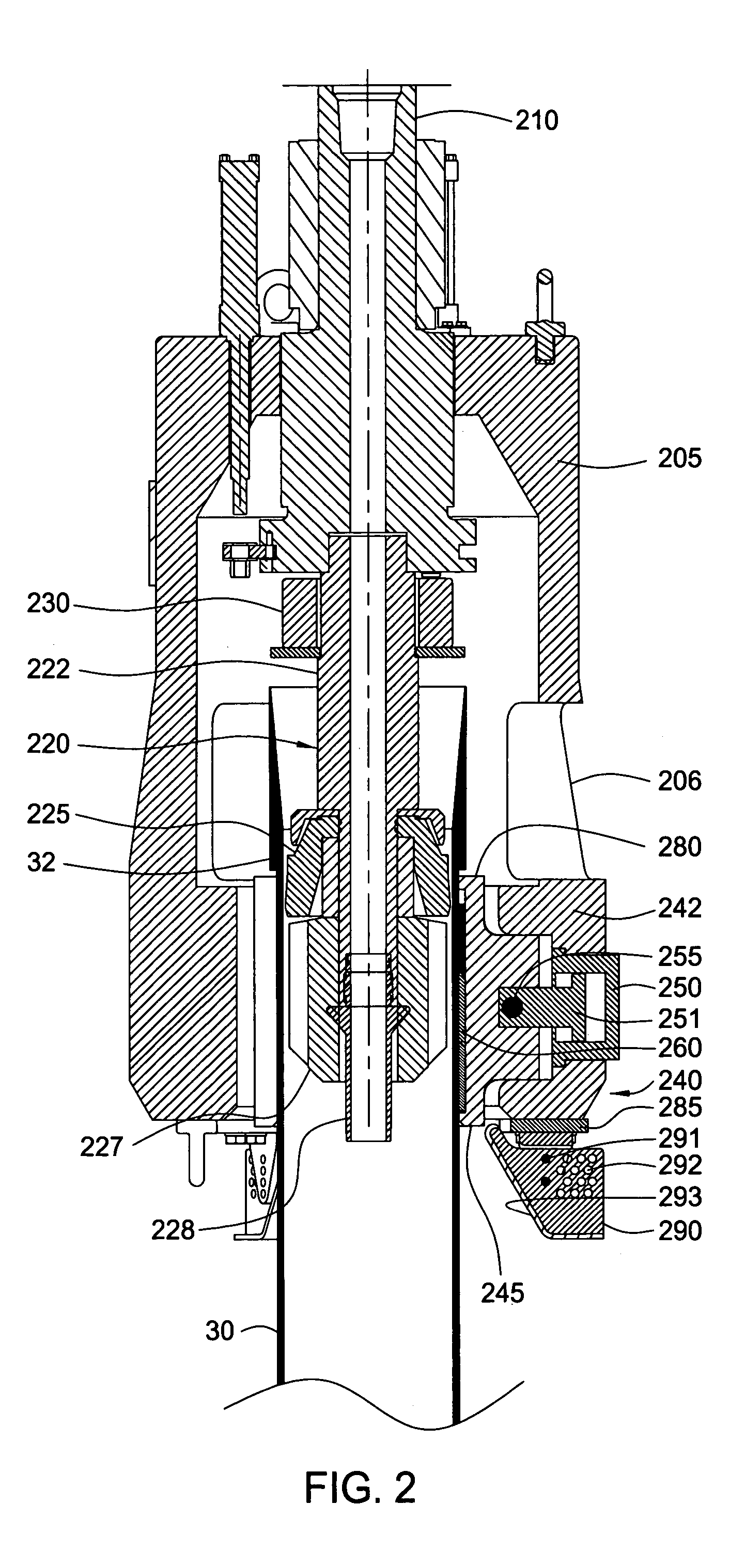

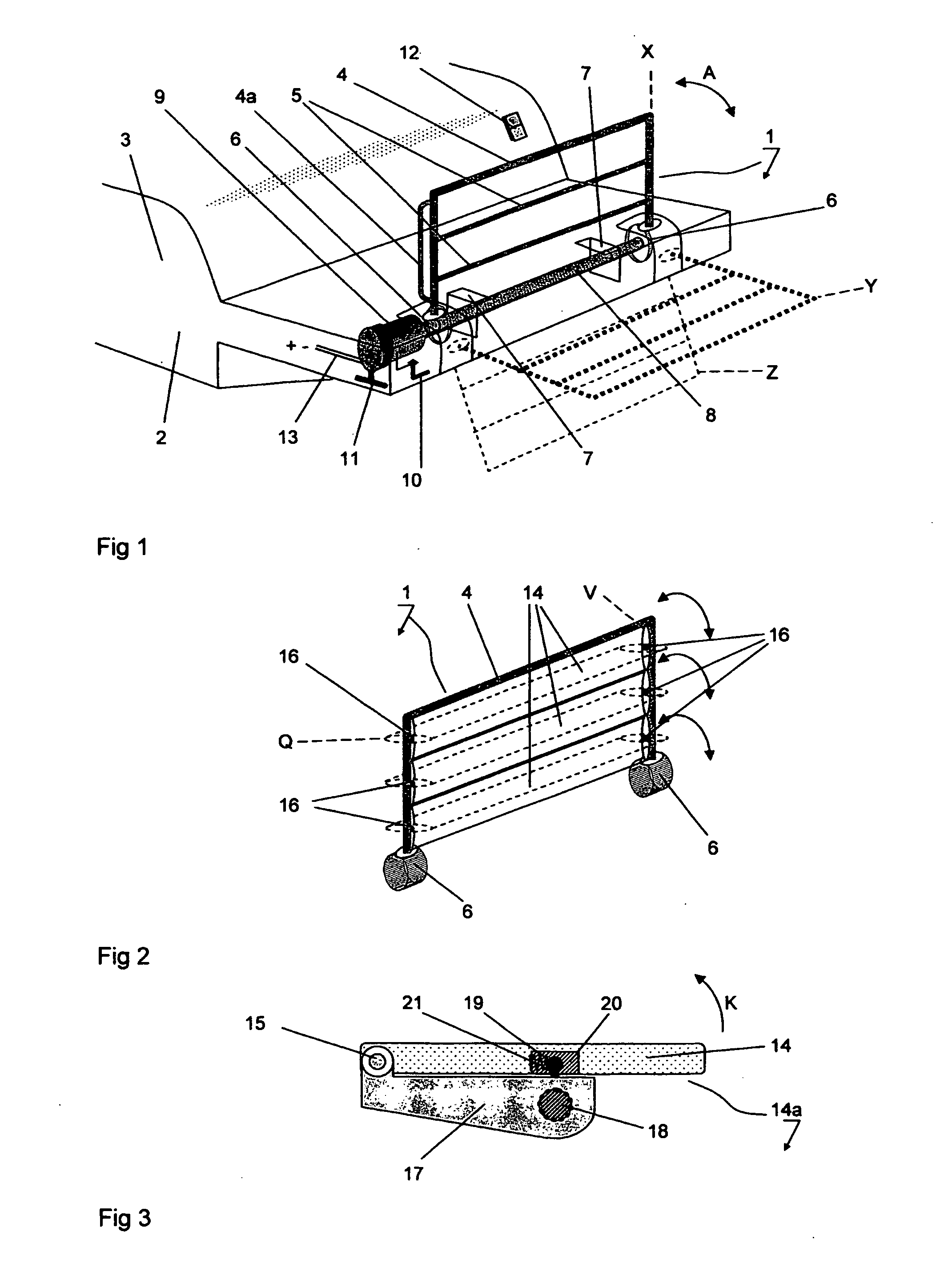

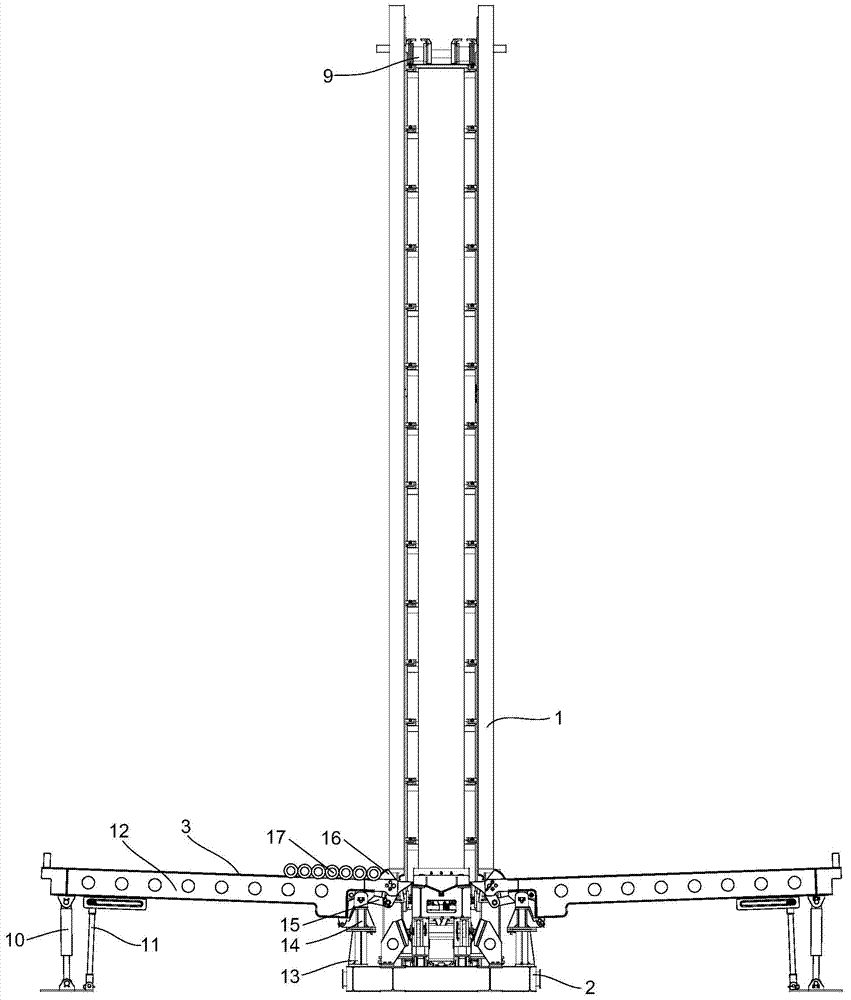

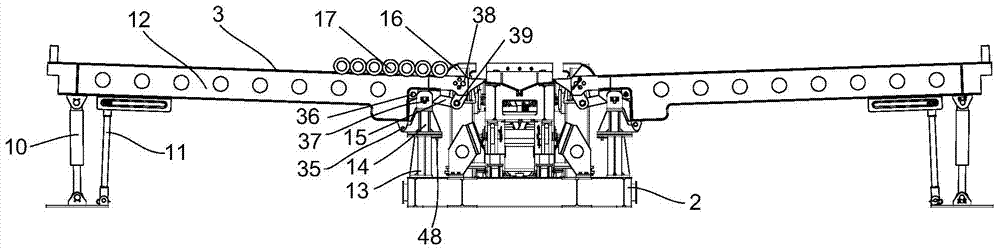

Method and apparatus for drilling with casing

InactiveUS7140445B2Operational securityEliminate needDrilling rodsConstructionsTop driveCasing string

Methods and apparatus for drilling with a top drive system are provided. In one aspect, a top drive system includes a top drive, top drive adapter, and a tubular positioning apparatus. In another aspect, the top drive adapter is pivotably connected to the top drive for pivoting the top drive adapter toward the casing string with respect to the top drive. In another aspect, the system includes a telescopic link system connected to a lower portion of the top drive adapter to move the casing string into engagement with the top drive adapter. In another aspect, the top drive adapter includes a housing operatively connected to the top drive and a plurality of retaining members disposed in the housing for gripping the tubular. In another aspect, the tubular positioning apparatus includes a gripping member for engaging a tubular and a conveying member for positioning the gripping member. A spinner may be provided to rotate the tubular.

Owner:WEATHERFORD TECH HLDG LLC

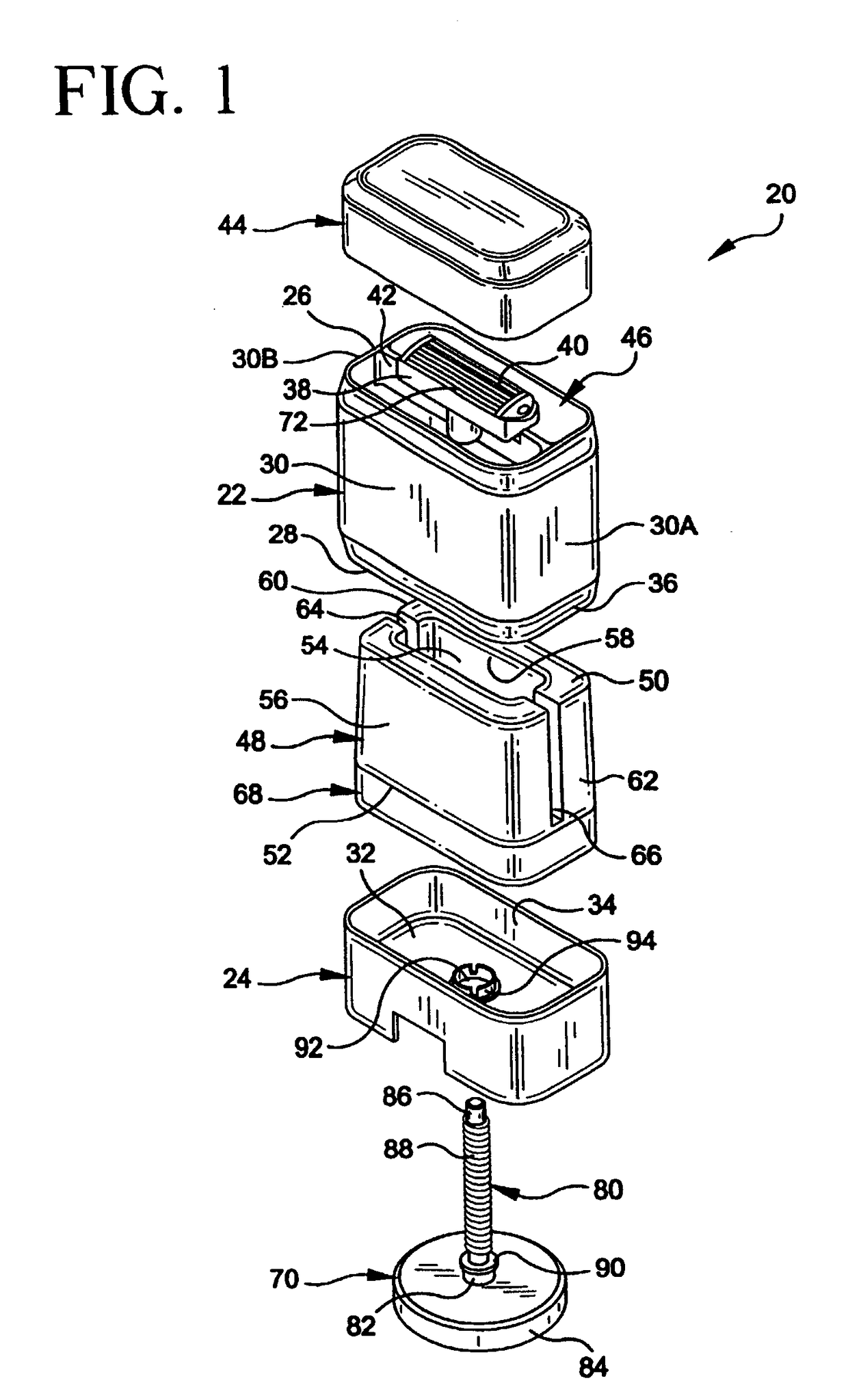

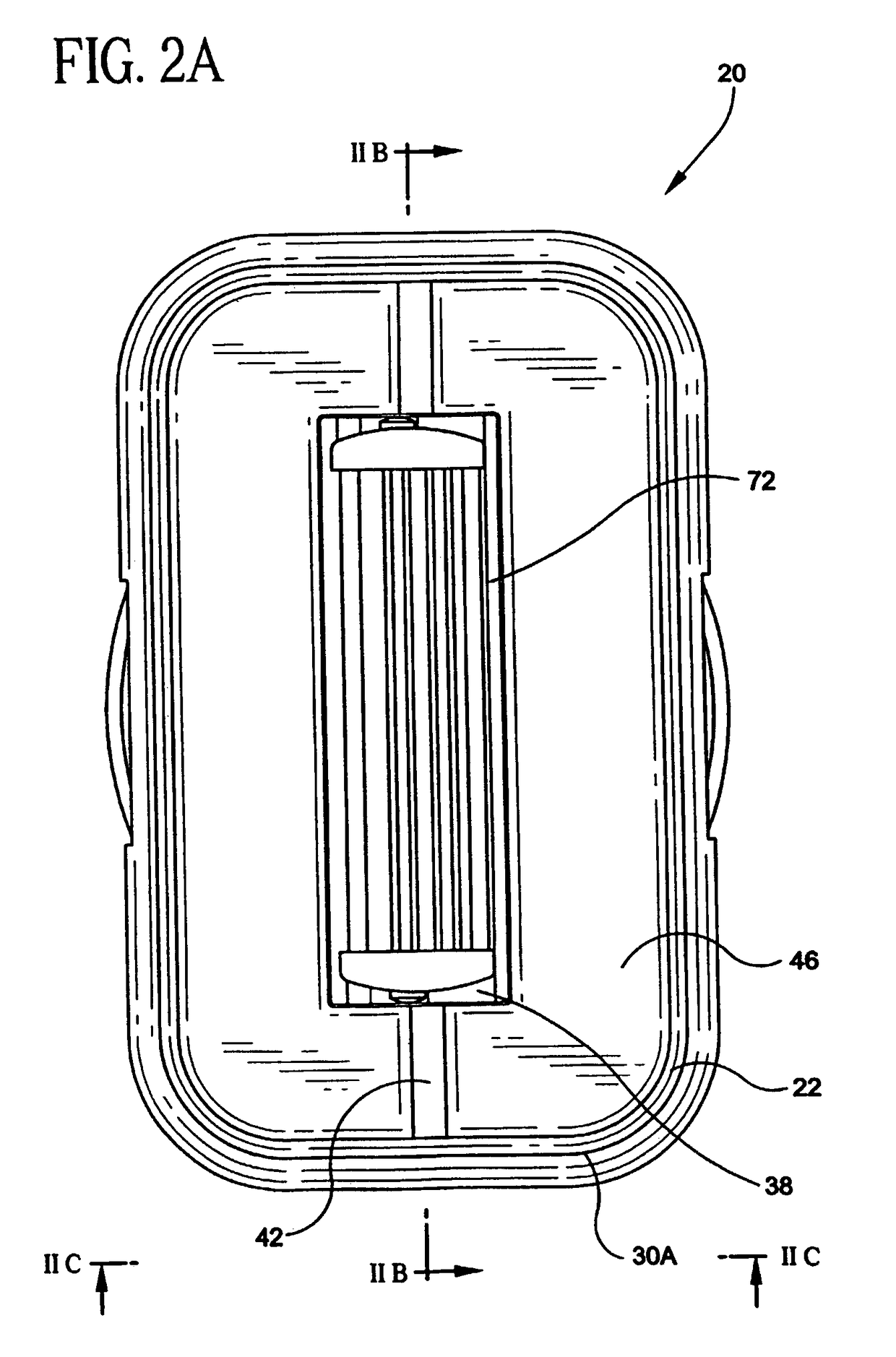

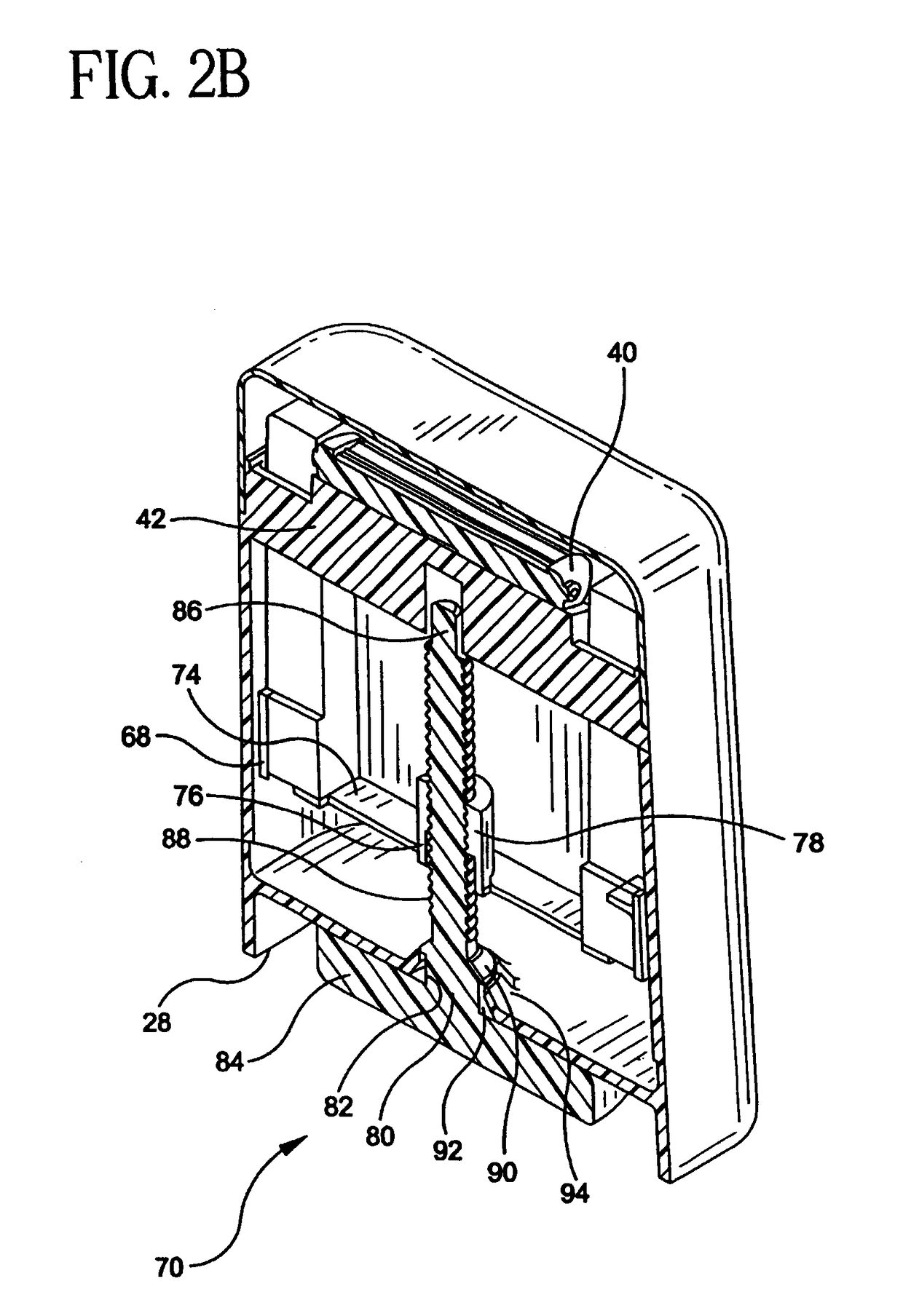

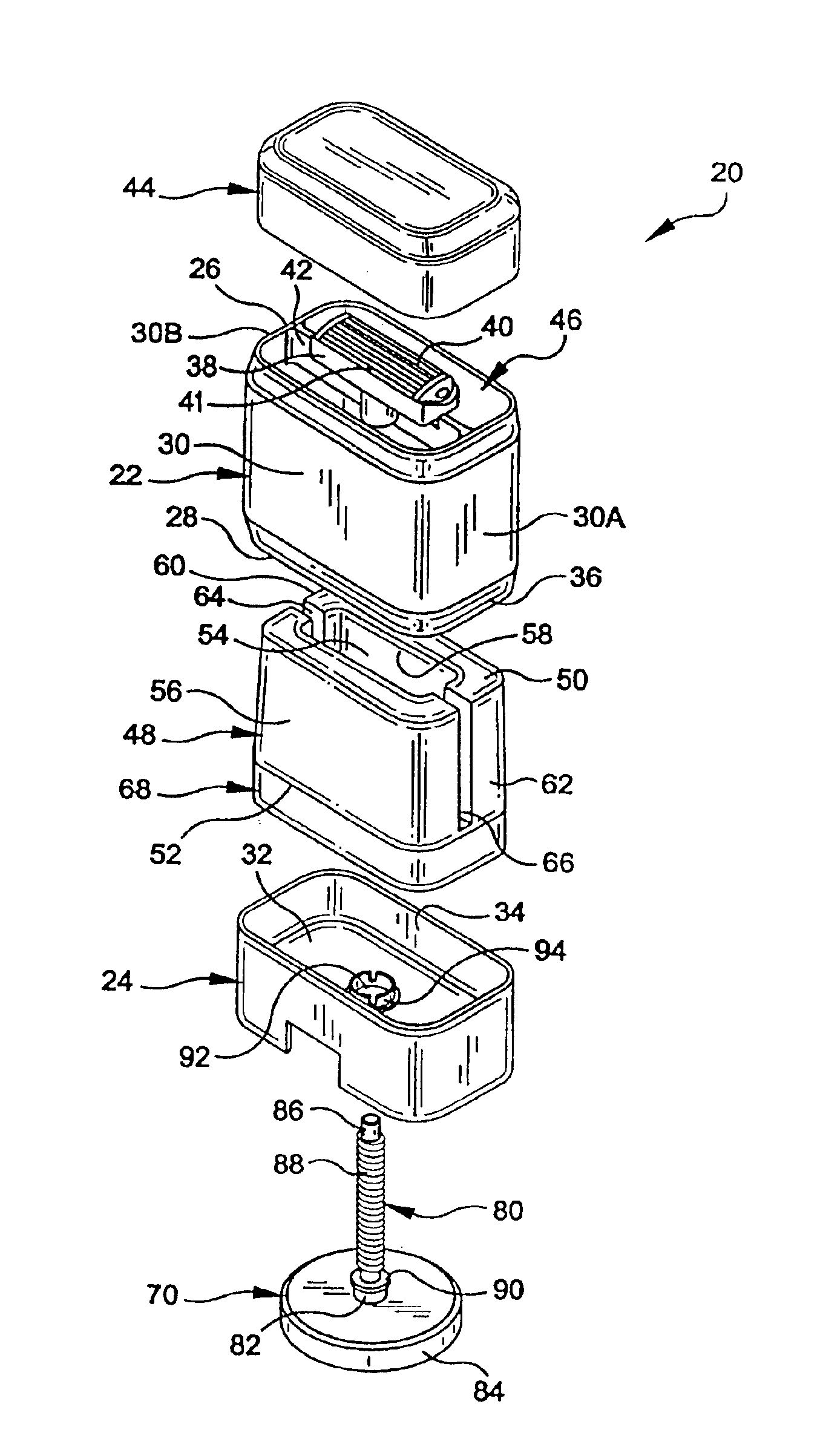

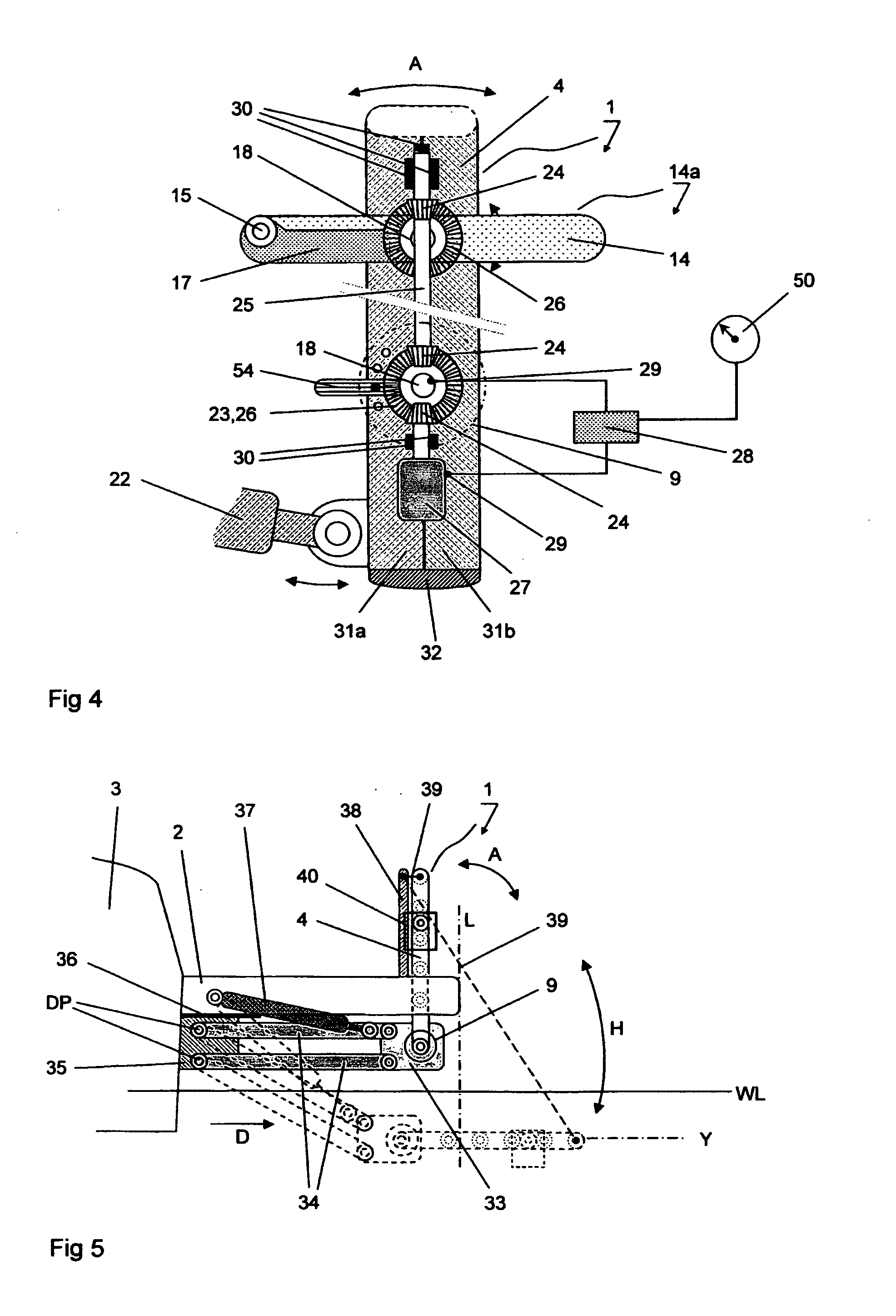

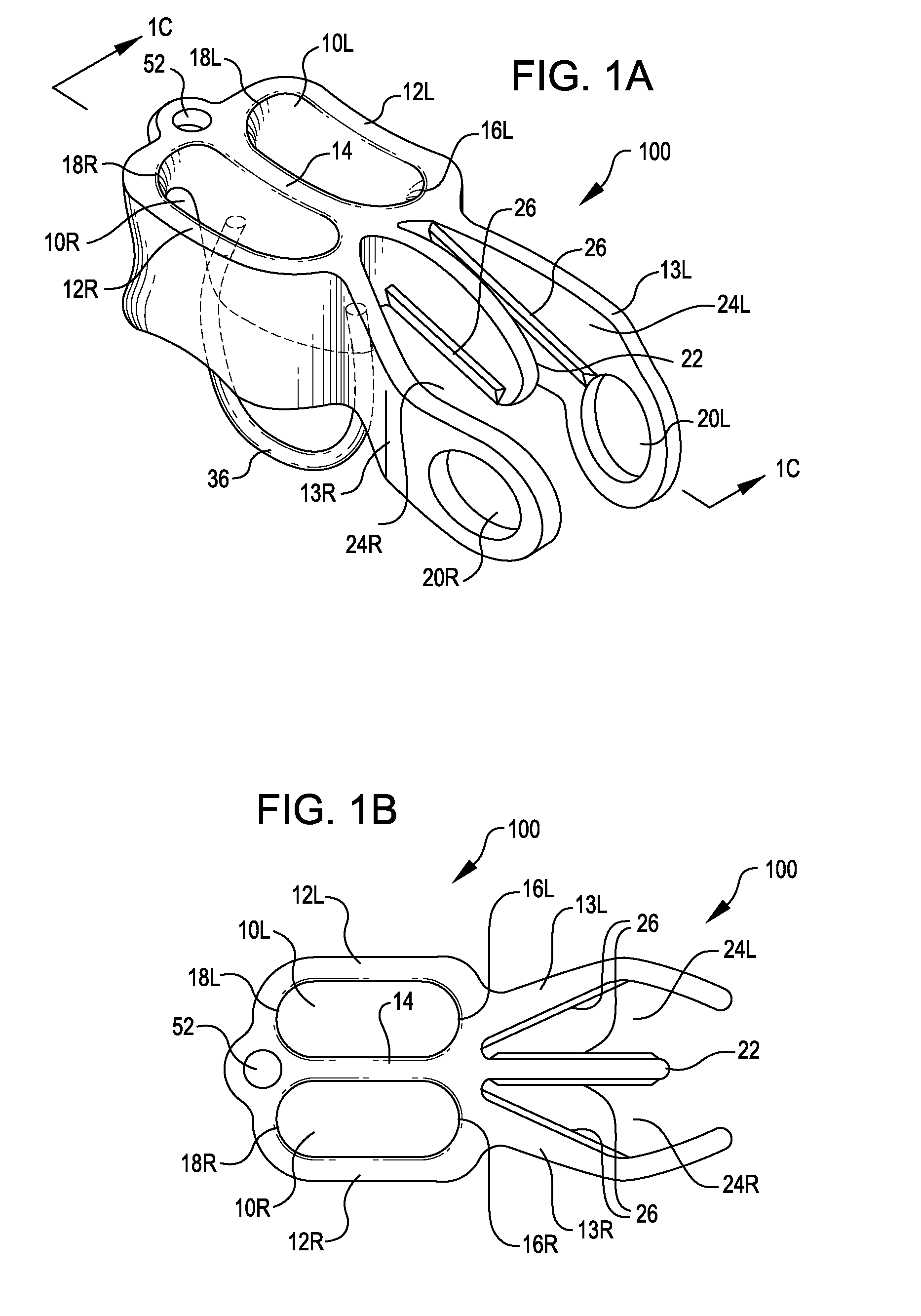

Shaving preparation for wet shaving assembly

InactiveUS7127817B2Guaranteed to move normallyPrevent leakageWriting implementsMetal working apparatusShaving creamRemoving hair

A shaving assembly for simultaneously applying a shaving preparation and removing hair in a single step includes a base having an upper end, a lower end and a hollow space between the upper and lower ends, whereby the hollow space defines an opening at the upper end of the base. The shaving assembly includes a receiver for a razor, such as a cartridge receiver for a razor blade cartridge, that is connected with the base and that is disposed at the opening at the upper end of the base. The cartridge receiver has a perimeter and the opening at the upper end of the base completely surrounds the perimeter of the cartridge receiver. The hollow space of the base is adapted for containing a shaving preparation, such as a soap cake, a liquid soap, shaving cream or a body wash and may be combined with skin beneficial ingredients and / or scent. In one embodiment, the body of the shaving assembly includes an adjusting element so that an adequate supply of the shaving preparation may be supplied completely around the perimeter of the cartridge receiver. In other embodiments, the shaving assembly includes a resilient element for urging the shaving preparation toward the upper end of the body. The cartridge receiver may also be movable for changing the position of the razor blade relative to the shaving preparation. The shaving assembly may also include a razor embedded in a mass of shaving preparation so that the cutting blades of the razor lie in substantially the same plane as the top surface of the shaving preparation.

Owner:EVEREADY BATTERY CO INC

Wet shaving assembly

InactiveUS6996908B2Improve gripComfortable gripWriting implementsMetal working apparatusEngineeringMechanical engineering

A shaving assembly operable in dry shaving environments and wet shaving environments is provided that includes a razor assembly and a shaving preparation cake. The razor assembly, which includes a razor cartridge attached to a handle, is operable in dry shaving environments and wet shaving environments. The shaving preparation cake includes an upper surface, a lower surface, one or more side surfaces extending between the upper surface and the lower surface, and an axial bore extending between the upper surface and the lower surface. The shaving preparation cake is operable in a wet shaving environment, and is selectively attachable to the razor assembly for wet shaving environment applications. When the shaving preparation cake is attached to the razor assembly, the razor cartridge is disposed within the axial bore of the shaving preparation cake. The shaving preparation cake is selectively detachable from the razor assembly to facilitate use of the razor assembly in dry shaving environment applications.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

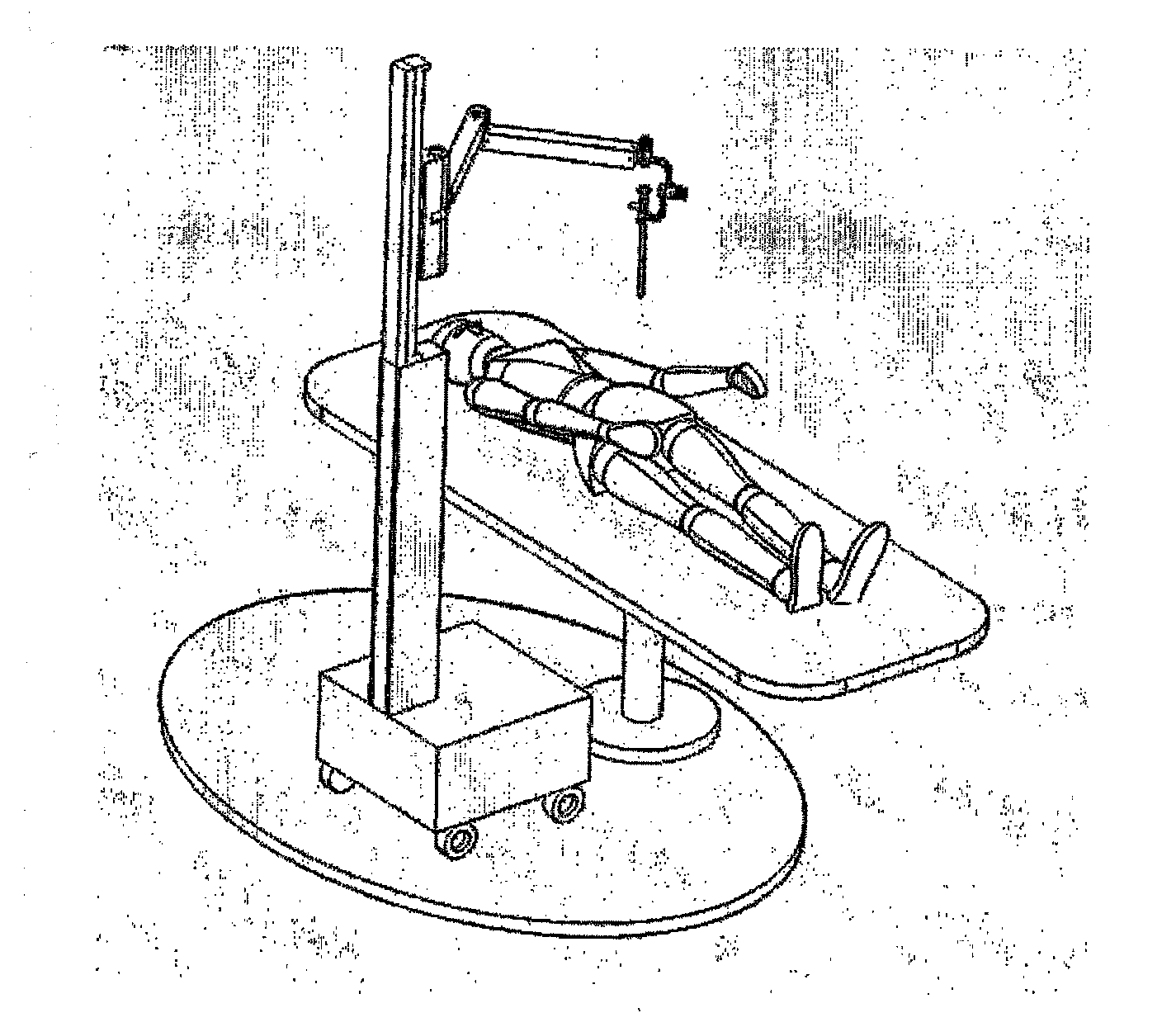

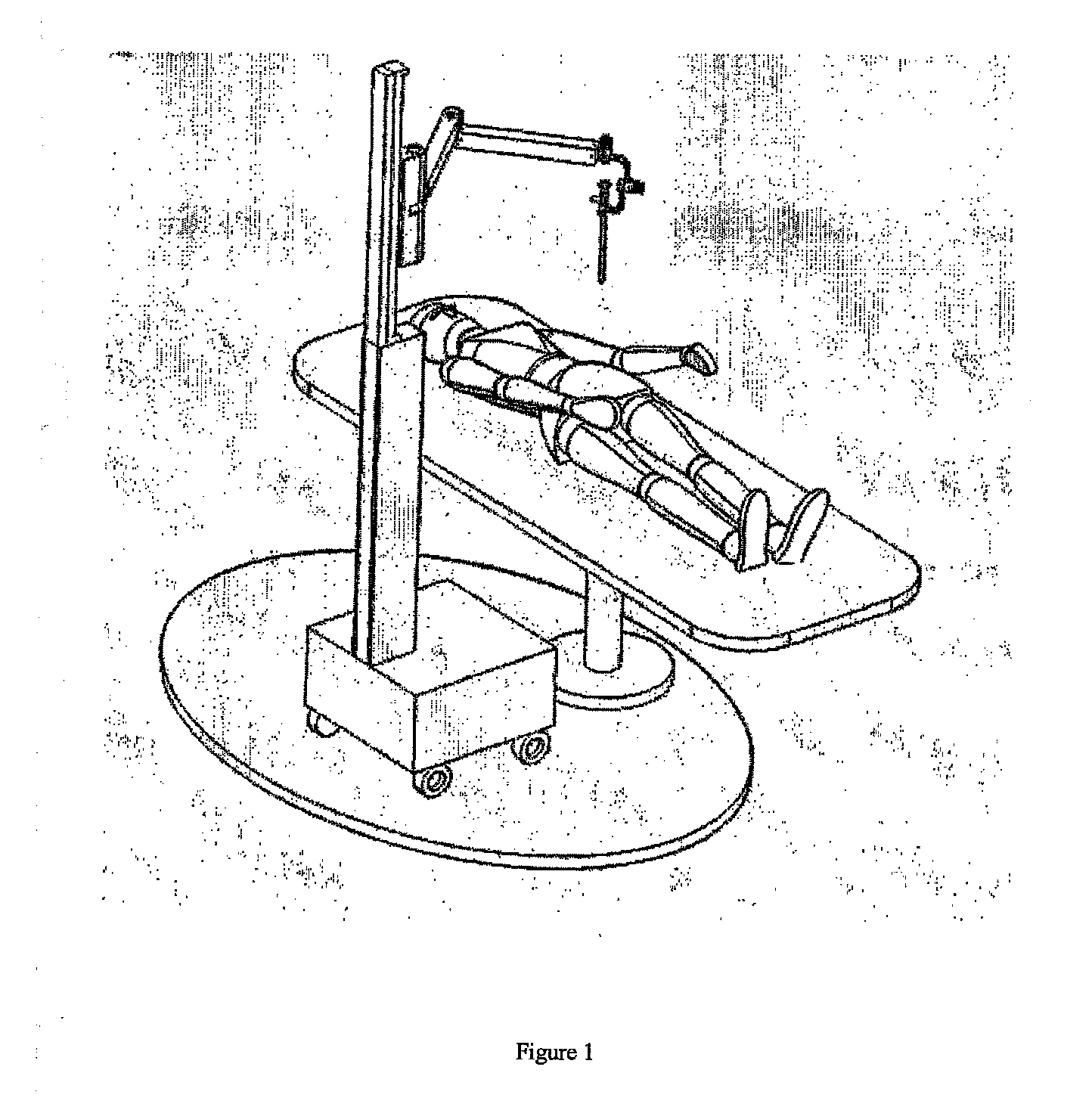

Robotic system for assisting in minimally-invasive surgery, which can position a surgical instrument in response to orders from a surgeon, is not attached to the operating table and does not require pre-calibration of the insertion point

InactiveUS20090326324A1Easily and rapidly removedEasy system integrationEndoscopesSurgical robotsEngineeringActuator

Robotic system for assisting in minimally-invasive surgery, which can position a surgical instrument in response to orders from a surgeon, is not attached to the operating table and does not require pre-calibration of the insertion point. The system includes: a manipulator robot having three active degrees of freedom, which is provided with an end actuator having two passive degrees of freedom, said actuator being used to attach a surgical instrument; a robot controller built into the structure thereof, which can perform a method for calculating the movement to be imparted to the carried surgical instrument so that it reaches the desired location without requiring pre-calibration and without the assembly having to be attached to the operating table; and an interface system for ordering the system to perform the desired actions. The assembly comprising the robot, the controller and the interface system is battery operated.

Owner:UNIV DE MALAGA

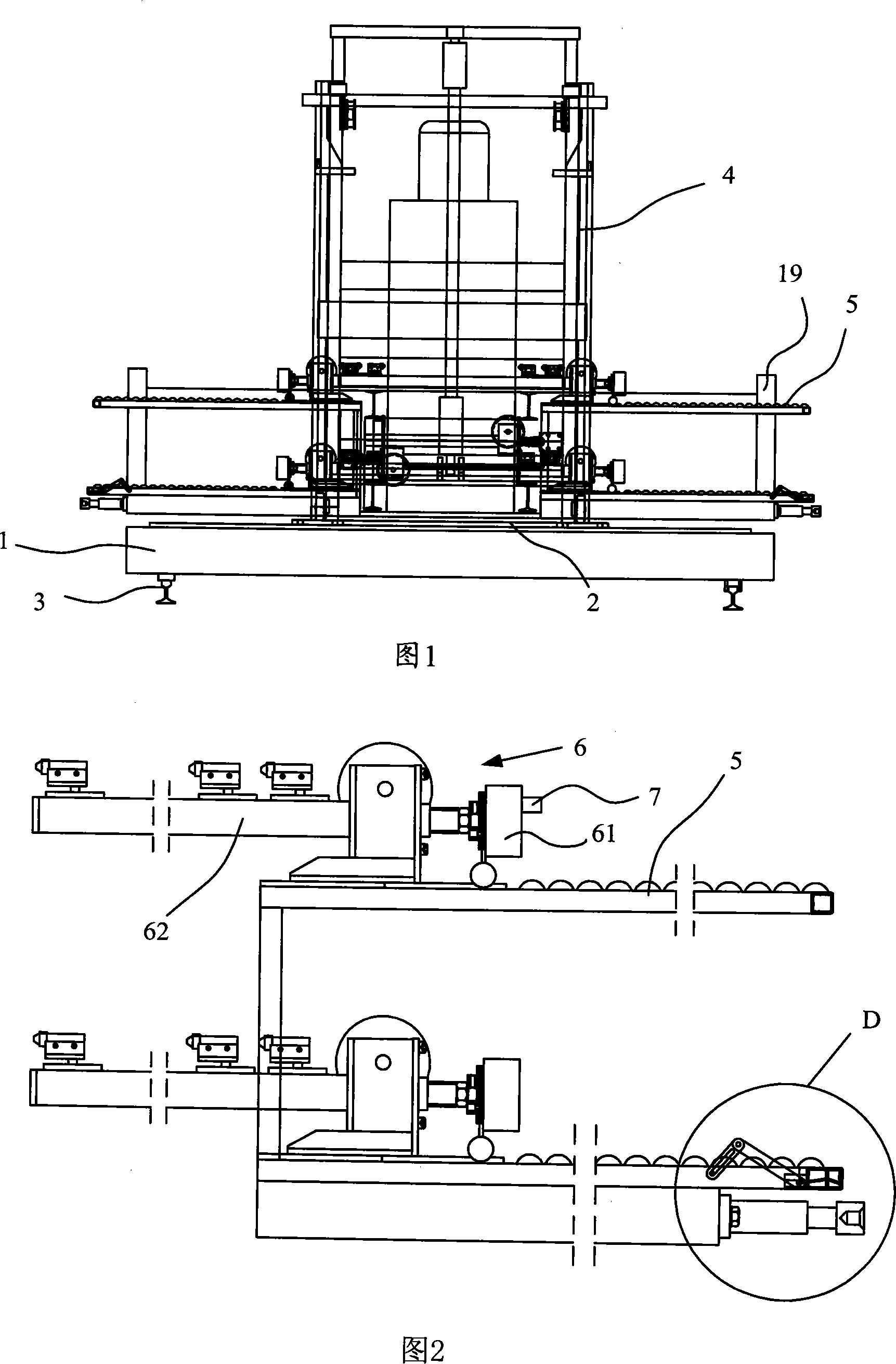

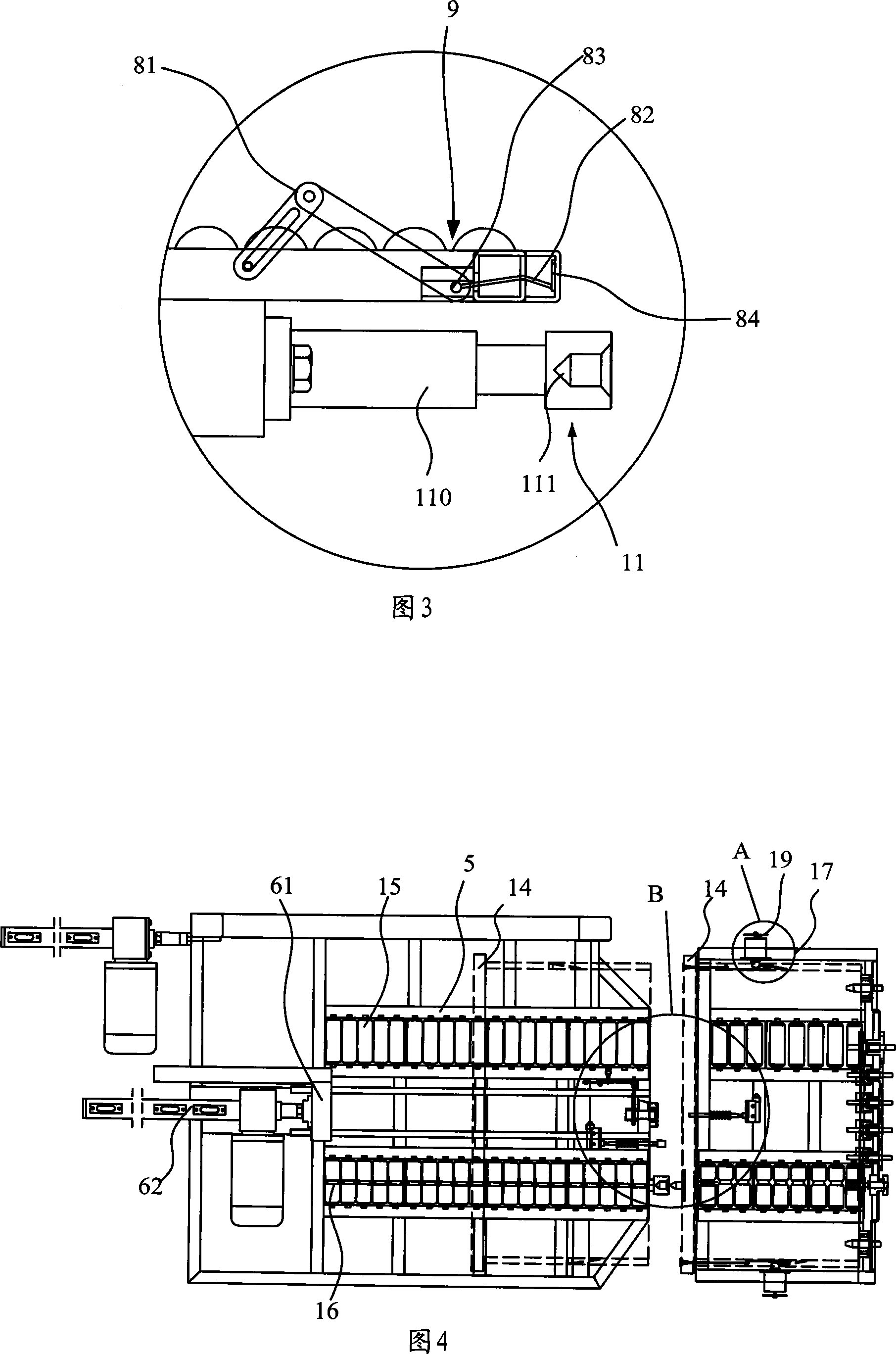

Vehicle mounted dynamic battery changing system

InactiveCN101214814ANot easy to damageAccurate placementElectric propulsion mountingElectric/fluid circuitPower batteryEngineering

The invention discloses a battery replacement system for power battery loaded on a vehicle. The system comprises a parallel mobile platform, a rotating platform, a track, a vertical lifting device and a battery tray. The parallel mobile platform is positioned on the track and moves along the track. The rotating platform is positioned on the parallel mobile platform. The battery tray is positioned on the rotating platform via the vertical lifting device. The battery tray is equipped with an electromagnetic suction device for drawing the battery box. The invention has the advantages of more convenient unloading of the battery box, more accurate positioning, and realizing the single loading and unloading of the battery box to be controlled within 3 minutes.

Owner:BEIJING DIANBA TECH CO LTD +1

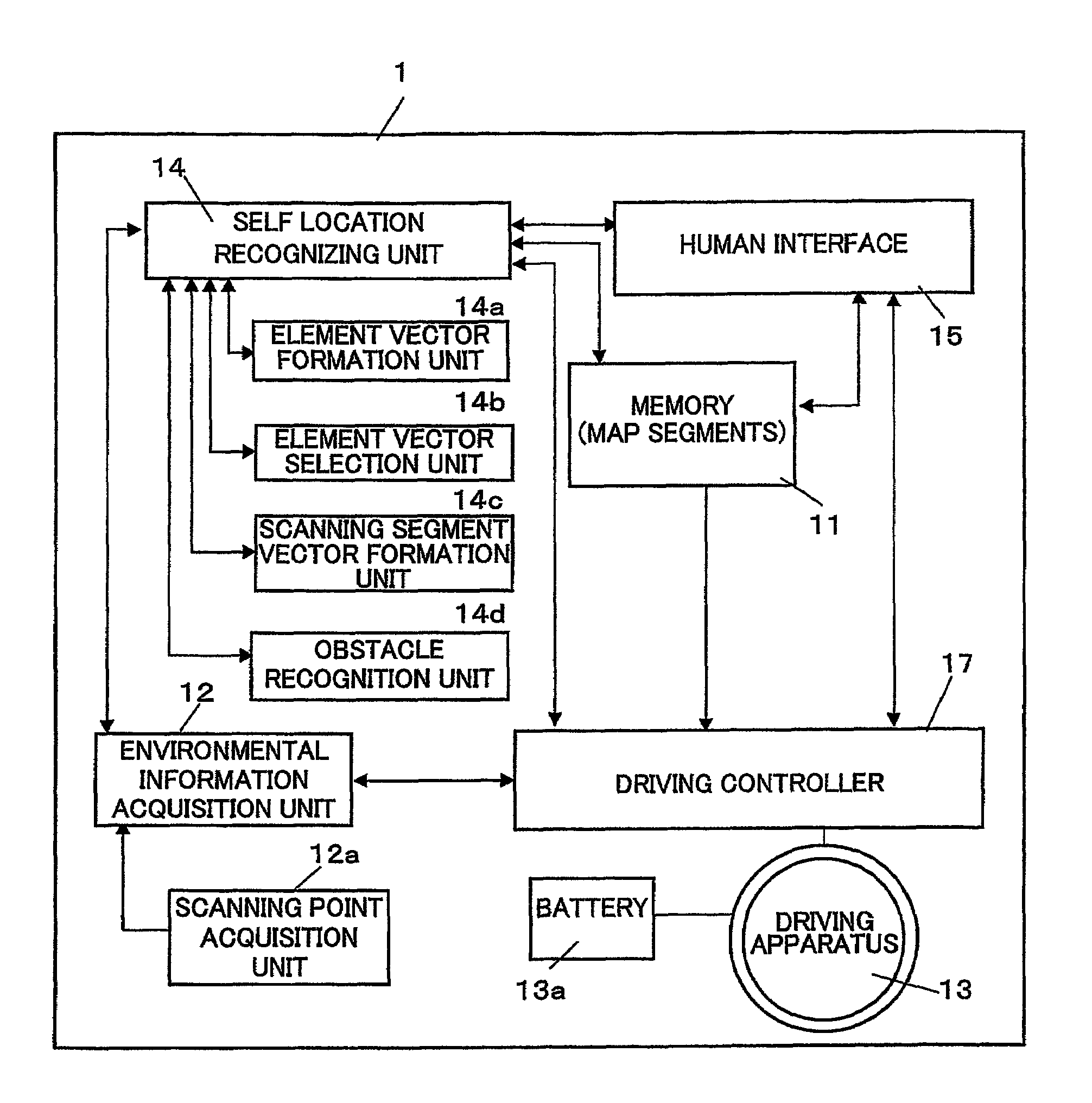

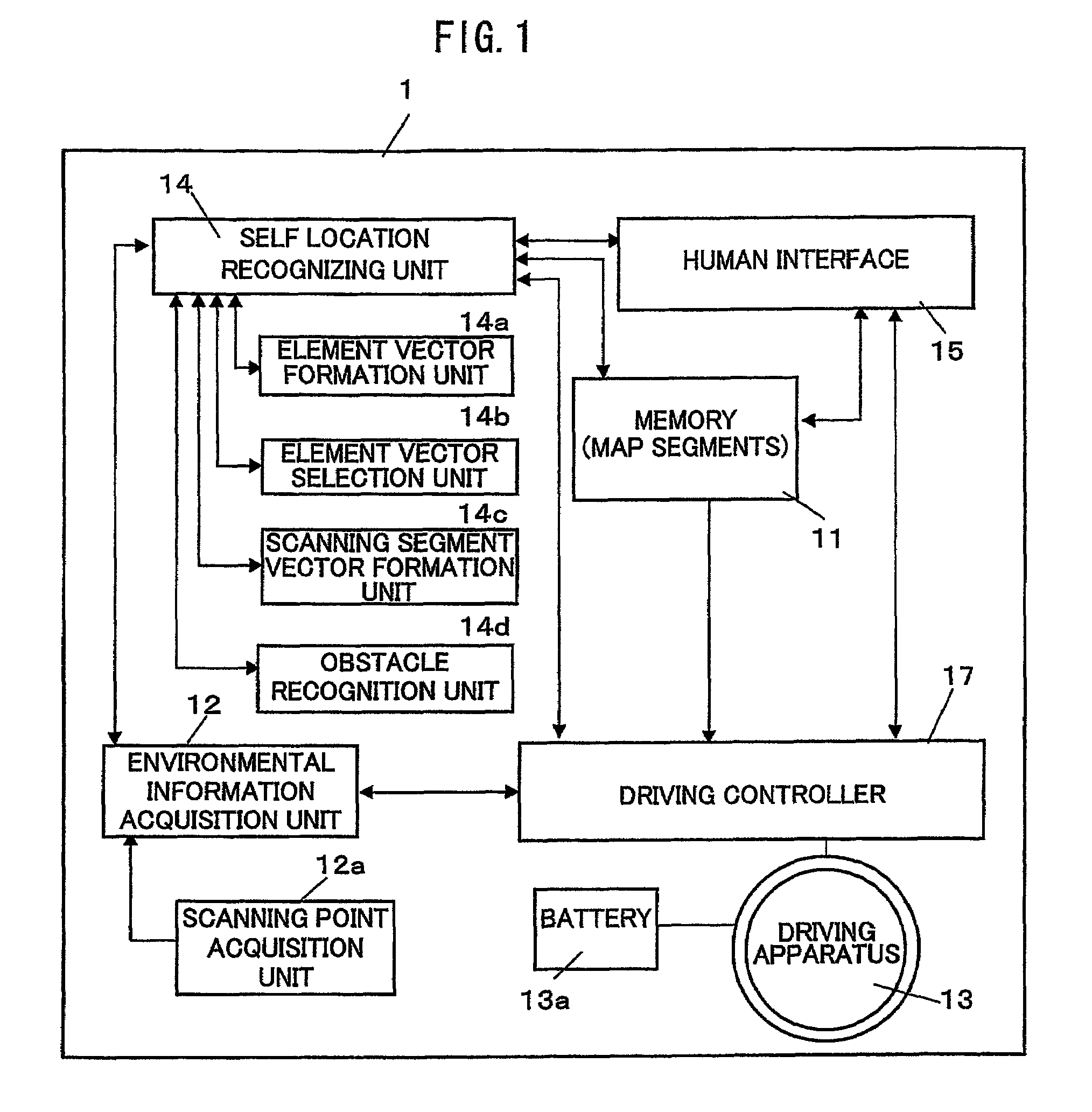

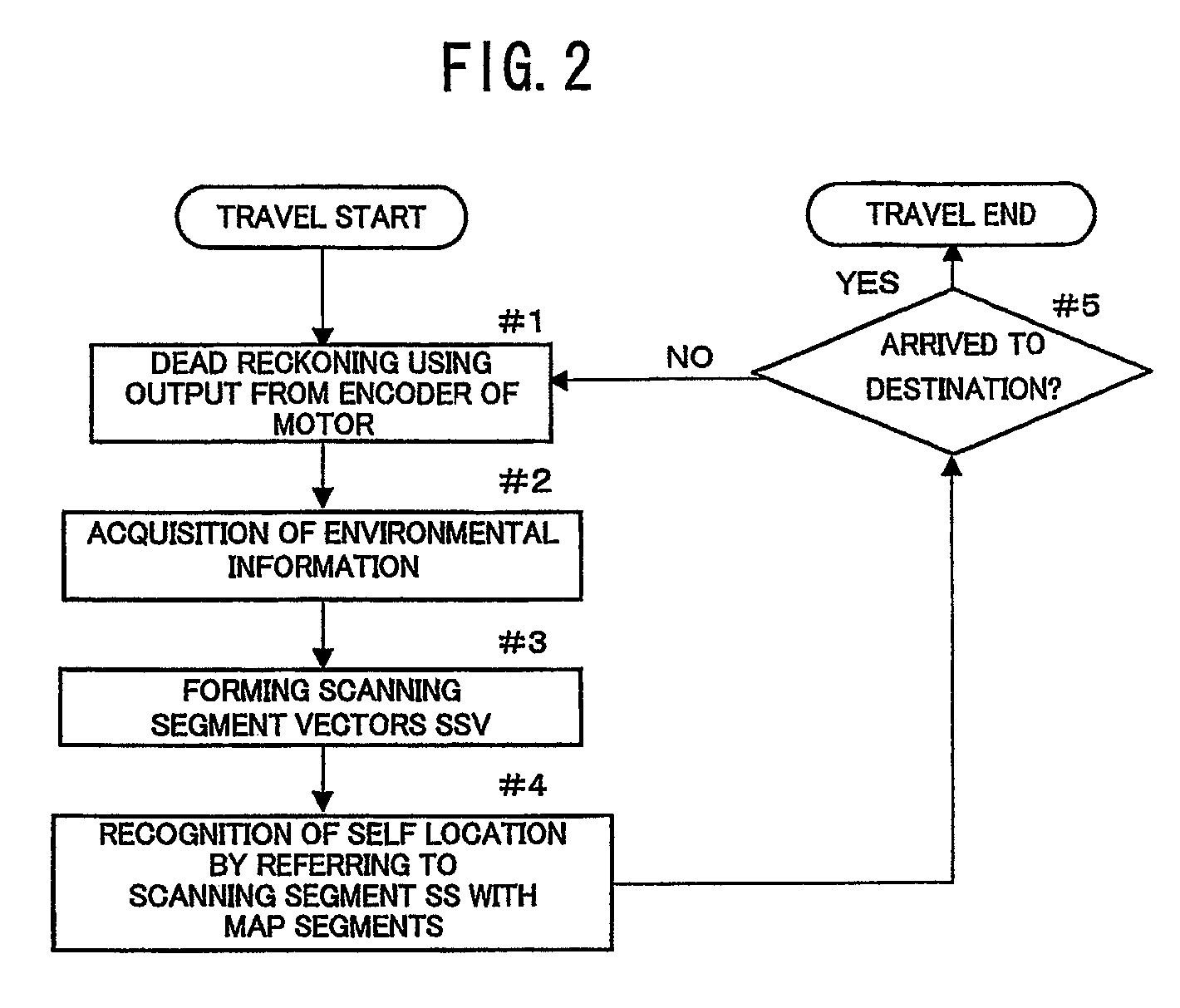

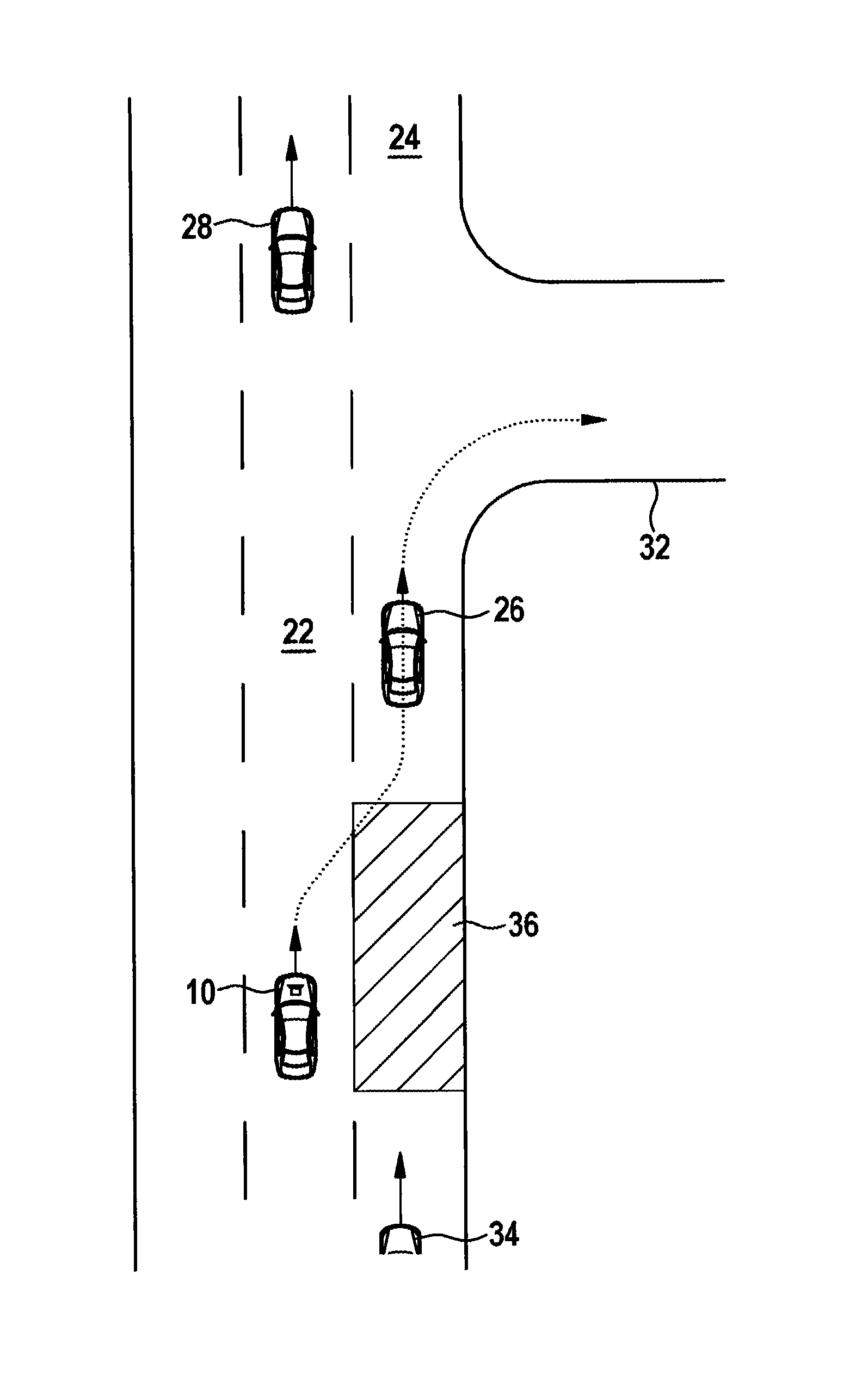

Autonomous vehicle and planar obstacle recognition method

InactiveUS7742841B2Guaranteed to move normallyEffective autonomous travelImage analysisComputer controlLaser rangingEngineering

In an autonomous vehicle, position of a planar obstacle such as a wall or a fence having apertures is determined. A horizontal plane is scanned with a laser range tinder so as to acquire positional coordinates of a plurality of scanning points. An element vector is formed with each two scanning points so that one acquired former is used as a start point and the other acquired later as an end point of the vector. A plurality of continuous element vectors which satisfy predetermined conditions is selected among the element vectors, and a scanning segment vector is formed by composition of the selected element vectors. When a length of the scanning segment vector is equal to or longer than a predetermined length, it is possible to recognize that a planar obstacle exists along the scanning segment vector.

Owner:MATSUSHITA ELECTRIC WORKS LTD

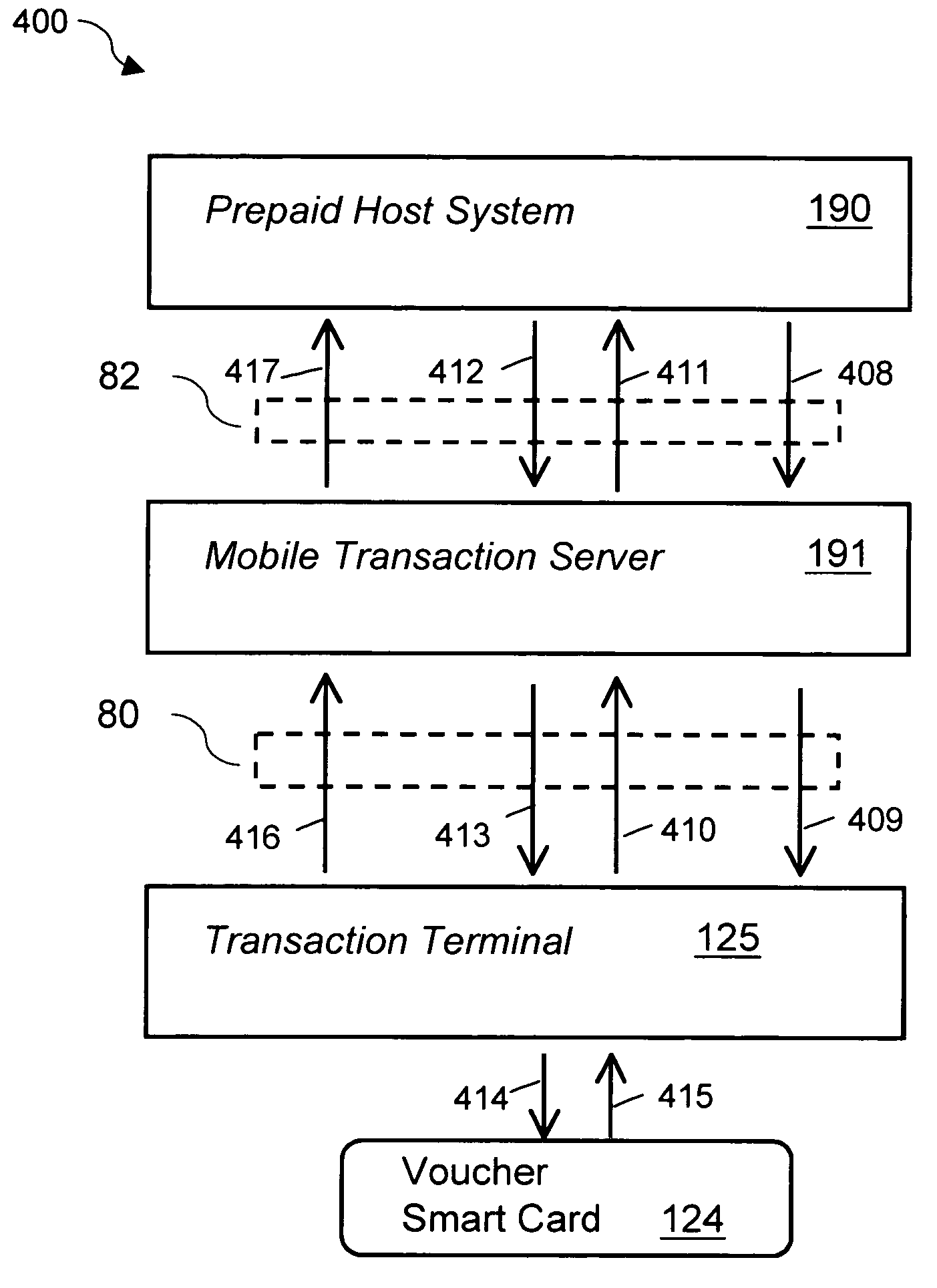

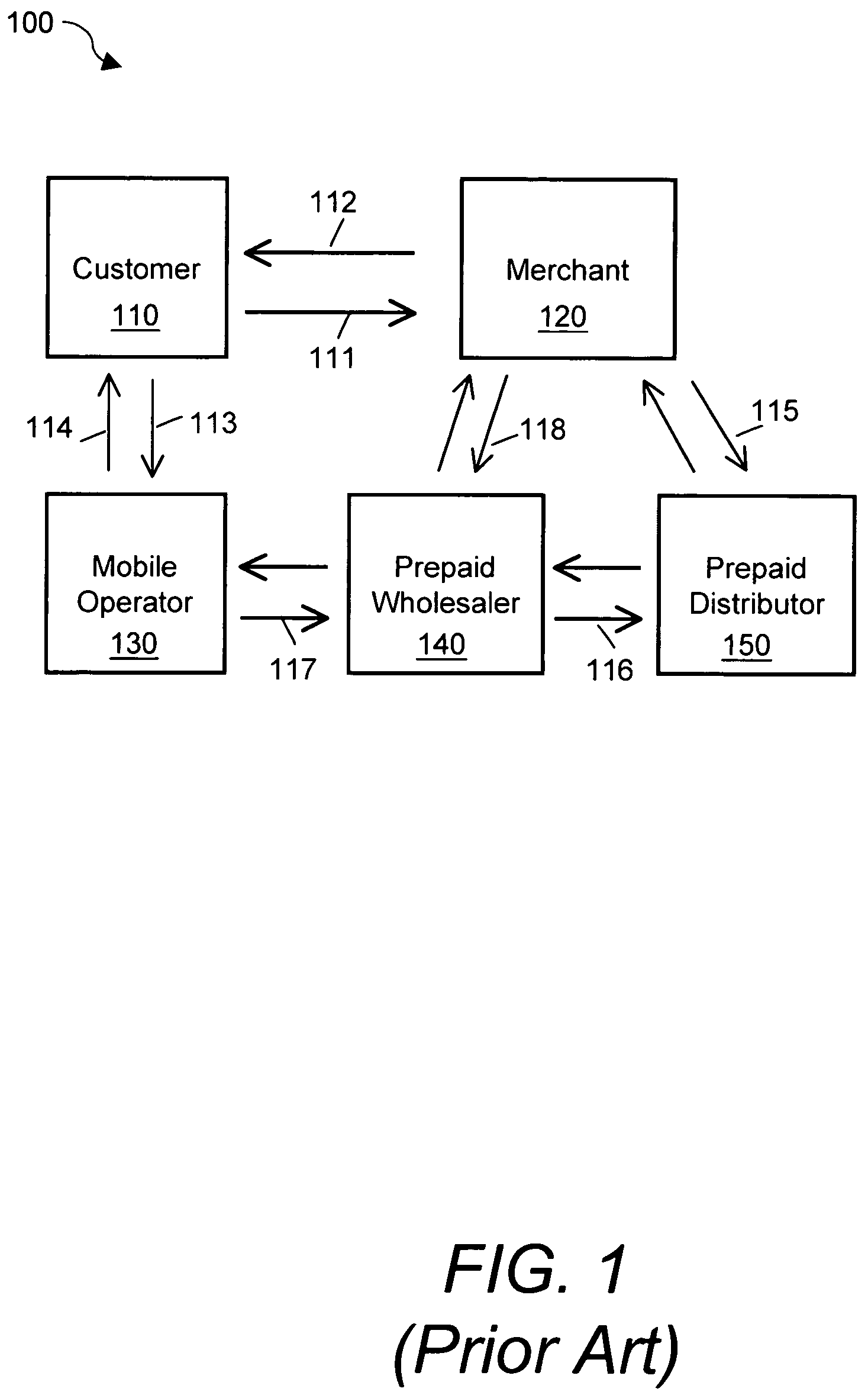

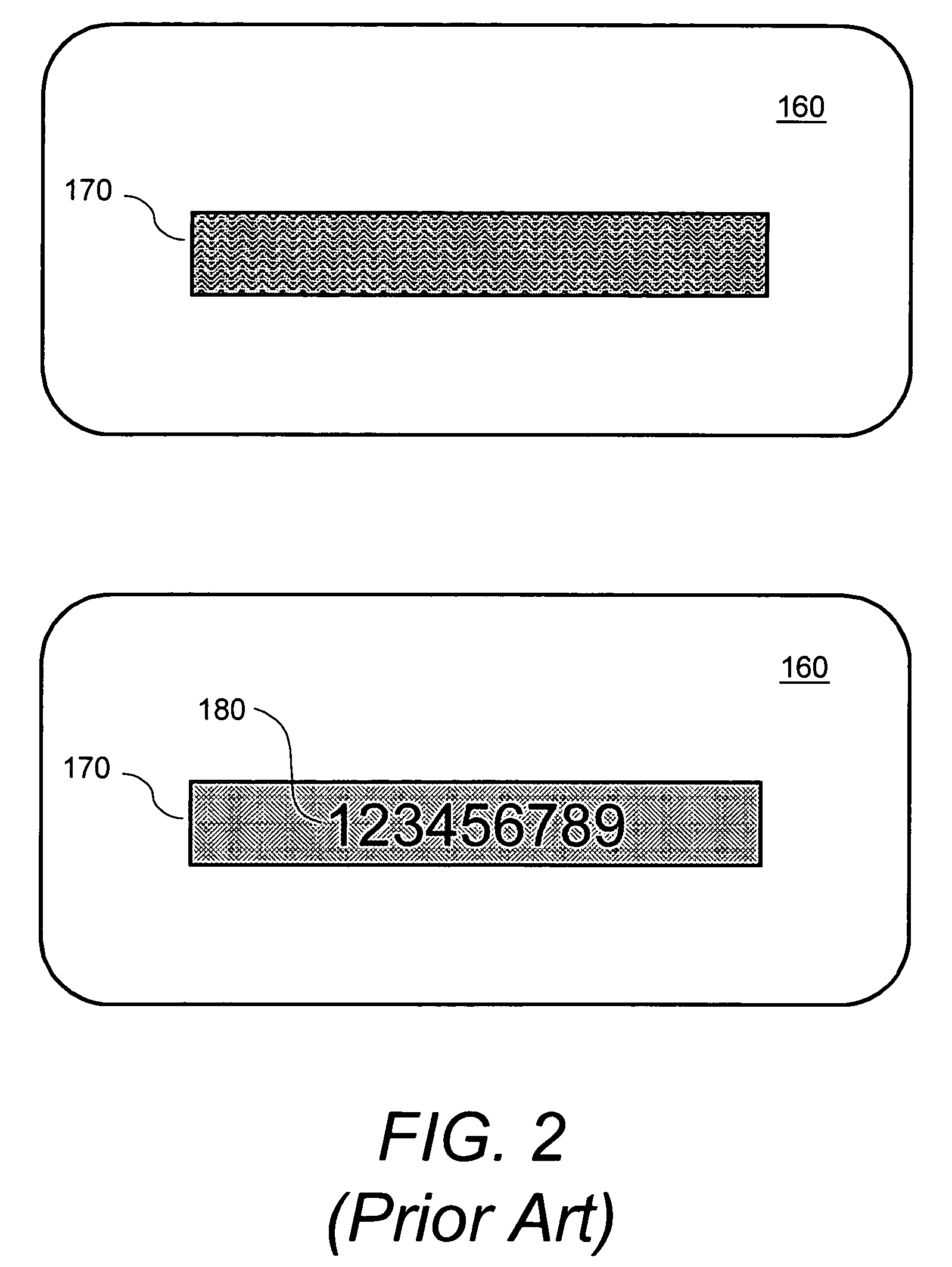

System and method for securely storing, generating, transferring and printing electronic prepaid vouchers

InactiveUS7188089B2Security is importantTimelyCredit registering devices actuationDevices with card reading facilityHardware security moduleMobile transaction

A system and a method that utilizes transaction terminals equipped with smart card readers to download and store a batch of multiple prepaid electronic vouchers to a smart card, retrieve and decrypt individual prepaid vouchers from the smart card and print a voucher receipt with a printer in connection with the transaction terminal. The transaction terminals are in connection with a mobile transaction server that acts as a gateway to a prepaid system and routes transactions between transaction terminals and the prepaid system and between transaction terminals. A method for storing a voucher encryption key on a second smart card or hardware security module. The voucher encryption key is utilized to decrypt encrypted vouchers on a voucher repository smart card. The transaction terminals are mobile devices communicating to the mobile transaction server over wireless networks.

Owner:VERIFONE INC

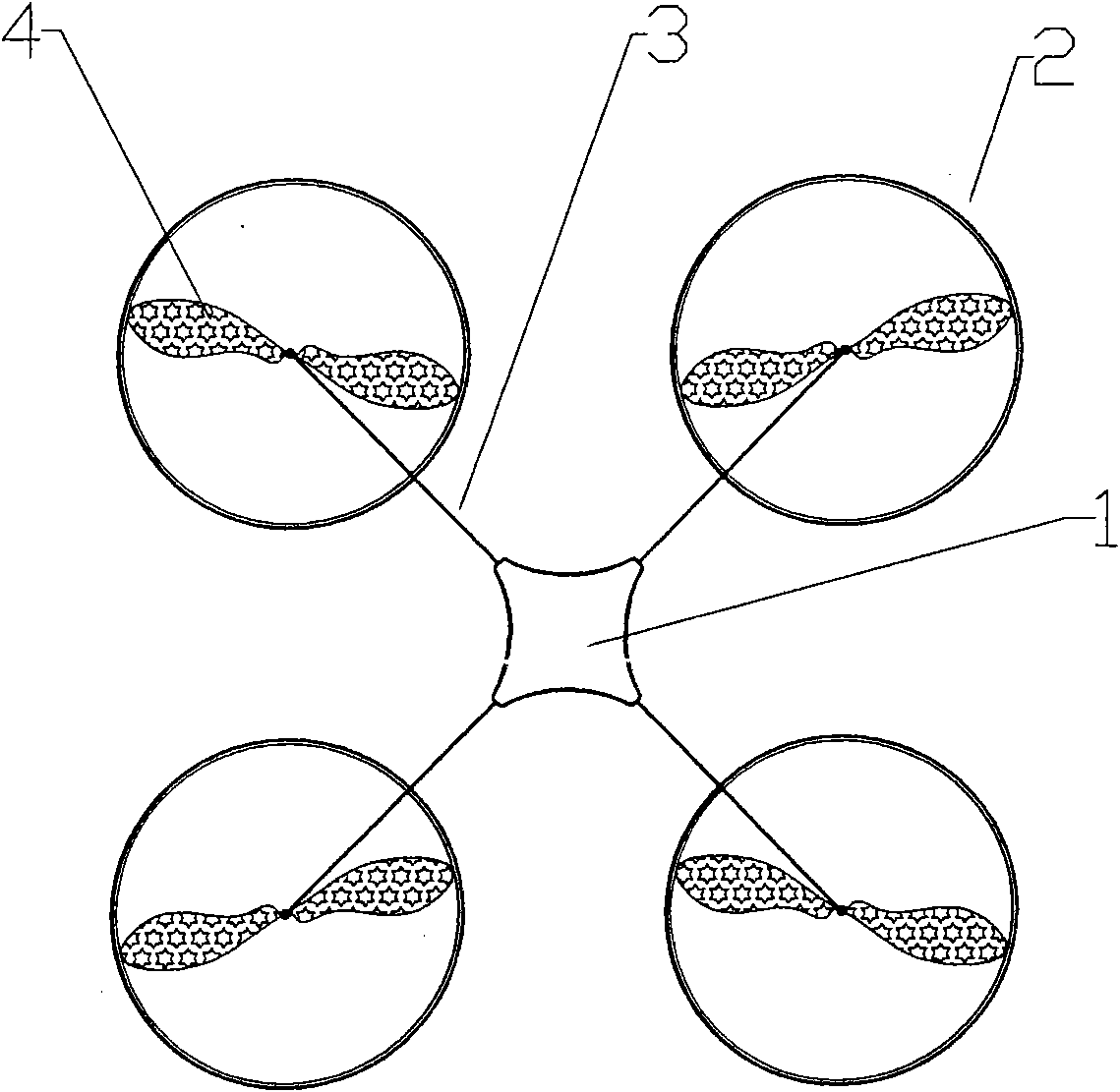

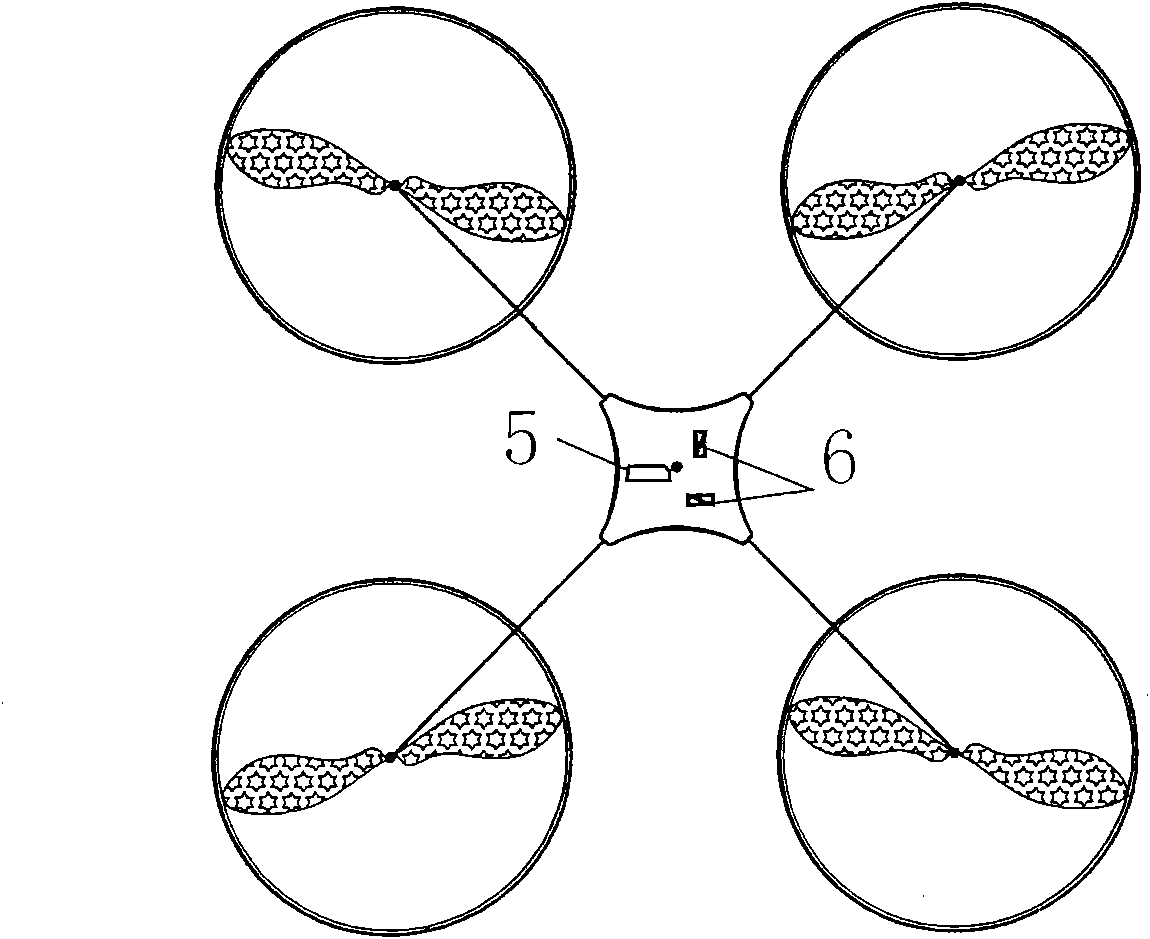

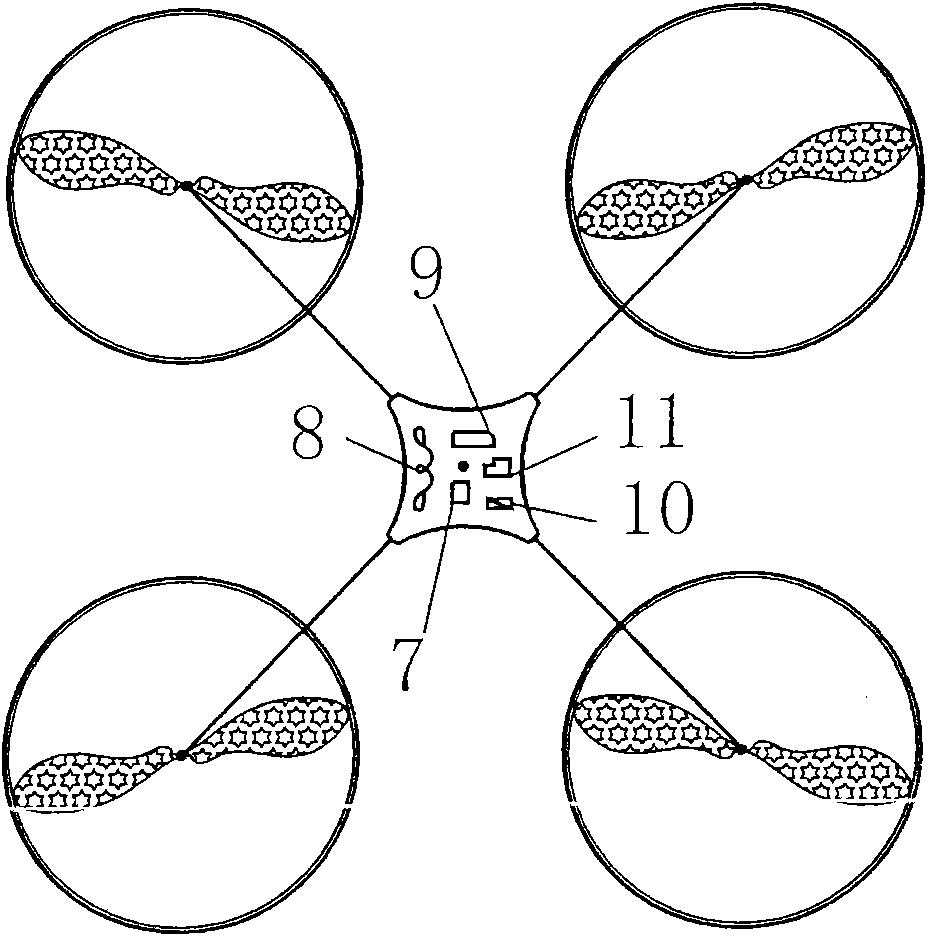

Bridge detection robot based on four-axle aircraft

InactiveCN101914893AEasy to detectGuaranteed tiltPhotogrammetry/videogrammetryBridge structural detailsBridging positionData processing system

The invention discloses a bridge detection robot based on a four-axle aircraft, comprising the four-axle aircraft. The main machine body of the four-axle aircraft is axially provided with a trough installation channel; the installation channel is internally provided with a self-adaptation matching regulation device; the main machine body is also provided with an onboard flight control unit and an installation platform, wherein the installation platform is connected with the main machine body through the self-adaptation matching regulation device and is provided with a shooting unit; a master control system consists of the onboard flight control unit and a ground control unit; and an image data processing system consists of the shooting unit and a ground image processing unit. The invention realizes the automatic sensing and line walking of a bridge detection position through a wireless shooting controller and high-accuracy distancer by utilizing the four-axle aircraft with superhigh stability in the sky as a basic equipment carrier and can also move high-accuracy photographing equipment to a bridge position to be detected, thereby realizing the automatic bridge damage detection and identification under no-man control.

Owner:CHONGQING JIAOTONG UNIVERSITY

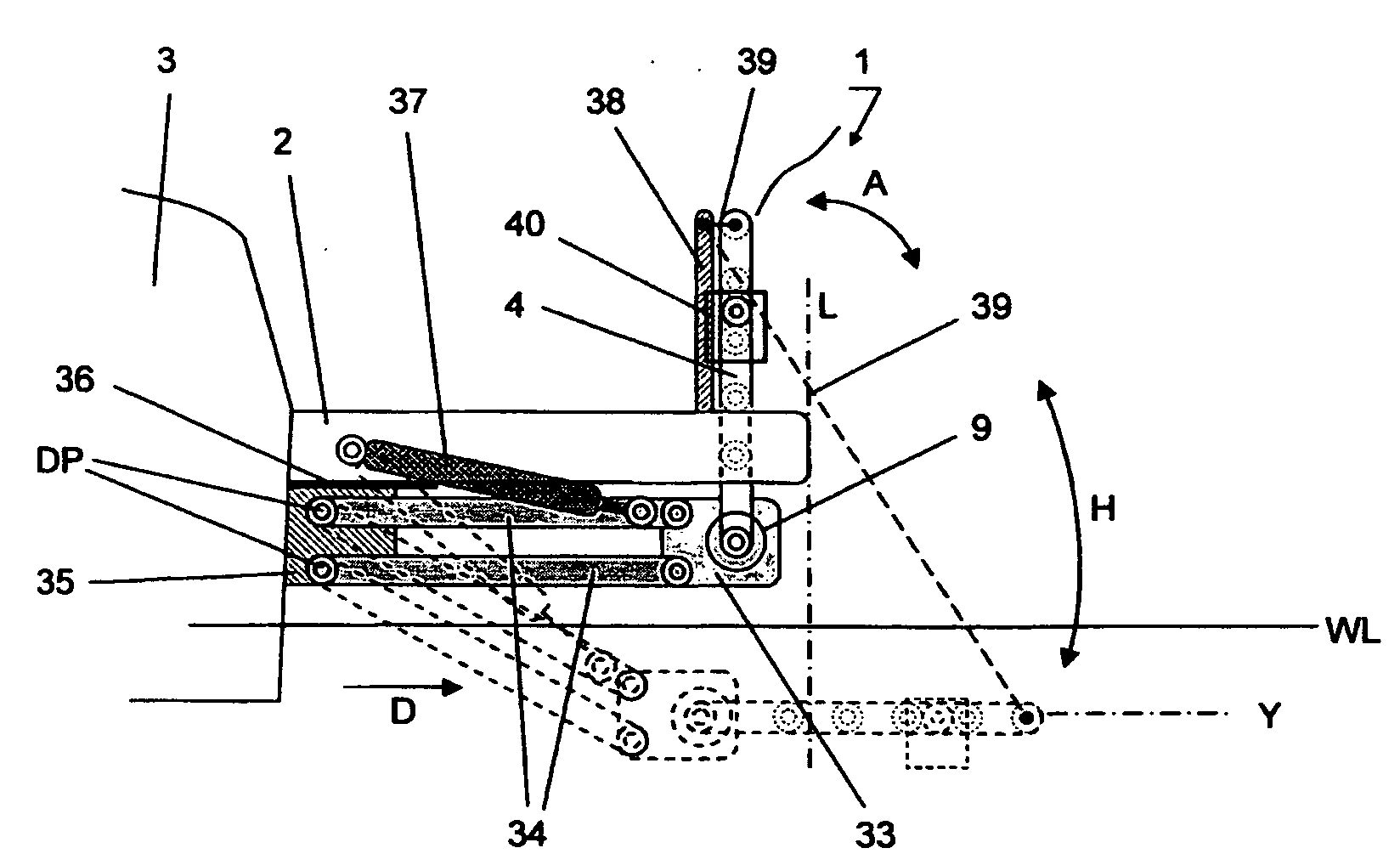

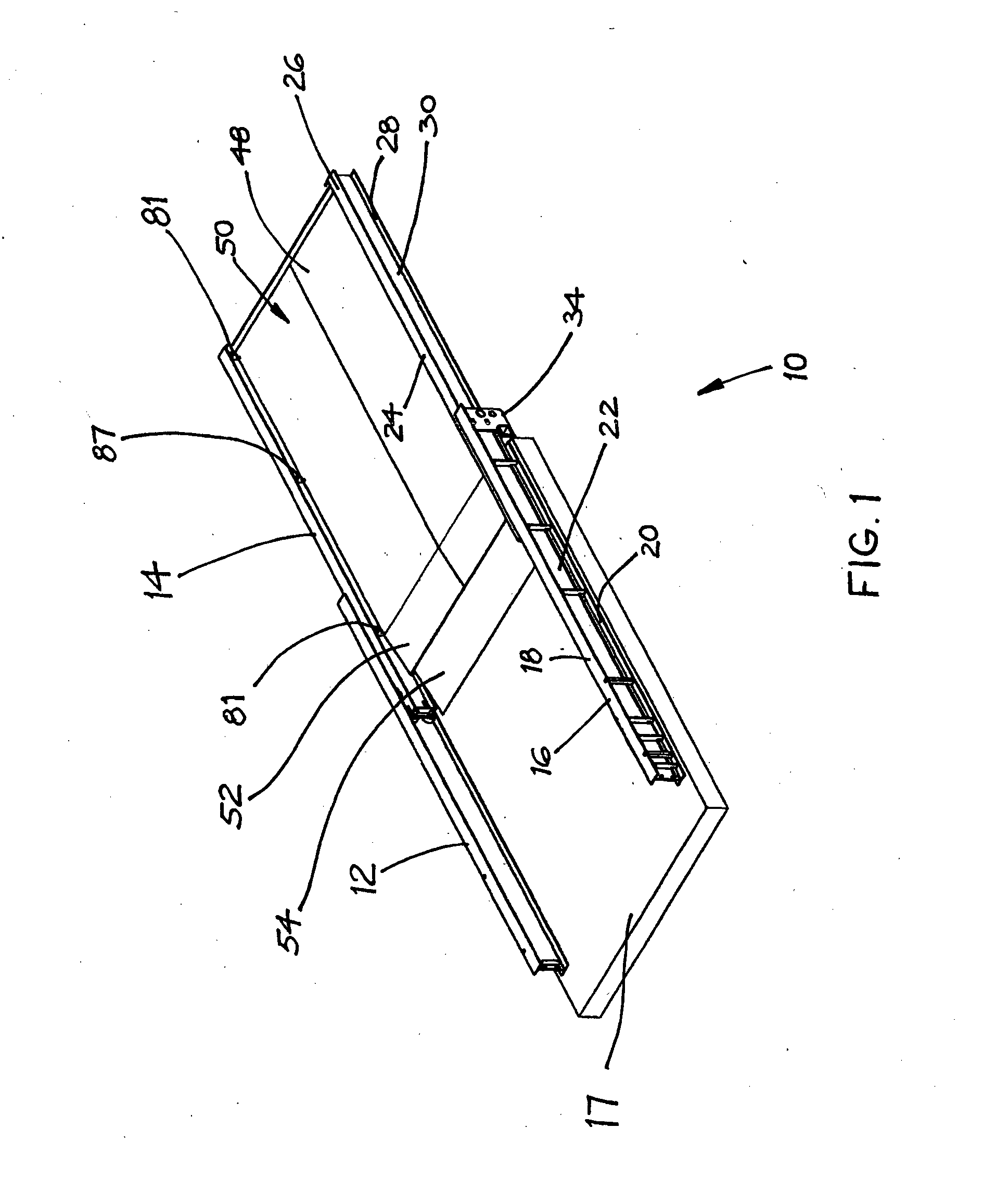

Dropdown railing for watercraft

InactiveUS20130000542A1Guaranteed to move normallyFunction increaseCargo handling apparatusVessel partsVisibilityEngineering

The invention comprises of a railing (1) which is foldable or and height adjustable or and extendable lengthwise and has rungs (5) or pivotable safety footsteps (14a) which, if necessary, can be kept in the vertical position (V) or horizontal position (Q) or and when tilting down the railing (1) remain in a stable position. The railing (1) has technical mean (4a,40,43a,45a,51) as well as an emergency mean (10,11) and can if necessary take up a tender (42) and other objects and the footsteps (14) can be transparent for example to improve visibility to the rear.

Owner:MULLER PETER A

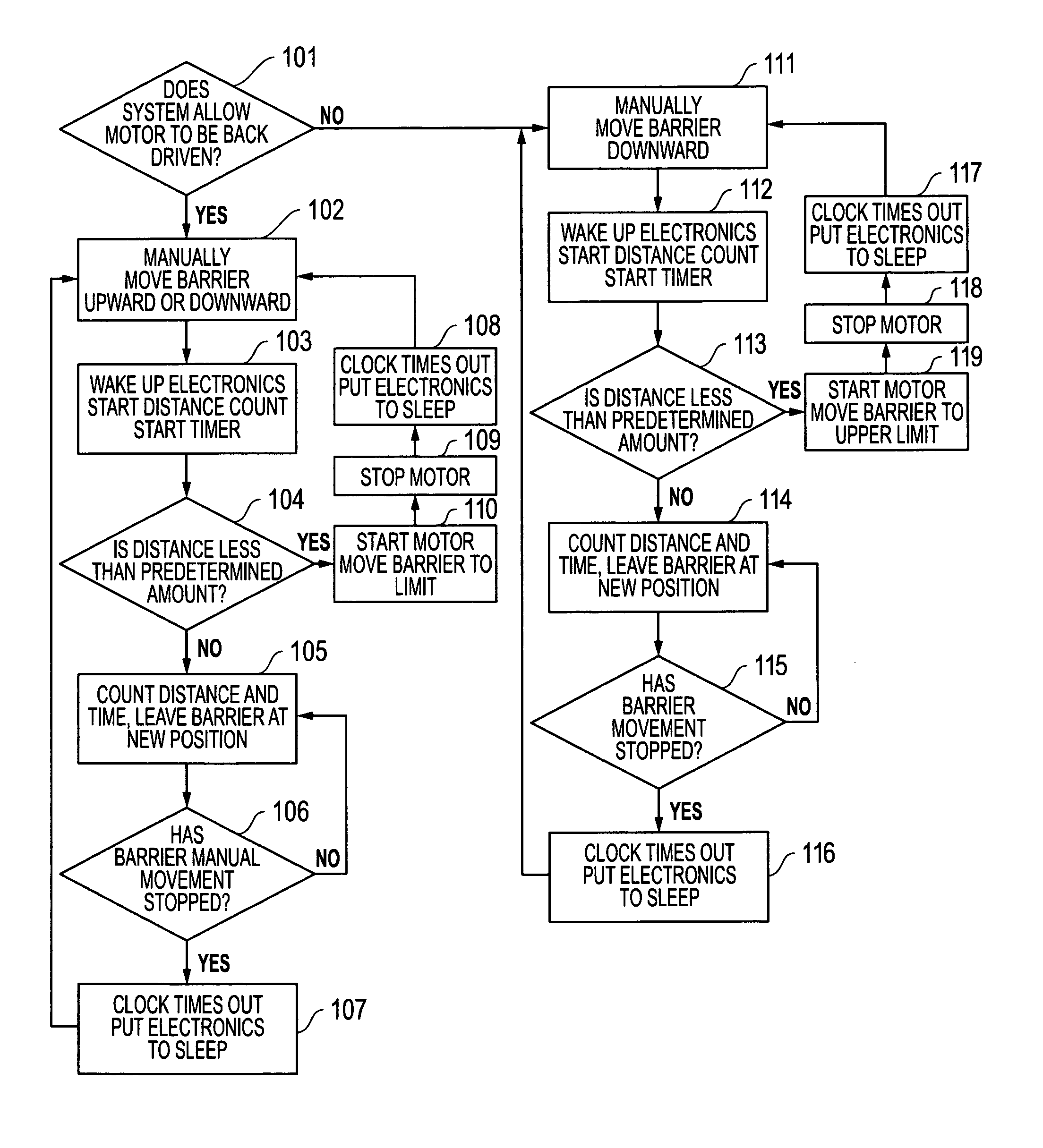

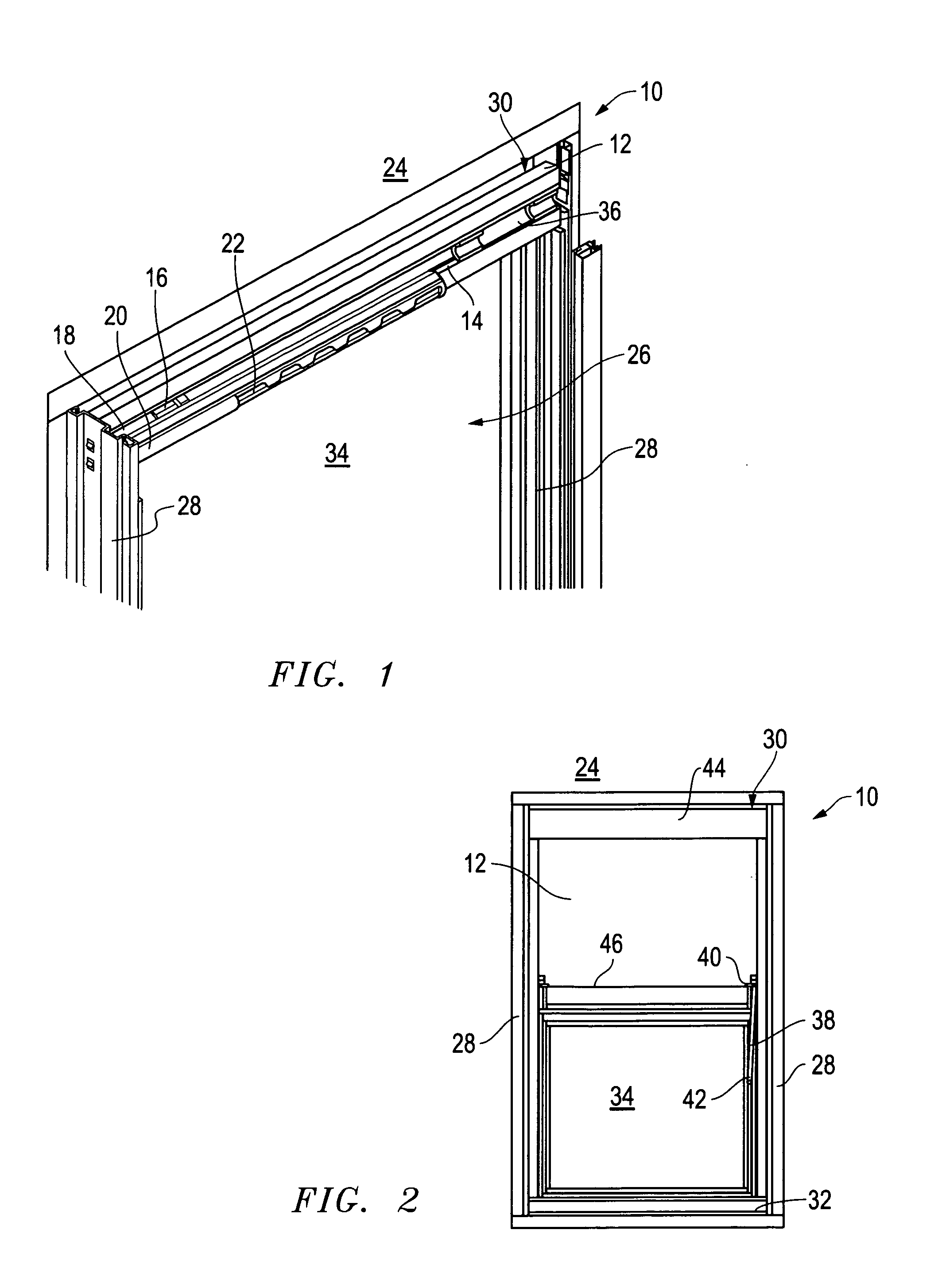

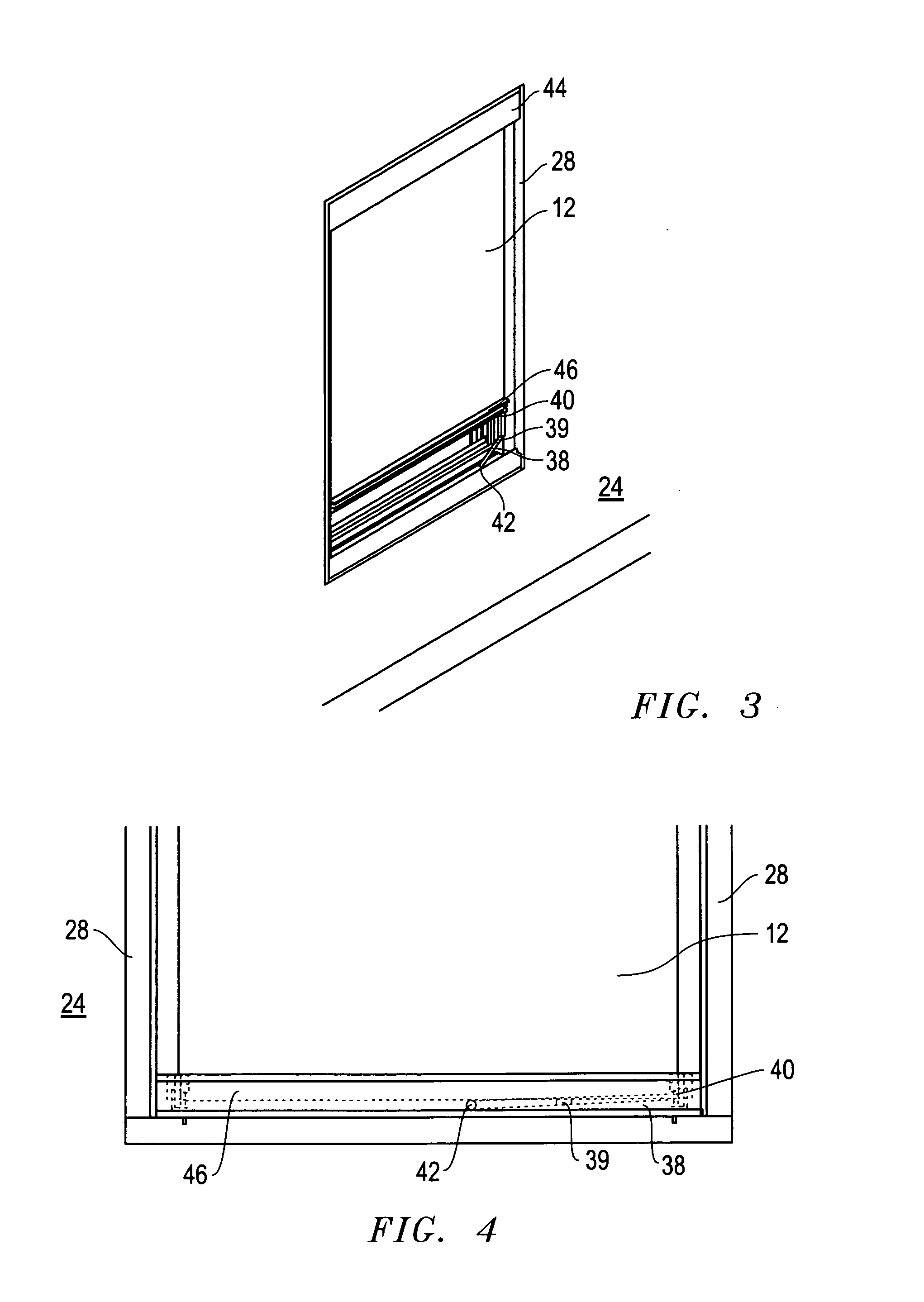

Motorized barrier adjustment apparatus and method

ActiveUS8125167B1Preventing need to disassembleSafely movedDC motor speed/torque controlDynamo-electric converter controlEngineeringElectric motor

Owner:THE WATT STOPPER

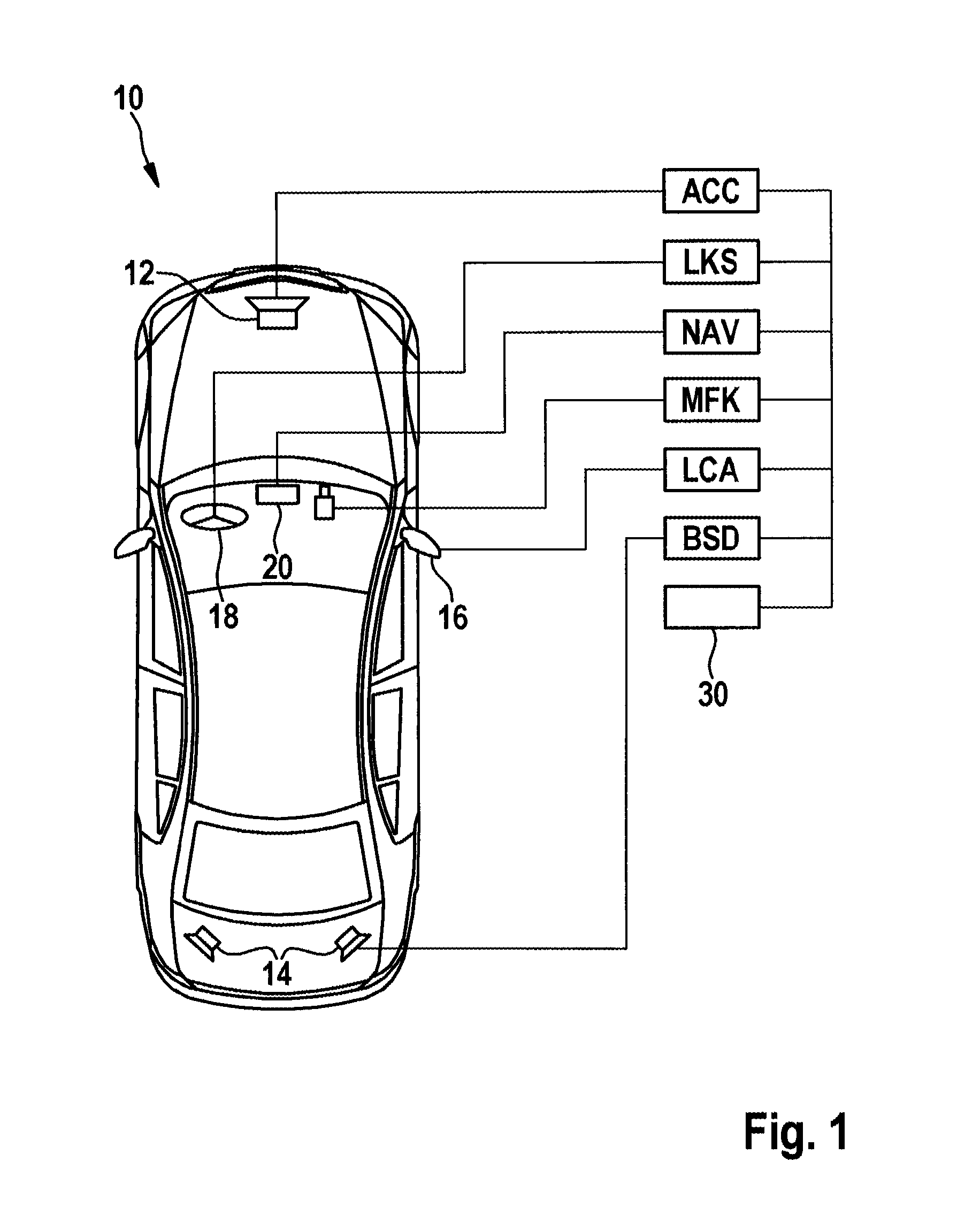

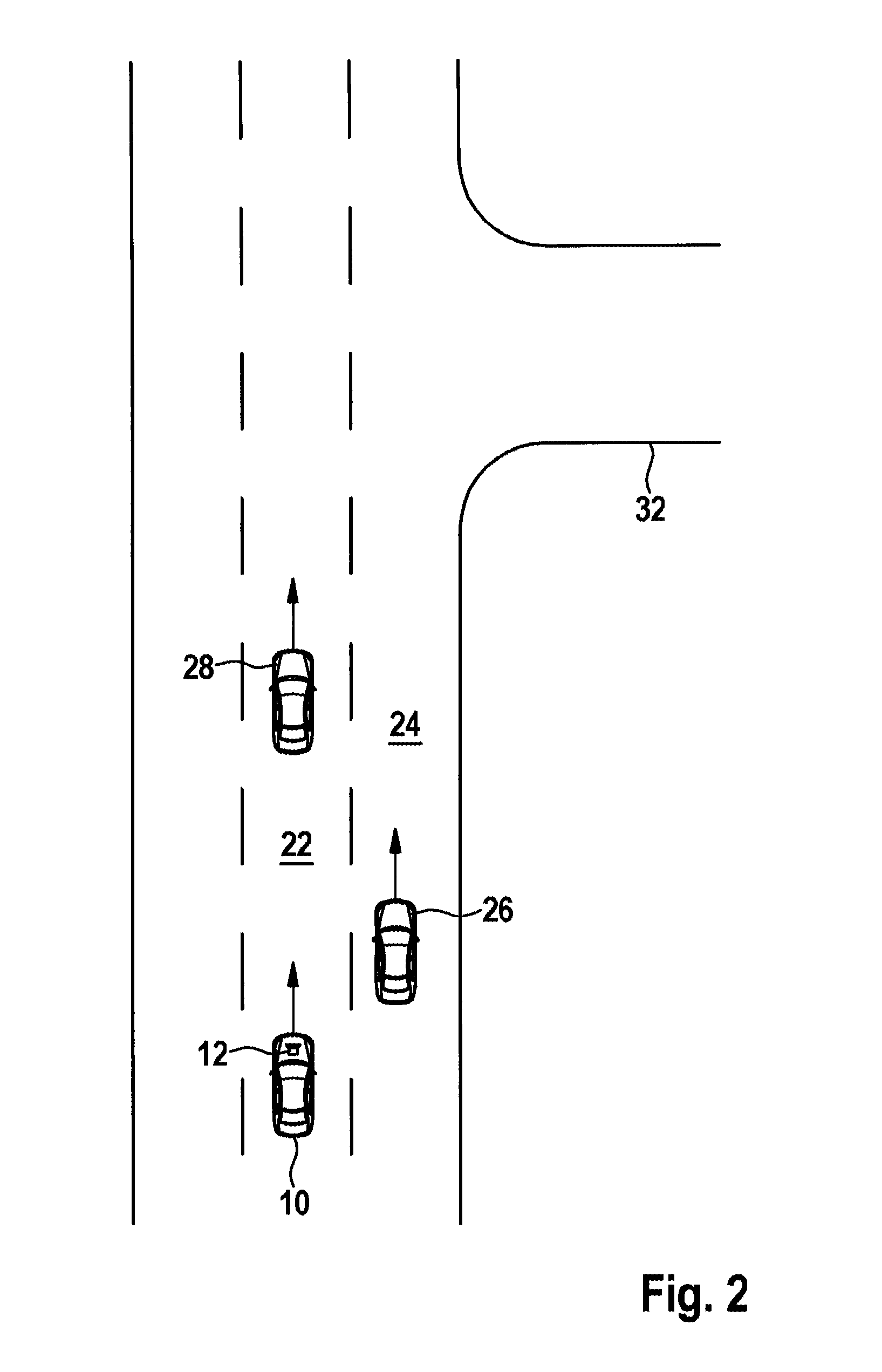

Driver assistance system for motor vehicles

ActiveUS20160082971A1Improve securityImprove ride comfortInstruments for road network navigationDigital data processing detailsMobile vehicleDriver/operator

A driver assistance system for motor vehicles, having a velocity regulation function for regulating the velocity of the subject vehicle to a nominal velocity, and having an adjacent-lane monitoring function, characterized by a turning assistance function which, when the velocity regulation function is active and an incoming signal indicates an imminent turning process that requires crossing an adjacent lane, monitors the traffic in the adjacent lane with the aid of the adjacent-lane monitoring function, and, as a function of locations and velocities of traffic participants in the adjacent lane, determines a spatial and temporal window for moving into the adjacent lane and adapts the nominal velocity to this window.

Owner:ROBERT BOSCH GMBH

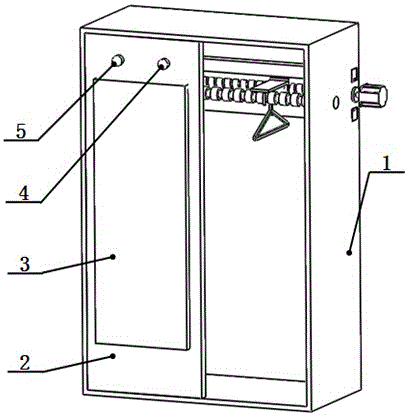

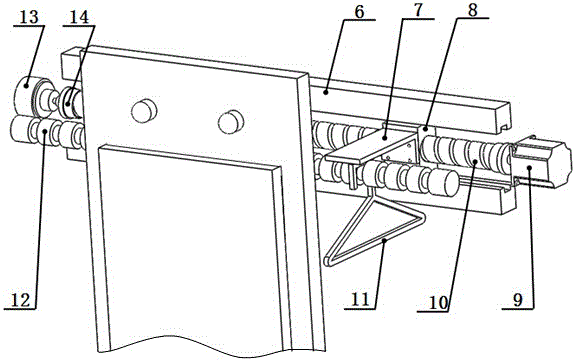

Intelligent wardrobe based on Internet of Things

InactiveCN105747560AShorten the timeReduce wasted energyWardrobesFittingInformation transmissionDisplay device

The invention discloses an intelligent wardrobe based on the Internet of Things, and belongs to the field of furniture. The intelligent wardrobe is composed of a shell and a sliding door. A sliding rail, a lead screw, a hanger rod, a stepping motor and an encoder are installed on the shell. A mirror surface displayer, a high-definition camera and an infrared camera are installed on the sliding door. The intelligent wardrobe can be connected with a computer or a mobile phone through the Internet of Things, control and information transmission can be carried out through application software, the application software can carry out analysis according to weather conditions and special requirements of a user in combination with clothes information stored in the computer or the mobile phone, information such as clothes pictures is transmitted to the mirror surface displayer through the Internet of Things, the user can pick out satisfactory clothes through the mirror surface displayer, the clothes selected by the user are automatically moved out, and the clothes can be automatically put back to the corresponding original position when the user puts back the clothes.

Owner:杨鑫嵘

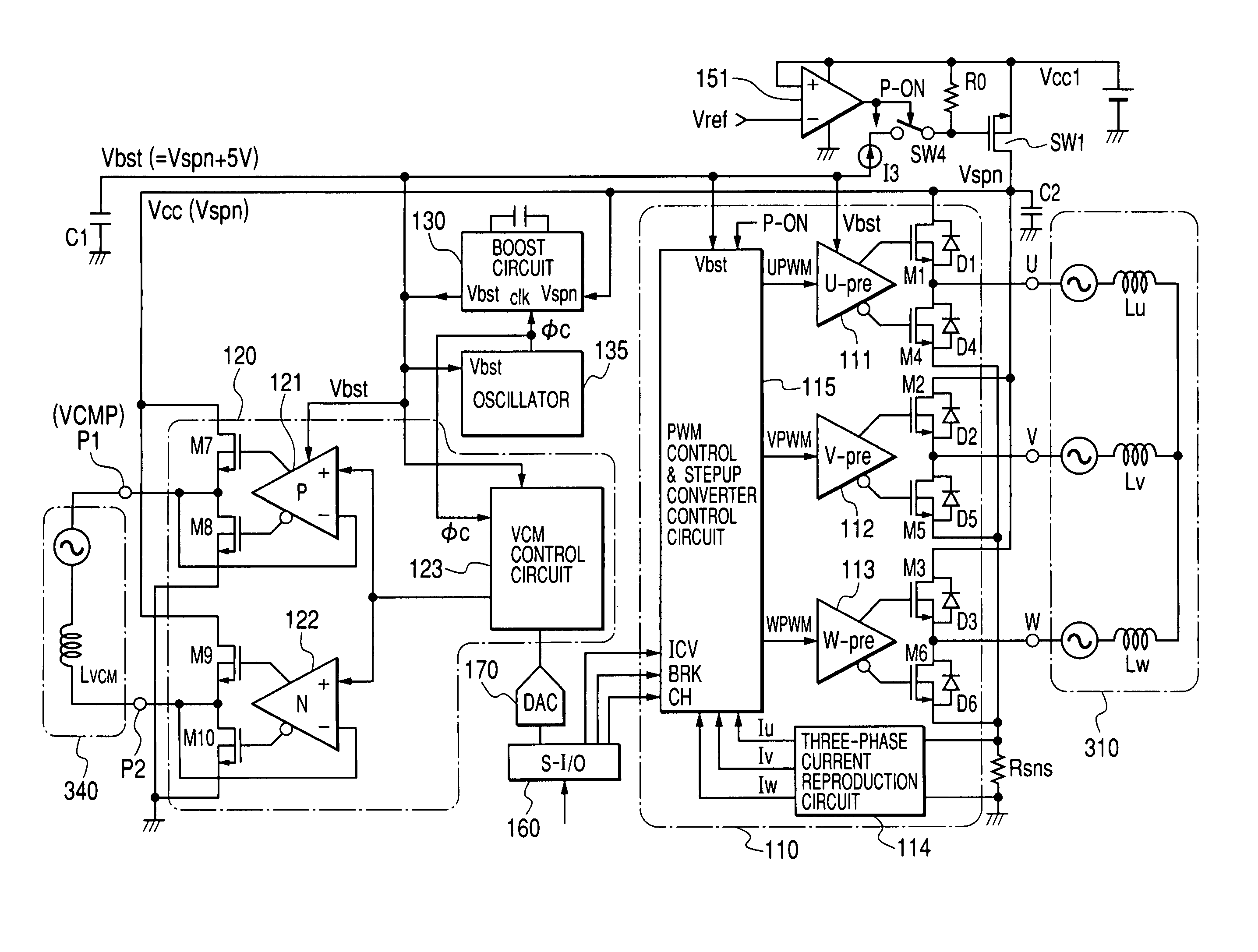

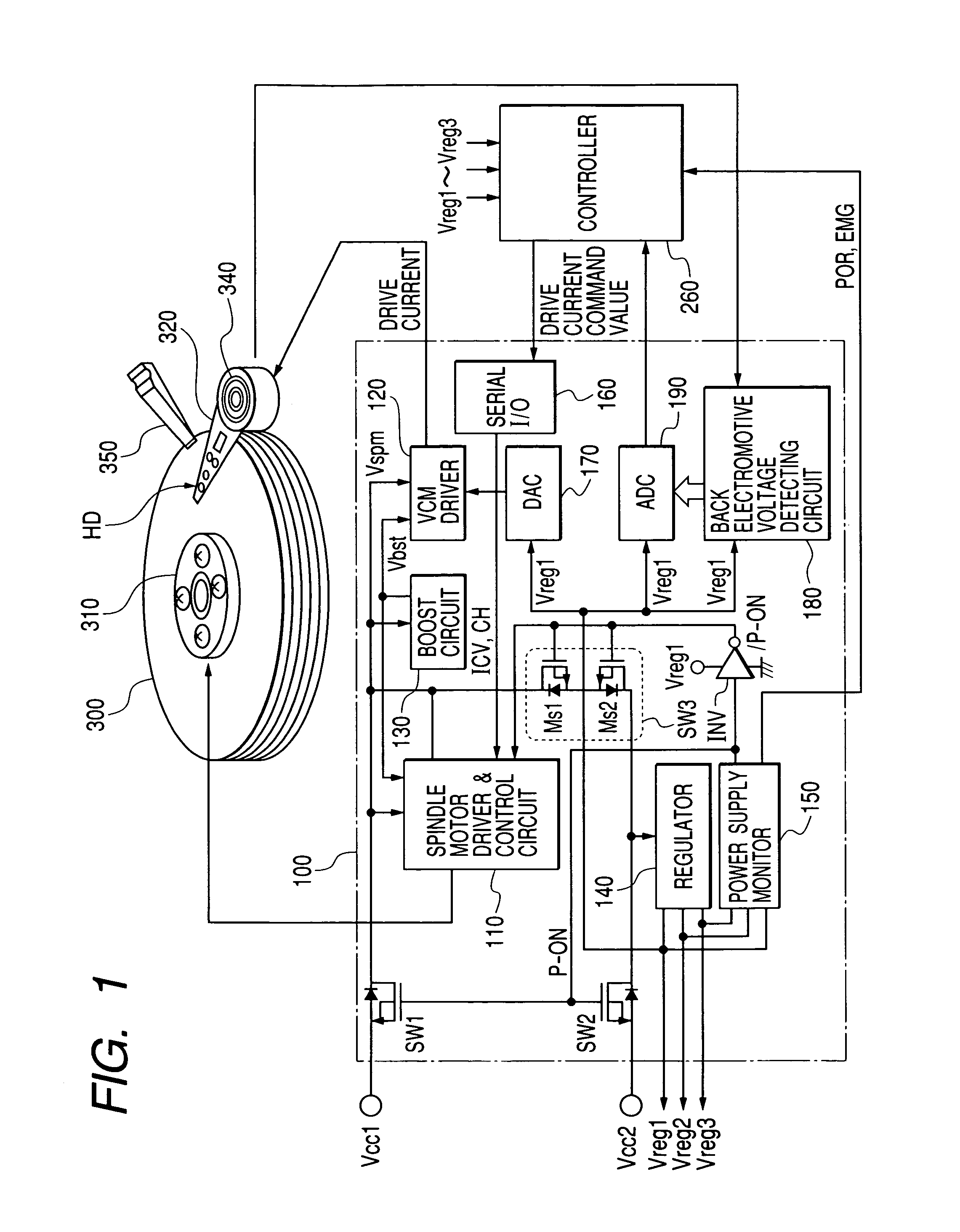

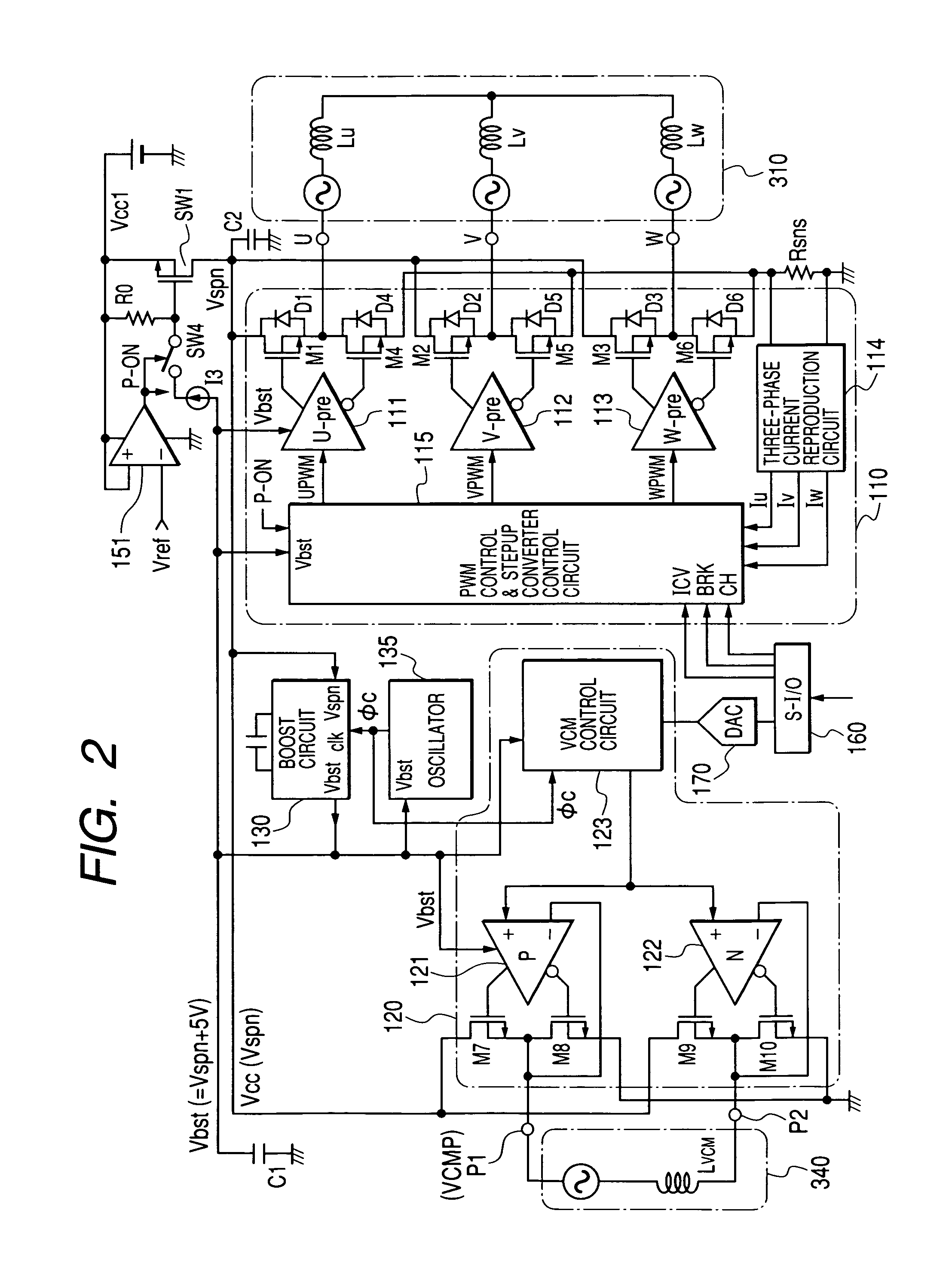

Magnetic disk storage system

InactiveUS7054089B2Small roughnessReduce gapDisposition/mounting of recording headsDriving/moving recording headsMotor driveElectric machine

The present invention provides a magnetic disk storage system including a spindle motor that rotates a magnetic disk, a spindle motor drive circuit that rotatably drives the spindle motor, a magnetic head that performs reading of information on the magnetic disk, a voice coil motor that moves the magnetic head, and a voice coil motor drive circuit that drives the voice coil motor. When the magnetic head is loaded from a standby position to the surface of the magnetic disk, the rotational speed of the spindle motor is made slower than a rotational speed at a normal operation. Upon power-off, the spindle motor drive circuit is caused to carry out a stepup converter operation to thereby generate a voltage higher than a back electromotive voltage, and causes a control circuit and a drive circuit to operate by the high voltage to thereby enable speed control at the movement of the magnetic head to a predetermined standby position.

Owner:RENESAS TECH CORP +1

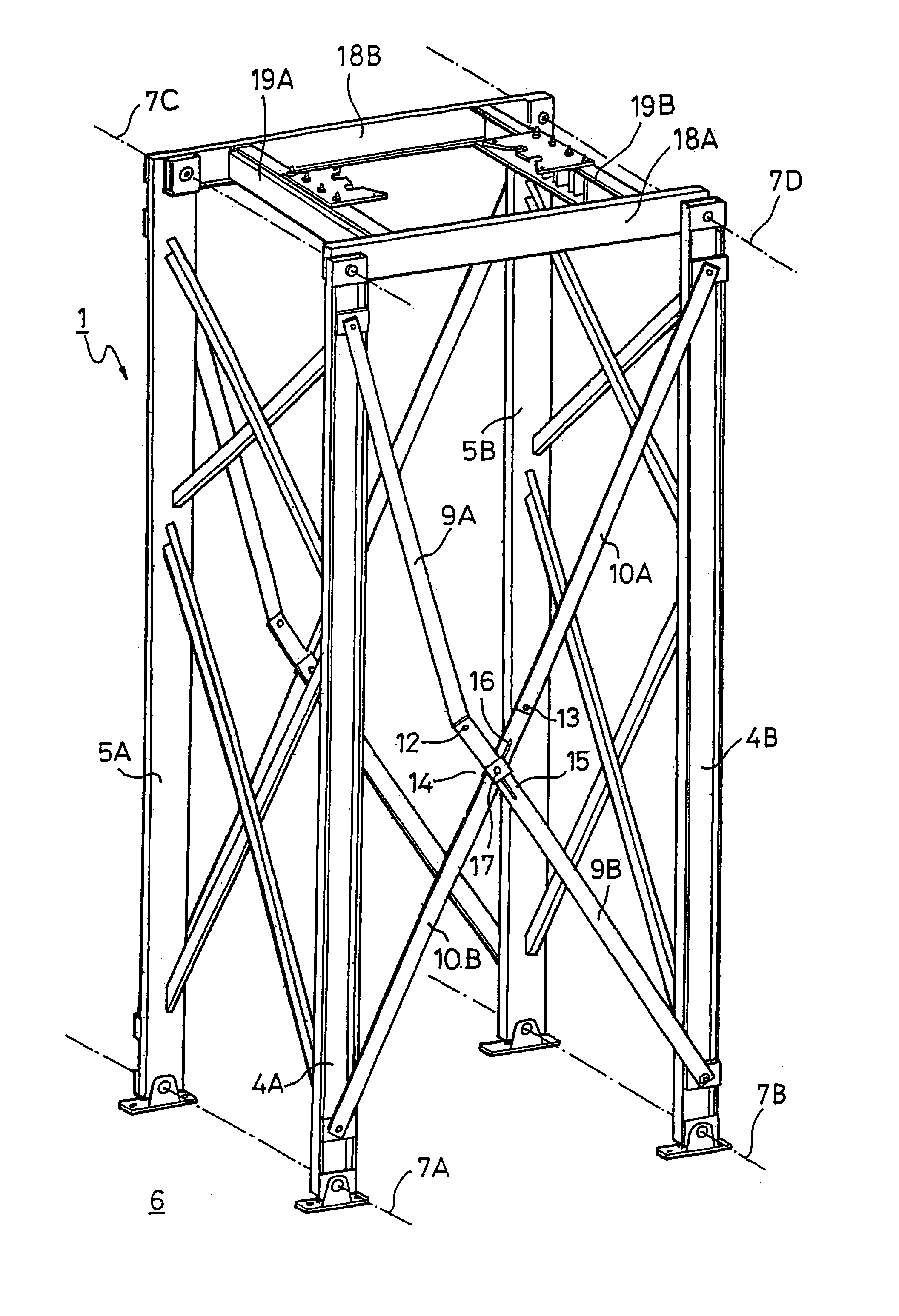

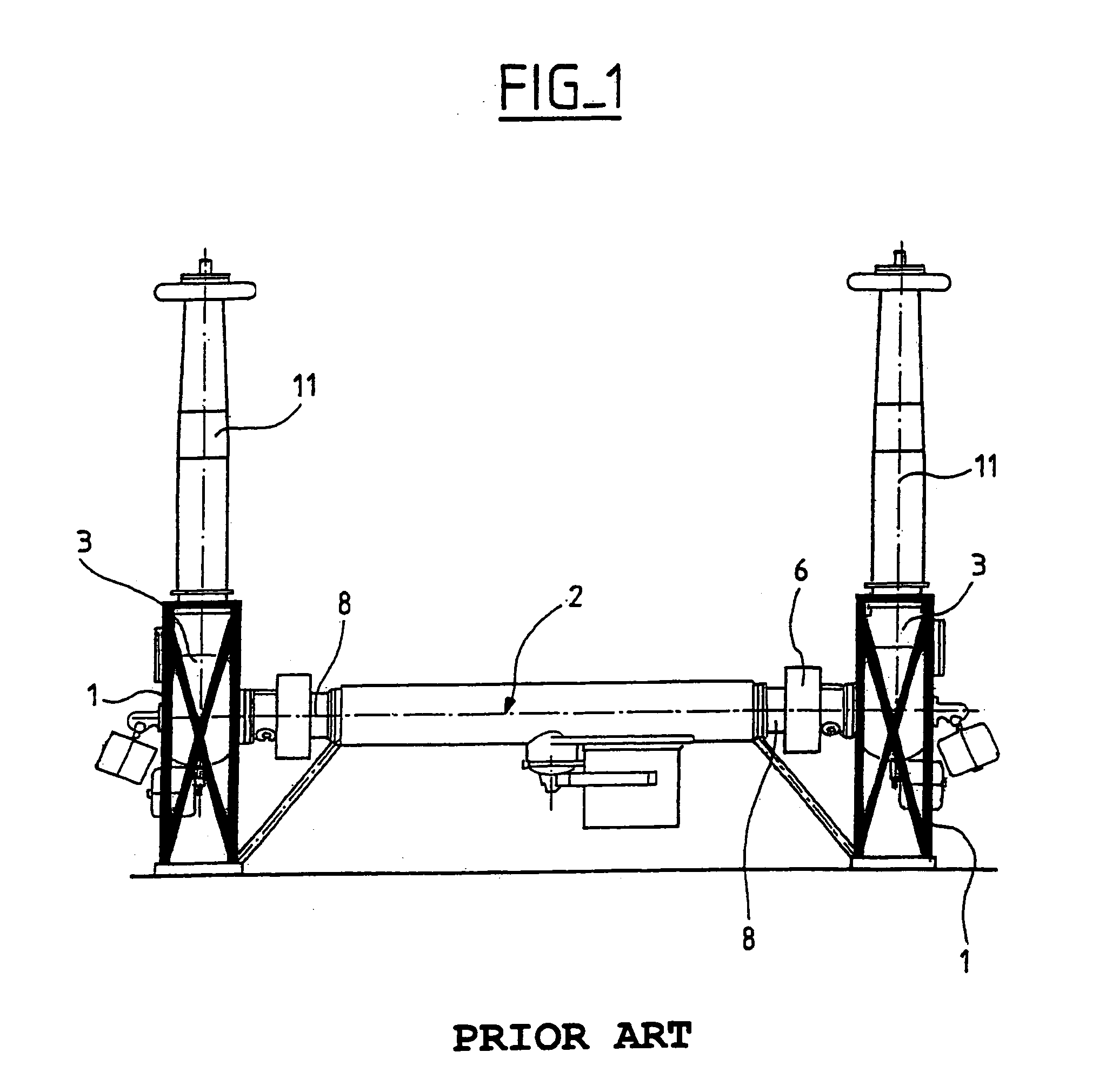

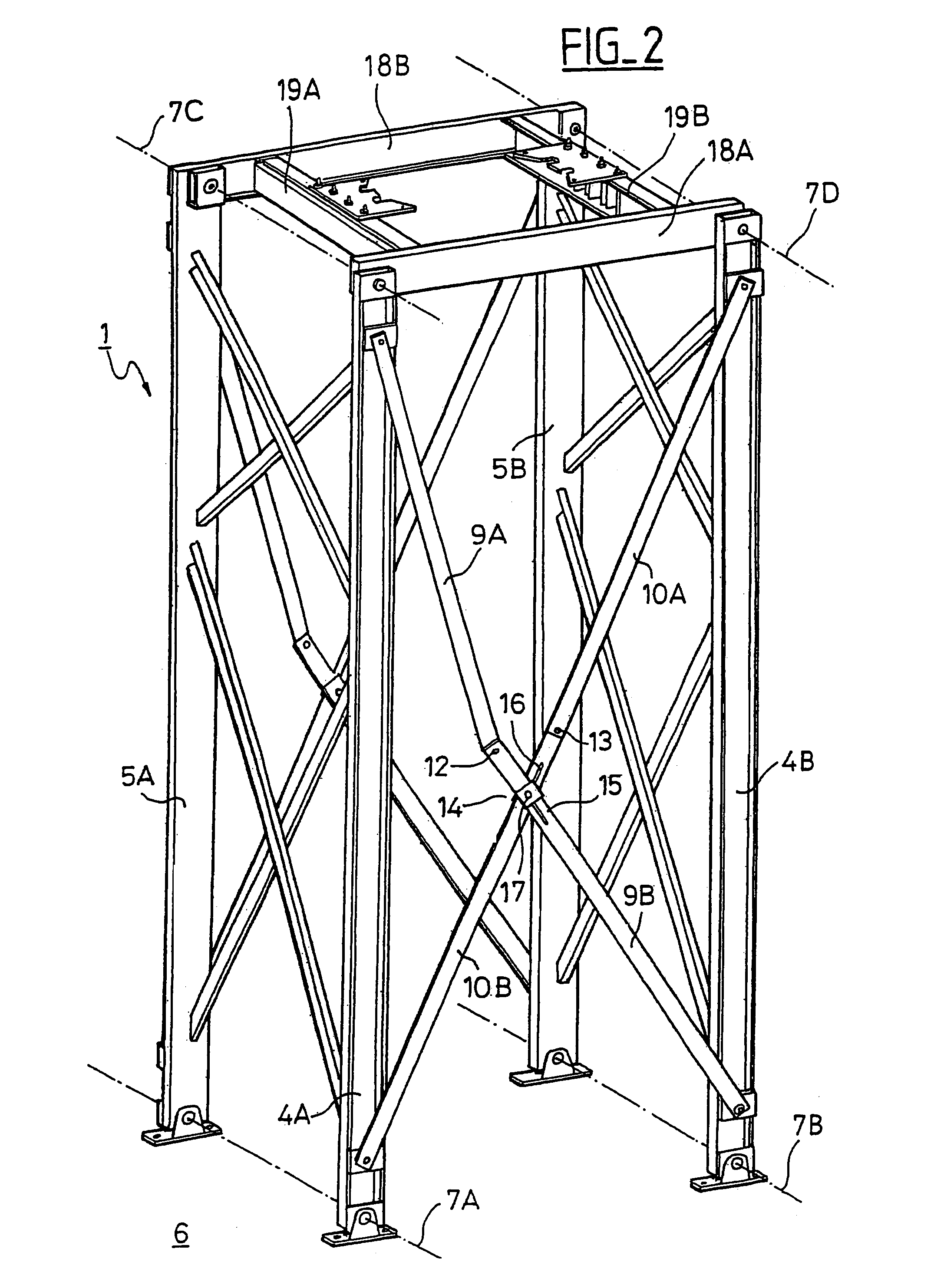

Articulated support with lateral movement for high-voltage or medium-voltage electrical plant

InactiveUS7090176B2Guaranteed to move normallyPortable framesStands/trestlesHorizontal axisHigh pressure

A support for high-voltage or medium-voltage electrical plant comprises four columns placed on a support surface and connected in pairs by crossmember assemblies. The columns are each articulated to rotate about a first horizontal axis at their end resting on the support surface and about a second horizontal axis on a top crossmember at their other end. The first and second axes are parallel. Two opposite crossmember assemblies allow the two columns connected by one or the other of these two assemblies to move in a stable manner in their rotation plane.

Owner:ALSTOM TECH LTD

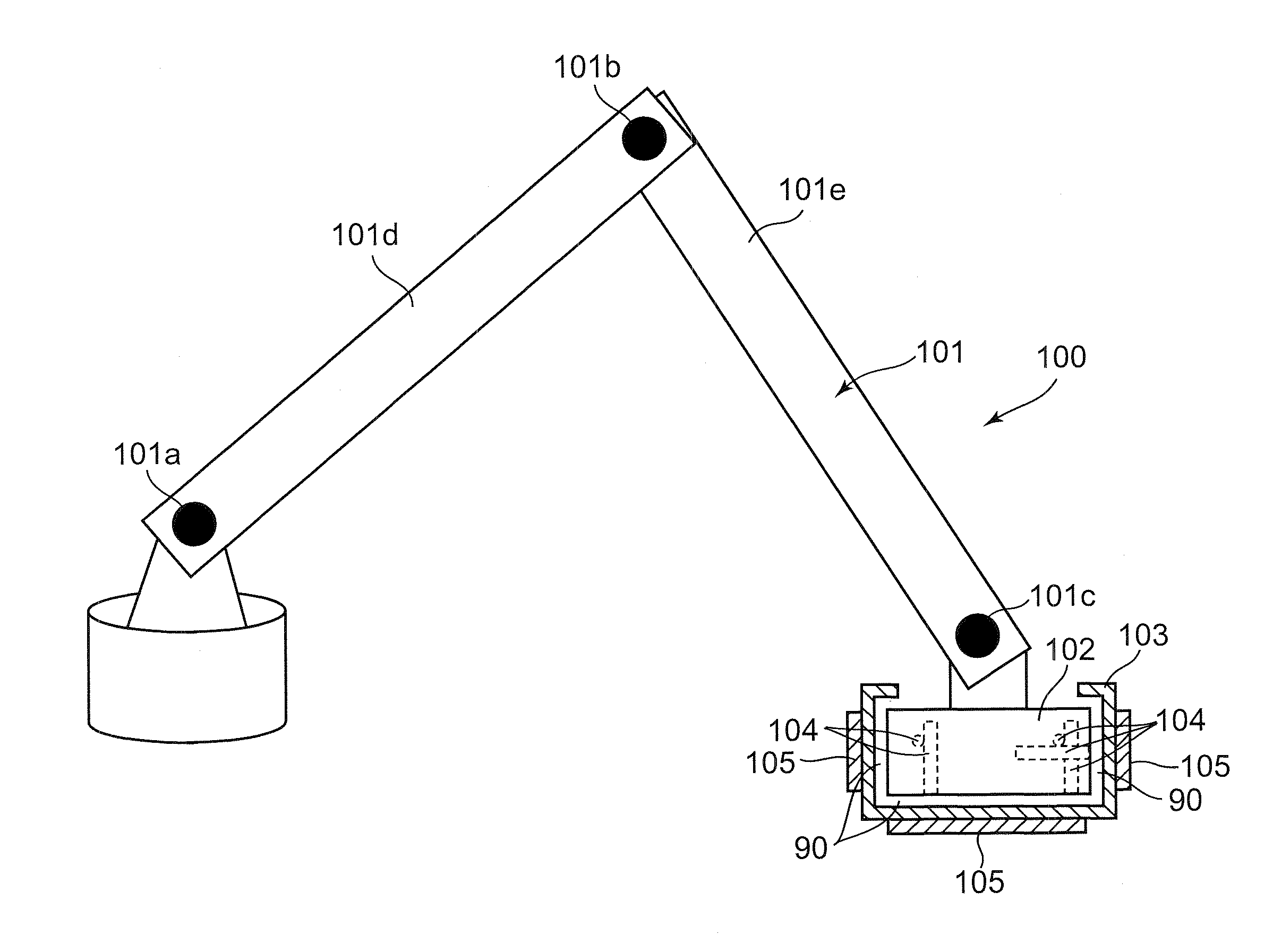

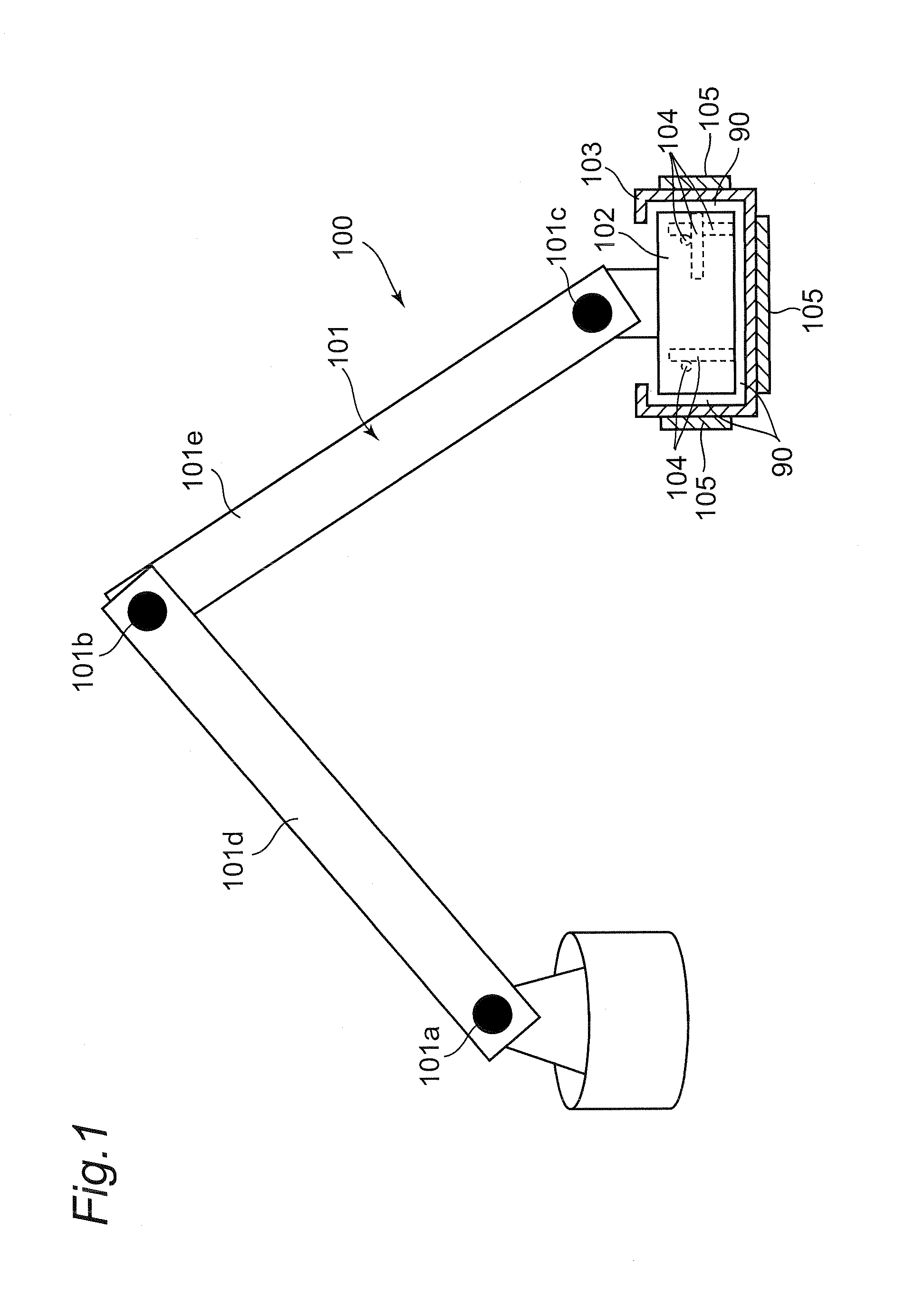

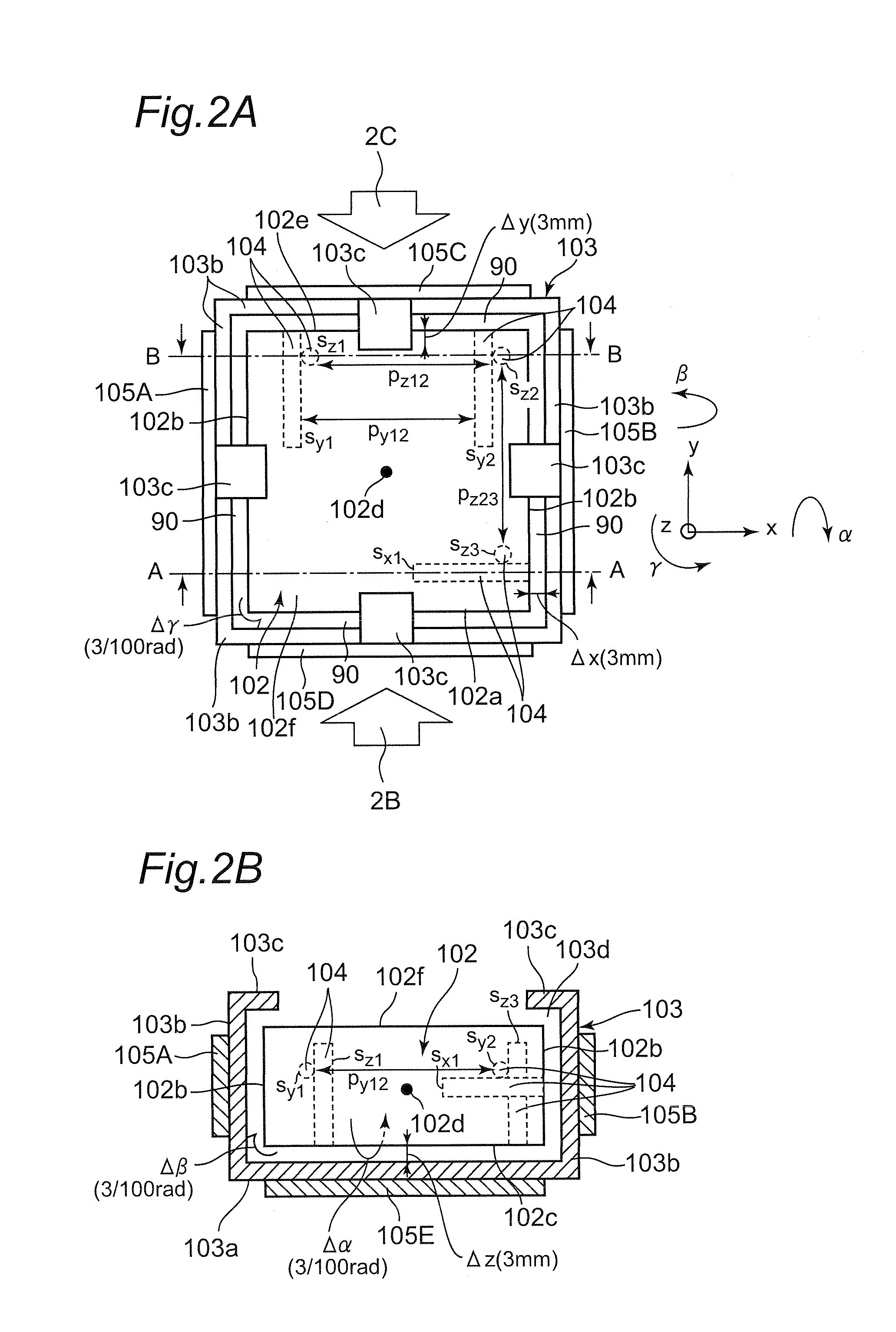

Robot arm control apparatus, robot arm control method, robot, robot arm control program, and integrated electronic circuit

ActiveUS20130184871A1Exclude influenceEasy to operateProgramme controlComputer controlActuatorControl theory

A robot arm includes a grip part which is structured to be separated from an end effector attached to the robot arm. When the grip part is gripped by the user and shifted, the robot arm shifts tracking the grip part. Further, the grip part includes contact sensors, and a tracking control method is switched according to the value of the contact sensors.

Owner:PANASONIC CORP

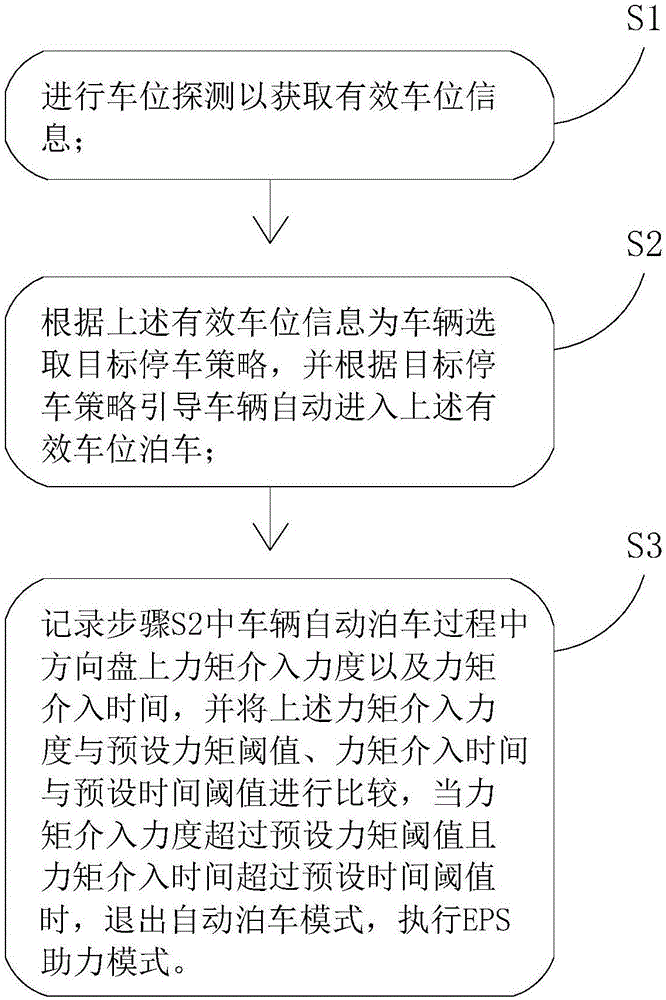

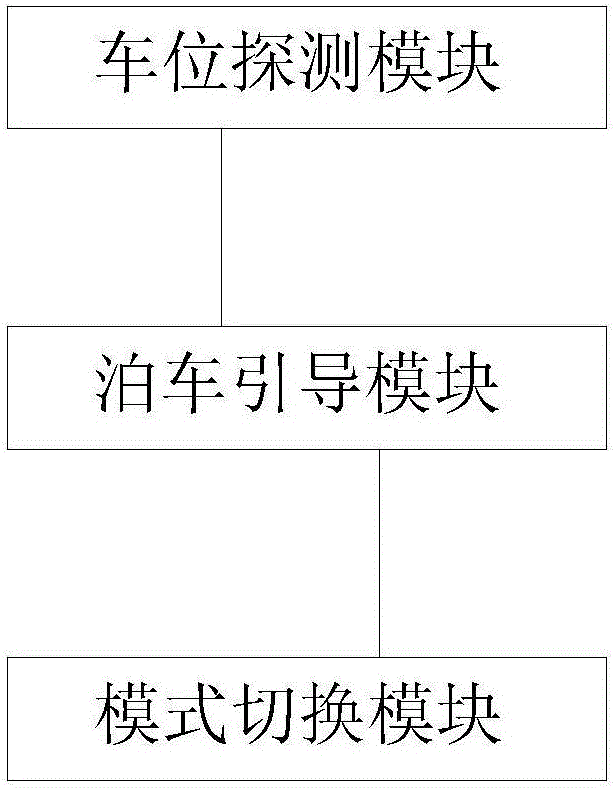

Automatic parking route planning method and system based on EPS (electric power storage)

ActiveCN106740818AGuaranteed to move normallyConvenient parkingExternal condition input parametersSteering wheelElectric power system

The invention discloses an automatic parking route planning method based on an EPS. The method includes the steps: S1 detecting a parking space to obtain effective parking space information; S2 selecting a target parking strategy for a vehicle according to the effective parking space information, and guiding the vehicle to automatically enter an effective parking space to park according to the target parking strategy; S3 recording torque intervention intensity and torque intervention time on a steering wheel in automatic parking process of the vehicle, comparing the torque intervention intensity with a preset torque threshold value, comparing the torque intervention time and a preset time threshold value, and entering an assistant mode of the EPS when the torque intervention intensity exceeds the preset torque threshold value and the torque intervention time exceeds the preset time threshold value. The invention discloses an automatic parking system based on the EPS. A parking guide module selects target parking strategies according to results of a parking space detection module, and a mode switching module switches parking modes according to torque intervention intensity and torque intervention time on a steering wheel in the automatic parking process.

Owner:HEFEI UNIV OF TECH

Steel truss girder assembling, erecting and construction process

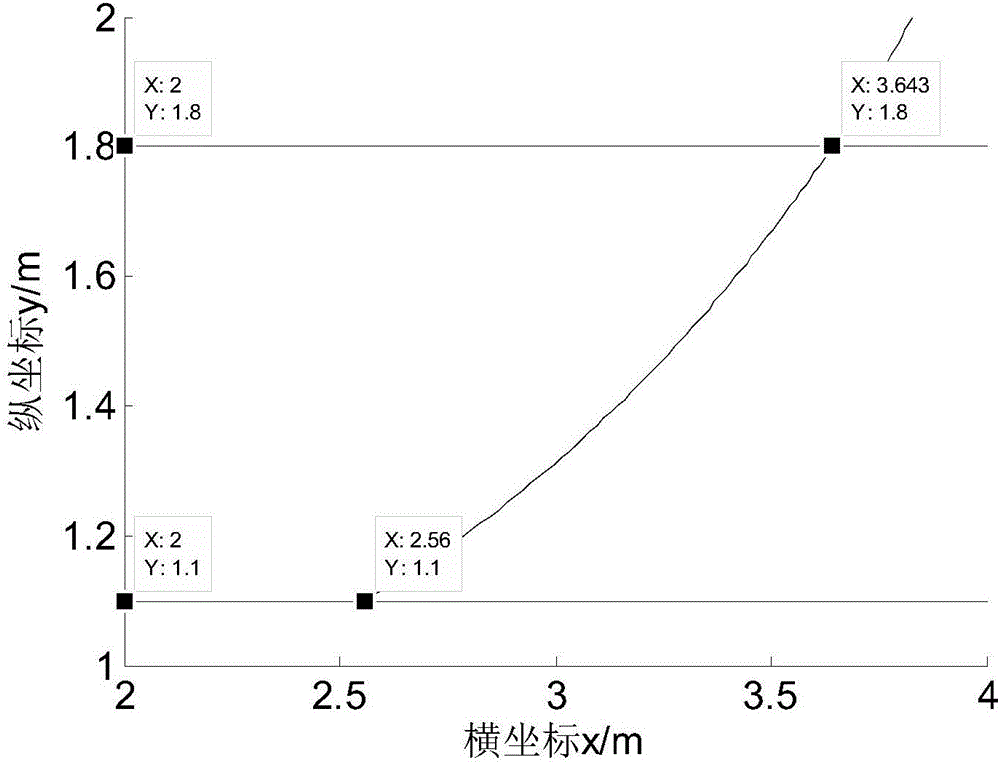

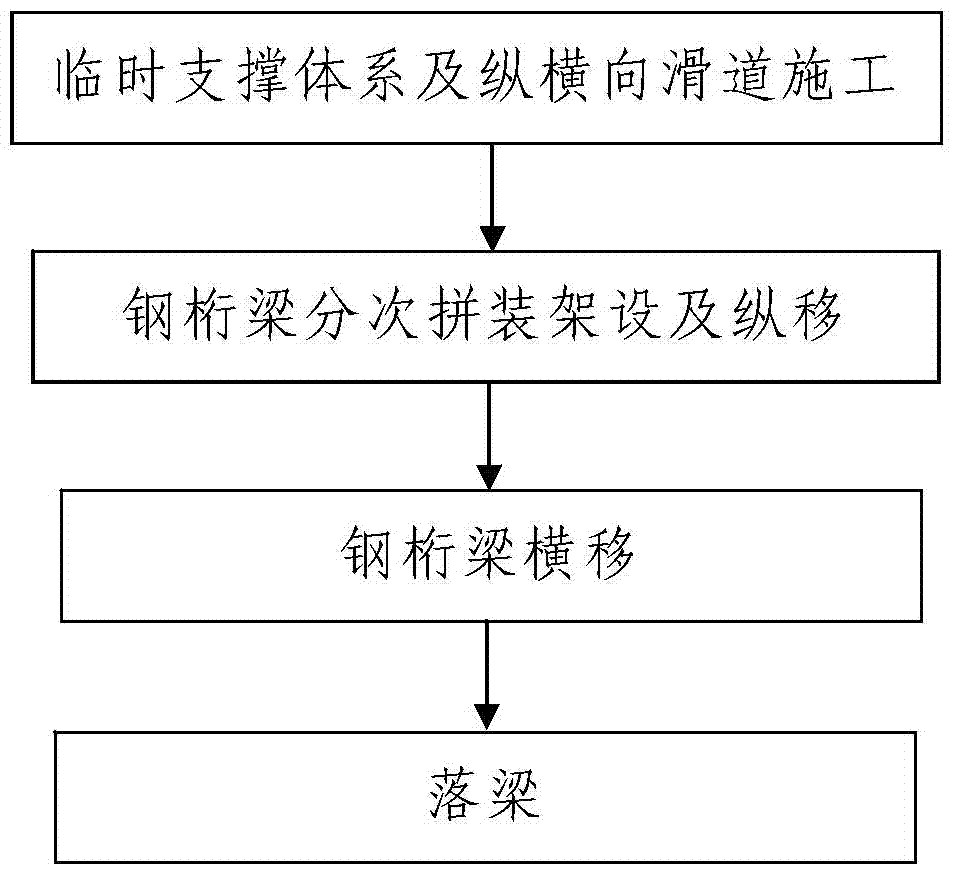

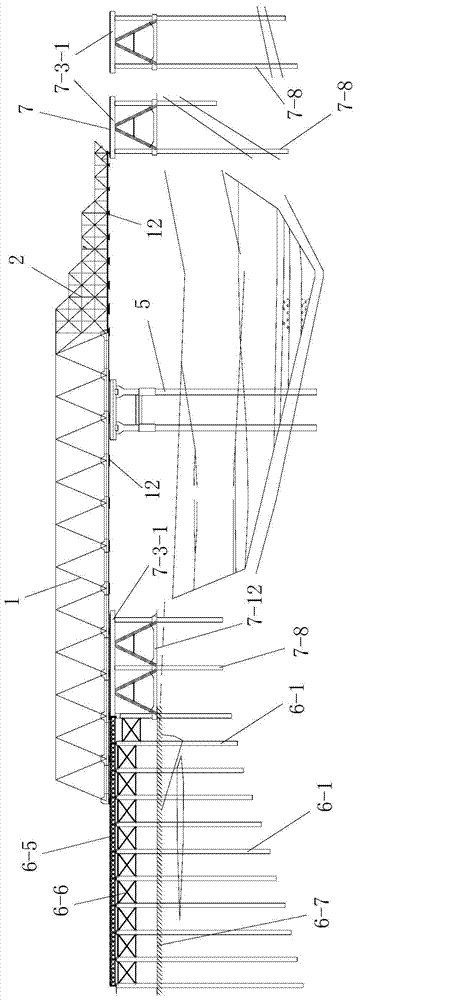

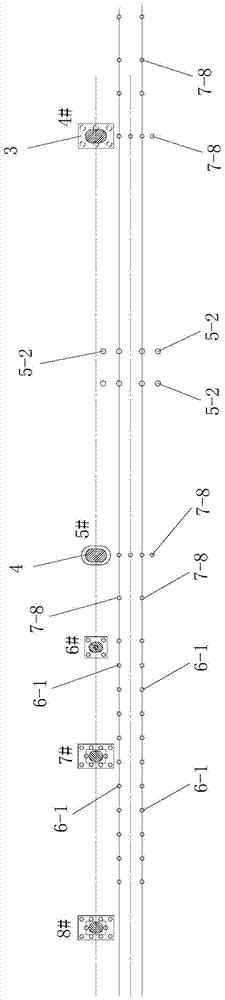

ActiveCN103614969AThe construction process steps are simpleSimple and fast operationBridge erection/assemblyButtressSupporting system

The invention discloses a steel truss girder assembling, erecting and construction process. A steel truss girder is a girder body, the front end and the rear end of an erected steel truss girder are supported on a first permanent buttress and a second permanent buttress respectively, the steel truss girder is formed by splicing a plurality of steel truss girder segments in an end-to-end mode, and the first permanent buttress and the second permanent buttress are located on the two sides of a main riverway of a river respectively. Assembling and erecting of the steel truss girder include the first step of construction of temporary supporting systems, longitudinal sliding rails and transverse sliding rails, the second step of assembling, erecting and longitudinal moving of the steel truss girder at different times, the third step of transverse moving of the steel truss girder and the fourth step of setting of the girder, wherein in the first step, the temporary supporting systems are constructed on one side of the first permanent buttress and on one side of the second permanent buttress respectively, the two longitudinal sliding rails used for the steel truss girder to move longitudinally and the two transverse sliding rails used for the steel truss girder to move transversely are distributed on the temporary supporting systems; in the second step, the steel truss girder segments are assembled more than once from front to back and are longitudinally moved many times. The steel truss girder assembling, erecting and construction process is simple in process, reasonable in design, convenient to achieve, good in construction effect and little in construction difficulty, and the assembling and erecting processes of the steel truss girder can be conveniently and quickly achieved.

Owner:NO 1 ENG LIMITED OF CR20G

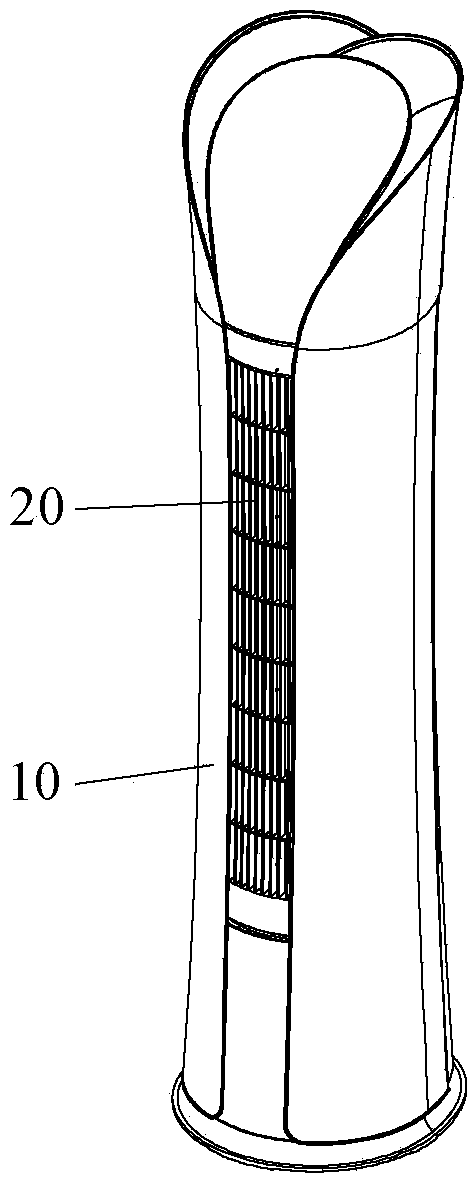

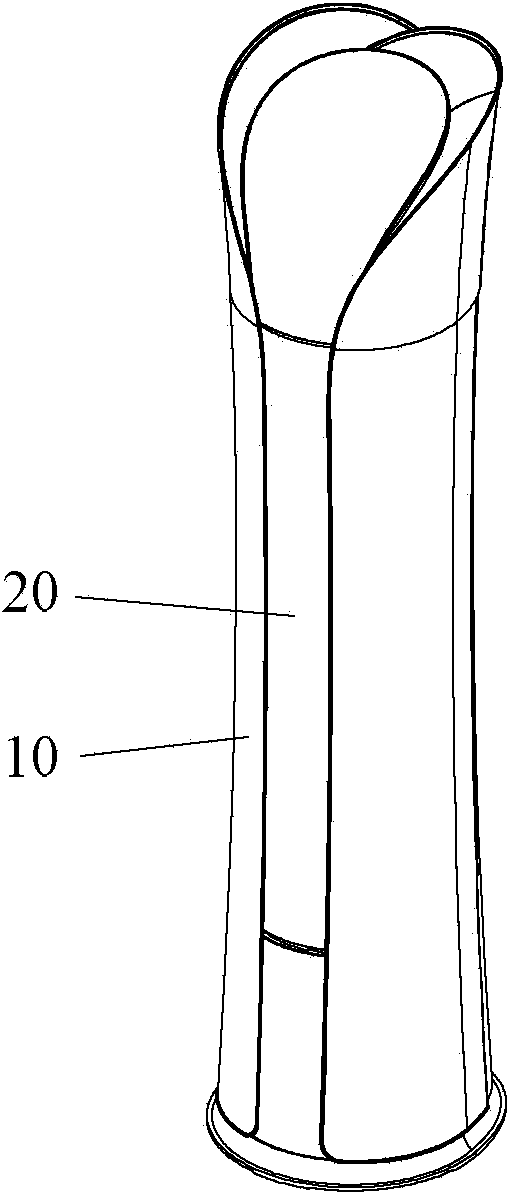

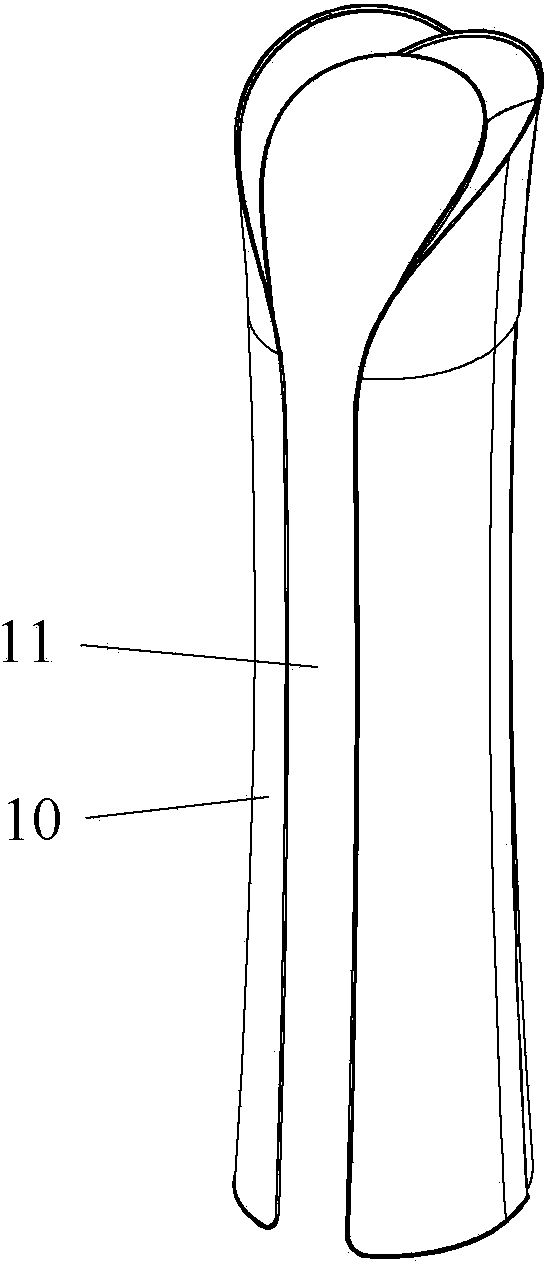

Air conditioner

InactiveCN103900158AReduce frictionSmooth rotationLighting and heating apparatusNoise suppressionEngineeringDriving mode

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

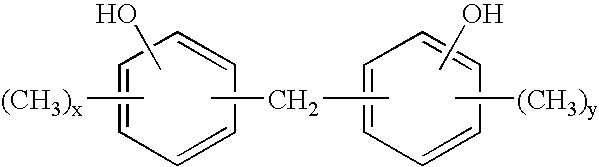

Negative electrode active material for charging device

ActiveUS20090023066A1Improve low temperature performanceIncrease energy densityHybrid capacitor electrolytesCarbon compoundsLithiumOrganic solvent

To present a carbon material which provides an electrical storage device not only ensuring a high energy density but also realizing a high output and an excellent low temperature performance.A negative electrode active material for an electrical storage device employing an aprotic organic solvent electrolyte solution containing a lithium salt as an electrolytes characterized in that it is made of a carbon material having a specific surface area of from 0.01 to 50 m2 / g and a total mesopore volume of from 0.005 to 1.0 cc / g, wherein volumes of mesopores having pore diameters of from 100 to 400 Å occupy at least 25% of the total mesopore volume.

Owner:SUBARU CORP

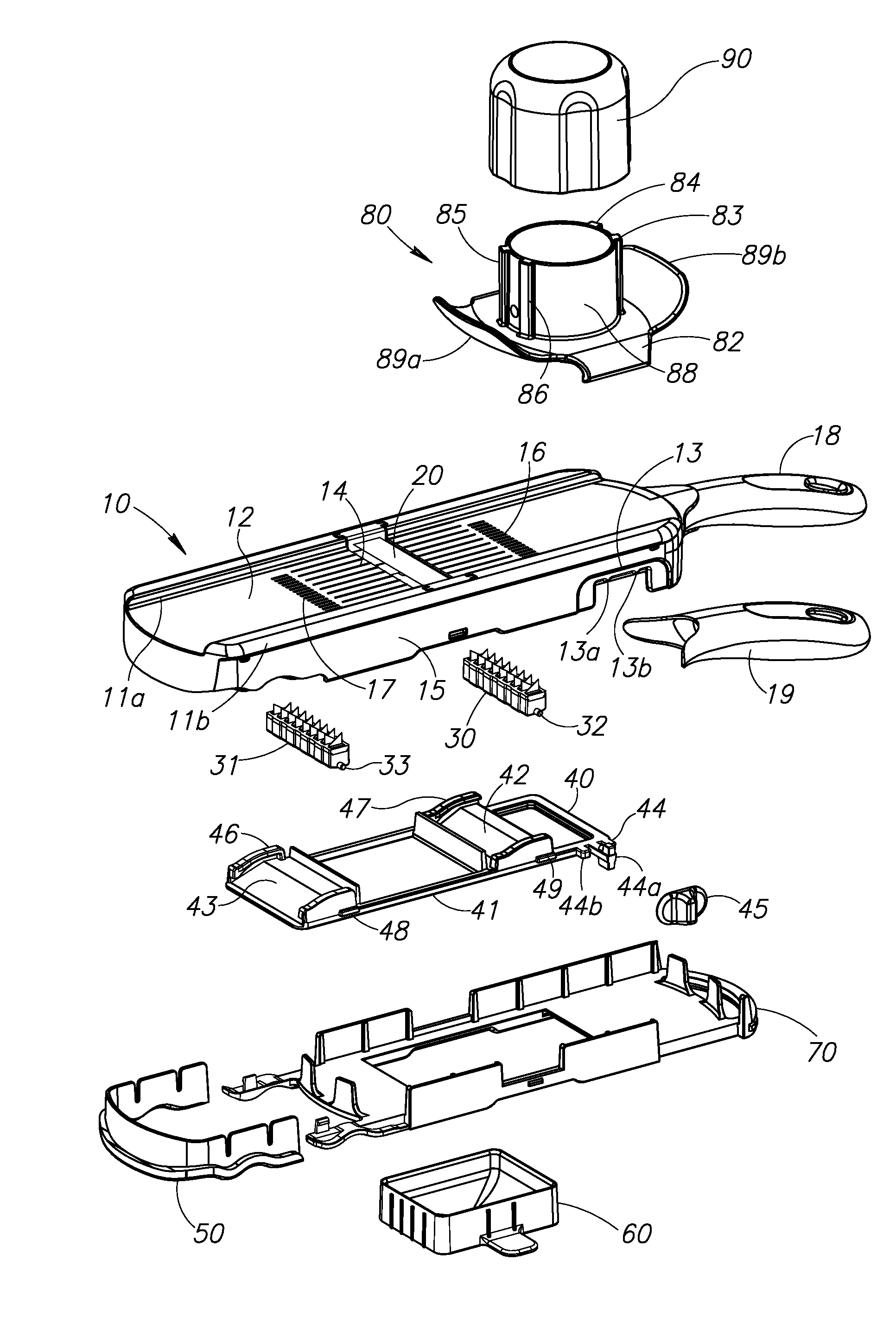

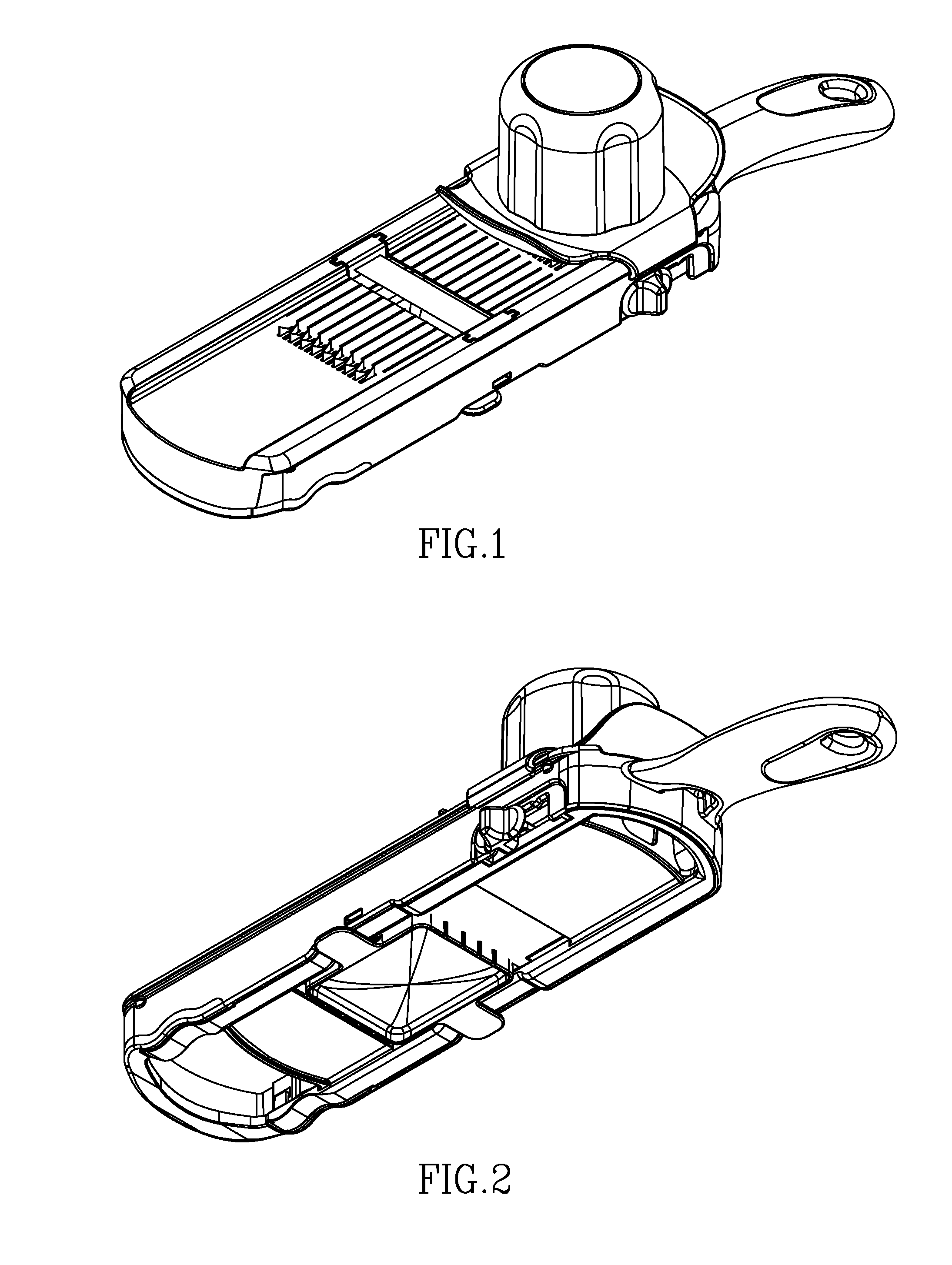

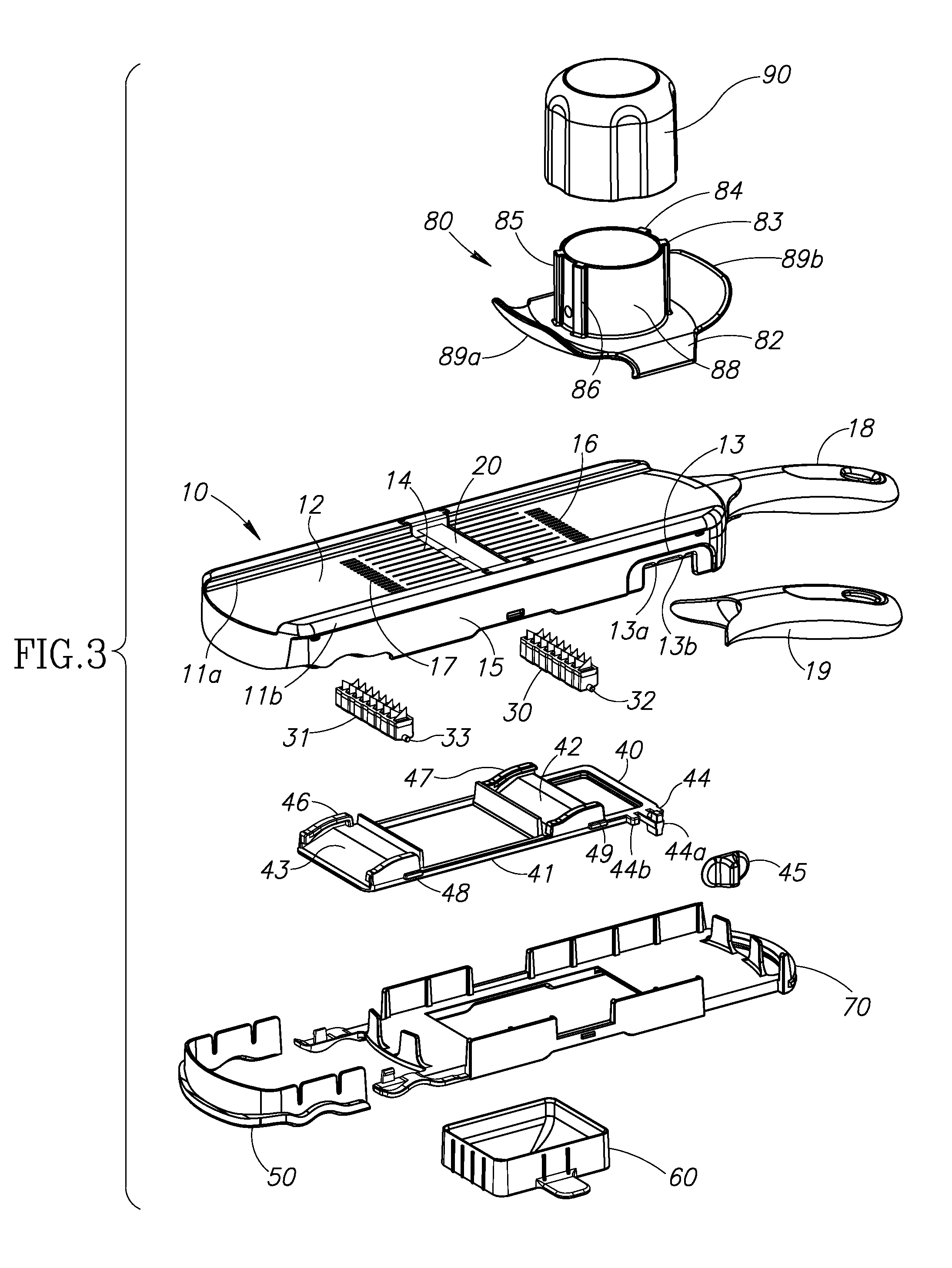

Food processing tool

ActiveUS8181560B2Easy to slideReduce frictionFruit stoningGang saw millsEngineeringMechanical engineering

A food processing tool particularly suited for processing garlic and the like generally includes a main body having a tray configured to allow garlic to be passed back and forth across the tray for processing as desired. The main body optionally includes a pair of opposing guides positioned on opposing lateral sides of the tray and a plurality of ribs provided along either a portion or the entirety of the tray to reduce friction and improve the sliding ability of the garlic along the ribs and therefore the tray. A main slicing blade and one or more pluralities of blades are provided to slice, mince, or julienne cut the garlic. A pusher and cap is configured to selectively allow or restrict rotational movement of the cap and garlic for different orientations when cutting.

Owner:PROGRESSIVE INT

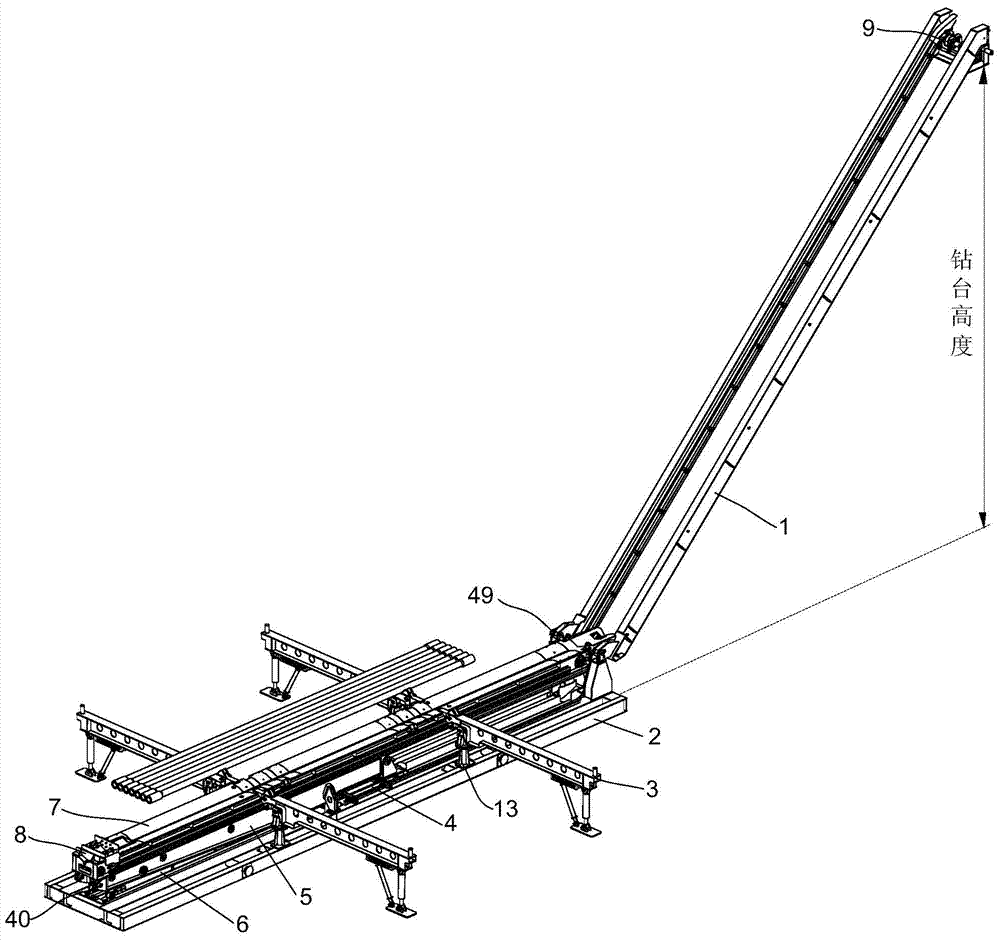

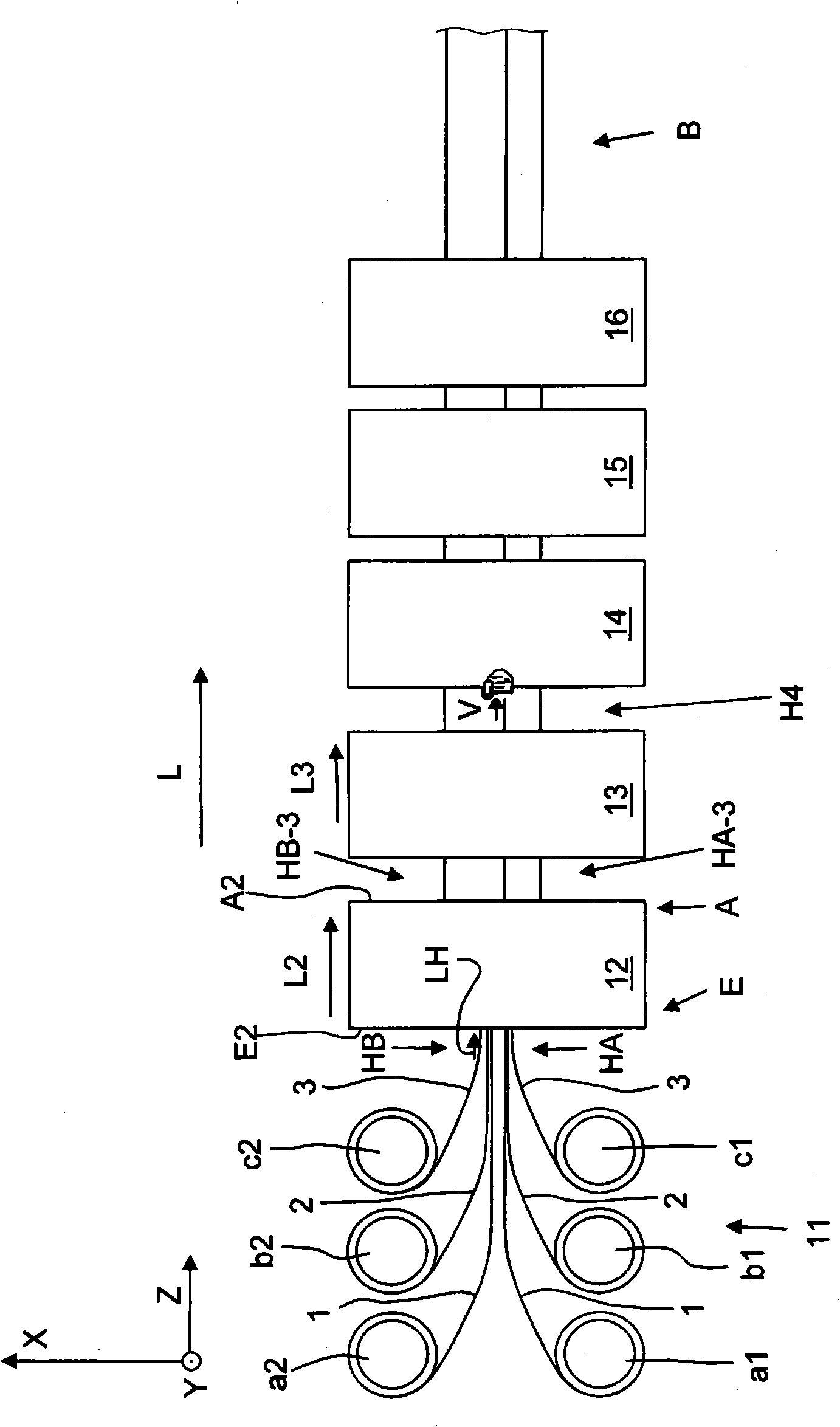

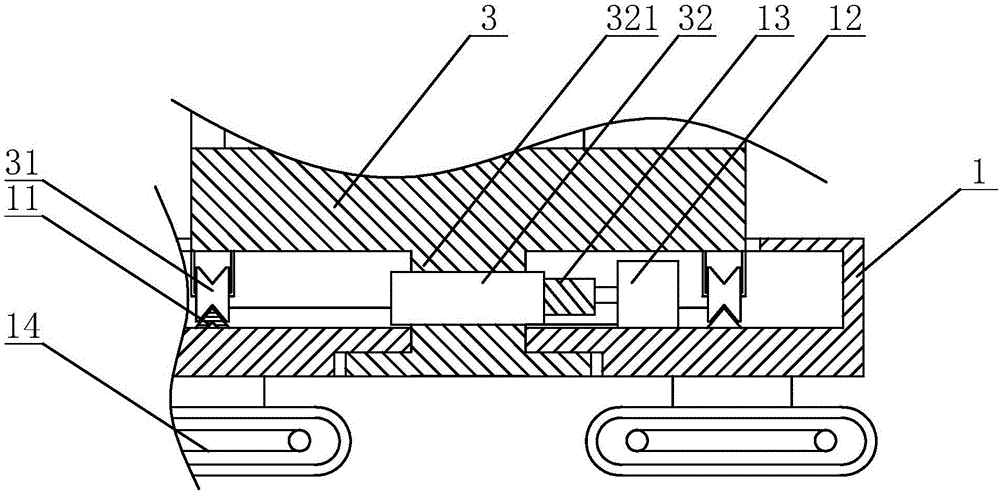

Hoisting land power catwalk of cylinder

ActiveCN104265207AImprove work efficiencyThe drill effect is obviousDrilling rodsDrilling casingsOil drillingPulley

The invention discloses a hoisting land power catwalk of a cylinder and belongs to the technical field of oil drilling equipment. The hoisting land power catwalk comprises a ramp, a pedestal, a rotating arm and a V-shaped drilling tool support beam, the upper end of the ramp is provided with a ramp guide pulley which is positioned at the connection part of the ramp and the drilling platform; the bottom of the V-shaped drilling tool support beam is provided with a support beam guide rail combined with the ramp guide pulley, and the support beam guide rail can be moved with respect to the ramp guide pulley. The hoisting land power catwalk is characterized in that the support beam guide rail at the V-shaped drilling tool support beam bottom is combined with the ramp guide pulley on the upper end of the ramp to directly convey the drilling rod near the well mouth, thereby improving drill-feeding working efficiency, in particular, the structure has the more obvious drill-feeding effect in the high drilling platform.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

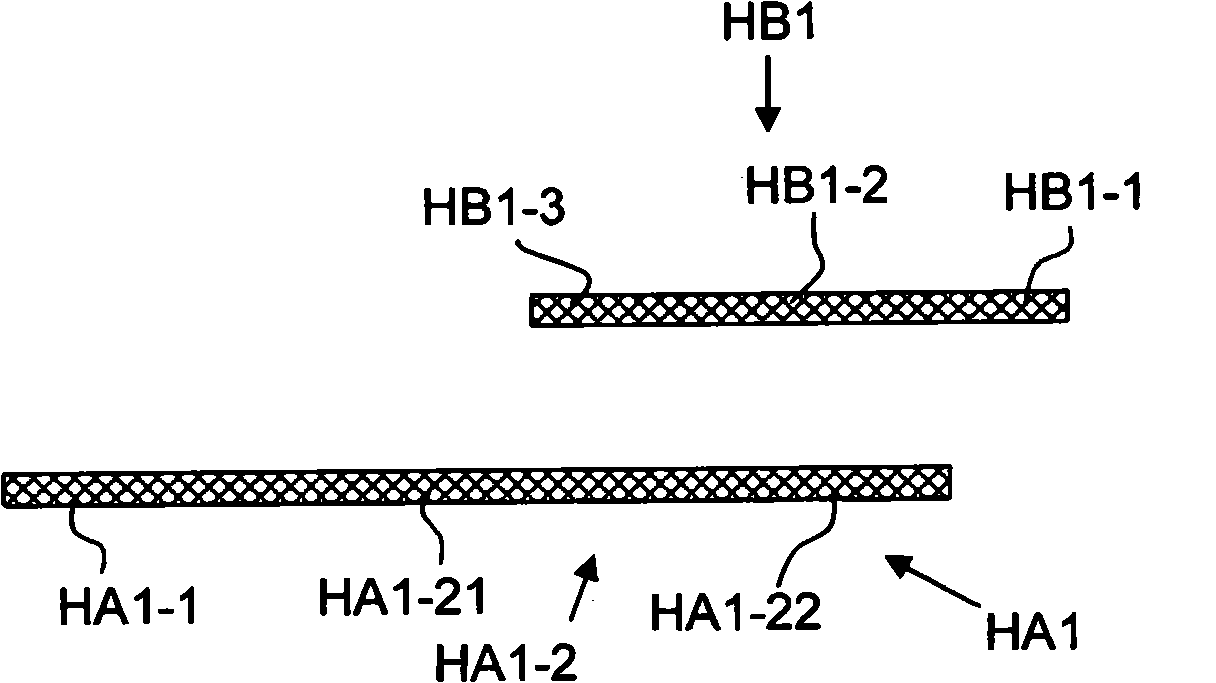

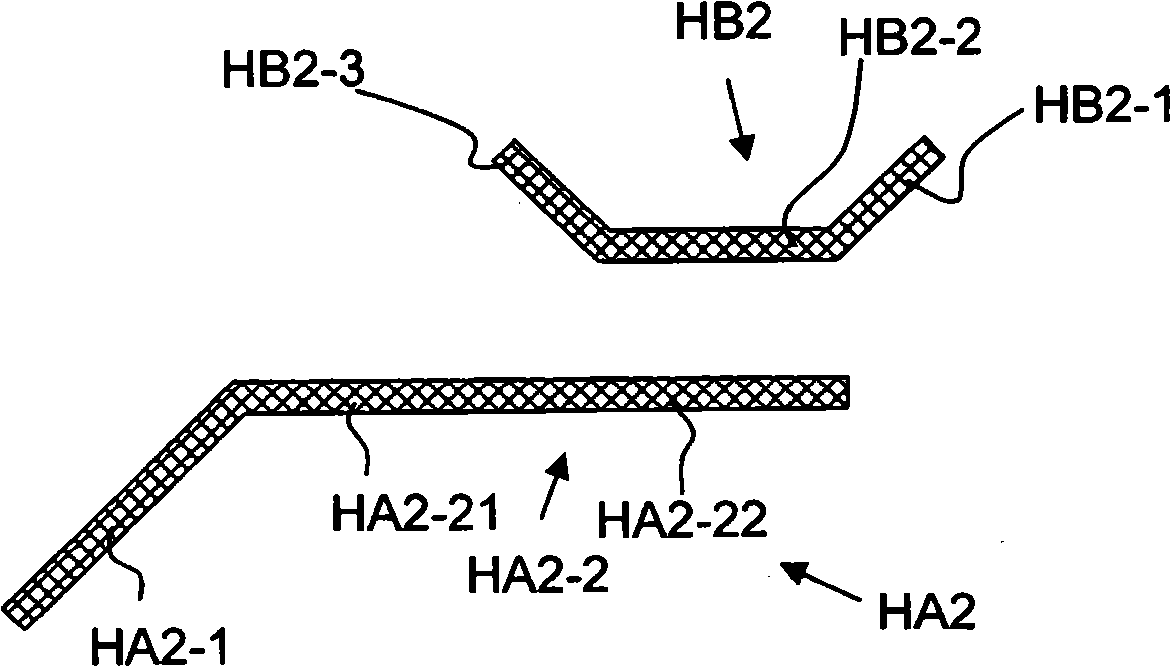

Method for the production of a profiled preform or a profiled fiber composite-plastic component

Owner:AIRBUS OPERATIONS GMBH

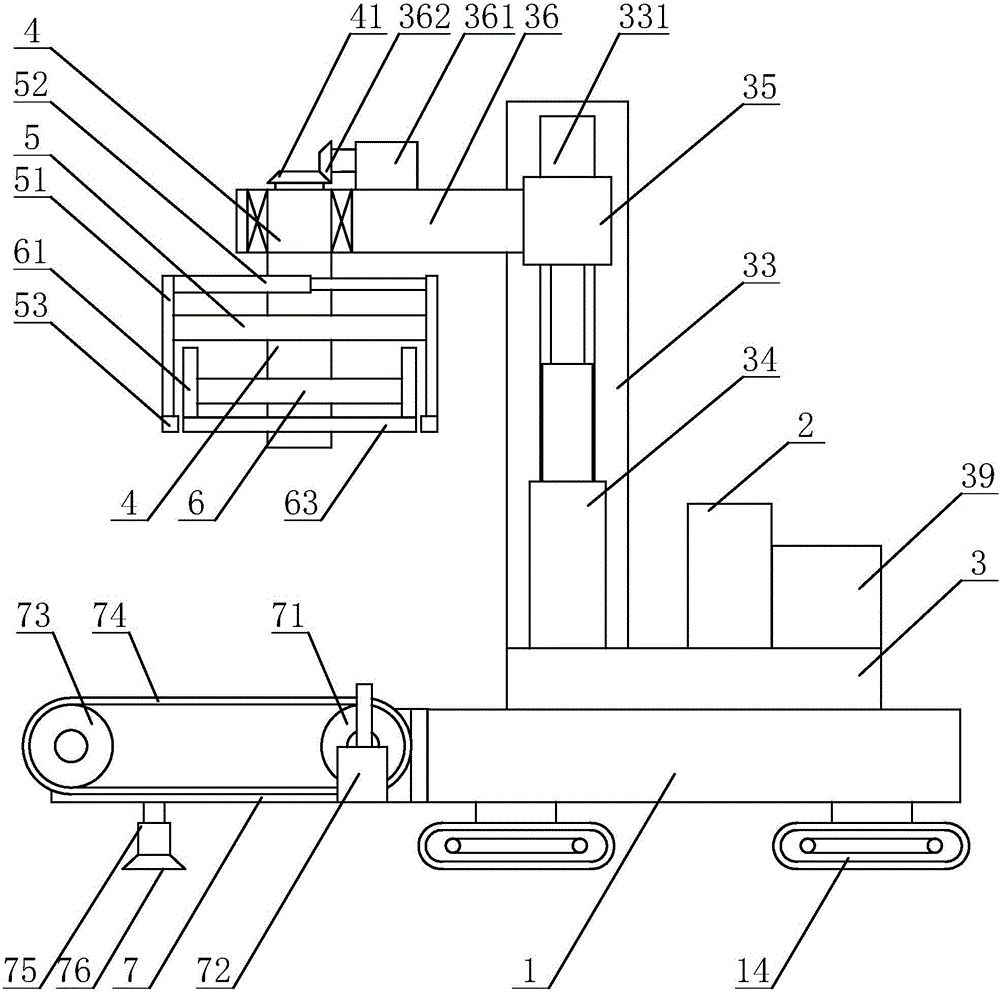

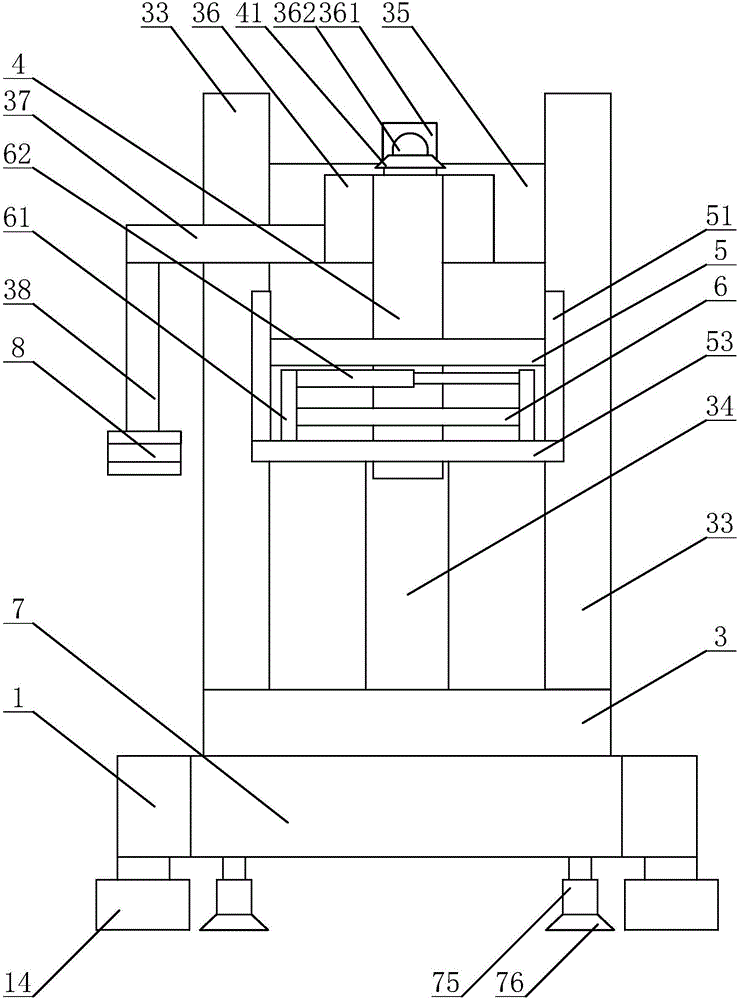

Intelligent brick stacking machine

ActiveCN106429465AMake sure to staggerStack stableStacking articlesConveyor partsBrickAgricultural engineering

The invention discloses an intelligent brick stacking machine and mainly relates to the technical field of building material machinery. The intelligent brick stacking machine comprises a support and a PLC controller, wherein a rotating platform is arranged on the support; a supporting frame and a servo air cylinder are arranged on the rotating platform; a bearing frame is arranged at the upper end of the servo air cylinder; a bearing cross rod is arranged at the front end of the bearing frame; a transmission rod is vertically arranged at the front end of the bearing cross rod; one end, far away from the bearing cross rod, of the transmission rod is connected with a clamping mechanism; the clamping mechanism comprises a transverse clamping part and a longitudinal clamping part; a balancing weight is arranged on the rotating platform. The intelligent brick stacking machine has the beneficial effects that the intelligent brick stacking machine can stack the bricks quickly and efficiently, can increase the working frequency, can move automatically according to the actual stacking requirement and can adjust the placing position of the bricks so as to guarantee the brick stacking stability.

Owner:LUOYANG INST OF SCI & TECH

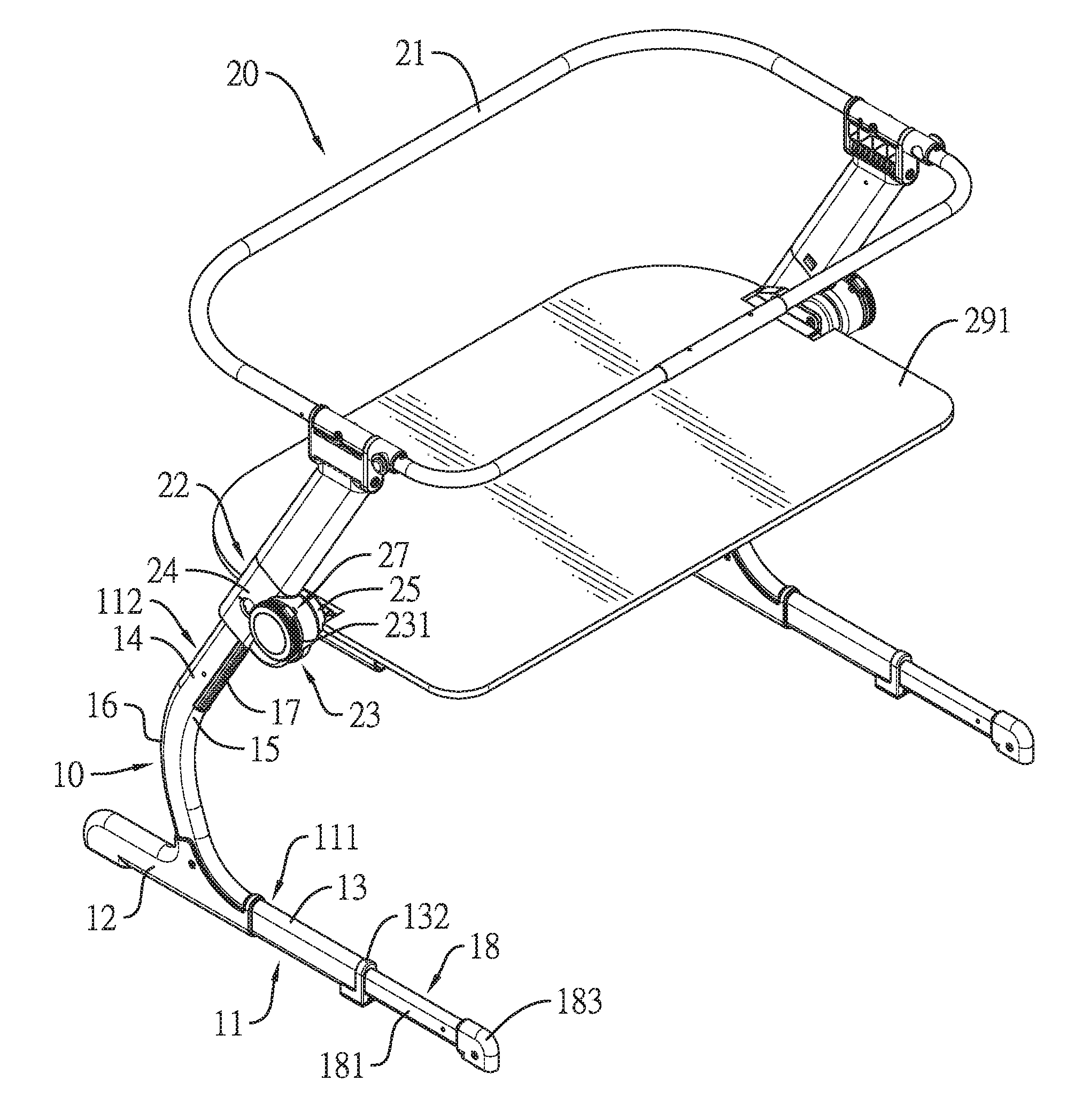

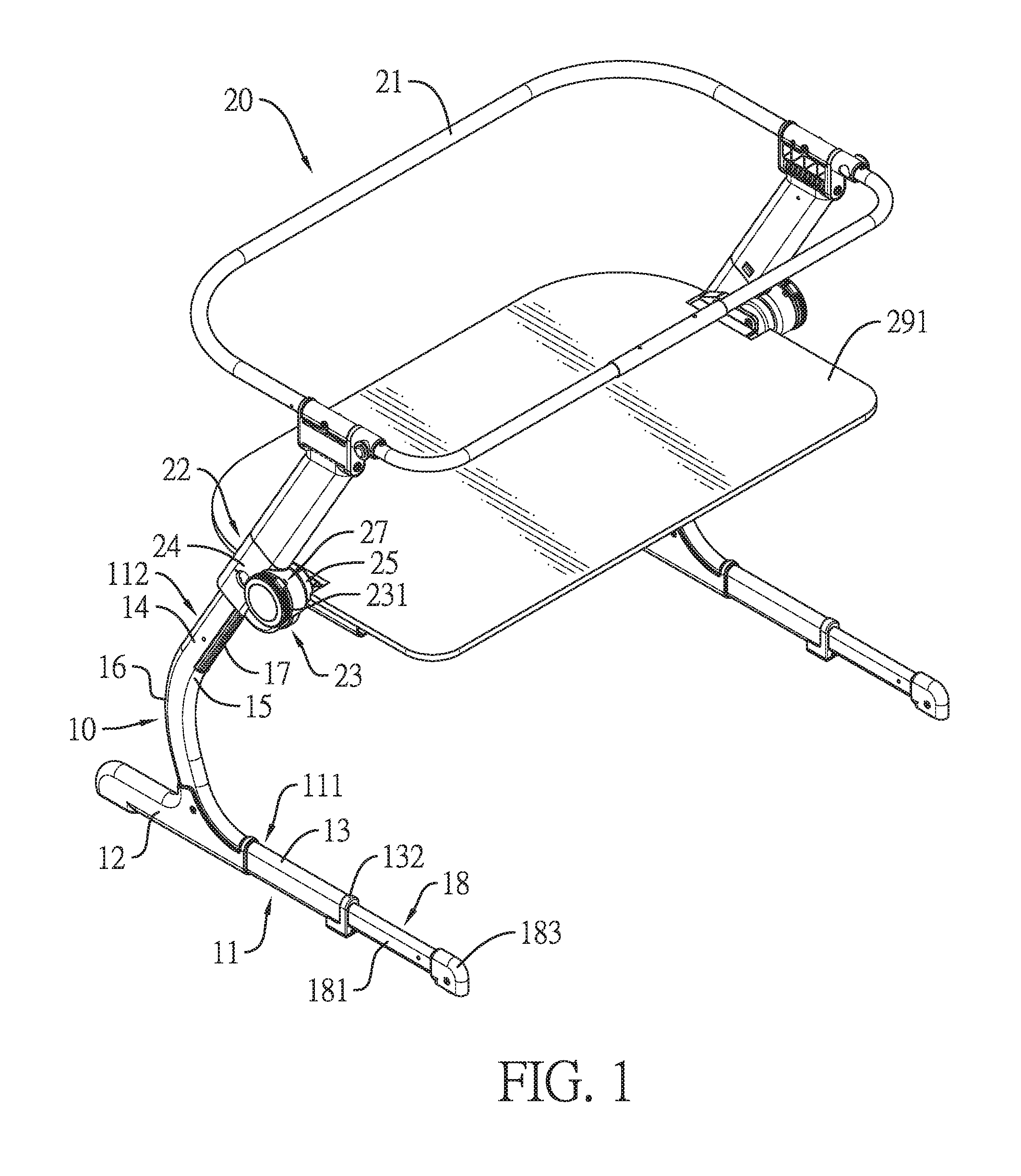

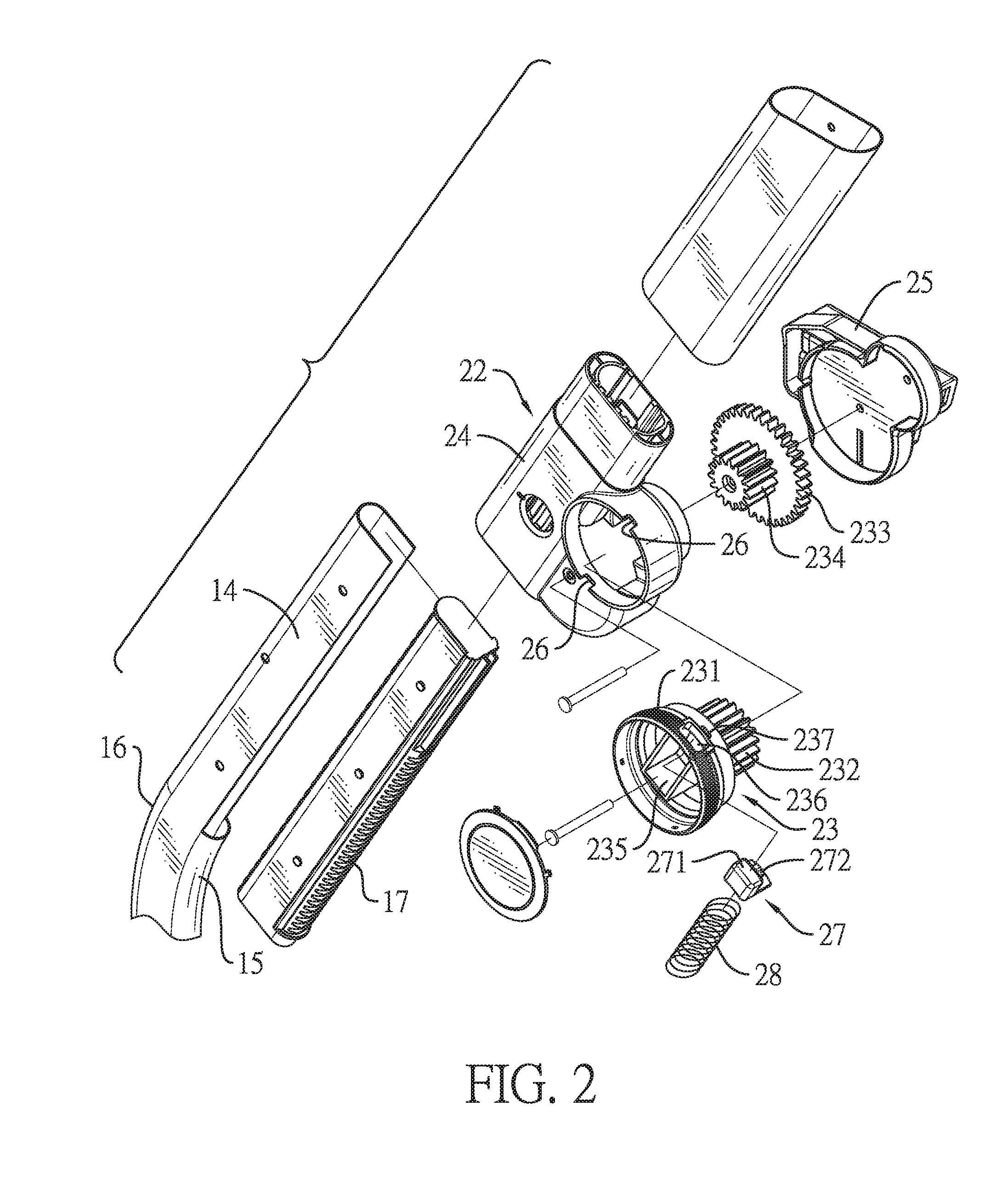

Supporting apparatus for a crib

ActiveUS20160198864A1Guaranteed to move normallyCradleSofasClassical mechanicsMechanical engineering

A supporting apparatus for a crib has two legs and a frame. Each leg has a rack. The frame is moveably mounted between the legs and has a body, two moving seats and two adjustment members. The moving seats are mounted on the body, and the legs are inserted into the moving seats respectively. The adjustment members are mounted on the moving seats respectively and engage with the racks of the legs respectively, and each adjustment member is rotatable and moveable upward and downward along a corresponding one of the racks of the legs. The supporting apparatus can be steplessly adjusted to adjust the height of a bed surface of the crib to improve safety.

Owner:B & B BEST IND

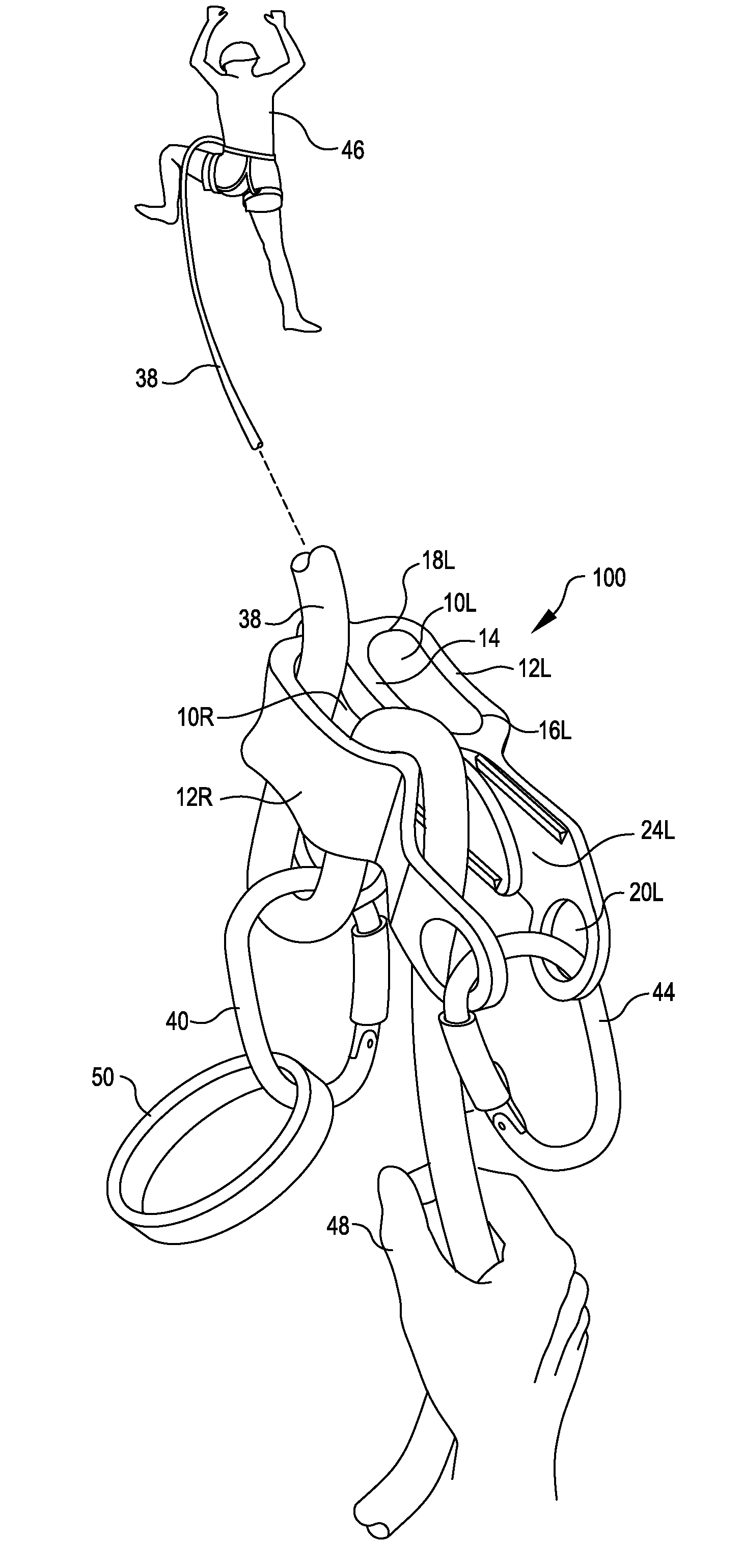

Rope handling device with secondary locking feature

InactiveUS20110284323A1Arresting a fall or lowering the climberEasy and convenient and secure lockingSafety beltsMountaineeringMechanical engineering

Rope handling devices that can be used for belaying, descending and rappelling are disclosed and provide a secure lock off without requiring the use of specialized knots. A secondary rope lock off feature, which provides for locking the ends of two ropes using a single snap link is also disclosed. In general, rope handling devices of the present invention have a body with at least one closed-ended slot and at least one open-ended slot. A loop of rope may be passed through the closed-ended slot(s) from an upper area and retained within the closed-ended slot by attachment of a first snap link to the loop of rope from below the lower area of the slot. A brake strand of rope may be positioned within the open-ended slot to aid in arresting a fall or lowering a climber. Further, the brake strand may be entrapped within the open-ended slot by attaching a second snap link through at least one aperture proximal to the open-ended slot.

Owner:AYRE WILLIAM H

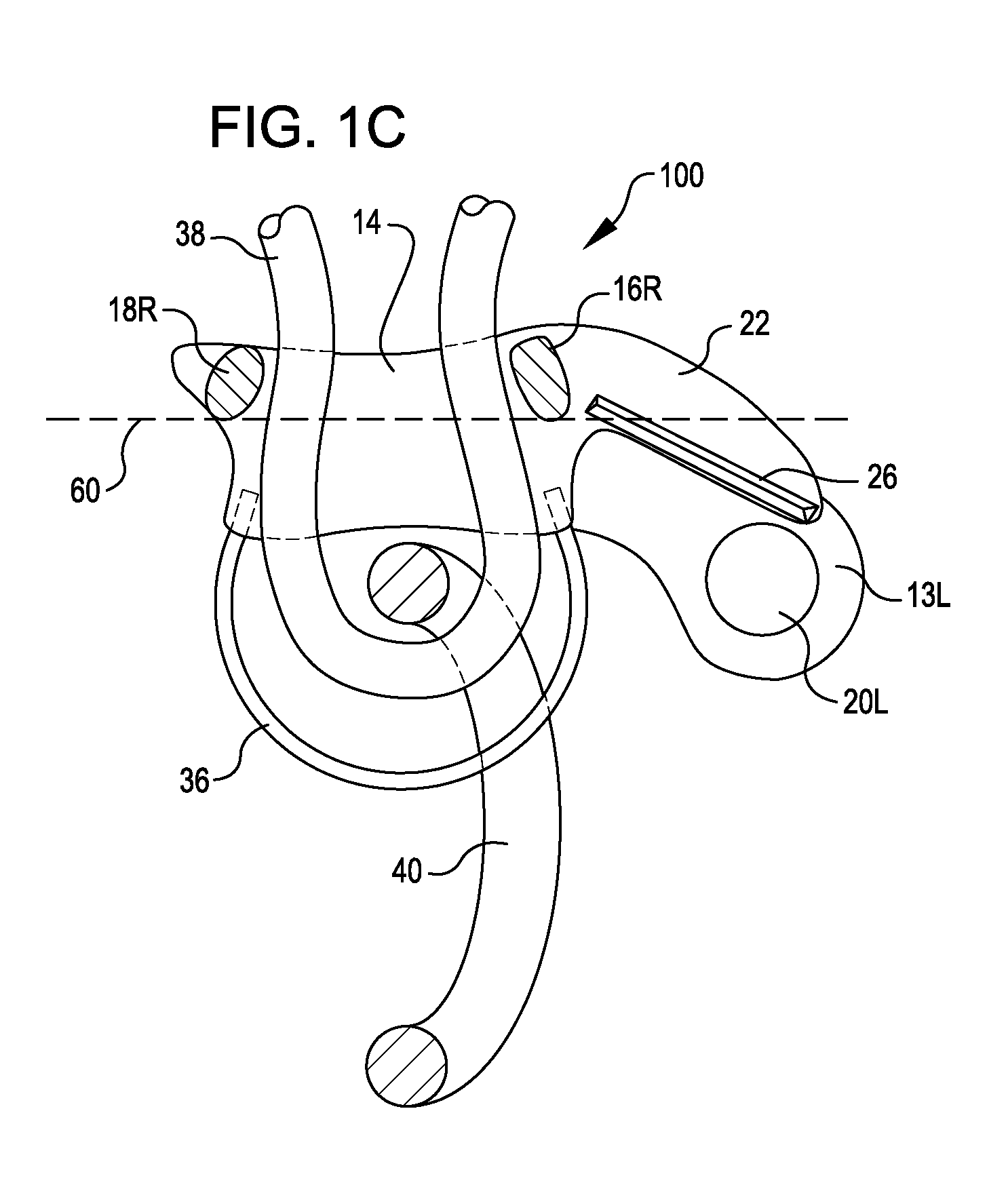

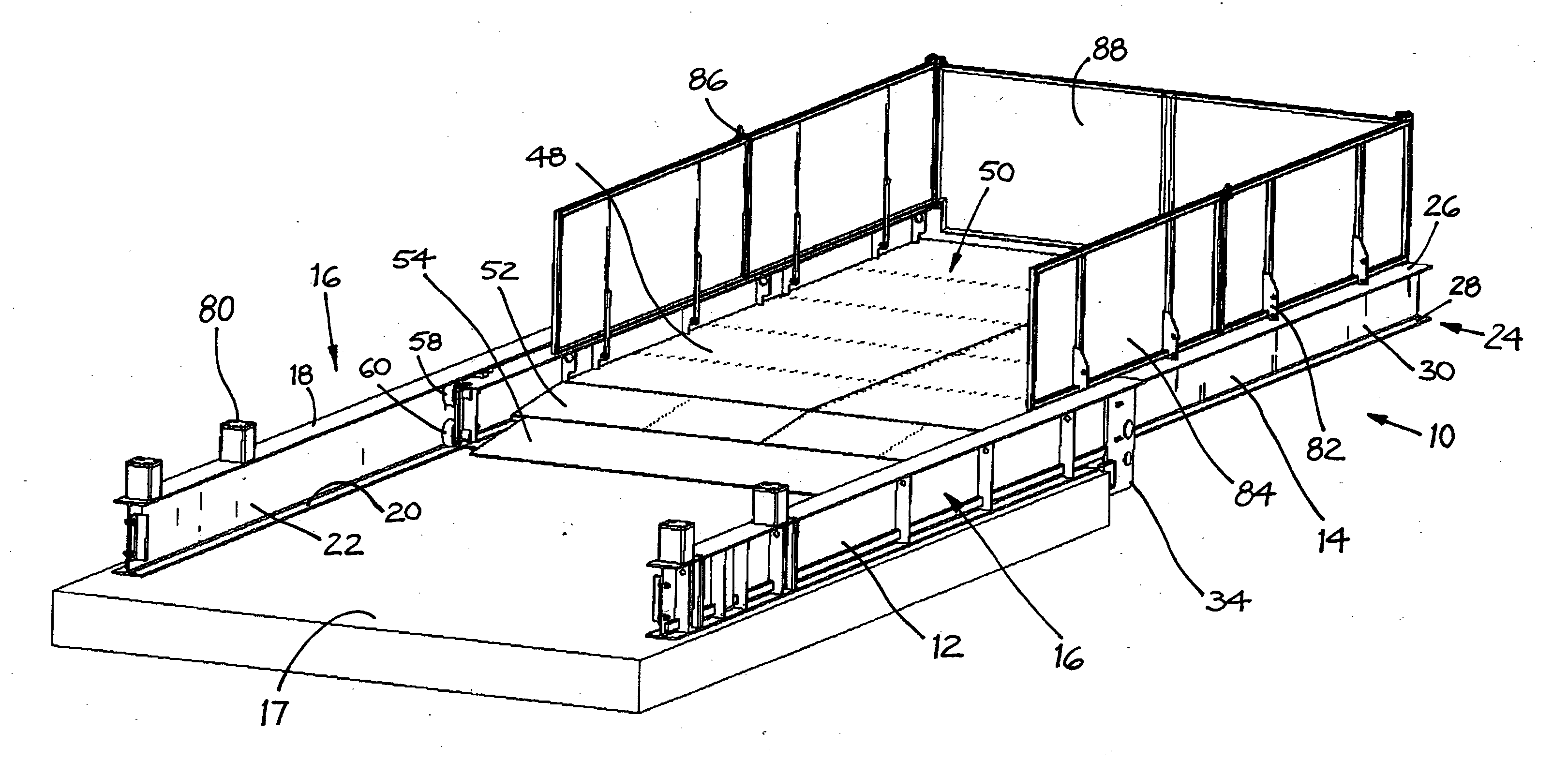

Load carrying platform shuttle

ActiveUS20150152656A1Increase the number ofGuaranteed to move normallySemiconductor/solid-state device manufacturingStands/trestlesLoad carryingAerospace engineering

A load carrying platform shuttle (10) has a static frame (12) and a movable carriage (14). The frame is securable to a mounting location, such as a given working level of a multi-storey building under construction, and the carriage is arranged to telescope into the static frame between an extended position outboard of the mounting location and a retracted position inboard of the mounting location. The movable carriage can move between the extended position and the retracted position while carrying a load. The shuttle includes a motor (76) and gear assembly (72, 74, 78) for driving the movement of the carriage between the extended position and the retracted position while carrying the load.

Owner:CONCRETE CANVAS TECH LTD

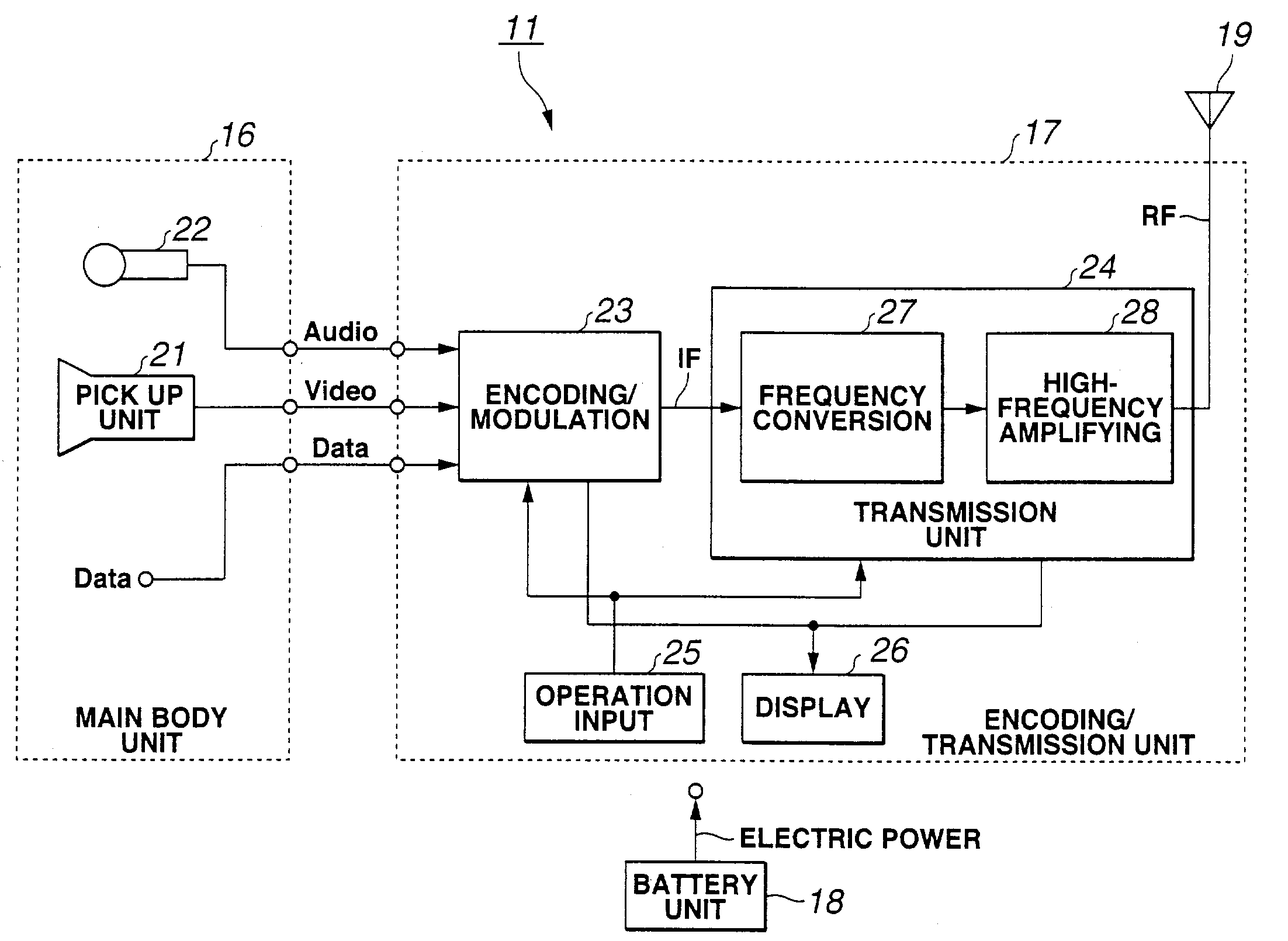

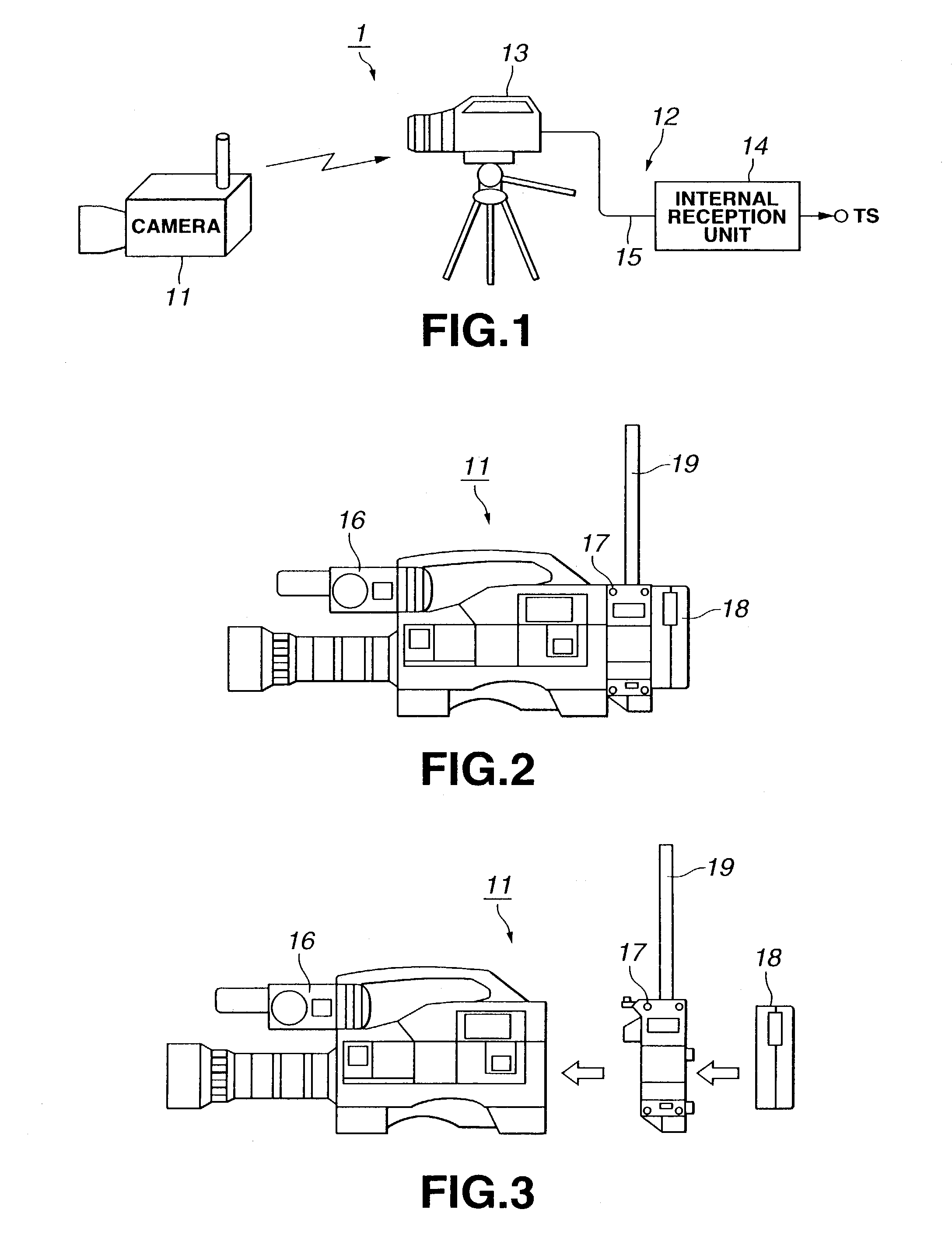

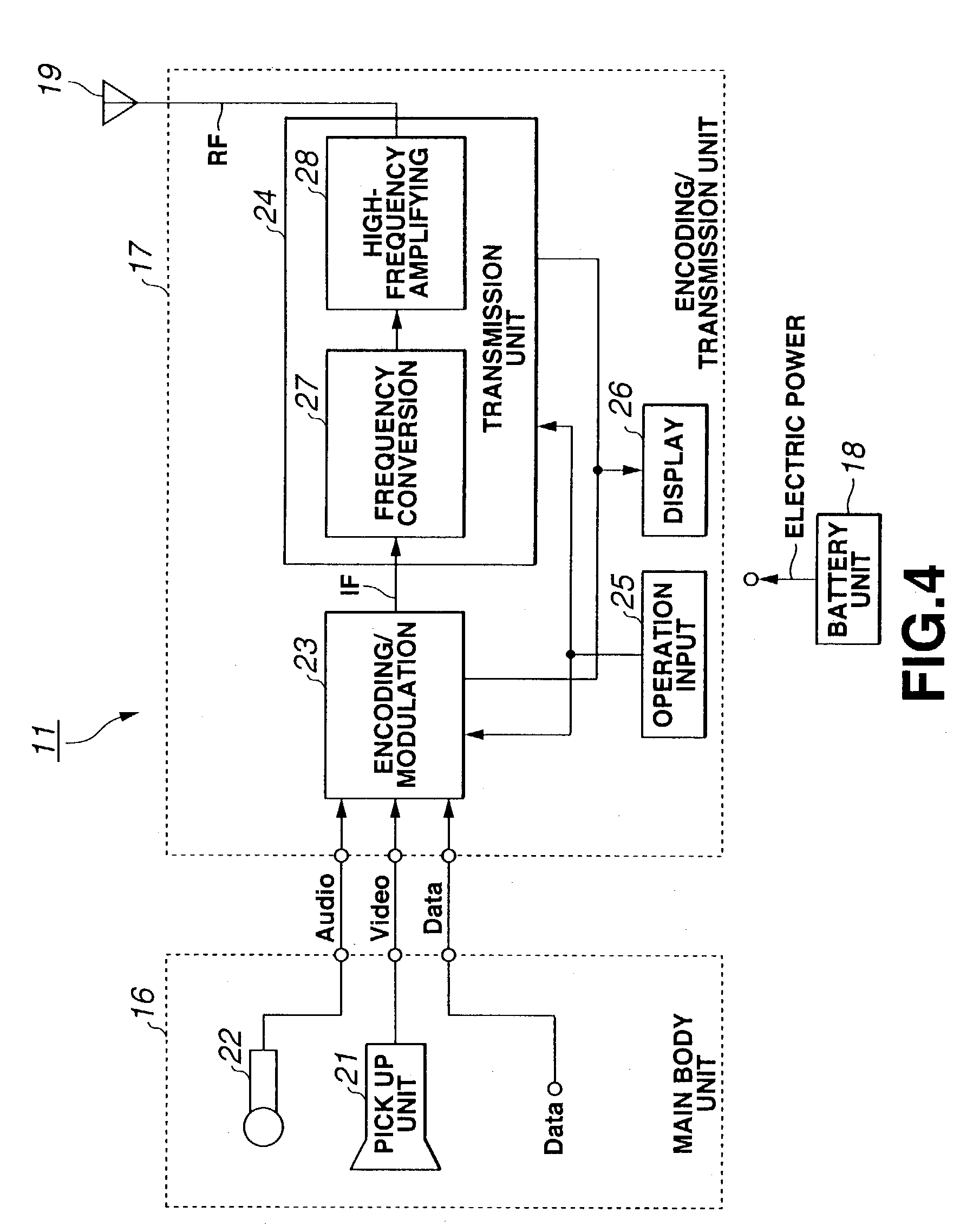

Wireless camera

InactiveUS7030910B2Guaranteed to move normallyTelevision system detailsColor television detailsEngineeringWireless camera

A wireless camera 11 includes a main body unit 16, encoding / transmission unit 17, and a battery unit 18. The encoding / transmission unit 17 includes a encoding / modulation unit 23 for performing MPEG 2 encoding and OFDM modulation, frequency converter 27, high-frequency amplifier 28, and a transmission antenna 19. The main body unit 16, encoding / transmission unit 17, and battery unit 18 are unitedly configured.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com