Patents

Literature

151results about How to "Small roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

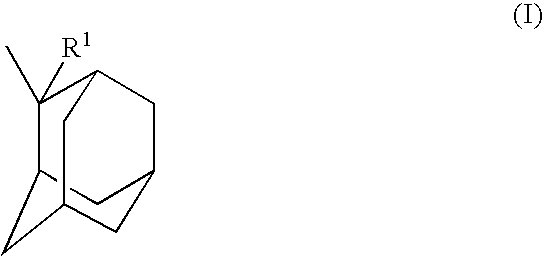

Positive resist composition and method of forming resist pattern from the same

InactiveUS20040110085A1Small line edge roughnessHigh resolutionRadiation applicationsSemiconductor/solid-state device manufacturingSolubilityMethacrylate

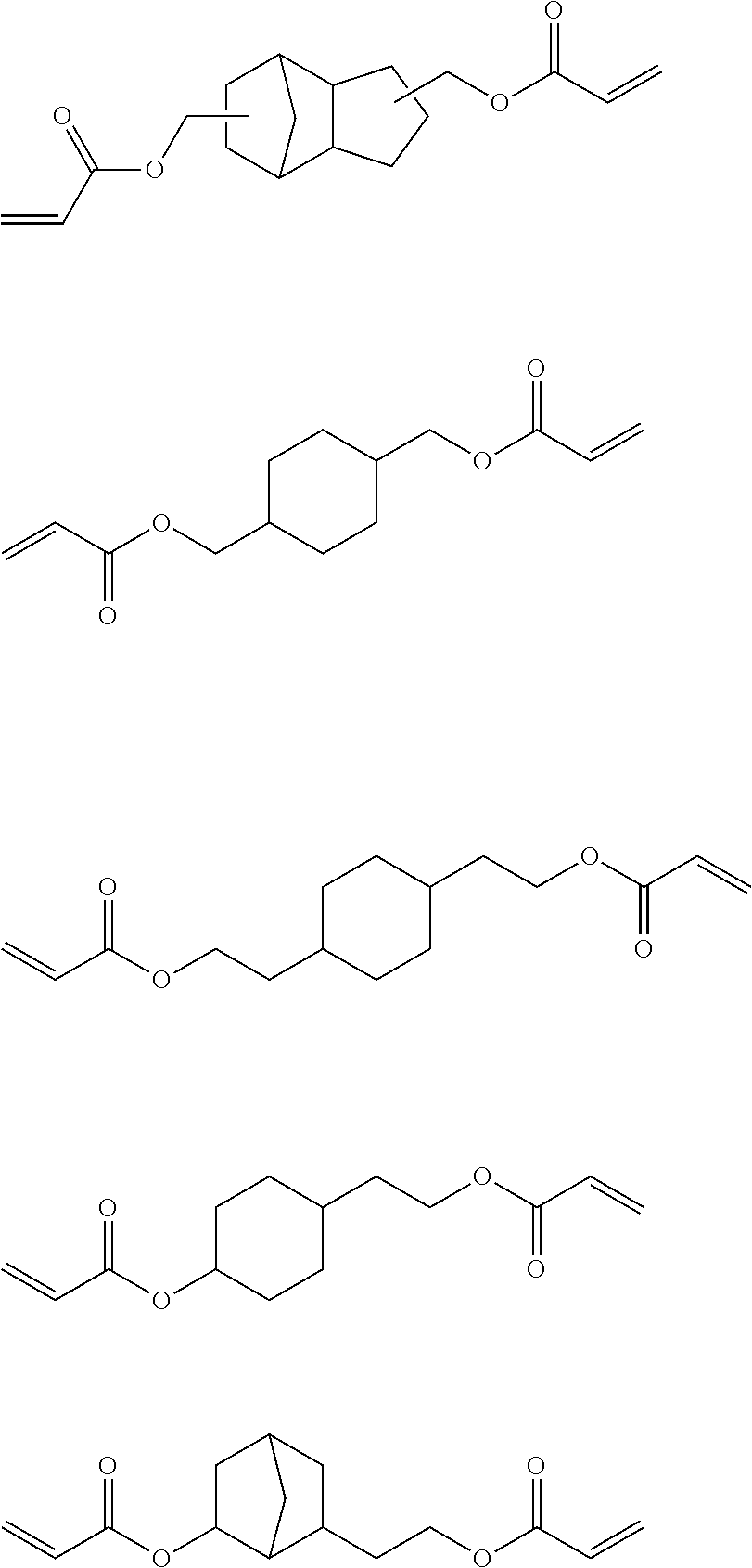

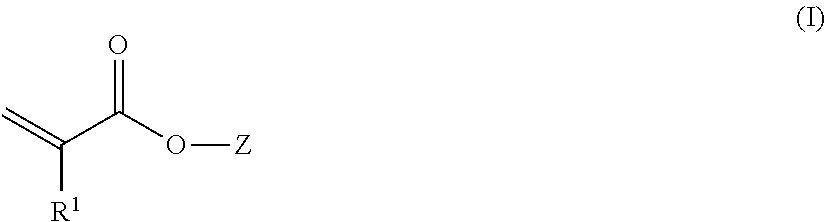

There is provided a positive type resin composition comprising (A) a resin component comprising within the principal chain a structural unit derived from a (meth)acrylate ester and incorporating an acid dissociable, dissolution inhibiting group containing a polycyclic group on an ester side chain section, for which the solubility in alkali increases under the action of acid, (B) an acid generator component which generates acid on exposure, and (C) an organic solvent, wherein the component (A) comprises both a structural unit derived from a methacrylate ester and a structural unit derived from an acrylate ester. According to such a resist composition, a resist pattern can be formed which displays little surface roughness and line edge roughness on etching, and also offers excellent resolution and a wide depth of focus range.

Owner:TOKYO OHKA KOGYO CO LTD

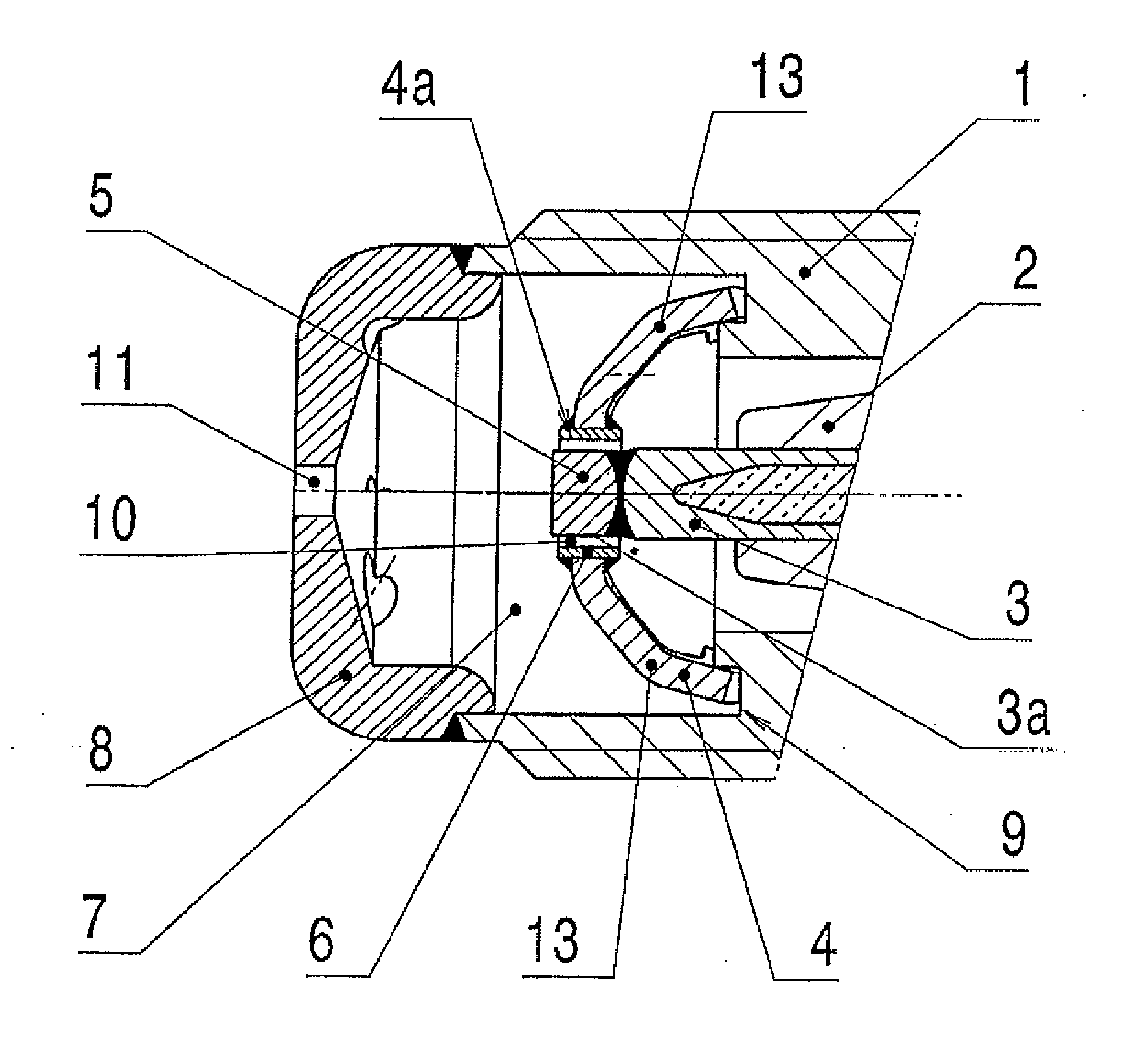

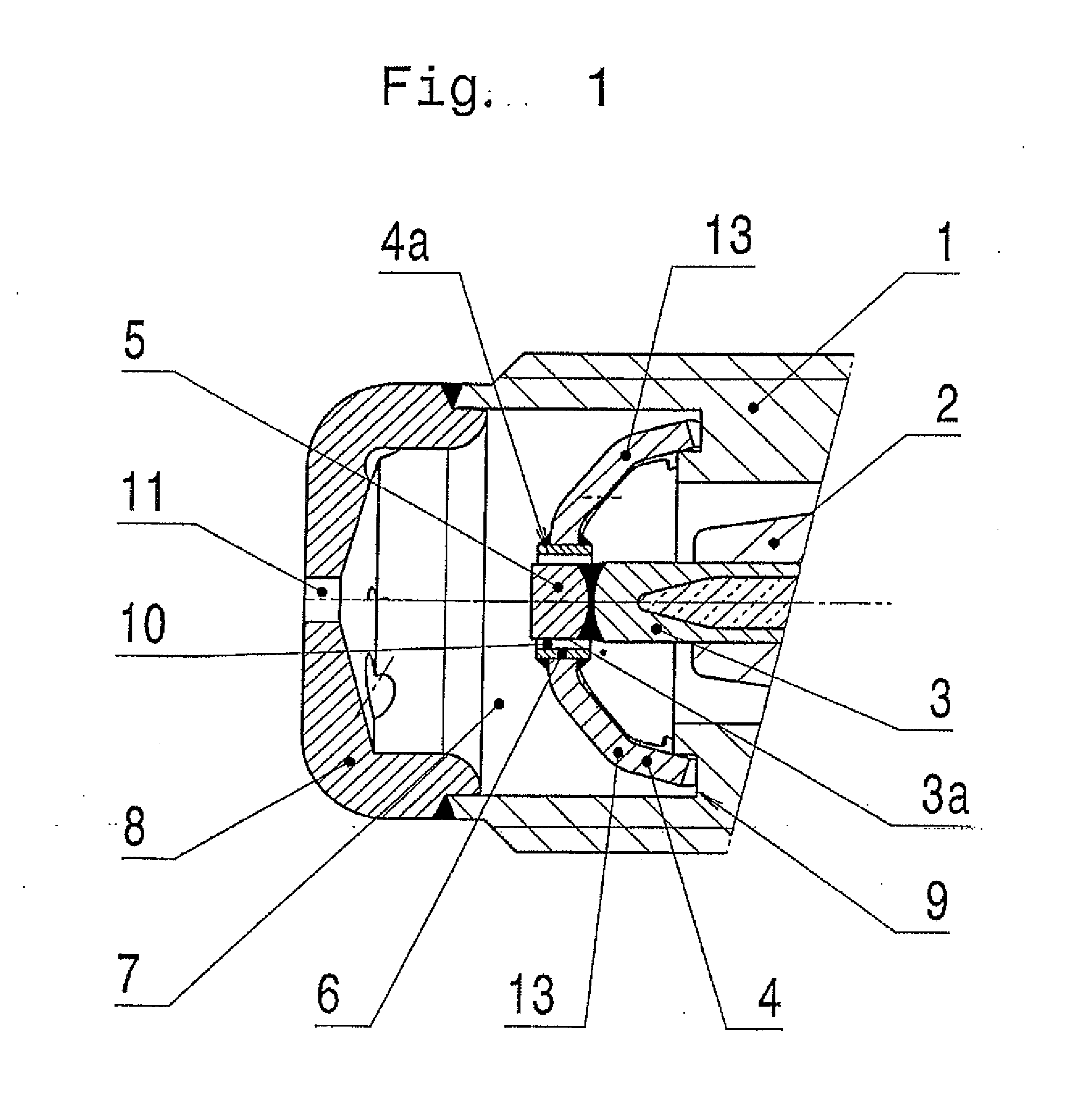

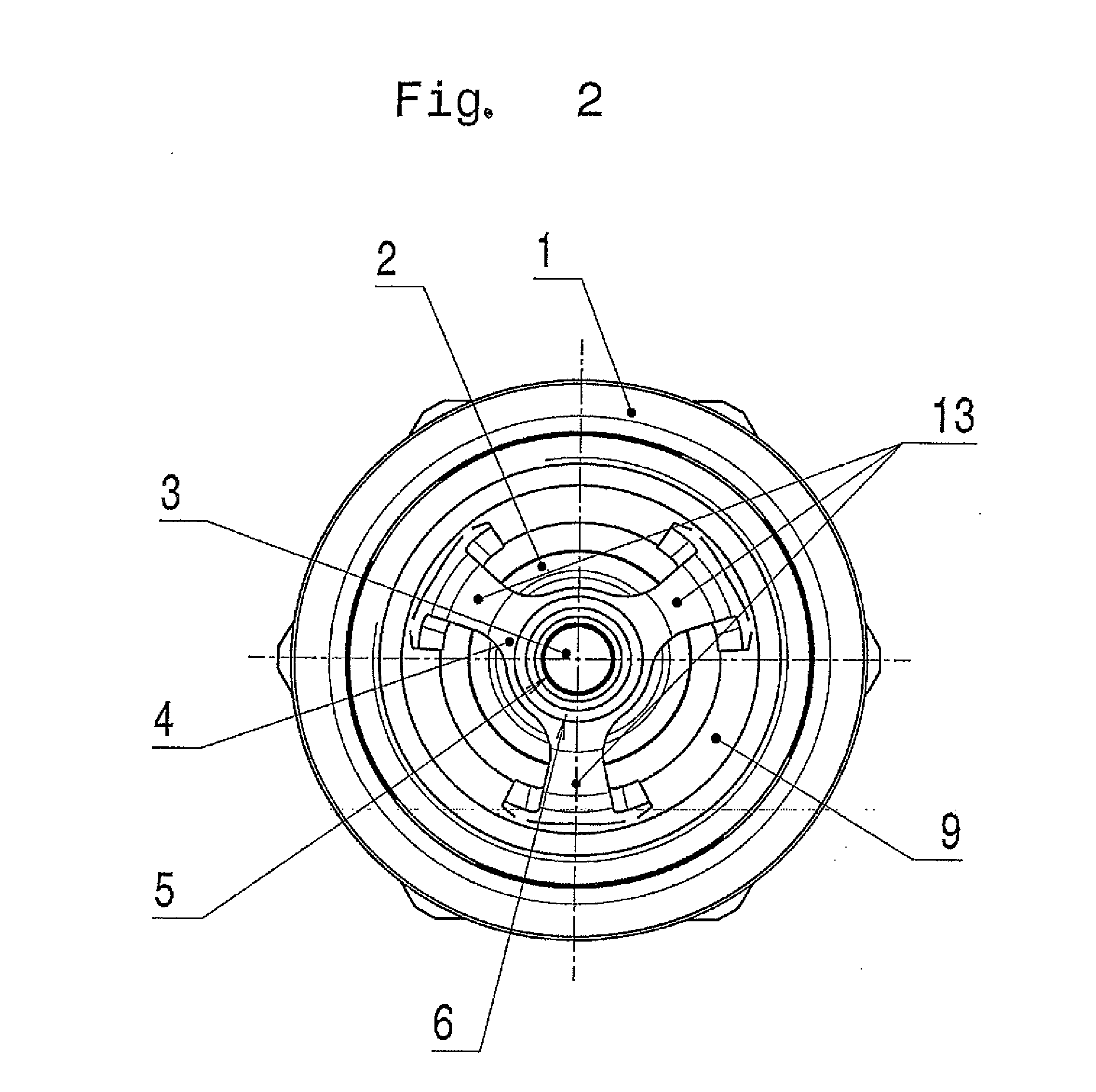

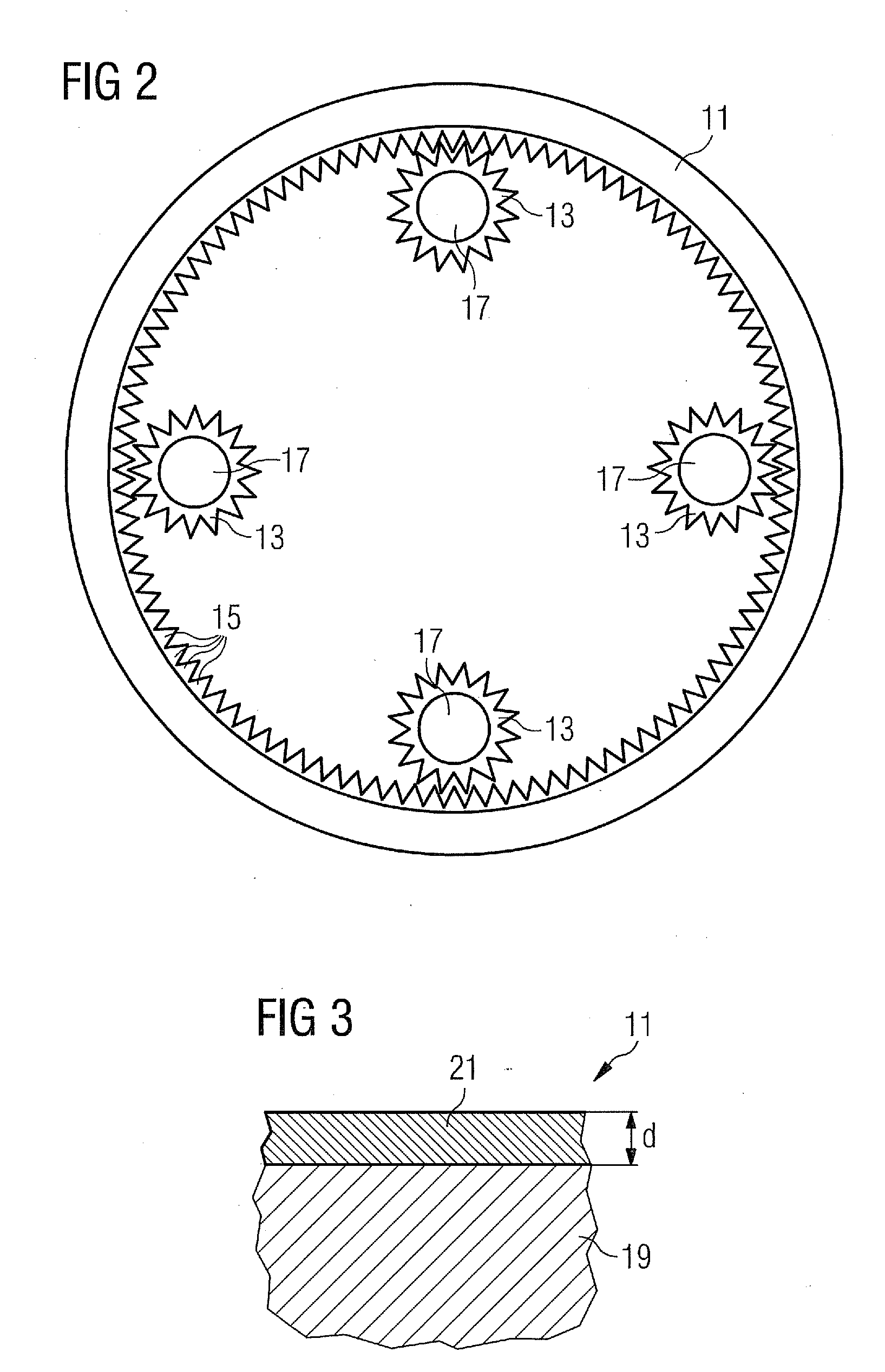

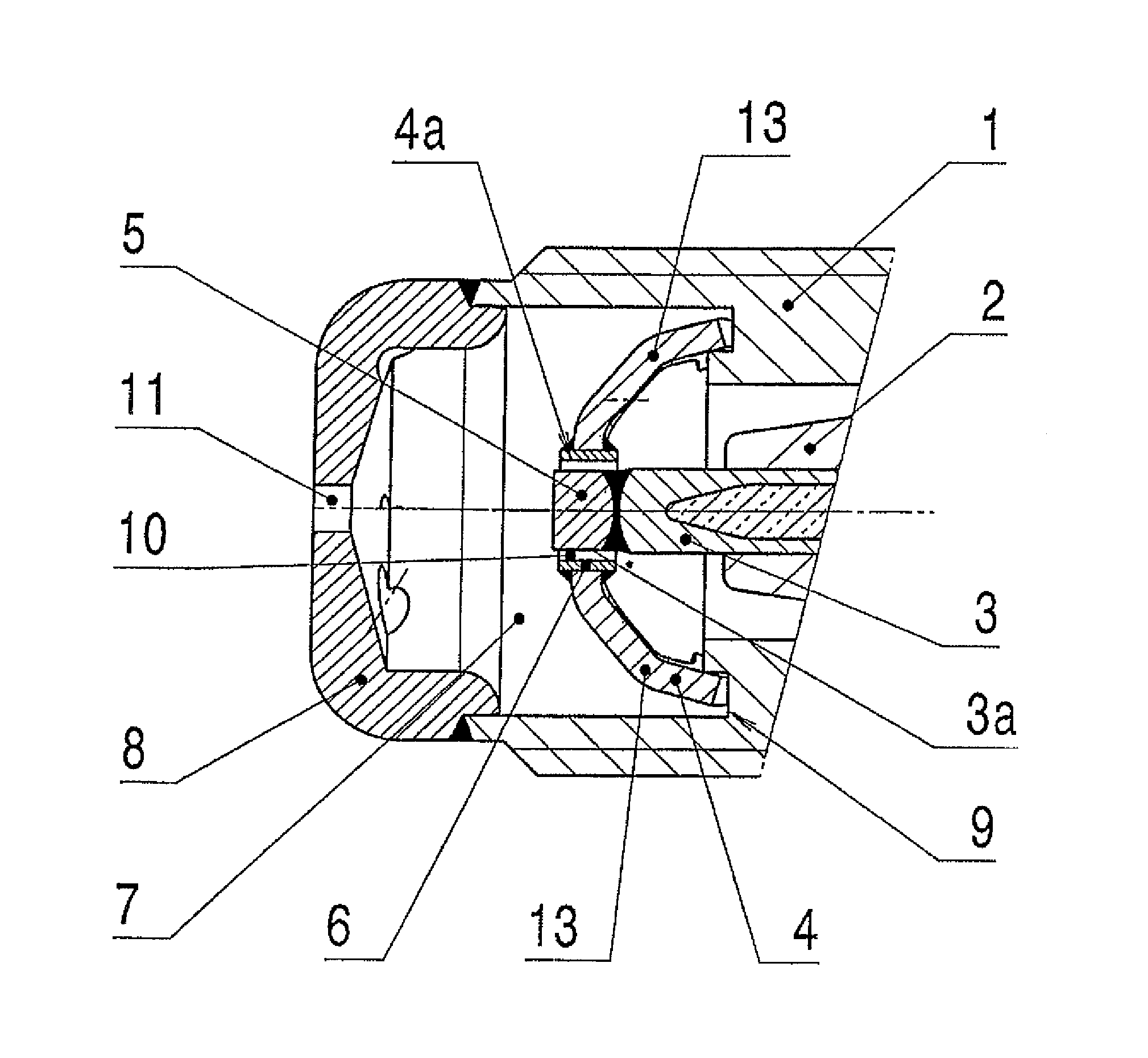

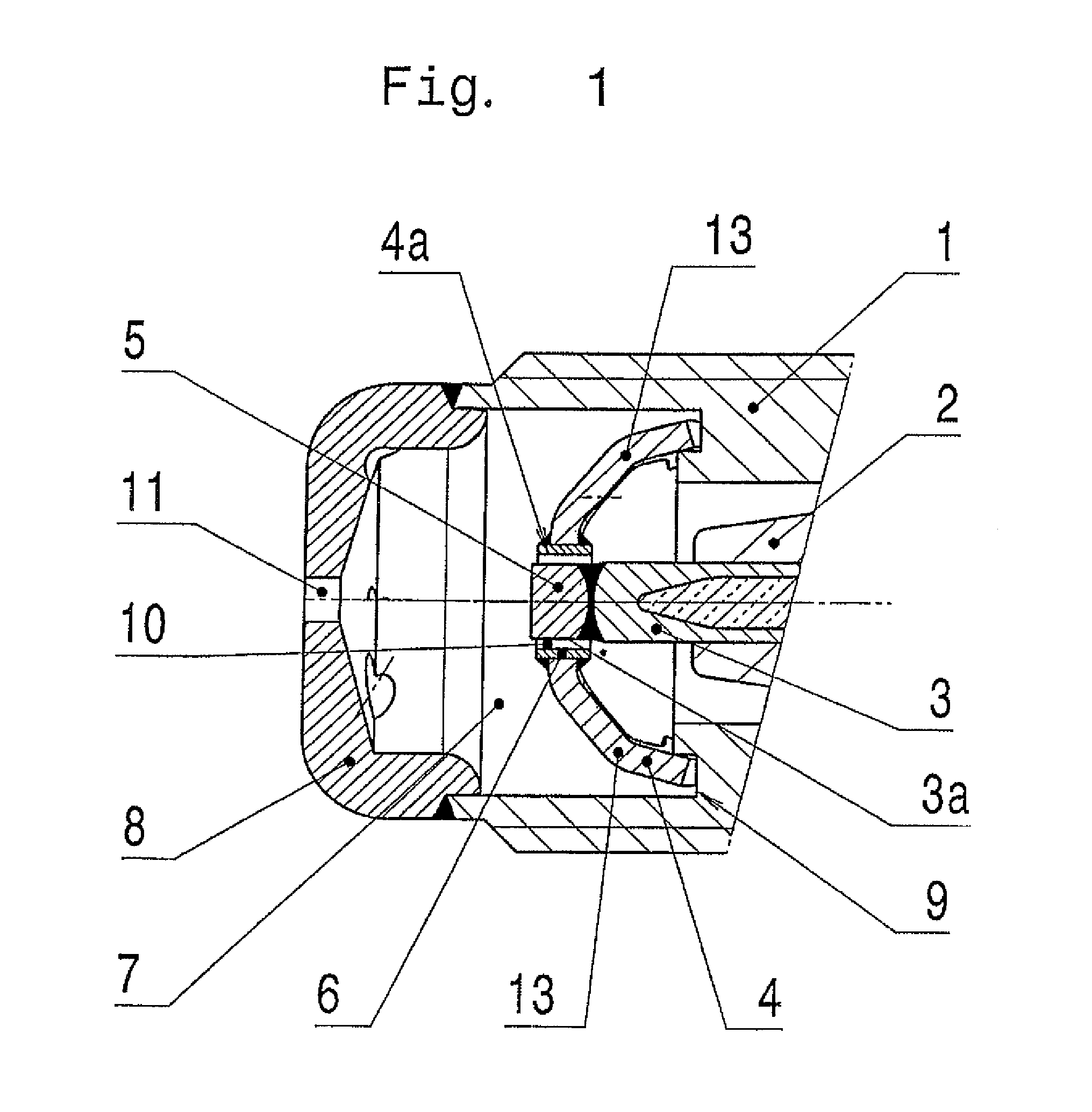

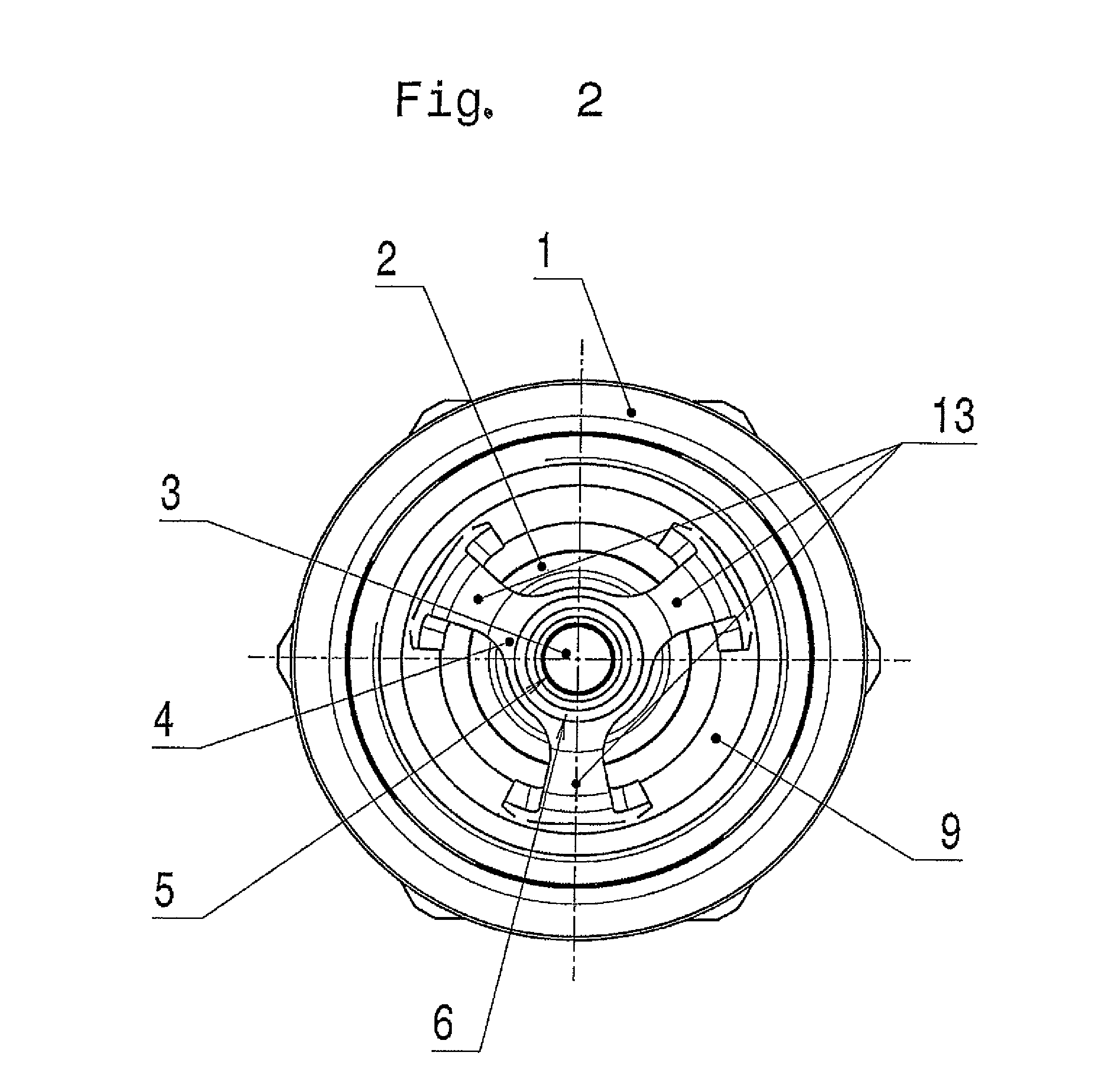

Spark Plug for a Gas-Operated Internal Combustion Engine

ActiveUS20110148274A1Extended service lifeIncrease volumeSparking plugsExternal combustion engineEngineering

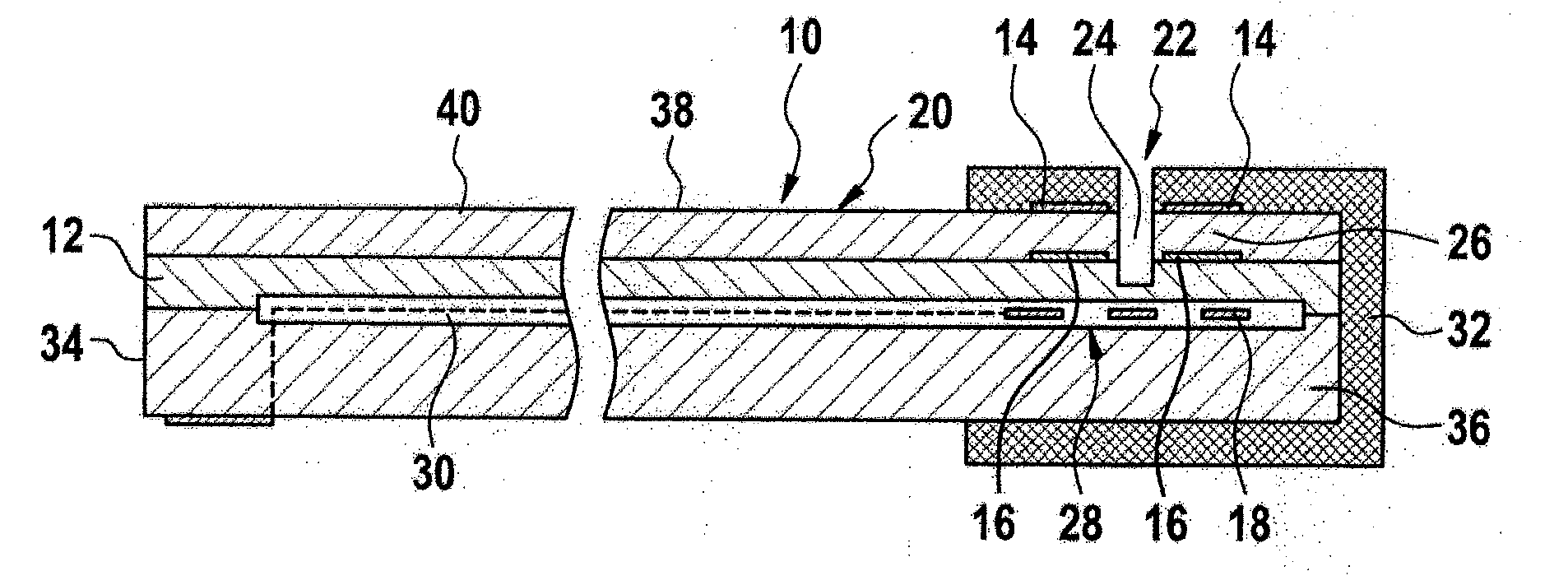

The invention relates to a spark plug for a gas-fired internal combustion engine, and Includes a metallic body, with an insulator fastened in the body. A central electrode, leads through the insulator and includes a protruding end of a precious metal alloy. An annular ground electrode is fastened to the body and surrounds the end of the central electrode which, at the inside thereof facing the central electrode is provided with a precious metal or with a precious metal alloy. The mutually facing surfaces of the central electrode and ground electrode formed by the precious metal or the precious metal alloy are coaxially disposed cylinder surfaces. A cap is provided and attached to the body and which, after installation of the spark plug into a combustion chamber of the internal combustion engine, shields the central electrode and the ground electrode from the combustion chamber. Together with the body of the spark plug, the central electrode forms an ante-chamber, in which the central electrode and the ground electrode are disposed. The cap having at least one opening, which enables a gas exchange between the ante-chamber and the space outside of the ante-chamber. According to the invention, a deviation of the cylinder surfaces from the ideal cylinder geometry is less than +−20 μm, and a deviation of the positions of the axes of the cylinder surfaces from their ideal coaxial position is less than +−50 μm.

Owner:FEDERAL MOGUL IGNITION

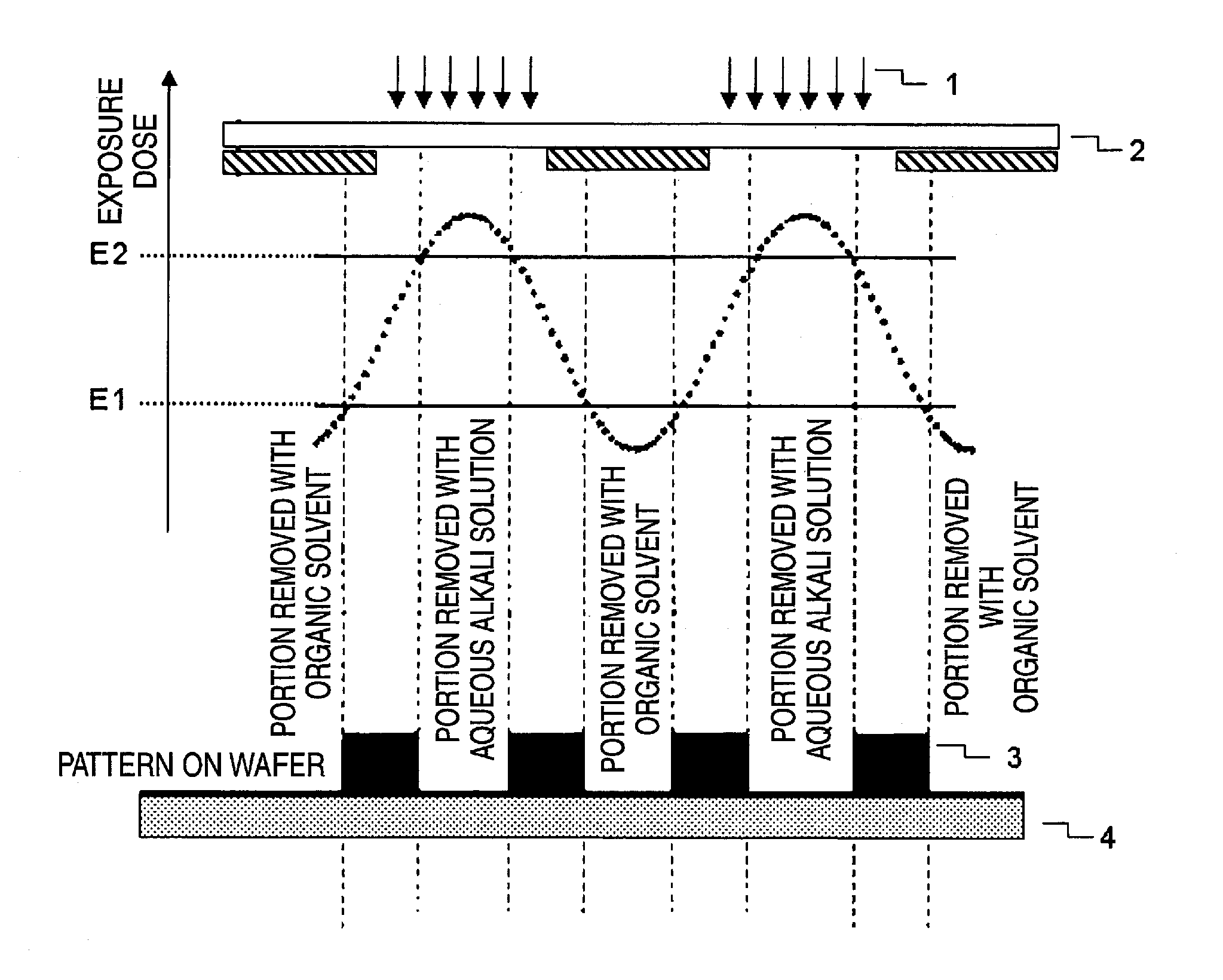

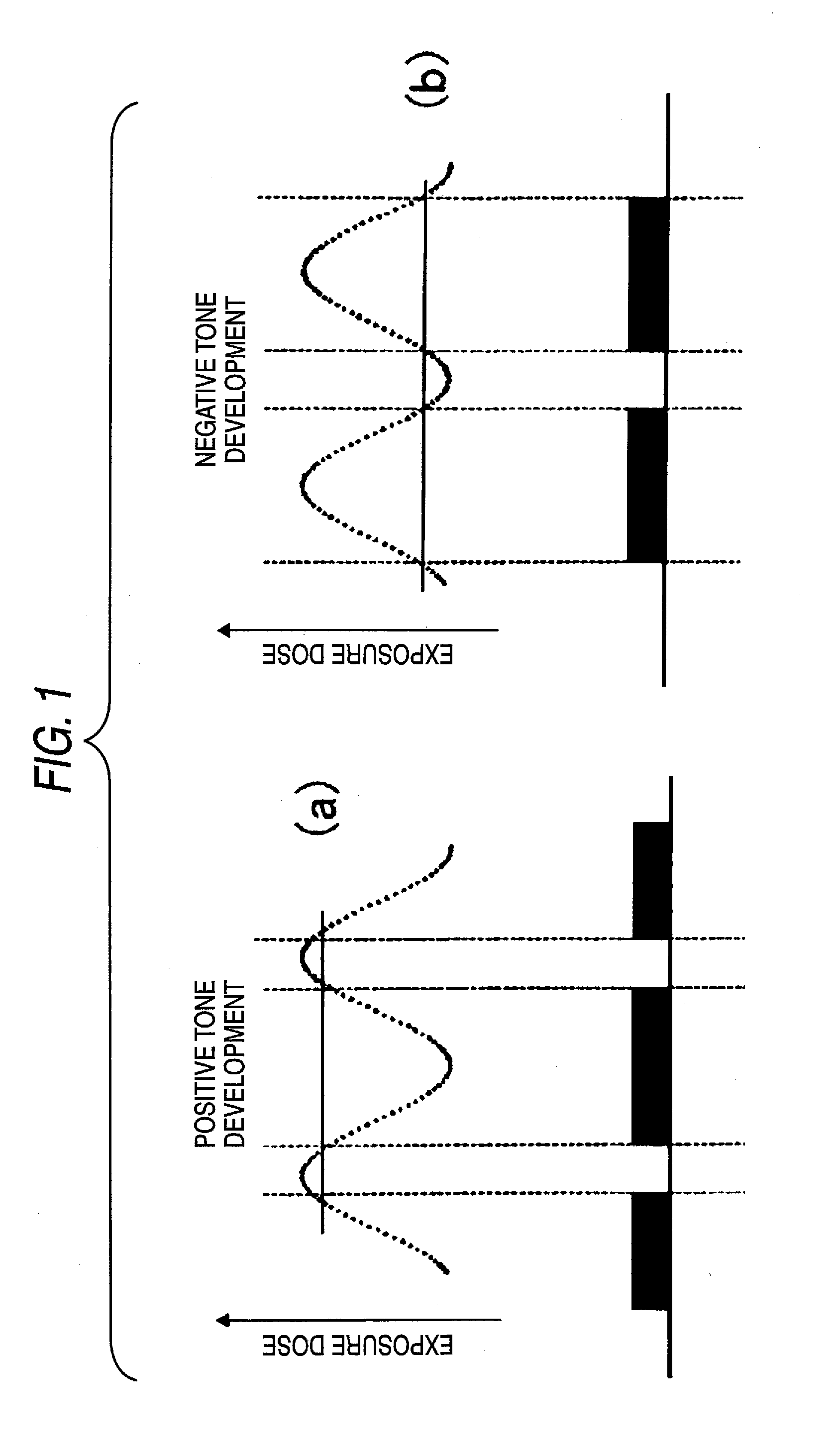

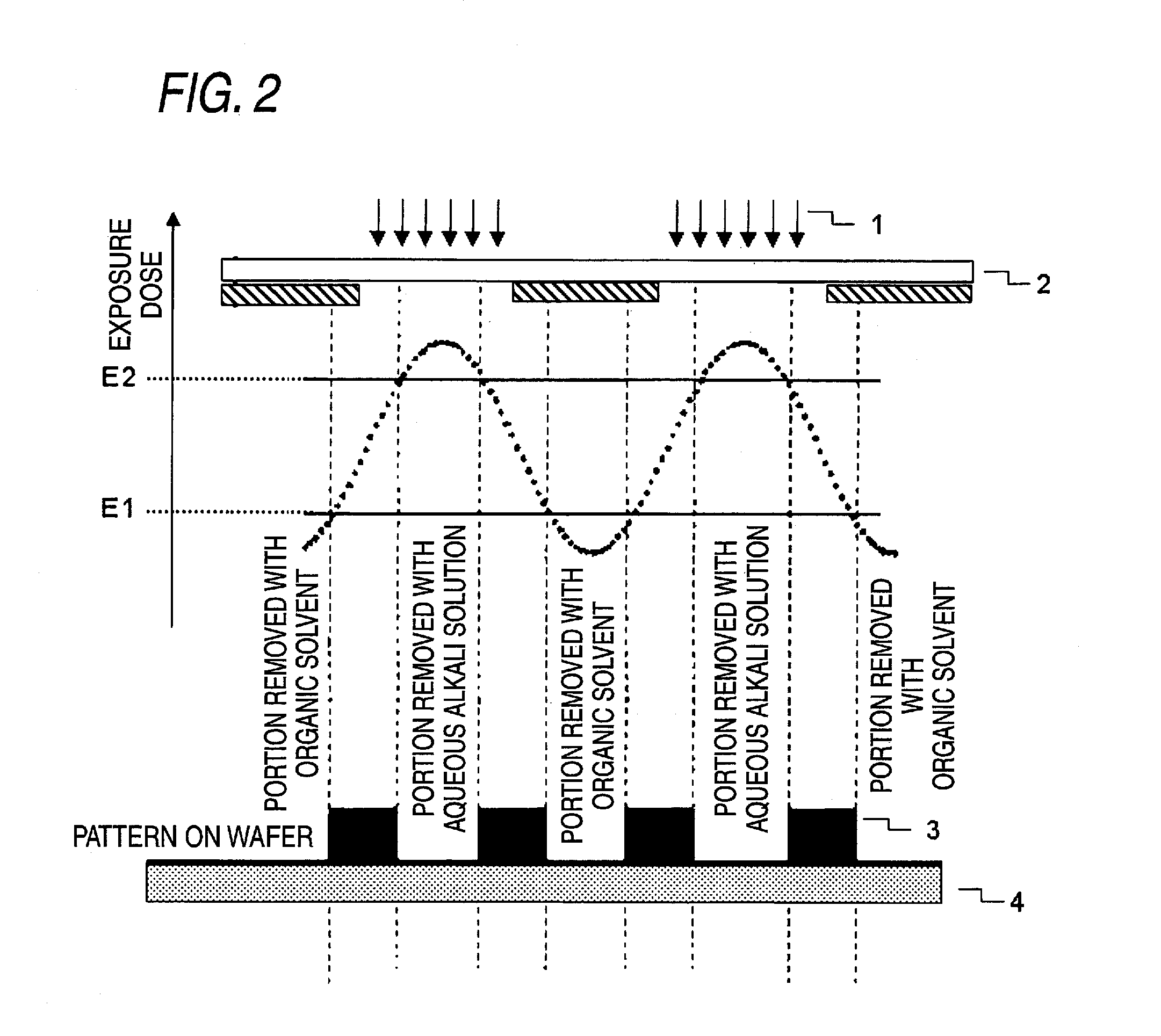

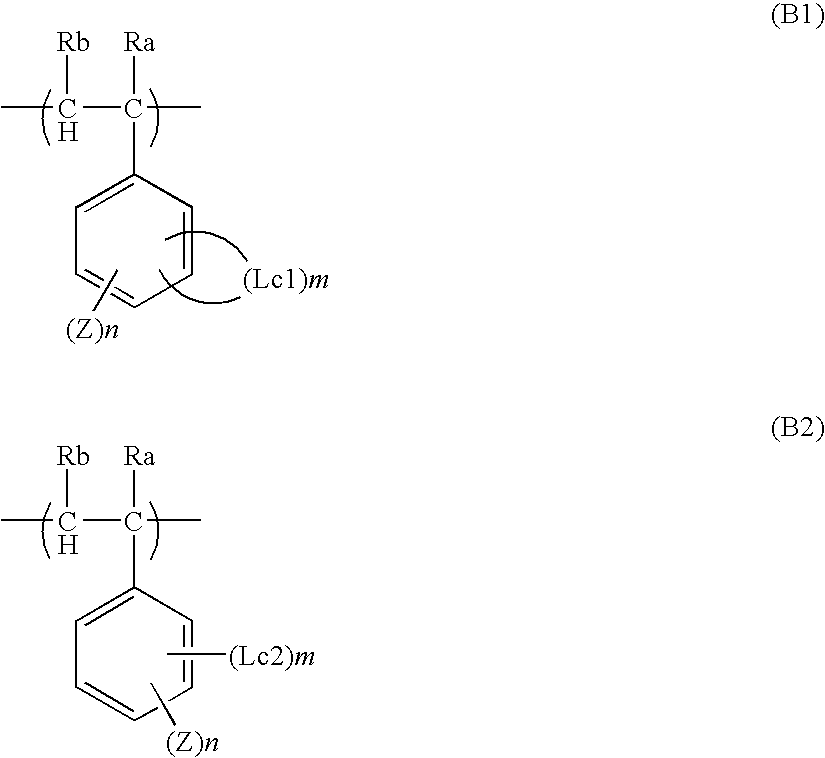

Resist composition for negative tone development and pattern forming method using the same

ActiveUS20100190106A1Improve accuracySmall line edge roughnessPhotosensitive materialsPhotomechanical exposure apparatusIn planeActinic Rays

For stably forming a high-precision fine pattern and thereby producing a highly integrated electronic device with high precision, a resist composition for negative tone development, which can reduce the line edge roughness and enhance the in-plane uniformity of the pattern dimension and furthermore, can ensure excellent bridge margin, and a pattern forming method using the same are provided.A resist composition for negative tone development, comprising (A) a resin capable of increasing the polarity by the action of an acid to increase the solubility in a positive tone developer and decrease the solubility in a negative tone developer, (B) a compound capable of generating an acid upon irradiation with an actinic ray or radiation, and (C) a solvent, wherein the logP value of the acid generated from the (B) compound capable of generating an acid upon irradiation with an actinic ray or radiation is from 1.5 to 12.0; and a pattern forming method using the same.

Owner:FUJIFILM CORP

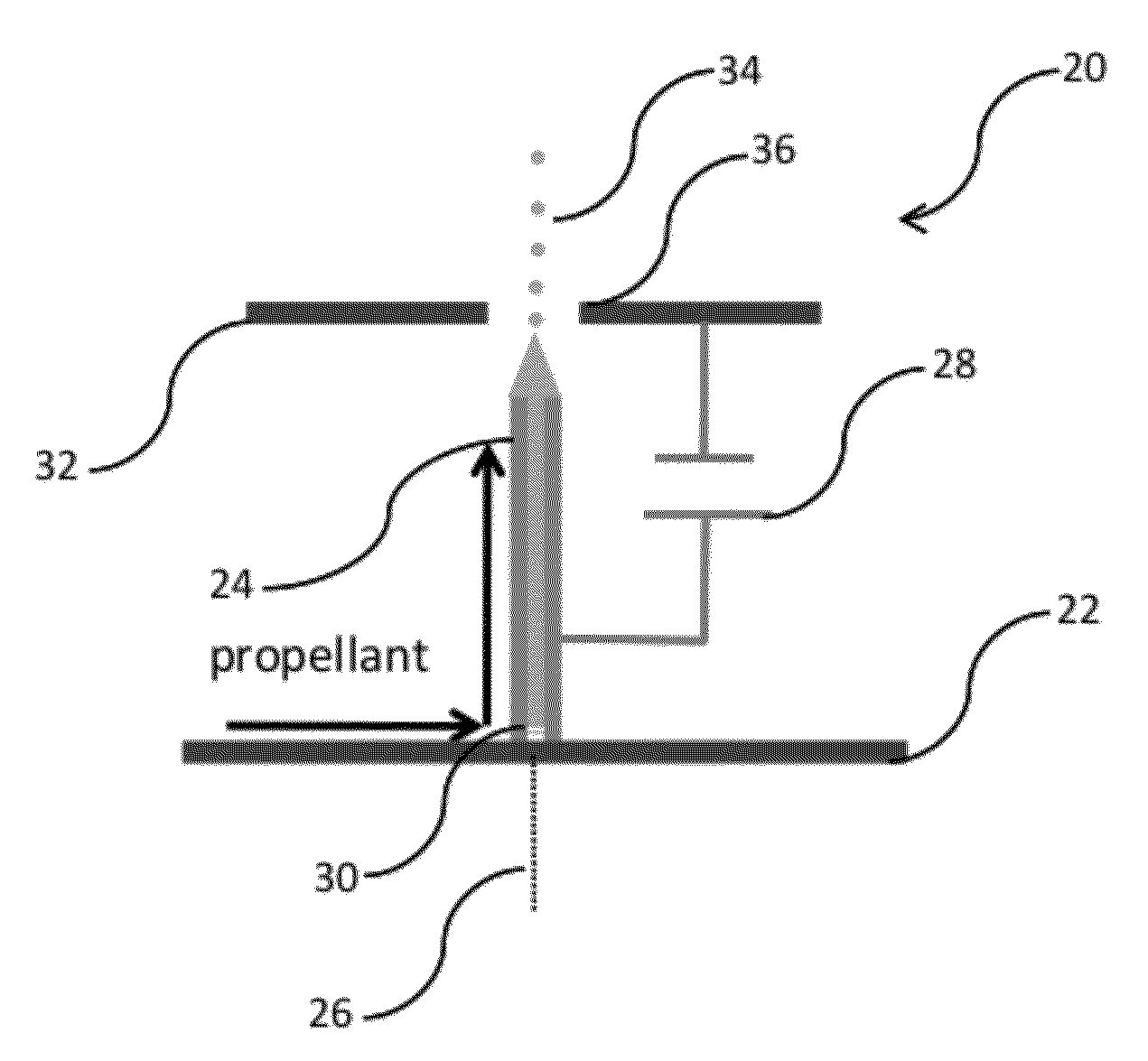

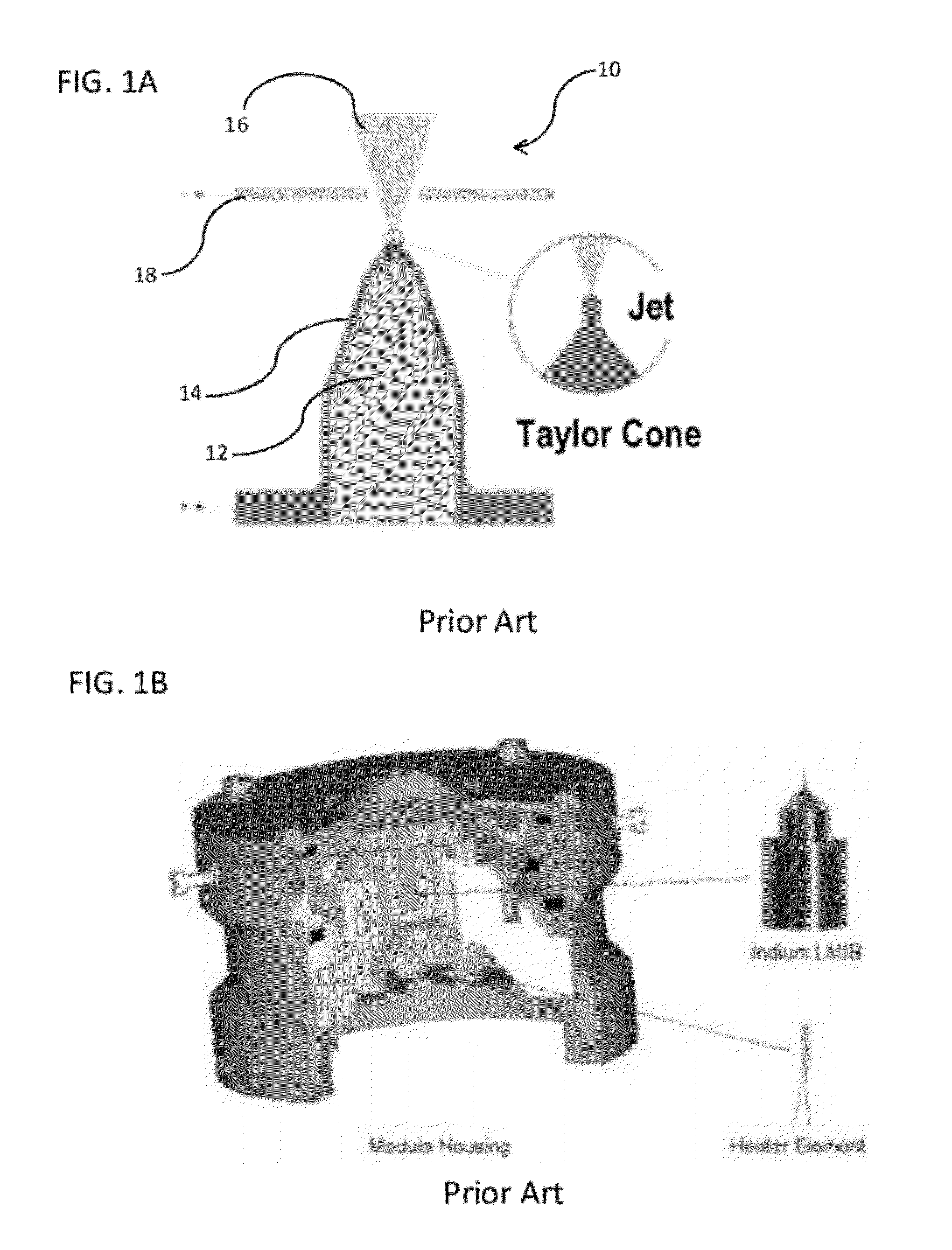

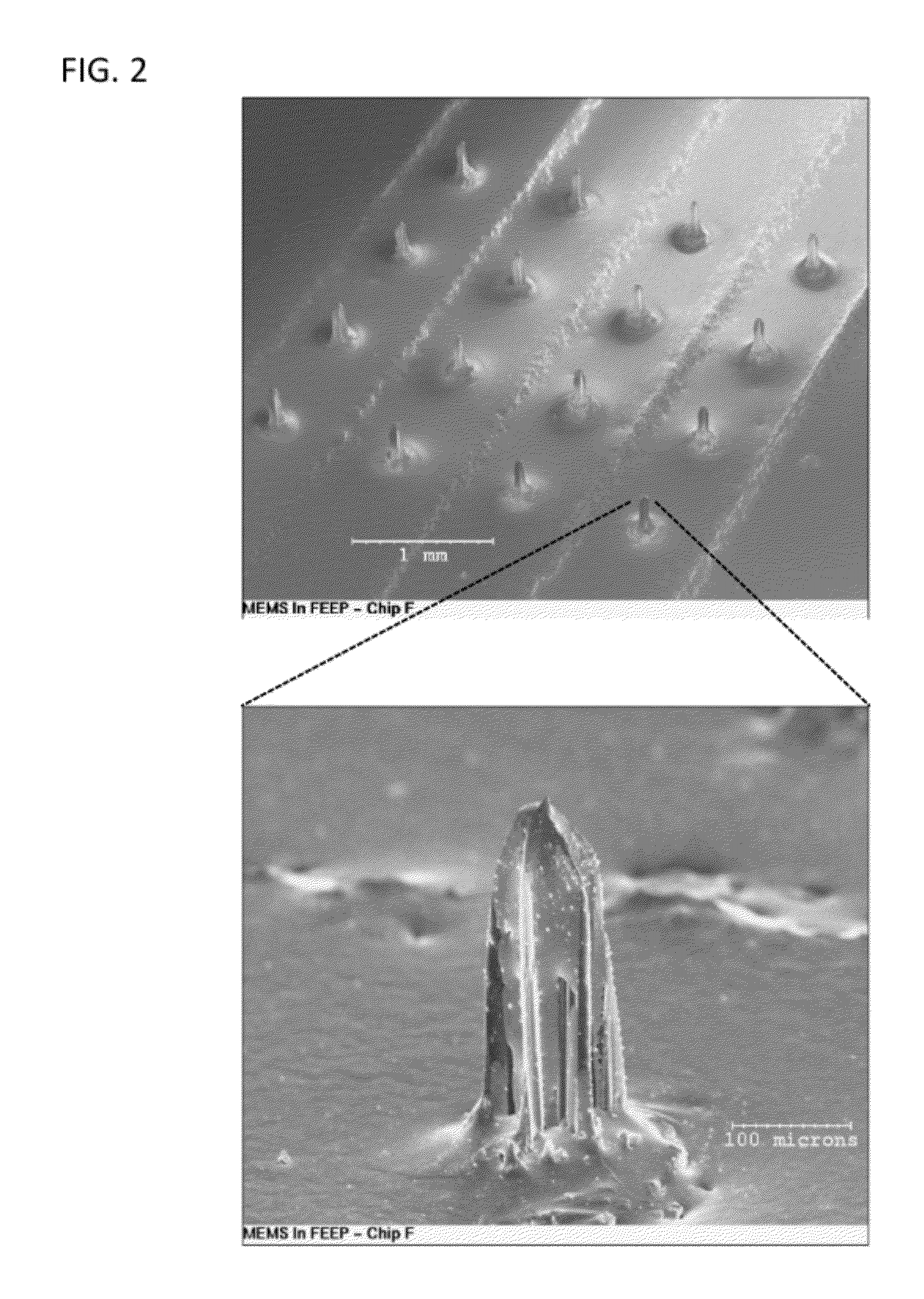

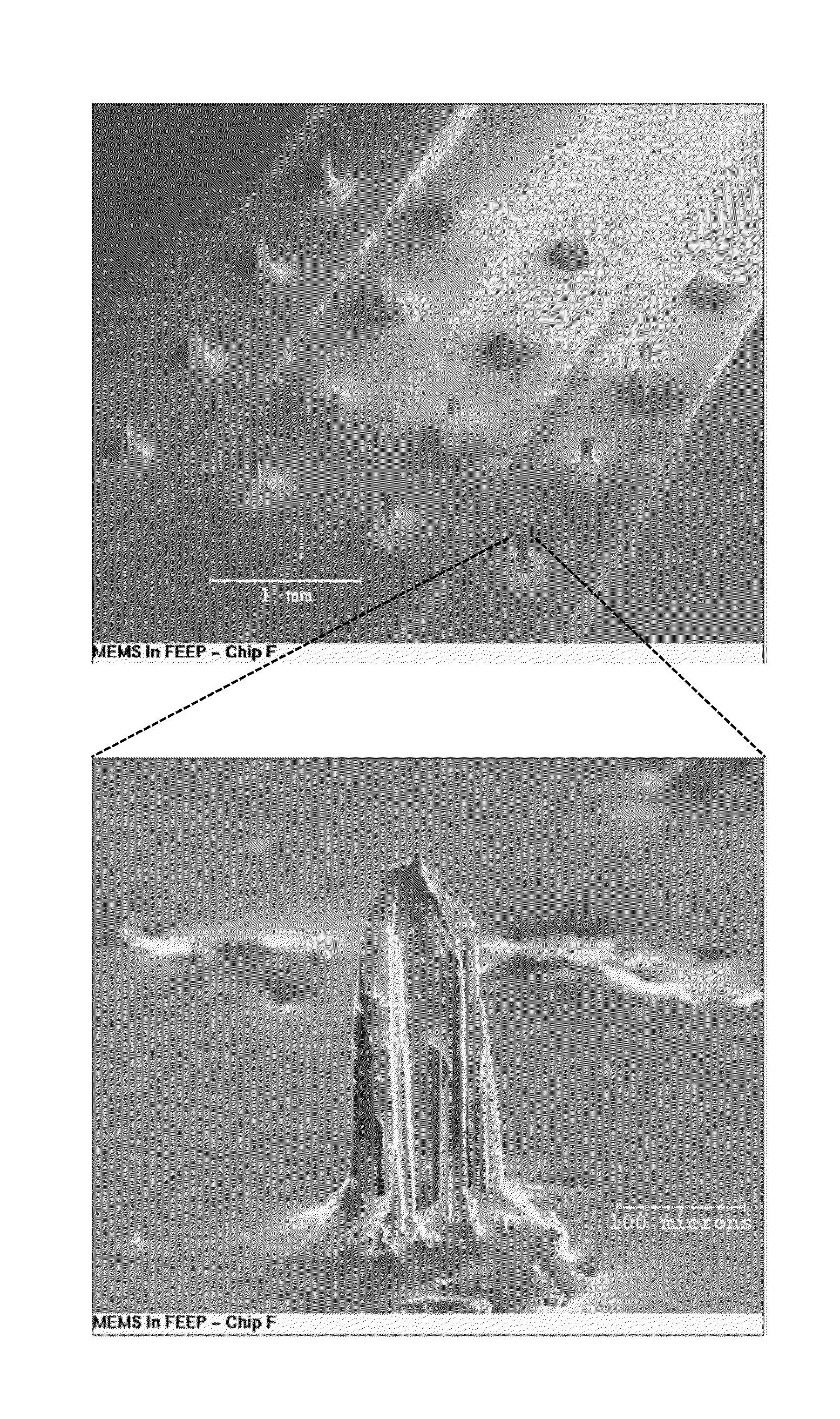

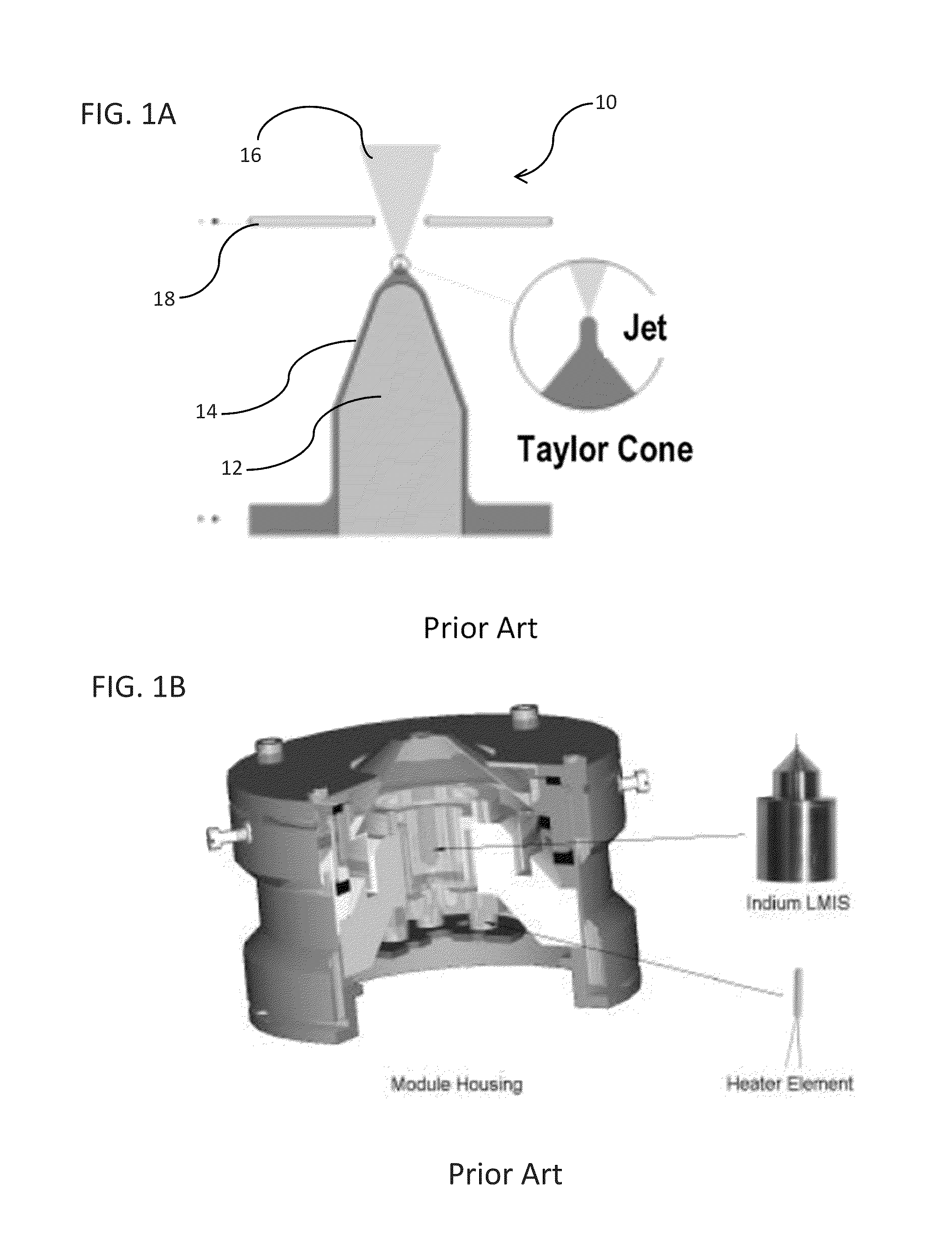

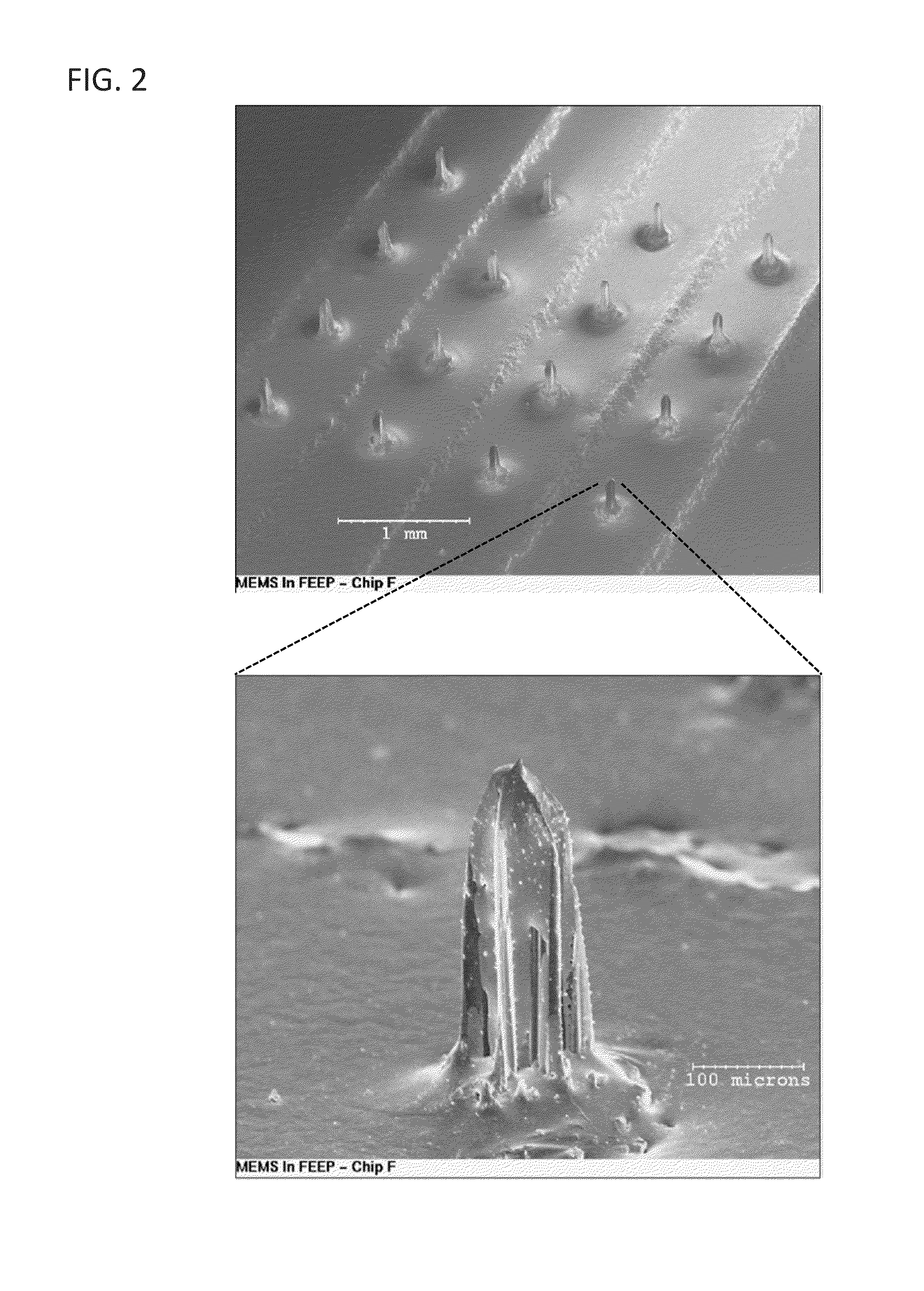

Microfluidic electrospray thruster

InactiveUS20120144796A1Low viscosityHeating evenlyCosmonautic vehiclesVolume/mass flow measurementElectrosprayCharged particle

An electrospray thruster and methods of manufacturing such thrusters are provided. The micro-electrospray thruster increases the thrust density of conventional electrospray thrusters by miniaturizing the individual components of the thruster thereby allowing for the increase in the number and density of the charged particle emitters.

Owner:CALIFORNIA INST OF TECH

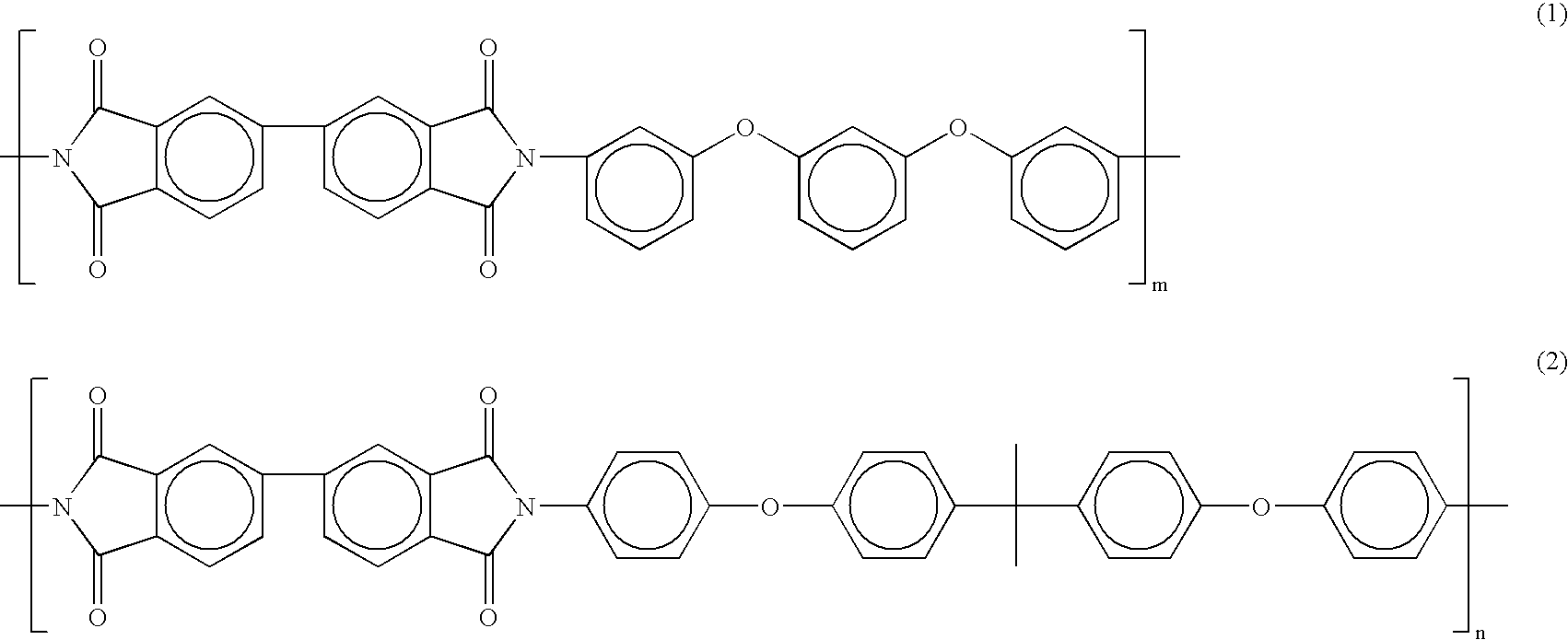

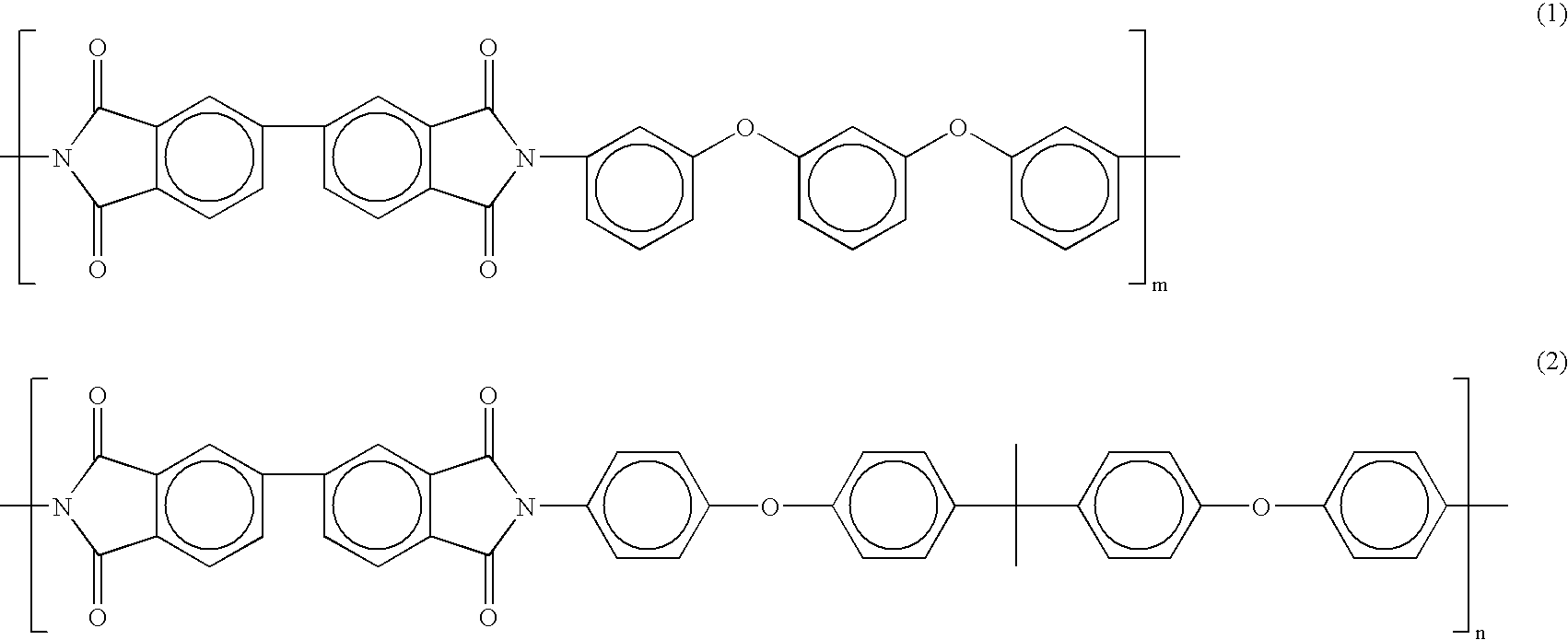

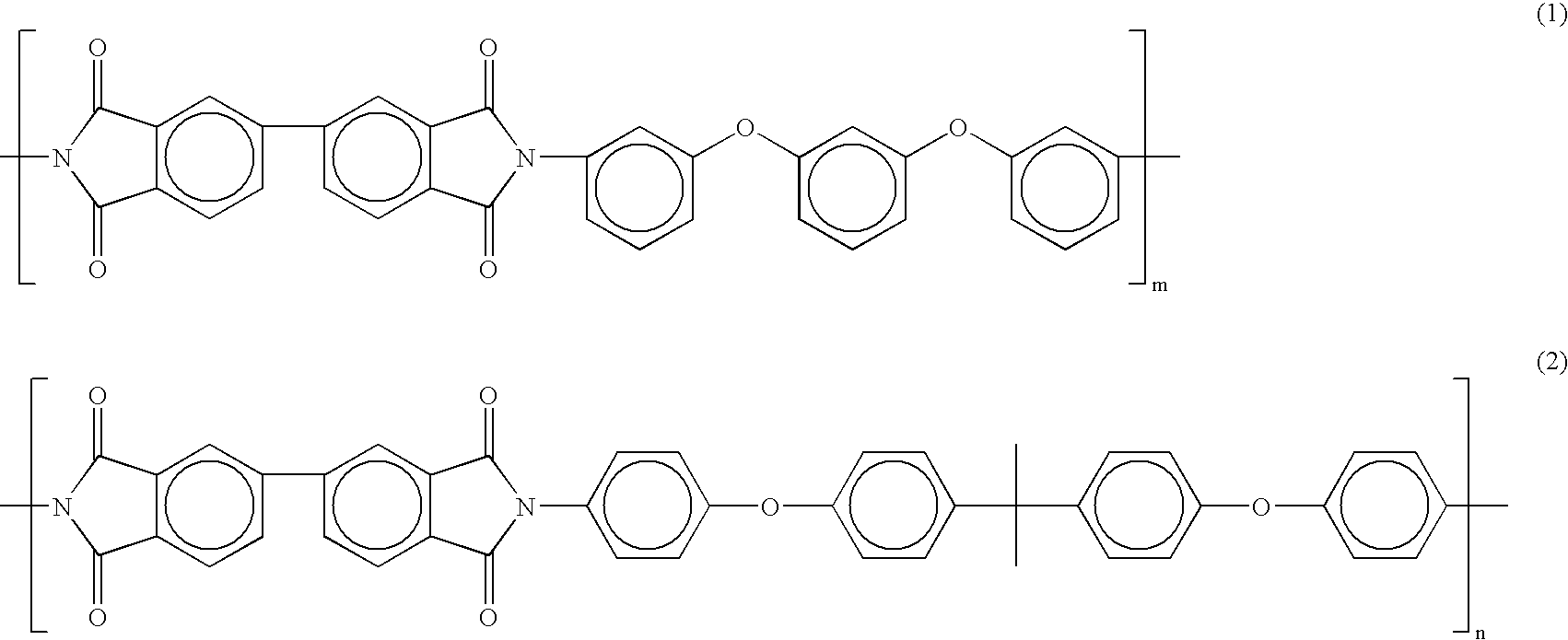

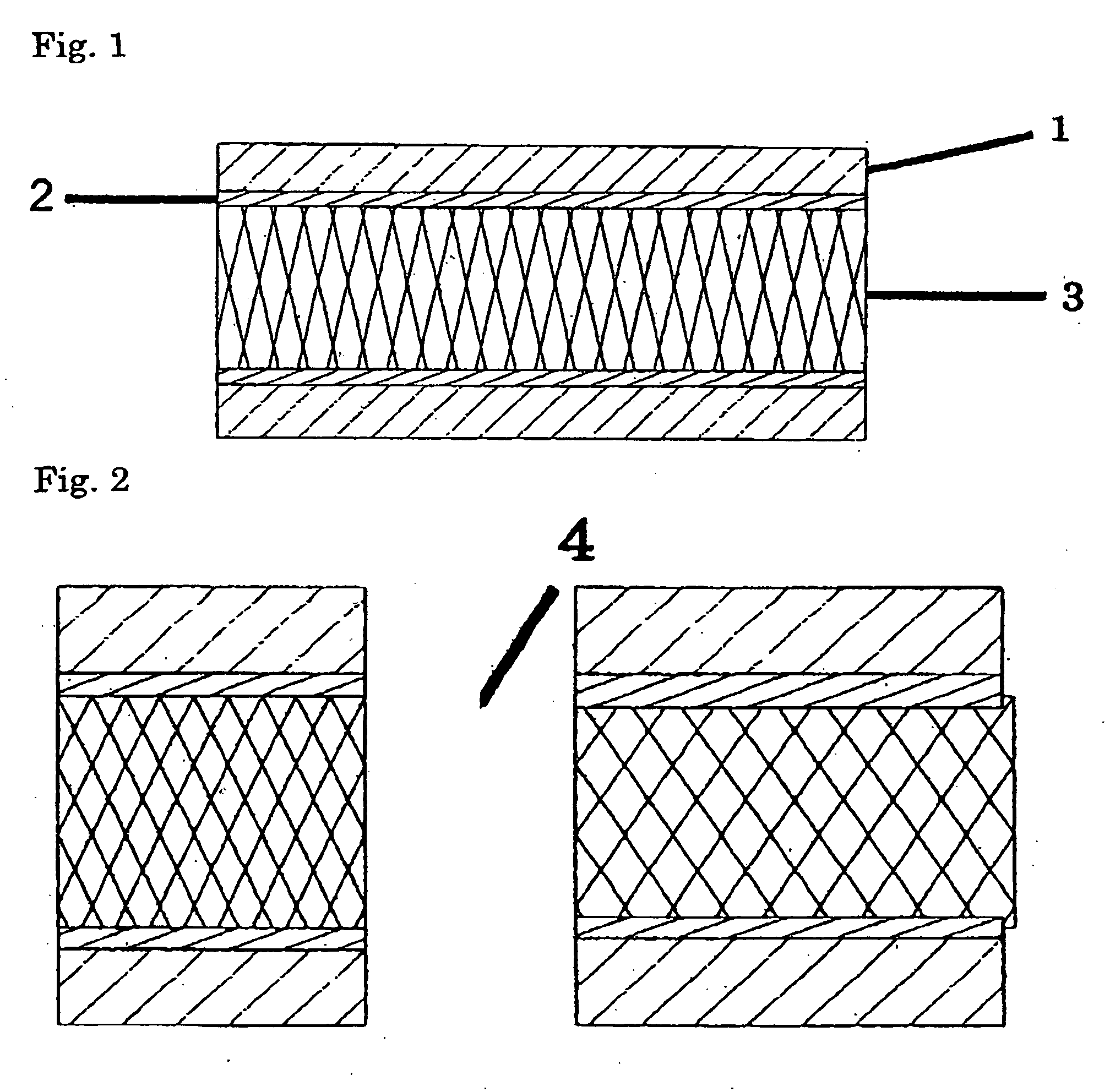

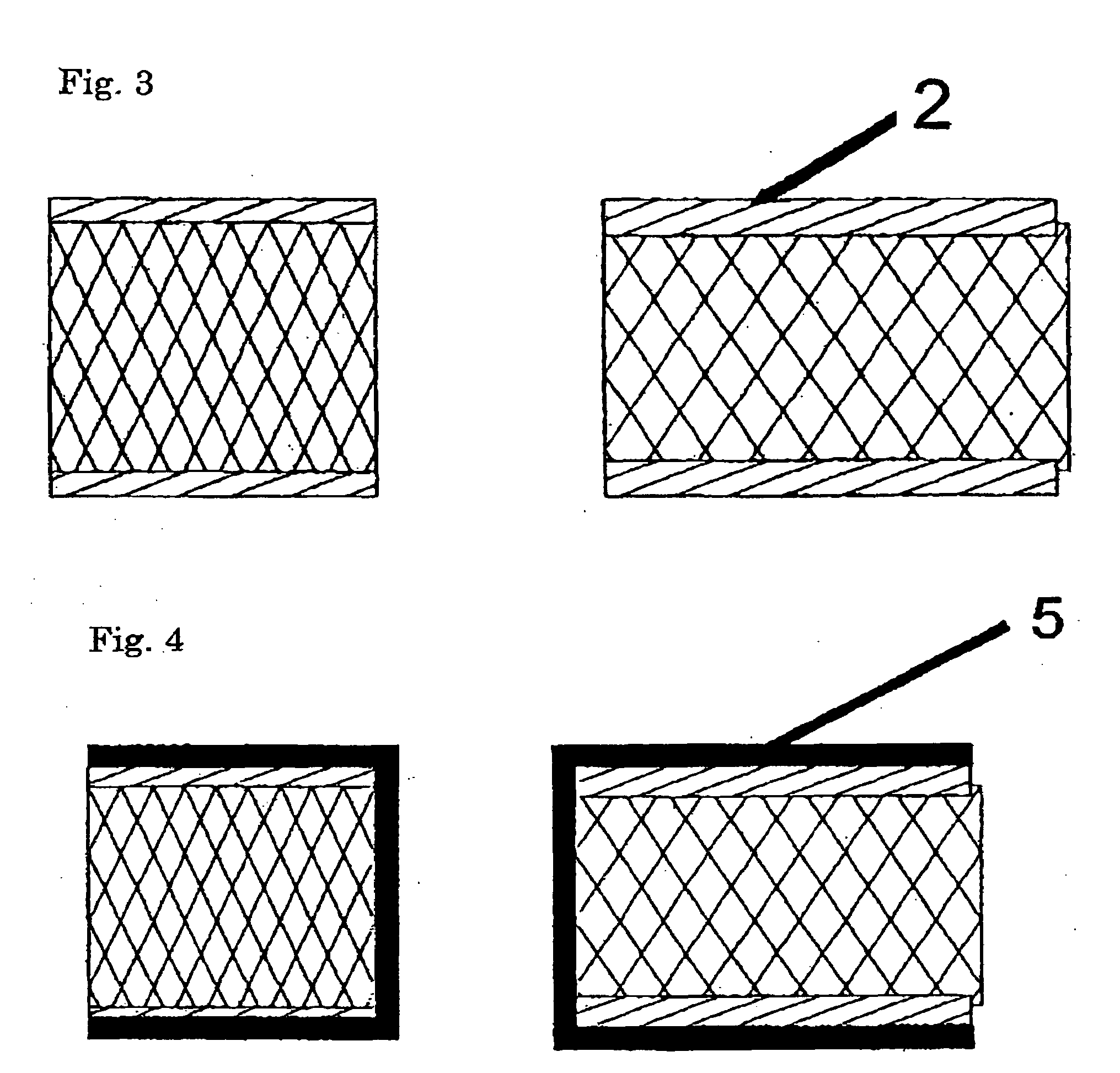

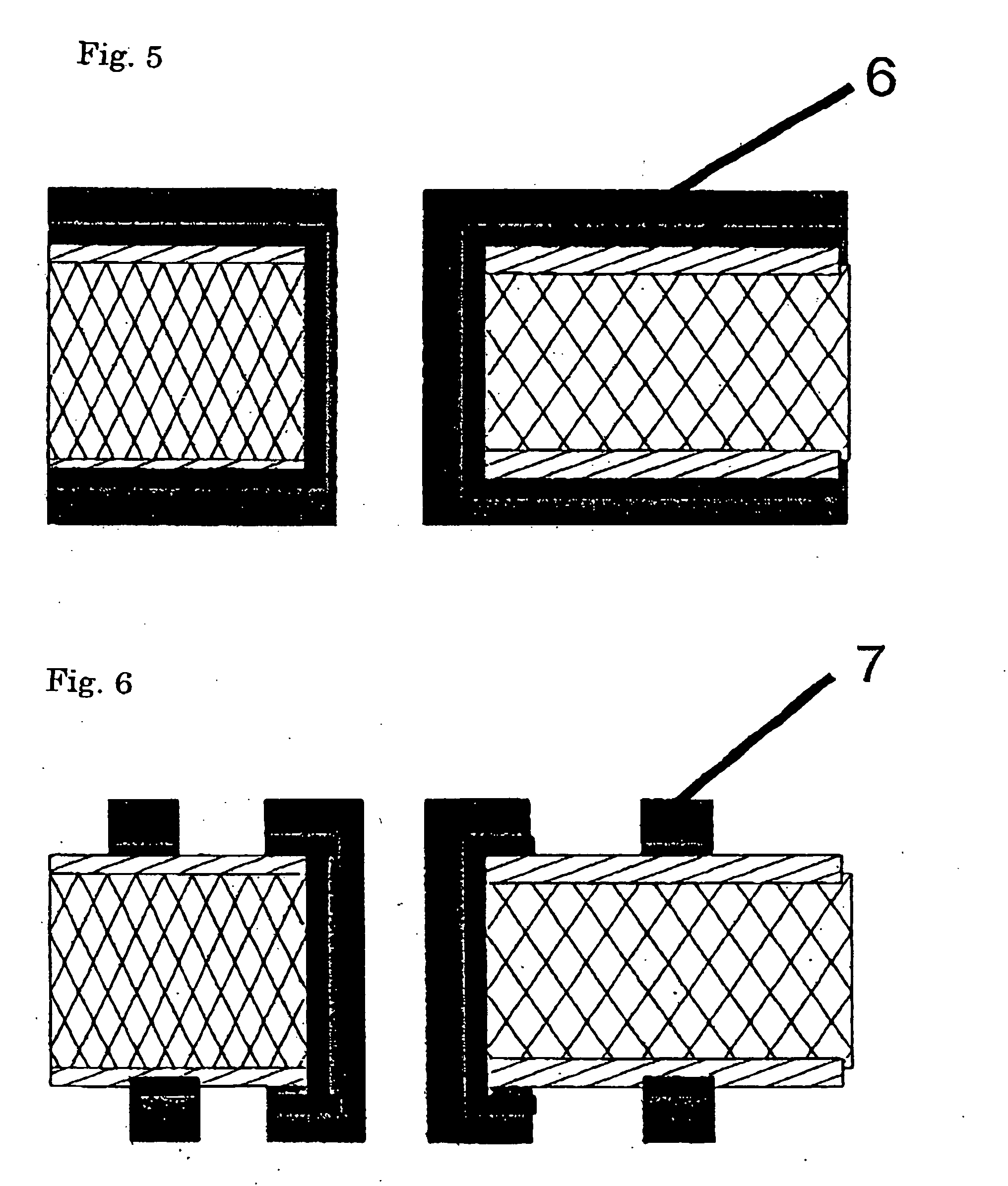

Resin composite metal foil, laminate and process for the production of printed wiring board using the laminate

ActiveUS20060054589A1Small roughnessImprove adhesion strengthPrinted circuit manufactureSurface layering apparatusMetal foilPolyimide

A resin composite metal foil comprising a metal foil and a layer of a block copolymer polyimide resin formed on one surface of the metal foil, a metal-foil-clad laminate using the above resin composite metal foil, a printed wiring board using the above metal-foil-clad laminate, and a process for the production of a printed wiring board comprising removing an external layer metal foil of a metal-foil-clad laminate and forming a conductor layer on an external layer insulating layer by plating, wherein the metal-foil-clad laminate comprises a layer of a block copolymer polyimide resin which layer is in contact with the external layer metal foil.

Owner:MITSUBISHI GAS CHEM CO INC

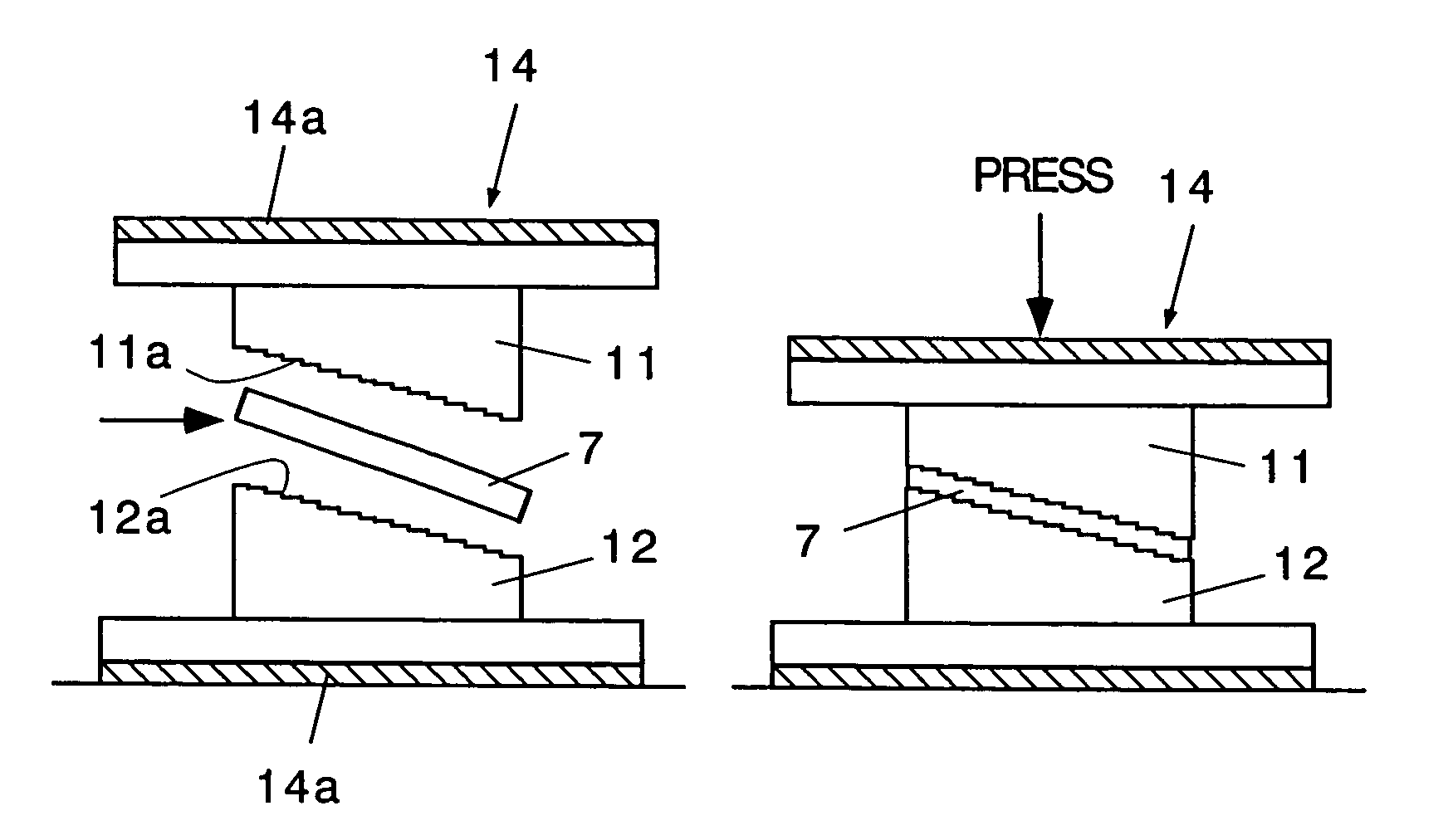

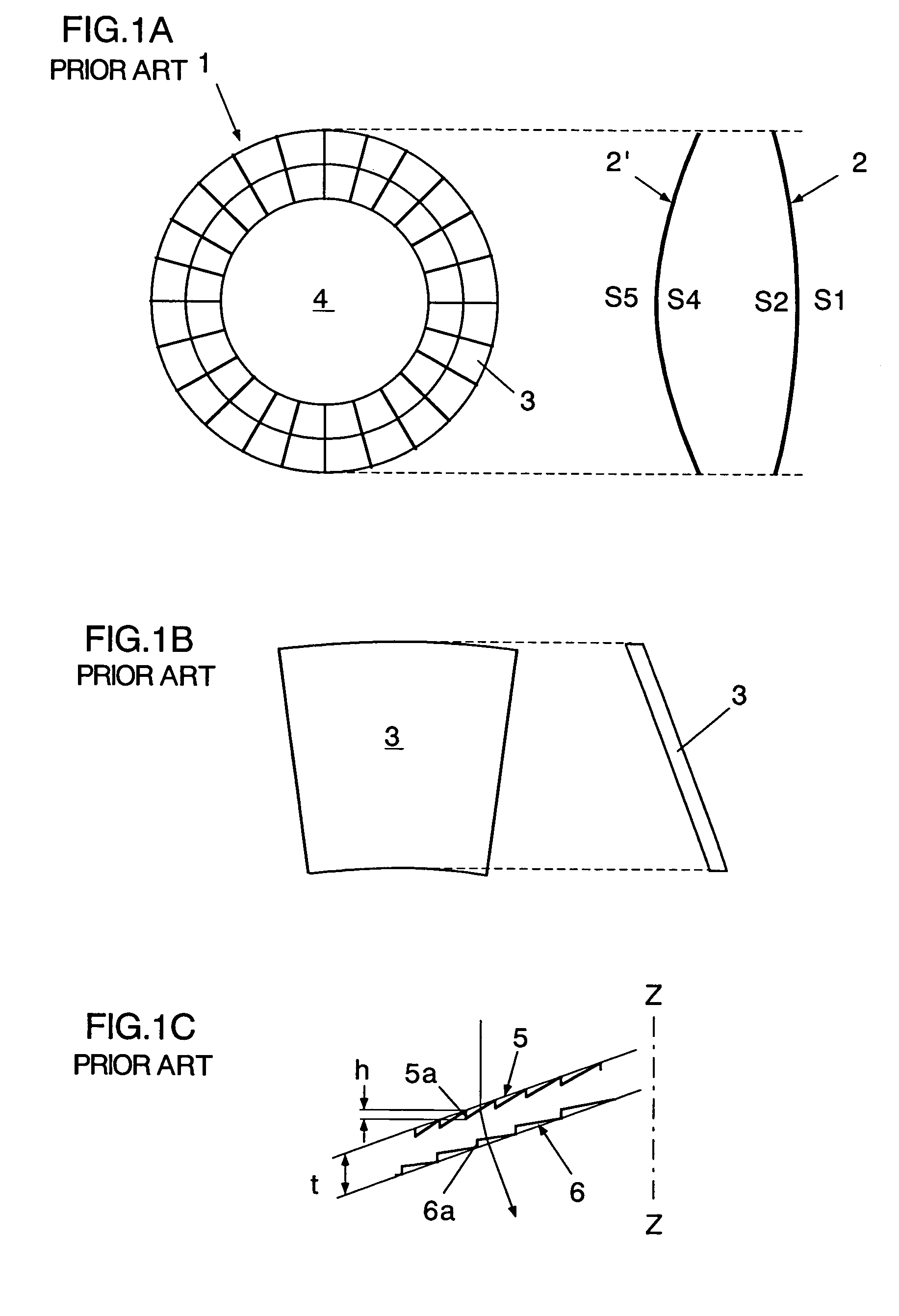

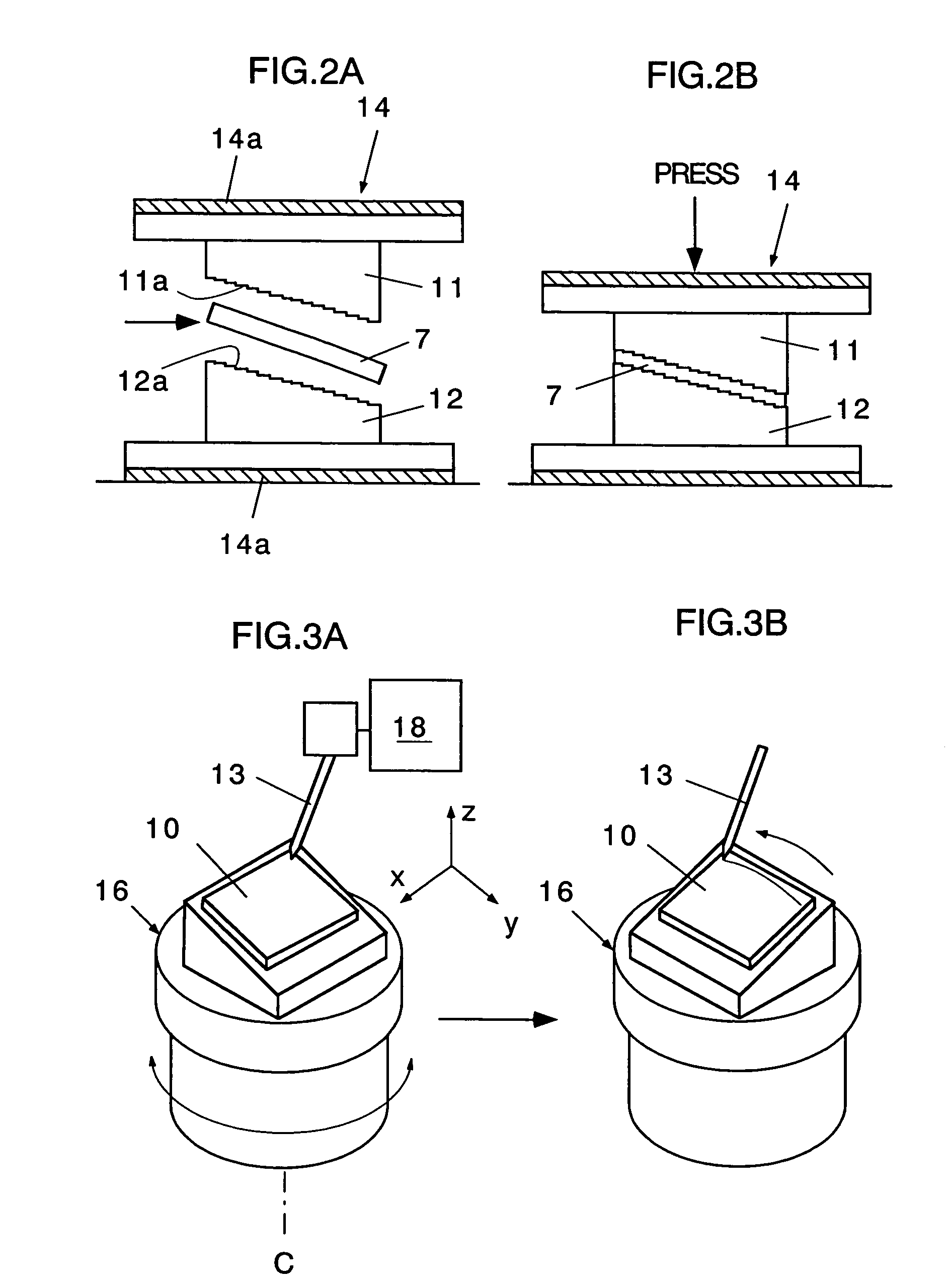

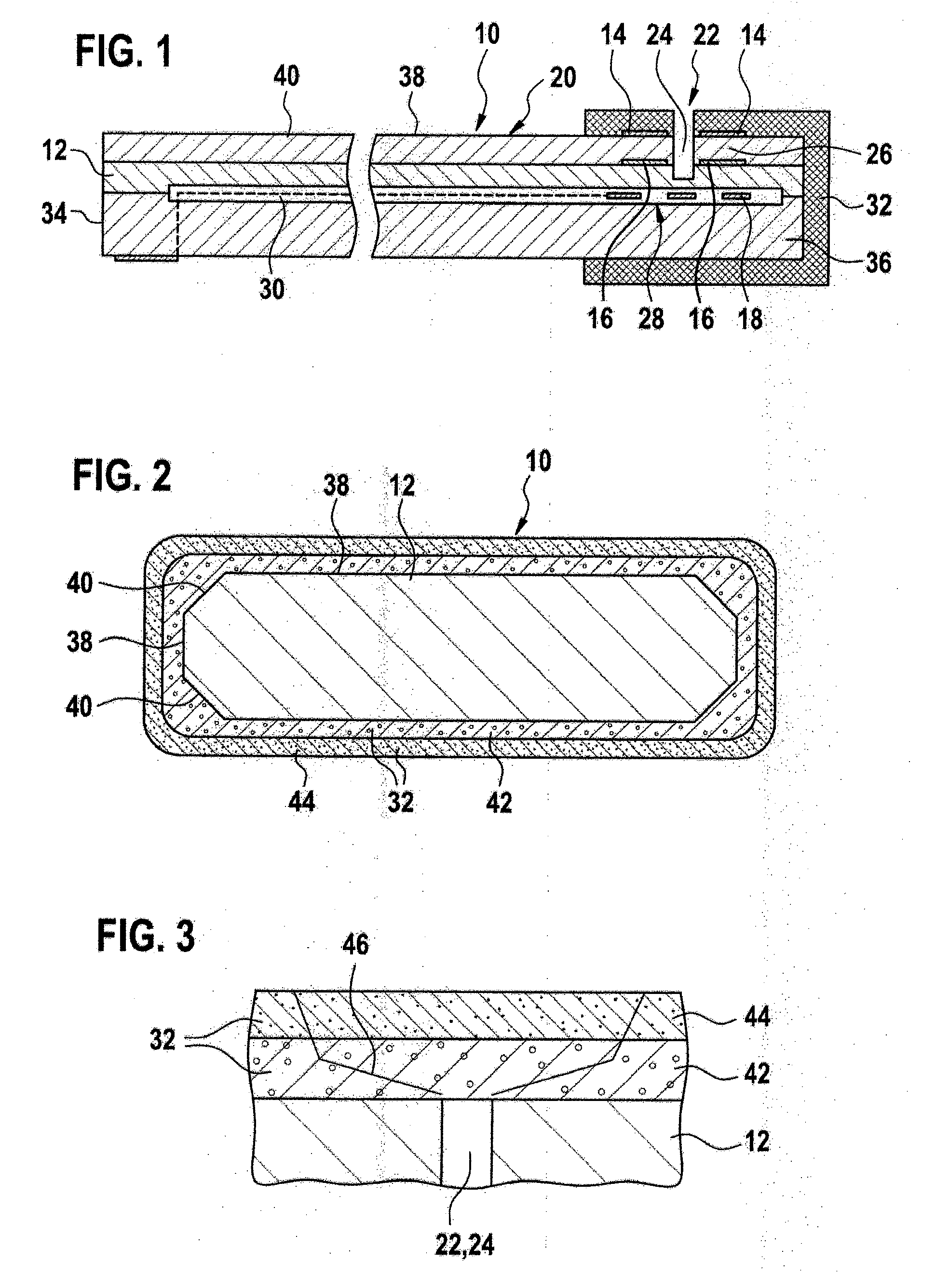

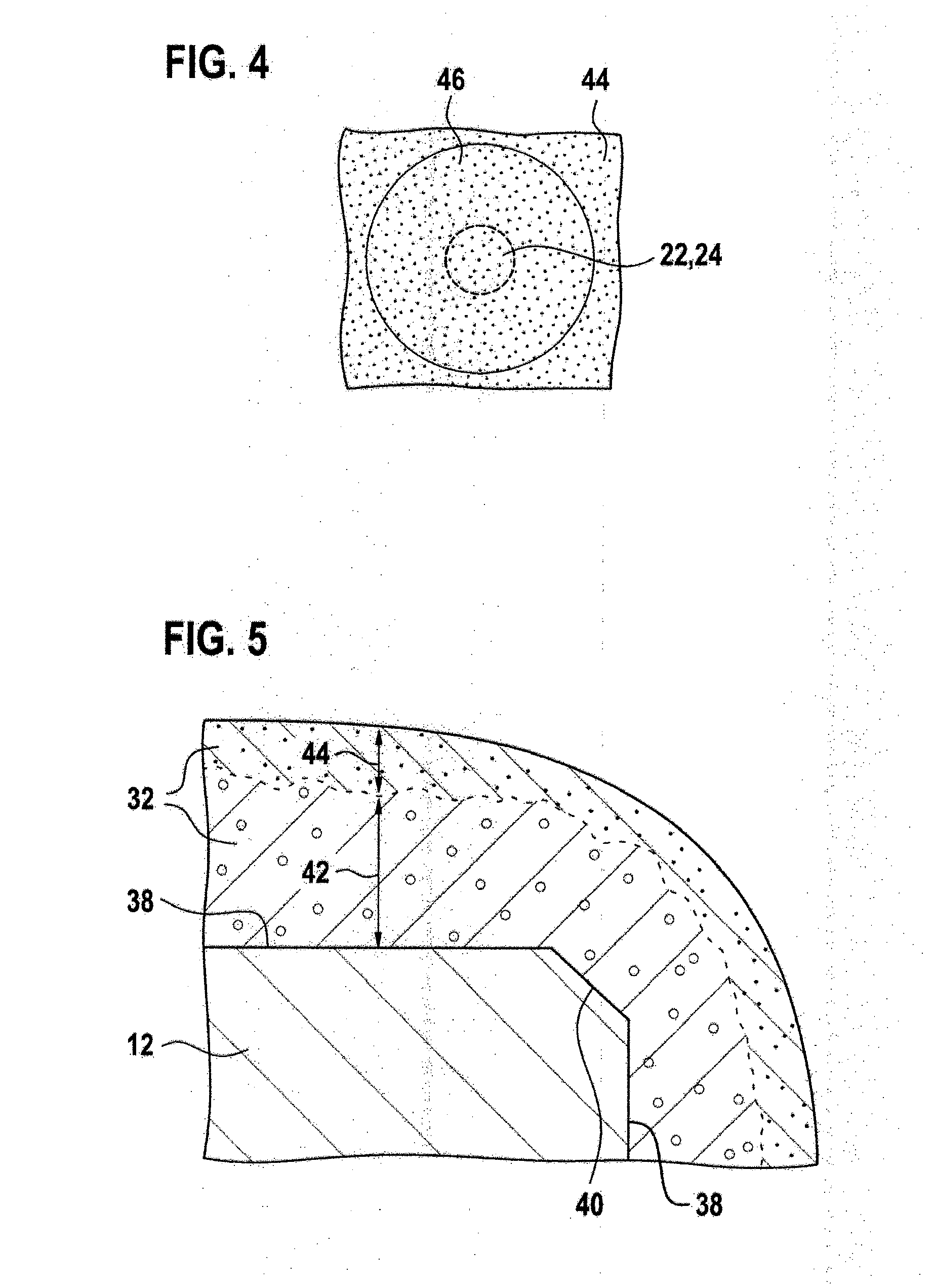

Method and apparatus for manufacturing large double-sided curved Fresnel lens

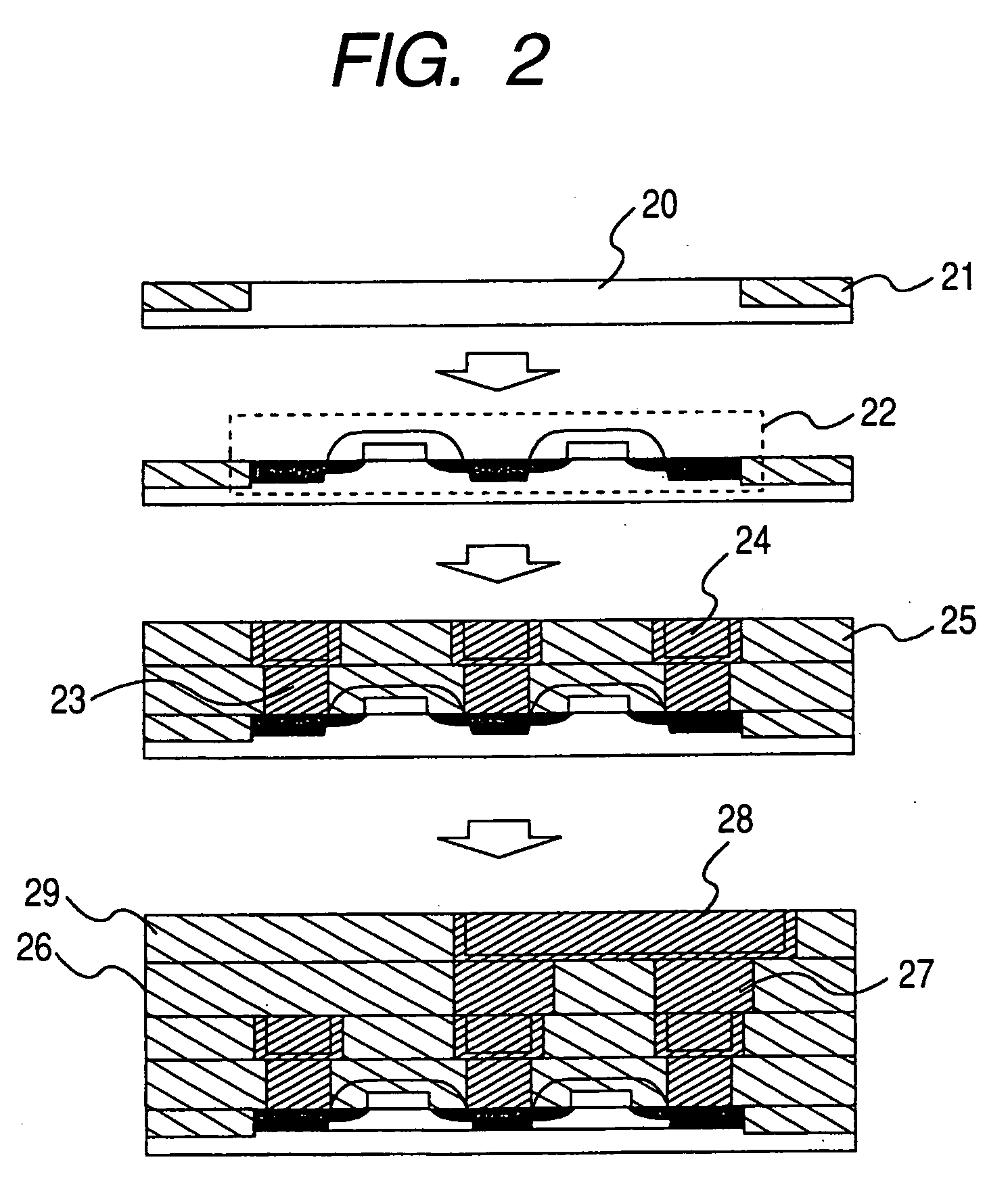

InactiveUS7106528B2Efficient preparationSmall roughnessOptical articlesCeramic shaping mandrelsFresnel lensShell molding

A method of manufacturing a large double-sided curved Fresnel lens. The method includes a machining step (A) of performing ultra-precise three-dimensional machining on an upper mold and a lower mold to each have an upper transfer surface and a lower transfer surface engaging an upper surface and a lower surface of a thermoplastic resin plate, respectively. Further, the method includes a hot press molding step (B) of pressing the thermoplastic resin plate between the upper and lower molds by a predetermined pressure with the resin plate being held at a temperature higher than a softening temperature thereof and lower than a melting temperature thereof so that the thermoplastic resin plate is curved, and both lens surfaces for the double-sided Fresnel lens are respectively transferred to an upper surface and a lower surface of the thermoplastic resin plate.

Owner:RIKEN

Glass ceramic panel with a pleasing black decoration applied with a decorative paint

InactiveUS20080139375A1Smoother and less rough surfaceColor depthStoves/ranges topsHot plates heating arrangementsGlass-ceramicPigment

Decorative paints are typically burned in at relatively high temperatures, preferably in connection with the thermal ceramicizing process. In order to provide a glass ceramic panel having a cooking surface with a pleasing deep black, very smooth decoration by a burned-in decorative paint, the glass ceramic panel is formed from a melt that is black and the decorative paint on the black glass ceramic panel contains a colorless glass flux and from 0 to 10 percent by weight of at least one black pigment. The decorative paint can consist of the colorless melted-on glass flux. The glass flux preferably has a composition in percent by weight of Li2O, 0-5; Na2O, 0-5; K2O, <2; ΣLi2O+Na2O+K2O, 1-10; MgO, 0-3; CaO, 0-4; SrO, 0-4; BaO, 0-4; ZnO, 0-4; B2O3, 15-27; Al2O3, 10-20; SiO2, 43-58; TiO2, 0-3; ZrO2, Sb2O3, 0-2; F, 0-3.

Owner:SCHOTT AG

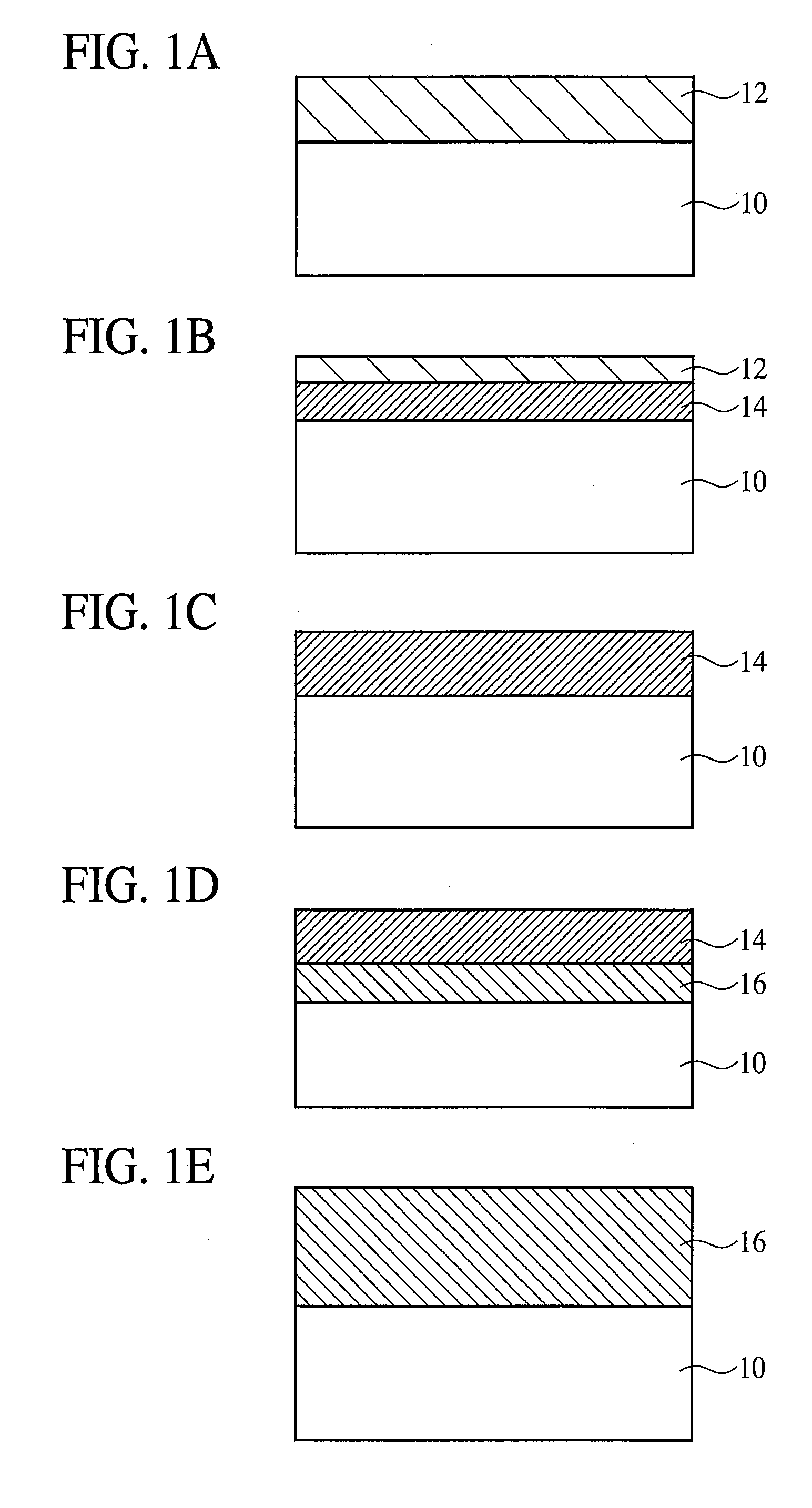

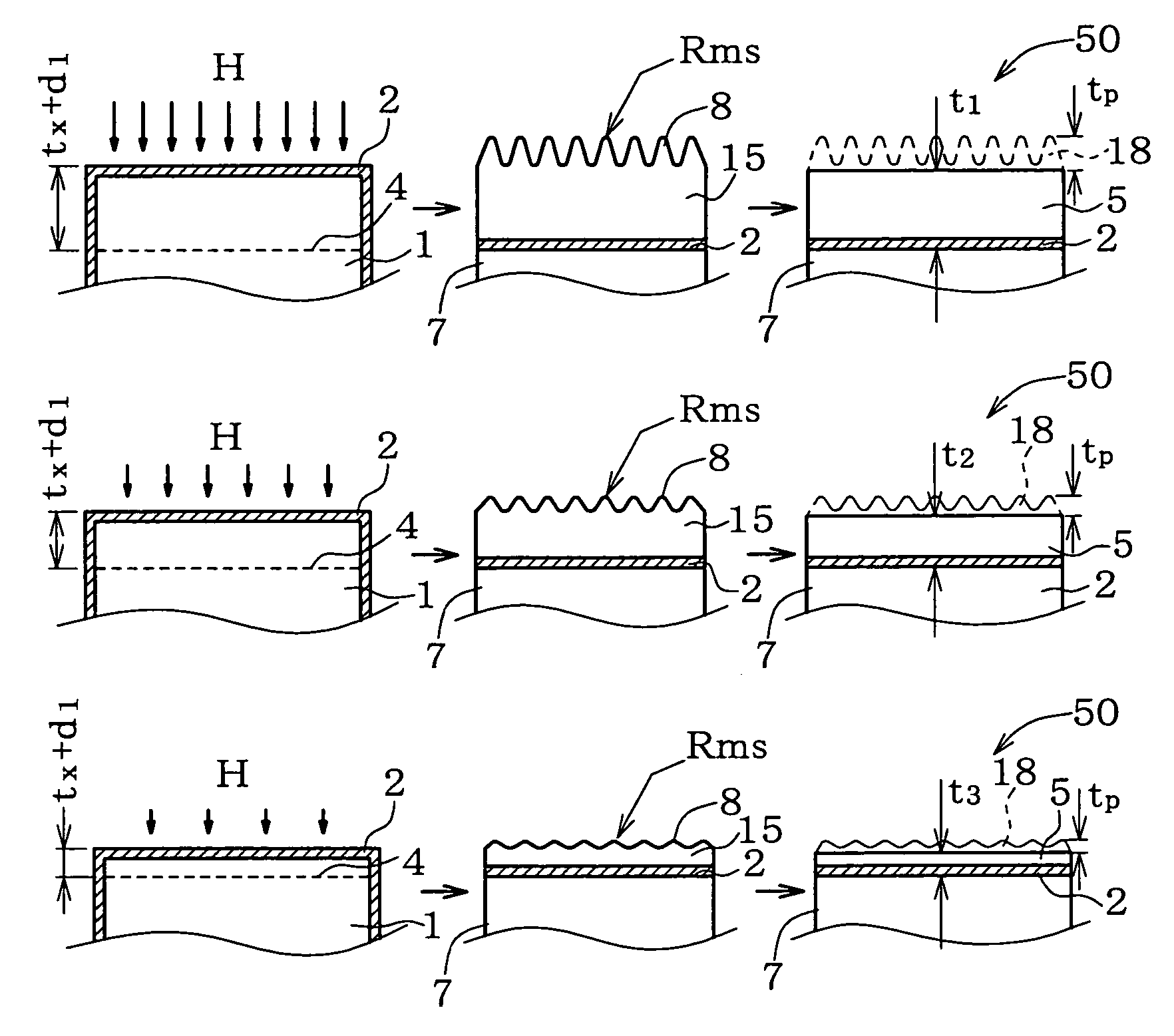

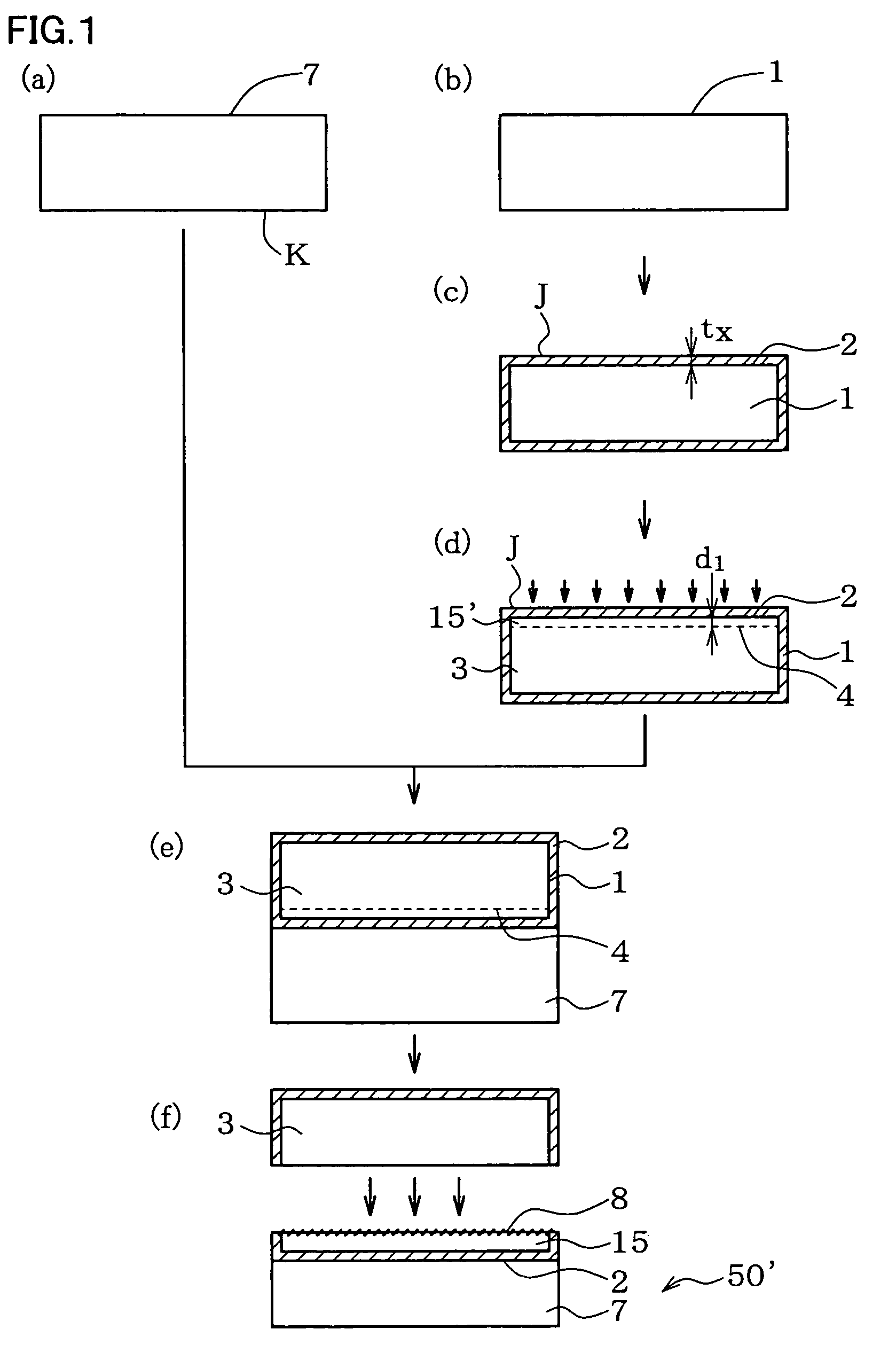

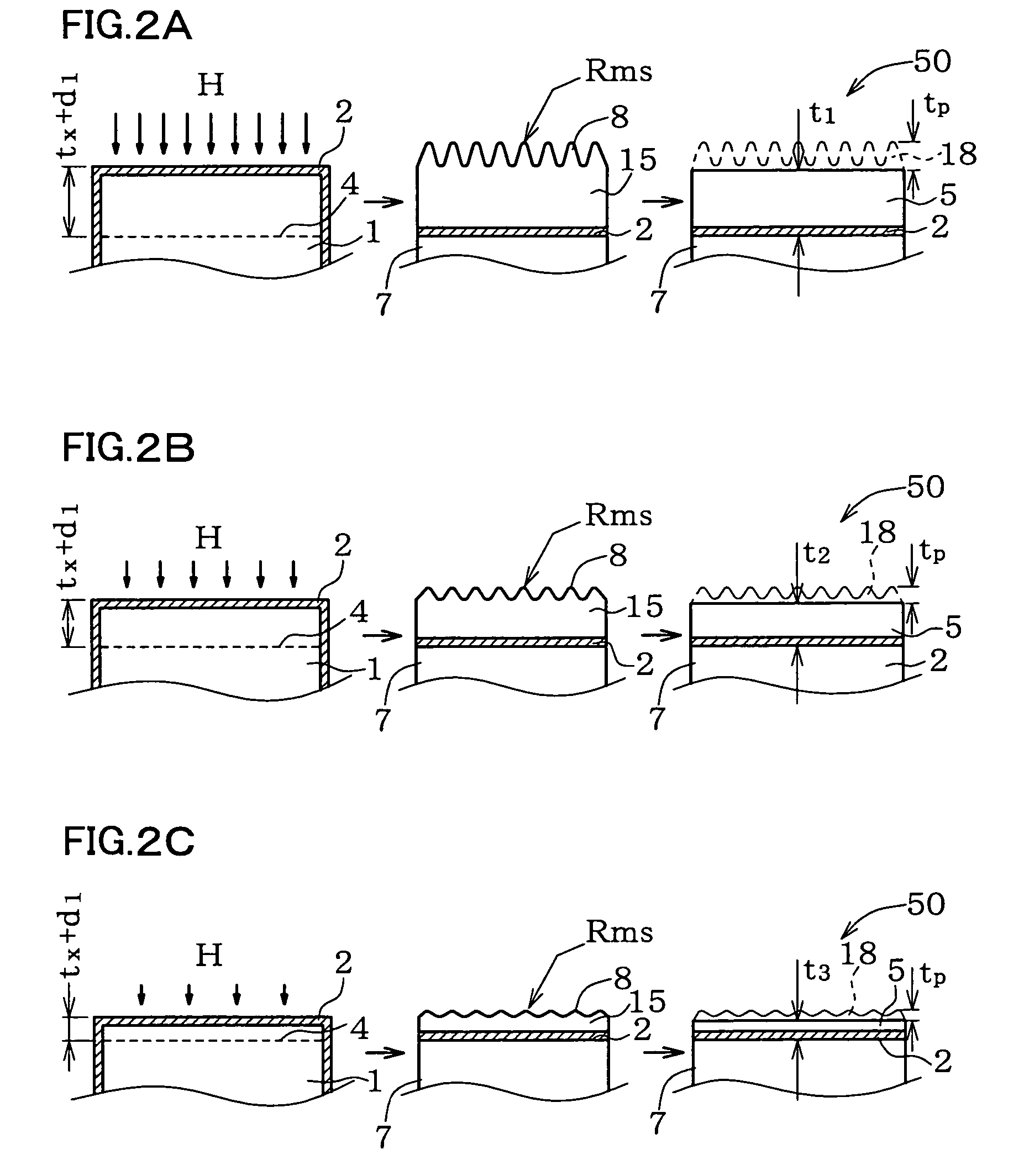

Soi wafer manufacturing method

ActiveUS20060040469A1Reduce roughnessImprove uniformitySolid-state devicesSemiconductor/solid-state device manufacturingWaferingSurface roughness

In order to adjust thickness of a bonded silicon single crystal film 15 depending of thickness of an SOI layer 5 to be obtained, depth of formation d1+tx of a separatory ion implanted layer 4, measured from a first main surface J, in the separatory ion implanted layer formation step is adjusted through energy of the ion implantation. Dose of the ion implantation is set smaller as the depth of formation measured from the first main surface J becomes smaller. A smaller dose results in a smaller surface roughness of the separation surface, and makes it possible to reduce polishing stock removal of the separation surface of the bonded silicon single crystal film in the planarization step. Uniformity in the thickness of the SOI layer can consequently be improved even for the case where a thin SOI layer has to be formed. The present invention is therefore successful in providing a method of fabricating an SOI wafer capable of suppressing variations in the intra-wafer and inter-wafer uniformity of the thickness of the SOI layer to a sufficiently low level, even for the case where a required level of the thickness of the SOI layer is extremely small.

Owner:SHIN-ETSU HANDOTAI CO LTD

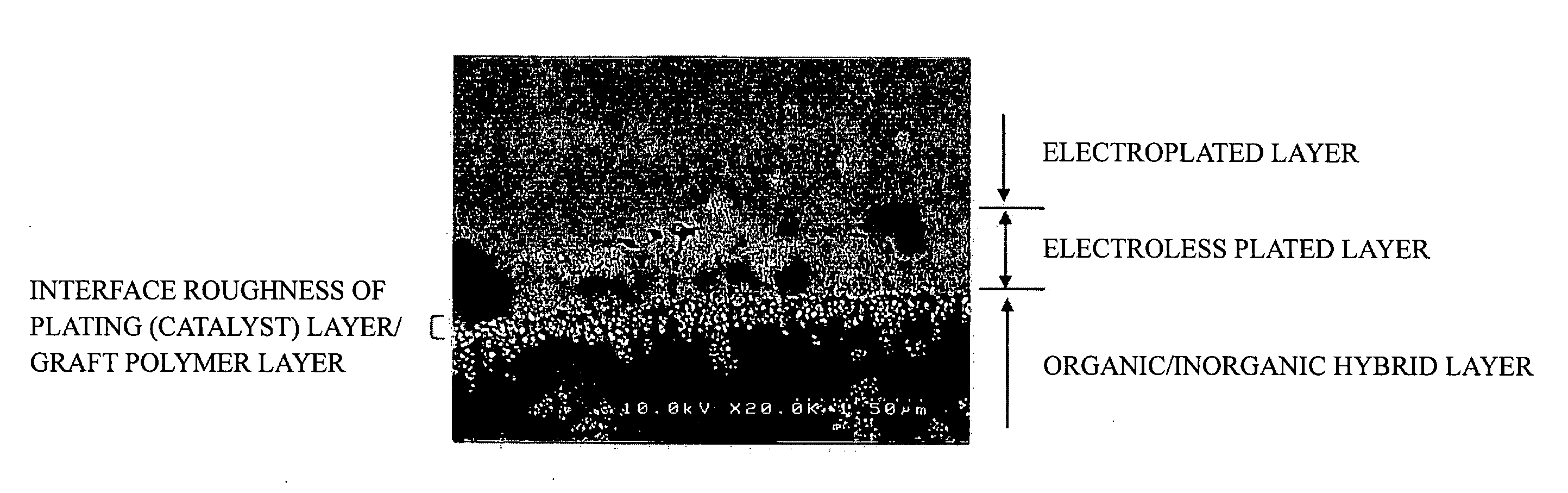

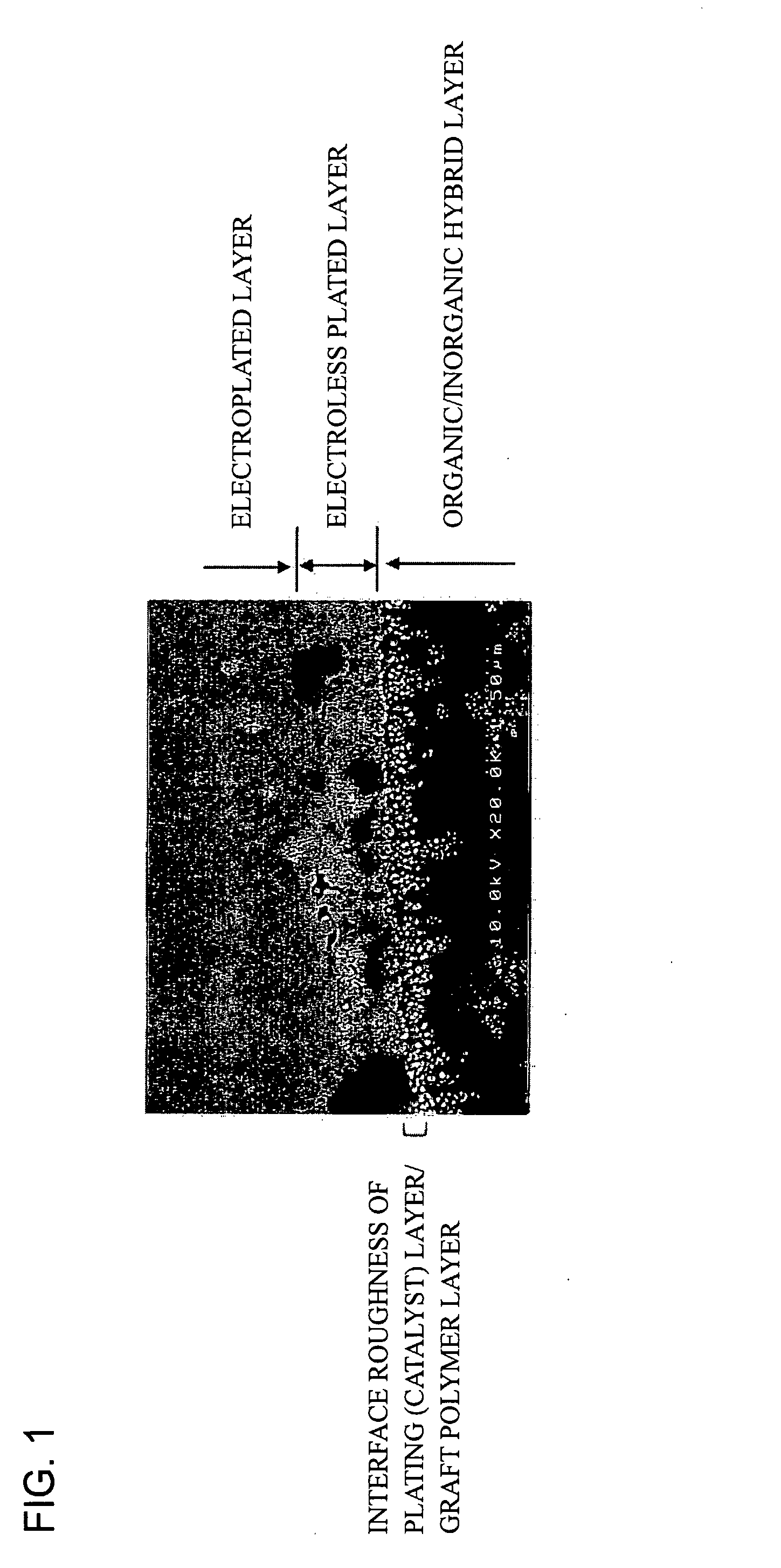

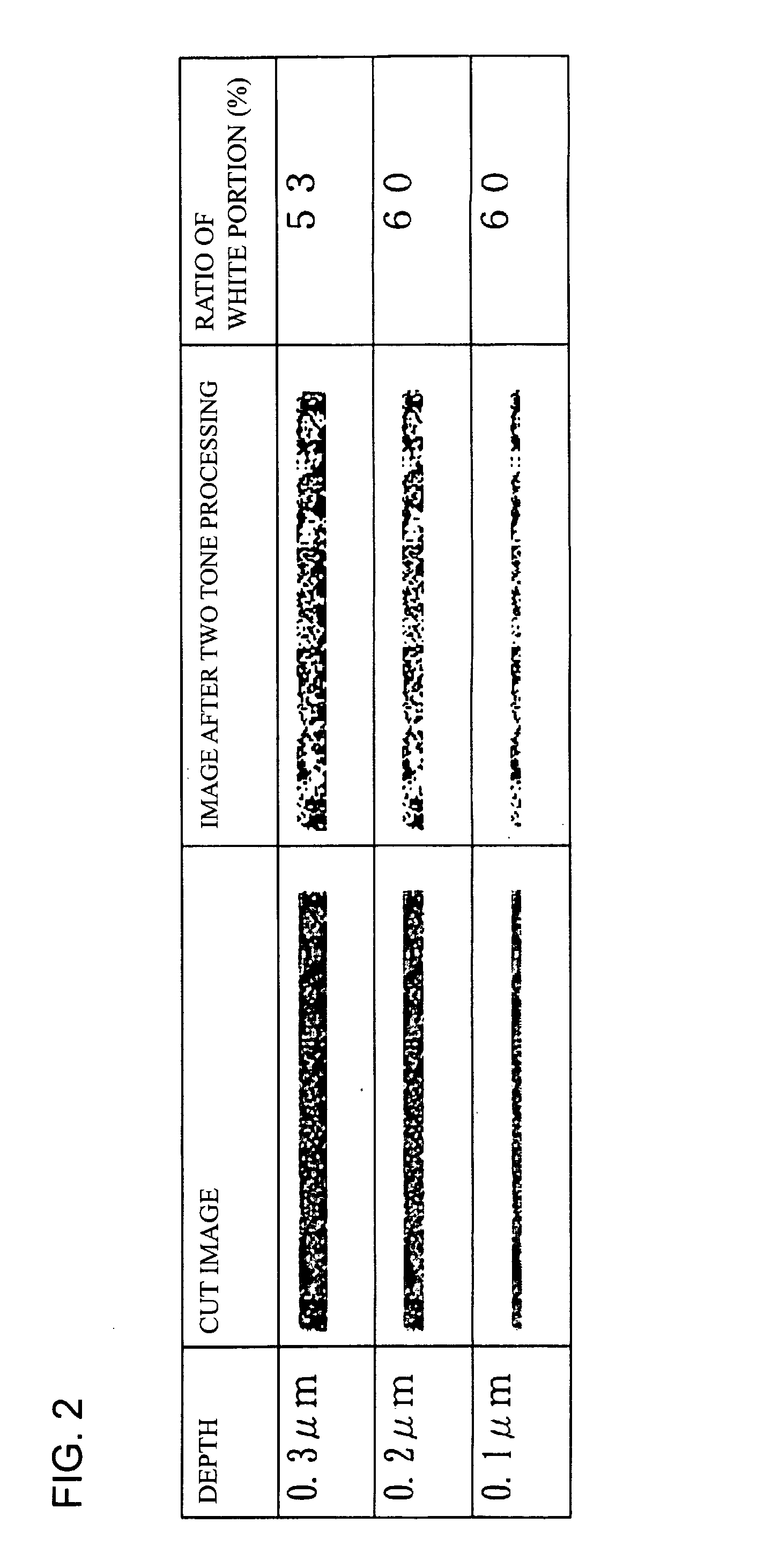

Metal Film Formation Method of Metal Film

InactiveUS20090004465A1Improve adhesionImprove mobilityHigh frequency circuit adaptationsPrinted circuit aspectsChemical LinkageSurface roughness

The present invention provides a metal film formed by applying an electroless plating catalyst or its precursor to a polymer layer on a base plate having a surface roughness of 500 nm or less and then carrying out electroless plating, the polymer layer containing a polymer which has a functional group capable of interacting with the electroless plating catalyst or its precursor and is chemically bonded directly to the base plate, wherein the adhesion strength between the base plate and the metal film is 0.2 kN / m or more.

Owner:FUJIFILM CORP

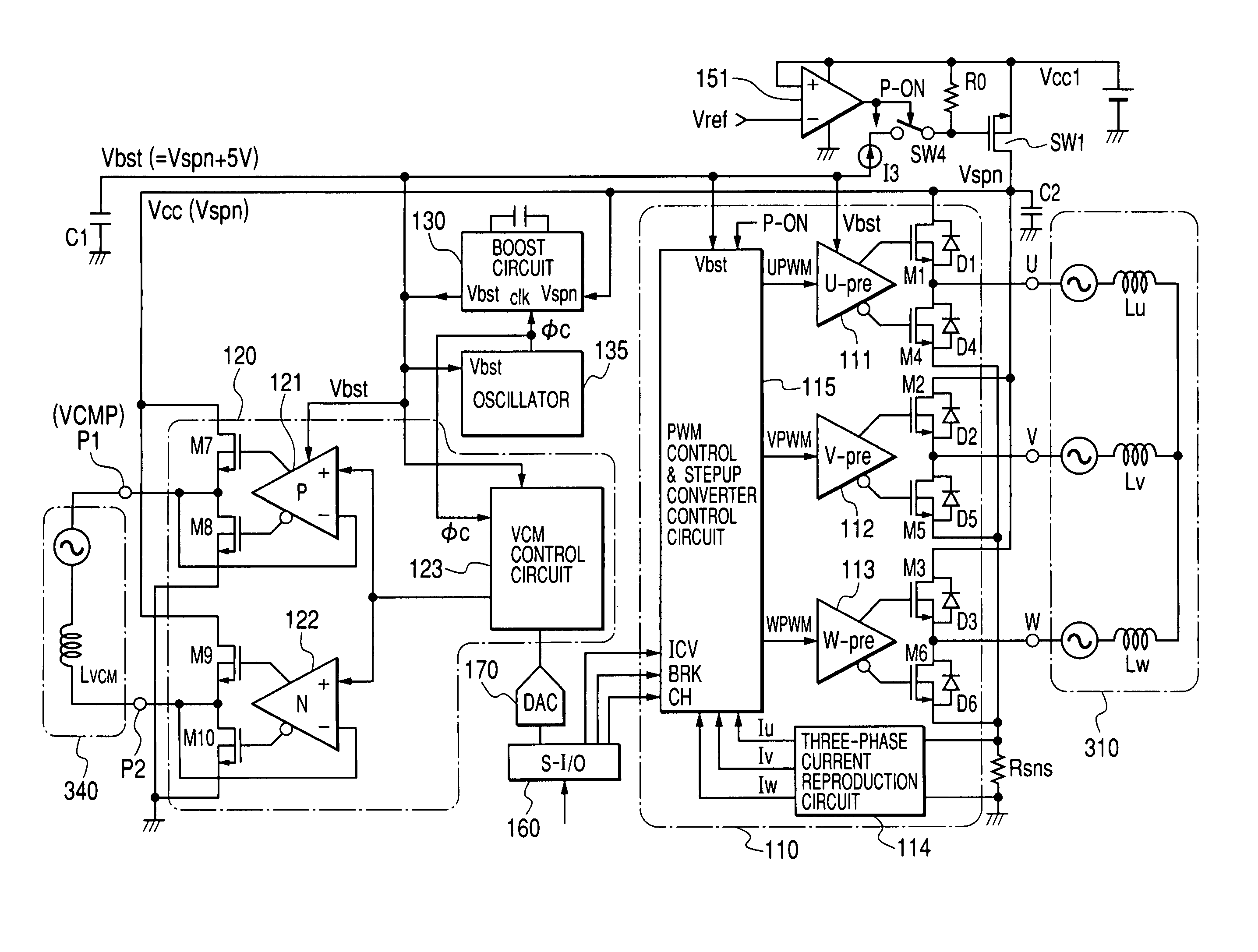

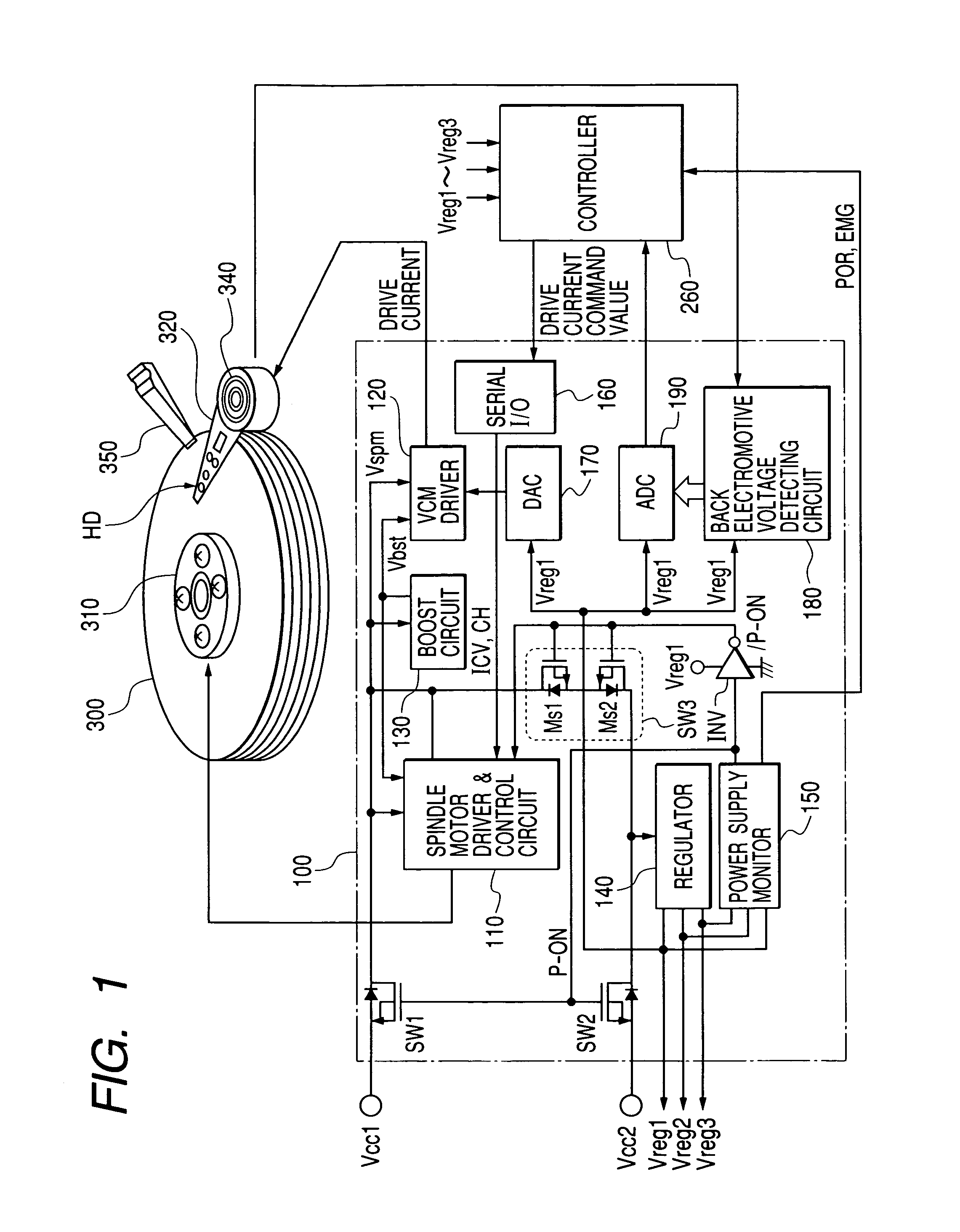

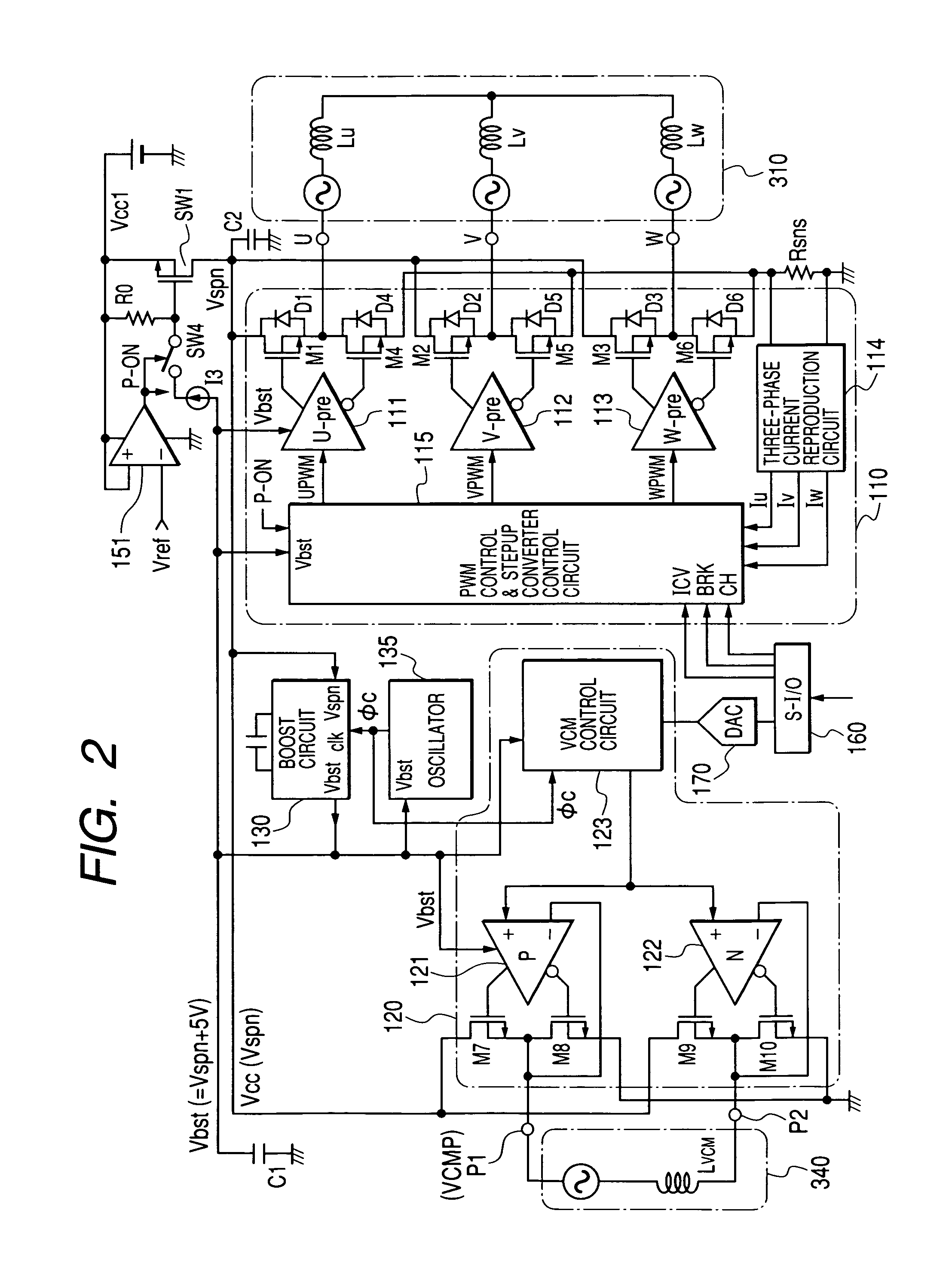

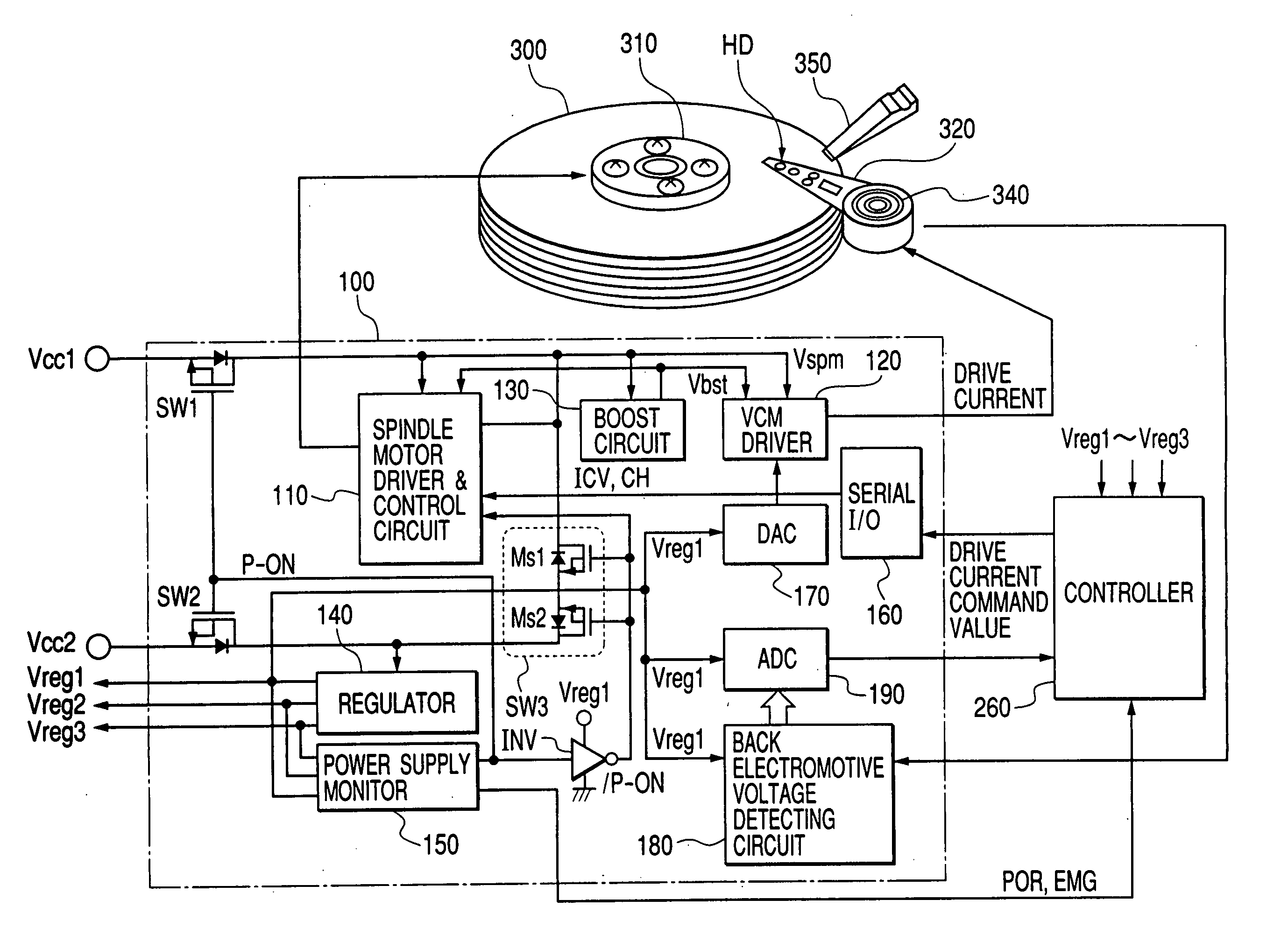

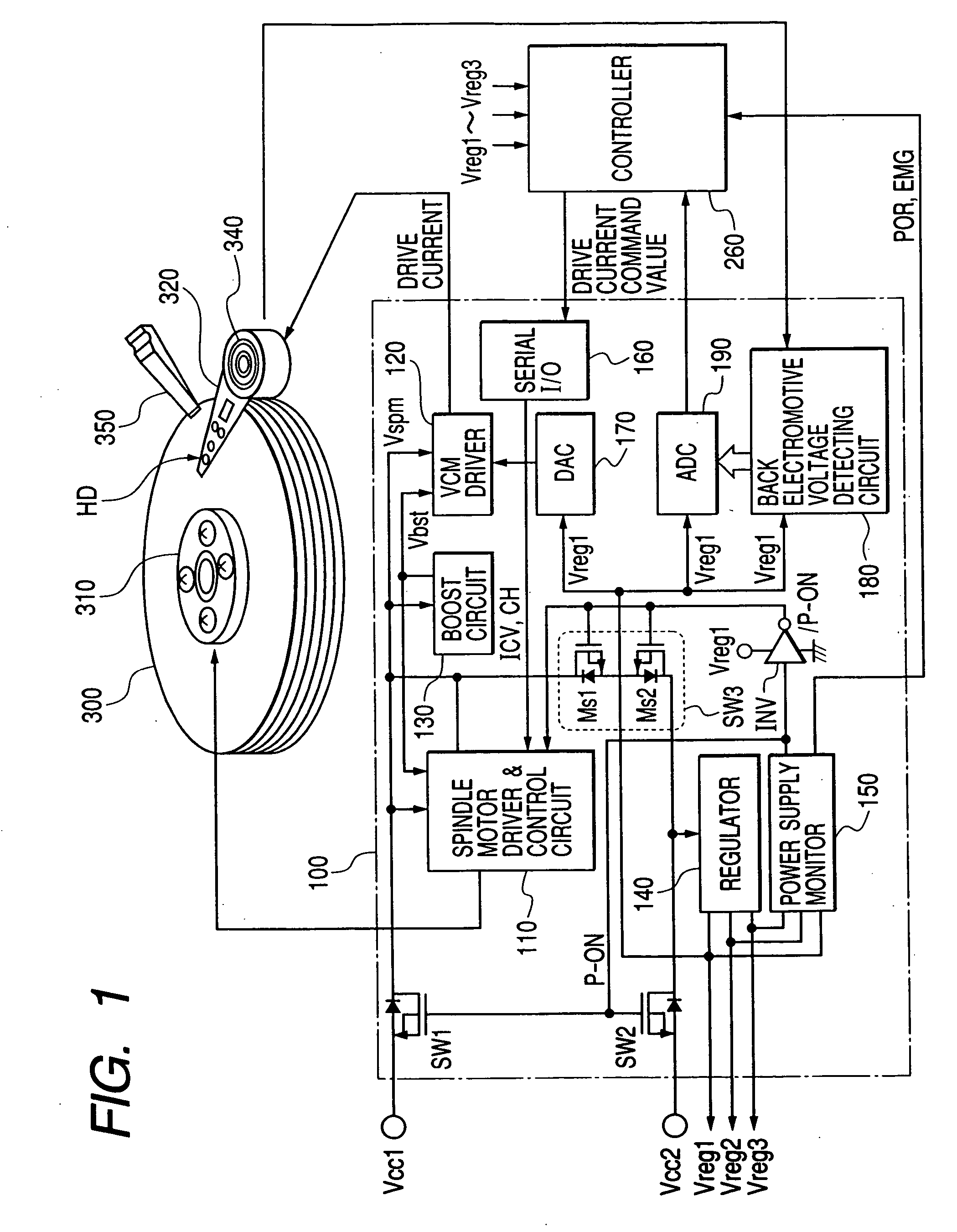

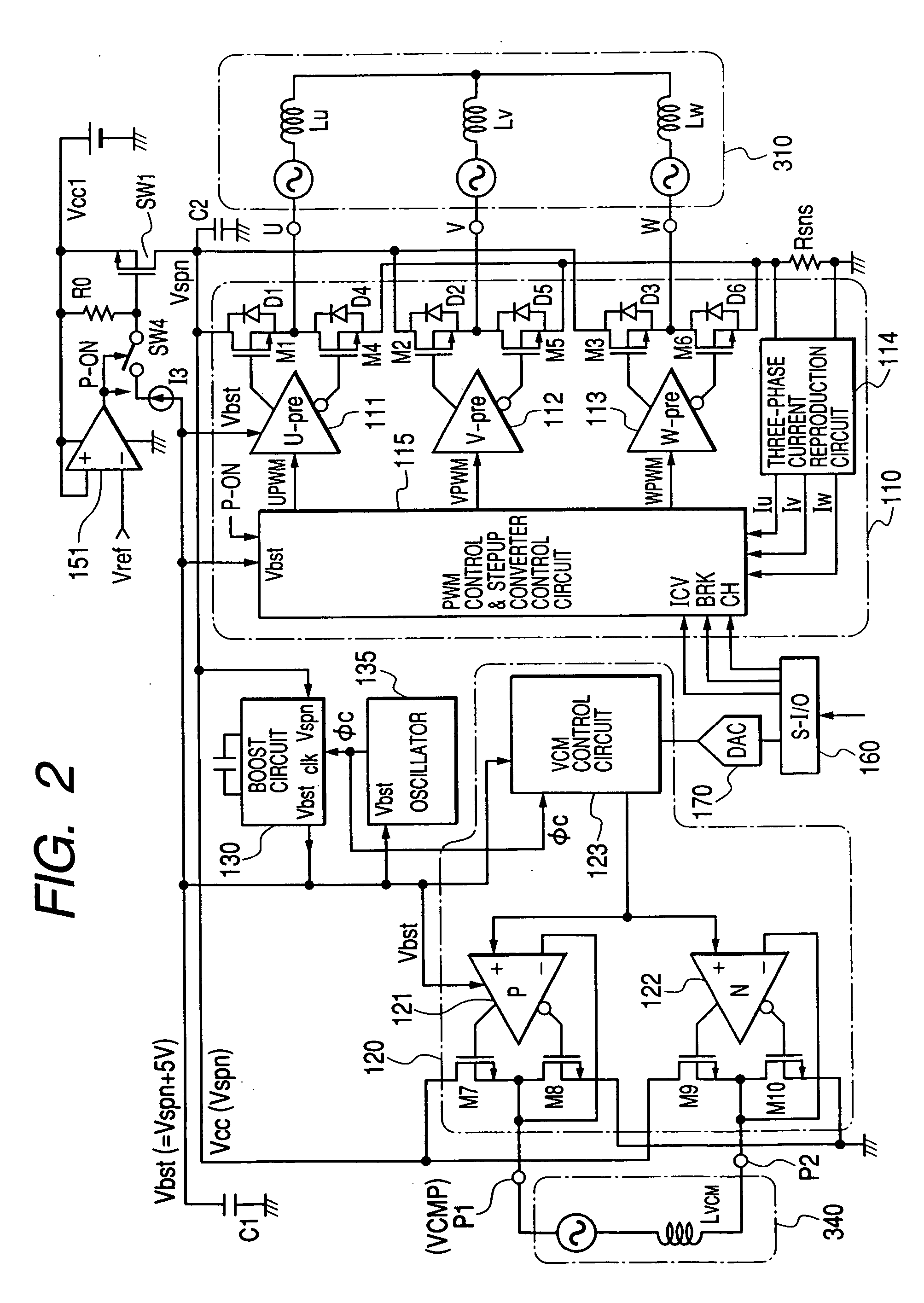

Magnetic disk storage system

InactiveUS7054089B2Small roughnessReduce gapDisposition/mounting of recording headsDriving/moving recording headsMotor driveElectric machine

The present invention provides a magnetic disk storage system including a spindle motor that rotates a magnetic disk, a spindle motor drive circuit that rotatably drives the spindle motor, a magnetic head that performs reading of information on the magnetic disk, a voice coil motor that moves the magnetic head, and a voice coil motor drive circuit that drives the voice coil motor. When the magnetic head is loaded from a standby position to the surface of the magnetic disk, the rotational speed of the spindle motor is made slower than a rotational speed at a normal operation. Upon power-off, the spindle motor drive circuit is caused to carry out a stepup converter operation to thereby generate a voltage higher than a back electromotive voltage, and causes a control circuit and a drive circuit to operate by the high voltage to thereby enable speed control at the movement of the magnetic head to a predetermined standby position.

Owner:RENESAS TECH CORP +1

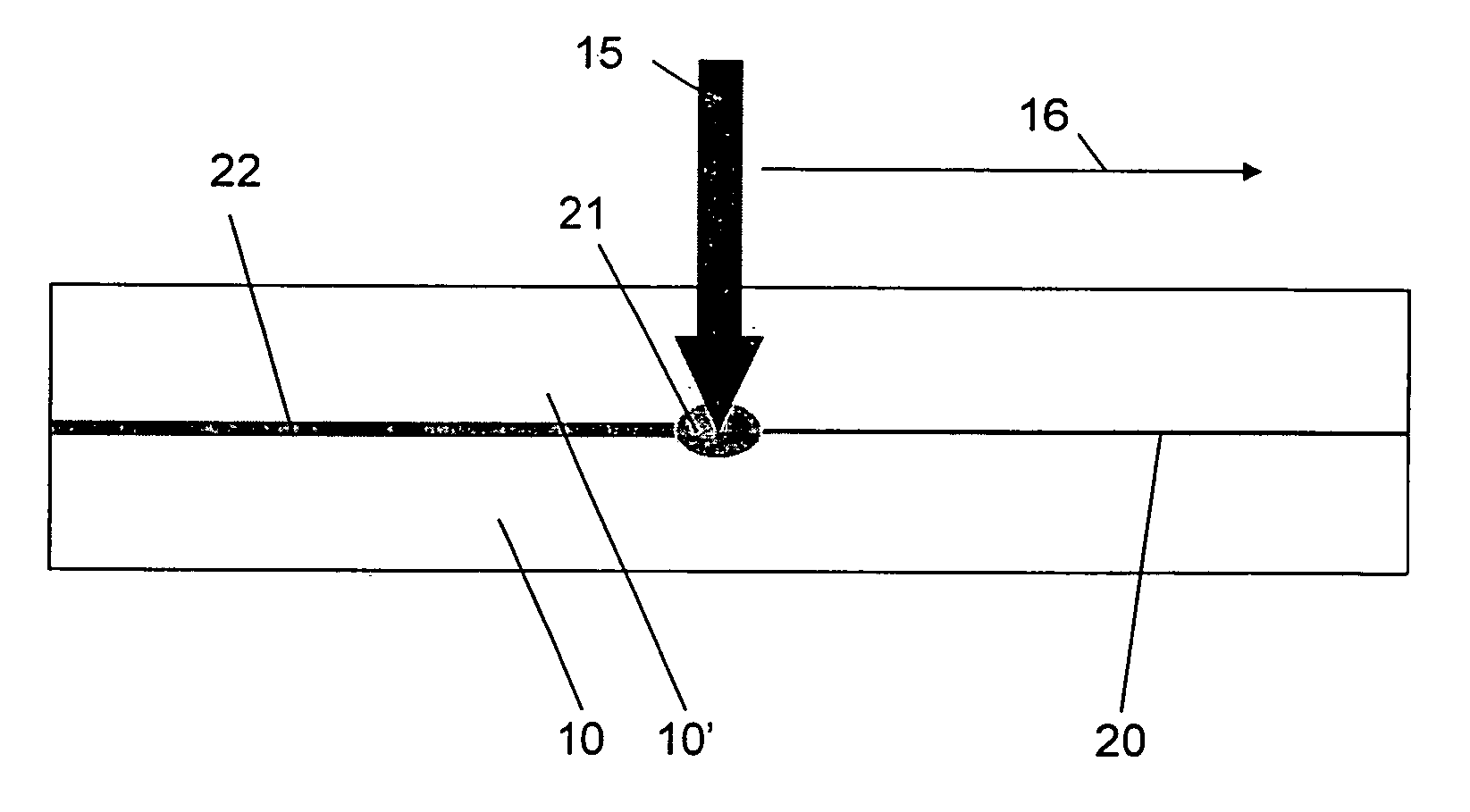

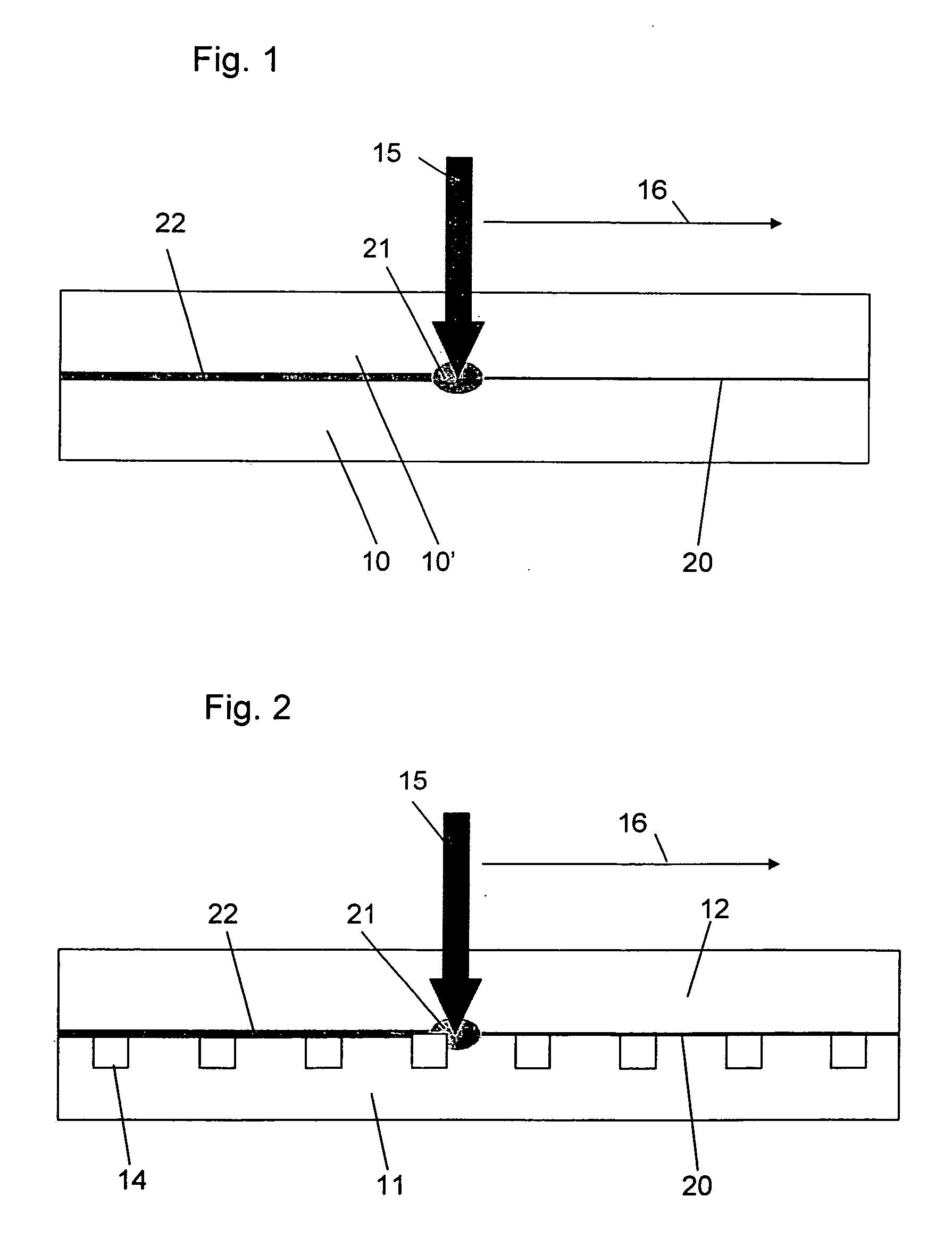

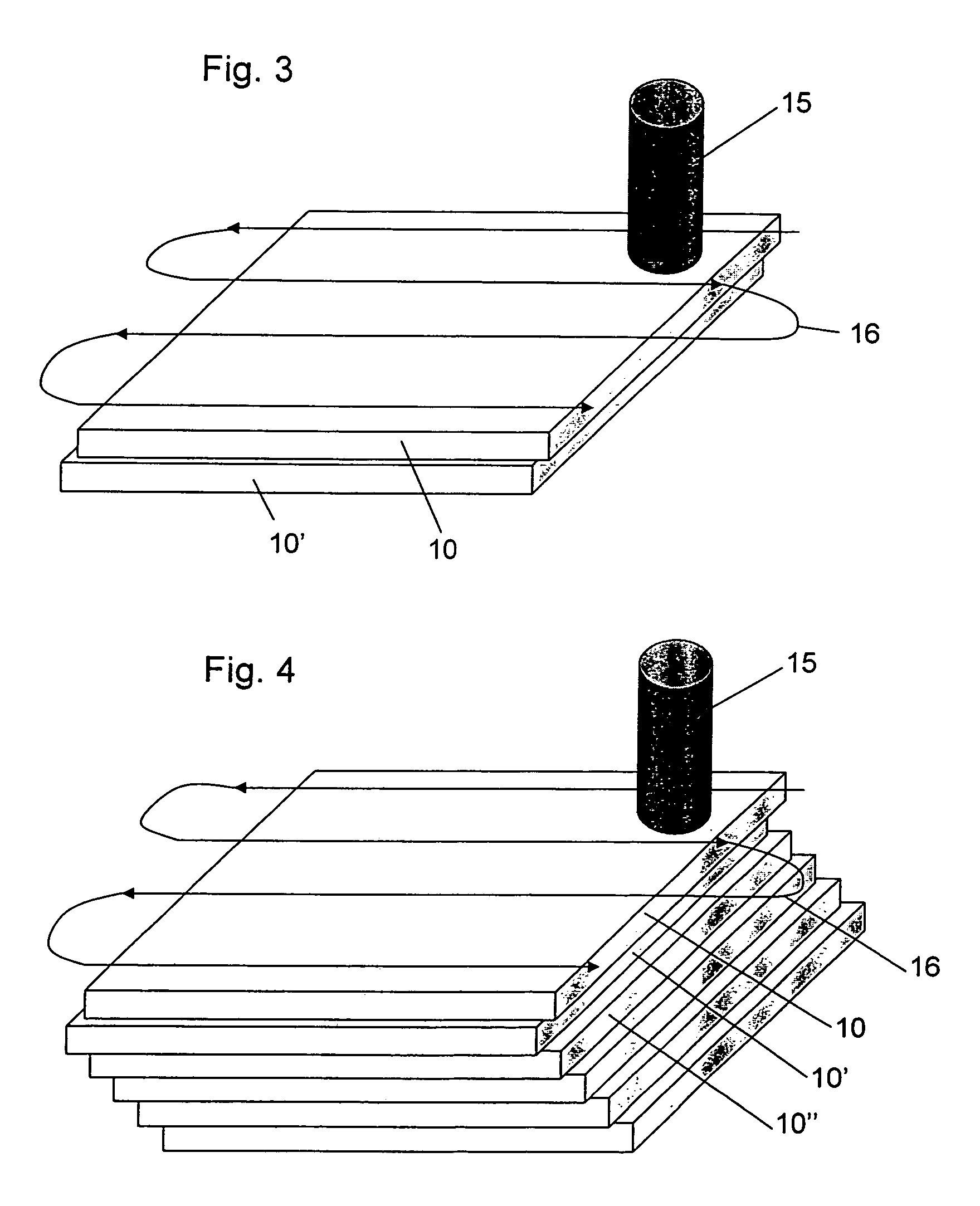

Method for joining plastic work pieces

InactiveUS20070051461A1High shape accuracySteep flankPrecision positioning equipmentLamination ancillary operationsEngineeringAbsorption layer

In a method for joining work pieces of transparent plastic material, wherein absorption layers are applied to an interface area between the work pieces to be joined and, wherein the work piece areas to be joined are firmly engaged and pressed together, and the interface area is subjected to laser radiation so that the absorption layer is heated and the work pieces are joined by welding, the absorption layer consists of carbon or gold with a thickness of 5 nm to 15 nm.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

Resin composite copper foil, printed wiring board, and production processes thereof

ActiveUS20070172674A1Improve adhesion strengthSmall roughnessSynthetic resin layered productsPrinted circuit aspectsCopper foilCopolymer

A resin composite copper foil comprising a copper foil and a resin layer containing a block copolymer polyimide and a maleimide compound, the resin layer being formed on one surface of the copper foil, a production process thereof, a copper-clad laminate using the resin composite copper foil, a production process of a printed wiring board using the copper-clad laminate, and a printed wiring board obtained by the above process.

Owner:MITSUBISHI GAS CHEM CO INC

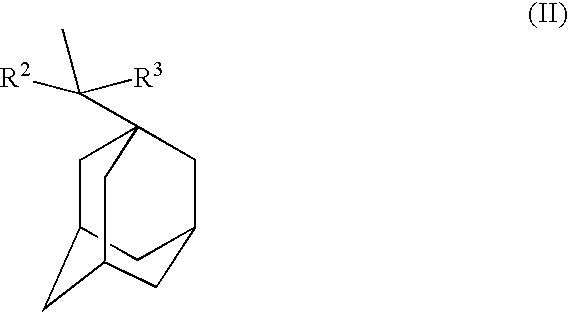

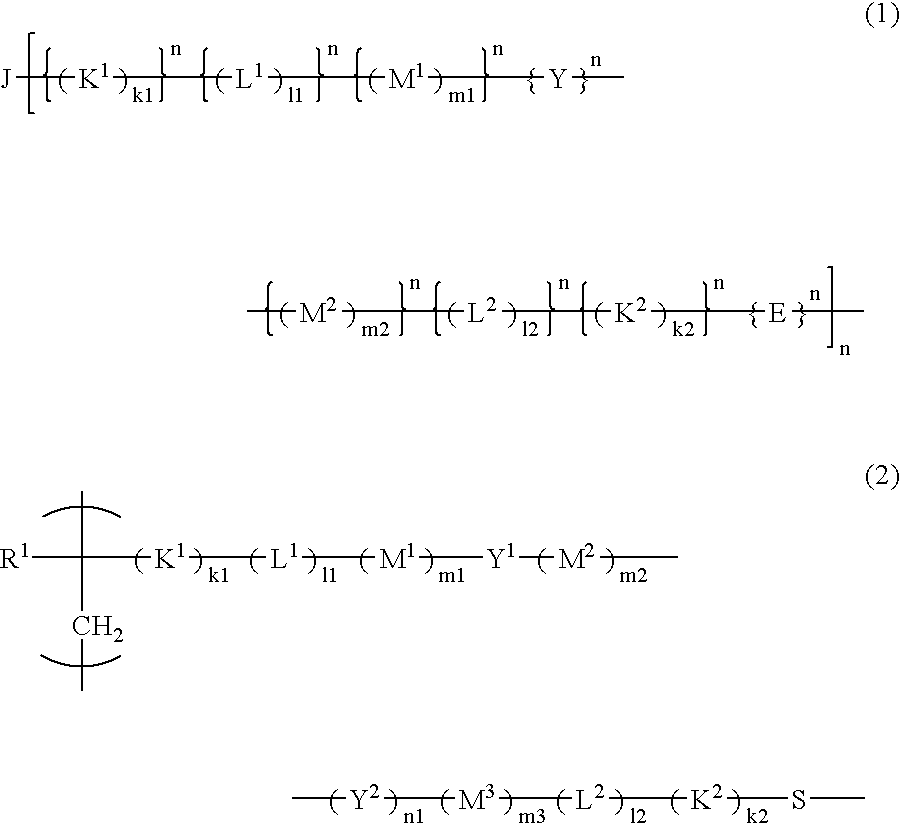

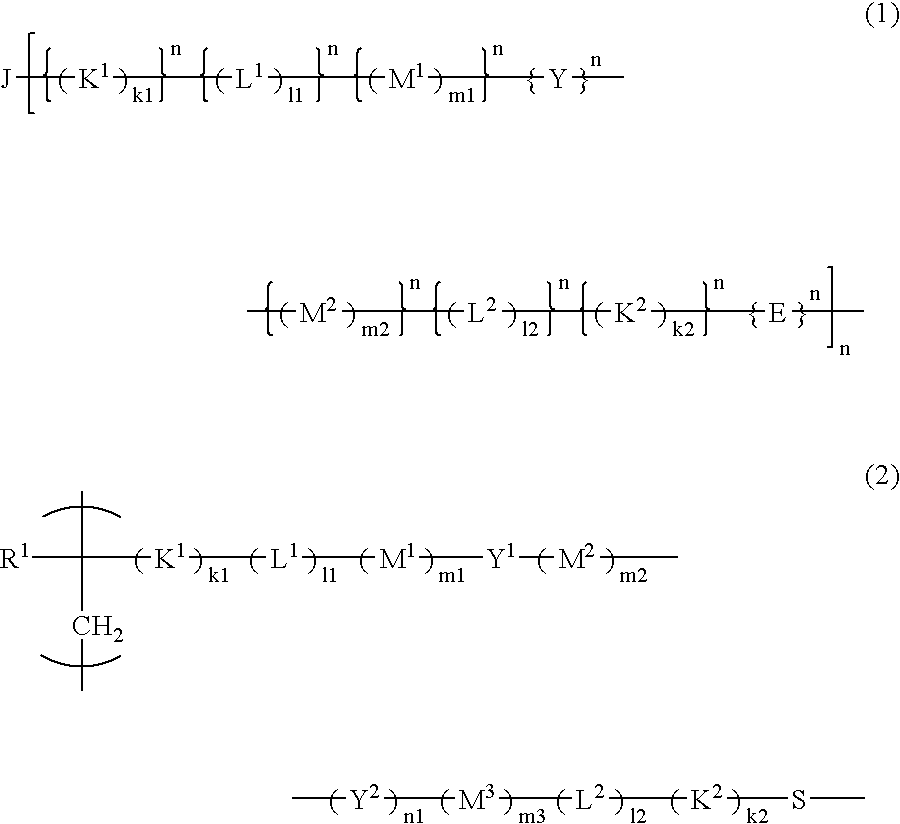

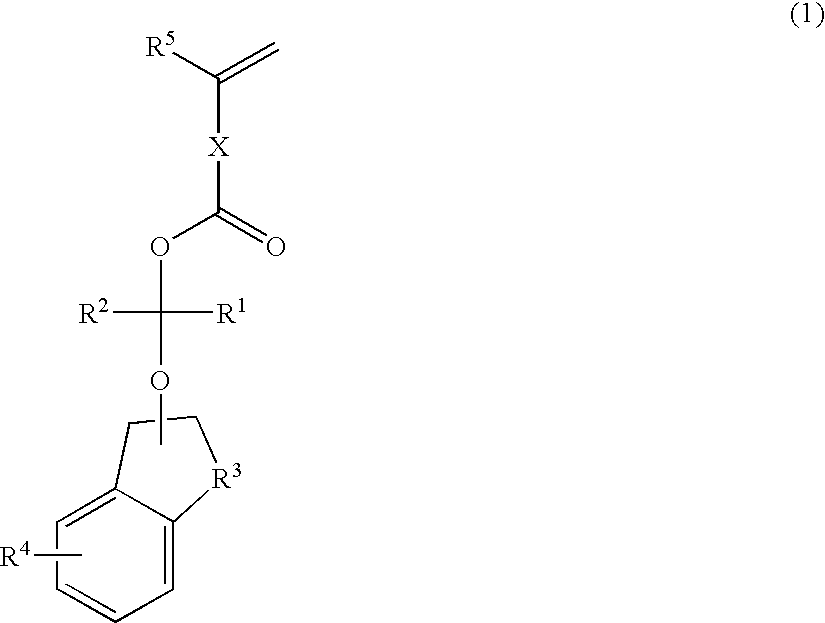

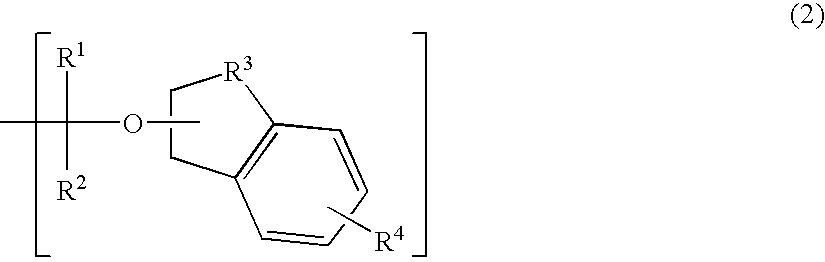

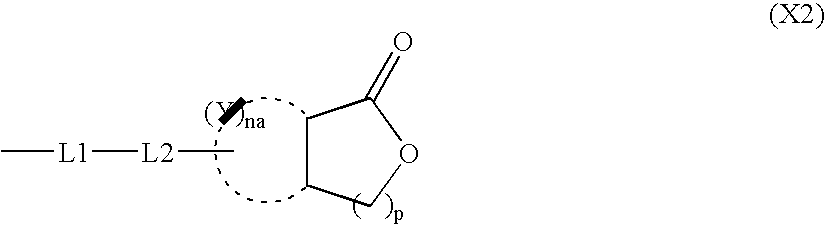

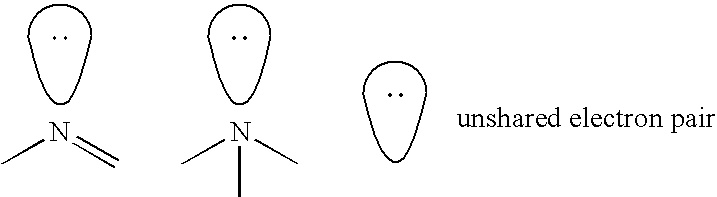

Resist polymer, resist composition, process for pattern formation, and starting compounds for production of the resist polymer

ActiveUS20070190449A1Improve solubilityInhibit productionPhotosensitive materialsPhotomechanical apparatusMethyl groupStructural unit

To provide a resist polymer comprising, as a structural unit, an acid-decomposable unit having a structure represented by formula (1) or (2) which exhibits a small line edge roughness and produces little defects in DUV excimer laser lithography or the like. In formulas (1) and (2), n represents an integer of 2 to 24; J represents a single bond or a divalent hydrocarbon group which may have a substituent / heteroatom when n=2, or represents an n-valent hydrocarbon group which may have a substituent / heteroatom when n≧3; E represents a residue of a polymerization terminator, a chain transfer agent or a polymerization initiator; K1 and K2 each represent at least one selected from alkylene, cycloalkylene, oxyalkylene, arylene, a divalent thiazoline ring, a divalent oxazoline ring and a divalent imidazoline ring; L1 and L2 each represent at least one selected from —C(O)O—, —C(O)— and —OC(O)—; M1, M2 and M3 each represent at least one selected from alkylene, cycloalkylene, oxyalkylene and arylene; Y, Y1 and Y2 each represent an acid-decomposable linkage; k1, k2, l1, l2, m1, m2, m3 and n1 each represent 0 or 1; and R1 represents H or a methyl group.

Owner:MITSUBISHI CHEM CORP

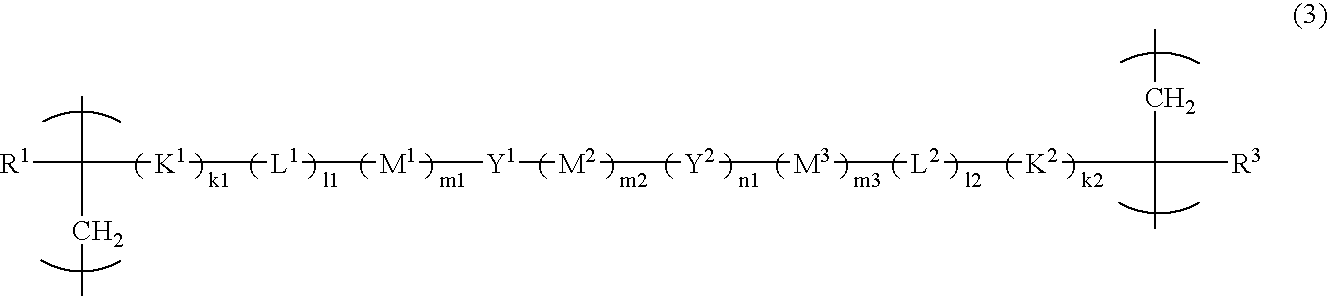

Method for producing electronic device

ActiveUS20060105273A1Low costImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingResistSolubility

There is a problem in that when the demand accuracy with respect to a semiconductor pattern dimension comes close to a resist molecule size with miniaturization, the device performance is deteriorated due to edge roughness of a resist pattern to exert a bad influence on the system performance. The present invention overcomes the problem by the procedure in which super-molecules which are small in dimension as compared with the conventional polymers are used as main components, the reaction number required for the change of molecule solubility is made constant and as large as possible, and an acid generator is made clathrate or combinatory n super molecules to make an acid catalyst concentration large. As a result, it is possible to form a pattern of molecular accuracy with high productivity even with respect to the pattern dimension less than 50 nm, thereby realizing the high performance system.

Owner:RENESAS ELECTRONICS CORP

Curable composition for imprints, patterning method and pattern

ActiveUS20140154471A1Pattern effect is goodLess producedLayered productsCeramic shaping apparatusHydroxy groupSilicon

Disclosed is a to provide a curable composition for imprints capable of keeping a good patternability and of producing less defects even after repetitive pattern transfer. The curable composition for imprints comprising: a polymerizable compound (A); a photo-polymerization initiator (B); and anon-polymerizable compound (C) having a polyalkylene glycol structure having at least one terminal hydroxy group, or at least one etherified terminal hydroxy group, and containing substantially no fluorine atom and no silicon atom.

Owner:FUJIFILM CORP

Method for manufacturing a solid electrolyte sensor element for detecting at least one property of a measuring gas in a measuring gas chamber, containing two porous ceramic layers

InactiveUS20160061767A1Increasing thermal massImprove robustnessWave amplification devicesMaterial analysis by electric/magnetic meansMetallurgyGas chamber

A method for manufacturing a sensor element is provided for detecting at least one property of a measuring gas in a measuring gas chamber, in particular for detecting a proportion of a gas component in the measuring gas or a temperature of the measuring gas. The method includes the following steps: providing at least one solid electrolyte which includes at least one functional element; applying, at least in sections, at least one first layer made of a ceramic material to the solid electrolyte, the first layer having a first porosity after the application; and applying, at least in sections, at least one second layer made of a ceramic material, the second layer having a second porosity after the application, and the first layer differing from the second layer with respect to at least one material property. Moreover, a sensor element which is manufacturable according to this method is provided.

Owner:ROBERT BOSCH GMBH

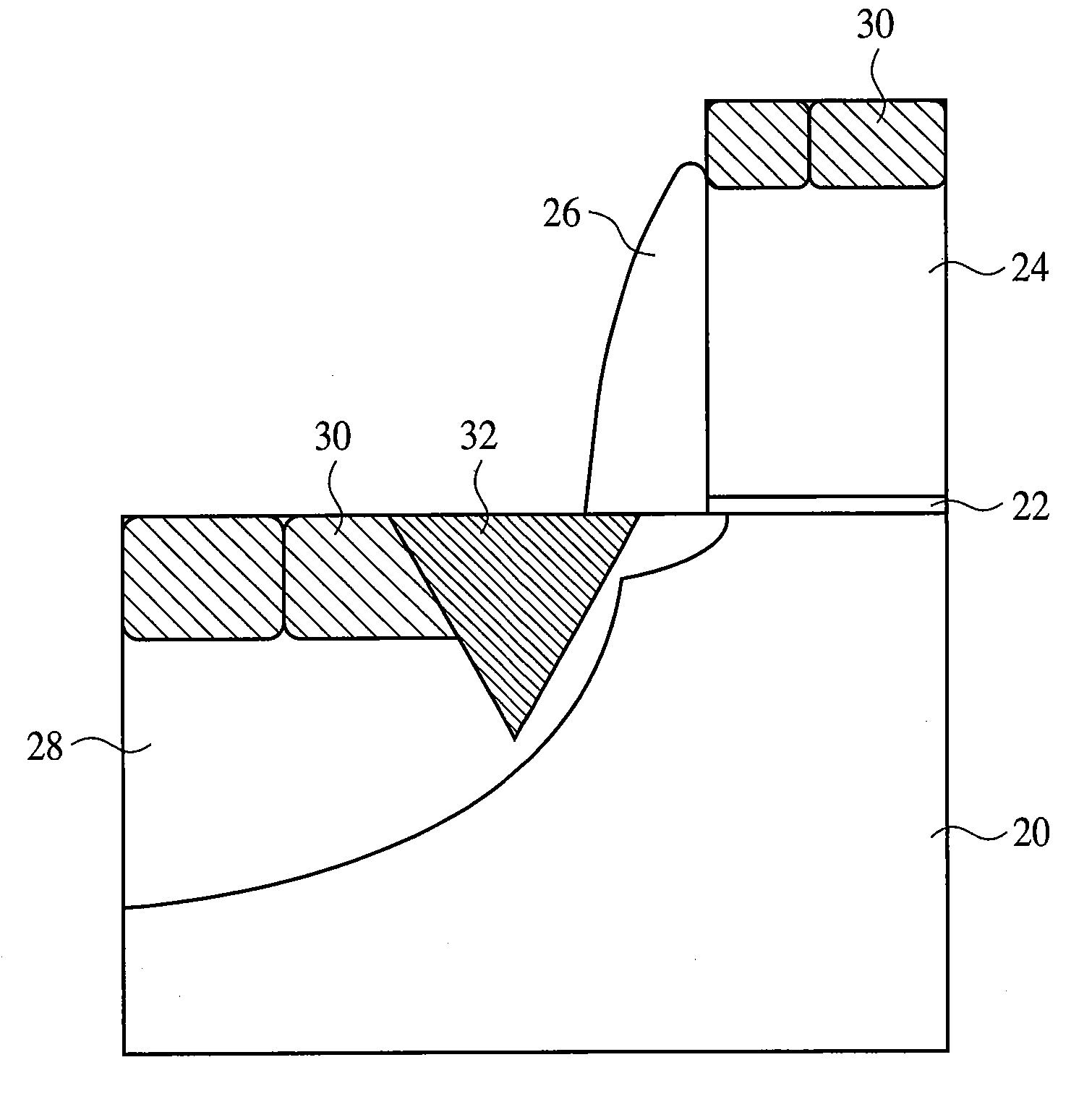

Spark plug for a gas-operated internal combustion engine

ActiveUS8890396B2Extended service lifeIncrease volumeSparking plugsExternal combustion engineEngineering

The invention relates to a spark plug for a gas-fired internal combustion engine, and Includes a metallic body, with an insulator fastened in the body. A central electrode, leads through the insulator and includes a protruding end of a precious metal alloy. An annular ground electrode is fastened to the body and surrounds the end of the central electrode which, at the inside thereof facing the central electrode is provided with a precious metal or with a precious metal alloy. The mutually facing surfaces of the central electrode and ground electrode formed by the precious metal or the precious metal alloy are coaxially disposed cylinder surfaces. A cap is provided and attached to the body and which, after installation of the spark plug into a combustion chamber of the internal combustion engine, shields the central electrode and the ground electrode from the combustion chamber. Together with the body of the spark plug, the central electrode forms an ante-chamber, in which the central electrode and the ground electrode are disposed. The cap having at least one opening, which enables a gas exchange between the ante-chamber and the space outside of the ante-chamber. According to the invention, a deviation of the cylinder surfaces from the ideal cylinder geometry is less than +−20 μm, and a deviation of the positions of the axes of the cylinder surfaces from their ideal coaxial position is less than +−50 μm.

Owner:FEDERAL MOGUL IGNITION

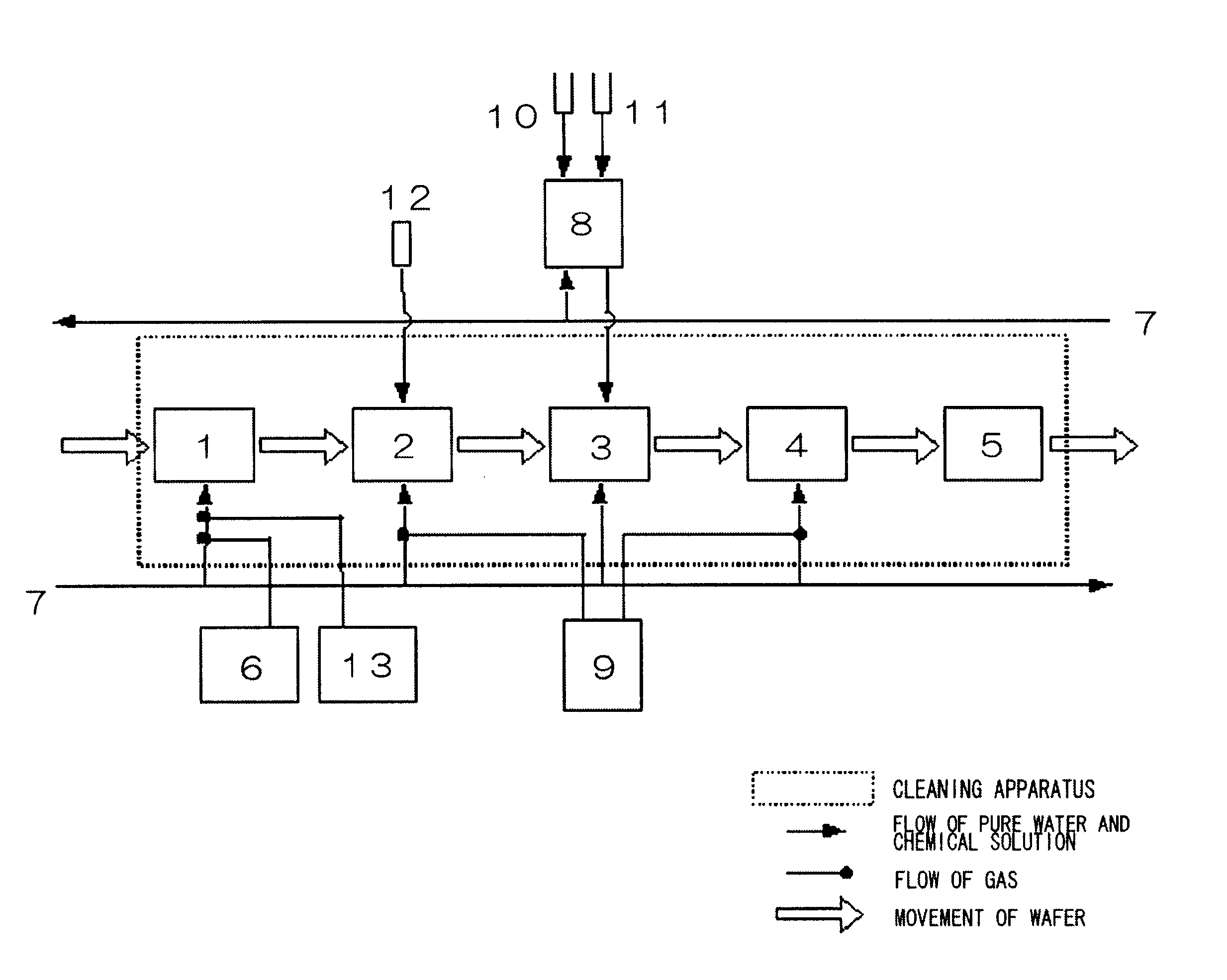

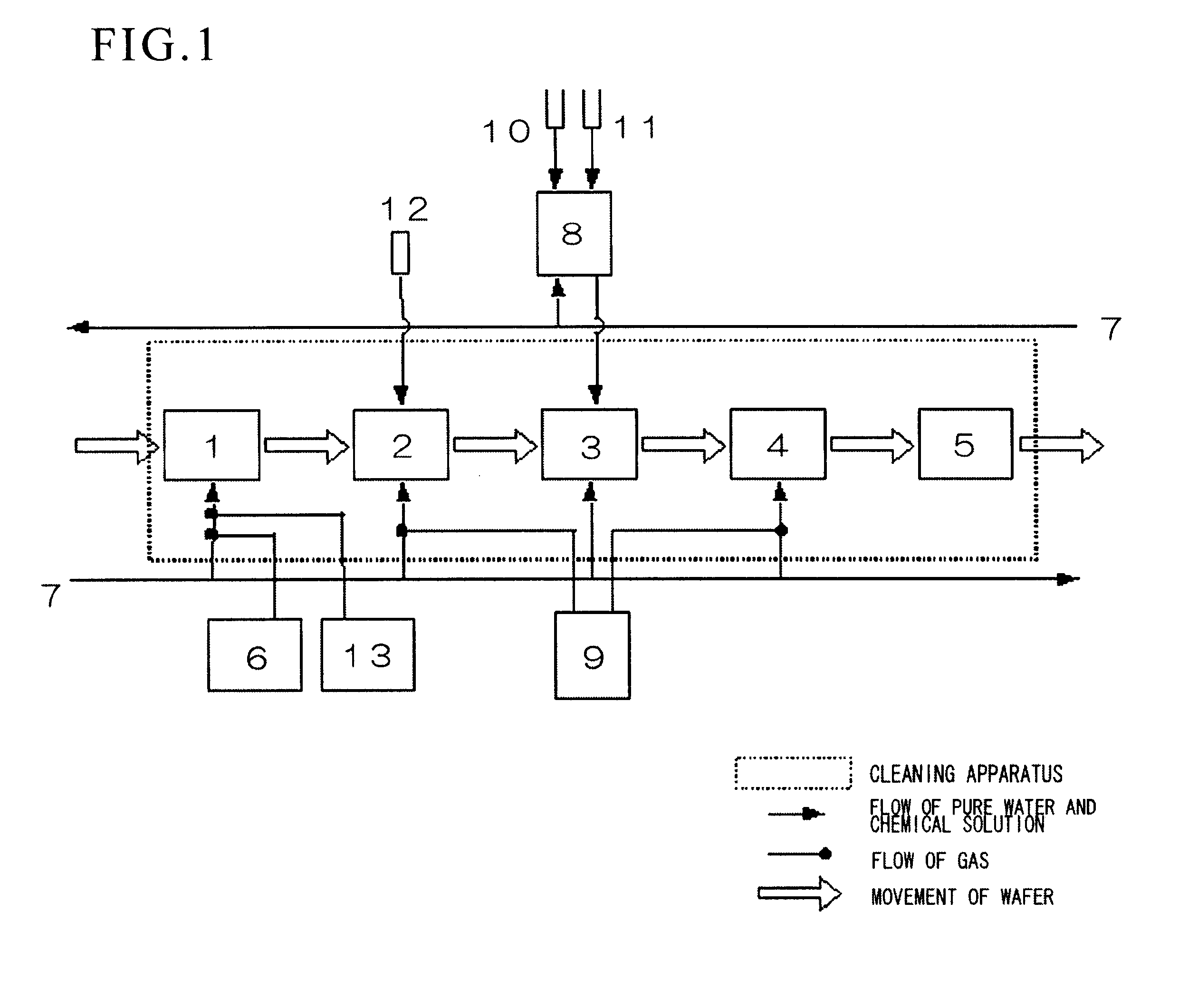

Cleaning method

InactiveUS6416586B1Not to damageReduce the number of processesSemiconductor/solid-state device manufacturingElectrostatic cleaningHydrogenCompound (substance)

The present invention has as an object thereof to provide a cleaning method which realizes, in the cleaning process, (1) a reduction in the number of processes, (2) a simplification of the cleaning apparatus, and (3) a reduction in the amount of chemicals and pure water employed, and which has highly superior cleaning effects and does not damage the substrate body, as well as to provide a rinsing method which aids in the hydrogen termination of silicon atoms.

Owner:ULTRACLEAN TECH RES INST +2

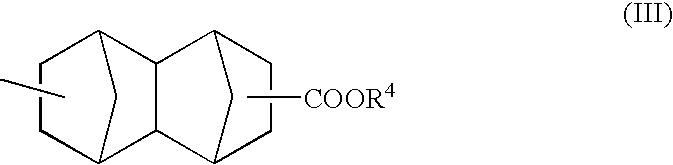

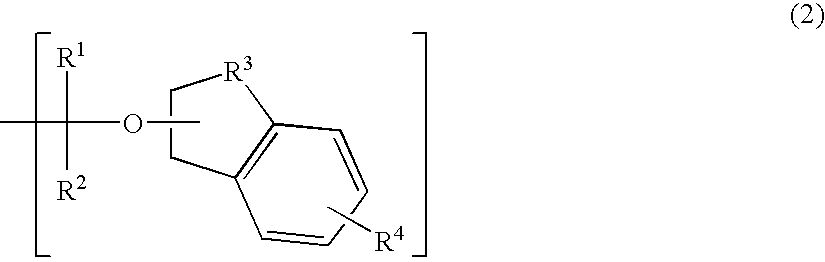

Polymerizable compound, polymer, positive resist composition, and patterning process using the same

ActiveUS20090297979A1High sensitivity and resolutionPattern configurationOrganic chemistryOrganic compound preparationResistSize difference

The present invention provides; a polymer suitable as a base resin for a positive resist composition, in particular a chemically amplified positive resist composition, having a higher resolution, a larger exposure allowance, a smaller sparse-dense size difference, a better process applicability, a better pattern configuration after exposure, and in addition, a further excellent etching resistance, than a conventional positive resist; a positive resist composition using the same; a patterning process; and a novel polymerizable compound to obtain a polymer like this.The present invention was accomplished by a polymer whose hydrogen atom of at least a carboxyl group is substituted by an acid labile group represented by the following general formula (2), a positive resist composition using the same, a patterning process, and a novel polymerizable compound to obtain a polymer like this.

Owner:SHIN ETSU CHEM IND CO LTD

Positive resist composition and pattern forming method using the same

InactiveUS20060216635A1High resolutionHigh sensitivityPhotosensitive materialsRadiation applicationsActinic RaysImage resolution

The invention provides a positive resist composition for the pattern formation by the use of actinic rays or radiation, ensuring that the sensitivity, resolution and pattern profile are good, the line edge roughness is small and the surface roughness is satisfied, and a pattern forming method using the composition, wherein the positive resist composition is a positive resist composition comprising (A) a compound capable of generating an acid upon irradiation with actinic rays or radiation, and (B) a resin of which solubility in an alkali developer increases under the action of an acid, the resin comprising a specific repeating unit; and a pattern forming method using the composition.

Owner:FUJIFILM CORP +1

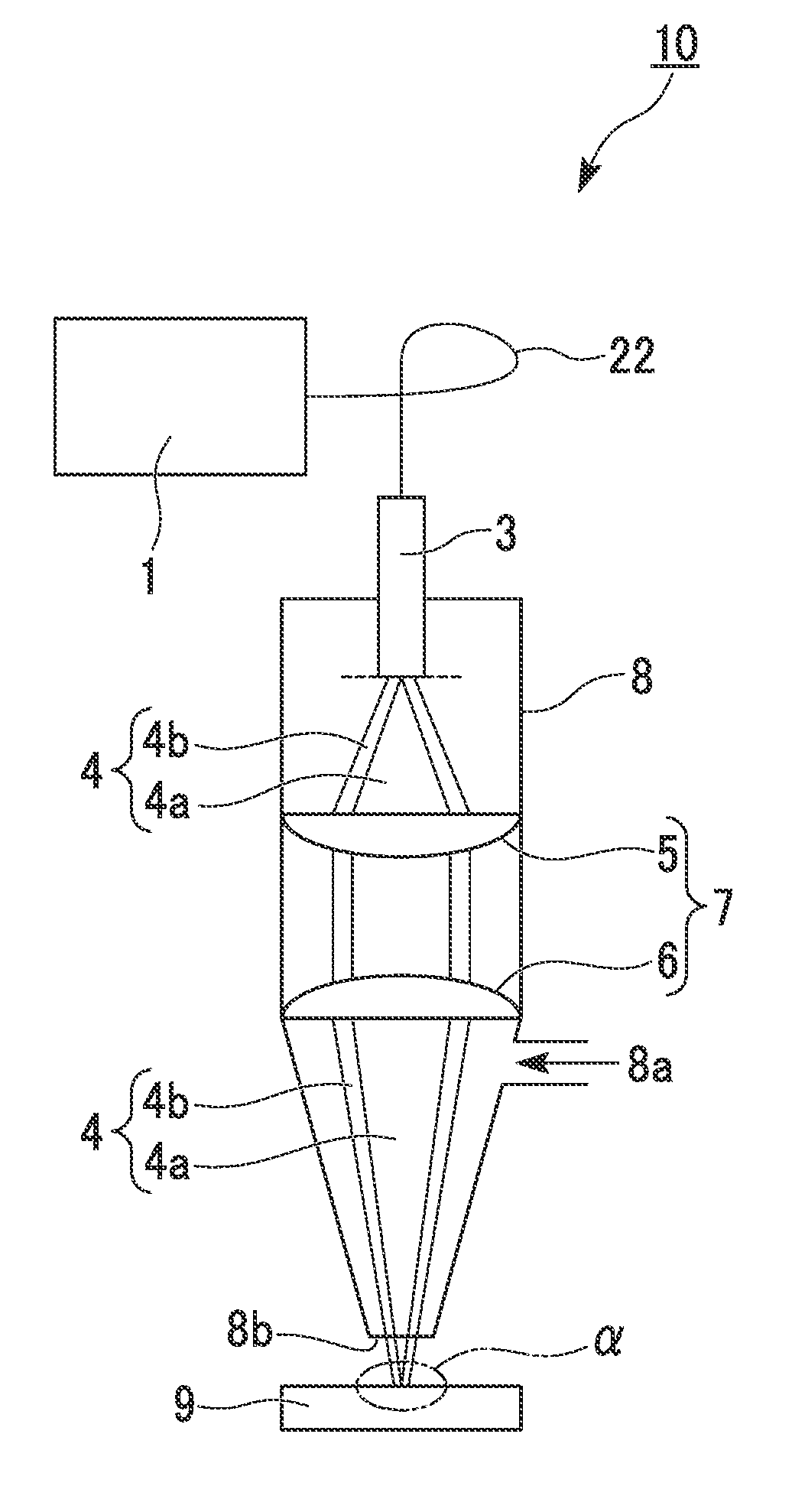

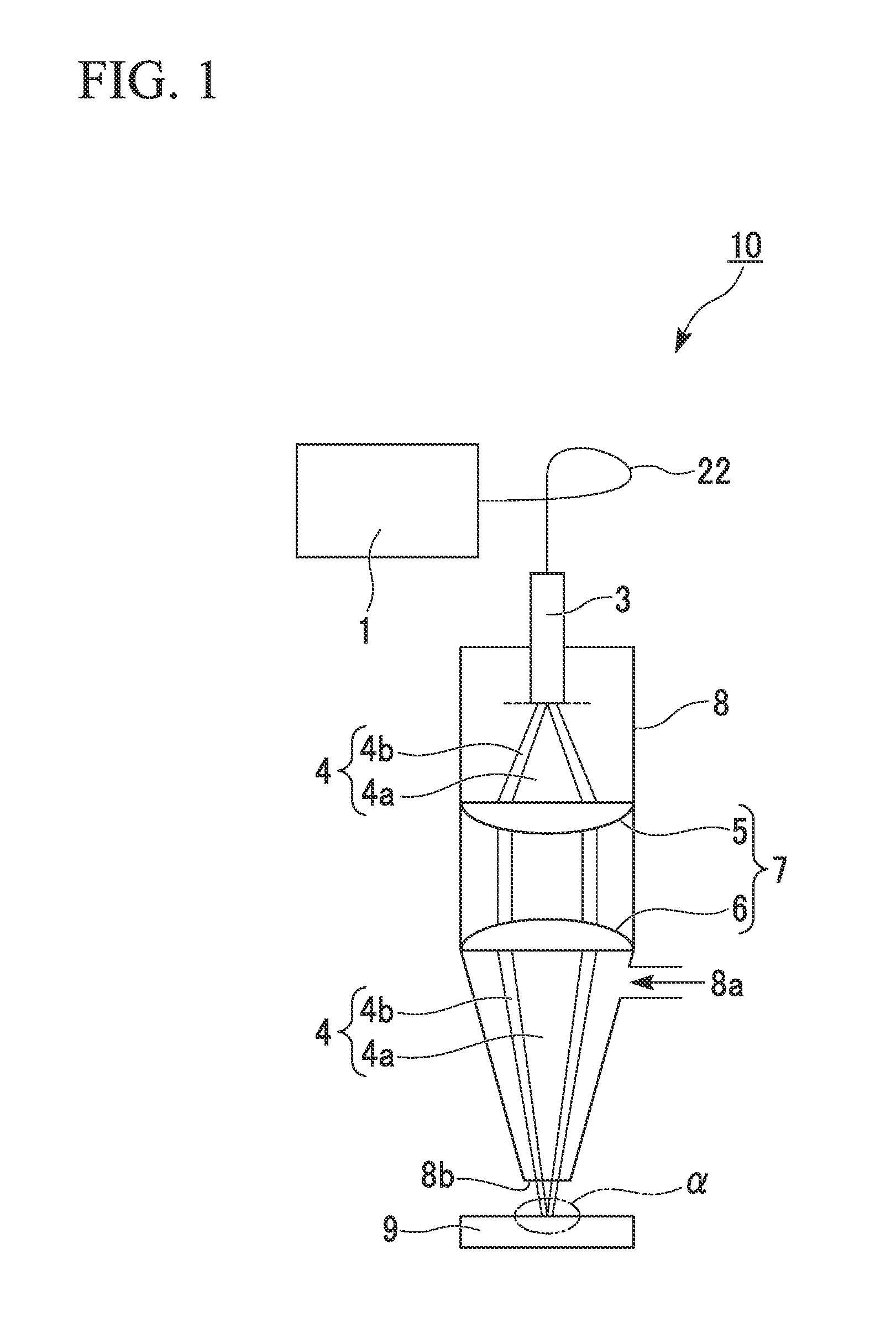

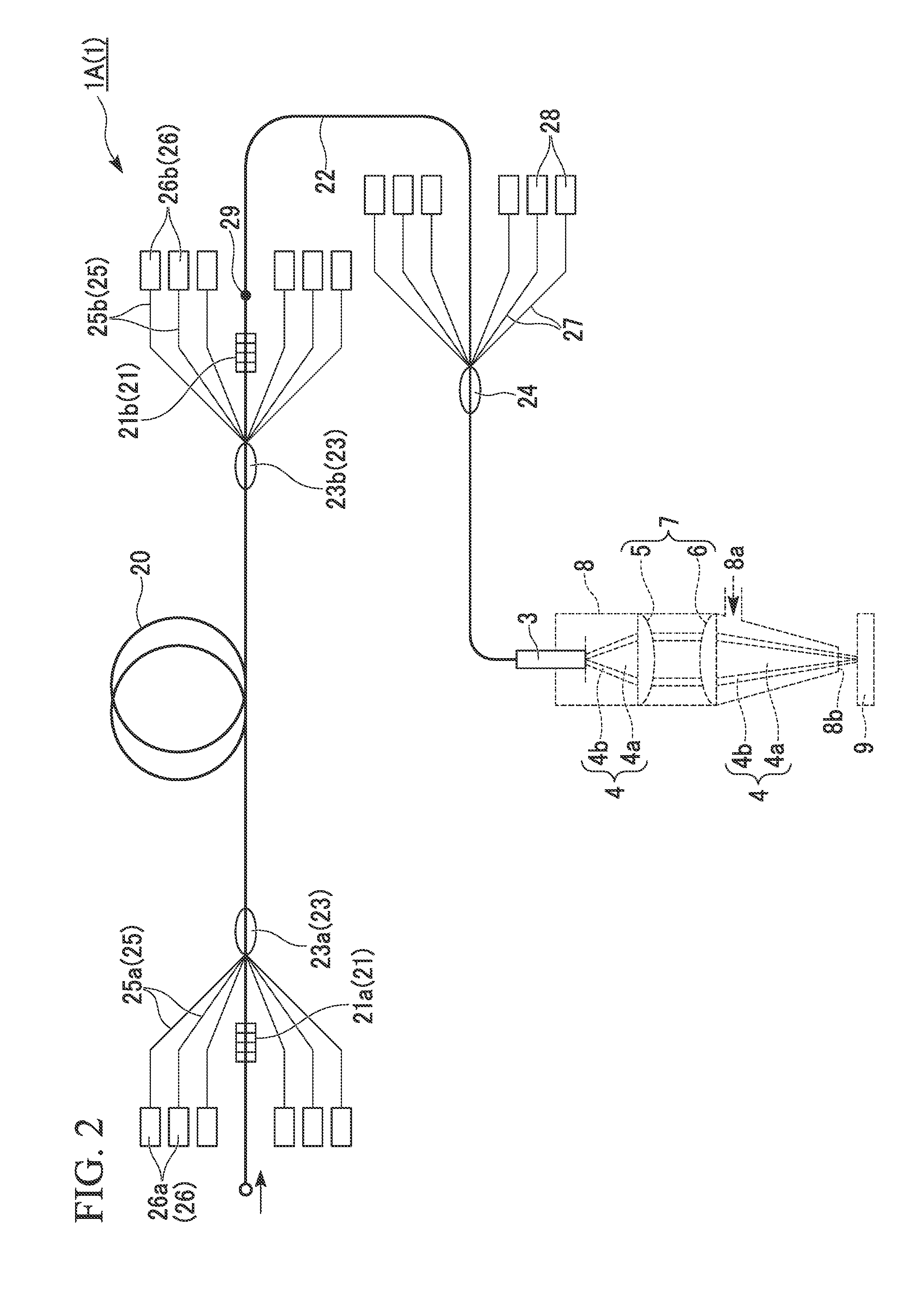

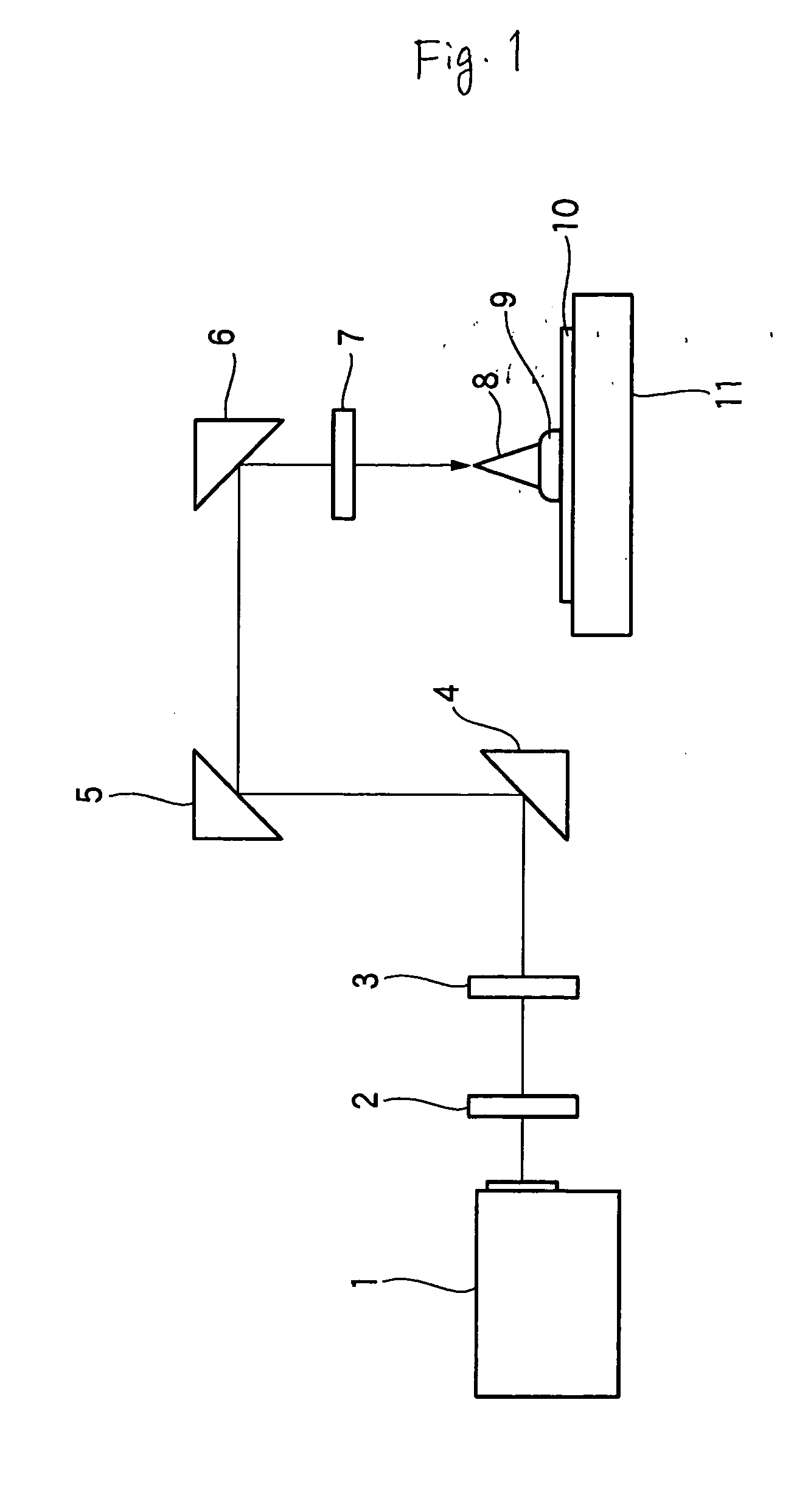

Laser apparatus and laser materials processing apparatus provided with same

ActiveUS20130215914A1Improve processing qualityReduce the amount requiredLaser using scattering effectsLaser arrangementsFiberDouble-clad fiber

A laser apparatus of the present invention has a first laser oscillator that emits a first laser beam; a passive fiber that is a double-clad fiber that transmits the first laser beam through a core; and a second laser oscillator that emits a second laser beam that is coupled into inner cladding of the passive fiber. Additionally, a laser materials processing apparatus of the present invention is provided with the laser apparatus; and an irradiation optical system having a collimating lens and a condenser lens.

Owner:NIPPON STEEL CORP

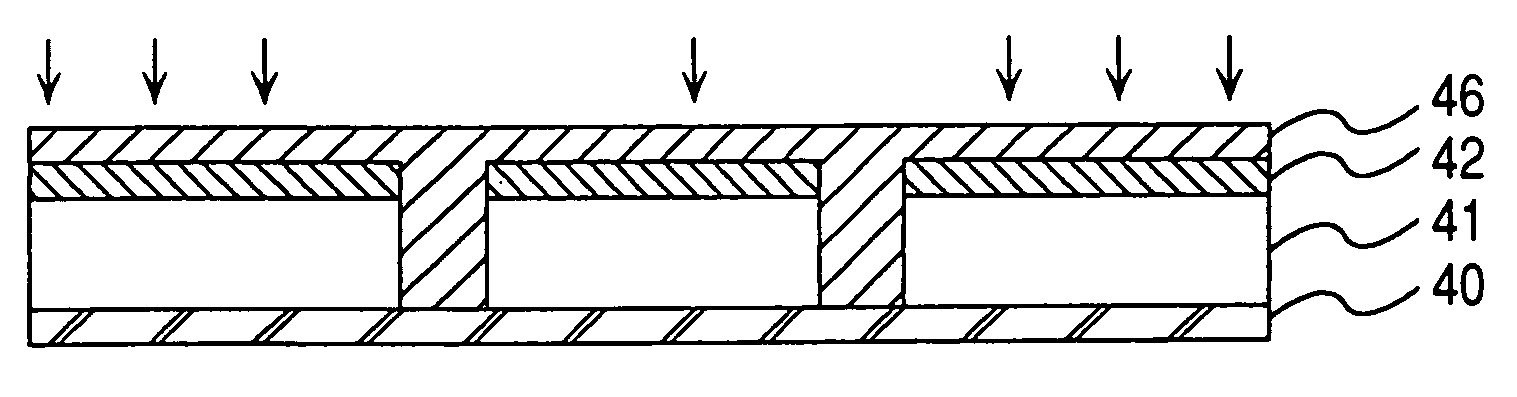

Semiconductor device and method for fabricating the same

InactiveUS20070018255A1Quality improvementLower resistanceTransistorSemiconductor/solid-state device manufacturingDevice materialSemiconductor

The method for fabricating a semiconductor device according to the present invention comprises the step of forming a Ni film 66 on source / drain diffused layers 64, the step of performing a first thermal processing to react a lower part of the Ni film 66 and an upper part of the source / drain diffused layers 64 with each other to form Ni2Si films 70b on the source / drain diffused layers 64, the step of etching off selectively a part of the Ni film 66, which has not reacted, and the step of performing a second thermal processing to further react the Ni2Si film 70b and an upper part of the source / drain diffused layers 64 with each other.

Owner:FUJITSU SEMICON LTD

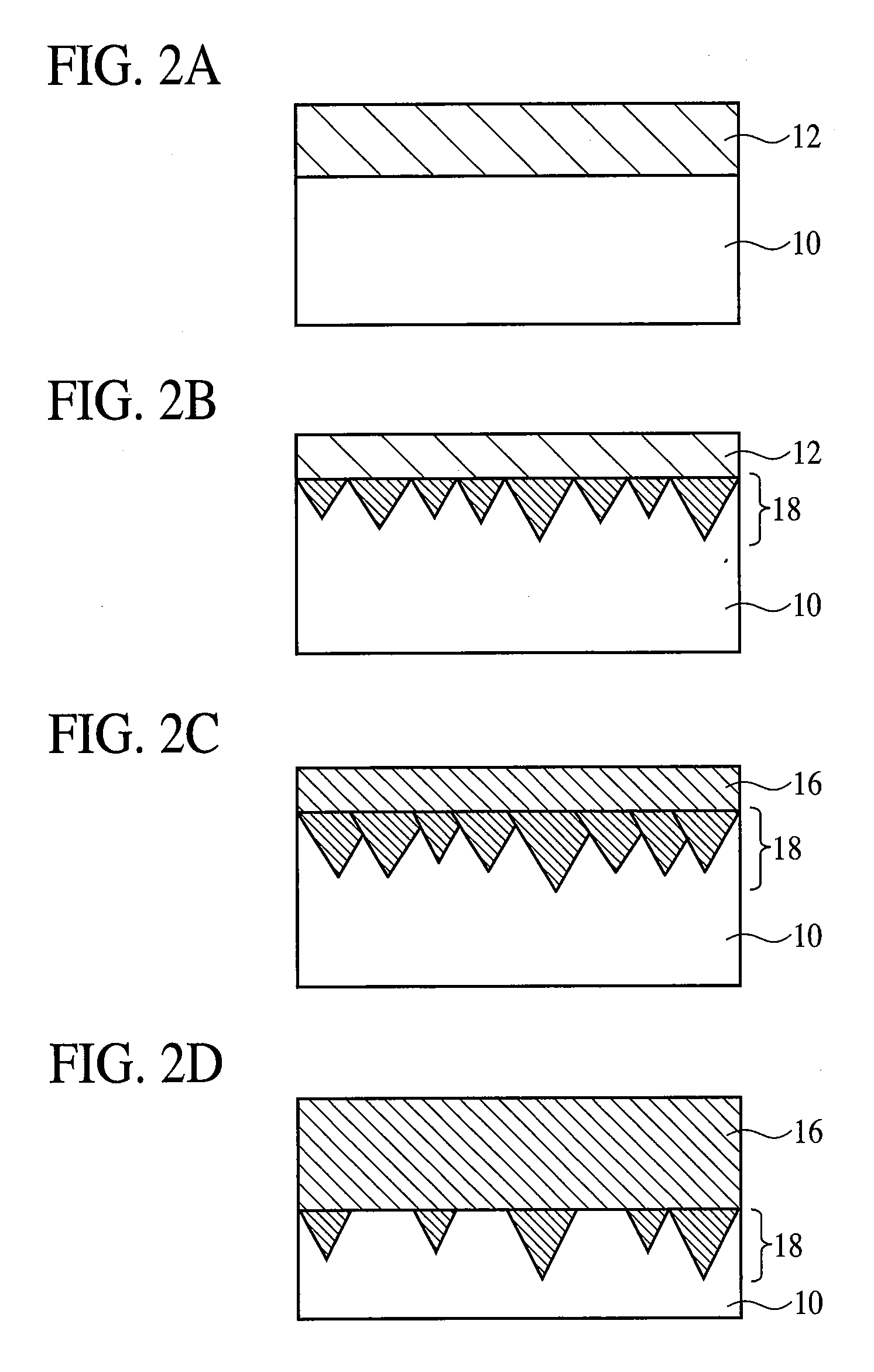

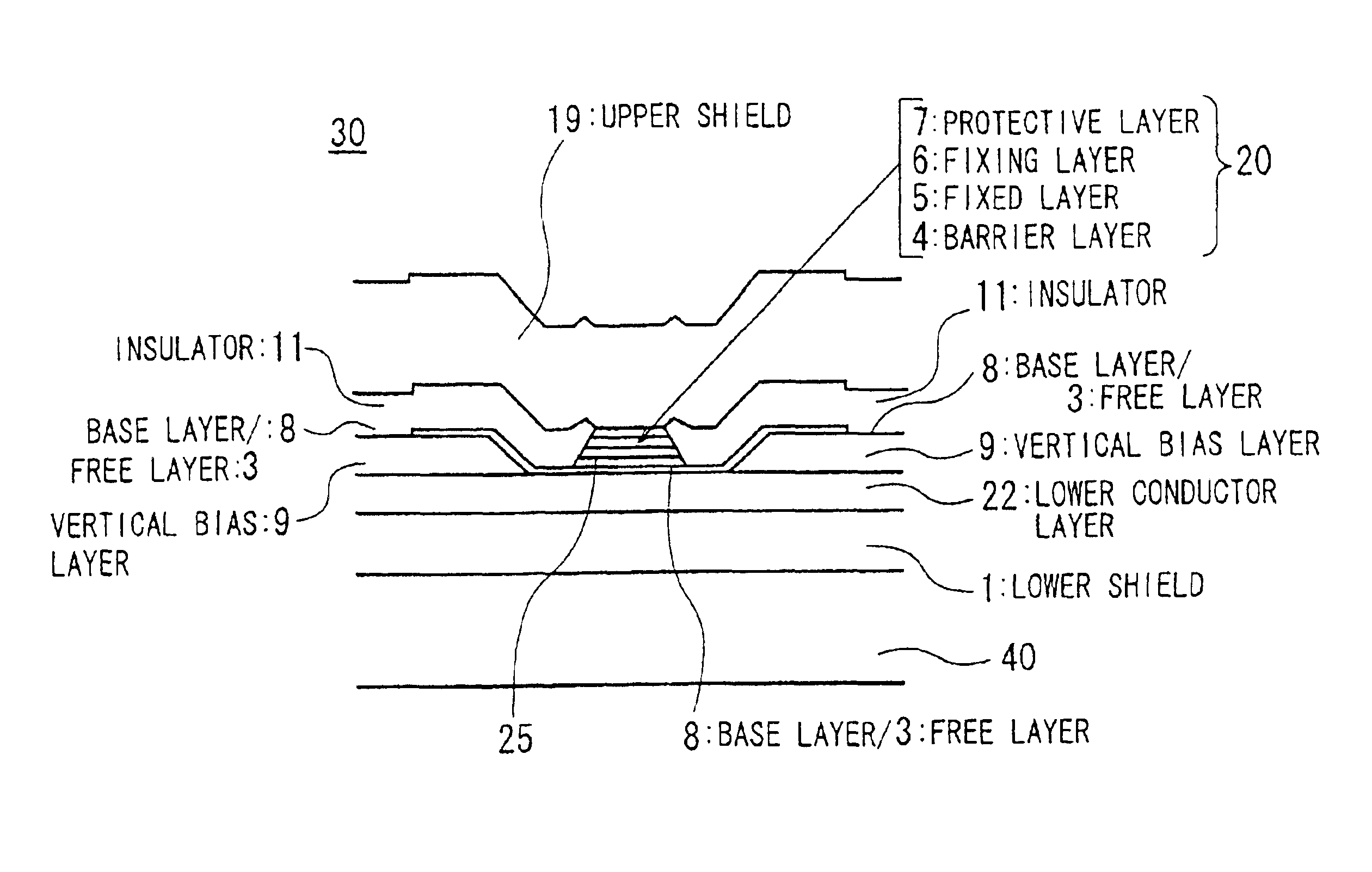

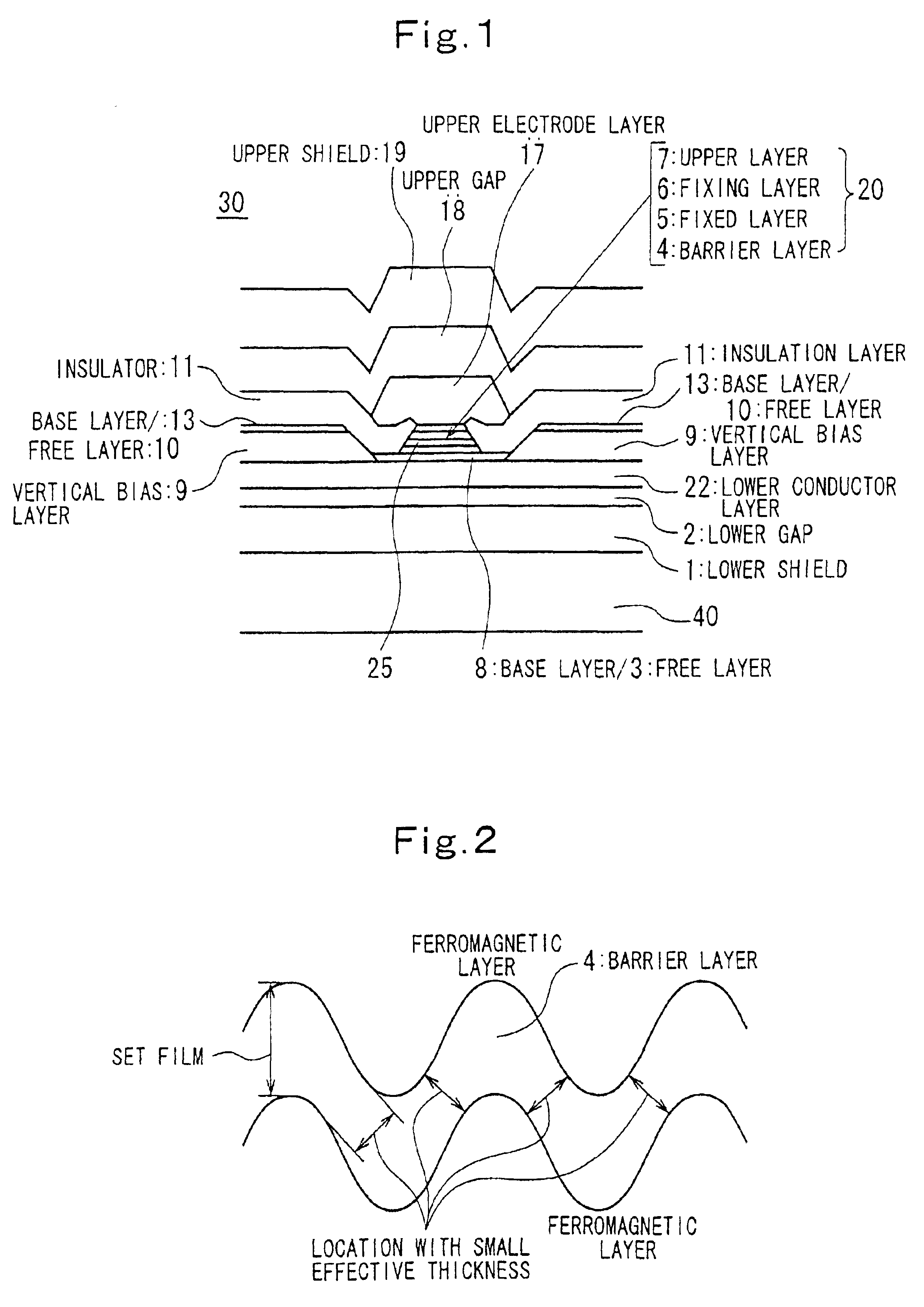

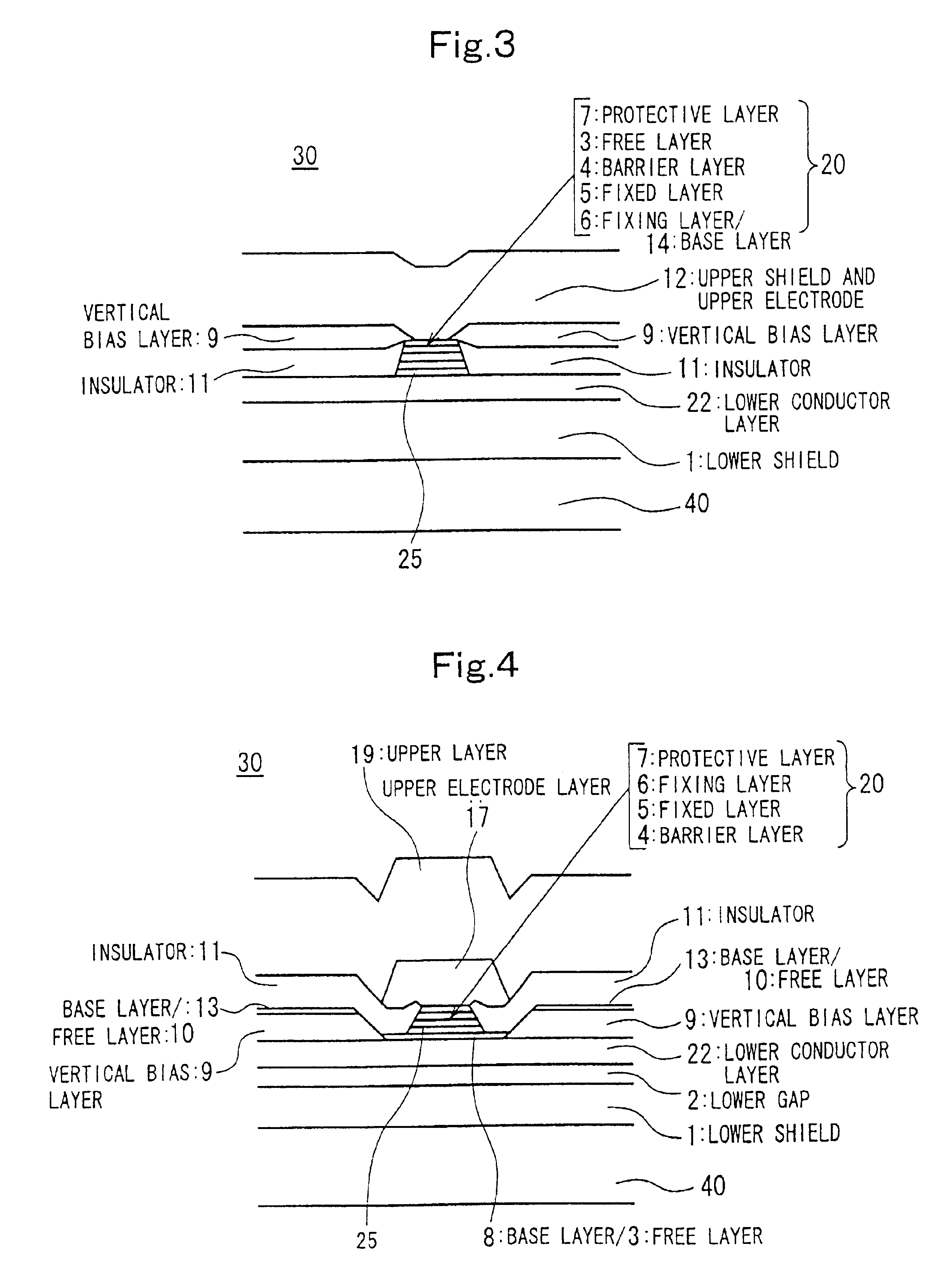

Magnetoresistive effect sensor with barrier layer smoothed by composition of lower shield layer

InactiveUS6903908B2Deterioration of characteristicSmall roughnessLiquid surface applicatorsNanomagnetismMagnetoresistanceMedicine

Owner:FUJIFILM HLDG CORP +1

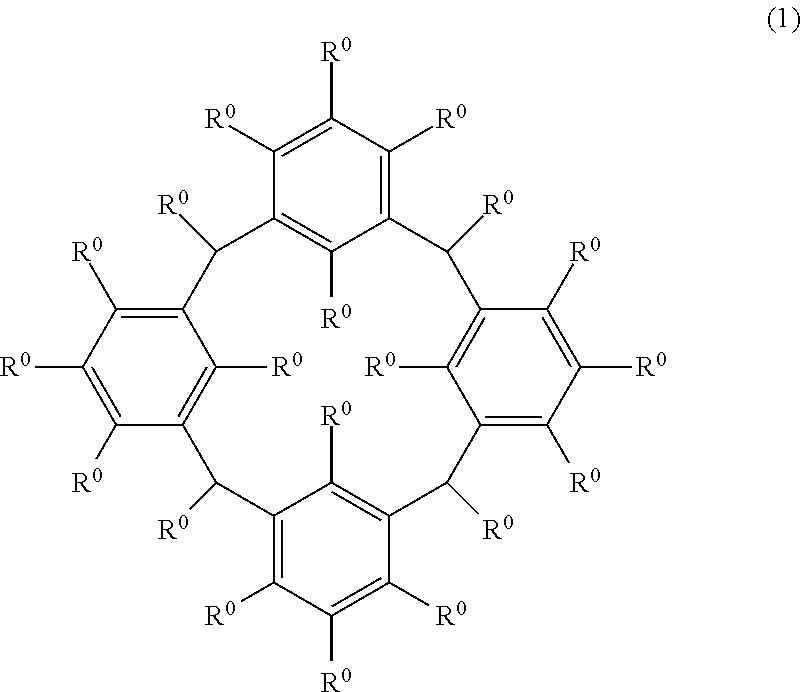

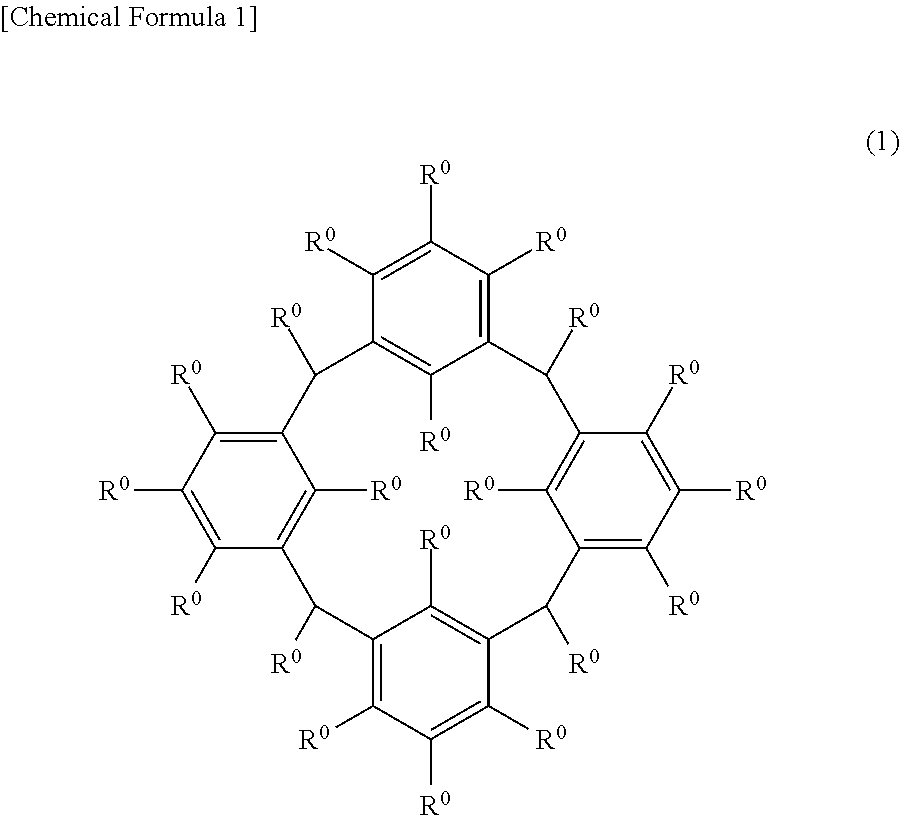

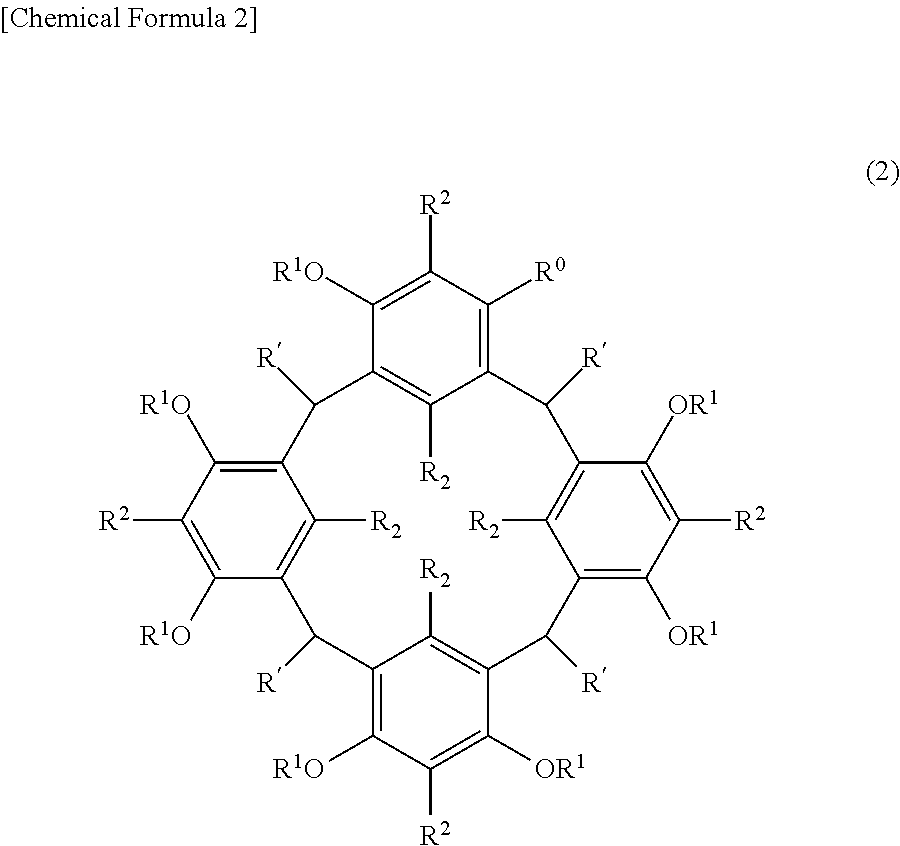

Cyclic compound, method for producing same, composition, and method for forming resist pattern

ActiveUS9122153B2Improve solubilityEasy to shapeOrganic chemistryOrganic compound preparationResistCyclic compound

A cyclic compound having a molecular weight of 500 to 5000 is represented by the following formula (1),wherein at least one of R0 is a monovalent group containing an iodine atom. Also disclosed are a method for producing the cyclic compound, a composition containing the cyclic compound, and a method for forming a resist pattern using the composition.

Owner:MITSUBISHI GAS CHEM CO INC

Microfluidic electrospray thruster

InactiveUS8850792B2Low viscosityHeating evenlyCosmonautic vehiclesVolume/mass flow measurementElectrosprayCharged particle

An electrospray thruster and methods of manufacturing such thrusters are provided. The micro-electrospray thruster increases the thrust density of conventional electrospray thrusters by miniaturizing the individual components of the thruster thereby allowing for the increase in the number and density of the charged particle emitters.

Owner:CALIFORNIA INST OF TECH

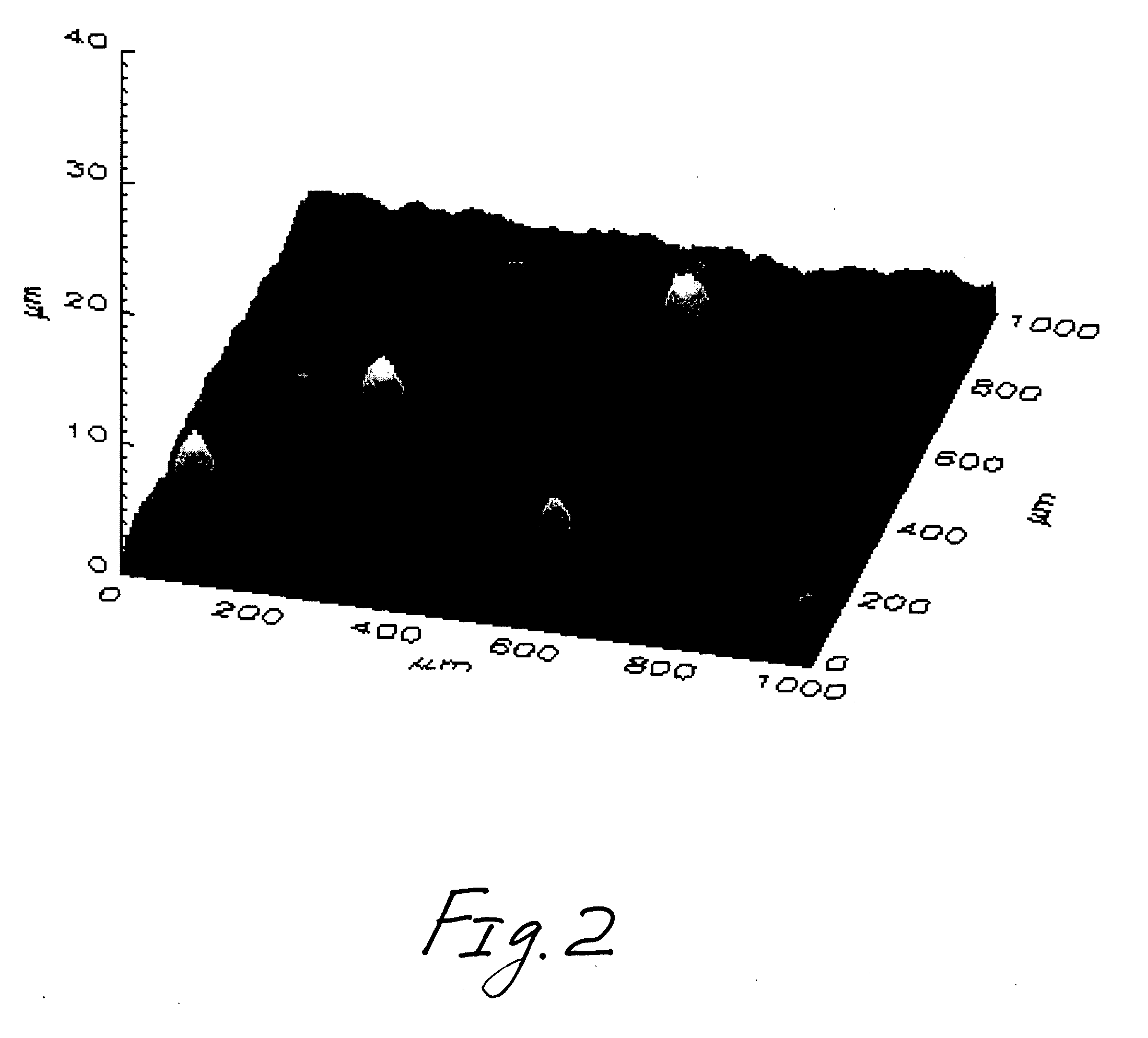

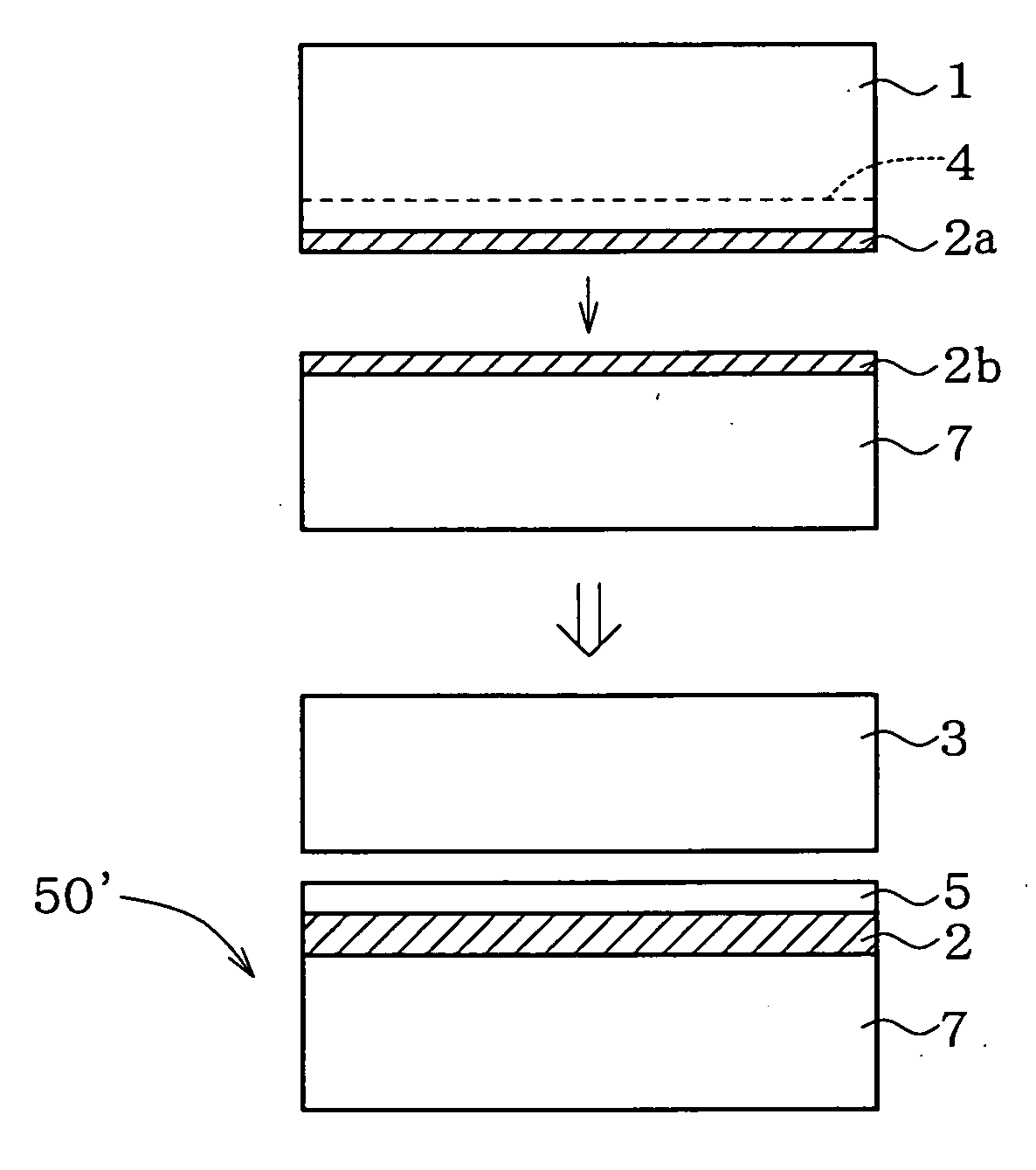

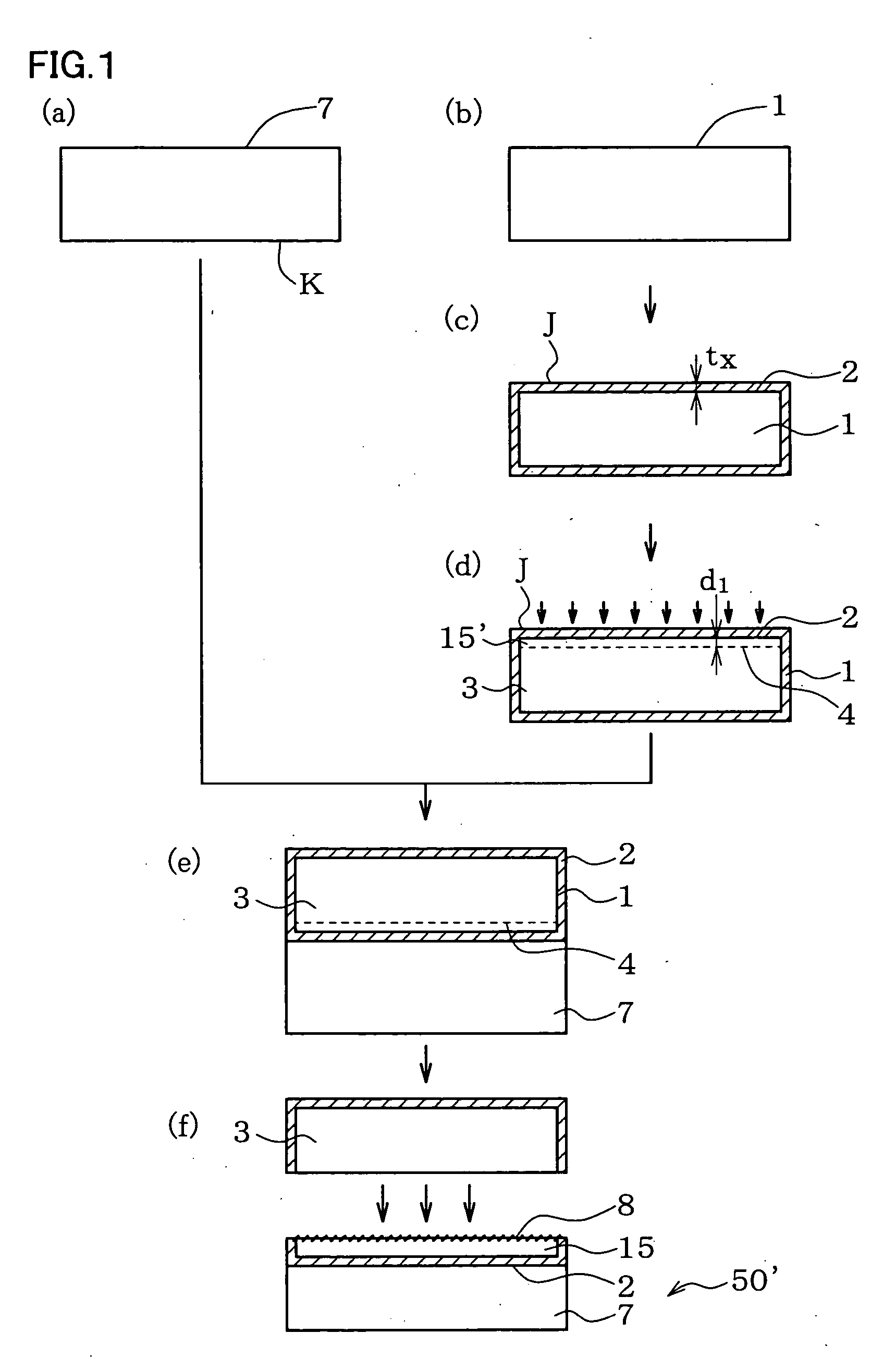

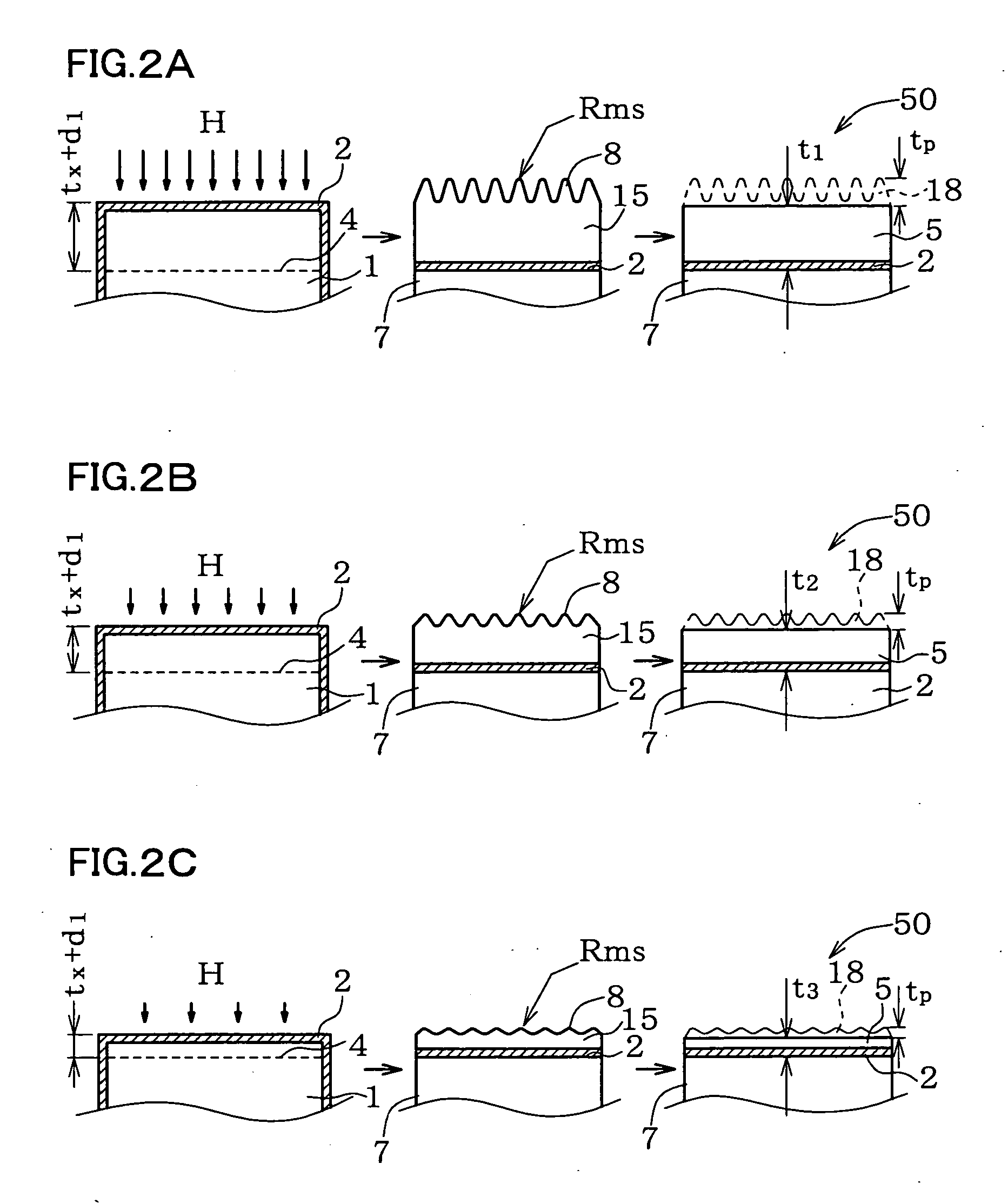

Method of fabricating SOI wafer

InactiveUS7320929B2Reduce roughnessImprove uniformitySolid-state devicesSemiconductor/solid-state device manufacturingSurface roughnessSingle crystal

In order to adjust thickness of a bonded silicon single crystal film 15 depending of thickness of an SOI layer 5 to be obtained, depth of formation d1+tx of a separatory ion implanted layer 4, measured from a first main surface J, in the separatory ion implanted layer formation step is adjusted through energy of the ion implantation. Dose of the ion implantation is set smaller as the depth of formation measured from the first main surface J becomes smaller. A smaller dose results in a smaller surface roughness of the separation surface, and makes it possible to reduce polishing stock removal of the separation surface of the bonded silicon single crystal film in the planarization step. Uniformity in the thickness of the SOI layer can consequently be improved even for the case where a thin SOI layer has to be formed. The present invention is therefore successful in providing a method of fabricating an SOI wafer capable of suppressing variations in the intra-wafer and inter-wafer uniformity of the thickness of the SOI layer to a sufficiently low level, even for the case where a required level of the thickness of the SOI layer is extremely small.

Owner:SHIN-ETSU HANDOTAI CO LTD

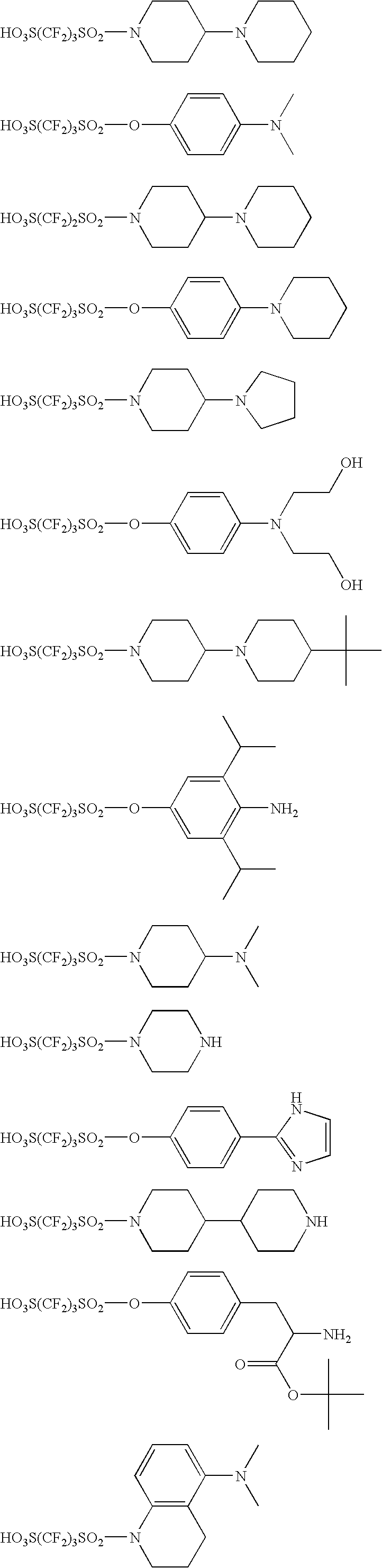

Photosensitive composition, compound for use in the photosensitive composition and pattern forming method using the photosensitive composition

ActiveUS20060172228A1Improve resolutionHigh sensitivityOrganic chemistryPhotomechanical apparatusOrganic acidActinic Rays

The invention provides a photosensitive composition for use in the production process of a semiconductor such as IC, in the production of a circuit substrate of liquid crystal, thermal head and the like or in other photofabrication processes, a pattern forming method using the photosensitive composition, and a specific organic acid, which are: a photosensitive composition comprising a compound having a proton acceptor functional group and producing a sulfonic acid group upon irradiation with actinic rays or radiation to reduce or lose the acceptor property or change the proton acceptor functional group to be acidic, or a compound capable of generating a specific organic acid upon irradiation with actinic rays or radiation; a pattern forming method using the photosensitive composition; and a specific organic acid.

Owner:FUJIFILM CORP +1

Electrolytic copper foil and method for producing the same

ActiveUS20140193660A1High elongationMaintain good propertiesThin material handlingElectroforming processesCopper foilLithium

An electrolytic copper foil is provided. The electrolytic copper foil has a shiny side and a matte side opposing to the shiny side, wherein the difference in roughness between the shiny side and the matte side is 0.5 μm or less. The electrolytic copper foil has a tensile strength of 45 kg / mm2 or above, and is particularly suitable for applications in a lithium ion secondary battery.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

Magnetic disk storage system

InactiveUS20060072237A1Reduce rotation speedIncrease in circuit scale can be avoidedDisposition/mounting of recording headsDriving/moving recording headsMotor driveElectric machine

The present invention provides a magnetic disk storage system including a spindle motor that rotates a magnetic disk, a spindle motor drive circuit that rotatably drives the spindle motor, a magnetic head that performs reading of information on the magnetic disk, a voice coil motor that moves the magnetic head, and a voice coil motor drive circuit that drives the voice coil motor. When the magnetic head is loaded from a standby position to the surface of the magnetic disk, the rotational speed of the spindle motor is made slower than a rotational speed at a normal operation. Upon power-off, the spindle motor drive circuit is caused to carry out a stepup converter operation to thereby generate a voltage higher than a back electromotive voltage, and causes a control circuit and a drive circuit to operate by the high voltage to thereby enable speed control at the movement of the magnetic head to a predetermined standby position.

Owner:RENESAS TECH CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com