Patents

Literature

129 results about "Black glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

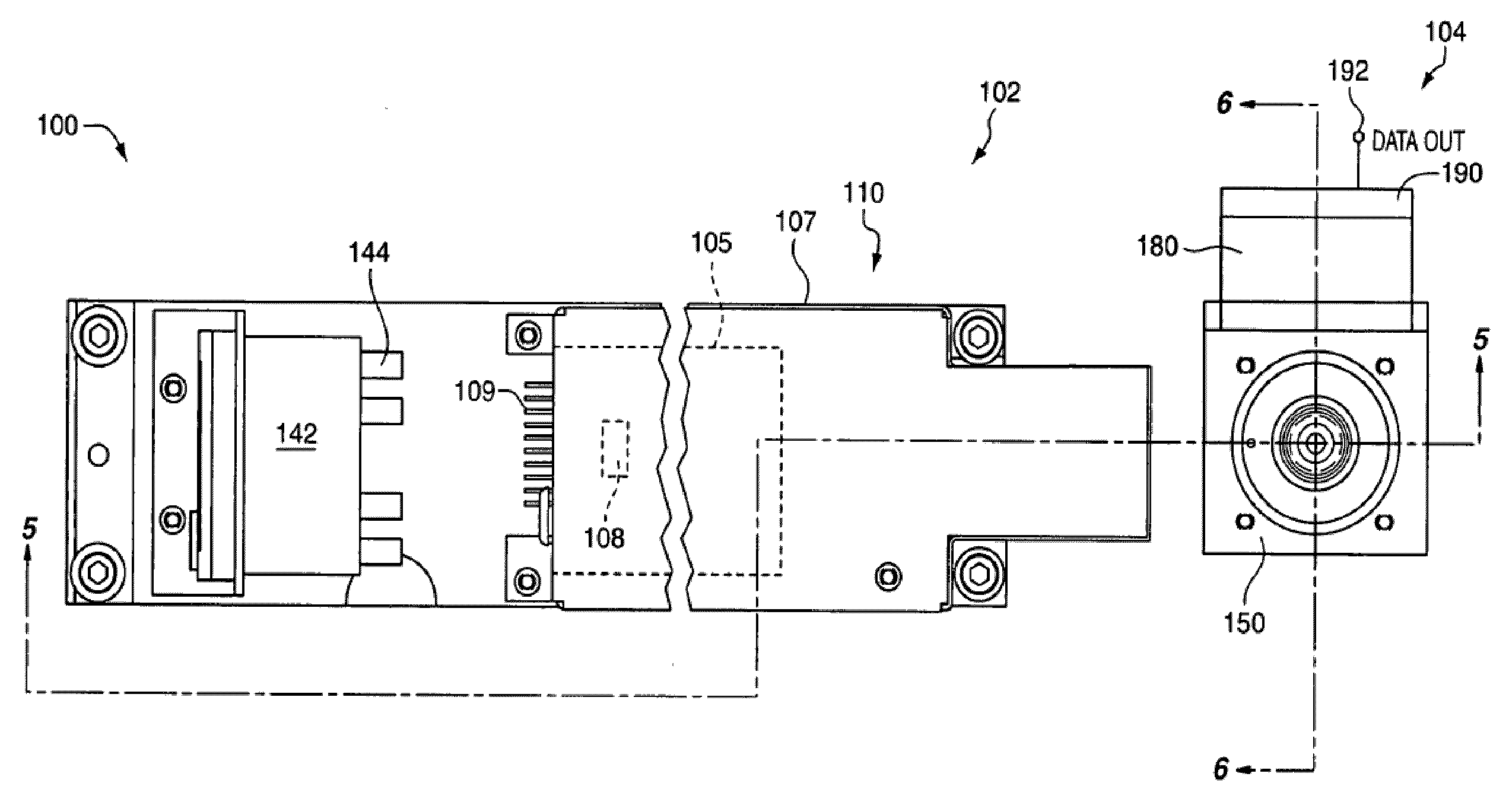

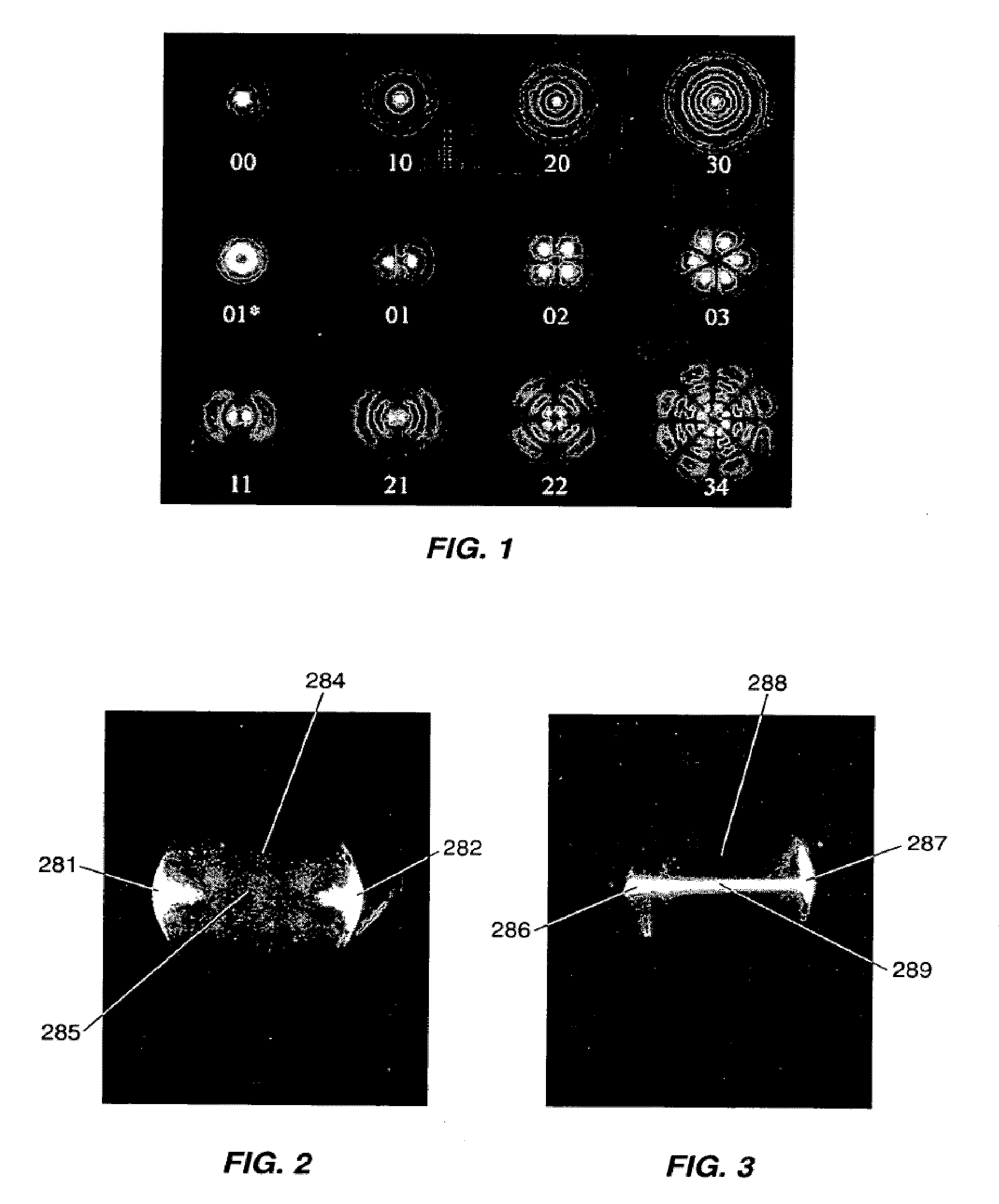

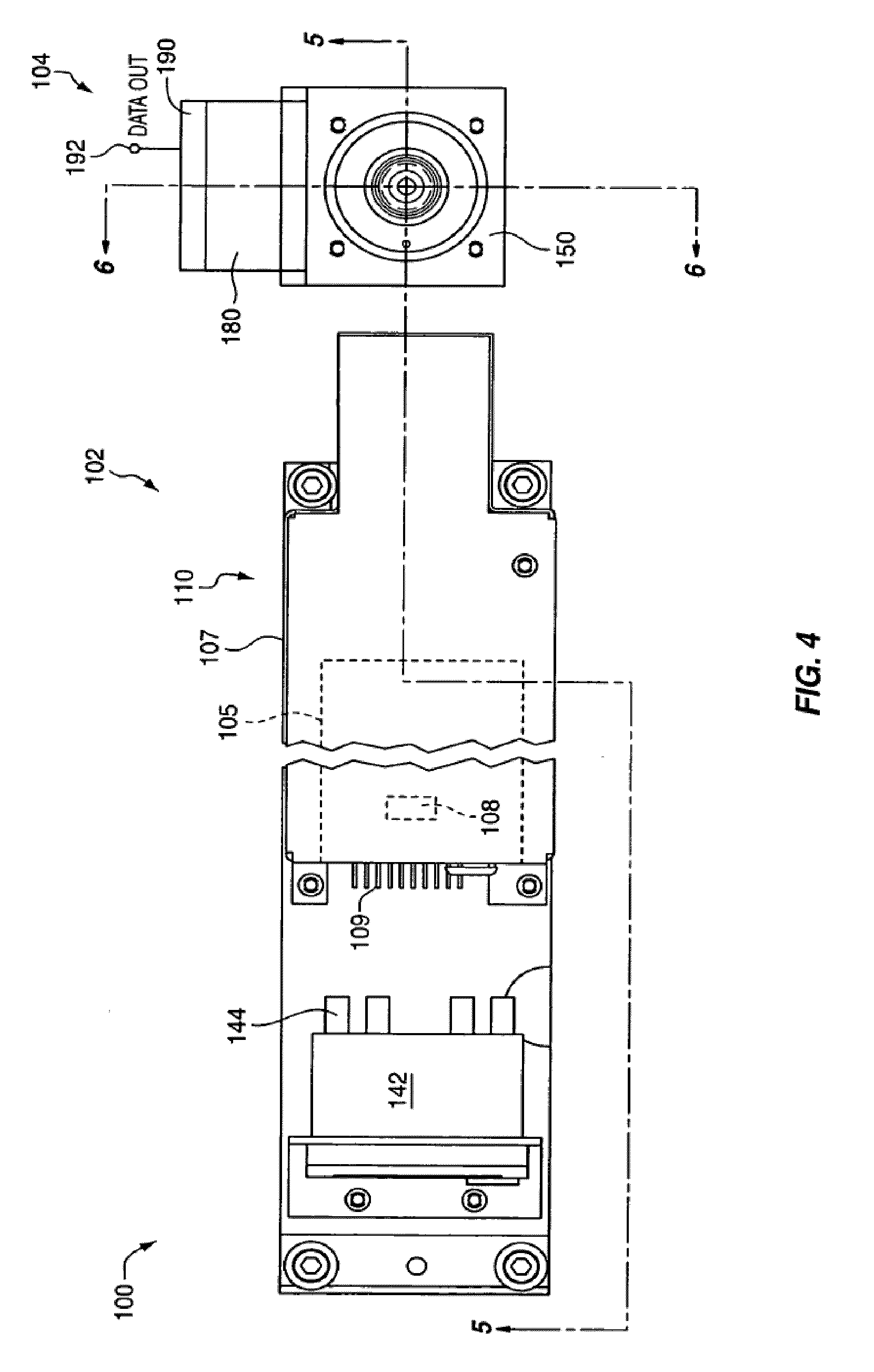

Particle Counter with Laser Diode

InactiveUS20090268202A1Reduce noiseQuick checkScattering properties measurementsEnergy based chemical/physical/physico-chemical processesStray lightOptical detector

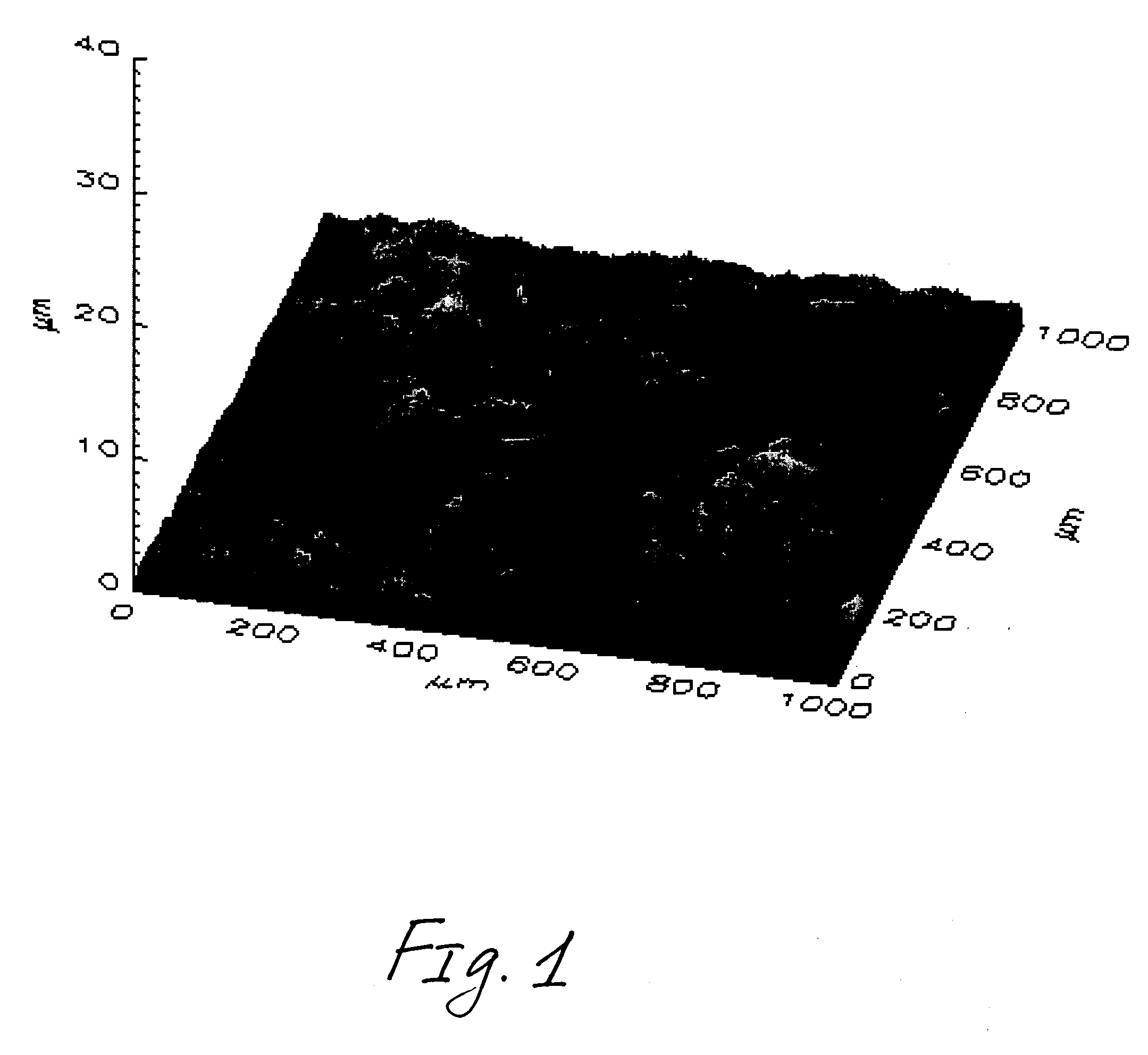

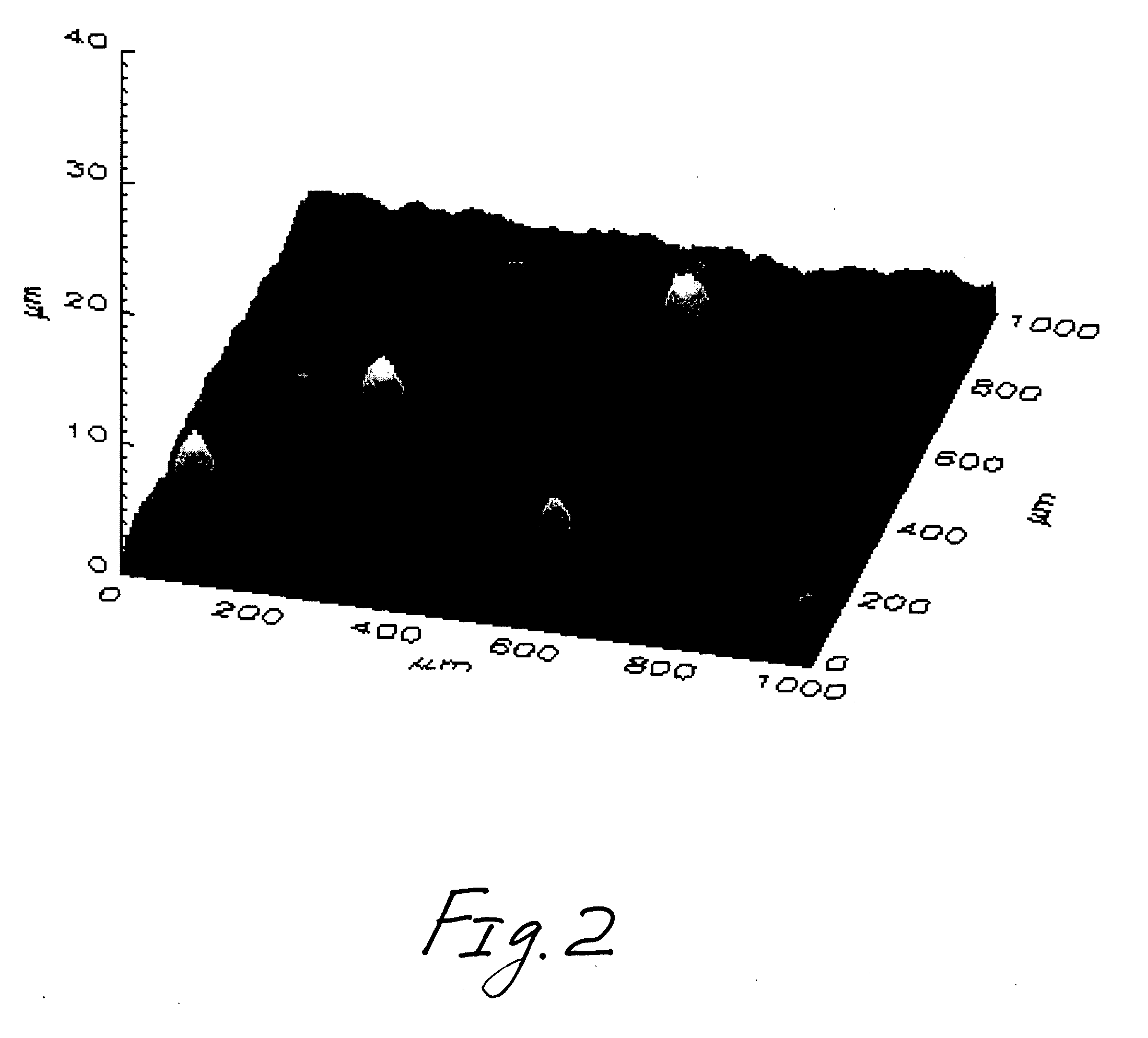

A liquid particle counter for optically detecting an unconstrained particle suspended in a flowing liquid includes a sample chamber having a liquid inlet and a liquid outlet; a laser diode module producing a symmetrically collimated laser beam; a beam shaping optical system directing the laser beam at the sample chamber; and an optical detector located to detect light scattered by the particle in the sample chamber, the detector producing an electric signal characteristic of a parameter of the particle. The laser beam has an energy of a watt or more and passed through an aperture in a black glass aperture element in the sample chamber. The black glass aperture element removes diffracted and stray light from the beam without damage to the sample chamber.

Owner:PARTICLE MEASURING SYST

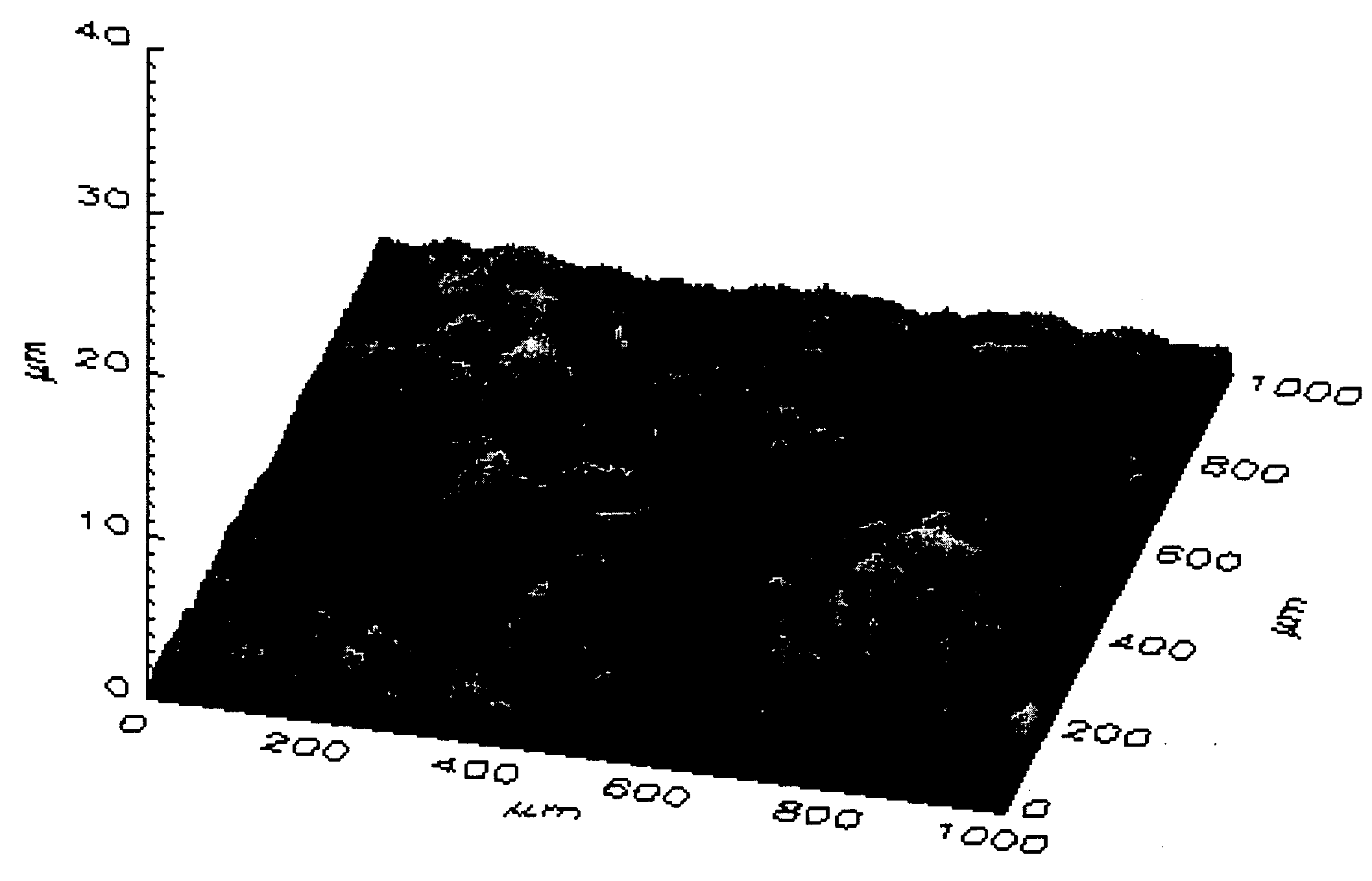

Glass ceramic panel with a pleasing black decoration applied with a decorative paint

InactiveUS20080139375A1Smoother and less rough surfaceColor depthStoves/ranges topsHot plates heating arrangementsGlass-ceramicPigment

Decorative paints are typically burned in at relatively high temperatures, preferably in connection with the thermal ceramicizing process. In order to provide a glass ceramic panel having a cooking surface with a pleasing deep black, very smooth decoration by a burned-in decorative paint, the glass ceramic panel is formed from a melt that is black and the decorative paint on the black glass ceramic panel contains a colorless glass flux and from 0 to 10 percent by weight of at least one black pigment. The decorative paint can consist of the colorless melted-on glass flux. The glass flux preferably has a composition in percent by weight of Li2O, 0-5; Na2O, 0-5; K2O, <2; ΣLi2O+Na2O+K2O, 1-10; MgO, 0-3; CaO, 0-4; SrO, 0-4; BaO, 0-4; ZnO, 0-4; B2O3, 15-27; Al2O3, 10-20; SiO2, 43-58; TiO2, 0-3; ZrO2, Sb2O3, 0-2; F, 0-3.

Owner:SCHOTT AG

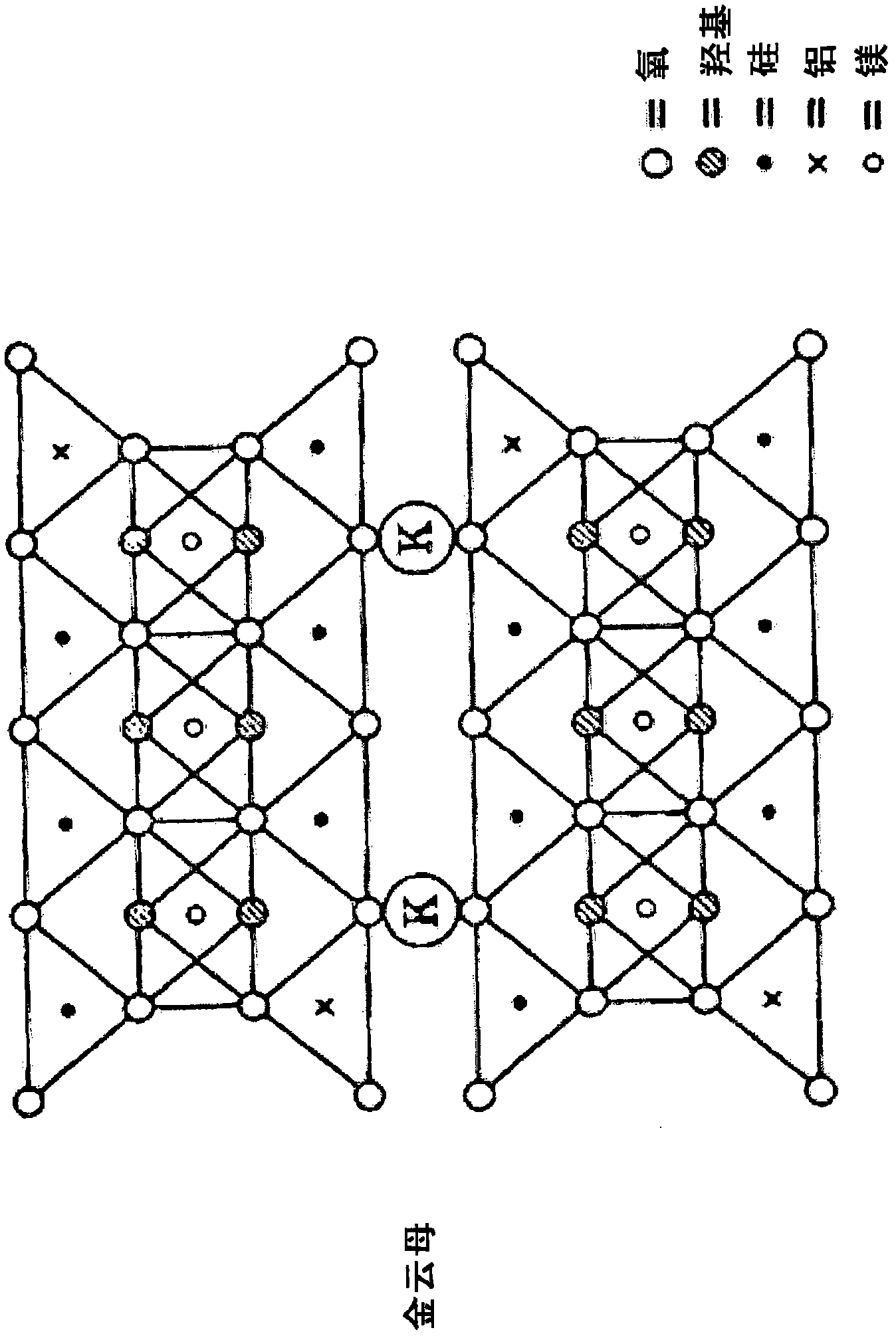

Black glass ceramic and production method thereof

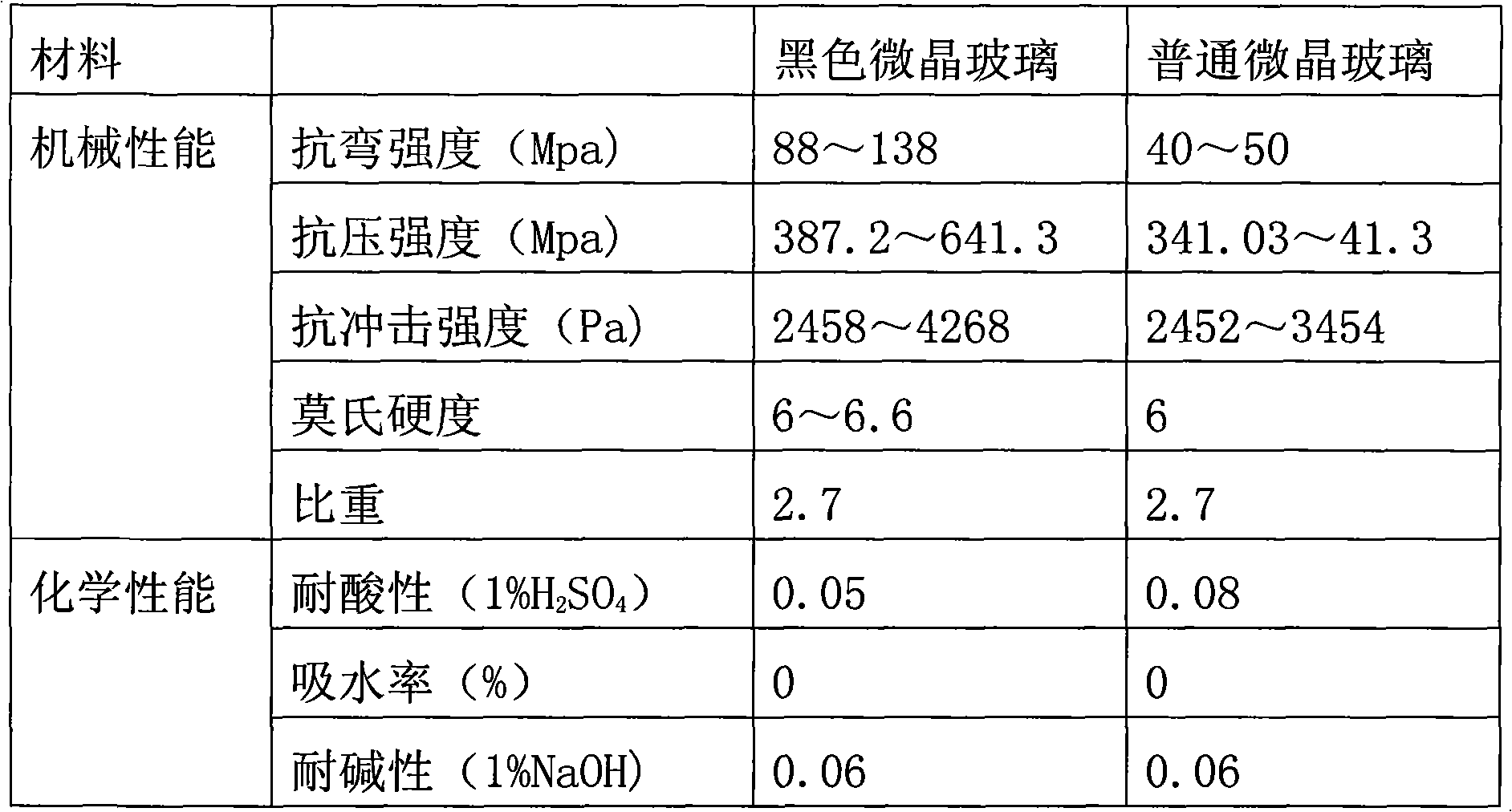

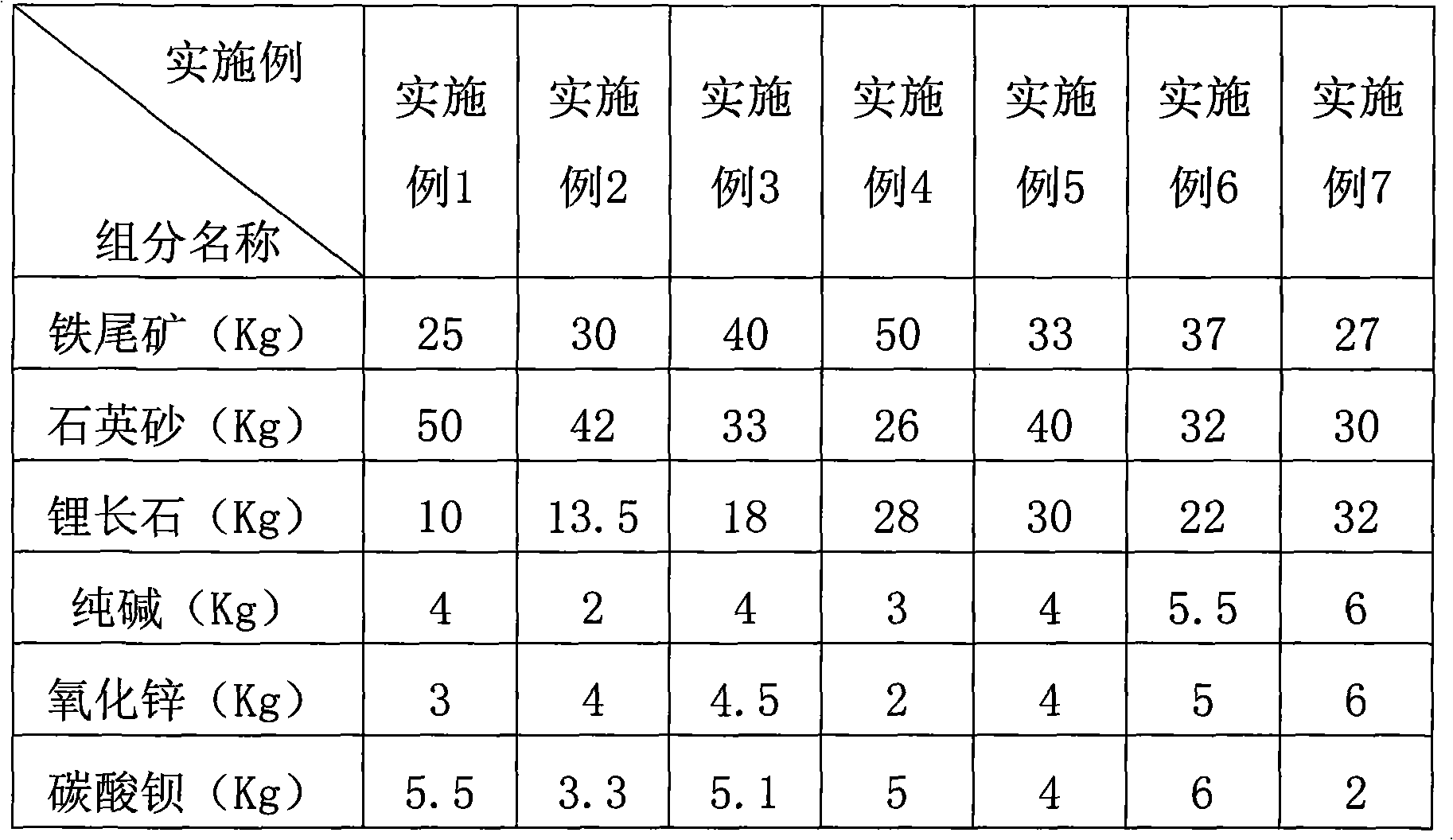

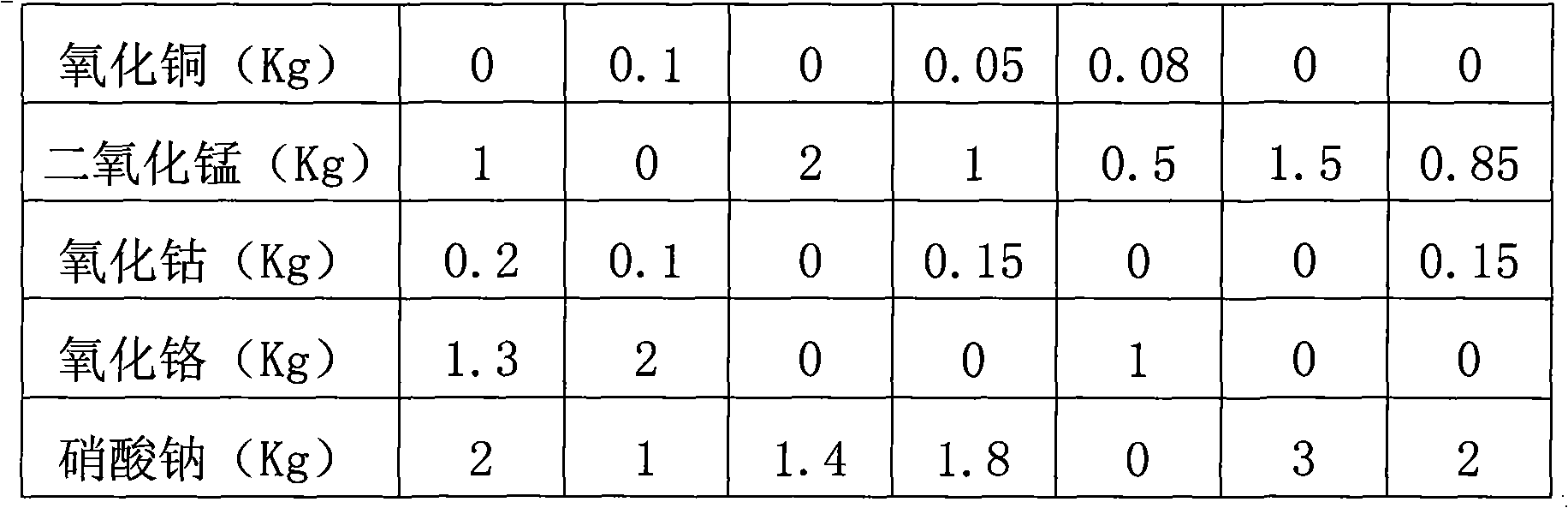

The invention discloses a black glass ceramic and a production method thereof in order to solve the problems of the conventional glass ceramic, i.e. single color and high production technique cost. The black glass ceramic is produced with the following components in part by weight: 25 to 50 parts of iron tailings, 20 to 50 parts of quartz sand, 10 to 32 parts of petalite, 2 to 6 parts of sodium carbonate, 2 to 6 parts of zinc oxide, 2 to 6 parts of barium carbonate, 0 to 0.1 part of copper oxide, 0 to 2 parts of manganese dioxide, 0 to 0.2 part of cobalt oxide, 0 to 2 parts of chromic oxide and 0 to 3 parts of sodium nitrate. Since the invention utilizes the discarded iron tailings as the material of the black glass ceramic, the waste is made profitable, pollution is reduced, the environment is protected, moreover, the physicochemical performance of the product can be enhanced, and the single-color problem of the black glass ceramic is solved; the corrosion of the refractory material of a glass furnace by molten glass is reduced, and thereby the service life of the equipment is prolonged; and the application range of the black glass ceramic is wide.

Owner:浮山县晋盛新型建筑材料有限责任公司

High gain transmissive viewing screen

A high-gain transparent screen belongs to the field of transparent screen comprises a front-end transparent layer, a fiber transmission layer, a micro-lens layer and a back-end transparent layer through compounding. Wherein, the micro-lens layer is provided with a light spreading lens characterized by a horizontal spreading angle of 70 degrees to 120 degrees and a vertical spreading angle of 40 degrees to 80 degrees. The micro-lens is directly attached to a fiber head top or etched onto transparent materials of the back-end transparent layer. The fiber transmission layer is provided with even fiber diameters. The back-end transparent layer is black glass, a black real-time adhesive film, black anti-dazzle glass or a black real-time anti-dazzle adhesive film to enhance screen contrast and prevent screen reflection. The screen has the advantages of high gain, wide visual angle, lower cost, easy production of various screens with nonstandard size and seamless assembling.

Owner:BEIJING FANGRUI BOSHI DIGITAL TECH

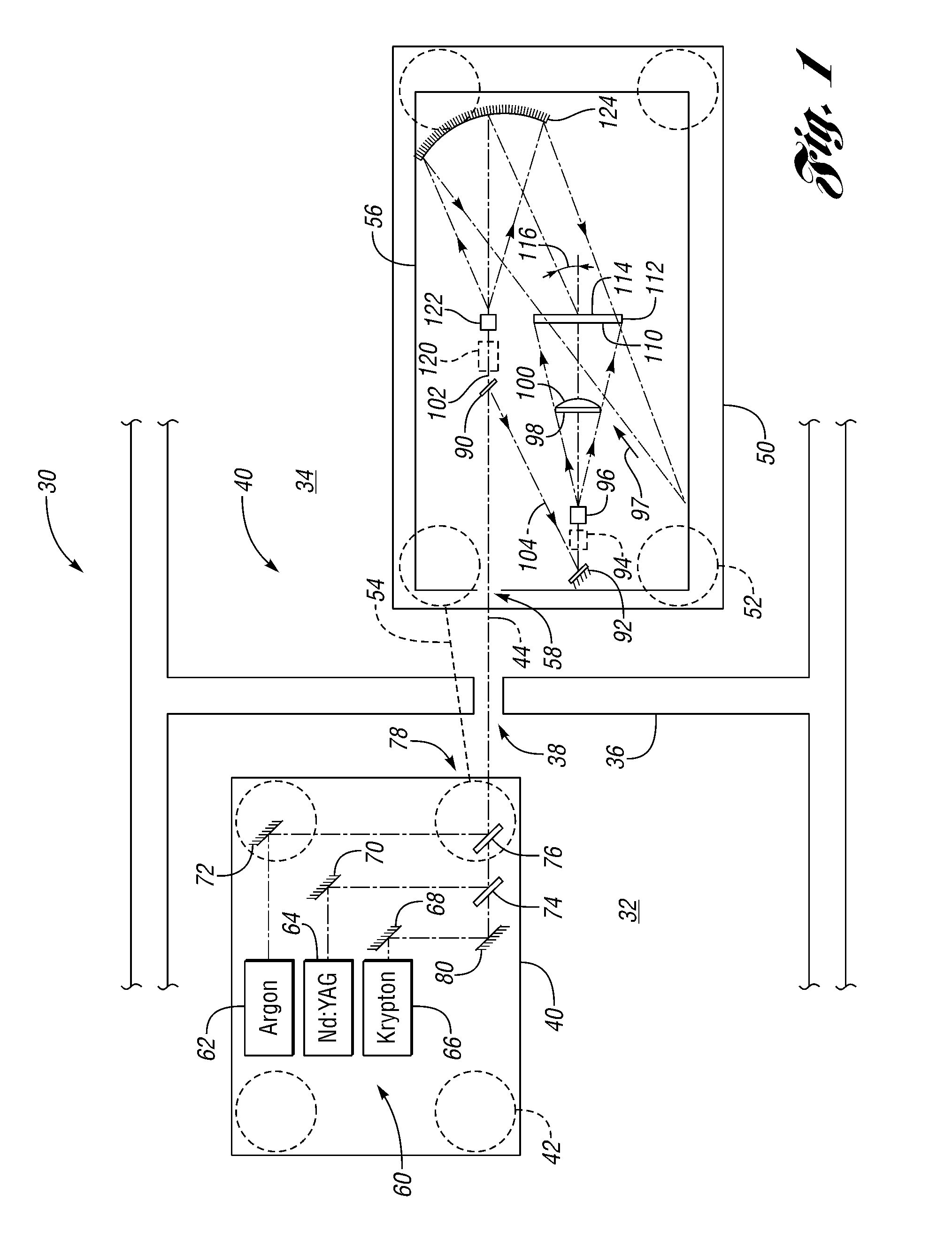

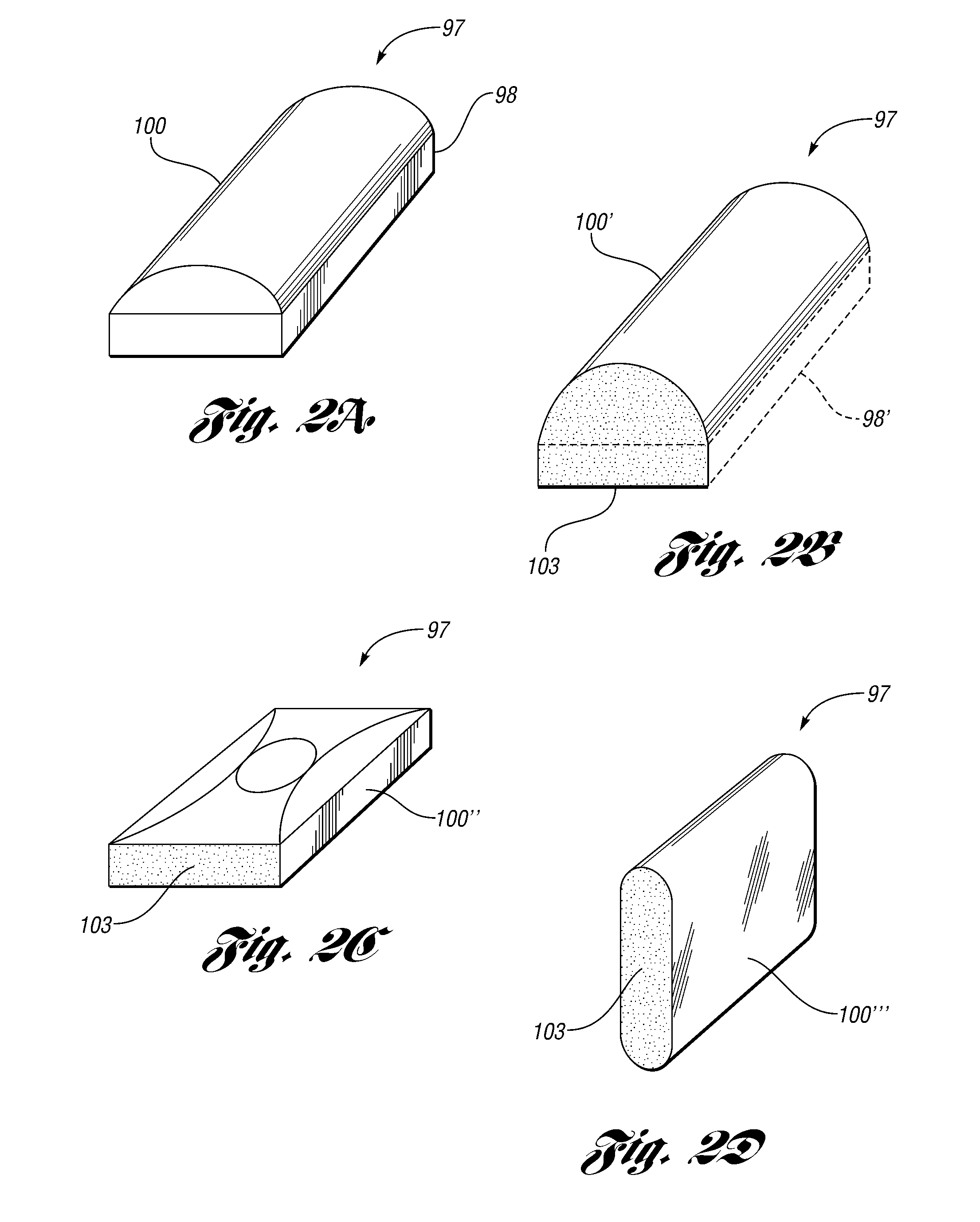

System and Method for Autostereoscopic Imaging

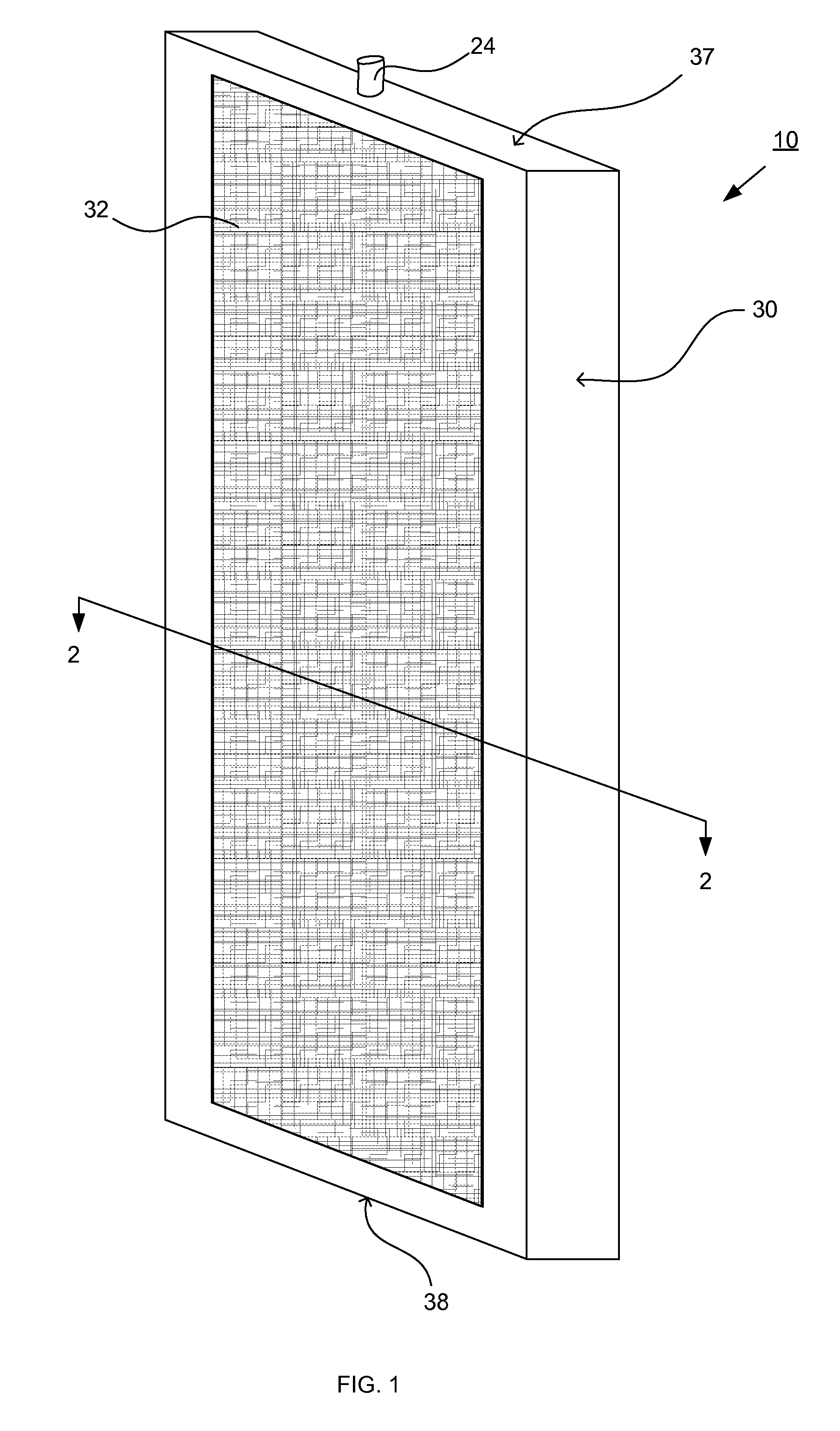

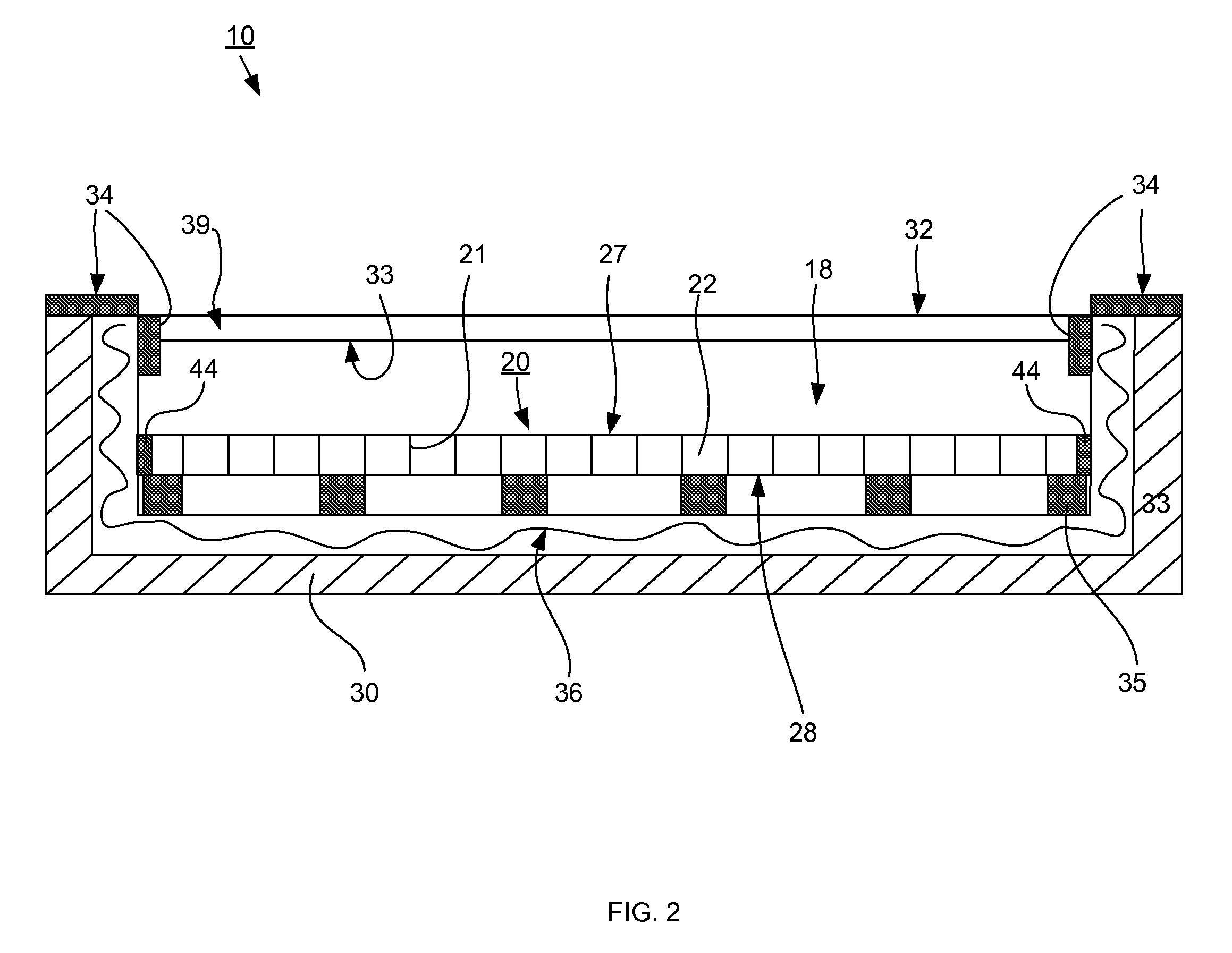

InactiveUS20110032587A1High resolutionHigh color fidelityHolographic light sources/light beam propertiesPhotomechanical apparatusOptical bondingDisplay device

Systems and methods for autostereoscopic display of three-dimensional images include a holographic optical element made by preparing a silver halide gelatin emulsion, coating one side of a glass substrate with the emulsion, holographically recording an eyebox on the coated glass substrate using at least three wavelengths of coherent light combined in a source beam that is divided into a reference beam and object beam with at least one of the reference and object beam passing through a beam shaping device to substantially uniformly illuminate the glass substrate from opposite sides, processing the coated glass substrate, and sealing the coated glass substrate by covering the coated side of the glass substrate with an optical cement and securing to a black glass plate. The element may be mounted in a display and illuminated with at least one projector having optical keystone correction with source wavelengths aligned or matched with the recording wavelengths.

Owner:KUGHN ABSOLUTE HLDG

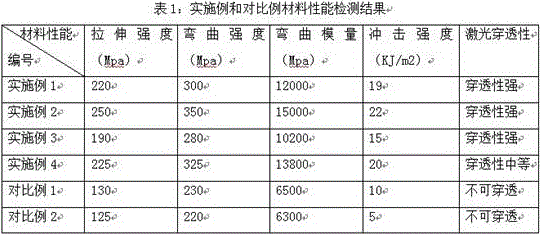

Black glass fiber reinforced nylon 6 material for laser welding and preparing method thereof

The invention discloses black glass fiber reinforced nylon 6 material for laser welding, comprising the following components, by weight percentage: 25 - 85% of nylon 6, 10 - 50% of glass fiber, 1 - 20% oftransparent modifier, and 0. 1 to 5% of laser-penetrating black powder; the preparing method comprises the following steps: weigh the various materials except for glass fiber according to the above composition ratio, and after high-speed mixing, melt and extrude them together with side-fed glass fiber through twin screw extruder melt extrusion; then cut them by the granulator, and keep the resulting pellets dried in an oven at 80 to 90 o C for 2 to 4 hours and finally the laser-penetrating black powder is produced by injection molding at a temperature of 200 to 280 o C; the material overcomes the shortcomings of the traditional black fiberglass reinforced nylon that the latter cannot be transmitted by laser. Besides, it has the advantages of high strength, high laser penetration and shortening of the welding period. The material is excellent in process science, convenient in production, low in cost, and has long service life and wide applicability, which makes it conducive to large quantities of industrial production.

Owner:5ELEM HI TECH CORP

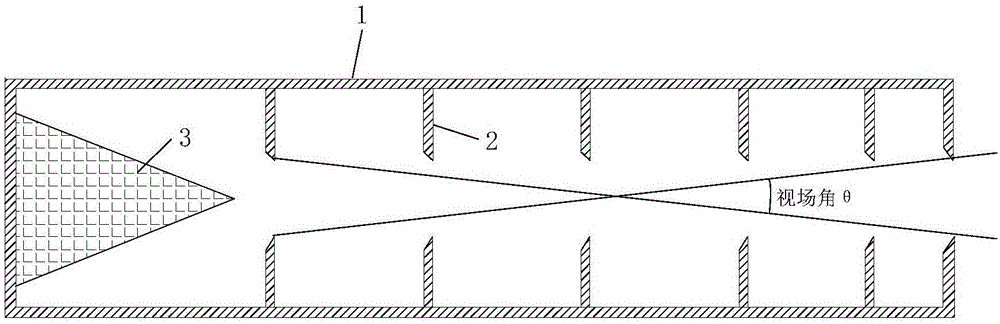

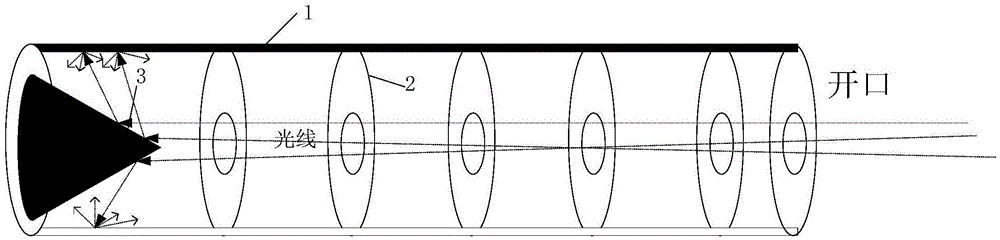

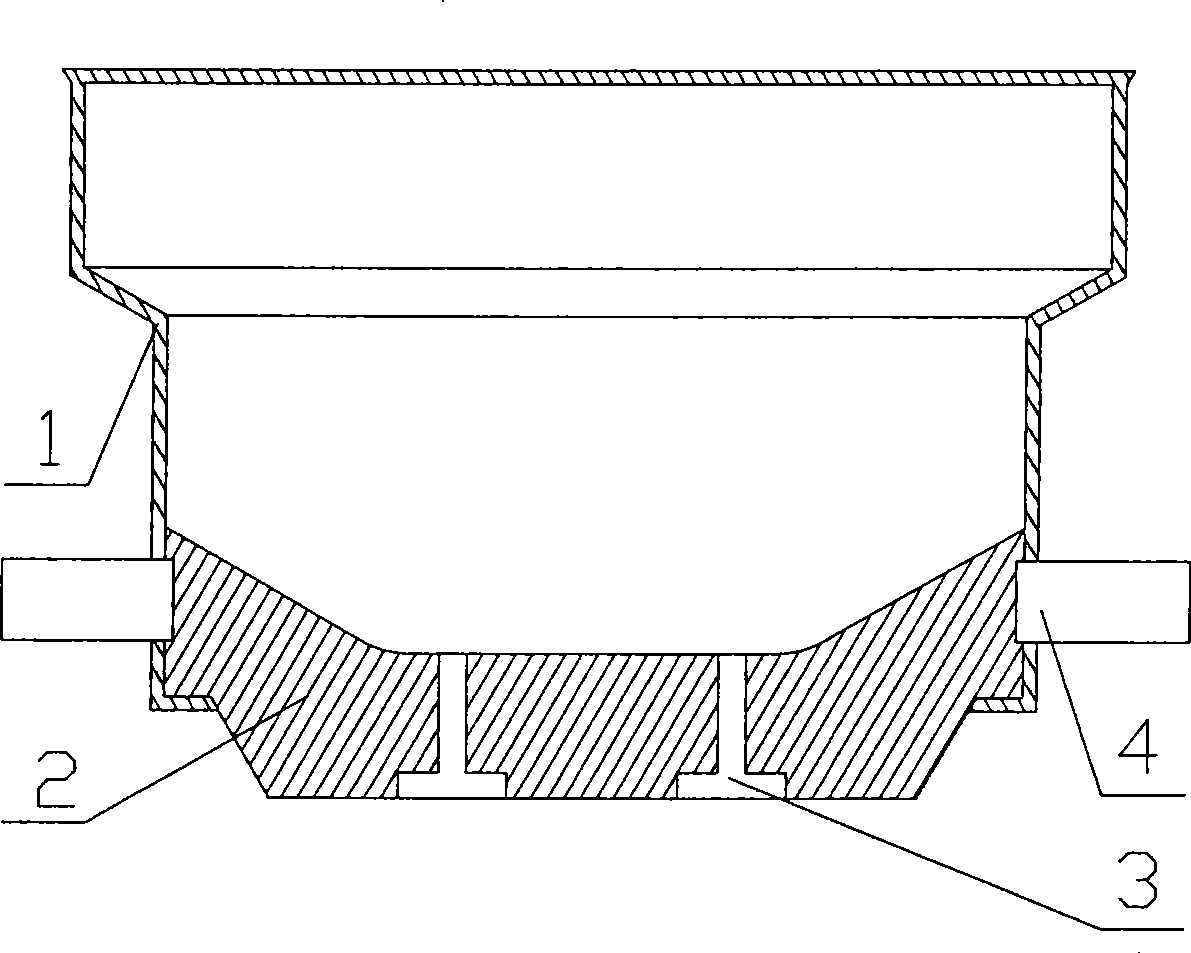

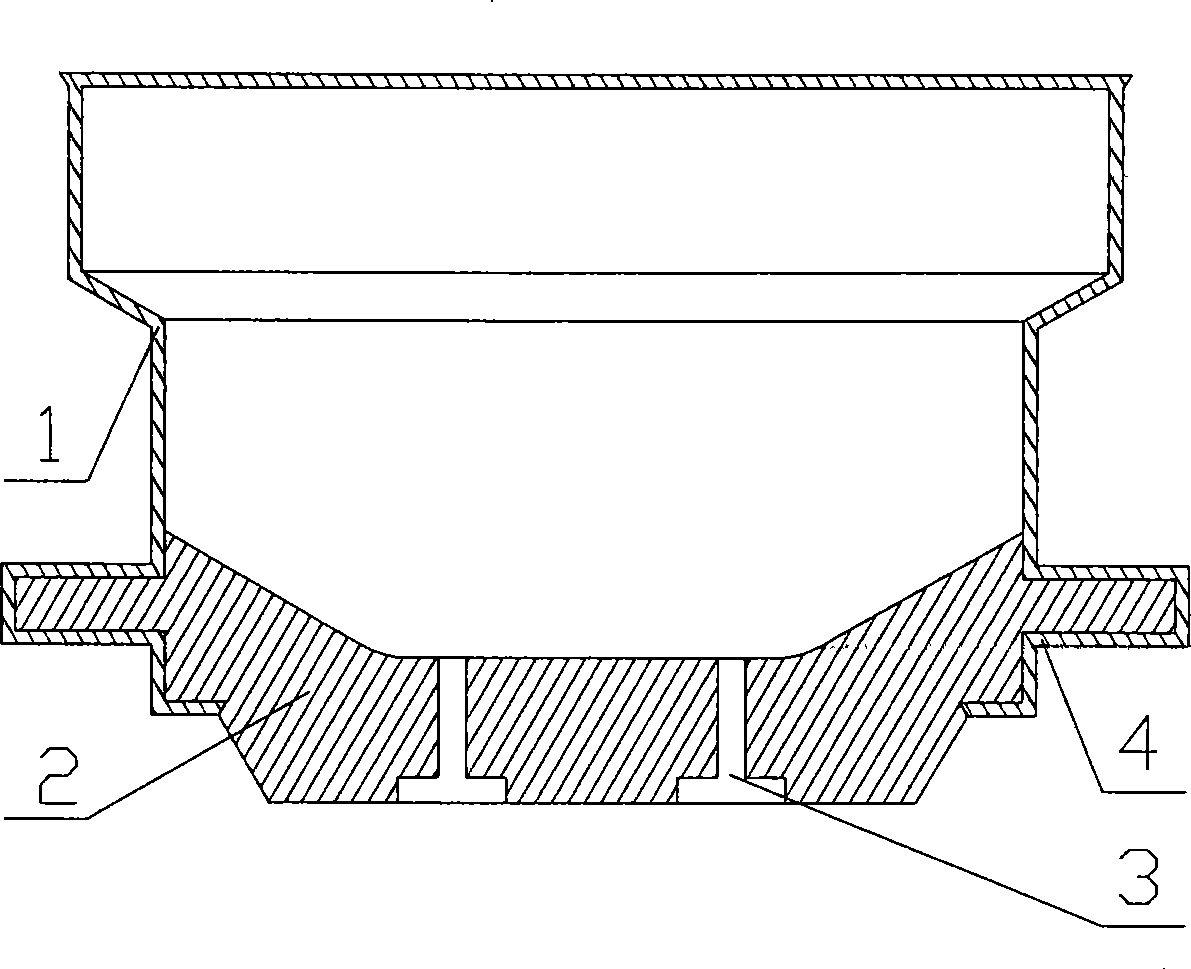

System-level stray light test unit attenuator

ActiveCN105092219ASimple designRealize dark target simulationTesting optical propertiesExtinctionBlack paint

The invention discloses a system-level stray light test unit attenuator which is mainly composed of an external cover (1), an internal diaphragm (2) and a black glass reflector (3) of a central taper angle. The internal diaphragm is arranged between the external cover and the black glass reflector. The internal surface of the external cover and the surface of the internal diaphragm are coated by high-absorptivity extinction black paint which is used for absorbing light rays entering the attenuator. Better extinction ratio can be achieved under the premise of minimizing shielding of optical load incident lighting so that dark object simulation in a system-level ground stray light test can be realized.

Owner:SHANGHAI SATELLITE ENG INST

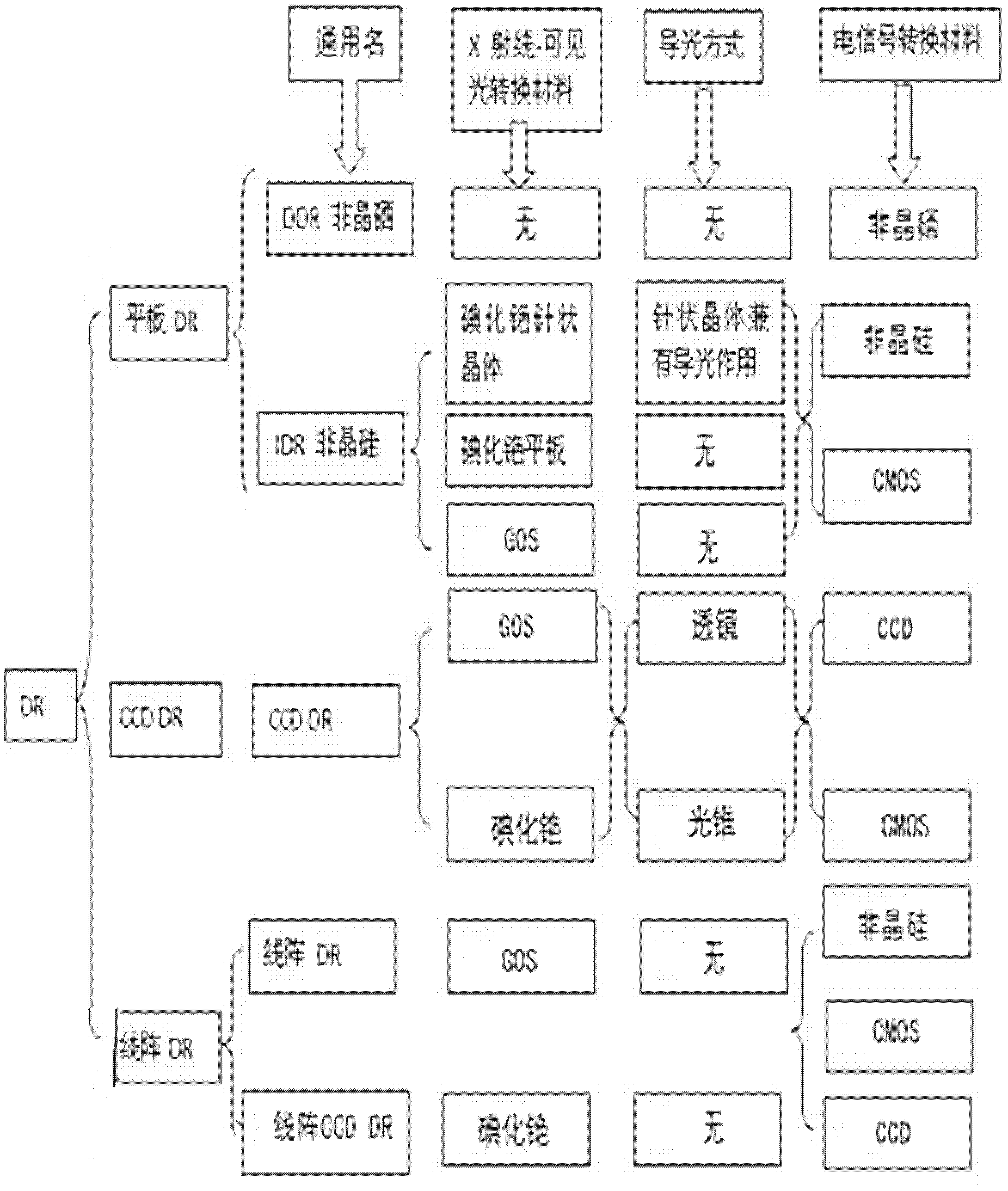

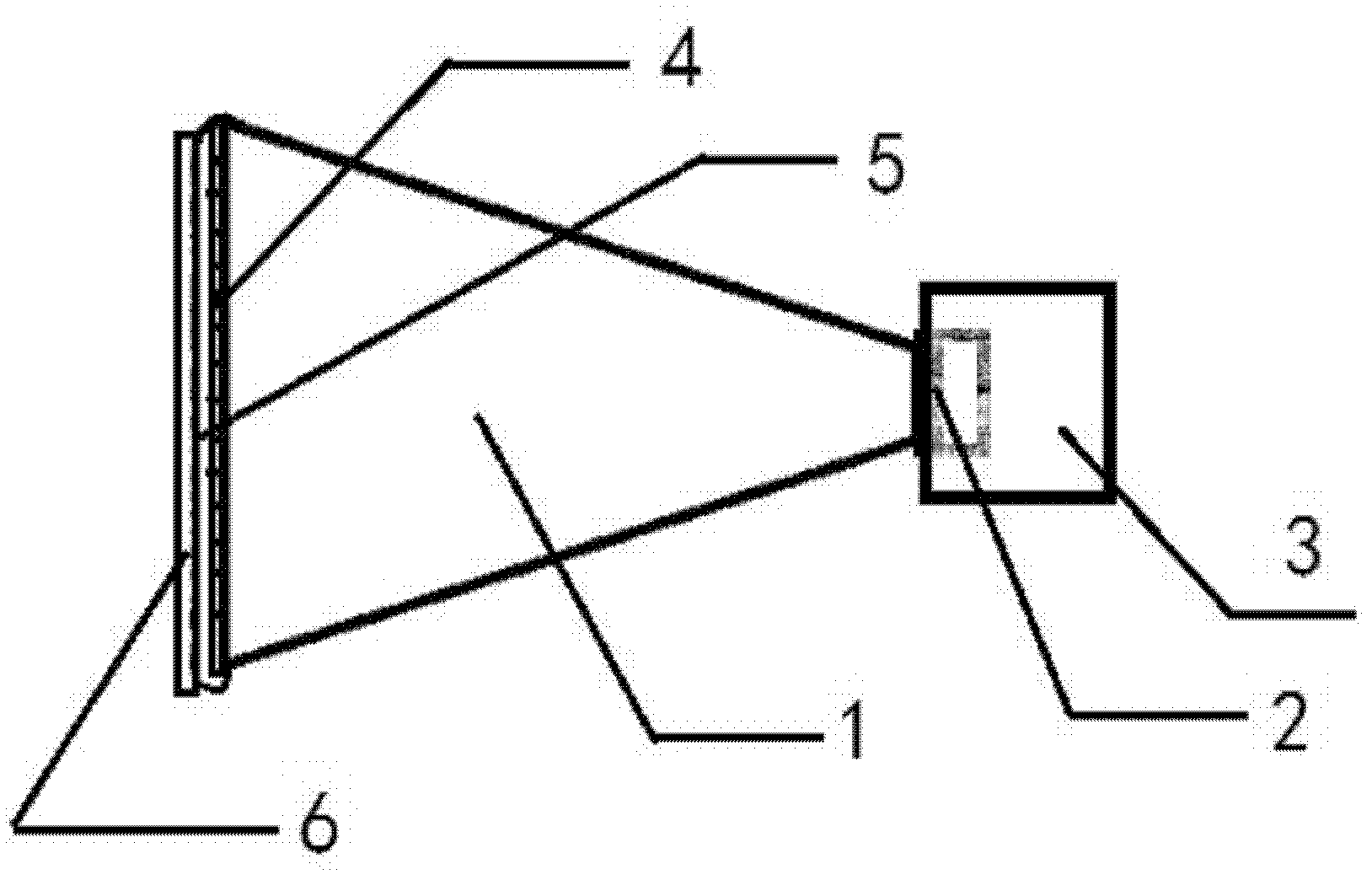

X-ray camera and manufacturing method thereof

InactiveCN102547150AImproved Modulation Transfer FunctionHigh-resolutionTelevision system detailsColor television detailsReduction treatmentRefractive index

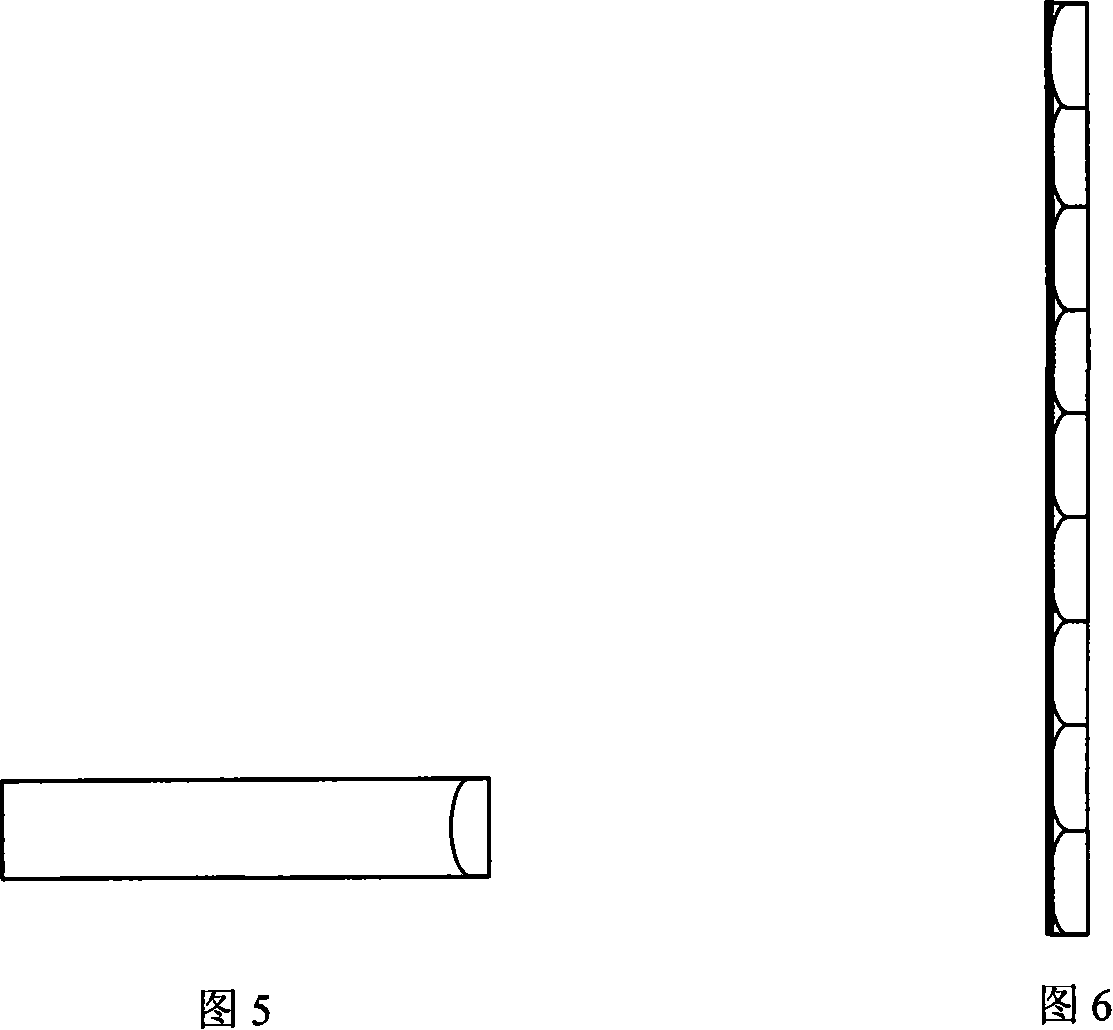

The invention discloses an X-ray camera and a manufacturing method thereof. The X-ray camera is manufactured by coupling a fiber optic taper with a CCD (Charge Coupled Device) or CMOS (Complementary Metal-Oxide-Semiconductor) camera, wherein a needle-like CsI (Cesium Iodide) crystal, a moisture sealer and an aluminium coating or a silicon nitride film are arranged on a big end of the fiber optic taper in order; the fiber optic taper is manufactured by the steps of: sleeving a low-refractive-index cladding on a high-refractive-index core material of an ordinary fiber optic taper, on the basis, sleeving a black glass or lead silicate glass sleeve matching with the fiber optic taper in thermophysical properties, manufacturing a fiber array cylinder according to a front-end process of manufacturing a fiber optic panel, and then drawing the cylinder according to the proportion between the big end and a small end of the fiber optic taper, wherein the fiber optic taper made of the lead silicate glass sleeve requires hydrogen reduction treatment; and after the needle-like CsI crystal, the moisture sealer and the aluminium coating or silicon nitride film are manufactured in order on the big end of the fiber optic taper, the small end of the fiber optic taper is coupled with a light-sensitive surface of the camera by using optical cement. The X-ray camera manufactured in such a way has the minimum pixel reaching 5 micrometers and the resolution ratio being above 301p / mm with good MTF (Modulation Transfer Function).

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

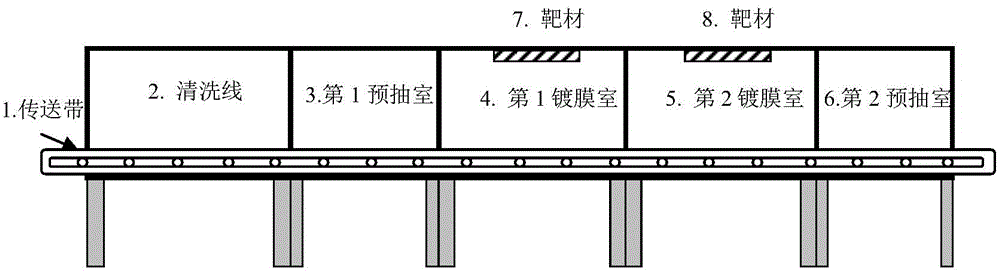

Method for manufacturing high-temperature-resisting black borosilicate glass

The invention discloses a method for manufacturing high-temperature-resisting black borosilicate glass by adopting the continuous multi-cavity magnetron sputtering technology. According to the method, before being coated, the glass is cleaned up firstly; then, the glass is conveyed to a pre-vacuum chamber of a continuous type vacuum coating machine through a conveying device and then sequentially enters a plurality of sputtering coating chambers matched with large type titanium aluminum magnetic control targets and silicon targets later on; argon and nitrogen mixed gas is led into the coating chambers, the reactive sputtering gas ratio is adjusted, glow discharge characteristics of the magnetic control targets are modulated, a black TiAlN function thin film is deposited on the surface of the borosilicate glass in a reactive sputtering manner firstly; then, the glass enters the next vacuum chamber, and an SiN protection thin film is deposited in a reactive sputtering manner; and finally coated annealing treatment is carried out, internal stress of the thin film is further reduced, and the film-based interface combination force is improved. The method for manufacturing the high-temperature-resisting black borosilicate glass by vacuum coating can obviously improve the high-temperature resisting performance of the black borosilicate glass through design of a composite thin film, the black glass can bear the temperature of 600 DEG C, and the color of the glass is not changed.

Owner:宁波海燕新材料有限公司

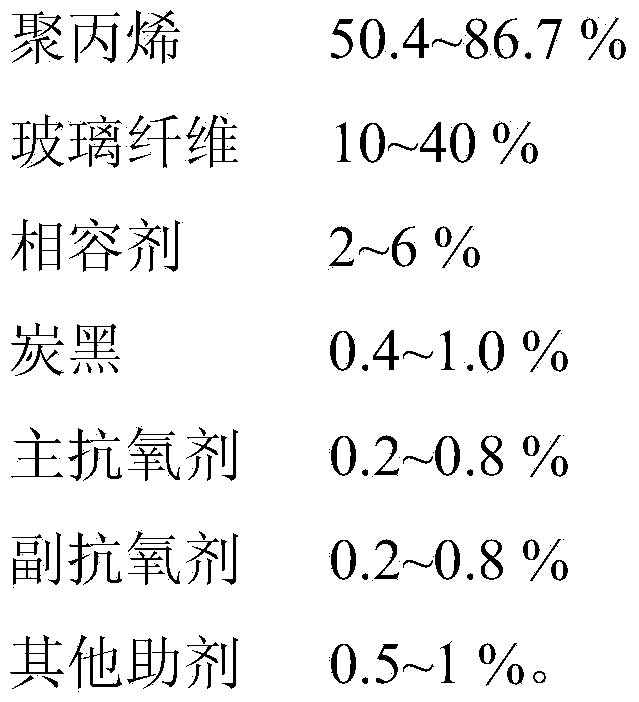

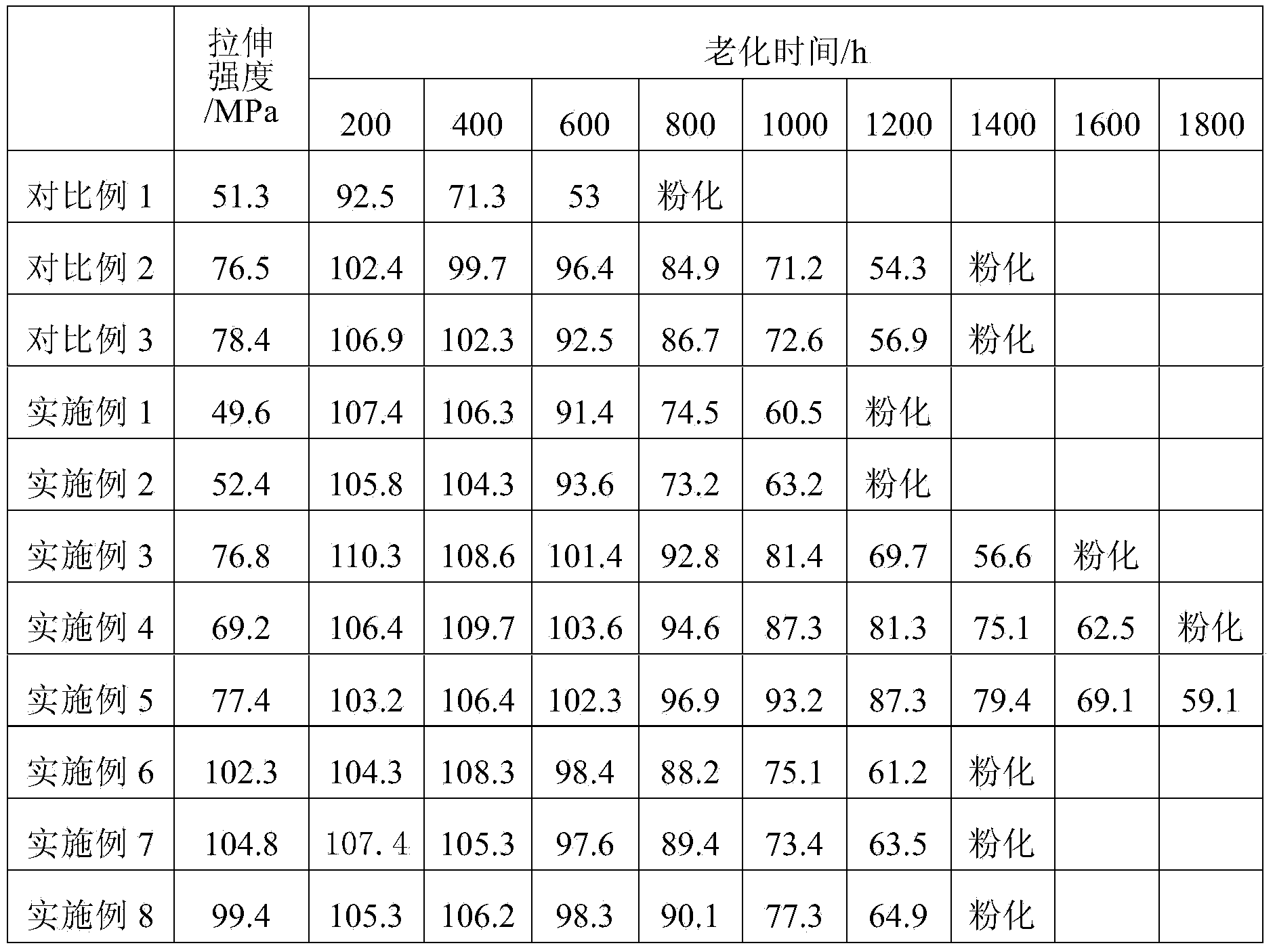

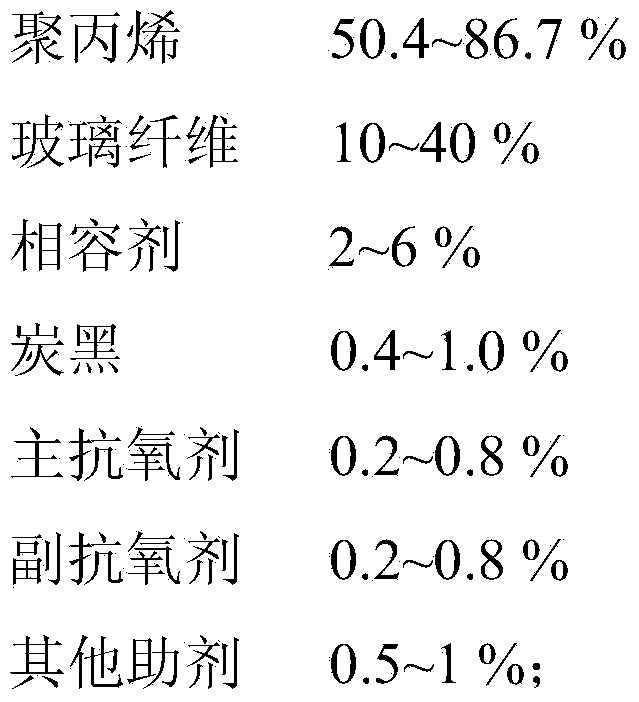

Black glass fiber reinforced polypropylene composite and preparation method and application of same

InactiveCN103467856AReduces adverse effects of thermo-oxidative agingReduced antioxidant contentPolypropylene compositesGlass fiber

The invention belongs to the field of polypropylene composites, and discloses a black glass fiber reinforced polypropylene composite and a preparation method and application of the black glass fiber reinforced polypropylene composite. The black glass fiber reinforced polypropylene composite comprises the flowing components, by mass, 50.4-86.7% of polypropylene, 10-40% of glass fibers, 2-6% of compatilizer, 0.4-1.0% of carbon black, 0.2-0.8% of primary antioxidants, 0.2-0.8% of auxiliary antioxidants and 0.5-1% of other auxiliaries, and the carbon black is furnace carbon black with the 45-145mg / g iodine absorption value. Because the furnace carbon black with the proper iodine absorption value is added to the black glass fiber reinforced polypropylene composite, the adverse effect of the furnace carbon black on the hot oxygen aging resisting performance of the polypropylene composite is reduced, the antioxidant content in the polypropylene composite is reduced and the hot oxygen aging resisting performance of the black glass fiber reinforced polypropylene composite is improved. The black glass fiber reinforced polypropylene composite keeps good dispersity and pigmentation degree and meanwhile reduces the using amount of the antioxidants and product cost.

Owner:TIANJIN KINGFA NEW MATERIAL +1

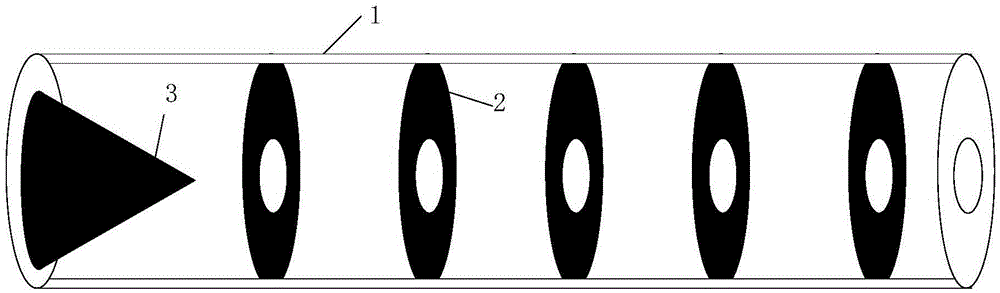

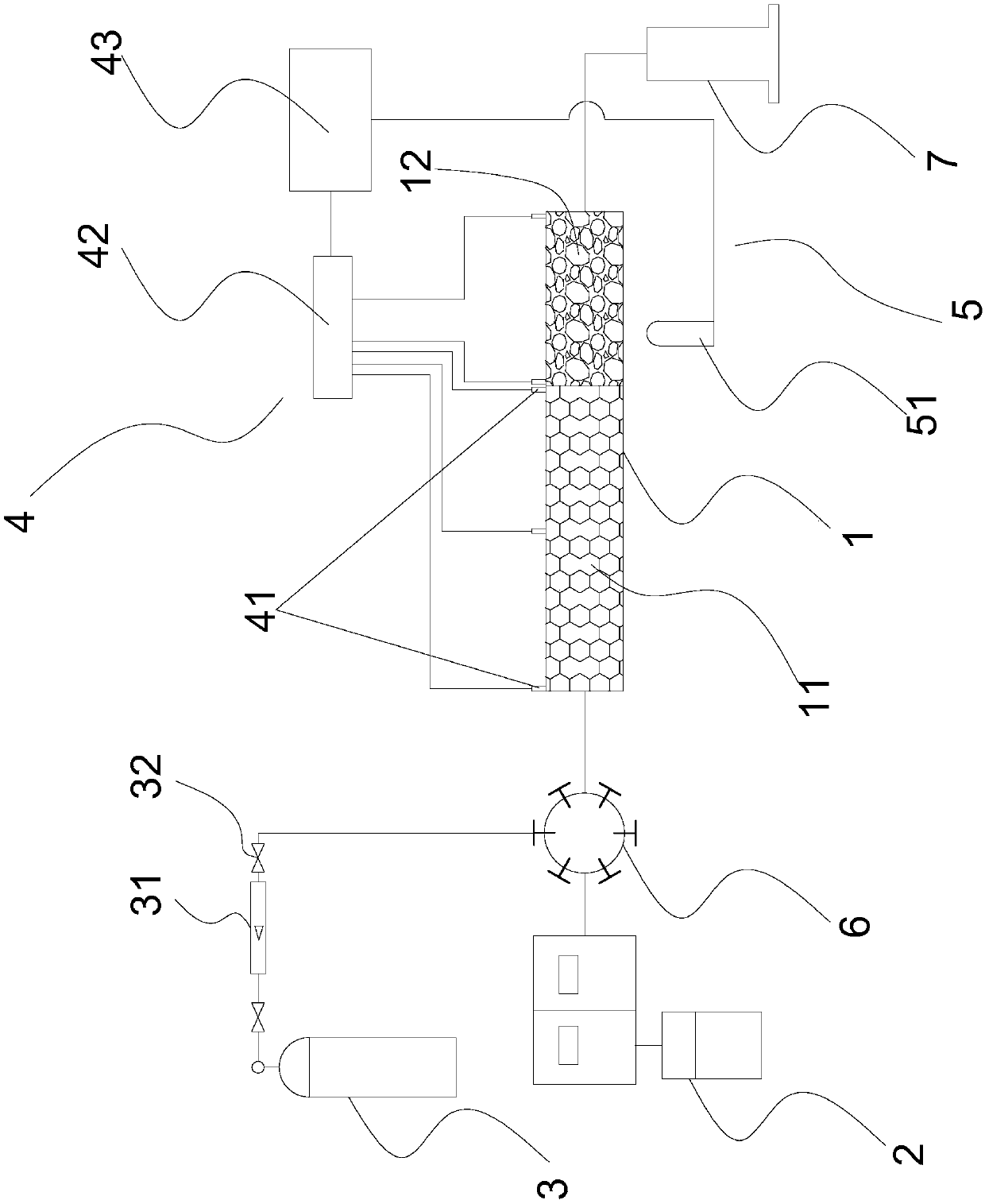

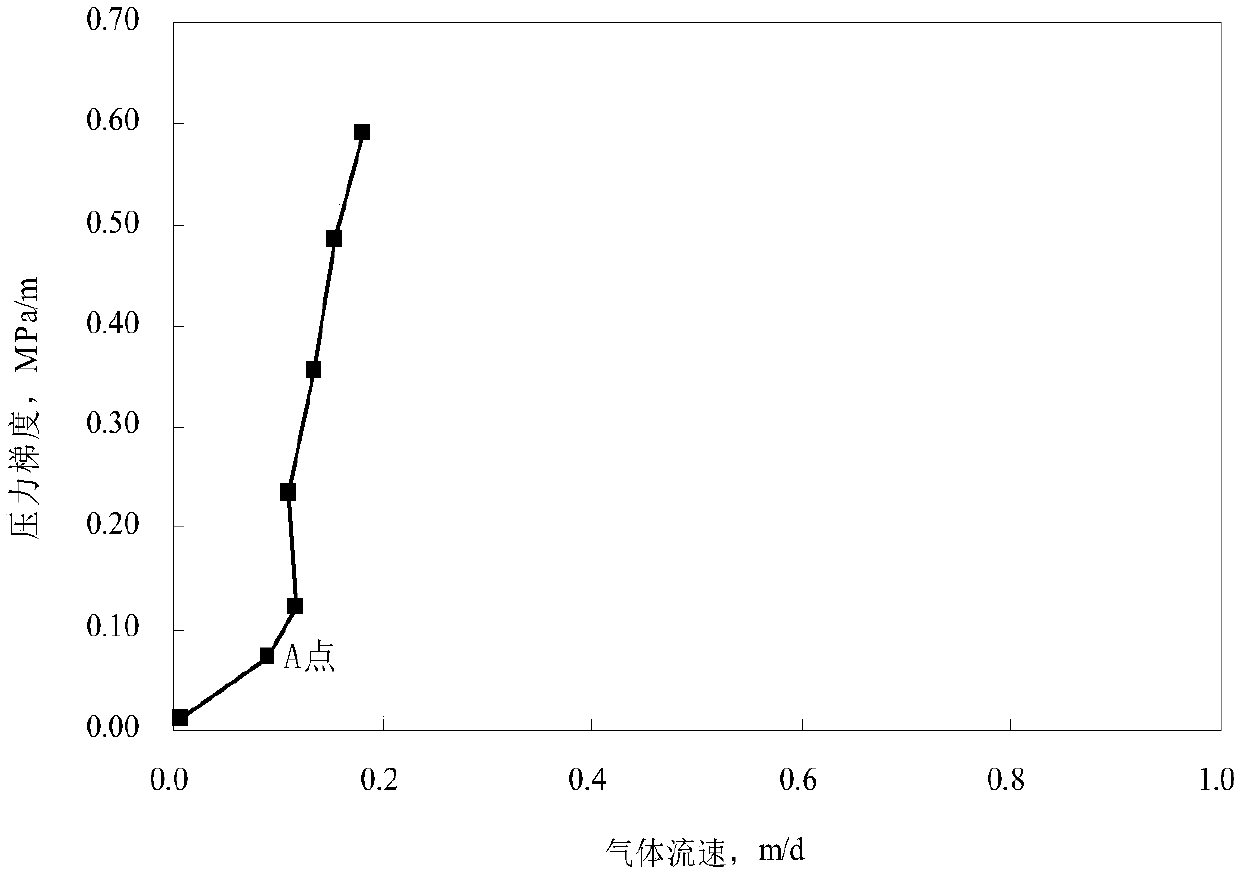

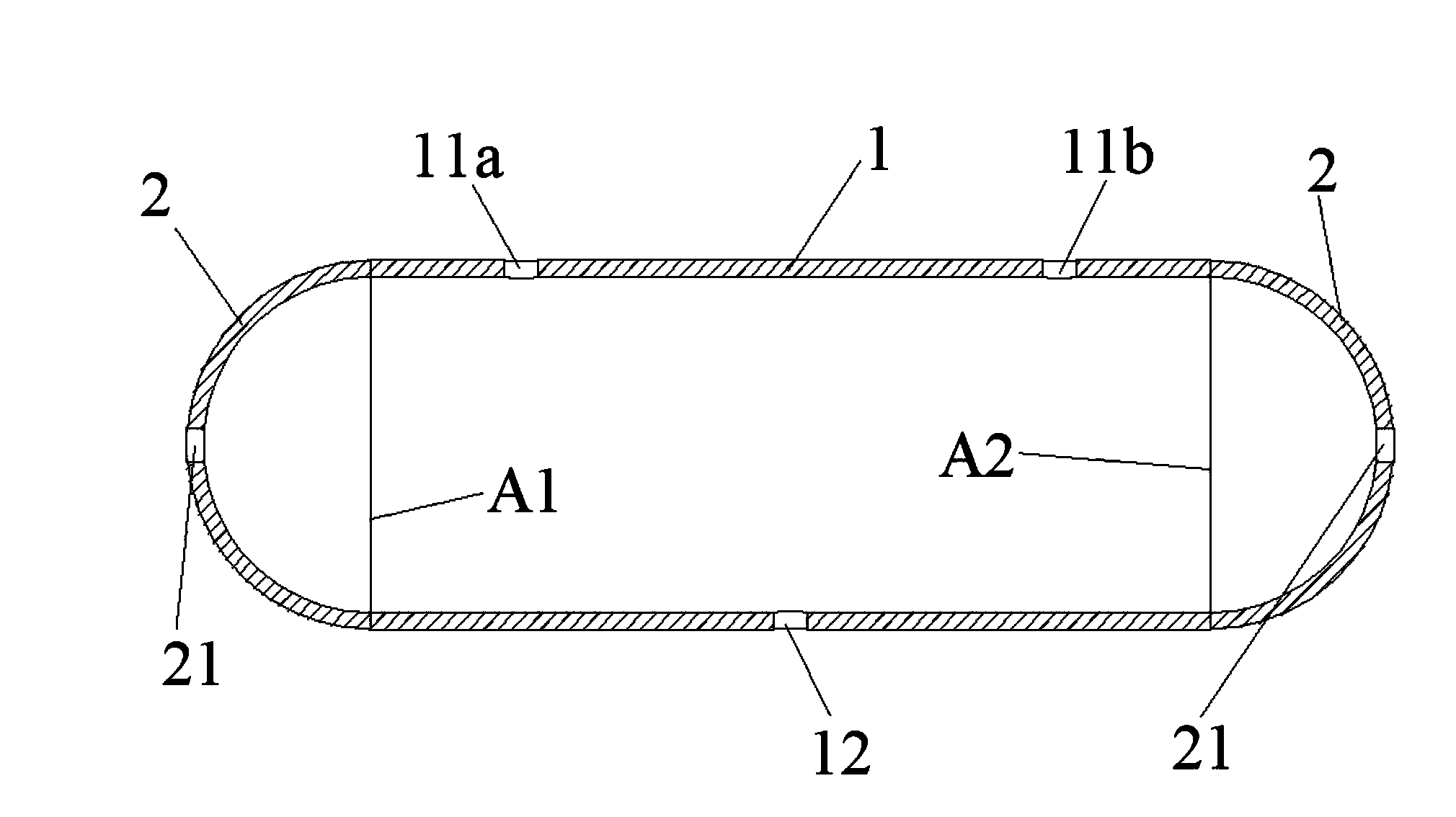

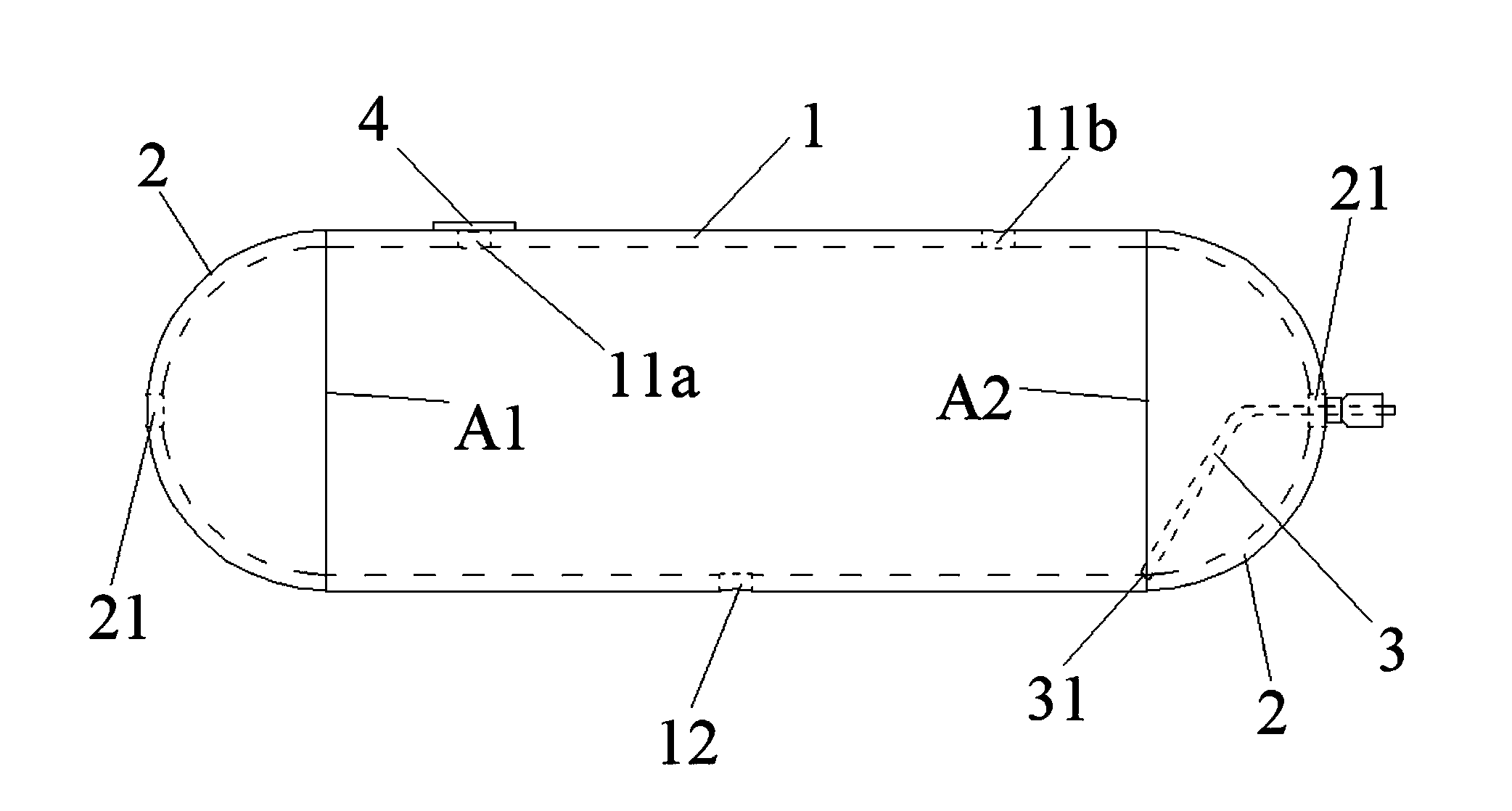

System for determining critical pressure gradient of foams generated at permeability mutation site

ActiveCN107727527AWell formedImprove calculation accuracyPermeability/surface area analysisRate of penetrationPorous medium

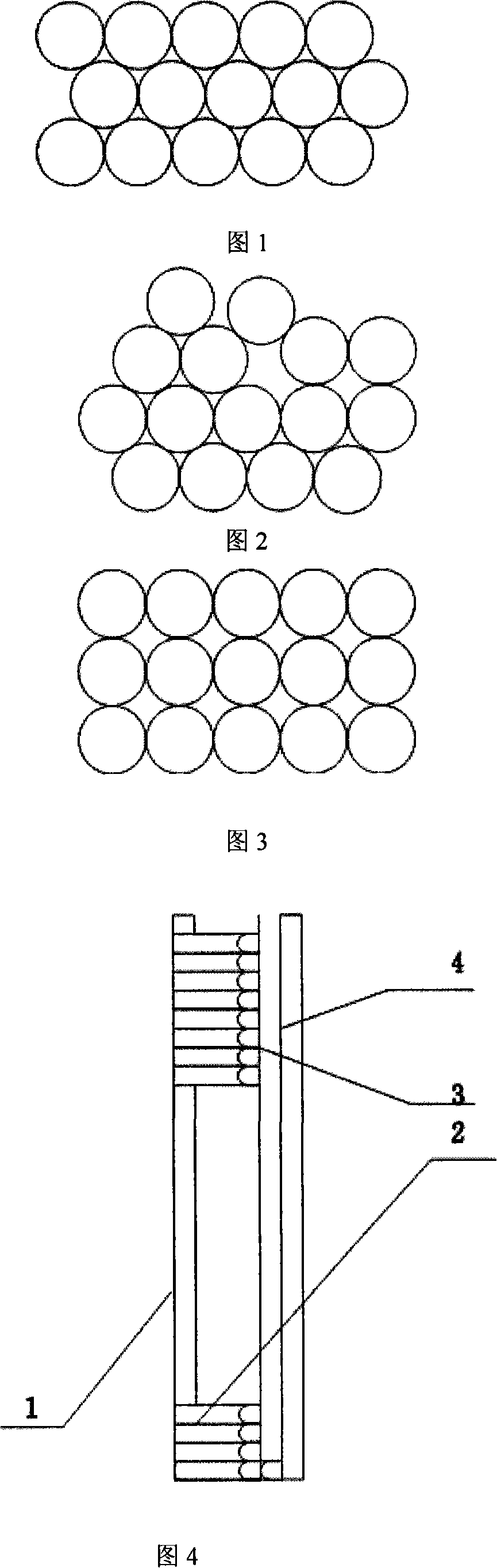

The invention belongs to the field of air driving exploitation of reservoirs and particularly relates to a system for determining a critical pressure gradient of foams generated at a permeability mutation site. The system comprises a sand filling pipe, a liquid supplying device, an air supplying device, a data collection device and an observation device, wherein the data collection device is connected with the sand filling pipe; the sand filling pipe is provided with an injection end and a flow-out end, two sections of filling mediums with different grain diameters are arranged in the sand filling pipe, the filling mediums with relatively small grain diameters are used for filling close to the injection end to form a front sand filling section, the filling mediums with relatively large grain diameters are used for filling close to the flow-out end to form a rear sand filling section, the sand filling pipe is a transparent tempered glass pipe, and the filling mediums are black glass beads; and the observation device comprises a microscope and a computer, the microscope is arranged opposite to the outer circumferential surface of the sand filling pipe, the computer is connected withthe microscope, and a camera is arranged on the microscope. According to the system, the critical pressure gradient of the foams at the permeability mutation site can be determined, and the foams arearranged in a porous medium environment to be researched, so that the influences caused by the mutation of the permeability in a heterogeneous reservoir to the generation of the foams are truly reflected.

Owner:ZHEJIANG OCEAN UNIV

3650nm ultraviolet transmissible blue-black glass pipe and mfg. method thereof

InactiveCN1401602AExcellent physical and chemical propertiesFulfil requirementsGlass drawing apparatusUltravioletHigh pressure

Owner:LUOJIN GLASS SHANGHAI

Colored machinable glass-ceramics

The invention relates to opaque, colored glass ceramic articles and to the production of opaque, colored glass-ceramic articles which can be readily formed to a desired shape using standard metal-working tools. The glass-ceramic material used to make such articles contains mica crystals as the predominant phase. The desired color is obtained through the addition of a colorant system to the precursor glass. In a particular embodiment the invention is directed to a black glass ceramic article, the black color being obtained by the addition of iron oxides in levels as high as 20 wt%, which can yield a glass ceramic having an iron rice mica phase and / or a glass ceramic having an iron rich mica phase plus an iron oxide phase.

Owner:CORNING INC

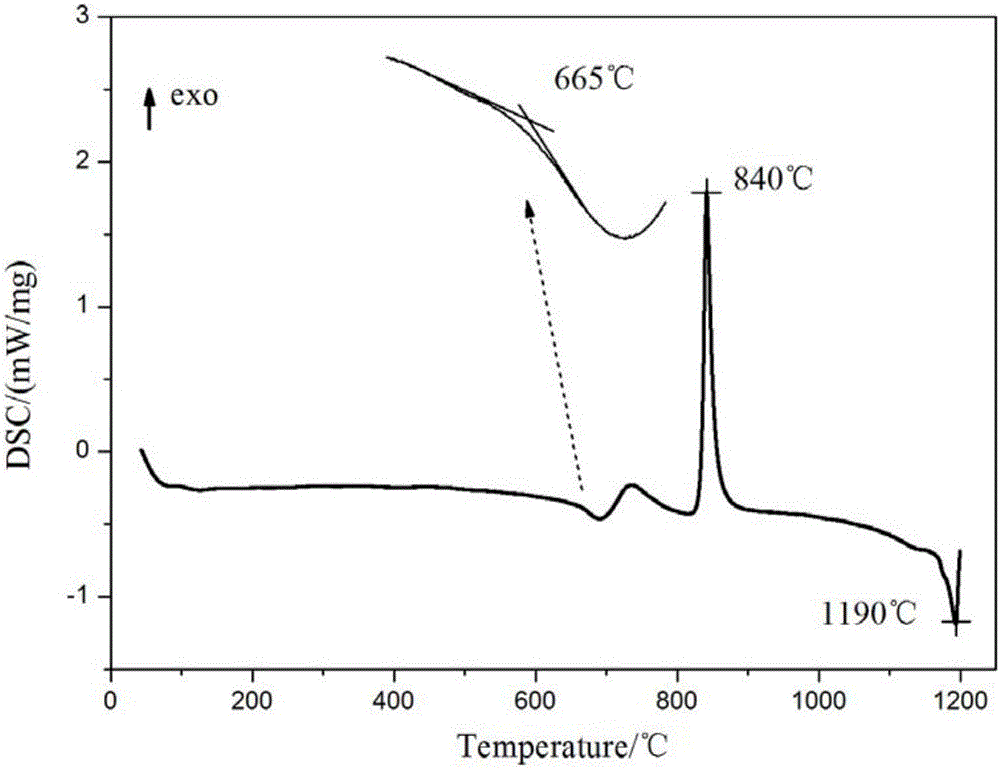

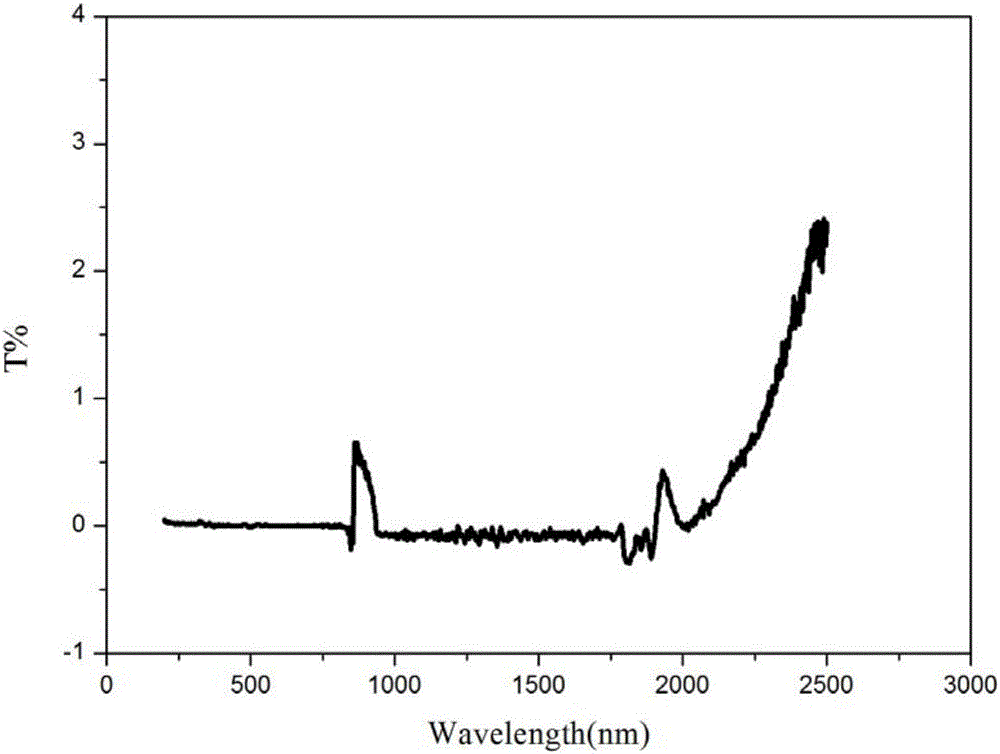

Black glass capable of highly absorbing earth surface sunlight and preparation method thereof

The invention discloses a black glass for highly absorbing earth surface sunshine and preparation method thereof. The black glass is prepared with borosilicate glass and colouring agent, the colouring agent comprises cobalt oxide or cobaltous oxide, chrome oxide and copper oxide, in every 100 moles borosilicate glass, cobalt ions are 0.1-3 moles, chromium ions are 0.1-3 moles, copper ions are 0.5-4 moles. First, mixing borosilicate glass with the colouring agent uniformly in proportion, melting at 1300-1500 DEG C 1-6 hours; molding in moulds then processing annealing treatment in a annealing furnace at 450-600 DEG C 1-3 hours, then natural cooling to room temperature. The invention produces black glass compound colored by cobalt, chromium and copper ions, the black glass has good absorbing effect of sunshine of the entire sunshine wave band range (200nm-2500nm) reaching on earths surface.

Owner:HUAZHONG UNIV OF SCI & TECH

Electrode paste, electrode made from same, manufacturing methods thereof and PDP display screen provided with electrode

InactiveCN101728148ASimple manufacturing processLower sintering temperatureGas discharge electrodesAlternating current plasma display panelsSilver electrodeMetallurgy

The invention provides electric paste and preparation method thereof. The electrode paste comprises silver powder, black glass paint, low melting point glass powder and organic matter ingredients, wherein the black low melting point glass powder comprises 5-20 percent of black glass paint and low melting point glass powder by weight; the silver powder comprises 40-70 percent of high tap density spherical silver powder and 5-10 percent of microcrystal silver powder by weight; and the organic matter ingredients comprises high molecular copolymer, photoinitiator, a solvent, a defoaming agent, a surfactant and a pH regulating agent, and the like. The invention also provides a photosensitive silver electrode made from the electrode paste, a manufacturing method thereof and a PDP display screen provided with the electrode. By using the electrode paste, the electrode with high electrical conductivity can be obtained only by using one layer of paste and carrying out once drying and sintering process.

Owner:SICHUAN COC DISPLAY DEVICES

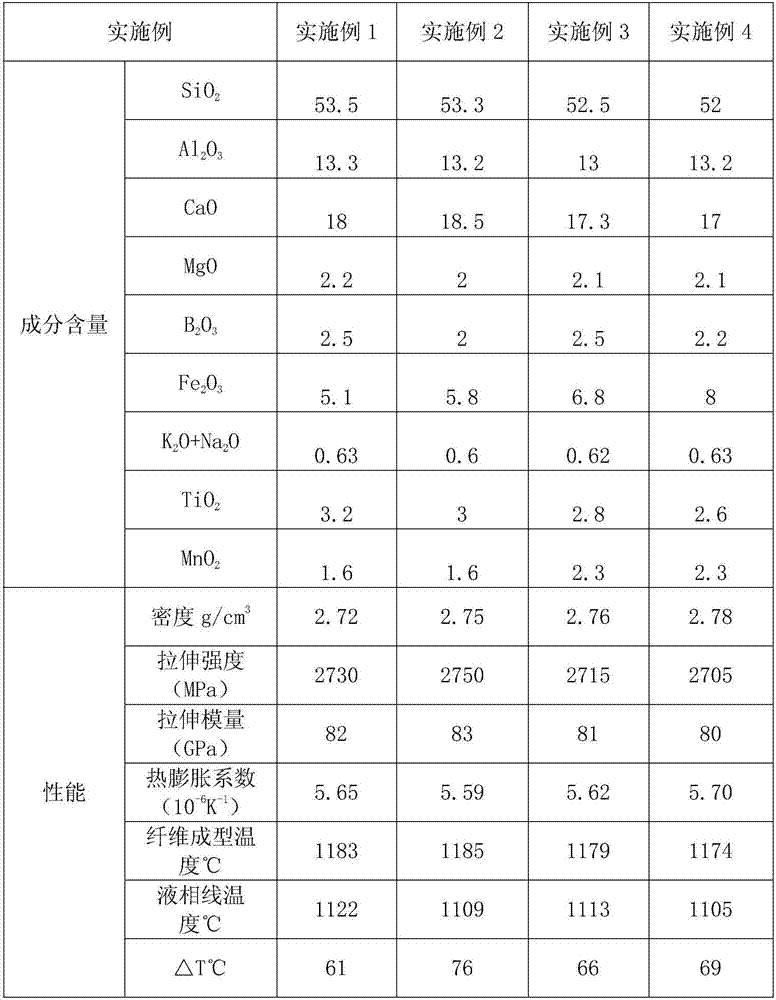

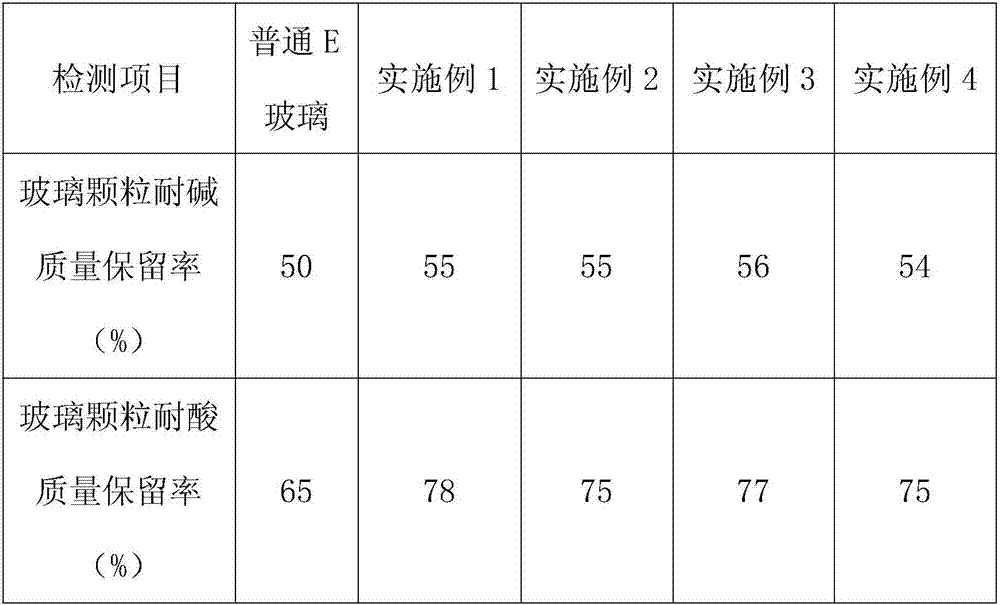

Black glass fiber and preparation method thereof

InactiveCN106927672AImprove coloring abilityGood crystallization performanceGlass making apparatusFiberGlass fiber

The invention provides black glass fiber and a preparation method thereof. The black glass fiber prepared by virtue of the preparation method contains SiO2, Al2O3, CaO, MgO, B2O3, Fe2O3, TiO2, MnO2 and K2O+Na2O. The black glass fiber is prepared through direct wiredrawing in a preparation process, and secondary dip dyeing is omitted, so that the problems in the prior art that the dyeing is not uniform, the dyeing adhesive force is poor and the fiber is easy to fall in a secondary dip dyeing process are solved. The preparation method provided by the invention has the beneficial effects that the prepared black glass fiber is low in melting temperature and high in acid-base resistance, and the main raw material is basalt which is widely distributed, high in reserve and low in cost, so that the production cost is greatly lowered.

Owner:TAISHAN FIBERGLASS INC

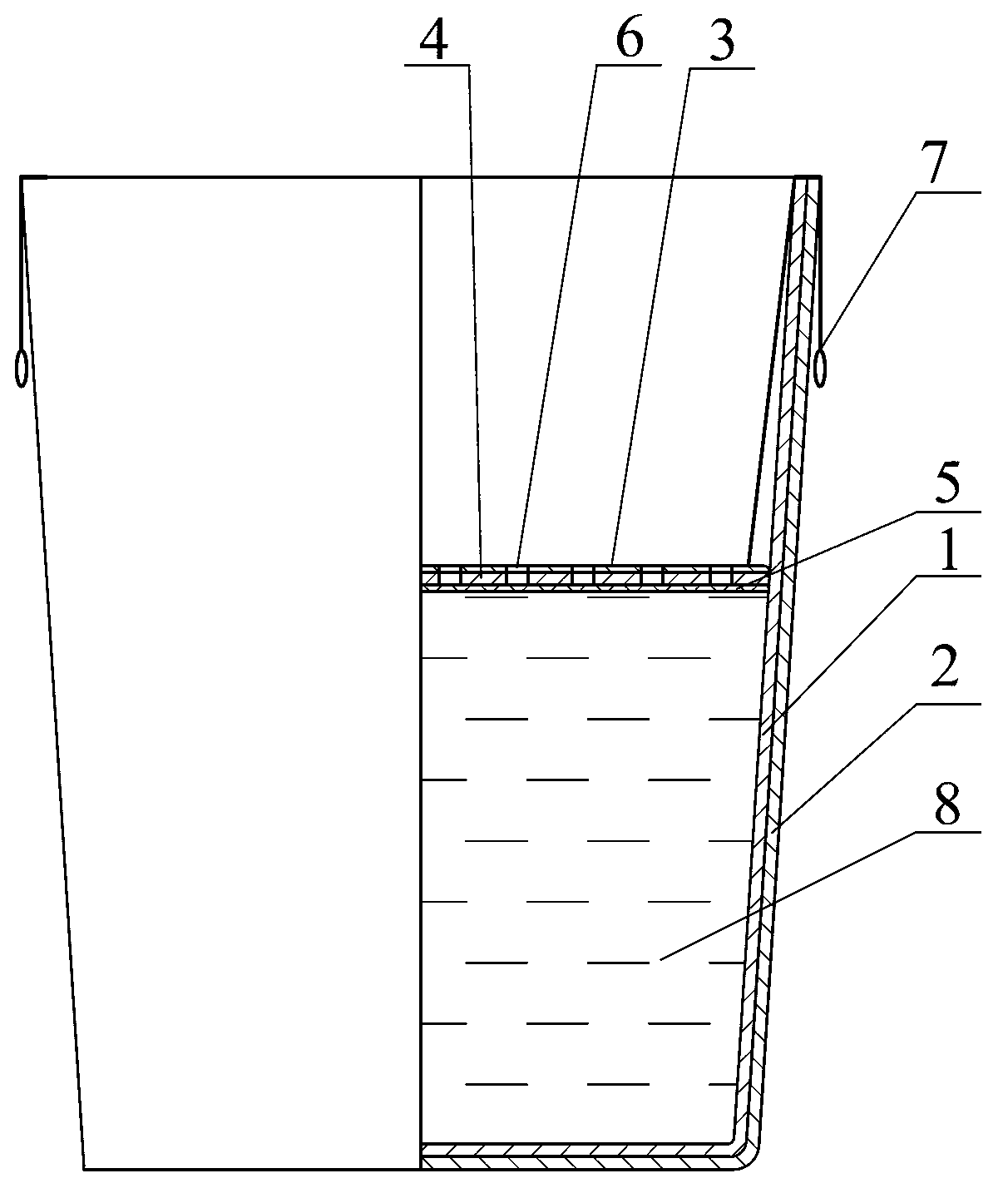

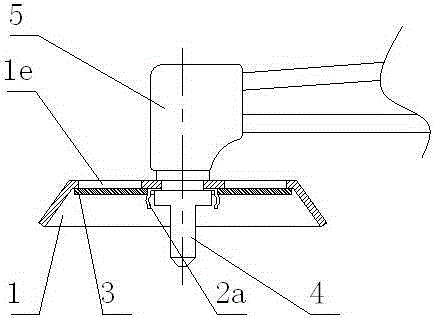

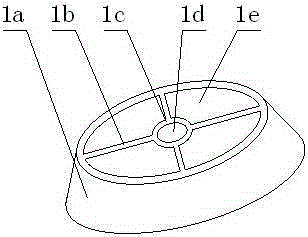

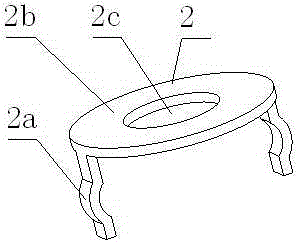

Hydroponic device convenient for research on plant root systems and application thereof

InactiveCN103210829AEasy to take outEasy to removeAgriculture gas emission reductionCultivating equipmentsPlant rootsEngineering

The invention provides a hydroponic device convenient for the research on plant root systems, which is characterized by comprising a transparent glass, a black glass sleeved outside the transparent glass, and a supporting floating plate arranged in the transparent glass, wherein the supporting floating plate is formed by combining black shading plastic cloth, a floating plate with the thickness of 0.3-1cm and a window gauze from top to bottom, small holes not penetrating through the window gauze are uniformly distributed in the supporting floating plate, and the supporting floating plate is provided with a lifting rope lifted upwards. The application of the device comprises the following steps: (1) germinal seeds are gently put into the small holes of the supporting floating plate, and the roots of the seeds penetrate through the window gauze; (2) the supporting floating plate carrying the seeds is put into the transparent glass, the supporting floating plate floats on nutrient solution, and the black glass is sleeved outside the transparent glass; and (3) the hydroponic device carrying the germinated seeds is moved into a sterile artificial climate box or sterile room for the hydroponics of plants. The hydroponic device can effectively prevent the influence of illumination on root system growth and development, and is convenient for the research on the root system growth and development, morphological structures and the like.

Owner:SHANDONG UNIV OF TECH

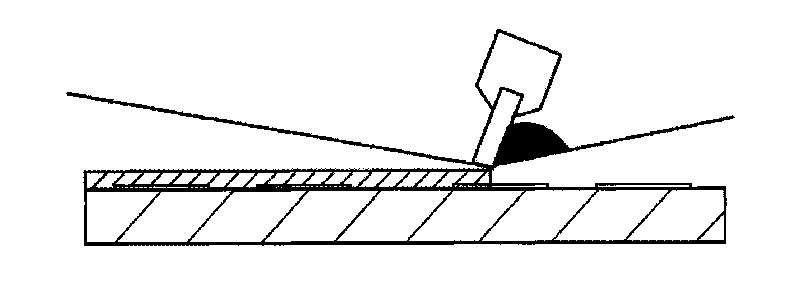

Protective cover for cutting gun

The invention relates to a protective cover for a cutting gun. The protective cover comprises a protective cover body and black glass. The black glass is fixed to the protective cover body through a clamping ring which is fixed to the protective cover body. The protective cover body comprises a main cover body, a fixing ring A and a sight window. The fixing ring A and the main cover body are connected through ribs. A fixing hole A is formed in the fixing ring A. The clamping ring comprises a fixing ring B and clamping strips. An arc protrusion is arranged at the position, facing the outside, of each clamping strip, and the clamping strips on the clamping ring are evenly distributed on the outer side of the clamping ring. A cutting torch is placed in the fixing hole A in the protective cover body and a fixing hole B in the clamping ring, the cutting torch and a cutting gun head are fastened, and therefore the fixing ring A and the fixing ring B are fixedly clamped between the cutting torch and the cutting gun head through the cutting torch. The protective cover is simple in structure, economical, practical and rapid to mount, can play a role of preventing splashing and does not affect observation of the moving direction of the cutting torch by an operator, so that the precision of gas cutting is guaranteed.

Owner:TONGCHENG LIQIONG METAL PROD

Method for reworking surface defect on back surface of weld joint of small container

ActiveCN103769725AReduce grinding processReduce rework workloadArc welding apparatusDomestic vesselsShielding gasWorkload

The invention relates to the field of welding, aims to solve the problems of high workload, long reworking time consumption and great secondary reworking risks during the reworking of a surface defect on the back surface of a weld joint of a small container, and discloses a method for reworking the surface defect on the back surface of the weld joint of the small container. The method comprises the following steps of determining an observation hole and a welding hole, and finding the surface defect on the back surface of the weld joint; filling protective gas into the small container, and discharging air; bending a tungsten electrode for reworking, performing wire addition-free welding on the surface defect on the back surface of the weld joint by using the tungsten electrode, and observing the welding progress through black glass until the surface defect observed through the observation hole is completely removed; performing appearance inspection again, and finishing the reworking when the surface defect on the back surface of the weld joint is completely removed; when the surface defect on the back surface of the weld joint is not completely removed, refilling the protective gas, and repeating the operation to weld the remaining surface defect on the back surface of the weld joint until the surface defect is reworked. The reworking method is low in workload and secondary reworking risks, short in time consumption, simple and easy to operate.

Owner:CHINA NUCLEAR IND 23 CONSTR +1

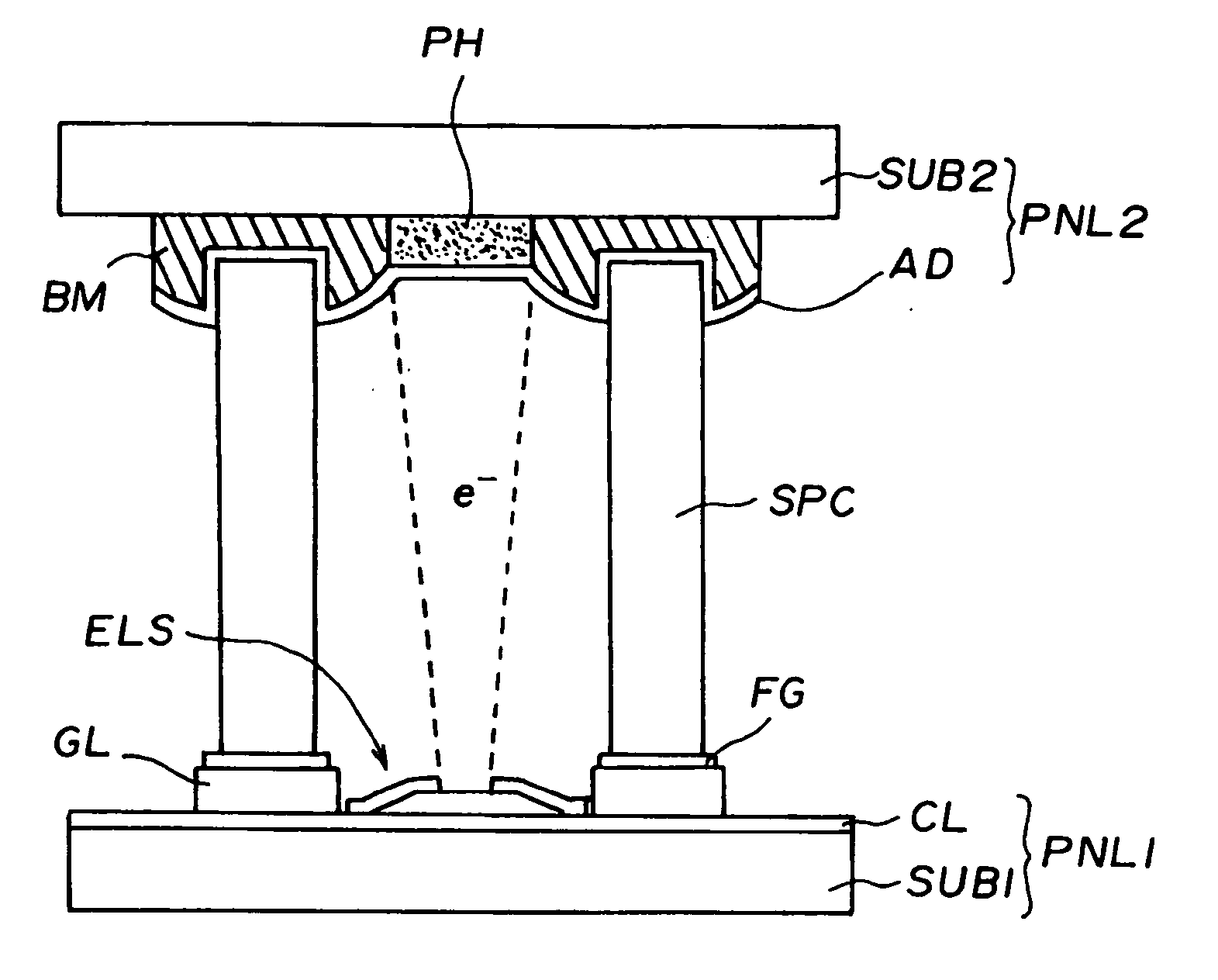

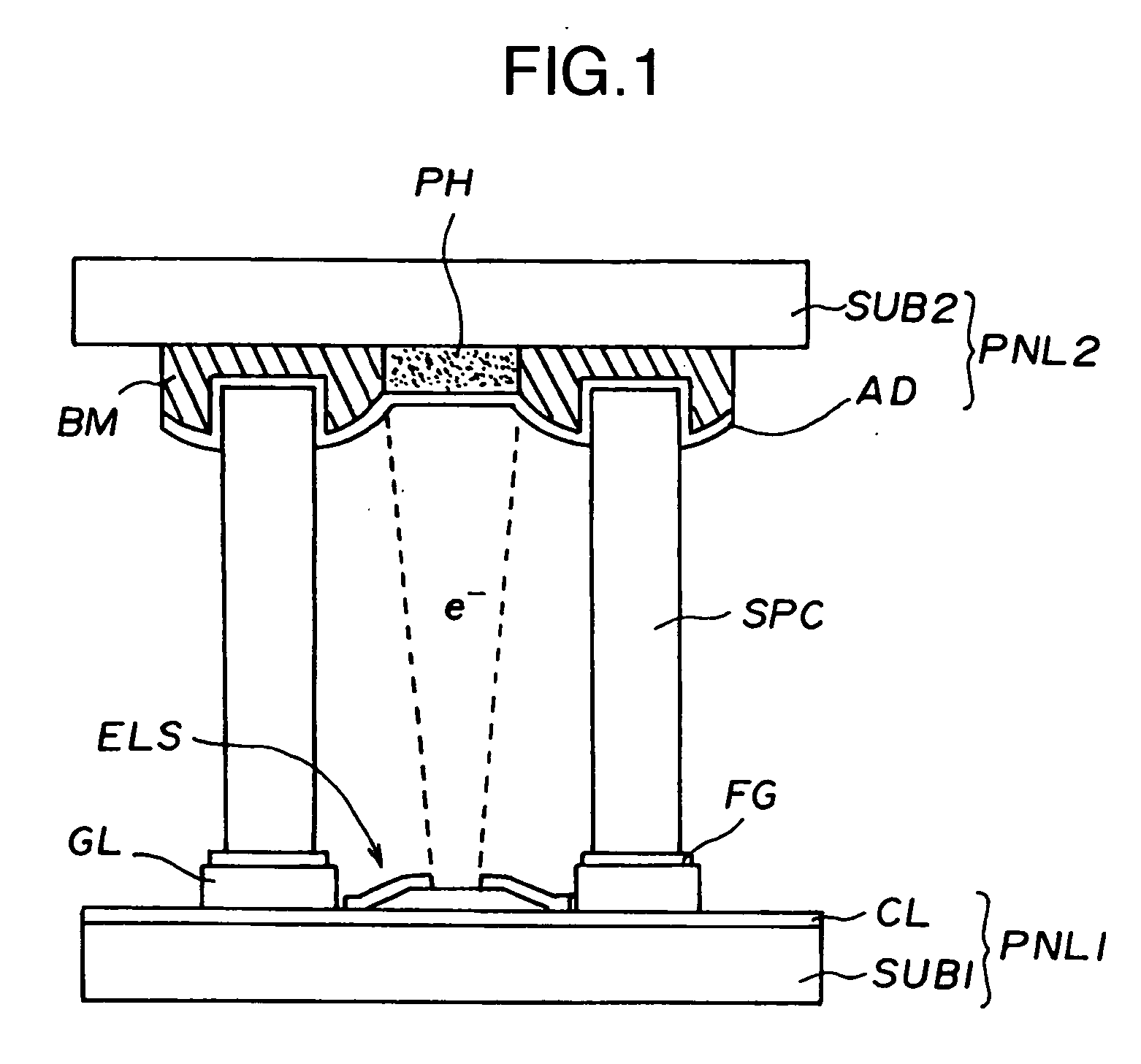

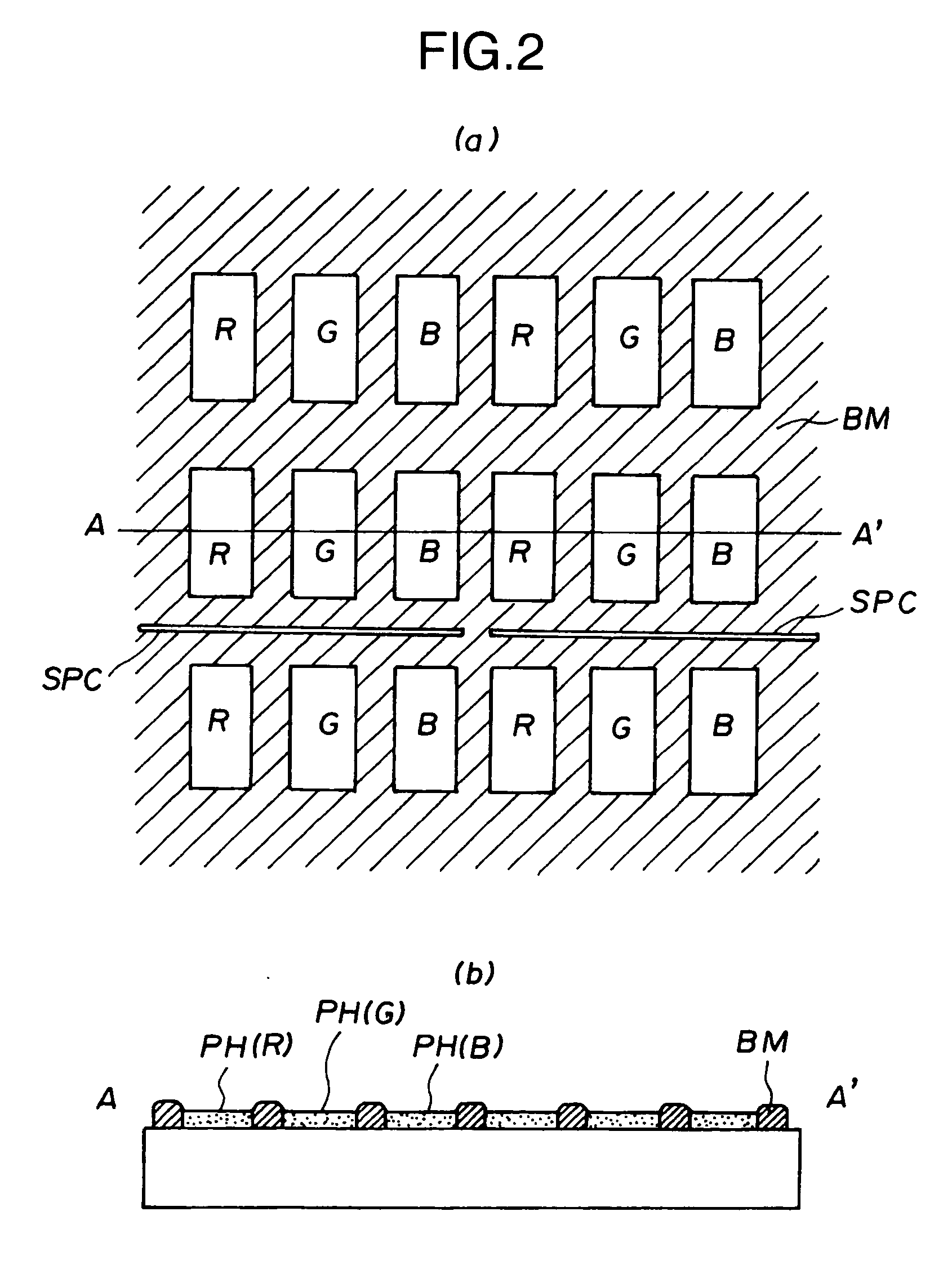

Display device

InactiveUS20070029920A1Inhibit deteriorationPrevent partial lowDischarge tube luminescnet screensCathode ray tubes/electron beam tubesDisplay deviceEngineering

It is an object to provide a high-quality display device which prevents deterioration of color purity by use of a black matrix whose openings have sufficiently high partitions by a simple procedure. The black matrix BM is formed using an electroconductive black glass, comprising a glass incorporated with a black additive and electroconductive filler. The glass is mainly composed of V2O5, SnO2, Bi2O3, Ag2O or a combination thereof.

Owner:JAPAN DISPLAY INC

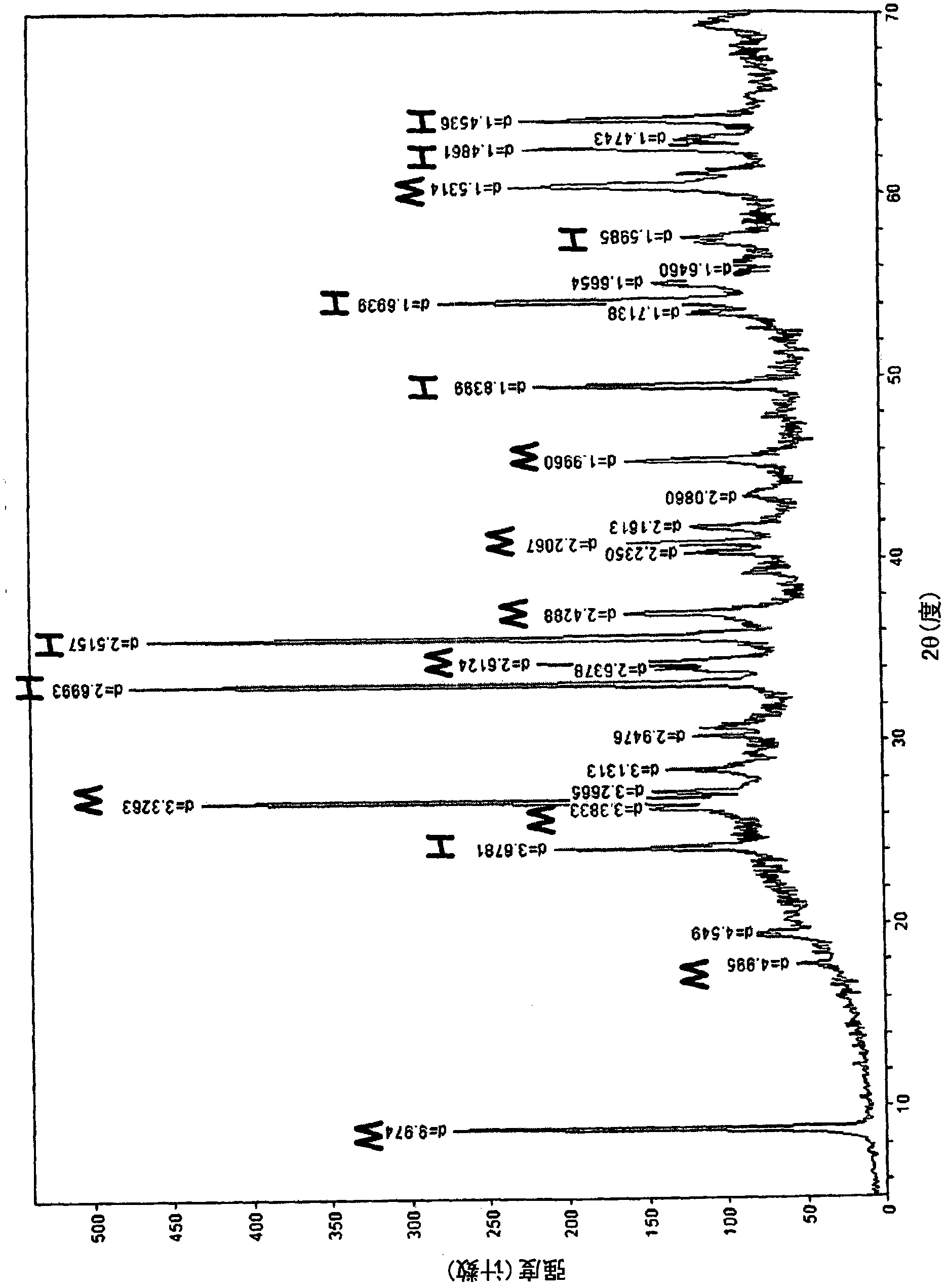

Manufacturing method for sparkling black glass

InactiveCN1583618APrevent color impurityMethod for making crystal black glass to prevent color impurityGlass furnace apparatusColoring agentsBlack glass

A black sparkling glass comprises: Fe2O3 0.13-0.20, NiO 0.15-0.19, CoO 0.014-0.019. It is produced by: melting stably at 1560-1570deg.c, removing carbon powder and having sal mirabile content<4%, and stirring mechanically. The method can be used to eliminate black strips and bubbles.

Owner:JINGNIU GLASS CERAMICS GROUP

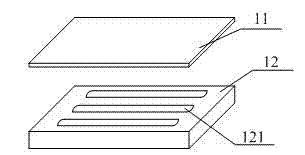

Sequencing reaction platform and nucleic acid sequence detection device

ActiveCN103087905ASimple structureEasy to useBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlNucleic acid sequencing

The invention relates to the field of gene sequencing, and provides a sequencing reaction platform and a nucleic acid sequence detection device. The sequencing reaction platform comprises a backlight sequencing reaction chamber which comprises a load sample and a first slide, wherein the upper surface of the load sample is contacted with the lower surface of the first slide, and at least one groove is formed on the load sample; each groove on the load sample and the first slide form a channel; and the first slide is the slide made of black glass. The nucleic acid sequence detection device comprises a temperature control device and a sequencing reaction platform which comprises the backlight sequencing reaction chamber. The sequencing reaction platform and the nucleic acid sequence detection device related by the invention are simple in structure and further convenient to use.

Owner:盛司潼

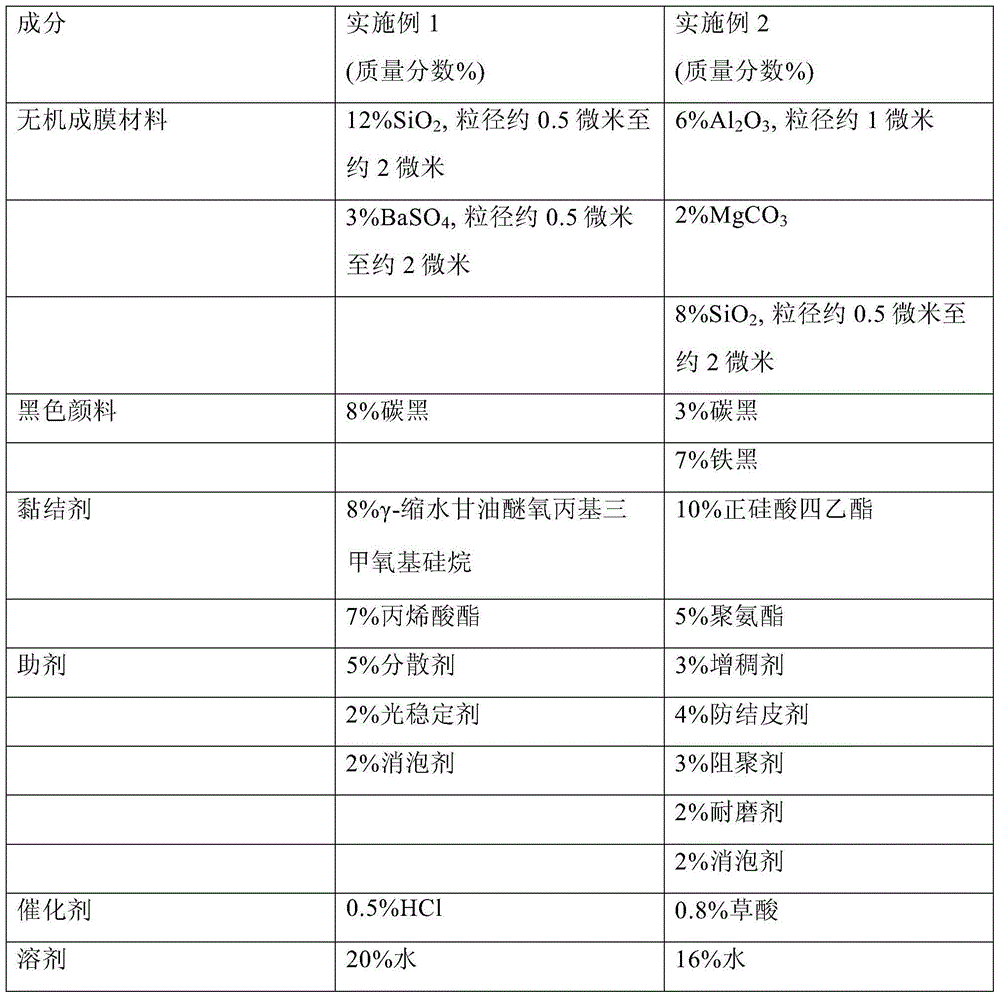

Black coated glass and solar battery assembly with black coated glass

The subject invention is related to a black glass and a solar cell assembly comprising the same. The subject invention provides a black glass comprising a glass substrate; and a black coating formed on the glass substrate, wherein the black coating comprises an inorganic film-forming material, a black pigment and an adhesive. The subject invention also provides a solar cell assembly comprising: a front glass substrate; the aforementioned black glass; and a photovoltaic cell sealed between the front glass substrate and the black glass. The black glass of the subject invention has a good thermal conductivity, waterproof performance, mechanical properties and weather resistance such that the black glass is not only aesthetically pleasing but also useful as a backside protection material of a solar cell assembly for long-term outdoor use.

Owner:CHANGZHOU ALMADEN

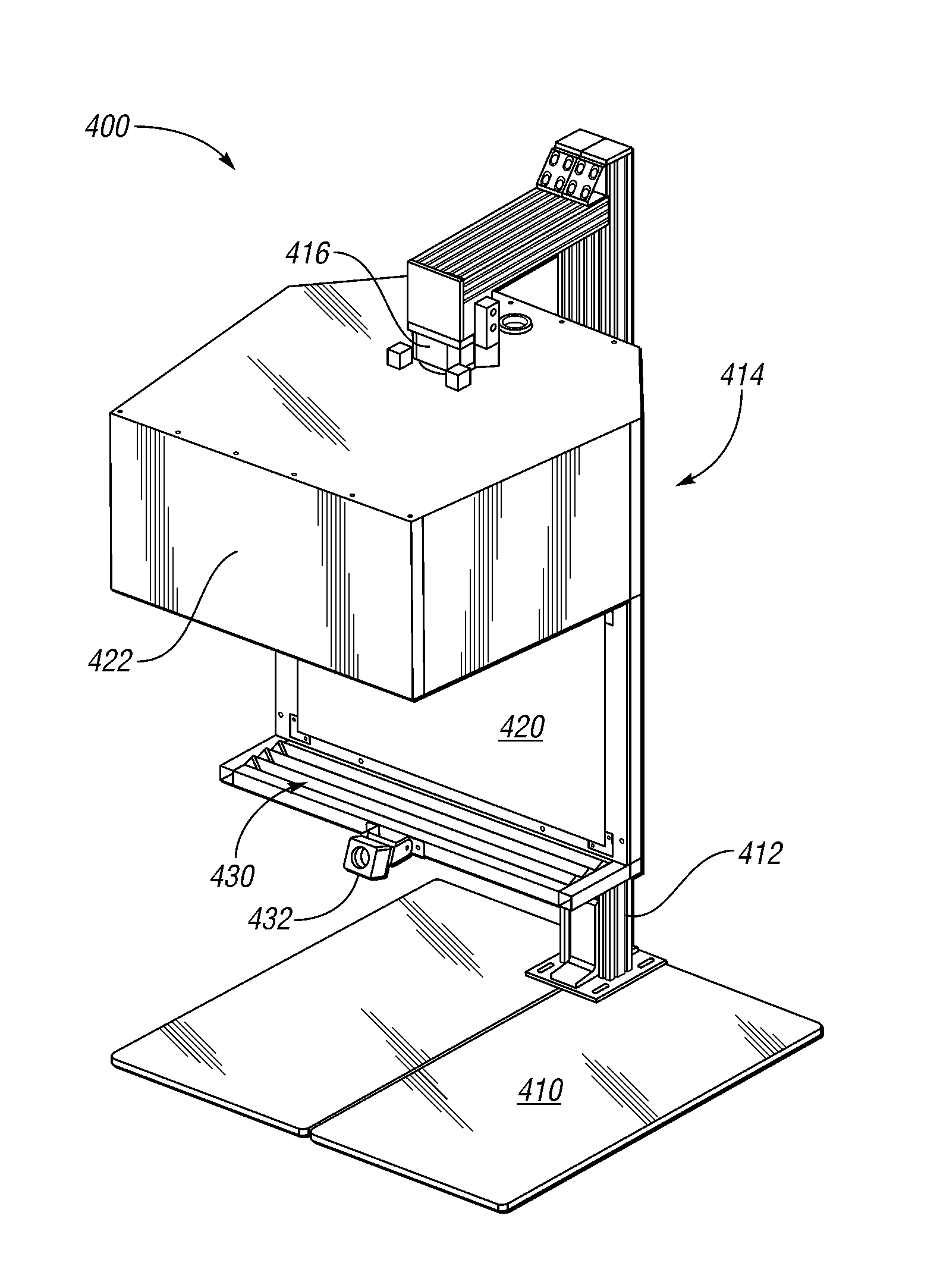

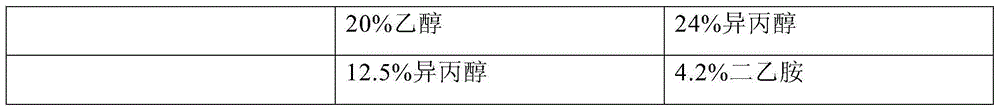

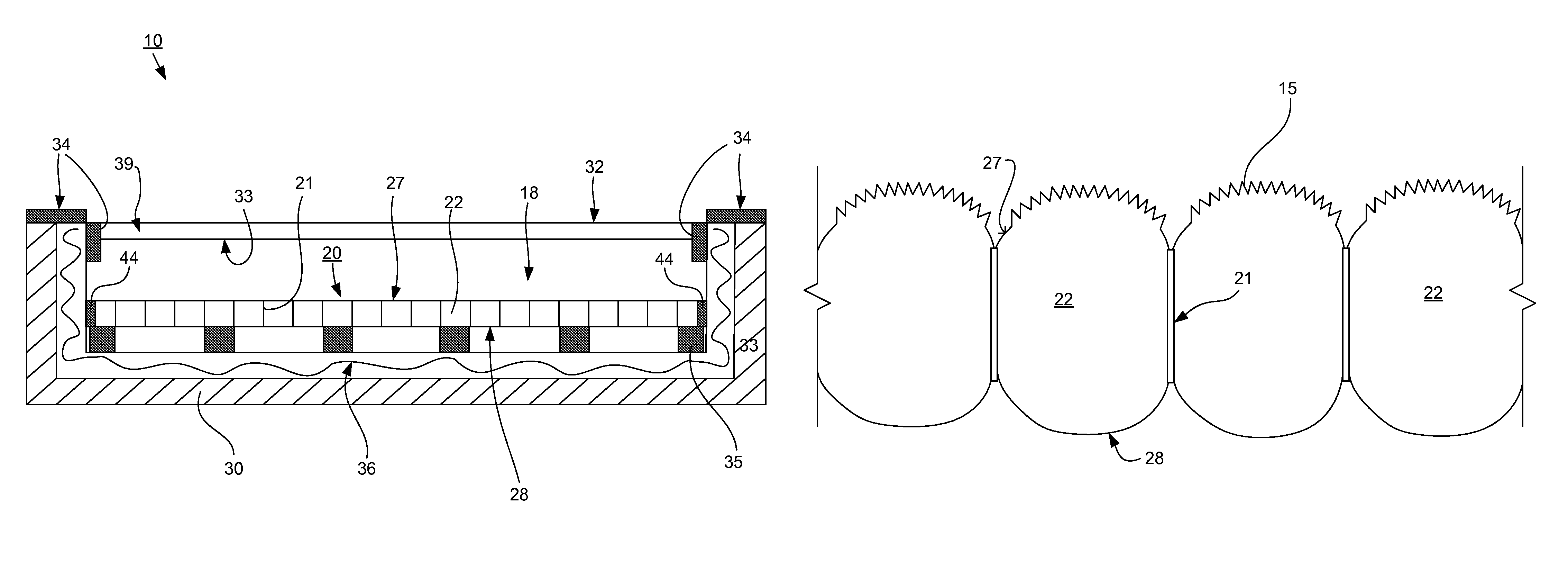

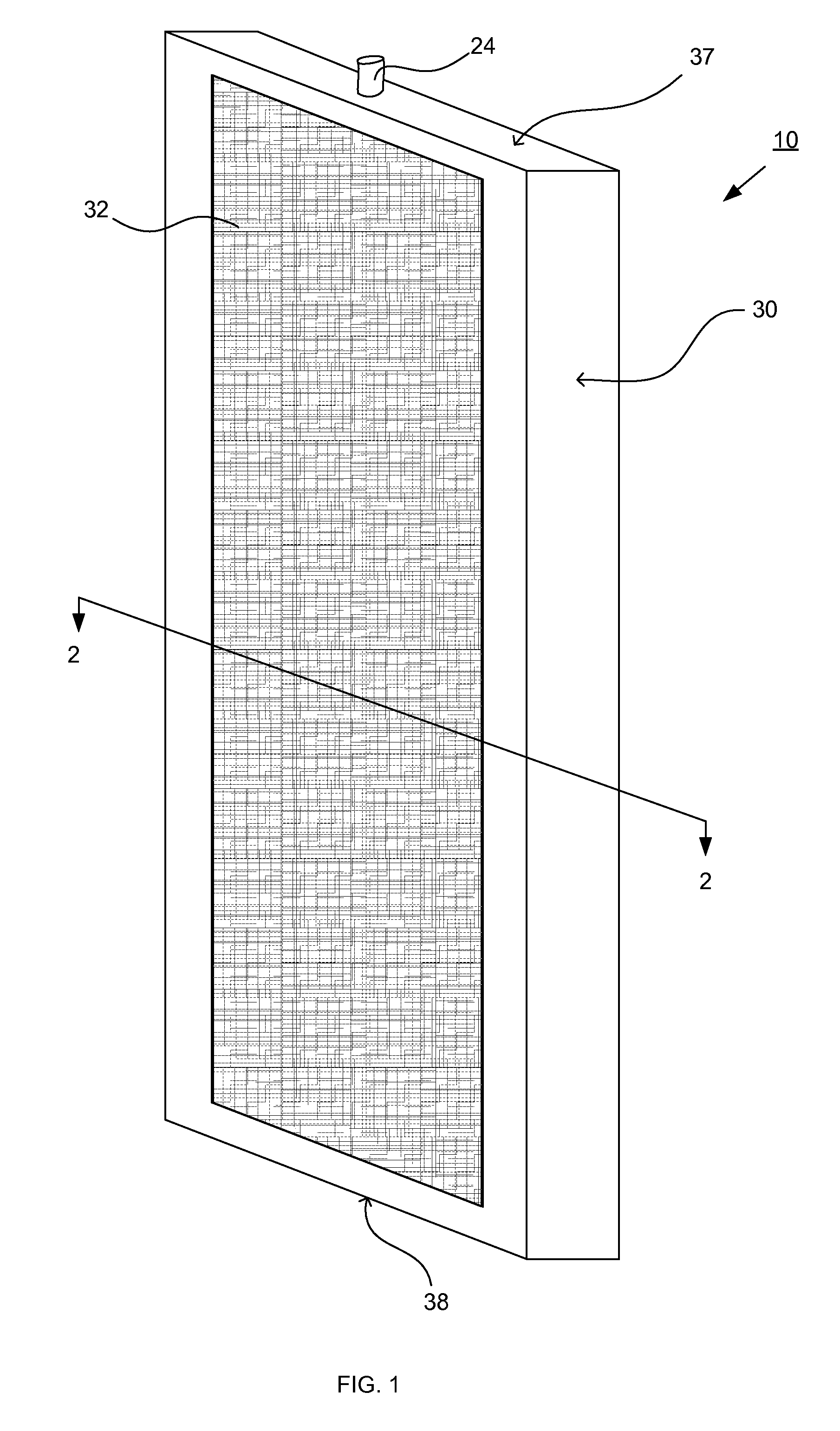

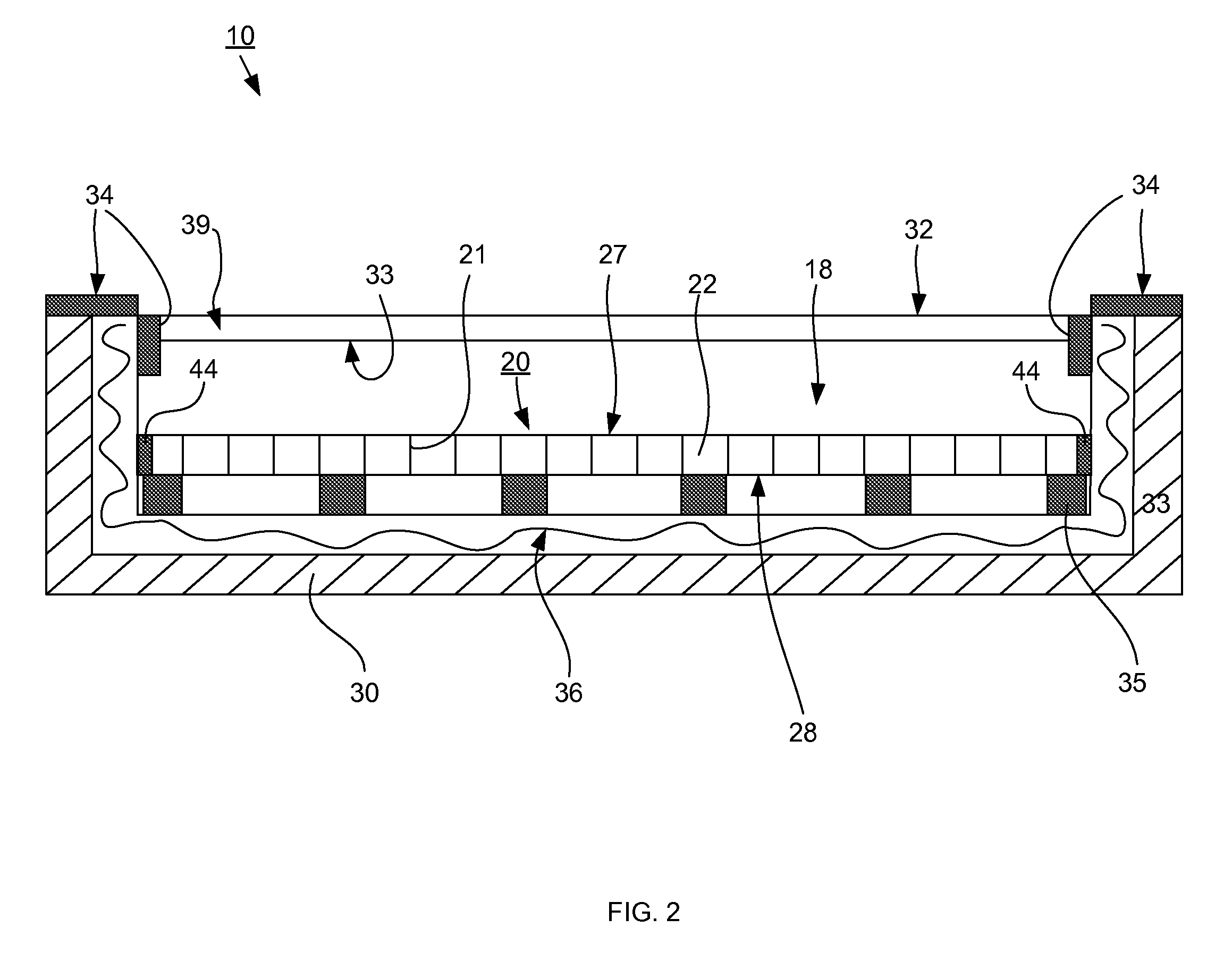

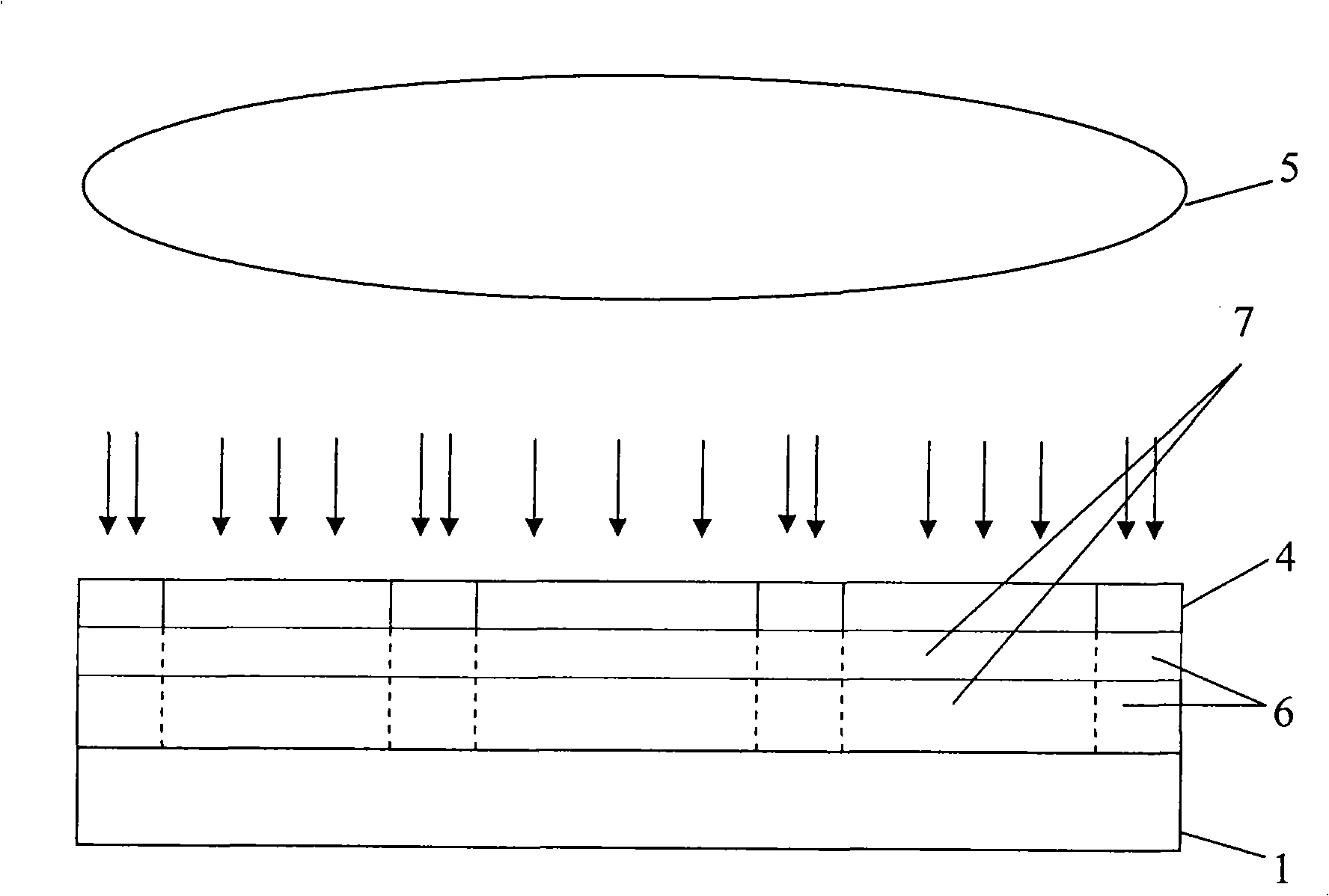

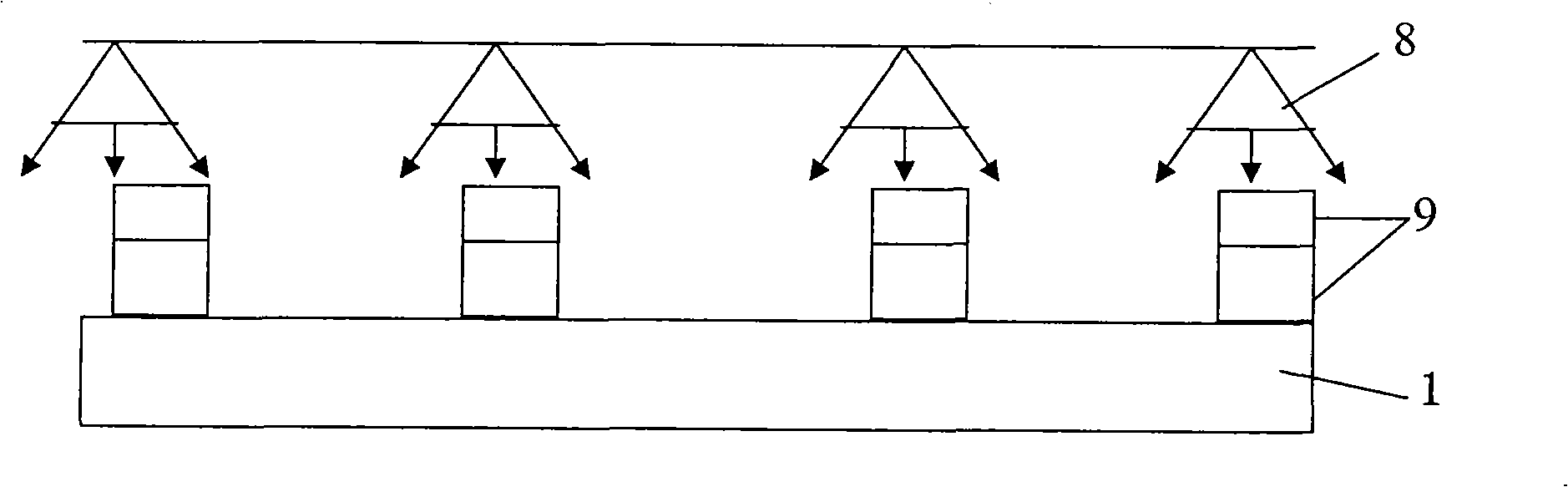

System for solar heating water using a glass absorber

InactiveUS20100132697A1Easy to installEasy to captureSolar heating energySolar heat devicesWater useEngineering

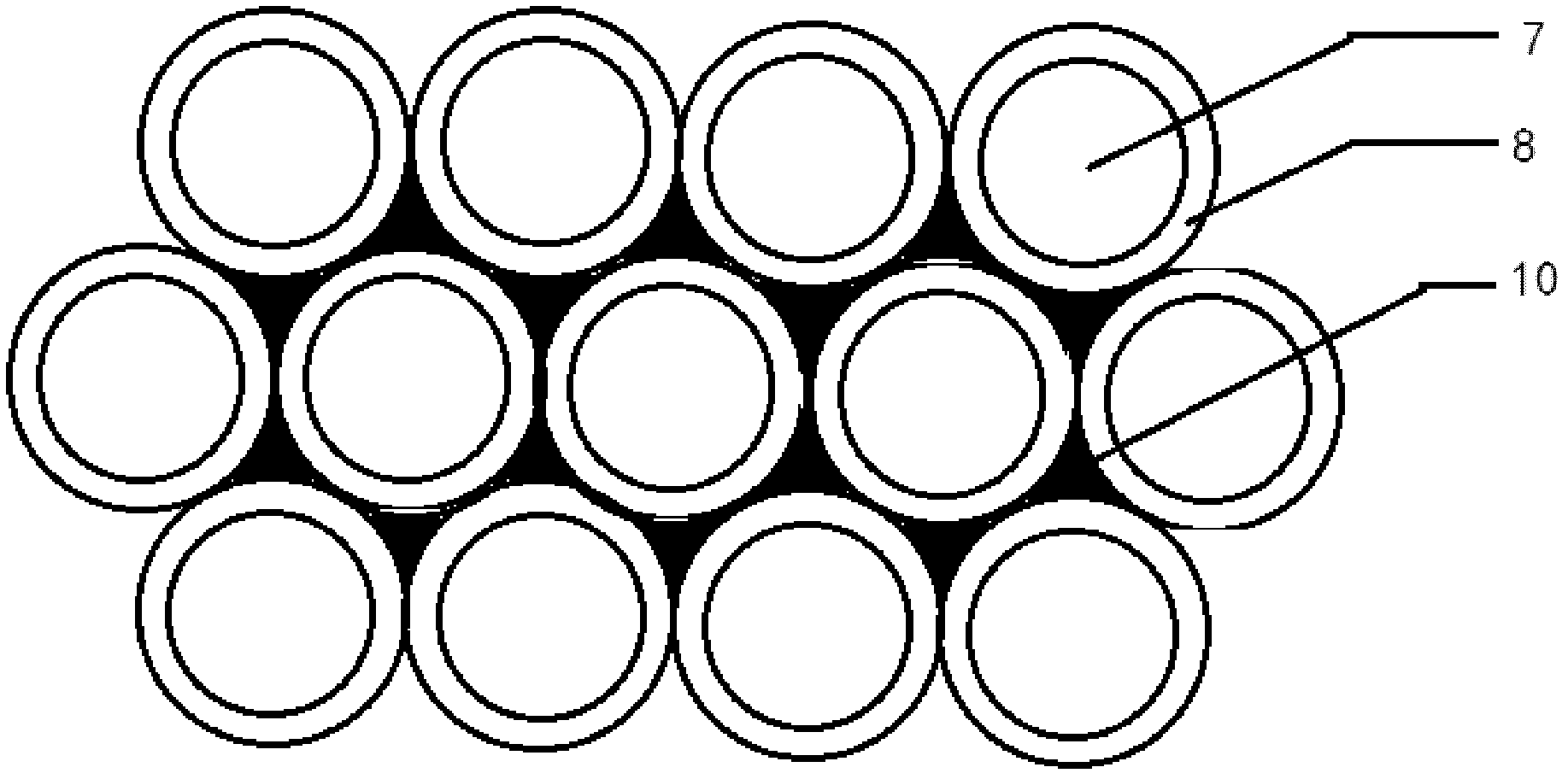

A system of passively heating water using solar energy and an absorber formed from two identical halves of molded darkened glass that are fused together. The absorber is essentially a plurality of black glass struts that are sandwiched between two black glass surfaces. The struts act as baffle plates and define cells. Water is carried through the system via the thermosiphoning effect.

Owner:MUELLER MARK A

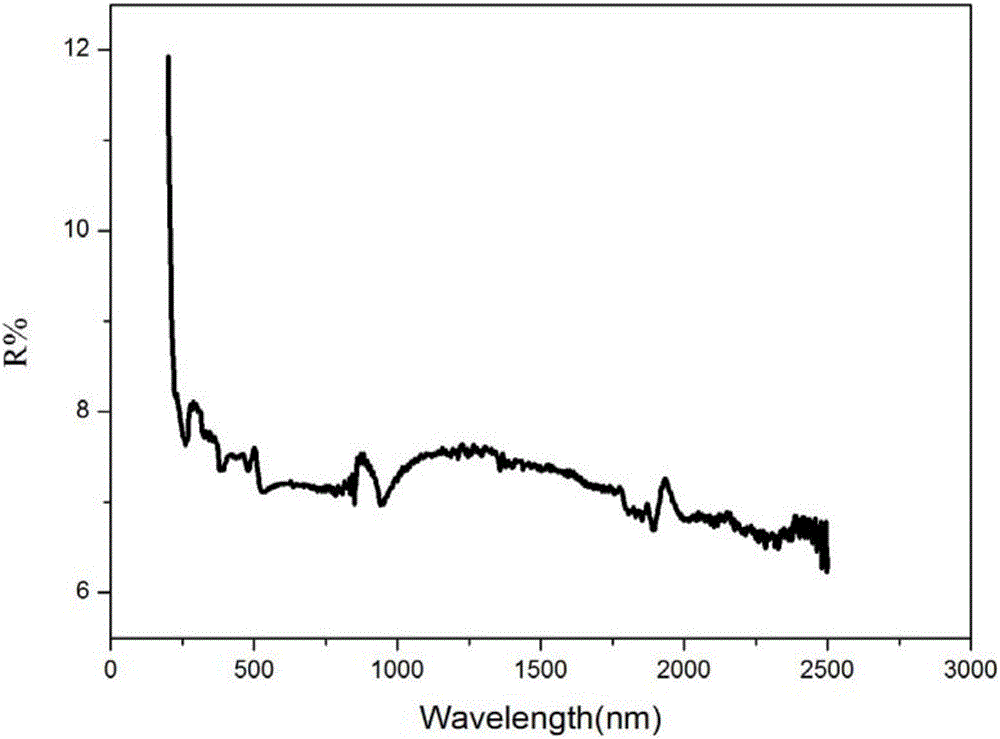

Wide-spectrum high-absorption-rate black glass and preparation method and application thereof

InactiveCN106242281AImprove absorption rateHigh light wave absorptionSolar heating energySolar heat devicesHigh absorptionAbsorption rate

The invention relates to wide-spectrum high-absorption-rate black glass and a preparation method and application thereof. The wide-spectrum high-absorption-rate black glass is prepared from the following raw materials in parts by weight: 40 to 60 parts of iron tailings, 5 to 15 parts of silicon dioxide, 2 to 5 parts of sodium carbonate, 5 to 10 parts of magnesium oxide, 10 to 20 parts of aluminum hydroxide, 0.5 to 1 part of sodium hexametaphosphate, 1 to 2 parts of potassium carbonate, 10 to 20 parts of calcium carbonate and 2 to 3 parts of titanium dioxide. The preparation steps include material proportioning, material mixing, high-temperature fusion, forming and annealing. Test results prove that the prepared black glass has the advantages that the folding resistance strength is great, and reaches 100 to 140 Mpa; a high light absorption rate is realized in the wide spectrum range of 250 nm to 2500 nm, and reaches 90 percent or higher; the black glass can be applied to the preparation of solar energy heat absorption materials, building heat insulation energy-saving materials and the like.

Owner:WUHAN UNIV OF TECH

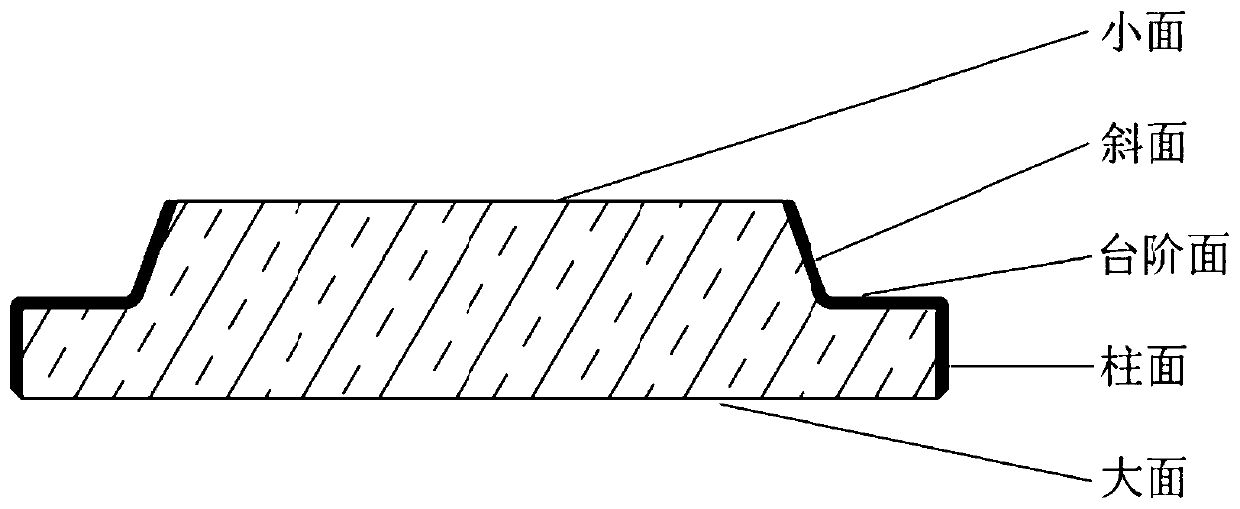

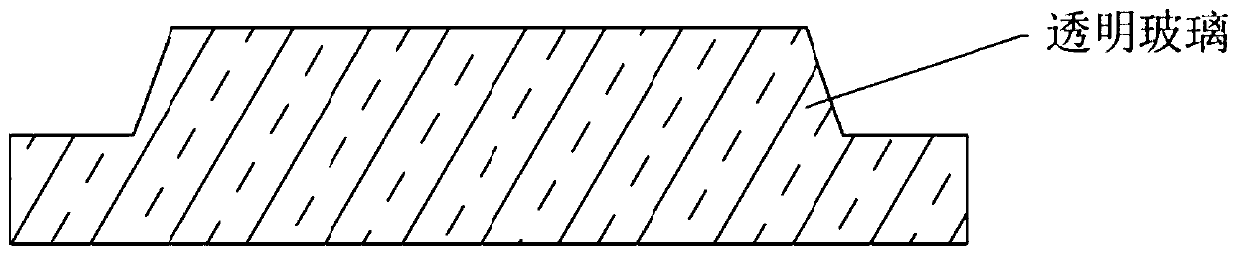

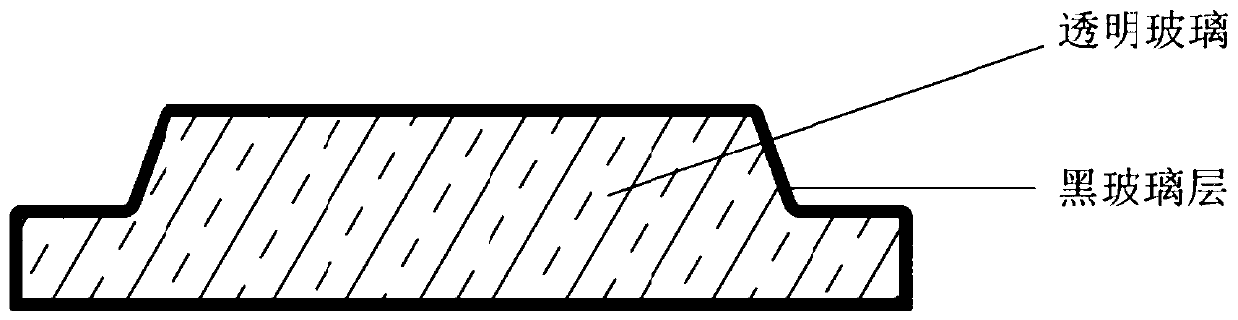

Fire-polishing blackening preparation method of anti-halation step-like glass

ActiveCN109704555AShort processing time for the preparation processImprove efficiencyRoom temperatureImpurity

The invention discloses a fire-polishing blackening preparation method of anti-halation step-like glass. The preparation method includes the steps of: 1) placing anti-halation step-like glass roughcast in a sealed furnace and feeding a reductive gas in a flowing manner of simultaneously feeding and discharging the gas; 2) heating the sealed furnace from room temperature to a preheating temperature, removing impurities of the anti-halation step-like glass roughcast, heating the roughcast to blackening temperature to blacken the roughcast, and heating the roughcast to a fire-polishing temperature to perform fire-polishing treatment. The preparation method is short in treatment time and high in efficiency. The black glass can achieve the polishing effect in finish degree without any treatment.

Owner:GUANGZHOU HONSUN OPTOELECTRONICS

System for solar heating water using a glass absorber

InactiveUS8381717B2Easy to installPromote sportsSolar heating energySolar heat devicesWater useEngineering

A system of passively heating water using solar energy and an absorber formed from two identical halves of molded darkened glass that are fused together. The absorber is essentially a plurality of black glass struts that are sandwiched between two black glass surfaces. The struts act as baffle plates and define cells. Water is carried through the system via the thermosiphoning effect.

Owner:MUELLER MARK A

Production method of shadow mask type plasma display board front plate metal electrode

InactiveCN101320665AReduce manufacturing costPrevent yellowing reactionCold cathode manufactureSlurryMetal electrodes

The invention discloses a manufacturing method for shadow mask type plasma display panel front substrate metal electrode, which takes general sodium-calcium glass as the shadow mask type plasma display board front substrate and black glass slurry excluding sliver particles as bottom layer isolating material to increase thickness of the black glass slurry coated on the glass substrate, to reduce sintering temperature of the electrode, and to prevent sliver irons from dispersing into the glass substrate and reacting with elements like Na, K and so on in the process of sintering, thus reaching the effect of etiolation of the panel, in the meantime, the shadow mask type plasma display panel front substrate metal electrode whose parameters like size, shape and resistance meet the design requirement is obtained. The invention replaces PD200 glass with higher price and special for the plasma display panel by the general sodium-calcium glass and replaces the black glass slurry comprising silver by the black glass slurry excluding the sliver particles, which are both beneficial for lowering the manufacturing cost of the shadow mask type plasma display panel front substrate metal electrode. The invention uses the black glass slurry as the bottom layer isolating material to promote contrast grade of the shadow mask type plasma display panel and intensify adhesive force between the electrode and the glass substrate.

Owner:NANJING HUAXIAN HIGH TECH CO LTD

Lamp holder and manufacturing method therefor

ActiveCN101364528APrevent looseningInhibit sheddingElectric discharge tubesElectric discharge lampsLight headCopper

The invention discloses a lamp cap and a manufacturing method thereof. The lamp cap comprises a shell body and a pin connected with the shell body as a whole structure; the pin is a cylindrical cavity with the diameter being 2mm and the protruding height being 2.3mm; black glass is filled in the cylindrical cavity; the shell body and the pin are made of copper, aluminum or steel. The manufacturing method comprises the steps of using a pressing machine to press the material into the shell body; extruding the shell body through an extruder to form a pin structure; placing an electric contact piece; and pouring the black glass to enable the black glass to be filled in the pin. The lamp cap can effectively avoid the loosening and falling-off of the pin, and the safety is high.

Owner:江西晨航照明科技有限公司

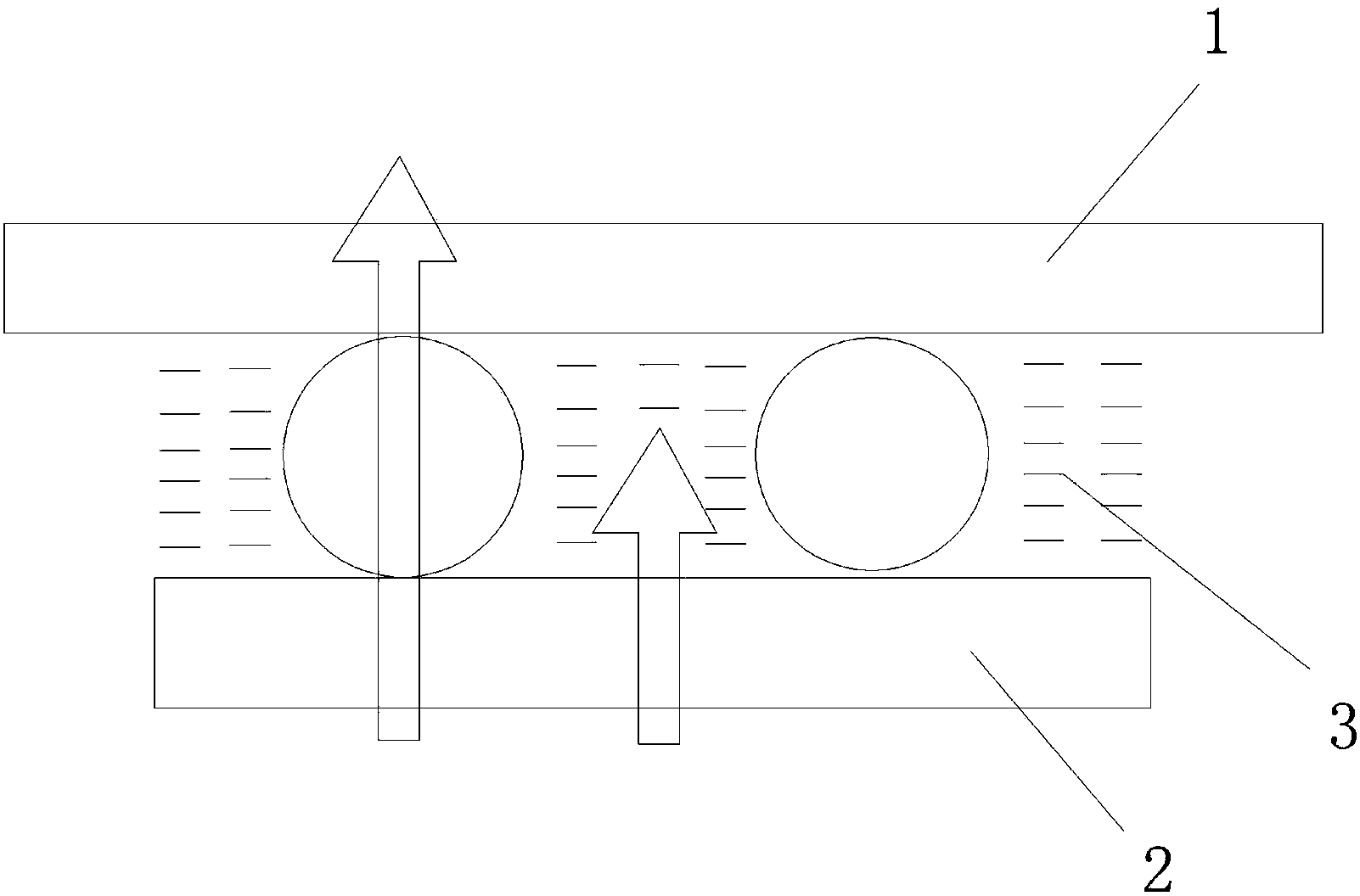

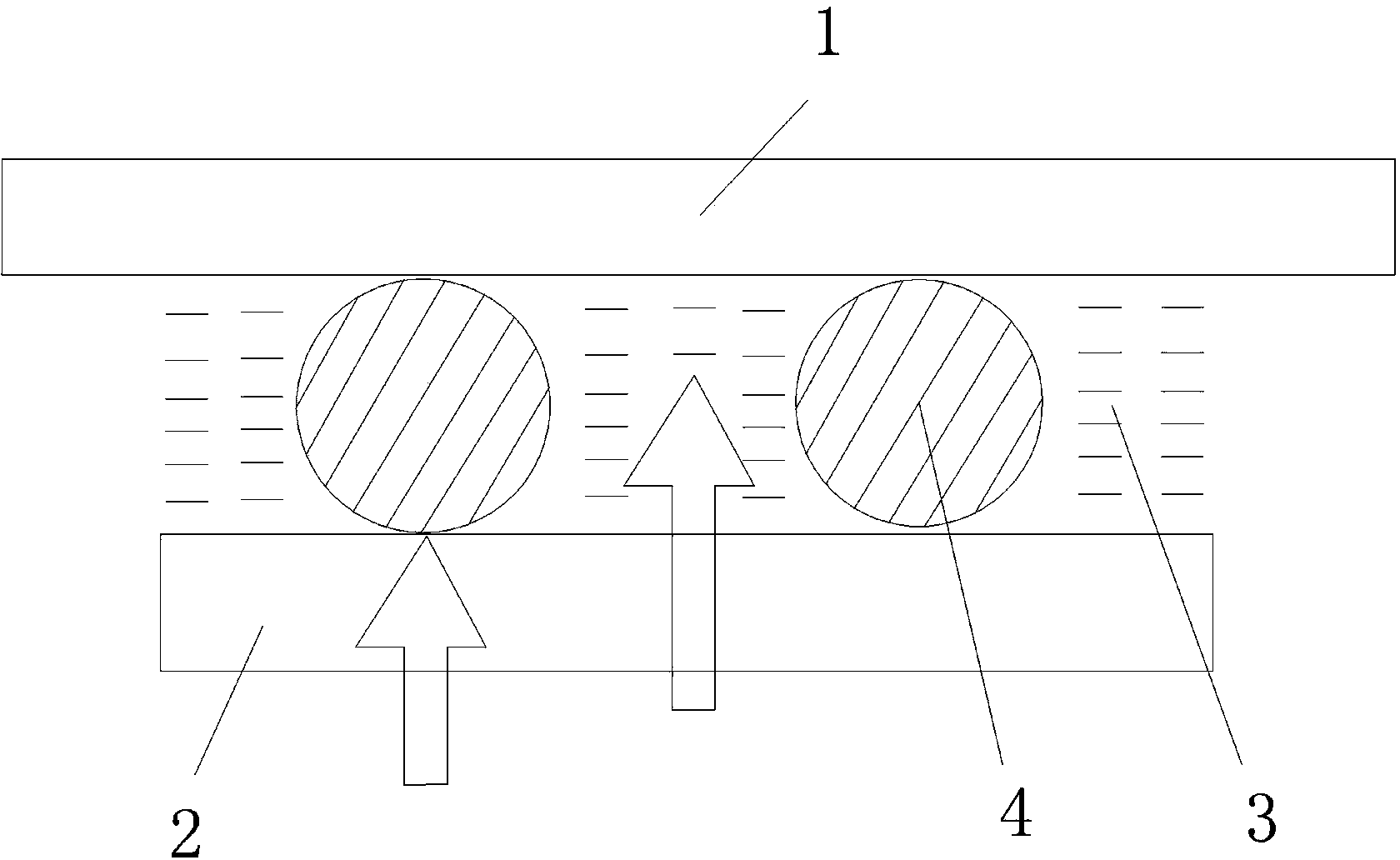

Anti-light-leakage and high-contrast liquid crystal display structure and display method thereof

The invention provides an anti-light-leakage and high-contrast liquid crystal display structure and display method thereof. The anti-light-leakage and high-contrast liquid crystal display structure comprises an upper polarizer, a lower polarizer and a liquid crystal layer clamped between the upper polarizer and the lower polarizer. A plurality of glass beads are placed on the liquid crystal layer. The glass beads are lighttight. The glass beads bear the upper polarizer and the lower polarizer and stops light from leaking outwardly at the positions of the glass beads. The invention further provides a display method using the display structure. Due to the fact that the glass beads are black and lighttight, when people watch a screen, white light generates linear amplification at nerve cells, the edges of the black points are dimmed by the surrounding white light, compared with white light-permeable glass beads, the displayed black points look smaller by visual effects in coordination with the black glass beads, overall definition is enhanced, and speckles are few.

Owner:东莞通华液晶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com