Black glass fiber reinforced polypropylene composite and preparation method and application of same

A composite material and polypropylene technology, which is applied in the field of black glass fiber reinforced polypropylene composite material and its preparation, can solve the problems of reducing product competitiveness and increasing product cost, and achieves improvement of thermal oxygen aging performance, reduction of product cost, The effect of reduced tint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

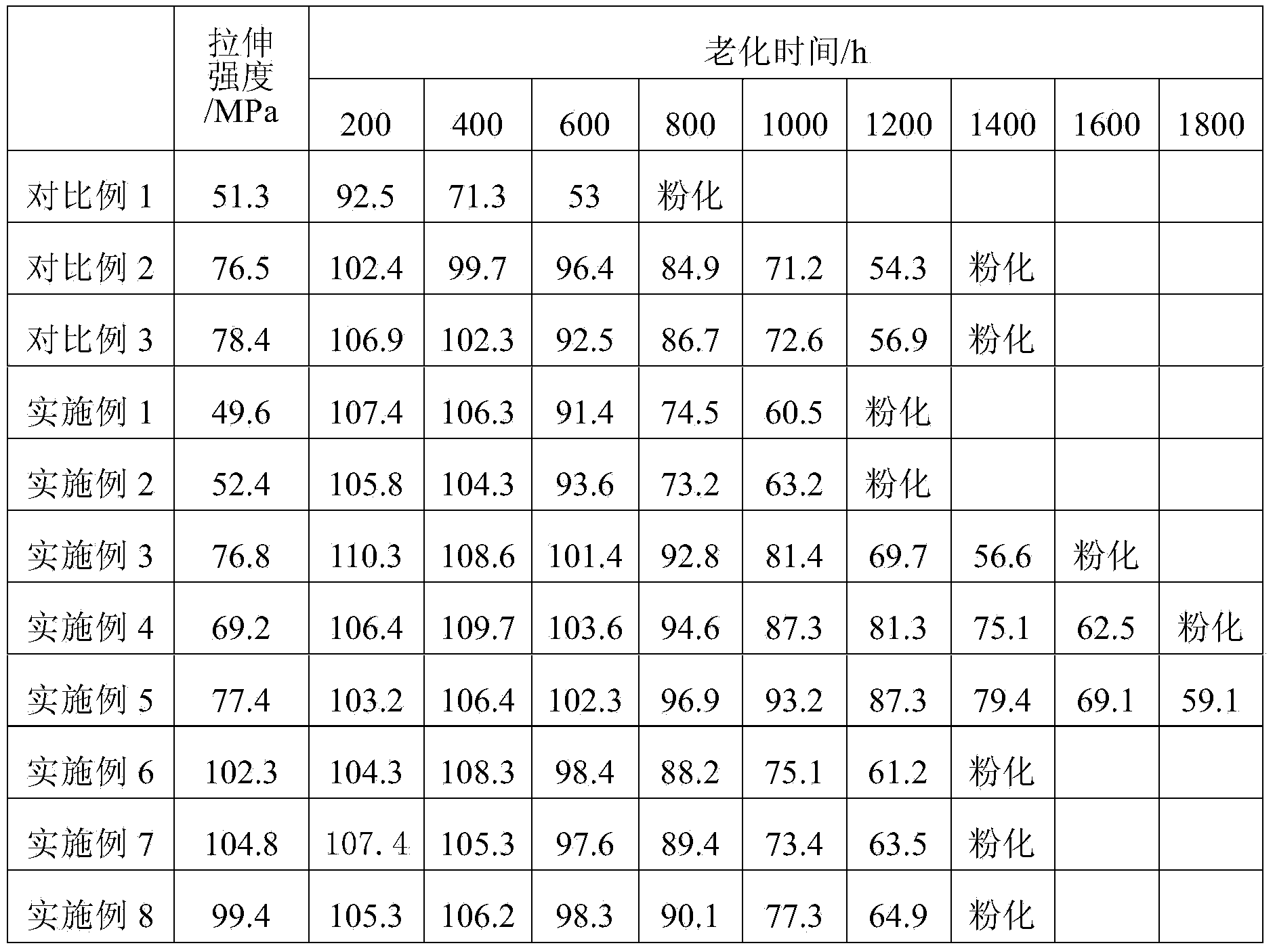

[0046] Embodiment 1: Preparation of black glass fiber reinforced polypropylene composite material

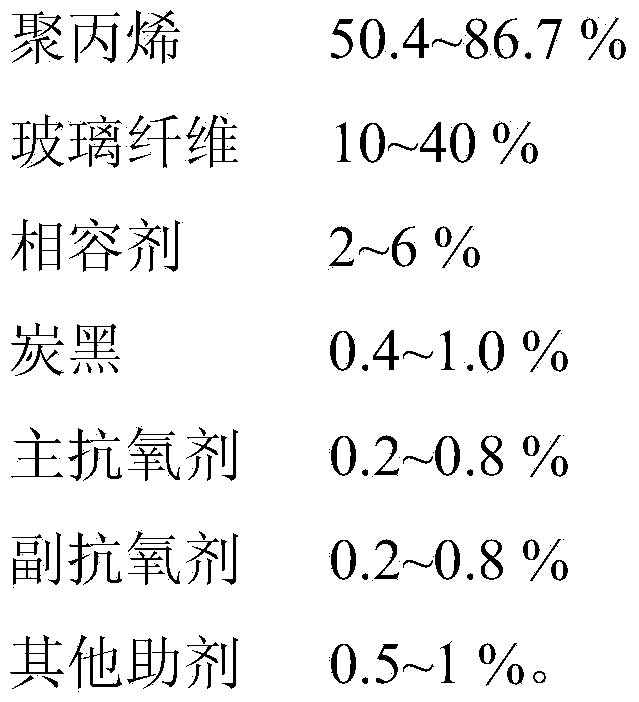

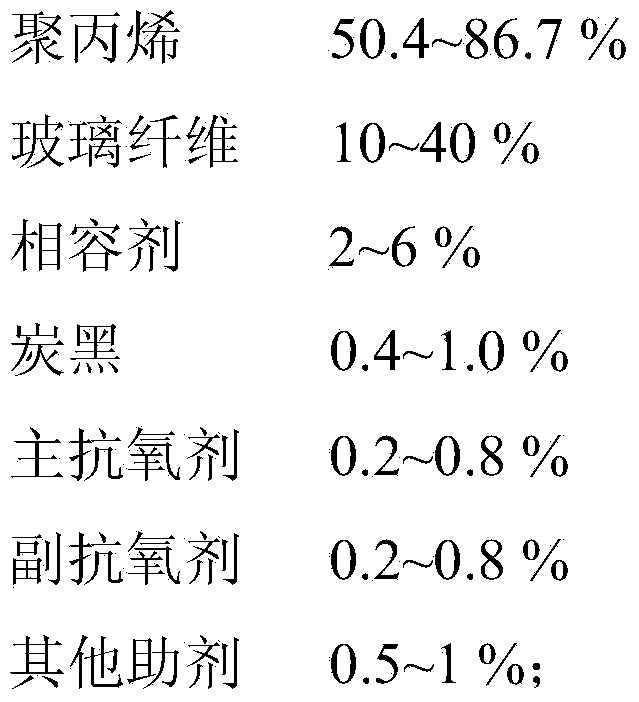

[0047] It is composed of the following raw materials in weight percentage: polypropylene (PP HP500N, melt index 12g / 10min, CNOOC Shell Petrochemical Co., Ltd.) 86.5%; glass fiber 10%; compatibilizer (Orevac CA100, Arkema) 2% ; carbon black 0.4%; primary antioxidant additives 0.2%; secondary antioxidant 0.2%, other additives 0.7%.

[0048] The carbon black is N330 (iodine absorption value 82mg / g); the main antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant Agent 1010), the secondary antioxidant is dioctadecyl thiodipropionate (DSTP); the other additives are 0.5% ethylene bisstearamide, stearic acid Calcium 0.2%.

[0049] The preparation steps are as follows: the polypropylene, compatibilizer, carbon black, antioxidant, and other additives are uniformly mixed by a high mixer, and then passed into the extrusion through the...

Embodiment 2

[0050] Embodiment 2: Preparation of black glass fiber reinforced polypropylene composite material

[0051] It is composed of the following raw materials in weight percentage: polypropylene (PP N-Z30S, melt index 25g / 10min, Maoming Petrochemical) 86%; glass fiber (ECS13-04-508A, diameter 13μm, Jushi Group) 10%; compatible agent (Orevac CA100, Arkema) 2%; carbon black 0.6%; primary antioxidant additives 0.4%; secondary antioxidant 0.2%, other additives 0.8%.

[0052] The carbon black is N330 (iodine absorption value 82mg / g); the main antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant agent 1010), the secondary antioxidant is tris[2,4-di-tert-butylphenyl] phosphite (antioxidant 168); the other additives are 0.5% ethylene bisstearamide, light Stabilizer (T81, Beijing Tiangang Auxiliary Co., Ltd.) 0.3%.

[0053] The preparation steps are as follows: the polypropylene, compatibilizer, carbon black, antioxidant, and other ad...

Embodiment 3

[0054] Embodiment 3: Preparation of black glass fiber reinforced polypropylene composite material

[0055] It is composed of the following raw materials in weight percentage: polypropylene (PP N-Z30S, melt index 25g / 10min, Maoming Petrochemical) 72.8%; glass fiber (ECS13-04-508A, diameter 13μm, Jushi Group) 20%; compatible agent (Orevac CA100, Arkema) 4%; carbon black 0.6%; primary antioxidant additives 0.8%; secondary antioxidant 0.8%, other additives 1%.

[0056] The carbon black is N220 (iodine absorption value 121mg / g); the main antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant Agent 1010), the secondary antioxidant is dioctadecyl thiodipropionate (DSTP); the other additives are 0.5% ethylene bisstearamide, stearic acid Calcium 0.2%, light stabilizer (81, Beijing Tiangang Auxiliary Co., Ltd.) 0.3%.

[0057] The preparation steps are as follows: the polypropylene, compatibilizer, carbon black, antioxidant, and oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com