Patents

Literature

584results about How to "Improve aging performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Expansion flame-proof organosilicon fluid sealant and method of producing the same

InactiveCN101368080AEnsure the safety of personnel and propertyGood fire performanceOther chemical processesAdhesivesOrganosiliconPlasticizer

The invention relates to an expansion flame retardant organosilicon sealant and a manufacturing method thereof. The sealant comprises the following components by weight portion: 100 portions of Alpha, Omega-dihydroxyl polysiloxane; 5 to 30 portions of plasticizer; 20 to 100 portions of filler; 50 to 150 portions of inorganic flame retardant; 5 to 30 portions of expansion fire retardant; 1 to 30 portions of cross-linking agent; 0.1 to 1 portion of catalyzer; 1 to 5 portions of viscosity increaser and 0.1 to 5 portions of inorganic pigment. The manufacturing method comprises the following steps: the Alpha, Omega-dihydroxyl polysiloxane, the filler, the inorganic flame retardant and the expansion fire retardant are dehydrated at 80 to 150 DEG C in a vacuum triple motion agitator, and are mixed for 0.5 to 2 hours before the mixture is cooled to the room temperature; the silane cross-linking agent, the viscosity increaser, the catalyzer and the plasticizer are added and mixed for 0.5 to 2 hours. The expansion flame retardant organosilicon sealant has excellent mechanical property, fire retardancy, adhesion and storage stability, which is primarily used as a sealant in devices that cables are threaded through on watercrafts as well as used for closing off various openings formed in the way that cables, air conduits, oil tubes and so on pass through walls, bulkheads, floor slabs, decks and so on in buildings or power supply systems.

Owner:陈栋梁 +1

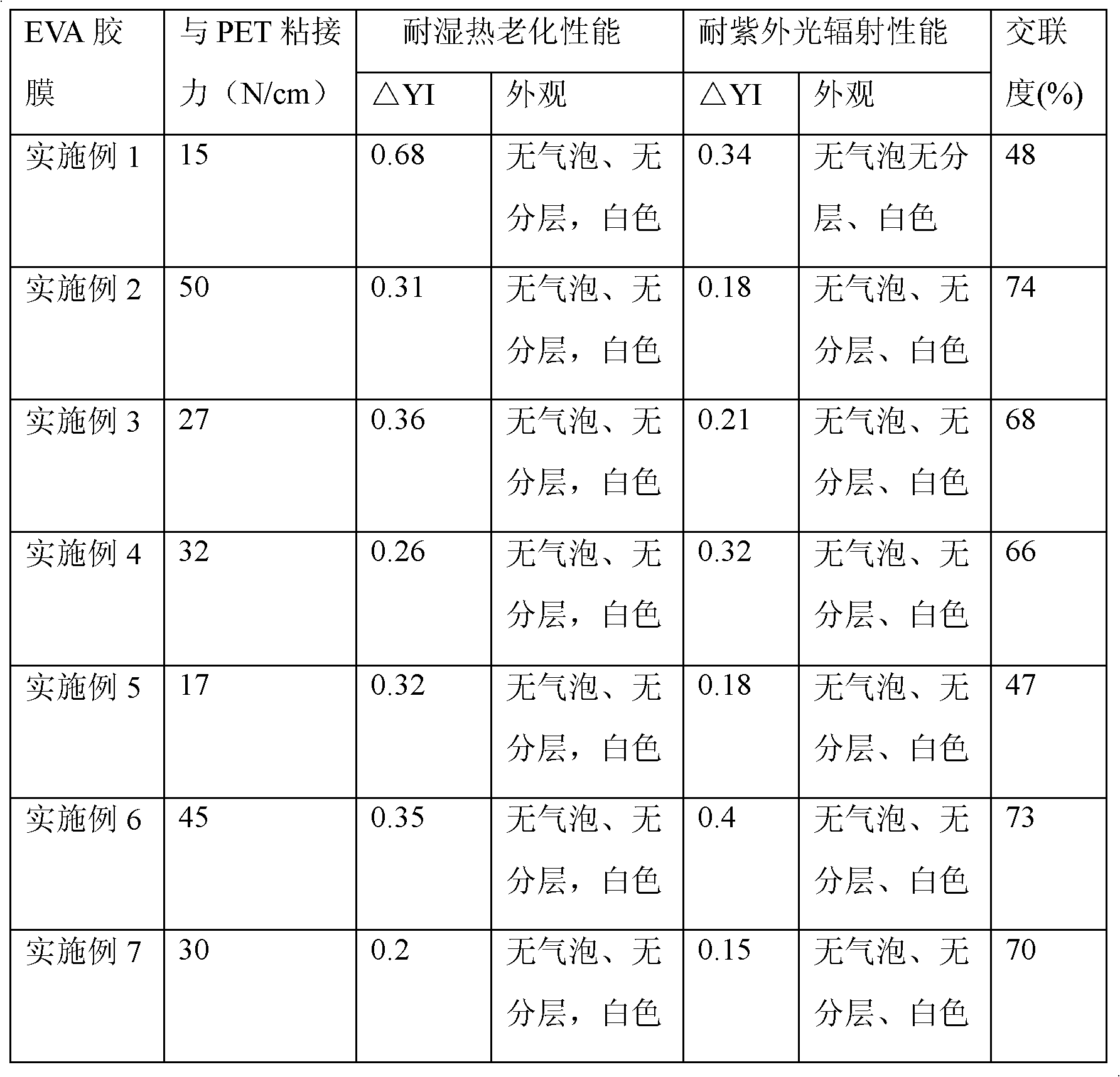

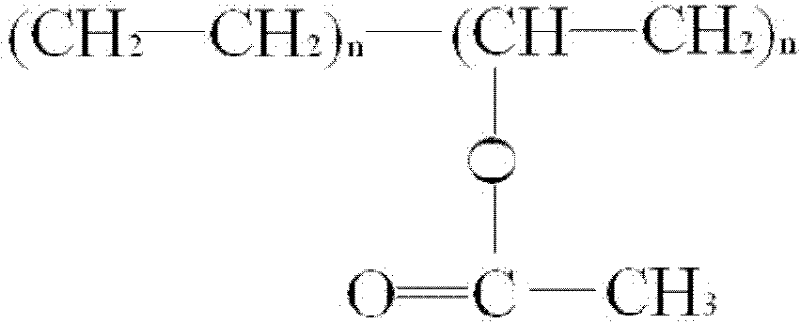

Solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging

InactiveCN101626039AIncrease crosslink densityModerate reaction temperatureElectrical equipmentGlass/slag layered productsAntioxidantPhosphate

The invention relates to a solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging, which comprises the following materials by weight portions: 100 portions of copolymer of ethylene vinyl acetate, 0.8-1.4 portions of crosslink curing agent, 0.05-0.15 portion of crosslink curing accelerator, 0.2-0.6 portion of tackifier, 0.1-0.5 portion of antioxidant, 0.05-0.25 portion of ultraviolet light stabilizer and 0.1-0.3 portion of ultraviolet light absorbent, wherein the crosslink curing agent is tert butyl peroxy 2-ethyl hexyl carbonate; the crosslink curing accelerator is triallyl isocyanurate; the tackifier is r-glycidyl ether oxy-propylltrimethoxysilane; the antioxidant is one or two selected from the group consisting of bis(2,4-dicumylphenyl)pentaerythritol diphosphite, distearyl pentaerythritol diphosphite, tris(nonyl phenyl)phosphate and tris(2,4-butylphenyl)phosphate; and ultraviolet light absorbent is gas phase silicon dioxide. The solar cell packaging EVA adhesive film can resist high temperature of 85 DEG C, humidity of 85 percent, ultraviolet light and thermal oxidative aging.

Owner:苏州爱康商务咨询服务有限公司

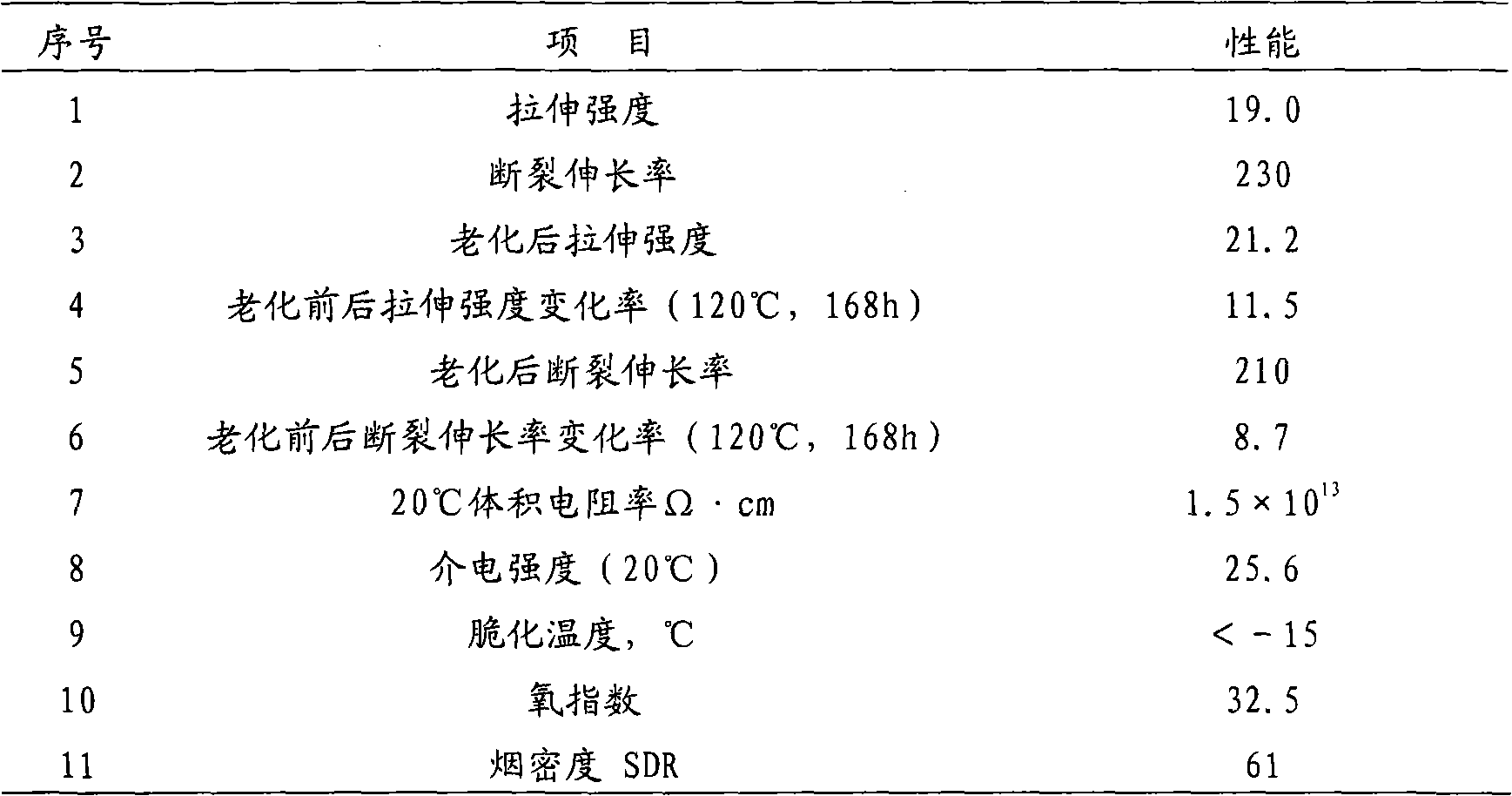

Silane cross-linked polyethylene insulating material and production method thereof

InactiveCN102532664AEvenly dispersedIncrease the degree of cross-linkingPlastic/resin/waxes insulatorsSilanesAntioxidant

The invention provides a silane cross-linked polyethylene insulating material composition, which comprises a material A and a material B, wherein the material A is composed of the following components in parts by weight: 100 parts of polyethylene, 0.01-1 parts of initiator, 0.2-5 parts of silane cross-linking agent, and 0.1-0.5 parts of antioxidant; the material B is composed of the following components in parts by weight: 100 parts of polyethylene, 0.5-5 parts of catalyst, 0.01-5 parts of processing aid, and 0.1-0.5 parts of antioxidant; and the material A is mixed and extruded by a reciprocating single-screw extruder.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI

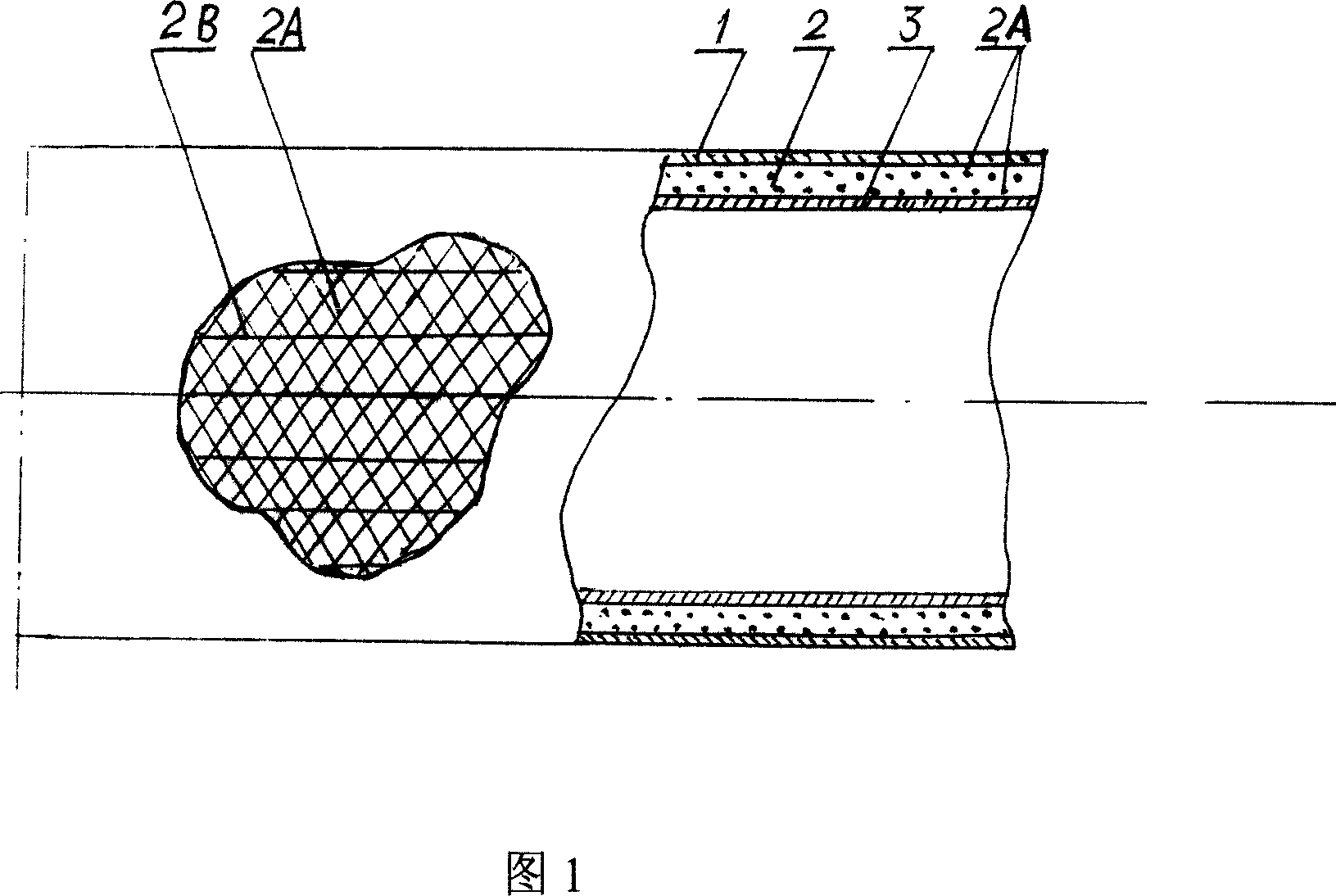

Plant root proof roof covering plant water-proof coiled material and producing method thereof

InactiveCN101100889AReduce construction costsHigh strengthOther chemical processesRoof covering using flexible materialsBituminous waterproofingPlant root

A water proof coil material of good plant piercing resistance is made by a modified asphalt water proof layer and polymer sheet with texture. The polymer sheet is stick to polymer cement gel. The modified asphalt layer is of good resistance of aging and crake. The polymer sheet is covered by texture on one or both sides.

Owner:莫方强

Halogen-free flame retardant thermoplastic compositions for wire and cable applications

ActiveUS20120261163A1Maintain good propertiesIncrease resistancePlastic/resin/waxes insulatorsInsulated cablesThermoplastic elastomerNitrogen

Disclosed is a halogen-free, flame retardant thermoplastic resin composition based on polypropylene and one or more thermoplastic elastomers with an organic nitrogen- and / or phosphorus-based intumescent flame retardant comprising a piperazine component. The composition is processed easily to make a wire and cable sheath exhibiting a balance of high flame retardancy, good flexibility, high wet electrical resistance and excellent heat deformation properties, and which passes the VW-I flame retardancy test, the UL1581 heat deformation test at 150° C. and the wet electrical resistance test, and also exhibits good tensile and flexibility properties. Also disclosed is a wire and cable sheath made from the composition.

Owner:DOW GLOBAL TECH LLC

Silicone hydride crosslinked non-halogen flame-proof smoke-restraining polyvinyl chloride cable material and manufacturing process thereof

InactiveCN101319079AEasy to processPromote degradationInsulated cablesInsulated conductorsPolyvinyl chlorideFire retardant

The invention discloses a silane crosslinking HFFR flame retardant polyvinyl chloride cable material and a preparation technique thereof. The compositions by weight portion of the cable material are: 100 portions of polyvinyl chloride resin, 10 to 100 portions of a plasticizer, 0.5 to 10 portions of a silane cross-linking agent, 0.5 to 6 portions of a heat stabilizer, 30 to 100 portions of a metal hydroxide flame retardant, 1 to 10 portions of a metallic compound flame retardant synergist, 0.1 to 5 portions of a preventing cross-linking agent, 0.1 to 5 portions of a lubricant, 0.1 to 0.5 portion of an antioxidizer, 0.05 to 0.1 portion of dibutyl tin dilaurate and appropriate amount of a colorant. The cable material has the characteristics that the mechanical property is good, the mechanical intensity is increased by 20 to 30 percent compared with the uncrosslinked PVC cable material, the heat resistance is good, the electrical property is good, the specific volume resistance is increased by 3 to 5 times compared with the uncrosslinked PVC cable material, the insulating property of the cable is improved and the aging property is good.

Owner:LIAOCHENG UNIV

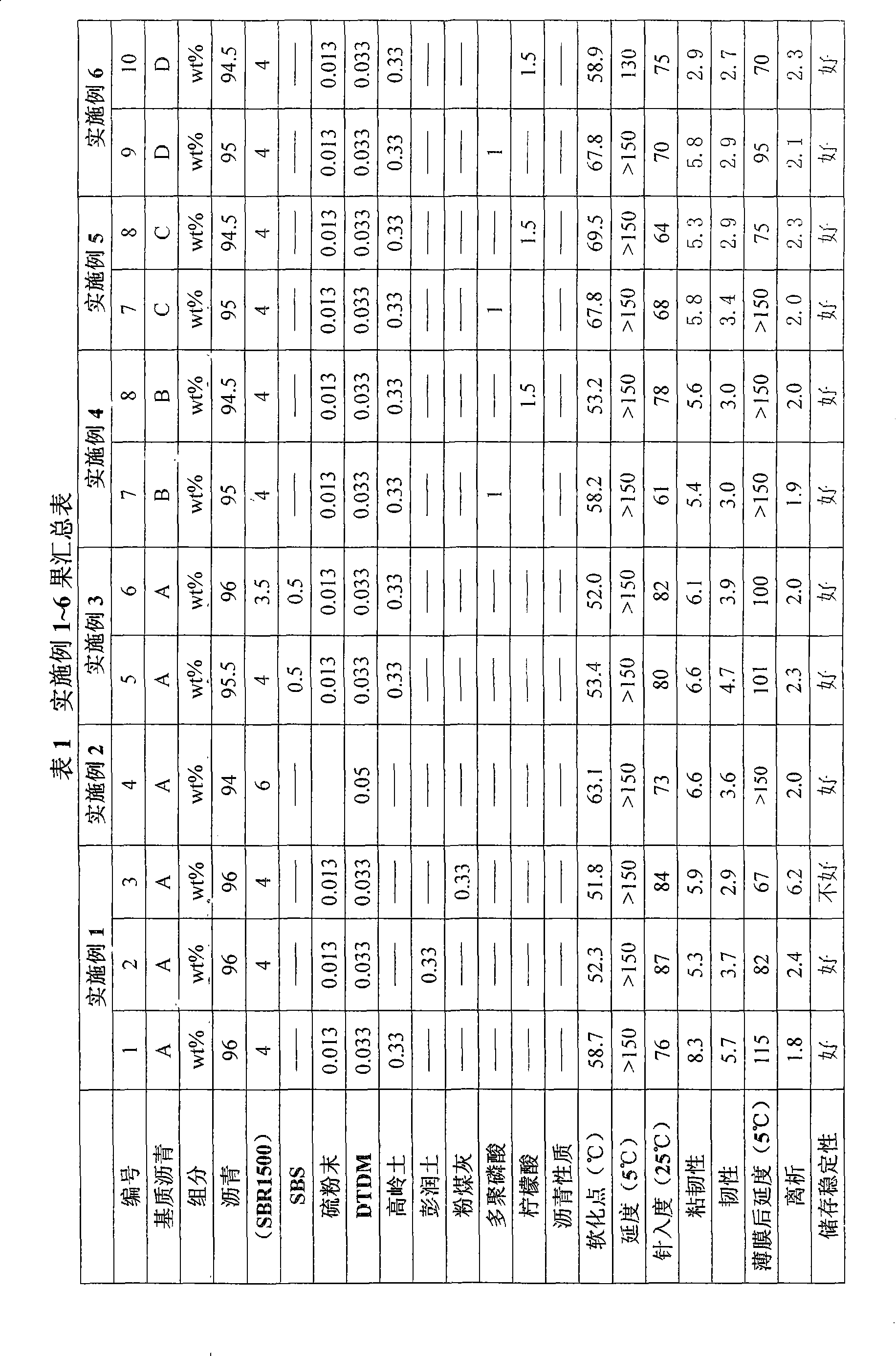

Polymer chemically-modified asphalt composition capable of being stably stored at high temperature and preparation method thereof

InactiveCN101613533AGood storage stability at high temperatureMeet usable requirementsBuilding insulationsElastomerViscous liquid

The invention relates to a high polymer chemically-modified asphalt composition and a preparation method thereof. The preparation method comprises the following steps: chemically modifying rubber, elastomer and base asphalt, and additionally matching stuffing and processing aids; premixing the materials by high polymer processing equipment to prepare the master batch of the modified asphalt; and fully dispersing the master batch into the asphalt by a high-speed shear mixer or by mechanical stirring. Or the modified asphalt material can be prepared by firstly pre-preparing a viscous liquid mixture of modified asphalt and then stirring and mixing the viscous liquid mixture of modified asphalt with the base asphalt. The modified asphalt material prepared by the invention has stable storage performance at high temperature, good performance at high temperature and low temperature, stable processing and preparation and simple and convenient method, and not only can be directly used in factory production but also can be used for road laying sites and in the construction of waterproofing materials.

Owner:NORTHWEST NORMAL UNIVERSITY

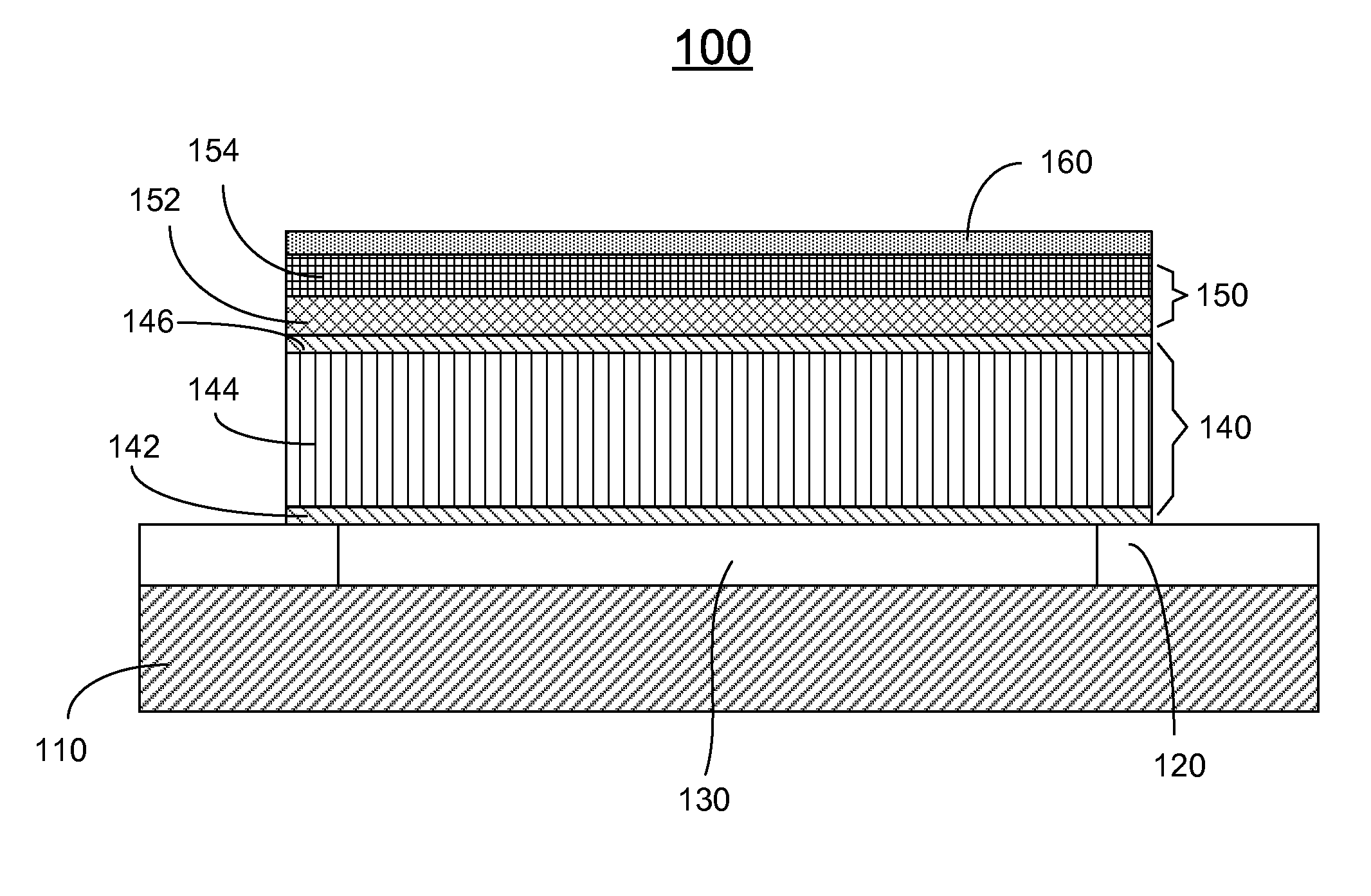

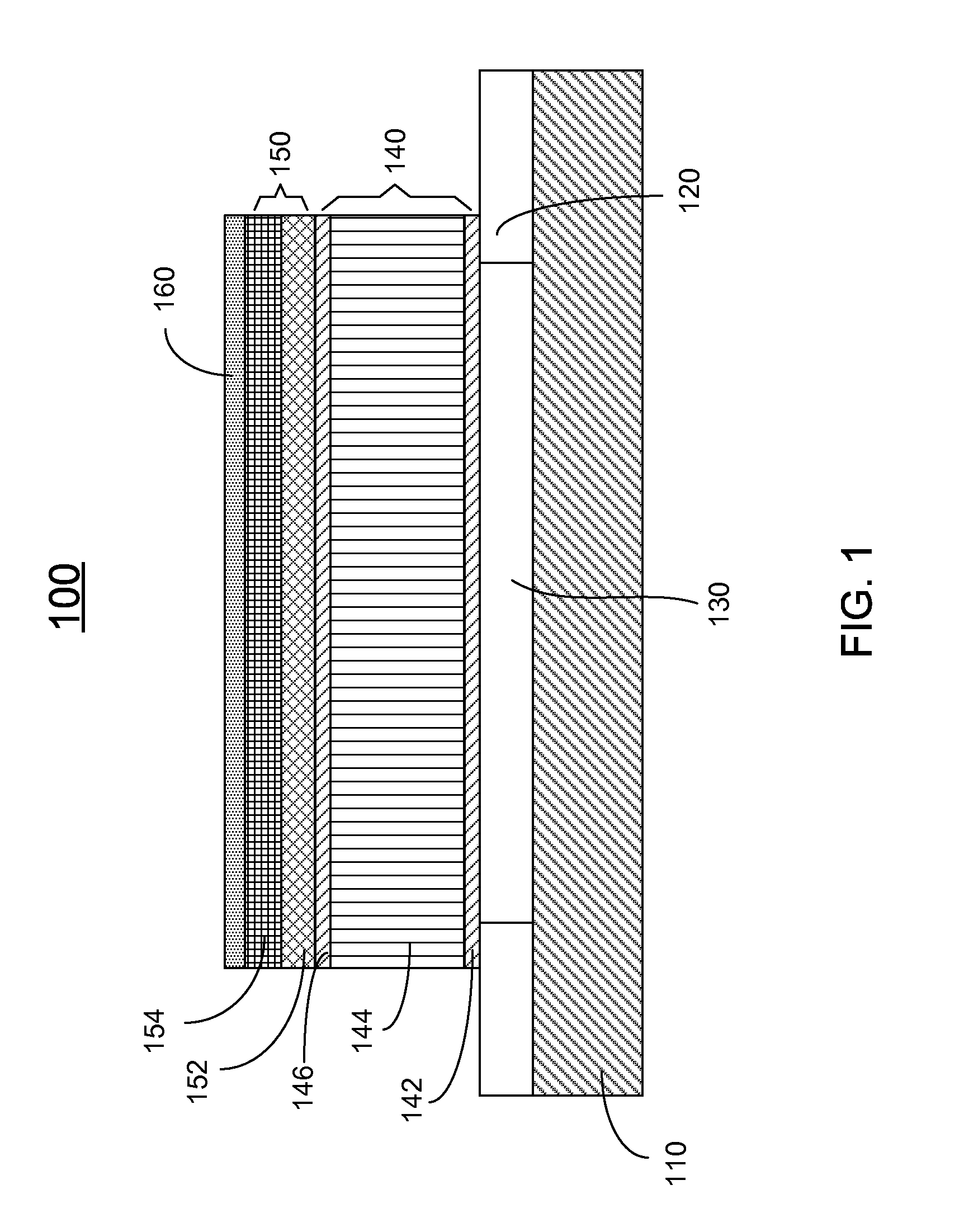

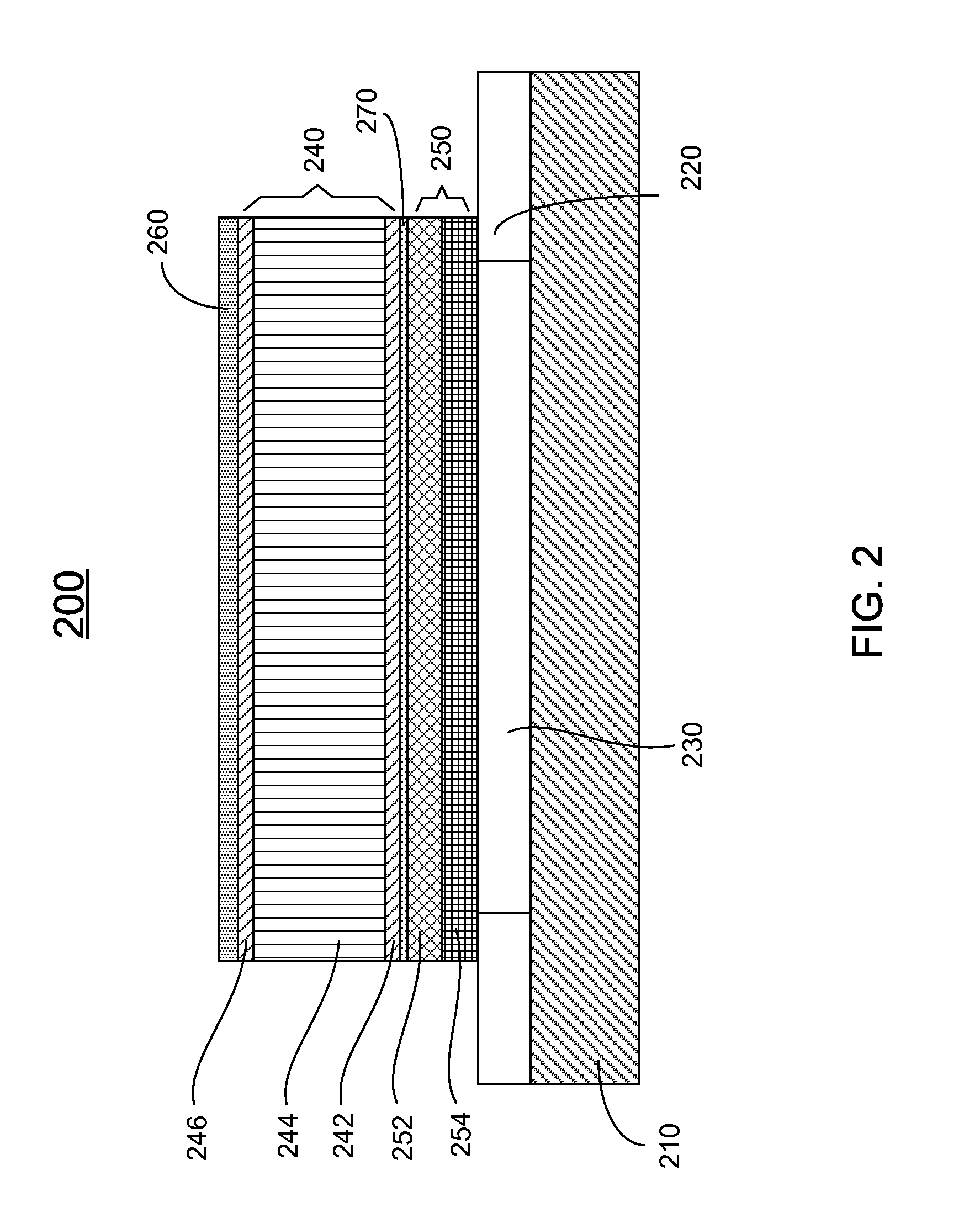

Composite bulk acoustic wave resonator

ActiveUS20120056694A1Good aging effectRich change effectImpedence networksAcoustic waveLayered structure

In one aspect of the invention, the acoustic wave resonator includes a resonator structure having a first electrode, a piezoelectric layer formed on the first electrode, and a second electrode formed on the piezoelectric layer, and a composite layered structure associated with the resonator structure such that the immunity of the acoustic wave resonator to environmental change and aging effects is improved, the trimming sensitivity is substantially minimized, and / or dispersion characteristics of the acoustic wave resonator is optimized.

Owner:AVAGO TECH INT SALES PTE LTD

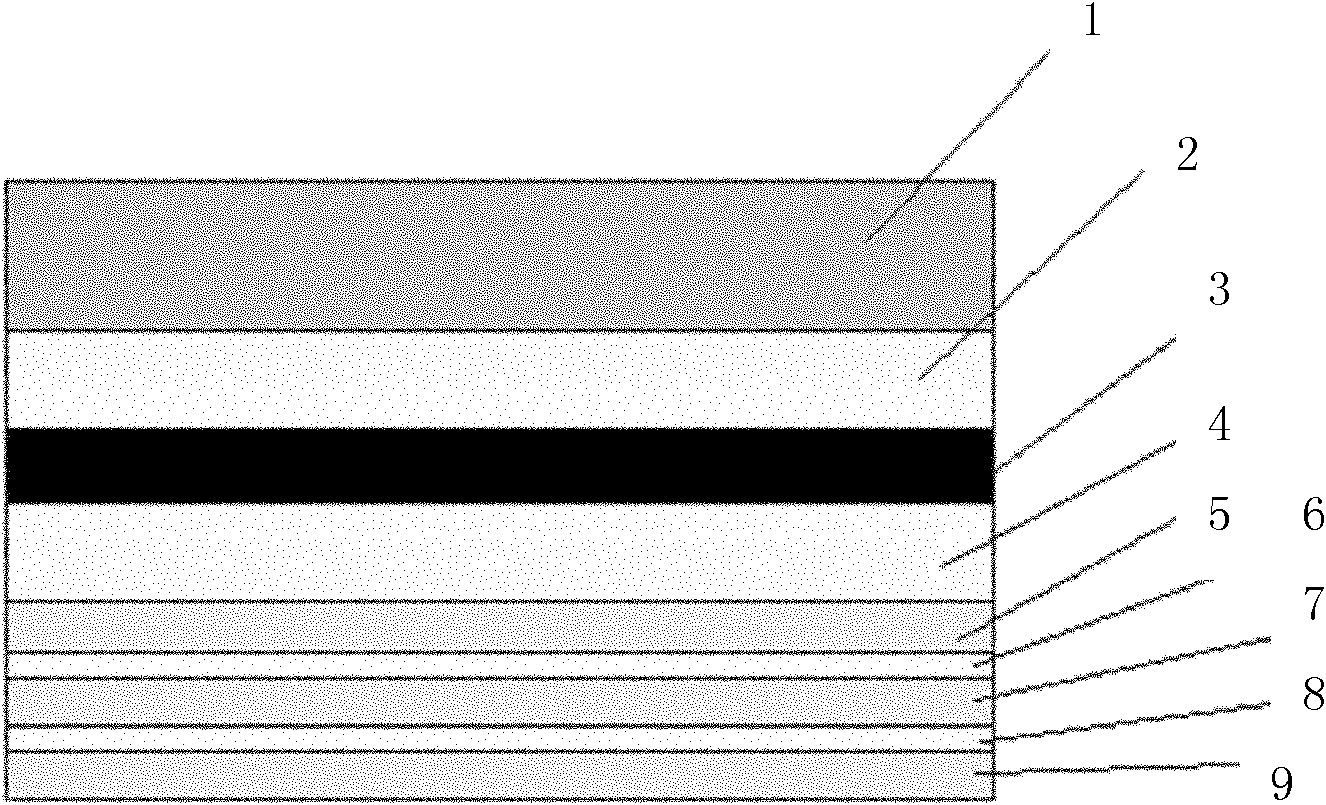

EVA (ethylene vinyl-acetate copolymer) adhesive film capable of simplifying packaging structure of solar battery

ActiveCN102115642AIncrease reflectionImprove photoelectric conversion efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryTitanium dioxide

The invention relates to an EVA (ethylene vinyl-acetate copolymer) adhesive film capable of simplifying a packaging structure of a solar battery. The EVA adhesive film is prepared from the following raw materials in parts by weight: 100 parts of EVA, 0.5-1.0 part of crosslinking agent, 0.5-5 parts of compatilizer, 0.5-1 part of antioxidant, 0.05-1 part of light stabilizer, 1-10 parts of titanium dioxide and 0.5-1.5 parts of tackifier. The EVA adhesive film is prepared by the following steps: mixing the EVA with other assistants, carrying out melt extrusion, casting to form a film, and finallyrolling to obtain the finished product. The adhesive film provided by the invention is mainly used between a solar battery component and a back panel; and unlike the common EVA packaging adhesive film and back panel material, the adhesive film provided by the invention can simplify the packaging structure of the solar battery, can effectively lower the cost of the solar battery pack, and is beneficial to the further popularization of the solar battery.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

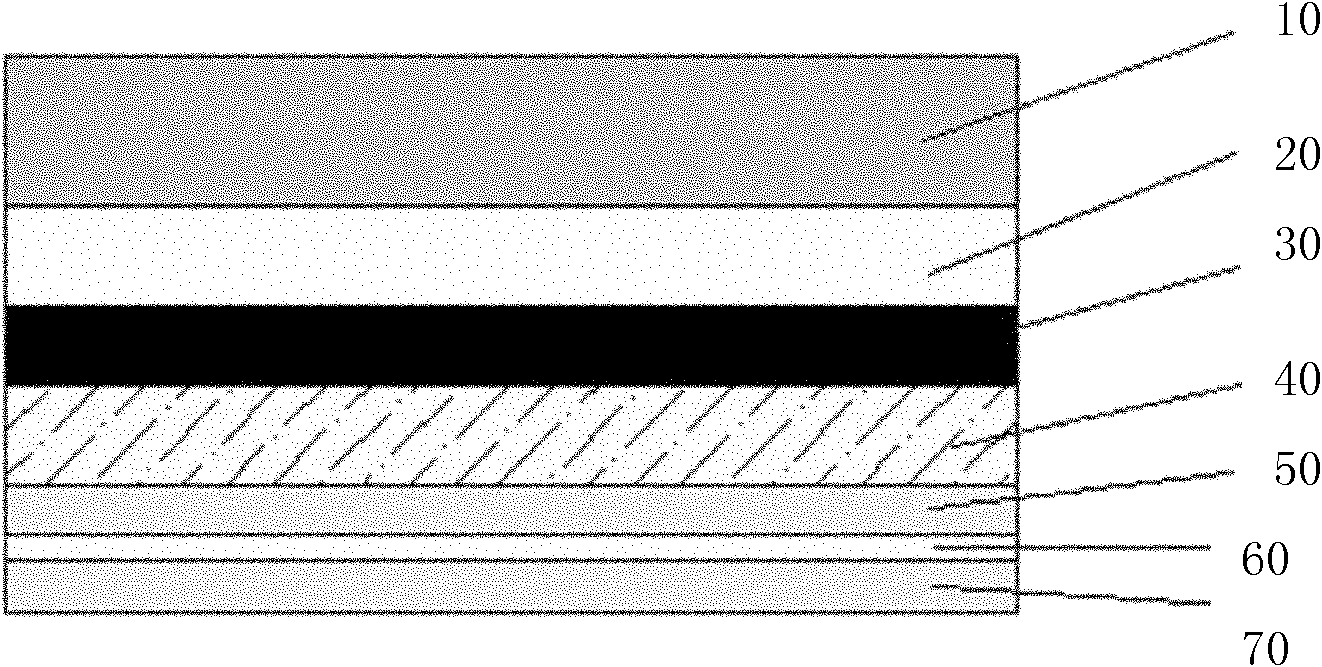

Optical conversion luminous film and preparation method thereof

ActiveCN101571235AGood luminous consistencyPrevent glareLuminescent paintsSynthetic resin layered productsChemistryColor rendering index

The invention relates to an optical conversion luminous film and a preparation method thereof. The optical conversion luminous film is formed by a diffusion film and a mixed paint layer on the diffusion film; the optical conversion luminous film has the thickness of 30-200mum, wherein, the thickness of the diffusion film is 20-70mum; the mixed paint layer is made of 10.000-30.000% of yellow luminous fluorescent material, 0.001-2.000% of red luminous fluorescent material, 60.000-89.000% of polymer resin, 1.000-5.000% of bi-amino silane, 0.000-20.000% of diluting agent and 0.000-5.000% of accessory ingredient. By combining the yellow luminous fluorescent material and the red luminous fluorescent material, the invention can realize the aim of regulating chromaticity coordinate, color temperature and color rendering index, thus preparing the optical conversion luminous film which is made of the fluorescent materials and has the advantages of high color rendering index of the photodiffusion effect, good property of uniform light, anti-dazzle, high light conversion efficiency, low cost, excellent aging characteristic and simple production technique.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

Aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material

InactiveCN104610663AHigh strengthGood air aging resistanceRubber insulatorsPlastic/resin/waxes insulatorsCalcium silicateElastomer

The invention discloses an aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material. The material comprises raw materials as follows: EPDM rubber, natural rubber, an ethylene-butene elastomer, superfine talc powder, nano calcium carbonate, modified superfine desulfurization ash, active calcium silicate, zinc methacrylate modified nano silicon nitride, pre-dispersed hollow phenolic microspheres, reinforcing fibers, zinc oxide, stearic acid, dicumyl peroxide, sulfur, N,N'-meta phenylene bismaleimide, diphenylmethane bismaleimide, DIPDIS, coumarone-indene resin, APP (ammonium polyphosphate), ADP, an MPE (metallocene polyethylene) elastomer, N-(4-anilino phenyl maleimide and 2-mercapto benzimidazole. The aging-resistant and low-temperature-resistant EPDM rubber cable material is high in strength, good in aging resistance and low-temperature resistance, excellent in insulating property and flame retardation and long in service life.

Owner:无为县华祥电缆材料有限公司

Ethylene-propylene-diene monomer rubber used for manufacturing wind energy cable and preparation method thereof

ActiveCN102617942AImprove mechanical propertiesEasy to stretchPolymer scienceDecabromobiphenyl ether

The invention discloses an ethylene-propylene-diene monomer rubber used for manufacturing a wind energy cable and a preparation method thereof. The ethylene-propylene-diene monomer rubber comprises the following components: 90-110 parts of ethylene-propylene-diene monomer rubber, 1-4 parts of anti-aging agent, 0.2-0.5 part of stearic acid, 2-9 parts of paraffin oil, 2-5 parts of lead sulfate tribasic, 1-4 parts of zinc oxide, 80-120 parts of activated kaolin, 0.3-1.5 parts of coupling agent, 0.5-2.6 parts of cross-linking agent, 0.5-2.0 parts of assistant crosslinker, 1-3 parts of semi-reinforcing carbon black, 1-4 parts of plasticizer, 0.5-2 parts of antimonous oxide, 0.5-2 parts of zinc borate, 1-5 parts of basic magnesium carbonate, 1-4 parts of antioxygen, 0.1-0.5 part of sulphur, 2-5parts of epoxidized soybean oil, 5-15 parts of decabromodiphenyl ether, 12-30 parts of antimony oxide and 2-5 parts of organic modified bentonite. The material has the advantages of wide applicable temperature range, god performance and long service life.

Owner:无锡市远登电缆有限公司

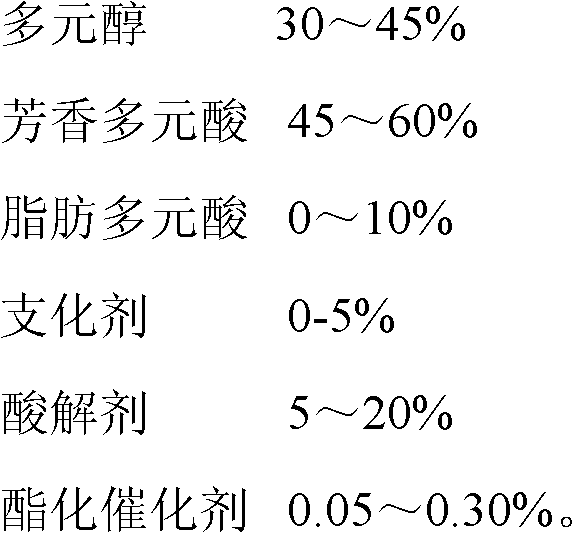

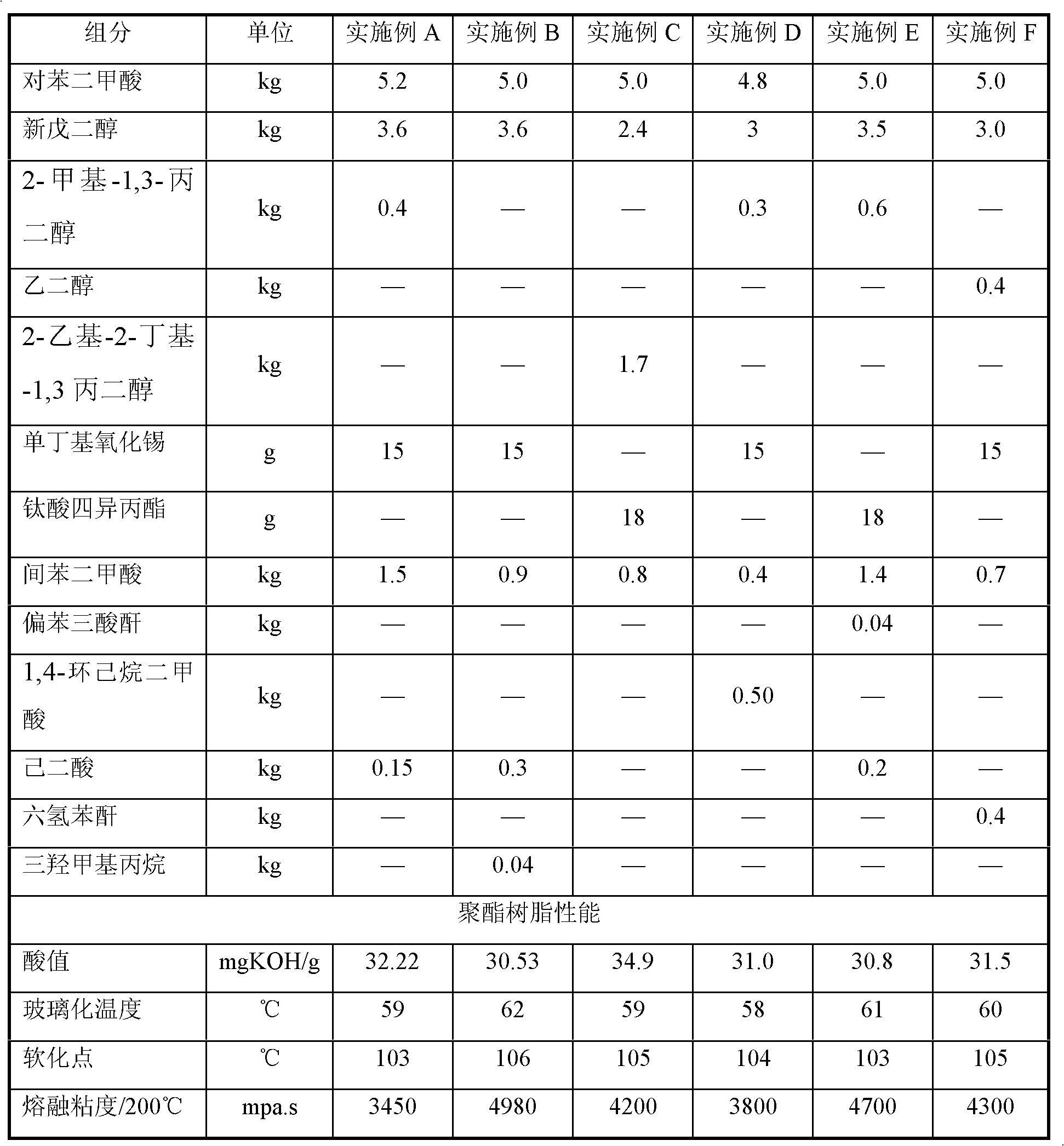

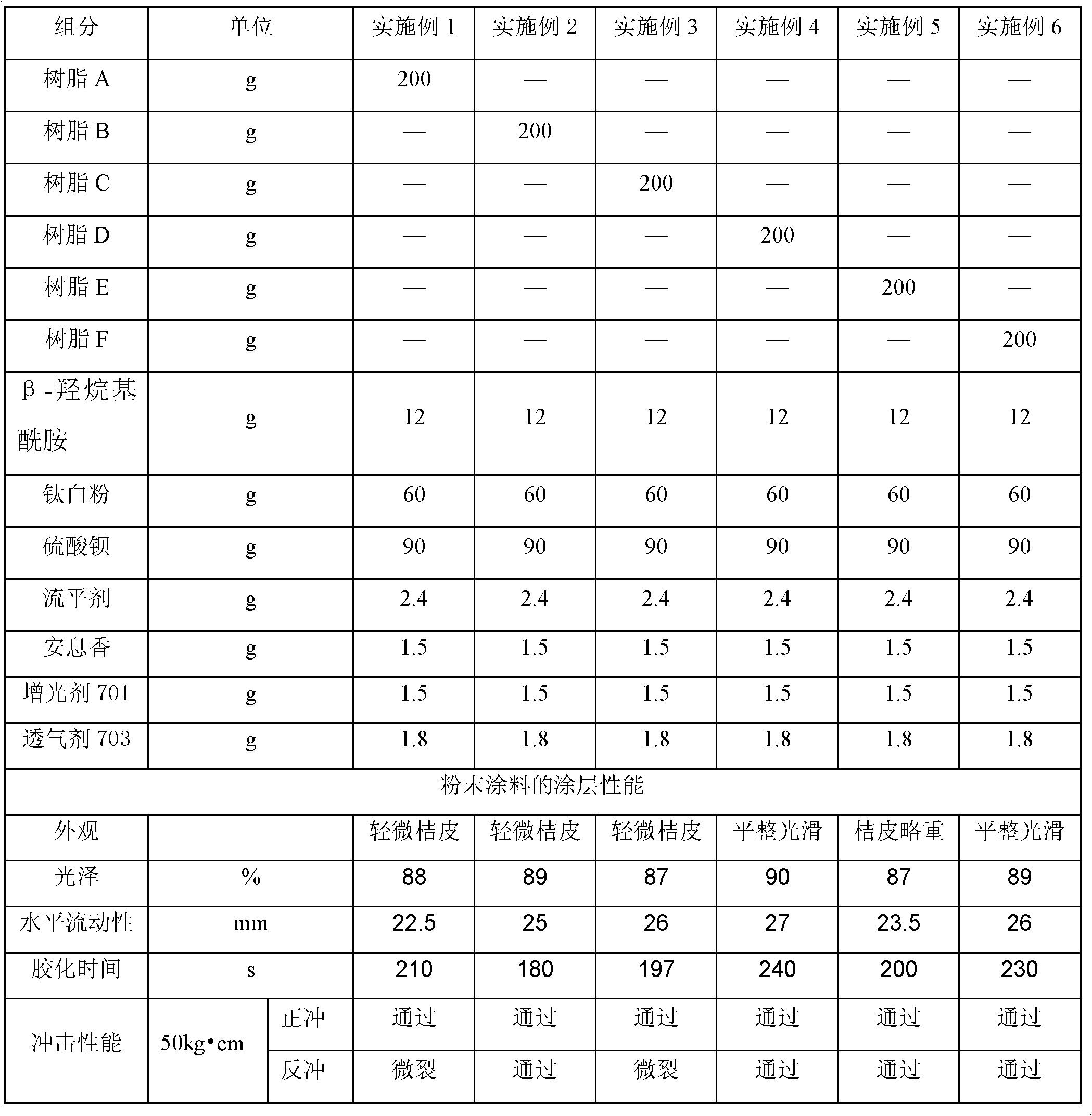

Polyester resin for rapid curing of weather-durable powdery paint by beta-hydroxyalkylamide and preparation method thereof

InactiveCN102443148AHigh glass transition temperatureGood storage stabilityPowdery paintsPolyester coatingsChemistryPowder coating

The invention discloses a polyester resin for the rapid curing of a weather-durable powdery paint by a beta-hydroxyalkylamide. The polyester resin is obtained through carrying out a melting polycondensation reaction on the following components, by weight, 30-45% of a polyol, 45-60% of an aromatic polyprotic acid, 0-10% of an aliphatic polyprotic acid, 0-5% of a branching agent, 5-20% of an antiacid and 0.05-0.30% of an esterification catalyst. The invention also discloses a preparation method of the polyester resin. The polyester resin provided in the invention has the advantages of high glass-transition temperature and softening point, and appropriate melting viscosity and storage stability; and powdery paints prepared with the polyester resin have the advantages of excellent levelability, excellent mechanical performance, good thick film pinhole resistance and the like.

Owner:GUANGZHOU QINGTIAN INDAL

Novel preparation method for polyether amine composite material

The invention discloses a novel preparation method for a polyether amine composite material, which comprises the following preparation steps: (1) preparing refined polyether polyol; and (2) preparing polyether amine. In the invention, upstream raw materials are used as starting raw materials, various monomer raw materials are used to produce a hydroxyl polyol with a multi-functional group structure, a high-activity catalyst is combined, the activity of the catalyst is improved, many tests are carried out, the tested product has high comprehensive performance, production cost is reduced, and the product is suitable to be used in more industries. In the invention, new varieties of upstream raw materials of the polyether amine product are added, the polyether products are diversified, the application adaptability of the product in the composite material is improved, product quality is improved, product cost is reduced, reaction pressure and temperature are lowered, the production safety coefficient is high, equipment manufacturing cost is lowered, energy consumption is reduced, and continuous large-scale production is promoted.

Owner:东莞市科道玛电子复合材料有限公司

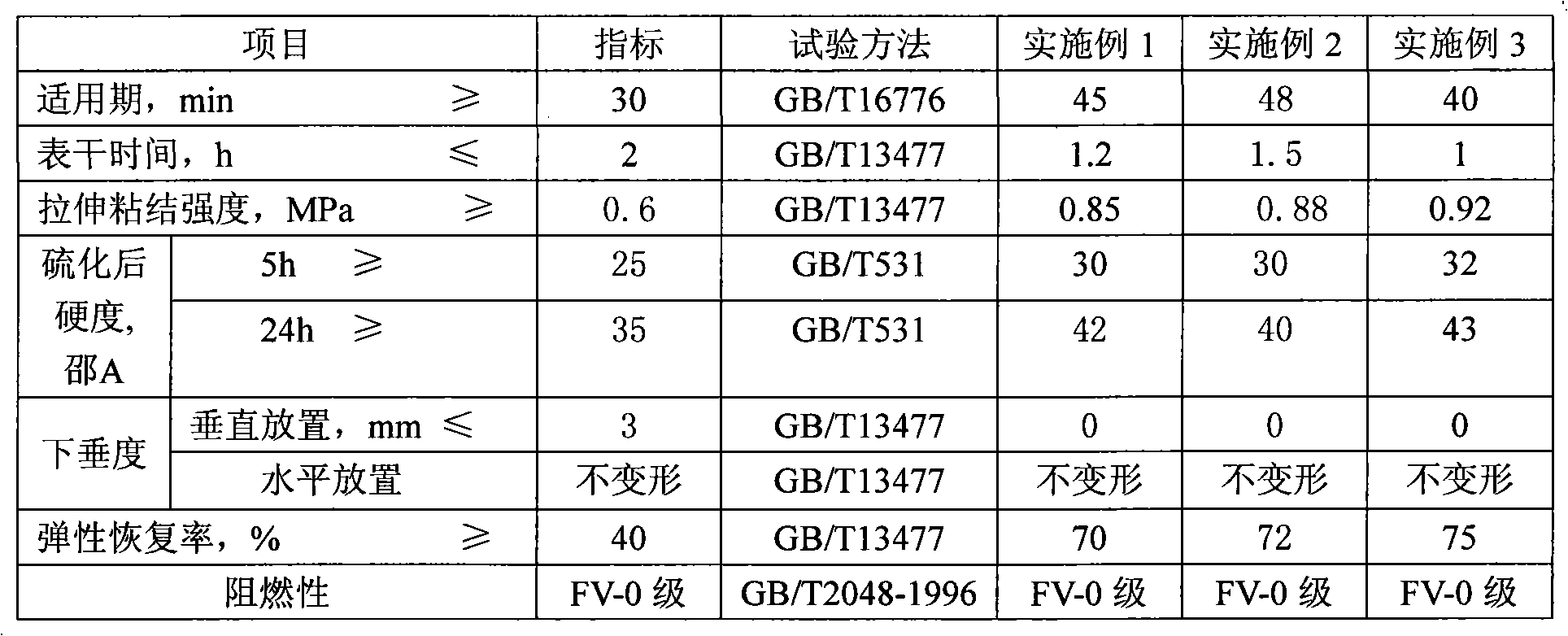

Bi-component polysulfide fireproofing flame retardant sealant and preparation method thereof

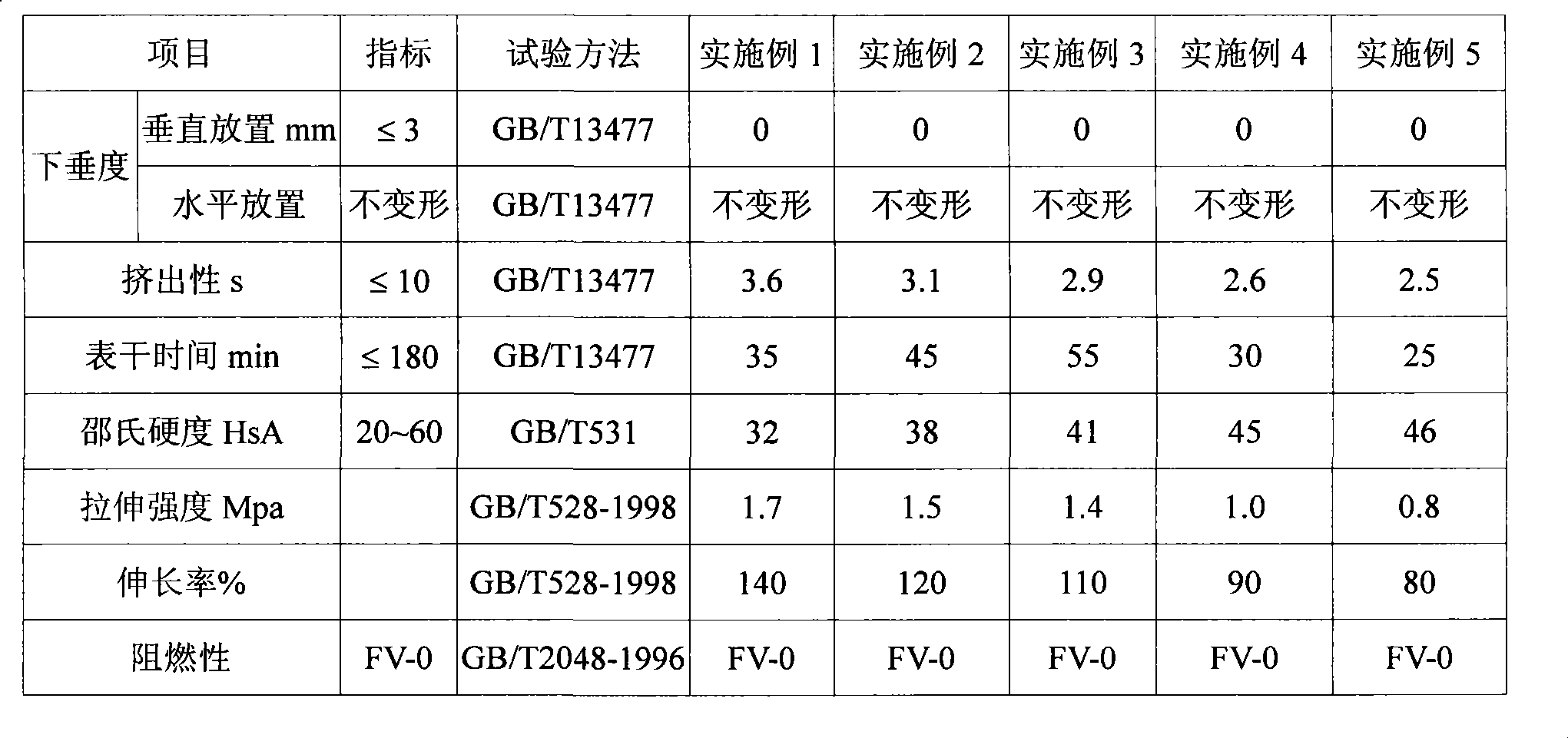

ActiveCN101575493AImprove fire performanceNot corrosiveNon-macromolecular adhesive additivesOther chemical processesPolysulfide rubberPlasticizer

The invention relates to a bi-component polysulfide fireproofing flame retardant sealant and a preparation method thereof, wherein the bi-component polysulfide fireproofing flame retardant sealant is prepared from the following components according to parts by weight: component A: 50-100 parts of liquid polysulfide rubber, 30-70 parts of flame retardant plasticizer, 50-150 parts of flame retardant filler, 60-200 parts of calcium carbonate, 0.3-1.2 parts of main agent micro-molecular finishing agent and 0.5-1.5 parts of silane coupling agent; component B: 10-30 parts of manganese dioxide, 20-60 parts of plasticizer, 1-3 parts of semi-strengthening agent carbon black and 0.4-1.5 parts of accelerant. The preparation method comprises the following steps of: mixing, stirring, vacuumizing, inspecting and packaging all the ingredients of component A; and mixing, stirring, vacuumizing, grinding, inspecting and packaging all the ingredients of component B. The sealant can be used by uniformly mixing A and B according to the mass rate of A: B being equal to 100:6-100:12. the sealant has good flame retardant property that is tested to be FV-0 level according to GB / T 2408-1996, and the oxygen index is tested to be 36.6 percent according to GB / T 2406-1993, and the both levels reach or exceed state-specified standards,.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

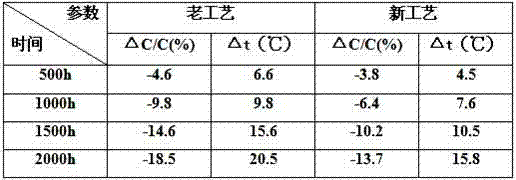

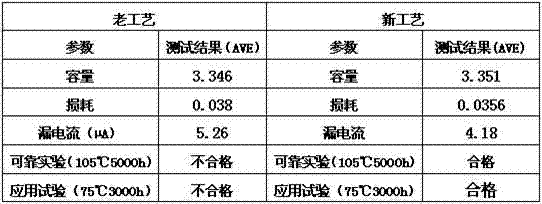

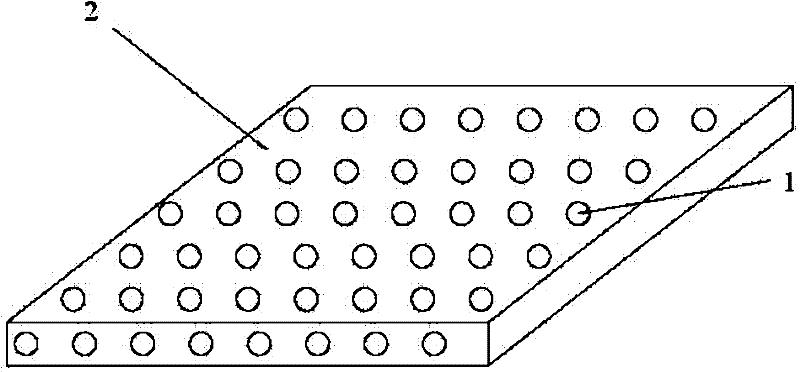

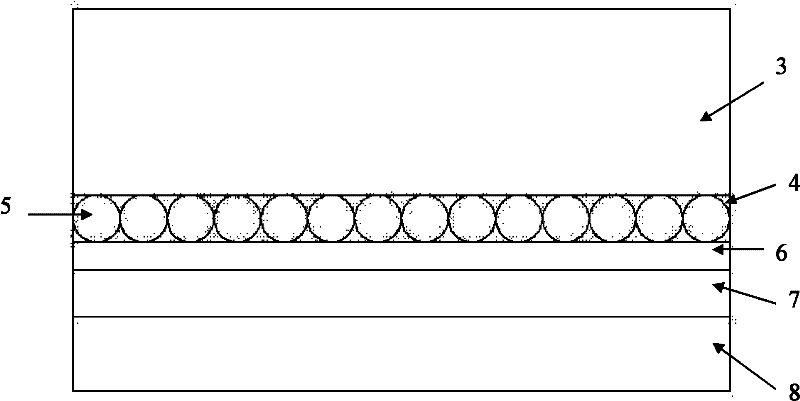

Novel aging technology of mesohigh voltage aluminum electrolytic capacitor

ActiveCN102646514AImprove aging performanceRepair defectsElectrolytic capacitorsElectrolysisAlternating current

The invention discloses a novel aging technology of a mesohigh voltage aluminum electrolytic capacitor. The novel aging technology adopts an aging mode of adding alternating current and the direct current and comprises the following steps that: 10+ / -0.5 V alternating-current voltage can be applied for the preaging of a cathode first, the aging time can be 9-11 min, direct-current pulse current can be then applied for two anode and cathode ends of the capacitor for the direct-current pulse aging, the direct-current pulse aging can be subjected to section processing by a 12-stage power supply, wherein 1-8 stages of the power supply are used for normal-temperature aging, 9-12 stages of the power supply are used for high-temperature and constant-voltage aging, the direct-current pulse aging time is totally to be 180+ / -5 min, the aging voltage value of the eighth stage is set to be 1.15-1.2 times than that of the rated voltage of the capacitor, the aging temperatures for the high-temperature and constant-voltage of the 9-12 stages are set to be 105+ / -2 DEG C, and the aging voltage set value and the aging voltage value of the eighth stage are the same. By adopting the aging mode by adding the alternating current and the direct current, the effect of simultaneously repairing an anode oxidation film and a cathode oxidation film is reached, the problem that a whole energy-saving lamp is easily broken when an upper line of the energy-saving lamp is aged, the leakage of electricity of a product is reduced, the heat emission of the whole energy-saving lamp is reduced under a high-frequency condition, the ability of adapting to a high ripple wave of the aluminum electrolytic capacitor can be increased , and the reliability of the product is increased.

Owner:NANJING YIPIN MACHINERY ELECTRONICS

Ethylene-vinyl acetate adhesive film containing quantum dots as well as preparation method and application thereof

ActiveCN102226064AImprove efficiencyHigh fluorescence quantum efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesOperabilityCarvacryl acetate

The invention discloses a preparation method of an ethylene-vinyl acetate adhesive film containing quantum dots, which comprises the following steps: using a modifier to perform hydrophilic or lipophilic modification on the surfaces of the semiconductor quantum dots, further uniformly dispersing the semiconductor quantum dots after modification into a solvent for forming semiconductor quantum dotink, then mixing the semiconductor quantum dot ink, an ethylene-vinyl acetate copolymer and an assistant, and performing hot compression molding or extrusion molding for getting the ethylene-vinyl acetate adhesive film containing the semiconductor quantum dots. The preparation method is simple, good in controllability, strong in operability and easy for industrial production. The invention further discloses the ethylene-vinyl acetate adhesive film containing the quantum dots, which is applied in solar cells and can effectively improve the utilization efficiency of the solar cells.

Owner:ZHEJIANG UNIV

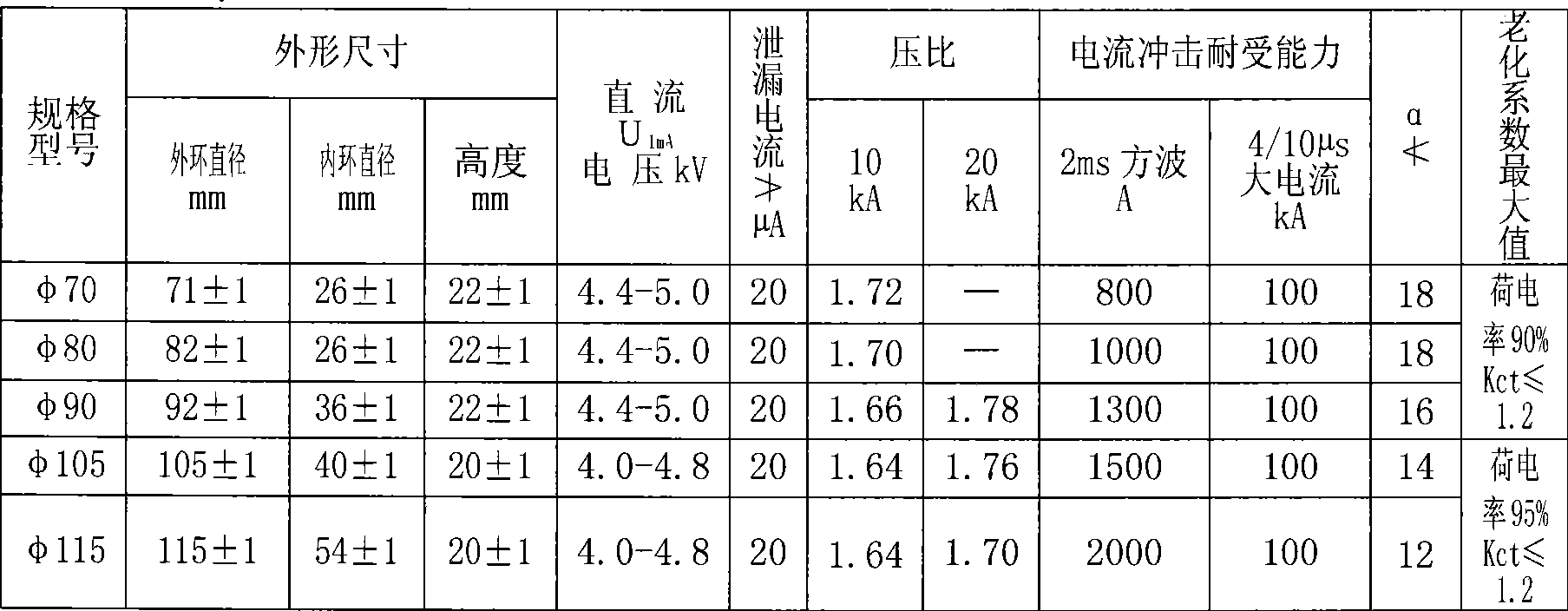

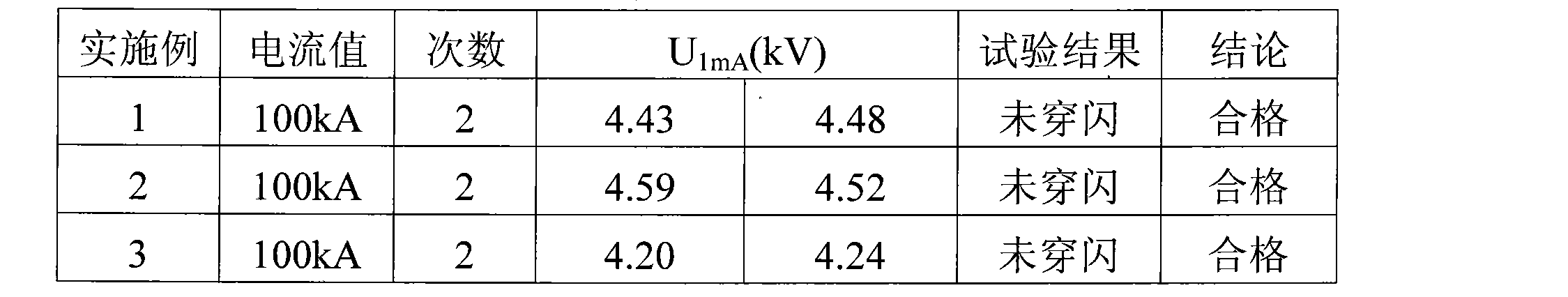

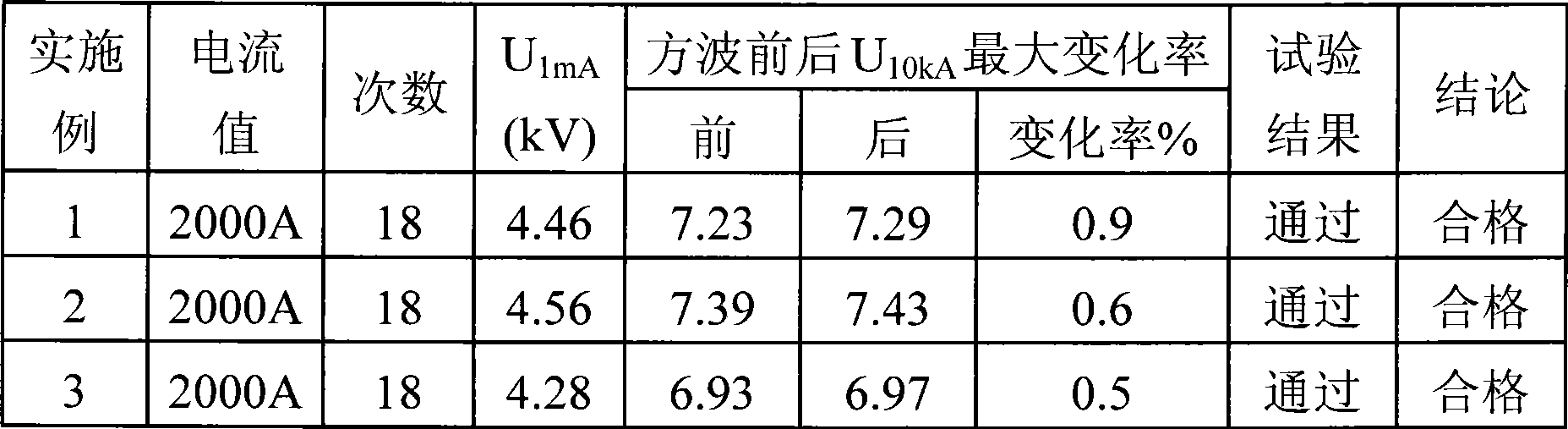

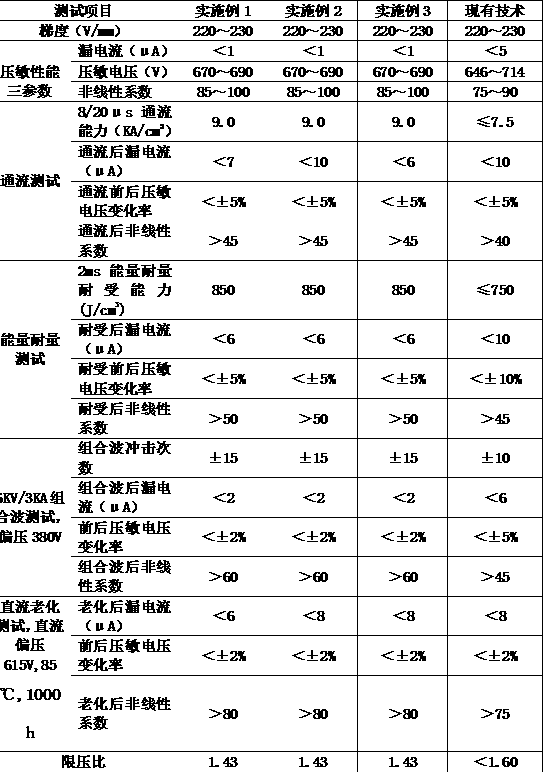

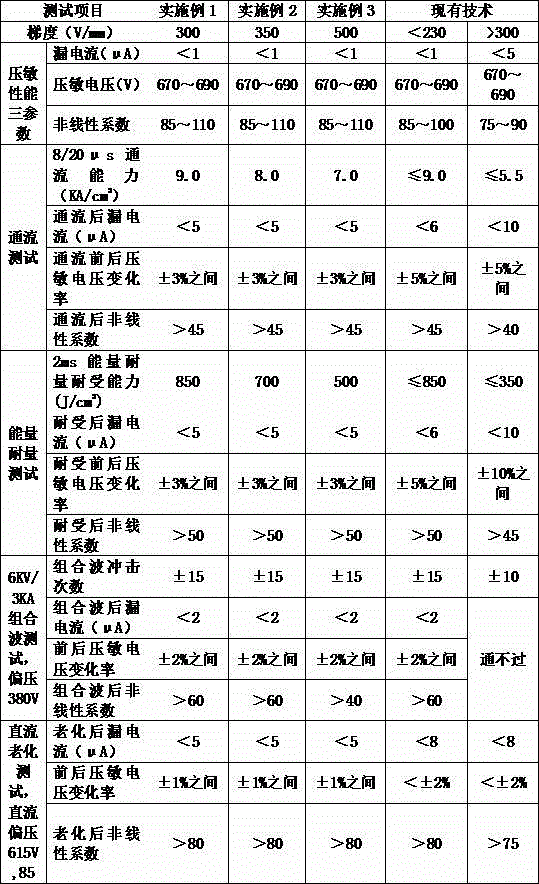

Formula of direct current zinc oxide resistance chip

ActiveCN101503292AUniform and stable structureReduce defect concentrationVaristor coresSesquioxideAntimony trioxide

The invention discloses a formulation of an AC zinc oxide resistance chip. The formulation is characterized by comprising the following additives and a main material ZnO by weight percentage: 4.0 to 4.9 percent of Bi2O3, 3.0 to 4.0 percent of Sb2O3, 0.5 to 1.0 percent of SiO2, 2.0 to 3.0 percent of Co2O3, 0.50 to 0.80 percent of Cr2O3, 0.50 to 0.80 percent of MnCO3, 0.70 to 0.90 percent of NiO, 0.03 to 0.05 percent of aluminum nitrate, 0.10 to 0.20 percent of glass dust, 0.07 to 0.10 percent of B2O3 and 85.0 to 88.0 percent of ZnO. The formulation of the resistance chip has the following characteristics and advantages: the nickel protoxide and the glass dust are introduced into the formulation, so that the stability and the aging performance of the internal structure of the resistance chip is more excellent; and 2, dosage of cobalt sesquioxide, dibismuth trioxide and diantimony trioxide are added in the formulation, the mixture ratio of each composition is more reasonable, and the non-linearity coefficient of the resistance chip can be improved, the pressure ratio is reduced, the circulation capability is improved, and the comprehensive performance is excellent.

Owner:FUSHUN ELECTRIC PORCELAIN MFG CO LTD

High-joule type voltage dependent resistor and production method thereof

The invention discloses a high-joule type voltage dependent resistor and a production method thereof. The voltage dependent resistor mainly comprises ZnO, and then raw materials of Bi2O3, Co3O4, Sb2O3, MnCO3, Ni2O3, ZrO2, Y2O3, SiO2, SnO2, MgO, H3BO3, Al(NO3)3.9H2O, AgNO3 and home-made ultrafine ZnTiNb2O8 powder are added to obtain the voltage dependent resistor. The production method comprises the steps that the ultrafine ZnTiNb2O8 powder is self-produced by using a conventional solid-phase synthesis method; then the ultrafine ZnTiNb2O8 powder, other additives and ZnO powder are subjected to ball-milling and mixed; and processes such as spray granulation, dry-pressing molding, binder removal and sintering are achieved to obtain a sintered ceramic chip, and the sintered ceramic chip is subjected to screen printing of silver paste, reduced, welded and packaged, so that the high-joule type voltage dependent resistor is obtained. According to the production method, the process is simple, and the produced voltage dependent resistor is low in cost, good in aging performance, high in combination wave resistance and energy density, environment-friendly and capable of achieving mass production.

Owner:GUANGXI NEW FUTURE INFORMATION IND

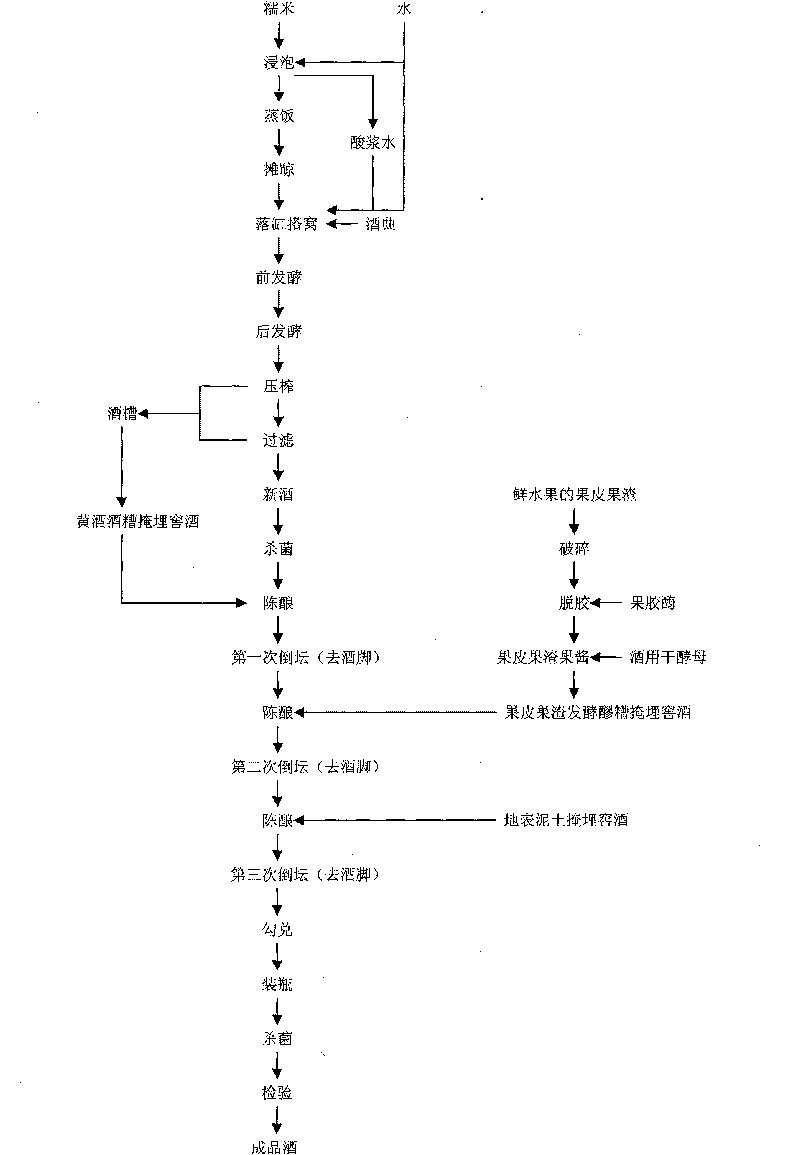

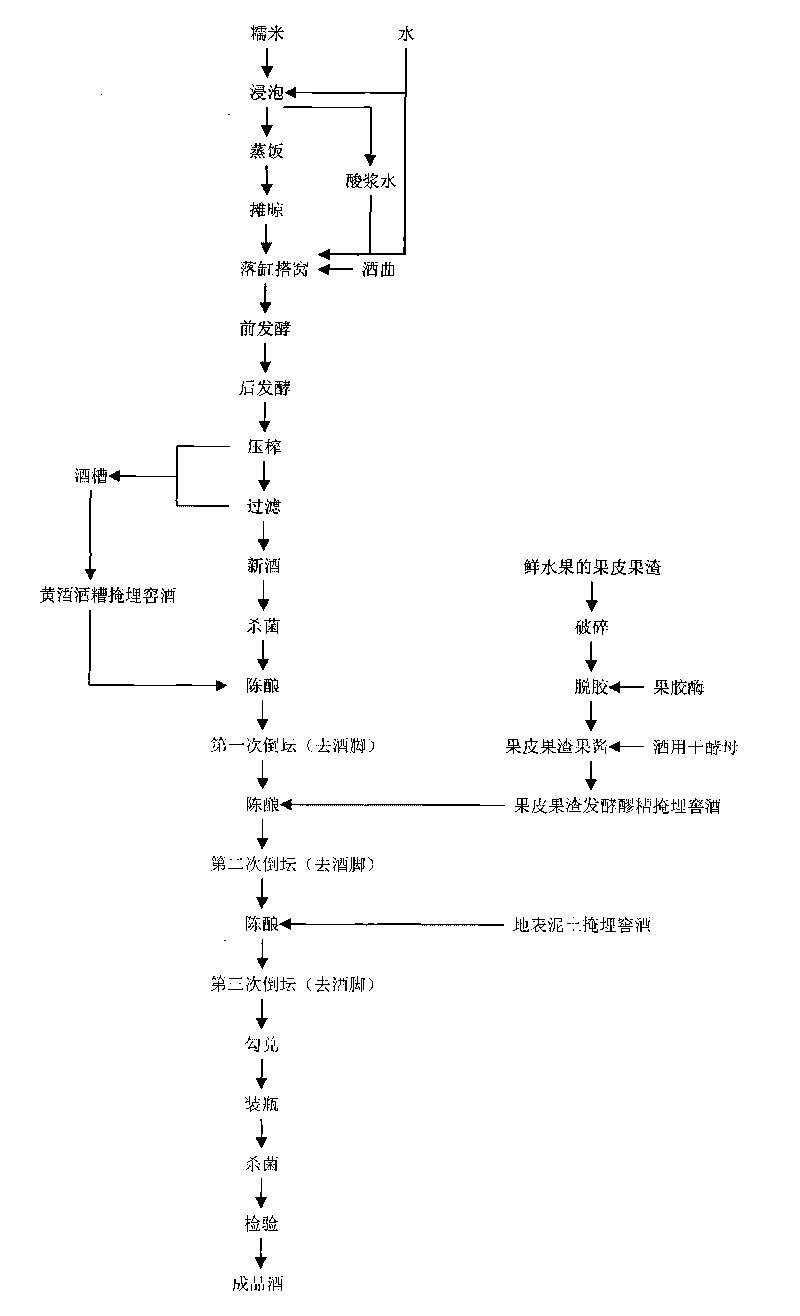

Buried type wine cellaring method

The invention discloses a buried type wine cellaring method, which aims to overcome shortcomings that the common storage method for a yellow wine has technical problems on shortening the storage period, adding aroma, improving mouthfeel, coordinating alcohol blending degree and the like. The invention adopts the following technical scheme: because an earthen jar (pot or vat) has characteristic of good air permeability when used to accommodate wine, yellow wine vinasse, fruit skin and fruit residue fermented glutinous rice wine and surficial soil are used for burying a cellared wine respectively for three times to effectively form favorable conditions, such as a microcirculatory respiratory system, a cold and hot interactive mechanism and a microbiological ecological environment, in the cellared wine; and combined with the natural environmental conditions of a cave (or an underground cellar), such as a constant temperature and a proper humidity, the alcoholization and aging of the yellow wine can be quickened, and the aims of shortening the storage period, improving the wine quality, increasing the aroma and the taste, improving the mouthfeel, coordinate the alcohol blending degree, reducing the wine storage cost and maintaining the quality of the wine after long-term storage are achieved.

Owner:刘名汉

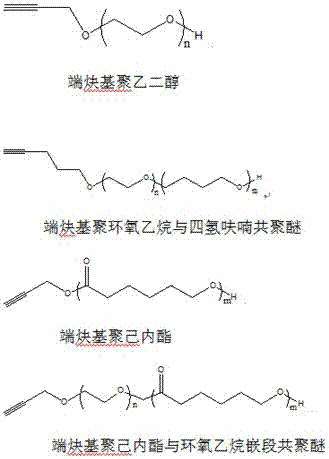

Nitrine solid propellant and preparation process thereof

ActiveCN107879868AImprove mechanical propertiesImproved tensile strength and elongationExplosivesPressure gas generationChemistrySide chain

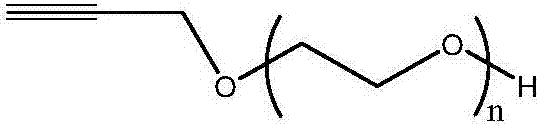

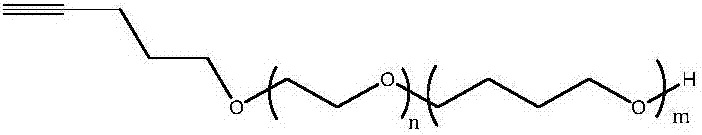

The invention relates to a nitrine solid propellant and a preparation process thereof. The preparation process comprises the following steps: by taking nitrine polyether glycol or polyhydric alcohol as an adhesive, nitrate as a plasticizer, terminal alkynyl polyether or terminal alkynyl polyester as an alkynyl curing agent and diisocyanate or polyisocyanate as an isocyanate curing agent, carryingout Huisgen 1,3-dipolar cycloaddition reaction on nitrinyl of a side chain of a nitrine polyether adhesive and the terminal alkynyl polyether or terminal alkynyl polyester to form a polyurethane elastomer containing a triazole ring; and introducing a Huisgen click chemosetting system based on a polyurethane curing system. The invention relates to the nitrine solid propellant. The propellant has apolyurethane curing mode and a click chemosetting mode at the same time. The prepared propellant has more excellent tensile strength and modulus on the premise of keeping relatively high elongation. The propellant has good mechanical property and structural stability.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

Multi-layer coating system for jacquard woven airbags

InactiveUS20060014456A1Reduce air permeabilityConvenient coatingEnvelopes/bags making machineryProtective equipmentMethacrylateEffective potential

Novel airbag coating compositions comprising at least two separate and distinct layers are provided. The first layer (base coat), being in contact with the airbag surface, comprises a composition of at least one coating material which may comprise up to 30% by parts of the total amount of material in the first layer of a silicone resin which provides excellent adhesion, excellent tensile strength, and overall lower cost than standard silicone airbag coating materials. The second layer, being a coating for the first layer, provides excellent reinforcement and blocking characteristics to permit effective potential long-term storage and optimum use upon the occurrence of a collision. Such a second layer (topcoat) is preferably a silicone material but may also be selected from the group consisting of homopolymer and coplymer resins based on ethylene, propylene, acrylates, methacrylates, vinyl esters, acrylic acid, methacrylic acid, polyurethanes, polyamides, and inorganic materials such as talc, silica, silicate, calcium carbonate, alumina, and the like. This two-layer system permits excellent strength and blocking properties to prevent undesired adhesion between portions of the target airbag when stored as well as to prevent seam combing at relatively low cost due to the materials and the relatively low amount required for the topcoat. An airbag fabric coated with this inventive two-layer system is also contemplated within this invention.

Owner:MILLIKEN & CO

Polypropylene composite capable of resisting thermal oxidizing aging

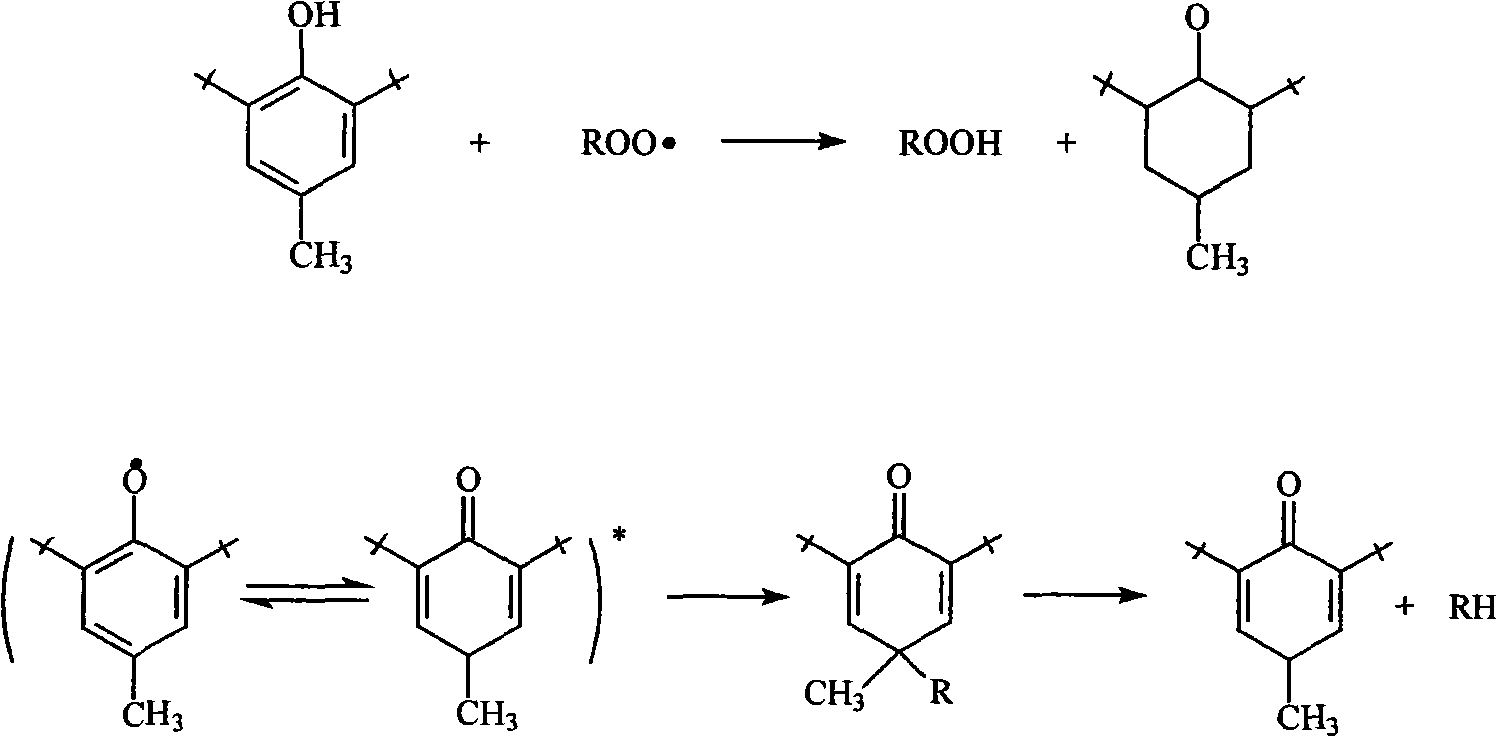

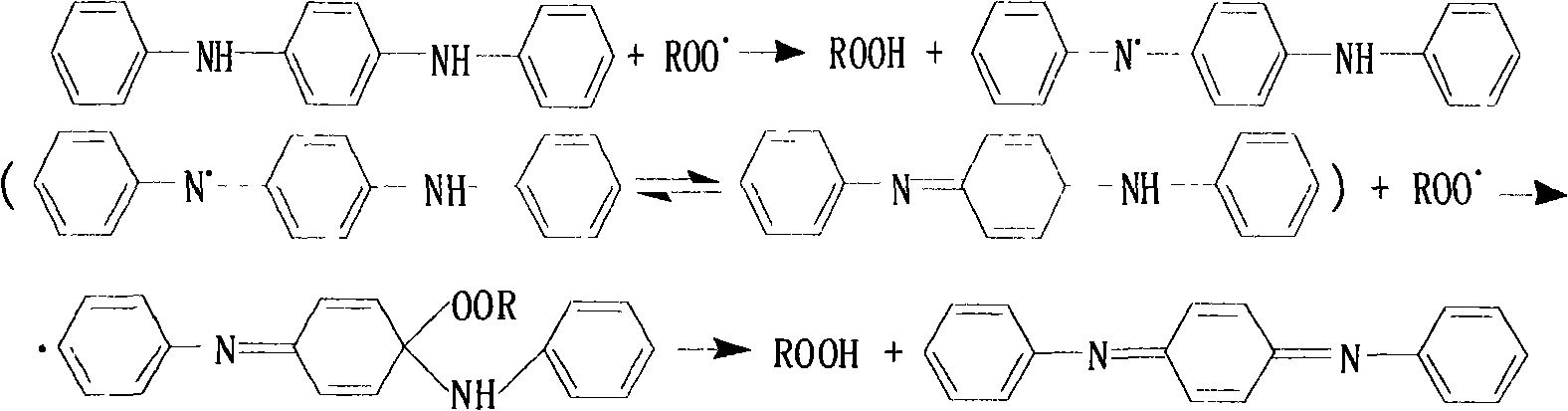

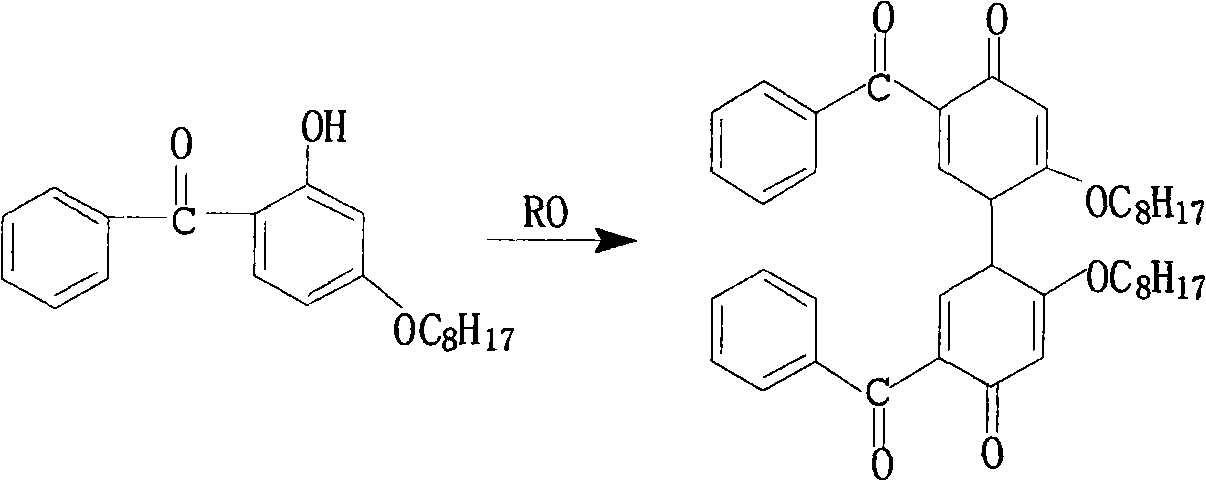

InactiveCN102408630AImprove interface bonding performancePrevent free diffusionPolypropylene compositesPolymer science

The invention discloses a polypropylene composite capable of resisting thermal oxidizing aging, comprising the following components based on weight percentages: 40-82% of polypropylene resin, 2-10% of compatilizer, 10-40% of filler, 0.2-0.5% of nucleating agent, 2-10% of anti-oxidant synergistic agent, 0.2-1.0% of anti-oxidant and 0.2-1.0% of processing agent, wherein the polypropylene resin is a mixture of homopolymerized polypropylene and block copolymerization polypropylene; the compatilizer is graft polymer of polypropylene and unsaturated carboxylic acid or its anhydride. The advantages are as follows: the nucleating agent is a substance which makes the sphaerocrystal of the polypropylene more refine, the crystallization more homogenized and regularized, and increases the crystallinity; the anti-oxidant synergistic agent is one of or a mixture of fluoropolymer and polysiloxane. The composite has both mechanics performance and performance of resisting thermal oxidizing aging. In addition, the anti-oxidant synergistic agent has a very low surface tension and has a trend of migrating and assigning to the surface of the composite during the forming and use process. The configuration of the anti-oxidant synergistic agent has an effect of separating oxygen molecules, and can lower the ratio of the oxygen entering the base body through the surface of the composite such that the performance of resisting thermal oxidizing aging for the polypropylene is increased.

Owner:KINGFA SCI & TECH CO LTD +1

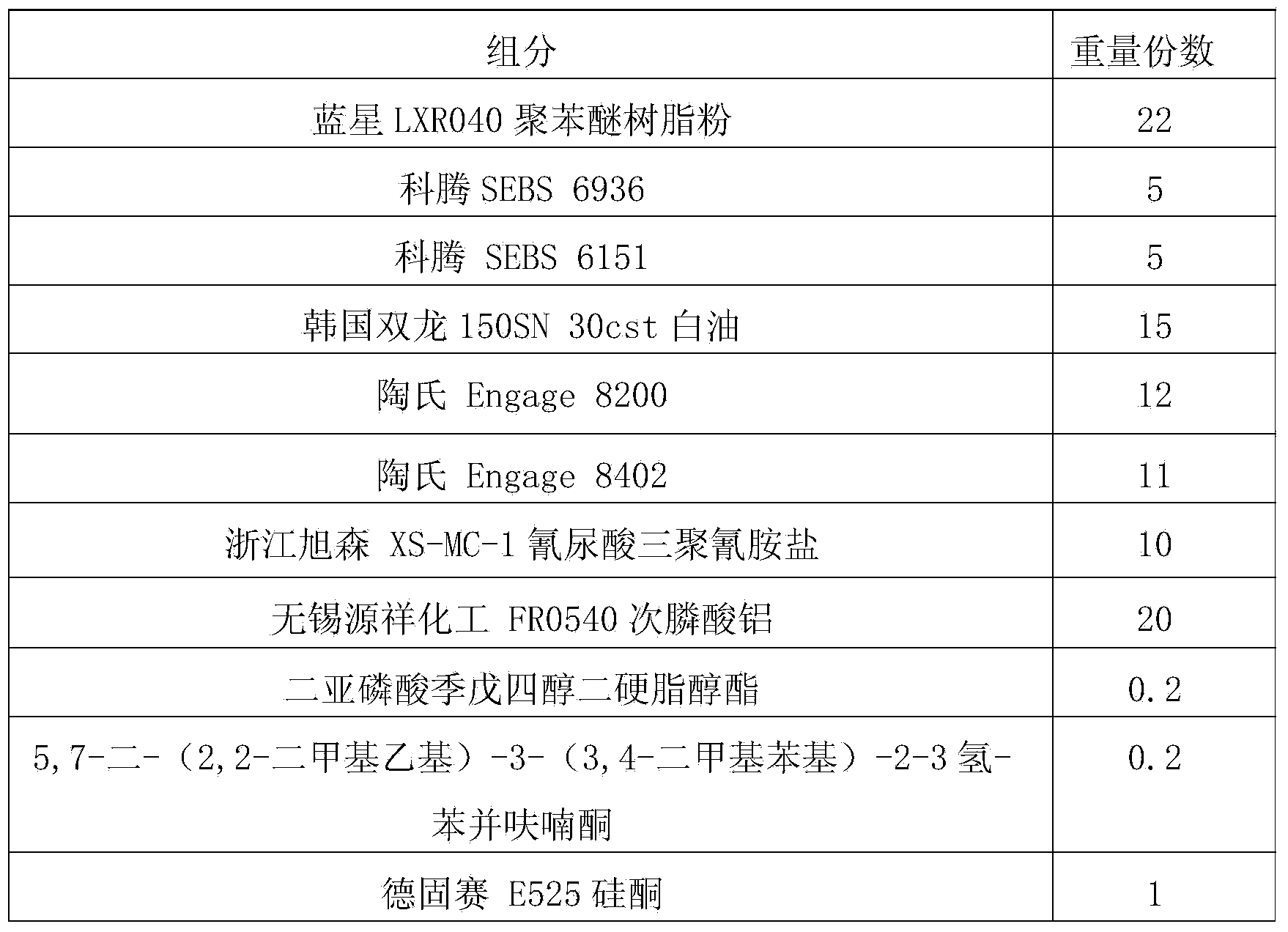

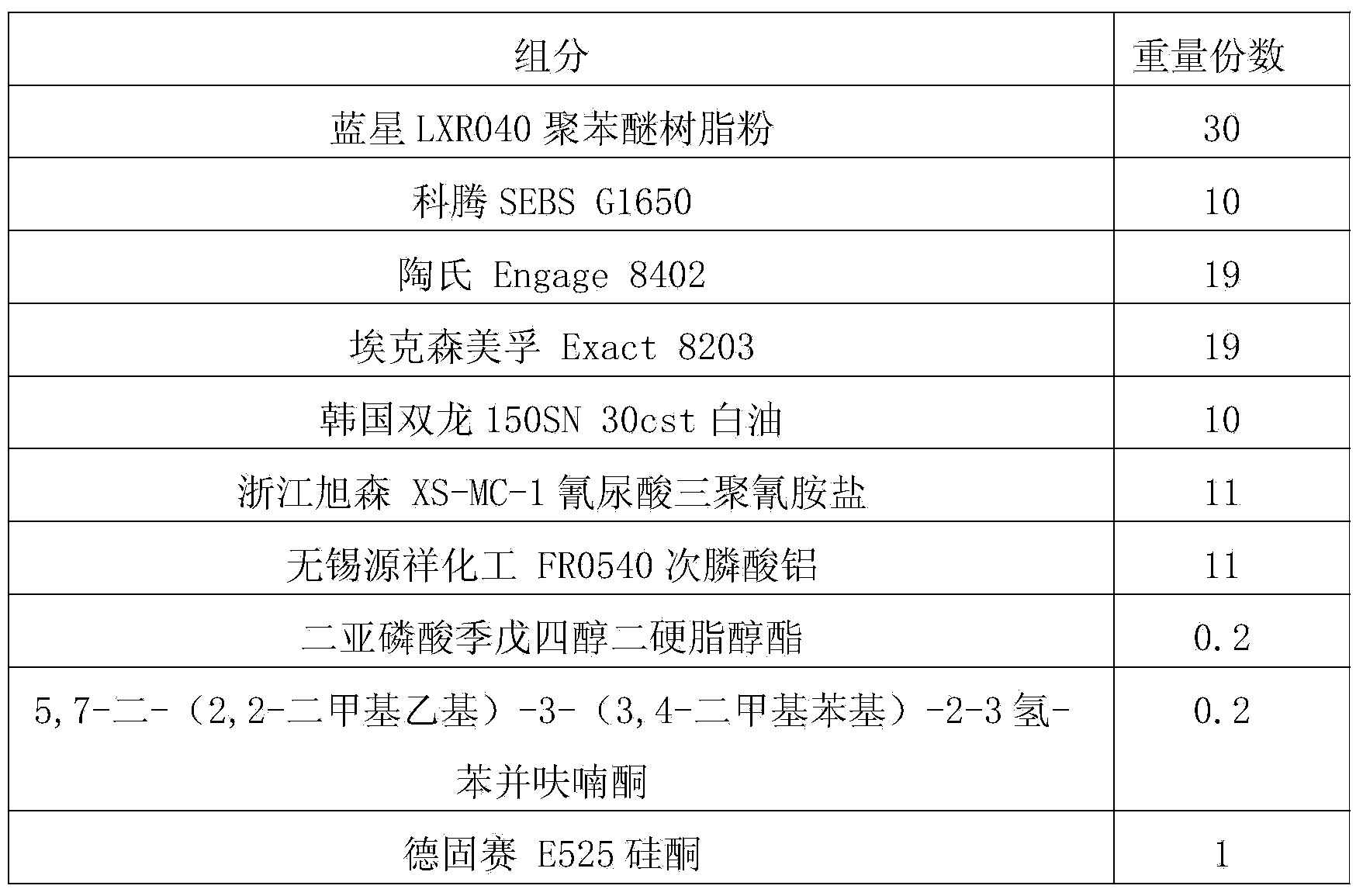

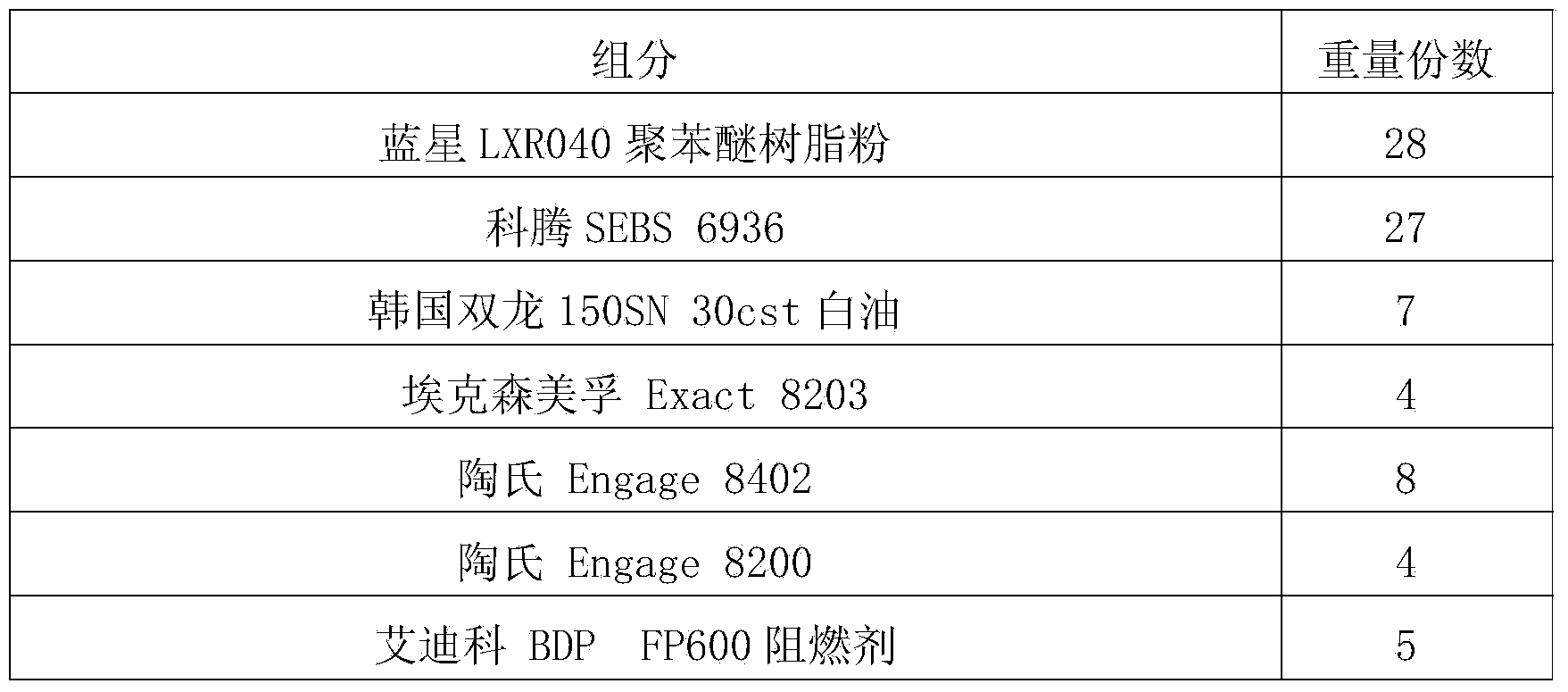

Thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material and preparation method thereof

ActiveCN103910990ASimplify the proportioning processSimplify the manufacturing processThermoplasticElastomer

The invention discloses a thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material and a preparation method thereof. The cable material is used for a soft type electric wire and cable coating, and comprises the following components: polyphenyl ether resin powder, styrene-series elastomers, a plasticizer, a polyolefin elastomer, a compound phosphor-nitrogen flame retardant, an antioxidant and a lubricant. The material components are uniformly stirred in a high-speed mixer, extruded by a twin-screw extruder, pelletized in water, dried and then packaged to obtain a thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material finished product. The thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material designed by the invention has excellent performance such as good processing performance, halogen-free and flame-retardant performance, low density, high tensile strength, good scraping resistance, good softness, good low temperature resistance, capacity of being extruded at a processing temperature of 200 DEG C-280 DEG C and not decomposed, free of cracks on a sample sheet for seven days under a high-temperature high-humidity environment with 98% humidity and a temperature of 85 DEG C, free of precipitates on surface, and the like.

Owner:JIANGSU LINRY NEW MSTAR TECH

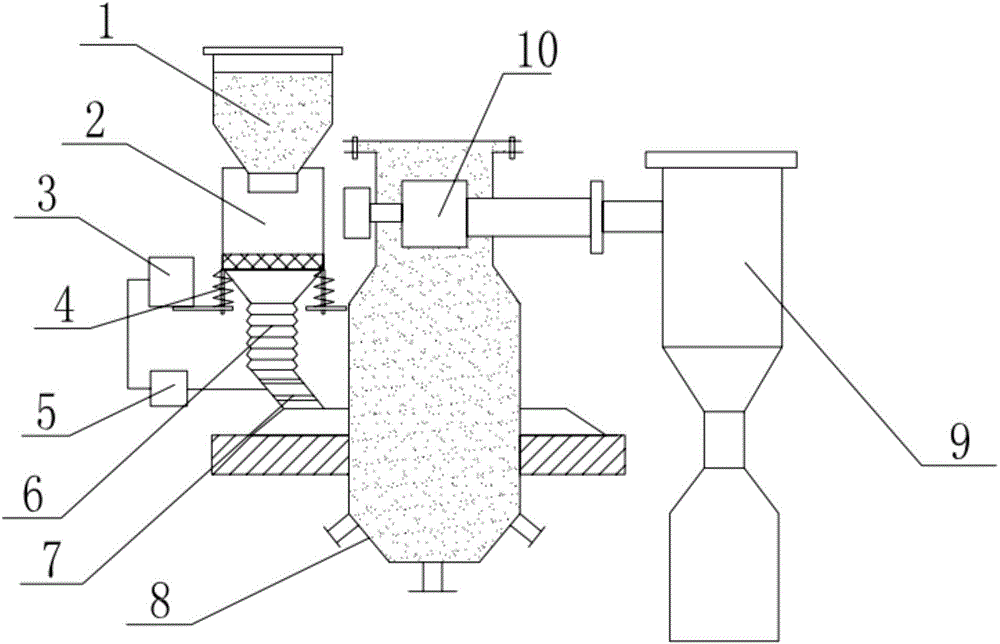

Production technology of Nd-Fe-B (neodymium-iron-boron) permanent-magnet material and corresponding jet-milling crusher

The invention relates to a production technology of an Nd-Fe-B (neodymium-iron-boron) permanent-magnet material and a corresponding jet-milling crusher. The technology sequentially comprises steps as follows: mixing, smelting, hydrogen decrepitation, jet-milling, shaping and sintering, wherein smelted cast sheets become particles in the range of 45-355 mu m due to the hydrogen decrepitation technology. The technology is characterized in that the particles of overlarge sizes are sieved and separated out by the aid of a screen of 60-80 meshes firstly during blanking in the jet-milling step, and then the particles enter a milling chamber. According to the production technology and the corresponding jet-milling crusher, the particles of ideal sizes are separated by the aid of a sieving structure, the milling speed is increased, and liquid-phase sintering is facilitated.

Owner:NINGBO HUAHUI MAGNETIC IND

Elevator cable with high safety factor

InactiveCN102087889AGood chemical stabilityImprove aging performanceBiocidePest repellentsProtection layerElectrical and Electronics engineering

The invention provides an elevator cable with a high safety factor. A sheath of the elevator cable comprises an outer sheath, a safety protection layer and an inner sheath, wherein the raw material formula of the outer sheath contains 0.5-5wt% of antibacterial ratproof drug components; and the matrix resin of the outer sheath is fluororubber. In the invention, the high safety factor operating condition is provided in the aspect of non-electrical property design capability, so the elevator cable is suitable for working continuously and uninterruptedly in any extremely harsh environment.

Owner:江苏河阳线缆有限公司 +1

High-potential gradient zinc oxide voltage piezo-resistor material and preparation method thereof

The invention discloses a high-potential gradient zinc oxide piezo-resistor material and a preparation method thereof. The piezo-resistor material is prepared from industrial superior ZnO powder having the purity being greater than or equal to 99.97%, analytically pure raw materials Bi2O3, Co2O3, Sb2O3, MnCO3, Ni2O3, Y2O3 and Nb2O5 having the purity being greater than or equal to 99%, and independently prepared lead-free superfine silver glass powder. A 300V / mm-500V / mm high-potential gradient zinc oxide piezo-resistor can be prepared by virtue of the steps of accurately weighing the raw materials, evenly mixing the raw materials, pre-sintering after drying, crushing, granulating, molding by dry-pressing, degumming, performing microwave sintering, and then performing surface electric polarization, welding and encapsulating. According to the preparation method, the independently prepared lead-free superfine silver glass powder is added, and the microwave sintering technology and the pre-sintering technology are adopted to effectively overcome the intrinsic defects of the product due to abnormal crystal grain growth, and finally, the prepared high potential gradient zinc oxide voltage dependent resistor is excellent in electrical properties.

Owner:GUANGXI NEW FUTURE INFORMATION IND

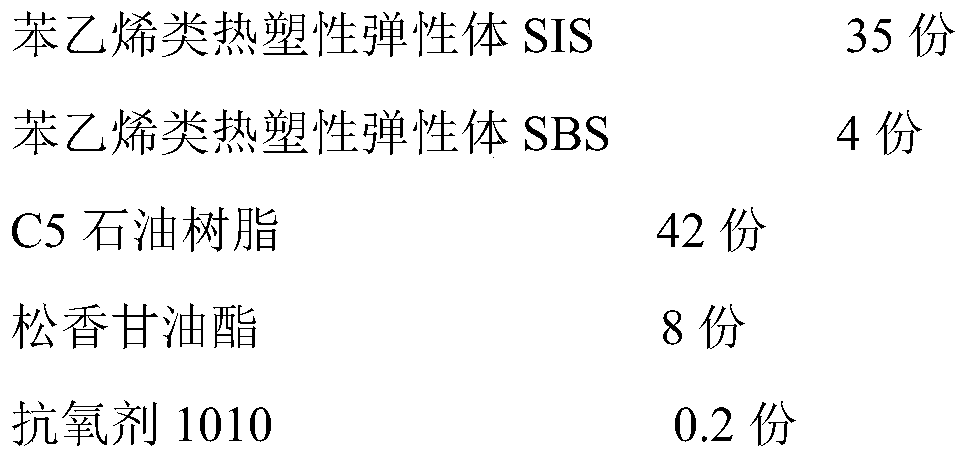

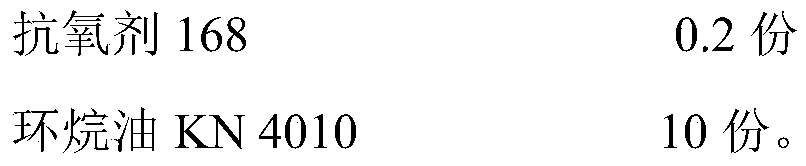

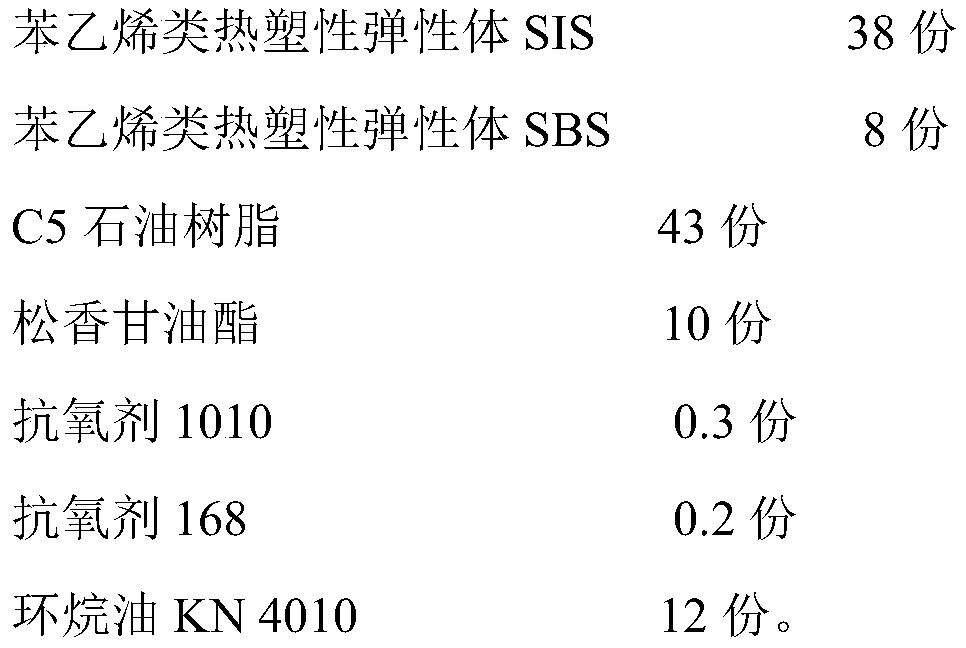

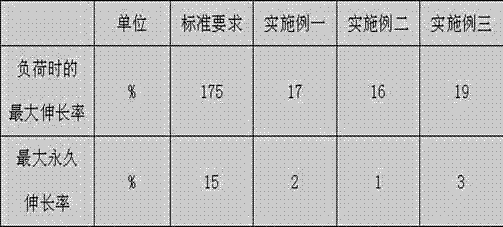

Hot-melt pressure sensitive adhesive for adhesive tapes, and preparation method thereof

InactiveCN110437778AImprove ring tackImprove peel forceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPetroleum resinAntioxidant

The invention relates to a hot-melt pressure sensitive adhesive, and concretely relates to a hot-melt pressure sensitive adhesive for adhesive tapes, and a preparation method thereof. The hot-melt pressure sensitive adhesive comprises a styrenic thermoplastic elastomer SIS, a styrenic thermoplastic elastomer SBS, petroleum resin, rosin glyceride, a primary antioxidant, an auxiliary antioxidant anda softener, wherein the styrenic thermoplastic elastomer SIS is a linear structure, the styrene content is 20-28%, and the diblock content is 20-28%; and the styrenic thermoplastic elastomer SBS is astar structure, the styrene content is 28-32%, and the diblock content is 12-18%. The purpose of the invention is to solve the problem of poor use performance of the adhesive tapes, caused by failedcombination of the initial adhesion, the permanent adhesion and the aging resistance of existing hot-melt pressure sensitive adhesives for adhesive tapes. The initial adhesion (the initial adhesion includes ring initial adhesion and 180 DEG peel strength) of the hot-melt pressure sensitive adhesive of the invention meets use requirements, and has a high adhesion and a good aging resistance. The present invention also provides the preparation method of the hot-melt pressure sensitive adhesive for adhesive tapes.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

Antistatic flame-proof light high-intensity resin steel mesh composite tube and production technique

ActiveCN101012901AImprove corrosion resistanceImprove aging performanceNon-macromolecular adhesive additivesRigid pipesFiberAntistatic agent

The invention relates to an anti-static fireproof light high-strength resin steel network composite tube and relative production. The tube comprises three layers as the liner layer with anti-leakage or abrasion-resistant function, a strength layer coiled by strength fiber and added steel base material, and a surface layer coiled with dense fiber at the face. The invention is characterized in that: 1, the composite adhesive solidifier of liner layer (1) is added with 5-10 deals of glass scales and / or 5-15 deals of graphite scales; 2, each 100 deals of resin of composite adhesive solidifier is added with 0.5-5 deals of antioxidant; 3, each 100 deals of resin of composite adhesive solidifier is added with 2-10 deals of short tangent fiber to form slurry composite adhesive solidifier coiled with the mesh steel wire to form the strength layer.

Owner:TANGSHAN JIAJI COMPOSITE PIPE CORP

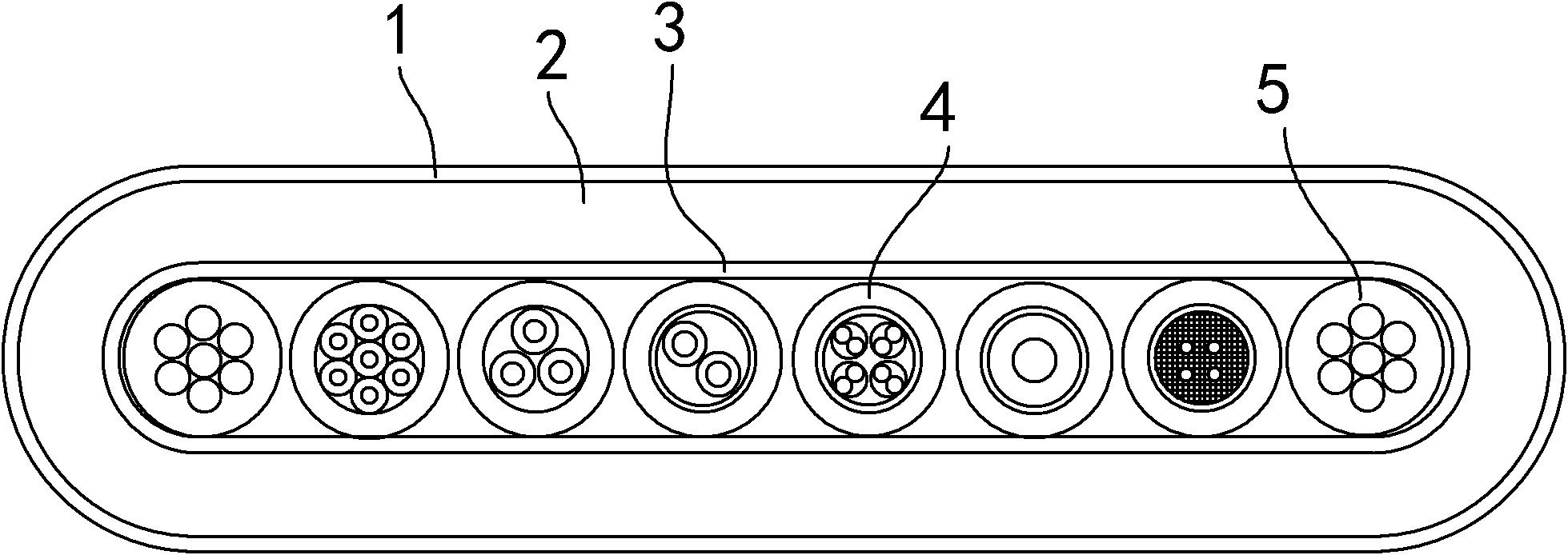

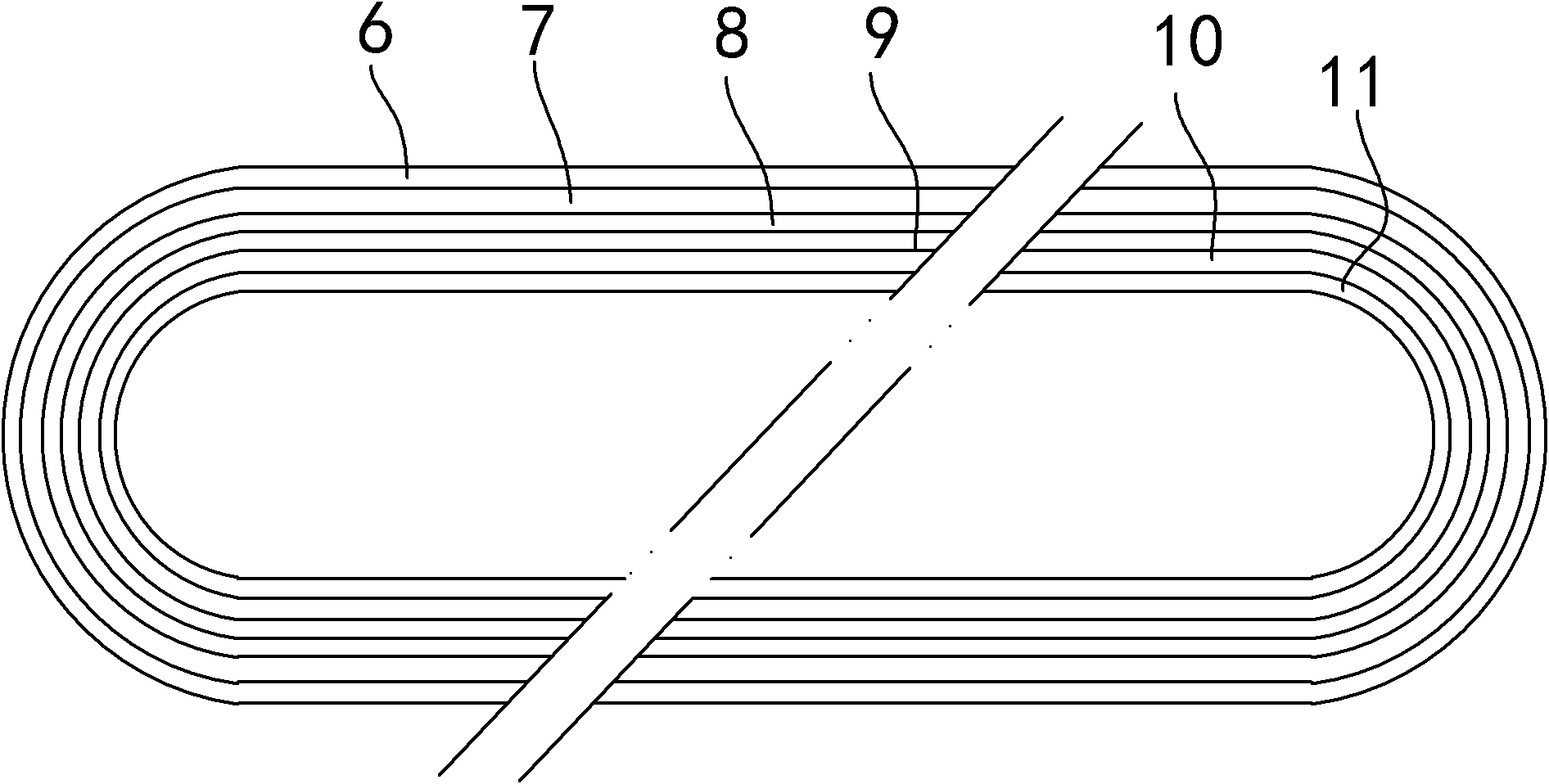

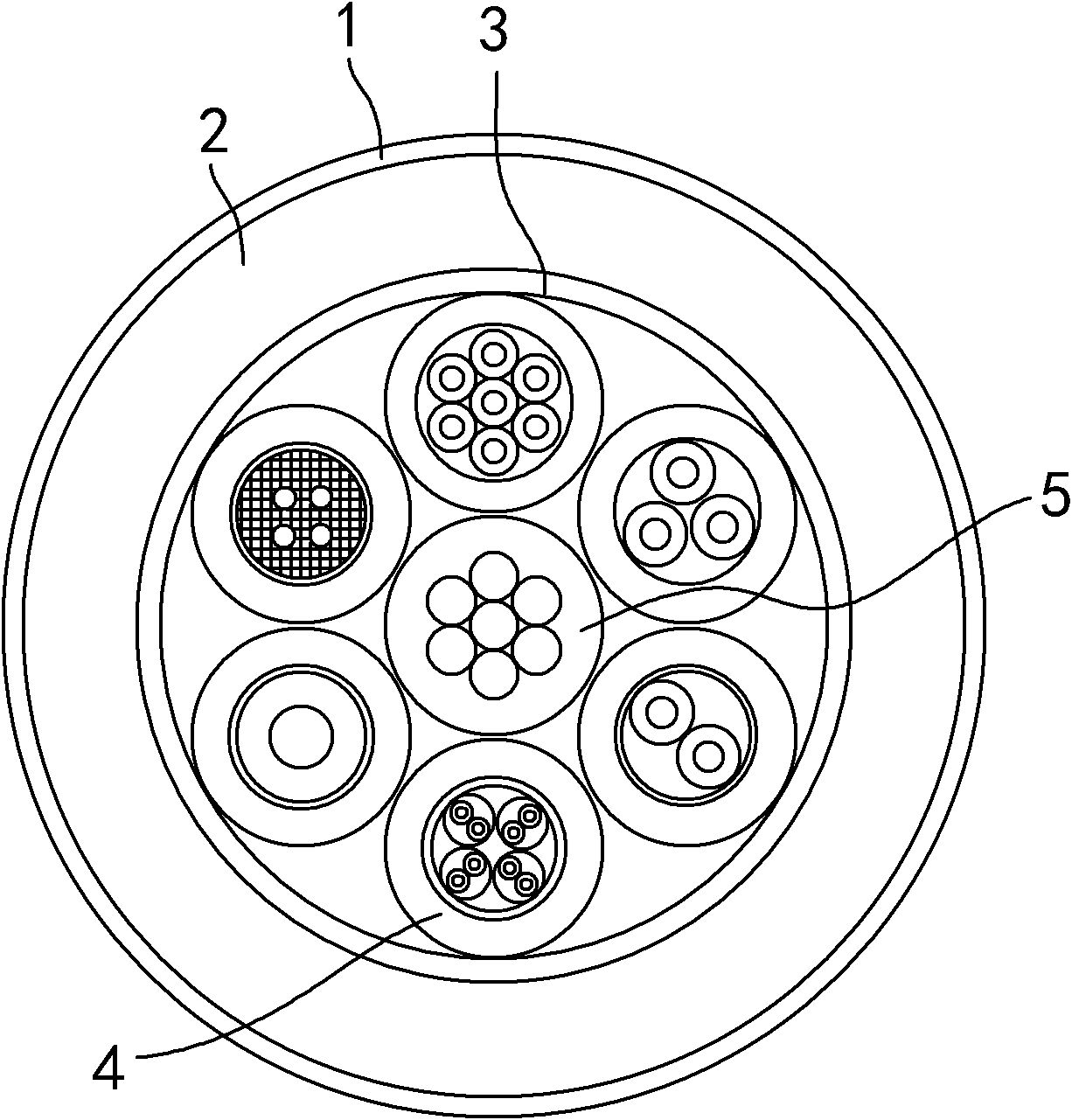

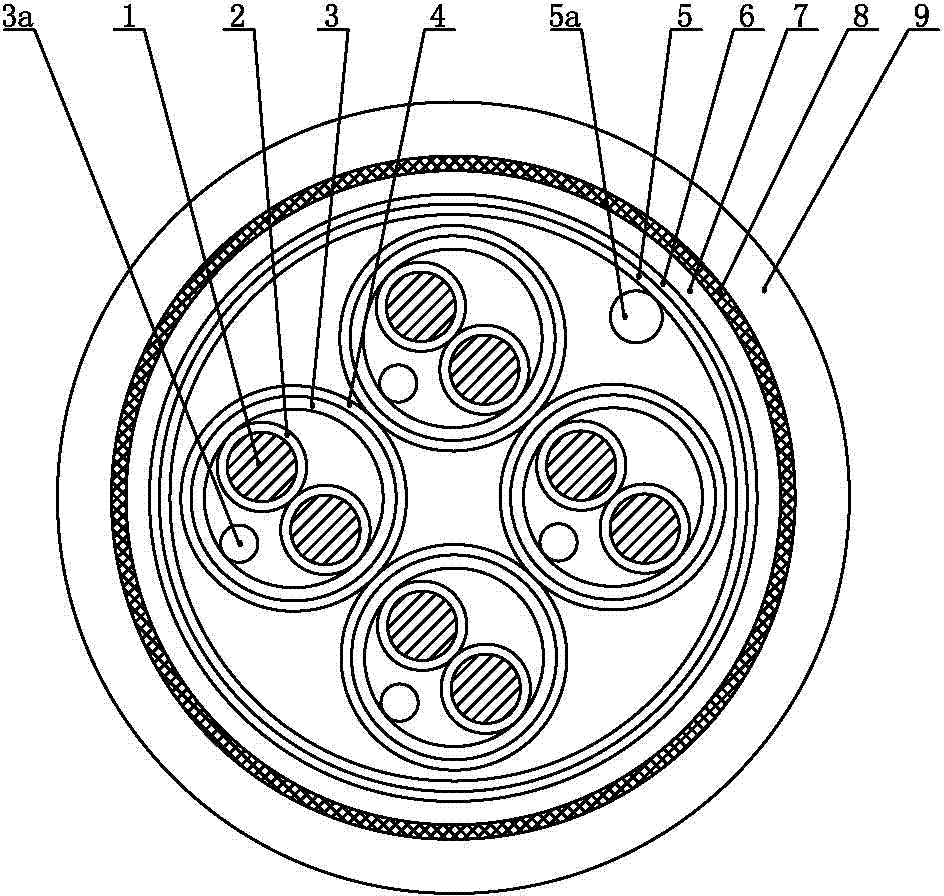

Whitening ultraviolet-proof double-shield instrument cable for ships and manufacturing method thereof

InactiveCN102969046AColor whiteGood physical and mechanical propertiesClimate change adaptationInsulated cablesCopper foilInsulation layer

The invention relates to a whitening ultraviolet-proof double-shield instrument cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form an insulation wire core; every two insulation wire cores are twisted to form twisted wire pairs; each twisted wire pair is wrapped with a wire core copper foil polyester composite tape shielding layer at the periphery; the wire core copper foil polyester composite tape shielding layers are each wrapped with a wire core polyester tape at the periphery to form a pair-twist group; all the pair-twist groups are stranded to the right at 16-24 times of stranding lay ratio to form a cable core; the cable core is wrapped with a cable core copper foil polyester composite tape shielding layer at the periphery; the cable core copper foil polyester composite tape shielding layer is wrapped with a cable core polyester tape at the periphery; an inner sheath is extruded at the periphery of the cable core polyester tape; the inner sheath is coated with a copper alloy wire weaving armor layer at the periphery; and an outer sheath is extruded at the periphery of the copper alloy wire weaving armor layer. The insulation layer of the double-shield cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com