Nitrine solid propellant and preparation process thereof

A kind of solid and propellant technology, applied in the direction of offensive equipment, compressed gas generation, explosives, etc., can solve the problems of insufficient mechanical properties and bonding properties, restrictions on the flexibility of the polymer main chain, and difficult mechanical properties of propellants, etc., to achieve Good aging resistance, improved tensile strength and elongation, good aging performance and energy performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

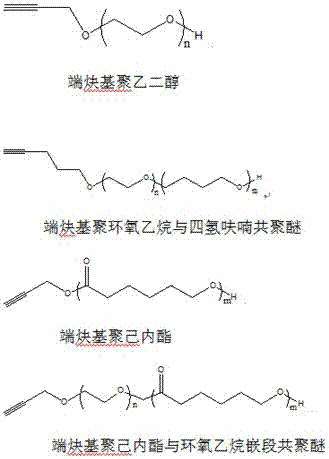

[0045] (1) Synthesis of alkynyl-terminated polyethylene glycol

[0046] Pour 0.2g of propargyl alcohol into a 250ml three-necked flask, add 2g of catalyst boron trifluoride ether, stir evenly, and slowly add 10g of ethylene oxide dropwise through a constant pressure dropping funnel under cooling in an ice-water bath, and stir for a certain period of time After that, the reaction system became viscous, and a certain amount of deionized water was added to terminate the reaction. Neutralize with 10% sodium carbonate solution to make the pH of the system = 7, then add deionized water to wash to remove impurities and low molecular weight products, heat the mixture, let it stand to separate layers, and separate the liquid through a separatory funnel. The product is dehydrated by the method of pressure distillation to obtain the product terminal alkyne group polyethylene glycol, molecular weight M n = 4450 g / mol (GPC). The structural formula is as follows:

[0047]

[0048] (2)...

Embodiment 2

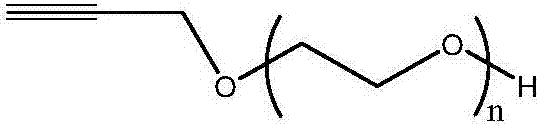

[0053] (1) Synthesis of alkynyl-terminated polyethylene oxide and tetrahydrofuran copolyether

[0054] Add 2.0g of 3-butyn-1-ol, 50.0ml of tetrahydrofuran, and 3.0g of boron trifluoride·ethyl ether into a 250ml three-neck flask in turn, cool the reaction vessel to below -5°C, keep it warm for 30min, and then add dropwise to the reaction solution 50.0ml of ethylene oxide, the rate of addition is controlled so that the temperature of the reaction system does not exceed 30°C (dropping is completed in 1h to 2h), and then the reaction is continued for 3h to 6h, adding 1% aqueous alkali solution to destroy the catalyst, stirring for 15min to 30min, and standing Separate the layers, take out the oil layer, filter off the residue, remove unreacted monomer and water, obtain the product, the molecular weight is 3330g / mol (GPC), and the molecular structure of the product is as follows:

[0055]

[0056] (2) Composition of azide solid propellants

[0057]

[0058] (3) Performance o...

Embodiment 3

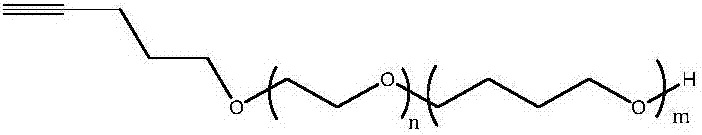

[0061] (1) Synthesis of alkyne-terminated polycaprolactone

[0062] Put a clean and dry 1000ml three-neck flask in an oil bath at 120°C for heating, and pass nitrogen gas to remove impurities such as moisture and oxygen in the reaction vessel. Then raise the temperature of the oil bath to 140°C-160°C, add 200ml of caprolactone monomer, 2.0ml of initiator propargyl alcohol and 1.0g of catalyst anhydrous zinc acetate, stir and react for 8 hours under nitrogen protection, and stop heating , continue stirring with nitrogen, and stop the reaction when the temperature of the reaction solution drops below 50°C. The resulting alkynyl-terminated polycaprolactone was cooled under nitrogen protection, dissolved in 200ml of chloroform, reprecipitated with 100ml of methanol, and filtered to obtain alkynyl-terminated polycaprolactone, and then dried in a vacuum oven at 50°C. Obtain product, molecular weight is 2560g / mol (GPC), and the molecular structure of product is as follows:

[0063]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com