Patents

Literature

1734results about "Pressure gas generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

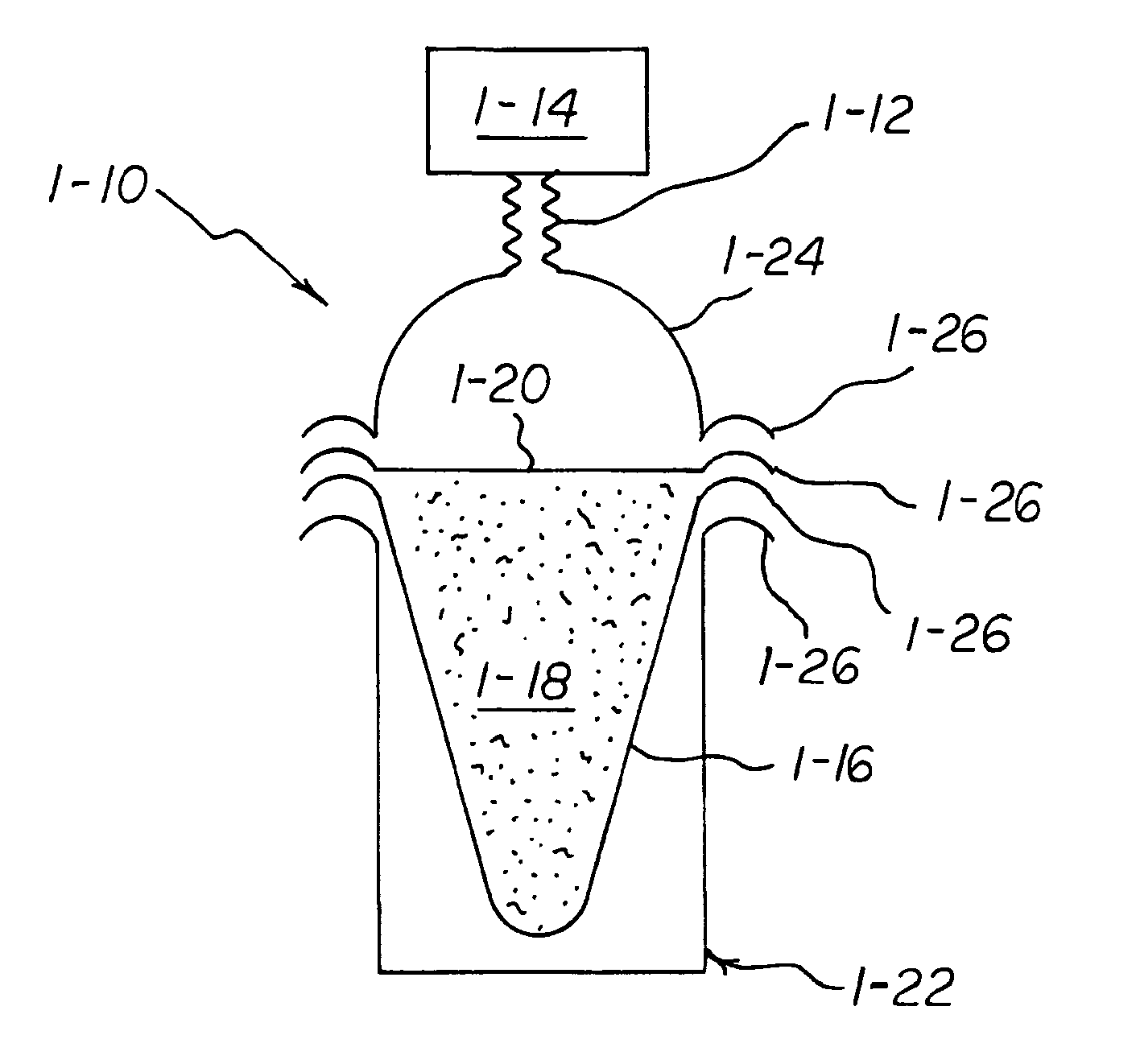

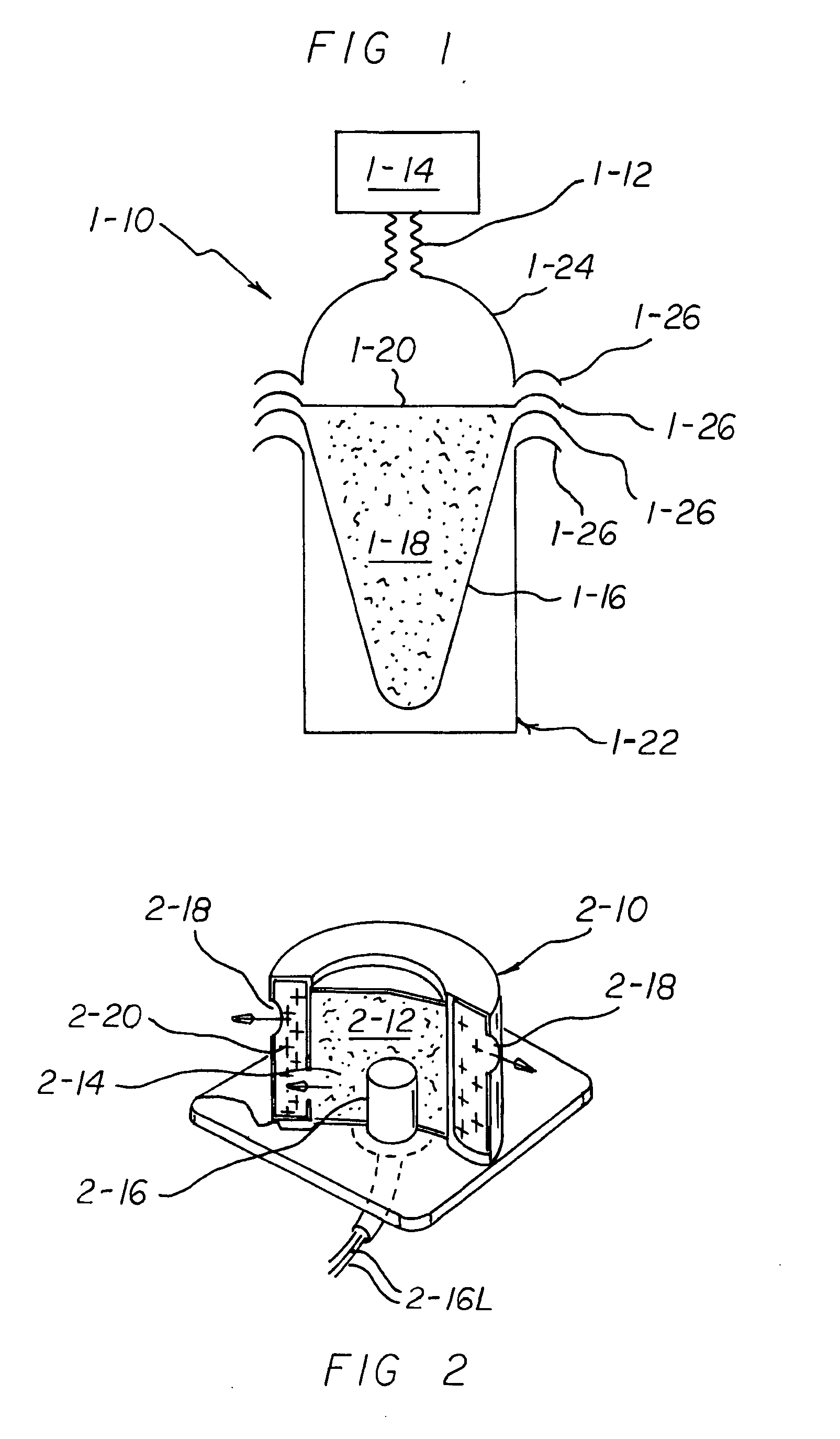

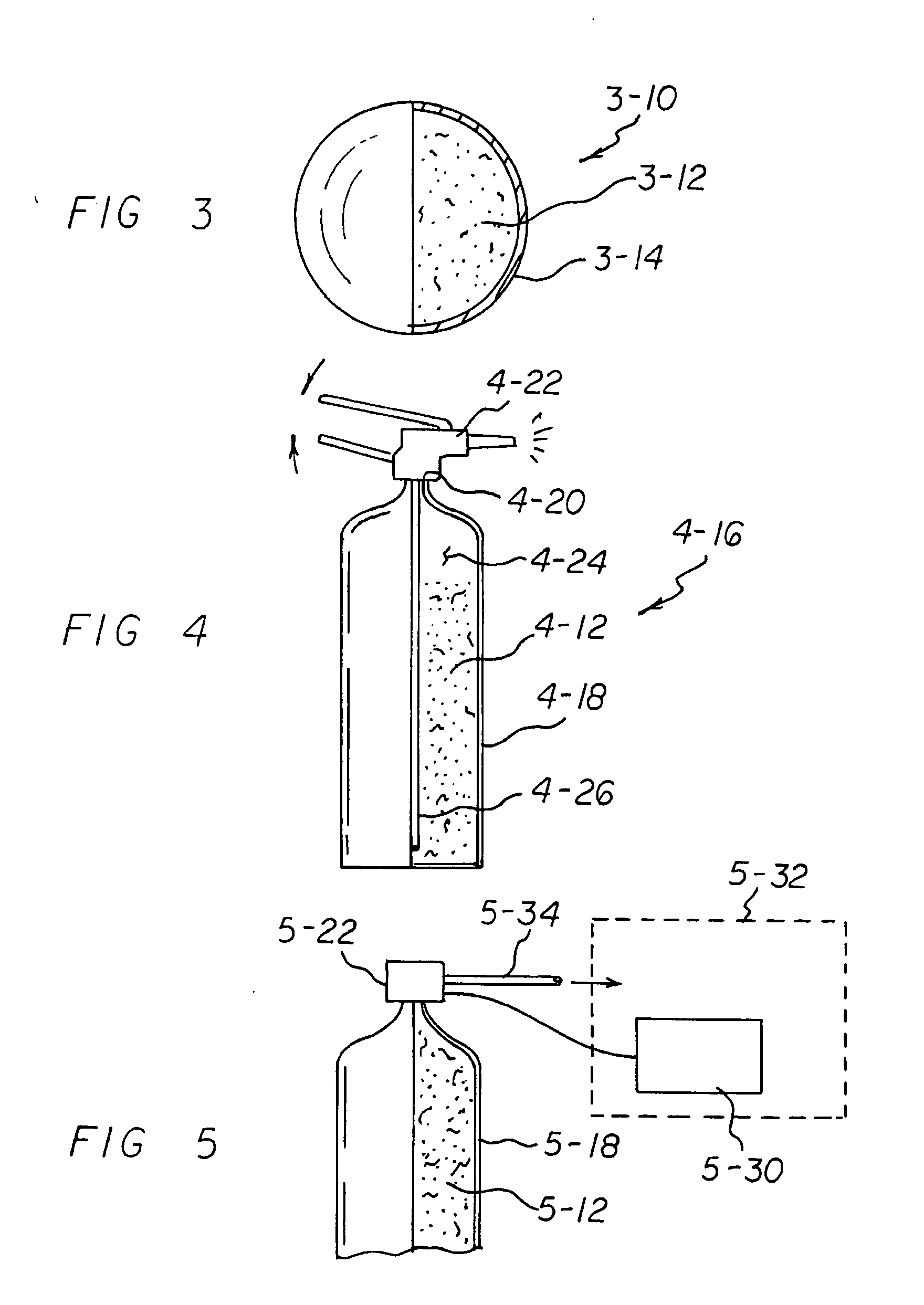

Method and apparatus for vaporizing a compound

ActiveUS7458374B2Heating fastBurn quicklyOther heat production devicesAerosol deliveryInhalationMedicine

Disclosed is a method and device for rapid heating of a coated substance which preferably includes a drug to vaporized for inhalation therapy. A device in accordance with the present invention preferably includes a substrate which has an interior surface surrounding an interior region and an exterior surface upon which the coated substance is to be adhered. Though the substrate is preferably metallic, it does not need to be. A combustible element is placed in the interior region of the rigid substrate and an igniter is connected to the combustible element. The igniter is for initiating oxidation of the combustible element. Preferably, the coated substance is vaporized inside of a housing to allow the vaporized drug to aerosolize and be inhaled by a user.

Owner:ALEXZA PHARMA INC

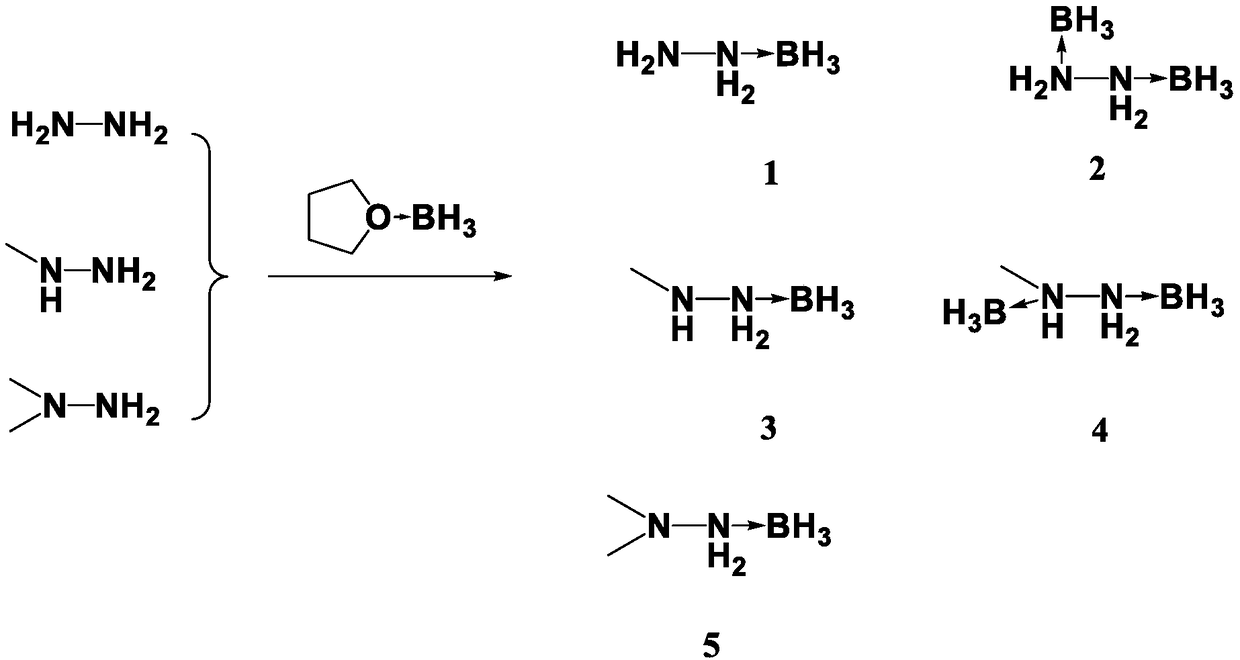

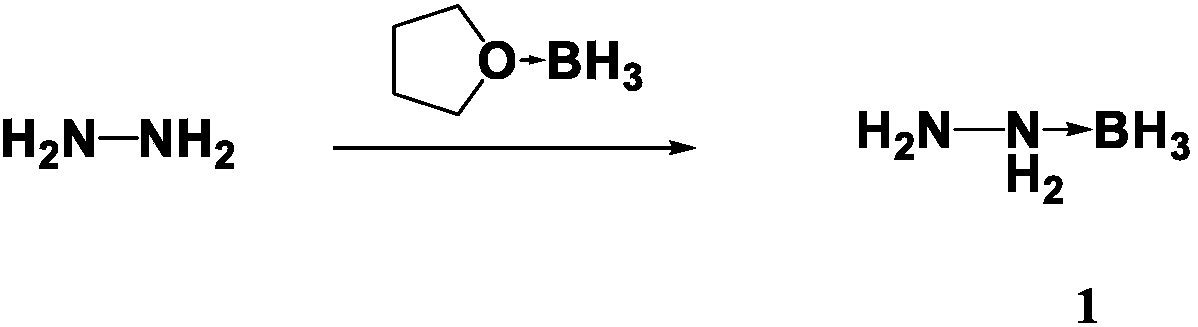

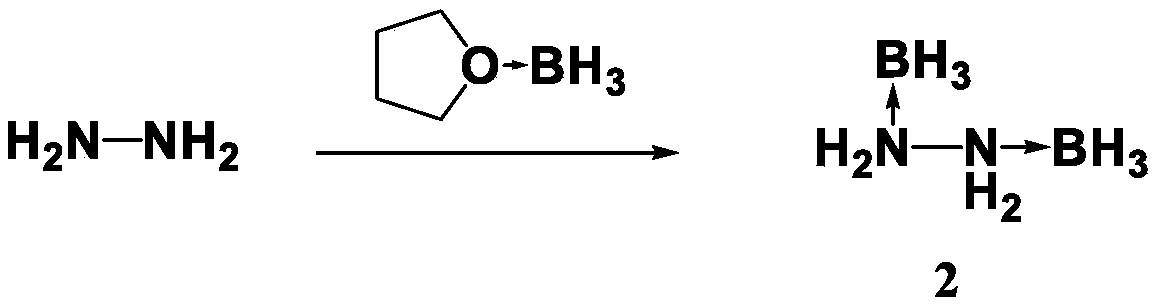

Preparation method for propellant fuel

InactiveCN108910843AShorter ignition delay timeHazard reductionOrganic chemistryHydrazineEvaporationIgnition delay

The invention discloses a preparation method for propellant fuel. The preparation method comprises the following steps: uniformly mixing hydrazine or a methyl derivative thereof with a tetrahydrofuransolution of borane to perform a reaction, and after the reaction, performing rotary evaporation on the tetrahydrofuran solution to obtain a first product; adding a first solvent into the first product, then performing washing, and then performing rotary evaporation to remove the first solvent, so as to obtain a hydrazinoborane derivative. According to the method, hydroboration is carried out on ahighly-volatile hydrazine fuel and a methylated derivative of hydrazine, the obtained borohydride of the hydrazine is a colorless non-volatile liquid or a white solid, has no volatility and greatly reduces hazard of the hydrazine fuel, and is a novel aerospace propellant fuel since the ignition delay time of the hydrazine borofluoride is extremely short.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

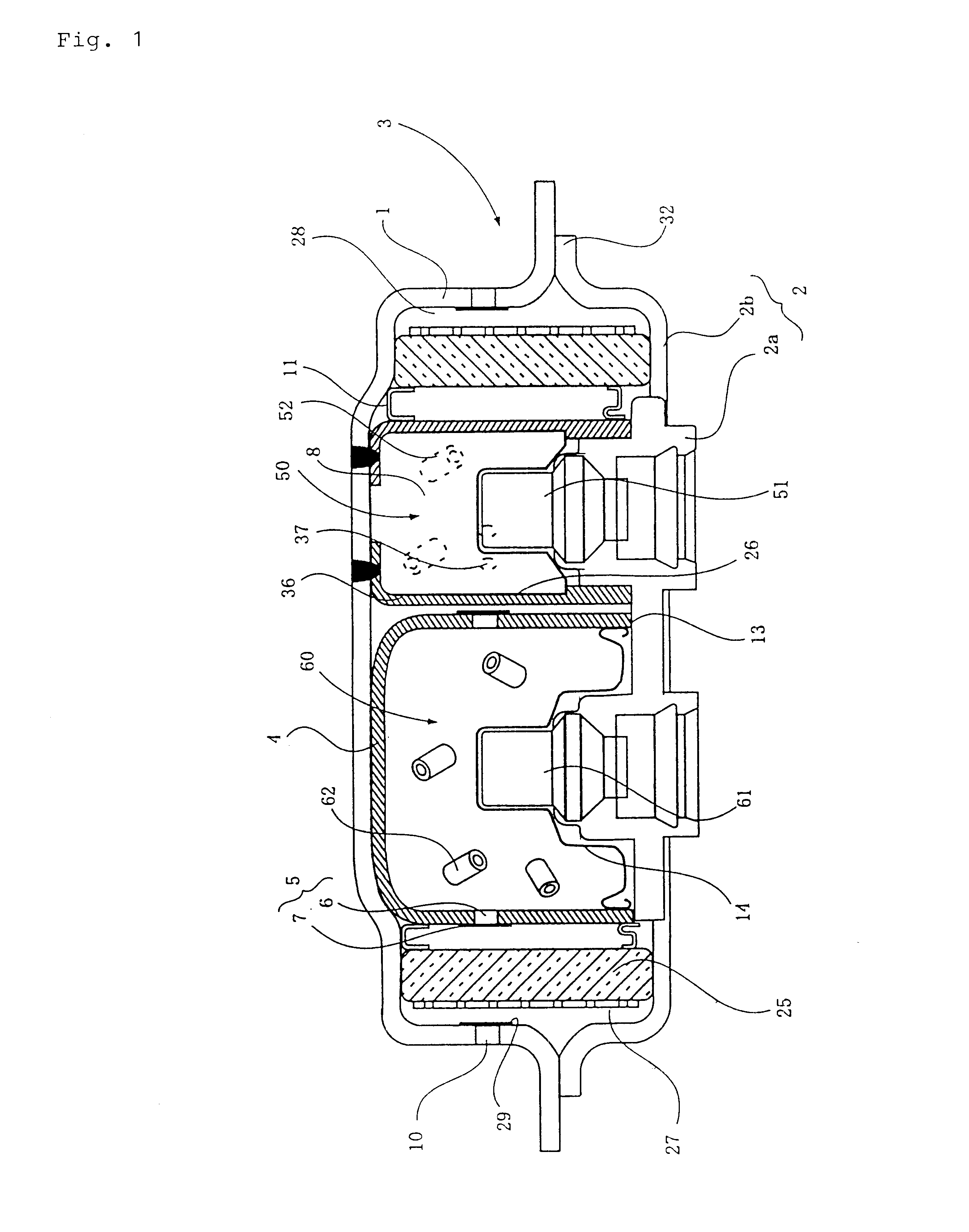

Dual stage inflator

InactiveUS6474684B1Reduced weight and sizeFew constraintsPedestrian/occupant safety arrangementIgnitorsDual stageEngineering

A non-hybrid pyrotechnic filterless inflator, i.e., gas generator, for an automotive passive restraint air bag having a generally discoidally-shaped pressure vessel having a diameter that preferably is greater than or about equal to its height formed of a cup-shaped closure cap and a base member and having at least one exhaust nozzle for directing gaseous products out of the inflator and into the air bag. The pressure vessel contains two separated and independently initiated initiator assemblies. By initiating either one or both initiator assemblies, the inflator can generate a modulated gas output between a first minimum output level and a second maximum output level in response to passenger and driver conditions.

Owner:TALLEY DEFENSE SYST

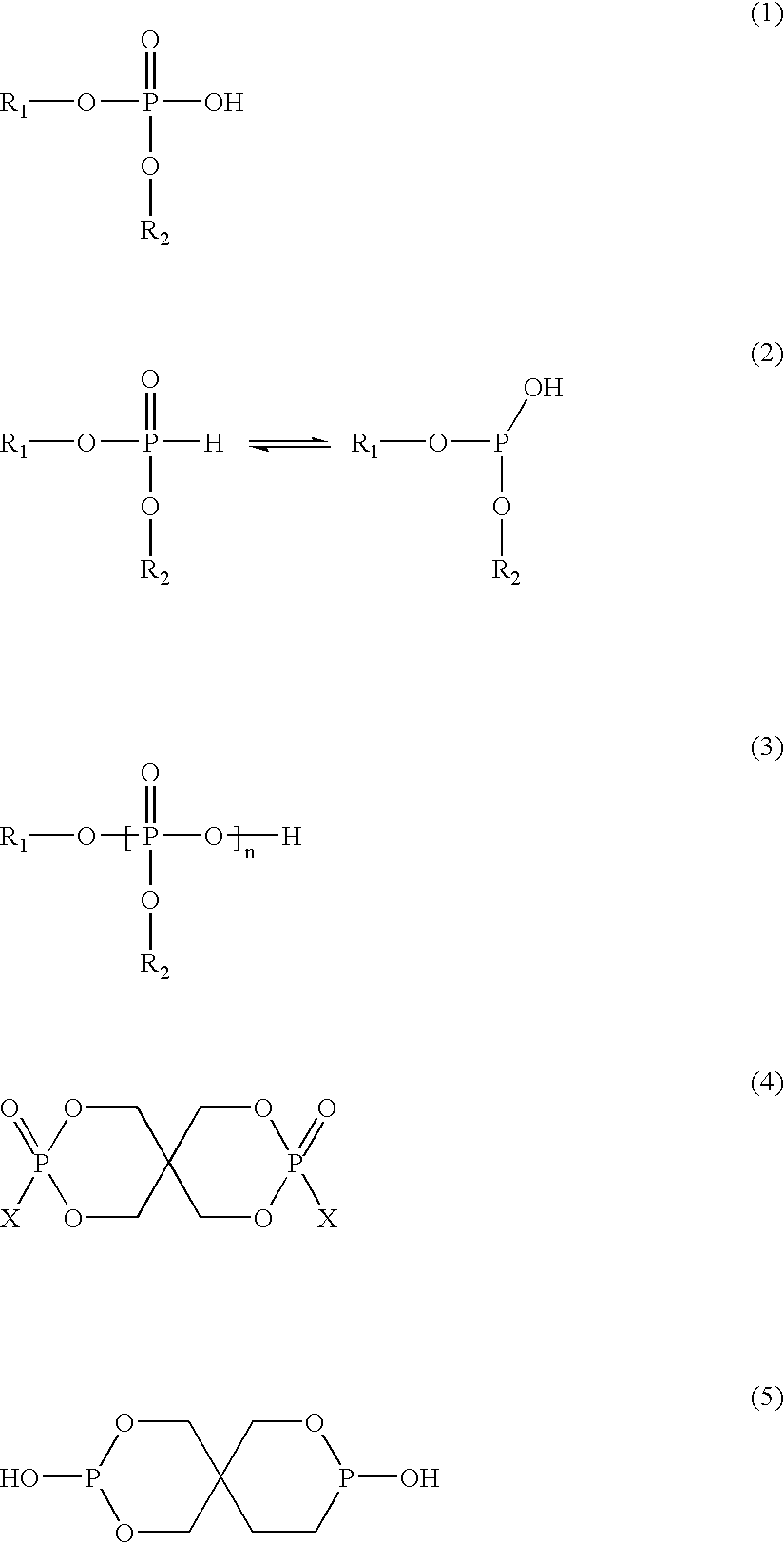

Smokeless gas generant compositions

Thermally stable gas generant compositions incorporate a combination of one or more primary nonazide high-nitrogen fuels selected from a group including tetrazoles, bitetrazoles, and triazoles, and salts thereof; and one or more secondary nonazide high nitrogen fuels selected from azodicarbonamide and hydrazodicarbonamide. The primary and secondary fuels are combined with phase-stabilized ammonium nitrate that when combusted, results in a greater yield of gaseous products per mass unit of gas generant, a reduced yield of solid combustion products, lower combustion temperatures, and acceptable burn rates, thermal stability, and ballistic properties. These compositions are especially suitable for inflating air bags in passenger-restraint devices.

Owner:AUTOMOTIVE SYST LAB

Air bag inflator with heat sink and retainer

InactiveUS6142515APart can be impactedPedestrian/occupant safety arrangementPressure gas generationHeat spreaderPropellant

An inflator (10) for inflating an inflatable vehicle occupant protection device includes a housing (20) defining a generally ring-shaped propellant chamber (200) extending around an axis (50) of the inflator. The housing (20) has a fluid outlet (52) for directing flow of inflation fluid out of the housing to the inflatable device. A quantity of ignitable propellant (240) is located in the propellant chamber for, when ignited, producing inflation fluid for inflating the inflatable device. The housing (20) has a fluid passage (90) between the propellant chamber (200) and the fluid outlet (52). The fluid passage (90), which is normally closed, opens upon actuation of the inflator (10) to enable fluid flow from the propellant chamber (200) to the fluid outlet (52). The fluid passage (90), when open, has a variable flow area depending upon the pressure in the housing (20). A heat sink (270) is located in the propellant chamber (200) between the ignitable propellant (240) and the fluid passage (90) for cooling and filtering inflation fluid flowing from the propellant chamber through the fluid passage. The inflator (10) includes a retainer (280) in the propellant chamber (200) between the ignitable propellant (240) and the fluid passage (90) for retaining the heat sink (270) in the propellant chamber upon actuation of the inflator.

Owner:TRW INC

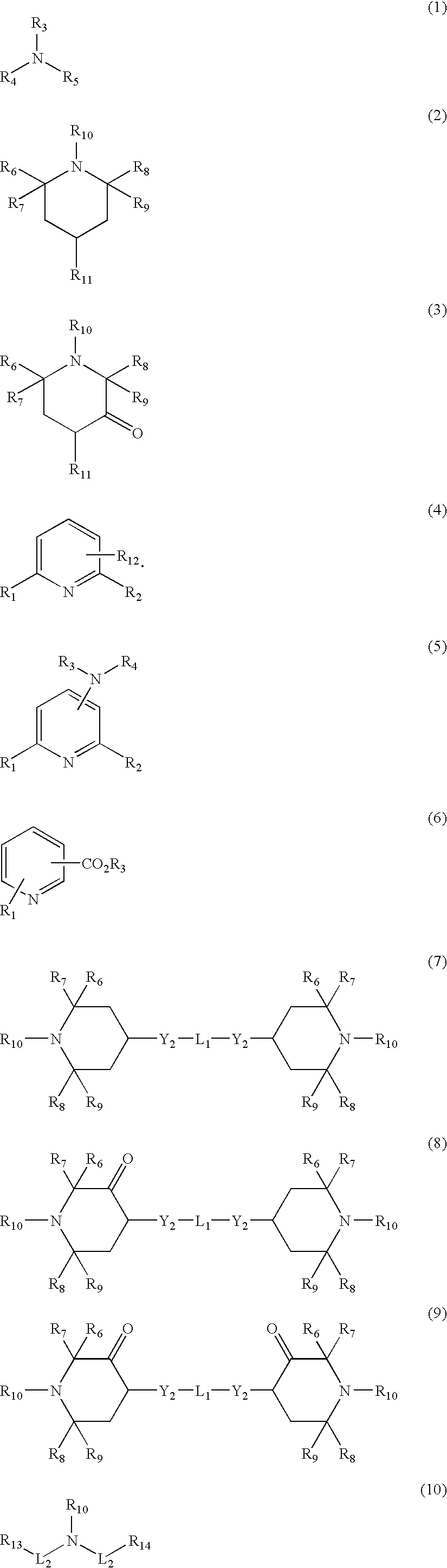

Gas generants comprising transition metal nitrite complexes

InactiveUS6077371AMetal azide explosive compositionsAlkali metal salt explosive compositionsNitriteHydrazine compound

High nitrogen gas generant compositions, useful for inflating passenger restraint gas inflator bags, comprise a nitrogen rich coordination compound selected from coordination complexes comprised of anionic nitro and nitrito ligands coordinated with a transitional metal template, and nonmetallic or nonmetallic / metallic cations. The gas generant compositions generate relatively more gas and less solids, and are safer than known gas generant compositions. Certain gas generant compositions ignite at lower autoignition temperatures thereby facilitating the use of an aluminum or light weight metal pressure vessel. Other gas generants self-deflagrate eliminating the need for other constituents in the composition. Novel methods for the synthesis of nonmetal derivative coordination complexes, guanidine and hydrazine for example, are also presented.

Owner:AUTOMOTIVE SYST LAB +1

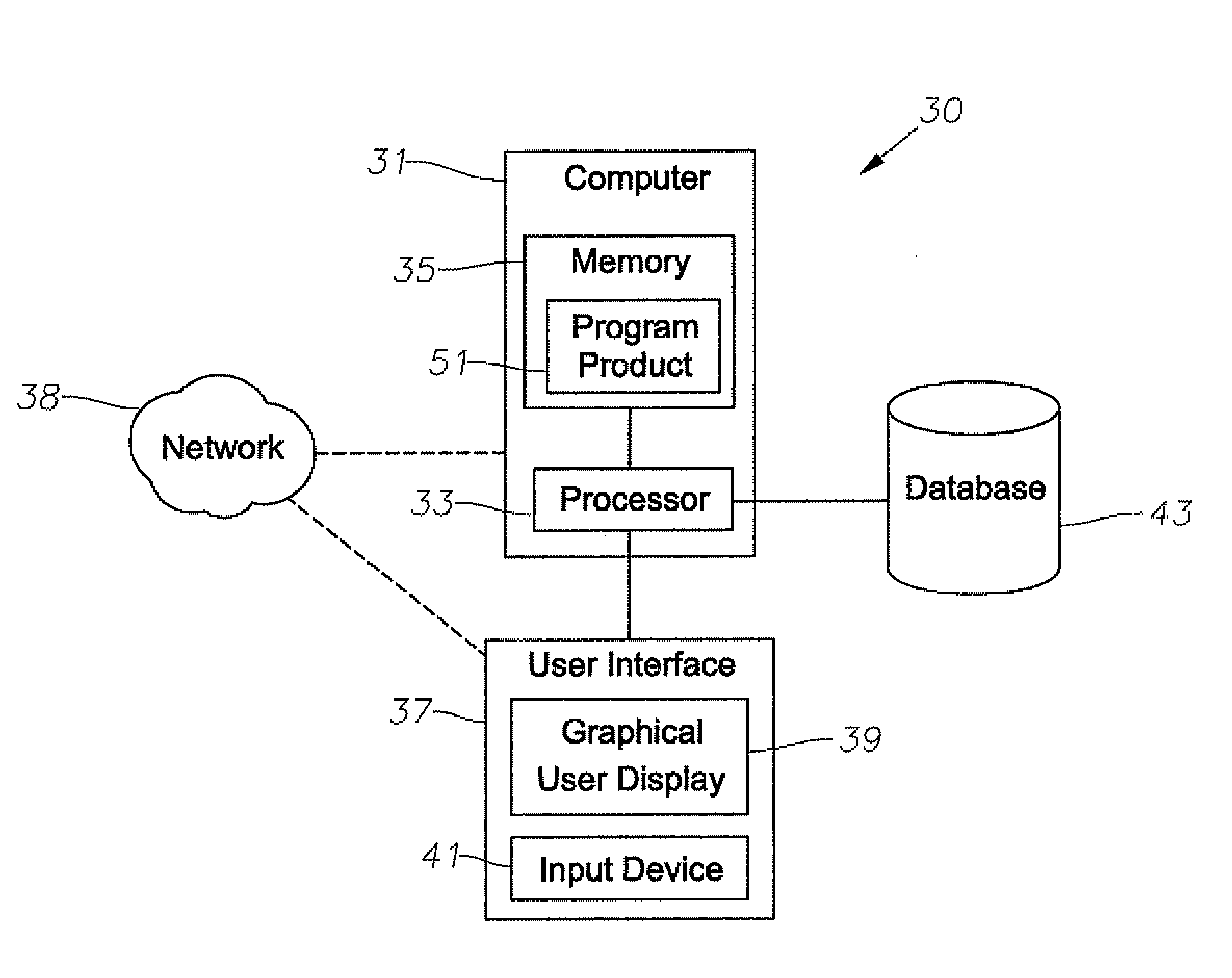

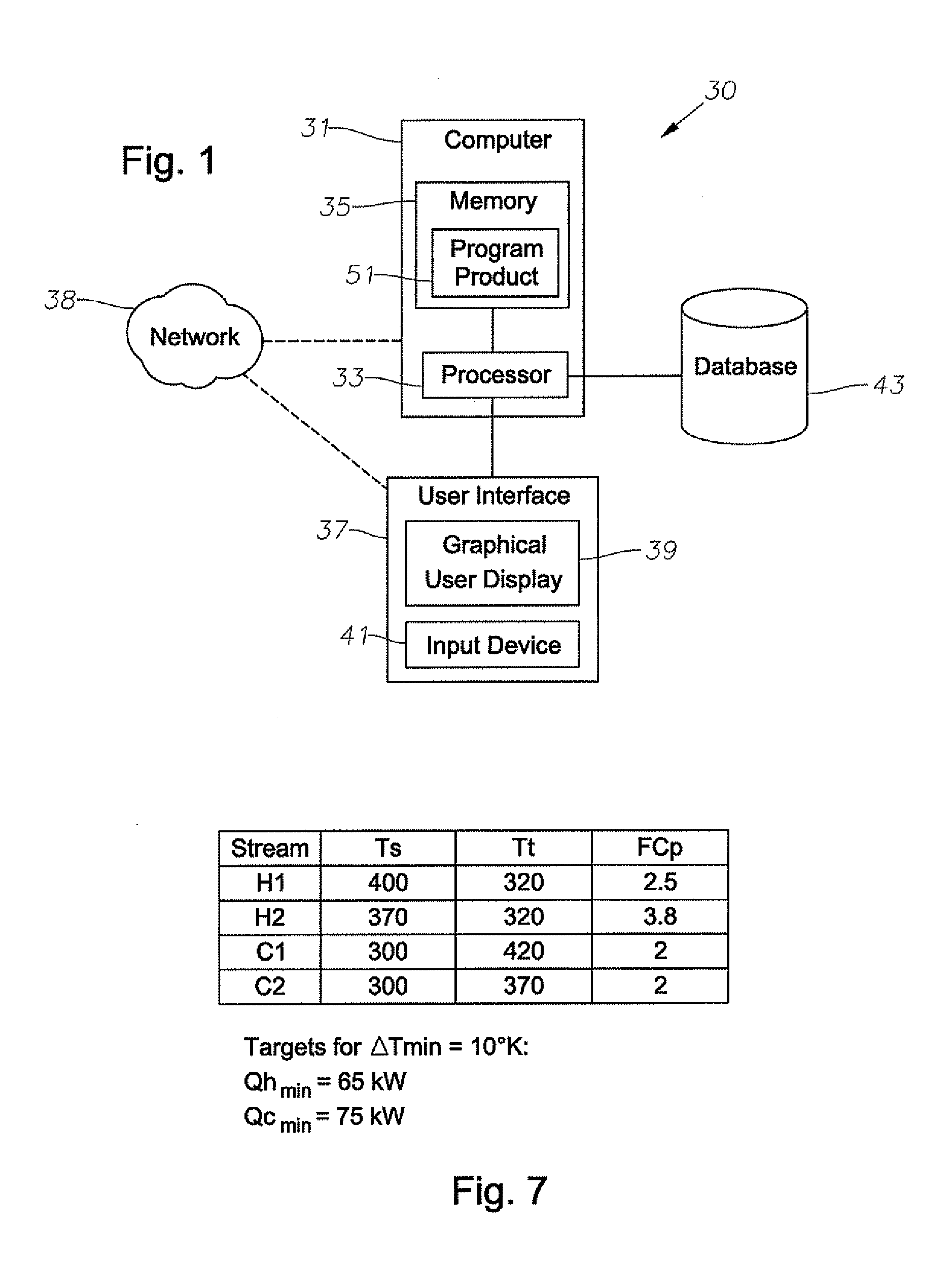

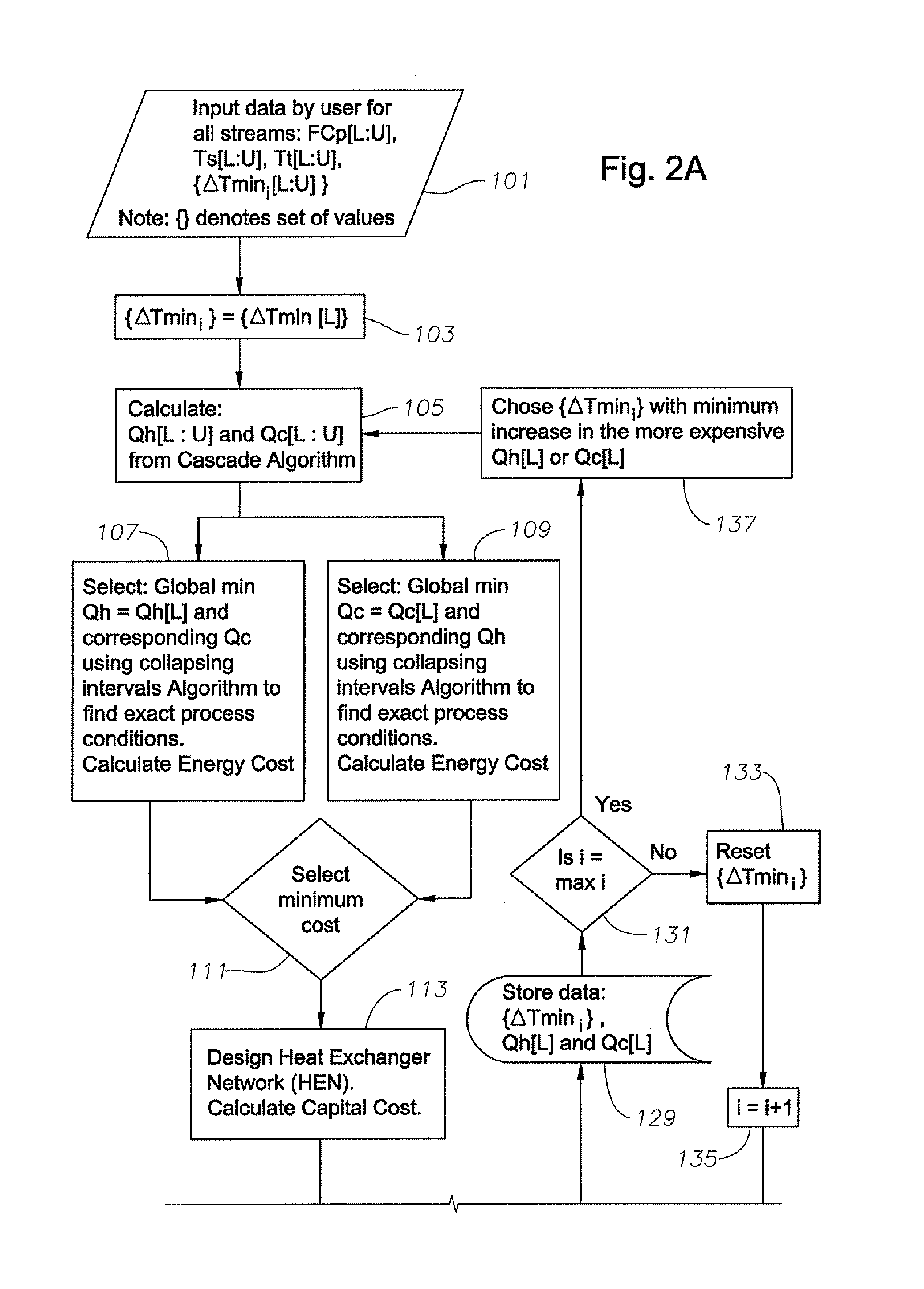

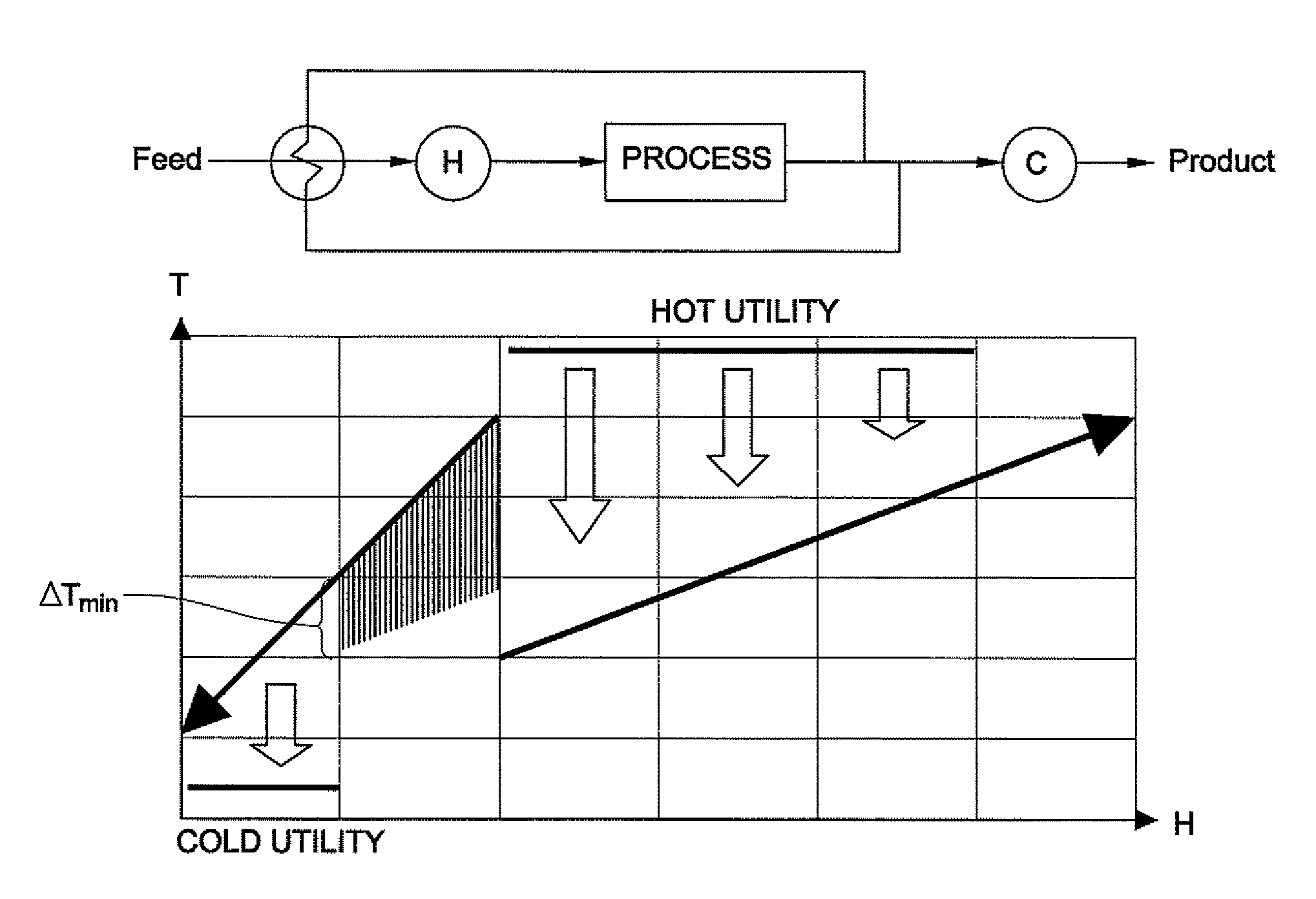

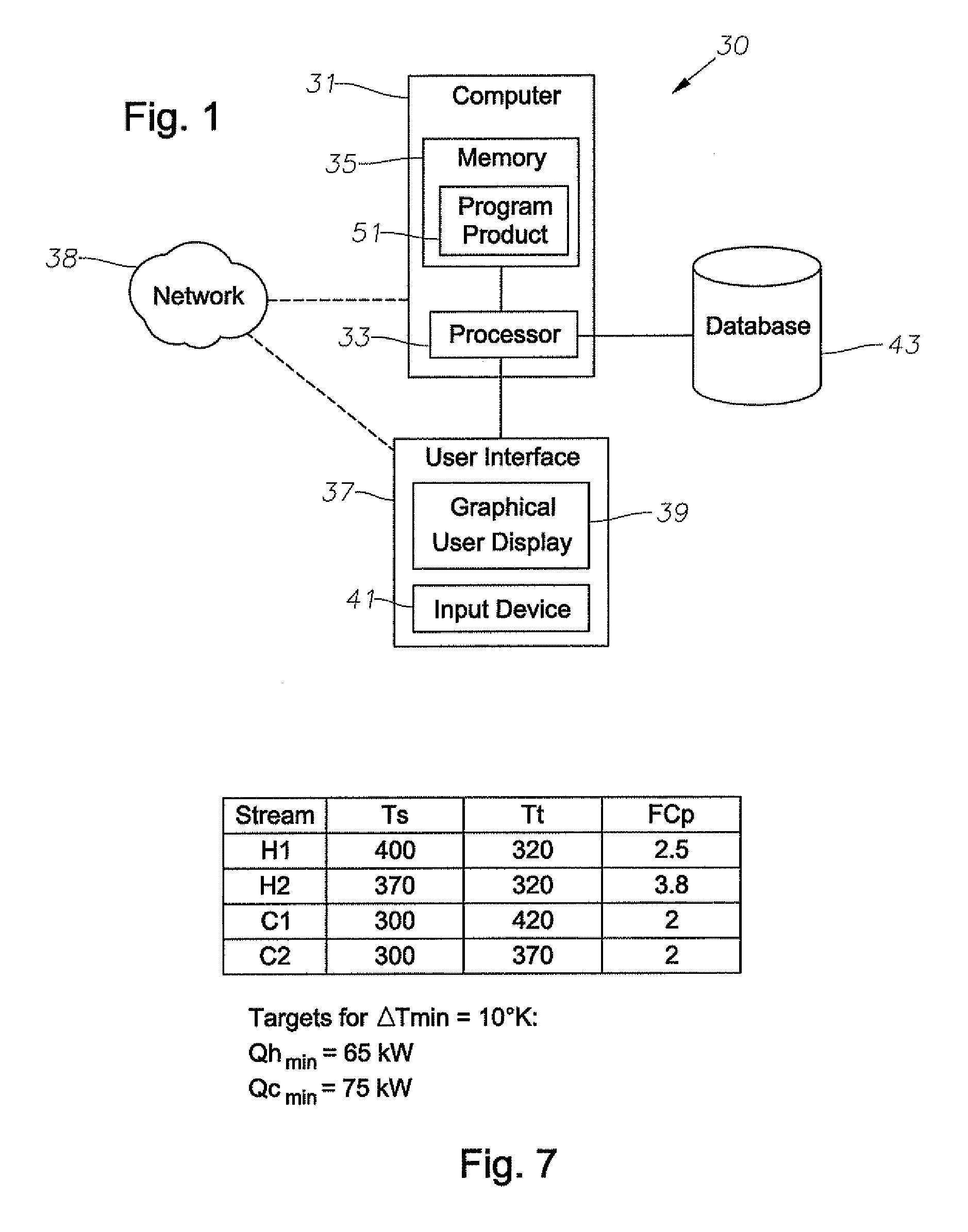

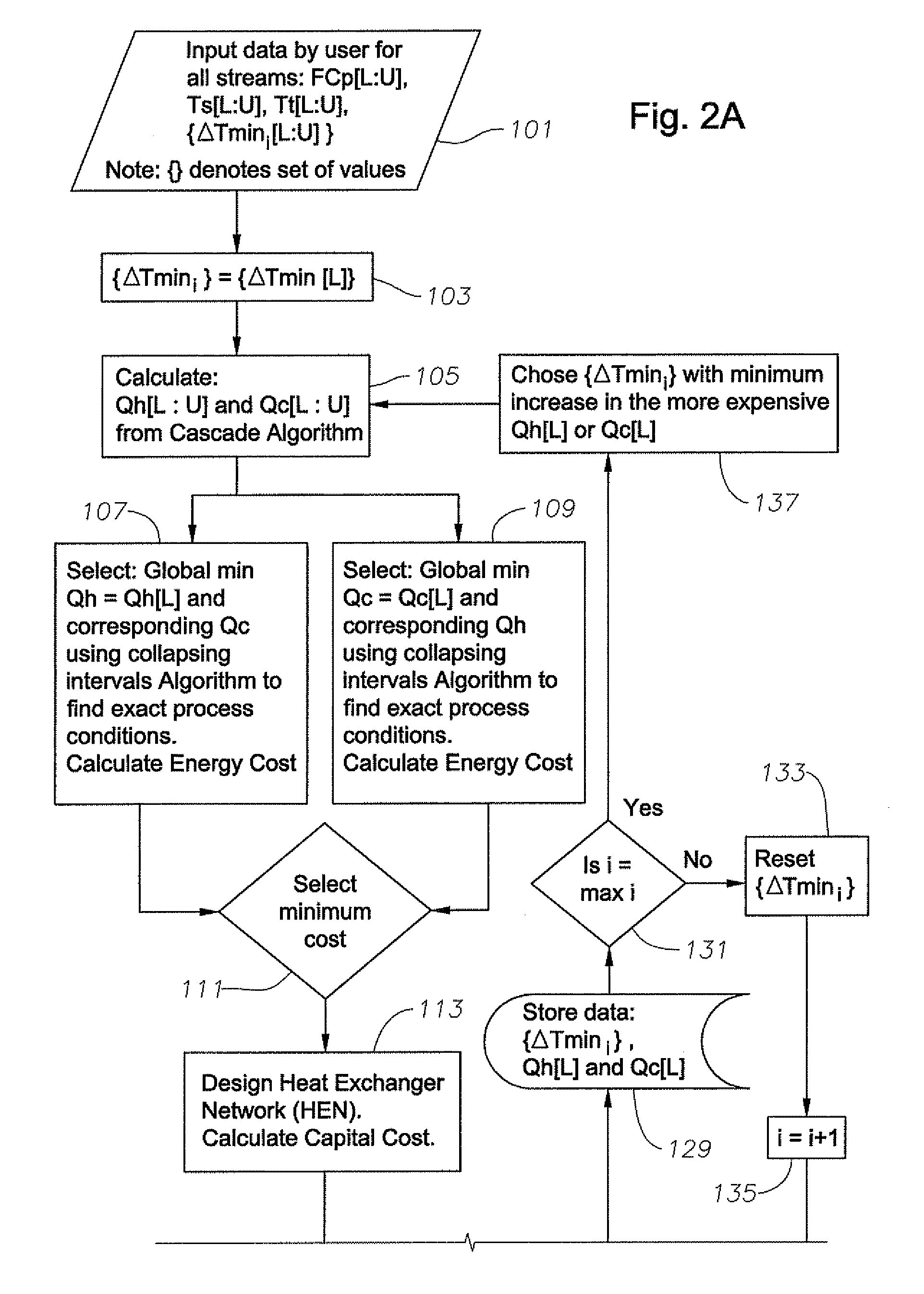

System, Method, and Program Product for Targeting and Optimal Driving Force Distribution in Energy Recovery Systems

ActiveUS20080015839A1Efficient designGuaranteed uptimeLevel controlTemperatue controlEnergy recoveryTrade offs

A system, methods, and user-friendly program product to calculate global energy utility targets and define optimal driving force distribution for a process or cluster of processes under all possible process changes and streams specific minimum temperature approach values, simultaneously, and without enumeration, are provided. The program product can utilize stream-specific minimum temperature approach values ΔTmini, where the superscript i represents the specific hot stream, as the optimization parameters instead of the single global ΔTmin currently used, in addition to identifying the optimal operating conditions. The program product can define optimal process conditions and an optimal driving force distribution in heat recovery systems, and can produce an optimal Pareto-curve that shows the rigorous trade off between energy cost and capital cost for any energy recovery system.

Owner:SAUDI ARABIAN OIL CO

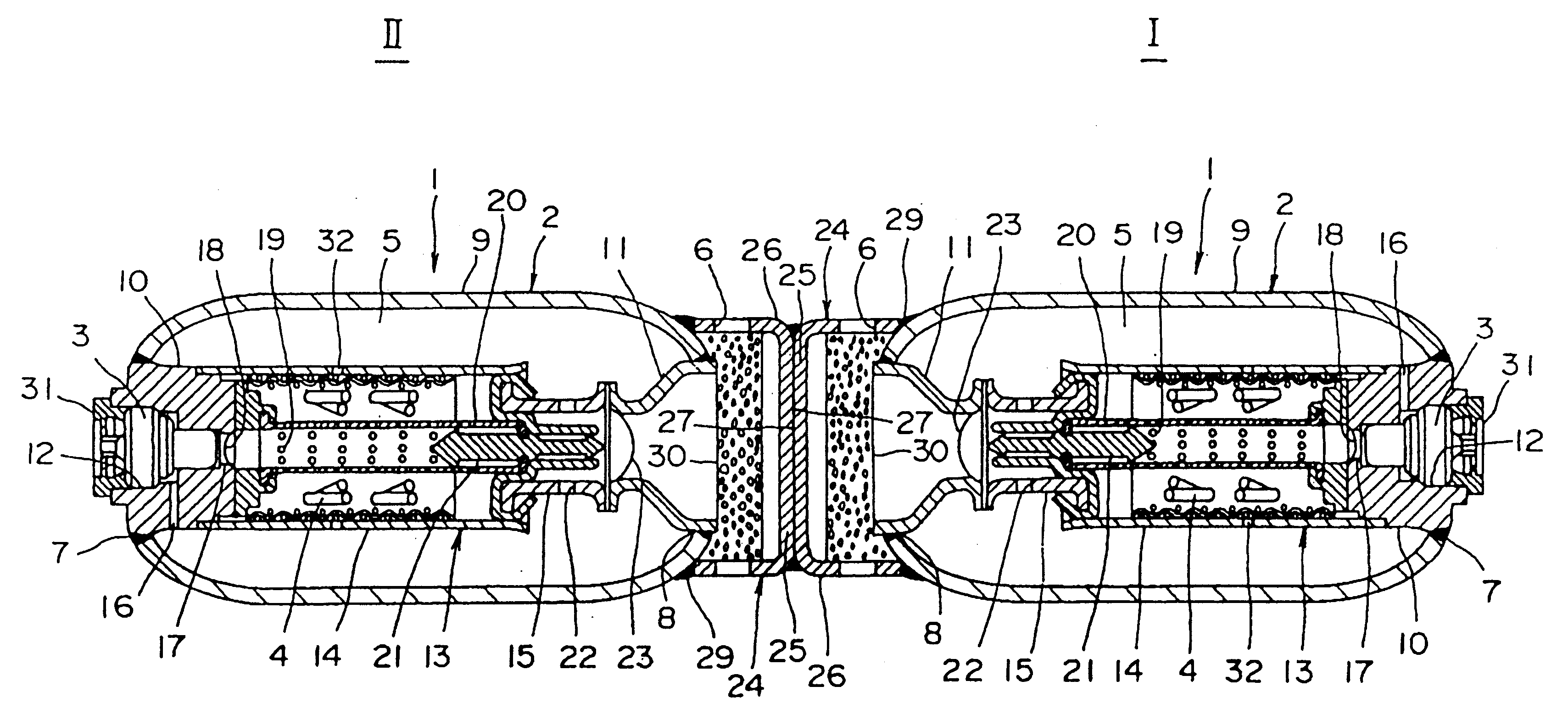

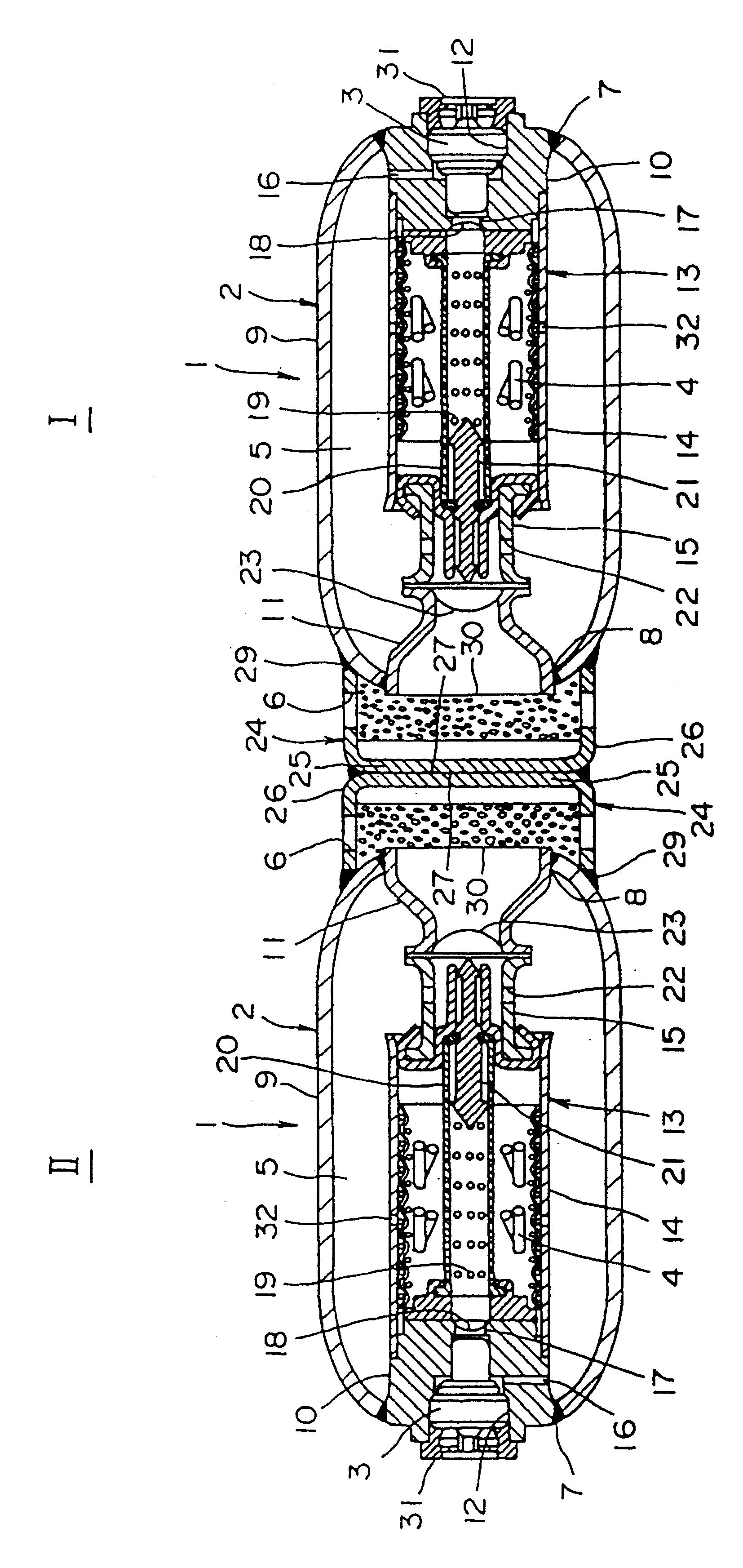

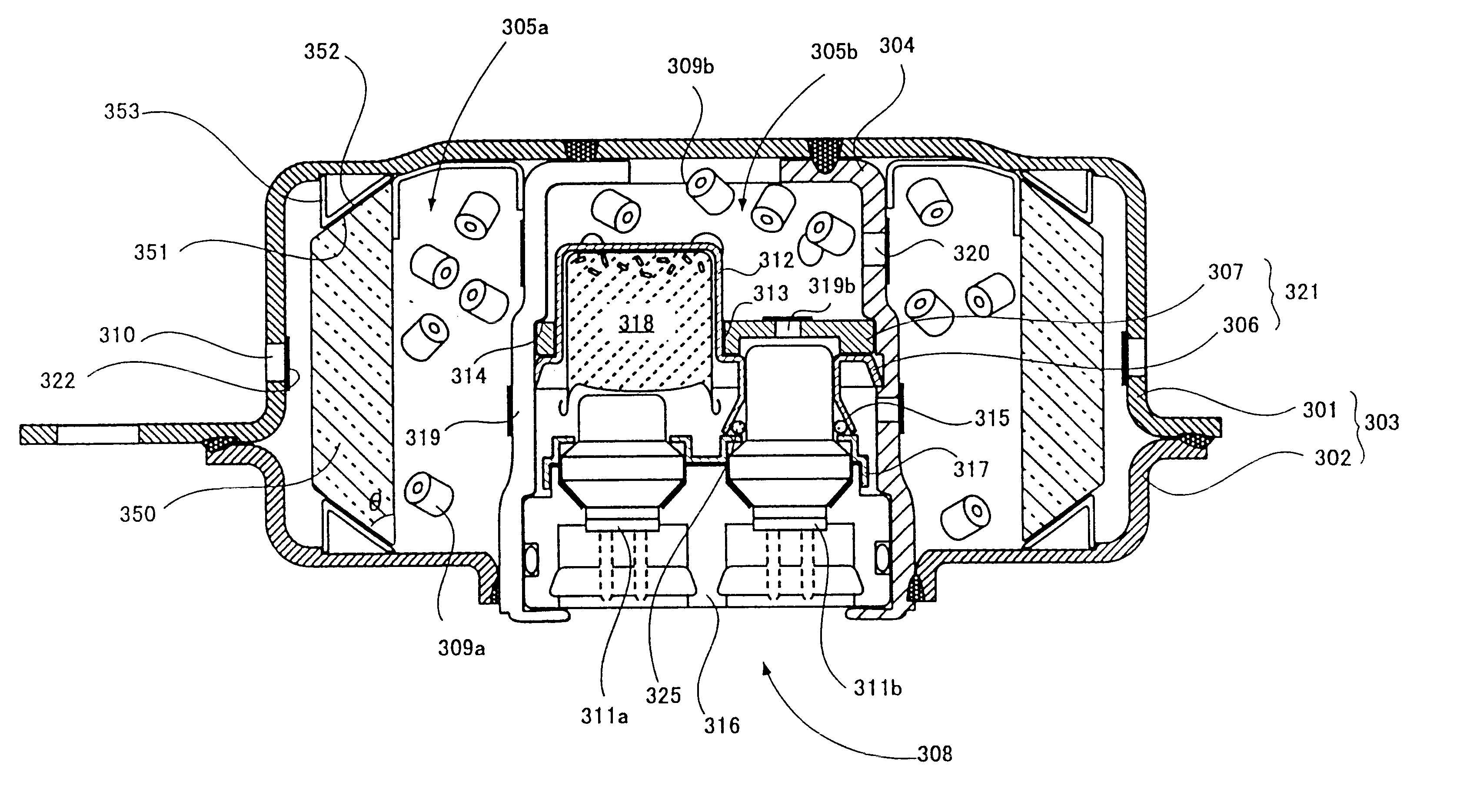

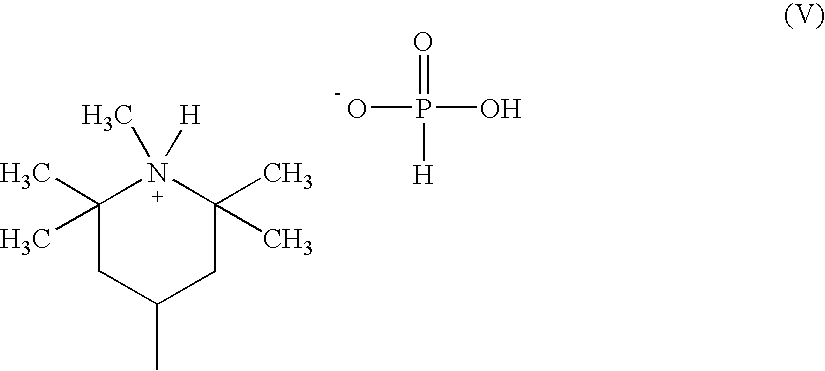

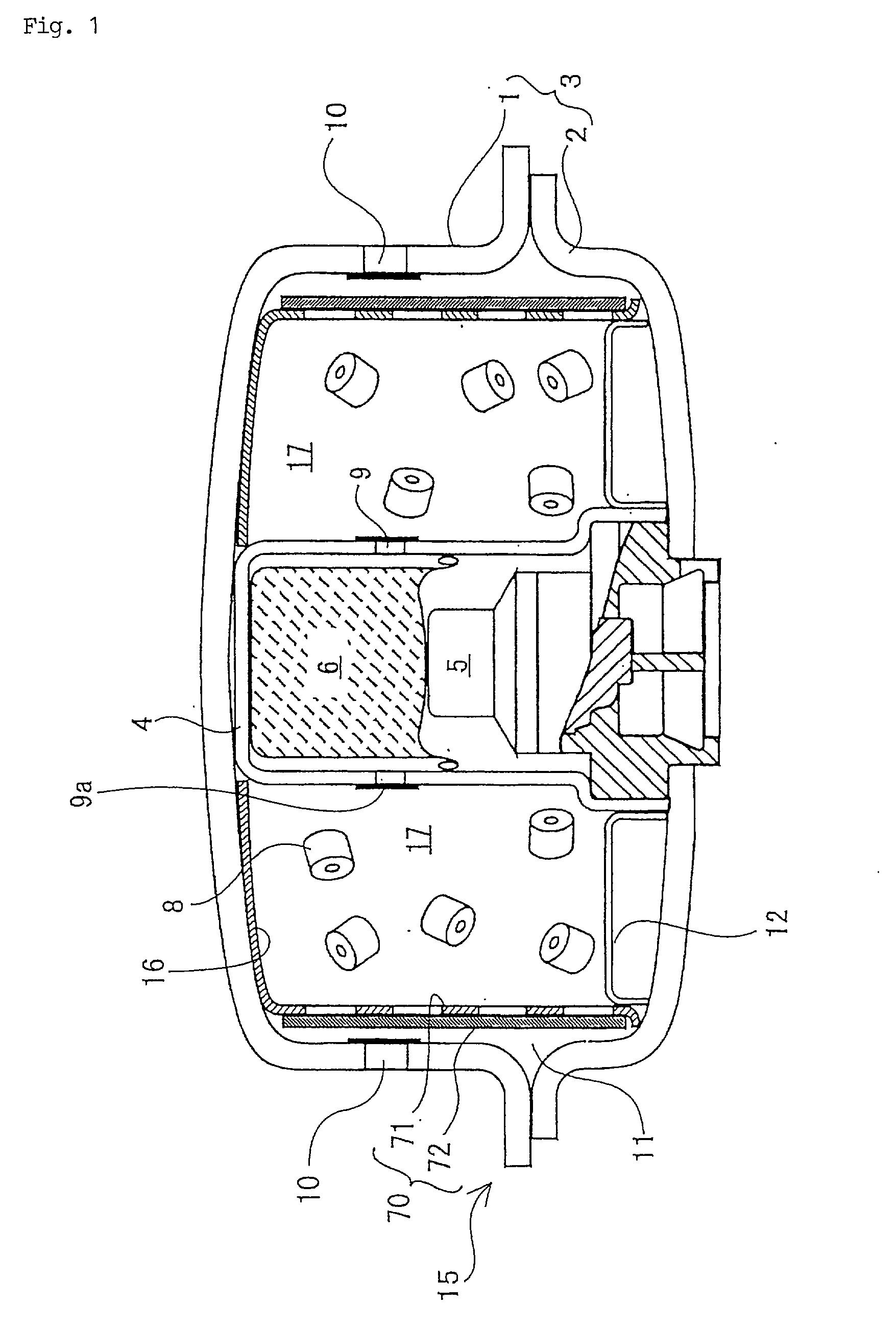

Air bag gas inflator

InactiveUS6253683B1Increase inflation rateFast inflationPedestrian/occupant safety arrangementPressure gas generationCombustionProduct gas

A gas generator for an air bag that can change deployment pattern of the air bag is provided. The gas generator includes two gas generating units connected in the axial direction, each of the gas generating units including a cylindrical housing, an igniter disposed in the cylindrical housing and operates upon receiving an operation signal, a gas generating agent ignited by the igniter to generate a combustion gas, a pressurized gas sealed within the housing and heated by the combustion gas of the gas generating agent to generate a mixture gas together with the combustion gas, and a gas exhaust outlet disposed at one side end of the housing and from which the mixture gas within the housing is injected. The two gas generating units are joined by welding one end of each of the housings of the gas generating units together.

Owner:DAICEL CHEM IND LTD

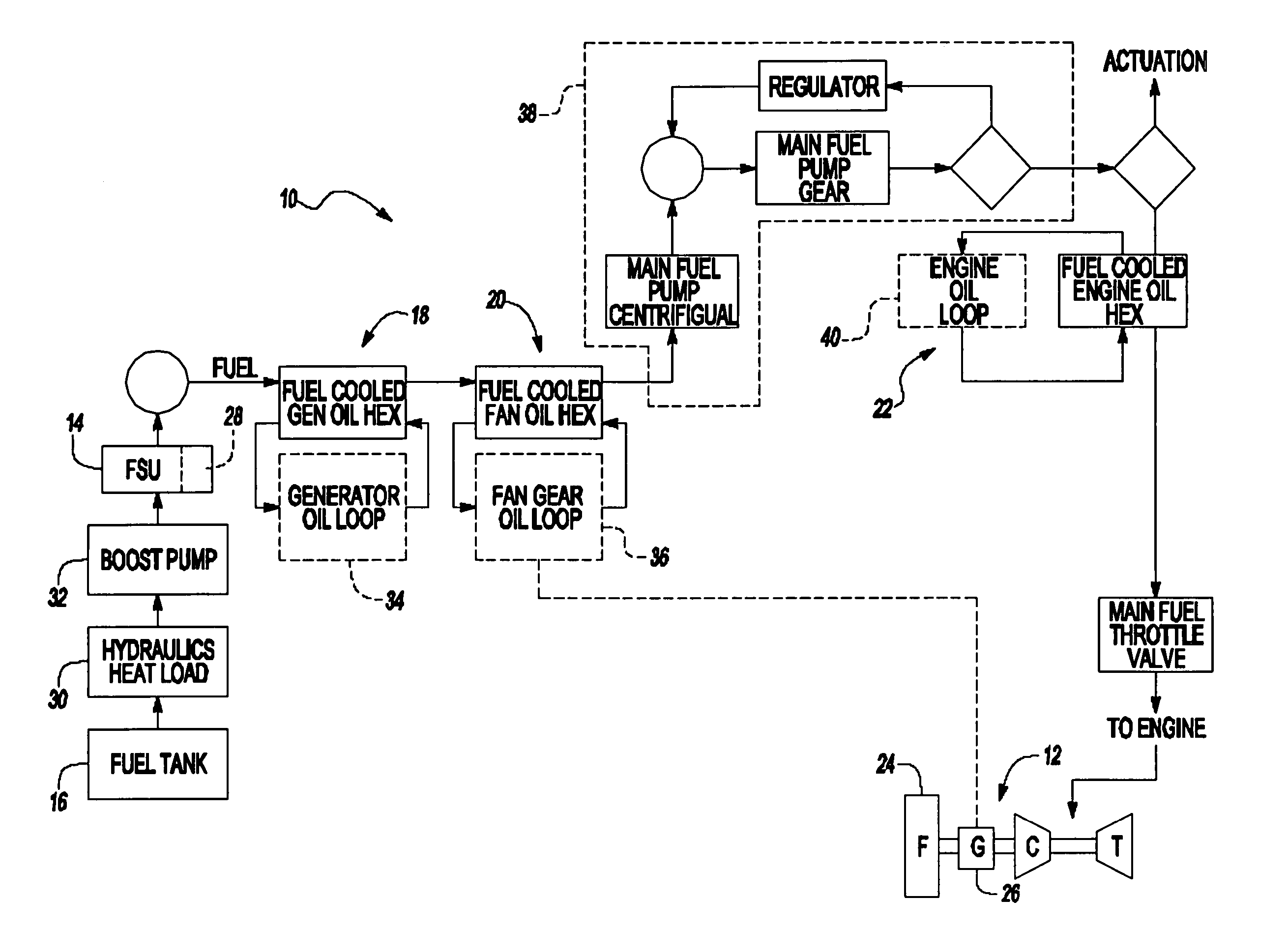

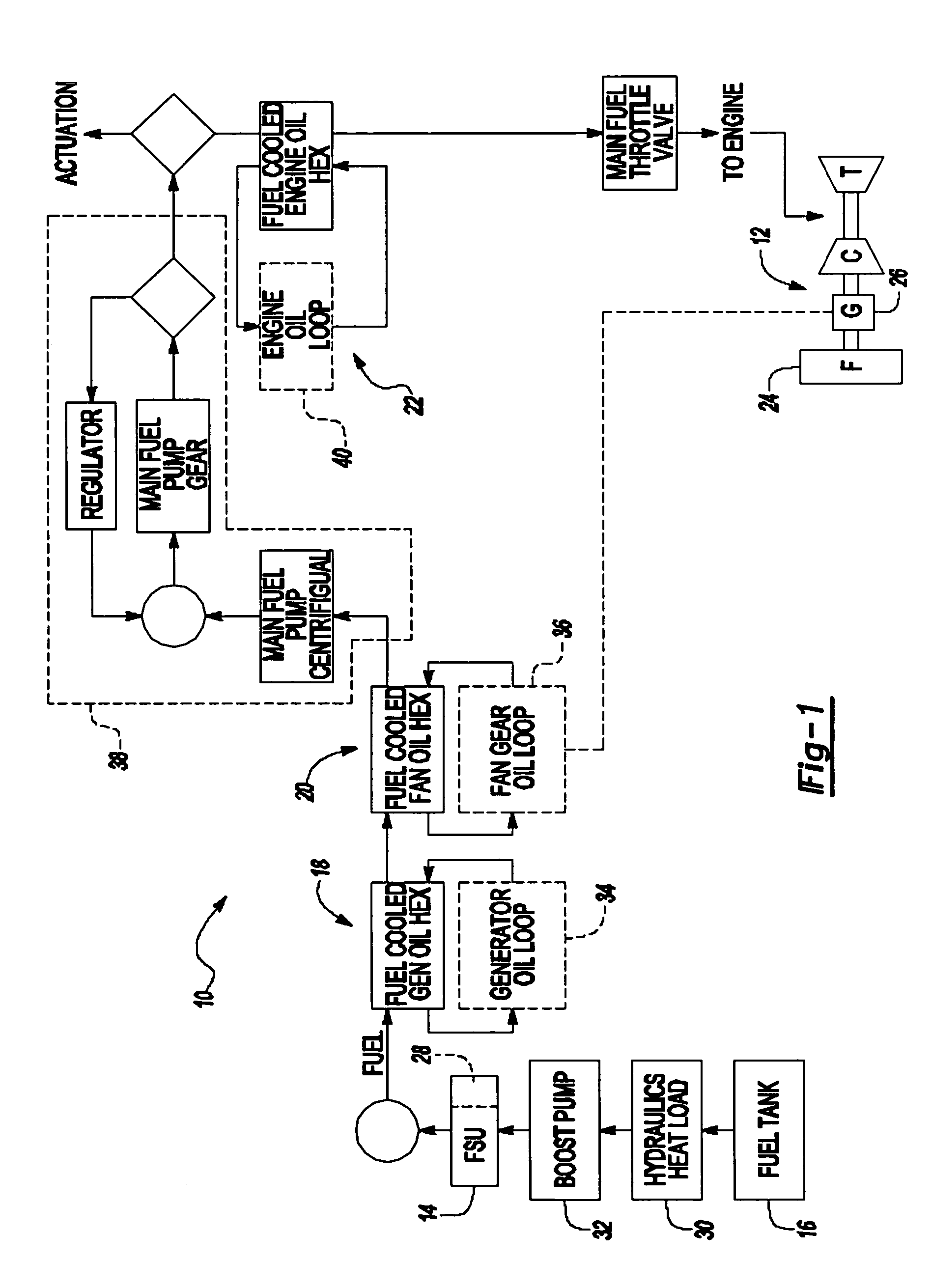

Thermal management system for an aircraft

ActiveUS7260926B2Minimizes air-to-liquid heat exchangersEngine fuctionsTurbine/propulsion fuel deliveryThermal management systemProcess engineering

A fuel based thermal management system includes a fuel stabilization system which permits the fuel to exceed the traditional coking temperatures. High temperature components are arranged along the fuel flow path such that even at the higher operating temperatures the fuel operates as a heat sink to transfer heat from high temperature components to the fuel. An optimal high temperature ester-based oil permits an oil-loop to exceed current oil temperature limits and achieve a high temperature to permit efficient rejection of heat to the fuel late in the fuel flow path.

Owner:RTX CORP

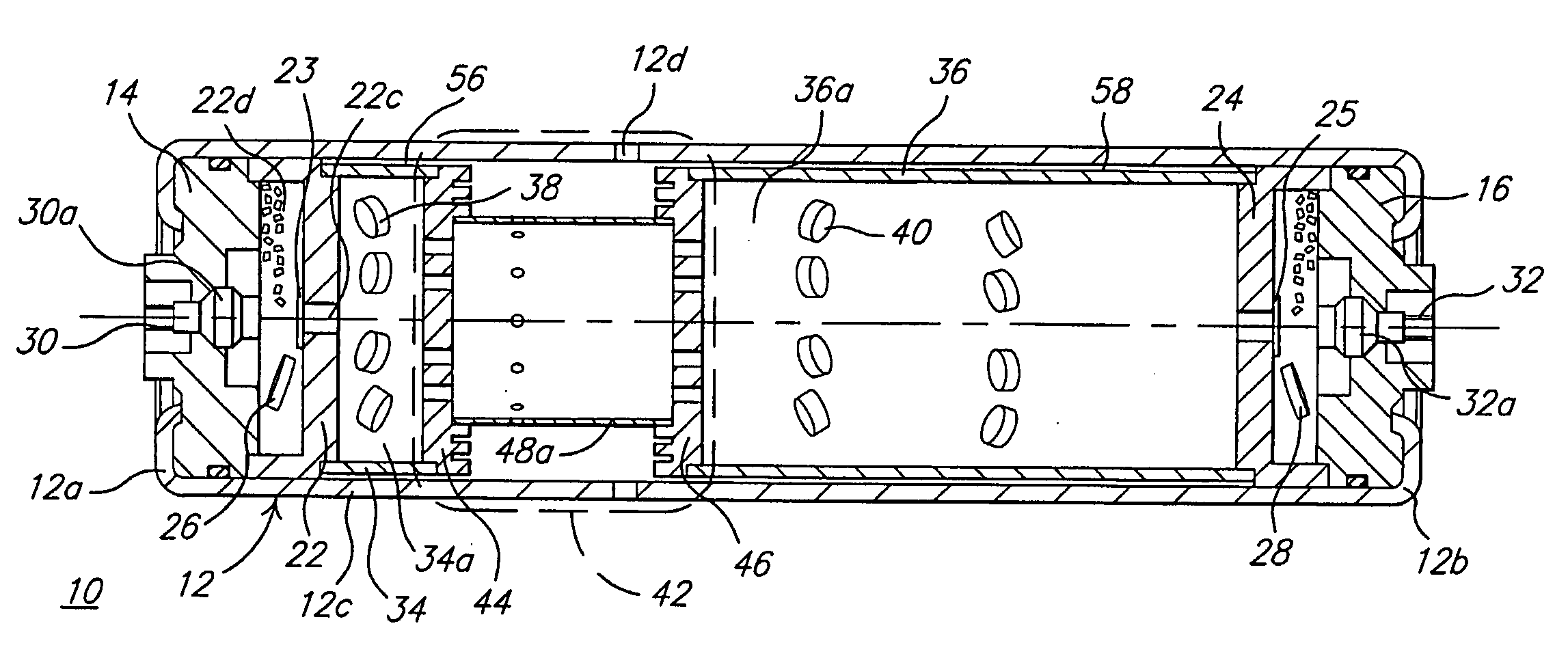

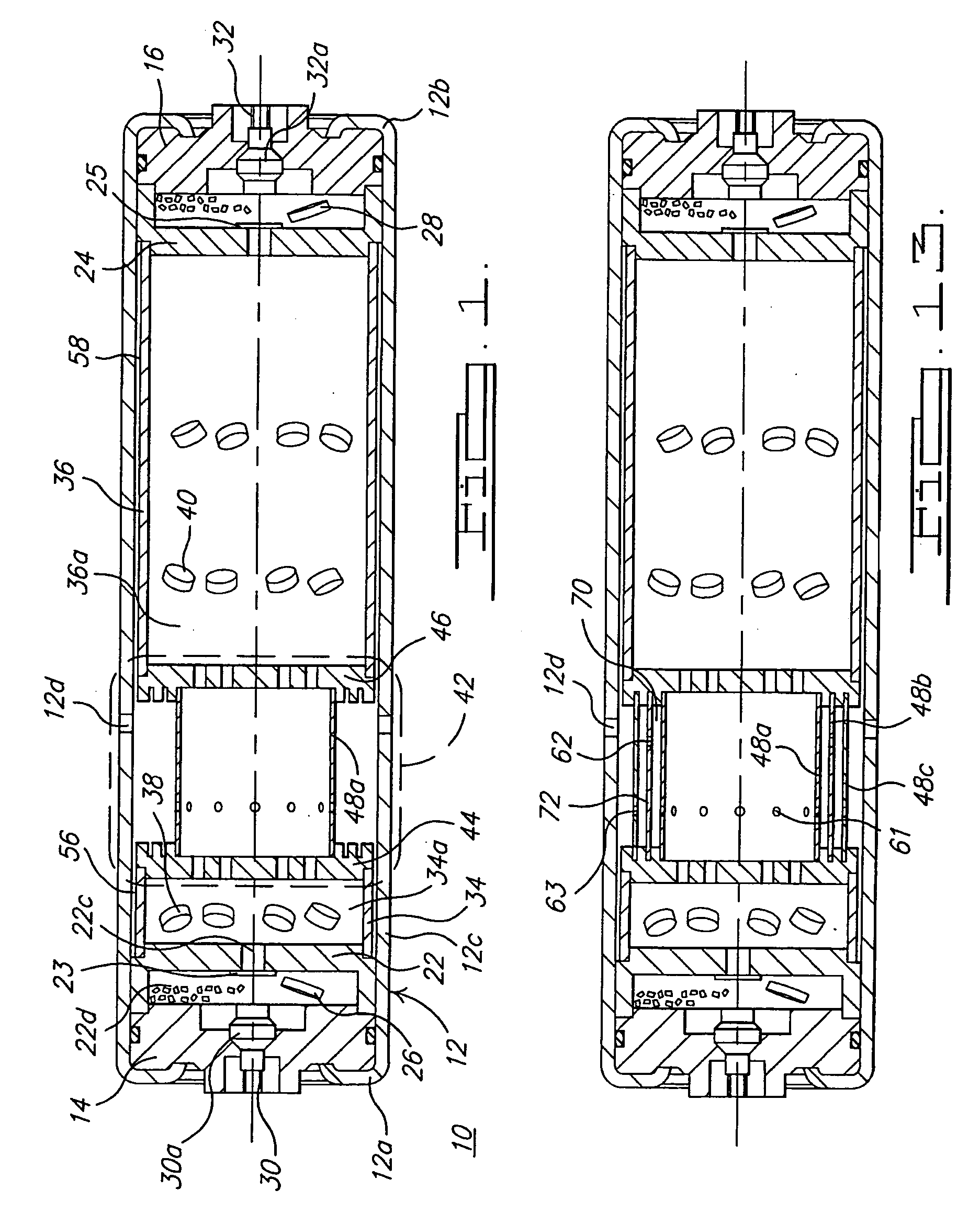

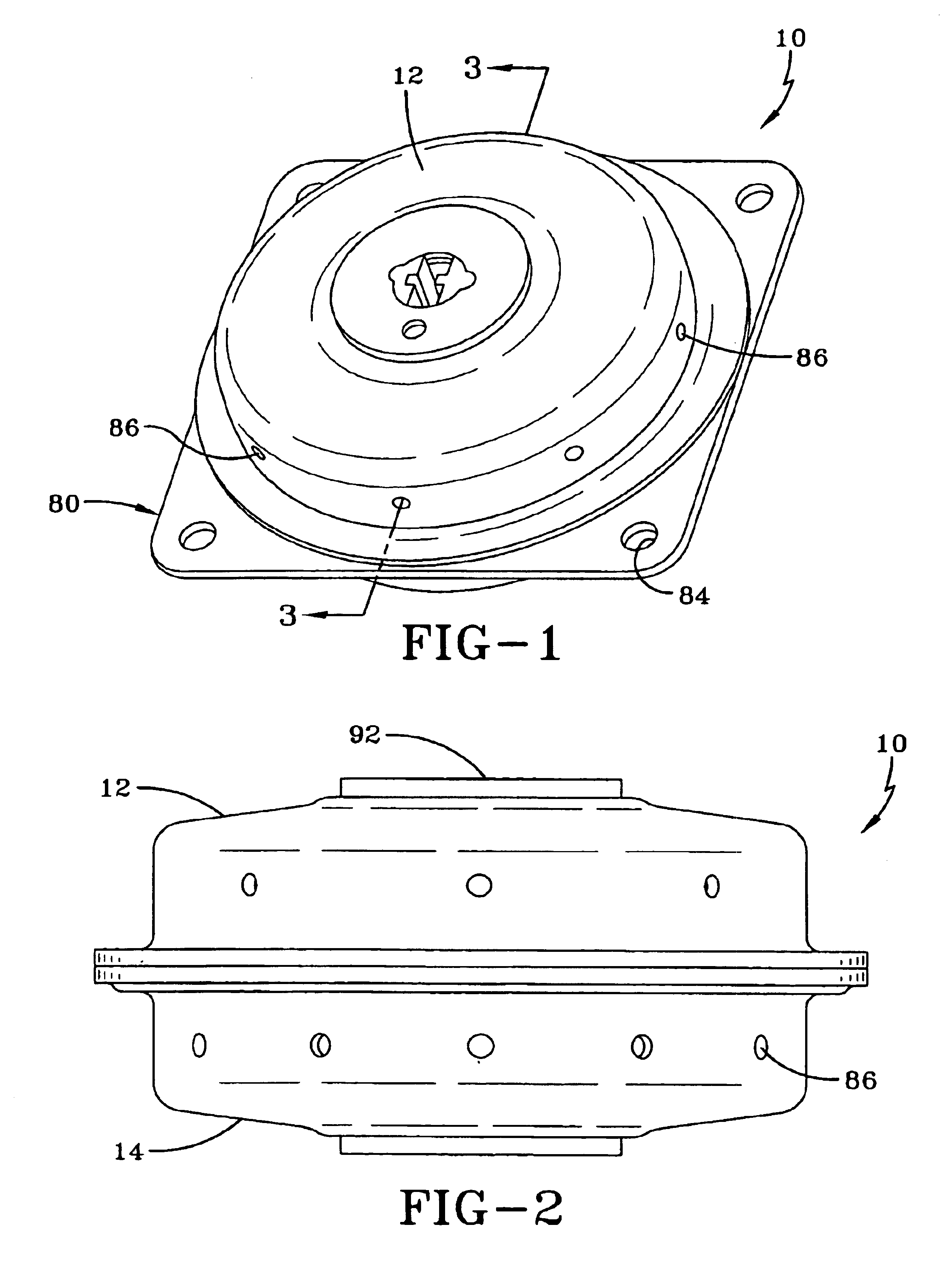

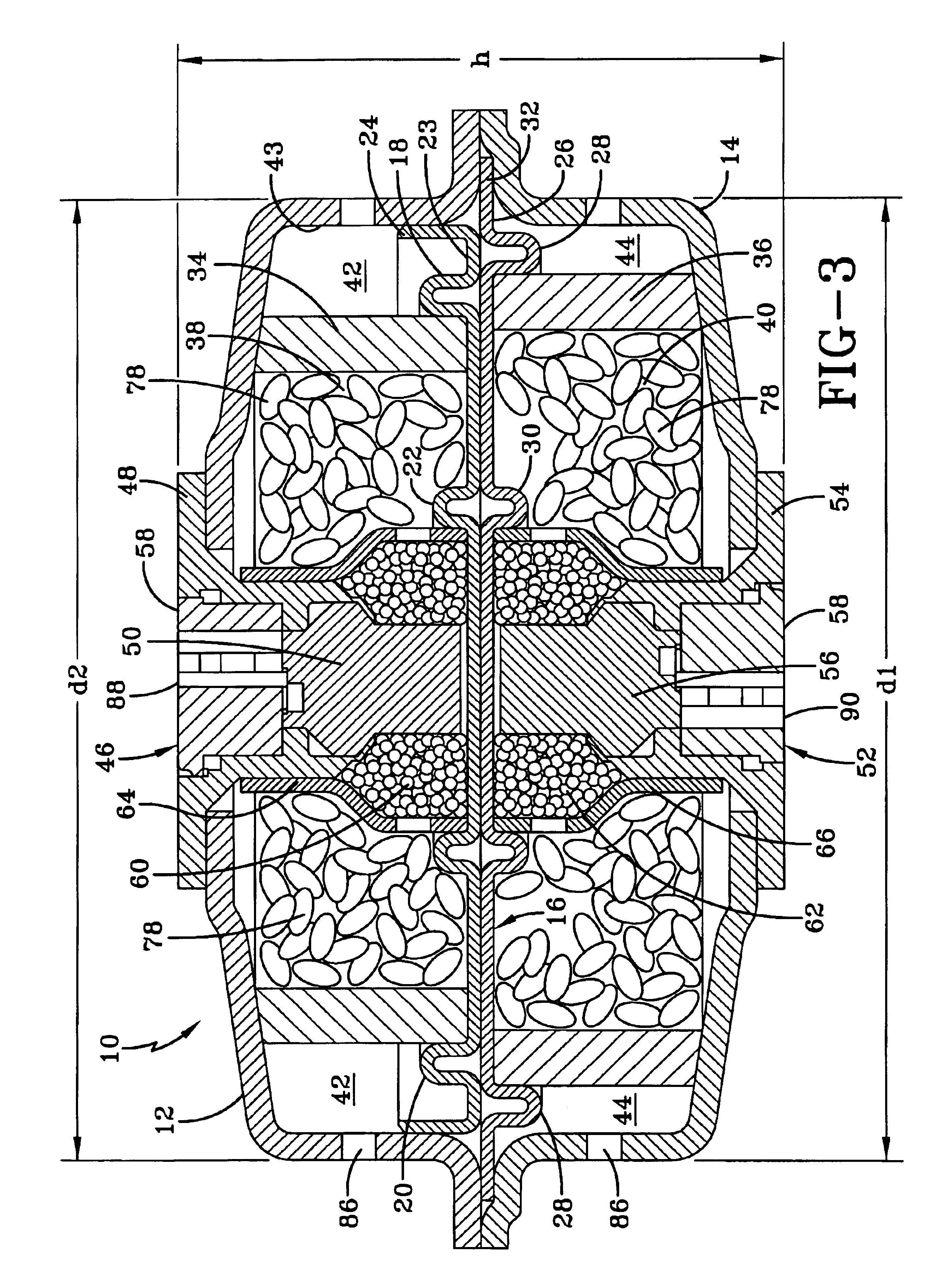

Gas generating system

InactiveUS20060005734A1Pedestrian/occupant safety arrangementPressure gas generationParticulatesCombustion chamber

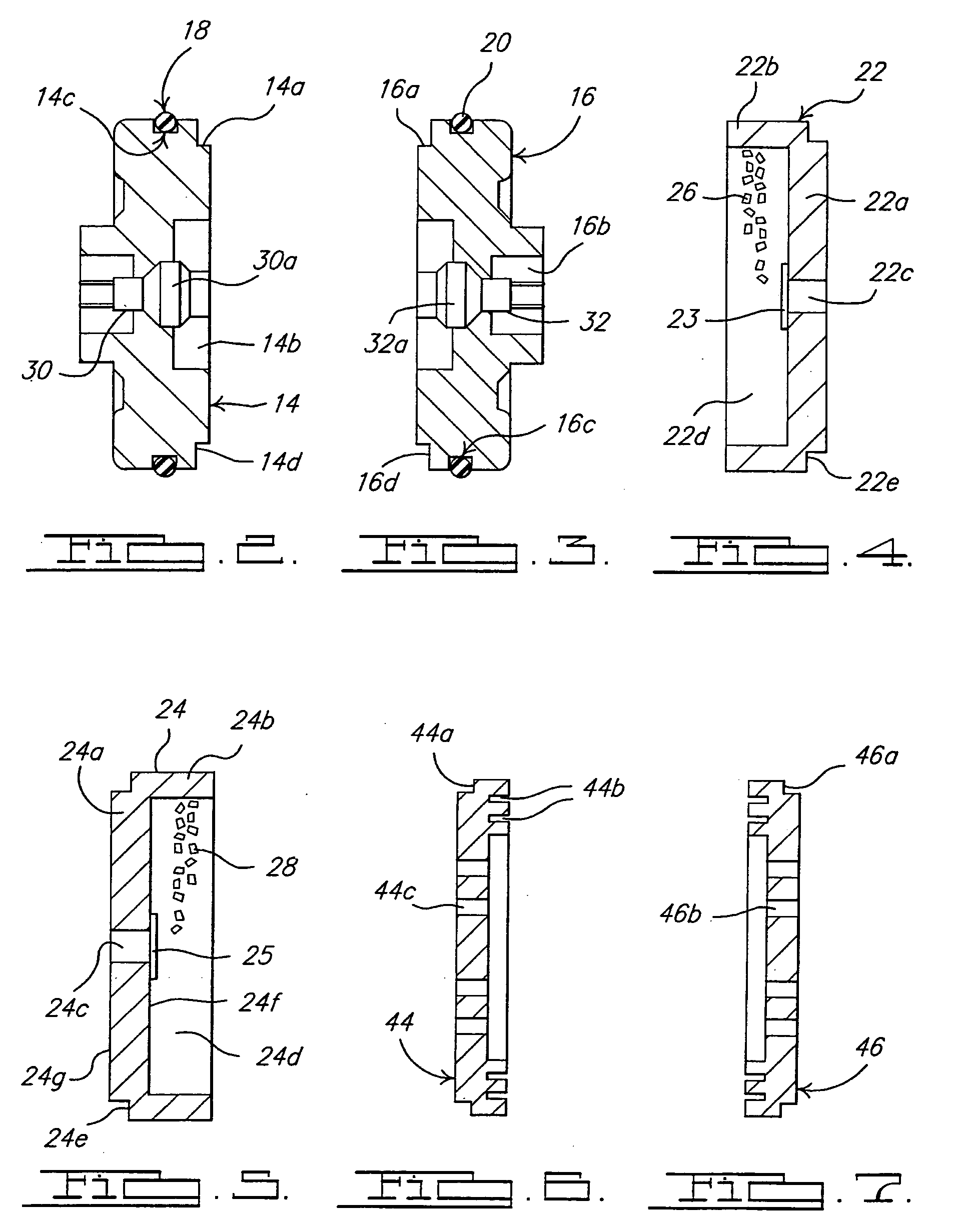

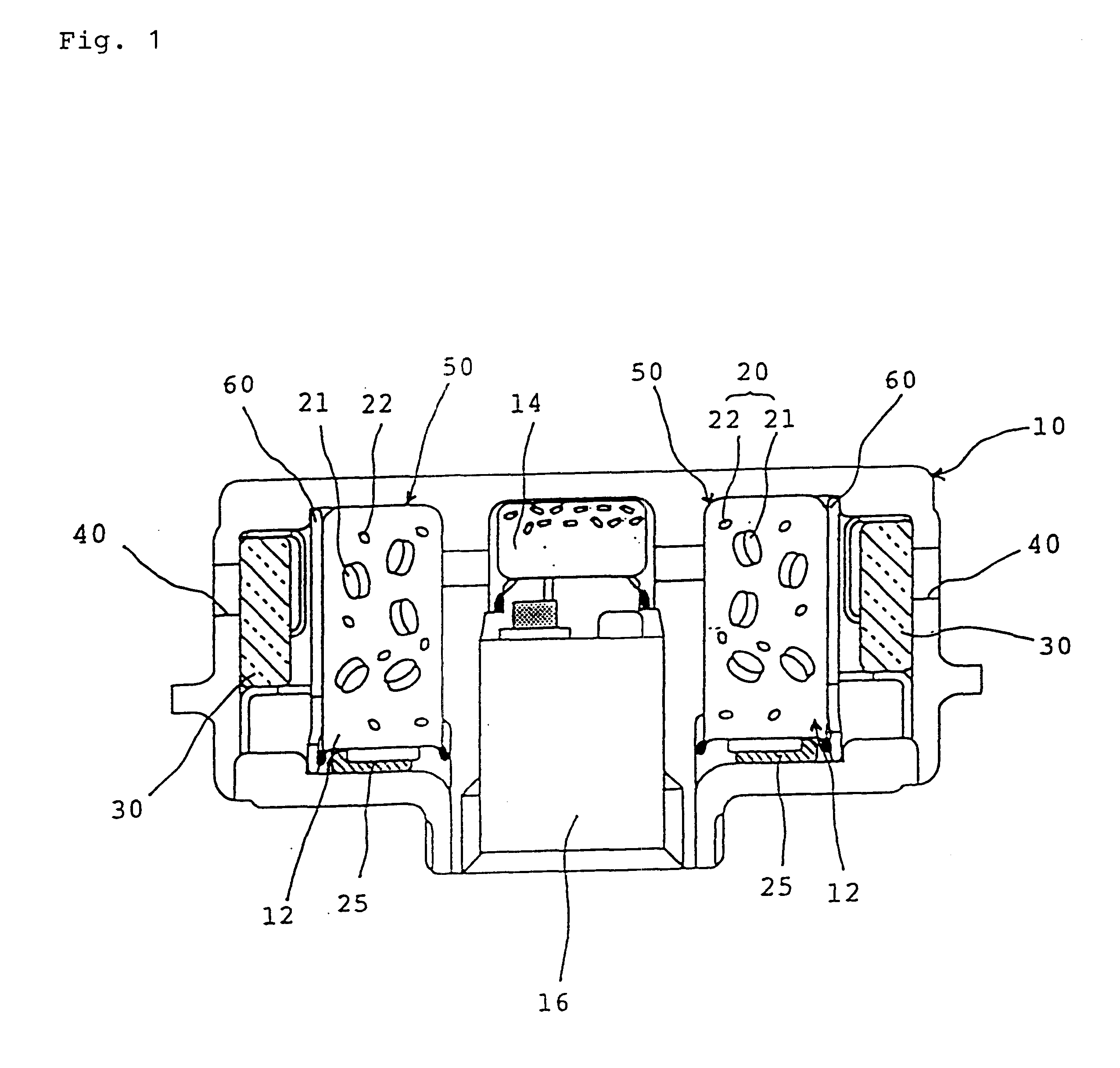

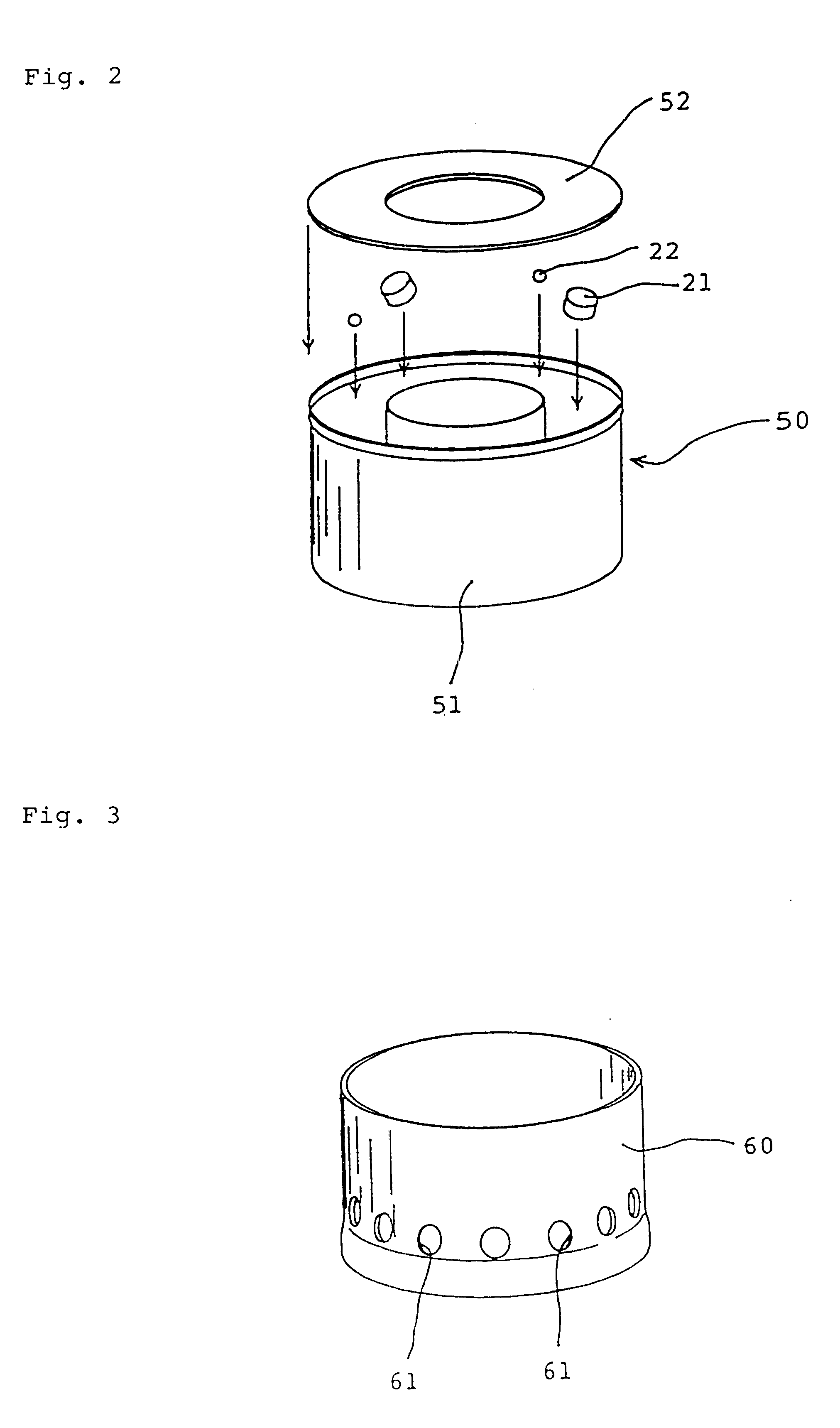

A gas generating system (10) including a baffle system (42) for modifying the temperature and pressure of a gas generated by the system, and to remove particulates from the gas. The gas generating system includes a first combustion chamber (34a), a second combustion chamber (36a), and the baffle system (42) adjacent both the first and second combustion chambers so as to enable fluid communication with the combustion chambers upon activation of the gas generating system. In another aspect of the present invention, a baffle system (42) is provided including a first end plate (44) having an opening (44b) formed therein for enabling fluid communication with a first fluid source (34a), a second end plate (46) having an opening (46b) formed therein for enabling fluid communication with a second fluid source (36a), and a sequence of baffle elements (48) extending between the first and second end plates. A first baffle element (48a) of the sequence of baffle elements defines a chamber (60) for receiving therein a fluid through the openings in the first and second end plates. Each additional baffle element in the sequence of baffle elements is spaced outwardly apart from a preceding baffle element in the sequence of baffle elements. In another aspect of the invention, a method is provided for producing, in a gas generating system, a gas having a pressure within a predetermined pressure range and a temperature within a predetermined temperature range. In another aspect of the present invention, a vehicle occupant protection system is provided.

Owner:JOYSON SAFETY SYST ACQUISITION LLC

Gas generating agent composition and gas generator

InactiveUS6517647B1Improve thermal stabilityImprove reliabilityNon-explosive desensitisers/phlegmatisersPressure gas generationSorbentDecomposition

A gas generating composition having an improved thermal stability of a fuel is obtained.A gas generating compostion comprising a gas generating agent containing a non-sodium azide compound fuel and an oxidizing agent, and an adsorbent. Since substances accelerating decomposition of a fuel, such as radicals generating by decomposition of the fuel are adsorbed and kept on the adsorbent, further decomposition of the fuel is inhabited, so that the thermal stability is increased.

Owner:DAICEL CHEM IND LTD

Apparatus and Method for Using Tetrazine-Based Energetic Material

InactiveUS20090301601A1Fast coolingInternal combustion piston enginesBlasting cartridgesEngineeringEnergetic material

The present invention comprises apparatus and methods employing a gas produced from a tetrazine-based energetic material such as that known as “BTATz” containing 3;6-BtS(1H-1,2,3,4-Tetrazol-5-ylamino)1-,2,4,5-tetrazine 3;6-BtS(1H-1,2,3,4-Tetrazol-5-ylamino)1-,2,4,5-tetrazine or salts thereof. The tetrazinebased energetic material is ignited through the use of a percussion cap, a piezoelectric crystal or a battery-supplied electric spark or by encapsulating it in a container that is then exposed to a burning flame. The gas produced upon ignition is employed a propellant such as to inflate life rafts, life vests, emergency evacuation slides, tires, air bags and other inflatable devices. The gas produced upon ignition is alternatively employed to power an engine and many other applications such as a fire suppressant.

Owner:ENERSON JON R +4

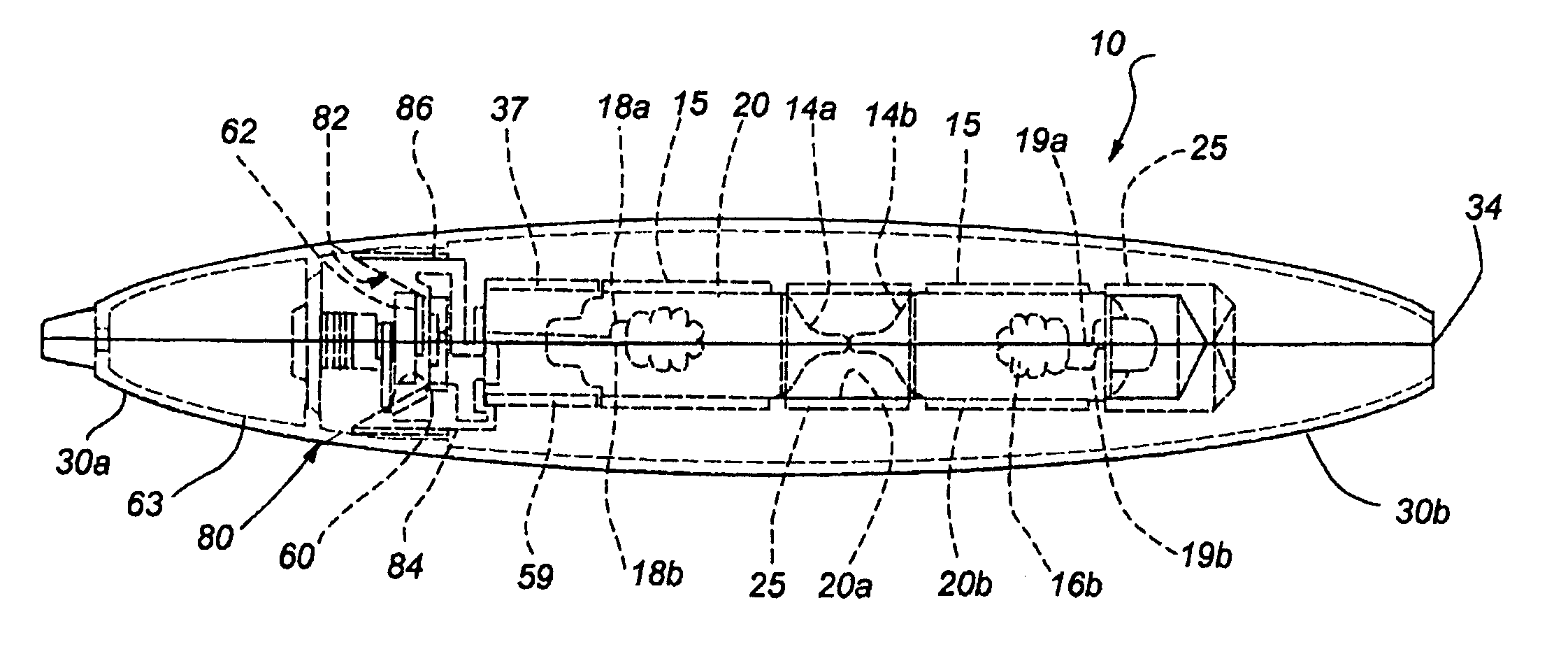

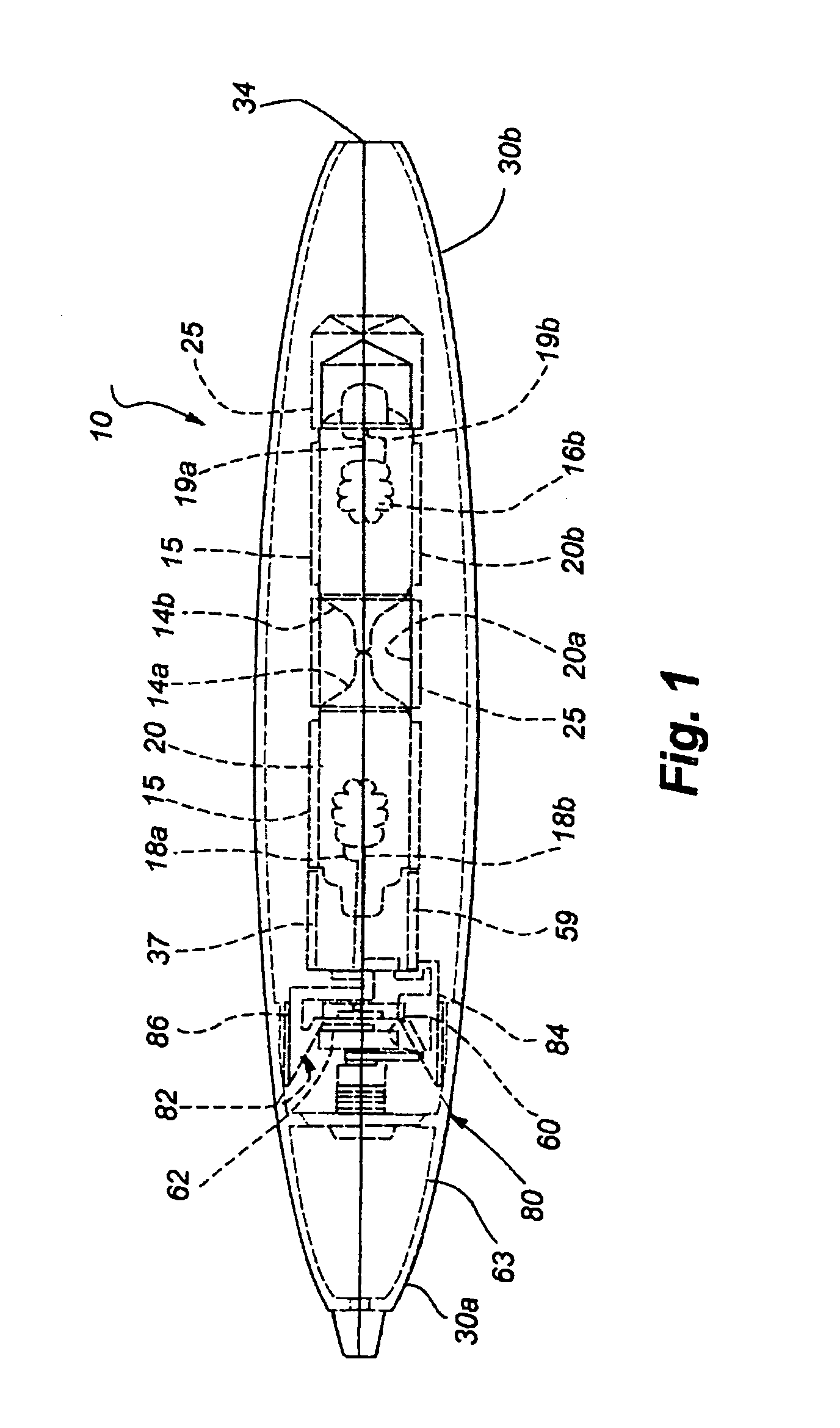

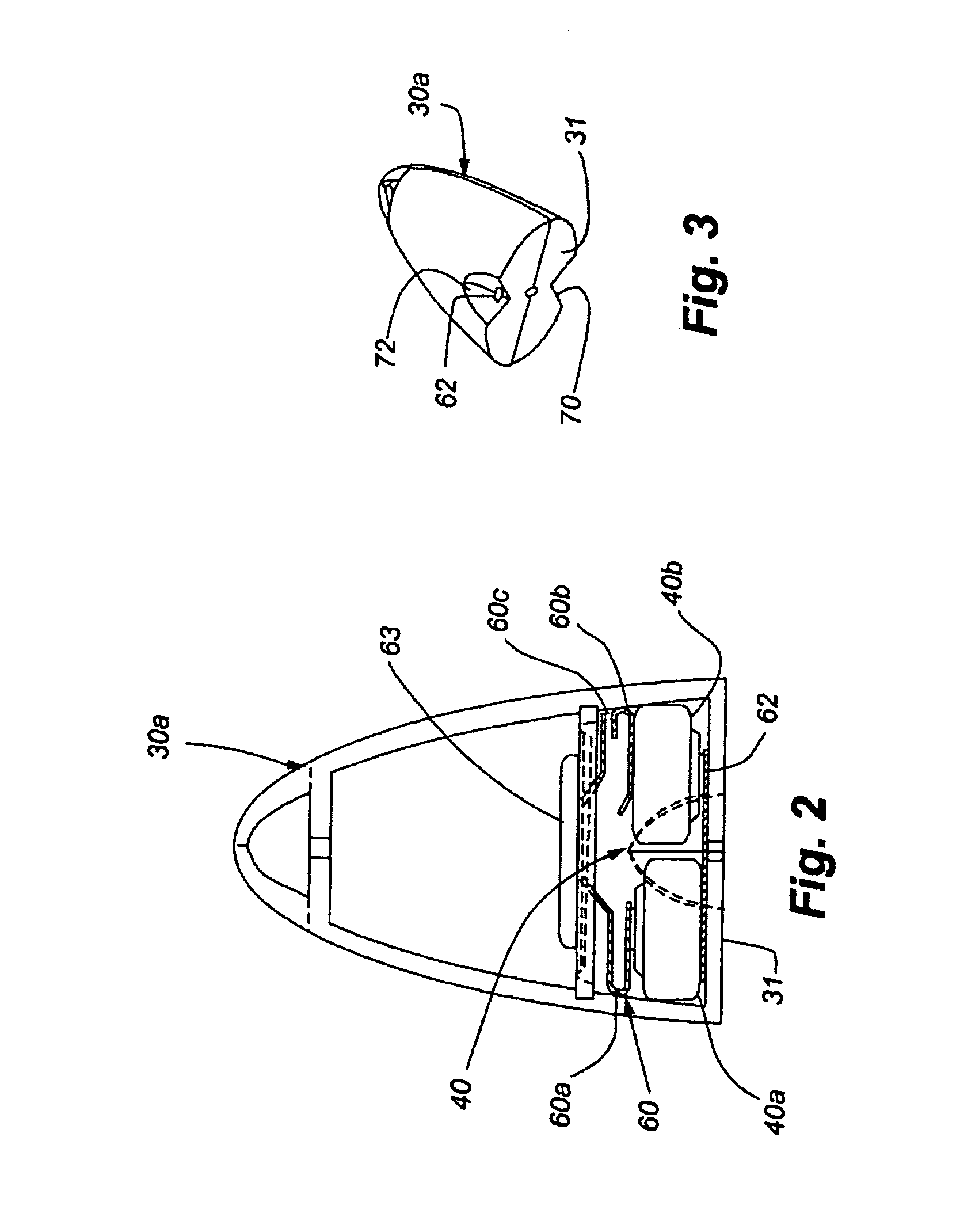

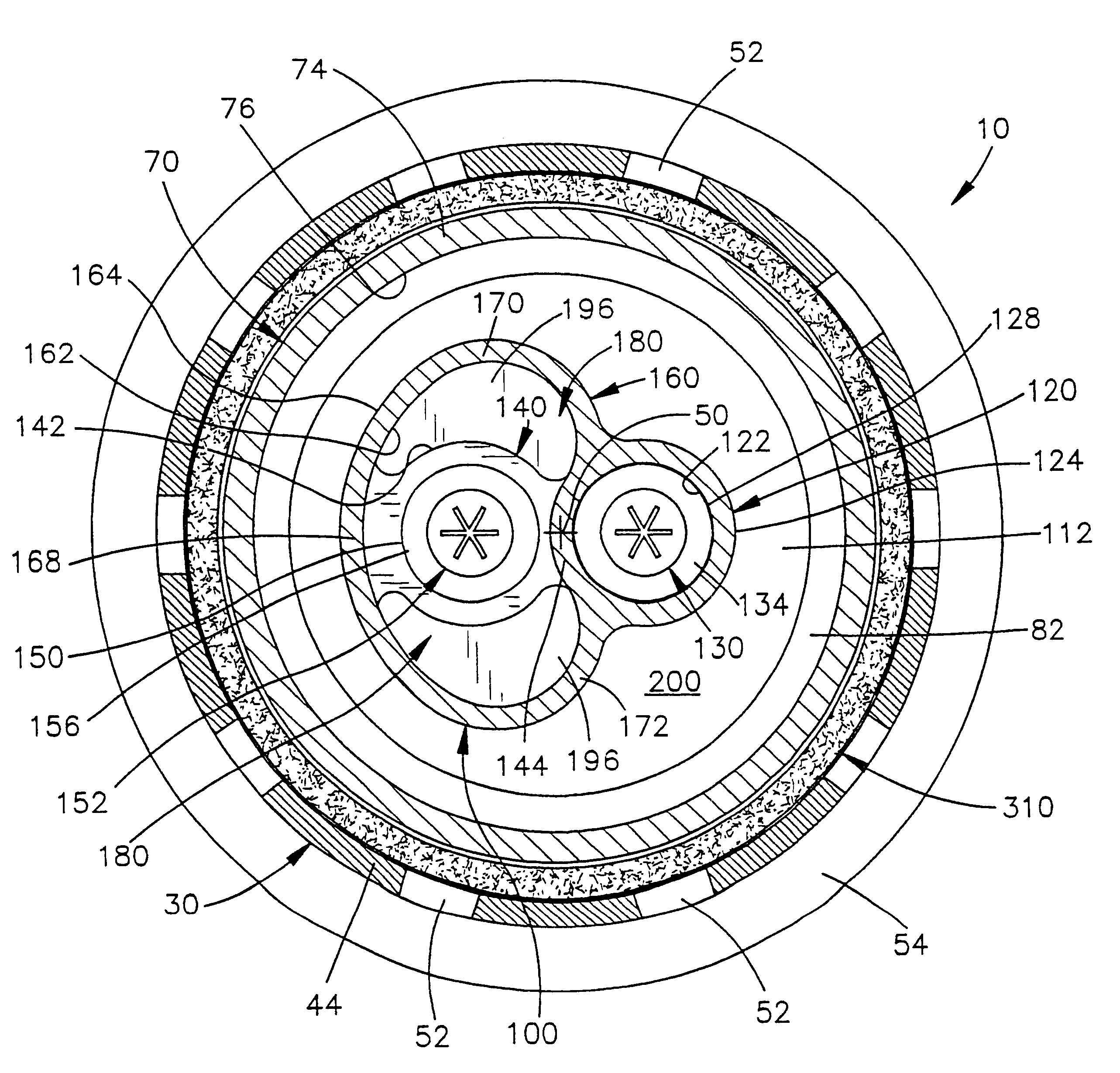

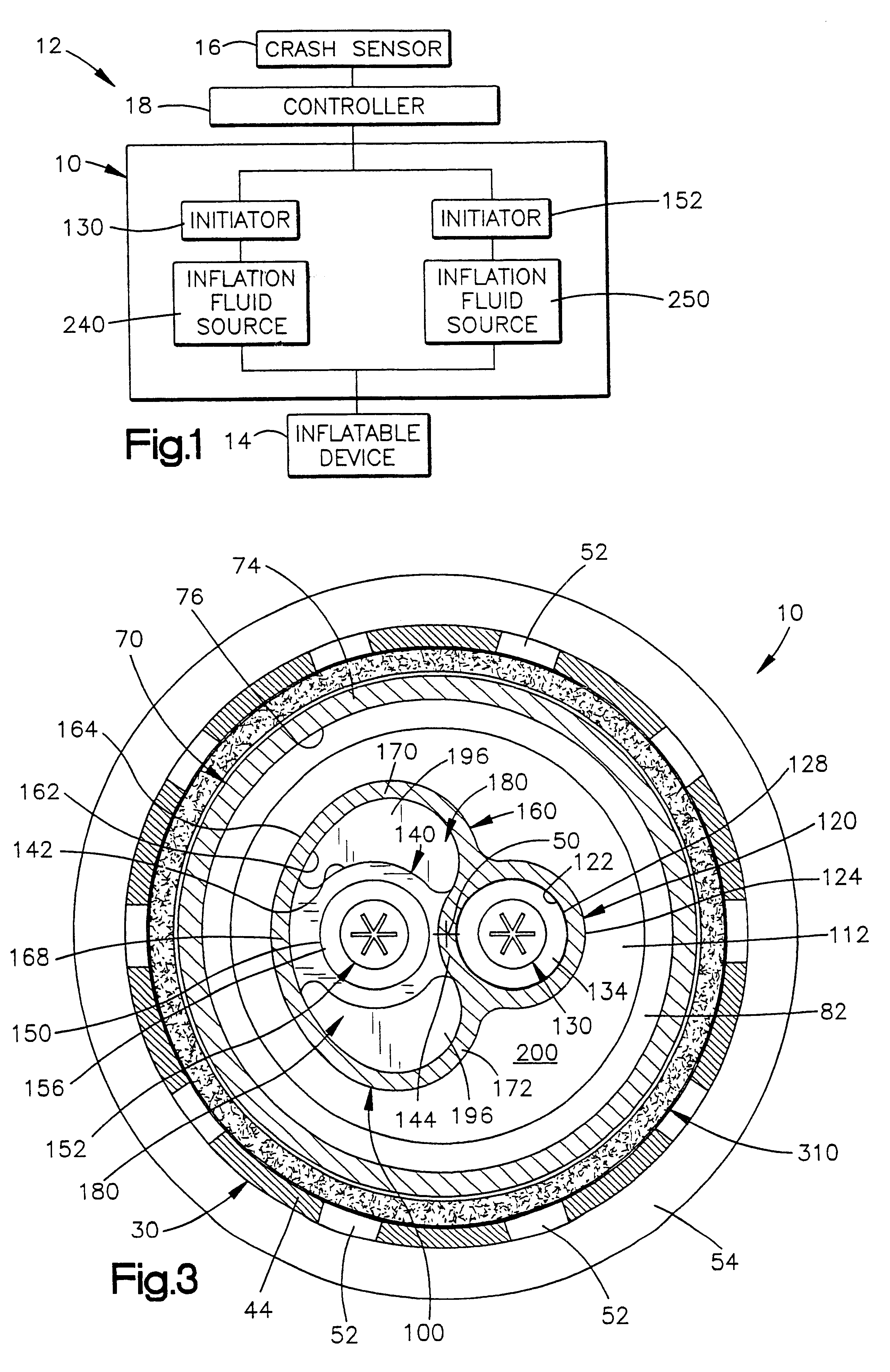

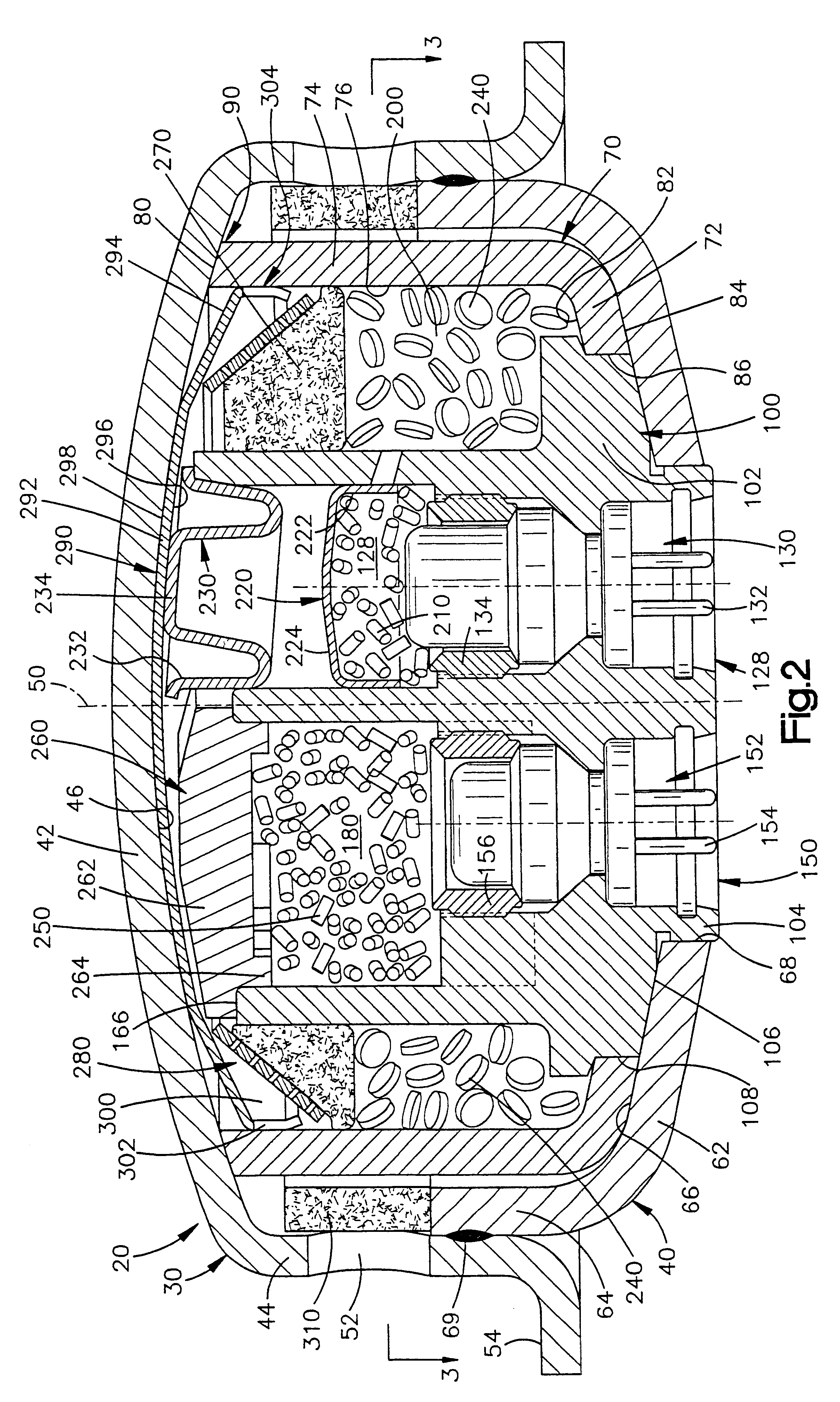

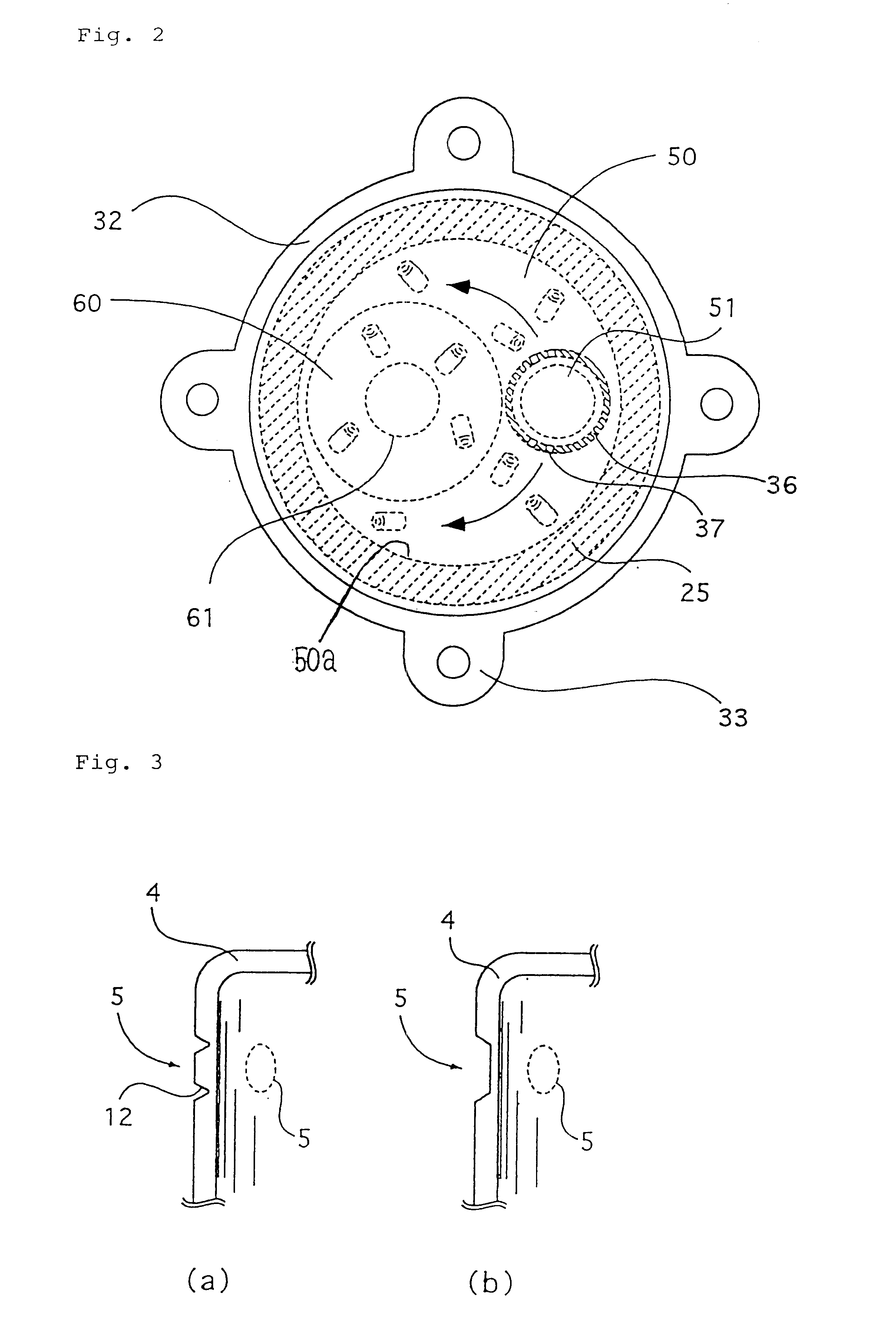

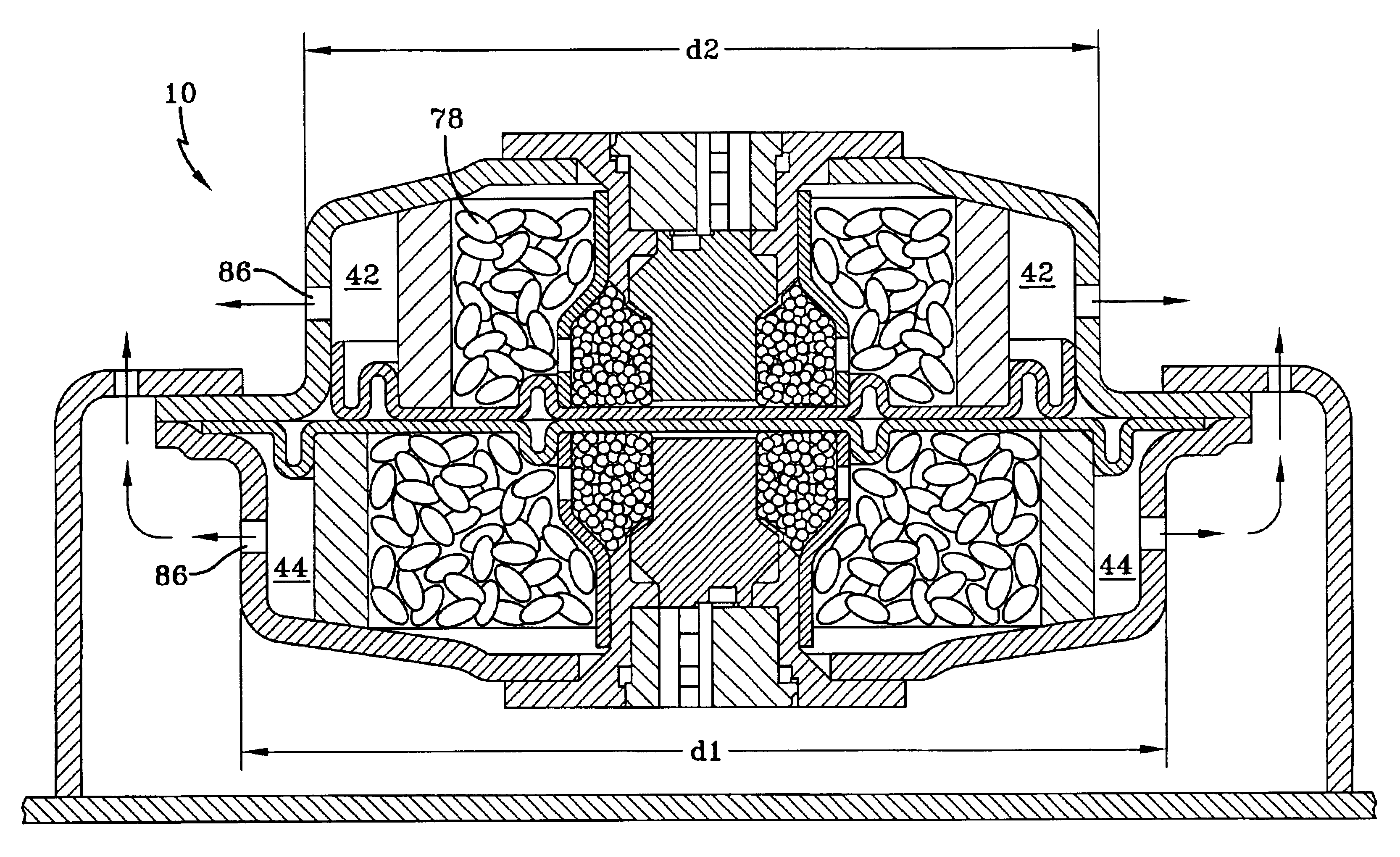

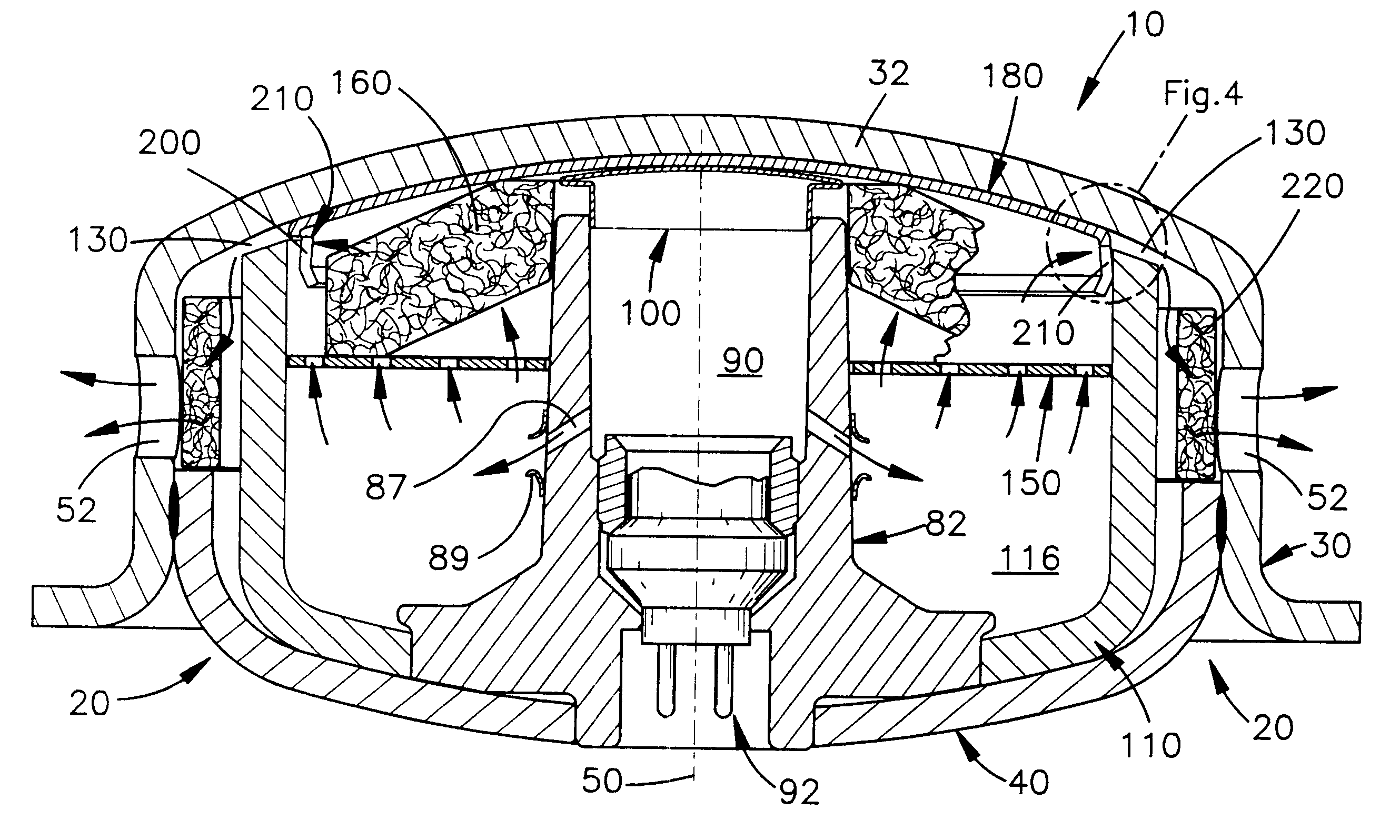

Dual stage air bag inflator

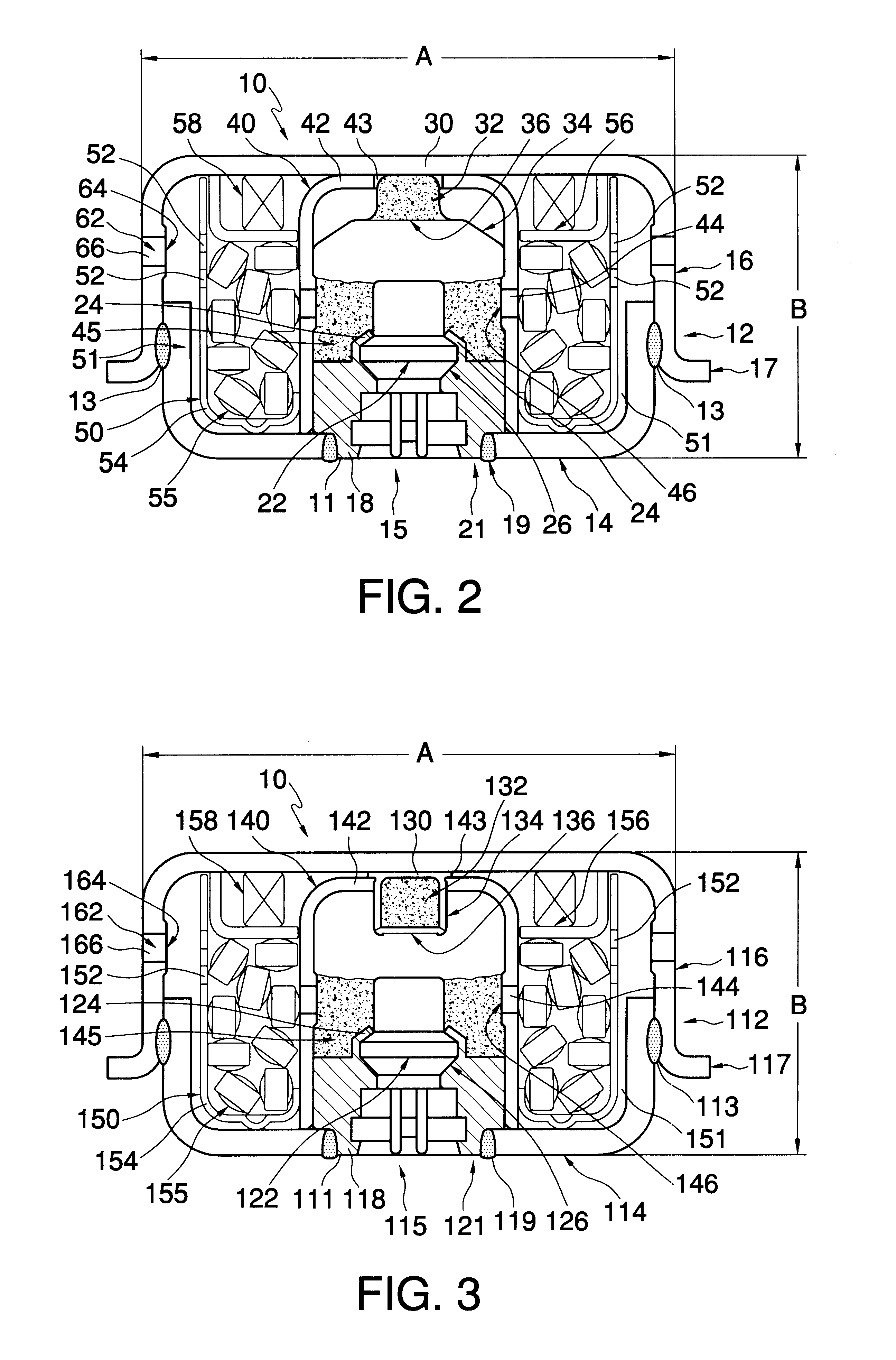

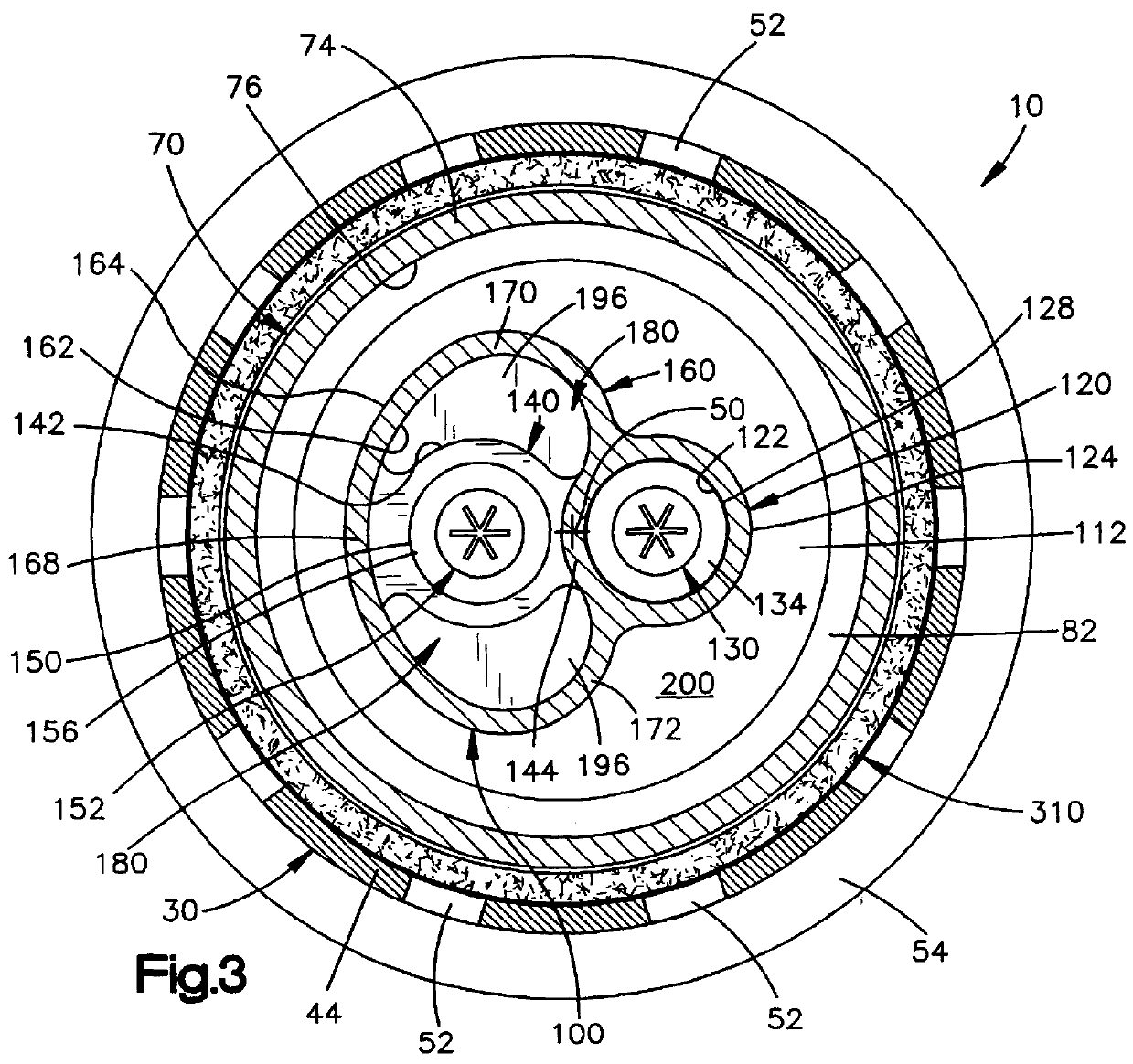

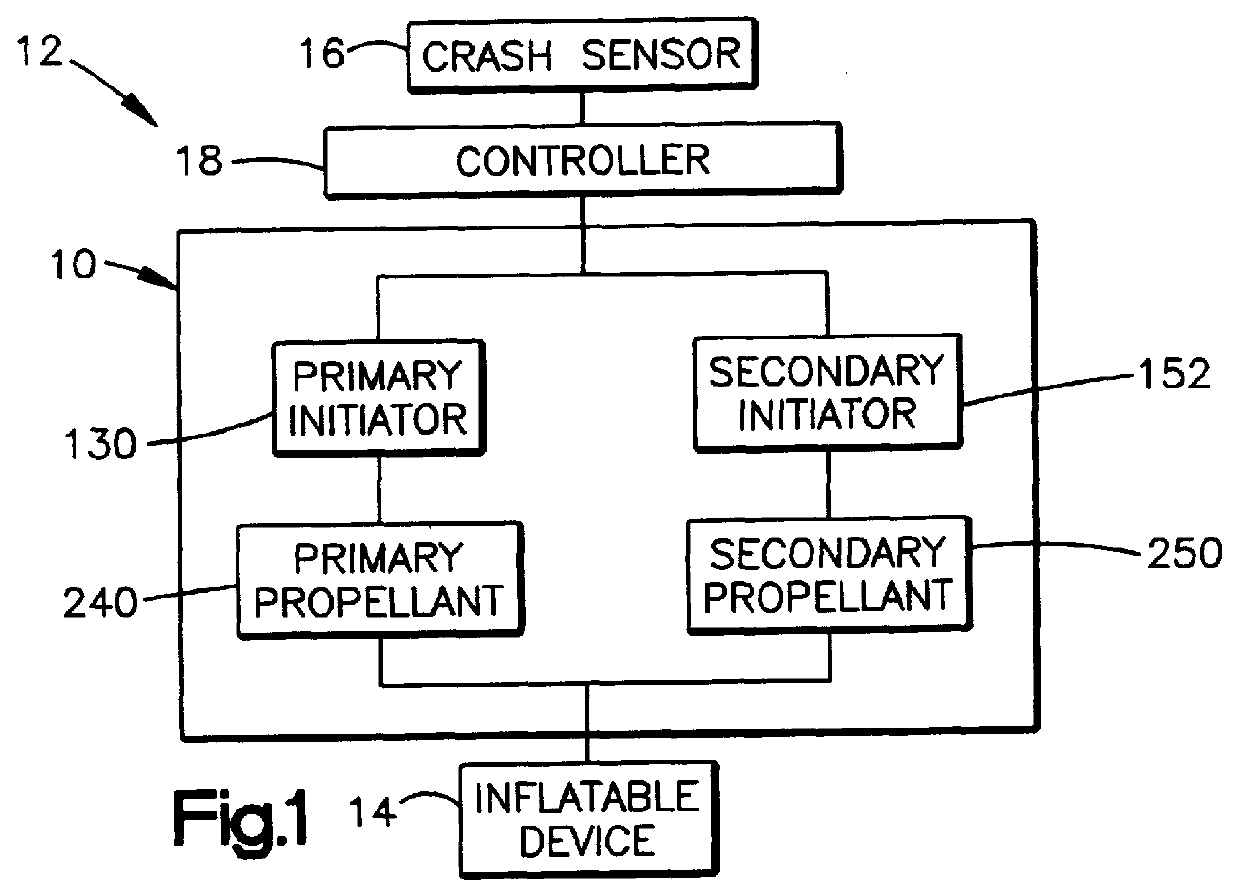

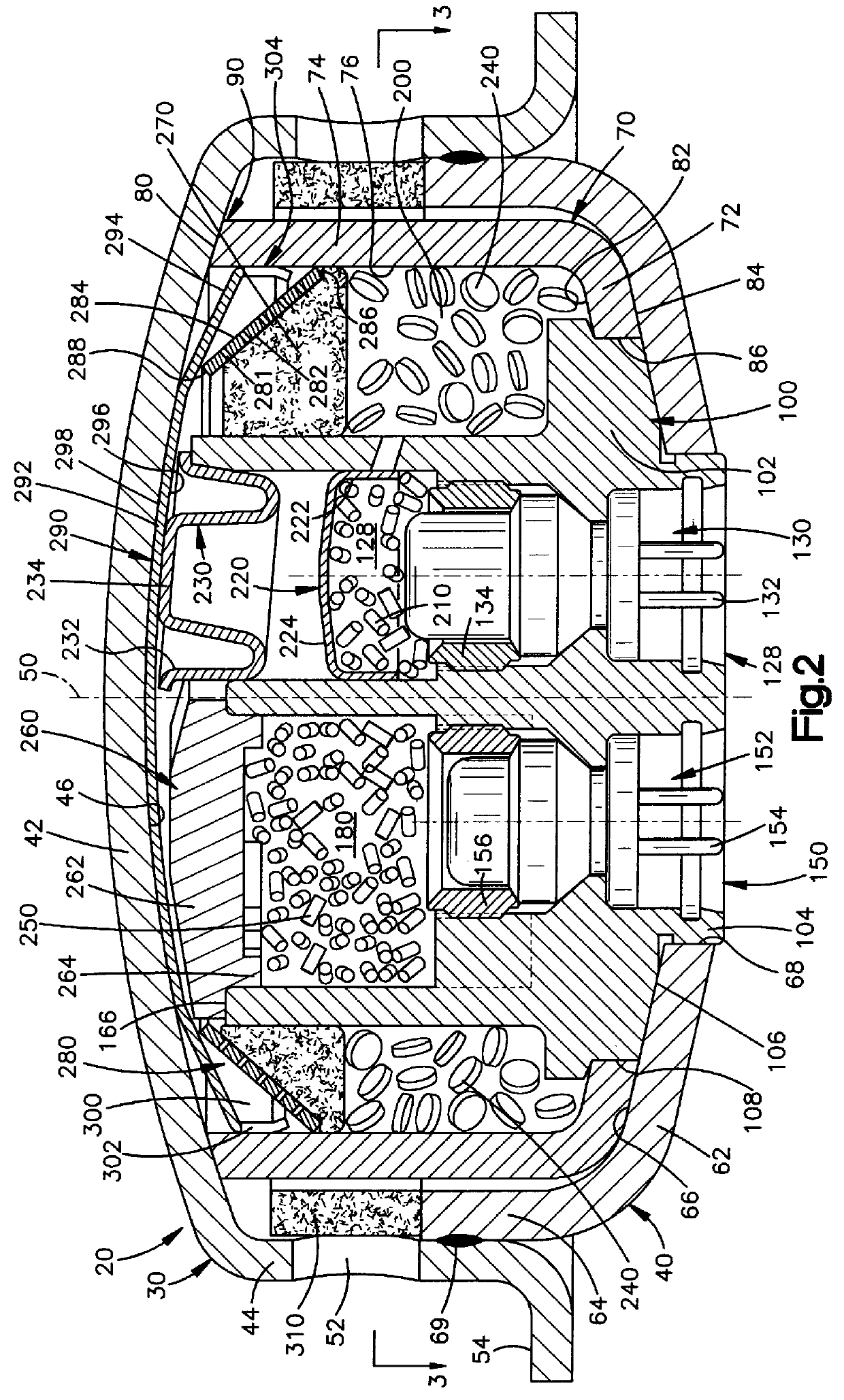

InactiveUS6543805B2Part can be impactedPedestrian/occupant safety arrangementPressure gas generationDual stageEngineering

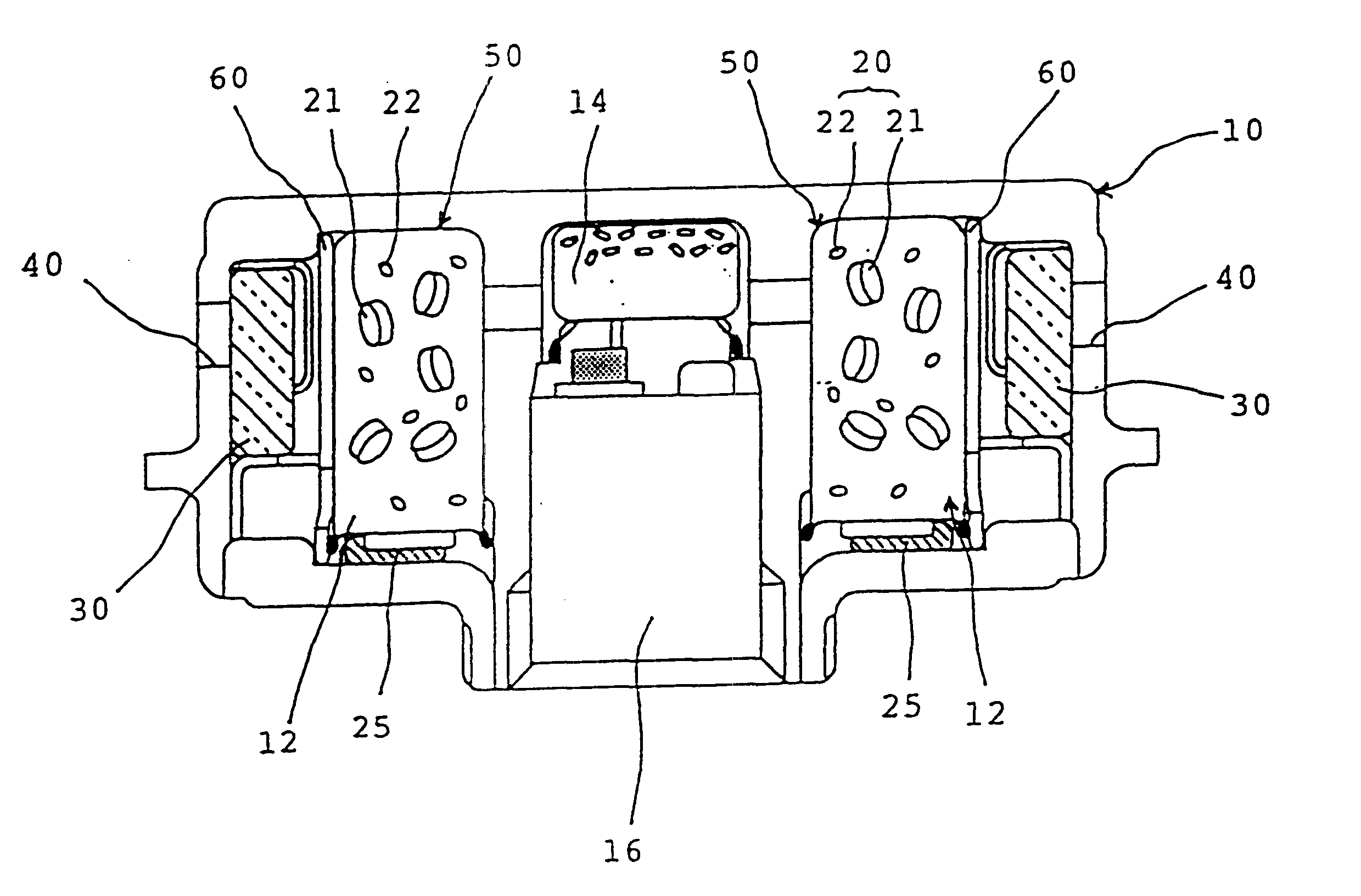

An inflator (10) includes a housing (20). A first inflation fluid source (240) in the housing (20) is actuatable to effect flow of inflation fluid to inflate an inflatable device. A first actuatable initiator (130) in the housing (20), when energized, effects actuation of the first inflation fluid source (240). A second inflation fluid source (250) in the housing (20) is actuatable to effect flow of inflation fluid to inflate the inflatable device. A second actuatable initiator (152) in the housing (20), when energized, effects actuation of the second inflation fluid source (250). The housing (20) has a fluid passage (90) for directing flow of inflation fluid out of the housing (20) to the inflatable device. The housing (20) deforms due to the pressure of inflation fluid in the housing upon actuation of one or both of the inflation fluid sources (240, 250). The flow area of the fluid passage (90) increases due to deformation of the housing (20) and varies in accordance with the pressure of inflation fluid in the housing.

Owner:JPMORGAN CHASE BANK NA

Airbag inflator and an airbag apparatus

InactiveUS6234521B1Complex clearance structureExcellent arresting capabilityGas treatmentDispersed particle filtrationCombustionEngineering

An airbag inflator includes non-azide gas generating propellants, surrounding an ignition device, disposed inside a housing. The gas generating propellants are surrounded by a coolant / filter device having a pressure loss of 0.3x10-2 to 1.5x10-2 kg / cm2 at a flow rate of 100 l / min / cm2. A space is provided between an outer periphery of the coolant / filter device and the housing such that the combustion gas passes through the entire area of the coolant / filter device. The coolant / filter device is also surrounded by a swell suppressing layer which prevents the coolant / filter device from swelling due to a combustion of the gas generating propellants.

Owner:DAICEL CHEM IND LTD

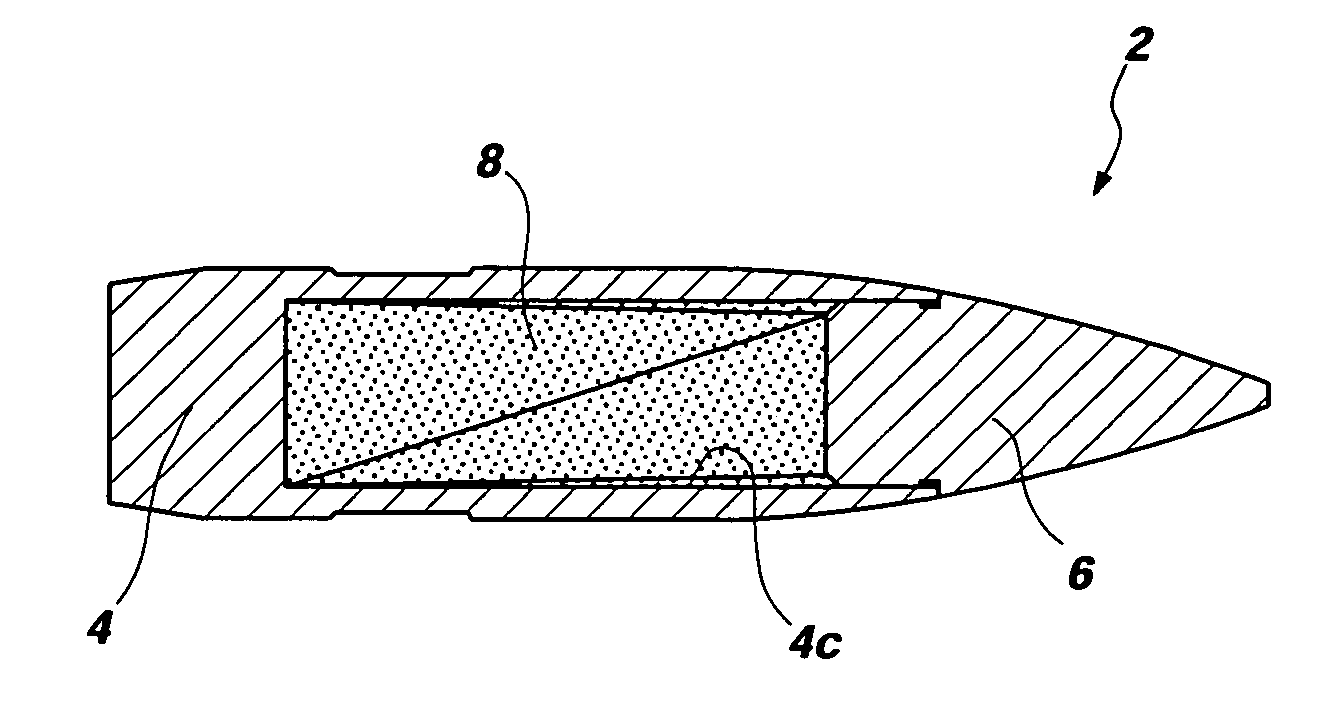

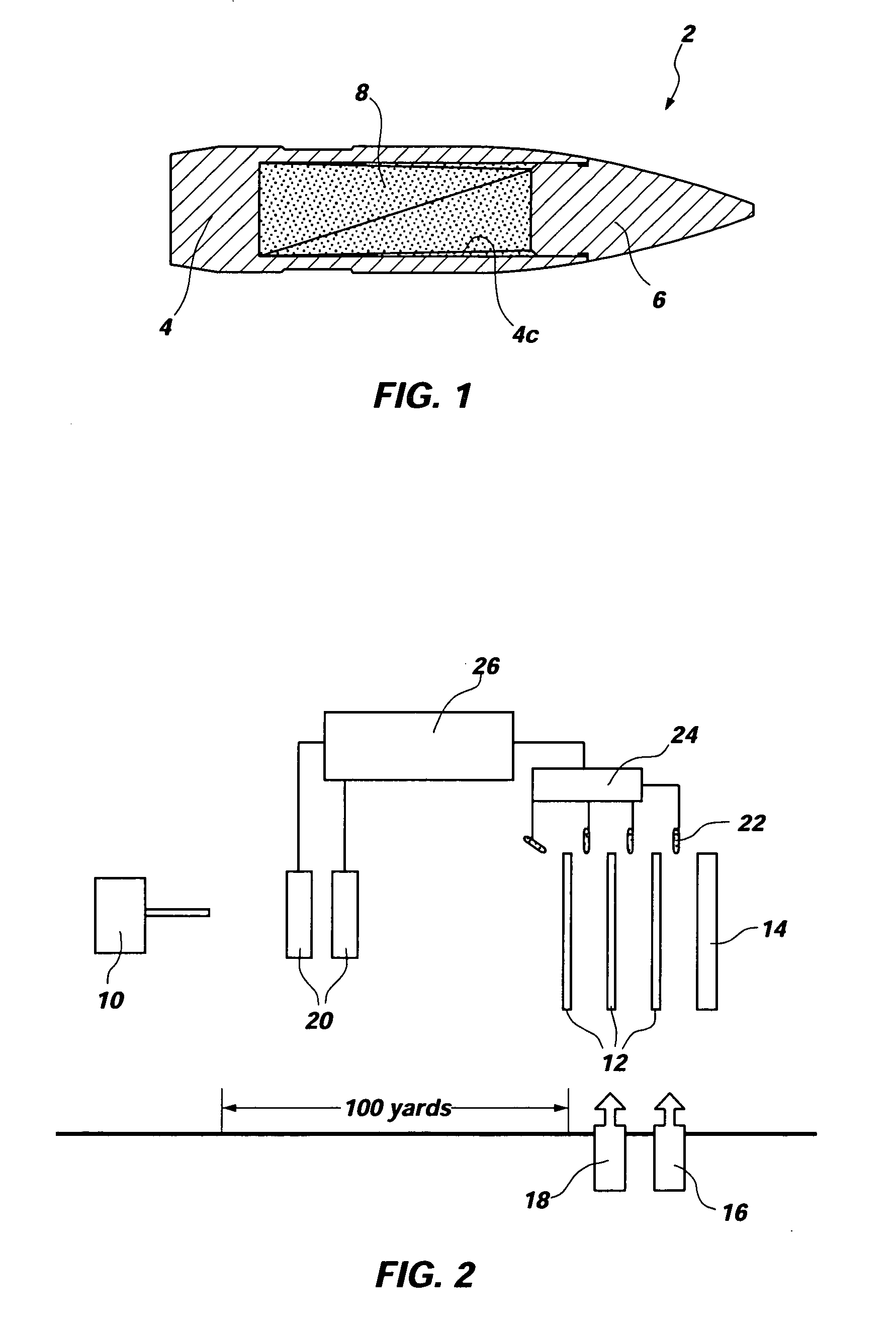

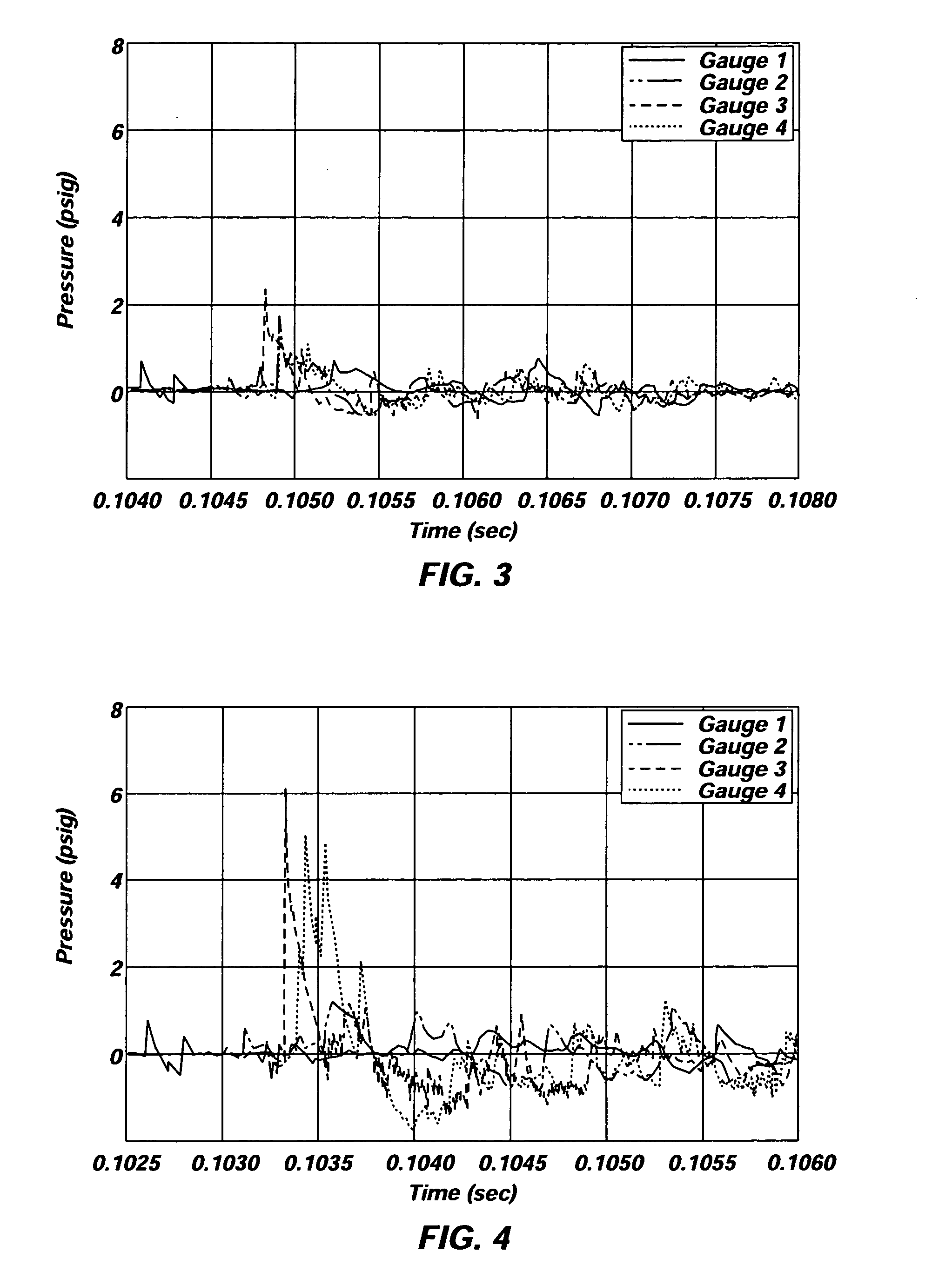

Reactive material enhanced munition compositions and projectiles containing same

A reactive material that includes at least one of a fuel, an oxidizer, and a class 1.1 explosive and is formulated for use in a reactive material projectile. The reactive material is formulated to provide at least one of an overpressure of greater than approximately 9 pounds per square inch at a radial measurement of 12 inches from a point of impact on a target, a hole greater than approximately 2 square inches at an optimum penetration level in a target, and pressure, damage, and a flame when the reactive material bullet impacts a target. The fuel may be a metal, a fusible metal alloy, an organic fuel, or mixtures thereof. The oxidizer may be an inorganic oxidizer, sulfur, a fluoropolymer, or mixtures thereof. A reactive material projectile having the reactive material disposed therein is also disclosed.

Owner:ORBITAL ATK INC

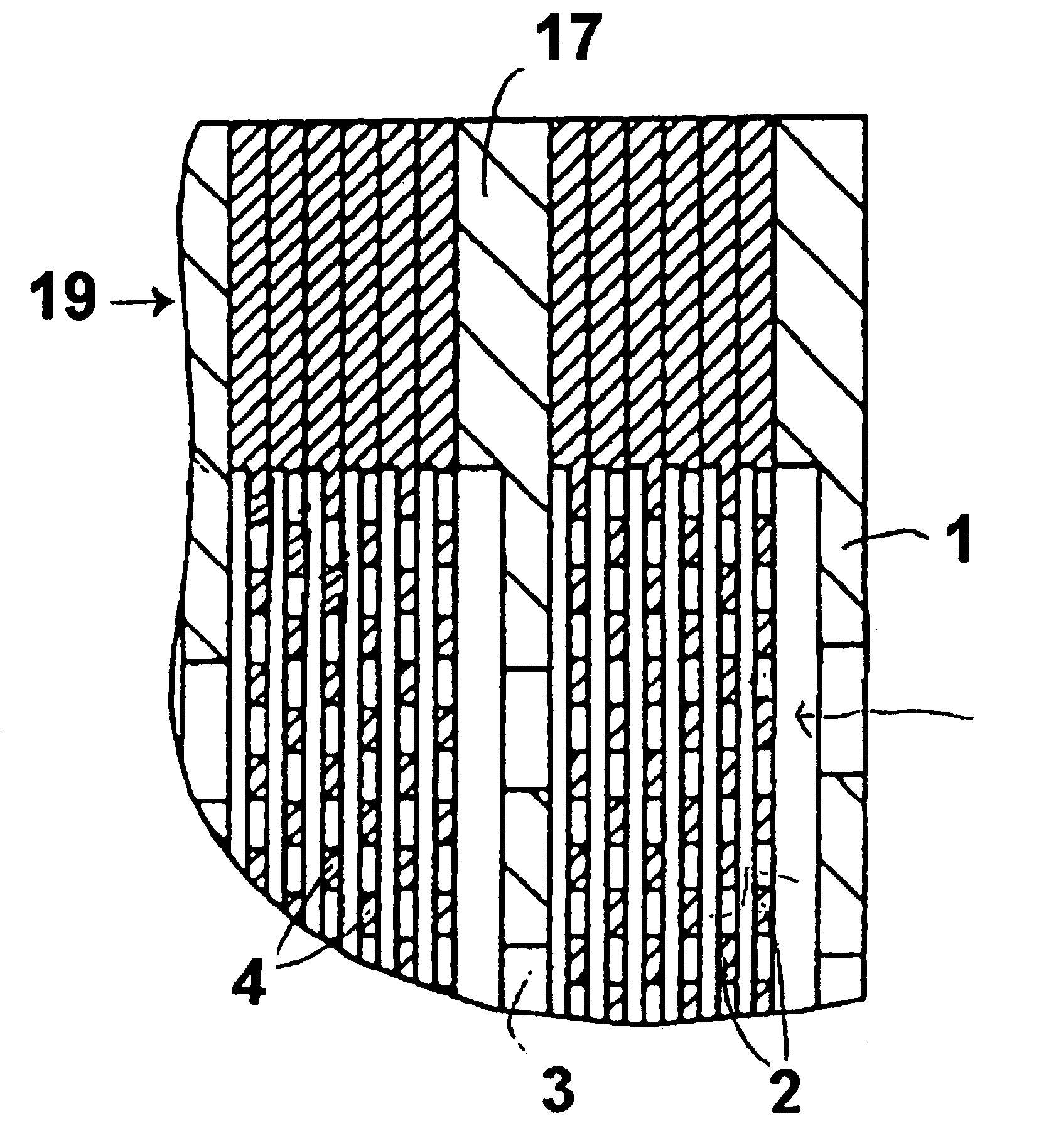

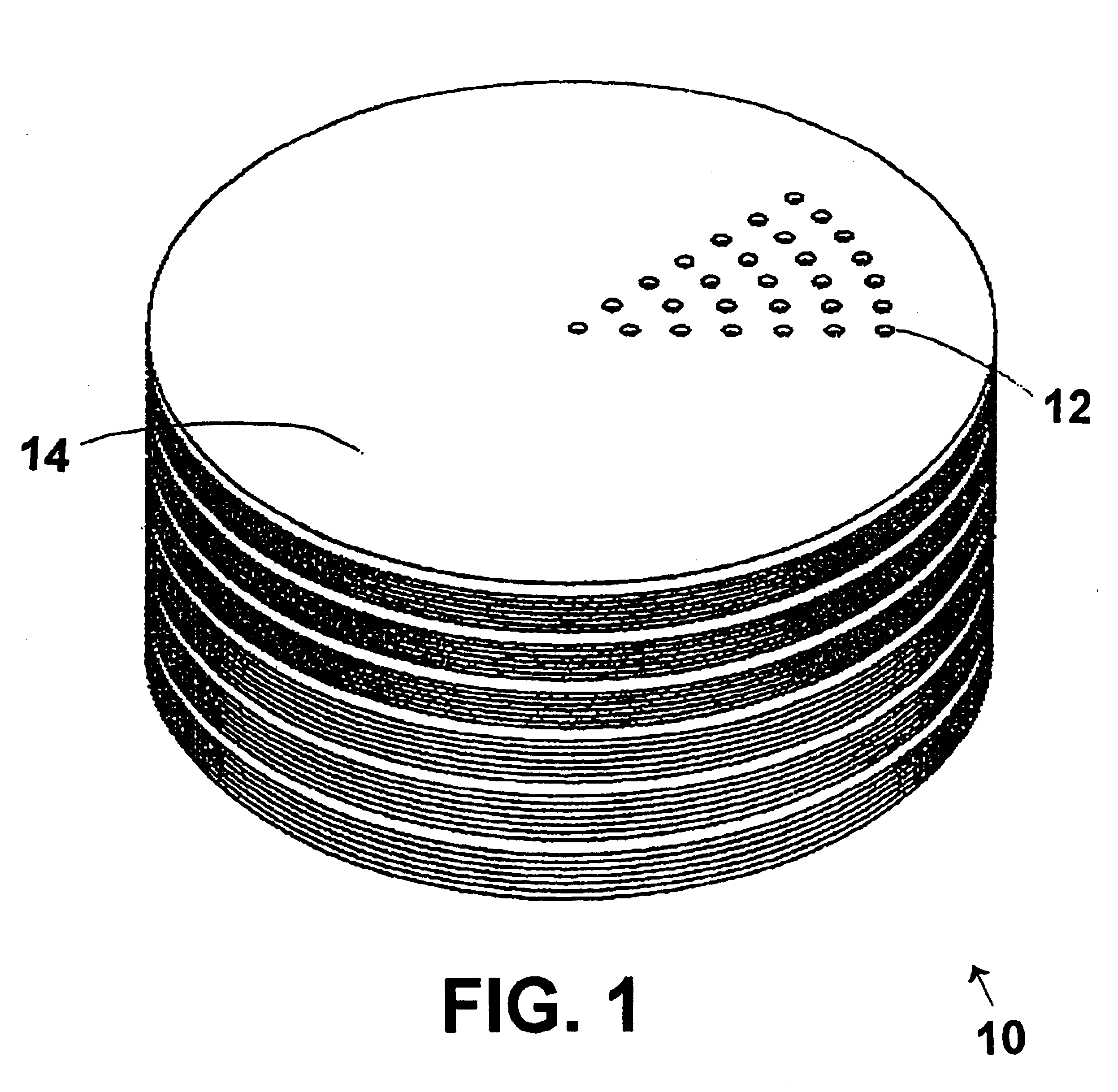

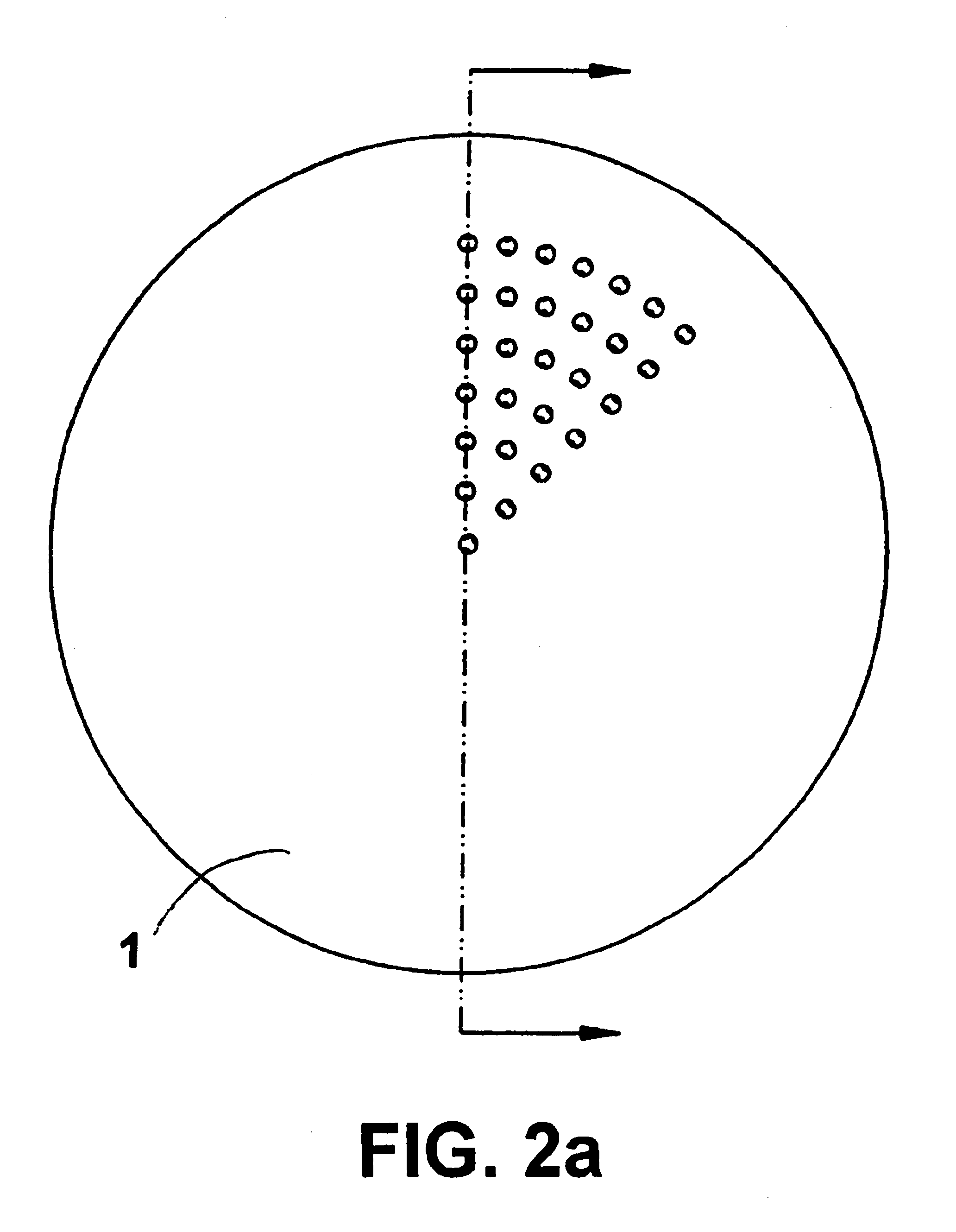

Axial flow catalyst pack

InactiveUS6746651B1Promote uniform mixingEffective contactHydrogen productionChemical/physical/physico-chemical stationary reactorsCatalytic decompositionEngineering

A stack of very thin metal plates provides high surface area for catalytic decomposition of a fluid flowing axially from upstream to downstream through the stack. Each plate has flow-through passages of selected size and location to promote uniform flow and good surface contact with a catalyst surface on the plates. The downstream surface of each plate is etched to provide gaps between plates for lateral fluid flow. The plates are divided into groups separated by metering plates that promote more uniform flow from group to group.

Owner:AEROJET ROCKETDYNE INC

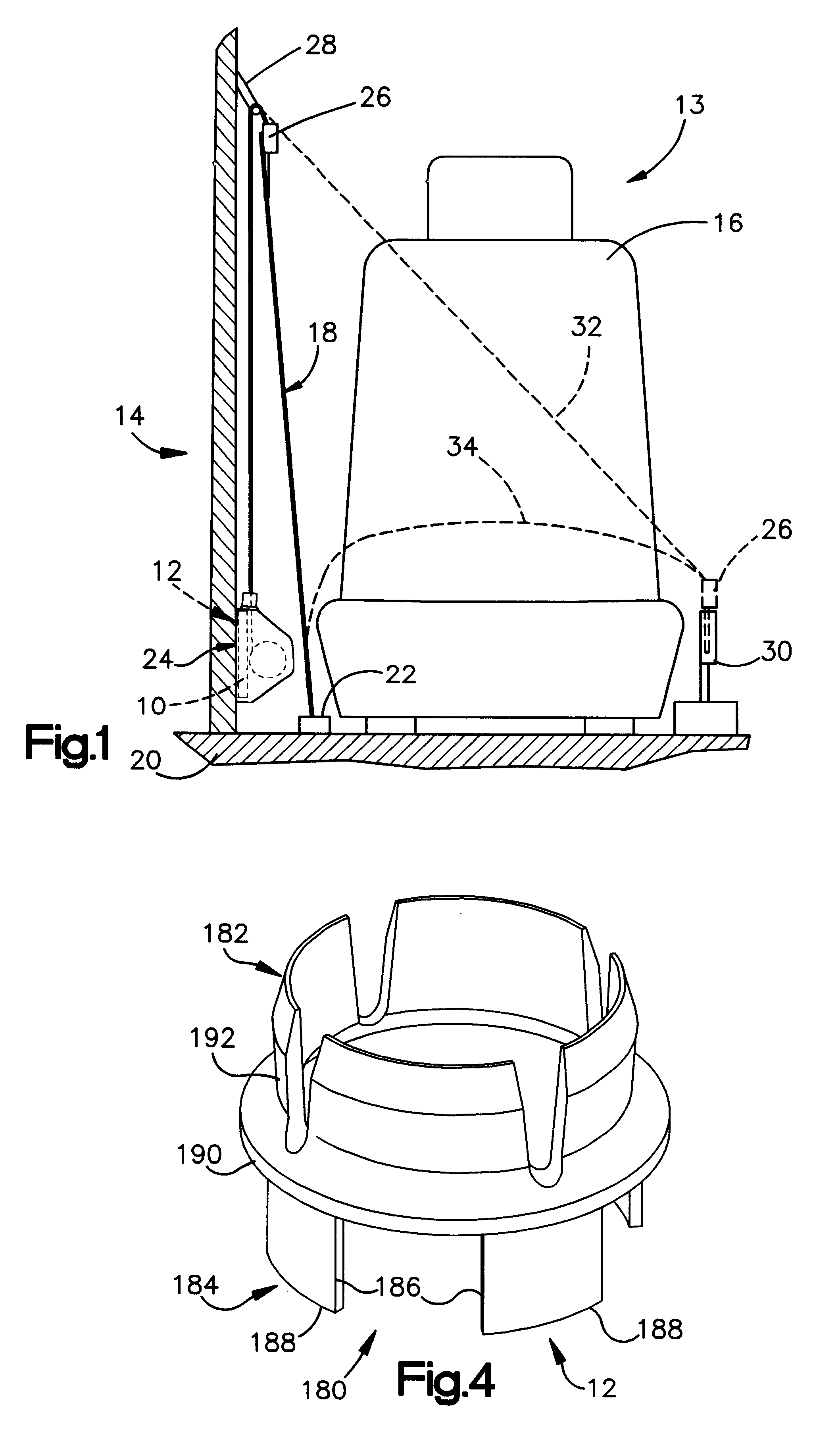

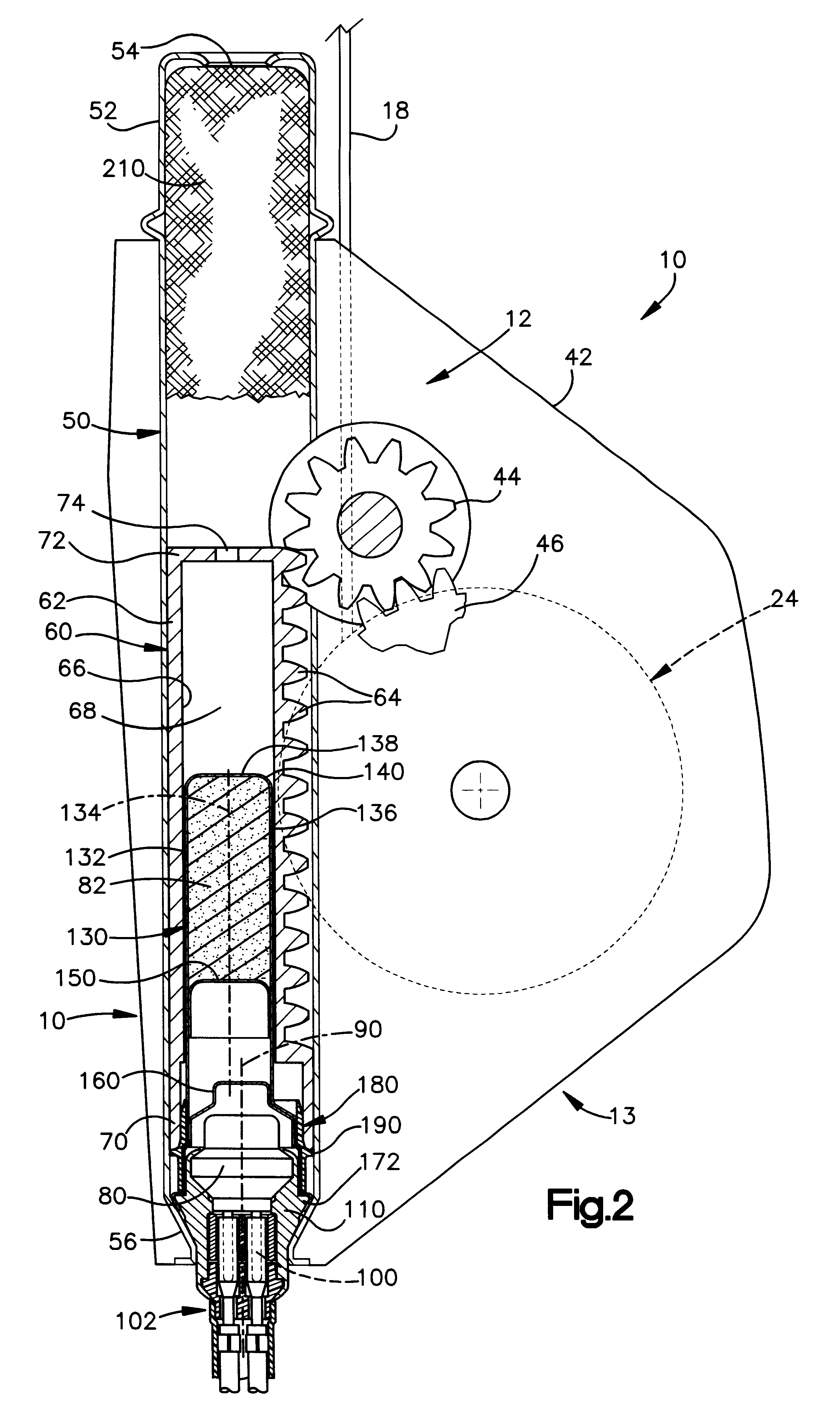

Gas generator for seat belt pretensioner

An apparatus (10) for providing fluid under pressure for actuating a vehicle occupant protection device comprises an electrically actuatable initiator (80) having terminal pins (100). A hermetically sealed metal propellant container (130) contains a propellant (82) ignitable by the initiator (80) to produce fluid under pressure. The propellant container (130) is secured to the initiator (80) by crimping. The apparatus (10) also comprises a member (86) electrically insulating between the metal propellant container (130) and the terminal pins (100) of the initiator (80) to isolate the initiator electrically from the propellant container.

Owner:TRW INC

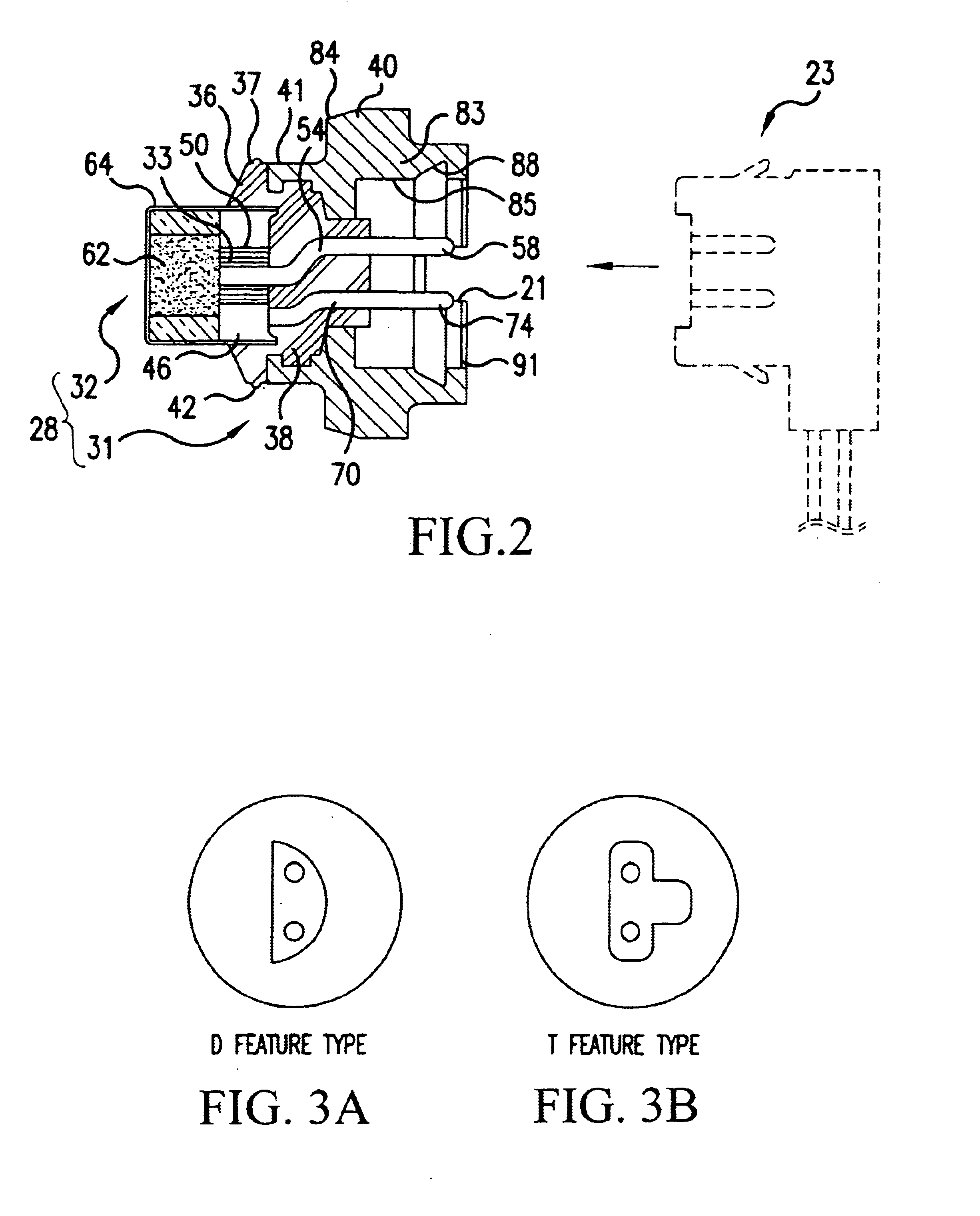

Initiator assembly

InactiveUS6718884B1Avoid deformationFirmly connectedBlasting cartridgesPedestrian/occupant safety arrangementMobile vehiclePlastic materials

The invention provides an initiator assembly that can be easily manufactured without increasing cost, and can be easily and securely connected to a connector when it is used. The initiator assembly includes a priming for being used in a motor vehicle, an initiator used for igniting the priming and having at least one conductive pin and a metal collar for fixing the initiator assembly on an inflator that are integrally formed by an insulating material injection-molded therebetween. The insulating material is a resin made of a plastic material that surrounds a metal eyelet of the initiator.

Owner:DAICEL CHEM IND LTD

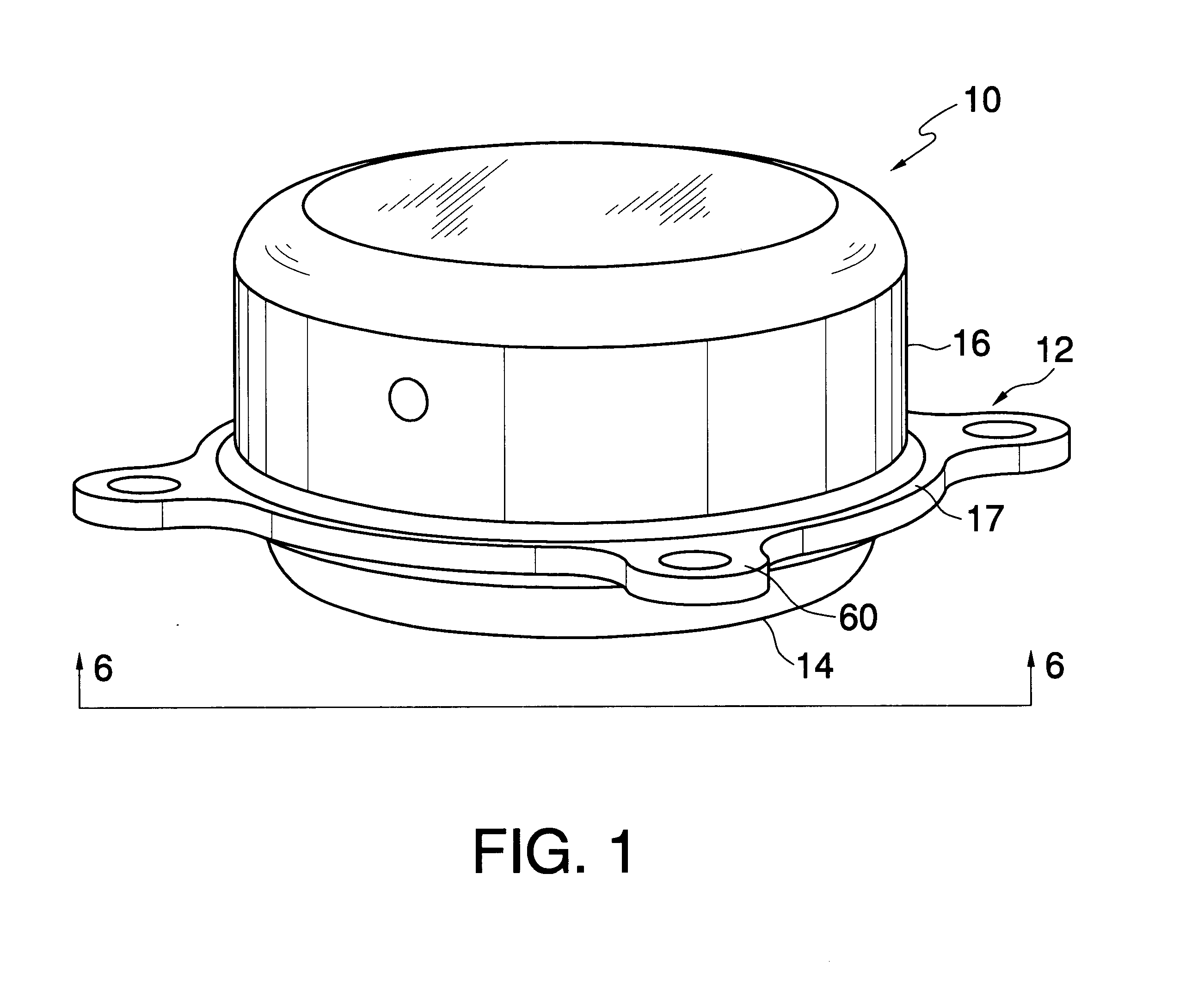

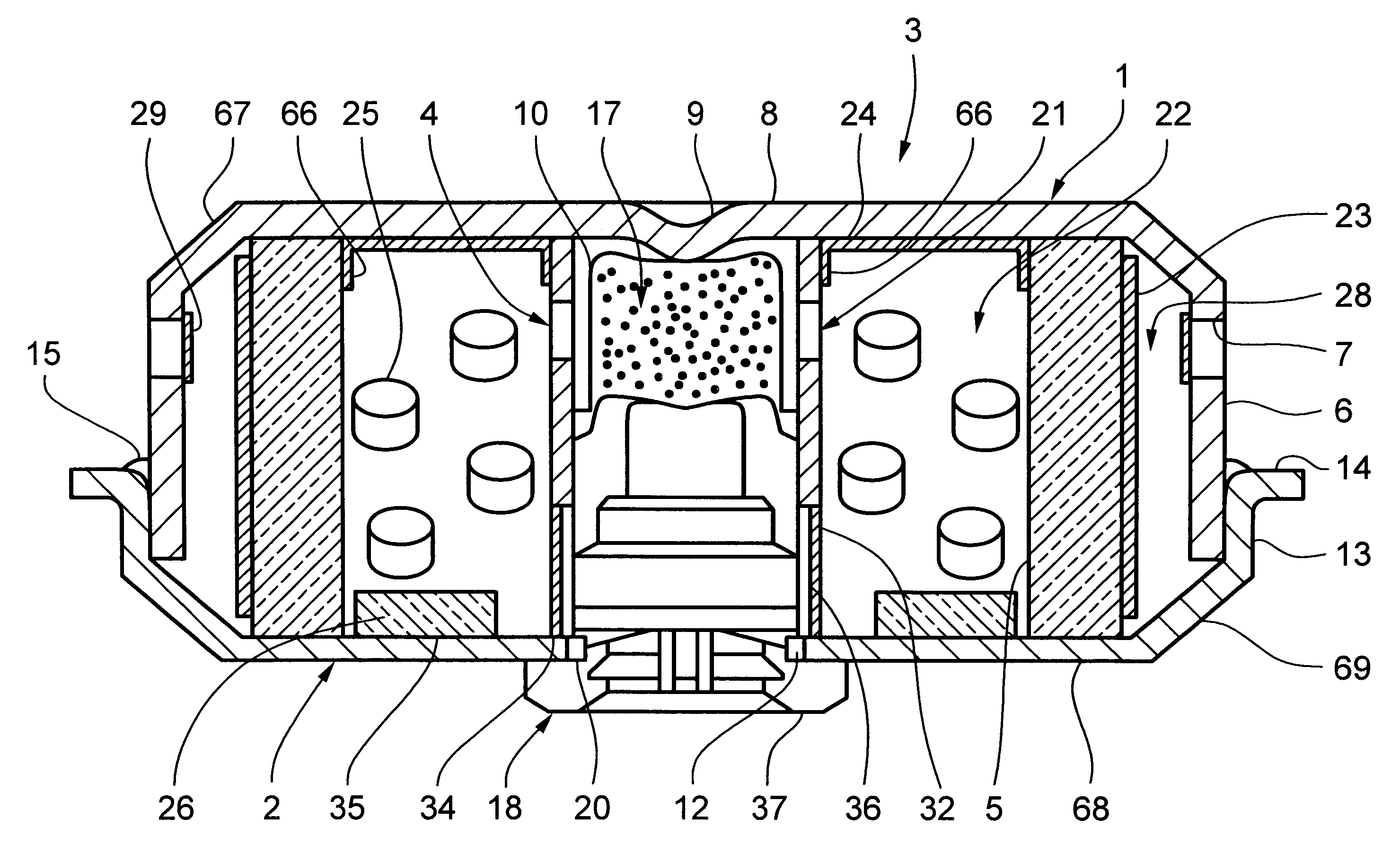

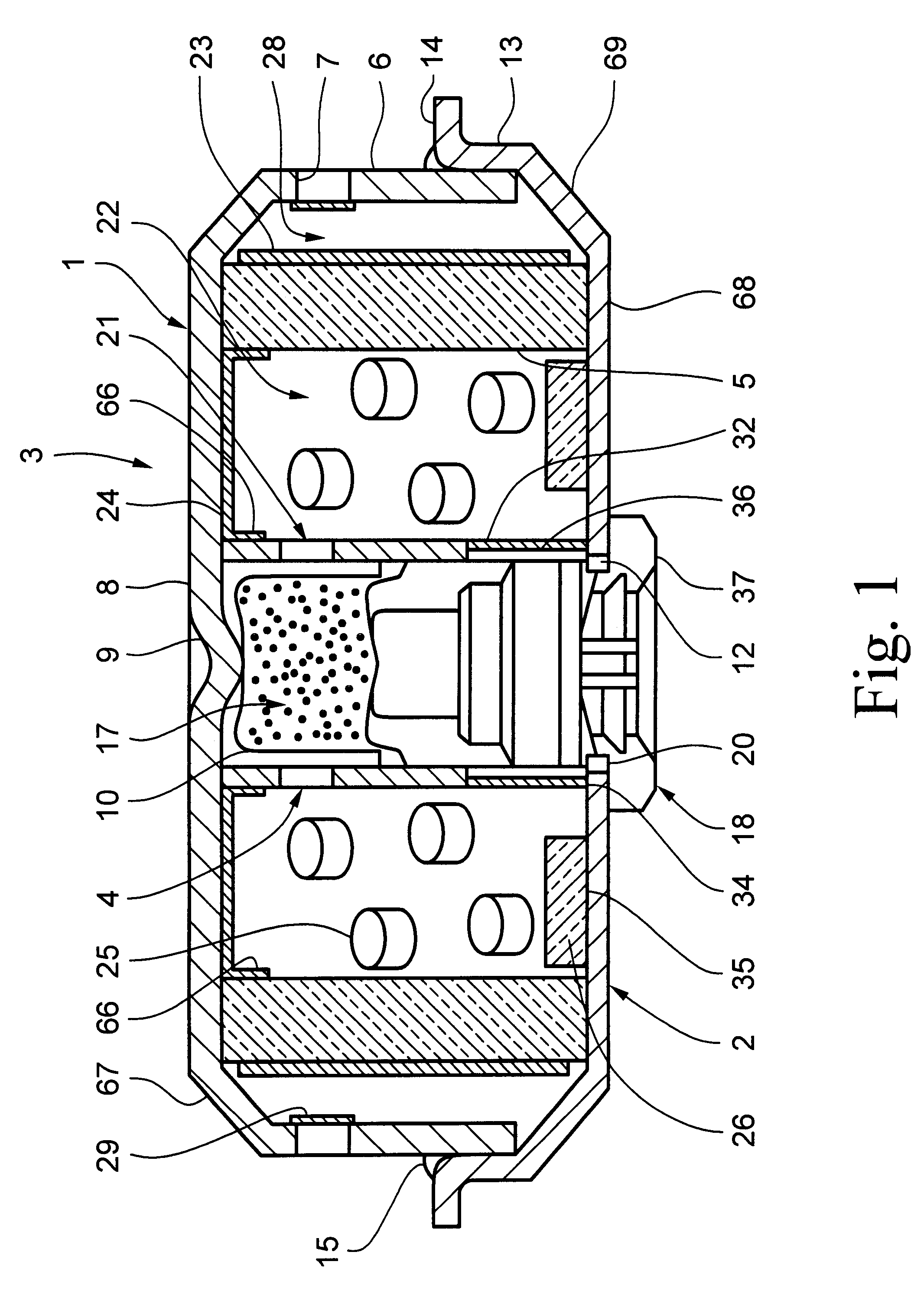

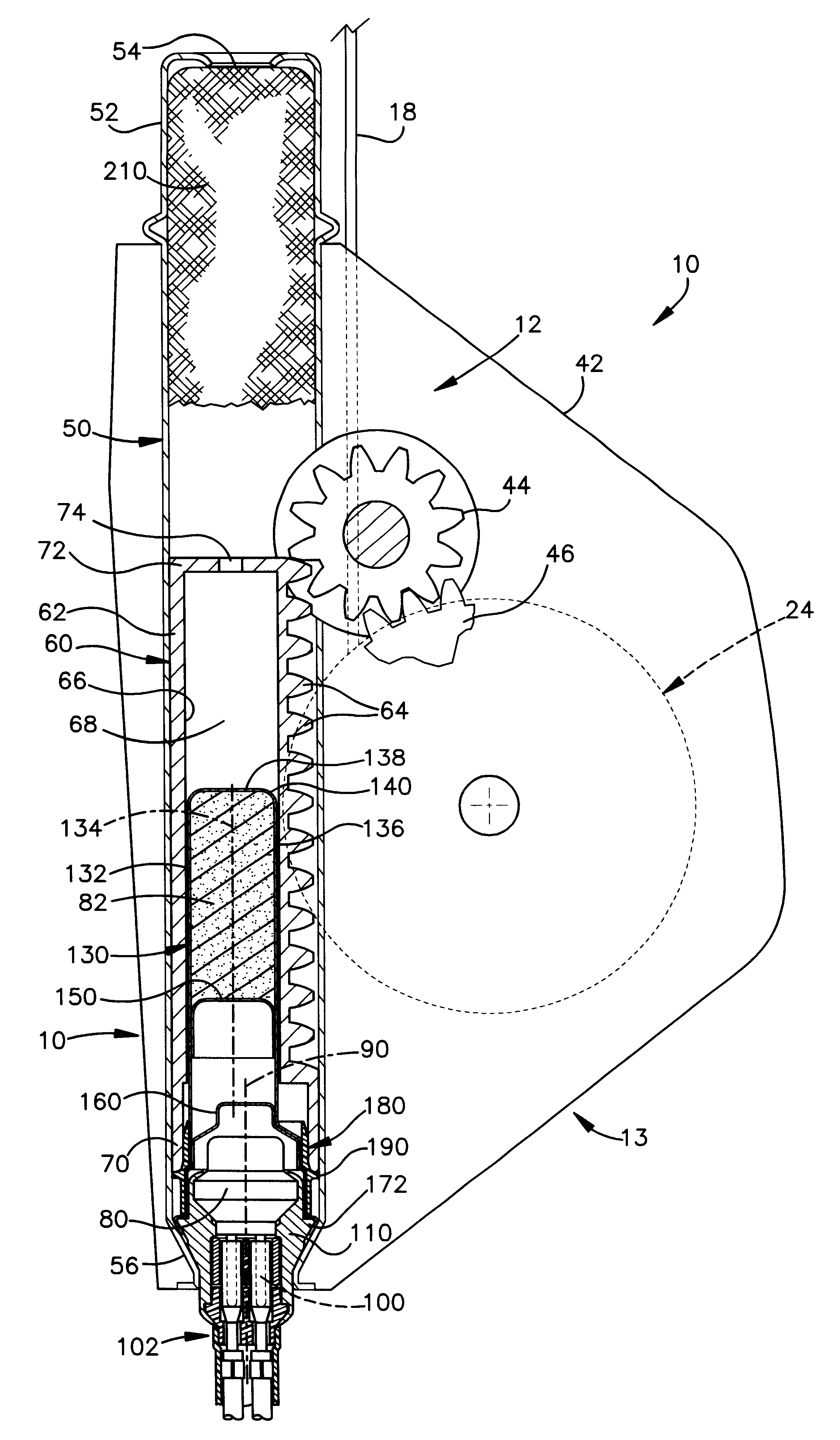

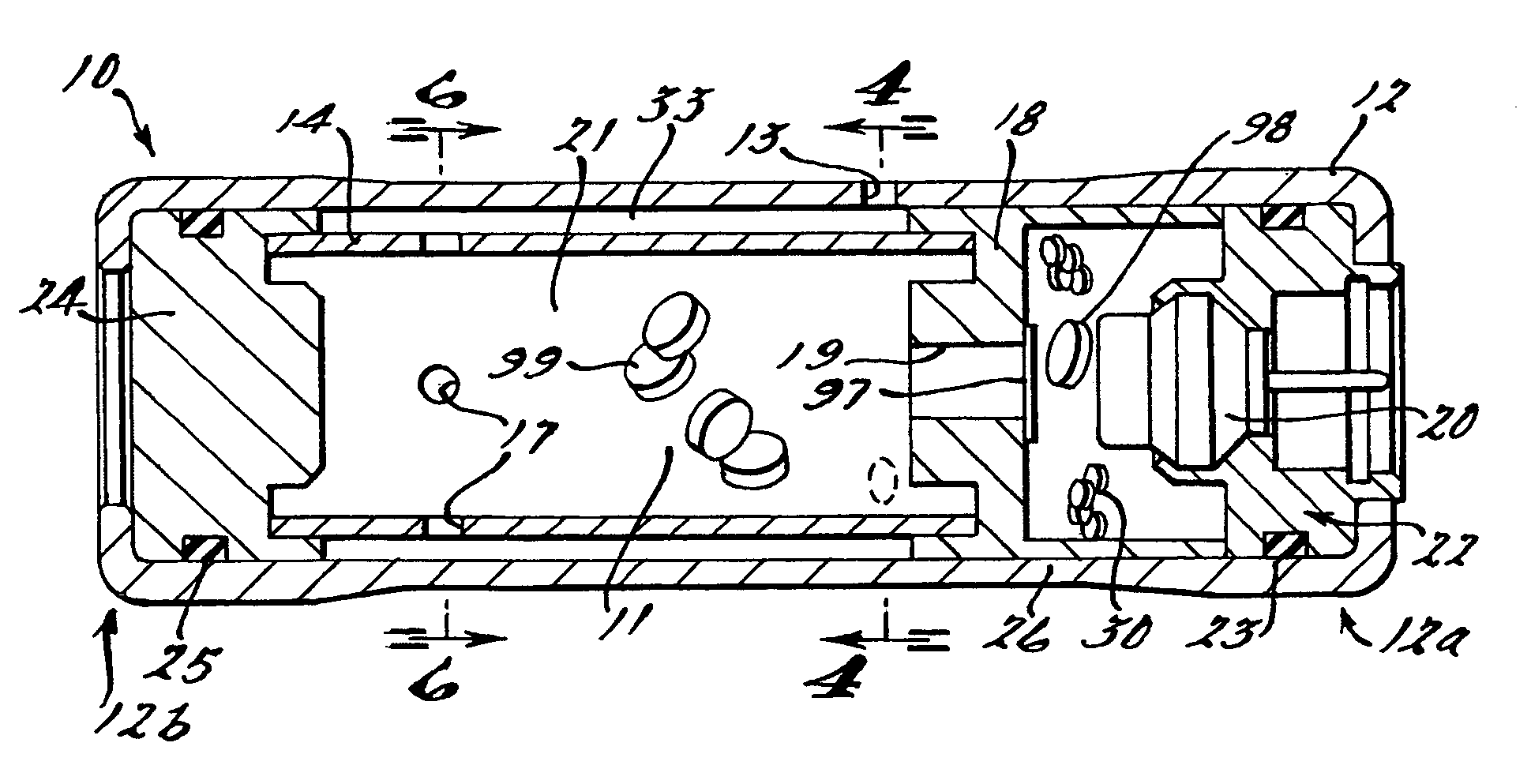

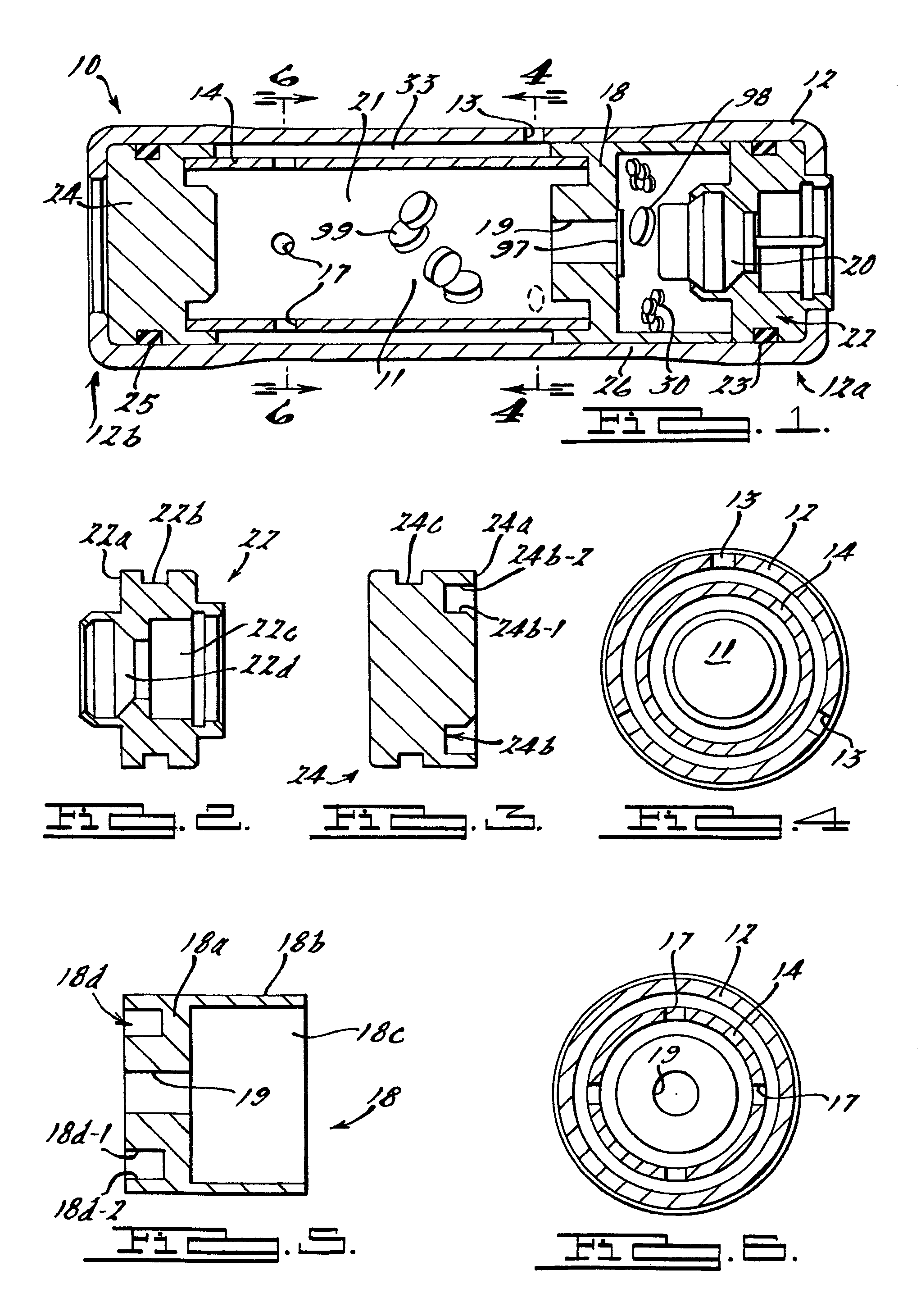

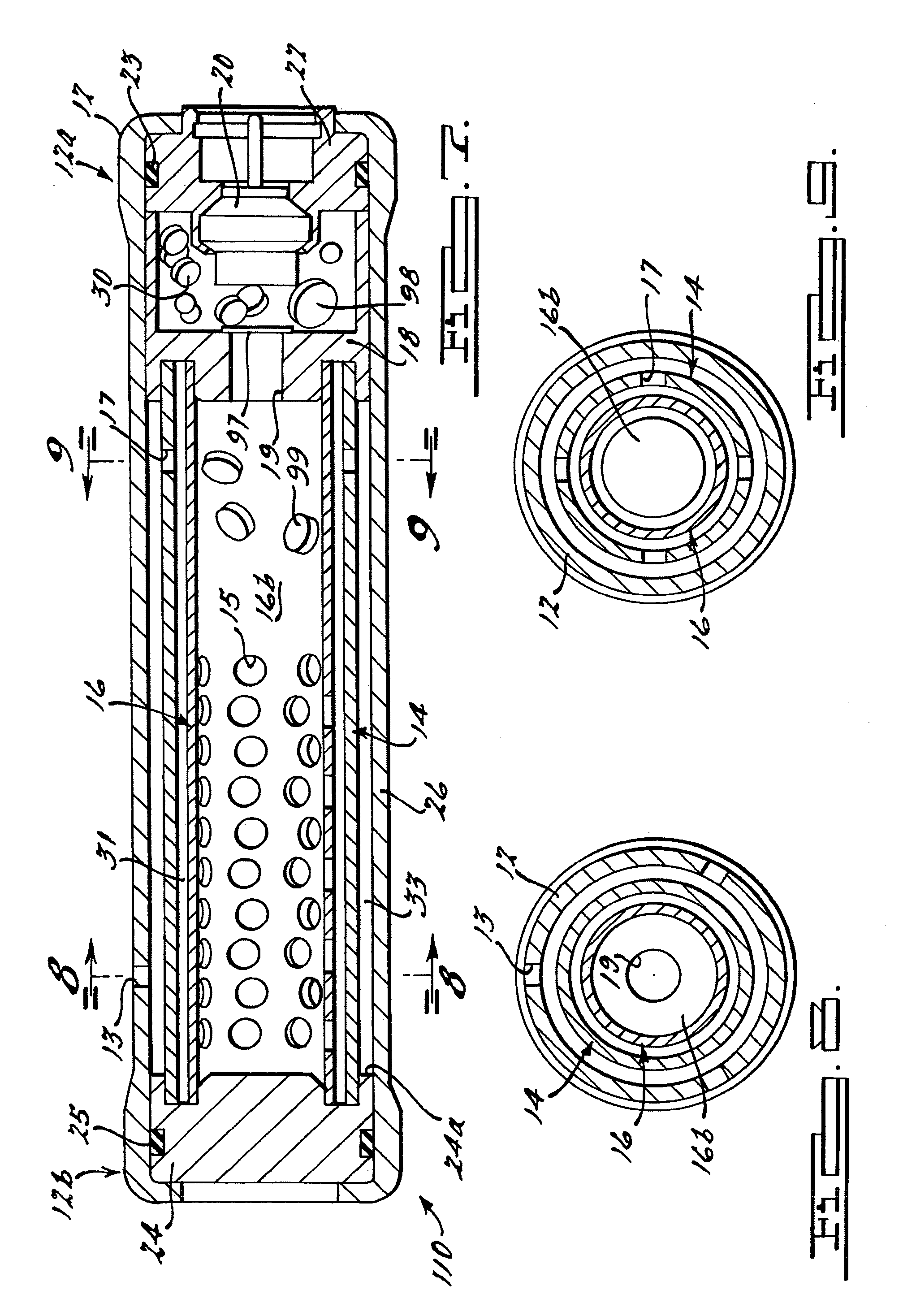

Inflator

InactiveUS7073820B2Pedestrian/occupant safety arrangementPressure gas generationEngineeringParticulate material

An inflator (10) for a vehicle occupant restraint system. The inflator (10) includes a housing (12) having apertures (13) formed therealong to enable fluid communication between an interior of the housing (12) and an exterior of the housing. A first baffle (14) is positioned in the housing interior. The baffle (14) is spaced apart from the housing (12) to define a fluid channel (33) therebetween in communication with the housing apertures (13). The baffle (14) includes a first opening (17) for fluid communication between an interior of the baffle (14) and the fluid channel (33), and an open end portion for fluid communication between the baffle interior and the baffle exterior. A spacer (18) positioned in the housing interior cavity defines an enclosure (18c) and includes an aperture (19) formed therein for fluid communication between the enclosure (18c) and the open end portion of the baffle. A gas generant (30) is positioned within the spacer enclosure (18c). The gas generant (30) may be a smokeless gas generant composition. An initiator (20) is coupled to the housing (12) for initiating combustion of the gas generant (30) upon activation of the inflator. The inflator (10) provides a continuous, tortuous fluid path through the fluid channel (33) for cooling inflation gases. In addition, the use of a smokeless gas generant composition allows the inflator (10) to operate without the need for a filter to remove particulate materials from the inflation gas.

Owner:AUTOMOTIVE SYST LAB

System, method, and program product for targeting and optimal driving force distribution in energy recovery systems

ActiveUS7698022B2Facilitate energy recoveryEasy to calculateLevel controlTemperatue controlEnergy recoveryTrade offs

A system, methods, and user-friendly program product to calculate global energy utility targets and define optimal driving force distribution for a process or cluster of processes under all possible process changes and streams specific minimum temperature approach values, simultaneously, and without enumeration, are provided. The program product can utilize stream-specific minimum temperature approach values ΔTmini, where the superscript i represents the specific hot stream, as the optimization parameters instead of the single global ΔTmin currently used, in addition to identifying the optimal operating conditions. The program product can define optimal process conditions and an optimal driving force distribution in heat recovery systems, and can produce an optimal Pareto-curve that shows the rigorous trade off between energy cost and capital cost for any energy recovery system.

Owner:SAUDI ARABIAN OIL CO

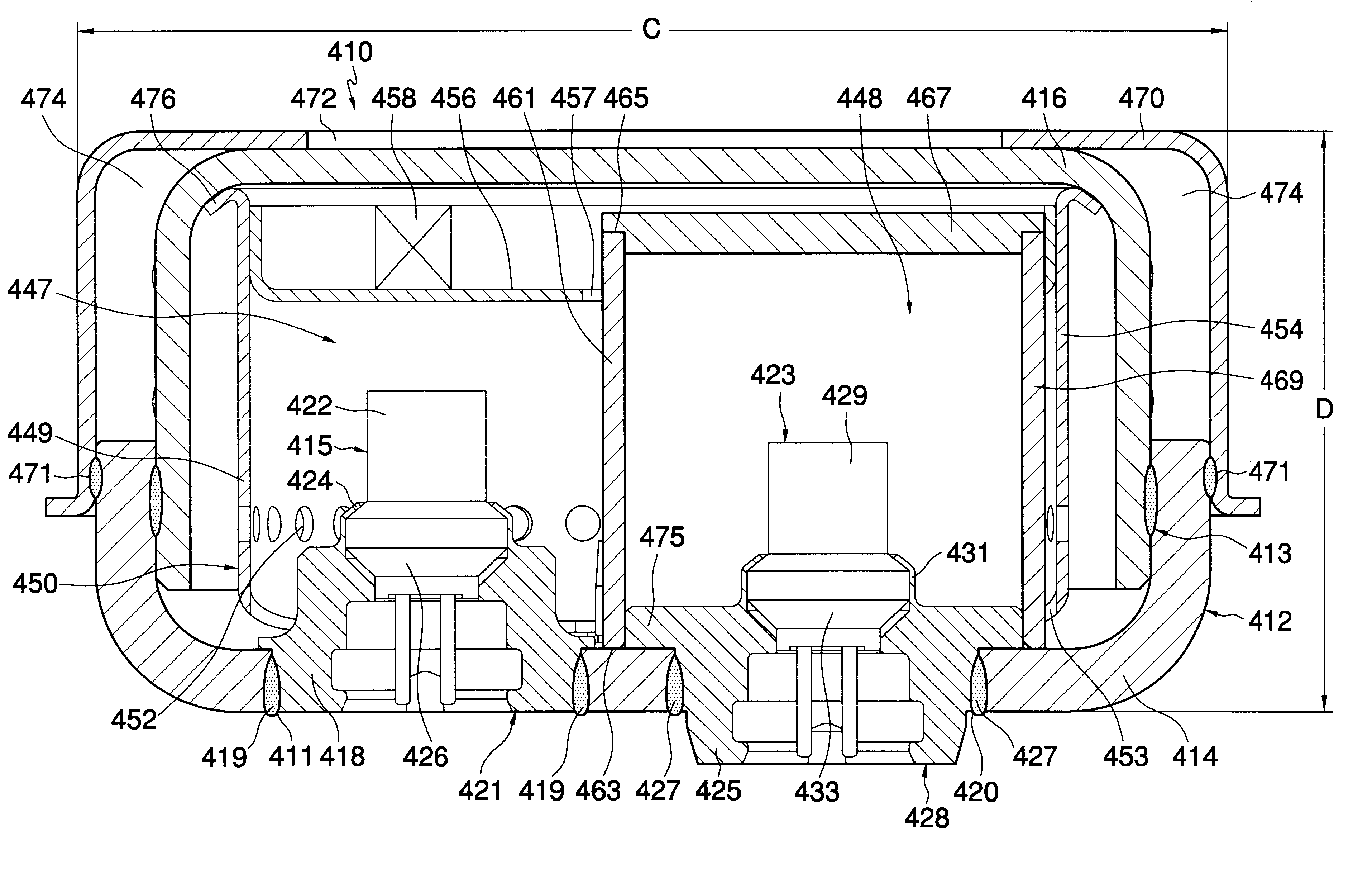

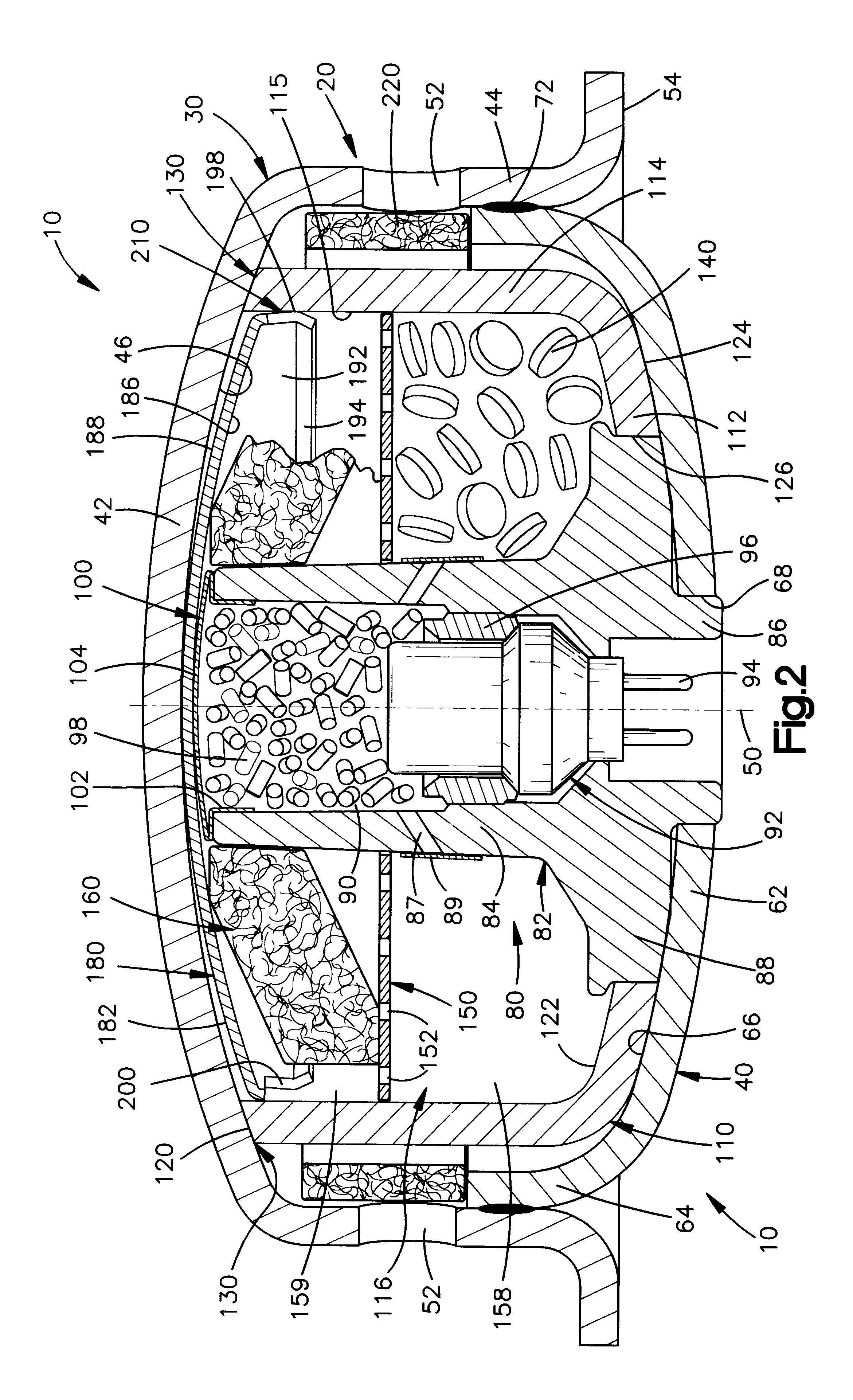

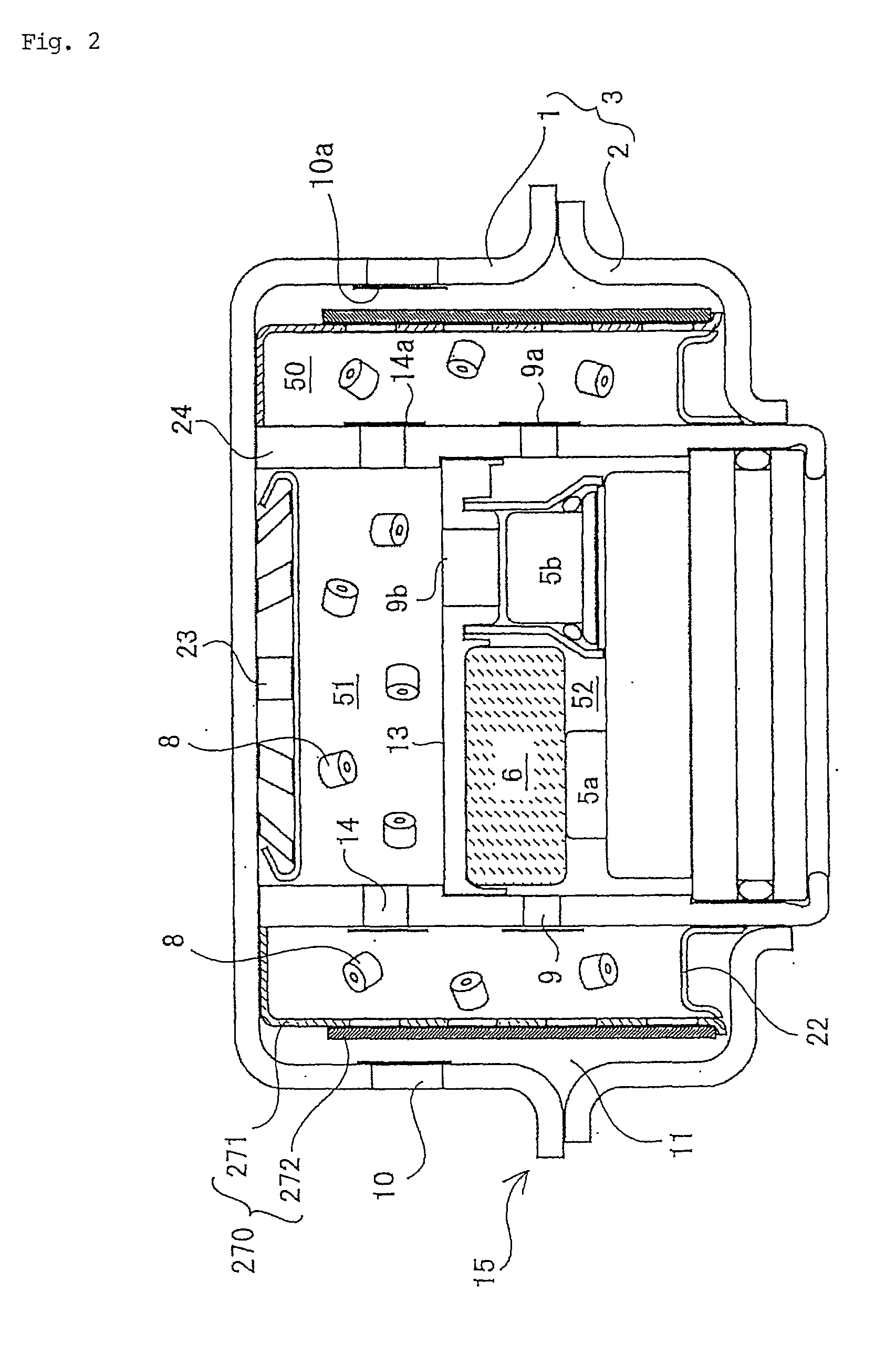

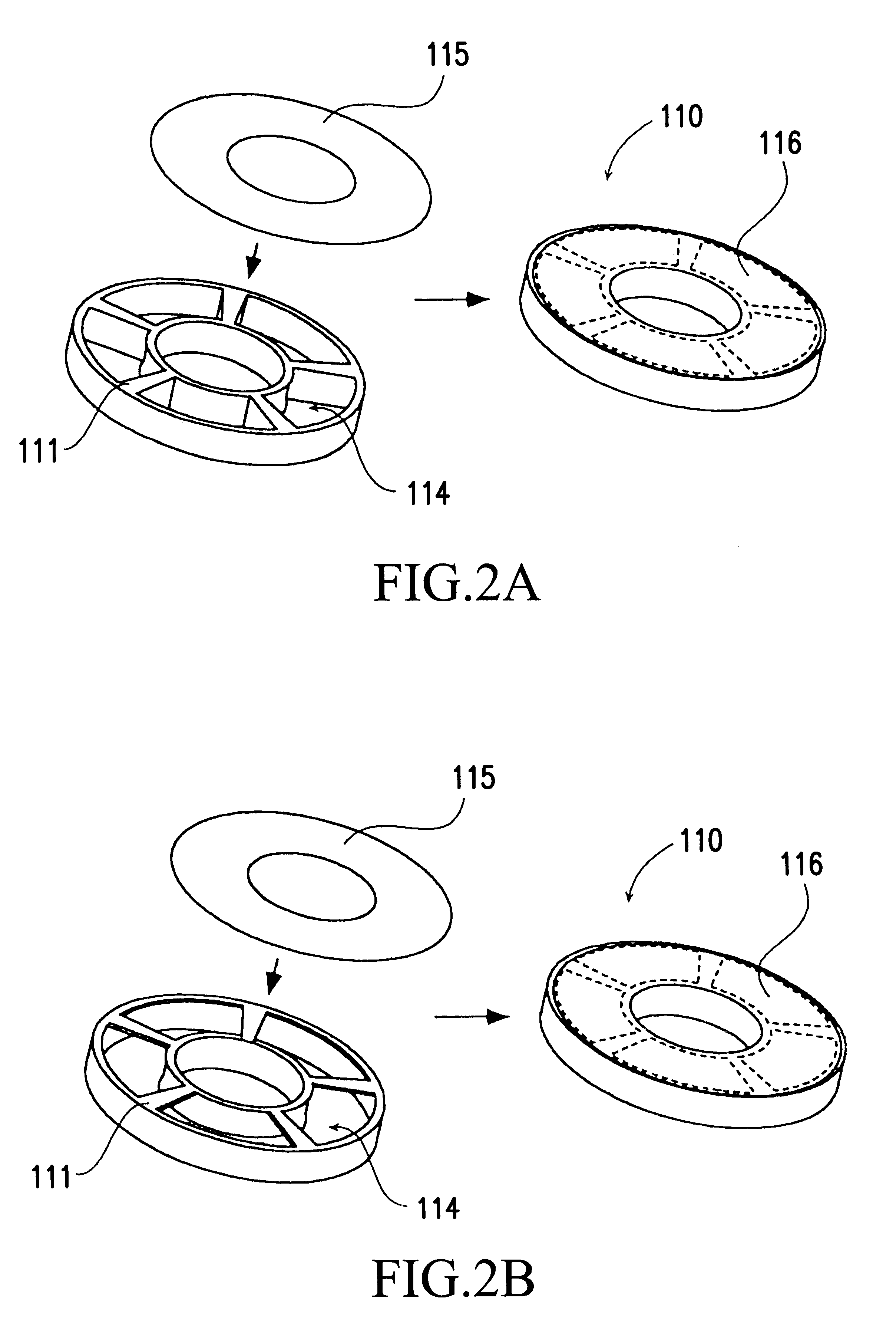

Multistage gas generator for air bag and air bag apparatus

InactiveUS6491321B1Reduce sizeShort pass of the activation gas can be effectively avoidedGas treatmentDispersed particle filtrationCombustionProduct gas

A gas generator for an air bag includes: a housing having top and bottom plates and a cylindrical wall provided between those plates; a cylindrical filter unit, provided inside the housing, at least one end of the filter unit having an inclining end surface such that the length of the filter unit in an axial direction thereof decreases as the distance from a central axis of the filter in a radial direction increases, an outer peripheral surface of the filter unit and an inner surface of the cylindrical wall defining a plenum; and a supporting portion formed inside the housing and having an inclining surface substantially parallel to the inclining end surface of the filter unit. The supporting portion engages with the inclining end surface such that the plenum is maintained even when the filter unit is urged to expand in the radial direction by the combustion gas.

Owner:DAICEL CHEM IND LTD

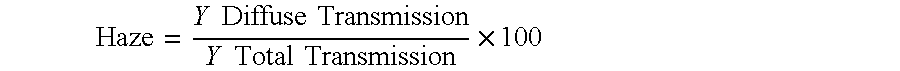

Aluminum/alkaline or alkali/titanium containing polyesters having improved reheat, color and clarity

ActiveUS20070066735A1Improving reheat rateIncrease ratingsHydrogenOther chemical processesPolyesterPolymer science

A polyester composition containing: a) aluminum atoms; and b) alkaline earth atoms or alkali metal atoms or alkali compound residues such as lithium atoms; and c) particles comprising titanium, zirconium, vanadium, niobium, hafnium, tantalum, chromium, tungsten, molybdenum, iron, or nickel atoms or combinations thereof, where the particles improve the reheat rate of the polyester composition. The polyester polymer compositions may also contain phosphorus catalyst deactivators / stabilizers. The polyester compositions and the articles made from the compositions such as bottle preforms and stretch blow molded bottles have improved reheat rate while maintaining low haze, high L*, a b* below 3, and have low levels of acetaldehyde. In the process for making the polyester polymer, the polymer melt is polycondensed in the presence of a) and b), with the particles c) added in a melt phase process or added to the polymer in an injection molding machine or extruder. The polyester polymer composition can be made to high IV from the melt phase while avoiding solid state polymerization.

Owner:ALPEK POLYESTER SA DE CV

Dual stage inflator

InactiveUS6886856B2Pedestrian/occupant safety arrangementPressure gas generationDual stageEngineering

An inflator for inflating an airbag has a housing with a first housing portion defining a first chamber and a second housing portion defining a second chamber. A gas generant disposed in the first and second chambers. A barrier separates the first and second chambers. Each of the chambers has an ignition enhancer tube disposed therein with a portion of an ignition unit being located therein. Each of the ignition enhancer tubes has at least one outlet defined therein. Each ignition enhancer tube holding an ignition enhancer such that when the associated ignition unit ignites the ignition enhancer combusts and exits through said outlet and then reacts with the gas generant in the associated chamber.

Owner:KEY SAFETY SYST

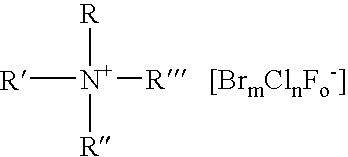

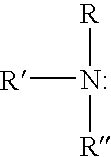

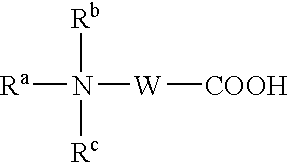

Composition for the production of chlorine dioxide using non-iodo interhalides or polyhalides and methods of making and using the same

ActiveUS7087190B2Reduce microbial countQuick buildBiocideLiquid degasificationChlorine dioxideCHLORITE ION

A composition for the generation of chlorine dioxide including at least one non-iodo interhalide, polyhalide or salt thereof having the formulaBrmClnFoXpwherein m=0–3, n=0–4, o=0–3, p=0–2, X is a cationic moiety and with the provisos that m+n+o cannot be zero; if m+n+p<2, or mixtures thereof, and at least one source of chlorite ions.

Owner:ECOLAB USA INC

Oxygen scavenging monolayer bottles

Monolayer packages comprised of an oxygen scavenging composition suitable for direct contact with package contents and recycle with other polyester bottles are disclosed. The oxygen scavenging composition is comprised of a modified copolymer which is comprised of predominantly polyester segments and an oxygen scavenging amount of oxygen scavenging segments. The polyester segments comprise segments derived from typical bottling and packaging polyesters such as PET and PEN. Use of these oxygen scavenging copolymers in bottles provides a clear and rigid monolayer bottle similar in appearance to unmodified polyester bottles. In a series of preferred embodiments, bottles fabricated with the oxygen scavenging copolymers of this invention are over 99 wt % PET and contain less than 50 ppb of extractable components.

Owner:COLORMATRIX HLDG

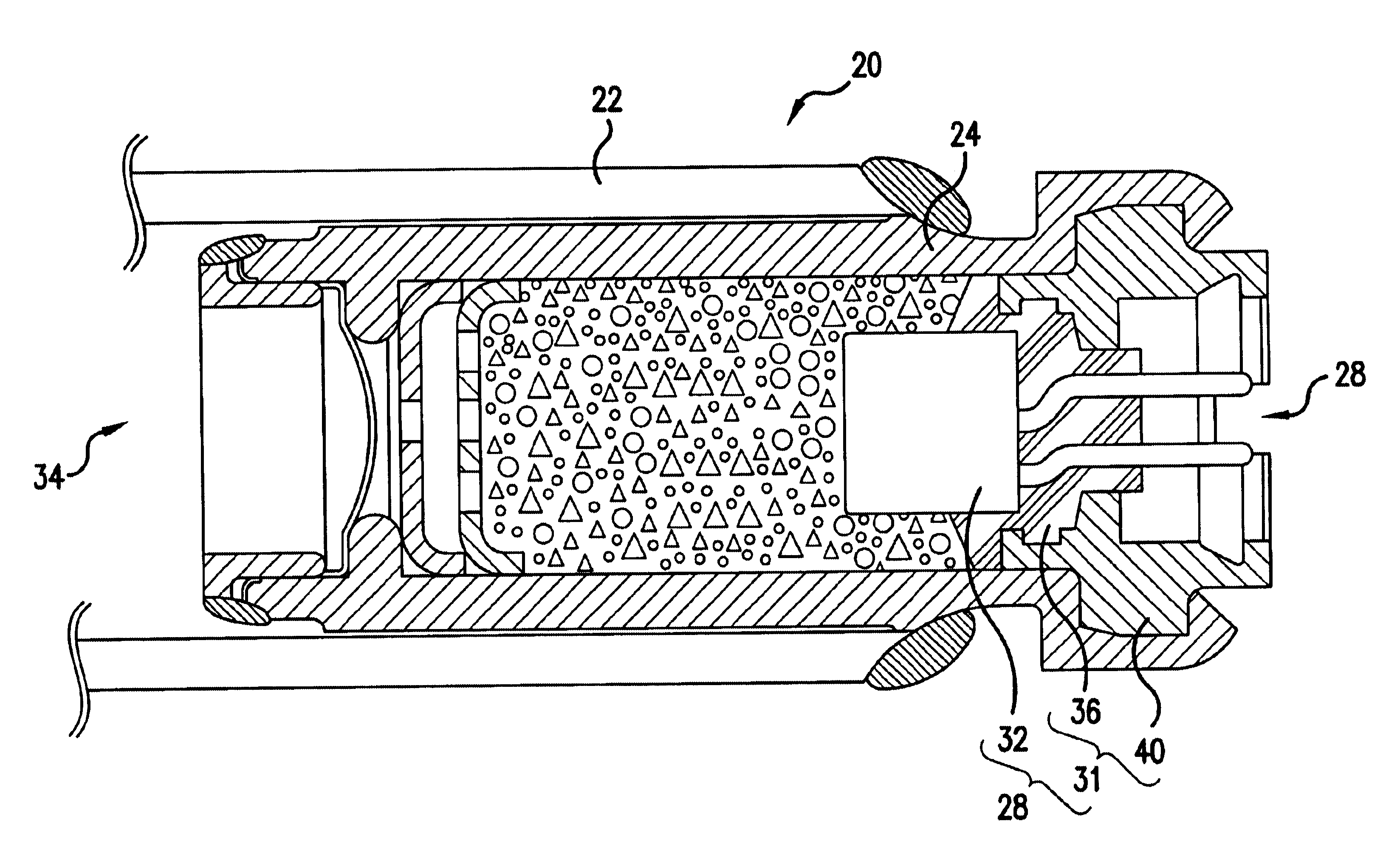

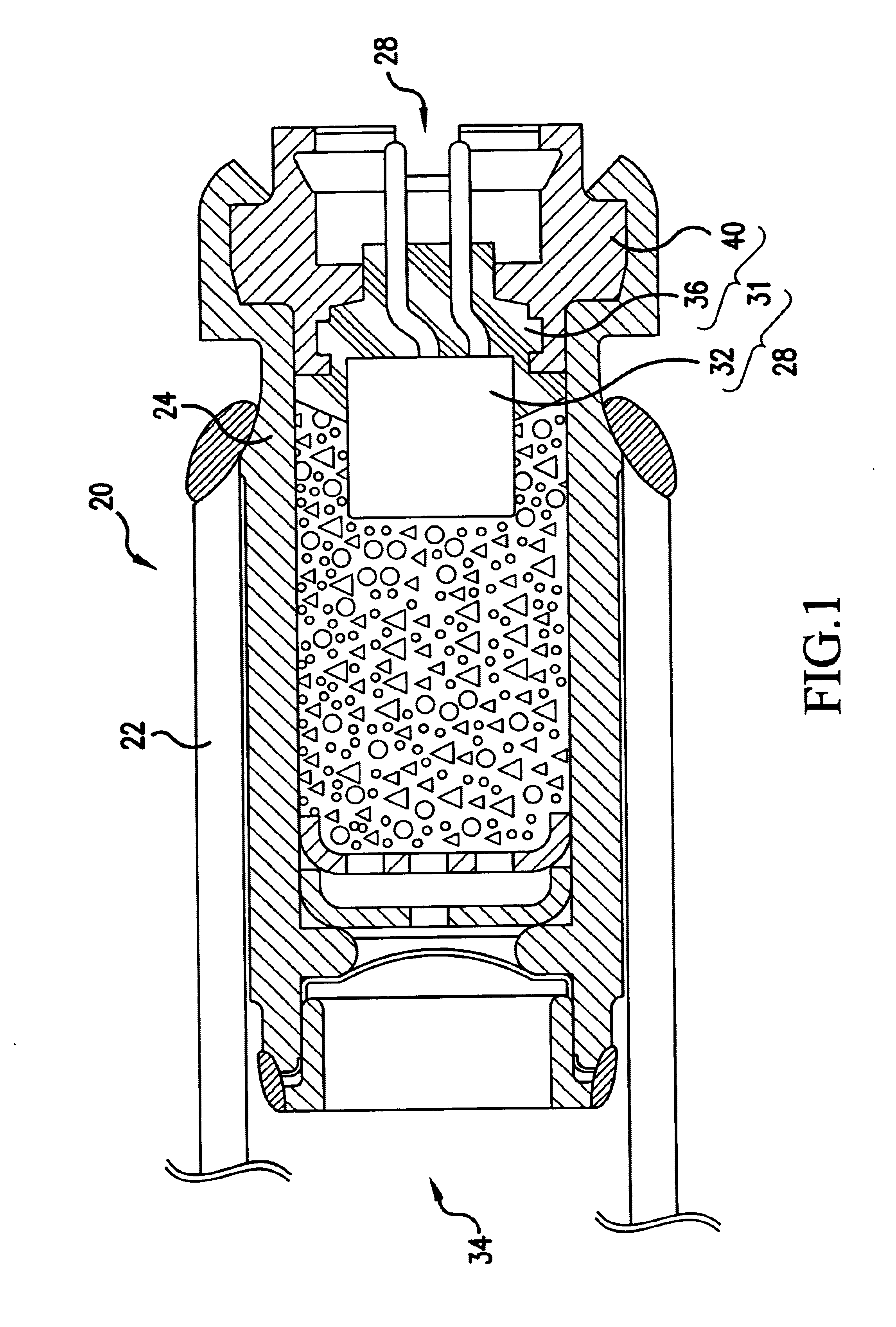

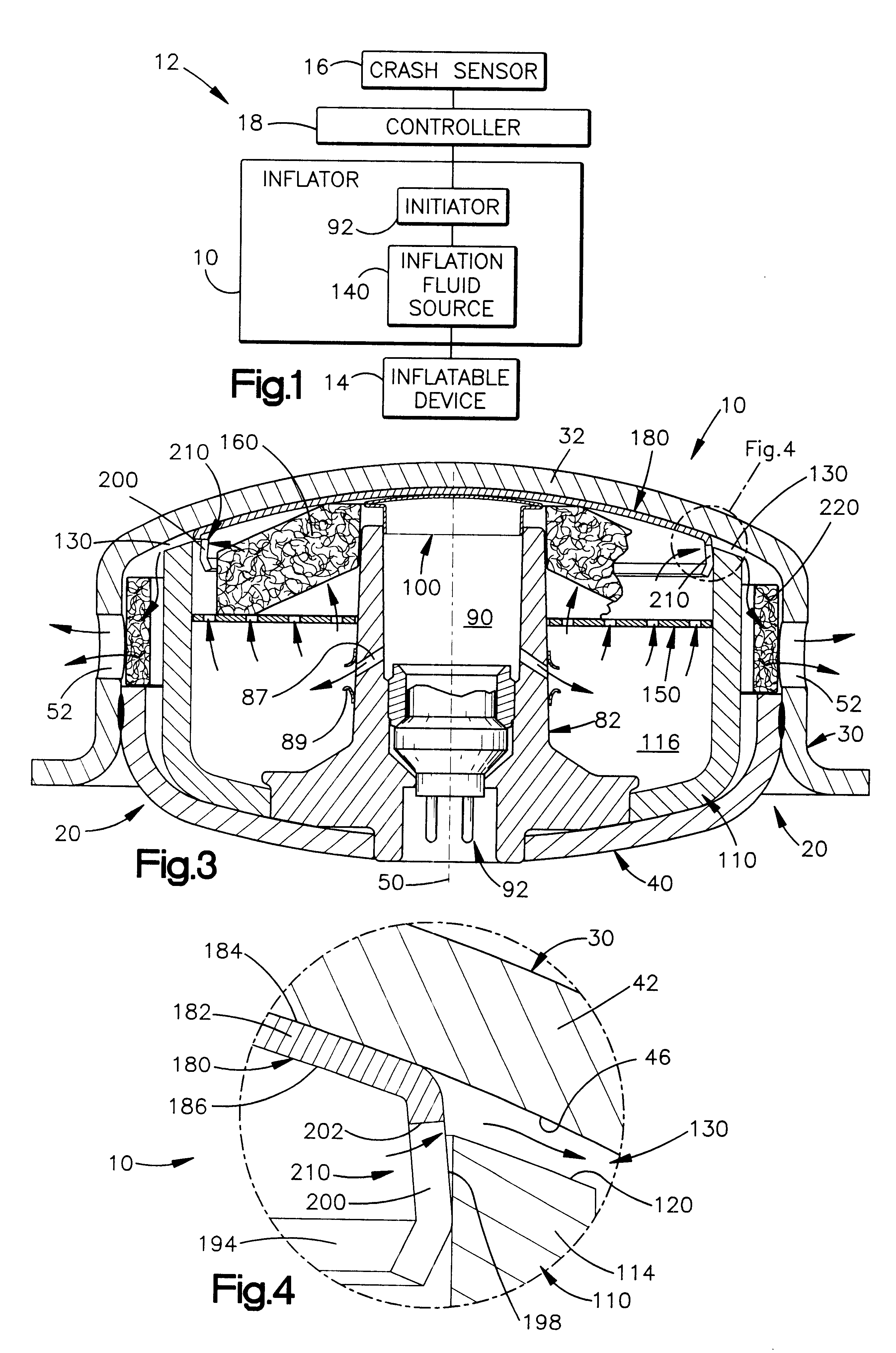

Air bag inflator with pressure regulation

InactiveUS6227565B1Avoid shockPedestrian/occupant safety arrangementPressure gas generationEngineeringStreamflow

An apparatus (10) for providing inflation fluid for inflating an inflatable vehicle occupant protection device (14) includes a housing (20) and an inflation fluid source (140) in the housing actuatable to provide inflation fluid under pressure. The housing (20) has a fluid passage (130) for directing flow of inflation fluid out of the housing (20) to the inflatable device (14). The housing (20) deforms due to the pressure of inflation fluid in the housing upon actuation of the inflation fluid source (140). The flow area of the fluid passage (130) increases due to deformation of the housing (20) and varies in accordance with the pressure of inflation fluid in the housing upon actuation of the inflation fluid source (140). The apparatus also includes a flow control member (180) defining a control passage (210) located between the inflation fluid source (140) and the fluid passage (130). The control passage (210) has a smaller flow area than the fluid passage (130). The flow area of the control passage (210) increases due to deformation of the housing (20) and varies in accordance with the pressure of inflation fluid in the housing (20) upon actuation of the inflation fluid source (140).

Owner:TRW INC

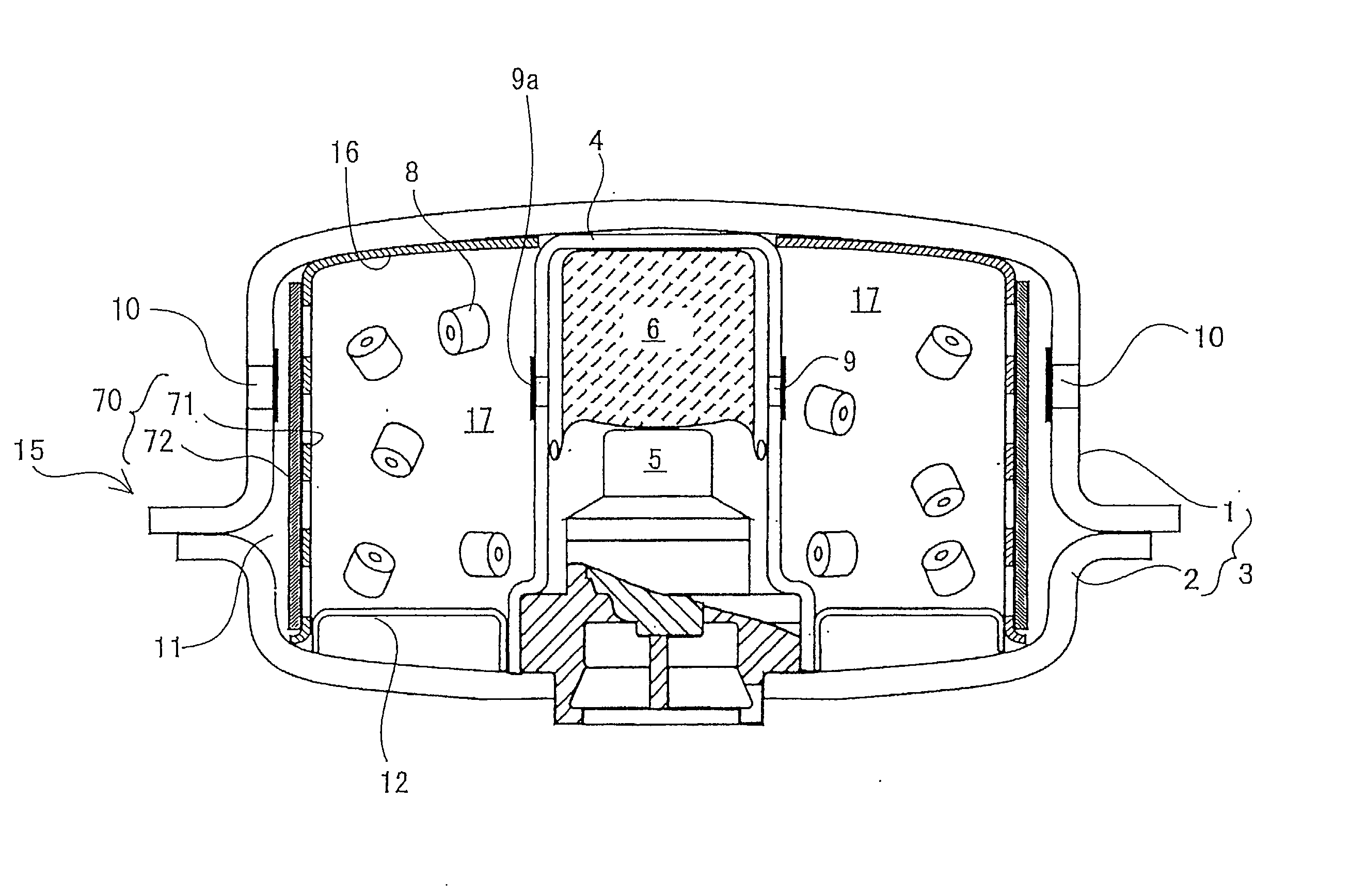

Inflator for an air bag

InactiveUS20030051630A1Easy to separatePedestrian/occupant safety arrangementExplosivesCombustion chamberShell molding

The present invention provides an inflator capable of realizing downsizing and weight reduction. An inflator for an air bag comprising, in a housing having a gas discharging port, a combustion chamber accommodating a molded article of a gas generating composition which is burnt to generate a gas and an ignition means to ignite the molded article of a gas generating composition, wherein the molded article of the gas generating composition contains a metal component and meets the requirement (A) the (theoretical) combustion flame temperature of the molded article of the gas generating composition is 2000° C. or less, and part or the whole of the metal or metal oxide after combustion of the molded article of the gas generating composition has a melting point not lower than the combustion flame temperature, and the requirement (B) bulk combustion residues remain in the combustion chamber at the time of combustion of the molded article of the gas generating composition.

Owner:DAICEL CHEM IND LTD

Gas generating composition for inflator containing melamine cyanurate

InactiveUS20050263224A1Low toxicitySafe handlingExplosivesPressure gas generationSimple Organic CompoundsBurn rate

To provide a gas generating composition for air bag which is low in toxicity, large in burning rate, and low in combustion temperature. Gas generating compositions comprising (a) melamine cyanurate or a mixture of melamine cyanurate and nitrogen-containing organic compound and (b) oxygen-containing oxidant, and gas generating compositions comprising (c) binder and (d) additive are provided.

Owner:DAICEL CHEM IND LTD

Airbag gas generator and an airbag apparatus

InactiveUS6540256B2Easy constructionImprove protectionPedestrian/occupant safety arrangementExplosivesGas-discharge lampCombustion

Owner:DAICEL CHEM IND LTD

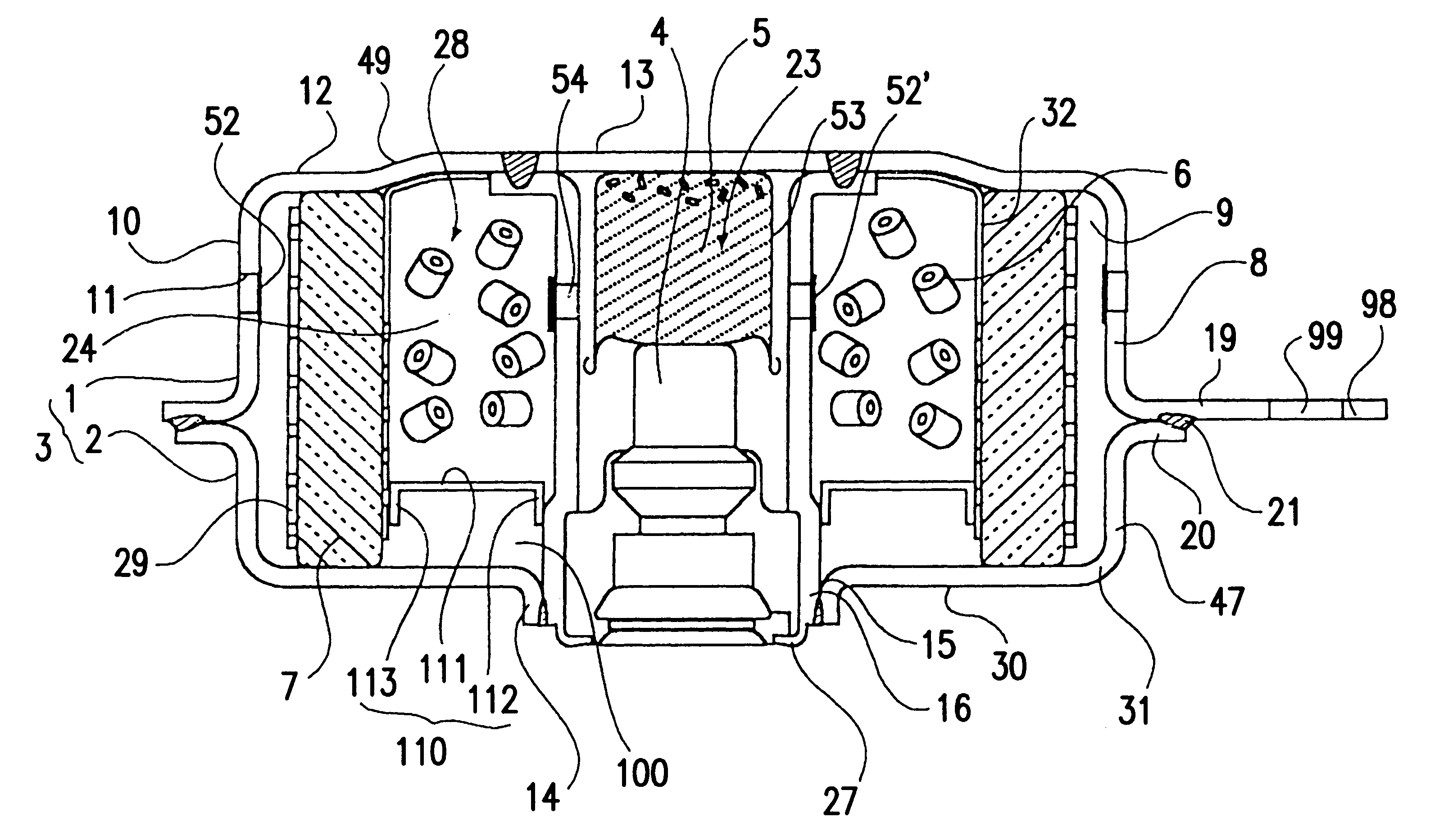

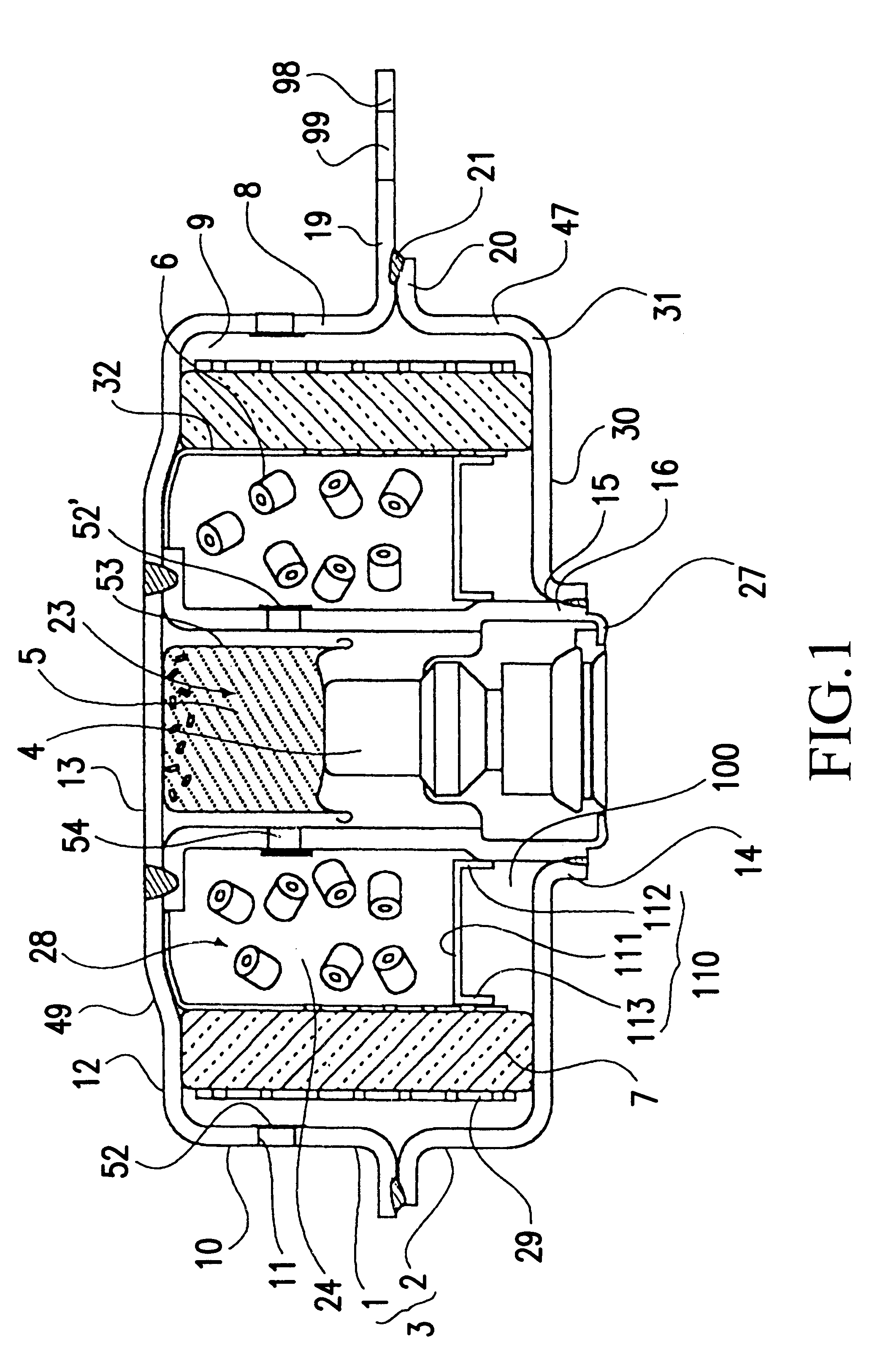

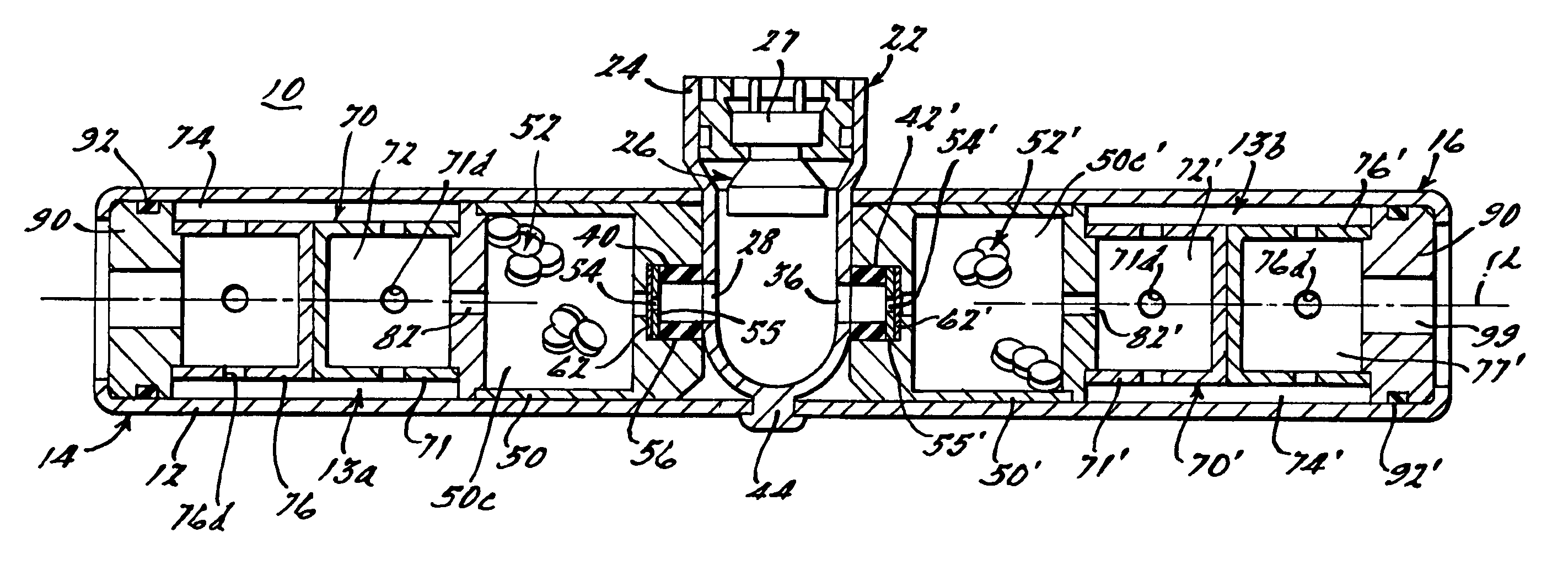

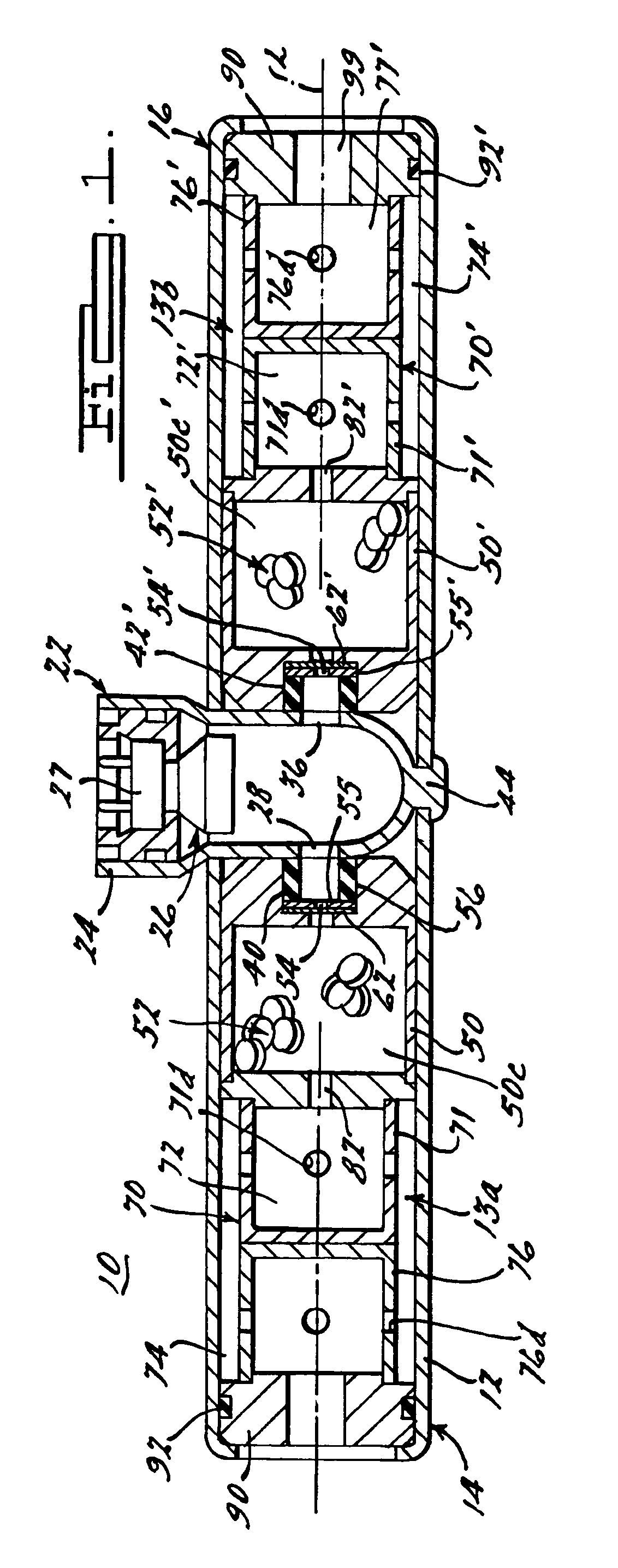

Gas generating system

InactiveUS20050230949A1Prevent exitPedestrian/occupant safety arrangementPressure gas generationCombustion chamberNuclear engineering

A gas generator (10) includes an igniter (27) and first and second inflation gas generant compositions (52, 52′) positioned to enable fluid communication with the igniter (27) upon activation of the igniter. Flow regulators (54, 54′) are provided to regulate a flow of combustion products from the igniter (27) to the first and second inflation gas generant compositions (52, 52′), to correspondingly regulate a time period between activation of the igniter (27) and initiation of combustion of the first and second inflation gas generant compositions (52, 52′). In another aspect, the gas generator (10) includes a modular baffle system (70) including a first baffle chamber (71) in fluid communication with an inflation gas generant combustion chamber (50) for receiving therein combustion products from combustion of an inflation gas generant (52) positioned in the combustion chamber. An outer baffle chamber (74) is also positioned radially outwardly from the first baffle chamber (71) for receiving therein combustion products from the first baffle chamber. In yet another aspect, the gas generator includes a first enclosure (12), a second enclosure (24), and a projection (44) formed on one of the first enclosure and the second enclosure. An aperture (46) is formed in the other one of the first enclosure (12) and the second enclosure (24) for receiving the projection (44) therein. At least a portion of the projection (44) is fixed within the aperture (46) to prevent withdrawal of the projection (44) from the aperture (46), thereby securing together the first enclosure (12) and the second enclosure (24).

Owner:AUTOMOTIVE SYST LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com