Reactive material enhanced munition compositions and projectiles containing same

a technology of enhanced munition and projectiles, which is applied in the field of reactive materials, can solve the problems of fuel-filled targets, mk211, m8 and m20 api projectiles having limited effectiveness against thin-skinned targets, and it is difficult to inflict catastrophic damage on thin-skinned targets using long-range guns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Formulations of the Reactive Materials

[0037] Formulations of the reactive materials of the present invention are shown in Tables 1-3. Formulations of intermetallic and thermite compositions are shown in Table 1.

TABLE 1Formulations of Intermetallic and Thermite Reactive Materials.Ingredient 1Ingredient 2Ingredient 3Ingredient 4Mix NumberNameWt. %NameWt. %NameWt. %NameWt. %1791-97-10Zr34.62CuO60.82Viton A5——1791-97-11Al17.52CuO77.48Viton A5——STR: 22235Al-5μ44.2PTFE55.8————STR: 22037Al-5μ28.3PTFE71.7————STR: 22080Al-H9528.3PTFE71.7————1836-90CPhenolphthalein20.5KNO3-15μ46.5KClO4-9μ30 PVA3 1836-90DPhenolphthalein15.6KNO3-15μ51.4KClO4-9μ30 PVA3 STR: 22610SrNO366.54Mg31.71Nylon 1.75——1791-100-1W-690 nm82.2KP-5μ10.3Viton A 7.5——1791-100-2W-690 nm72.2KP-5μ20.3Viton A 7.5——1943-77ANano-Al26PTFE74————2002-1-1Zr47.7PTFE52.3————1943-77BNano-Al27MoO323PTFE50 ——1943-77DZn56.75PTFE43.25————1661-60AMagnalium24.5BCN-12.5μ68.5Ethyl Cellulose7——1661-60DAl27.5BCN-12.5μ68.1Ethyl Cellulose 4.5——...

example 2

Safety Testing of the Reactive Material Formulations

[0041] Safety testing was performed on the reactive material formulations described in Example 1. Friction properties of the formulations were measured using a friction test developed by Allegheny Ballistics Laboratory (“ABL”). Onset of ignition exotherms and sensitivity to elevated temperatures of the formulations was measured using a Simulated Bulk Autoignition Test (“SBAT”). Electrostatic discharge (“ESD”) of the formulations was measured using an ESD test developed by Thiokol Corporation (“TC”). Impact properties of the formulations were measured using an impact test developed by TC and an impact test developed by ABL. Deflagration to detonation (“DDT”) transitions of the formulations was also measured. These tests are known in the art and, therefore, details of these tests are not included herein. The safety properties were used to determine whether the reactive materials had a low level of sensitivity (green line (“GL”)), an...

example 3

Reactive Material Bullets Including the Reactive Material Formulations

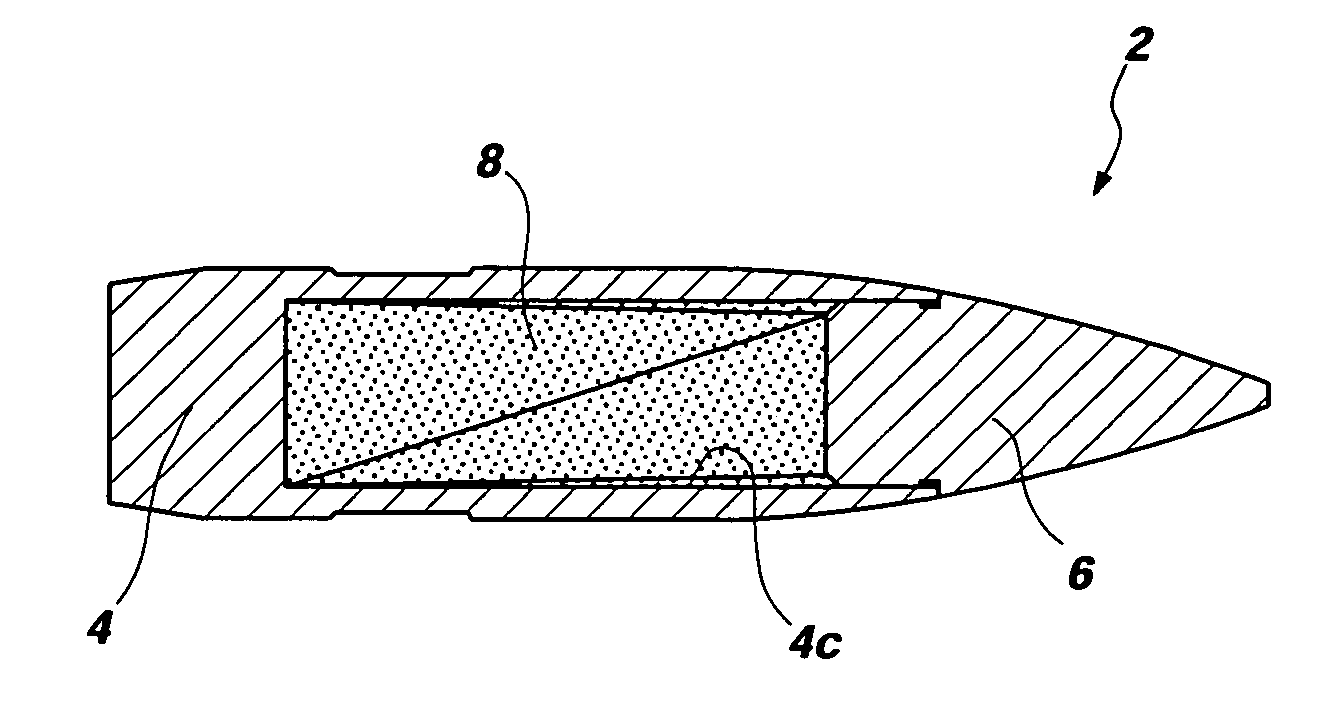

[0046] Twenty four formulations were loaded into a reactive material bullet by pressing the reactive material into the core of the bullet case from the front. In addition to the formulations shown in Tables 7 and 8, Formulations 1943-32-02, 1943-32-04, 1943-32-05, 1943-32-06, 1943-32-08, 1943-32-09, 1943-32-10, 1943-32-17, and 1791-100-1 were also tested. The tip was then inserted into the case to form the reactive material bullet. The formulations were tested in a reactive material bullet designed to penetrate a thin-skinned target, referred to herein as the bullet for thin-skinned targets, or in a reactive material bullet having increased penetration and designed to penetrate a thicker-skinned target, referred to herein as the bullet for thicker-skinned targets.

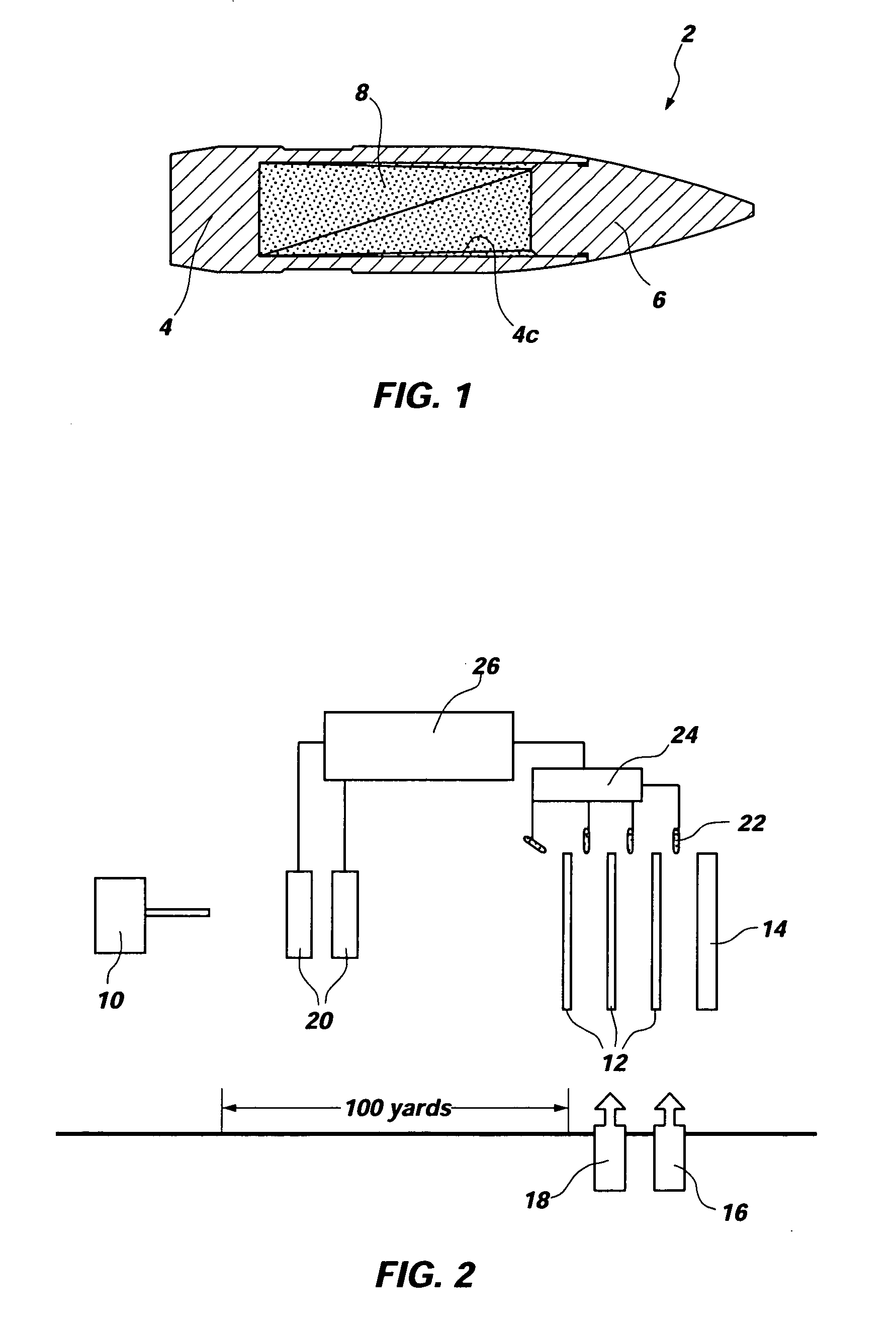

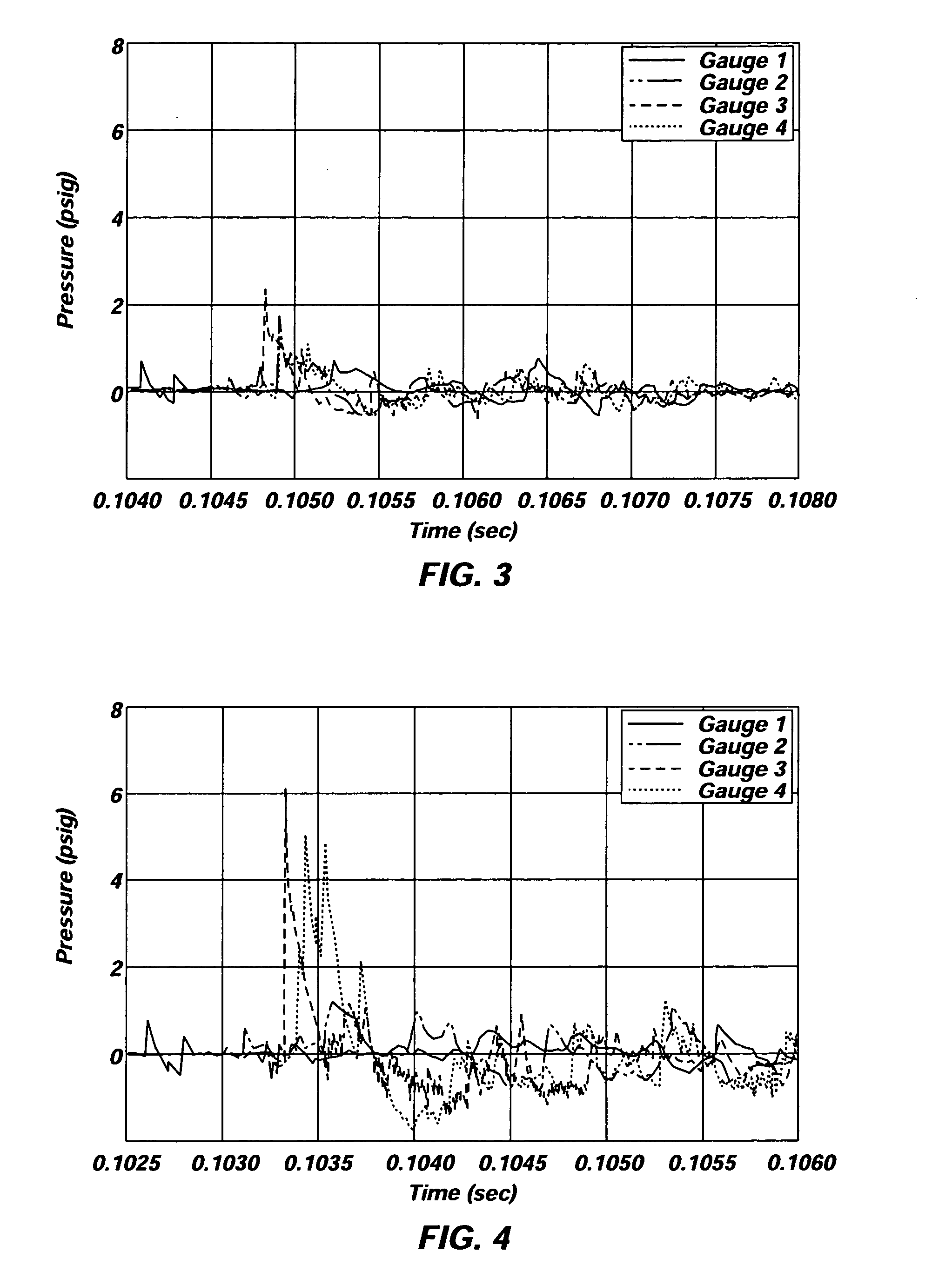

[0047] Energy release and initiation threshold of the reactive material formulations was determined by firing the reactive material bullets 2 from a 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com