Patents

Literature

317 results about "Composition B" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition B, colloquially "Comp B", is an explosive consisting of castable mixtures of RDX and TNT. It is used as the main explosive filling in artillery projectiles, rockets, land mines, hand grenades and various other munitions. It was also used for the explosive lenses in the first implosion-type nuclear weapons developed by the United States.

Polyurea grease composite

ActiveCN1657599AImprove extreme pressure and anti-wear performanceGood extreme pressure and anti-wear propertiesThickenersComposition BBase oil

Two lubricating polyurea-ester compositions with high stability and extreme-pressure antiwear performance contain proportionally basic oil, urea-based thickening agent, Ca-based thickening agent and extreme-pressure agent for composition A, or the composition A plus inorganic Ca salt for composition B.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ink-jet recording method and ink composition set

InactiveUS20060187285A1Measurement apparatus componentsDuplicating/marking methodsComposition BPolymer chemistry

The present invention provides an ink composition set comprising an ink composition A comprising at least a colorant and an interior curable photopolymerization initiator, and an ink composition B comprising at least a polymerizable compound, a surface curable photopolymerization initiator and a polymerization accelerator, and an ink-jet recording method using the ink composition set.

Owner:SEIKO EPSON CORP

Photocuable Ink Composition Set, Ink Jet Recording Method, and Recorded Matter

ActiveUS20090041946A1Quality improvementHighly curableLiquid surface applicatorsPhysical/chemical process catalystsCarbon numberHydrogen atom

A photocurable ink composition set includes ink composition A and ink composition B. Ink composition A contains a dendritic polymer and an monomer expressed by general formula (1): CH2═CR1—COO—R2—O—CH═CH—R3. Ink composition B contains a coloring agent and a monomer expressed by general formula (1). In the formula (1), R1 represents a hydrogen atom or a methyl group, R2 represents an organic moiety having a carbon number in the range of 2 to 20, and R3 represents a hydrogen atom or an organic moiety having a carbon number in the range of 1 to 11.

Owner:SEIKO EPSON CORP

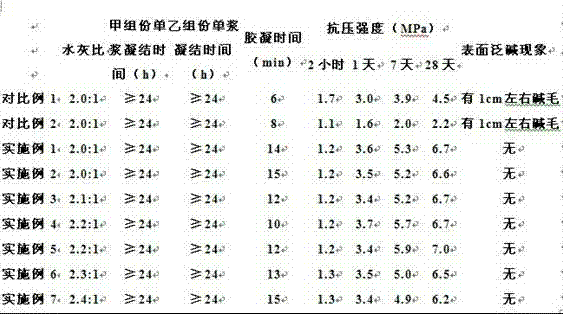

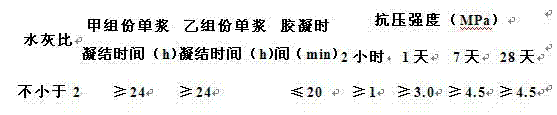

High-moisture filling material and preparation method thereof

The invention discloses a high-moisture filling material and a preparation method thereof. The high-moisture filling material comprises a composition A and a composition B, wherein the composition A comprises 52.4 to 95 by weight percent of sulfo-aluminate cement clinkers, 2.7 to 39 by weight percent of aluminate cement clinkers, 0.3 to 2 by weight percent of setting retarder, and 1.5 to 8 by weight percent of suspending agent; the composition B comprises the following ingredients: 40 to 80 by weight percent of anhydrite, 10 to 30 by weight percent of lime, and 10 to 36 by weight percent of compound additives. The high-moisture filling material has the advantages of easily-available raw materials, low price, good stability, high long-term strength and no risk of surface efforescence.

Owner:CCTEG CHINA COAL RES INST

Photo curable ink composition set, and recording method and recordings employing ink composition set

InactiveUS20080096998A1Good storage stabilityHigh sensitivityMixing methodsInksComposition BPhotoinitiator

A photo curable ink composition set, comprising: an ink composition A that includes at least a color material, a polymerizable compound, and a radical polymerization photoinitiator; and an ink composition B that includes at least a radical polymerizable compound and does not include the color material and the radical polymerization photoinitiator, wherein the ink composition A and / or B includes a sensitizer.

Owner:SEIKO EPSON CORP

Dry powder mortar packaged in grouping manner

The invention relates to a building material technology, in particular to a dry powder mortar packaged by composition separation, which is formed by classified packaging according to quality guarantee periods of material compositions, wherein a composition A consists of a filler, a pigment and an auxiliary agent the quality guarantee periods of which reach between 12 and 24 months; and a composition B consists of a hydraulic inorganic solidification material which only has three months of quality guarantee period. The dry powder mortar packaged by the composition separation has the advantage that the composition A has long storage and quality guarantee periods, and the waste of the filler, the pigment and the auxiliary agent is overcome and reduced; the important keeping and storage are convenient to the composition B with the short quality guarantee period, and the composition B can be extracted from unused mortar for hurry use or a novel composition B is replaced into the unused mortar when the quality guarantee period approaches to avoid engineering hidden trouble and energy waste; and dry powder mortar production enterprises can only produce the composition A to supply construction organizations or dealers, and the composition B adopts the nearby configuration, thus the quality of products can be ensured, and mass transportation and turnover cost can be reduced.

Owner:上海华力化工产品有限公司

Conductive plastic and preparation method thereof

The invention provides a conductive plastic and a preparation method thereof. The conductive plastic comprises the following blended compositions: a, thermoplastic resin; b, rubber particle with a crosslinking structure; c, a conductive filter; and d, a low-melting-point metal. The gel content of the composition b is 60% by weight or more, and the average particle size of the composition b is 0.02-1 mu m; the composition c is not fused at a thermoplastic-resin processing temperature; the composition d is at least one of a single-composition metal or metal alloy, the melting point of the composition d is 20-480 DEG C and is lower than the thermoplastic-resin processing temperature; and the weight ratio of the composition b to the composition a is 0.1:99.9-30:70. The conductive plastic is low in filling content of the conductive filler and the metal, is relatively low in conductive performance, can be prepared by using a common melt blending method, and can be used to prepare antistatic electromagnetic-wave-interference-resisting electron production equipment and tools with dust-free requirements, and electronic apparatuses, instrument housings and decoration materials of dust-free production workshops.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite water-soluble multicolor paint

A composite aqueous colorful coating comprises a composition A and a composition B. The coating is characterized in that the main ingredients of the coating include aqueous film forming material, filling, surfactant, aqueous resin, polysaccharide derivative, pigment, polymerization promoter, anti-mould agent, protective adhesive and water. Due to introduction of the polysaccharide derivative into preparation of the coating, lipophilic association and charge interaction between high molecular water-soluble polymers and the surfactant in water can form colloidal complexes of even higher molecular weights by which a colorful coating with patterns of different sizes and colors is produced so that particles cut by machines have excellent stability, and even when the pigment content is high, problems such as color bleeding and missing, which appear in the prior art, do not occur.

Owner:上海市涂料研究所有限公司

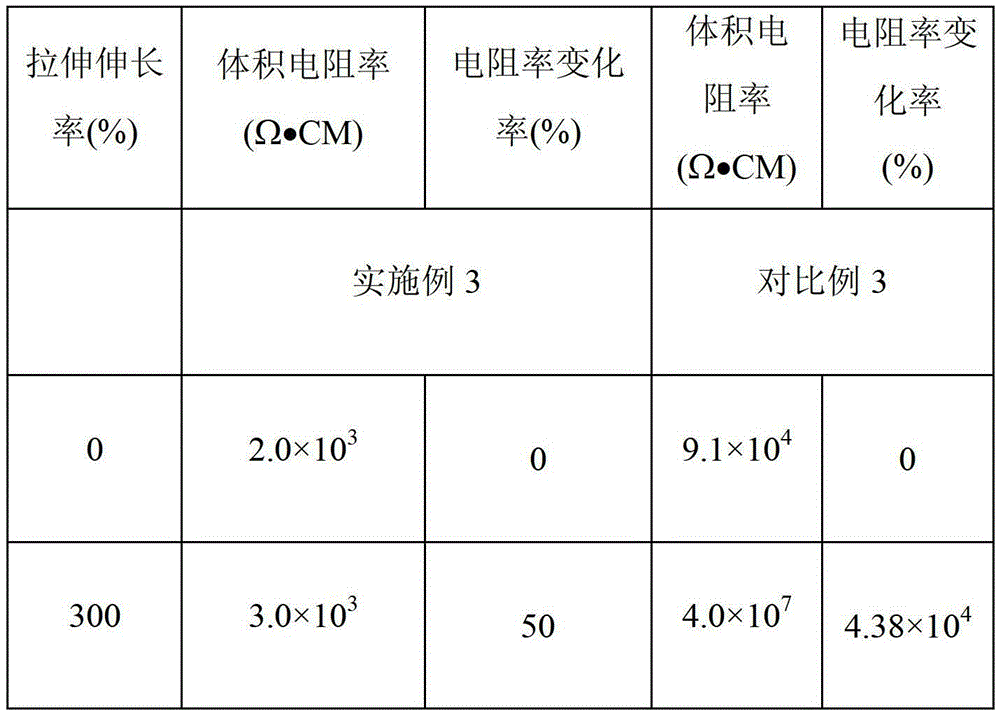

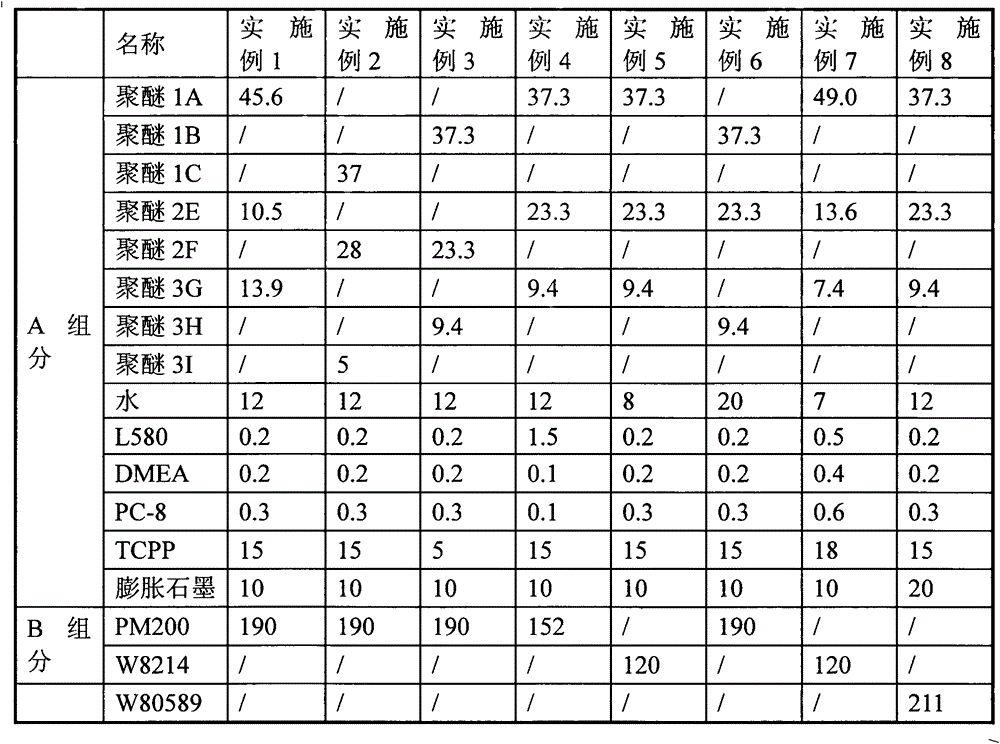

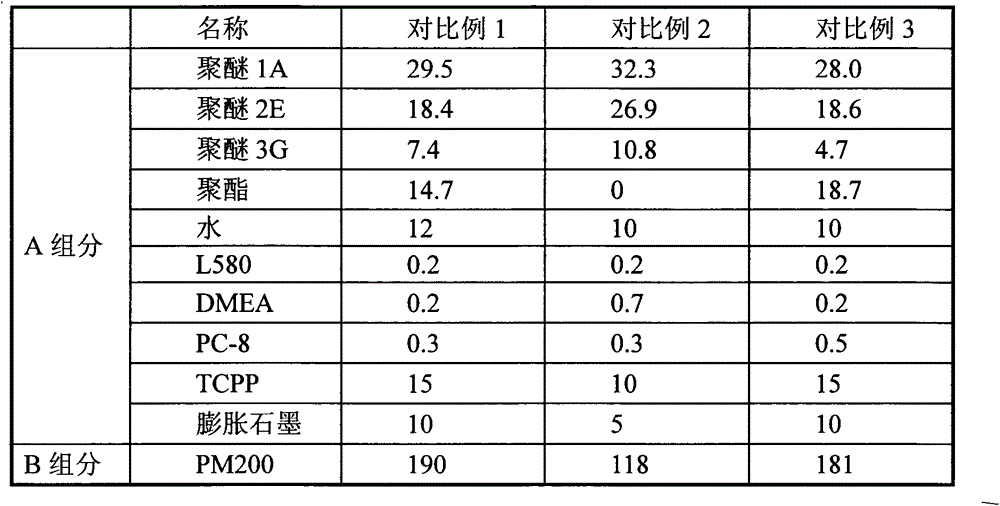

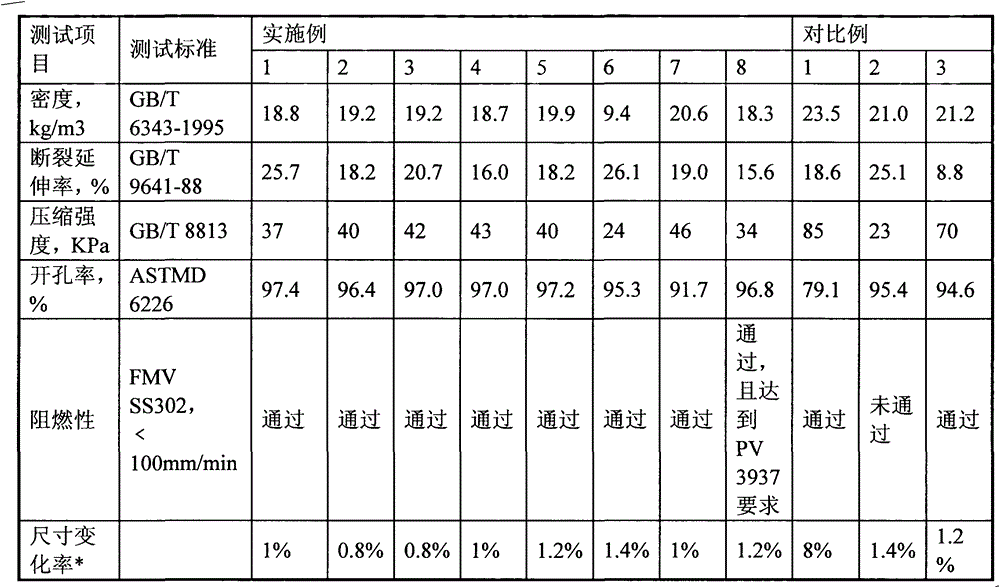

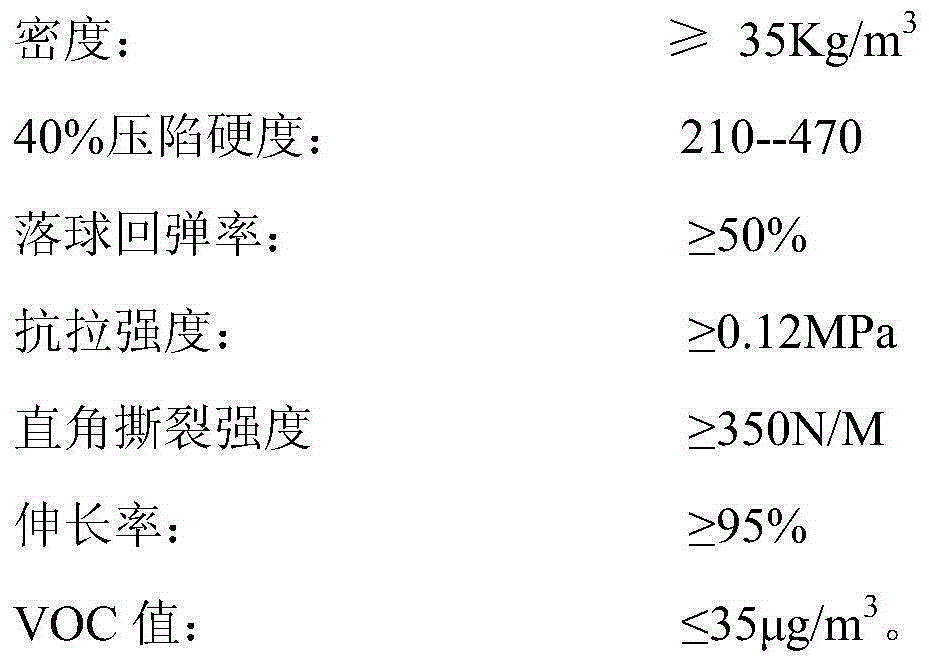

Low-density flame-retardant semi-rigid polyurethane foam and preparation method thereof

The invention discloses low-density flame-retardant semi-rigid polyurethane foam and a preparation method thereof. The low-density flame-retardant semi-rigid polyurethane foam is composed of an composition A and an composition B, the composition A comprises, in parts by weight, 70 parts of a combined polyether polyol, 0.2-1.5 parts of a surfactant, 0.1-1.0 part of a catalyst and 15-40 parts of a flame retardant; and the composition B comprises 110-230 parts by weight of MDI system isocyanate. The composition A and the composition B are fully mixed for reaction and further for forming polyurethane foam. The polyurethane foam has the density of 8-25 Kg / m<3>, the compression strength scope of 10-60 KPa, the rupture elongation of 12-50% and the open porosity of 90-99%, and the flame-retardant performance is capable of satisfying flame-retardant requirements of automobile interior trim flame retardance standard FMVSS302 and Volkswagen PV3937.

Owner:WANHUA CHEM BEIJING +2

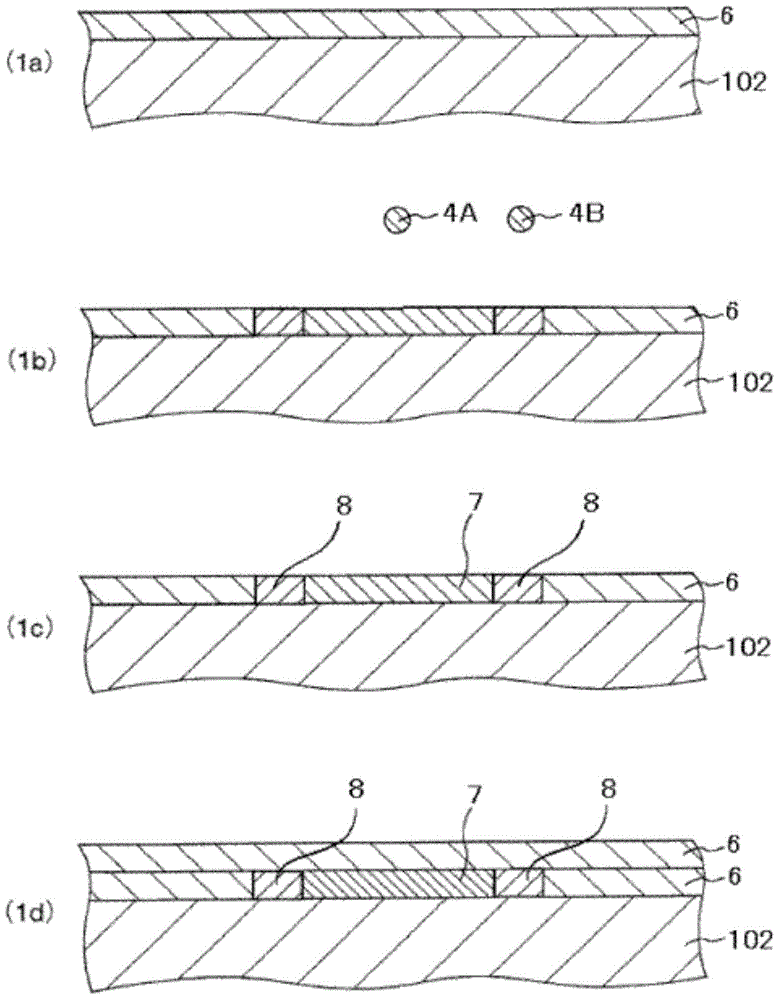

Process for the production of multi-layer coatings

A process for the production of multi-layer coatings comprising the successive steps: 1) applying an 8 to 20 μm thick coating layer from an aqueous coating composition A onto a substrate provided with an EDC primer, 2) applying a 5 to 15 μm thick base coat layer from an aqueous coating composition B onto the previously applied coating layer, 3) applying a clear coat layer onto the base coat layer, 4) jointly curing the three coating layers, wherein coating compositions A and B being different from each other and wherein the coating composition A contains at least one metal platelet pigment having a thickness from 10 to 100 nm in a proportion corresponding to a pigment / resin solids ratio by weight from 0.06:1 to 0.2:1.

Owner:EI DU PONT DE NEMOURS & CO

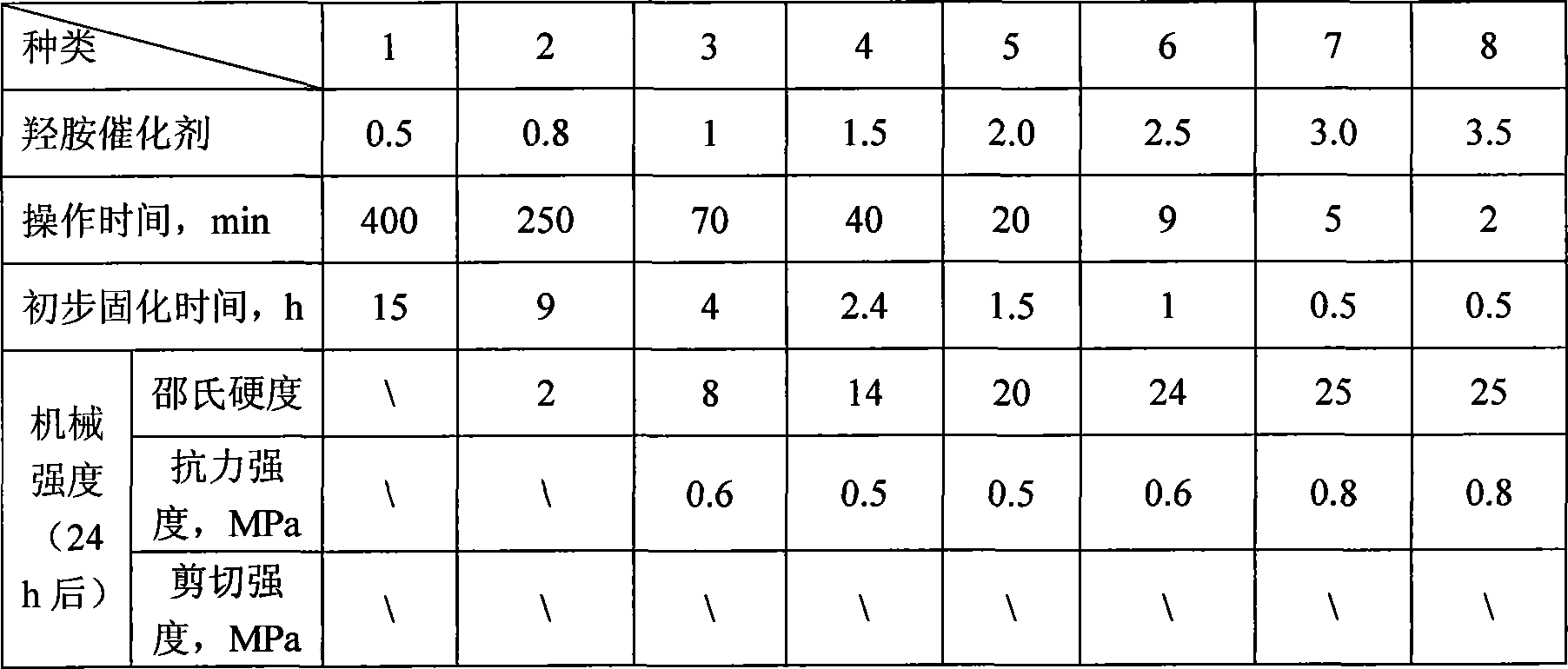

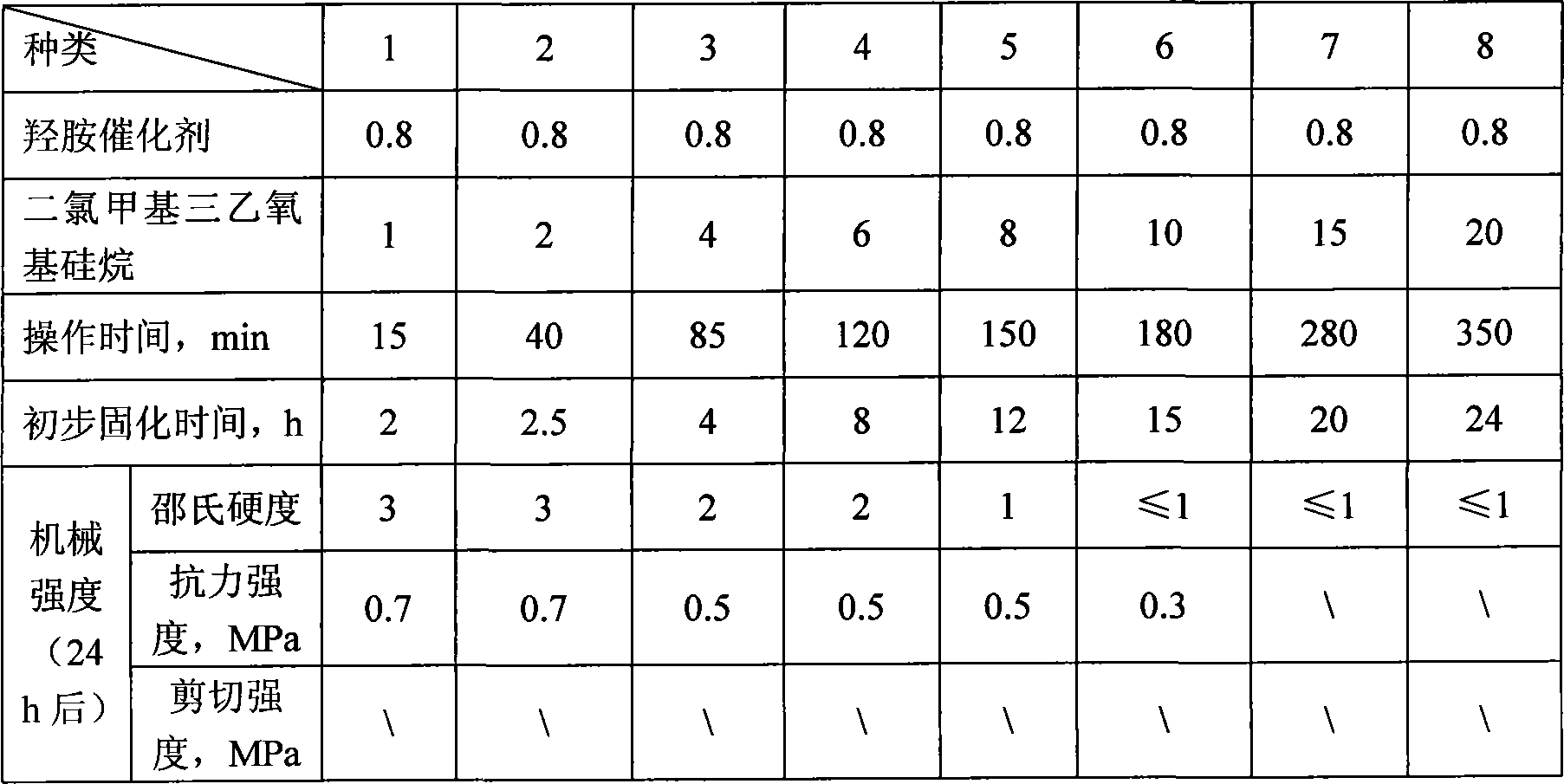

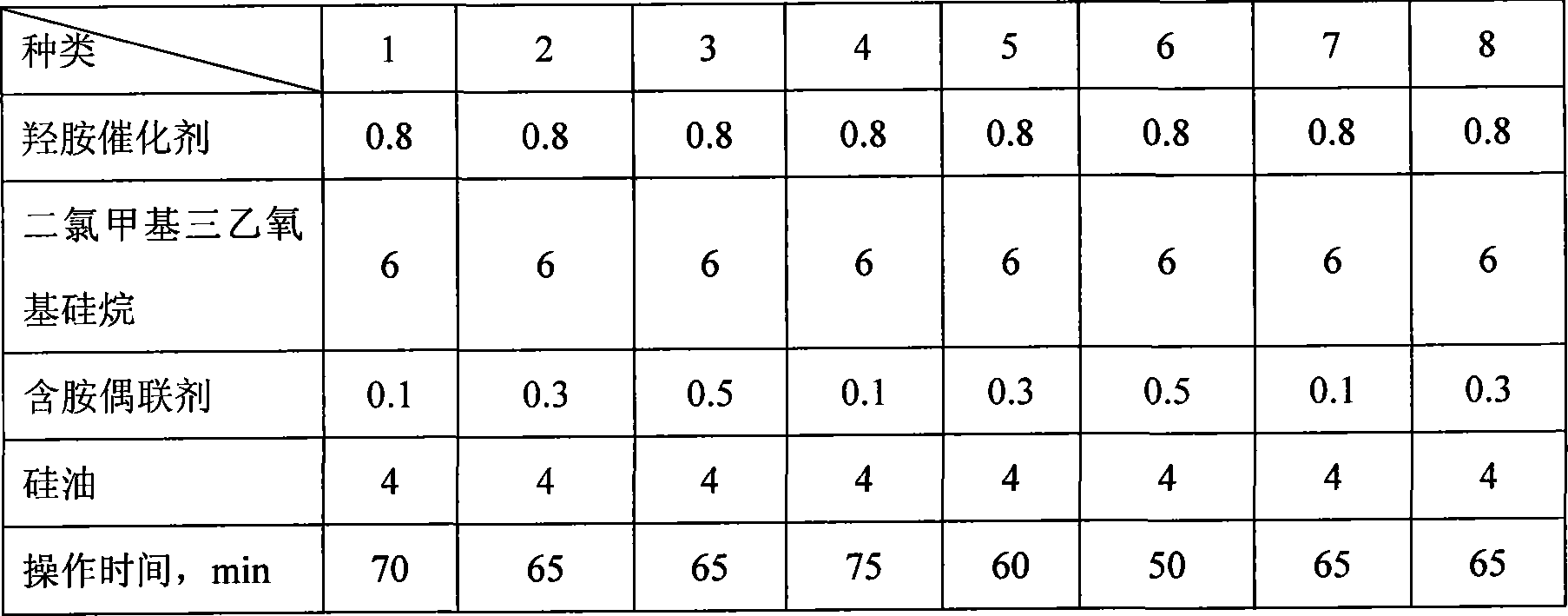

Dealcoholizing type organic silicon embedding glue

InactiveCN101121870AThe curing effect is achievedEffect achievedOther chemical processesAdhesivesHydroxylamineAdhesive

The invention discloses a novel de-alcoholized organosilicon potting adhesive, taking hydroxy-terminated dimethyl silicone polymer as the principal raw material, comprising composition A and composition B. Composition A includes (calculated by weight percent) 107 silicone rubber + base 100, plasticizer (5 to 15), filler (0 to 20), and solidifying accelerator (0.1 to 1). Composition B includes (calculated by weight percent) hydroxylamine catalyst (0.8), crosslinking agent (1 to 10), coupling agent (0.1 to 0.5) and plasticizer (3 to 5). The base adopts preprocessed 107 silicon rubber (107 silicon rubber: base = 30:70 to 50:50). The potting adhesive has excellent heat-resistance and electric performance; the volume resistance is as high as 1.0*1015 Omega question mark cm, and the dielectric coefficient reaches 25kv / question mark mm-1.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

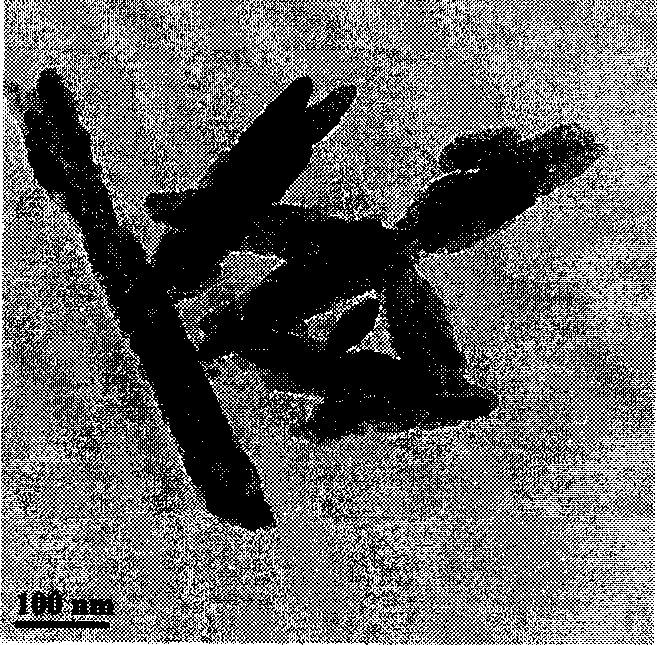

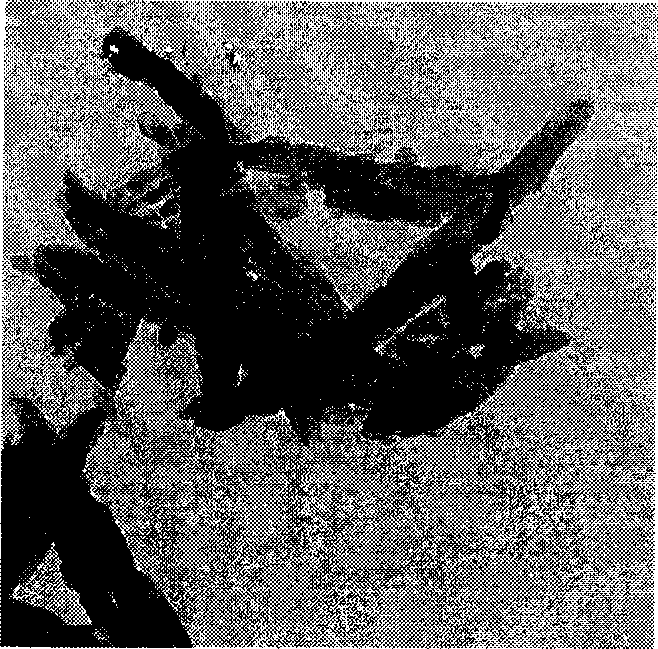

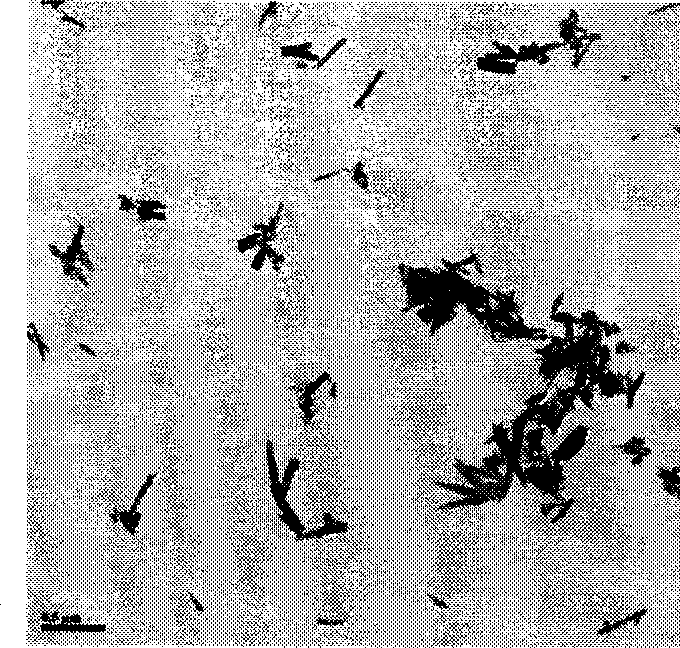

Industrial preparation of calcium carbonate nano bead string

InactiveCN101475199AImprove mechanical propertiesImprove the blocking effectCalcium/strontium/barium carbonatesCarbonizationComposition B

The invention discloses an industrial preparation method for calcium carbonate nanometer beads, which is an industrial preparation method for nanometer calcium carbonate with a bead-shaped structure, and comprises the following steps that: (1) natural limestone is crushed and calcined, then is added with hot water for digestion, and passes through a sieve for refining to be prepared into a refined calcium hydroxide material liquid; (2) the calcium hydroxide slurry is sent into a reactor system, proper kiln gas is aerated for carbonization reaction, the concentration of carbon dioxide in the kiln gas is between 10 and 50 percent, and a crystal control agent composition A and a crystal control agent composition B are added before the carbonization or at an initial carbonization stage; and (3) an obtained product is filtered, dried and crushed to obtain the bead-shaped nanometer calcium carbonate. The diameter of the bead-shaped nanometer calcium carbonate is between 20 and 50nm, the slenderness ratio is between 10 and 30, and the BET specific surface area is larger than 30m / g. The bead-shaped nanometer calcium carbonate has good dispersivity, improves the mechanical property of materials, and improves the barrier property of the materials to various gases and liquids, so the bead-shaped nanometer calcium carbonate can be widely applied to industries such as rubber, plastic, coating, printing ink, paper making, sealing gum and the like.

Owner:山东海泽纳米材料有限公司

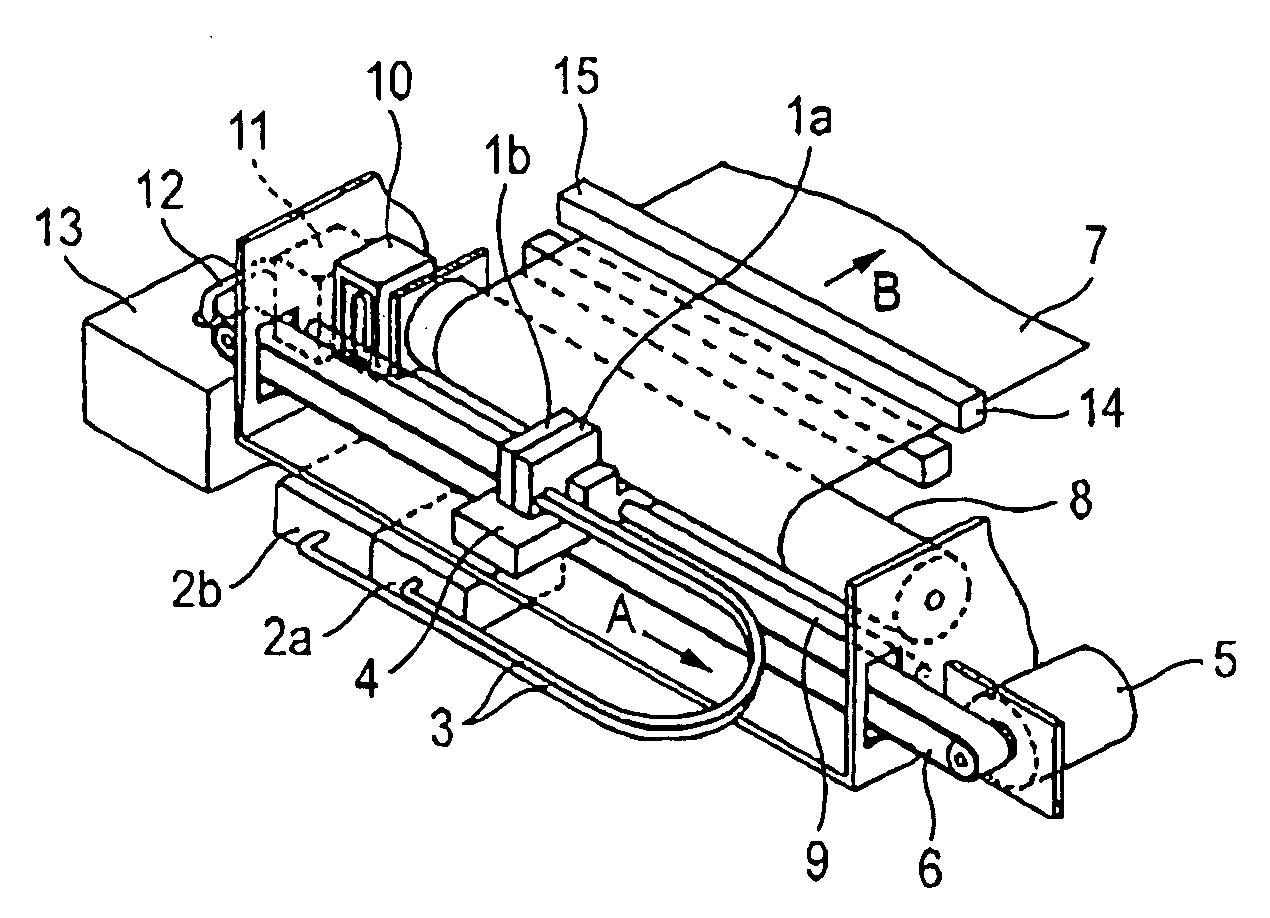

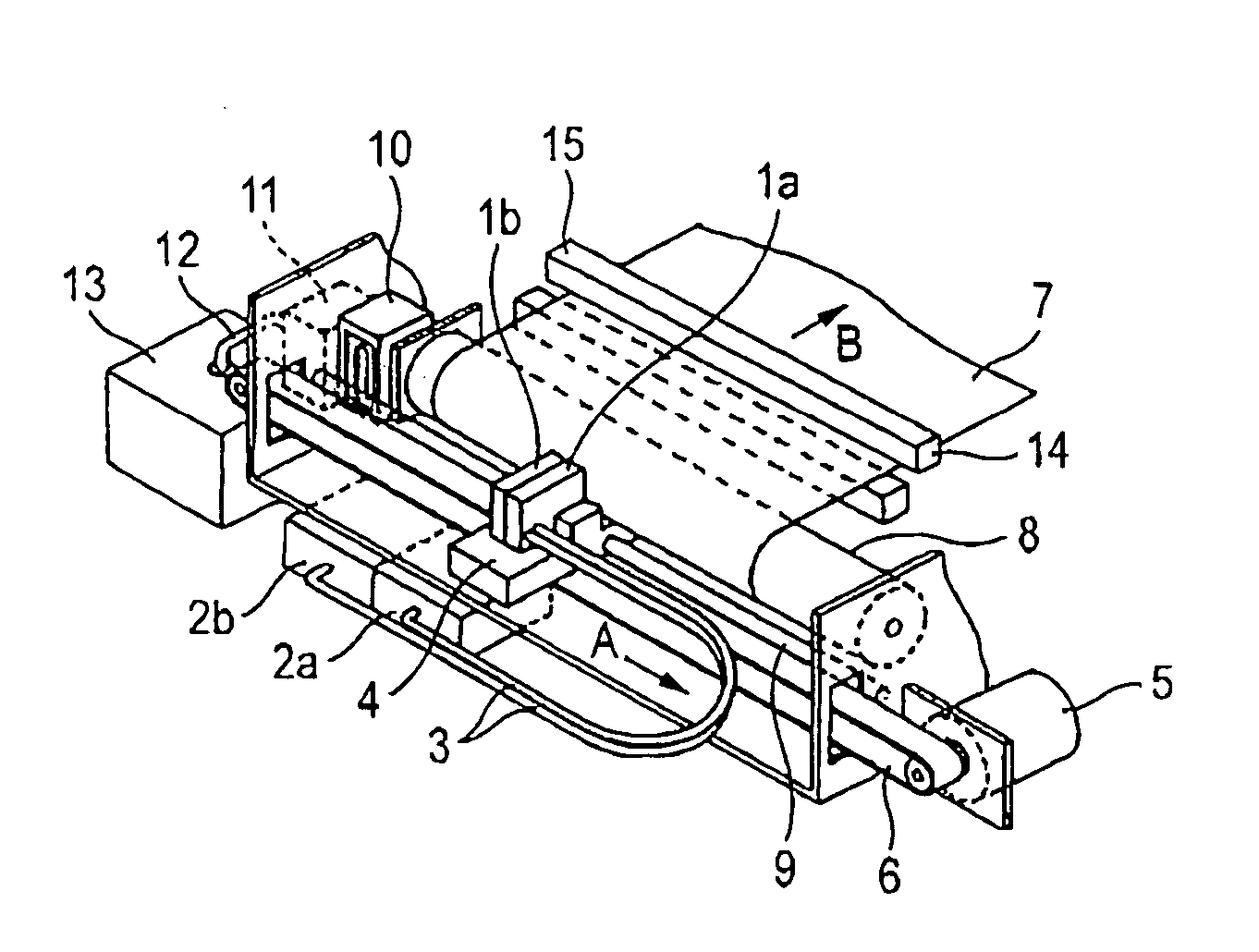

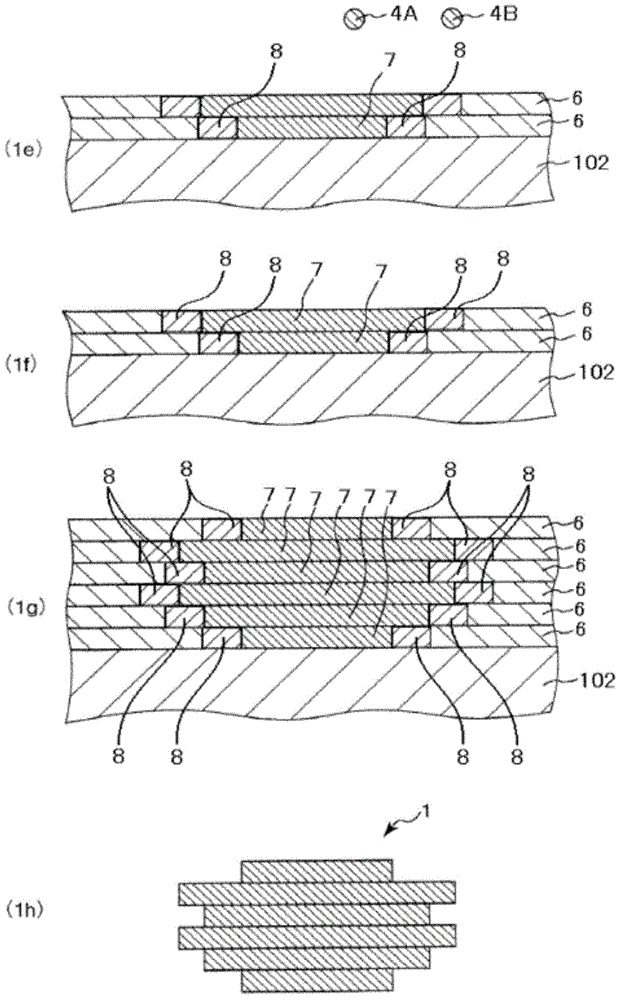

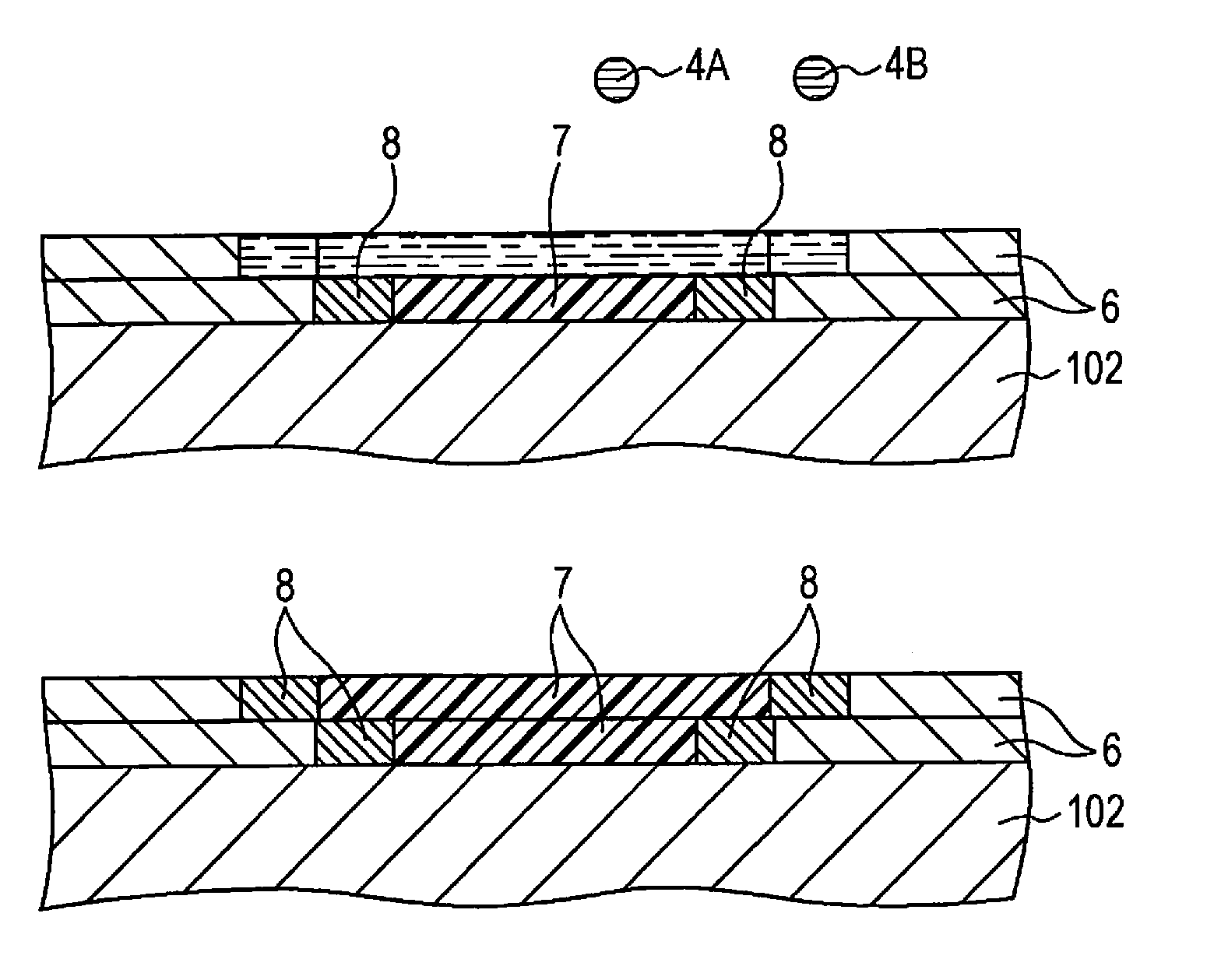

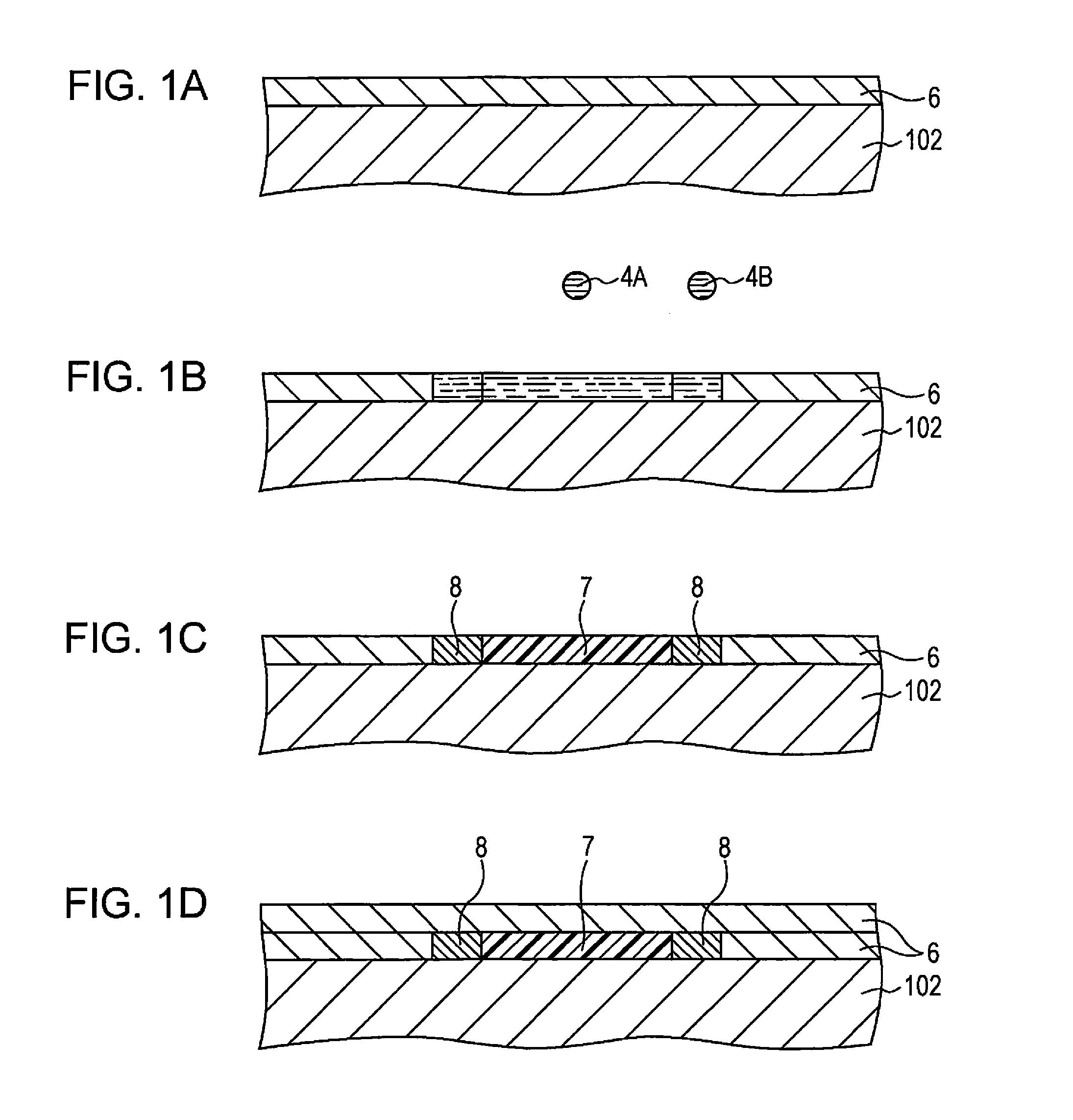

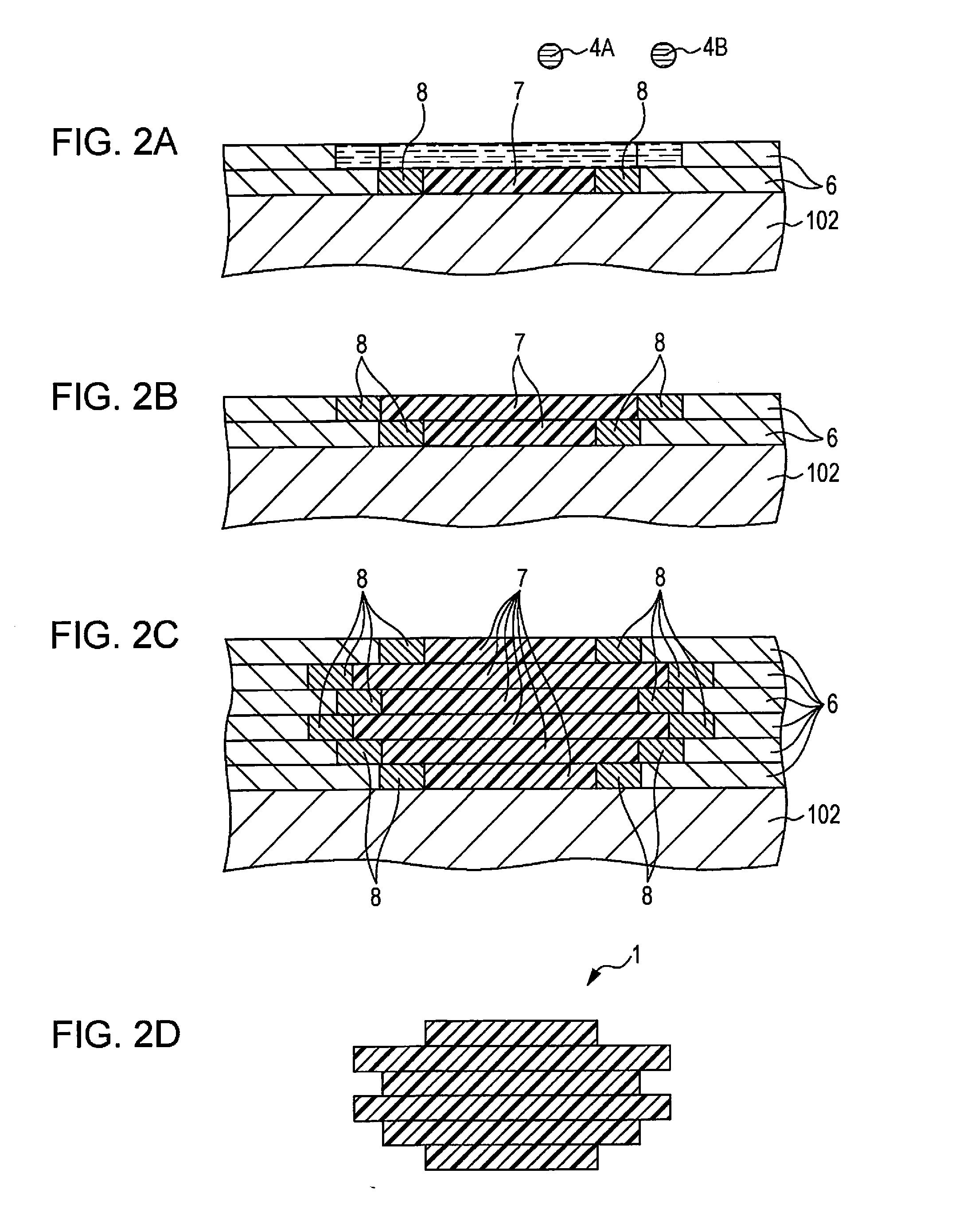

Manufacturing method of three-dimensional structure, three-dimensional structure manufacturing apparatus, and three-dimensional structure

Provided is a manufacturing method of a three-dimensional structure which manufactures a three-dimensional structure by laminating layers, the method including: forming the layers using a composition A containing three-dimensional formation powders and a solvent; discharging a binding solution for binding the three-dimensional formation powders to the layers; binding the three-dimensional formation powders by curing the discharged binding solution; removing the non-bound three-dimensional formation powders using the solvent; and additionally adding the three-dimensional formation powders to a mixed solution generated by the removing and containing the non-bound three-dimensional formation powders and the solvent, and preparing a composition B containing the three-dimensional formation powders and the solvent.

Owner:SEIKO EPSON CORP

Ink set

The present invention provides an ink set comprising a plurality of ink compositions including: an ink composition A containing at least a polymerizable compound and a photopolymerization initiator; and an ink composition B containing at least a polymerizable group, wherein each ink composition is not curable by itself.

Owner:SEIKO EPSON CORP

Molybdenum disulphide high dispersion modified epoxy resin wear-resistant coating material and preparation method thereof

InactiveCN101423726AGood dispersionGood compatibilityEpoxy resin coatingsLubricant compositionOrganic solventWear resistant

The invention relates to a wear-resistant epoxy resin coating material modified by high dispersibility of molybdenum disulfide and a preparation method thereof. The coating material comprises composition A and composition B, wherein the composition B is a curing agent, and the mass of the composition B is 5 to 30 percent of that of the composition A; and the composition A comprises the following components in percentage by mass: 25 to 45 percent of epoxy resin, 20 to 36 percent of solid lubricant, 1 to 4 percent of coupling agent, and 25 to 55 percent of organic solvent. The coating material improves the compatibility of the solid lubricant, namely the molybdenum disulfide and a bisphenol-A epoxy resin solution, solves the problem that the solid lubricant has poor dispersivity in the resin solution, and overcomes the defects that a polymeric solid lubricant coating has non-uniform concentration, more difficult thickness control, flawed coatings and so on. The preparation method for the coating material is simple and easy to operate.

Owner:SHANGHAI UNIV

Resin used for polyurethane cold-resistant flexible middle/low-density shoes and preparation method thereof

ActiveCN102504181AIt is not suitable to break the bottomRaw materials are readily availableFootwearPolyesterChemical reaction

The invention relates to a resin used for polyurethane cold-resistant flexible middle / low-density shoes and a preparation method of the resin, and belongs to the technical field of polyurethane resin preparation. The method comprises the following steps of: mixing compositions A and B, foaming the mixture with a polyurethane low-pressure foaming machine, injecting into a shoe mould and molding. The composition A is a mixture of polyester polyol A1, polyester polyol A2, a diol chain extender, a catalyst, an organic silicon foam stabilizer and water; the composition B is a prepolymer obtained by chemical reaction of polyisocyanate, polyester polyol A1, polyether glycol B1, polyether glycol B2 and a secondary reaction inhibitor. The product provided by the invention can maintain flexible and cold-resistant properties in case of low density, so that the shoe is flexible and the sole is not liable to break in winter. The invention has the advantages of easily-accessible raw materials, simple process, good product reproducibility and low cost, and can achieve mass production. The foaming process adopts only water, so that the whole production process is environment-friendly.

Owner:无锡双象新材料有限公司

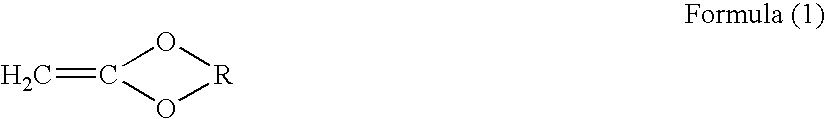

Resin particles and producing method thereof, toner for developing electrostatic latent image and producing method thereof, electrostatic latent image developer as well as image forming method

InactiveUS20050255397A1DevelopersElectrographic processes using charge patternLatent imageComposition B

A producing method of resin particles, which comprises at least an emulsification step of emulsifying a composition containing at least a polymerizable monomer and a polymerization step to form droplets of the composition, and a polymerization step of polymerizing the polymerizable monomer in the droplets to synthesize resin particles, wherein the composition is one selected from Composition A, Composition B, or Composition C: (Composition A): a composition containing a vinyl-based monomer, lactone, a vinyl-based monomer polymerization catalyst for polymerizing the vinyl-based monomer, and a lactone polymerization catalyst for polymerizing the lactone (Composition B): a composition containing a polyester resin, lactone, and a lactone catalyst for polymerizing the lactone (Composition C): a composition containing a vinyl-based monomer, a cyclic keteneacetal compound represented by the following general formula (1), and a radical polymerization initiator (in the general formula (1), R represents a chain or cyclic divalent aliphatic group optionally containing an ether linkage, and the aliphatic group may have a substituent.)

Owner:FUJIFILM BUSINESS INNOVATION CORP

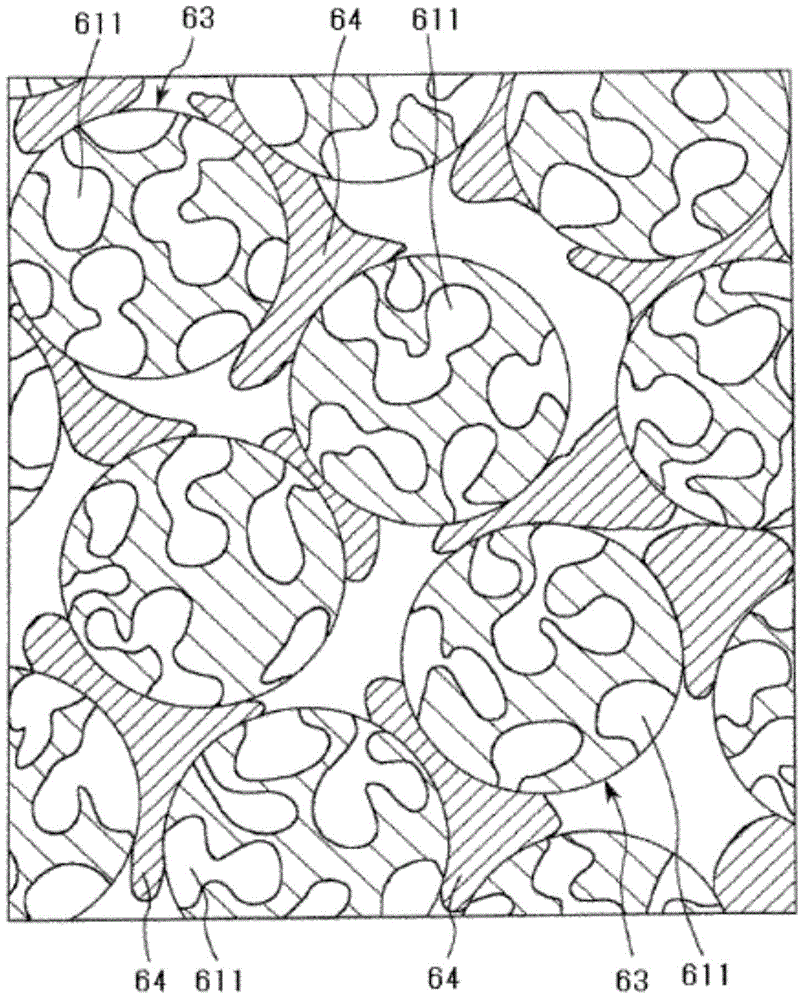

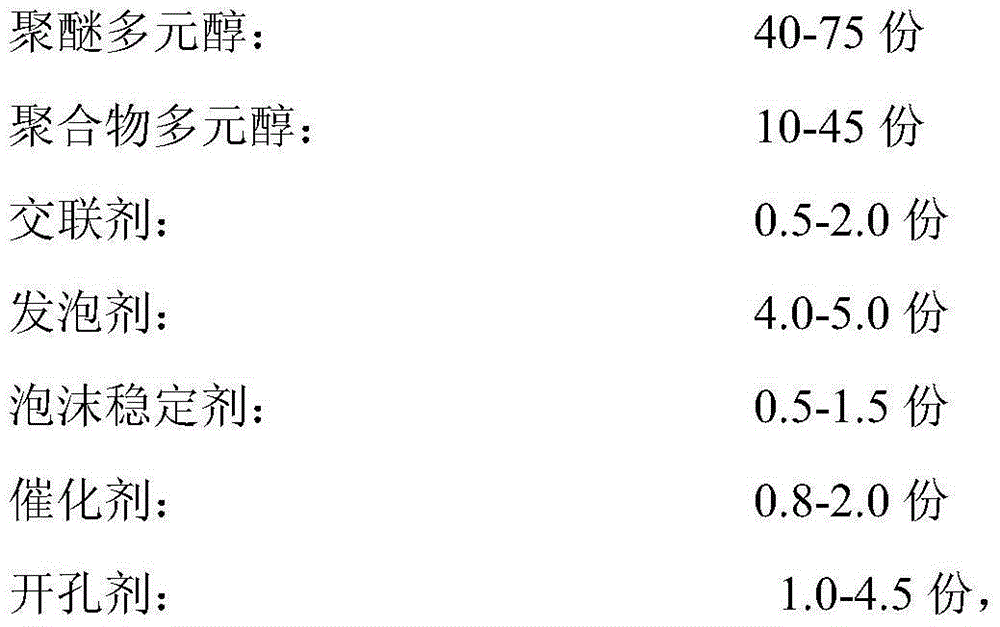

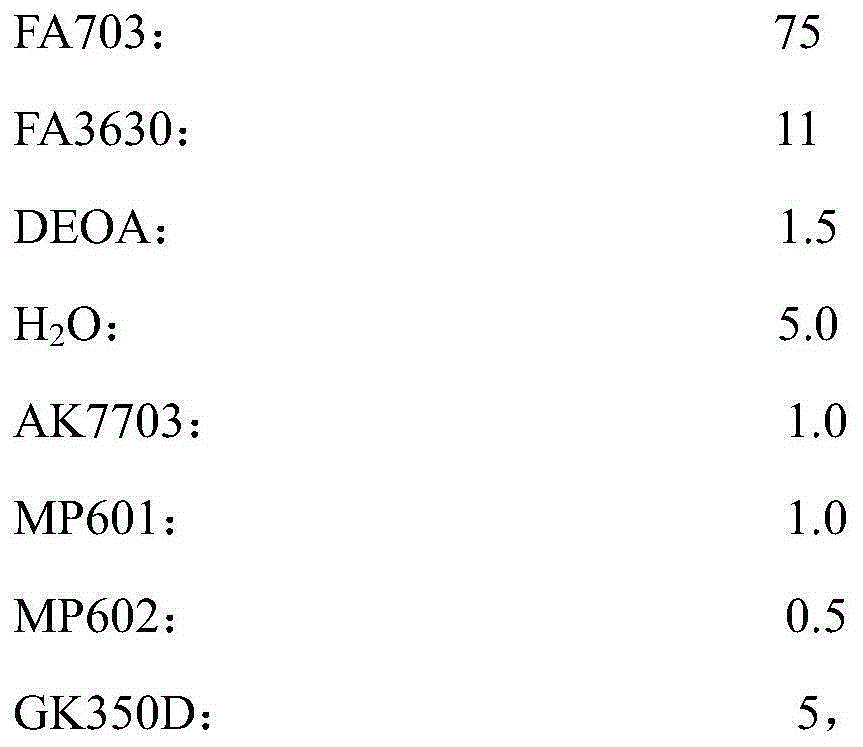

Polyurethane combined material for furniture sponge and preparation method thereof

The invention belongs to the field of polyurethane, and concretely relates to a polyurethane combined material for furniture sponge and a preparation method thereof. The combined material is prepared by mixing a composition A and a composition B, the composition A is prepared from polyether polyol, polymer polyol, a cross-linking agent, a foaming agent, a foam stabilizer , a pore-opening agent and a catalyst, and the composition B is prepared from polyether polyol, an isocyanate and a pore-opening agent. When the combined material is used, the composition A and the composition B are mixed according to the weight ratio of 100:75-110 and injected into a die, so that high-bearing low-density furniture sponge is prepared. The combined material employs low-volatilization low-atomization raw materials, and possesses advantages of low smell, good fluidity, wide applicable temperature scope and the like. The furniture sponge prepared from the combined material possesses the advantages of being basically odorless, safe, nontoxic, free of defects on the surface, good in elasticity, excellent in handfeel, low in density, good in bearing property and the like. The invention also provides a preparation method for the combined material, and the technology is reasonable.

Owner:SHANDONG INOV POLYURETHANE

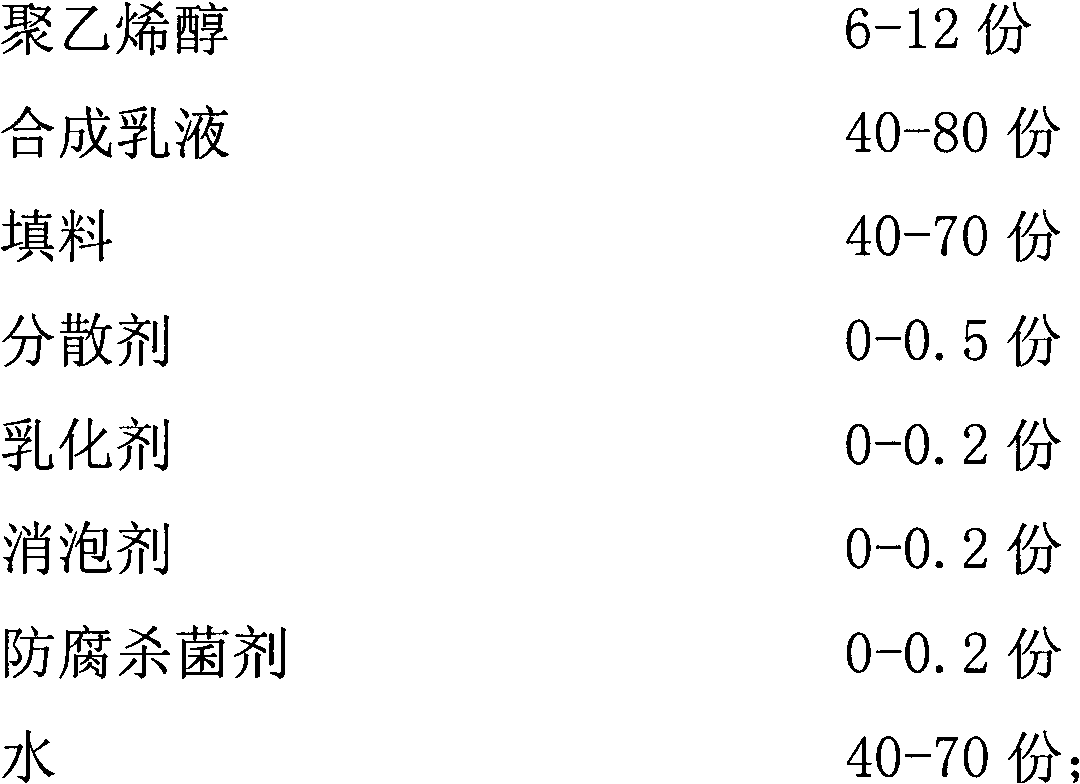

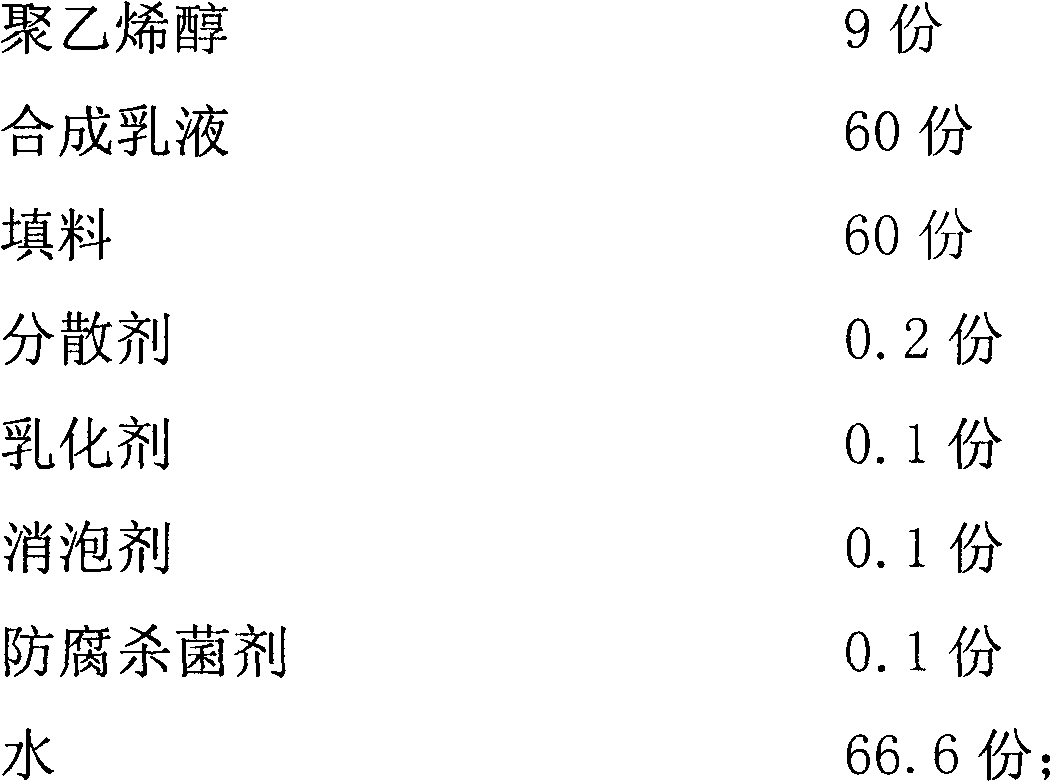

Formaldehyde-free cementing compound for profiled artificial board and preparation method thereof

ActiveCN102516857AReduce scrap rateImprove product qualityWood veneer joiningPolyurea/polyurethane coatingsBenzeneComposition B

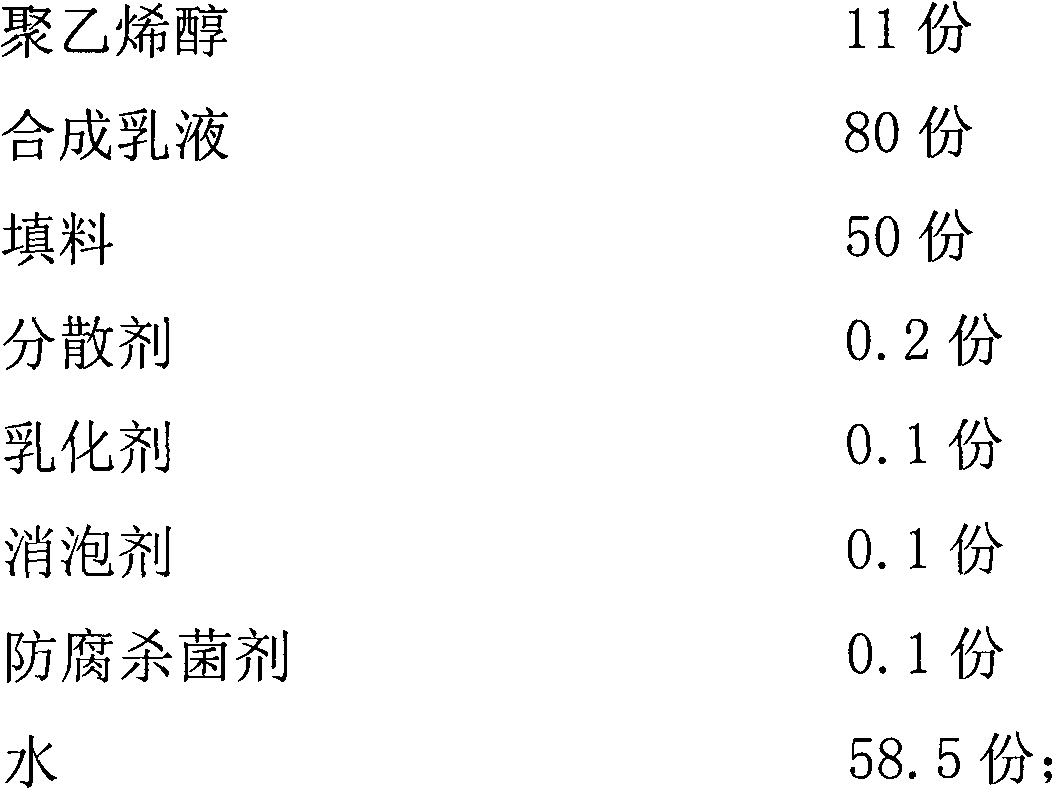

The invention discloses formaldehyde-free cementing compound for a profiled artificial board and a preparation method thereof. The preparation method comprises the following steps that: a composition A is firstly prepared: appropriate water is added into a reaction kettle with a stirring device, polyvinyl alcohol is slowly added when the water is heated to 30 DEG C, and the temperature is increased to 90 DEG C, so the polyvinyl alcohol is completely dissolved, and the temperature is preserved for one hour; then the raw materials are cooled down to 50 DEG C; synthesized liquid is added, and dispersant, emulsifier, defoaming agent and anticorrosion sterilizing agent are then added and stirred for 10 to 15 minutes; then stuffing is added and is dispersed for 45 to 60 minutes at a high speed, so all raw materials are uniformly mixed, and the mixture is filtered to obtain the composition A; and when in use, the composition A is coated after being uniformly mixed with a composition B according to a stipulated weight part. The production technique is simple, the adhesion strength can be improved, the elasticity property can be guaranteed, the product quality can be improved, no toxic substance such as formaldehyde, benzene, methylbenzene, dimethylbenzene and the like is contained, and no toxicity, no harm and environmental friendliness can be completely realized.

Owner:东营市盛基环保工程有限公司

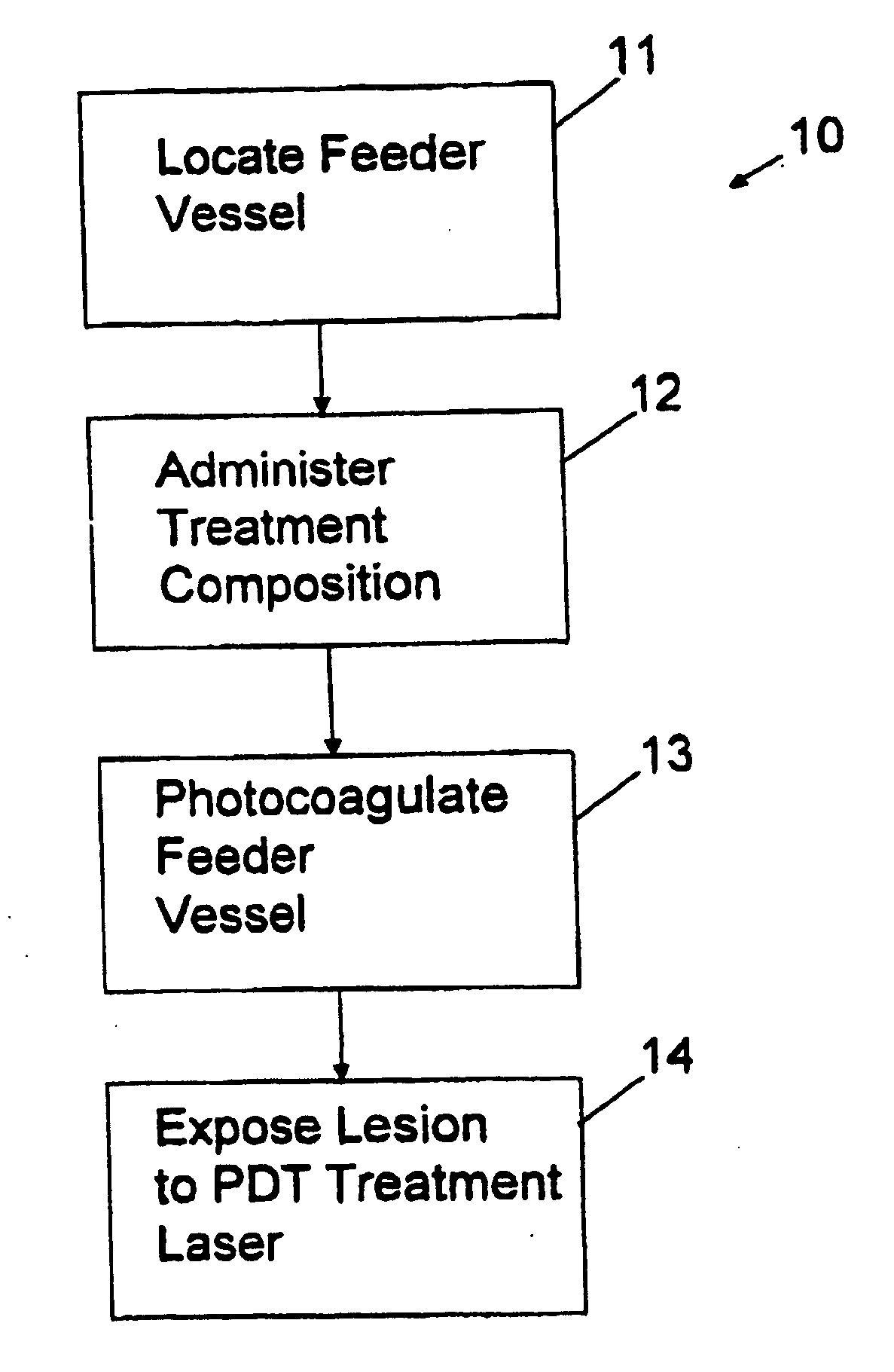

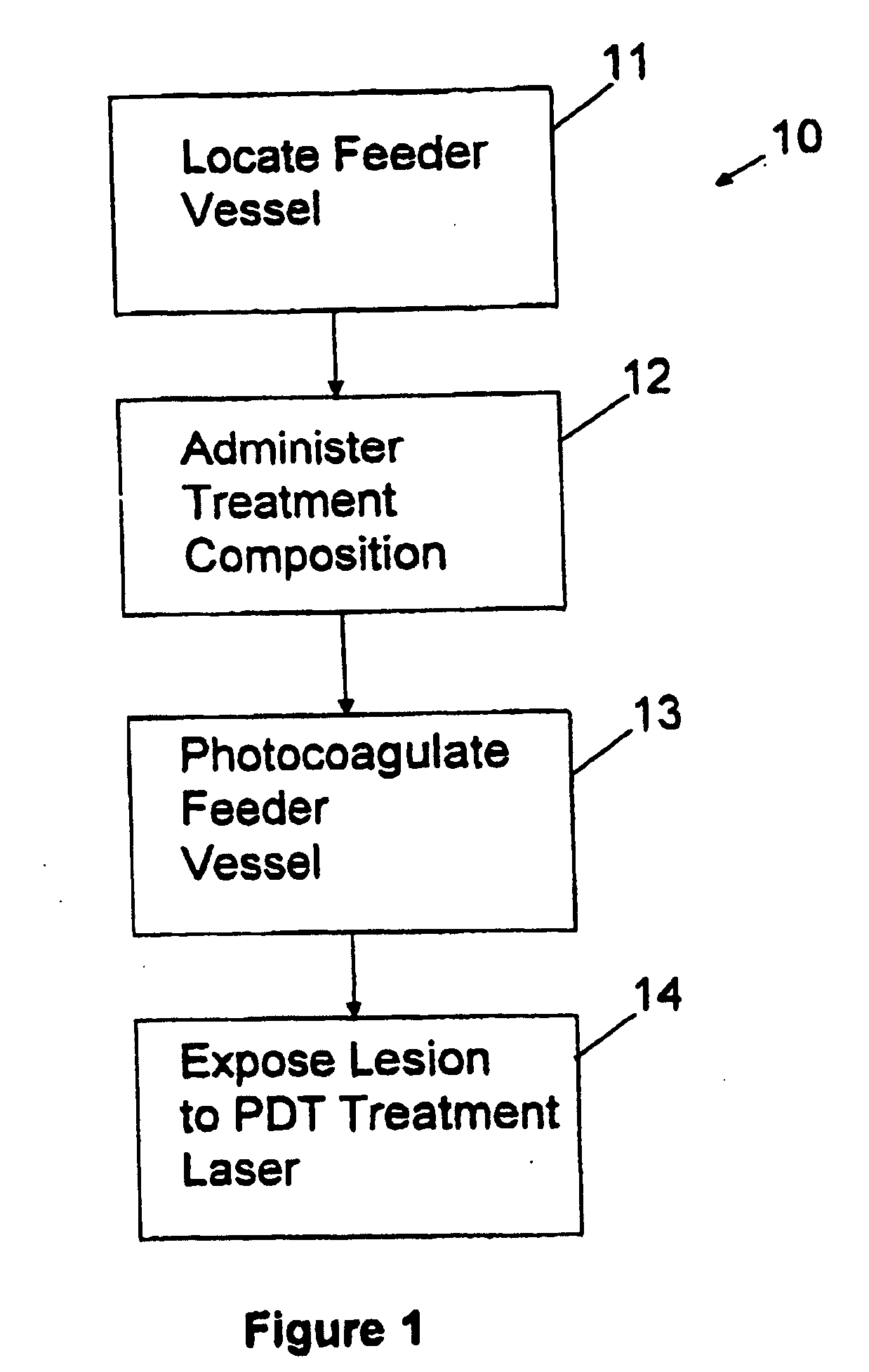

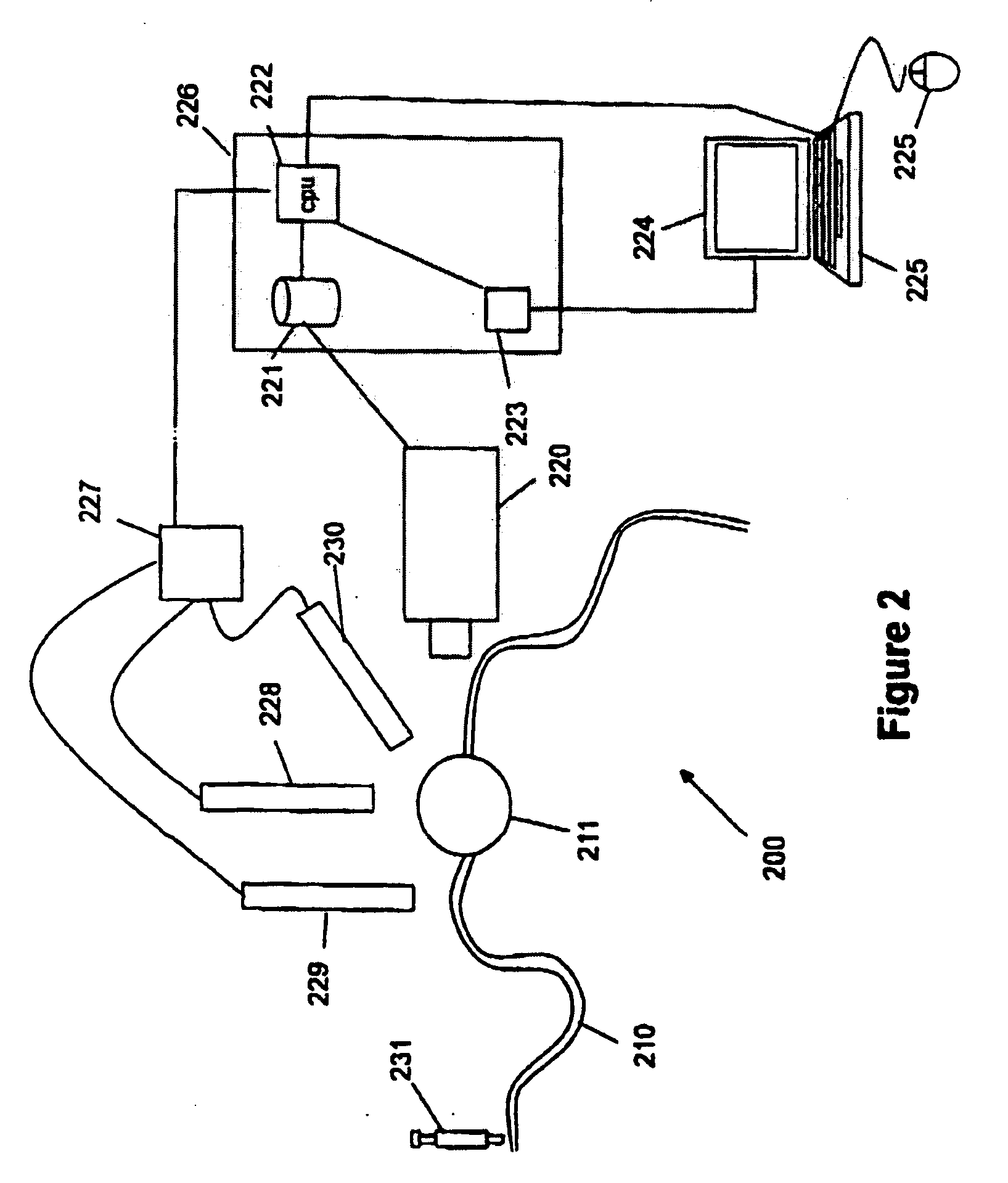

Combined photocoagulation and photodynamic therapy

InactiveUS20080221648A1Decreased blood flowHigh flush-out rateLaser surgerySurgical instrument detailsPhotodynamic therapyMedicine

A method for treating a lesion of an animal, the animal having at least one vessel that carries blood to the lesion, comprising locating the vessel, administering a composition comprising a photodynamic agent, applying energy to the vessel to photocoagulate the vessel and thereby reduce the rate at which the treatment composition exits said lesion and applying energy to said lesion, of a type and an amount sufficient to excite the photodynamic agent, causing the lesion to undergo photodynamic therapy. Preferably, a dye that is both a fluorescent dye and a radiation absorbing dye, such as indocyanine green dye, is added to the treatment composition to allow (a) confirmation of the presence of the treatment composition b the lesion to be detected by fluorescent angiography and (b) the rate of blow flow to be reduced in the blood vessel feeding the lesion using dye enhanced photocoagulation.

Owner:NOVADAG TECH INC

Two-part curable ink composition set and ink jet recording method, ink jet recording apparatus, and printed product using the same

Owner:SEIKO EPSON CORP

Organosilicon solvent-free dip varnish by modification of nano material and preparation method thereof

The invention relates to nano-material modified organic silicon solvent free impregnating varnish and a preparation method thereof. The nano-material modified organic silicon solvent free impregnating varnish comprises a composition A and a composition B. The composition A is produced by mixing the following compositions in weight portion: 100 portions of a silicone prepolymer, 10 to 80 portions of serous fluid of a heat-conducting filler and 0.1 to 5 portions of a catalyst; and the composition B is produced by mixing the following compositions in weight portion: 100 portions of the silicone prepolymer, 10 to 80 portions of the serous fluid of the heat-conducting filler and 0.1 to 5 portions of a curing agent. The varnish is mainly applied to a high-end electric motor. A curing material of the varnish has good mechanical performance and electrical performance and excellent heat conducting performance which is in particular prominent. The method adopts the mixing of the heat-conducting filler serous fluid and the silicone prepolymer in order that the heat-conducting filler is dispersed in the silicon impregnating varnish more evenly, thereby forming an effective heat-conducting passage and improving the heat conducting performance of a composite material.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

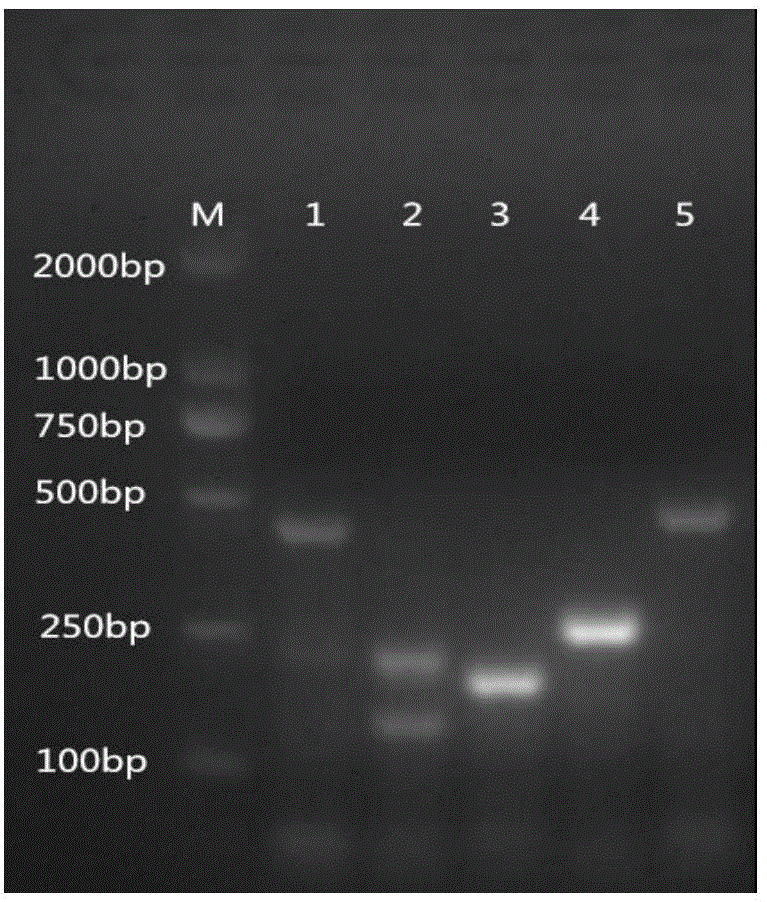

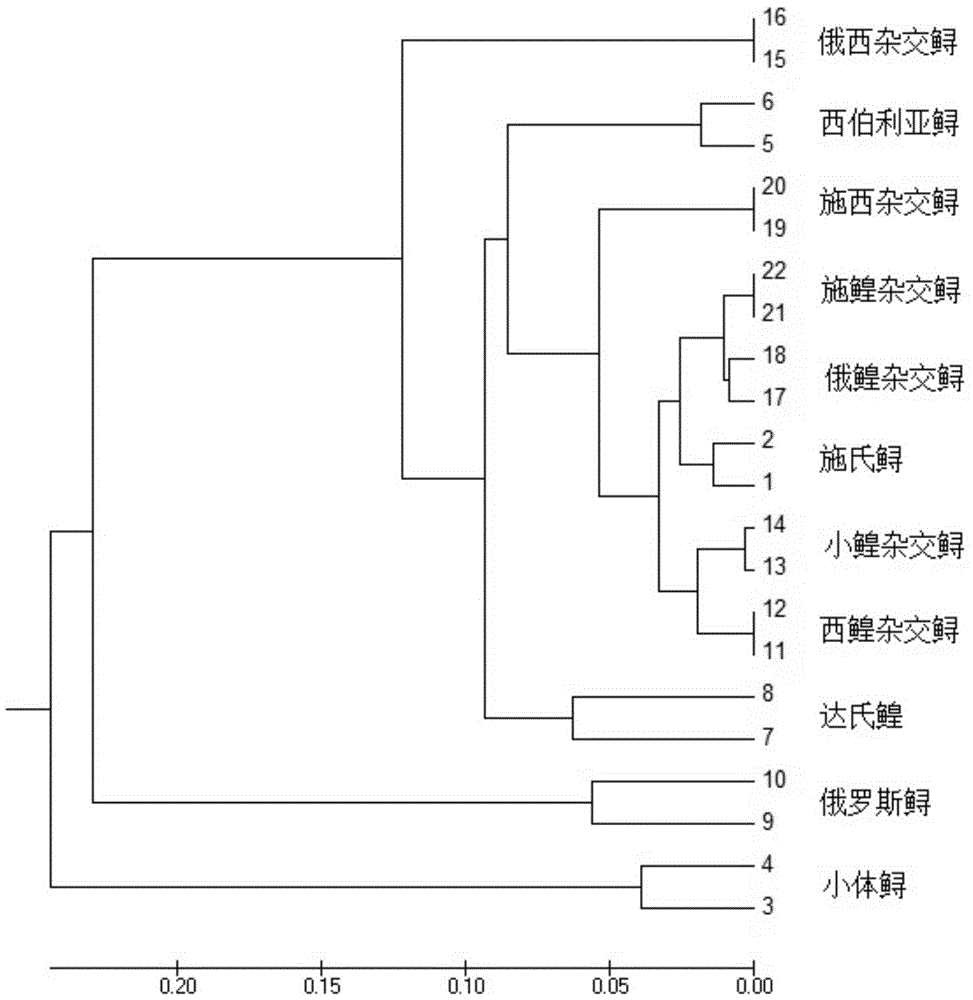

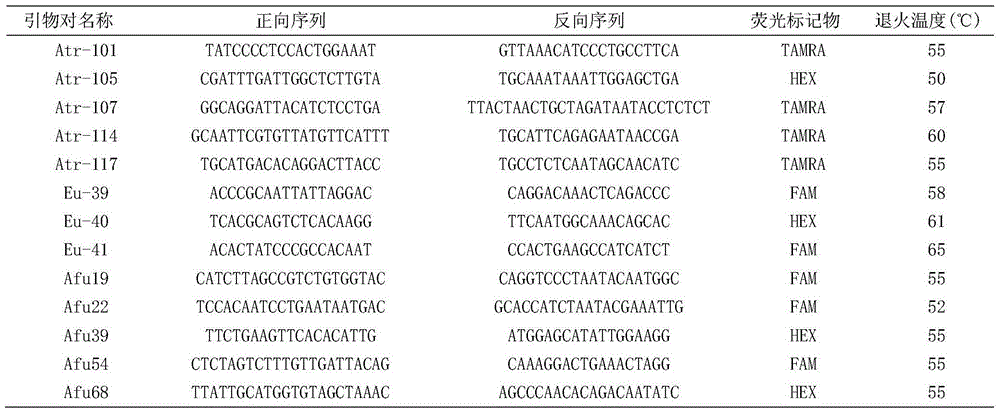

PCR primer pair composition for identification or assisted identification of idioplasm of sturgeon, and applications thereof

ActiveCN105567789AAvoid damageAvoid interferenceMicrobiological testing/measurementDNA/RNA fragmentationComposition BSturgeon

The present invention discloses a PCR primer pair composition for identification or assisted identification of the sturgeon female parent and the sturgeon male parent, and applications thereof. The composition comprises a composition A for identification or assisted identification of the sturgeon female parent, a composition B for identification or assisted identification of the sturgeon parent, and a composition C for identifying or assistedly identifying whether the sturgeon female parent is Acipenser ruthenus, wherein the compositions A, B and C are separately packaged, the composition A comprises AGF, ABF, ABRM, DauF and SchF, the composition B comprises Atr-101, Atr-105, Atr-107, Atr-114, Atr-117, Eu-39, Eu-40, Eu-41, Afu19, Afu22, Afu39, Afu54 and Afu68, and the composition C comprises RutF.

Owner:BEIJING FISHERIES RES INST

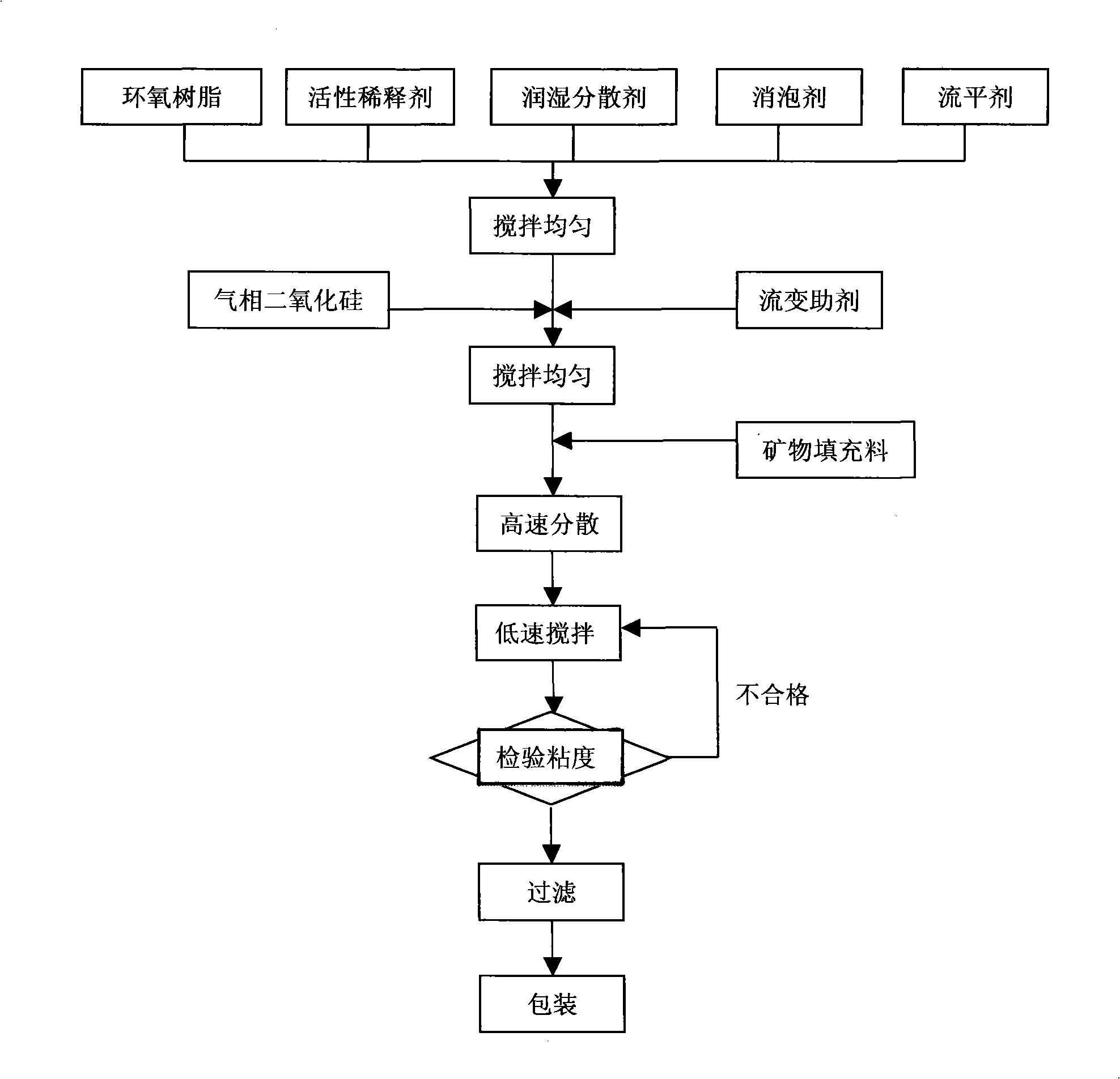

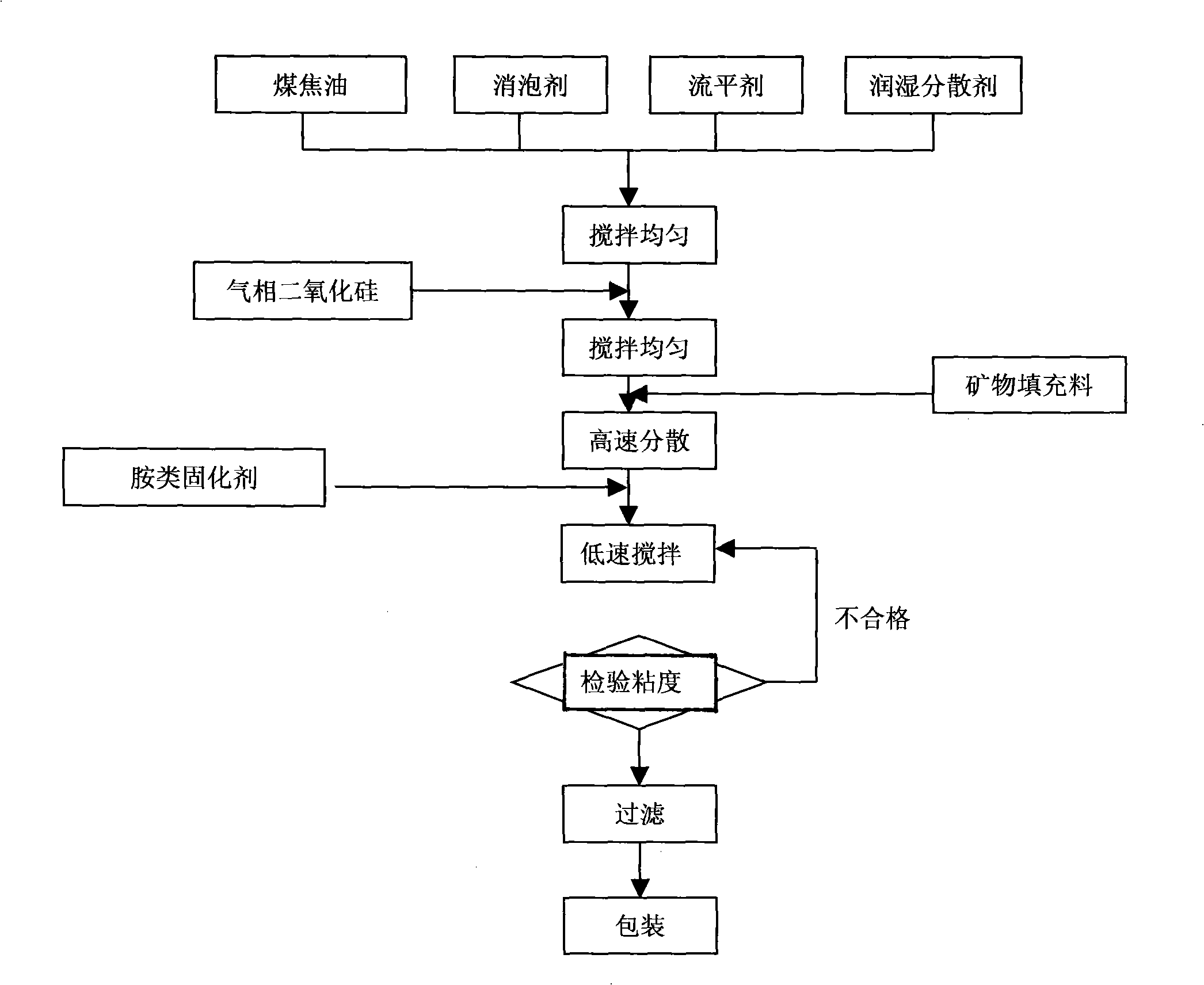

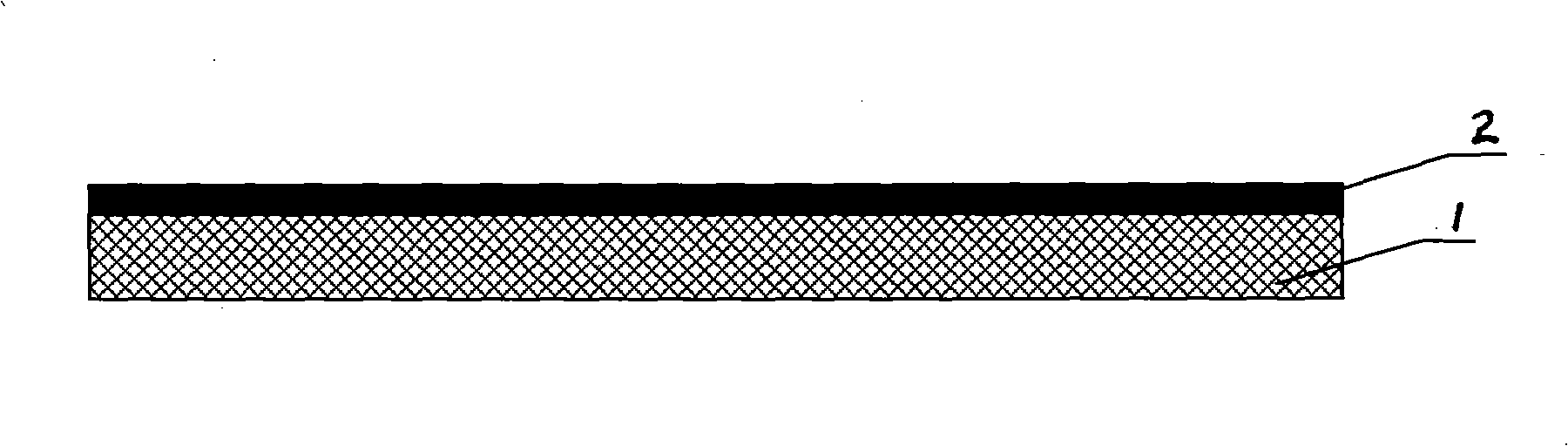

Solvent-free epoxy coal tar heavy duty anticorrosive coating and preparation process thereof

ActiveCN101284969AImprove anti-corrosion performanceGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsUnit massGas phase

The invention relates to solvent-free epoxy coal tar heavy anticorrosive paint and a process for making the same. The solvent-free epoxy coal tar heavy anticorrosive paint relates to the anticorrosive paint technical field and comprises two compositions A and B, wherein the composition A comprises 20 to 50 unit mass of epoxide resin, 10 to 15 unit mass of reactive diluent, 0.5 to 2 unit mass of rheological additive, 0.5 to 2 unit mass of defoaming agent, 0.5 to 2 unit mass of flatting agent, 1 to 3 unit mass of wetting dispersant, 0.5 to 2 unit mass of gas phased silicon dioxide and 36 to 55 unit mass of mineral filling material; the composition B comprises 15 to 20 unit mass of amine curing agent, 25 to 30 unit mass of coal tar, 0.5 to 2 unit mass of defoaming agent, 0.3 to 2 unit mass of flatting agent, 0.5 to 2 unit mass of wetting dispersant, 0.7 to 2 unit mass of gas phased silicon dioxide and 45 to 55 unit mass of mineral filling material.

Owner:XIAMEN SUNRUI SHIP COATING

Manufacturing method of three-dimensional structure, three-dimensional structure manufacturing apparatus, and three-dimensional structure

InactiveUS20150258705A1Improve recycling efficiencyDecorative surface effectsConfectioneryComposition BSolvent

Provided is a manufacturing method of a three-dimensional structure which manufactures a three-dimensional structure by laminating layers, the method including: forming the layers using a composition A containing three-dimensional formation powders and a solvent; discharging a binding solution for binding the three-dimensional formation powders to the layers; binding the three-dimensional formation powders by curing the discharged binding solution; removing the non-bound three-dimensional formation powders using the solvent; and additionally adding the three-dimensional formation powders to a mixed solution generated by the removing and containing the non-bound three-dimensional formation powders and the solvent, and preparing a composition B containing the three-dimensional formation powders and the solvent.

Owner:SEIKO EPSON CORP

High performance polyurethane waterproof coating material and preparation thereof

InactiveCN101475772AImprove flexibilityEasy to slipAntifouling/underwater paintsPaints with biocidesTO-18Polyester

The invention discloses a polyurethane waterproof coating for building and a method for preparing the same. The polyurethane waterproof coating consists of a composition A and a composition B according to the weight ratio of 1.0:1.0-2.5, wherein the composition A comprises 50 to 130 portions of polyester oligomer with high crystallization degree, 18 to 45 portions of polyisocyanate, 5 to 15 portions of phthalate and 0.1 to 0.8 portion of a catalyst; the composition B comprises 3 to 15 portions of a curing agent, 10 to 25 portions of a reinforcing agent, 17 to 35 portions of a lubricant, 20 to 36 portions of a filler, and 5 to 18 portions of paint. The method selects linear polyester with stronger polarity and higher crystallization degree and the polyisocyanate for reaction to prepare the composition A; the composition A and the composition B have good matching performance; and a high-elasticity material formed through the mixing and curing of two compositions is subjected to rapid oriented crystallization under the action of drawing force, so that the material has high tensile strength.

Owner:XIAN TONGRUI NEW MATERIAL DEV

Optical light color low stress modified epoxy adhesive and preparation of

InactiveCN101348701AGood flexibilityImprove heat resistanceEpoxynovolac adhesivesPolyether adhesivesComposition BGlycidol

The invention discloses a novel optical light-colored low-stress modified epoxy adhesive and a preparation method thereof. The adhesive consists of a composition A and a composition B, wherein the composition A comprises polyurethane modified epoxy resin (30 to 70 percent), novolac epoxy resin (20 to 40 percent), polyalcohol glycidol ether epoxy resin (10 to 30 percent), a mixed antiager (1 to 3 percent) and a plasticizer (5 to 20 percent), and the composition B comprises amine-terminated polyether (50 to 90 percent), a fatty amine epoxy hardener (10 to 50 percent), a silicane coupling agent (1 to 5 percent) and a curing accelerator (0 to 10 percent). The weight ratio of the composition A to the composition B is between 2.5 and 3.5 to 1, and the respective weight percentage of the two compositions is 100 percent. The epoxy adhesive prepared by the method has small shrinkage, good flexibility, small stress, strong bonding force, good weathering resistance and light color after cured, can be used for bonding a light path of an optical element with rigorous stress requirement and not high transmission requirement, and can be also used for bonding a non-light path of a precision optical instrument with rigorous stress requirement if a filler and a thixotropic agent are added.

Owner:云南光电辅料有限公司

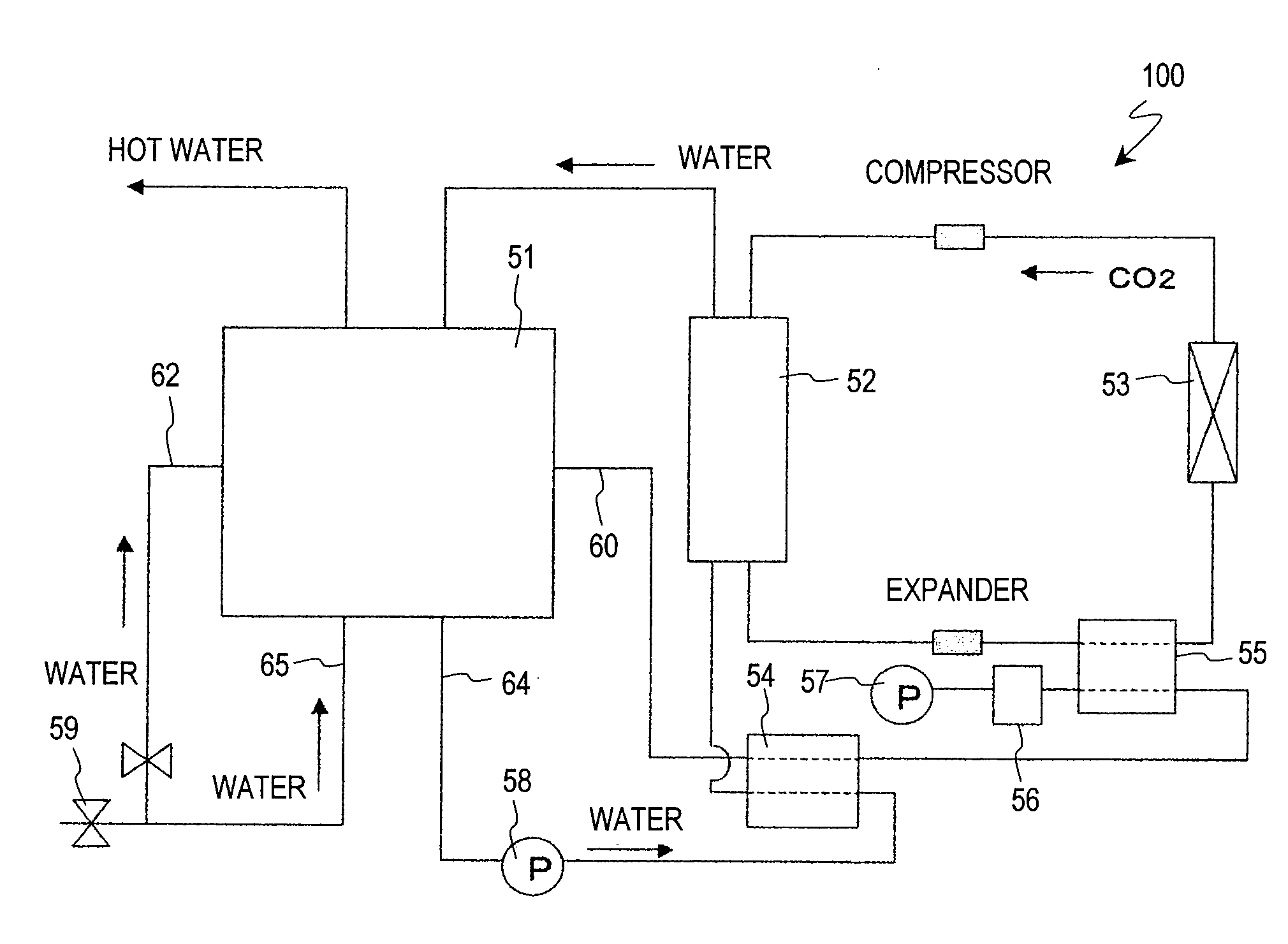

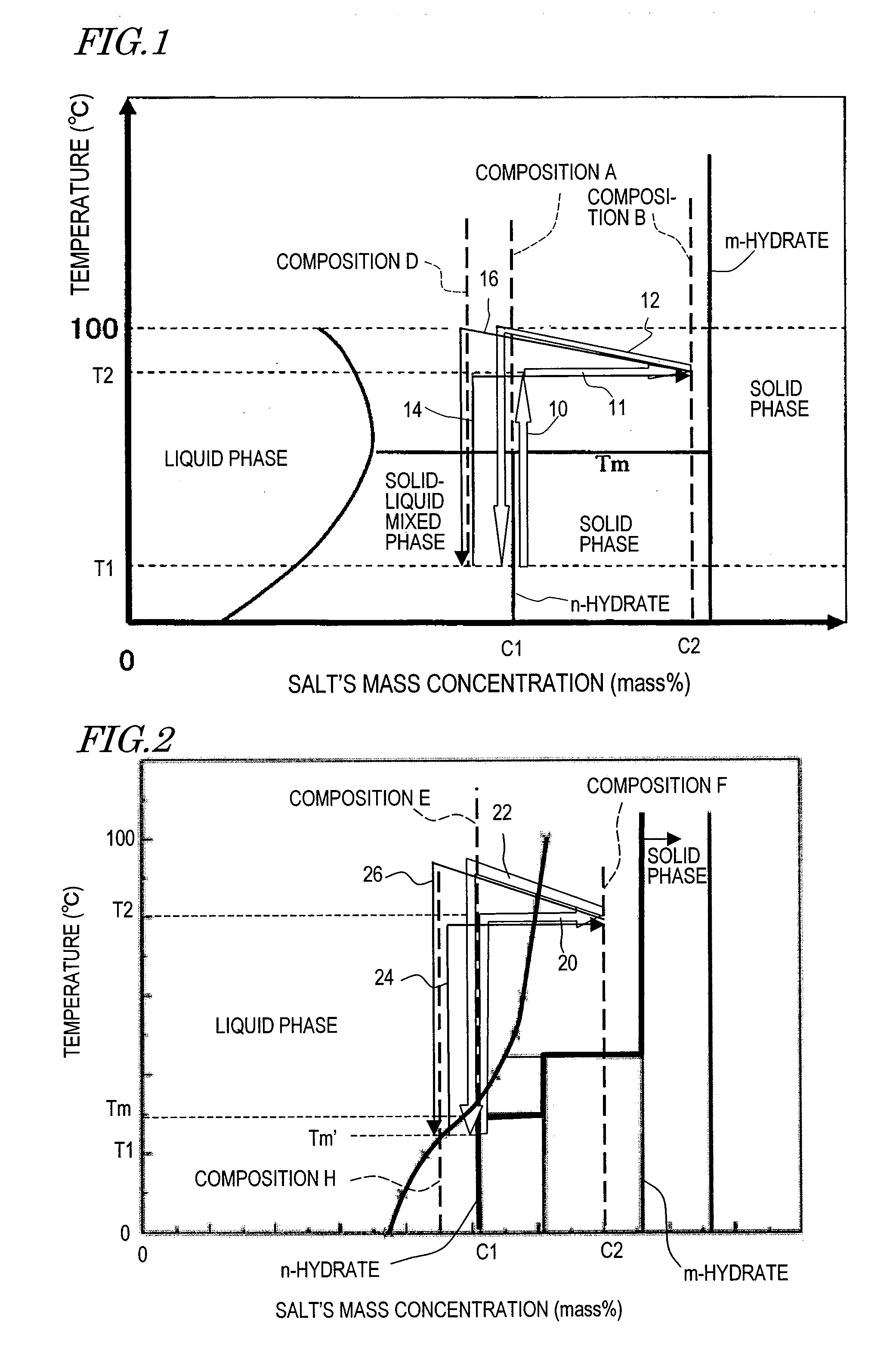

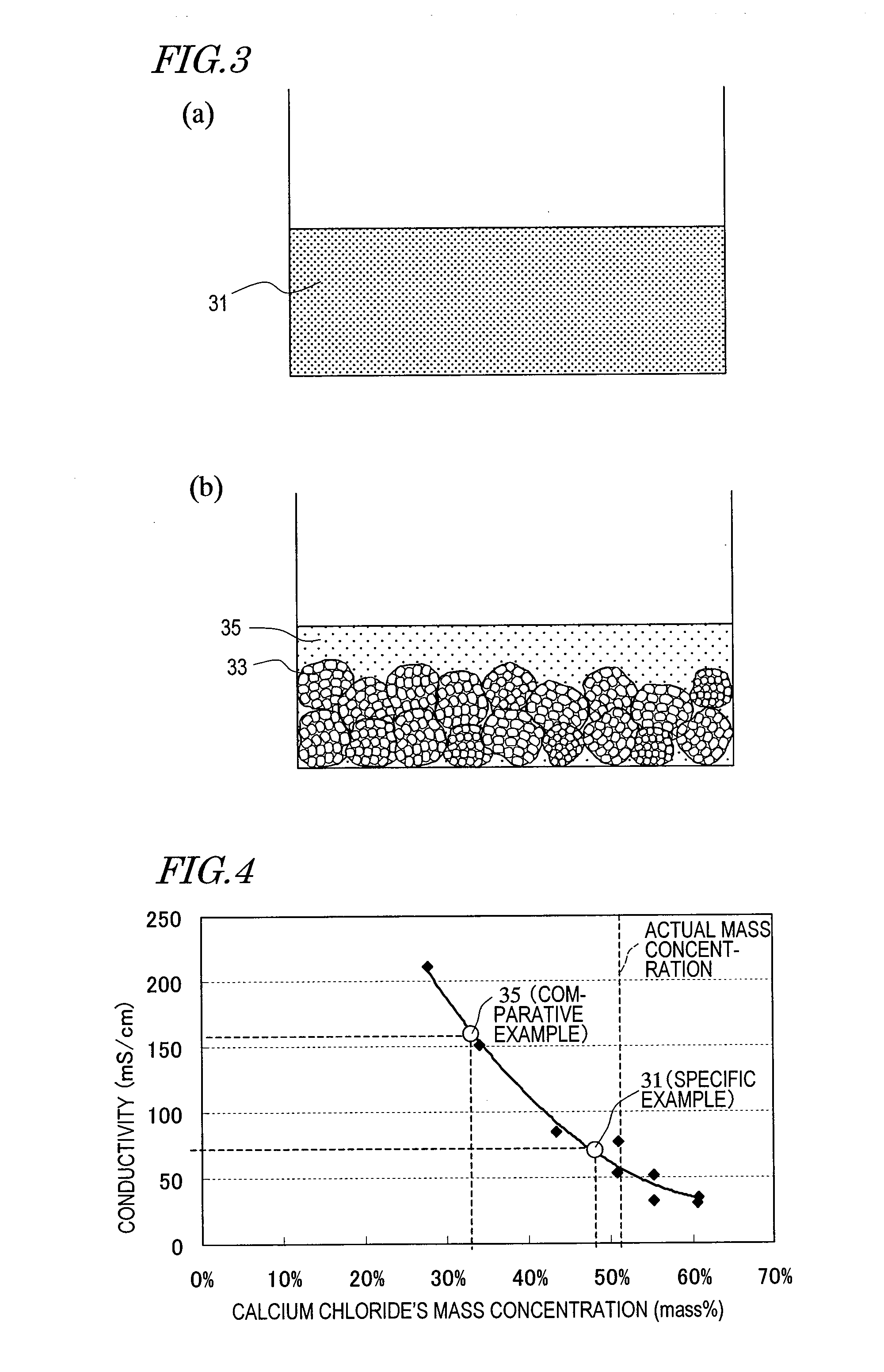

Method of heat accumulation and heat accumulation system

InactiveUS20090020264A1Increase the number ofThermal conductivityHeat storage plantsHeat-exchange elementsInorganic saltsComposition B

A thermal storage method according to the present invention includes the steps of: (A) putting a first composition A, including an n-hydrate (where n is a hydration number) of an inorganic salt in solid phase and having a phase change temperature Tm of 100° C. or less, in a thermal storage material container; (B) heating the first composition A to a temperature T2 that is higher than the phase change temperature Tm and removing water contained in the first composition A from the thermal storage material container, thereby obtaining a second composition B in which an m-hydrate (where m is also a hydration number and m<n) of the inorganic salt in solid phase and an aqueous solution of the inorganic salt are both included; (C) stopping removing the water from the thermal storage material container on sensing that the second composition B has been obtained; (D) reserving the second composition B; and (E) mixing the second composition B with water, thereby recovering at least a part of the heat that is stored in the second composition B.

Owner:PANASONIC CORP

Slow release bulk blend fertilizer and preparation method thereof

InactiveCN102924139AImprove absorption rateImprove fertilityBio-organic fraction processingOrganic fertiliser preparationDispersityAbsorption rate

The invention discloses a slow release bulk blend fertilizer and a preparation method thereof. The slow release bulk blend fertilizer comprises a composition A and a composition B, wherein the composition A contains urea, cellulose, tea seed cake, carbon black, polypropylene glycol, diammonium phosphate, triple superphosphate, potassium sulphate, potassium chloride, modified plant ash, sweet potato leaves, mushroom dreg, distillers' grains, water soluble phenol-formaldehyde resin, zinc sulfate, ferrous sulfate and nitrogen-fixing bacteria; and the composition B contains pond sludge, acrylic emulsion, ethyl acetate, ammonium acrylate, amino acid, calcium powder, alpha-pimacol, glucolactone, ammonium molybdate, micronutrients fertilizer, nano-montmorillonite and silicate potash fertilizer. Plant straws are incinerated and modified by using epoxidized soybean oil and calcium lignosulphonate, thus an absorption structure is increased, blocking is prevented and dispersity is increased; and resistance to lodging, diseases and drought of plants is effectively provided, the plant absorption rate is high, the damage to soil is correspondingly reduced, waste materials are recycled, and the fertility of a fertilizer is effectively increased.

Owner:ANHUI SUNSON CHEM

Electrolyte for dye-sensitized solar cell and preparation method thereof

InactiveCN101572192AReduce volatilityImprove long-term stabilityLight-sensitive devicesFinal product manufactureMass ratioAdhesive

The invention relates to electrolyte for a cell, in particular to electrolyte for a dye-sensitized solar cell. The electrolyte comprises a composition A, a composition B and a composition C, wherein the mass ratio of the composition A to the composition B to the composition C is 2-17:1-2:1-2; the composition A is a mixed solution formed by a redox couple, an additive which is chelated with a photo anode, and an ionic liquid; the redox couple comprises elementary iodine; the ionic liquid is an imidazole salt ionic liquid which is in the liquid state at room temperature; the molar ratio of the elementary iodine to the additive is 1:0.2-2; the concentration of the elementary iodine in the composition A of the mixed solution is between 0.01 and 1 mol / L; the composition B is an adhesive for increasing the viscosity of a system; and the composition C is a viscosity regulator for regulating the leveling property of the system under the condition of silk-screen printing. The invention has the advantages that the electrolyte system has small volatility and good long-term stability, and can perform silk-screen printing and meet the requirements of industrialized production.

Owner:IRICO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com