Dealcoholizing type organic silicon embedding glue

An organosilicon encapsulant and dealcoholization technology, applied in adhesives, other chemical processes, chemical instruments and methods, etc., can solve the problem of difficult breakthroughs in the catalytic system, and achieve novel catalytic system, good storage stability, excellent resistance. warm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

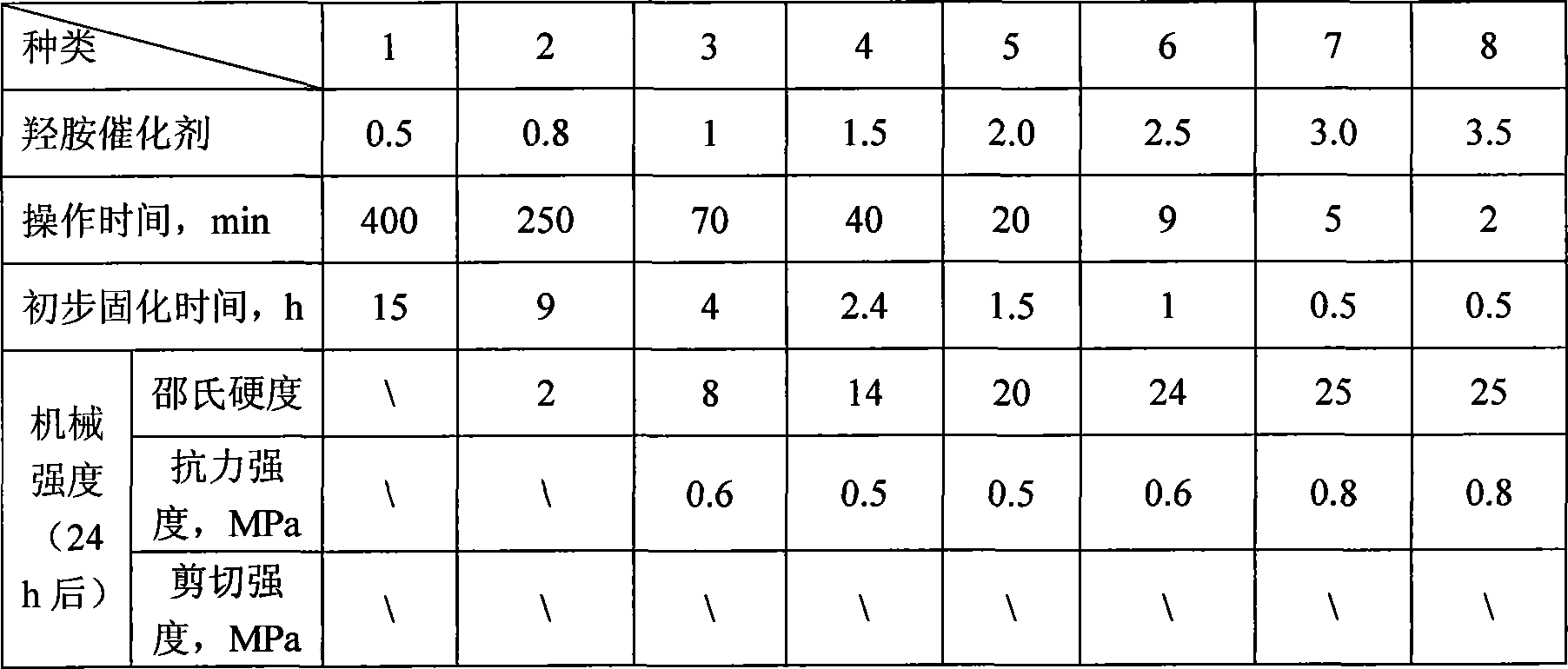

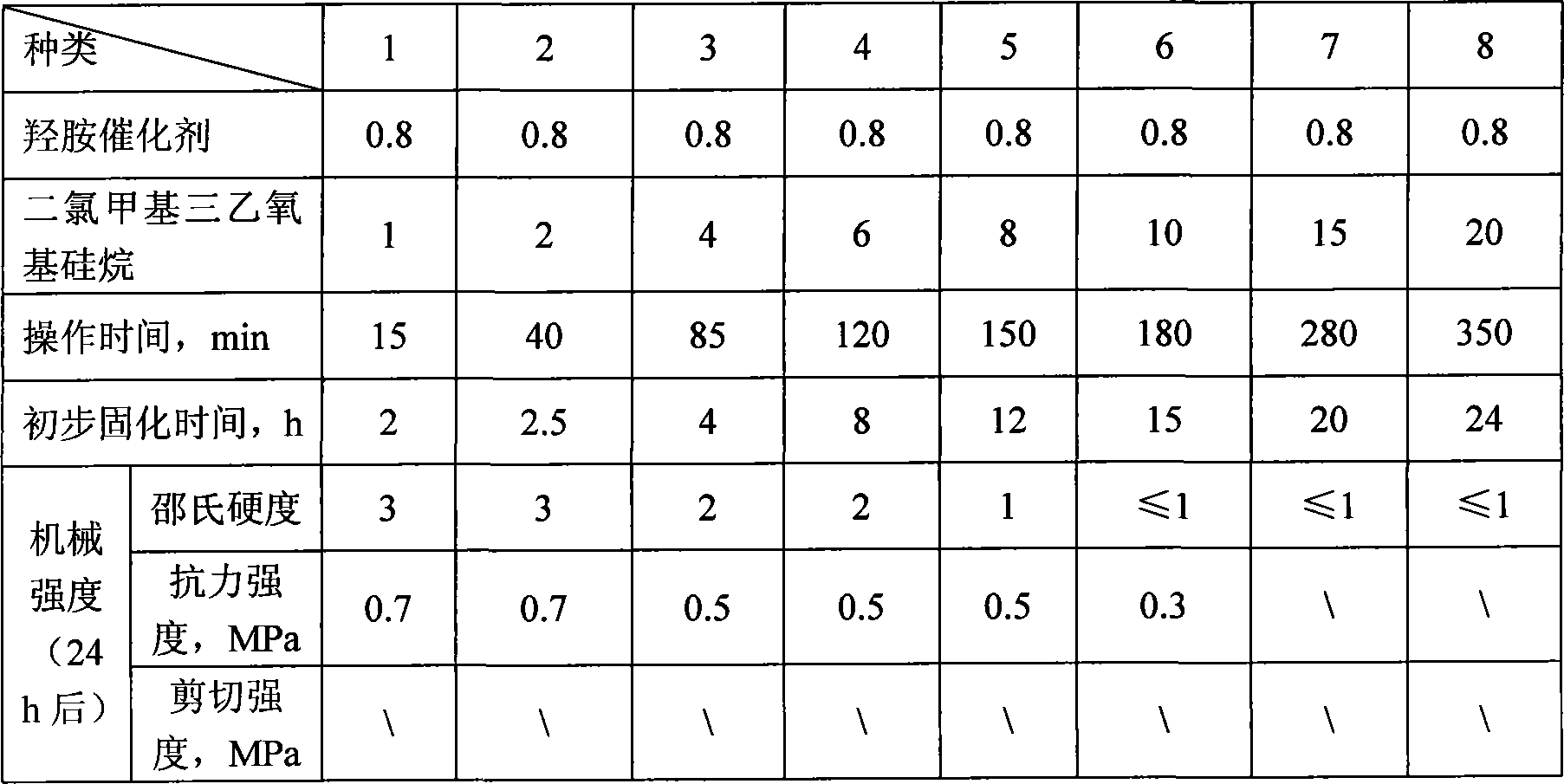

Method used

Image

Examples

Embodiment 1

[0040] A new type of dealcoholized silicone potting compound, which uses hydroxyl-terminated polydimethylsiloxane as the main raw material, and is formed by the reaction of two components A and B, wherein the component A is composed of 107 silicone rubber, The composition of base glue, plasticizer, filler and deep layer curing accelerator is by weight:

[0041] 107 silicone rubber 50

[0042] Base 50

[0043] Silicone oil 10

[0044] Fumed silica 5

[0046] Microsilica 5

[0047] Curing accelerator 0.2;

[0048] Described B component comprises catalytic system and plasticizer, and this catalytic system is made up of hydroxylamine catalyst, crosslinking agent and coupling agent, and each component is by weight:

[0049] Hydroxylamine catalyst 0.8

[0050] Dichloromethyltriethoxysilane 1

[0051] Coupling agent 0.1

[0052] Silicone oil 3;

[0053] Among them, the base rubber is pretreated 107 silicone rubber, and its preparation process i...

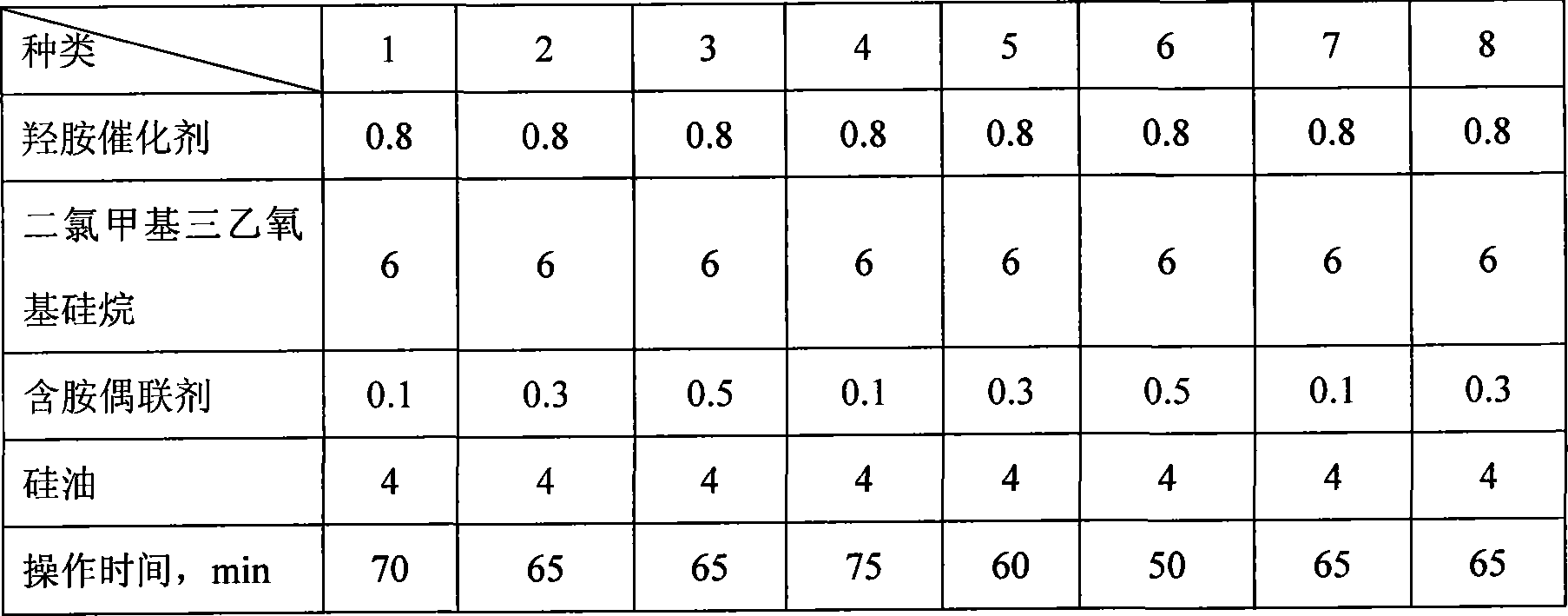

Embodiment 2

[0056] The preparation of A component is identical with embodiment 1.

[0057] Each component of component B is by weight:

[0058] Hydroxylamine catalyst 0.8

[0059] Dichloromethyltriethoxysilane 6

[0060] Coupling agent 0.5

[0061] Silicone oil 4.

Embodiment 3

[0063] The preparation of A component is identical with embodiment 1.

[0064] Each component of component B is by weight:

[0065]Hydroxylamine catalyst 0.8

[0066] Dichloromethyltriethoxysilane 10

[0067] Coupling agent 0.3

[0068] Silicone oil 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com