Patents

Literature

71results about How to "Good matte" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dealcoholizing type organic silicon embedding glue

InactiveCN101121870AThe curing effect is achievedEffect achievedOther chemical processesAdhesivesHydroxylamineAdhesive

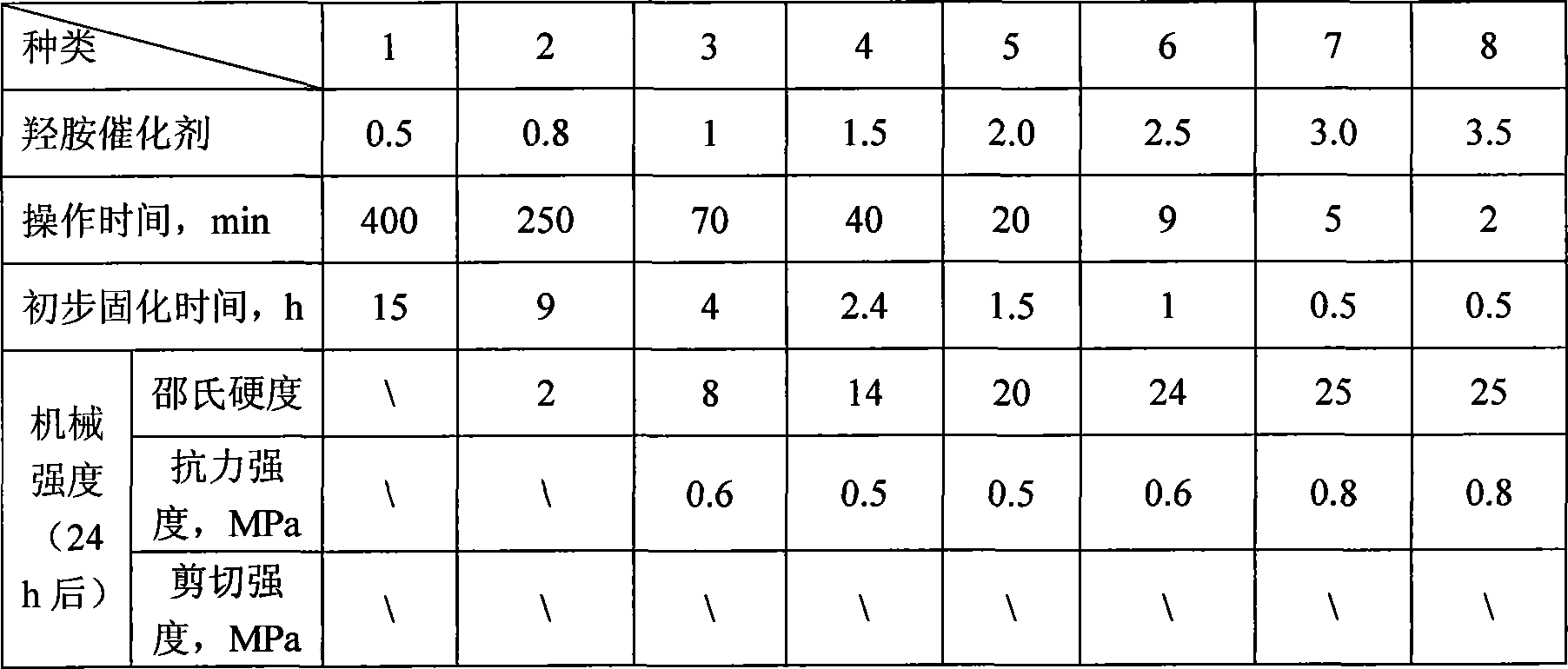

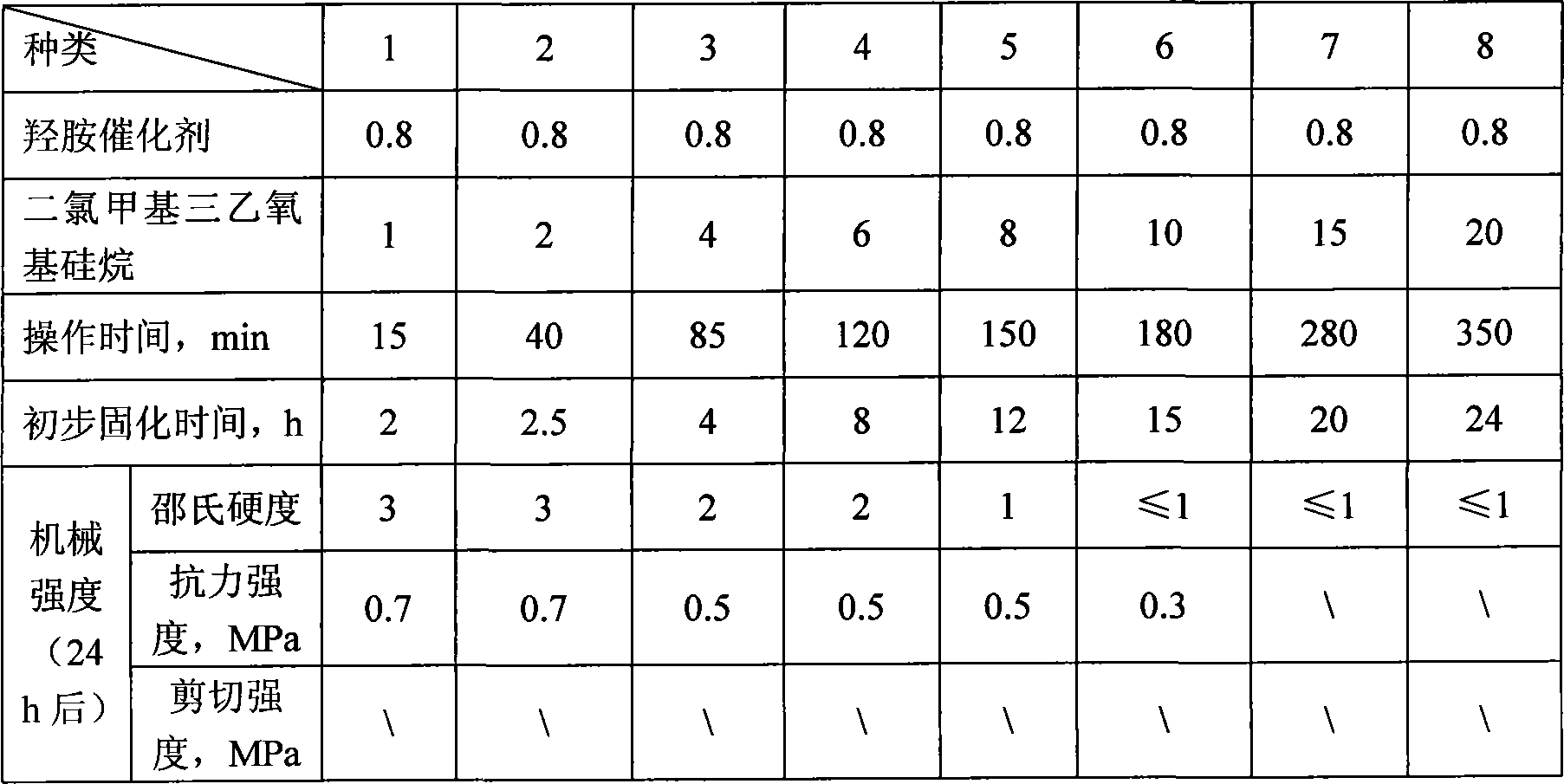

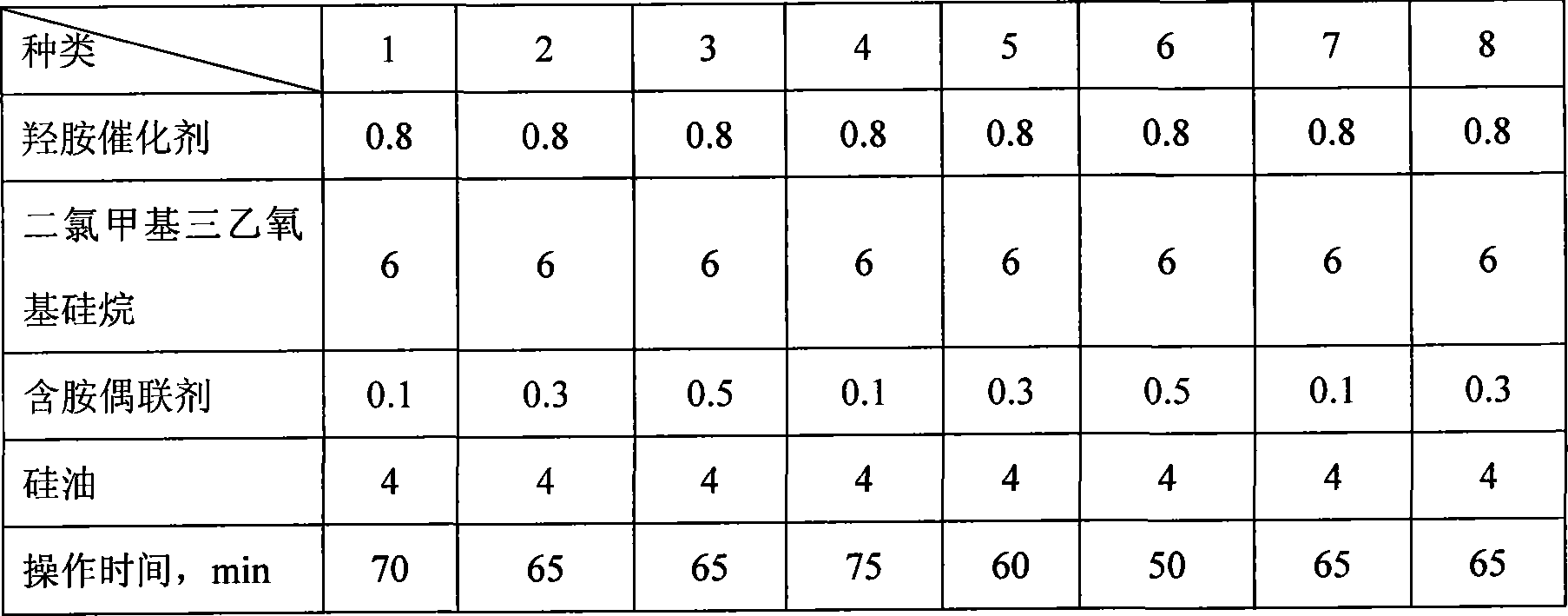

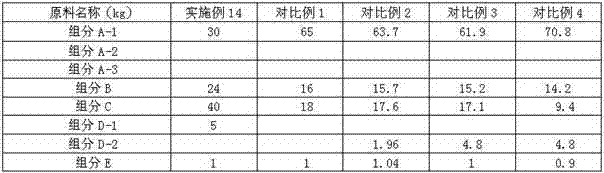

The invention discloses a novel de-alcoholized organosilicon potting adhesive, taking hydroxy-terminated dimethyl silicone polymer as the principal raw material, comprising composition A and composition B. Composition A includes (calculated by weight percent) 107 silicone rubber + base 100, plasticizer (5 to 15), filler (0 to 20), and solidifying accelerator (0.1 to 1). Composition B includes (calculated by weight percent) hydroxylamine catalyst (0.8), crosslinking agent (1 to 10), coupling agent (0.1 to 0.5) and plasticizer (3 to 5). The base adopts preprocessed 107 silicon rubber (107 silicon rubber: base = 30:70 to 50:50). The potting adhesive has excellent heat-resistance and electric performance; the volume resistance is as high as 1.0*1015 Omega question mark cm, and the dielectric coefficient reaches 25kv / question mark mm-1.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

Reactive extrusion matte agent, low gloss PC/ABS alloy and its preparation method

ActiveCN102382348AExcellent MatteImprove mechanical propertiesStyrene-acrylonitrile resinPolycarbonate

The invention relates to a reactive extrusion matte agent, a low gloss PC / ABS alloy by using the reactive extrusion matte agent and a preparation method thereof. The low gloss PC / ABS alloy comprises the following components of: by weight, 20-80% of a polycarbonate resin, 5-50% of an ABS resin, 5-40% of a styrene-acrylonitrile resin, 1-10% of the reactive extrusion matte agent and 0.1-1.5% of a processing aid. The preparation method provided by the invention comprises the following steps of: premixing the above materials in a high-speed mixer for 3-10 minutes, allowing the premix to enter intoa double screw extruder for melting extrusion at the temperature of 230-300 DEG C, cooling, followed by granulation to obtain the low gloss PC / ABS alloy. In comparison with the prior art, the preparation method provided by the invention has advantages of reasonable technology, low cost, high efficiency of reducing gloss and stable product performance.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

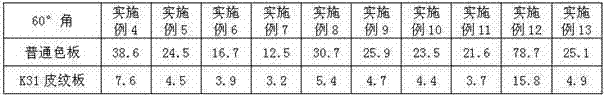

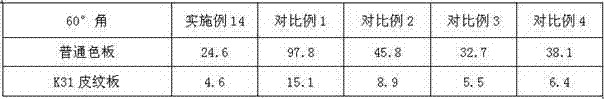

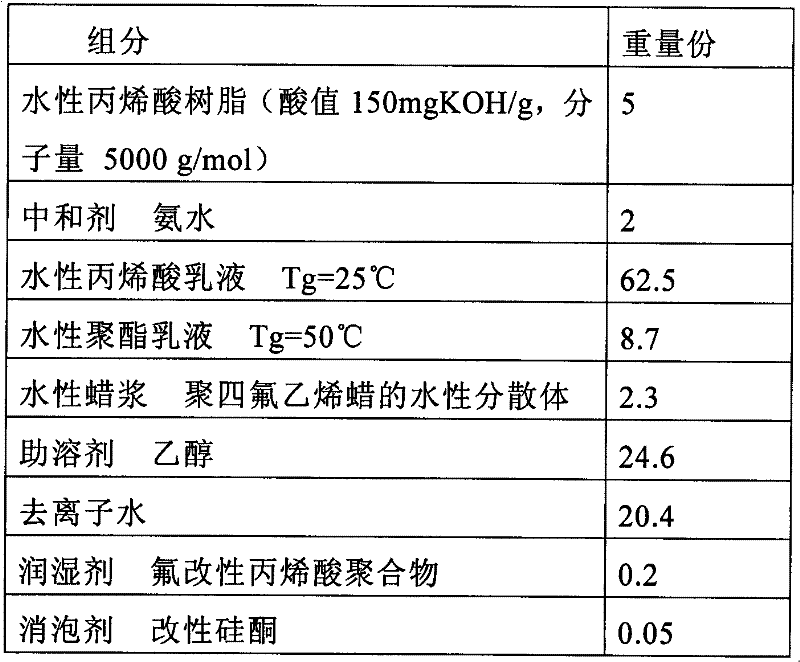

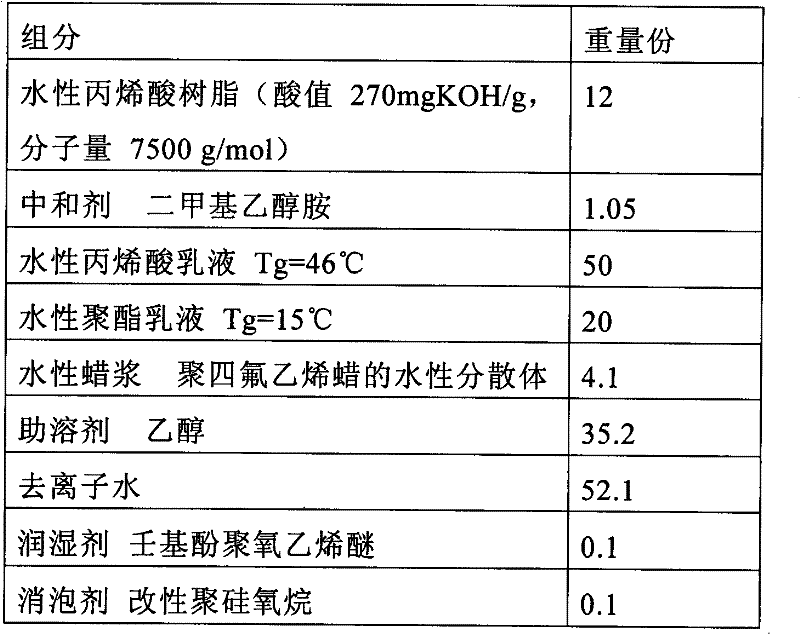

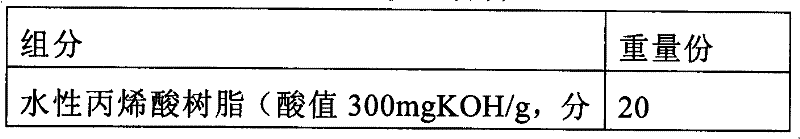

Environmentally-friendly aqueous matte aluminized paper undercoating paint and preparation method as well as application thereof

ActiveCN102363933AGood matte effectImprove wear resistanceDefoamers additionCoatingsEnvironmental resistancePolyester

The invention relates to an environmentally-friendly aqueous matte aluminized paper undercoating paint and a preparation method as well as application thereof. The paint comprises the following component raw materials in parts by weight: 5-20 parts of aqueous acrylic resin, 0.5-8 parts of neutralizing agent, 50-70 parts of aqueous acrylic emulsion, 10-20 parts of aqueous polyester emulsion, 1-5 parts of aqueous wax slurry, 20-45 parts of cosolvent, 20-80 parts of de-ionized water, 0.1-0.3 part of moistening agent, 0-0.2 part of rheological control agent and 0.05-0.2 part of defoaming agent, and can be used for surface treatment of cigarette inner lining paper. Compared with the prior art, the paint has the advantages of aqueous environmental friendliness, high metal glossiness, superior coverage and wear resistance; and the problem that directly plated paper made by the conventional paint cannot achieve effects of metal feeling and flatness of a matte aluminum foil is solved.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

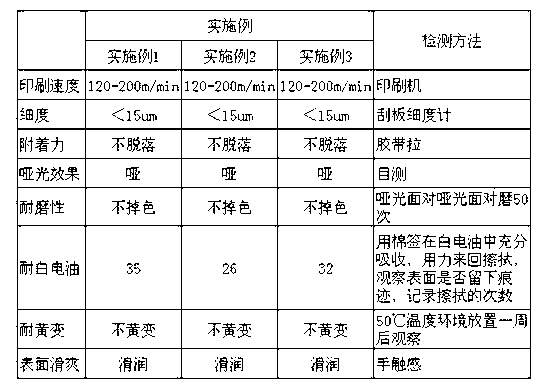

Surface printed solidified matte ink and preparation method thereof

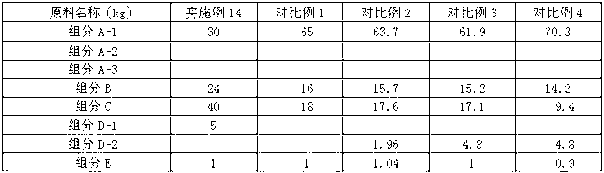

The invention relates to surface printed solidified matte ink and a preparation method thereof. The surface printed solidified matte ink is formed by adding a curing agent into an ink base material according to a ratio of 6-10% and stirring, wherein the ink base material comprises the following ingredients: 23 parts of n-propyl ester, 10 parts of butyl acetate, 8 parts of a polyurethane resin, 10 parts of aldehyde ketone resin, 1 part of a flatting agent, 40 parts of light removing slurry, 7 parts of ternary chlorine vinegar resin, 0.5 part of an antifoaming agent and 0.5 part of a dispersing agent; the n-propyl ester, the butyl acetate, the polyurethane resin, the ternary chlorine vinegar resin and the aldehyde ketone resin are firstly ground, combined with the flatting agent and the light emitting slurry, and are subjected to high-speed dispersion, the ingredients are filtered and packaged into finished products, and 6-10% of the curing agent is added, thus obtaining the ink which can be used for printing. The matte ink can be used for directly printing in a matte manner to form a film, personal hollow printing or conventional covering printing is realized, the adhesive force is high, the surface is smooth, the matte effect is remarkable, and the production cost is lowered. The surface printed solidified matte ink is applicable to printing on coiling drums of wall paper, chrome paper, kraft paper, leatherette paper and various special types of paper, and meanwhile the ink is applicable to printing on PE (Poly Ethylene), PET (Polyethylene Terephthalate), BOPP (Biaxially-oriented Polypropylene), pearly luster films and twisting films with corona layers.

Owner:ZHUANGLI PRINTING CHAOAN COUNTY

Mutton fat matt white glaze for ceramic decoration and preparation method of white glaze

The invention discloses mutton fat matt white glaze for a ceramic decoration and a preparation method of the white glaze. The white glaze is prepared from, by mass percentage, 15-25% of feldspar powder, 10-17% of calcium carbonate, 5-7% of dolomite, 6-12% of talc, 3-8% of barium carbonate, 15-20% of zirconium silicate, 10-15% of zirconium white frit, 0-6% of zinc oxide, 5-7% of aluminum oxide and 0-12% of kaolin. The components are weighed according to the formula, fully mixed and added into a grinding tank, water with the weight 45-50% that of dry powder is added for grinding for 10-15 h, then glaze slurry obtained after ball milling is subjected to iron removal and screening, and the concentration is adjusted till the true specific gravity is 50-54 degrees. A ceramic product is coated with the white glaze in a spraying mode or a soaking mode or other decoration modes. After drying, the ceramic product enters a kiln to be oxidized and fired for 8-11 h at the temperature of 1200-1235 DEG C, and the ceramic product is taken out of the kiln after being naturally cooled. The prepared mutton fat matt white glaze has the advantages of being high in processing property, high in operability and not prone to cracking.

Owner:XIAMEN EDUNUS CERAMIC IND CO LTD

Black matte polyimide film and preparation method thereof

The invention discloses a polyacrylonitrile-blended black matte polyimide film and a preparation method thereof. Polyacrylonitrile and polyamide acid are prepared by virtue of an in situ polymerization method to form a blended solution with a molecular interpenetrating network. The preparation method comprises the following steps: mixing polyacrylonitrile powder particles with a high-polarity nonprotic organic solvent, heating, stirring to adequately dissolve, cooling, adding aromatic binary primary amine, after the dissolving is complete, adding aromatic binary anhydride, heating and stirring to obtain a uniform blended solution in which polyacrylonitrile and polyamide acid are in micro-phase separation, wherein different separation phase domains can be obtained by selecting polyacrylonitrile with different weight-average molecular weights; and carrying out salivation, drying, heating and amination on the blended solution, so as to obtain the black matte polyimide film. The black matte polyimide film has relatively high power frequency electric strength, excellent mechanical properties, extremely low light transmittance and a good black matte effect.

Owner:无锡高拓新材料股份有限公司

Water-based paint for pipeline and preparing method of water-based paint

InactiveCN105255332ACorrosionStrong adhesionAntifouling/underwater paintsPaints with biocidesSODIUM METAPHOSPHATEMelamine phosphate

The invention relates to water-based paint for a pipeline. The water-based paint for the pipeline is prepared from modified phenolic resin, pitch, alcohol acid emulsion, chromium oxide green, an anti-rusting agent, low polymer polyhydric alcohols, maleic anhydride, methyl methacrylate, hydroxyl ethyl acrylate, hydroxylated fiber resin, polyether sulfone resin, polysorbate, sodium hexametaphosphate, organic silicon emulsion, epoxy silane modified silicon sol, crosslinked polyethylene, tert-butyl peroxybenzoate, sodium silicate, melamine phosphate, pentaerythritol, aluminum silicate fibers, silicon dioxide, antibacterial preservative, titanium dioxide, Ni, Zn, water and other raw materials. Due to the fact that the ingredients such as Ni and Zn are contained in the water-based paint for the pipeline, the water-based paint for the pipeline has the high-temperature resisting and corrosion resisting performance, is suitable for coating demands of various occasions, does not contain toxic organic solvents, is free of pollution and has the advantages that a paint surface cannot crack, and the paint is resistant to aging, high in adhesive force and the like.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

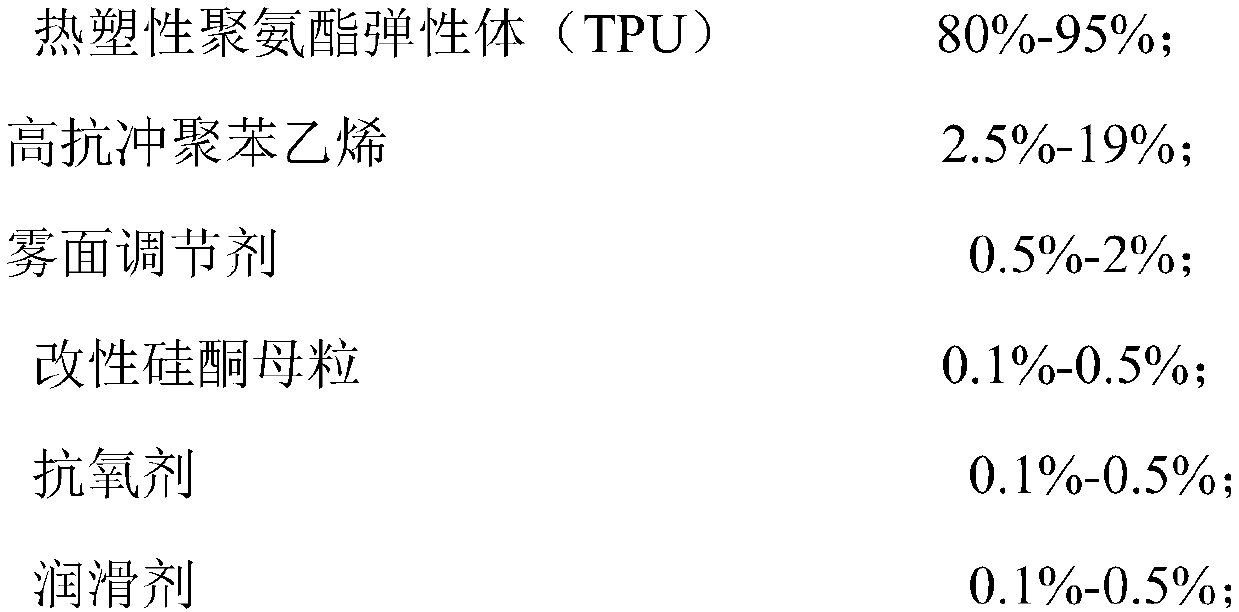

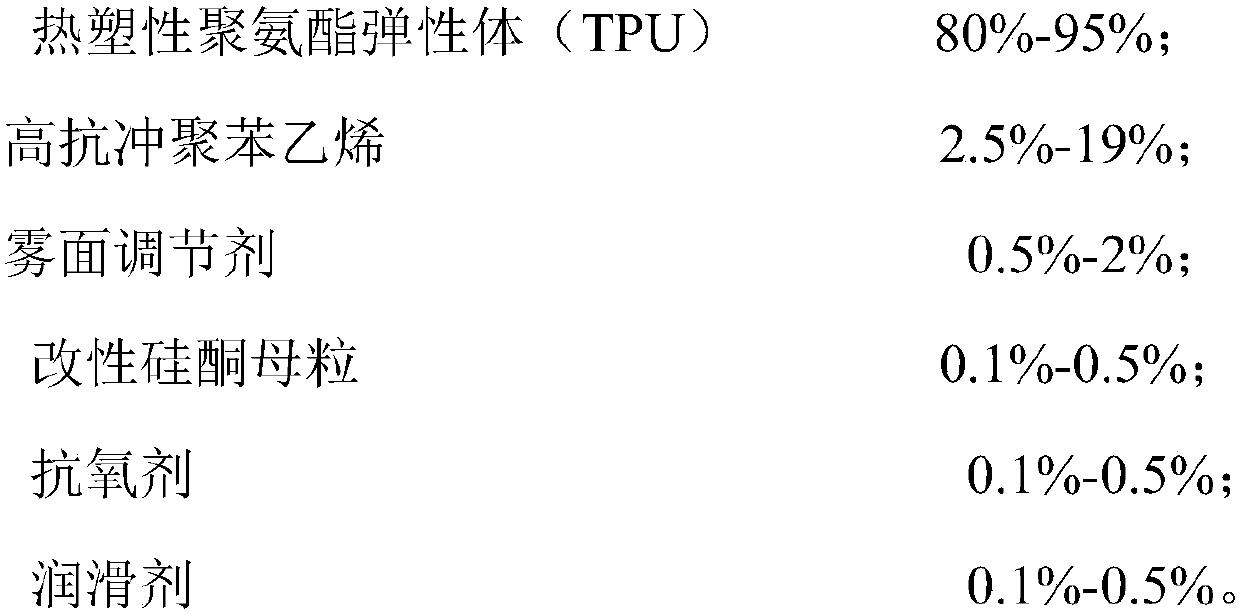

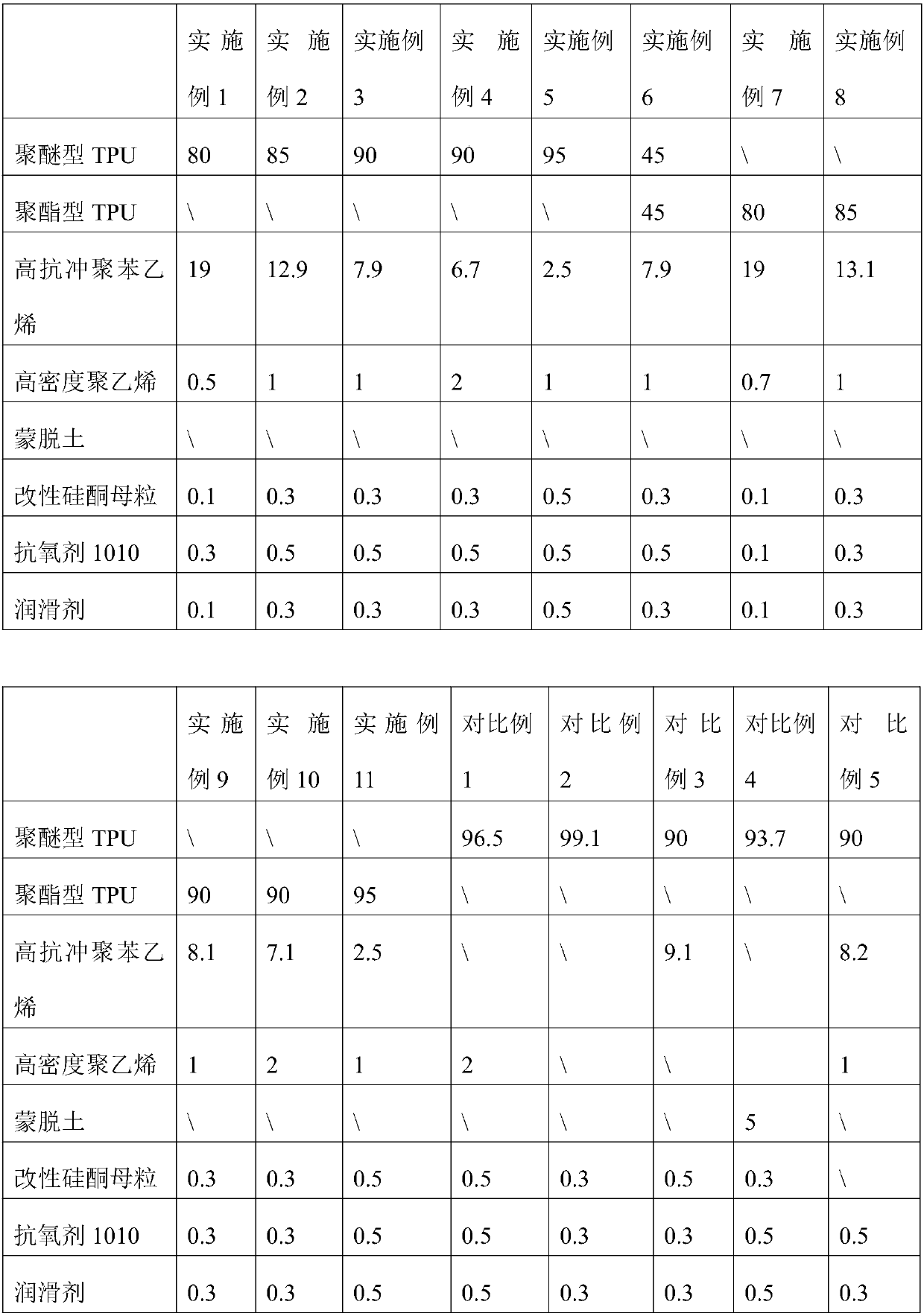

High-physical-property matte thermoplastic polyurethane elastomer and preparation method thereof

ActiveCN108102347AImprove the disadvantages of reduced physical properties and poor matte effectGood matte effectAntioxidantThermoplastic polyurethane

The invention discloses a high-physical-property matte thermoplastic polyurethane elastomer and a preparation method thereof. The high-physical-property matte thermoplastic polyurethane elastomer is prepared from the following ingredients in percentage by mass: 80 to 95 percent of thermoplastic polyurethane elastomer, 2.5 to 19 percent of high impact polystyrene, 0.5 to 2 percent of matte surfaceregulating agents, 0.1 to 0.5 percent of modified silicone master batch, 0.1 to 0.5 percent of antioxidant and 0.1 to 0.5 percent of lubricating agent. Compared with the prior art, the high-physical-property matte thermoplastic polyurethane elastomer has the advantages that the matte surface effect is good; the cost is lower; the defects of material physical property reduction due to the use of inorganic matte surface agent and poor matte surface effect are avoided; the defect of higher cost due to the use of other organic macromolecular material matte surface agents is avoided; in addition, the processing process can be regulated according to practical requirements to obtain the ideal matte effect.

Owner:ZHEJIANG HUAFENG THERMOPLASTIC POLYURETHANE

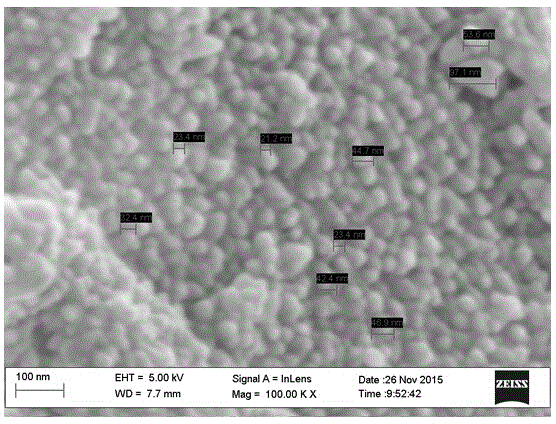

White and interference-color matte flaky cored pigment and preparation method thereof

ActiveCN105542517ASmall particle sizeGood skin affinityInorganic pigment treatmentInterference colorFiltration

The invention discloses a white and interference-color matte flaky core-covered pigment and a preparation method thereof and relates to the field of pearlescent pigments. A base material with the grain diameter D50<=5 micrometers is coated with white metallic oxide to form a coating layer. According to the method, the base material and water are mixed to form suspension liquid, a crystal grain modifier is put in the suspension liquid, a metallic oxide crystal type transforming agent is added into the suspension liquid, the pH value is regulated, a saline solution is added dropwise into the suspension liquid, the pH value of the suspension liquid is kept stable at the same time, stirring is continued after adding is over, the pH value of the solution is regulated, an anti-aggregation agent is added, and suction filtration, drying, calcining and cooling are performed on the solution after adding is over. Compared with the prior art, the pigment prepared through the method is small in grain diameter, very fine and smooth, quite obvious in skin effect, high in covering force, good in ultraviolet absorption effect, low in luster, remarkable in matte effect and capable of being widely applied to cosmetics, sun cream, pigment toning and other industries.

Owner:GUANGXI CHESIR PEARL MATERIAL CO LTD

Water-based PU matte surface finishing agent for synthetic leather

The invention discloses a water-based PU matte surface finishing agent for synthetic leather, which comprises the following materials in parts by weight: 30 to 40 parts of water-based polyurethane resin, 45 to 55 parts of water, 4 to 10 parts of modified organic silicon polymer, 0.5 to 1.5 parts of organic silicon flatting agent, 1 to 2 parts of organic silicon foam killer, 1 to 2 parts of water-based polyurethane thickening agent, and 3 to 5 parts of modified organic silicon matting agent. For the water-based PU matte surface finishing agent, the mixture ratio of the components is scientific and reasonable, and the components are coordinated with each other and act together. The matte surface finishing agent has the advantages of good film reforming property, firm bonding, solvent resistance, hydrolysis resistance and thermosenescence resistance of coating. The finished product made of the synthetic leather, the surface of which is treated by the matte surface finishing agent, has the advantages that the original effect of the leather surface is not affected, particularly the combined application of the modified organic silicon matting agent and the polyurethane resin ensures that the treated leather surface has unique matte surface effect, and the synthetic leather has good comprehensive effects of good air permeability, good hand feel, water resistance, cohesiveness and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Face washing salt sand and preparation method thereof

ActiveCN103027884AModerate grainModerate granularityCosmetic preparationsToilet preparationsBlackheadsMedicine

The invention discloses face washing salt sand and a preparation method thereof, and aims to overcome the defects that the conventional salt is mainly used for eating and has single function. The face washing salt sand comprises the following components in parts by weight: 80 to 90 parts of sea salt wrapped with Chinese medicinal extract, 10 to 15 parts of Chinese yam powder, 1 to 1.5 parts of bletilla powder, 1 to 3 parts of pearl powder, 0.2 to 0.5 part of aloe powder, 0.1 to 0.2 part of jojoba oil, and 0.1 to 0.3 part of glycerol. The face washing salt sand has the effects of cleaning, nutrition, skin protection and the like, and can be used for diminishing inflammation, removing acne, removing blackhead, reducing pores, clearing the pores, removing keratin, fading trails left by the acne and moisturizing, whitening and smoothing the skin; and the application range of the salt is widened, and the function of the salt is enriched.

Owner:ZHEJIANG BLUE STARFISH SALT PROD CO LTD

Color-staining process and preparation method of PET (polyethylene terephthalate) transfer membrane

ActiveCN103724647AReduce production processIncrease productivityDuplicating/marking methodsVacuum evaporation coatingPolymer sciencePolyethylene terephthalate

The invention relates to the technical field of transfer membranes, in particular to a color-staining process and a preparation method of a PET (polyethylene terephthalate) transfer membrane. The color-staining process of the PET transfer membrane comprises the steps of firstly, adding matt powder into resin and stirring uniformly to obtain primary matt coating; secondly, grinding the primary matt coating until the primary matt coating is changed to be a milk white state from a semi-transparent state, thereby obtaining secondary matt coating; thirdly, adding organic solvent and pigment powder into the secondary matt coating and stirring uniformly to obtain mixed color-staining coating; fourthly, coating the mixed color-staining coating onto a PET base membrane and drying, so as to form a matt color layer on the surface of the PET base membrane. According to the color-staining process of the PET transfer membrane, the production procedures can be reduced, the production efficiency is improved, the scrap rate of the transfer membranes is reduced and the production cost is reduced; the products have good matt effect, rich and mellow color and luster and good color accuracy.

Owner:HUNAN HERUI LASER TECH CO LTD

Matt polycarbonate styrene resin alloy and preparation method thereof

The invention relates to a matt polycarbonate styrene resin alloy. The matt polycarbonate styrene resin alloy contains following raw material constituents of, by weight part, 50-80 parts of polycarbonate resin, 15-48 parts of polycarbonate resin, 2-5 parts of isocyanate chemical compounds, 0.5-2 parts of compatible agent and 0.5-1 part of processing agent. A preparation method of the matt polycarbonate styrene resin alloy includes following steps: mixing the above raw material constituents in a high speed mixer in advance for 3-10min, and then extruding and granulating the premixed materials through a double screw extruder under 230-280 degree centigrade so as to obtain the matt polycarbonate styrene resin alloy. The matt polycarbonate styrene resin alloy has the advantages that compared with the prior art, no matt master particle needs to be prepared, the polycarbonate styrene resin alloy excellent in matt effect can be directly prepared through a one step method, and the preparation method of the matt polycarbonate styrene resin alloy is simple in technical process, solves the technical problems that glossiness distribution is uneven, physical and mechanical properties are deteriorated, preparation technology is complex and the like, and can reduce cost.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

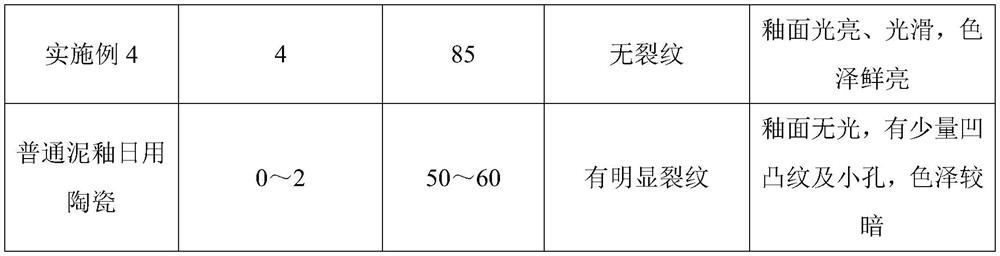

Slip glaze and preparation method of domestic ceramic with the same

The invention discloses a slip glaze and a preparation method of domestic ceramic with the same. The slip glaze comprises the following raw materials by weight: 25-32 parts of red clay, 6-9 parts of red loam, 18-22 parts of feldspar, 20-26 parts of quartz, 2.5-3.5 parts of niobium disilicide, 3-5 parts of nano silicon dioxide, 1.5-2 parts of nano boron nitride, 5-8 parts of nano zinc oxide, 1.7-2.4 parts of nano magnesium oxide and 5-7 parts of calcium hydroxyphosphate. The slip glaze disclosed by the invention is used for domestic ceramics, and is low in cost, high in yield and energy-saving;the wear resistance of the prepared domestic ceramic is far better than that of common slip glaze domestic ceramics, and the wear resistance is good; the glossiness is much higher than that of commonslip glaze domestic ceramics; the thermal shock resistance is obviously superior to that of common slip glaze domestic ceramics, and the thermal shock resistance is good; and the glaze surface is bright, smooth and bright in color.

Owner:德化县嘉祥陶瓷有限公司

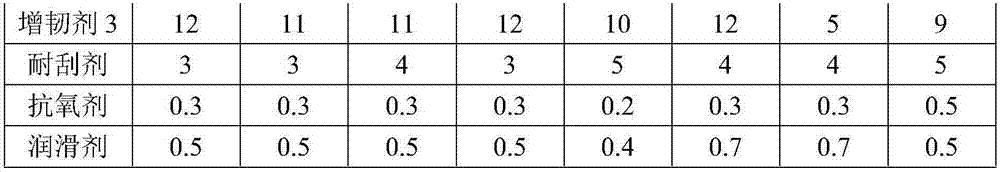

Scratch-resistant and high-impact matte oil-resistant and weather-proof ABS-PA-PMMA alloy material and preparation method thereof

InactiveCN107987523AImprove scratch resistanceImprove notched impact strengthWeather resistanceToughness

The invention discloses a scratch-resistant and high-impact matte oil-resistant and weather-proof ABS-PA-PMMA alloy material and a preparation method thereof. According to key points of the technicalscheme, the scratch-resistant and high-impact matte oil-resistant and weather-proof ABS-PA-PMMA alloy material comprises the following components in percentage by weight: 25-50% of PA, 10-35% of ABS,10-20% of PMMA, 3-8% of a compatilizer, 10-20% of a compound toughening agent, 3-5% of a scratch-resistant agent, 0.2-0.5% of an antioxidant and 0.4-0.7% of a lubricant. The scratch-resistant and high-impact matte oil-resistant and weather-proof ABS-PA-PMMA alloy material disclosed by the invention has good scratch resistance, good toughness, excellent matte effect, better dimensional stability, good oil resistance and good weather resistance.

Owner:GUANGDONG WAYLAM ENG PLASTICS

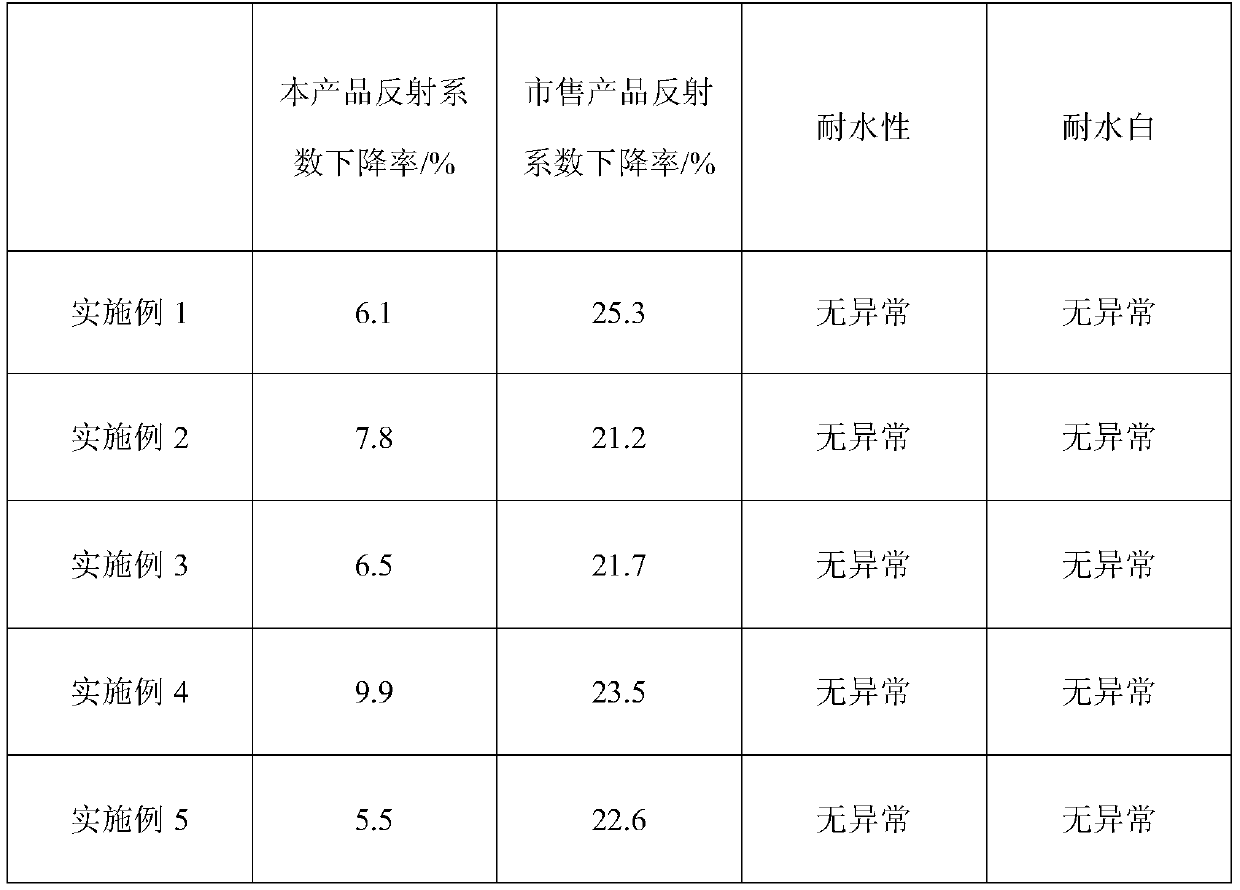

Matte finishing pure acrylic emulsion with excellent water resistance and stain resistance and preparation method thereof

InactiveCN111303719ASimple processExcellent matteAntifouling/underwater paintsPaints with biocidesIsooctyl acrylatePolymer science

The invention discloses a matte finishing pure acrylic emulsion with excellent water resistance and stain resistance. The matte finishing pure acrylic emulsion is prepared from the following raw materials in parts by weight: 15-30 parts of methyl methacrylate, 5-15 parts of 2-ethylhexyl acrylate, 10-15 parts of butyl methacrylate, 1-3 parts of an organosilicon assistant, 0.5-5 parts of a crosslinking monomer, 2-4 parts of a carboxyl functional monomer, 1-3 parts of an emulsifier, 0.5-1 part of an initiator, 1-5 parts of a coalescing agent, 1-5 parts of a pH regulator and 55-65 parts of deionized water. The pure acrylate emulsion provided by the invention has excellent water resistance, water white resistance, stain resistance, yellowing resistance and controllable glossiness, also has goodstability and universality, and is an urgently lacked product for matte finishing varnish in the market at present.

Owner:广东巴德富新材料有限公司

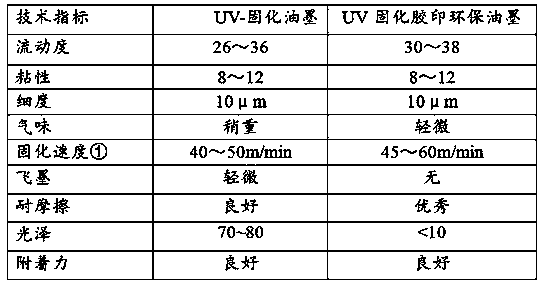

UV matte environment-friendly offset printing ink and preparation method thereof

The invention discloses UV matte environment-friendly offset printing ink and a preparation method thereof. The UV matte environment-friendly offset printing ink is composed of the following components in percentage by mass: 15-28% of an acrylic emulsion, 11-21% of polyester acrylic resin, 1-7% of polymethylurea resin, 1-7% of self-extinction polyurethane resin, 5-13% of a reactive diluent, 4-7% of a photoinitiator, 8-26% of a pigment and filler and 1-7% of auxiliaries, with the balance being deionized water, summing to 100%. According to the invention, the resin with an extinction effect andthe self-extinction polyurethane resin are compounded, and under the action of the auxiliaries, the glossiness of the UV offset printing ink is effectively reduced, so the prepared ink has an excellent matte effect; and the ink also has the advantages of good wear resistance, low irritation, good printability, safety, environmental friendliness and excellent comprehensive performance.

Owner:苏州市博来特油墨有限公司

Preparation method of organosilicon elastic gel

The invention belongs to the field of organosilicon, and more specifically relates to a preparation method of an organosilicon elastic gel. The preparation method comprises following steps: an organicsolvent, hydrogen containing silicone oil, and a polysiloxane containing at least two vinyl groups or a dialkene with nonsaturated double bonds on the two terminals are introduced into a reactor, uniform mixing is carried out, a catalyst is added, an obtained mixture is heated to 50 to 90 DEG C for 2 to 9h of deposition polymerization; after reaction, the mixture is cooled to be a temperature lower than 40 DEG C, filtering is carried out, an obtained solid powder is dried so as to obtain an organosilicon elastomer powder; the organosilicon elastomer powder is subjected to dilution swelling with a diluents, a stabilizing agent is added, and stirring is carried out for 1 to 2h at 70 to 90 DEG C at 30 to 90rpm to obtain the organosilicon elastic gel. The adopted organic solvent is a volatileorganic solvent capable of dissolving the reaction raw materials, but not capable of dissolving polymerization product, and the product can be mixed with an oil phase in the formula at random ratio at shearing conditions.

Owner:HUBEI XINHAIHONG CHEM

Matte waterborne coating and preparation method thereof

InactiveCN105219207AStrong adhesionImprove adhesionAntifouling/underwater paintsPaints with biocidesSODIUM METAPHOSPHATEBenzoic acid

The invention discloses a matte waterborne coating. The matte waterborne coating contains low polymer polyol, maleic anhydride, methyl methacrylate, hydroxyl ethyl acrylate, hydroxylation fiber resin, polyether sulfone resin, polysorbate, sodium hexametaphosphate, organic silicon emulsion, epoxy silane modified silica sol, cross-linked polyethylene, butyl peroxybenzoate, sodium silicate, melamine polyphosphate, pentaerythritol, aluminum silicate fiber, silica, hydroxyethyl cellulose, an antibacterial preservative, waterborne polyurethane resin, acrylate, polyvinyl alcohol, light calcium carbonate, titanium dioxide, waterborne epoxy modified resin, Ni, Zn, water and other raw materials. Due to the fact that the matte waterborne coating contains Ni, Zn and other components, the matte waterborne coating has high-temperature resistance and corrosion resistance, meets coating requirements in various occasions, does not contain a toxic organic solvent, is pollution-free, and also has the advantages of no cracking of a paint surface, ageing resistance, strong adhesive force and the like.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

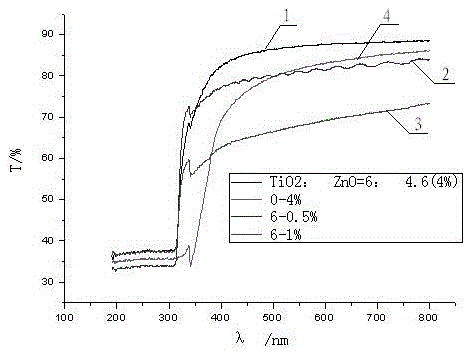

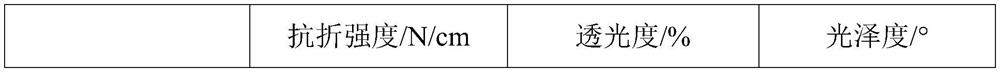

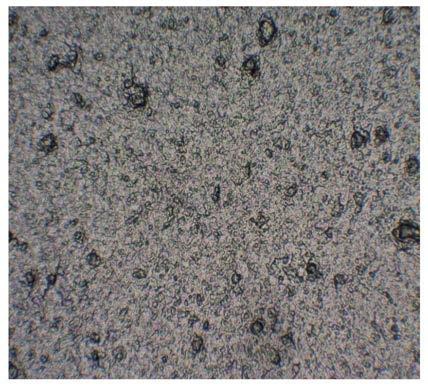

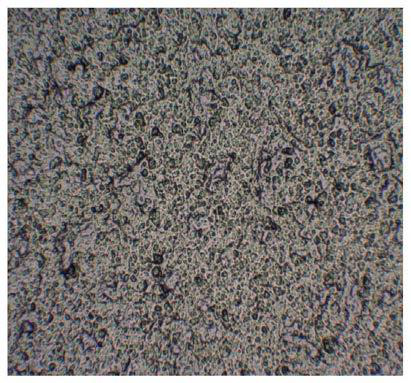

Matt glaze

The invention provides matt glaze which comprises dry granular glaze and protective glaze located on the surface of the dry granular glaze, the light transmittance of the protective glaze is not lower than 85%, and raw materials of the dry granular glaze comprise X-type carbon nanotubes and diatomite. The matt glaze has the advantages of excellent matt effect, low reflectivity to ambient light and excellent mechanical properties.

Owner:亚细亚新材料科技股份公司

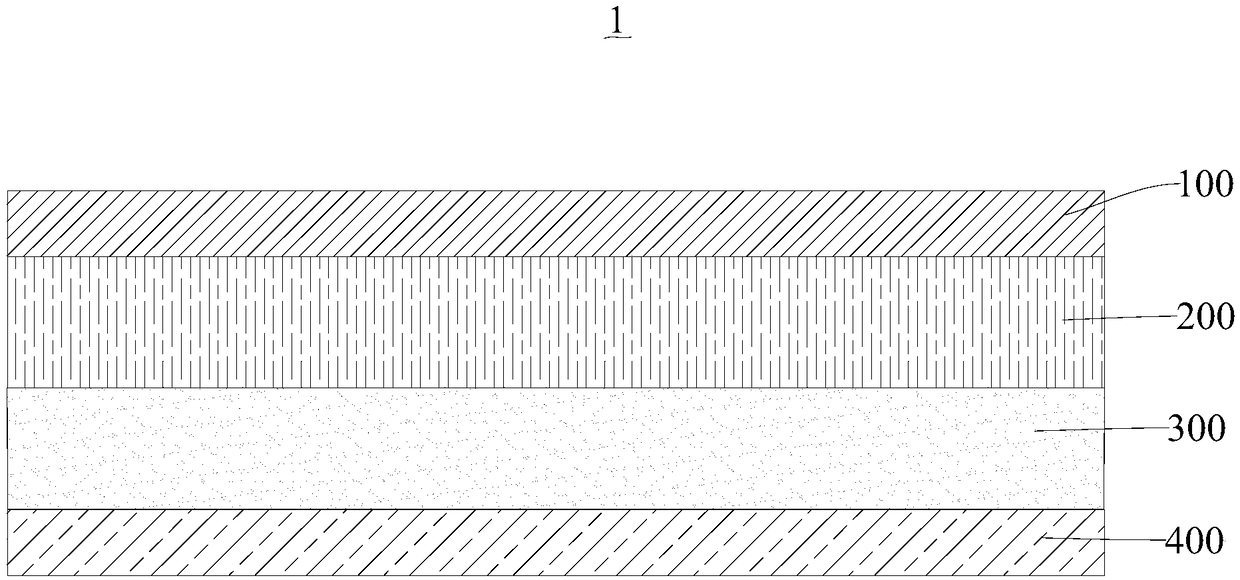

Matte PET film for decorative sheet and preparation method thereof

ActiveCN111234283ASolve the problem of poor light transmittanceEnsure transparencyPolyurea/polyurethane coatingsPolymer sciencePolyethylene terephthalate glycol

The invention discloses a matte PET (Polyethylene Terephthalate) film for a decorative sheet and a preparation method thereof. The matte PET film comprises a transparent PET film and a UV (Ultraviolet) light-cured coating coated on the transparent PET film, wherein the UV light-cured coating is used as a matte coating, and the UV light-cured coating is composed of a polyacrylate polymer with a crosslinking degree of 1-30%, a thermoplastic acrylate polymer with a molecular weight of 10000-200000, an acrylate monomer, acrylic resin, a photo initiator and an auxiliary agent, wherein the acrylatemonomer and the acrylic resin are UV crosslinkable. The provided matte PET film can ensure the transparency of a product and has a good matte effect.

Owner:佛山市菲锐表面科技有限公司

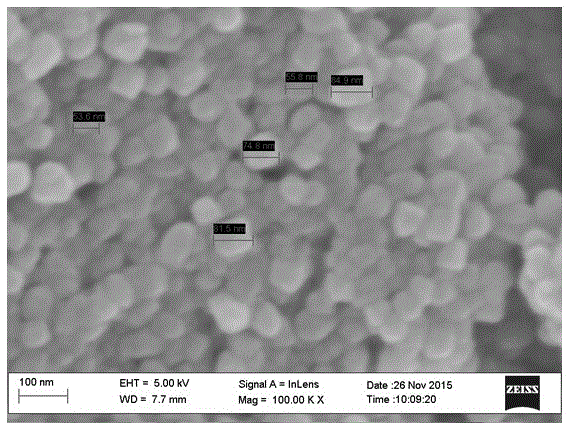

Iron-red-series low-gloss lamellar pigment and preparation method thereof

InactiveCN105623316AReduce glossGood mattePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsFiltrationHue

The invention discloses an iron-red-series low-gloss lamellar pigment and a preparation method thereof, relating to the field of pearlescent pigments. Mica with the particle size of 0.15-5 mu m is used as a substrate, and iron oxide is coated on the substrate to form an iron oxide coating, wherein the coating is formed by carrying out hydrolysis in a ferric iron salt solution. The method comprises the following steps: mixing mica powder and water to form a suspension, adding a crystal grain regulator into the suspension, regulating the pH value, adding the ferric iron salt solution while stirring to perform hydrolysis coating, keeping the pH value of the suspension stable, continuing dropwisely adding the ferric iron salt solution until the a slightly purple red color phase is obtained, stirring, regulating the pH value of the solution, carrying out vacuum filtration, drying, calcining and cooling. Compared with the prior art, the prepared product is approximately spherical, is delicate and smooth, is very skin-friendly, has the advantages of high covering power and low gloss, has the matt effect, and can be widely used in cosmetics, leather, plastics, inks and paints.

Owner:GUANGXI CHESIR PEARL MATERIAL CO LTD

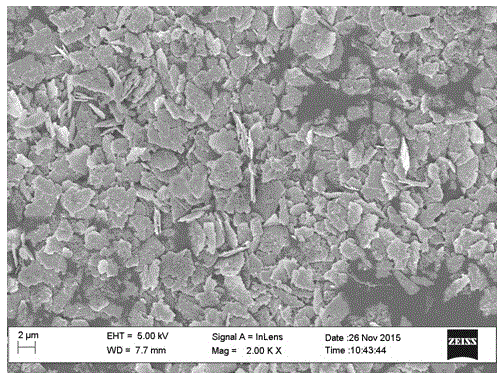

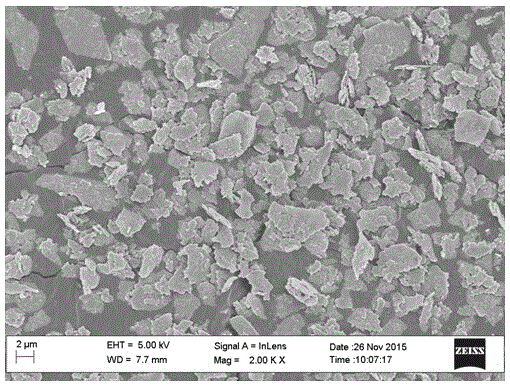

Thermoplastic resin composition and preparation method and application thereof

The invention discloses a thermoplastic resin composition which comprises the following components in parts by weight: 30-80 parts of polycarbonate; 5 to 50 parts of polyester; 2-25 parts of an impactmodifier; and 0.5 to 20 parts of boehmite, wherein the average particle size of the boehmite is 0.01-10 microns, and the Fe element does not exceed 100 ppm. On one hand, the Fe element content of theboehmite is controlled; the boehmite is not smooth on each surface of a cube except that the whole boehmite keeps the shape of the cube, and shows rough karst-shaped cliff morphology, and the morphology has a very excellent effect on reduction of glossiness, and on the other hand, the Fe element content is controlled, so that the boehmite is prevented from generating an obvious degradation effecton PC polyester alloy; and the particle size range is controlled, and the extinction performance of the boehmite is enhanced. Therefore, the thermoplastic resin composition provided by the inventionhas a good matte effect.

Owner:WUHAN JINFA TECH CO LTD +1

Matte single-component room temperature vulcanized silicone rubber and preparation method thereof

InactiveCN110028792AFix stability issuesSolve the technical problem of unreliable matte filmParticle acceleratorPolymer science

The invention relates to the technical field of rubber preparation, in particular to matte single-component room temperature vulcanized silicone rubber and a preparation method of the room temperaturevulcanized silicone rubber. The preparation method of the matte single-component room temperature vulcanized silicone rubber comprises the steps of: step 1: feeding 30-70 parts of polydimethylsiloxane containing an active end group, 2-10 parts of plasticizer and 20-60 parts of filling into a kneader, performing heating and dehydration at vacuum for 2-4h to prepare a base material, and step 2: cooling and feeding the base material into a power mixer, adding 3-15 parts of cross-linking agent, 1-6 parts of catalyst, 0.3-3 parts of coupling agent and 0.5-3 parts of matte accelerator, performing vacuum stirring and discharging, and packaging a product in an HDPE (high-density polyethylene) pipe to form the matte single-component room temperature vulcanized silicone rubber, wherein the matte accelerator comprises vinyl and phenyl. The silicone rubber solves the technical problems that the existing matte single-component cured silicone rubber is relatively complicated in technology and unstable in storage, and a matte film is insecure.

Owner:佛山市天宝利硅工程科技有限公司

Thermoplastic resin composition, preparation method and one application thereof

The invention discloses a thermoplastic resin composition, which comprises, by weight, 30-98 parts of a styrene-based anti-impact toughening agent, 10-80 parts of a copolymer of a vinyl aromatic monomer and an alkene-based unsaturated nitrile monomer, and 0.5-20 parts of boehmite, wherein the average particle size of the boehmite is 0.01-10 [mu]m, the specific surface area of the boehmite is 3.0-150 m<2> / g, and the Ca element content of the boehmite does not exceed 1000 ppm. By controlling the Ca element content of boehmite, a large number of micropores are formed in the surface of boehmite, so that boehmite has good compatibility with rubber particles in a matrix, and by controlling the particle size and the specific surface area of boehmite, boehmite easily achieves light extinction so as to bring light extinction effect.

Owner:WUHAN JINFA TECH CO LTD +1

Reactive extrusion matte agent, low gloss PC/ABS alloy and its preparation method

Owner:SHANGHAI KUMHO SUNNY PLASTICS

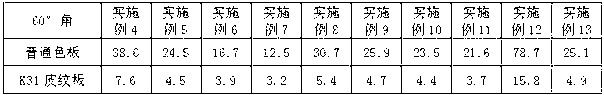

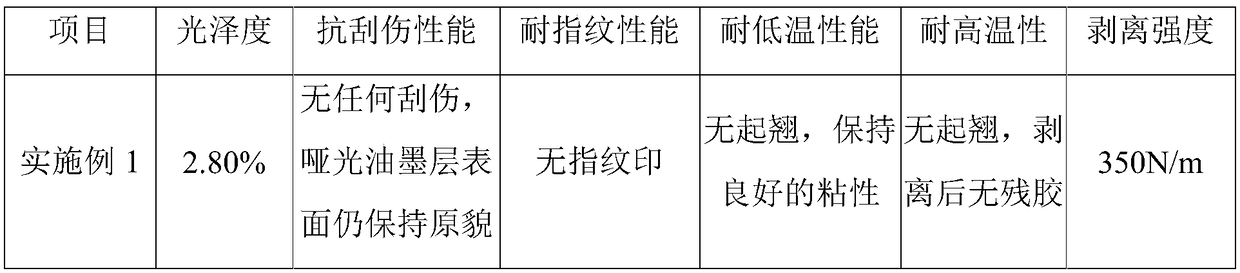

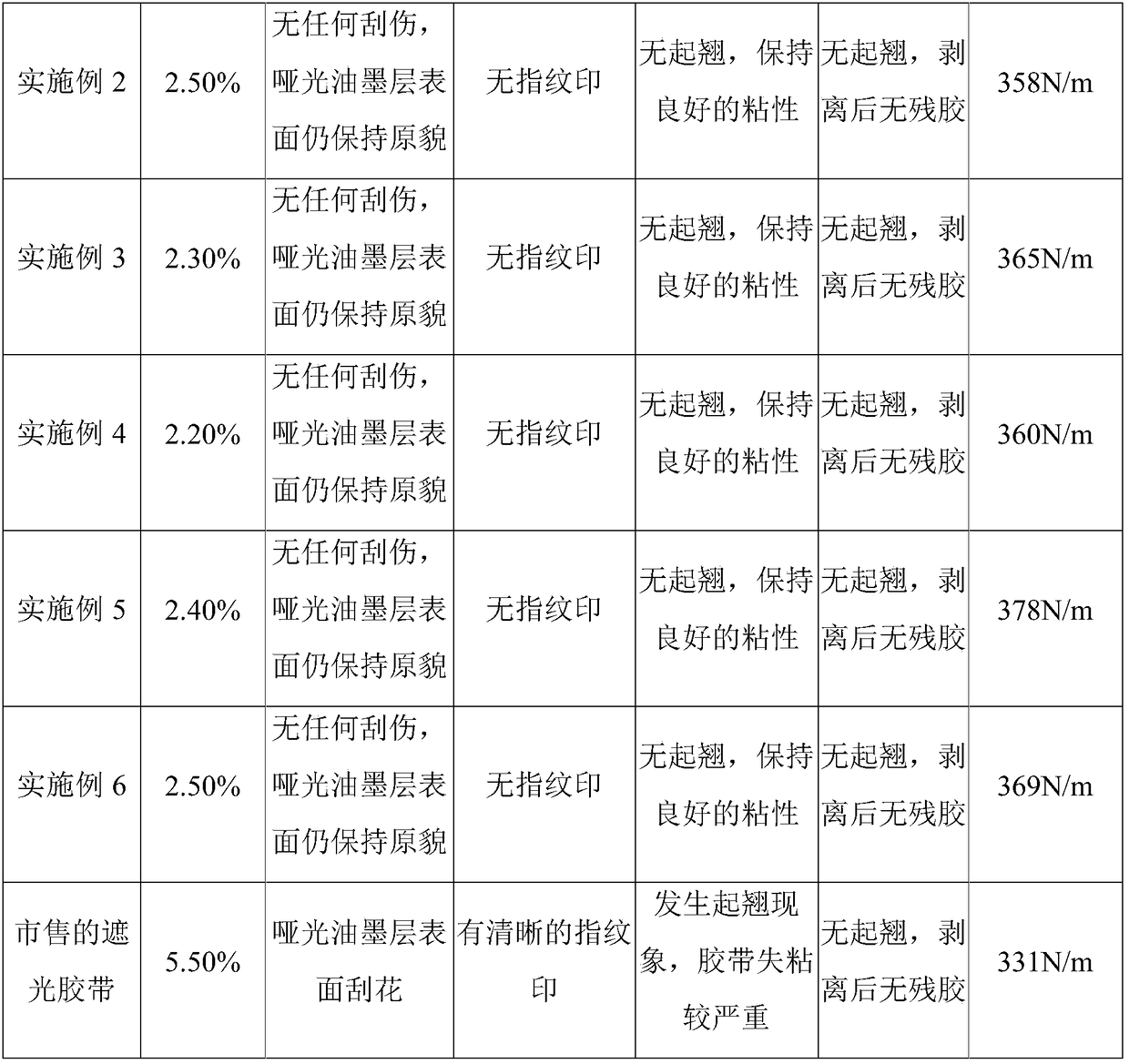

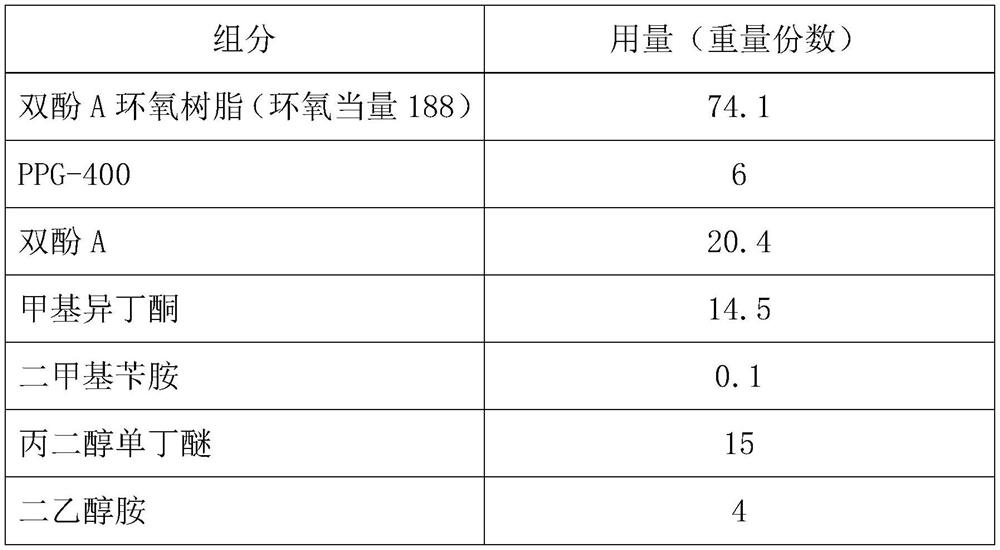

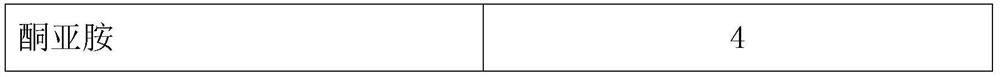

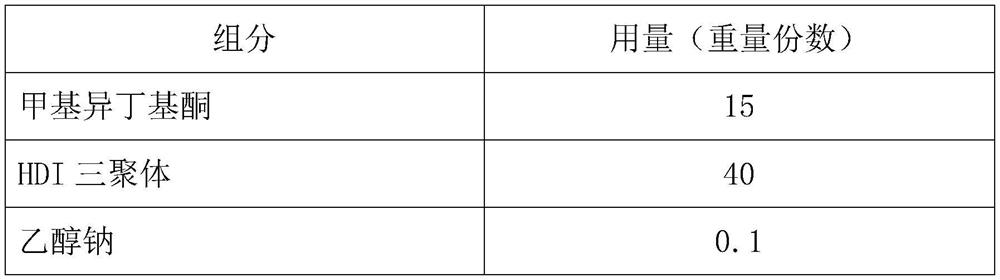

Matte printing ink, preparation method thereof and shading adhesive tape

InactiveCN109354923AGood matte effectExcellent fingerprint resistanceInksPressure sensitive film/foil adhesivesWaxFingerprint

The invention discloses matte printing ink, a preparation method thereof and a shading adhesive tape. The preparation method of the matte printing ink includes: grinding 92.8-98.8 parts of polyurethane modified acrylate resin, 0.5-3 parts of matting powder and 0.5-2 parts of wax powder after being mixed, adding 0.5-2.2 parts of first curing agent, and well mixing to obtain the matte printing ink.The matte printing ink is obtained by grinding the polyurethane modified acrylate resin, the matting powder and the wax powder after being mixed and adding the first curing agent. The matte printing ink is used for the shading adhesive tape of a liquid crystal display screen and has good matte effect, excellent fingerprint-resistant performance and good anti-scratching performance.

Owner:新丰杰力电工材料有限公司

Preparation method of high-insulation matte black polyimide film

The invention discloses a preparation method of a high-insulation matte black polyimide film, which comprises the following steps: dissolving polyaniline and aromatic diamine in a solvent, adding aromatic dianhydride to react, carrying out vacuum defoaming on the obtained polyaniline polyamide acid blended solution, and uniformly coating the base material with the solution to form an adhesive film, thereby obtaining the high-insulation matte black polyimide film. then removing a solvent, carrying out imidization treatment, and carbonizing polyaniline to obtain the high-insulation matte black polyimide film. The black polyimide film prepared by the method has the advantages of low gloss, high insulating strength, remarkable matte effect and good appearance, and can meet the use requirementof high insulation.

Owner:ANHUI GUOFENG PLASTIC

Extinction color master batch for polycarbonate (PC)

The invention discloses an extinction color master batch for polycarbonate (PC). The extinction color master batch comprises the following components by weight: 15%-30% of a carrier resin, 30%-50% of a flatting agent, 10%-15% of a stabilizer, 15%-25% of titanium dioxide, 5%-15% of a fluorescent whitening agent and 2%-5% of a dispersion agent. The invention has the beneficial effect that compared with the prior art, the extinction color master batch for polycarbonate (PC) provided by the invention has the characteristics of good dispersion, good low gloss matte effect, good appearance, convenience for usage, but also is conducive to industrial automation and clean production, so the invention has a good practical effect.

Owner:殷培花

Water-based environment-friendly low-temperature matte coating

ActiveCN114276735AReduce volatilityReduce energy consumptionChemical industryPaints for electrolytic applicationsElectrophoresesDiffuse reflection

The invention discloses a water-based environment-friendly low-temperature matt coating which comprises a low-temperature matt emulsion and low-temperature matt color paste in a weight ratio of 4: 1, according to the coating, methylene is introduced to generate an active hydrogen blocking effect, and a gradient de-blocking composite totally-closed curing agent is adopted, so that a coating film is subjected to a gradient curing process, the surface of the coating film is in a micro concave-convex shape, diffuse reflection of light is formed, the glossiness is greatly reduced, and a very good matte decorative effect is achieved; meanwhile, the components of the coating do not contain heavy metal, the coating has the advantages of being good in groove matching stability, convenient to construct, low in curing temperature and the like, and after electrophoretic coating, a coating film is flat in appearance and has very excellent salt fog resistance.

Owner:HAOLISEN CHEM TECH (JIANGSU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com