Patents

Literature

909results about How to "Reduce gloss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recording sheet for ink jet printing

InactiveUS20060078696A1Improve image qualityImprove water fastnessMaterial nanotechnologyPigmenting treatmentCompound (substance)Silicon dioxide

A method for the preparation of silicon dioxide dispersions is described, wherein the surface of the silicon dioxide is modified by a treatment with the reaction products of a compound of trivalent aluminum with least one aminoorganosilane. These reaction products are formed in a separate reaction step. The present invention also relates to recording sheets for ink jet printing having such a dispersion incorporated in an ink-receiving layer.

Owner:WIFAG POLYTPE HLDG AG

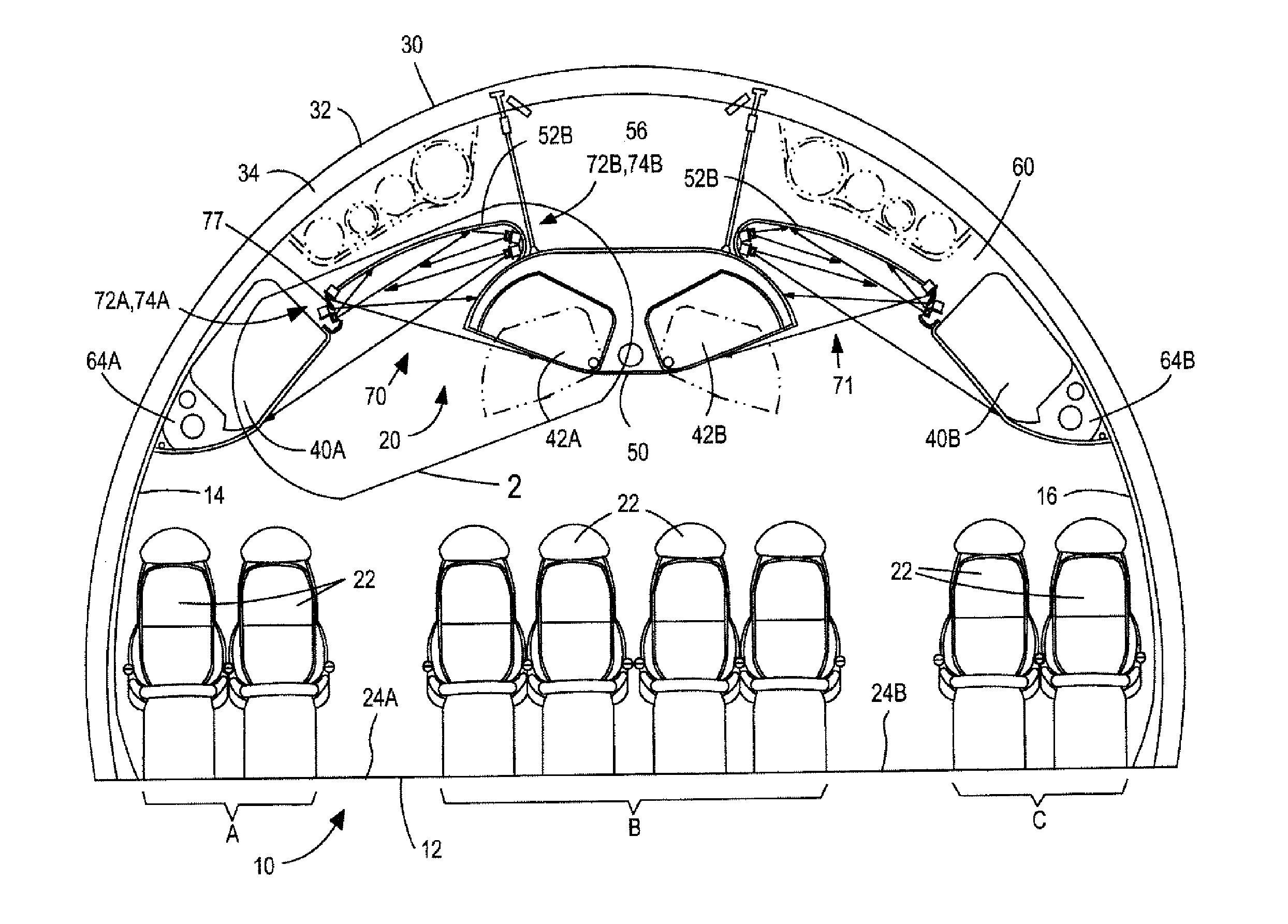

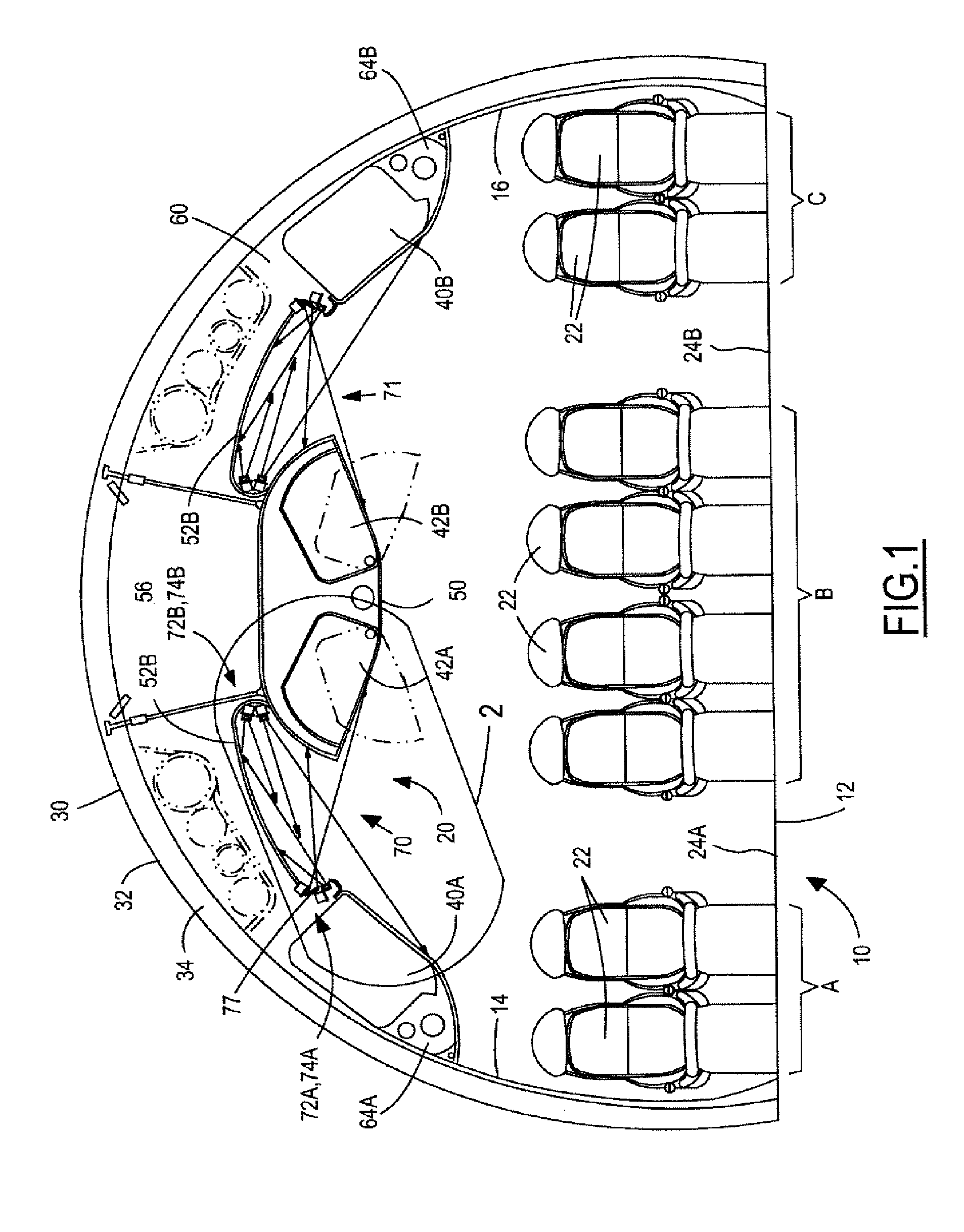

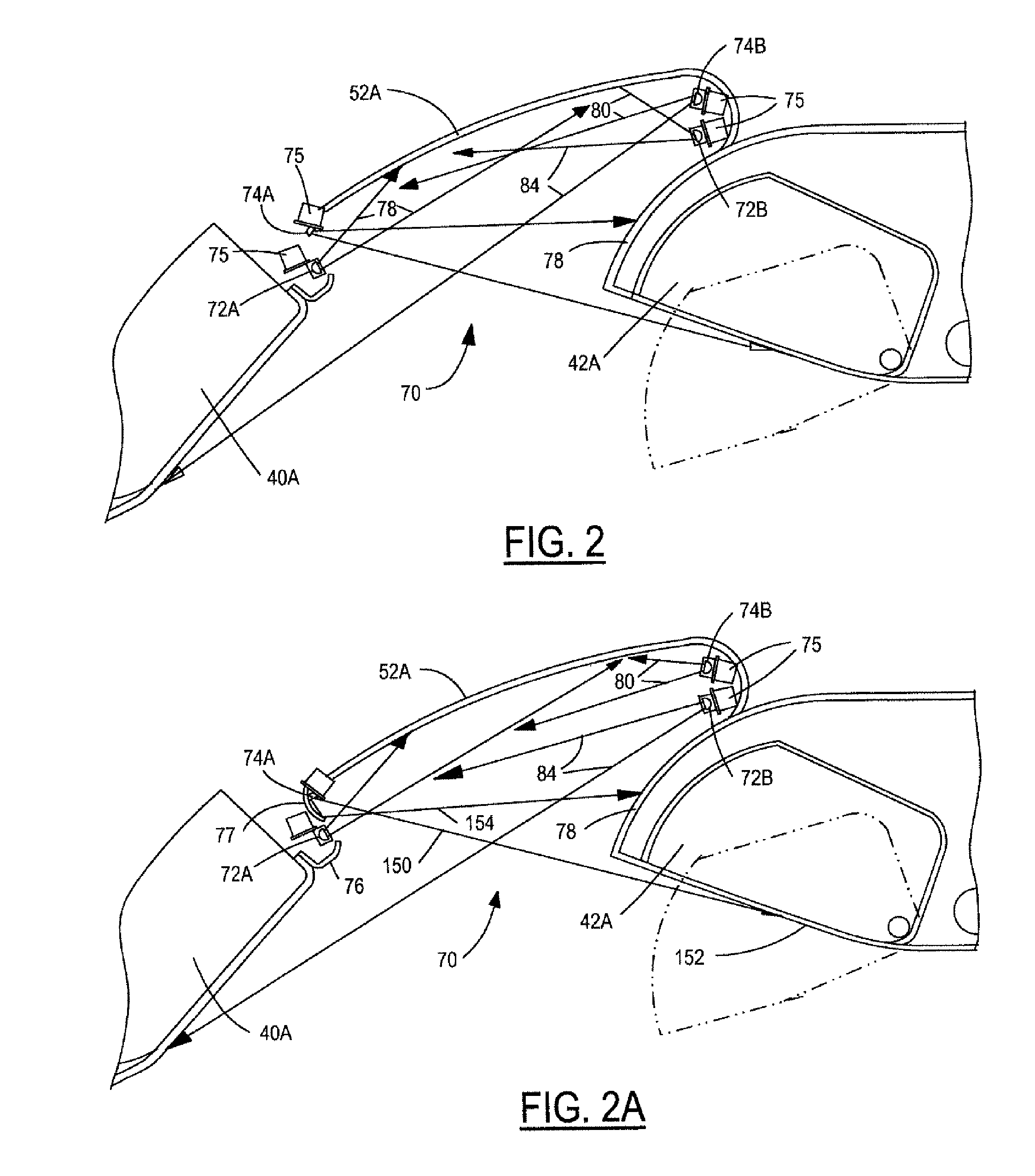

Ceiling illumination for aircraft interiors

ActiveUS20070109802A1Improve configuration and architecture and illumination and aestheticImprove perception and aesthetic of passenger spaceGeneral lightingNon-electric lightingLighting systemLED lamp

Interior lighting and illumination systems for aircraft, particularly commercial passenger airplanes. Opposing pairs of LED lamps are positioned in the ceiling panels above the aisles between sets of seats in the passenger cabins. One set of LED lights are directed to illuminate the ceiling panels and may be in a particular color. The other set of LED lights are positioned to shine their lights on storage / stowage bins positioned across the aisles, thus creating a cross-bin lighting system. This enhances the cabin architecture and provides cabin illumination. A reflector can be positioned to direct the light and reduce possible glare to the passengers. The reflector directs the light rays from the LED lights which emanate from the top of the reflector to shine on the lowest part of the bins. The light rays leaving the reflector cross in front of the reflector.

Owner:THE BOEING CO

Low gloss ASA resin

A thermoplastic molding composition comprising a grafted acrylate rubber (ASA) and a gloss reducing agent and a process for making the same are disclosed. The gloss reducing agent is the reaction product of (i) a compound having two or more epoxy groups per molecule and (ii) a compound having two or more amine groups per molecule, with the proviso that the total of epoxy groups of (i) and amine groups of (ii) per molecule is greater than 4. The gloss reducing agent may be either incorporated in ASA as the reaction product of (i) and (ii) or, in the alternative, formed upon the reaction of (i) with (ii) in the course of the thermal processing of the a blend containing ASA, (i) and (ii).

Owner:INEOS ABS JERSEY +1

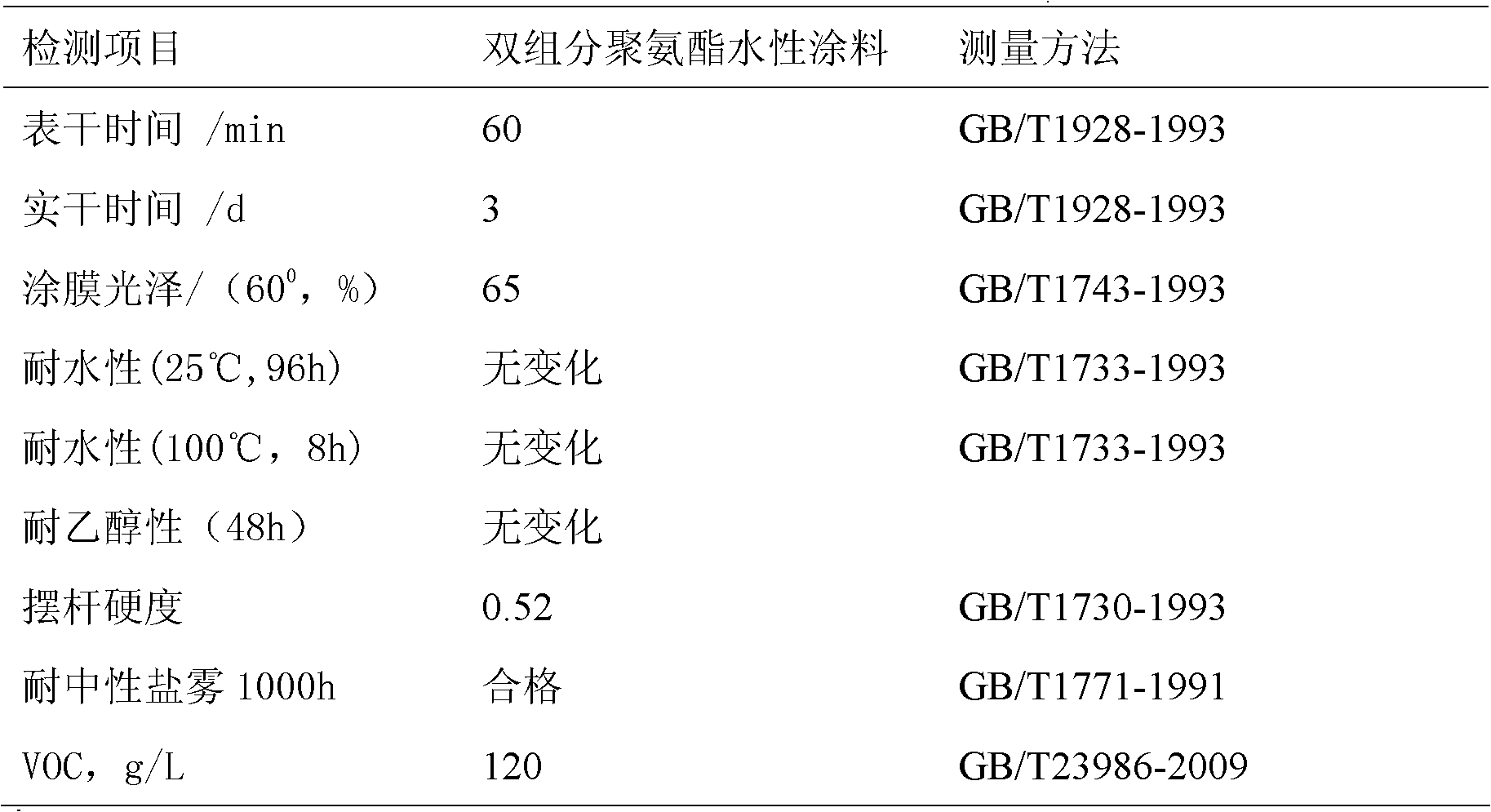

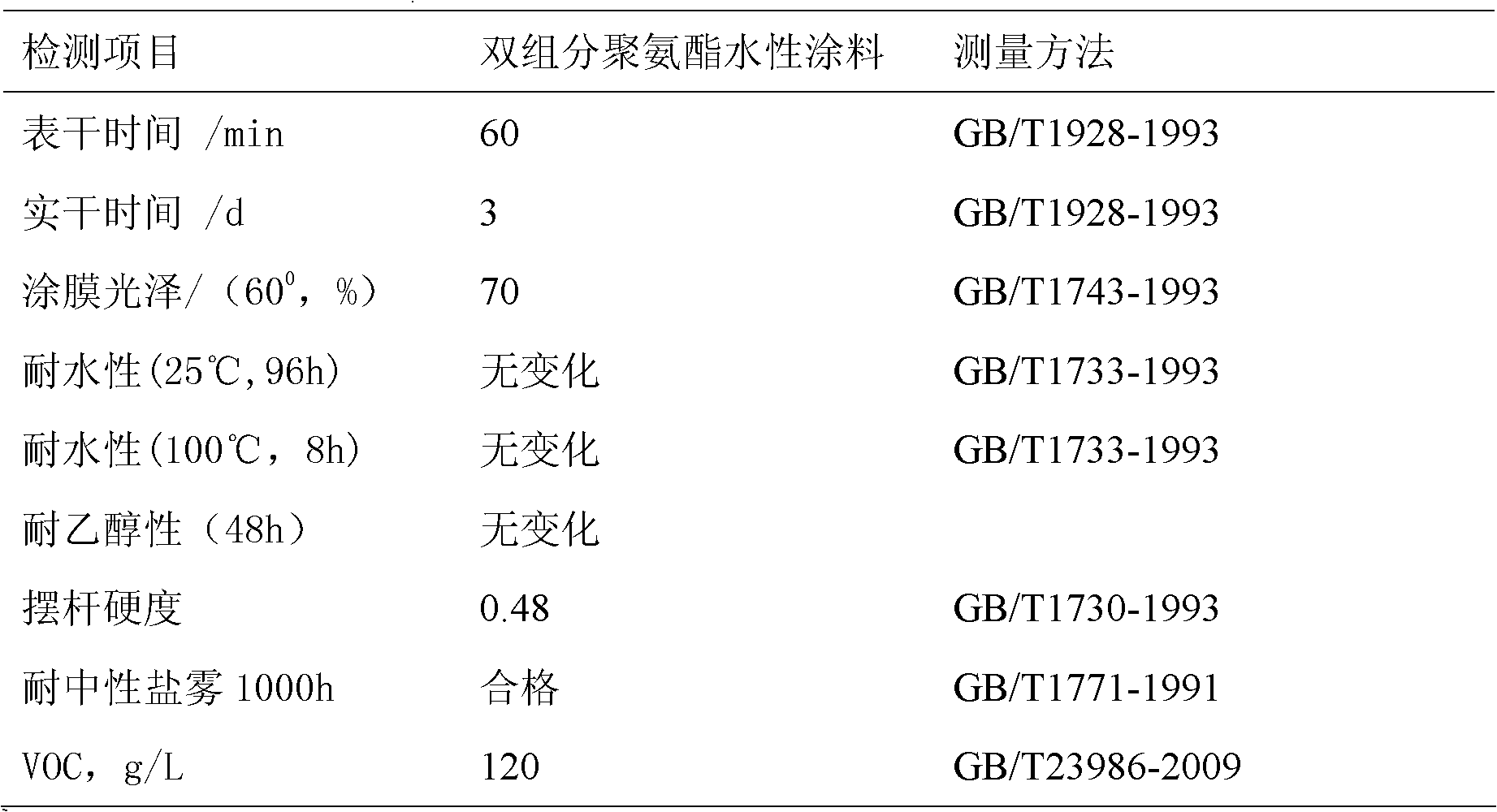

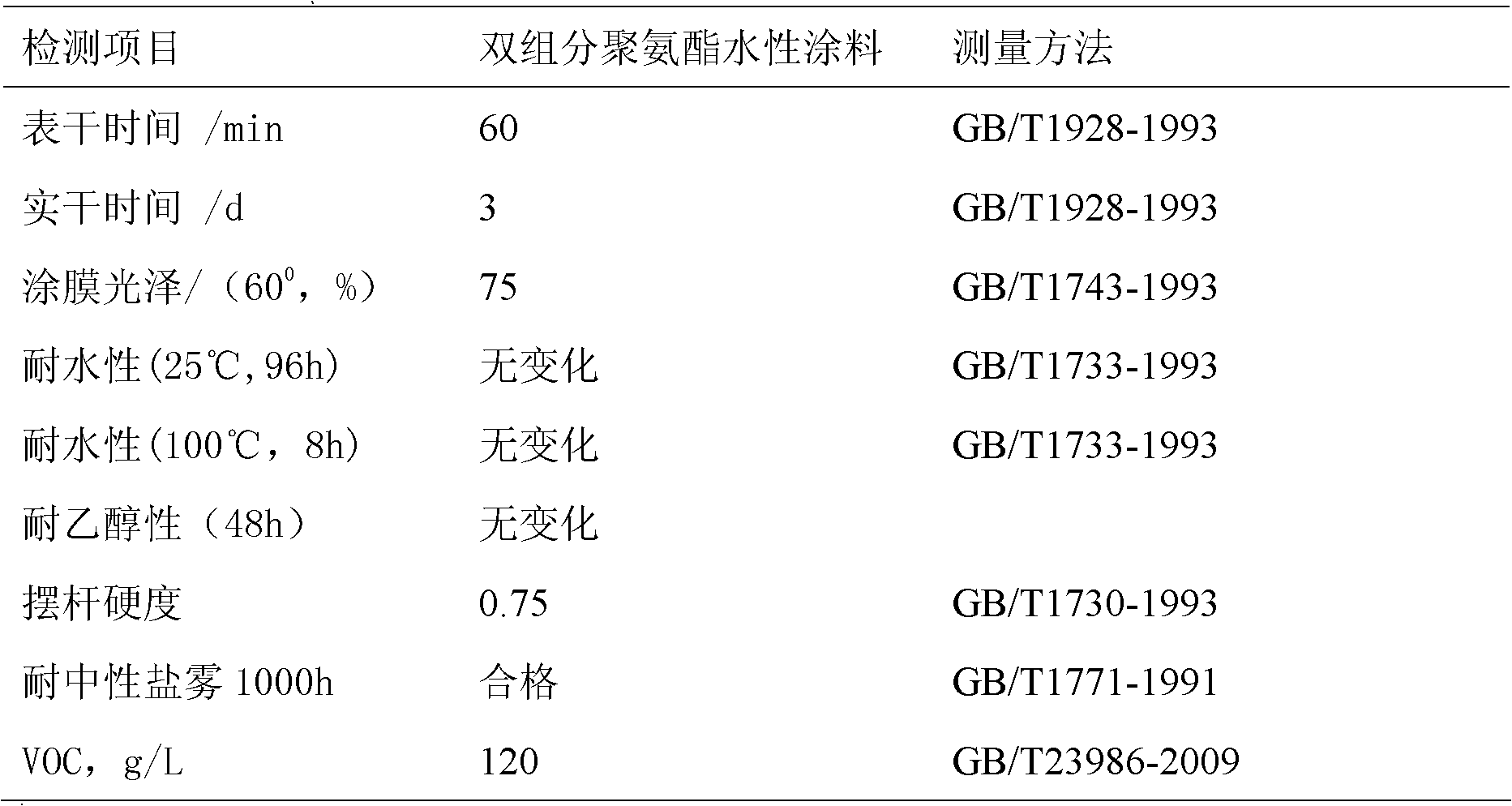

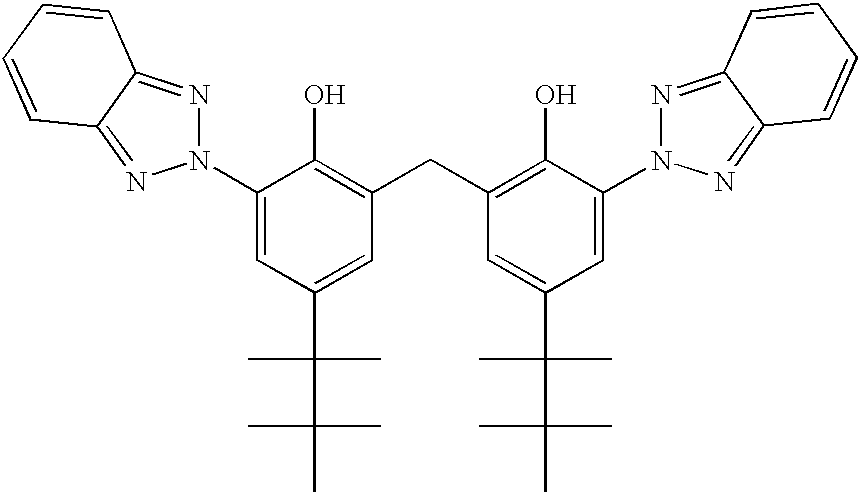

Double-component polyurethane water-based paint

InactiveCN102108246AIncrease roughnessImprove flatnessPolyurea/polyurethane coatingsWater basedPolymer science

The invention provides a double-component polyurethane water-based paint, belonging to the field of organic polymer compounds. The double-component polyurethane water-based paint comprises isocyanate curing agents component A and component B, wherein the molar ratio of OH groups of a polymer in the component A to NCO groups in the component B is 1: (1-2.2); and the component A contains polymer aqueous dispersion and polymer emulsion, wherein the content of OH in the polymer aqueous dispersion is 2.0-5.0% and the grain size of latex in the polymer aqueous dispersion is 10-100nm, the weight of the polymer emulsion is 0.05-16 times that of the polymer aqueous dispersion, the content of OH in the polymer emulsion is 0-2.0%, and the grain size of the latex in the polymer emulsion is 80-500nm. In the invention, the polymer aqueous dispersion which has small average grain size and contains -OH and the polymer emulsion which has large average grain size are compounded, wherein the latex with a large grain size can increase the roughness and unevenness of a film and reduce the gloss of the film, and the emulsion with small particles promotes the latex with the large grain size to aggregate, reduces the lowest film-forming temperature of the film, improves the film-forming capability of the film and decreases the usage amount of a film-forming additive; and the hardness, chemical-resistance and wear-resistance of the film are improved by using two different water-based polymers are used for compounding.

Owner:SOUTH CHINA UNIV OF TECH +1

Reactive self-delustering waterborne polyurethane resin, and preparation method and application thereof

InactiveCN104974324AIncreased surface roughnessReduce glossPolyurea/polyurethane coatingsIsocyanateParticle-size distribution

The invention discloses a reactive self-delustering waterborne polyurethane resin, and a preparation method and application thereof. The reactive self-delustering waterborne polyurethane resin has luster of no more than 20 at 60 DEG C when in a dry state and is prepared through reaction among the following components: 1, at least one aliphatic diisocyanate; 2, at least one carboxylic acid type hydrophilic dihydric alcohol; 3, at least one polymerized dihydric alcohol containing a water-dispersable group; 4, a catalyst used for synthesis of waterborne polyurethane; 5, at least one neutralizer; 6, at least one sulfonic acid type hydrophilic chain extender containing active hydrogen; and 7, at least one small molecule compound containing active hydrogen. The reactive self-delustering waterborne polyurethane resin has solid content of 25 to 40% and an average particle size of 500 to 5000 nm; no delustering agent is needed, and controllable generation of particles in certain particle size distribution can be realized in the process of synthesis; and the particles shrink after drying and dehydration of a film, which leads to increase of microscopic surface roughness and reduction in glossiness.

Owner:NANXIONG MATERIAL PRODION BASE OF CHINESE ACADEMY OF SCI GUANGZHOU CHEM +1

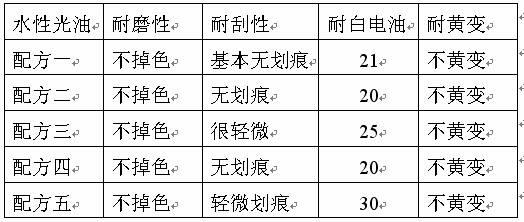

Water-based matte touch gloss oil and preparation method thereof

The invention discloses a water-based matte touch gloss oil and a preparation method thereof. The water-based matte touch gloss oil is prepared from the following raw materials in percentage by mass: 65-80% of water-based polyurethane dispersion, 10-20% of modified acrylic elastic emulsion, 1-3% of flatting agent, 3-5% of coupling agent, 3-5% of hand touch wax slurry, 1-3% of matting agent, 0.1-0.5% of defoamer, 0.5-2% of hand touch scratch-resistant agent, and 0-3% of water. The water-based matte touch gloss oil prepared from the materials is low in matte degree, and employs water as a diluent and contains no organic solvent or heavy metal; and the water-based matte touch gloss oil is natural and soft in color and luster without whiting, and good in color reveal property. Furthermore, the water-based matte touch gloss oil is suitable for surface coating treatment of high-quality paper, so that the coated paper feels like cotton, silk and velvet, and the paper finished product is good in matte degree and high in white gasoline resistance; the level of product packaging is greatly improved; and the water-based matte touch gloss oil is mainly applied to leatherette paper, imitation leather, calendered paper and some coated paper.

Owner:GUANGDONG YINGKE GRP CO LTD

Sub-smooth type polyester film at least in single side and fabricating method

InactiveCN1660568AGood processing performanceReduce glossSynthetic resin layered productsChemistryPolyester

A bidirectionally stretched polyester film has at least three extruded layers. At least one surface layer is dull. Its preparing process is also disclosed. Its advantage is adjustable low lustre.

Owner:SHANGHAI ZIDONG FILM MATERIAL CO LTD

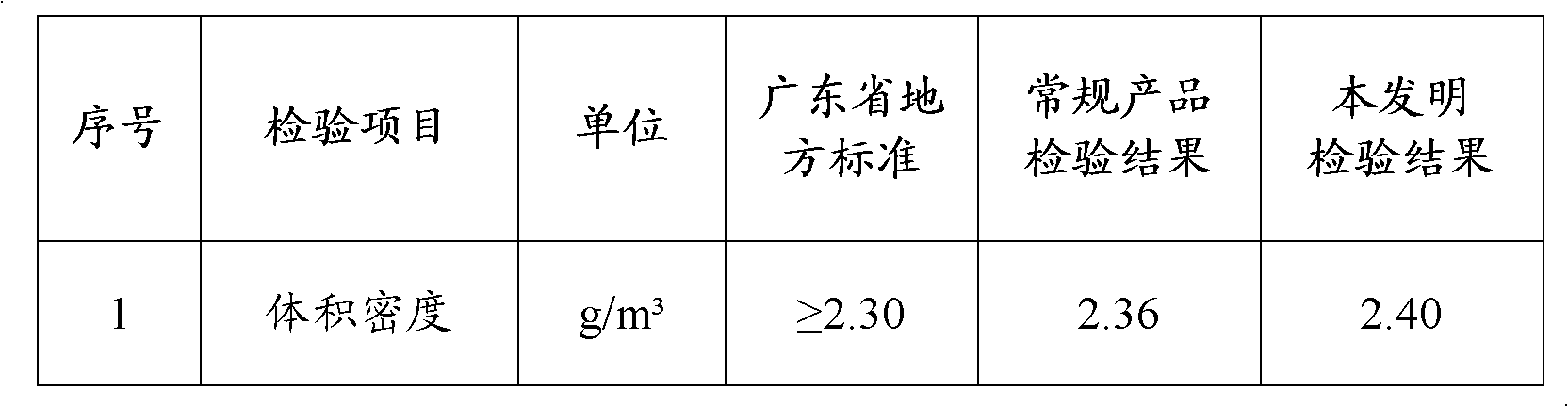

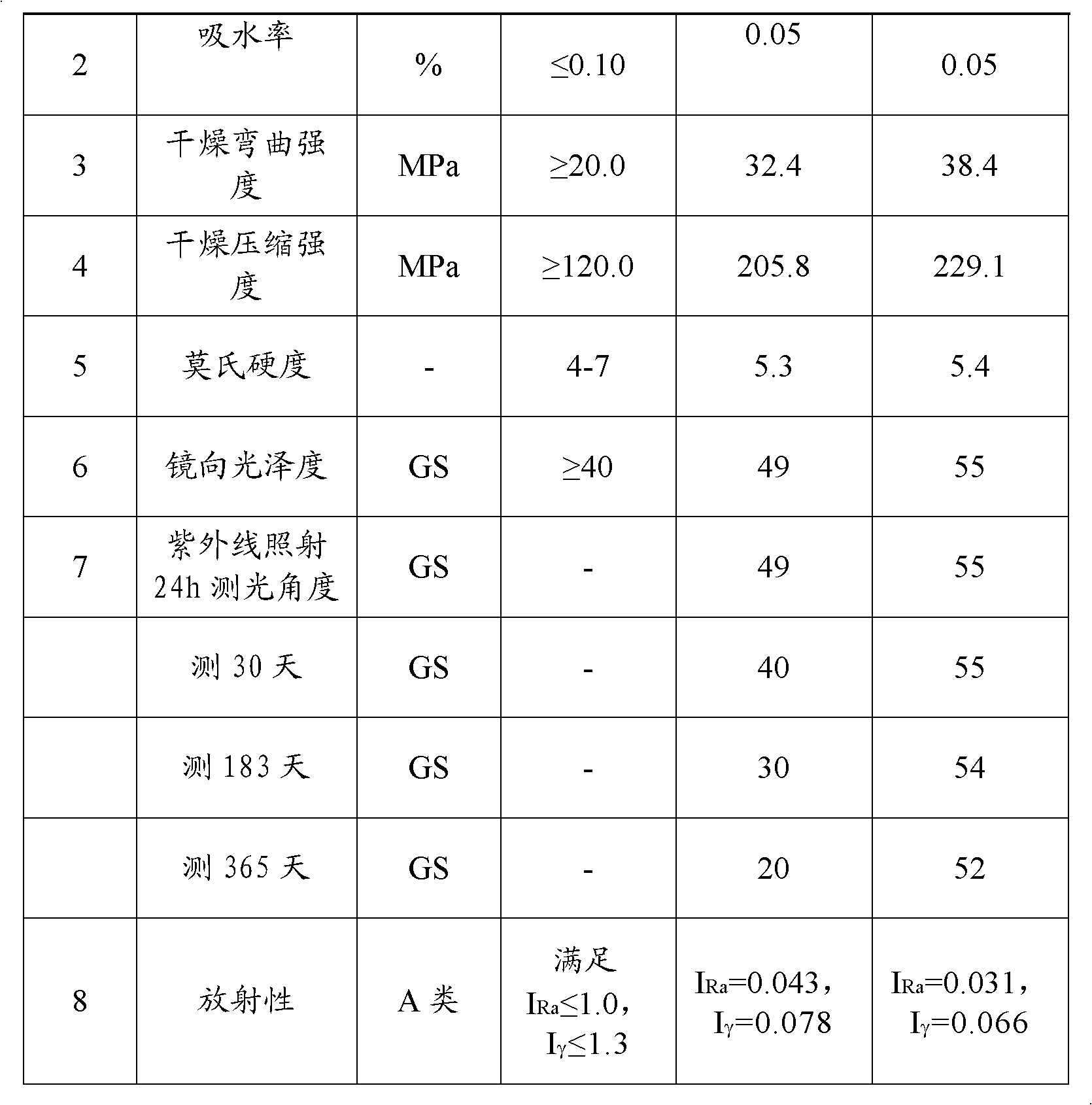

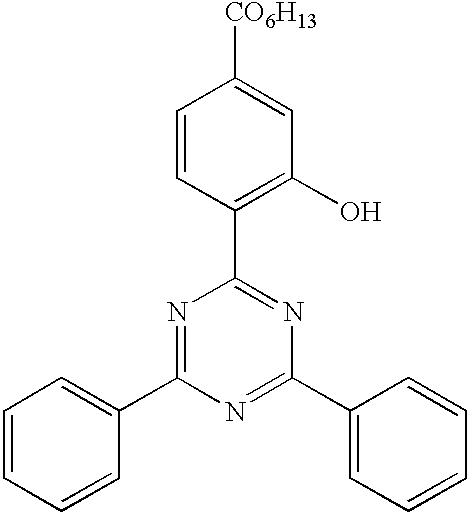

Quartzite material, artificial quartzite plate and manufacturing process thereof

ActiveCN102030497AExcellent physical and chemical propertiesGood anti-light aging performanceArtificial stonePolyresin

The invention discloses an artificial quartzite plate material which comprises the following components in percentage by total mass of quartzite plate: 60-63 percent of quartz sand with the grain size of 5-100 meshes and inorganic silicon materials of waste glass granules, and the like, 28-32 percent of quartzite powder with 320-3000 meshes, 7-9 percent of unsaturated resin and 0.4-0.6 percent ofpigment and a coupling agent as well as other components in percentage by mass of resin: 0.5-1 percent of ultraviolet absorber, 0.5-1 percent of disintegrant and 0.8-1 percent of curing agent. The invention also discloses the quartzite plate prepared from the raw materials and a manufacturing process thereof. In the invention, the quartzite plate is produced by the steps of vibrating and pressurizing the quartz sand, the quartzite powder, the inorganic silicon materials of waste glass granules, and the like and the unsaturated resin under the vacuum state and curing and synthesizing under theintermediate temperature. The quartzite plate overcomes the problem that the traditional artificial stone is aged under strong lights after long-term use outdoors and has favorable physical and chemical properties.

Owner:新云石业(云浮)有限公司

Capstock composition and process providing weatherability, reduced gloss, and high impact

Compositions are disclosed that are processable into capstocks having a reduced gloss appearance, high impact strength and superior weatherability. The capstocks described herein are especially useful for extrusion into articles. They are also useful for application to various poor weathering structural plastic articles for preparing multilayered composites having improved weatherability. Methods for manufacturing structural plastic capstocks and composites and articles produced therefrom having reduced gloss appearance are also described.

Owner:ROHM & HAAS CO

High-performance recovered PET/ABS alloy

The invention discloses a high-performance recycled PET / ABS alloy. The alloy comprises the following components in percentage by weight: 30 to 80 percent of recycled PET, 10 to 50 percent of ABS, 1 to 10 percent of reinforcing agent, 2 to 15 percent of compatilizer, 0.5 to 5 percent of flexibilizer, 0.5 to 3 percent of polyhydroxy chemical coupling agent, and 0.1 to 1 percent of antioxidant. The alloy can improve a recycled PET system by using reasonable matching of additives, effects of the polyhydroxy chemical coupling agent, and excellent physical mechanic properties of an ABS system. Therefore, the recycled PET / ABS alloy has the advantages of high compatibility, high tensile strength, high mobility, good machinability and the like, is particularly suitable for producing complicated components and parts and large plates, has a simple process, is suitable for mass production of medium-sized and small enterprises, and has obvious economic benefit and social benefit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

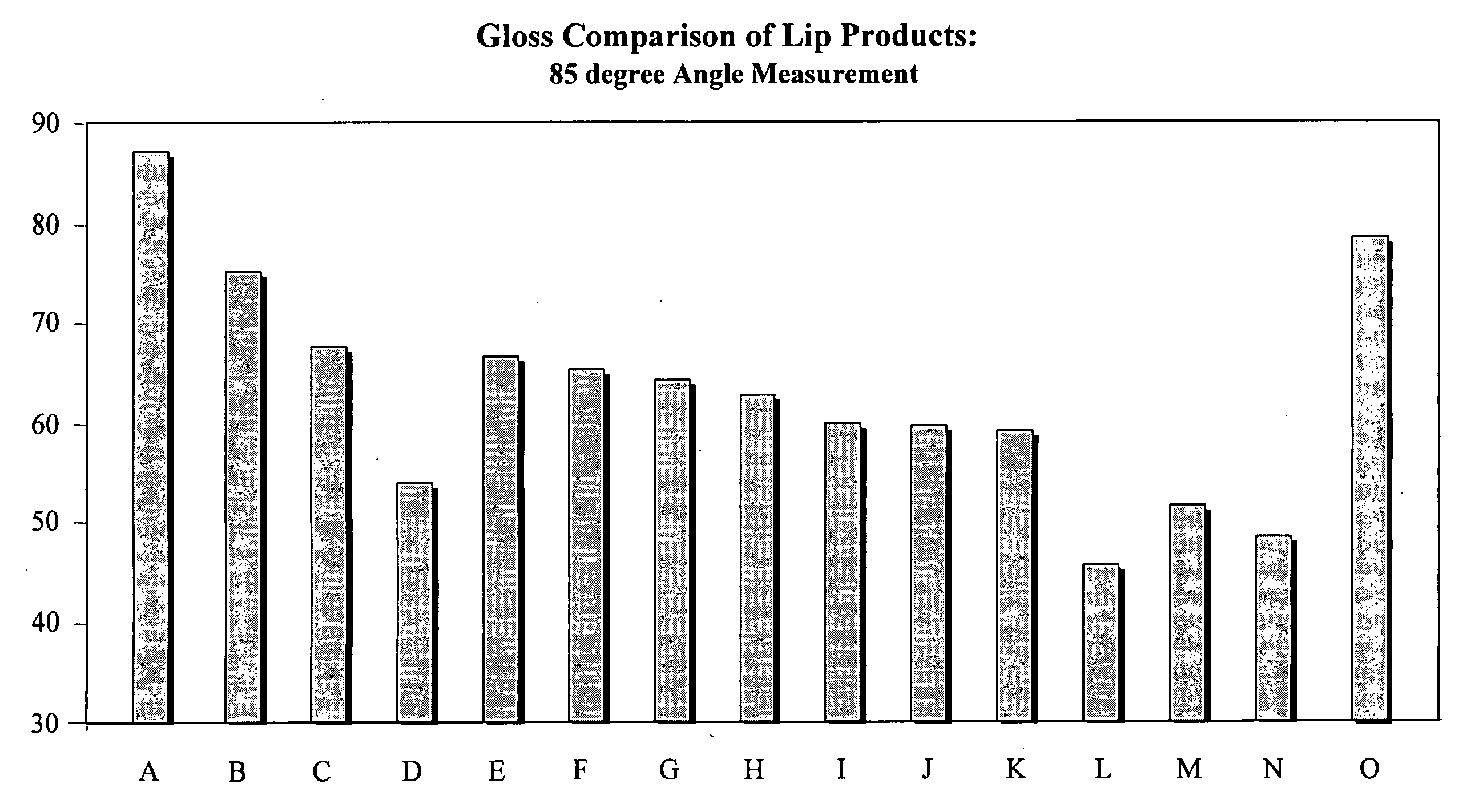

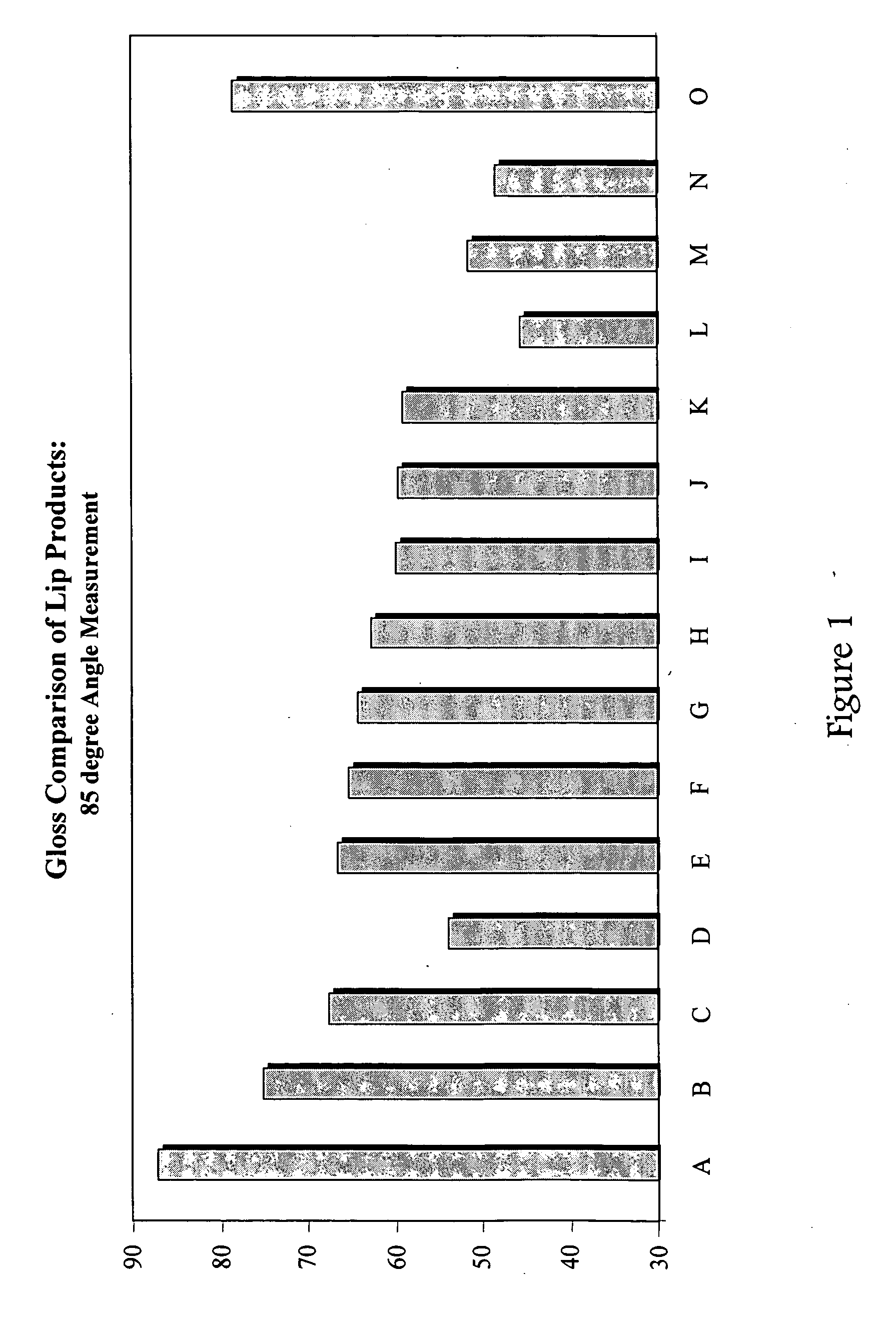

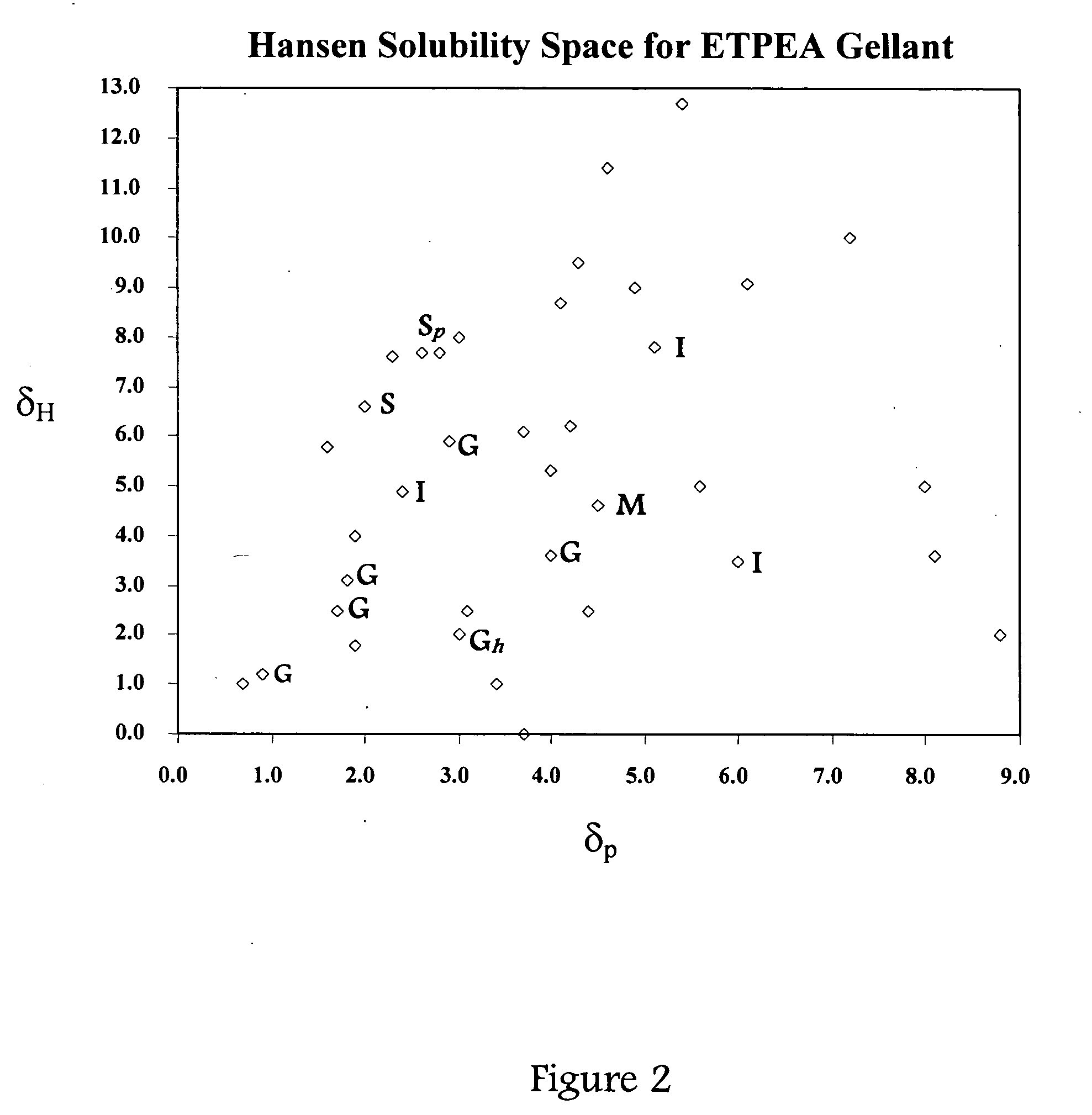

High gloss gel-based lipstick

ActiveUS20080152678A1Improve rheologyReduce wax contentOrganic active ingredientsCosmetic preparationsPolymer chemistryMelting point

Gel-based lipstick compositions are disclosed comprising an ester terminated poly(ester-amide) (ETPEA) polymeric gellant, a first wax component having a melting point above the sol-gel transition temperature of the ETPEA gellant, a second wax compositions having a melting point equal to of below the sol-gel transition temperature of the ETPEA gellant, optionally a silicone T-resin co-gellent, and one or more oils capable of forming a gel with the ETPEA gellant. The gel compositions are solid or semi-solid at room temperature and are capable of being molded into self-supporting sticks. The disclosed gels provide high gloss films when applied to the lips and / or provide a rheology characterized by a high viscosity over repeated shear cycles.

Owner:AVON PROD INC

UVV curable coating compositions and method for coating flooring and other substrates with same

InactiveUS20100276059A1Reduce power consumptionComposition is limitedOrganic chemistryMechanical working/deformationCoated surfacePolymer science

A floor covering includes a wear layer including a resin and a photoinitiator in which the composition of the wear layer is curable by radiation having the strongest wavelength in the UVV range of 400 to 450 nm. The gloss of the wear layer can be controlled by controlling the amount of flatting agent in the composition applied to the surface, the amount of power applied to the surface coated with the composition or the temperature of the surface coated with the composition when the coated surface is subjected to the UVV radiation.

Owner:AFI LICENSING

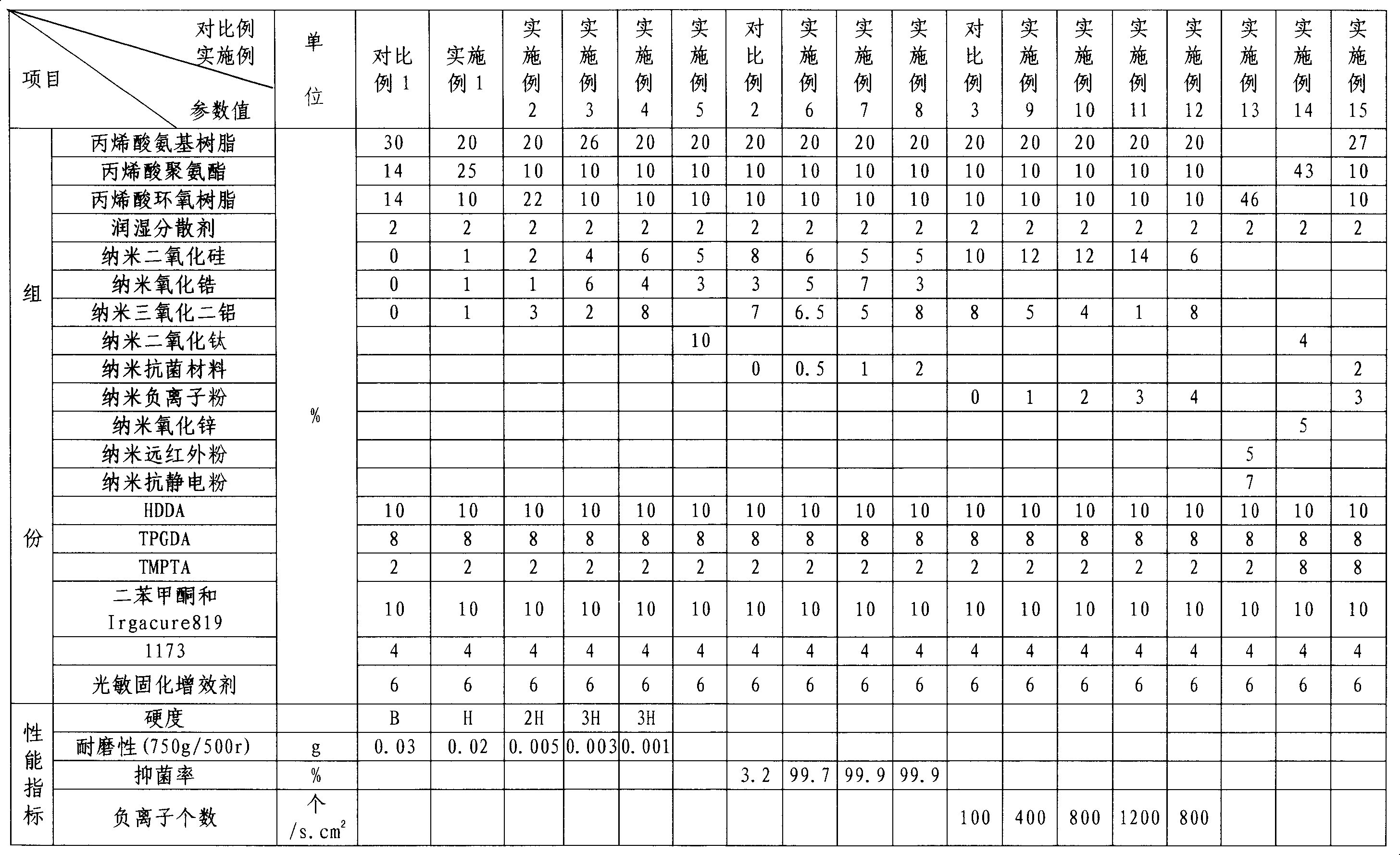

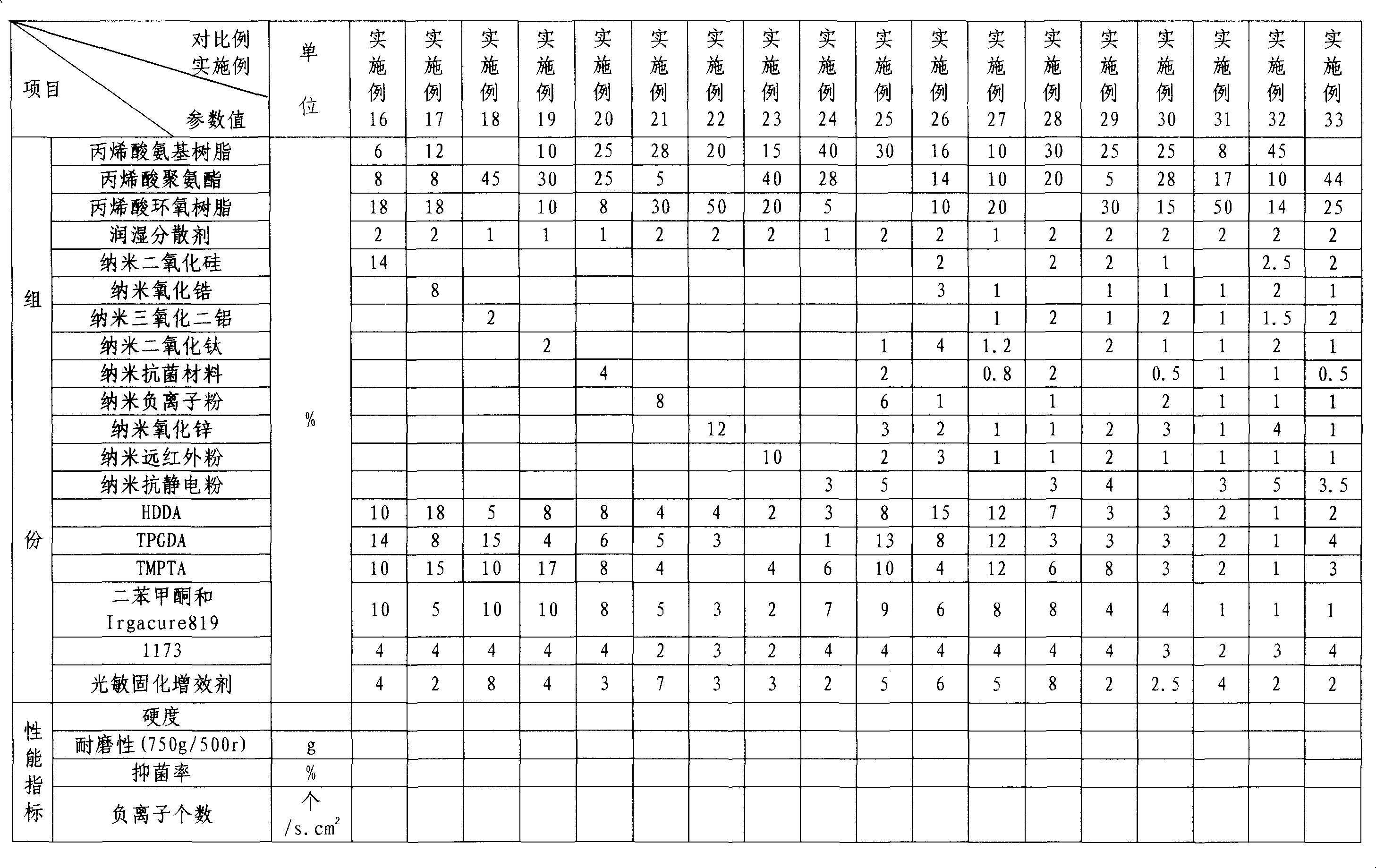

Nano technology modified ultraviolet solidified woodware paint

InactiveCN1554717AImprove wear resistanceHigh surface hardnessPaints with biocidesPolyurea/polyurethane coatingsEpoxyUltraviolet

The modified ultraviolet cured woodenware paint consists of one or several of nano silica, zirconia, titania, zinc oxide, negative ion powder, antibiotic material, far infrared powder, antistatic powder and alumina in 0.3-20 wt% and active oligomer comprisnig acrylic epoxy resin, acrylic polyurethane and acrylic amino resin in 30-76 wt%. The modified ultraviolet cured woodenware paint has the small size effect, surface effect, quantum size effect and macroscopic quantum tunnel characteristic of nano material, so that it has high antiwear property, hgih surface hardness, high toughness, high cracking resistance and many other advantages.

Owner:南京海泰纳米材料有限公司

Low gloss free radical powder coatings

InactiveUS6852765B2Reduce glossImprove smoothnessPretreated surfacesSpecial tyresMetallic substratePolymer chemistry

The present invention is directed to a powder coating composition that produces a low gloss coating upon cure. The powder coating composition includes one or more crosslinkable base polymer, a crosslinkable acrylic polymer and one or more free radical initiators. By adding spheroidal particles to the powder coating composition further reduction in gloss can be obtained while improving smoothness. These compositions are well suited to produce coatings on metallic substrates, such as automotive bodies and non-metallic substrates, such as reconstituted wood substrates, used for desk or table tops.

Owner:EI DU PONT DE NEMOURS & CO

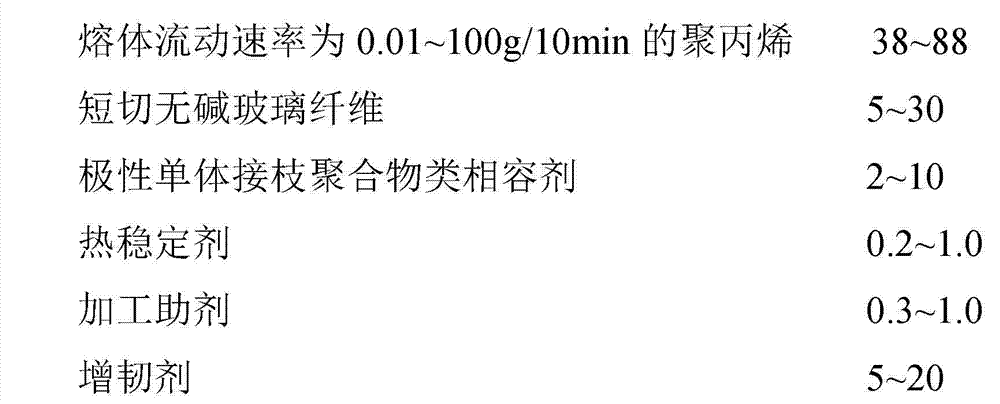

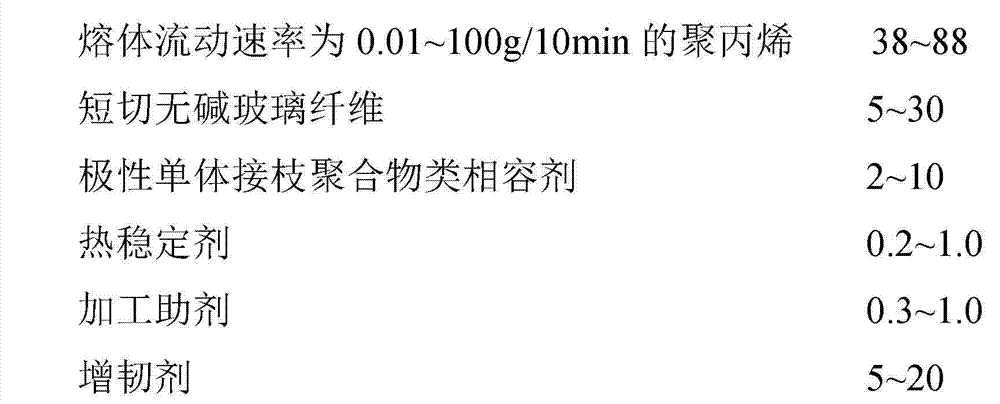

Low gloss scratch resistant glass fiber reinforced PP composite material and preparation method thereof

The invention discloses low gloss scratch resistant glass fiber reinforced PP (Propene Polymer) composite material and a preparation method thereof. The composite material comprises the following components in weight percentage: 38 to 88 wt% of polypropylene with the rate being of 0.01 to 100g / 10min, 5 to 30 wt% of chopped alkali-free glass fiber, 2 to 10 wt% of polar monomer graft polymer compatilizer, 0.2 to 1.0 wt% of heat stabilizer, 0.3 to 1.0 wt% of processing agent and 5 to 20 wt% of flexibilizer. The composite material has excellent rigidity, heat resistance, normal-temperature and low-temperature impact performance, low gloss and scratch resistance, the tensile strength is larger than or equal to 35Mpa, the elongation at break is larger than or equal to 5 percent, the bending modulus is larger than or equal to 2000 Mpa, the heat deflection temperature (0.45Mpa) is larger than or equal to 120 DEG C, the notch impact strength at 23 DEG C is larger than or equal to 35 KJ / m<2>, the notch impact strength at minus 30 DEG C is larger than or equal to 15KJ / m<2>, the gloss Gs (60 DEG C) is smaller than or equal to 2.4 GU, and the chromatic aberration Delta L of the composite material is smaller than or equal to 1.5 after the composite material is scratched by 10N force.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Low gloss powder coating composition

The present invention provides a low gloss powder coating composition comprising a glycidyl-containing acrylic polymer, a first acid functional crosslinking agent comprising a copolymer of an ethylenically unsaturated compound and an anhydride of a dicarboxylic acid and a second acid functional crosslinking agent comprising a dicarboxylic acid having 4 to 20 carbons.

Owner:REICHHOLD CHEM INC

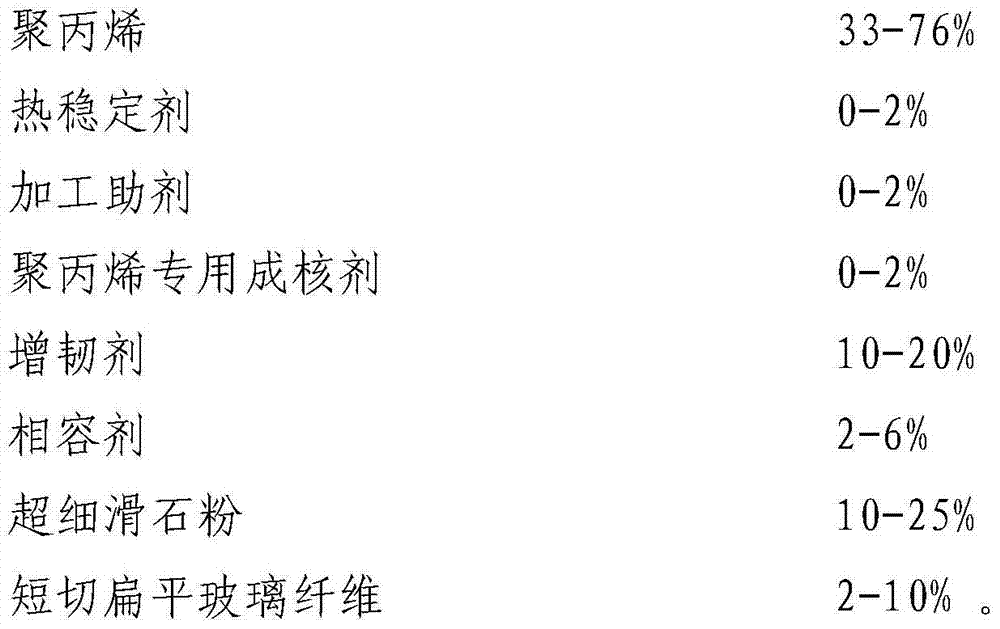

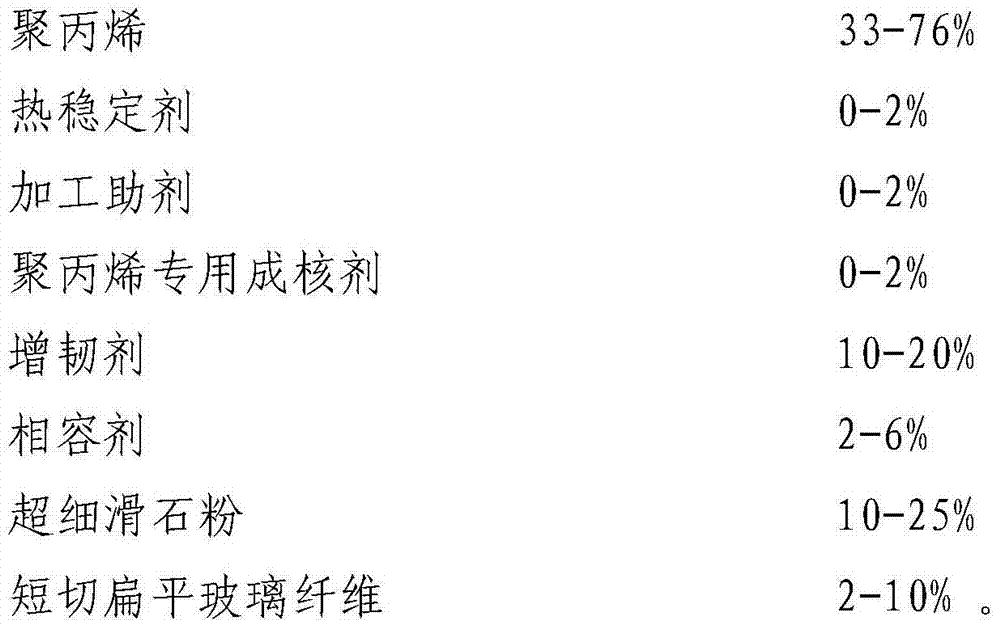

Polypropylene composite material for automobile hard plastic instrument panel and preparation method for polypropylene composite material

InactiveCN103756130AHigh surface hardnessImprove scratch resistanceGlass fiberPolypropylene composites

The invention belongs to the technical field of high polymer materials, and in particular relates to a polypropylene composite material for an automobile hard plastic instrument panel and a preparation method for the polypropylene composite material. The polypropylene composite material is prepared from the following raw materials in percentage by weight: 33 to 76 percent of polypropylene, 0 to 2 percent of heat stabilizer, 0 to 2 percent of processing aid, 0 to 2 percent of nucleating agent special for polypropylene, 10 to 20 percent of plasticizer, 2 to 6 percent of compatibilizer, 10 to 25 percent of superfine talc powder and 2 to 10 percent of chopped flat fiberglass. When the polypropylene composite material for the automobile hard plastic instrument panel is prepared, the chopped flat fiberglass is added, so that the surface hardness of the polypropylene composite material is increased, good scratch resistant effects are achieved without adding any scratch resistant agent, and a matte effect is also achieved; the polypropylene composite material also has the characteristics of high flowability, high rigidity, high heat resistance, high dimensional stability, high impact resistance, low glossiness and scratch resistance, and requirements on a material for the automobile hard plastic instrument panel are completely met.

Owner:SHANGHAI KINGFA SCI & TECH

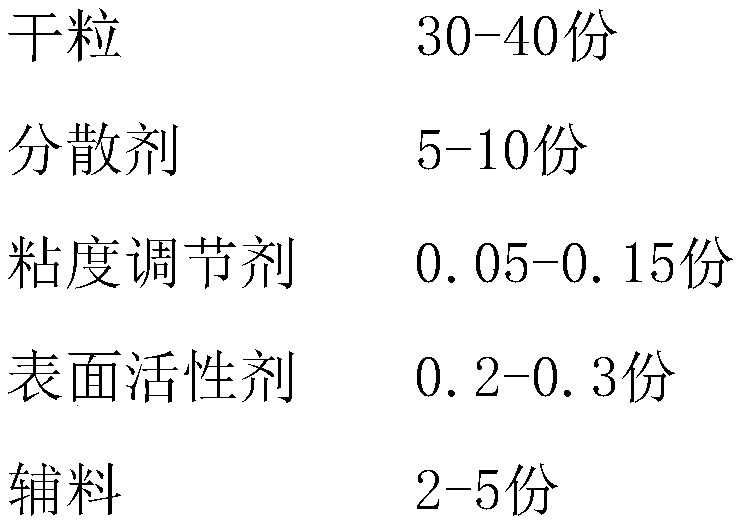

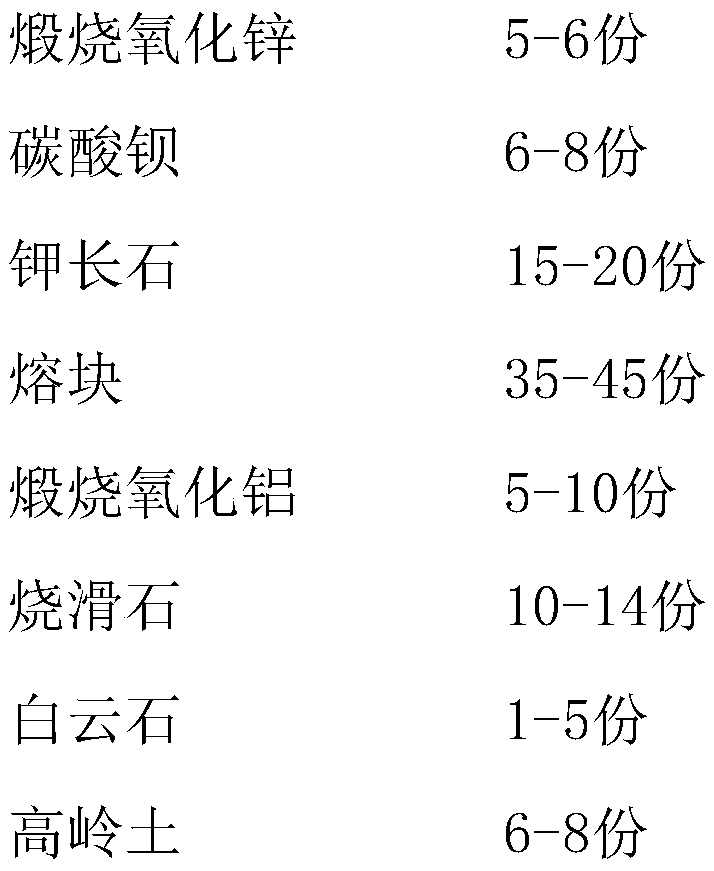

Ink-jet dry granular decorative ceramic tile and manufacturing method thereof

The invention relates to the technical field of ceramic tiles, in particular to an ink-jet dry granular decorative ceramic tile and a manufacturing method thereof. The manufacturing method includes the following steps: A. bottom glaze decoration; B. pattern decoration; C. drying for the first time; D. dry granular decoration; E. spraying a protective glaze; and F. calcining to obtain the product.The method for preparing the dry granular decorative ceramic tile has the advantages of simple operation steps, convenient control, simplified process flow, improved production efficiency, reduced production difficulty and production cost, so that the method is suitable for industrial large-scale production; by spraying with dry granular ink, spray printing can be carried out on a designated position on the surface of a blank body, so as to enable a spray printed texture to be accurately correspond to a pattern decorative texture, and thus the distribution uniformity and adhesion of dry granules on the surface of the blank body are improved, and the prepared ceramic tile product has clear and distinct patterns, low glaze gloss, good anti-skid effect, obvious dry granular feeling, strong stereoscopic impression, rich colors, stable physicochemical properties and wide temperature adaptation range.

Owner:JIANGXI HEMEI CERAMICS +3

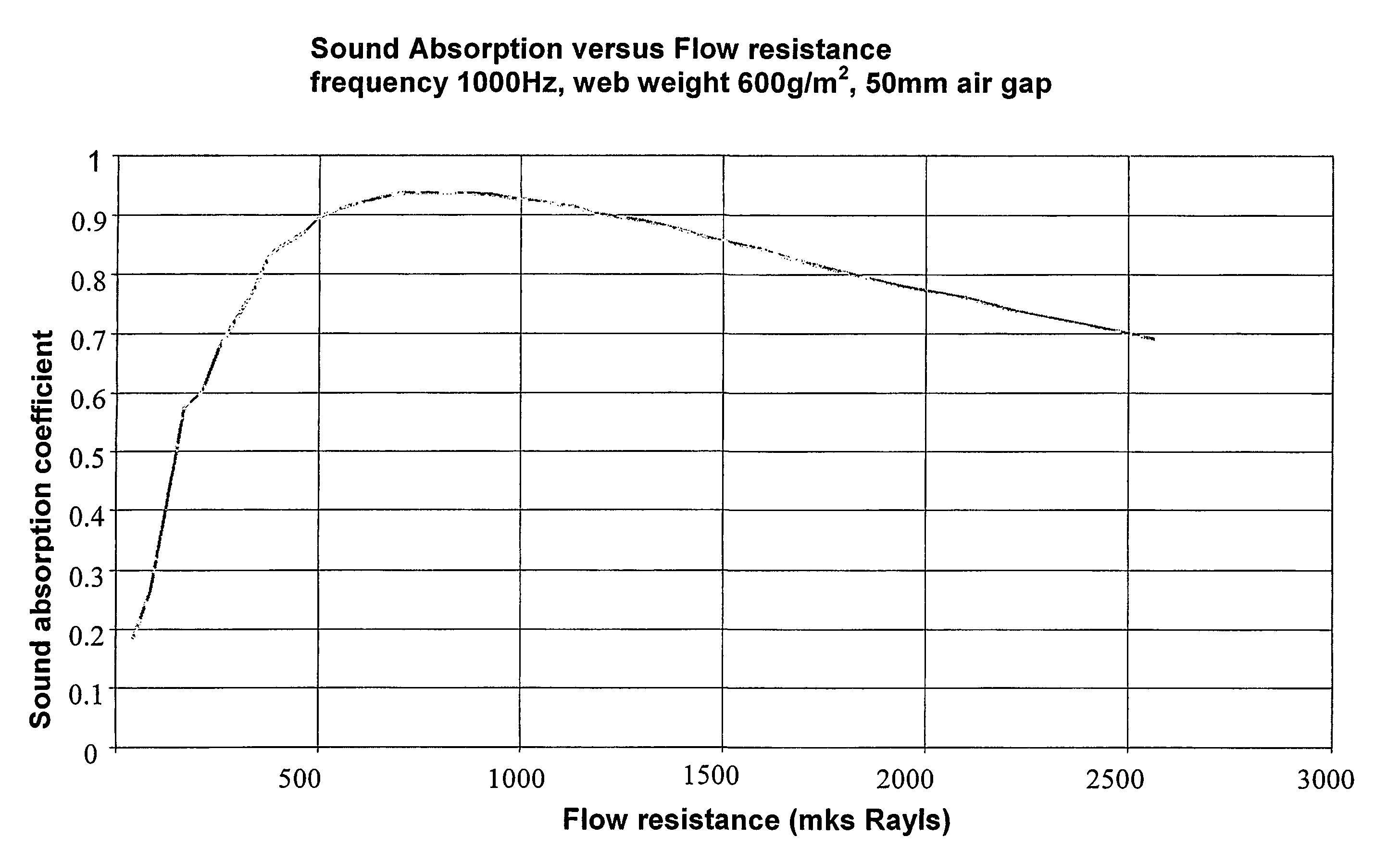

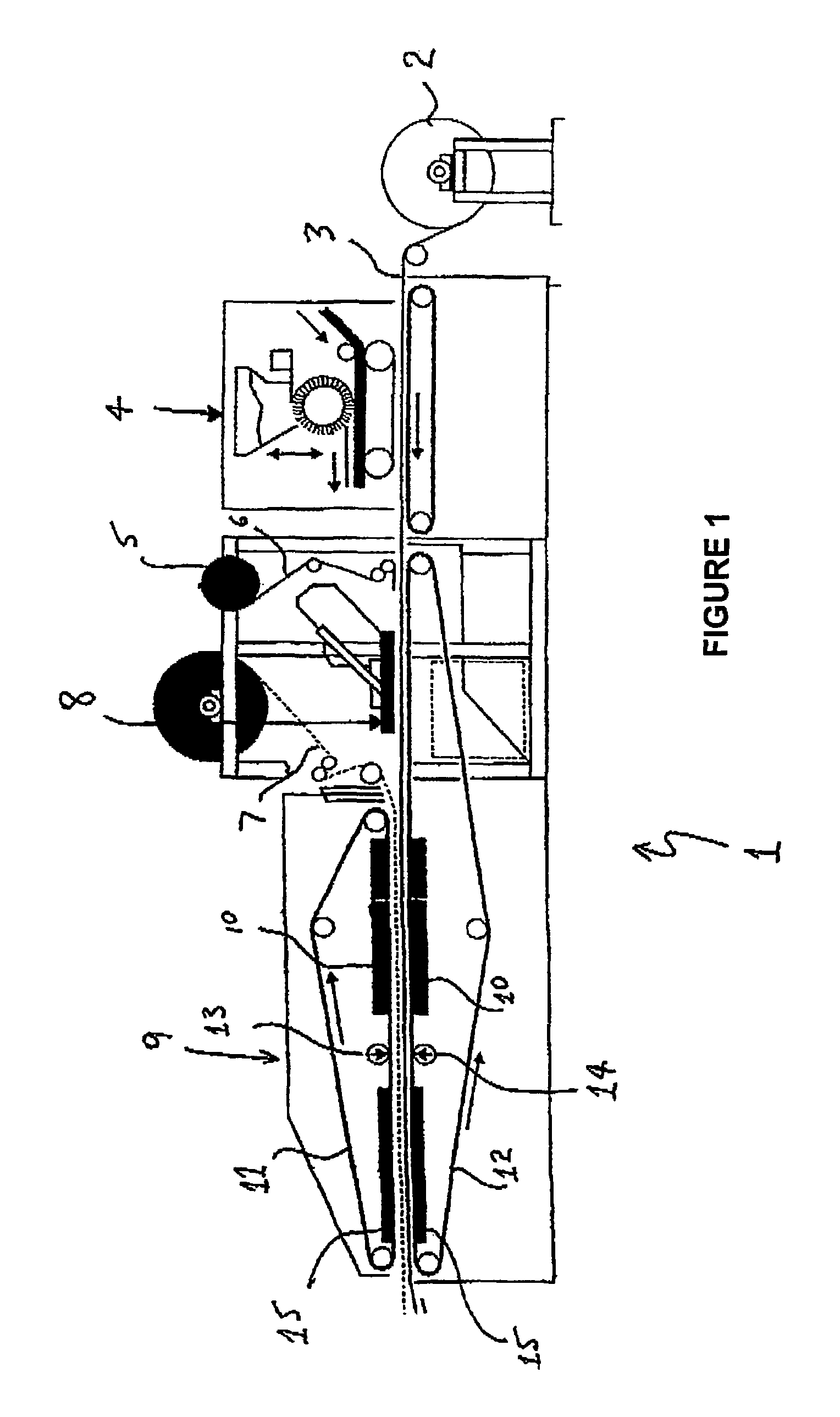

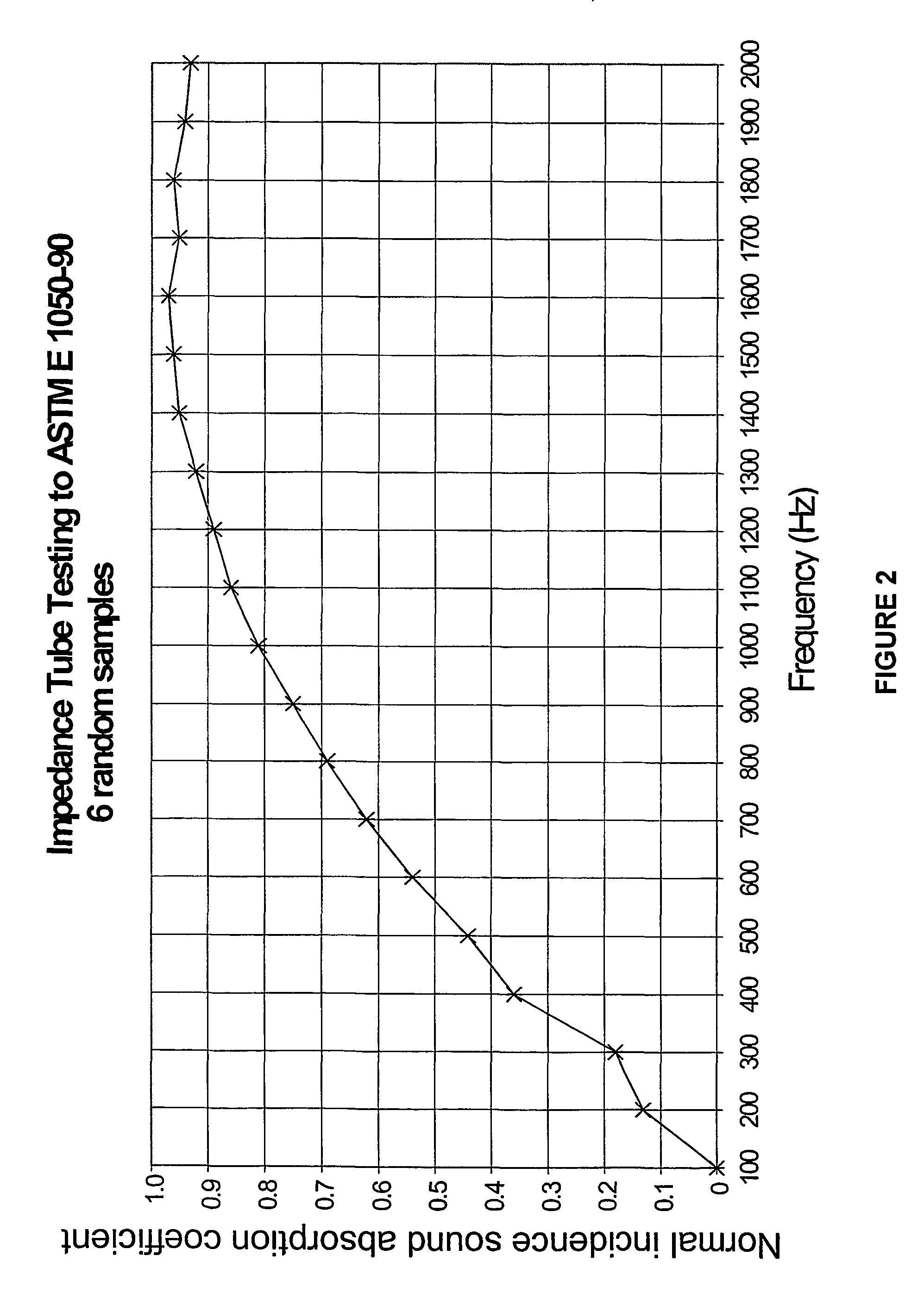

Thermoformable acoustic sheet

A thermoformable acoustic sheet formed by a compressed fibrous web including high melt and adhesive thermoplastic fibres in which the adhesive fibres are at least partially melted so that in the compressed web the adhesive fibres at least partially coat the high melt fibres and reduce the interstitial space in the fibre matrix. Also included is a method of producing a thermoformable acoustic sheet which includes the steps of heating a fibre web including high melt and adhesive thermoplastic fibres to at least partially melt the adhesive fibres and compressing the web to form a sheet so that the adhesive fibres at least partially coat the high melt fibres to reduce the interstitial space in the fibre matrix.

Owner:ZEPHYROS INC

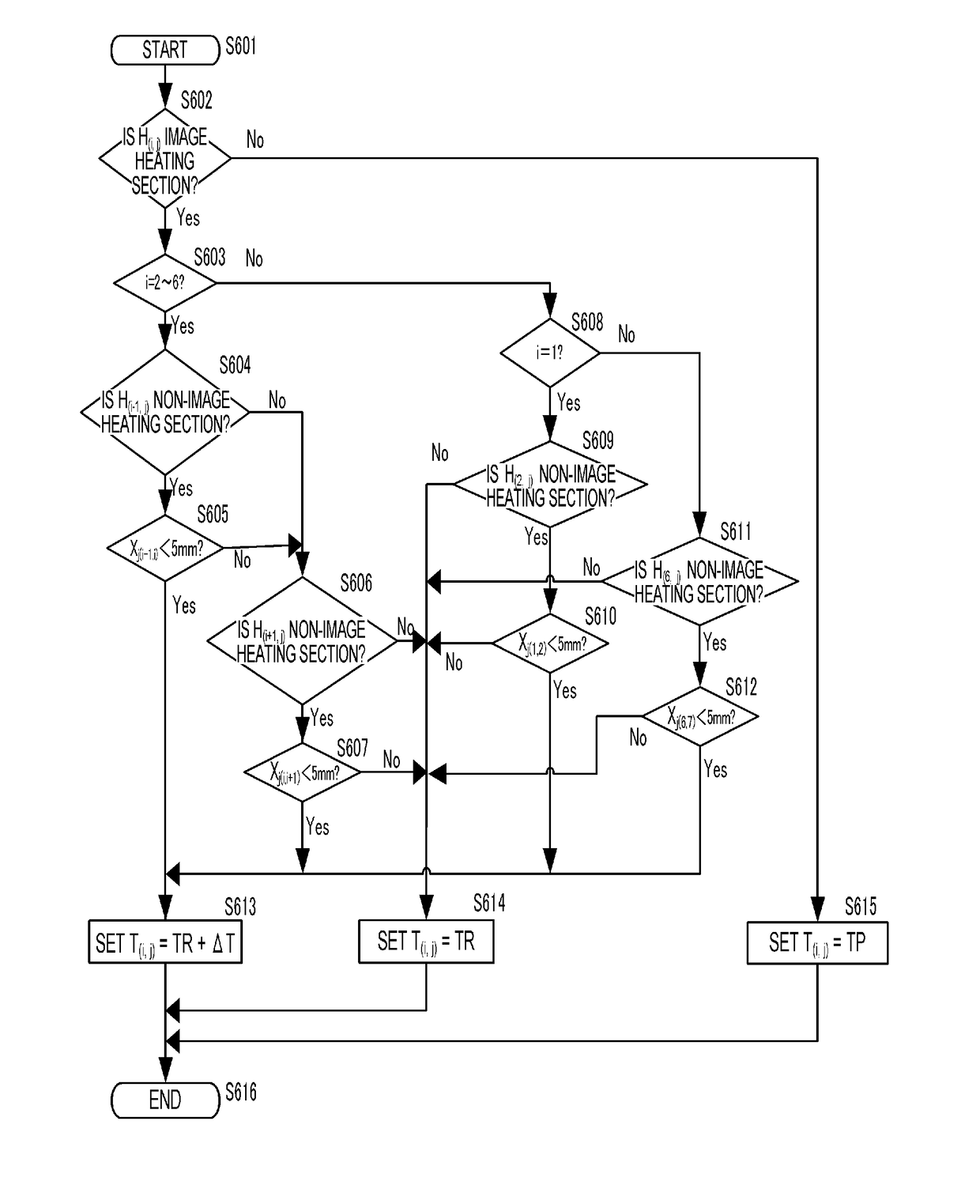

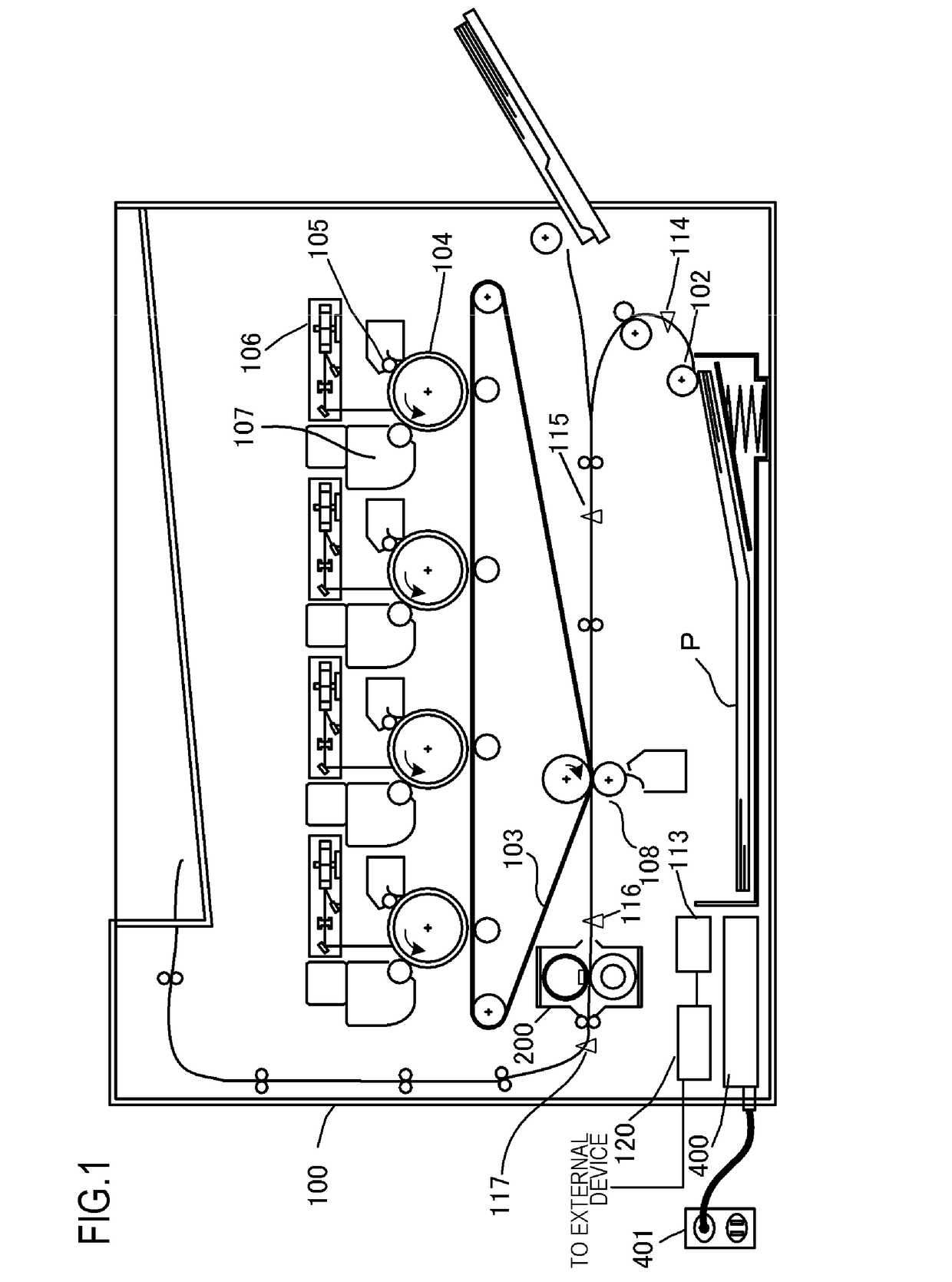

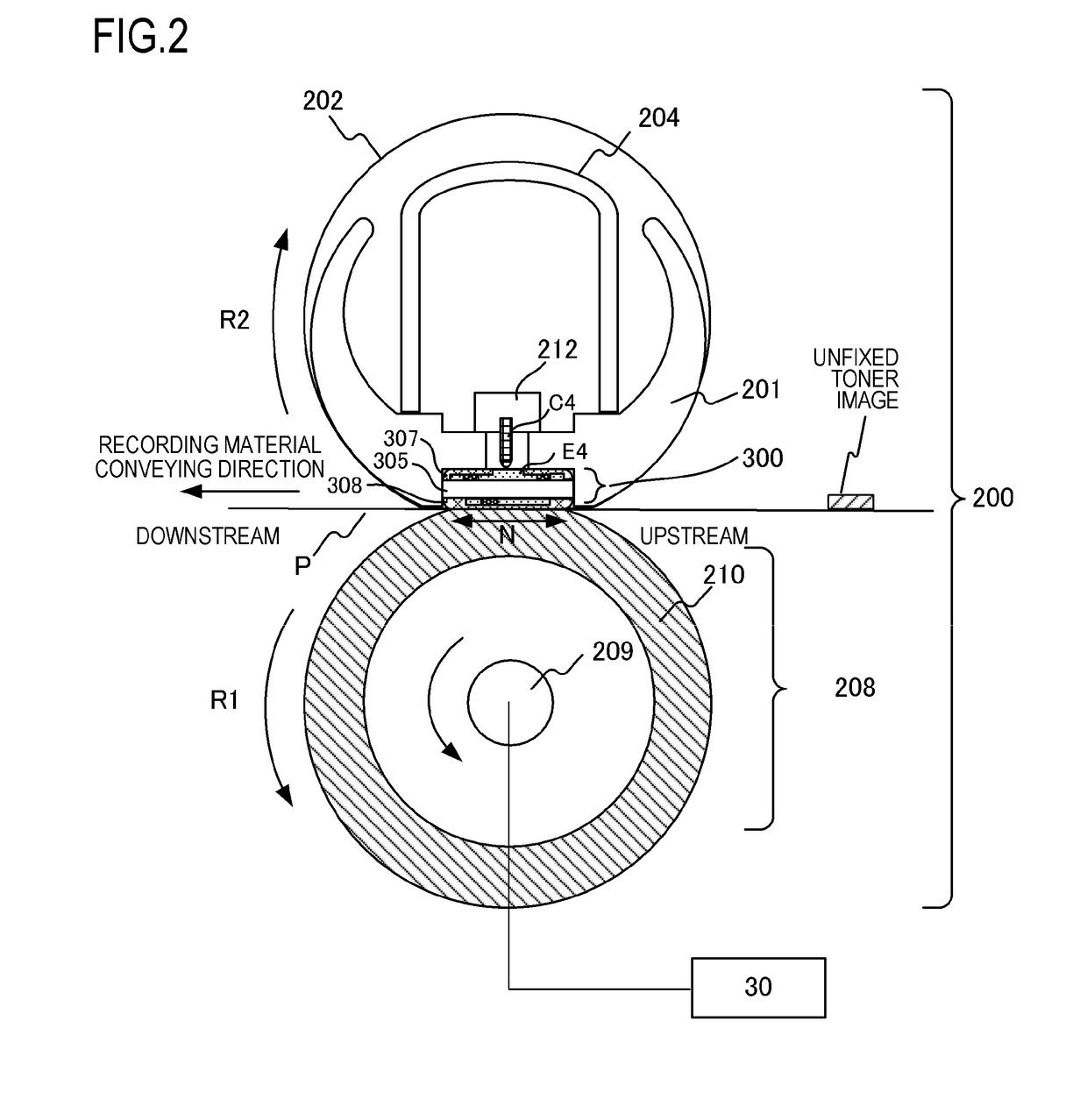

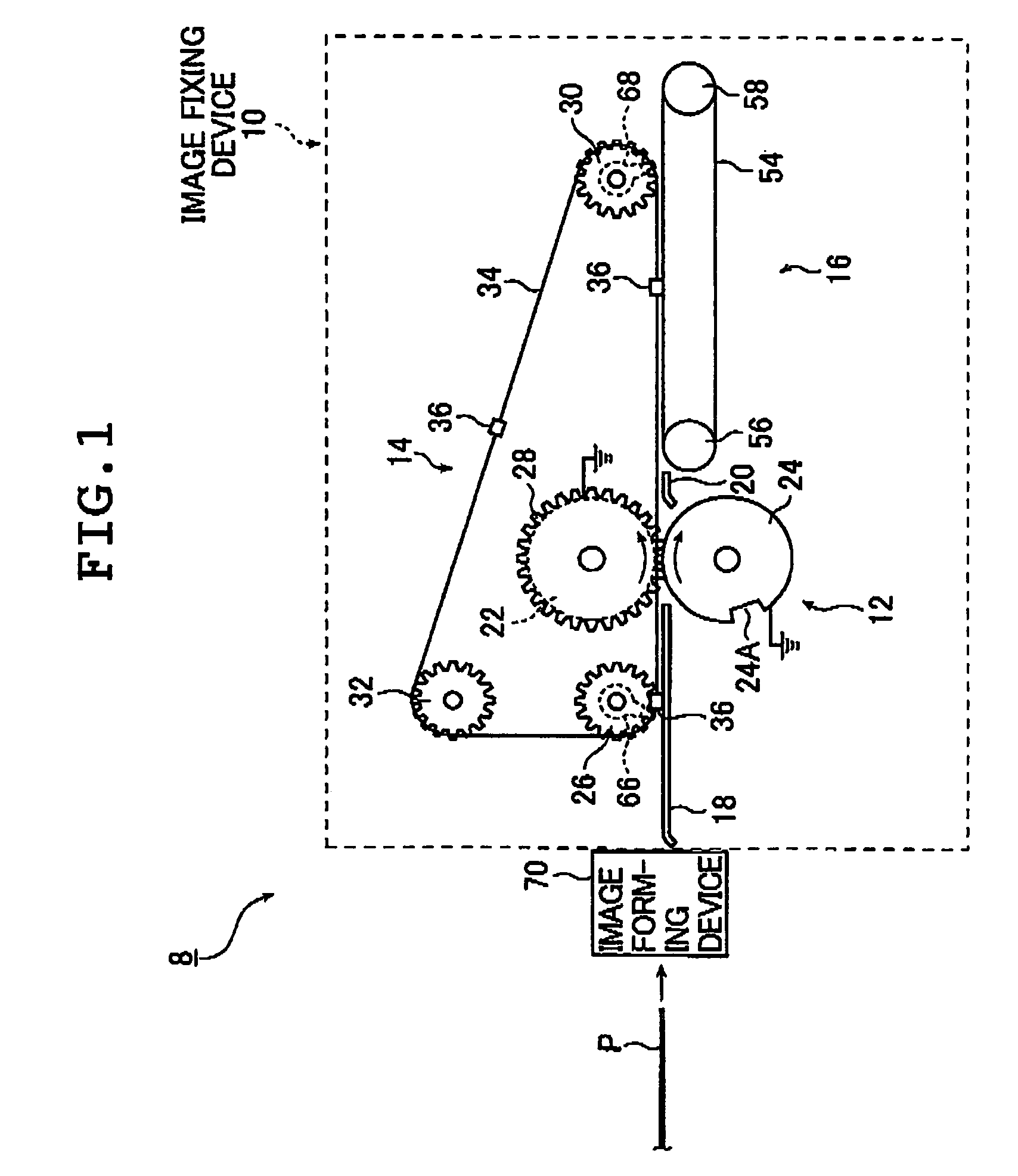

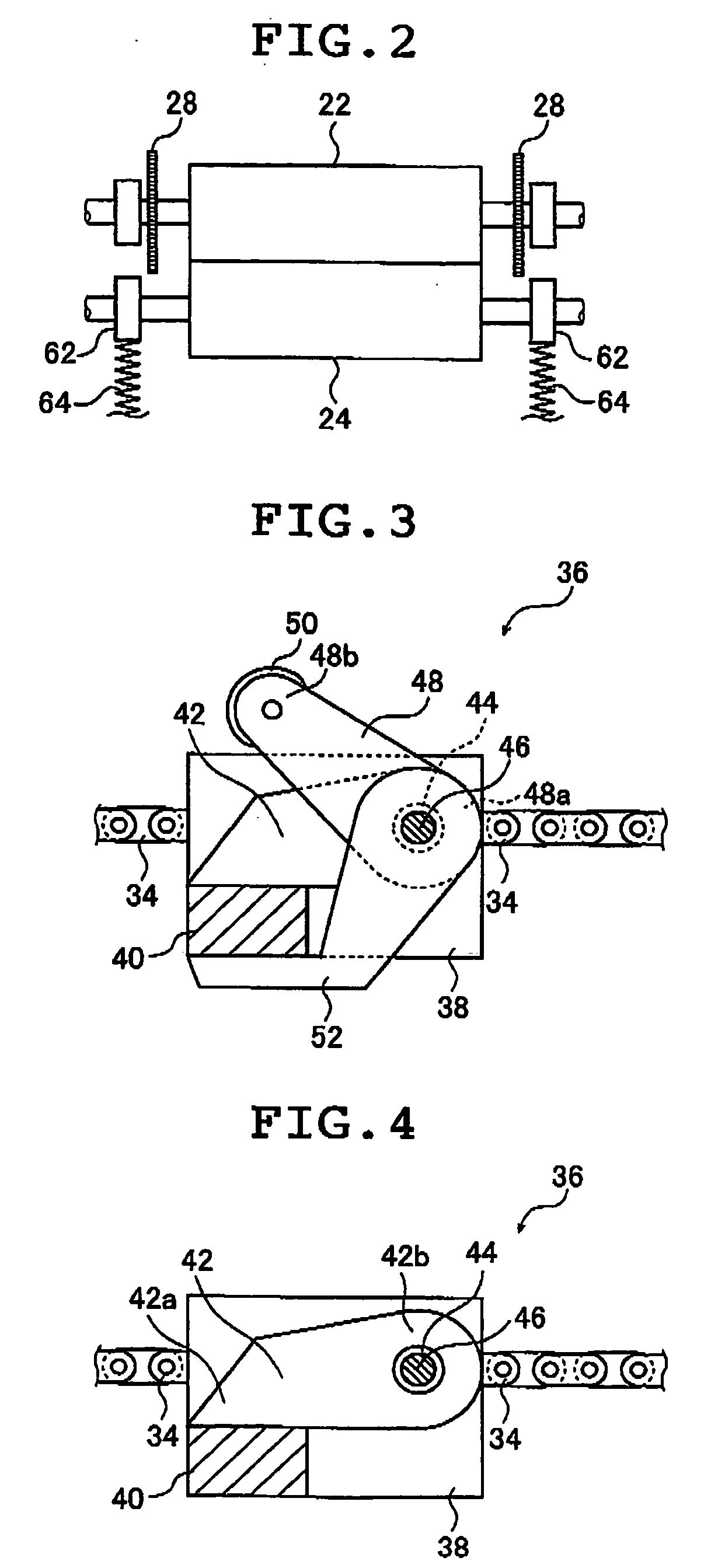

Image heating apparatus and image forming apparatus

ActiveUS20180004135A1InhibitionSave powerElectrographic process apparatusControl powerComputer science

Owner:CANON KK

Radiation polymerisable compositions having accelerated cure

InactiveUS20040044094A1Fast aggregationImprove adhesionMicrowave heatingAccelerated curingCharge-transfer complex

A radiation polymerisable composition comprising: (A) a donor / acceptor component for forming a charge transfer complex said component being selected from the group consisting of: (i) a bifunctional compound having an electron donor group and an electron withdrawing group and a polymerisable unsaturated group; (ii) a mixture of (a) at least one unsaturated compound having an electron donor group and a polymerisable unsaturated moiety; and (b) at least one unsaturated compound having an electron acceptor group and a polymerisable unsaturated group; and (B) a Lewis acid.

Owner:GARNETT JOHN LYNDON

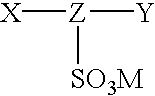

Matt , uv stable , flame-retardant co-extruded polyester film, a method for the production thereof and the use of the same

InactiveUS20030108754A1Improve tensile propertiesProduced cost-effectivelyStampsRecord information storagePolyesterPolyethylene terephthalate

The invention relates to a co-extruded, biaxially oriented polyester film consisting of a base layer and at least one outer layer. The film contains at least one flame-retardant agent, at least one UV-stabilizer and has a matt outer layer which contains a mixture and / or a blend of two components (I) and (II), whereby component (I) is substantially a polyethylene terephthalate homopolymer, or a polyethylene terephthalate copolymer, or a mixture of polyethylene terephthalate homopolymers or polyethylene terephthalate copolymers, and component (II) is a polymer containing at least one sulphonate group.

Owner:MITSUBISHI POLYESTER FILM

Dry erase surface

InactiveUS20040077497A1Reduce glossFine surfaceWriting boardsAblative recordingBiomedical engineeringMethods of production

Dry-erase surfaces and methods of production and use are provided. Improved dry-erase surfaces may be produced from heat-cured resins. Existing dry-erase surfaces such as white boards may be altered or repaired with sheets of dry-erase material.

Owner:TROY LAMINATING & COATING

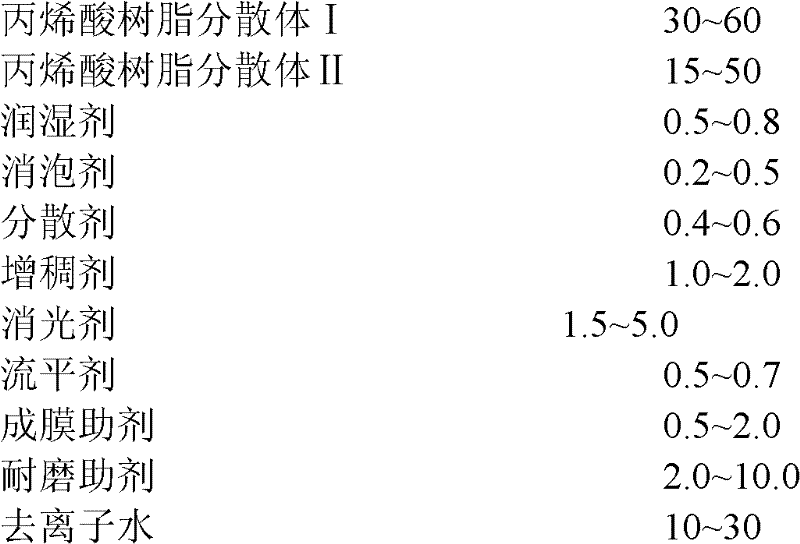

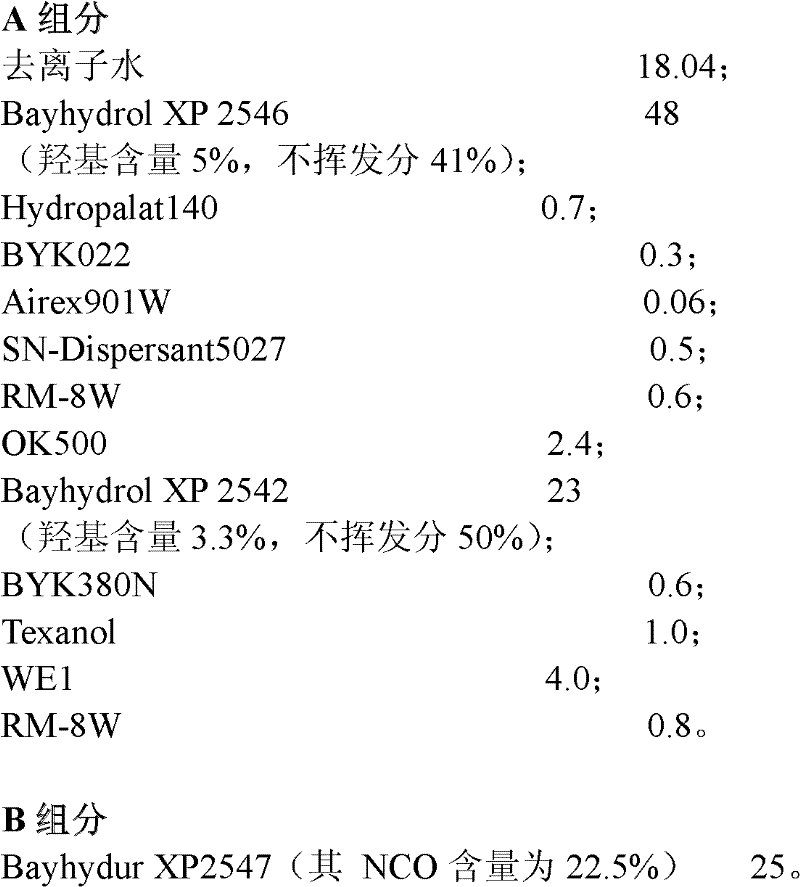

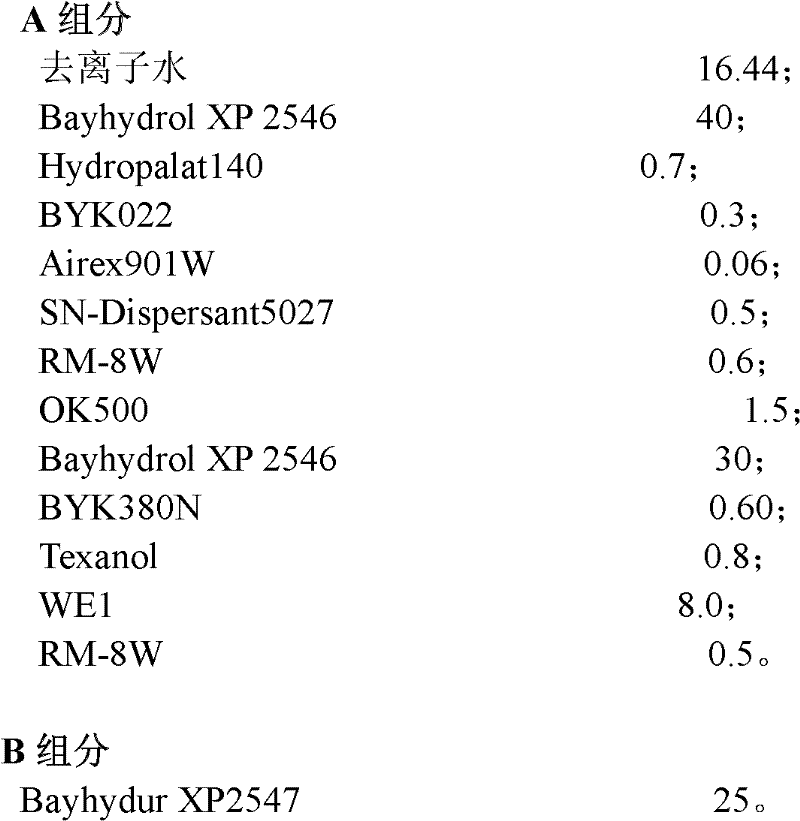

Double-component water-based polyurethane high-abrasion-resistance matte varnish and preparation thereof

InactiveCN102533077AReduce glossOvercome the disadvantage of uneven mattingPolyurea/polyurethane coatingsEpoxyAcrylic resin

The invention discloses a double-component water-based polyurethane high-abrasion-resistance matte coating and a preparation thereof. The coating comprises two components A and B, wherein the component A is prepared by using an acrylic resin dispersion body as a basic component and adding deionized water, a wetting agent, a defoaming agent, a dispersing agent, a thickening agent, a delustering agent, a leveling agent, a film forming additive and a water resistant additive to the acrylic resin dispersion body to disperse the acrylic resin dispersion body; and the component B is aliphatic polyisocyanate. The invention provides a water-based matte coating with low VOC (Volatile Organic Compounds), low gloss, good adhesion force, wear resistance and corrosion resistance; and the water-based matte coating can be very well combined with a water-based or solvent type epoxy resin floor coating and a polyurethane floor coating. The water-based matte coating disclosed by the invention has the advantages of low delustering agent adding quantity and stability in storage; the gloss of the coating system can be effectively reduced; and the comprehensive performance of the coating system is improved. By using the double-component water-based polyurethane high-abrasion-resistance matte coating disclosed by the invention, the water-based coating system solution with environment friendliness, high performance, stability in storage and low cost can be provided.

Owner:CENT SOUTH UNIV +1

PVC (polyvinyl chloride) decorative film surface treating agent, PVC decorative film treated with same and preparation method thereof

InactiveCN102702953AGood PVC adhesionImprove smoothnessOrnamental structuresSpecial ornamental structuresWater basedEmulsion

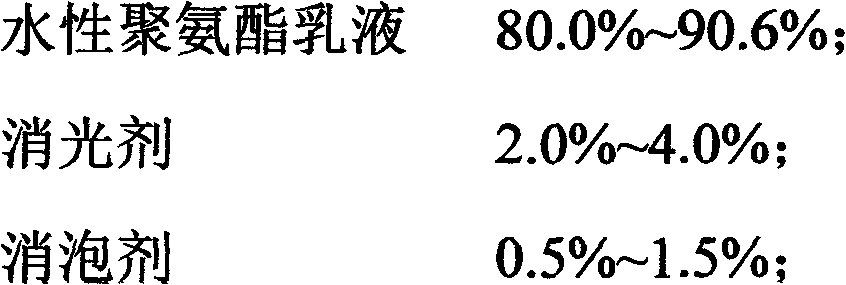

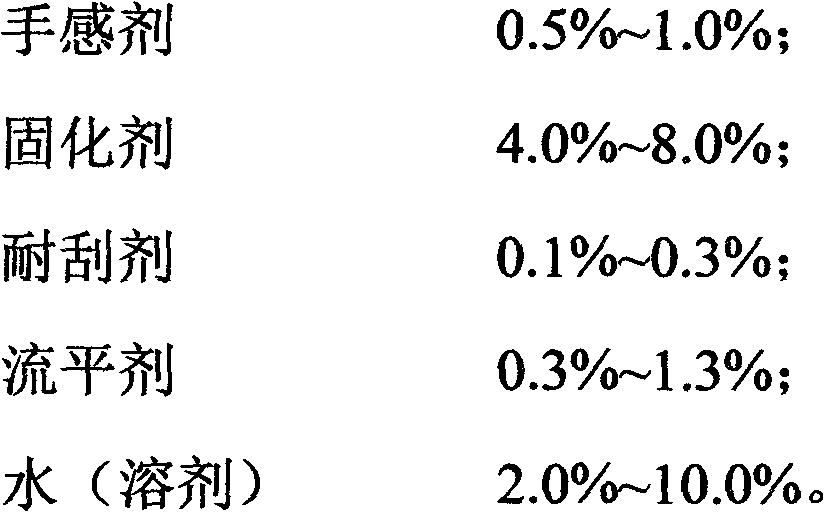

The invention discloses a PVC (polyvinyl chloride) decorative film surface treating agent and a PVC decorative film treated with the same. The surface treating agent comprises the following components in percentage by weight: 80.0-92.0% of water-based polyurethane emulsion, 2.0-4.0% of flatting agent, 0.5-1.5% of defoaming agent, 0.5-1.0% of hand feeling agent, 4.0-8.0% of curing agent, 0.1-0.3% of scraping inhibitor, 0.3-1.3% of leveling agent and 2.0-10.0% of water. The PVC decorative film treated with the surface treating agent has the advantages of excellent matte performance, scraping resistance, favorable compatibility with other decorating materials, and the like, and feels soft.

Owner:FOSHAN TIANJIN PLASTICS

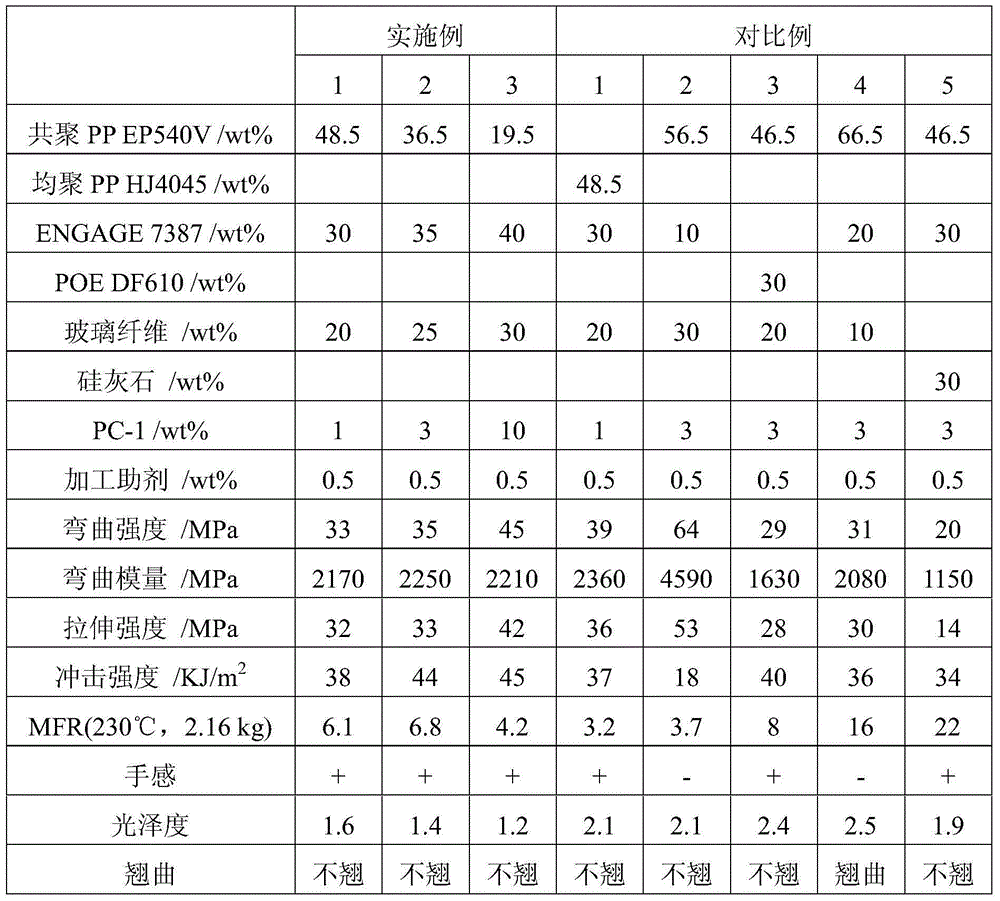

Low-gloss low-warpage soft-touch-feeling vehicle polypropylene composition as well as preparation method and application thereof

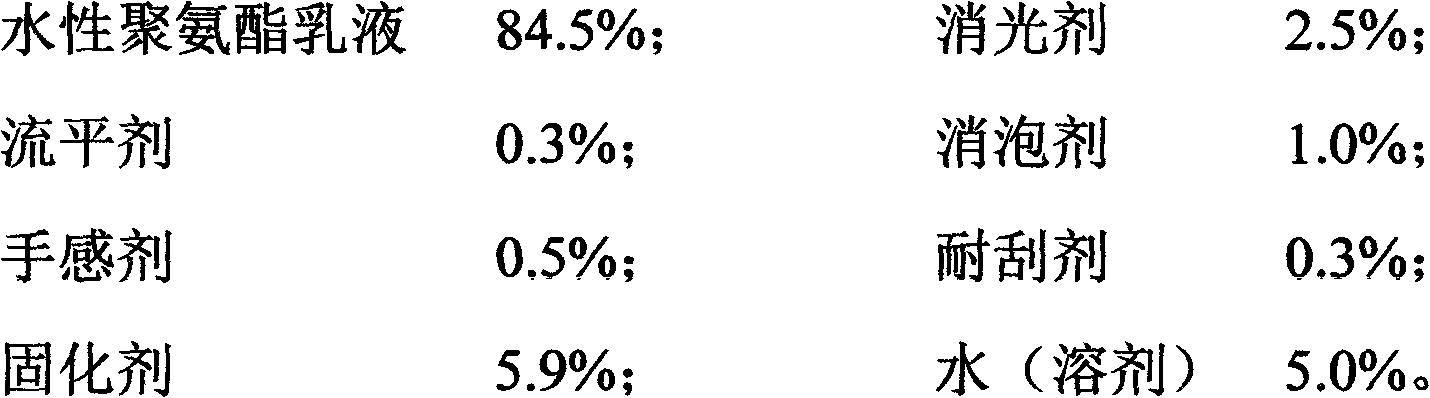

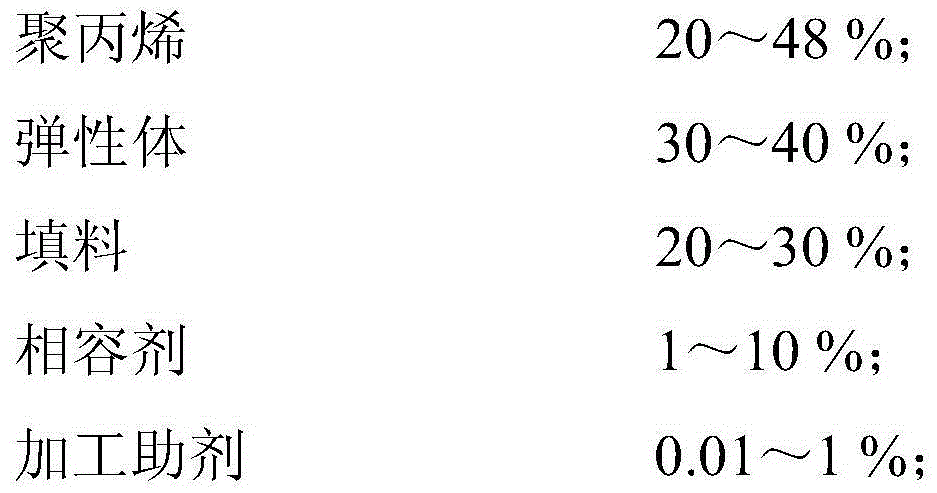

The invention belongs to the technical field of high-molecular polypropylene materials, and discloses a low-gloss low-warpage soft-touch-feeling vehicle polypropylene composition as well as a preparation method and application thereof. The composition comprises the following components in percentage by mass: 20-48 percent of polypropylene, 30-40 percent of an elastomer, 20-30 percent of filler, 1-10 percent of a compatilizer and 0.01-1 percent of a processing aid, wherein the polypropylene is copolymerized polypropylene, and the melt flow rate MFR is larger than 60g / 10min; the melt flow rate MFR of the elastomer is smaller than 0.5g / 10min. By limiting the melt flow rate of the raw materials such as the used polypropylene and elastomer and controlling the ratio of the used raw materials, the obtained composition product is extremely low in glossiness, flat, free of warpage, soft in hand touch feeling, balanced in toughness and capable of being widely applied to various fields, especially automotive trim products.

Owner:KINGFA SCI & TECH CO LTD +1

Matt, flame-retardant, co-extruded polyester film, a method for the production thereof and the use of the same

InactiveUS20030087105A1Improve mechanical propertiesHigh modulusFireproof paintsSignboardsPolyesterPolyethylene terephthalate

The invention relates to a co-extruded, biaxially oriented polyester film containing a flame-retardant agent which can be dissolved in the polyester. The film has a matt outer layer which contains a mixture and / or a blend of two components (I) and (II), whereby component (I) is a polyethylene terephthalate homopolymer, or a polyethylene terephthalate copolymer, or a mixture of polyethylene terephthalate homopolymers or copolymers and component (II) is a polymer containing at least one sulphonate group.

Owner:MITSUBISHI POLYESTER FILM

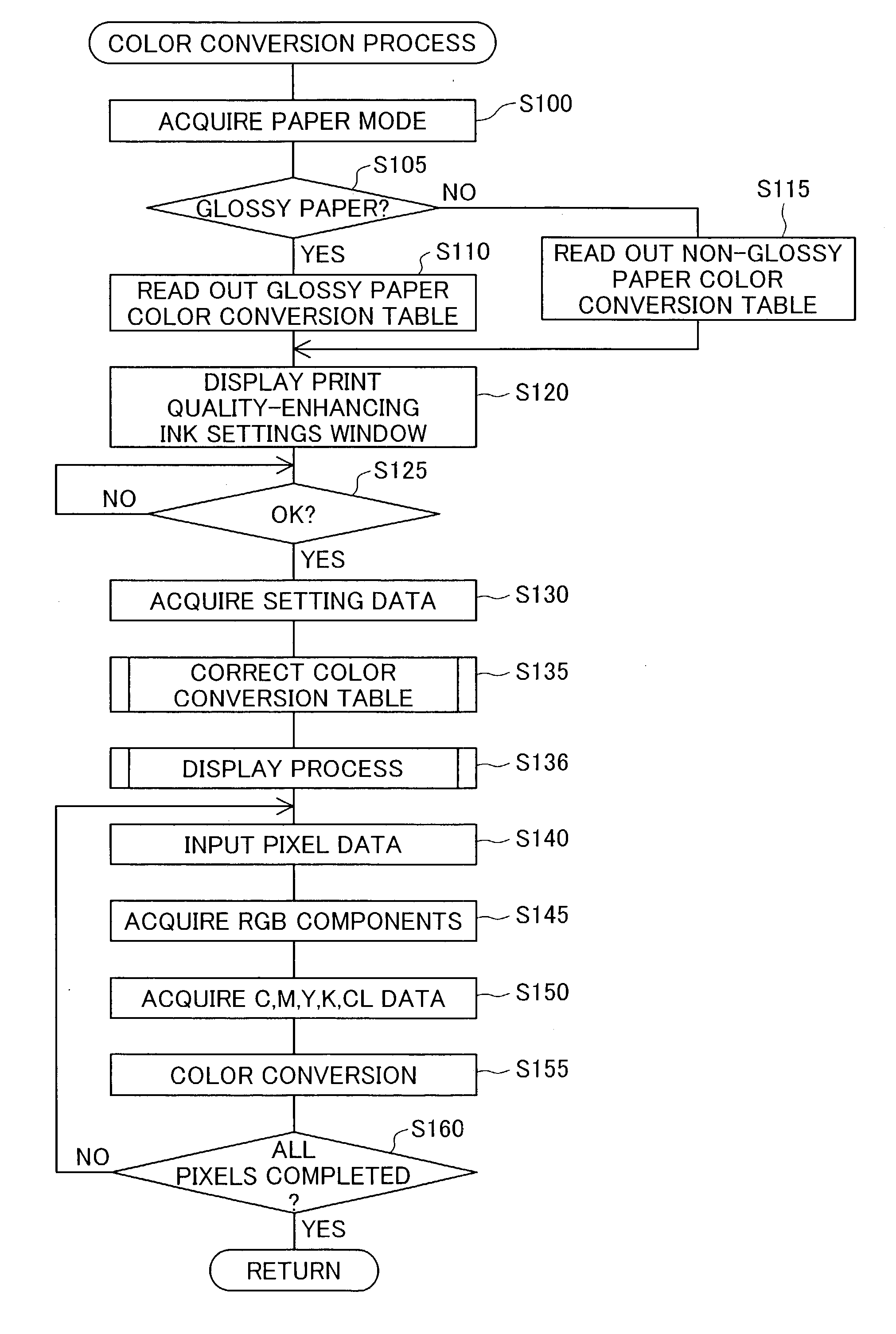

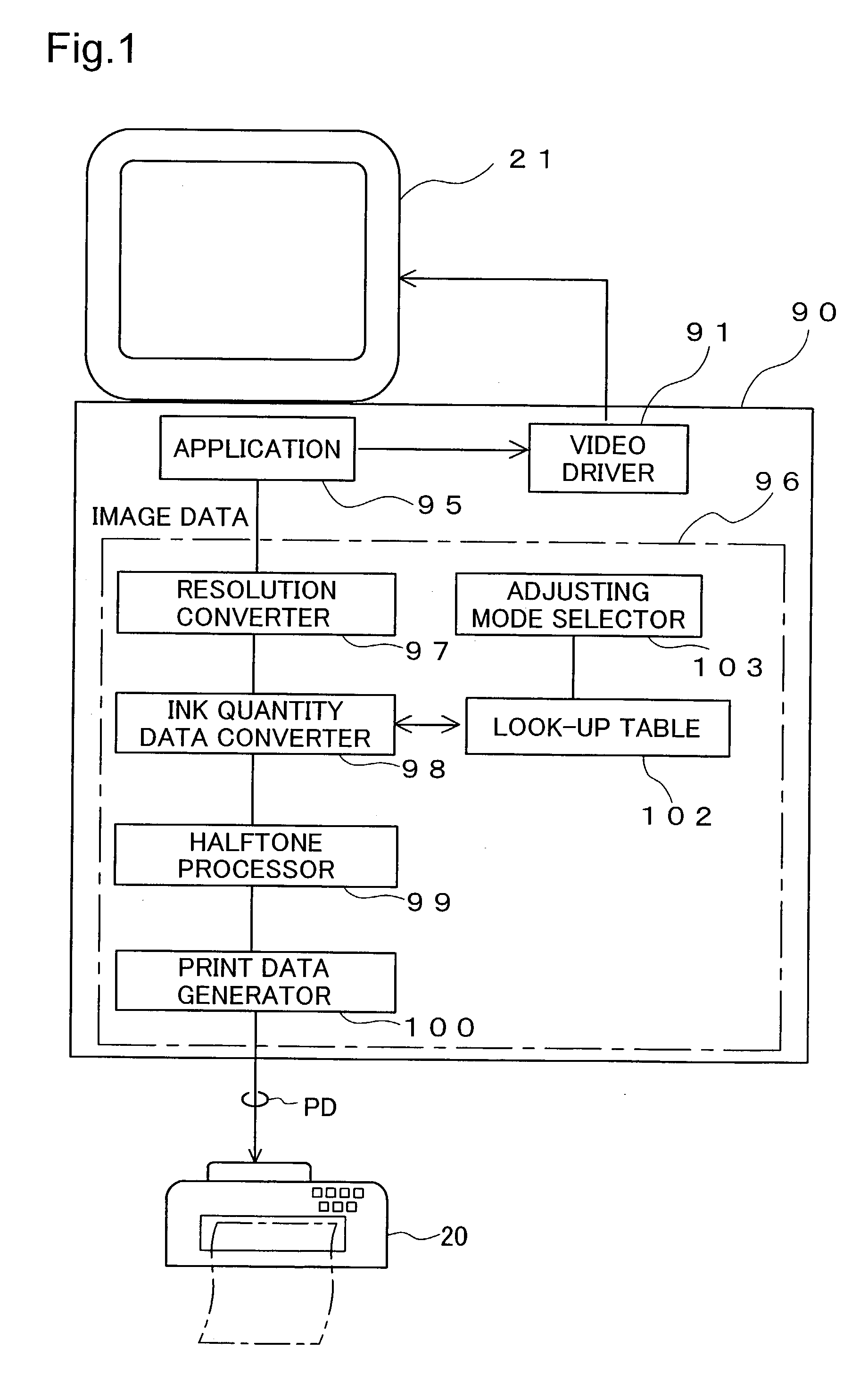

Image printing using print quality enhancing ink

Image quality is improved by adjusting the ejection amount of quality enhancing ink based on the ejection amount of colored ink containing colorant. When a relatively high gross printing medium is used, the quality enhancing ink is ejected in an image area where virtually no colored ink is ejected, thereby improving unevenness in gloss within the print image. When a relatively low gross printing medium is used, on the other hand, the quality enhancing ink is ejected in an image area where the colored ink is ejected on virtually all pixels, thereby improving unevenness in color within the print image. The relationship between the ejection amounts of the quality enhancing ink and the colored ink may be modified by the user.

Owner:NEC CORP +1

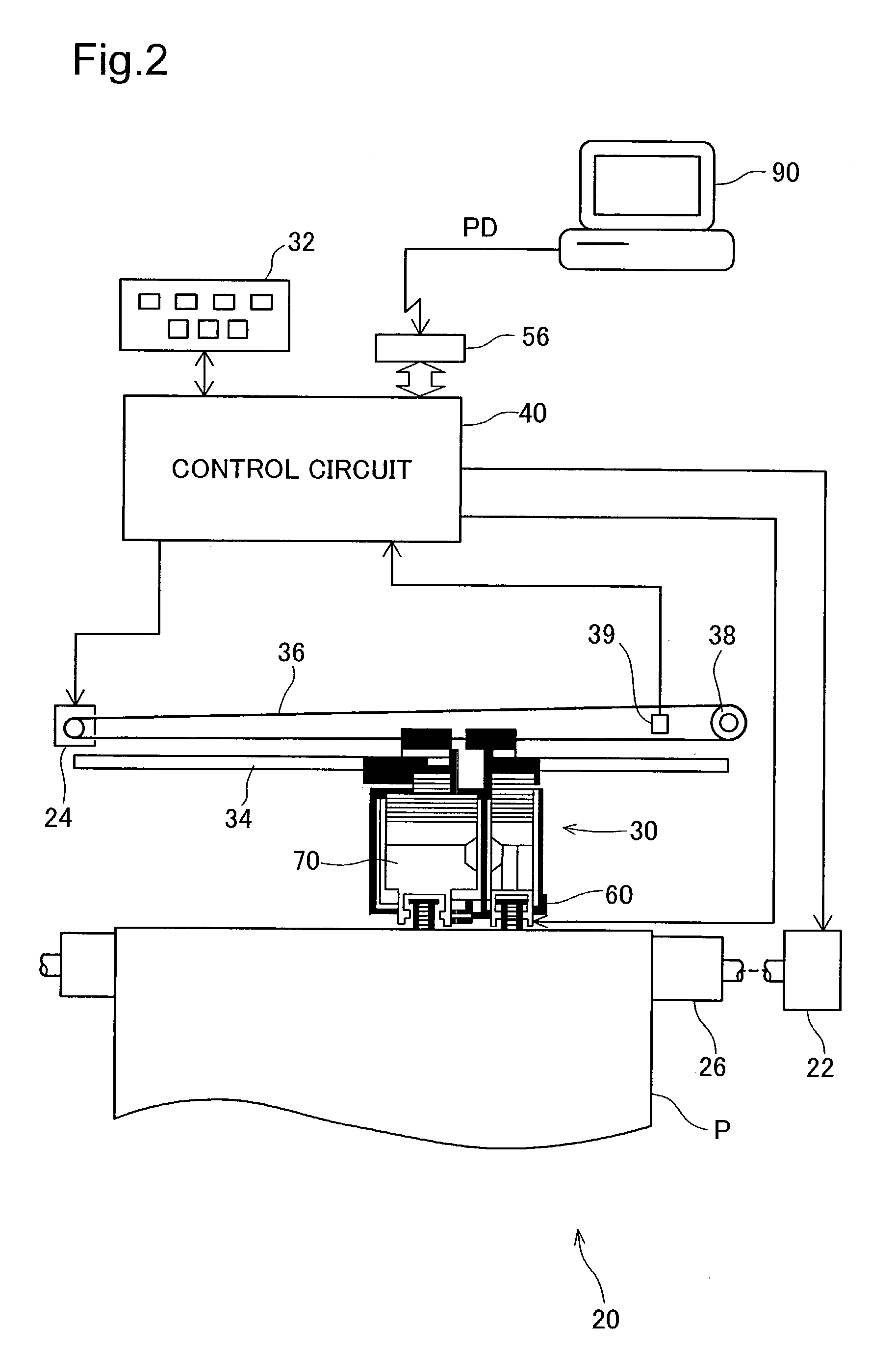

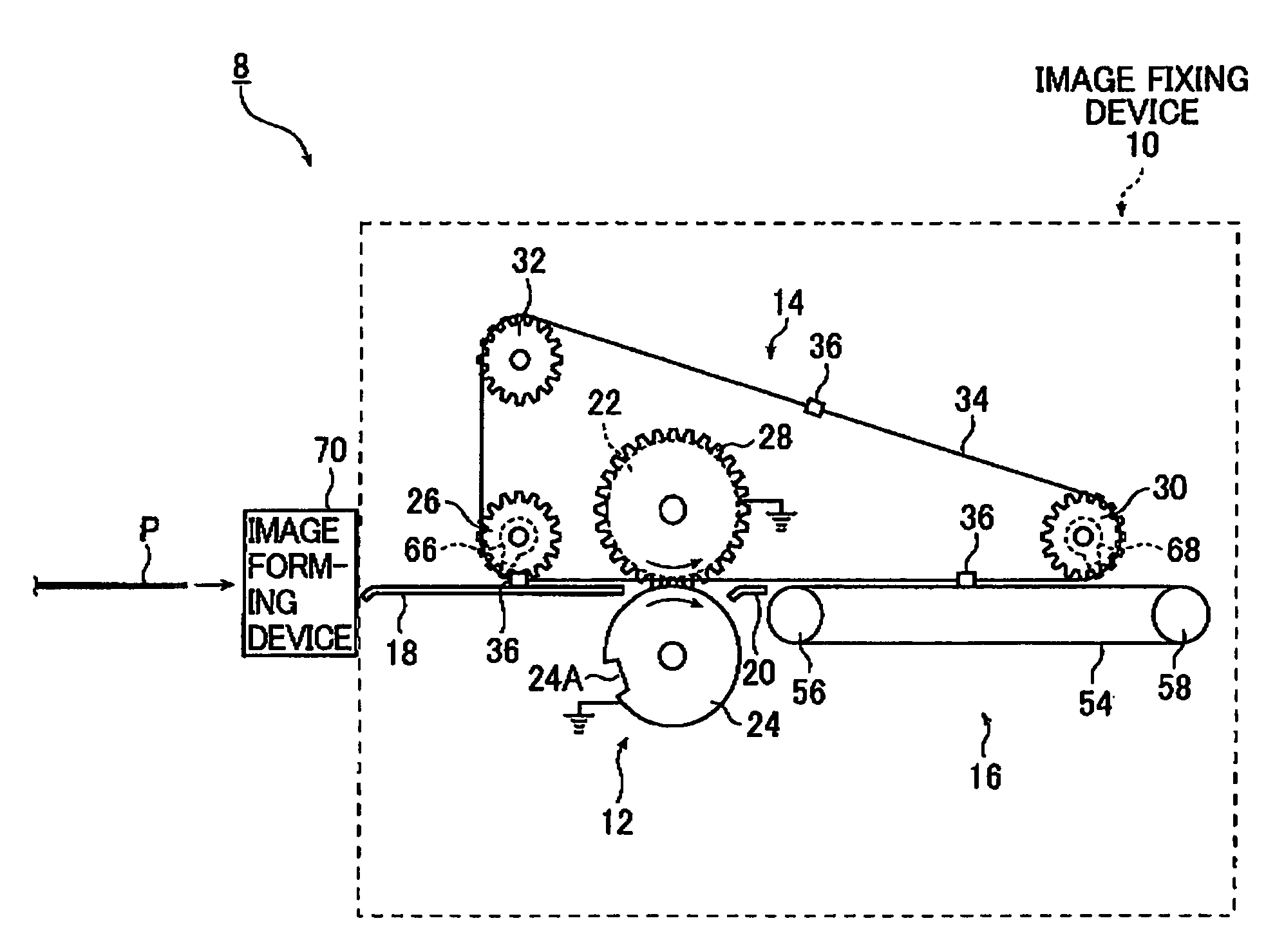

Image fixing device, image recording apparatus equipped with the same, and image fixing method

InactiveUS20060056886A1Quality improvementReduce glossElectrographic process apparatusOther printing apparatusLeading edgeImage recording

The image fixing device includes a fixing roller pair by which a recording medium having an image formed thereon is nipped and conveyed to fix the image, and a gripping / conveying unit which includes a gripping portion for gripping a leading edge of the recording medium and which conveys the recording medium between two fixing rollers while gripping the leading edge of the recording medium. In this device, at least one of the two fixing rollers of the fixing roller pair has a recess receiving the gripping portion, and is set such that when the leading edge of the recording medium gripped by the gripping portion is nipped between the two fixing rollers, the gripping portion is received by the recess. Alternatively, the device includes a roller moving unit for moving at least one of the two fixing rollers. The roller moving unit brings the two rollers of the fixing roller pair out of contact with each other before the gripping portion gripping the leading edge of the recording medium passes between the fixing rollers, and brings the fixing rollers into contact with each other after the gripping portion has passed between the fixing rollers.

Owner:FUJIFILM CORP +1

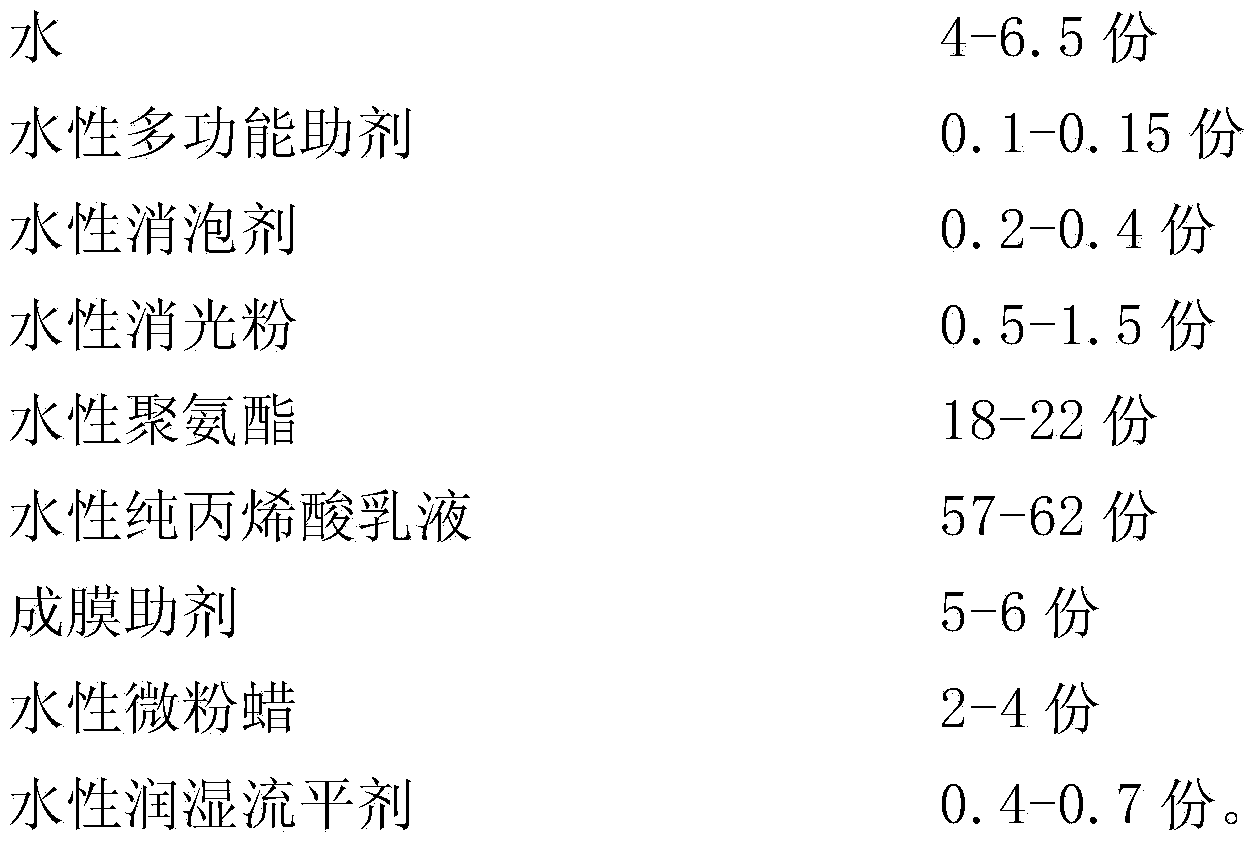

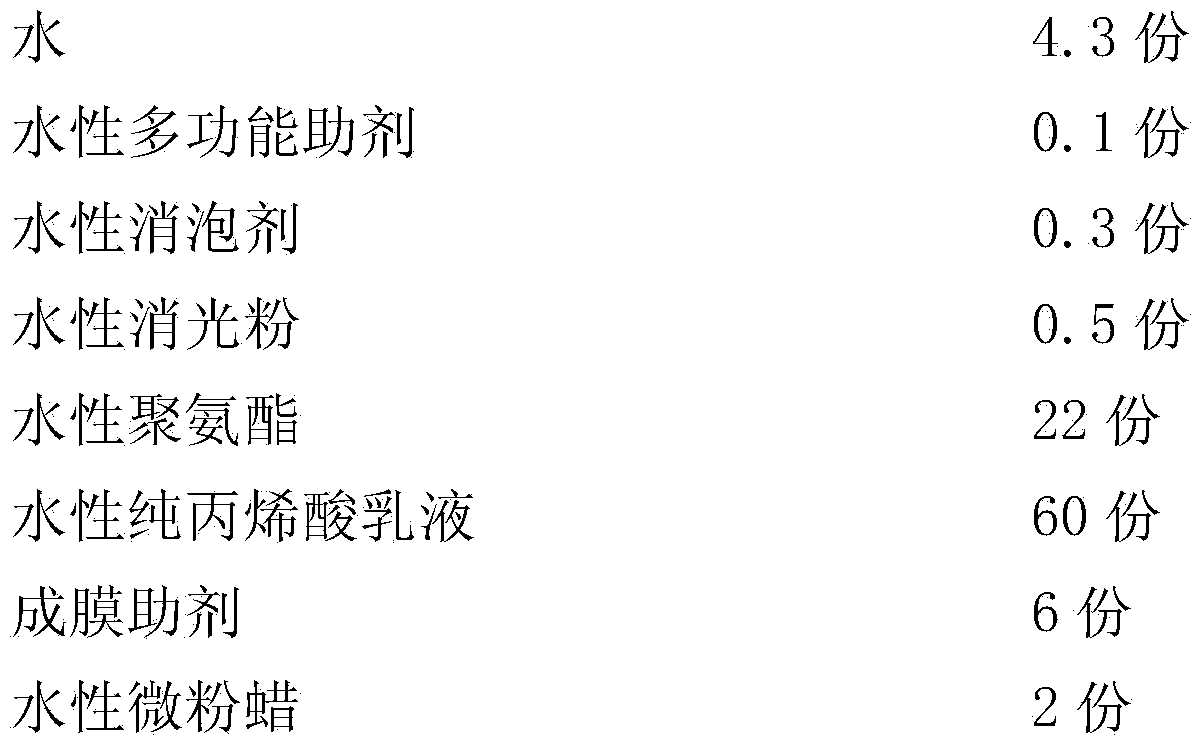

Aqueous woodenware matte clean finishing coat and its preparation method

The invention relates to a woodenware paint and a preparation method, and especially relates to an aqueous woodenware matte clean finishing coat and its preparation method, which belong to the paint field for building decoration. The provided aqueous woodenware matte clean finishing coat comprises the following raw materials by weight: 4-6.5 parts of water, 0.1-0.15 parts of aqueous multifunctional auxiliary agent, 0.2-0.4 parts of aqueous antifoaming agent, 0.5-1.5 parts of aqueous flatting silica, 18-22 parts of aqueous polyurethane, 57-62 parts of aqueous pure acrylic acid emulsion, 5-6 parts of film forming auxiliary agent, 2-4 parts of aqueous micro powder wax and 0.4-0.7 parts of aqueous wetting levelling agent. The prepared aqueous woodenware matte clean finishing coat has the advantages that the glossiness of a paint film is easily reduced, and the scratch resistance capability of the surface is strong.

Owner:SKSHU PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com