Patents

Literature

61results about How to "Outstanding resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low gloss ASA resin

A thermoplastic molding composition comprising a grafted acrylate rubber (ASA) and a gloss reducing agent and a process for making the same are disclosed. The gloss reducing agent is the reaction product of (i) a compound having two or more epoxy groups per molecule and (ii) a compound having two or more amine groups per molecule, with the proviso that the total of epoxy groups of (i) and amine groups of (ii) per molecule is greater than 4. The gloss reducing agent may be either incorporated in ASA as the reaction product of (i) and (ii) or, in the alternative, formed upon the reaction of (i) with (ii) in the course of the thermal processing of the a blend containing ASA, (i) and (ii).

Owner:INEOS ABS JERSEY +1

Cold-rolled steel sheet

InactiveUS20120009434A1Improves stretch flangeabilitySatisfactory resistanceSemiconductor/solid-state device detailsExtrusion containersFlangeFormability

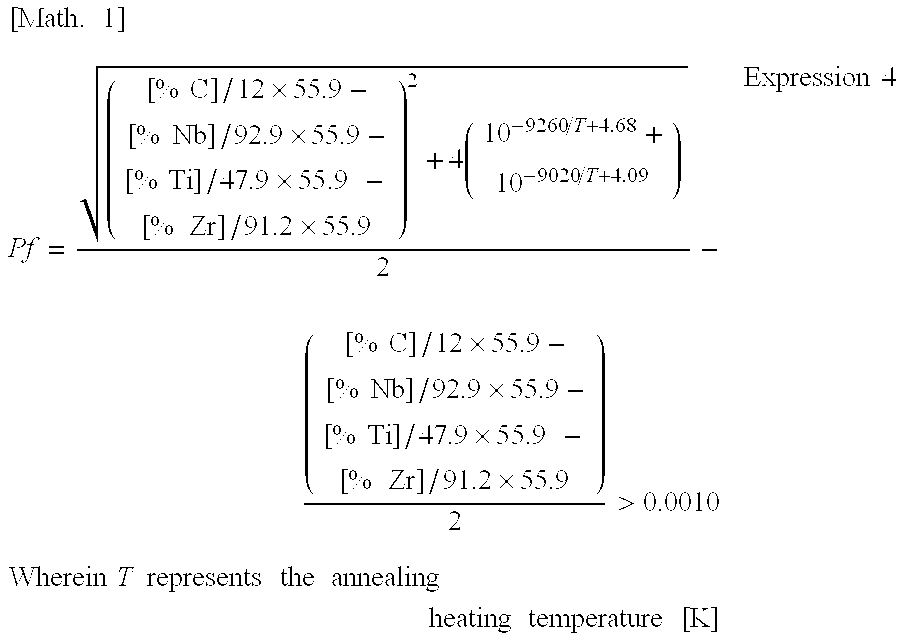

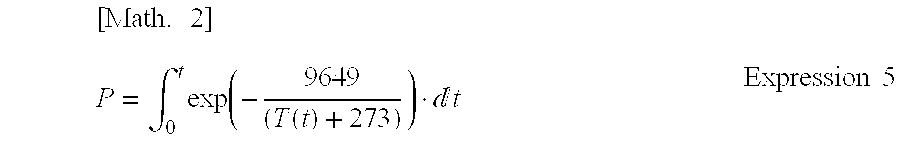

Disclosed is a high-strength cold-rolled steel sheet which has improved stretch-flange formability while keeping excellent hydrogen embrittlement resistance. The cold-rolled steel sheet comprises 0.03 to 0.30% by mass of C, 3.0% by mass or less (including 0% by mass) of Si, more than 0.1% by mass and not more than 2.8% by mass of Mn, 0.1% by mass or less of P, 0.005% by mass or less of S, 0.01% by mass or less of N, and 0.01 to 0.50% by mass of Al. The cold-rolled steel sheet additionally comprises V in an amount of 0.001 to 1.00% by mass or one or more elements selected from Nb, Ti and Zr in the total amount of 0.01% by mass or more, with the remainder being made up by iron and unavoidable impurities, wherein the contents of one or more elements selected from Nb, Ti and Zr fulfils the requirement represented by the following formula: [% C]−[% Nb] / 92.9×12−[% Ti] / 47.9×12−[% Zr] / 91.2×12>0.03. In the cold-rolled steel sheet, the area ratio of tempered martensite is 50% or more (including 100%), and ferrite makes up the remainder. In the cold-rolled steel sheet, the distribution of precipitates in the tempered martensite is as follows: the number of precipitates each having a circle-equivalent diameter of 1 to 10 nm is 20 particles or more per 1 μm2 of the tempered martensite and the number of precipitates each containing V or at least one element selected from Nb, Ti and Zr and each having a circle-equivalent diameter of 20 nm or more is 10 particles or less per 1 μm2 of the tempered martensite.

Owner:KOBE STEEL LTD

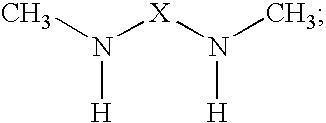

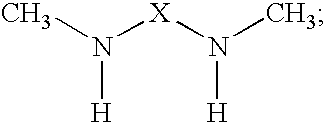

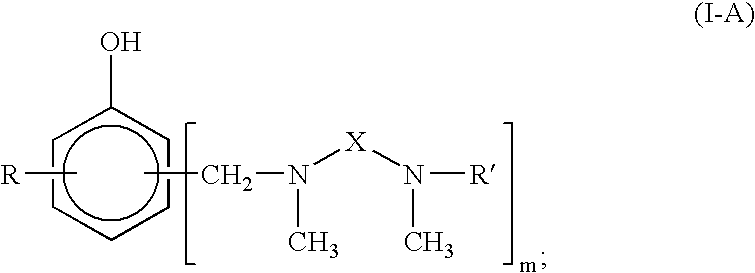

Curing agent for low temperature cure applications

InactiveUS20080194776A1Extended drying timeRapid hardness developmentThin material handlingEpoxyLow temperature curing

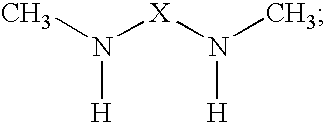

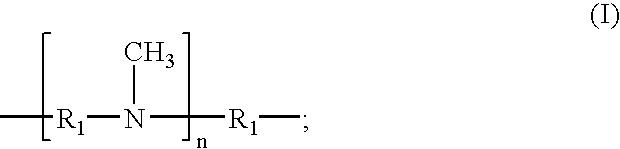

The present invention provides N,N′-dimethyl secondary diamine polymers including methylamine-terminated poly-(N-methylazetidine) and methylamine-terminated poly-(N-methylazacycloheptane). Amine compositions and amine-epoxy compositions comprising N,N′-dimethyl secondary diamine polymers are also disclosed.

Owner:EVONIK DEGUSSA GMBH

Highly durable polymer electrolytic membrane for a fuel cell having a cross-linked structure

InactiveUS20060134493A1Wide rangeGood dimensional stabilityCation exchanger materialsIon-exchanger regenerationCross-linkFunctional monomer

The objective of the invention is to solve the problems of conventional polymer electrolyte membranes, including small ion-exchange capacity and low oxidation and methanol resistance. A polymer film substrate is irradiated with γ-rays, electron beams or other radiations to perform multi-graft polymerization with functional monomers and then the polymer film substrate containing the grafted molecular chains or the graft molecular chains into which sulfonic acid groups have been introduced is crosslinked by irradiation to produce a polymer electrolyte membrane that has outstanding oxidation resistance, dimensional stability, electrical conductivity and methanol resistance and which can be controlled in ion-exchange capacity over a wide range.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP +1

Non-crystalline saliva-soluble coatings for elastomeric monofilament dental tapes

InactiveUS20050226820A1Substantivity of coatings onto flexible surfacesResistance to crackingCosmetic preparationsToilet preparationsMedicineControl substances

Owner:WHITEHILL ORAL TECH

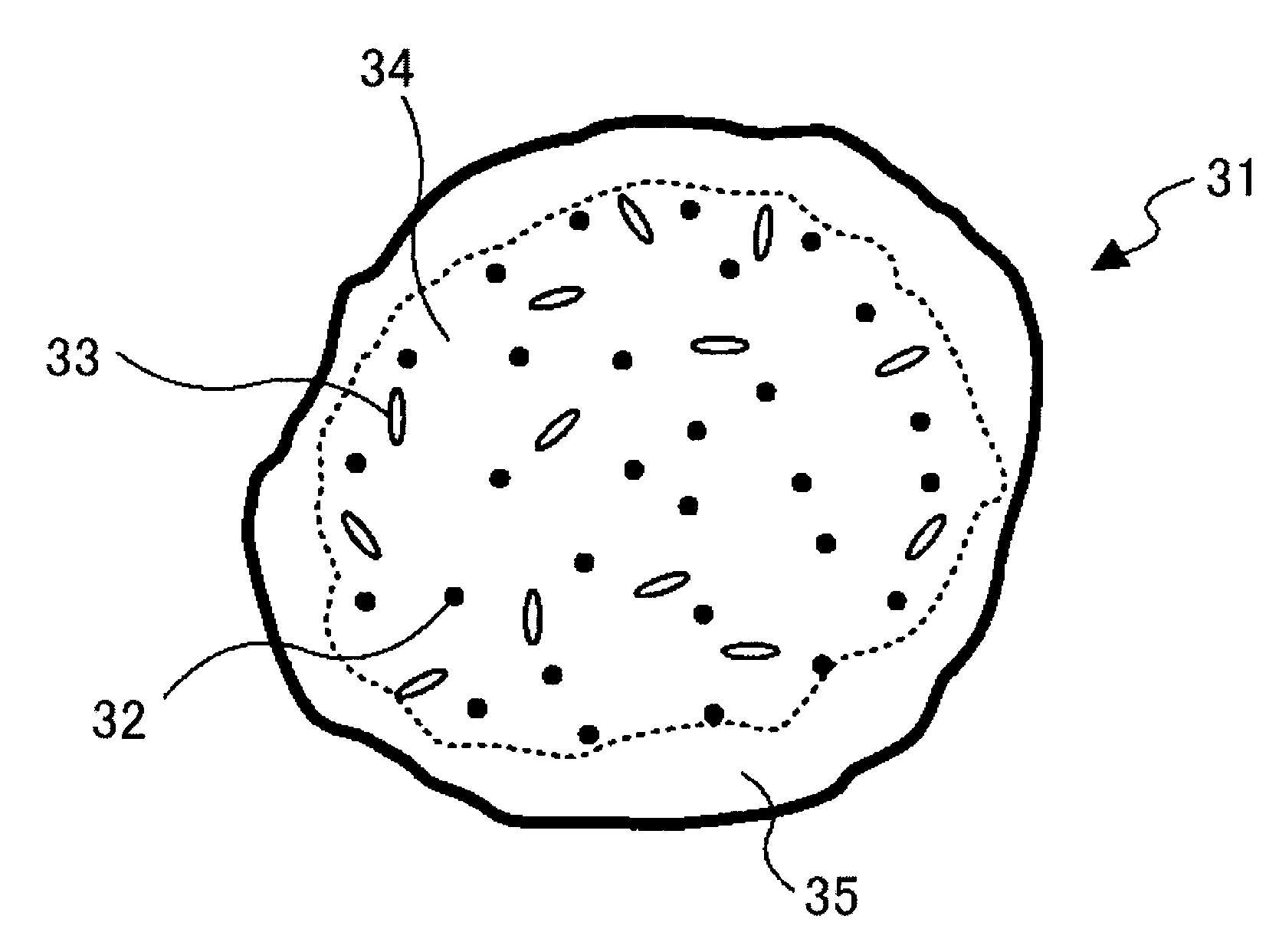

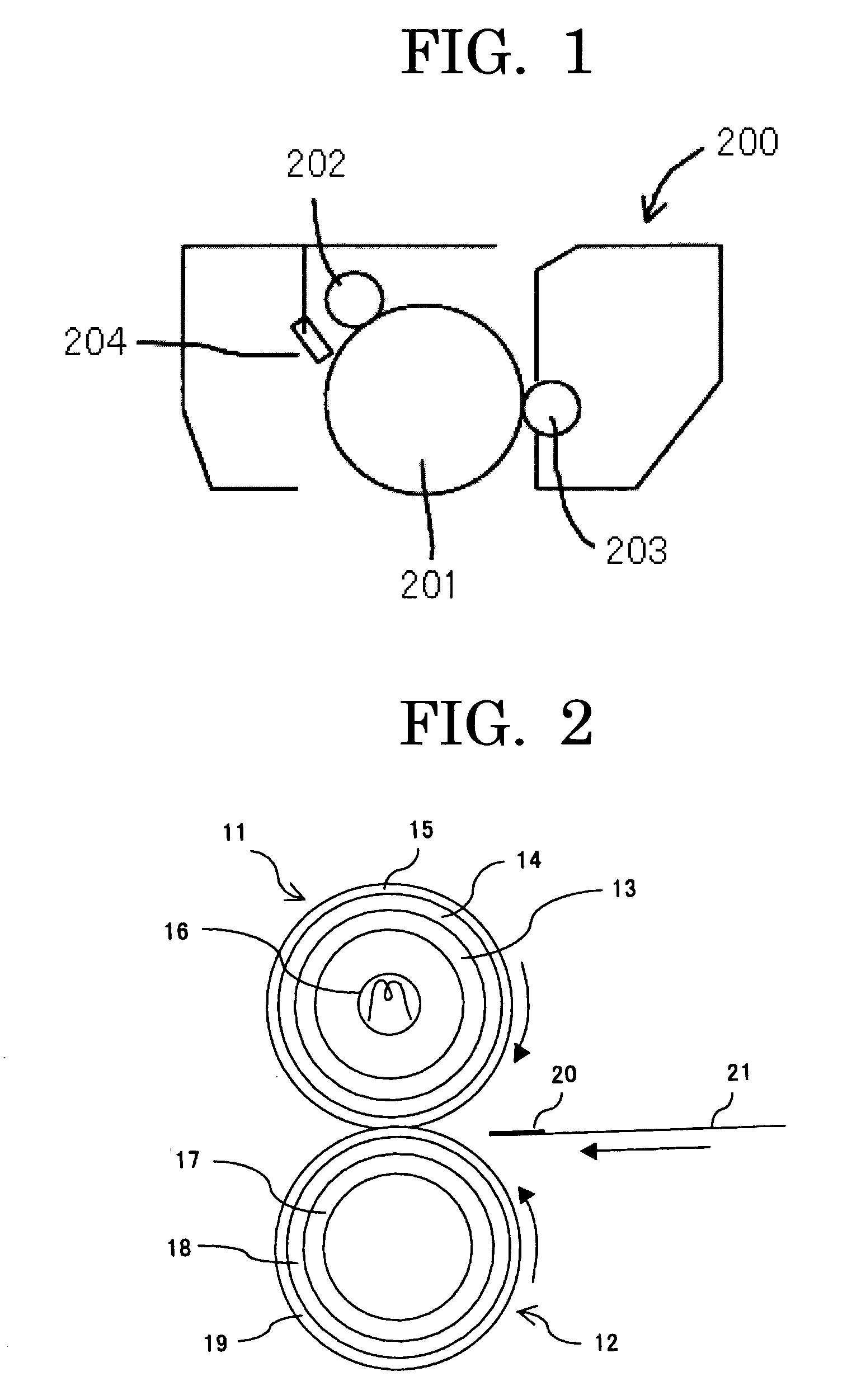

Toner for developing electrostatic images, production method thereof; developer, image forming method, image forming apparatus, and process cartridge

InactiveUS20070218390A1Improve charging effectOutstanding resistanceDevelopersElectrographic processes using charge patternHydrogenOrganic solvent

The present invention provides a toner which is obtained by dissolving and / or dispersing in an organic solvent a toner material that includes at least a functional group-containing modified polyester resin capable of undergoing an elongation reaction and / or a crosslinking reaction with an active hydrogen group-containing compound, a vinyl resin, a releasing agent, and a colorant to prepare a toner solution, then emulsifying and / or dispersing the toner solution in an aqueous medium to prepare an emulsified dispersion, and allowing the functional group-containing modified polyester resin to undergo an elongation reaction and / or a crosslinking reaction with the active hydrogen group-containing compound in the aqueous medium, wherein the vinyl resin is concentrated near the surface of the toner.

Owner:RICOH KK

Process for producing a dried composite semipermeable membrane

ActiveUS20080251447A1Good water permeabilityOutstanding durabilityMembranesSemi-permeable membranesHydrophilizationSemipermeable membrane

The present invention aims at providing a process for producing a dried composite semipermeable membrane having extremely small amount of content of unreacted components, outstanding water permeability and salt-blocking rate even after drying treatment, and outstanding contamination resistance and durability. The present invention relates to a process for producing a dried composite semipermeable membrane comprising the steps of: preparing a composite semipermeable membrane having a skin layer including a polyamide resin obtained by reaction between a polyfunctional amine component and a polyfunctional acid halide component formed on the surface of a porous support; preparing a washed composite semipermeable membrane by washing the composite semipermeable membrane; preparing a treated composite semipermeable membrane by contact of a moisturing solution including a moisturizer and a hydrophilization agent only to the surface of the porous support of the washed composite semipermeable membrane and by contact of a protecting solution only to the surface of the skin layer of the washed composite semipermeable membrane; and drying the treated composite semipermeable membrane.

Owner:NITTO DENKO CORP

Heat-curable powder coating composition

InactiveUS20090270533A1Excellent long-term heat resistanceOutstanding flexibilityAnti-corrosive paintsEpoxy resin coatingsPolymer sciencePolymer chemistry

Disclosed is a heat-curable powder coating composition that allows the formation of a coating film having outstanding long-term corrosion resistance, as well as outstanding chipping resistance, flexibility, and adhesion.The disclosed heat-curable powder coating composition is characterized by a resin having crosslinkable functional groups that are solid at room temperature (A), a curing agent capable of reacting with said crosslinkable functional groups (B), a fibrous filler (C), and heat-expandable resin particles (D).

Owner:BASF COATINGS JAPAN

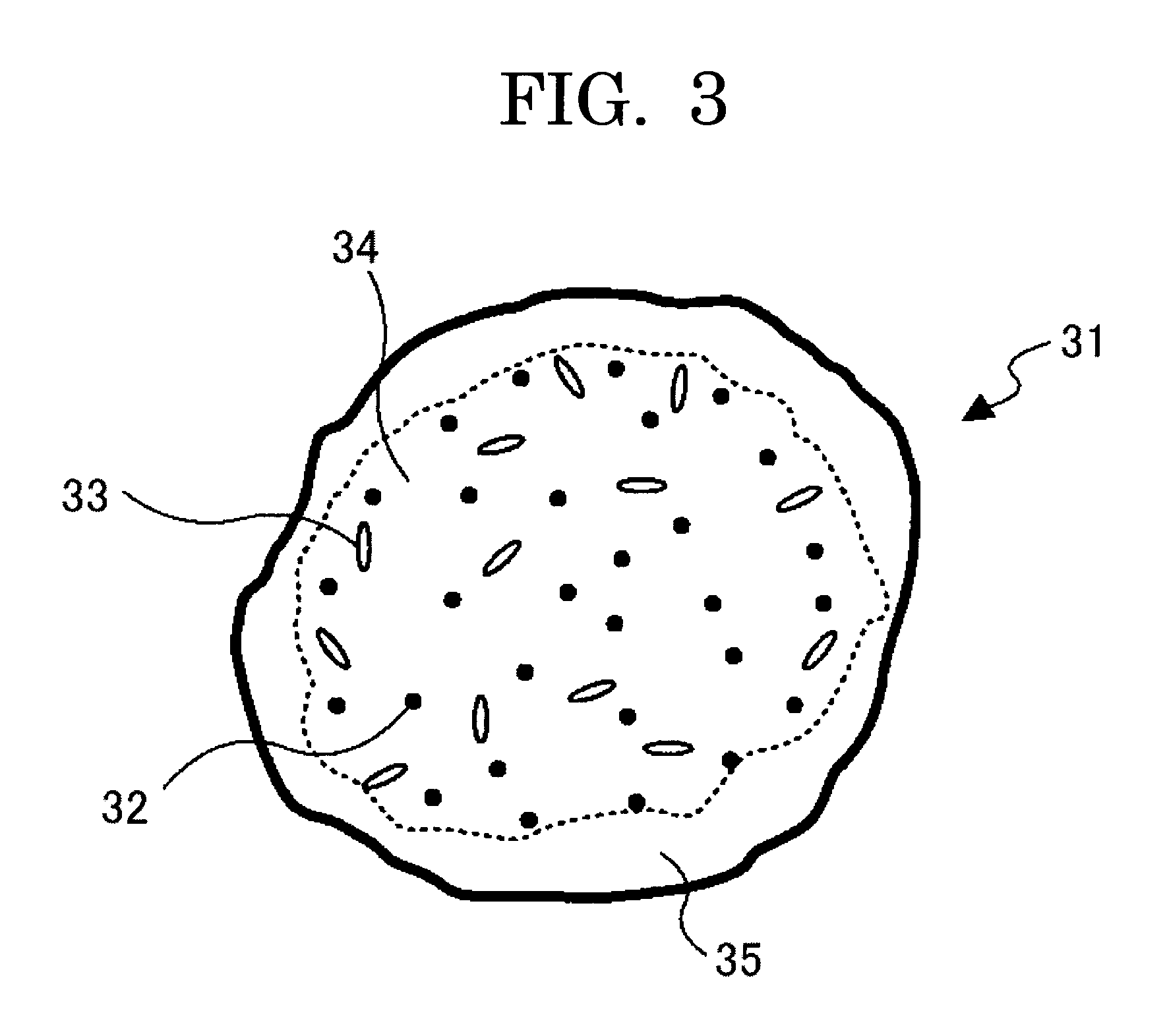

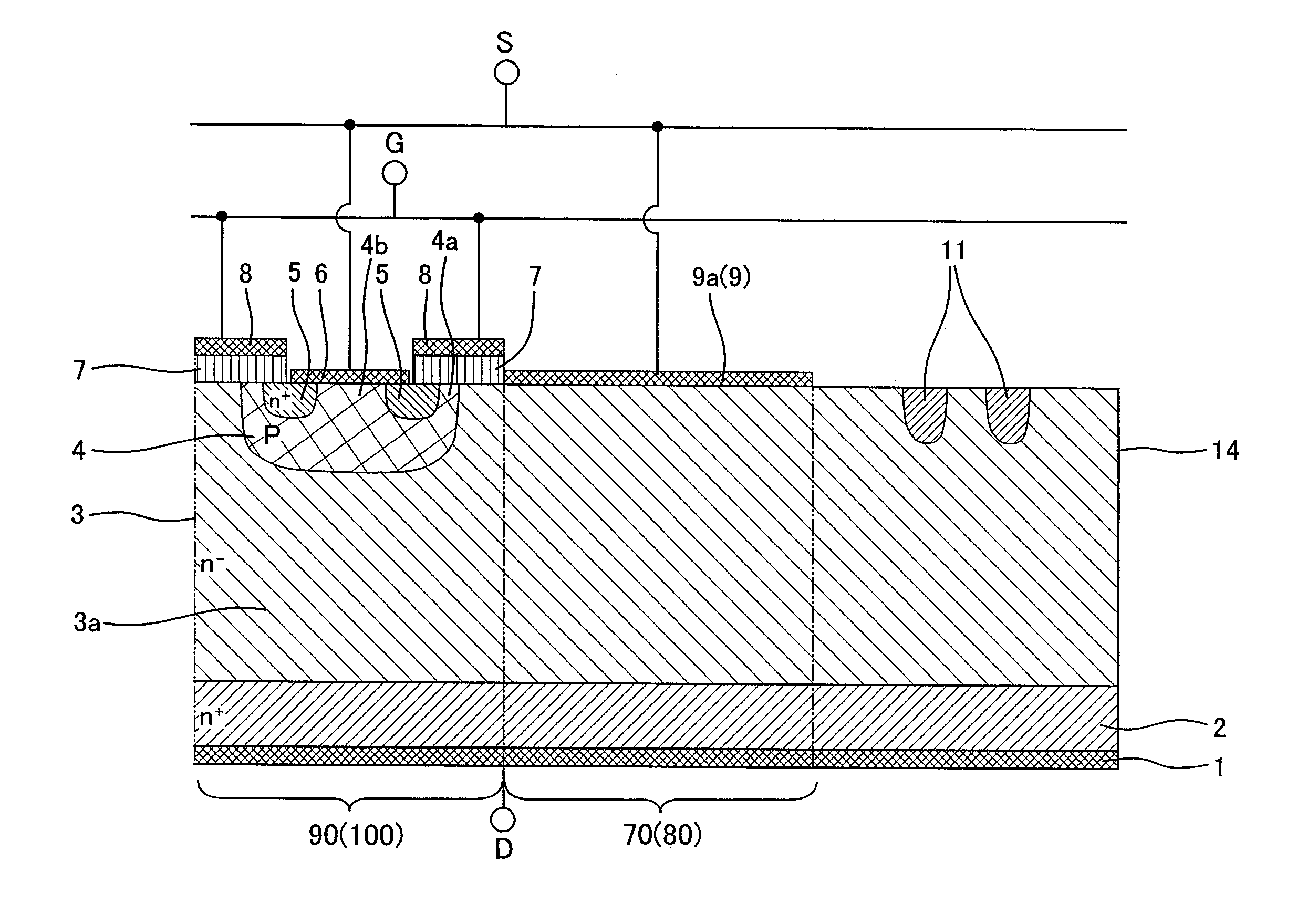

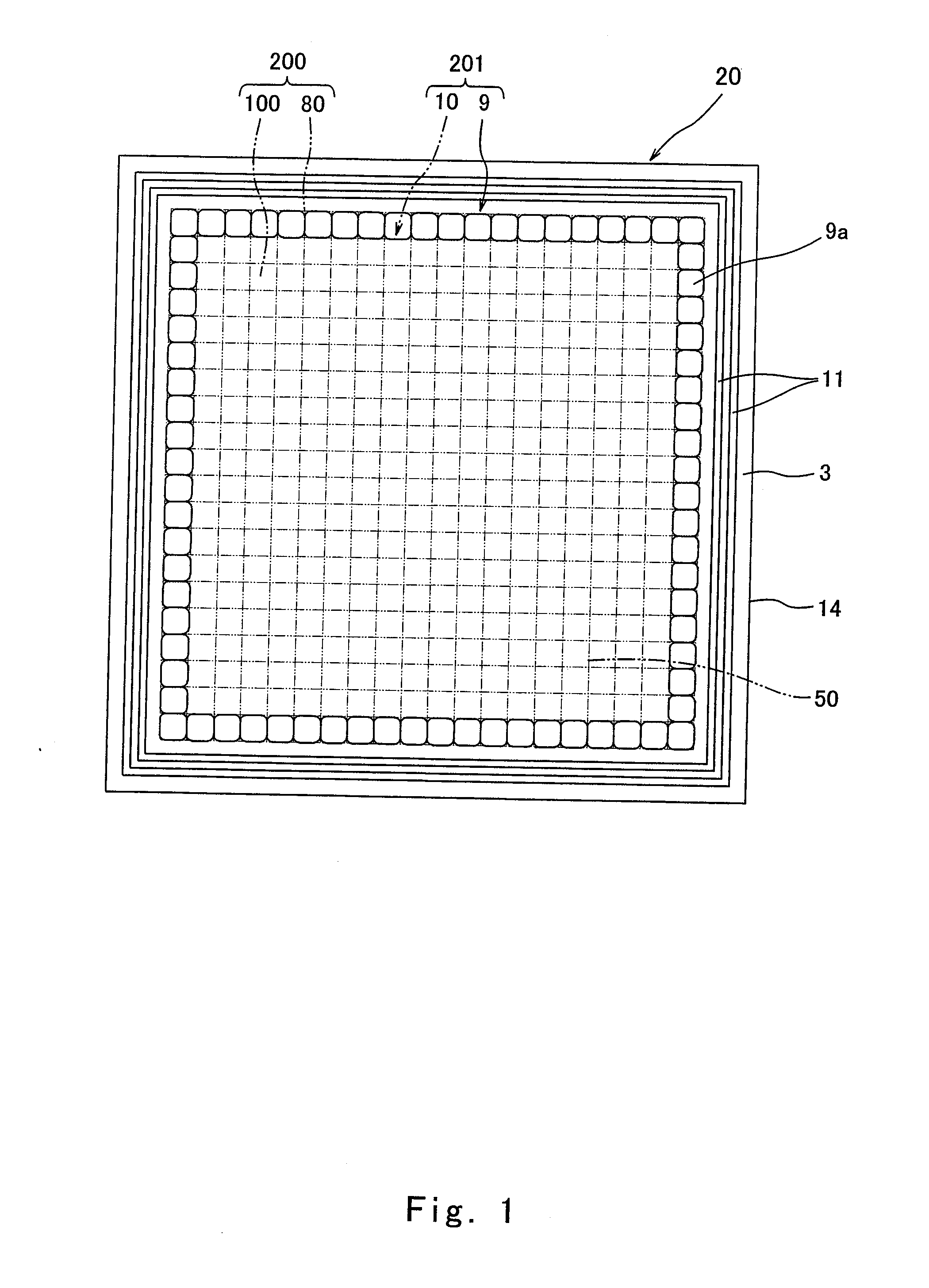

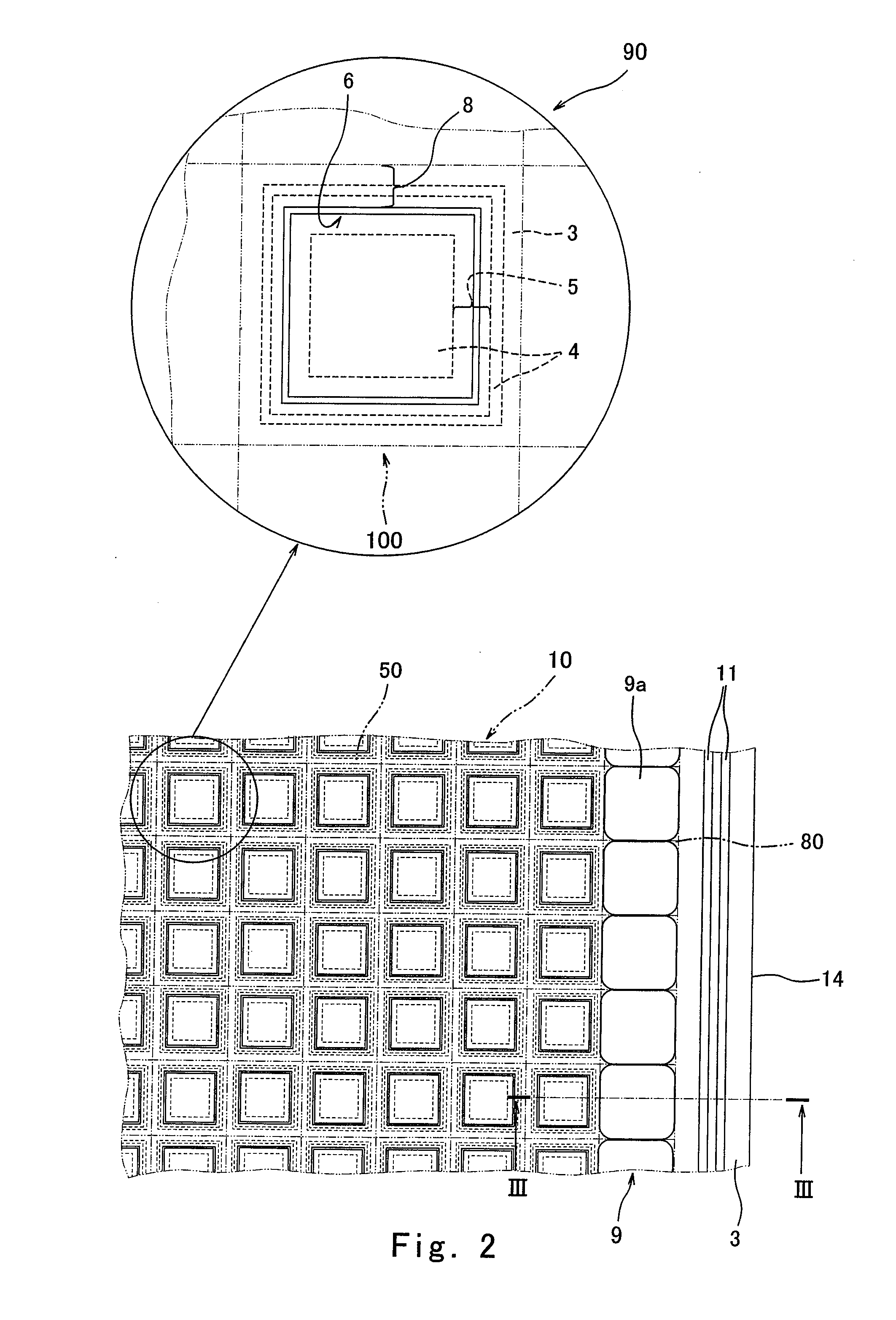

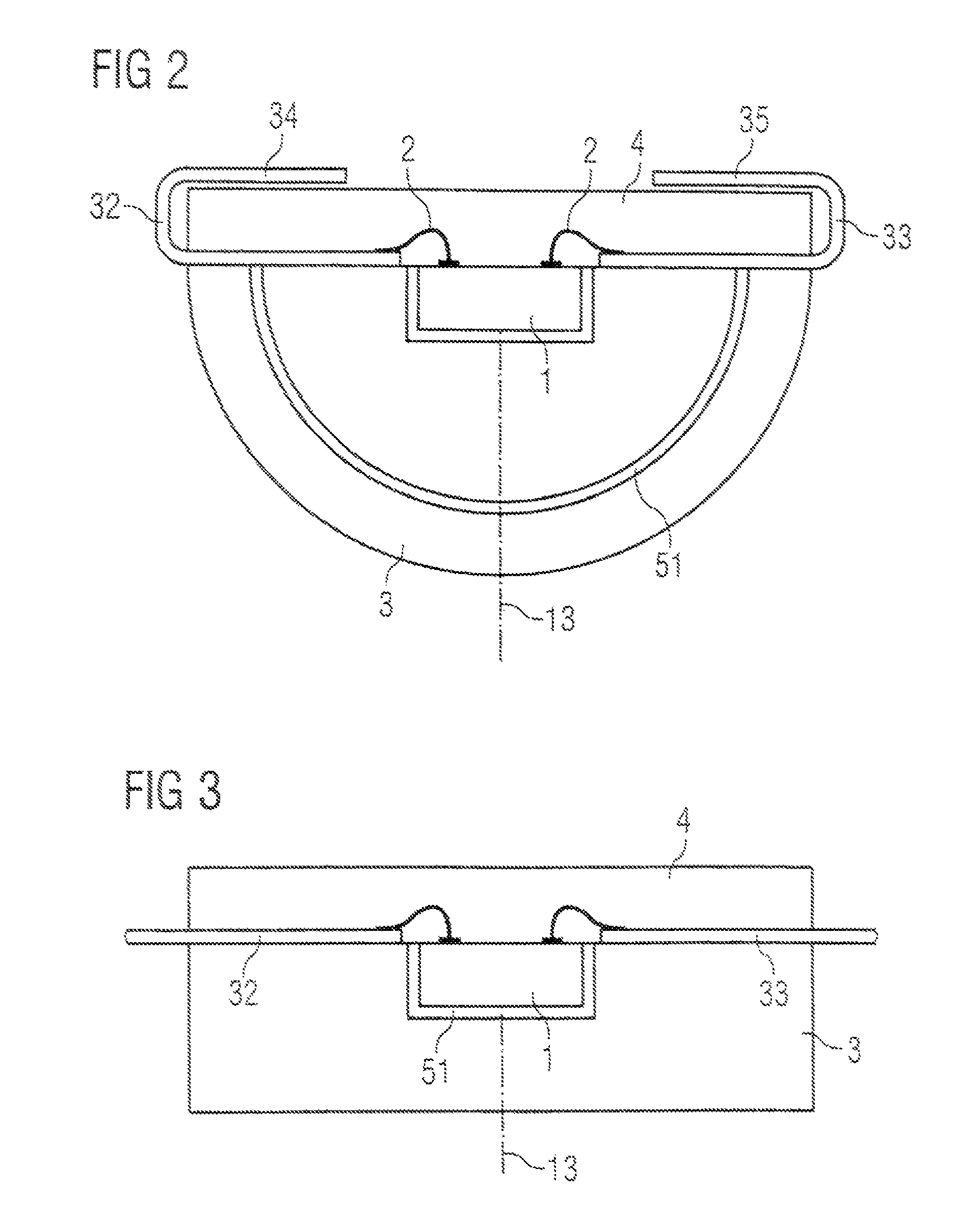

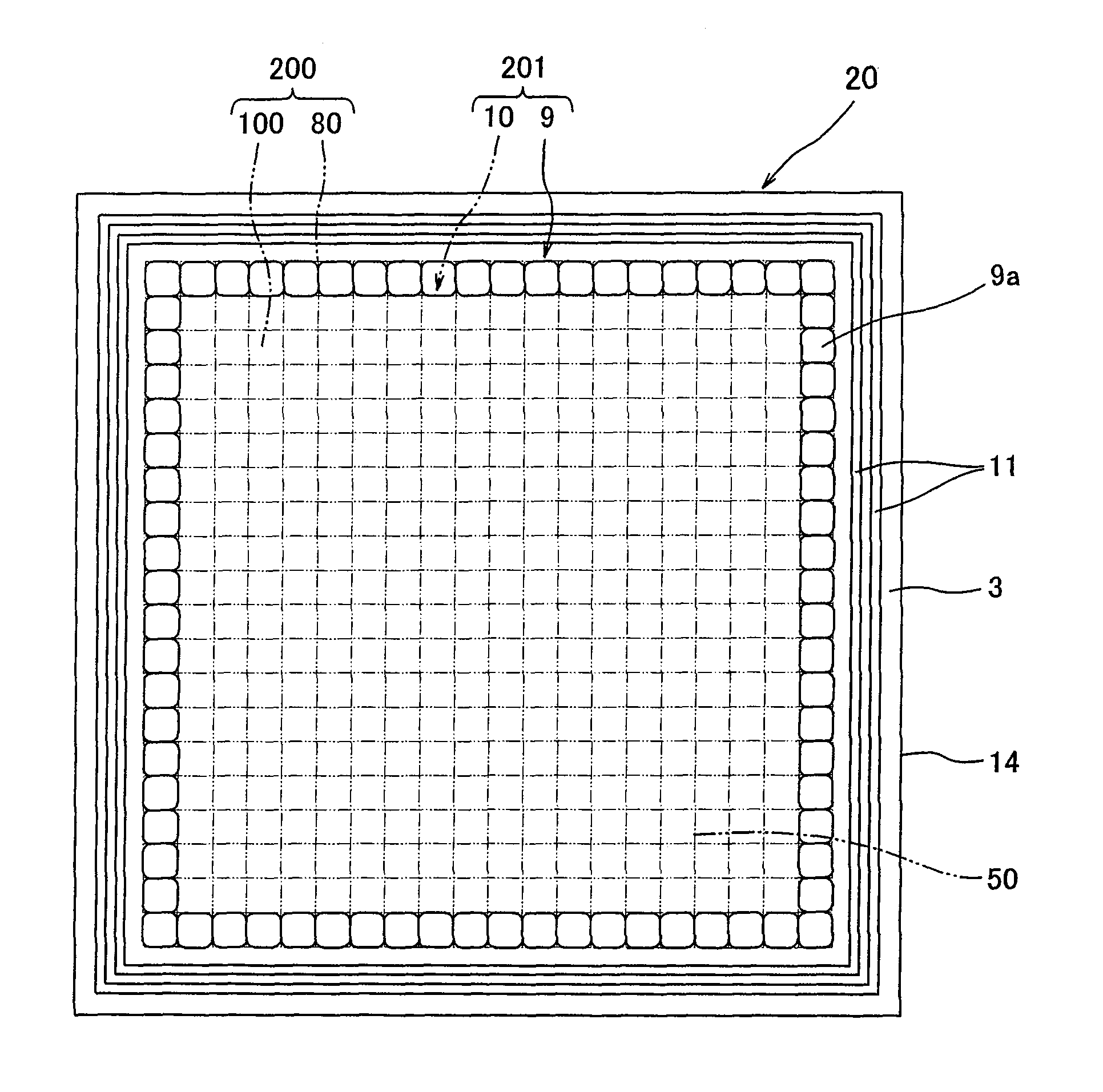

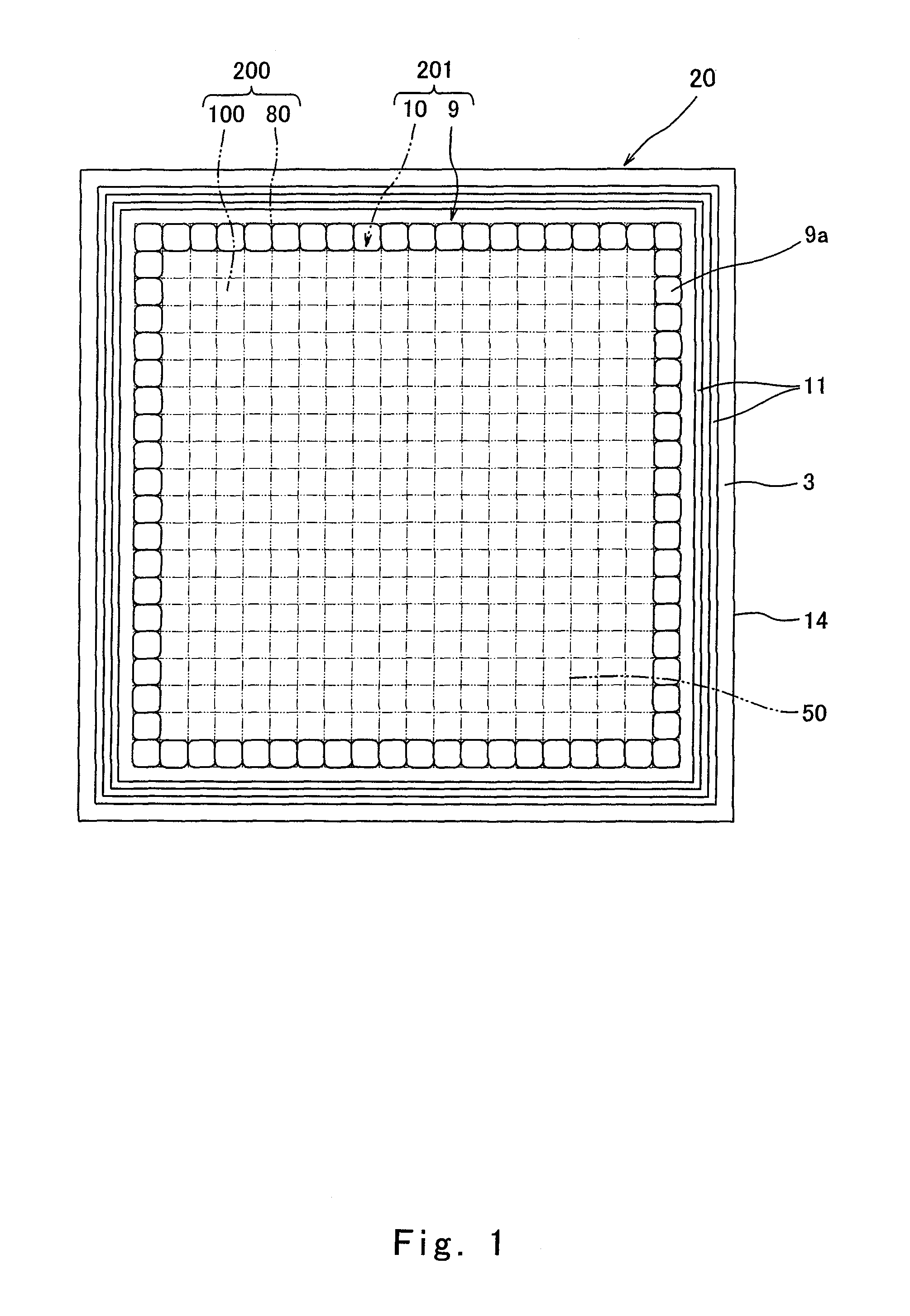

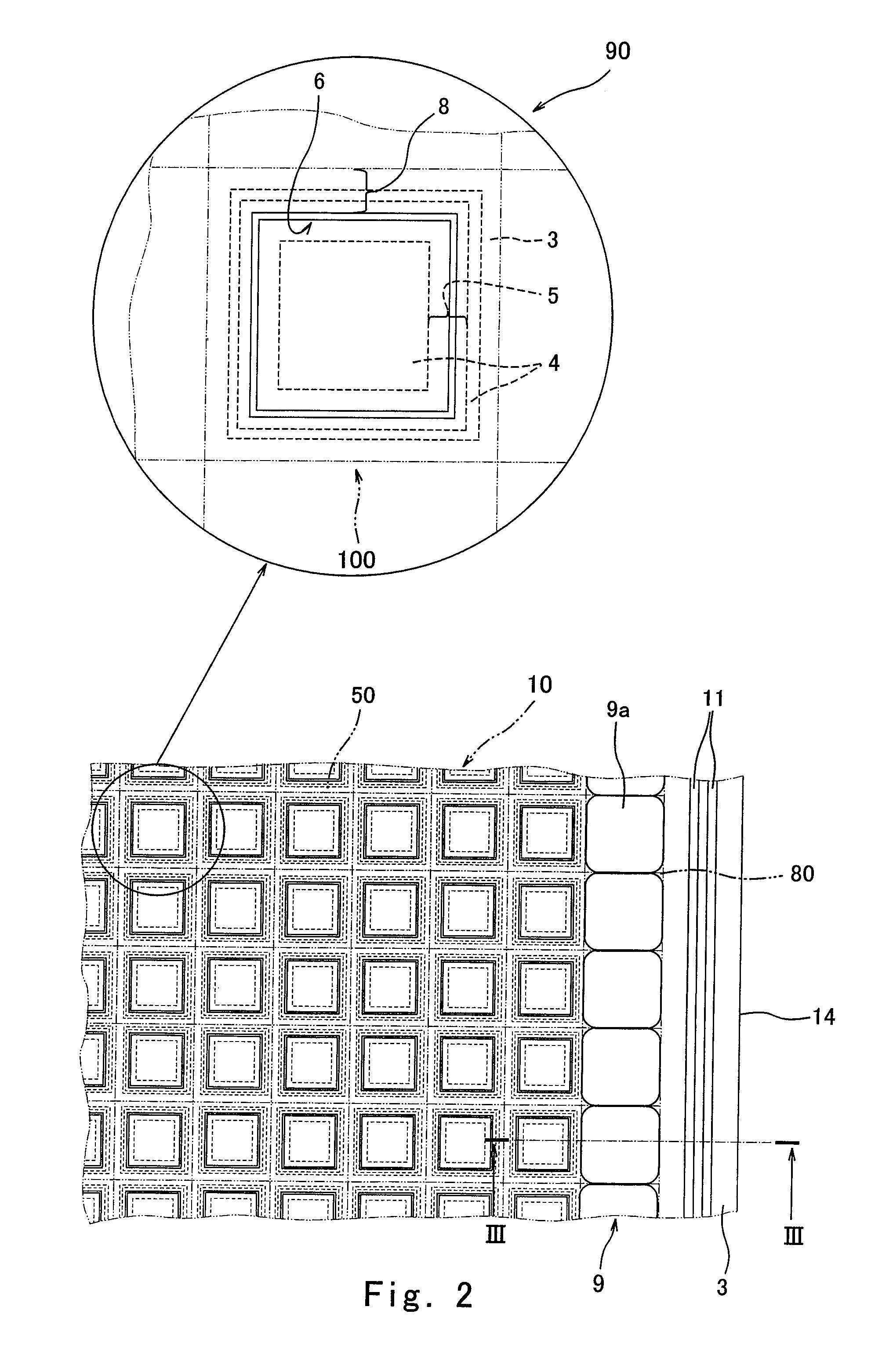

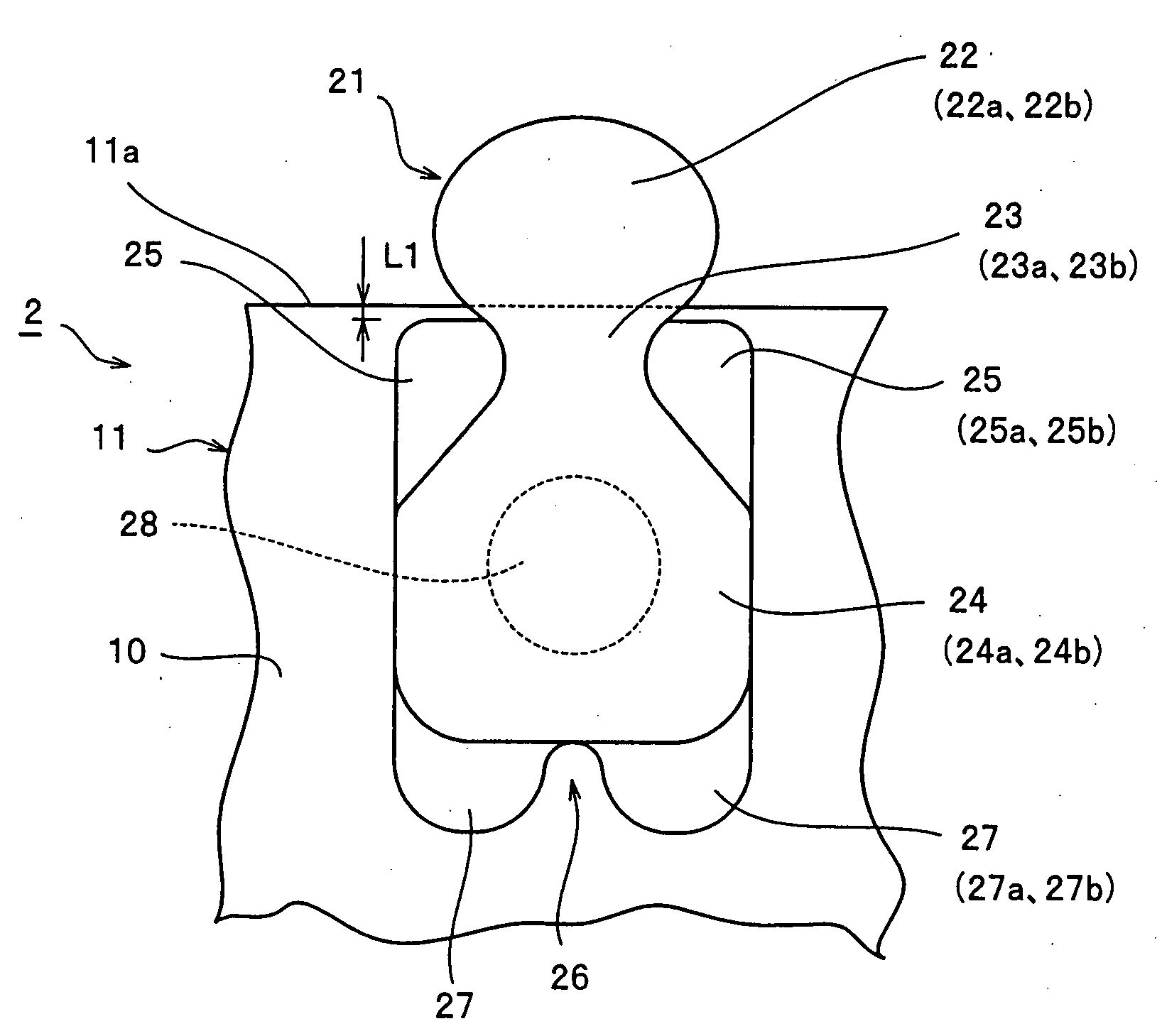

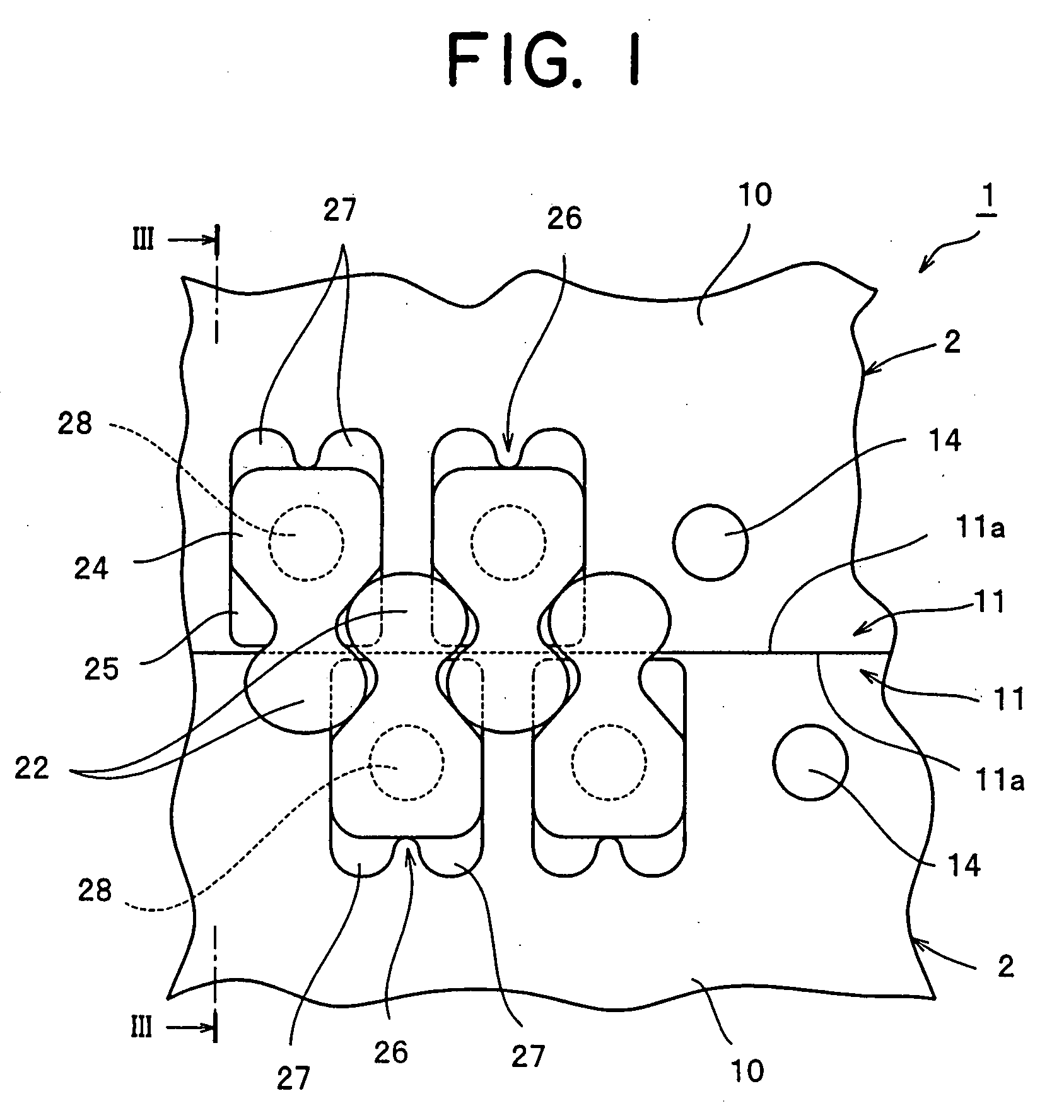

Semiconductor element and electrical apparatus

ActiveUS20100148718A1Run at high speedOutstanding resistanceTransistorAC motor controlEngineeringSemiconductor components

A semiconductor element (20) of the present invention includes a plurality of field effect transistors (90) and a schottky electrode (9a), and the schottky electrode (9a) is formed along an outer periphery of a region where the plurality of field effect transistors (90) are formed.

Owner:PANASONIC CORP

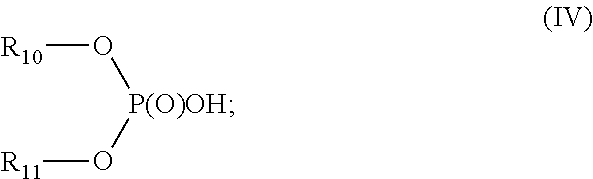

Coating agents having high scratch resistance and weathering stability

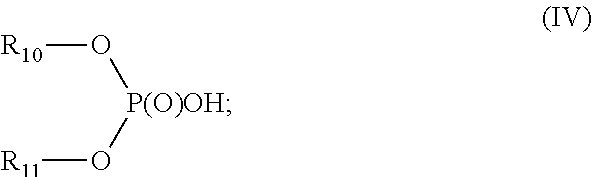

ActiveUS8569438B2Good reproducibilityEasy to preparePretreated surfacesPolyurea/polyurethane coatingsSilanesPolymer chemistry

Disclosed are coating compositions comprising (a) at least one hydroxyl-containing compound (A), (b) at least one compound (B) having isocyanate groups, and (c) at least one catalyst (D) for the crosslinking of silane groups, said catalyst (D) comprising phosphorus. It is an aspect of the disclosed coating compositions that (i) one or more constituents of the coating composition contain hydrolyzable silane groups and (ii) the coating composition can be finally cured to a coating which has statistically distributed regions of an Si—O—Si network.

Owner:BASF COATINGS GMBH

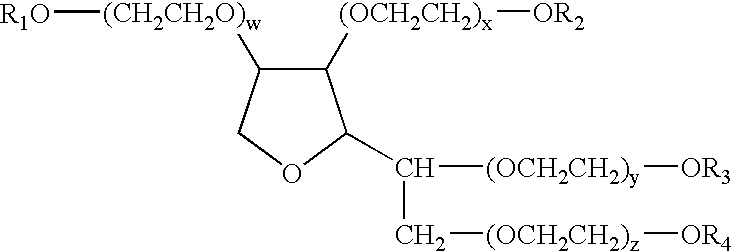

Resin Composition for Forming Fine Pattern and Method for Forming Fine Pattern

ActiveUS20070259287A1Low costAccurately miniaturizedPhotosensitive materialsSemiconductor/solid-state device manufacturingResistAlcohol

A resin composition which, in forming a fine pattern by a heat treatment of a resist pattern formed by using a photoresist, can be applied onto the resist pattern, can cause the resist pattern to smoothly shrink by heat treatment, and can be easily washed away by a treatment with an alkaline aqueous solution, and a method for efficiently forming a fine resist pattern using the resin composition are provided. The resin composition comprises a resin containing a hydroxyl group, a crosslinking component, and an alcohol solvent containing water in an amount of 10 wt % or less for the total solvent, wherein the alcohol in the alcohol solvent is a monovalent alcohol having 1 to 8 carbon atoms.

Owner:JSR CORPORATIOON

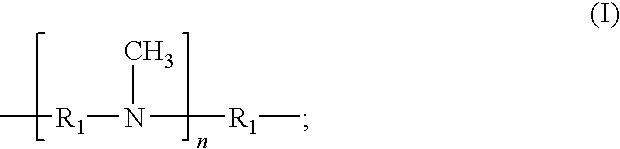

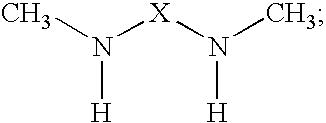

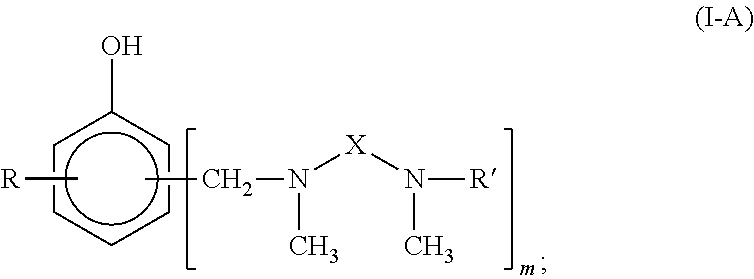

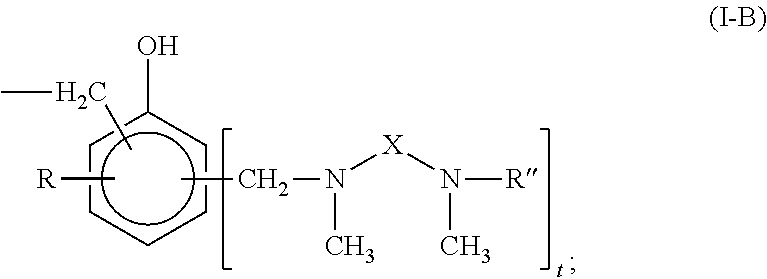

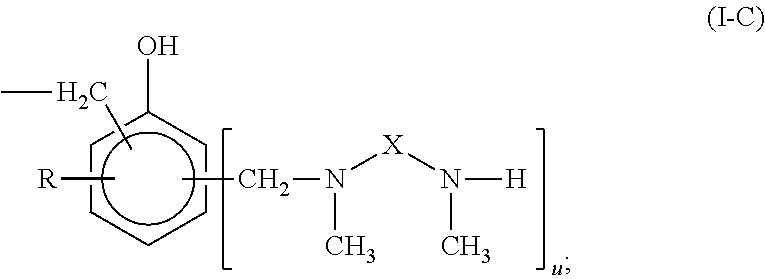

Epoxy resin amine curing agent of N,N′-dimethyl secondary diamine polymer

InactiveUS7666954B2Extended drying timeRapid hardness developmentThin material handlingEpoxyEndcapping

The present invention provides N,N′-dimethyl secondary diamine polymers including methylamine-terminated poly-(N-methylazetidine) and methylamine-terminated poly-(N-methylazacycloheptane). Amine compositions and amine-epoxy compositions comprising N,N′-dimethyl secondary diamine polymers are also disclosed.

Owner:EVONIK DEGUSSA GMBH

Thermoplastic composition having low gloss appearance

A thermoplastic molding composition comprising a grafted acrylate rubber (ASA) and a gloss reducing agent and a process for making the same are disclosed. The gloss reducing agent is the reaction product of (i) an epoxidized grafted rubber having two or more epoxy groups in its graft phase and (ii) a compound having two or more terminal primary amine groups per molecule The gloss reducing agent may be either incorporated in ASA as the reaction product of (i) and (ii) or, in the alternative, formed upon the reaction of (i) with (ii) in the course of the thermal processing of the a blend containing ASA, (i) and (ii).

Owner:INEOS ABS JERSEY +1

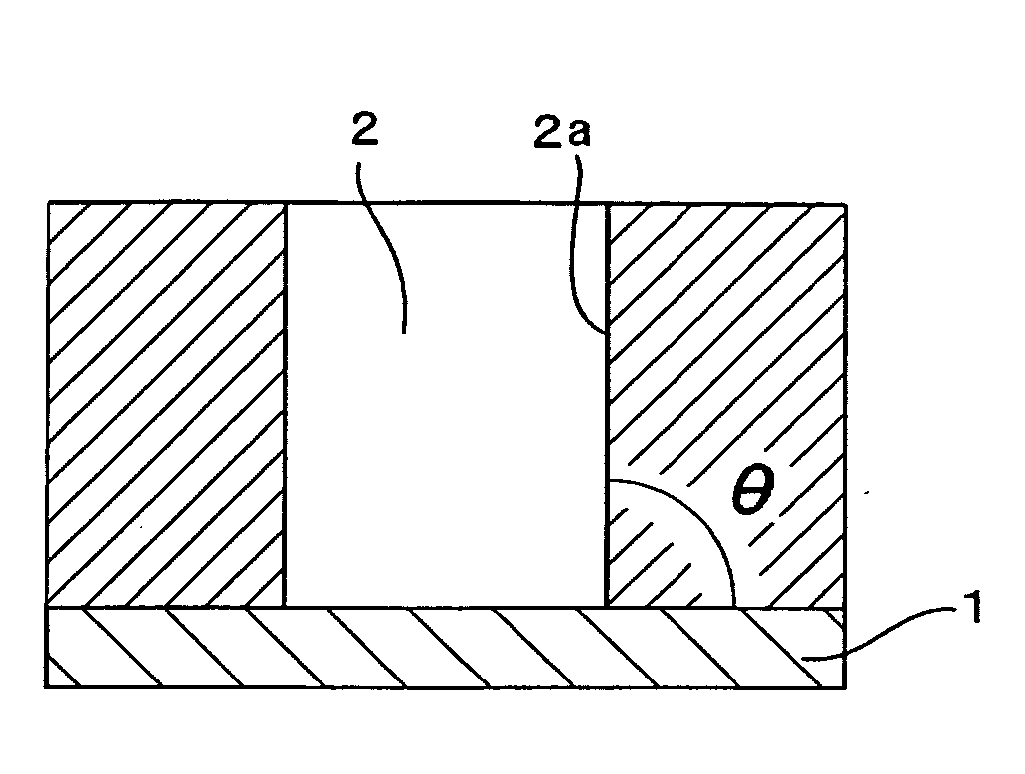

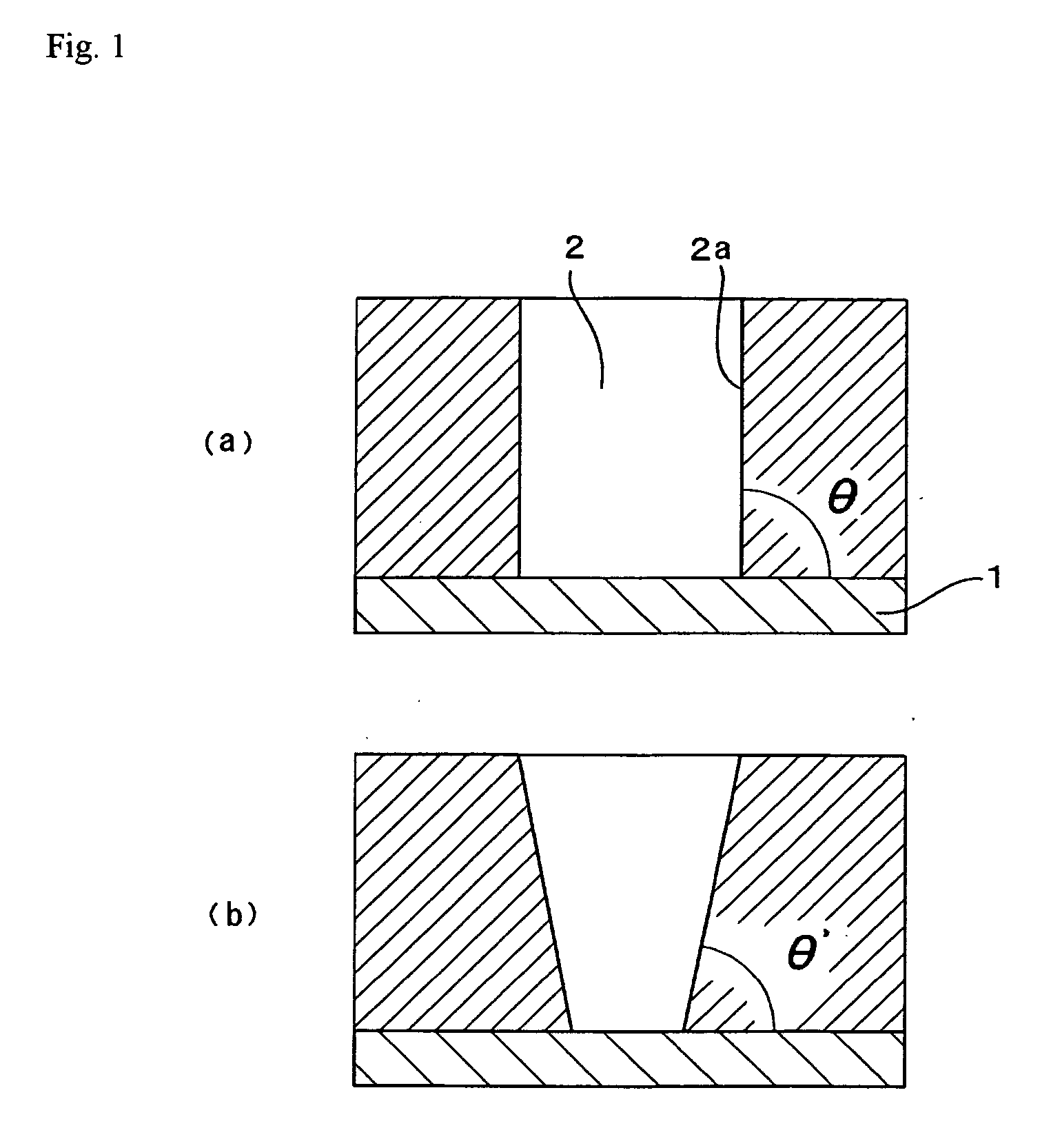

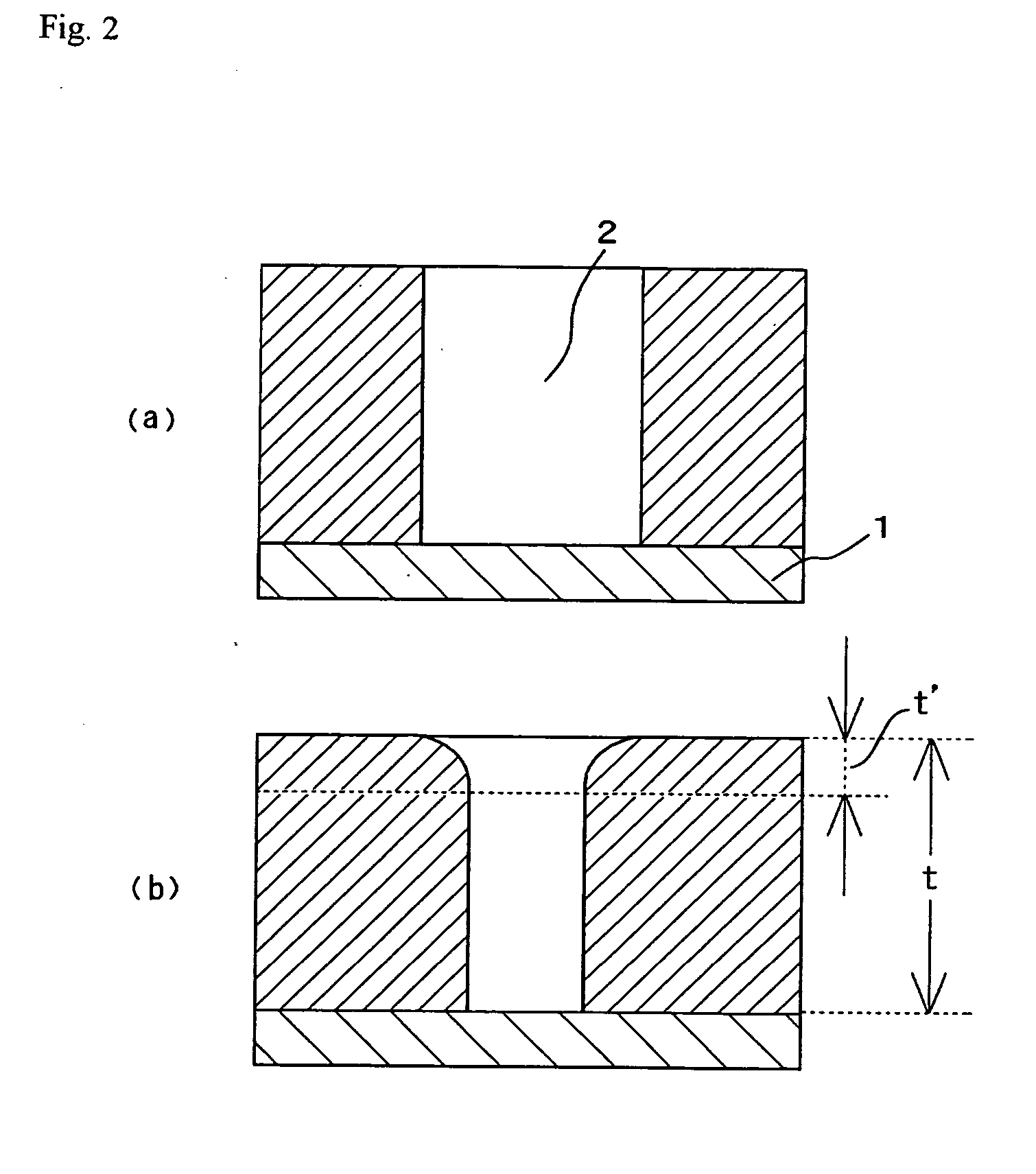

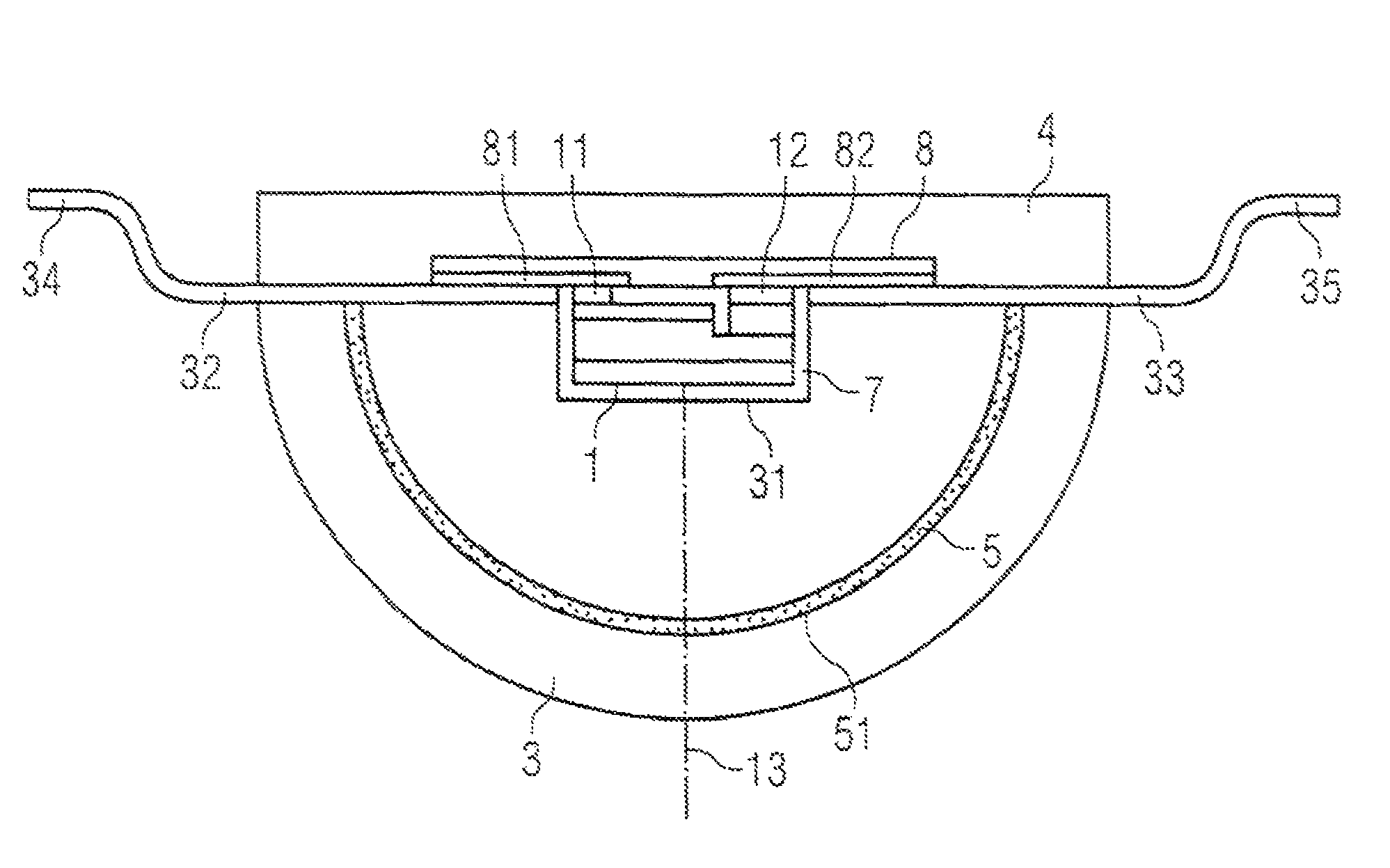

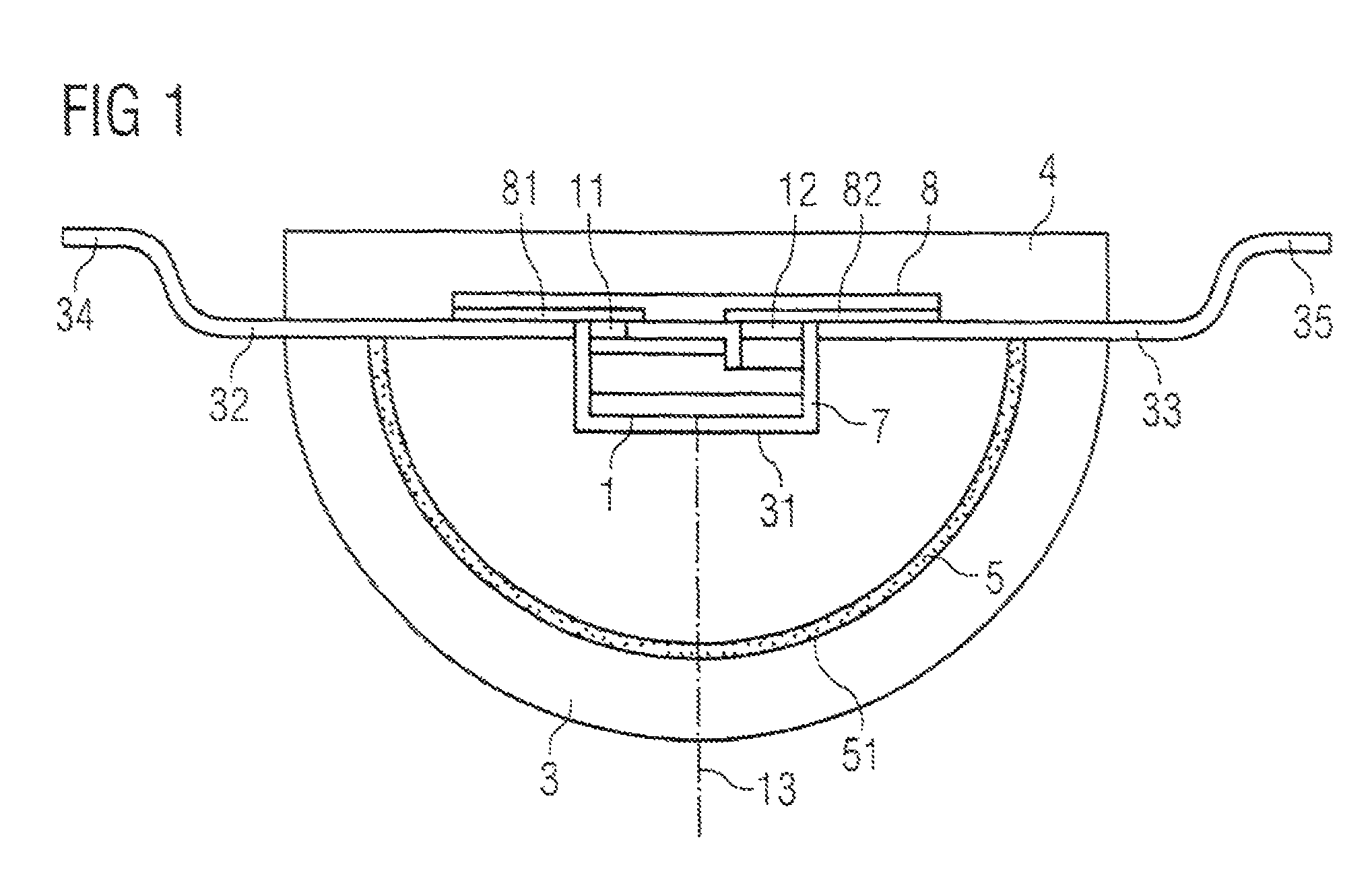

Optoelectronic component and package for an optoelectronic component

InactiveUS7893452B2Better mountingIncrease influenceSolid-state devicesSemiconductor devicesOptical axisSecondary radiation

Optoelectronic components with a semiconductor chip, which is suitable for emitting primary electromagnetic radiation, a basic package body, which has a recess for receiving the semiconductor chip and electrical leads for the external electrical connection of the semiconductor chip and a chip encapsulating eclement, which encloses the semiconductor chip in the recess. The basic package body is at least partly optically transmissive at least for part of the primary radiation and an optical axis of the semiconductor chip runs through the basic package body The basic package body comprises a luminescence conversion material, which is suitable for converting at least part of the primary radiation into secondary radiation with wavelengths that are at least partly changed in comparison with the primary radiation.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH

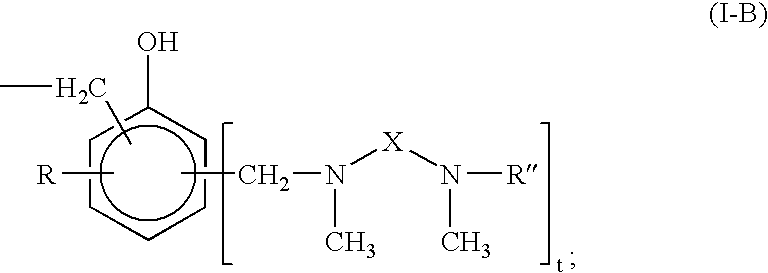

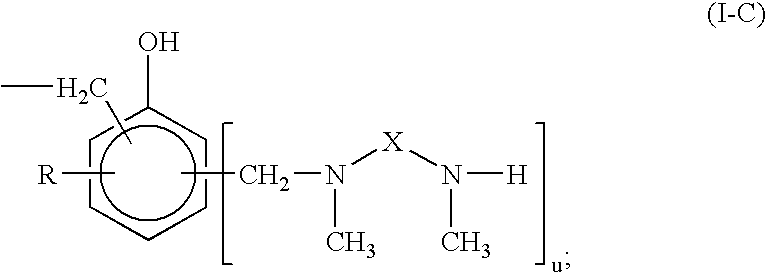

Curing Agent For Low Temperature Cure Applications

ActiveUS20090259003A1Improved “ walk-on ” dry timeRapid hardness developmentIsocyanic acid derivatives preparationOther chemical processesEpoxyEndcapping

The present invention provides Mannich base derivatives of N,N′-dimethyl secondary diamine polymers including Mannich base derivatives of methylamine-terminated poly-(N-methylazetidine) and Mannich base derivatives of methylamine-terminated poly-(N-methylazacycloheptane). Amine curing agent compositions and amine-epoxy compositions containing Mannich base derivatives of N,N′-dimethyl secondary diamine polymers are also disclosed.

Owner:EVONIK OPERATIONS GMBH

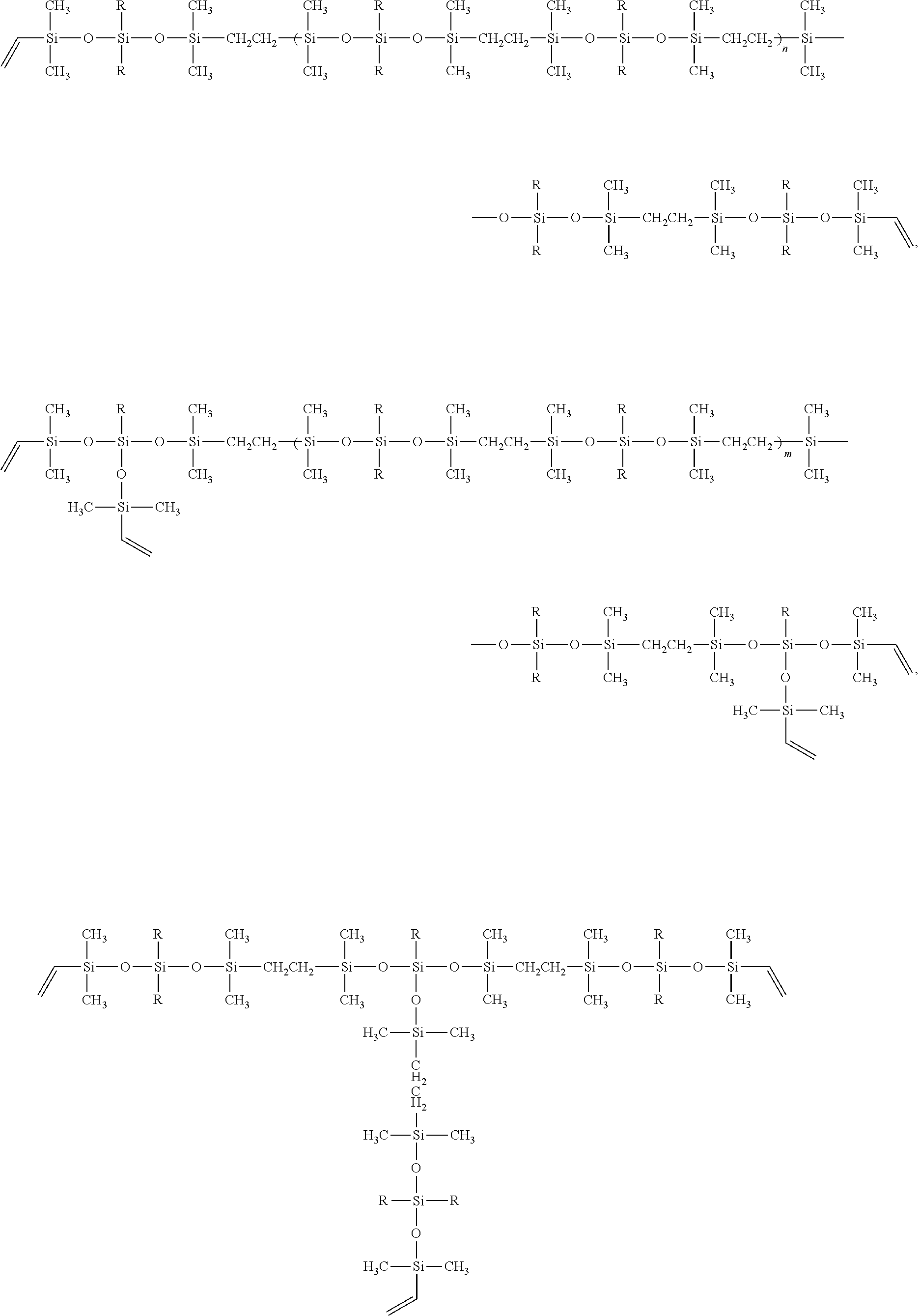

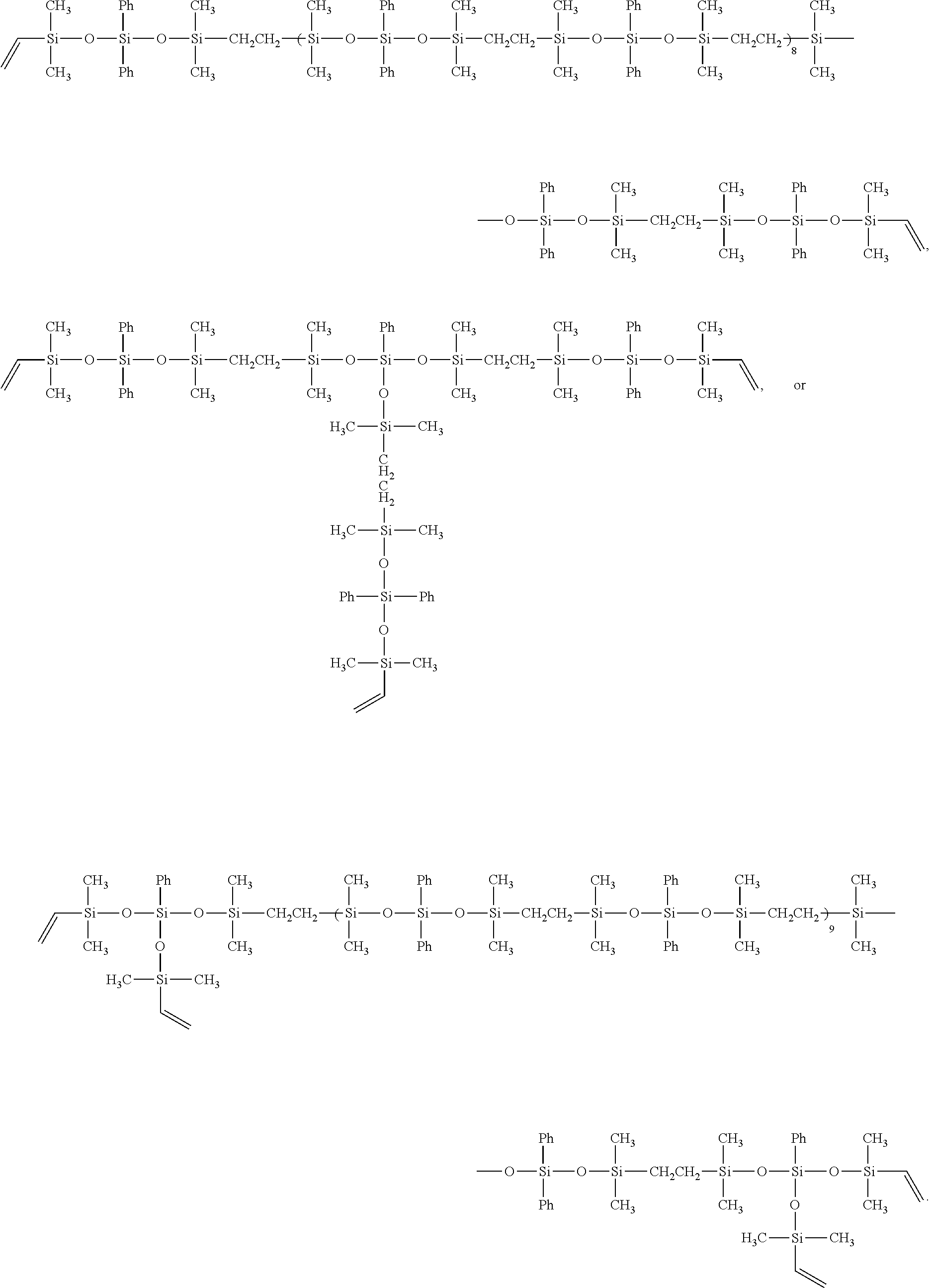

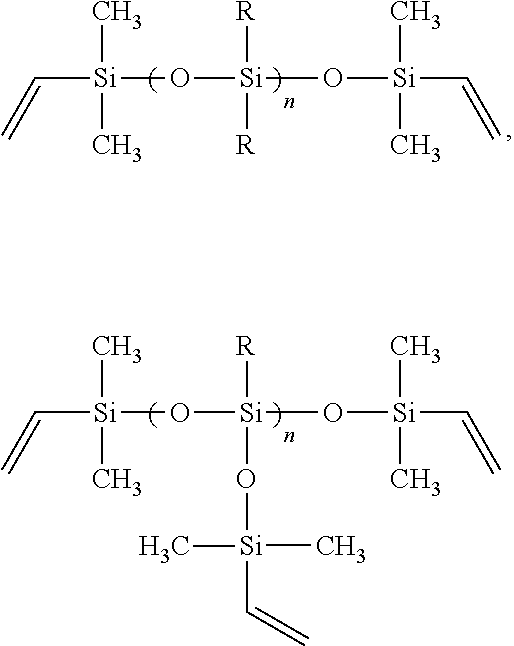

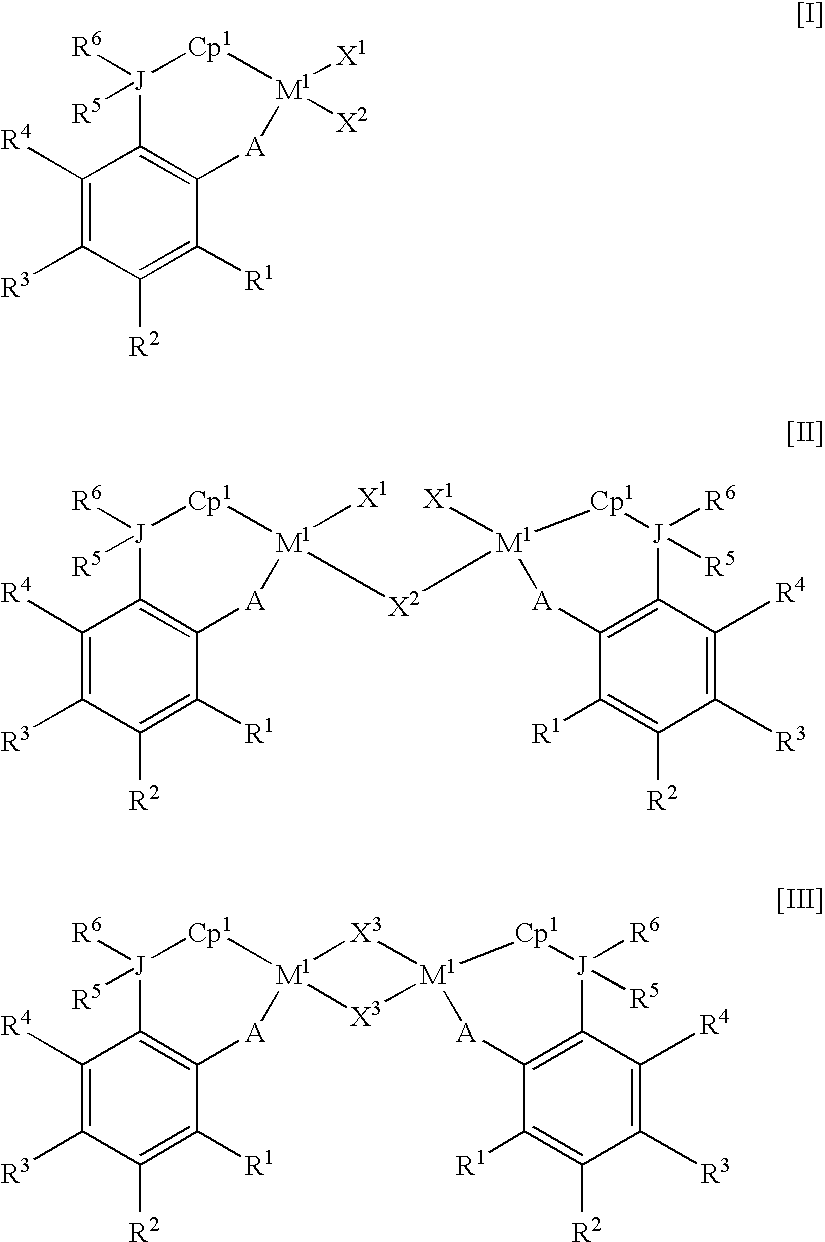

Curable organopolysiloxane composition and method for manufacturing the same

ActiveUS20120172544A1Outstanding indexOutstanding resistanceSemiconductor devicesPolymer scienceSilicon

A curable organopolysiloxane composition comprises the following: (A) an organopolysiloxane having at least two silicon-bonded alkenyl groups and having an average unit formula (I): (R12SiO2 / 2)a(R23SiO1 / 2)b(R3SiO3 / 2)c(SiO4 / 2)d(CH2CH2)e; (B) a branched organopolysiloxane having at least one silicon-bonded alkenyl group and having a siloxane unit of formula R4SiO3 / 2; (C) an organopolysiloxane having an average unit formula (II) being capped with H: (R52SiO2 / 2)f(R63SiO1 / 2)g(R7SiO3 / 2)h(SiO4 / 2)i(CH2CH2)j; and (D) a catalyst, wherein R1 to R7 and a to j are as defined in the specification.

Owner:ETERNAL MATERIALS CO LTD

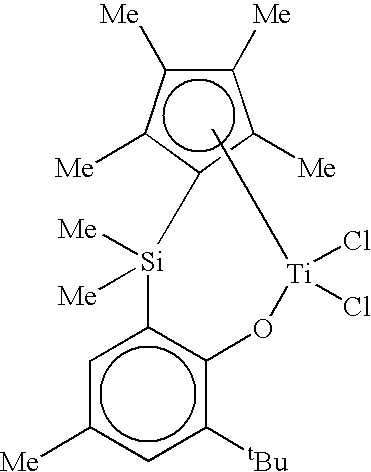

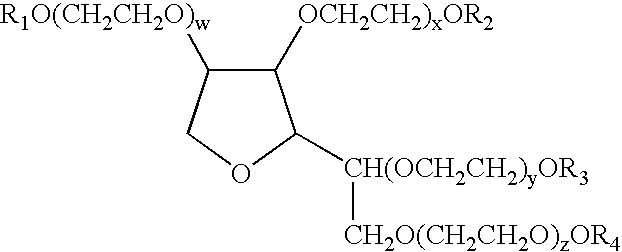

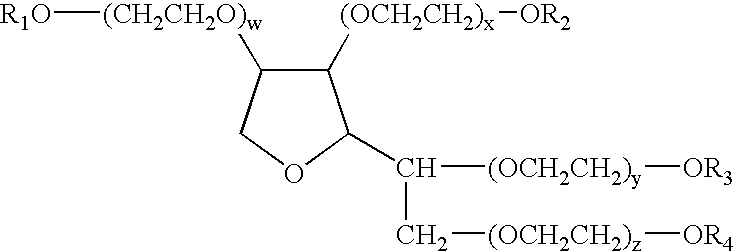

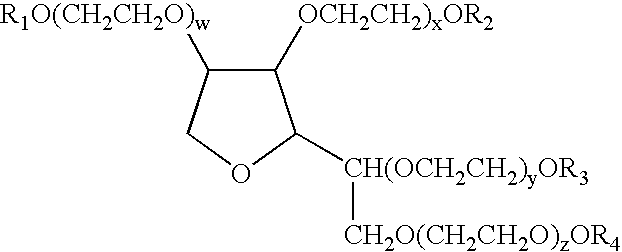

Olefin derived copolymer

InactiveUS6858676B1Outstanding to characteristicsOutstanding resistanceHeat-activated film/foil adhesivesCorrelation coefficientHorizontal axis

The present invention relates to an olefin derived copolymer and a thermoplastic resin composition using the olefin derived copolymer satisfying the following (1) and (2): (1) tensile strength at break measured based on JIS K6251 is 2.0 or less MPa; and (2) tensile elongation at break EB (%) of a resin composition obtained satisfies the following relational expression (expression 1) and (expression 2), when blended with a polypropylene derived resin that has 20 degree C. xylene soluble component of not more than 20 wt %.R[3 / 5]−R[2 / 6]≧0.15 (expression 1)S[2 / 6]≧−800 (expression 2)(R[3 / 5] and R[2 / 6] are obtained by the following methods: a curve is obtained by plotting tensile elongation at break EB (%) (based on JIS K6251) of resin composition taken as vertical axis, and weight part rate Pa of a content of an olefin derived copolymer contained in a resin composition taken as horizontal axis; a multiple regression curve in section regions of Pa=0.30-0.50 and Pa=0.20-0.60 (Pa represents content weight percentage of an olefin derived copolymer contained in a resin composition) of a multiple regression expression obtained by quintic multiple regression of the curve is obtained; R[3 / 5] and R[2 / 6] are defined as multiple correlation coefficients of a primary straight line obtained by approximating of the multiple regression curve by method of least squares. S[2 / 6] represent a gradient of a primary straight line (expression) obtained by approximating the above-mentioned multiple regression curve by a method of least squares in section region of Pa=0.20-0.60. In addition, in the above-mentioned multiple regression expression, it is indispensable that data at least seven points Pa=0.00, 0.20, 0.30, 0.40, 0.50, 0.60 and 0.70 are contained. Furthermore, when data at points of number beyond above case are contained, it is indispensable that total Pa values exist at 0.10 or less of fixed interval mutually.

Owner:SUMITOMO CHEM CO LTD

Non-crystalline saliva-soluble coatings for elastomeric monofilament dental tapes

InactiveUS6907889B2Substantivity of coatings onto flexible surfacesResistance to crackingCosmetic preparationsGum massageMedicineControl substances

Owner:WHITEHILL ORAL TECH

Semiconductor element and electrical apparatus

ActiveUS7791308B2Inhibition of fractureRun at high speedAC motor controlVector control systemsEngineeringField-effect transistor

A semiconductor element (20) of the present invention includes a plurality of field effect transistors (90) and a schottky electrode (9a), and the schottky electrode (9a) is formed along an outer periphery of a region where the plurality of field effect transistors (90) are formed.

Owner:PANASONIC CORP

Coating agent with high scratch resistance and weathering resistance

ActiveUS8808805B2Good reproducibilityEasy to preparePretreated surfacesPolyurea/polyurethane coatingsPolymer scienceO-Phosphoric Acid

The present invention relates to a coating composition comprising(d) at least one binder (A) having reactive groups,(e) at least one crosslinking agent (B) which is able to react, with crosslinking with the reactive groups of the binder (A),andat least one catalyst (C) for the crosslinking of silane groups, one or more constituents (A) and / or (B) and / or at least one further constituent of the coating composition containing hydrolyzable silane groups, wherein the catalyst (C) is a phosphoric acid compound, more particularly phosphoric acid or phosphonic acid, which is blocked with an amine having a pKb≧3 and a boiling point >100° C.

Owner:BASF COATINGS GMBH

Coating agent having high scratch resistance and high weathering resistance

ActiveUS8679589B2Good reproducibilityEasy to prepareSynthetic resin layered productsPretreated surfacesScavengerSilanes

The present invention relates to a coating composition comprising(a) at least one hydroxyl-containing compound (A),(b) at least one compound (B) having free and / or blocked isocyanate groups, and(c) at least one catalyst (C) for the crosslinking of silane groups,one or more constituents of the coating composition containing hydrolyzable silane groups, wherein the coating composition contains a water scavenger as further constituent (D).

Owner:BASF COATINGS GMBH

Use of vegetative material as a filler in composite materials

InactiveUS20050165137A1Poor processabilityKeep for a long timeWood treatment detailsHuskMaterials science

The present invention provides a filler for use in composite materials wherein said filler comprises a vegetative-based material and wherein said vegetative-based material can be fresh or carbonised. In one particularly preferred embodiment the present invention utilises carbonised rice husk. In a further aspect of the present invention there is provided a process for the production of a carbonised vegetative-based filler wherein said process comprises burning a fresh vegetative-based material at about 800° C. for about 4 seconds.

Owner:CONTRACT RES & DEV M +1

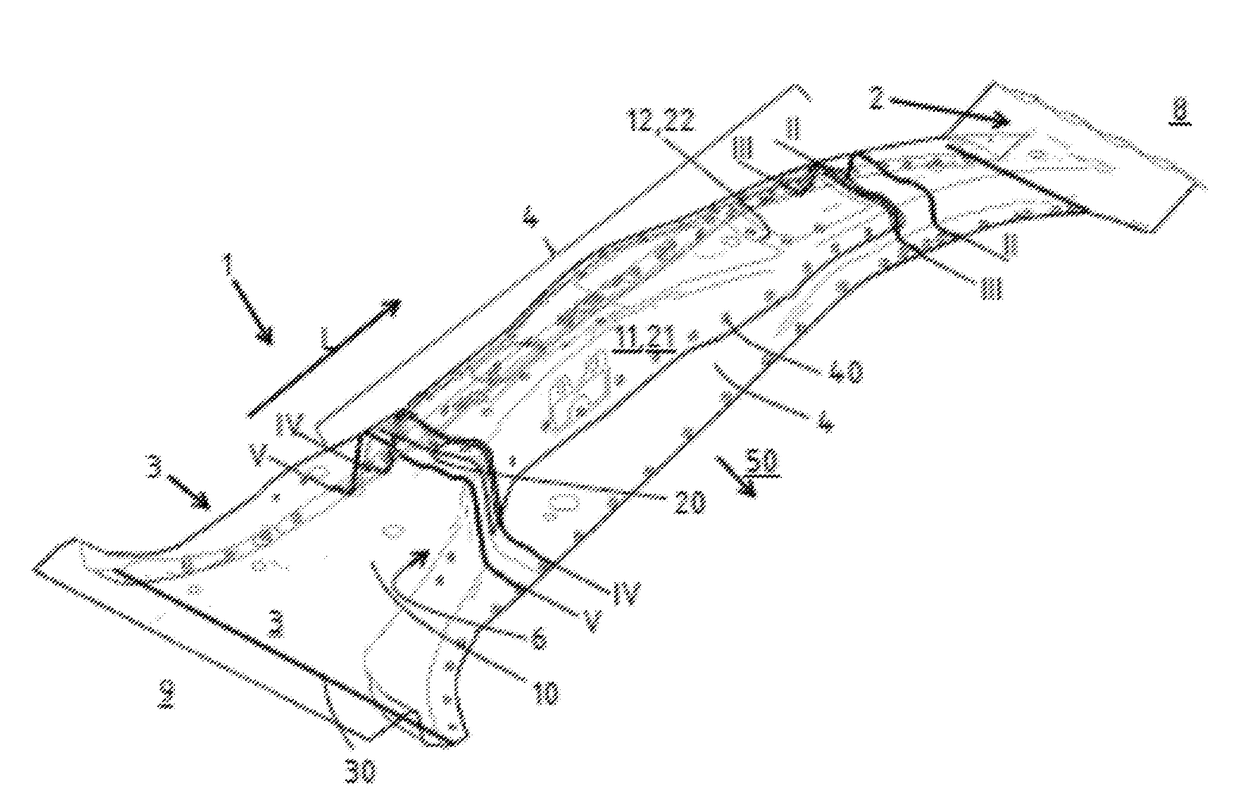

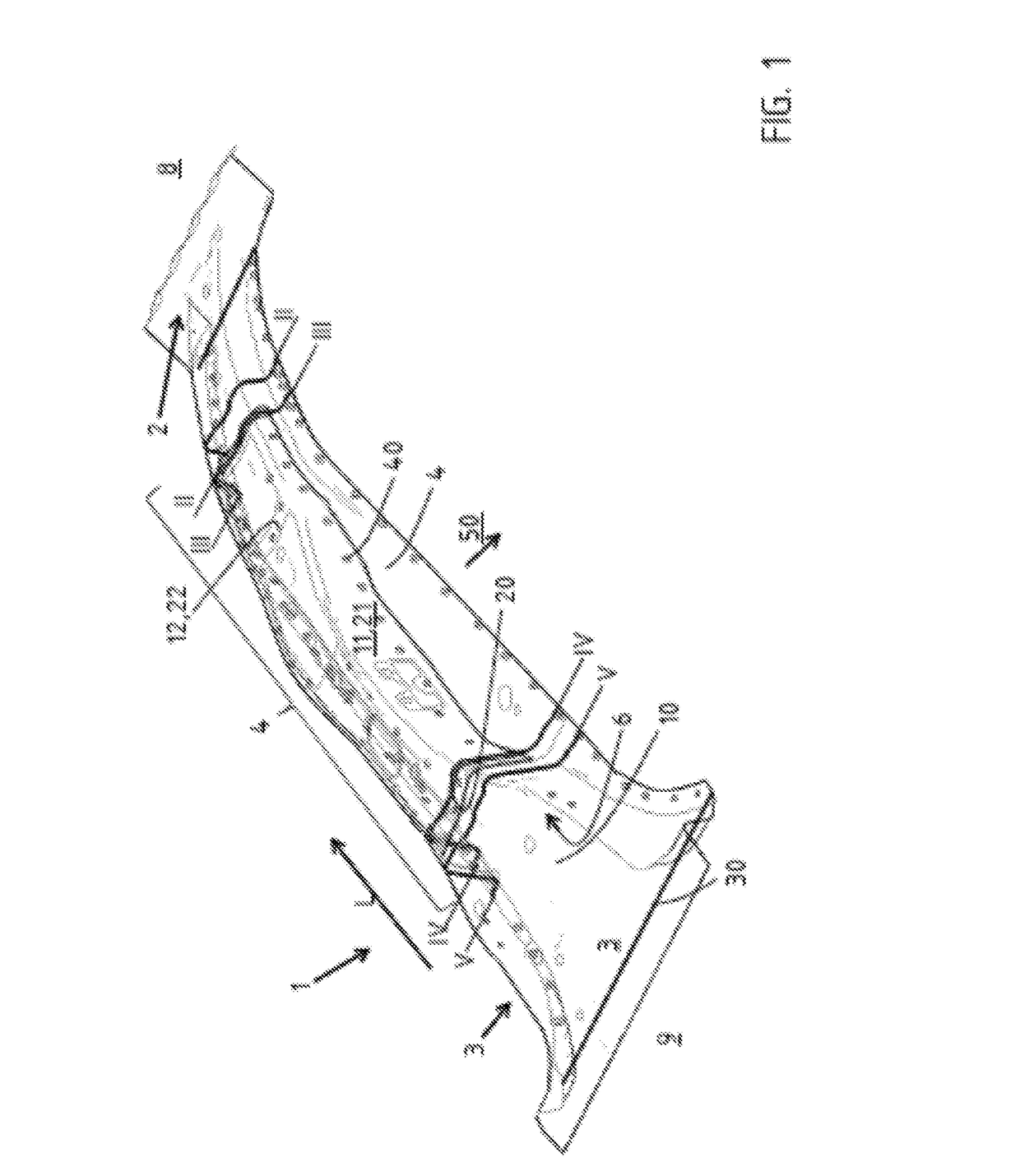

Pillar for a motor vehicle and method for manufacturing a pillar

InactiveUS20180029648A1Firmly connectedIncreased bending angleRailway componentsFurnace typesMobile vehicleCoupling

A pillar for a motor vehicle bodywork is disclosed having a main element with an upper coupling section for attaching to a roof frame, and a secondary element composed of metallic alloy. The secondary element is connected in a planar fashion at least over certain sections of the main element, and the main element has a middle layer composed of a hardened steel alloy, and at least one outer layer which bounds the middle layer toward the outside.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Waterproof slide fastener

InactiveUS20070226966A1Improve featuresHigh strengthSnap fastenersSlide fastenersPolyurethane elastomerPolymer alloy

A waterproof slide fastener comprising: a pair of fastener stringers in which a plurality of fastener elements are arranged in line by molding integrally along opposing element attaching edge portions of a pair of waterproof fastener tapes, in which a belt shaped core material composed of a woven fabric, knitted fabric or unwoven fabric is covered with a waterproof layer; and a slider for engaging and disengaging the fastener elements, wherein the waterproof layer is composed of a polyurethane elastomer and the fastener elements are composed of a polymer alloy of polyurethane resin and ABS resin, thereby providing the waterproof slide fastener in which its fastener tape has an excellent adhesion characteristic to an attachment object such as the one covered with urethane coating, an excellent bending characteristic, a high fixing strength between the fastener tape and the fastener elements an excellent engaging strength and water-tightness.

Owner:YKK CORP

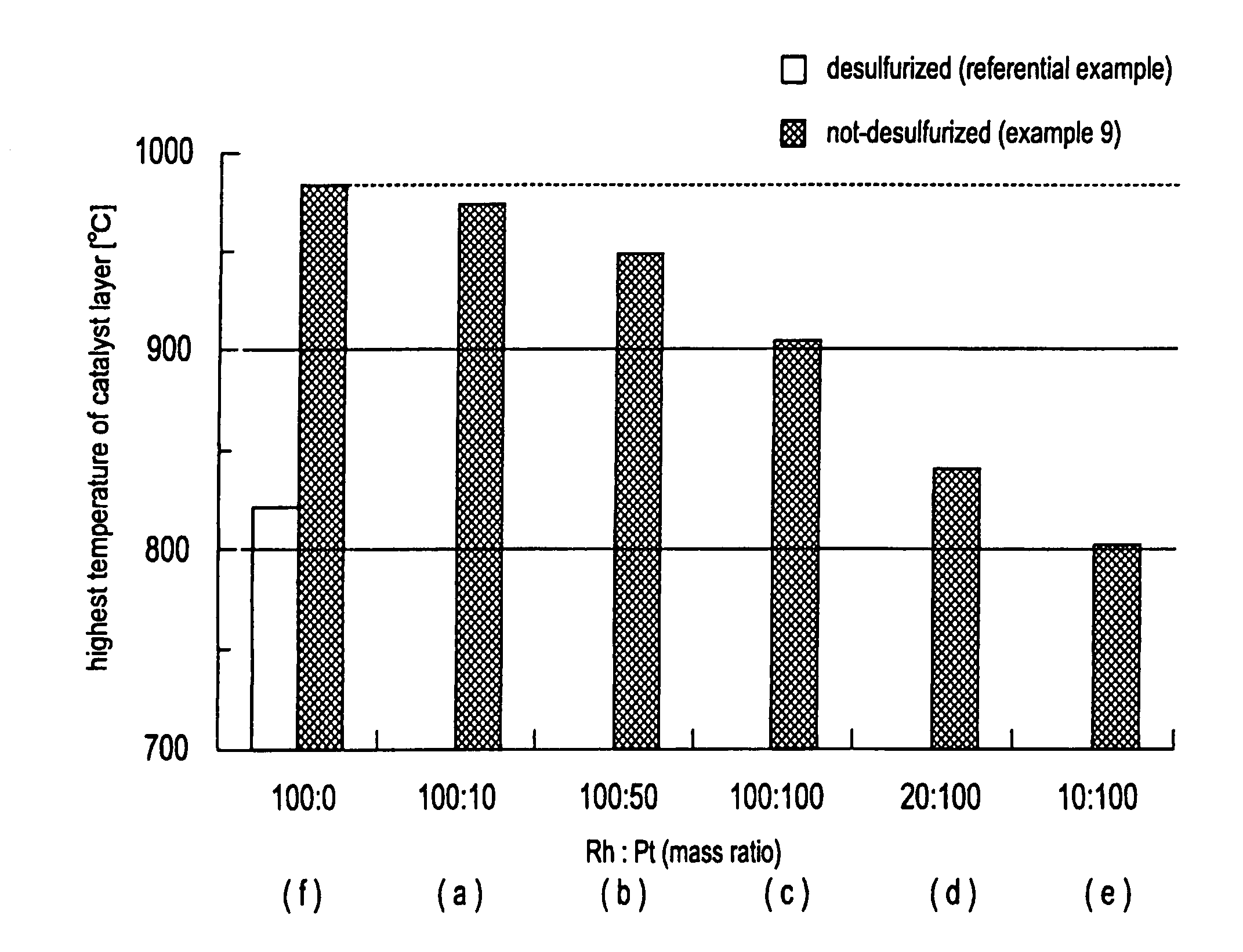

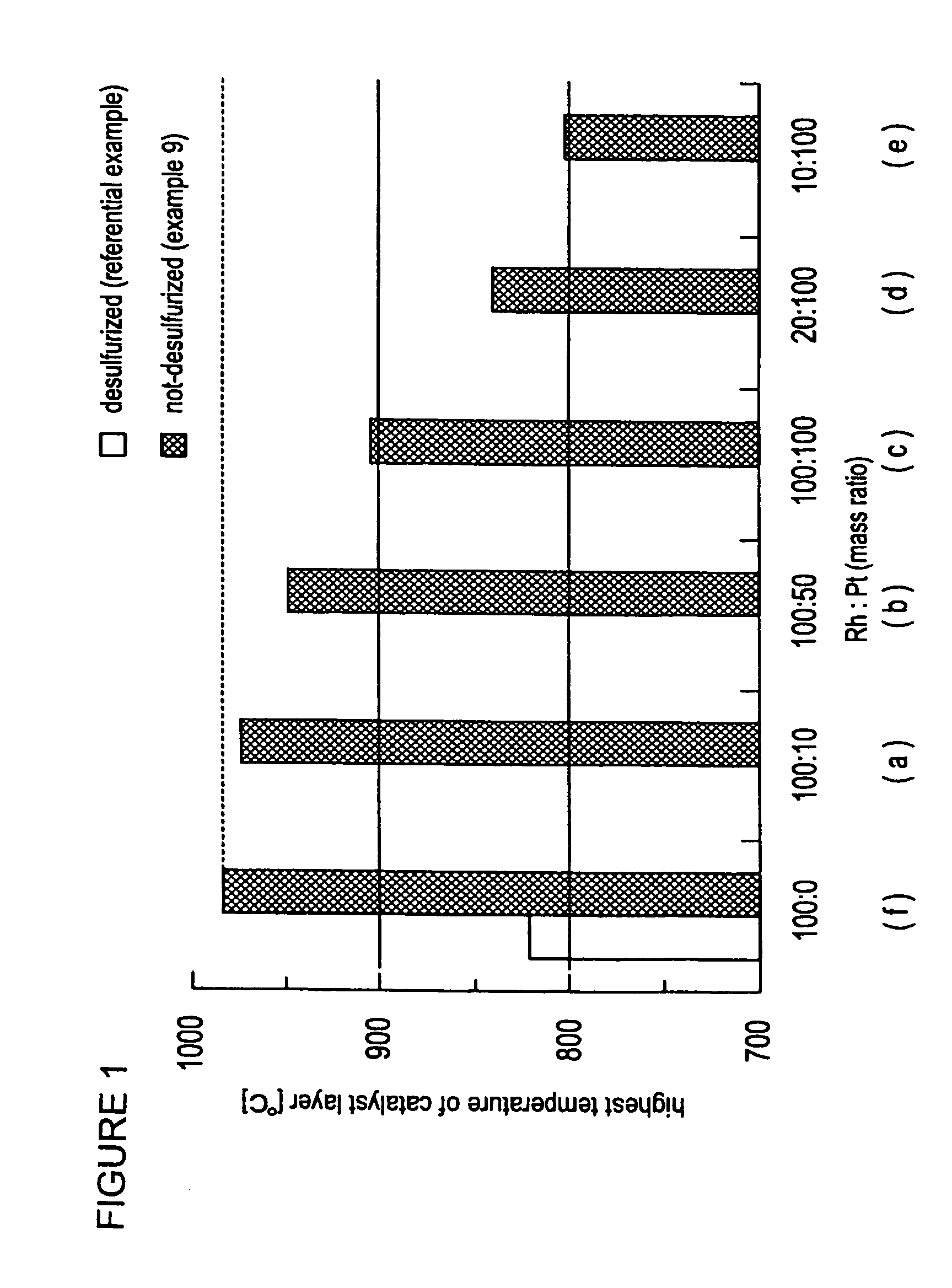

Modifying catalyst for partial oxidation and method for modification

InactiveUS7316806B2Short lifeRepresses deterioration of catalytic activityHydrogenCarbon compoundsPlatinumPartial oxidation

A reforming catalyst for partial oxidation to reform hydrocarbon compound including a sulfur-containing compound includes platinum and rhodium. Even in reforming a hydrocarbon compound including a sulfur-containing compound such as, for example, a town gas, the catalyst effectively prevents poisoning and elongates catalyst life.

Owner:NIPPON SHOKUBAI CO LTD

Use of vegetative material as a filler in composite materials

InactiveUS20050165140A1Poor processabilityKeep for a long timeWood treatment detailsBuilding insulationsHuskMaterials science

Owner:TADGELL DAVID JOHN +1

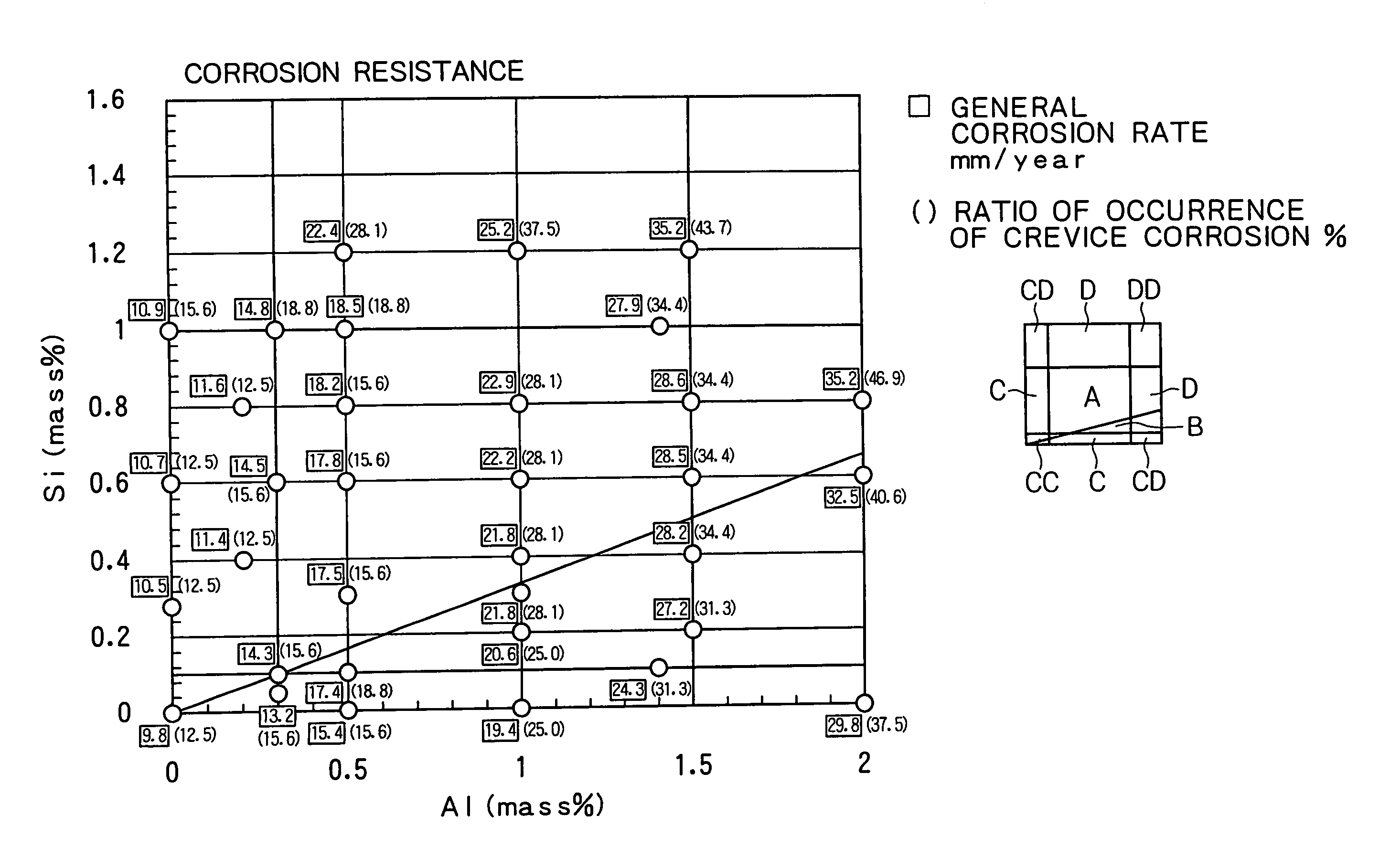

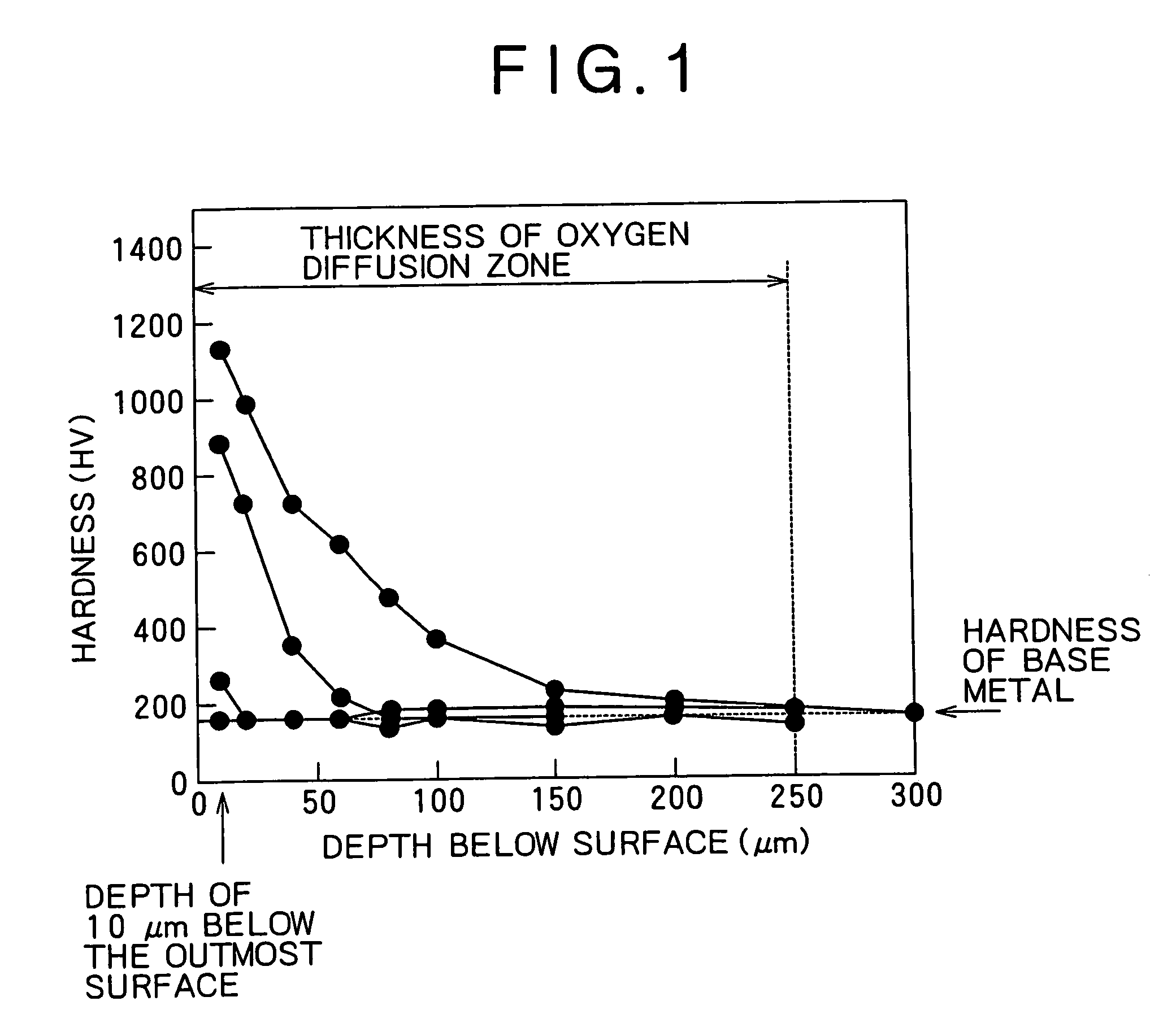

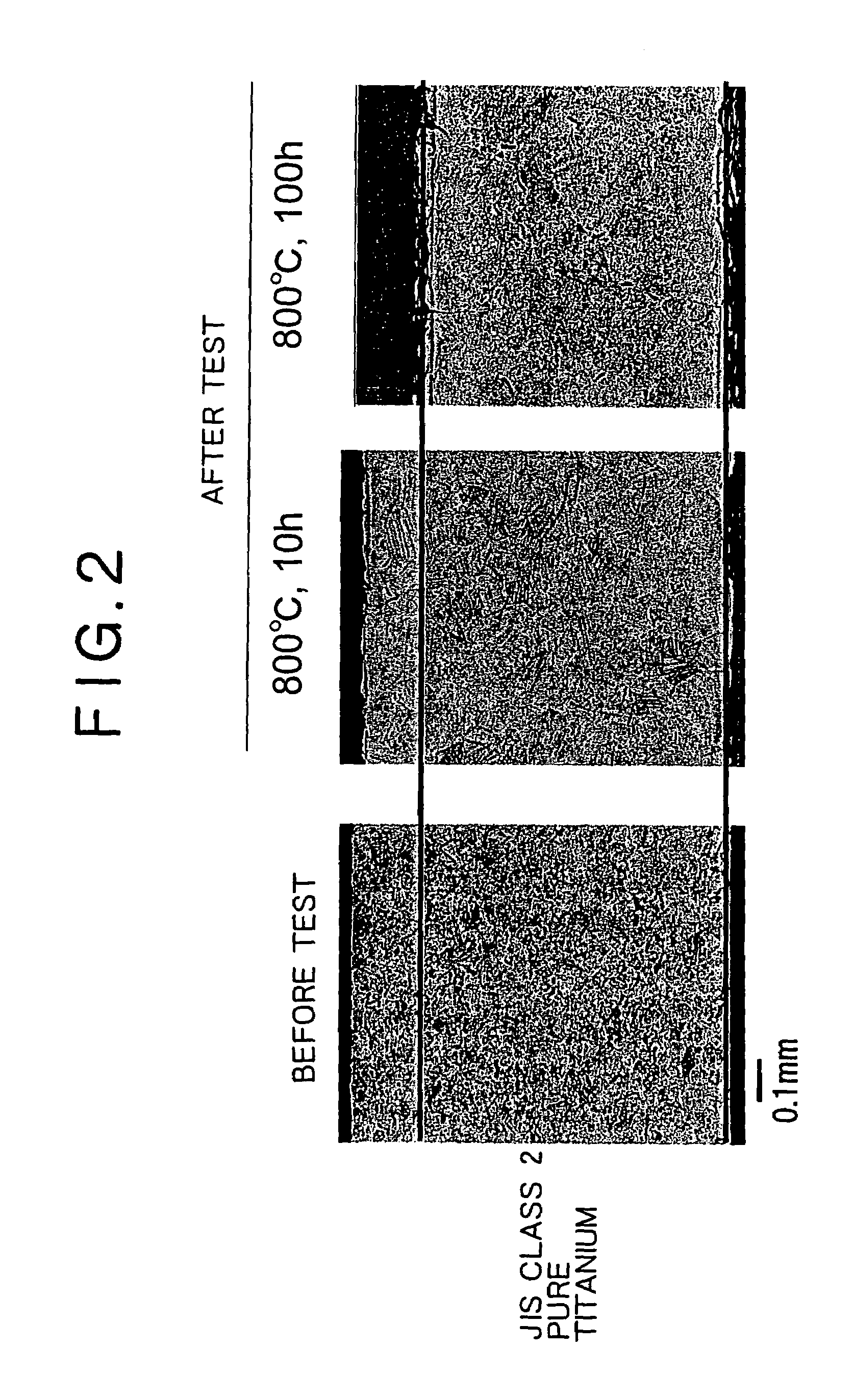

Titanium alloy having excellent high-temperature oxidation and corrosion resistance

ActiveUS7166367B2Excellent high-temperature oxidation resistanceOutstanding resistanceHot-dipping/immersion processesExhaust apparatusMachinabilityCorrosion

A titanium alloy having excellent high-temperature oxidation and corrosion resistance is disclosed which comprises, by mass, Al: 0.30–1.50%, and Si: 0.10–1.0%. Preferably, amass ratio Si / Al is not less than 1 / 3. More preferably, the titanium alloy further comprises Nb: 0.1–0.5% by mass. The titanium alloy is useful as an exhaust system material for a vehicle or a motorbike, which enhances corrosion and high-temperature oxidation resistance, while utilizing inherent lightness and corrosion resistance of an original titanium alloy without impairing economy and workability.

Owner:KOBE STEEL LTD

Use of vegetative material as a filler in composite materials

InactiveUS6875263B1Easy to processShorten the curing timeWood treatment detailsSpecial tyresMetallurgyMaterials science

Owner:CONTRACT RES & DEV M +1

Process for producing a dried composite semipermeable membrane

ActiveUS8518310B2Good water permeabilityOutstanding durabilitySemi-permeable membranesMembranesHydrophilizationSemipermeable membrane

Owner:NITTO DENKO CORP

Curing agent for low temperature cure applications

ActiveUS8735512B2Extended drying timeRapid hardness developmentIsocyanic acid derivatives preparationOrganic compound preparationEpoxyLow temperature curing

The present invention provides Mannich base derivatives of N,N′-dimethyl secondary diamine polymers including Mannich base derivatives of methylamine-terminated poly-(N-methylazetidine) and Mannich base derivatives of methylamine-terminated poly-(N-methylazacycloheptane). Amine curing agent compositions and amine-epoxy compositions containing Mannich base derivatives of N,N′-dimethyl secondary diamine polymers are also disclosed.

Owner:EVONIK OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com