Waterproof slide fastener

a technology of waterproof layer and fastener, which is applied in the direction of slide fasteners, press-button fasteners, snap fasteners, etc., can solve the problems of time and labor, poor adhesion characteristic of the fastener tape to the attachment object composed of polyurethane base, and inability to easily bond to a polyurethane base material or a polyurethane coated material. , to achieve the effect of improving the moldability of the fastener elemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

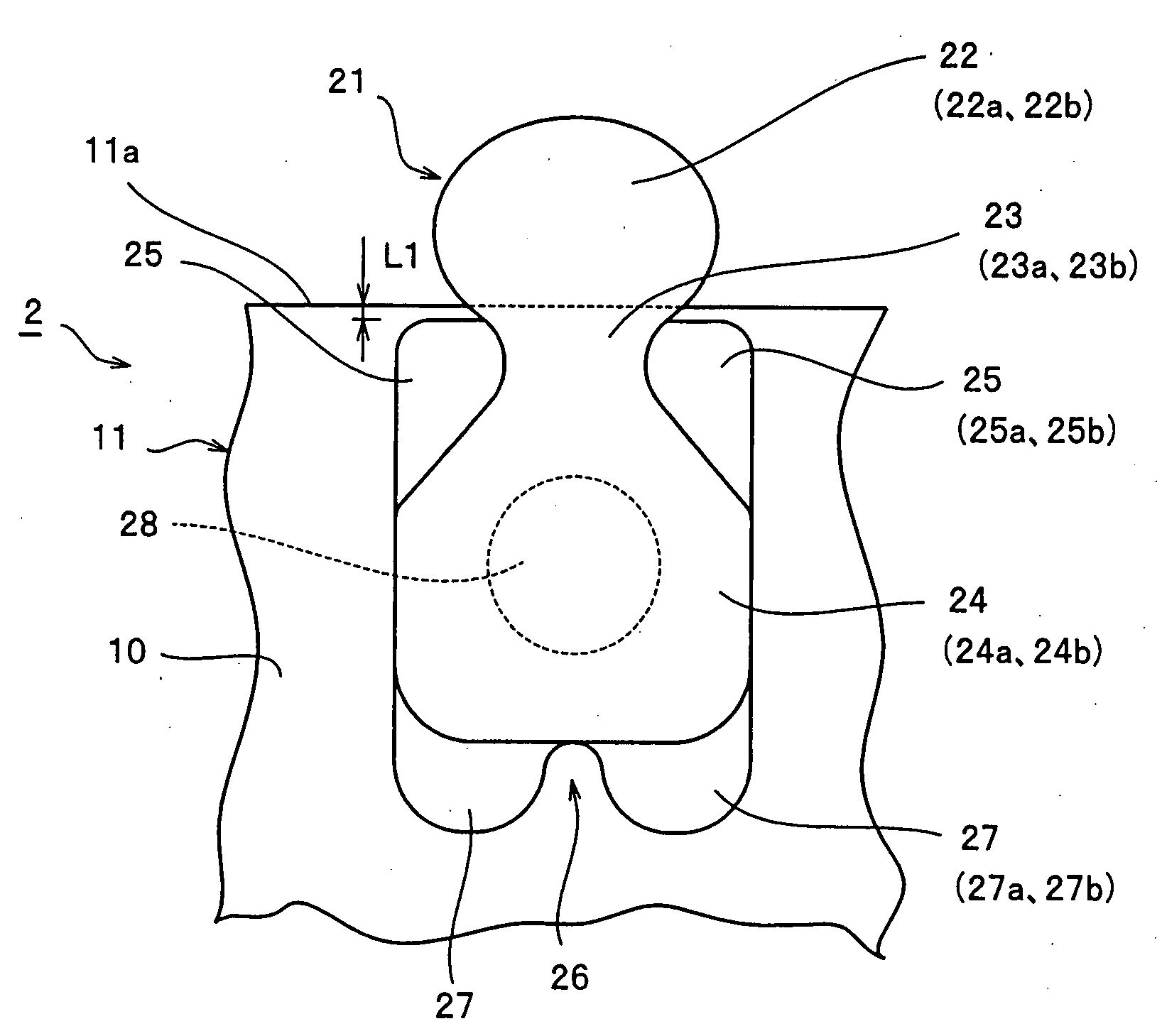

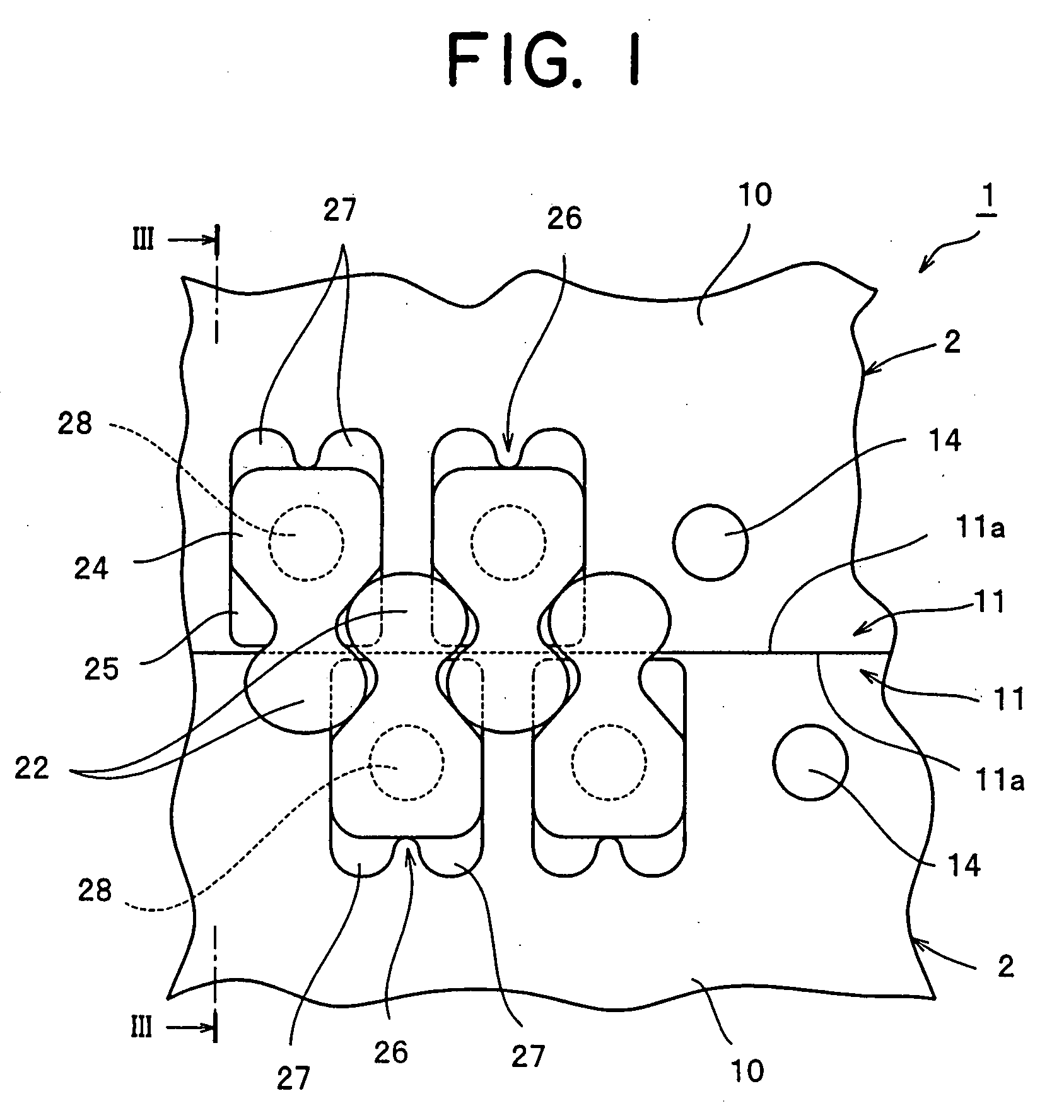

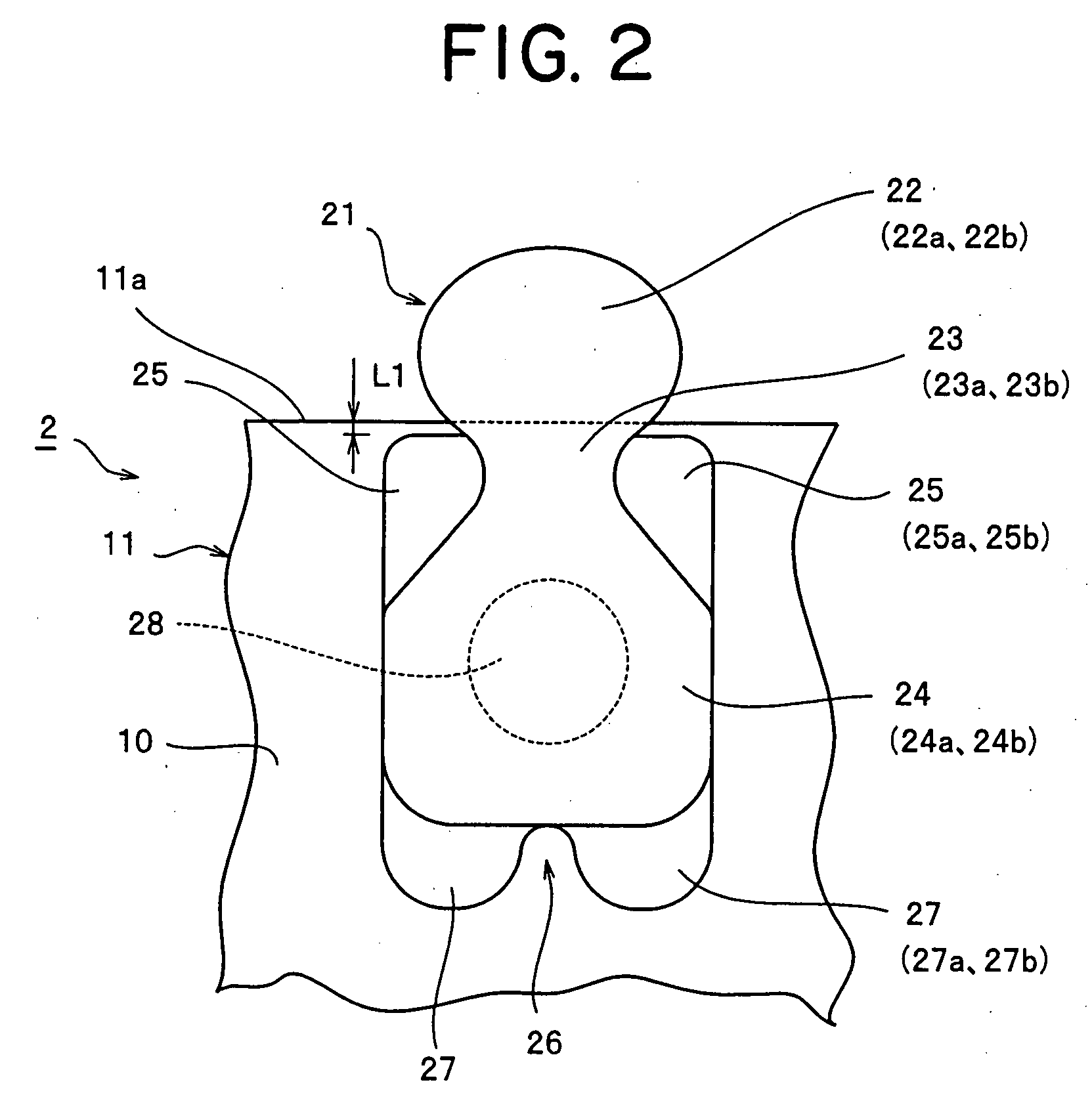

Image

Examples

examples

[0046]Hereinafter, examples of the present invention will be described in detail.

[0047]In the examples, five kinds of waterproof slide fasteners having different mixing ratios between polyurethane resin and ABS resin in a polymer alloy constituting fastener elements were manufactured, and the following evaluation was carried out about each slide fastener. As the five kinds of the waterproof slide fasteners to be evaluated, waterproof slide fasteners whose ratios between polyurethane resin and ABS resin were respectively 20 / 80 (Example 1), 30 / 70 (Example 2), 50 / 50 (Example 3) and 70 / 30 (Example 4) in terms of weight ratio were manufactured, and at the same time, a waterproof slide fastener (polyurethane resin / ABS resin=0 / 100) whose fastener elements were composed of only ABS resin without mixture of polyurethane resin was manufactured (Comparative Example).

[0048]Next, the obtained five kinds of the waterproof slide fasteners were evaluated about four items of traverse pulling resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com