Patents

Literature

1176results about How to "Improve the fixing strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

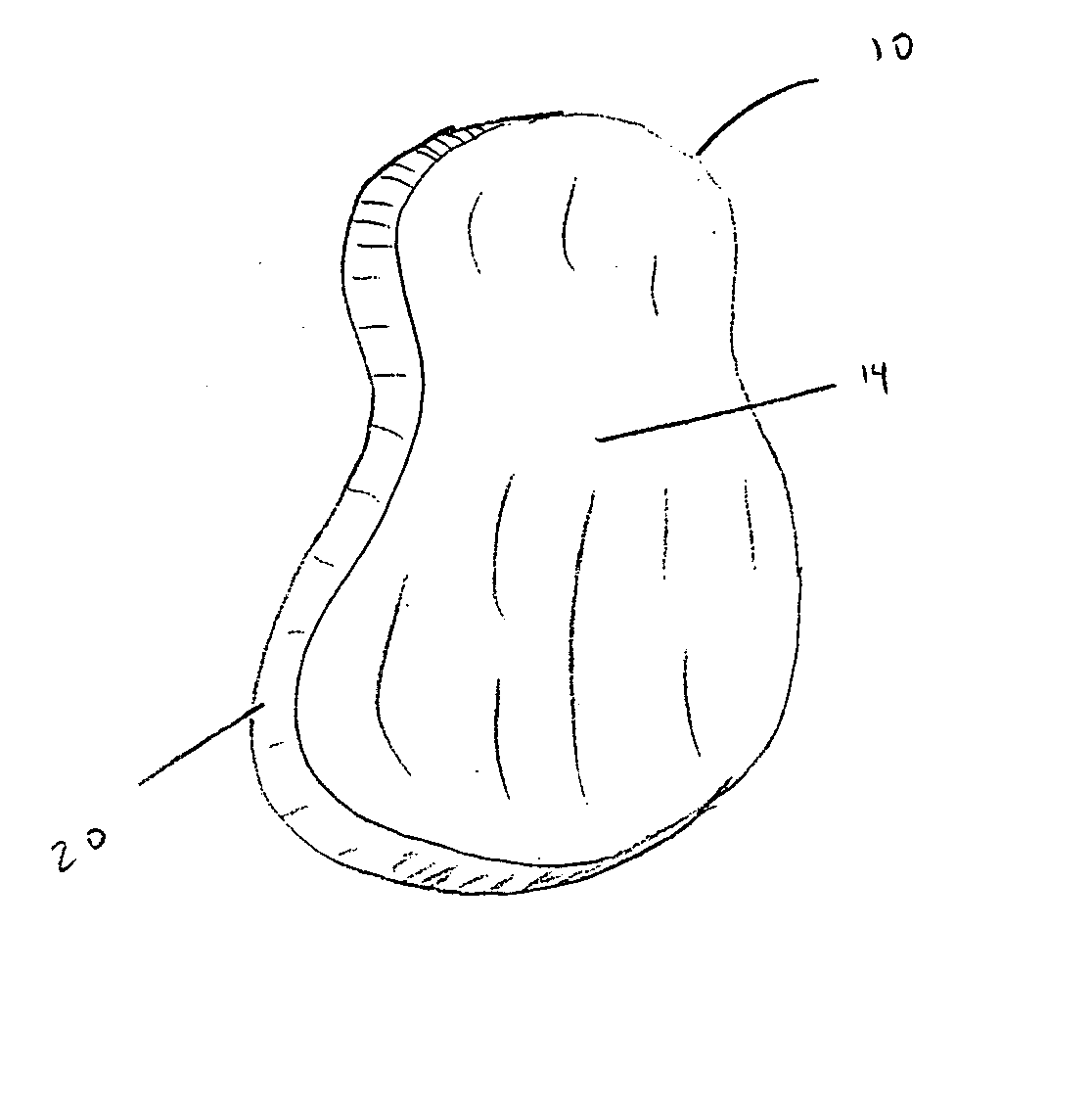

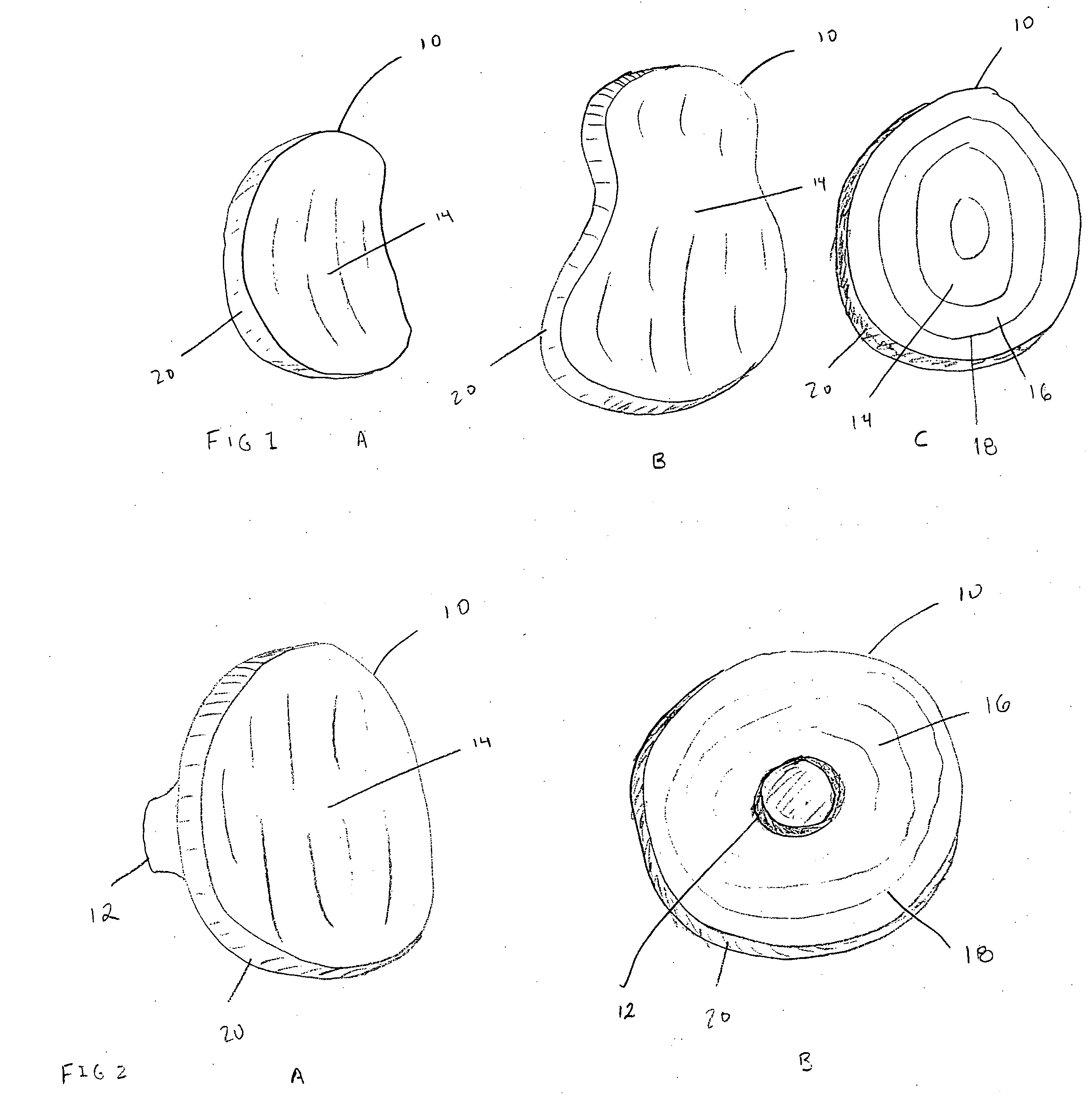

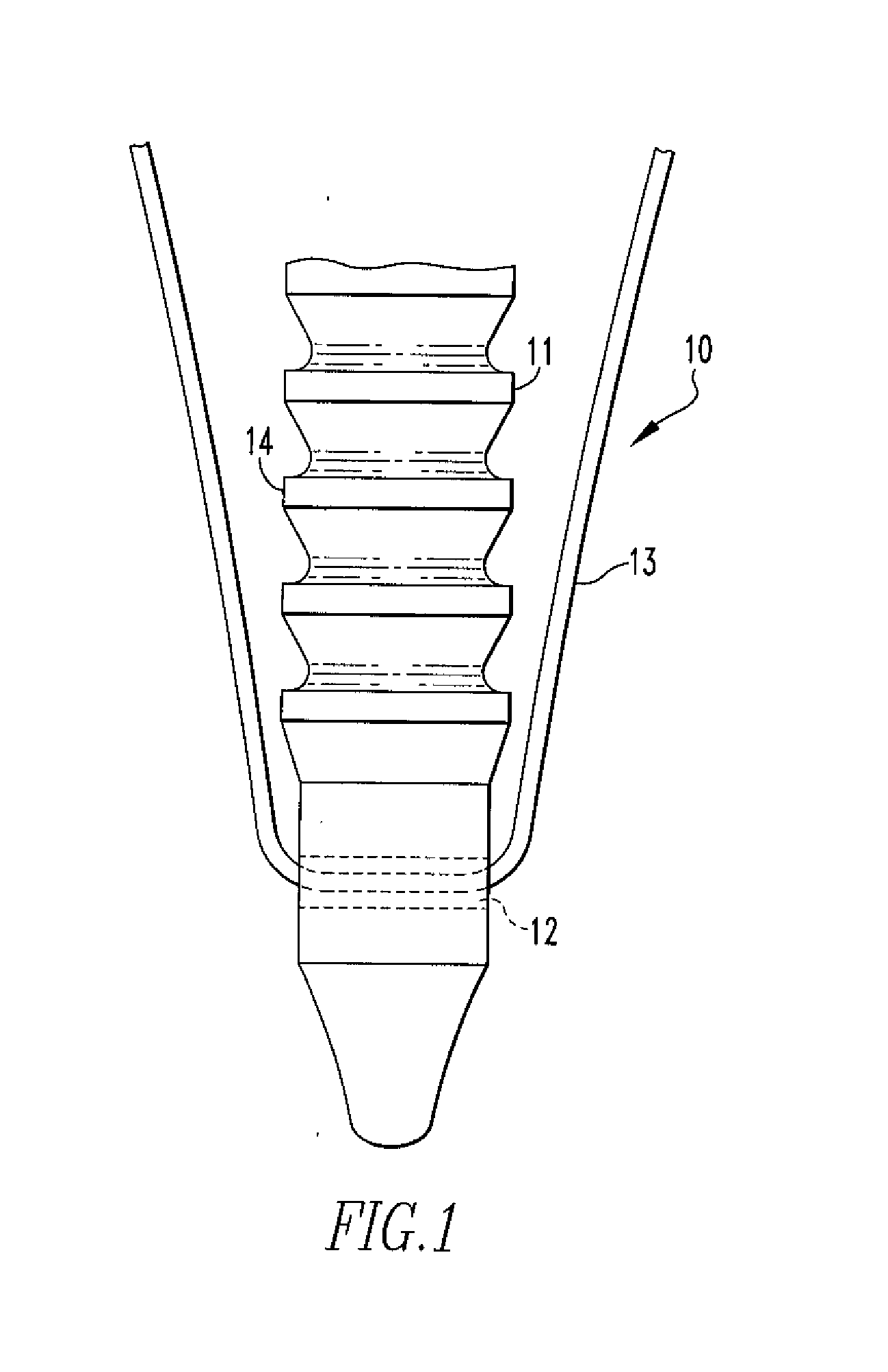

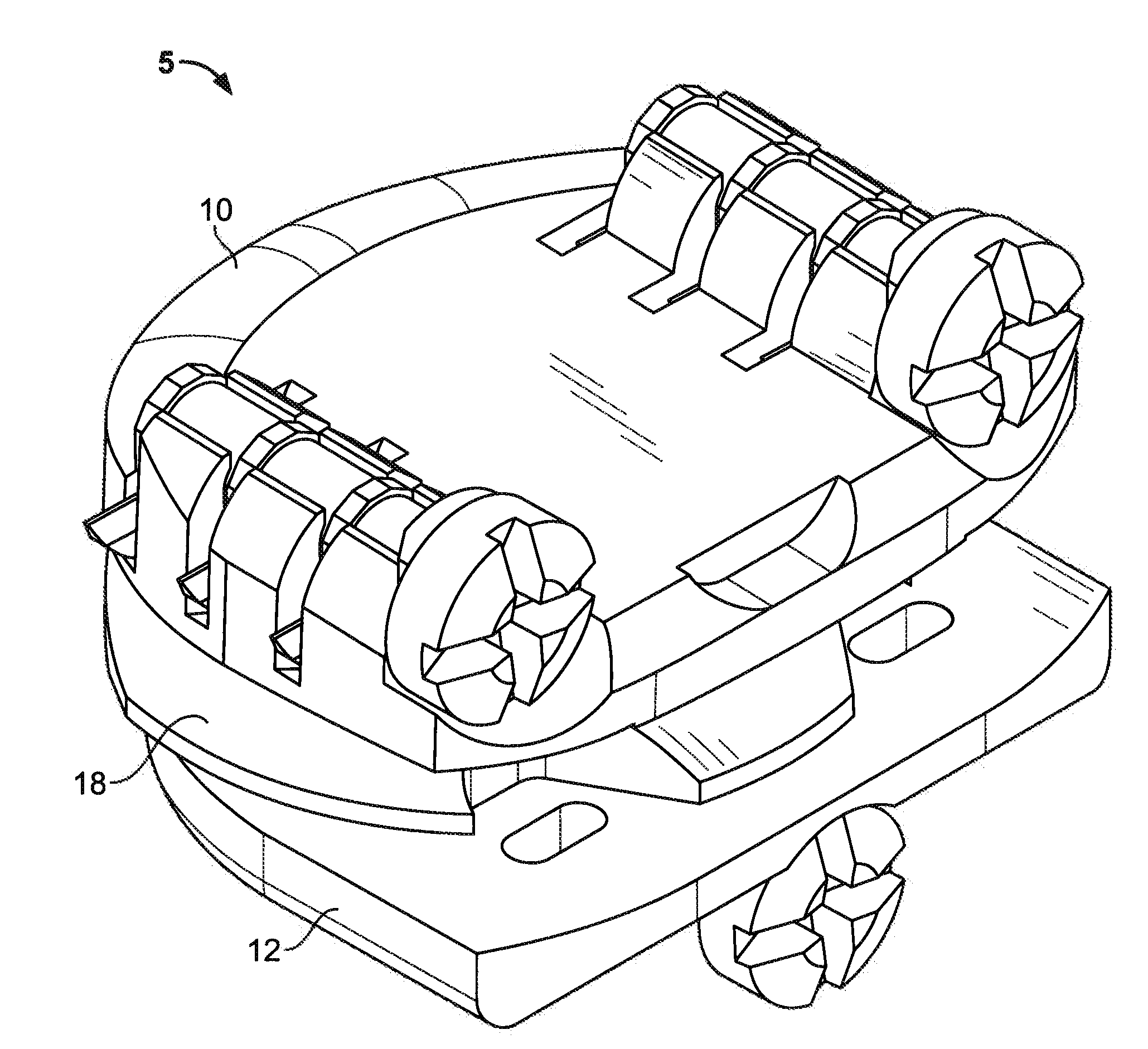

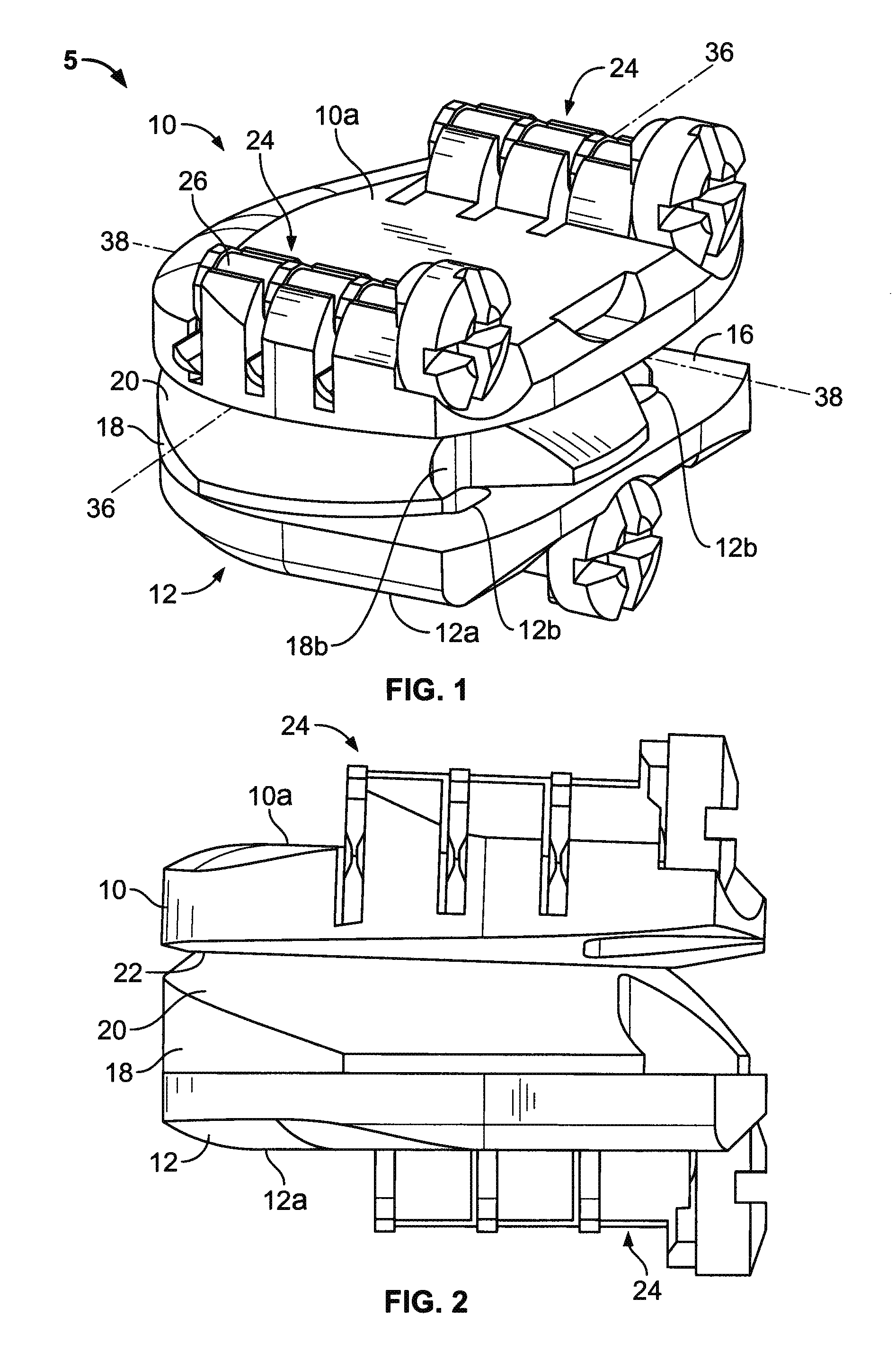

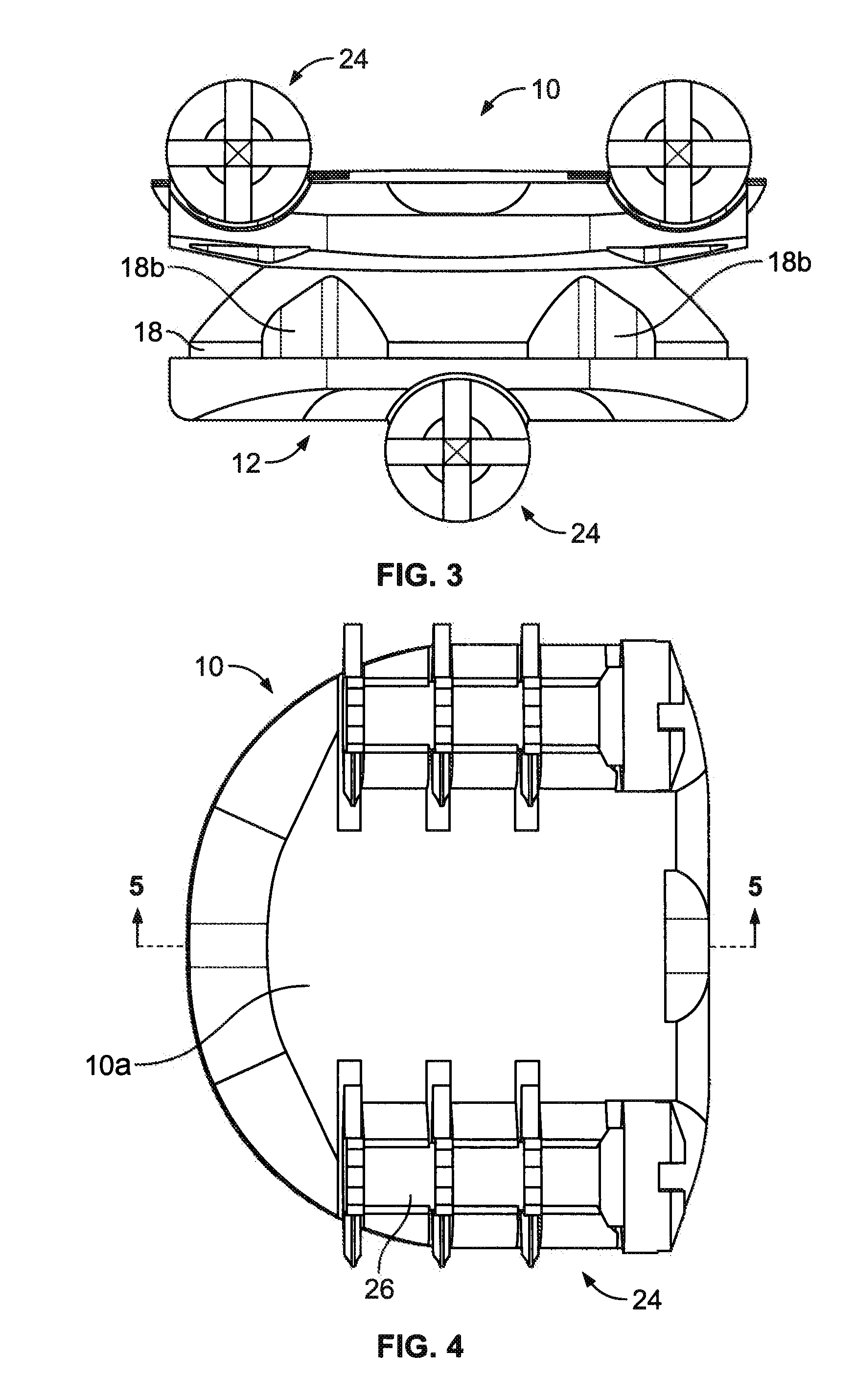

Shoulder implant for glenoid replacement and methods of use thereof

ActiveUS20060195194A1Few complicationLess difficultyJoint implantsNon-surgical orthopedic devicesHumerusSacroiliac joint

The invention features a glenoid (shoulder socket) implant prosthesis, a humeral implant prosthesis, devices for implanting glenoid and humeral implant prostheses, and methods of their use for the treatment an injured or damaged shoulder.

Owner:SHOULDER INNOVATIONS

Fixation Devices and Method of Repair

InactiveUS20080234730A1Easy to fixShorten the lengthSuture equipmentsLigamentsRepair methodSurgical device

In one aspect, the present disclosure relates to a surgical device including an anchor body having an opening, the anchor body having a copolymer composition including polylactide-co-glycolide and calcium carbonate, wherein the calcium carbonate comprises more than 30% but less than 40% of the weight of the composition; and a flexible member passing through the opening, wherein deformation of the device occurs at body temperature. The present disclosure also relates to an oriented polymer material having a copolymer composition including a polylactide-co-glycolide and calcium carbonate, the calcium carbonate comprising more than 30% but less than 40% of the weight of the composition, wherein the material changes shape upon introduction to an environment having a temperature that is lower than a relaxation temperature of the material. A method of repairing soft tissue and other surgical devices are also disclosed.

Owner:SMITH & NEPHEW INC

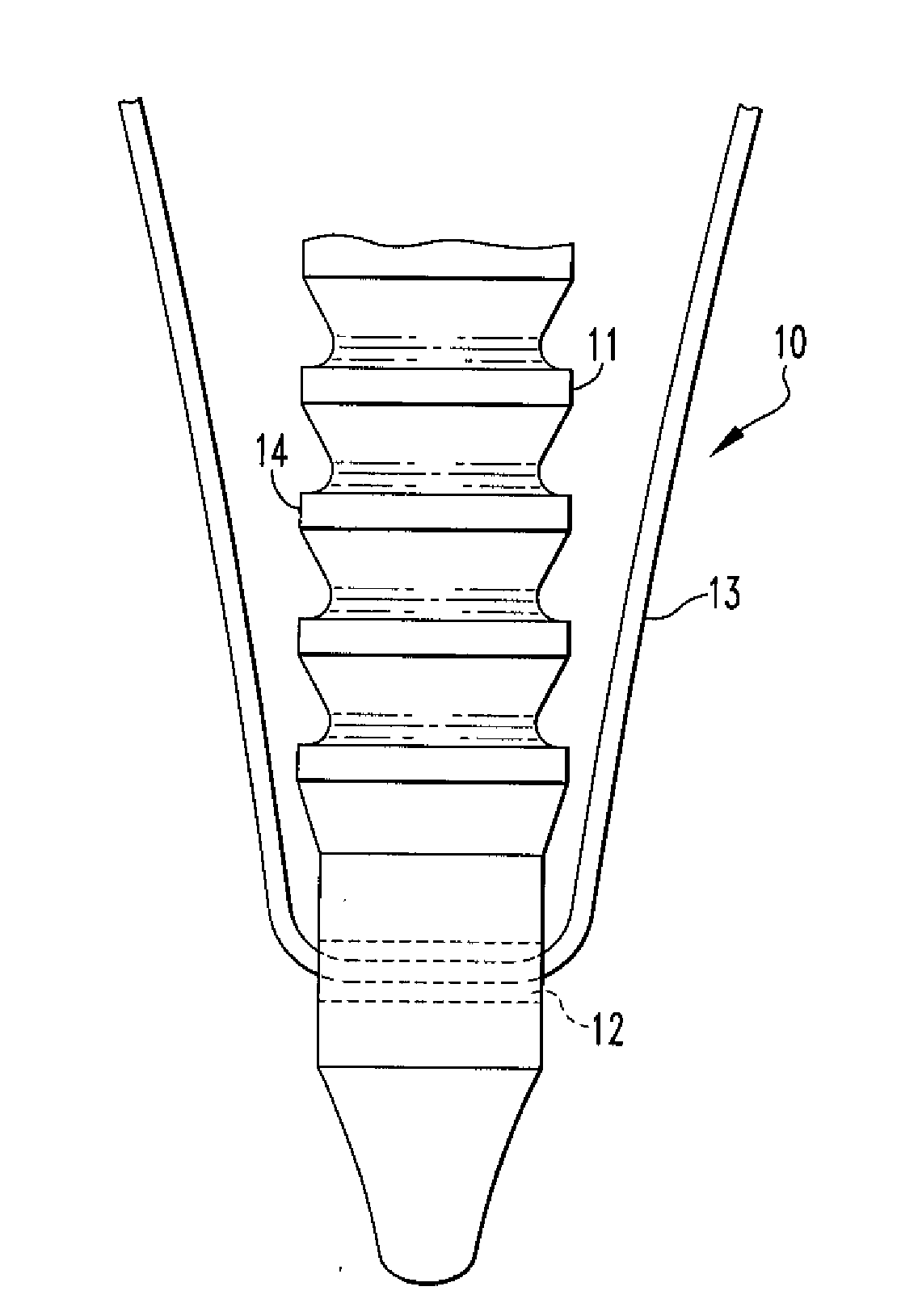

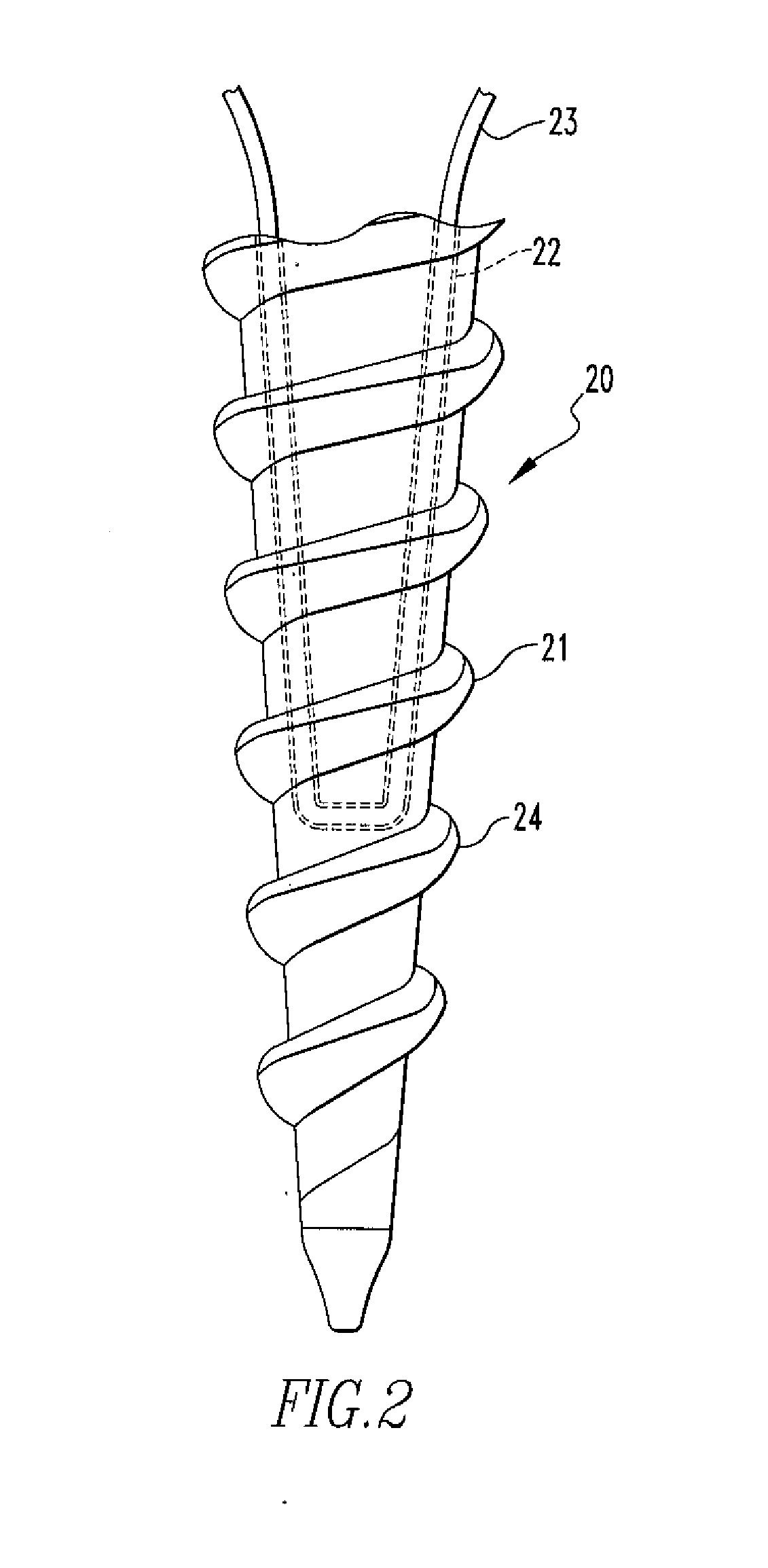

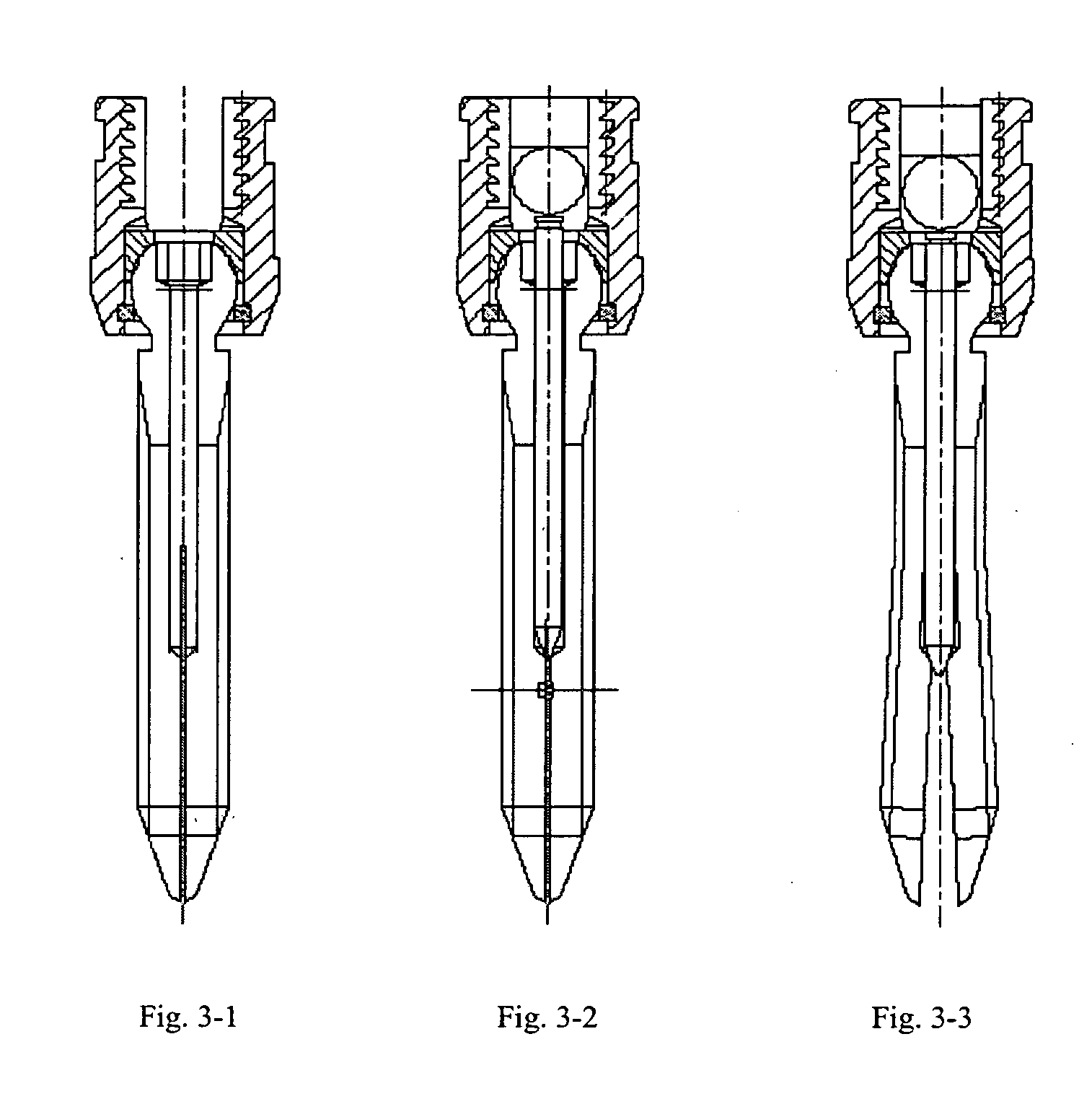

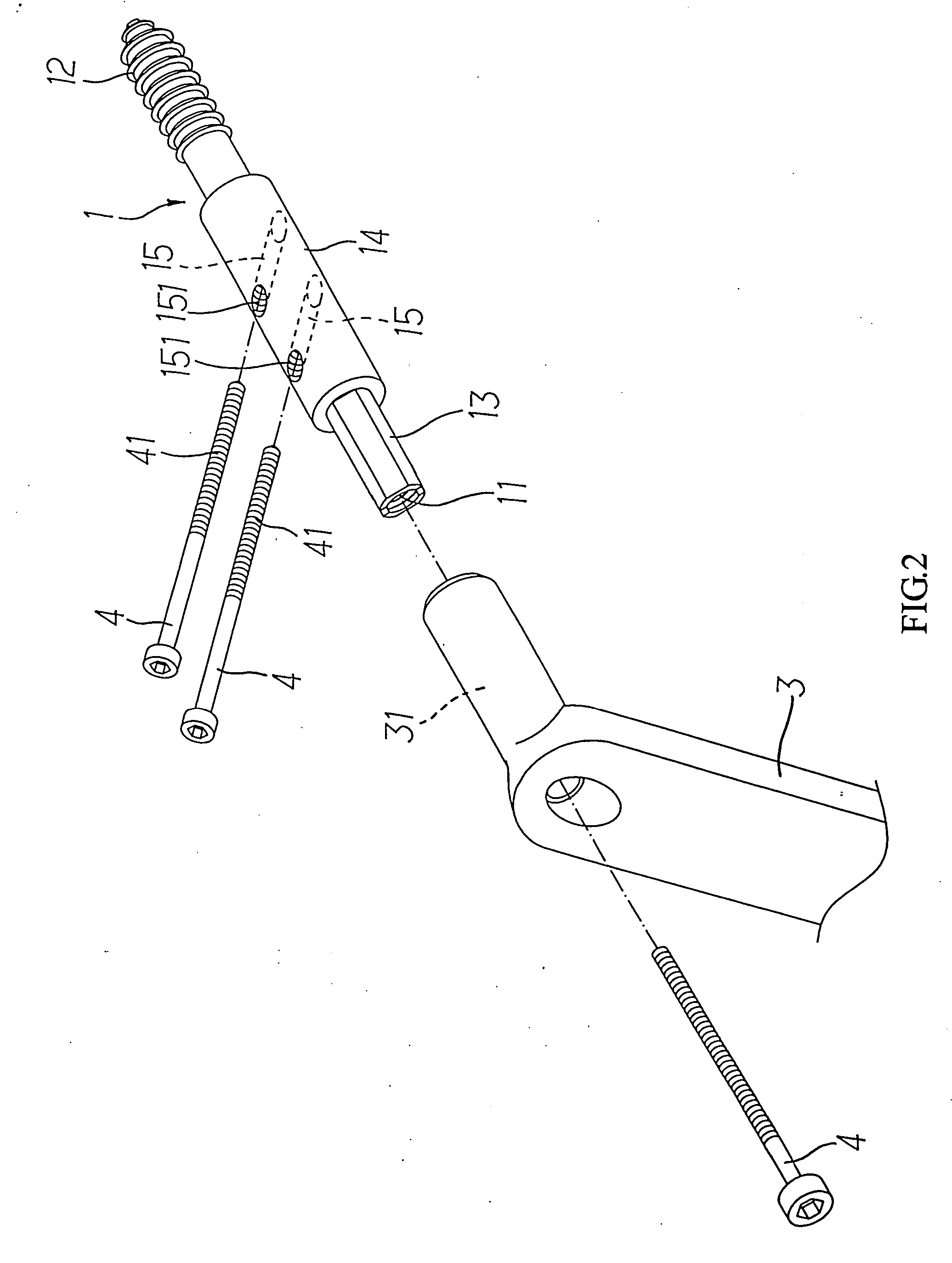

Multi-Axial Expandable Pedicle Screw and an Expansion Method Thereof

ActiveUS20090105771A1Reduce probabilityImprove stabilitySuture equipmentsInternal osteosythesisFailure rateUniversal joint

The invention disclosed a multi-axial expandable pedicle screw and an expansion method by using the same. Structure of the screw comprising a hollow screw being spherical shaped end connecting with an adapting piece, which is universal joint structure; an inner wall of the adapting piece connecting a lock bolt through screw threads; the hollow screw with sharp shaped on another end having a bore inside formed hollow structure in its entirety; the bore having taper shaped tip; expansion gaps uniformly setting up two, or three or four or more anterior fins on the hollow screw along its axial direction upward, prolonging from its tip to the bore; the inner needle is disposed in the bore. The invention can reduce the pedicle screw loose and even occurrence ratio of pull-out and increase the stability and reliability and reduce the failure rate of spinal surgeries at the same time. It is also easy to operate, and degree of expansion is of controllable level.

Owner:LEI WEI +1

Motion Preserving Artificial Intervertebral Disc Device

InactiveUS20090240333A1Promotes self-centeringExtend the lifespanSpinal implantsCoatingsRelative motionIntervertebral disk

A motion preserving implant having first and second bearing members and a biasing member disposed therebetween operable to provide resistance to the translation of the bodies with respect to one another. An intervertebral implant having first and second bearing members, a translatable member, a resilient connection between the translatable member and one of the bearing members to allow for relative motion therebetween and bearing surfaces of the translatable member and the other bearing member to allow complex, natural motion between the bearing members. A spinal implant having upper and lower bodies and an articulation surface that allows for polyaxial articulation and translation through a concave articulation surface having a first radius of curvature and a second radius of curvature in at least one plane, and a convex articulation surface having the first radius of curvature in the same plane.

Owner:PIONEER SURGICAL TECH INC

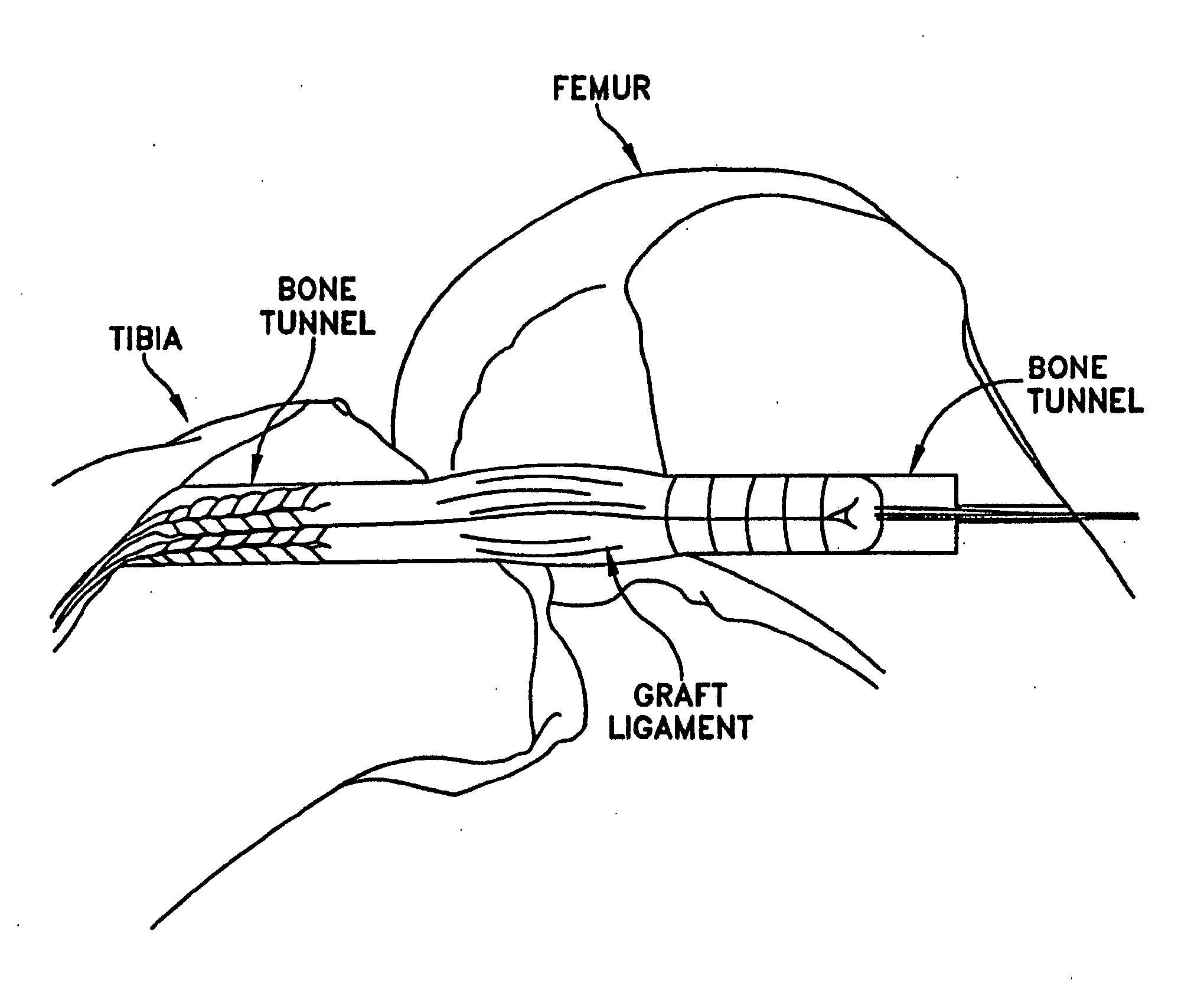

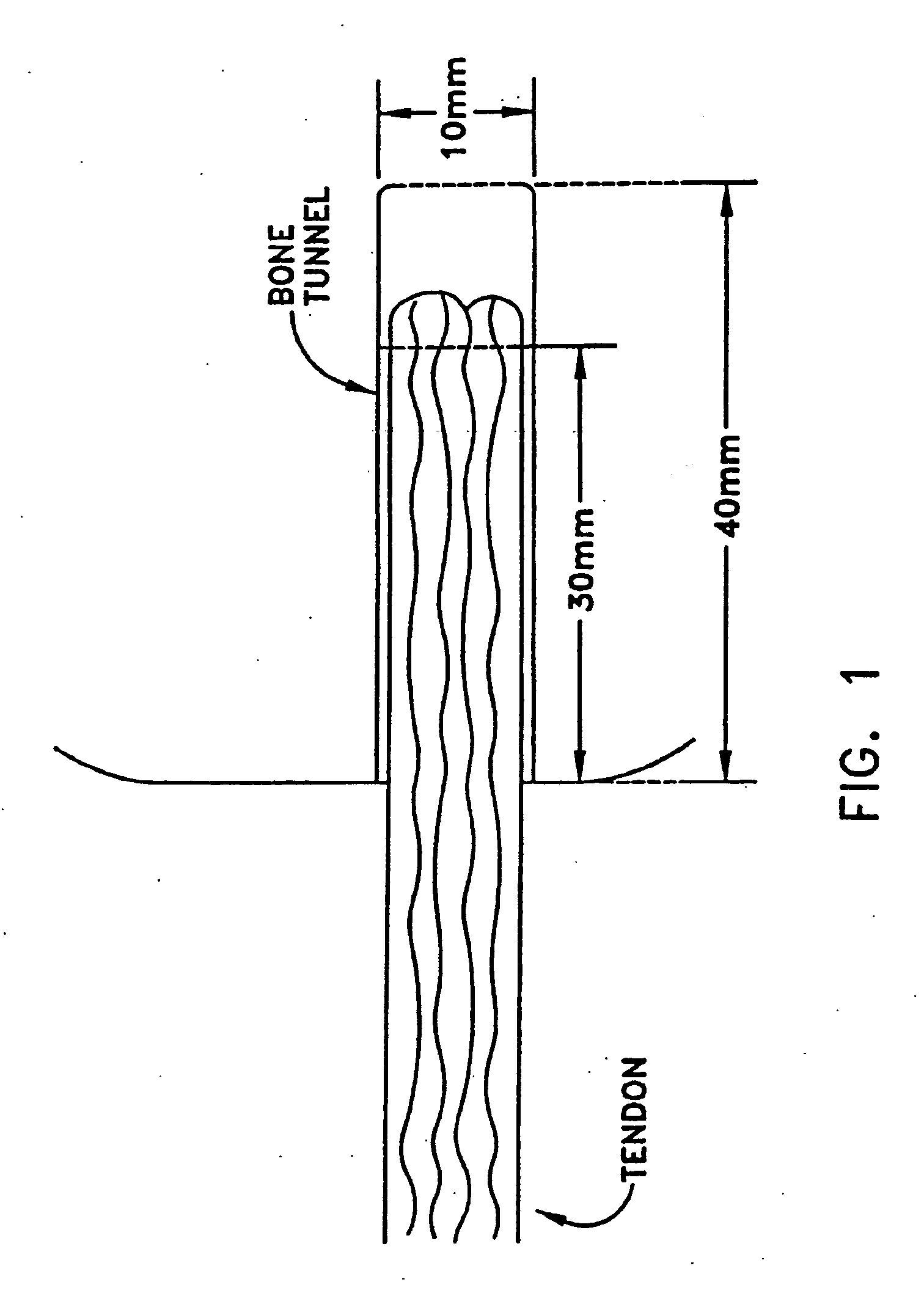

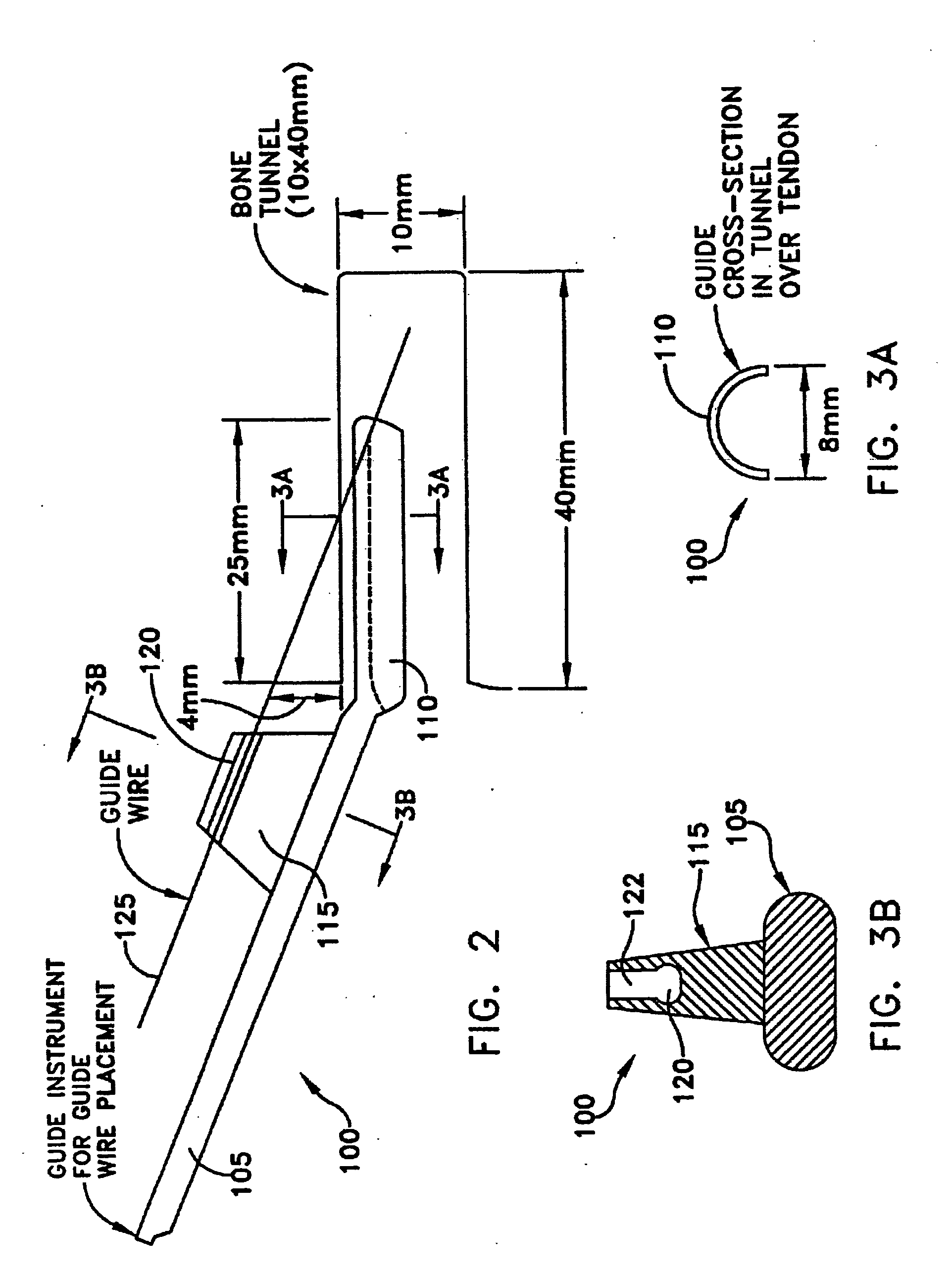

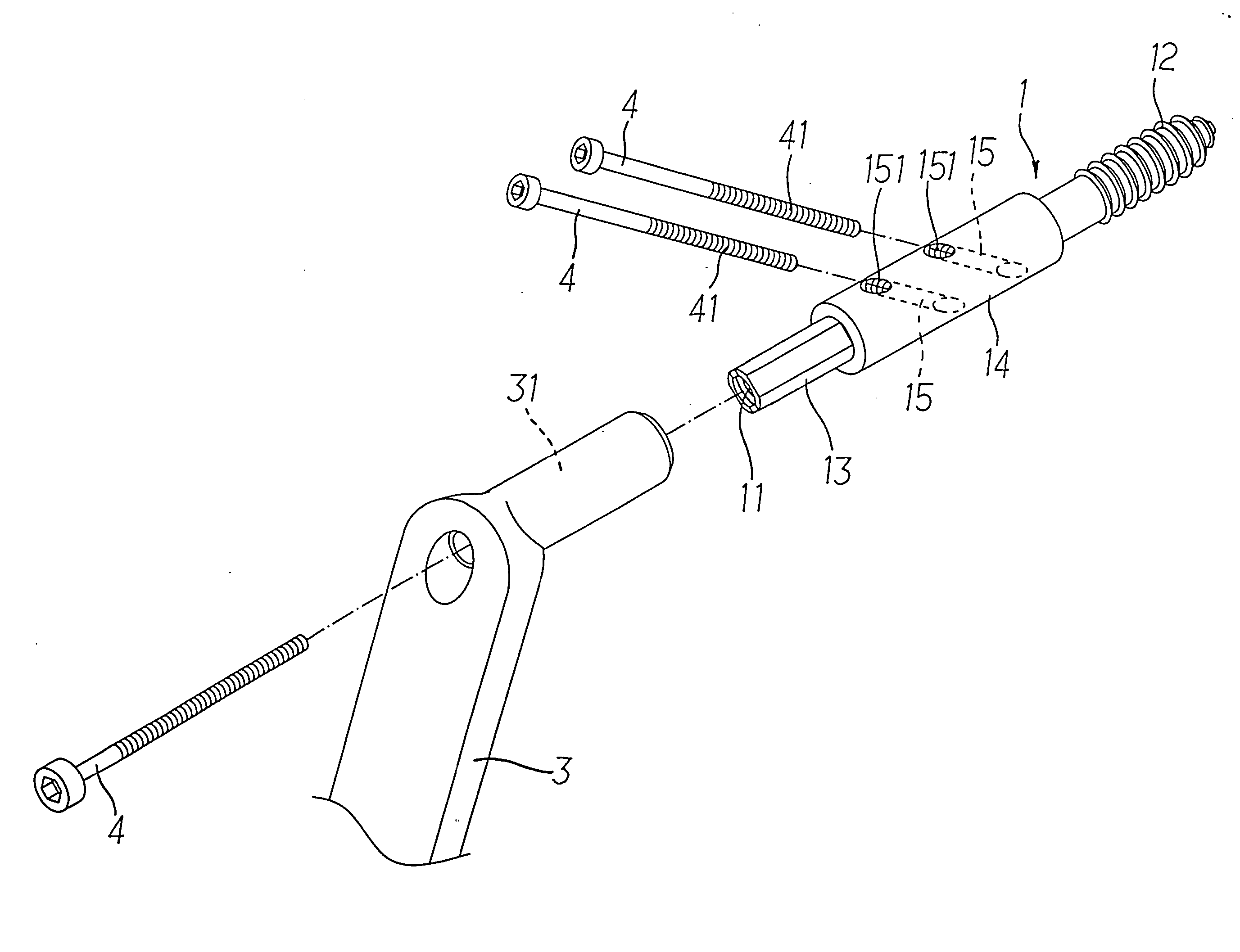

Method and apparatus for reconstructing a ligament

InactiveUS20050137704A1Easy to fixMiniaturization exerciseLigamentsMusclesBone tunnelThumb opposition

A new approach for reconstructing a ligament, the new approach comprising: creating a bone tunnel within a host bone, the bone tunnel having a proximal end and a distal end, and defining a central axis extending from the proximal end to the distal end; creating an intervening layer of bone between the central axis of the bone tunnel and a rigid portion of the host bone, the intervening layer having a first side and a second side in opposition to one another, the first side of the intervening layer facing toward the central axis of the bone tunnel and the second side of the intervening layer facing toward the rigid portion of the surrounding host bone; and compressing the intervening layer of bone against a graft ligament positioned within the bone tunnel.

Owner:KARL STORZ GMBH & CO KG

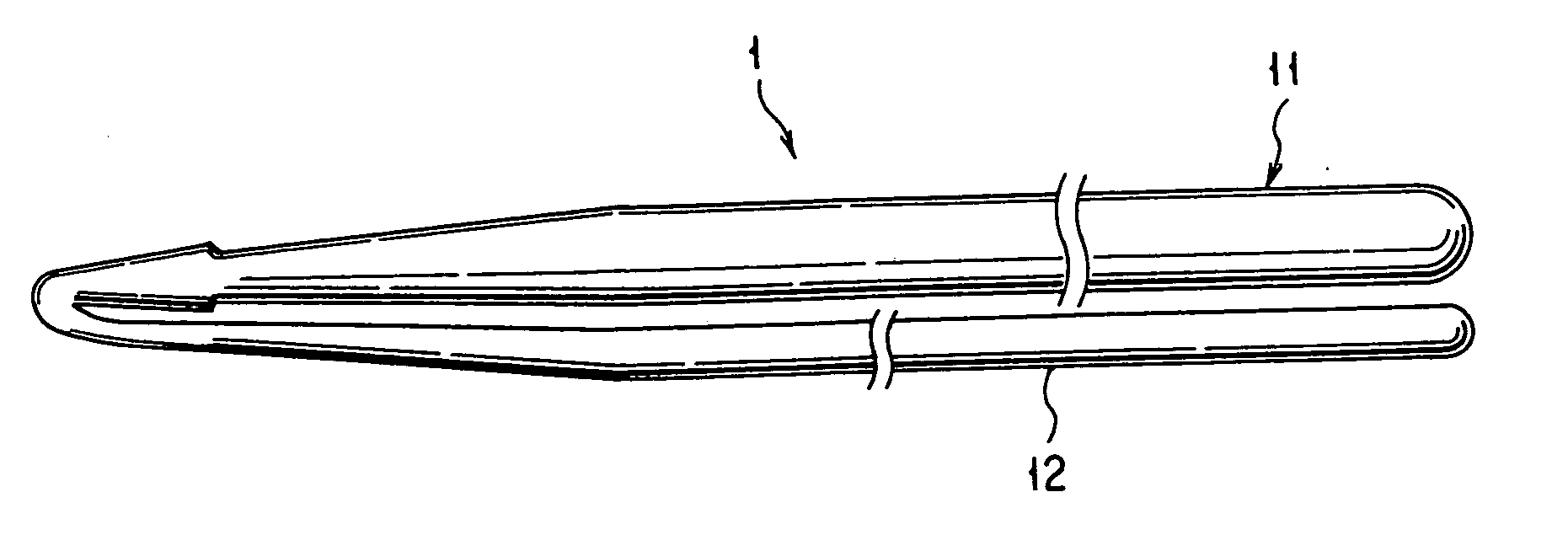

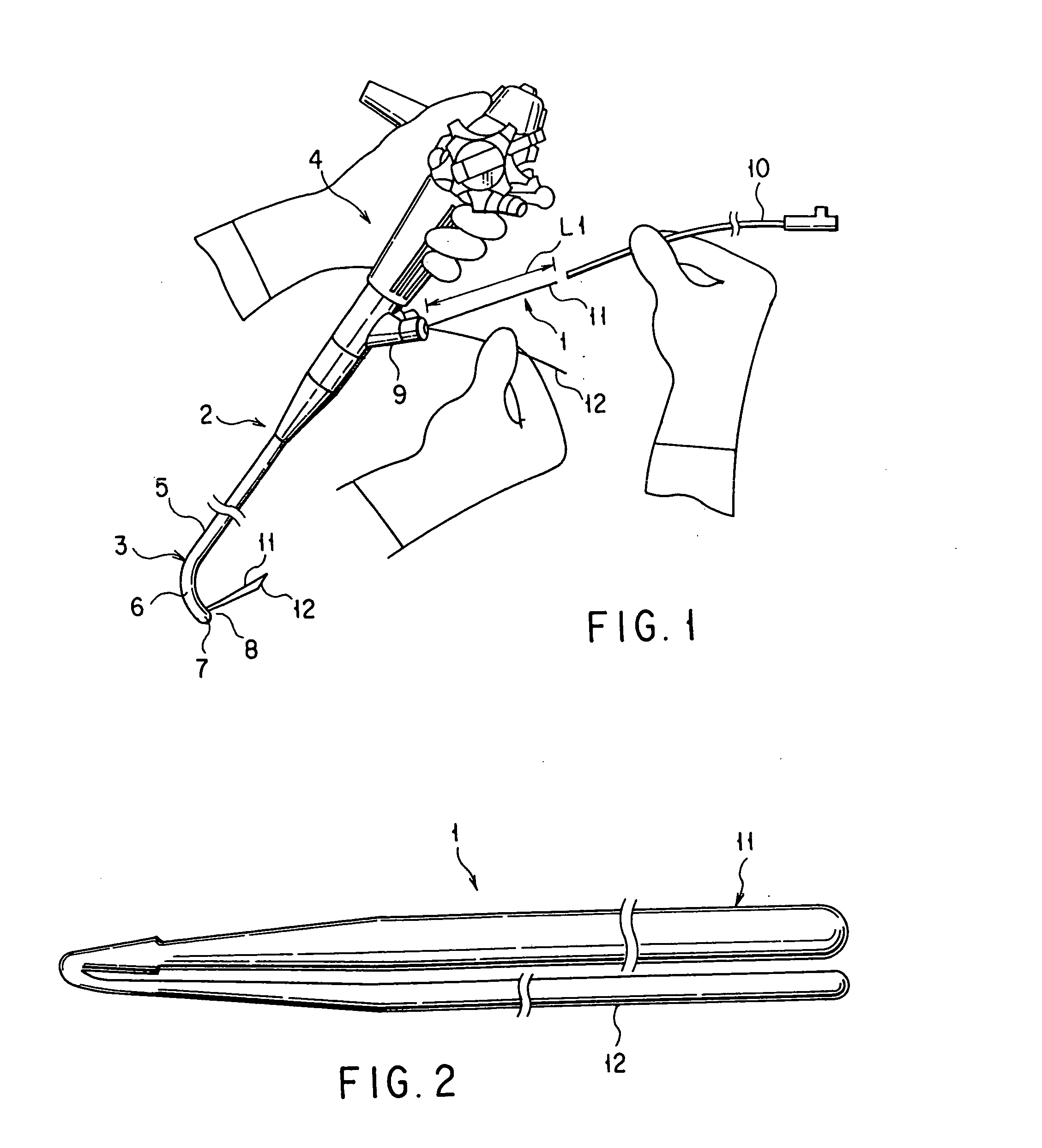

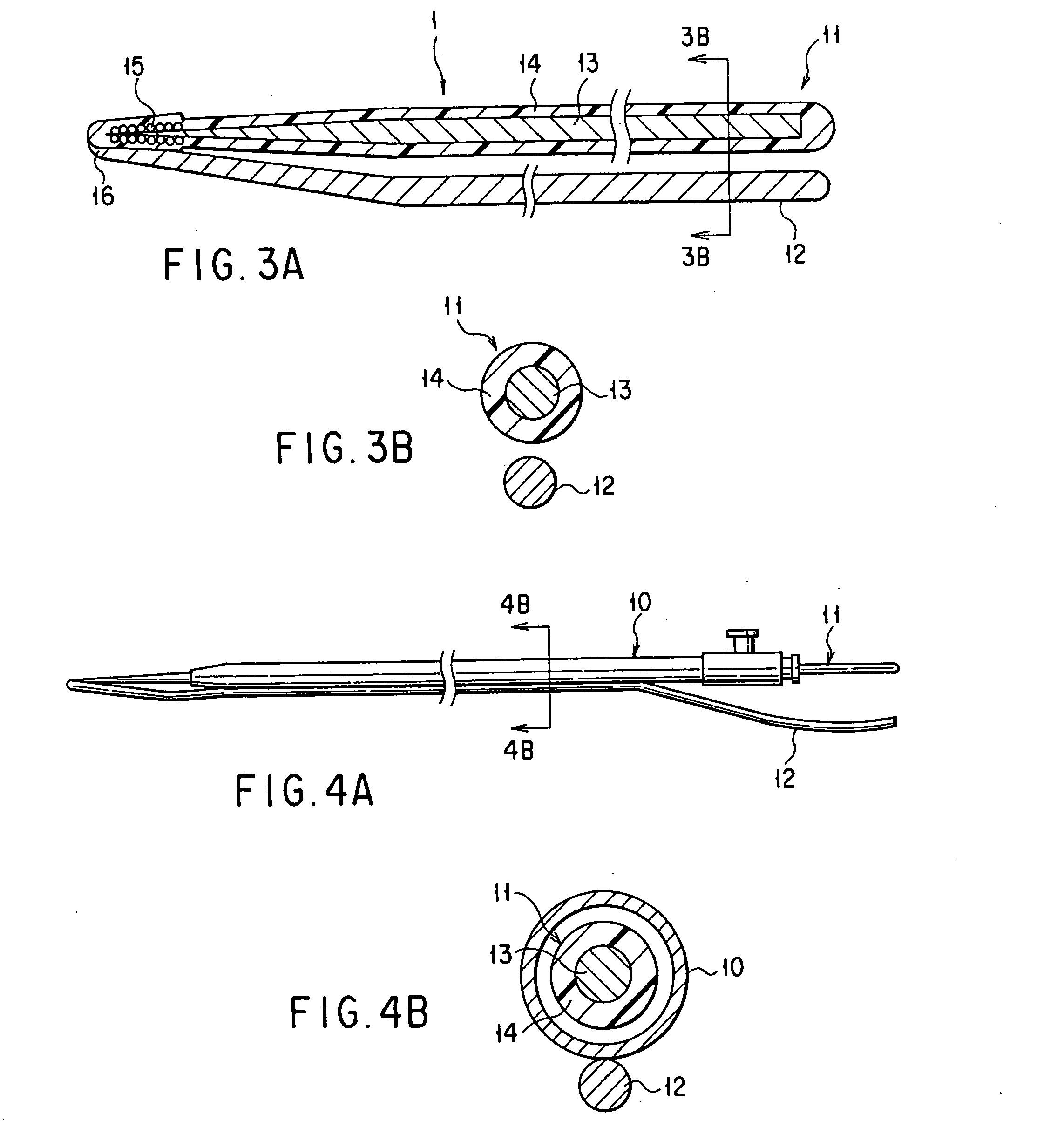

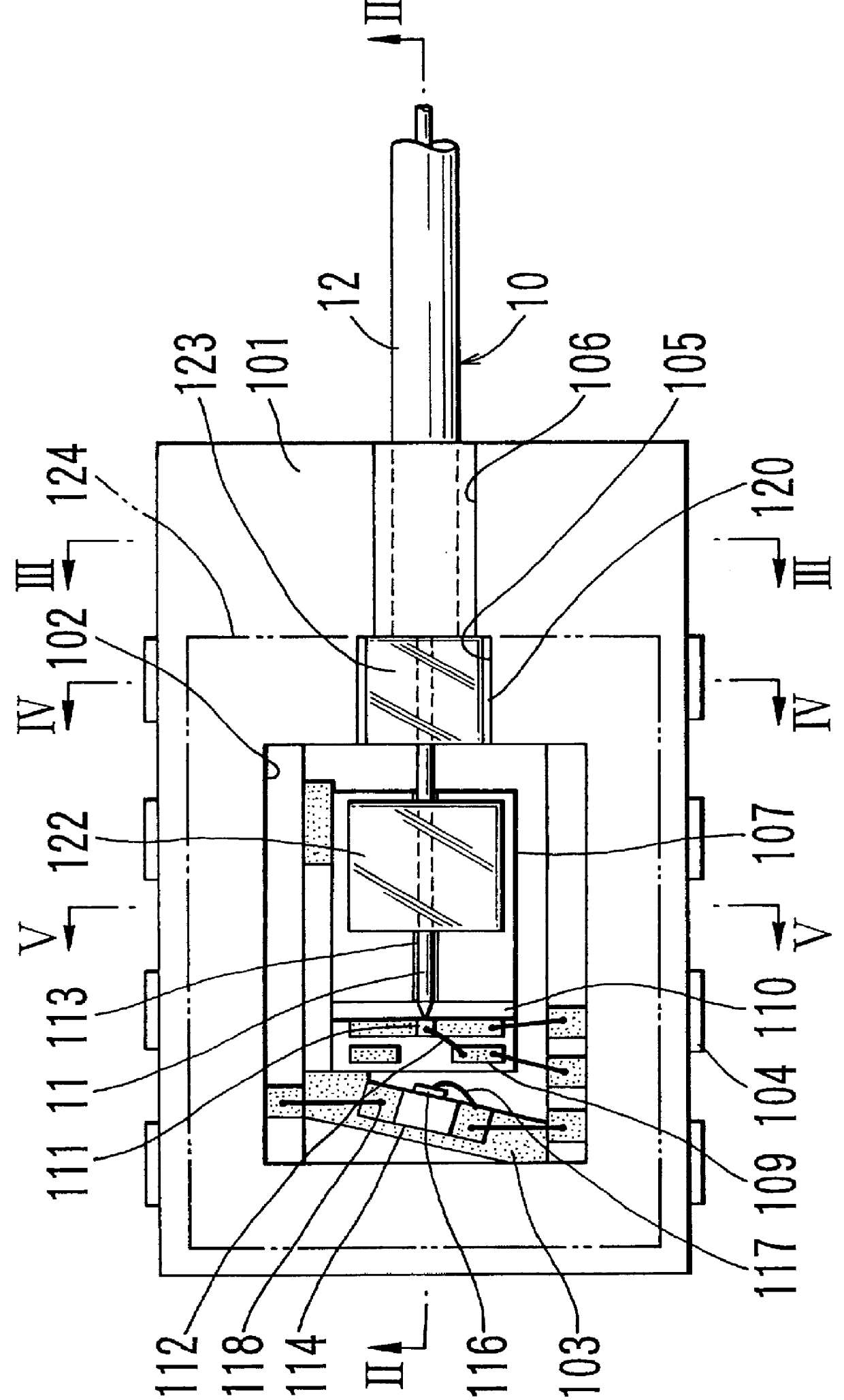

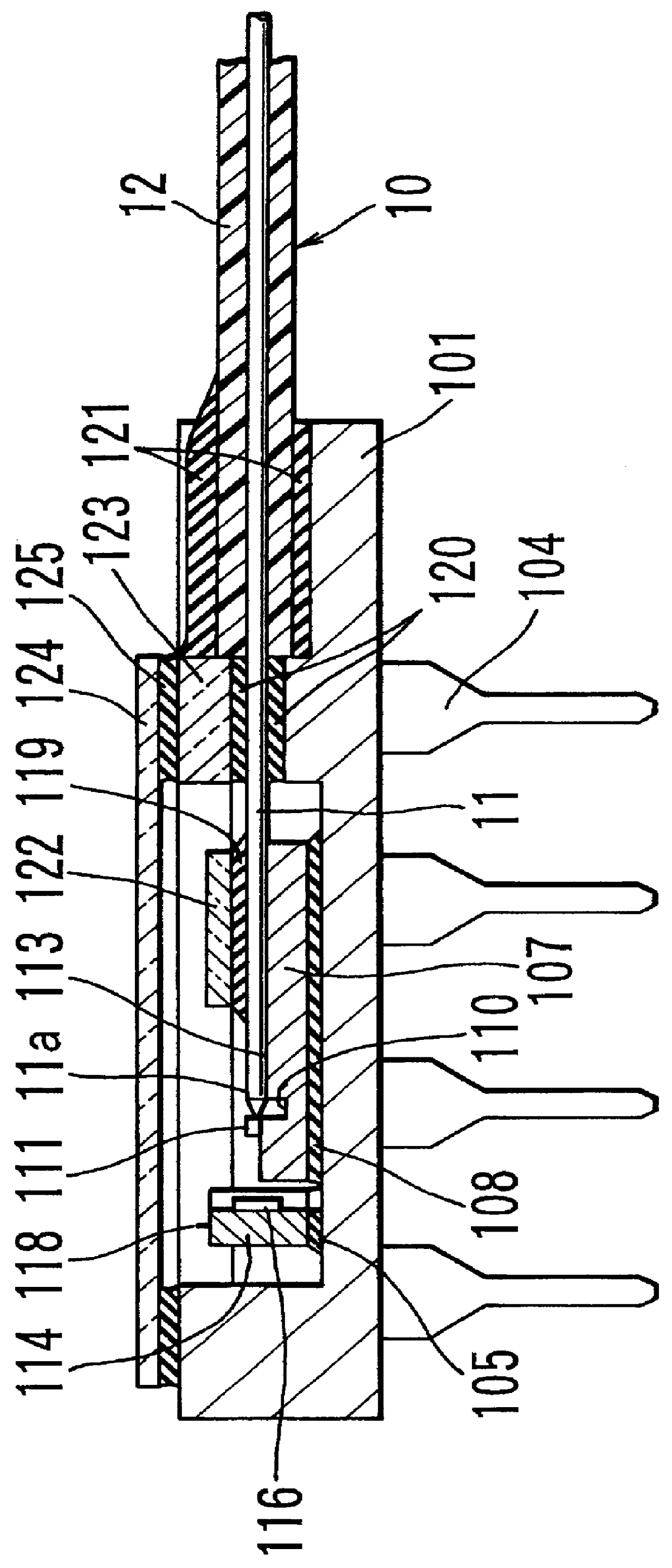

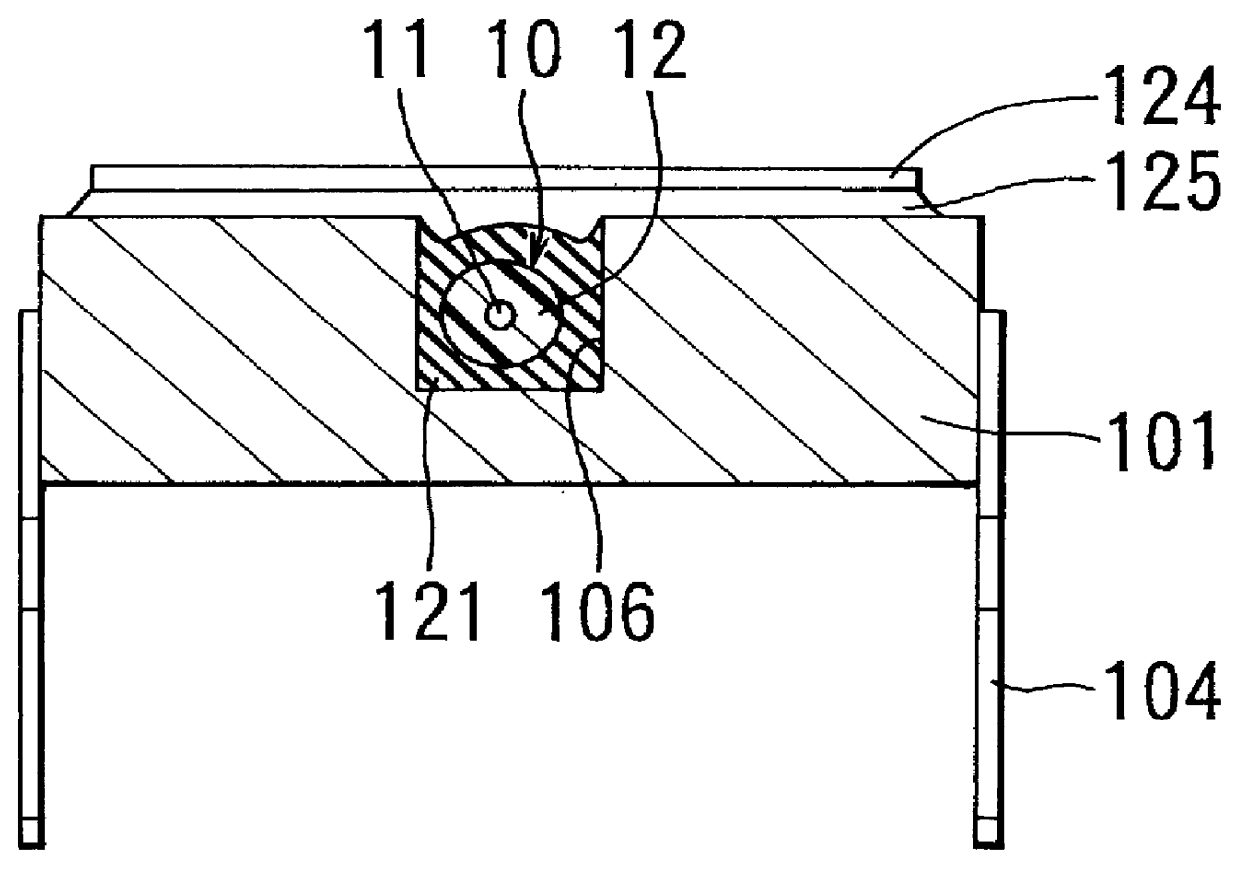

Medical guide wire

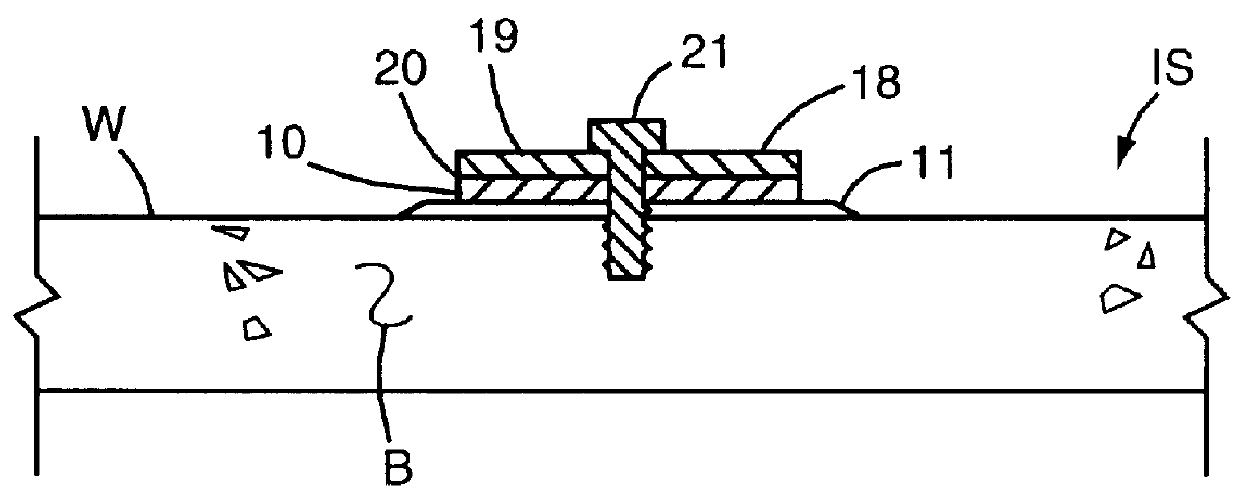

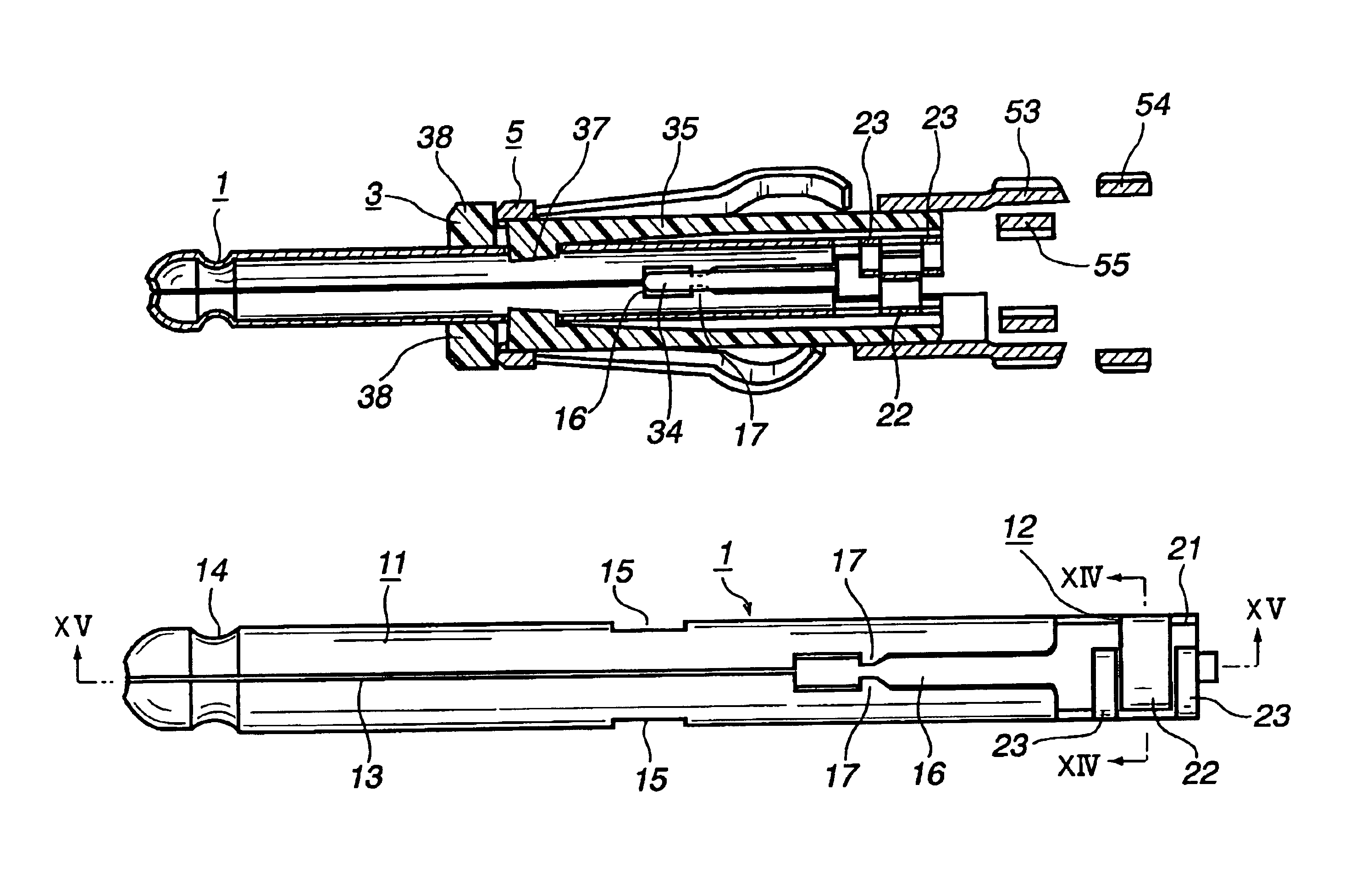

A fixing portion is provided so that the position of a guide wire (1) relative to an endoscope (2) is fixed lest it change by means of a retaining wire (12) that has one end coupled to the distal end portion side of a guide wire body (11) and the other end extending to the proximal end portion side of the guide wire body (11).

Owner:OLYMPUS OPTICAL CO LTD

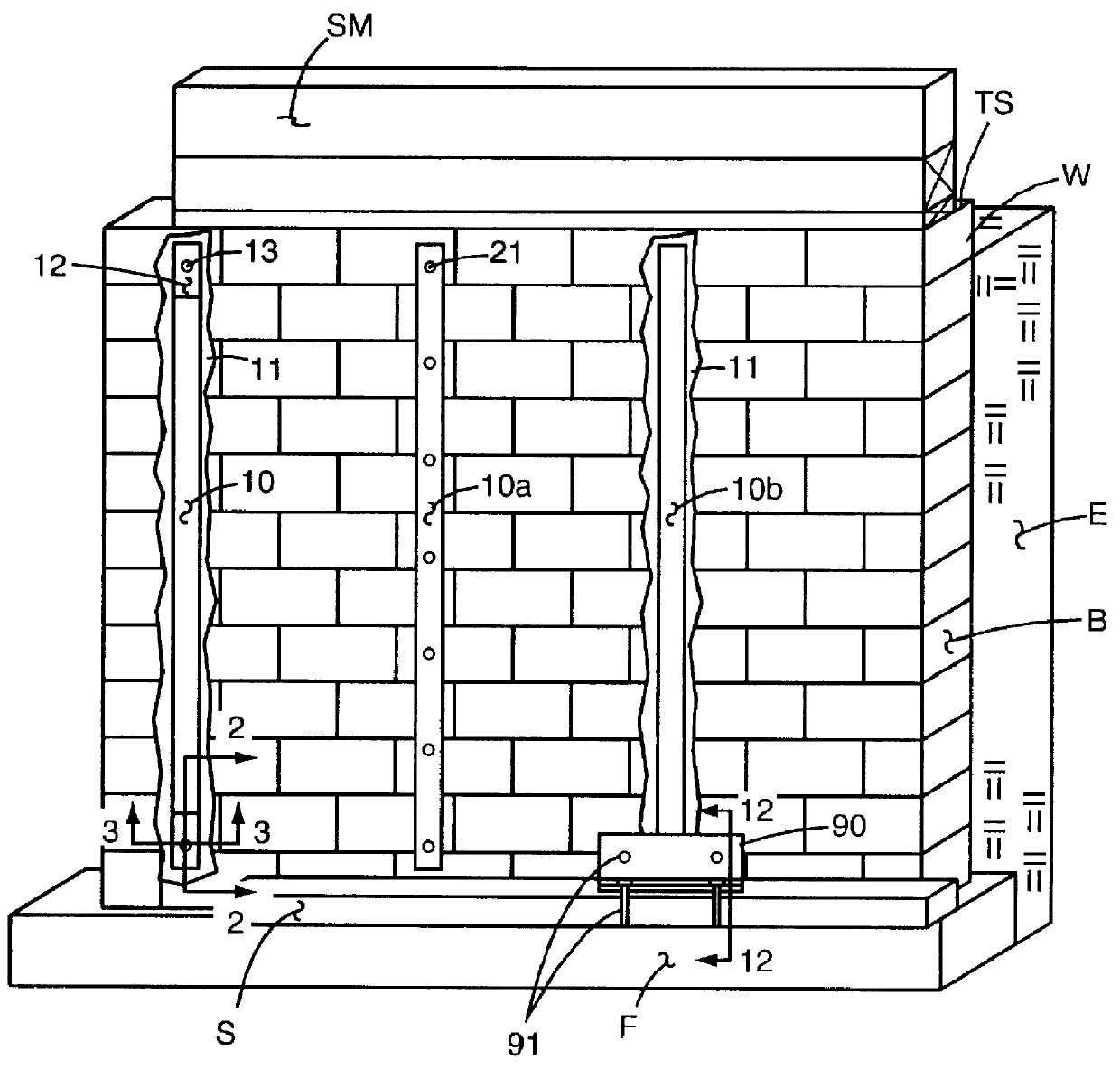

Wall reinforcing and waterproofing system and method of fabrication

A wall reinforcing system is provided for strengthening of walls formed of masonry or from wood, metal or other structural materials. A basic system comprises utilization of rigid, fiber reinforced polymer plates of a length to extend substantially the full vertical heigth of the wall. These plates incorporate a plurality of filamentary fibers of length to extend the full length of a plate with these fibers formed from carbon, glass or other material exhibiting high tensile strength and are affixed in a cured polymer matrix. A number of these plates are securely fixed to a wall in spaced parallel relationship by a resin bonding agent or by mechanical fastening devices, or by a combination of both. A plate may include a plurality of plates secured in stacked, superposed relationship and ridgidly secured together by a resin bonding agent into a unitary structure. A second system utilizes one or more sheets of flexible fabric-like material that is fabricated with tows of high tensile strength filamentary fibers of carbon, glass or other material. This fabric-like material is secured to the wall by a resin bonding agent with the tows vertically oriented thus utilizing their tensile strength for strengthening of the wall, either alone or in combination with the plates, and providing waterproofing.

Owner:NATIONWIDE REINFORCING +1

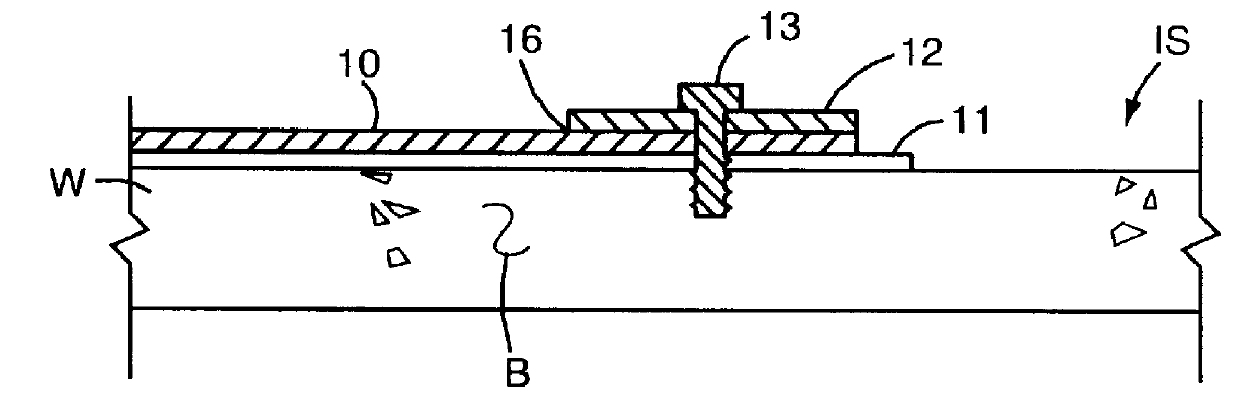

Fixing structure of insulation panel of prefabricated refrigerator and prefabricated refrigerator having the same

ActiveUS20070152551A1High insulation efficiencyImprove efficiencyShow cabinetsLighting and heating apparatusHeat flowRefrigerated temperature

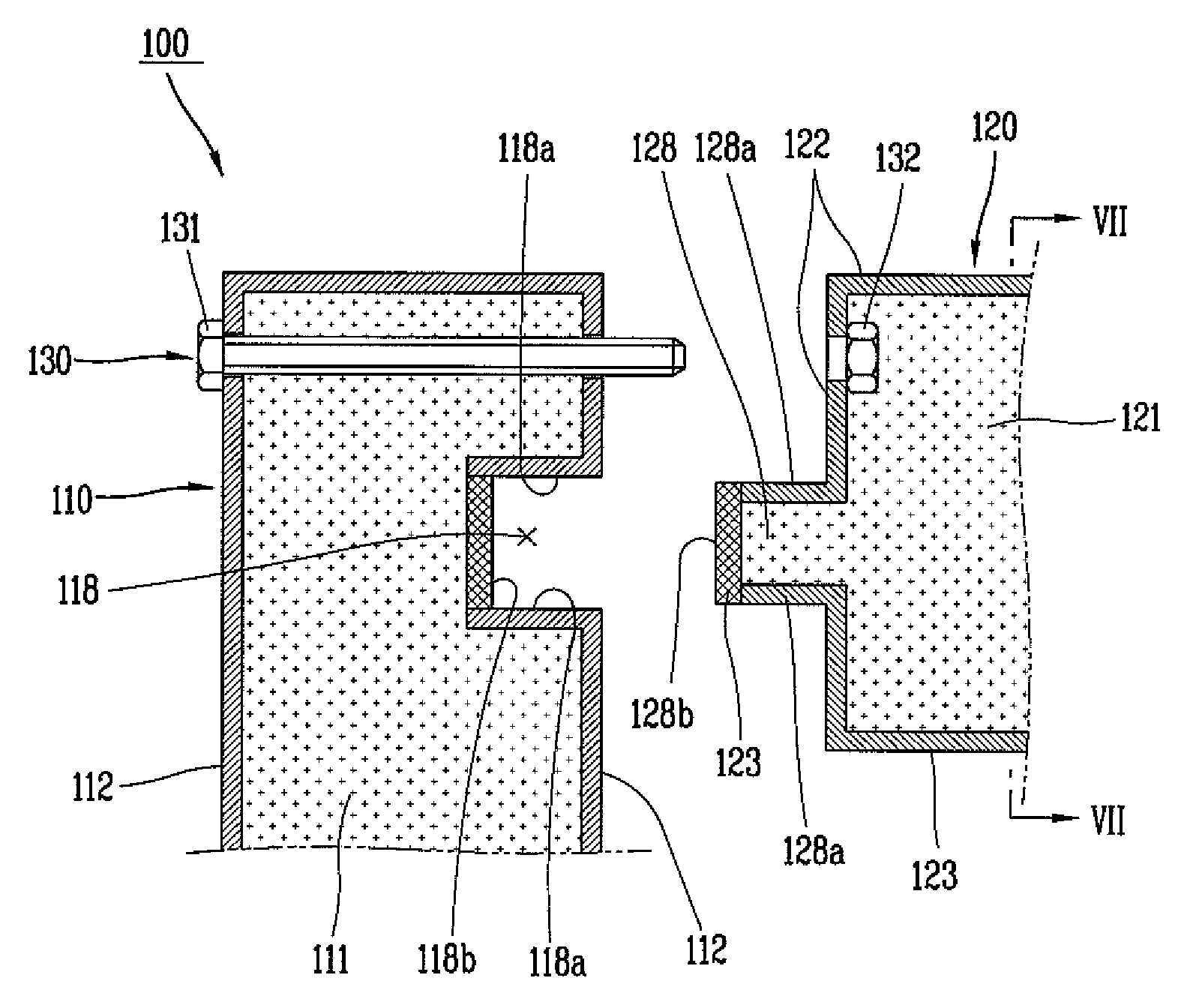

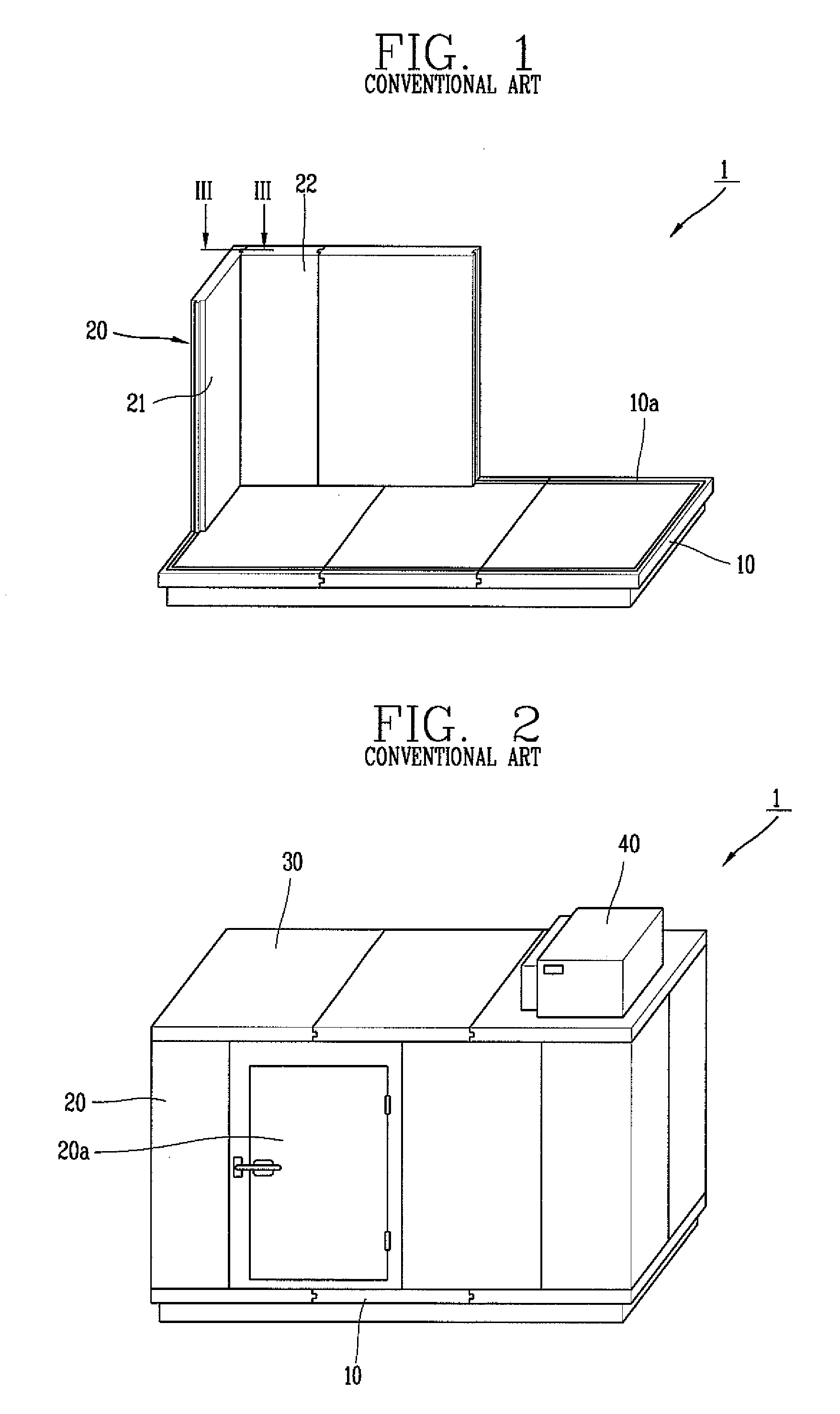

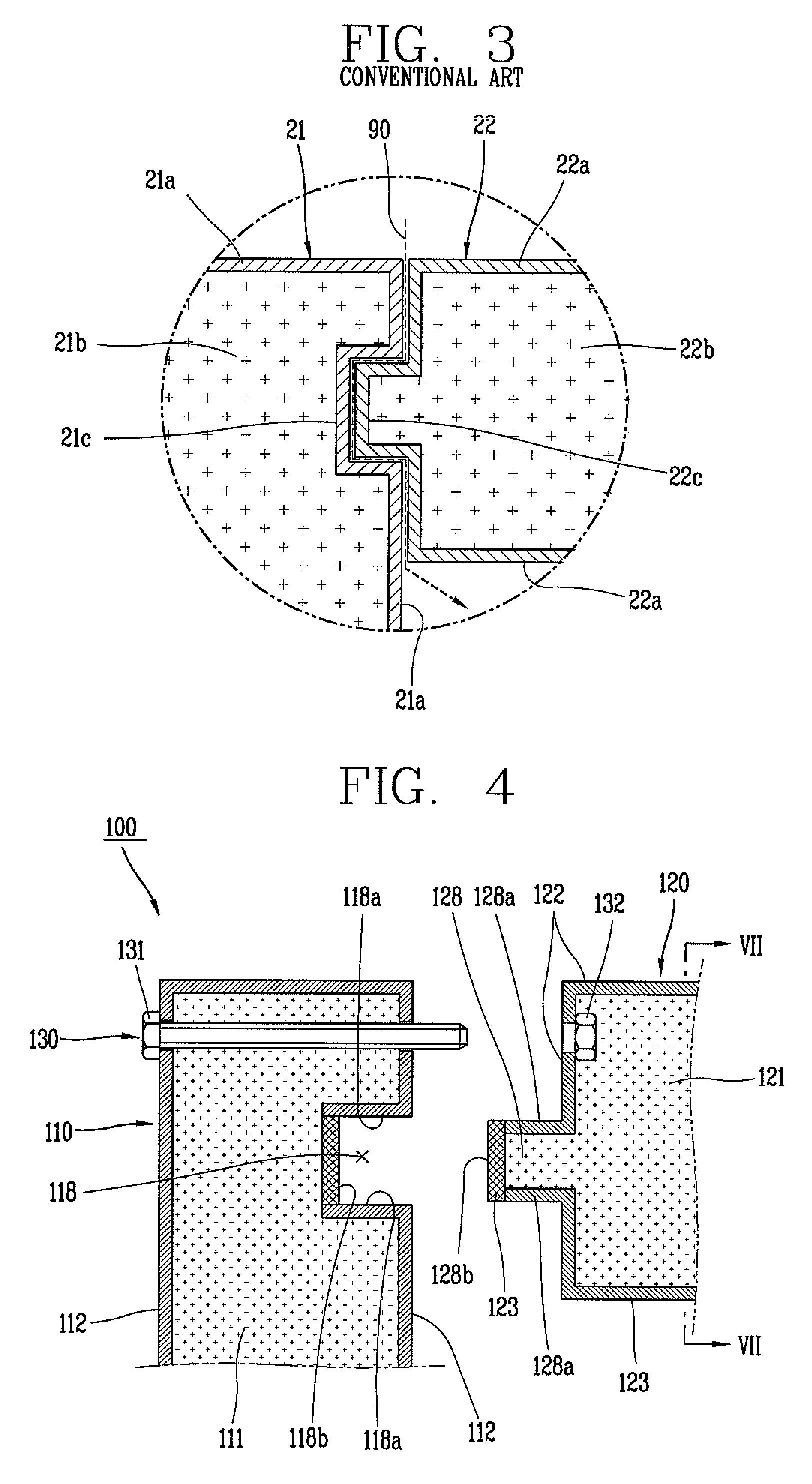

Disclosed are a fixing structure of insulation panels and a prefabricated refrigerator with the same. The fixing structure of insulation panels includes a recess recessed on one surface of a first insulation panel having an insulation portion inside a casing, and a protrusion formed to be inserted into the recess, on one surface of a second insulation panel having an insulation portion inside a casing, wherein the insulation portions of nonmetal material are exposed to a bottom of the recess and a front end of the protrusion so as to shield a transmission path of heat flowed along a casing contact surface of the insulation panels, thereby improving insulation efficiency.

Owner:LG ELECTRONICS INC

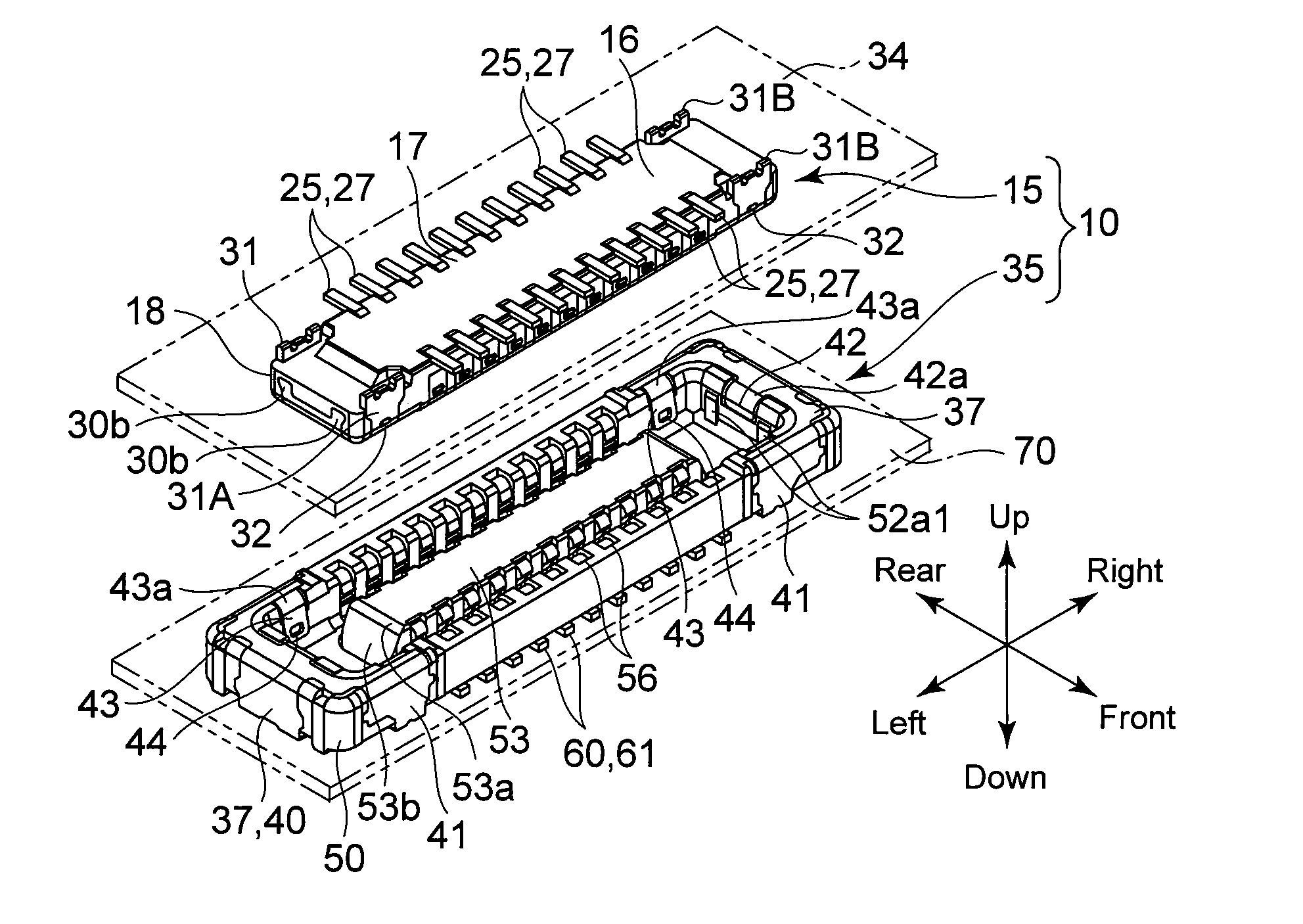

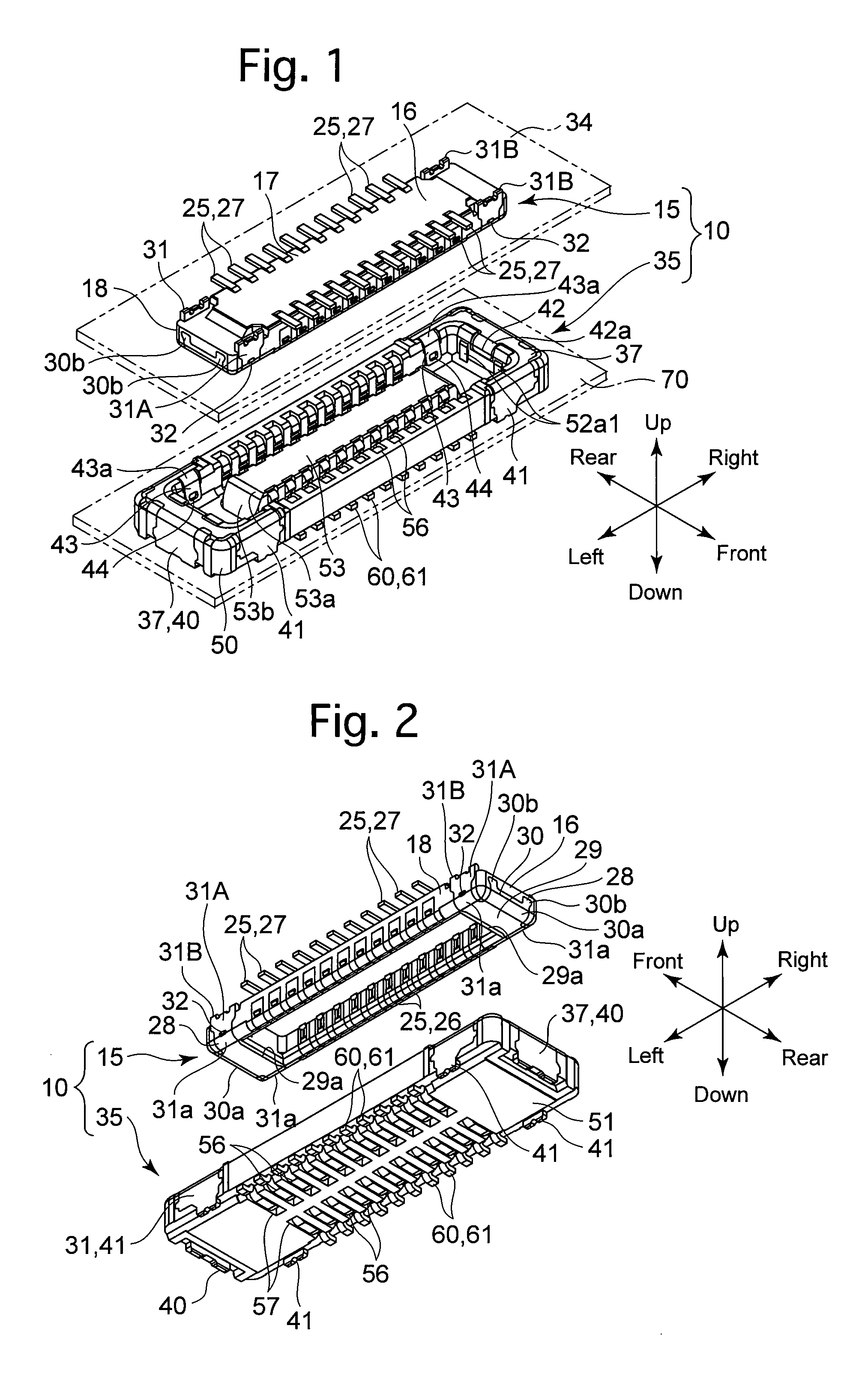

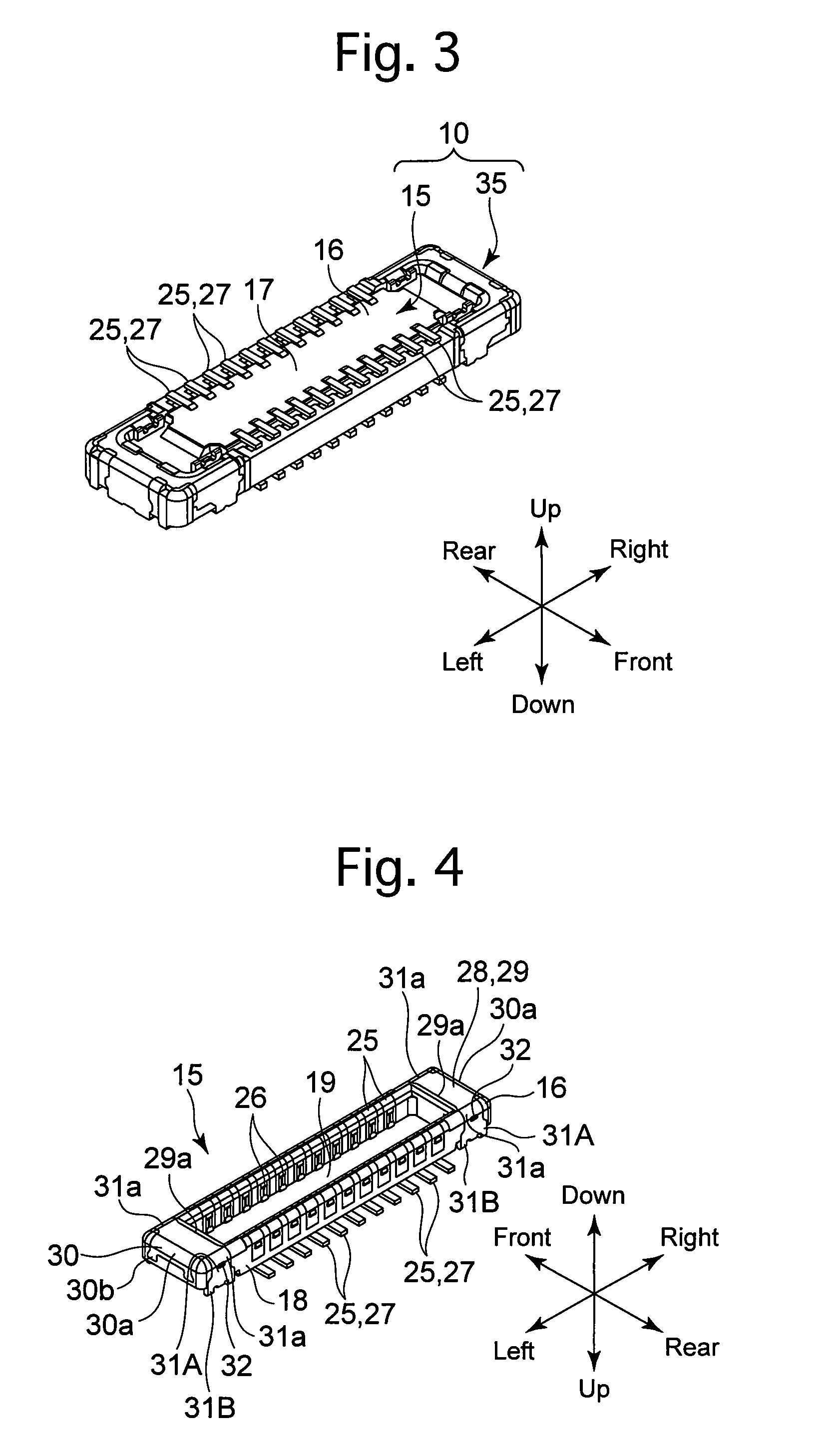

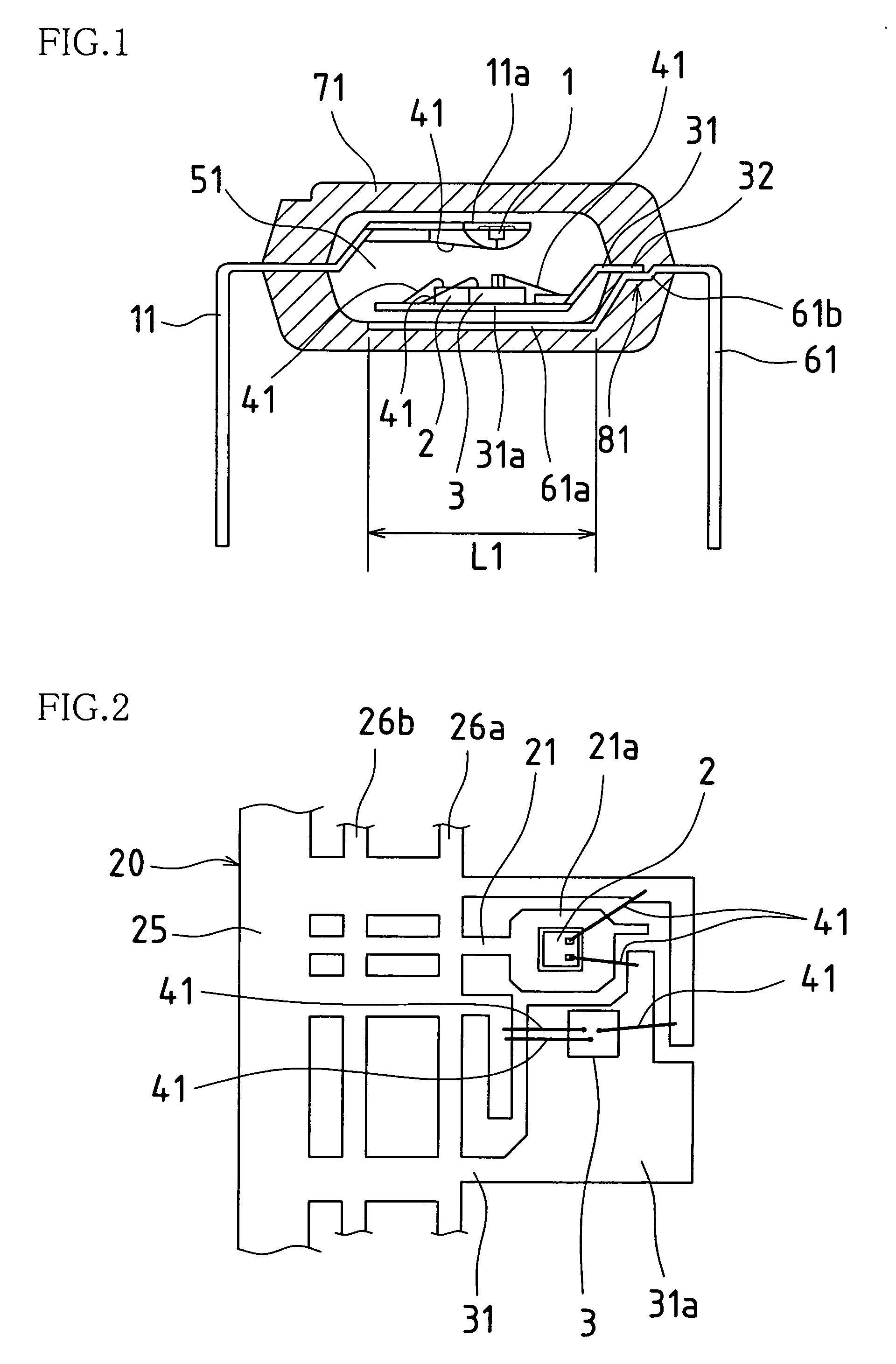

Receptacle connector and method of producing receptacle connector

InactiveUS20150140841A1Improve the fixing strengthHigh strengthContact member cases/bases manufactureTwo-part coupling devicesFree stateElectrical and Electronics engineering

A receptacle connector includes a receptacle insulator having an annular outer peripheral wall which defines a fitting recess; receptacle contacts; and a receptacle-side metal fixing member. When a projecting fitting portion of a plug insulator of a plug connector is fitted into the fitting recess, plug contacts of the plug connector come into contact with the receptacle contacts, and the plug connector comes into contact with the receptacle-side metal fixing member. The receptacle-side metal fixing member and the receptacle insulator are integrally formed by insert molding, and the receptacle-side metal fixing member includes a resilient contact portion which is spaced from a surface of the outer peripheral wall on the circumferentially inner side thereof when the resilient contact portion is in a free state.

Owner:KYOCERA CORP

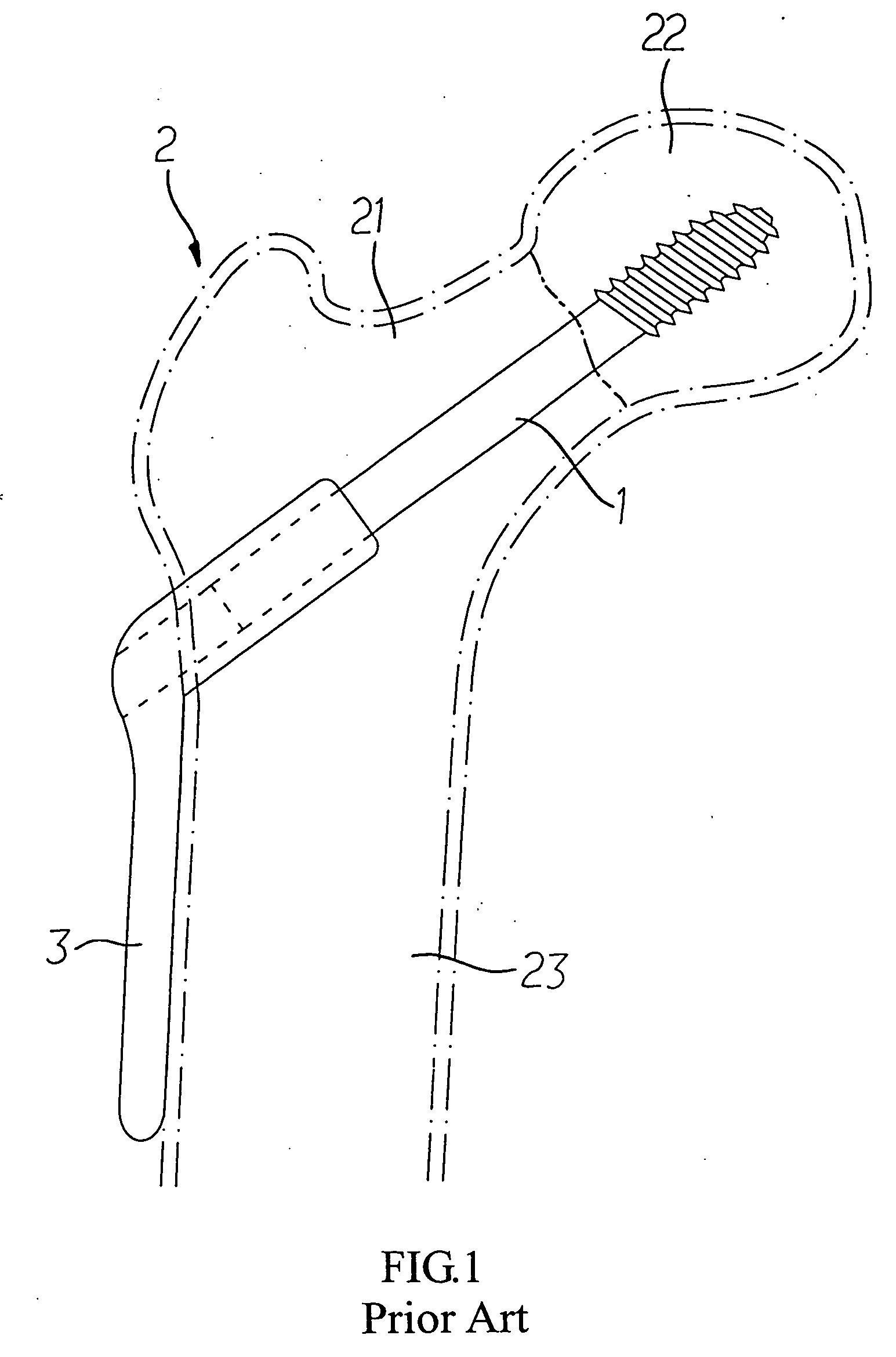

Interlocking hip screw

InactiveUS20070270848A1Increase fixation strengthEasily displacedInternal osteosythesisJoint implantsLeft femoral headFastener

A femur slide nail has one end penetrating into head of the femur through neck from side of the femur and another end fixed to shaft of the femur; a thickening section being disposed to the nail corresponding to the neck; one or multiple transverse holes being provided on the thickening section; and the hole being secured with a fastener so that the nail will not easily breaking away from femur head to improve fixation strength of the nail.

Owner:LIN SHIH WEI

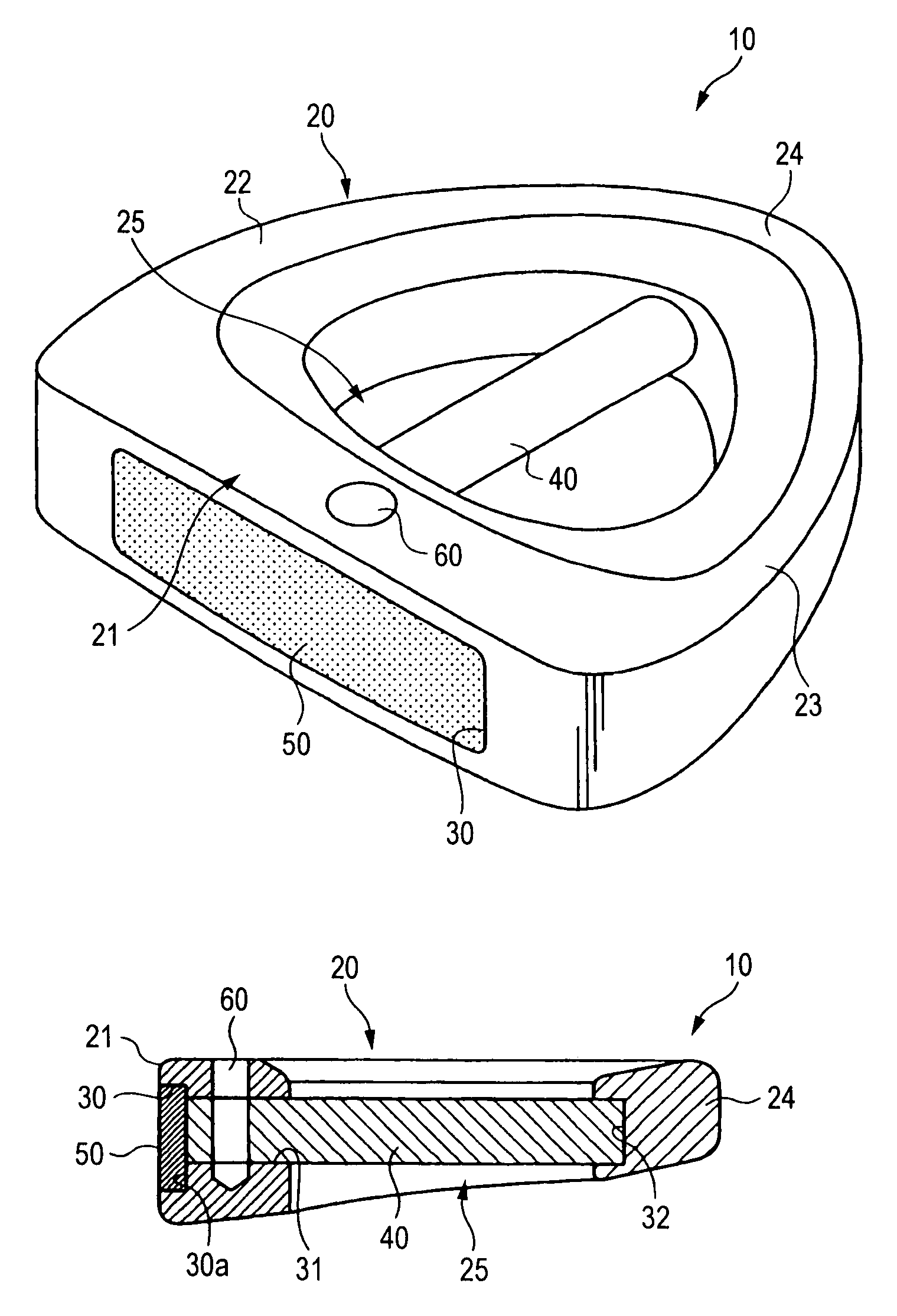

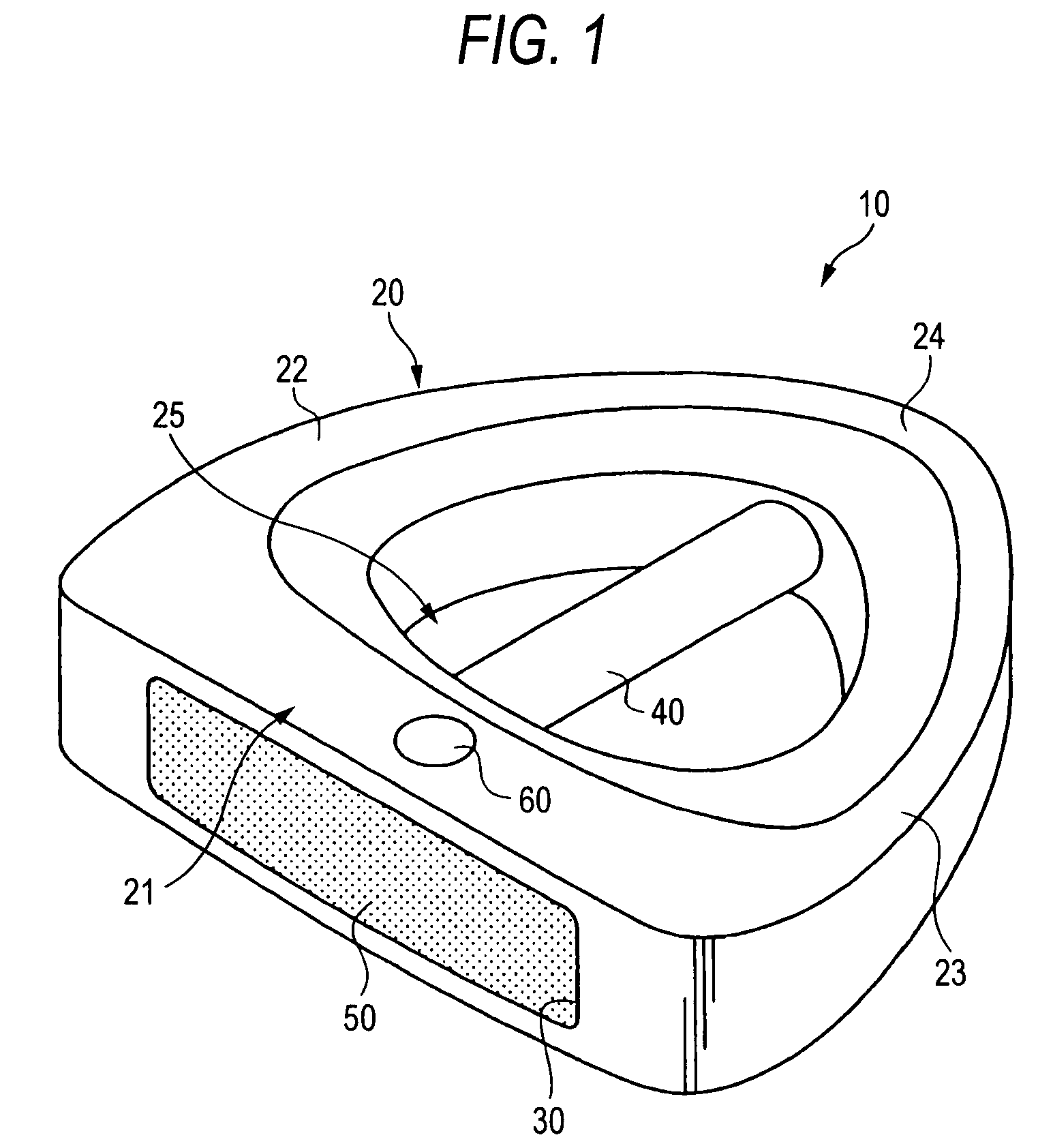

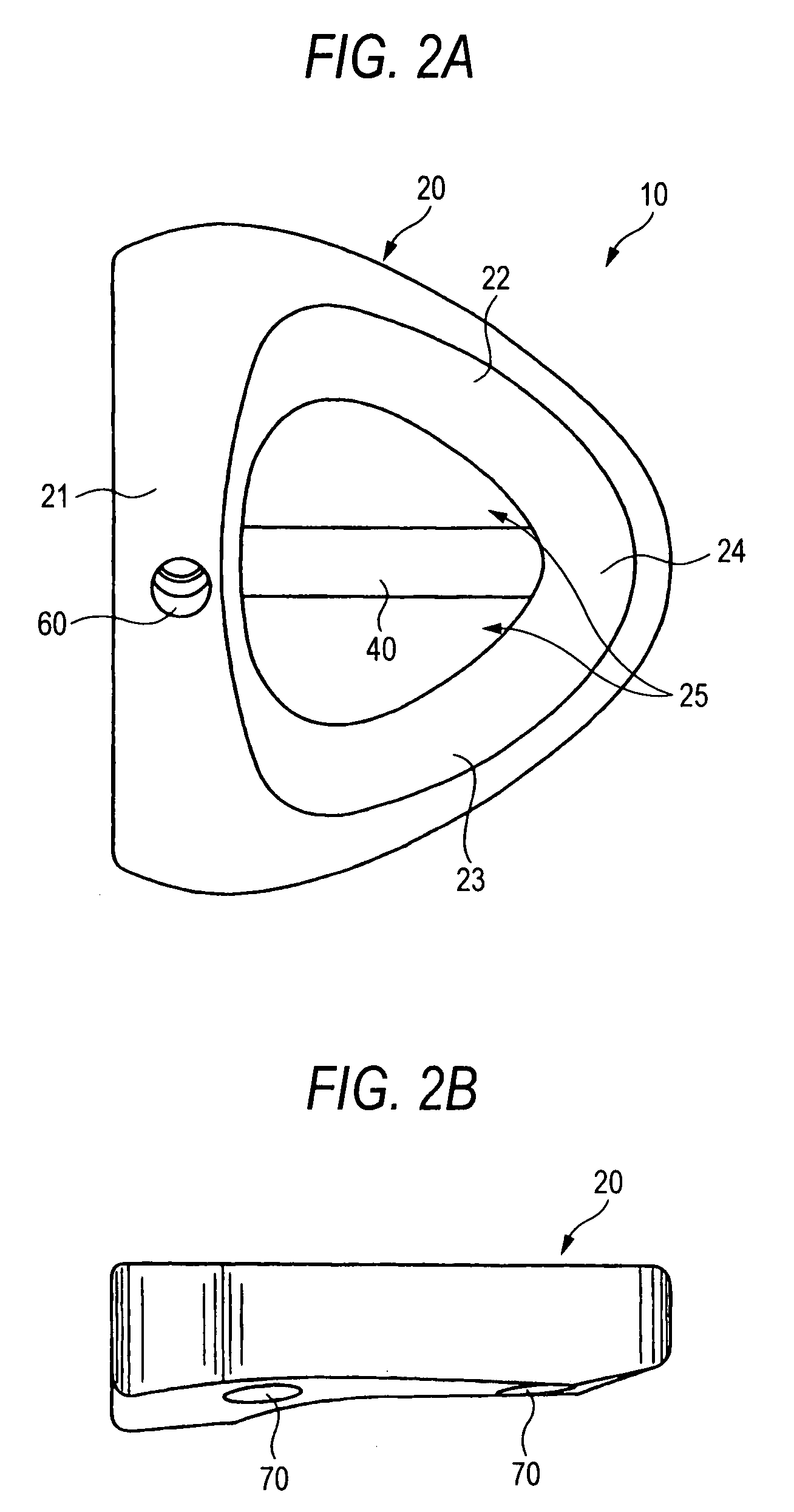

Putter head

InactiveUS7588499B2High dimensional accuracyEasy to manufactureGolf clubsRacket sportsAdhesiveEngineering

A putter head includes a head main body that defines a periphery of the putter head, and a bar that crosses a void space of the head main body in a forward-backward direction. The bar is inserted into insertion holes and fixed thereto by an adhesive. A face member is mounted on a recess. A shaft fixing hole is provided to pass through the bar from the top surface of a front portion of the head main body. A shaft is inserted into the shaft fixing hole and fixed thereto by an adhesive.

Owner:BRIDGESTONE SPORTS

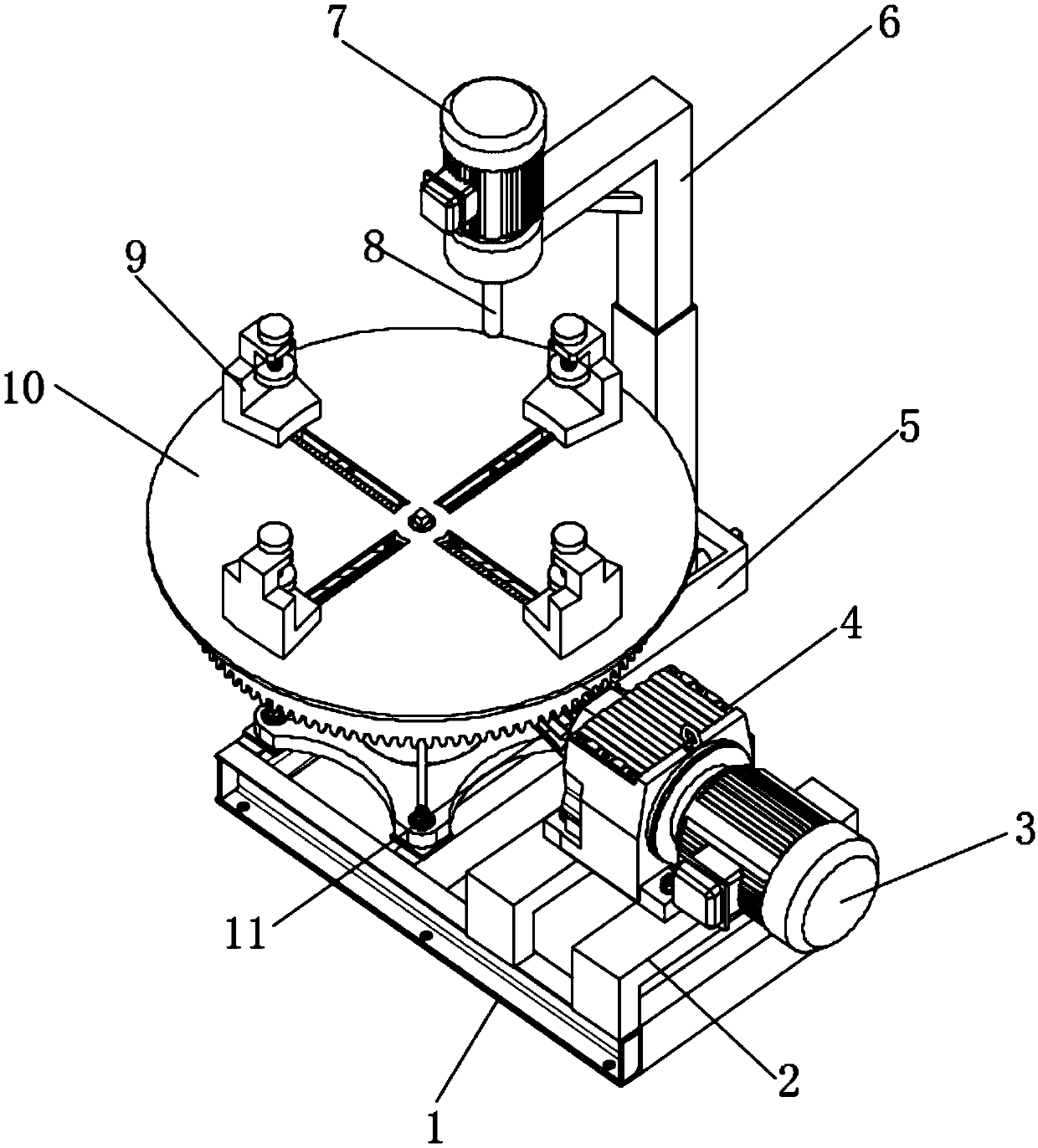

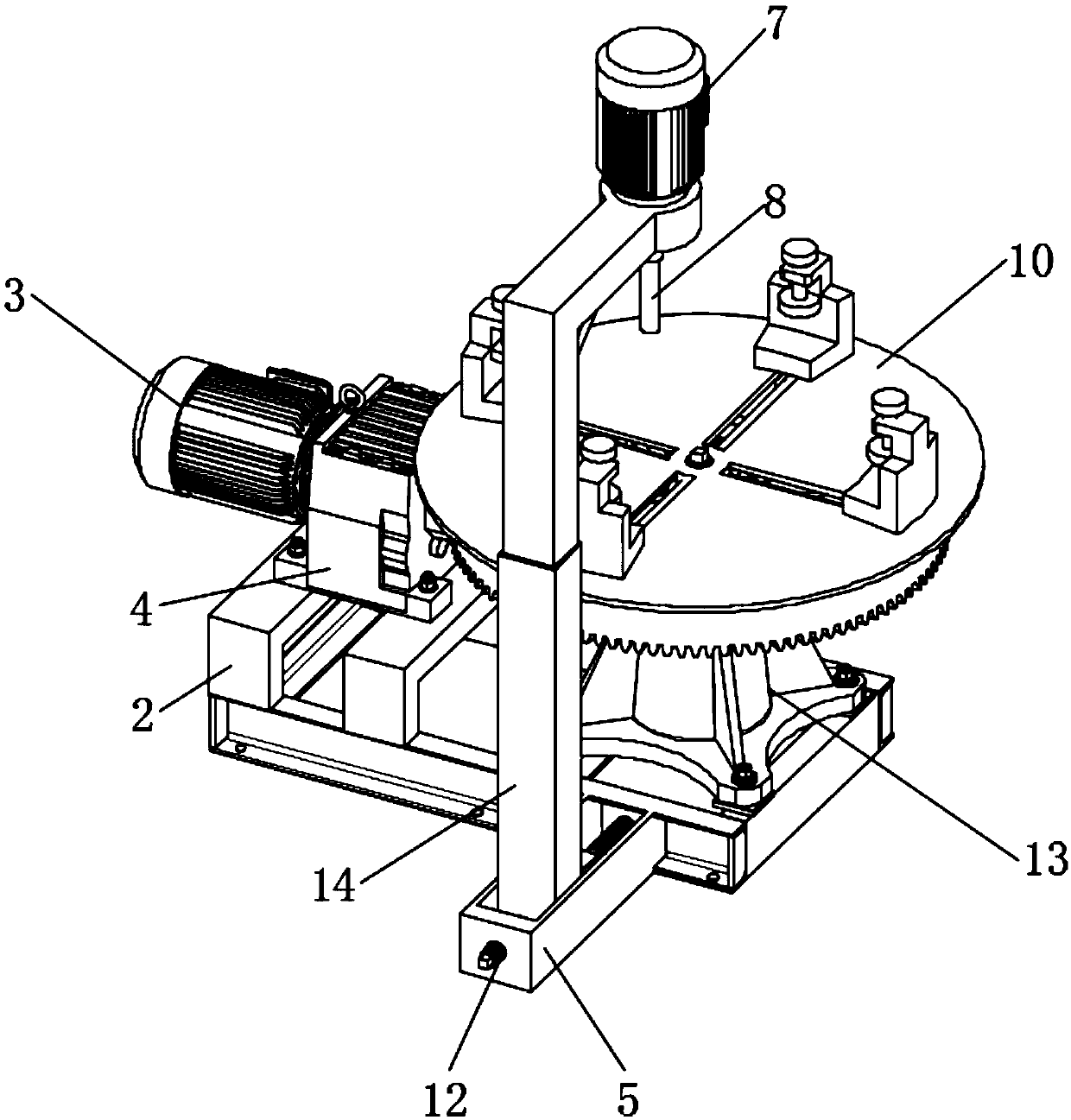

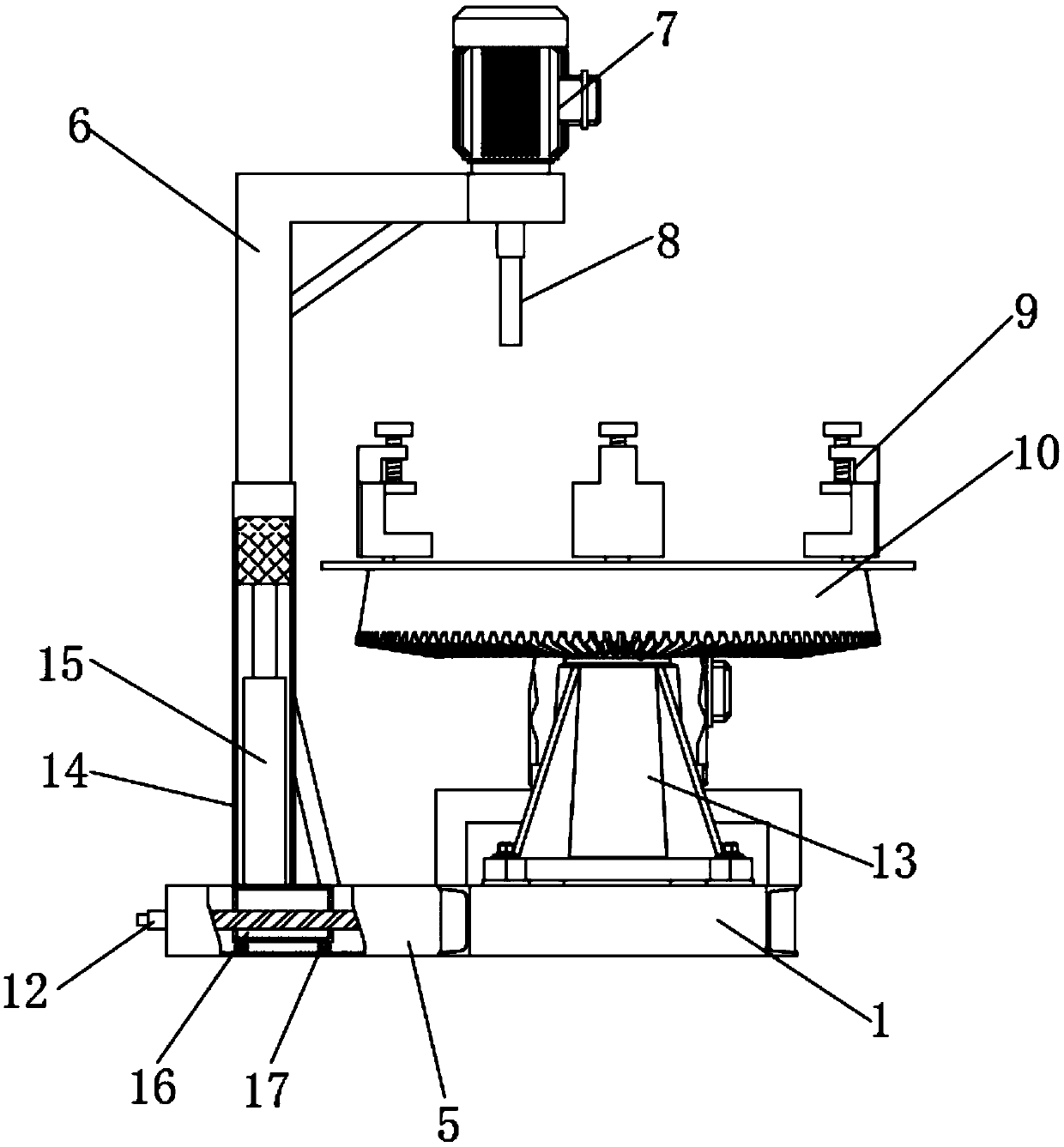

Inner ring grinding device and grinding method for rotating disc type bearing machining

InactiveCN109648411AImprove the fixing strengthImprove poor stabilityGrinding carriagesRevolution surface grinding machinesStructural stabilityEngineering

The invention discloses an inner ring grinding device and grinding method for rotating disc type bearing machining. The inner ring grinding device comprises a base, wherein a motor frame is welded toone side of the upper surface of the base, and the upper portion of the motor frame is connected with a speed reducer through bolts; a first motor which is in transmission connection with an input shaft is fixed to the side wall where the input shaft of the speed reducer is located through bolts, and a rotating seat is fixed on the other side of the upper surface of the base through bolts; and a supporting rod is movably connected with the interior of the rotating seat through a bearing, and a rotating disc is welded to the top of the supporting rod. According to the inner ring grinding deviceand grinding method, four bearing brackets can be controlled to move oppositely by only rotating a central rod, and the height and speed can be adjusted; the bearing brackets can clamp the outer wall, the upper surface and the lower surface of the bearing, and the fixing strength of the bearing is improved; and an upper movable frame is slidably connected in a lower supporting frame, and a movable block with the bottom provided with four pulleys is slidably connected inside a sliding frame, so that the stability of a milling cutter control structure is improved, and the machining precision ofan inner ring of the bearing is guaranteed.

Owner:MAANSHAN YUEMEI METAL PROD TECH IND

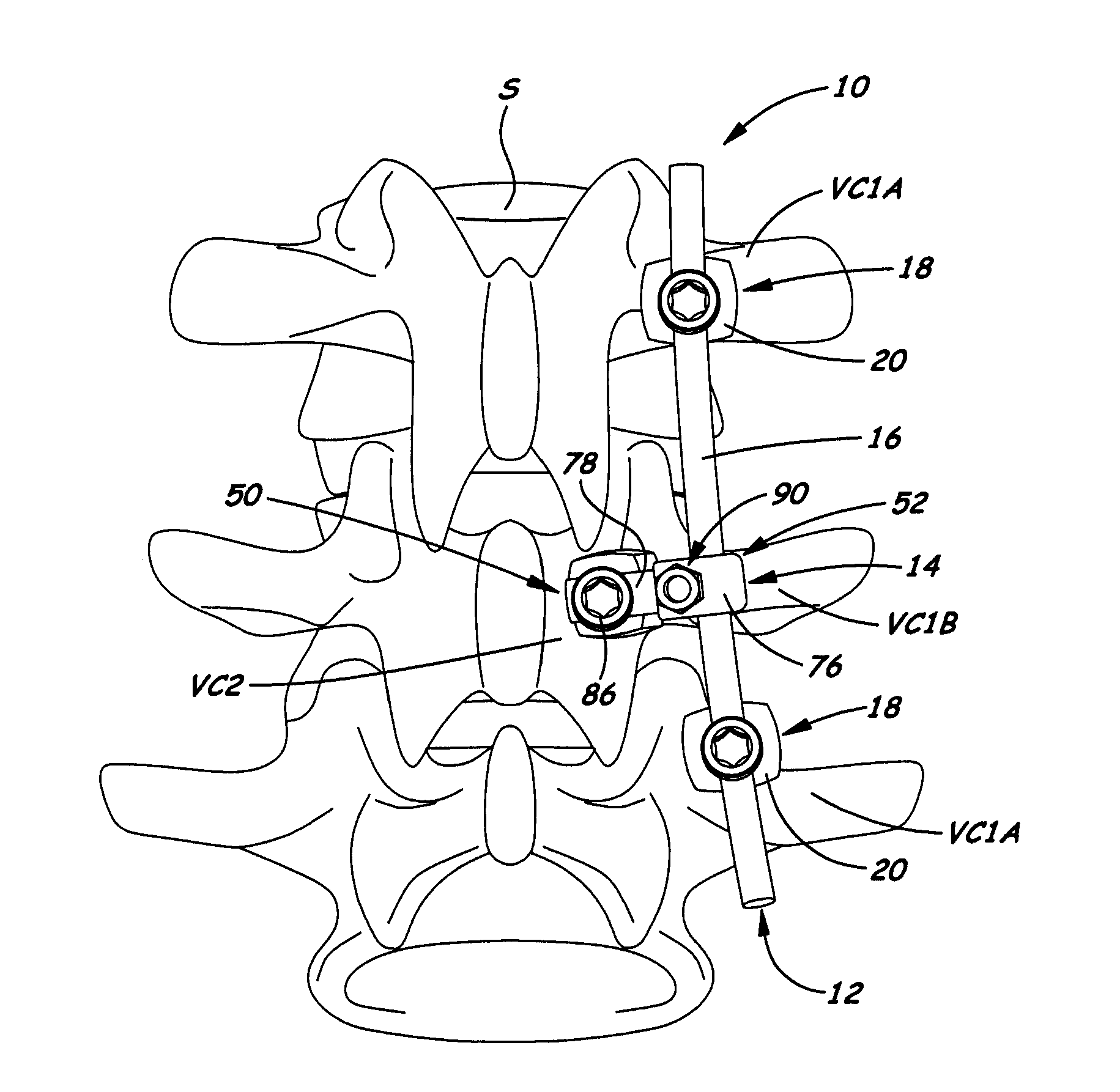

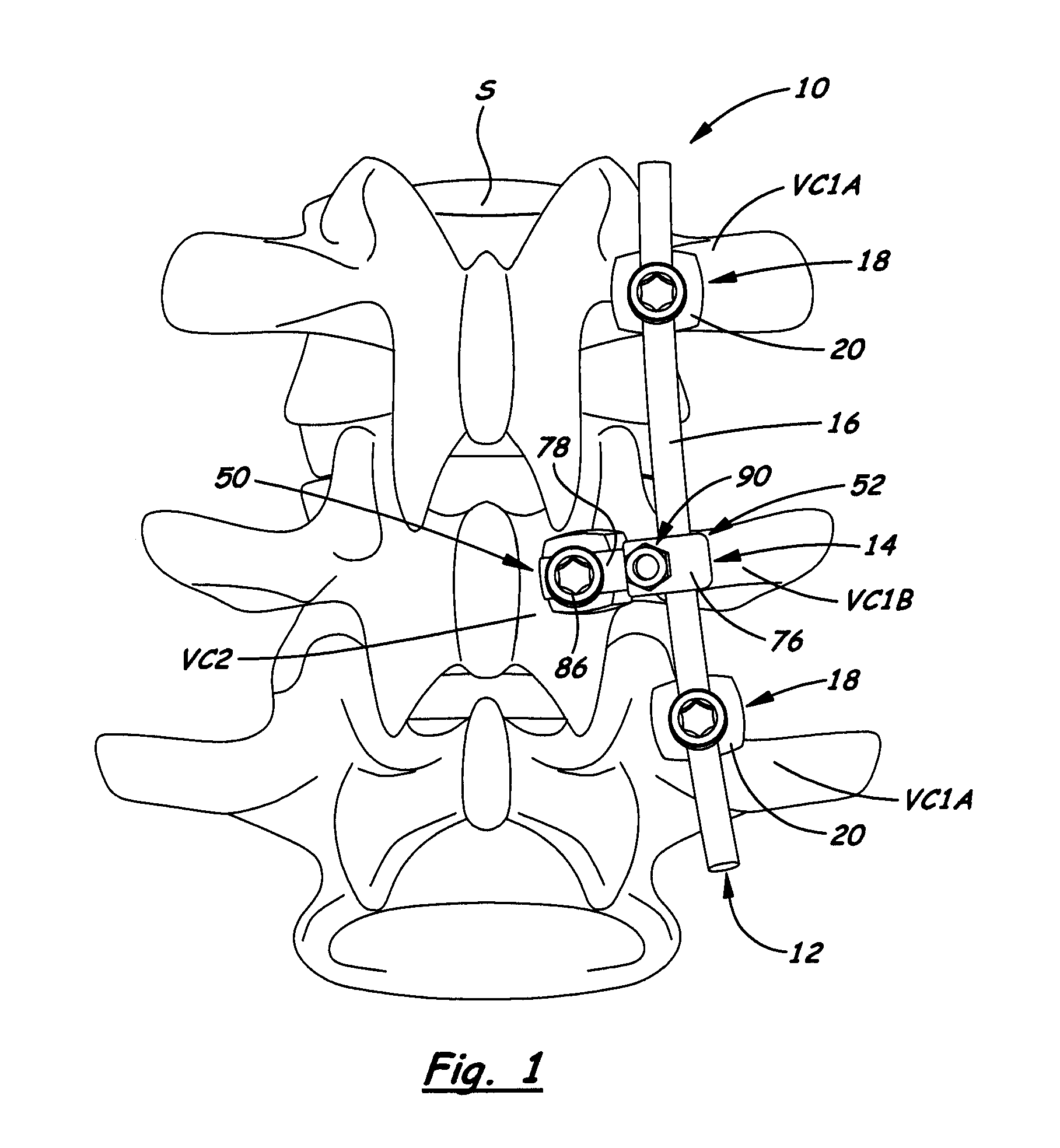

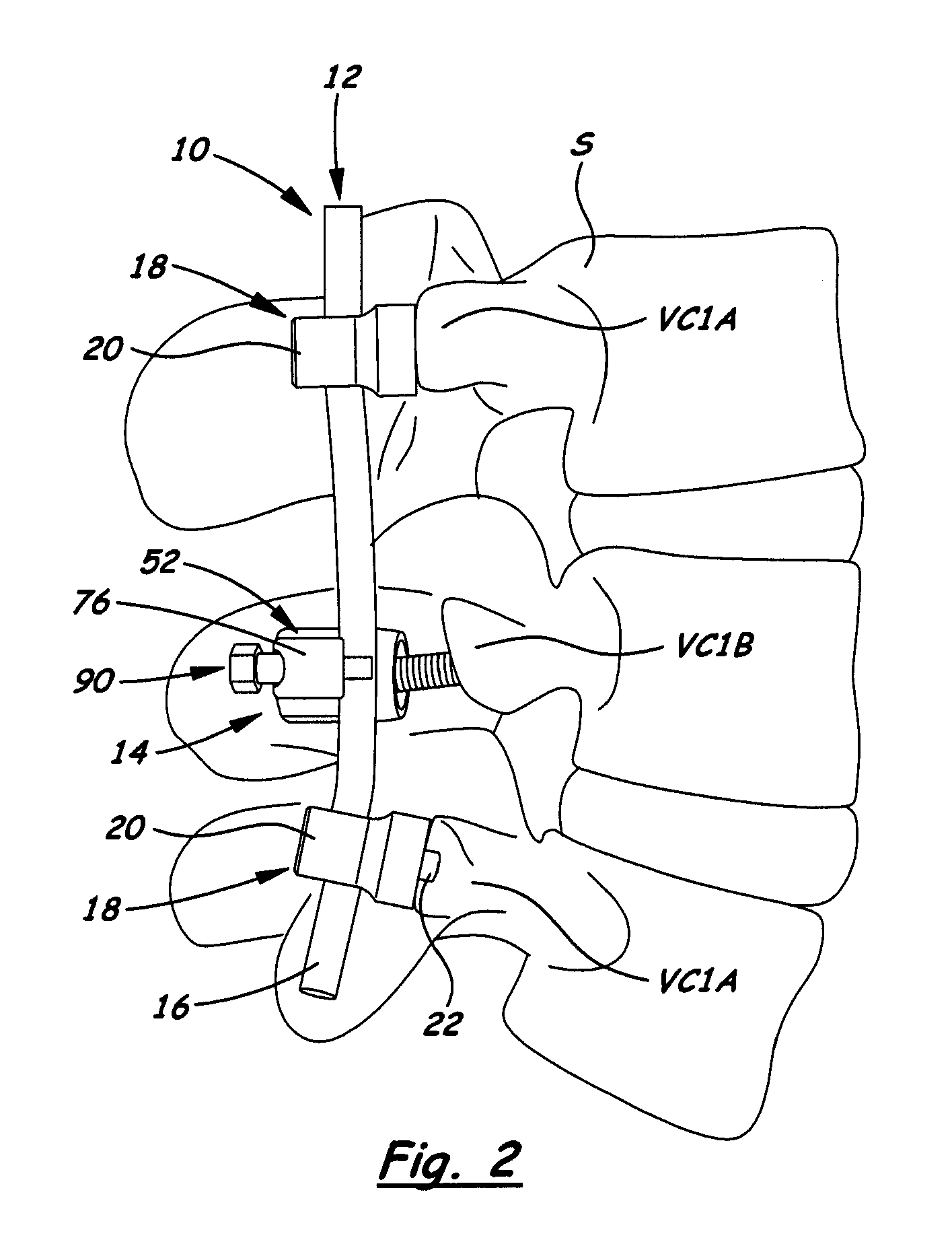

Apparatus for implementing a spinal fixation system with supplemental fixation

ActiveUS20110106164A1Improve the fixing strengthEasy to fixSuture equipmentsInternal osteosythesisFixation pointStructural condition

An apparatus for implementing a spinal fixation system with supplemental fixation includes a spinal fixation rod assembly and at least one supplemental fixation device. The spinal fixation rod assembly is adapted to provide primary fixation at a plurality of first fixation points by being secured to a plurality of first vertebral components except not into one of the first vertebral components of the plurality that is in a weakened structural condition and located between other of the first vertebral components of the plurality. The supplemental fixation device is adapted to provide supplemental fixation for the assembly at a second fixation point by being secured to a second vertebral component located adjacent to and offset from the one first vertebral component in the weakened structural condition and also to interconnect with the assembly to provide anchorage and thus additional fixation supplemental to the primary fixation.

Owner:WARSAW ORTHOPEDIC INC

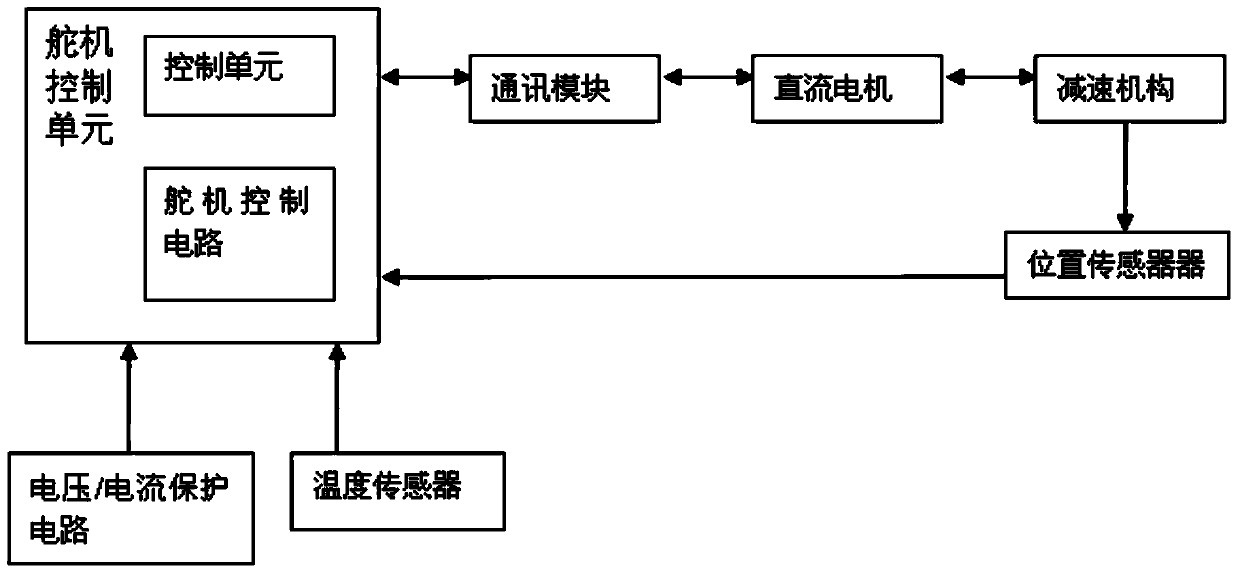

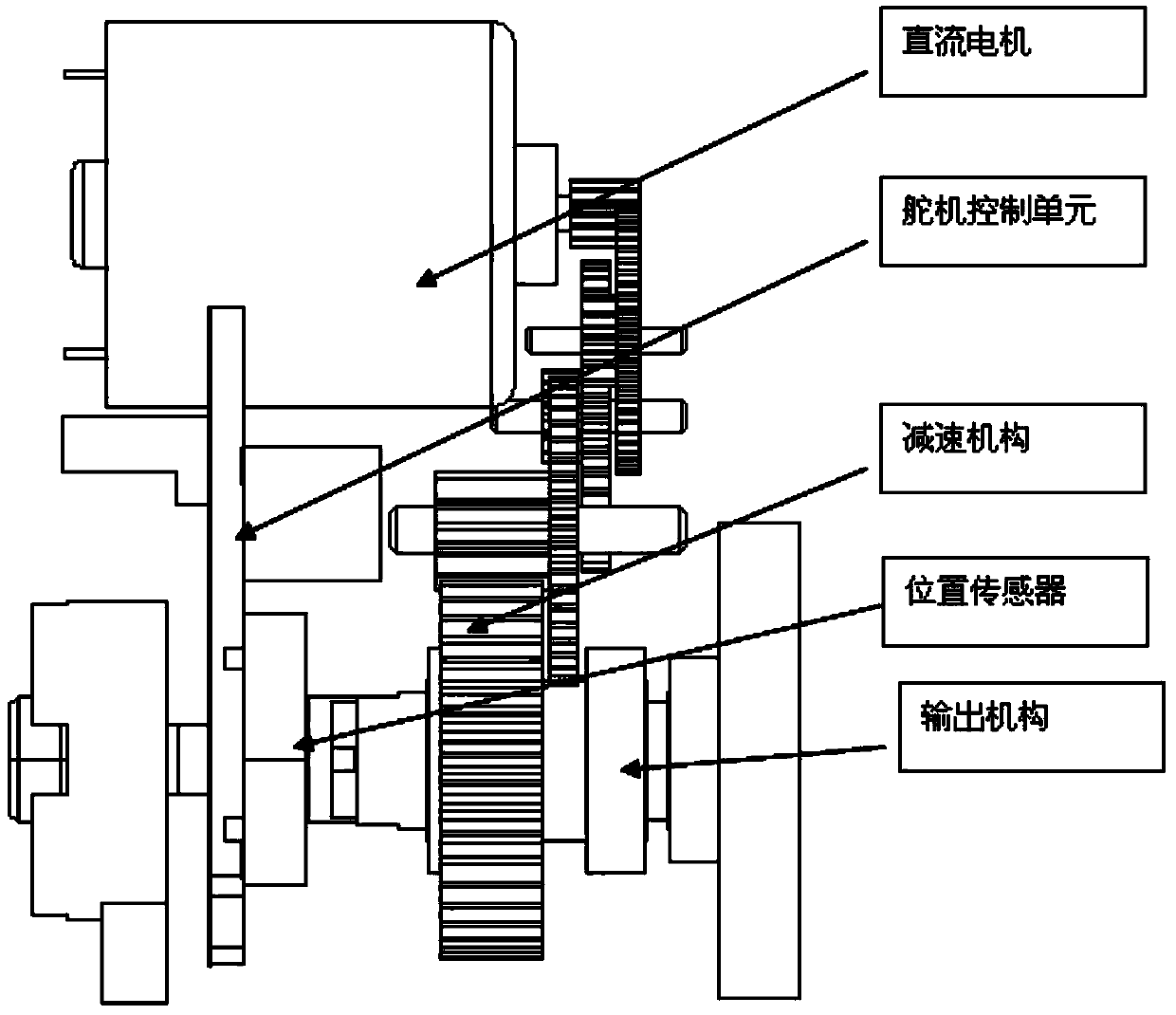

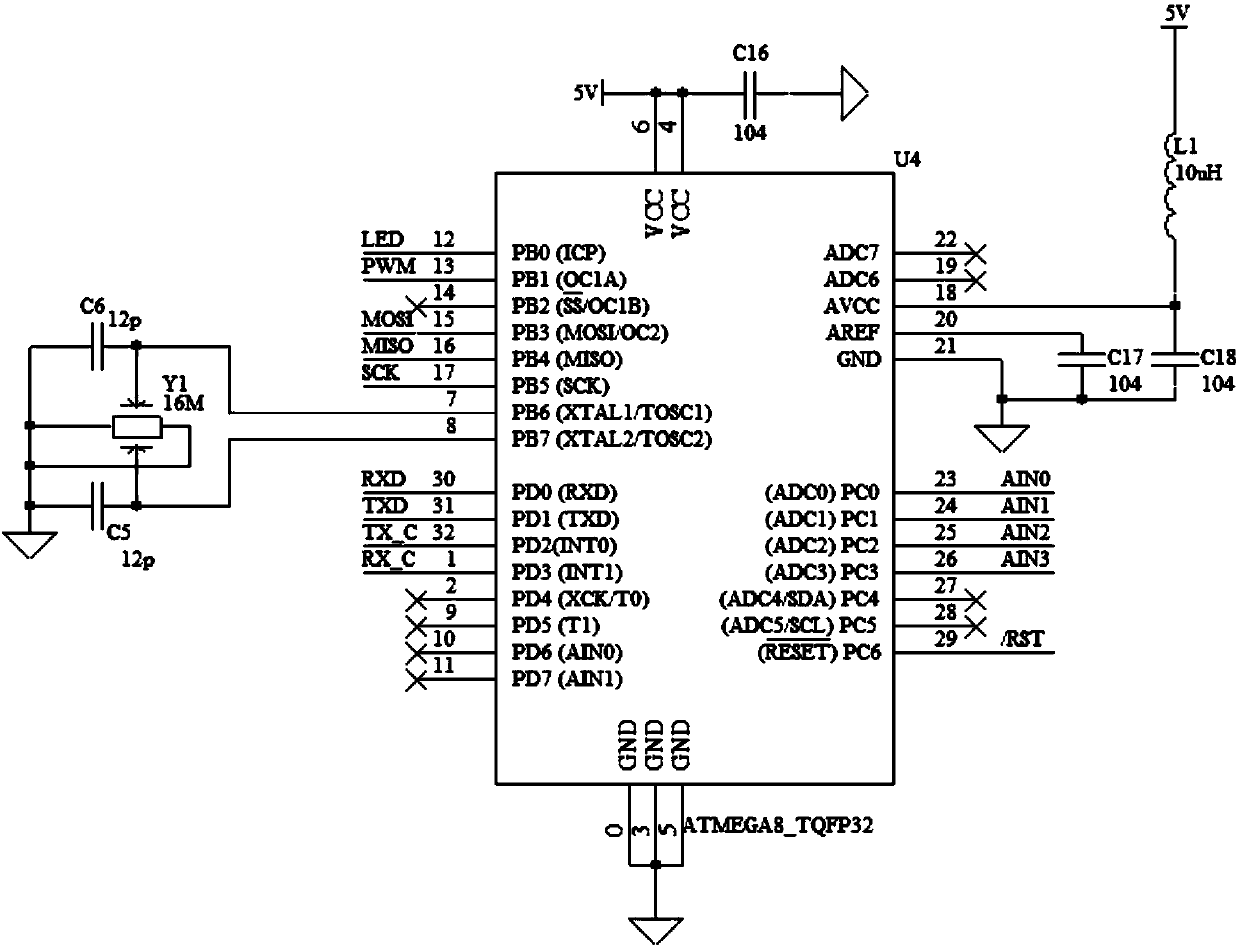

Device and method for controlling single-bus modular digital actuator of robot

ActiveCN103753535AImprove performanceQuick responseProgramme-controlled manipulatorJointsOvervoltageClosed loop

The invention relate to a device and a method for controlling a single-bus modular digital actuator of a robot. The device comprises an actuator control unit, a direct-current motor, a communication module, a speed reduction mechanism, position and temperature sensors and a current protection circuit. The method includes that the actuator control unit computes control parameters according to the running temperatures, driving currents of the motor and the position of the actuator and outputs the control parameters to a motor control circuit; the communication module receives control instructions of an upper computer and feeds information of the current position of the actuator, the current speed of the actuator and the like to the upper computer; a high rotational speed and low torque of the motor are converted into a low rotational speed and high torque by the speed reduction mechanism and an output mechanism, and the low rotational speed and the high torque are outputted by the speed reduction mechanism and the output mechanism; the position sensor, the temperature sensor and the current protection circuit are respectively used for feeding current position signals of the actuator, the running temperatures and the driving currents of the motor to the actuator control unit, so that closed-loop high-precision safety control can be implemented. The device and the method have the advantages of overcurrent, overvoltage and over-temperature protection, capability of preventing overload or over-temperature damage, high response speed, zero dead zones and high control precision.

Owner:UBTECH ROBOTICS CORP LTD +1

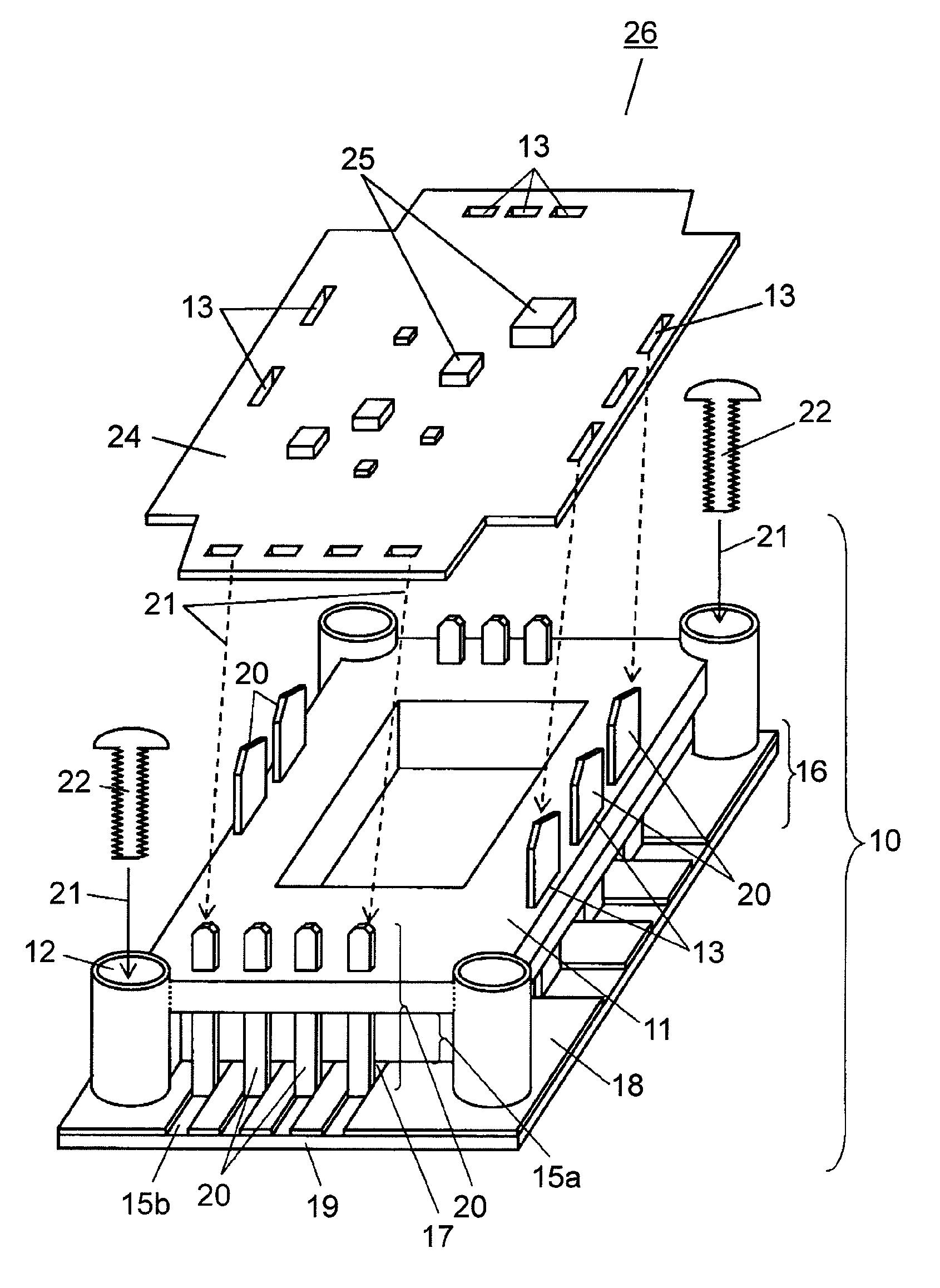

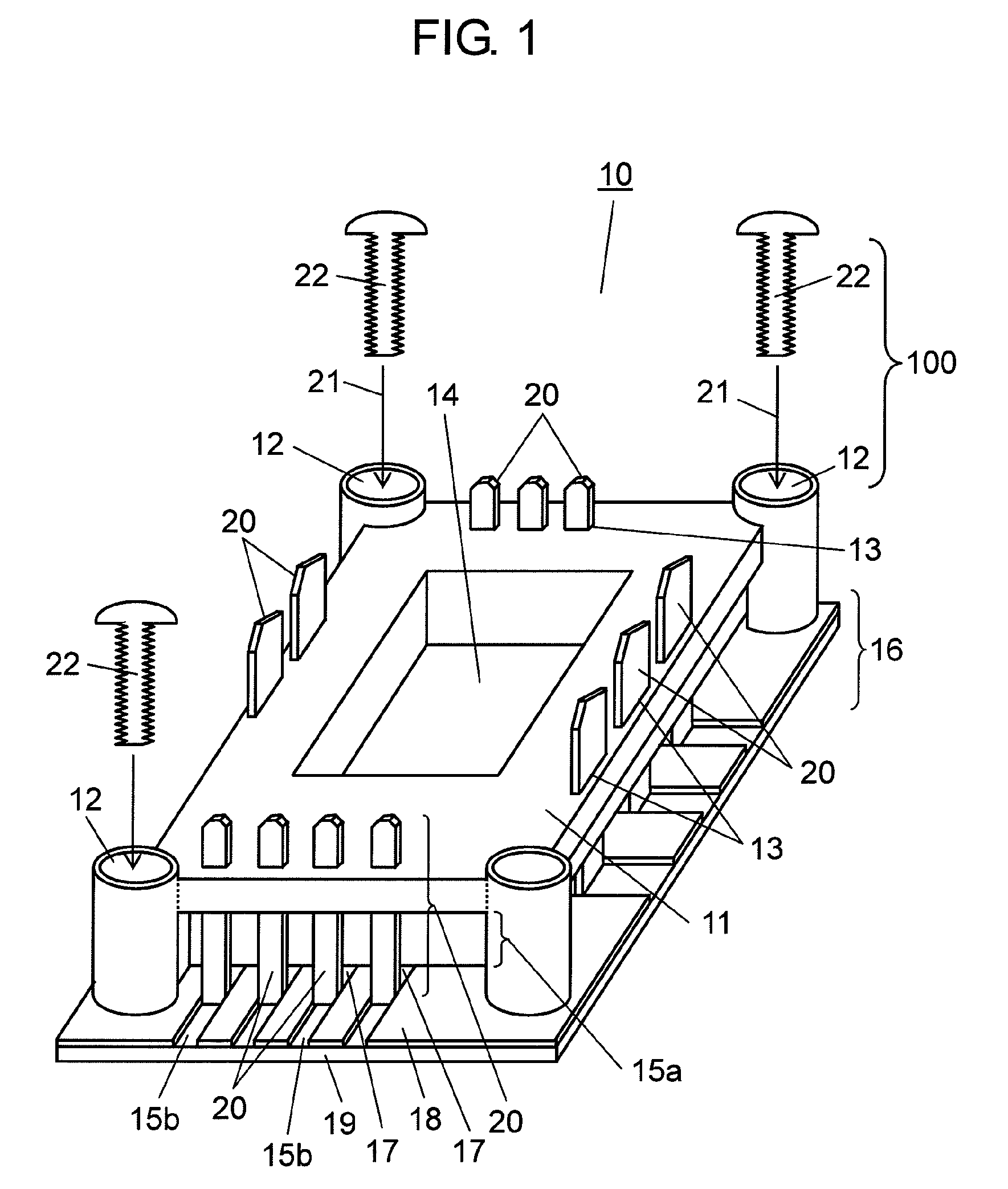

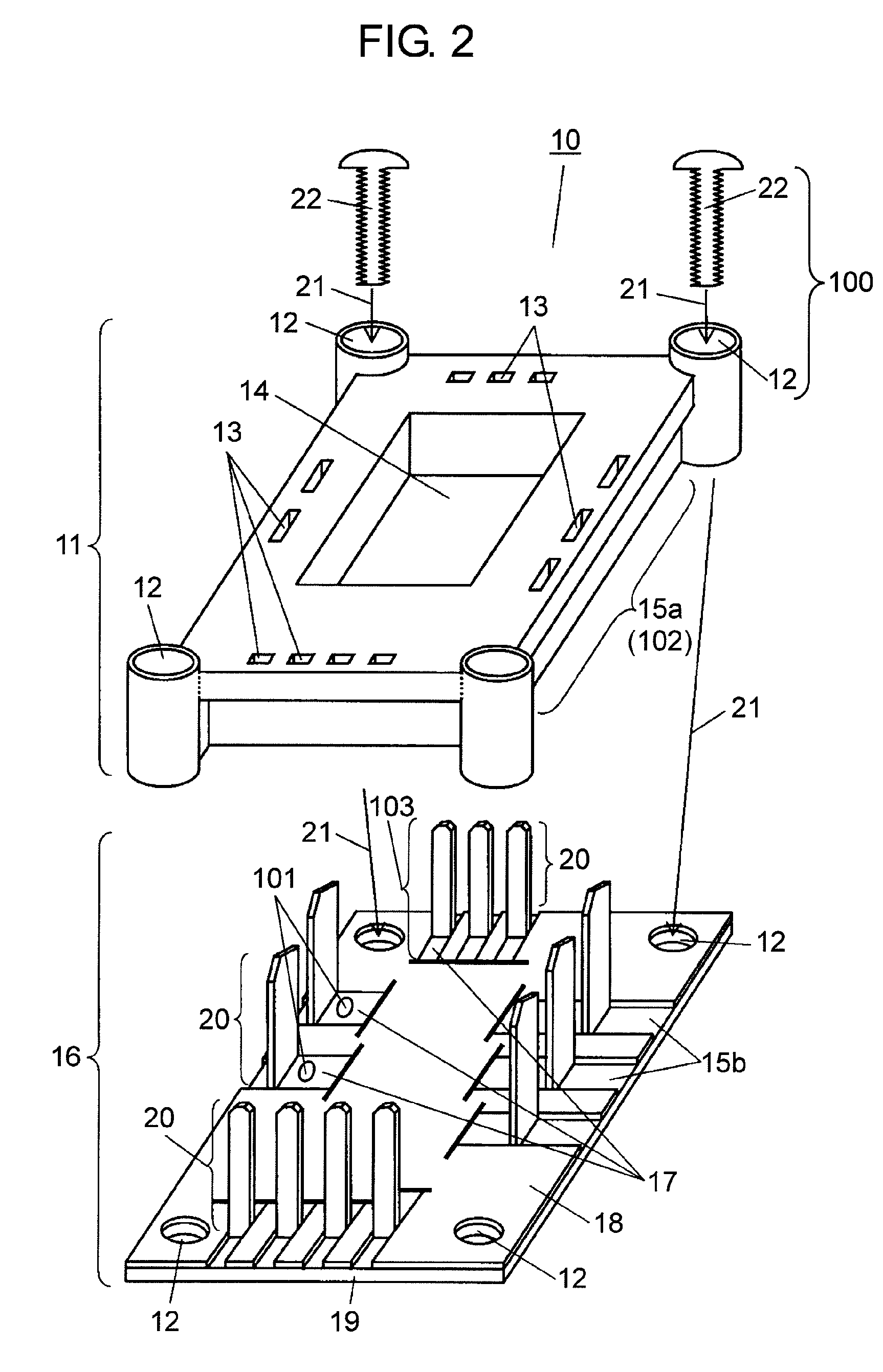

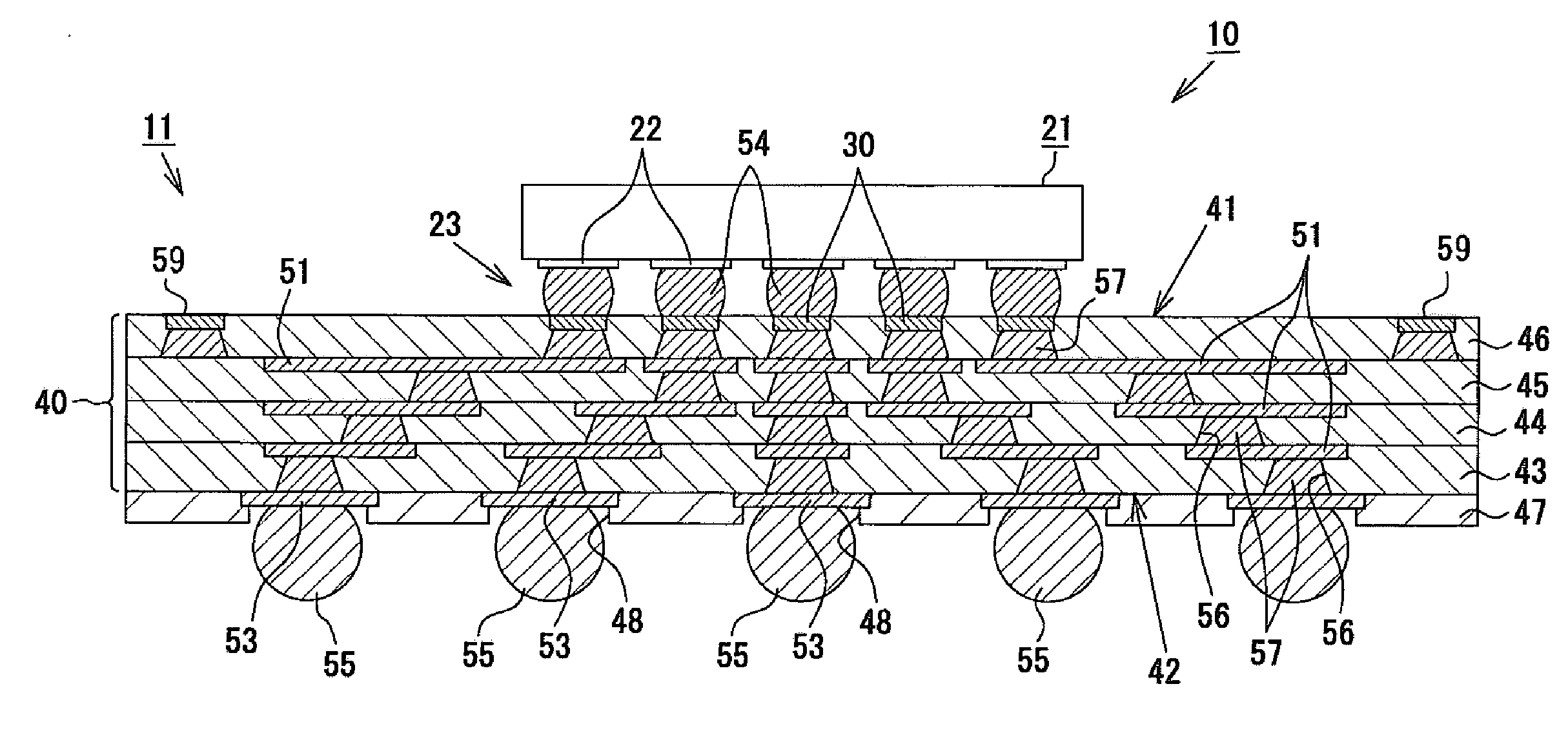

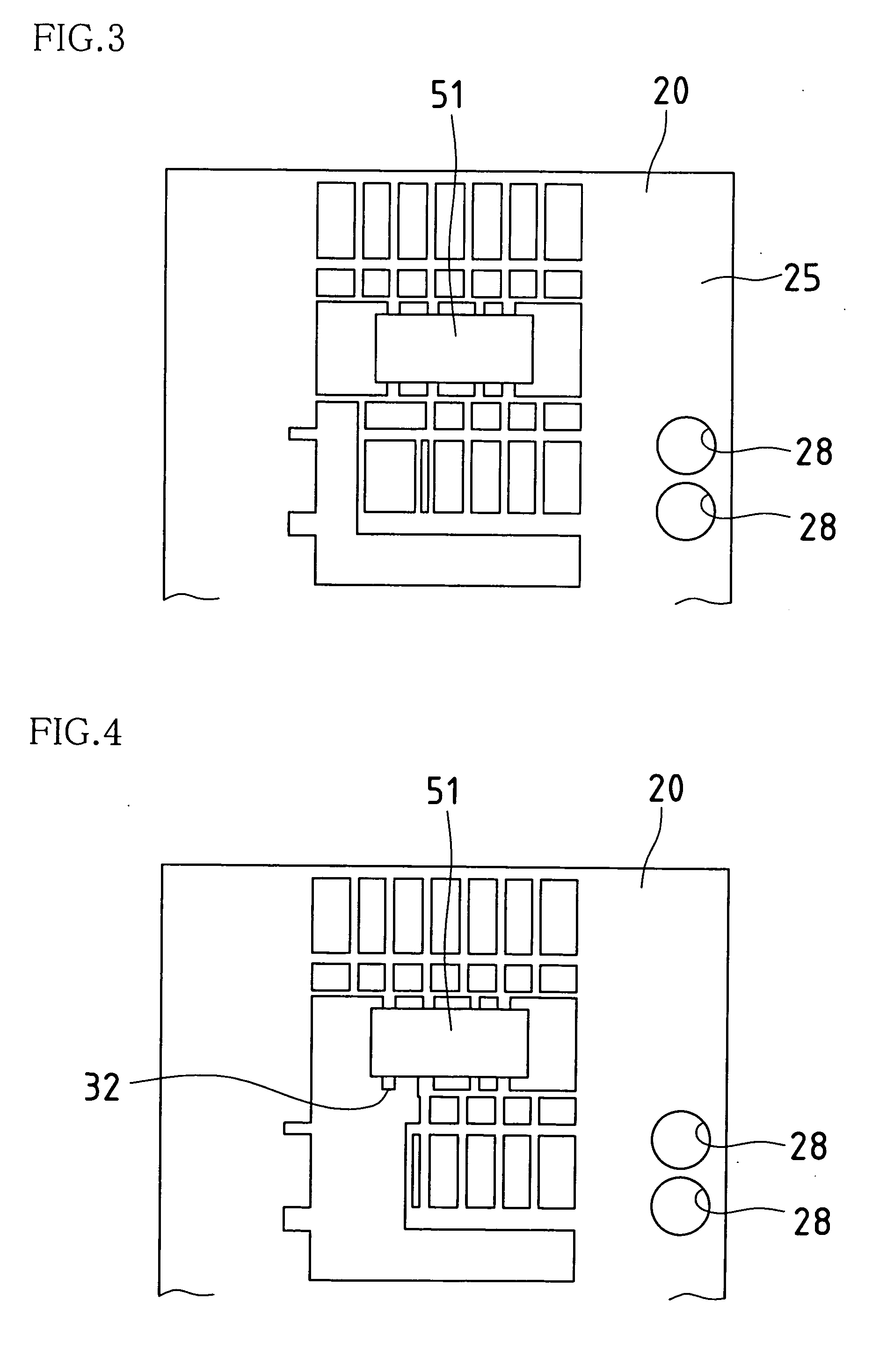

Heat dissipating structure base board, module using heat dissipating structure base board, and method for manufacturing heat dissipating structure base board

ActiveUS8130499B2Improve the fixing strengthNot easy to fixSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectric vehicle

The present invention relates to a heat dissipation structure board and a module using this heat dissipation structure used for purpose required of high reliability such as a hybrid vehicle or an electric vehicle and to a method of manufacturing the heat dissipation structure. A resin structure is disposed on a lead frame constituting a heat dissipation board and an odd-shaped electronic component or the like mounted on this lead frame or the like to cover up the lead frame and the odd-shaped electronic component or the like, and this resin structure is fixed to a metal plate, a chassis of a device and the like to constitute the heat dissipation structure board as a whole, whereby fixing strengths of fixing the lead frame and the odd-shaped electronic component or the like, a bonding strength at an interface between the lead frame and the heat transfer layer and the like can be reinforced.

Owner:PANASONIC CORP

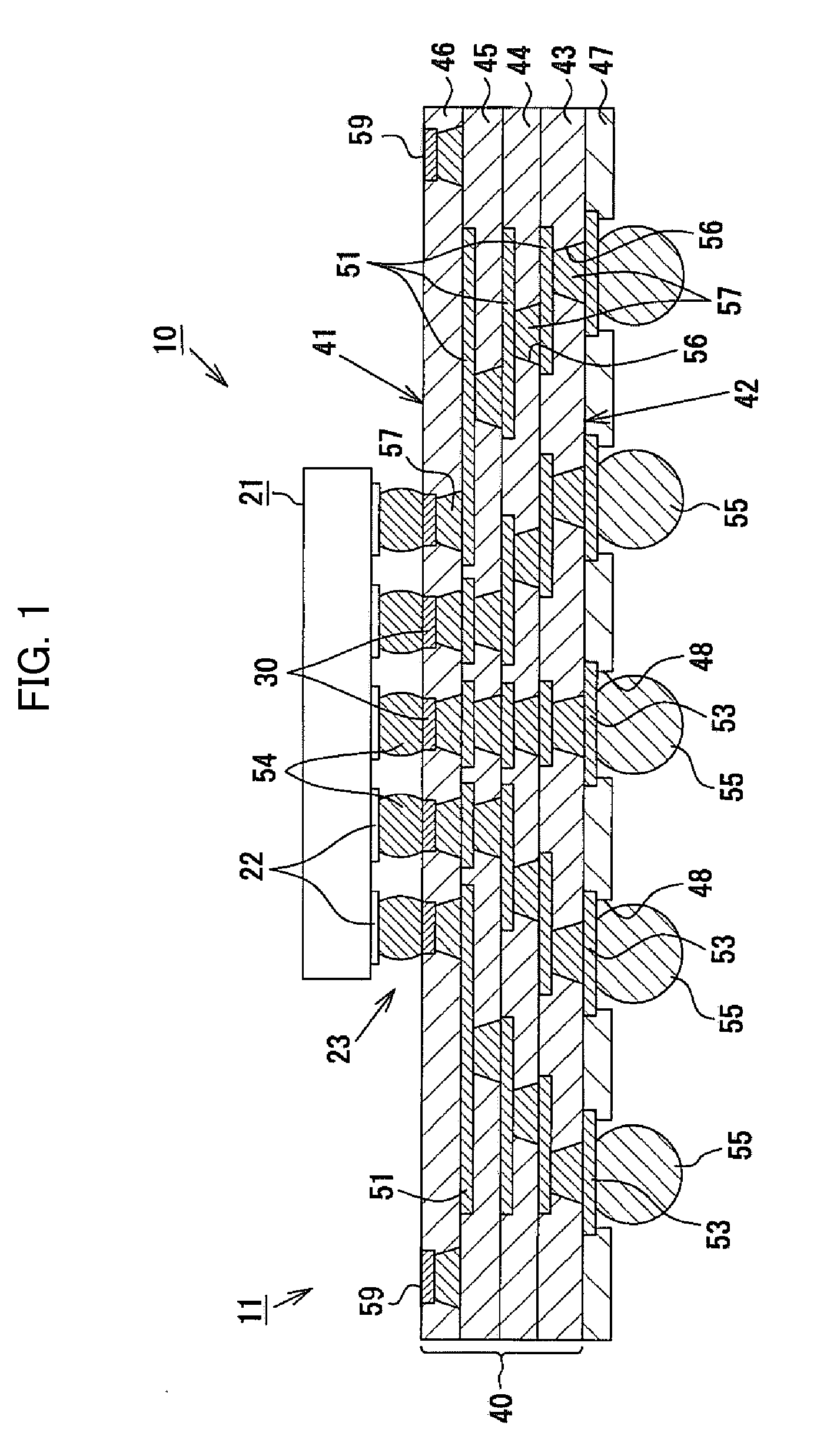

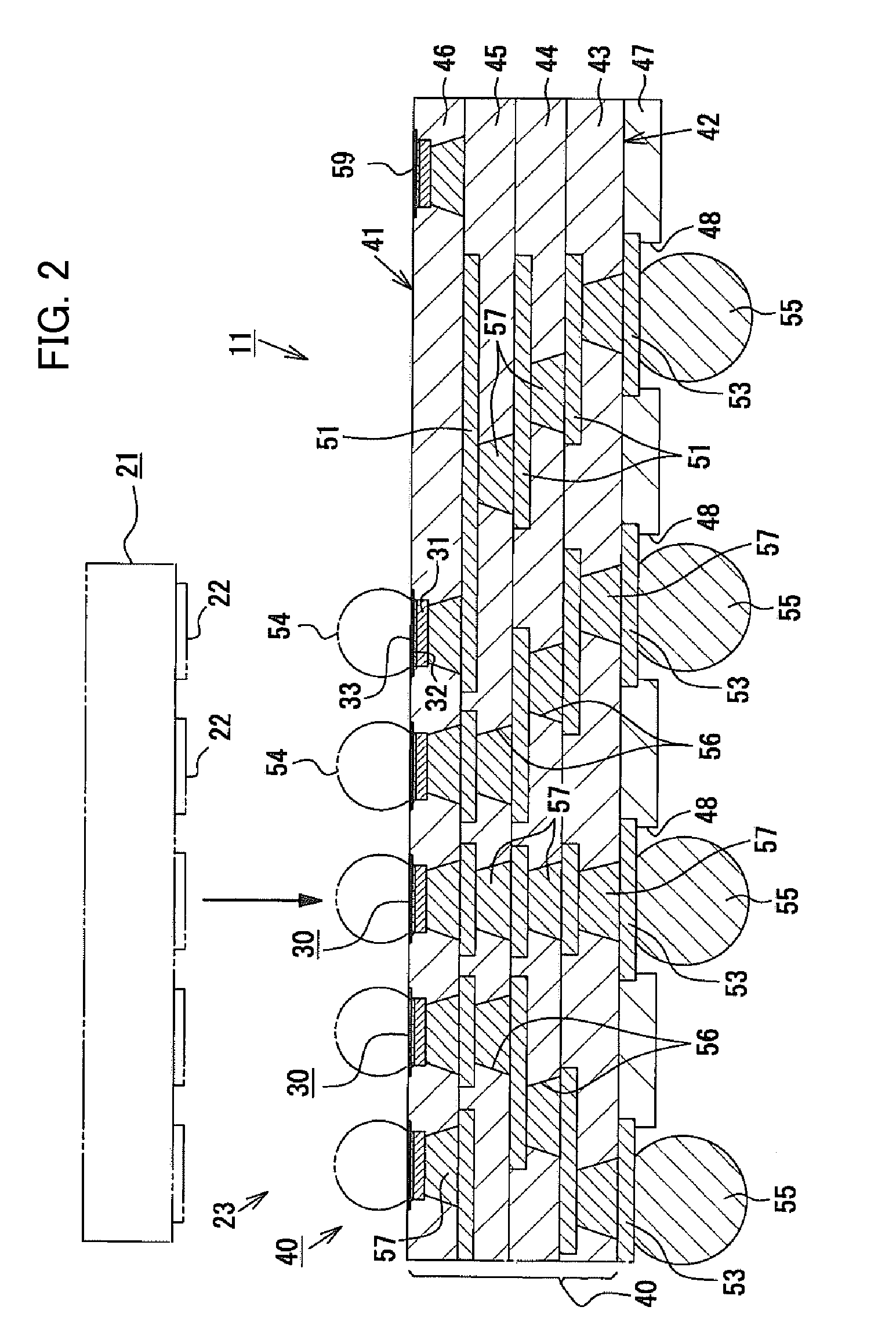

Multilayer wiring substrate and method for manufacturing the same

ActiveUS20100208437A1Low connection reliabilityDeterioration of surface shapeEarth drilling toolsDrill bitsElectrical conductorEngineering

A multilayer wiring substrate of the present invention has a laminated structure composed of conductor layers and resin insulating layers stacked alternately. A plurality of surface connection terminals to which terminals of a chip component are to be surface-connected are formed on a main face of the laminated structure. A plurality of via conductors connected to the plurality of surface connection terminals are formed in the resin insulating layers. Each of the plurality of surface connection terminals has a structure in which a copper layer, a nickel layer, and a gold layer are stacked in this sequence. The gold layer is larger in diameter than at least the copper layer. The gold layer has an overhanging portion which extends radially outward from a circumference of the copper layer.

Owner:NGK SPARK PLUG CO LTD

Optical fiber secured with a photosetting resin covered with a UV light-transmissive plate

InactiveUS6130444AImprove reliabilityReduce in quantitySolid-state devicesCoupling light guidesSurface layerSemiconductor

An optical semiconductor device, having an optical element mounted in a case and an optical fiber fixed to the case with a first photosetting resin, includes a transparent plate placed on a surface layer portion of the first photosetting resin to transmit light that cures the first photosetting resin. The transparent plate is integrated with the cured photosetting resin, and the optical element is a light emitting element.

Owner:RENESAS ELECTRONICS CORP

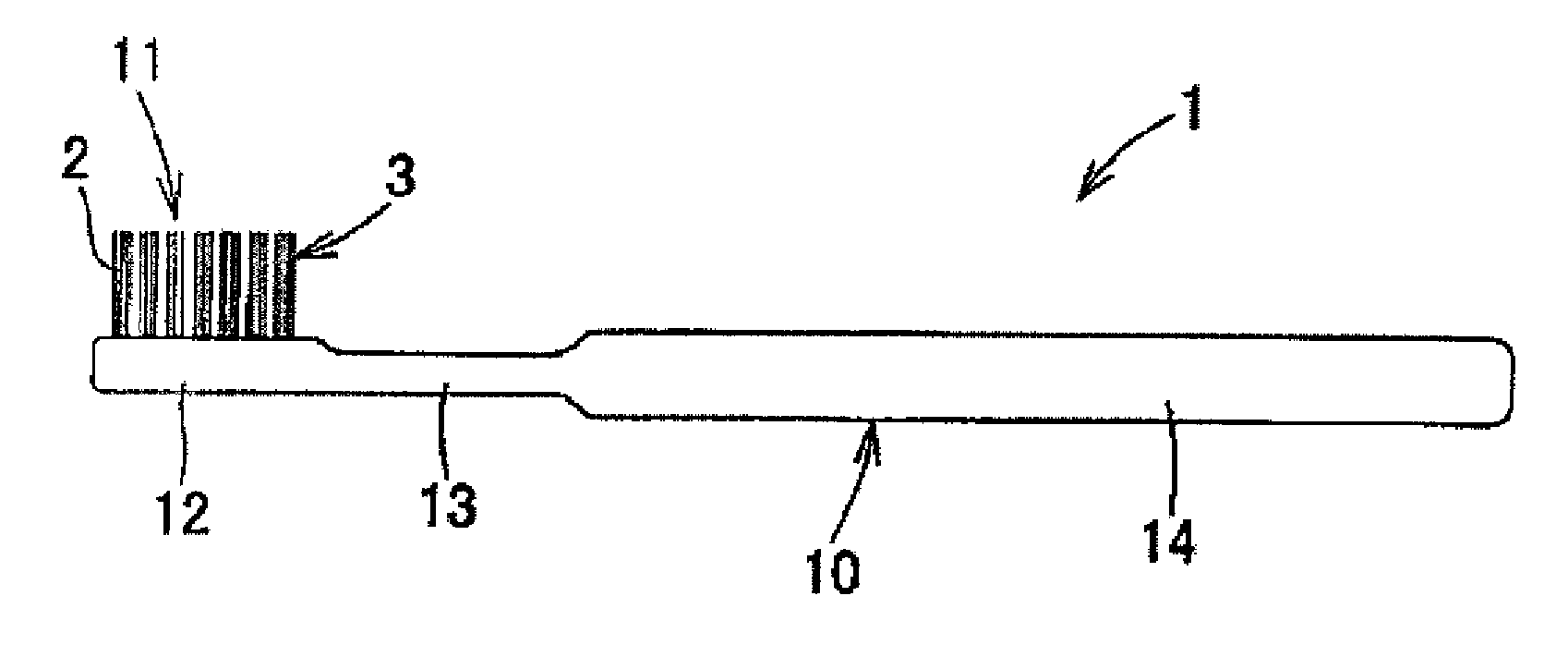

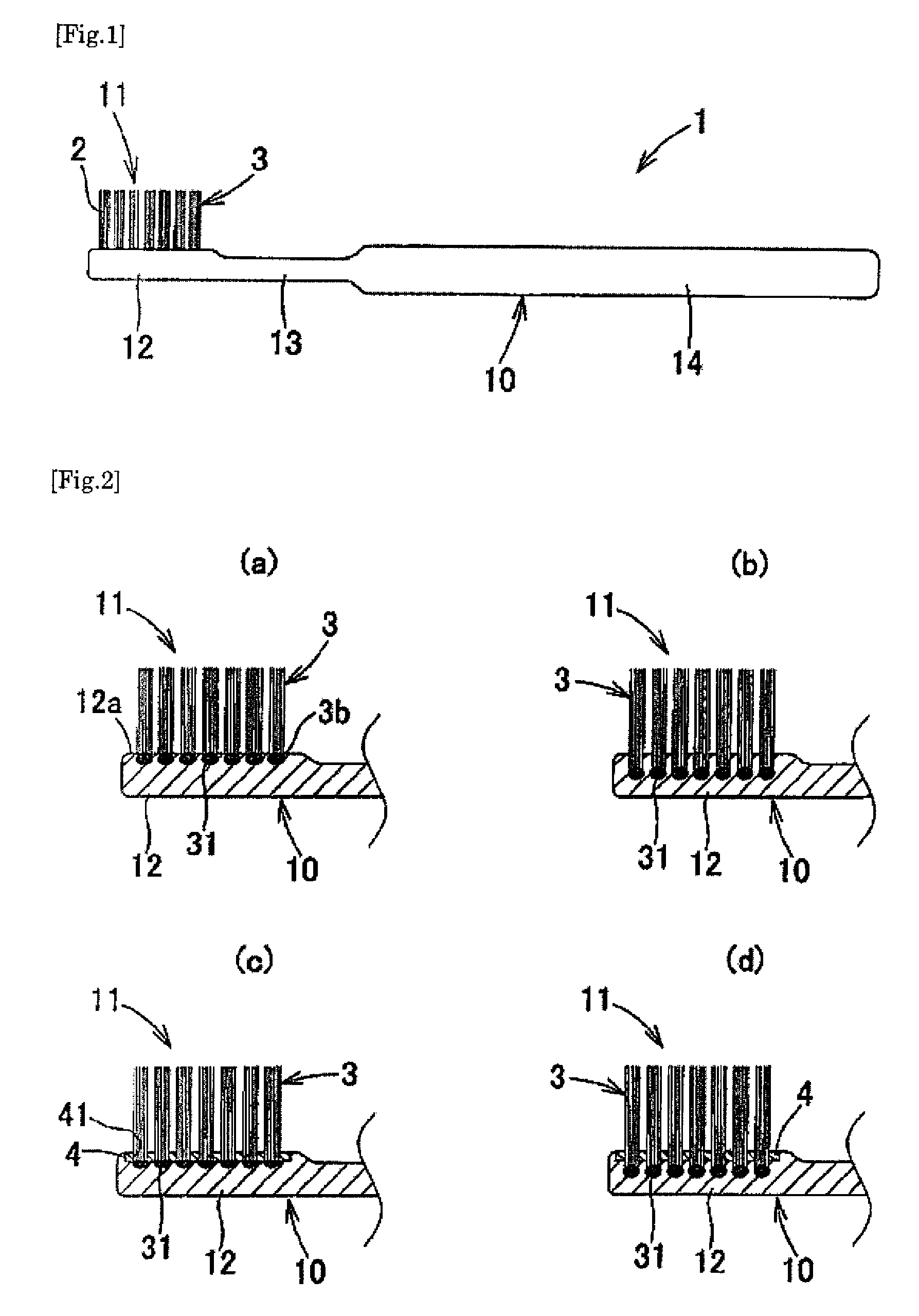

Toothbrush

InactiveUS20090013488A1Easy to useHighly attractive appearanceBristleDomestic articlesBristleEngineering

A toothbrush which comprises a brush main body made of a synthetic resin and having a bristle base and bristles made of a thermoplastic resin which have been fusion-bonded to the bristle base to constitute a bristled part, wherein the bristles constituting the bristled part at least partly comprise: tapered bristles which are bristles having split free ends, the split free ends having been tapered beforehand; tapered bristles which have a sectional shape having a core-sheath structure or islands in a sea structure; or tapered bristles in each of which a core bristle comprising a core or island part has been formed beforehand so as to be exposed at the free end. The toothbrush has excellent suitability for bristle insertion into narrow parts. It is highly effective in removing dental plaque and cleaning the teeth. It is highly easy to use in the oral cavity. It further has a highly attractive appearance.

Owner:SUNSTAR INC

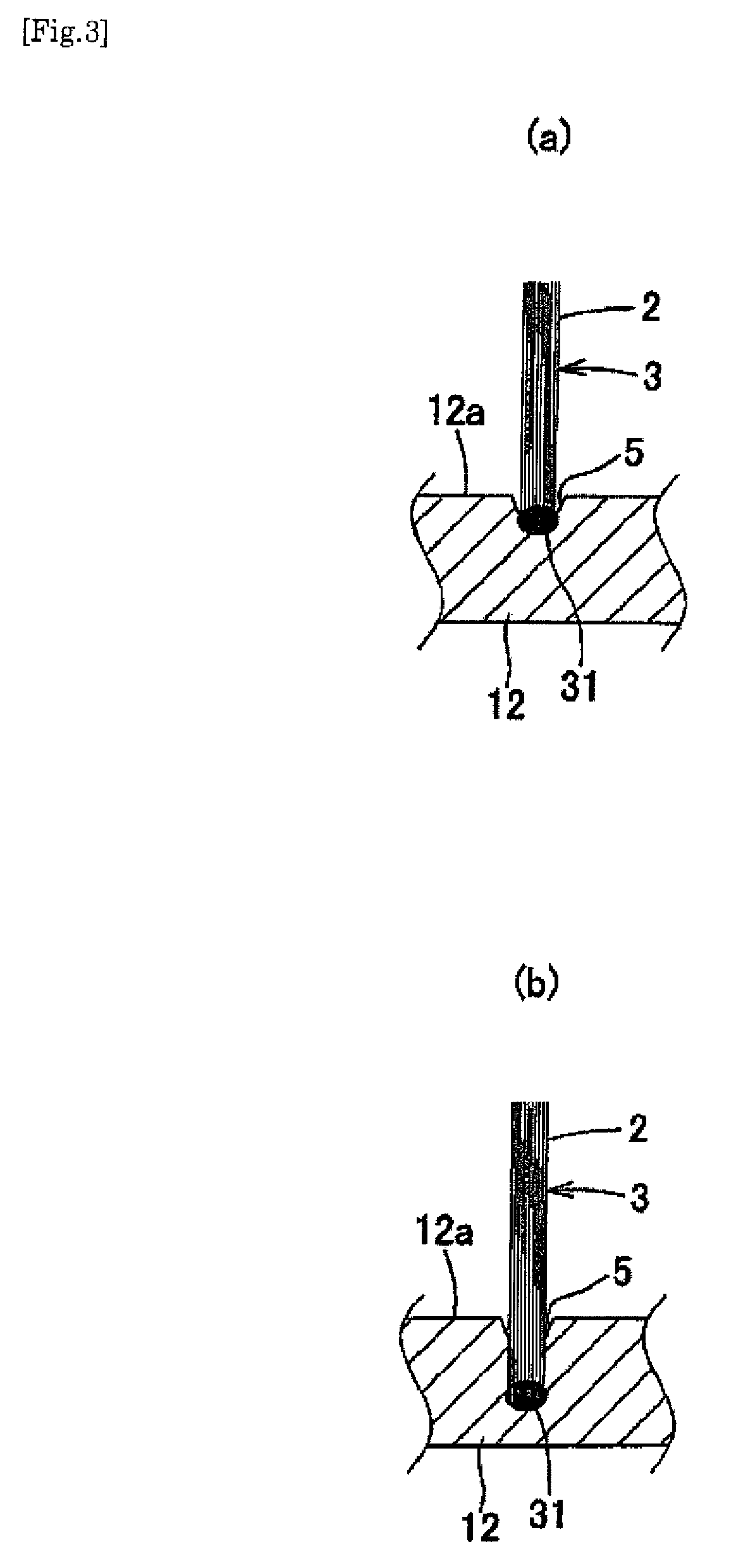

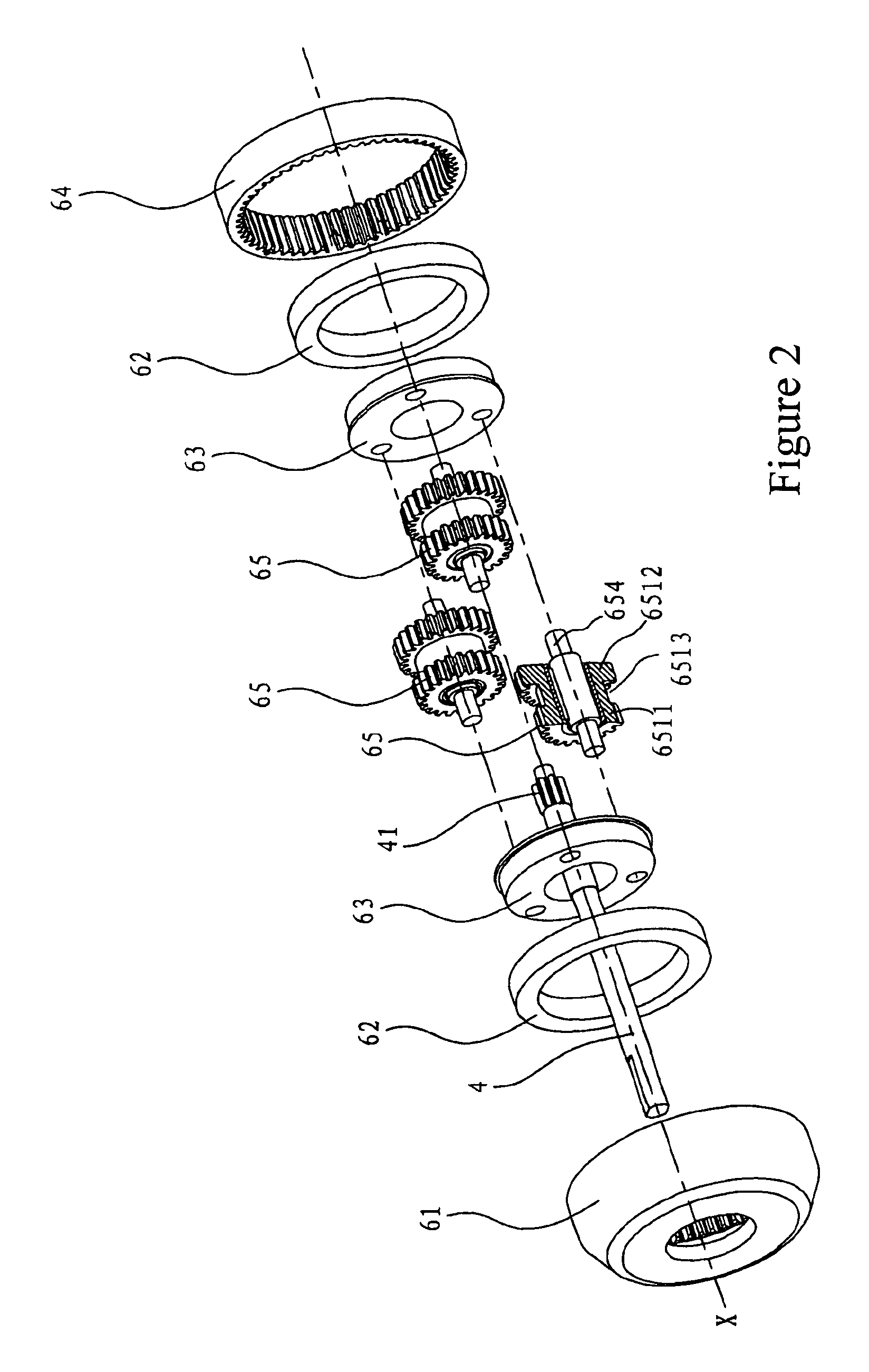

Winch

ActiveUS7614609B1Large speed ratioTransmission efficiency be highWinding mechanismsPower transmissionSingle stage

A winch including a drum, a motor and a power transmission device. The power transmission device includes a casing and a planetary mechanism assembly having first and second planetary carriers rotatably disposed in the casing; first to third planetary gears rotatably supported on the first and second planetary carriers and engaged with the transmission gear; an annular gear fixed in the casing and engaged with the first to third planetary gears respectively; and a power output member having an input gear portion and an output gear portion, the input gear portion engages with the first to third planetary gears respectively, and the output gear portion engages with the inner drum gear portion of the drum. The winch achieves deceleration function with large speed ratio by a single stage planetary mechanism.

Owner:HANGZHOU TIANMING TECH CO LTD

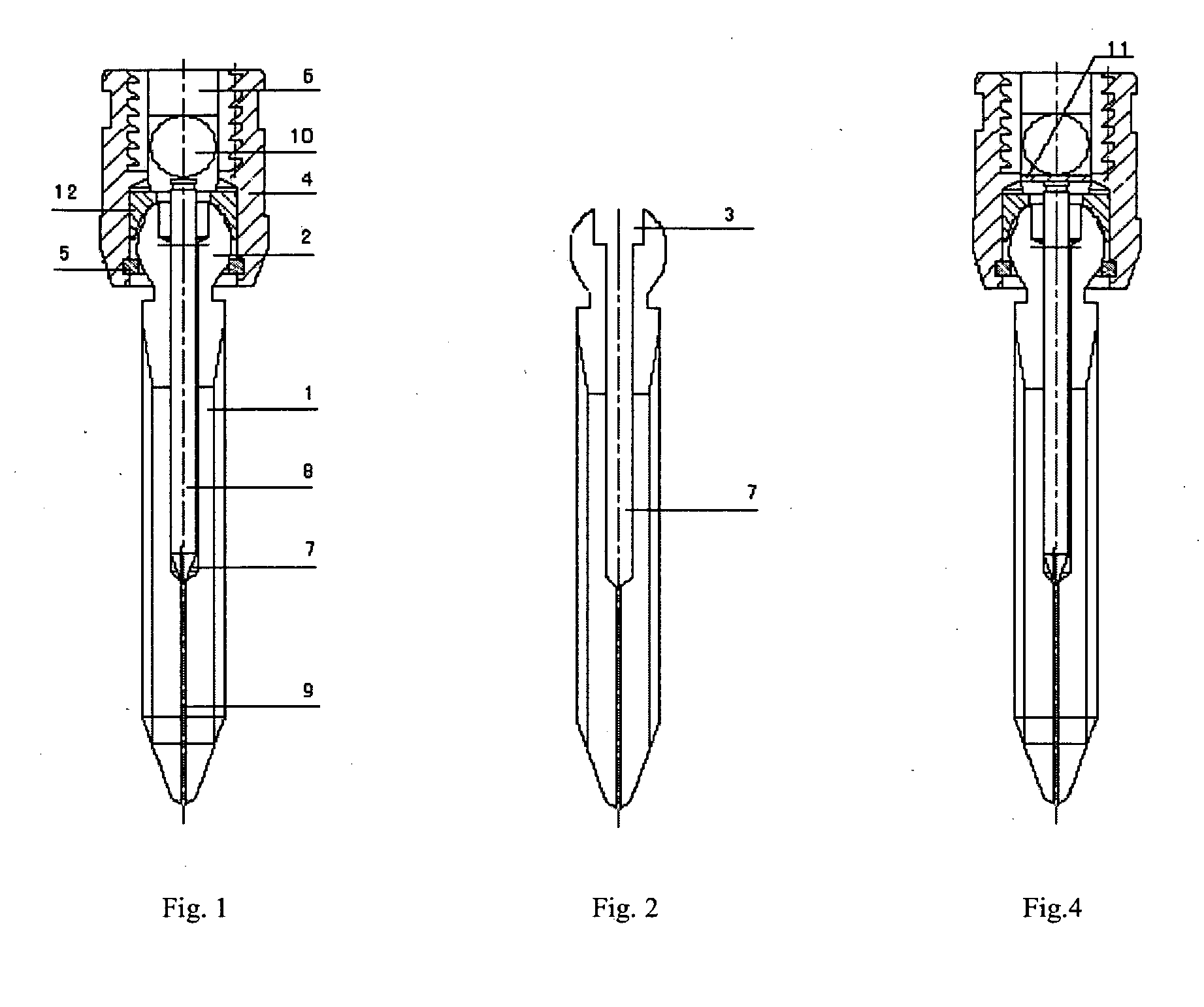

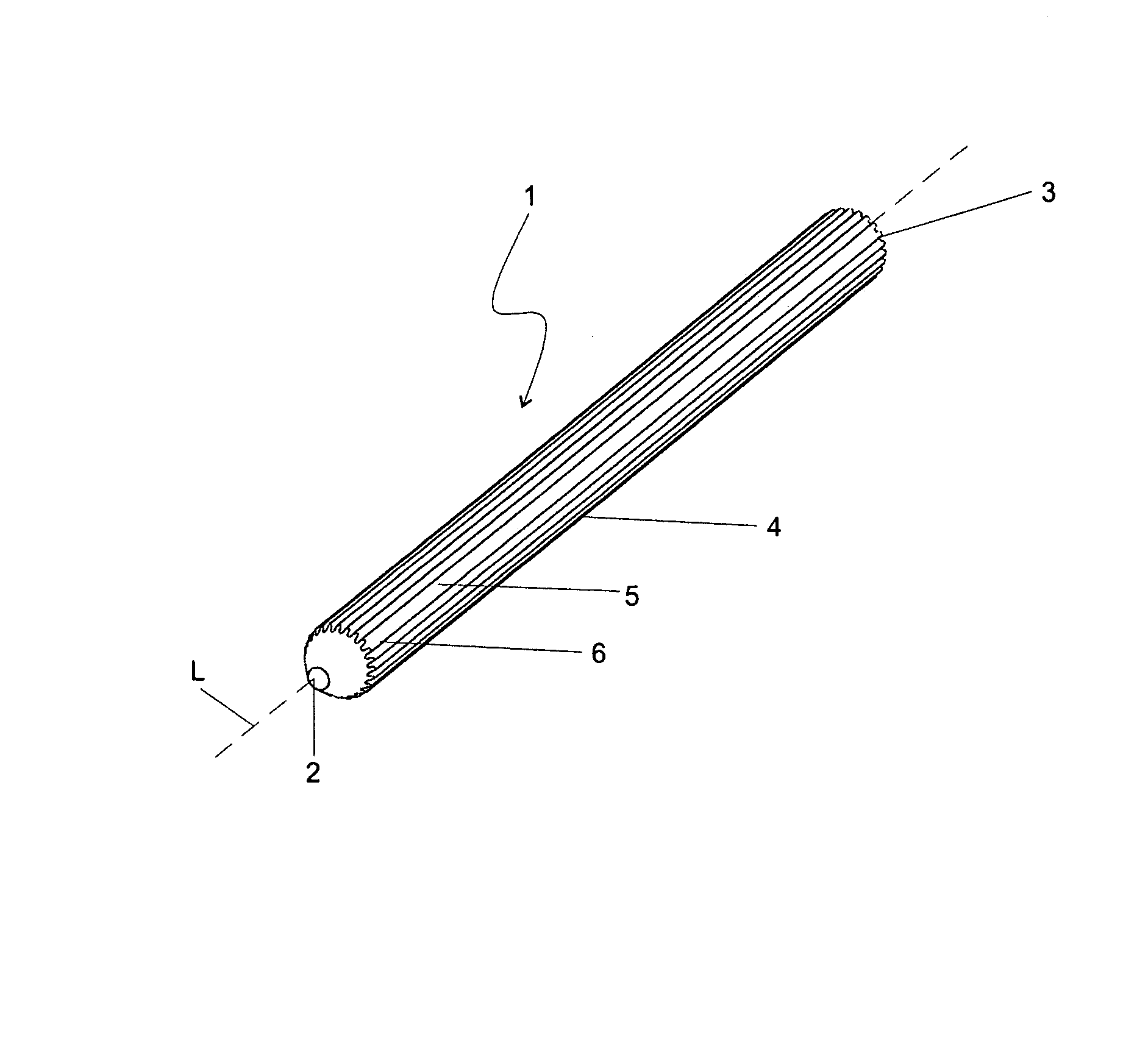

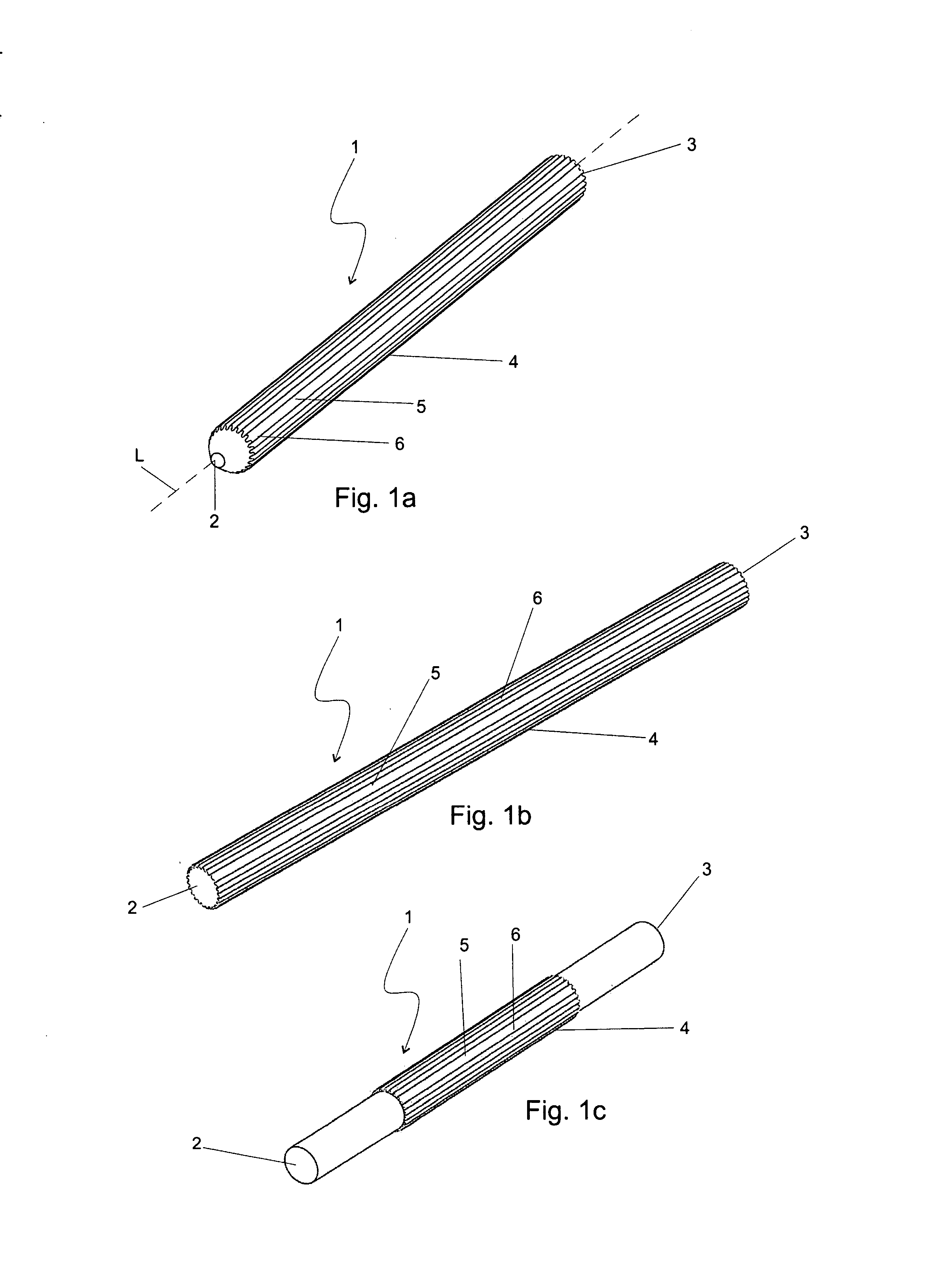

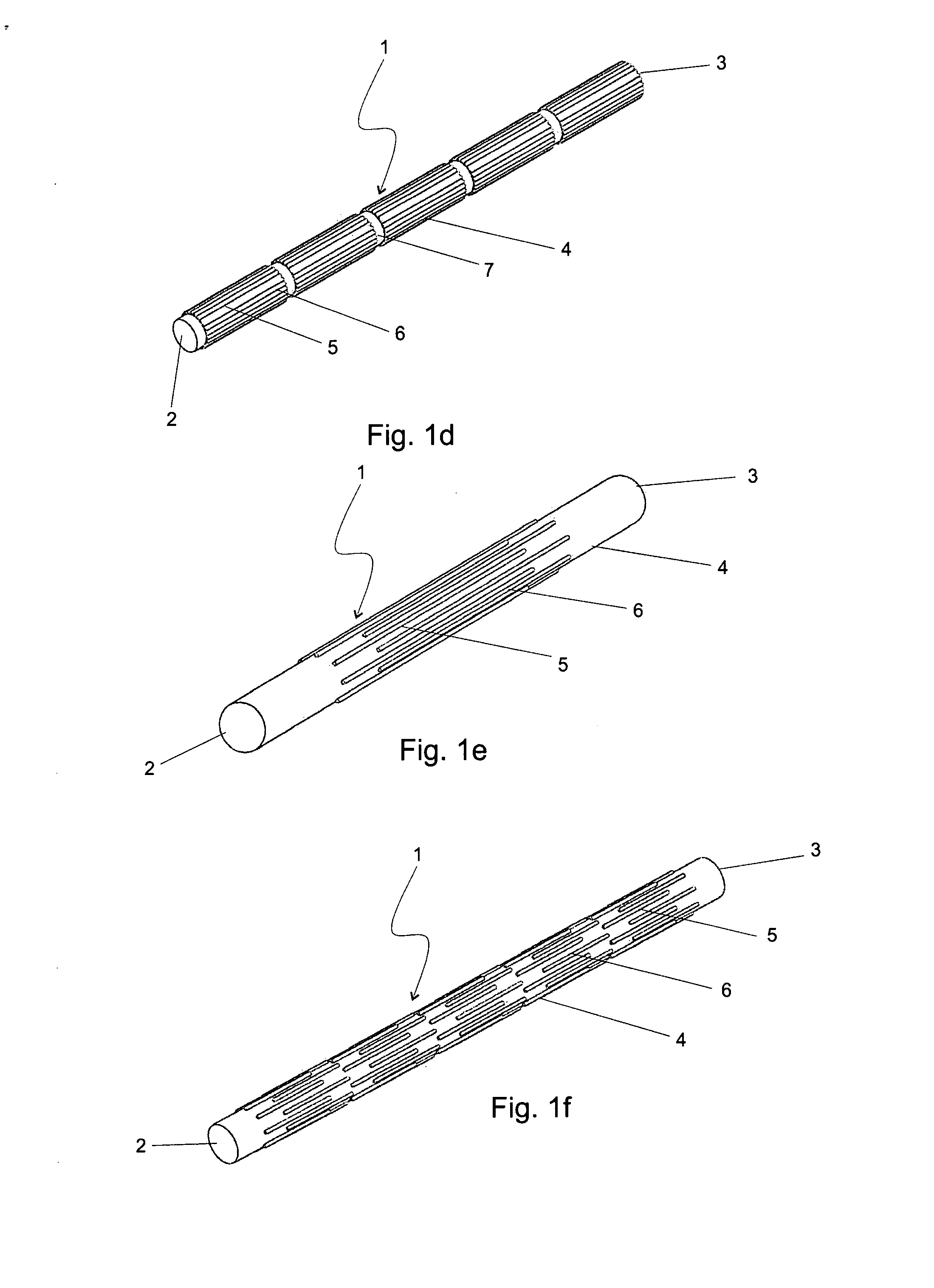

Bone fixation device

ActiveUS20070299449A1Good and tight fixation of boneHigh pull-out load carrying capacitySuture equipmentsInternal osteosythesisBone fixation devicesOsteotomy

The present invention relates to a bioabsorbable osteosynthesis fixation device for the fixation of bone fractures or osteotomies. The fixation device comprises a tip (2), a shaft (4) and a head (3). The periphery of the shaft (4) comprises ridges (6) which extend in a direction which forms an angle with the longitudinal axis of the shaft, the angle being between −45° and 45°. The present invention also relates to a method for manufacturing the bioabsorbable osteosynthesis fixation device.

Owner:BIORETEC

Connector

InactiveUS6860760B2Fixing strengthImprove the fixing strengthTwo pole connectionsSecuring/insulating coupling contact membersEngineeringElectrical and Electronics engineering

Owner:YAZAKI CORP +1

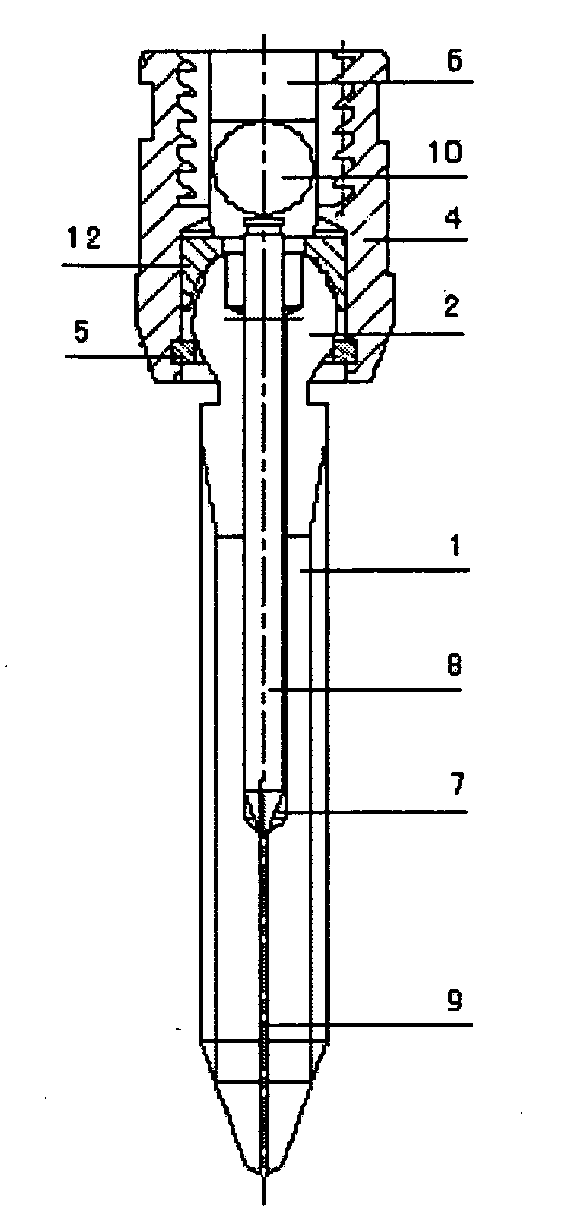

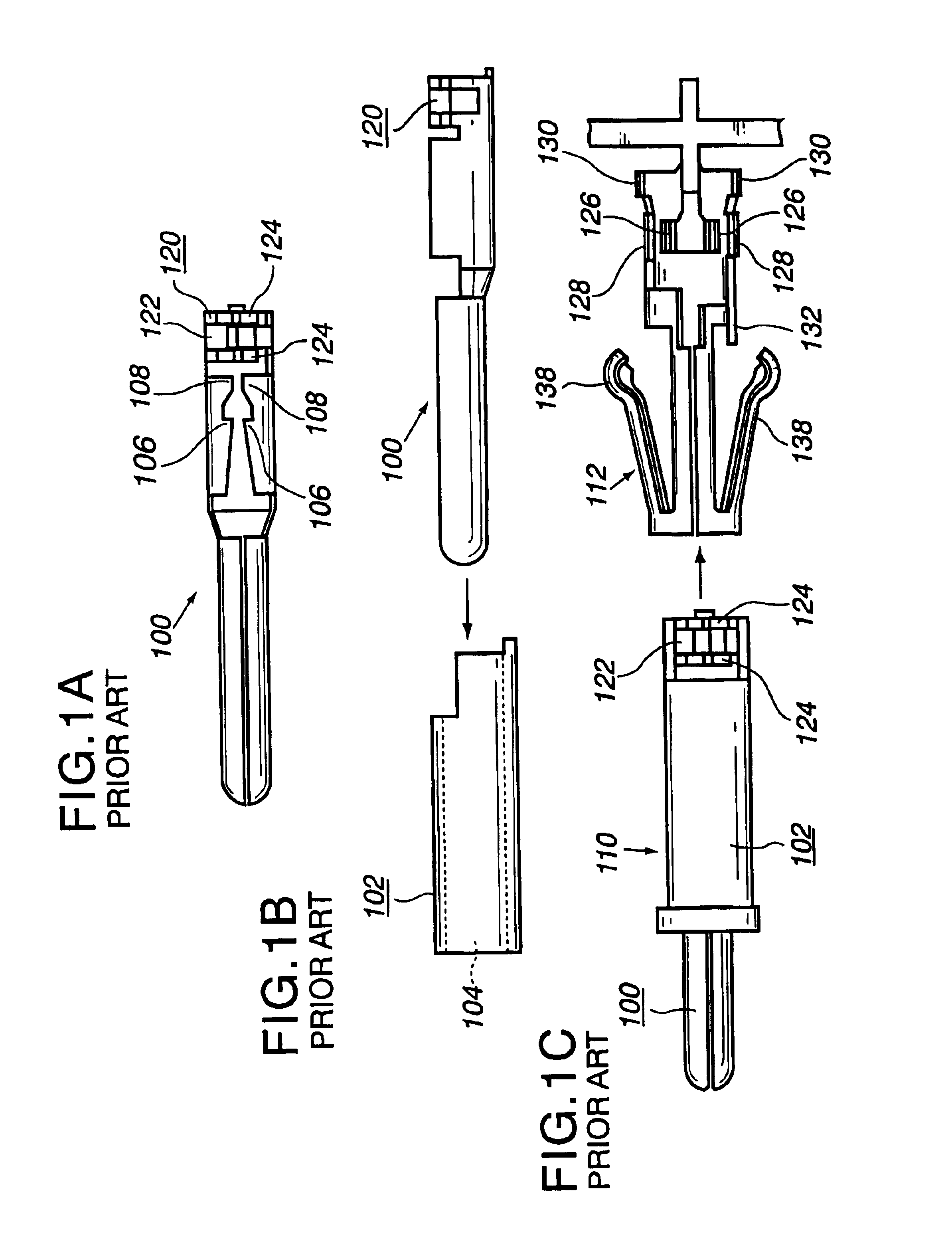

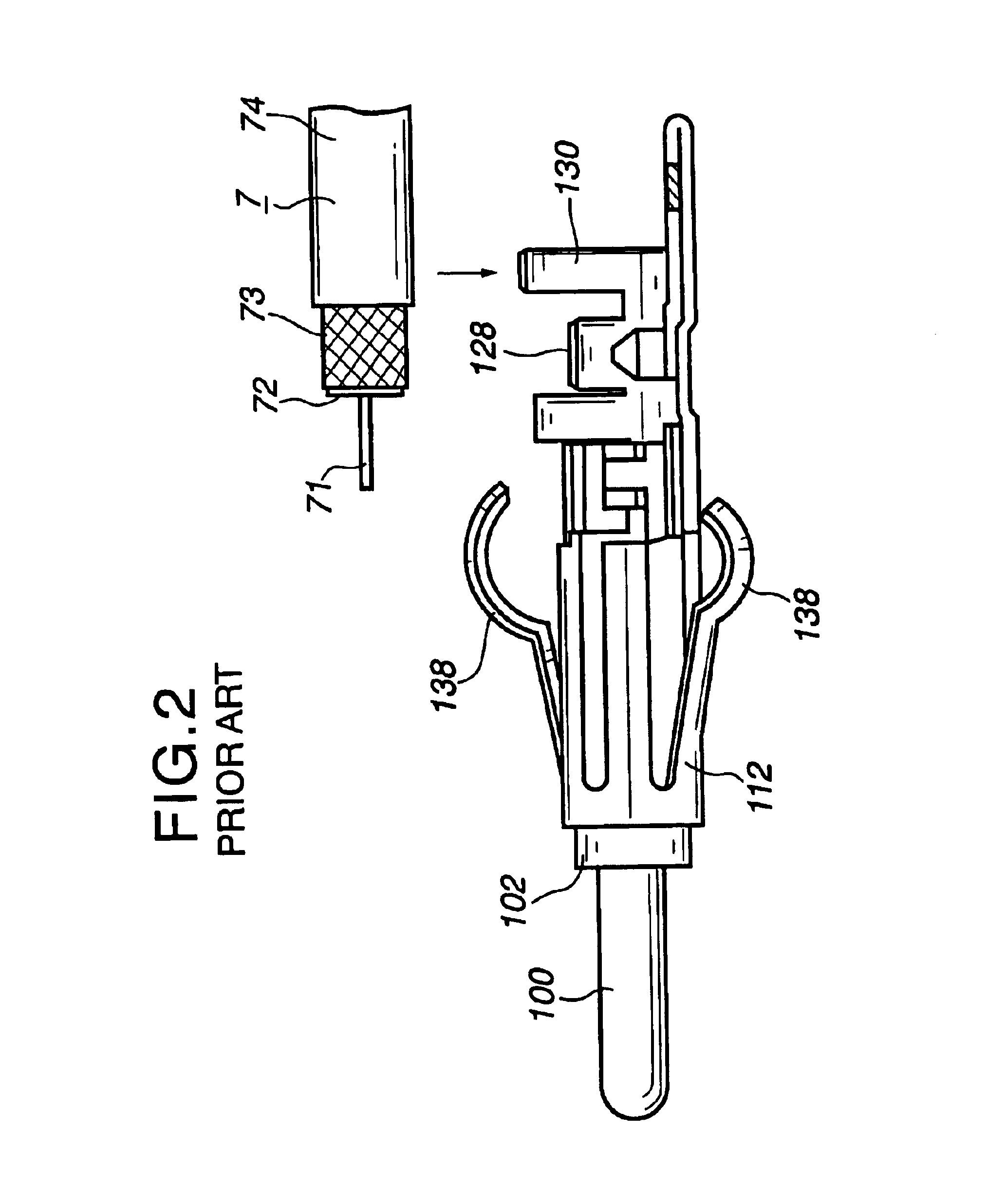

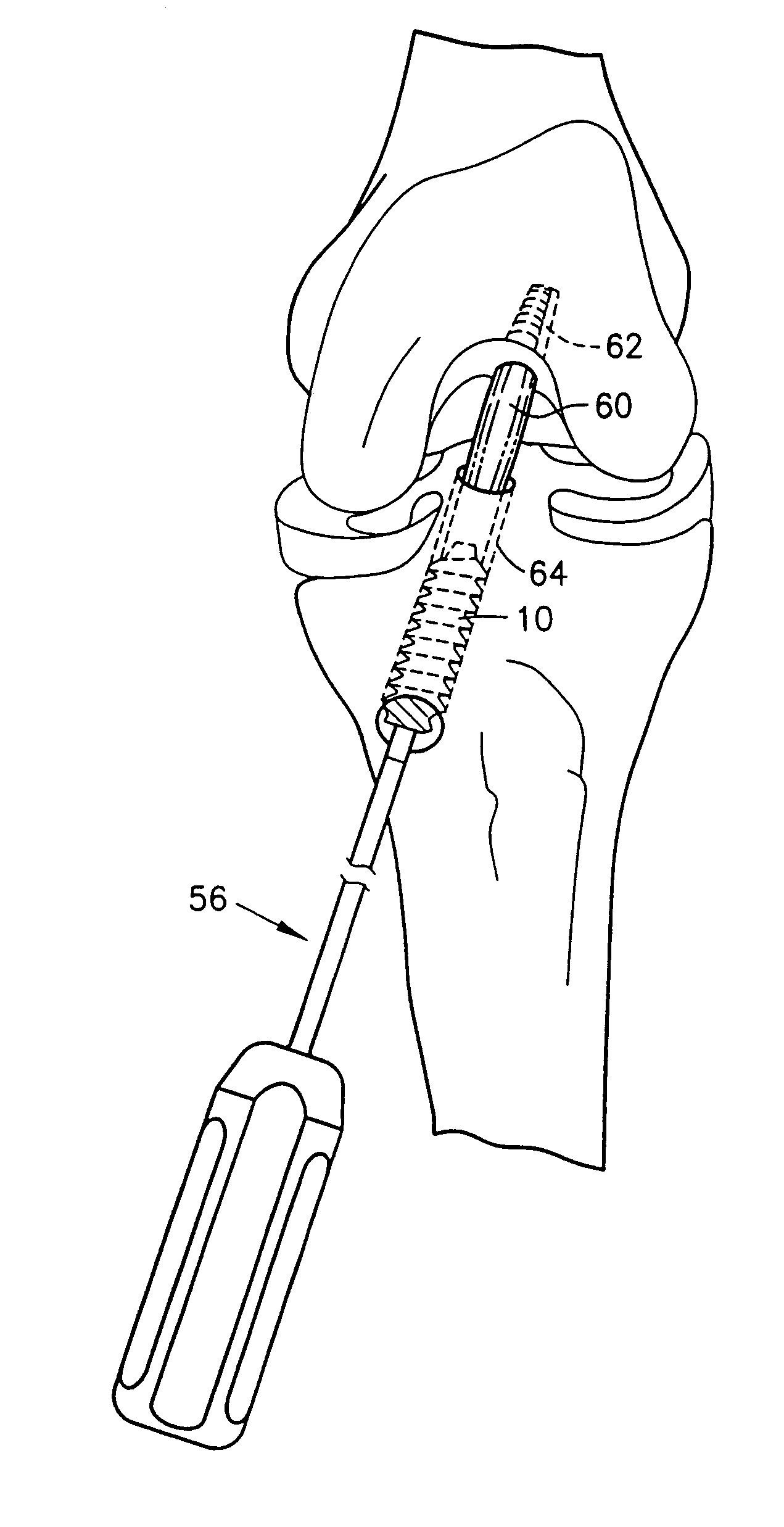

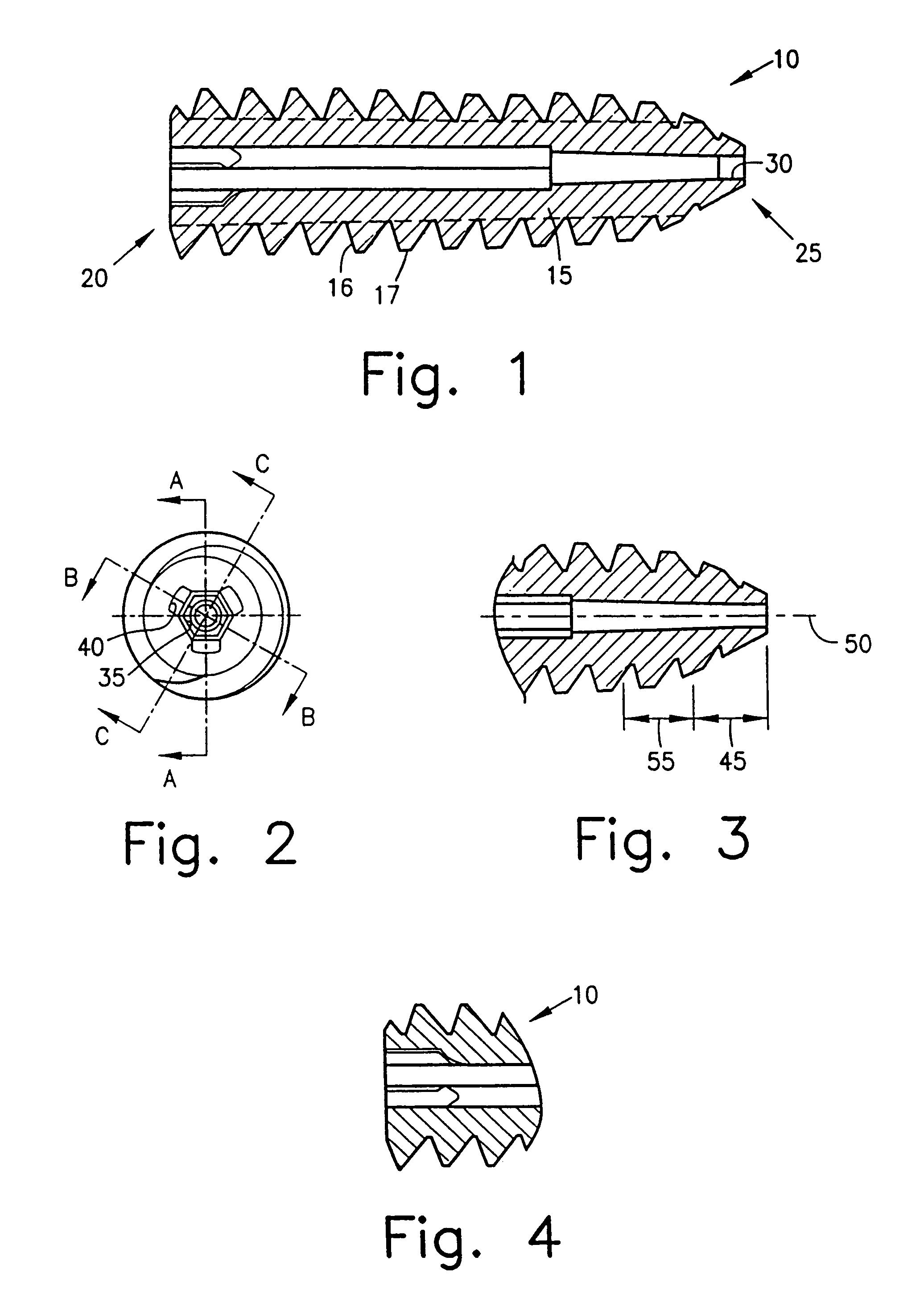

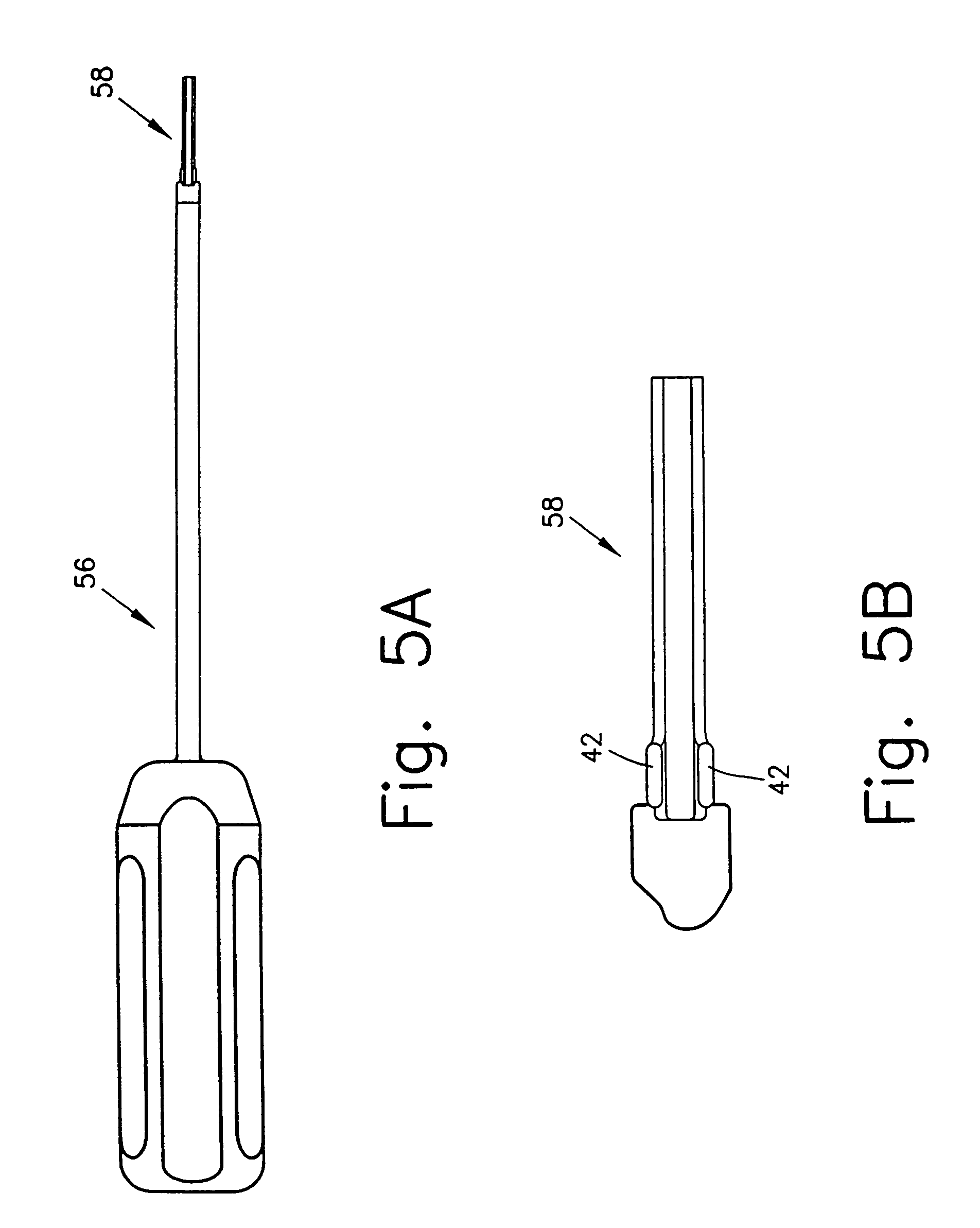

Bioabsorbable interference screw for endosteal fixation of ligaments

InactiveUS7322986B2Easy to insertEasy to fixSuture equipmentsInternal osteosythesisBone tunnelInterference screws

A bioabsorbable interference screw having a tapered profile which extends along substantially the entire length of the screw. The tapered profile makes the screw easy to insert while providing superior fixation resulting from a progressively increasing diameter. Upon insertion, the screw engages cortical bone at the back end of the bone tunnel and fills all but 5-10 mm. of the tunnel, thereby providing increased fixation strength while also promoting fast healing. The screw includes a head provided with a specially designed drive socket with radially extending slots at its outer end for receiving corresponding protrusions on the shaft of screwdriver. The drive socket optimizes the torque capacity of the screw. To maintain wall thickness, the socket has a taper corresponding to the tapered outer profile of the screw. The taper of the socket also permits easy insertion of the tip and shaft of the driver into the screw.

Owner:ARTHREX INC

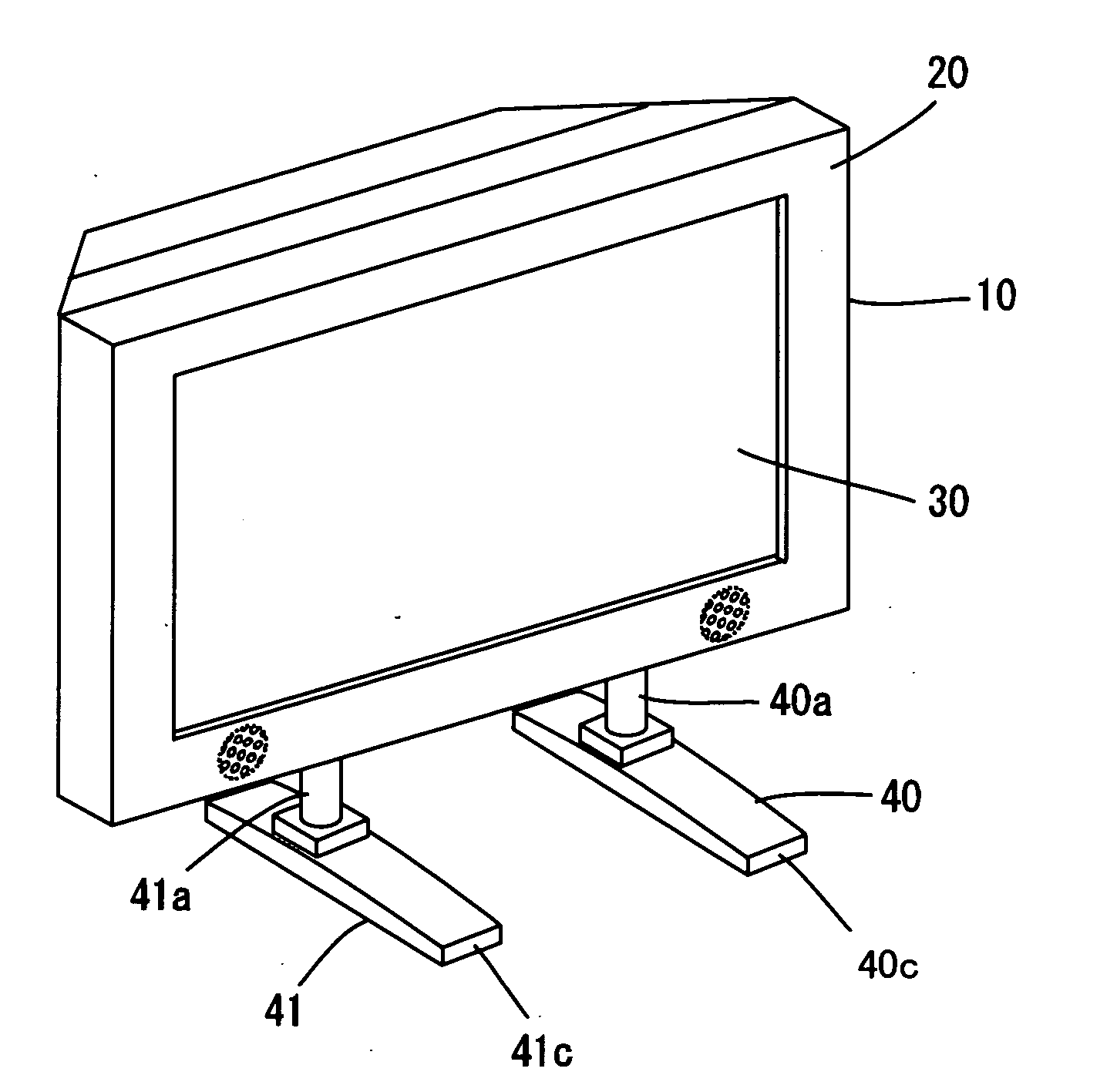

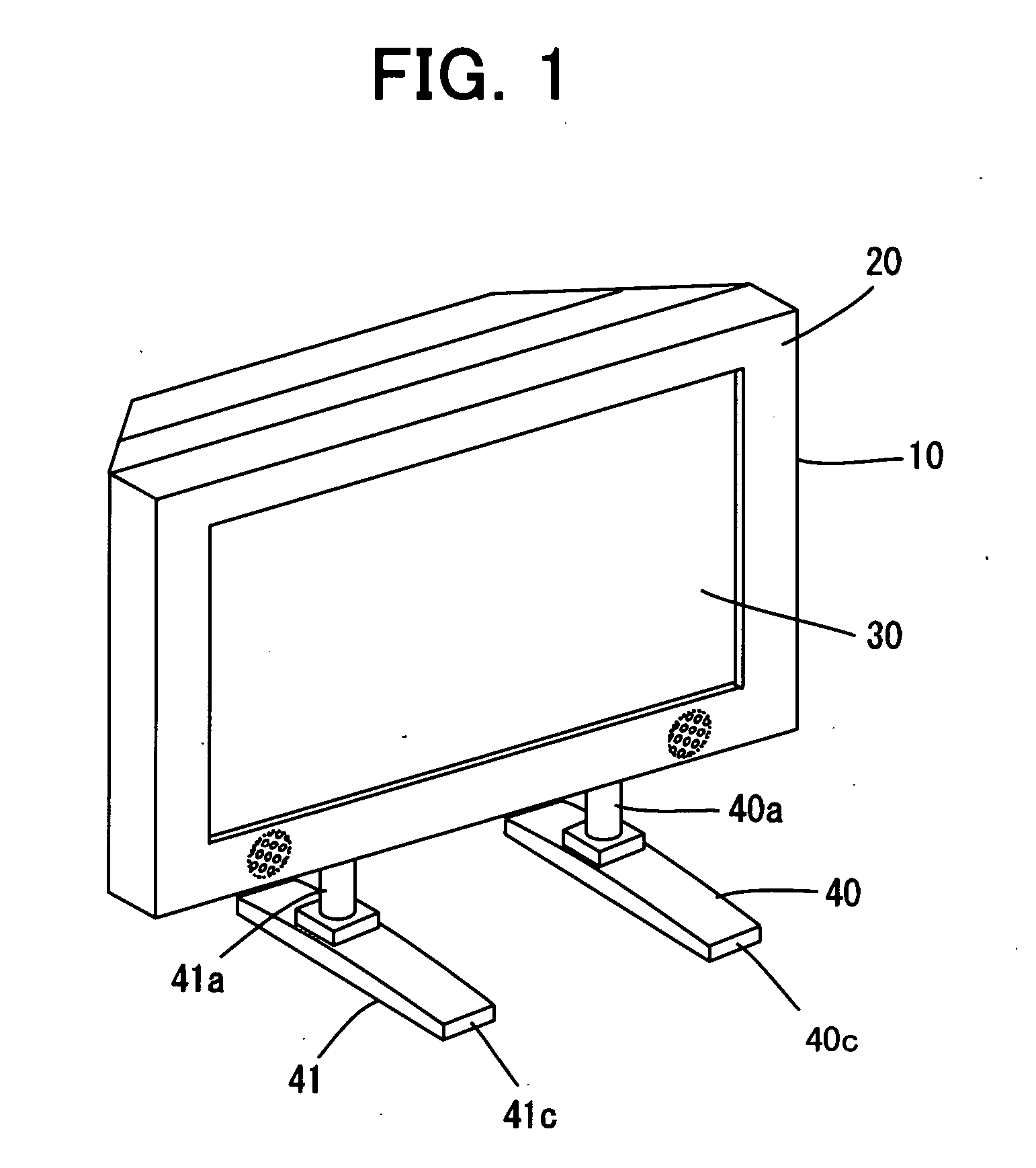

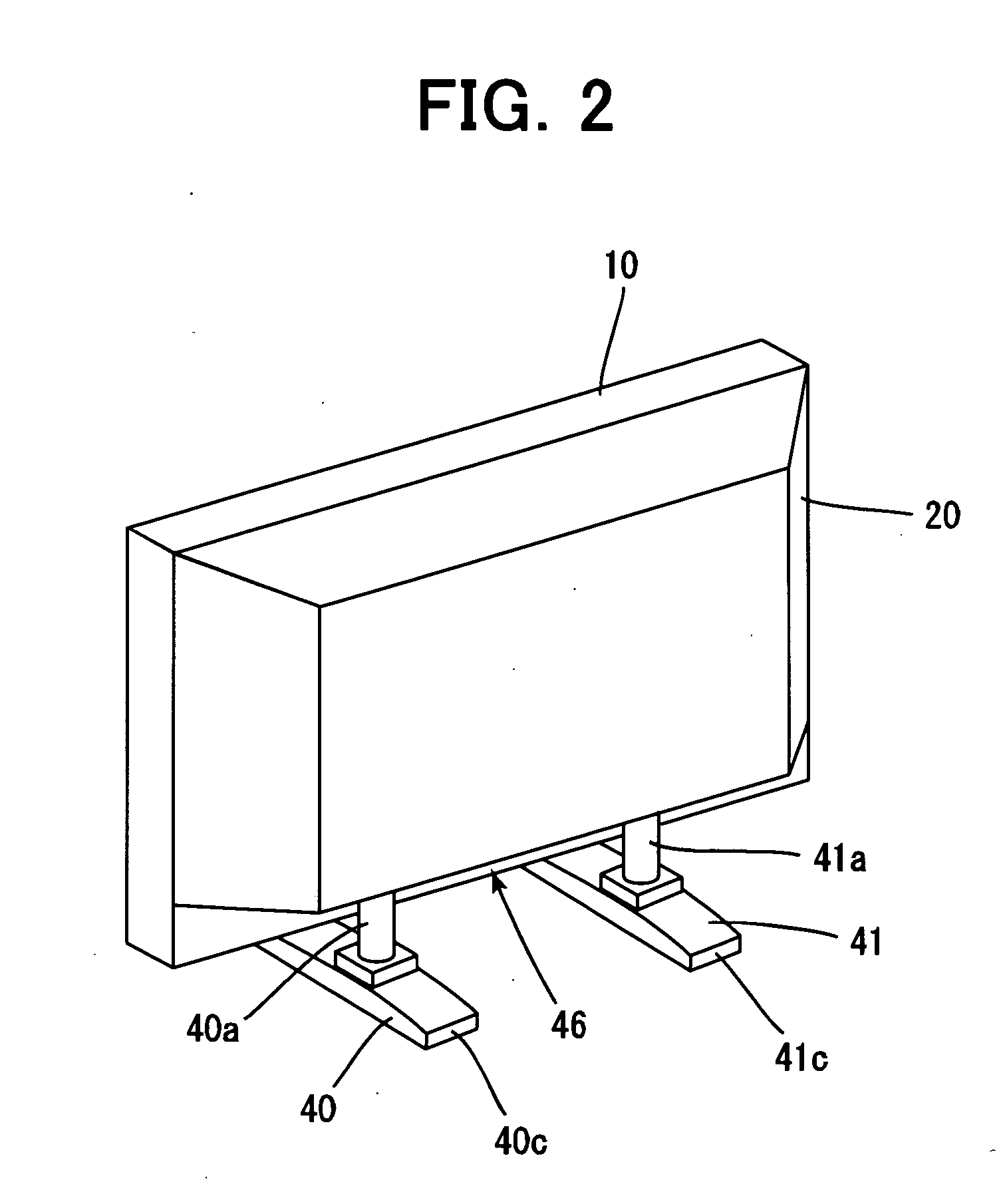

Panel-type television and plasma television

InactiveUS20070145212A1Promote lowerImprove the fixing strengthTelevision system detailsStands/trestlesEngineeringMechanical engineering

To prevent of a useless space from being produced in a package when the television is packed in the package, bolts 40b, 41b are located at terminals of horizontally extending through-slots 44a, 45a which are connected to vertically extending through-slots 44b, 45b. When the stands 40, 41 are to be stored, shafts of the stands 40, 41 are rotated such that the bolts 40b, 41b are guided at terminals of the horizontally extending through-slots 44a, 45a which are connected to the vertically extending through-slots 44b, 45b. When the stands 40, 41 are pushed upward to thereby cause the bolts 40 to arrive at upper terminals of the vertically extending through-slots 44b, 45b while being guided along the vertically extending through-slots 44b, 45b, the stands 40, 41 are accommodated in a storage space 46.

Owner:FUNAI ELECTRIC CO LTD

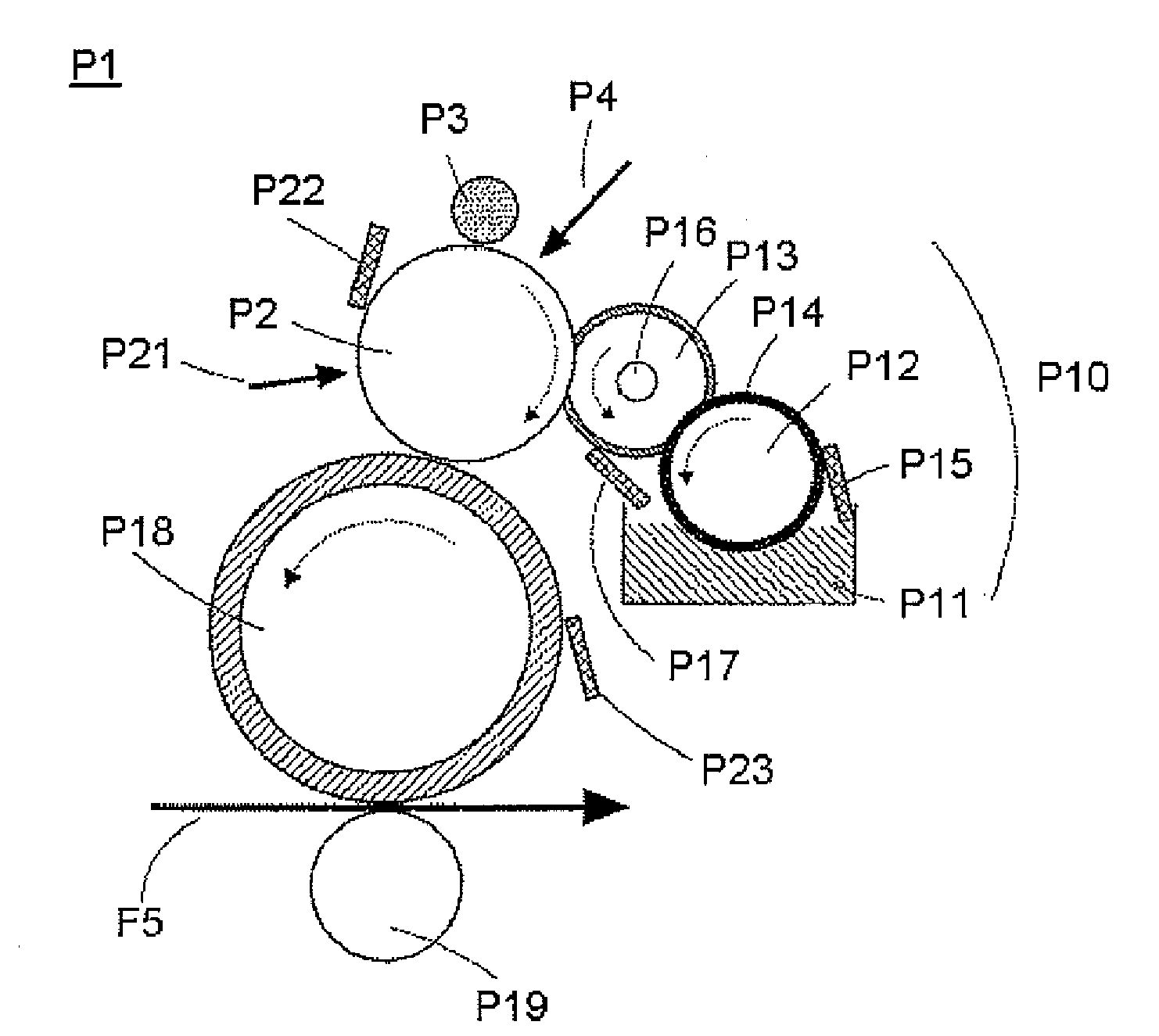

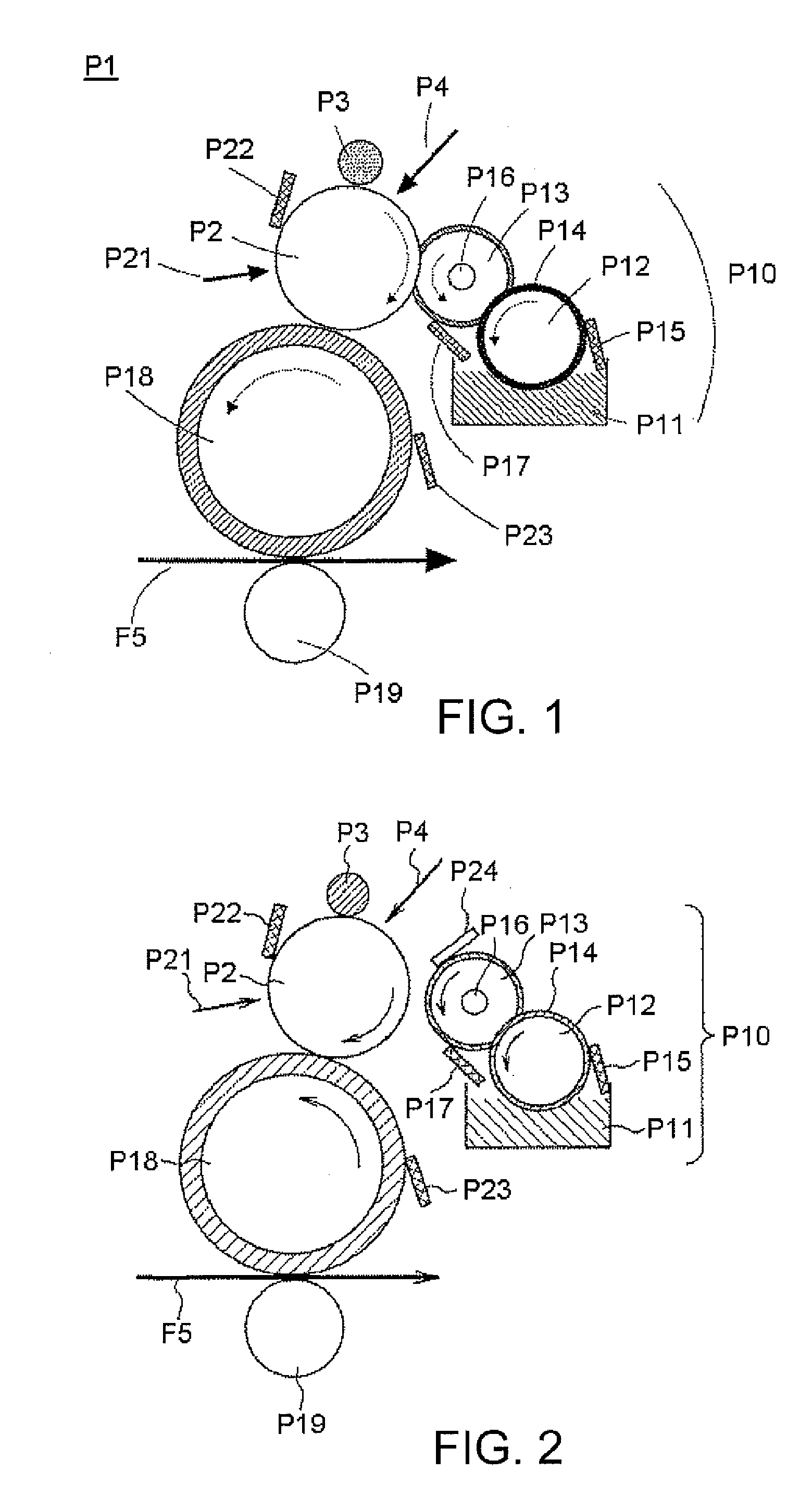

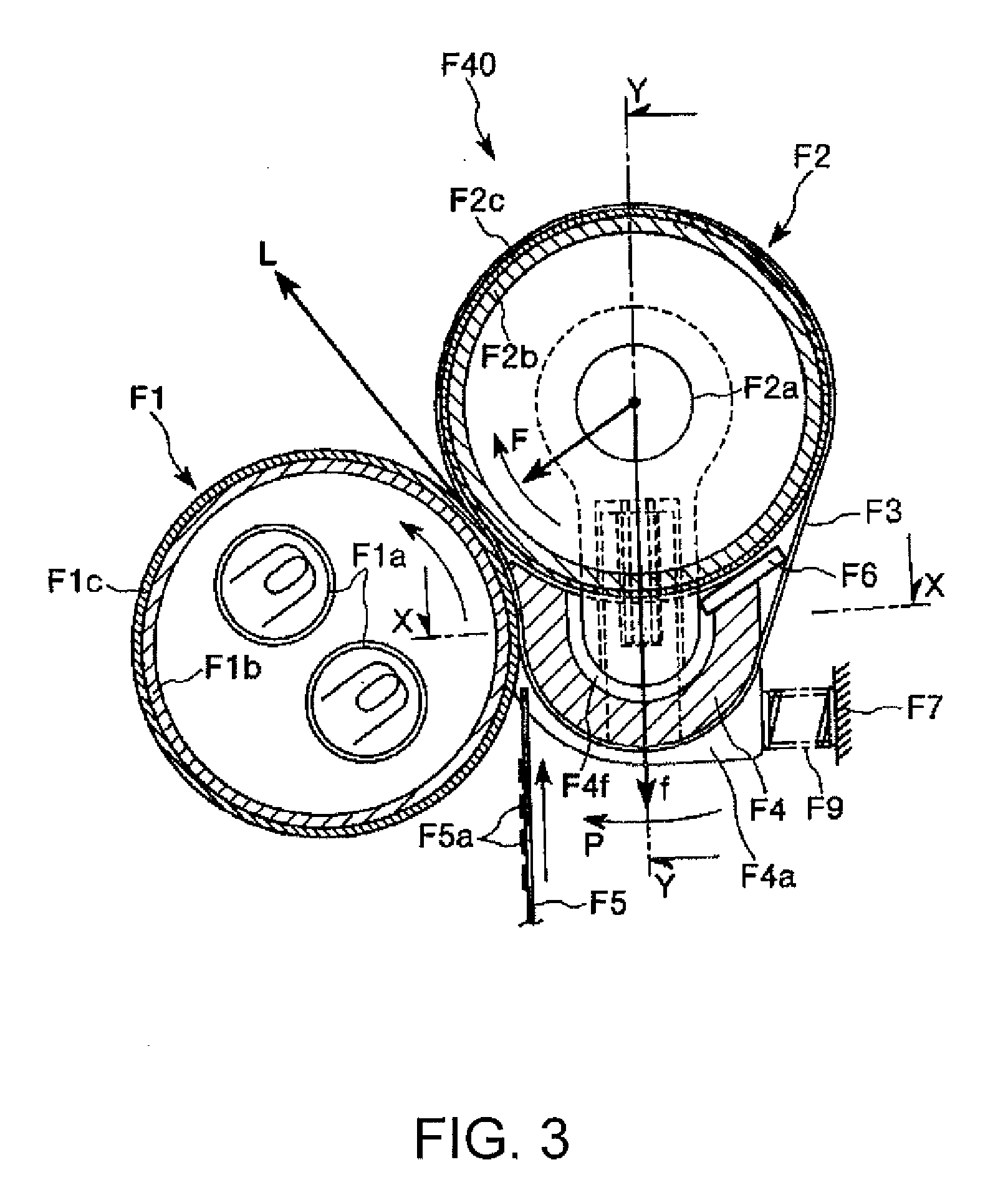

Liquid Developer, Method of Manufacturing Liquid Developer, and Image Forming Apparatus

InactiveUS20070258731A1Easy to fixImprove the fixing strengthInksElectrographic process apparatusUnsaturated fatty acidPolymer chemistry

A liquid developer includes an insulation liquid, and toner particles that are dispersed in the insulation liquid. Fatty acid monoester is unevenly distributed in the vicinity of surfaces of the toner particles, and the insulation liquid contains unsaturated fatty acid triglyceride.

Owner:SEIKO EPSON CORP

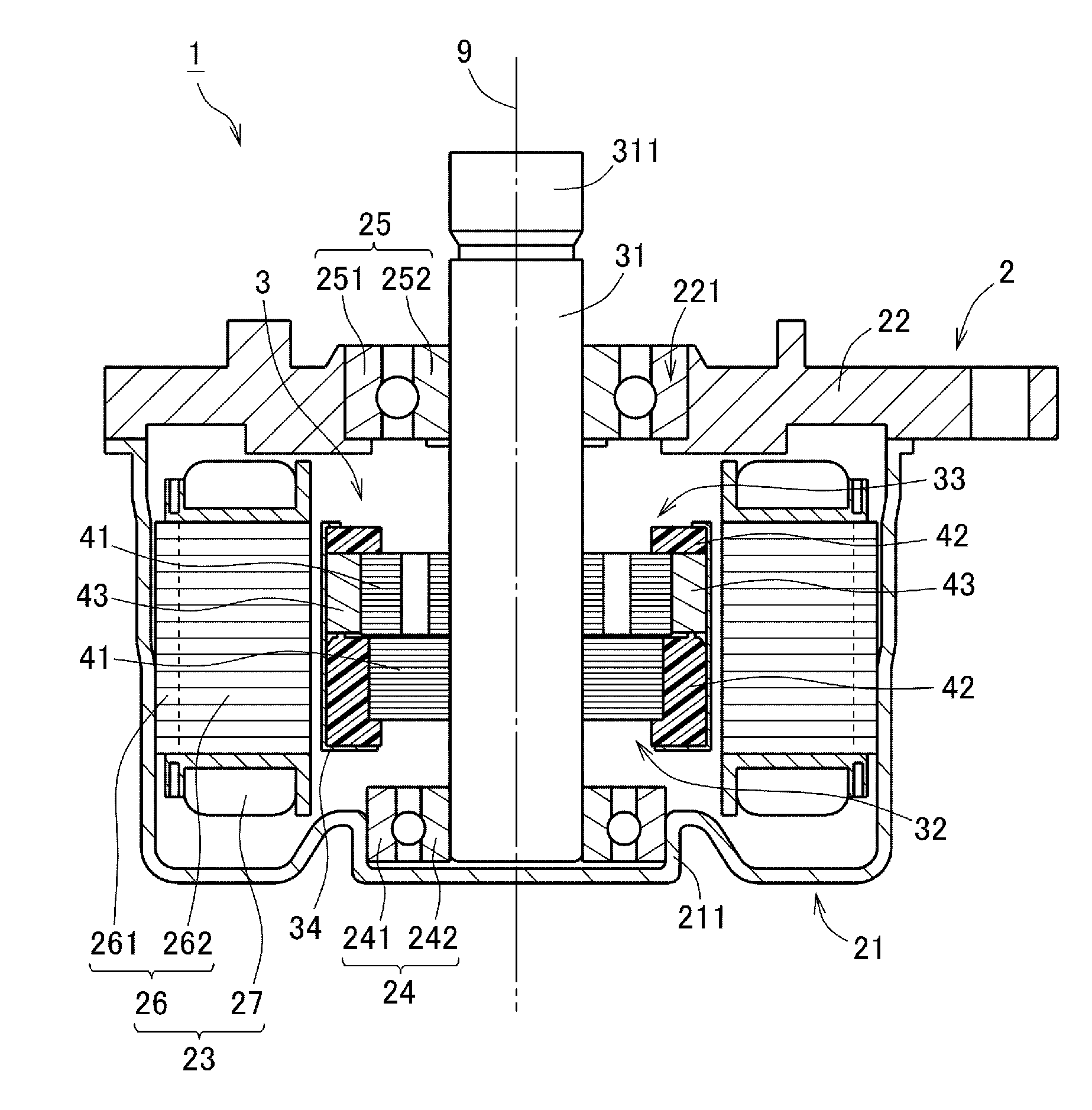

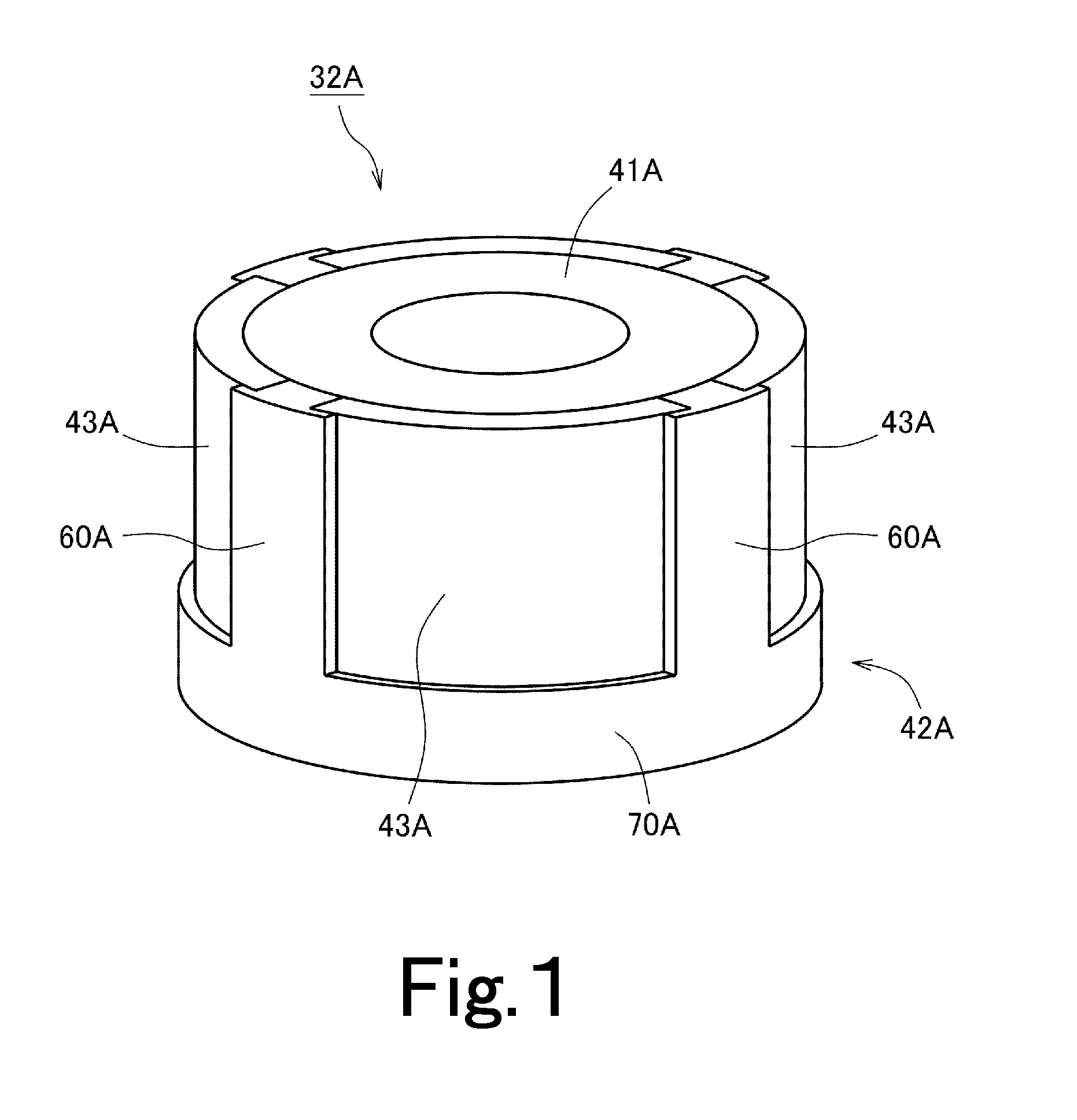

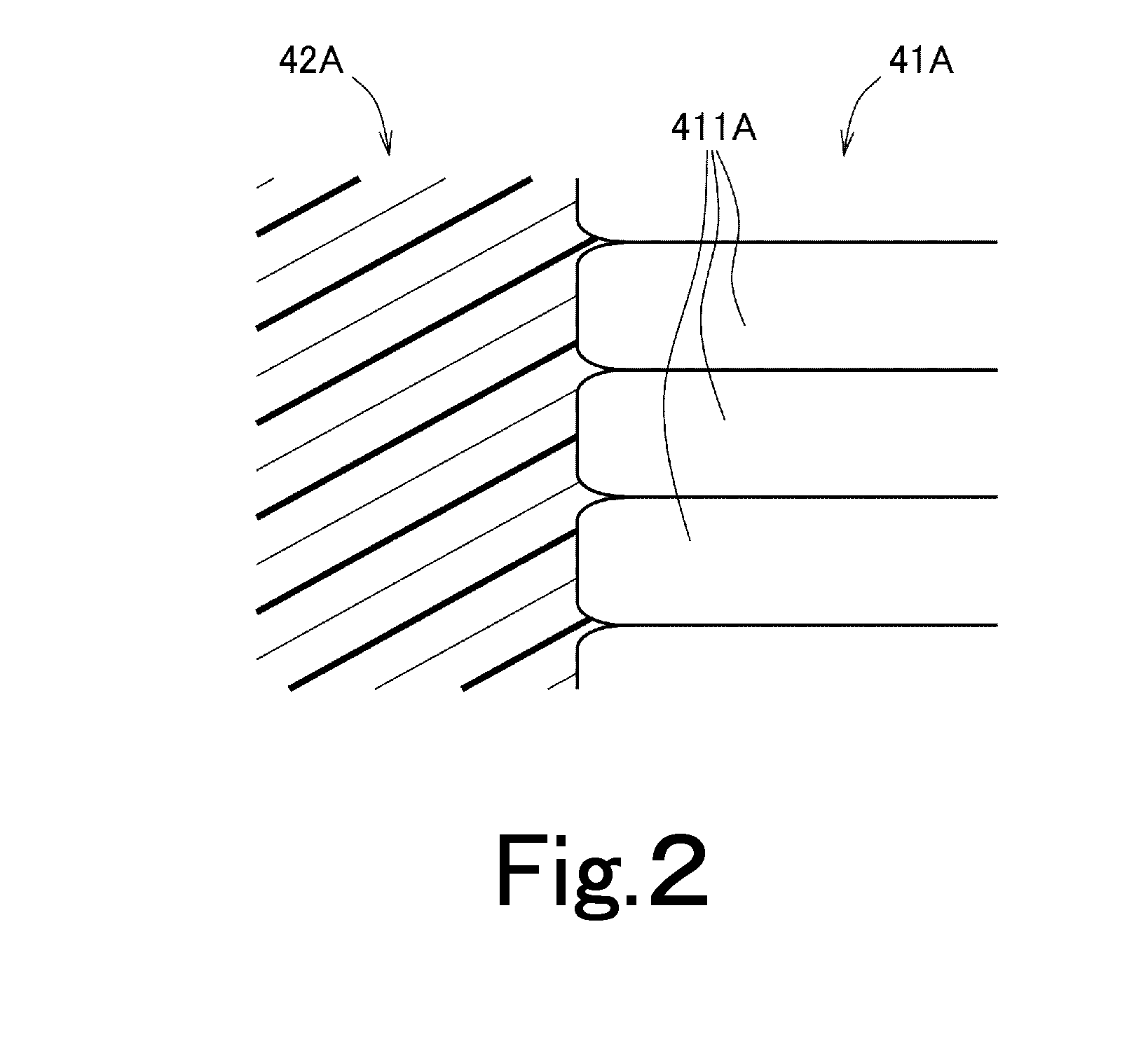

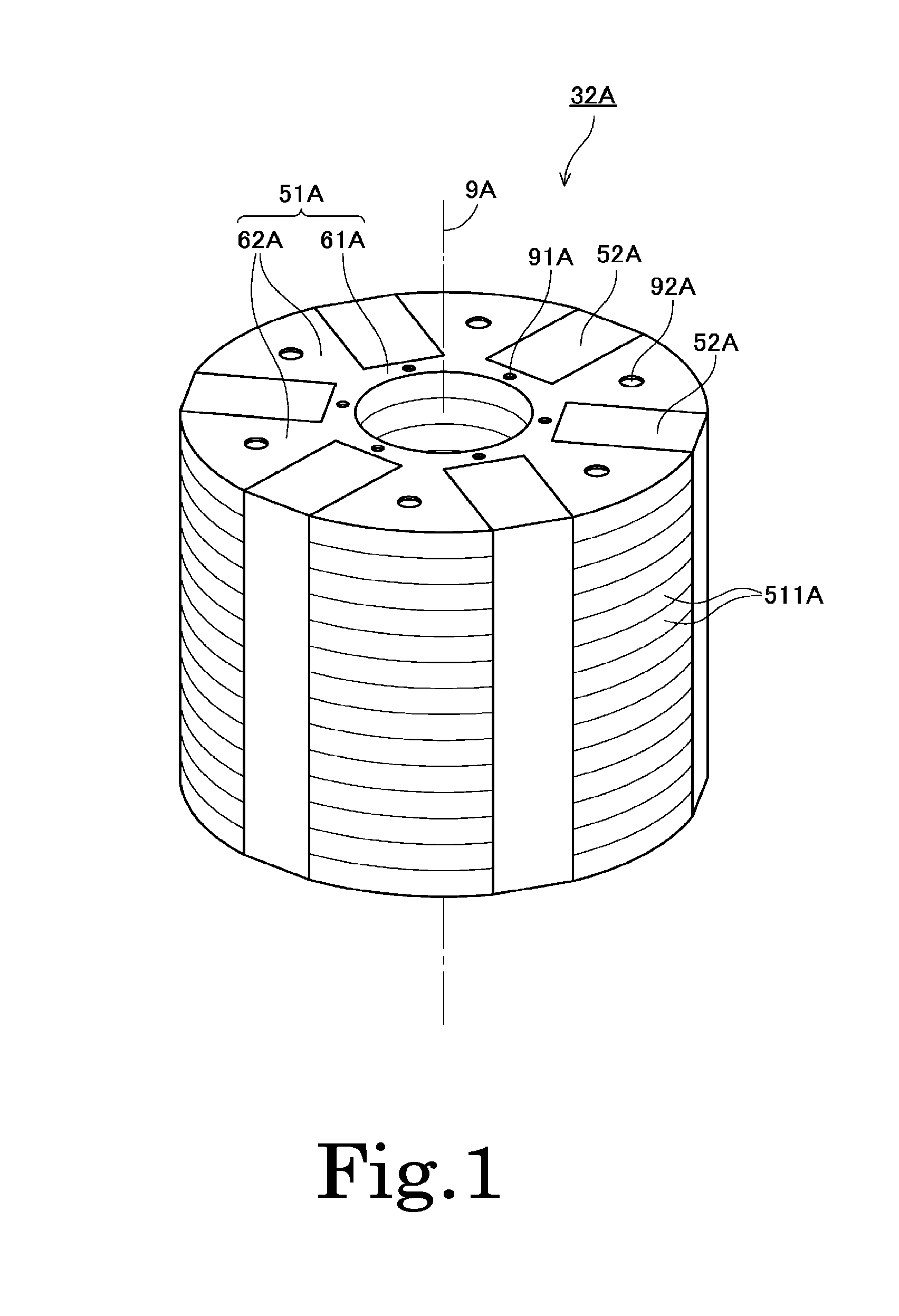

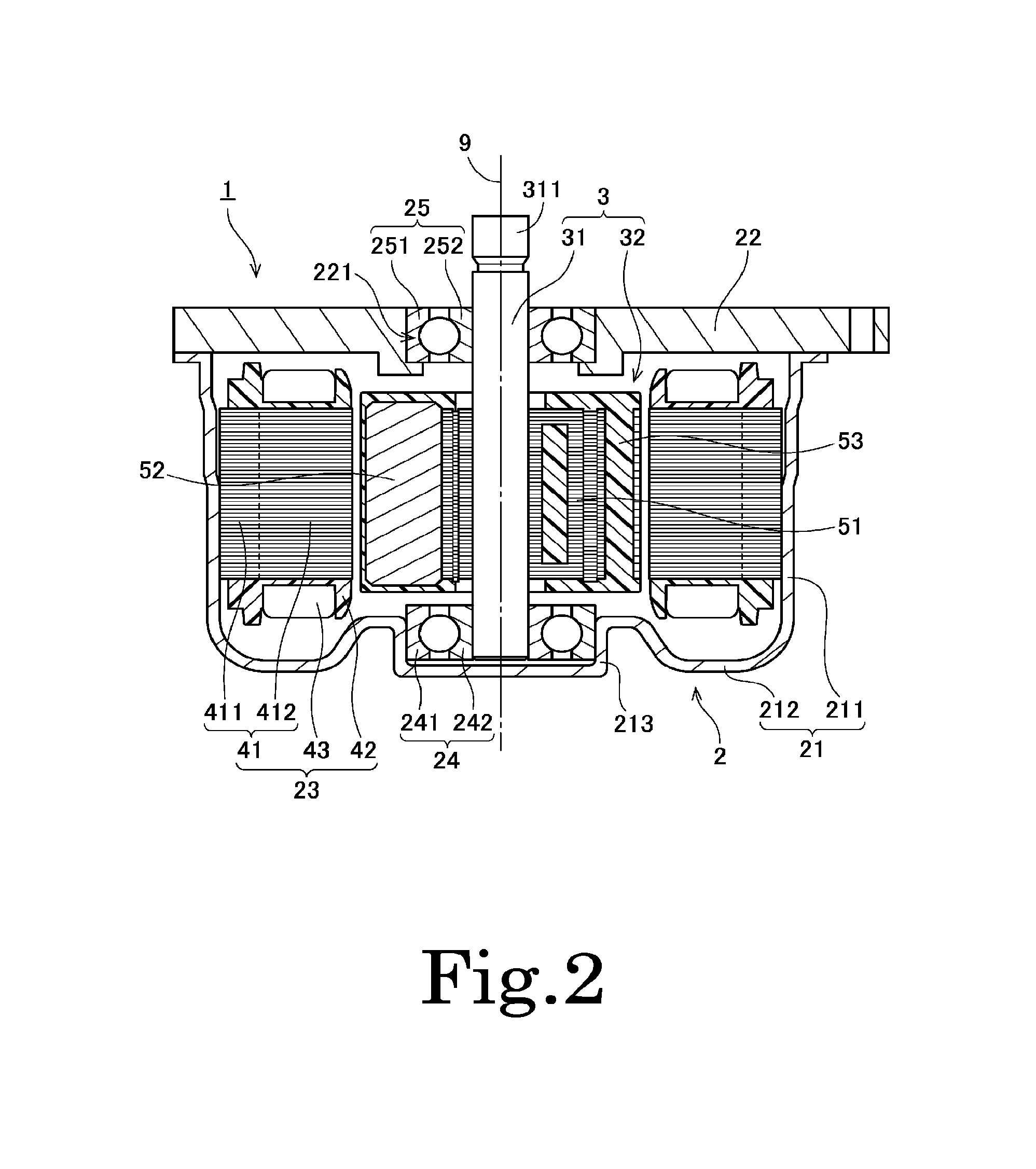

Rotor unit, rotating electrical machine, and method for manufacturing rotor unit

ActiveUS20130257184A1Improve the fixing strengthEasy to pressMagnetic circuit rotating partsElectrical steeringEngineeringUltimate tensile strength

A rotor unit includes a rotor core made of laminated steel sheets that are vertically laminated, and a holder made of resin. The rotor core and the holder are fixed together through insert molding. For this reason, the process of manufacturing the rotor core and the holder is shortened. Additionally, in the outer peripheral surface of the rotor core, a portion of resin that defines the holder is present between the plurality of steel sheets that defines the rotor core. For this reason, the fixing strength of the rotor core and the holder improves. Additionally, since a separation between the rotor core and the holder is prevented, magnets can be easily press-fitted.

Owner:NIDEC CORP

Optical coupling element, method for producing the optical coupling element, and electronic device equipped with the optical coupling element

InactiveUS20070052074A1Improve cooling effectSimple structureSemiconductor/solid-state device detailsSolid-state devicesLead frameOptical coupling

After a light emitting element is mounted to a header of a light emitting lead frame, a light receiving element is mounted to a header of a light receiving lead frame and a power element is mounted to a header of a power lead frame, the light emitting element, the light receiving element and the power element are connected to respective lead portions with wires, and in a state with the light emitting element, and the light receiving element and the power element, disposed facing each other, they are entirely coated with a primary molding resin, and the primary molding resin and a heat sink formed in a heat dissipating lead frame are coated with a secondary molding resin. Also, a structure is adopted in which the lead terminal of the power element and the heat dissipating lead frame are stacked together, and joined at this stacked portion.

Owner:SHARP KK

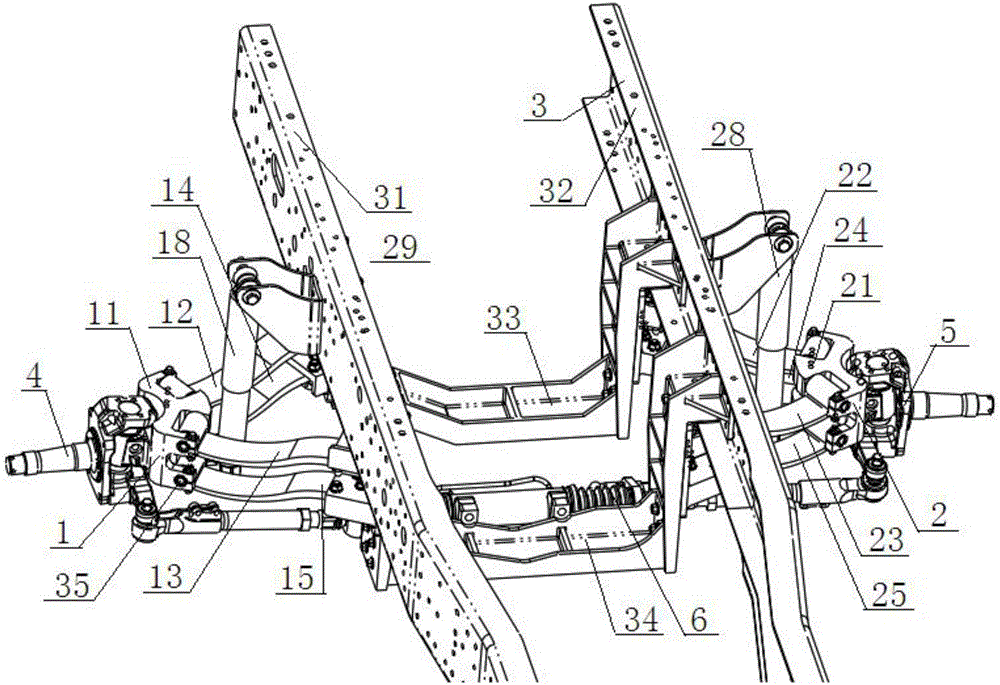

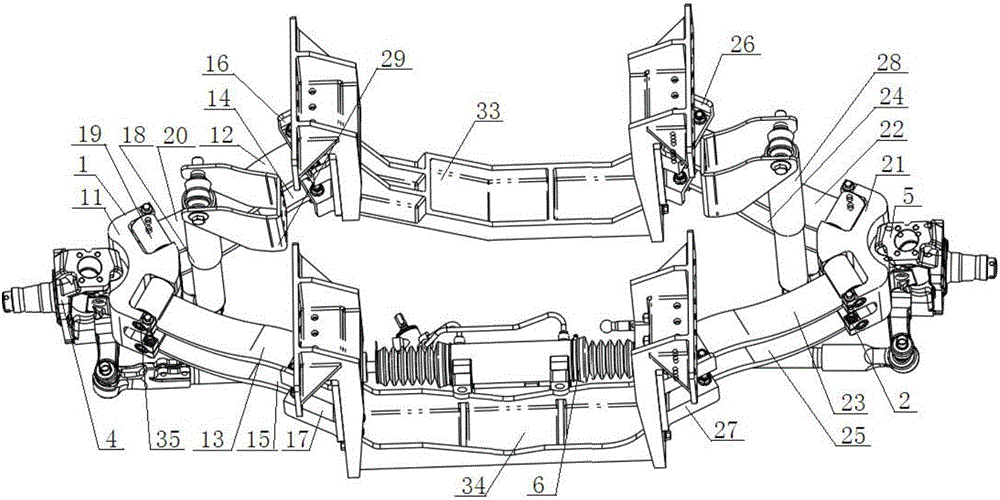

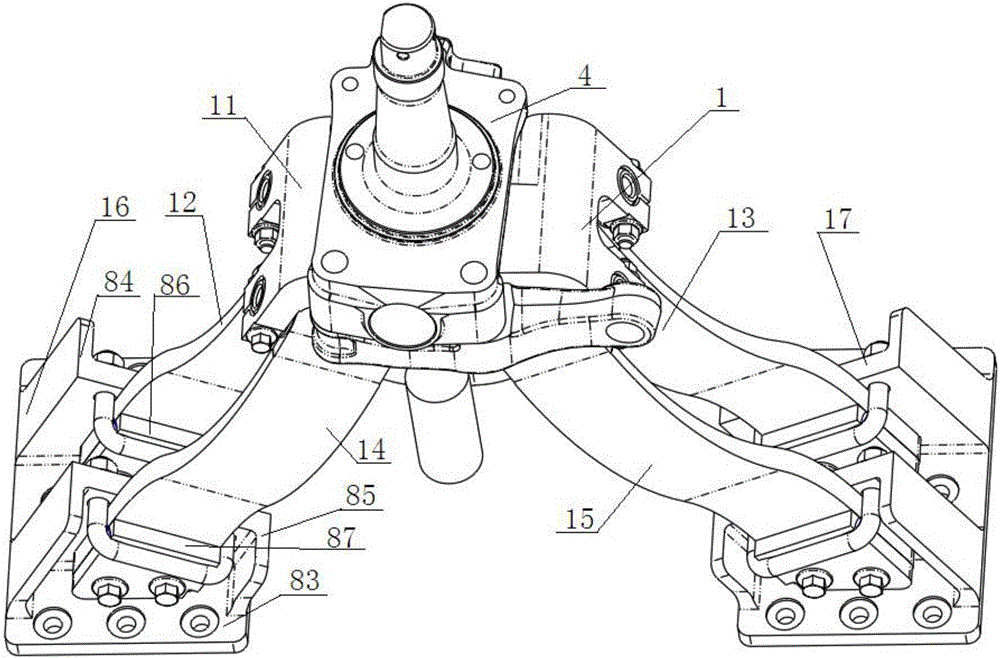

Commercial vehicle single front axle structure with independent suspensions

ActiveCN106394154AImprove the fixing strengthImprove carrying capacityMechanical steering gearsResilient suspensionsVehicle frameOperational stability

A commercial vehicle single front axle structure with independent suspensions comprises the left independent suspension and the right independent suspension which are arranged symmetrically. The left independent suspension is connected with the right independent suspension through a vehicle frame. The vehicle frame comprises a left longitudinal beam and a right longitudinal beam which are symmetrically arranged. The left longitudinal beam is fixedly connected with the right longitudinal beam through a front pocket beam and a rear pocket beam. The independent suspensions are connected with the front pocket beam and the rear pocket beam through connection brackets and four plate springs correspondingly. The bottoms of the connection brackets are connected with the longitudinal beams through shock absorbers. A gear rack steering system is connected with steering knuckles. The commercial vehicle single front axle structure is reasonable, high in mechanical strength, good in bearing characteristic and conductive to improving the smoothness and operation stability of a whole vehicle.

Owner:DONGFENG COMML VEHICLE CO LTD

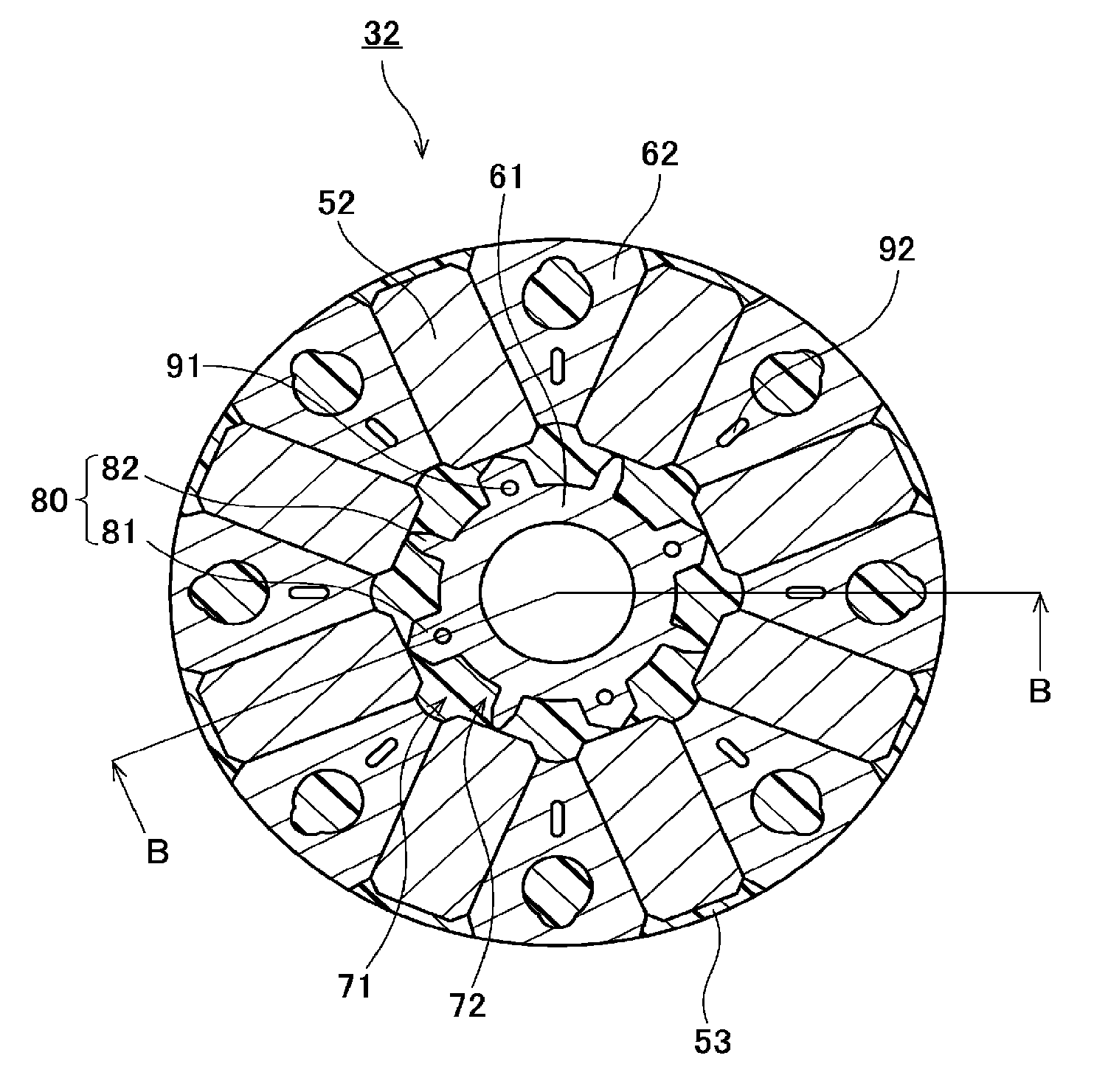

Rotor

ActiveUS8922083B2Improve the fixing strengthEasy to useMagnetic circuit rotating partsManufacturing stator/rotor bodiesNuclear engineeringMagnetic poles

A laminated core of a rotor includes an inner core portion and a plurality of outer core portions. The inner core portion axially extends in a cylindrical shape in a region located more radially inward than magnets. The outer core portions are arranged in a circumferential direction in a region located more radially outward than the inner core portion. The plurality of outer core portions and a plurality of the magnets are alternately arranged in the circumferential direction. Accordingly, magnetic flux generated from a pair of magnetic pole surfaces of the plurality of magnets can be effectively used. In addition, the laminated core includes caulking portions in each of the inner core portion and the plurality of outer core portions. Accordingly, a plurality of thin plate cores are firmly fixed.

Owner:NIDEC CORP

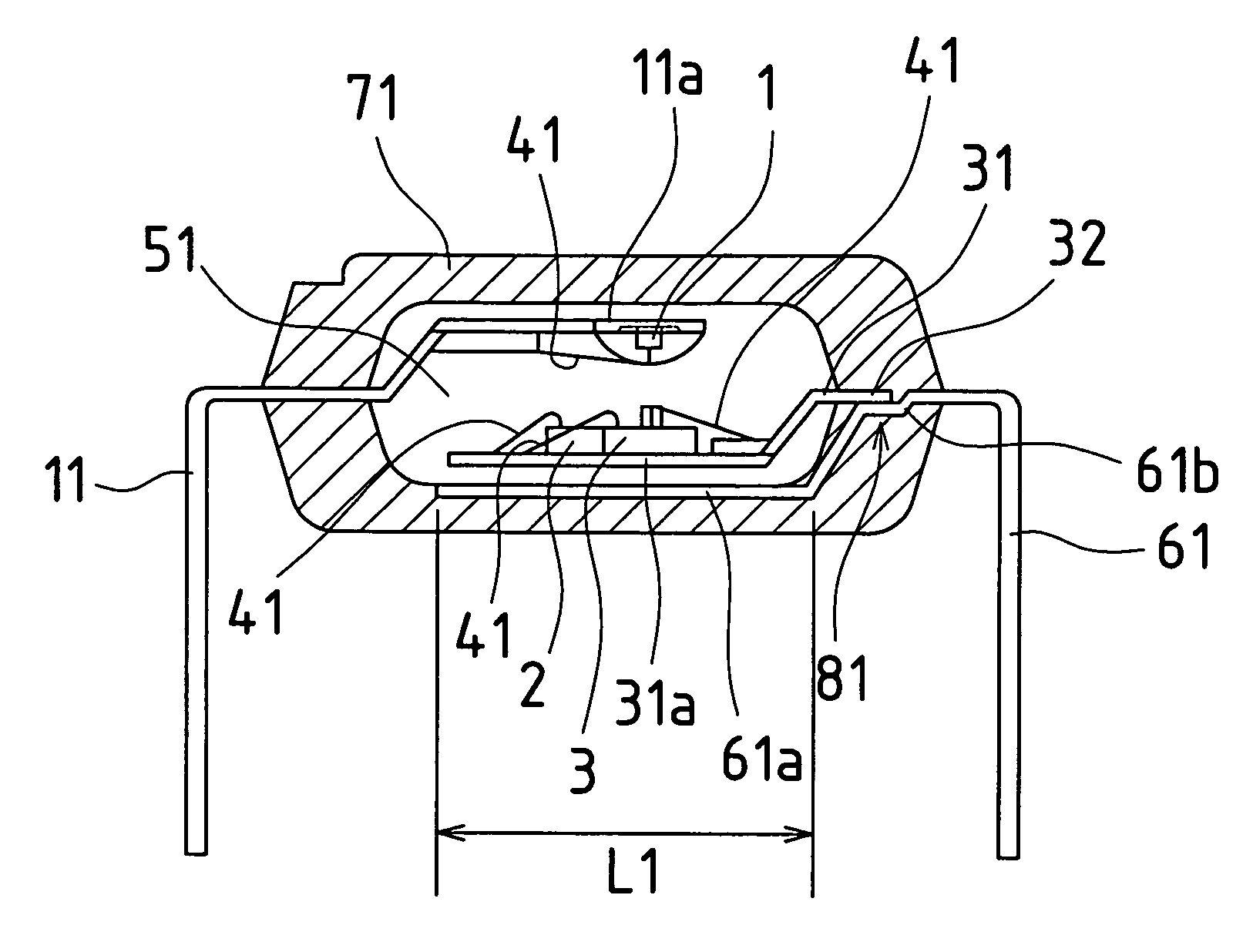

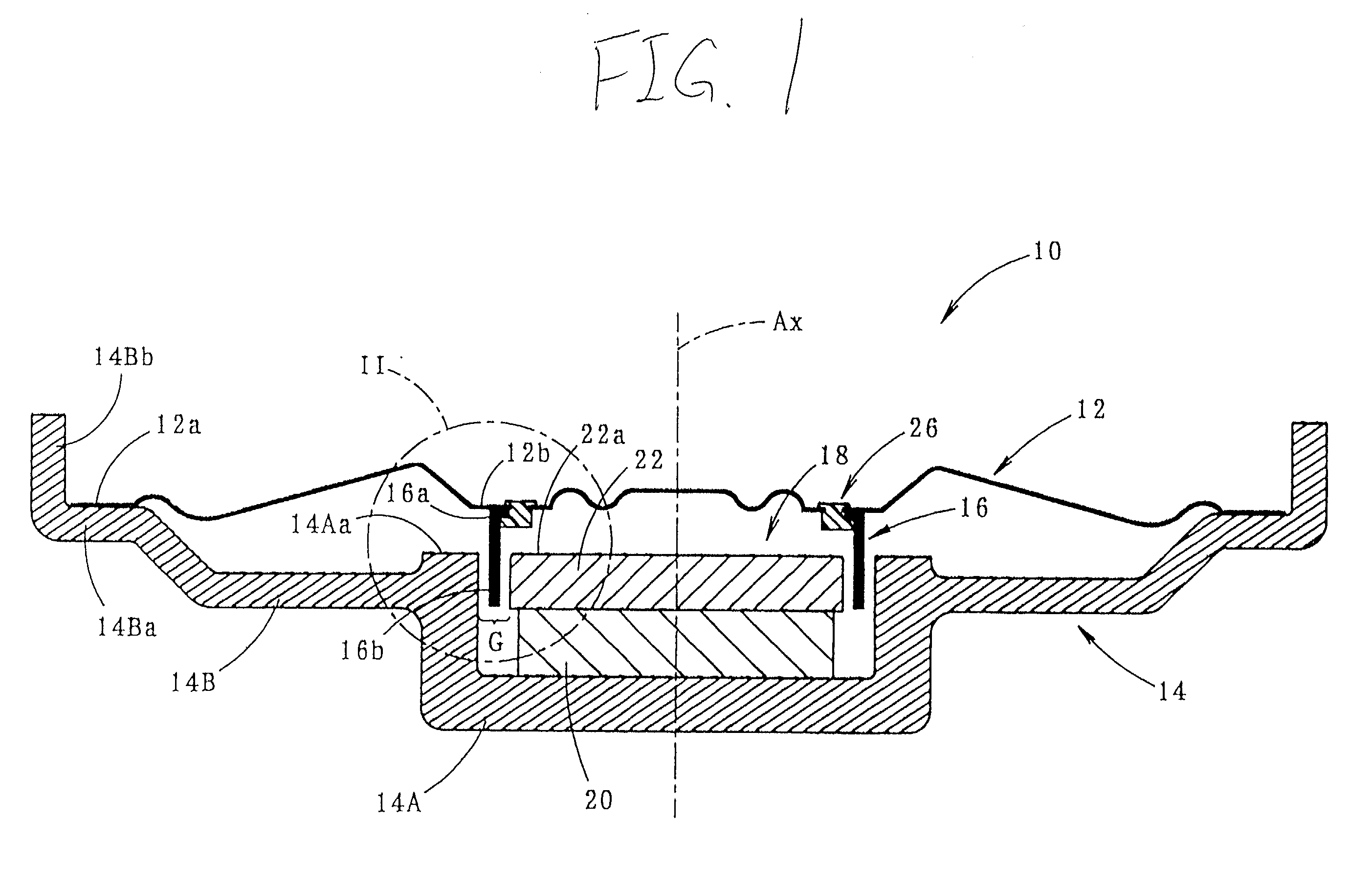

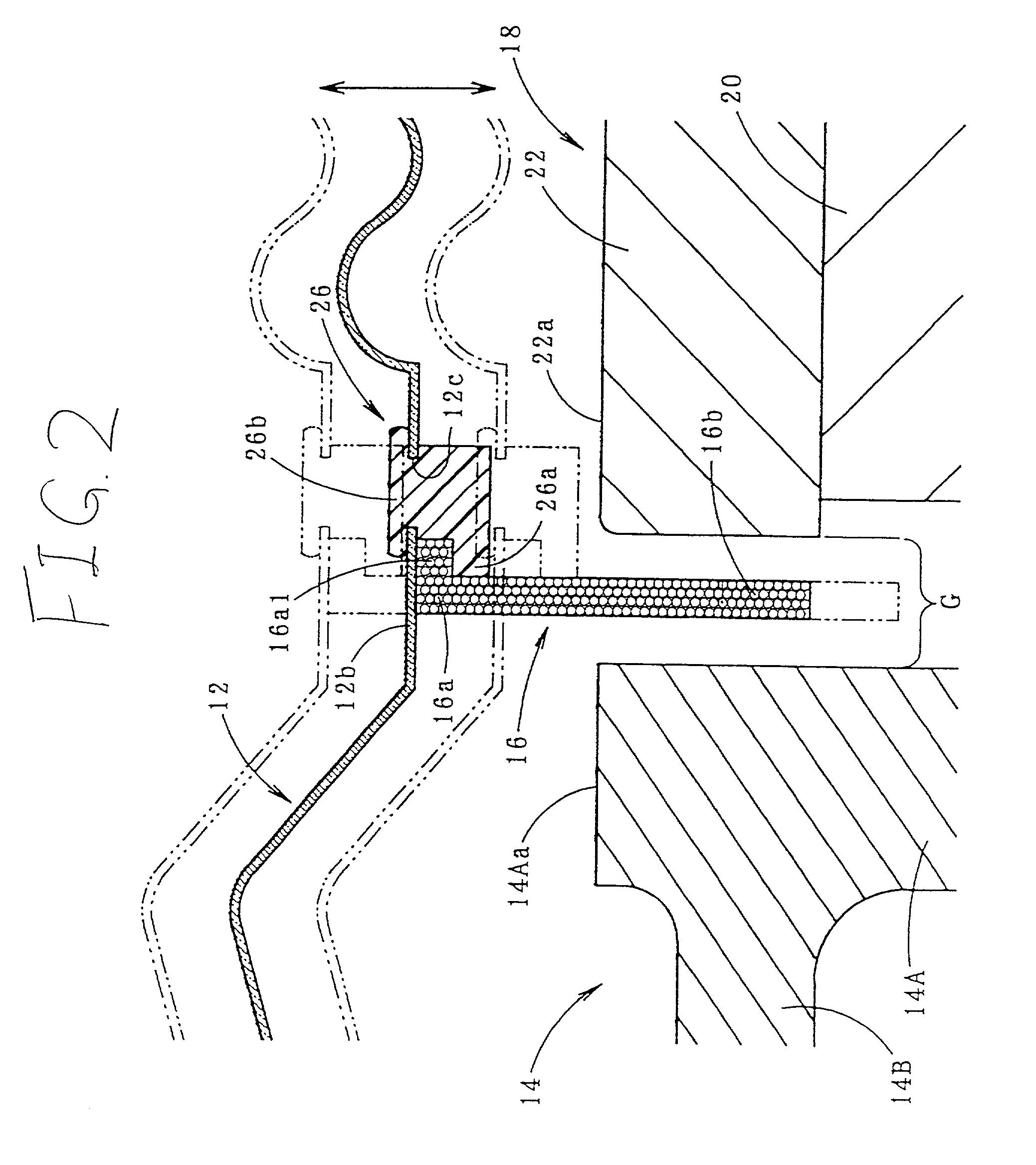

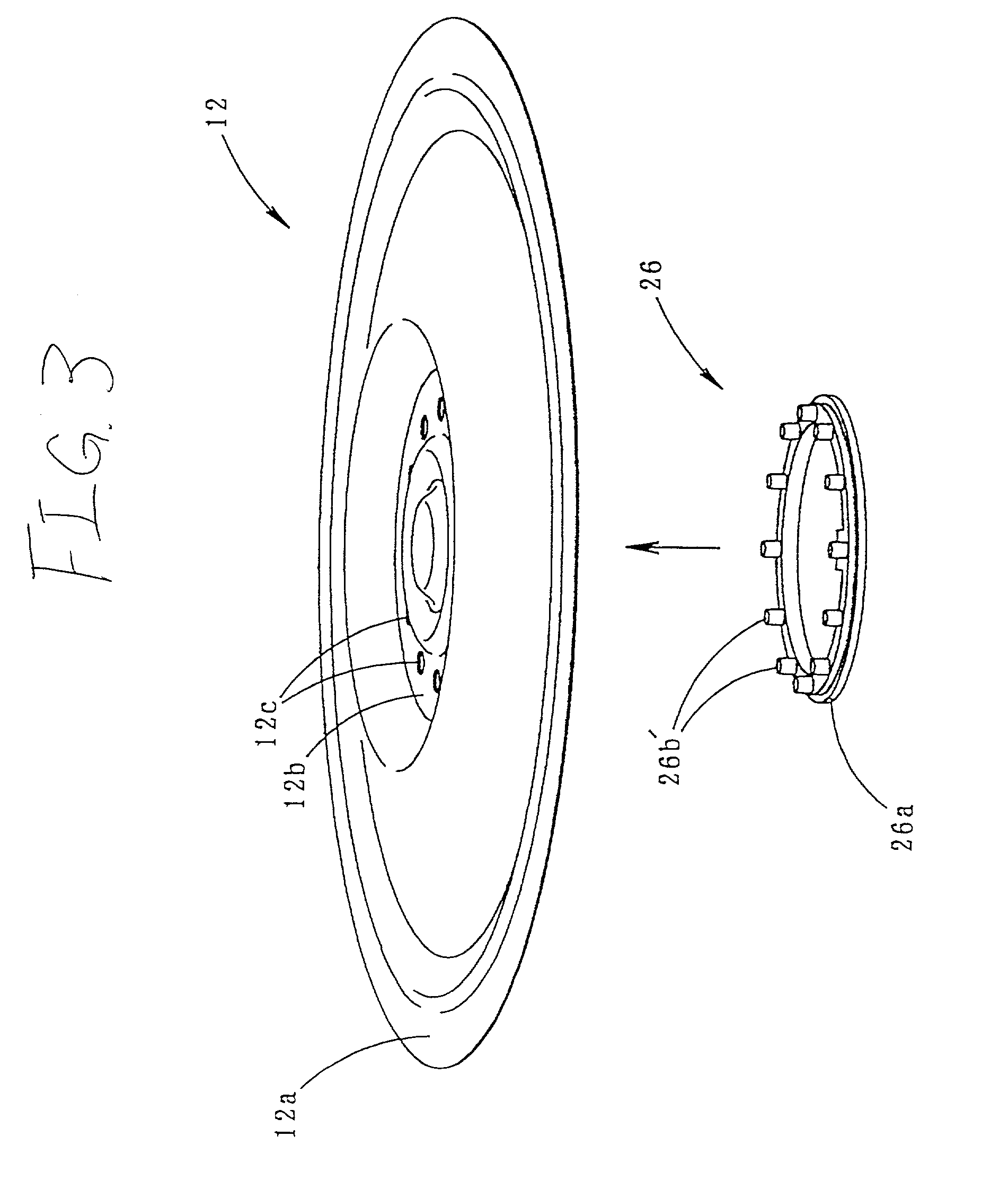

Speaker

InactiveUS20010017928A1Reliable supportImprove the fixing strengthTransducer detailsBroadcast circuit arrangementsEngineeringLoudspeaker

Fixing of a voice coil 16 to a diaphragm 12 is performed by caulk-fixing a coil supporting member 26 to the diaphragm 12 and by fit-supporting the voice coil 16 by the coil supporting member 26. Hereby, the voice coil 16 is physically fixed to the diaphragm 12 and its fixing strength is heightened. The caulk-fixing is performed by subjecting a caulking projection of the coil supporting member 26 to a plastic deformation thereby to provide a caulk-fixed portion 26b, whereby deformation injurious to the acoustic property does not occur in the diaphragm 12. Further, the fit-supporting is performed by interposing a flange portion 16a1 formed at an upper end portion 16a of the voice coil 16 between an engaging engaging portion 26a of the coil supporting member 26 and a central flat portion 12b of the diaphragm 12 and holding it by them from upper and lower sides.

Owner:STAR MICRONICS

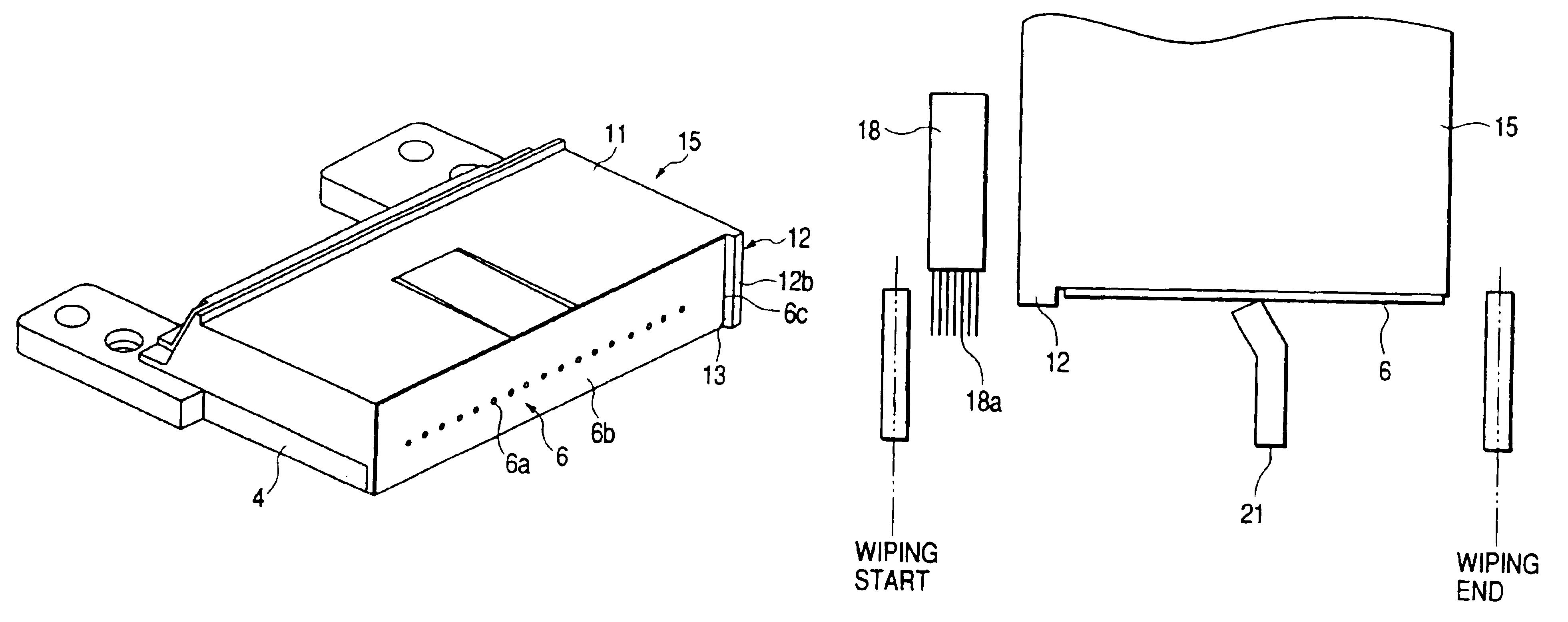

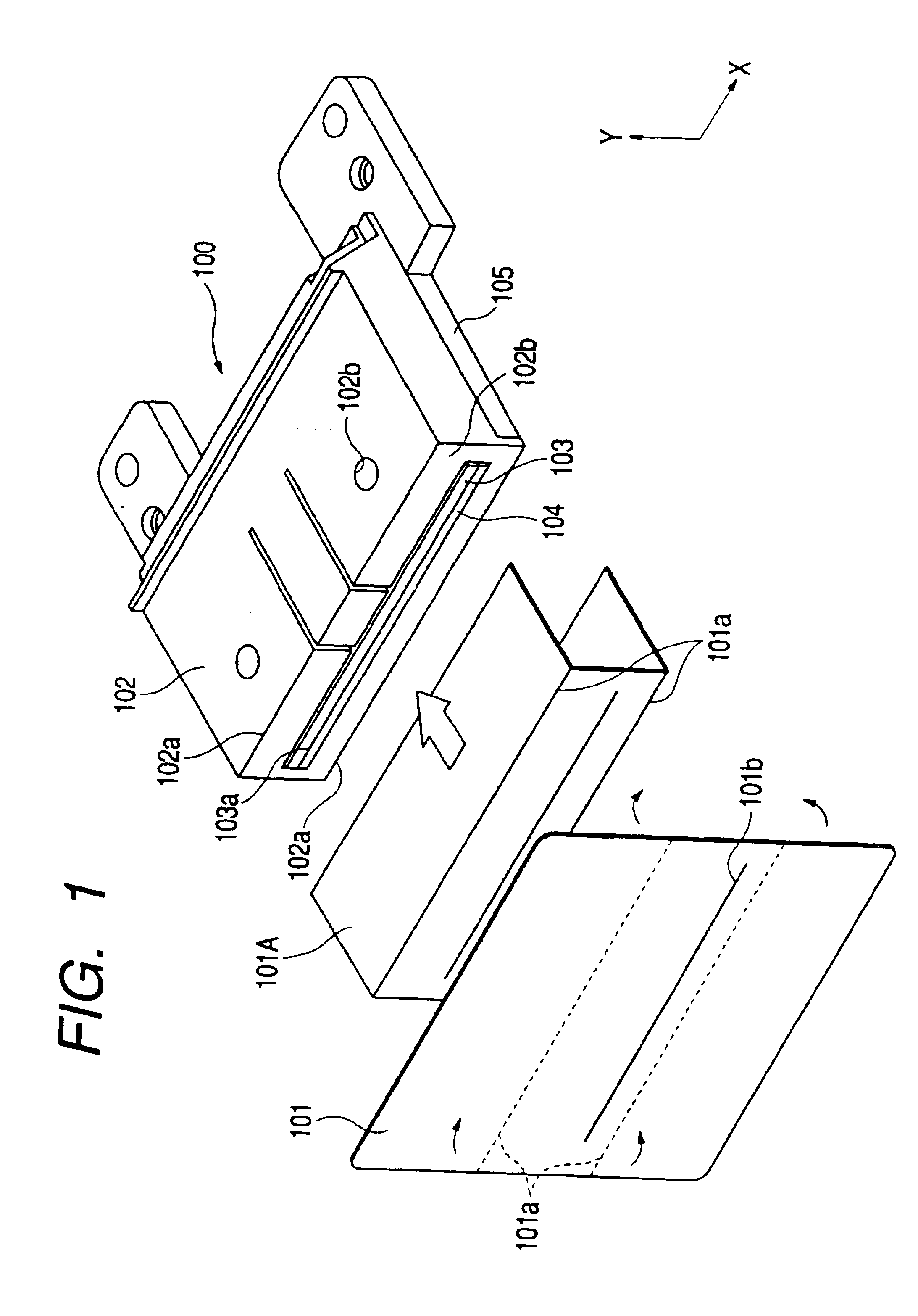

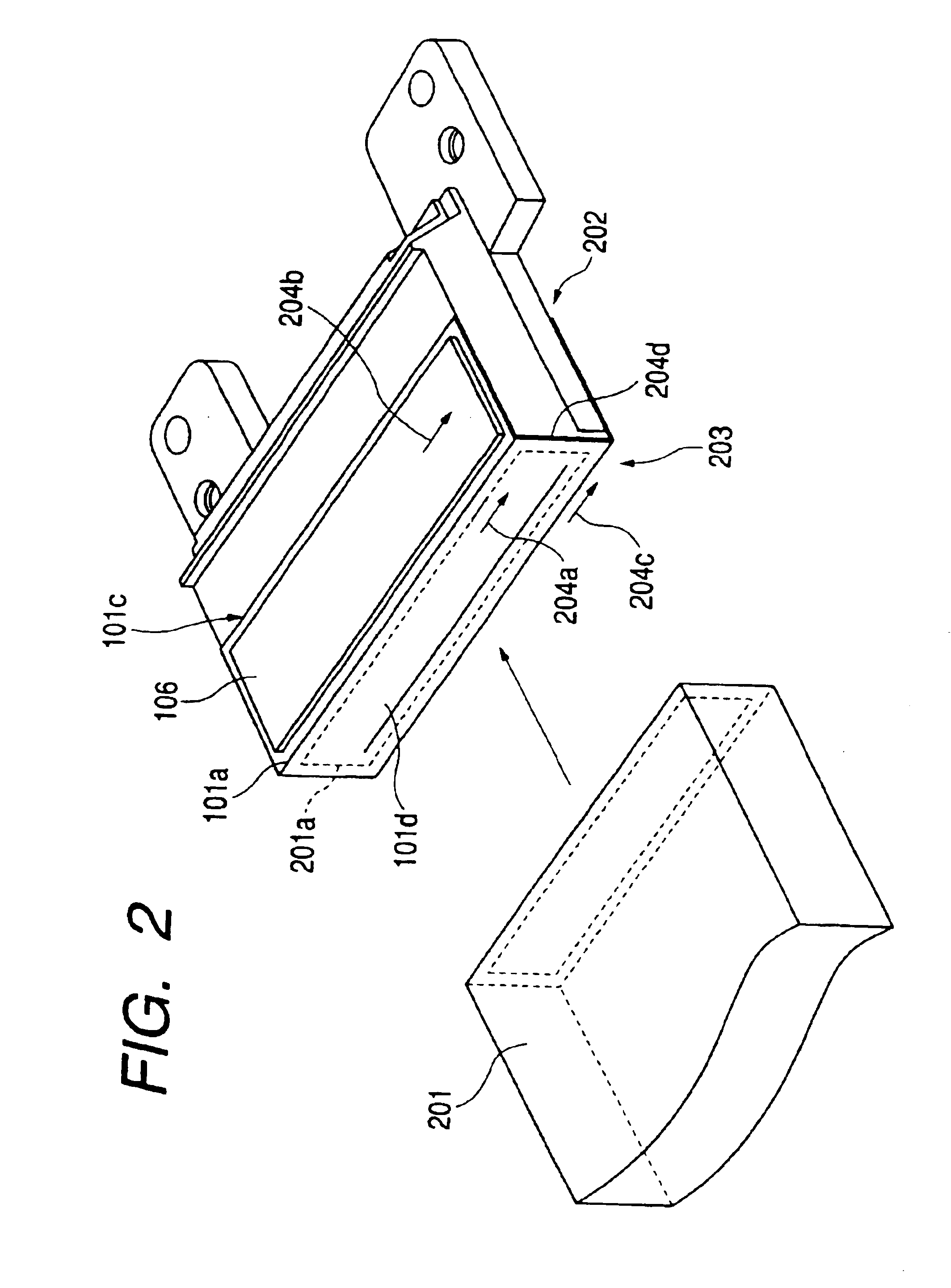

Liquid discharge recording head, liquid discharge recording apparatus, and method for manufacturing liquid discharge head

InactiveUS6975466B2Improve the fixing strengthWider capping areaMountingsPrintingVena contracta diameterOrifice plate

A liquid discharge recording head comprising a recording head main body provided with a plurality of liquid flow paths communicated with a plurality of discharge ports for discharging liquid, respectively, and energy generating means for generating energy utilized for discharging the liquid filled in the liquid flow paths from the discharge ports, and an orifice plate provided with a discharge port array having the plurality of discharge ports aligned in one straight line, and bonded to the front face of the recording head main body having openings of the plurality of discharge ports formed therefor, wherein the orifice plate is provided with the extended portion in the alignment direction of the discharge port array or in the direction orthogonal to the alignment direction, being extended more than the width of the front face of the recording head main body, and the extended portion is fixed to the adjacent face of the front face of the recording head main body.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com