Patents

Literature

422 results about "Resin bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

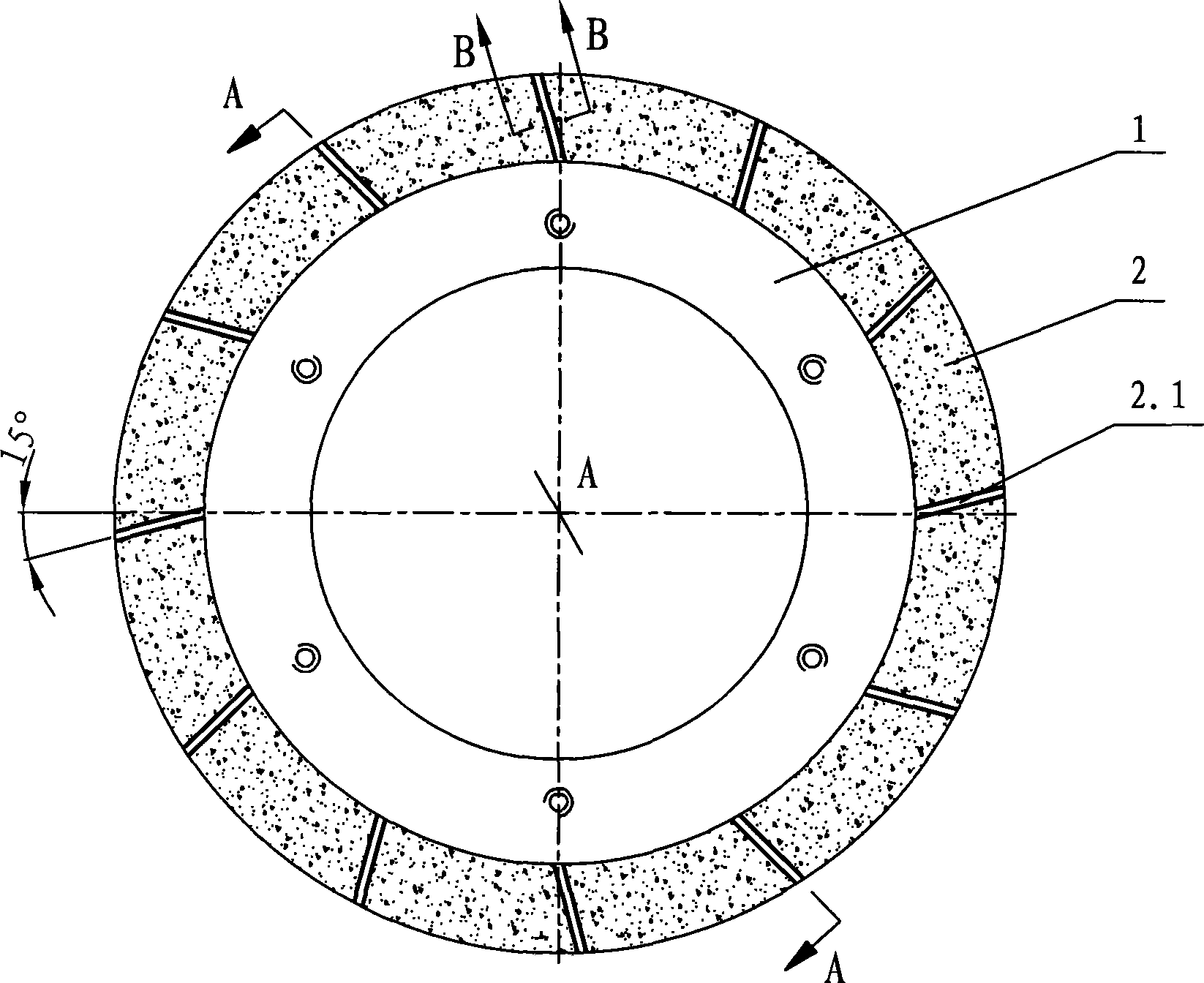

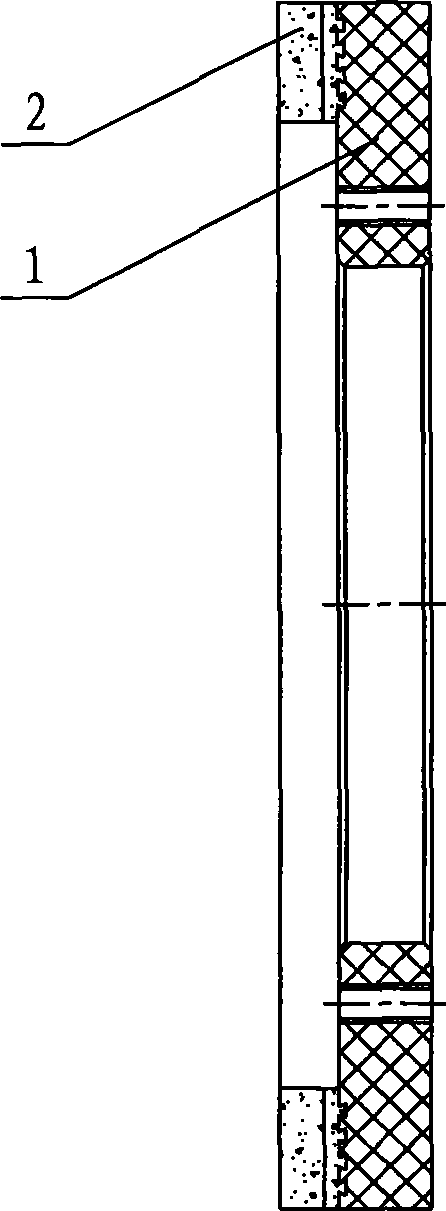

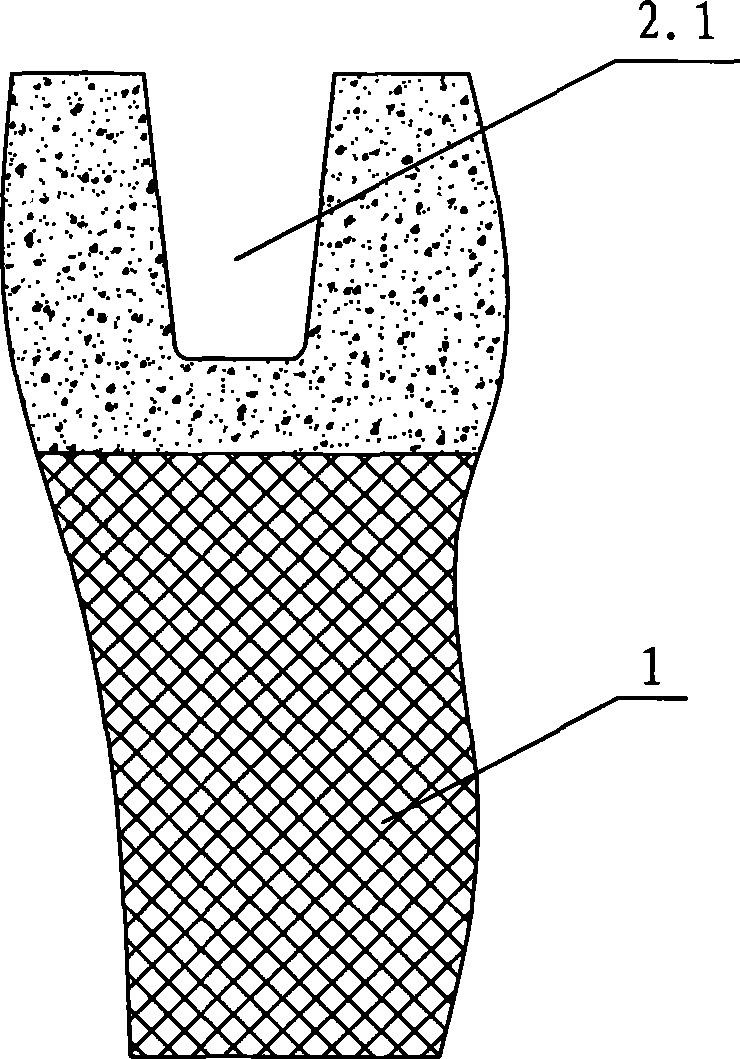

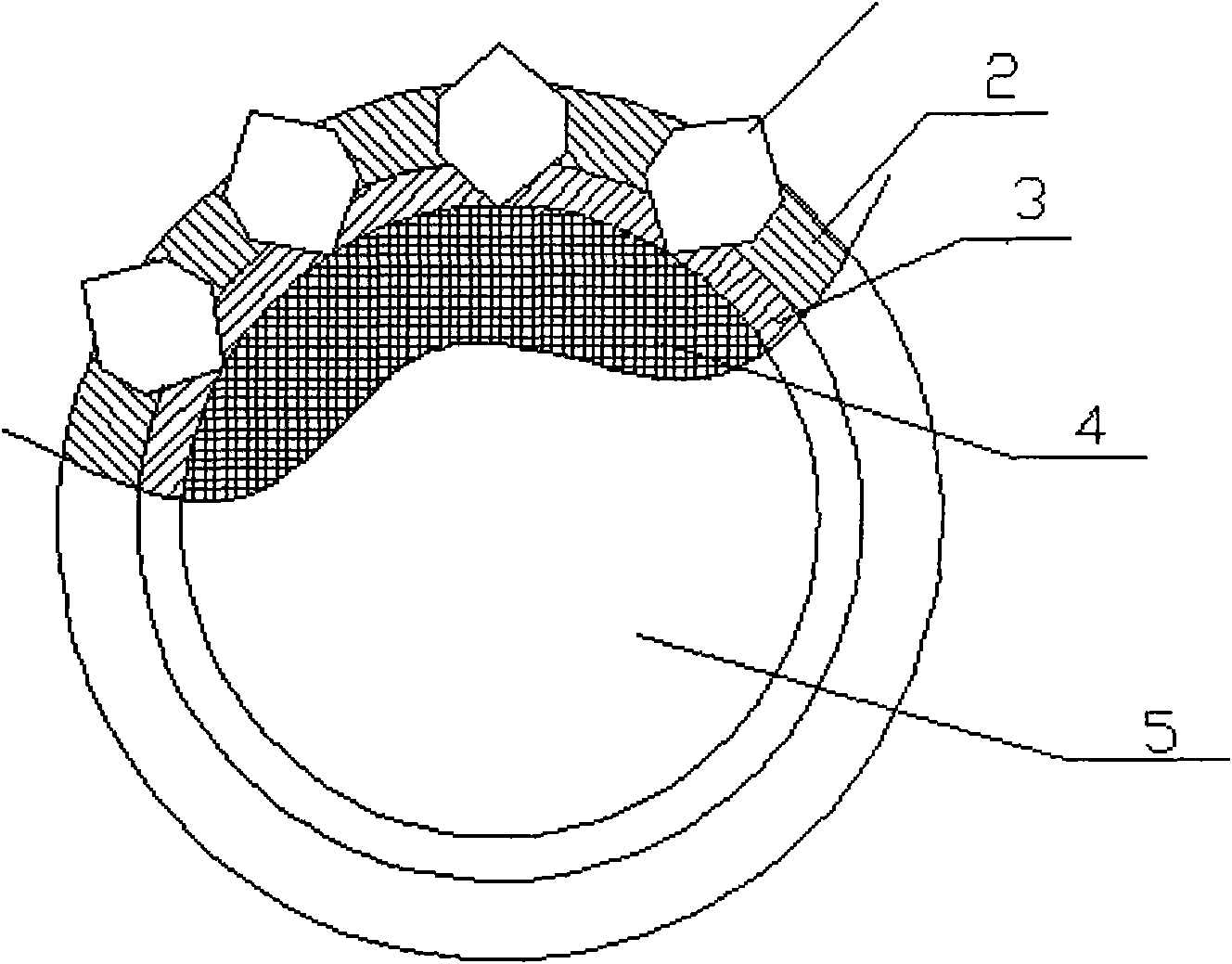

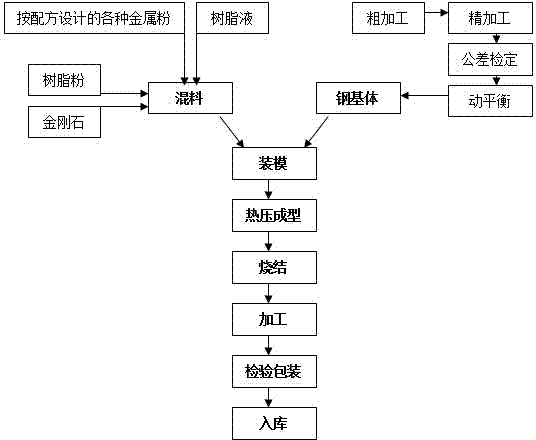

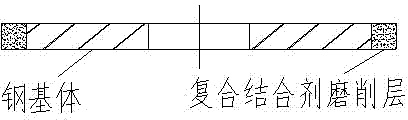

Resin anchoring agent diamond grinding wheel and production method thereof

ActiveCN101386154AIncreased durabilityImprove adhesionAbrasion apparatusGrinding devicesBoron carbideZirconia alumina

The invention relates to a resin bonding agent diamond grinding wheel and a manufacturing method thereof, and the grinding wheel comprises a grinding medium layer and a base body, wherein, the grinding medium layer is arranged on the base body and comprises diamond grinding medium, resin bonding agent, filling reinforcement which is a copper cladded iron powder and auxiliary abrasives which can be one or the combination of carborundum, boron carbide, white alundum, single alundum and fused zirconia alumina. The grinding medium layer comprises 5-15% of diamond grinding medium, 10-25% of auxiliary abrasive, 25-50% of thermosetting polyimide resin, 3-10% of copper cladded iron powder, 15-40% of silicon carbide powder and 0-8% of filling of metallic oxide in terms of volume percent. The diamond grinding wheel is characterized by low production cost, strong adhesive force, good sharpness and self-sharpness, long service life and good abrasion cutting effect.

Owner:广东奔朗新材料股份有限公司

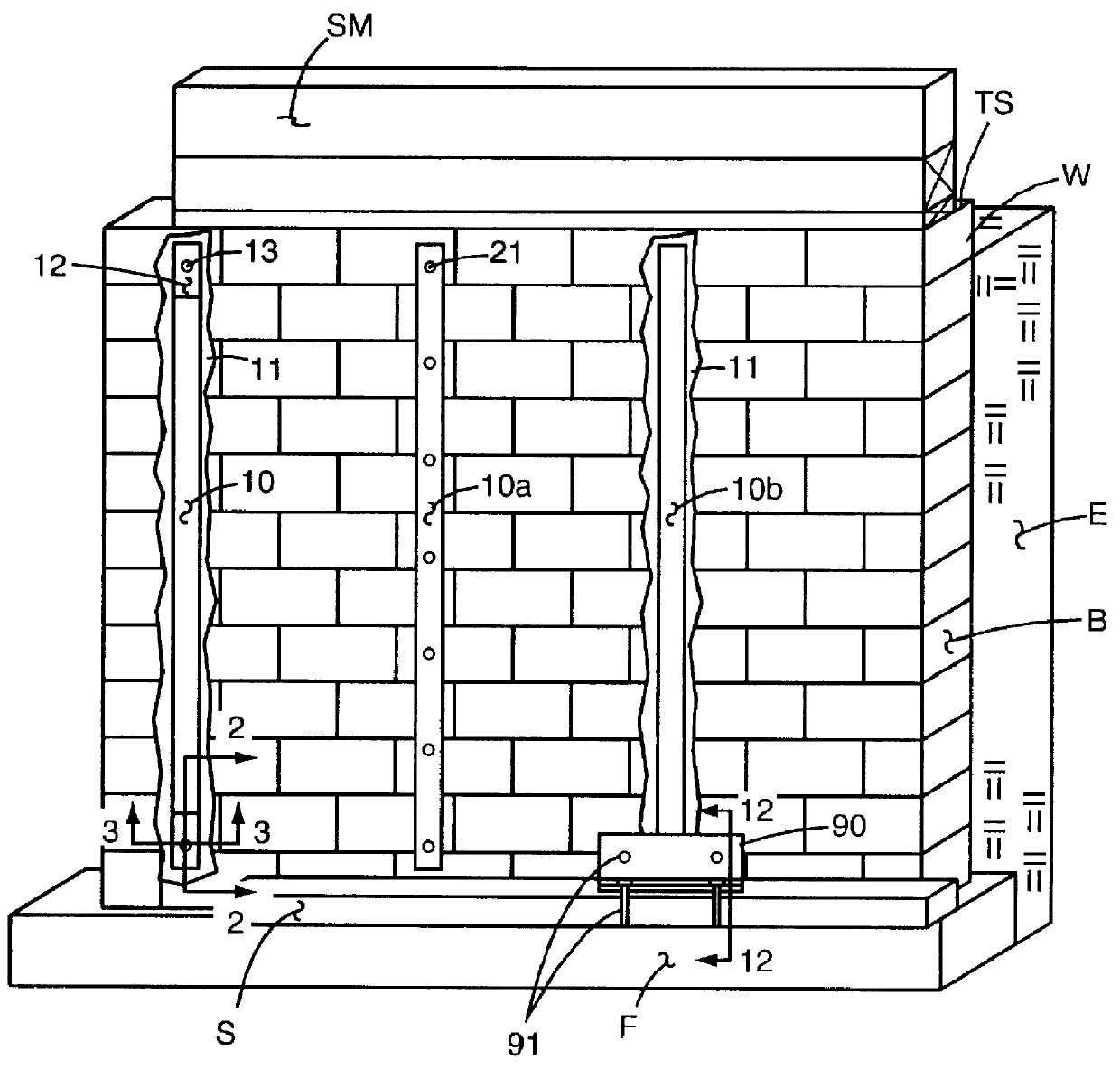

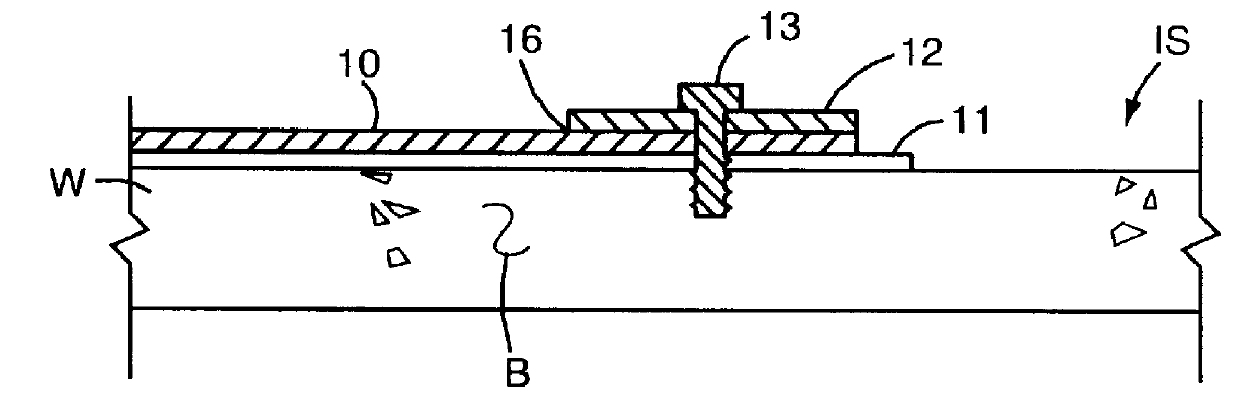

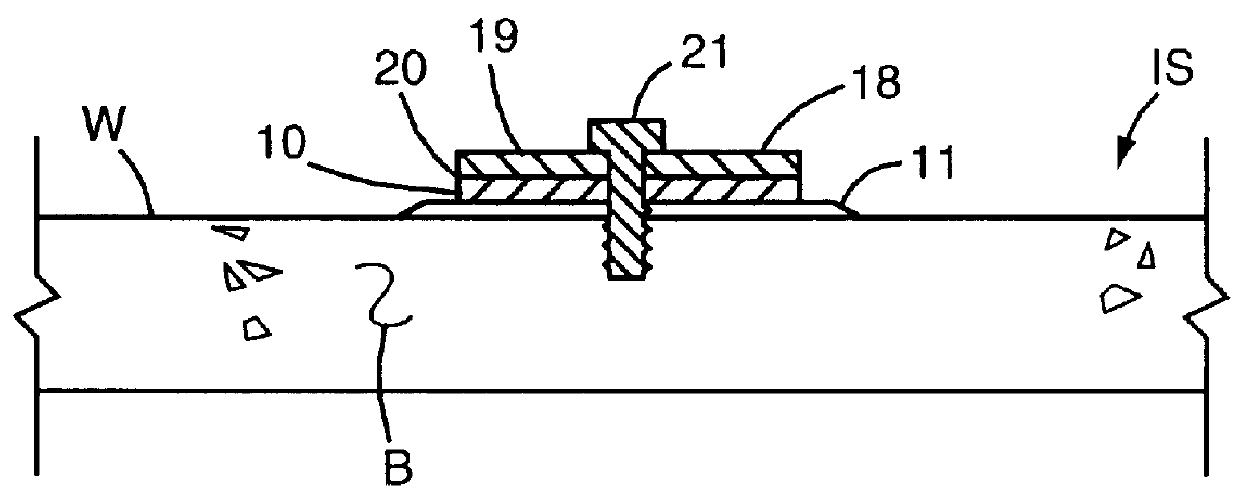

Wall reinforcing and waterproofing system and method of fabrication

A wall reinforcing system is provided for strengthening of walls formed of masonry or from wood, metal or other structural materials. A basic system comprises utilization of rigid, fiber reinforced polymer plates of a length to extend substantially the full vertical heigth of the wall. These plates incorporate a plurality of filamentary fibers of length to extend the full length of a plate with these fibers formed from carbon, glass or other material exhibiting high tensile strength and are affixed in a cured polymer matrix. A number of these plates are securely fixed to a wall in spaced parallel relationship by a resin bonding agent or by mechanical fastening devices, or by a combination of both. A plate may include a plurality of plates secured in stacked, superposed relationship and ridgidly secured together by a resin bonding agent into a unitary structure. A second system utilizes one or more sheets of flexible fabric-like material that is fabricated with tows of high tensile strength filamentary fibers of carbon, glass or other material. This fabric-like material is secured to the wall by a resin bonding agent with the tows vertically oriented thus utilizing their tensile strength for strengthening of the wall, either alone or in combination with the plates, and providing waterproofing.

Owner:NATIONWIDE REINFORCING +1

Wire saw for cutting hard and fragile materials and manufacturing method thereof

InactiveCN101564828AReduce sheddingImprove bindingAbrasion apparatusGrinding machinesCopper platingUV curing

The invention relates to a wire saw for cutting hard and fragile materials and a manufacturing method thereof. The wire saw is fixed with an grinding material on a core wire through a bonding agent and is characterized in that the bonding agent consists of an inner layer UV resin bonding agent and an outer layer heat reactive resin bonding agent; and the grinding material is evenly and continuously distributed in a monolayer mode around the core wire, partial grinding material is embedded in the UV resin bonding agent, other partial grinding material is exposed outside the heat reactive resin bonding agent to form an exit lip, and the rest part is enwrapped by the outer layer heat reactive resin. The grinding material adopts a diamond or CBN adopting surface metal plating; and the core wire adopts a copperized music wire. The manufacturing method is performed continuously and quickly according to the following steps: under the traction of a driving device, setting out the core wire continuously through a wire plate, surface preparation, cleaning, drying, coating with the inner layer UV resin bonding agent, grinding material cementation, UV curing, coating with the outer layer heat reactive resin bonding agent, thermocuring and drawing in a cable to form a plate. The wire saw and the method solve the problem of driving aspects before cured resin is completely cured, and can effectively solve the problem that the grinding material in the prior art is easy to agglomerate.

Owner:NANJING NORMAL UNIVERSITY

high-filling-content micro-nano powder/polymer composite material for 3D printing and preparation method and product thereof

ActiveCN103980592AEnhanced interactionImprove performance3D object support structuresCross-linkAntioxidant

The invention relates to a high-filling-content micro-nano powder / polymer composite material for 3D printing and a preparation method and a product thereof. The material contains the following raw materials, by weight, 10-30 parts of a polymer, 90-70 parts of a micro-nano powder, 0.05-0.2 part of an irradiation sensitizer and 0.01-0.02 part of an antioxidant. The micro nano powder is used as a main material and polymer resin is used as a binding agent, and moulding is finished by a 3D printing mode. Simultaneously, the irradiation sensitizer is added, and the polymer resin forms a three-dimensional cross-linked network after electron beam irradiation. Then, strength, heat resistance and chemical corrosion resistance are raised after resin bonding. The high-filling-content micro-nano powder endows the moulding material with excellent mechanical properties. In addition, according to changes of product usage environment and demand, types of the micro-nano powder are changed so as to obtain a material with special functionality, such as excellent conductivity, thermal conductivity, flame resistance, impact resistance and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Resin metal composite bonding agent and composite bonding agent diamond grinding wheel

InactiveCN102350667AImprove temperature resistanceGood self-sharpeningAbrasion apparatusGrinding devicesNumerical controlHeavy load

The invention belongs to the field of diamond grinding wheels, and in particular relates to a resin metal composite bonding agent and a composite bonding agent diamond grinding wheel prepared by adopting the resin metal composite bonding agent. The resin metal composite bonding agent consists of the following raw materials in percentage by weight: polyimide resin powder, copper powder, tin powder, zinc powder, phosphorus powder and lead powder; and the composite bonding agent diamond grinding wheel consists of the following raw materials: 65 to 85 volume percent of composite bonding agent, 15to 35 volume percent of diamond abrasive, and 0.5 to 1 volume percent of resin liquid. When the diamond grinding wheel prepared by adopting the resin metal composite bonding agent is used on a numerical control grinder, the diamond grinding wheel has the original characteristics of high grinding efficiency and good self-sharpening property of a resin bonding agent diamond grinding wheel and also has the advantages of high rigidity, high heat resistance and good profile retaining property of a metal bonding agent diamond grinding wheel, one-way cutting depth of heavy-load powerful grinding canreach 6 millimeters, and the comprehensive economic benefit can be improved by over 100 percent.

Owner:SUZHOU SAILI PRECISION TOOLS

Uv-curable optical resin adhesive composition

InactiveUS20120115976A1Increased durabilityImprove reliabilityEster polymer adhesivesOrganic non-macromolecular adhesiveMeth-Side chain

A UV-curable optical resin adhesive composition is provided, which is excellent in transparency, adhesive reliability and durability and suitable for rework (repair) without an adverse influence on the brightness, the contrast and the Quality of a display image. The UV-curable optical resin adhesive composition is used for filling a gap between an image display panel and a protective cover plate, and comprises: (A) an acryl polymer having a (meth)acryloyl group at its side chain; and (B) a photopolymerization initiator.

Owner:NITTO DENKO CORP

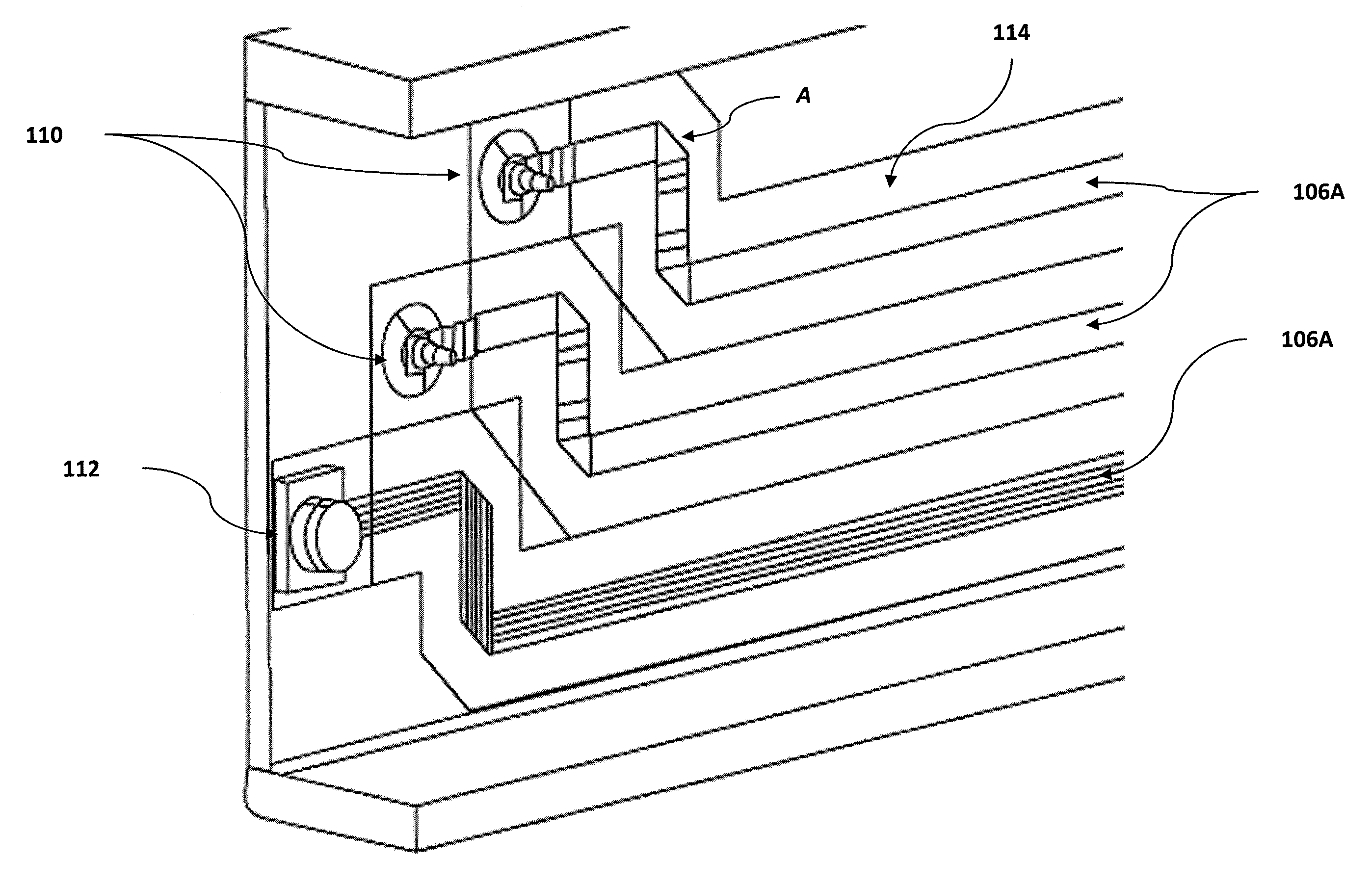

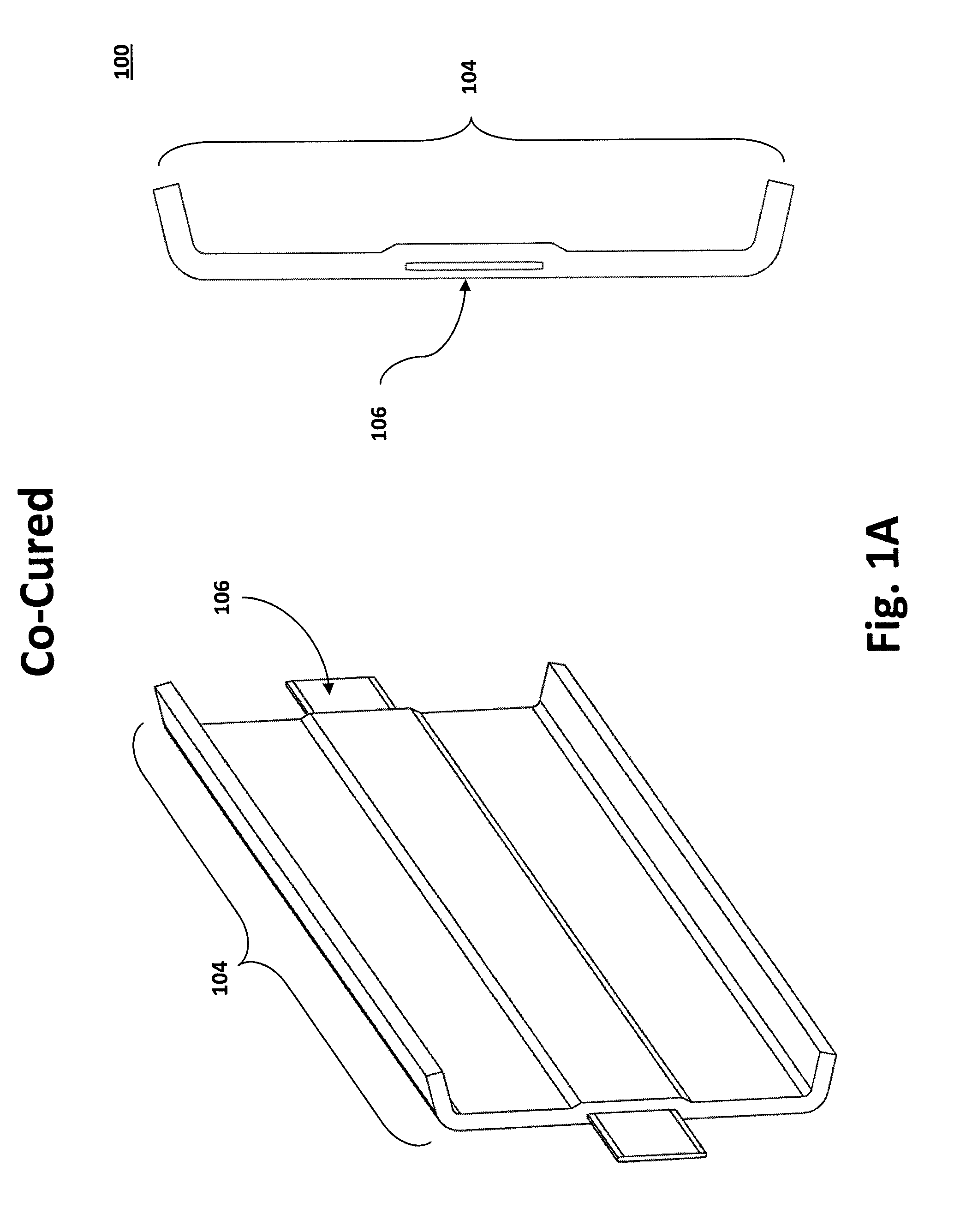

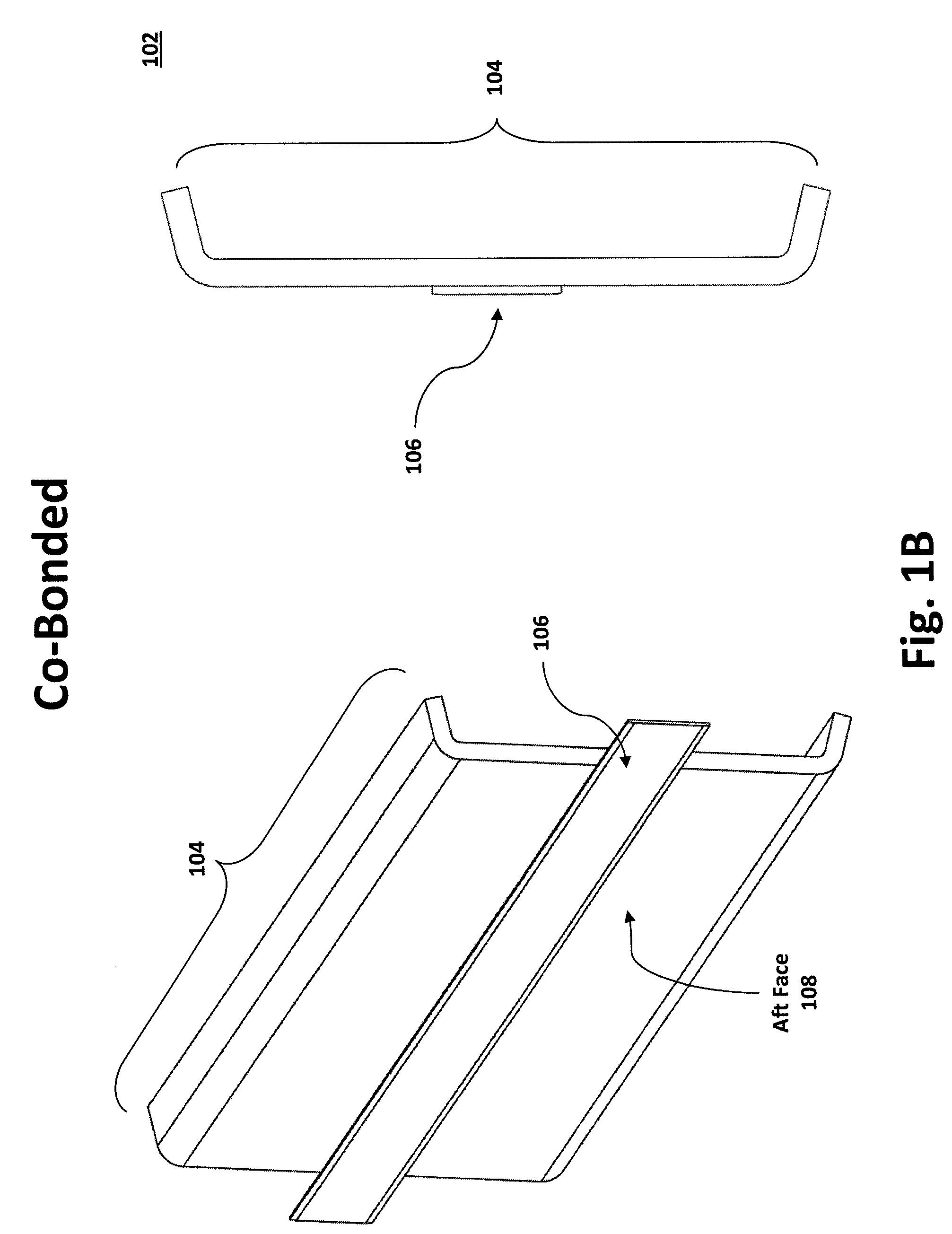

Apparatus and method for an aircraft conductor sandwich assembly embedded to an aircraft structure

ActiveUS8937254B2Reduce eliminateReduce weightElectric power distributionLaminationElectrical conductorStructural engineering

An aircraft conductor sandwich assembly configured to be embedded in a composite aircraft structure. The conductor sandwich assembly comprises a plurality of carbon conductors disposed between two sheets of insulating layers and an adhesive resin bonding the plurality of carbon conductors and the two sheets of insulating layers into a carbon sandwich assembly such that (i) the conductors are electrically isolated and (ii) structural loads can be passed through said conductor sandwich assembly.

Owner:AURORA FLIGHT SCI CORP

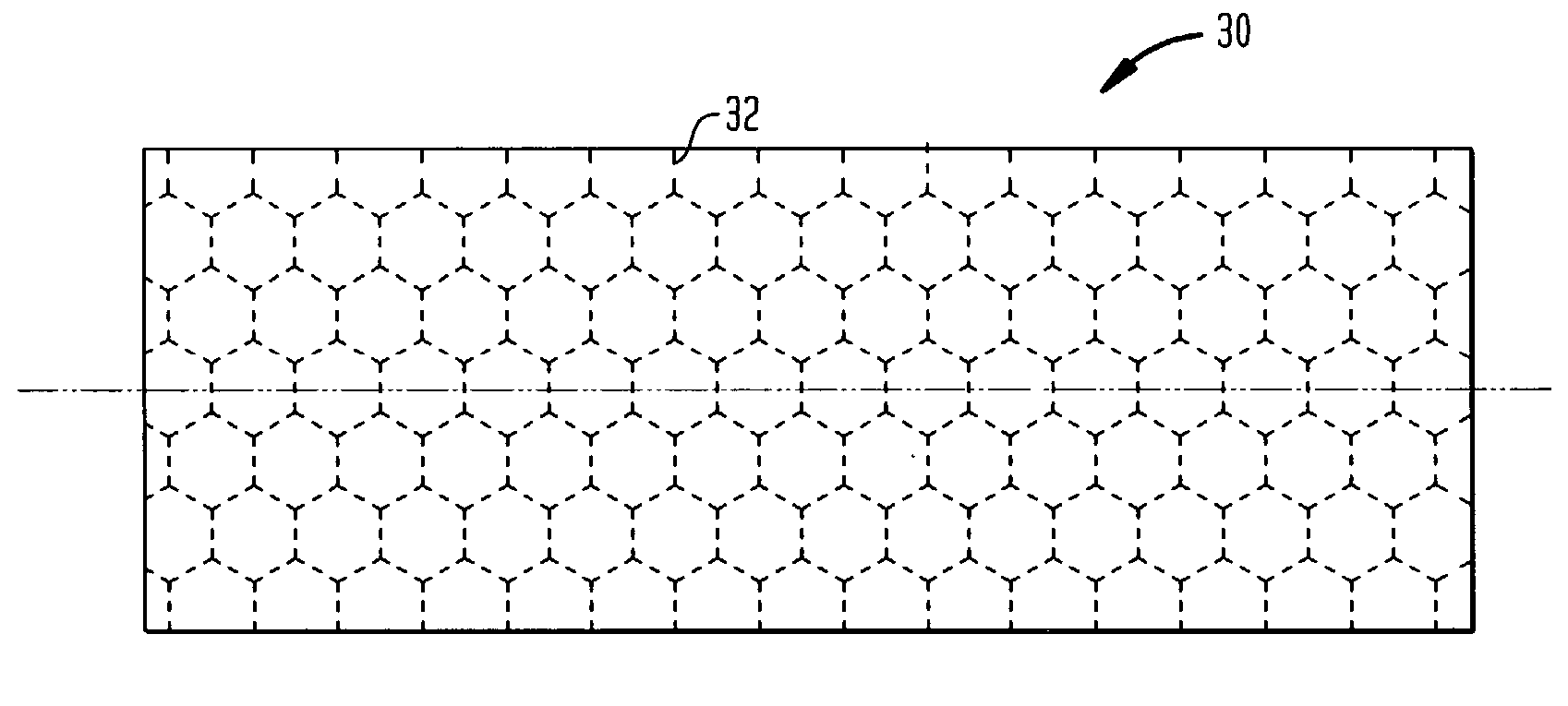

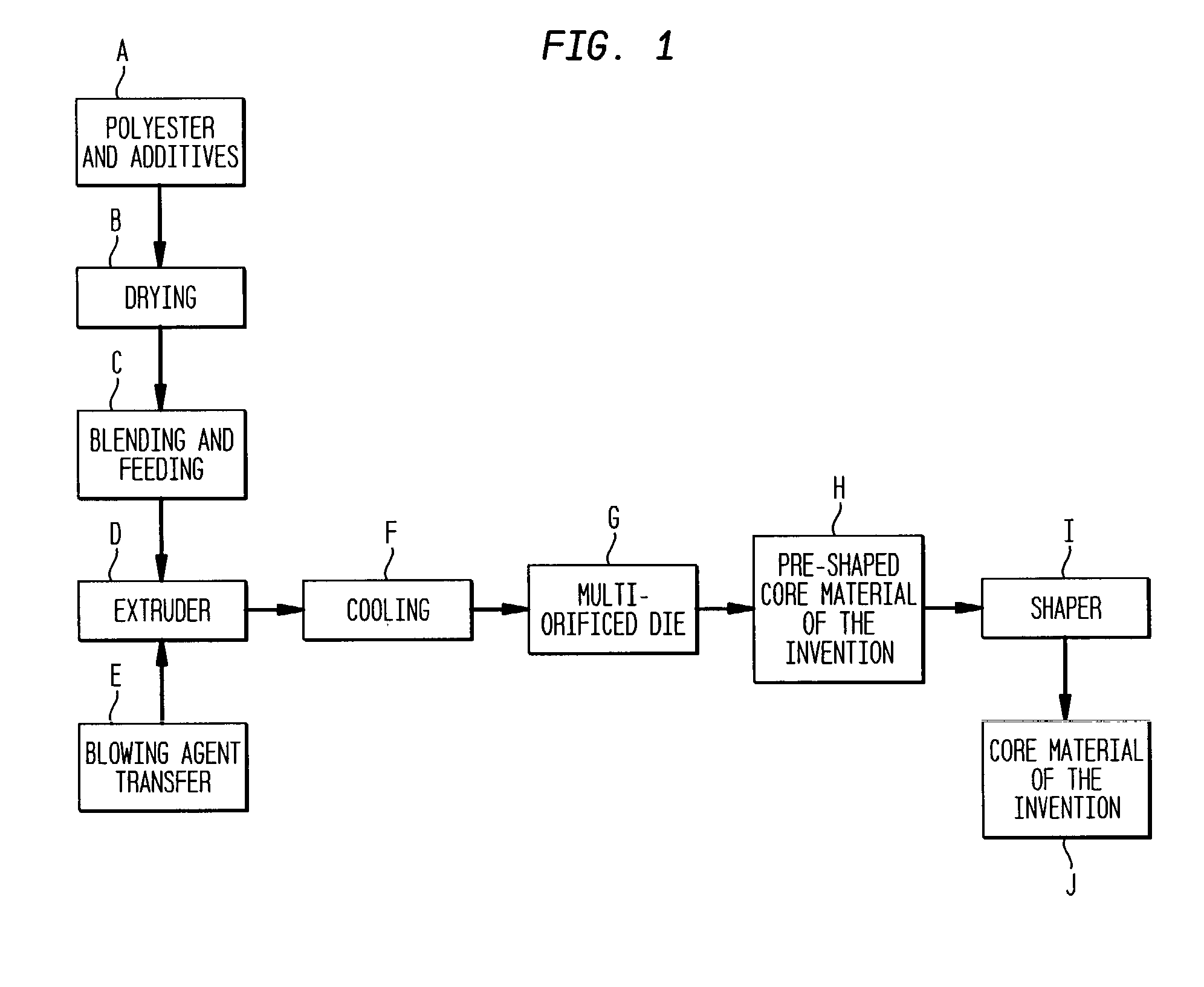

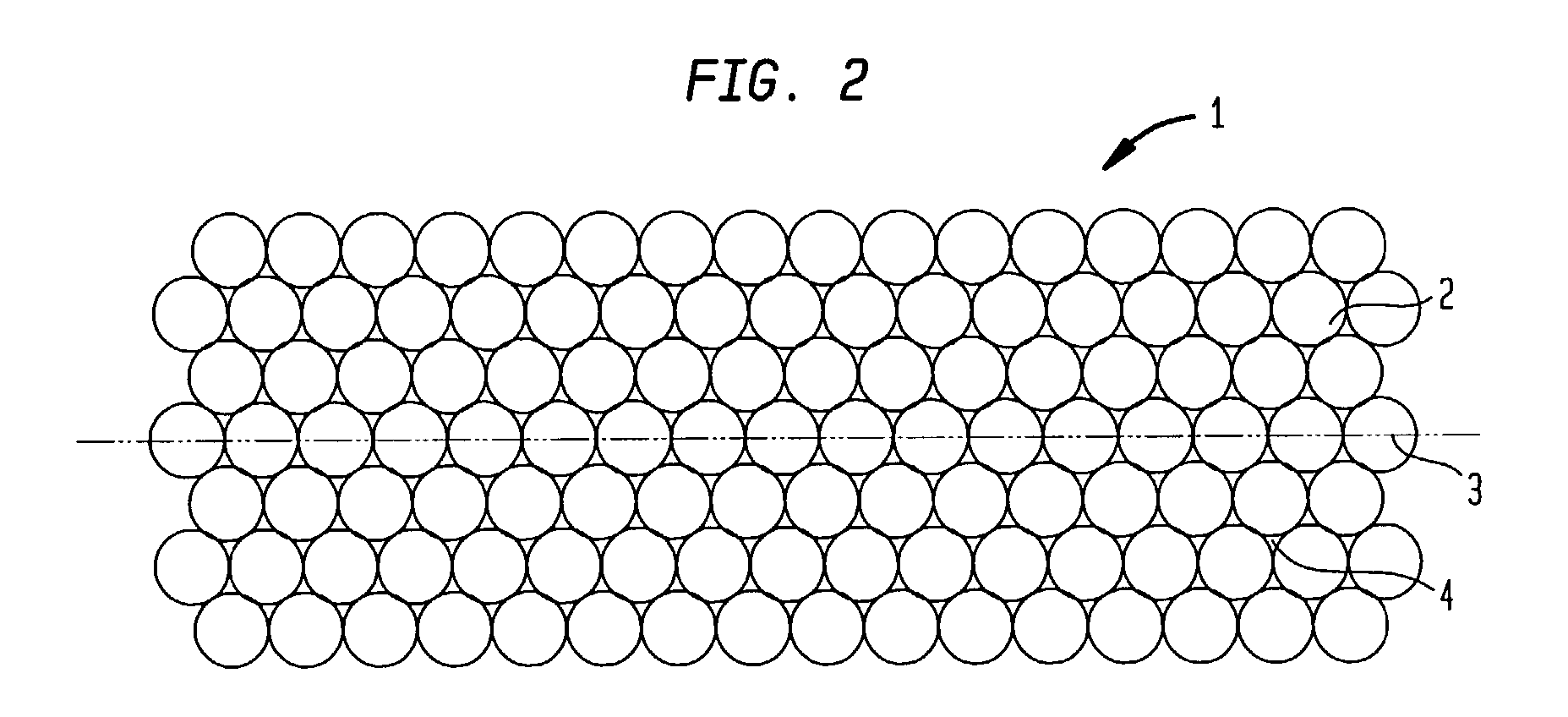

Polyester core materials and structural sandwich composites thereof

ActiveUS20040001946A1Increase resistanceImprove pressure resistanceSynthetic resin layered productsBuilding componentsPolyesterHigh intensity

High-strength, chemically and thermally stable, closed-cell foams, useful as structural core materials in sandwich composites. The core materials of the invention display anisotropic properties. The core materials of the invention are amenable to vacuum-mediated resin bonding to composite skins to provide lightweight, high-strength structural sandwiches suitable for use in a variety of applications, such as marine applications, construction, aviation, rapid transit, and recreational vehicles.

Owner:AIREX

Water gap lining layer material for continuous casting

The invention discloses a water gap lining layer material for continuous casting. The material is prepared from the following components in percent by weight: 20-60 percent of corundum, 0-30 percent of electrofusion zirconium mullite, 0-40 percent of fused silica, 3-40 percent of ceramic hollow sphere, 1-10 percent of light burning alumina, 2-6 percent of sintering assistant, 2-6 percent of phosphate bonding agent and 4-8 percent of solid phenolic resin bonding agent. A water gap for continuous casting produced by adopting the material is suitable for cold casting, and a lining basically has no nodule blocking phenomenon; the lining has high strength and does not have phenomena of chambering and abnormal erosion; a water gap has long service life; and the continuous casting production efficiency is improved.

Owner:SHANGHAI BAOMING REFRACTORIES CO LTD

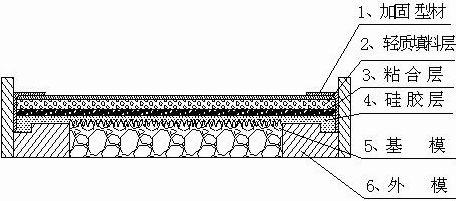

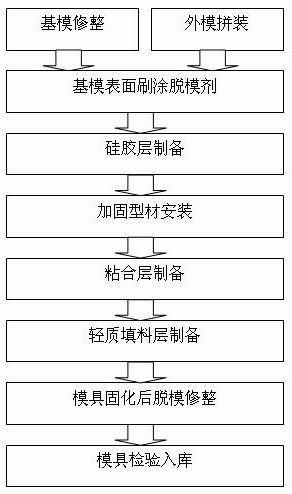

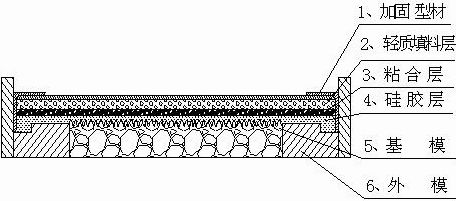

Die for building materials products and preparation method thereof

The invention discloses a die for building materials products and a preparation method thereof. The die provided by the invention contains a preformed female die and is prepared by the following steps of: cleaning the female die by an air pump, coating a mold releasing agent on the surface of the female die, uniformly laying a silica gel surface layer on the surface of the female die coated with the mold releasing agent to form a nonstick material surface layer, placing a bar of angle iron at each long side of the die; successively laying a silica gel bonding coat and a layer of gauze on the silica gel surface layer after its gelation, laying an epoxy resin bonding layer and a layer of glass fiber grid cloth after coagulation of the silica gel bonding layer to form a bonding layer; laying an insulation plate and flat iron on the bonding layer, pressing tightly by using a steel plate and simultaneously installing seal section bars at the four corners of the die; laying epoxy resin mortar on the surface of the insulation plate to form a light filling layer; laying a layer of glass fiber biaxial cloth on the light filling layer, and laying an epoxy adhesive coat on the glass fiber biaxial cloth to form a hard base material. The die provided by the invention has a simple structure, is easy to demould, and can be used to effectively guarantee the quality of moulded products. In the meantime, the preparation method provided by the invention is convenient to operate, requires low cost, and is easy to maintain.

Owner:ENERGY EFFICIENCY TECH

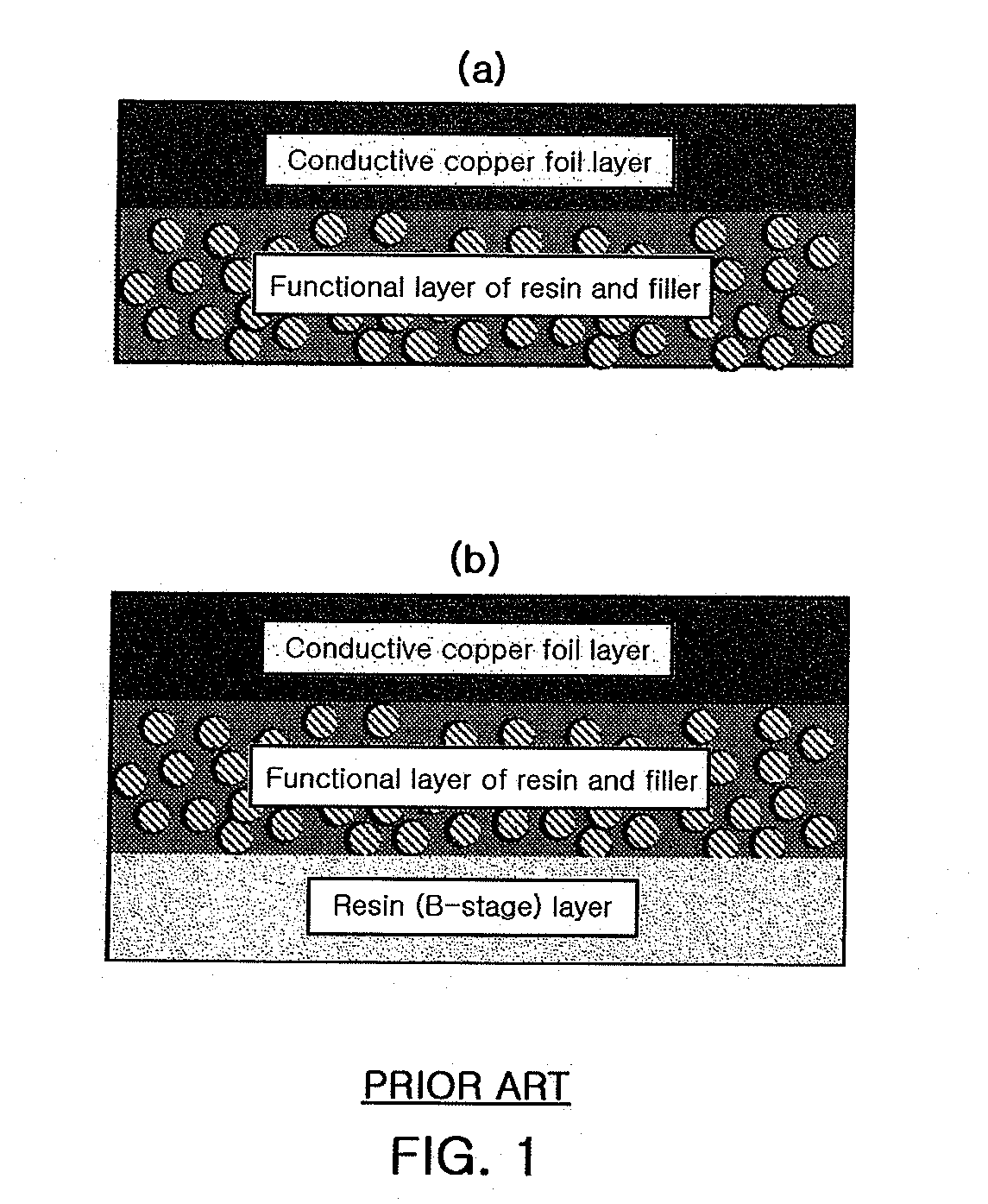

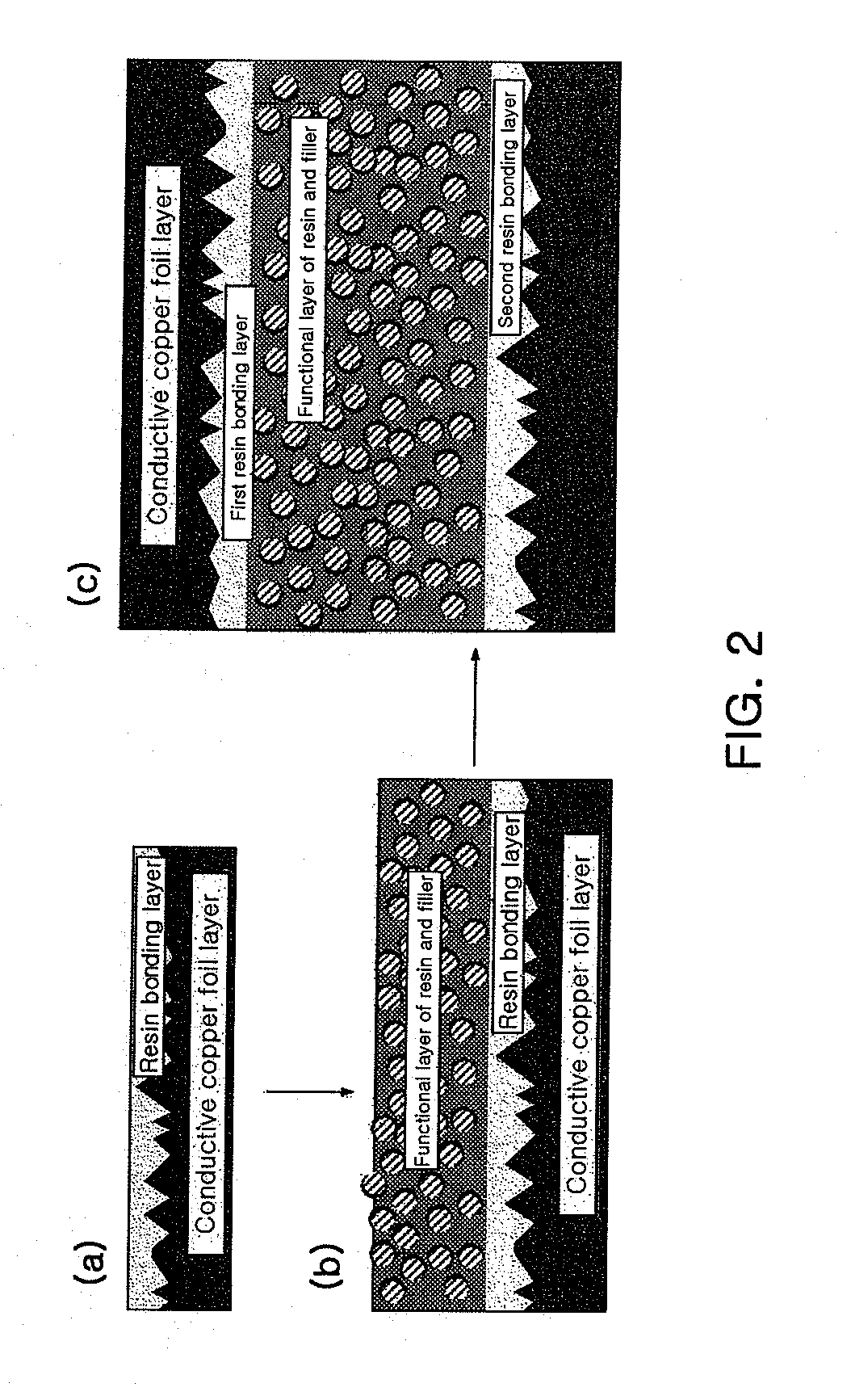

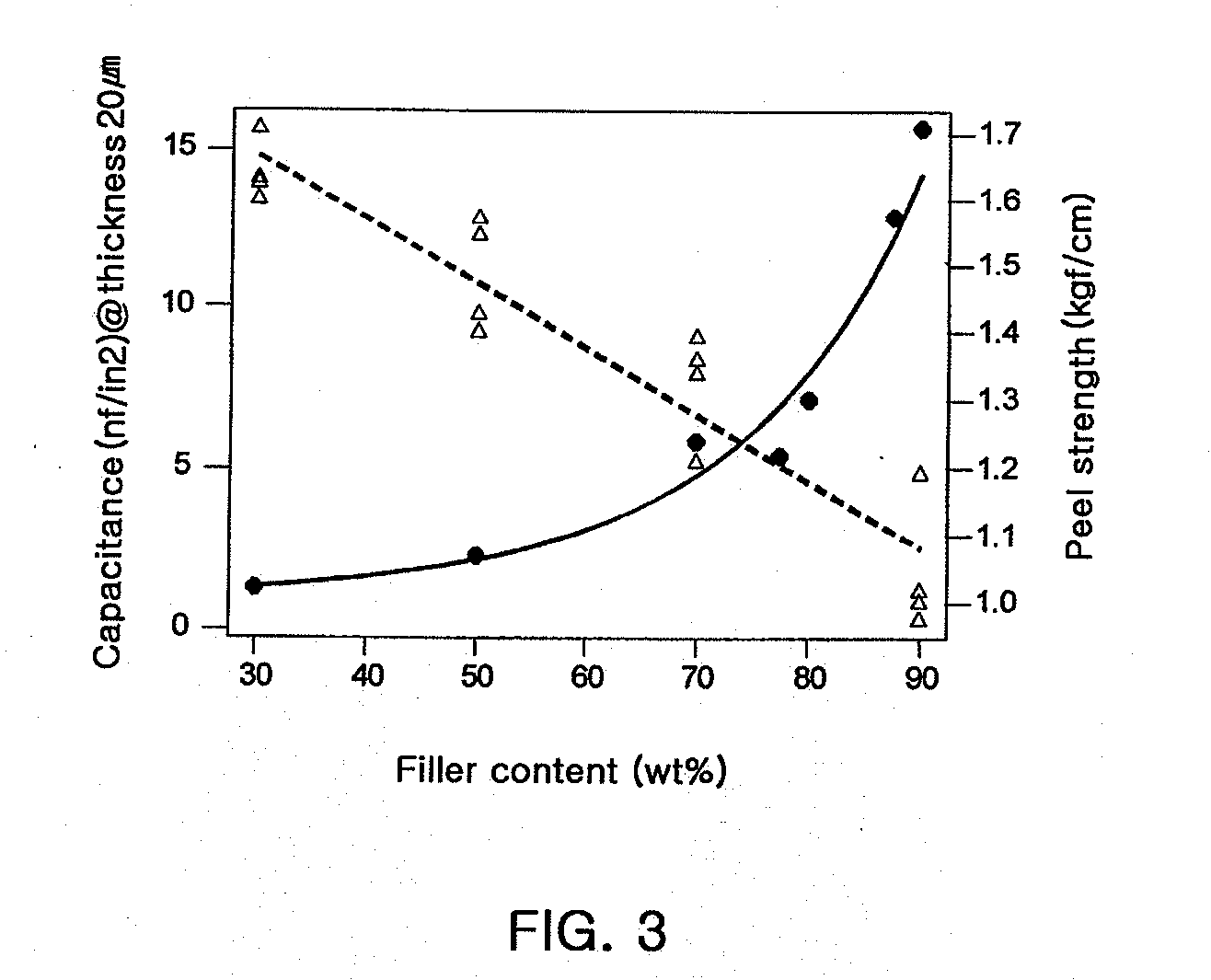

Printed circuit board material for embedded passive devices and preparing method thereof

InactiveUS20070148421A1Excellent electromagnetic property and reliabilityExcellent in dielectric and magnetic property and adhesion strengthPorous dielectricsPrinted capacitor incorporationCopper foilResin bonding

A printed circuit board material for embedded passive devices, which has excellent electromagnetic properties and reliability is provided. The invention provides a printed circuit board material comprises: a conductive copper foil layer; a resin bonding layer formed on the conductive layer and including above 70-100 vol % of resin and 0-30 vol % of filler; and a functional layer formed on the resin bonding layer and including resin and filler. The printed circuit board material has the resin bonding layer interposed between the copper foil layer and the functional layer. Thus, even when the content of fillers in the functional layer is increased, the adhesion strength between the conductive layer and the functional layer is ensured without deteriorating the properties of the functional layer, such as dielectric and magnetic properties.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

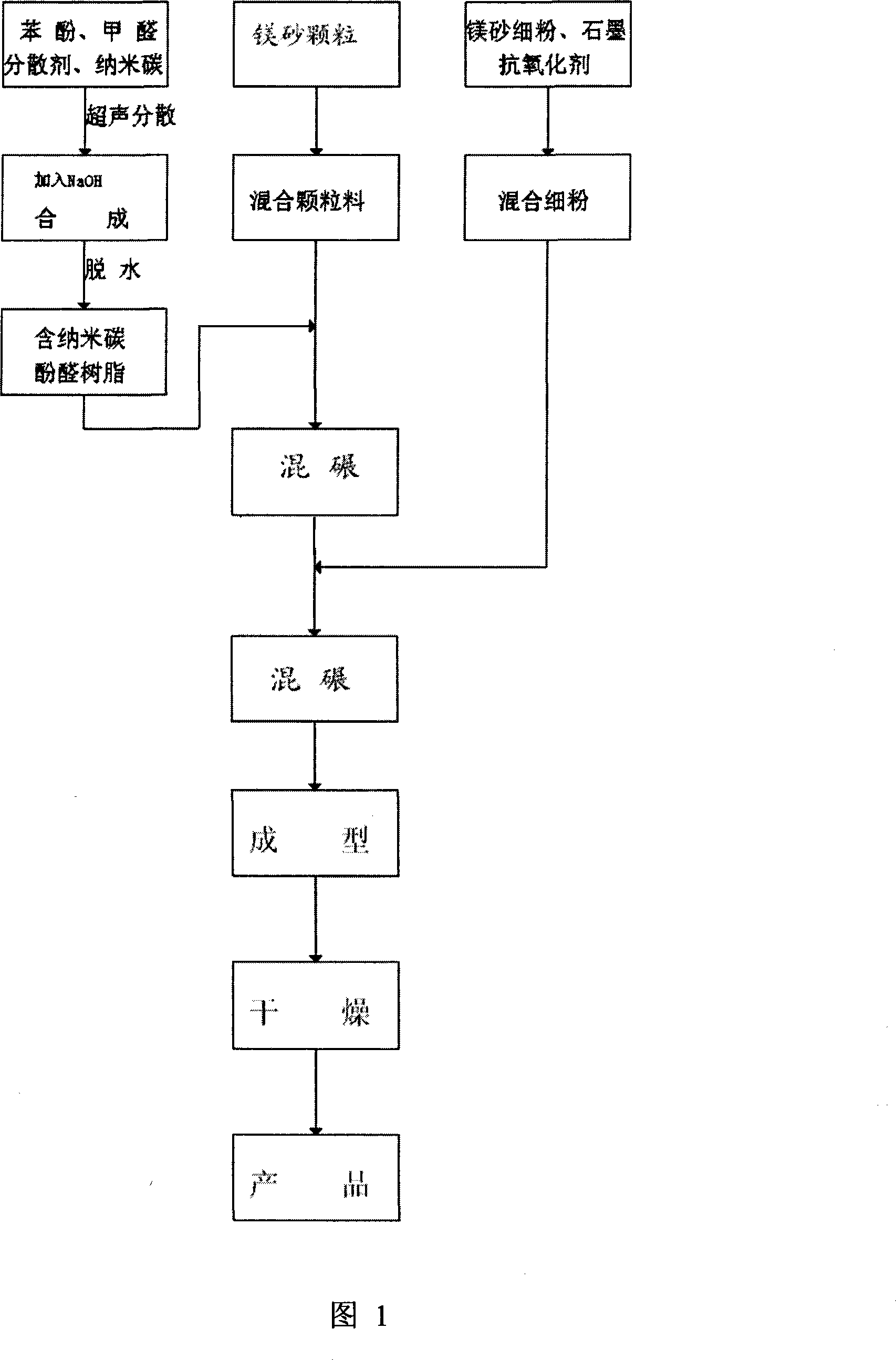

Phenolic resin containing nano-carbon powder, nano-carbon modified low carbon magnesium carbon brick and production method thereof

The invention relates to a low-carbon MgO-C brick containing modified phenolic resin and nanocarbon which are produced by nano carbon powder and a preparation method thereof. Phenolic resin bonding agent containing nano carbon powder is produced by ohenol, formaldehyde, a dispersant and nano carbon powder; the low-carbon MgO-C brick is produced by adopting fused magnesite, graphite, phenolic resin and an antioxidant as raw materials. The ultrasonic dispersion method adopted by the invention replaces partial graphite with the nano carbon powder and leads the nano carbon powder into the low-carbon MgO-C brick, thus obviously improving the anti-erosion ability and the oxidation resistance of the MgO-C brick. The brick has comparatively low thermal expansion coefficient, low thermal conductivity, low oxidative mass loss and thinner decarburized layer; a slag resistance experiment under conditions of 1600 DEG C, 3h heat preservation and carbon sequestration shows that erosion and osmosis phenomenon of the brick are not obvious, thereby being applicable to sites of converters, electric furnaces and ladle working linings, external scouring of furnaces, key components for continuous castings and refractories for blast furnace ironmaking etc., thus having comparatively large application range.

Owner:ZHENGZHOU UNIV +1

Method for preparing tungsten carbide abrasion resistant composite coating by penetration brazing method

ActiveCN101637838AHigh bonding strengthFast heat conductionSoldering apparatusWelding/soldering/cutting articlesEpoxyBond interface

The invention relates to a method for preparing tungsten carbide abrasion resistant composite coating by a penetration brazing method, belonging to the field of coating preparation in materials processing engineering. The invention comprises the following steps: (1) pasting coating metal powder cloth containing tungsten carbide-cobalt (WC-Co), nickle (Ni) and chromium (Cr) mixed powder on a metalsubstrate by using epoxy resin bonding agent; (2) preparing welding material metal powder cloth from BNi-2 brazing material and pasting the welding material metal powder cloth on the coating metal powder cloth obtained in the step (1); and (3) carrying out penetration brazing in a vacuum furnace to form a metallurgical bonded interface. The tungsten carbide abrasion resistant composite coating canbe applicable to protection of mechanical elements in the field of generating plant, petroleum, aviation, food, plastics and the like.

Owner:JIANGXI HENGDA HI TECH CO LTD

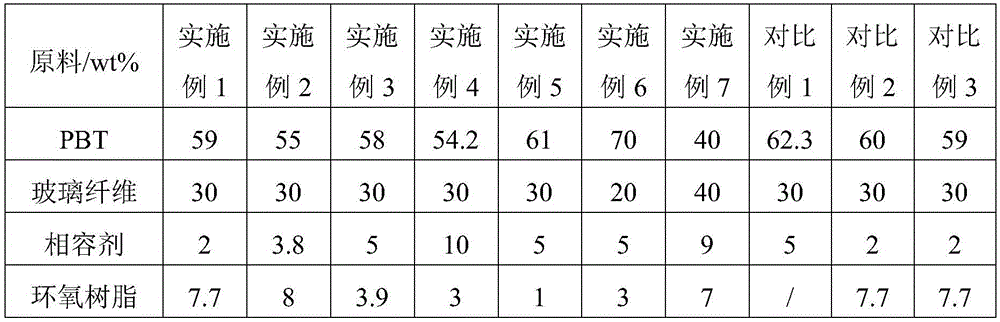

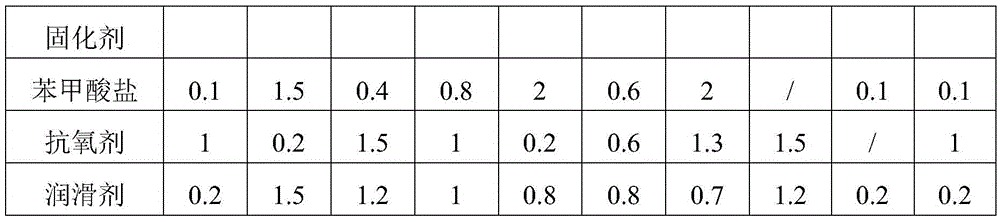

A kind of PBT material with good epoxy resin adhesion and preparation method thereof

Owner:上海日之升科技有限公司

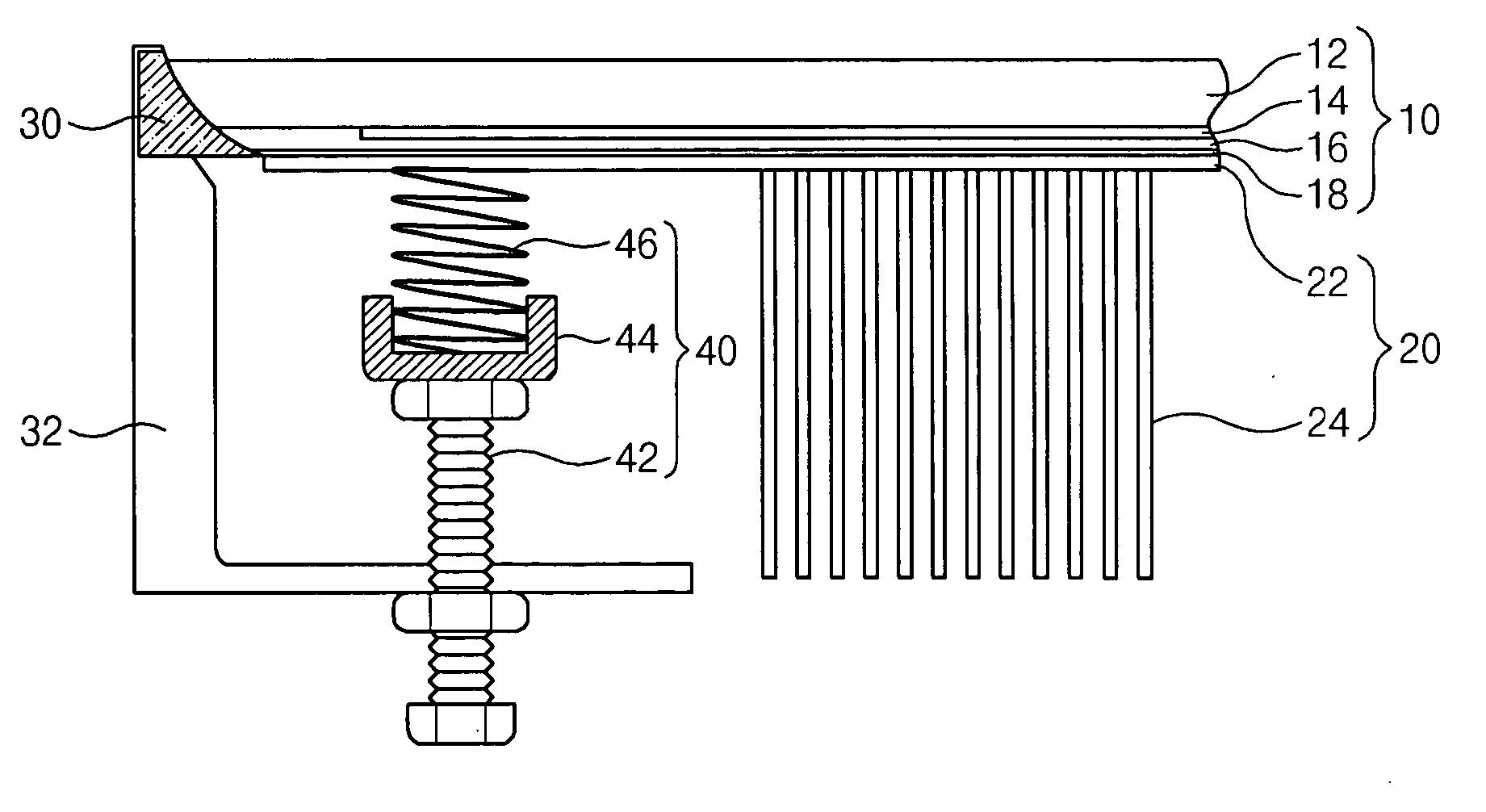

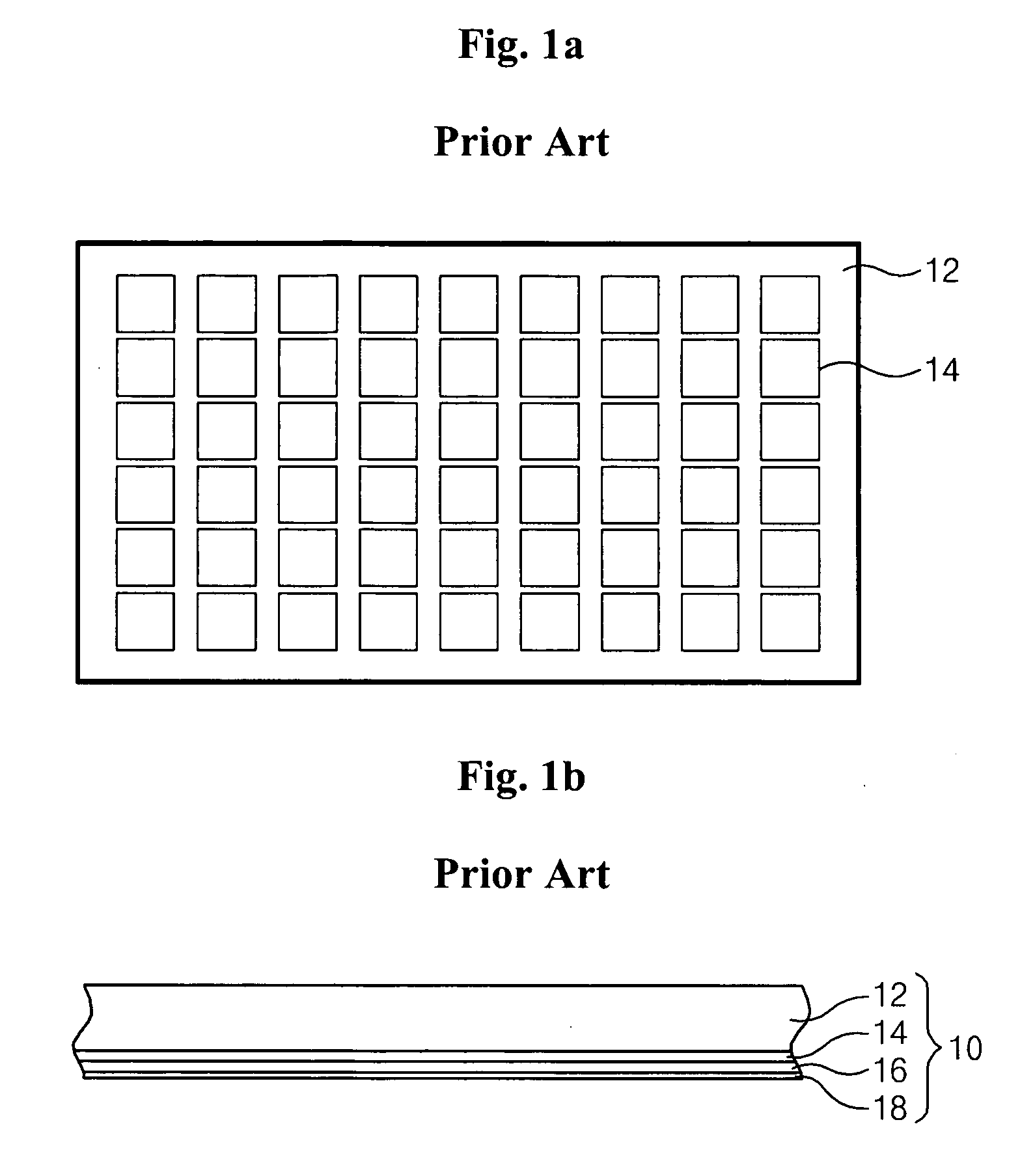

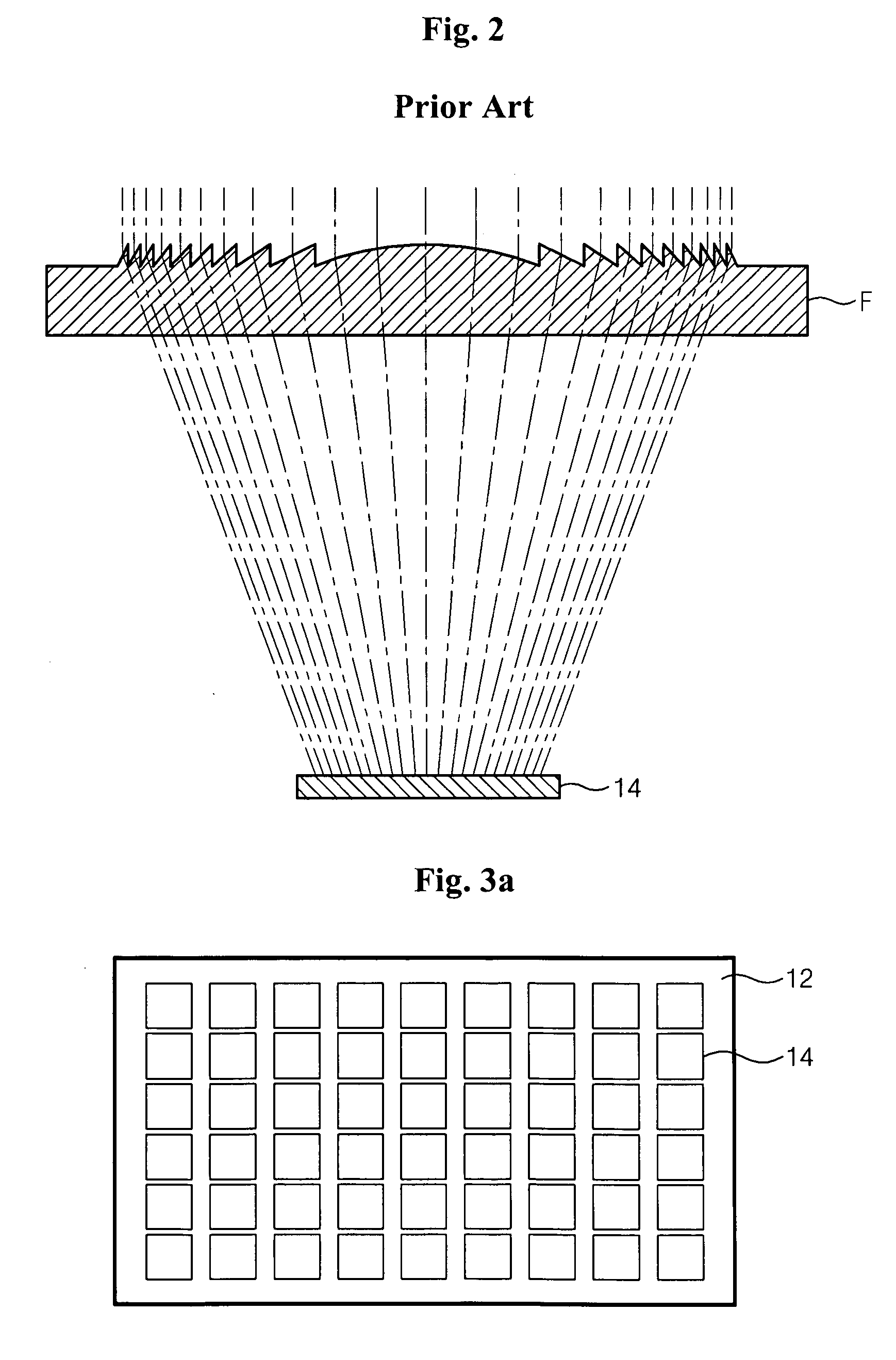

Photovoltaic power generating unit having radiating fins

A photovoltaic power generating unit is disclosed. The photovoltaic power generating unit includes a plurality of solar cells, a concentrating lens for concentrating sun light on the solar cell, which is installed on the vertical upper part of the solar cell, and a concentrating type solar cell module provided with a protective member which is attached to the lower part thereof for protecting the solar cell from external impact. In addition, the photovoltaic power generating unit of the present invention includes a radiating part for dissipating heat created in the solar cell module to the atmosphere. The radiating part consists of a radiating plate bonded to the lower part of the protective member through a thermal resin bonding agent and a plurality of radiating fins protruding downwardly from the radiating plate. Meanwhile, a frame is installed on both edges of the solar cell module to entirely support the solar cell module, and a frame extension part protruding downwardly from the frame is arranged. At least one elastic force fixation device is installed between the frame extension part and the radiating plate to stably fix the radiating part to the solar cell module.

Owner:TAIHAN TECHREN

Staple fiber durable nonwoven fabrics

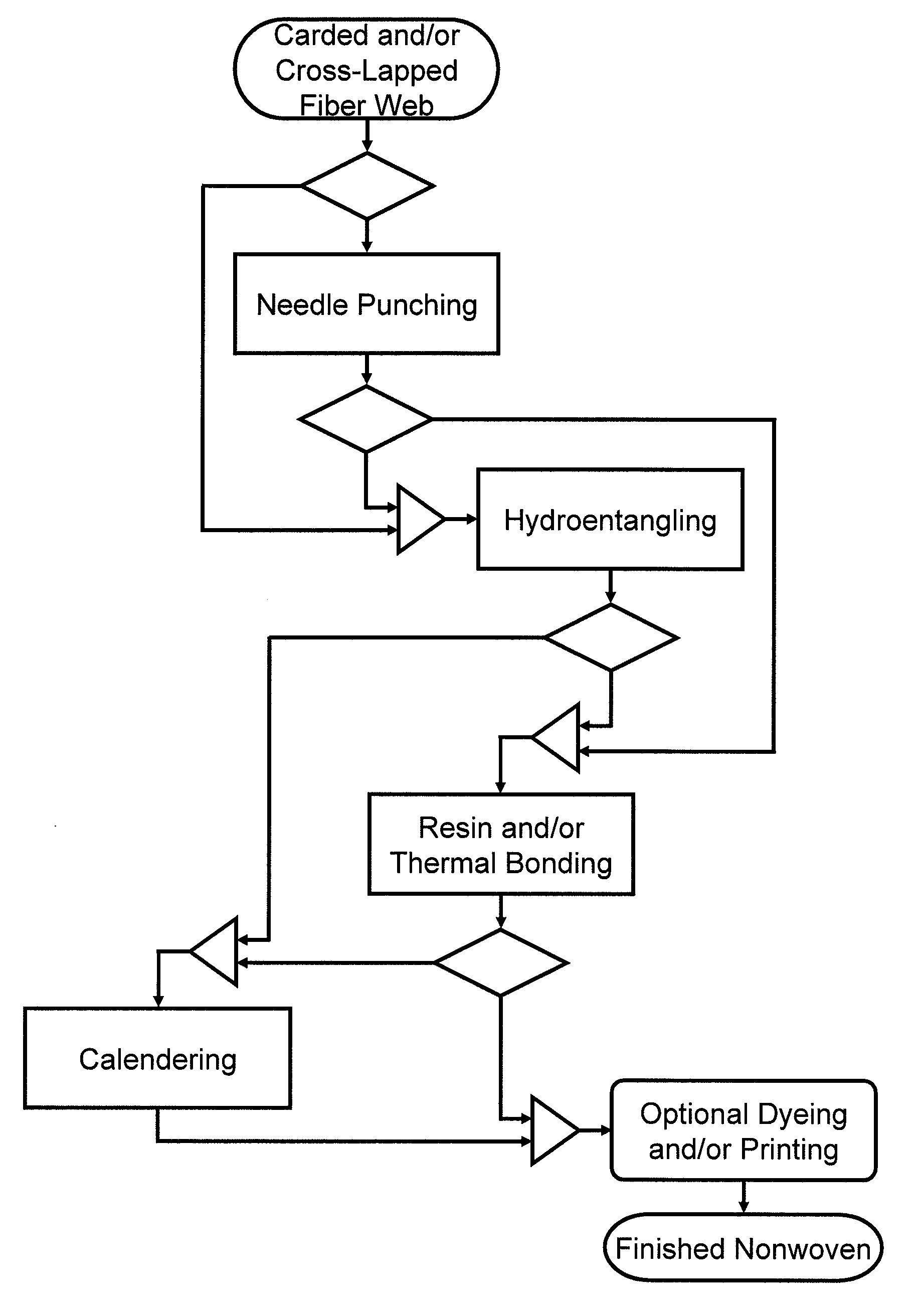

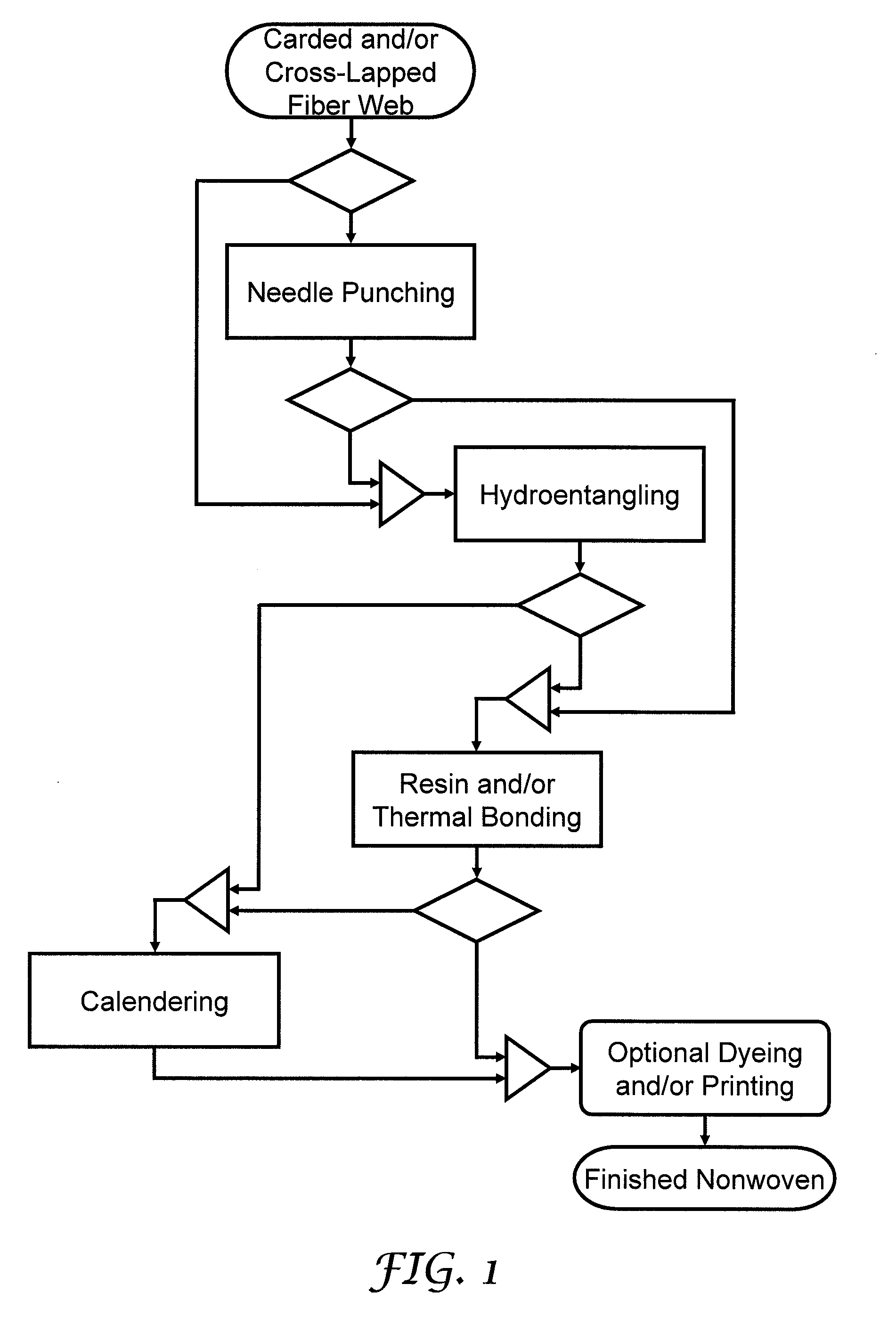

ActiveUS20090258559A1Improve strength and durabilityLayered productsWoven fabricsPunchingEngineering

The invention provides durable nonwoven fabrics comprising staple fibers. Methods of preparing durable nonwoven fabrics based on staple fibers are also provided. The methods can include the steps of at least one of needle punching and hydroentangling. The durable nonwoven fabric can be subjected to additional bonding techniques, such as resin bonding and / or thermal bonding. The durable nonwoven fabrics of the invention provide improved durability over conventional nonwoven fabrics. Further advantages of the inventive nonwoven fabrics include maintaining the smooth surface qualities of the fabric and desirable feel of the fabric even with the enhanced durability. The inventive nonwoven fabrics can also be subjected to additional post-processing techniques that conventional nonwoven fabrics would otherwise be unable to withstand. Further, inks and / or dyes can more readily become adhered to the smooth nature of the surfaces of the inventive durable nonwoven fabrics.

Owner:NORTH CAROLINA STATE UNIV

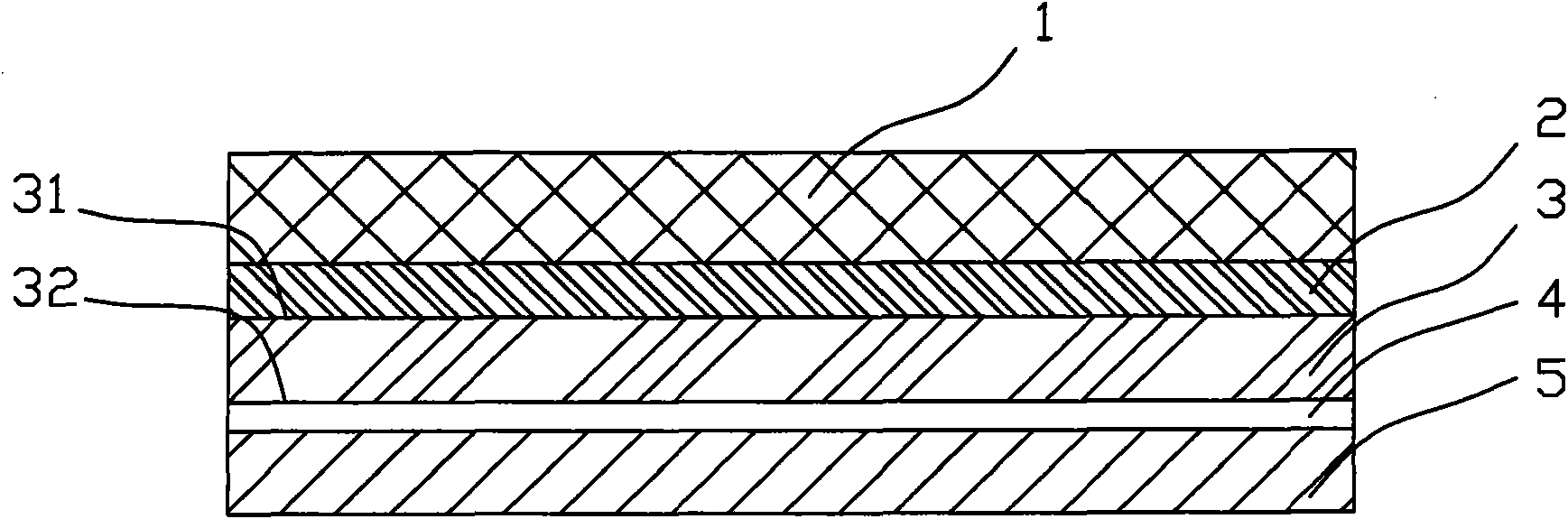

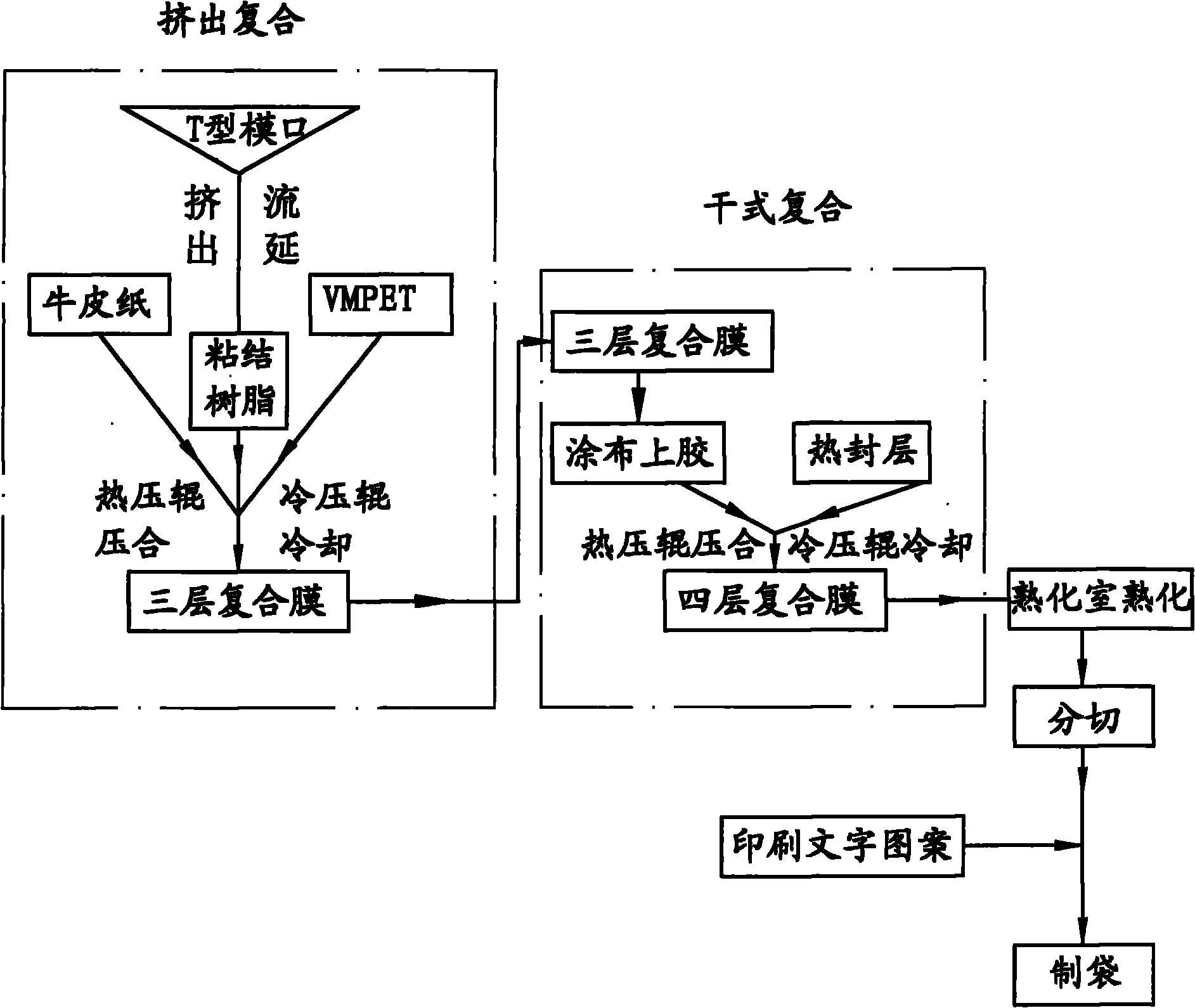

Paper-plastic composite film and production process thereof

ActiveCN101871187AImprove barrier propertiesGood crisp appearanceSpecial paperSynthetic resin layered productsComposite filmPolyethylene glycol

The invention discloses a paper-plastic composite film, which consists of kraft paper, a resin bonding layer, a vacuum aluminizing polyethylene glycol terephthalate film, an adhesive layer and a heat sealing layer which are connected in sequence from the top to the bottom. The invention also provides a production process of the paper-plastic composite film, which comprises the following steps of: 1) compounding films by extruding; 2) compounding films in a dry method; and 3) curing and slitting the composite film in a curing chamber. The production process of the paper-plastic composite film combines extrusion compounding with dry compounding, wherein the kraft paper and an aluminum coated layer of VMPET are subjected extrusion compounding to avoid the phenomenon of the transfer of the aluminum coated layer occurring in the conventional dry compounding and ensure the separating performance of the paper-plastic composite film; and higher compounding strength is provided by the dry compounding, so that the paper-plastic composite film has short production period, high compounding firmness and low solvent residue.

Owner:浙江粤海包装新材料有限公司

Anhydrous resin bonding agent for fireproof material and preparation method thereof

ActiveCN101538451AViscosity can be controlled and adjustedGood adaptability to molding processAldehyde/ketone condensation polymer adhesivesBrickRefractory

The invention discloses an anhydrous resin bonding agent for a fireproof material and a preparation method thereof. The anhydrous resin bonding agent is characterized in that after phenol and aldehyde are synthetized into phenol aldehyde linear resin under the action of an acid composite catalyst, a solvent without hydroxide radicals is added for dissolving; and isocyanate is used for modifying to prepare the anhydrous resin bonding agent. The anhydrous resin bonding agent for the fireproof material contain no water, has moderate viscosity, generate no water in the process of solidifying and is particularly suitable for manufacturing alkaline fireproof material products containing calcium, such as magnesia-calcium bricks, dolomite bricks, and the like. The alkaline fireproof material products have long storage time, no easy aquation, no generation of volumetric expansion and high product strength and effectively improve the quality of the fireproof material.

Owner:SHANDONG LAIWU RUNDA NEW MATERIAL

High-utilization-ratio reproduced MgO-C brick and manufacturing method thereof

The invention discloses a high-utilization-ratio reproduced MgO-C brick which is prepared by the following raw materials by weight percentage: 10-12% of fused magnesite, 1-4% of additive, 25-28% of 5-3mm MgO-C brick reproduction particle, 22-25% of 3-1mm MgO-C brick reproduction particle, 20-22% of 1mm-75-micrometer MgO-C brick reproduction particle, 15-18% of MgO-C brick reproduction micropowder less than or equal to 75 micrometers, 3-5% of graphite powder, and 3.6-4.2% of phenolic resin bonding agent. A manufacturing method of the brick comprises the following steps of (1) raw material sorting and deslagging, (2) twice crushing and magnetic separation, and (3) reproduced brick preparation. Compared with the prior art, the brick has the significant advantages that the problems that the reproduced MgO-C brick is poor in comprehensive performance index and short in service life due to an unreasonable production technology in the existing MgO-C brick reproduction recycling process can be solved, the added waste MgO-C brick can reach 80%, and a utilization ratio is higher.

Owner:长兴南冶冶金材料有限公司

Wax sizing and resin bonding of a lignocellulosic composite

InactiveUS6113729AReduce thickness swellReduces caul plate stickingFibreboardBaby linensCelluloseWax

There is provided a method for producing lignocellulosic composites. This method is useful in reducing the thickness swell of these composites on their exposure to water. This method also is useful in reducing the hot-press times required to make lignocellulosic composites. Furthermore, there is provided a method by which wax sizing may be used without the previously expected reduction in physical properties. Also, there is provided a method by which caul plate sticking may be reduced when hydrogen peroxide is used as a furnish add-on.

Owner:BORDEN CHEMCIAL INC

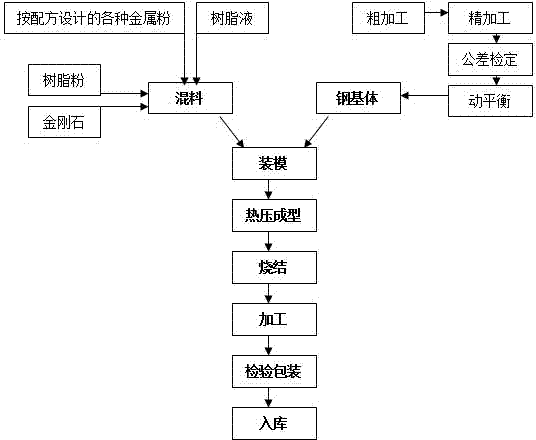

Method of manufacturing resin bonding grinding wheel

InactiveCN1958238AReduced risk of cracksShorten drying timeAbrasion apparatusChemical reactionFoaming agent

Method of manufacturing resin bonding grinding wheel with stomatal in a structure utilizing resin adhesive to fixing wear particles by which resin bonding grinding wheel with uniform stomatal size and distributing can be manufactured as well as granding wheel having improved mechanical strength and good grinding performance. The method comprises: uniformly mixing the wear particles, phenolic resin adhesive, water and foaming agent together; adding solidifying promoter and uniformly mixing the mixer; casting the obtained fluidity mixer into a prescribed mold, solidifying the mixer by the effect of the solidifying promoter; thereafter removing the water contained in the solidified body by a drying process, air bubbles are generated in the fluidity mixer by utilizing the chemical reaction of the foaming agent, the bubbles forms the stomatal of the grinding wheel structure after solidification.

Owner:KURE GRINDING WHEEL

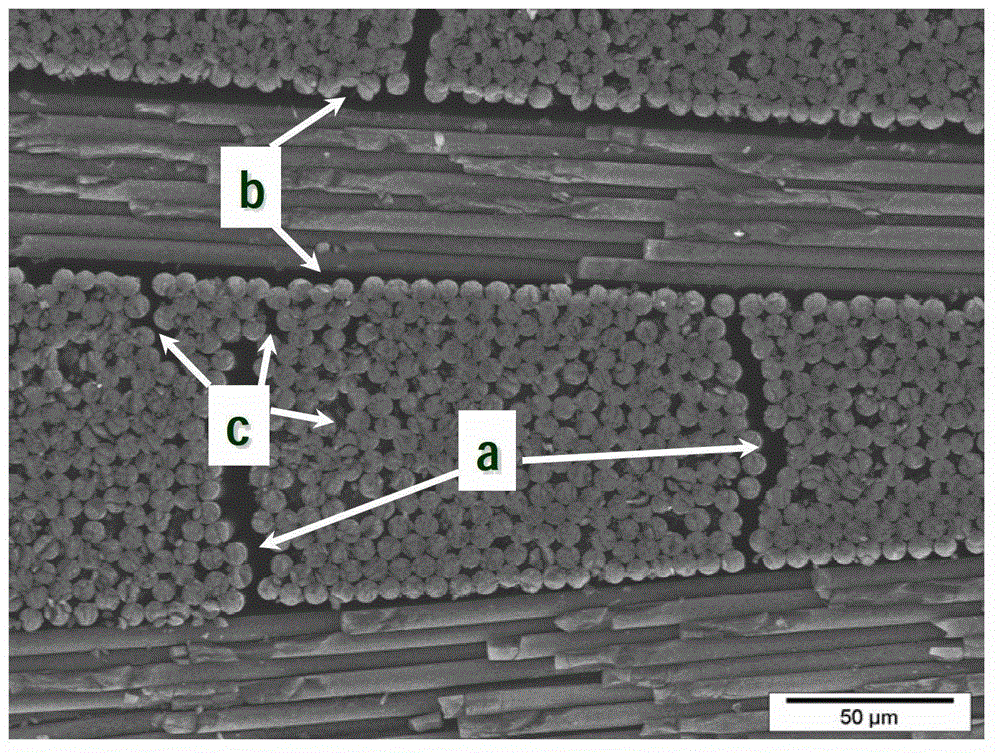

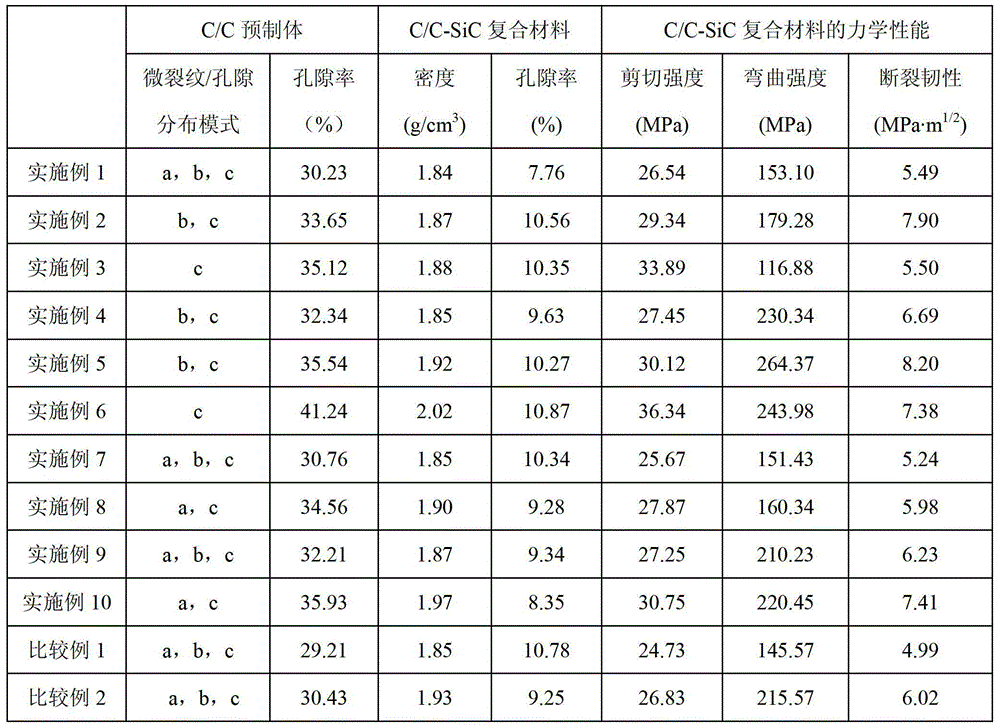

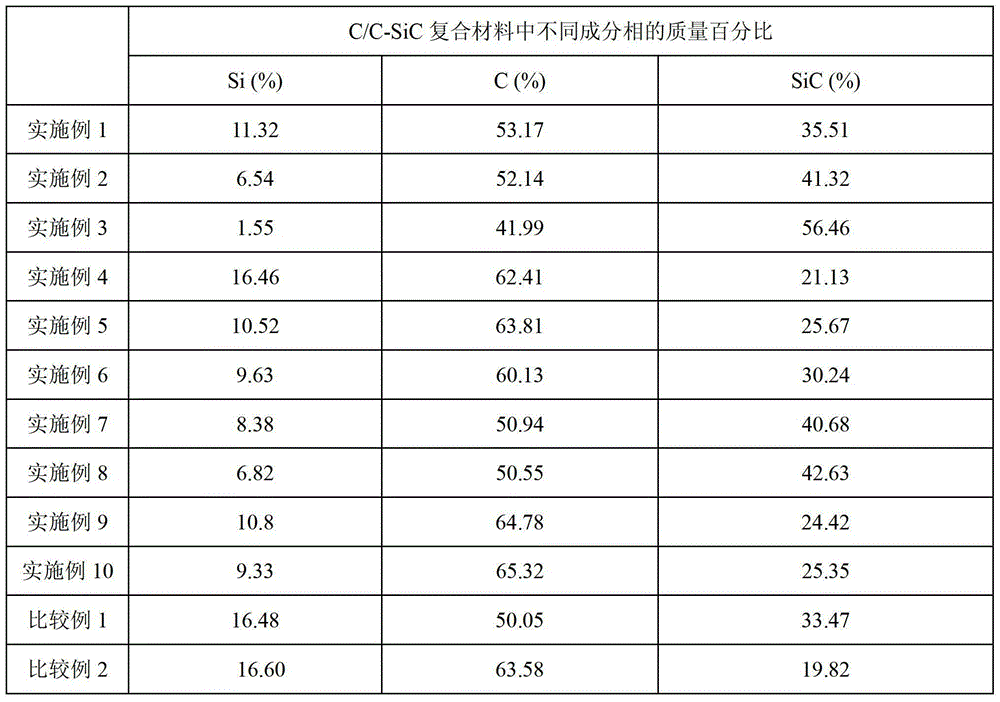

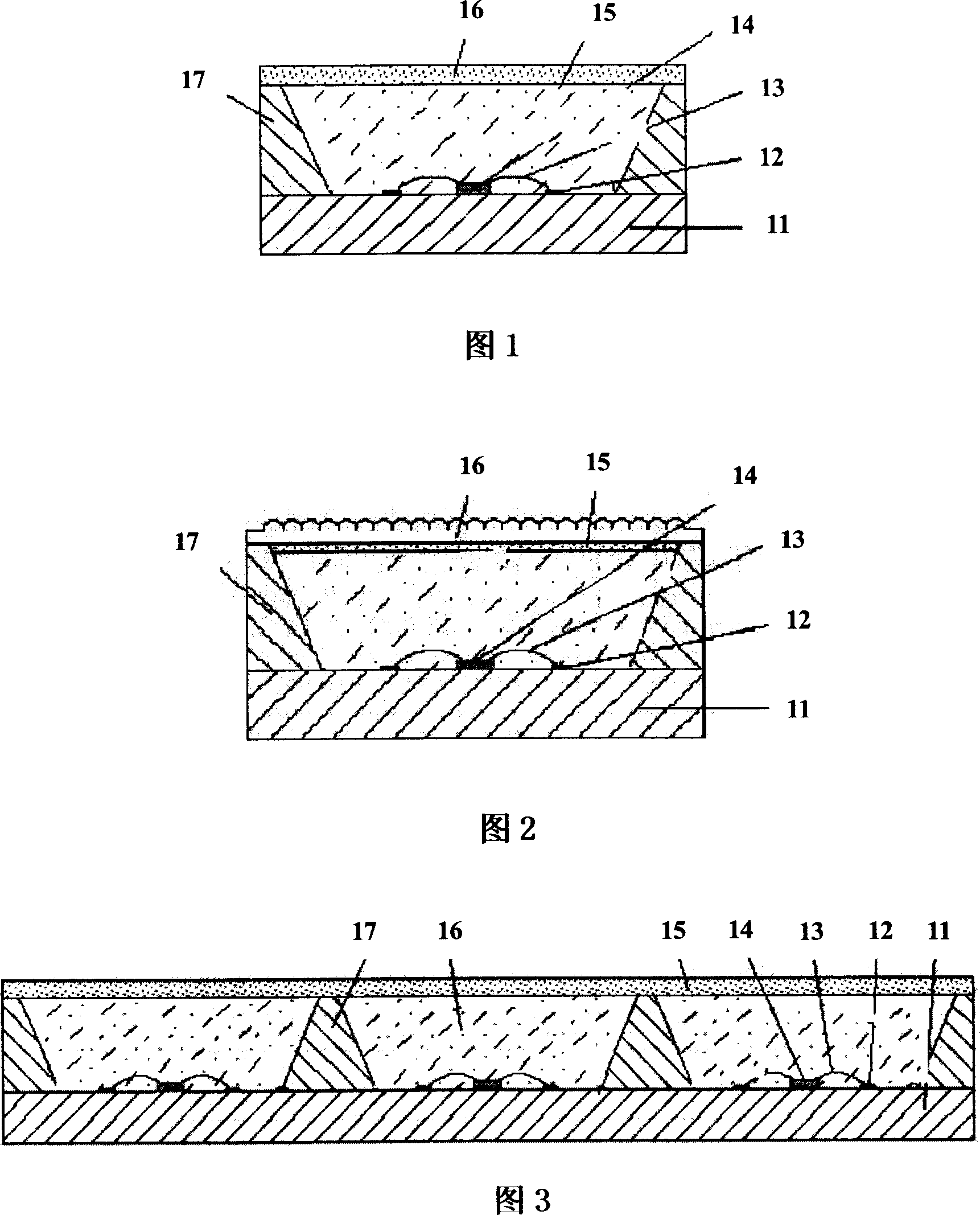

Microstructure design and performance control method for preparing carbon-ceramic-based composite materials based on liquid silicon melt infiltration method

The invention provides a microstructure design and performance control method for preparing carbon-ceramic-based composite materials based on the liquid silicon melt infiltration method. The method comprises the following steps: (a) two-dimensional carbon fiber cloths are treated to obtain two-dimensional carbon fiber cloths with different surface activities, (b) the two-dimensional carbon fiber cloths obtained from a are soaked into a phenolic resin gel solution fully, and dried, the obtained fiber cloths are then overlaid in dies continuously, after being overlaid, the fiber cloths are subjected to curing and post-curing to prepare fiber-reinforced green bodies with different fiber / resin bonding strengths, (c) the fiber-reinforced green bodies obtained from b are placed in a high-temperature graphite furnace, heated to above 900 DEG C under nitrogen condition, and subjected to pyrolysis to prepare carbon / carbon preforms with different microstructures, (d) the carbon / carbon performs obtained from c are placed in the high-temperature graphite furnace, and subjected to liquid silicon melt infiltration at the temperature of 1450-1550 DEG C to prepare carbon-ceramic-based composite materials with different microstructures, matrix structural components and performances.

Owner:DALIAN UNIV OF TECH

LED encapsulation structure and method

InactiveCN101123286AImprove quality uniformityImprove uniformity of light emissionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight-emitting diode

A packaging structure and method of light-emitting diode mainly comprises a monochromatic LED chip, a lead wire, a substrate, a condensing lens, a phosphor, a reflecting bowl and a radiating substrate. The invention is characterized in that the chip is formed by the sintering process after adding the phosphor into the raw material and uniform mixing them, the substrate containing the phosphor is fixed at the top surface of the reflecting bowl around the chip, and the LED chip is fixed in the chip area of the radiating substrate by metal welding, anodic bonding or resin bonding. The invention has the advantages that the invention can accurately control the dose of phosphor, promote the light quality and luminescence uniformity of white LED after packaging, meanwhile avoid the adverse effect on the phosphor from high temperature during use, and promote the reliability of LED after packaging.

Owner:GUANGDONG REAL FAITH OPTO

Glass fiber soaking agent and preparation method thereof

The invention discloses a glass fiber soaking agent, which is mainly prepared from the following ingredients in percentage by weight: 2 to 6 percent of modified straight chain starch, 1 to 5 percent of modified amylopectin, 0.5 to 5 percent of microcrystalline wax, 0.5 to 5 percent of hydrogenated vegetable oil, 0.1 to 1 percent of quaternary ammonium salt cation lubricating agents, 0.1 to 1 percent of span 80, 0.01 to 0.5 percent of alkane sulfonate surfactants, 0 to 2.0 percent of modified epoxy resin bonding agents, 0 to 0.05 percent of defoaming agents and the balance water. The glass fiber soaking agent has the advantages that the physical and chemical properties of the glass fiber electronic weaving yarn can be fully improved, the stiffness is between 50 and 80, the tensile intensity is higher than 52 CN / TEX, and the yarn fracture and fuzzing problems in the weaving process are effectively solved.

Owner:ANHUI DANFENG ELECTRONICS MATERIAL

Unfired magnesia-calcium brick and preparation method thereof

The invention discloses an unfired magnesia-calcium brick which is prepared from the following raw materials in percentage by weight: 9-16 percent of 5-7mm magnesia-calcium sand, 9-16 percent of 3-5mm magnesia-calcium sand, 9-16 percent of 1-3mm magnesia-calcium sand, 9-16 percent of 0.5-1mm magnesia-calcium sand, 4-16 percent of 0.5-1 mm magnesia sand, 5-25 percent of not larger than 0.5mm magnesia sand, 1-10 percent of graphite, 2-5 percent of anhydrous resin bonding agent and 1-3 percent of additive formed by mixing magnesia powder and zircon sand. The processing method comprises the following steps of: crushing, grinding, compounding, pressing and forming, heating, baking and carrying out waterproof treatment. In the invention, the unfired magnesia-calcium brick with great volume density and high compression strength can be prepared due to reasonable compounding and a scientific treatment process, and particularly, the additive formed by mixing the magnesia powder and the zircon sand is used, therefore, the product has good medium-temperature strength, waterproofness and crack resistance.

Owner:浙江金磊耐火材料有限公司

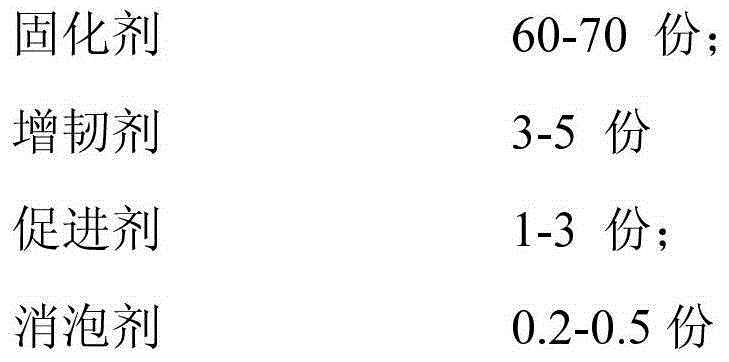

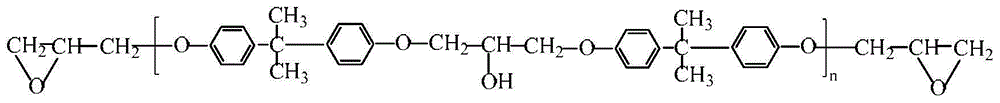

Epoxy resin bonding agent cured at normal temperature for roads and bridges and preparation method of epoxy resin bonding agent

InactiveCN104449514AImprove toughnessIncreased durabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyBridge deck

The invention discloses an epoxy resin bonding agent cured at the normal temperature for roads and bridges. The epoxy resin bonding agent comprises a component A and a component B, wherein the component A comprises the following ingredients in parts by mass: 100 parts of epoxy resin, 30-40 parts of flexible epoxy resin, and 5-15 parts of a diluent; the component B comprises the following ingredients in parts by mass: 60-70 parts of a curing agent, 3-5 parts of a flexibilizer, 1-3 parts of an accelerant, and 0.2-0.5 part of a defoaming agent; the ratio of the component A to the component B is (100:80)-(100:100). According to the invention, the flexible epoxy resin is added into the commonly-used epoxy resin, and after the flexible epoxy resin reacts with the curing agent, a thermoset three-dimensional crosslinking structure is formed, so that the good flexibility, better bonding capacity and water resistance are achieved; cashew nut shell oil modified amine is used as the curing agent, so that the water resistance and low temperature resistance of the bonding agent are improved effectively; in addition, since novel multiple-alcohol derivative is used as the flexibilizer of the epoxy resin, the toughness of the epoxy resin is effectively improved, so as to adapt to deformation of steel bridge decks or cement concrete bridge decks during vibration, and realize the purpose of high durability of the epoxy resin bonding agent solidified at the normal temperature for roads and bridges. The epoxy resin bonding agent solidified at the normal temperature for roads and bridges is suitable for bonding and water resistance of steel bridge decks, urban viaducts, cement concrete bridge decks, tunnels and pavements of expressways and the like. The invention further discloses a preparation method of the epoxy resin bonding agent.

Owner:NANJING UNIV +1

Degradable environmental protection chopstick and production technology thereof

InactiveCN104877367APromote decompositionWide variety of sourcesTablewaresMolding machineVegetable fibers

The invention discloses a degradable environmental protection chopstick. The chopstick is produced from 40-60wt% of vegetable fiber, 15-20wt% of starch, 20-40wt% of resin bonding powder and 2-10wt% of water. A production technology of the degradable environmental protection chopstick comprises the following steps: 1, cleaning the vegetable fiber to remove silt and rotten materials; 2, crushing the cleaned vegetable fiber; 3, taking 40-60wt% of the crushed vegetable fiber, adding 15-20wt% of starch, 2-10wt% of water and 20-40wt% of the resin bonding powder, and uniformly stirring to prepare vegetable fiber mixed powder; 4, injecting the vegetable fiber mixed powder into a molded chopstick die, and carrying out hot molding in a hot pressing molding machine at 125-143DEG C to obtain a product; and 5, finishing the product, disinfecting, and packaging to obtain the degradable environmental protection chopstick.

Owner:SHANGHAI SHENGJIAN ENVIRONMENTAL PROTECTION SCI & TECH

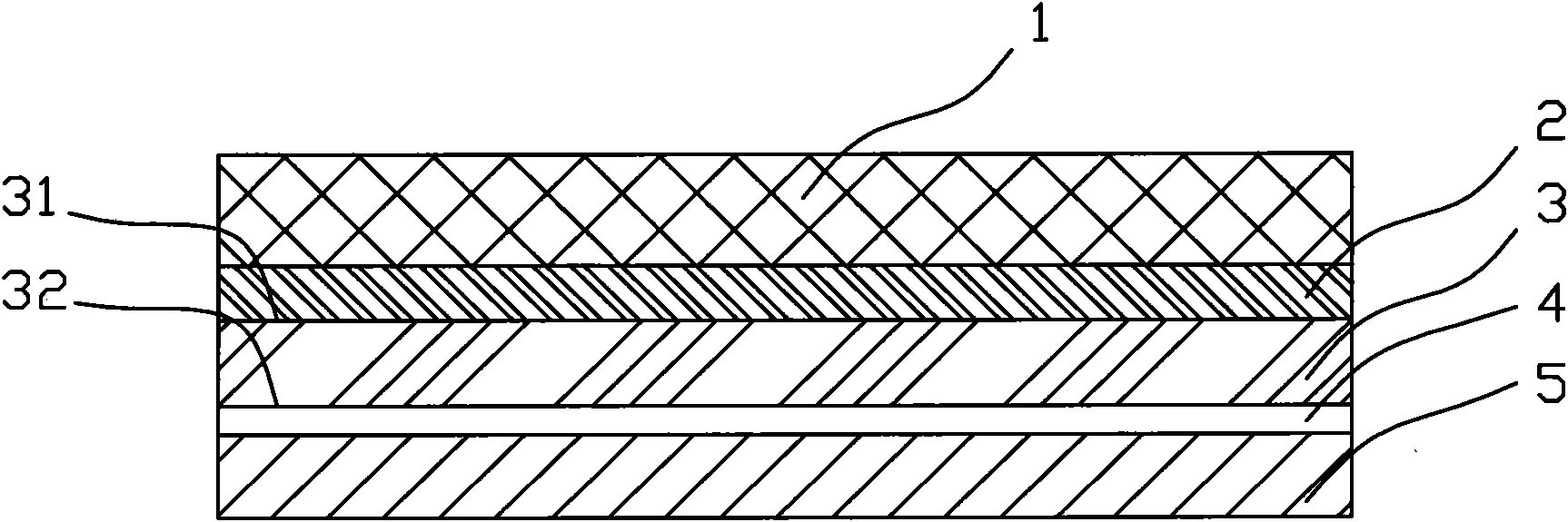

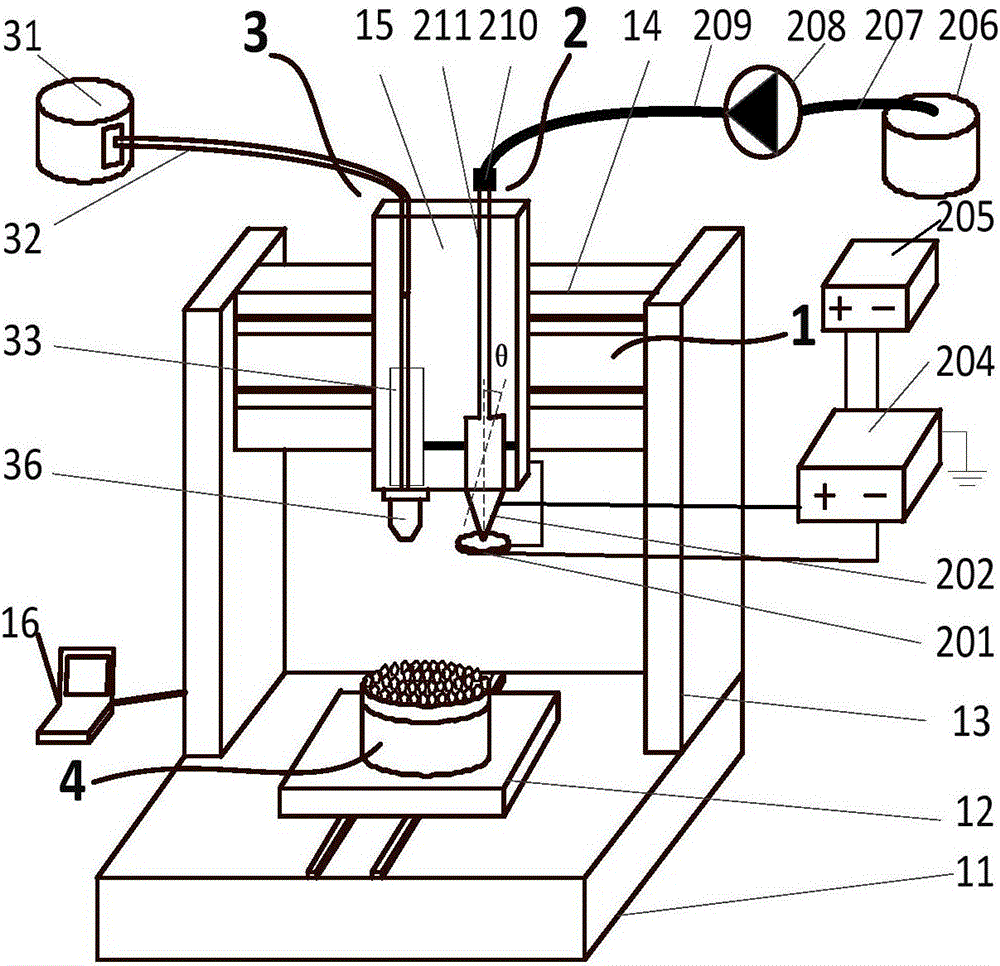

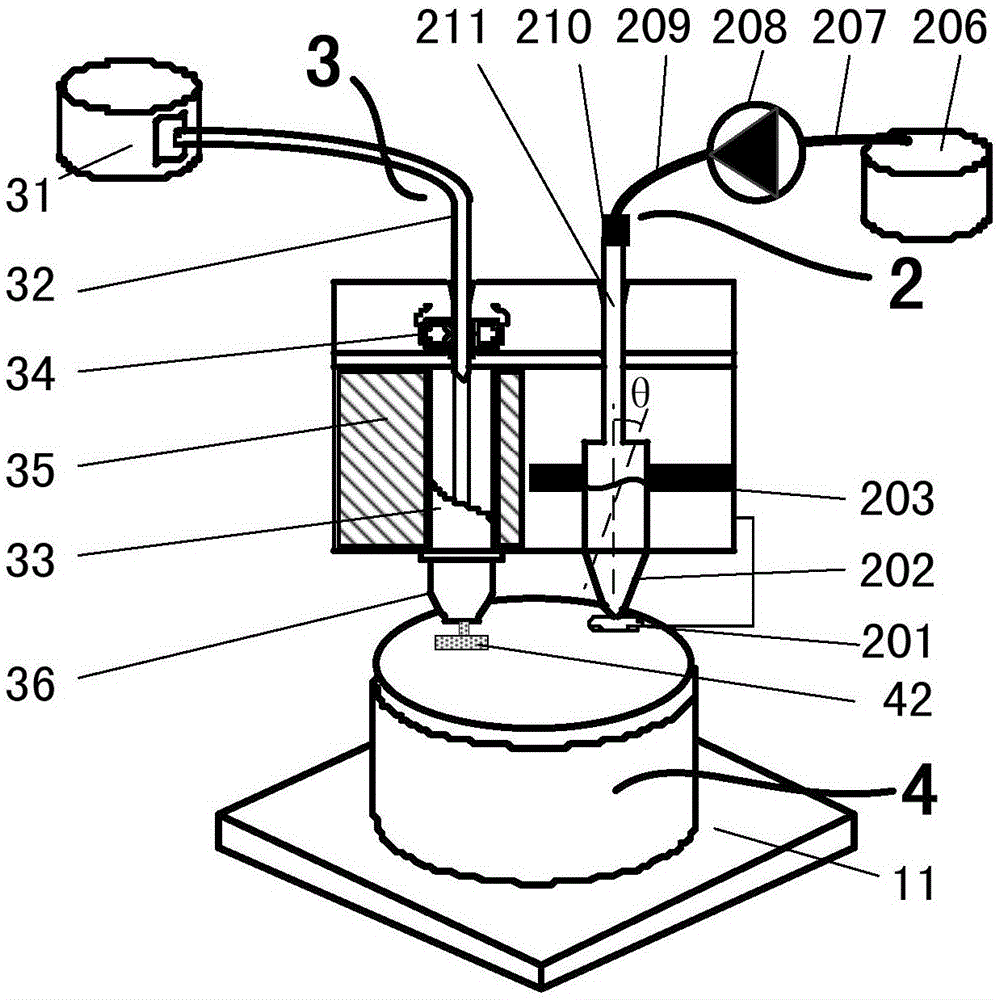

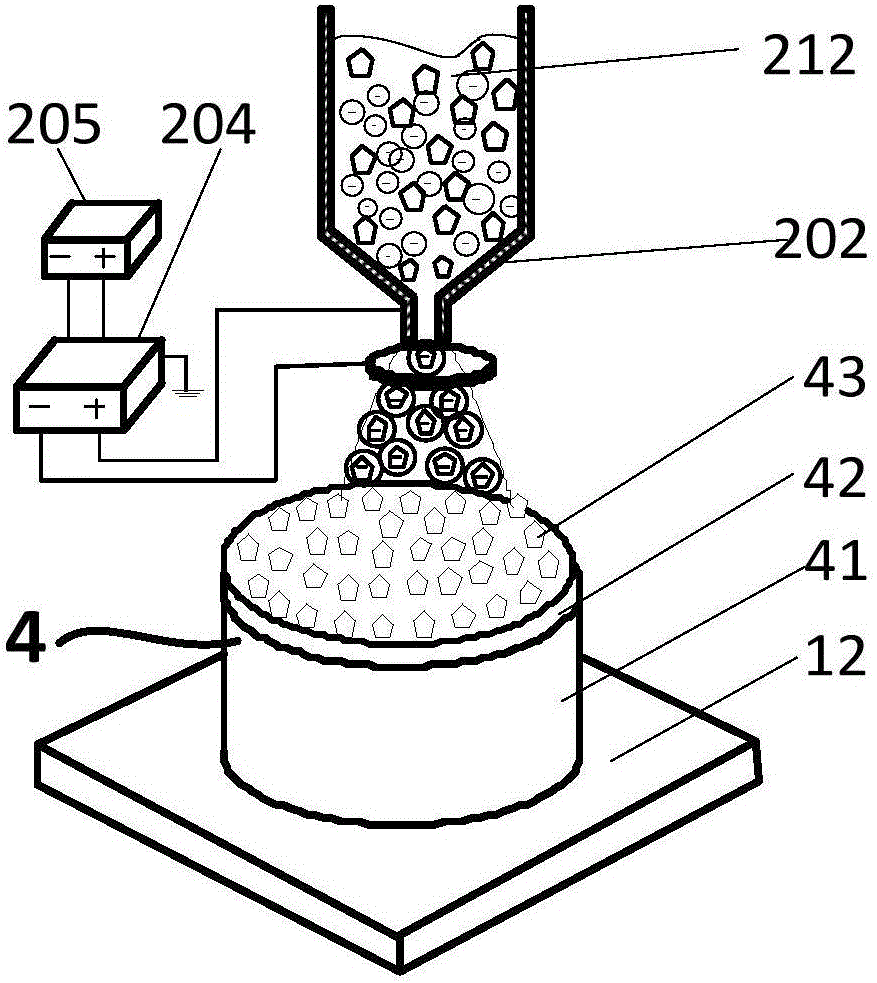

Manufacturing device and method of diamond resin abrasive wheel

ActiveCN106553137AImprove grinding efficiencyUniform grinding forceGrinding devicesMovement controlResin bonding

The invention belongs to the technical field of electrostatic atomization and heat fused deposition modeling, and relates to a manufacturing device and method of a diamond resin abrasive wheel with uniformly-distributed abrasive particles. The device mainly comprises a movement control platform, an electrostatic atomization system, an abrasive wheel printing system and a printed abrasive wheel. The movement control platform comprises a basic platform, a lifting platform, a horizontal movement platform, a movement control device and a supporting frame. The electrostatic atomization system comprises an annular electrode, an electrostatic nozzle, a supporting block, a high-voltage electrostatic generator, a power source, an electrostatic liquid container, connecting pipes, an injection pump and a connector. The abrasive wheel printing system comprises a wire material box, a resin bond wire material, a sleeve, a wire feeding mechanism, a heating mechanism and a forming nozzle. The printed abrasive wheel comprises an abrasive wheel basic body, a resin bonding agent and diamond abrasive particles. The abrasive particles are uniformly distributed in the abrasive wheel. When the abrasive wheel conducts grinding operation, the processed surface quality is high, the grinding force is uniform, the grinding efficiency is high, and a certain polishing effect is achieved.

Owner:HUNAN UNIV

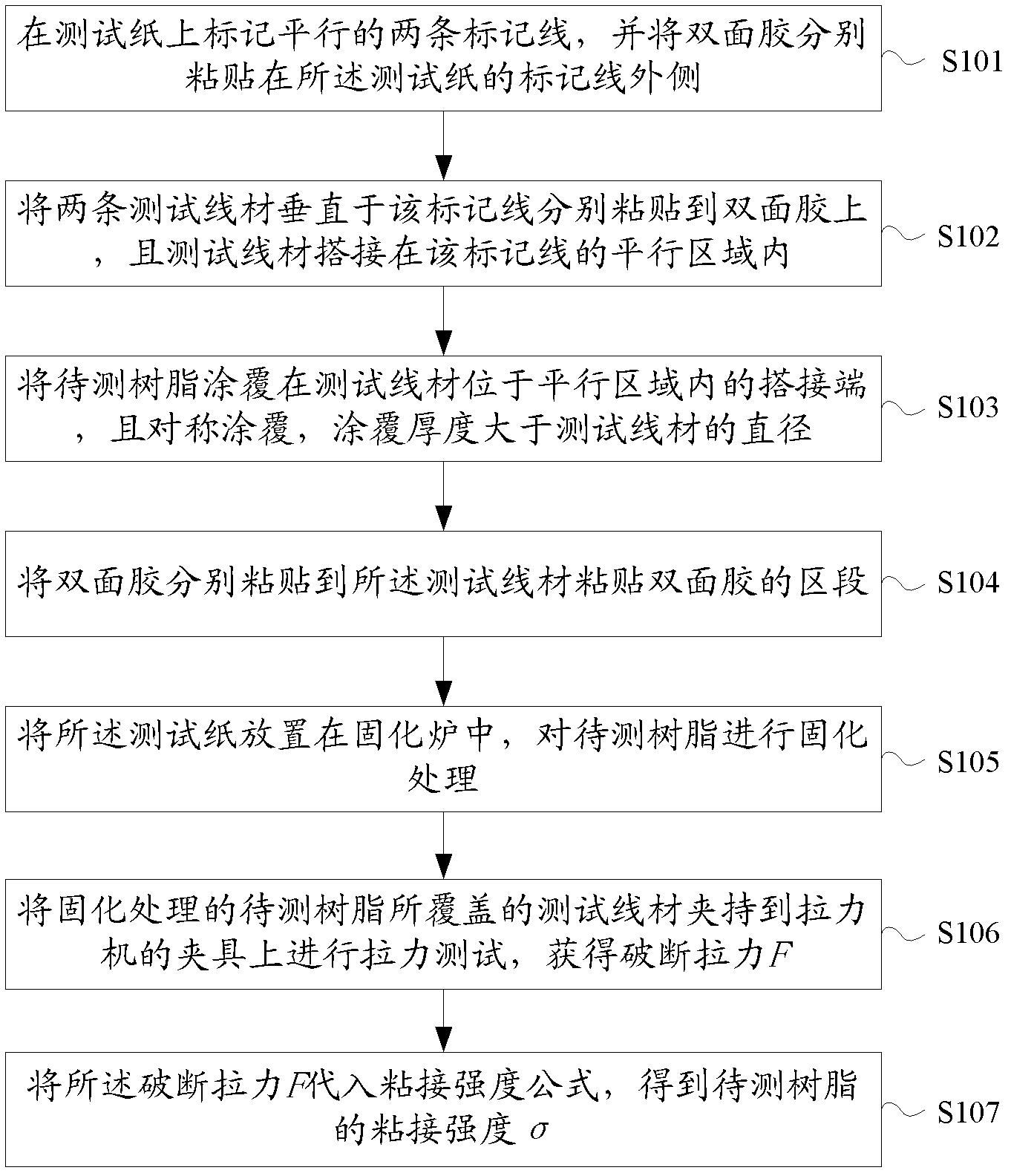

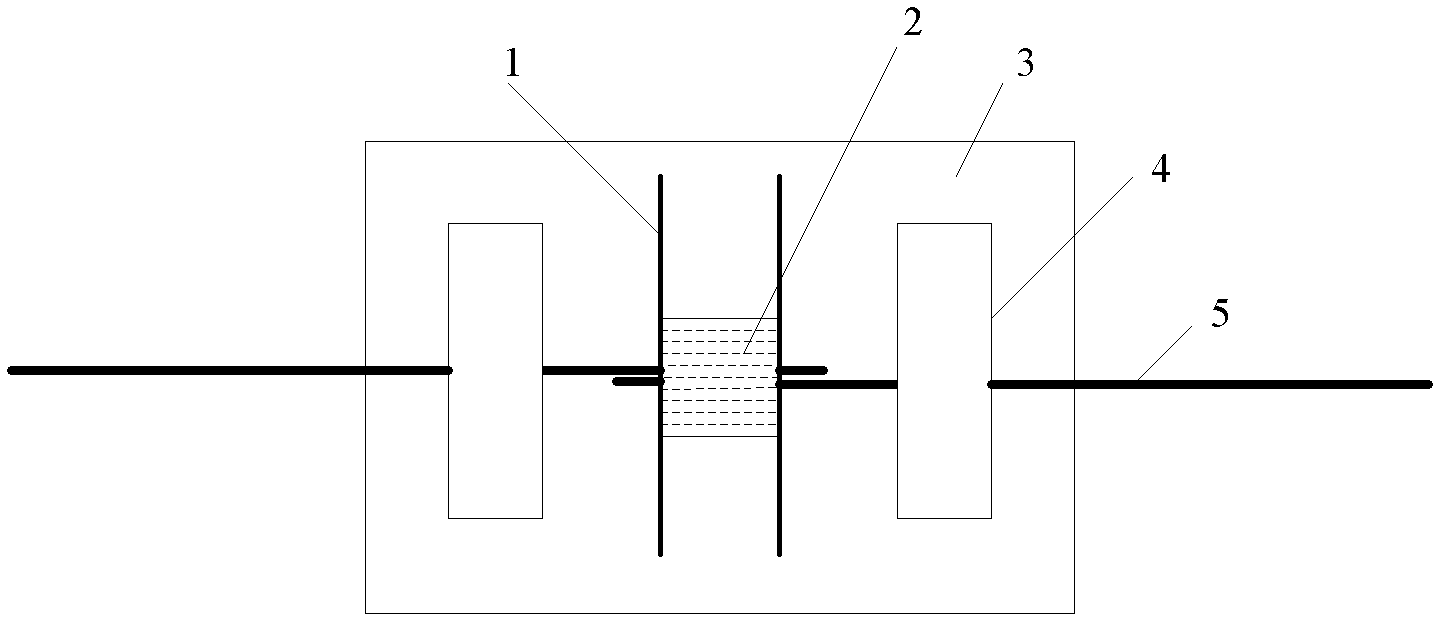

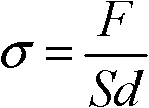

Detection method for resin bonding strength

ActiveCN102854133AImprove detection accuracyNot prone to foamingUsing mechanical meansMaterial analysisEngineeringResin bonding

The invention discloses a detection method for resin bonding strength. The method includes parallelly marking two marking lines on test paper, bonding double-side adhesive tapes at the outer sides of the marking lines of the test paper, respectively; bonding two test wire materials onto the double-side adhesive tapes perpendicular to the marking lines, respectively, and lapping the test wire materials in the parallel region of the marking lines; coating to-be-detected resin at the lapping parts of the test wire materials; performing fixing treatment to the sections of the test wire materials bonded with the double-side adhesive tapes; performing curing treatment to the to-be-detected resin; holding the test wire materials covered by the to-be-detected resin subjected to the curing treatment onto the fixture of a tension machine for tension testing to obtain fracture tension F; and substituting the fracture tension F into the bonding strength formula to obtain the bonding strength Sigma. Owing to the scheme, the method can improve the detection accuracy of the bonding strength of brittle resins, thus, is suitable for detecting the bonding strength of resins with brittleness characteristic.

Owner:浙江东大树脂科技股份有限公司

Ceramic resin composite bonding agent grinding wheel and preparation method thereof

ActiveCN104526577AImprove grinding efficiencyImprove heat resistanceAbrasion apparatusGrinding devicesCompression moldingPolymer science

The invention discloses a ceramic resin composite bonding agent grinding wheel and a preparation method thereof, comprising the steps as follows: step I, a resin bonding agent, a grinding material, filler, and a pore forming agent are subjected to compression molding, and sintering is conducted at the high temperature of 700 to 850 DEG C so as to form a ceramic grinding wheel; step II, the resin bonding agent is dissolved by acetone or alcohol, a curing agent is added therein so as to blend resin bonding agent liquid; step III, the resin bonding agent liquid prepared in step II is put into a rubber mold, simultaneously, the ceramic grinding wheel is put into the rubber mold, the opening of the rubber mold is sealed, and the sealed mold is put into a cold isostatic press for pressing; step IV, the resin bonding agent grinding wheel subjected to processing of step III is put into an oven for roasting. The ceramic resin composite bonding agent grinding wheel not only keeps the original characteristics of a resin bonding agent diamond grinding wheel that the grinding efficiency is high, and the self-sharpening property is good, but simultaneously has the advantages of a metal bonding agent diamond grinding wheel that the rigidity is high, the heat resistance is high, and the molded surface is kept well.

Owner:ZHENGZHOU BERLT HARD MATERIALS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com