Patents

Literature

481results about How to "Improve uniformity of light emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

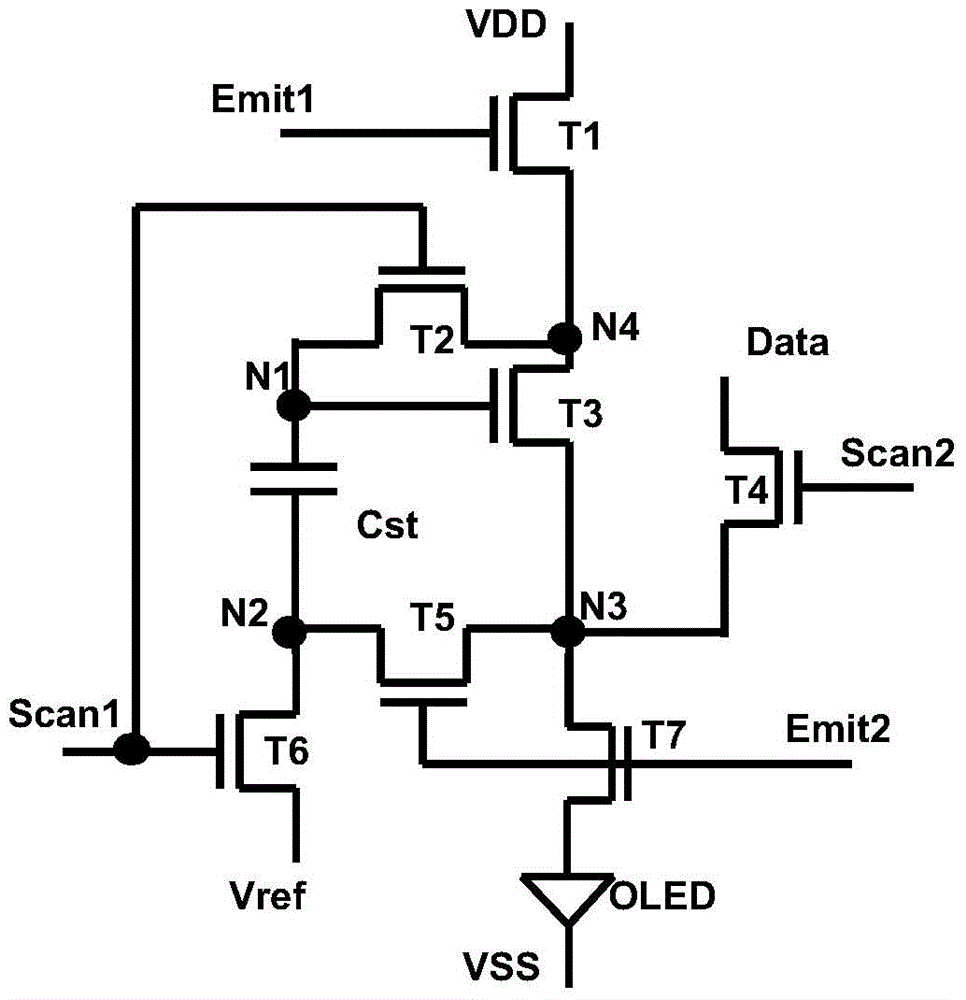

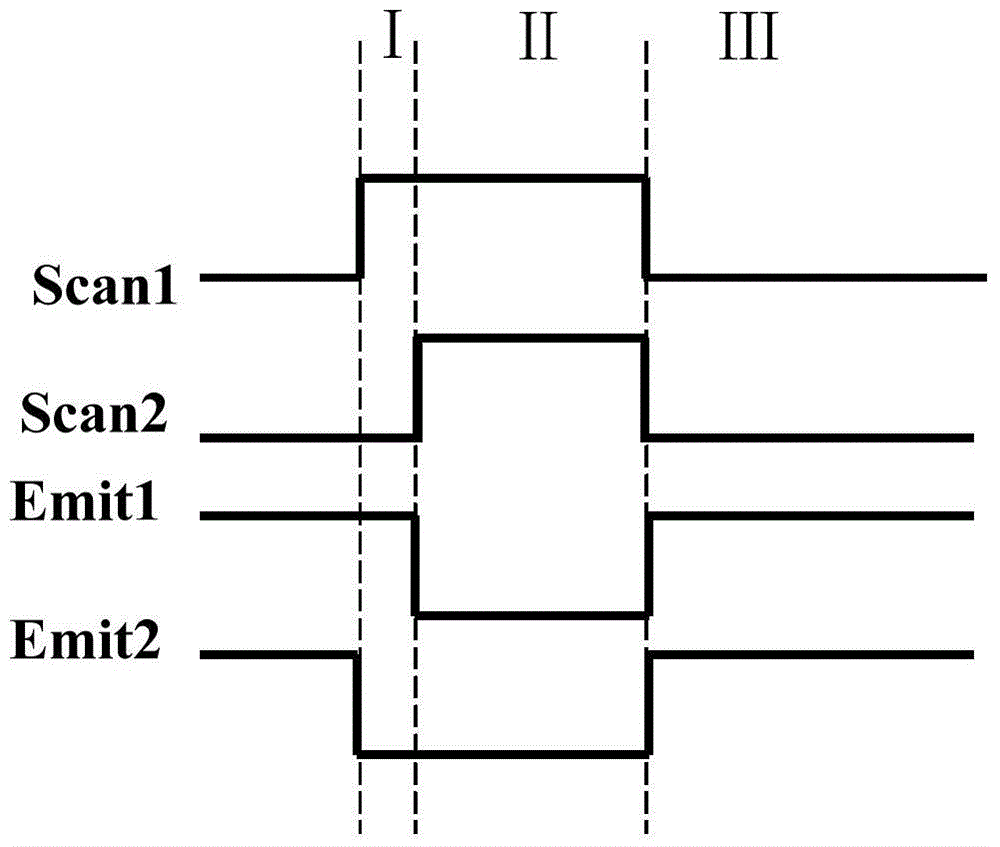

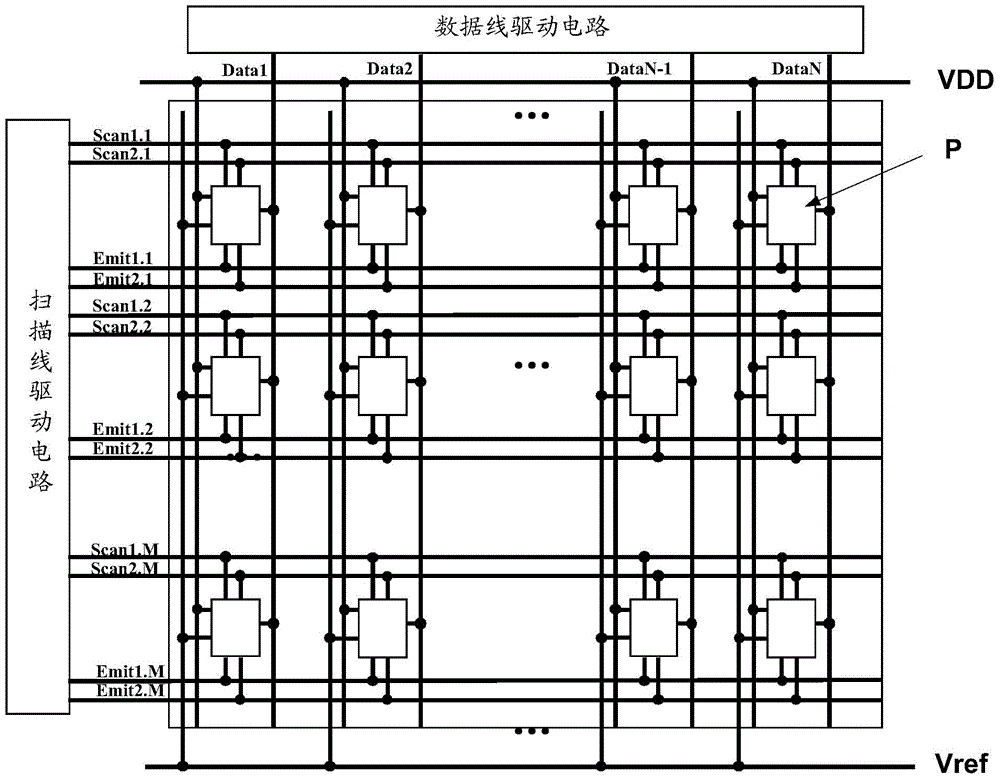

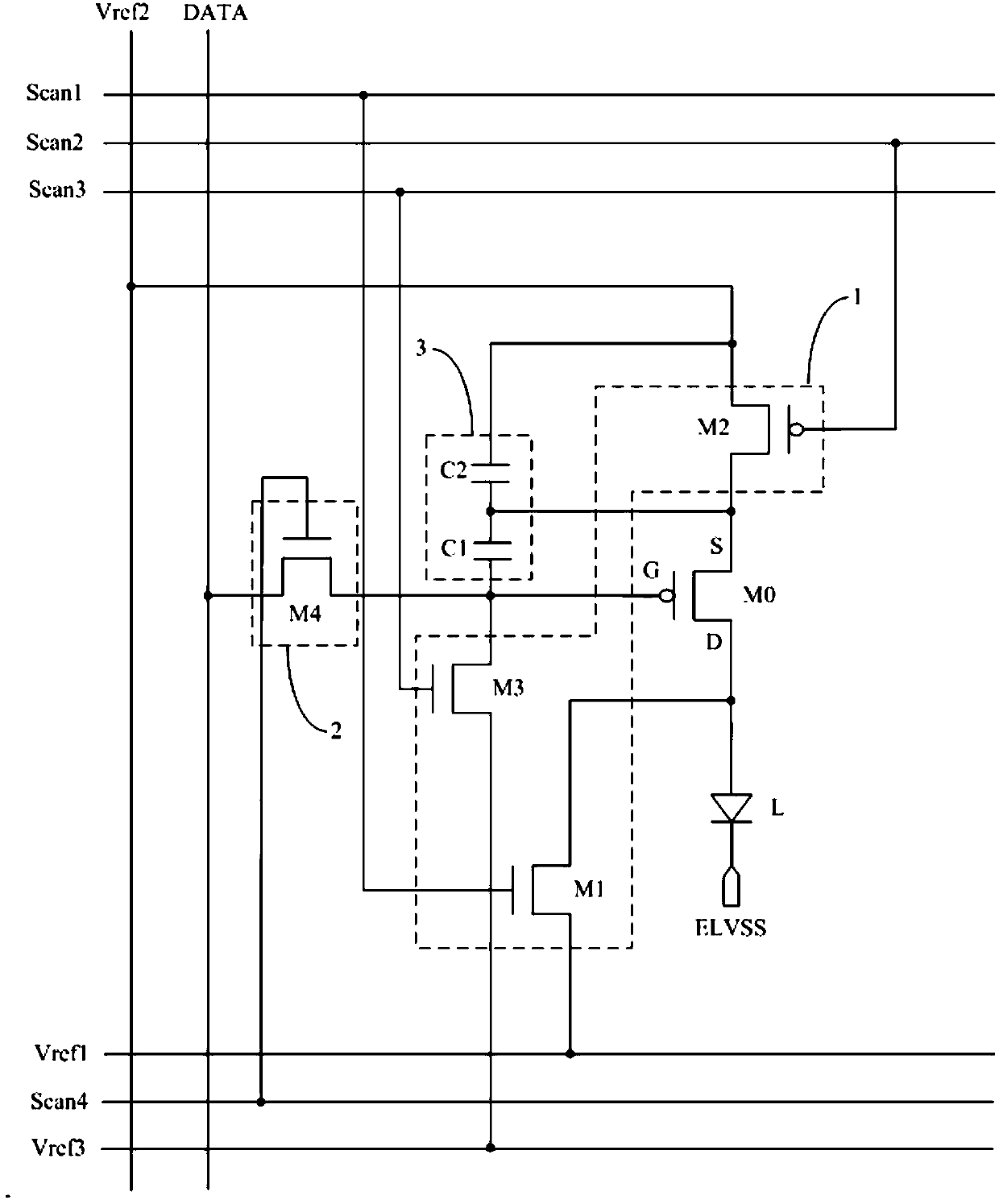

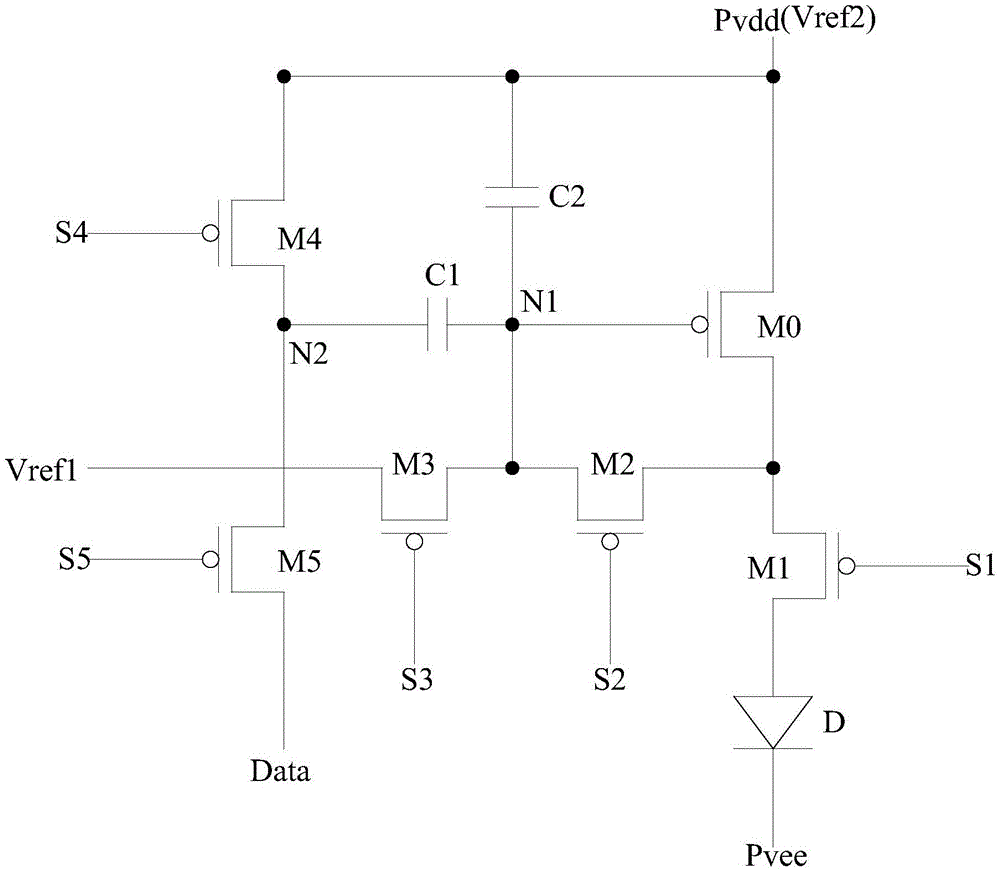

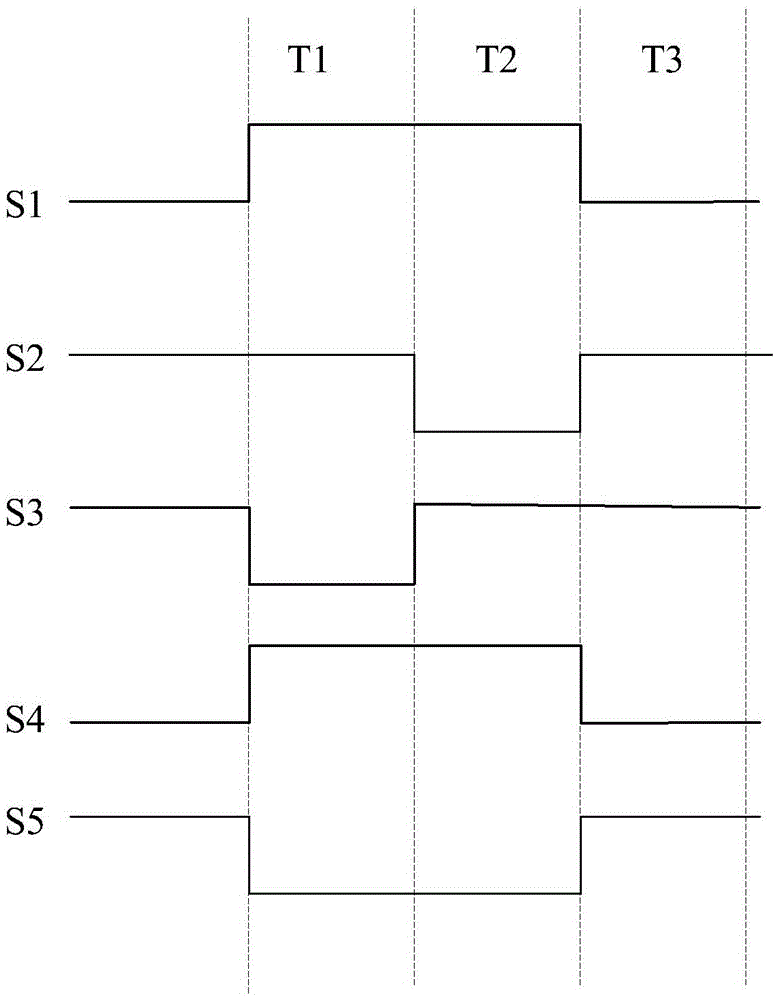

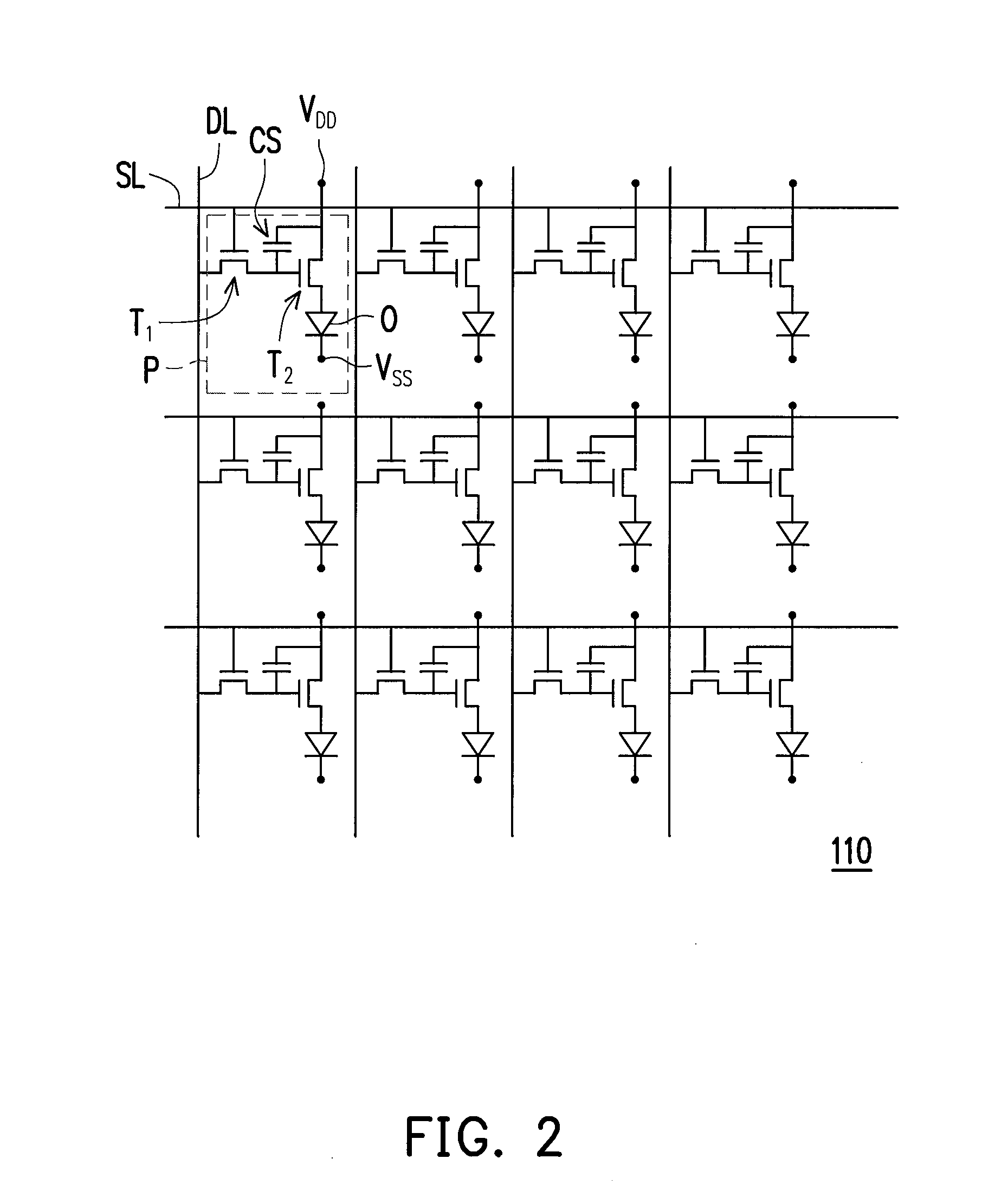

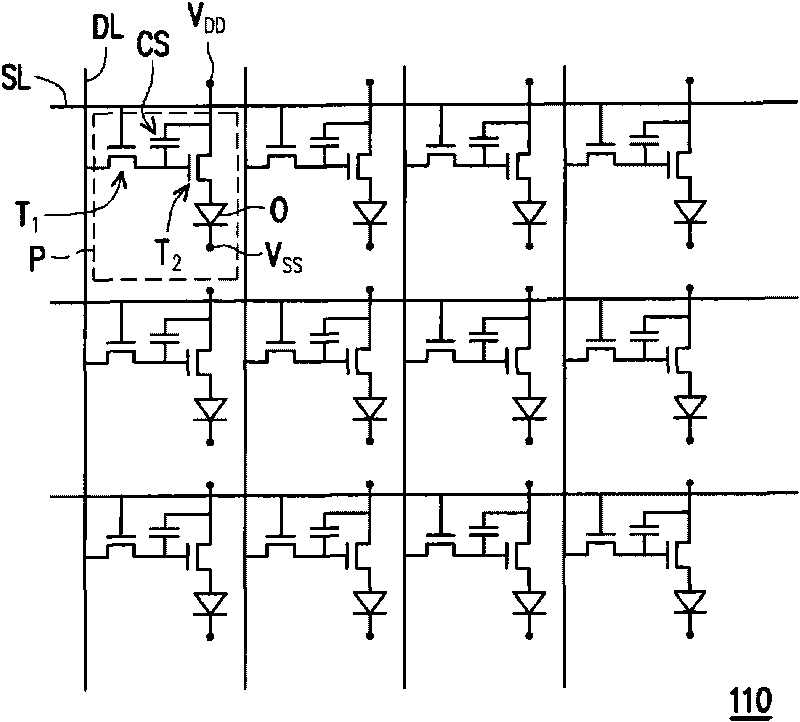

Pixel circuit, driving method, display panel and display device

ActiveCN104465715AImprove uneven lightingImprove uniformity of light emissionStatic indicating devicesElectroluminescent light sourcesDriving currentCapacitance

The invention provides a pixel circuit, a driving method, a display panel and a display device. The pixel circuit comprises a first transistor, a second transistor, a third transistor, a fourth transistor, a fifth transistor, a sixth transistor, a driving transistor, a storage capacitor and a light emitting element. Through cooperative driving of all the transistors and the storage capacitor, the driving current of the driving transistor can be unrelated to the gate-source voltage and the threshold voltage of the driving transistor, so adverse influences are eliminated, the phenomenon that the display panel and the display device are non-uniform in light emission is effectively relieved, and the light emission uniformity and the display effect of pictures displayed by the display panel and the display device are improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +2

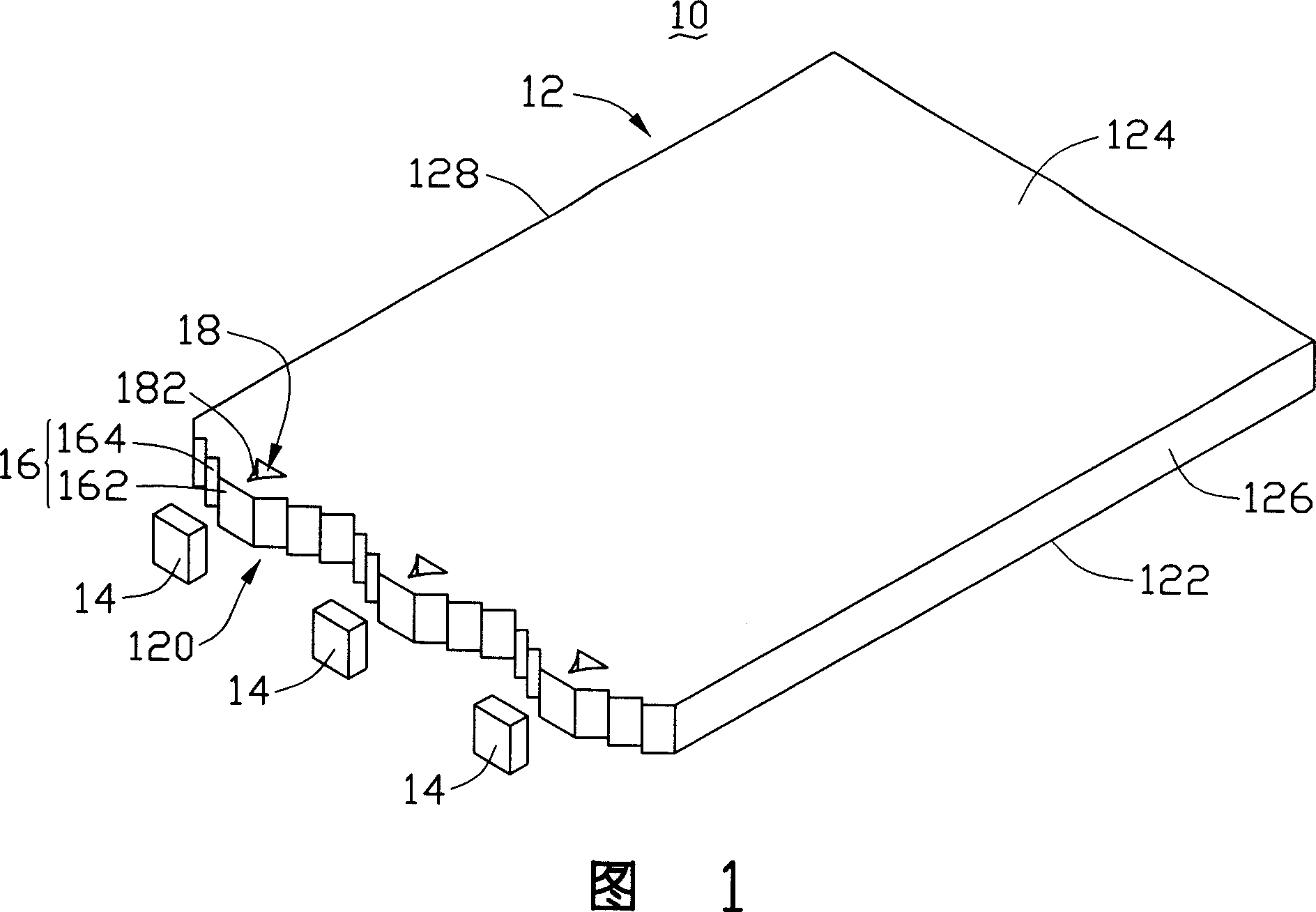

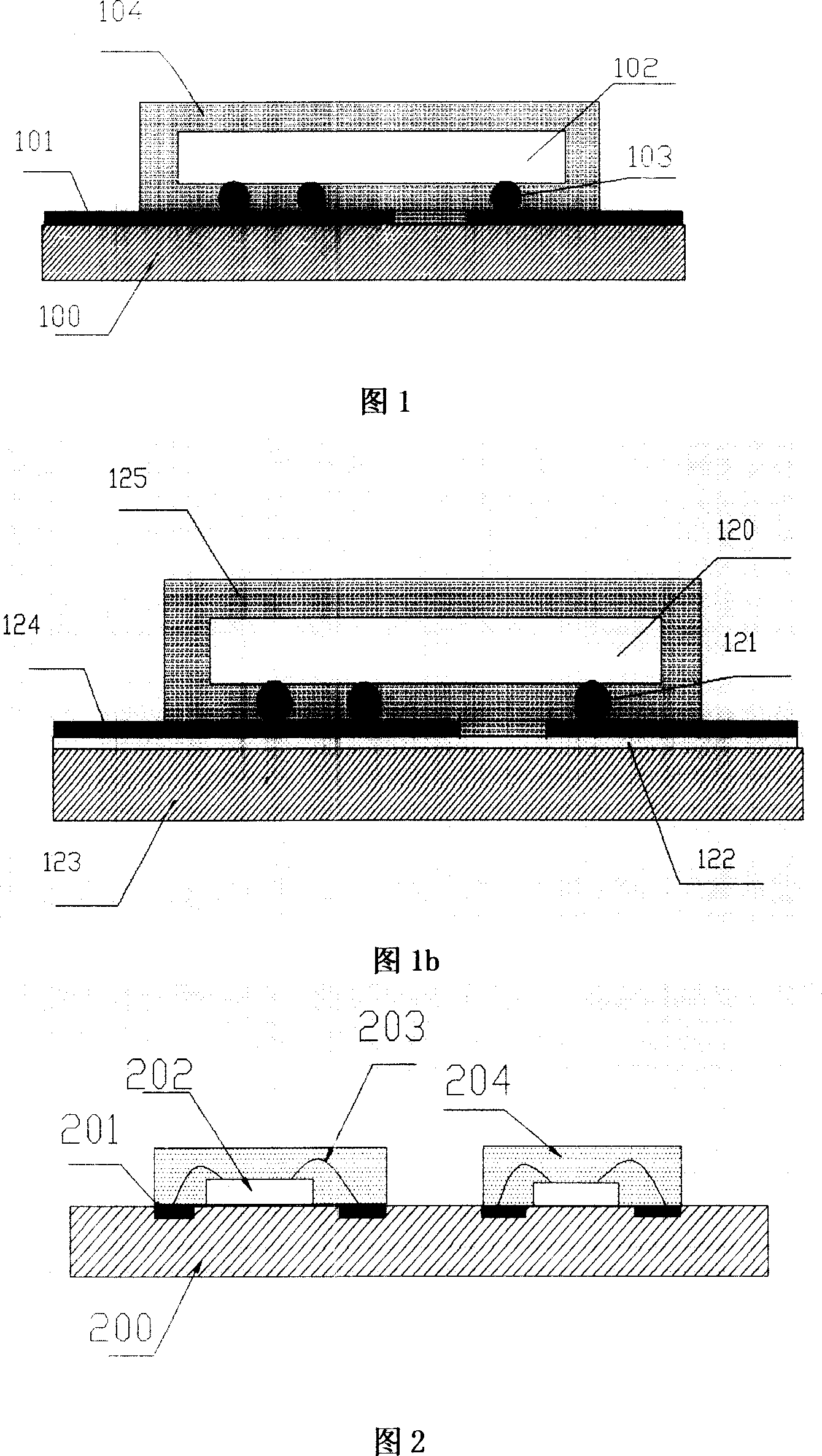

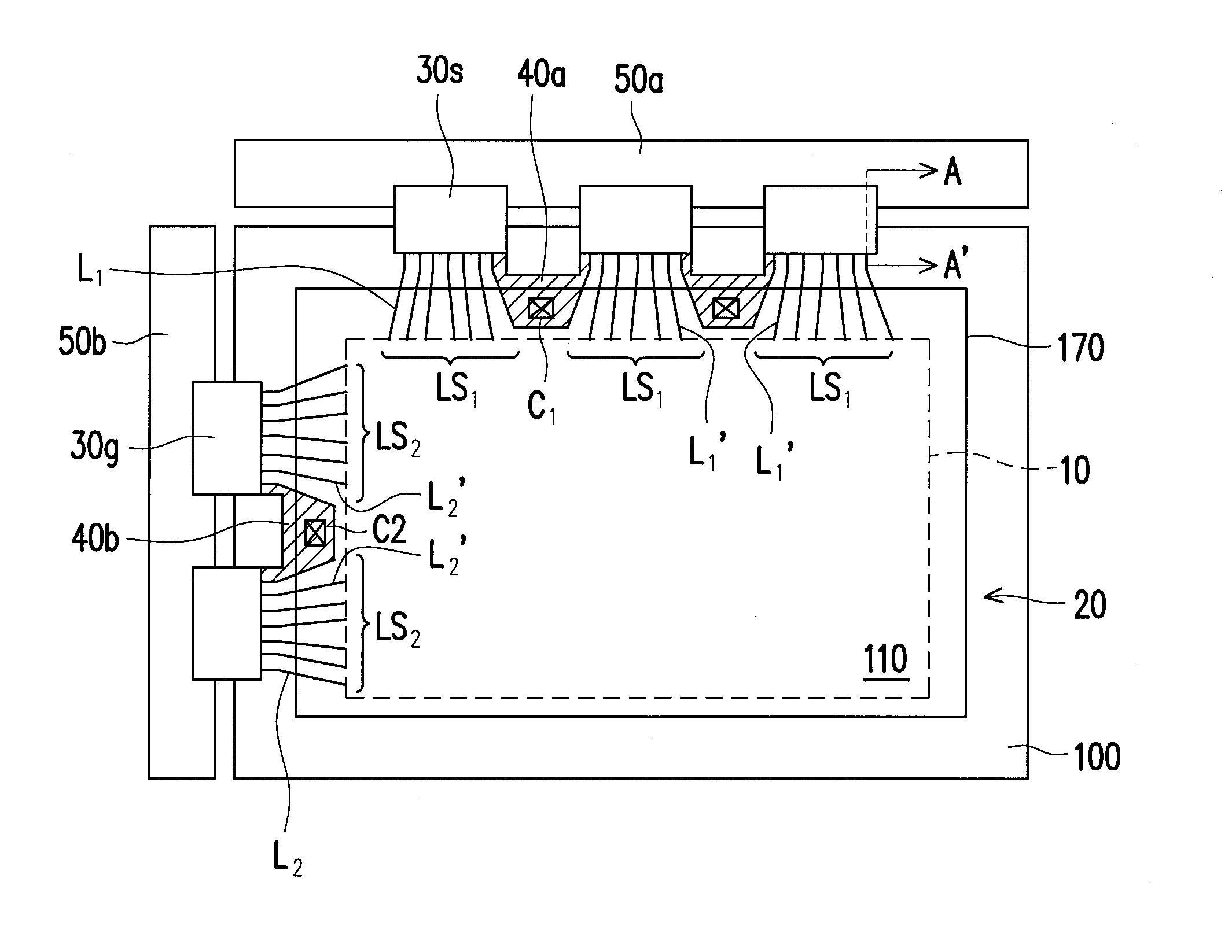

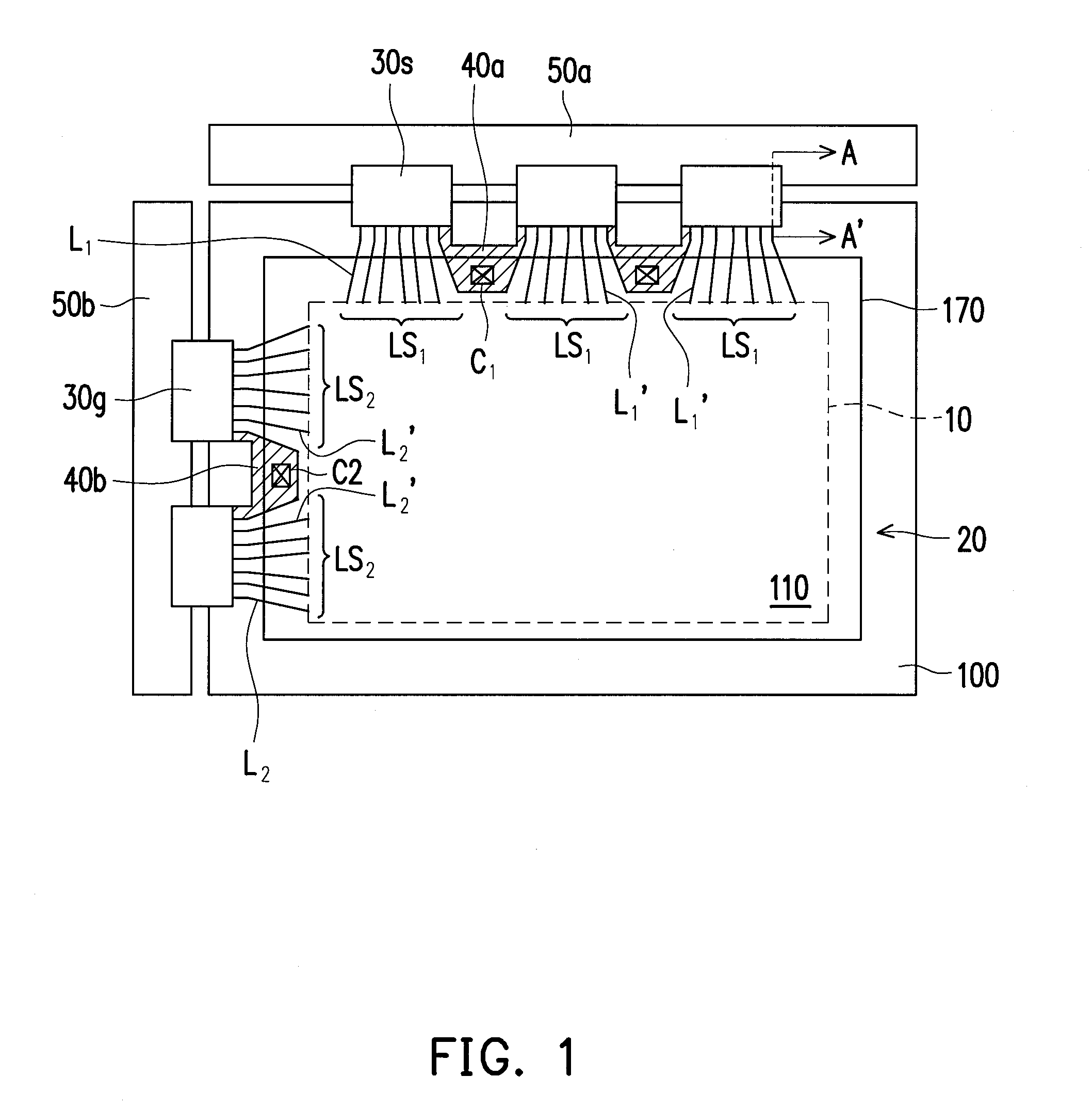

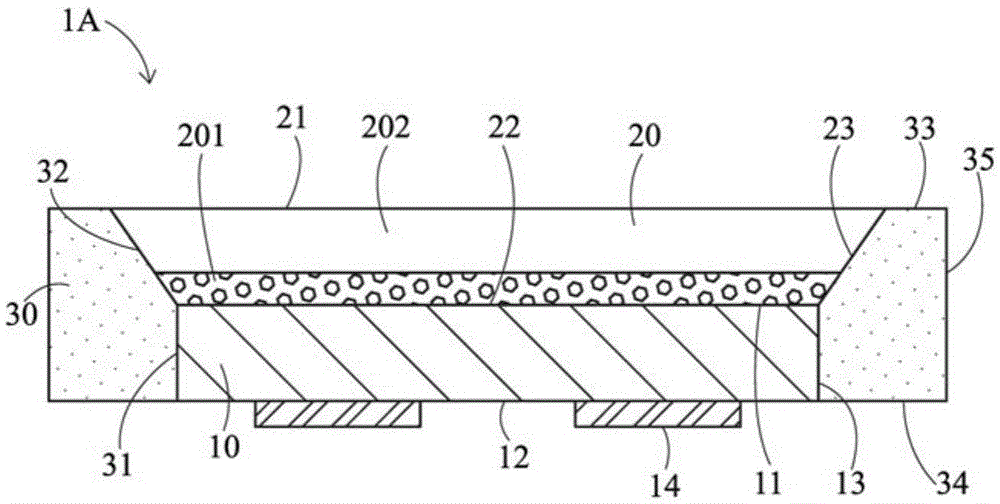

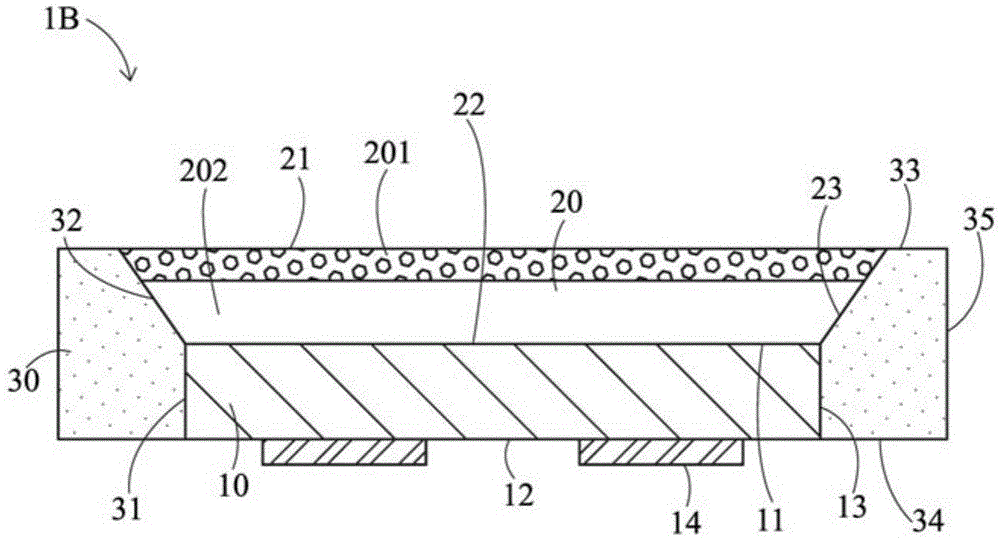

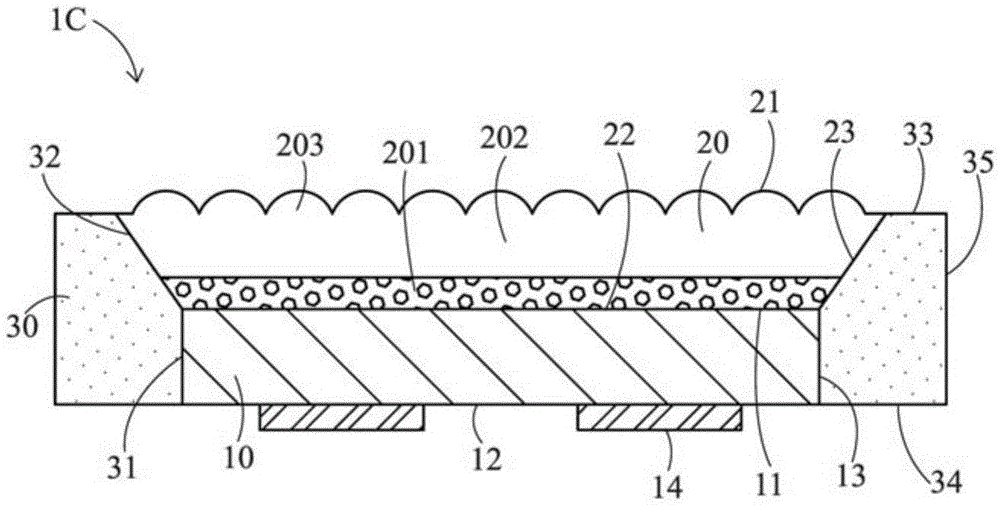

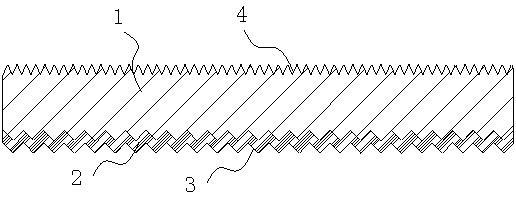

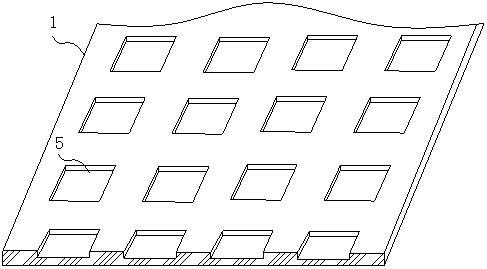

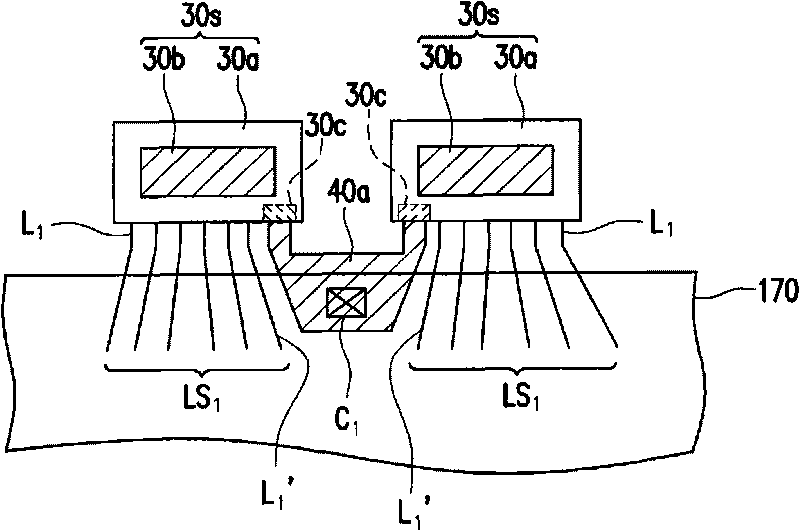

Light conducting board and backlight module

ActiveCN101078795AImprove uniformity of light emissionImprove light energy utilizationPlanar/plate-like light guidesNon-linear opticsDiffusionLight guide

The invention relates to a light guide plate, comprising a light inputting face, a light outputting face connected with the light inputting face and a reflection face opposite to the light outputting face. Whereinto, at least an extrusive diffusion part is set on the light inputting face on the light guide plate. A reflection hole is set at one side of the reflection face of light guide plate by the light diffusion part. The invention also provides a backlight module, comprising a light guide plate. The light guide plate comprises a light inputting face, a light outputting face connected with the light inputting face, a reflection face opposite to the light outputting face and at least a light source with lighting face. The light source is set at one side of light inputting face of light guide plate and the lighting face of light source is faced to the light inputting face of light guide plate. Whereinto, at least an extrusive diffusion part is set on the light inputting face on the light guide plate at the corresponding position of light source. A reflection hole is set at one side of the reflection face of light guide plate by the light diffusion part.

Owner:TSINGHUA UNIV +1

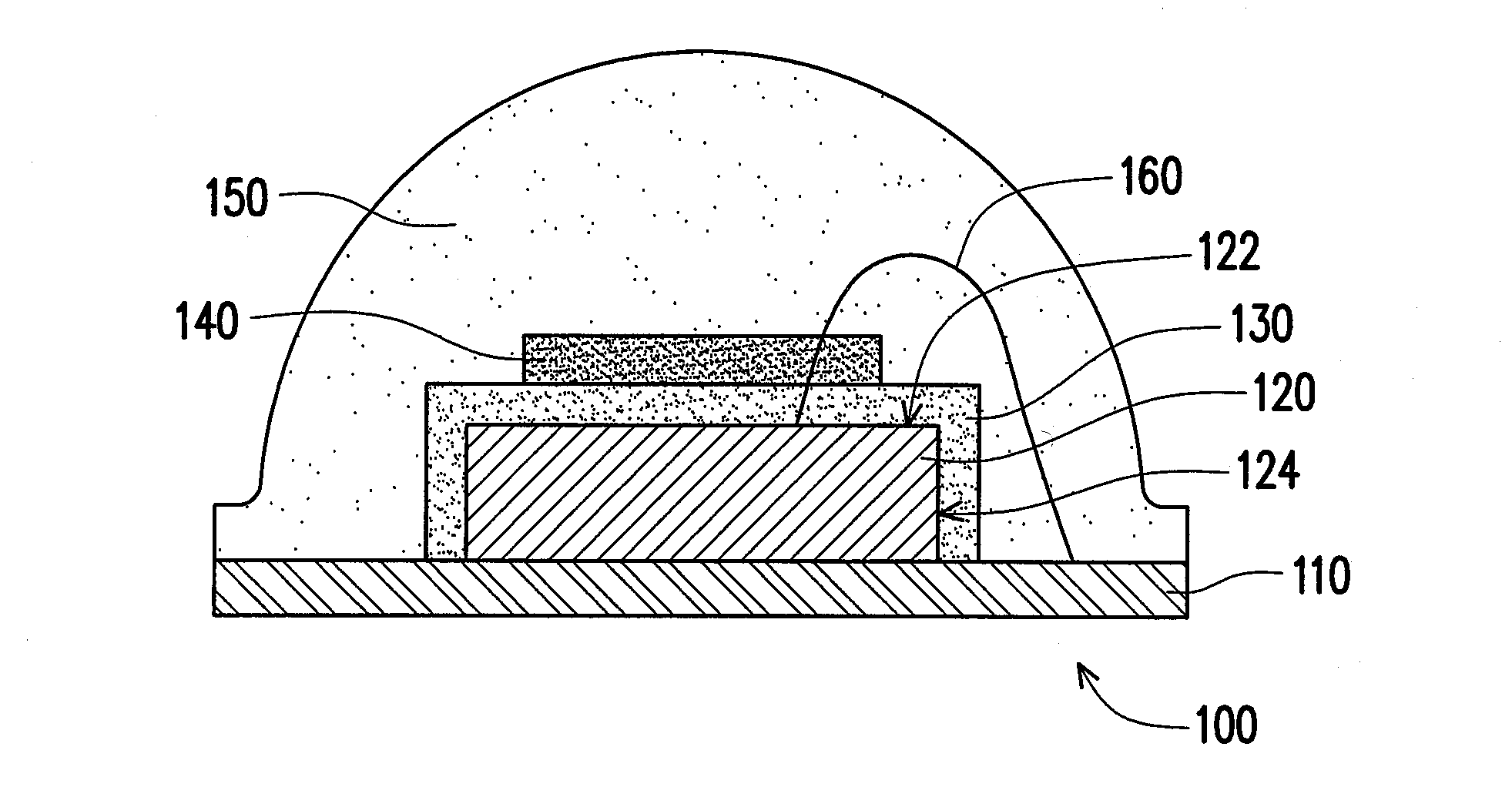

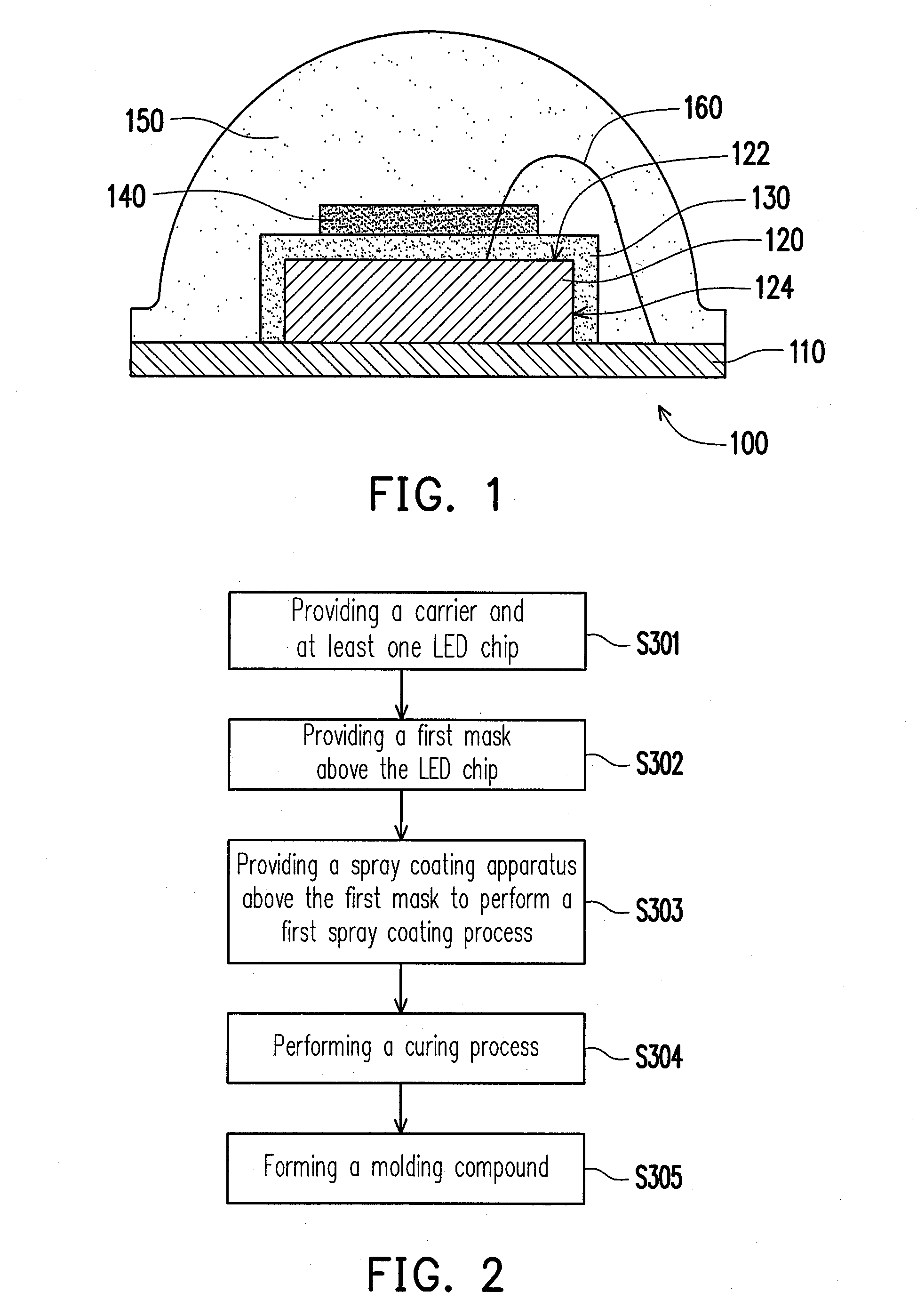

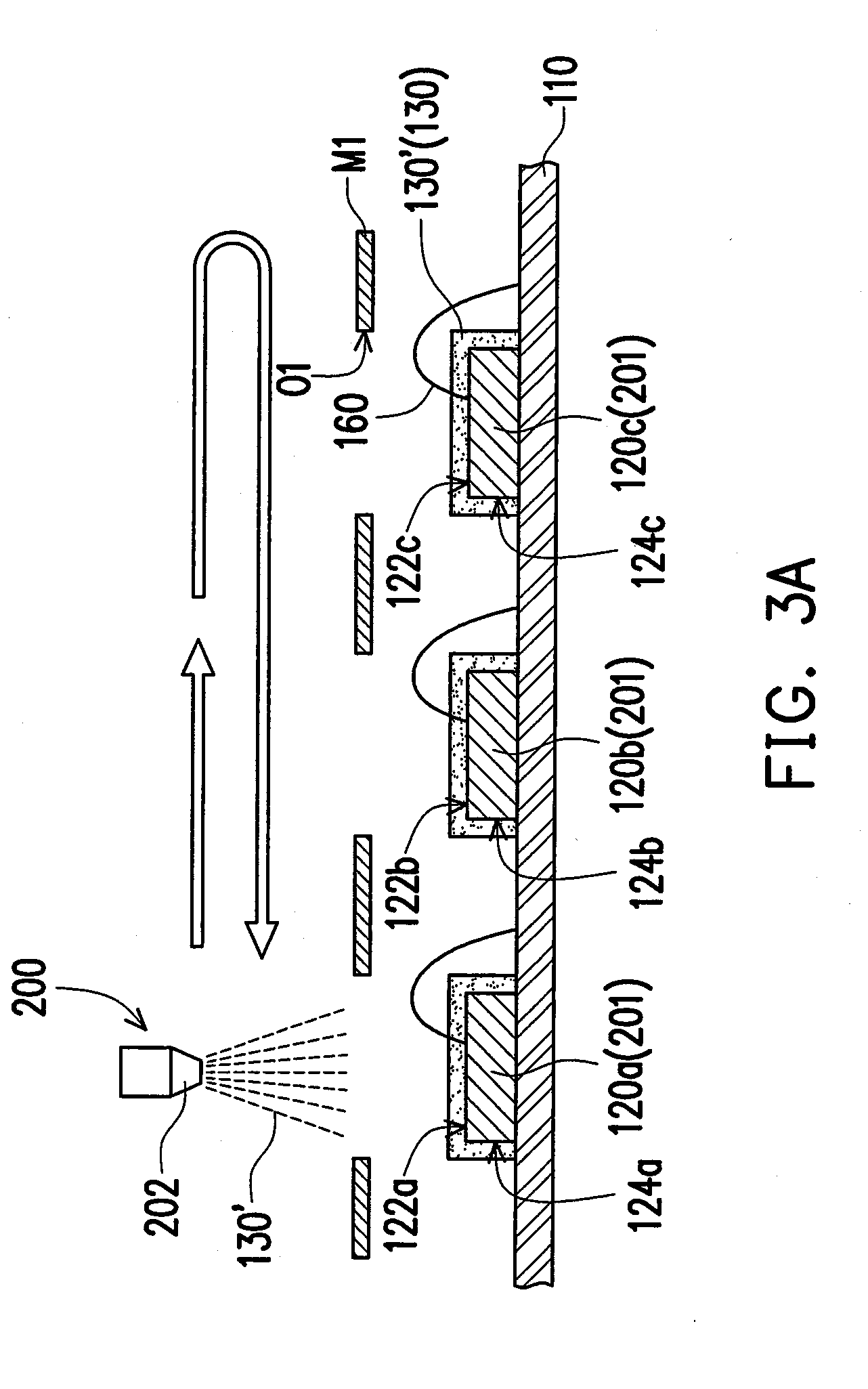

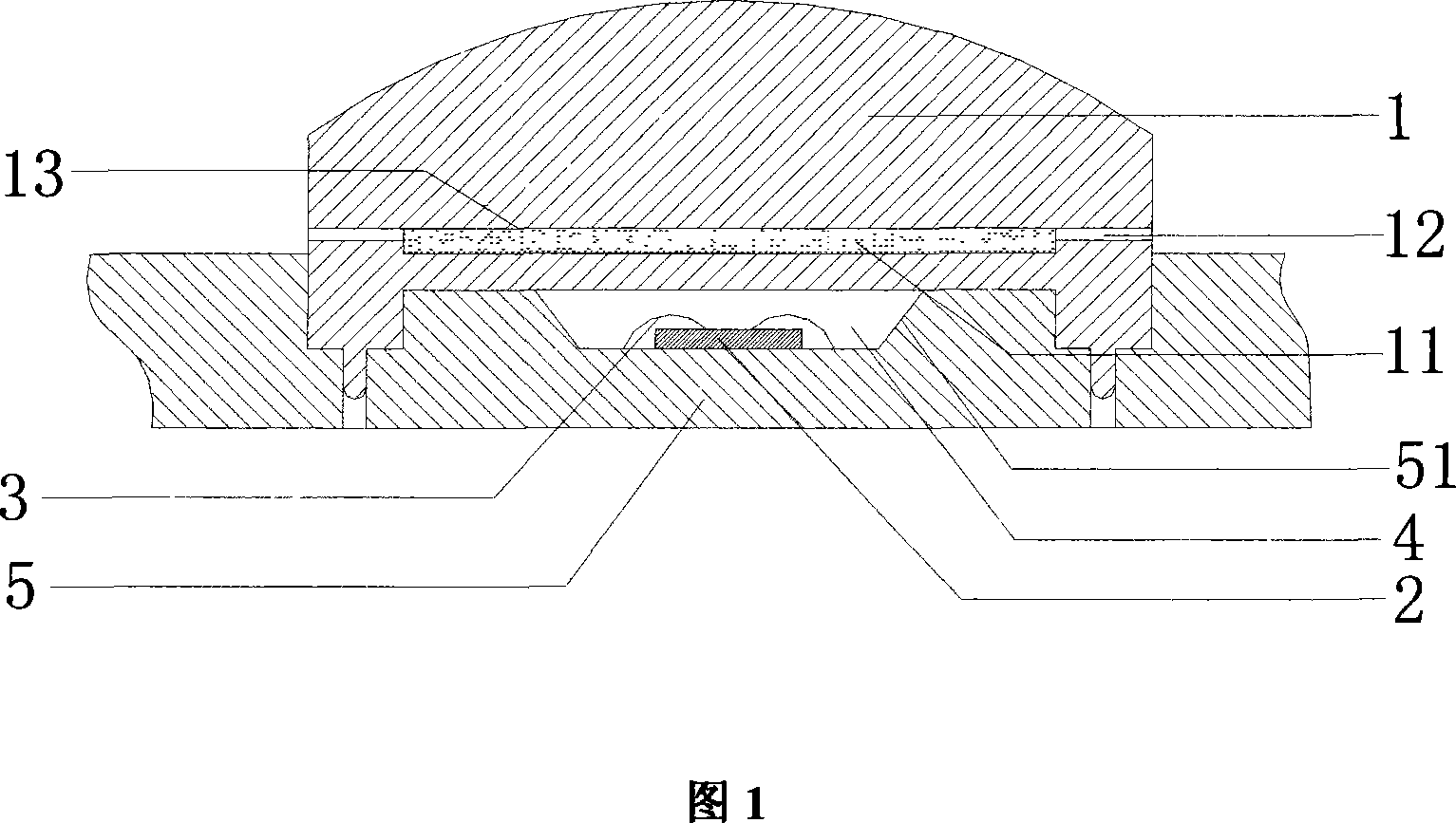

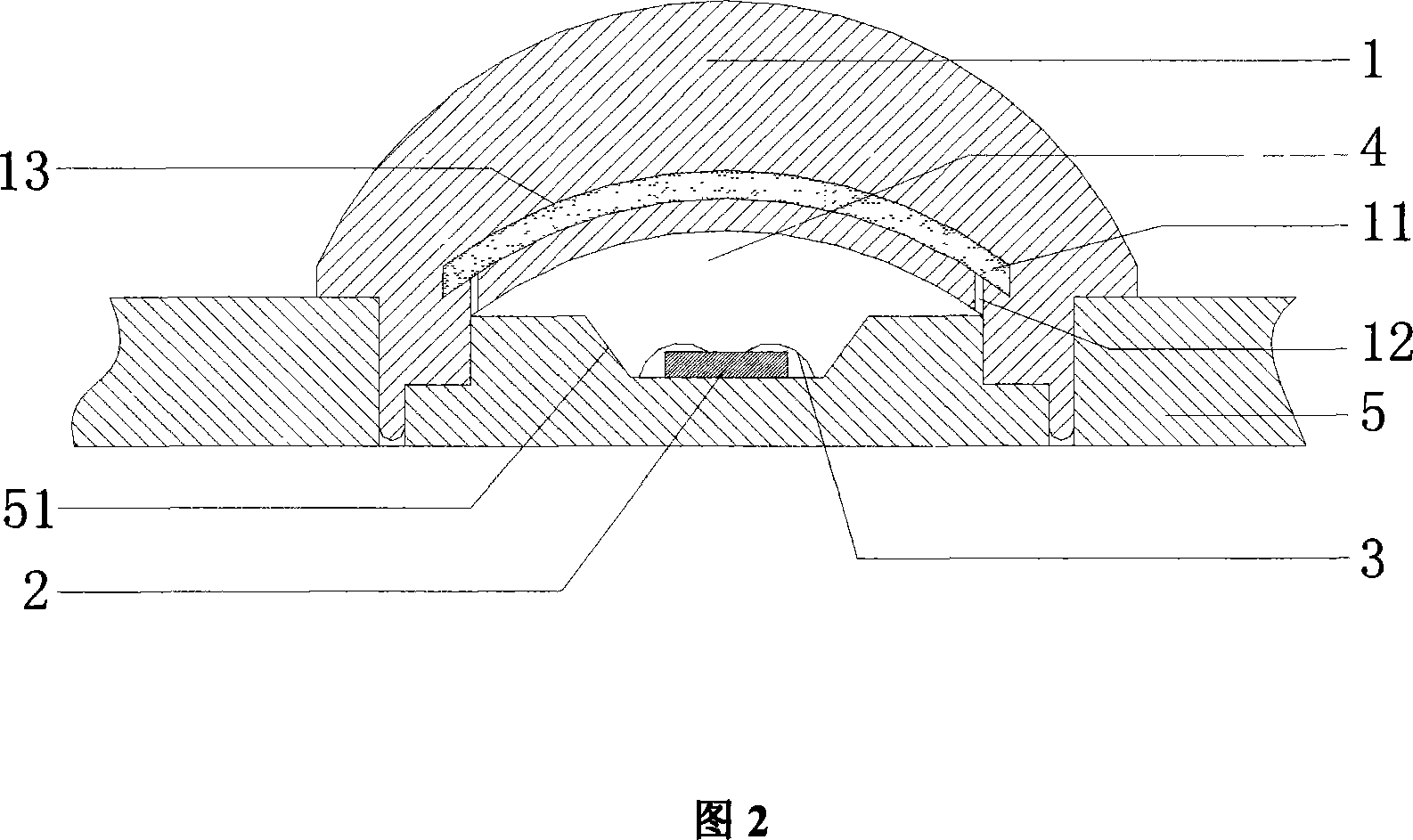

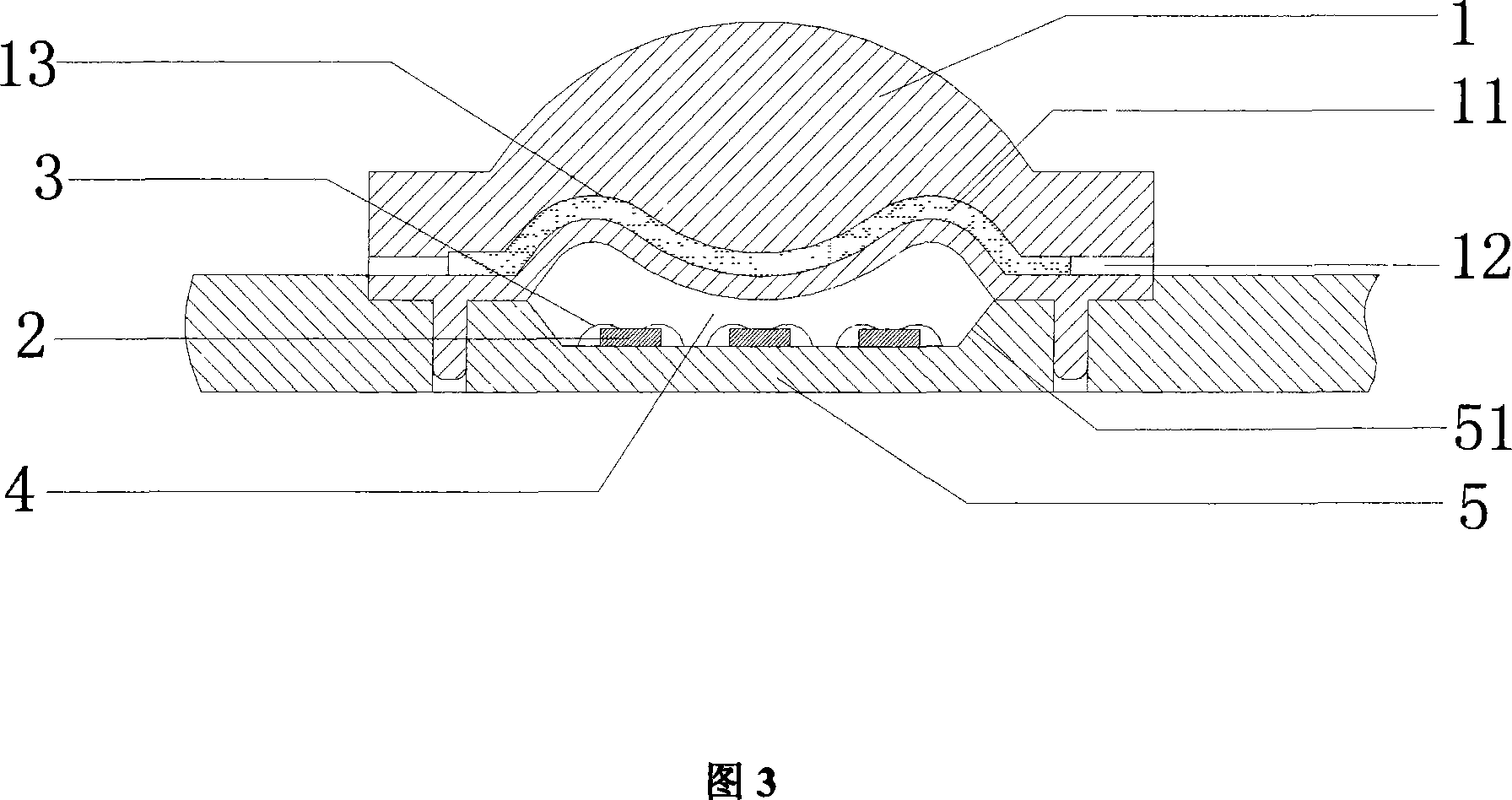

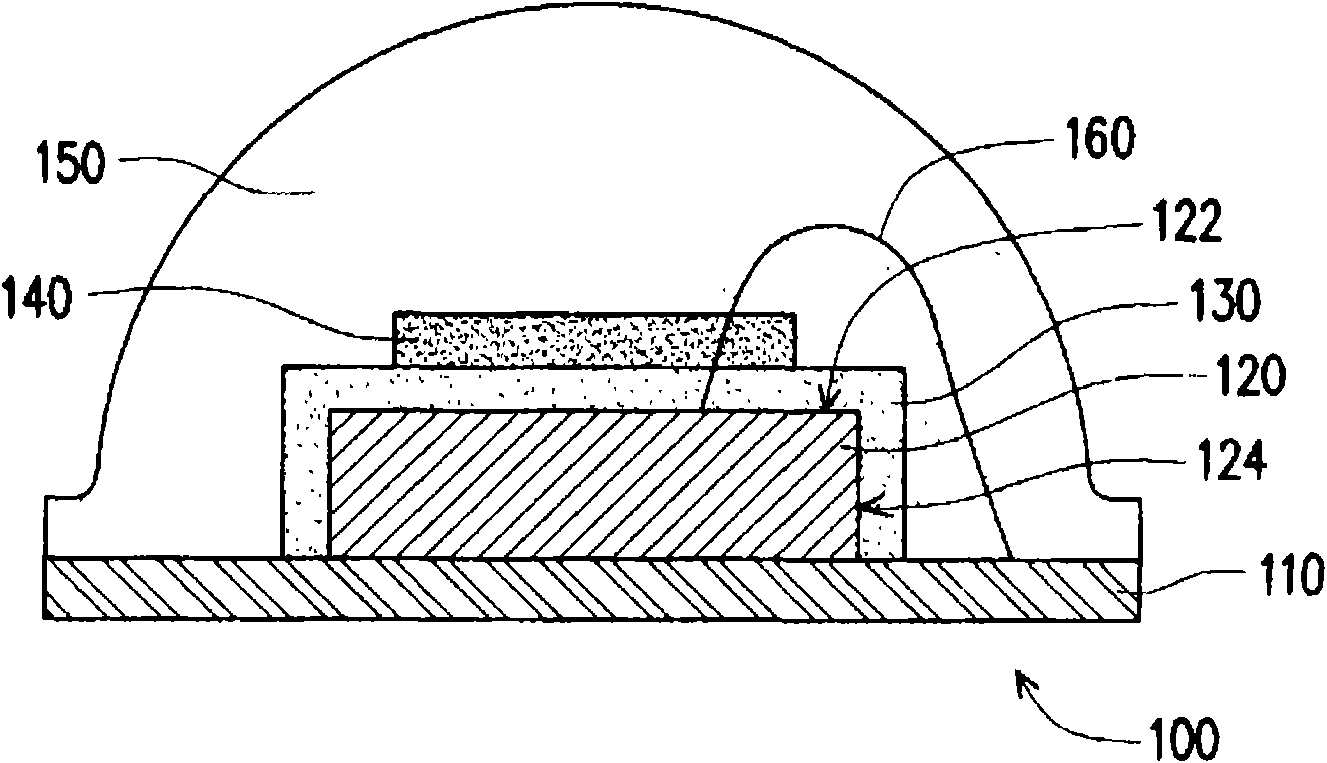

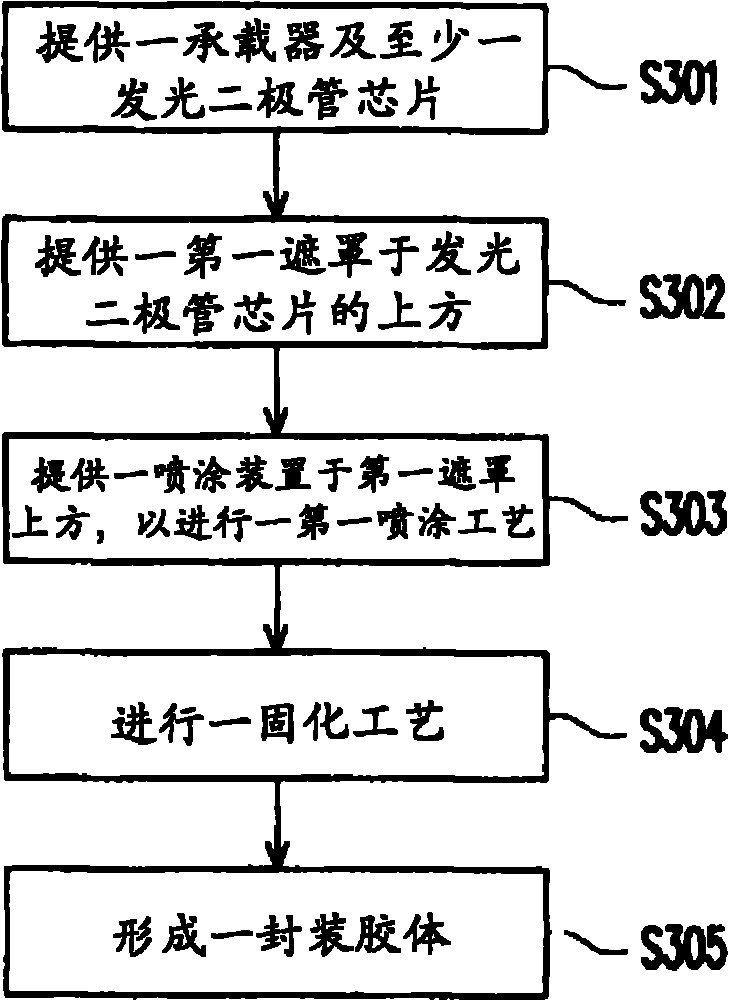

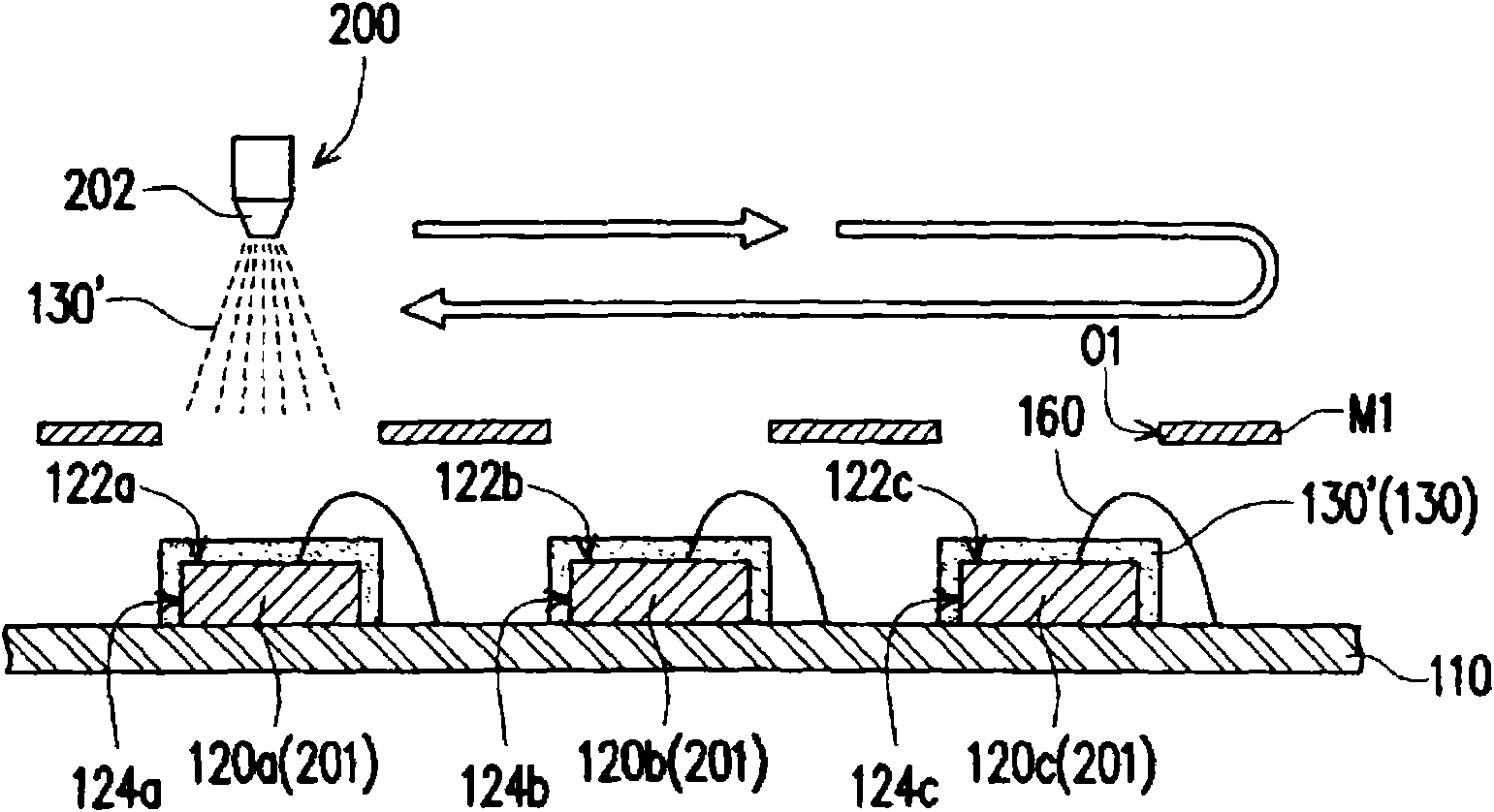

Light emitting diode package structure and manufacturing method thereof

InactiveUS20100237775A1Improve uniformity of light emissionLight emitting uniformityDischarge tube luminescnet screensLamp detailsPhosphorSpray coating

A method of fabricating a light emitting diode (LED) package structure is provided. A carrier and at least one LED chip having a light emitting surface and a plurality of side surfaces are provided. A first mask having at least one first opening is provided, and the first opening at least exposes the LED chip. A spray coating apparatus is provided above the first mask to perform a first spray coating process. The spray coating apparatus moves back and forth to spray a first phosphor solution over the LED chip so that the light-emitting surface and the side surfaces of the LED chip can be conformally covered by the sprayed first phosphor solution. The first phosphor solution is cured to form a first fluorescent layer by performing a curing process. A molding compound is formed to encapsulate the first fluorescent layer and a portion of the carrier.

Owner:EVERLIGHT ELECTRONICS

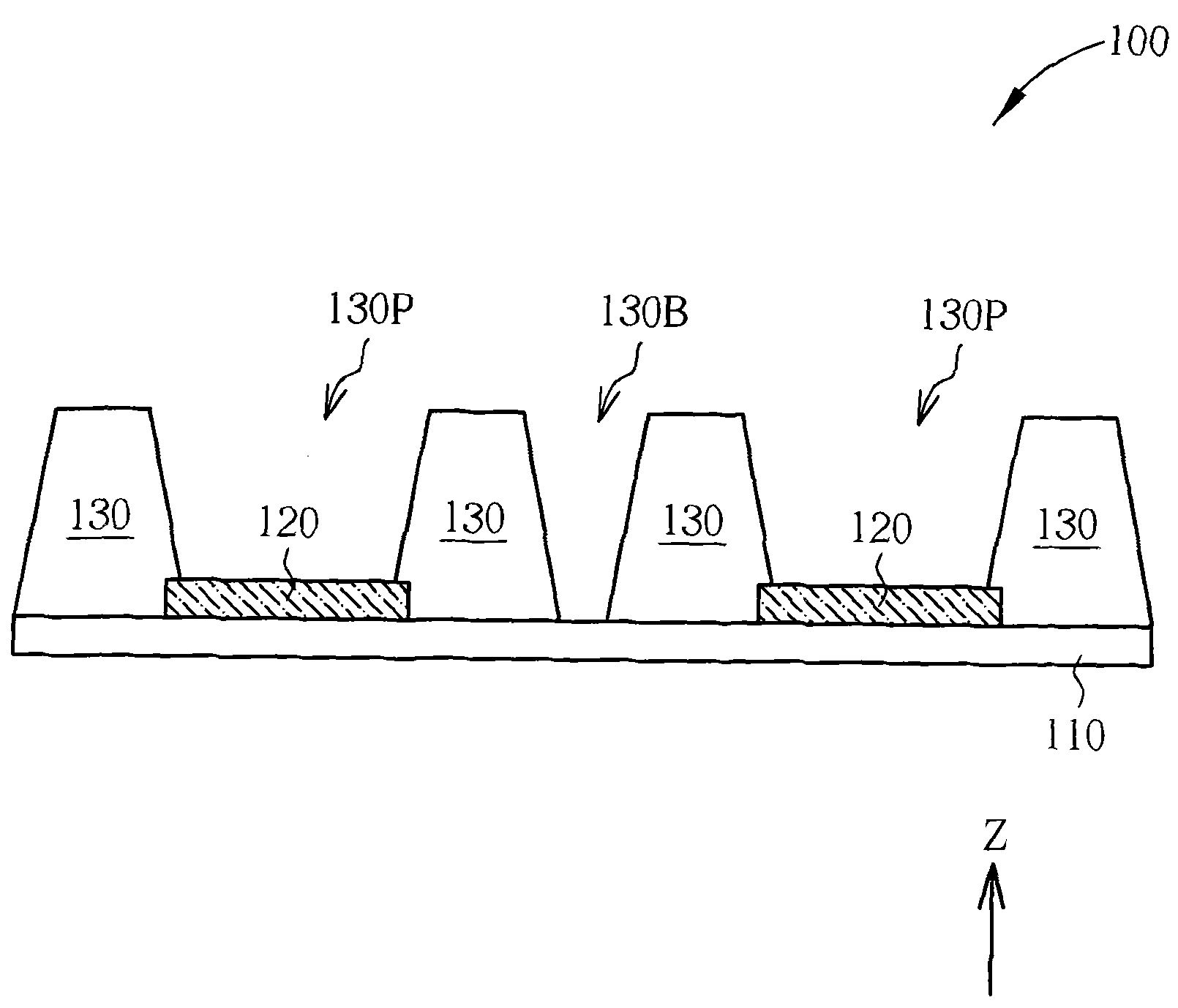

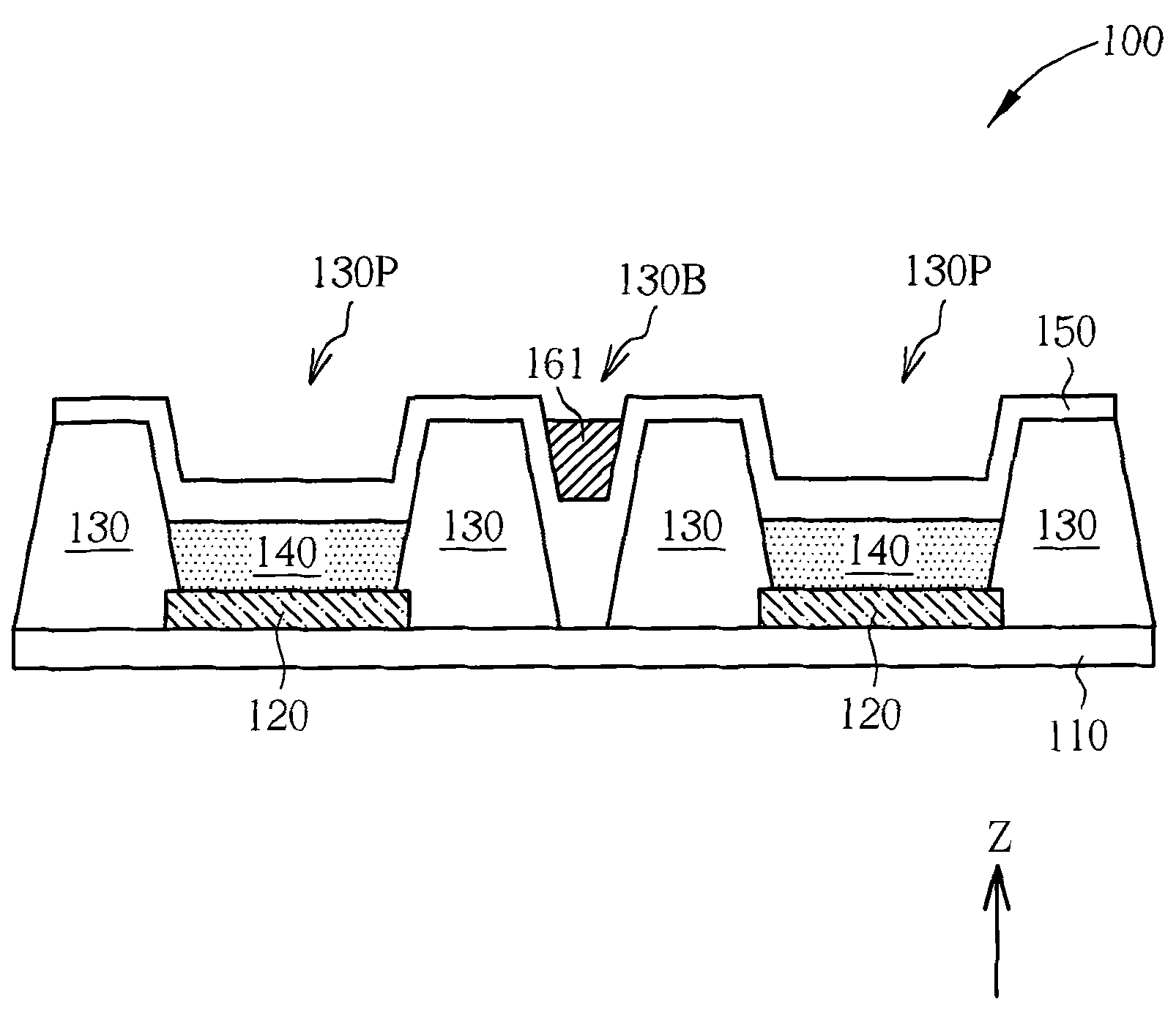

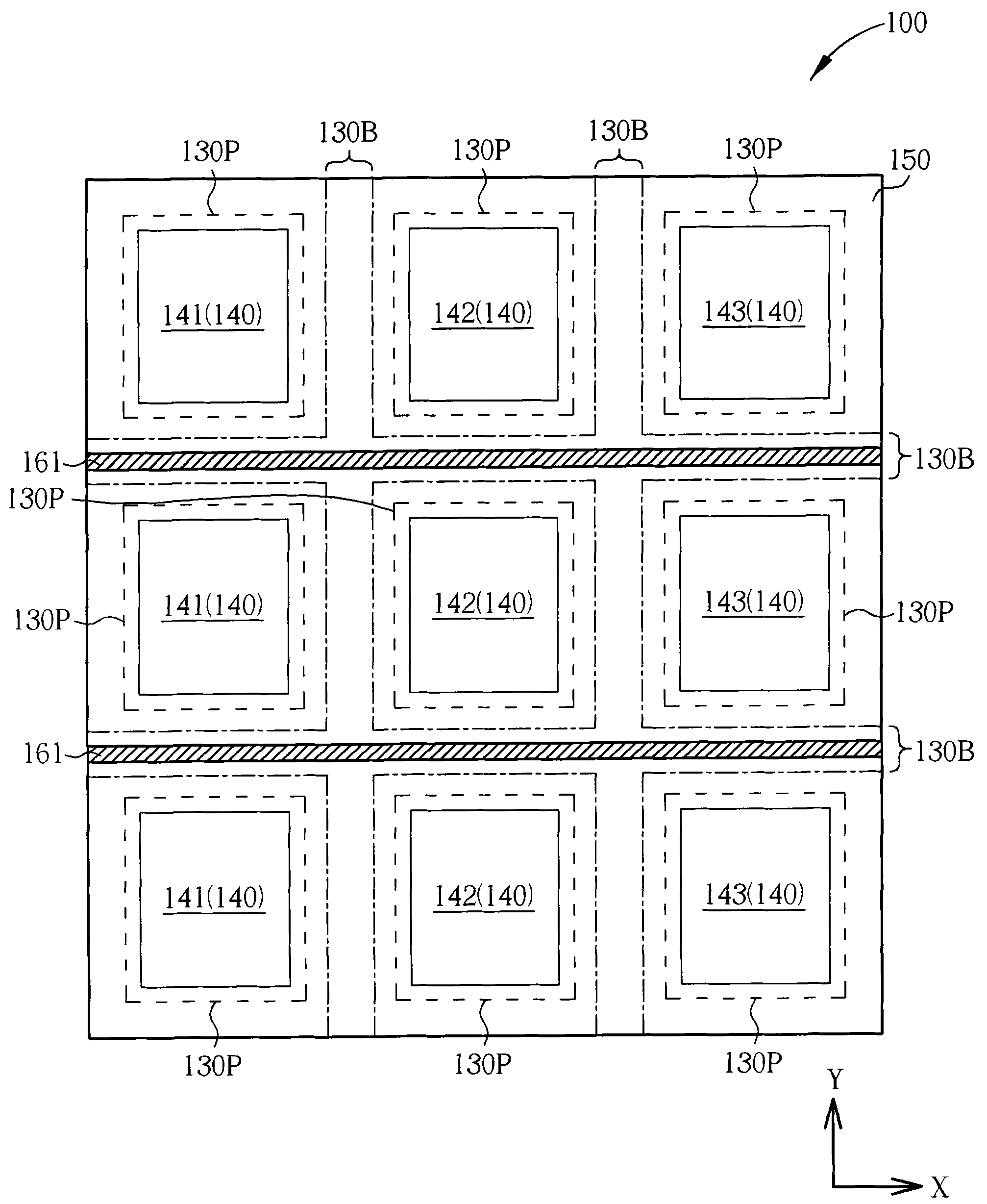

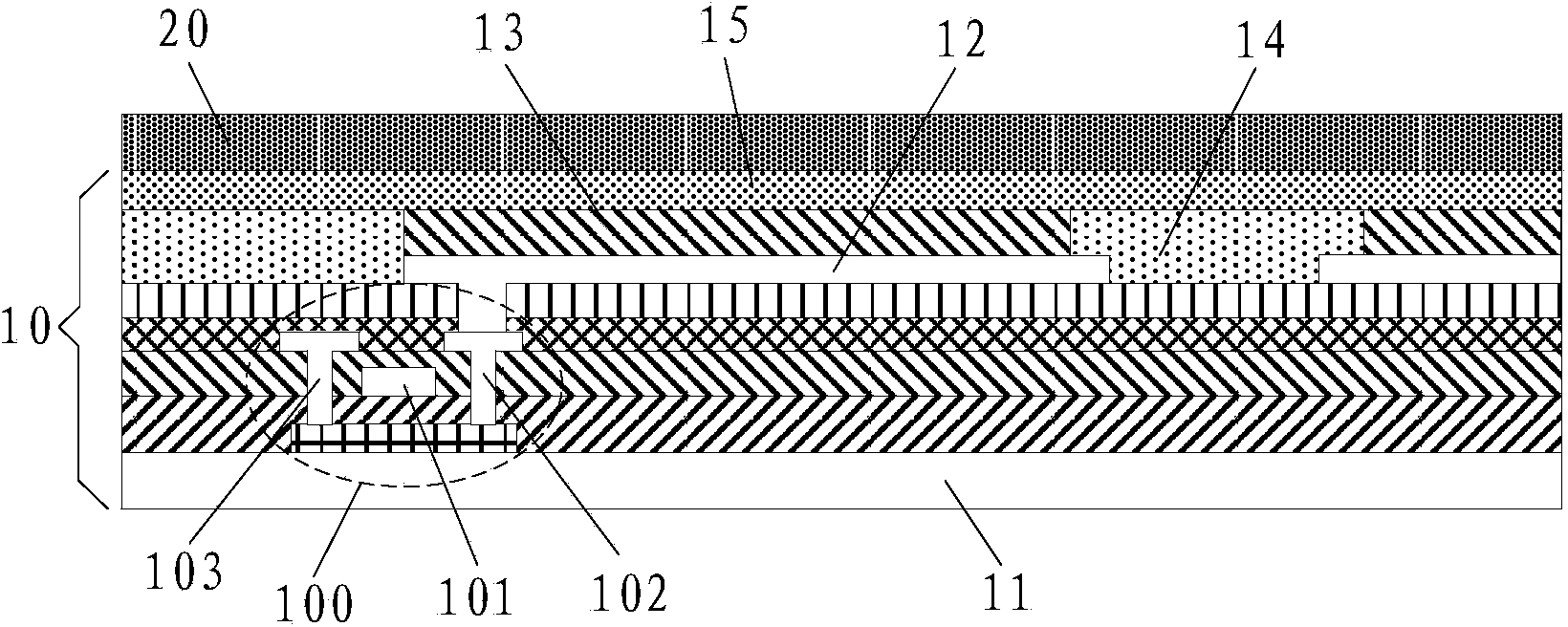

Display panel and manufacturing method thereof

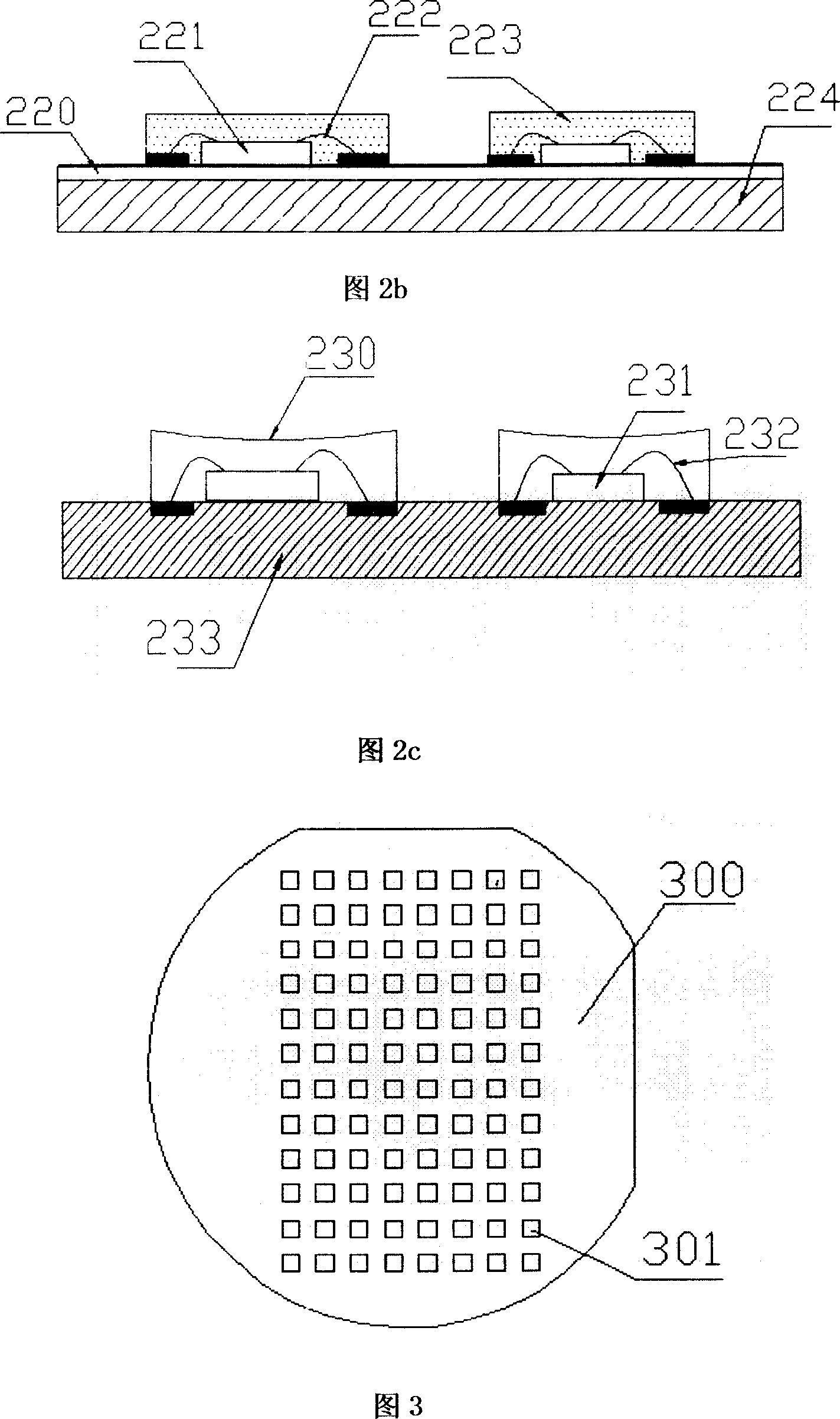

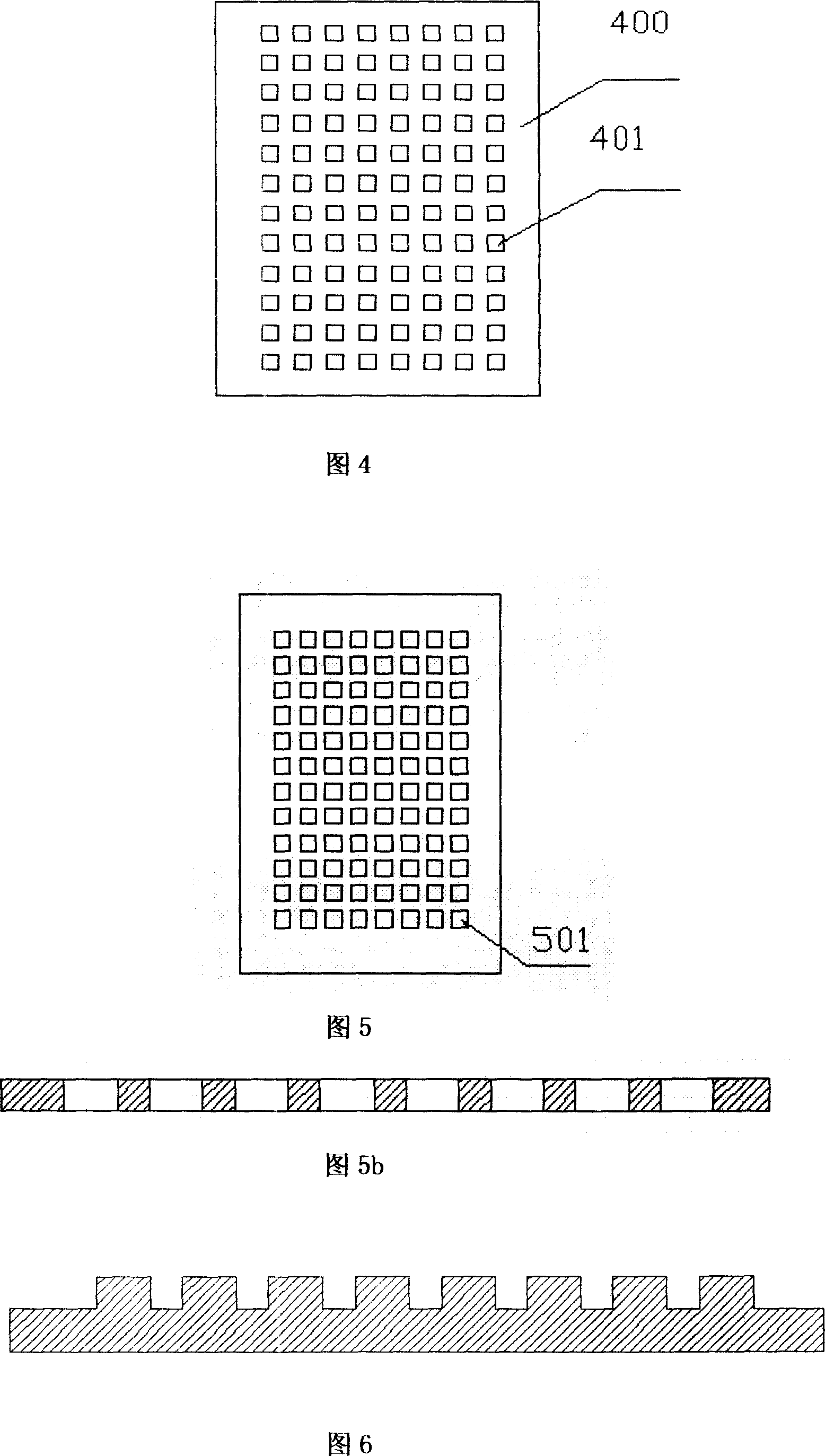

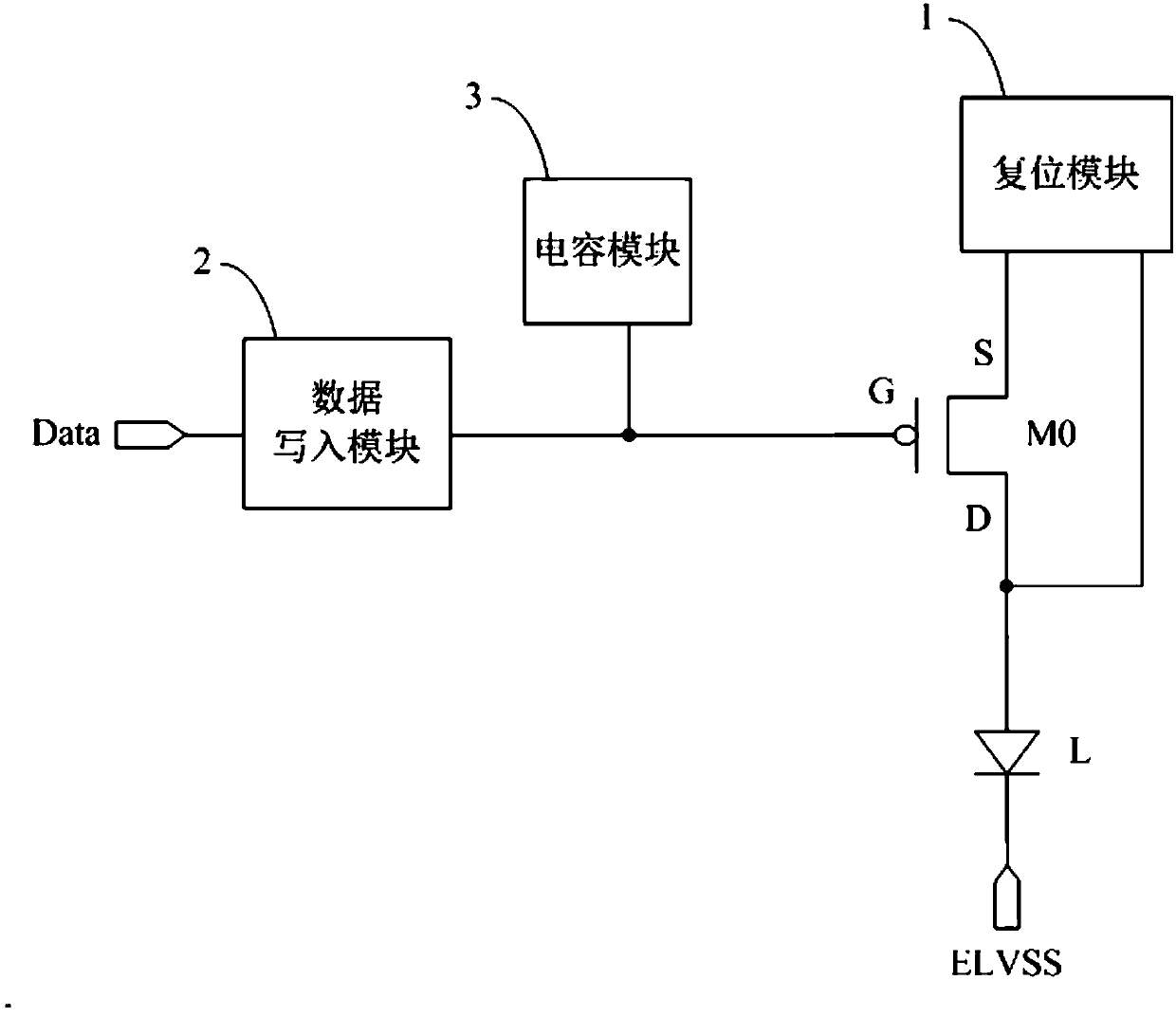

InactiveCN102623644AImprove uniformity of light emissionSimple processSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringAuxiliary electrode

The invention discloses a display panel and a manufacturing method thereof. The display panel comprises a substrate, multiple lower electrodes, a separating layer, multiple light-emitting layers, an upper electrode and at least a first auxiliary electrode. The lower electrodes and the separating layer are arranged on the substrate. The separating layer has multiple pixel region openings and at least one buffer region. The pixel region openings expose the corresponding lower electrodes, respectively. The buffer region is disposed between two adjacent pixel region openings. The light-emitting layers are arranged on the corresponding lower electrodes, respectively. The upper electrode covers the light-emitting layers, the separating layer and the buffer layer. The first auxiliary electrode is provided in the buffer layer.

Owner:AU OPTRONICS CORP

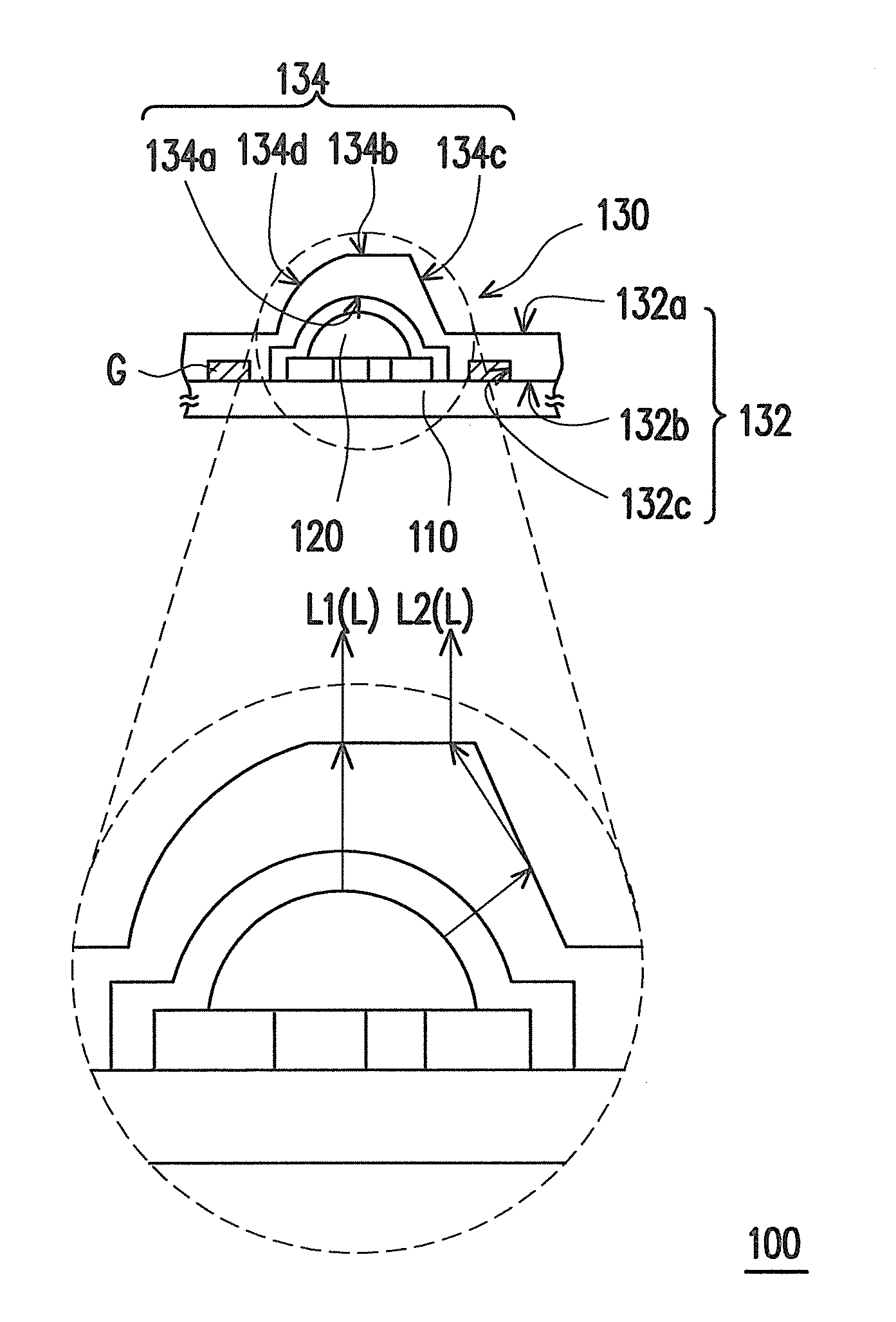

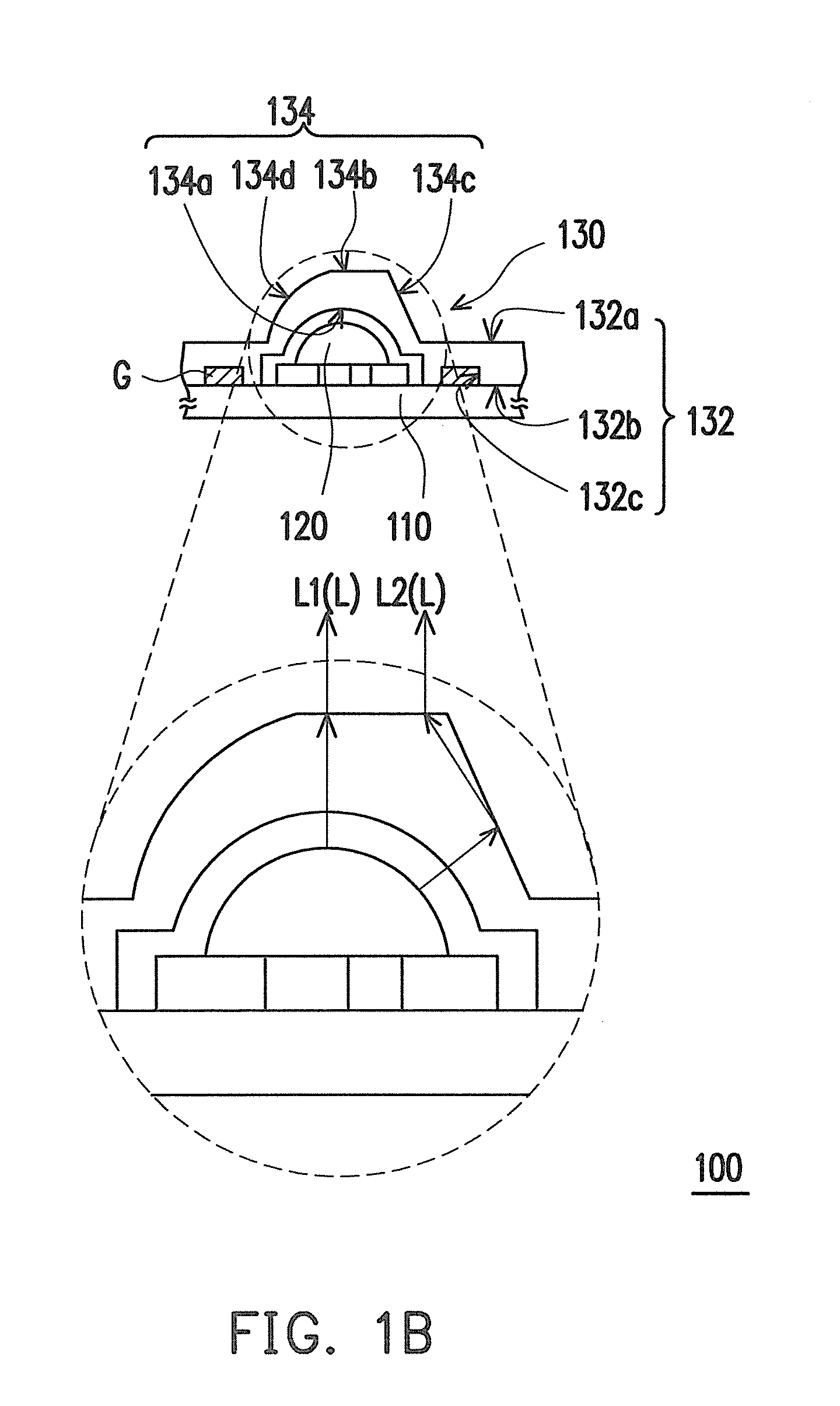

Light emitting device

InactiveUS20100295071A1Improve uniformity of light emissionLight intensityPlanar light sourcesPoint-like light sourceLight beamLight emitting device

A light emitting device includes a carrier, a light emitting element electrically connected to the carrier, a transparent plate having at least one through hole formed therein and including a flat-portion and a lens-portion and a permeable membrane structure disposed on a surface of the transparent plate. The lens-portion covers the light emitting element and has a light incident surface, a light emitting surface, a first and a second side surfaces. A first partial beam of the light beam passes through the light incident surface and leaves from the light emitting surface. A second partial beam of the light beam passes through the light incident surface and is transmitted to the first or the second side surface. The first or the second side surface reflects at least a part of the second partial beam of the light beam to be passed through the light emitting surface.

Owner:EVERLIGHT ELECTRONICS

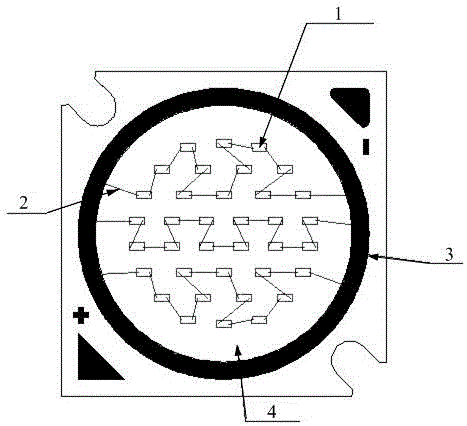

Encapsulation method for high-brightness white light LED

ActiveCN101123284AImprove uniformity of light emissionImprove consistencySolid-state devicesSemiconductor/solid-state device manufacturingPhosphorLuminescence

A packaging method for high-brightness light-emitting diode of white light mainly comprises a light-emitting diode chip, a radiating substrate and a phosphor glue film. The invention is characterized in that the light-emitting diode chip is welded on the substrate, a mould coated with the mould release is positioned on the radiating substrate by pressurizing, the package resin containing phosphor is poured into the mould, then glue film with uniform thickness and containing phosphor is formed on the upper surface and lateral surface of the light-emitting diode chip after evacuation, solidification and mold release. The invention has the advantages that a glue film containing phosphor with uniform thickness formed on the external surface of the light-emitting diode chip promotes the uniformity and consistency of luminescence from the light-emitting diode chip, and promotes the production efficiency of packaging.

Owner:GUANGDONG REAL FAITH LIGHTING TECH

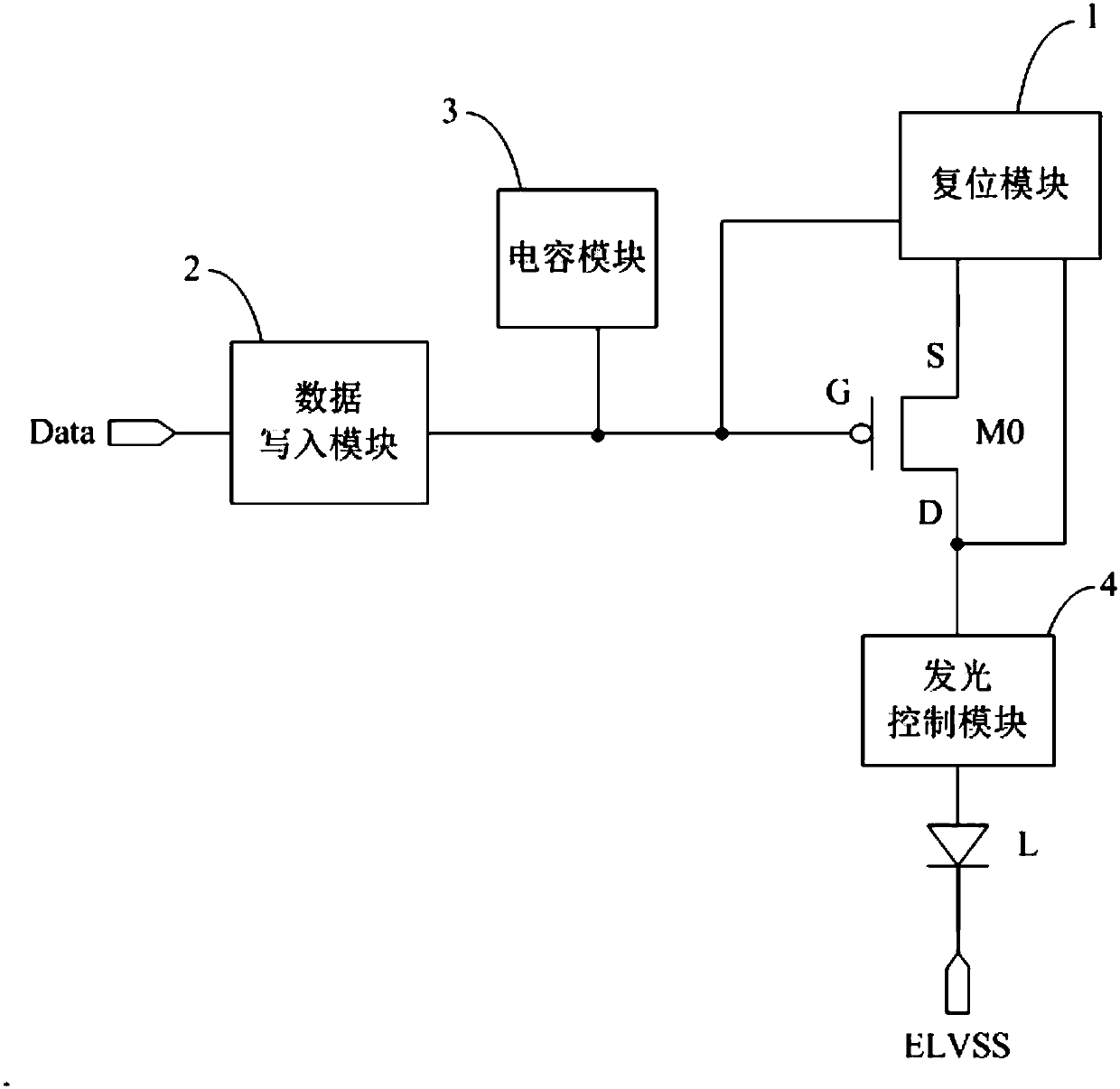

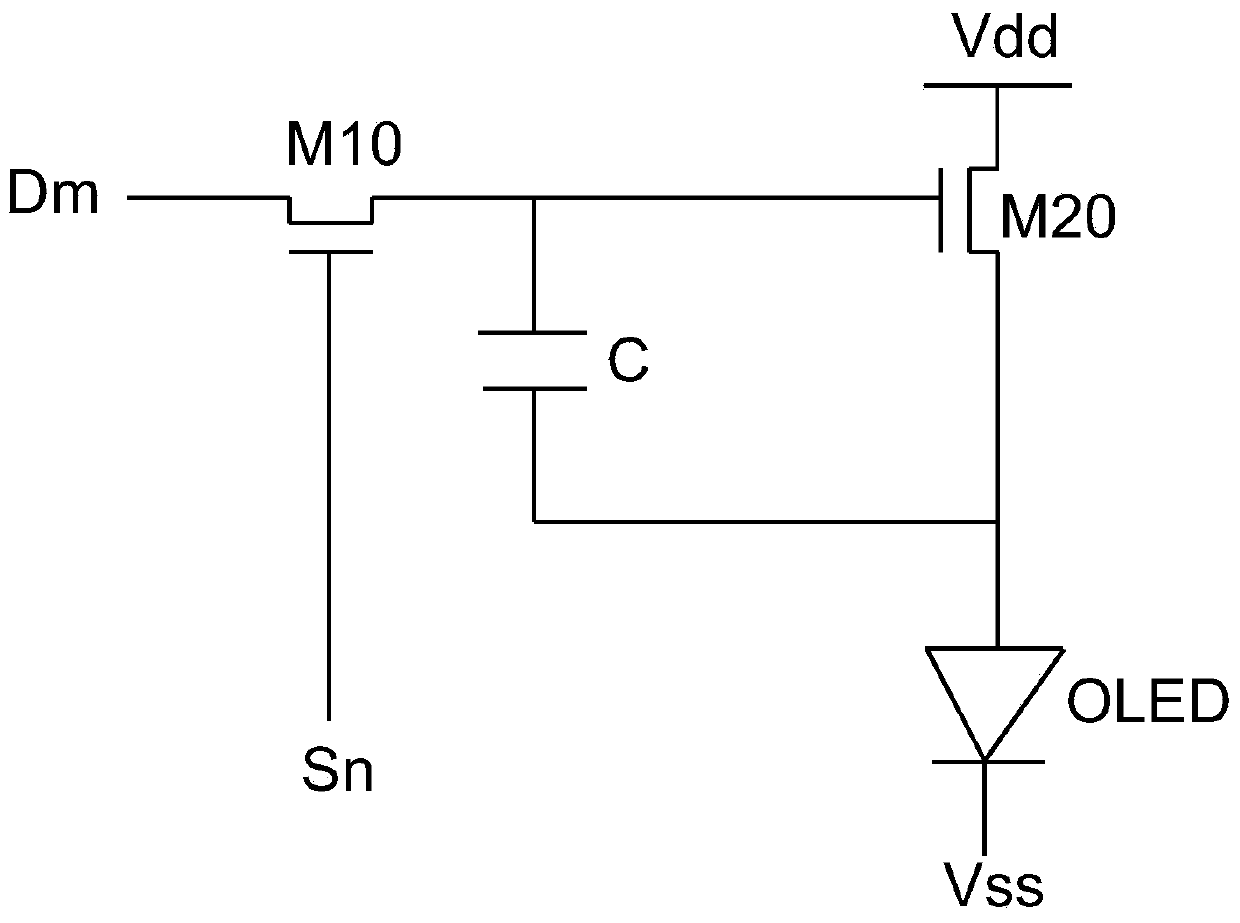

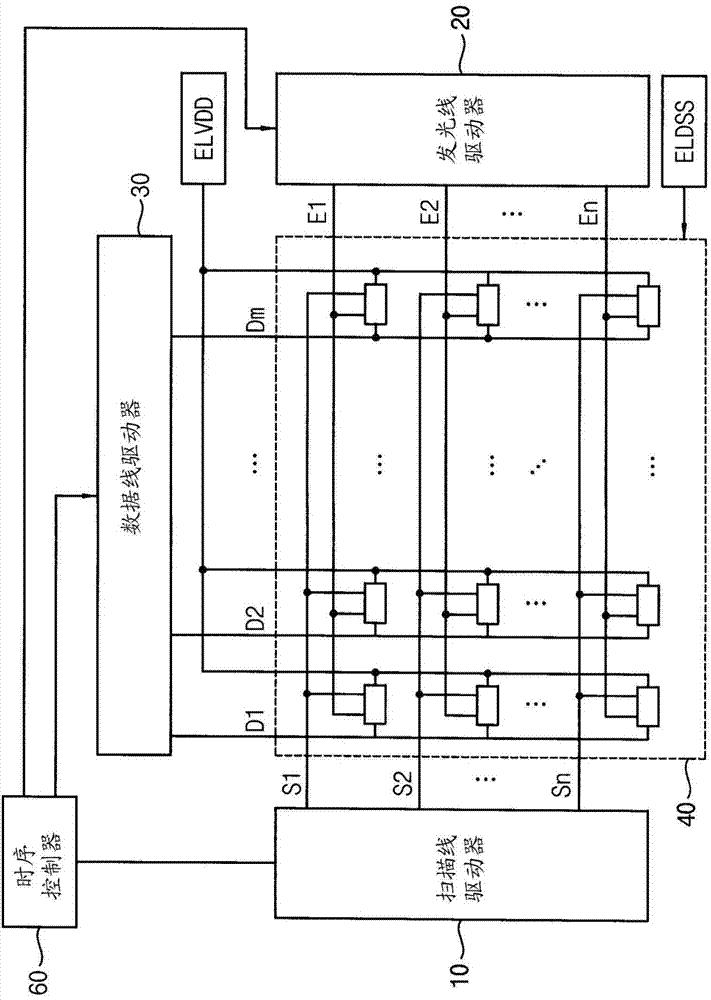

Pixel circuit, driving method, electroluminescent display panel and display device

ActiveCN108206008AImprove uniformity of light emissionAvoid the effects of lightStatic indicating devicesDriving currentElectricity

The invention discloses a pixel circuit, a driving method, an electroluminescent display panel and a display device. A first pole and a second pole of a driving transistor can be reset in the reset phase by a reset module, and then data signals are written by a data writing module into a grid of the driving transistor, and a driving current is generated by the driving transistor to drive a light emitting device to emit light. In this way, the voltage of the first pole of the driving transistor can be set to a fixed voltage and the voltage of the second pole of the driving transistor can be setto a fixed voltage before each writing of the data signals, so that the influence of the residual voltage of a previous frame on the light emission of the frame can be avoided, and the uniformity oflight emission of the display panel can be improved.

Owner:BOE TECH GRP CO LTD

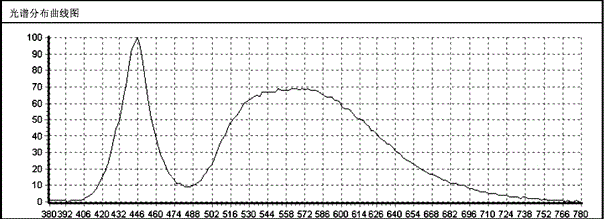

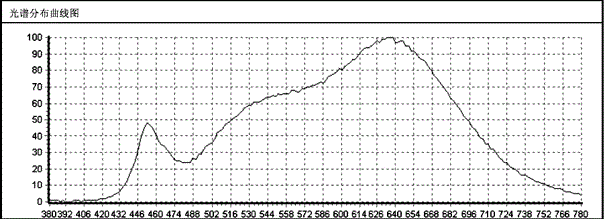

Full-spectrum LED light source

ActiveCN105870303ASave resourcesImprove uniformity of light emissionSolid-state devicesSemiconductor devicesSolar lightFluorescence

The invention discloses a full-spectrum LED light source. The full-spectrum LED light source comprises a substrate, an LED chip packaged on the substrate and fluorescent glue used for packaging the LED chip, wherein the fluorescent glue is formed by silica gel and fluorescent powder in a mixed manner; the fluorescent powder consists of yellow powder with the emission peak wavelength of 550-565nm, blue-green powder with the mission peak wavelength of 485-495nm, green powder with the mission peak wavelength of 515-525nm, yellow-green powder with the mission peak wavelength of 530-540nm and red powder with the mission peak wavelength of 650-660nm; and the weight ratio of the yellow powder to blue-green powder to green powder to yellow-green powder to red power is 1 to (0.1-0.5) to (0.2-0.4) to (0.15-1.2) to (0.08-0.5). By adoption of the full-spectrum LED light source, the LED light source spectrum can be closer to the solar spectrum, so that the full-spectrum LED light source is high in color rendering, and the color temperature of the full-spectrum LED light source is within the ideal solar light range.

Owner:FOSHAN EVERCORE OPTOELECTRONICS TECH

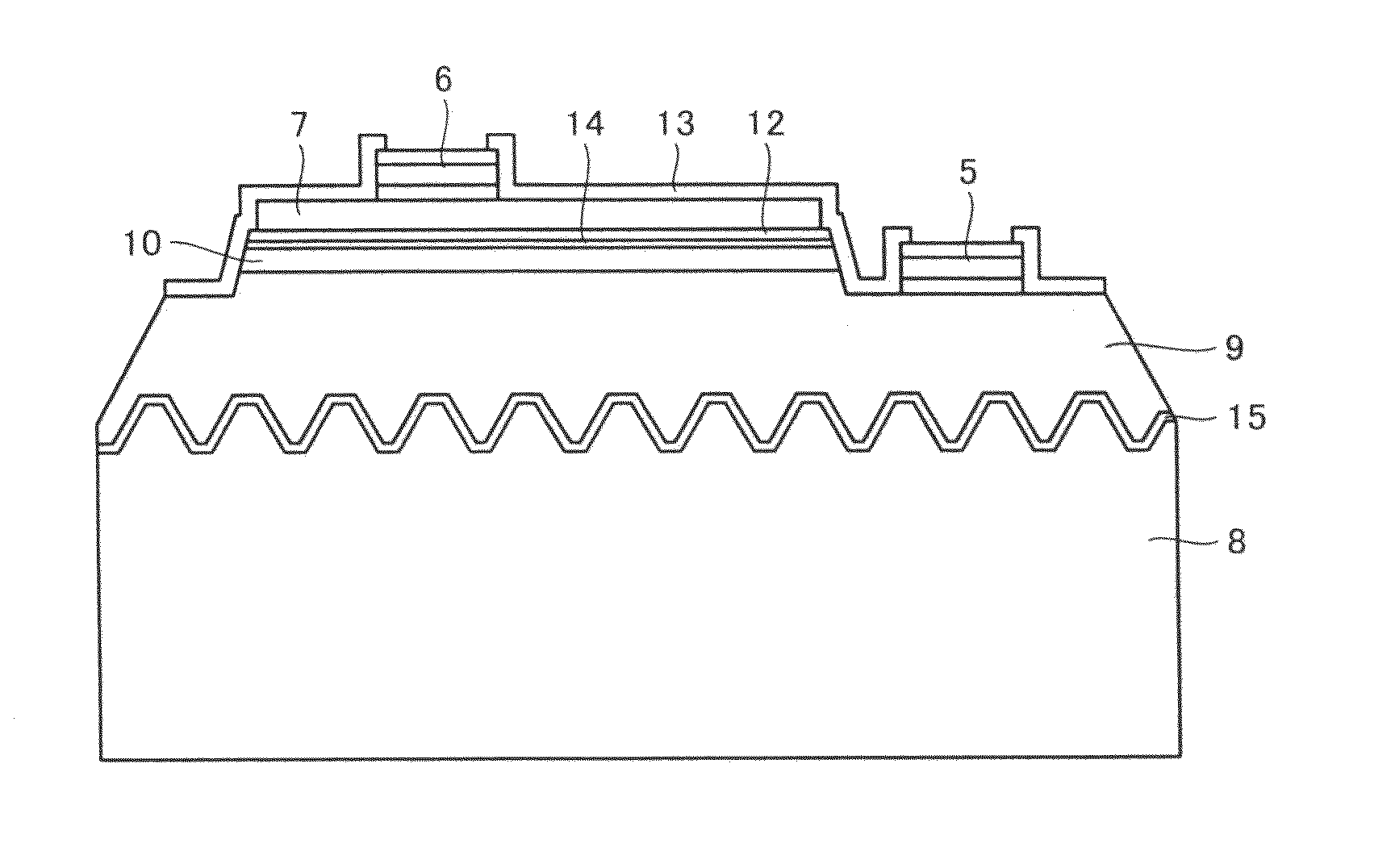

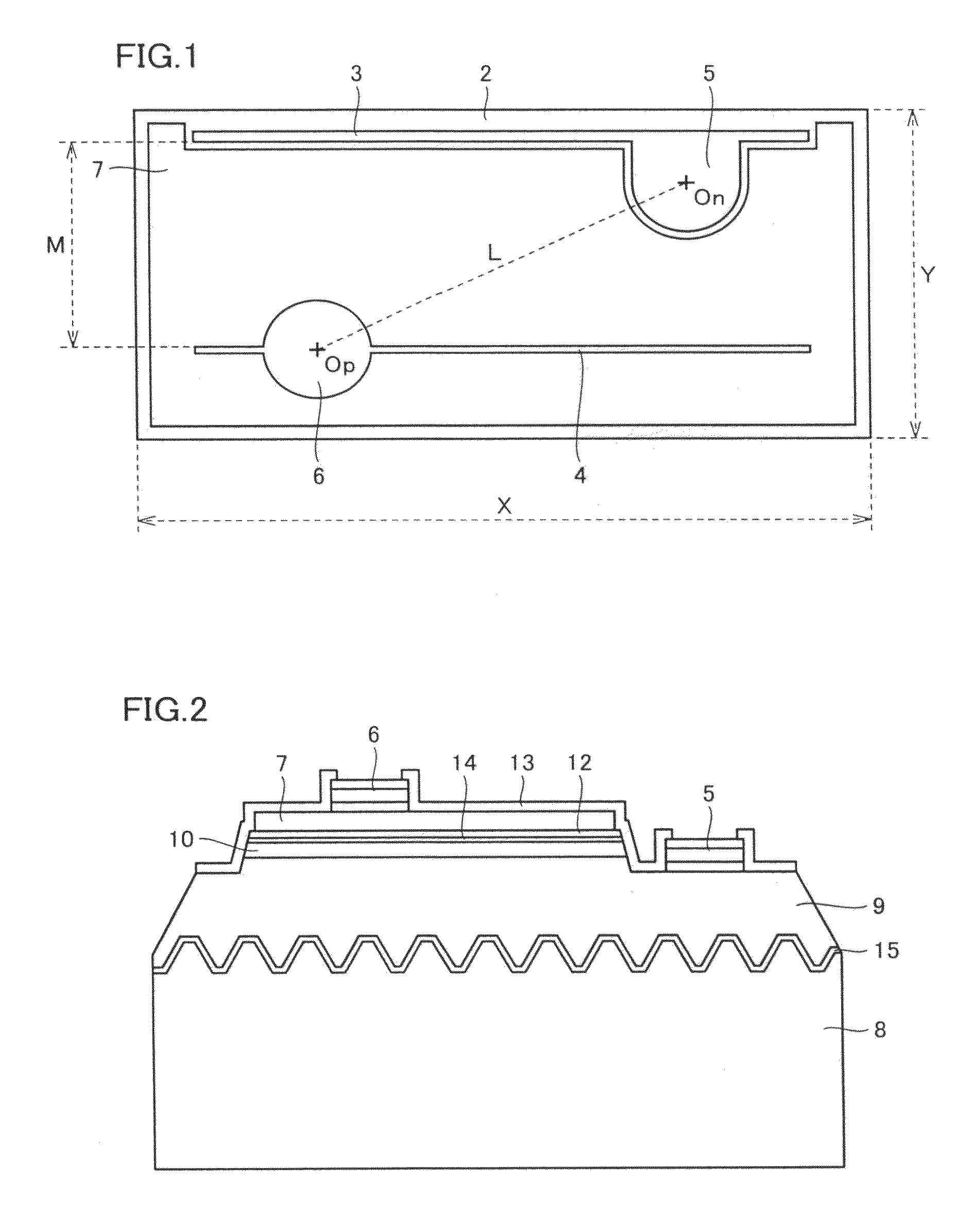

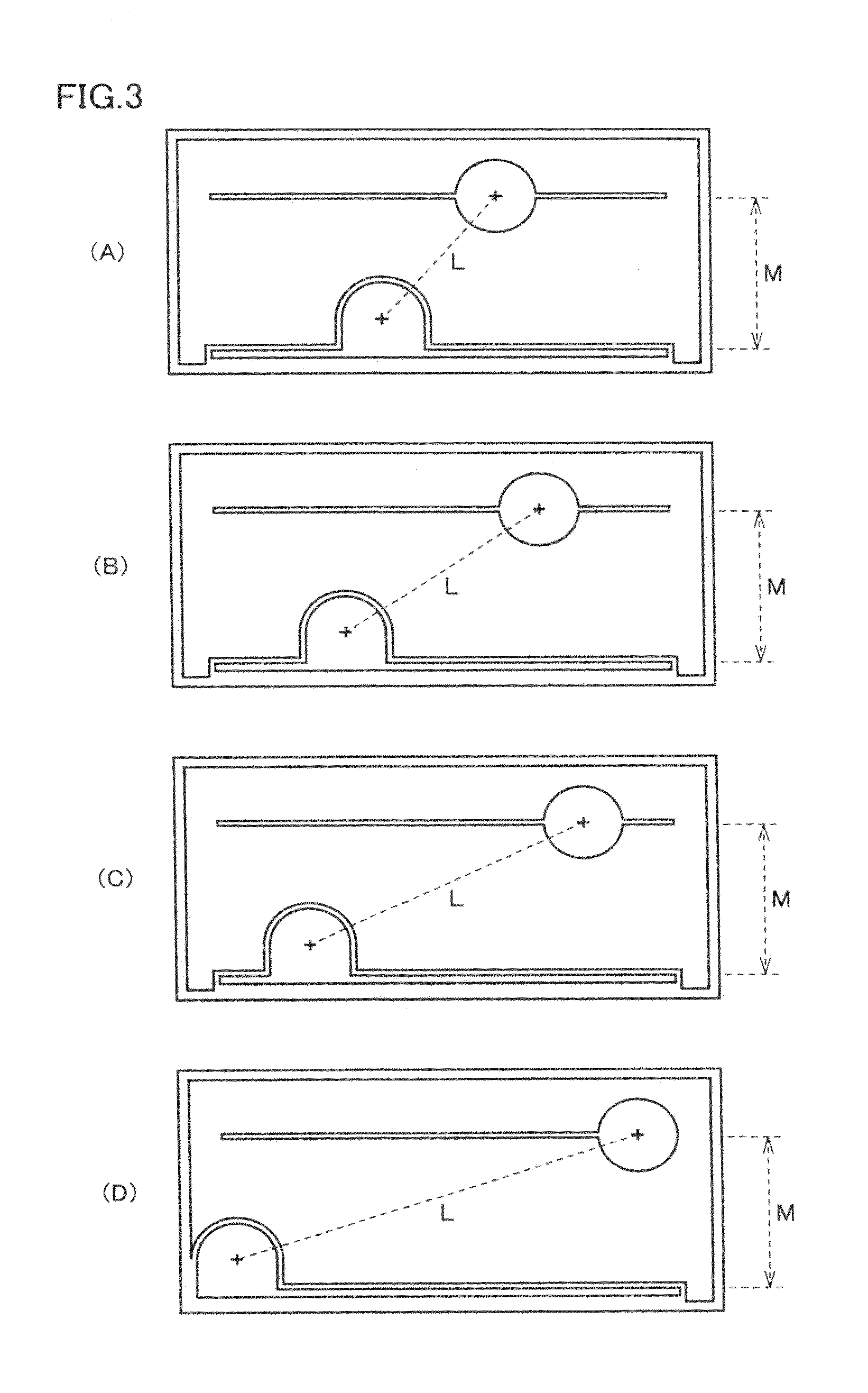

Nitride semiconductor light-emitting device

InactiveUS20120098023A1Improve current spreading efficiencyLow working voltageSemiconductor devicesActive layerLight emitting device

A nitride semiconductor light-emitting device includes at least one n-type semiconductor layer, an active layer and at least one p-type semiconductor layer within a rectangle nitride semiconductor region on a substrate. The n-type semiconductor layer has a partial exposed area, a p-side branch electrode integral with a p-side electrode pad formed on a current diffusion layer formed on the p-type semiconductor layer, an n-side branch electrode integral with an n-side electrode pad formed on the partial exposed area of the n-type semiconductor layer, the p-side and n-side branch electrodes extend parallel to each other along two opposite sides of the semiconductor region, and conditions of 0.3<M / L<1.1 and L<Lmax are satisfied; L is the distance between centers of the p-side and n-side electrode pads, M is the distance between the p-side and n-side branch electrodes, and Lmax represents a distance between the centers of the p-side and n-side electrode pads.

Owner:SHARP KK

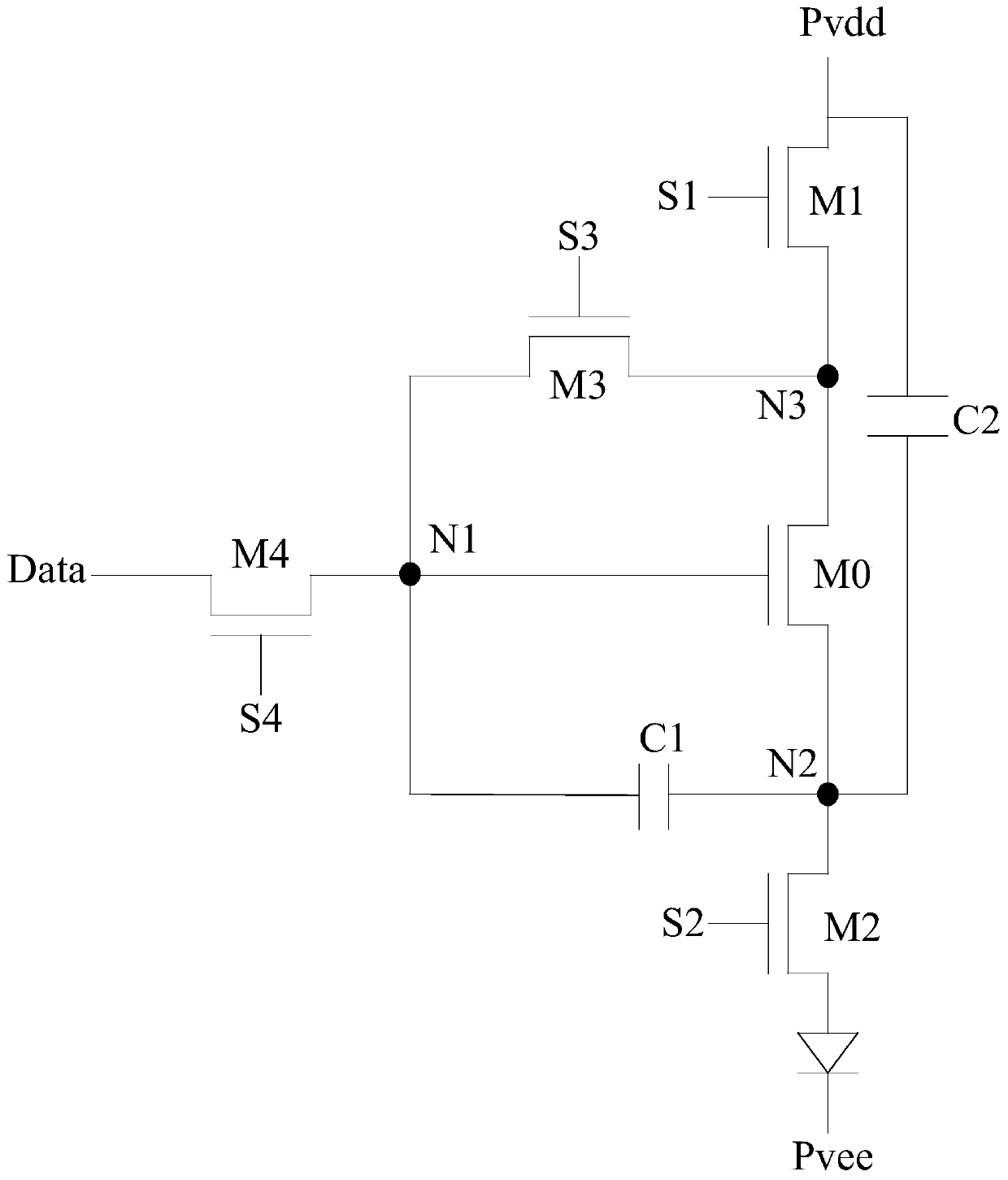

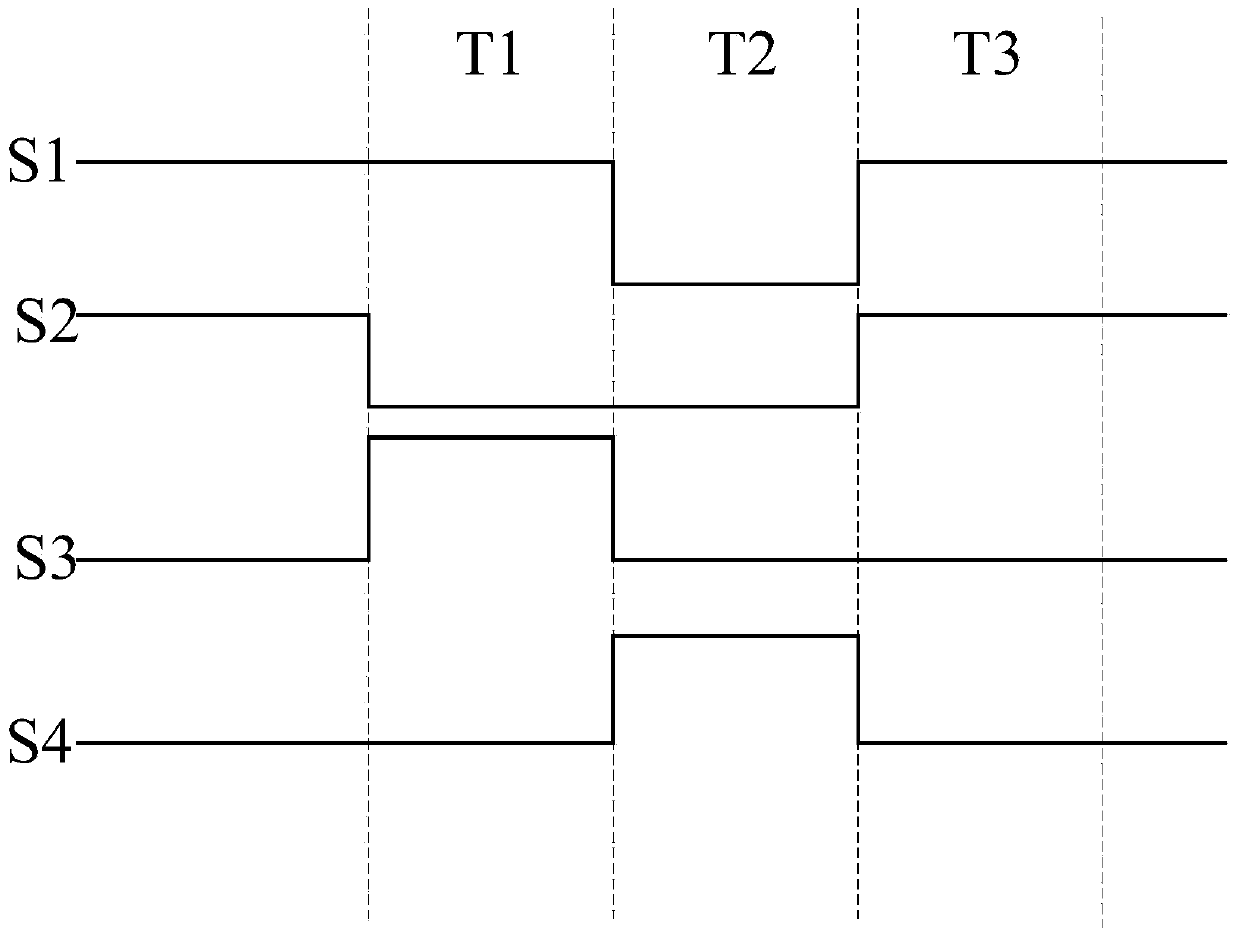

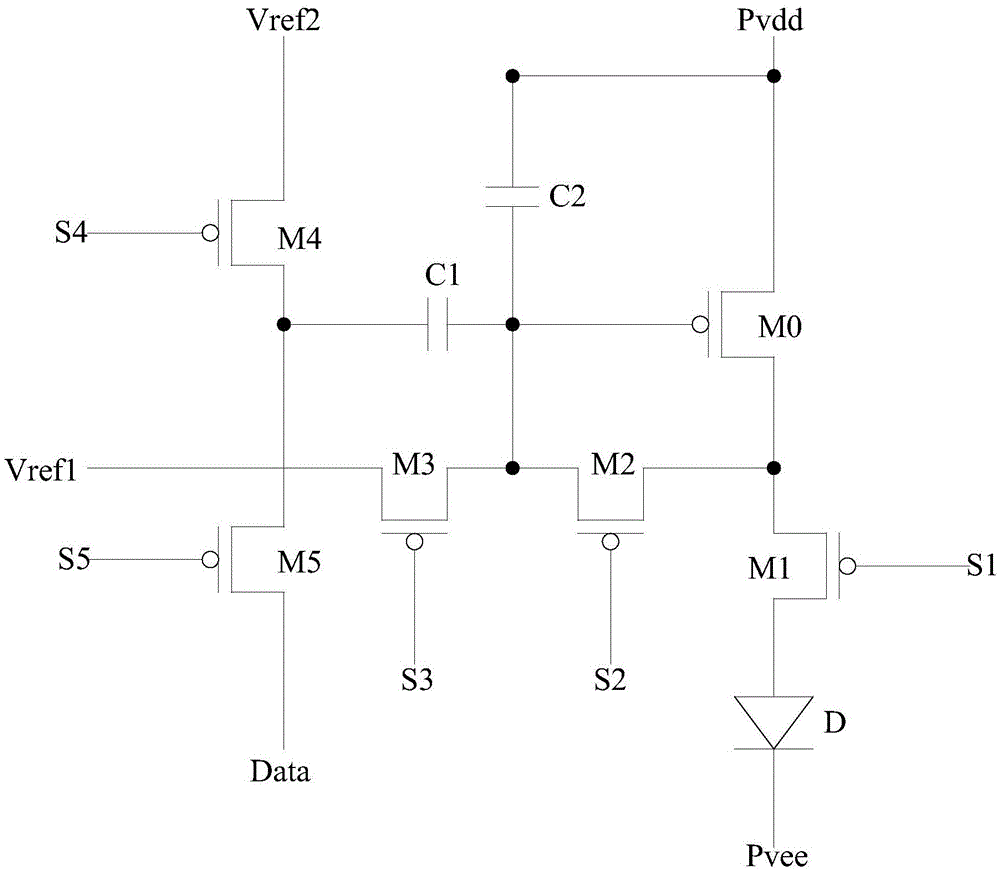

Pixel circuit as well as driving method, display panel and display device thereof

ActiveCN104200778AImprove uneven lightingImprove uniformity of light emissionStatic indicating devicesCapacitanceDriving current

The invention discloses a pixel circuit as well as a driving method, a display panel and a display device thereof. The pixel circuit comprises a first transistor, a second transistor, a third transistor, a fourth transistor, a driving transistor, a first capacitor, a second capacitor and a light-emitting element, through the cooperating driving between all transistors and the two capacitors, the driving current is enabled to be unrelated to the threshold voltage of the driving transistor and the step voltage of the two ends of the light-emitting element finally. According to the pixel circuit as well as the driving method, the display panel and the display device thereof, the influence of undesirable factors is eliminated, the problem that the conventional display device is uneven in light emission is further improved effectively, and the uniformity of luminance and the display effect of the display device are improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

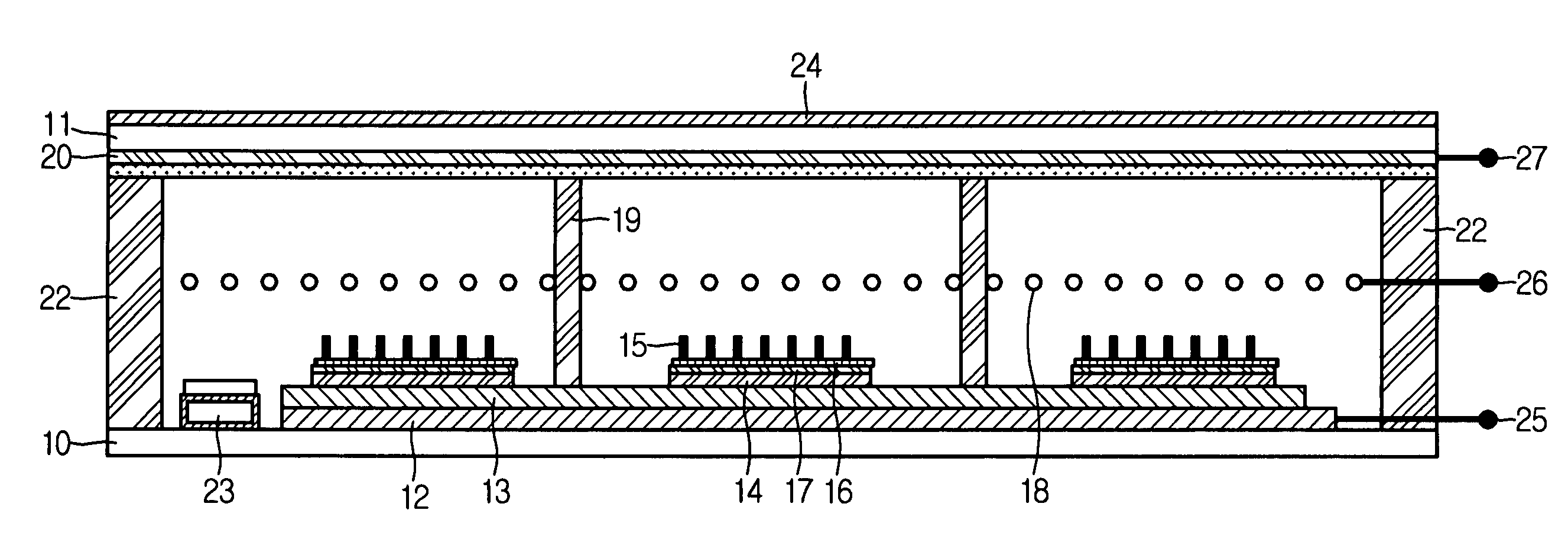

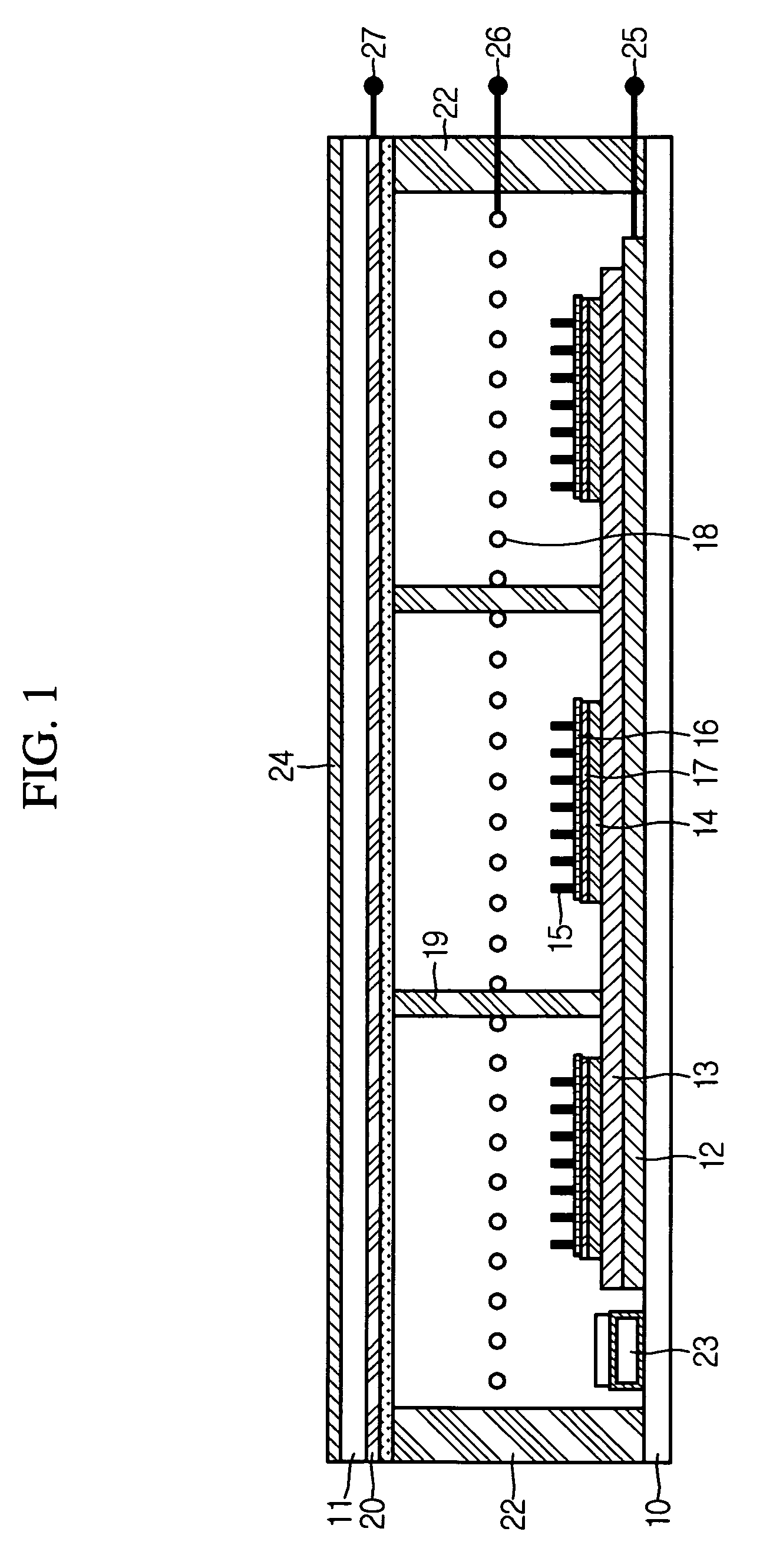

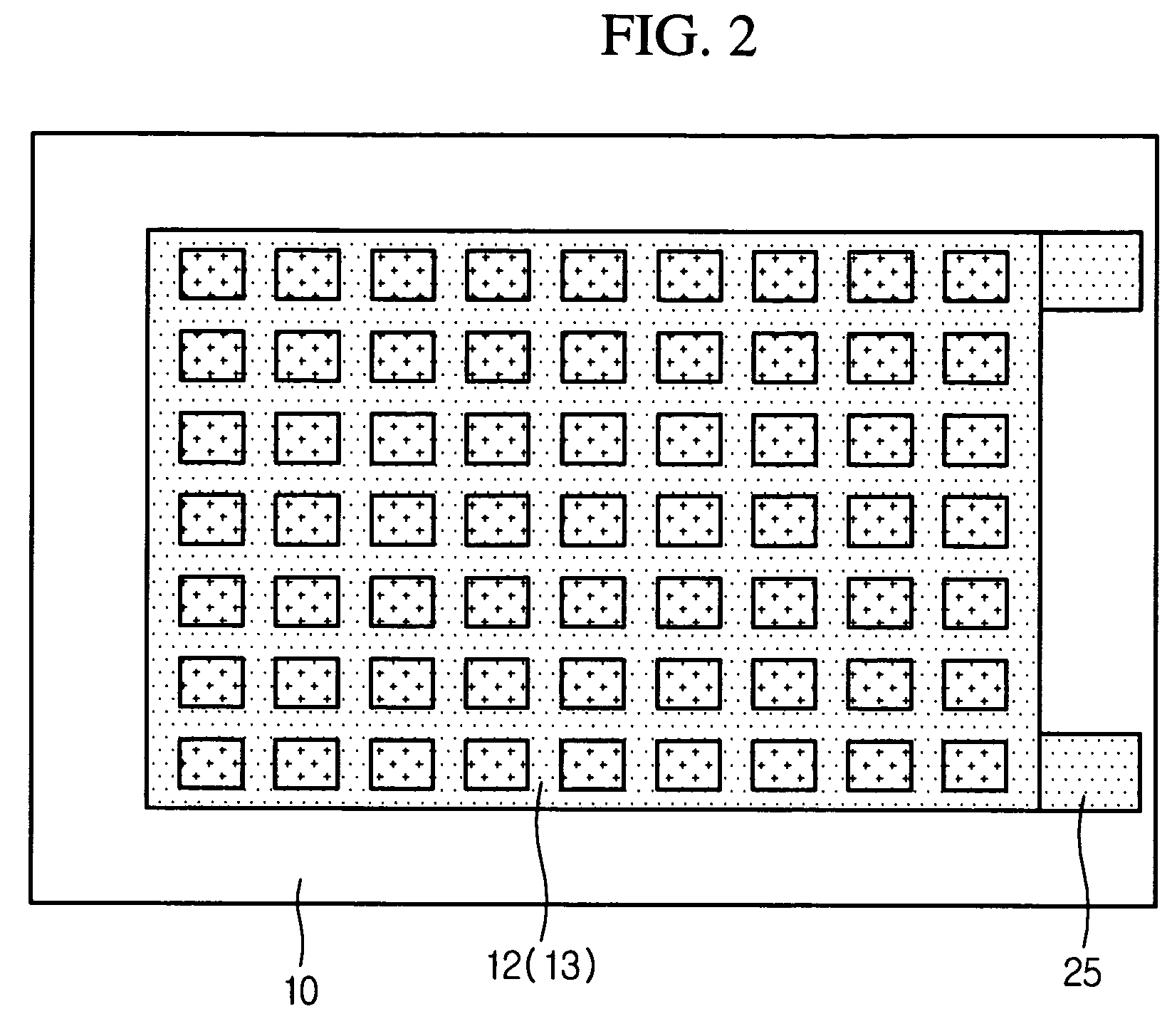

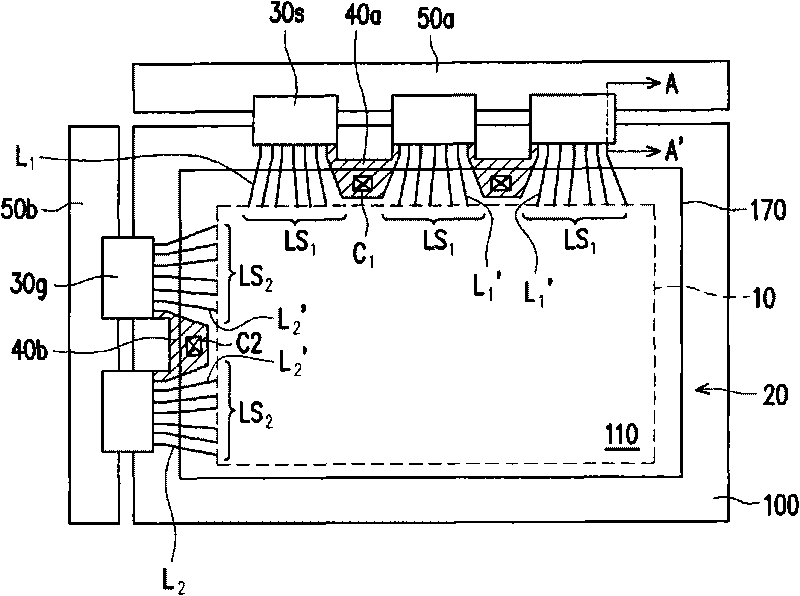

Flat lamp device with multi electron source array

InactiveUS20060244357A1Excellent light emission uniformityImprove uniformity of light emissionDischarge tube luminescnet screensElectroluminescent light sourcesCarbon nanotubeEngineering

Disclosed is a flat lamp device, including lower and upper glass plates facing each other in parallel; spacers interposed between the plates to keep distance therebetween; a cathode electrode singly formed over the entire upper surface of the lower glass plate; an insulation film formed on the cathode electrode; semiconductor films independently patterned on the insulation film at intervals; a catalyst-metal layer laminated on the buffer metal to improve the adhesion of catalyst metal formed on the semiconductor films; carbon nano-tubes formed on the catalyst-metal layer; a grid electrode installed on the carbon nano-tubes between the plates to guide electron emission from the carbon nano-tubes with a mesh shape having an opening for passage of the emitted electrons; an anode electrode formed below the upper glass plate to accelerate the emitted electrons; and a fluorescent layer formed below the anode electrode to emit light by collision with the accelerated electrons.

Owner:LEE SEUNG HO

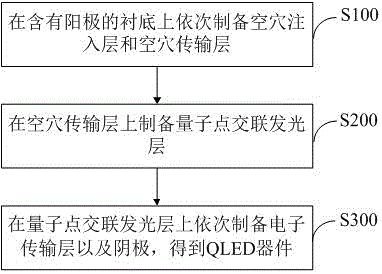

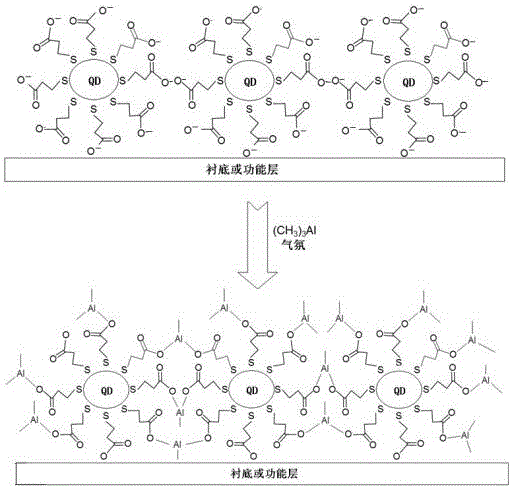

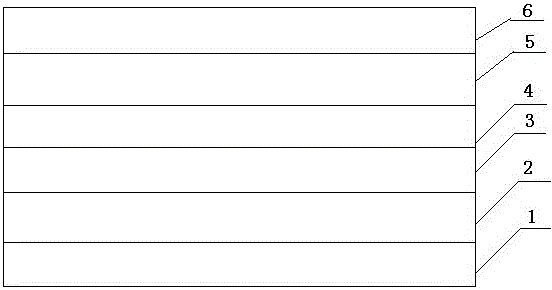

Quantum dot luminescent layer and device, and preparation methods thereof, luminescence module and display device

ActiveCN106531860AImprove uniformity of light emissionImprove luminescence stabilitySemiconductor devicesQuantum dotDisplay device

The present invention discloses a quantum dot luminescent layer and device, and preparation methods thereof, a luminescence module and a display device. The preparation method of the quantum dot luminescent layer comprises the steps: the quantum dots having the surfaces coated with ligand are dissolved in solvent to obtain the quantum dot solution; the quantum dot solution is deposited on the substrate or a function layer by employing the solution method to obtain a quantum dot luminescent layer; the quantum dot luminescent layer is arranged in a vacuum cavity, and organic metal compounds are pumped in to process for 0.5-30 mins, wherein the pressure in the cavity is 0.01-1mbar, the partial pressure of the organic metal compounds after gasification is 0.001-0.1mbar, the temperature in the cavity is 10-25 DEG C; and the quantum dot luminescent layer is taken out to obtain the quantum dot crosslinking luminescent layer. The quantum dot film is not only uniform flat and has a stable film, so that the quantum dot film is difficult to be redissolved to take away or wash away by the solvent when the subsequent other function layers are deposited so as to effectively improve the luminescence uniformity and the stability of the QLED.

Owner:TCL CORPORATION

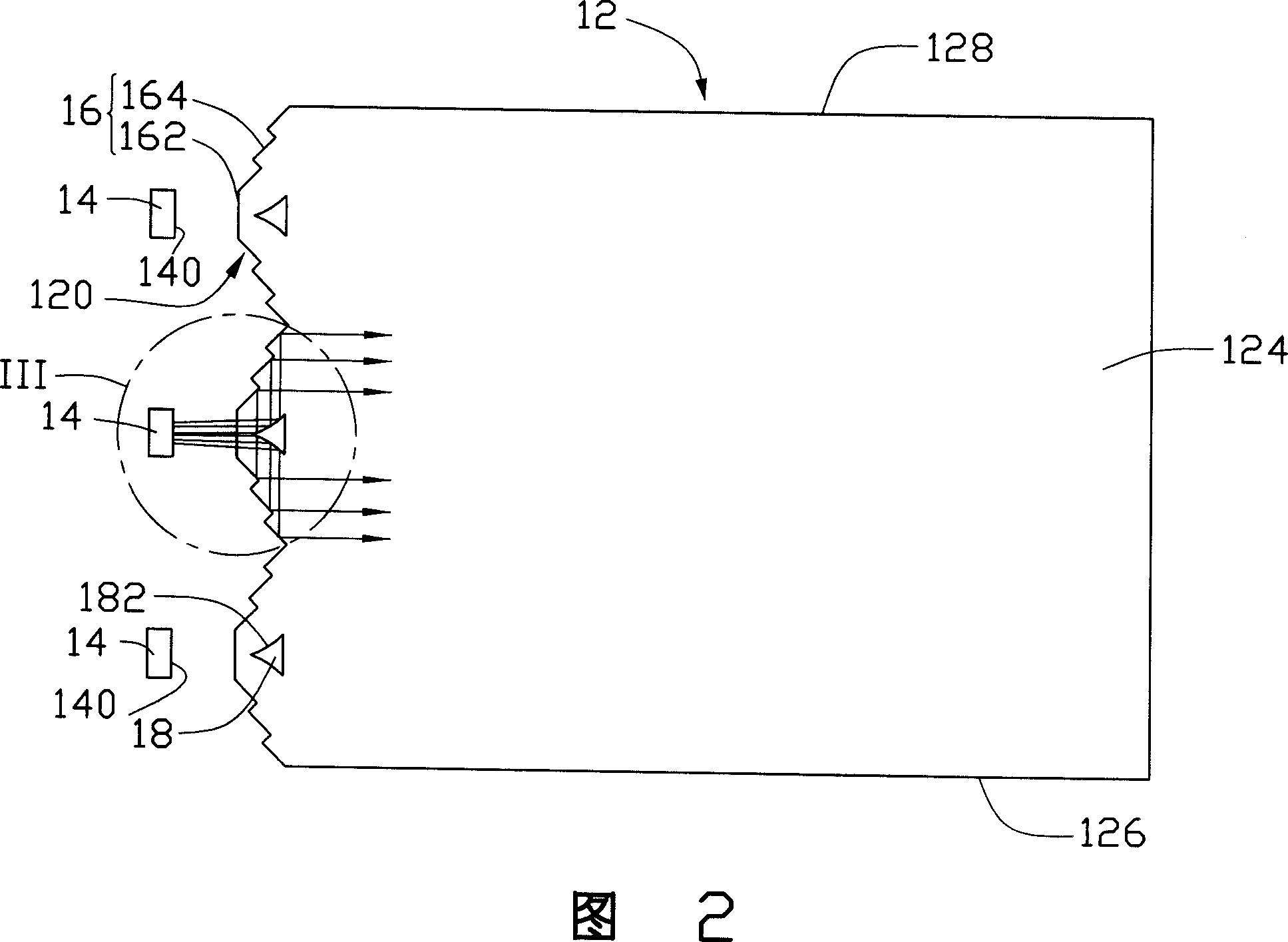

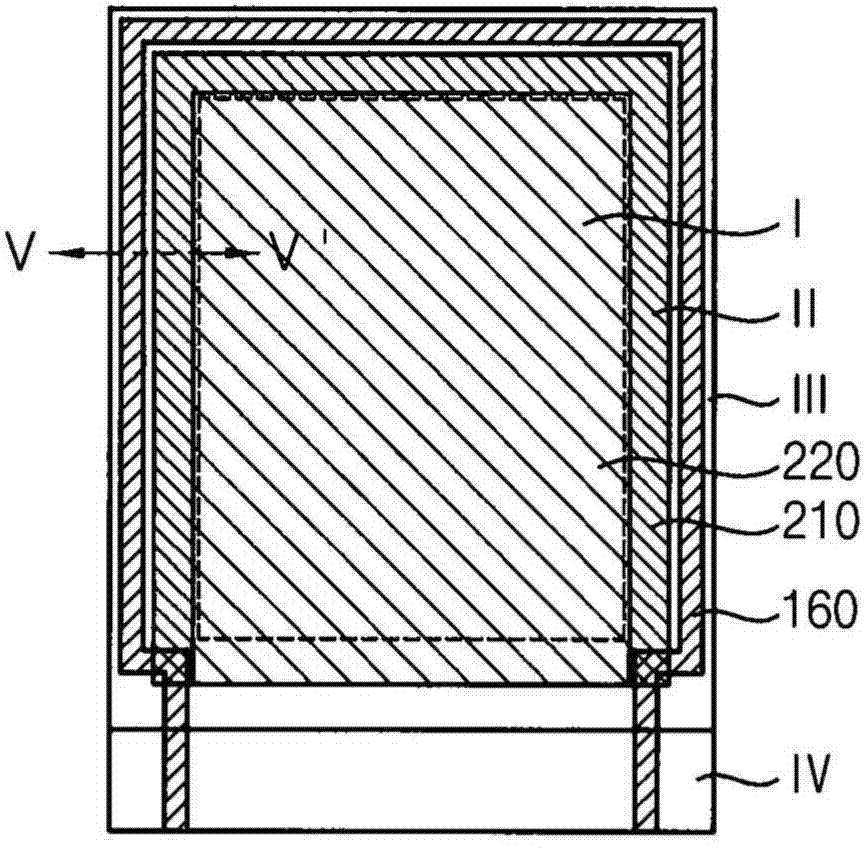

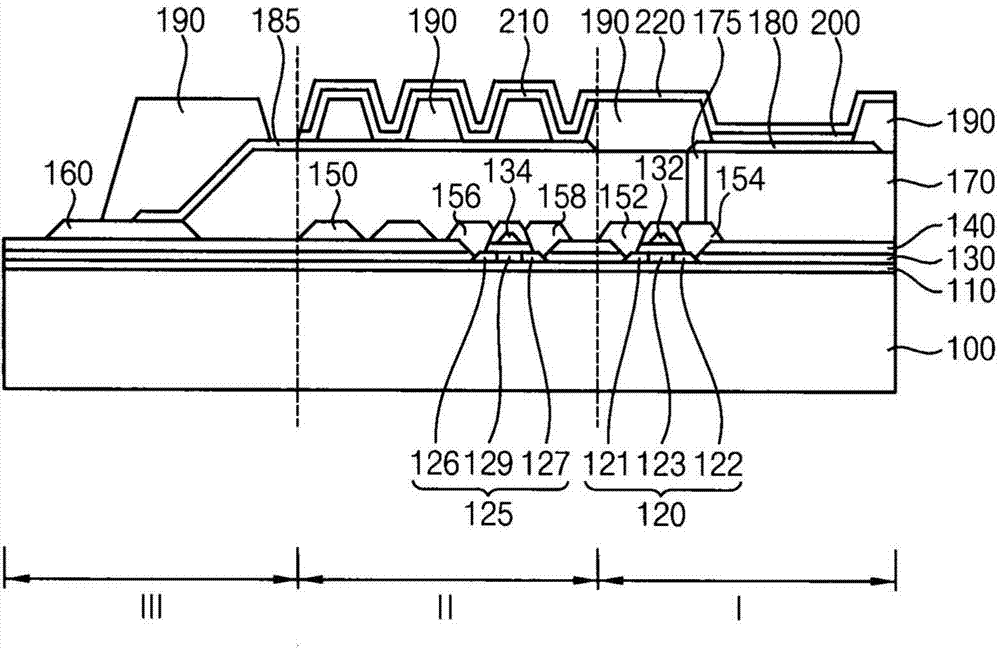

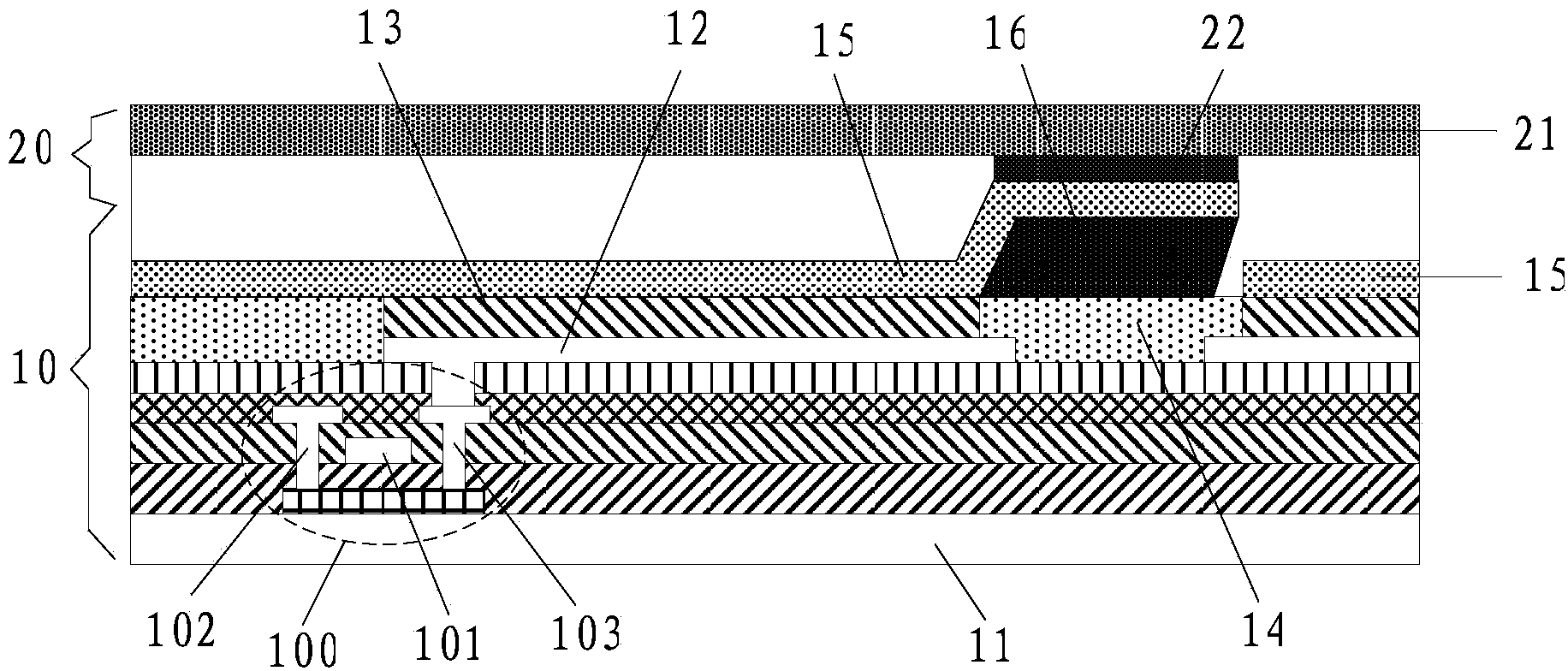

Organic light emitting display devices and methods of manufacturing organic light emitting display devices

InactiveCN104282724ANo reduction in light output efficiencyImprove uniformity of light emissionSolid-state devicesSemiconductor/solid-state device manufacturingPower couplingInter layer

An inter-layer bridging connection is provided in an organic light emitting display and a method of manufacturing the same is provided. The organic light emitting display device is subdivided into a major interior, first region I, an auxiliary power coupling region II and a peripheral power line region III where the second region (II) extends at least partially around the first region, and the third region (III) extends at least partially around the second region. Additionally, the display device includes a substrate, a first electrode, a second electrode, an interposed light emitting structure, a power line, a conductive pattern and an auxiliary electrode. The first electrode and the light emitting structure are both disposed in the first region. The power line is disposed in the third region. The second electrode is at least partially transparent and is disposed in the first region and extends into the second region (II). The conductive pattern electrically connects the second electrode with the power line. The auxiliary electrode has reduced resistivity per unit area and directly contacts the second electrode. The auxiliary electrode is disposed in the second region.

Owner:SAMSUNG DISPLAY CO LTD

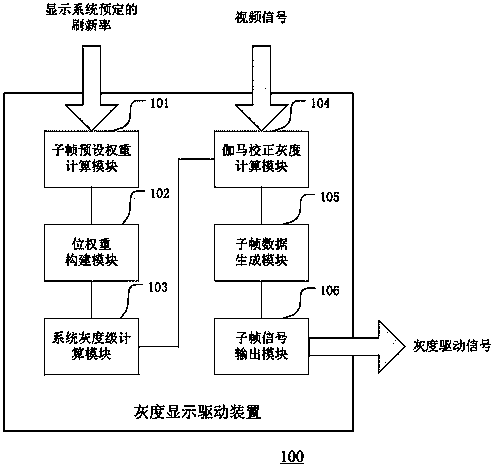

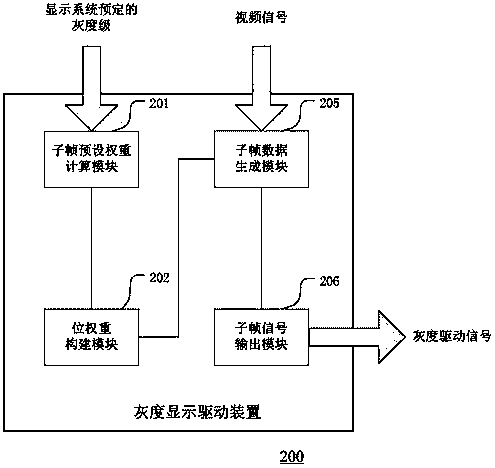

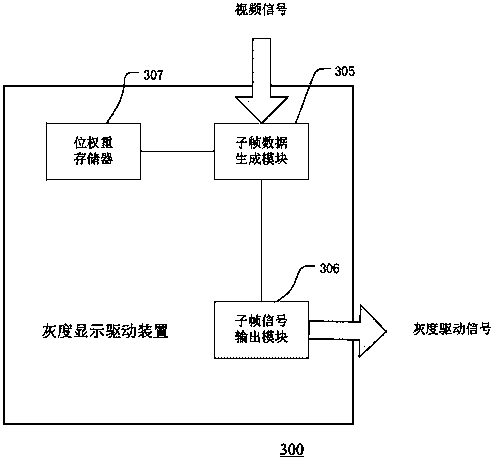

Gray scale display driving method and device for LED display

InactiveCN103871366ASame length of timeImprove uniformity of light emissionStatic indicating devicesLED displayComputer science

The invention discloses a gray scale display driving method and device for an LED display. The gray scale display driving method comprises the steps that all the n data bits of a gray scale datum are divided into m subframes, wherein n is an integer larger than or equal to 2, and m is an integer larger than or equal to 1; the preset weight C of each subframe is calculated; the weights of all the n data bits are established so that the combination of the weights can represent all gray scales; all the n data bits are combined into m subframes to enable the weight of each subframe is approximately equal to the preset weight of the corresponding subframe; the corresponding data bit of each subframe is displayed. The gray scale display driving method and device for the LED display can ensure uniformity of luminance on the premise that the refresh rate of a display system is increased, and then the display effect is improved.

Owner:宁波凯睿信息技术咨询有限公司

Preparation method of luminescent polyamide composite material

InactiveCN105419309AGood dispersionImprove uniformity of light emissionLuminescent compositionsGlass fiberNylon material

The invention discloses a preparation method of a luminescent polyamide composite material. The method comprises the following steps of (1) preparing a graphene / red-light phosphor / SiO2 composite material; (2) weighing the following materials in parts by weight: 60 to 70 parts of nylon resin, 30 to 40 parts of hybrid glass fiber reinforcement, 1 to 5 parts of nylon master batch, 1 to 5 parts of graphene / red-light phosphor composite material and 0.1 to 0.3 part of antioxygen; extruding the materials by a double-screw extruder and pelleting, wherein the hybrid glass fiber reinforcement is added through a side-feeder, the screw speed of the double-screw extruder is 120 to 150r / min, the temperature is 265 to 280 DEG C, and then the polyamide composite material is obtained. The preparation method of the luminescent polyamide composite material can enhance the dispersity and the luminance uniformity of phosphor in the luminescent polyamide composite material, and the high luminescent intensity is obtained.

Owner:黄志华

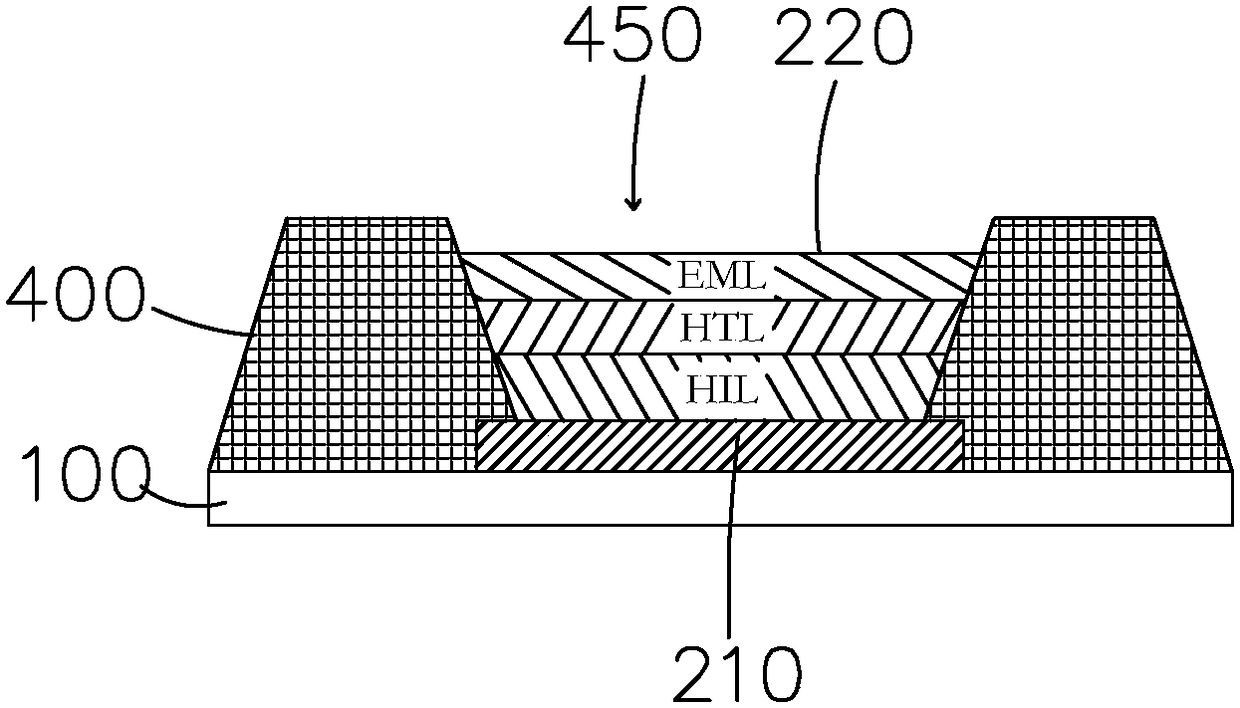

OLED display panel and preparation method thereof

InactiveCN110993806AAvoid crosstalkImprove uniformity of light emissionSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerCharge generation

The invention discloses an OLED display panel and a preparation method thereof, and the method comprises the steps: blocking a light-emitting function layer of an OLED device in a non-light-emitting region between two adjacent columns of sub-pixels, so as to enable an electron not to transversely migrate in a hole injection layer and a charge generation layer to generate a leakage current; and ensuring a cathode layer to be in a whole-surface communication state in a light-emitting region corresponding to the sub-pixels and the non-light-emitting region between the sub-pixels, so that the pixels normally emit light.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

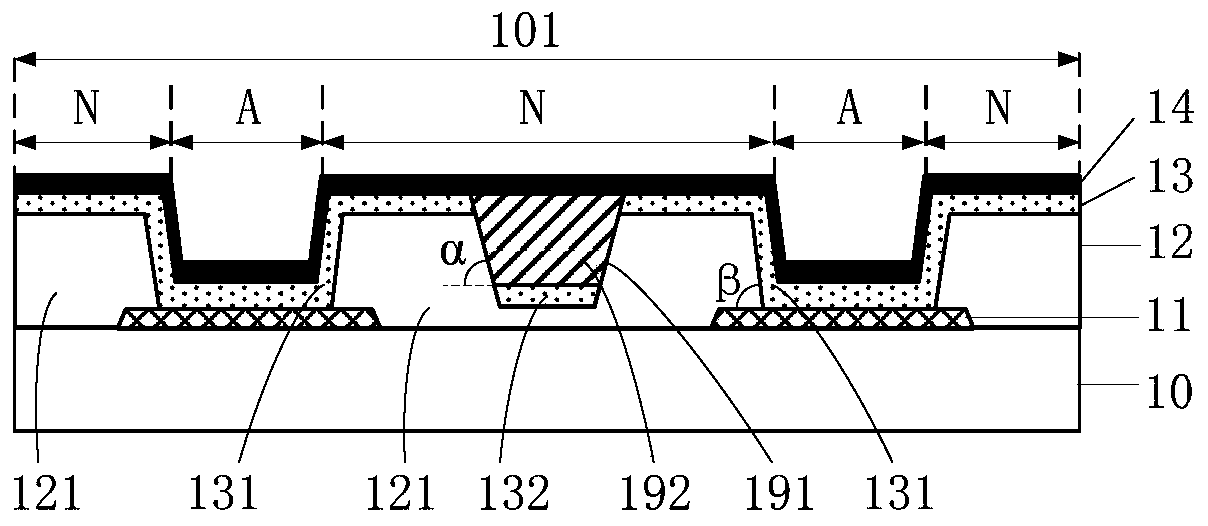

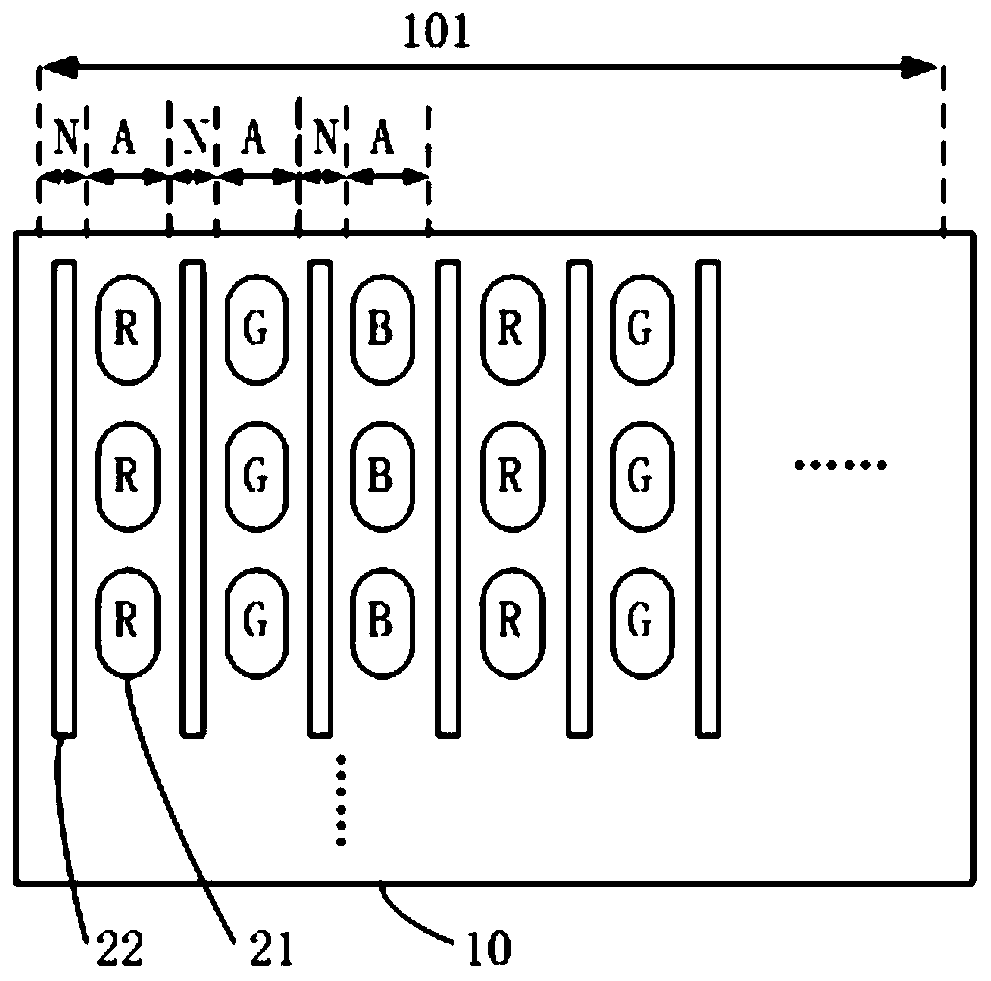

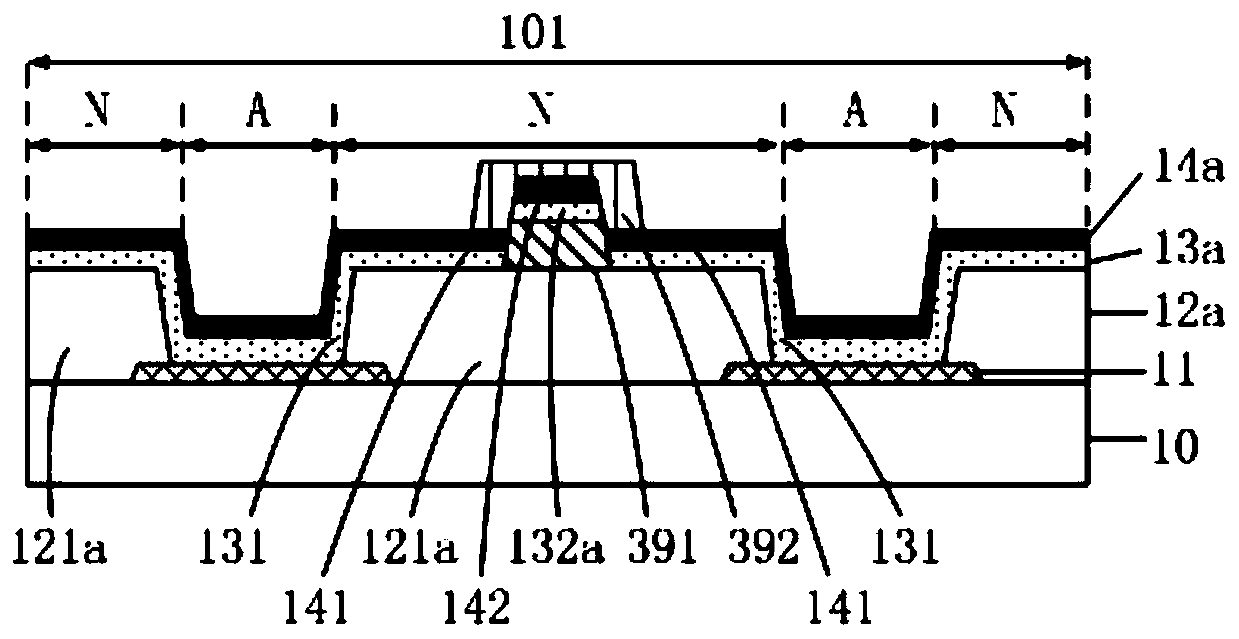

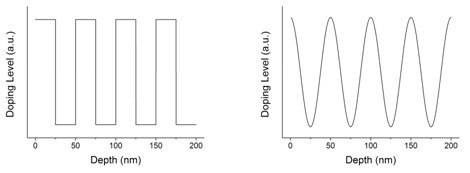

III-group nitride light-emitting diode (LED) and manufacturing method thereof

ActiveCN102185062AIncreased longitudinal resistivityImprove crystal qualitySemiconductor devicesNitrideLight-emitting diode

The invention discloses a III-group nitride light-emitting diode (LED) and a manufacturing method thereof. The LED comprises a substrate and a semiconductor epitaxial laminate which is laminated on the substrate, wherein the semiconductor epitaxial laminate sequentially comprises an N type layer, a luminescent layer and a P type layer from top to bottom. The LED is characterized in that: an N type layer table face is formed in the N type layer by etching a part of the semiconductor epitaxial laminate; an N type electrode is arranged on the N type layer table face; a P type electrode is arranged on the upper surface of the un-etched part of the P type layer; the N type layer also comprises a uniformly doped layer of which the doping concentration is consistent and a modulation doped layer of which the doping concentration is changeable; and the modulation doped layer is arranged between the uniformly doped layer and the luminescent layer. A doped mode of the modulation doped layer is gradual transition doping which connects uniformly doped layer and the luminescent layer of which the doping concentration is consistent. The concentration change trend is decrease progressively change from the uniformly doped layer to the luminescent layer. By the LED and the manufacturing method, the crystal quality and the luminance uniformity can be obviously improved, and the lighting effect is improved.

Owner:SUN YAT SEN UNIV

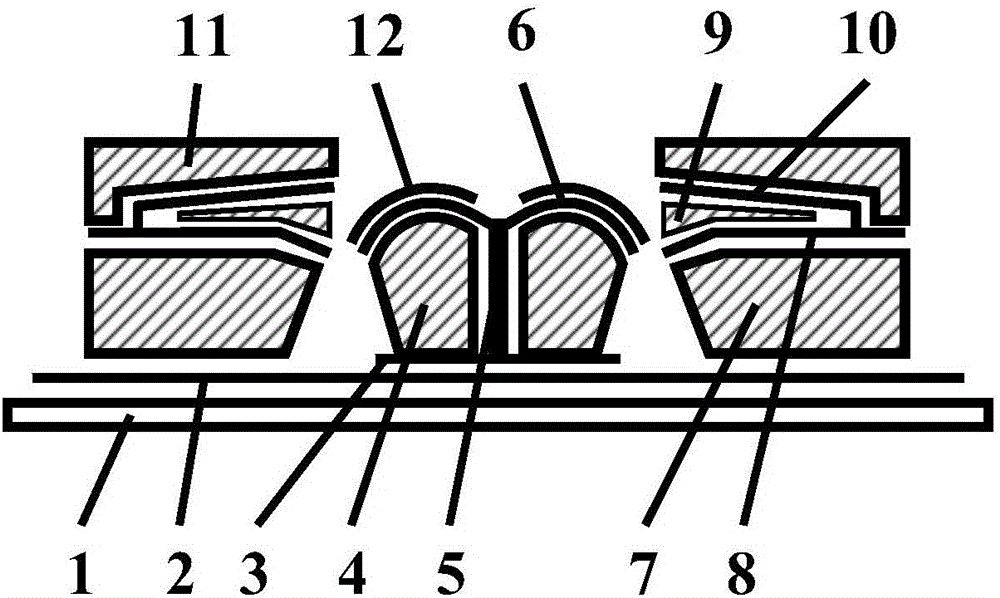

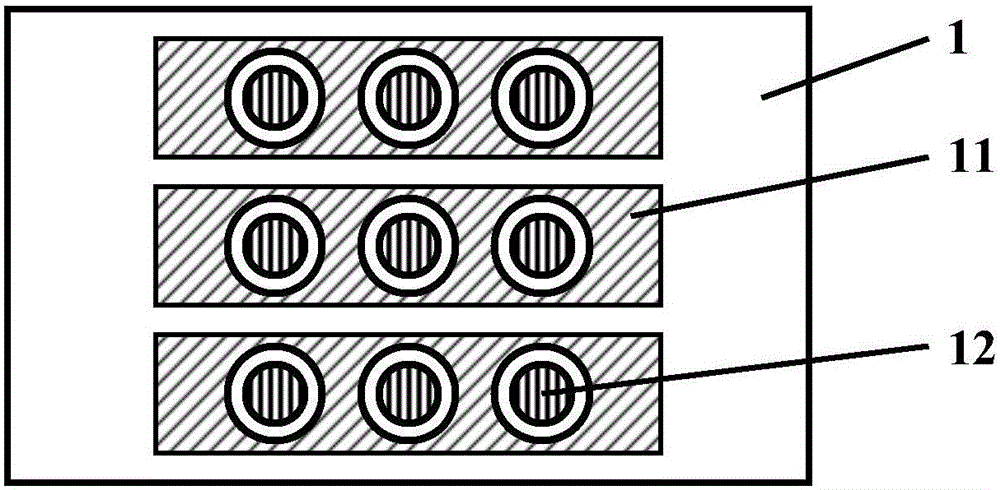

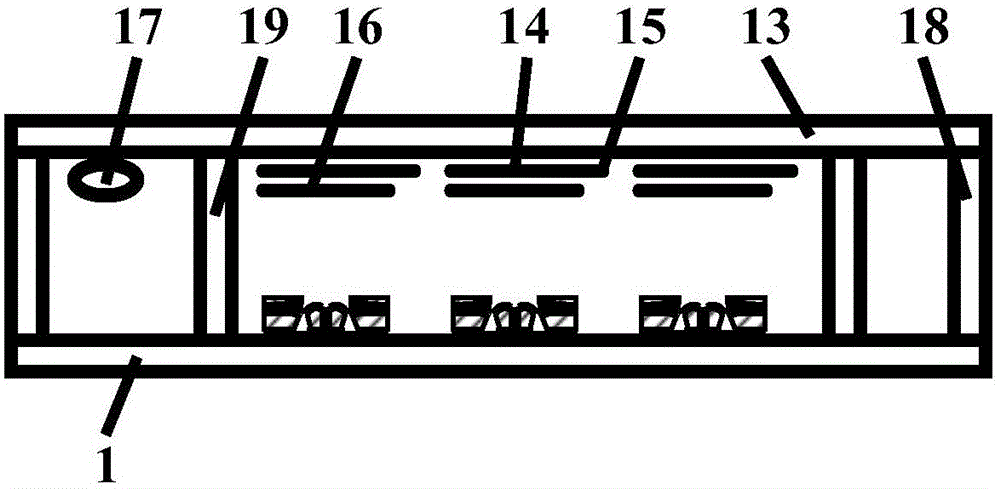

Luminous display with round tip-shaped double-gate controlled spring water-sprayed cathode structure

ActiveCN106024555AIncrease contact areaImprove uniformity of light emissionImage/pattern display tubesCold cathode manufactureGetterDouble gate

The invention discloses a luminous display with round tip-shaped double-gate controlled spring water-sprayed cathode structure, which comprises a vacuum chamber formed by a front glass sealing panel, a back glass sealing panel and a transparent glass frame. The front glass sealing panel is provided with an anode conductive layer, a luminescent layer on the anode conductive layer and an anode outer wiring layer connected with the anode conductive layer. The back glass sealing panel is provided with the round tip-shaped double-gate controlled spring water-sprayed cathode structure. The display also comprises isolation walls and getter attached components in the vacuum chamber. The luminous display of the invention has the advantages of being manufactured at low production cost and through simple production process while achieving high brightness.

Owner:山东千沐云物联科技股份有限公司

Pixel circuit and display device

InactiveCN105489166AImprove uneven lightingImprove uniformity of light emissionStatic indicating devicesCapacitancePower flow

The invention discloses a pixel circuit and a display device. The pixel circuit comprises a first transistor, a second transistor, a third transistor, a fourth transistor, a fifth transistor, a driving transistor, a first capacitor, and a second capacitor. According to the pixel circuit and the display device, the driving current and the driving transistor are finally prevented from being influenced by threshold voltage via cooperative driving of the transistors and the two capacitors, the influence of adverse factors is eliminated, the problem of non-uniform light emission of the display device is effectively improved, and the light-emitting uniformity and the display effect of the display device are improved.

Owner:SHANGHAI TIANMA AM OLED +1

Electroluminescence device

InactiveUS20110157114A1Improve uniformity of light emittedImprove uniformity of light emissionCathode-ray tube indicatorsInput/output processes for data processingElectric power transmissionPeripheral

An electroluminescence device includes a substrate, a pixel array, lead line sets, driving devices and at least one power transmission pattern. The substrate has a display region and a peripheral circuit region. The pixel array is disposed in the display region and includes pixel structures. Each pixel structure has at least one active element and a light emitting element. The lead line sets are disposed in the peripheral circuit region and electrically connected to the pixel array, and each lead line set has multiple lead lines. Each driving device is electrically connected to one lead line set. The power transmission pattern is disposed in the peripheral circuit region and between adjacent lead line sets. One end of the power transmission pattern is electrically connected to the light emitting element and another end of the power transmission pattern is electrically connected to one corresponding driving device.

Owner:AU OPTRONICS CORP

Generator of white-light surface light source

InactiveCN101075655AResolve Excitation Wavelength ShiftSolve efficiency problemsSolid-state devicesSemiconductor devicesQuantum efficiencySemiconductor chip

An illumination device using white light as illumination source includes a semi-conducting chip, base and lens with cavum filled in photo-transmission material. The lens are fixed on the chip top and separated with the chip. By using lens it could effectively reduce excitation wavelength excursion, quanta efficiency decrease and aging raised by chip heat radiation. The illuminating rate, color temperature, chroma and coincidence of illumination device are improved.

Owner:诸建平

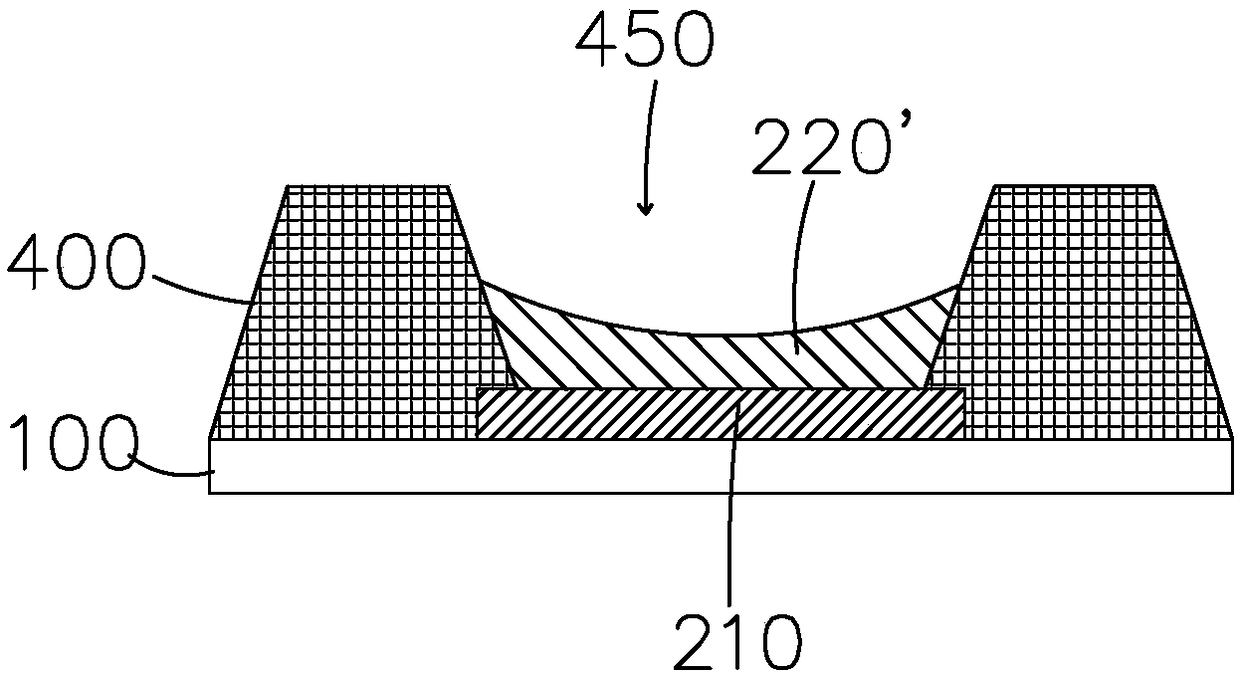

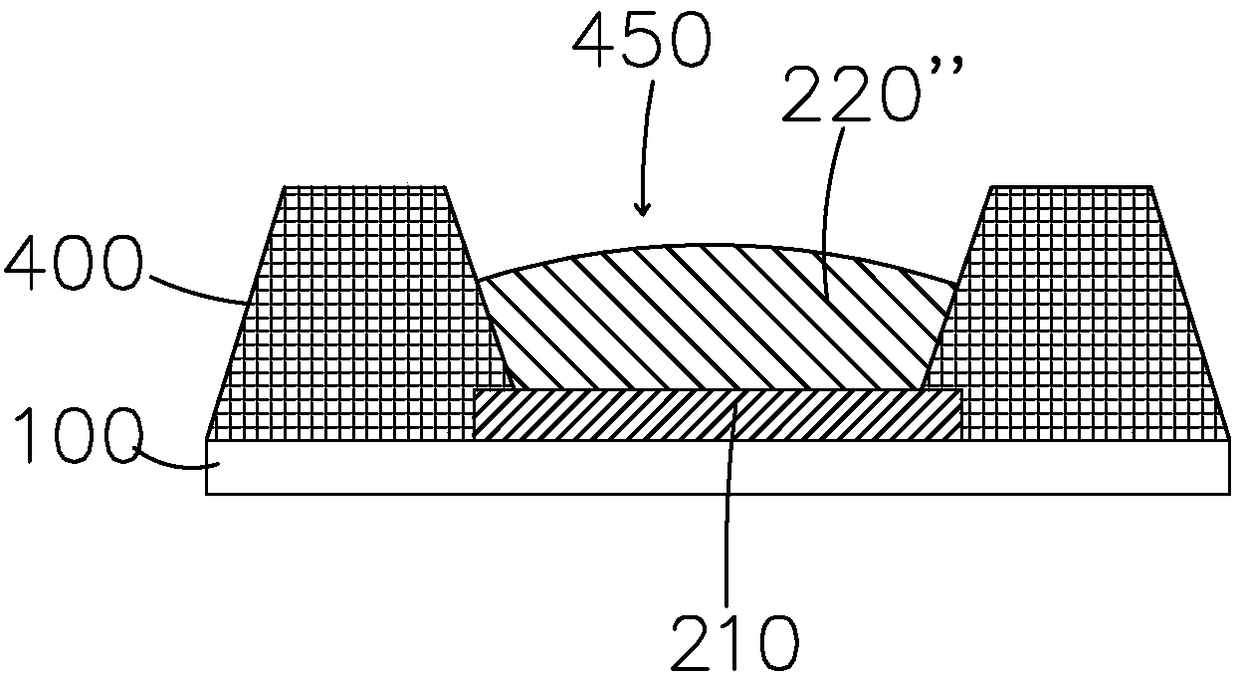

OLED device

ActiveCN108598110AImprove uniformity of light emissionUniform film formationSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsAnode

The invention provides an OLED device, comprising a substrate, an anode layer, a pixel definition layer and an organic functional layer, wherein the pixel definition layer consists of a hydrophobic dam layer and a hydrophilic dam layer; a plurality of ladder-like step platforms are arranged on the hydrophobic dam layer; the hydrophobic dam layer defines a pixel opening area of which the upper partis wide and the lower part is narrow above the anode layer through the plurality of step platforms; and the hydrophilic dam layer is arranged on the upper surface of each step platform. Thereby, whenmanufacturing the organic functional layer by using an ink-jet printing technology, the film surface of an ink material that forms the organic functional layer can be leveled in the pixel opening area, and thus the uniform film formation of the organic functional layer in the pixel opening area can be achieved, the uniformity of luminance of the OLED device can be effectively improved, and the microcavity effect of top-emitting OLED devices can also be accurately controlled.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

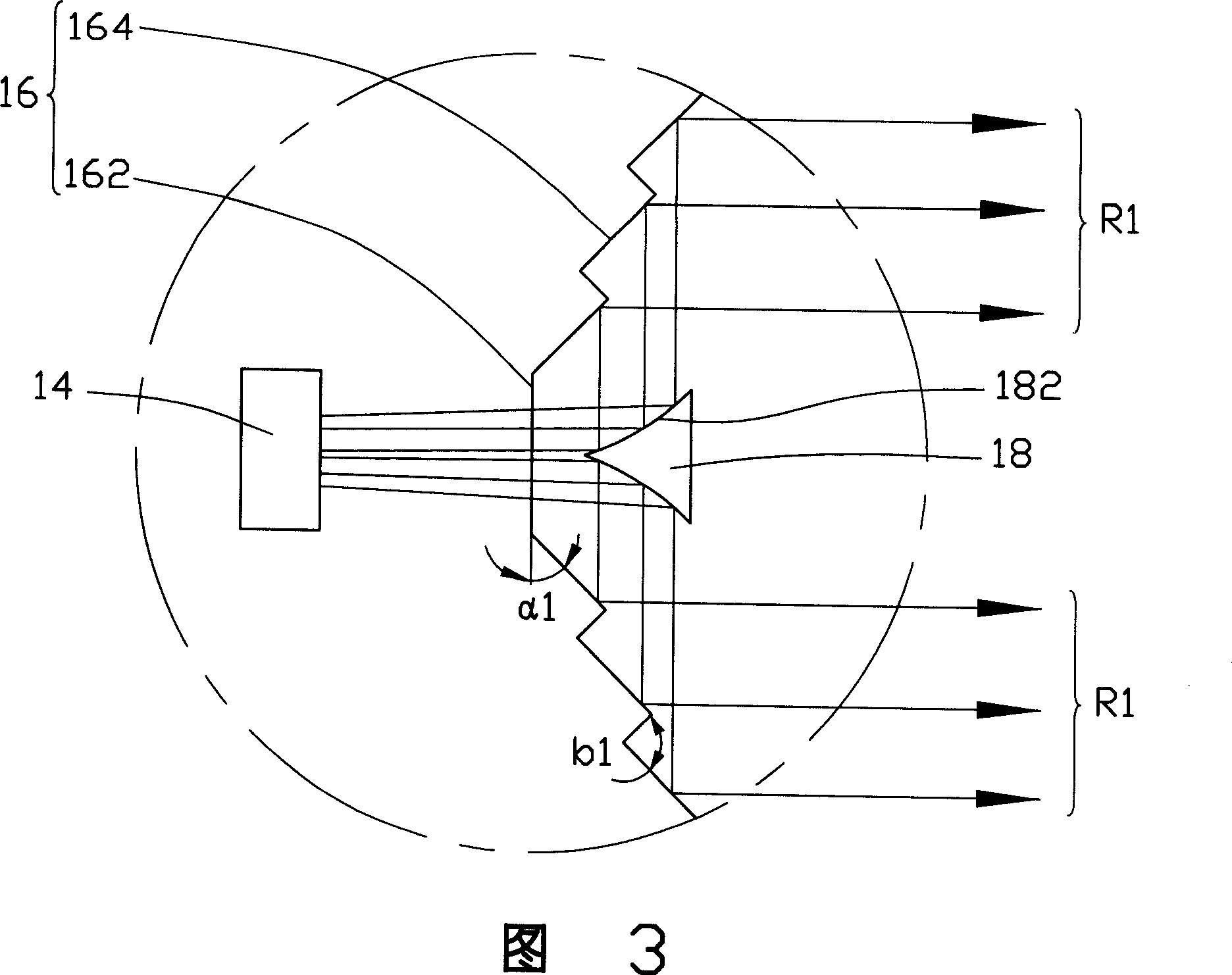

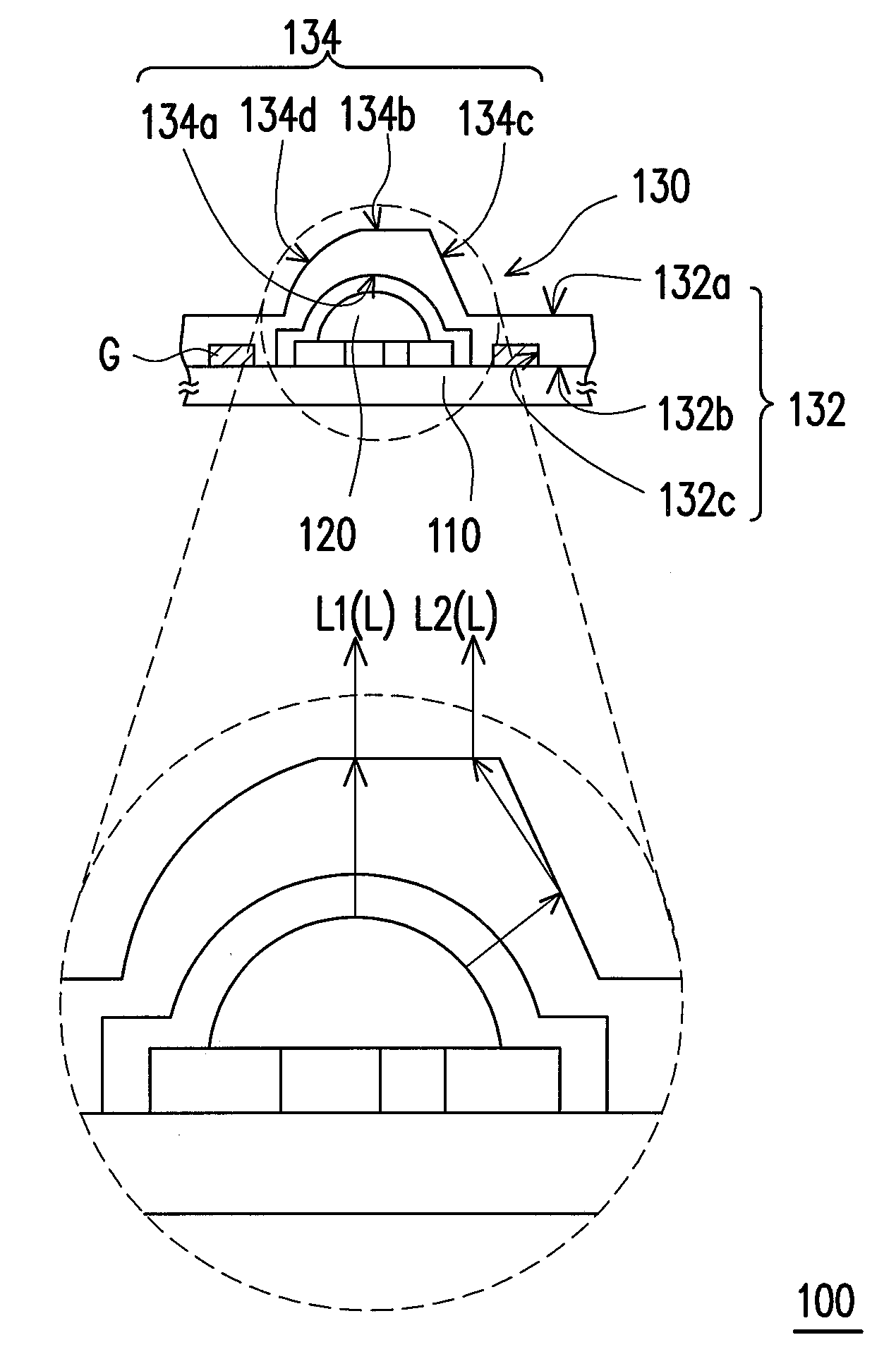

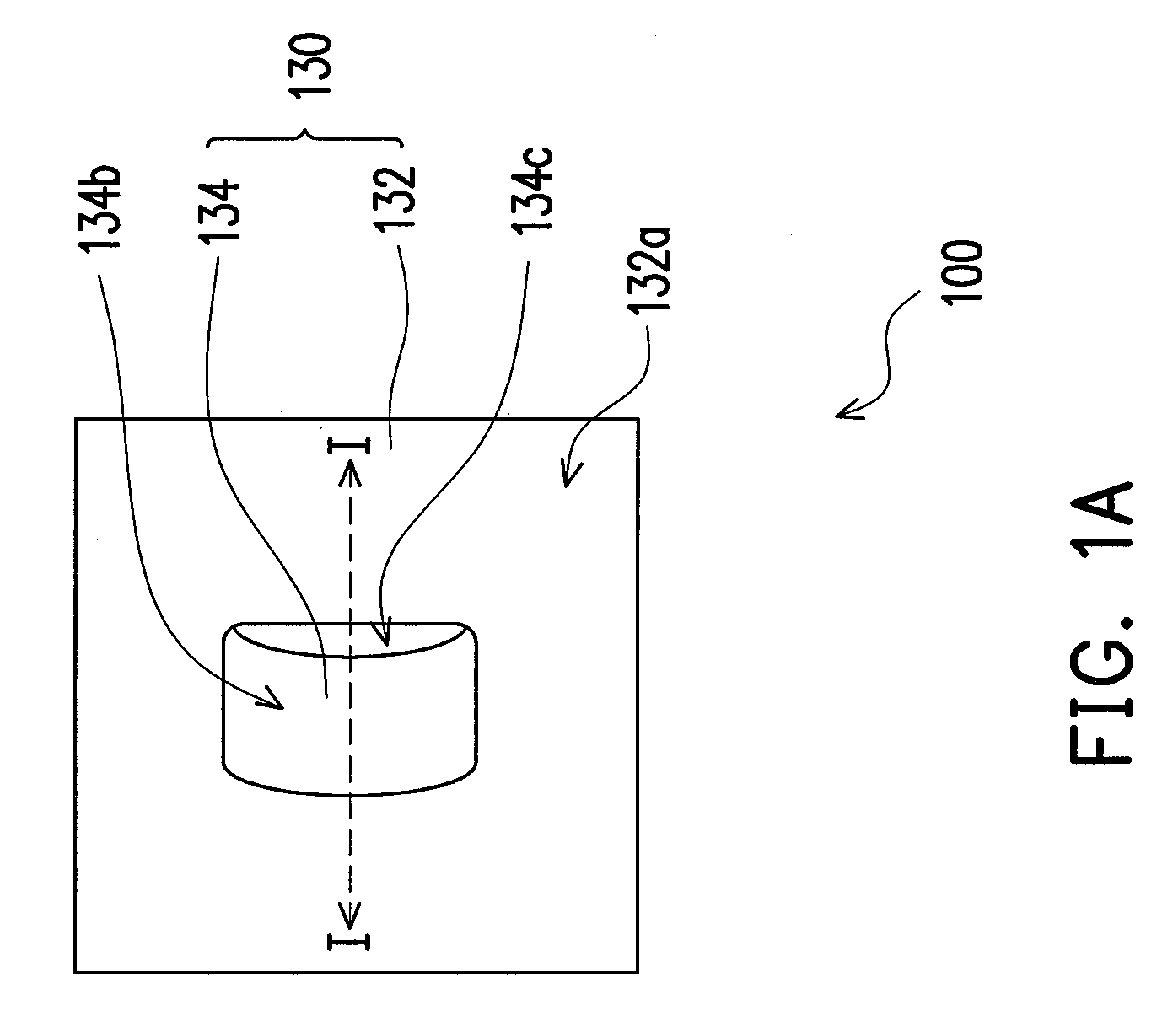

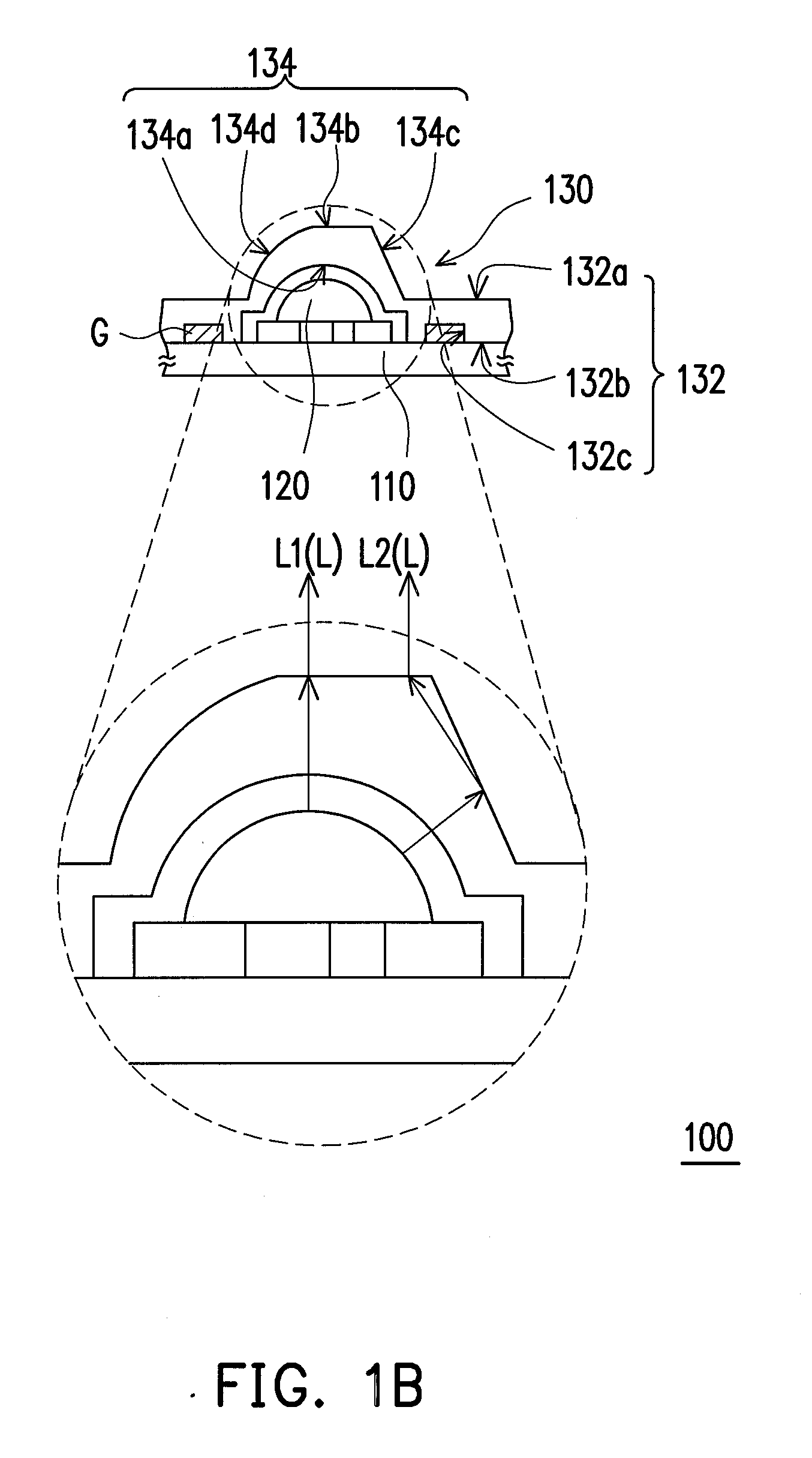

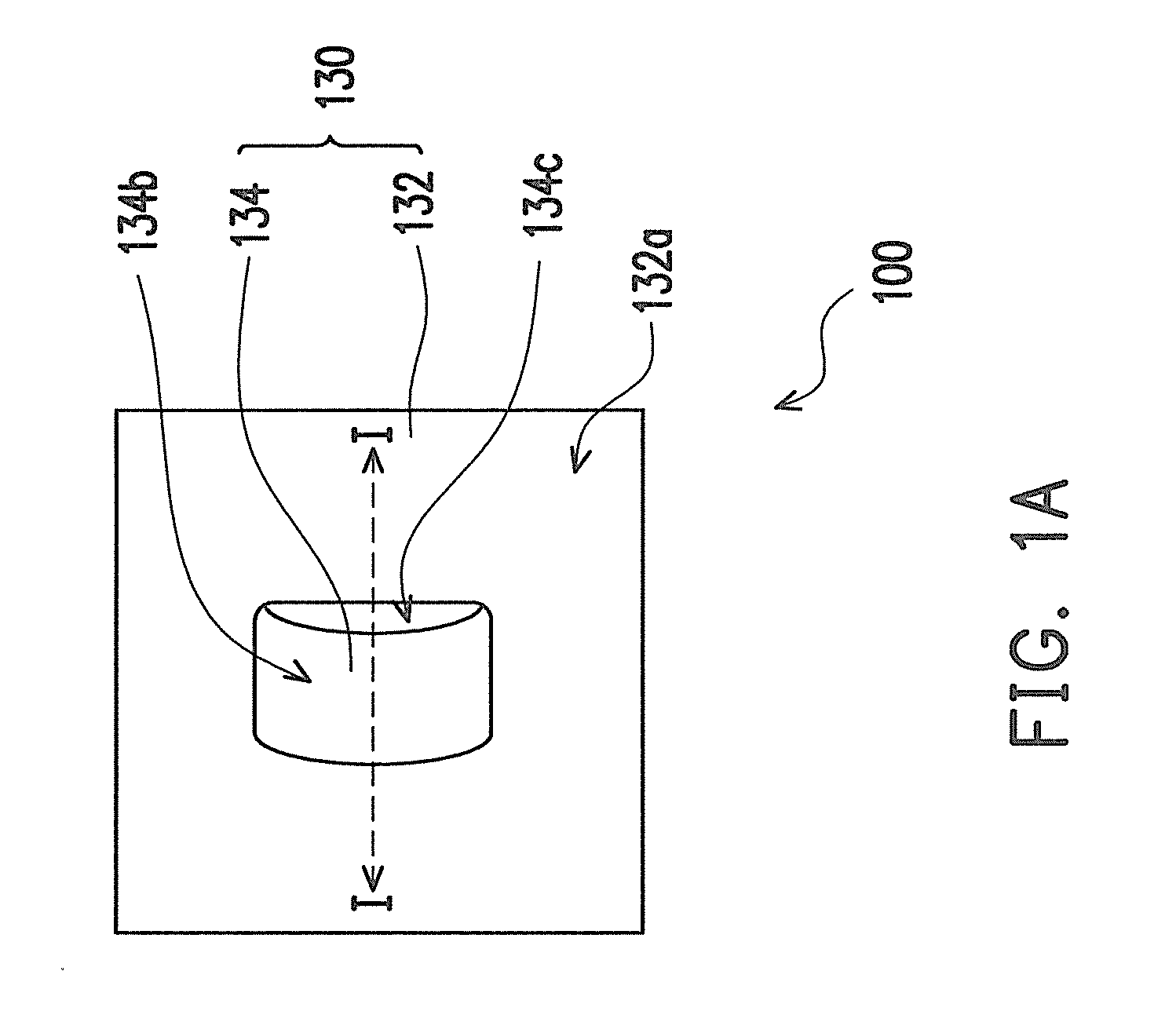

Light emitting device

InactiveUS20100207131A1Improve uniformity of light emissionEmission angle is smallPlanar light sourcesPoint-like light sourcePhysicsLight beam

A light emitting device includes a carrier, a light emitting element disposed and electrically connected to the carrier, and a transparent plate disposed on the carrier and including a flat-portion and a lens-portion. The lens-portion covers the light emitting element and has a light incident surface, a light emitting surface, a first side surface and a second side surface. The light emitting element is adapted to emit a beam. A first partial beam of the beam passes through the light incident surface and emerges from the light emitting surface. A second partial beam of the beam passes through the light incident surface and is transmitted to the first side surface or the second side surface, and the first side surface or the second side surface reflects at least a part of the second partial beam of the beam which then emerges from the light emitting surface.

Owner:EVERLIGHT ELECTRONICS

OLED display device

InactiveCN103943663AReduce areaUniform luminanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The invention provides an OLED display device, and relates to the technical field of display. The OLED display device solves the problem that an existing OLED sub-pixel is uneven in light-emitting brightness. The OLED display device comprises an array substrate and a package substrate which are packaged together, the array substrate comprises a first electrode layer, a second electrode layer and a light-emitting function layer located between the first electrode layer and the second electrode layer. The first electrode layer comprises a plurality of pixel electrodes which do not make contact with one another. The OLED display device is characterized in that the second electrode layer comprises a plurality of second electrodes which do not make contact with one another, and each second electrode corresponds to at least one pixel electrode. The display device further comprises transmission leads, and each transmission lead corresponds to one second electrode so as to input electric signals into the corresponding second electrode.

Owner:HISENSE VISUAL TECH CO LTD

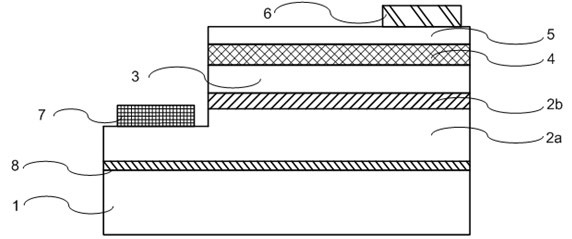

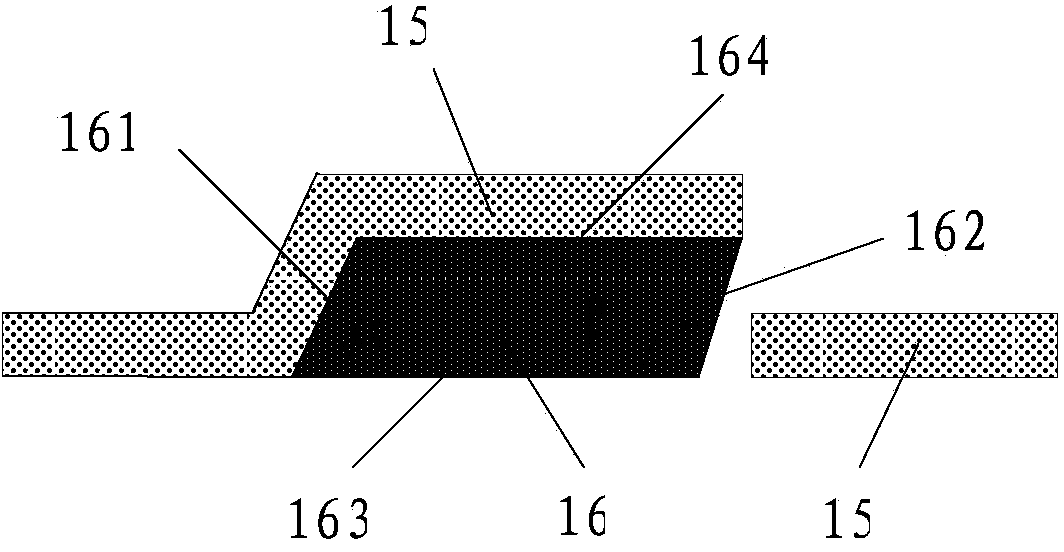

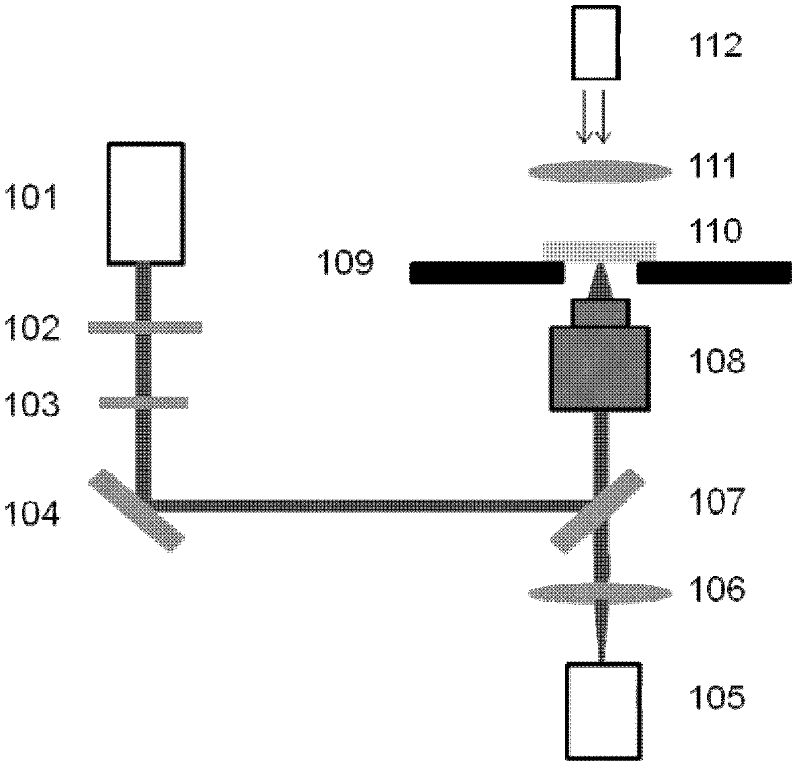

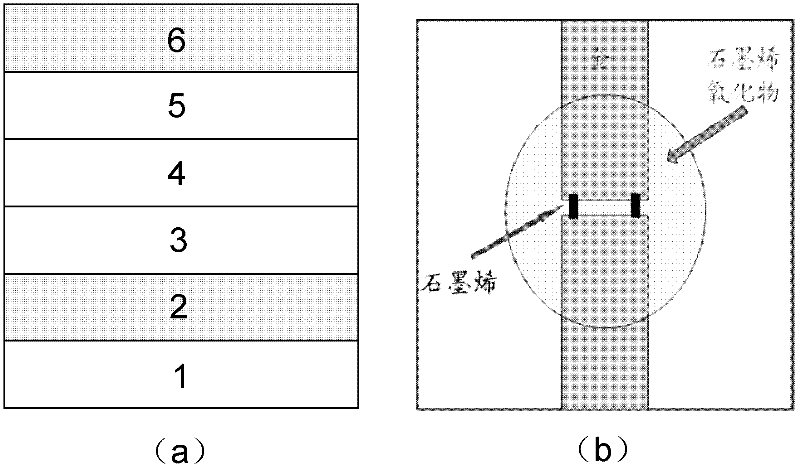

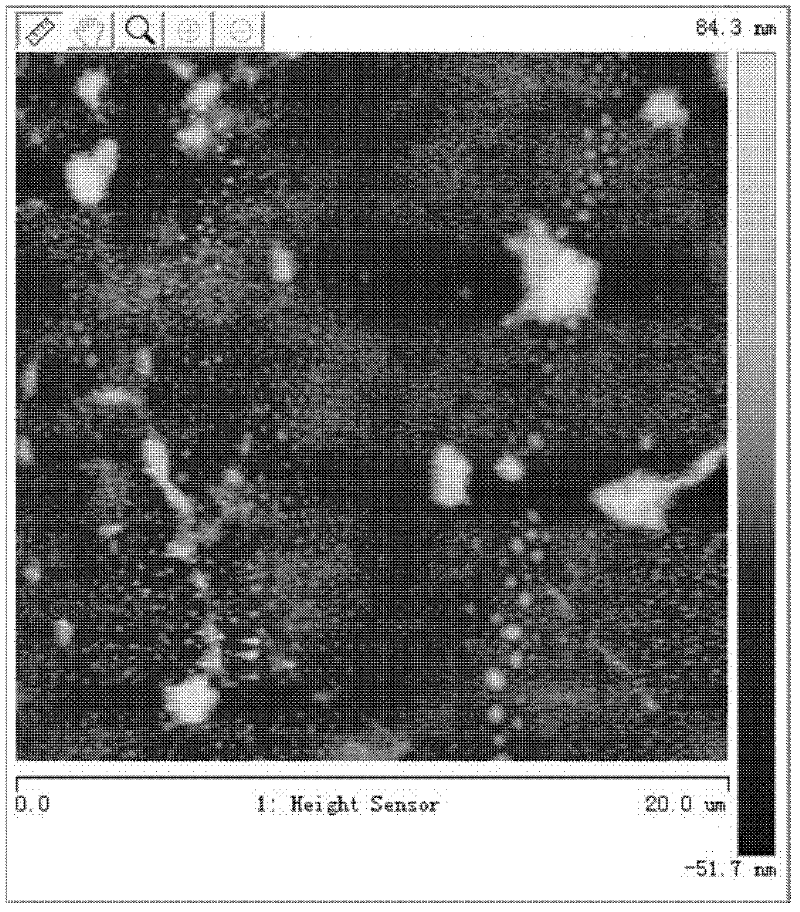

Organic electroluminescence device for reducing patterning graphene electrodes based on laser and manufacturing method therefor

ActiveCN102646795AImprove uniformity of light emissionImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceGraphene electrode

The invention belongs to the technical field of photoelectron and particularly relates to an organic electroluminescence device for reducing patterning graphene electrodes based on laser and a manufacturing method for the organic electroluminescence device. The organic electroluminescence device consists of a substrate, a gold electrode, the micron-dimension patterning graphene electrodes, an organic function layer and a cathode in sequence, wherein the gold electrode serves as an extraction electrode and is in a channel structure, the micron-dimension patterning graphene electrodes are lapped on the gold electrode at the two sides of each channel, and the micron-dimension patterning graphene electrodes are prepared by a laser write-through machining system capable of realizing laser point-by-point scanning. The obtained graphene electrodes are lower in the surface roughness and smoother in the surface, and therefore, the bottom-emission organic electroluminescence device prepared by the electrodes are higher in the degree of light-emitting homogeneity. The organic electroluminescence device and the manufacturing method break through the conventional concept for manufacturing the original large-area devices, the areas of the electrodes are reduced to the micron dimension, and patterns are led into the electrodes, so that the light-emitting area of the device is in a miniaturized pattern structure, thereby combining the organic electroluminescence device and the laser micro-nanomachining skillfully.

Owner:中科精仪科技(广东)有限公司

Light Emitting Device With Beveled Reflector And Manufacturing Method Of The Same

InactiveCN106560933ALight extractionPromote absorptionSolid-state devicesSemiconductor devicesFluorescenceEngineering

The present invention provides a light emitting device with a beveled reflector and a manufacturing method of the same. The light emitting device includes an LED semiconductor die, a photoluminescent structure and a reflector. The photoluminescent structure is disposed on the LED semiconductor die, the side surface of the photoluminescent structure is beveled , and a lower surface of the photoluminescent structure adheres to an upper surface of the LED semiconductor die. The reflector wraps the side surface of the LED semiconductor die, and the side surface of the photoluminescent structure is beveled. A method to manufacture the above light emitting device is also disclosed. Advantages of this light emitting device with beveled reflector include increasing the light extraction efficiency, making the viewing angle tunable, improving spatial color uniformity and reducing the light source etendue realized in a compact form-factor size.

Owner:MAVEN OPTRONICS CO LTD

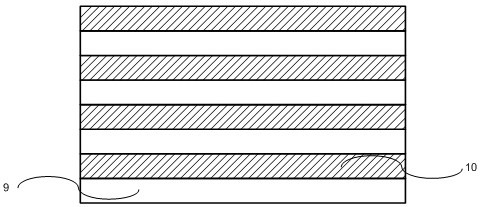

Photoluminescent wafer as well as preparation method and application thereof

InactiveCN102140690ALattice integrityReduce surface recombinationPolycrystalline material growthSolid-state devicesRare-earth elementWafering

The invention relates to the manufacturing field of light emitting diodes (LED), in particular to a photoluminescent wafer for the LED as well as preparation method and application thereof. The photoluminescent wafer is a slice-shaped crystal in a garnet structure with a general formula of A3B5O12 without doping any resins and other bonding agents, the thickness of the photoluminescent wafer is not less than 20 um, and the size of the crystal particle is not less than 10 um; moreover, the photoluminescent wafer comprises a first element A, a second element B and an active element, wherein thefirst element A is at least one of rare-earth elements Y, Lu, La, Gd or Sm; the second element B is at least one of the elements Al, Ga or In; and the active element is at least one of the rare-earthelements Ce, Pr, Tb and Dy. The photoluminescent wafer has the characteristics of high light emitting efficiency and good light emitting uniformity; the light transmission of the light emitting layercan not be reduced by light adsorption of the bonding agent; and the surface of the photoluminescent wafer is easy for people to carry out various optical treatments.

Owner:ZHEJIANG SHENDU LIGHTING

Electroluminescent device

ActiveCN101764148ASmall pressure dropImprove uniformity of light emissionSemiconductor/solid-state device detailsSolid-state devicesPixel arrayPeripheral

An electroluminescent device comprises a substrate, a pixel array, a plurality of lead groups, a plurality of driving devices and at least one power supply transmission pattern, wherein the substrate comprises a display area and a peripheral circuit area arranged on the periphery of the display area; the pixel array is arranged in the display area of the substrate and provided with a plurality of pixel structures, each pixel structure contains at least one active element and at least one light-emitting element which is electrically connected with the active element; the lead groups are arranged in the peripheral circuit area of the substrate and are electrically connected with the pixel array, wherein each lead group contains a plurality of leads; each driving device is electrically connected with one lead group; and the power supply transmission pattern is arranged in the peripheral circuit area of the substrate and positioned between adjacent two lead groups, wherein one end of the power supply transmission pattern is electrically connected with the light-emitting element of the pixel array and the other end of the power supply transmission pattern is electrically connected with the corresponding driving device.

Owner:AU OPTRONICS CORP

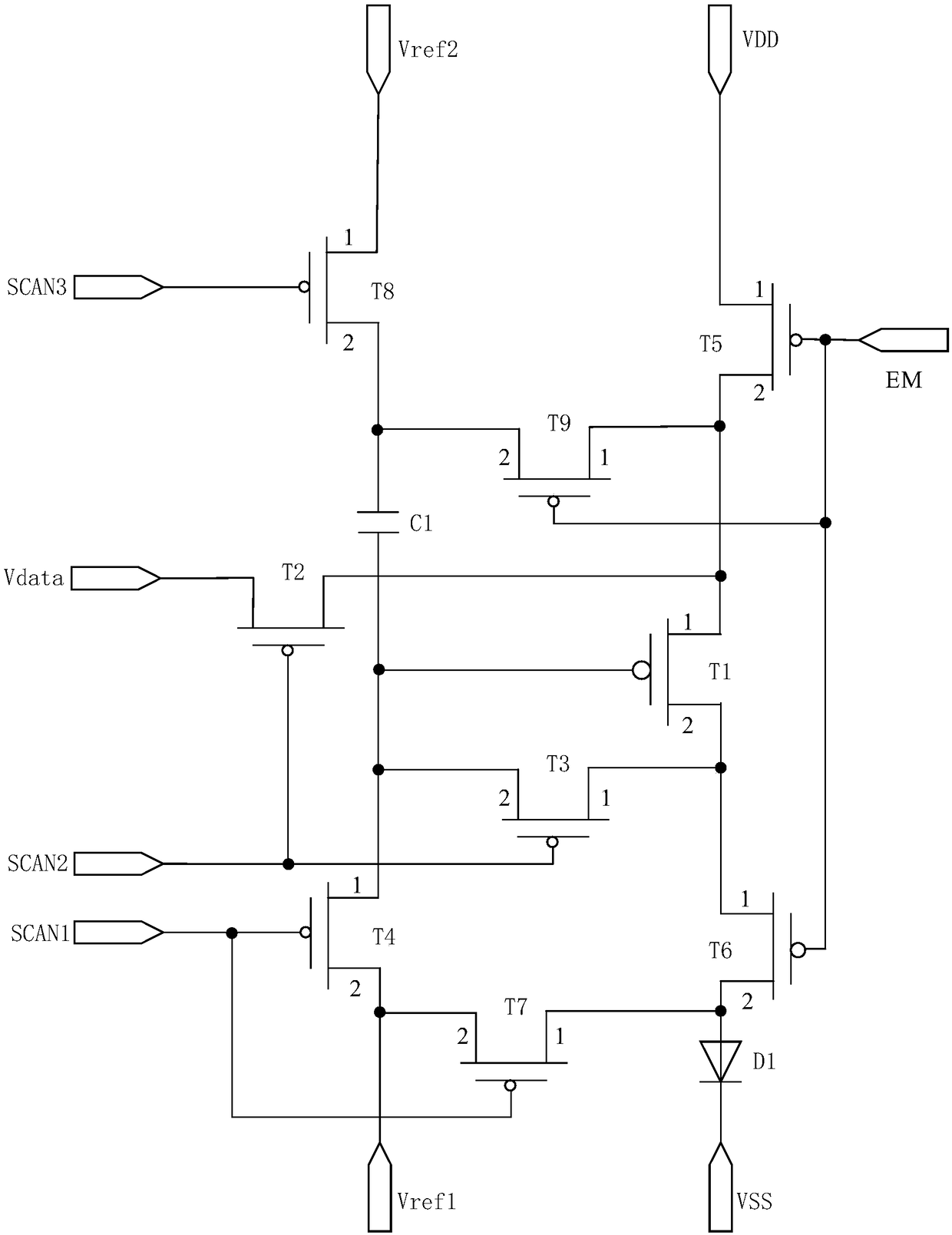

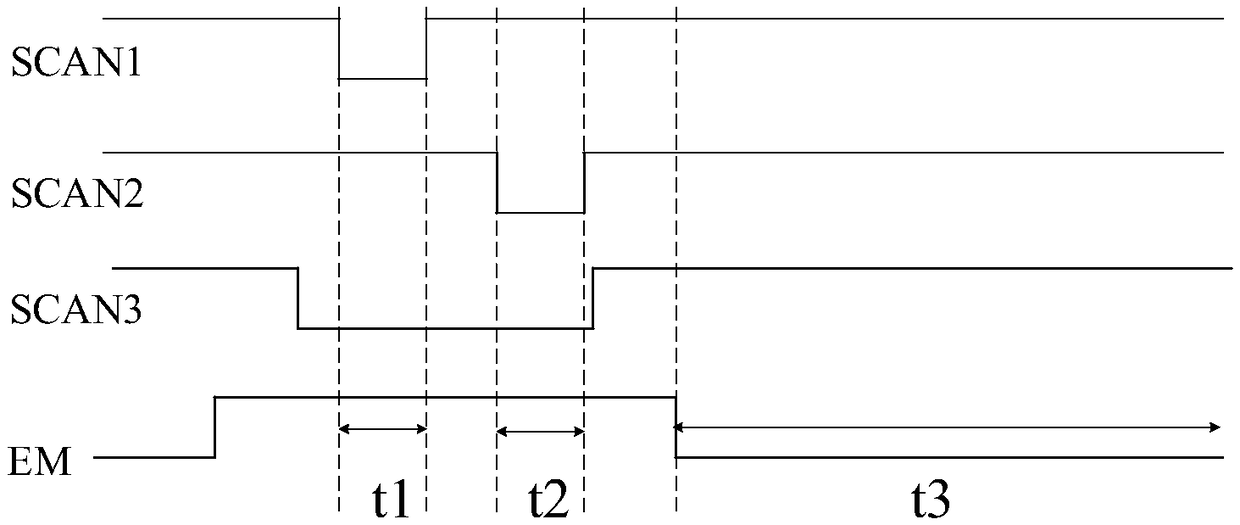

Pixel circuit, control method thereof, display panel and display device

InactiveCN109147676AImprove the uniformity of light emissionCompensation for the effect of luminescence currentStatic indicating devicesCapacitanceDriving current

The invention relates to a pixel circuit, a control method thereof, a display panel and a display device. The pixel circuit includes a transistor T1, a transistor T2, a transistor T3, a transistor T4,a transistor T5, a transistor T6, a transistor T7, a transistor T8, a transistor T9, a capacitor C1, and a light emitting diode D1. The pixel circuit uses a second reference voltage Vref2 to compensate a control terminal of the transistor T1 through the capacitor C1 so as to make a driving current flowing through the transistor T1 is related to the second reference voltage Vref2 and independent of first power supply VDD. Since the driving current flows through a power supply line, when the driving current is independent of first power supply VDD, current-resistance voltage drop on the power supply line has no effect on the driving current, thereby improving the illumination uniformity of a screen.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Light emitting diode encapsulating structure and manufacturing method thereof

InactiveCN101840973AImprove uniformity of light emissionSolid-state devicesSemiconductor devicesSpray coatingColloid

The invention discloses a manufacturing method of a light emitting diode encapsulating structure, which provides a loader and at least one light emitting diode chip which is provided with a light outlet surface and a plurality of side surfaces. The invention provides a first shade which is provided with at least one first opening; and the first opening at least exposes out of the light emitting diode chip. A spray coating device is arranged above the first shade for carrying out a first spray coating technology. The spray coating device is used for carrying out reciprocating spray coating on first fluorescent solution along a route so that the light outlet surface and the side surfaces of the light emitting diode chip are coated conformally by the first fluorescent solution. A first curing technology is carried out for curing the first fluorescent solution into a first fluorescent layer. An encapsulating colloid is formed for coating the first fluorescent layer and a part of the loader.

Owner:EVERLIGHT ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com