Encapsulation method for high-brightness white light LED

A technology of light-emitting diodes and packaging methods, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve problems such as low production efficiency, application limitations, unfavorable large-scale production, etc., to improve production efficiency, improve uniformity and consistency of light emission sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

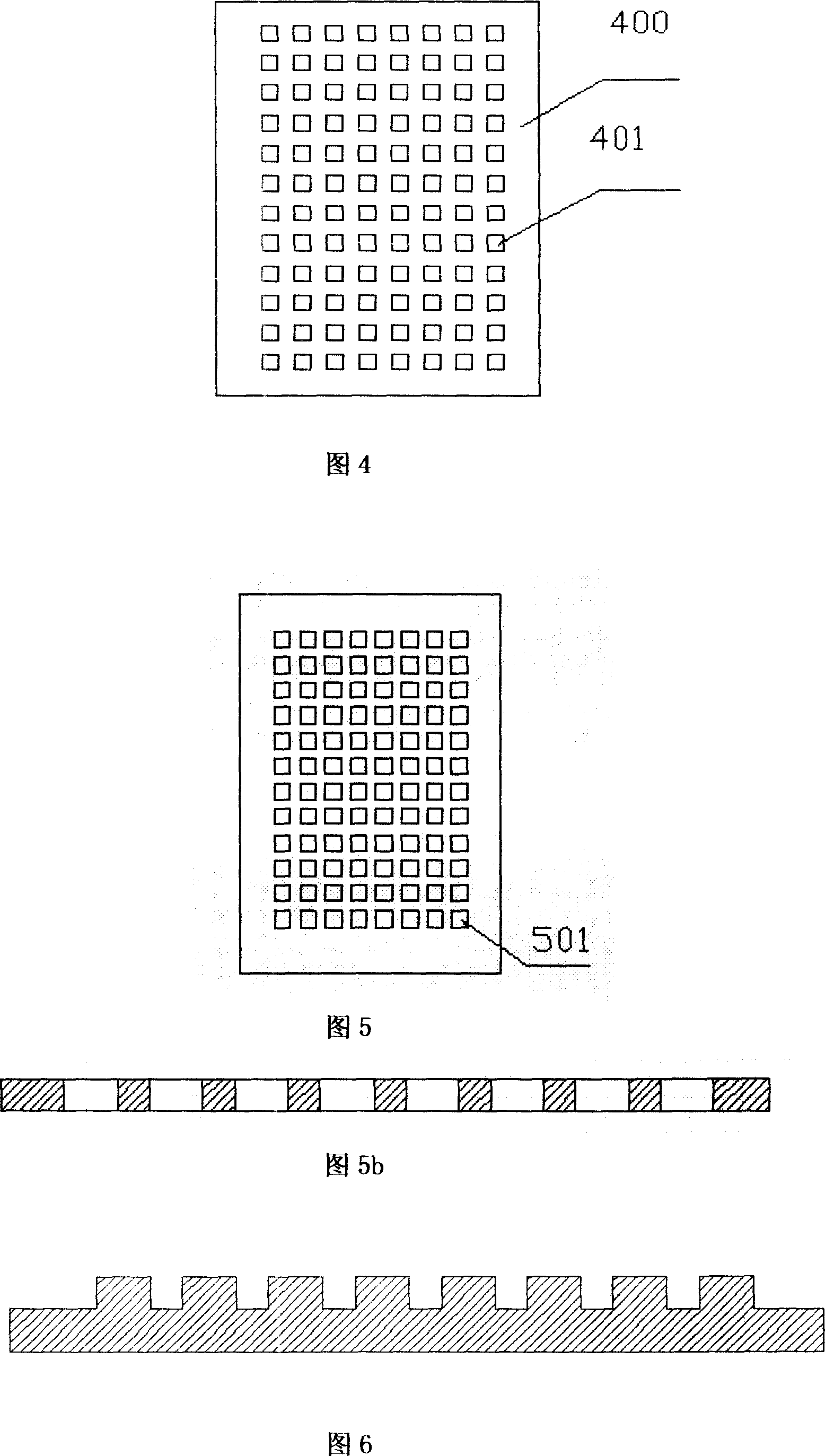

[0022] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0023] The packaging process is as follows: A. Weld the light-emitting chip or its array to the heat dissipation substrate with IC circuit; B. Align the mold with the light-emitting chip and press it tightly; C. Inject an appropriate amount of fluorescent powder into the mold Potting glue; D. Degassing and curing under vacuum; E. Demoulding.

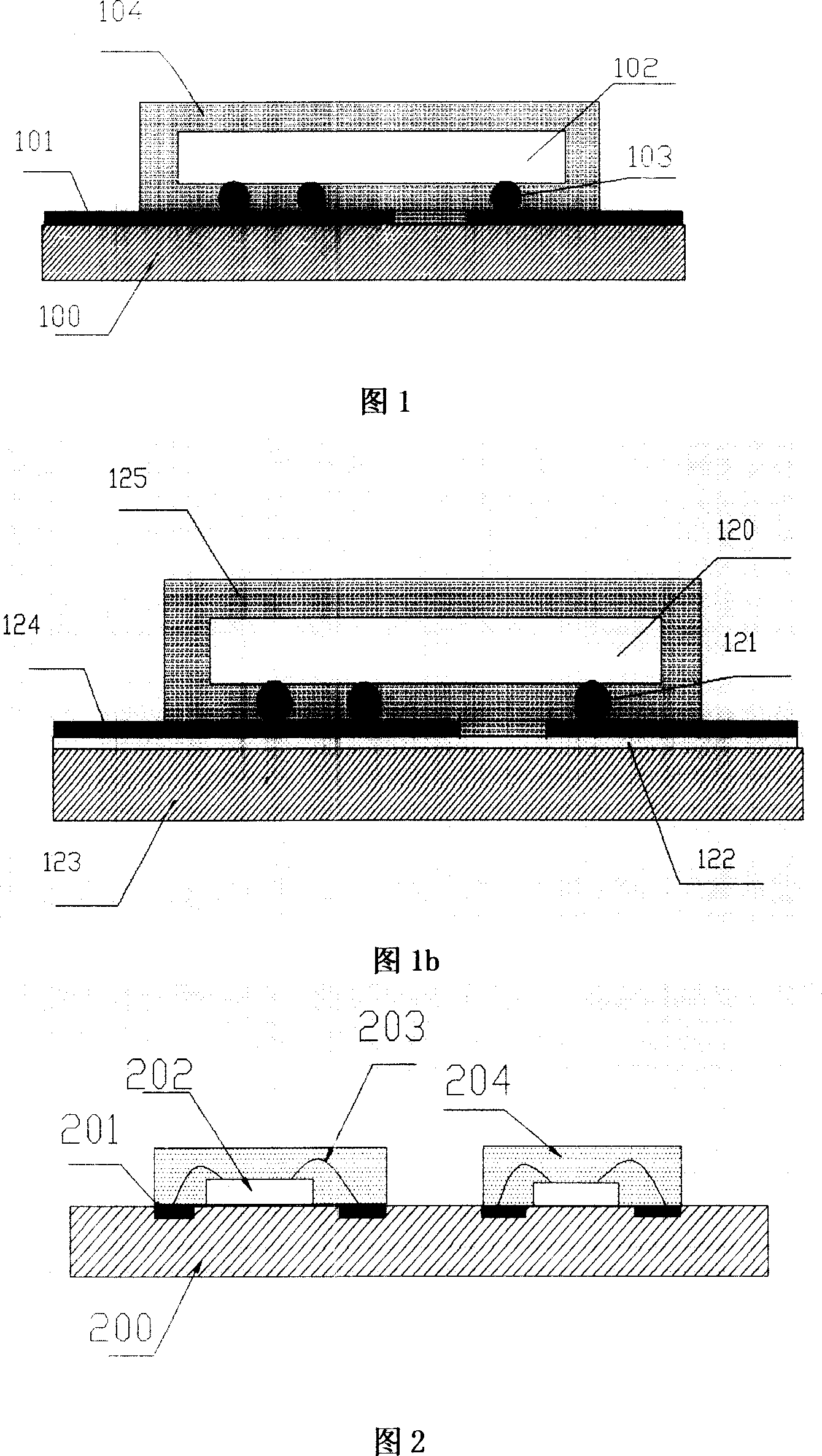

[0024] Referring to FIG. 1 , the figure shows the packaged structure of the flip-chip light-emitting diode chip. The blue light chip 102 is fixed on the silicon substrate or the ceramic substrate 100 by flip-chip soldering balls 103, the silicon substrate or the ceramic substrate 100 is provided with a wire layer 101, and the outer surface of the blue light chip 102 is evenly attached with a ring containing phosphor powder. Oxygen glue or silica gel 104.

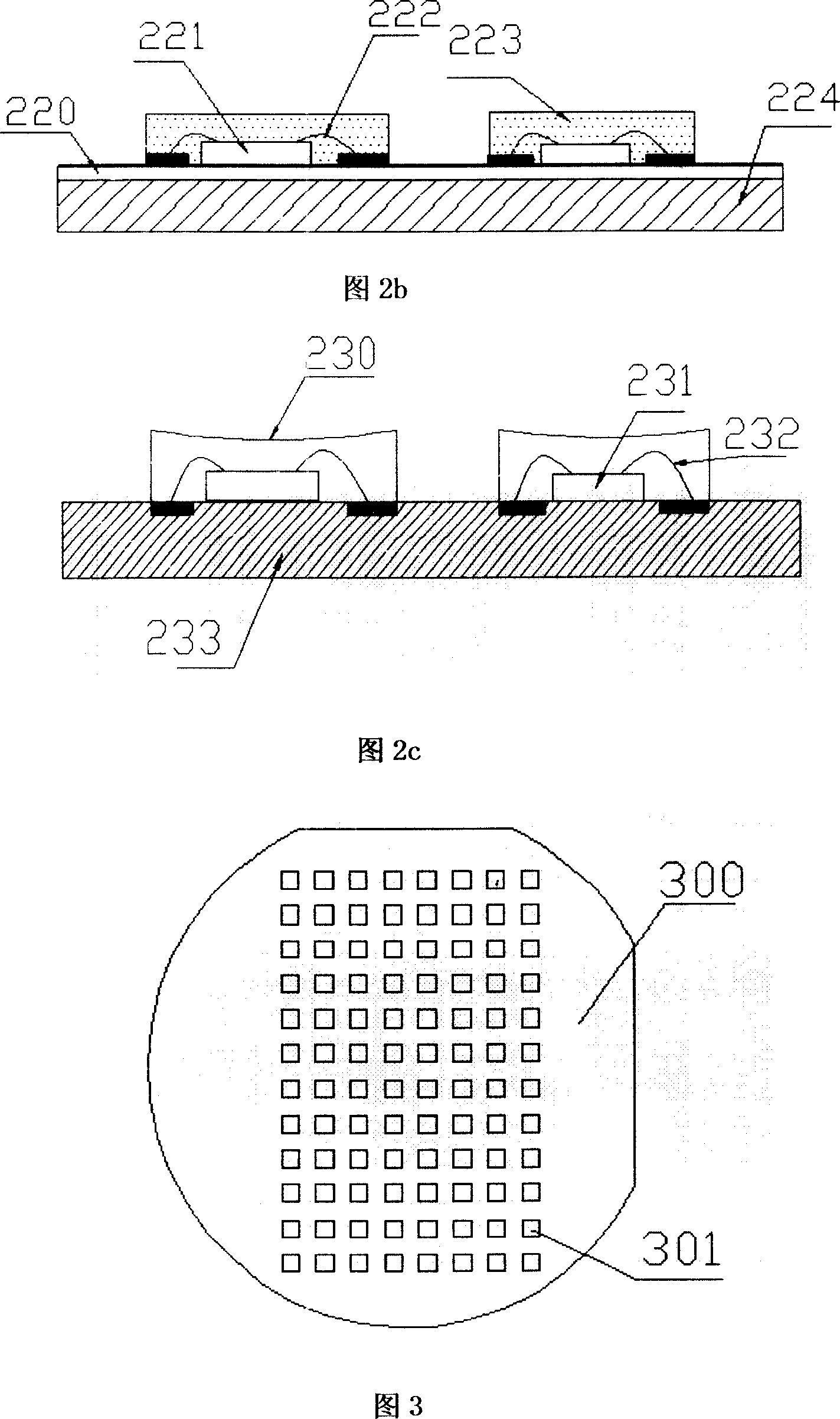

[0025] Referring to FIG. 2 , the figure shows the packaged st...

Embodiment 2

[0037] Embodiment 2 is the same as Embodiment 1, the difference is:

[0038] 1. The heat dissipation substrate in Figure 1b is a metal substrate with a passivation layer. The blue light chip 120 is welded on the electrode 124 through flip-chip solder balls 121, the passivation layer 122 is on the metal substrate 123, and the electrode 124 is on the passivation layer 122. The outer surface of the blue light chip 120 is evenly attached with a layer containing Epoxy glue or silica gel 125 for phosphor. See Figure 1b.

[0039] 2. Figure 2b is a package diagram of a wire-bonded LED chip. The heat dissipation substrate is a metal substrate 224 with a passivation layer. The light emitting diode chip 221 is connected to the electrode through the lead wire 222 , the insulating passivation layer 220 is on the metal substrate 224 , and the light emitting diode chip 221 is bonded and fixed on the insulating passivation layer 220 . A layer of epoxy glue or silica gel 223 containing flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com