Generator of white-light surface light source

A technology of light-emitting device and white light surface, which is applied to electrical components, electric solid-state devices, circuits, etc., can solve the problems of very high processing technology requirements, difficult to control thickness and uniformity, and difficult to control white light uniformity and color temperature consistency, etc. Achieving the effect of solving excitation wavelength shift, shortening production process, improving chromaticity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiment:

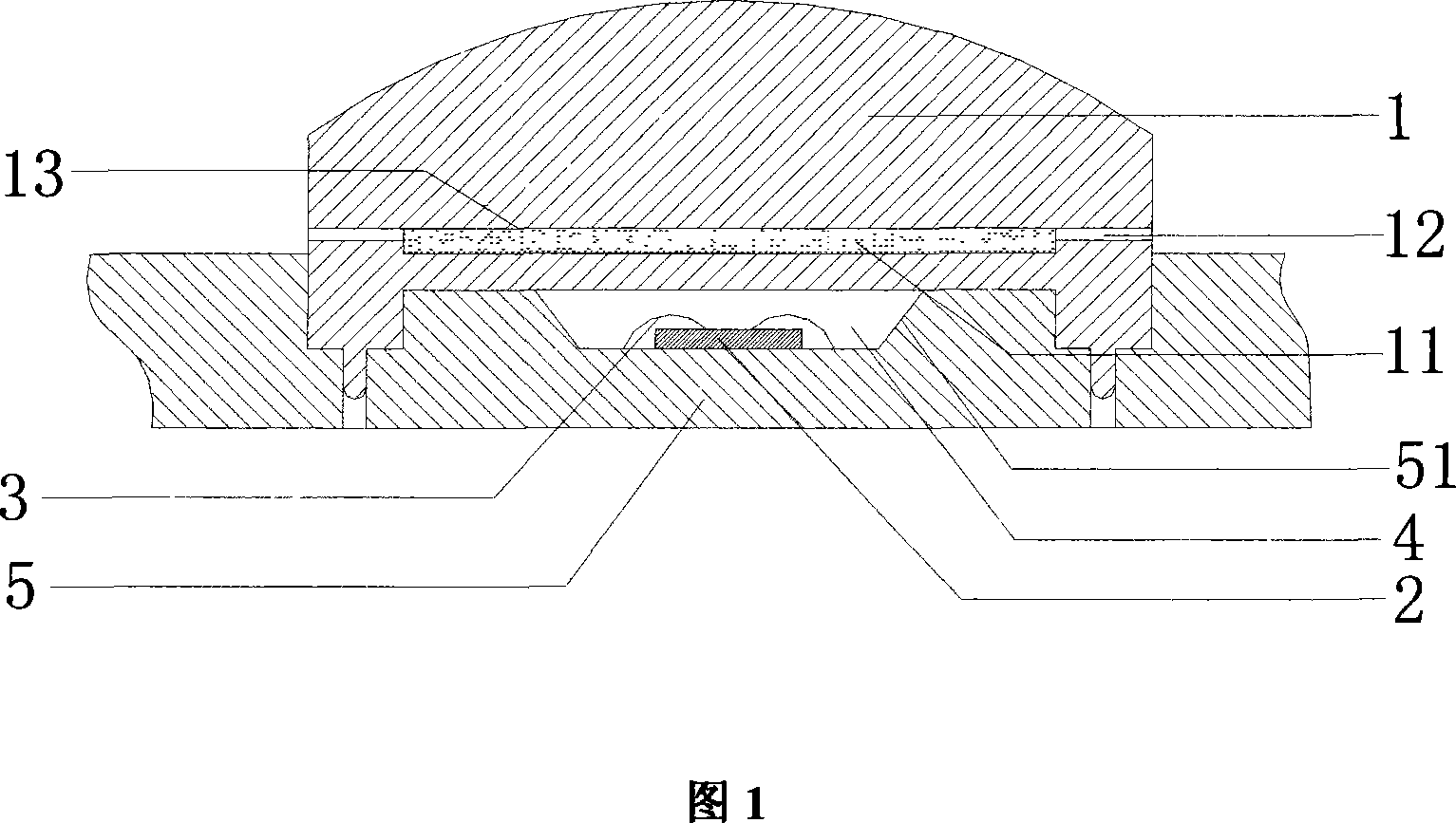

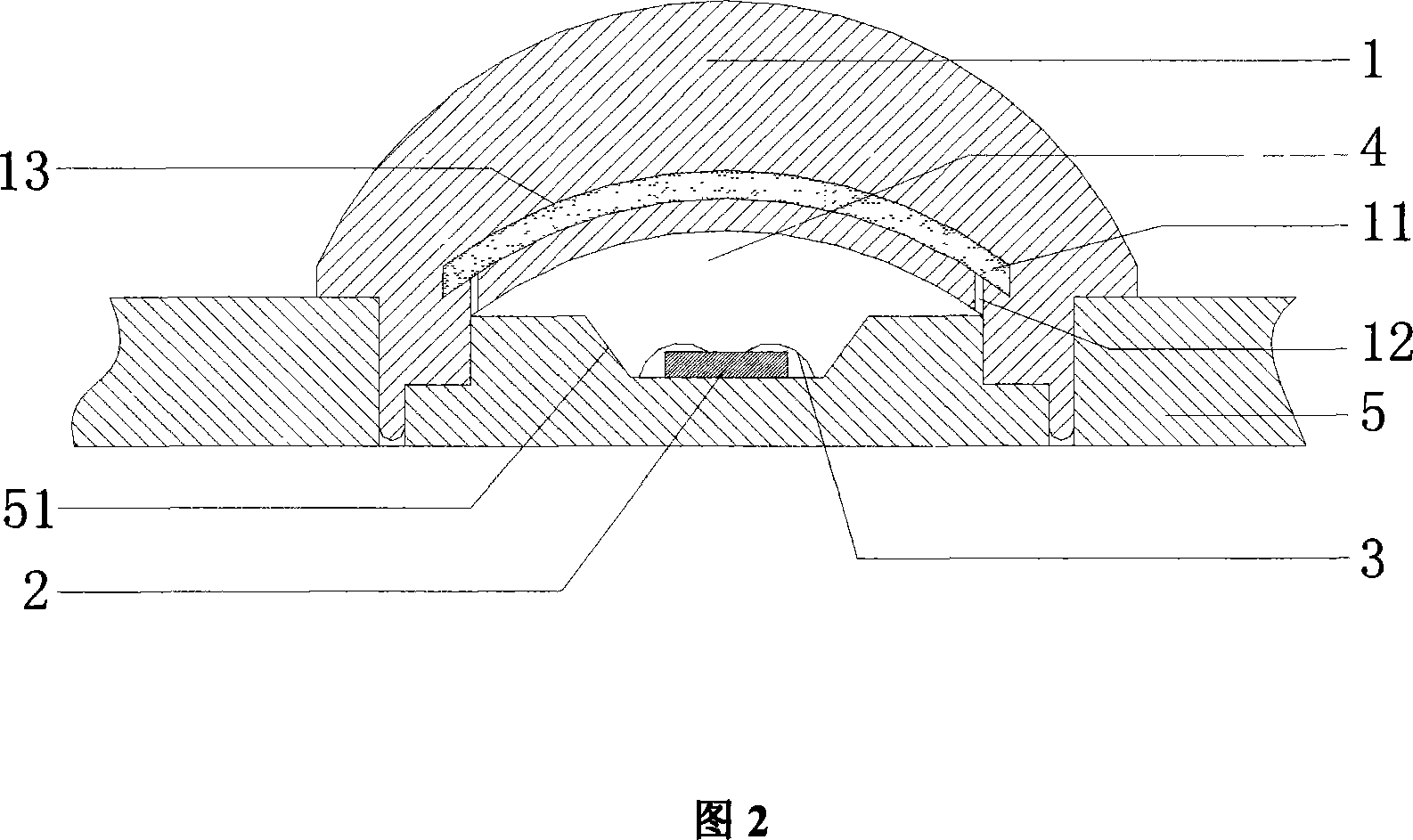

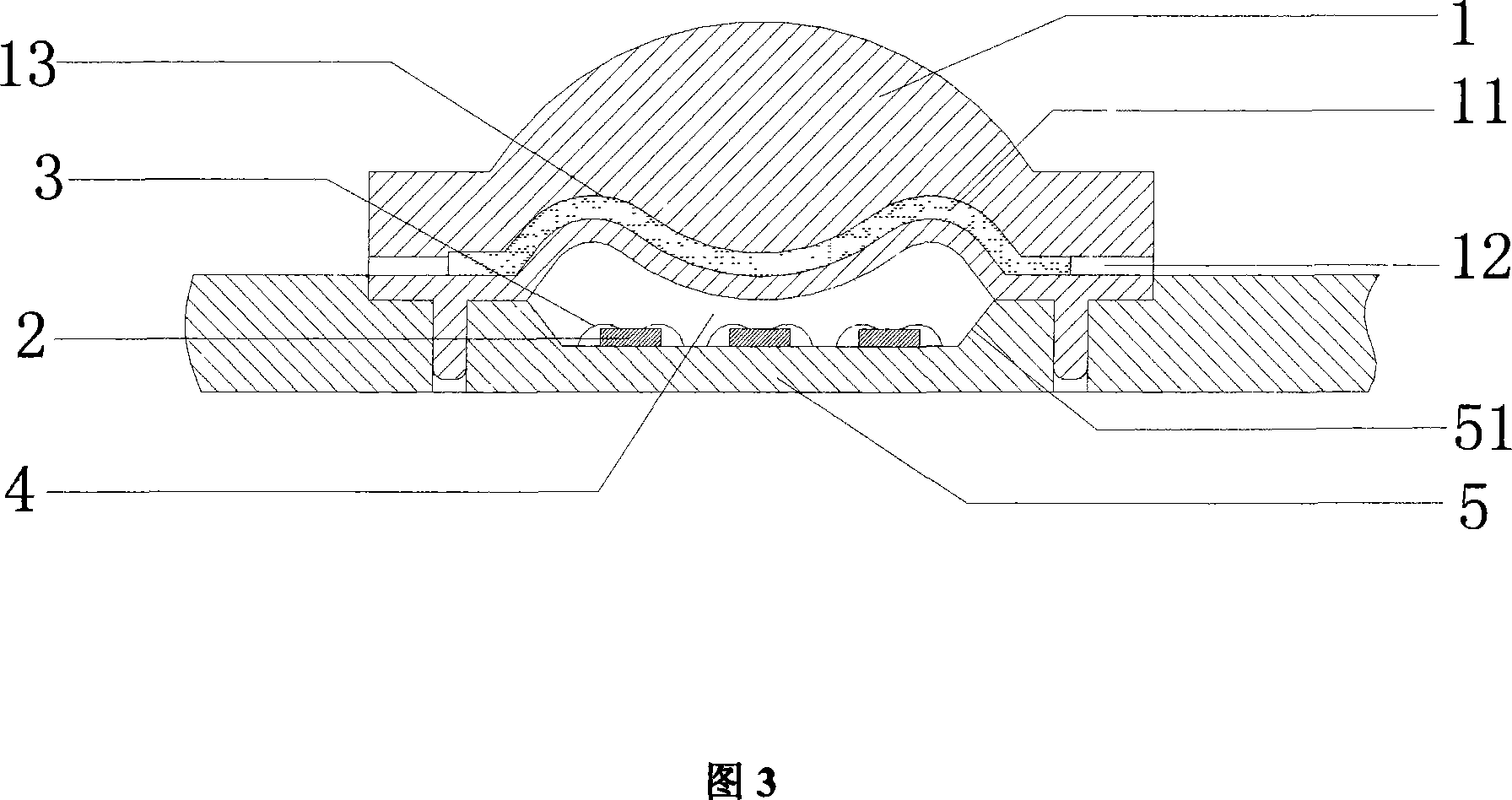

[0027] As shown in FIG. 1 , which is a cross-sectional view of Embodiment 1 of the present invention, the lens 1 is a fabricated overall structure. Among them, the lens 1 is composed of several parts, and the parts are combined into an integral structure by one or more methods of ultrasonic welding, adhesive bonding, bayonet, and thread structure, and a cavity 13 is formed inside it. and the opening 12 , the light conversion material 11 is filled in the cavity 13 through the opening 12 . The cross-section of the cavity 13 can be square, circular or other irregular shapes; the inner surface of the cavity 13 can be a smooth and flat surface, or a rough or uneven non-smooth surface or concave-convex surface. Wherein, if the parts of the lens 1 are bonded with an adhesive, the adhesive can be any one of materials such as epoxy resin, silicone resin, acrylic resin, UV glue, ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminous wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com