Patents

Literature

6985results about How to "Simple processing technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of wet process mixed natural rubber material

ActiveCN102153792AGood dispersionImprove uniformityRolling resistance optimizationRubber materialPolymer science

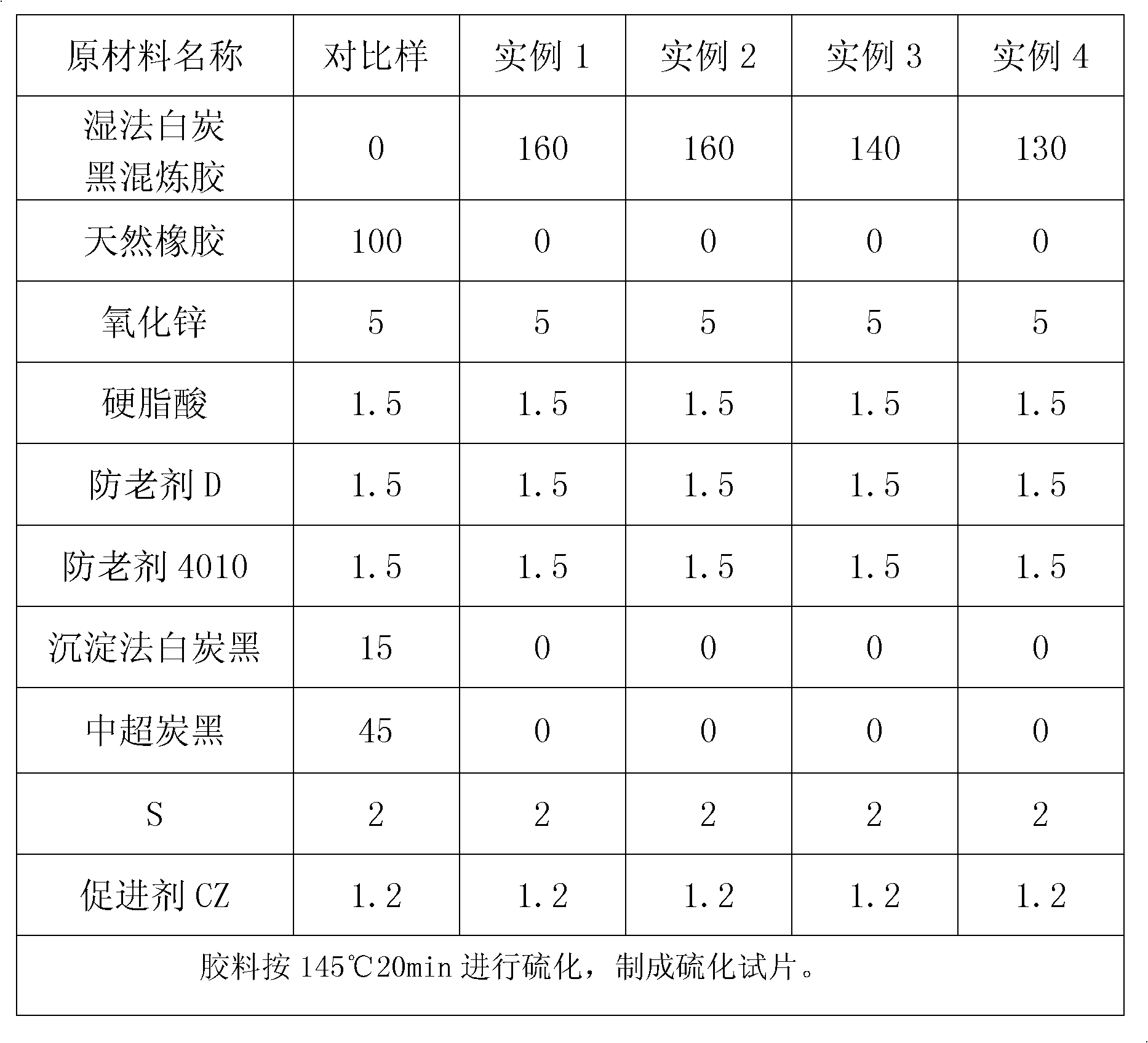

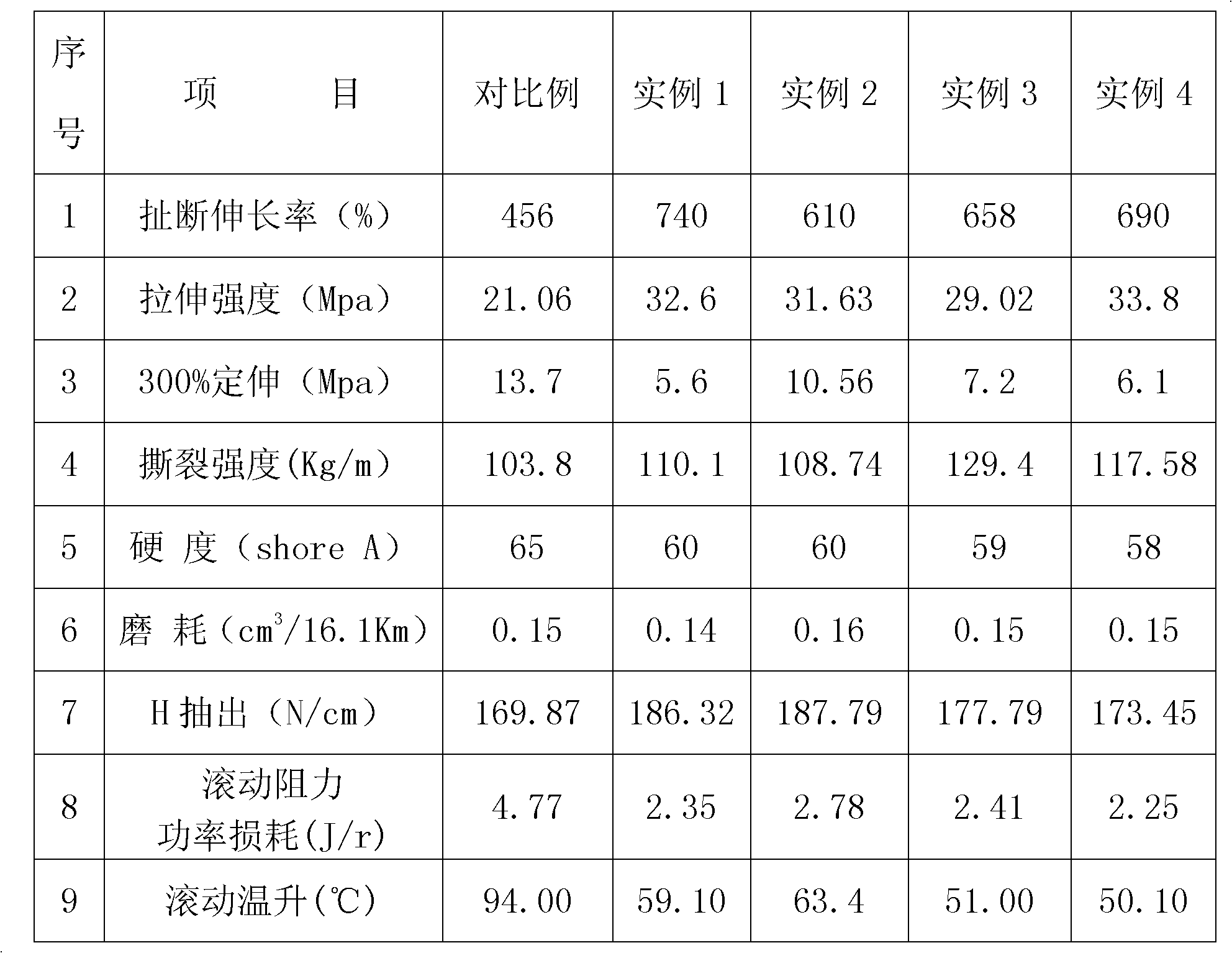

The invention relates to a preparation method of a wet process mixed natural rubber material. The method comprises the following steps of: preparing slurry and soaking 15-40 percent of dry white carbon black in 60-85 percent of deionized water; adding a coupling agent and a surfactant, uniformly mixing, grinding, preparing latex mixed liquor, extracting natural latex and adding white carbon black water dispersoid into the latex; stirring and mixing to obtain a latex mixed liquor, flocculating and adding acetic acid into the mixed liquor; performing rubber washing and dehydration by using a rubber washing machine and feeding to a rubber pelletizer for pelletizing; and feeding rubber particles into a box drying cabinet for drying. The preparation method has the advantages of simple machining process, small equipment investment, realization of various ideal performances with the most ordinary white carbon black, low dust pollution in the entire production process and energy saving. A tire manufactured with the method has small rolling resistance, low heat generation, high tensile strength, high tearing strength and high rubber material ageing resistance. Mixing of the white carbon black is performed in a liquid phase, so that the dispersivity and uniformity are enhanced.

Owner:ZHUZHOU ANBAOLINFENG NEW MATERIALS

Method for preparing graphene-doped anode material for lithium-ion batteries

ActiveCN101800310AImprove conductivitySimple processing technologyCell electrodesLithium iron phosphateElectrical battery

The invention discloses a method for preparing a graphene-doped anode material for lithium-ion batteries. The main component of the anode material is lithium iron phosphate nanoparticles. The method comprises the following steps of: firstly preparing the graphene, graphene oxide, and intercalation graphene respectively; secondly, doping the mixture of the graphene, the graphene oxide and the intercalation graphene in the synthetic material of the lithium iron phosphate nanoparticles or directly mixing the lithium iron phosphate nanoparticles and the intercalation graphene, the graphene oxide,or chemically reduced graphene after the preparation of lithium iron phosphate nanoparticles; and finally, synthesizing the graphene or graphene oxide bridged or lithium iron phosphate nanoparticle-clad material after the treatment of drying, filtering, eluting, re-drying, and annealing. The lithium iron phosphate nanoparticles prepared by the method of the invention are characterized by the capability of greatly improving electron conductivity and providing the lithium-ion batteries anode material having the advantages of simple processing technique, low cost, high capacity and safety for lithium-ion batteries.

Owner:苏州格瑞丰纳米科技有限公司

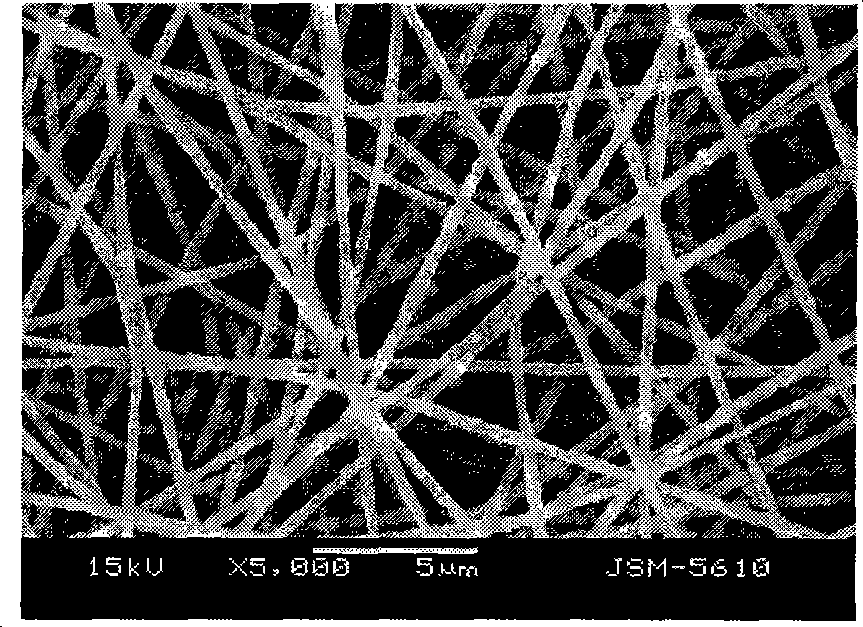

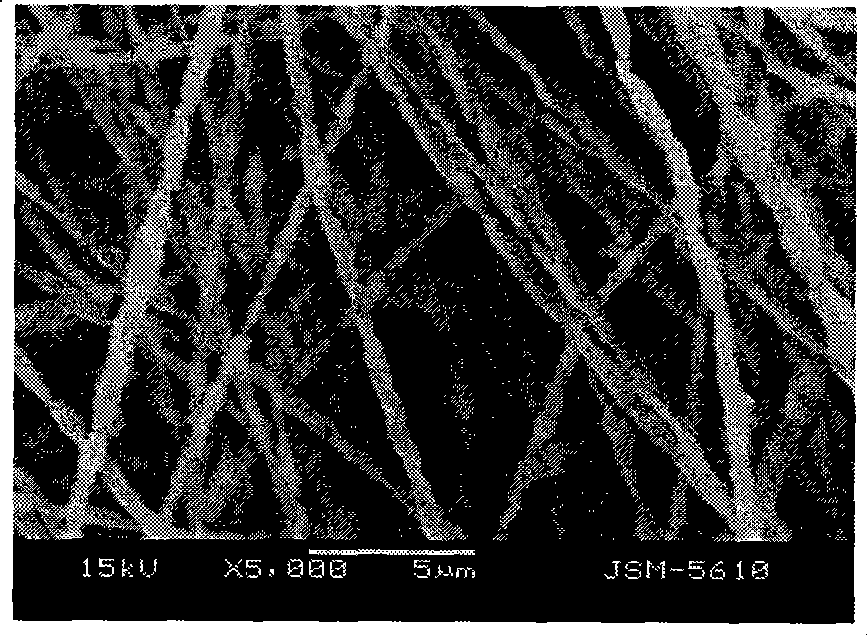

Preparation method of polytetrafluoroethylene superfine fiber porous membrane

InactiveCN101530750AUniform pore sizeHigh porositySemi-permeable membranesHigh concentrationVoid ratio

The invention discloses a preparation method of polytetrafluoroethylene superfine fiber porous membrane. In the method, high concentration polytetrafluoroethylene aqueous emulsion is mixed with matrix polymer uniformly to prepare spinning solution. With the effect of high voltage electric field, polytetrafluoroethylene / matrix polymer composite superfine fiber porous membrane with the diameter of 100 nm to 2 [mu]m is obtained by electrostatic spinning, and then polytetrafluoroethylene superfine fiber porous membrane is formed at the conditions of sintering temperature being 330 to 500 DEG C and the sintering time lasting 30s to 5min so that the aperture diameter is 100 nm to 10 [mu]m and the porosity is 50% to 80%. The polytetrafluoroethylene superfine fiber porous membrane prepared by using the method has uniform aperture diameter and high porosity, and can be widely applied to filter material. Compared with the existing technology, the preparation method has the characteristics of simple processing technology, short process and low cost.

Owner:ZHEJIANG SCI-TECH UNIV

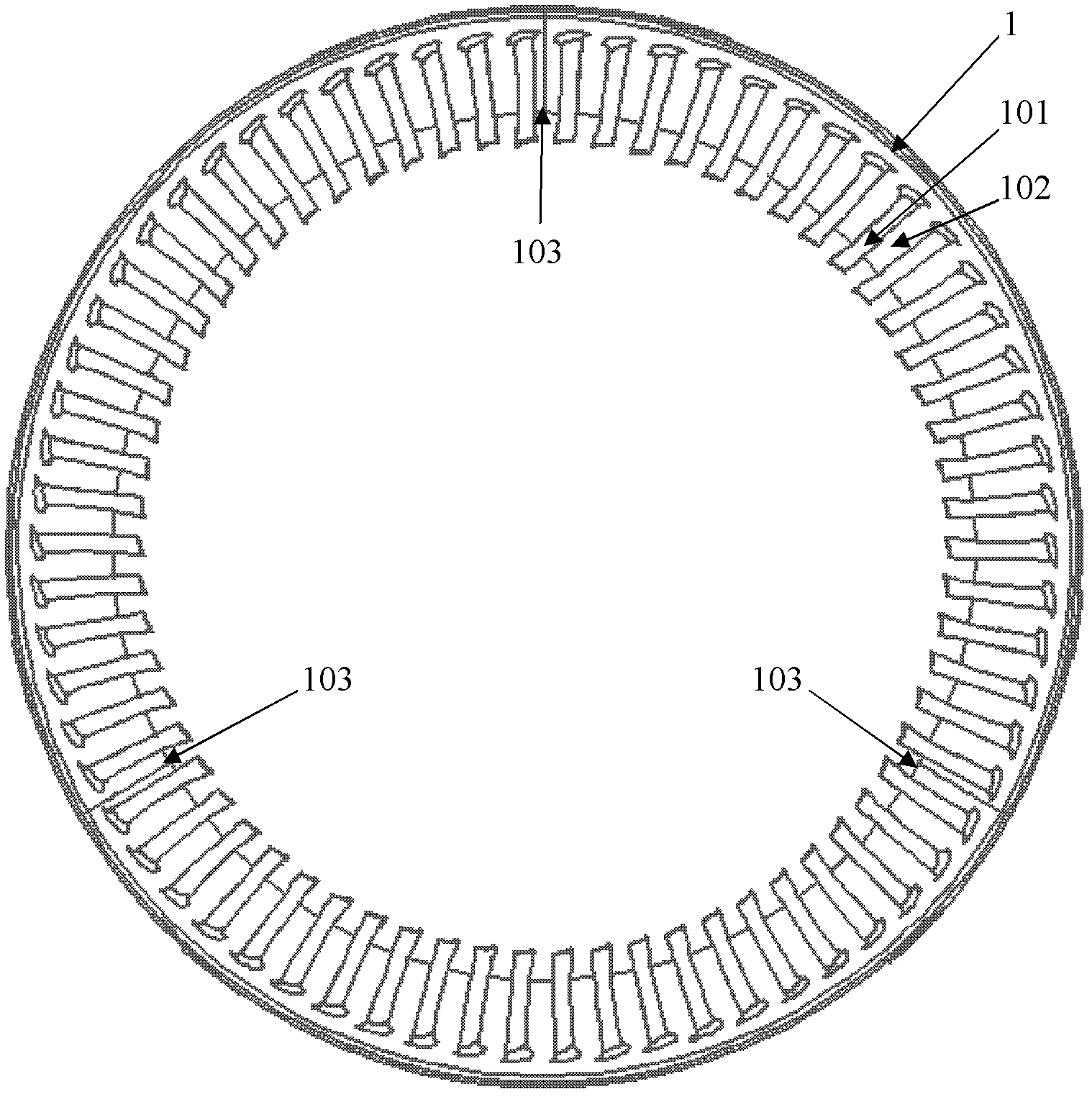

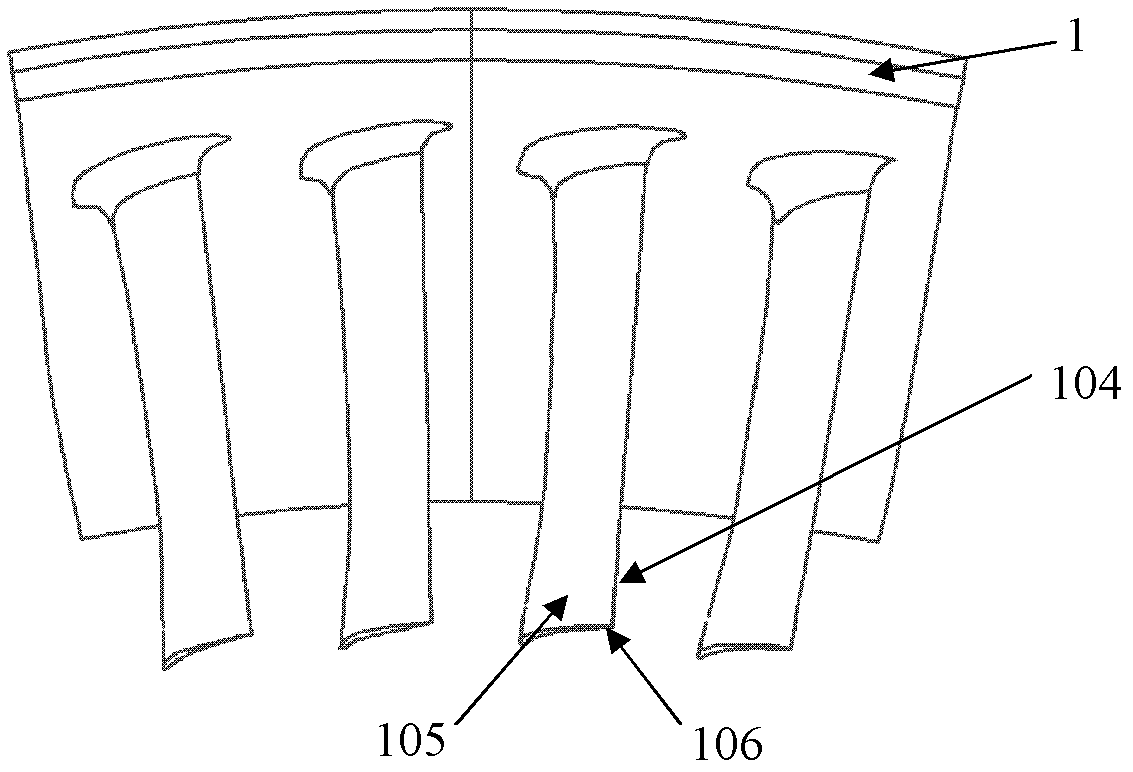

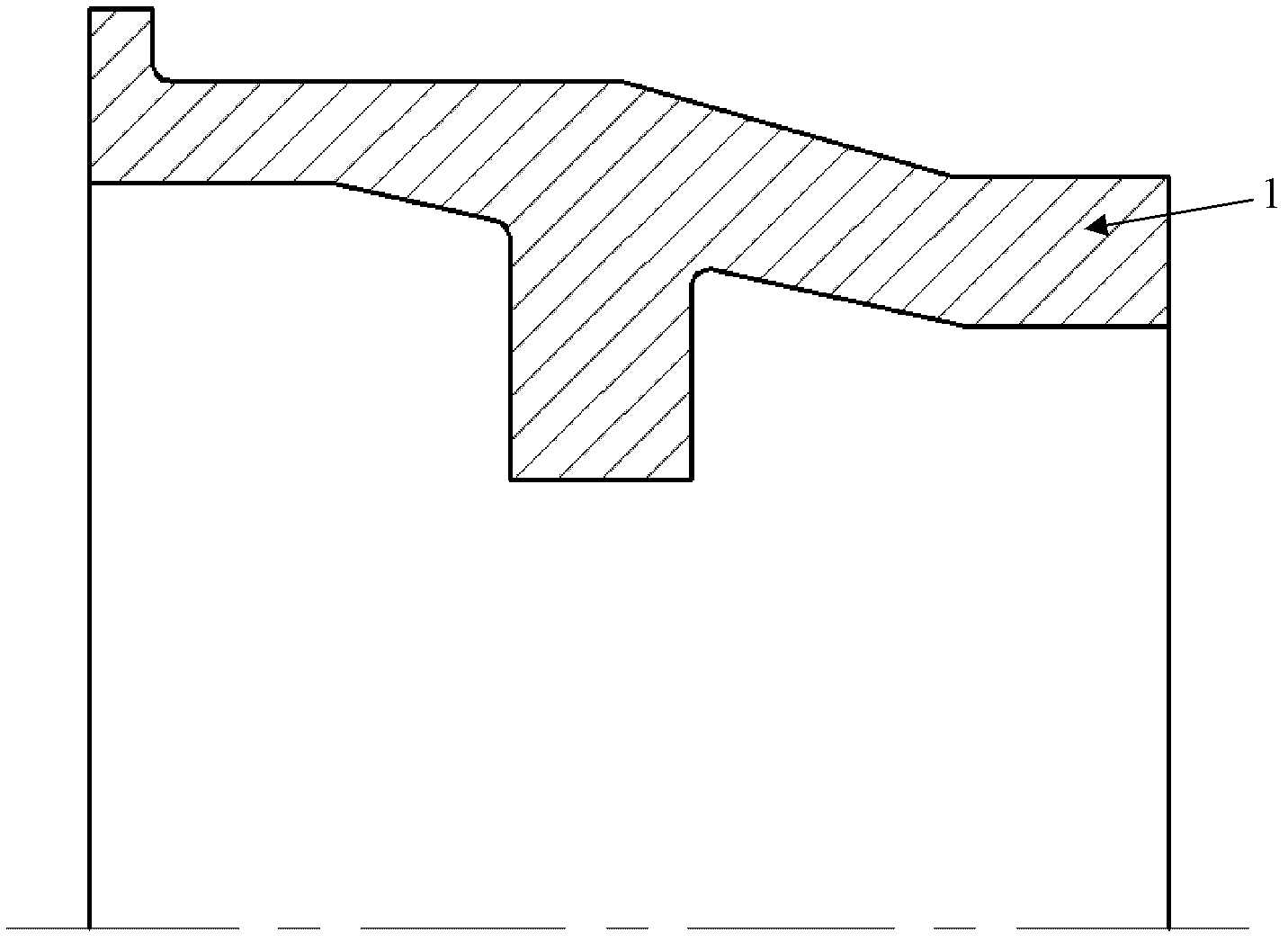

Method for processing integral casing of engine

The invention relates to a method for processing an integral casing of an engine, which is characterized by mainly comprising the steps of: inspecting blanks, carrying out rough turning on inner and outer shapes of the casing, carrying out numerical control milling on the outer shape of the casing and engraving lines for trisection, carrying out wire cutting and trisecting on the casing on the basis of the trisection lines, carrying out aging and stress-relieving treatments, grinding upper and lower end faces and processing two dowel holes in the lower end face, carrying out blade slot treatment and processing a faying surface and a flange hole, carrying out finish milling on the outer shape of the casing, carrying out the aging treatment again, assembling the trisected modules and establishing a benchmark again, carrying out finish turning on the inner surface of the casing, disassembling the modules of the casing, carrying out the finish milling on blades and assembling the modules of the casing, wherein a fillet variable-axis plunge milling method, a blade spacing processing method and a flexible supporting method are adopted in the blade finish milling process. The method provided by the invention has the advantages: the technical process is simple; the produced integral casing has higher precision; the advantages of good consistency, little deformation and high efficiencyare provided in the blade processing; the technical problem that the integral casing is difficult in numerical control is solved by means of the trisection processing method; and the process method can also be used for the development of multilevel integral casings.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

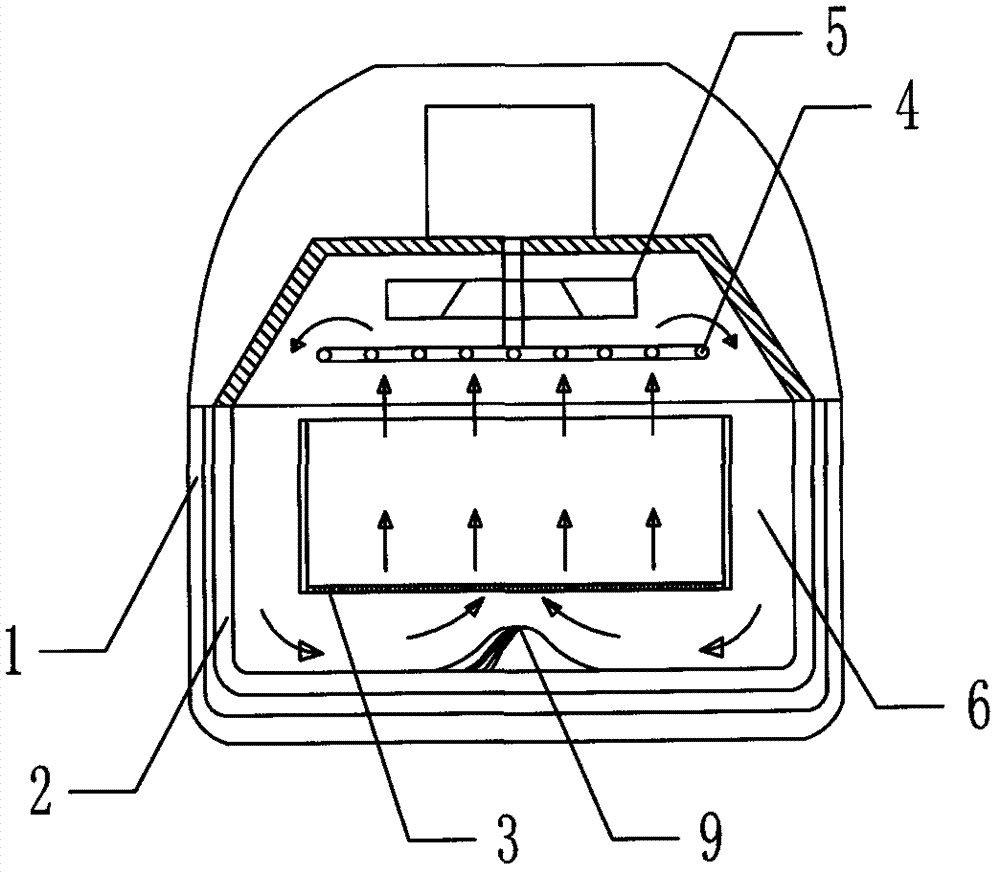

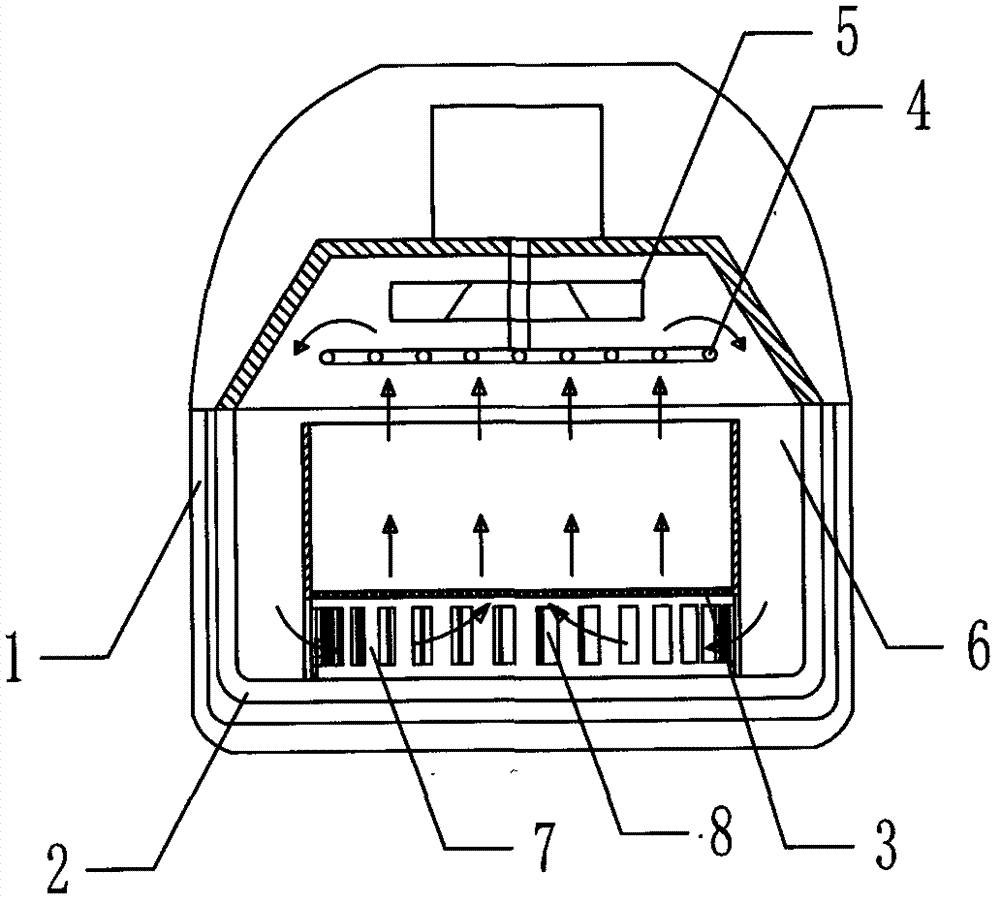

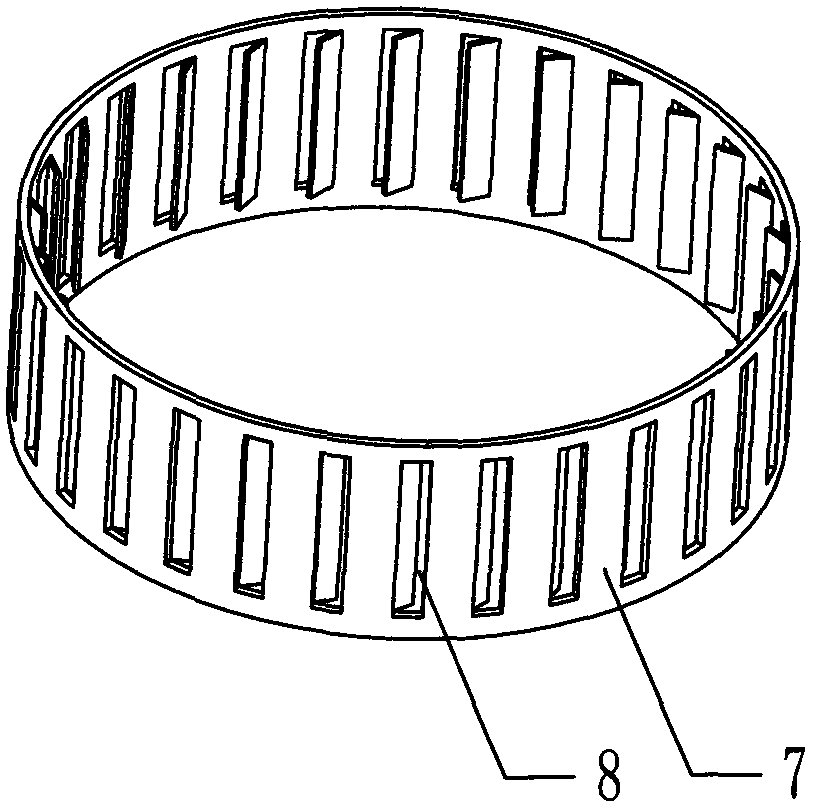

Air frying pan

The invention belongs to the field of family kitchen electric appliance manufacturing and specifically relates to an air frying pan. The air frying pan is mainly composed of a pan body (1), a liner (2), a frying basket (3) arranged in the liner (2), an electric heating pipe (4) arranged above the frying basket (3) and a fan (5) located above the electric heating pipe (4); the sidewalls of the frying basket (3) are formed by metal sheets and the bottom of the frying basket (3) is formed by a screen; an air flow channel (6) is arranged between the liner (2) and the frying basket (3); the air frying pan is characterized in that the outer periphery of the bottom of the frying basket (3) extends downwards to form a guide cylinder (7) and air inflow inclined holes (8) for guiding airflow to rotate are evenly formed in the sidewall of the guide cylinder (7). The air inflow inclined holes (8) are leftward or rightward slit holes toward the same direction. The air frying pan of such a structure has the advantages that the frying basket is simple in structure, the bottom of the liner is easy to manufacture and easy to clear, and is well supported.

Owner:严绍基

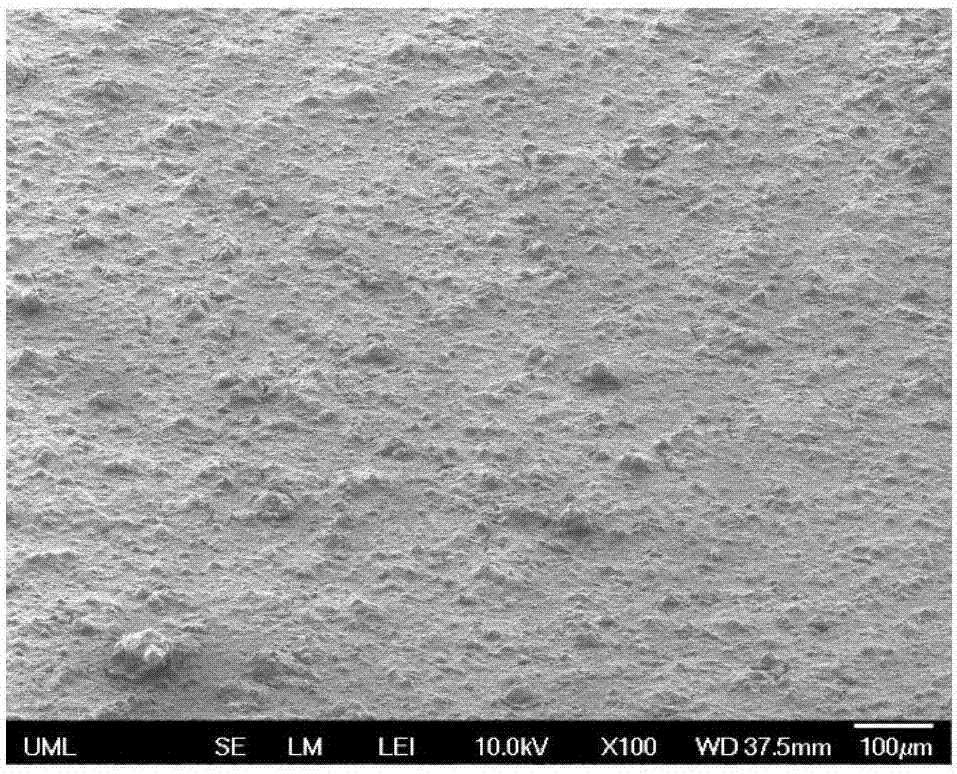

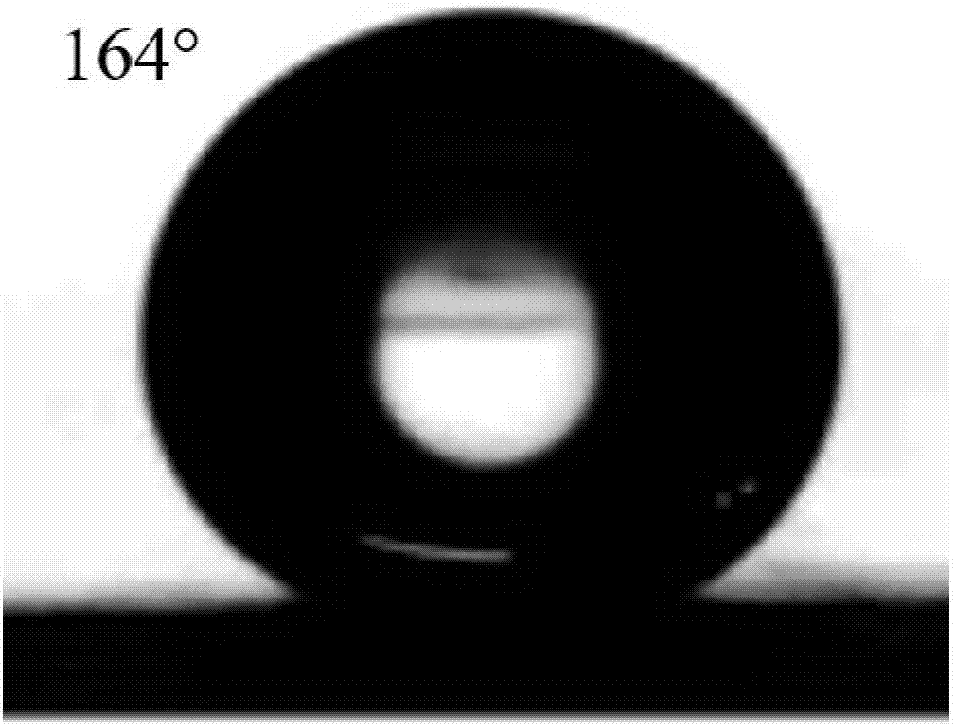

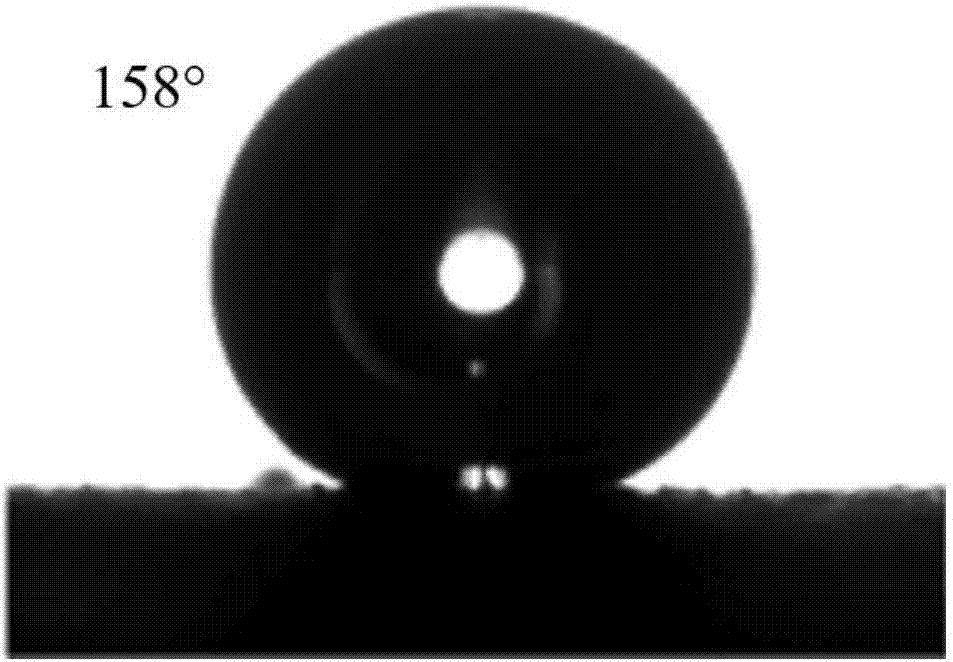

Wear-resisting super-hydrophobic coating composition as well as preparation method and application thereof

InactiveCN107987675AImprove protectionLong-term effective superhydrophobic propertiesLiquid surface applicatorsPolyurea/polyurethane coatingsMicro nanoNanoparticle

The invention relates to a wear-resisting super-hydrophobic coating composition as well as a preparation method and application thereof. The composition is prepared from a nano-material dispersion solution and a binding material dispersion solution. The nano-material dispersion solution is prepared by mixing a nanoparticle material, a hydrophobic silane coupling agent and a volatile solvent, wherein nanoparticles form a rough structure with a micro-nano dual scale through a mutual effect of the nanoparticles and the structure is dispersed in the solution of the hydrophobic silane coupling agent; the hydrophobic silane coupling agent has one or more groups and covalent bond connection is formed by the hydrophobic silane coupling agent and the micro-nano dual rough structure; meanwhile, thewear-resisting super-hydrophobic coating composition at least contains one hydrophobic group. A super-hydrophobic coating layer formed by the super-hydrophobic coating composition keeps a long-term effective super-hydrophobic property; the coating composition adopts a binding material so that the binding force between a super-hydrophobic structure and a matrix is enhanced and the protection effectof the coating layer is enhanced; a processing technology of the super-hydrophobic coating layer is simple and convenient and large-area construction is facilitated.

Owner:杭州纳微生物化学有限公司

Compound vegetable healthcare product and method for preparing same

InactiveCN102228242ATo promote metabolismPromote peristalsisFood preparationBiotechnologyFood additive

The invention relates to a nutrient healthcare product and a method for preparing the same, in particular to a compound vegetable healthcare product and a method for preparing the same. The compound vegetable nutrient powder of the invention consists of the following components in part by weight: 0.1 to 100 parts of dried vegetable powder, 0 to 10 parts of alga-type plant regulating powder, 0 to 96 parts of auxiliary component, 0 to 5 parts of natural flavoring agent and 0 to 5 parts of food additive. The preparation method adopts a simple production process and is suitable for industrialized production, and the product prepared by the method is rich in nutrition and stable in quality, meets the demands of people on various nutrients, regulates the intestines and stomach, improves enterogastric peristalsis, enhances in vivo metabolism of sulfur-contained substances, avoids the adverse effects of human body caused by malnutrition and unbalanced nutrition and prevents and helps to treat diseases such as ulcerative stomatitis, diabetes and constipation. The product has also the advantages of convenience for carrying and long storage period.

Owner:肖天存

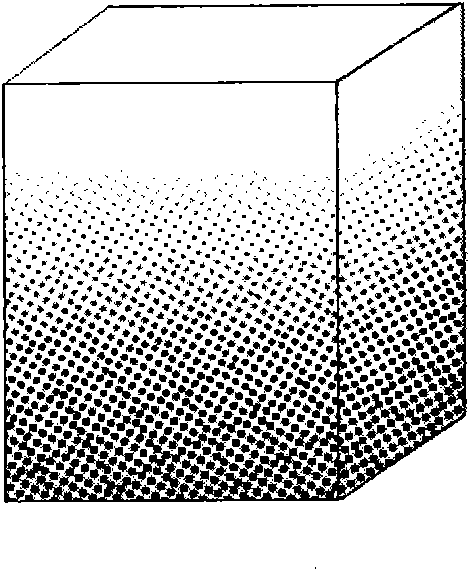

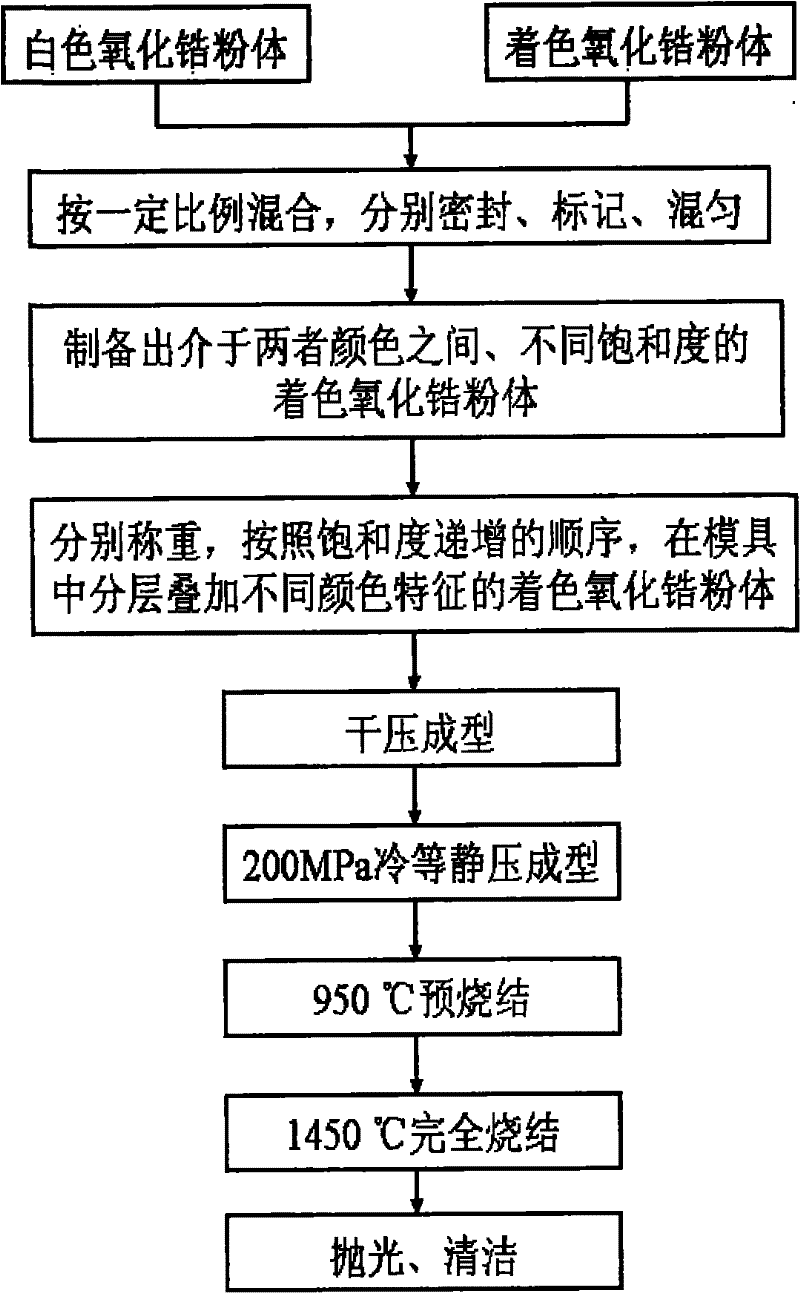

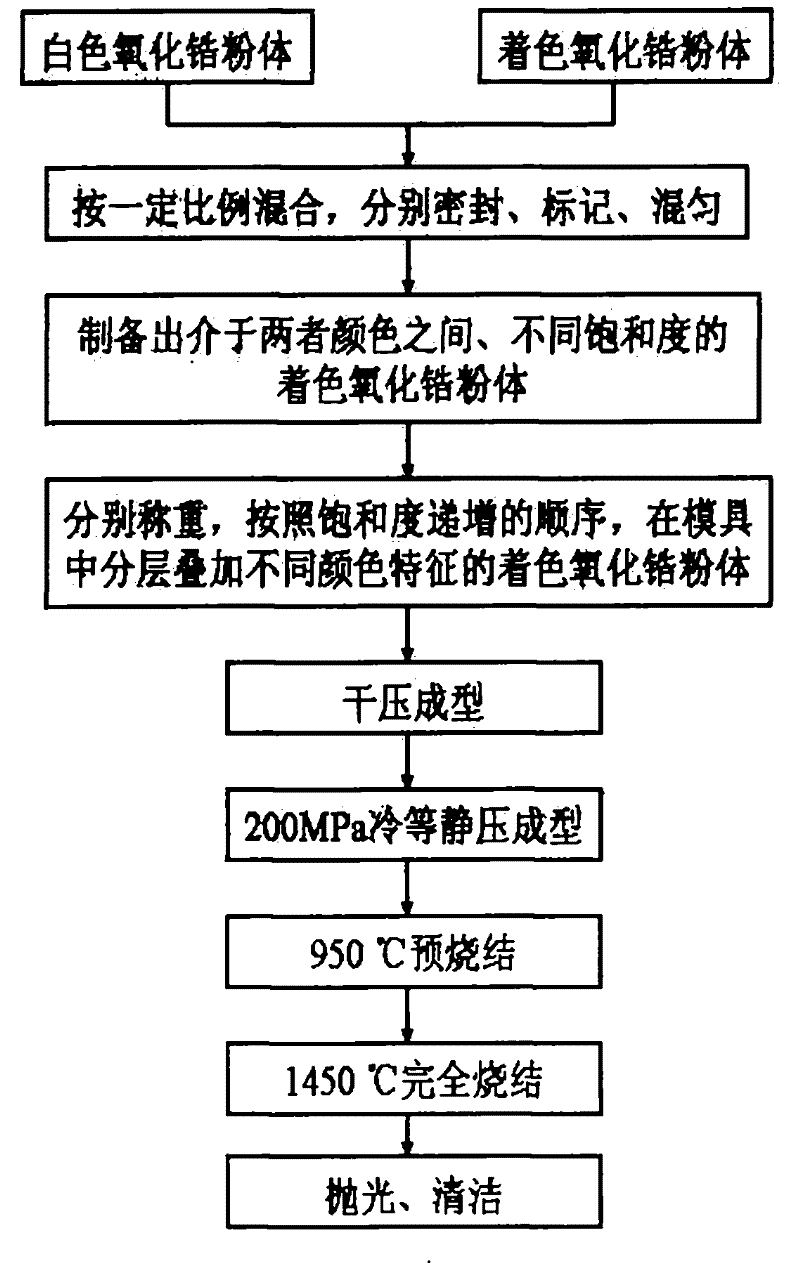

Dental complex color machinable zirconia ceramics and preparation method

InactiveCN102285795AHigh simulationFull aestheticsImpression capsDentistry preparationsAll ceramicAbutment

A dental multi-color machinable zirconia ceramic and its preparation method. The zirconia ceramic has the characteristics of translucence and color gradient, and contains more than five porcelain layers with the same hue and different saturation. The lightness gradually decreases from the top of the ceramic to the bottom layer, and the saturation The density gradually increases, and the color transitions naturally with a sense of hierarchy; the pre-sintered porous ceramic body of the zirconia ceramic is easy to cut and shape, and can be used to make personalized and beautiful dental zirconia all-ceramic restorations through the CAD / CAM system, which is conducive to preserving the abutment teeth. Improve the repair success rate. The preparation method of the dental complex color machinable zirconia ceramic is simple, effective and easy to popularize.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY +1

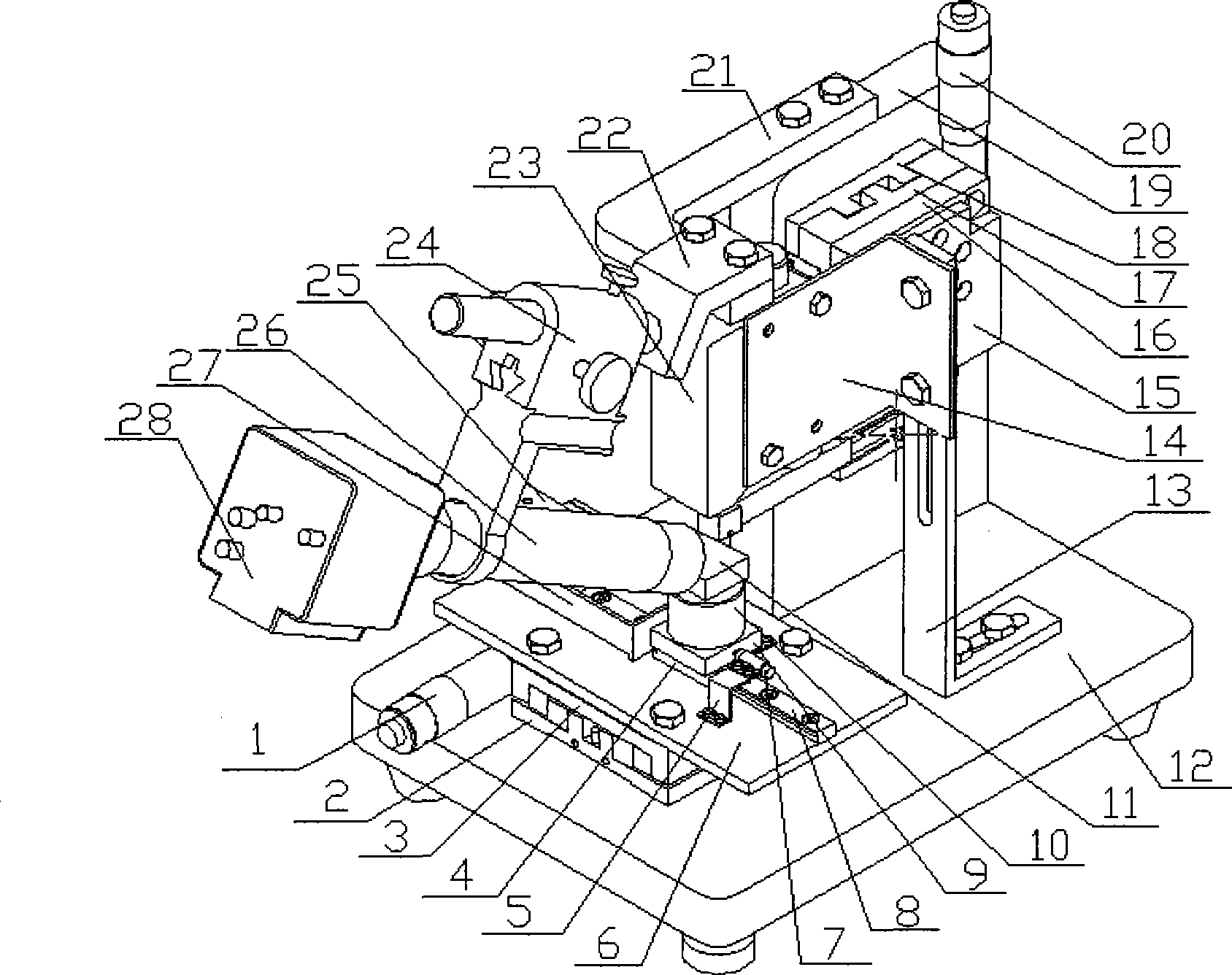

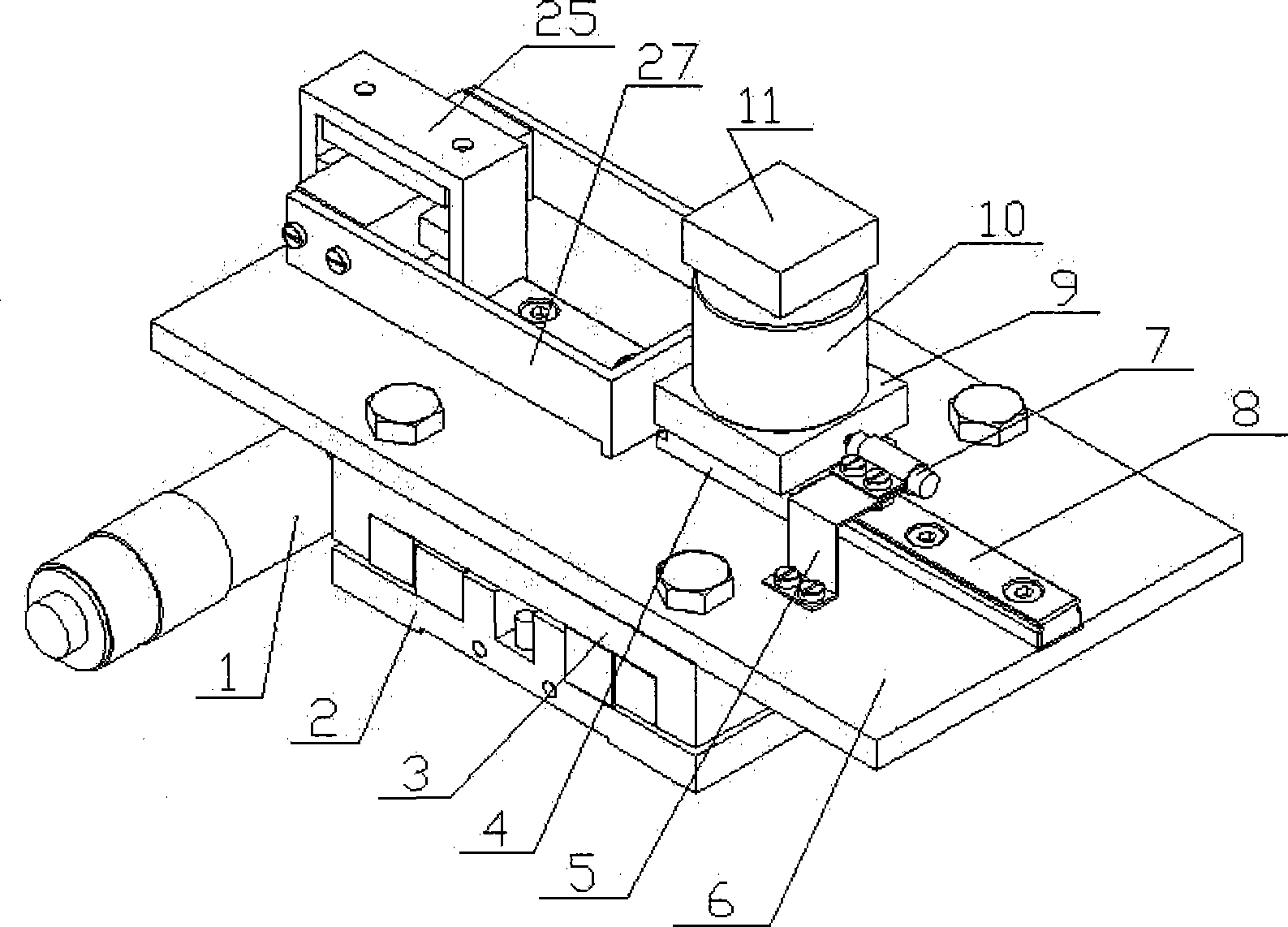

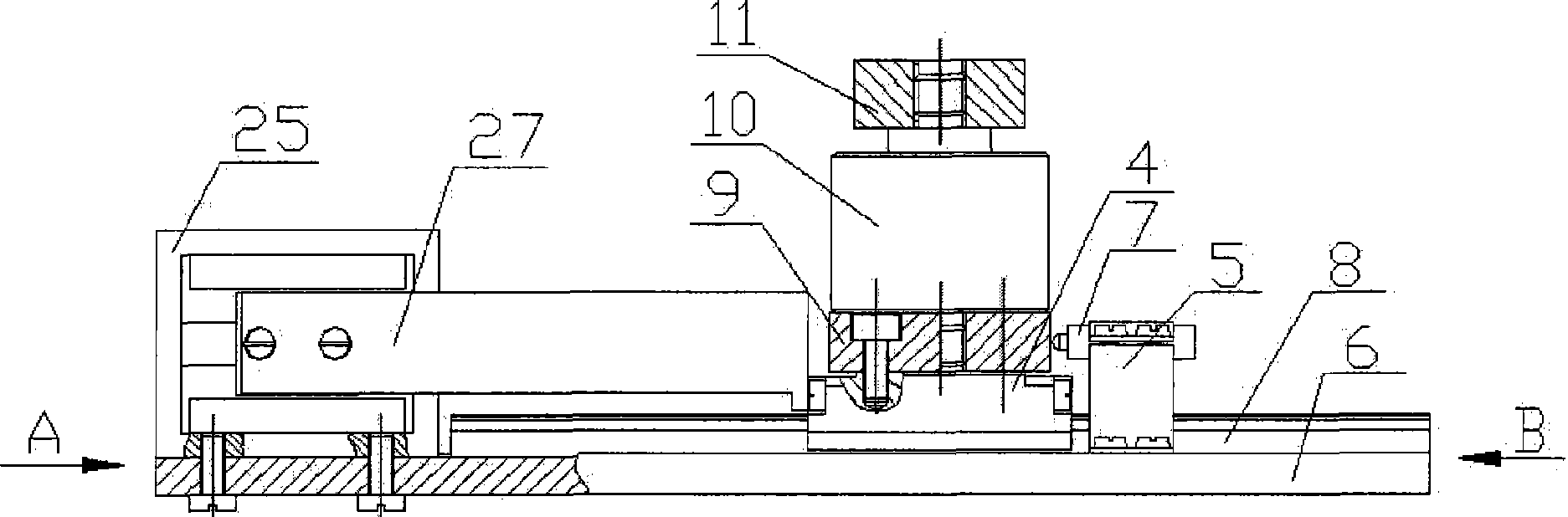

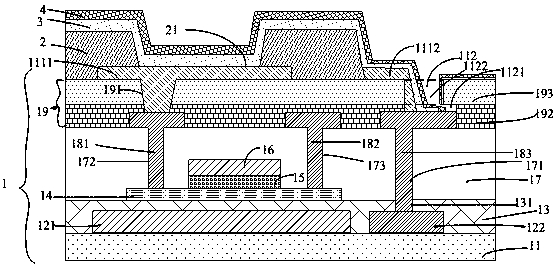

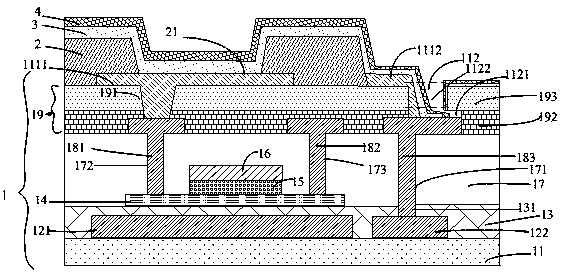

Super-precision trans-scale in-situ nanometer indentation marking test system

ActiveCN101520389AThe test method is accurateAccurate and effective research and testing methodsUsing optical meansInvestigating material hardnessHead pressingImage resolution

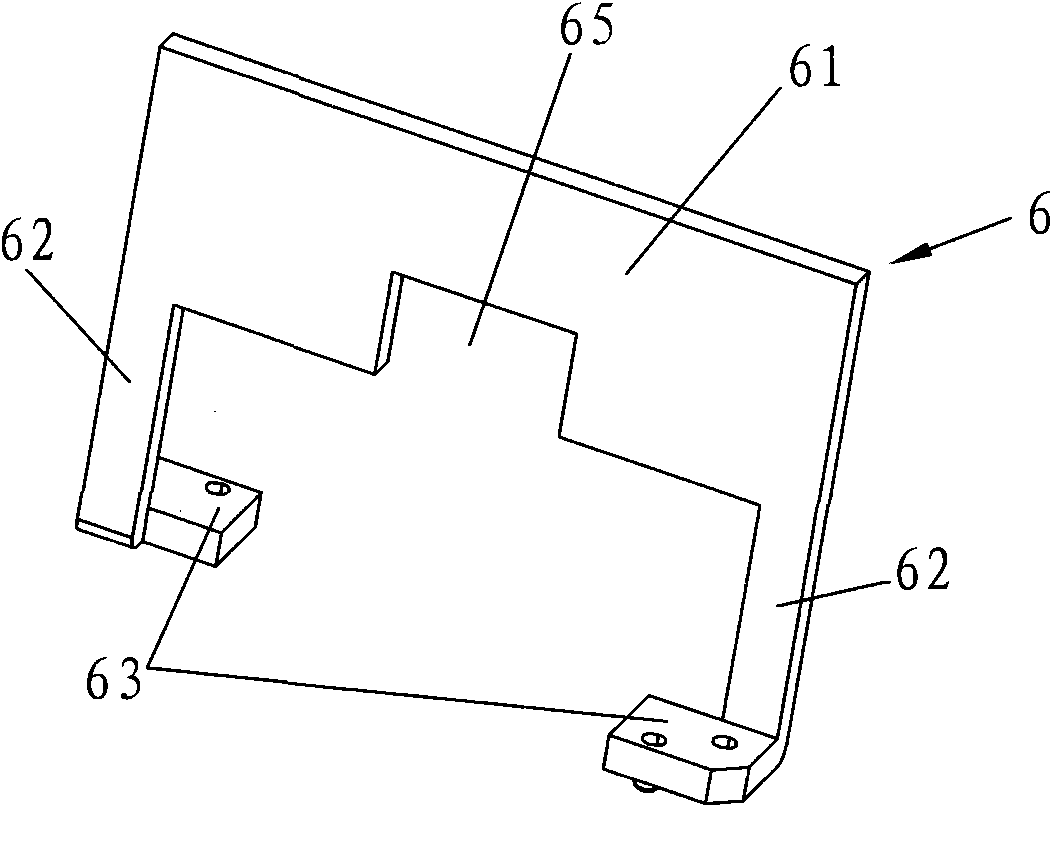

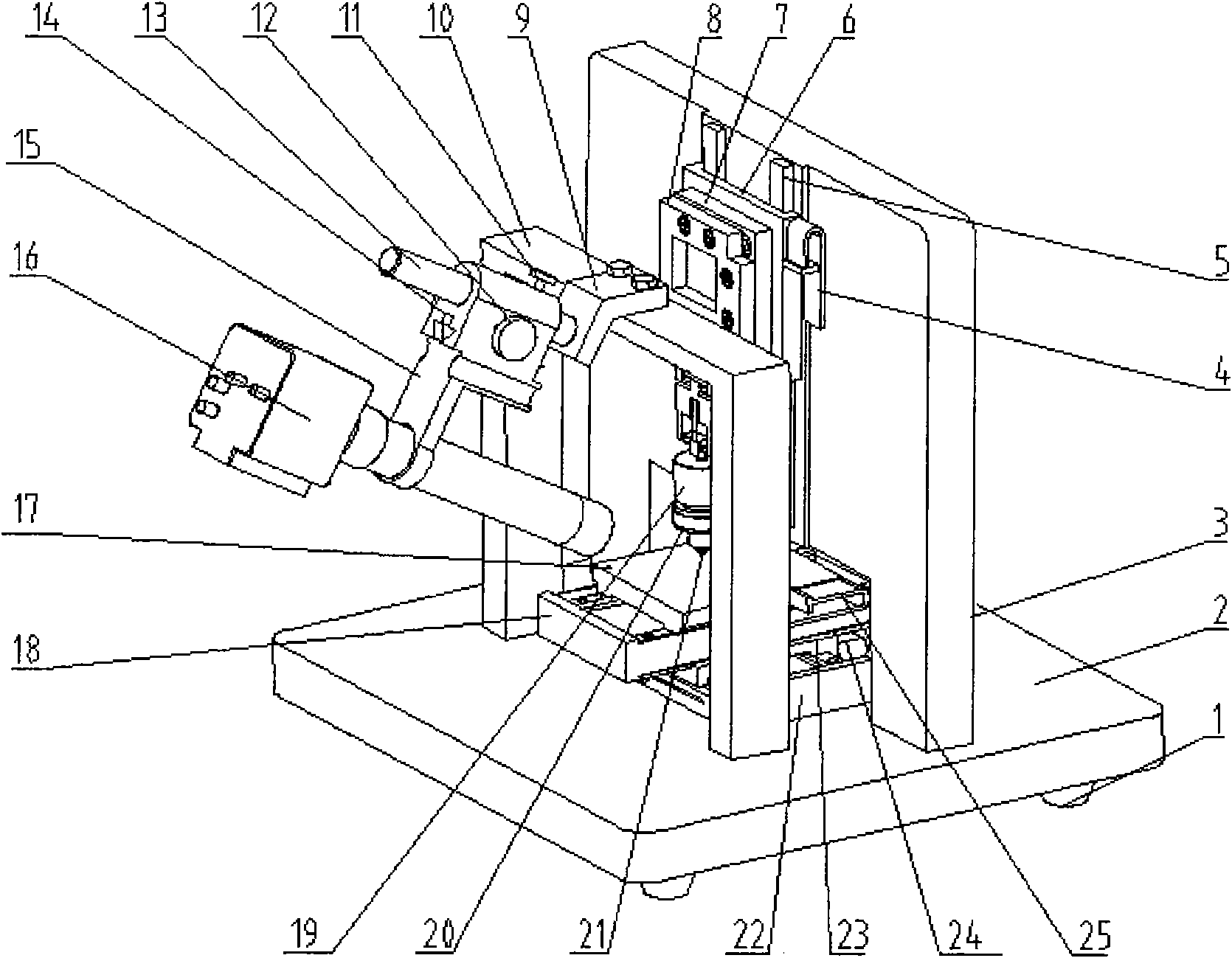

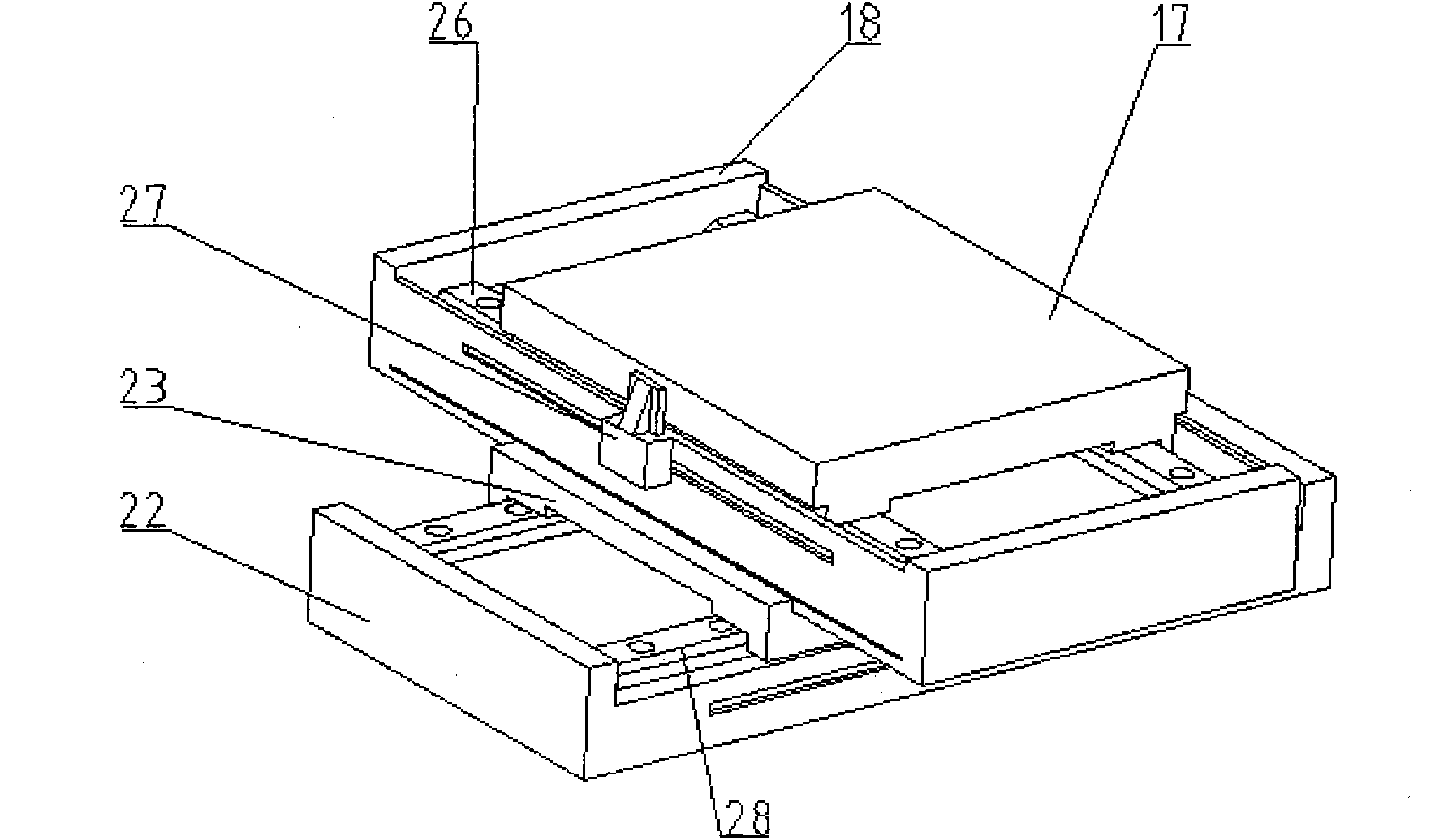

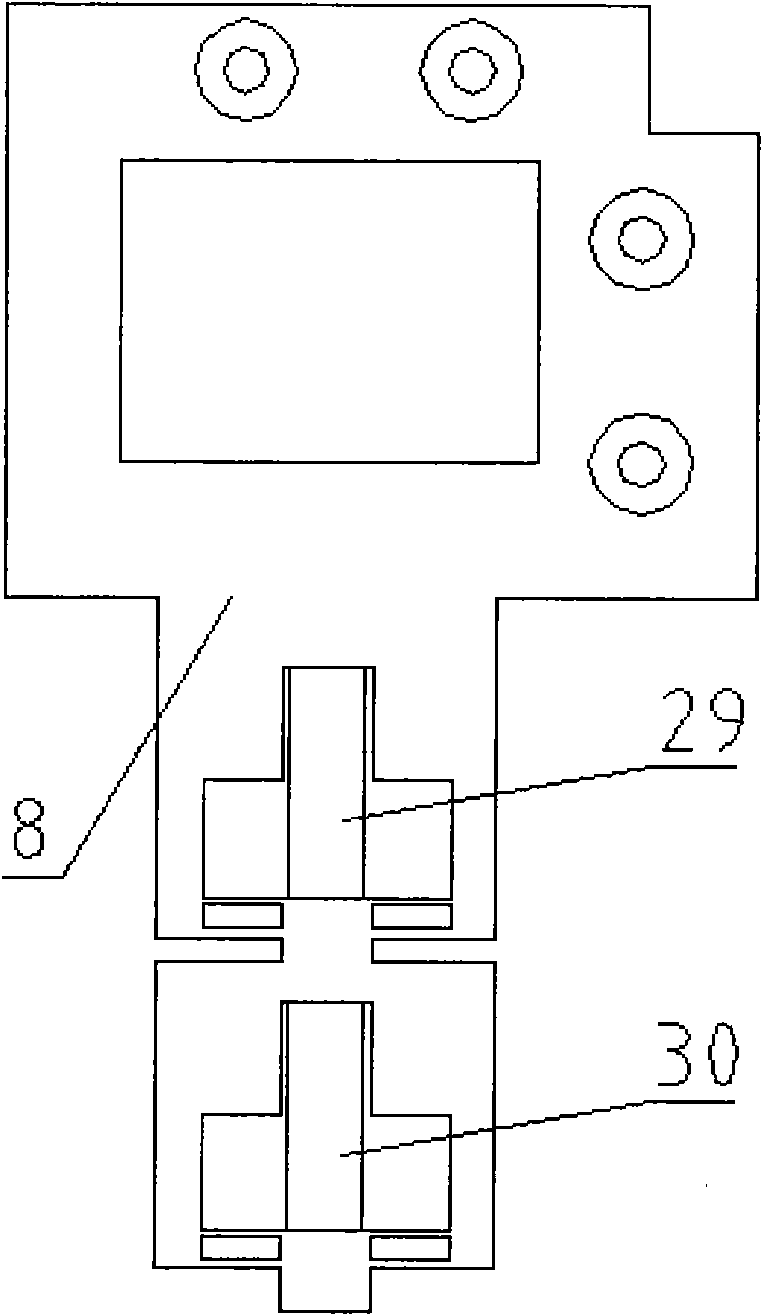

The invention relates to a super-precision trans-scale in-situ nanometer indentation marking test system which integrates driving, loading, detecting and micro-nanometer dynamic performance tests, super-precision marking processing and in-situ observation into a whole. The system mainly comprises an objective table, a regulation mechanism, a detection unit, a precise pressed-into driving unit, a detection unit of load signals and displacement signals and a high-resolution digital microscopic imaging system, wherein the objective table is precisely positioned along the directions of the X axis and the Y axis; the regulation mechanism and the precise pressed-into driving unit are in the direction of the Z axis and are assembled on a base; the high-resolution digital microscopic imaging system is used for observing the deforming and damaging conditions of the material in the storing and testing process; the objective table as well as the regulation mechanism and the precise pressed-into driving unit in the direction of the Z axis are assembled on a base; the high-resolution digital microscopic imaging system is arranged on the objective table; a precise dynamic sensor detecting the pressure of a diamond tool head pressed into a material and a sensor I detecting the precise displacement of the objective table in the directions of the X axis and the Y axis are arranged on the objective table; and a sensor II used for detecting the precise displacement of a diamond tool head in the direction of the Z axis of pressed-into depth is arranged on the base by a support I.

Owner:JILIN UNIV

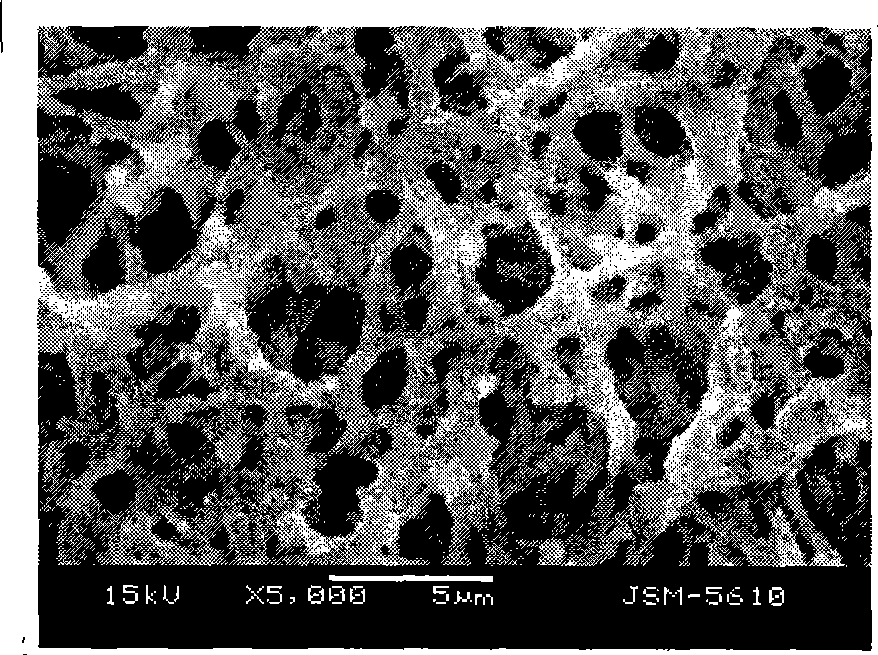

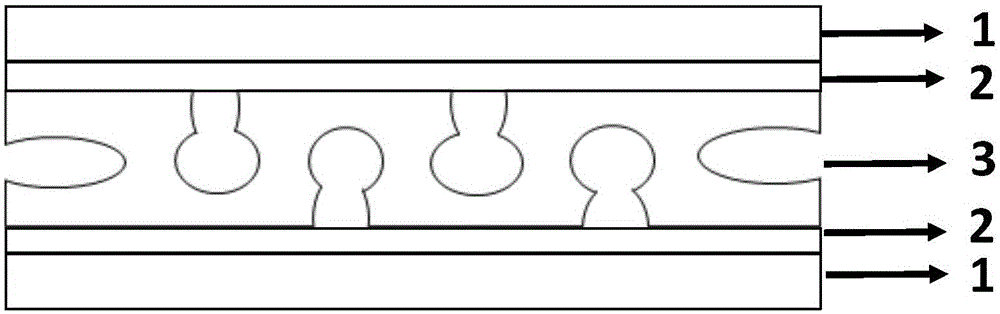

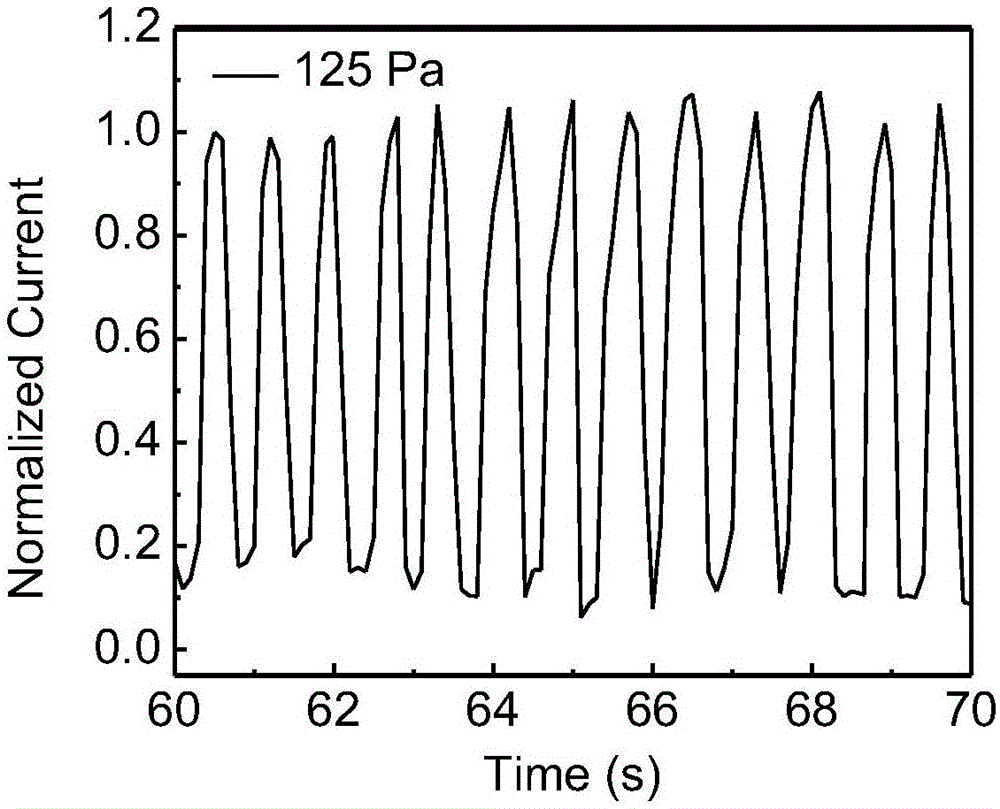

Resistor-type pressure sensor and making method thereof

ActiveCN105021329AIncreased sensitivityLarge pressure rangeForce measurementPressure senseConductive materials

The invention discloses a resistor-type pressure sensor and a making method thereof. The resistor-type pressure sensor is composed of a sensitive layer and two substrates containing electrodes. The sensitive layer is disposed between the two electrode layers. The sensor is characterized in that the sensitive layer is a conducting porous elastic film. Since the sensitive layer of the sensor provided by the invention adopts the conducting porous elastic film, when the film is pressed, the deformation of the film increases, the contact resistance of the conducting material in the film is reduced, the sensitivity of the pressure sensor to pressure is enhanced and the pressure sensing range of the pressure sensor is enlarged. The film is made of material at a low cost, and processing technique is simple, so that the cost of the pressure sensor is reduced.

Owner:SHANGHAI JIAO TONG UNIV

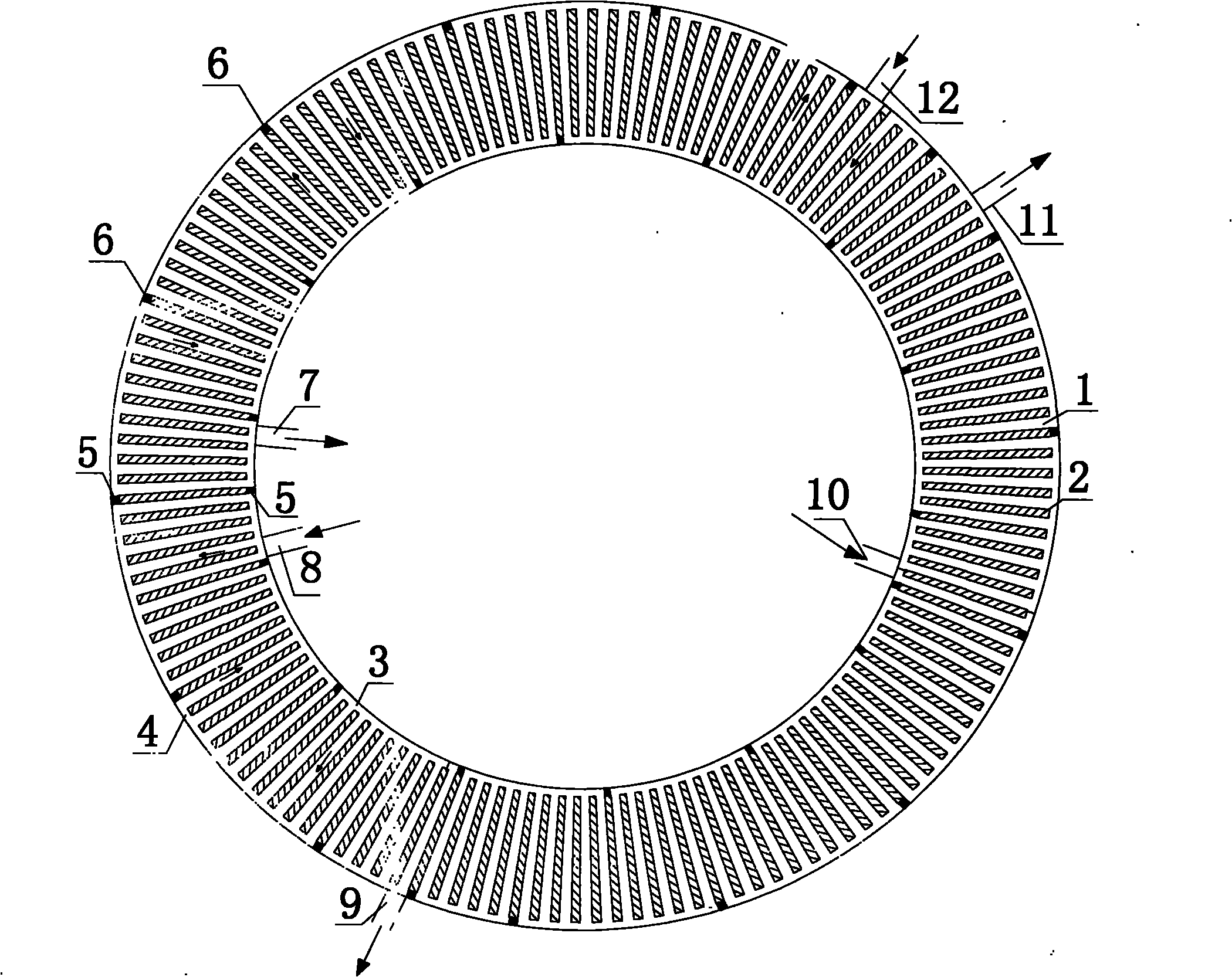

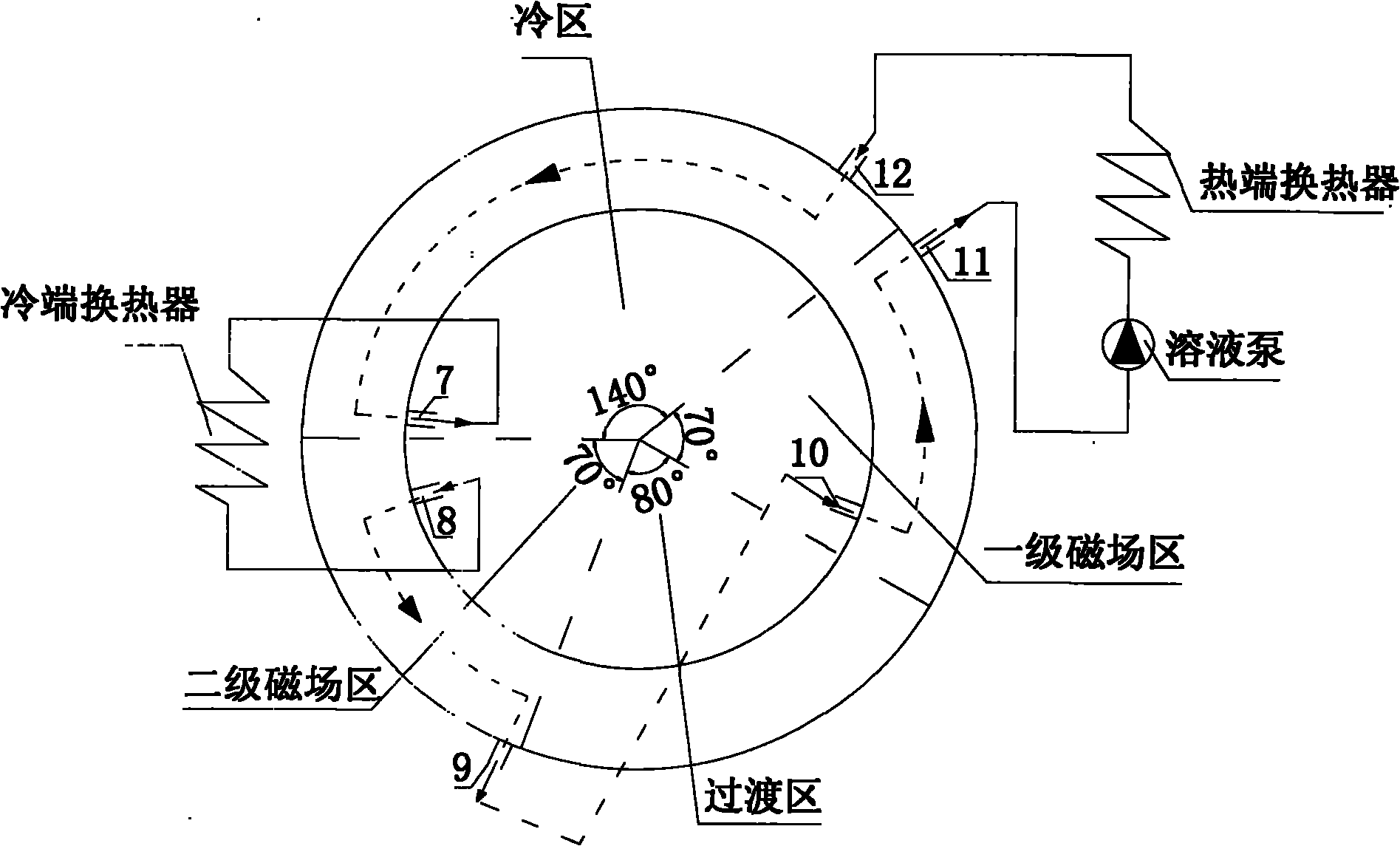

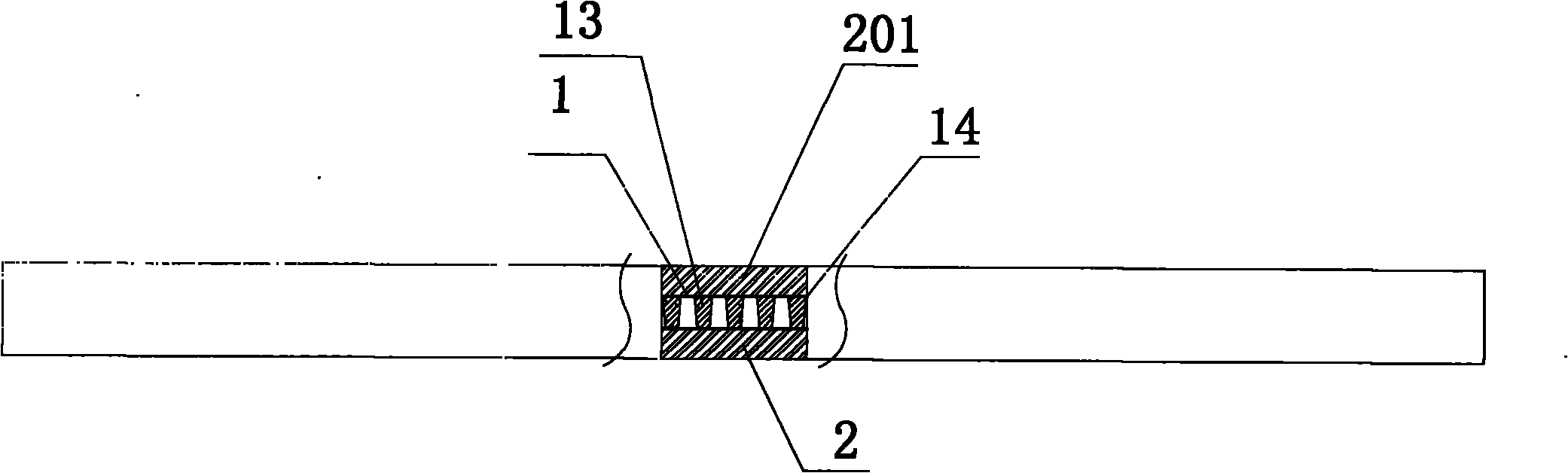

Microchannel enhanced heat exchange system of rotary room-temperature magnetic refrigerator and heat transfer method thereof

InactiveCN101788207AAchieve refrigerationGuaranteed safe operationEnergy efficient heating/coolingMachines using electric/magnetic effectsRoom temperatureEngineering

The invention discloses a microchannel enhanced heat exchange system of a rotary room-temperature magnetic refrigerator and a heat transfer method thereof. The system comprises a refrigerant disc, a cold end heat exchanger, a hot end heat exchanger and a solution pump, wherein the cold end heat exchanger and the hot end heat exchanger are connected with the refrigerant disc. the refrigerant disc comprises a refrigerant bed, an inner circle collecting tank, an outer circle collecting tank, four pairs of interzone adiabatic baffles and a plurality of intra-zone adiabatic baffles; the refrigerant bed comprises a plurality of trapezoidal microchannel flat tubes, an upper magnetic refrigerant plate and a lower magnetic refrigerant plate; the trapezoidal microchannel flat tubes, the upper magnetic refrigerant plate and the lower magnetic refrigerant plate are arranged between the inner circle collecting tank and the outer circle collecting tank; and the trapezoidal microchannel flat tubes are arranged between the upper magnetic refrigerant plate and the lower magnetic refrigerant plate. The heat transfer method is characterized in that the heat transfer fluid experiences a cycle of adiabatic excitation and demagnetization after passing through the different zones of the microchannel enhanced heat exchange system; and the rotary magnetic refrigerator recirculates the processes to realize refrigeration. In the invention, the characteristic that the microchannel can effectively enhance heat exchange due to scale effect is adopted and the microchannel is applied to the refrigerant bed, thus improving the efficiency of the refrigerating system and reducing corrosion of the heat transfer fluid to the magnetic refrigerant.

Owner:SOUTH CHINA UNIV OF TECH

Hydrogenation modification process for low grade gasoline

ActiveCN1621495AGood activity at low temperatureLow reaction temperatureRefining by aromatic hydrocarbon hydrogenationRefining to eliminate hetero atomsPre treatmentLow graded

The inferior gasoline hydrogenating modification process includes cutting the material gasoline at 60-90 deg.c into light fraction and heavy fraction; mixing the heavy fraction with hydrogen, reacting with hydrogenating and desulfurizing catalyst via contact, and reacting the effluent with aromatizing modification catalyst for aromatizing modification to obtain high octane number and low sulfur gasoline fraction; and mixing the modified heavy gasoline fraction with the light fraction or the light fraction after mercaptol eliminating pre-treatment to obtain the product gasoline. The said process makes the gasoline product possess S content not more than 150 ppm, olefin content not more than 20 %, arene content not more than 40 % and 1-3 unit raised RON.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Waterborne heat-insulating flame-retardant multifunctional nano coating and preparation method thereof

InactiveCN101824270AImprove performanceSimple preparation processFireproof paintsPolyurea/polyurethane coatingsTin dioxideMicrosphere

The invention relates to a waterborne heat-insulating flame-retardant multifunctional nano coating and a preparation method thereof. The coating consists of the following components in part by weight: 48 to 52 parts of waterborne resin and 30 to 50 parts of nano pigment fillers (nano titanium dioxide, nano titanium dioxide-coated hollow glass microspheres, nano titanium dioxide-coated hollow ceramic microspheres and nano antimony-doped tin dioxide (ATO) particles), size and auxiliary materials such as film-forming additive and coupling agent. The preparation method includes the steps that: the nano fillers and the size are first dipped into the waterborne resin, the auxiliary materials are then sequentially added and stirred, and thereby the heat-insulating flame-retardant multifunctional nano coating is obtained. The processing technique is simple, the component proportion is reasonable, and the prepared coating has the advantages of high heat resistance, high reflectivity, high radiative heat conductivity, certain fire resistance, high-efficient heat insulation, excellent mechanical and chemical properties, environment-friendliness, stain resistance, flame retardance and energy saving. The coating can be coated on outside facilities such as outer walls and building roofs.

Owner:长沙新凯化工有限公司

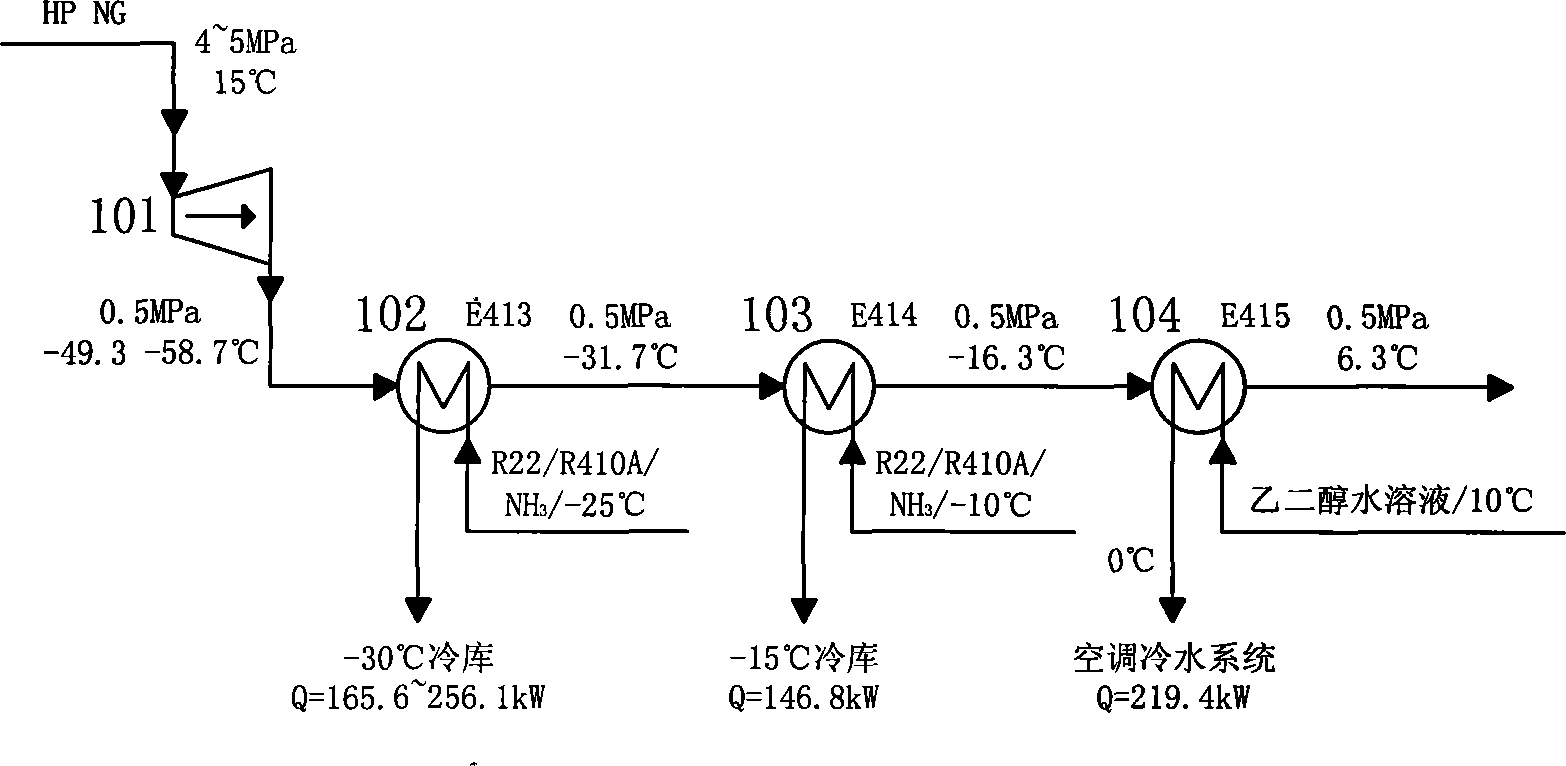

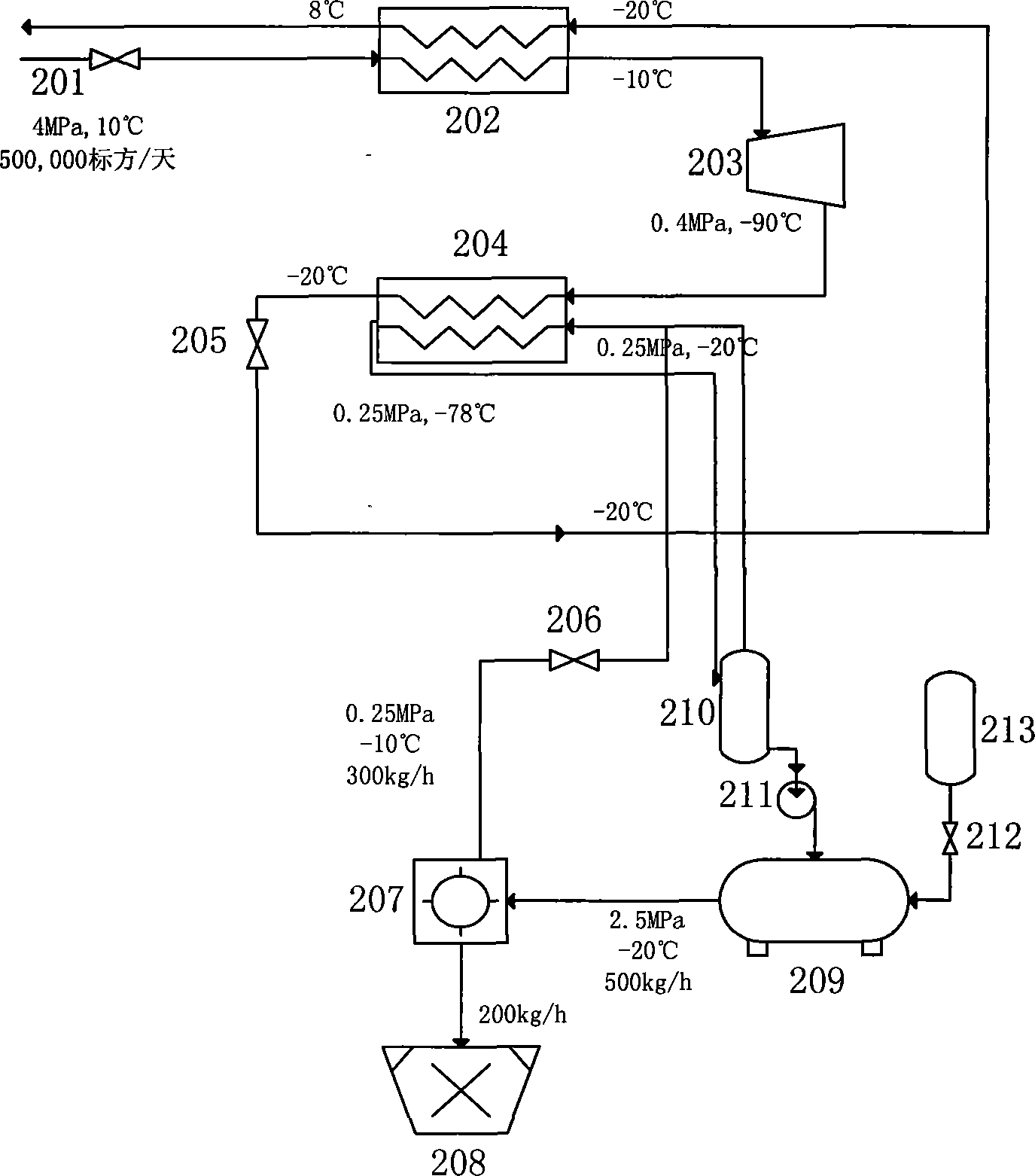

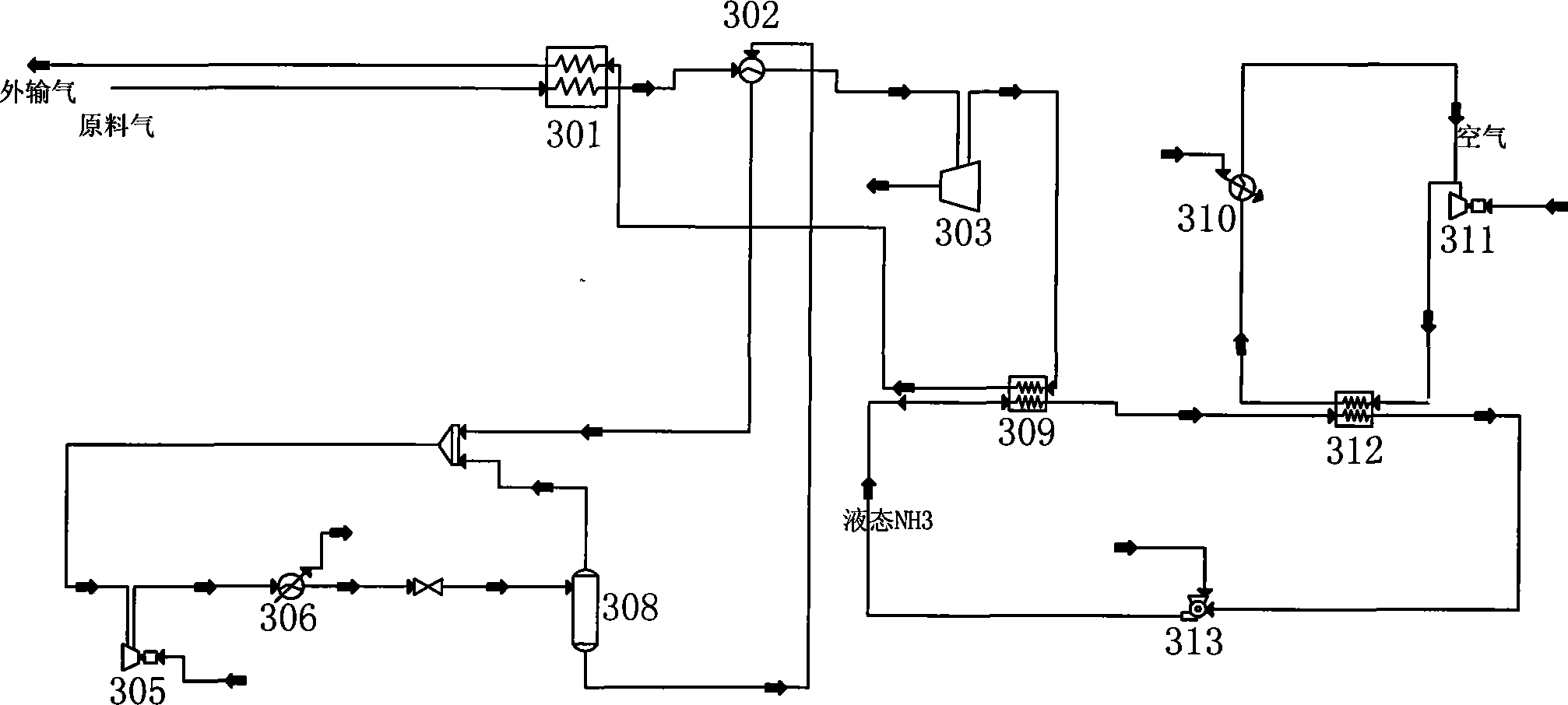

Method for utilizing pressure energy of natural gas

InactiveCN101245956AImprove utilization efficiencySimple processing technologyCompression machinesStationary plate conduit assembliesWaste rubberEngineering

The invention discloses a method which utilizes natural gas pressure energy; namely, the pressure and the temperature of the natural gas in a high pressure pipeline are reduced by a no-power refrigerator so as to gain low temperature natural gas which then exchanges the heat with a normal-temperature refrigerant which is sent by a normal-temperature tank; the low temperature refrigerant with temperature reduced enters a refrigerant storage tank for standby and is finally delivered to a cold energy user; the normal-temperature natural gas with temperature increased enters the pipeline. The method which utilizes natural gas pressure energy has convenient and practical whole process technique and high efficiency, spends little investment on the self-pressure energy in the pressure reduction process of the high pressure natural gas which is recovered by a pressure modulating station, converts the pressure energy into the cold energy with low operation cost, leads the cold energy to be used by cold quantity users of cold storages, cold water air conditioners, wasted rubber deep-cold crushing round the pressure modulating station by means of the refrigerant, etc., or to be made into ice blocks and dry ice products for abroad sale, etc., thus gaining huge economic benefits, improving the utilization ratio of the energy resource and eliminating the safe hidden trouble which is generated by sudden coolness of the equipment in the normal pressure modulating process.

Owner:GUANGZHOU GAS

Children pigment composed of edible composition

InactiveCN104017436AImprove securityLow priceArtist's paintsPigment pastesBiotechnologyFood coloring

The invention discloses a children pigment composed of edible composition. The pigment is characterized by comprising 0.1-20 g of edible pigment, 0.1-20 g of a stabilizer, 0.1-20 g of an anti-caking agent, 0.1-20 g of a filler, 0.1-20 g of a thickening agent, 0.1-20 g of an emulsifier, 0.01-5 g of a preservative and 100 ml of water. The children pigment has improved usage safety.

Owner:NANCHANG UNIV

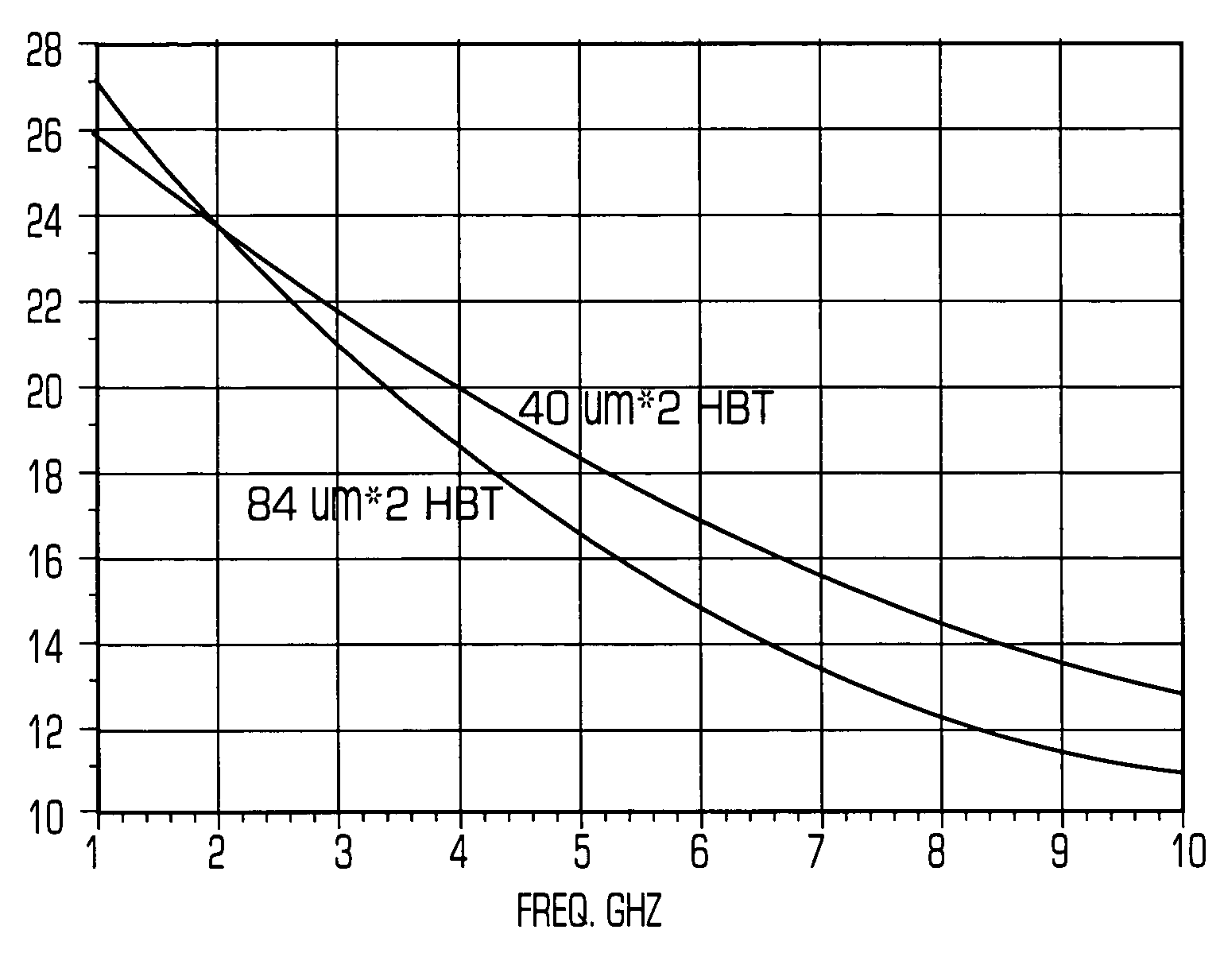

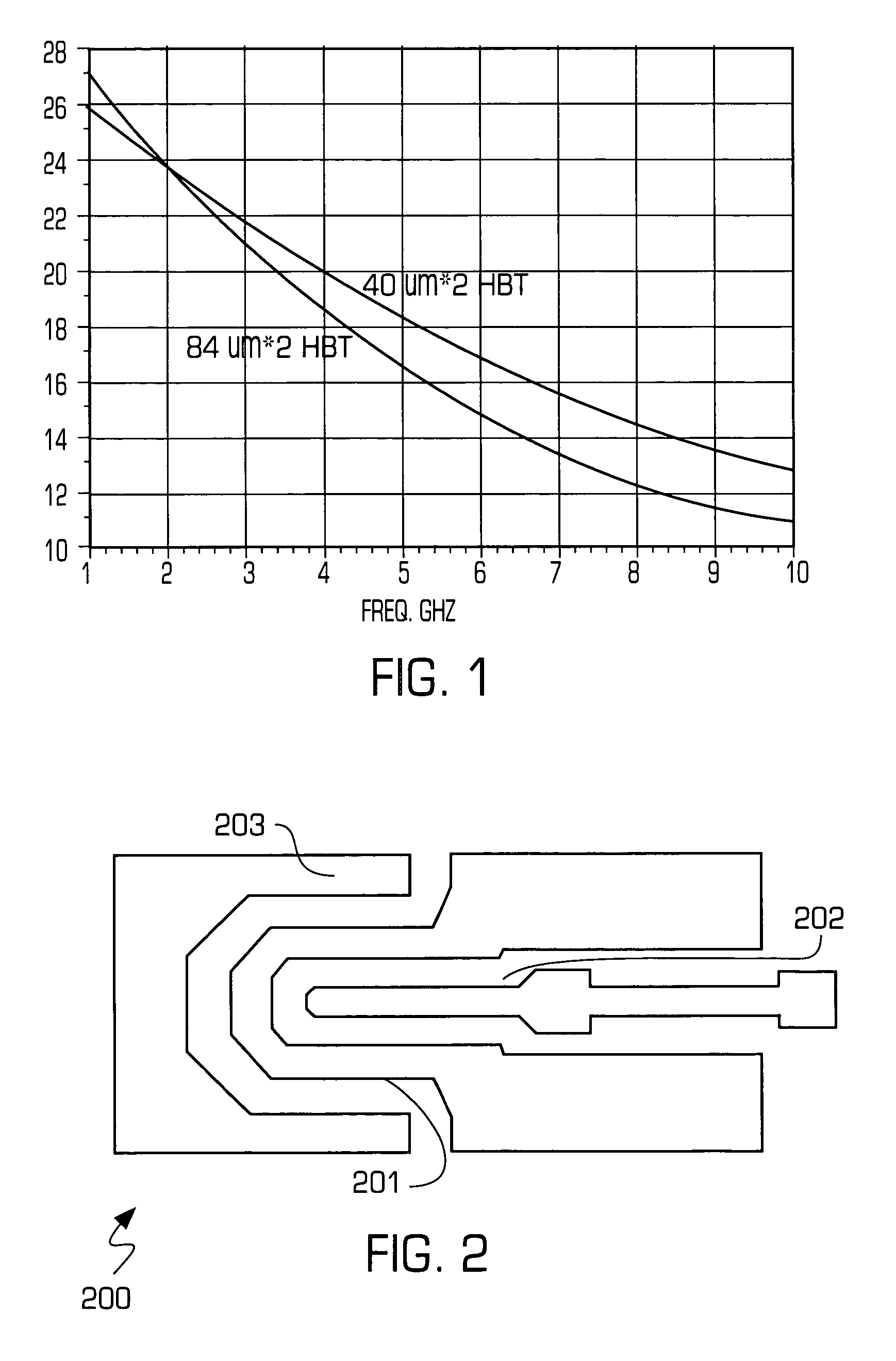

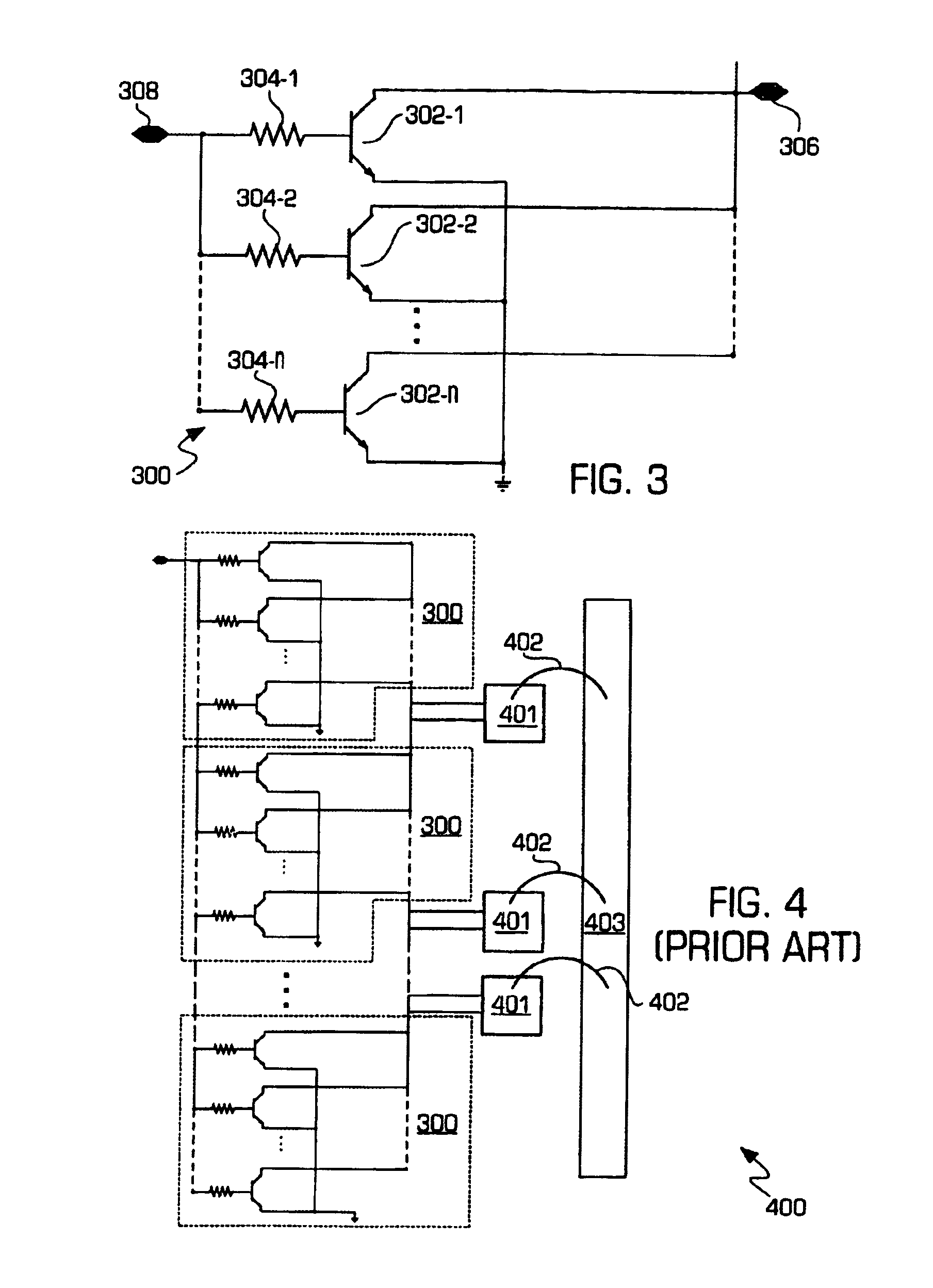

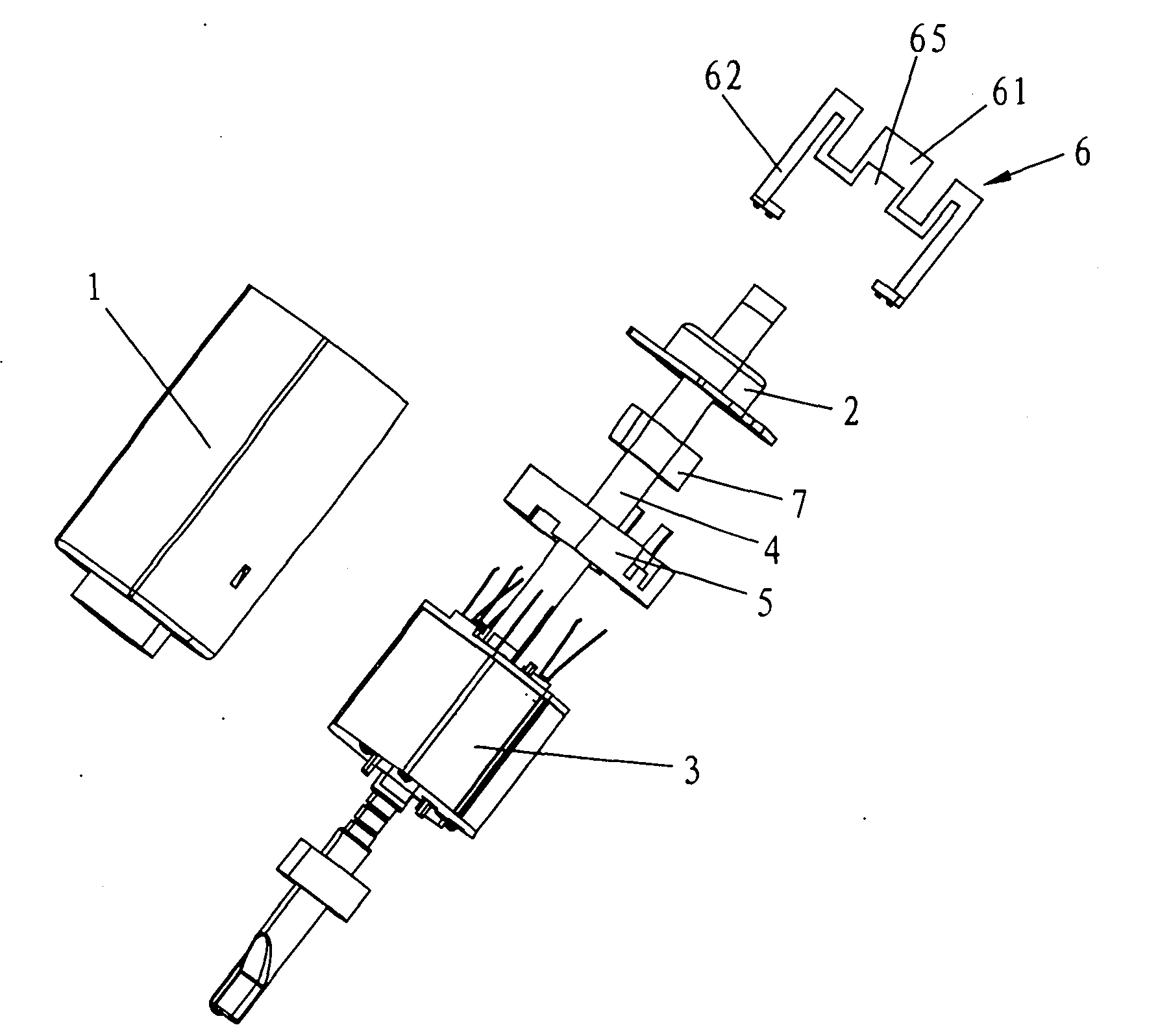

High linearity smart HBT power amplifiers for CDMA/WCDMA application

ActiveUS7026876B1Increase power gainImprove RF efficiencyHigh frequency amplifiersAmplifier combinationsTransistor arrayHbt power amplifier

A power amplifier includes larger size transistors to provide higher power gain at lower frequencies. Transistors of transistor unit cells include a horseshoe-shaped emitter and a strip-shaped base to increase gain. Transistors are combined at a first level to form transistor arrays, which are combined with bonding wires at a second level to an output micro strip transmission line. A Vbe referenced bias circuit may include a smart function to lower quiescent current.

Owner:CALLAHAN CELLULAR L L C

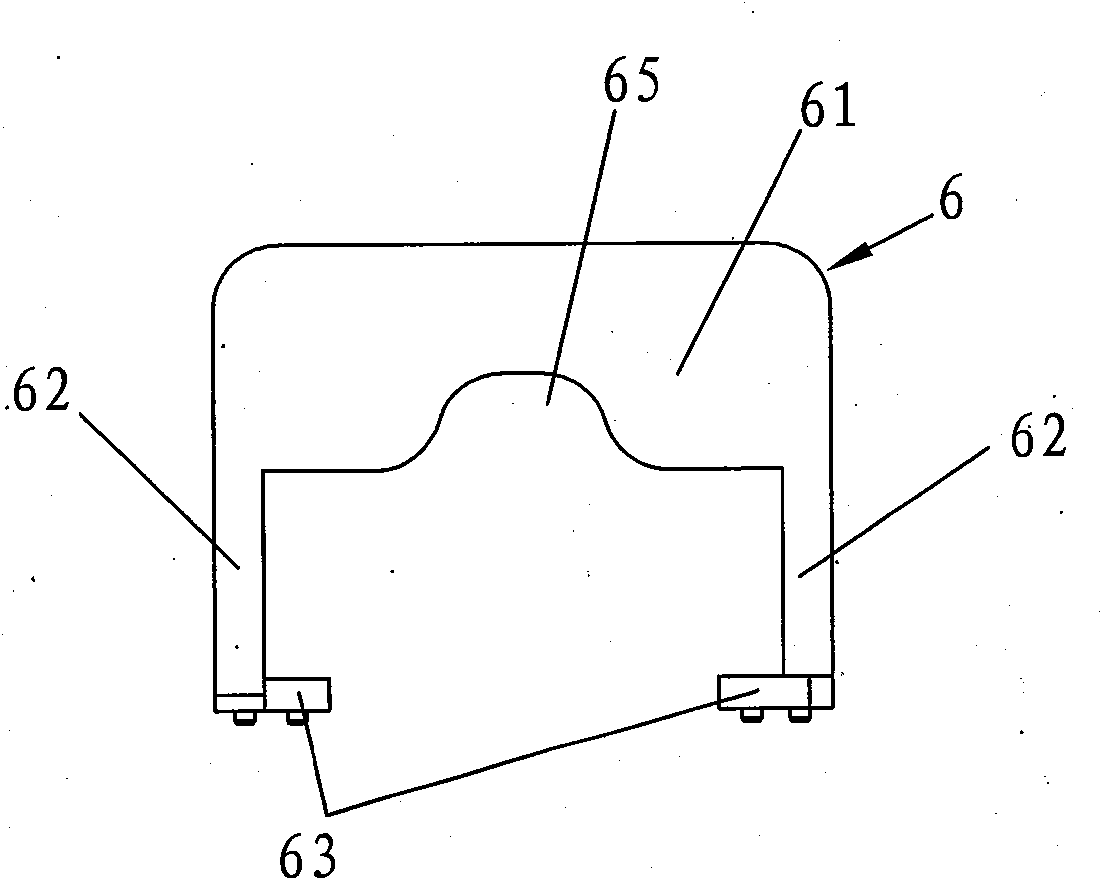

High-frequency vibration motor for electric toothbrush

ActiveCN102111032AReduce in quantityReasonable structureMechanical energy handlingTooth cleaningVibration amplitudeReciprocating motion

The invention relates to the technical field of electric toothbrushes, in particular to a high-frequency vibration motor for an electric toothbrush. The high-frequency vibration motor for the electric toothbrush comprises a shell and a rear cover, wherein a stator, a rotating shaft and an adjusting pad are arranged in the shell; the output end of the rotating shaft is connected with the rear cover through a spring piece; the spring piece comprises a spring piece main body and an elastic arm; the motor generates power to drive the rotating shaft to rotate reciprocally so as to drive the springpiece connected with the rotating shaft to twist to generate torsional deformation; when the frequency of the motor generating reciprocating movement is close to or reaches the torsional resonant frequency of the spring piece, the torsional vibration amplitude of the spring piece reaches the maximum so that the swinging amplitude of the motor reaches the maximum; because of the influence of the reluctance force of the motor per se, the vibration amplitude of an overall system reaches a balanced state, and the spring piece and the motor generate movement under the balanced condition. The high-frequency vibration motor for the electric toothbrush is easy to manufacture and position, along with reasonable structure, less elements, simple machining process, low cost and long service life.

Owner:DONGGUAN LEBOND ELECTRONICS TECH CO LTD

High-count smooth double-faced wool and production process thereof

The invention discloses high-count smooth double-faced wool which is double-layer texture structure cloth with upper portion and lower portion connected. The front texture of the high-count smooth double-faced wool is 2 / 2 twill, and the back texture of the cloth is 2 / 2 herringbone. A production process of the high-count smooth double-faced wool includes: respectively performing loose fiber dying on wool fibers, dacron fibers and modal fibers, then performing full sliver mixing, and spinning the mixed fibers into 20 / 1 and 24 / 1 yarns with an open-end spinning mode; weaving the high-count smooth double-faced wool cloth on a rapier loom through yarns; and performing blank checking, mending, reviewing, hemming, wool washing, dehydration, milling, wool jigging, dehydration, rotary width drying, wool steaming, fluffing, shearing, squeezing, burring galling, rolling, drying, polishing, polishing shearing, wool steaming and finish inspection on the weaved cloth to manufacture finished products. The high-count smooth double-faced wool is full in hand feeling, elastic, natural and gentle in gloss, and smooth and ordered in villus, cannot cause bottom explosion and depilation, and is rich and smooth in hand feeling and suitable for manufacturing high-grade clothing.

Owner:苏州优布纺织科技有限公司

Heat-preservation and heat-insulation crack-resisting brick made from modified vitrified micro beads

ActiveCN101725208ASolve the weakness of high water absorptionNo pollution in the processSolid waste managementBuilding componentsSocial benefitsBrick

The invention relates to a heat-preservation and heat-insulation crack-resisting brick made from modified vitrified micro beads and effectively resolves the problems of large contractibility rate, poor stability, easy cracking and high cost of masonry walls. According to parts by weight, the brick is composed of the following raw materials: 100 parts of cement, 5-20 parts of coal ash, 0.005-0.015 part of polypropylene fiber, 10-50 parts of modified vitrified micro beads, 10-30 parts of activating agent, 1-5 parts of sodium silicate, 10-50 parts of sand, 10-200 parts of fine stone and 110-330 parts of water. The method for preparing the brick comprises the following steps: evenly stirring and mixing the modified vitrified micro beads, 50 parts of the cement and the activating agent to form material A, then evenly stirring and mixing the fine stone, the sand, the coal ash, the polypropylene fiber and the remaining 50 parts of cement to form material B; adding water to stirring the material A and material B into uniform brick material; pressing the brick material into block-shaped bricks by a die and curing the block-shaped bricks at 10-40 DEG C for 7-30 days, thus obtaining the final product. The brick of the invention features scientific and reasonable components, simple process, stable quality, low contractibility rate, low coefficient of heat conductivity, good heat-preservation and heat-insulation property, low cost, environmental friendliness, economy and tremendous economic and social benefits.

Owner:BEIJING TIANJI NEW MATERIALS

Micron-nano scale in-situ nano indentation and scratching test system

InactiveCN101876609AThe test method is accuratePrecision equipmentUsing optical meansInvestigating material hardnessImage resolutionEngineering

The invention relates to a micron-nano scale in-situ nano indentation and scratching test system which integrates driving, precise loading and signal detection, micron-nano scale mechanics performance testing, ultraprecise scratching processing and high resolution in-situ observing as one. The system is mainly composed of a precise positioning platform at X-axis and Y-axis directions, a precise linear positioning platform at Z-axis direction, a precise indentation driving unit, a load signal and displacement signal detection unit and a high resolution digital microscopic imaging system for observing and storing material deformation and damage conditions in the test process. The precise positioning platform at the X-axis and Y-axis directions is assembled on a base, the precise linear positioning platform at the Z-axis direction is assembled on a side plate, the precise indentation driving unit, a precise mechanical sensor for detecting the indentation material pressure of a diamond tool head and a precise displacement sensor for detecting the indentation depth of the diamond tool head to along the Z-axis direction are assembled on the precise linear positioning platform at the Z-axis direction, and the high resolution digital microscopic imaging system is assembled on a beam.

Owner:赵宏伟

Low coefficient of thermal expansion thermoplastic resin composition, preparation method and application thereof

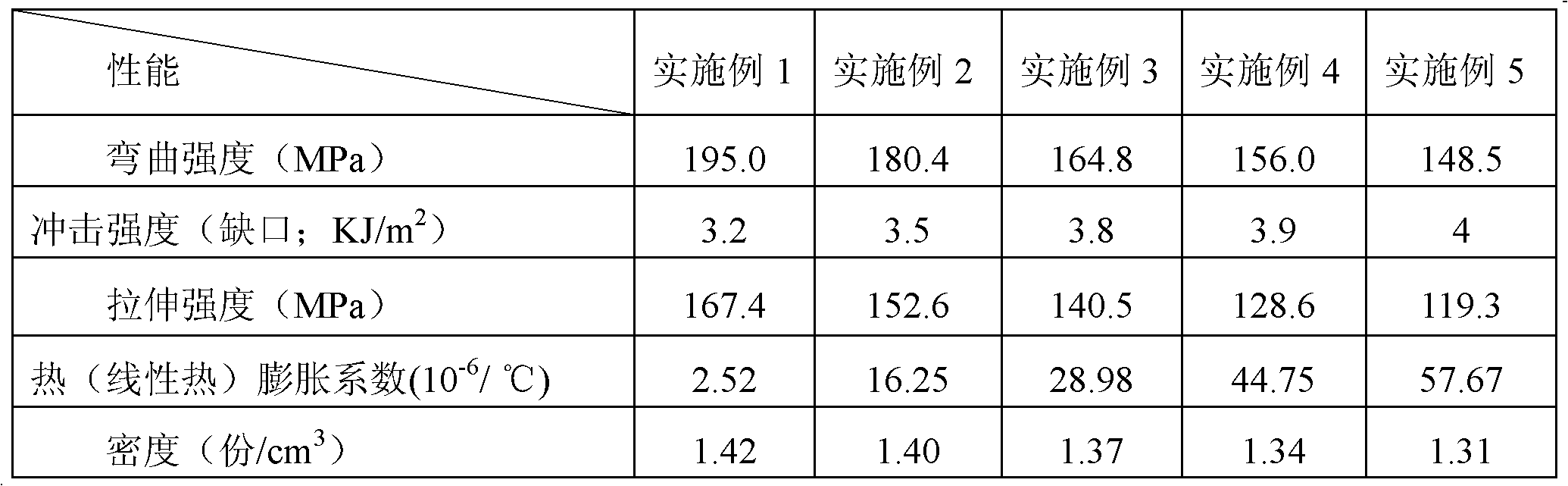

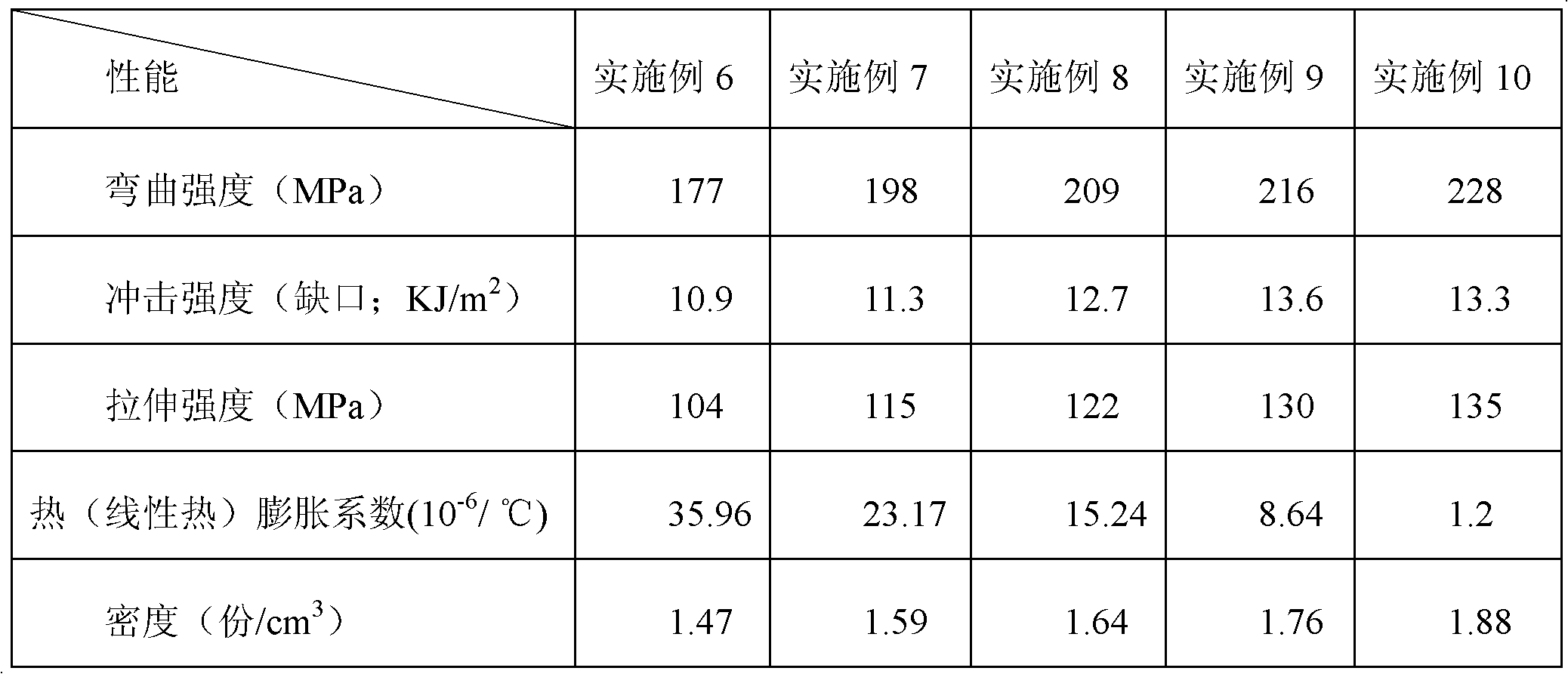

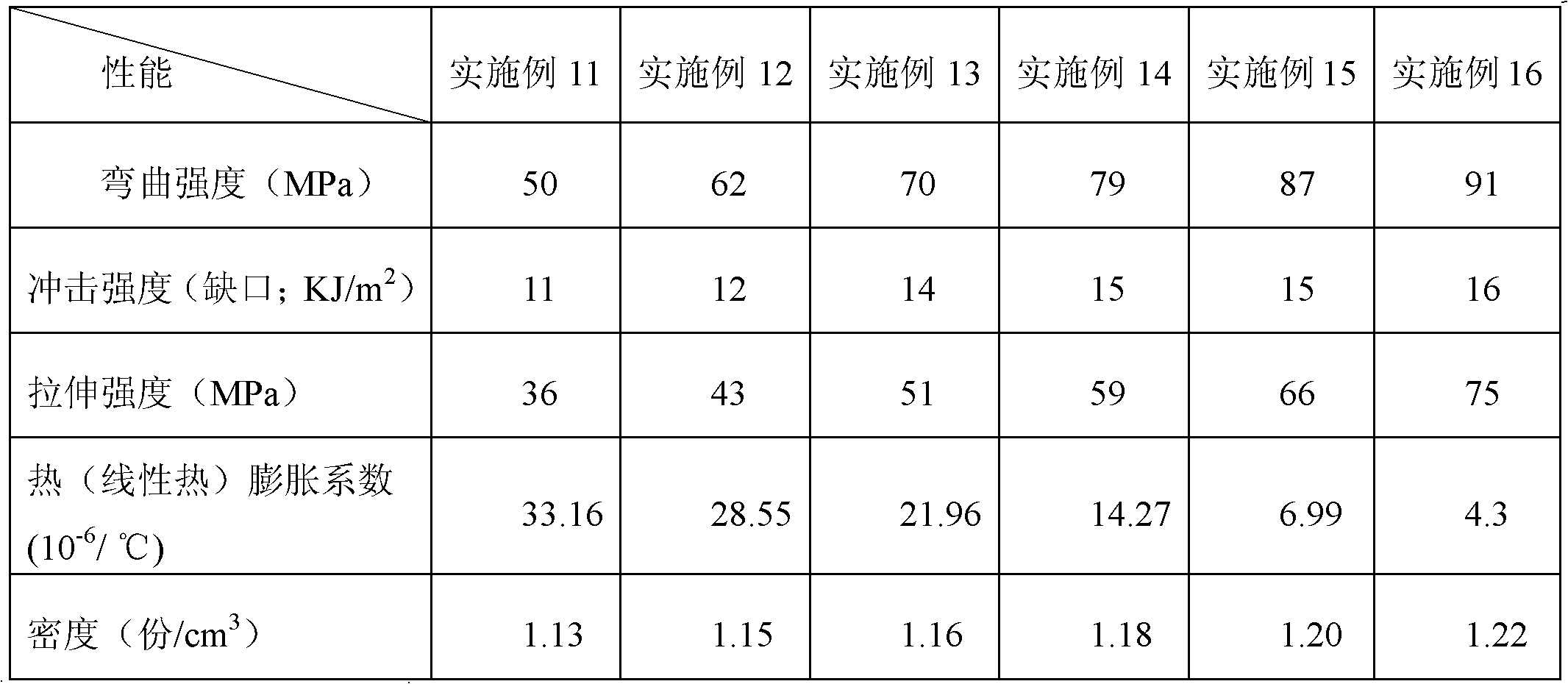

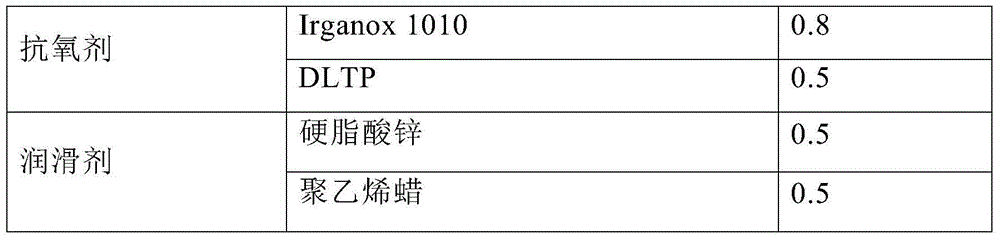

The invention belongs to the technical field of high polymer materials, and discloses low coefficient of thermal expansion thermoplastic resin composition, a preparation method and application of the low coefficient of thermal expansion thermoplastic resin composition. The resin composition is composed of, by weight, 340 to 900 parts of thermoplastic resin, 100 to 500 parts of carbon fibers, 0 to 5 parts of antioxygen, 0 to 5 parts of lubricating agent and 0 to 150 parts of flexibilizer. The preparation method comprises adding the 340 to 900 parts of the thermoplastic resin, the 0 to 5 parts of the antioxygen, 0 to 5 parts of the lubricating agent and the 0 to 150 parts of the flexibilizer to a high mixing machine to mix for 1 to 30 min, adding the mixture to a double-screw extruder, adding the 100 to 500 parts of the carbon fibers from the glass fiber feeding port or the side feeding port of the double-screw extruder to mix evenly, and carrying out extruding, dragging and prilling on mixed materials in the double-screw extruder to obtain the low coefficient of thermal expansion thermoplastic resin composition. The use of the low coefficient of thermal expansion thermoplastic resin composition applied to the fittings of a metal piece is provided. The thermoplastic resin is high in flexural modulus, tensile strength and impact strength, and low in linear expansion coefficient.

Owner:HEFEI GENIUS NEW MATERIALS

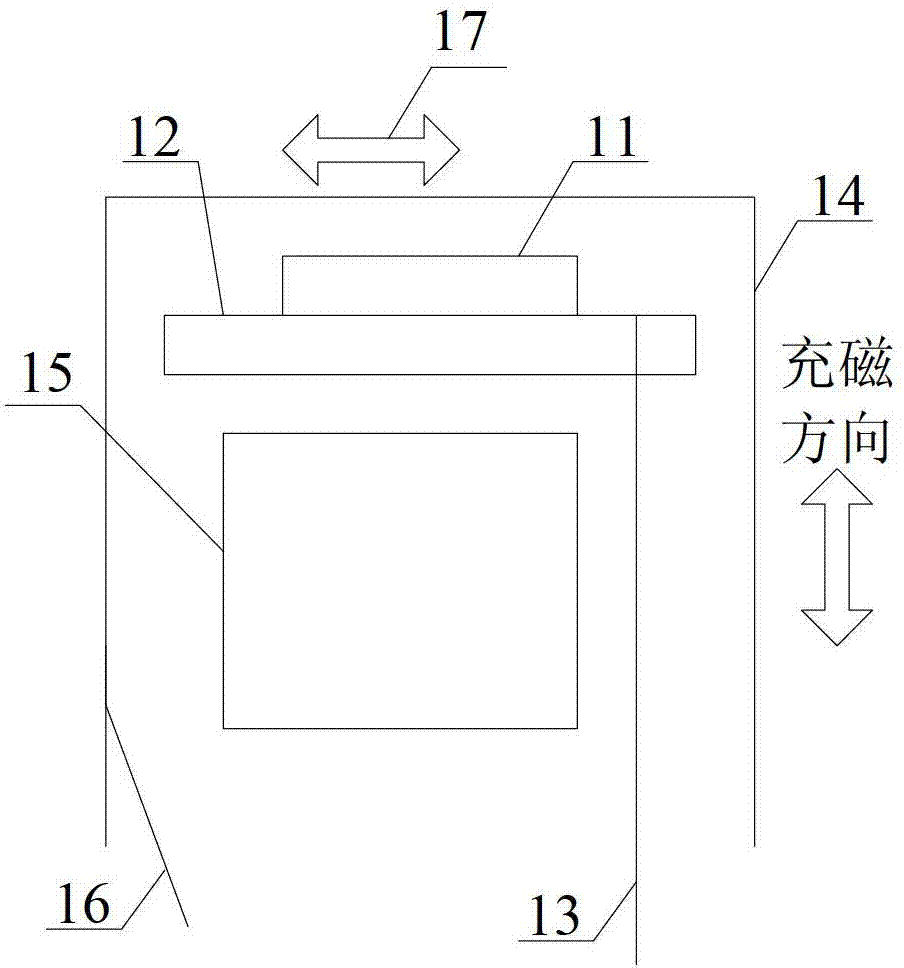

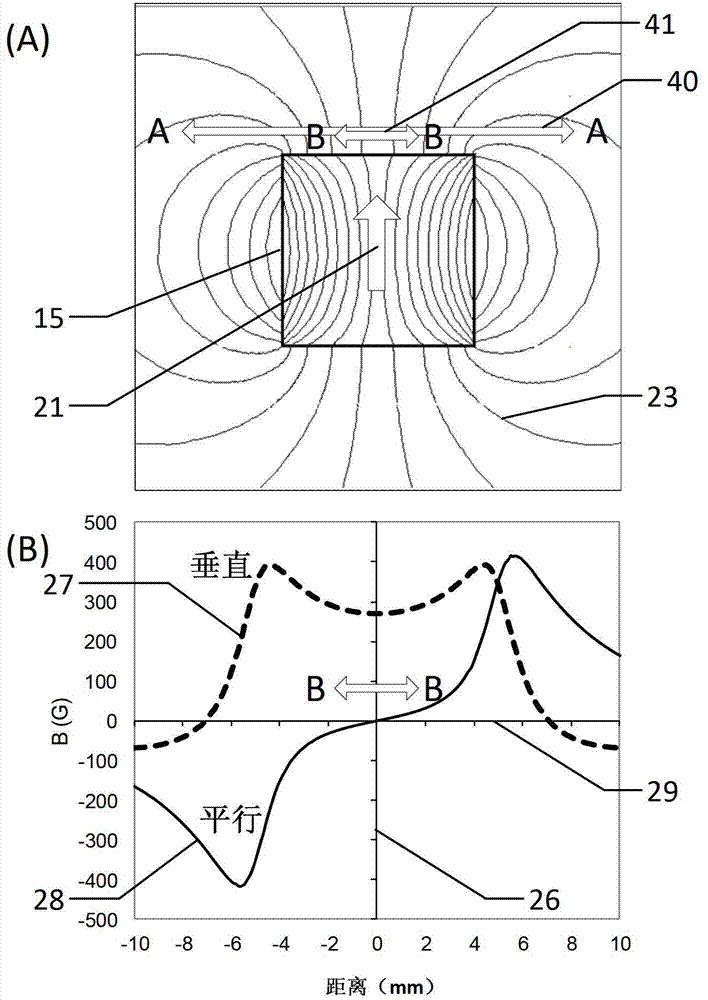

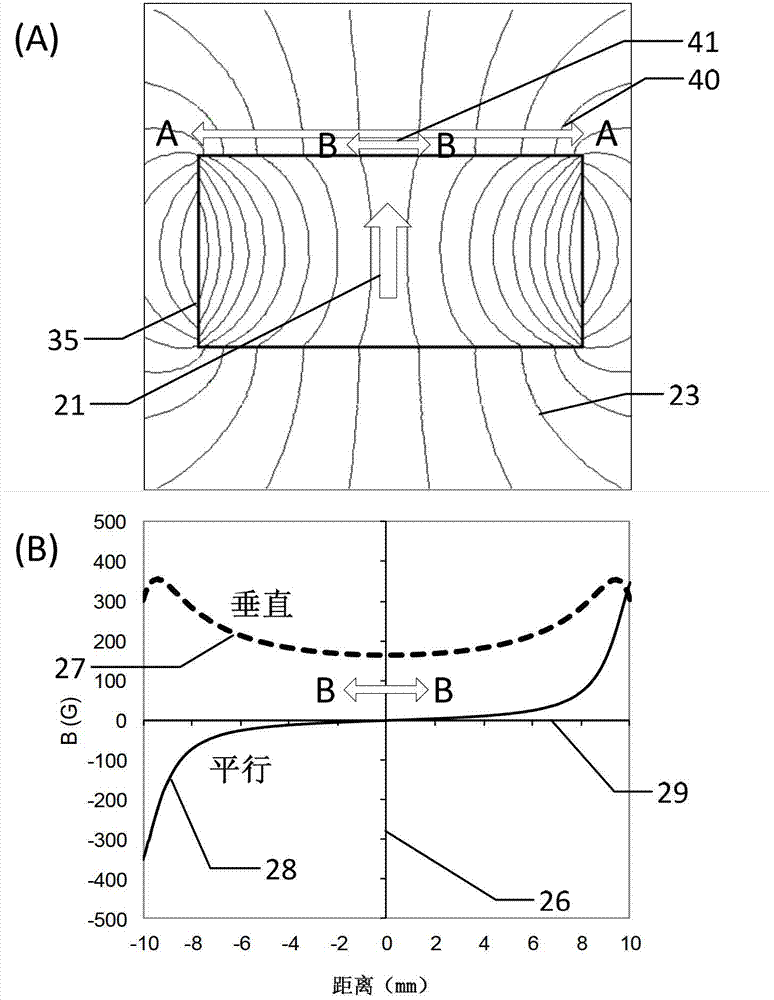

Magnetic-bias currency detecting magnetic head with sensitive direction parallel to detection face

ActiveCN102968845AHigh sensitivityImprove signal-to-noise ratioPaper-money testing devicesDigital storageLinear regionSignal-to-noise ratio (imaging)

Owner:MULTIDIMENSION TECH CO LTD

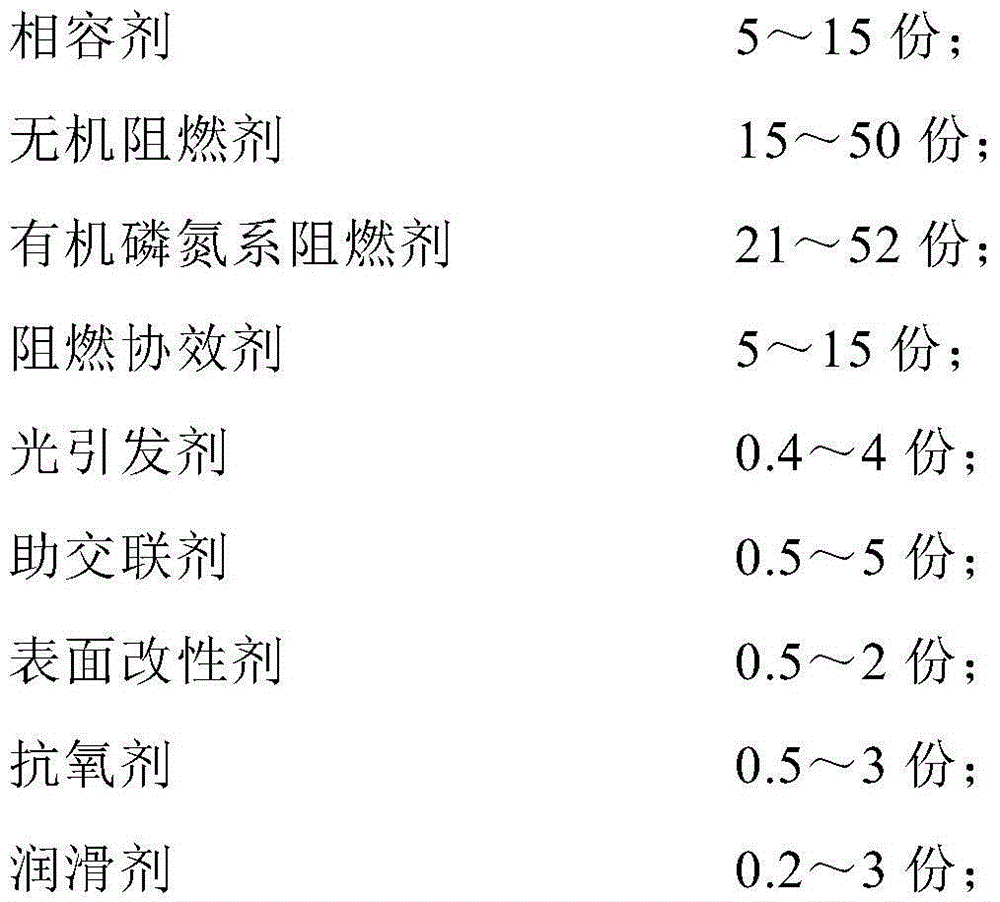

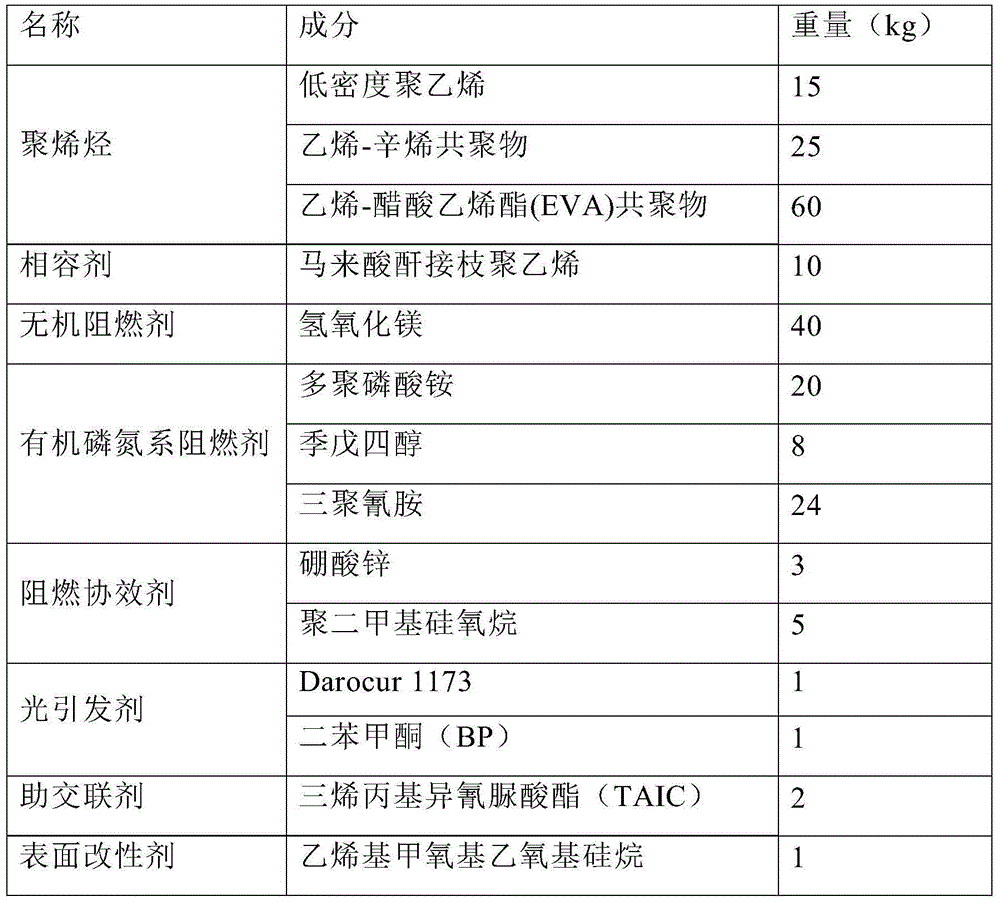

Ultraviolet light crosslinking low-smoke zero-halogen flame-retardant cable material and preparation method thereof

ActiveCN104893088AImprove mechanical propertiesImprove flame retardant performancePlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention provides an ultraviolet light crosslinking low-smoke zero-halogen flame-retardant cable material. The cable material comprises polyolefin, a compatilizer, an inorganic flame retardant, an organic phosphorus-nitrogen-containing flame retardant, a flame-retardant synergist, a photoinitiator, an assistant crosslinker, a surfactant, an antioxidant and a lubricant, wherein polyolefin contains low-density polyethylene, an ethylene-octylene copolymer and an ethylene-vinyl acetate copolymer in the weight proportion being (10-25):(20-35):(55-65); the compatilizer is polyethylene for grafting of maleic anhydride; the inorganic flame retardant is selected from magnesium hydroxide and aluminum hydroxide; the organic phosphorus-nitrogen-containing flame retardant contains polyphosphoric acid, pentaerythritol and melamine in the weight proportion being (10-20): (4-8): (15-30); the flame-retardant synergist contains zinc borate and / or polydimethylsiloxane. The cable material has good thermal resistance and anti-aging performance, can be used at the temperature of 125 DEG C for a long time and is excellent in comprehensive mechanical performance and better in flame retardance.

Owner:上海至正新材料有限公司

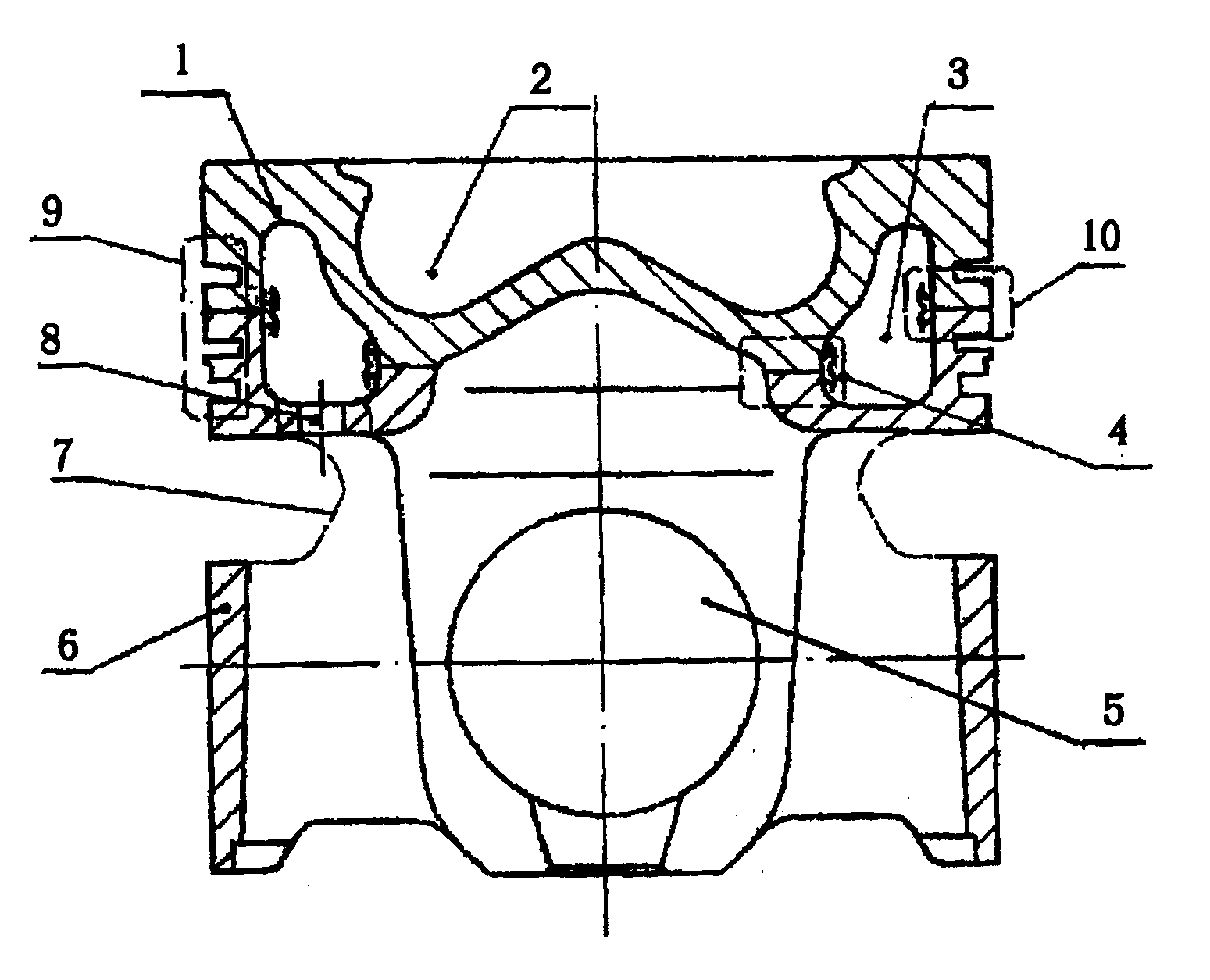

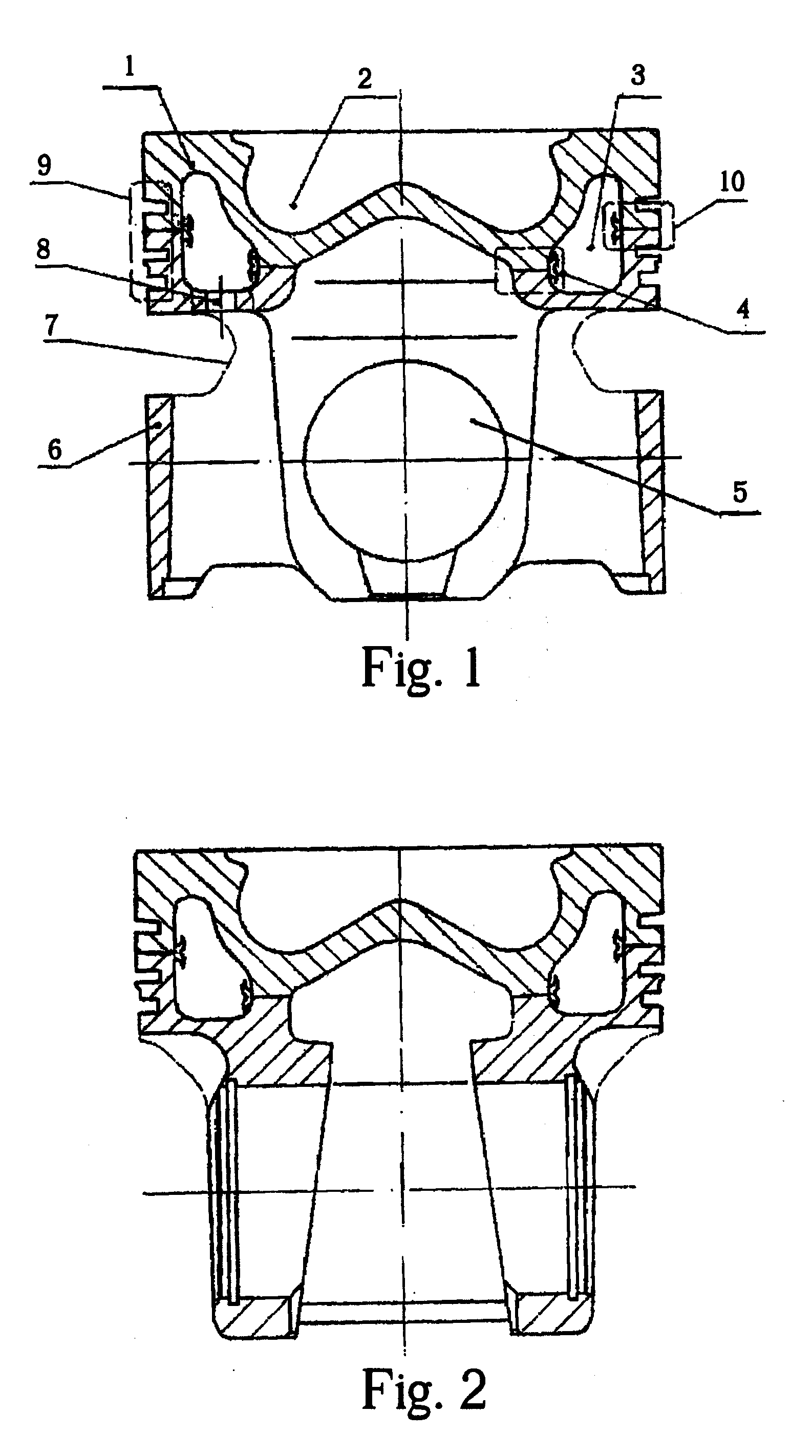

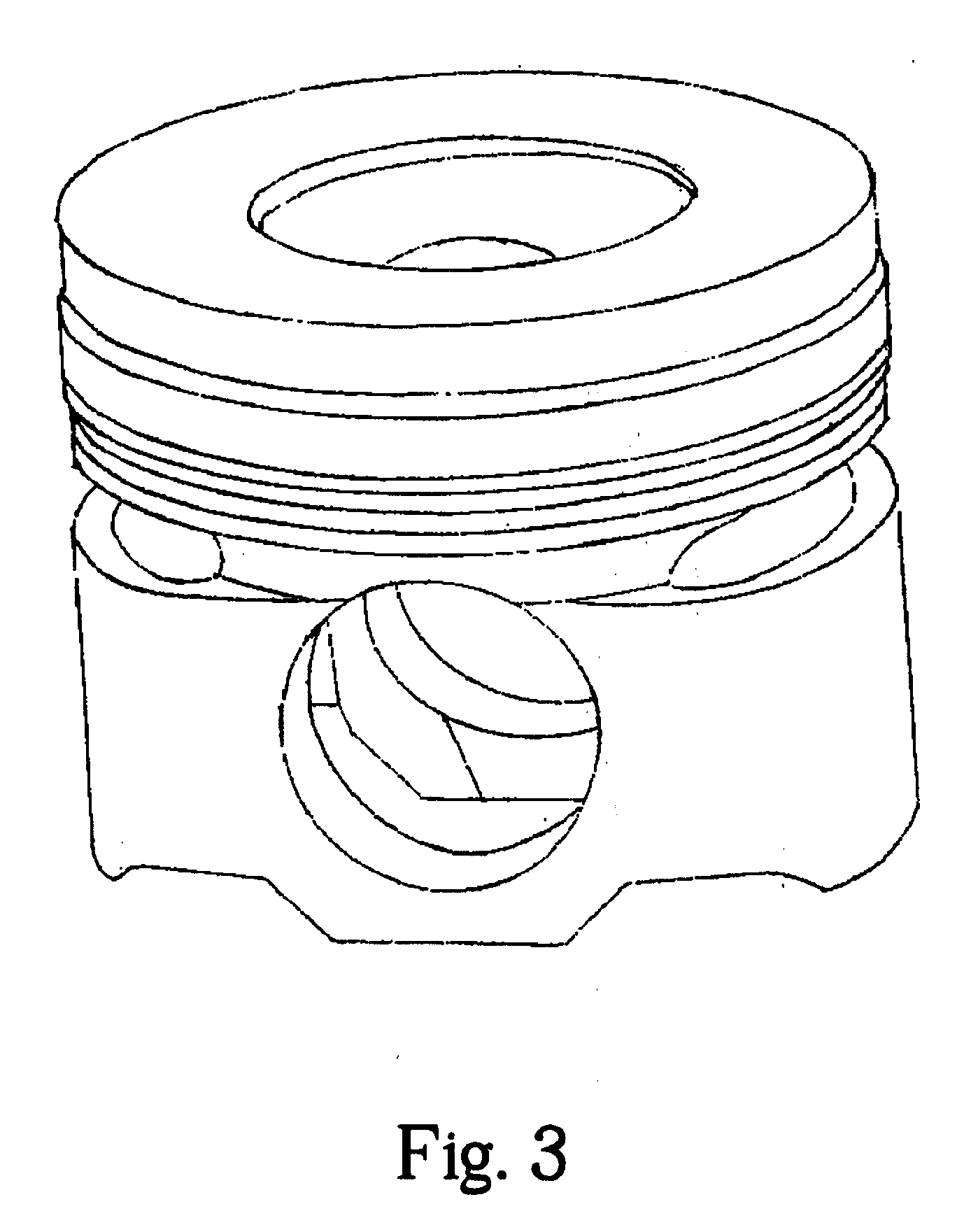

Welding Forged Steel Single Piece Piston and Its Manufacturing Methods

InactiveUS20070079775A1Simple manufacturing processImprove structural strengthAir coolingMachines/enginesFriction weldingCombustion chamber

The present invention has provided a welding forged steel single piece piston and its manufacturing methods. A semi-finished head and a semi-finished skirt are forged respectively; the semi-finished head and semi-finished skirt are heat-treated respectively; rough machining is carried out respectively to the semi-finished head and the semi-finished skirt, and a face of weld between the two adjacent ring grooves is higher than the one under the combustion chamber; the head and the skirt are welded together through friction welding; an annular groove, a combustion chamber, a ring groove, a pinhole, an outer annulus and oil inlet / outlet holes are manufactured respectively; and the surface of the piston is phosphorized and graphitized. Compared with one-piece forged piston, it has better processing technology, because the head and skirt are forged respectively and then welded together. Over-all structural rigidity of the piston has been increased, and distortion of the ring groove in high temperature is slight because the cooling oil recess is sealed through welding. As the annular groove is located on the upper part of skirt, the weight of body of the piston is lowered and this kind of structure can accelerate engine oil returning on, decrease the clearance between the piston and the cylinder and reduce the engine oil consumption.

Owner:SHANDONG BINZHOU BOHAI PISTON

Nano silver-tin oxide electric contact and its prepn

InactiveCN1417817AImprove plasticityImprove conductivityContact materialsMetal/alloy conductorsRare earthTitanium oxide

The present invention belongs to metal-based composite material technology. The electric contact material consists of Ag 70-97 wt%, nanometer tin oxide 3-22 wt% and RE elements 0.1-8 wt%. The electric contact is produced through the processes of preparation of zine oxide or titanium oxide doped nanometer tin oxide, mixing metal oxide powder, pressing the mixture to form, sintering, extruding, drawing wire and forming into rivet type or stripe contact. The pressure in pressing the mixture to form is 150-400 MPa and the sintering temperature is 800-900 deg.c. The electric contact can be used inelectric appliance, instrument and switch.

Owner:TIANJIN UNIV

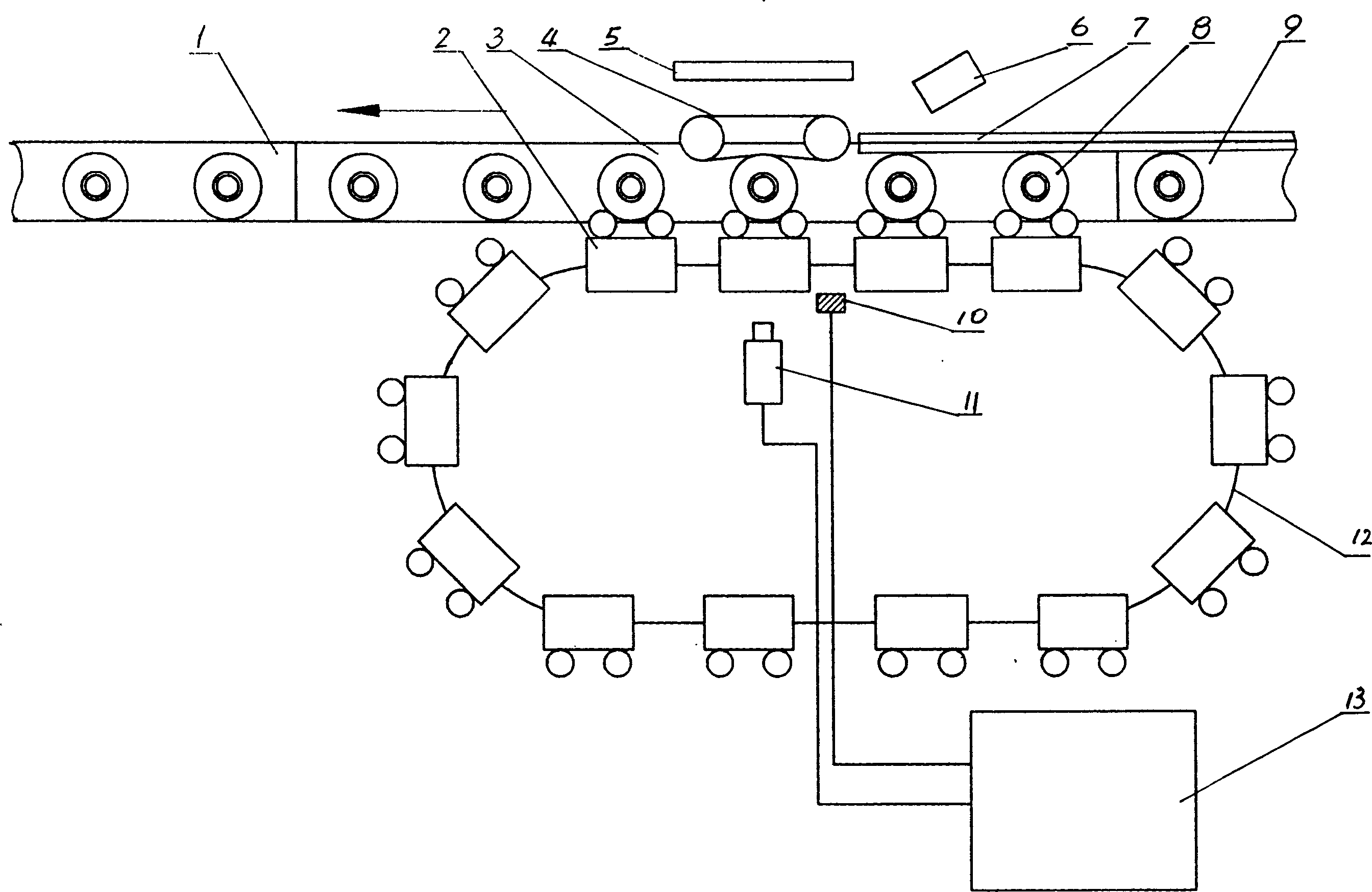

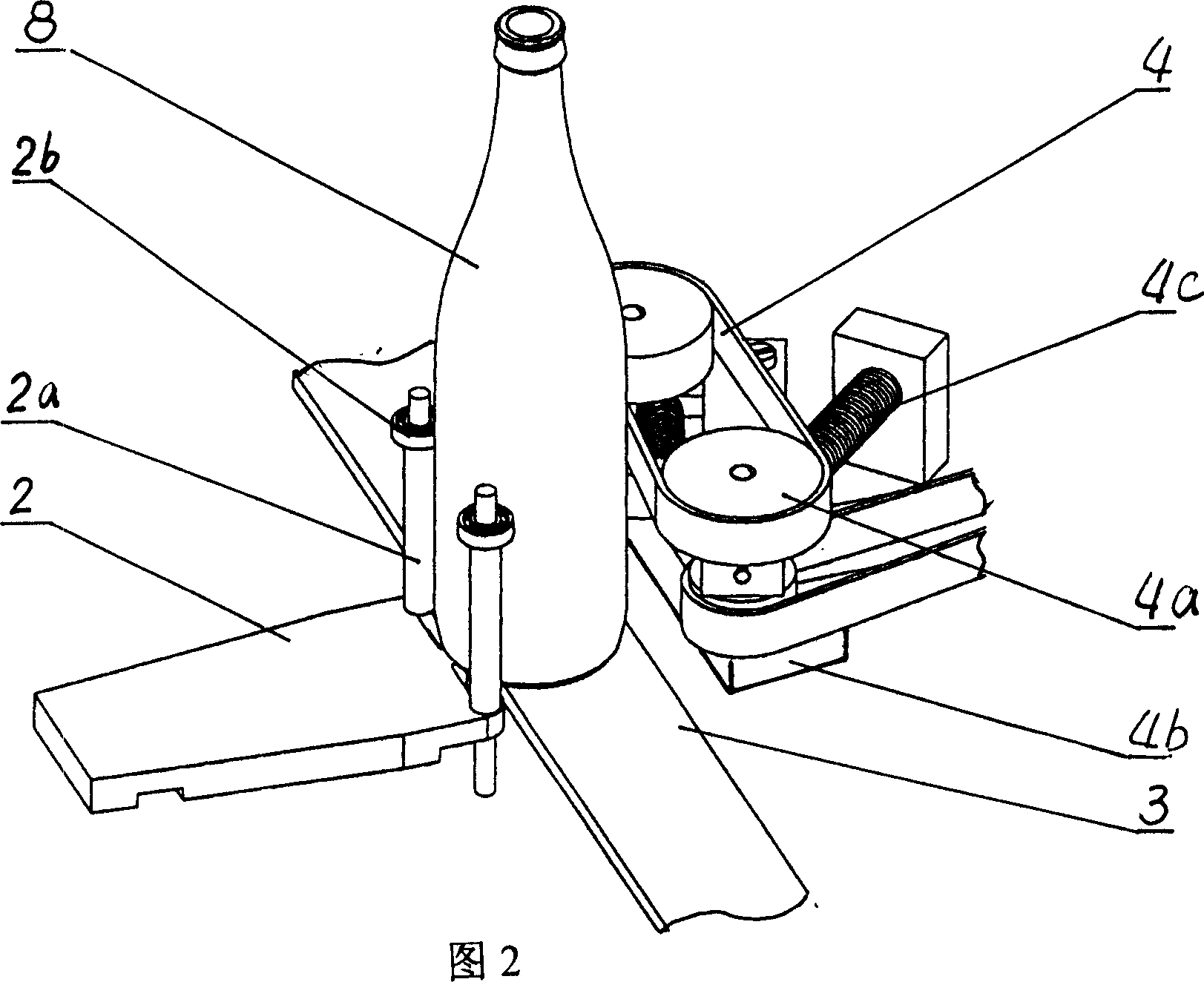

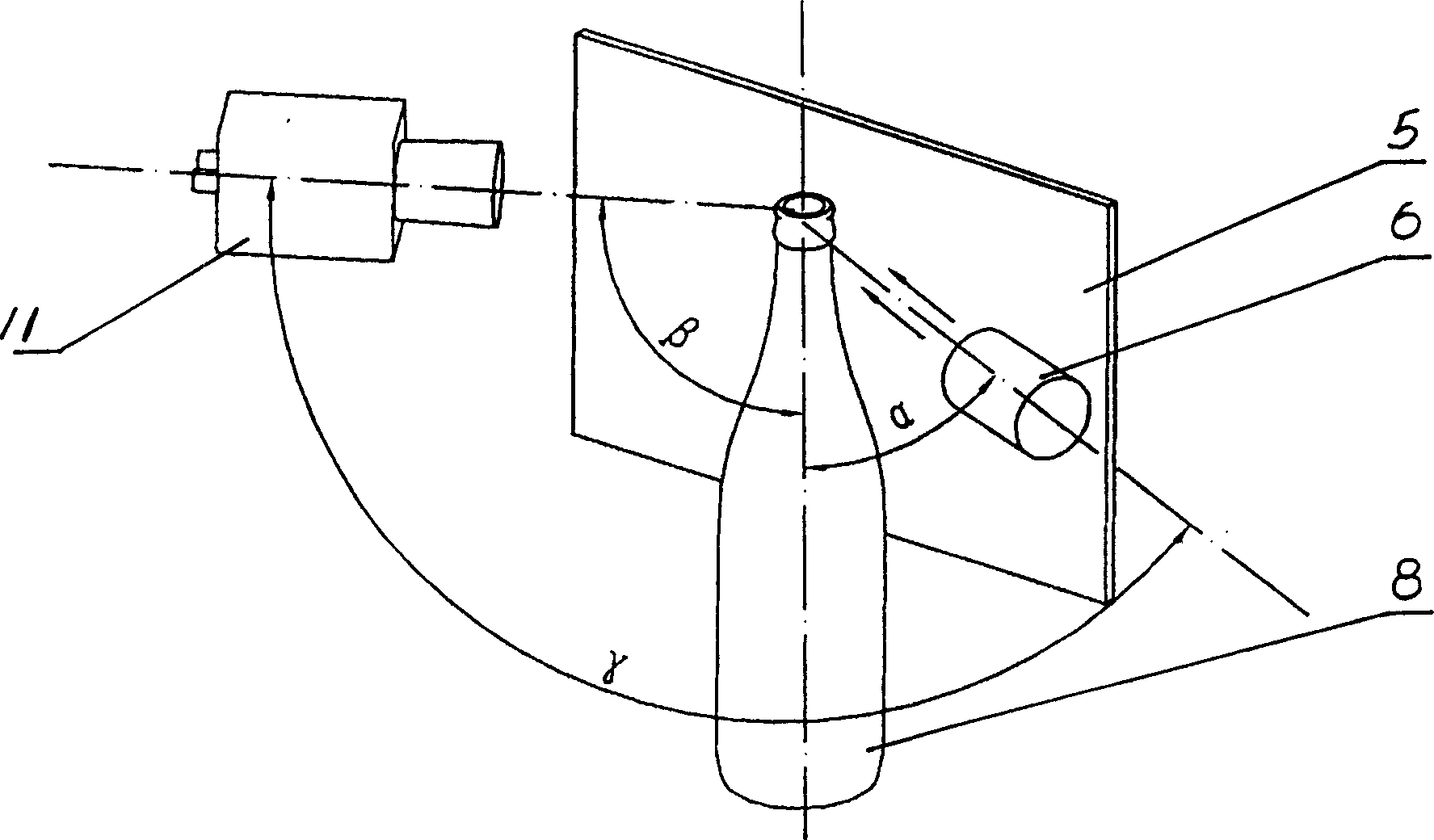

Glass Bottle and can detecting method and detecting device

InactiveCN1475795ANo missed detectionRealize online automatic detectionOptically investigating flaws/contaminationUsing optical meansBottleCrack mouth

A method and apparatus for in-line checking of glass bottles without contact features that under the control of computer, the multiple mouth images of a rotating bottle is picked up and then processed one by one to finde the bright sport reflected by the mirror of cracked mouth, so determining that the bottle mouth is cracke and rejecting out the bottle automatically. Its advantages are high accuracy and no leakage detection.

Owner:GUANGXI NORMAL UNIV +1

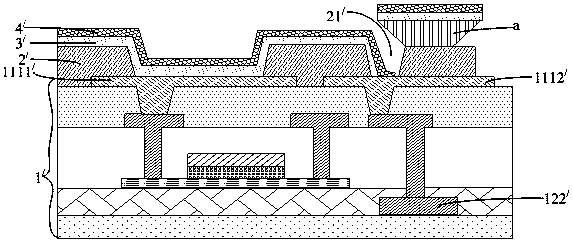

Organic light-emitting display device

InactiveCN108538890ALower resistanceImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceAuxiliary electrode

The invention provides an organic light-emitting display device which comprises an array substrate provided with a pixel electrode, a metal connection electrode and an auxiliary electrode; the metal connection electrode is connected with the auxiliary electrode through a concave hole positioned above the auxiliary electrode; the concave hole forms a first cavity and a second cavity which are interconnected, and the first cavity extends in the direction away from the pixel electrode from an edge line, away from one side of the pixel electrode, of the second cavity; a pixel definition layer is above the array substrate, and grooves corresponding to the concave hole and the pixel electrode are respectively reserved; an OLED semiconductor layer is above the pixel definition layer, covers the pixel electrode and the metal connection electrode and also extends into the first cavity to be connected with the auxiliary electrode; a cathode is above the OLED semiconductor layer, extends into thefirst cavity to be connected with the auxiliary electrode and is in a discontinuous connection state by taking the concave hole as a breaking point. Through the implementation of the organic light-emitting display device provided by the invention, the manufactory process can be simplified through omitting inverted trapezoidal column legs, the electrical conductivity of the cathode on the OLED semiconductor layer can be improved, and the purpose of reducing pressure drop is achieved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

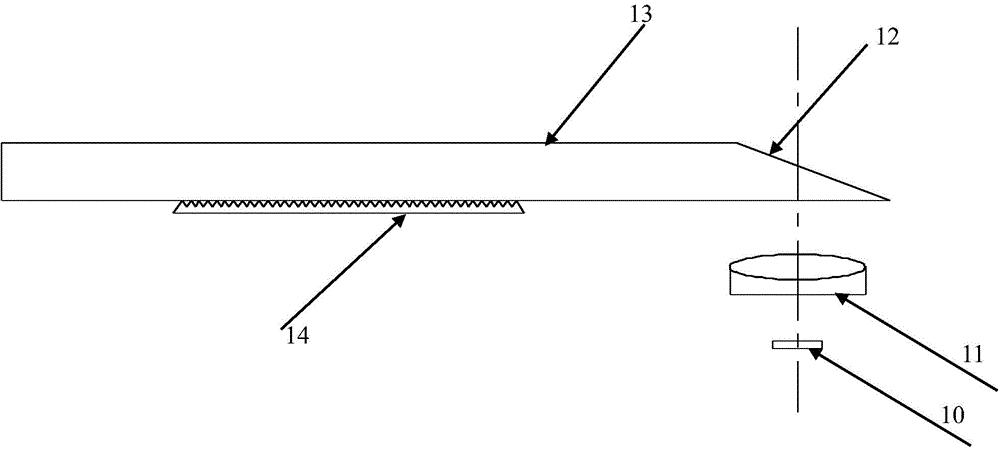

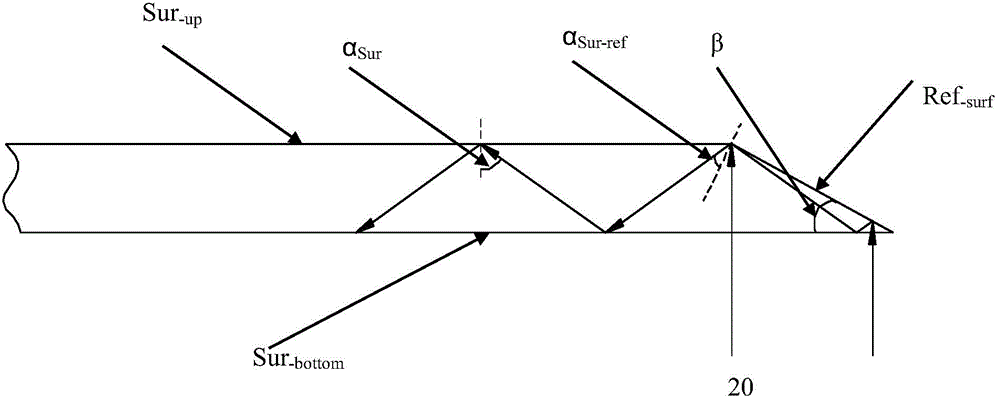

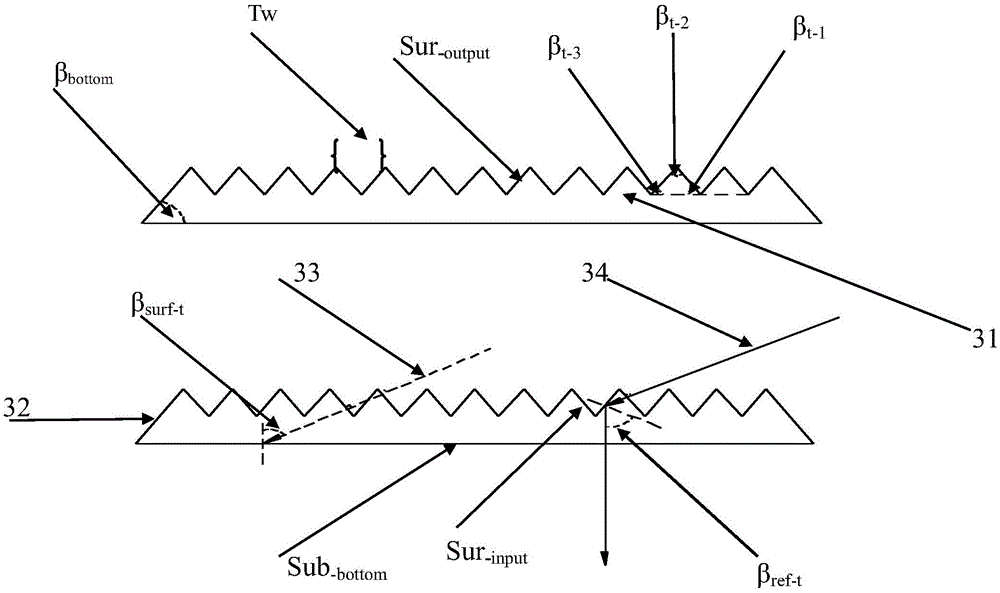

Dentiform embedded planar waveguide optical device

ActiveCN104536088AFlexible field of viewLarge field of viewPlanar/plate-like light guidesCoupling light guidesWaveguideLight source

The invention provides a dentiform embedded planar waveguide optical device which comprises an image light source, a collimating lens, a coupling input surface, a planar waveguide substrate and a micro dentiform structure, wherein the image light source is used for emitting display optical waves for displaying a required image, the collimating lens is used for collimating the optical waves emitted by the light source, the coupling input surface is used for coupling the collimated optical waves into a planar waveguide, the planar waveguide substrate is used for performing reflecting propagating on the coupled optical waves to form total reflection optical waves, and the micro dentiform structure is used for outputting the total reflection optical waves in a coupled manner. The dentiform embedded planar waveguide optical device has characteristics of being simple in processing process, easy to realize, light in weight, compact in structure, flexible in vision field increase and high in optical wave coupling efficiency, not only can be used for wearable display, but also can be used for the application fields such as extension uniform illumination, naked eye 3D display and mobile screen display.

Owner:SHANGHAI RAYPAI PHOTONIC CRYSTAL LTD

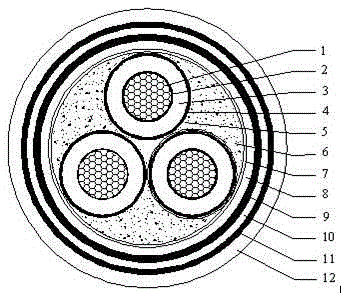

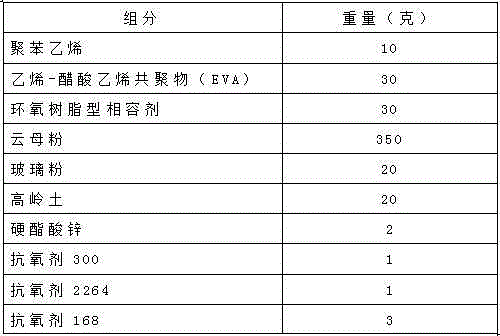

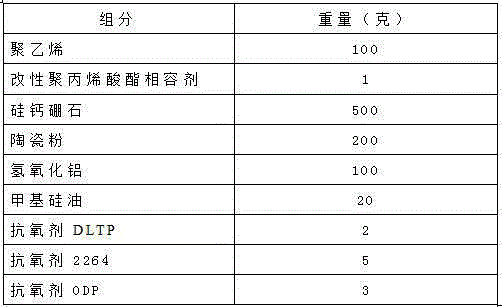

Ceramifying polyolefin fireproof cable material

InactiveCN105348627ALow priceSimple processing technologyPlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention provides a ceramifying polyolefin fireproof cable material. The material is prepared by the following components in parts by weight: 40-100 parts of polyolefin; 1-30 parts of a compatilizer; 350-450 parts of ceramifying powder; 20-200 parts of a flux; 20-90 parts of a fire retardant; 2-20 parts of a lubricant; and 1-10 parts of an anti-oxidant. Polyolefin is selected from one or more of an ethane-vinyl acetate copolymer, polypropylene, polystyrene, polyethylene and a polyolefin elastomer. The ceramifying powder is selected from one or more of pottery clay, powdered steatile, mica powder, pyrophillite, ascharite, datolite, calcite, limestone, spodumene and clay. The ceramifying polyolefin fireproof cable material has the advantages of good fireproof performance, environmental protection, low cost, easy processing and good application prospect.

Owner:SUZHOU CPLUS NEW MATERIAL

Plaster for curing rheumatoid pains in neck, shoulders, waist and legs

InactiveCN101905007AGood effectImprove efficiencyNervous disorderHydroxy compound active ingredientsBruiseRemove blood

The invention discloses a plaster for curing rheumatoid pains in a neck, shoulders, a waist and legs, which is prepared from the following raw materials by weight: musk, radix notoginseng, ligusticum wallichii, lycopodium clavatum, garden balsam stem, red flower, processed radix aconiti kusnezoffii, processed radix aconiti, radix clematidis, processed semen strychni, frankincense, myrrh, asarum, radix angelicae pubescentis, pawpaw, curcuma zedoary, rhizoma sparganii, Chinese angelica, borneol and decumbent corydalis tuber. The plaster has the effects of promoting blood circulation, removing blood stasis, relaxing tendons, activating collaterals, dispelling wind, removing heat, resolving hard lump and relieving bruises and pains; when the plaster of the invention is coated on a fracture and reduced joint after fracture and reduced joint integration, local revascularization can be improved, and porosis is generated quickly; the plaster has good recovery effects on sequelae such as pains, joint swelling, inconvenient activity, stiffness and the like caused by the plaster immobilization and dermatoplasty; and the medicament of the invention has the advantages of simple preparation process, convenient using method, safety, no side effect, obvious curing effect and high efficiency.

Owner:徐利华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com