Patents

Literature

67results about How to "Large pressure range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resistor-type pressure sensor and making method thereof

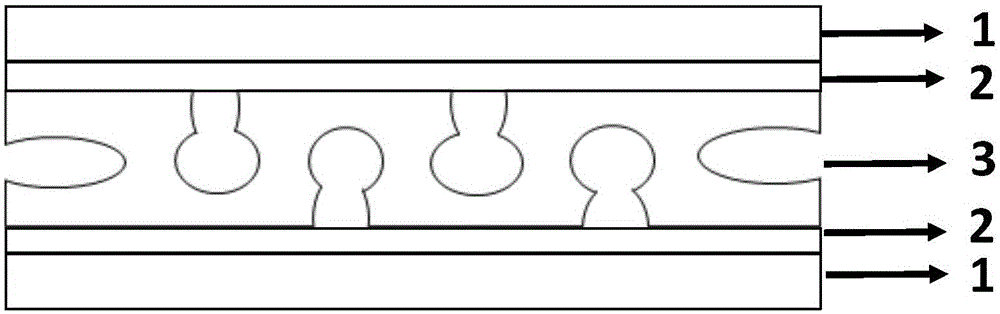

ActiveCN105021329AIncreased sensitivityLarge pressure rangeForce measurementPressure senseConductive materials

The invention discloses a resistor-type pressure sensor and a making method thereof. The resistor-type pressure sensor is composed of a sensitive layer and two substrates containing electrodes. The sensitive layer is disposed between the two electrode layers. The sensor is characterized in that the sensitive layer is a conducting porous elastic film. Since the sensitive layer of the sensor provided by the invention adopts the conducting porous elastic film, when the film is pressed, the deformation of the film increases, the contact resistance of the conducting material in the film is reduced, the sensitivity of the pressure sensor to pressure is enhanced and the pressure sensing range of the pressure sensor is enlarged. The film is made of material at a low cost, and processing technique is simple, so that the cost of the pressure sensor is reduced.

Owner:SHANGHAI JIAO TONG UNIV

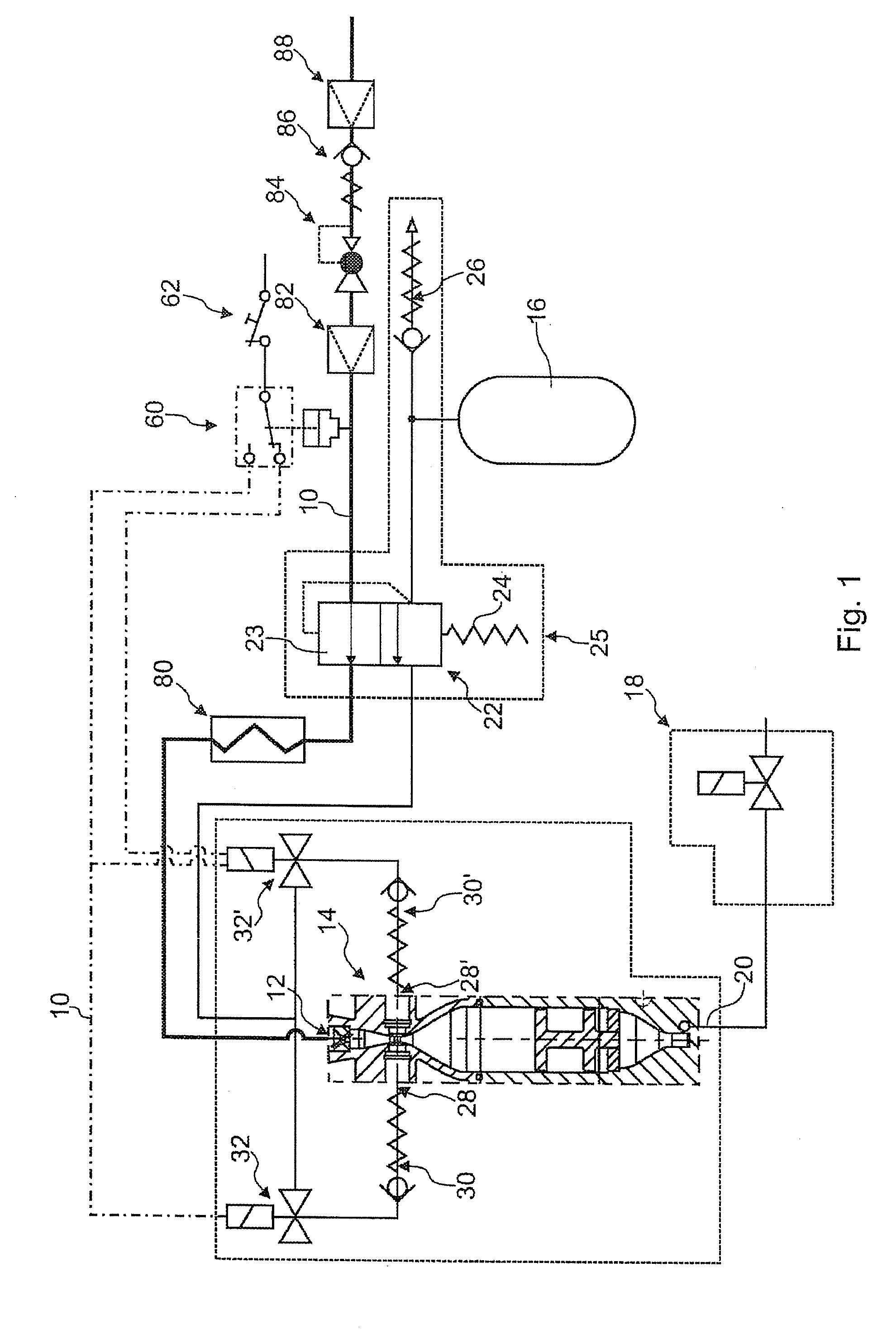

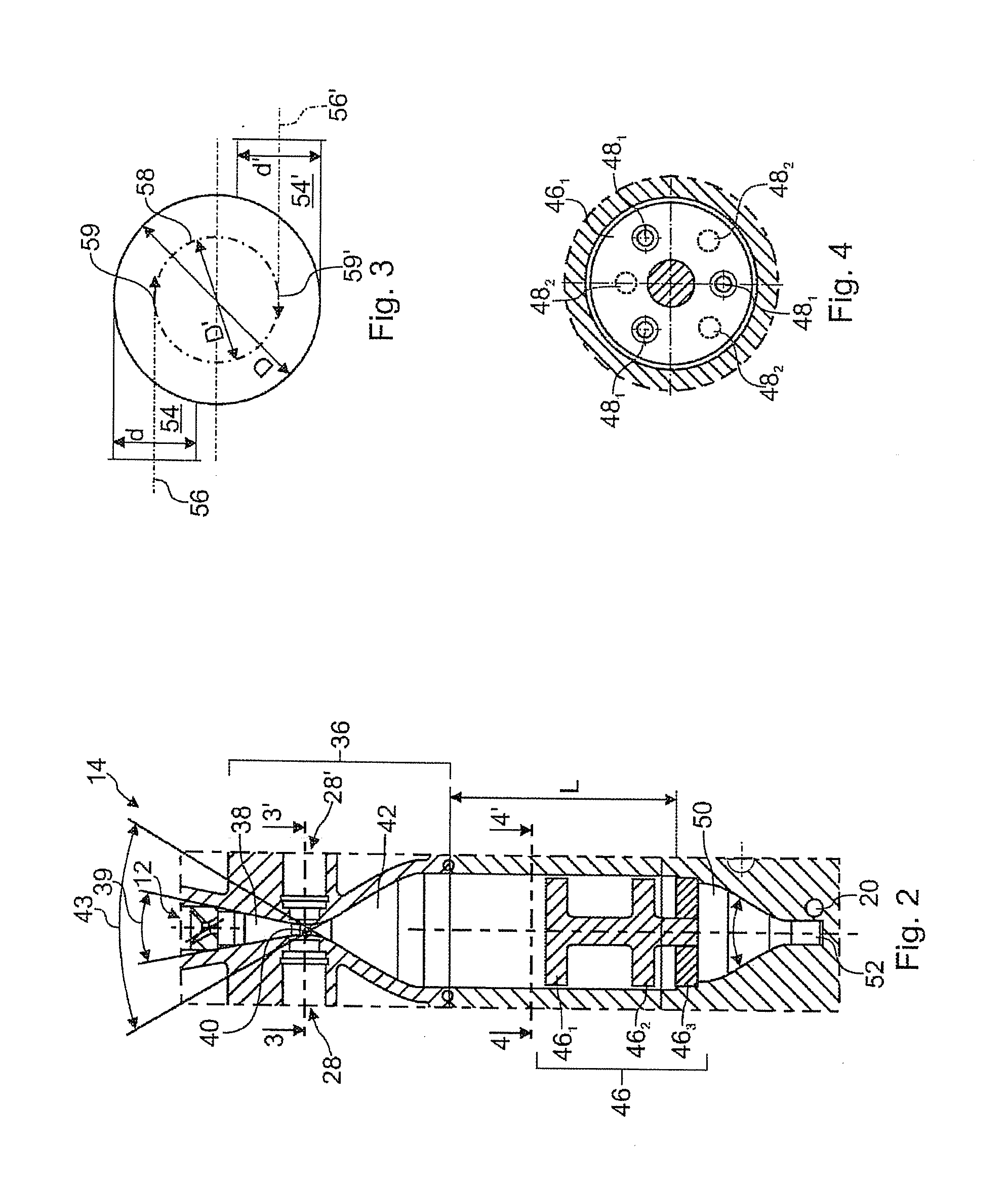

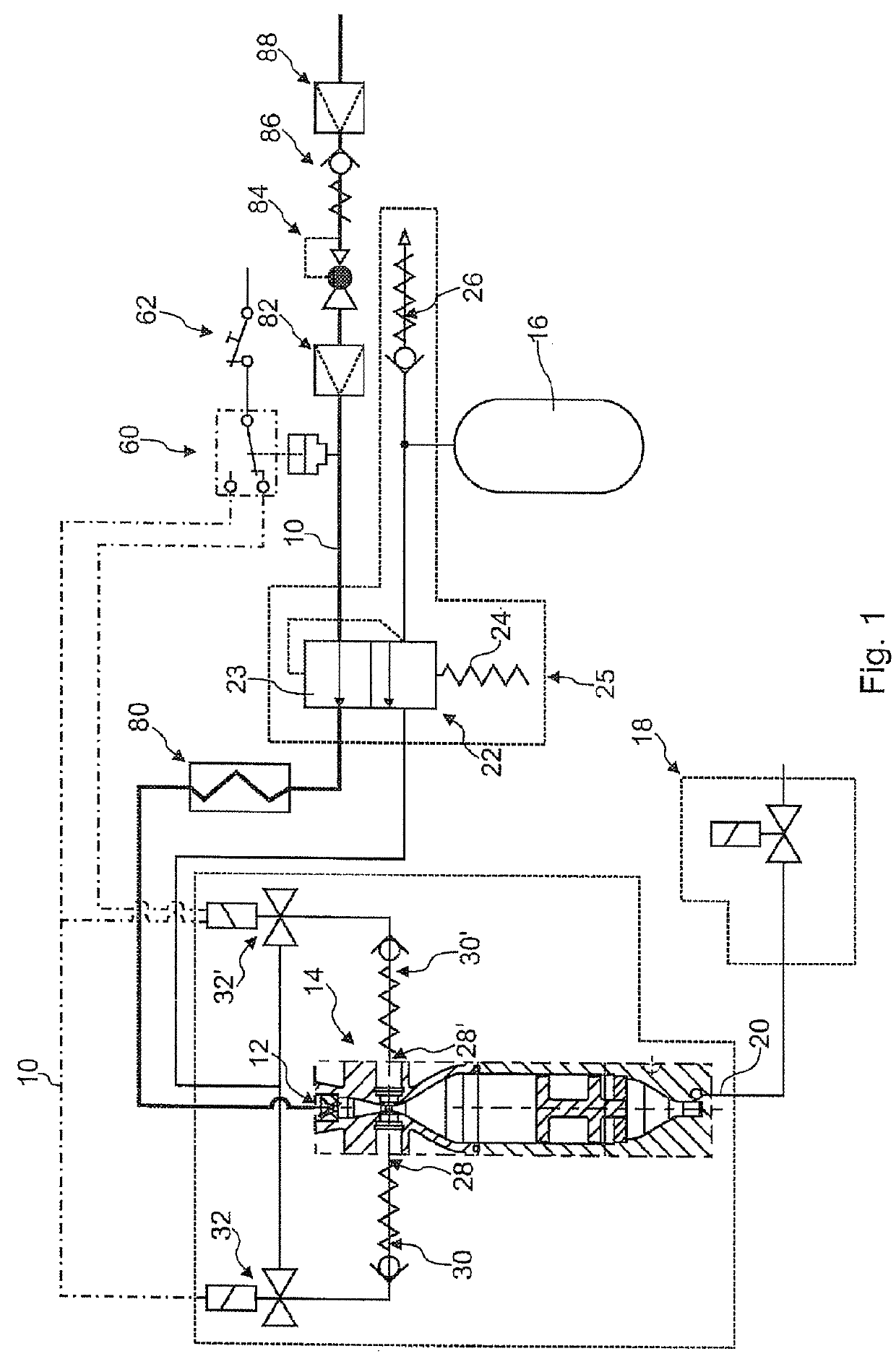

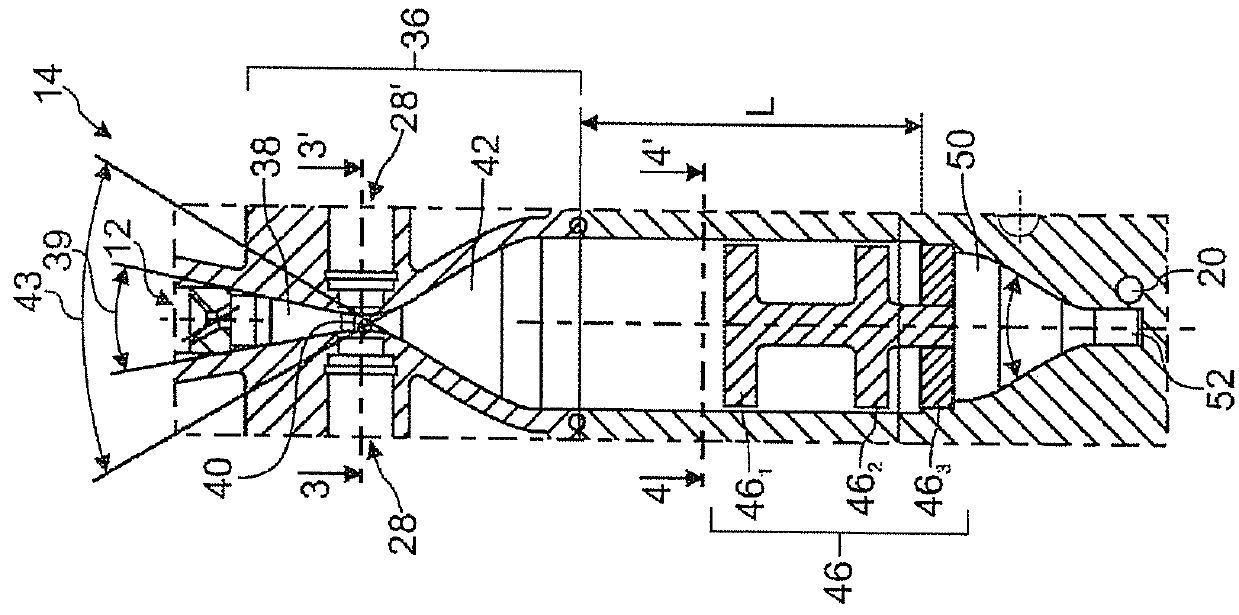

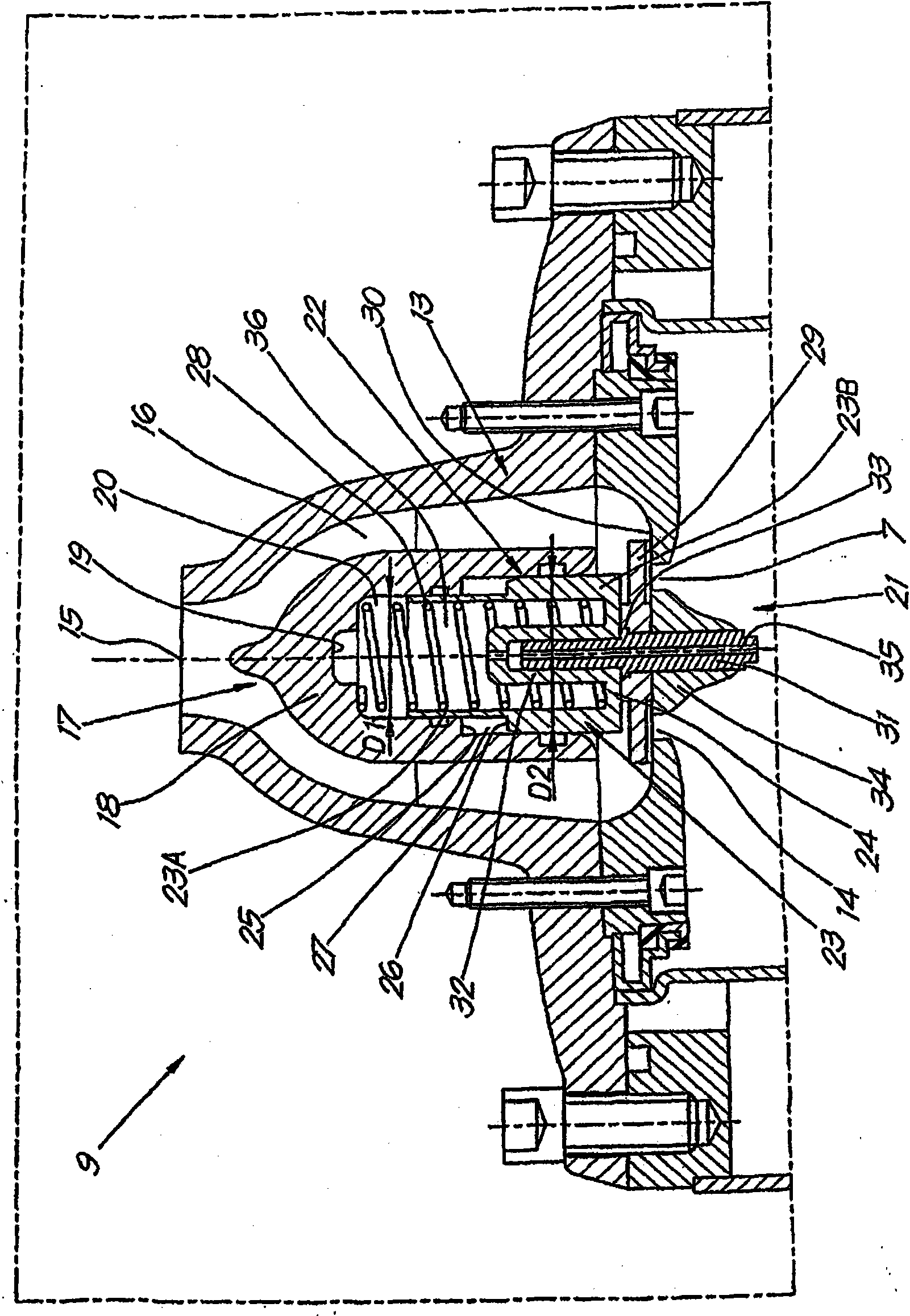

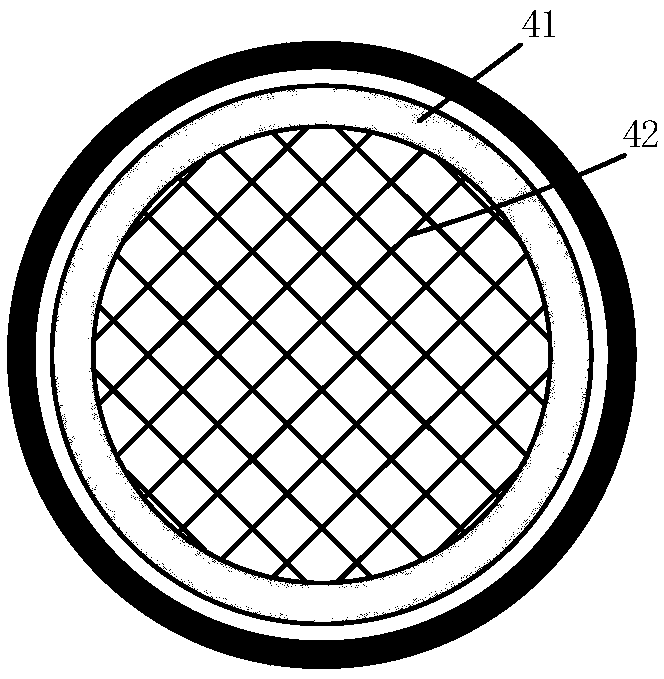

Device for the enrichment of a liquid stream with a gas

ActiveUS20120038068A1Simple equipmentBetter enrichment of a liquid streamFlow mixersLighting and heating apparatusEngineeringNozzle

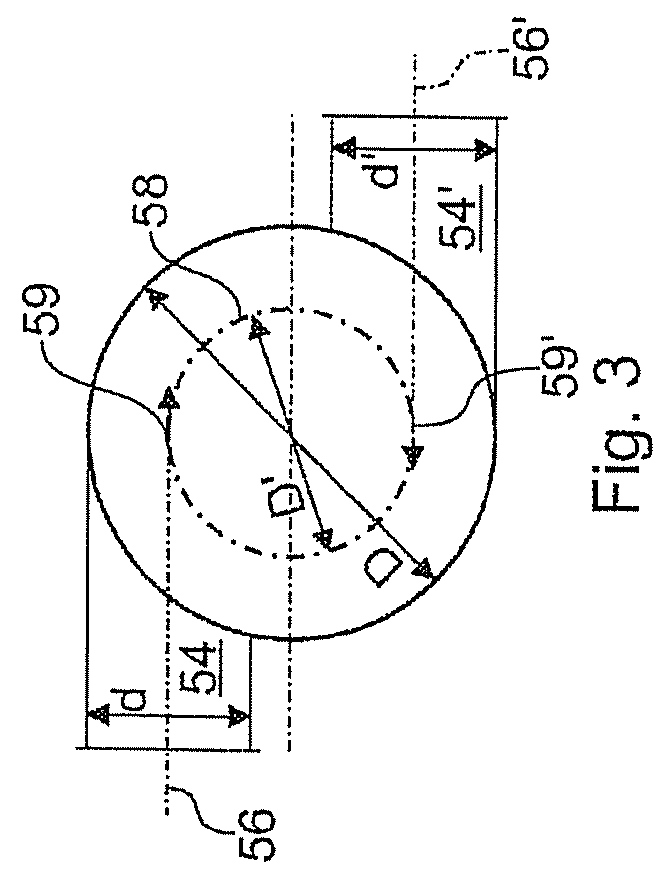

The invention relates to a device for the enrichment of a liquid stream with a gas, comprising a flow mixer (14) with a venture nozzle (36), having a rotationally symmetrical contraction (40) with a diameter D and being flown through axially by the liquid stream. The invention further comprises a gas feed for the lateral feed of the gas into the contraction (40) of the venture nozzle (36). The gas feed comprises at least one gas channel (54, 54′) with a diameter d<0,5*D, ending laterally in the contraction (40) of the venture nozzle (36) in a way, such that the elongated longitudinal axis (56, 56′) thereof is tangential to an imaginary cylinder surface (58), which is coaxial to the contraction (40) and comprises a diameter D′>d.

Owner:ROTAREX SA

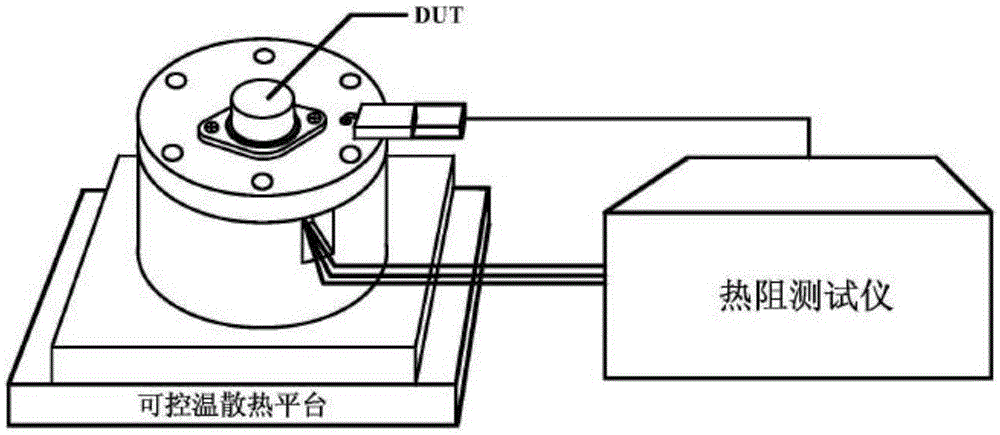

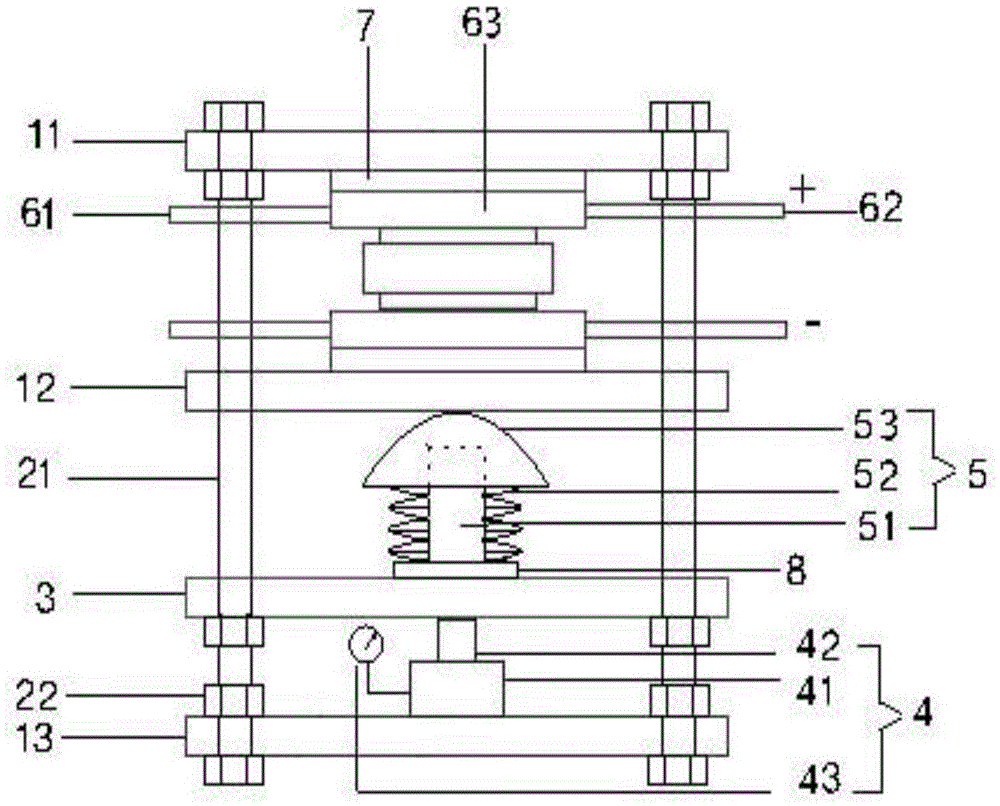

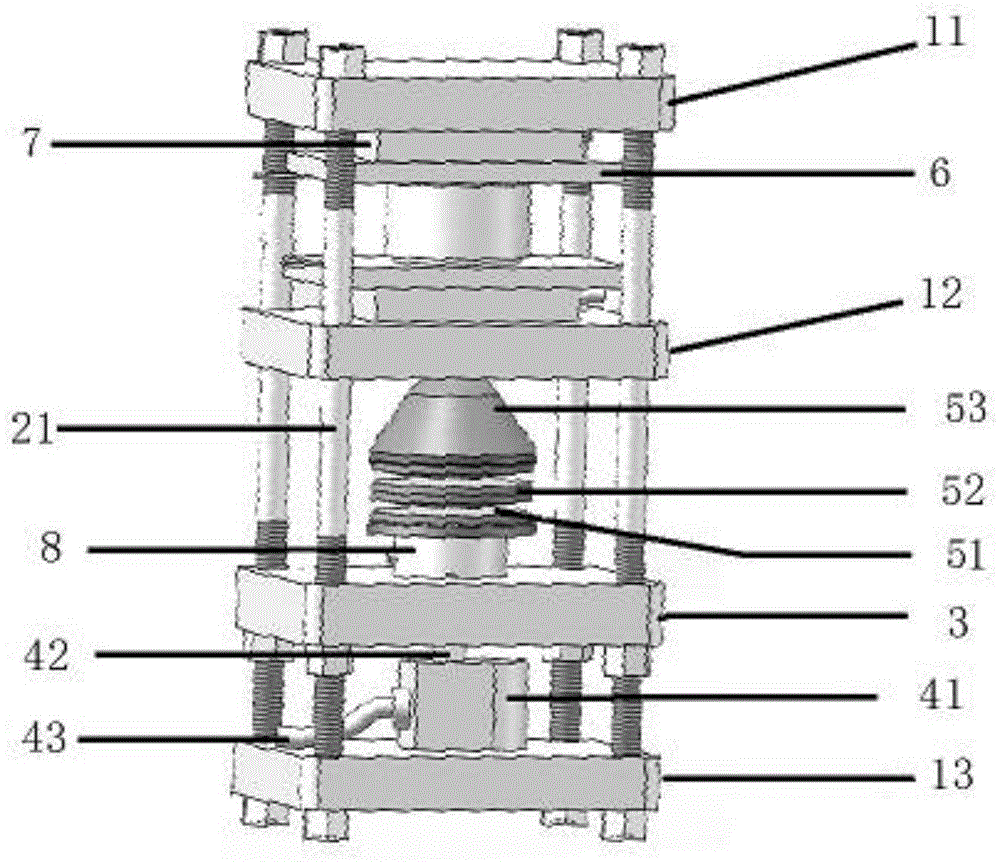

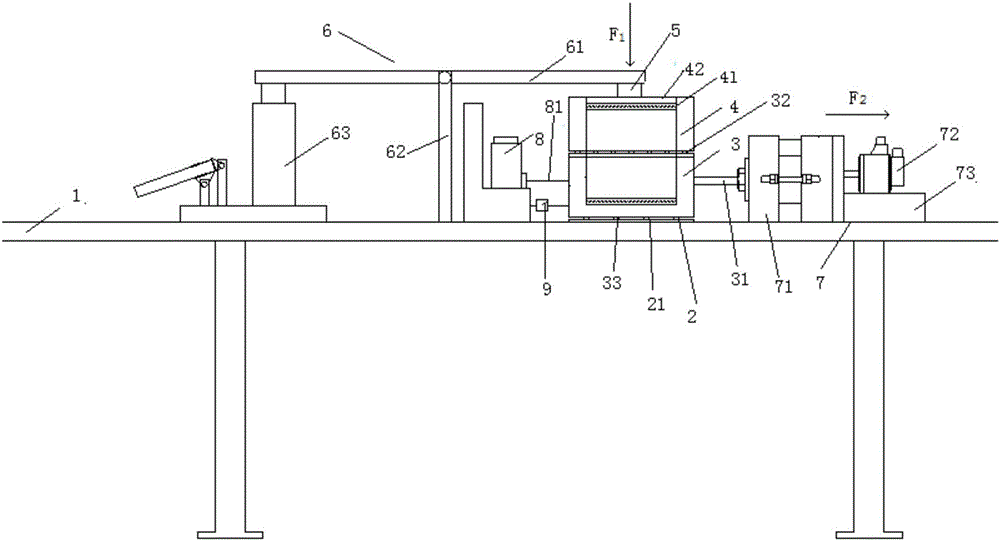

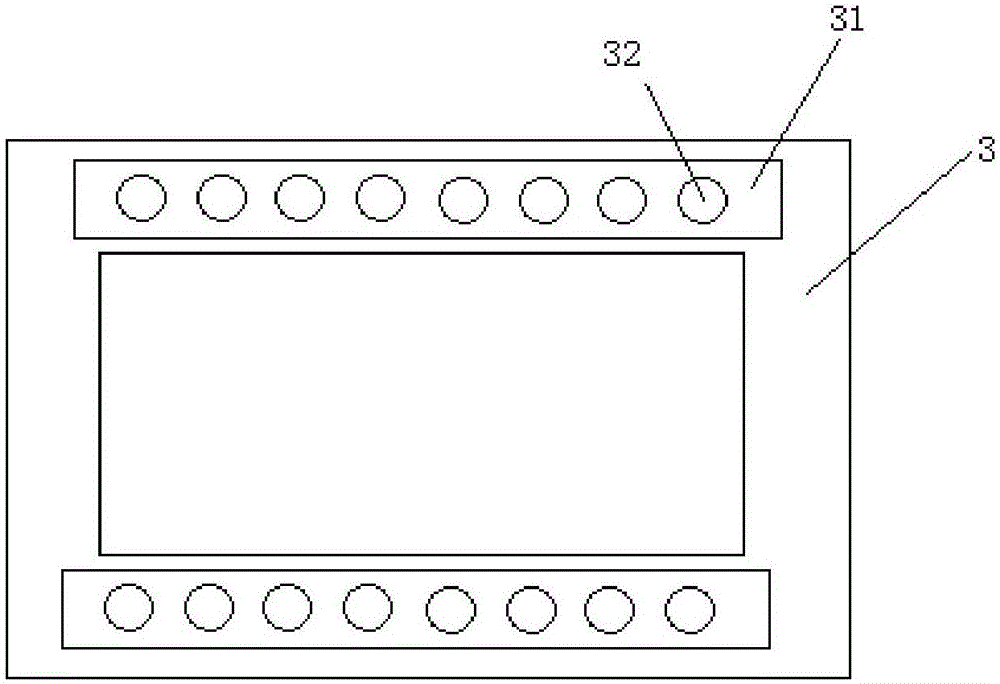

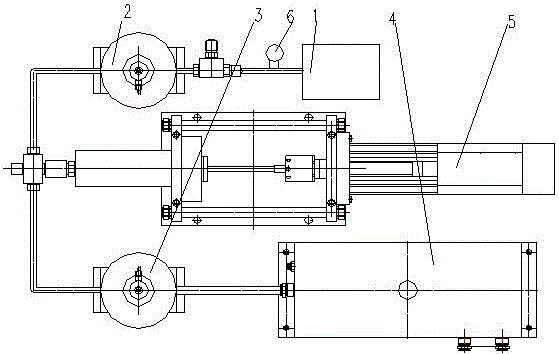

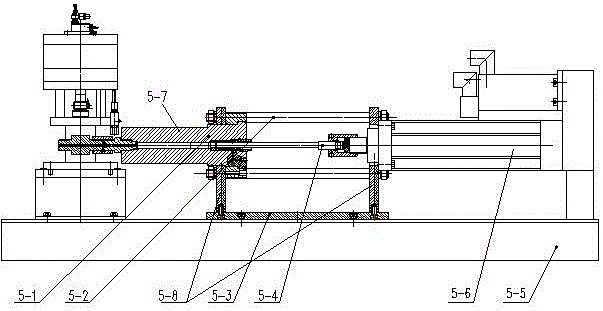

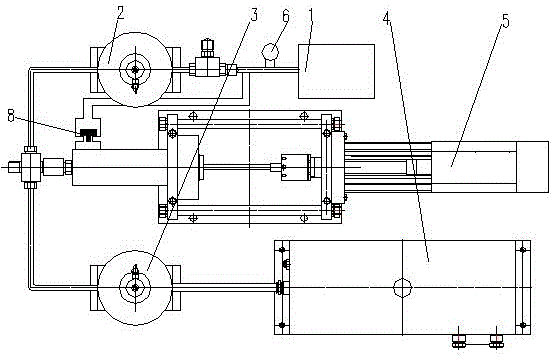

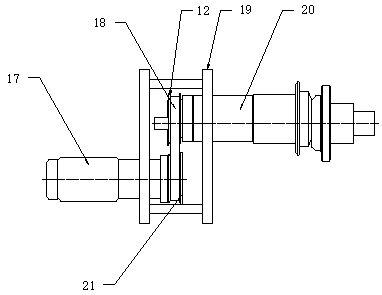

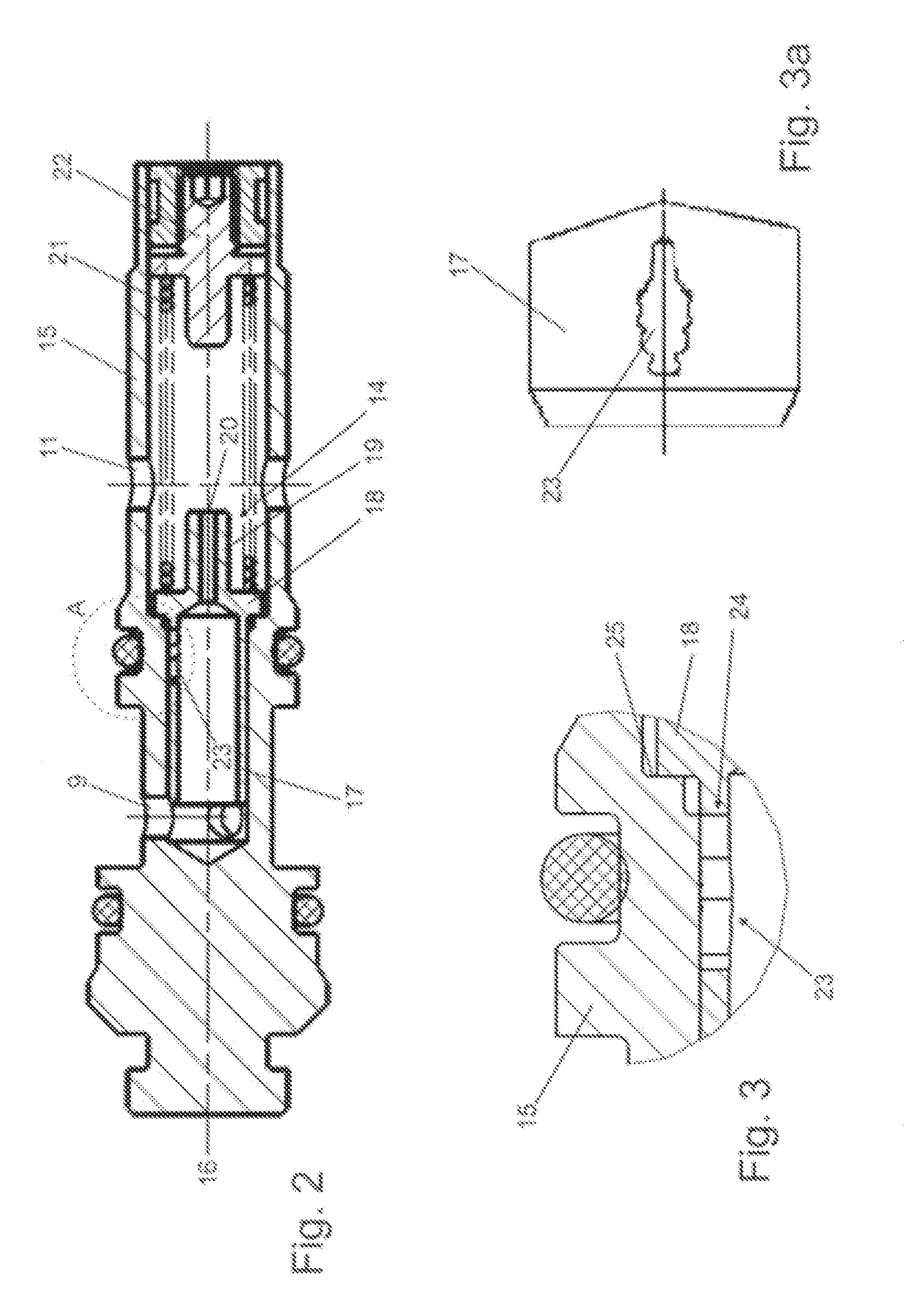

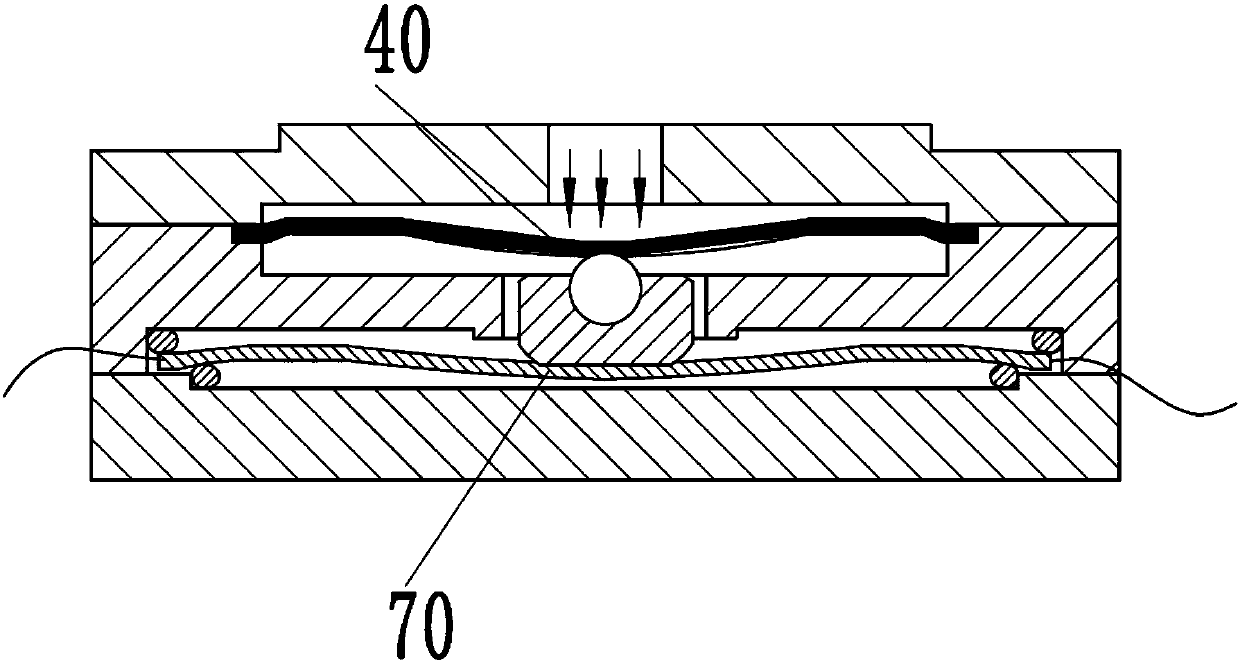

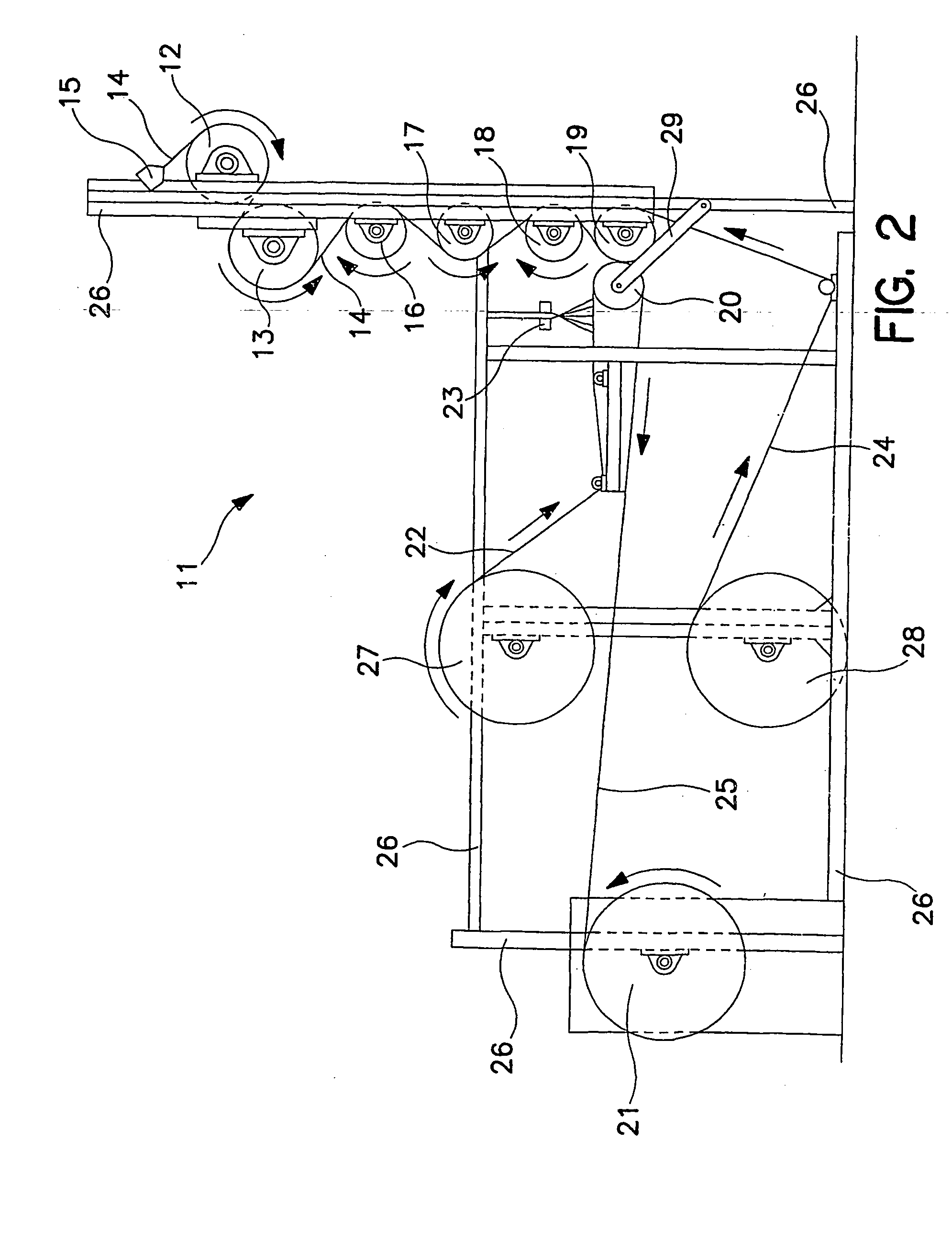

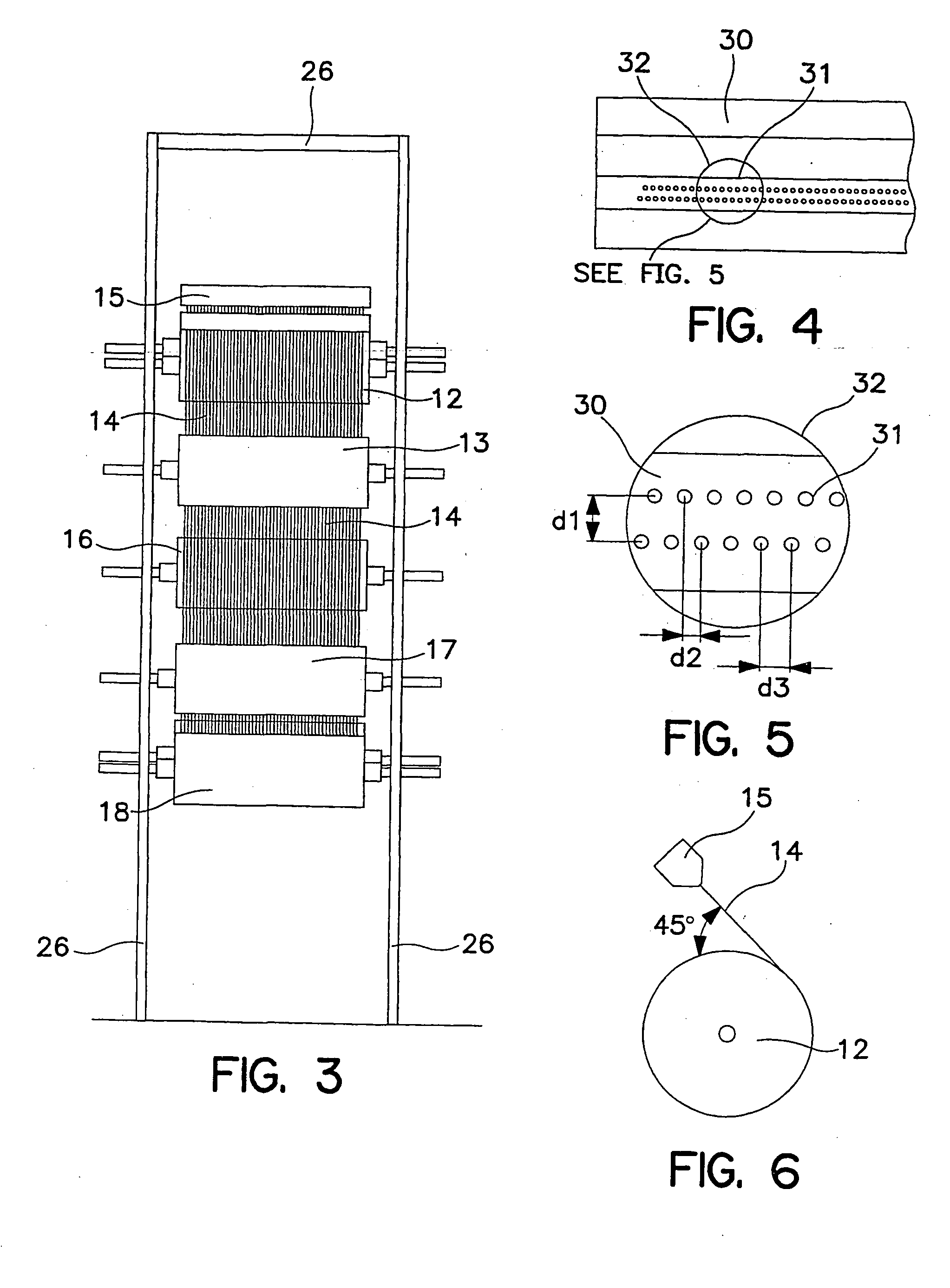

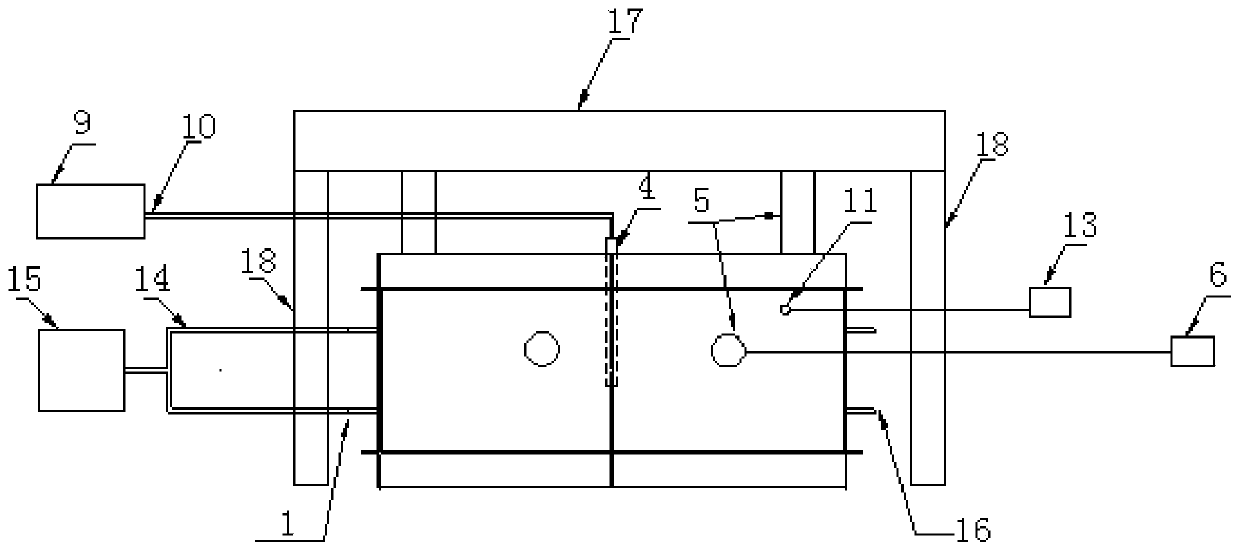

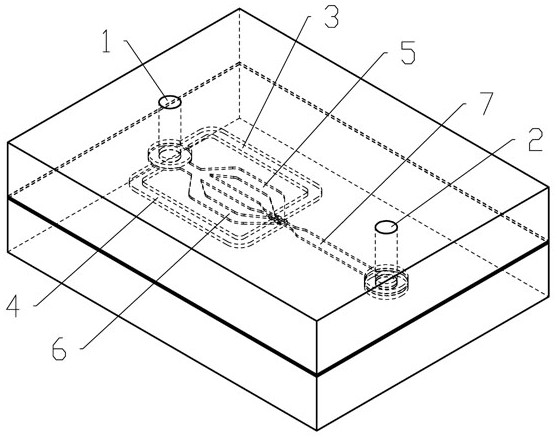

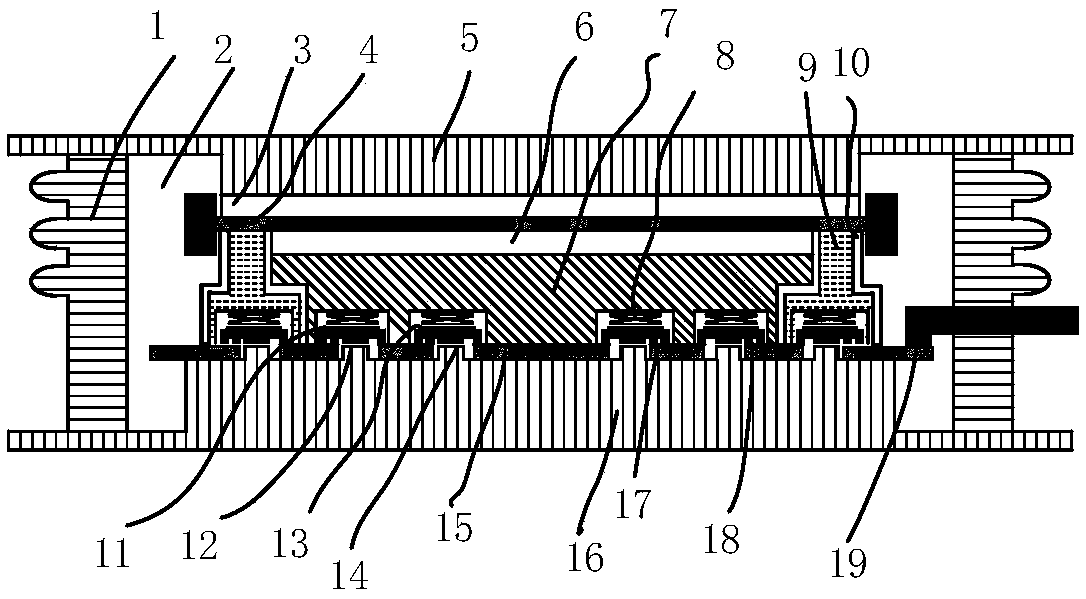

Compression-joint type power device thermal resistance testing and detecting device

InactiveCN105548249AMeet the thermal resistance test requirementsPrecise and stable pressureMaterial heat developmentHydraulic pumpThermocouple

The invention provides a compression-joint type power device thermal resistance testing and detecting device. The thermal resistance testing and detecting device comprises a frame formed by arranging members in the horizontal direction on stand columns (21) in the vertical direction. The stand columns are provided with height adjusting parts and limiting parts. As a hydraulic pump is adopted for applying pressure, compared with a traditional rotating threaded rod for applying pressure, the thermal resistance testing and detecting device is large in adjustable range, high in precision and good in uniformity, has good transportability, and can meet the requirements of a traditional thermocouple measuring method and a transient heat interface method; moreover, thermal resistance testing in the single-face and double-face heat dissipating process of a compression-joint type power device can be achieved, and the device is very suitable for thermal resistance testing of the compression-joint type power device.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

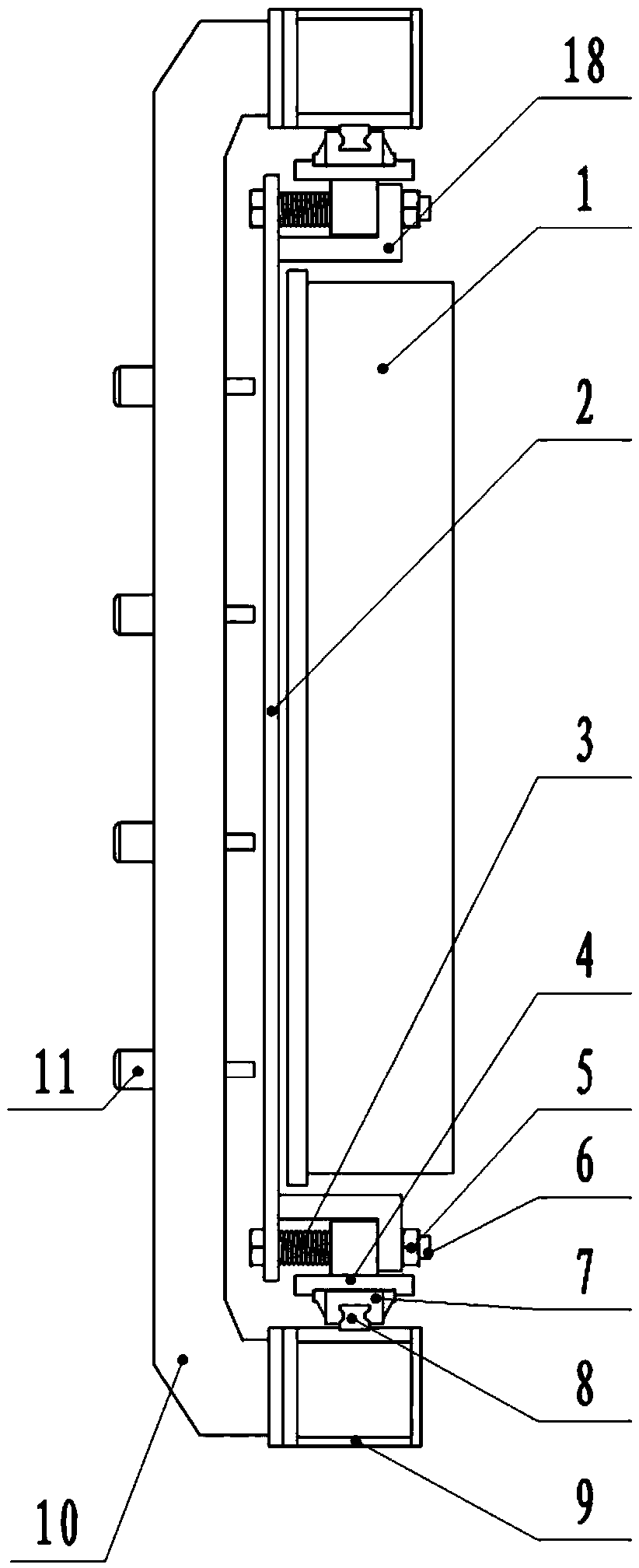

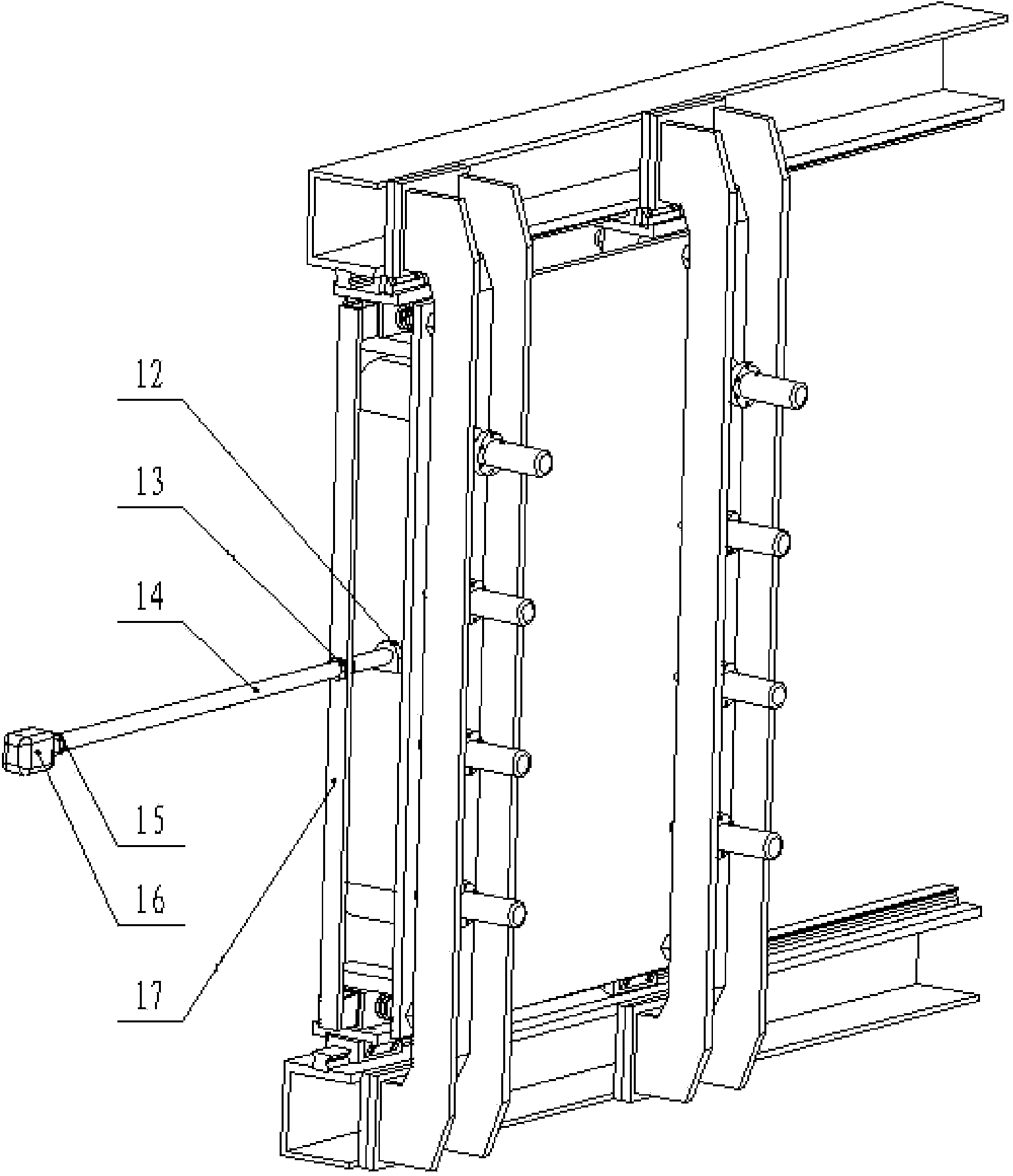

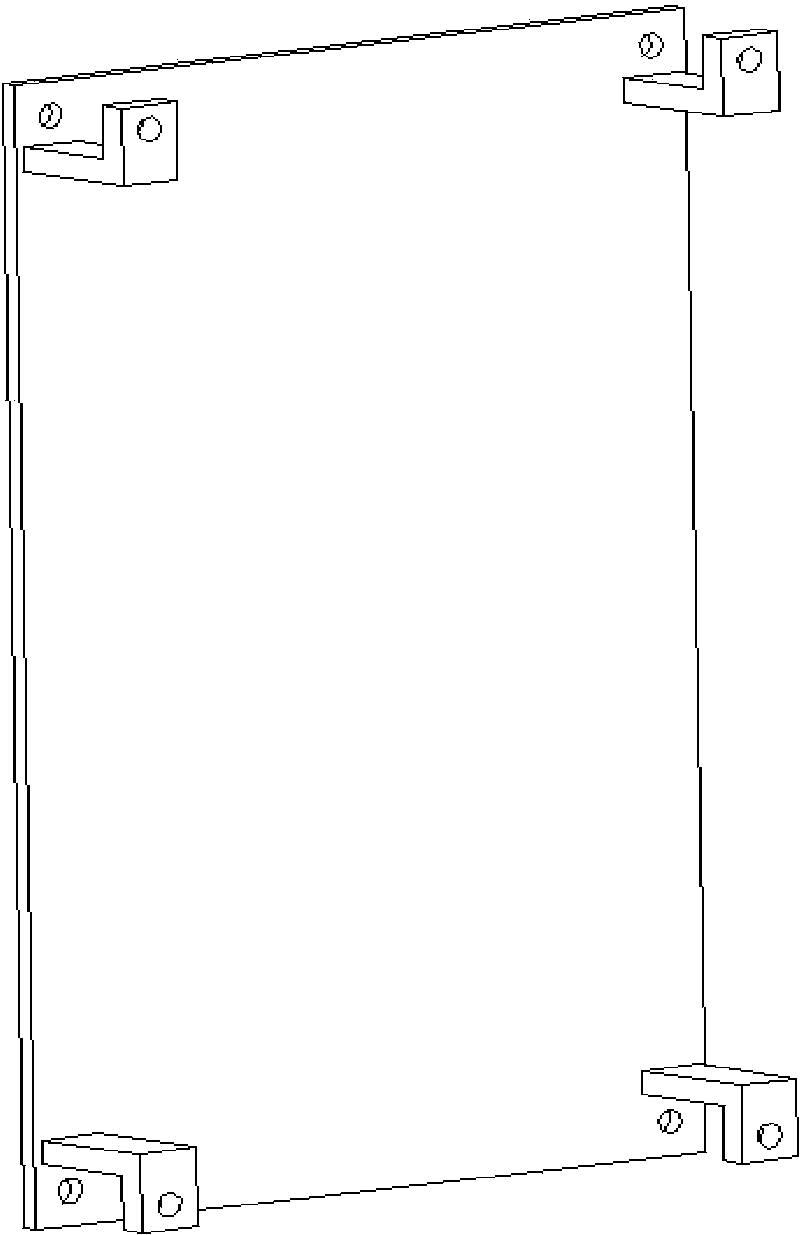

Side door opening/closing mechanism for hypersonic velocity wind tunnel test section

InactiveCN103487228ALarge pressure rangeReliable vacuum sealAerodynamic testingHydraulic cylinderInternal pressure

A side door opening / closing mechanism for a hypersonic velocity wind tunnel test section. Hydraulic cylinders and springs act on a side door together to make the side door move in the direction perpendicular to a door frame so as to ensure that the side door and the door frame are sealed. A motor and a ball screw act on the side door together to make the side door move in the horizontal direction so as to open or close the side door. When positive pressure exists in the hypersonic velocity wind tunnel test section, pressing force applied on the side door is provided by the hydraulic cylinders, and the number and specification of the hydraulic cylinders can be adjusted according to the value of the pressure in the hypersonic velocity wind tunnel test section so that the side door opening / closing mechanism can be adapted to a wide pressure-bearing range; when the inside of the hypersonic velocity wind tunnel test section is in a vacuum state, the hydraulic cylinders push the side door so that the side door can be attached to the side door frame, quite high pressing force is not needed, and the side door can be sealed through self suction. The side door opening / closing mechanism is wide in pressure-bearing range and capable of realizing both internal pressure seal and vacuum seal, thereby meeting operating requirements of the hypersonic velocity wind tunnel test section and being capable of being popularized to other equipment for use.

Owner:BEIJING AEROSPACE YISEN WIND TUNNEL ENG TECH

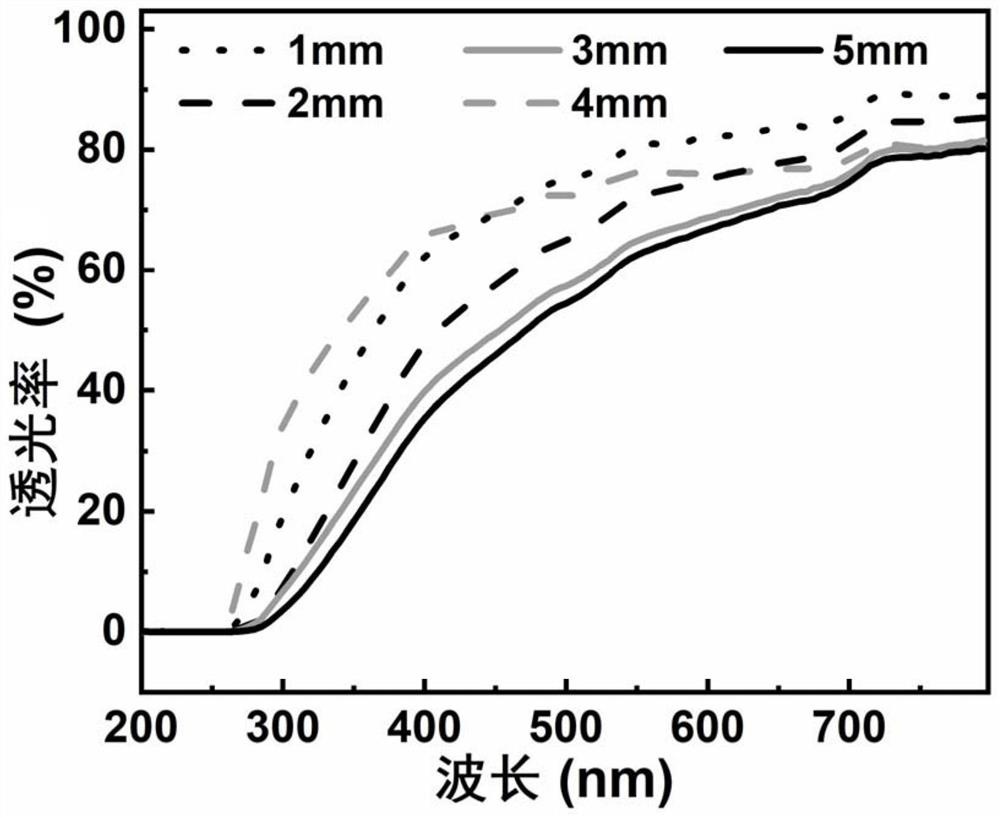

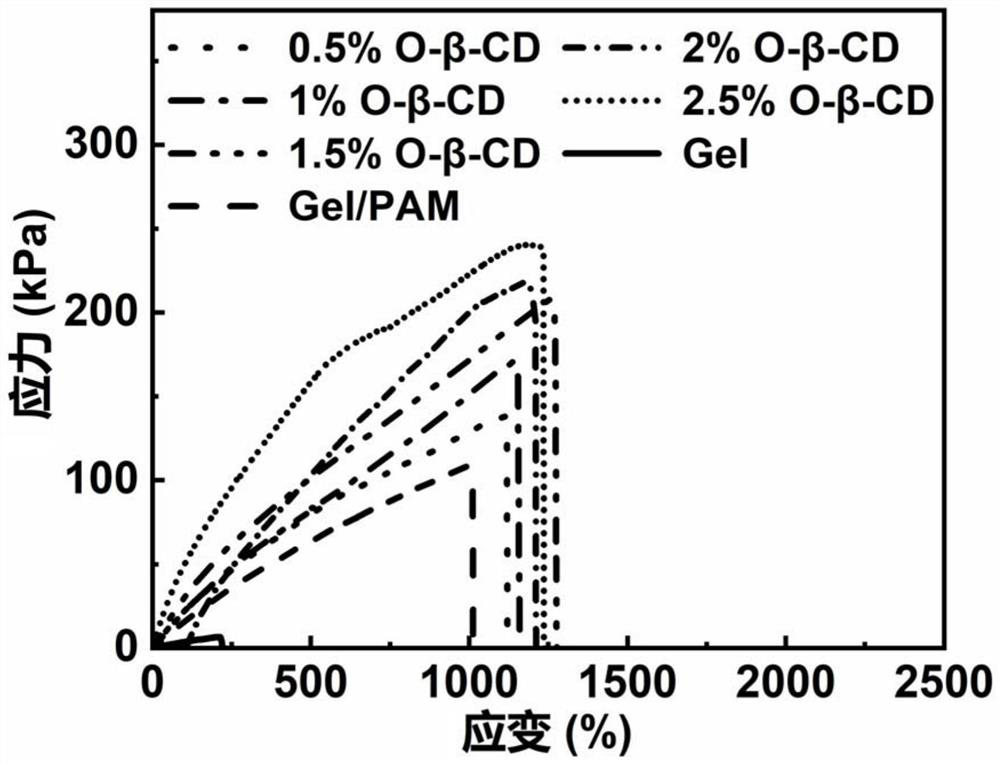

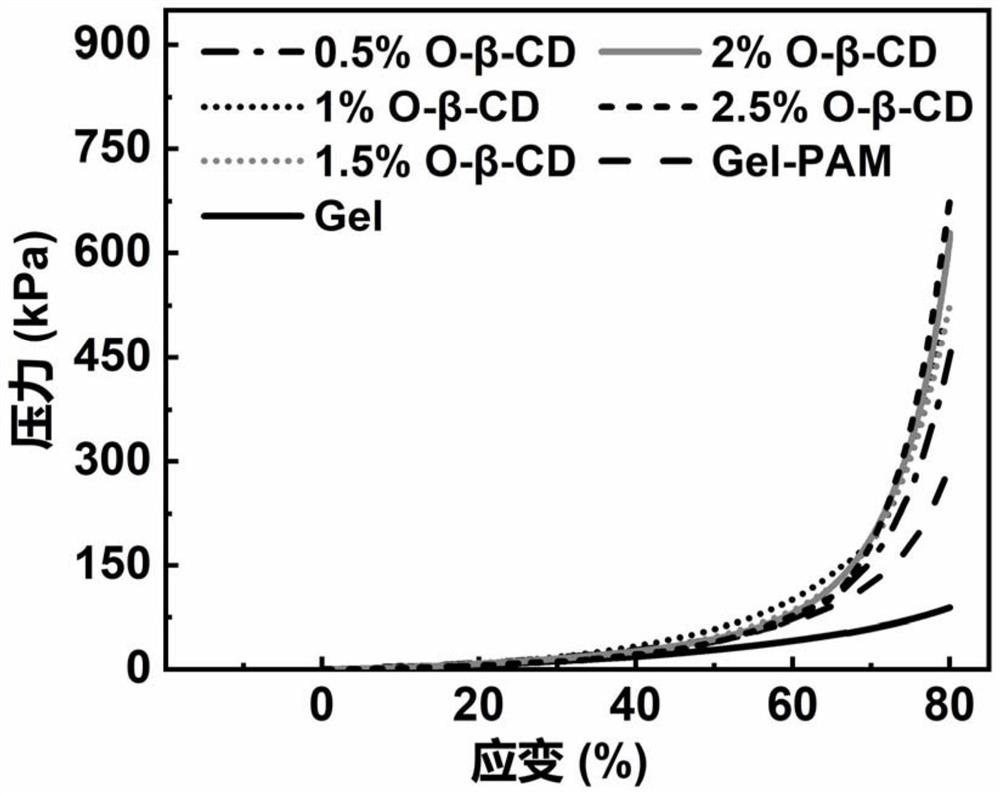

Ionic conductive hydrogel and preparation method and application thereof

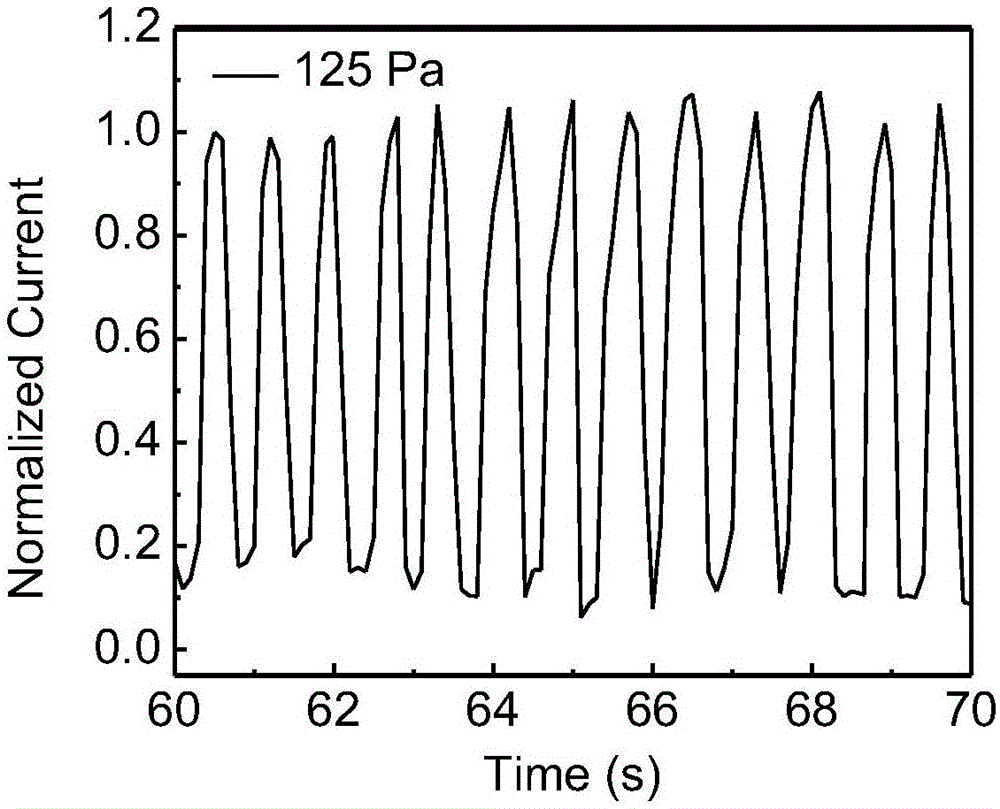

InactiveCN112608431AHigh strengthGood flexibilityForce measurement using piezo-resistive materialsSensorsInorganic saltsPtru catalyst

The invention discloses ionic conductive hydrogel and a preparation method and application thereof. The ionic conductive hydrogel comprises gelatin, aldehyde beta-cyclodextrin, polyacrylamide and inorganic salt, and the preparation method comprises the following steps: 1) adding water into the gelatin, the acrylamide and the aldehyde beta-cyclodextrin to prepare a solution, adding a cross-linking agent and the inorganic salt, and stirring for dissolving to obtain a viscous solution; and 2) adding an initiator and a catalyst into the viscous solution, pouring the viscous solution into a mold, and curing to obtain the ionic conductive hydrogel. The ionic conductive hydrogel has the advantages of high conductivity, high mechanical strength, high linear sensitivity, high reliability, bacteriostasis and the like, is simple in preparation process, and has a very good application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Device for the enrichment of a liquid stream with a gas

ActiveUS9227161B2Simple equipmentBetter enrichment of a liquid streamFlow mixersTransportation and packagingEngineeringNozzle

Owner:ROTAREX SA

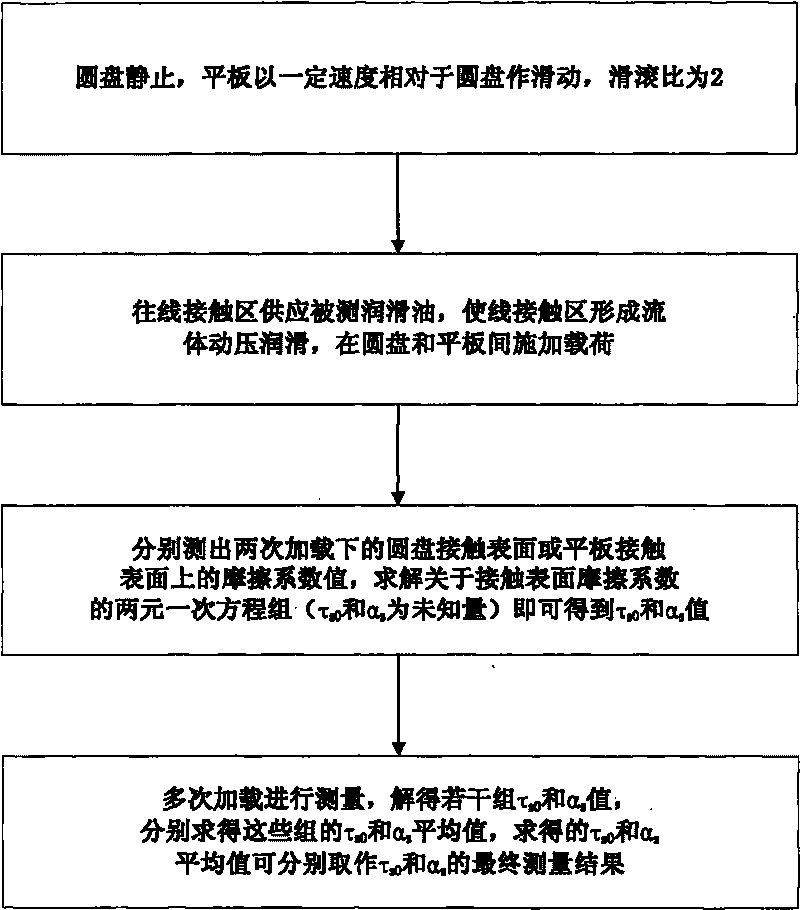

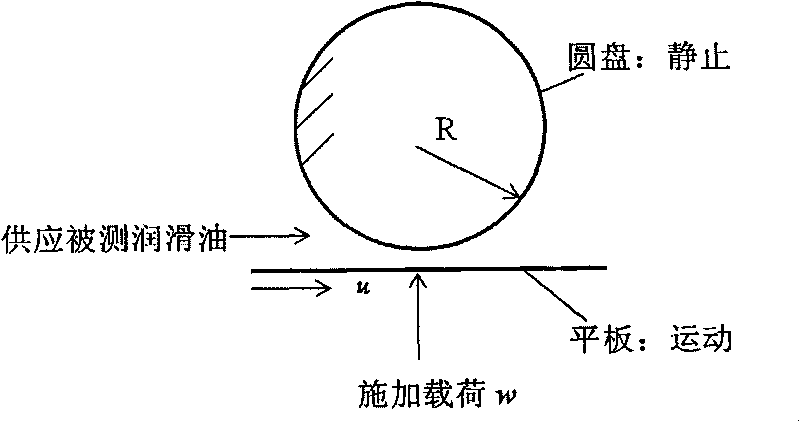

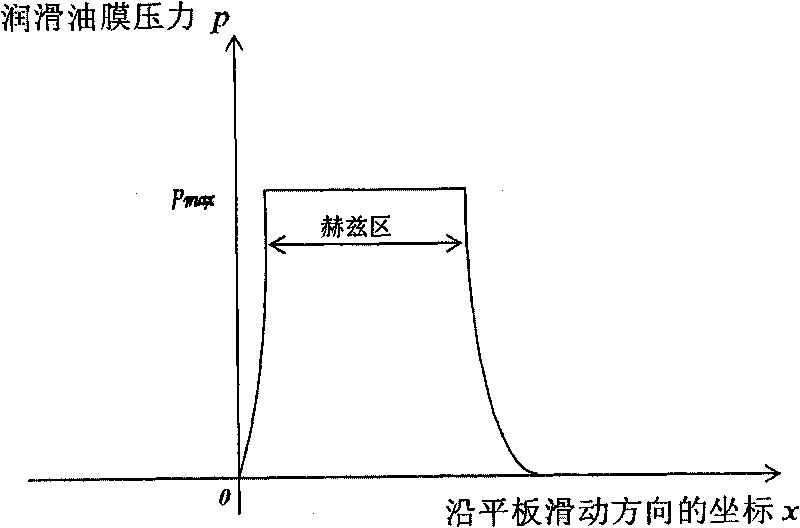

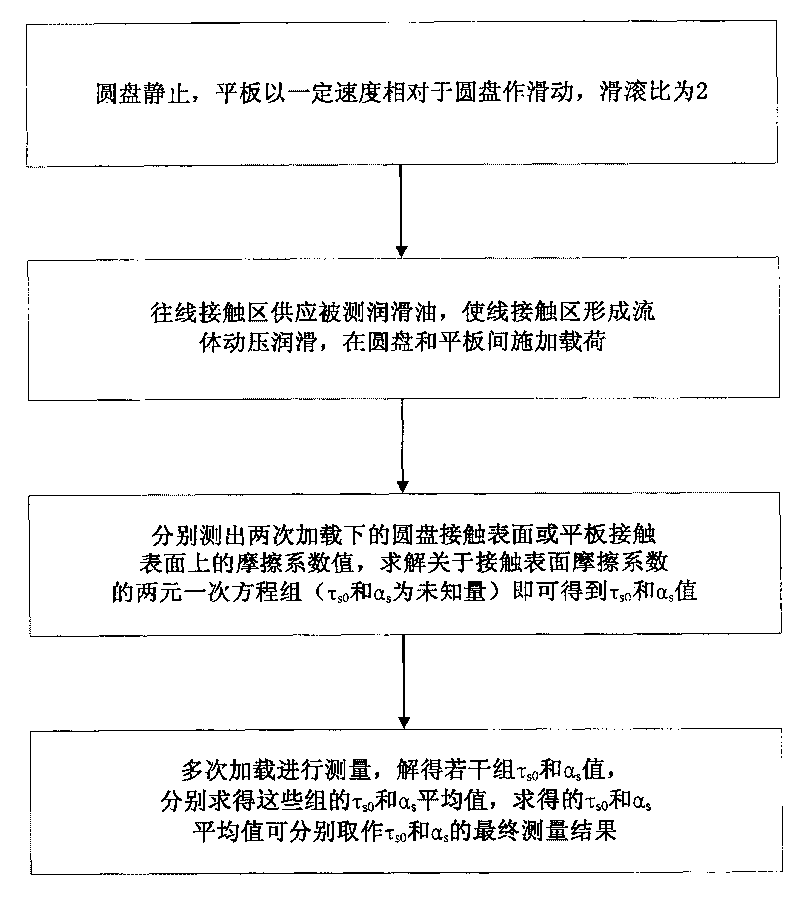

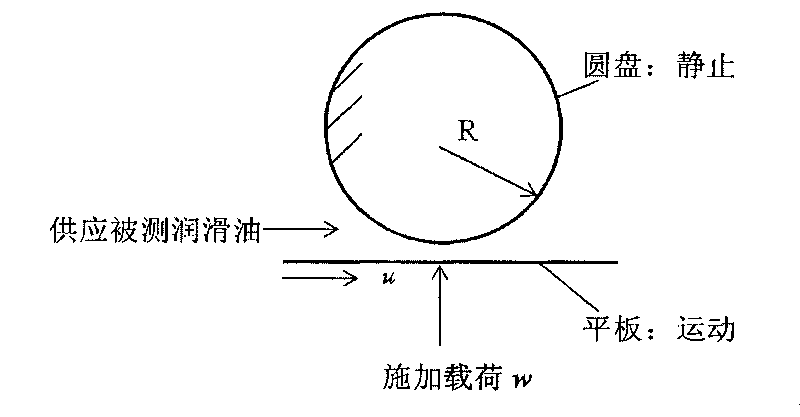

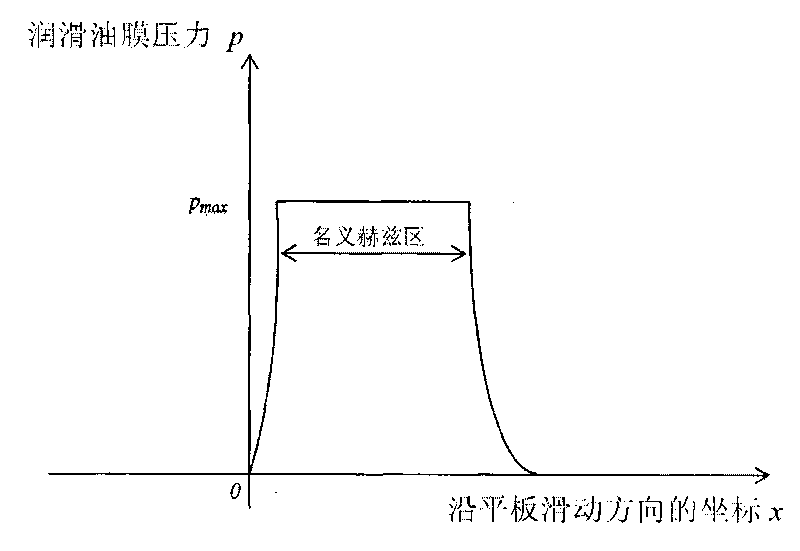

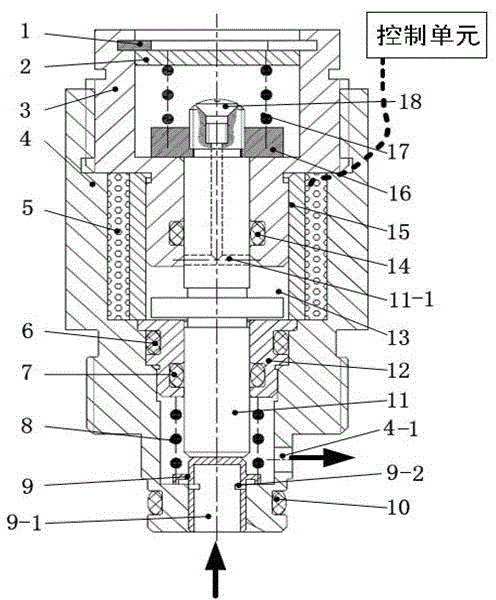

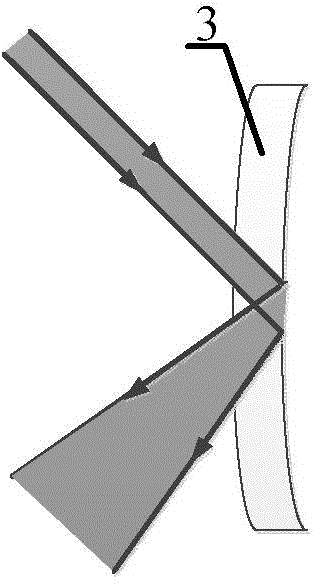

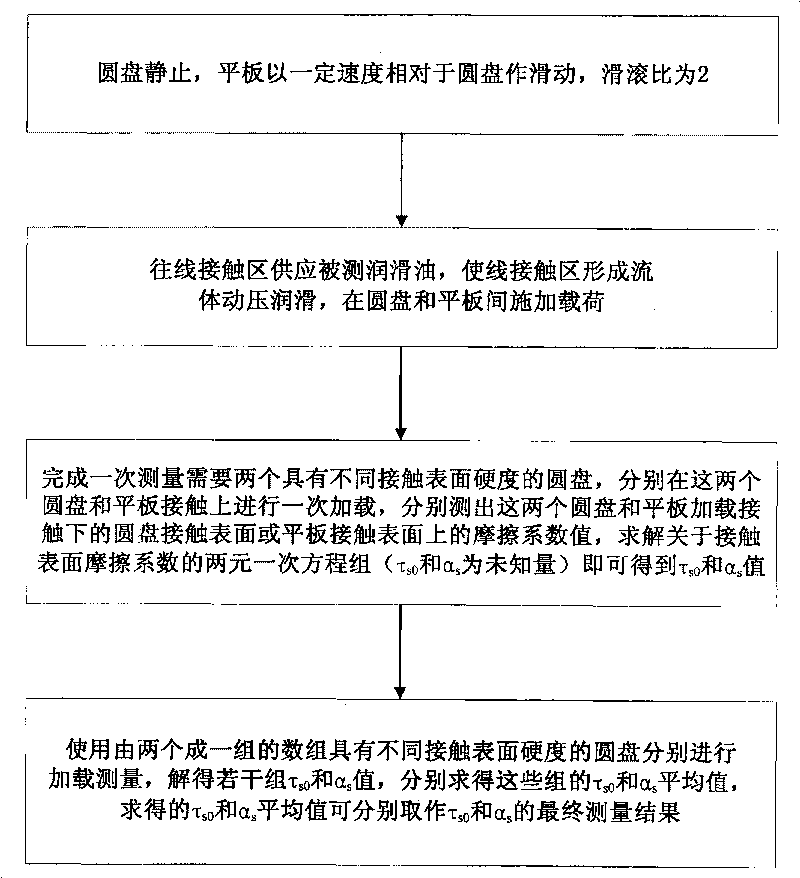

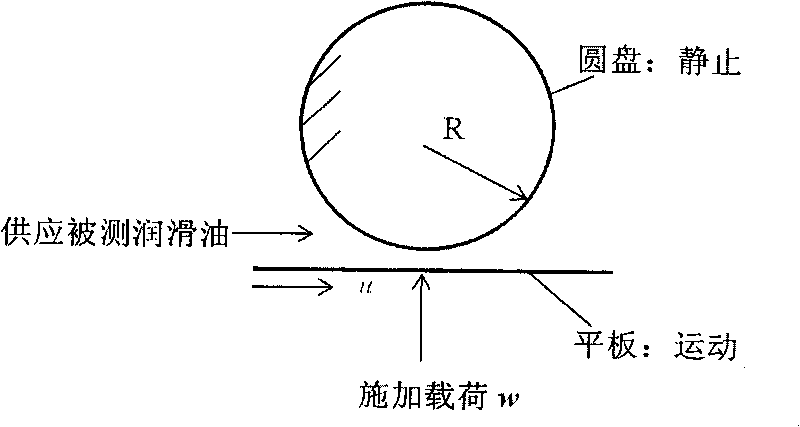

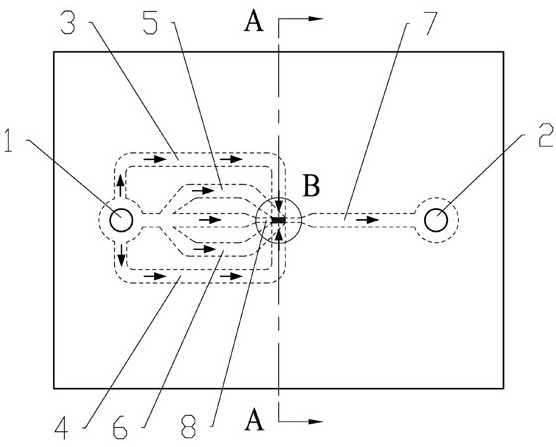

Method and device for measuring interfacial shearing strength under the connection of disc and flat plate

ActiveCN101701901ASimple structureEasy to manufactureUsing mechanical meansMaterial analysisStrength parameterMeasurement device

The invention relates to a method and a device for measuring interfacial shearing strength under the connection of a disc and a flat plate. The method comprises the following steps: A, the flat plate slides relative to the static disc at a speed u, with the slide-roll ratio being 2; B, the measured lubricating oil is fed to a line contact area, so as to form the hydrodynamic lubrication in the line contact area, and load is applied between the disc and the flat plate to ensure that the maximum Hertzian contact pressure of the line contact is larger than 0.4GPa; and C, the friction coefficients of the contact surface of the disc or the flat plate under the load are measured twice, and the binary linear equations for the friction coefficients of the contact surface are solved. By using the method and the device, the invention has significant technical effect and has the advantages of larger pressure measurement range of lubricating oil, simple and compact structure, easy implementation, lower manufacturing and servicing cost, easy measurement and higher measurement accuracy; moreover, the device of the invention is capable of measuring the shearing strength parameters of two interfaces at the same time, therefore, the invention is of significant practical value. The device of the invention can substitute for the high-pressure chamber measurement device and other measurement devices.

Owner:JIANGSU FEIER ELECTRICAL TECH

Method for measuring interface shear strength under elastoplastic contact of disk and slab and device thereof

ActiveCN101713717ASimple structureReduce manufacturing costUsing mechanical meansMaterial strength using steady shearing forcesCircular discMeasurement device

Owner:SUZHOU CHINT ENTERPRISE DEV

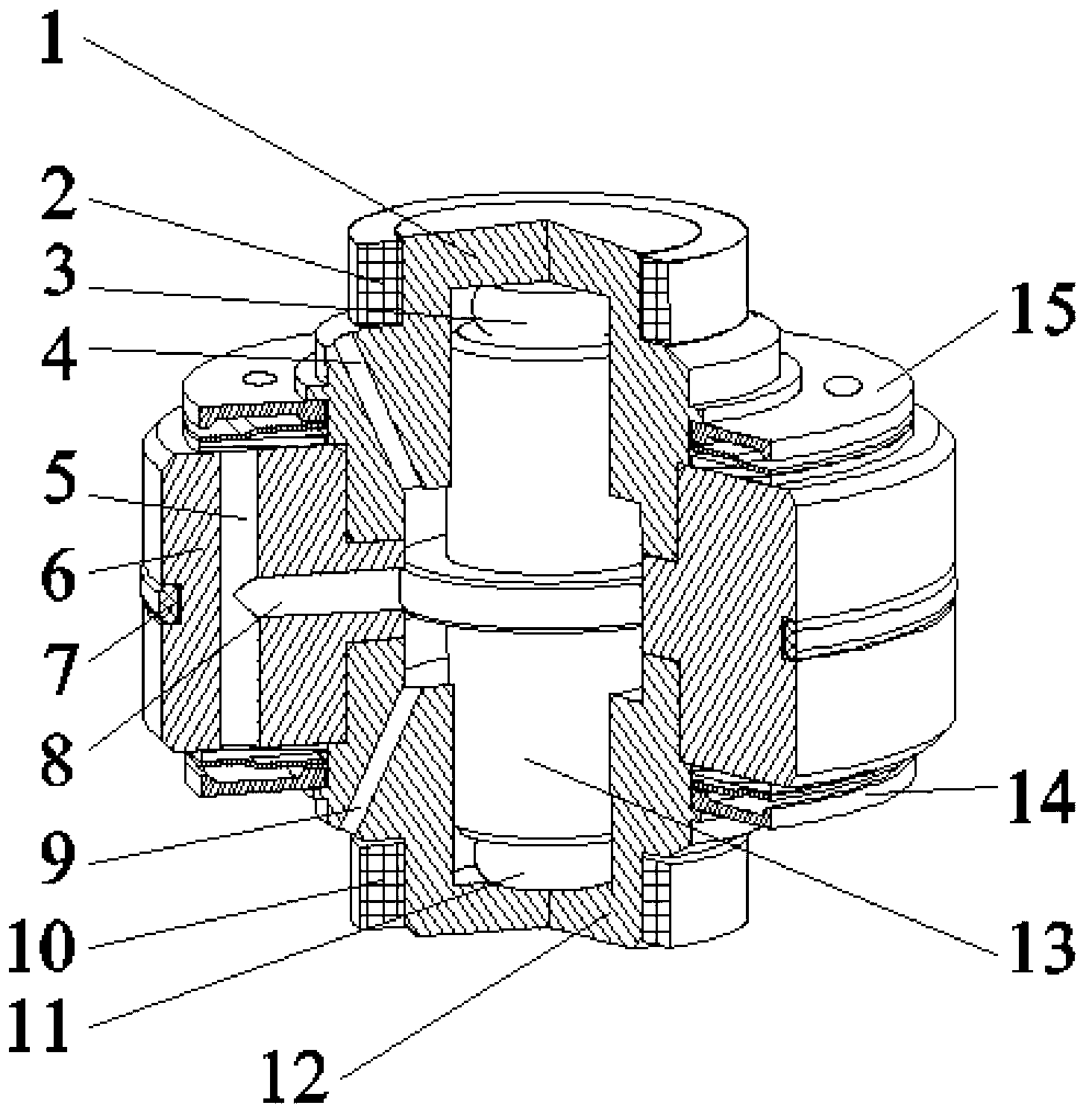

Magnetorheological flow control valve

ActiveCN103148257AEasy to controlQuick response to yield strength changeOperating means/releasing devices for valvesMagnetic currentMagnetorheological fluid

The invention relates to a flow control valve, in particular to a magnetorheological flow control valve which realizes flow control through the opening degree of the control valve. The flow control valve comprises a jump ring, an upper end cover, an upper valve body, a lower valve body, a coil, a lower thrust spring, a valve core, a thrust shaft, an inner valve body, a working cavity, a magnetic isolation sleeve, a spring seat, an upper thrust spring, a seal bolt and a plurality of rubber seal rings; and according to the magnetorheological flow control valve, the shifting position of the valve core is controlled through a technical method in which the magnetic field intensity which acts on magnetorheological fluid in the working cavity formed between the magnetic isolation sleeve and the upper valve body is controlled, so that the magnetorheological fluid yield strength is affected and the action force of magnetorheological fluid to the thrust shaft is controlled, so that different circulation areas are obtained and the the control over the fluid flow is realized.

Owner:JILIN UNIV

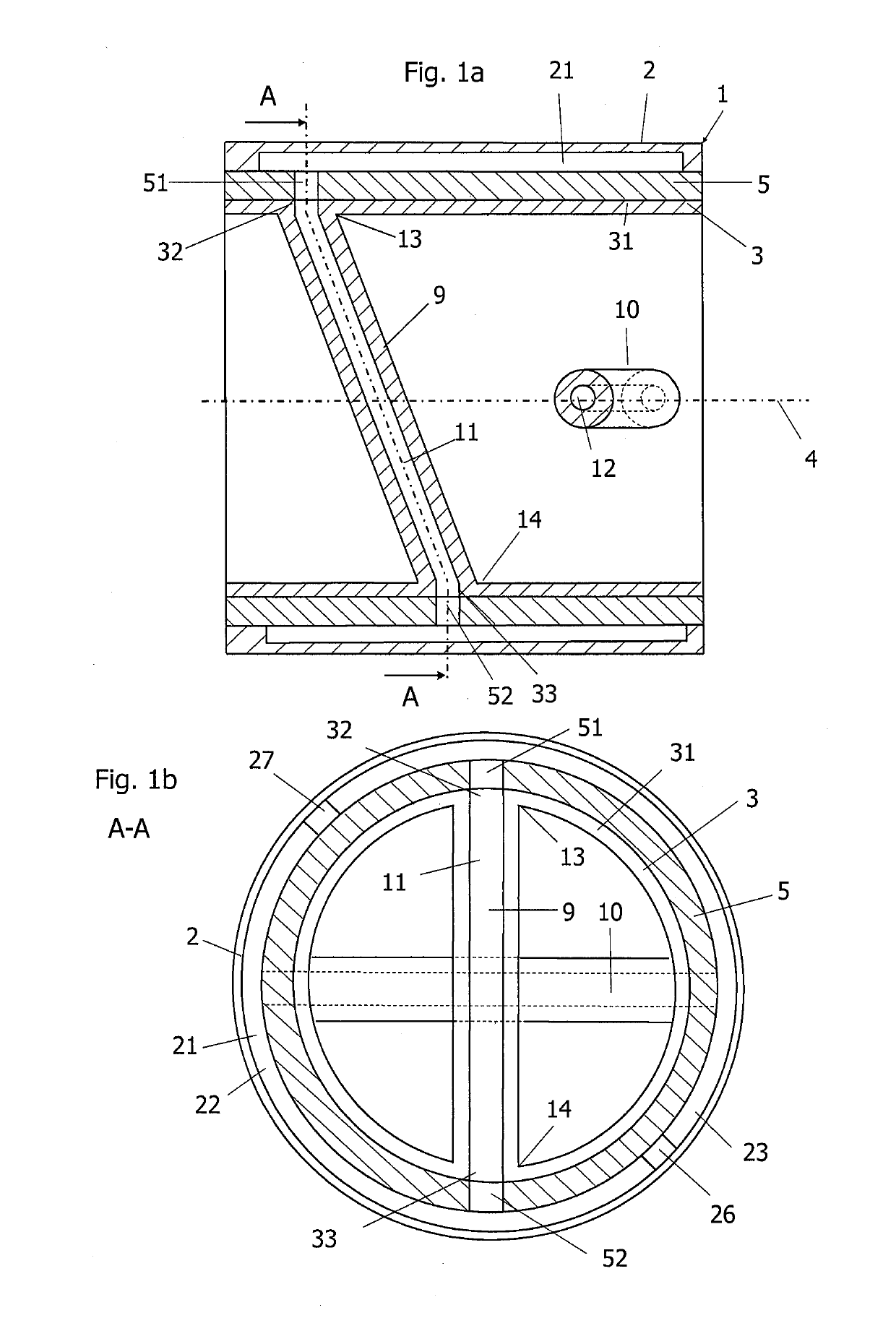

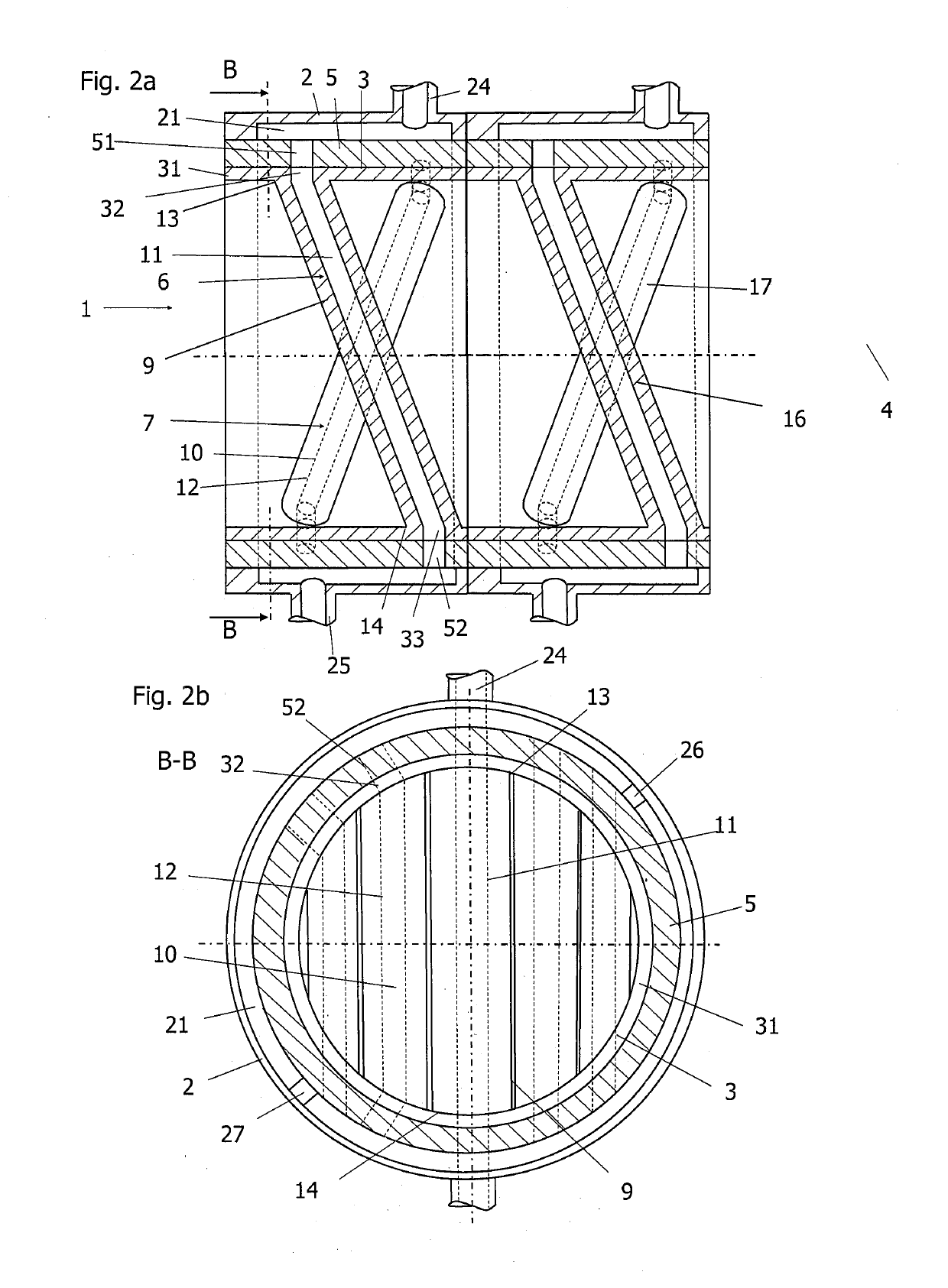

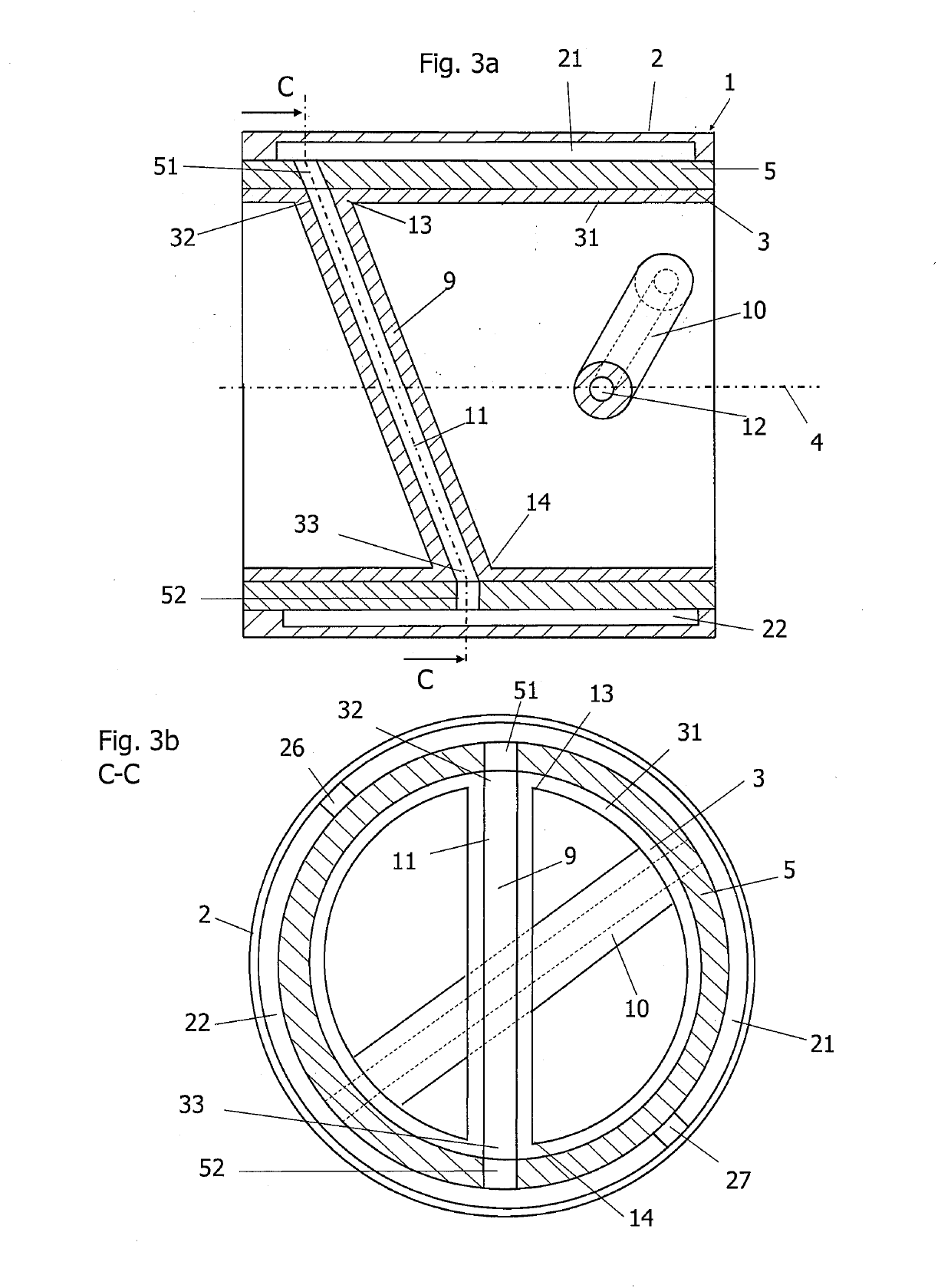

Heat Exchanger

ActiveUS20190162490A1Quality improvementImprove thermal conductivityFlow mixersTransportation and packagingEngineeringMechanical engineering

The heat exchanger (1) contains a jacket element (2) and an insert element (3), wherein the insert element (3) is arranged in the operating state in the interior of the jacket element (2). The insert element has a longitudinal axis (4). The insert element (3) contains an insert jacket element (31) and a plurality of web elements (9, 10), the web elements (9, 10) having a first end (13) and a second end (14). The first end (13) and the second end (14) of each web element (9, 10) are connected to the insert jacket element (31) at different locations. At least a portion of the web elements (9, 10) includes web element channels (11, 12), the web element channels (11, 12) extending from the first end (13) of the web element (11) to the second end (14) of the web element (11). An intermediate jacket element (5) is arranged between the insert jacket element (31) and the jacket element (2).

Owner:PROMIX SOLUTIONS

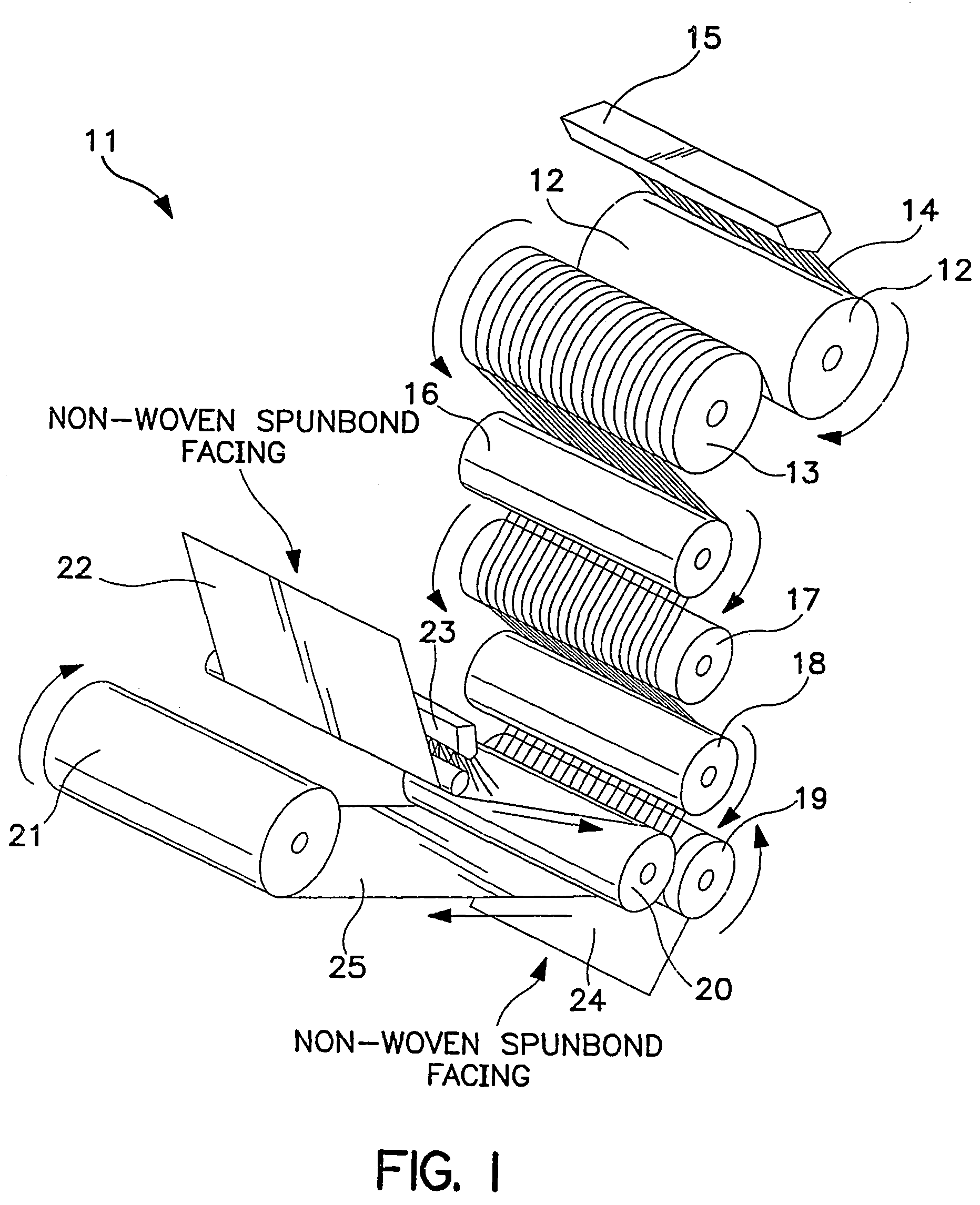

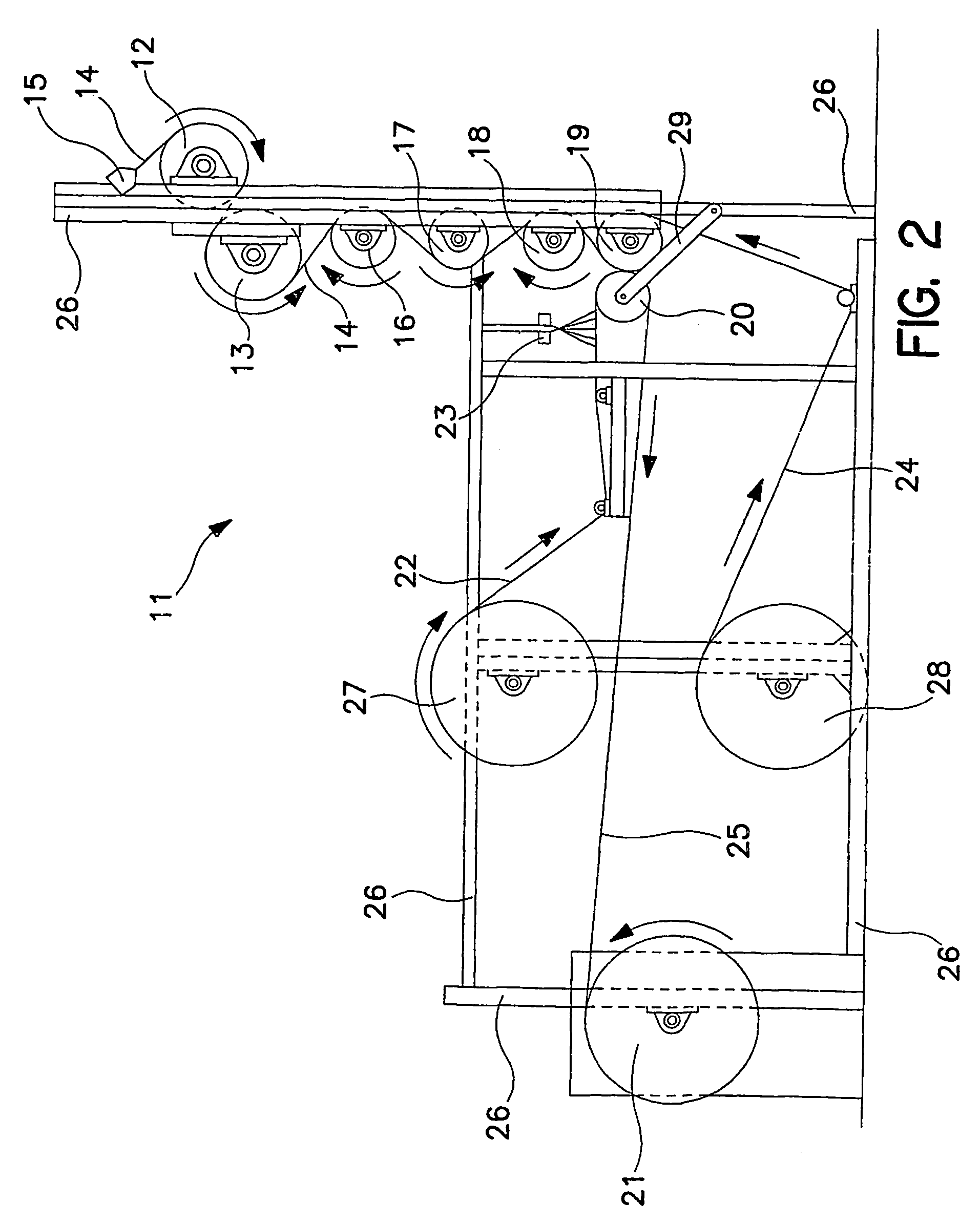

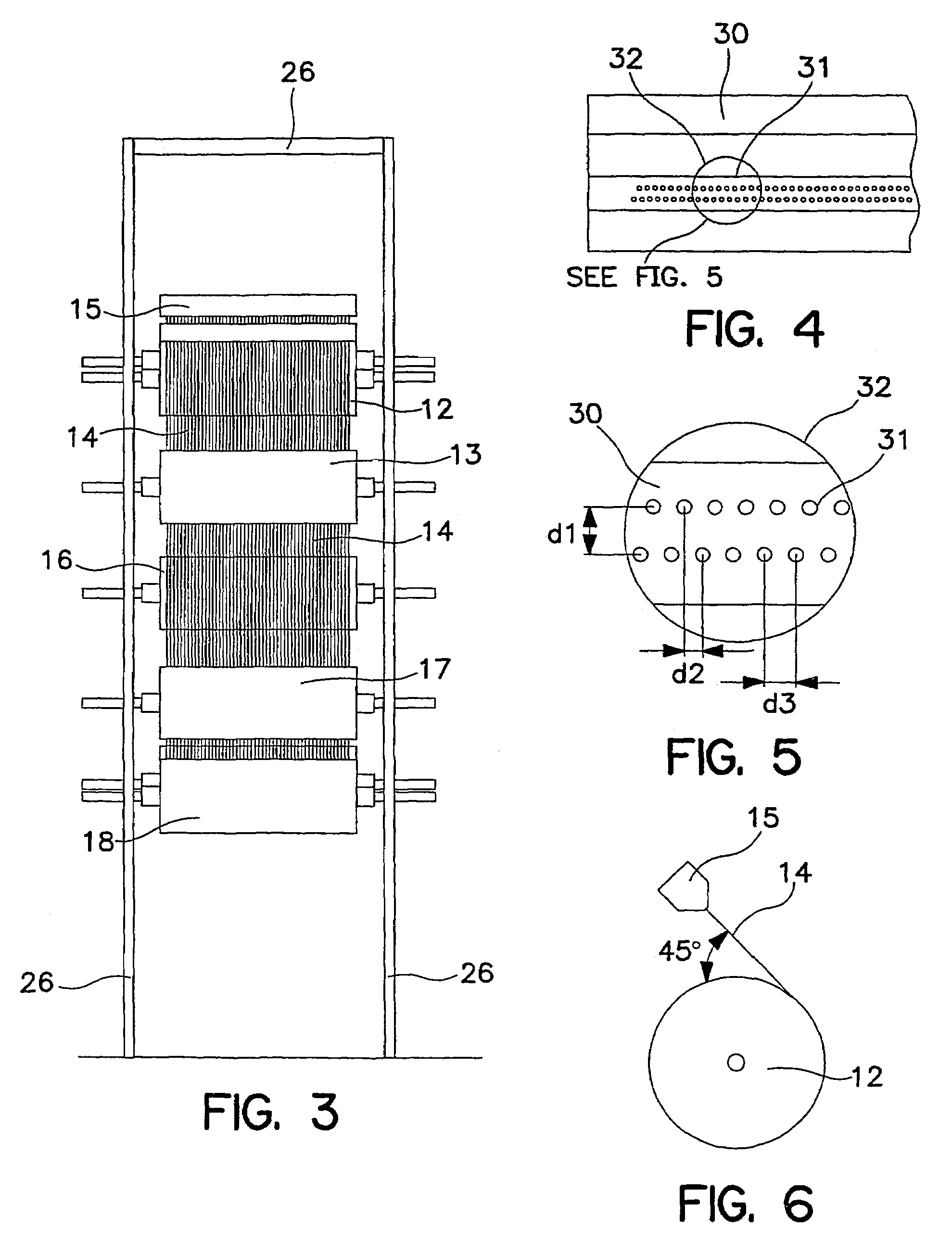

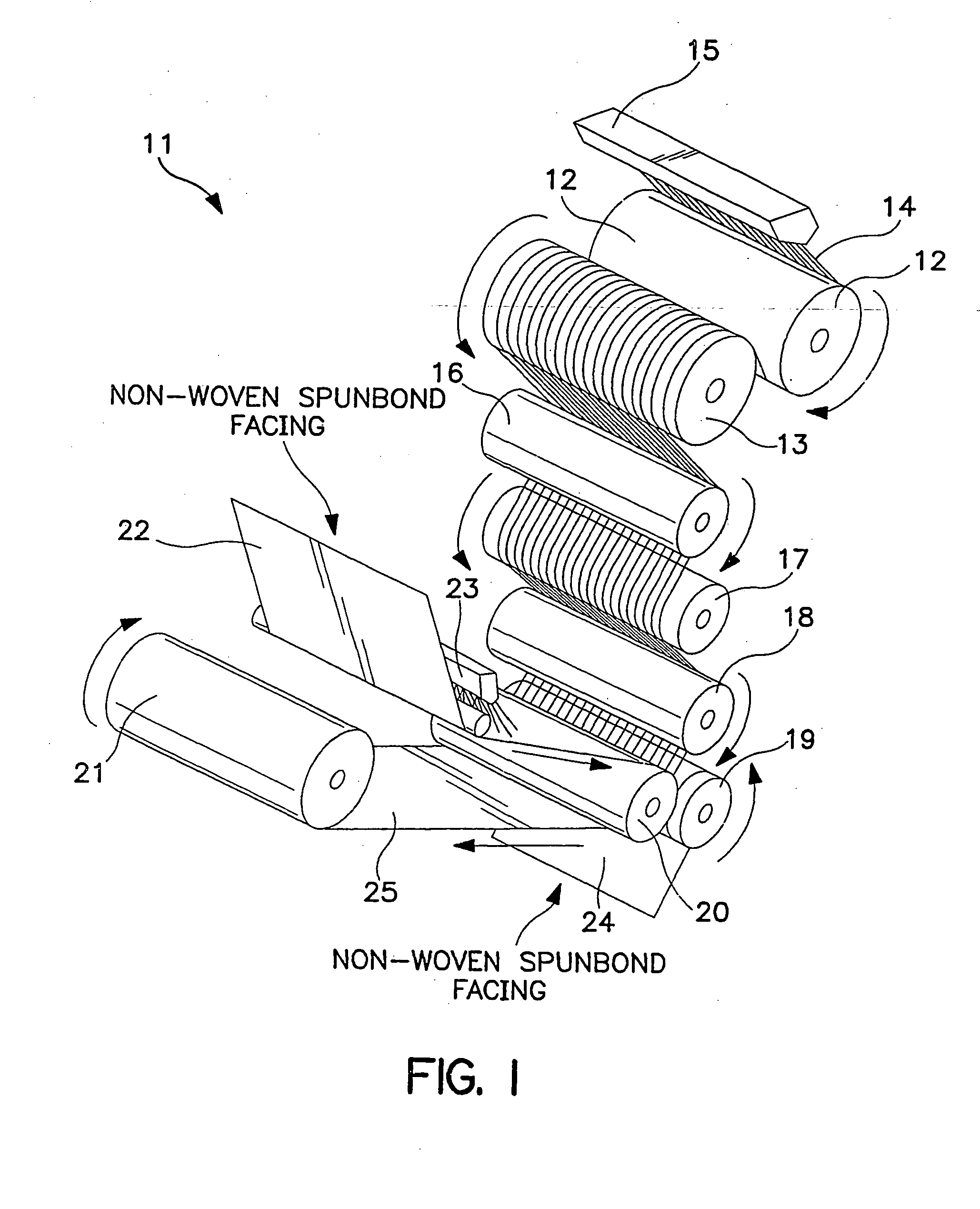

Method of thermally processing elastomeric compositions and elastomeric compositions with improved processability

InactiveUS7326751B2Lower extrusion temperatureEasy to processNon-woven fabricsArtifical filament manufactureElastomerChemistry

Owner:KIMBERLY-CLARK WORLDWIDE INC

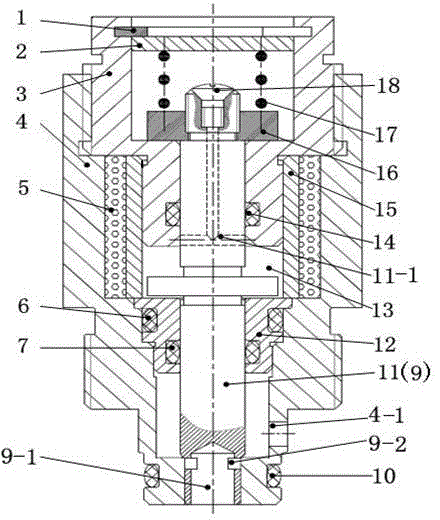

Double-acting magneto-rheological pressure and flow control valve

ActiveCN103267159AControl flowEasy to controlOperating means/releasing devices for valvesEngineeringMagneto rheological

The invention discloses a double-acting magneto-rheological pressure and flow control valve which comprises an upper end cover and a lower end cover. The upper end cover and the lower end cover are arranged in a longitudinal symmetry manner, and a thrust shaft is slidably connected into a cavity formed between the upper end cover and the lower end cover; two cavities are formed in rooms among two ends of the thrust shaft, the upper end cover and the lower end cover, and an upper flow control cavity and a lower flow control cavity are respectively mounted in the two cavities; the upper end cover is fixed to the lower end cover by a piston, an upper auxiliary damping hole and a lower auxiliary damping hole are respectively machined on the upper end cover and the lower end cover, and an auxiliary channel which is communicated with the damping holes is arranged in an inner ring of the piston; and the opening of the auxiliary channel is determined by the sliding stroke of the thrust shaft. The double-acting magneto-rheological pressure and flow control valve has the advantages of high response speed and extremely wide bearing pressure range owing to fast yield strength variation response and wide range of magneto-rheological fluid. Besides, the double-acting magneto-rheological pressure and flow control valve is simple and compact in structure, convenient to manufacture and high in portability, and can be connected into an electronic control unit, so that a bidirectional flow can be intelligently and steplessly controlled.

Owner:JILIN UNIV

Rock-soil mass direct-shear test apparatus capable of quickly and accurately compressing

PendingCN106840919AAccurate recordImprove efficiencyMaterial strength using steady shearing forcesSoil scienceSoil mass

The invention discloses a rock-soil mass direct-shear test apparatus capable of quickly and accurately compressing. The rock-soil mass direct-shear test apparatus comprises a platform and a default sliding rail arranged in the middle of the platform, wherein the default sliding rail comprises a long side; a lower shear box is arranged at the upper part of the default sliding rail; the lower shear box slides along the long side of the default sliding rail; an upper shear box is arranged at the upper part of the lower shear box; a rigid transfer rod is arranged in the normal direction of the upper shear box; the rigid transfer rod is fixedly connected with a normal compression system; the normal compression system transfers default stress generated by the normal compression system to the normal direction of the upper shear box through the rigid transfer rod; one side of the lower shear box is connected with a tangential compression system; the other side of the lower shear box is connected with a displacement measurement system and a pull pressure measurement system. The rock-soil mass direct-shear test apparatus can quickly and accurately compress, the direct-shear test efficiency and accuracy are improved and the rock-soil mass direct-shear test apparatus is suitable for research on various rock-soil mass shear properties.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Minimum pressure valve

ActiveCN101836020AReduce pressure differenceIncrease heightPressure relieving devices on sealing facesCheck valvesInterior spaceEngineering

Owner:ATLAS COPCO AIRPOWER NV

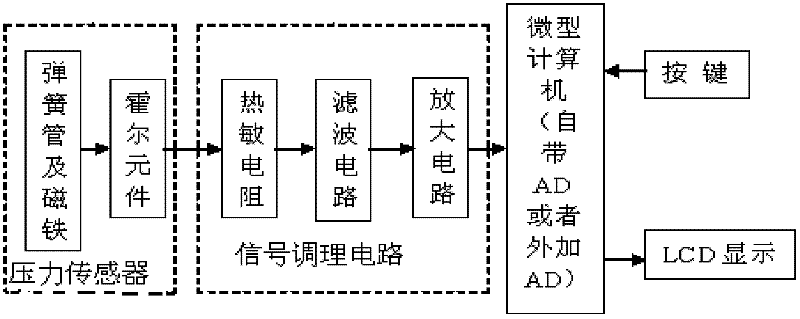

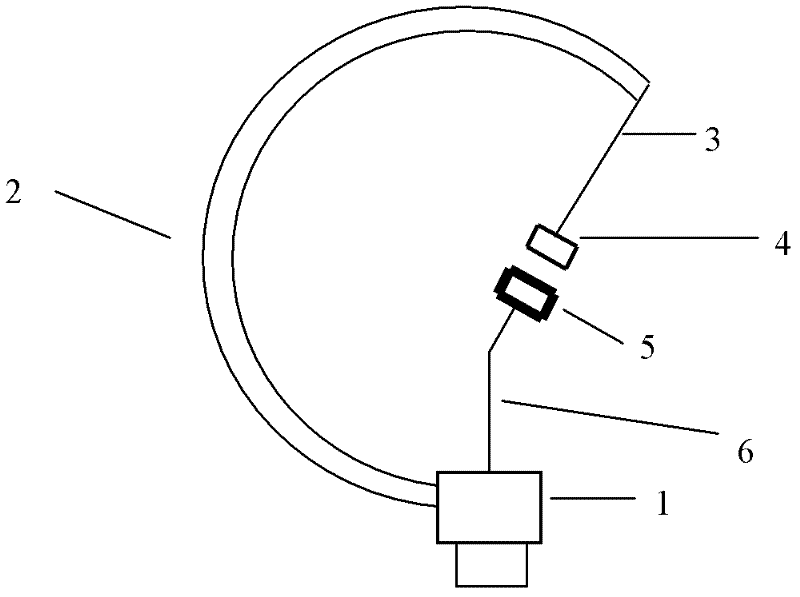

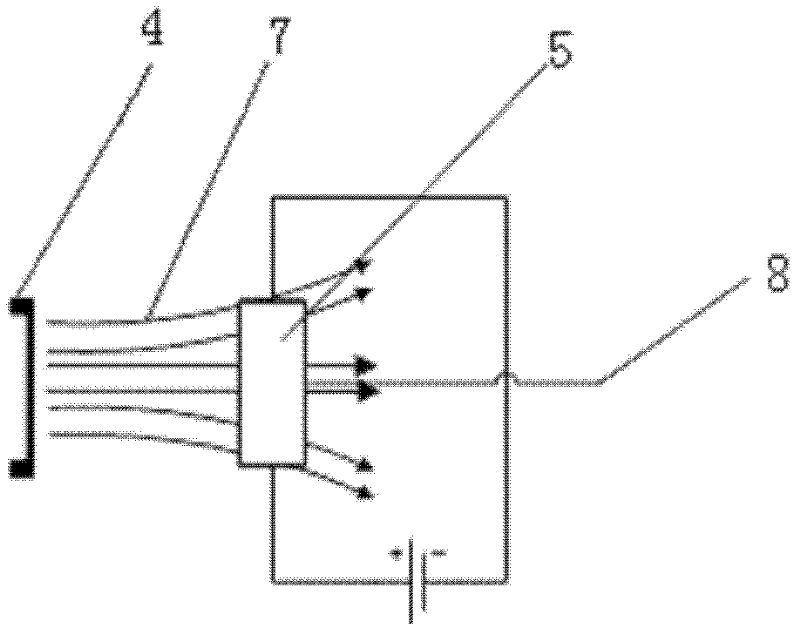

Spring tube digital compression gauge based on Hall effect

InactiveCN102519660AHigh precisionGood value for moneyFluid pressure measurement using magnet displacementMicrocomputerKey pressing

The invention provides a spring tube digital compression gauge based on a Hall effect. The spring tube digital compression gauge comprises a pressure sensing element, a signal conditioning circuit, a microcomputer, an analog-to-digital converter, a display screen, a button, a power supply and a joint. The pressure sensing element comprises a spring tube, a magnet, and a Hall element. One end of the spring tube is provided with the joint which is connected with a pressure source, and the other end is enclosed as a free end. A blind end is connected with a magnet support which is installed with the magnet. An upper part of the joint is installed with a Hall element support which is installed with the Hall element. An induction surface of the Hall element directly faces the magnet and is close to the magnet. An output terminal of the Hall element is connected with an input terminal of the signal conditioning circuit. An output terminal of the signal conditioning circuit is connected with the microcomputer and the analog-to-digital converter. The microcomputer is connected with the display screen and the button. The pressure sensing element is installed in a shell of the gauge. A bottom of the spring tube is connected with the power supply. The compression gauge has auxiliary functions of unit switching, zero point calibration, non-linear compensation, temperature compensation and the like, precision is high, a life is long, a measuring range is large, and cost is low.

Owner:WUHAN UNIV OF TECH

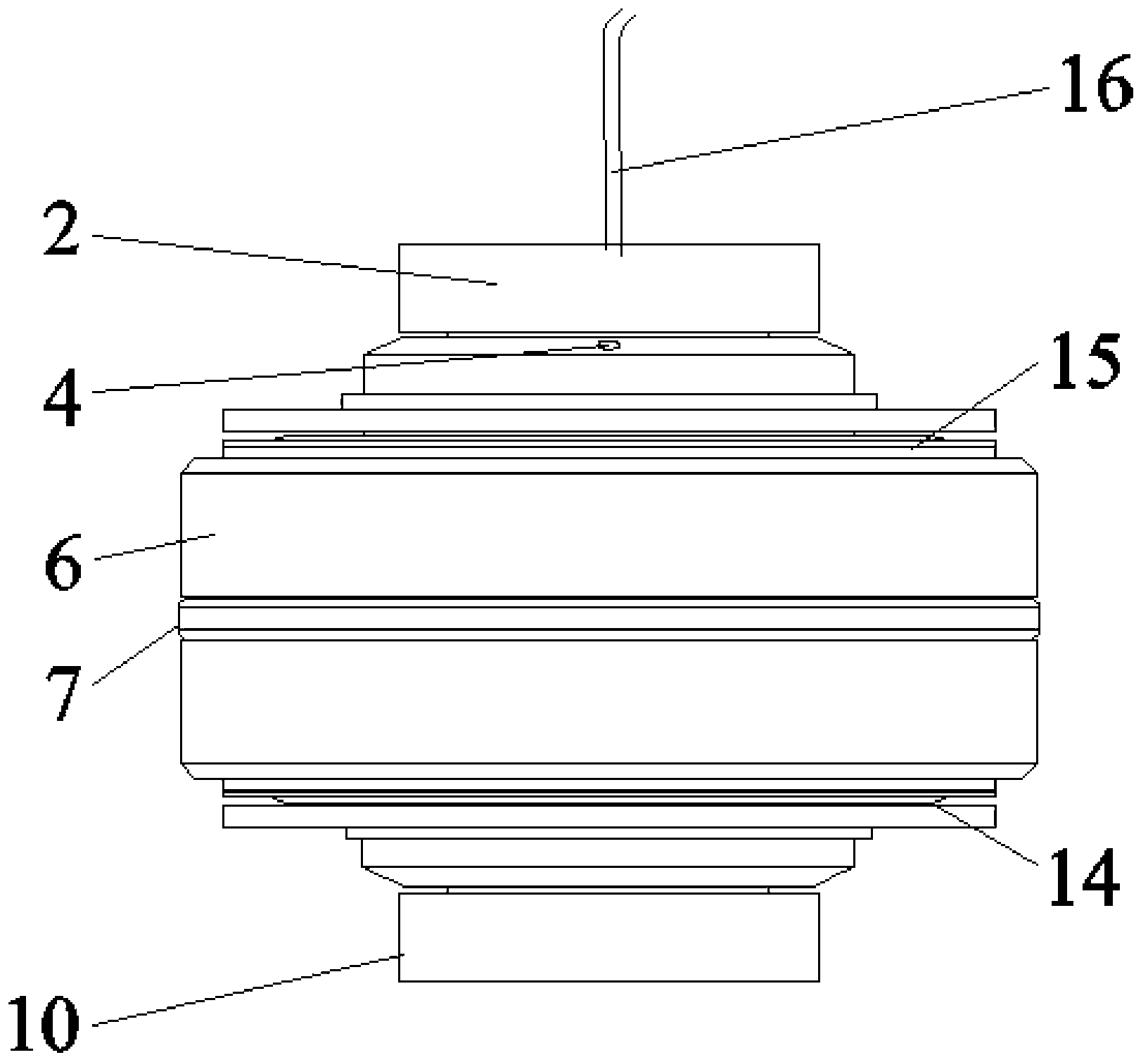

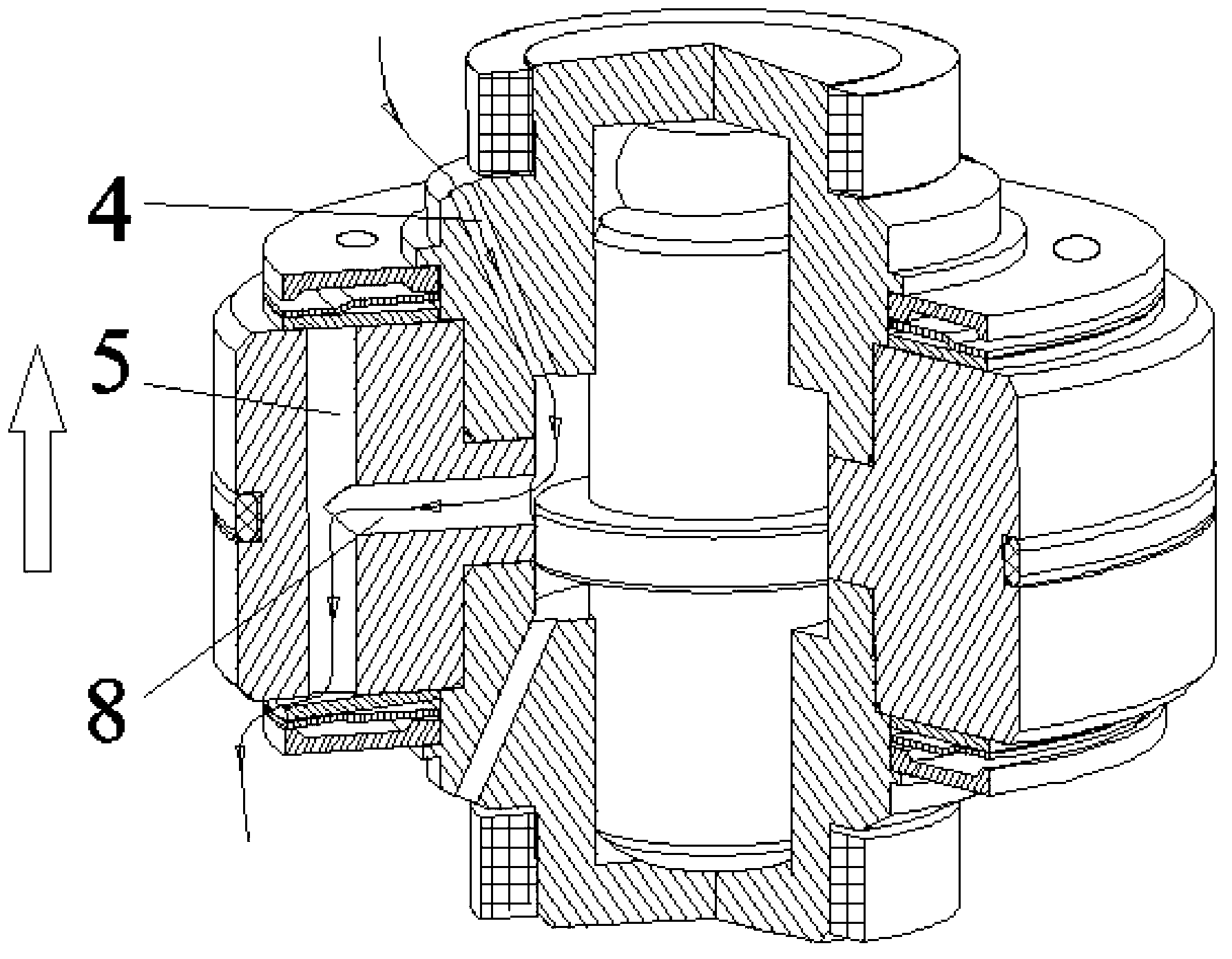

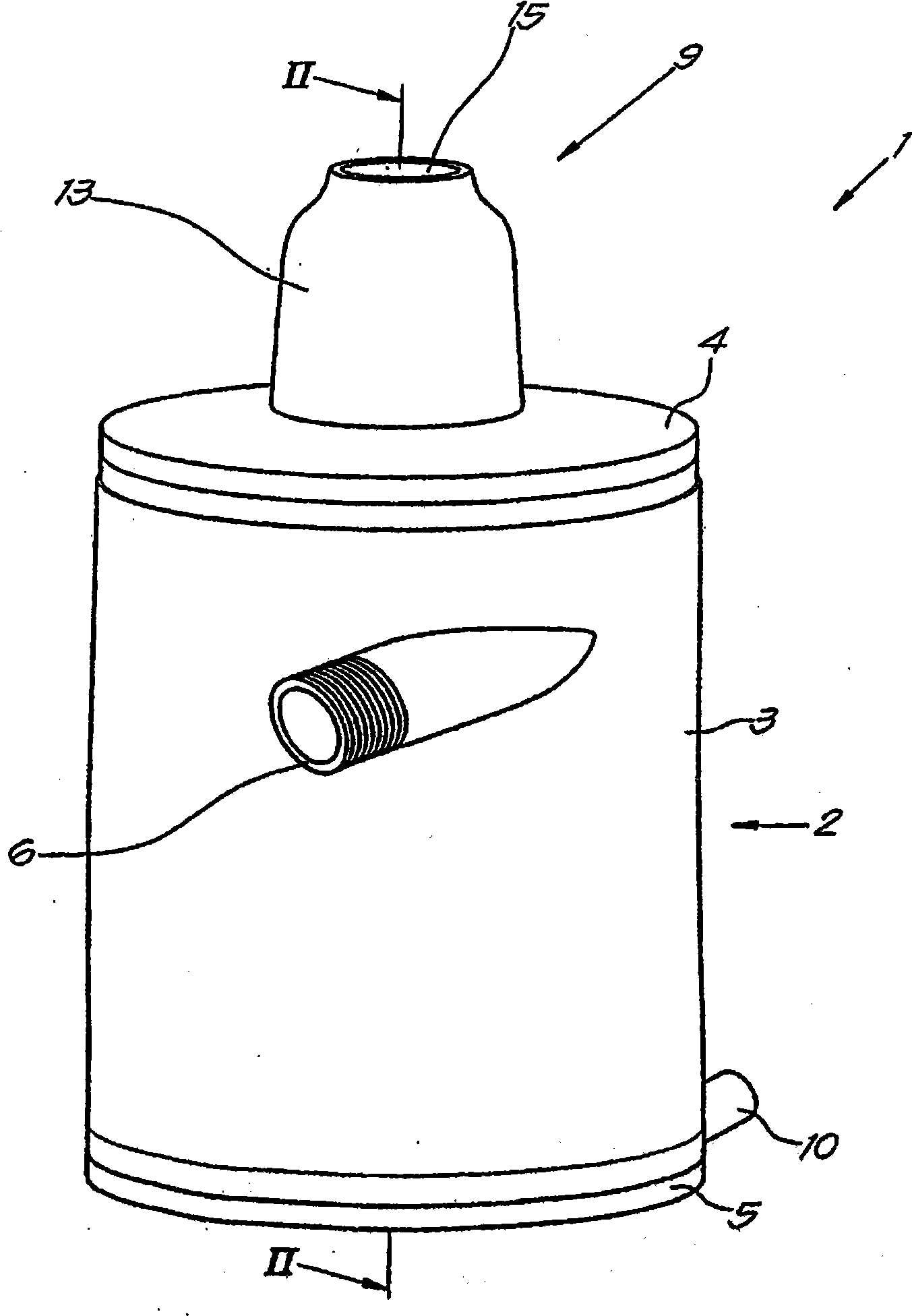

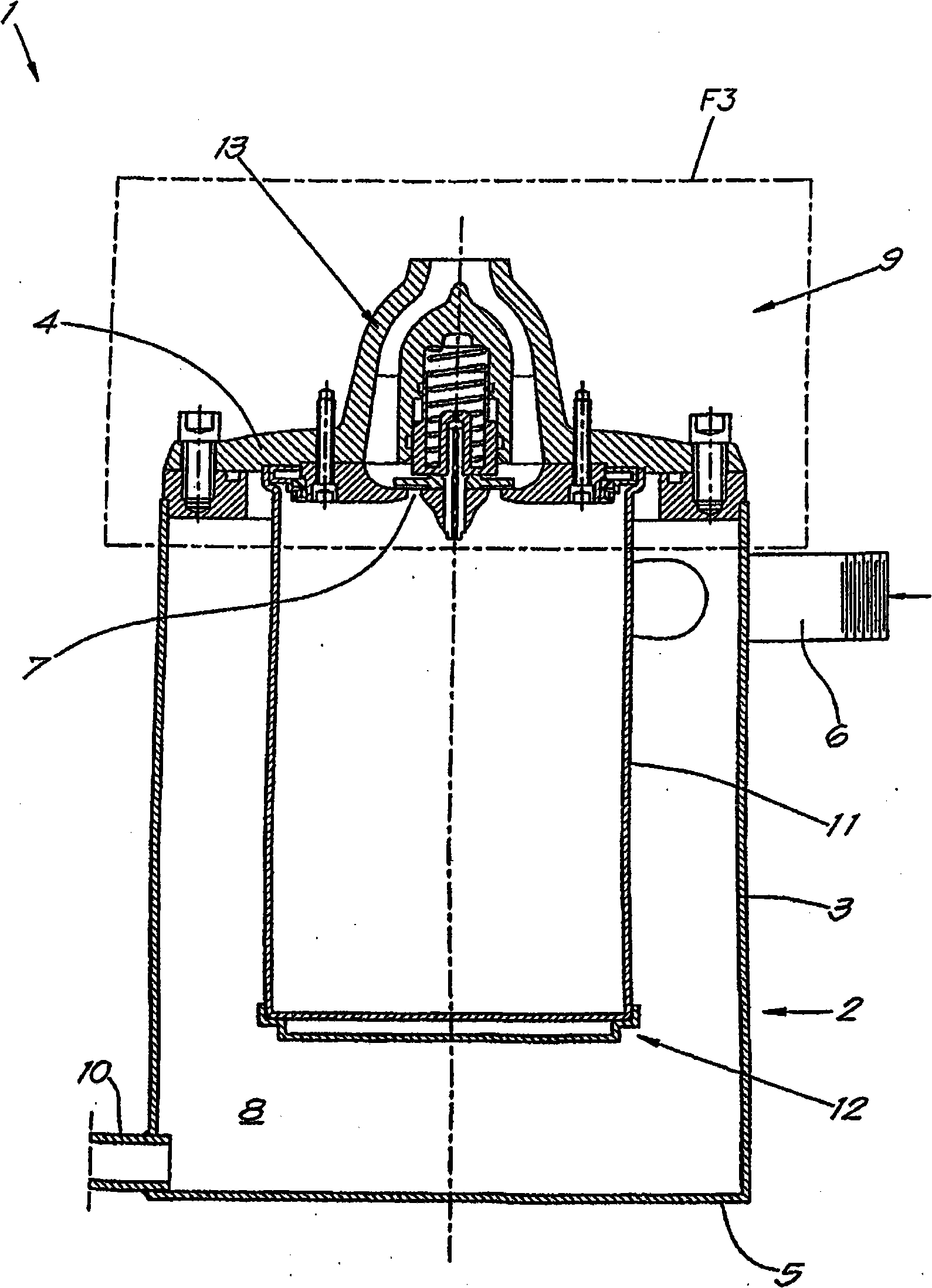

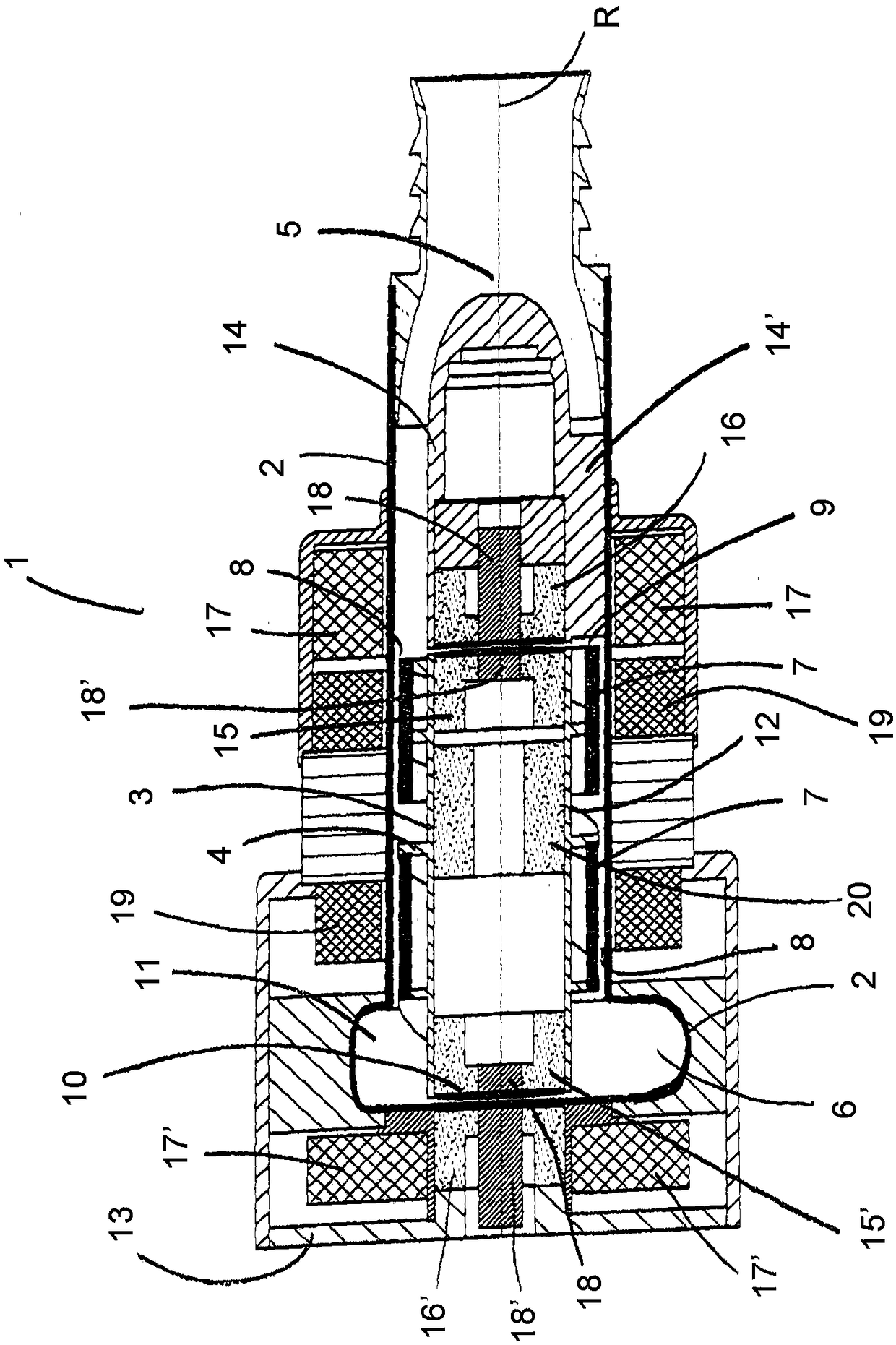

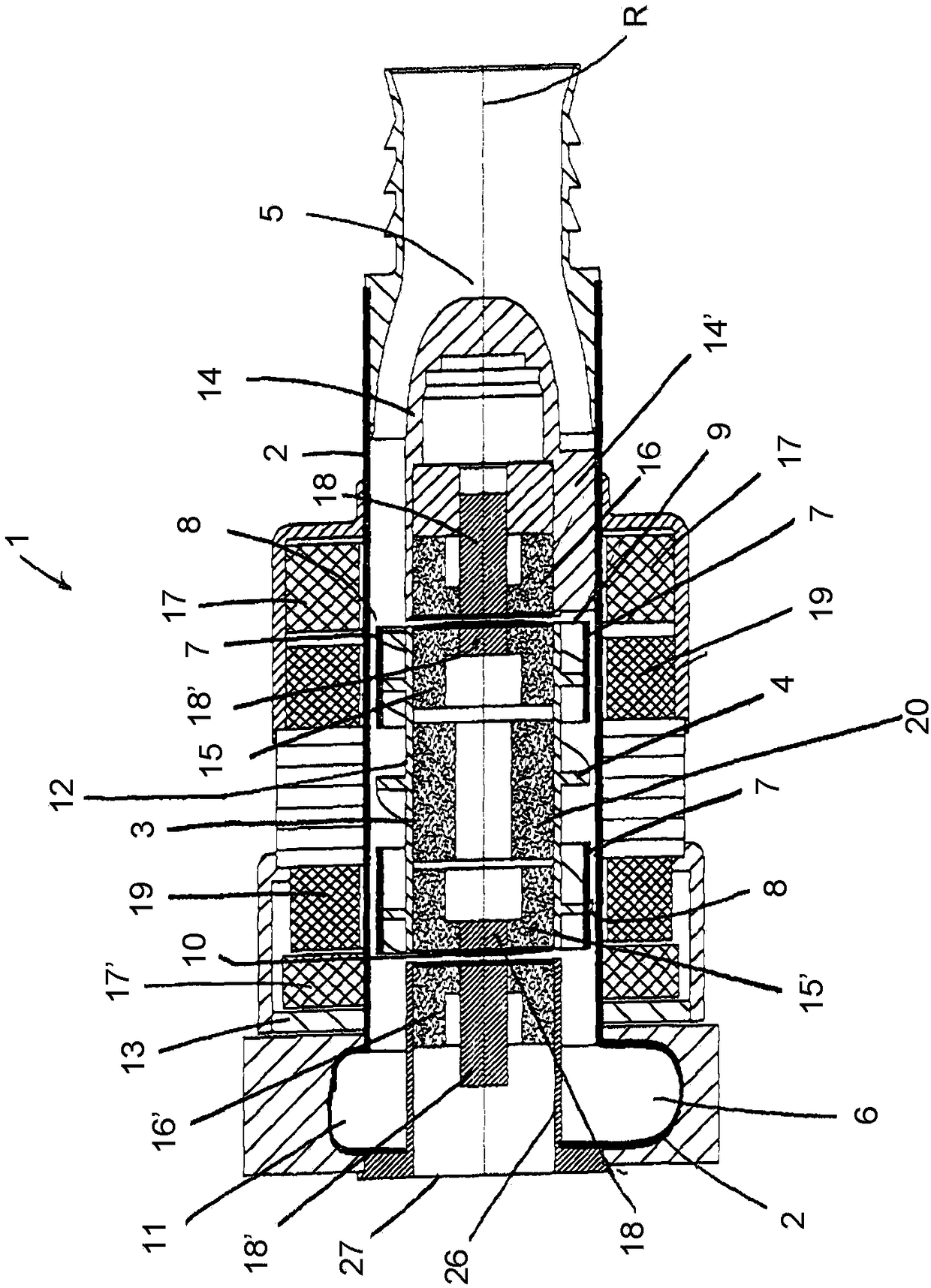

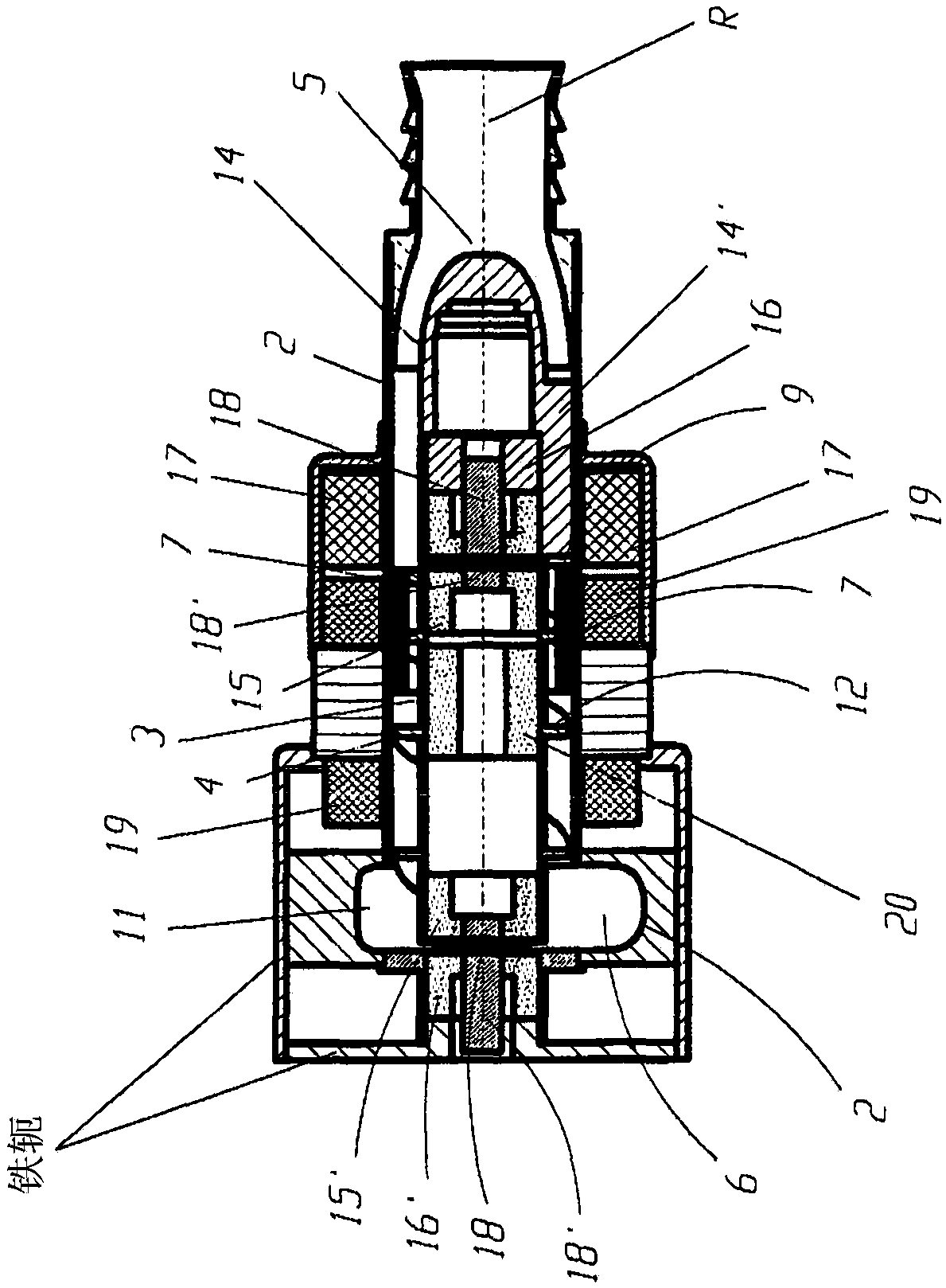

Blood pump

InactiveCN108514661AImproved kineticsAdjust the transmission effectControl devicesIntravenous devicesImpellerMagnetic bearing

The invention relates to a blood pump (1). The blood pump comprises a hollow body (2) and magnetic bearing devices (15, 15', 16, 16', 17, 17', 18, 18'), all of which at least partially and actively stabilize. The hollow body is equipped with an impeller (3) having a blade device (4), which is used for generating axial propulsion of blood along the impeller (3). The impeller is set to rotate arounda rotary axis (R) of the impeller (3) by means of a motor stator (10). The hollow body (2) comprises an inlet (5) and an outlet (6). The inlet enables blood to flow into the hollow body (2) in an inflow direction (E) basically parallel to the rotary axis (R). The outlet (6) enables blood to flow out of the hollow body (2) along an outflow direction (A).

Owner:BERLIN HEART GMBH

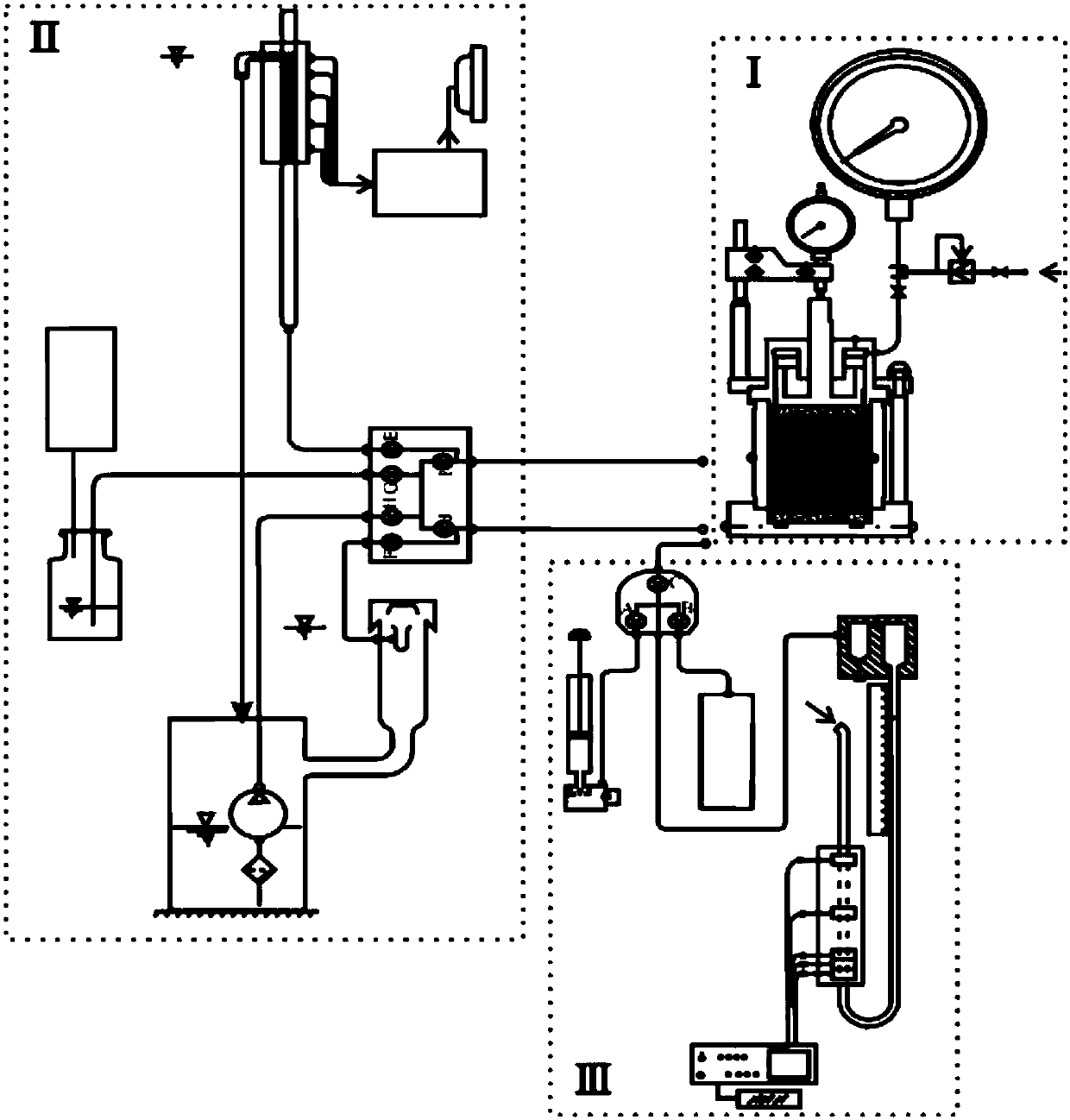

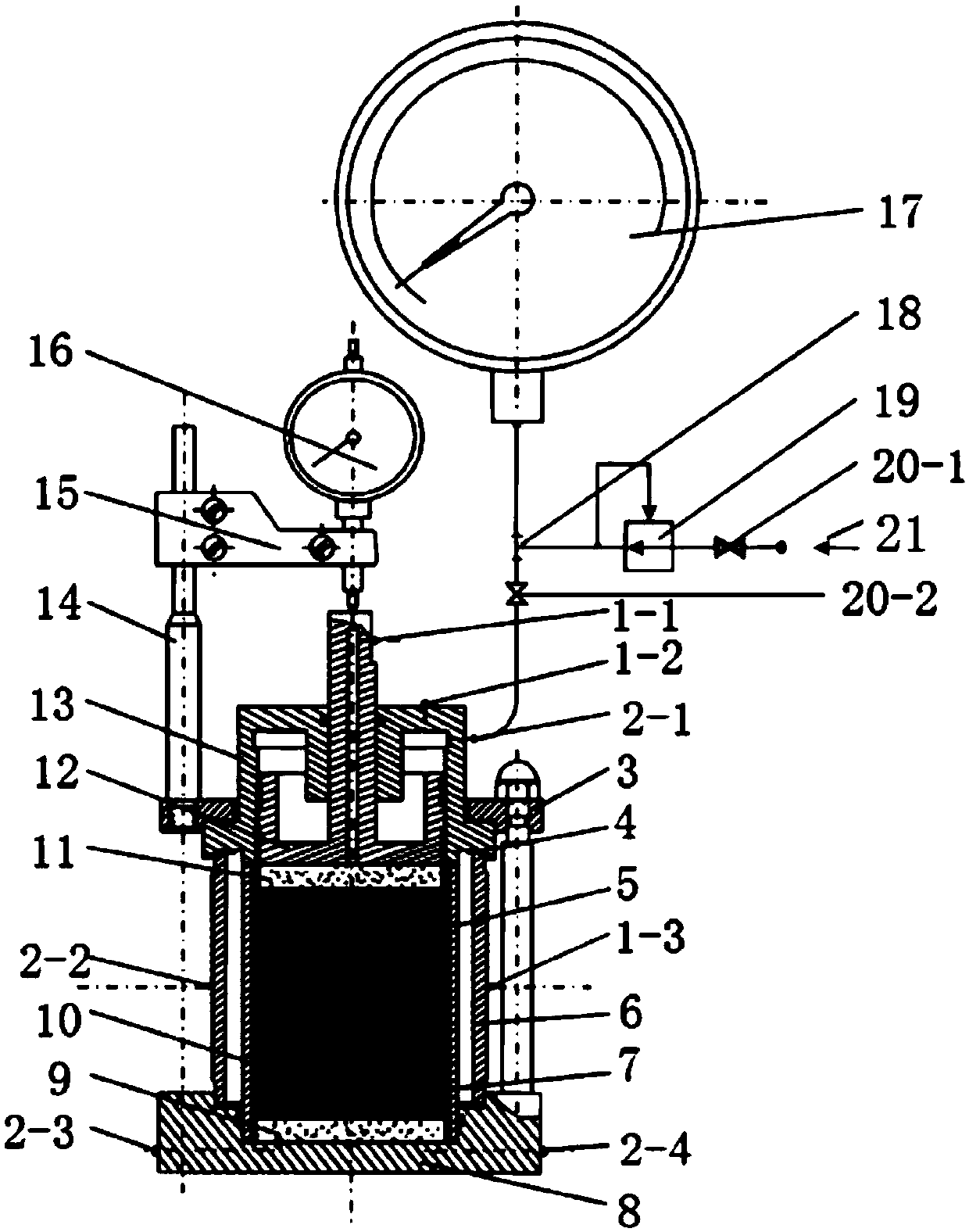

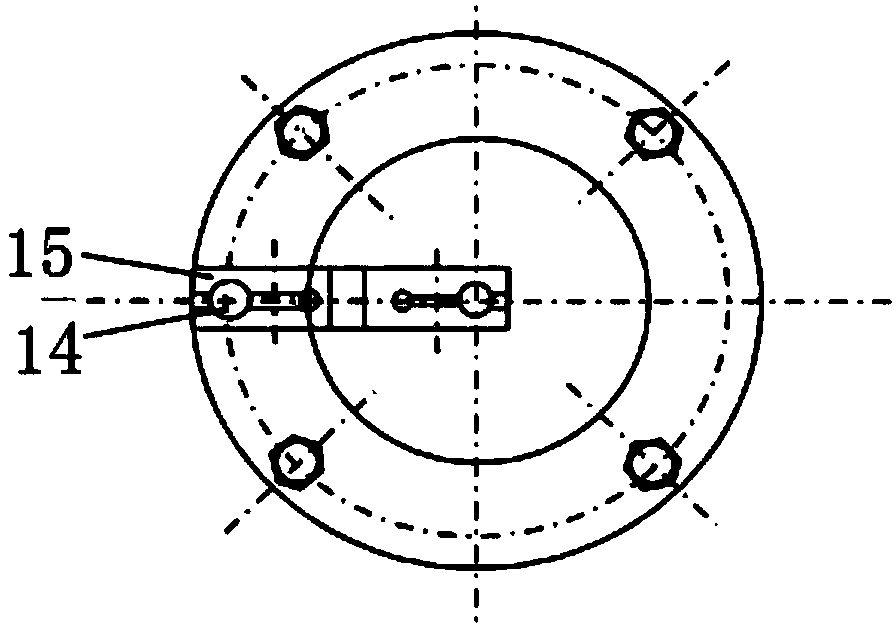

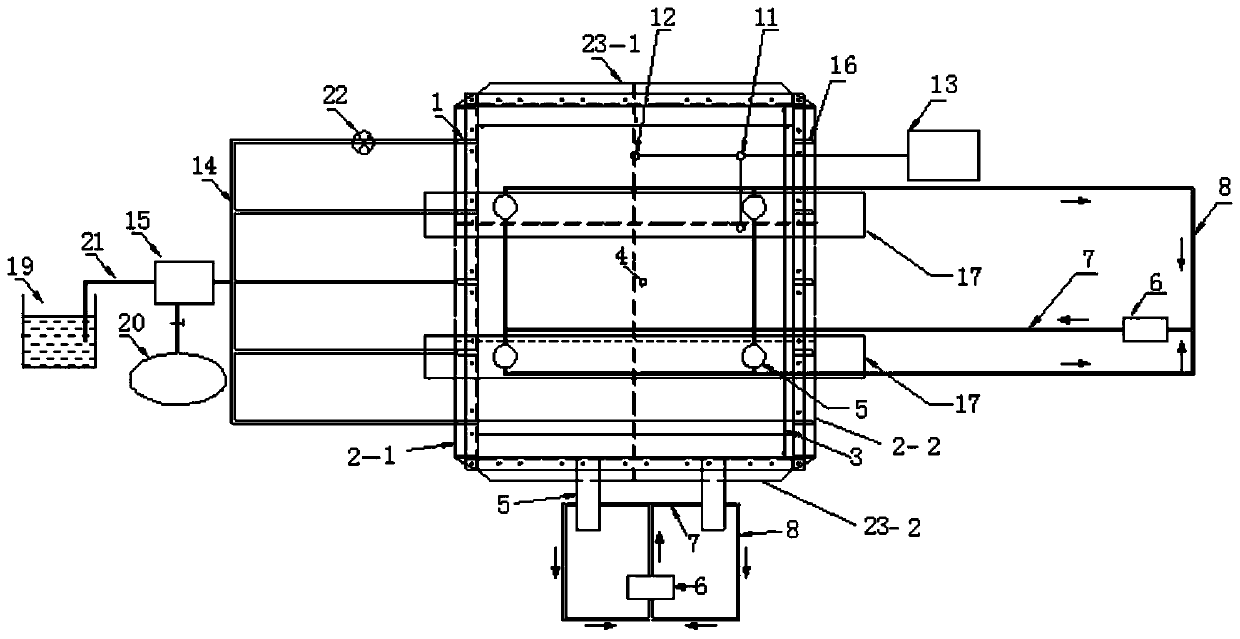

A Combined Measuring Instrument for Consolidation and Permeability of Soil Water-Air Collapse

InactiveCN106092853BIncrease flexibilityPressurized and stableEarth material testingPermeability/surface area analysisMeasuring instrumentOsmotic coefficient

The invention discloses a soil water-gas collapsibility-consolidation-penetration combined determinator. The determinator comprises a collapsibility-consolidation-penetration permeameter, a water seepage coefficient determination system and an air permeation coefficient determination system. The collapsibility-consolidation-penetration permeameter comprises a base and a cutting ring. The cutting ring is filled with a soil sample. The top end of the soil sample is provided with a pressurization control system. The pressurization control system is provided with a dial indicator for determining displacement of a piston in the pressurization control system and a compression gauge for determining air pressure. The water seepage coefficient determination system and the air permeation coefficient determination system are connected to the collapsibility-consolidation-penetration permeameter through pipe ports. The determinator utilizes a modularization design, can carry out a standard height soil sample test, can prepare soil samples with different heights according to demands and test them and can realize simultaneous determination of a penetration coefficient, an air permeation coefficient, a concretion coefficient, a loess collapsibility coefficient and a penetration coefficient and air permeation coefficient after loess collapse. The determinator has the characteristics of good flexibility, short test period, stable and reliable pressure control, labor and time saving and high cost performance.

Owner:CHANGAN UNIV

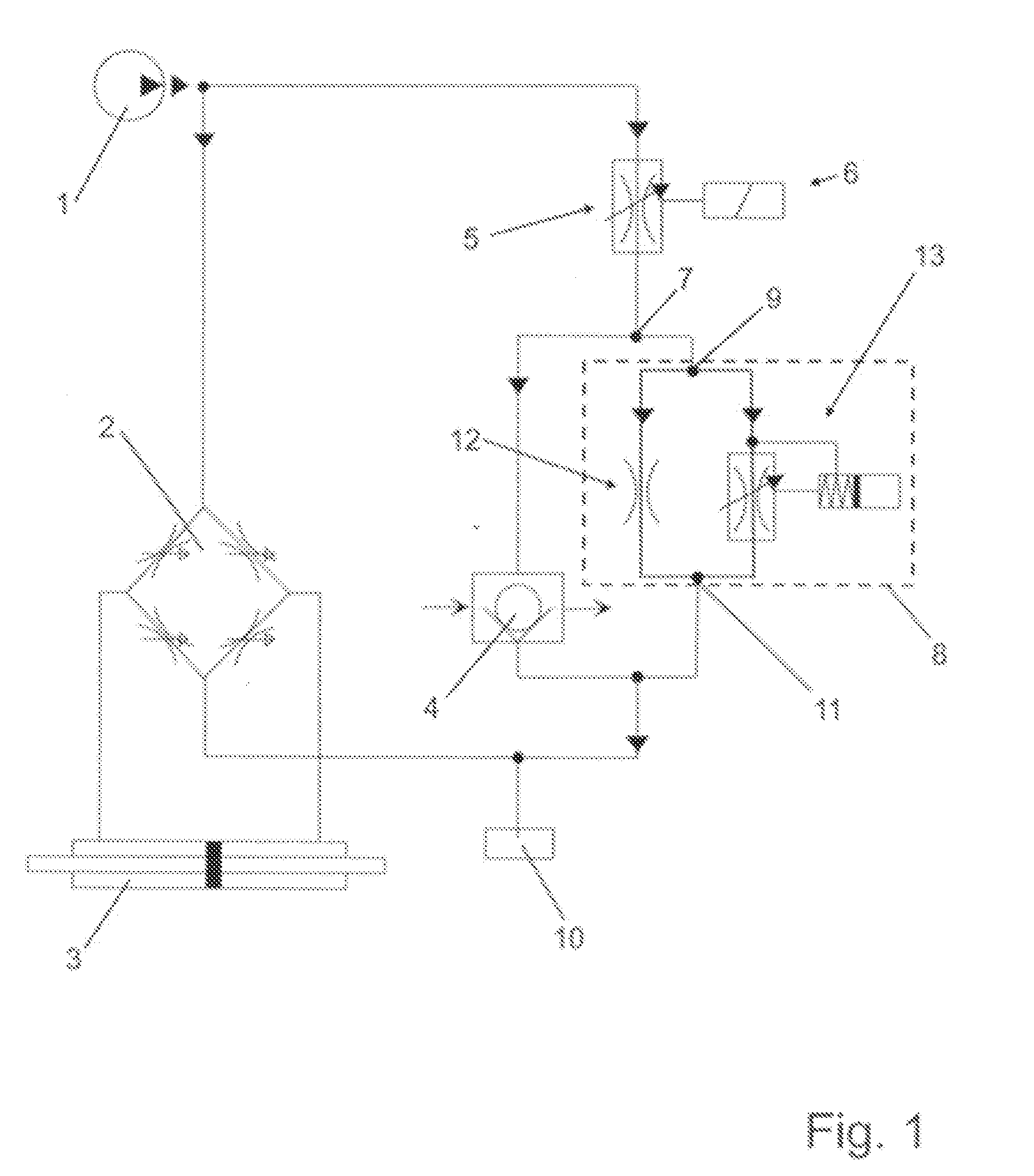

Ultrahigh pressure testing system and control method thereof

ActiveCN106094913AUnder high pressurePrecise position controlMaterial strength using tensile/compressive forcesFluid pressure control using electric meansPressure riseAutomatic control

The invention discloses an ultrahigh pressure testing system and a control method thereof. The ultrahigh pressure testing system comprises a liquid box, a first control valve and a servo supercharger. The liquid box is connected with the first control valve and the servo supercharger in sequence. The servo supercharger is connected with a pressure testing device. A second control valve is connected between the servo supercharger and the pressure testing device. A first pressure detection module is arranged between the first control valve and the second control valve. A second pressure detection module is arranged between the pressure testing device and the second control valve or in the pressure testing device. The technical purpose of the invention is to provide the ultrahigh pressure testing system which uses the servo supercharger as a power source to ensure high precision and high pressure of medium pressurization and intelligently control the pressure rising / reducing rate, and provide the control method of the ultrahigh pressure testing system to realize automatic control in the pressure testing process.

Owner:四川杰特机器有限公司

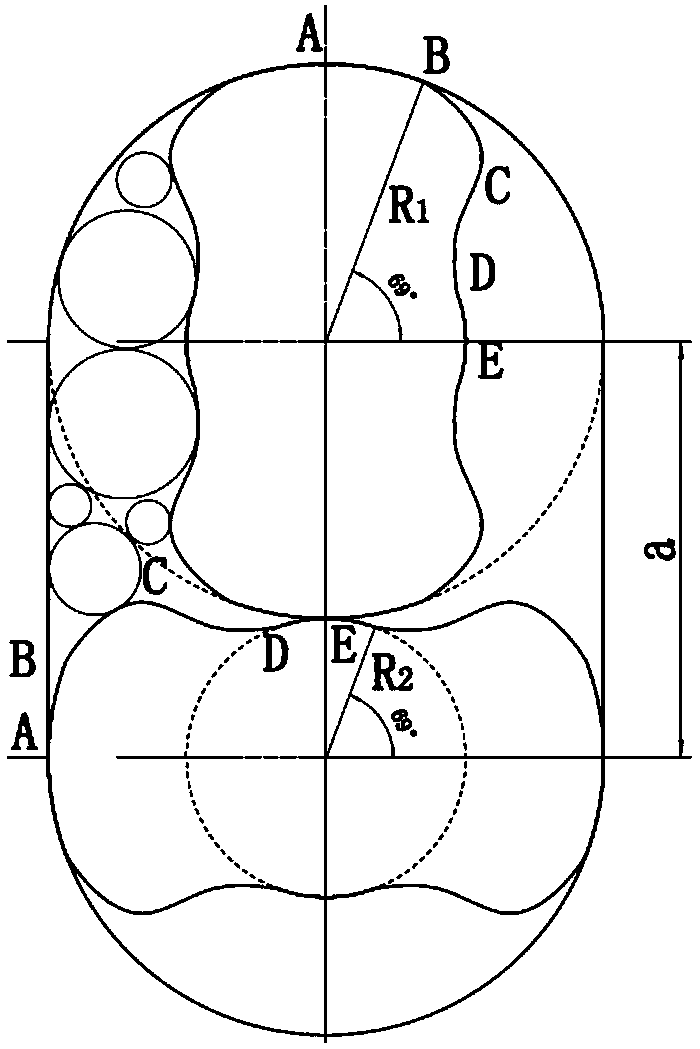

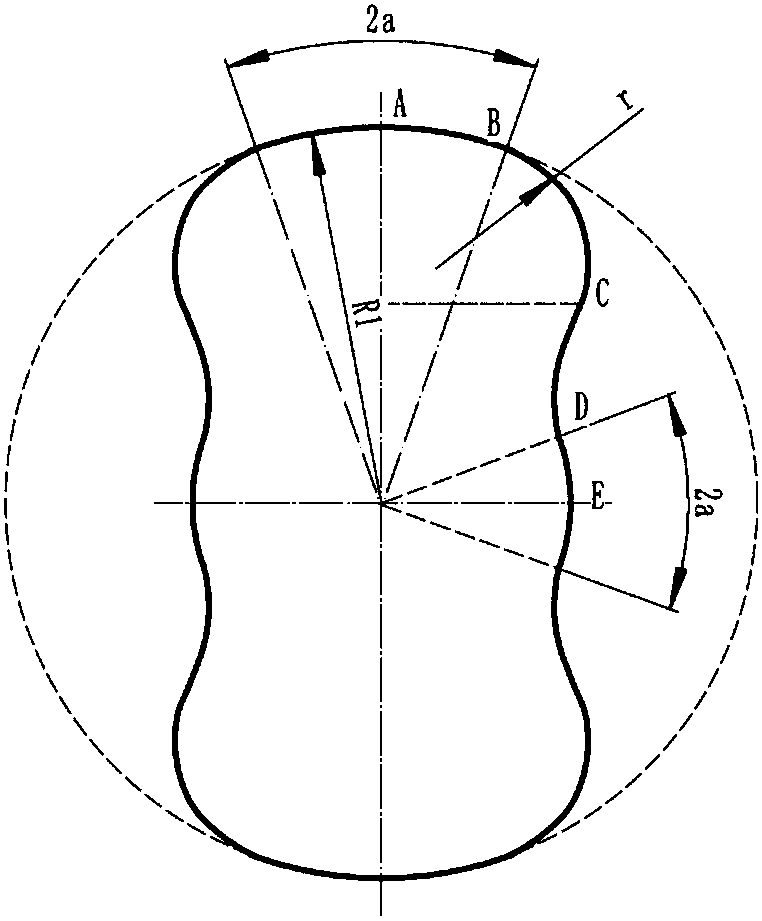

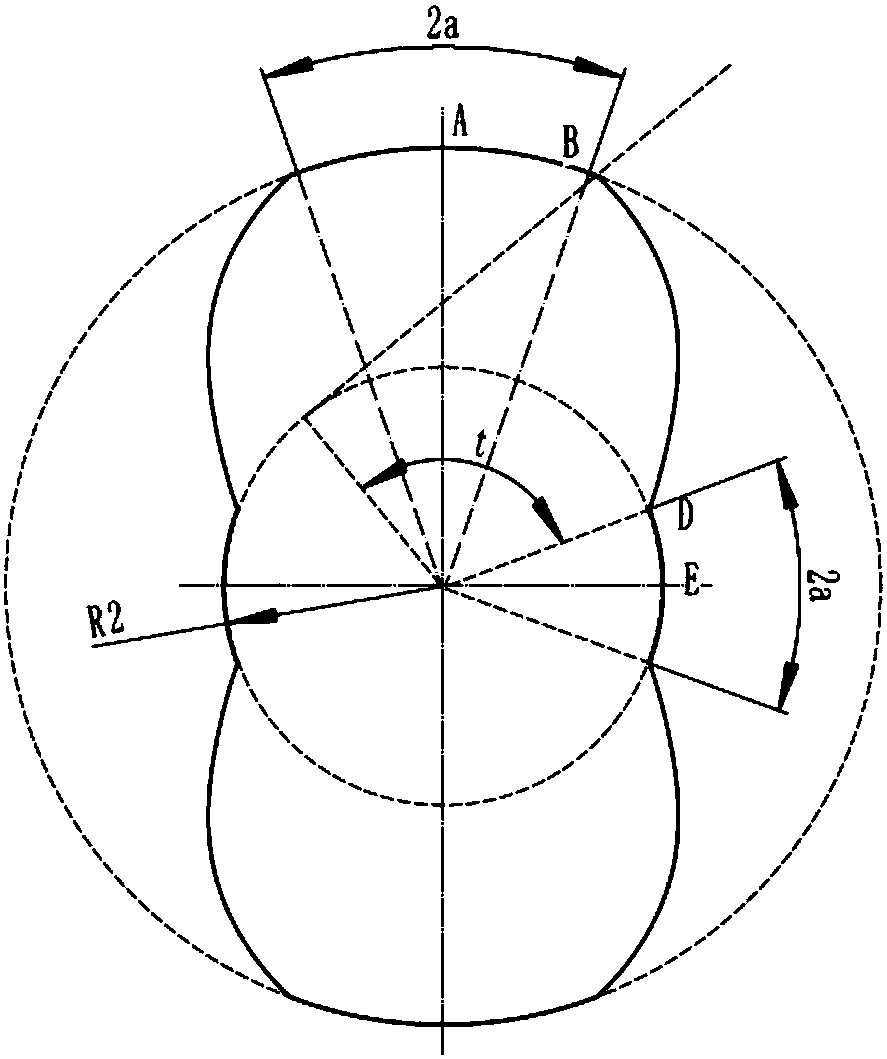

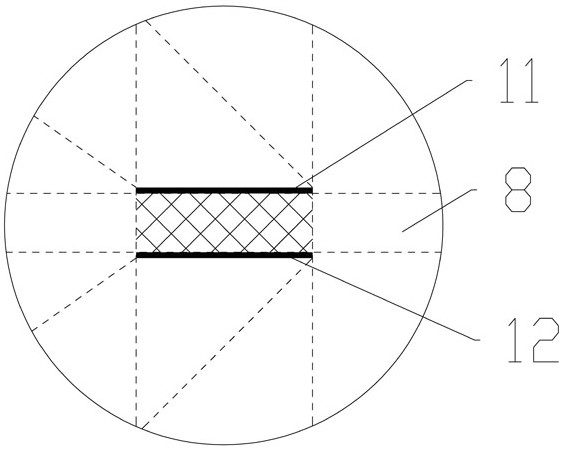

Wide head rotor of high vacuum displacement pump

ActiveCN107061271AWide working pressure rangeIncrease the shaft diameterPump componentsRotary piston pumpsMetal frameworkEngineering

The invention discloses a wide head rotor of a high vacuum displacement pump. In an existing cam pump technology, seal between a pump body and a rotor is linear pump, and therefore, vacuum capacity is easily caused to drop after the rotor and the pump body are worn. The end surface of the wide head rotor of the high vacuum displacement pump is of an axisymmetric structure, and a 1 / 4 molded line of the end surface consists of three parts: a top end wide head circular arc AB, a transition curve BD and an intermediate circular arc DE, and the rotor is formed by wrapping a metal framework and rubber; and the top end wide head circular arc AB and the intermediate circular arc DE of the wide head rotor are two conjugate curves. The wide head rotor effectively increases a working pressure range of the high vacuum displacement pump, ensures lasting stability of conveying pressure, reduces pulsation and improves working efficiency.

Owner:HANGZHOU DIANZI UNIV

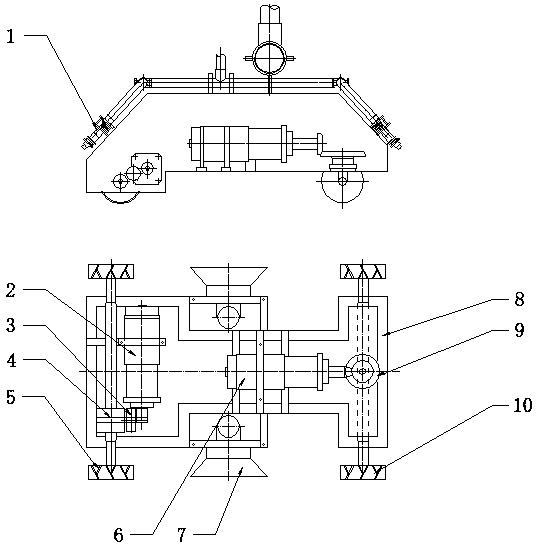

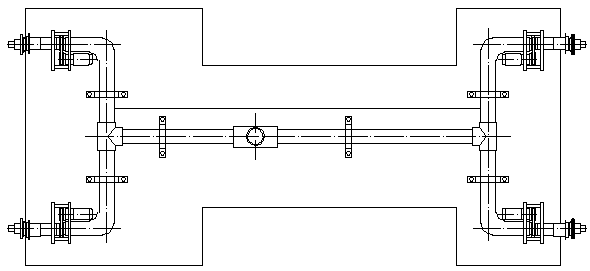

Urban pipeline mobile cleaning device

The invention discloses an urban pipeline mobile cleaning device. The urban pipeline mobile cleaning device is composed of a power device, a high-pressure water device, a wheel type moving trolley driven by a miniature servo motor, and a post-processing device. The urban pipeline mobile cleaning device comprises a power system, a water jet flow system, a siphon system, a sealing system, a controlsystem, a line receiving and releasing mechanism, and a sewage disposal system. The control system is adopted to control the trolley to move in a pipeline according to a preset track. During moving, high-pressure water is conveyed to the water jet flow system by the high-pressure water device. An eccentric rotating high-pressure nozzle is adopted to the high-pressure water jet flow system to stirup sludge deposited at the bottom of the pipeline and fluidizes the sludge. The siphon system is adopted to convey the fluidized sludge to the post-processing device outside the pipeline for processing until all sludge in the pipeline is cleared. The structure is simple and compact, the manufacturing cost is low, and pipeline cleaning efficiency and the automation degree are greatly improved.

Owner:DONGGUAN UNIV OF TECH

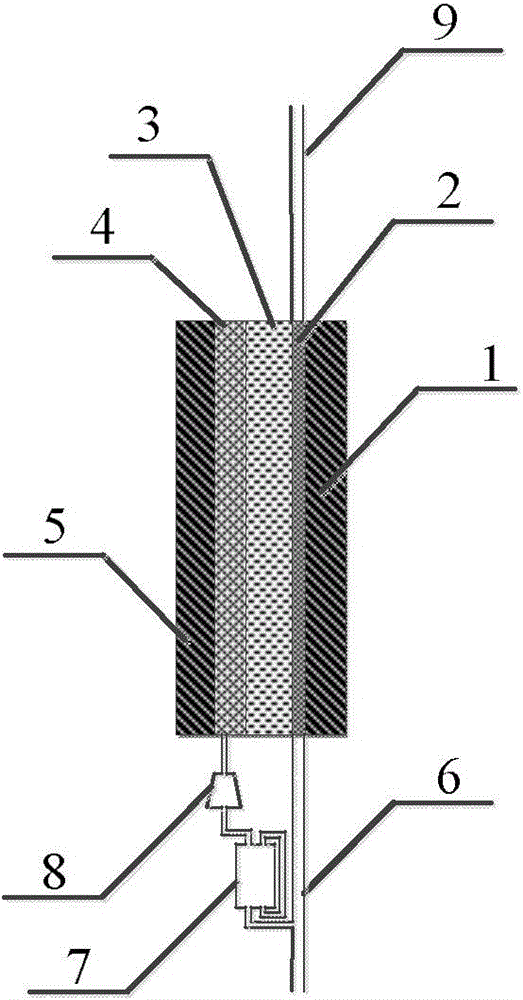

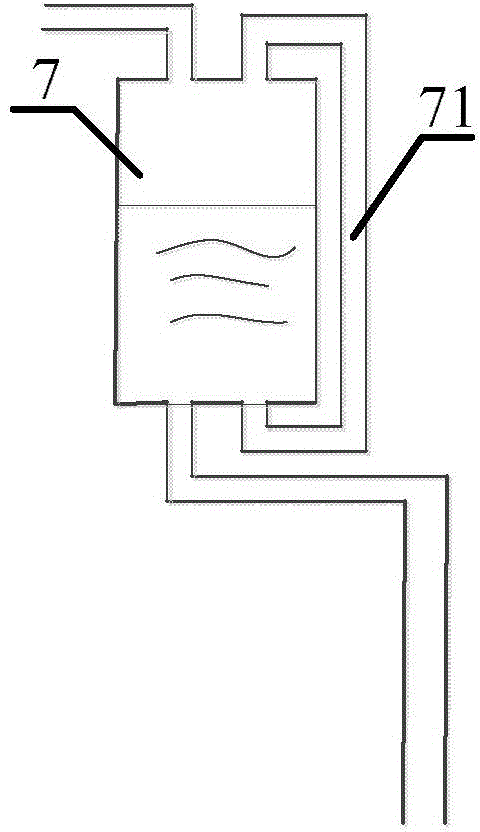

Pressure automatic balance laser head device

InactiveCN104617469APressure balanceIncrease the amount of gasLaser detailsLiquid layerAudio power amplifier

The invention discloses a pressure automatic balance laser head device and belongs to the field of laser amplifiers. The pressure automatic balance laser head device comprises a cooling liquid layer, a gain medium, a liquid inlet channel, a balance air pressure layer, an air sealing window, an air storage tank and a drying box, wherein the liquid inlet channel is a three-way liquid inlet channel; the air sealing window, the balance air pressure layer, the gain medium and the cooling liquid layer are plate-strip shapes with almost equal areas and are sequentially arrayed in parallel; the two ends of the three-way liquid inlet channel are connected with the cooling liquid layer and the balance air pressure layer respectively; the air storage tank and the drying box are connected between the three-way liquid inlet channel and the balance air pressure layer in series; air pressure of the balance air pressure layer is equal to hydraulic pressure of the cooling liquid layer; pressure on the two sides of the gain medium can be balanced by the device so that the deformation of the gain medium, caused by single-end cooling hydraulic pressure, is eliminated; wave-front distortion of laser after reflection, caused by the medium deformation, is eliminated; the pressure automatic balance laser head device has the advantages of simple structure and low construction cost, is easy to realize and the like.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

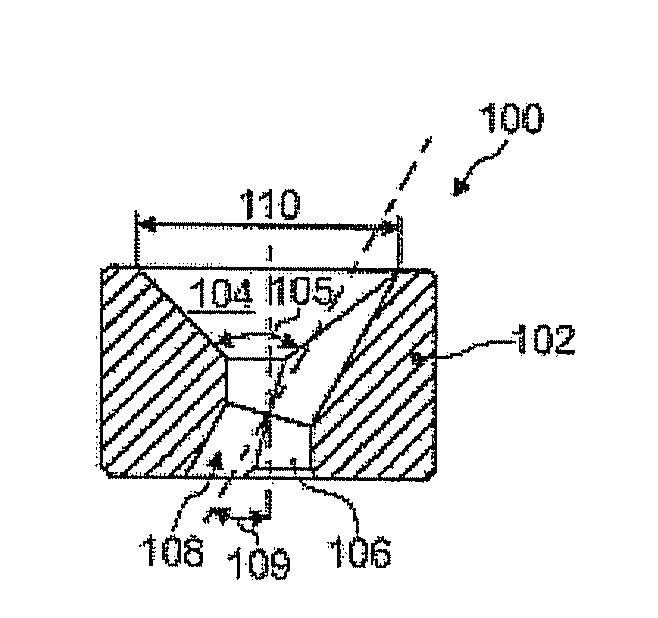

Control Valve for a Servo Steering System

InactiveUS20080010982A1Improve featuresLarge pressure rangeFluid couplingsServomotorsControl valvesSteering system

A control valves for a servo steering system, having an inlet for supplying a hydraulic liquid at a first pressures and an outlet for discharging the hydraulic liquid into a region having a smaller, second pressure, especially into a pressureless reservoir. The control valve has a guide and a valve slide accommodated in the guide so as to be movable therein along an axis. The valve slide is acted upon on one side by the hydraulic liquid with the first pressure and on the opposite side by a defined supporting force. An opening structure is provided on at least one of the valve slide and guide. A cover corresponding to the opening structure is provided on the other of the guide and valve slide. A movement of the valve slide relative to the guide effects a change of a free passage area of the opening structure that is not closed off by the cover, whereby the hydraulic liquid is able to flow from the inlet, through the free passage area, to the outlet. The opening structure has a defined shape such that the free passage area of the opening structure does not depend linearly on the movement of the valve slide

Owner:THYSSENKRUPP PRESTA STEERTEC

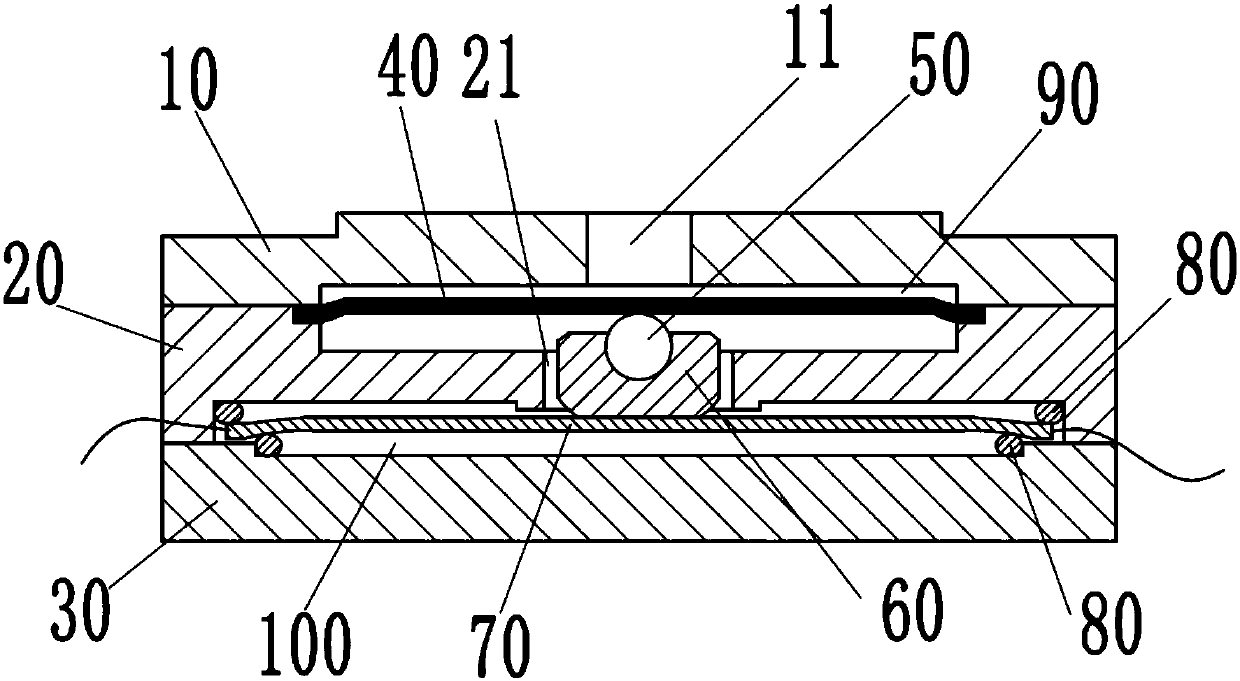

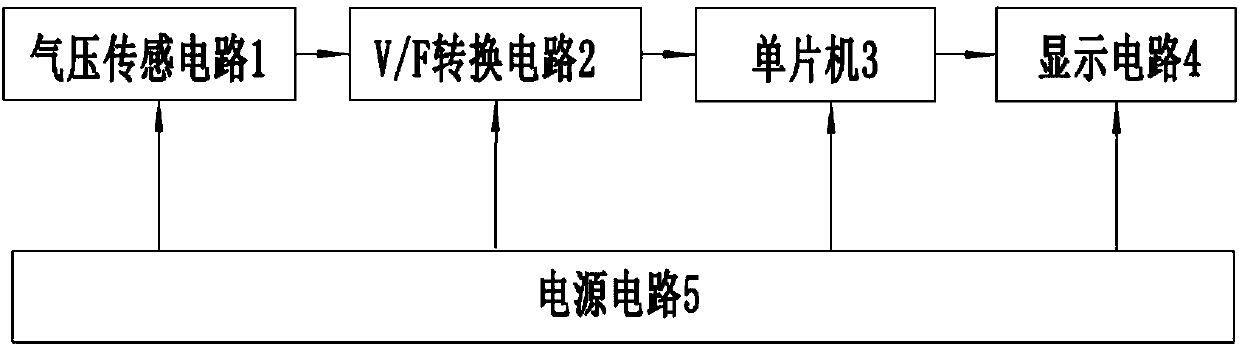

Sensor

ActiveCN107727304ALarge pressure rangeLow costFluid pressure measurement using ohmic-resistance variationMicrocomputerMicrocontroller

The invention discloses a sensor, which comprises an upper shell, a middle shell, a lower shell, an elastic deformation disc, a resistive pressure sensor, a floater, a steel ball and a single chip microcomputer, wherein an air inlet hole is formed in the middle part of the upper shell, a middle hole is formed in the middle part of the middle shell, the upper shell is mounted on the middle shell, the middle shell is mounted on the lower shell, the elastic deformation disc is mounted at a joint of the upper shell and the middle shell, the middle part of the elastic deformation disc is positionedjust below the air inlet hole, the resistive pressure sensor is mounted at a joint of the middle shell and the lower shell, the float is placed on the upper surface of the resistive pressure sensor and passes through both ends of the middle hole, the steel ball is arranged at the upper part of the floater and is in contact with the lower surface of the elastic deformation disc in a pressed manner, and the single chip microcomputer is electrically connected with the resistive pressure sensor by means of a detection circuit. By adopting the structure, the sensor has the advantages of high detection precision and wide application range.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

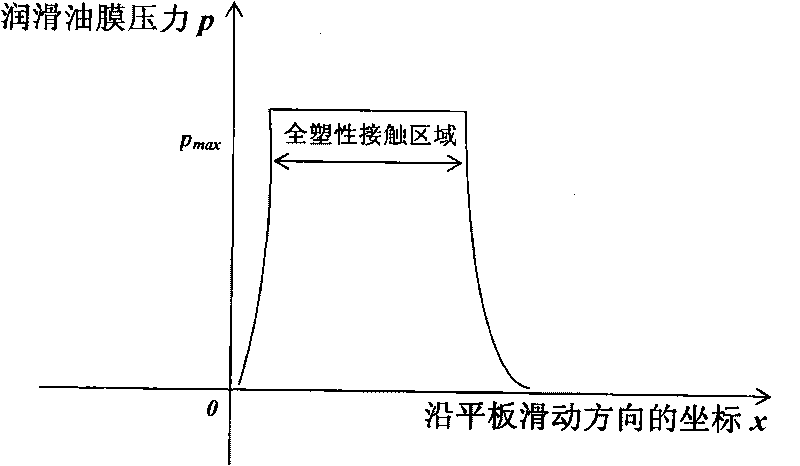

Method for measuring interfacial shear strength under full plastic contact of discs and flat plate and device thereof

InactiveCN101710060ASimple structureEasy to manufactureUsing mechanical meansMaterial analysisCircular discContact pressure

The invention relates to a method for measuring interfacial shear strength under full plastic contact of discs and a flat plate, which comprises the following steps of: A, making a disc still and the flat plate slide with the speed mu relative to the disc, wherein the rolling-sliding ratio is 2; B, supplying measured lubricating oil to a linear contact area to ensure that the hydrodynamic pressure lubrication is formed in the linear contact area, and applying a load between the disc and the flat plate to ensure that the maximum hertzian contact pressure of linear contact is more than 0.4GPa; and C, needing two discs with different contact surface hardnesses if the single measurement is to be finished, performing the loading on contact surfaces of the two discs and the flat plane respectively, measuring friction coefficient values on contact surfaces of the discs or contact surfaces of the flat plate under loading contact of the two discs and the flat plate respectively, and solving a binary linear equation group about the friction coefficients of the contact surfaces to obtain ts0 and an alphas value. The adoption of the method and a device thereof has remarkable technical effect, and has the advantages of larger pressure range of the measured lubricating oil, simple and compact structure, easy realization, lower manufacturing cost and using cost, easy measurement, higher measurement accuracy and the like.

Owner:南通鼎强机械科技发展有限公司

Pressure sensor arrangement for detecting a pressure of a fluid medium in a measurement area

InactiveUS20140224028A1Large pressure rangeAvoid disadvantagesFluid pressure measurement using inductance variationMetal working apparatusEngineeringPressure sensor

A pressure sensor system for acquiring a pressure of a fluid medium in a measurement chamber, and a method for the production thereof, are provided, having a sensor housing, at least one sensor element that is situated on a bearer such that it can be exposed to the medium in order to measure a pressure of the medium, and an evaluation circuit for outputting a signal that indicates the pressure acting on the sensor element. The evaluation circuit is situated outside the medium and is energetically connected to the sensor element in contactless fashion. The bearer is connected to the sensor housing such that the evaluation circuit is situated inside the sensor housing.

Owner:ROBERT BOSCH GMBH

Method of thermally processing elastomeric compositions and elastomeric compositions with improved processability

ActiveUS20050119410A1Improve processabilityLower extrusion temperatureArtifical filament manufactureNon-woven fabricsElastomer

Owner:KIMBERLY-CLARK WORLDWIDE INC

Three-dimensional adjustable high-pressure-bearing high dynamic water grouting system and testing method

ActiveCN110411906AImprove adjustabilityIncrease profitSurface/boundary effectPermeability/surface area analysisStress conditionsMonitoring system

Owner:SHANDONG JIANZHU UNIV

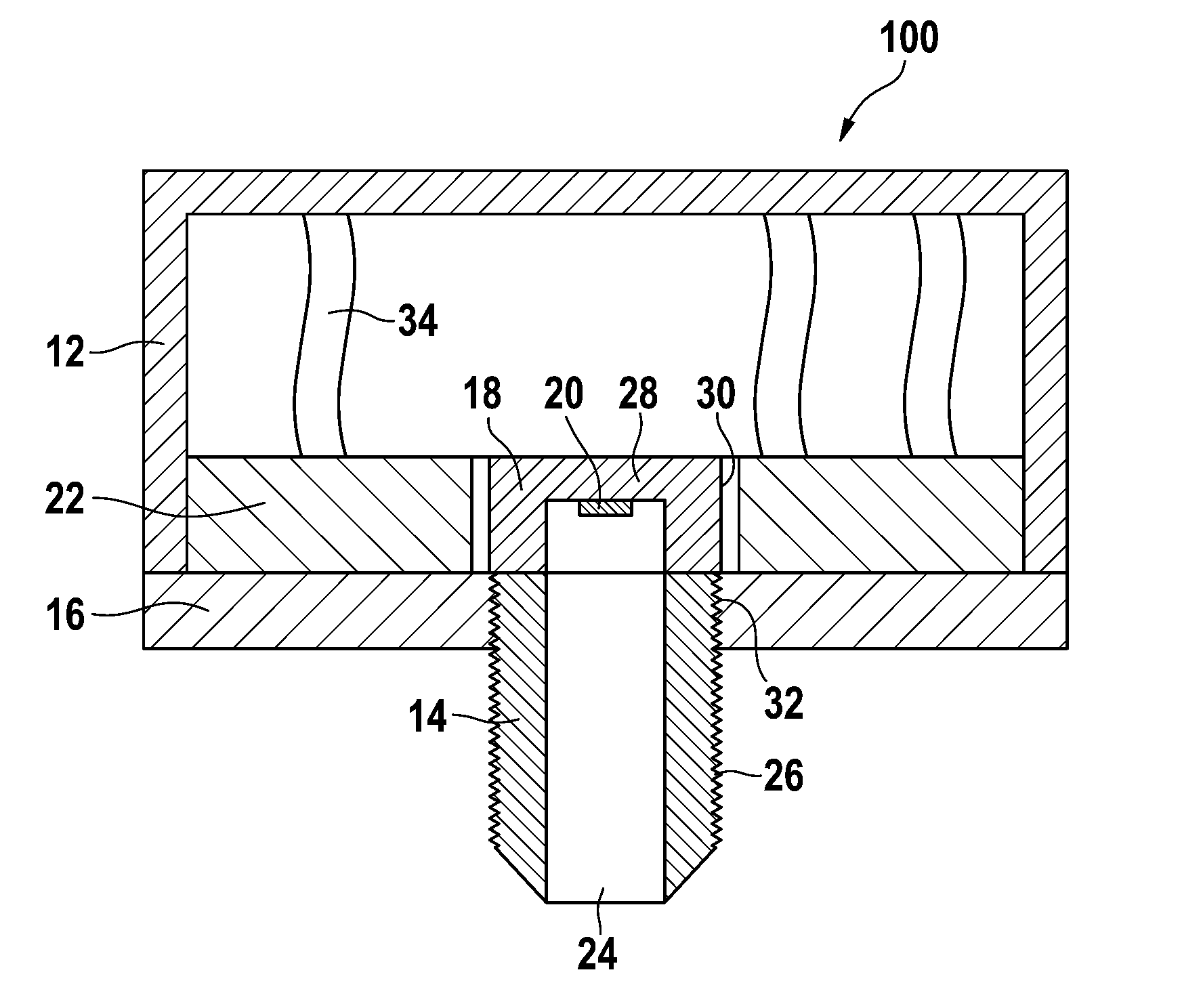

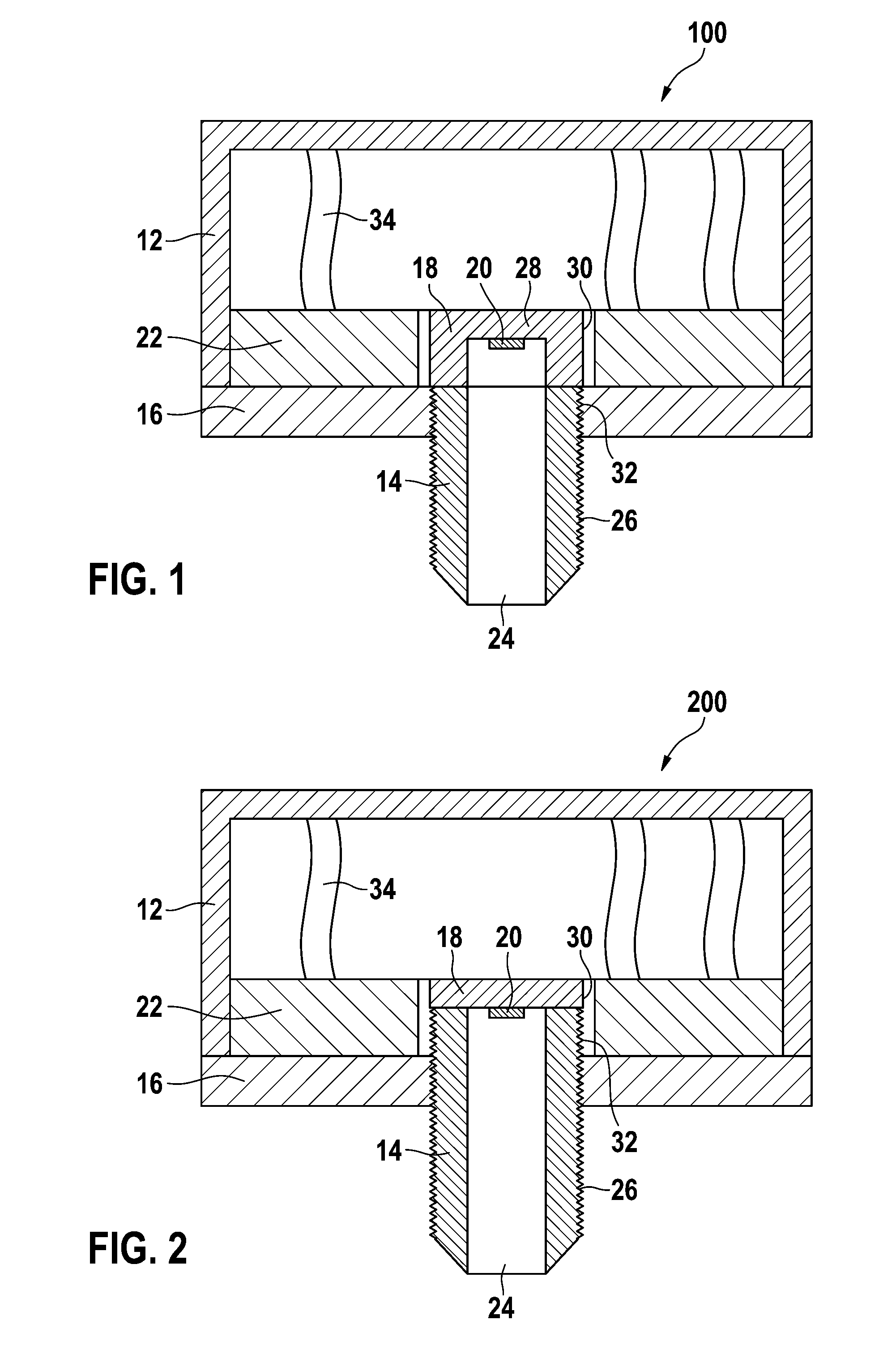

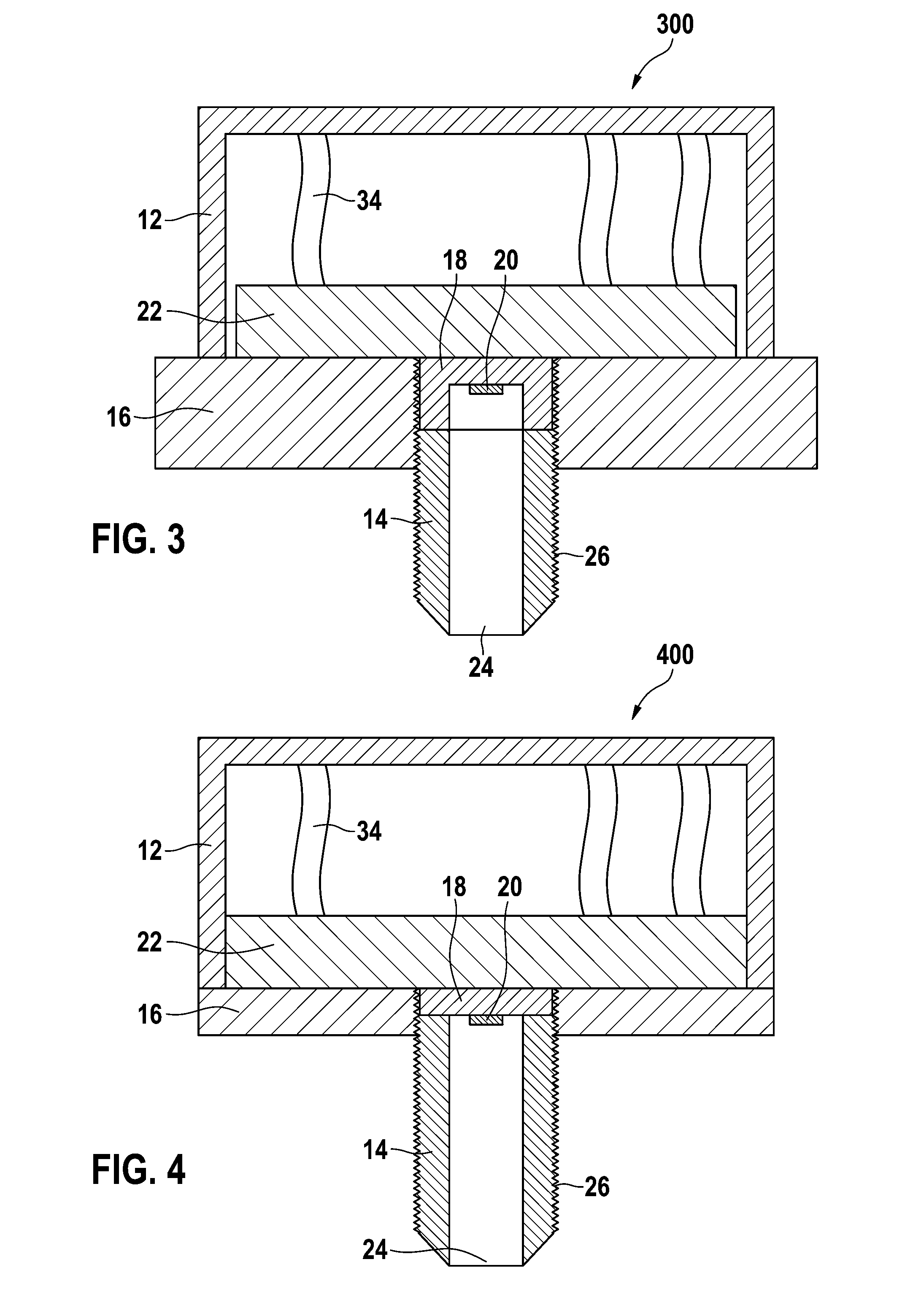

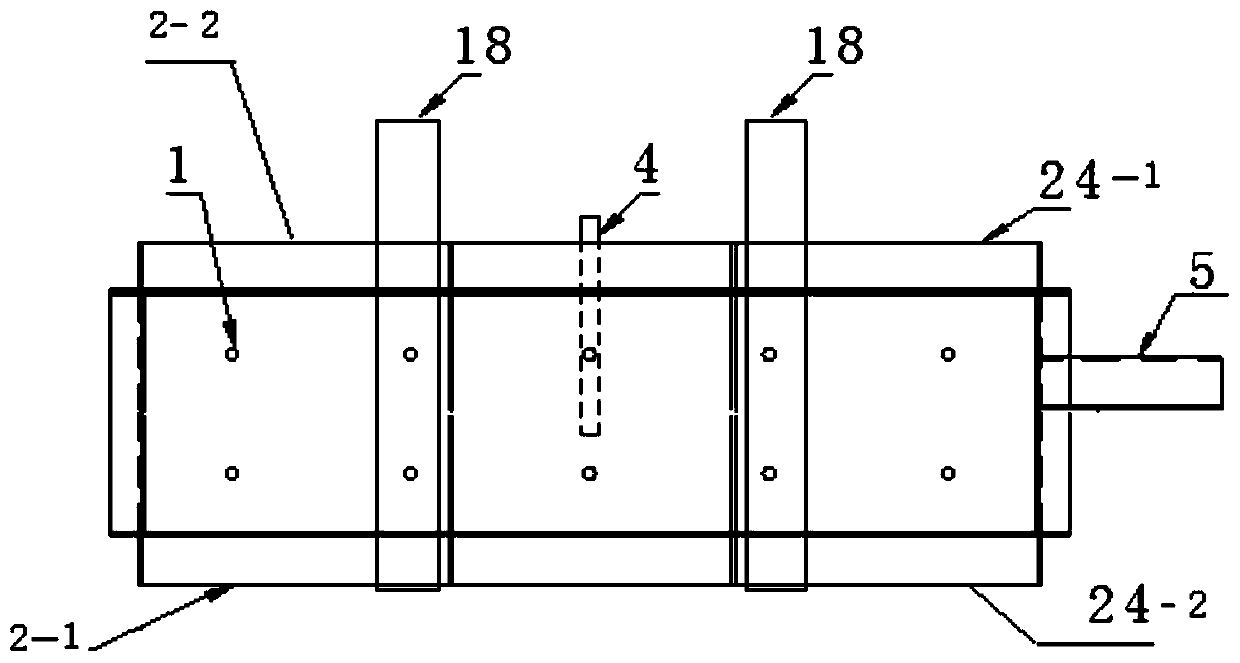

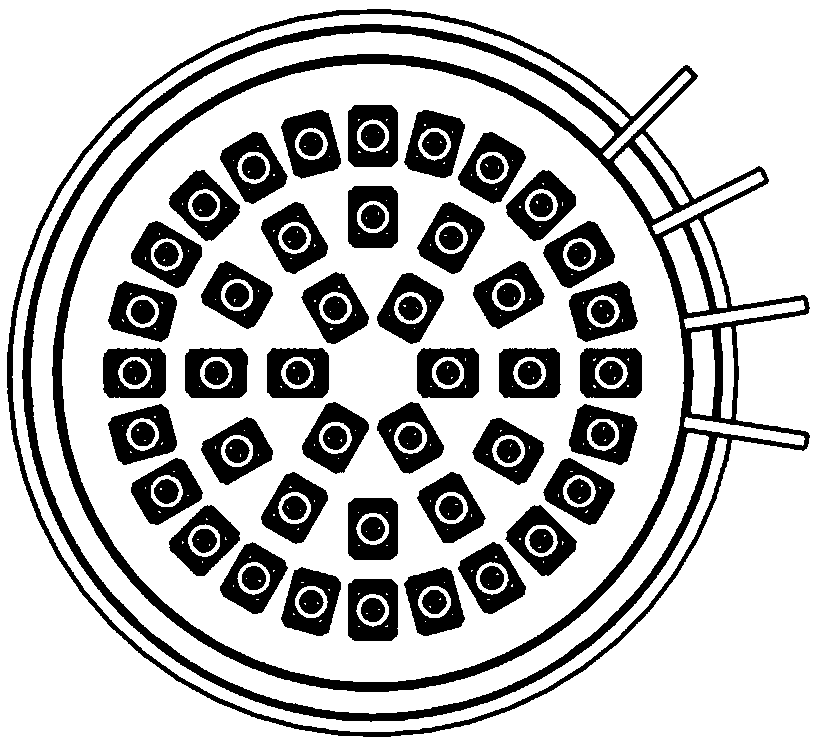

Press fitting structure applied to pressure welding type MOSFETs

PendingCN110767637ASimple structureCompact structureSemiconductor/solid-state device detailsSolid-state devicesMOSFETEngineering

The invention provides a press fitting structure applied to pressure welding type MOSFETs. The press fitting structure comprises a first copper block, an elastic structure, the pressure welding type MOSFEs, a circuit board and a second copper block. The multiple pressure welding type MOSFEs can form a parallel array and are arranged in a ring or matrix shape. The press fitting structure is simpleand compact in structure, the flow capacity and the heat dissipation capacity are enhanced, and the applicable range is widened.

Owner:TSINGHUA UNIV

Double-symmetric parallel film micro-constant flow valve and flow regulation and control method

PendingCN112240411ARegulation automaticPrecise regulationDiaphragm valvesOperating means/releasing devices for valvesStream flowThin membrane

The invention discloses a double-symmetric parallel film micro-constant flow valve and a flow regulation and control method. The double-symmetric parallel film micro-constant flow valve comprises twocontrol flow channels which are separately arranged up and down, two control flow channels which are arranged left and right, a fluid main flow channel, a narrow flow channel and four elastic films which are parallel in pairs. The inlets of the four control flow channels communicate with the fluid main flow channel, and the outlets of the control flow channels are sealed by the elastic films and are separated from the narrow flow channel. According to the flow regulation and control principle of the double-symmetric parallel film micro-constant flow valve, the four elastic films are used for generating elastic deformation under the action of the pressure of microfluid in the control flow channels, the microfluid in the narrow flow channel is extruded, the flow resistance of the valve is changed so as to compensate the change of the pressure intensity of the fluid in real time, and finally constant regulation and control of the flow of the microfluid are realized. According to the valve, the driving pressure intensity required for realizing constant flow regulation and control is small (less than 20kPa), the output flow range is wide, and the valve has wide application value in thefields of medicine injection, integrated microchip laboratories, portable instant detection instruments and the like.

Owner:CHANGZHOU INST OF LIGHT IND TECH

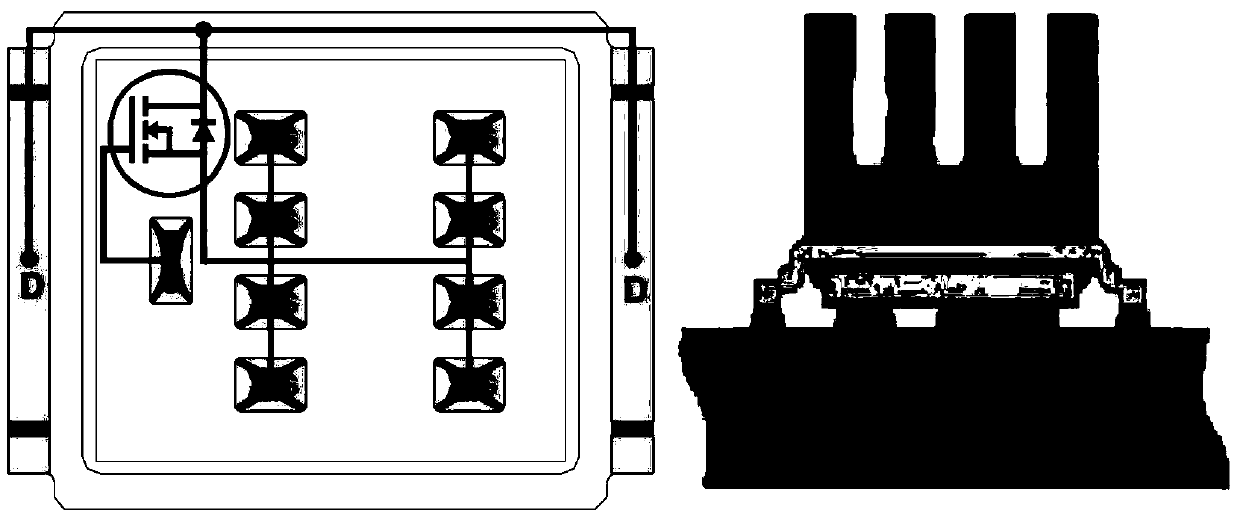

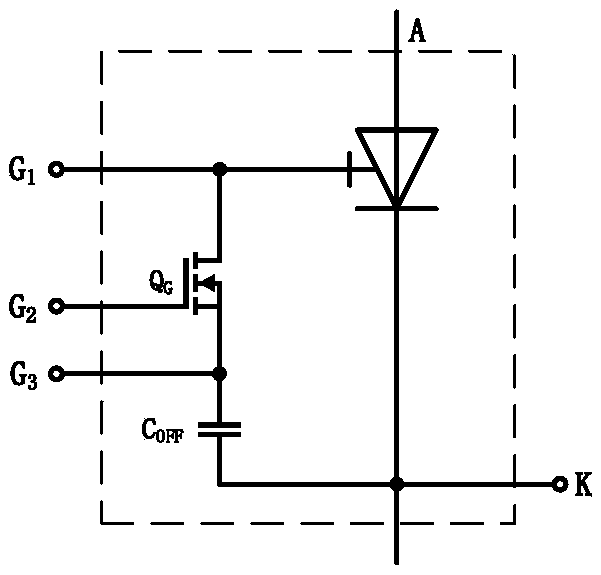

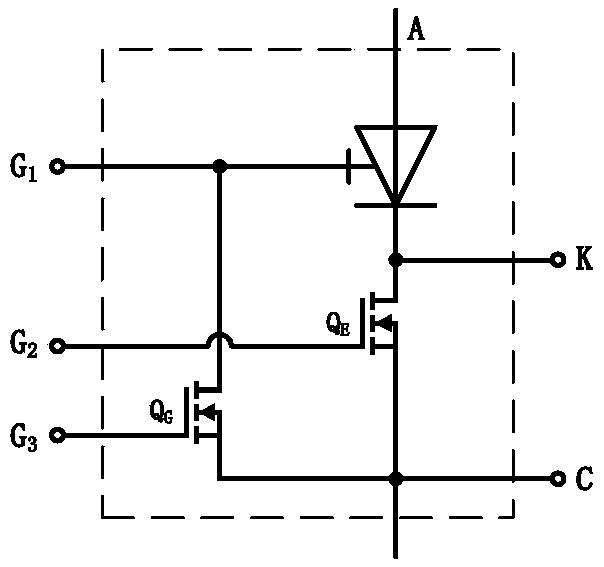

Electrical device

PendingCN110767643AReduce areaReduce stray inductanceSemiconductor/solid-state device detailsSolid-state devicesStray inductanceEngineering

The invention discloses an electrical device. The electrical device comprises a power semiconductor element, a driving module, one or more first conductive blocks and one or more elastic structures, wherein a control electrode and a current electrode of the power semiconductor element are annularly arranged, the control electrode is arranged on the annular outer ring, and the current electrode isarranged on the inner ring; the driving module comprises one or more switch elements, and is used for driving the power semiconductor element; the one or more first conductive blocks are arranged on one side of the power semiconductor element, and are used for providing connection from the switch elements to the current electrode; and the elastic structures comprise bases, auxiliary elastic piecesand springs. The electrical device has the characteristics of small commutation circuit area, low commutation circuit stray inductance and high commutation speed, the elastic structures in the electrical device provide pressure for the contact surface between the conductive blocks and a circuit board, the contact resistance is decreased, and the upper limit of the pressure borne by the surfaces of the switch elements can be limited.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com