Minimum pressure valve

A pressure valve, the smallest technology, applied in the direction of valve details, control valves, valve devices, etc., can solve the problems of increasing spring force, large opening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

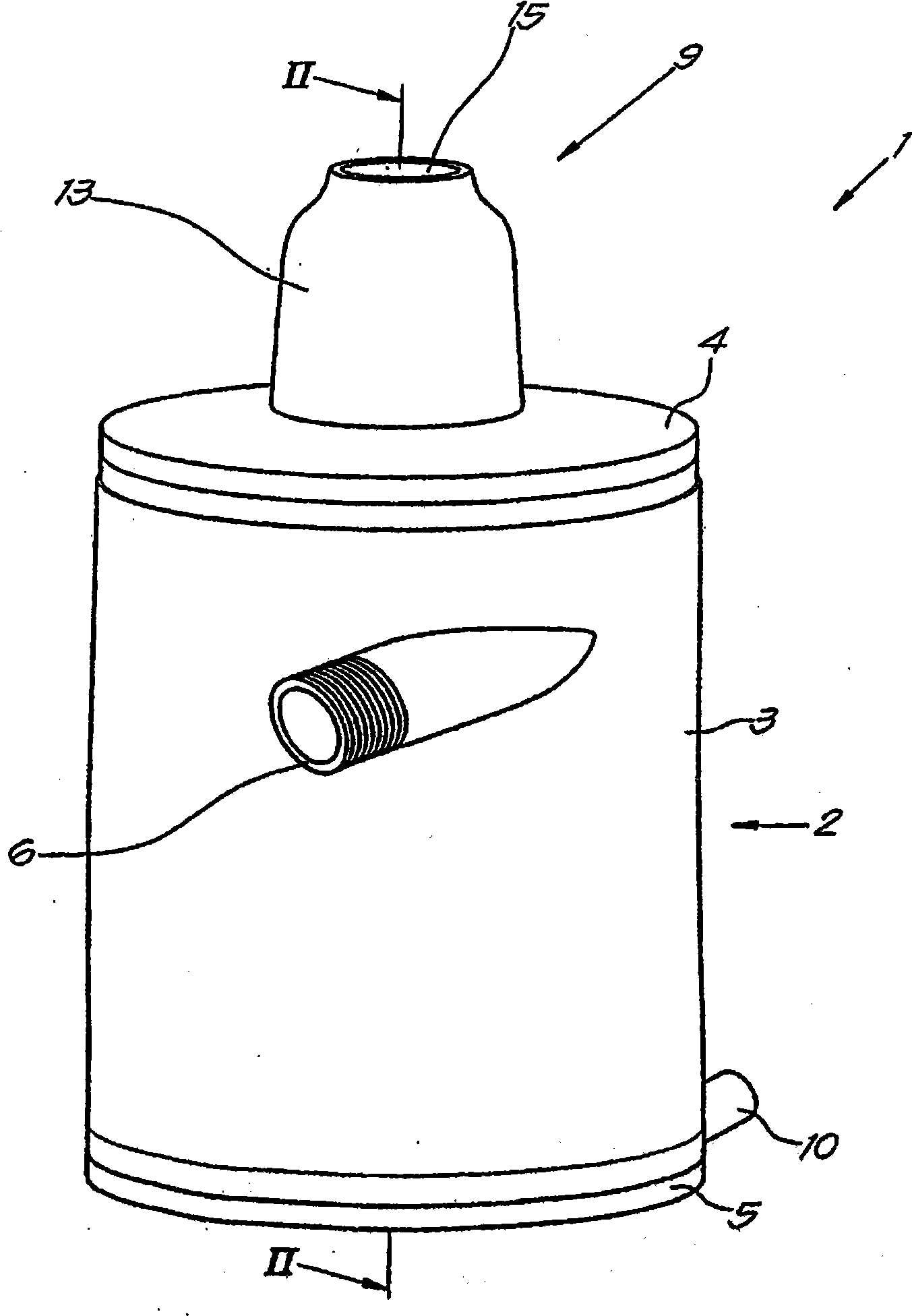

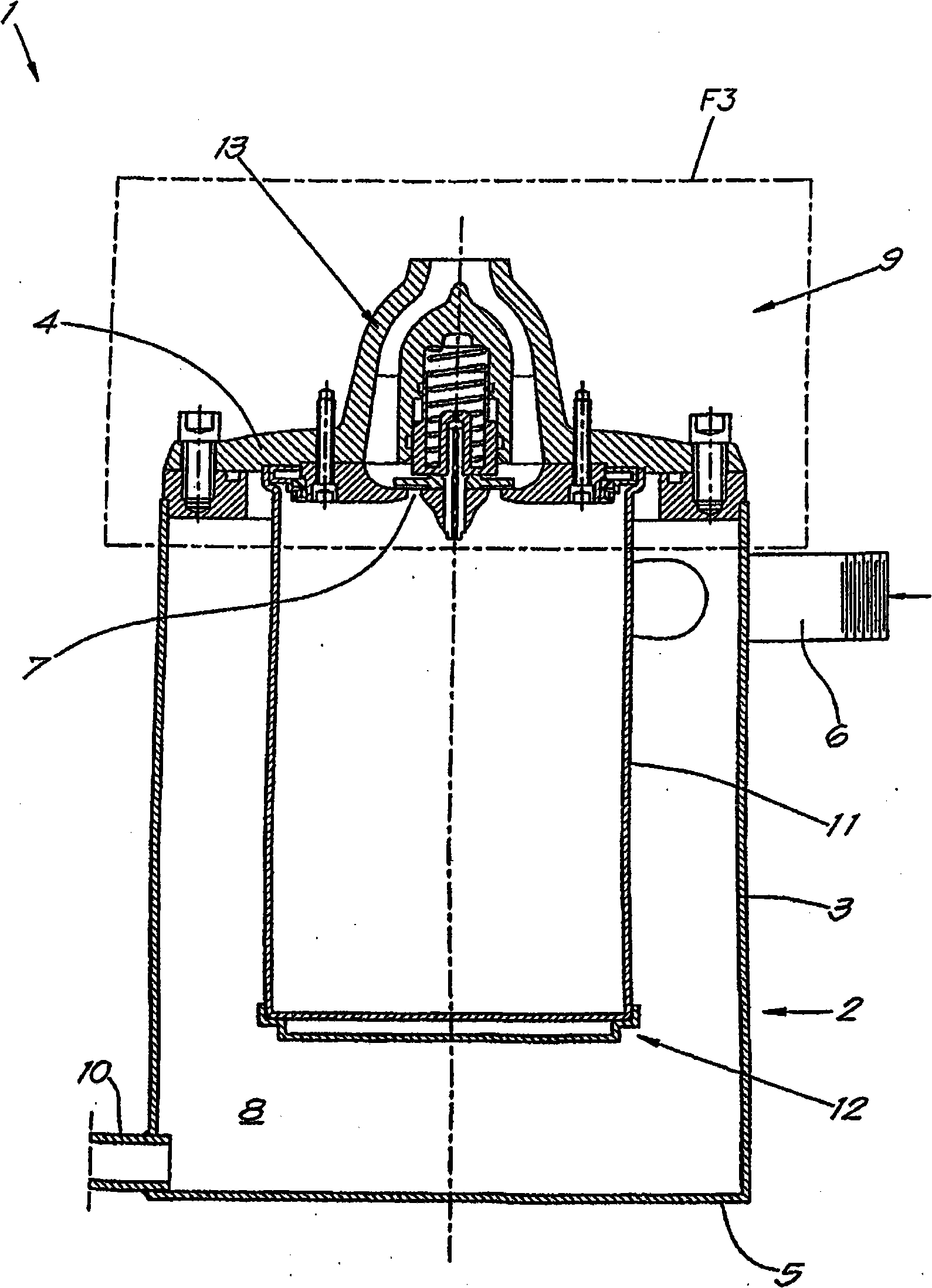

[0034] The figures show a liquid separator 1 provided with a centrifugal separator 2 consisting of a cylindrical housing 3 with an upper wall 4 and a lower wall 5 and a tangential inlet 6 and an axial outlet 7 , The housing 3 defines an inner space 8 .

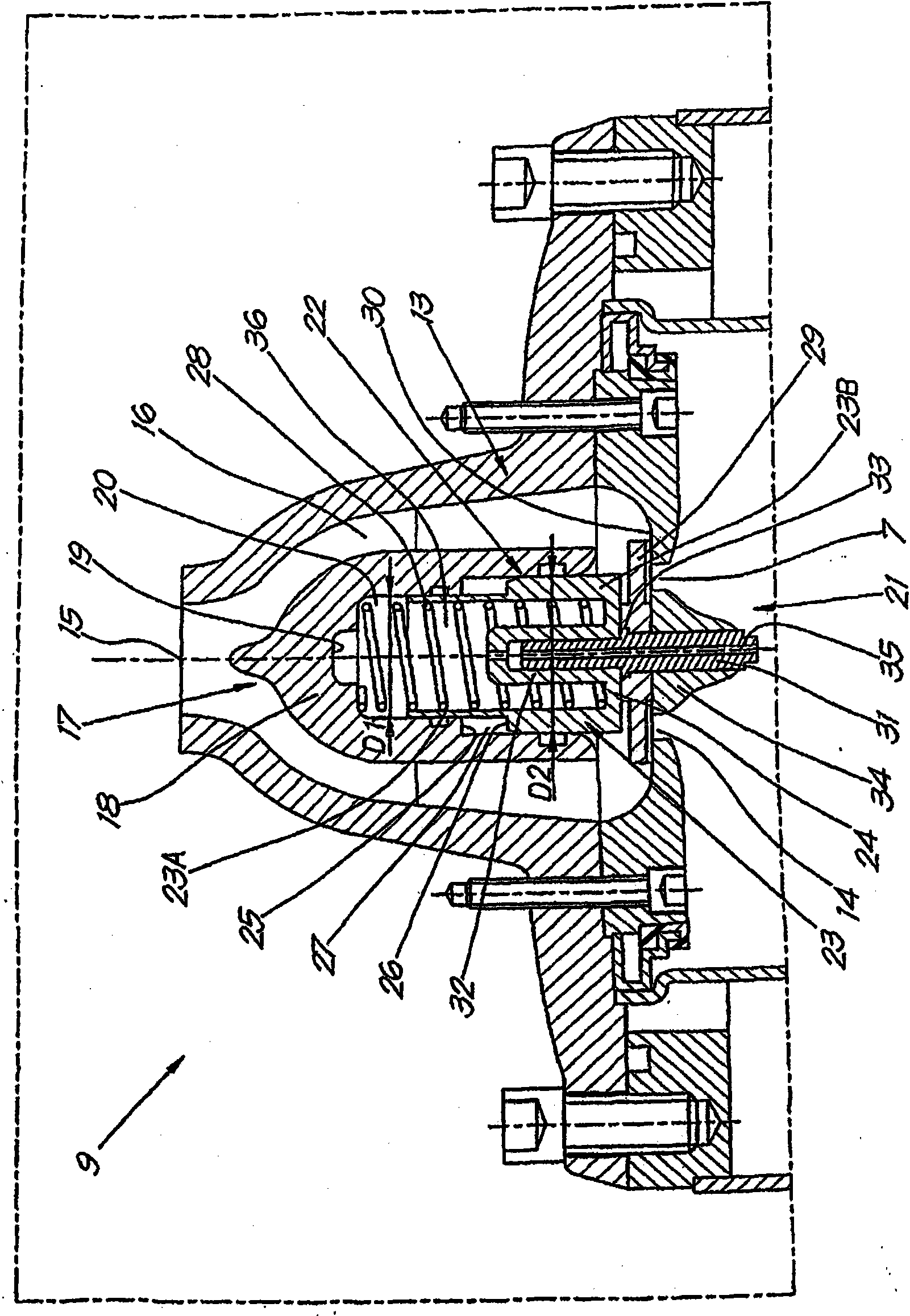

[0035] The aforementioned outlet 7 is preferably arranged in the middle of the upper wall of the housing 3 and is closed by a minimum pressure valve 9 according to the invention, which forms a connection between the space 8 and the tap point for the purge gas.

[0036] In the present example, the centrifugal separator 2 also comprises a drain hole 10 for the separated liquid, preferably located at the bottom of the centrifugal separator 2 in the installed state, on or near the aforementioned lower wall 5 .

[0037] In the present example, a flow-through element 11 (for example in the form of a coalescing filter or another type of fine filter, or in other words able to remove filter for residual droplets).

[0038] In the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com