Valve for controlling a gas flow, liquid separator, ventilation system and internal combustion engine comprising such a valve

A liquid separation and separator technology, applied in the field of air flow valves, can solve the problems of inability to provide scalability, difficult sealing, difficult engine adaptation, etc., and achieve the effects of small space requirements, low cost, and a small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

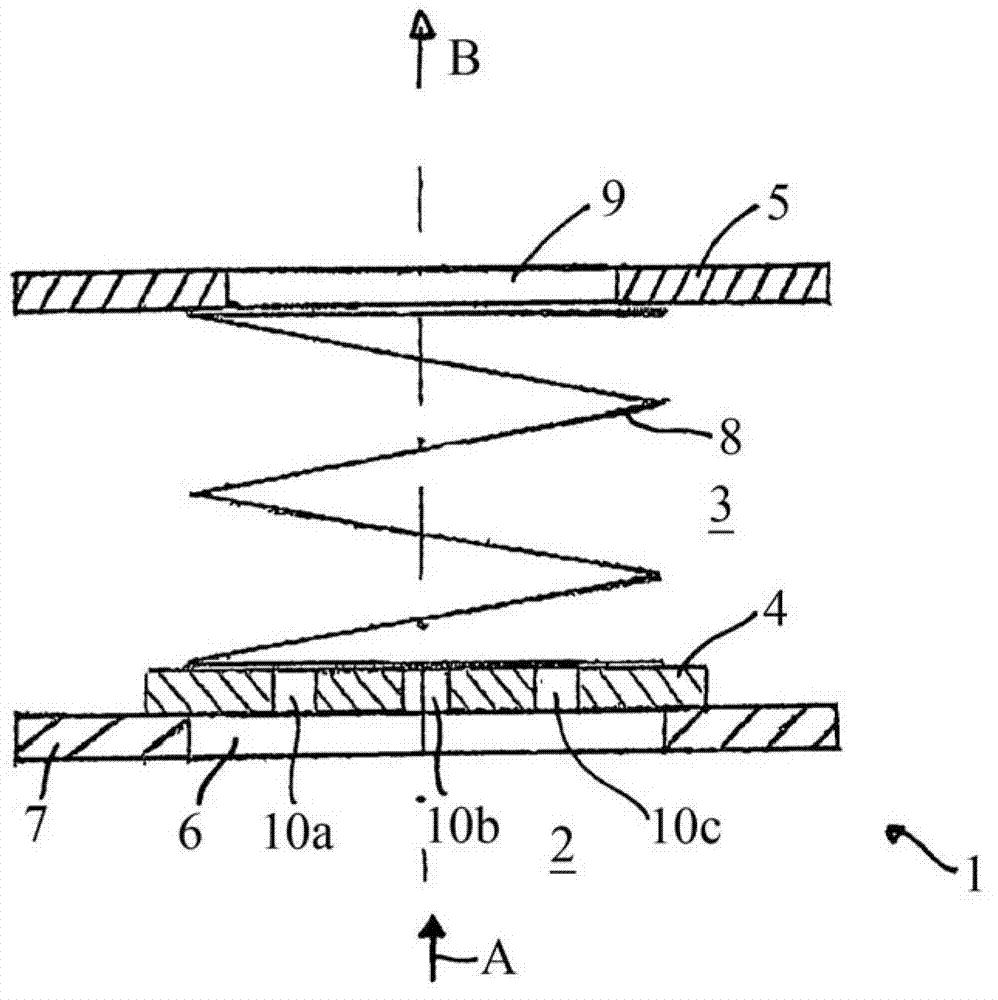

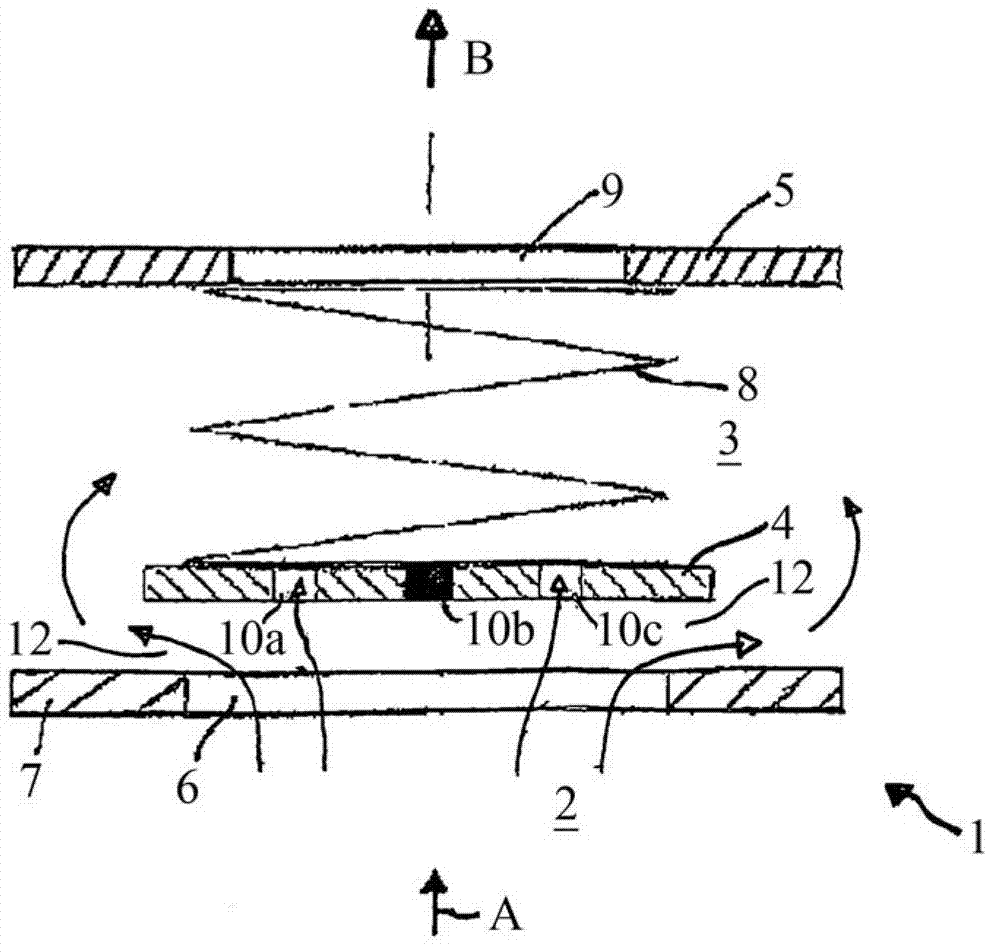

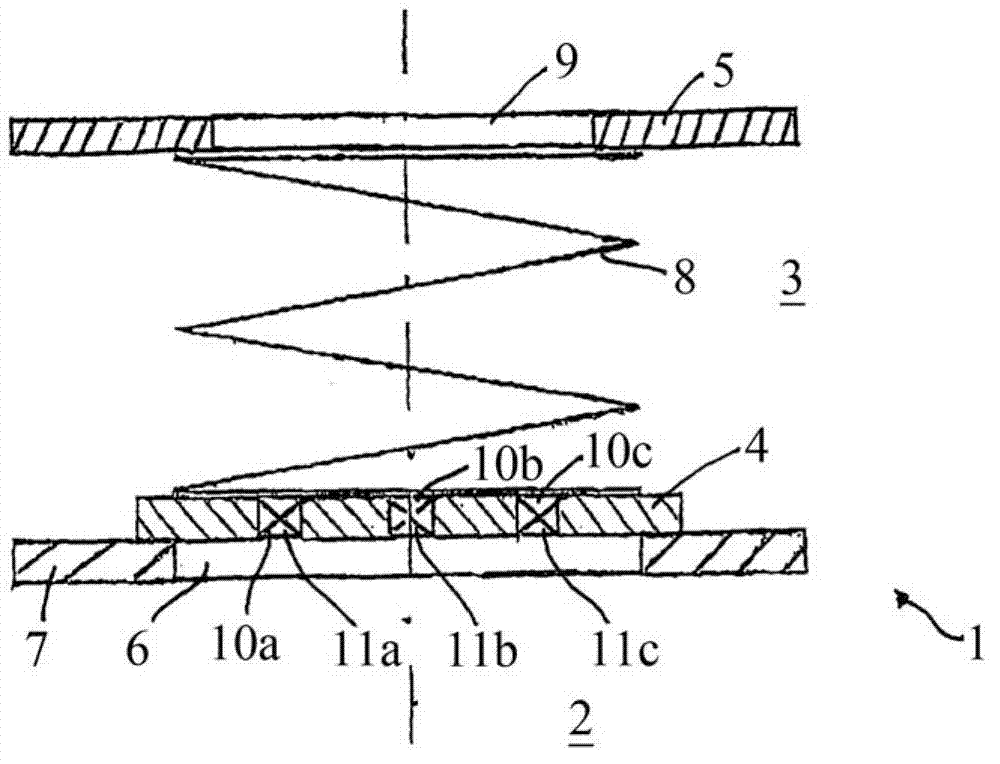

[0040] Figure 1a A valve 1 is shown, which includes a base plate or valve seat 7. The valve seat 7 includes a valve port 6. If the pressure difference between the pressure side 2 and the suction side 3 of the valve 1 is given, the valve port gas can flow through the valve port 6 from the first pressure side 2 of the valve to the valve The second suction side 3. If necessary, the valve port 6 is closed by the valve disc 4. The valve disc 4 is located on the valve seat 7. In FIG. 1, the valve disc is supported by an elastic coil spring 8 on the valve support 5, which includes a gas passage opening 9. The disc spring 8 as a compression spring is used to preload the valve disc in the direction opposite to the valve port, so that the valve disc 4 only detaches upward after exceeding a certain pressure difference between the pressure side 2 and the suction side 3 The valve seat 7 and the valve port 6 are opened. It is also possible to install the spring without preloading, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com