Patents

Literature

714results about "Flow control without auxillary power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

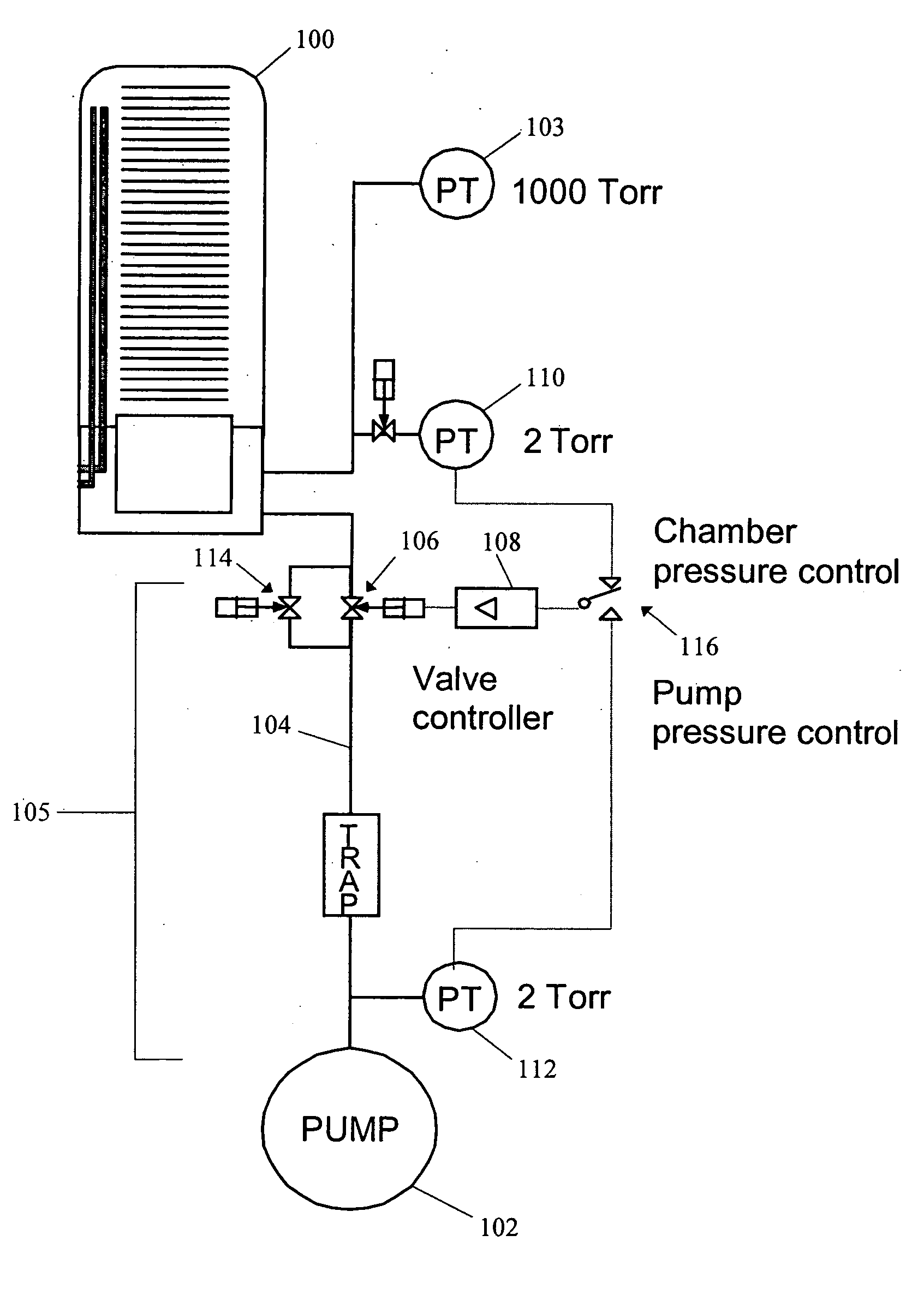

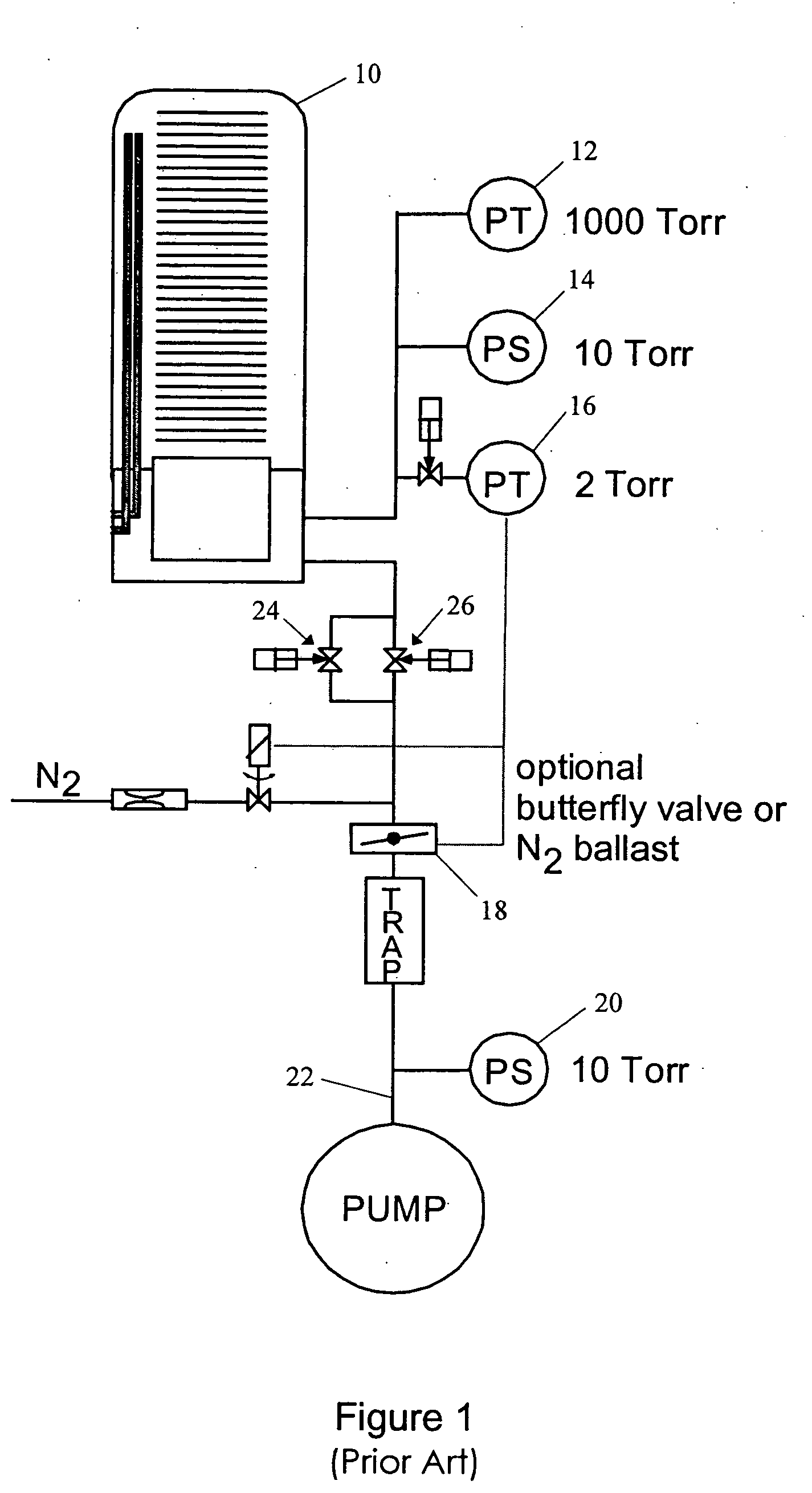

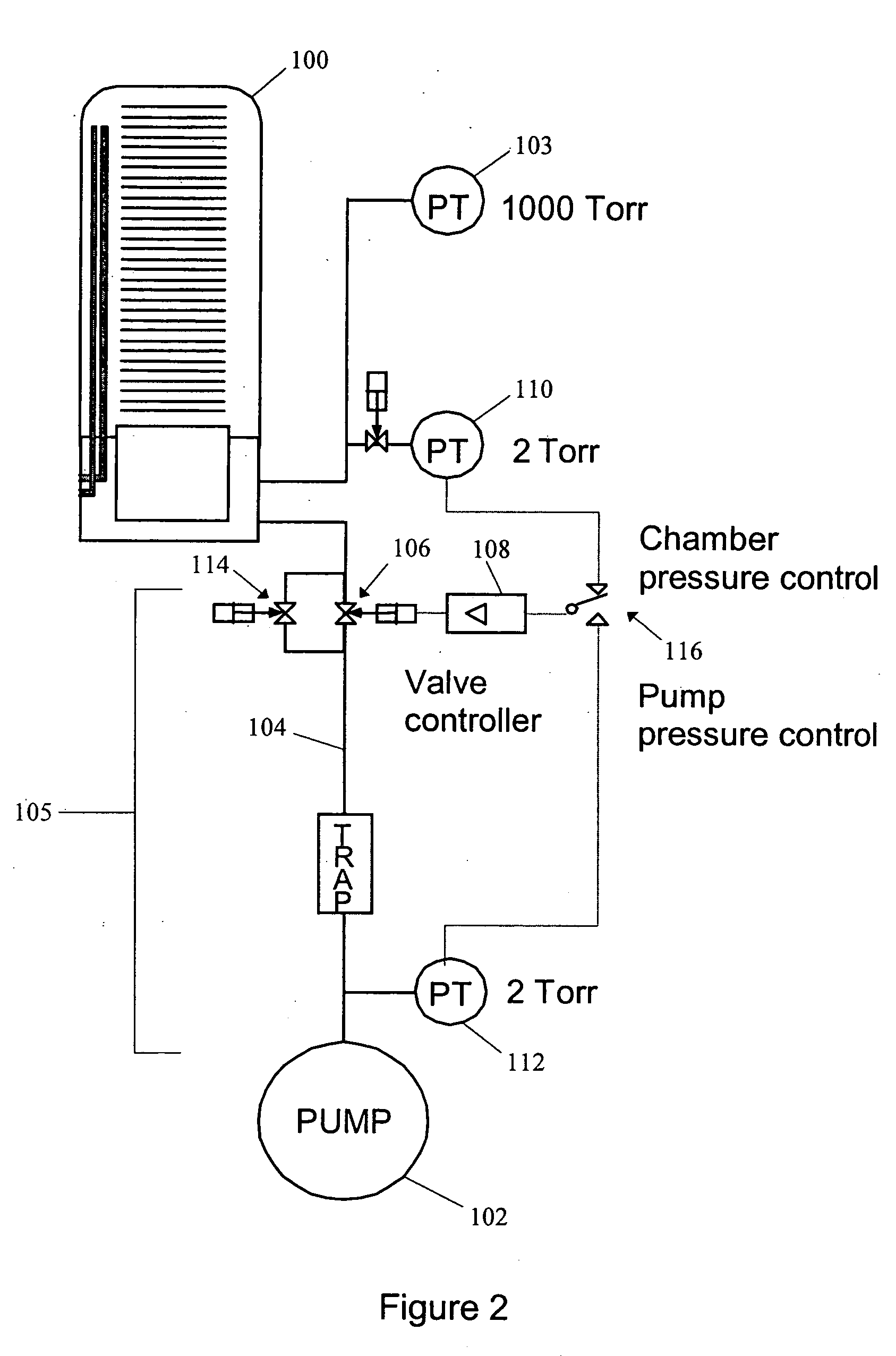

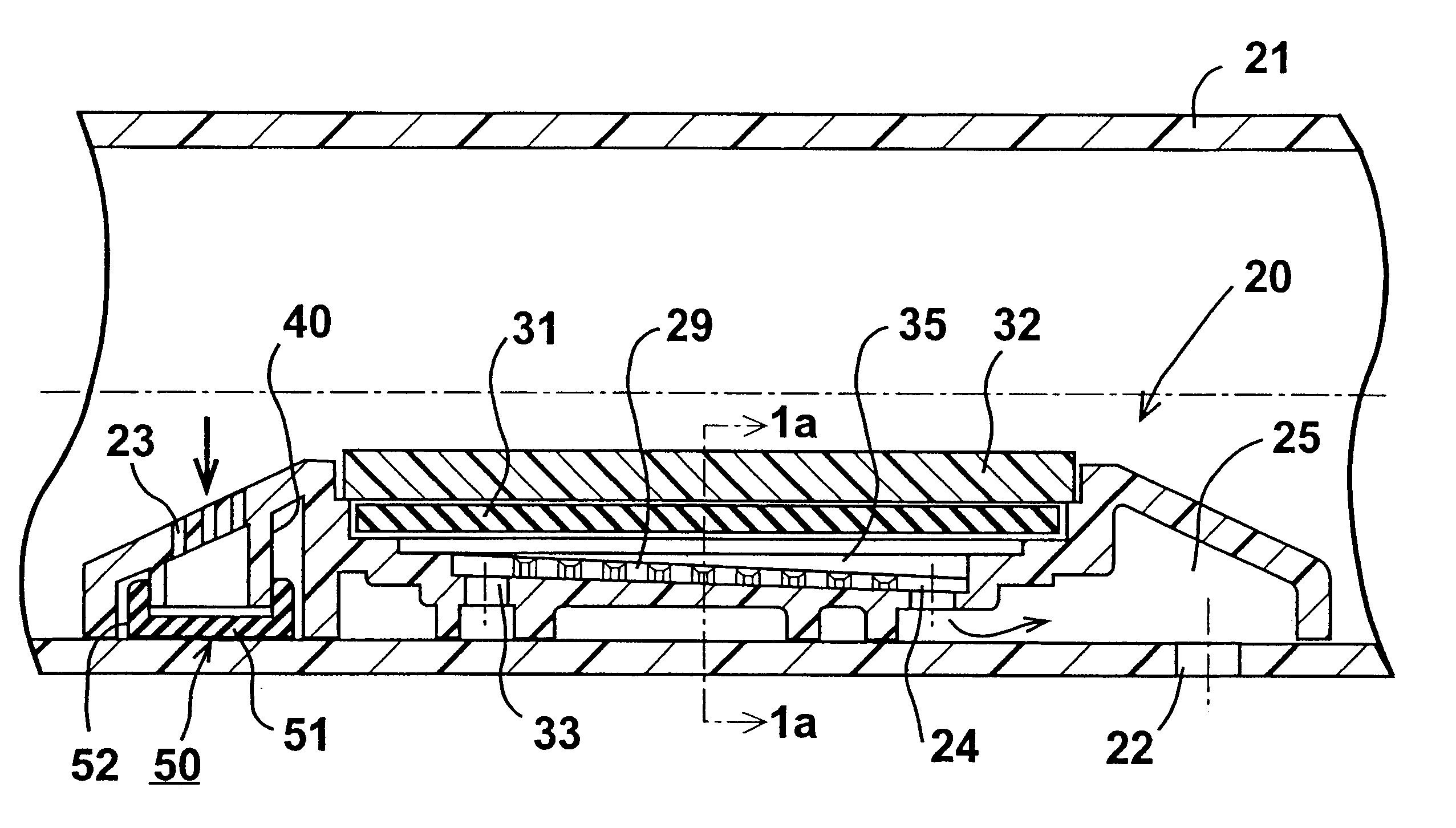

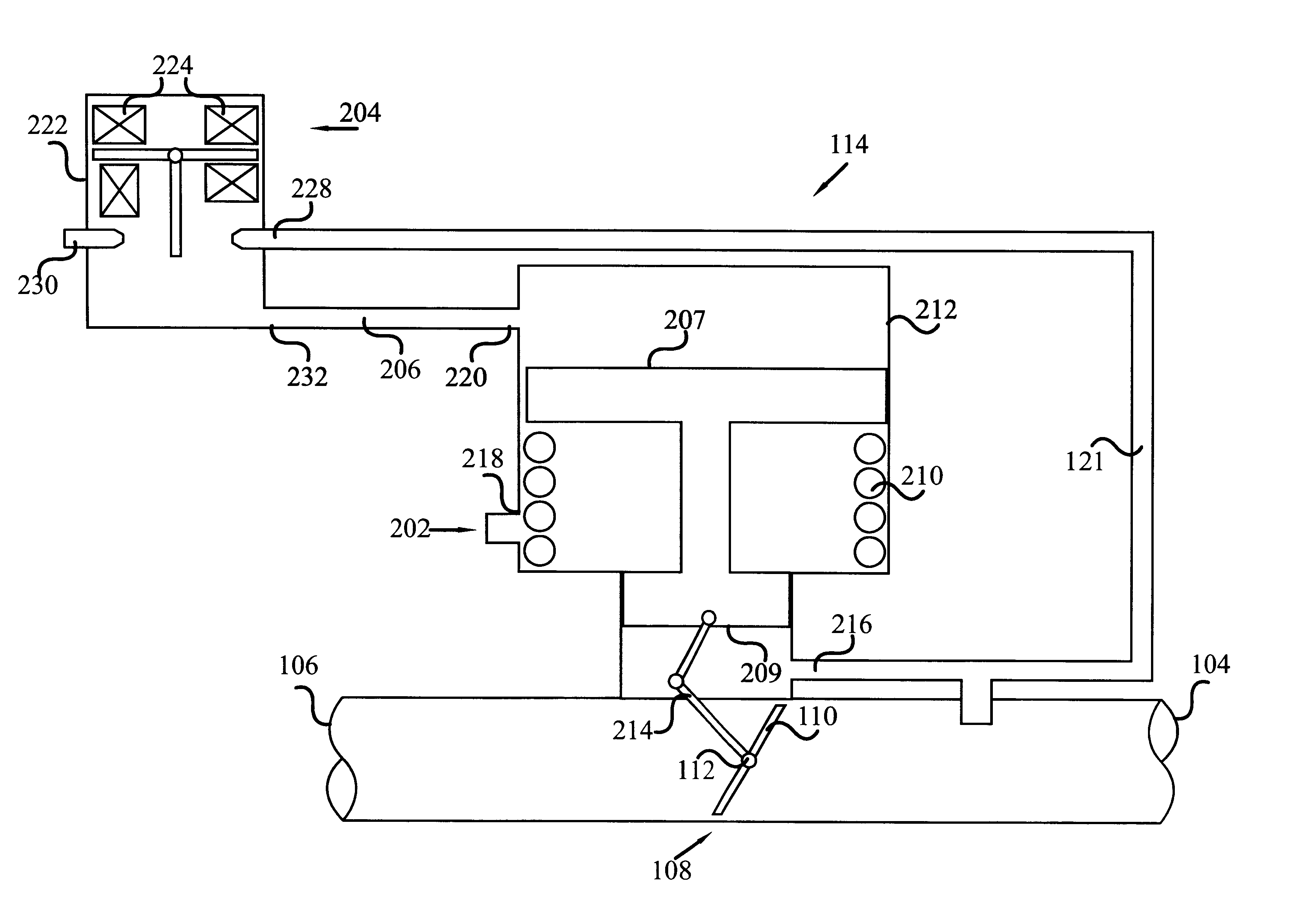

Pressure control system

ActiveUS20050279454A1Semiconductor/solid-state device manufacturingFluid pressure control using electric meansControl systemVacuum pump

A pressure control system allows gas to be evacuated out of a semiconductor process chamber at a substantially constant rate of mass flow. A gas line connects the process chamber to a vacuum pump. A controllable valve having a variable sized opening is positioned between the process chamber and the vacuum pump. A pressure sensor is in turn positioned between the valve and the vacuum pump, proximate the inlet to the vacuum pump. The size of the variable sized opening is regulated based upon the pressure in the gas line measured by the pressure sensor. The size of the valve opening is varied to maintain the pressure measured by the pressure sensor at a constant value. As a result, because the quantity of gas flowing through the gas line is proportional to the gas pressure, a substantially constant mass flow of gas out of the chamber and into the pump can be achieved.

Owner:ASM INTERNATIONAL

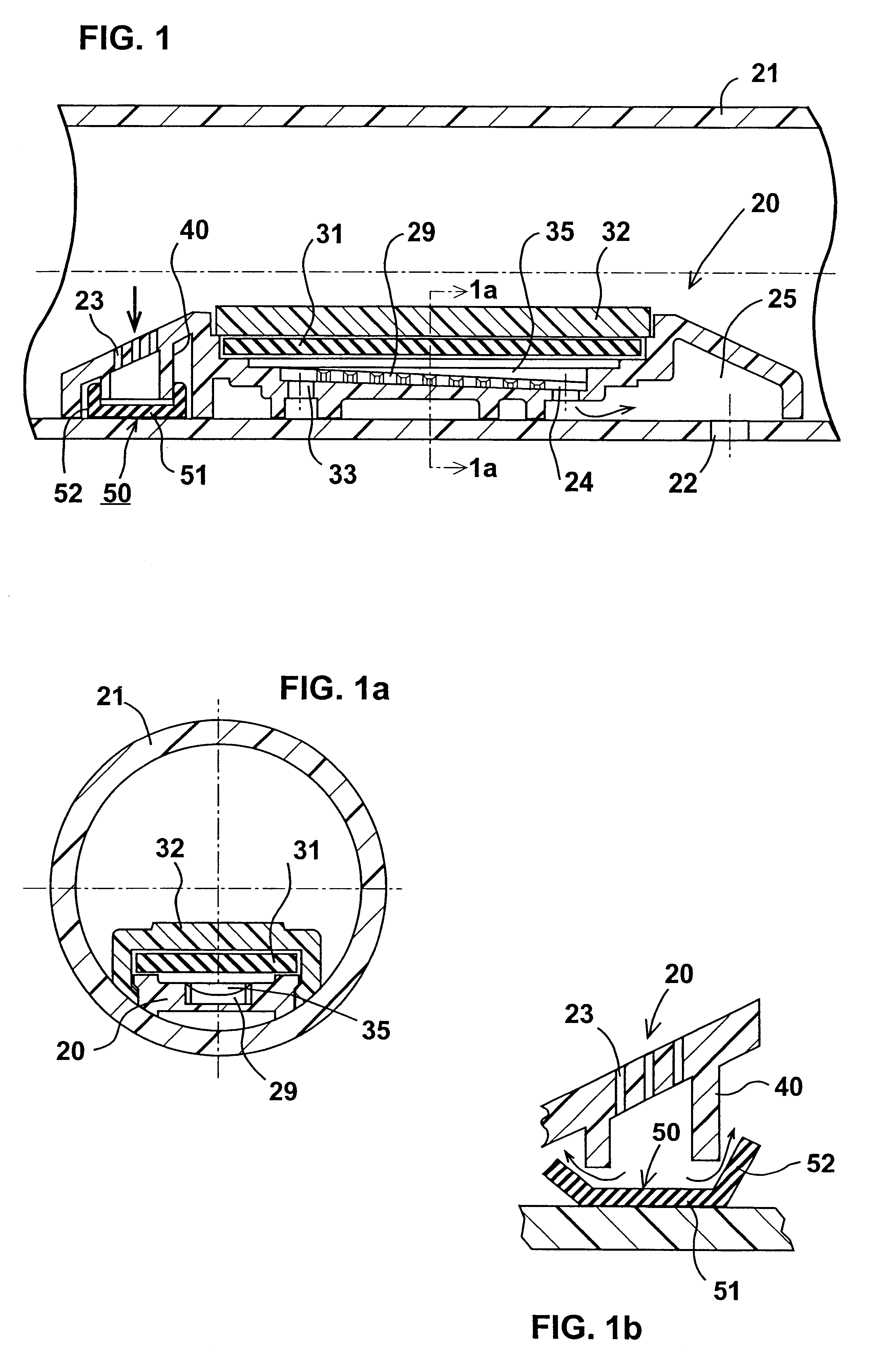

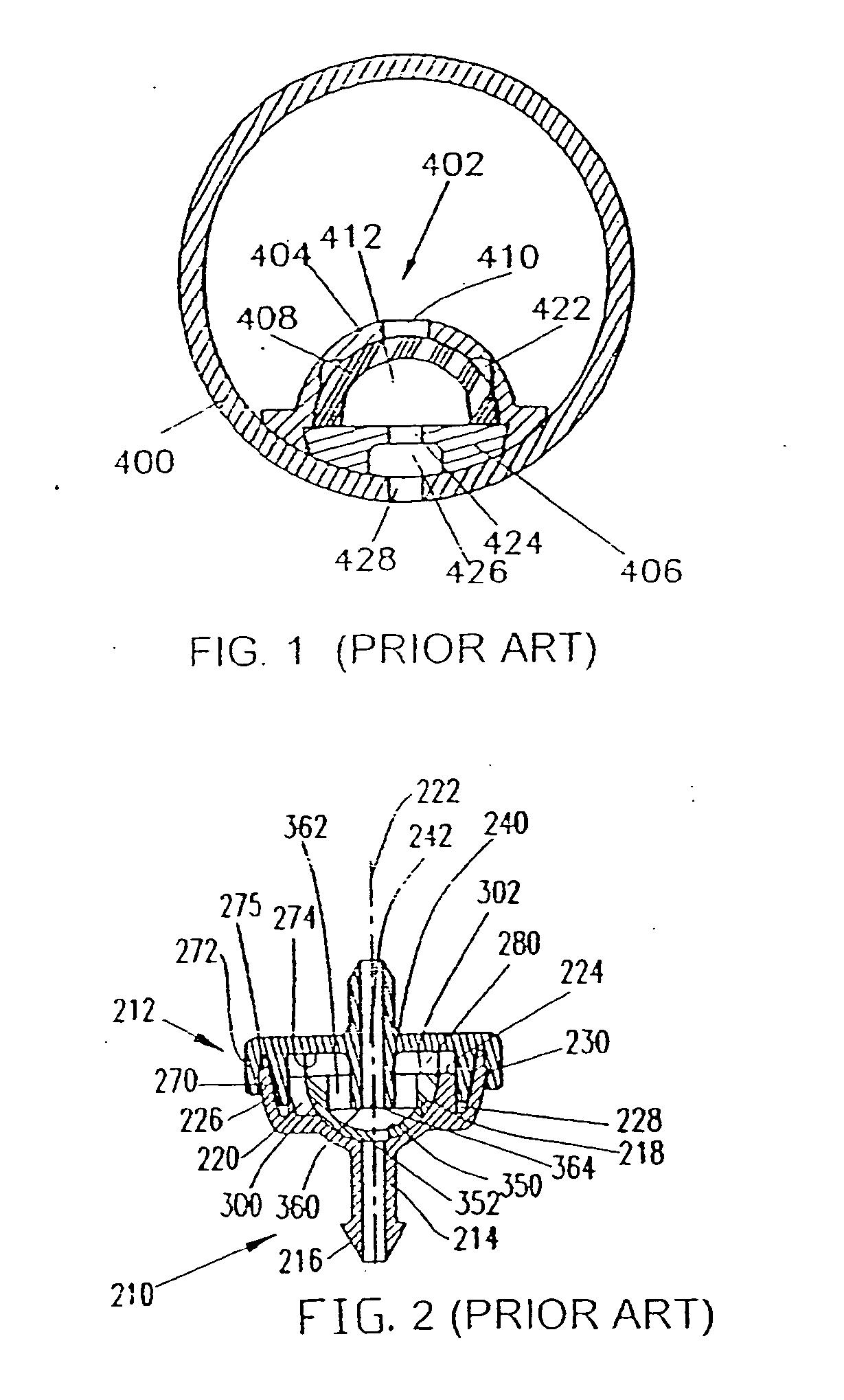

Drip irrigation lines

InactiveUS6302338B1Reduce sensitivityAbility to saveClimate change adaptationWatering devicesWater dischargePore water pressure

A drip irrigation line includes a plurality of emitter units secured within a water supply tube such that each emitter unit defines with the tube a flow-control passageway having an inlet port communicating with the interior of the water supply tube and an outlet port communicating with a water discharge opening in the water supply tube. Each emitter unit includes a one-way valve at one of the ports. Such port has an opening circumscribed by a cylindrical boss, and the one-way valve thereat includes a cap having a skirt of elastomeric material normally engaging the outer surface of the cylindrical boss to block reverse water flow into the flow-control passageway, but is deformable under water pressure to permit forward flow from the tube interior into the flow-control passageway.

Owner:COHEN

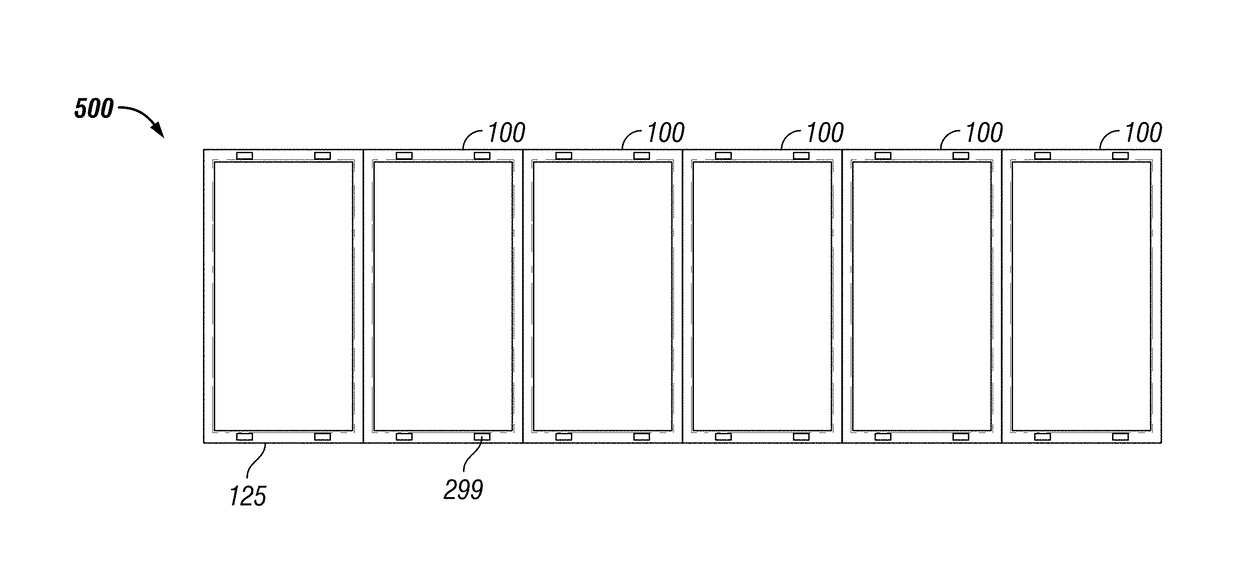

High pressure manifold, assembly, system and method

The present application is directed to a manifold system for low pressure and high pressure fluids. The manifold system may include one or more manifold sub-assemblies that may be assembled together, separated apart and replaced as desired. In oil and gas hydraulic fracturing operations, each manifold sub-assembly includes two or more low pressure fluid lines and two or more high pressure fluid lines for fluidly communicating with hydraulic fracturing pumps. High pressure fluid may exit the manifold system via a single line or multiple lines.

Owner:MGB OILFIELD SOLUTIONS LLC

Device and method for creating hydrodynamic cavitation in fluids

A device and method for creating hydrodynamic cavitation in fluid is provided. The device can include a flow-through chamber having a first portion and a second portion, and a plurality of baffles provided within the second portion of the flow-through chamber. One or more of the plurality of baffles can be configured to be selectively movable into the first portion of the flow-through chamber to generate a hydrodynamic cavitation field downstream from each baffle moved into the first portion of the flow-through chamber.

Owner:ARISDYNE STSTEMS INC

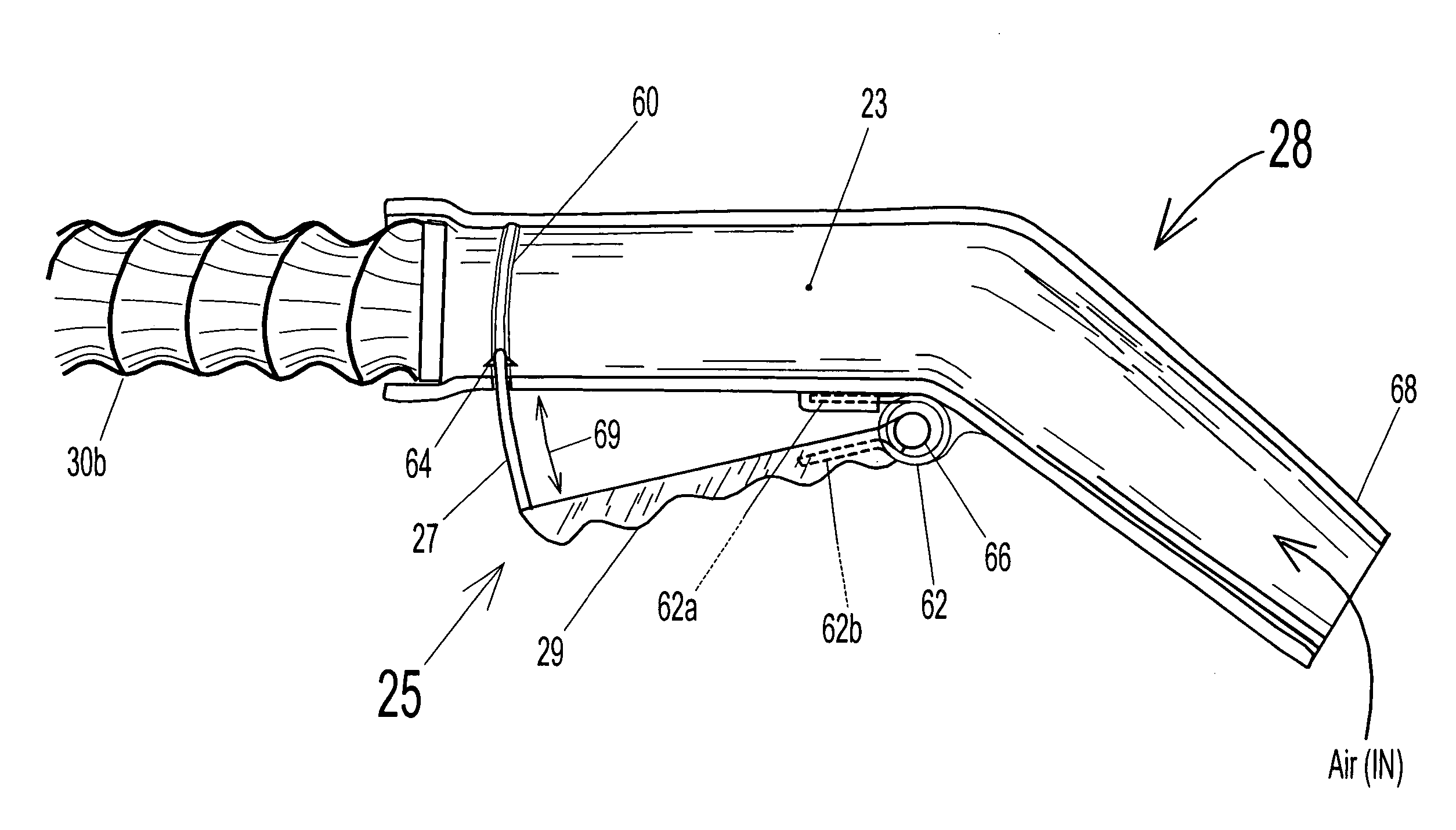

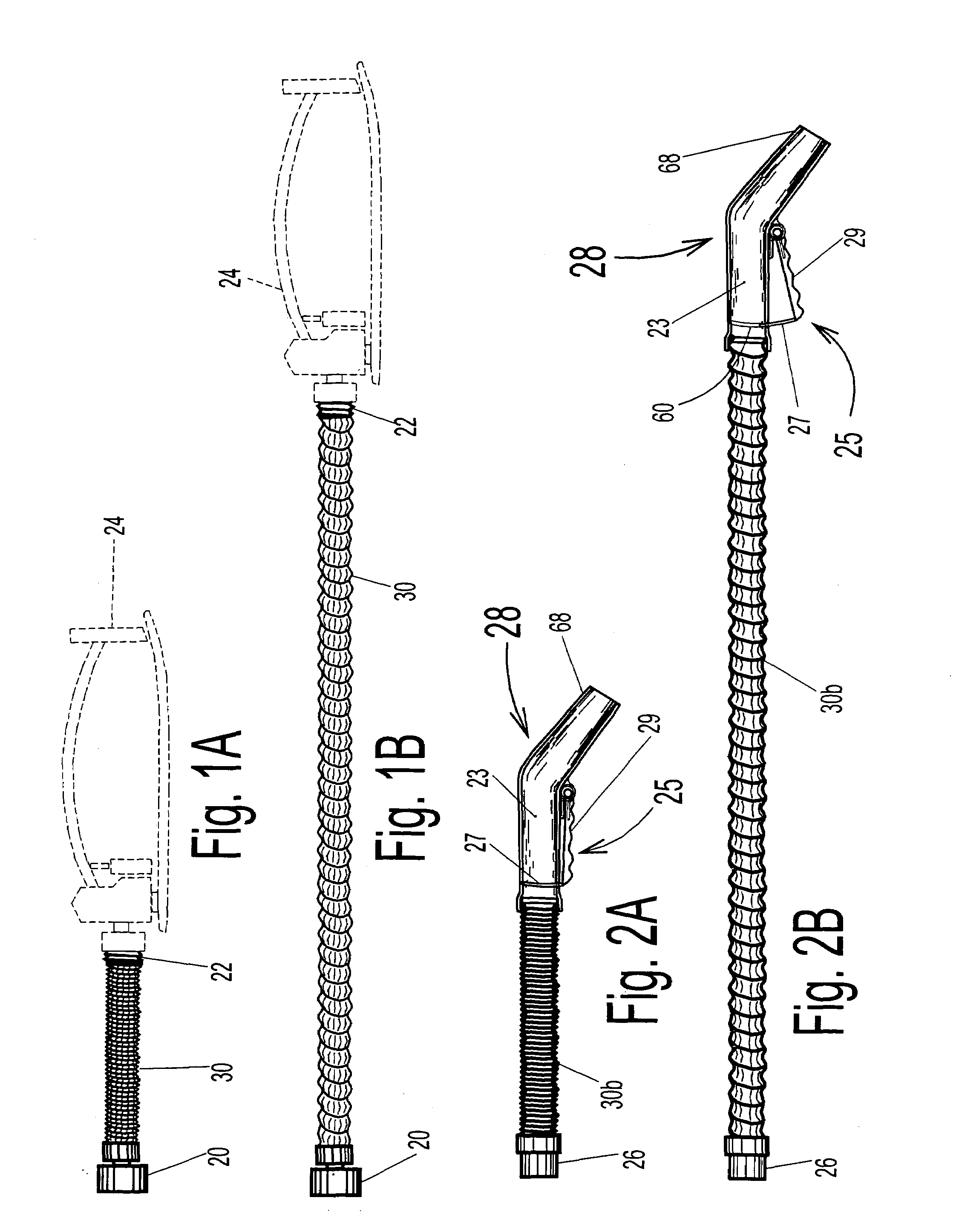

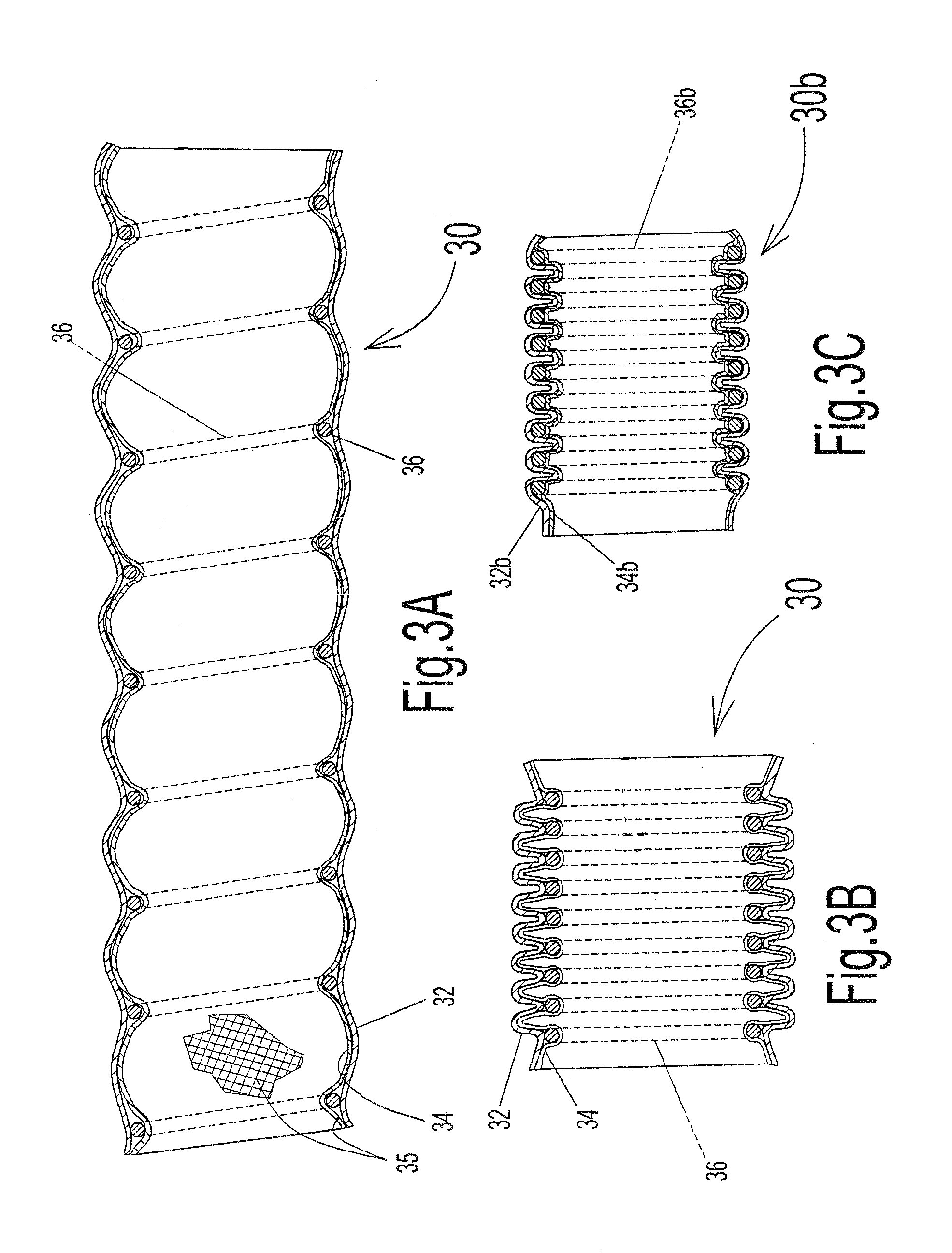

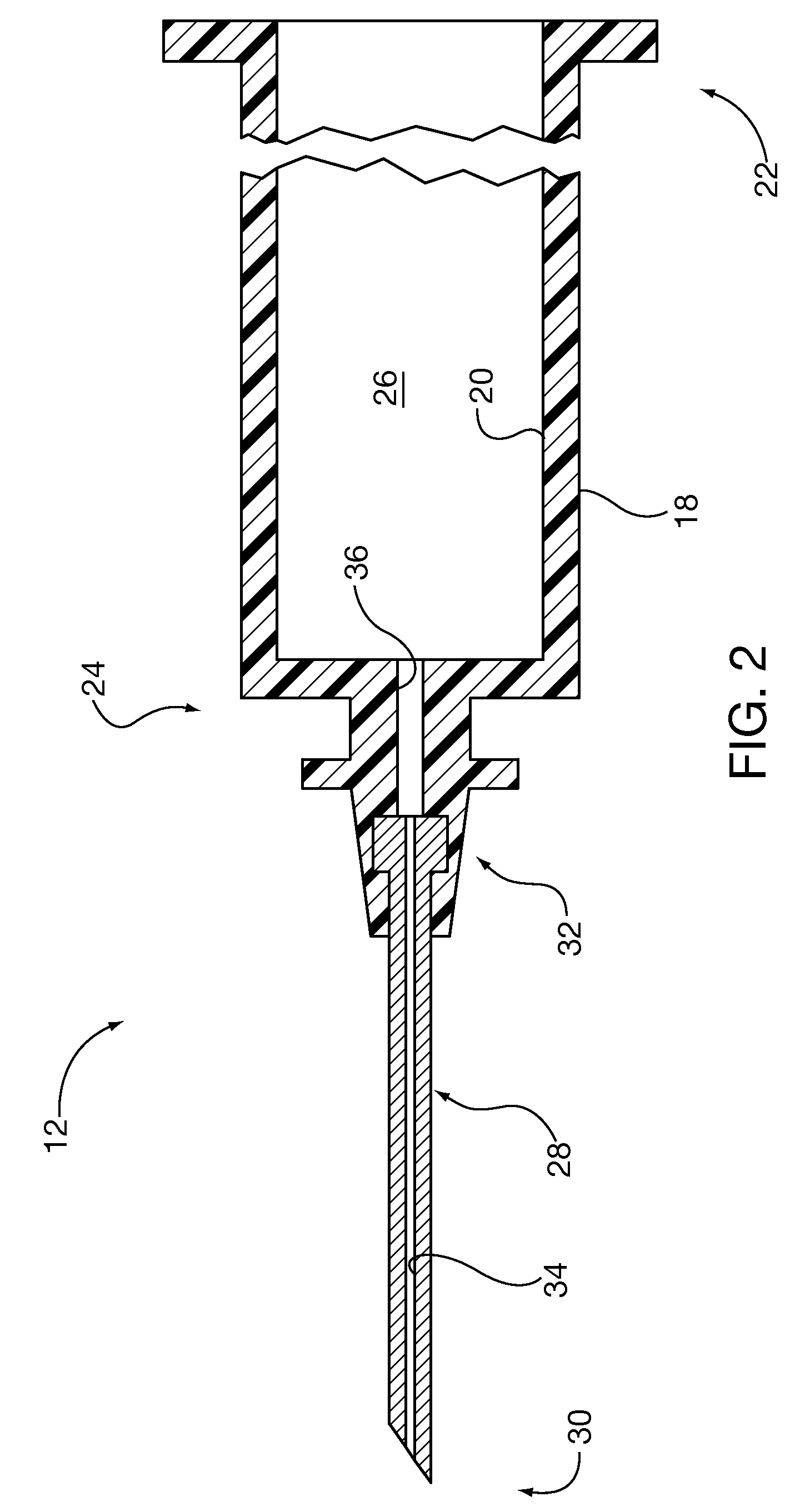

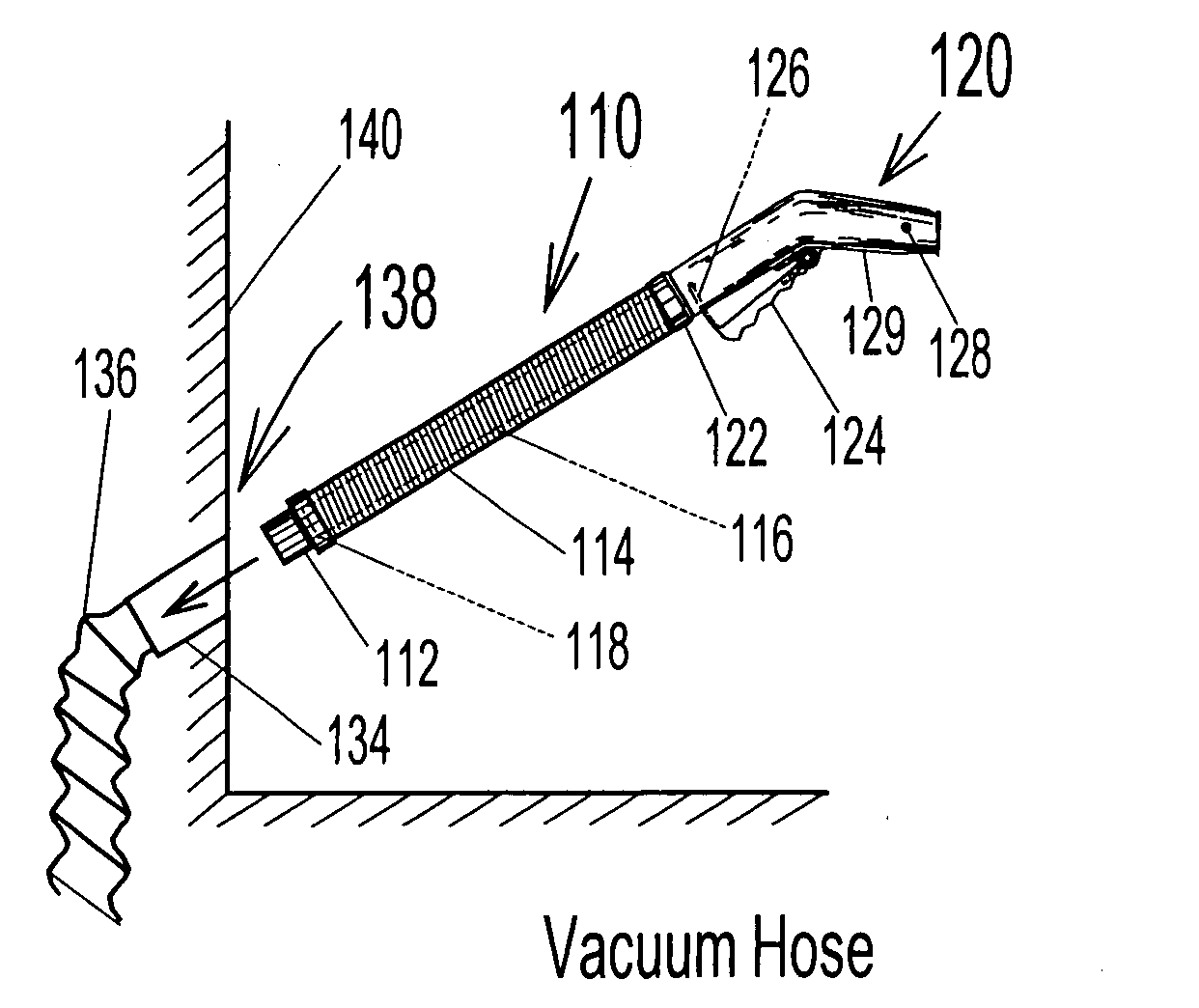

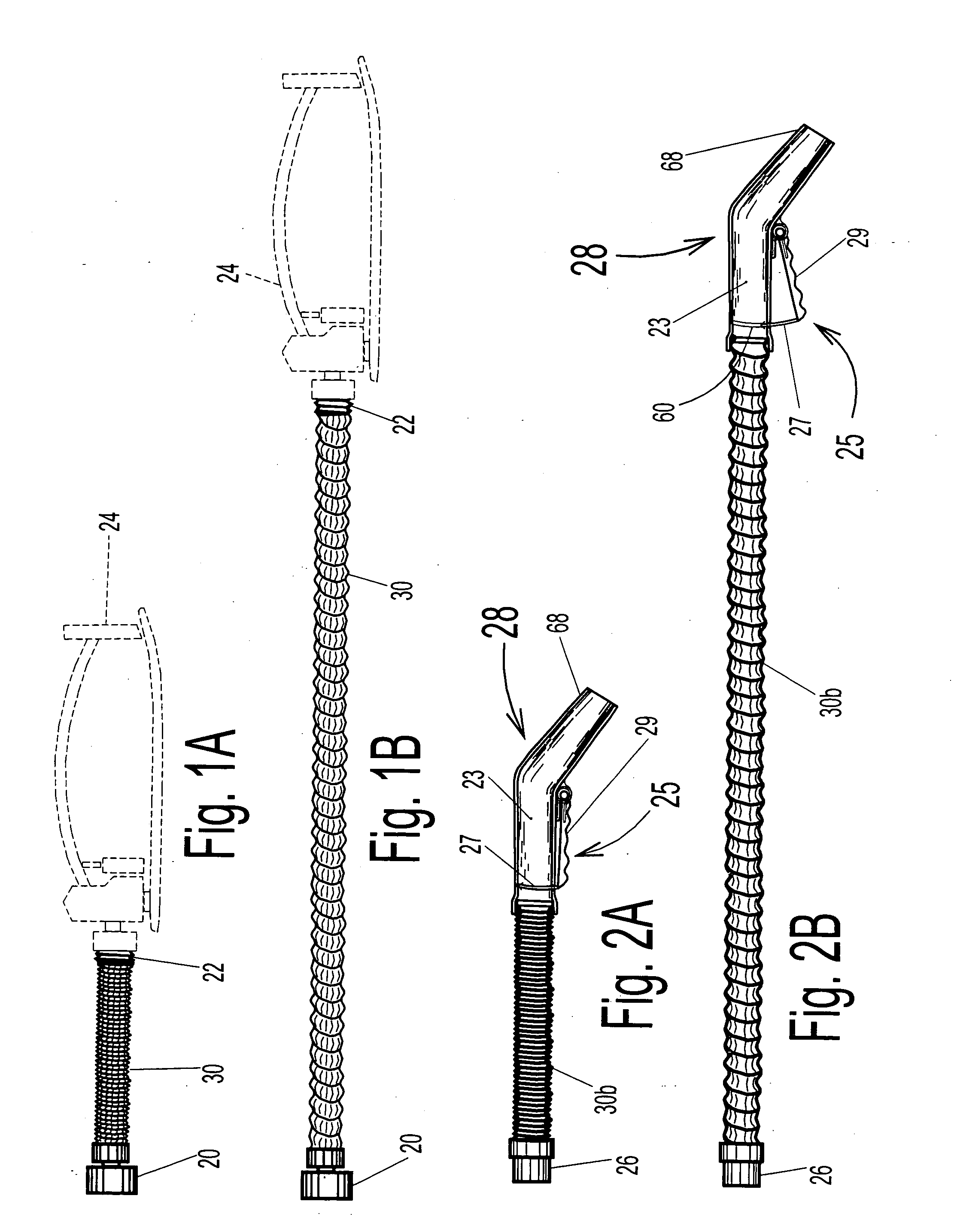

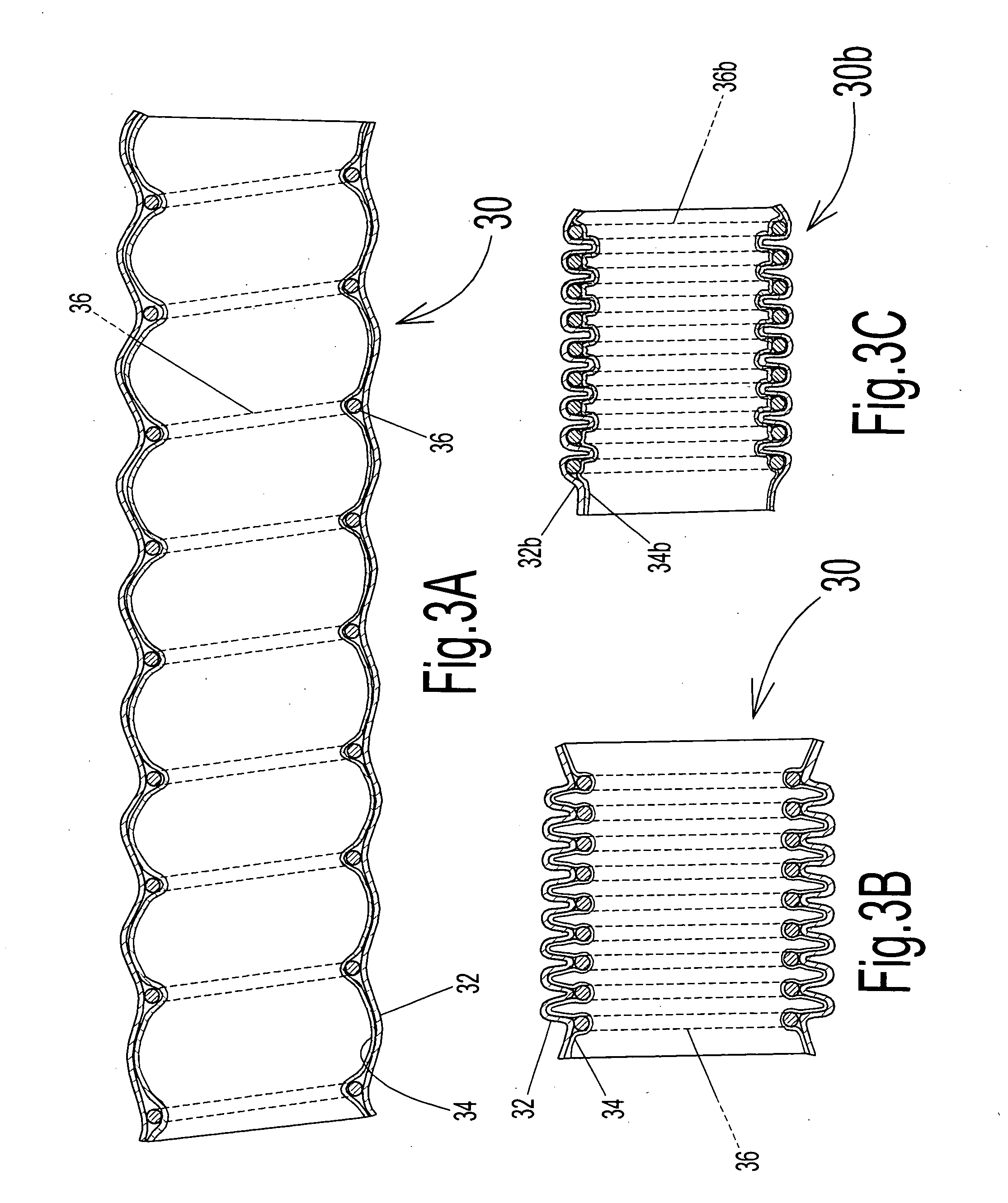

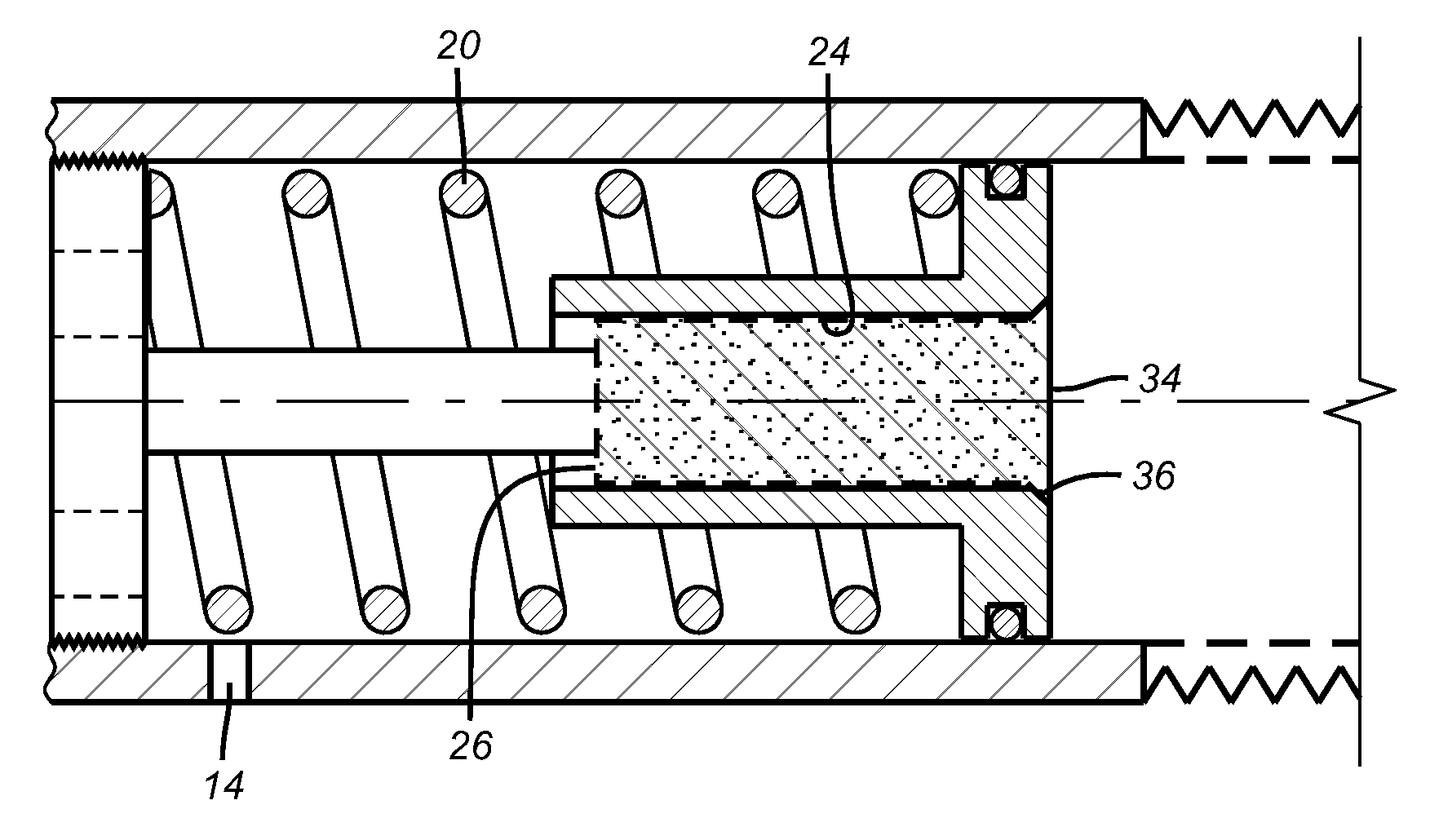

Linearly retractable pressure hose

A linearly self-actuated hose for use in transporting fluids (liquids, gases, solid particles, and combinations of these three). Hose (30) has a biasing spring (36) that extends along its full length, and can comprise single or multiple springs and / or multiple diameter spring coils. Spring (36) is covered with hose cover material (32) on the outside and hose cover material (34) on the inside to form a sealed hose and are bowed inward or outward radially between the individual spring coils depending on the intended use of hose (30) to give the cover materials room to move out of the way when the hose retracts and the coils of spring (36) are forced close together. The Linearly Retractable Hose is operated by changing internal pressure within the hose relative to the ambient pressure on the exterior of the hose. Control of fluid pressure within hose (30) is what allows the hose to operate as an automatically extendable and retractable hose. The biasing of spring (36) depends on the type of use for the hose. For hose (30b), which will be used as a vacuum hose then the biasing spring (30b) must exert an extending force on the cover material (opposite that for a pressure hose). If the hose is to be used as a pressure hose (garden hose, etc.), spring (36) will need to have a bias that exerts a retracting force on cover materials (32) and (34).

Owner:TELEBRANDS CORP

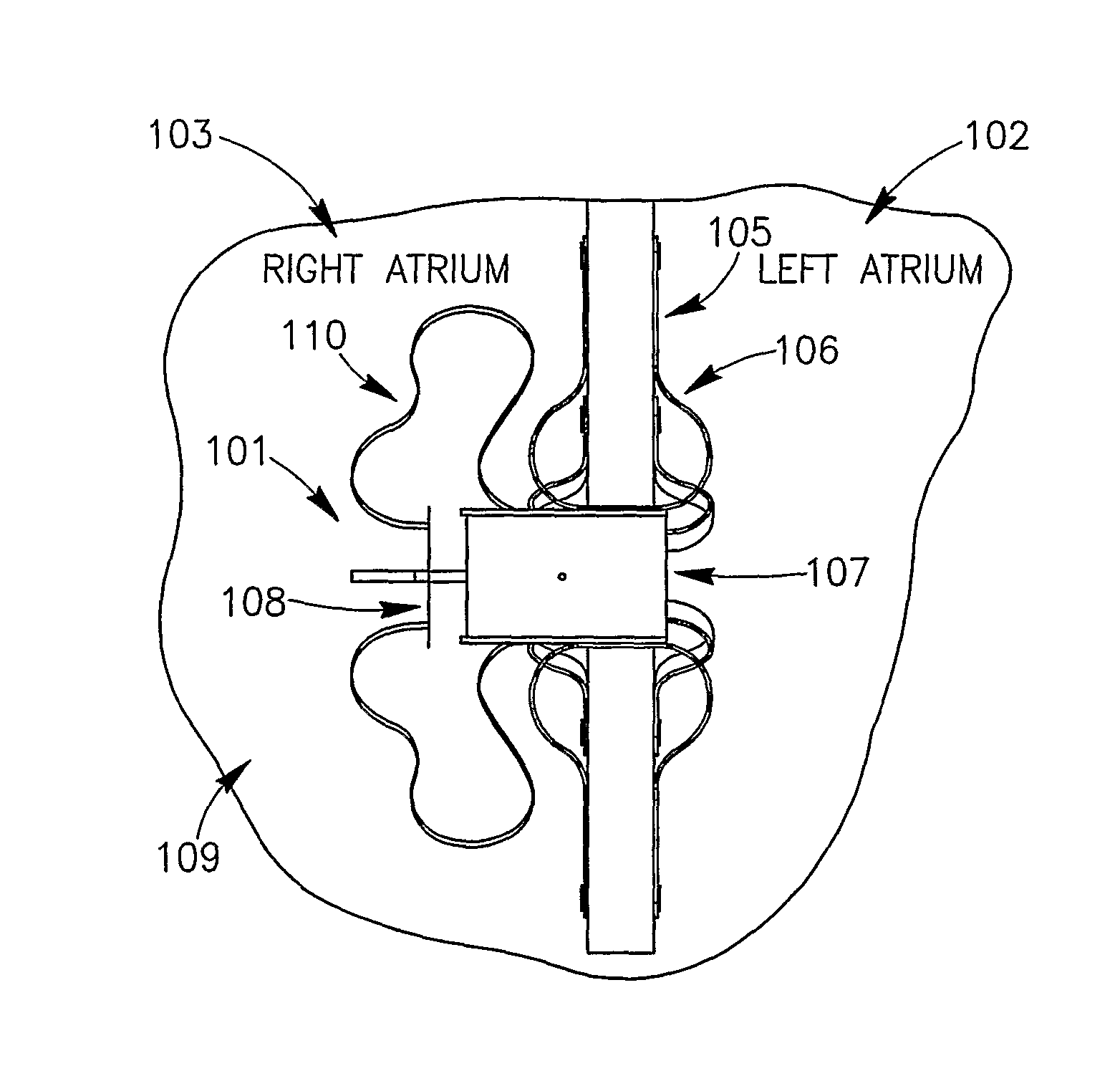

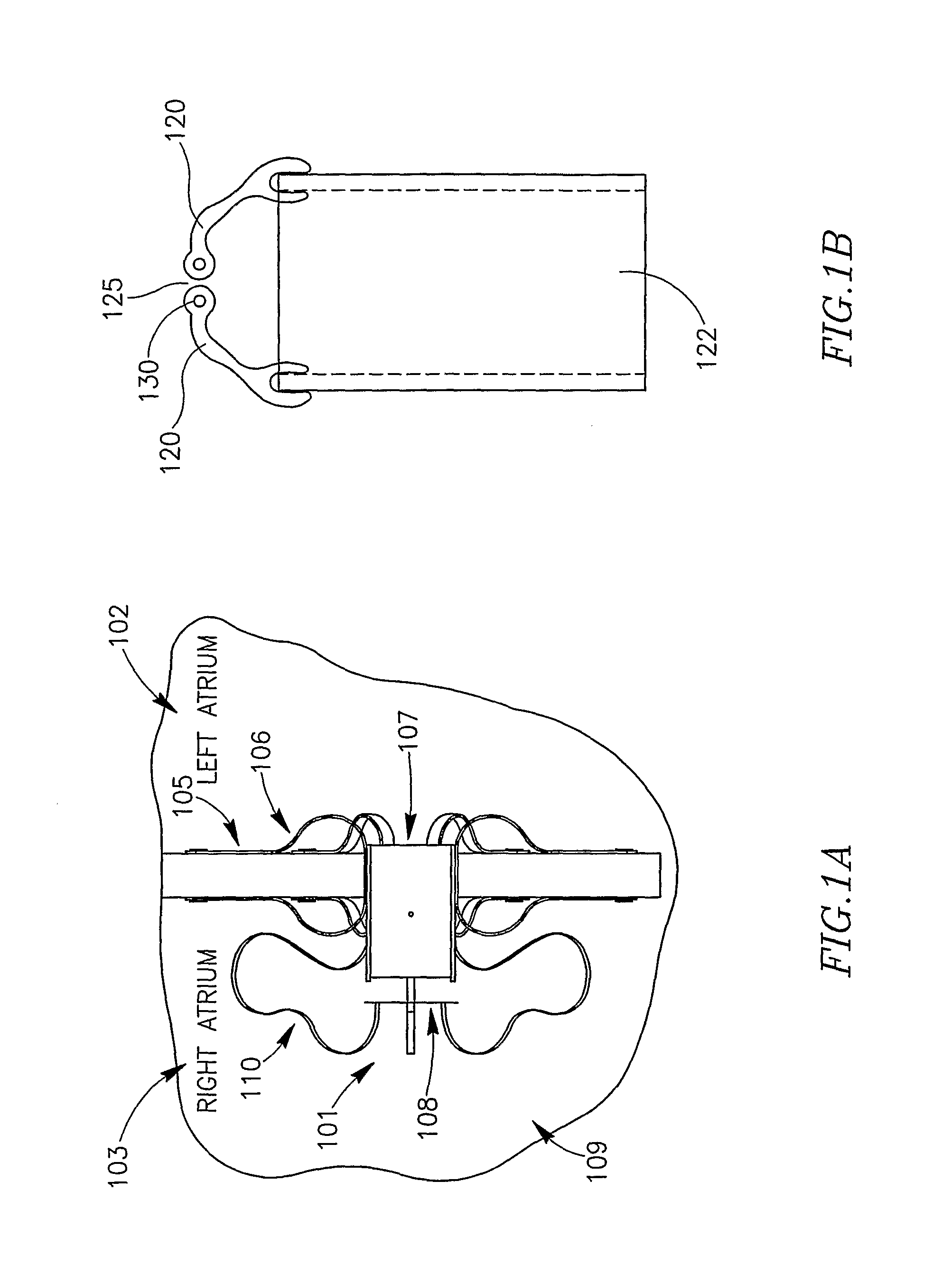

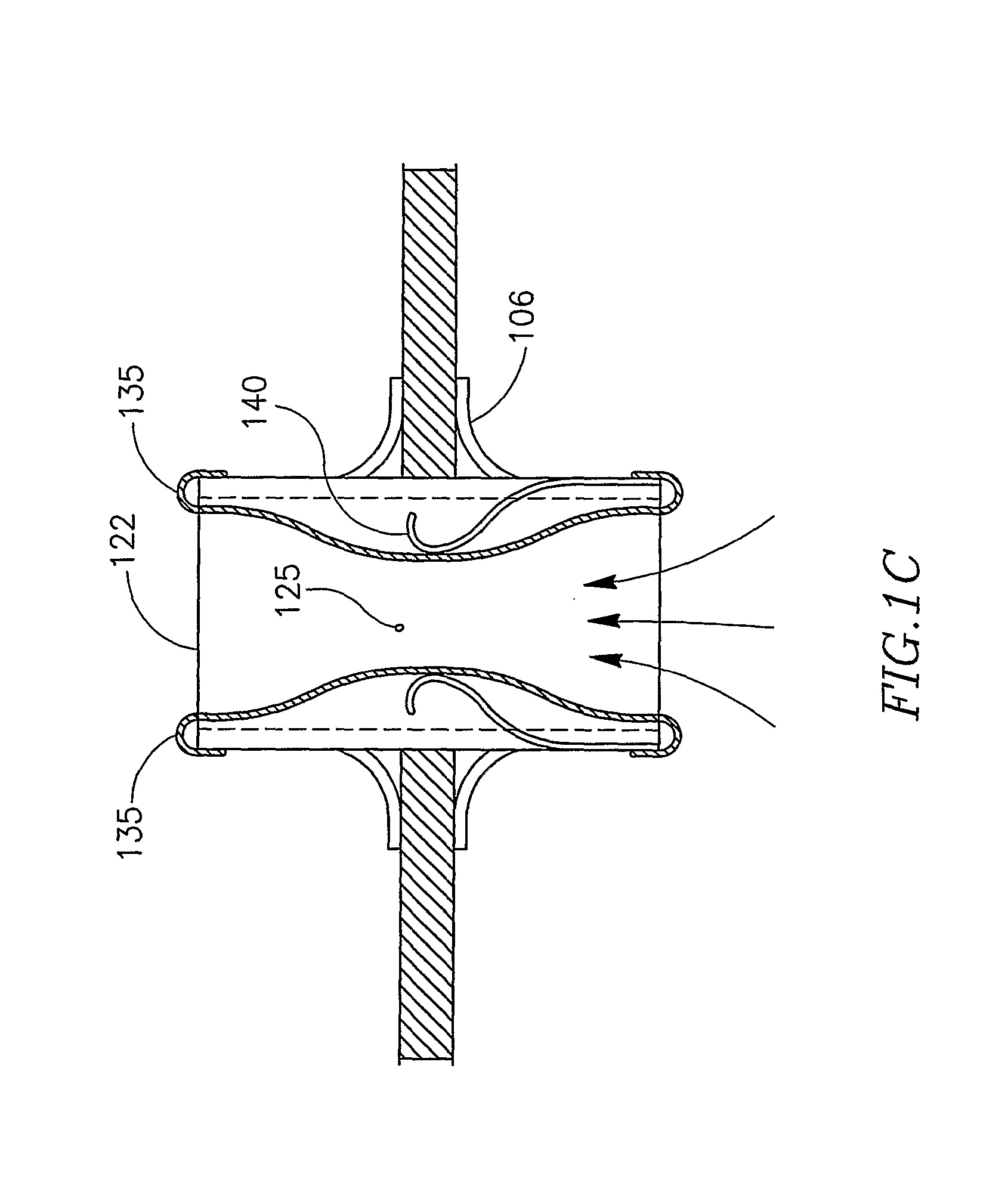

Device And Method For Controlling In-Vivo Pressure

A differential pressure regulating device is provided for controlling in-vivo pressure in a body, and in particularly in a heart. The device may include a shunt being positioned between two or more lumens in a body, to enable fluids to flow between the lumens, and an adjustable flow regulation mechanism being configured to selectively cover an opening of the shunt, to regulate the flow of fluid through the shunt in relation to a pressure difference between the body lumens. In some embodiments a control mechanism coupled to the adjustable flow regulation mechanism may be provided, to remotely activate the adjustable flow regulation mechanism.

Owner:WAVE LTD V

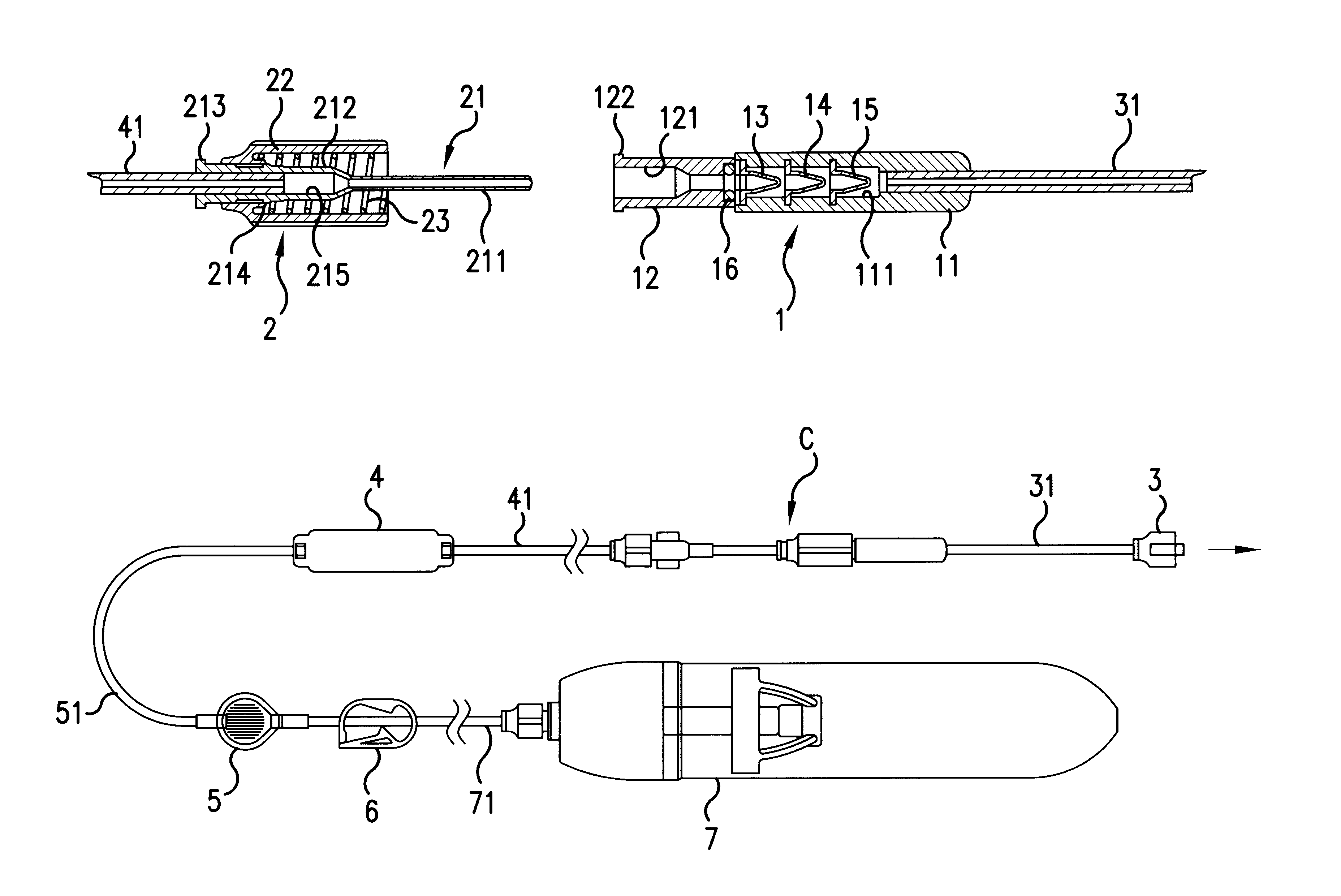

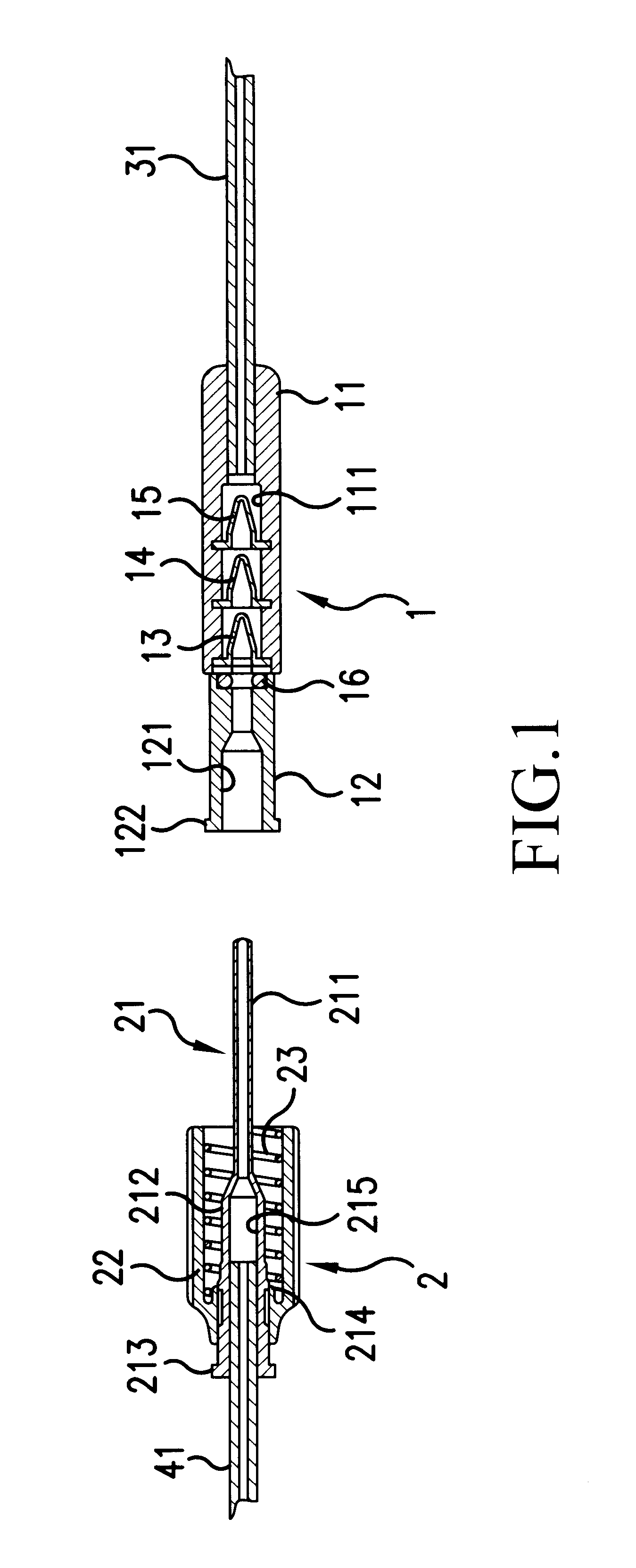

Infusion rate adjusting device for drug solution injector

Owner:NIPRO CORP

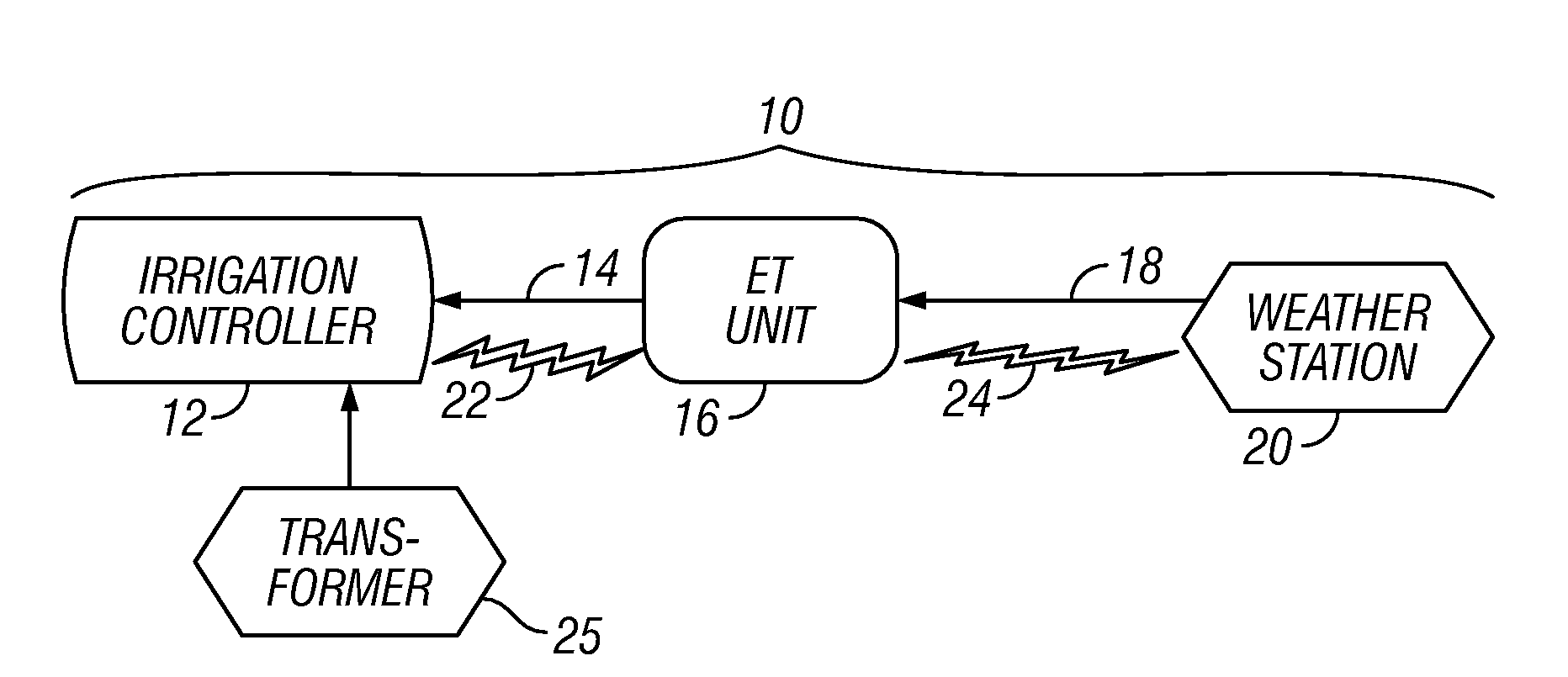

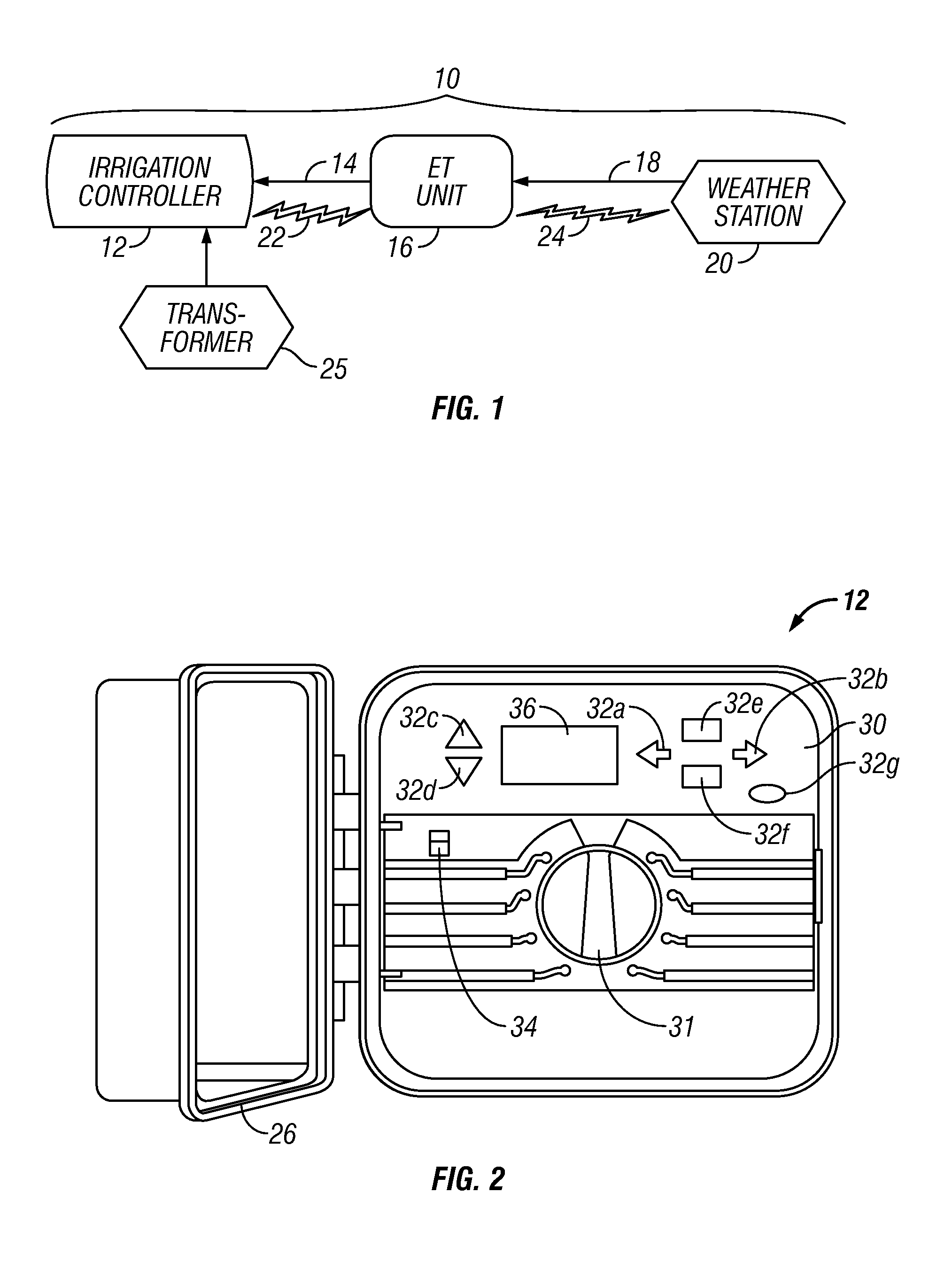

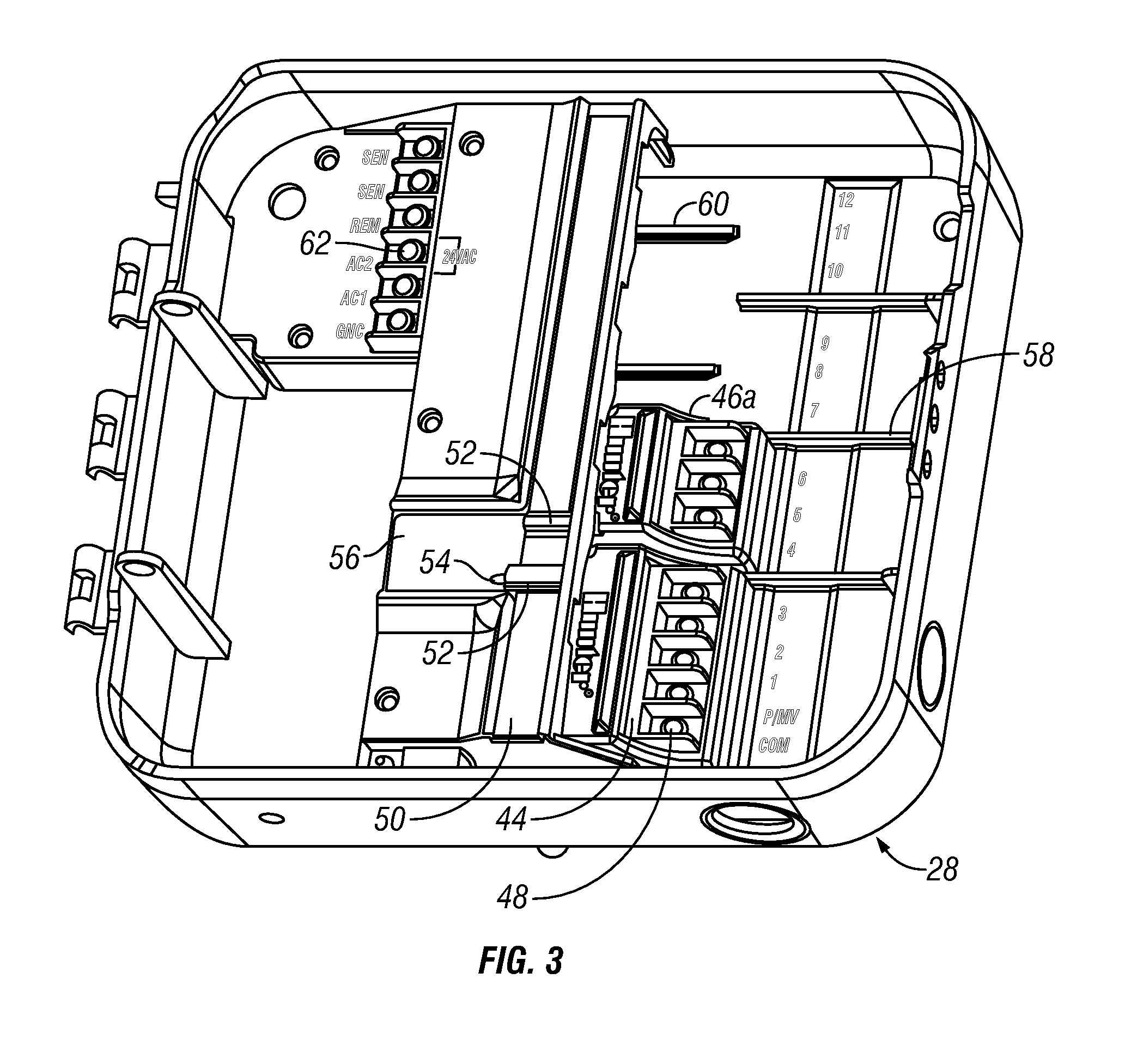

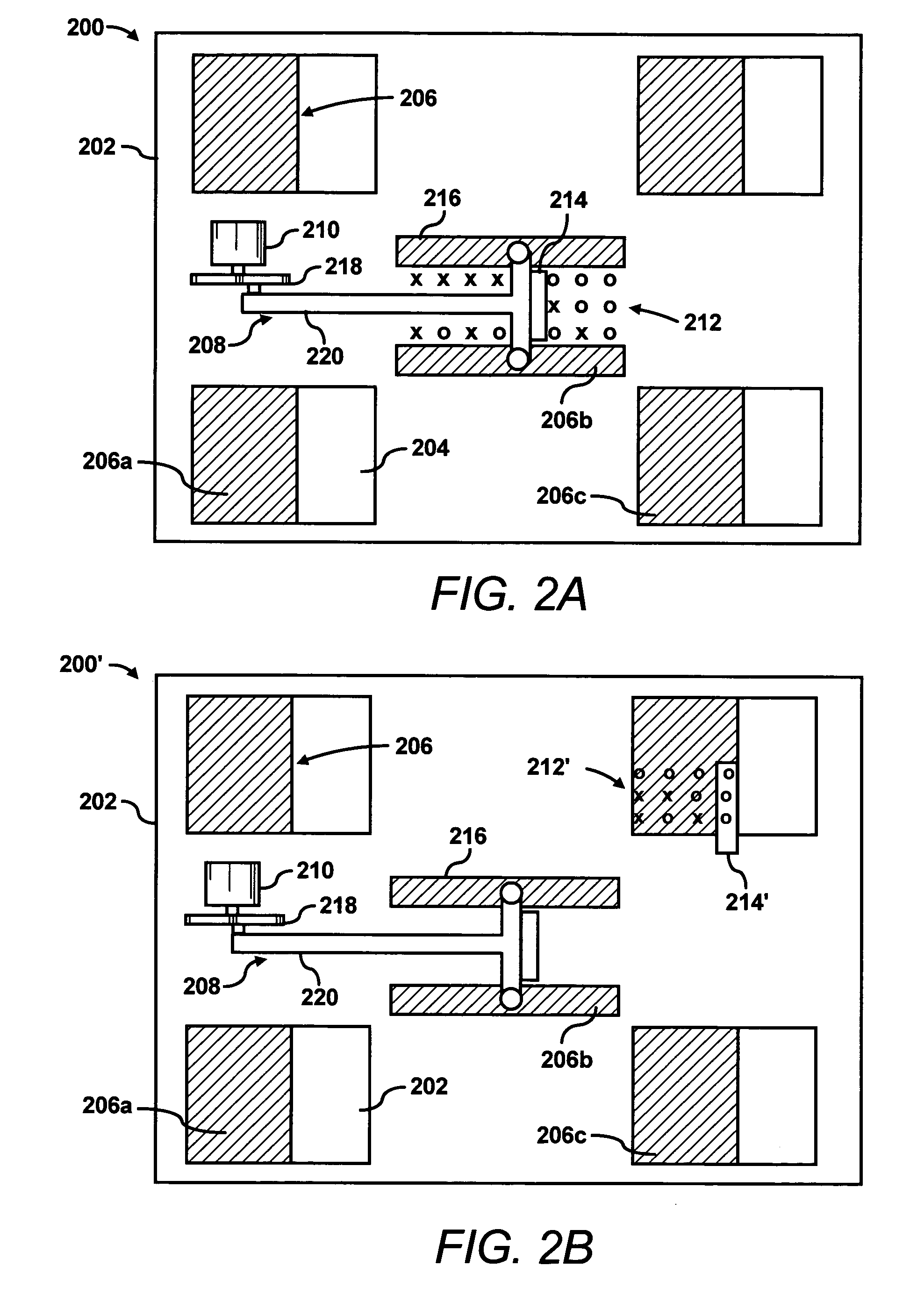

Irrigation System with ET Based Seasonal Watering Adjustment

InactiveUS20100030476A1Conserve waterMaintaining plant healthWatering devicesFlow control using electric meansEngineeringWeather station

An ET based irrigation system includes a stand alone irrigation controller with a seasonal adjust feature and a stand alone weather station including at least one environmental sensor. The ET based irrigation system further includes a stand alone ET unit operatively connected to the irrigation controller and the weather station. The ET unit includes programming configured to calculate an estimated ET value using a signal from the environmental sensor and to automatically modify a watering schedule of the irrigation controller through the seasonal adjust feature based on the estimated ET value to thereby conserve water while maintaining plant health.

Owner:HUNTER INDUSTRIES

Constant flow valve

InactiveUS6209578B1Operating means/releasing devices for valvesFlow control without auxillary powerEngineeringVariable pressure

A regulating valve is disclosed for controlling the flow of fluid from a variable pressure fluid supply. The valve includes a diaphragm which is resiliently biased into a normally closed position, and which shifts to an open position when exposed to a fluid pressure above a predetermined minimum level.

Owner:GLOBAL AGRI TECH & ENG

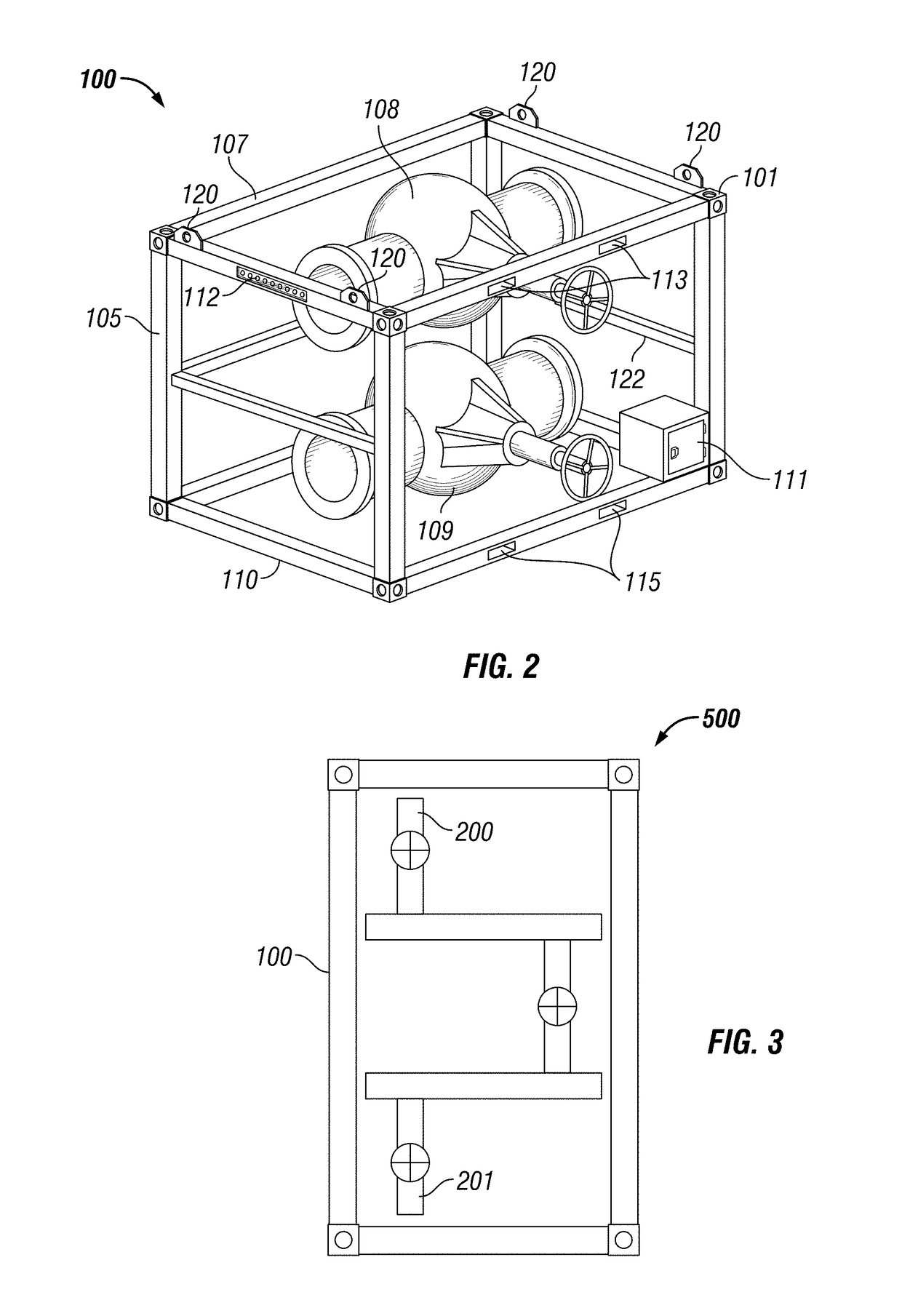

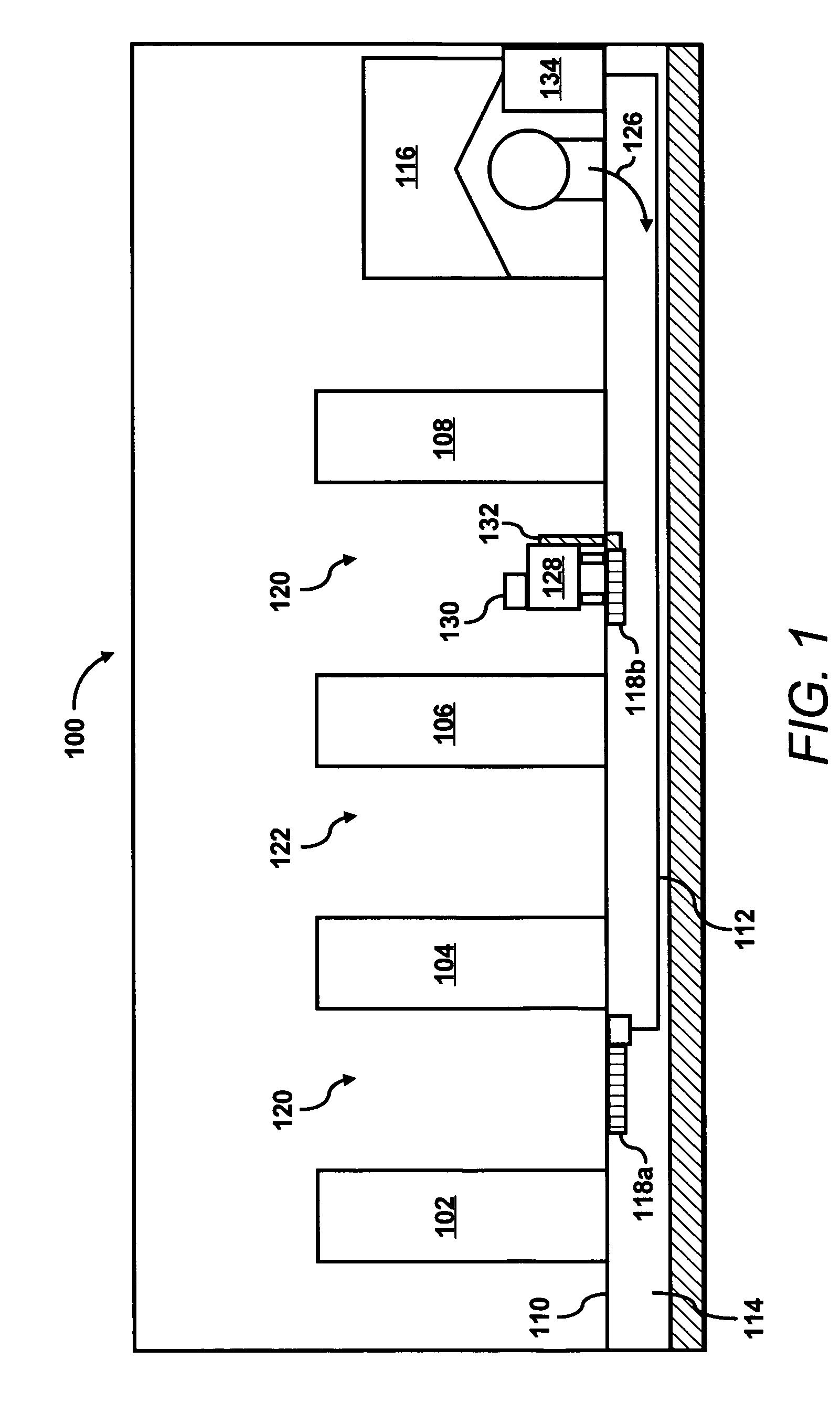

Airflow volume control system

A control system for controlling airflow through a vent. The system includes a vent assembly having a frame. The frame includes an opening to allow air to flow through the frame. The vent assembly also includes a movable damper for variably restricting the fluid flow through the opening in the vent assembly, a motor for controlling movement of the damper, and a sensor for determining the position of the damper. In addition, a controller is provided to control the motor to vary the position of the damper to thereby vary the airflow through the opening in the vent assembly.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Combination valve and regulator with vented seat for use with pressurized gas cylinders, particularly oxygen cylinders

Owner:LUXFER INC

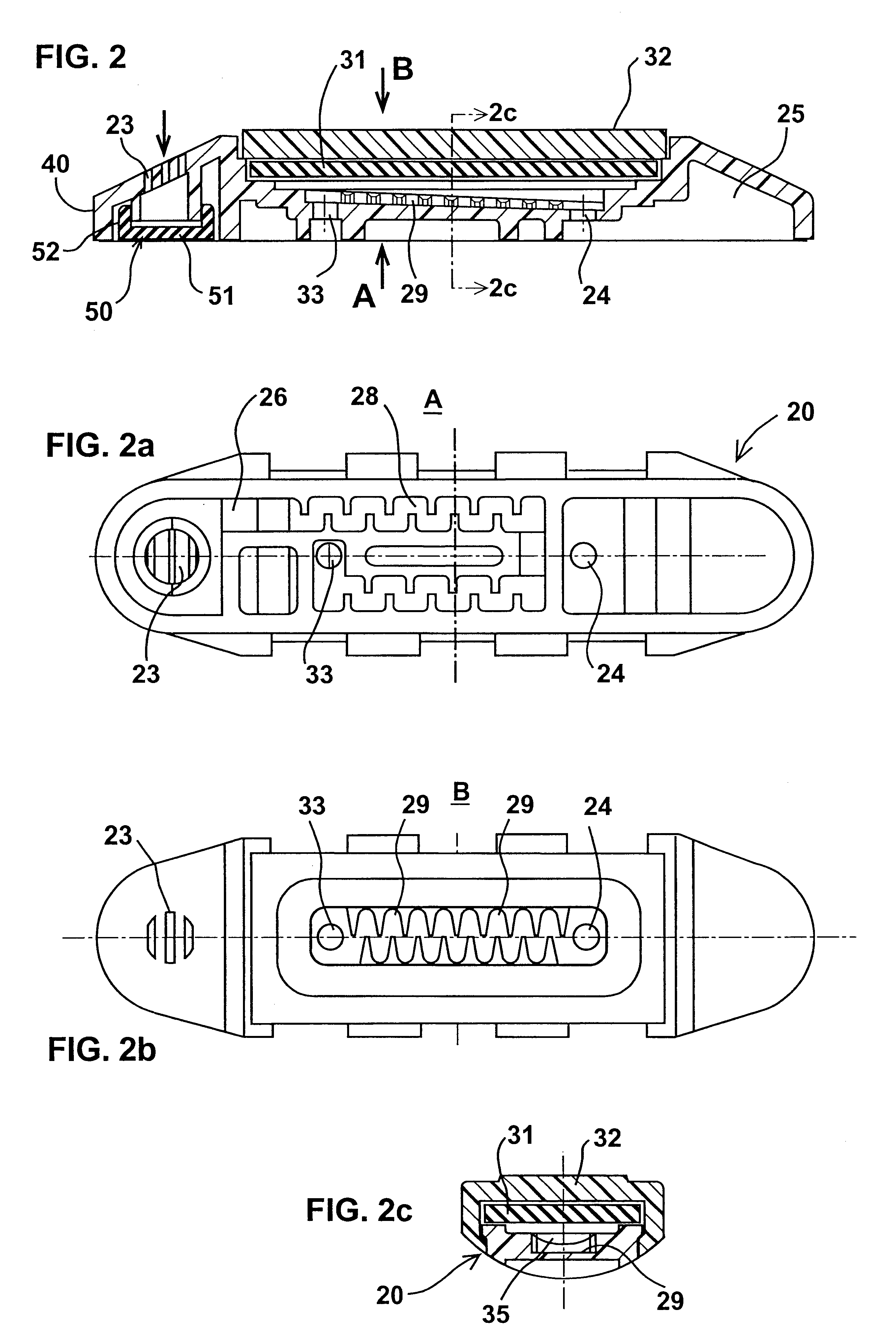

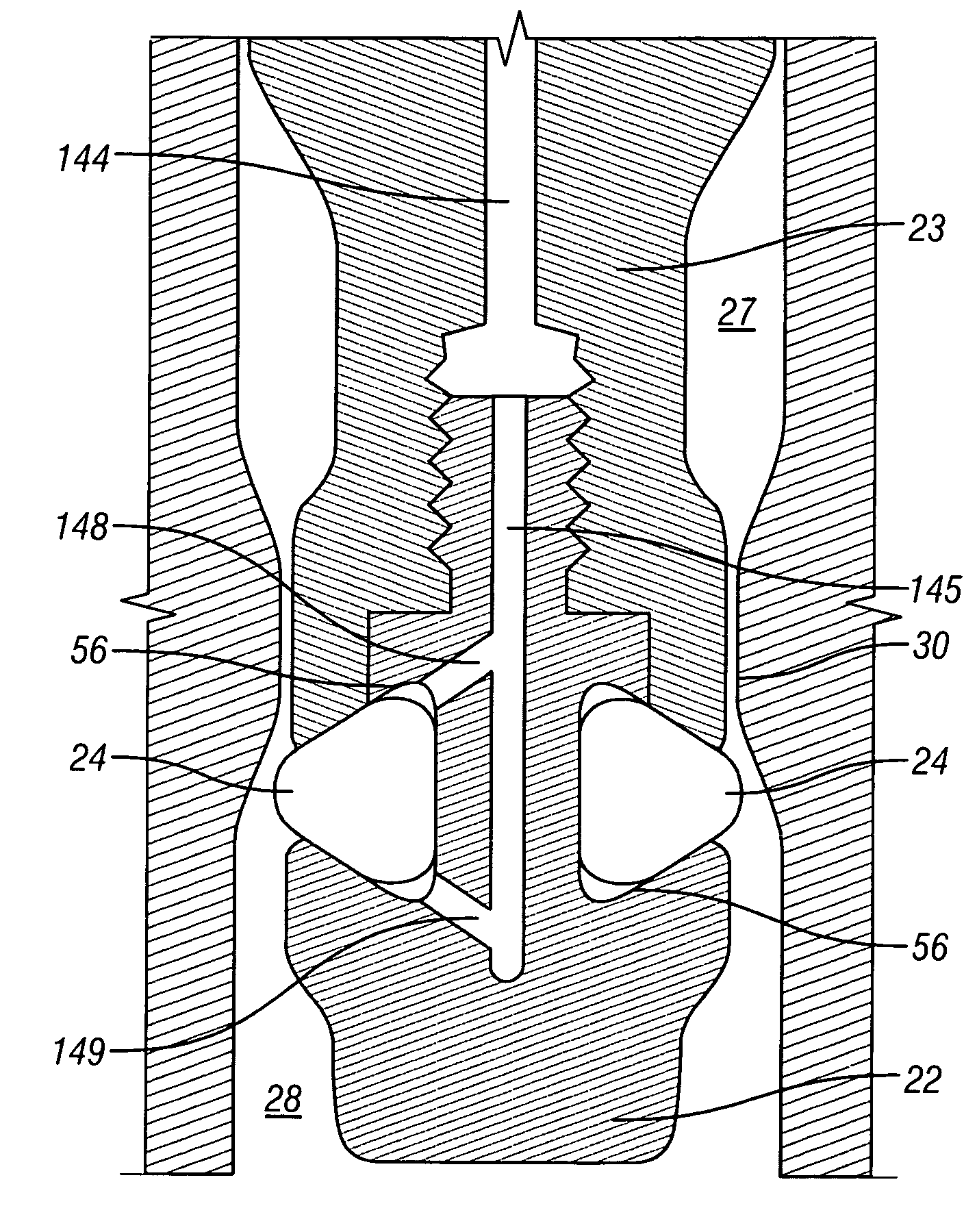

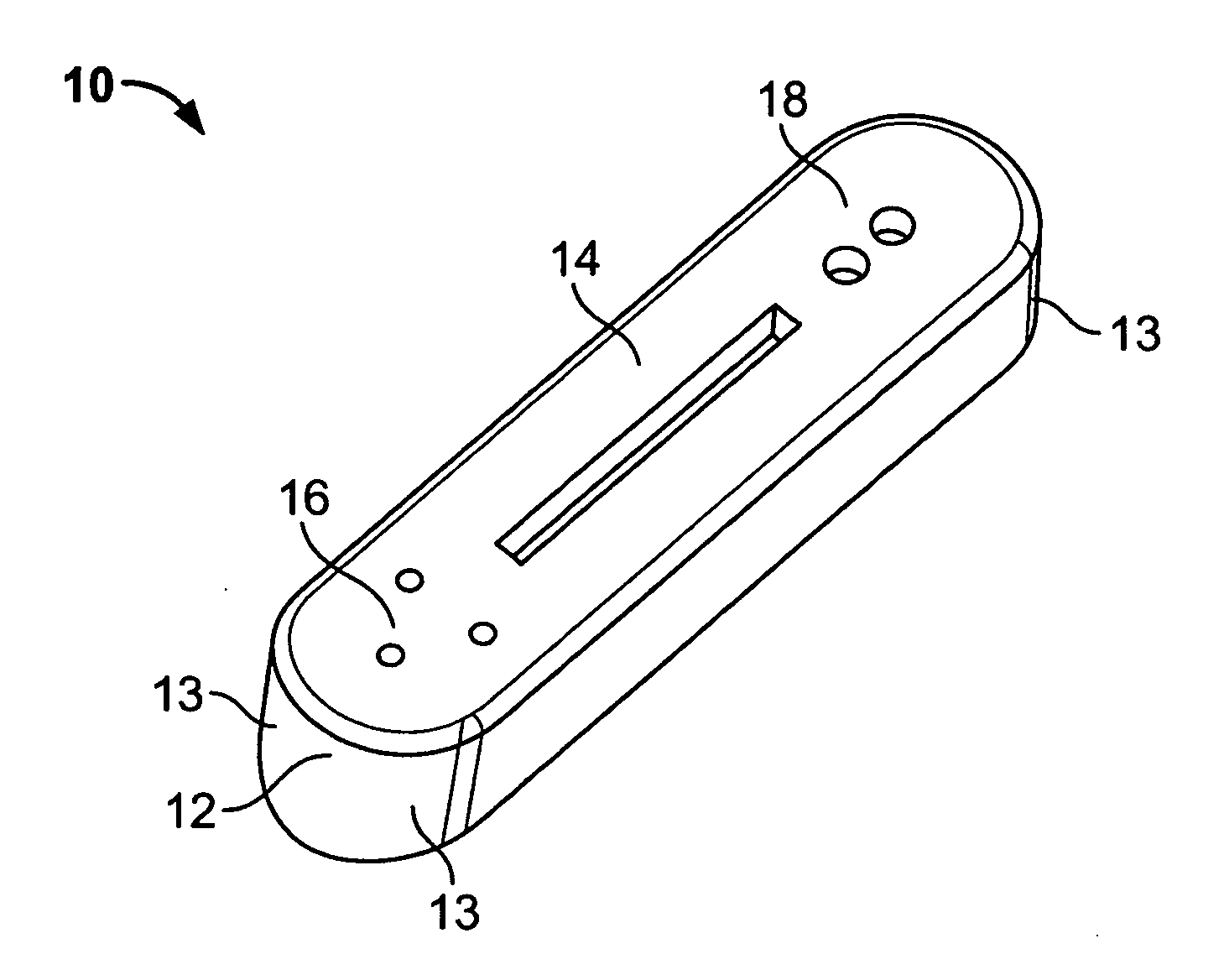

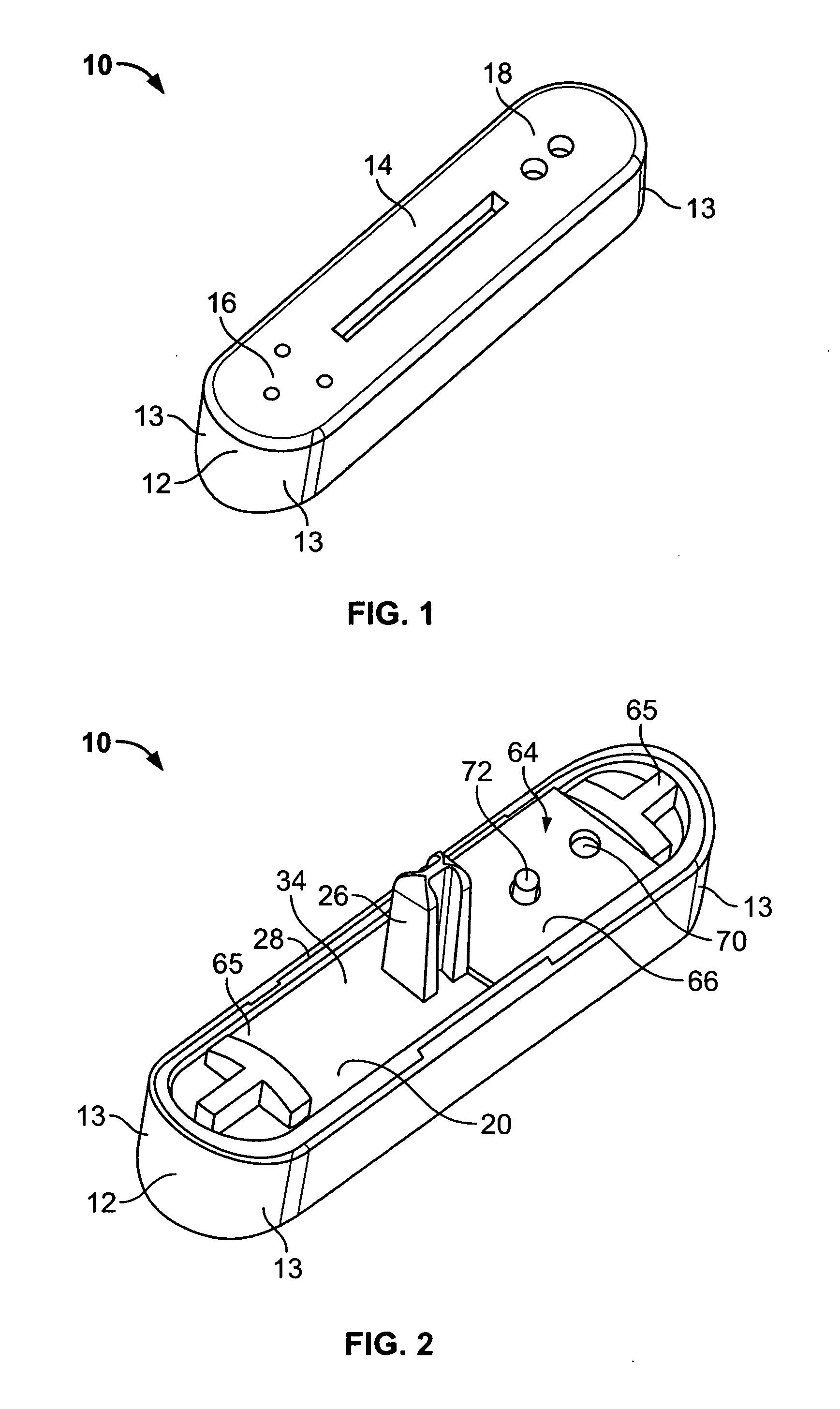

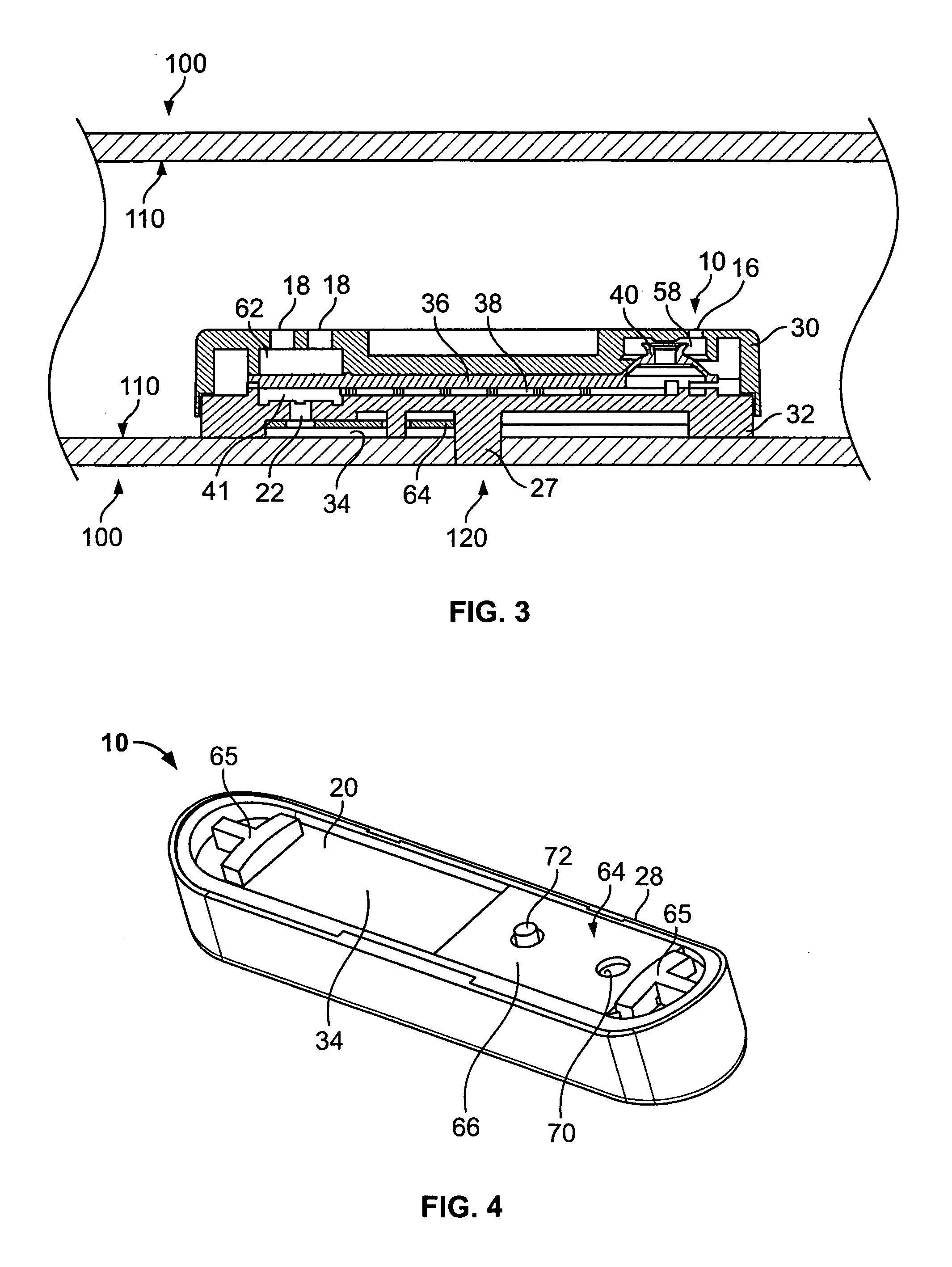

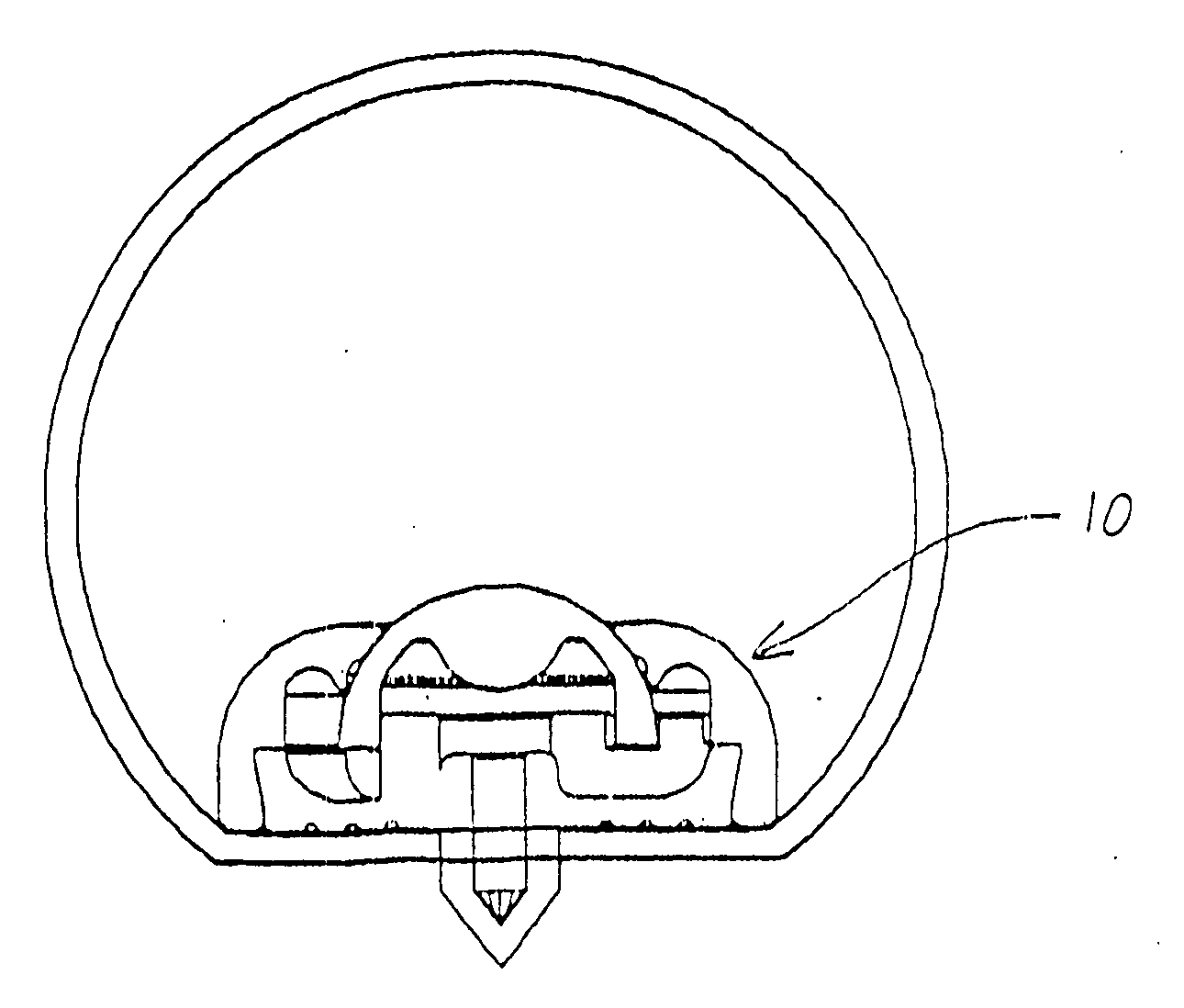

Drip emitter

A drip emitter is provided for delivering irrigation water from a supply tube to an emitter outlet at a reduced and relatively constant flow rate. Water enters the emitter through a first inlet and proceeds into a first chamber. When the water pressure is above a predetermined level, a one-directional valve opens to allow fluid flow past the first chamber, through a tortuous path flow channel, and through an emitter outlet. A second inlet is used to compensate for water pressure fluctuations in the supply tube to maintain output flow at a relatively constant rate. Water enters the second inlet and presses a flexible diaphragm toward a water metering surface to provide pressure-dependent control of the output flow. A copper member is mounted to the emitter over the emitter outlet to prevent plant root intrusion into the emitter outlet.

Owner:RAIN BIRD CORP

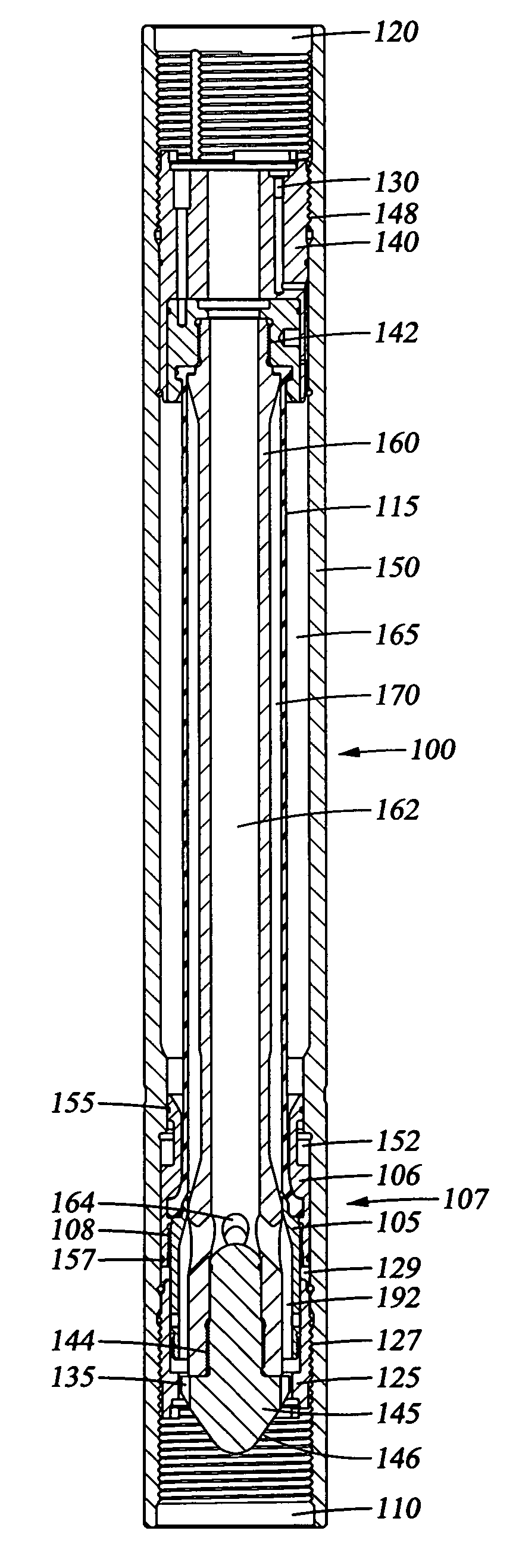

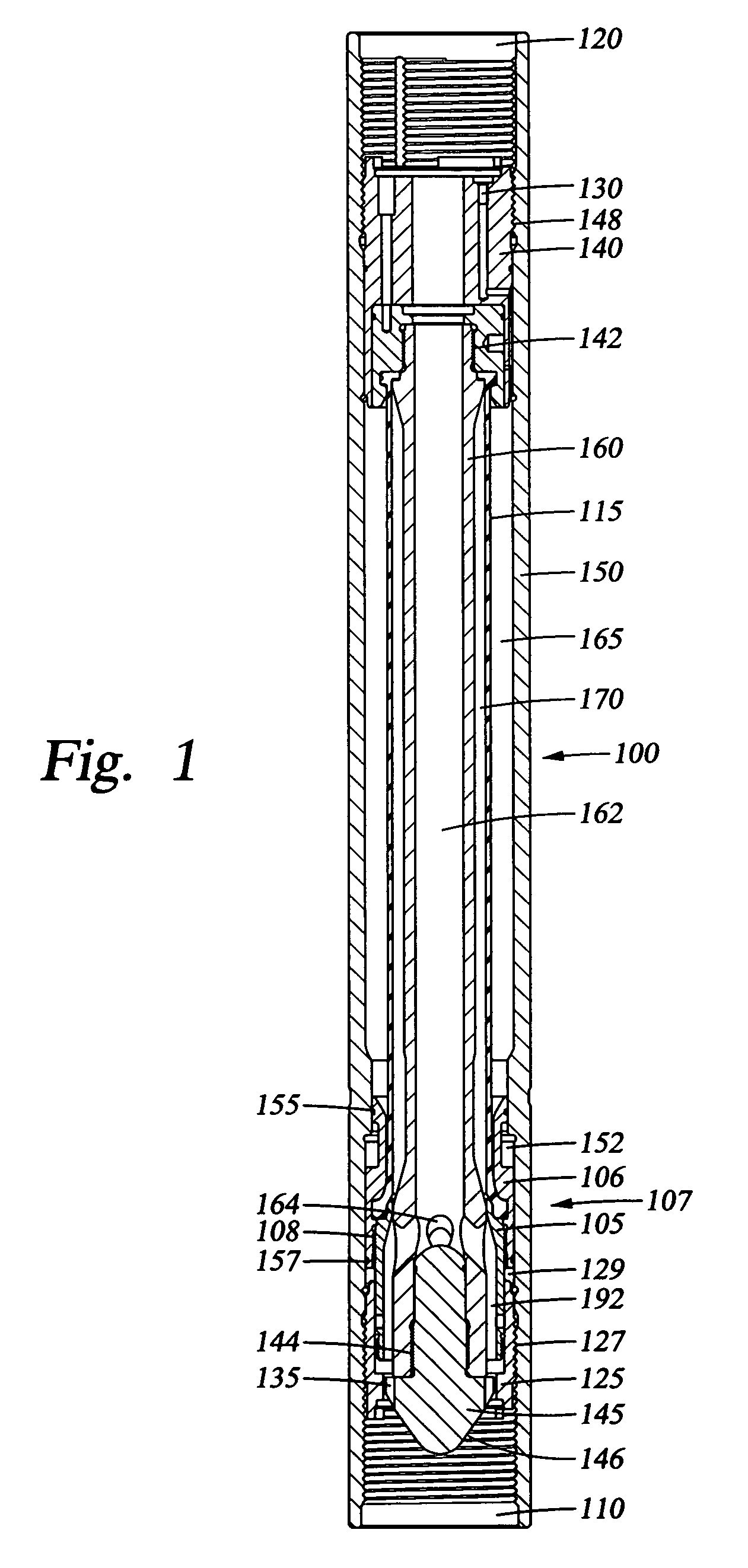

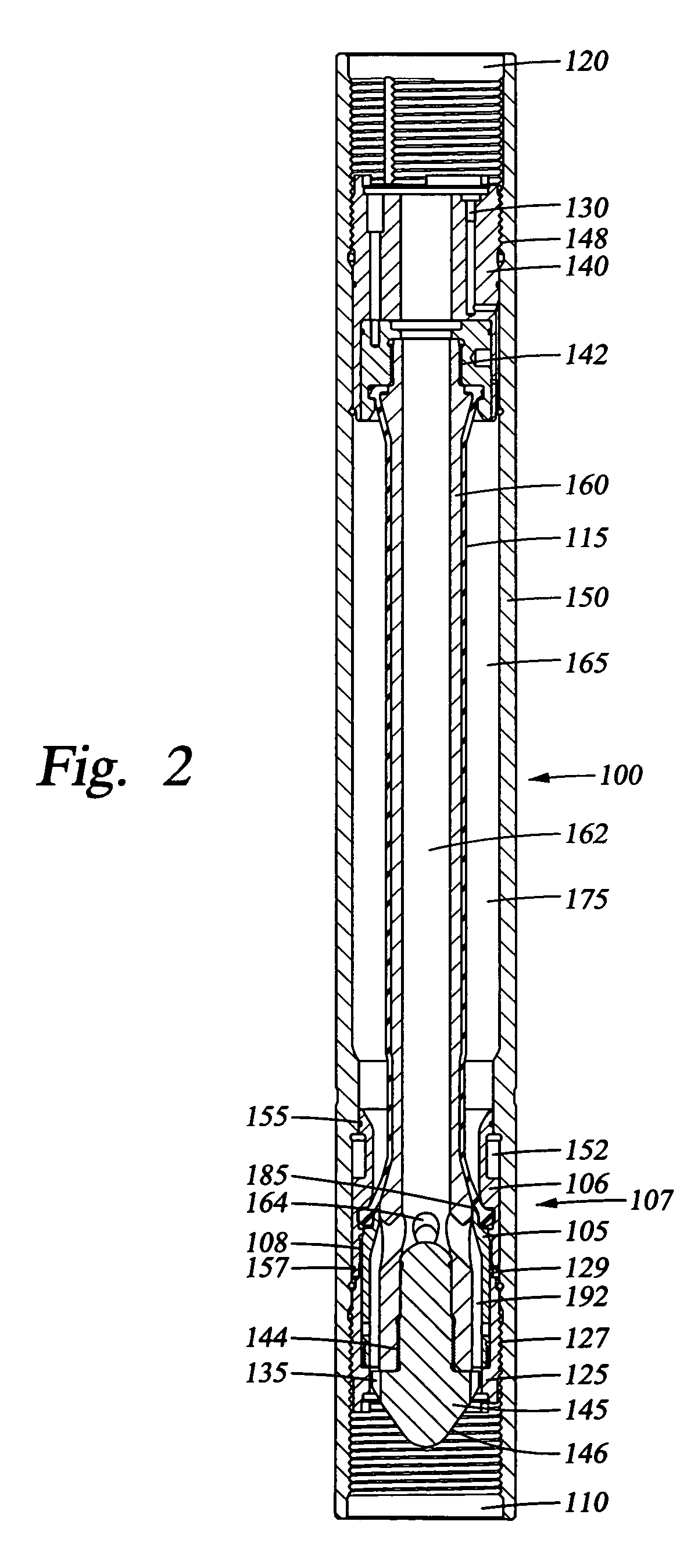

Inline bladder-type accumulator for downhole applications

InactiveUS7353845B2Good fluid performanceAccumulator installationsPressure pumpsFluid compartmentsEngineering

An accumulator comprises a housing connected to a hydraulic system, an elastomeric bladder separating a gas compartment from a fluid compartment, and an anti-extrusion device. A method for operating an accumulator comprises connecting the accumulator to a hydraulic system, injecting an inert gas into a gas compartment to a precharge pressure, moving an anti-extrusion device to prevent a bladder from extruding into the hydraulic system, running the accumulator and the hydraulic system downhole, moving the anti-extrusion device to allow fluid communication between the hydraulic system and a fluid compartment, generating pressure fluctuations within the hydraulic system, and expanding or contracting the bladder in response to the pressure fluctuations without moving the anti-extrusion device. A method of improving fluid hammer performance comprises connecting the fluid hammer to an accumulator that produces a greater delivered horsepower from the fluid hammer as compared to a baseline horsepower when operating without the accumulator.

Owner:SMITH INT INC

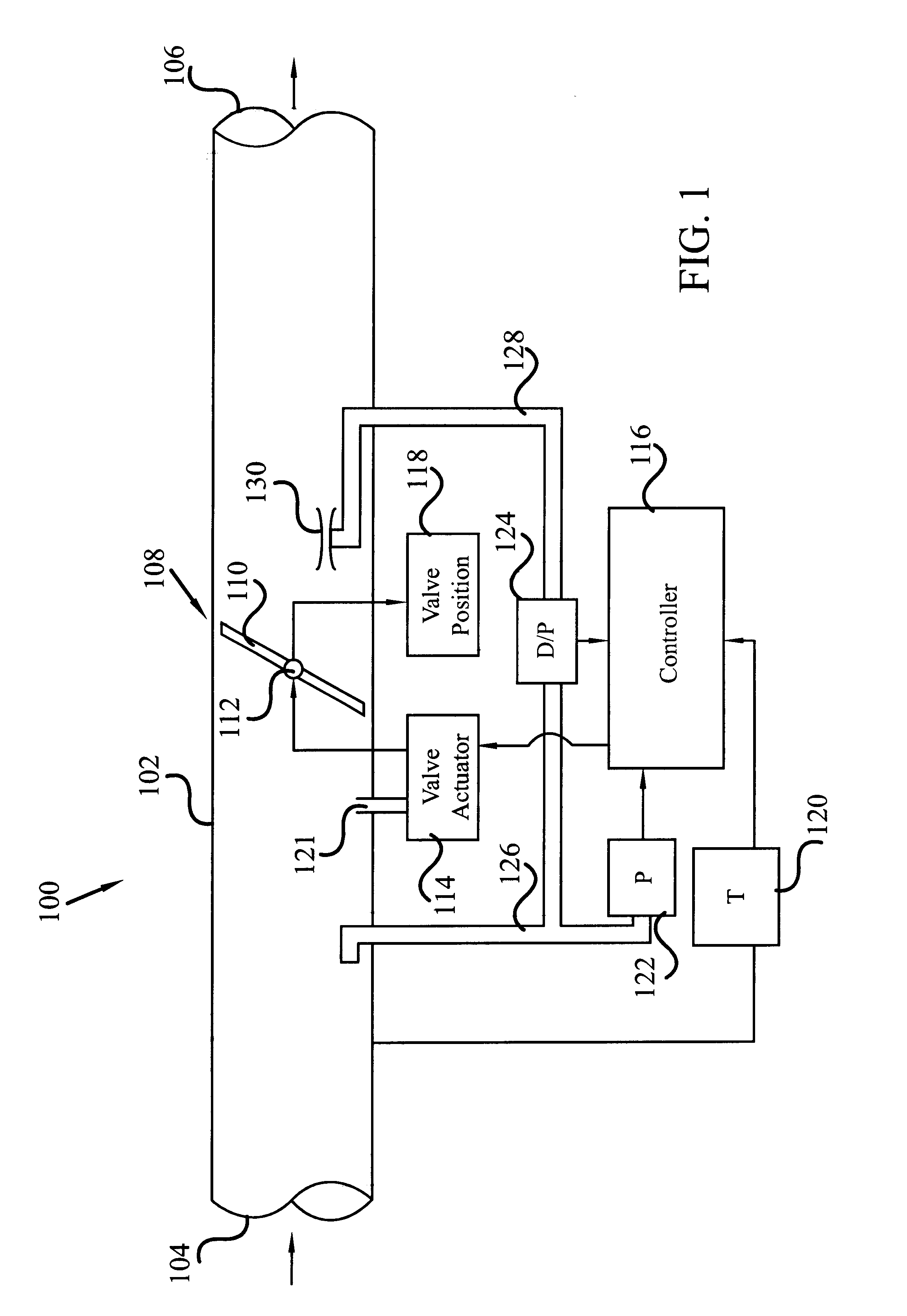

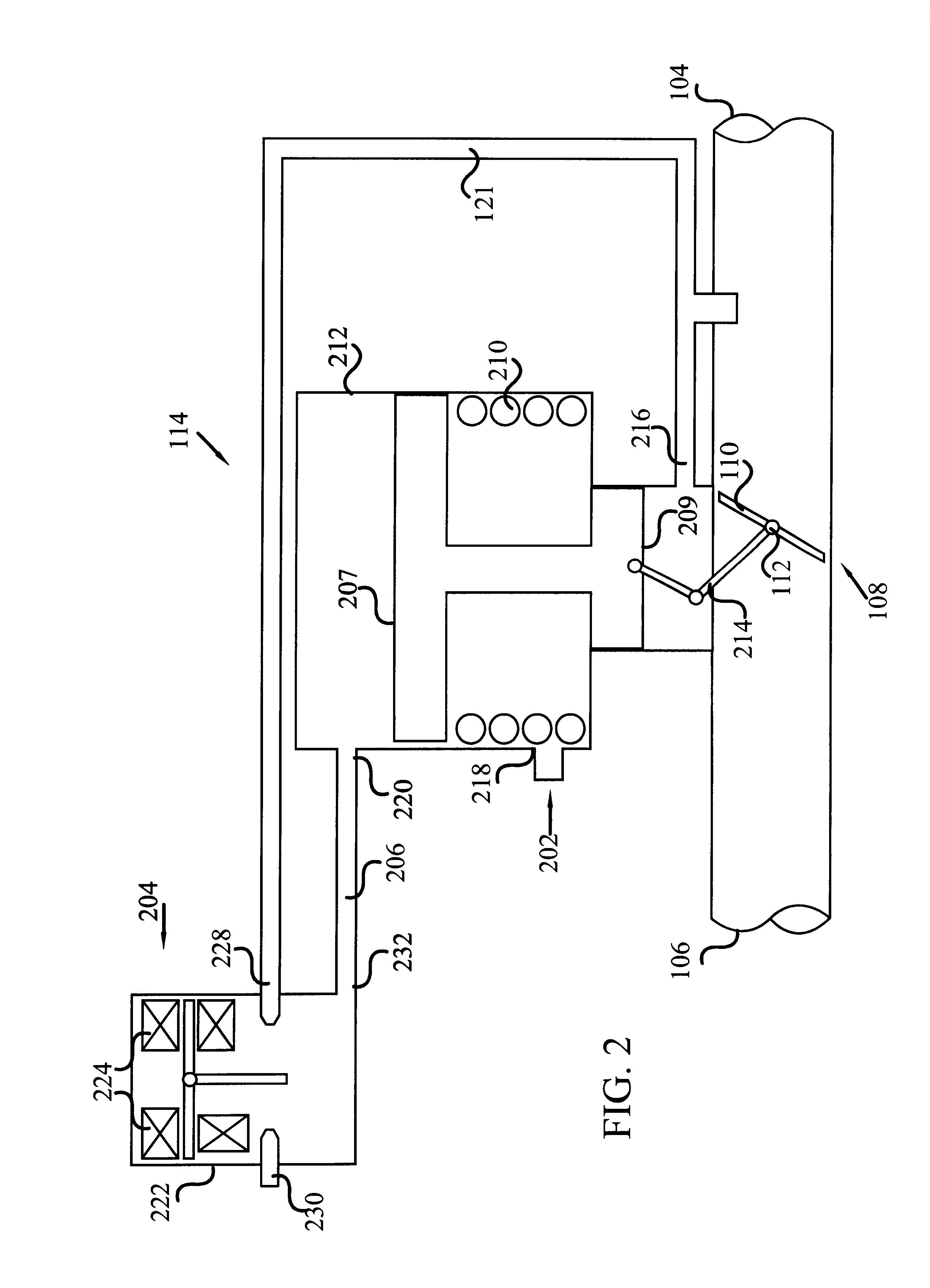

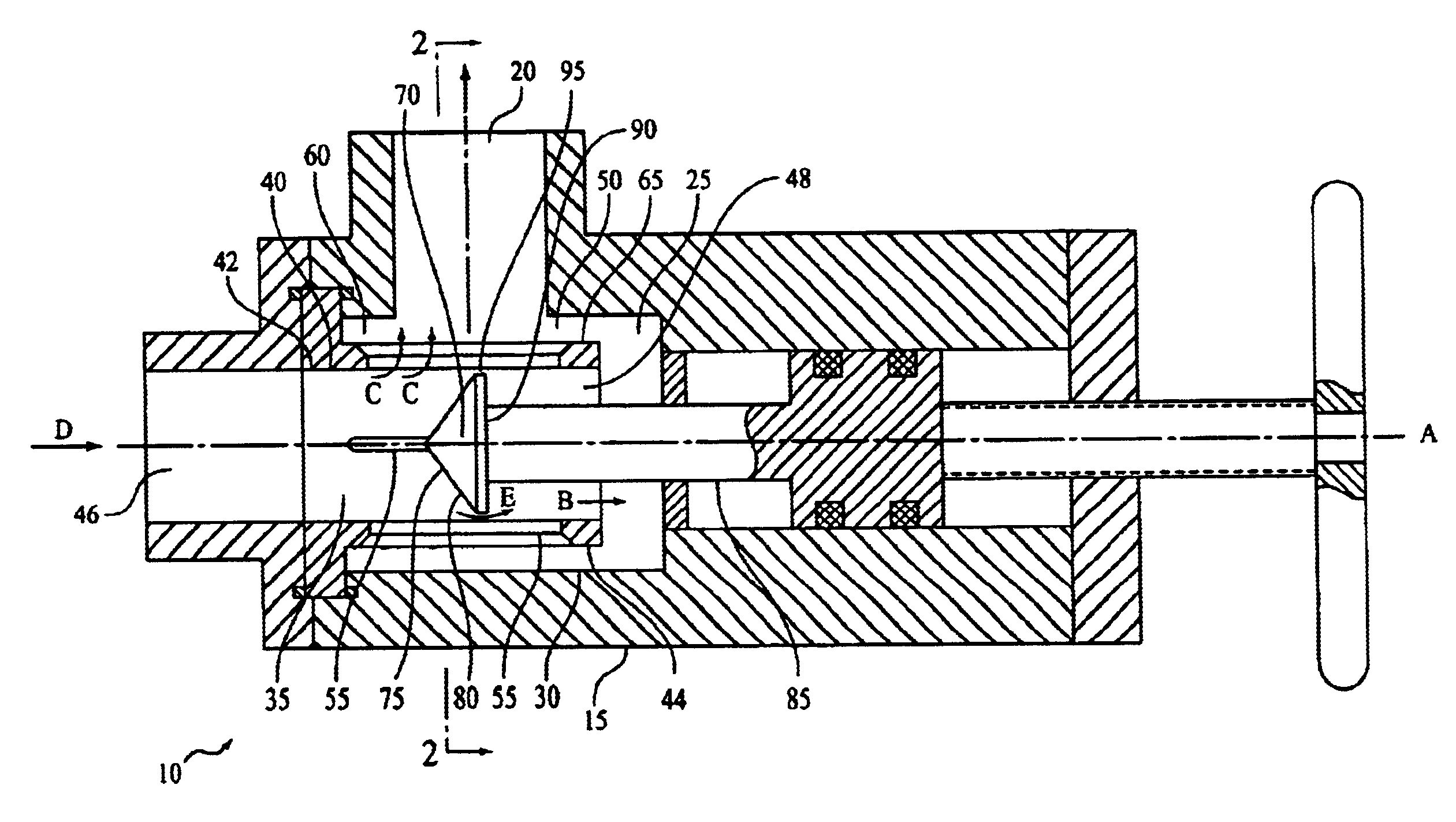

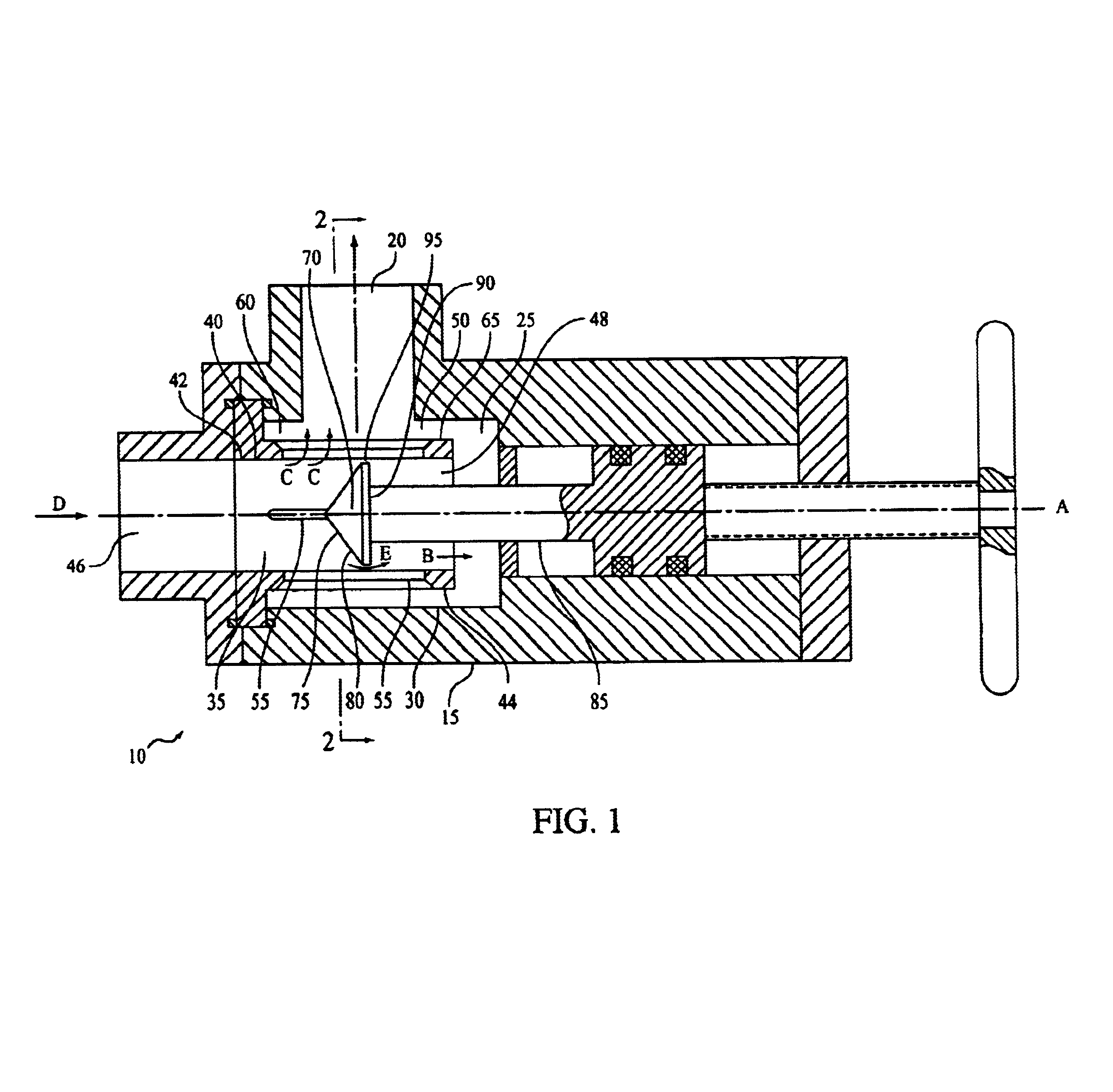

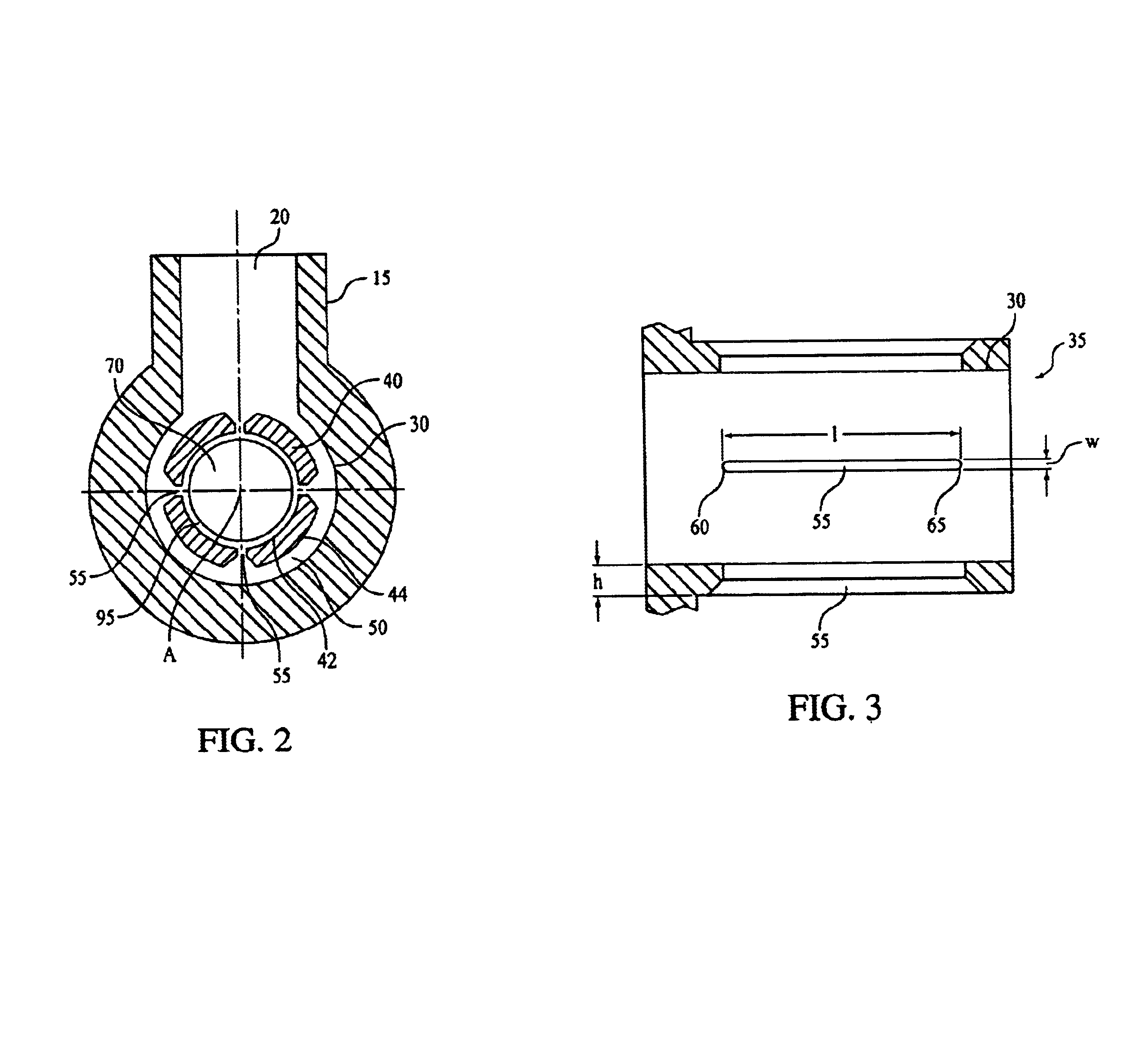

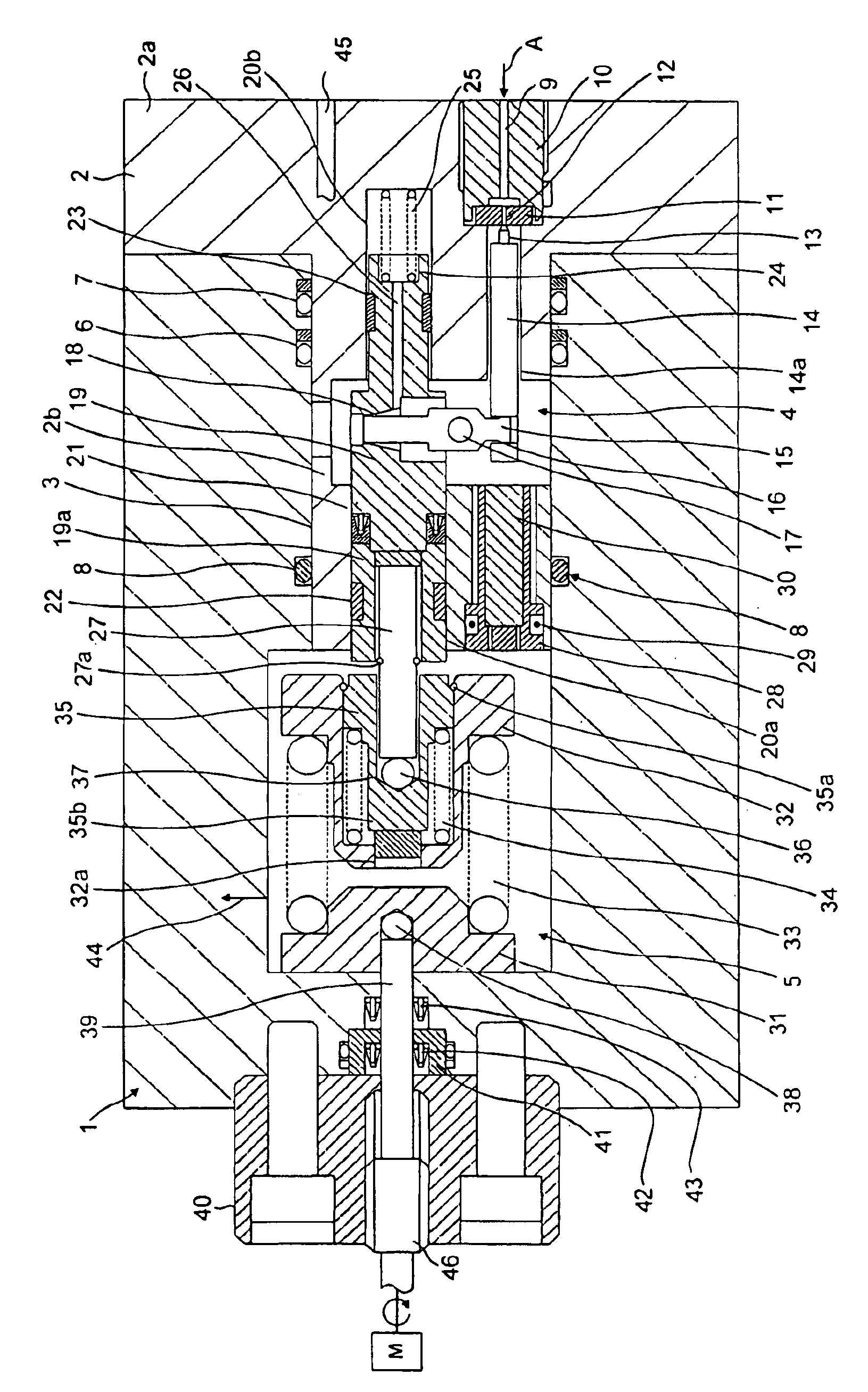

Flow control valve with integral sensor and controller and related method

ActiveUS6892745B2Simple designWide measurement rangeOperating means/releasing devices for valvesFlow control using electric meansDifferential pressureEngineering

A flow control valve assembly, and a method of determining and controlling fluid flow through the valve, that is relatively simple in design, is relatively inexpensive, is accurate, and has a relatively wide measurement range. The flow control valve is relatively compact and includes all of the flow measurement and control components in a single, relatively compact assembly. Such components may include a differential pressure sensor, pressure sensor, a temperature sensor, a position sensor, and a processor. The differential pressure sensor senses differential pressure across the variable area flow orifice. The pressure sensor senses fluid pressure within the valve and supplies a fluid pressure signal. The temperature sensor senses fluid temperature and supplies a fluid temperature signal. The position sensor senses the position of the variable area flow orifice and supplies a position signal. The processor receives the differential pressure signal, the fluid pressure signal, the fluid temperature signal, and the position signal and uses these signals to determine and control fluid flow parameter in the passageway.

Owner:HONEYWELL INT INC

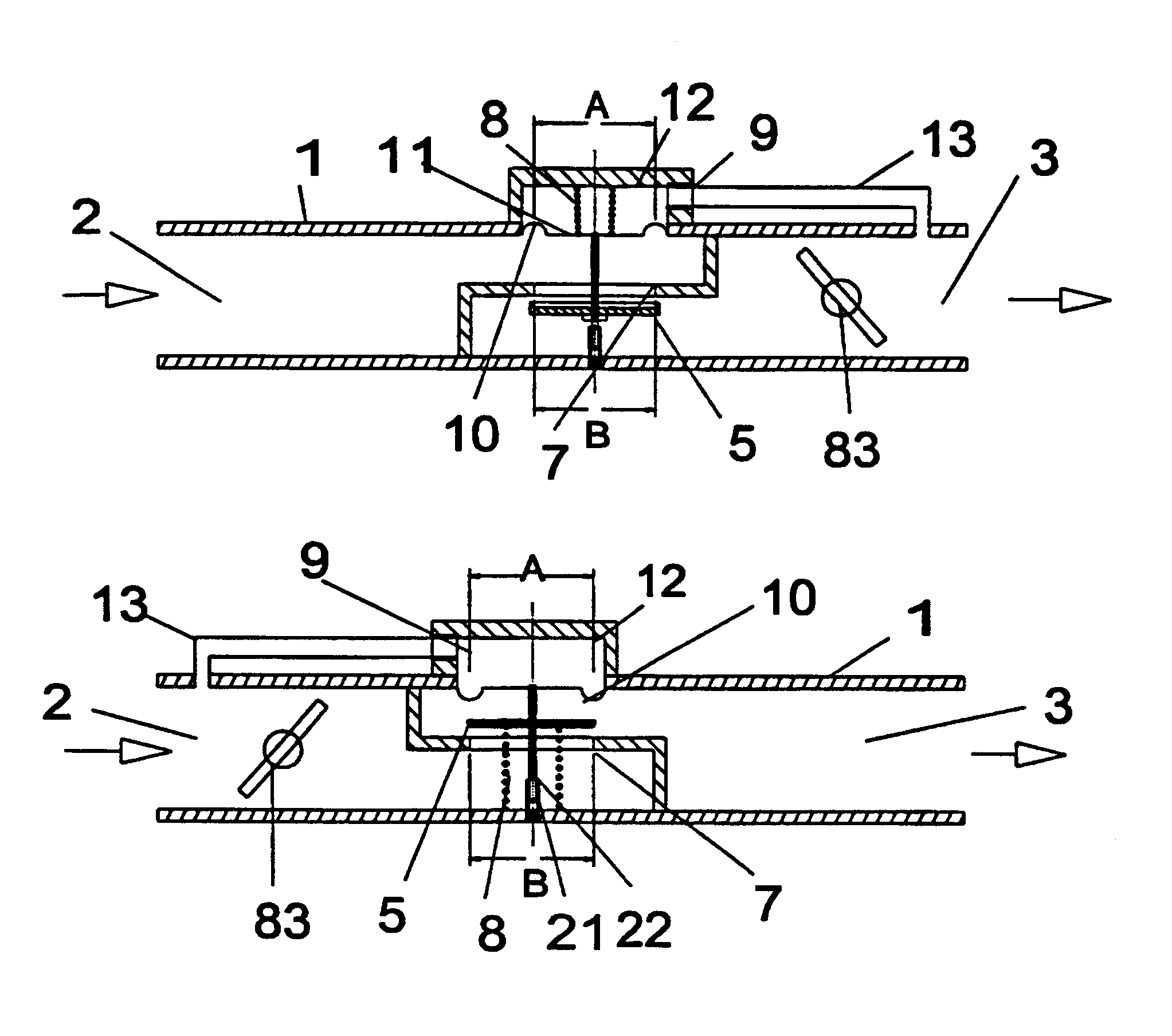

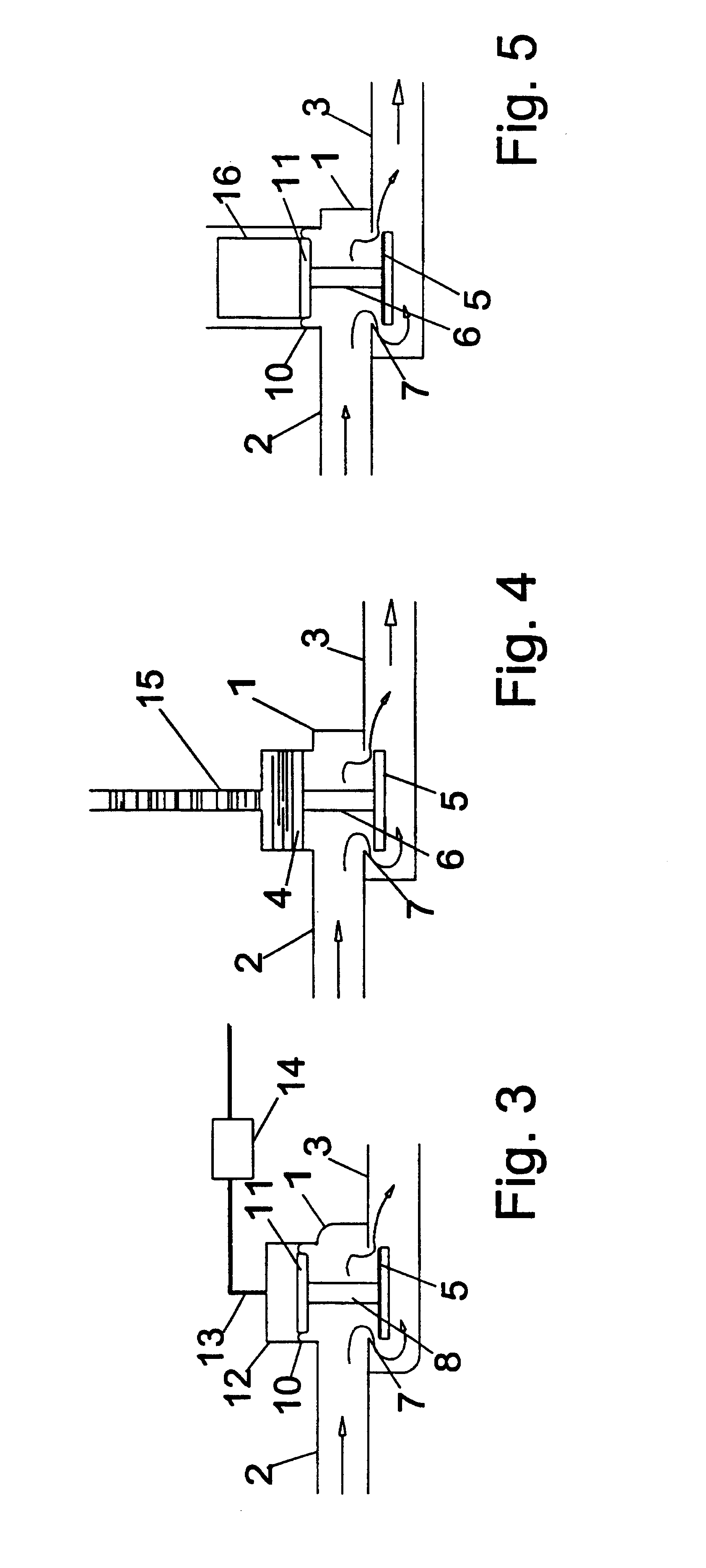

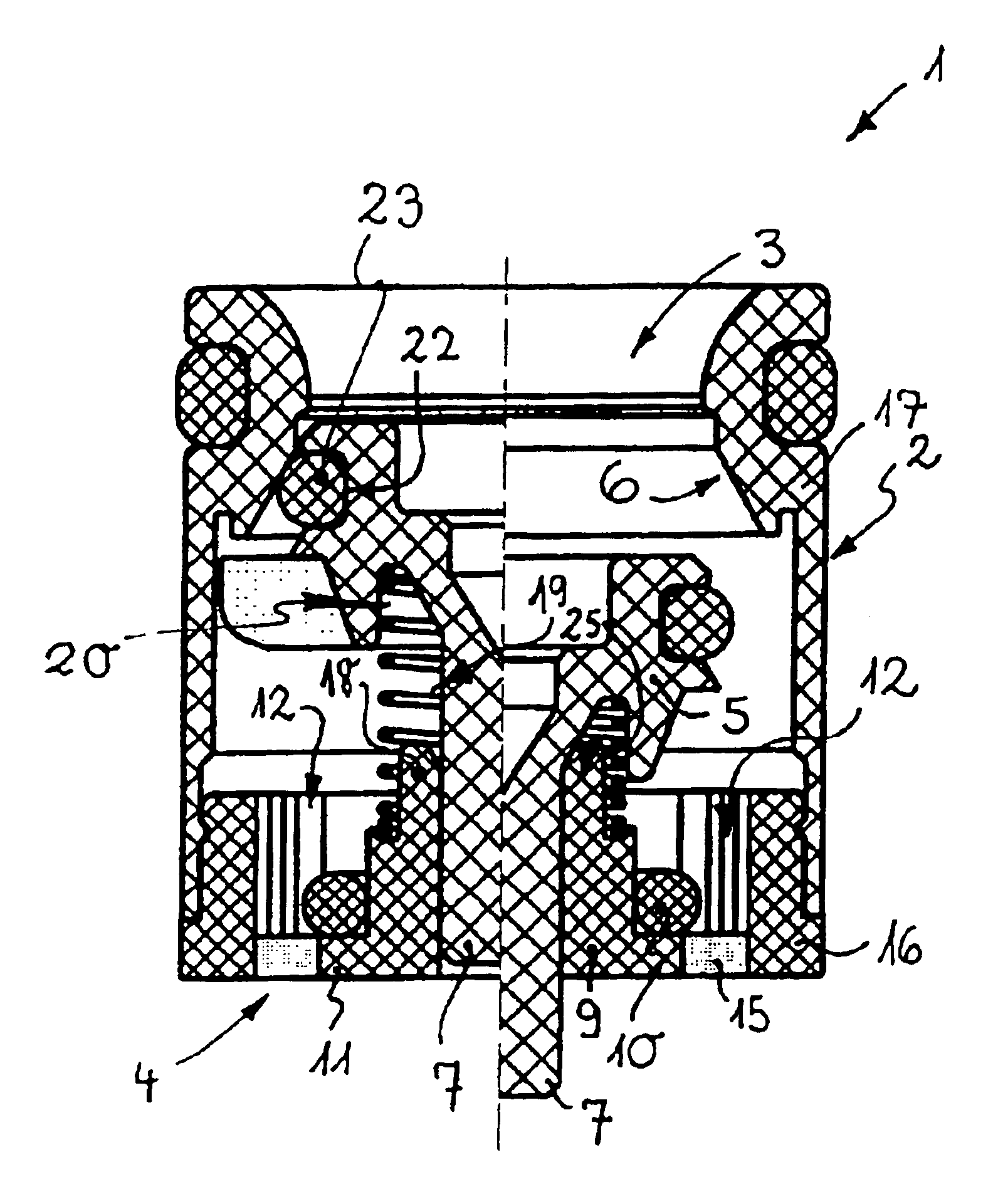

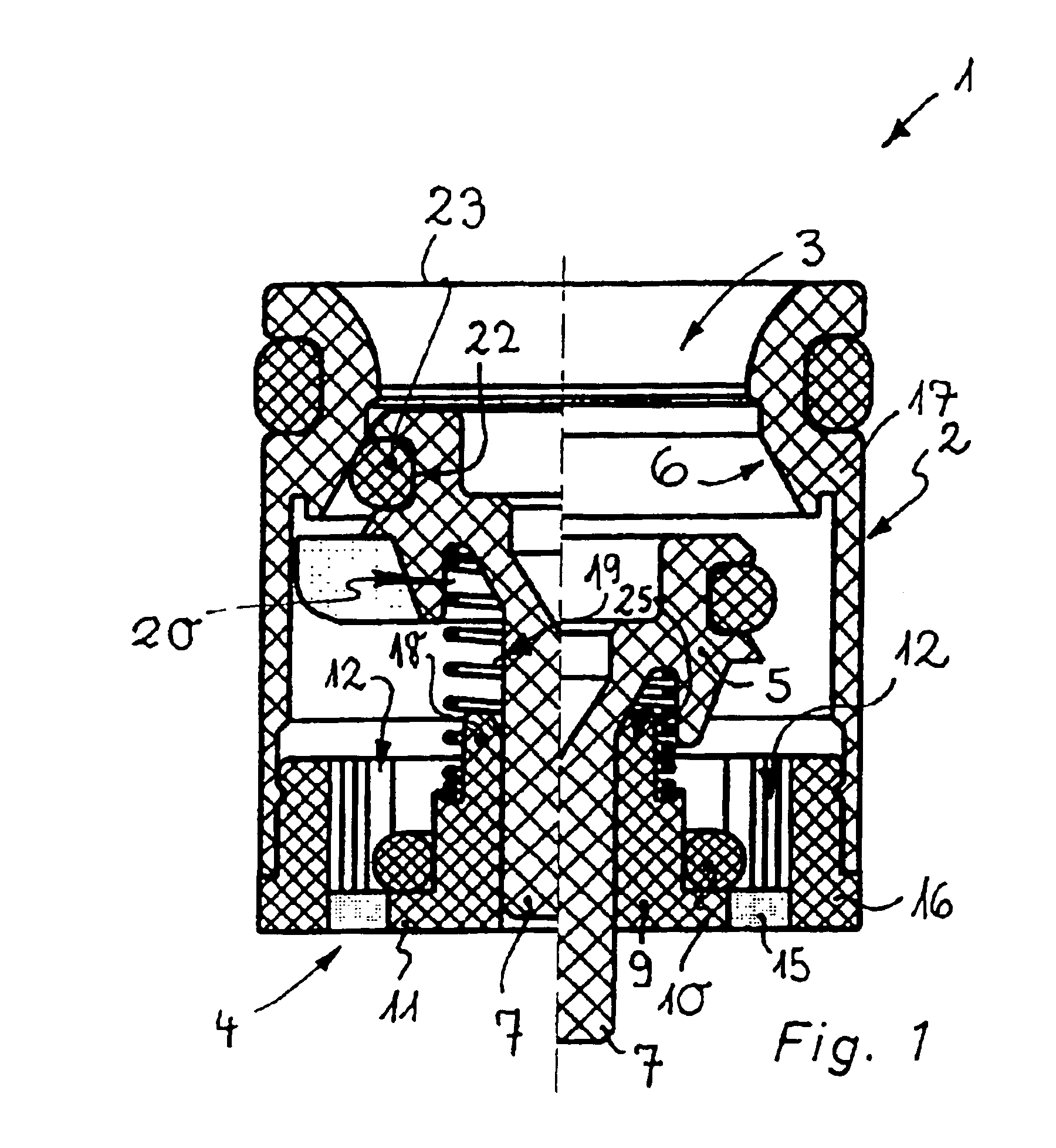

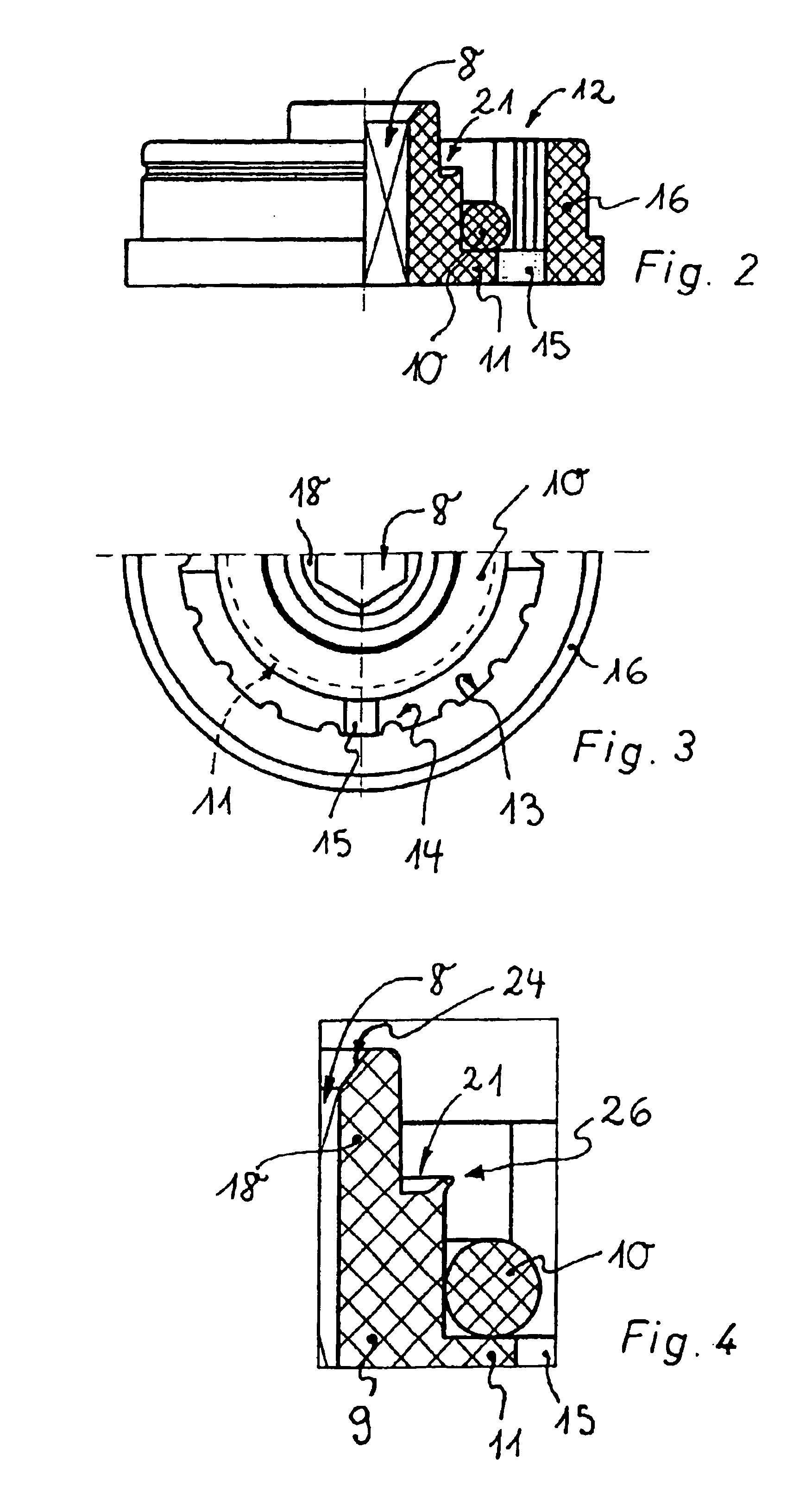

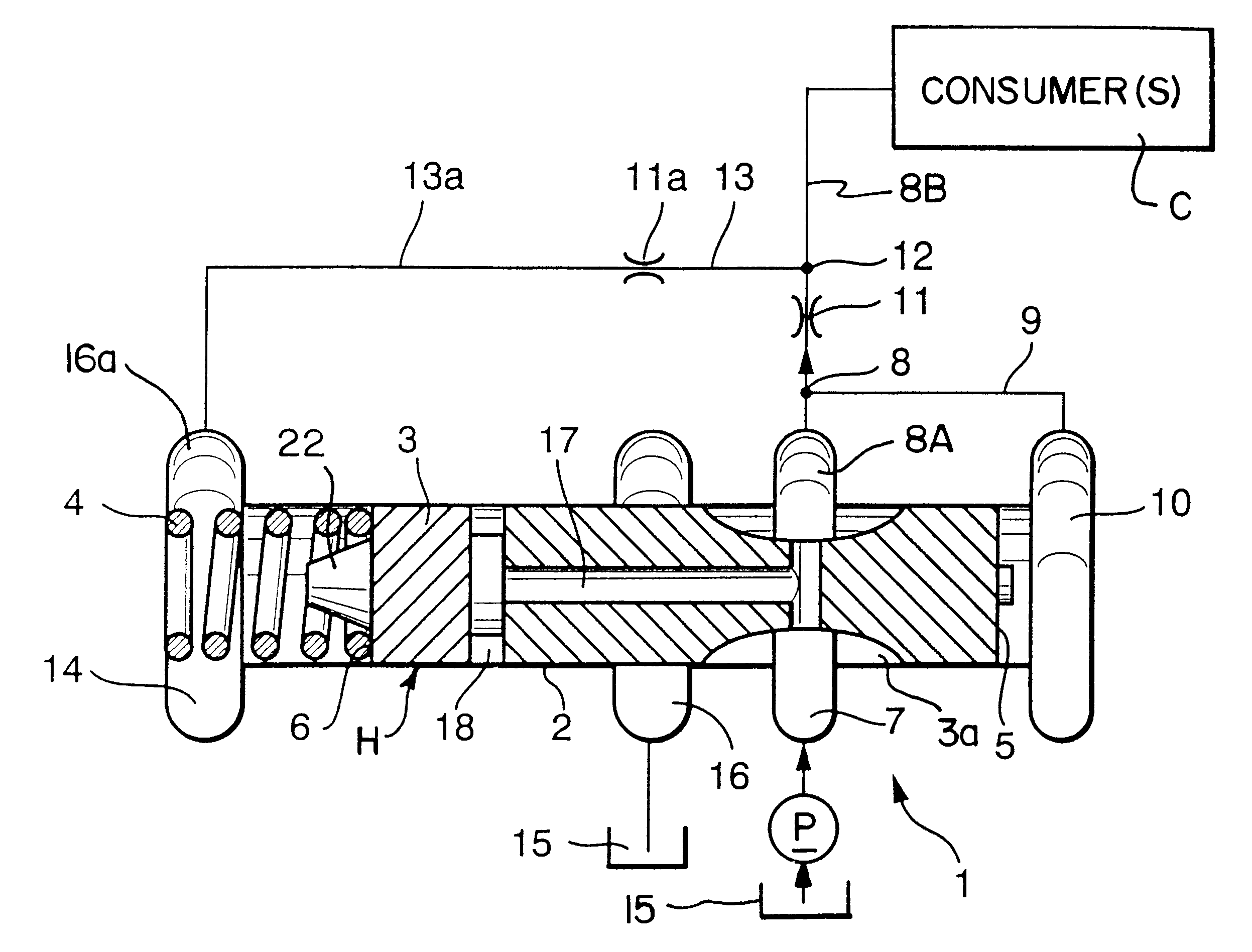

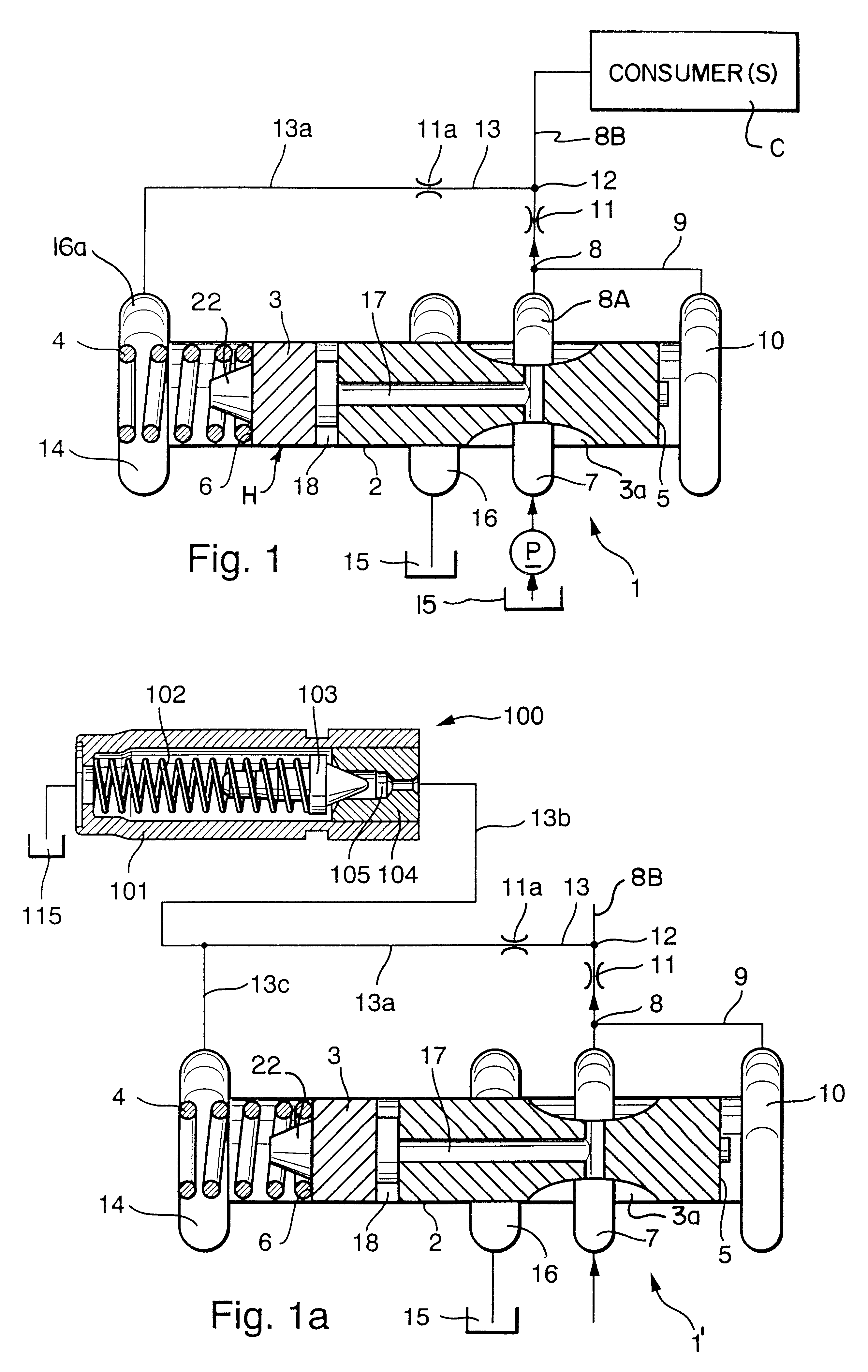

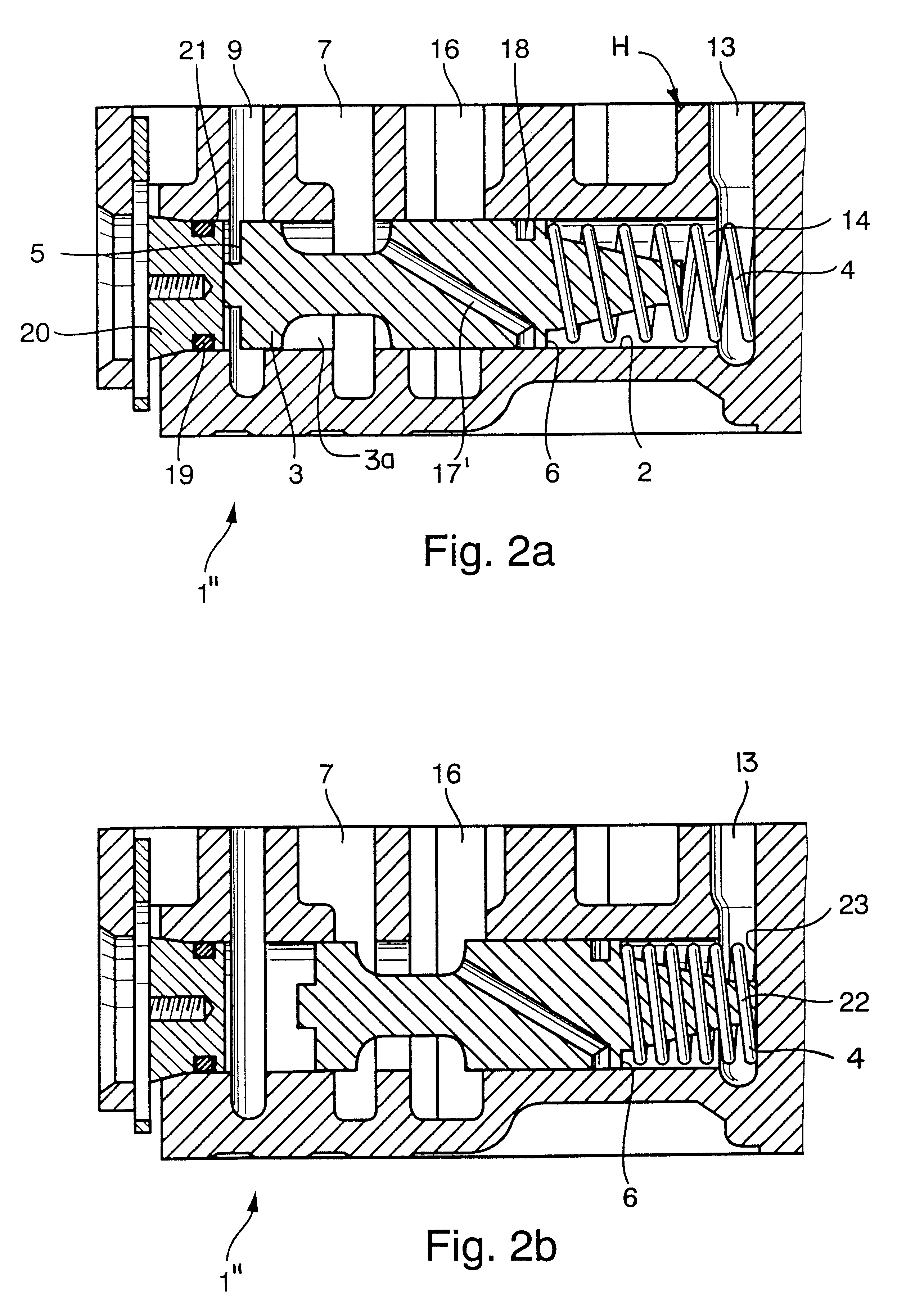

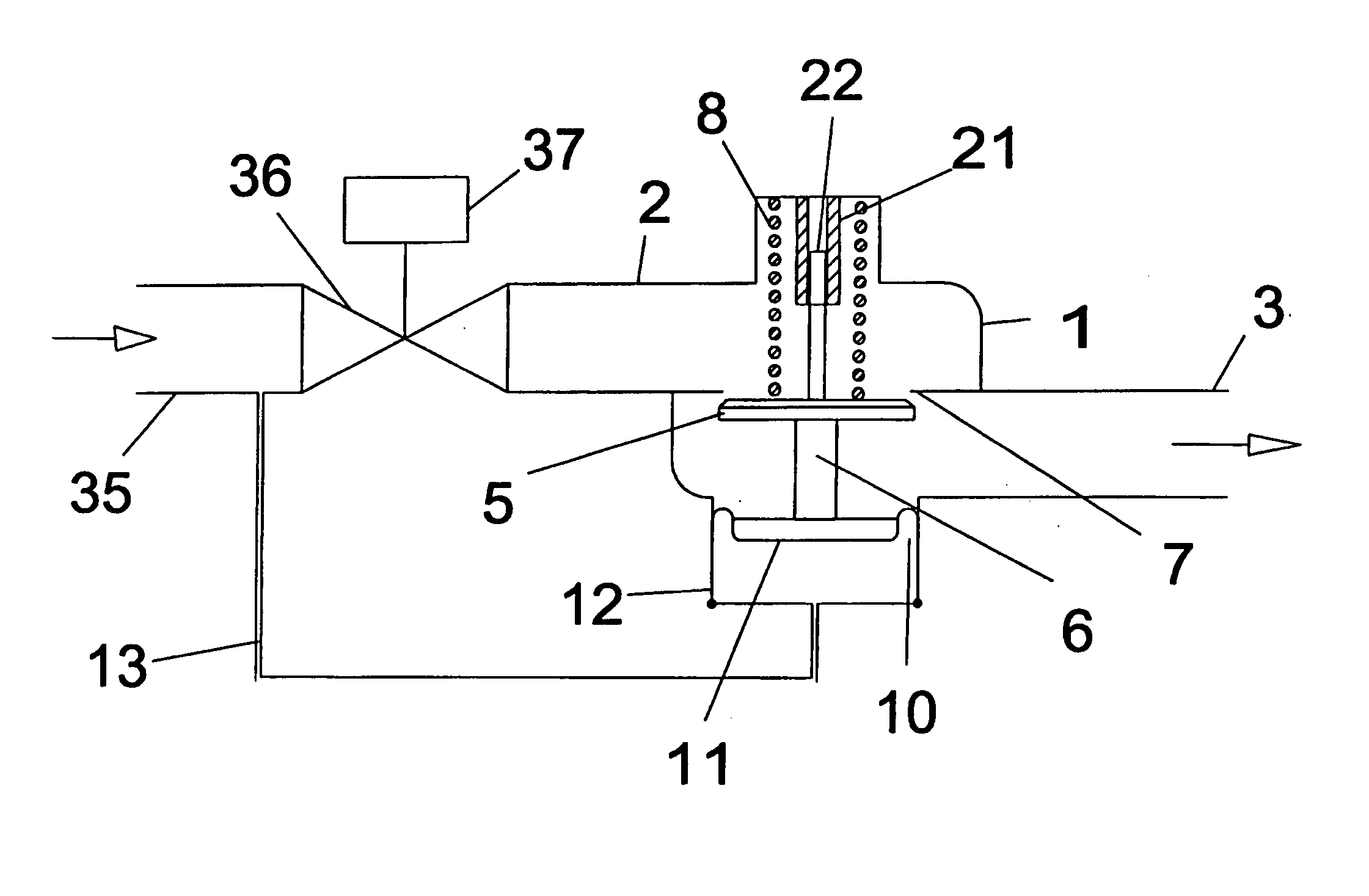

Pressure independent control valve

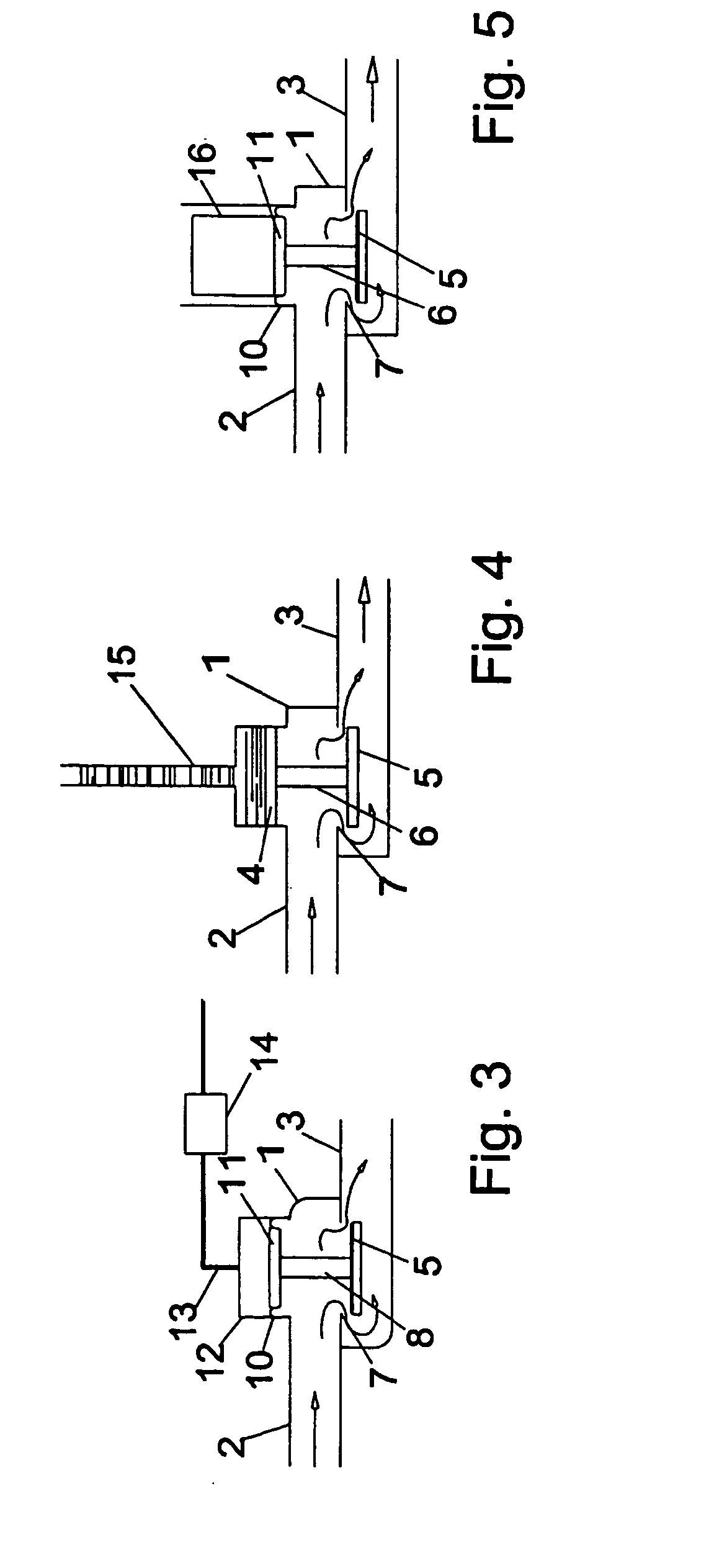

InactiveUS6827100B1Operating means/releasing devices for valvesFlow control without auxillary powerLine tubingAtmospheric air

Simple APCV, ADPCV and PICV's are provided. The APCV's are referenced to the atmosphere and control the gauge pressure, either upstream or downstream. The ADPCV's are the same as the APCV's, differing in that they are not referenced to the atmosphere. They are instead referenced to a second point in the fluid flow system and control the differential pressure. The PICV's are control valves connected in series with ADPCV's and control the fluid flow rate through the valve independently of variations in the line pressure. A preferred APCV has a valve body (1) with connections for a single-phase fluid line and a flow passage between the inlet (2) and the outlet (3) of said fluid line, with an opening having a defined seat orifice (7) intersecting the flow passage. A moveable assembly, comprising a disk (5) or cup is connected to a pressure sensing member (4), having essentially the same effective surface area. The moveable assembly, is biased by a force, and is free to automatically move to any intermediate position between fully open and closed, producing a desired outlet pressure which minus the reference pressure, times the effective surface area of the disk or cup generates an opposing force equal to the biasing force.

Owner:BELIMO HOLDING AG

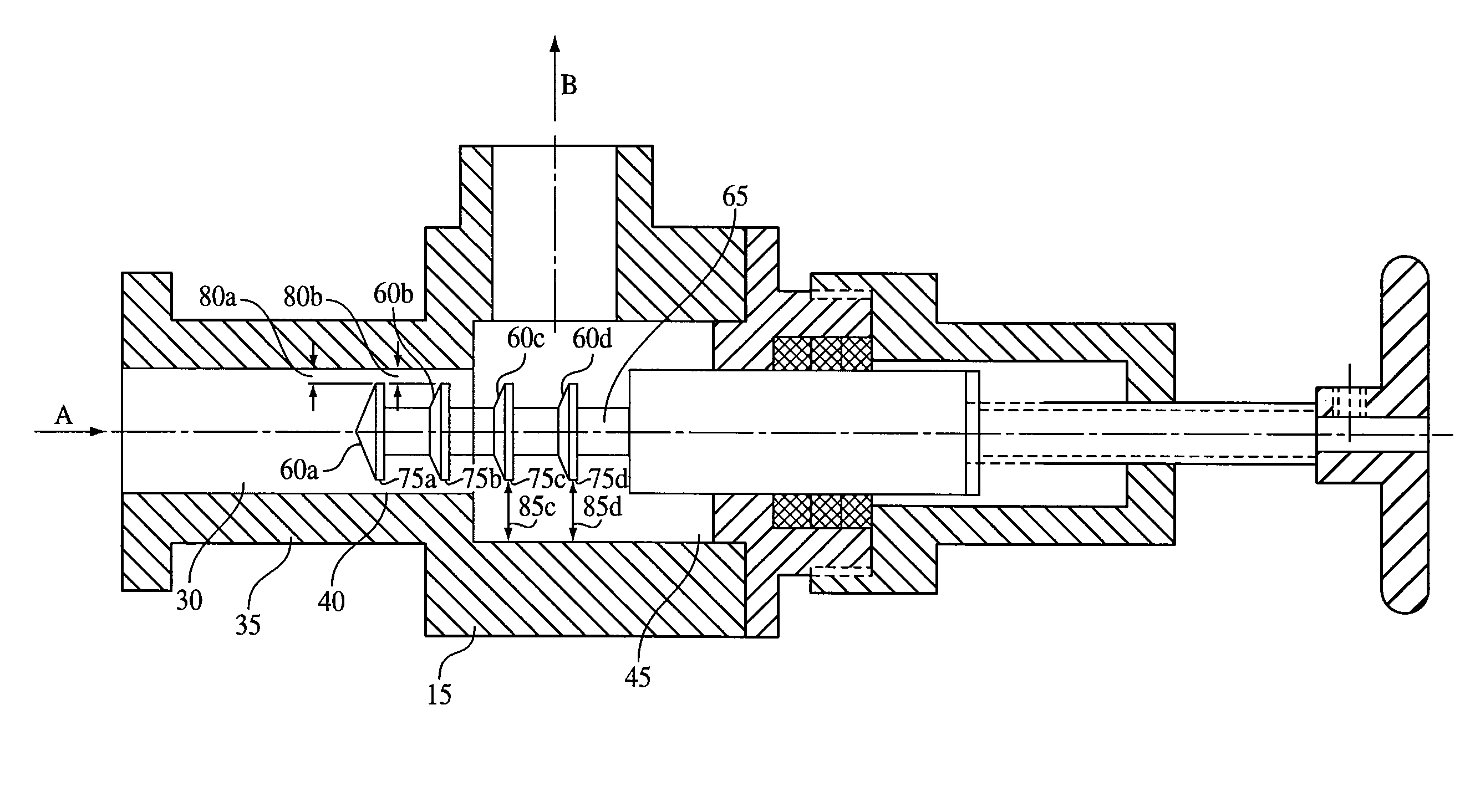

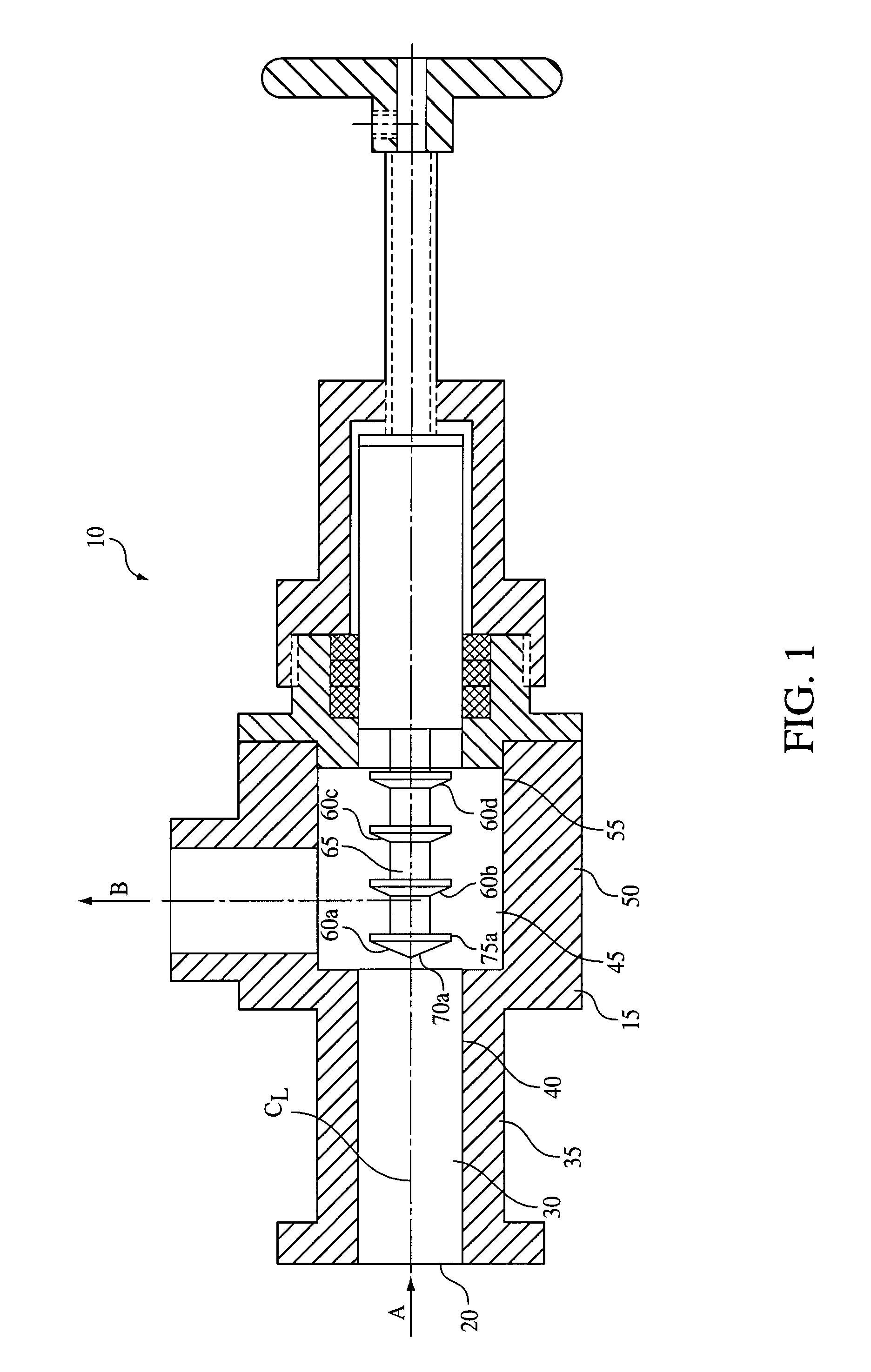

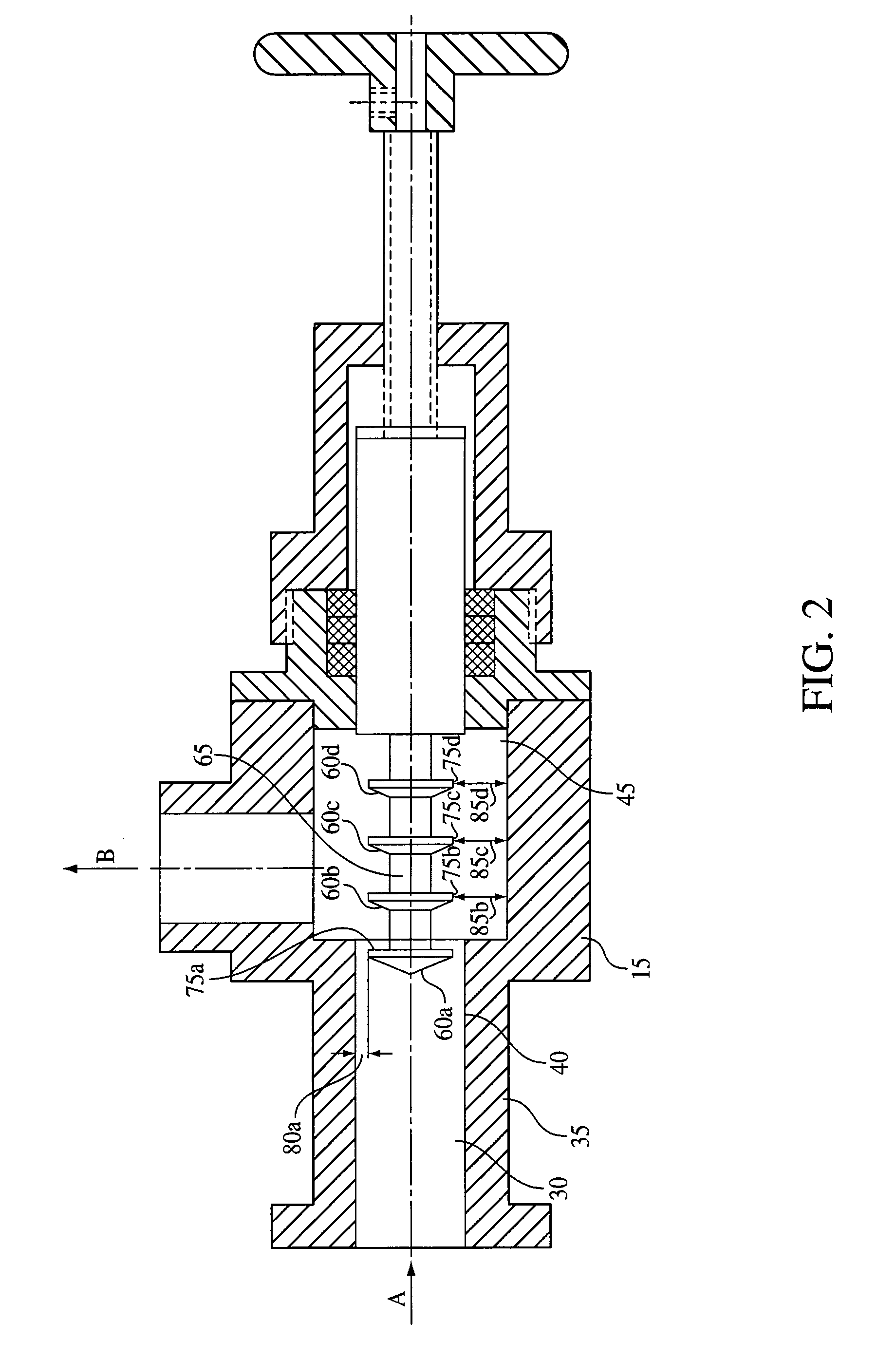

Homogenization device and method of using same

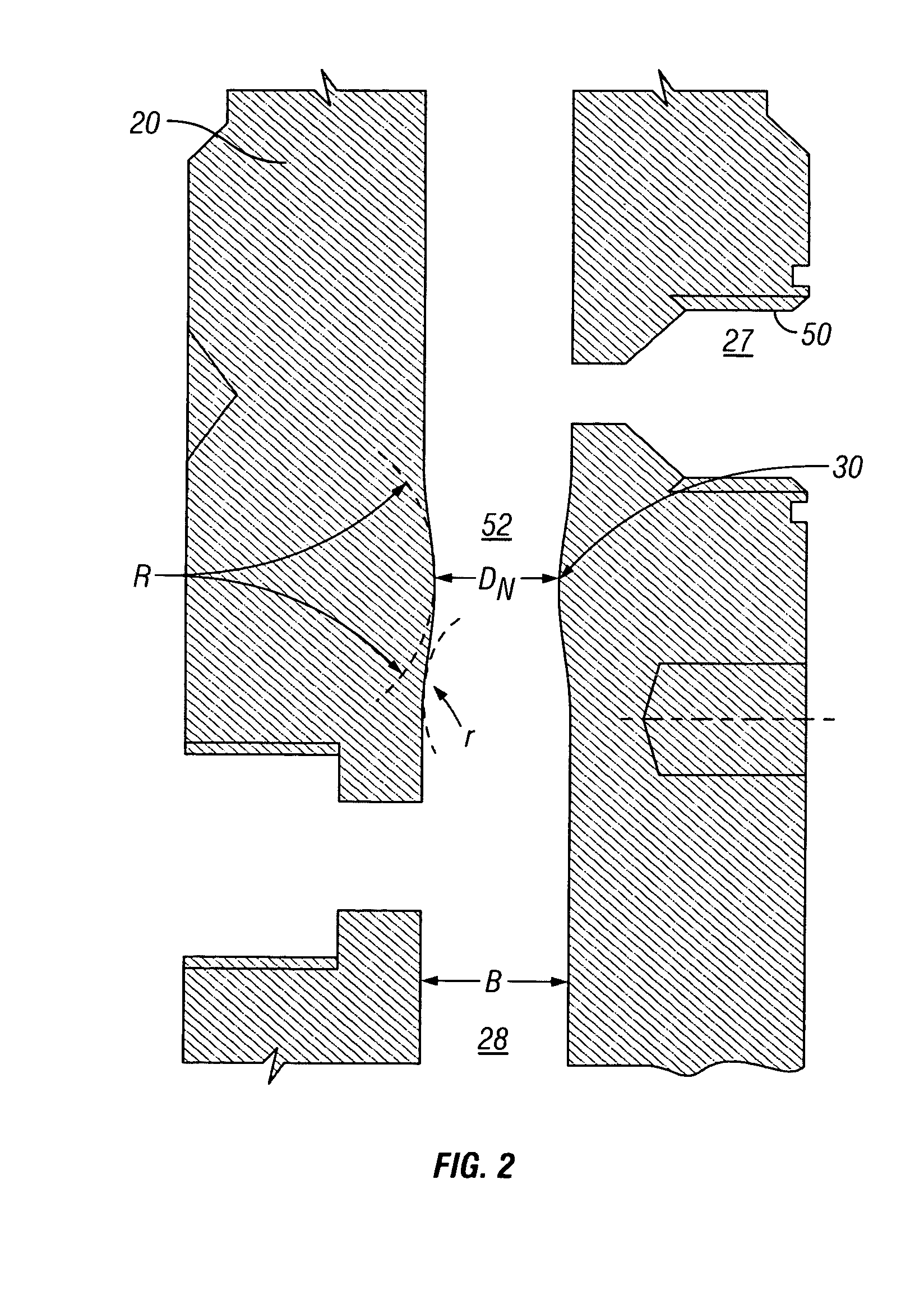

InactiveUS6802639B2Inexpensive and readily adjustable mannerMaintain qualityFlow mixersTransportation and packagingEngineeringConstriction

A homogenization device comprising a flow-through channel having at least two local constrictions of flow wherein the size of a first local constrictions is adjustable thereby permitting variable flow rate through one portion of the device and the size of a second local constriction is fixed thereby permitting constant flow rate through another portion of the device.

Owner:ARISDYNE STSTEMS INC

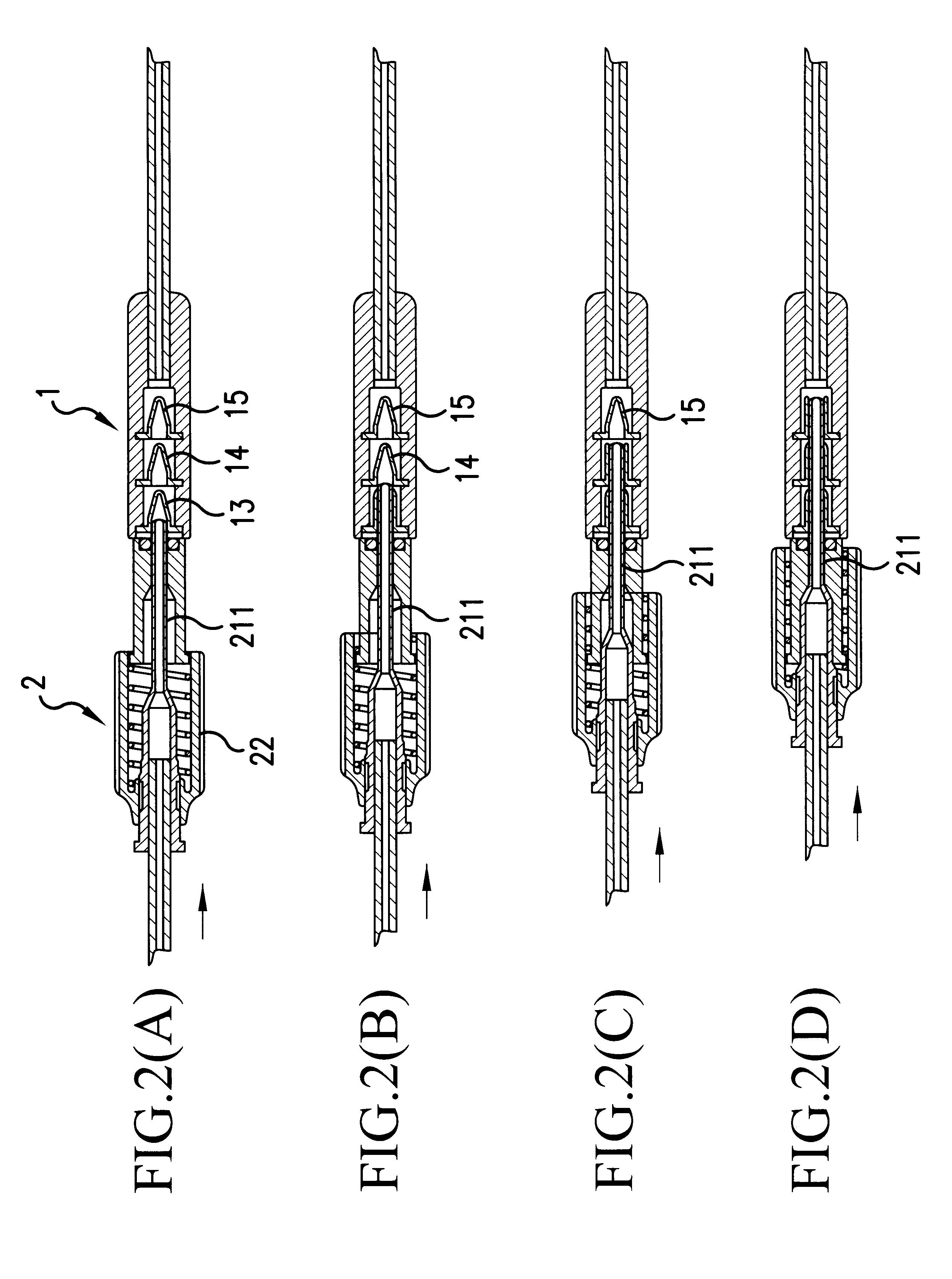

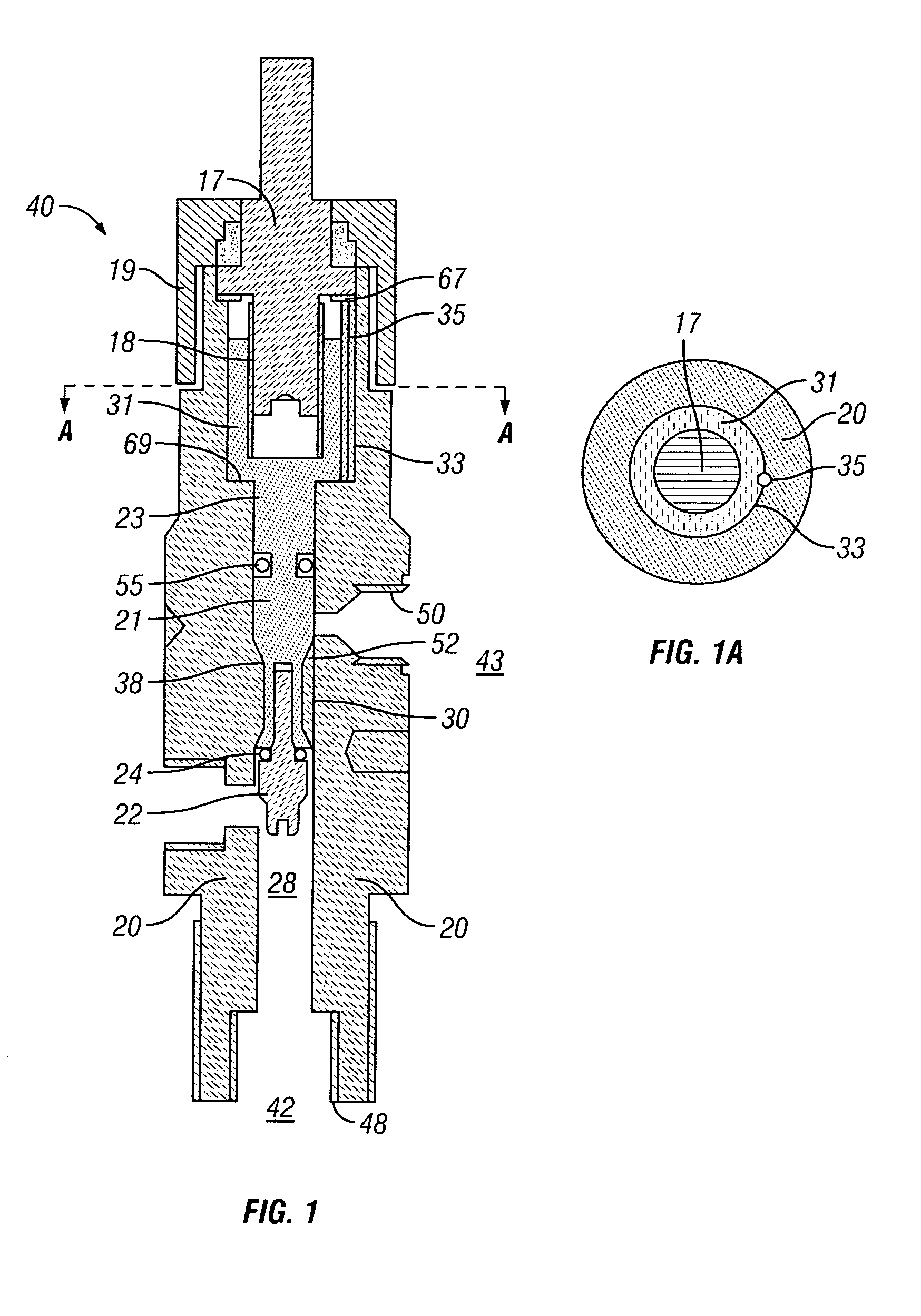

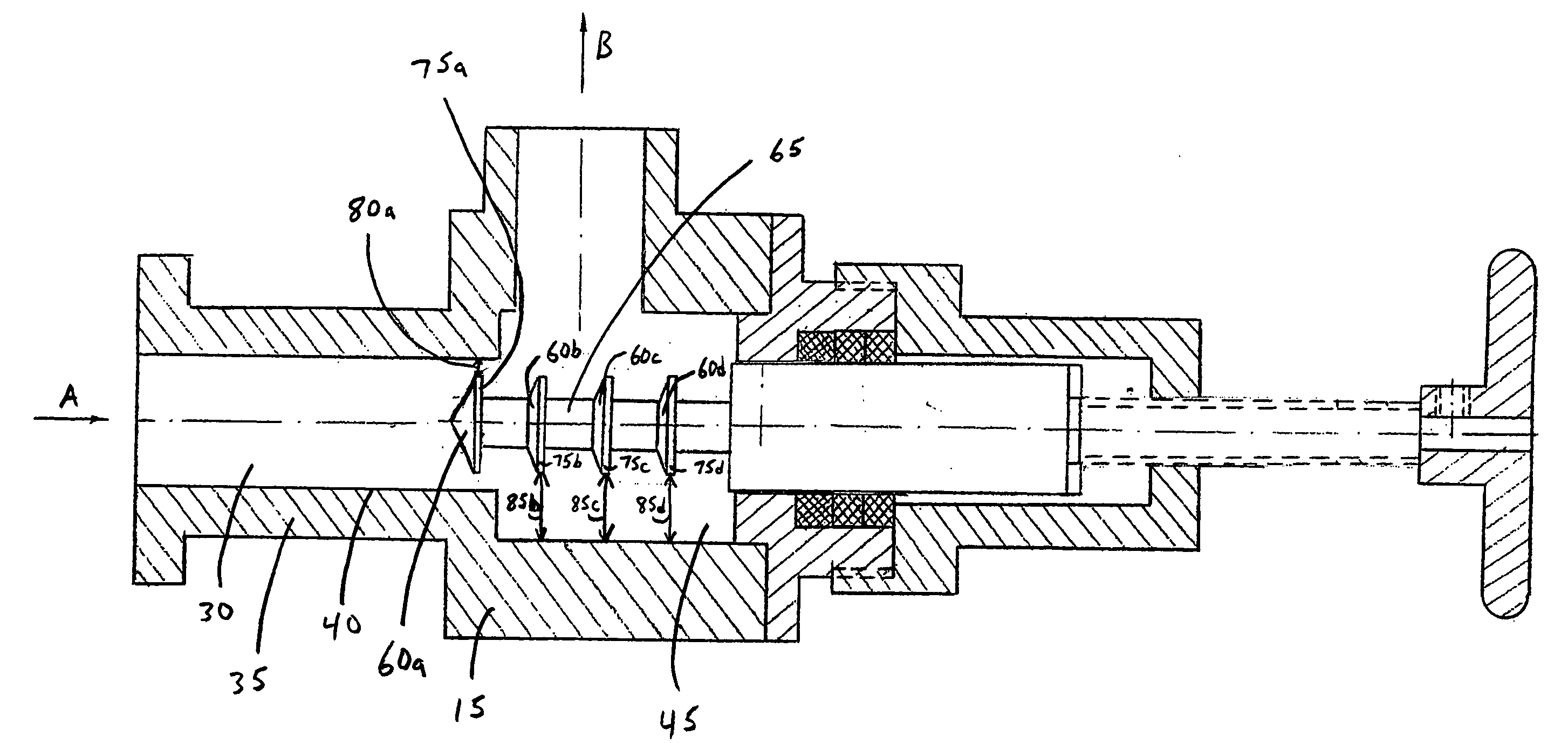

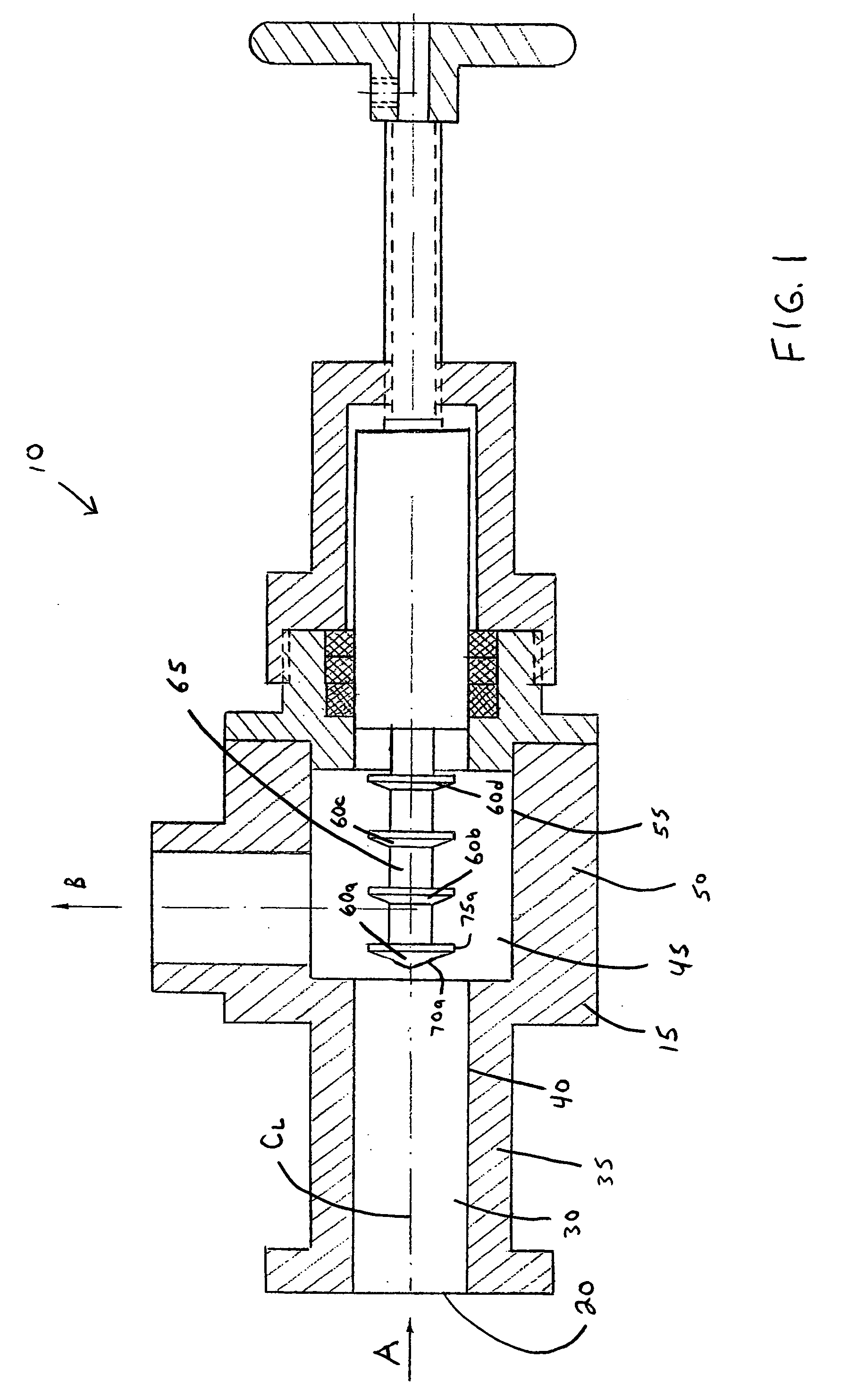

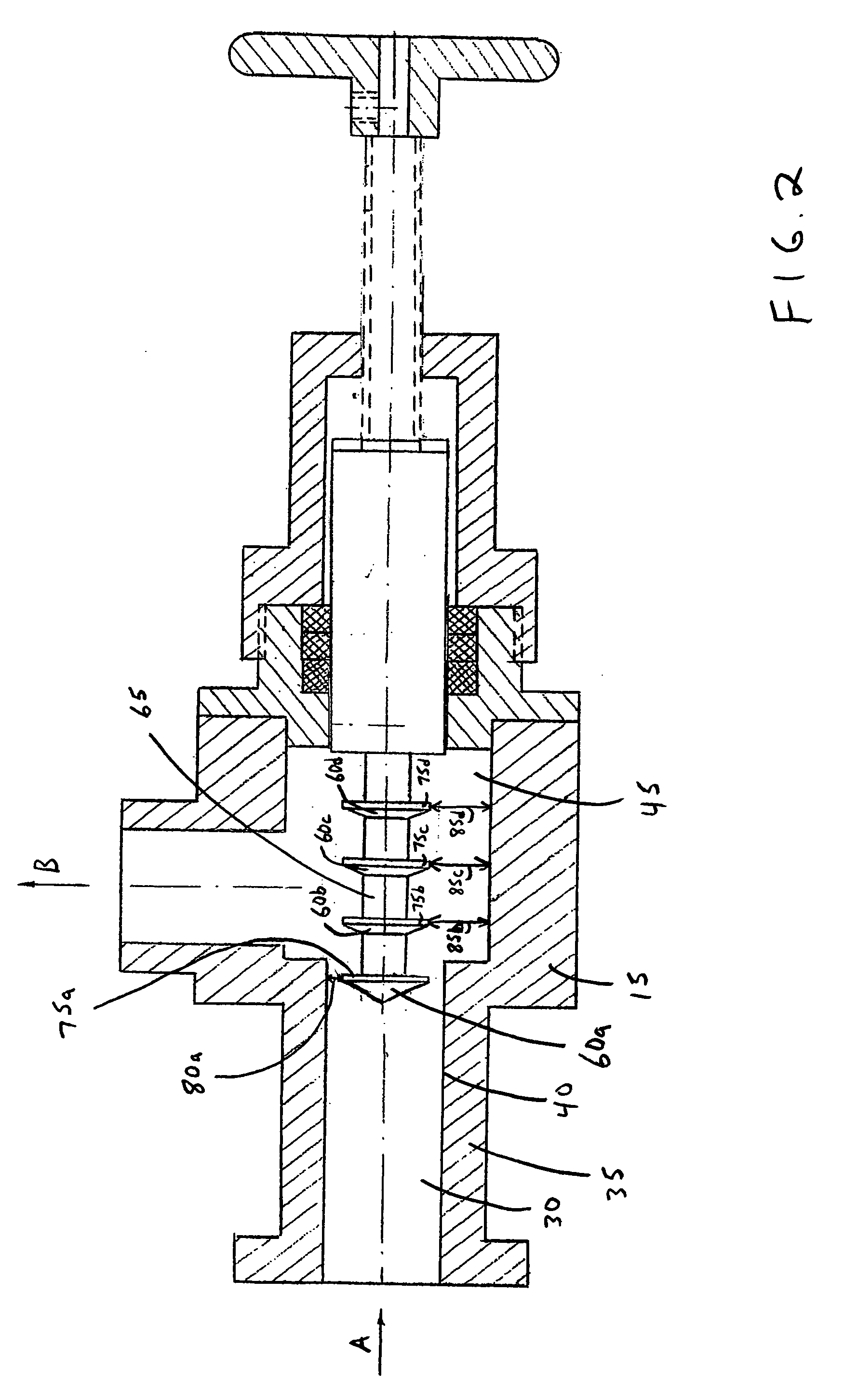

Cartridge insert for a fluid line

InactiveUS6837267B2Small space requirementEconomically manufacturedServomotor componentsCheck valvesValve seatCentral governor

A cartridge insert for insertion in a fluid line is provided having a cartridge housing within which is located at least one backflow inhibitor and downstream at least one flow regulator. The backflow inhibitor has a closing element, which, in a closed position thereof, lies tightly sealed on a valve seat of the cartridge housing and which may be displaced from the closed position against a return force into an open position. A downstream guide pin projects from the closing element, and extends into a guide opening of a central regulator core of the flow regulator, and the flow regulator is formed from a regulator element made from an elastic material that surrounds the regulator core, which rests on an annular shoulder and defines a control gap, which changes with pressure between the above and an opposing enclosing wall. The cartridge insert is compact and space saving in that the flow regulator terminates generally flush with the downstream side of the cartridge and the annular shoulder projects from the regulator core and the control gap is provided between the regulating element and an inside of the cartridge housing which forms the enclosing wall.

Owner:NEOPERL

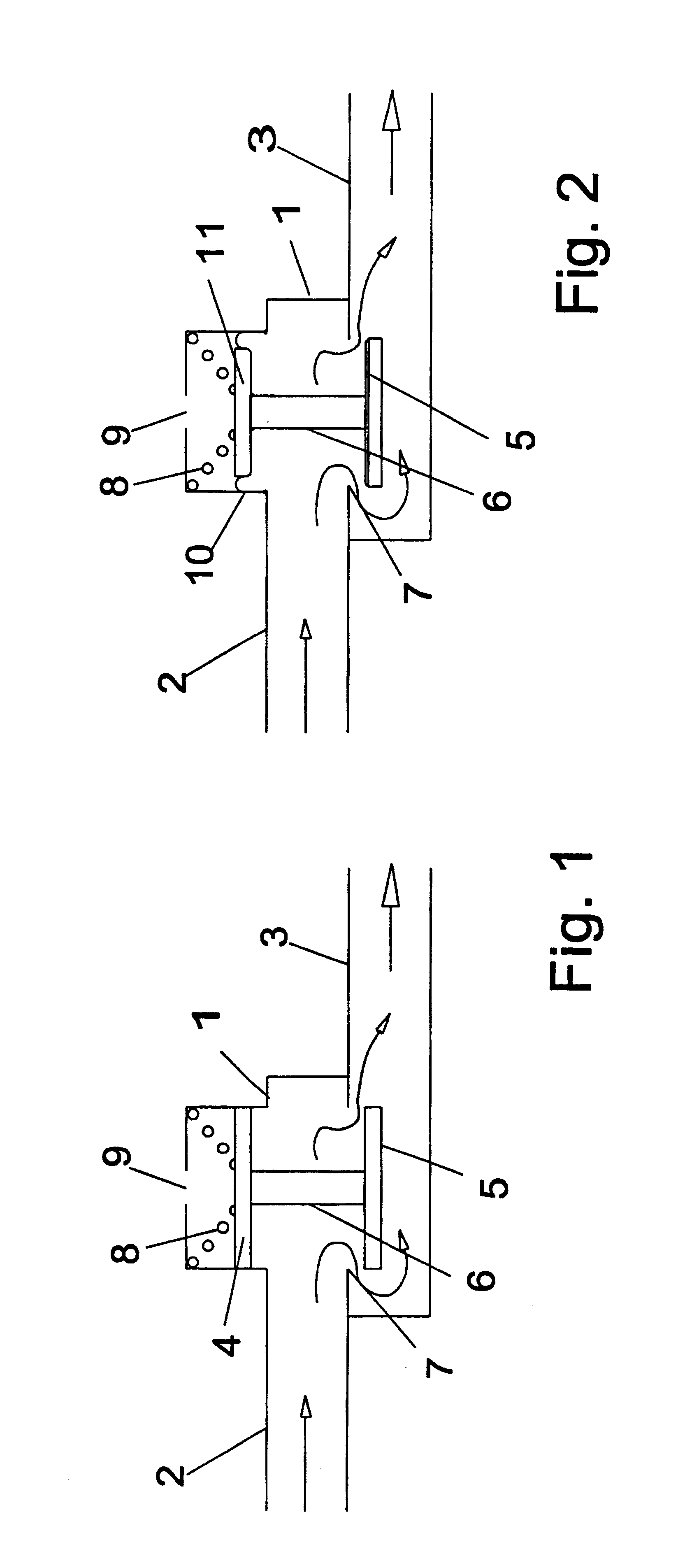

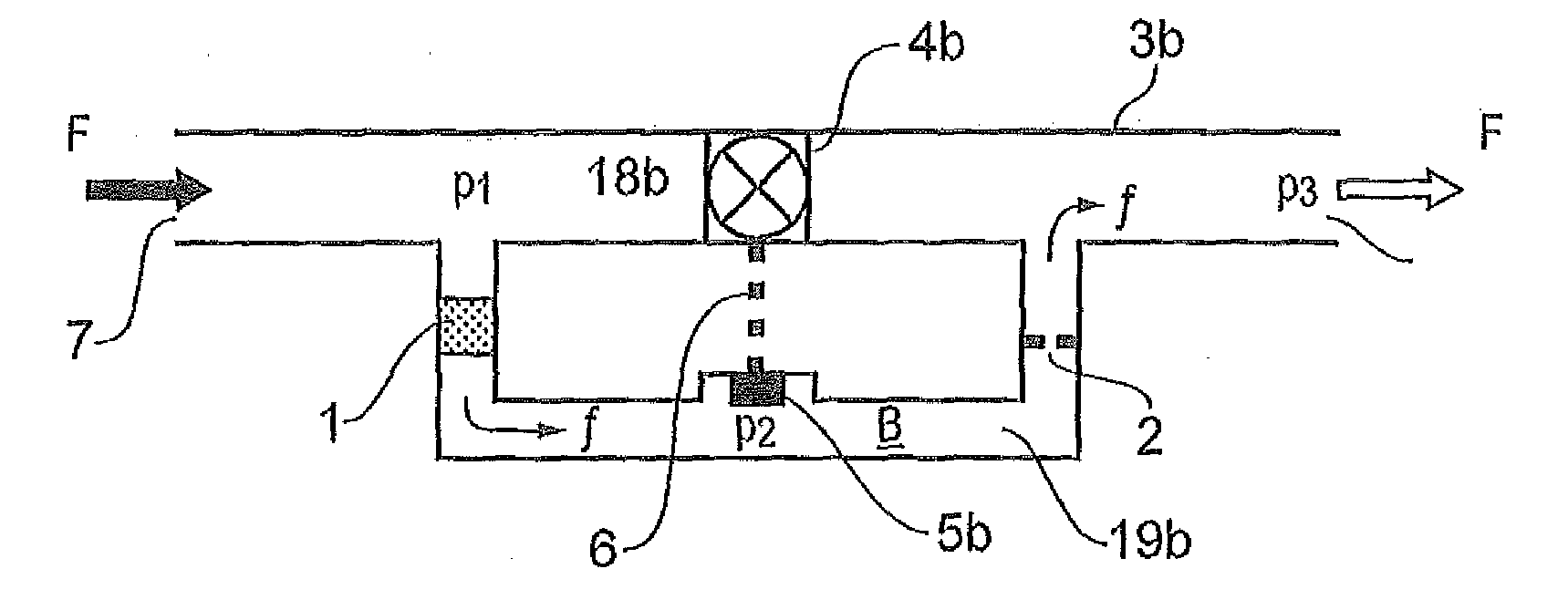

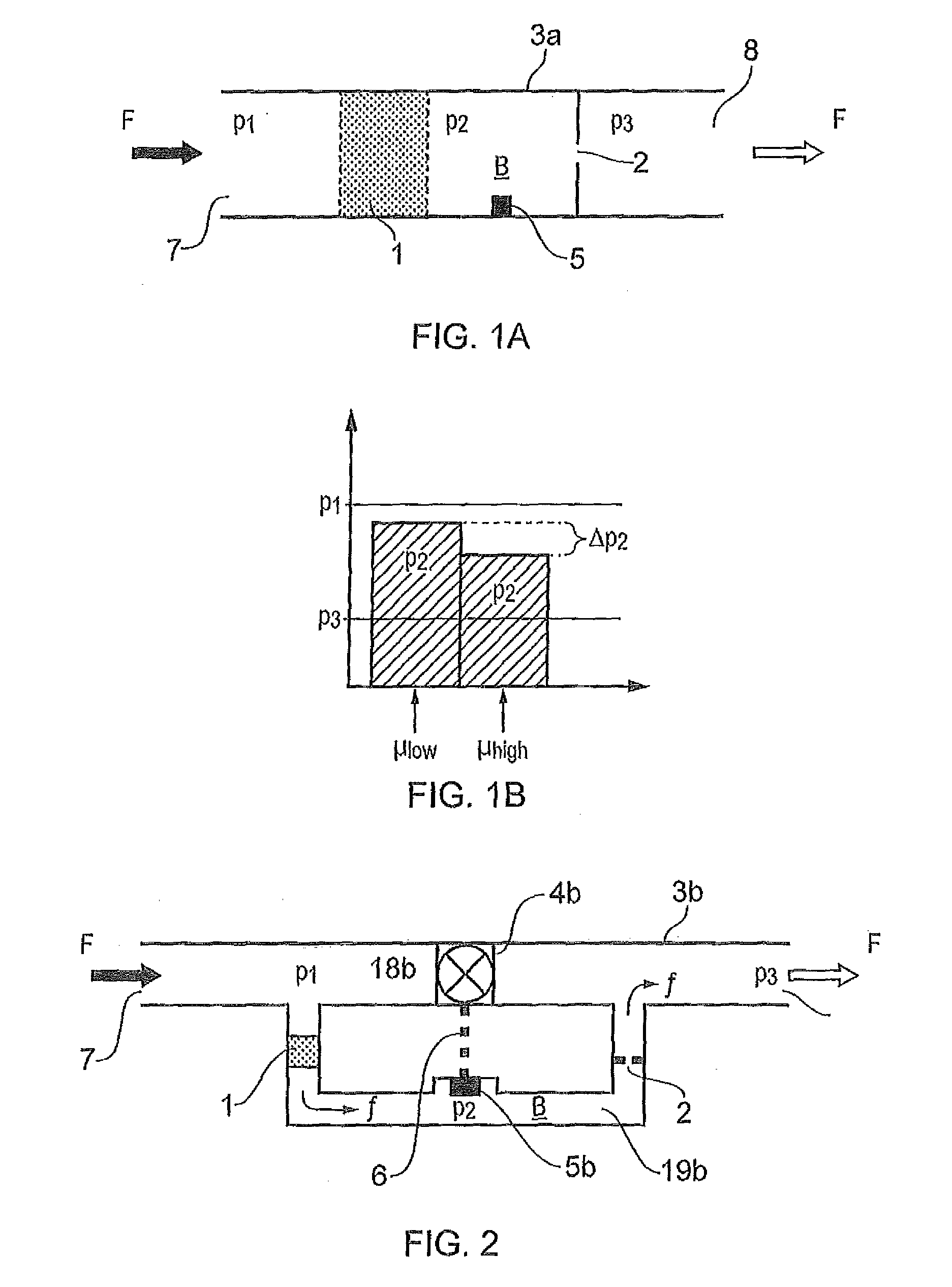

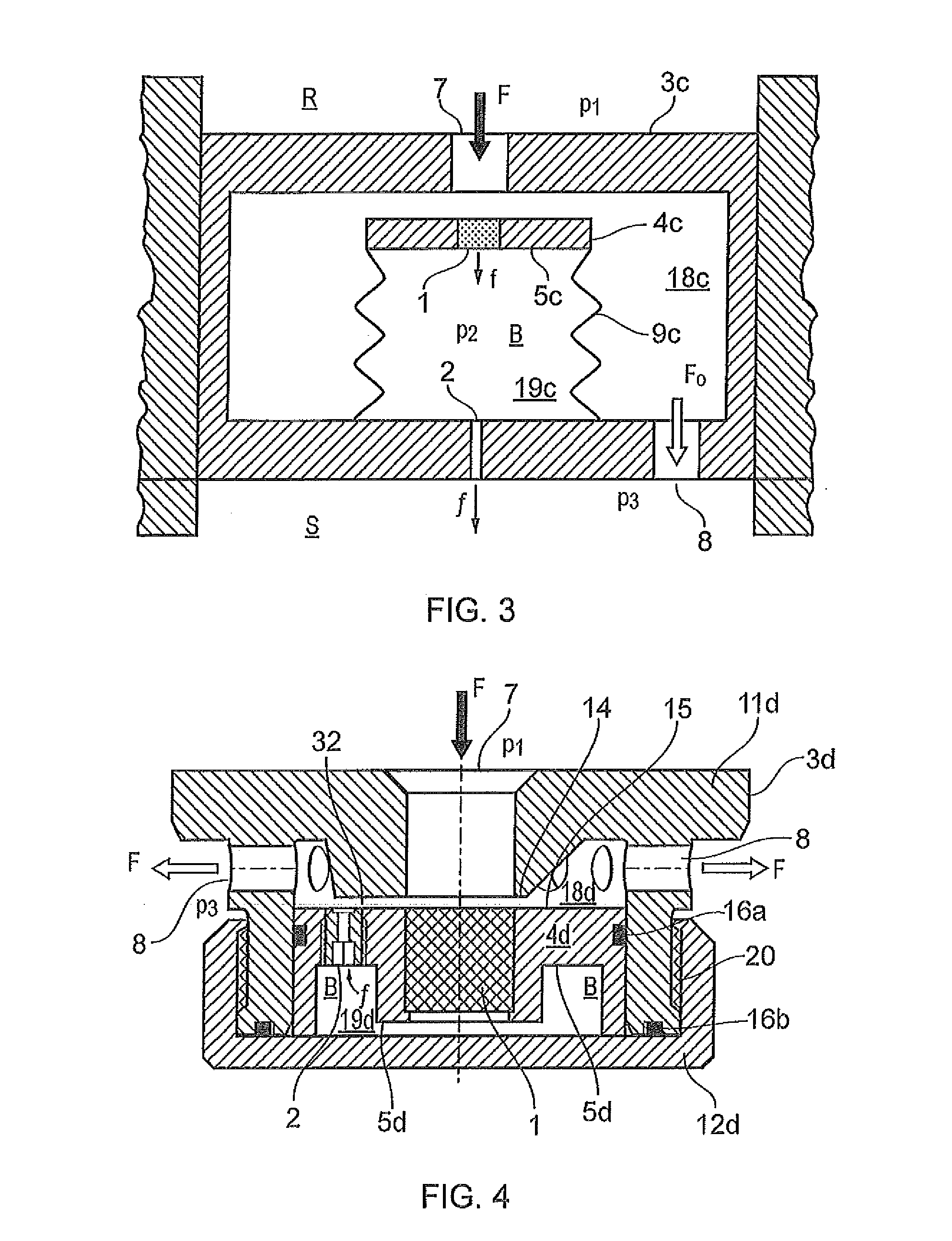

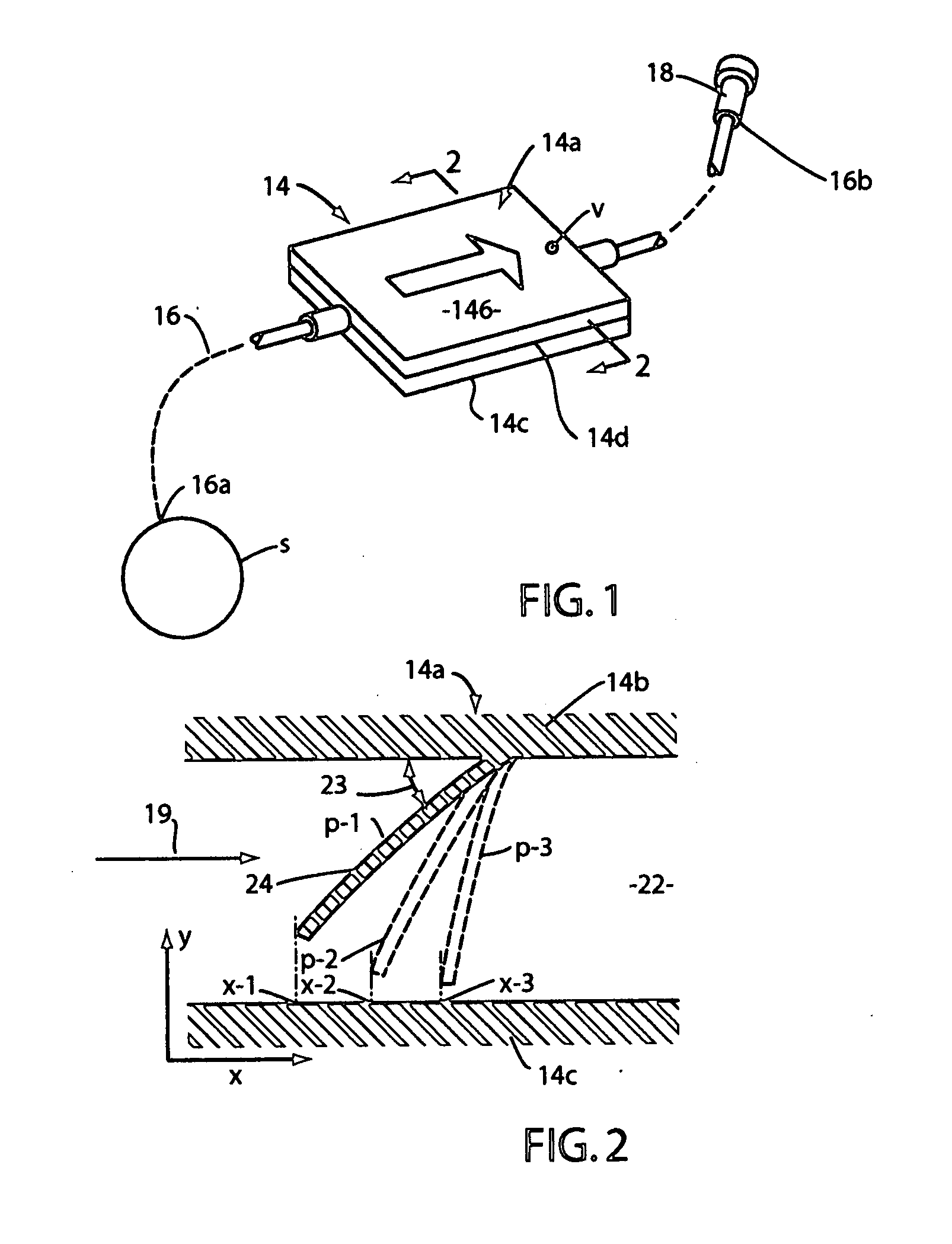

Flow control device and method

ActiveUS20150040990A1Avoid suffocationHigh degreeOperating means/releasing devices for valvesFluid removalEngineeringFluid pressure

A fluid flow control device includes a housing having a fluid inlet (7) and at least one fluid outlet (8). A first fluid flow restrictor (1) serves as an inflow port to a chamber (B) in the housing, and a second fluid flow restrictor (2) serves as an outflow port from the chamber (B). The first fluid flow restrictor and the second fluid flow restrictor are configured to generate different fluid flow characteristics; and the chamber (B) includes an actuating device (5a-1) that is responsive to fluid pressure changes (ΔP2) in the chamber. The first fluid flow restrictor (1) and the second fluid flow restrictor (2) are configured to impose respective different fluid flow characteristics based on different fluid properties.

Owner:INFLOWCONTROL

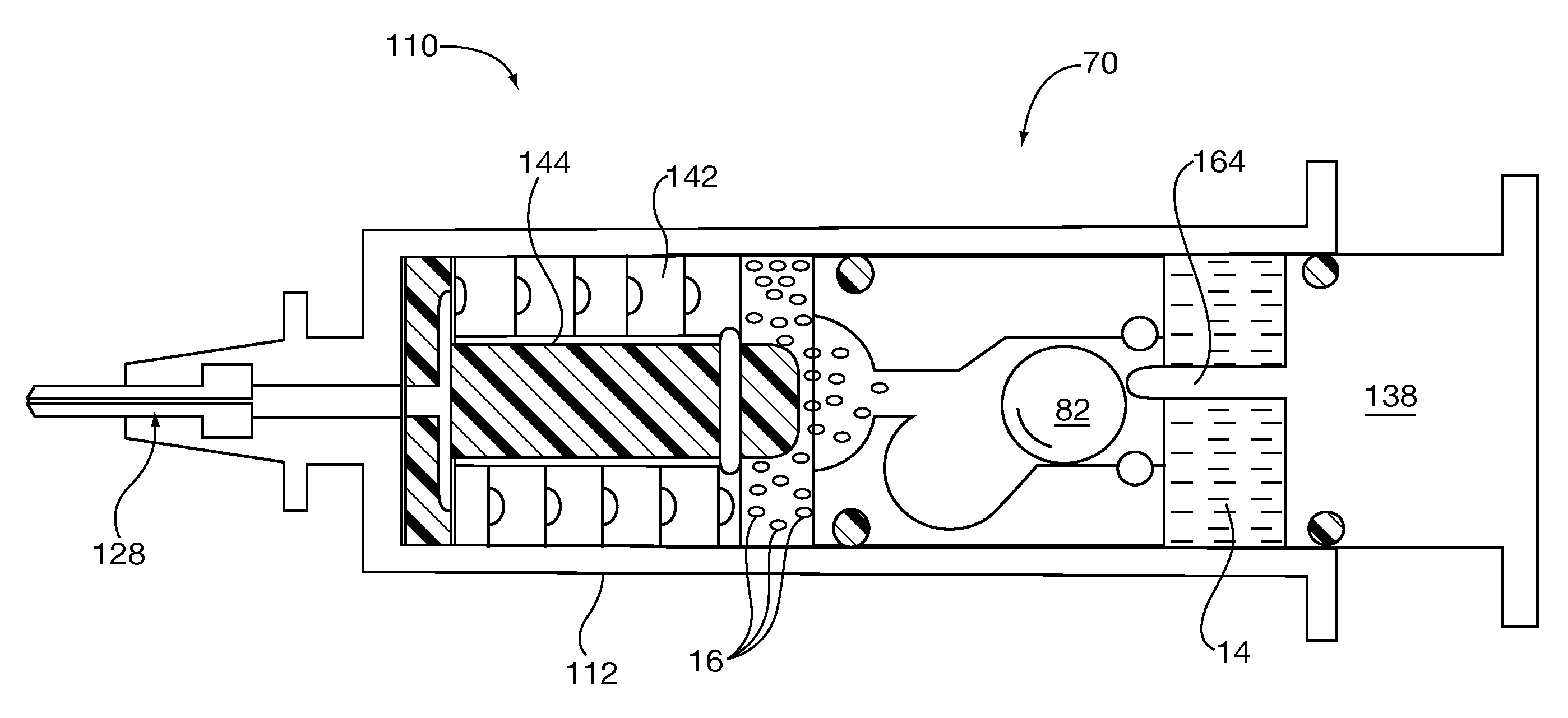

Syringe having extended blending path

InactiveUS20100274184A1Inexpensive to fabricateEffective serviceAmpoule syringesMedical devicesHelical coilSolvent

An injection device such as a syringe, which has a helical flow path for a solution in which the solvent and solute have been introduced. The helical flow path is formed by a helically configured member which has general overall configuration of a helical coil spring. Individual coils may be formed to have a groove located along the length of the helix. When compressed, the novel member effectively takes on a cylindrical outer configuration. Because the groove is covered and sealed by the surface of the next turn of the helix when compressed, an enclosed helical flow path is formed in the compressed member. The invention may be an injection device using the novel flow path forming member or alternatively, the flow path forming member itself.

Owner:CHUN THOMAS

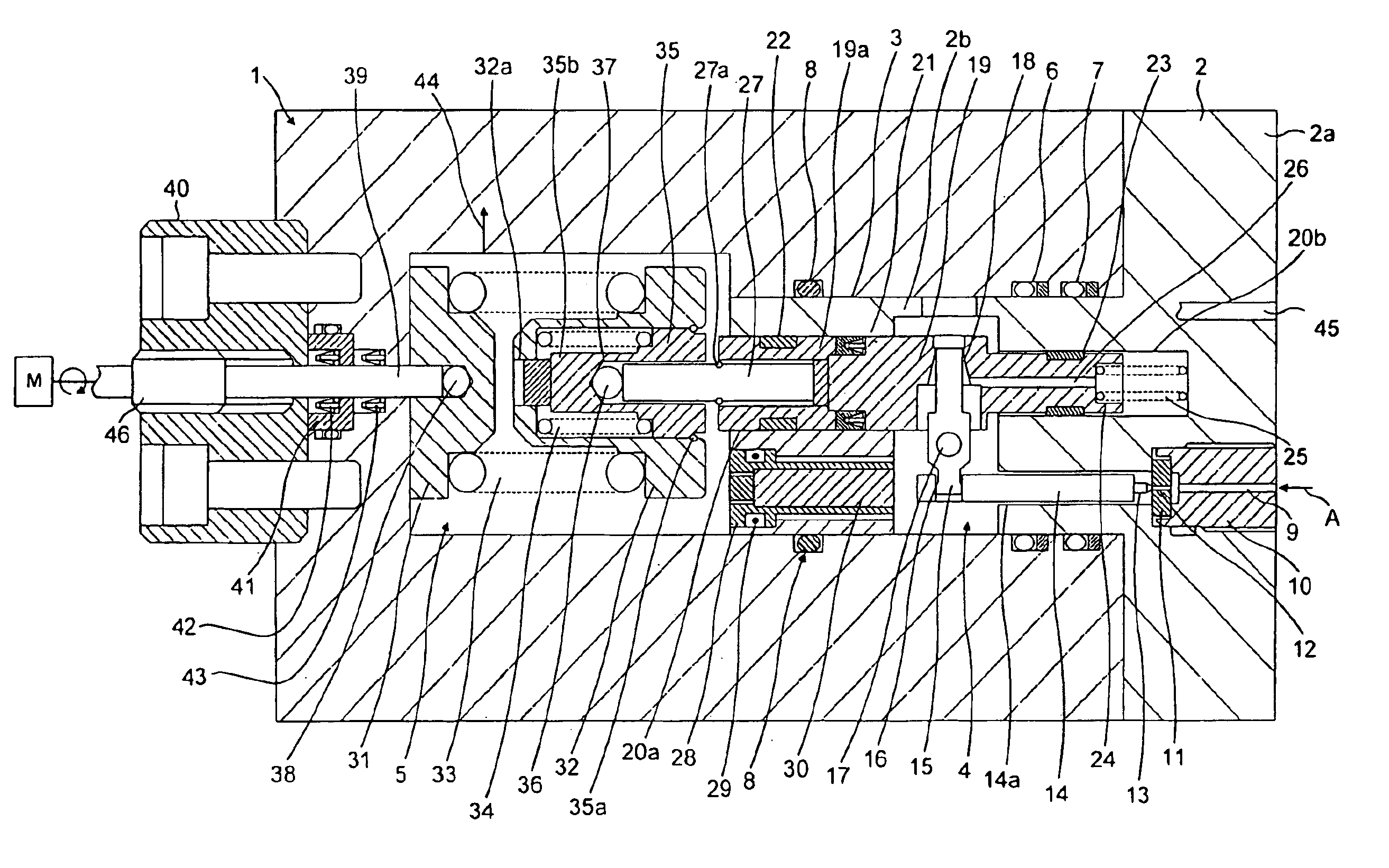

Fluid flow regulating valve and method

InactiveUS6170508B1Reduce the possibilityImproved valveGearingEqualizing valvesMotorized vehicleGuide tube

A valve for regulating the rate of flow and / or the pressure of oil flowing to a transmission or another consumer in the power train of a motor vehicle has a piston which defines with the valve housing a chamber for one or more springs and for oil being admitted through a first inlet by way of a first conduit containing a first throttle. A second inlet admits pressurized oil from a pump, and such oil can be admitted into the consumer by way of a first outlet and a second conduit containing a second throttle and supplying oil to the first conduit. A second outlet can deliver oil from the second inlet to the sump in response to shifting of the piston. A hydraulic seal is established between the piston and the housing intermediate the chamber and the second outlet to prevent leakage of oil from the chamber into the second outlet. Oil leaking from the chamber could adversely influence the characteristics of oil flowing into the consumer.

Owner:LUK GETRIEBE SYST

Device and method for creating hydrodynamic cavitation in fluids

A device and method for creating hydrodynamic cavitation in fluid is provided. The device can include a flow-through chamber having a first portion and a second portion, and a plurality of baffles provided within the second portion of the flow-through chamber. One or more of the plurality of baffles can be configured to be selectively movable into the first portion of the flow-through chamber to generate a hydrodynamic cavitation field downstream from each baffle moved into the first portion of the flow-through chamber.

Owner:ARISDYNE STSTEMS INC

Liquid flow regulator

InactiveUS6895995B2Operating means/releasing devices for valvesFlow control using electric meansDifferential pressureInlet valve

A flow regulator particularly for sub-sea chemical injection at low continuous rates includes a piston moveable in response to differential pressure and controlling via a lever connection an inlet valve. The differential pressure is balanced by a dual rate spring assembly which is positionally adjustable by means of a screw-threaded adjusting rod.

Owner:AKER SOLUTIONS LTD

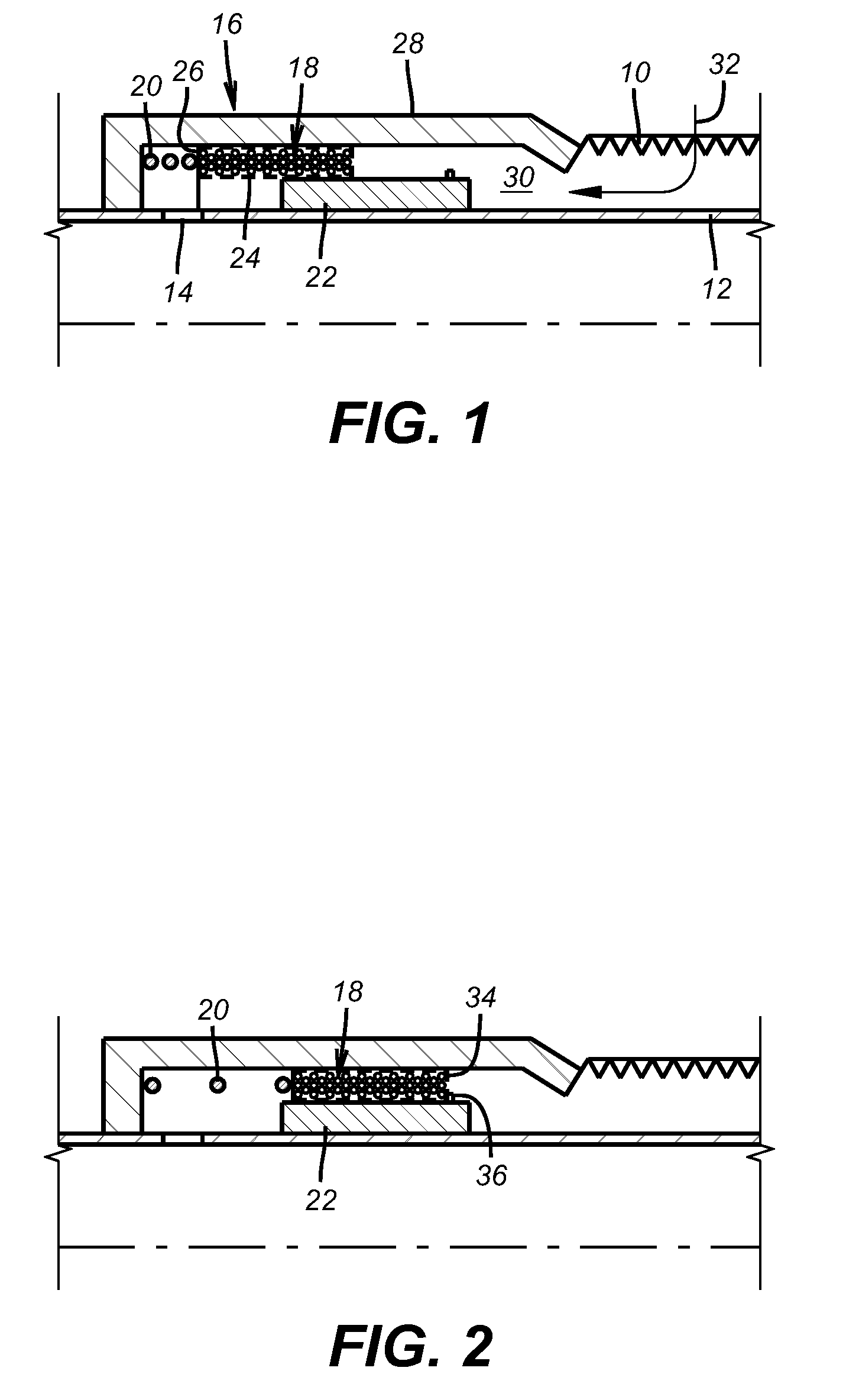

Linearly retractable pressure hose

A linearly self-actuated hose for use in transporting fluids (liquids, gases, solid particles, and combinations of these three). Hose (30) has a biasing spring (36) that extends along its full length, and can comprise single or multiple springs and / or multiple diameter spring coils. Spring (36) is covered with hose cover material (32) on the outside and hose cover material (34) on the inside to form a sealed hose and are bowed inward or outward radially between the individual spring coils depending on the intended use of hose (30) to give the cover materials room to move out of the way when the hose retracts and the coils of spring (36) are forced close together. The Linearly Retractable Hose is operated by changing internal pressure within the hose relative to the ambient pressure on the exterior of the hose. Control of fluid pressure within hose (30) is what allows the hose to operate as an automatically extendable and retractable hose. The biasing of spring (36) depends on the type of use for the hose. For hose (30b), which will be used as a vacuum hose then the biasing spring (30b) must exert an extending force on the cover material (opposite that for a pressure hose). If the hose is to be used as a pressure hose (garden hose, etc.), spring (36) will need to have a bias that exerts a retracting force on cover materials (32) and (34).

Owner:TELEBRANDS CORP

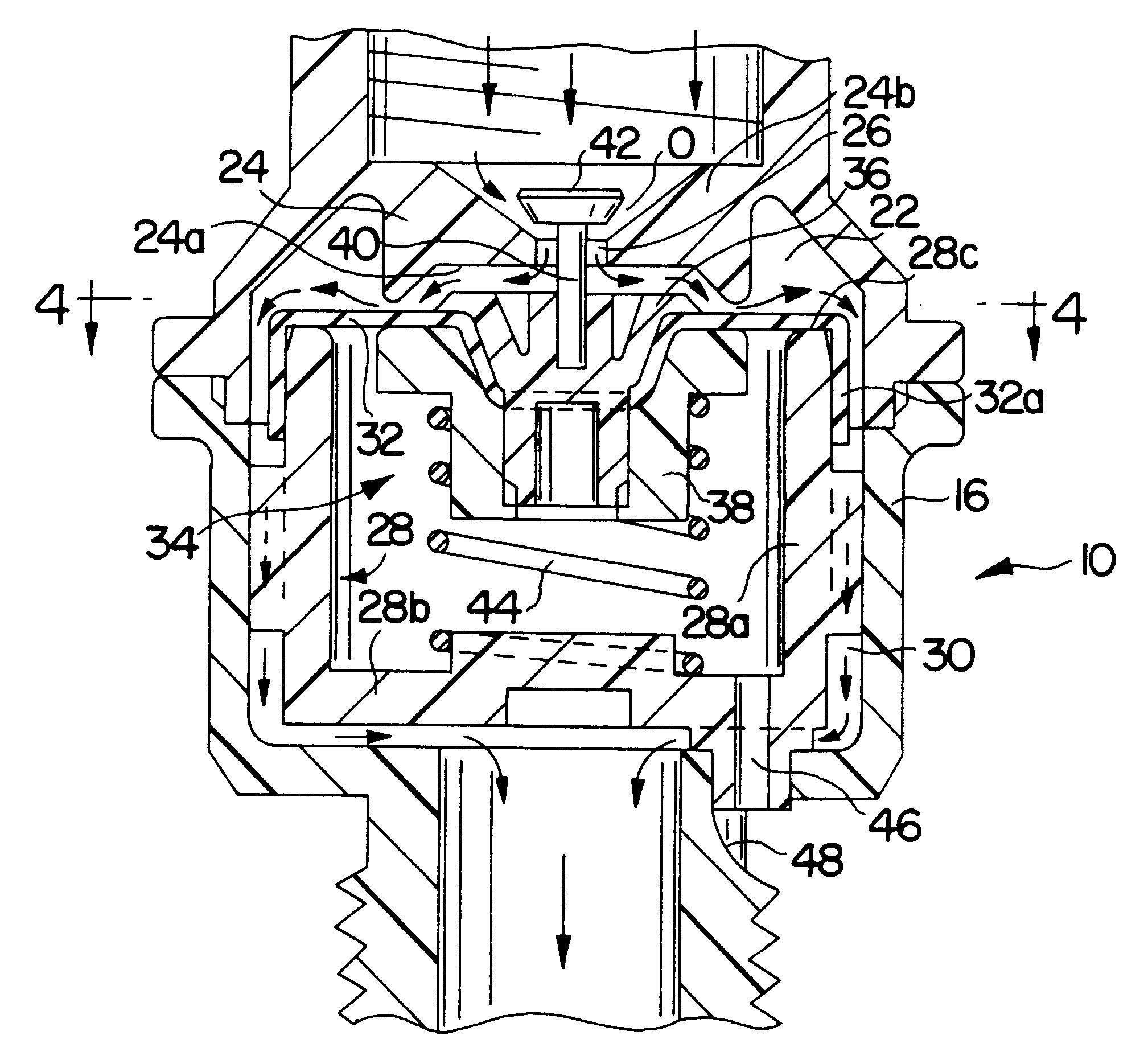

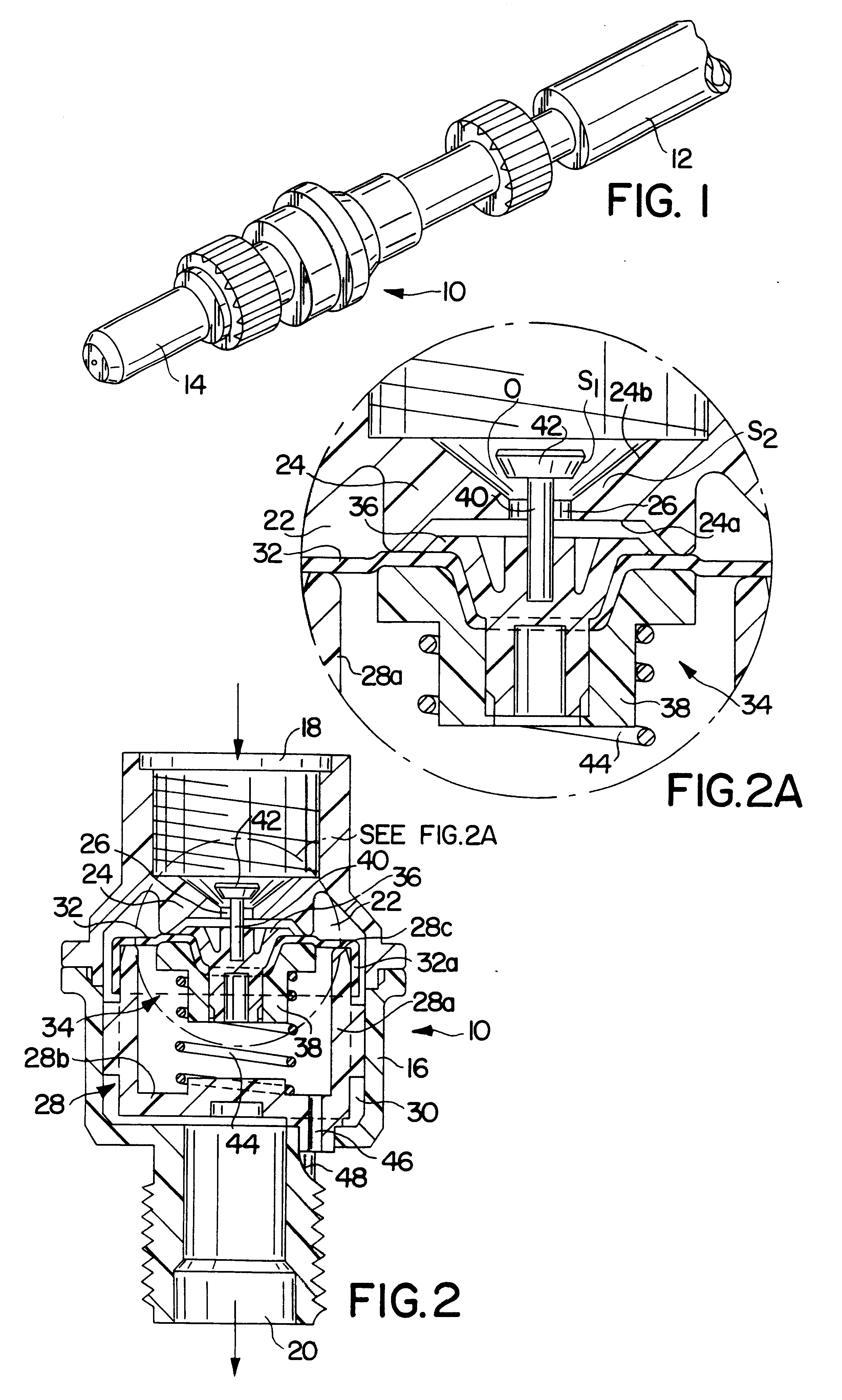

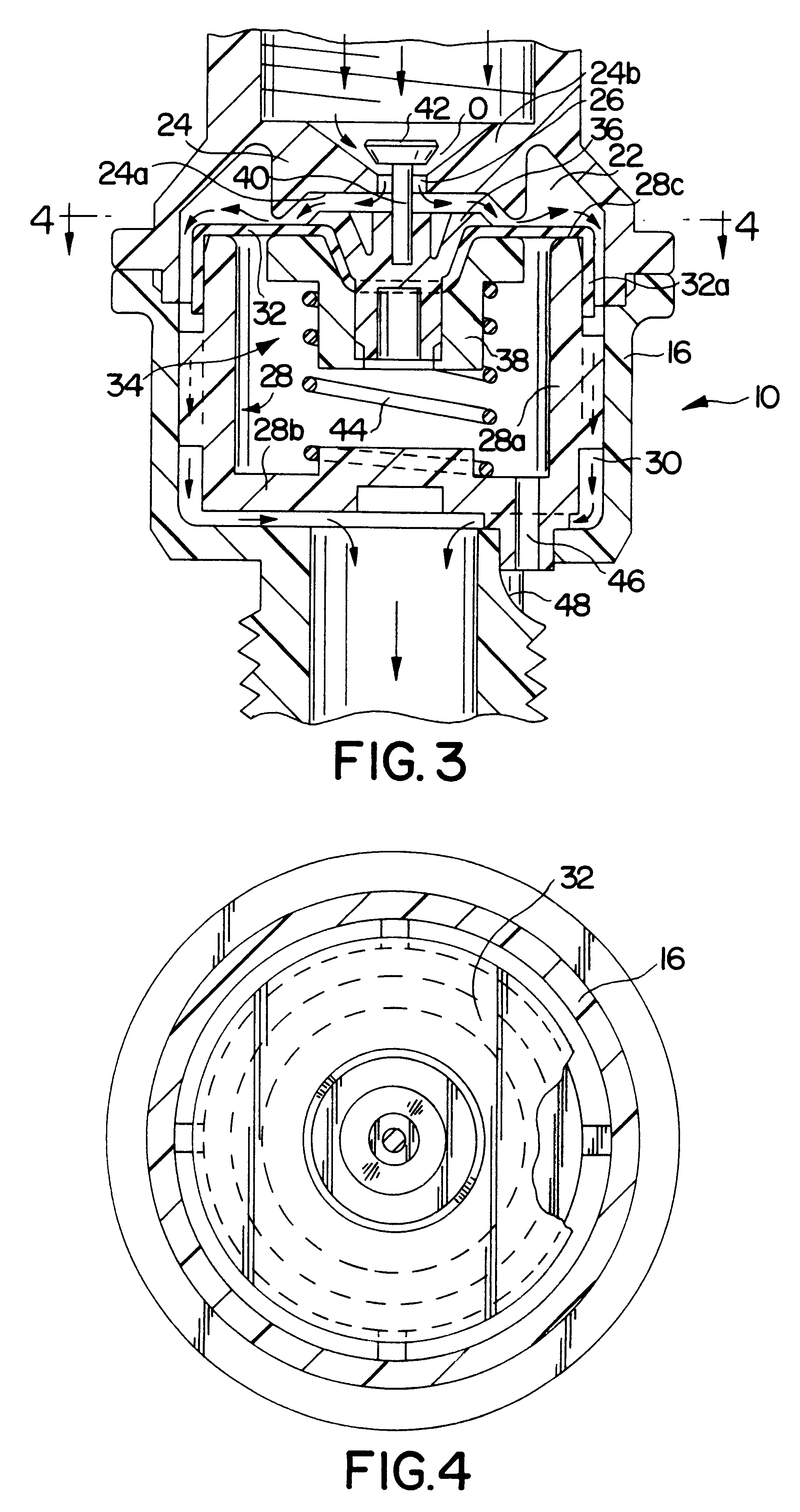

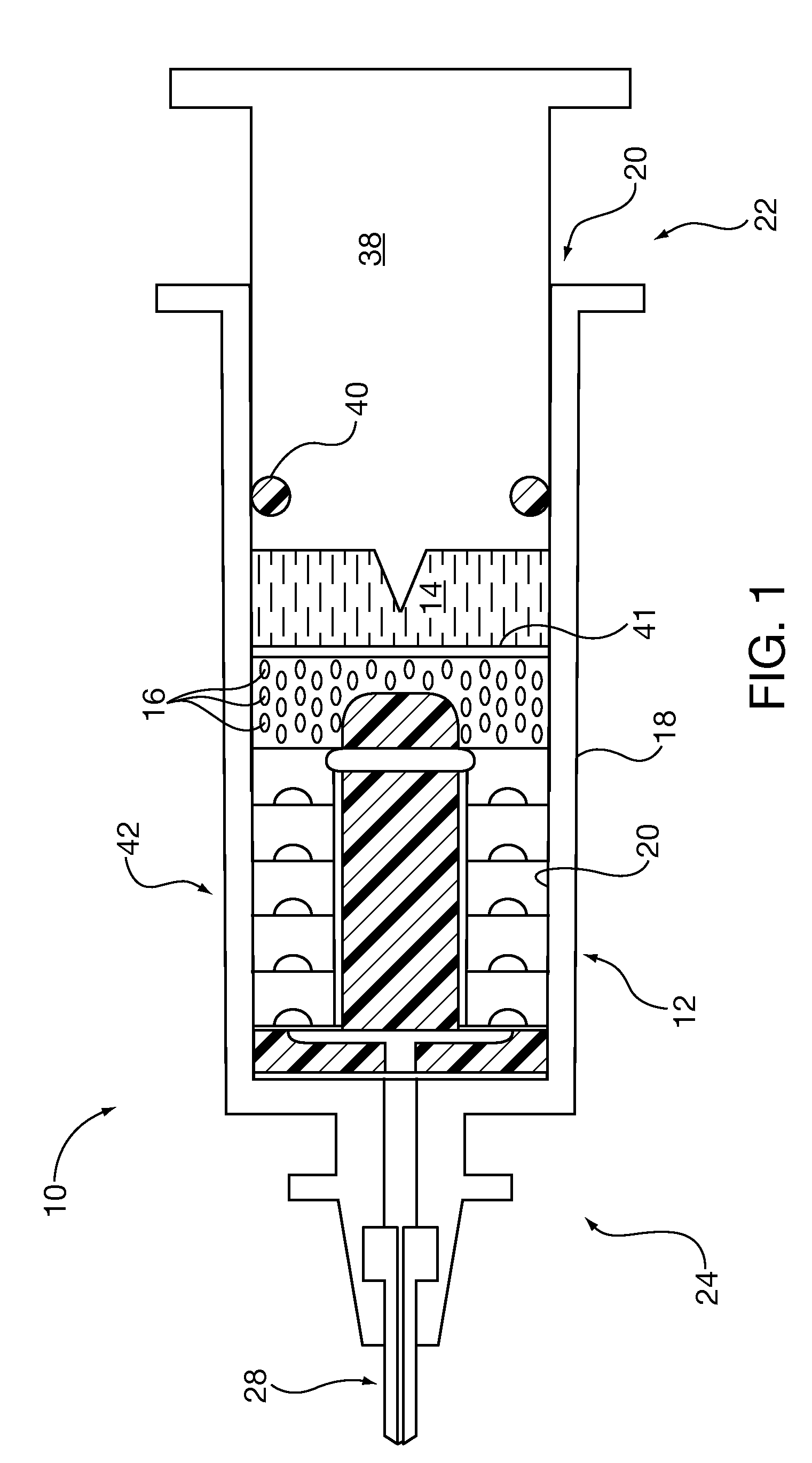

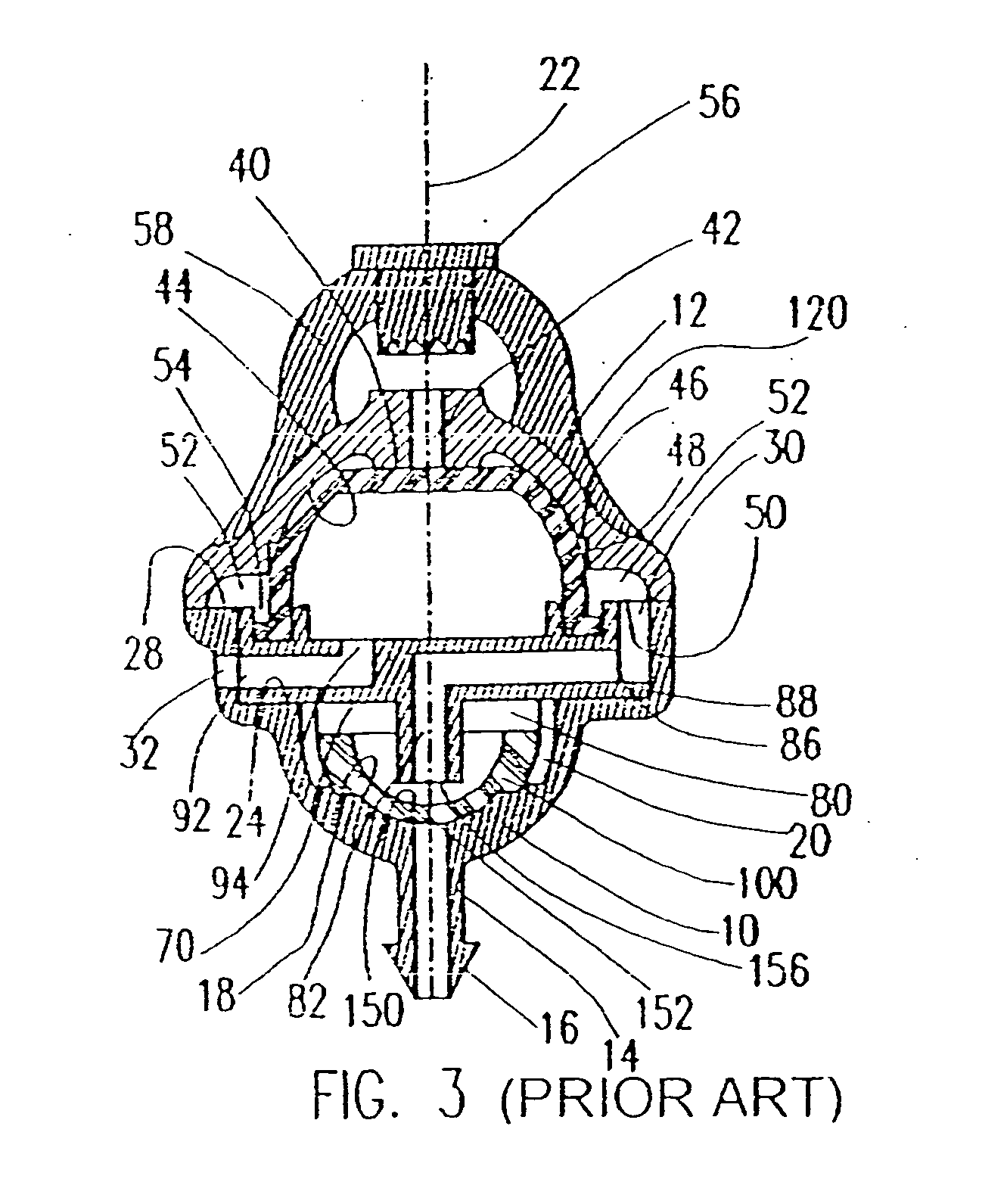

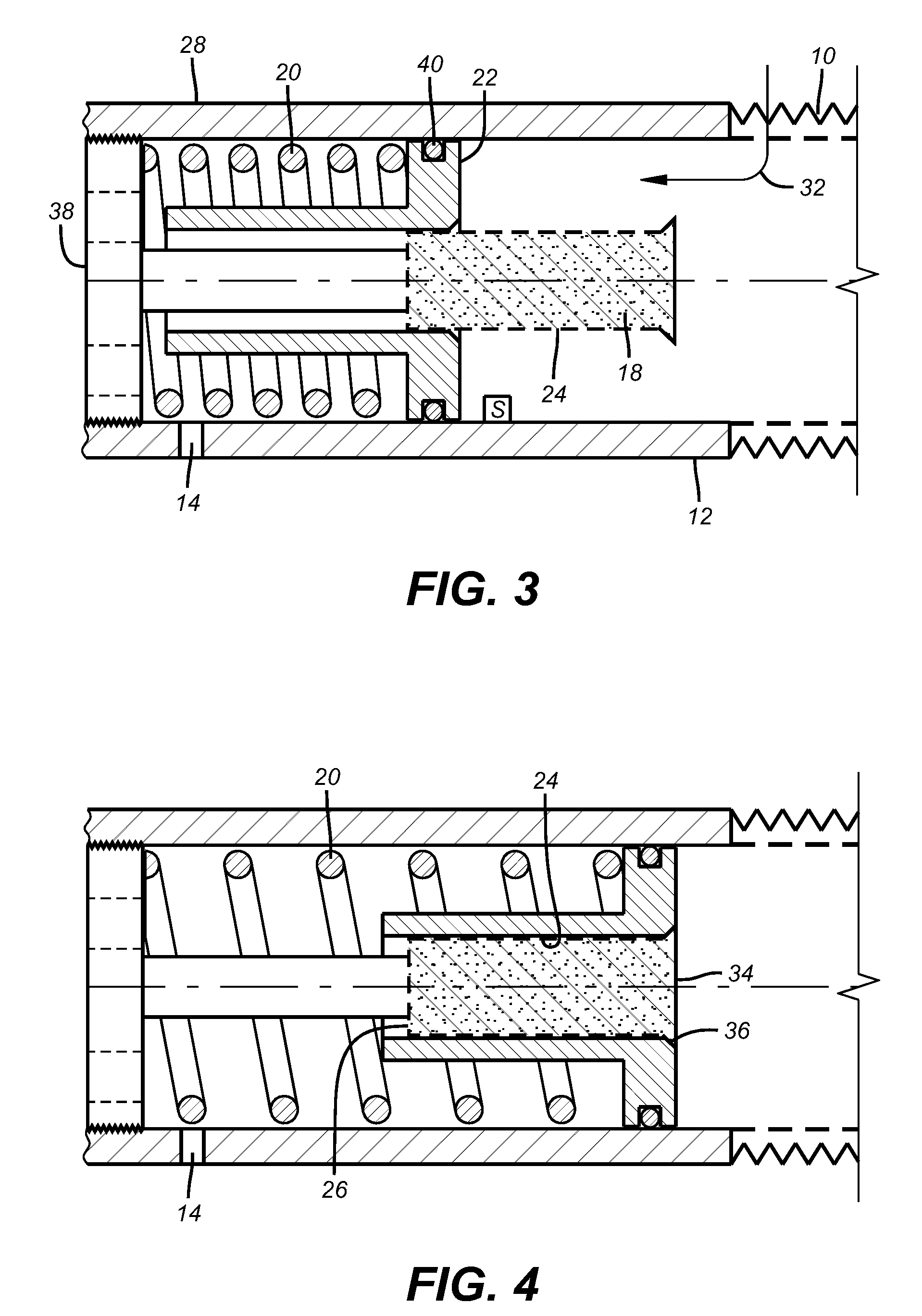

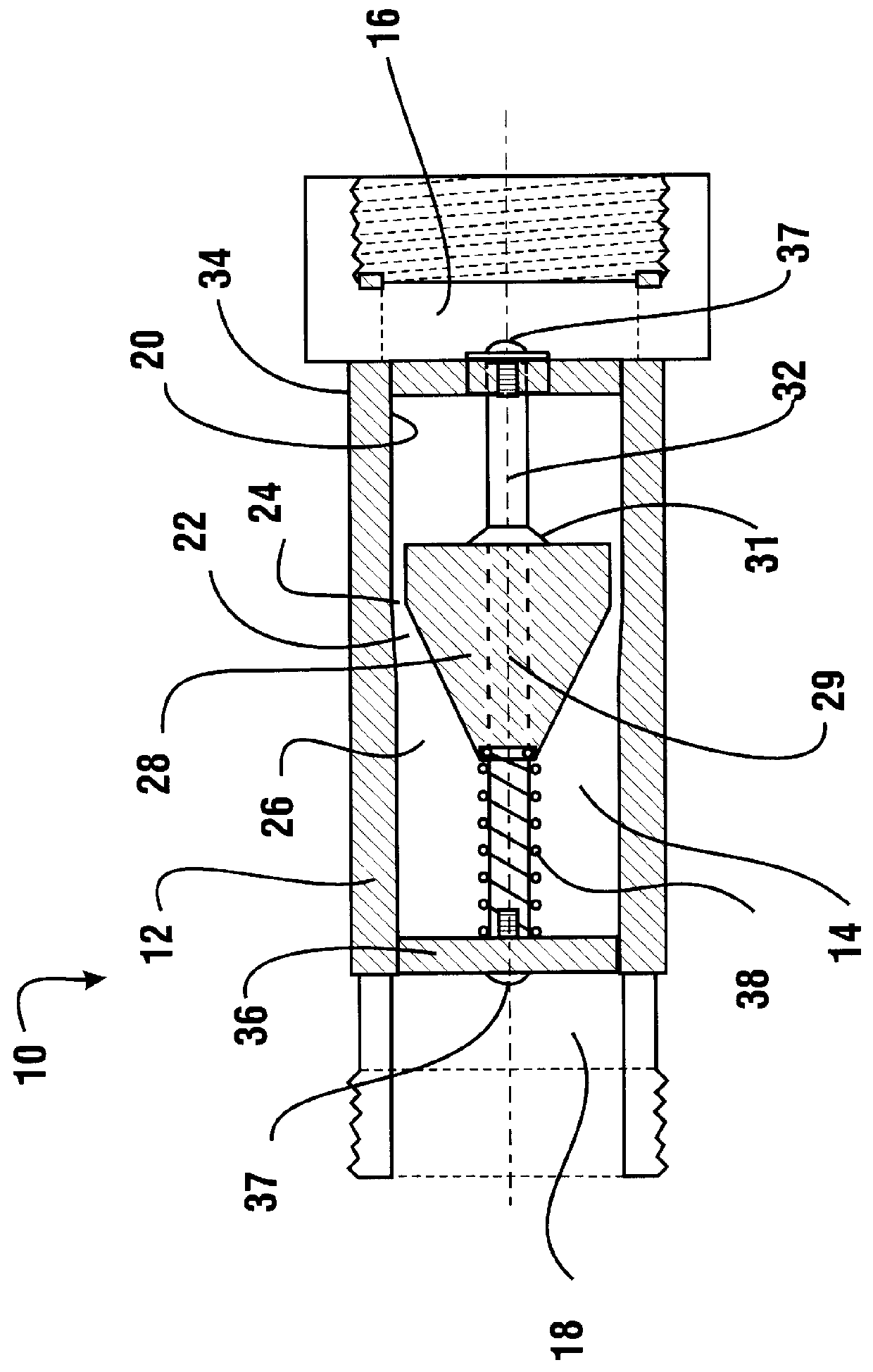

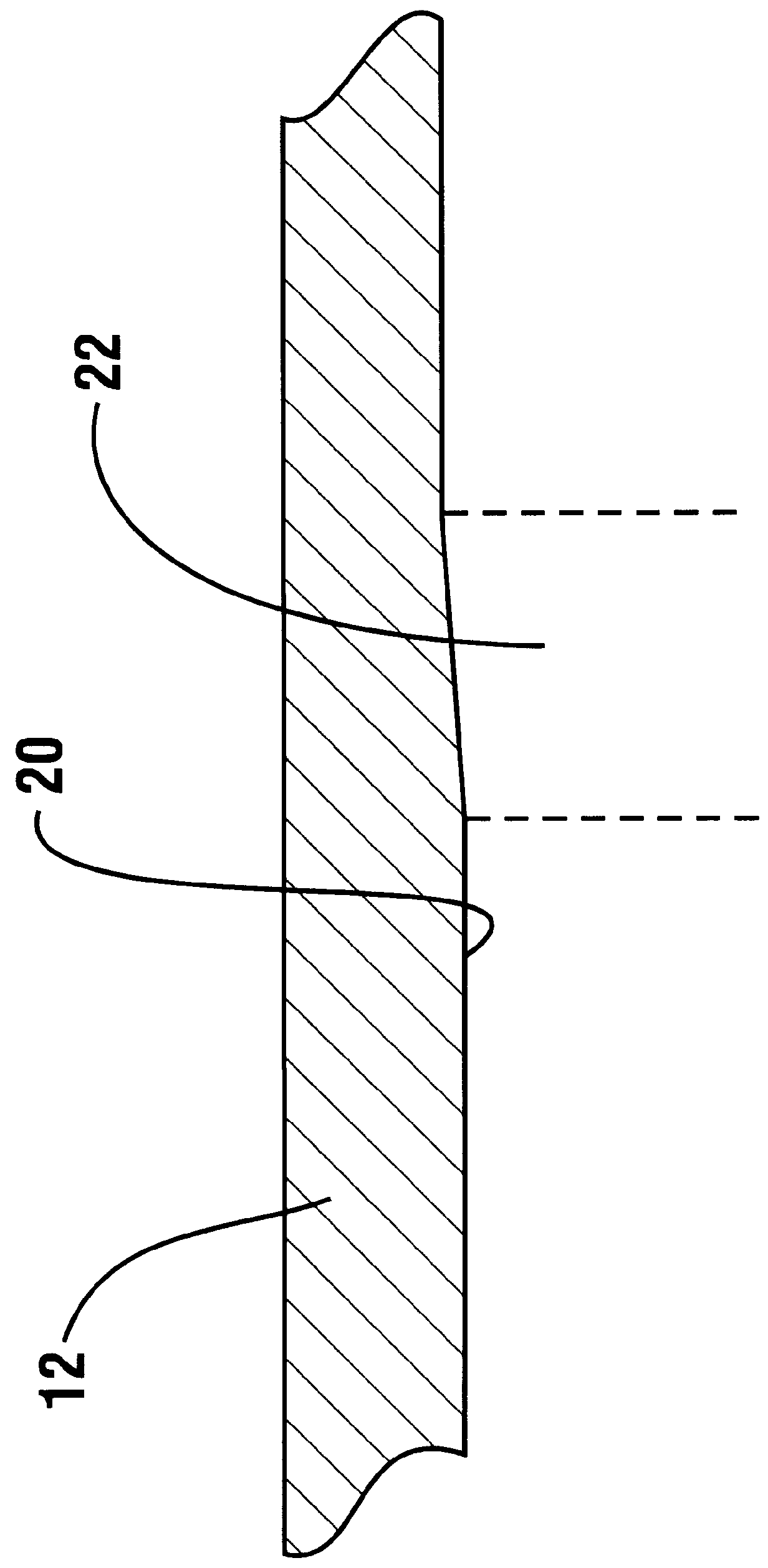

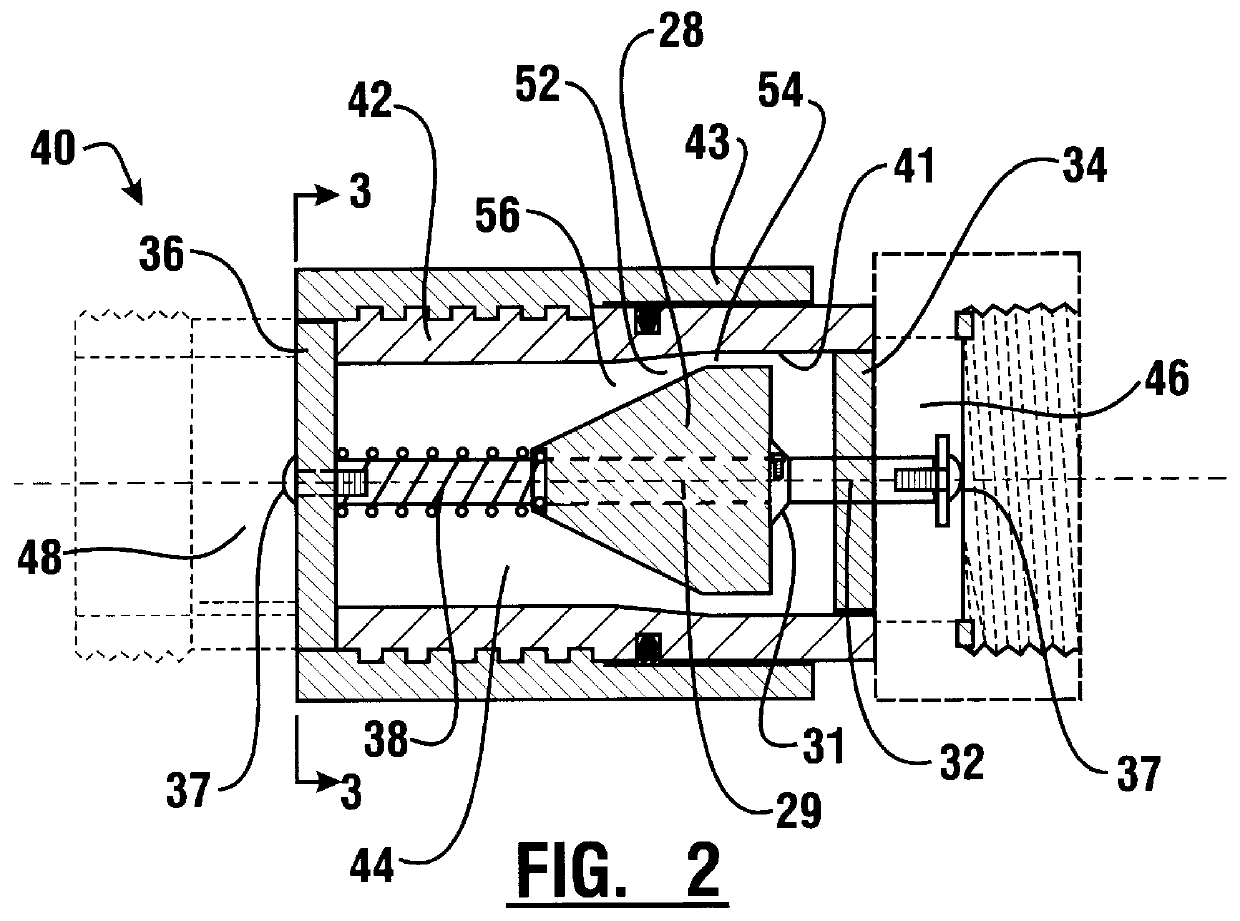

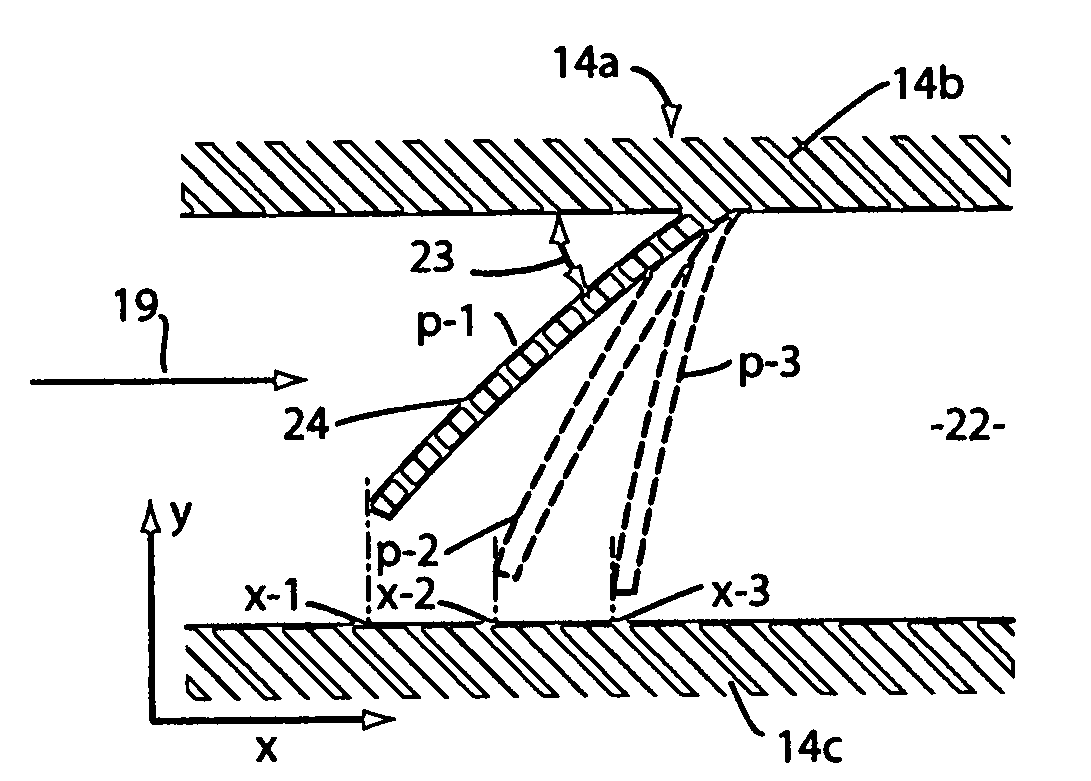

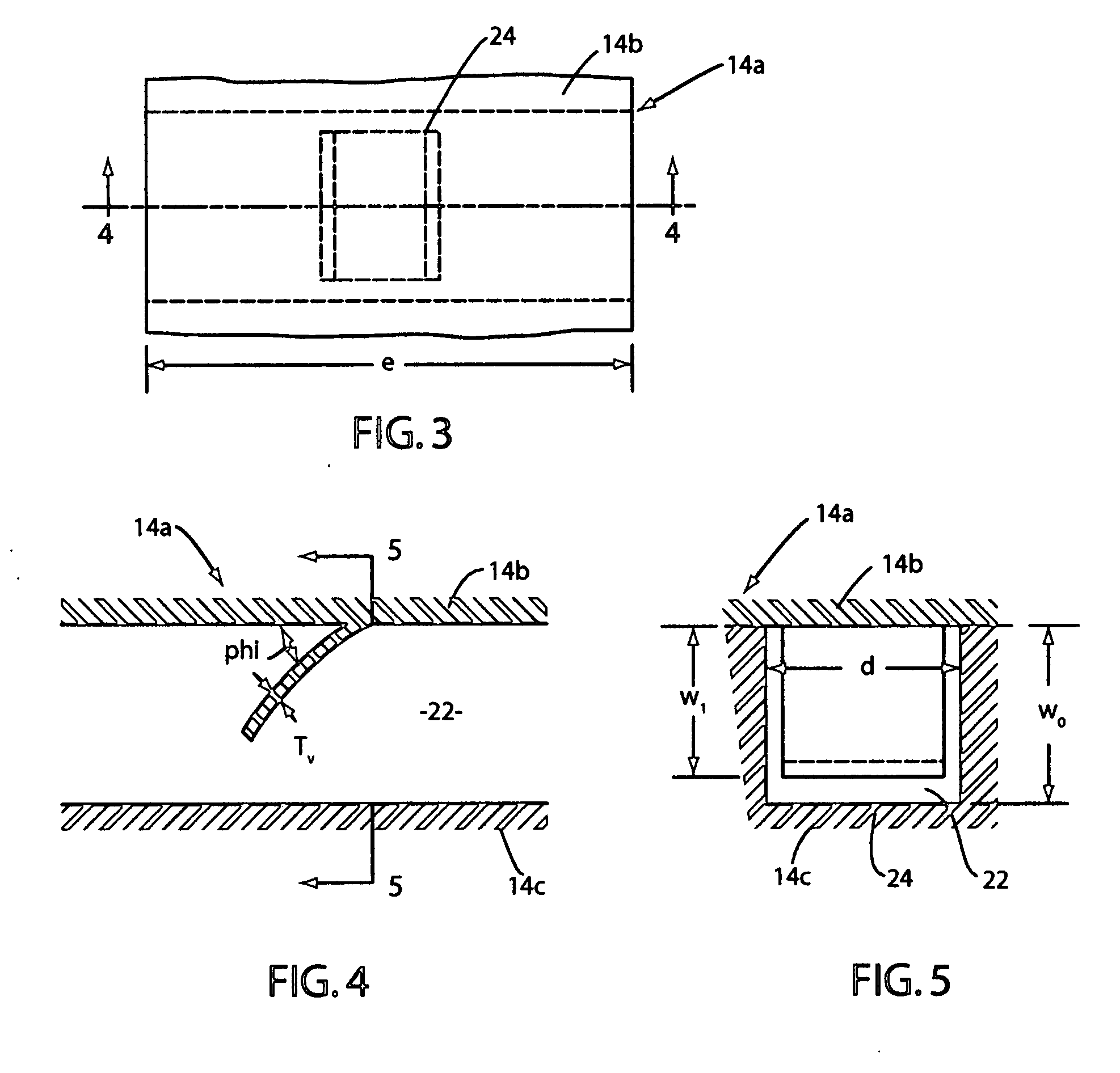

Flow regulators with flexible diaphragms

InactiveUS20050224607A1Spraying apparatusFlow control without auxillary powerEngineeringMechanical engineering

A flow regulator (10) for regulating a rate of flow of a liquid from an inlet flow path to an outlet flow path. The flow regulator includes a housing (14) with one wall or more which defines, at least in part, a regulation chamber (16) with all annular surface (18) and an outlet aperture (20) in fluid communication with the outlet flow path. The flow regulator also includes a flexible diaphragm (22) deployed at least partially within the regulation chamber (16), the diaphragm (22) having a first surface (24) part of which faces towards the annular surface (18) and a second surface (26) part of which face towards the outlet aperture (20), the diaphragm (22) assuming an initial unflexed position in which part of the first surface (24) lies adjacent to the annular surface (18), the diaphragm (22) is displaceable under pressure applied from the inlet flow path to a flexed position in which the first surface (24) is at least partially removed from the annular surface (18) and a contact portion of the second surface (26) obstructs the outlet aperture (20).

Owner:NAANDAN JAIN IRRIGATION C S

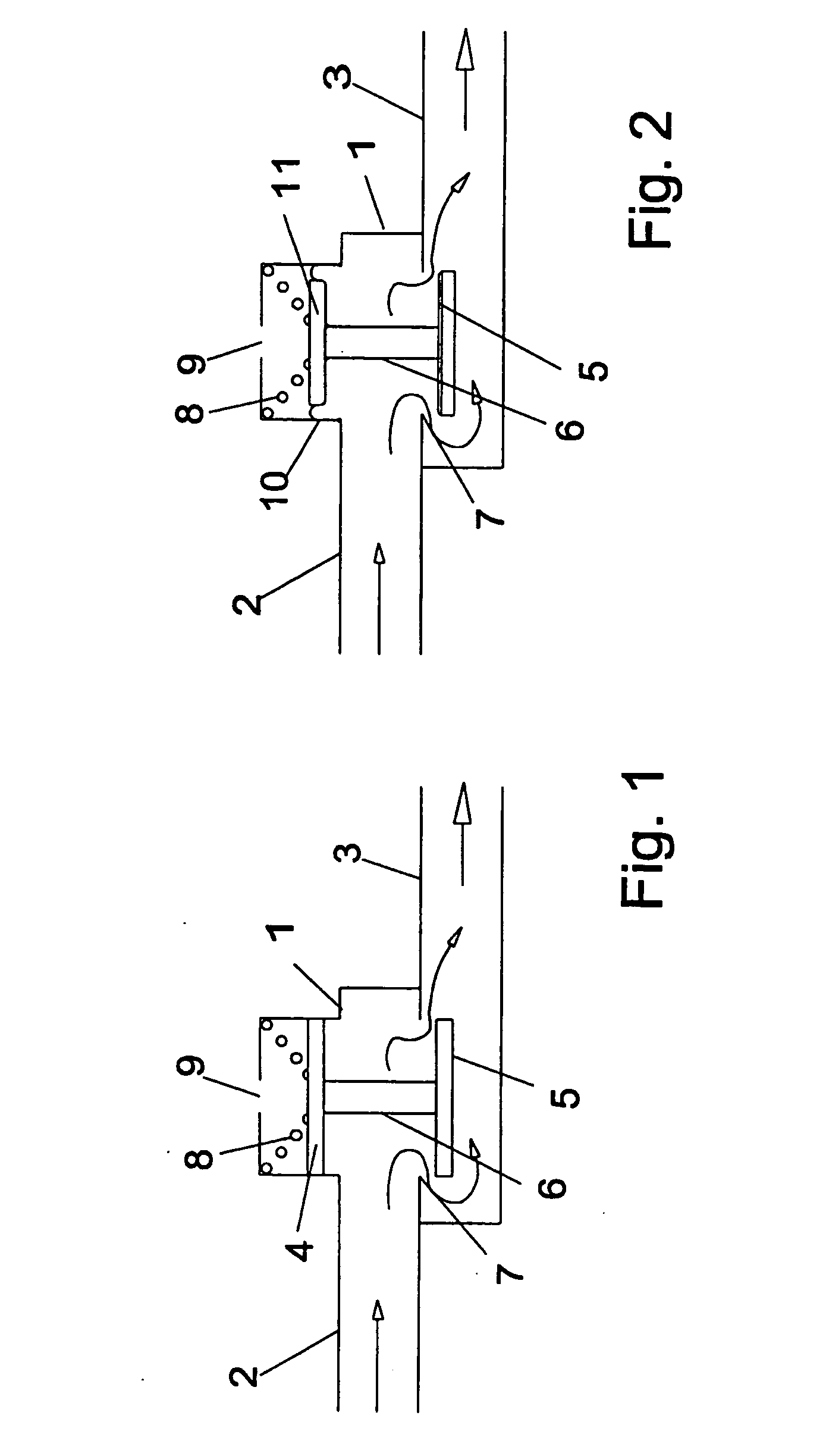

Valve Responsive to Fluid Properties

InactiveUS20090145609A1Easy to moveHigh viscosityCheck valvesFluid removalFluid viscosityWater production

A valve for downhole use has the ability to throttle between fully open and closed and is fully variable in positions in between. The valve is preferably responsive to flowing fluid viscosity and uses a three dimensional flow through restrictor in combination with a relatively movable cover. At a given flow, a higher viscosity fluid will create a greater relative movement and make it possible for flowing fluid to bypass more of the flow through member. In a particular application involving production from a zone, an array of such valves can allow more production where the viscosity is higher and less production where the viscosity drops due to, for example, water production.

Owner:BAKER HUGHES INC

Pressure independent control valve

InactiveUS20050039797A1Increase flow resistanceReduce pressureOperating means/releasing devices for valvesFlow control without auxillary powerCircular discAtmospheric layer

Simple APCV, ADPCV and PICV's are provided. The APCV's are referenced to the atmosphere and control the gauge pressure, either upstream or downstream. The ADPCV's are the same as the APCV's, differing in that they are not referenced to the atmosphere. They are instead referenced to a second point in the fluid flow system and control the differential pressure. The PICV's are control valves connected in series with ADPCV's and control the fluid flow rate through the valve independently of variations in the line pressure. A preferred APCV has a valve body (1) with connections for a single-phase fluid line and a flow passage between the inlet (2) and the outlet (3) of said fluid line, with an opening having a defined seat office (7) intersecting the flow passage. A moveable assembly, comprising a disk (5) or cup is connected to a pressure sensing member (4), having essentially the same effective surface area. The moveable assembly, is biased by a force, and is free to automatically move to any intermediate position between fully open and closed, producing a desired outlet pressure which minus the reference pressure, times the effective surface area of the disk or cup generates an opposing force equal to the biasing force.

Owner:CARLSON BENGT A

Control valve apparatus

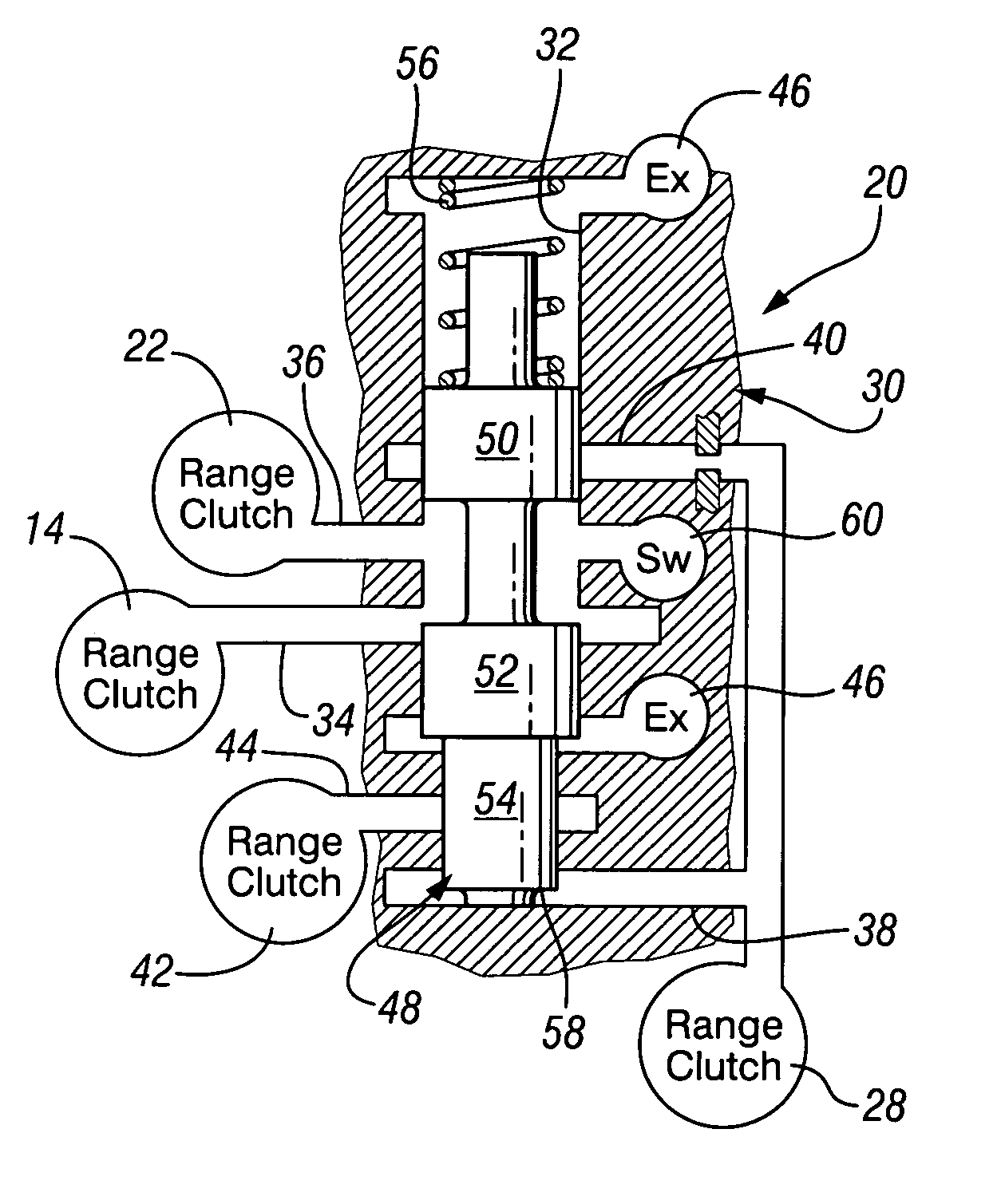

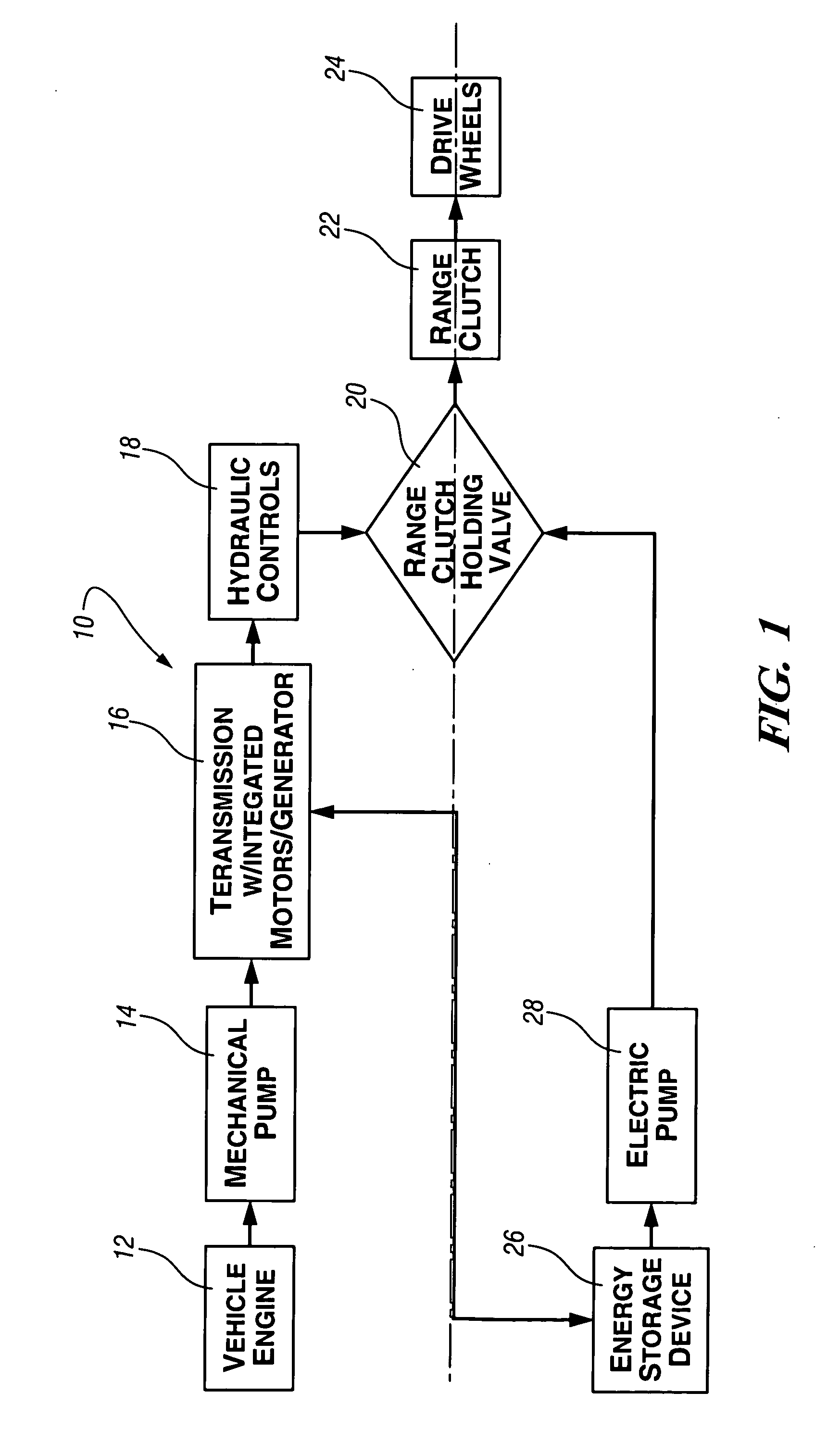

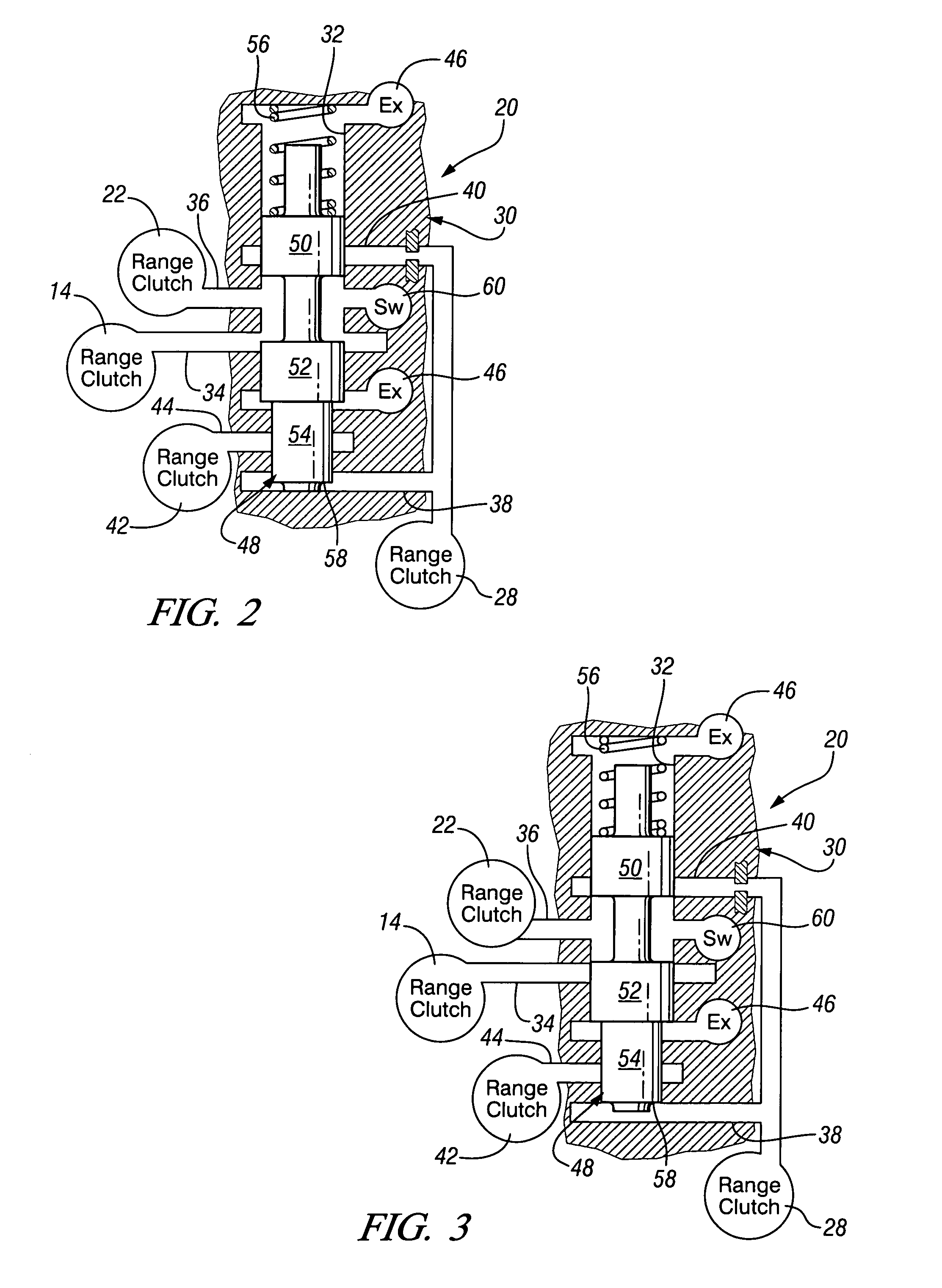

ActiveUS20050211295A1Gearing controlFluid pressure control using electric meansTorque transmissionEngineering

A control for parallel hybrid transmission has a valve mechanism, which is operable to supply fluid pressure to a torque-transmitting mechanism with or without the operation of the vehicle engine. The valve mechanism is responsive to an electrically driven pump to supply fluid pressure whenever the engine is discontinued and the electric driven pump is operated.

Owner:GM GLOBAL TECH OPERATIONS LLC

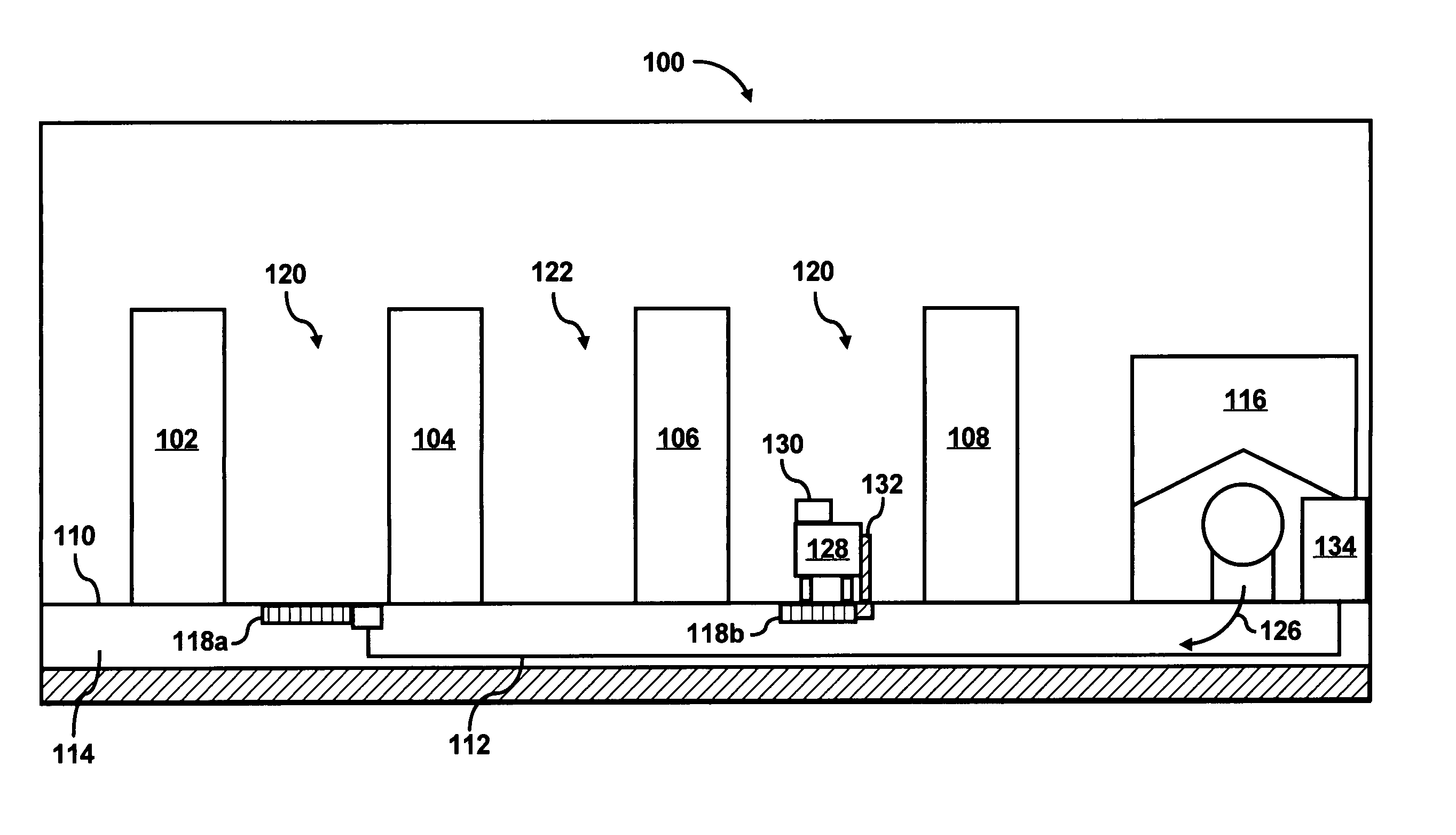

Hose nozzle apparatus and method

InactiveUS6089474AShorten the axial distanceMore aerodynamicOperating means/releasing devices for valvesCheck valvesSpray nozzleEngineering

An apparatus (100) for selectively discharging a stream of liquid has a body (102) adapted for connection to a source of liquid under pressure, a throttle valve assembly (120) for maintaining a constant output flow throughout changes in supply pressure, a smooth bore barrel (140) for providing a deluge stream, a fog tip (160) for providing an aspirated fog spray and a shut off valve (180). The fog spray pattern is variable from a straight stream parallel to the axis of the apparatus to a wide spray at an angle to the axis of the apparatus. The deluge stream and the fog spray are selectable separately or in combination.

Owner:WS ACQUISITION LLC

Fluid flow control device

InactiveUS20080000539A1Reduce manufacturing costConstant flowFluid heatersFlow mixersEngineeringTemperature and pressure

A flow control device of the character having a fluid pathway for permitting fluid flow therealong under conditions of varying temperature and pressure for achieving substantially constant output flow rate from the fluid pathway. One or more flexibly deformable vanes, which extend into the fluid pathway, are constructed and arranged to flexibly deform in a manner to further occlude the fluid pathway when the pressure within said fluid path way increases.

Owner:BIOQ PHARMA

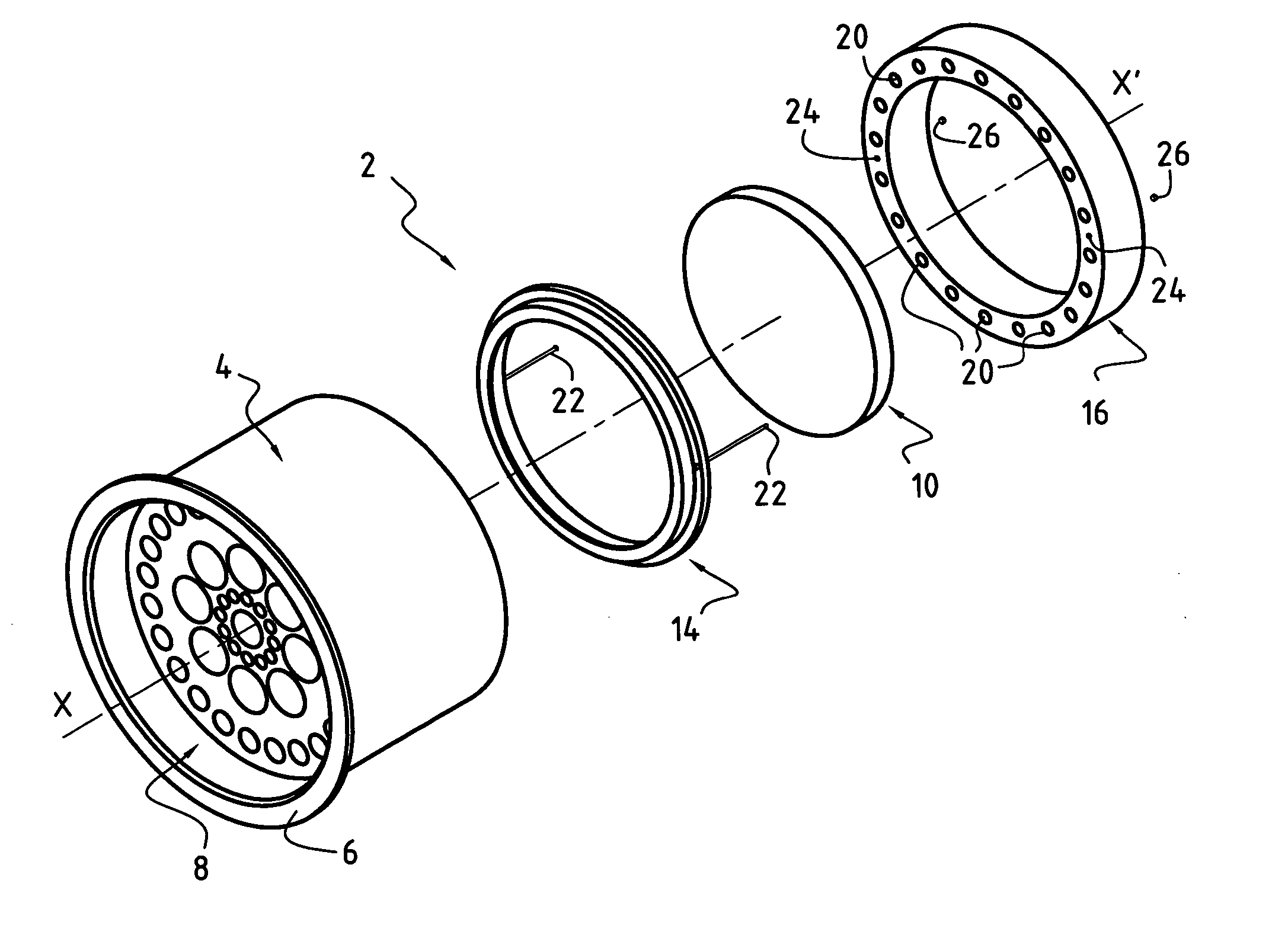

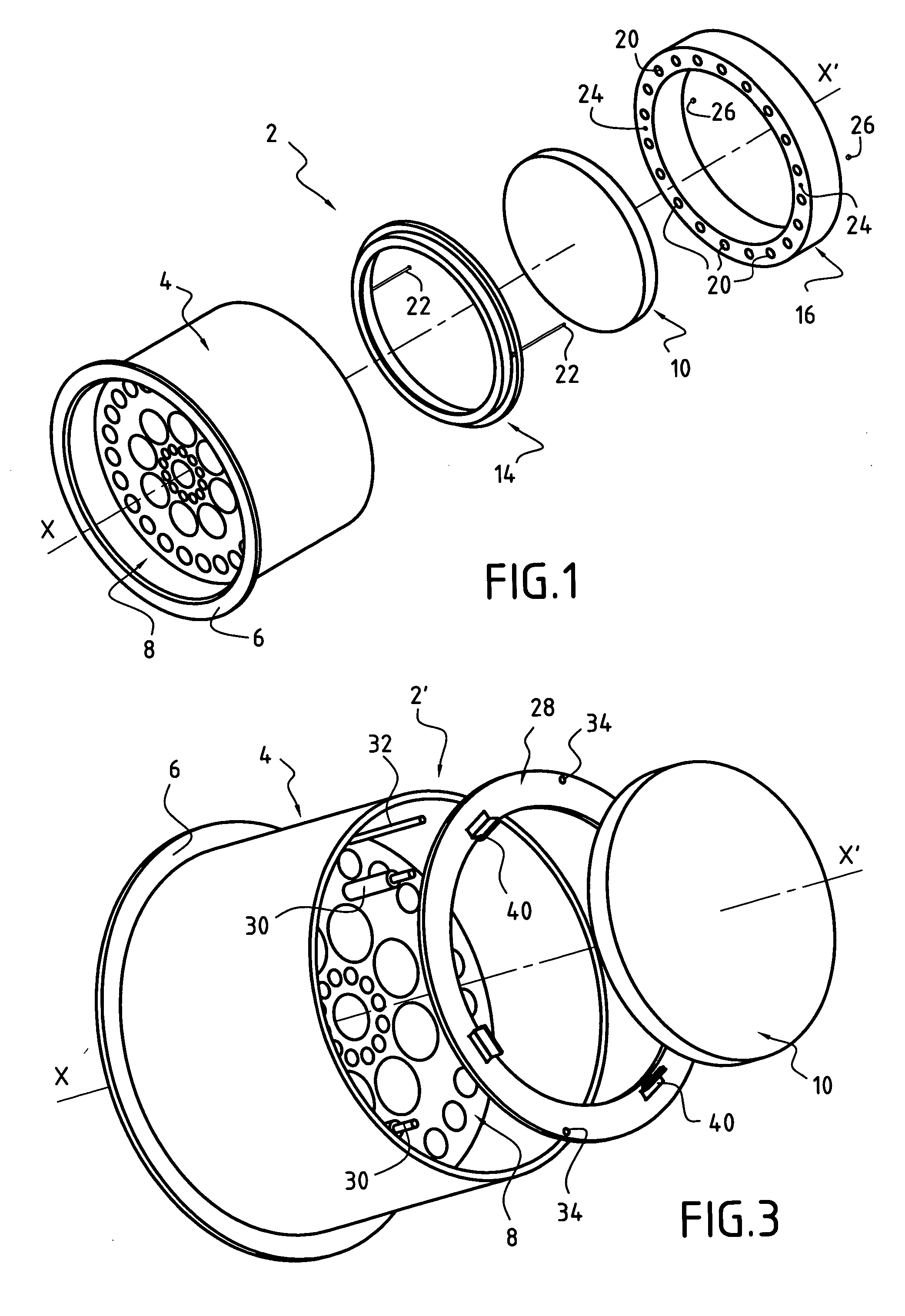

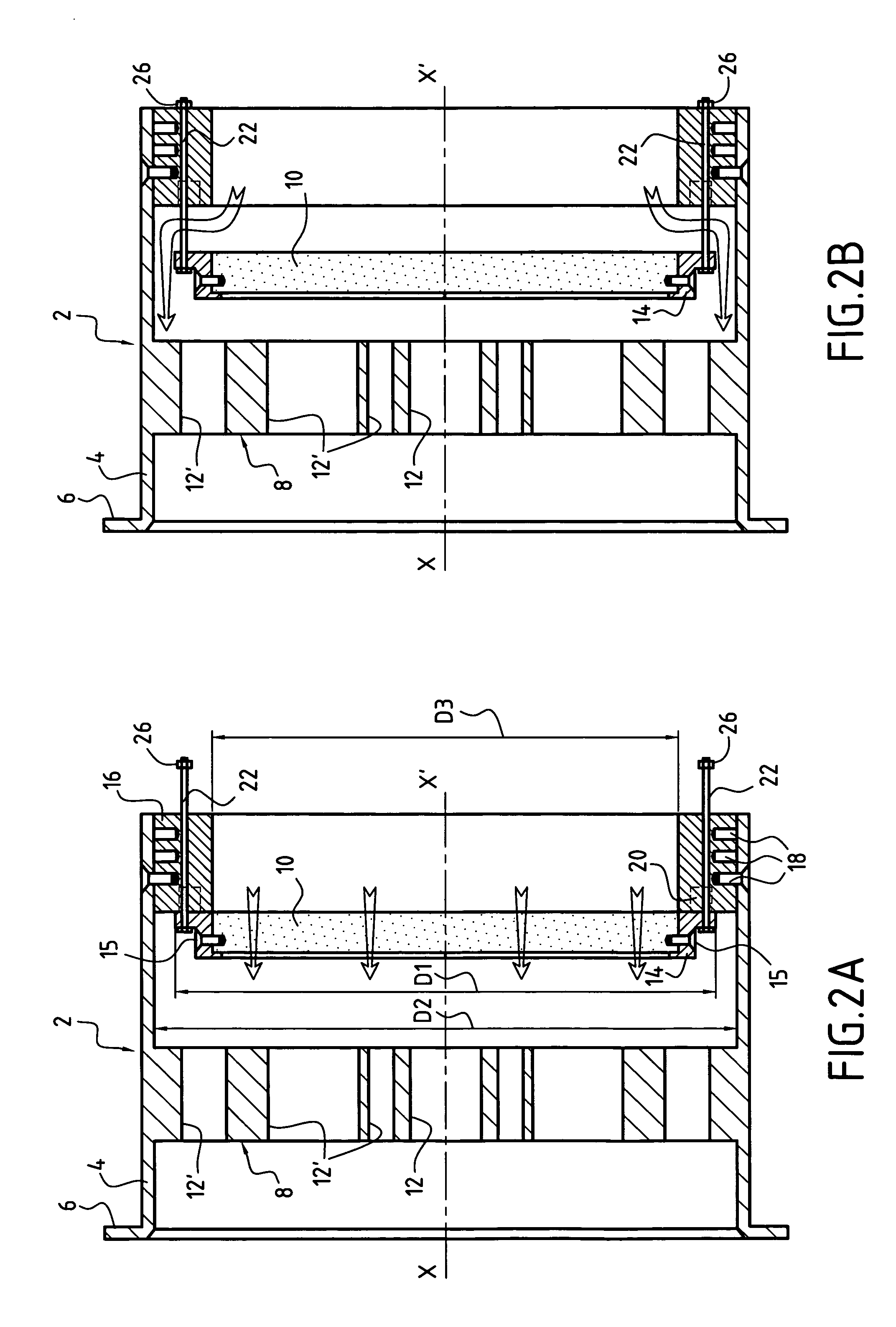

Flow conditioner for a fluid transport pipe

ActiveUS20050178455A1Reduce riskMitigate such drawbackFlow mixersFluid dynamicsFluid transportMechanical engineering

The flow conditioner for a fluid transport pipe, comprises a support-forming substantially tubular main body, at least one flow rectifier disposed inside the main body essentially perpendicularly to the axis XX′ thereof, and a porous plate disposed inside the main body upstream from the flow rectifier and parallel thereto. The elements of the conditioner are disposed in such a manner that a substantial fraction of the fluid flow passes through the flow rectifier and the porous plate in the absence of the porous plate becoming clogged. A bypass circuit is provided to ensure fluid flow continuity in the event of the porous plate becoming clogged.

Owner:GRTGAZ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com