Patents

Literature

4331results about "Fluid-delivery valves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

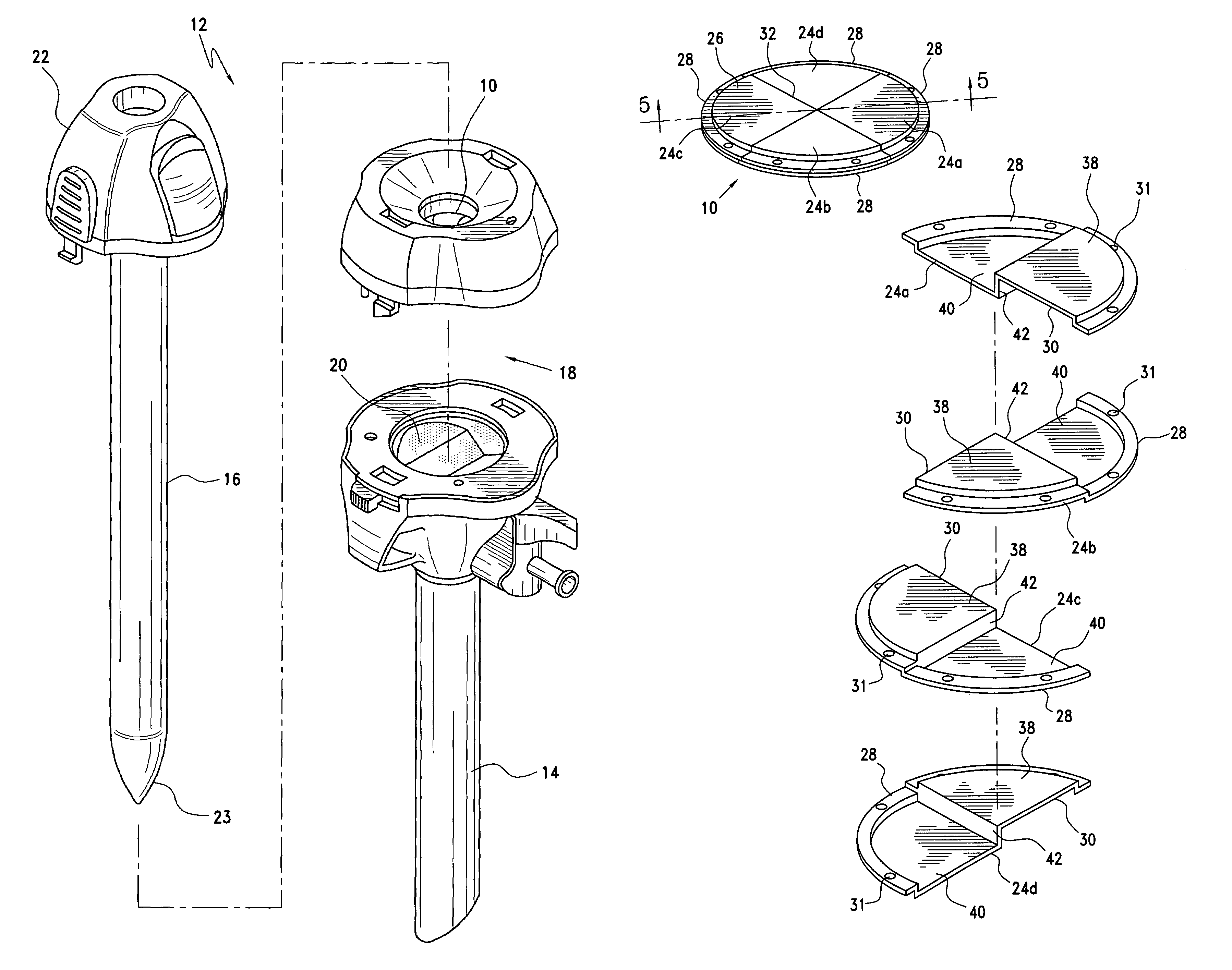

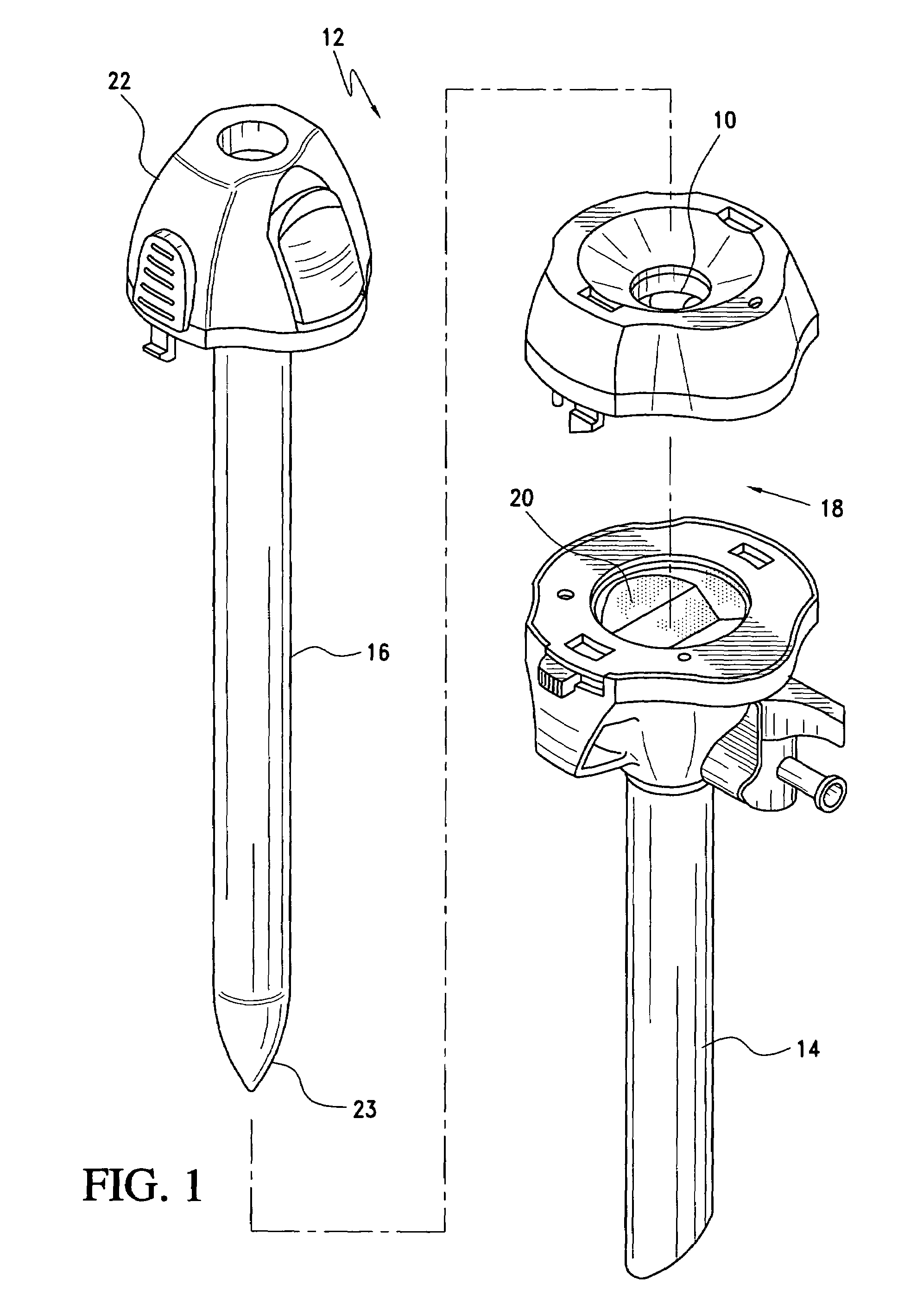

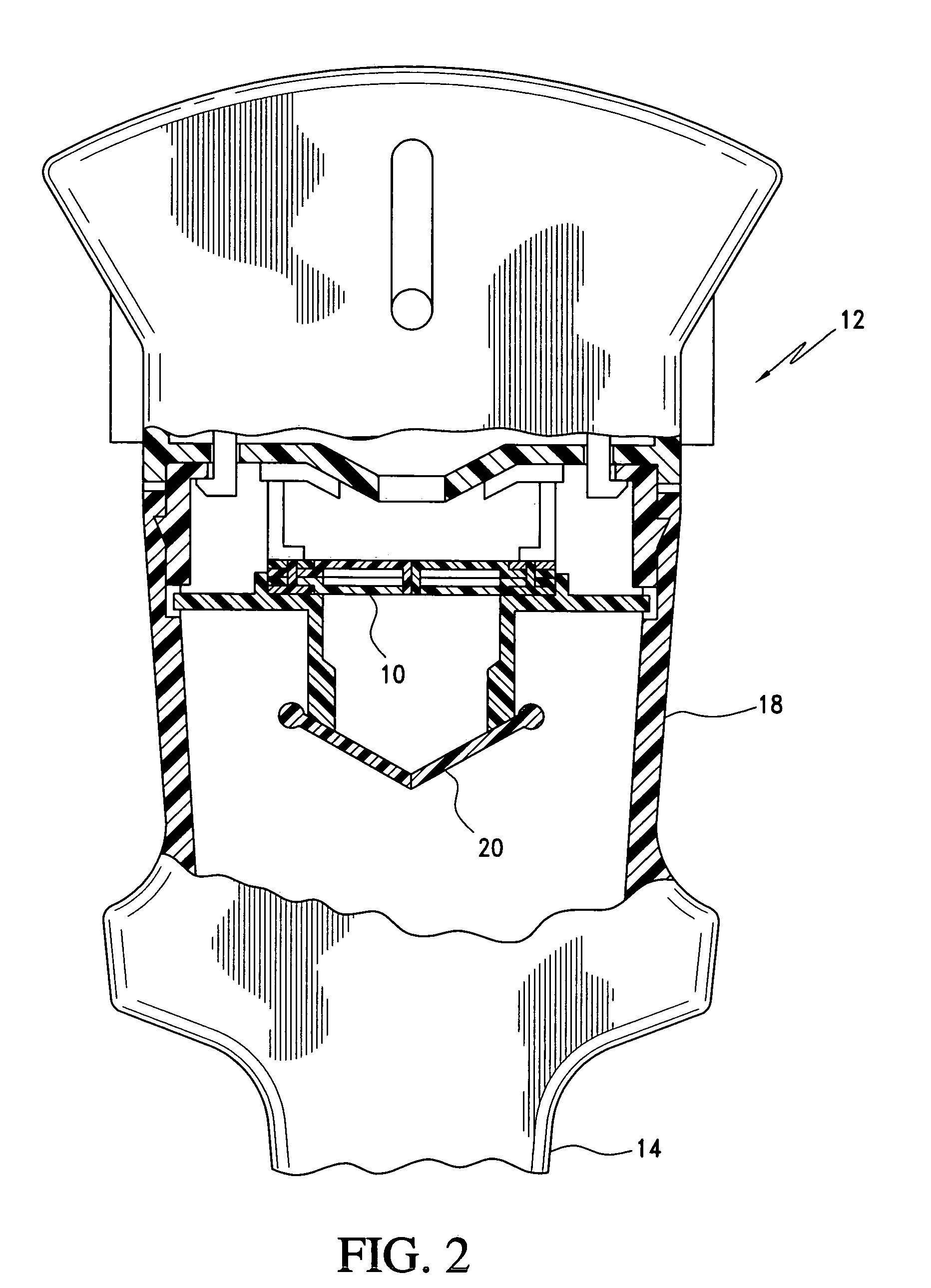

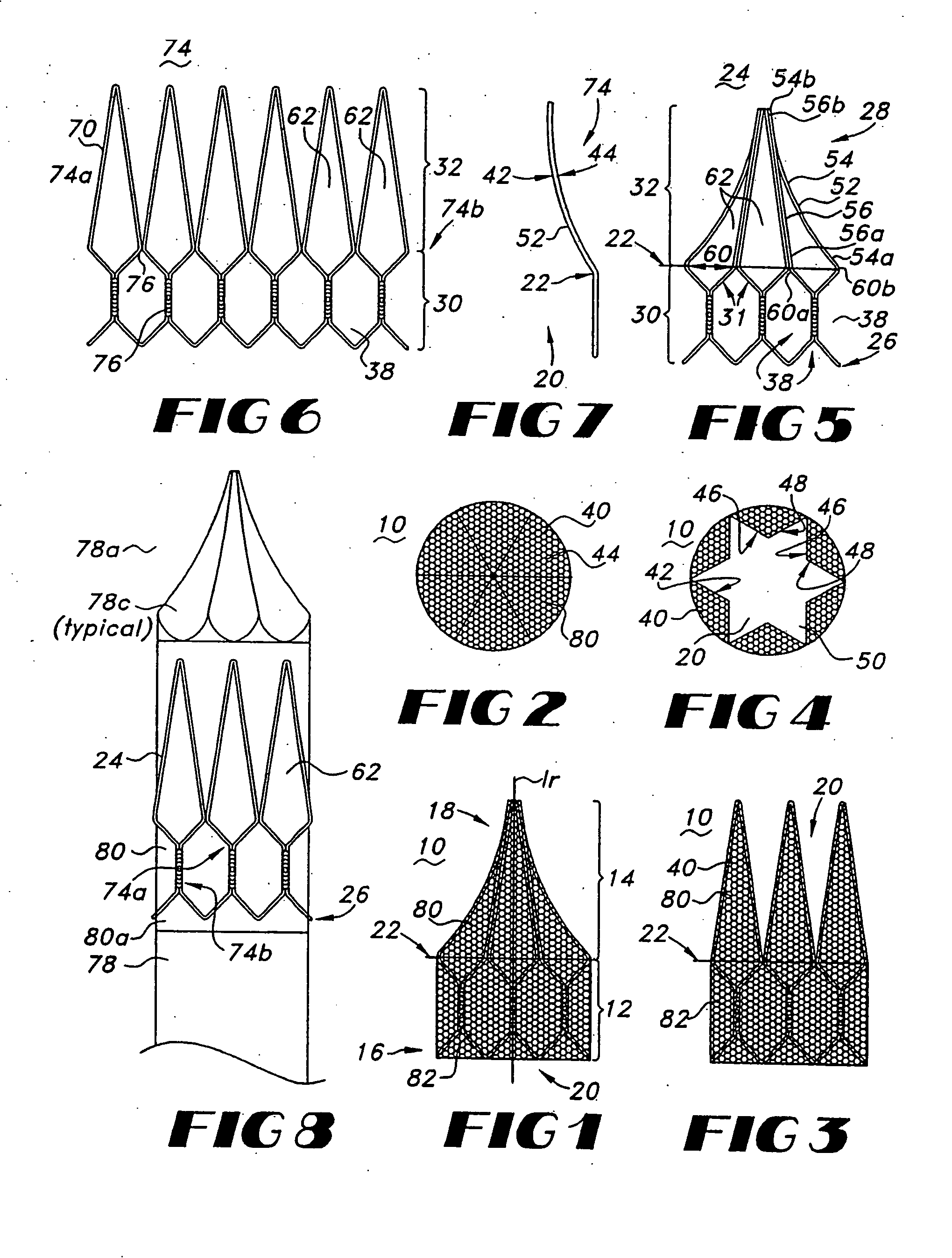

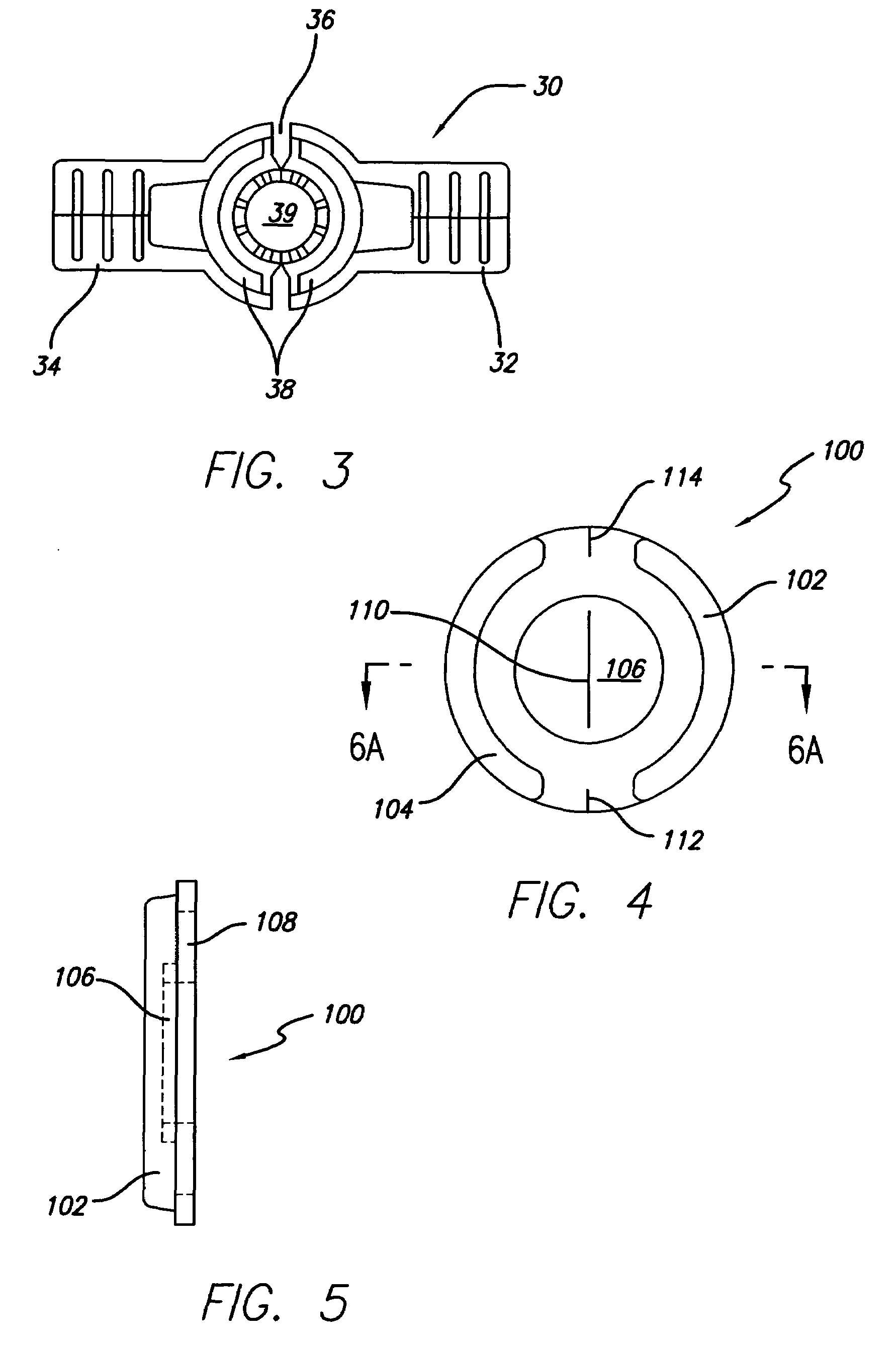

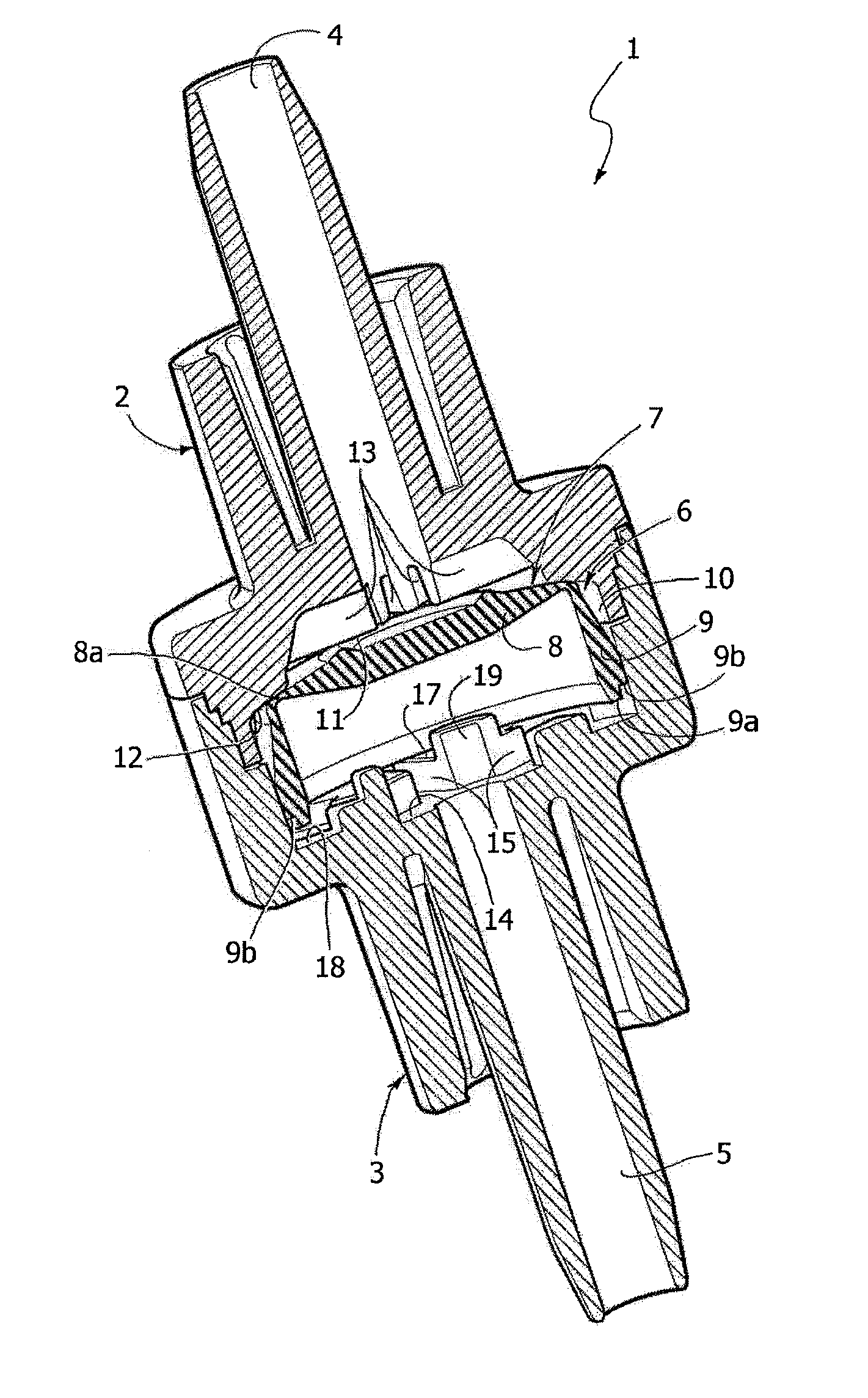

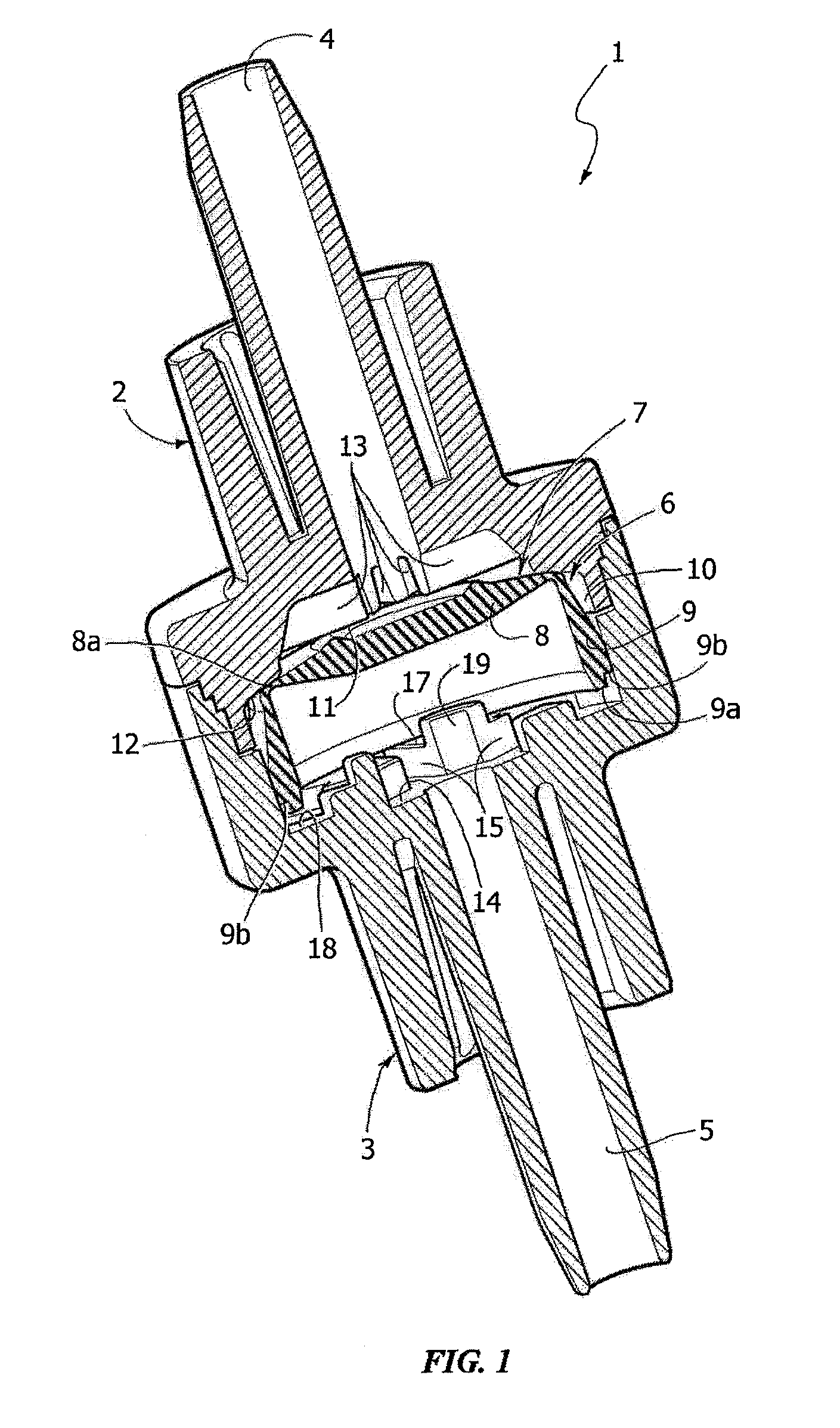

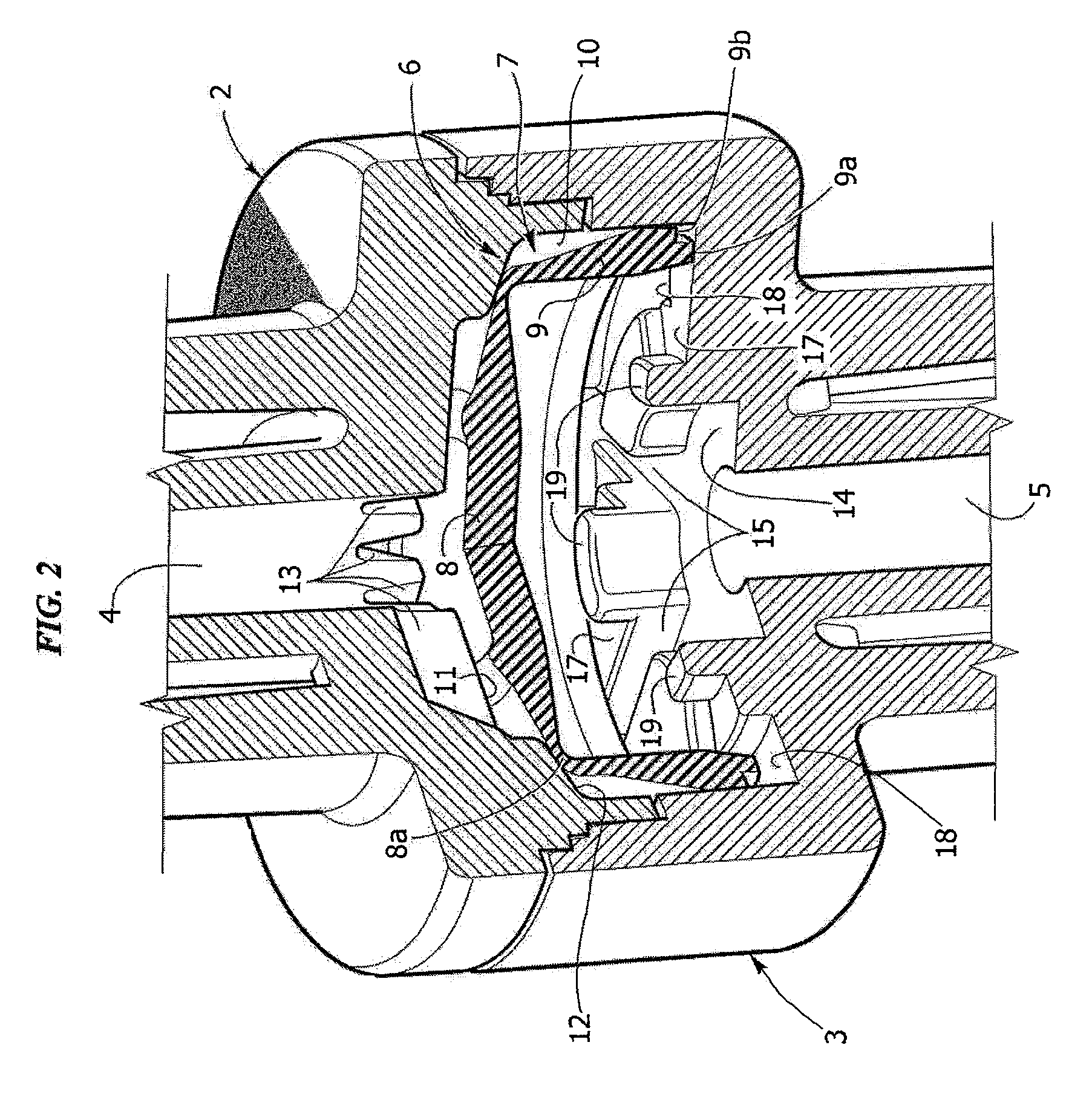

Trocar seal assembly

A seal assembly adapted for use in conjunction with a trocar assembly includes a plurality of seal segments, each seal segment including a peripheral edge and a seam edge. Each seal segment further includes a first section and a second section with a vertical wall connecting the first section and the second section in such a way that the first section is displaced relative to the second section such that the first section of a first seal segment may be placed upon the second section of a second seal segment with the first sections of the first and second seal segments lying in the same plane and the second sections of the first and second seal segments lying in the same plane. The seal segments are assembled in an overlapping woven arrangement to provide a complete seal body without the need for a secondary seal.

Owner:CILAG GMBH INT

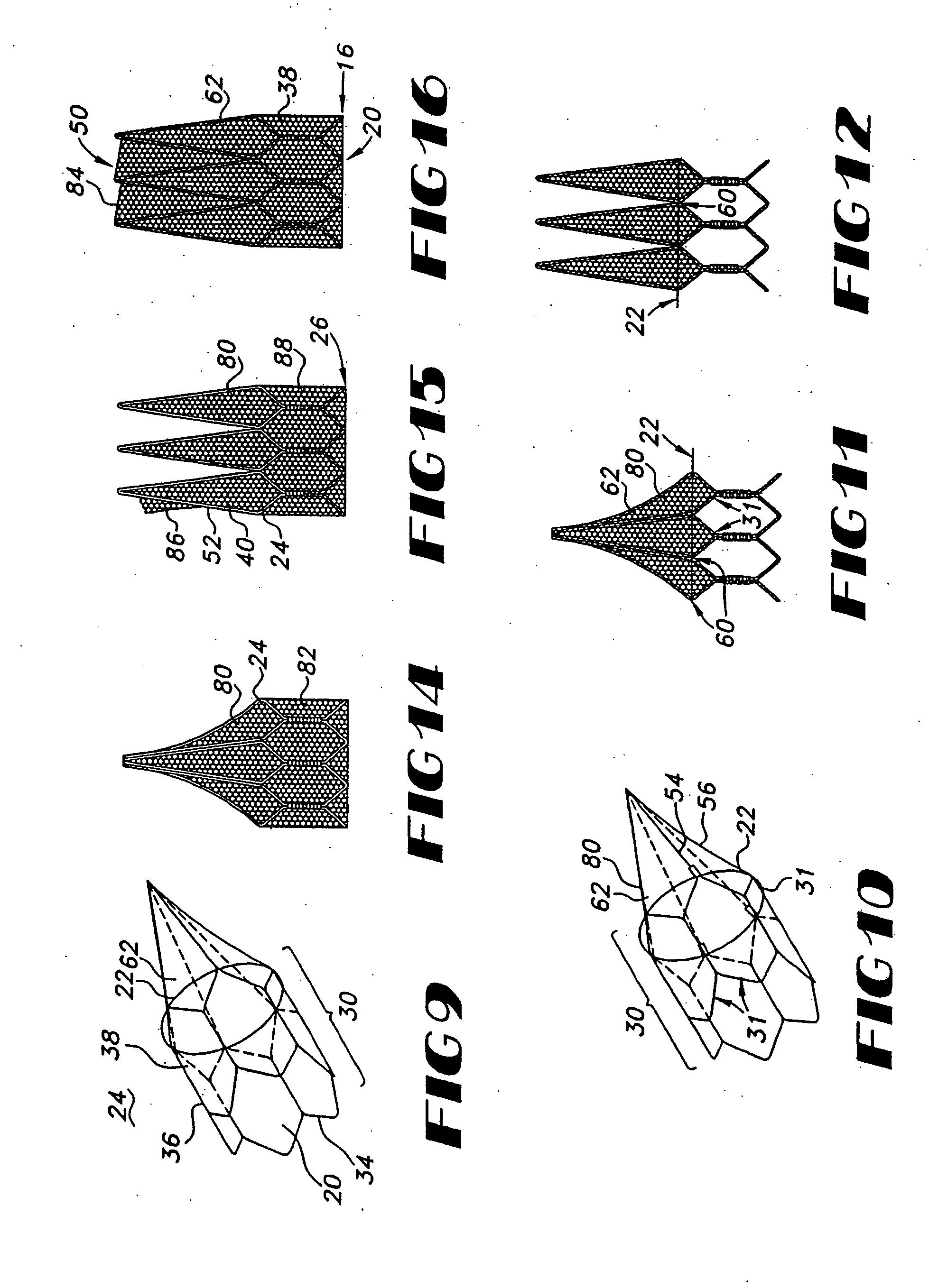

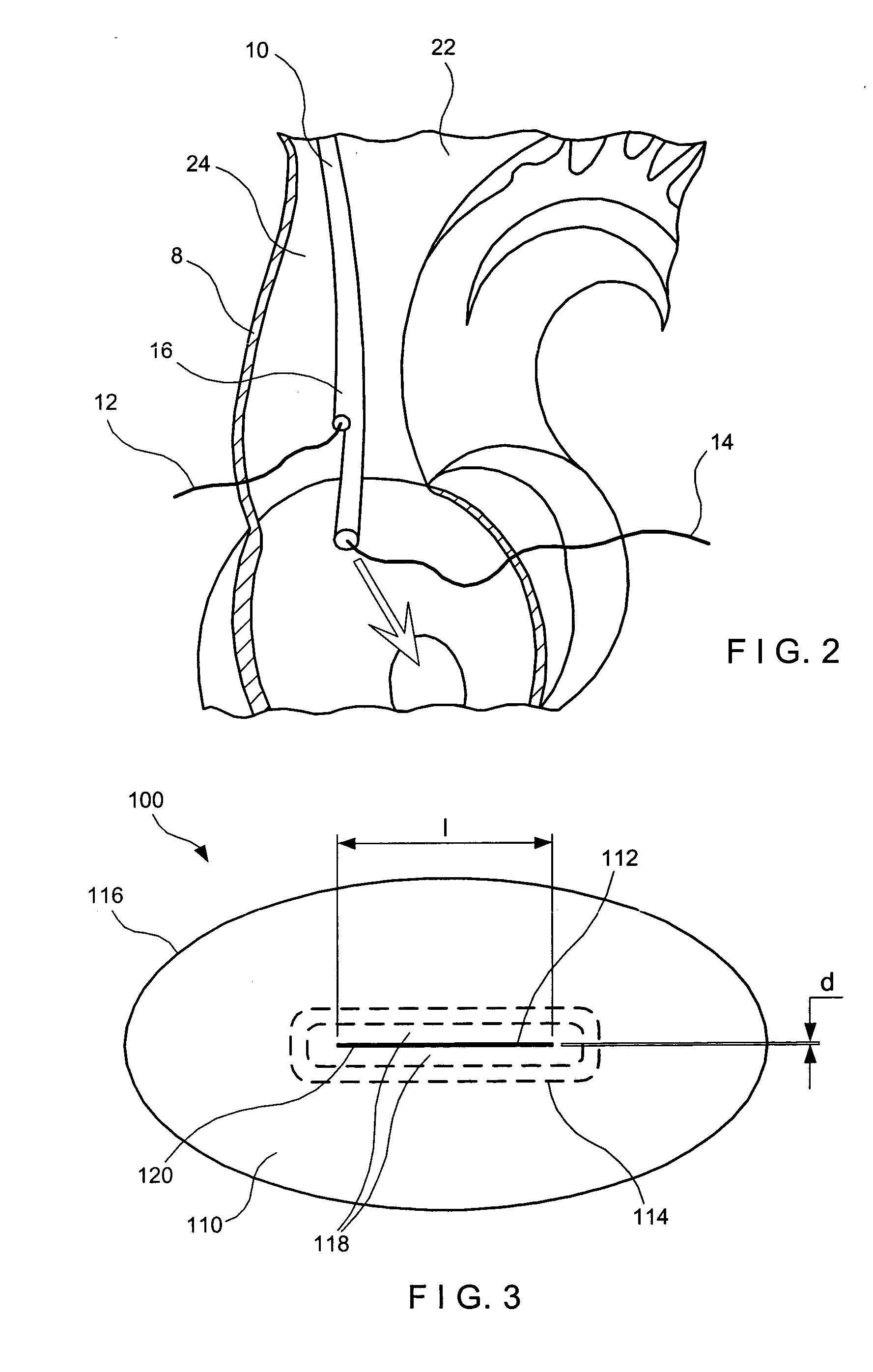

Implantable prosthetic valve

InactiveUS20050065594A1Undesirable biological responseAdd supportStentsDiaphragm valvesProsthetic valveProsthesis

A prosthetic valve for implantation within a fluid conducting lumen within a body includes an elongate generally cylindrical radially collapsible valve body scaffold defining a fluid passageway therethrough for retentive positioning within the lumen. A radially collapsible leaf valve member is supported by the scaffold includes a number of valve leafs deflectable between a closed position restricting fluid flow through the passageway and an open position permitting fluid flow through the passageway. The leaf valve member includes an interior leaf valve frame defining a valve leaf aperture which is sealed by a fluid impermeable non-thrombogenic lining to prevent fluid flow therethrough.

Owner:BOSTON SCI SCIMED INC

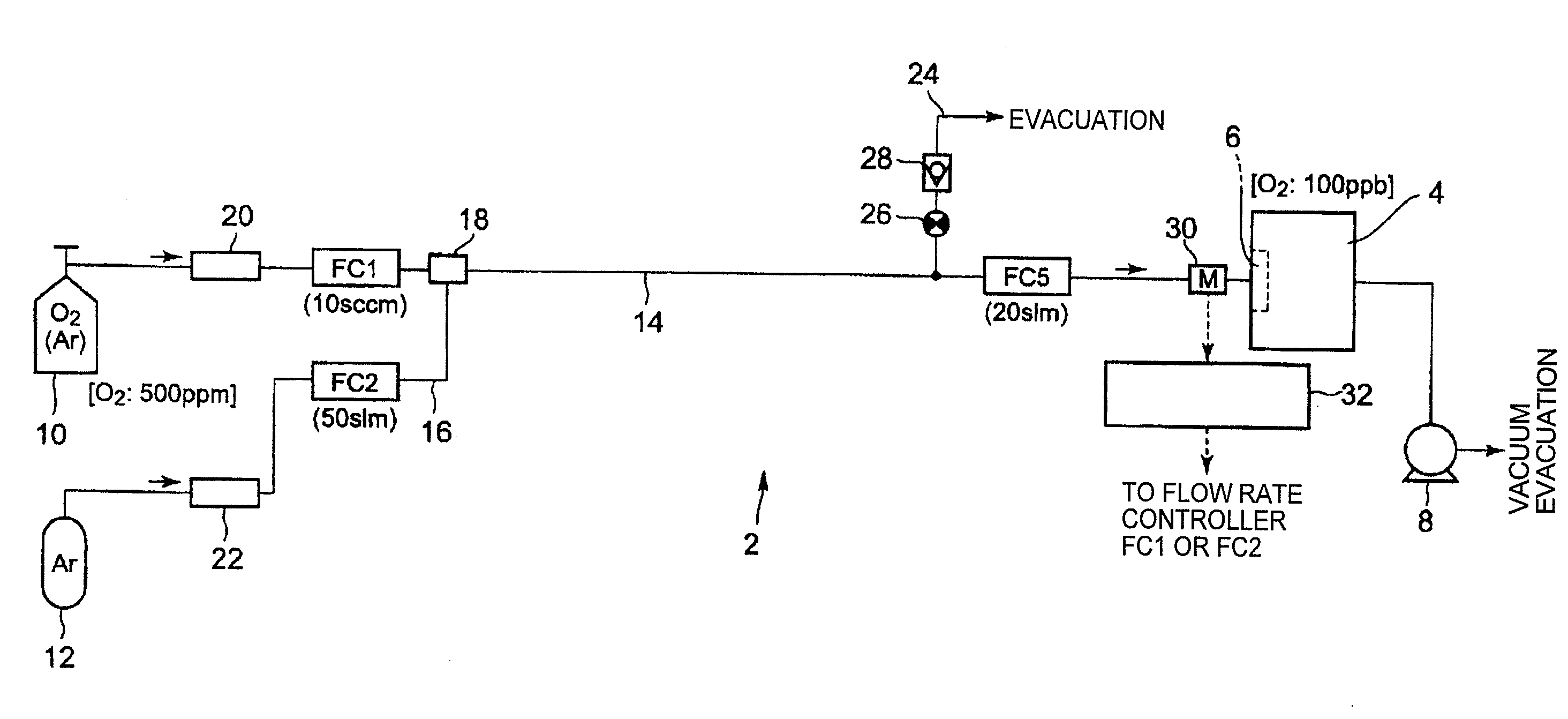

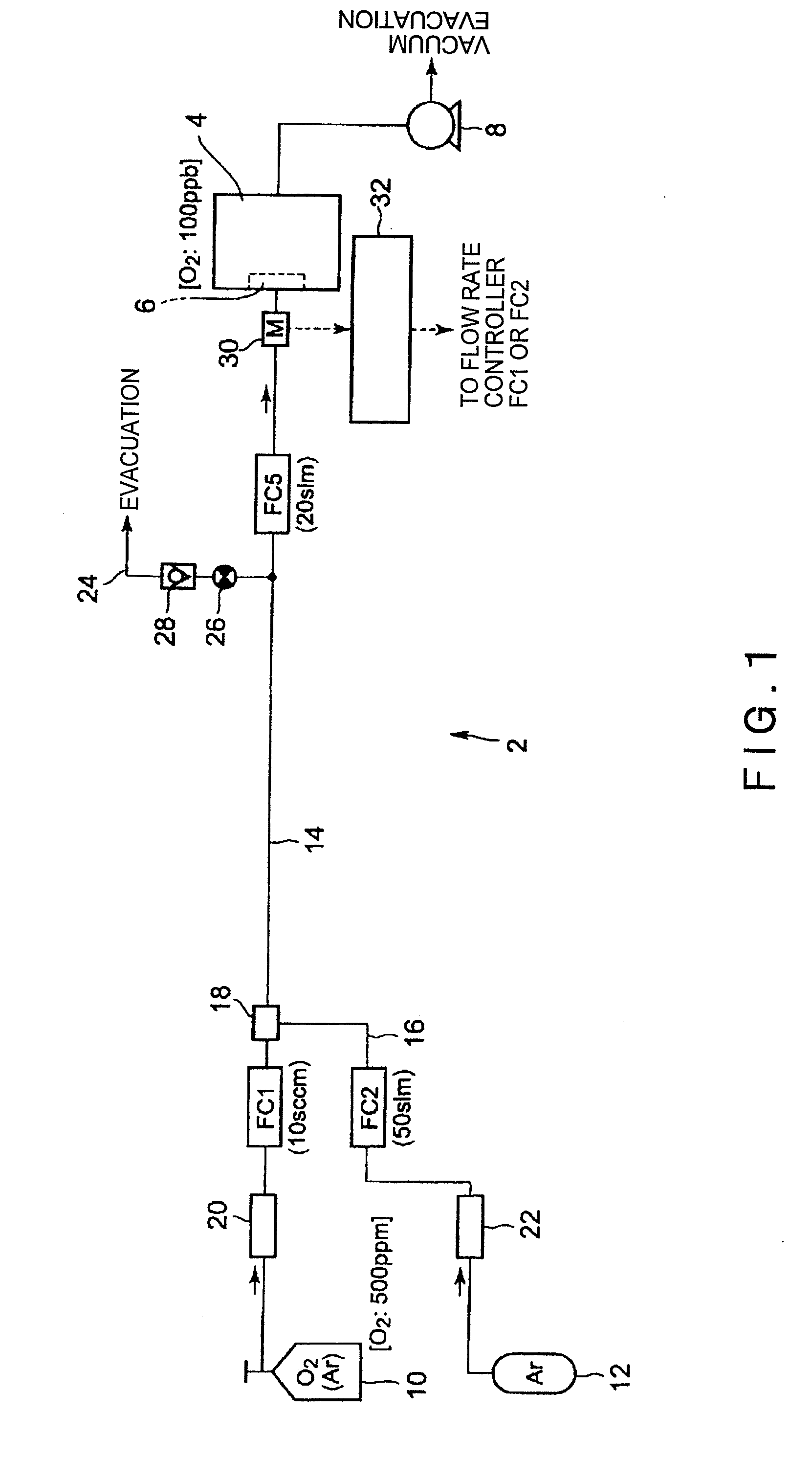

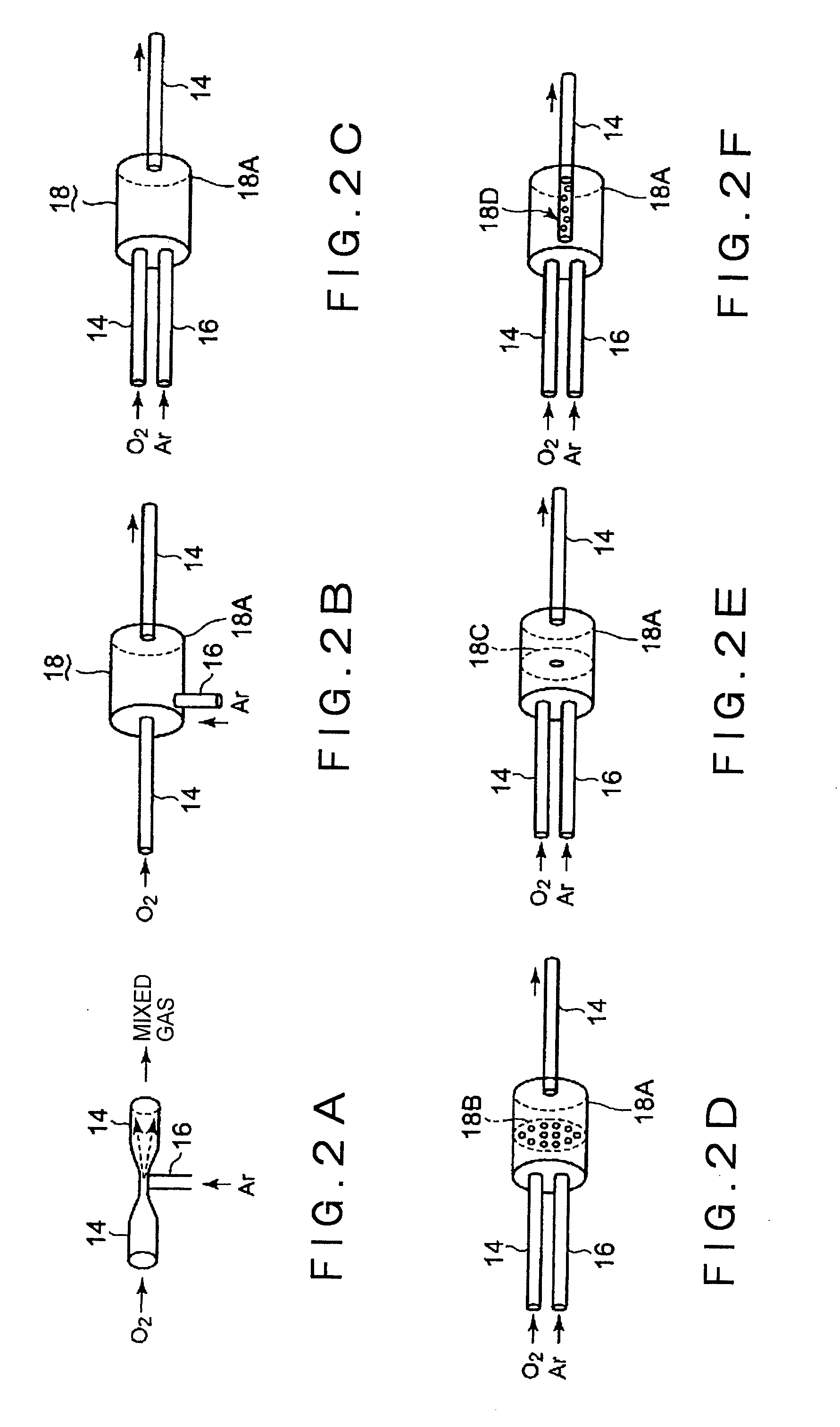

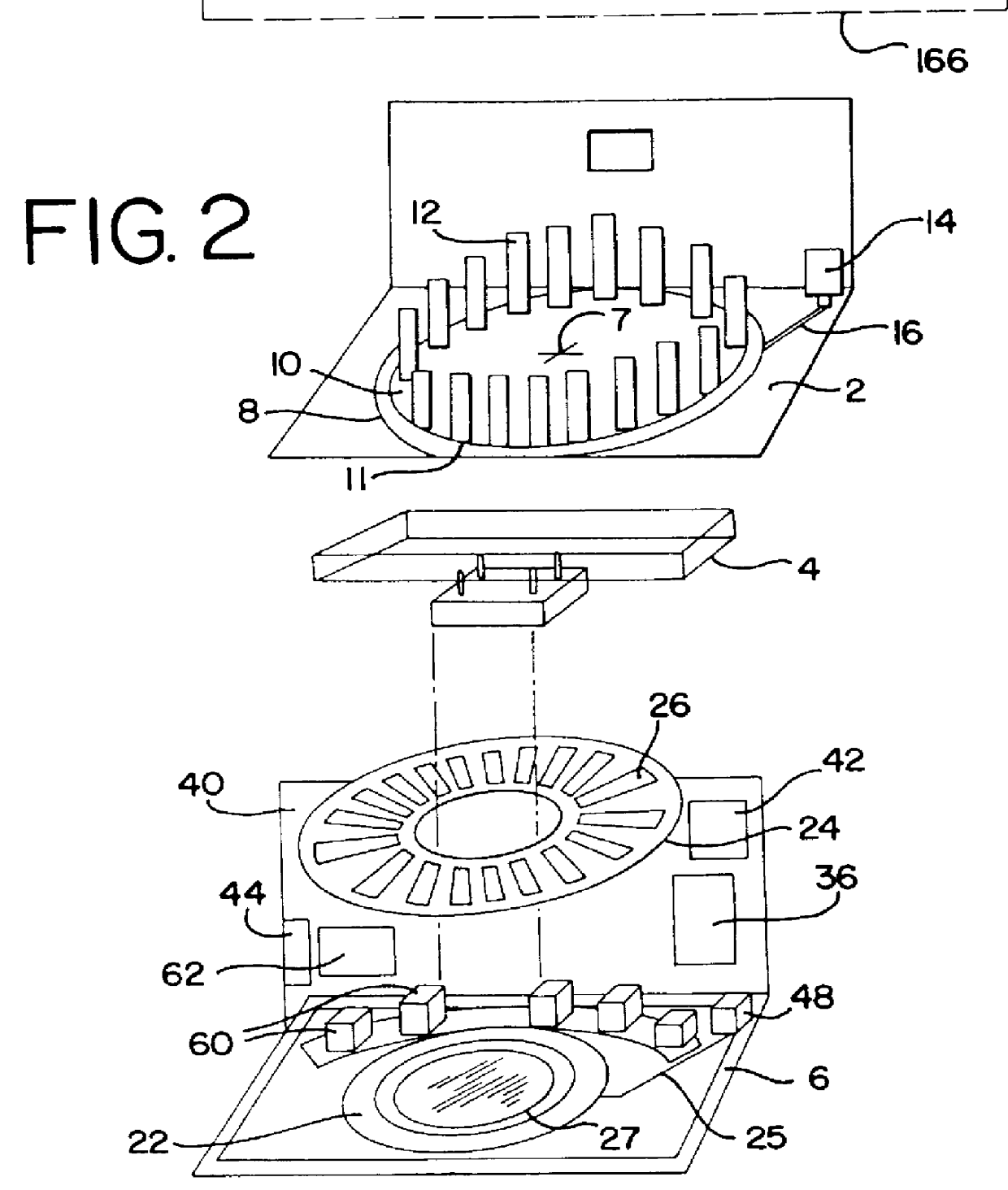

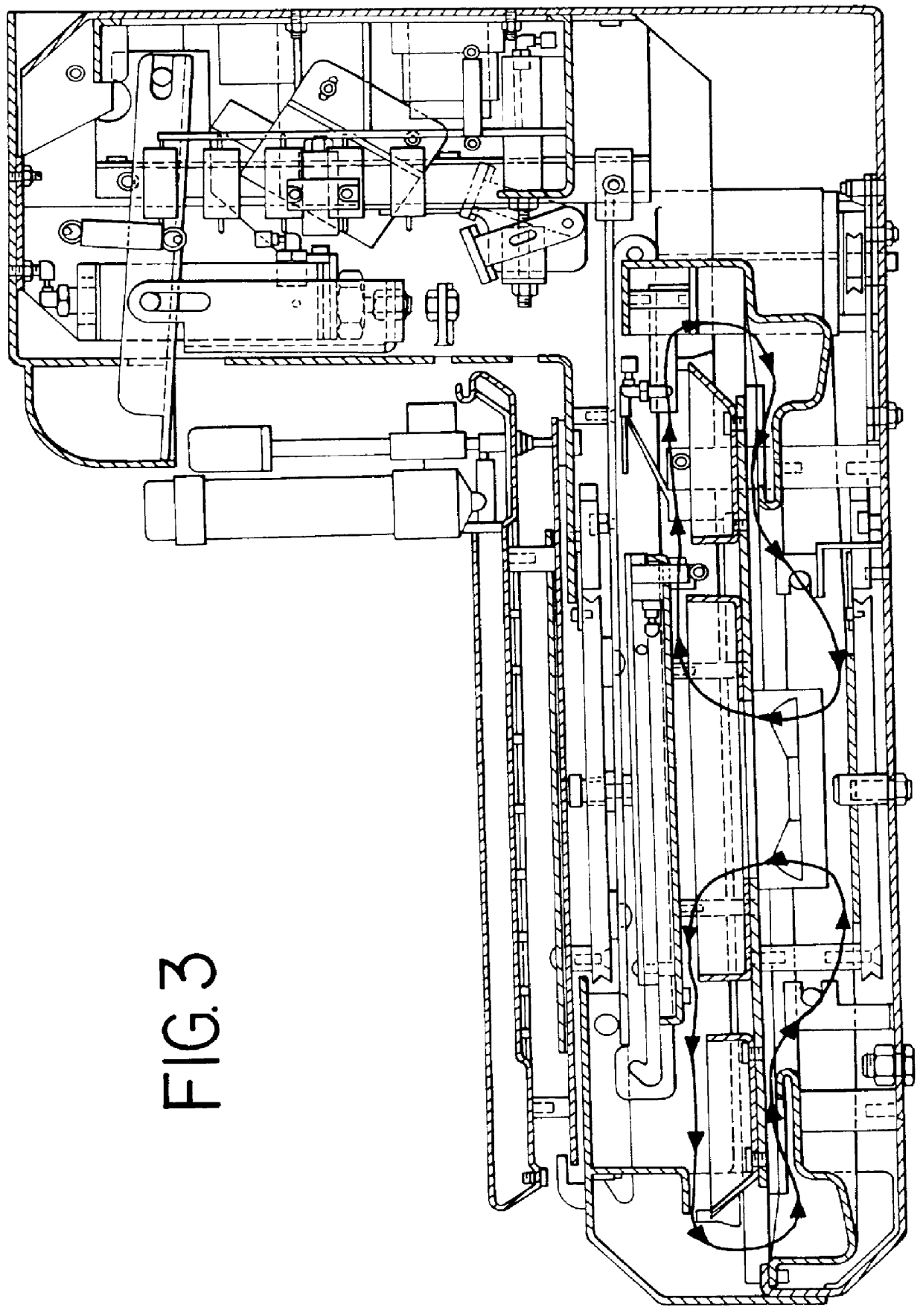

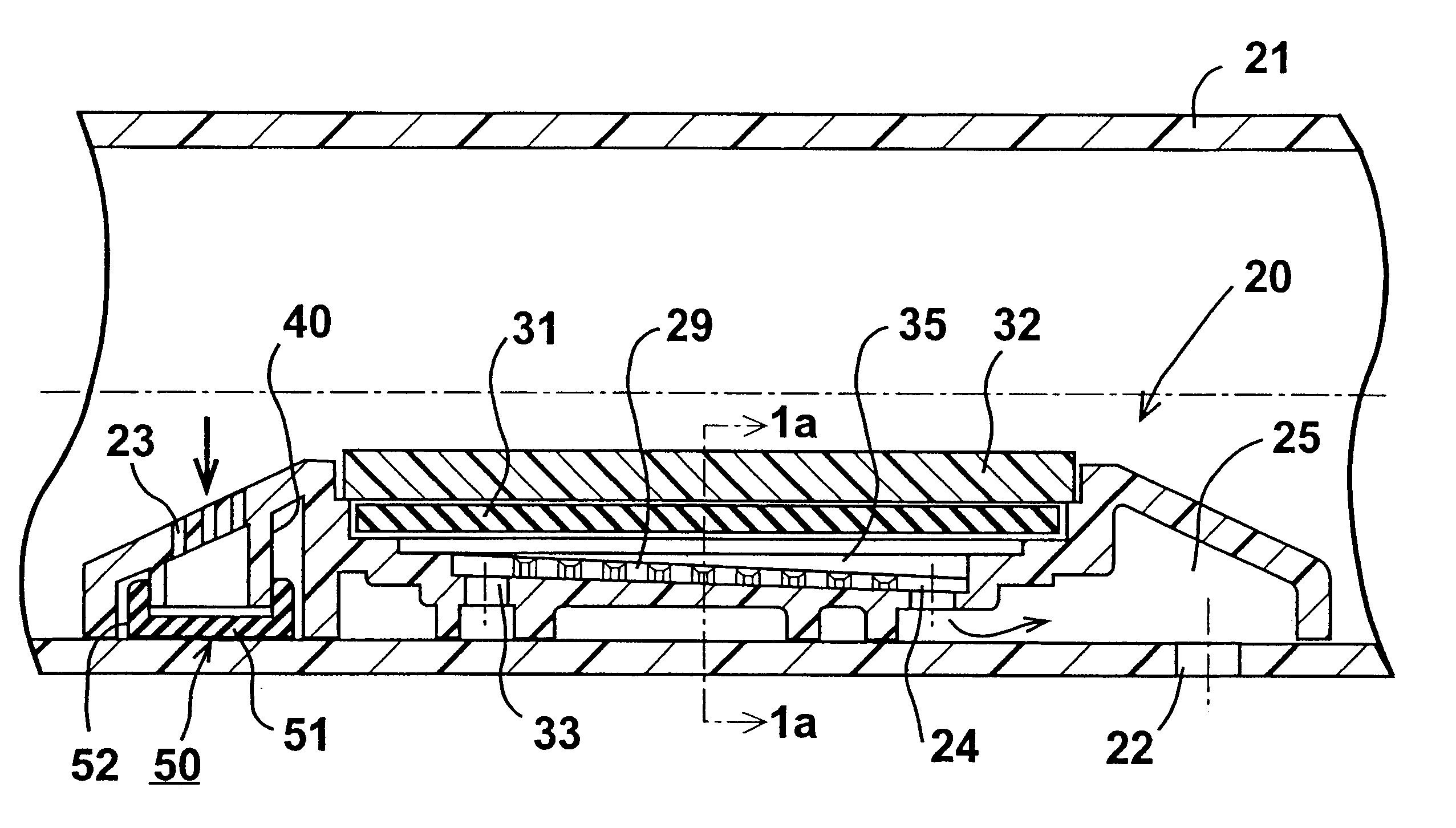

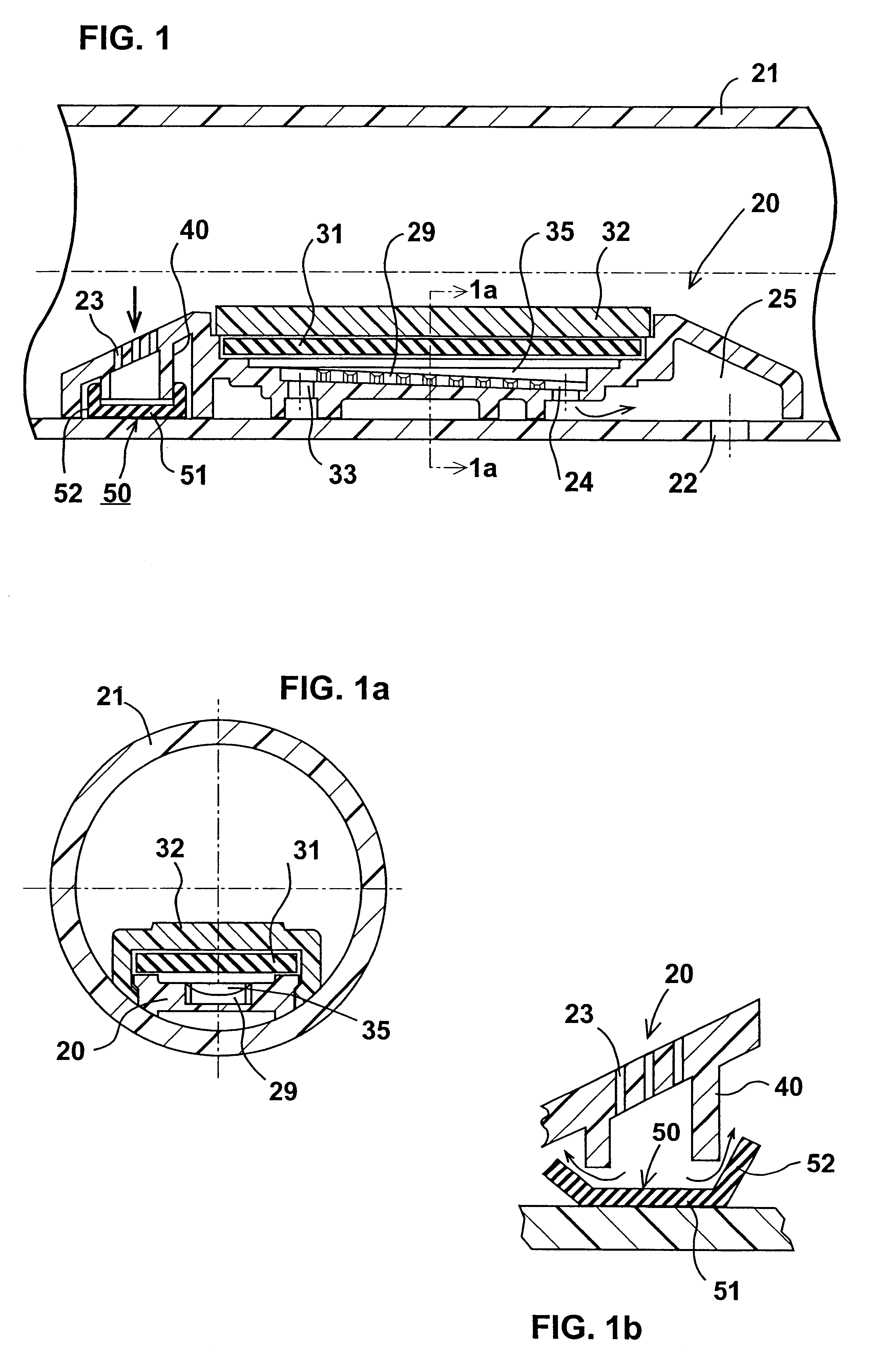

Process-gas supply and processing system

InactiveUS20110139272A1Efficient solutionLow costPipe supportsServomotor componentsProcess engineeringGas supply

A process-gas supply system 2 supplies a process gas diluted with a diluent gas to a gas using system 4. The process-gas supply system 2 includes a process gas tank 10, a diluent gas tank 12, a main gas duct 14 connecting the process gas tank 10 and the gas using system 4, and a diluent gas duct connecting the diluent gas tank 12 to the main gas duct. The respective main gas duct 14 and the diluent gas duct are provided with flow rate controllers FC1, FC2, and FC5. The diluent gas duct is connected to the main gas duct at a position on an immediately downstream side of one of a plurality of flow rate controllers other than the flow rate controller on the most downstream side. There is further provided a surplus-gas discharge duct 24 through which a surplus diluted process gas is discharged, the surplus-gas discharge duct 24 being connected to the main gas duct at a position on an immediately upstream side of one the flow rate controllers other than the flow rate controller on the most upstream side.

Owner:TOKYO ELECTRON LTD

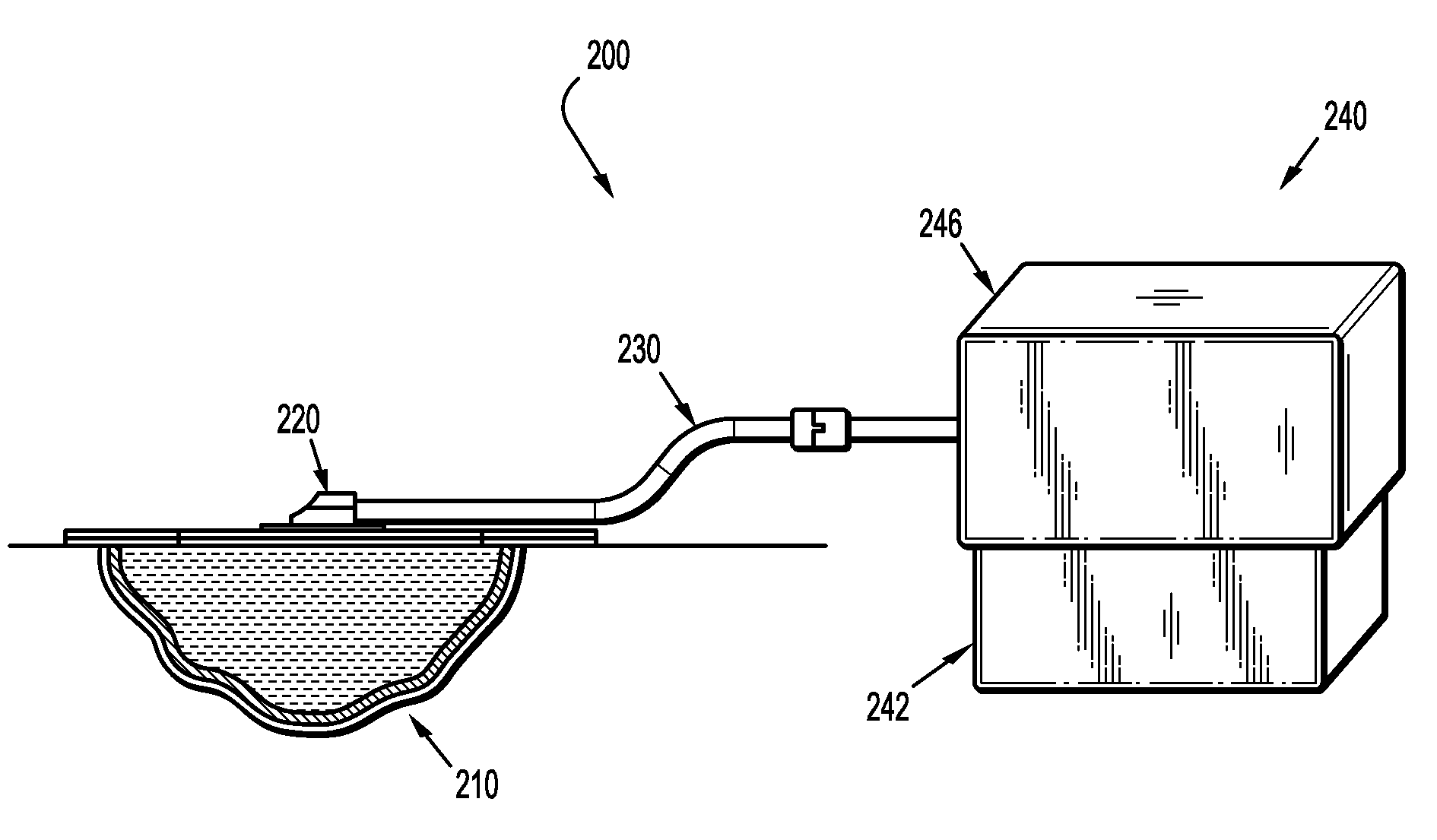

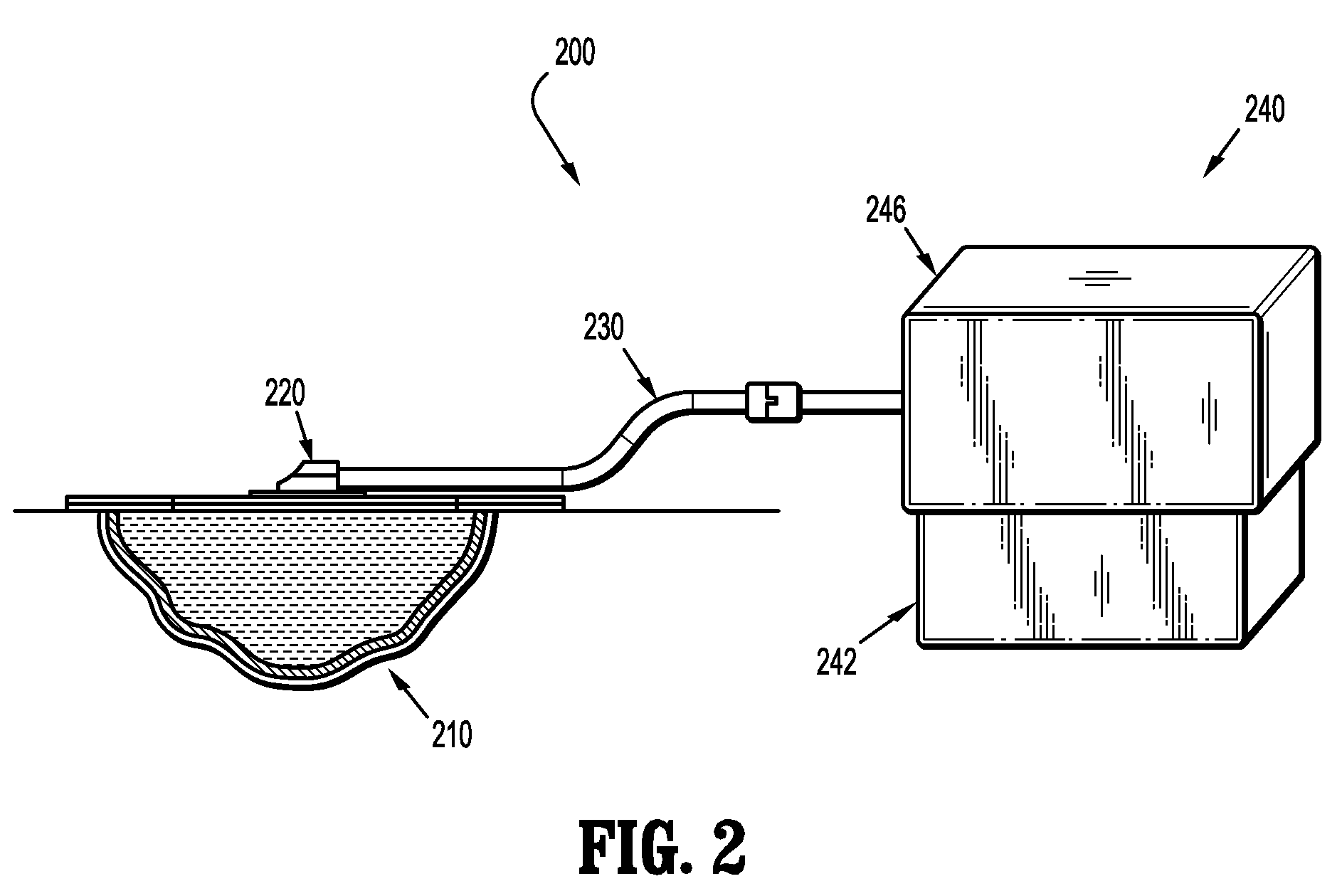

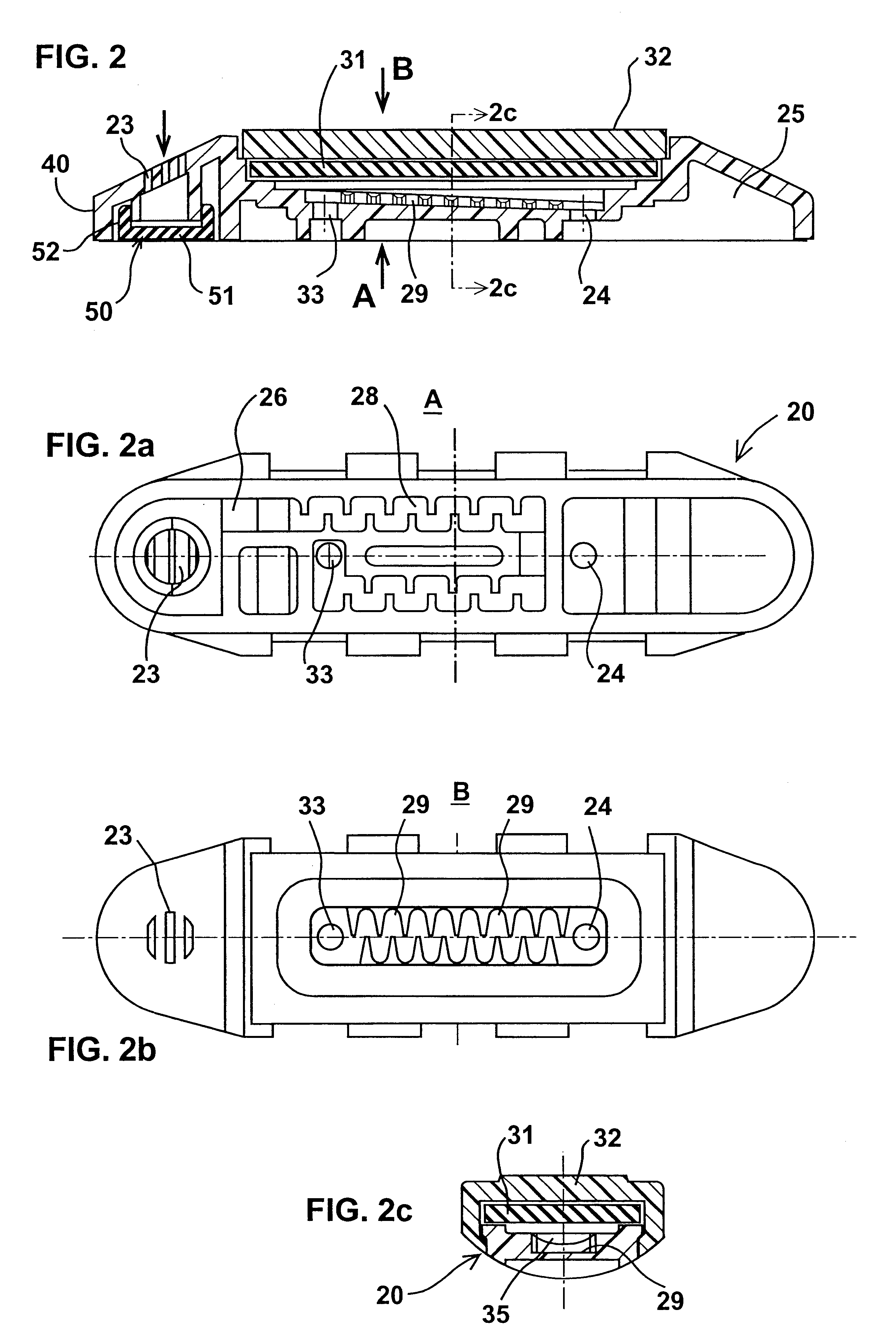

Orientation independent canister for a negative pressure wound therapy device

Owner:SMITH & NEPHEW INC

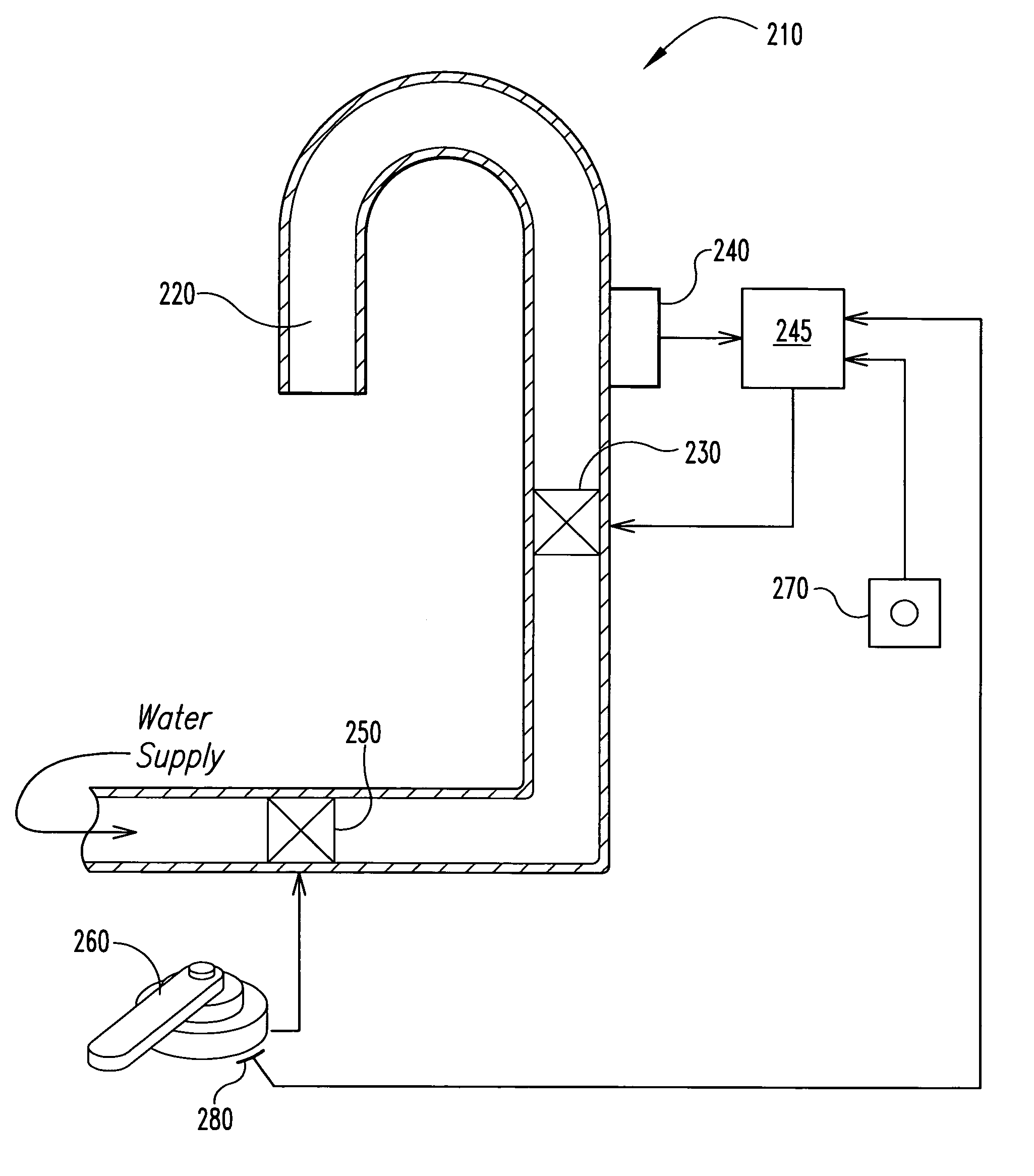

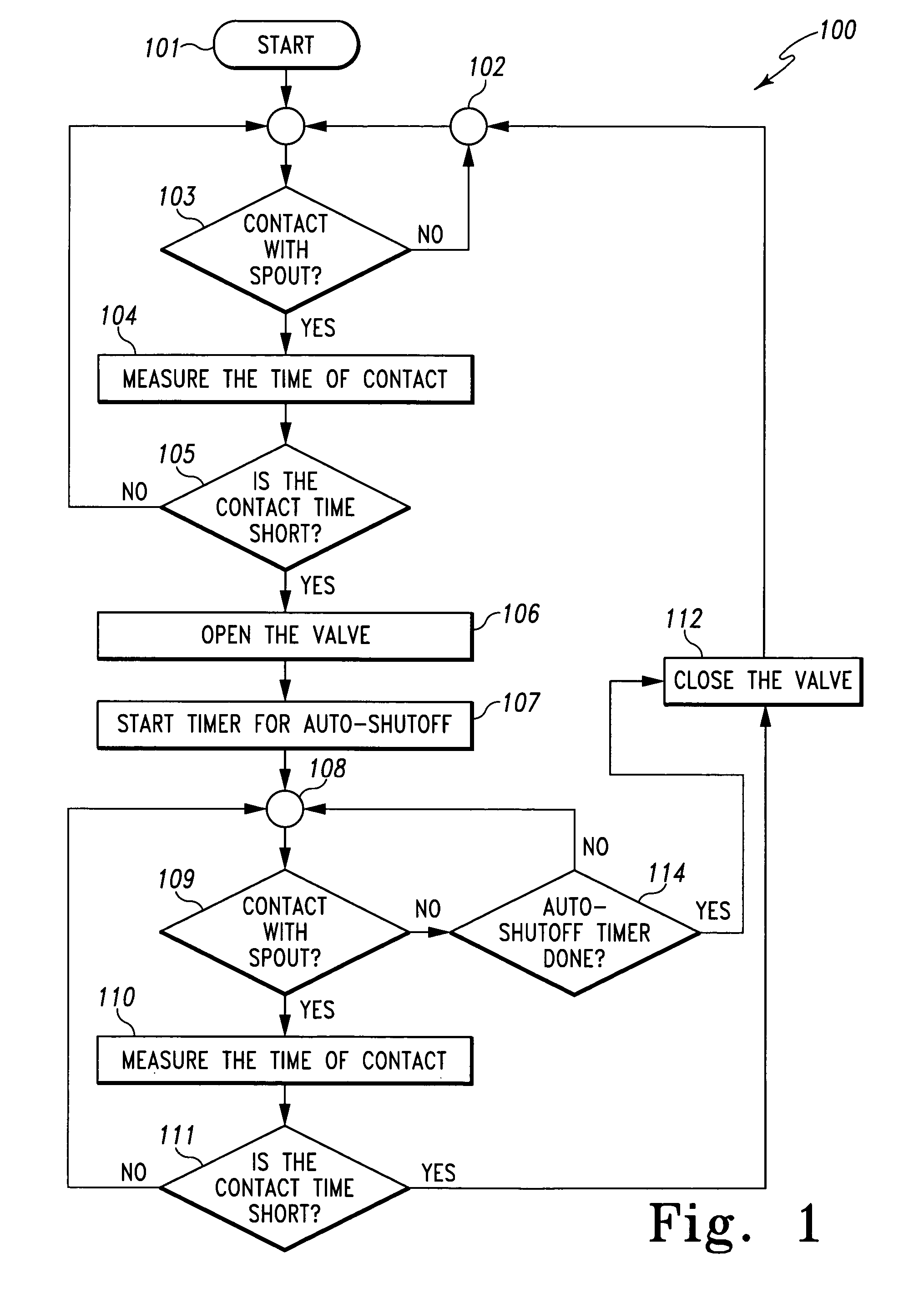

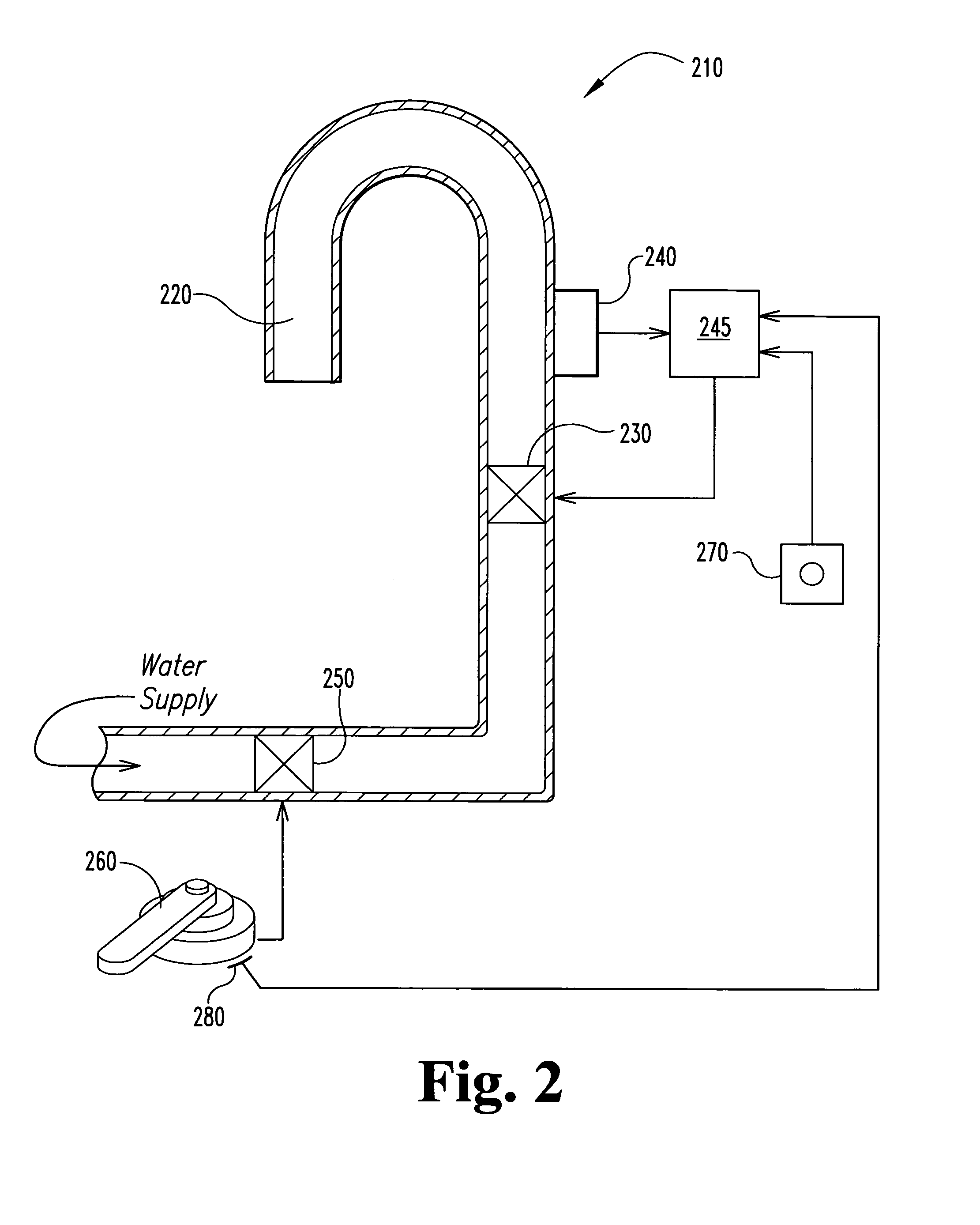

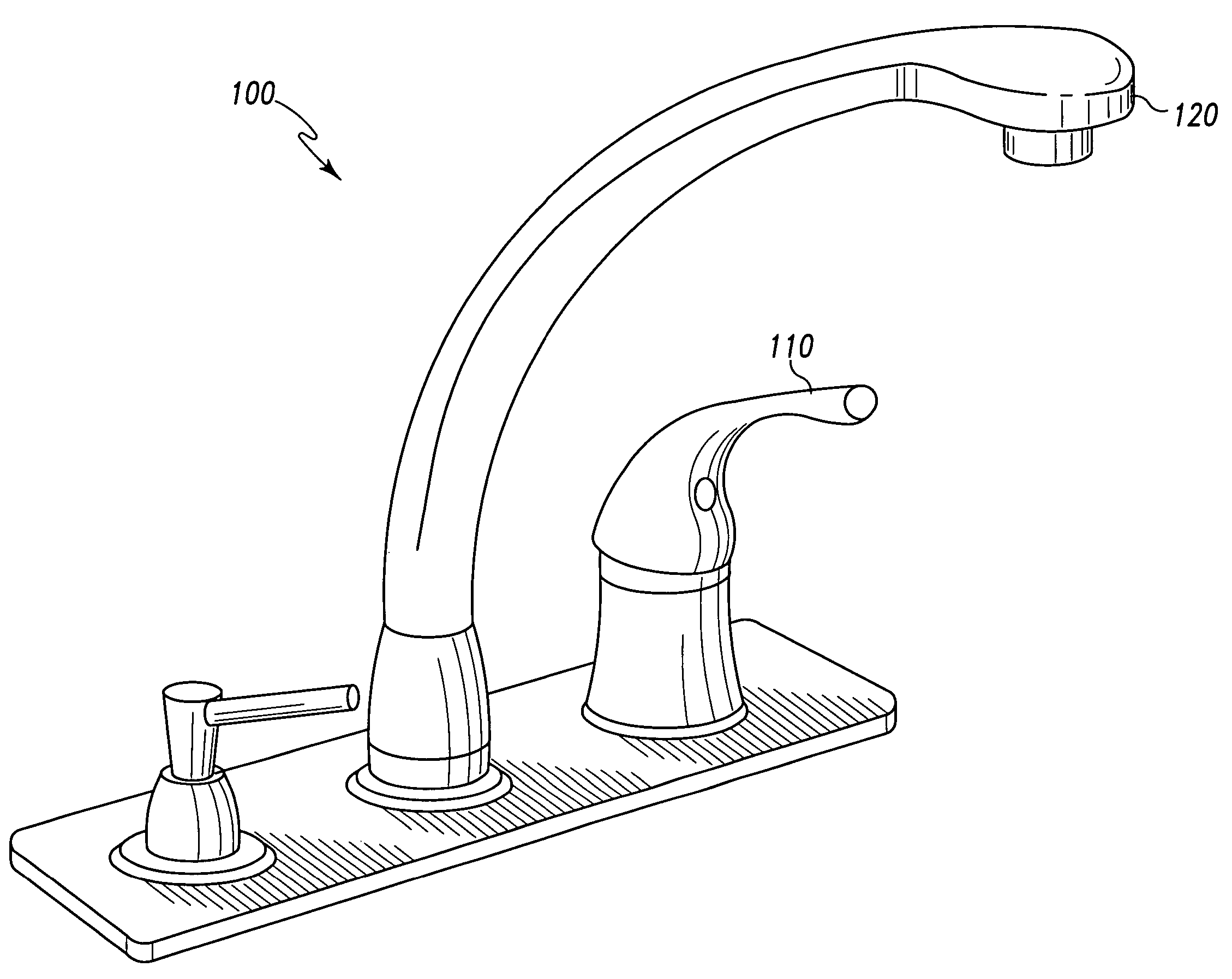

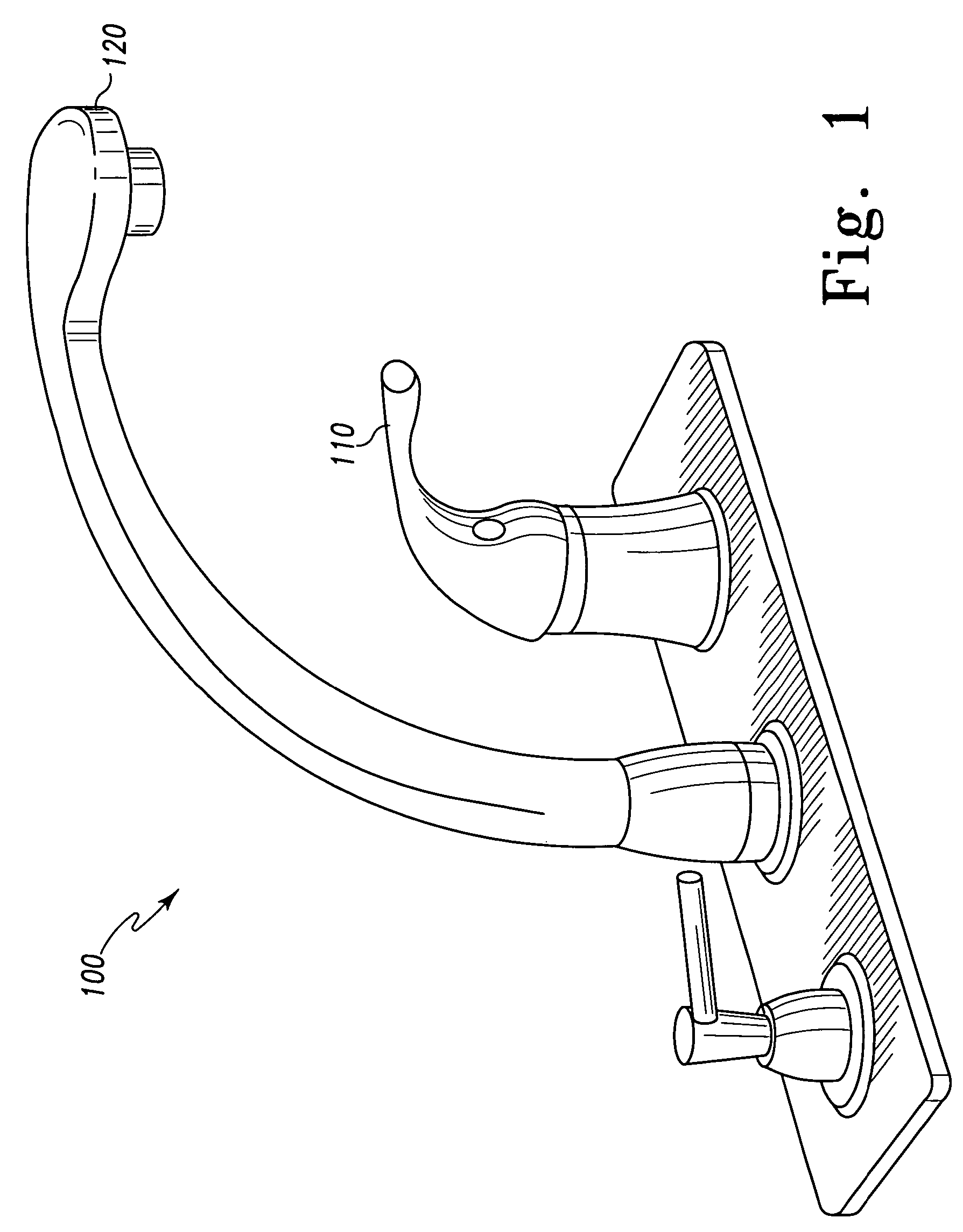

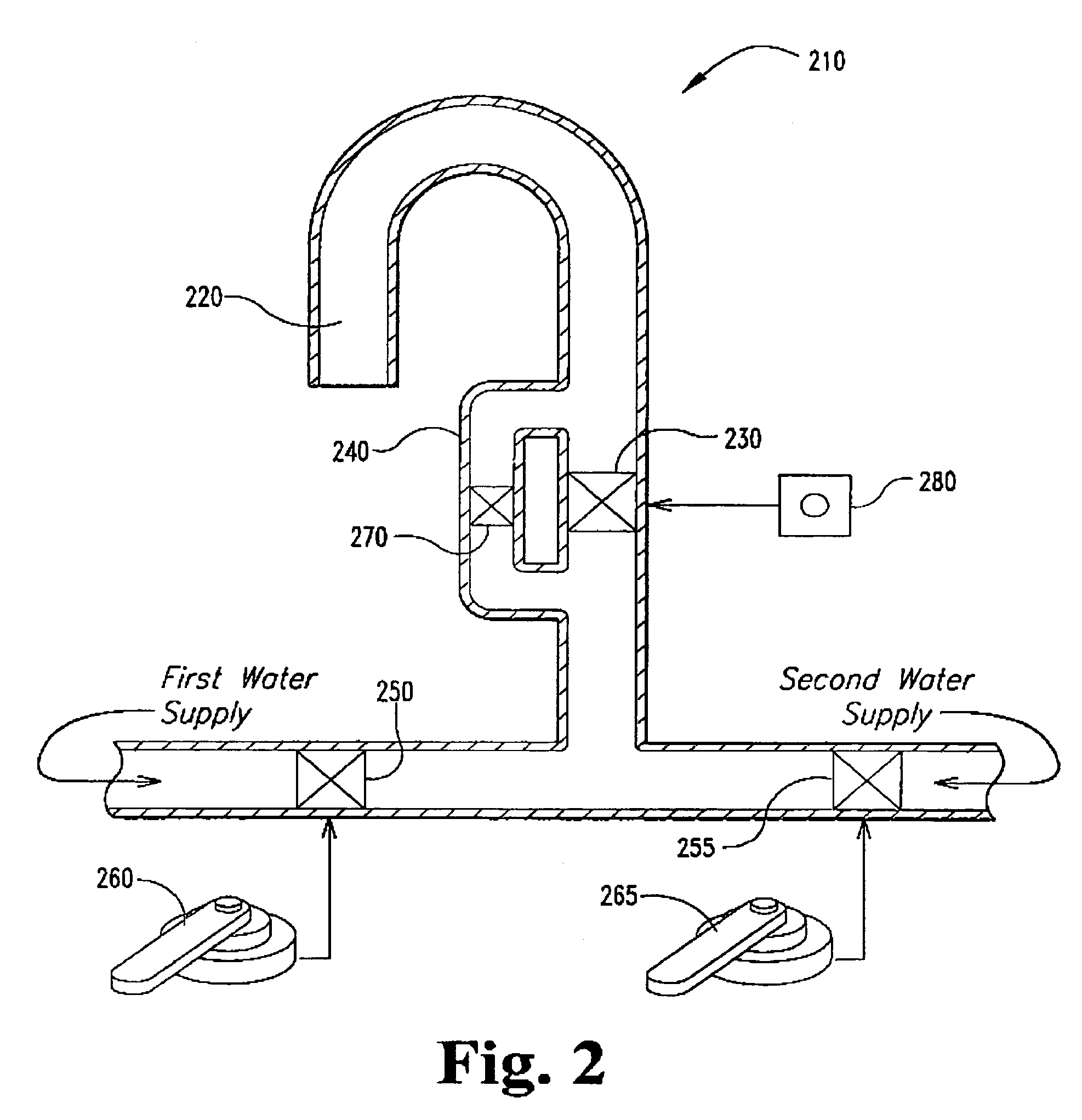

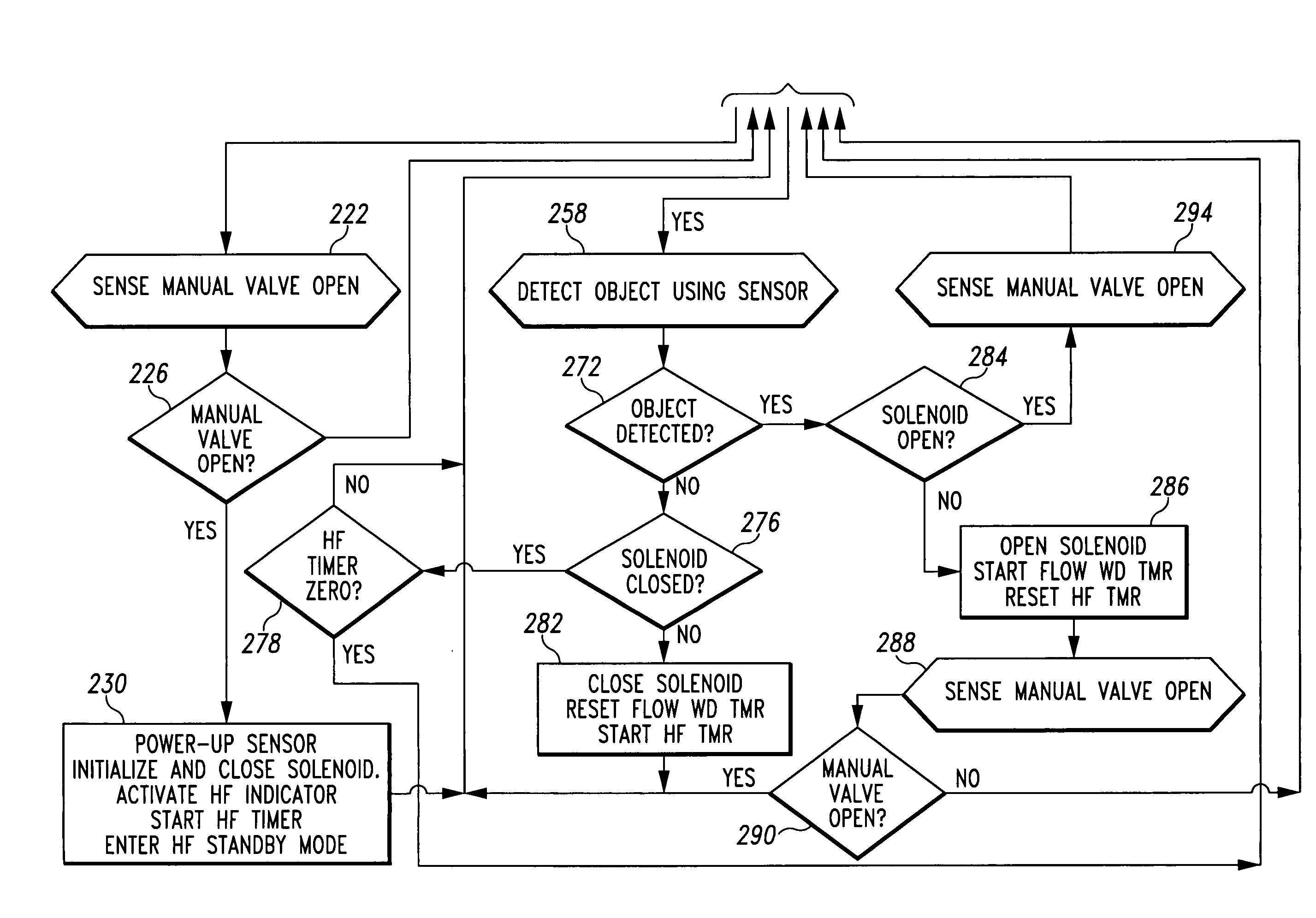

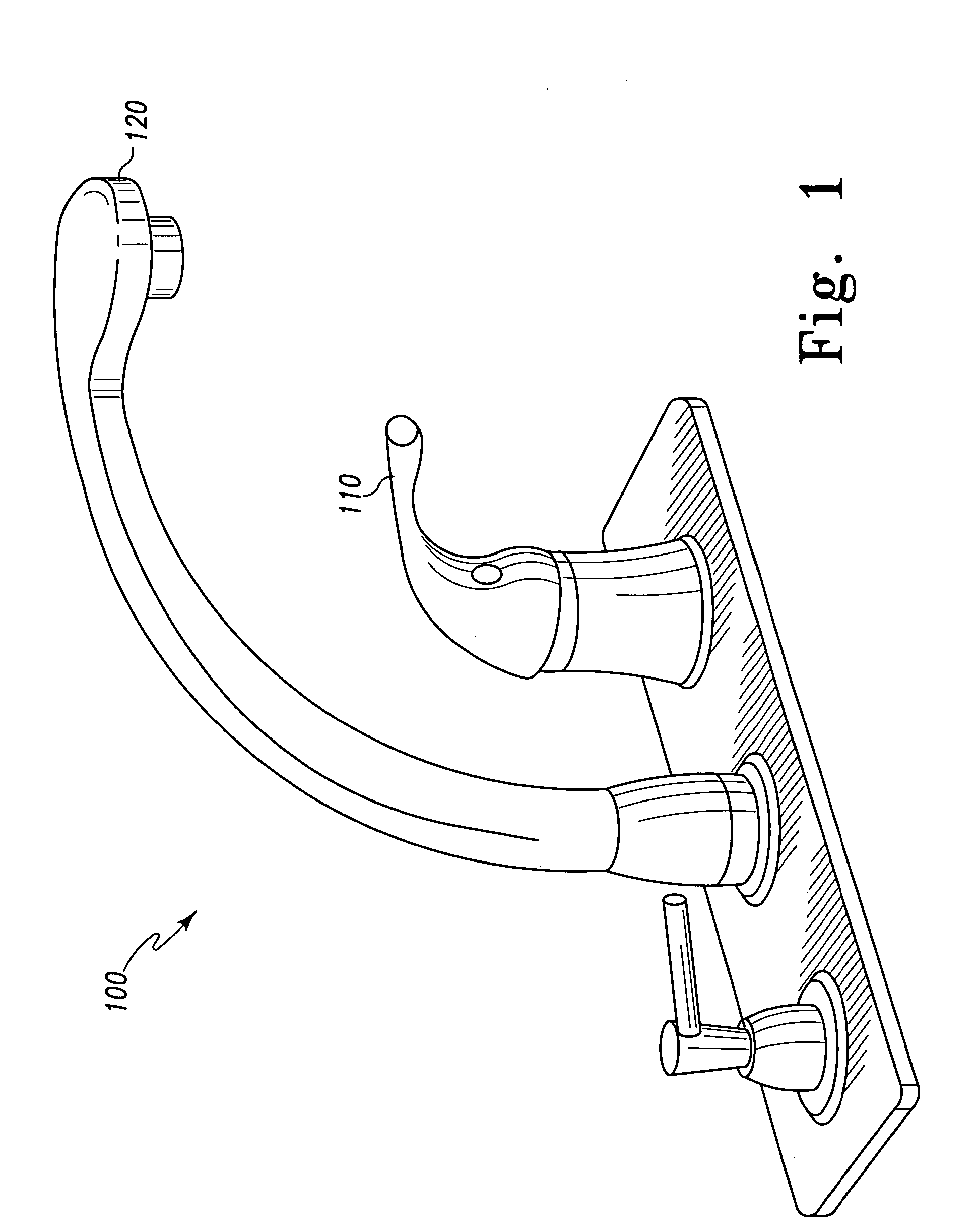

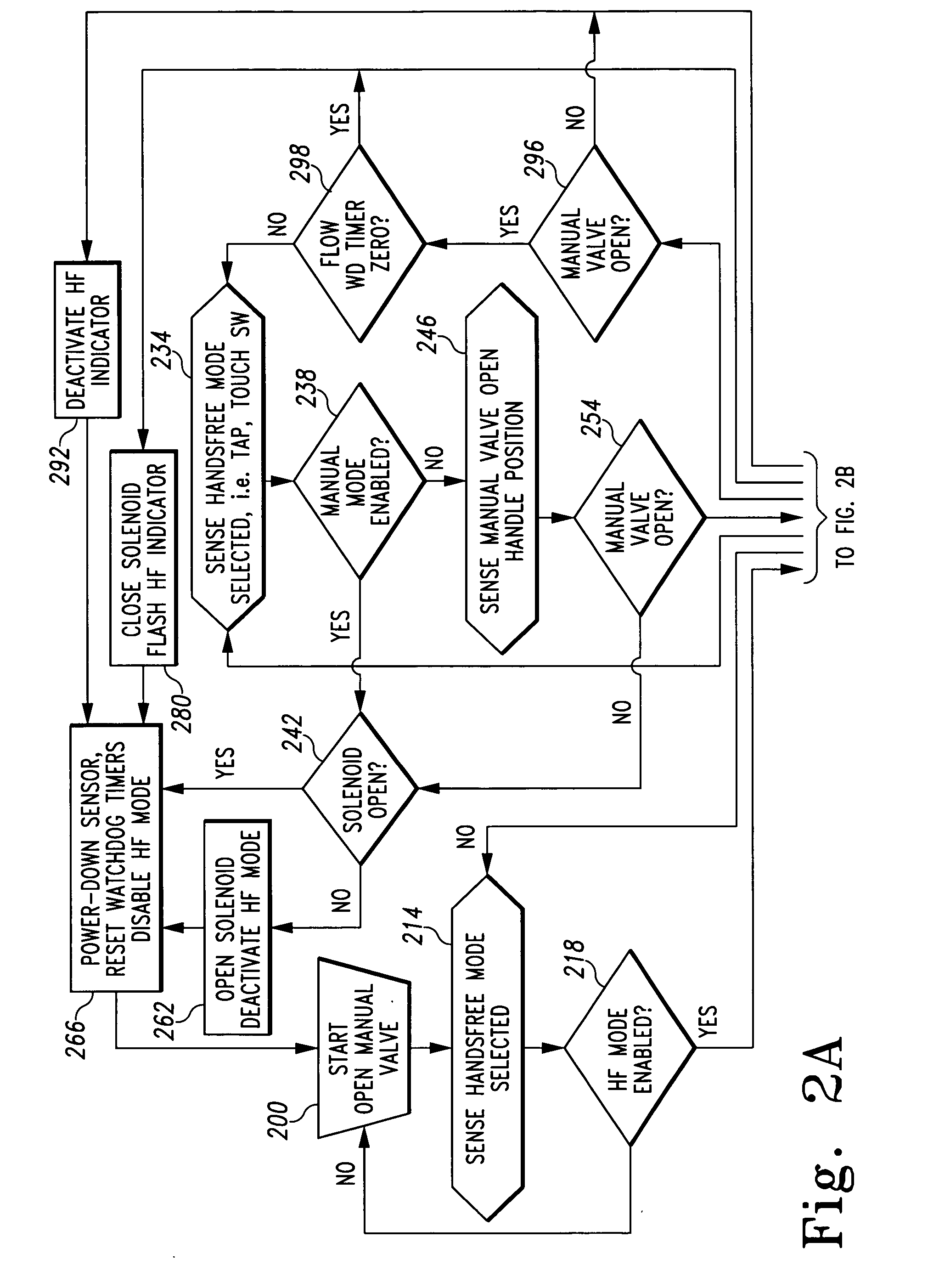

Capacitive touch on/off control for an automatic residential faucet

ActiveUS6962168B2Operating means/releasing devices for valvesServomotor componentsProximity sensorWater flow

A capacitive touch-controlled automatic faucet comprises: a spout, a magnetically latching valve, a proximity sensor, a handle, a capacitive touch-control, and a logical control. The proximity sensor is sensitive to motion of objects within a detection zone of the proximity sensor. The handle determines a water flow rate and temperature. The capacitive touch-control is positioned in the spout and generates an output signal while the touch-control is in contact with a user. The logical control receives the output signal, and toggles the magnetically latching valve when the output signal begins and ends within a period of time less than a predetermined threshold, but does not toggle the magnetically latching valve when the output signal persists for a period longer than the predetermined threshold. The faucet has a manual mode, wherein the proximity sensor is inactive, and a hands-free mode, wherein water flow is toggled in response to the proximity sensor.

Owner:DELTA FAUCET COMPANY

Pressure actuated valve with improved slit configuration

Owner:NAVILYST MEDICAL

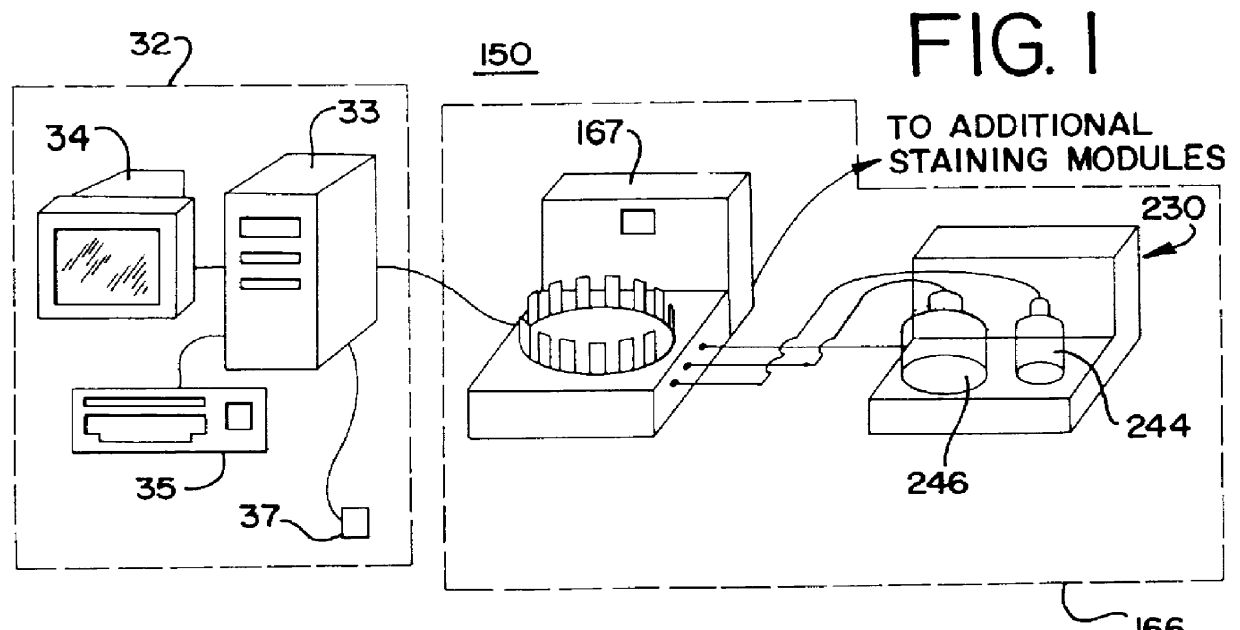

Fluid dispenser

InactiveUS6045759AEfficient and reliableEasy to manufactureCheck valvesLarge containersModularityReactive system

A method and apparatus for an automated biological reaction system is provided. In the processing of a biological reaction system, there is a need for consistently placing an amount of fluid on a slide. In order to accomplish this, several methods are used including a consistency pulse and a volume adjust means. Moreover, in order to reliably operate an automated biological reaction system, the dispenser must be reliable, easy to assemble and accurate. Among other things, in order to accomplish this, the dispense chamber is substantially in line with the reservoir chamber, the reservoir chamber piston is removed, and the flow of fluid through the dispenser is simplified. Further, in order to operate the automated biological reaction system more reliably, the system is designed in modular pieces with higher functions performed by a host device and the execution of the staining operations performed by remote devices. Also, to reliably catalog data which is used by the automated biological reaction system, data is loaded to a memory device, which in turn is used by the operator to update the operator's databases. The generation of the sequence of steps for the automated biological reaction device based on data loaded by the operator, including checks to determine the ability to complete the run, is provided.

Owner:VENTANA MEDICAL SYST INC

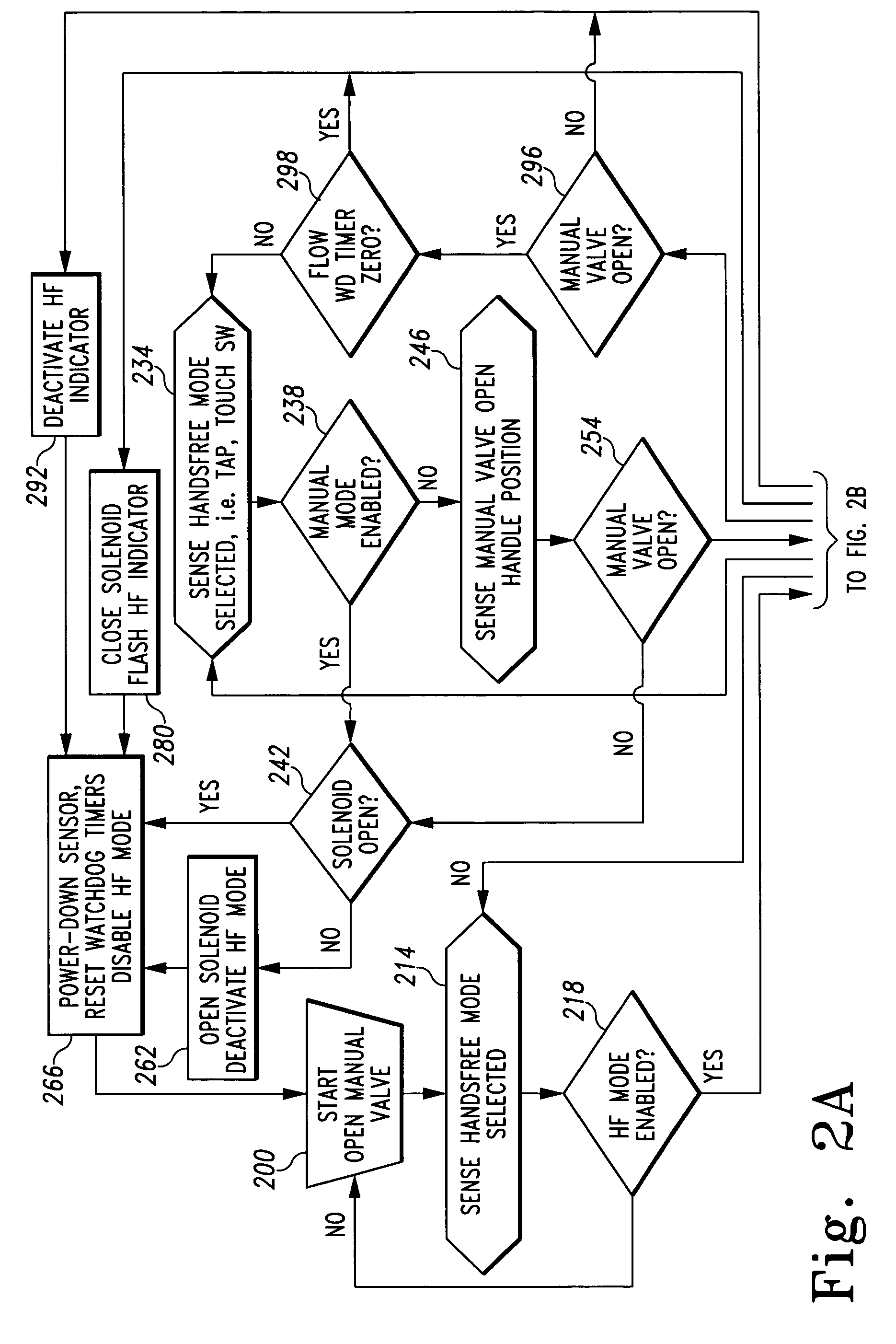

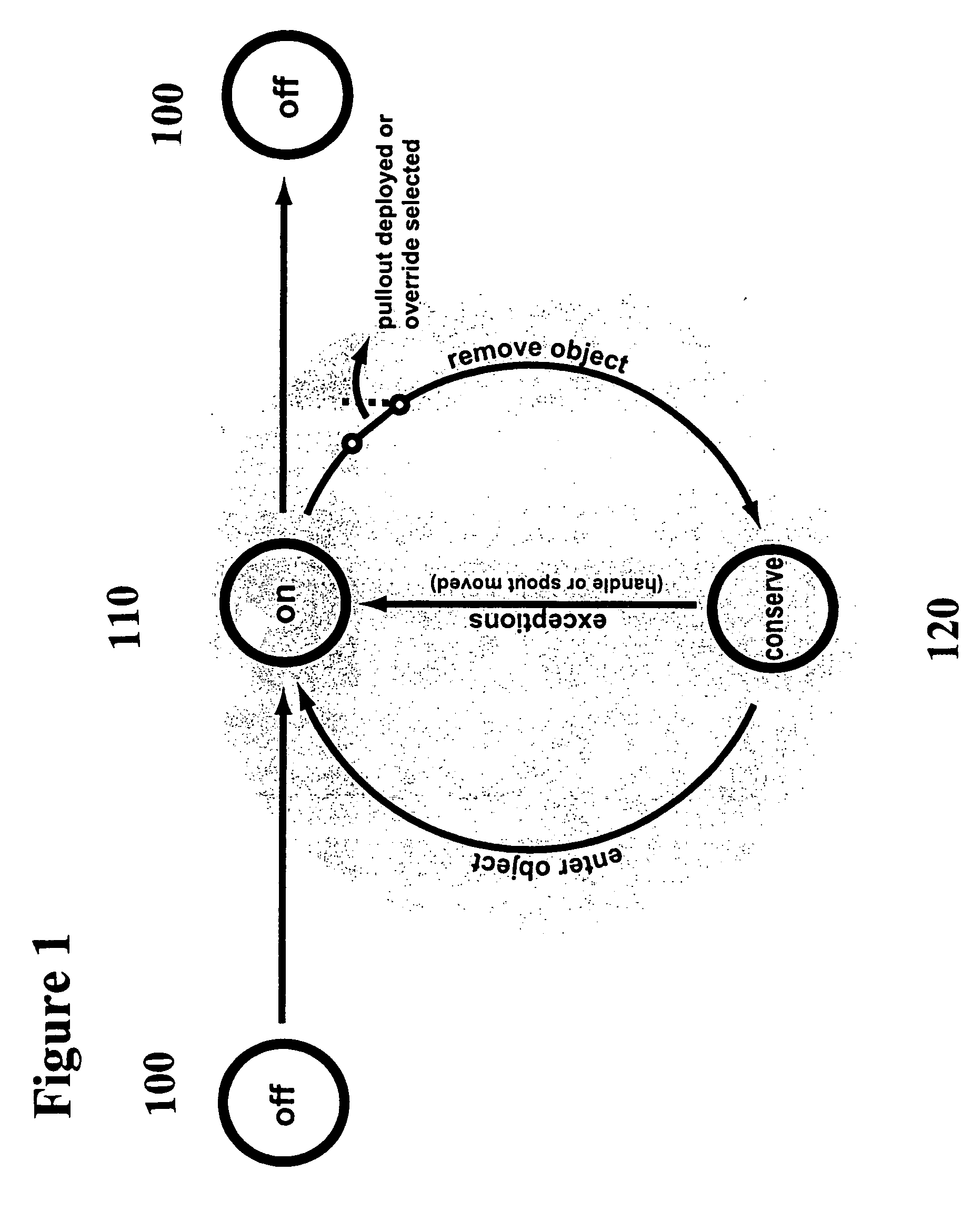

Multi-mode hands free automatic faucet

ActiveUS7150293B2Operating means/releasing devices for valvesServomotor componentsProximity sensorWater flow

A hands-free faucet comprises a proximity sensor, a logical control, a handle including a first touch control, a second touch control, and a mode indicator. The logical control has a manual mode (wherein the proximity sensor is inactive, and water flow is toggled on and off by positioning the handle) and a hands-free mode (wherein water flow is toggled on and off in response to the proximity sensor). The first touch control puts the faucet in the hands-free mode when touched by a user. The second touch control toggles the logical control between the hands-free mode and the manual mode when touched by a user. The mode indicator indicates which mode the faucet is presently in. The water flow has a temperature and a flow rate that are determined by the position of the handle.

Owner:DELTA FAUCET COMPANY

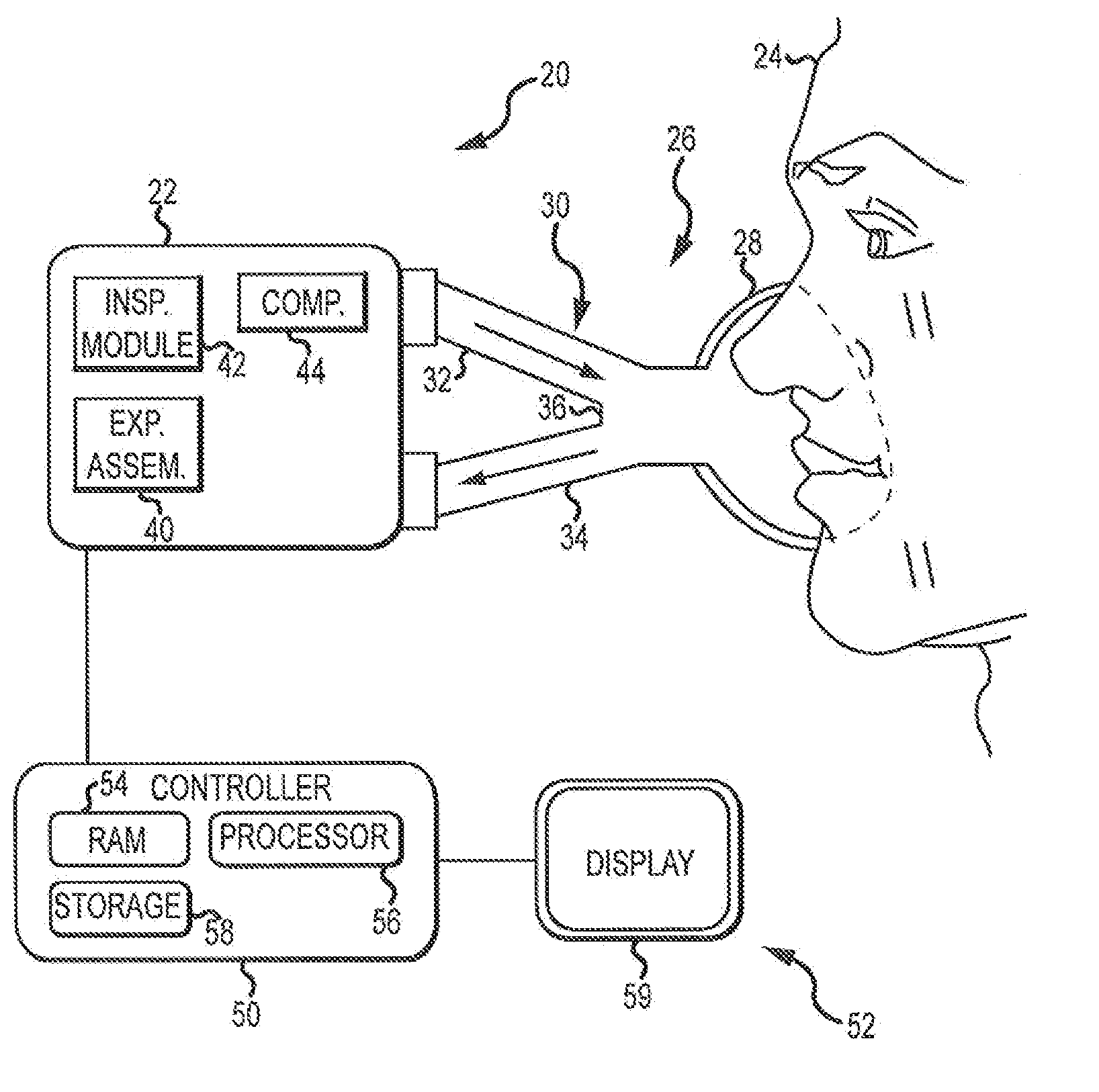

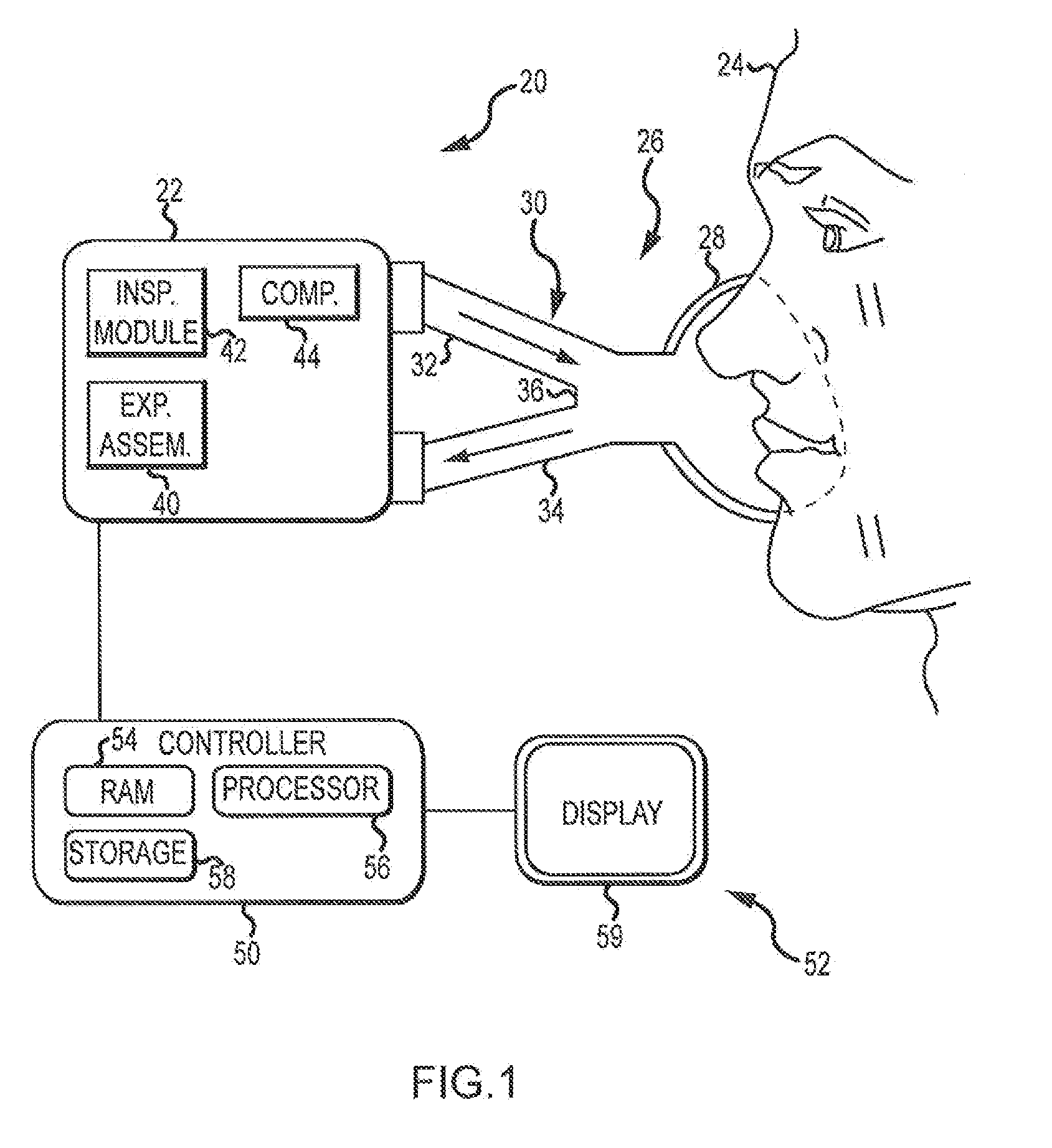

Exhalation Valve Assembly

An exhalation valve assembly that controls the pressure of exhaled gas in a ventilation system is described. The exhalation valve assembly includes an actuator module that may be fixed to the ventilation system and a valve module, removable for cleaning or disposal, through which the exhaled gas flows and that controls the pressure and release of the exhaled gas to the environment. Other components may also be incorporated into the assembly including a filter module, a flow meter and a condensate trap.

Owner:TYCO HEALTHCARE GRP LP

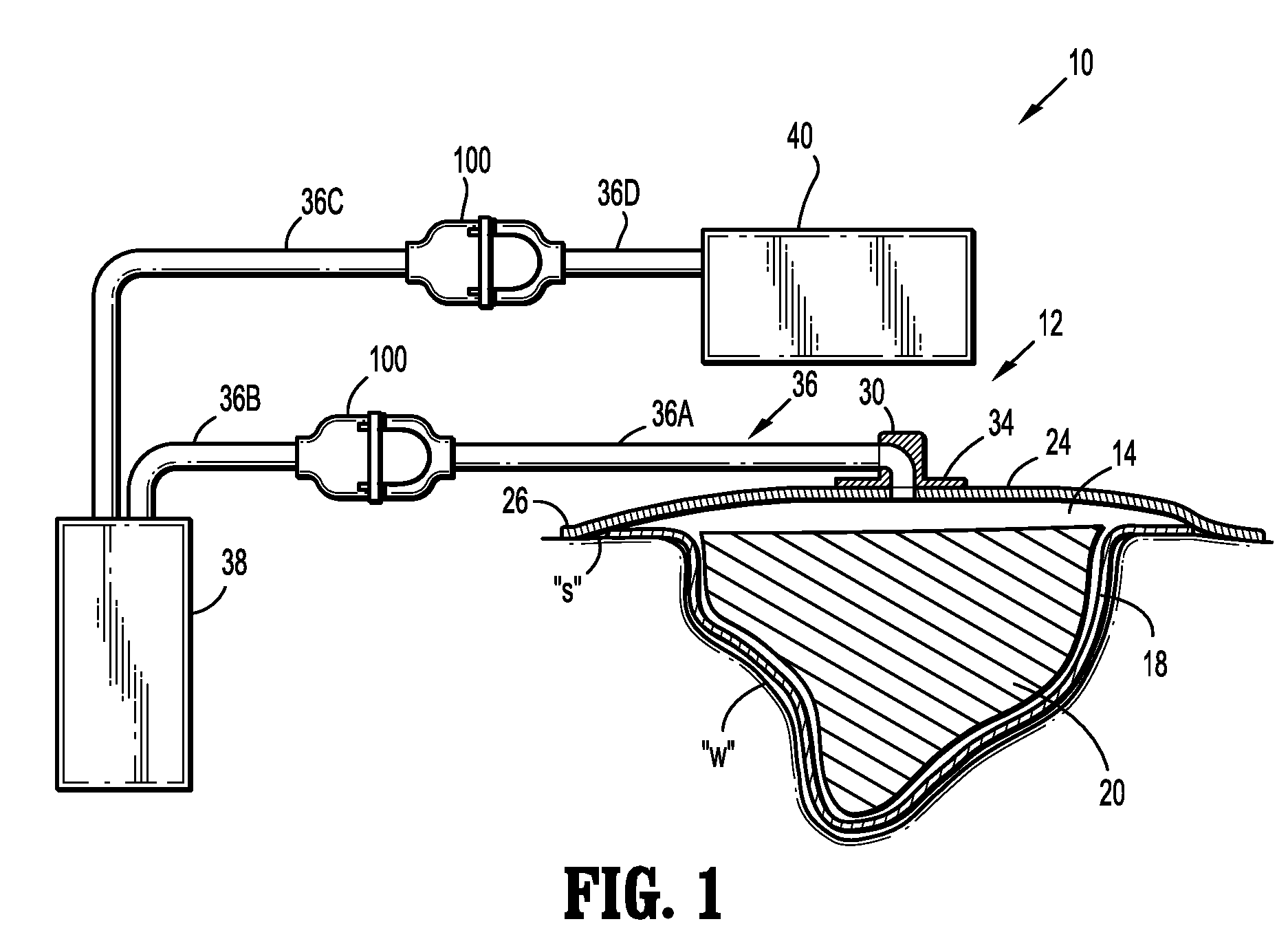

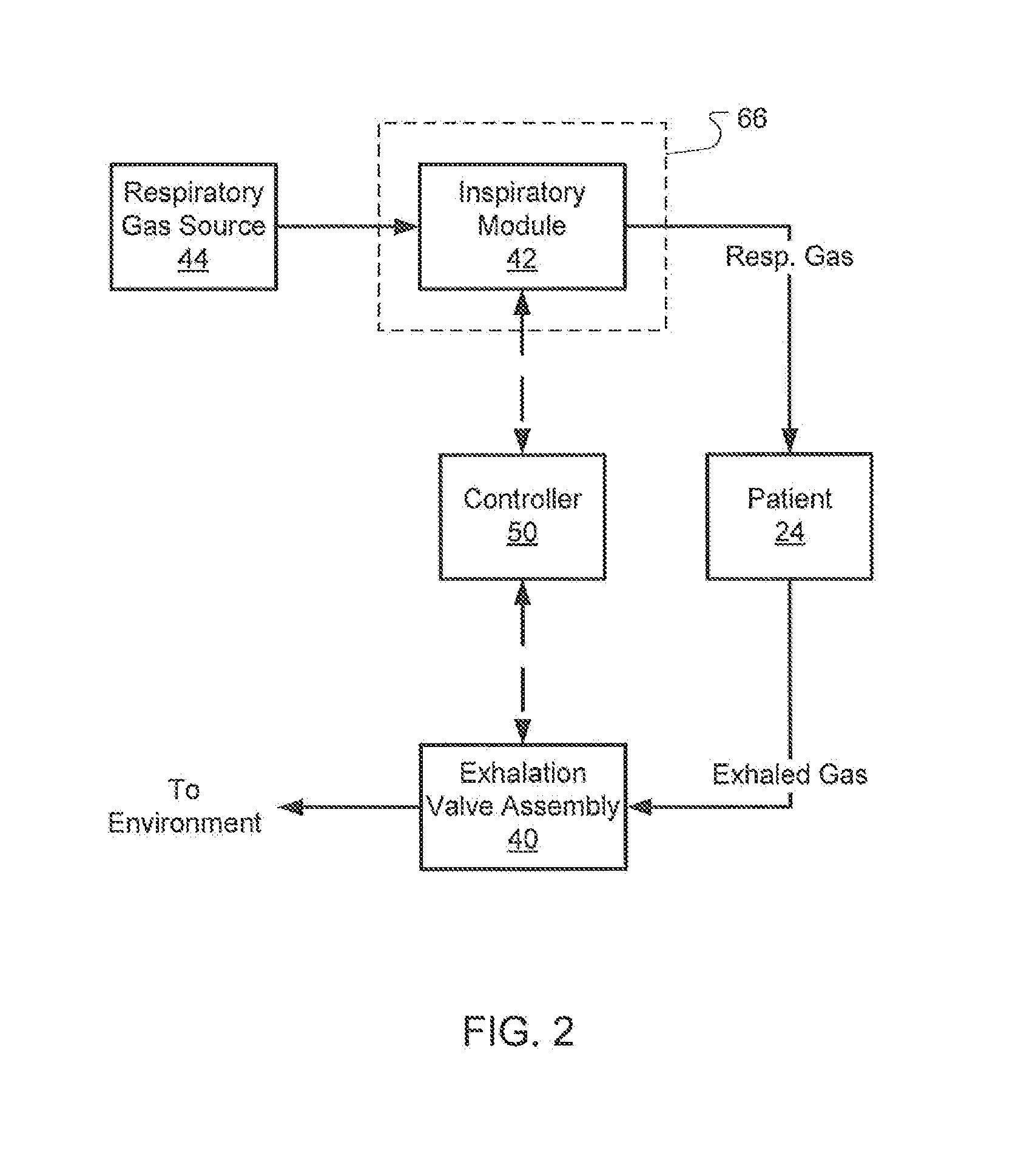

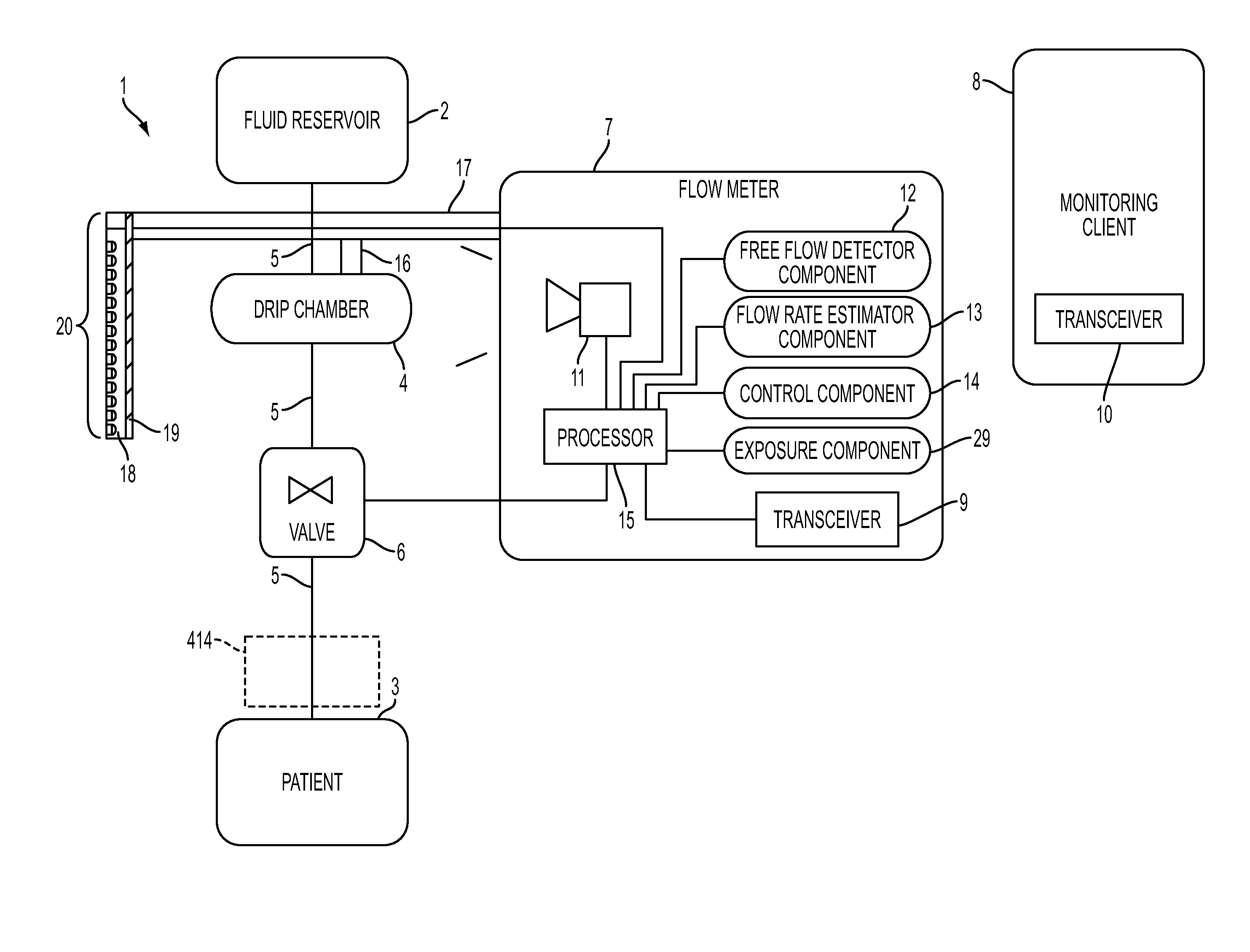

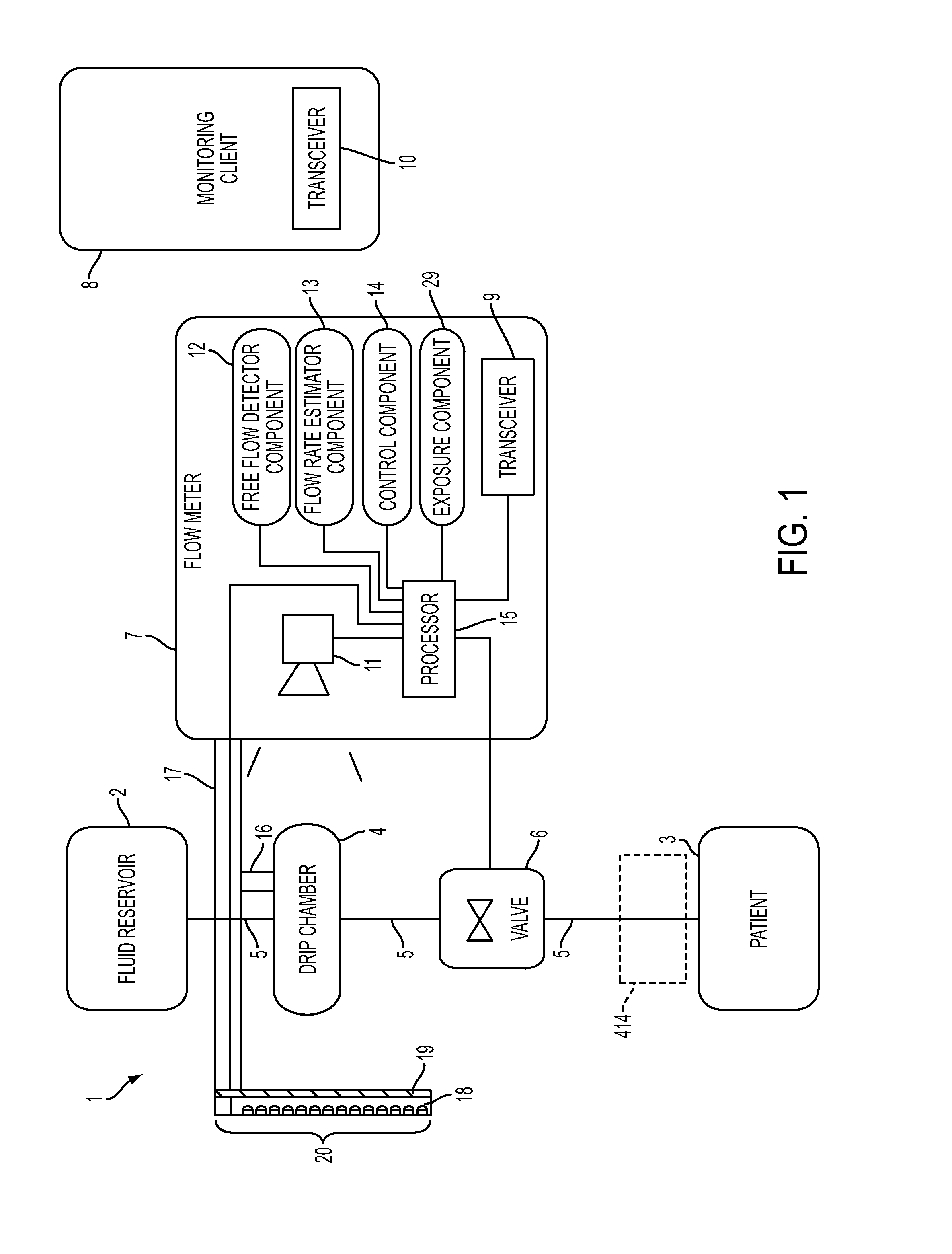

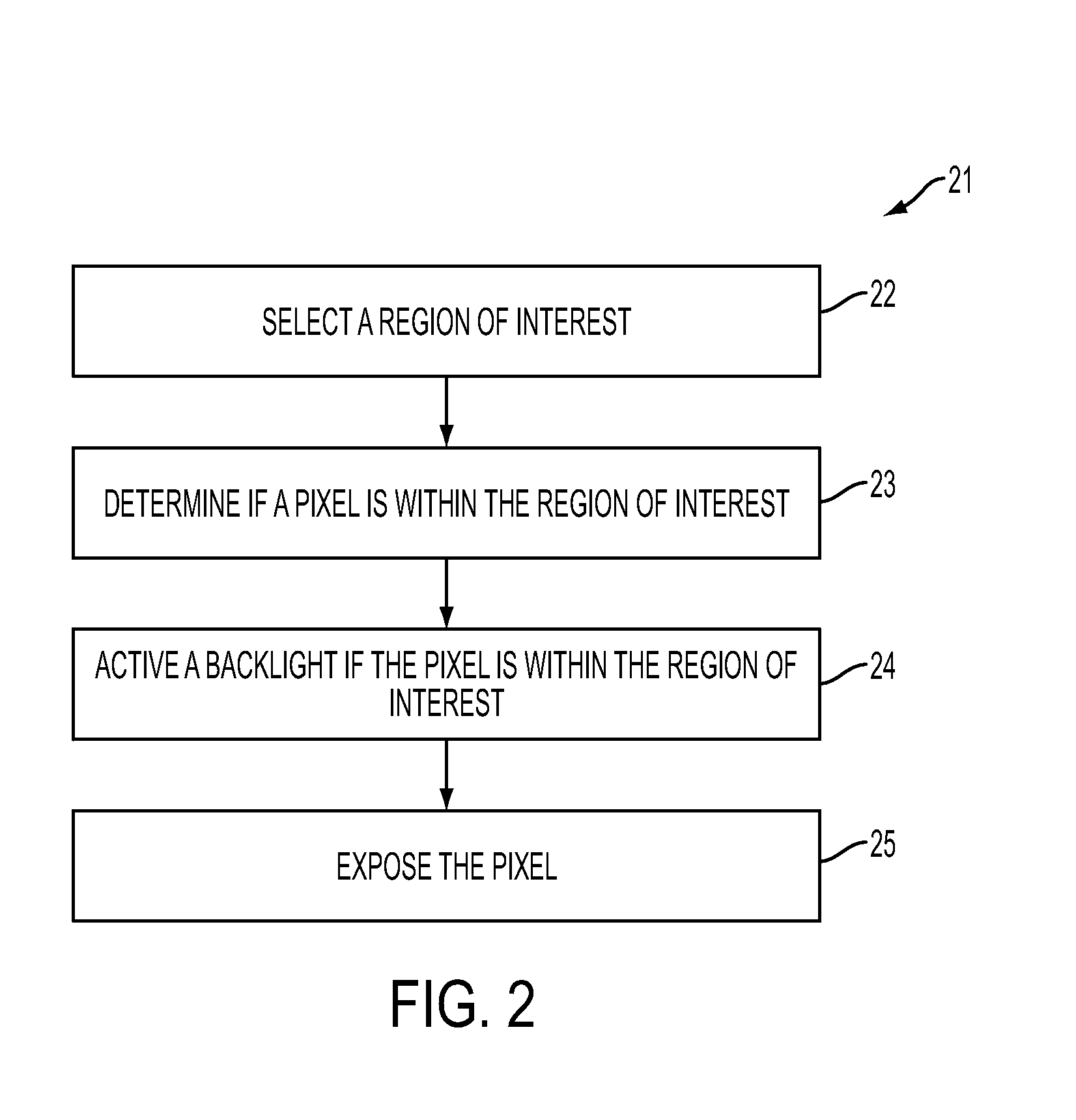

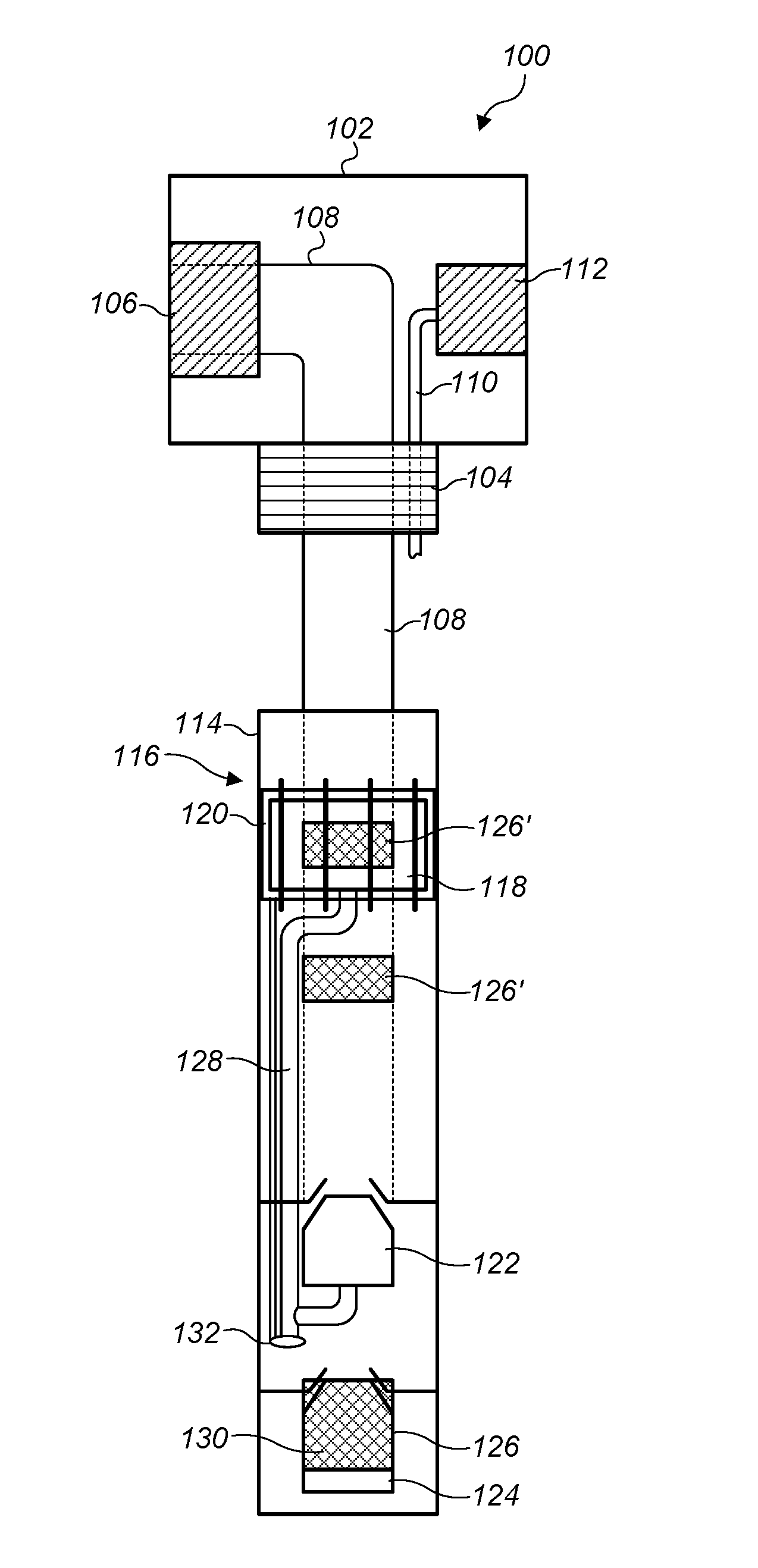

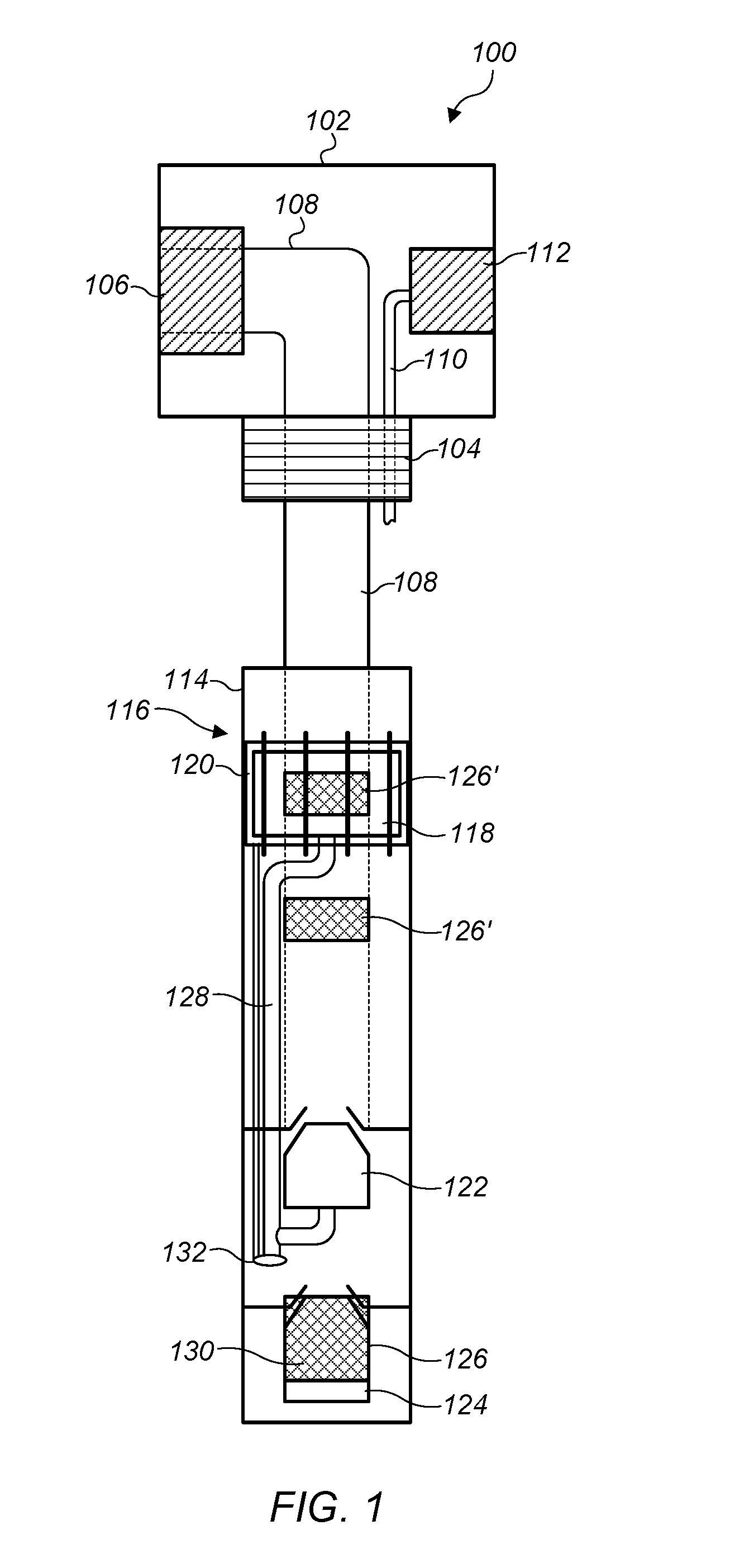

System, Method, and Apparatus for Monitoring, Regulating, or Controlling Fluid Flow

ActiveUS20140318639A1Reduce internal volumeAmount being removedEngine diaphragmsDrug and medicationsControl flowEngineering

An apparatus, system and method for regulating fluid flow are disclosed. The apparatus includes a flow rate sensor and a valve. The flow rate sensor uses images to estimate flow through a drip chamber and then controls the valve based on the estimated flow rate. The valve comprises a rigid housing disposed around the tube in which fluid flow is being controlled. Increasing the pressure in the housing controls the size of the lumen within the tube by deforming the tube, therefore controlling flow through the tube.

Owner:DEKA PROD LLP

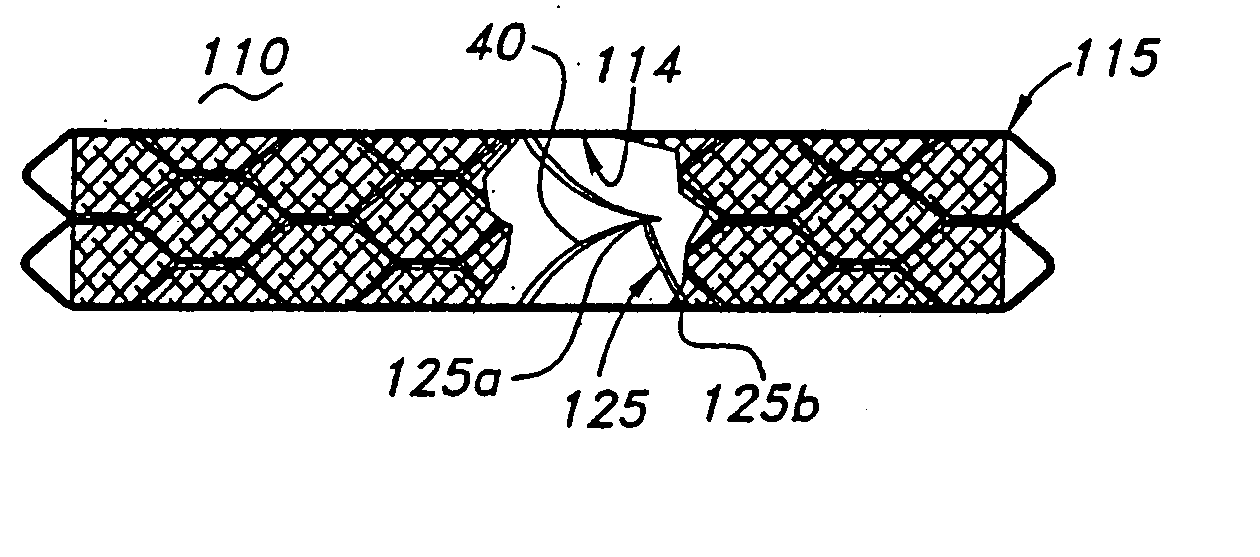

Drip irrigation lines

InactiveUS6302338B1Reduce sensitivityAbility to saveClimate change adaptationWatering devicesWater dischargePore water pressure

A drip irrigation line includes a plurality of emitter units secured within a water supply tube such that each emitter unit defines with the tube a flow-control passageway having an inlet port communicating with the interior of the water supply tube and an outlet port communicating with a water discharge opening in the water supply tube. Each emitter unit includes a one-way valve at one of the ports. Such port has an opening circumscribed by a cylindrical boss, and the one-way valve thereat includes a cap having a skirt of elastomeric material normally engaging the outer surface of the cylindrical boss to block reverse water flow into the flow-control passageway, but is deformable under water pressure to permit forward flow from the tube interior into the flow-control passageway.

Owner:COHEN

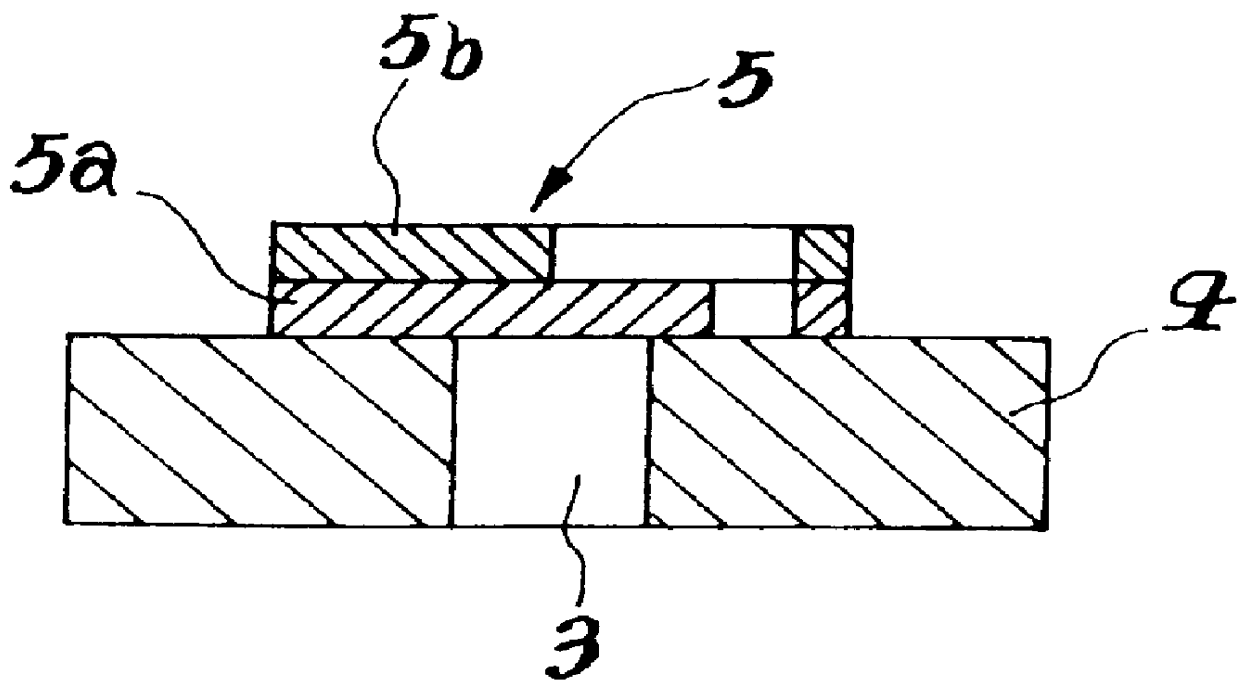

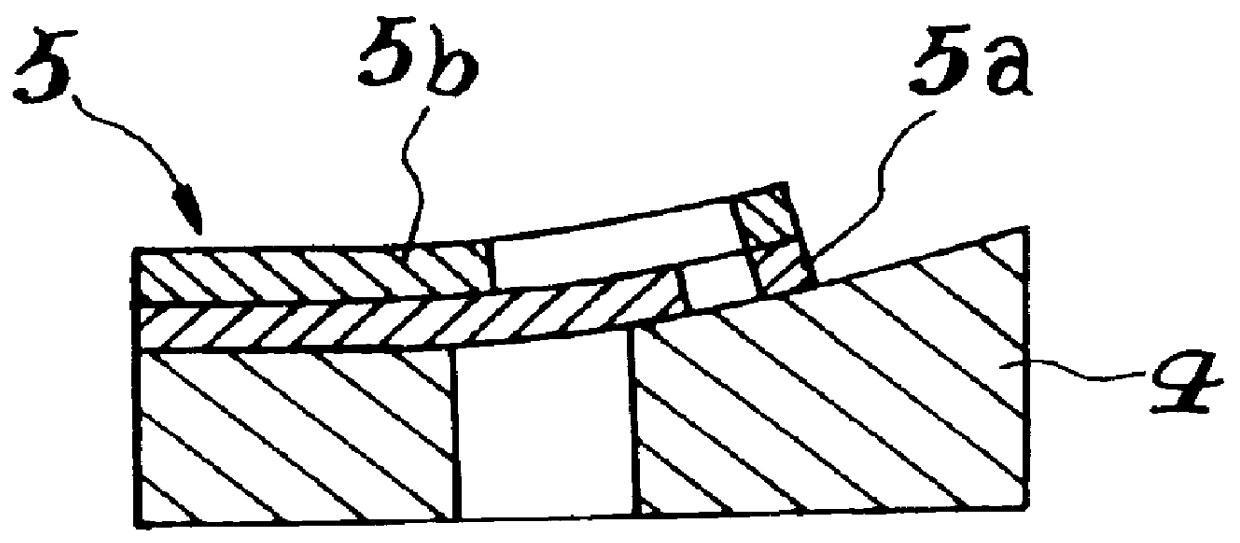

Reed valve for a pump

InactiveUS6116866APrevent backflowImprove sealingPositive displacement pump componentsFlexible member pumpsEngineeringReed valve

A reed valve is disclosed for use with a pump having a casing. A check valve unit is provided within the casing for preventing counterflow of fluids to be carried. A suction port communicates with a suction line into which the fluids to be carried flow, and a discharge port communicates with discharge line from which the fluids to be carried out are discharged. Reed valves are mounted on the suction port and on the discharge port of the check valve, respectively, in such a manner that the reed valves cover the suction port and the discharge port so as to be able to open and close. Each reed valve includes a first reed valve and second reed valve. The first reed valve is made of pliable material, and is formed to have a size capable of covering the entire respective suction port and discharge port. The second reed valve is smaller than first reed valve and is superposed on the first reed valve to engage the first reed valve such that the first reed valve can open and close, while enhancing sealability thereof.

Owner:NITTO KOHKI CO LTD

Valve guide and spring retainer assemblies

InactiveUS6910871B1Improve volumetric efficiencyEasy to insertPositive displacement pump componentsCheck valvesStress reliefEngineering

Valve guide and spring retainer assemblies are described for use in plunger pump housings that incorporate structural features for stress-relief. These pump housing structural features accommodate correspondingly-shaped valve guides and / or spring retainers that are internally fixed in place using one or more non-threaded spacers. Plunger pumps so constructed are relatively resistant to fatigue failure because of stress reductions, and they may incorporate a variety of valve styles, including top and lower stem-guided valves and crow-foot-guided valves, in easily-maintained configurations. Besides securing valve guides and / or spring retainers, non-threaded spacers may be shaped and dimensioned to aid in further reducing stress and to improve volumetric efficiency of the pumps in which they are used.

Owner:ALTIS INVESTMENTS LLC

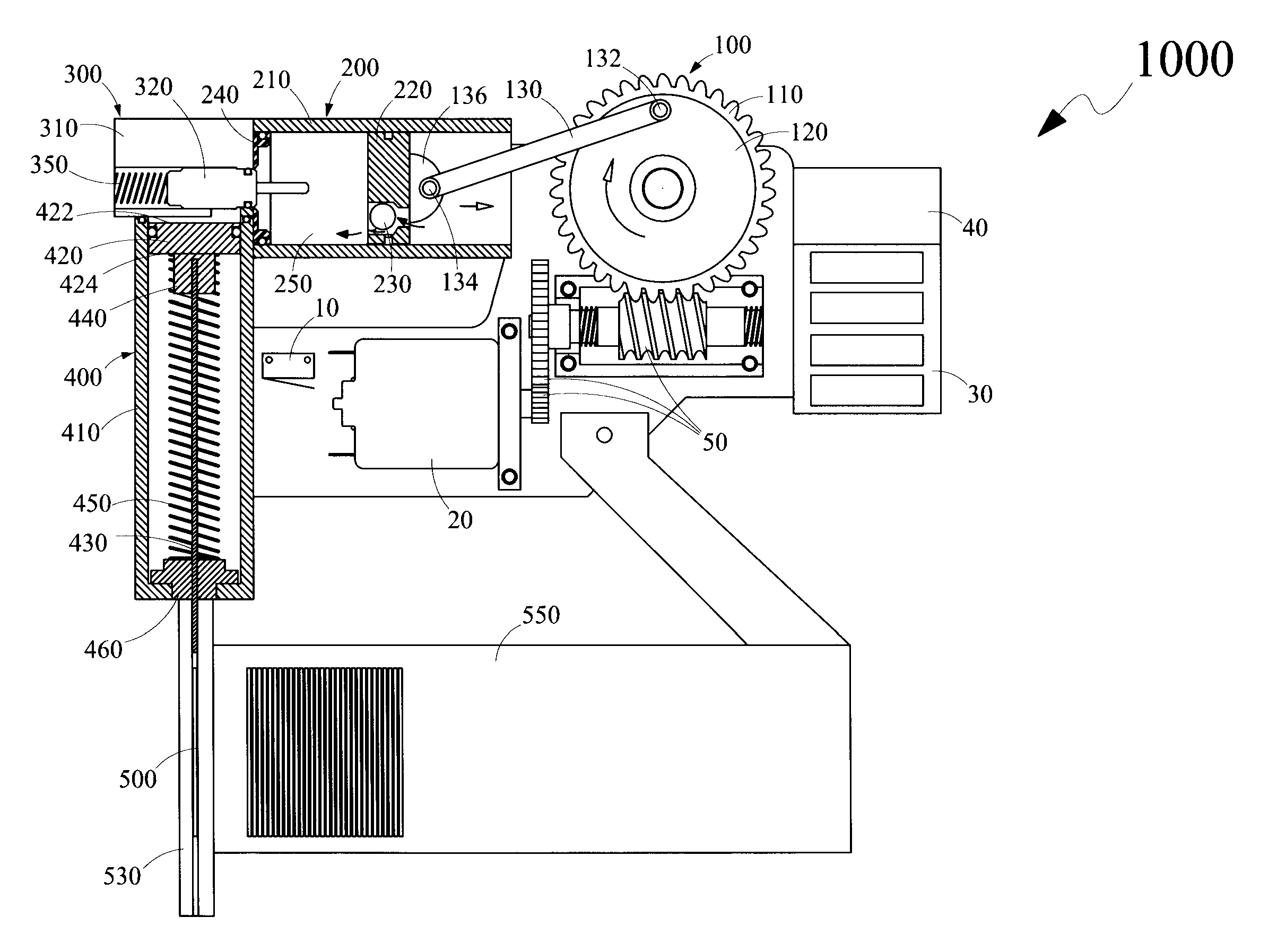

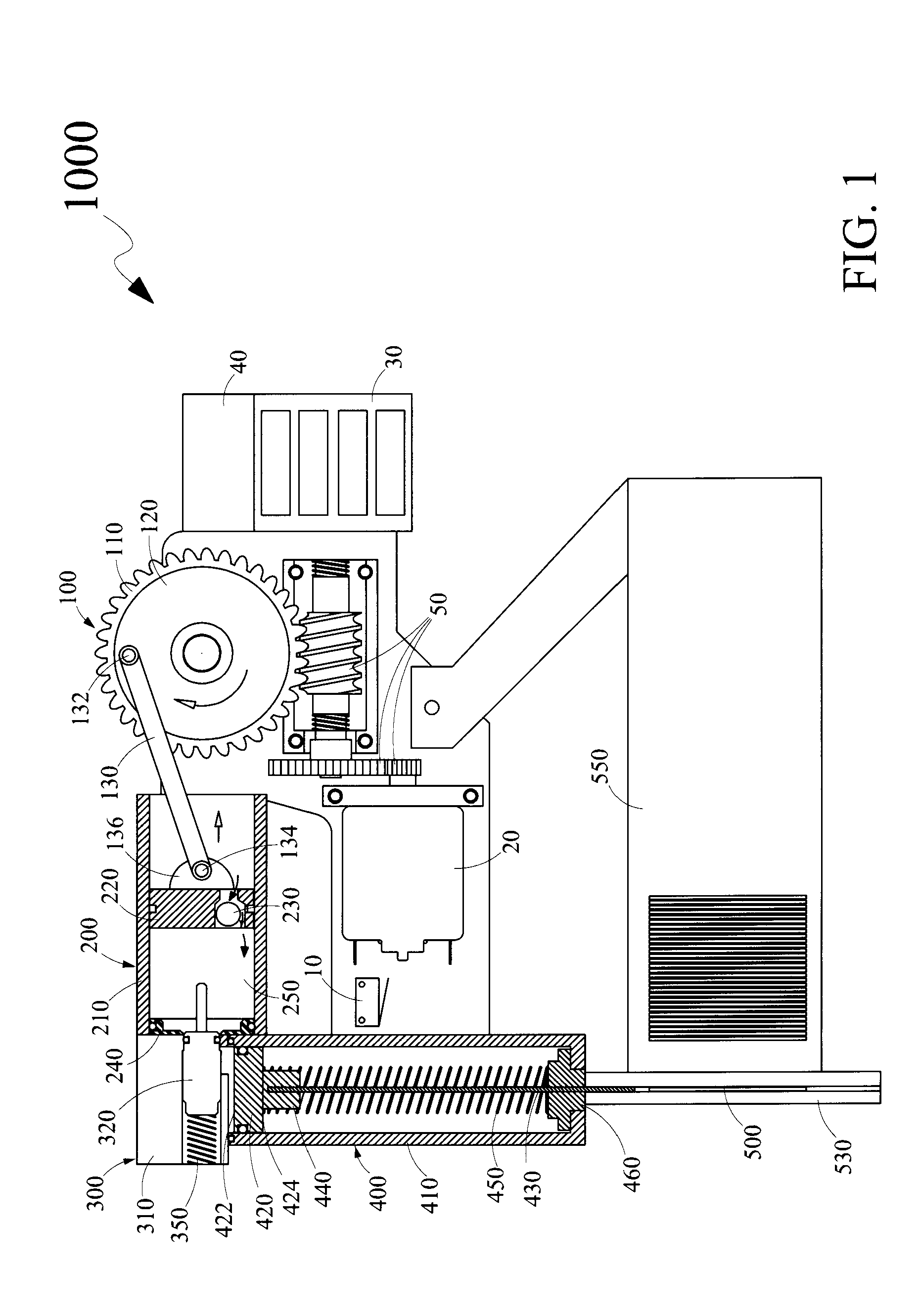

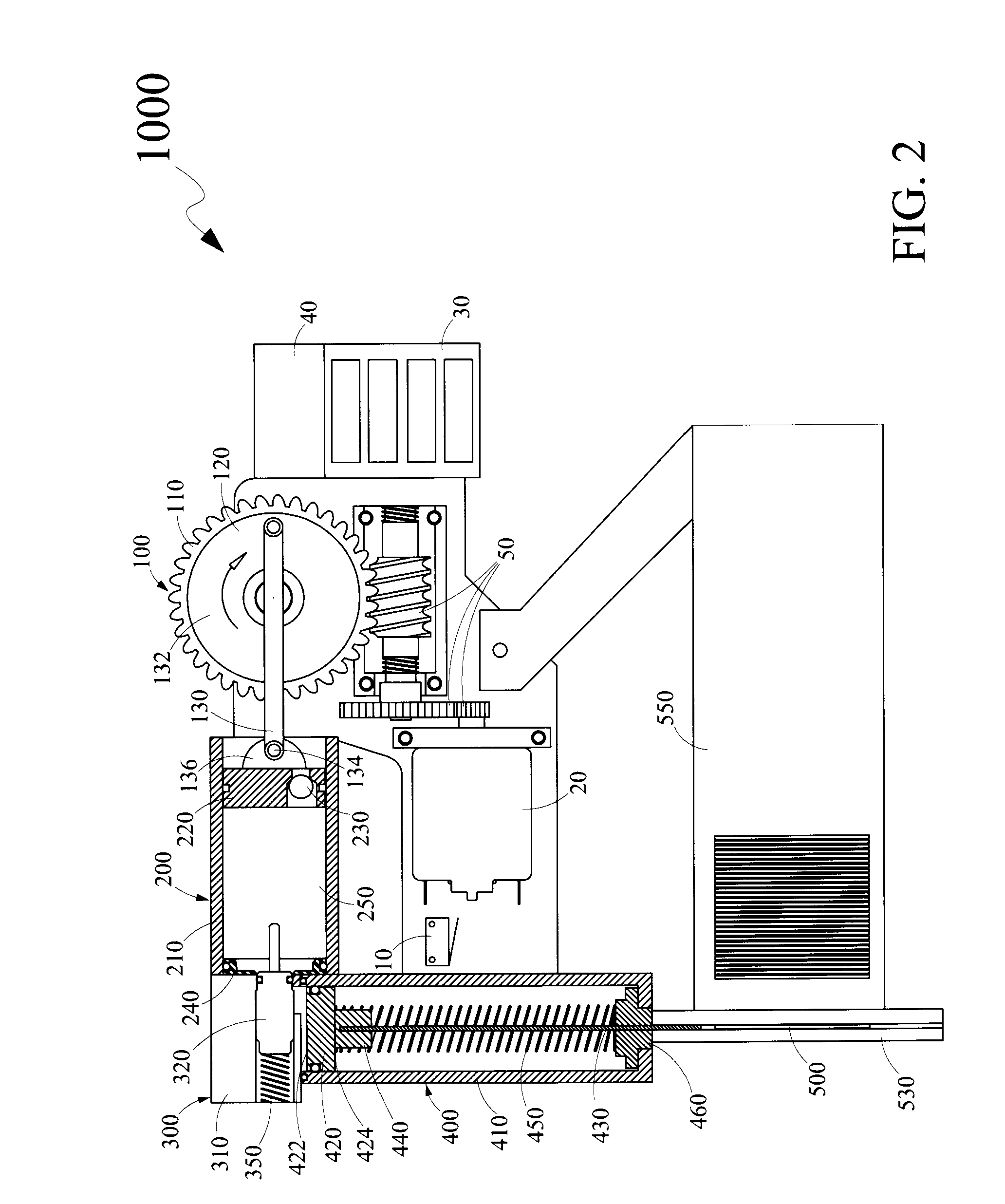

Fastener Driving Apparatus

Disclosed is a fastener driving apparatus for driving fasteners into a substrate. The fastener driving apparatus is a combination of a motor driven linear motion converter; a compression cylinder; an expansion cylinder and a valve arrangement. The linear motion converter converts a rotational motion of a motor to a linear motion of a compression piston within the compression cylinder causing a gas within the compression cylinder to be compressed. The compressed gas is communicated to the expansion cylinder through the valve arrangement wherein the compressed gas expands causing an anvil coupled to an expansion piston within the expansion cylinder to move axially. The axial movement of the anvil causes a fastener to be driven into the substrate. The fastener driving apparatus is an ergonomically designed portable hand held tool providing comfort to a user, meeting safety standards and performance efficiency requirements.

Owner:TRICORD SOLUTIONS

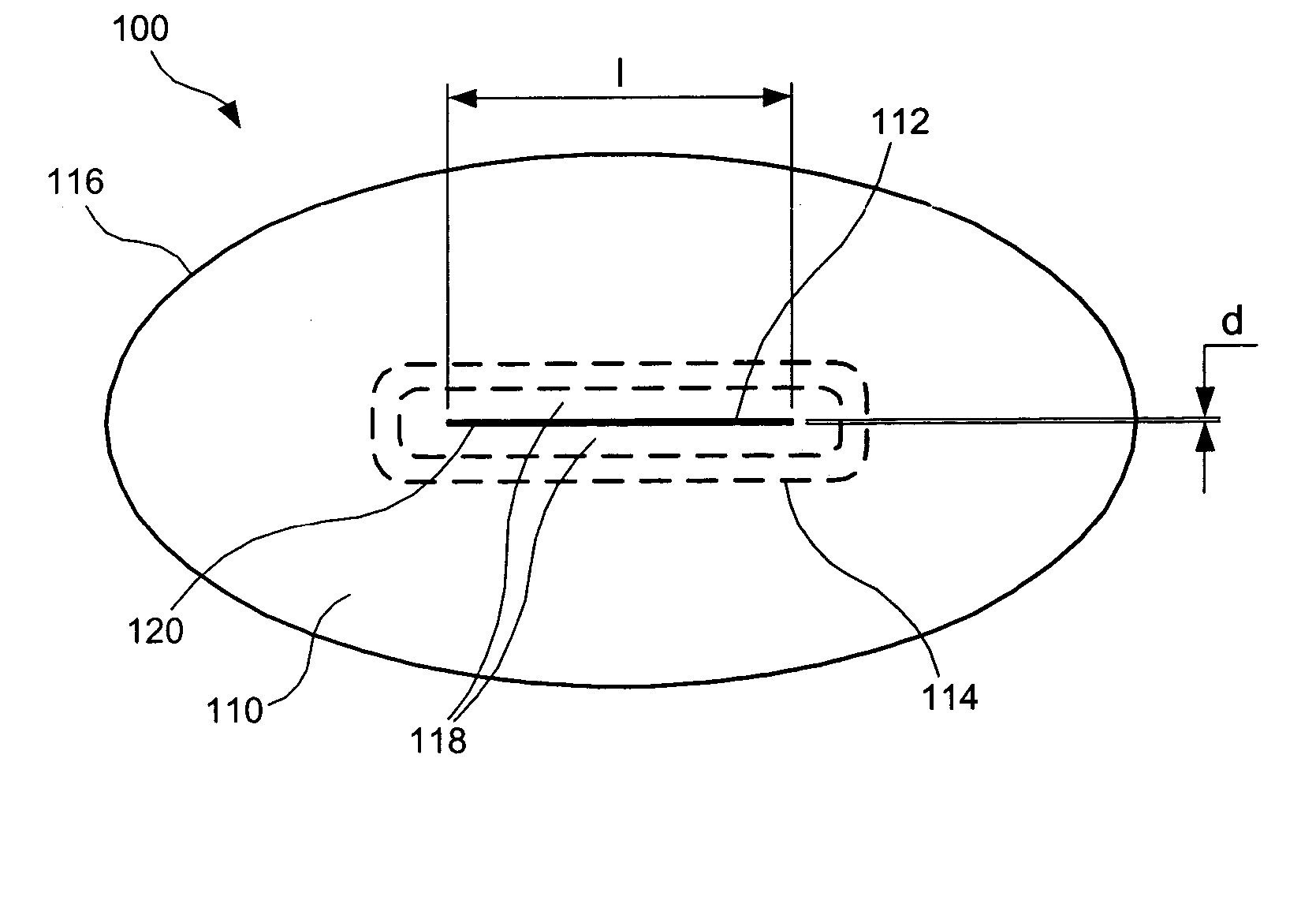

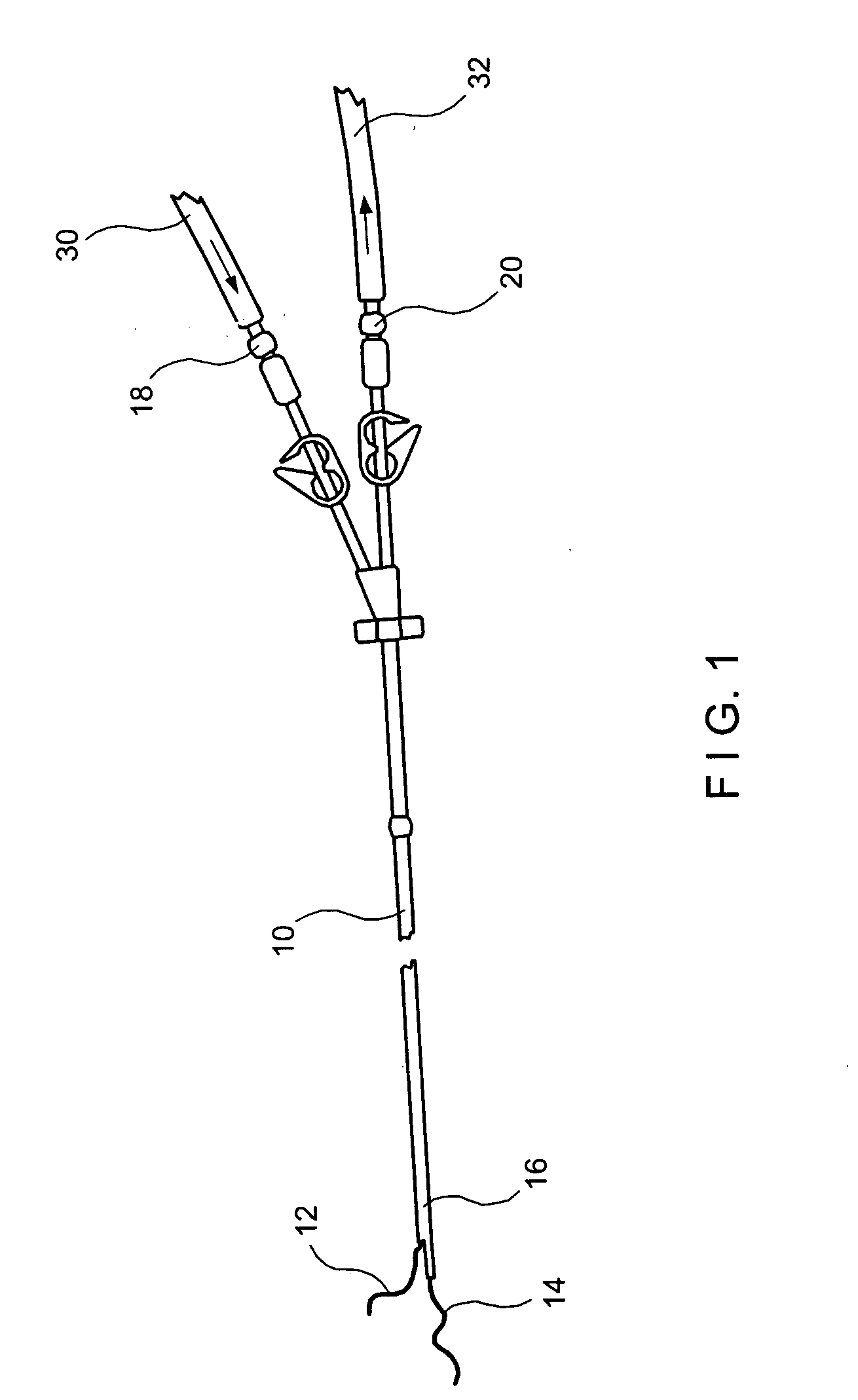

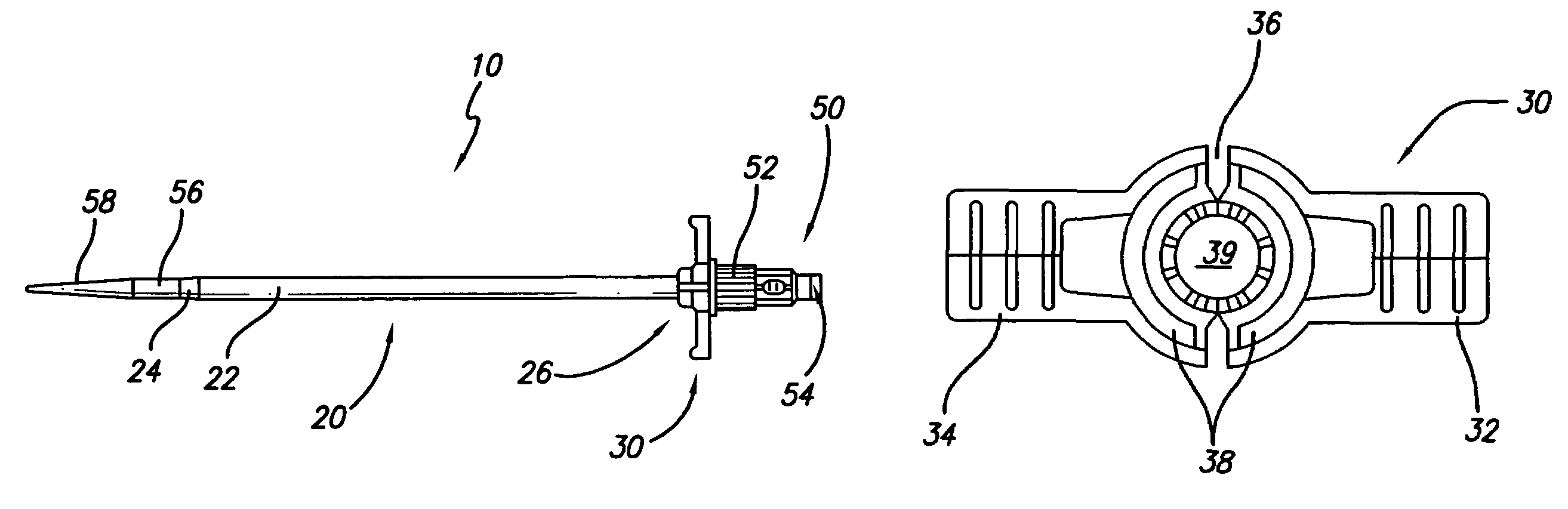

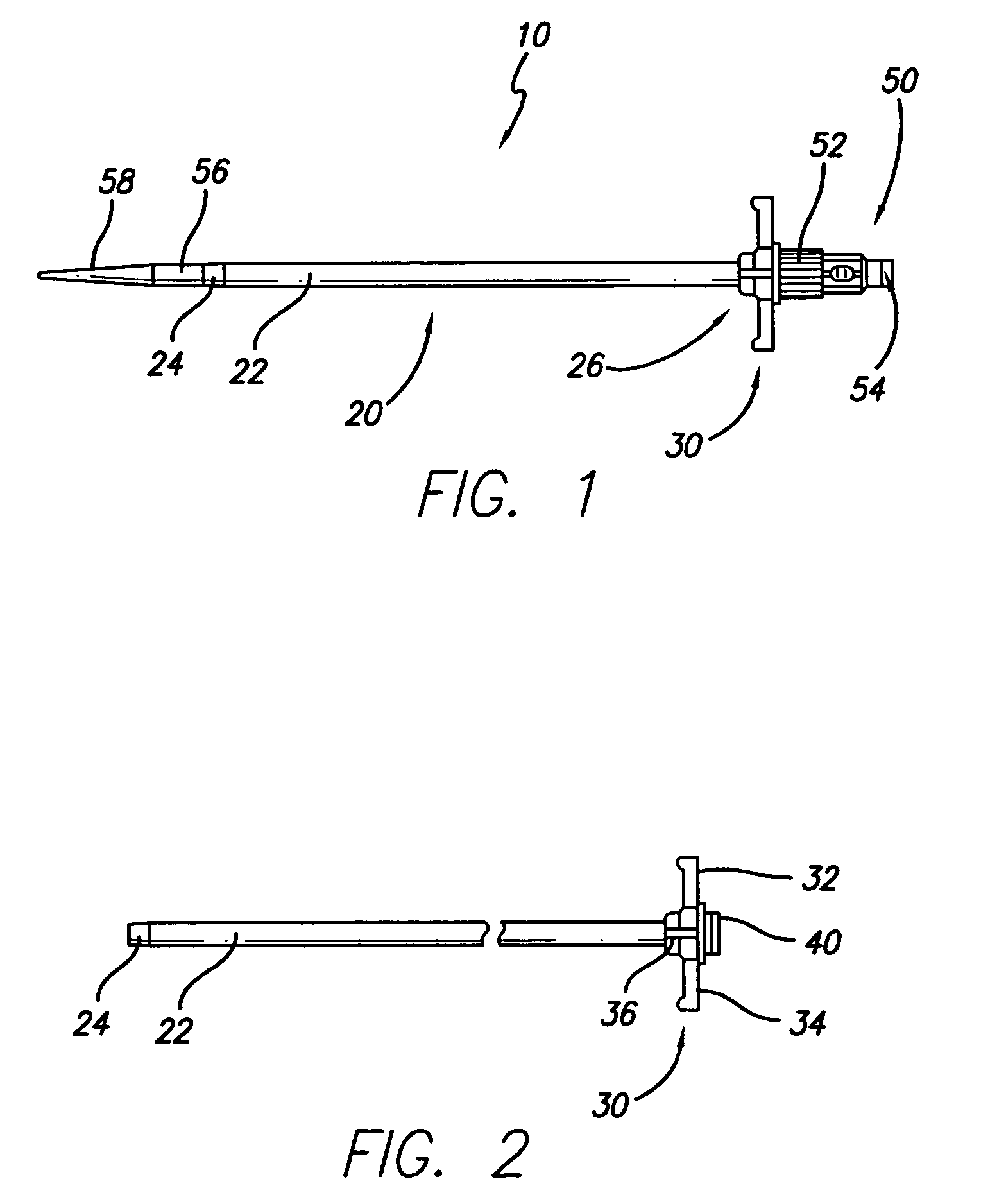

Valved sheath introducer for venous cannulation

ActiveUS7637893B2Easy to separatePromotes optimal resealingAmpoule syringesEar treatmentVeinVenous cannulation

A valved sheath introducer for venous cannulation, including a valve, sheath, handle and cap. The valve is configured to permit safe introduction and removal of medical instruments through the sheath introducer. The valve may have one or more anchoring members and a thickened central portion through which a slit is formed. The central portion may have one or more concave surfaces and the slit can be angled with respect to the top surface of the valve. The cap is attached to the handle, compressing a portion of the valve therebetween.

Owner:CR BARD INC

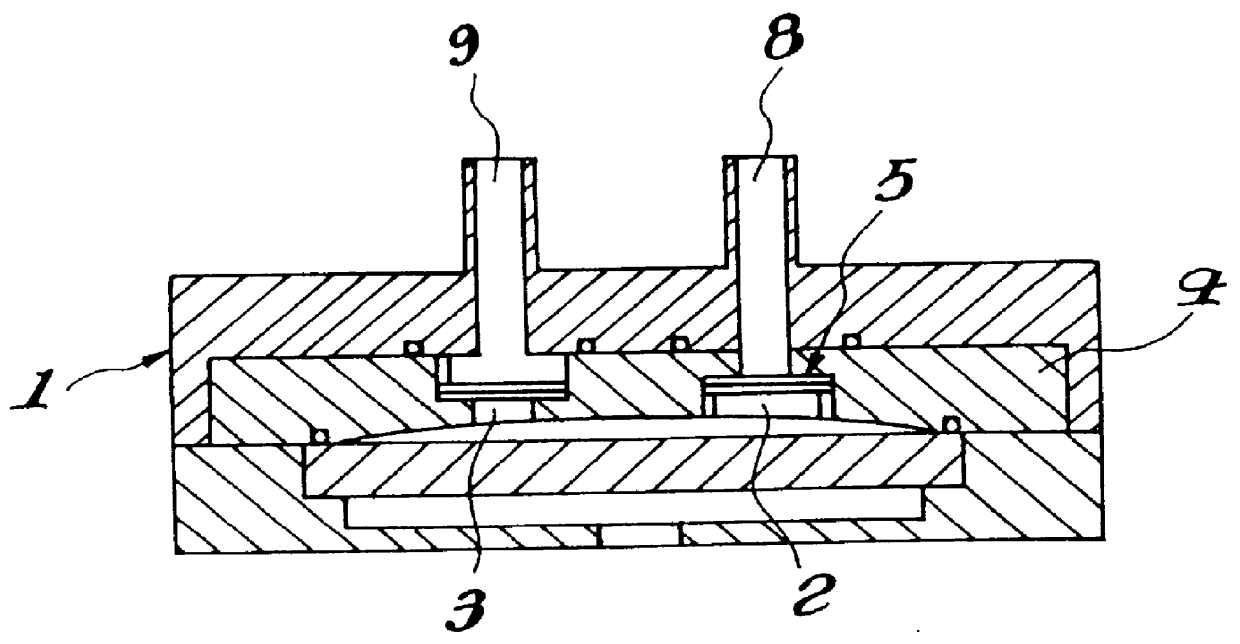

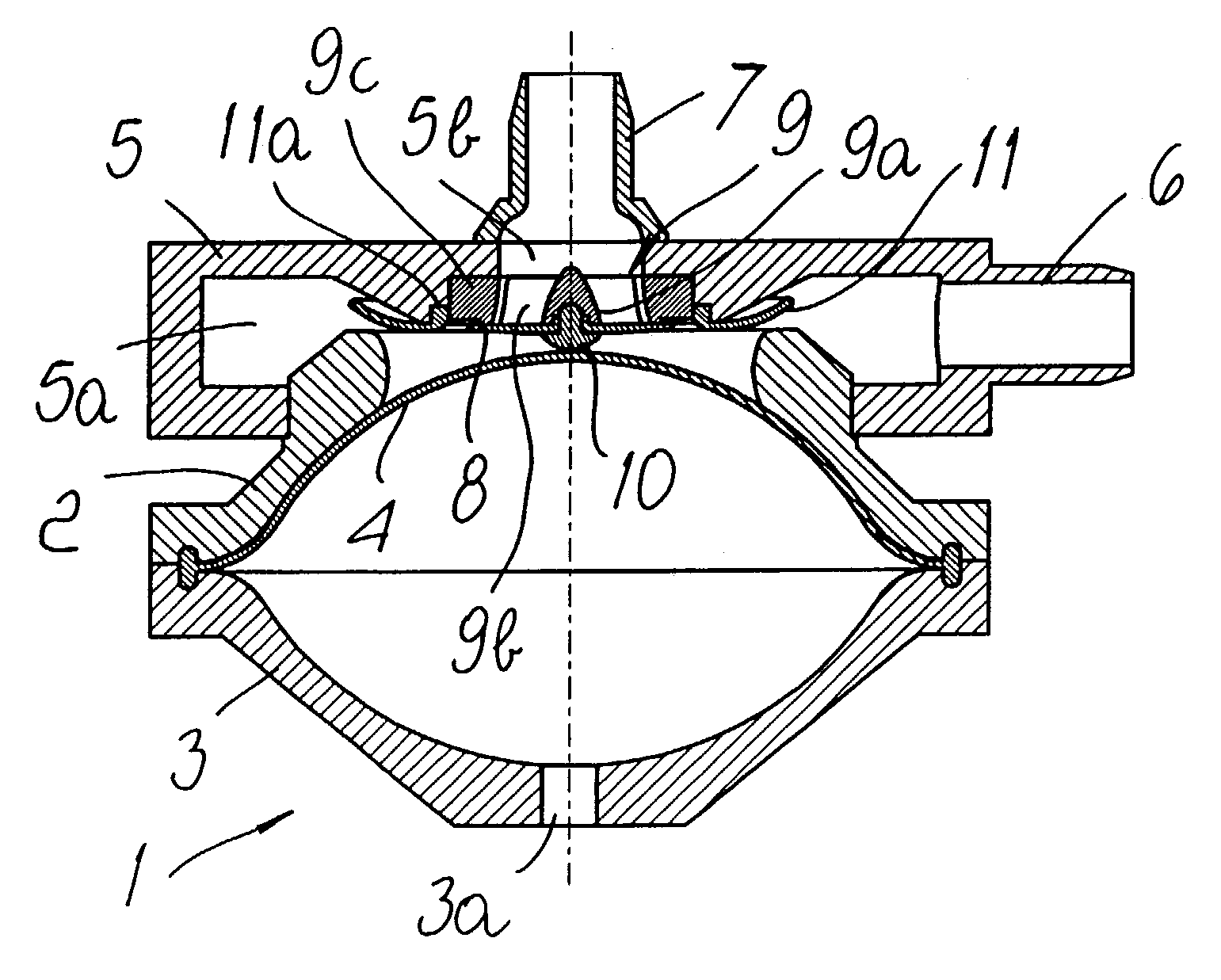

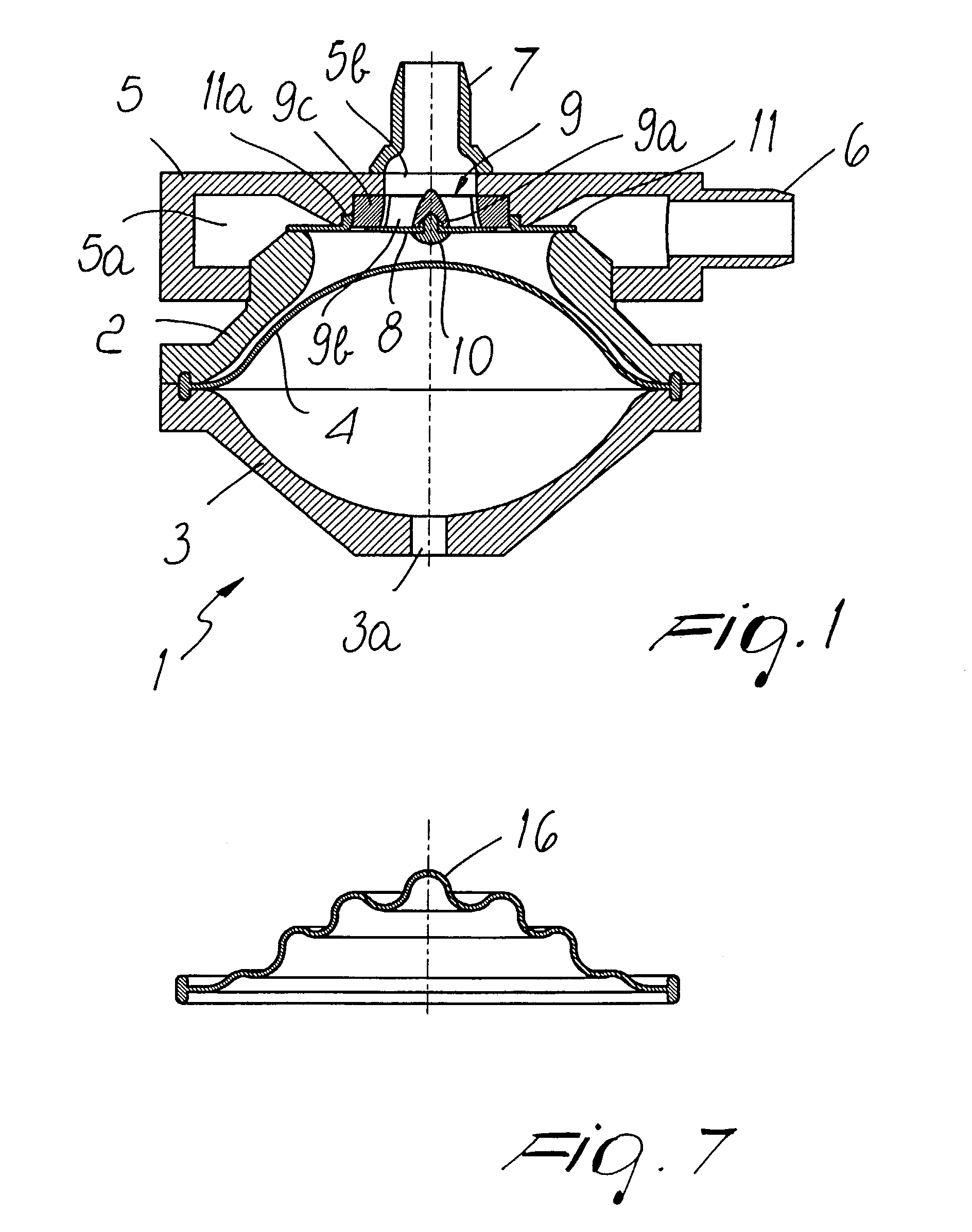

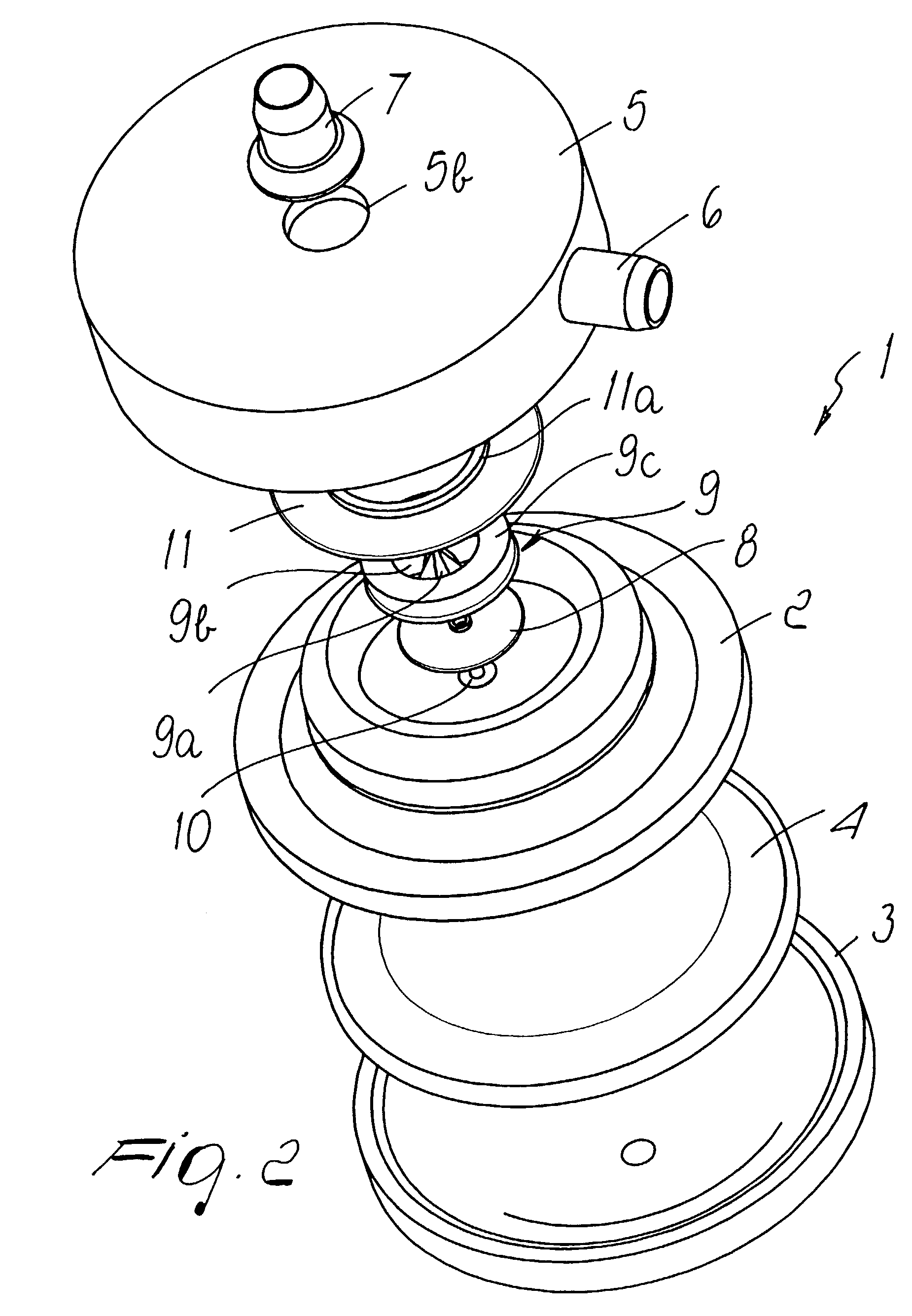

Blood pumping unit, with a coplanar disk inlet valve and an annular outlet valve

InactiveUS7029245B2Maximum of constructive simplicityLow costFlexible member pumpsDialysis systemsWorking fluidInlet valve

A unit for pumping fluid, particularly blood, is provided with an enclosure that has two half-shells and an elastic membrane fixed perimetrically to the enclosure in order to divide its space into two parts. One of the half-shells is provided with valves that are located at the opening of two connecting ducts for the intake and delivery of the fluid, and the other half-shell is connected to a line of working fluid that is alternately pressurized and depressurized. The first valve is a disk-shaped sheet made of elastic material. The first valve is in a central position with a support that is fixed to the opening of the first duct for connection to the outside and is suitable to rest at its peripheral region on the support. A second valve is a sheet of elastic material located at the peripheral region of the disk at the opening of the second duct for connection to the outside which lies at the peripheral region of the opening of the first duct.

Owner:SORIN GRP ITAL SRL

Check valve

InactiveUS20110186151A1Maximum vacuum boostIncrease airflowCheck valvesEqualizing valvesEngineeringInternal combustion engine

A check valve which is positioned in the vacuum air line of an internal combustion engine. The check valve includes a single-piece valve body having an outlet port and two or more inlet ports, with one outlet port located substantially in line with the inlet port and connected by a venturi tube. The second inlet port is separated from the main air flow line by the valve stem and a diaphragm which allows communication there between and prevents back pressure. The second inlet port communicates with the outlet port through the valve stem and a second venturi tube which provides a vacuum boost to a device, usually vehicle brakes, connected to the inlet. The use of seal diaphragms having a non-constant radius allows for faster recovery time for replenishment than prior art devices.

Owner:TECHNIPLAS US LLC

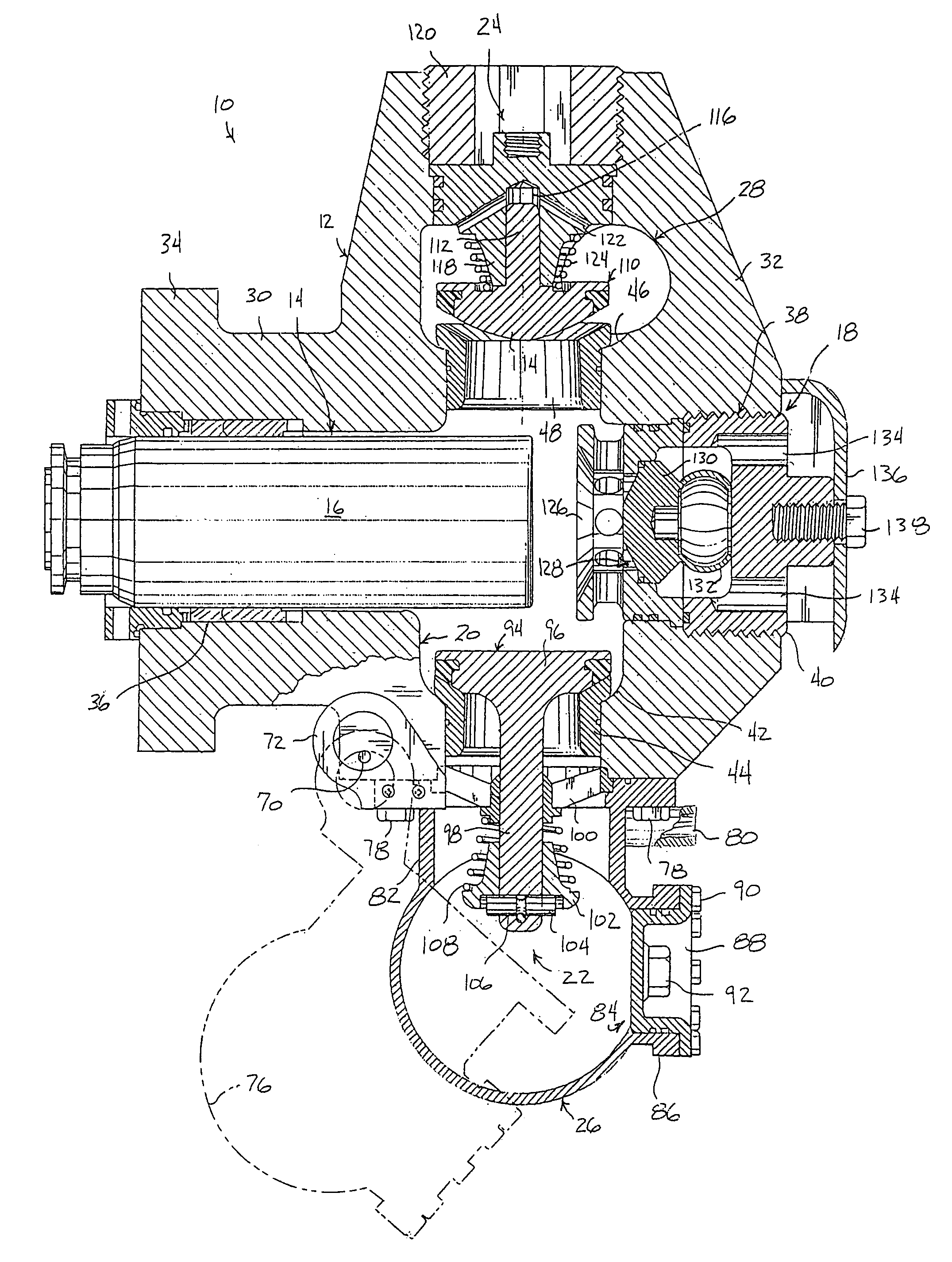

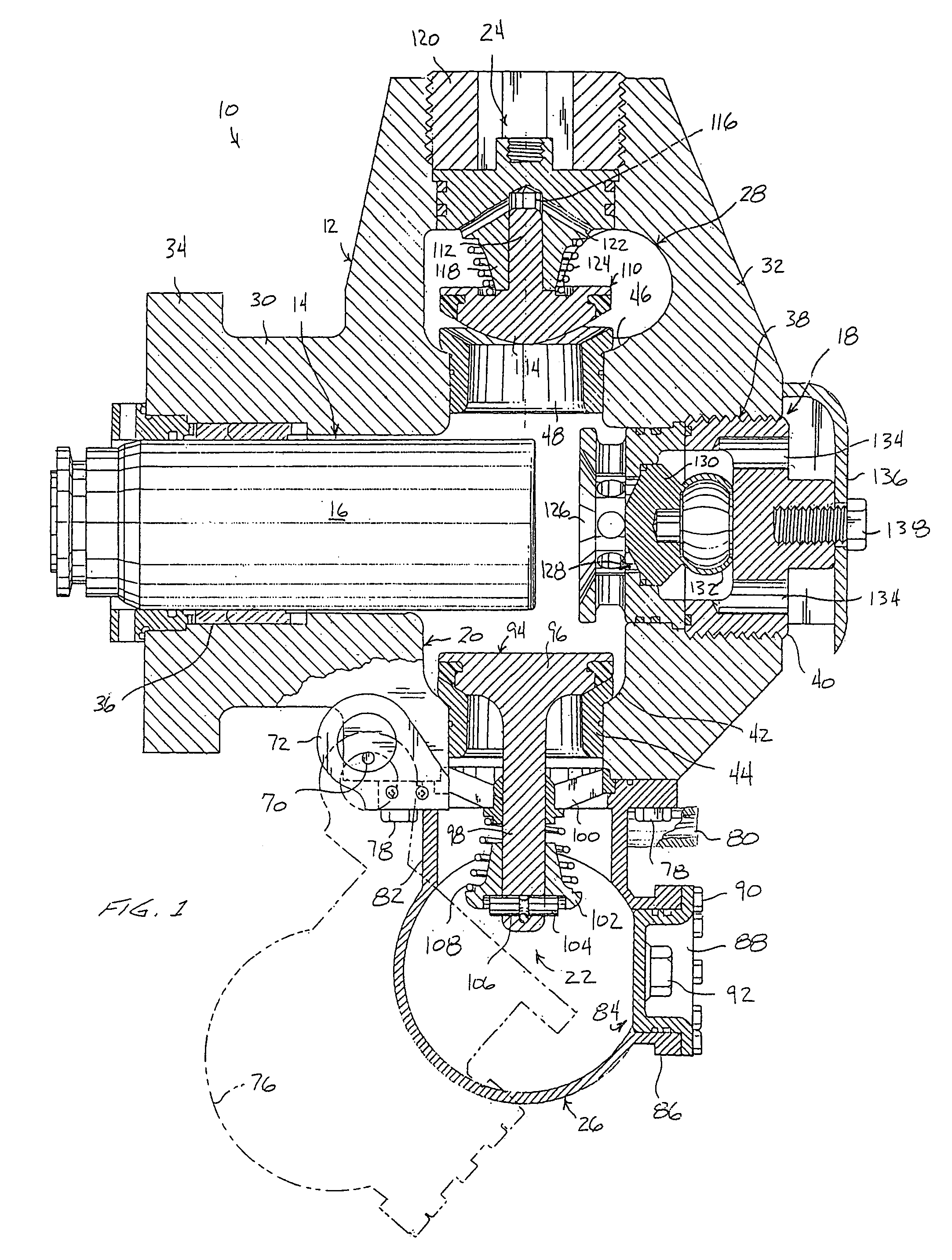

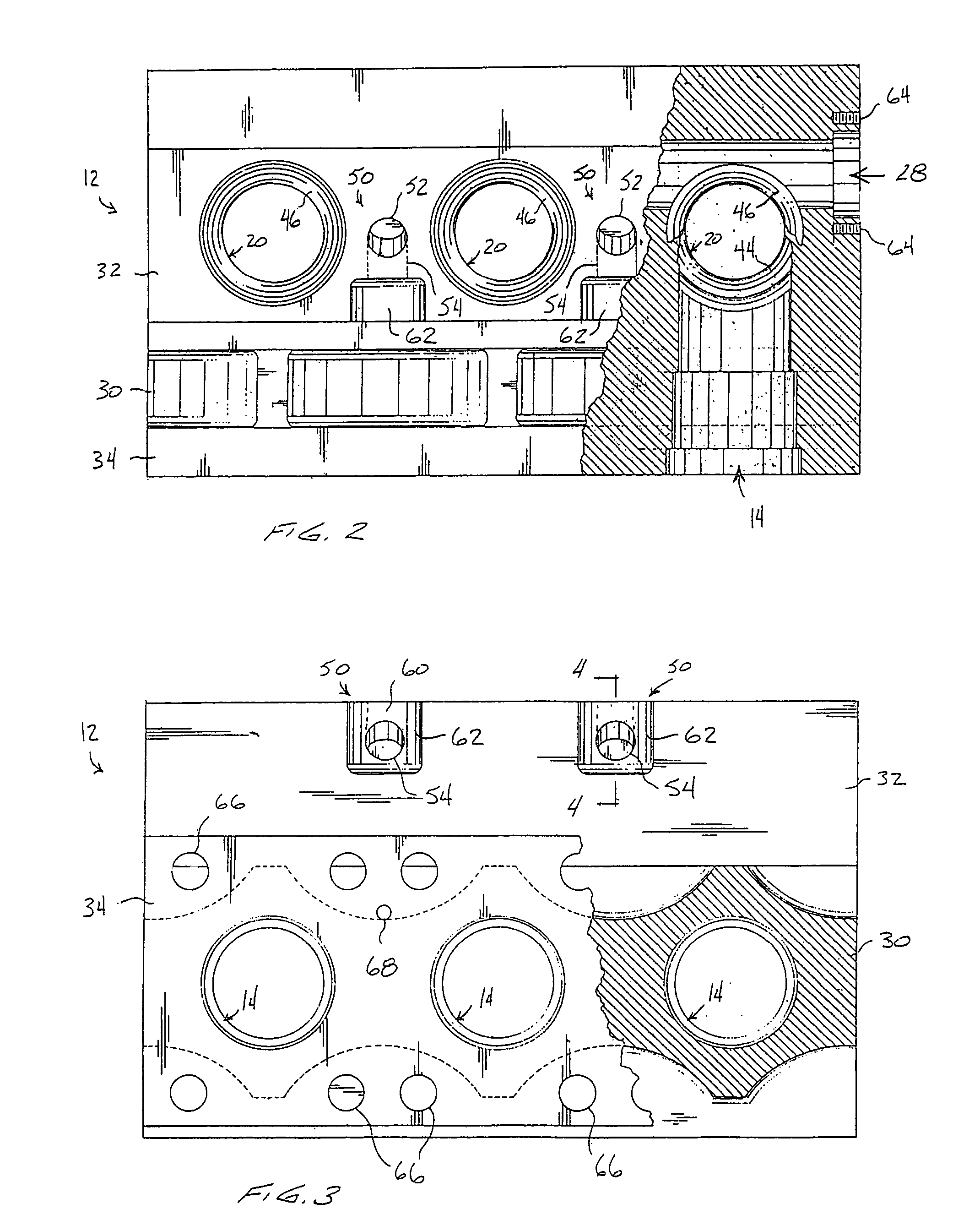

Fluid end

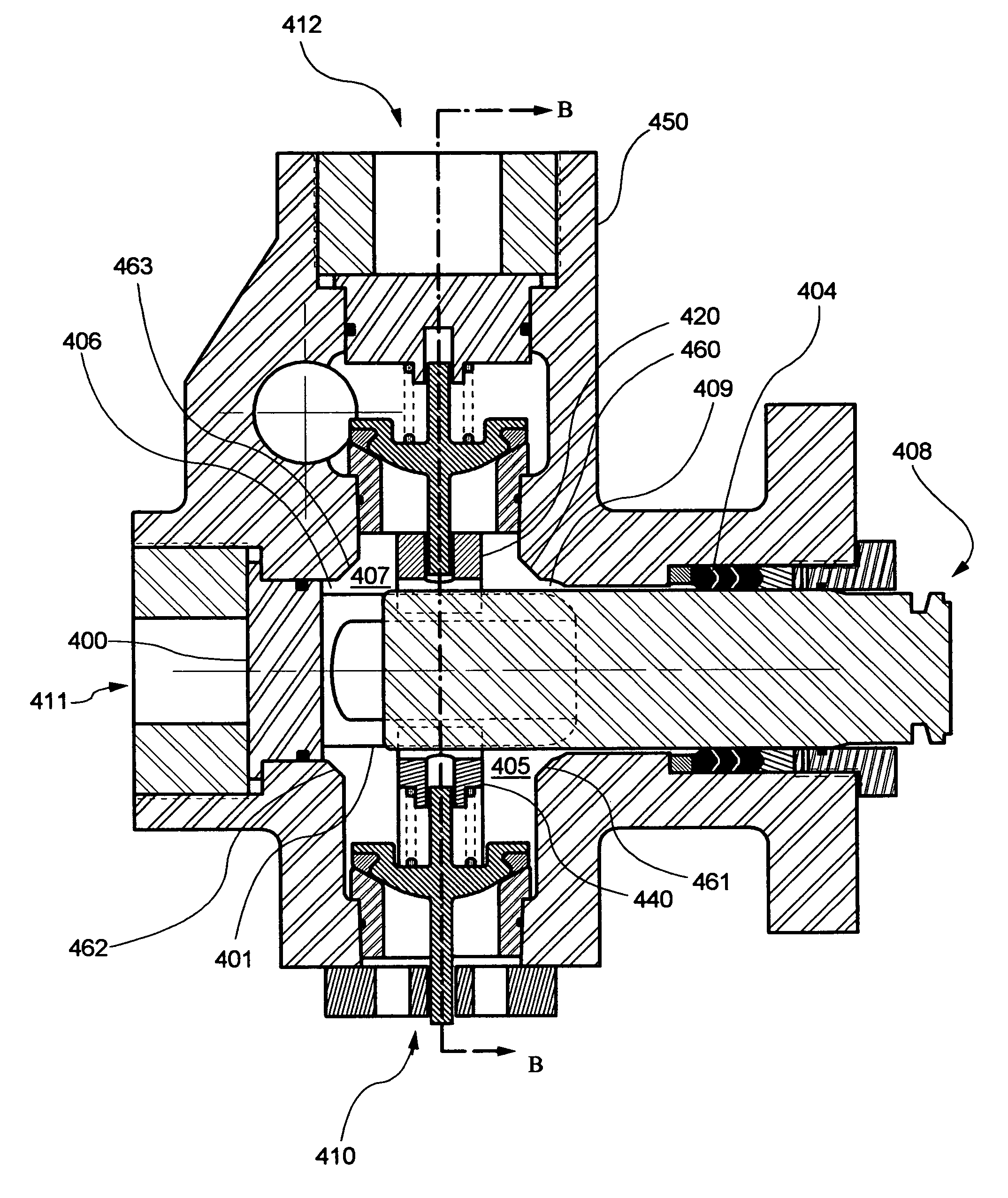

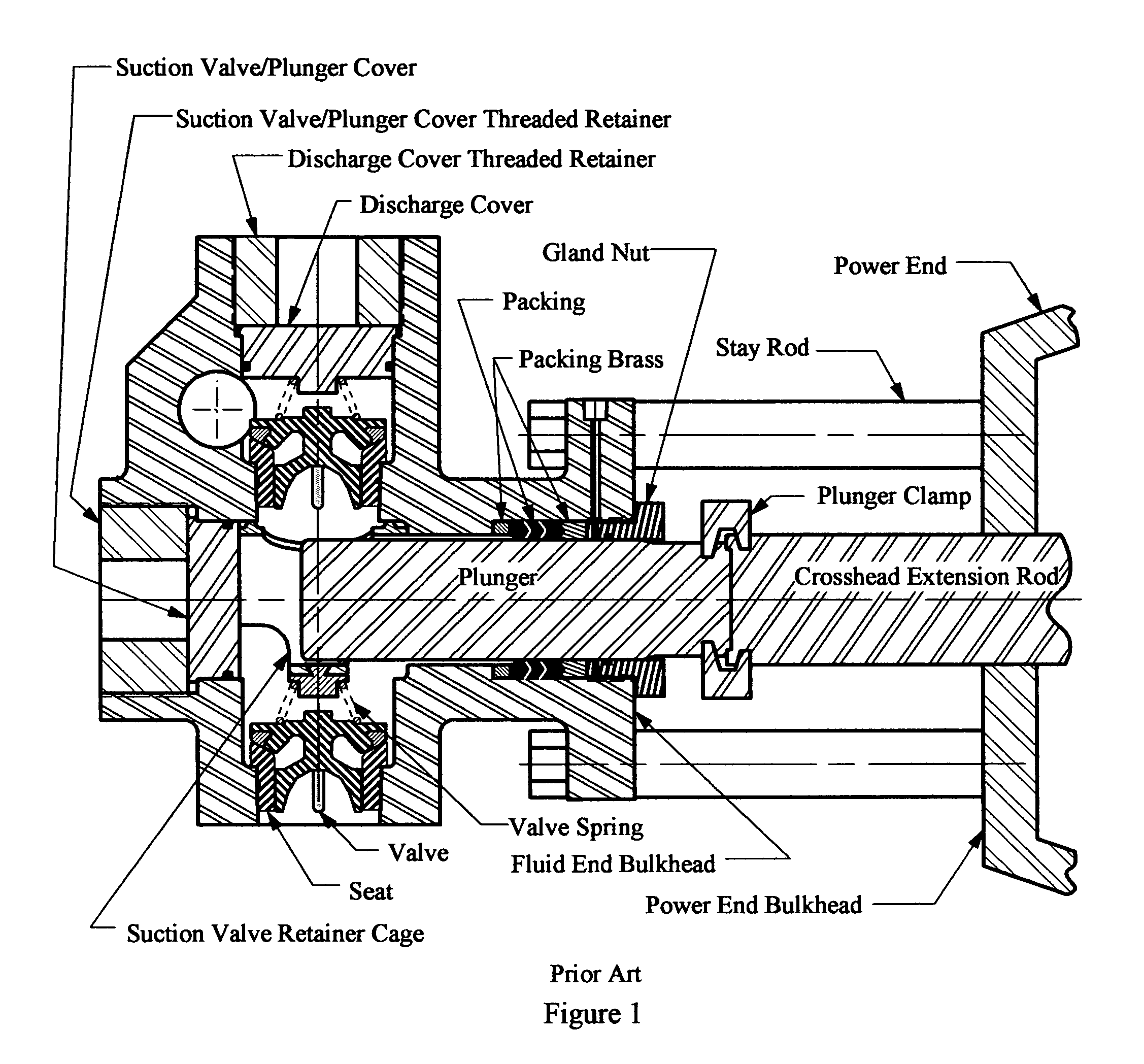

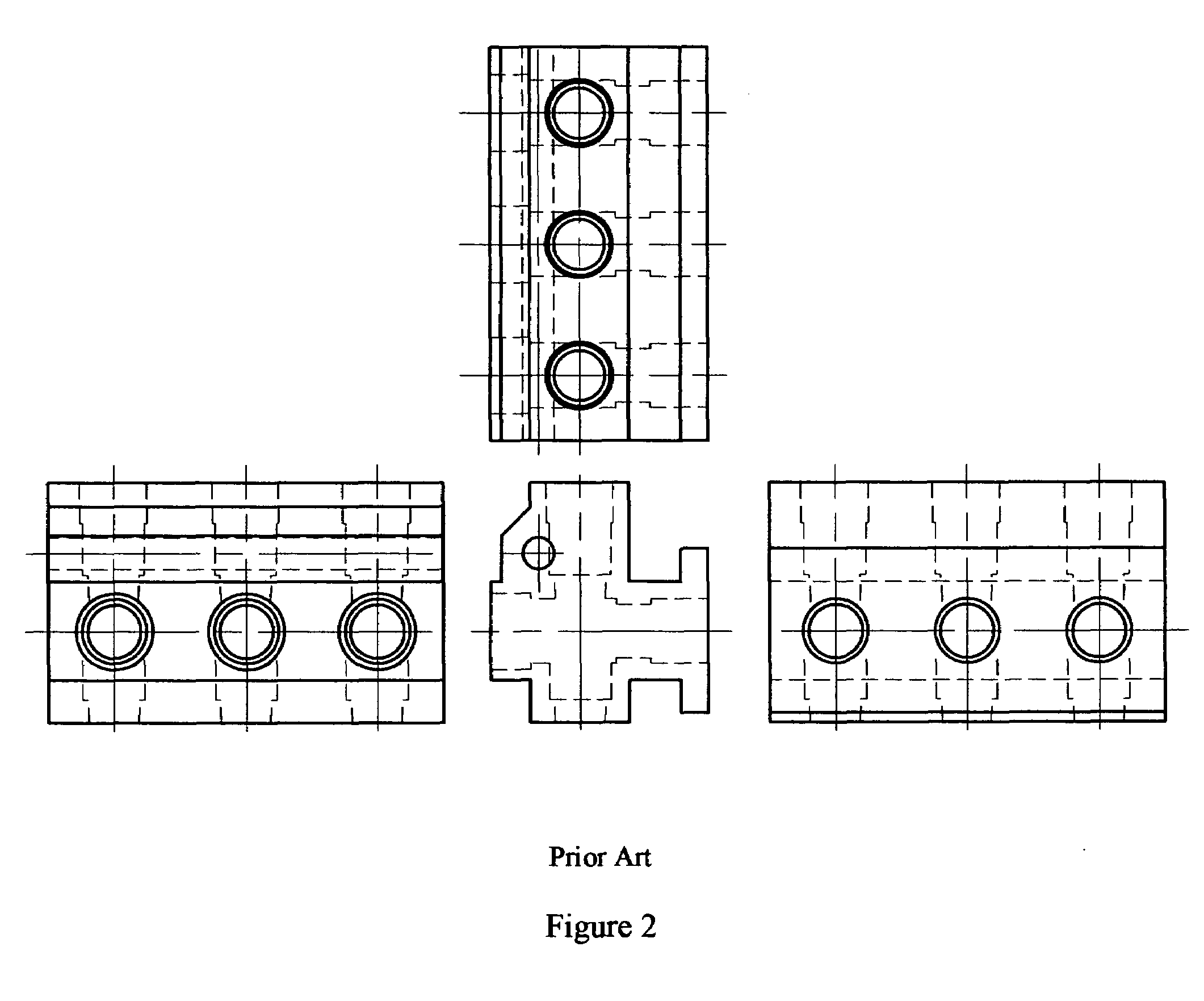

ActiveUS7335002B2High strengthIncreased durabilityPositive displacement pump componentsServomotor componentsEngineeringHigh pressure

A fluid end for a high-pressure pump including a unitary body with a plurality of horizontal passages each for receiving a reciprocating plunger at one of its ends and a pressure relief valve at the other of its ends. The body is provided with a corresponding number of vertical passages each of which intersect one of the horizontal passages and contains a suction valve at its bottom and a discharge valve at its top. A suction manifold is hingedly attached to the bottom of body to provide a flow of fluid into the body via the suction valves. A discharge passage intersects the vertical passages and receives fluid pressurized by the plungers via discharge valves and ports such from the fluid end.

Owner:GD ENERGY PROD LLC

Device for automatically filling fracking pump fuel tanks

InactiveUS20170009905A1Avoid flowOperating means/releasing devices for valvesFluid removalFuel tankAutomotive engineering

A system for automatically filling a fuel tank coupled to a fracking pump is described. The filling system includes a device that automatically opens and closes fuel flow to the fuel tank based on a level of fuel in the fuel tank. The device may close fuel flow to the fuel tank when a fill capacity of the fuel tank is reached. The device may open fuel flow to the fuel tank when a fuel level in the fuel tank drops below a selected level (e.g., below 1 / 4 of the fill capacity of the fuel tank). The device may be used to substantially continuously supply fuel to the fuel tank.

Owner:ARNOLD OIL CO OF AUSTIN LP

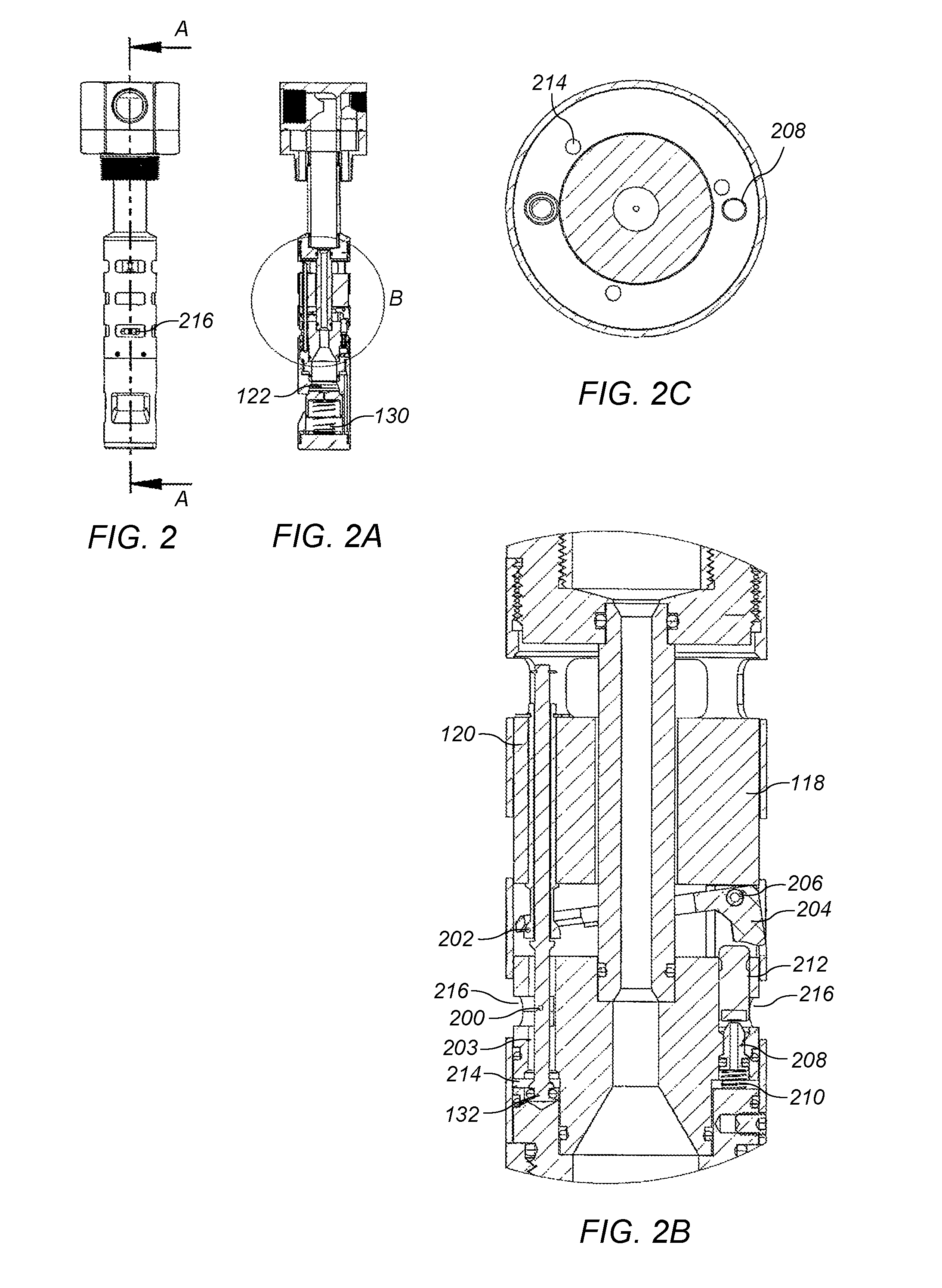

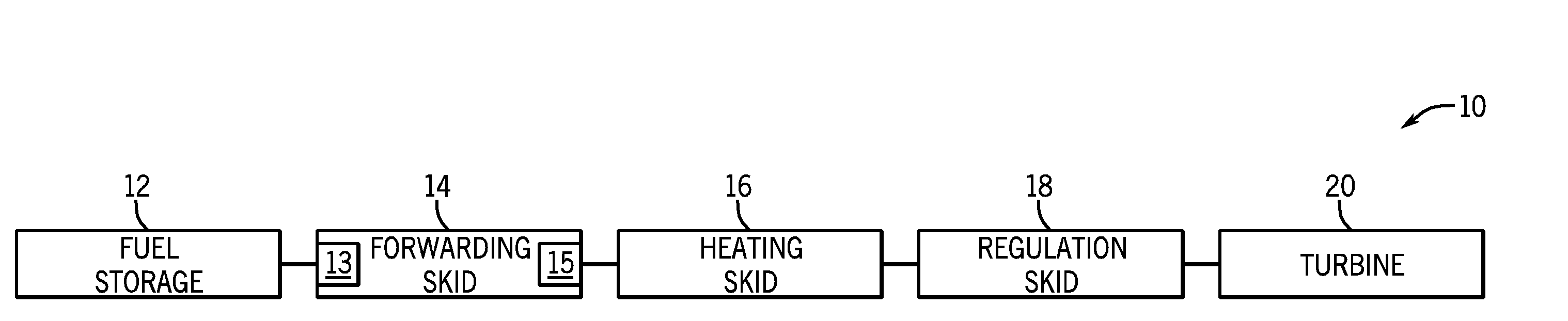

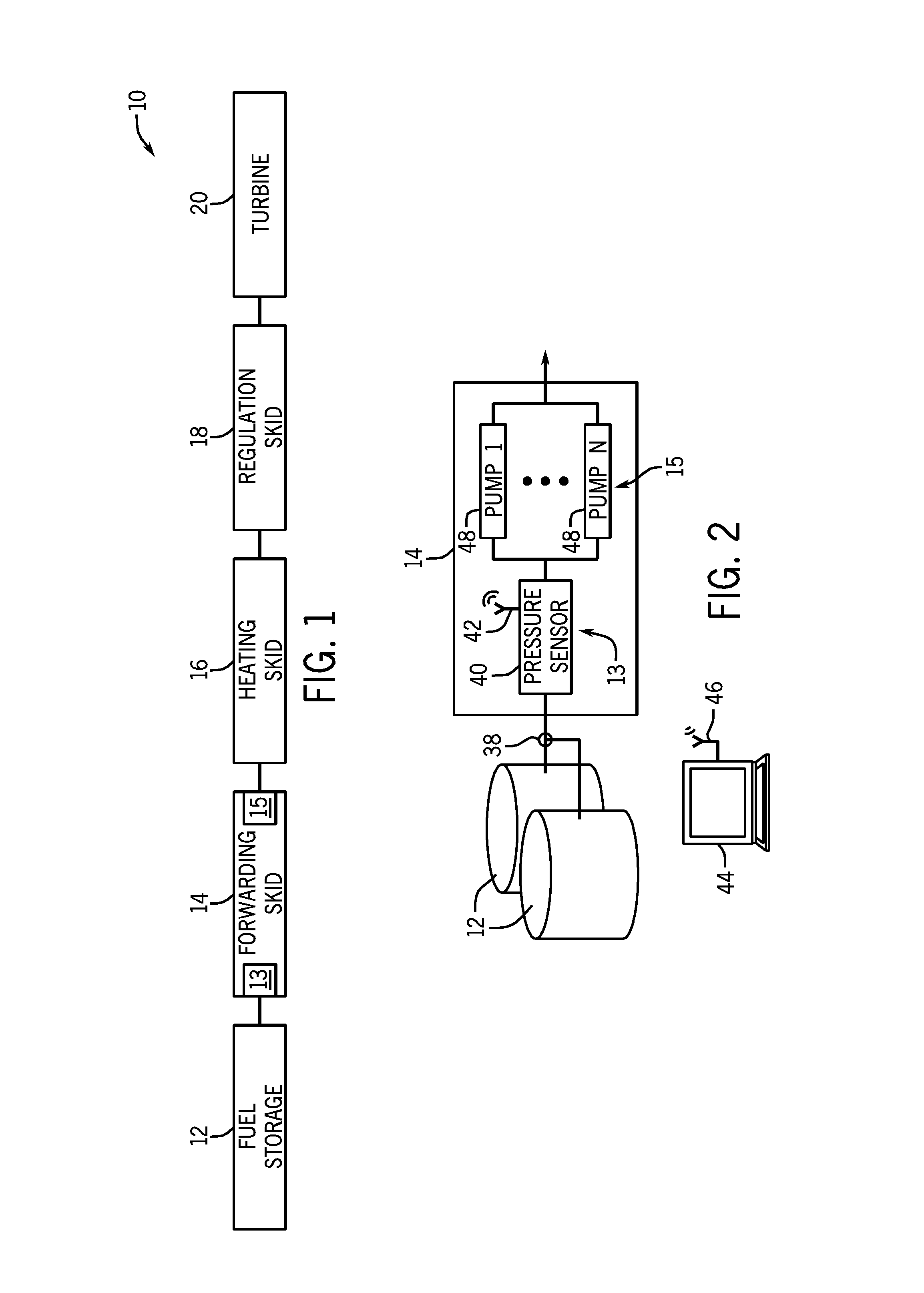

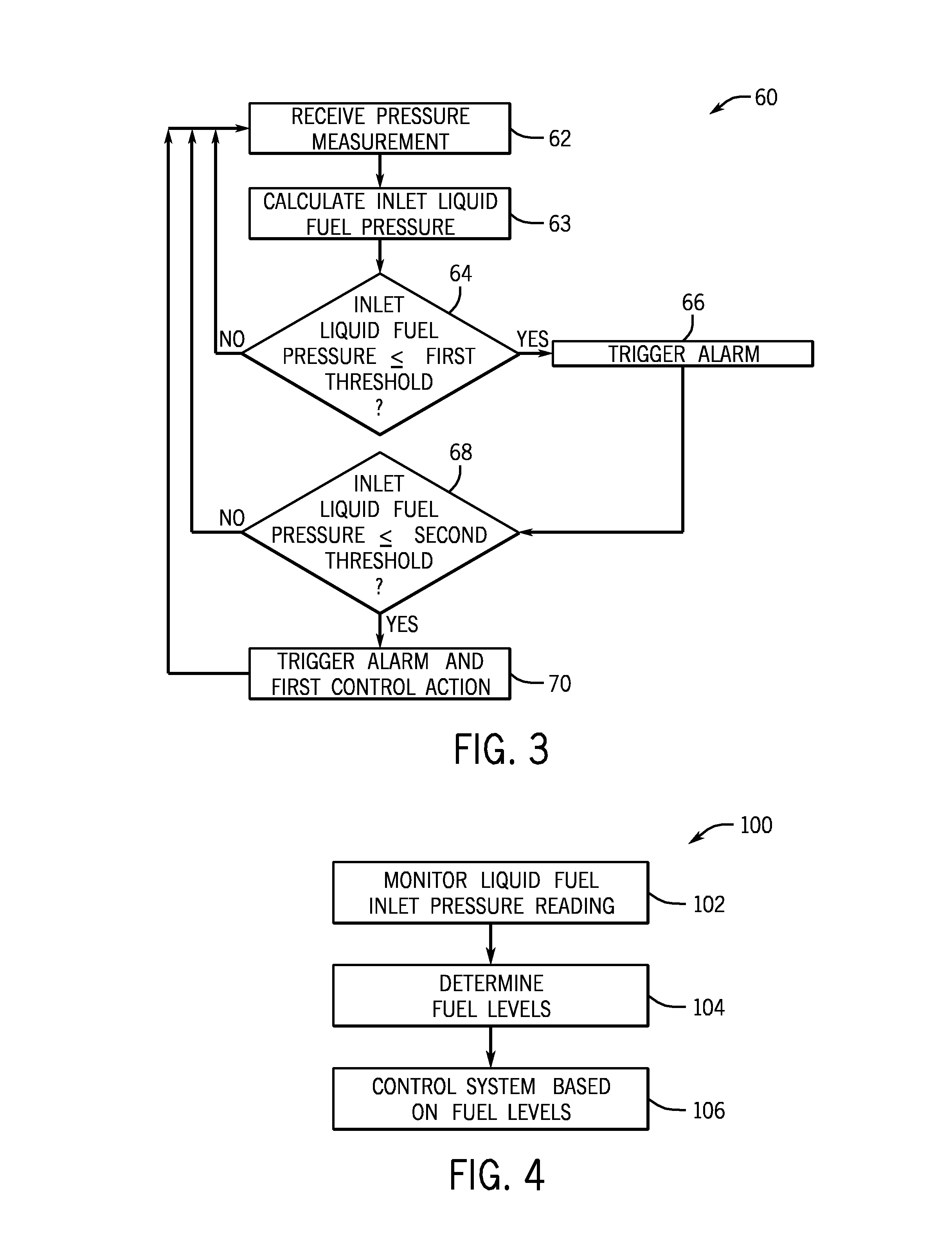

System and method for monitoring fuel at forwarding skid for gas turbine engine

InactiveUS20130068307A1Turbine/propulsion fuel deliveryDomestic plumbingMonitoring systemEngineering

A system includes a forwarding skid configured to forward a liquid supply from a liquid storage vessel toward a downstream component. The forwarding skid includes a pumping system configured to receive a gravity feed of the liquid supply from the liquid storage vessel, and the pumping system is configured to pump the liquid fuel supply toward the downstream component. The forwarding skid also includes a monitoring system configured to obtain at least one sensed parameter of the gravity feed of the liquid supply received at the forwarding skid upstream from the pumping system. The at least one sensed parameter is indicative of a supply level remaining at the liquid storage vessel.

Owner:GENERAL ELECTRIC CO

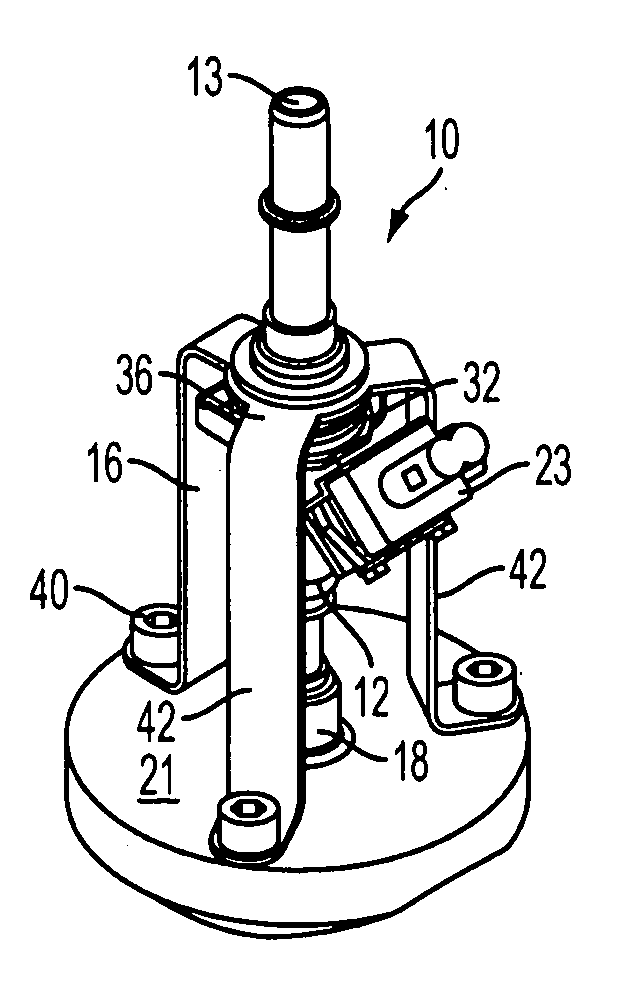

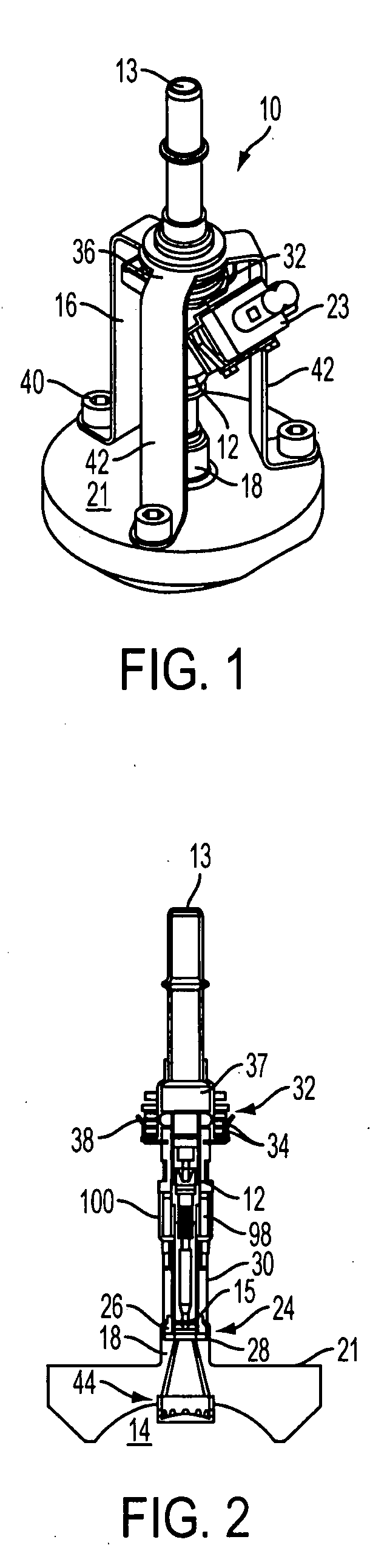

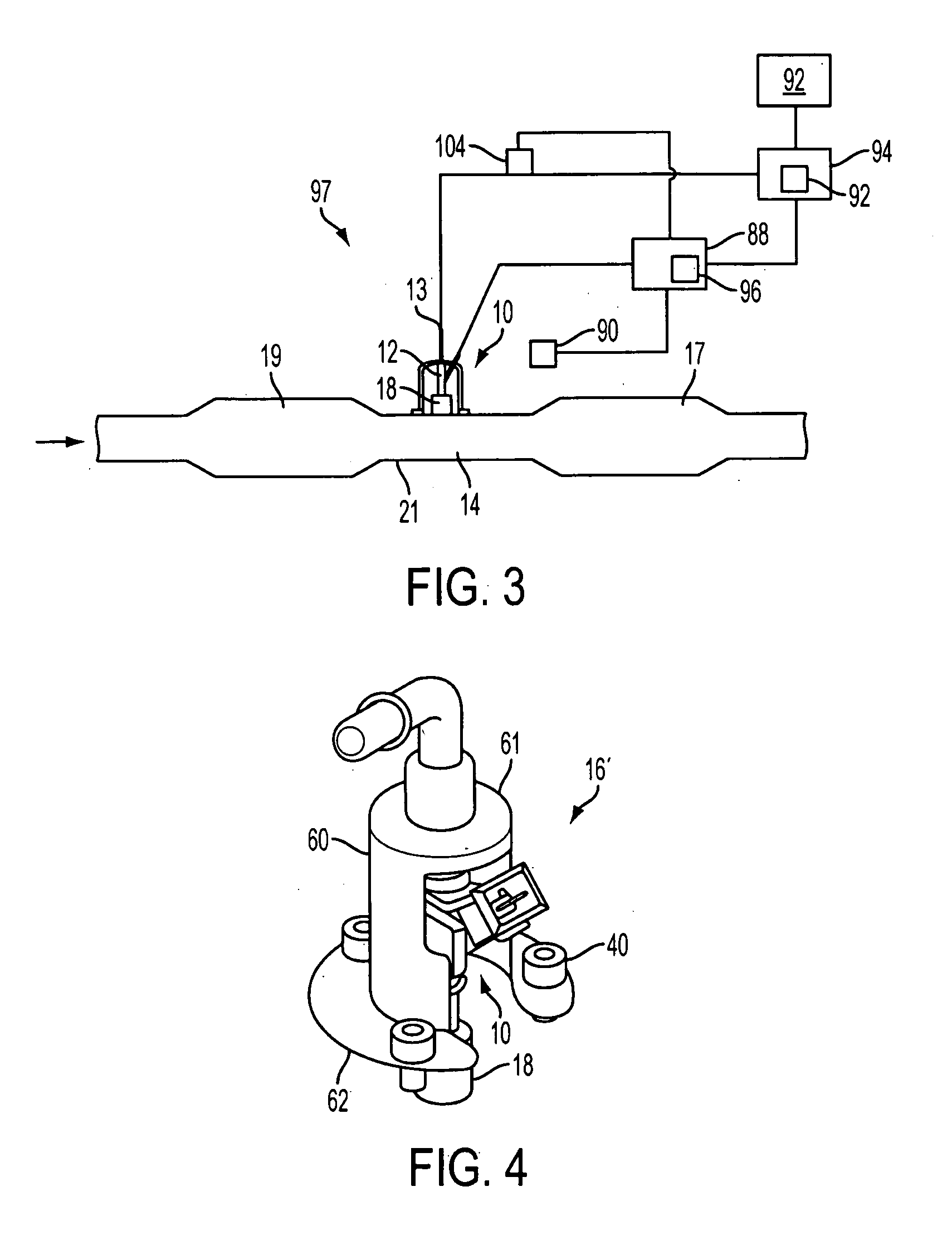

Reductant delivery unit for selective catalytic reduction

ActiveUS20080236147A1Avoid boilingInternal combustion piston enginesExhaust apparatusAfter treatmentExhaust fumes

Owner:CONTINENTAL AUTOMOTIVE SYST INC

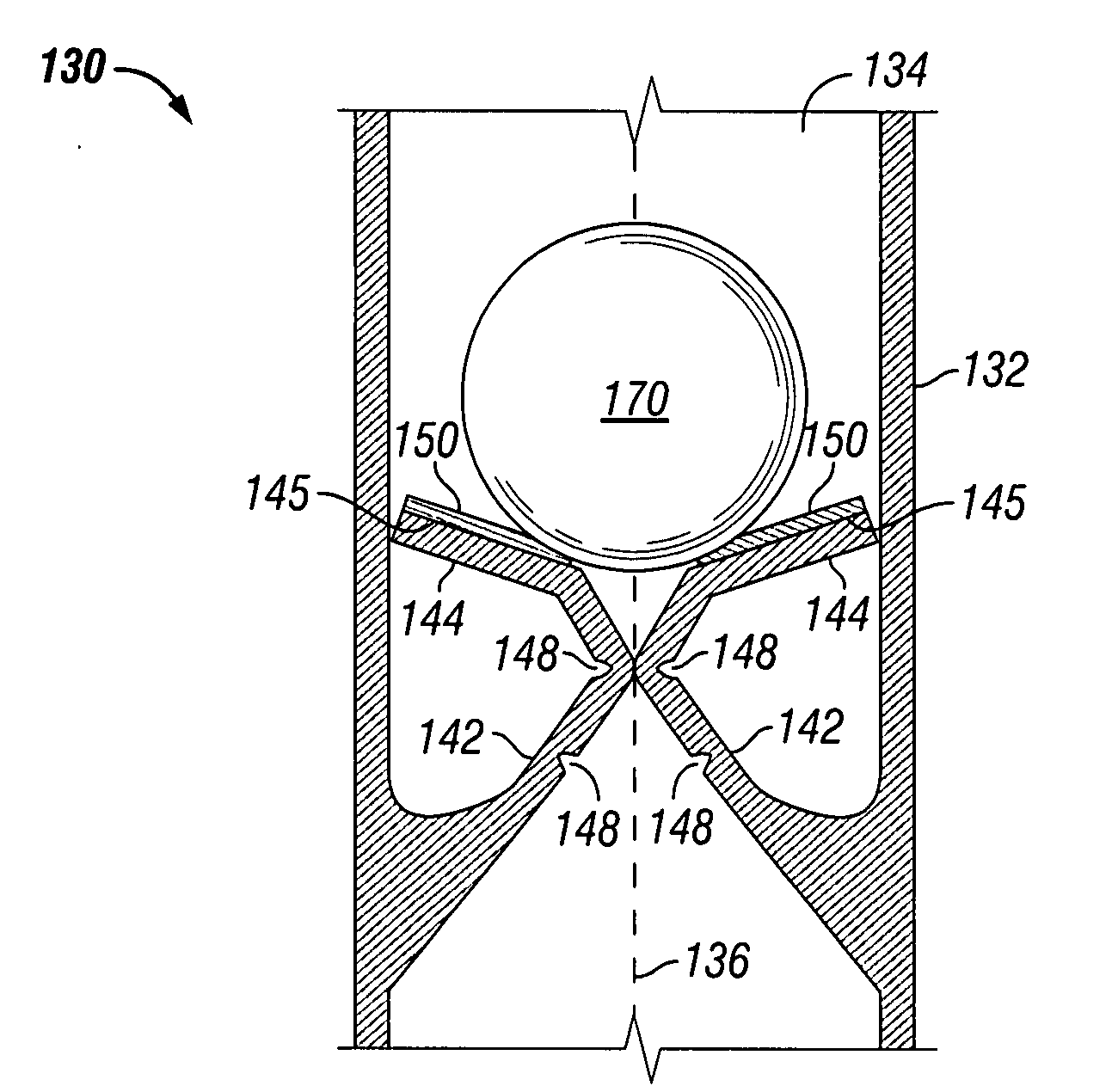

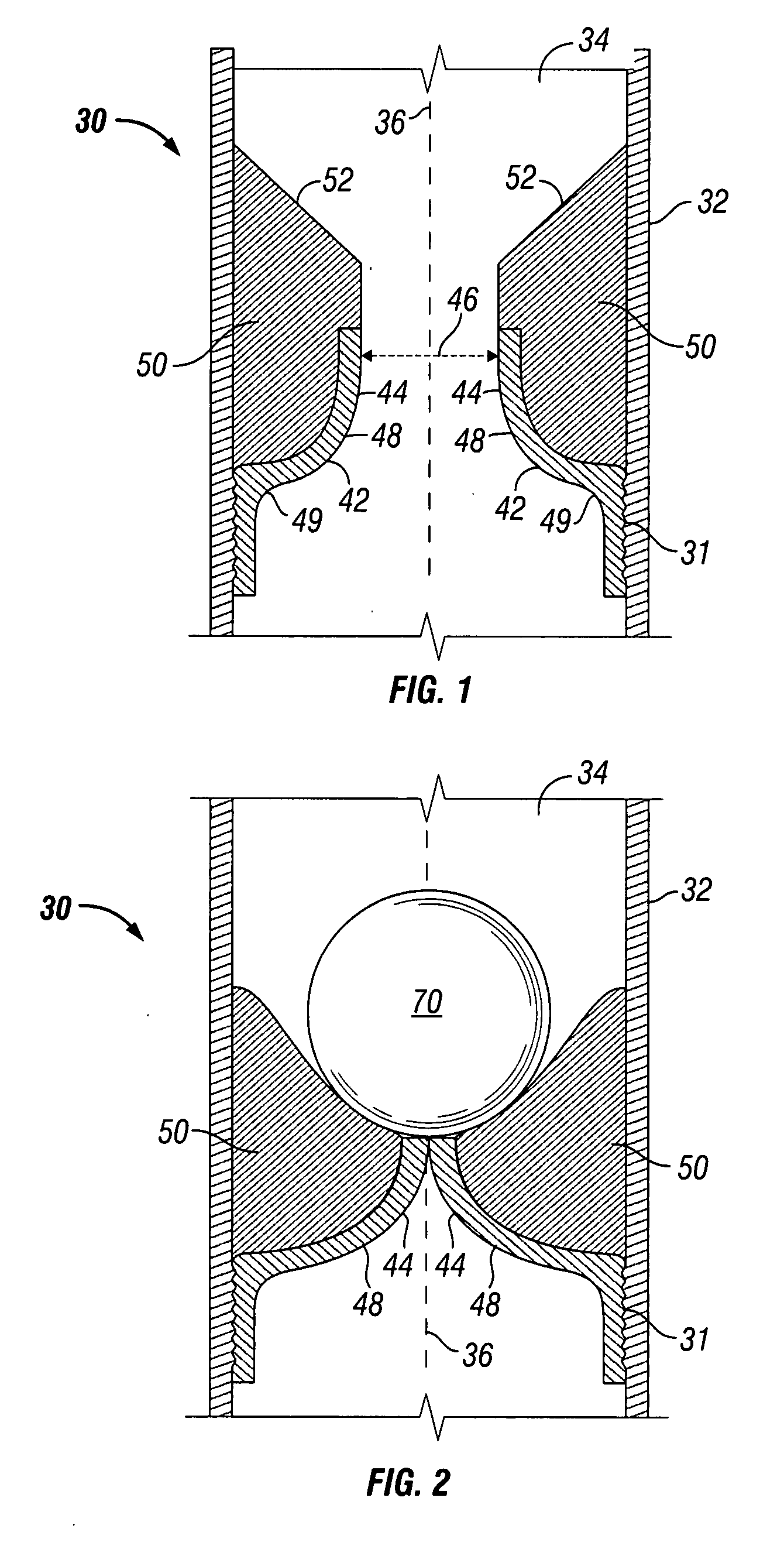

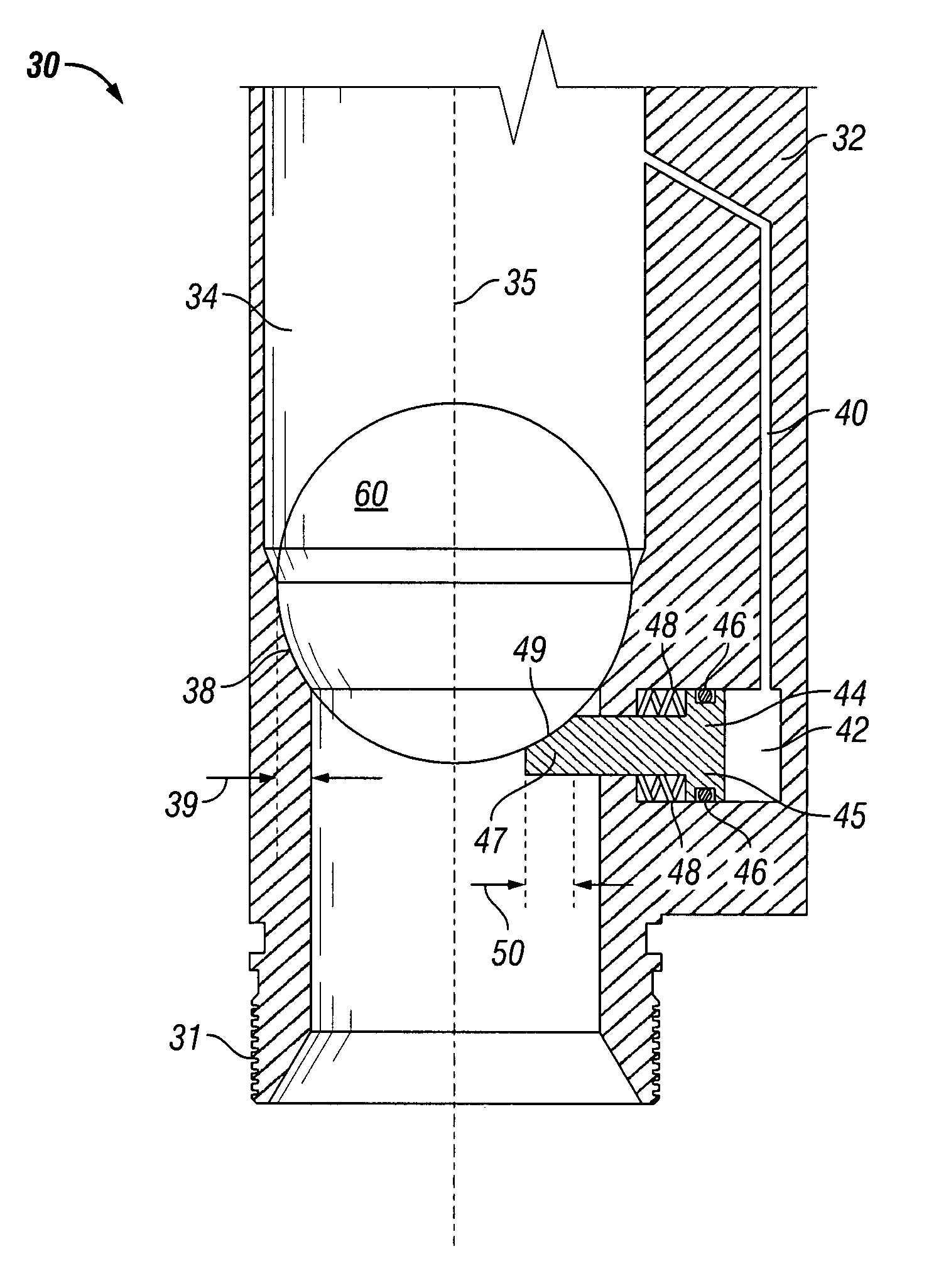

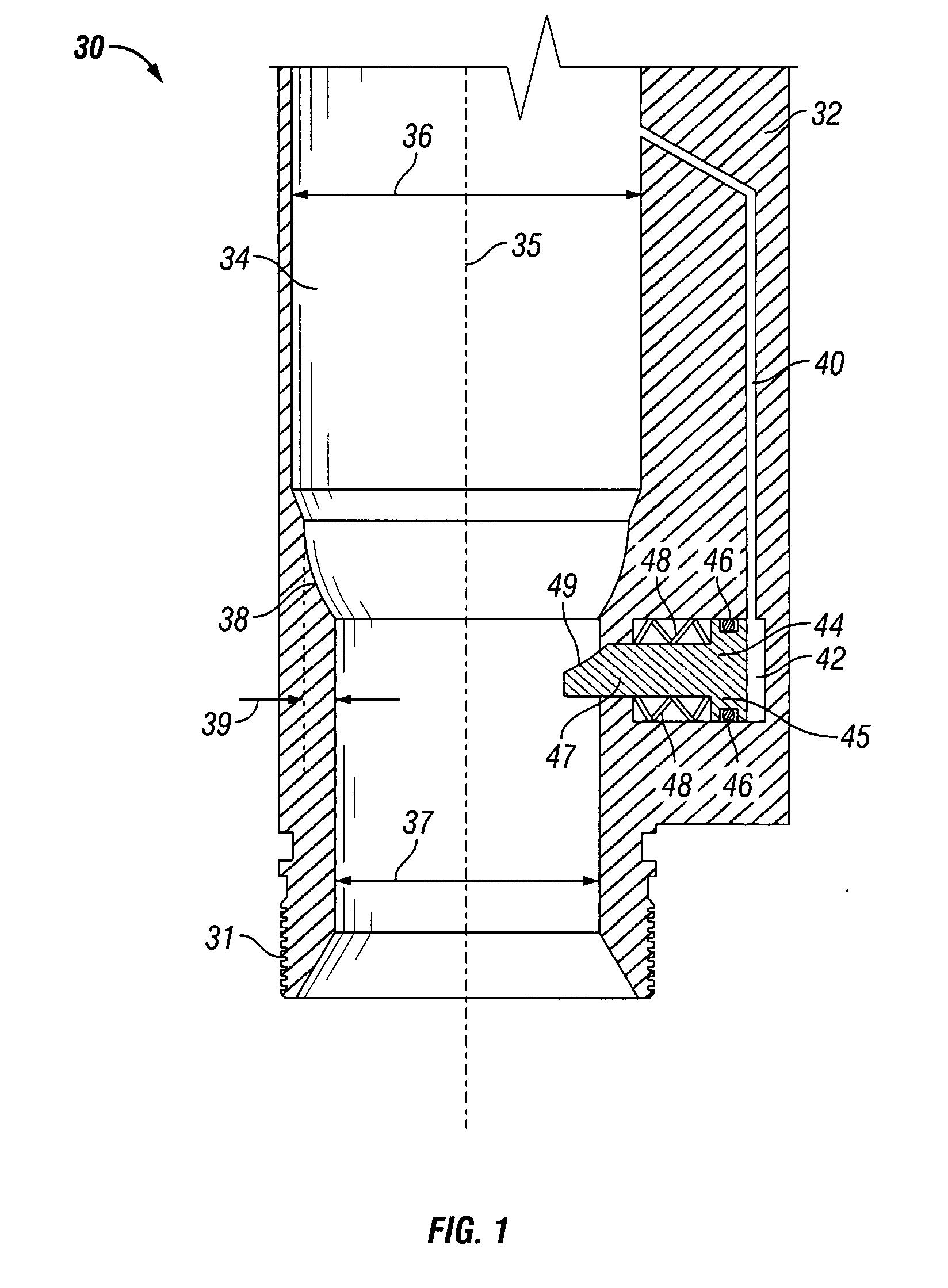

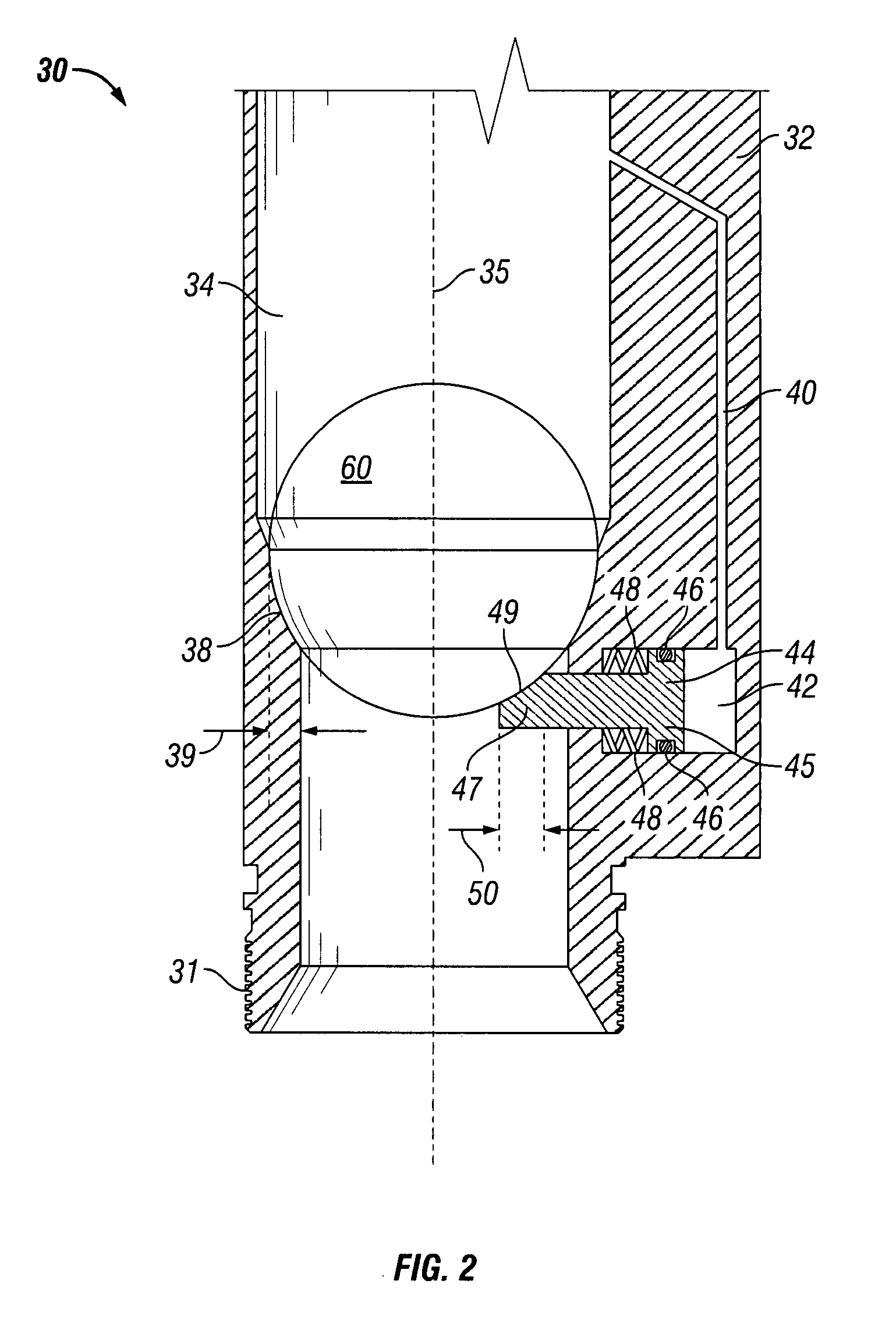

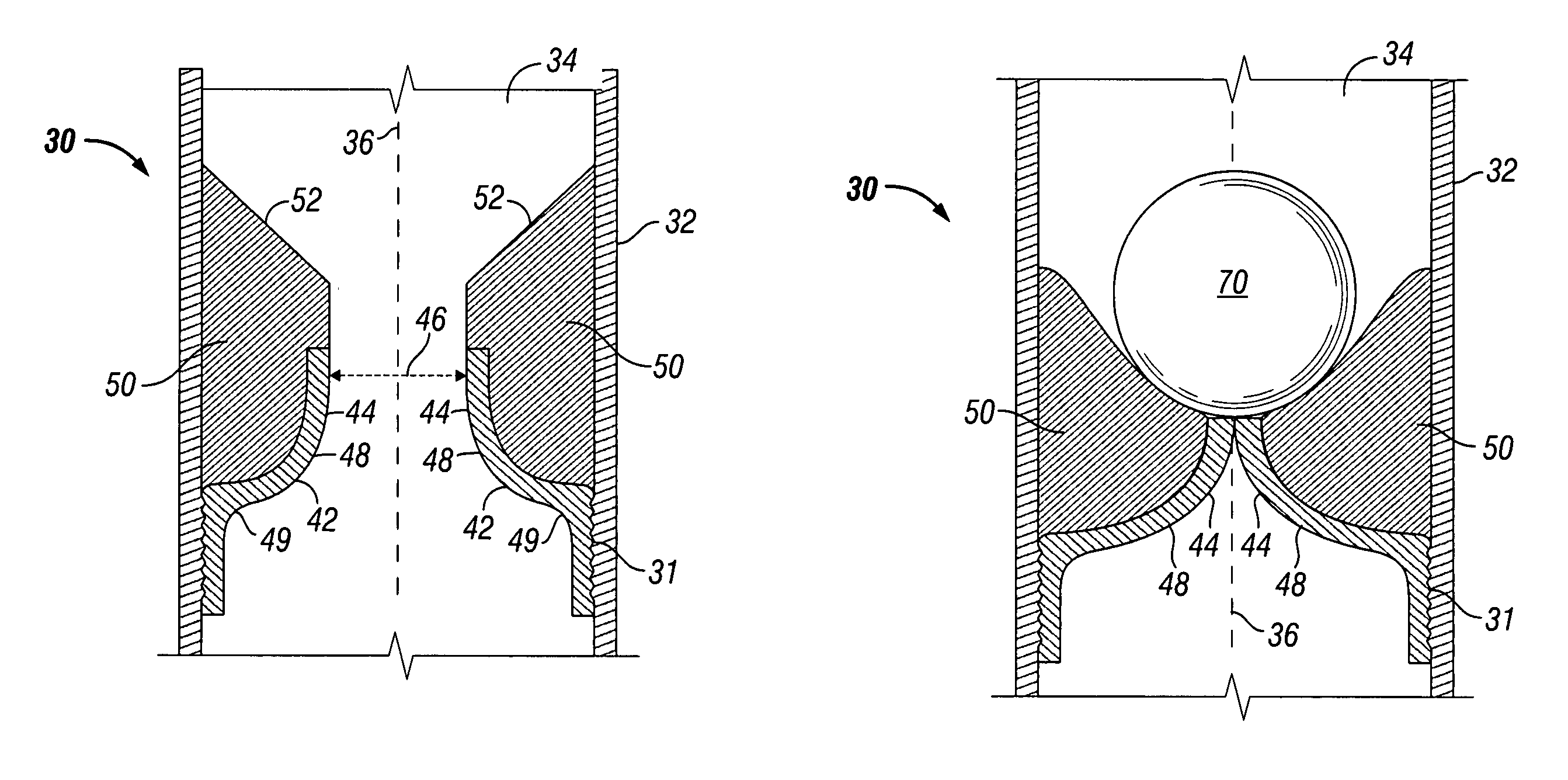

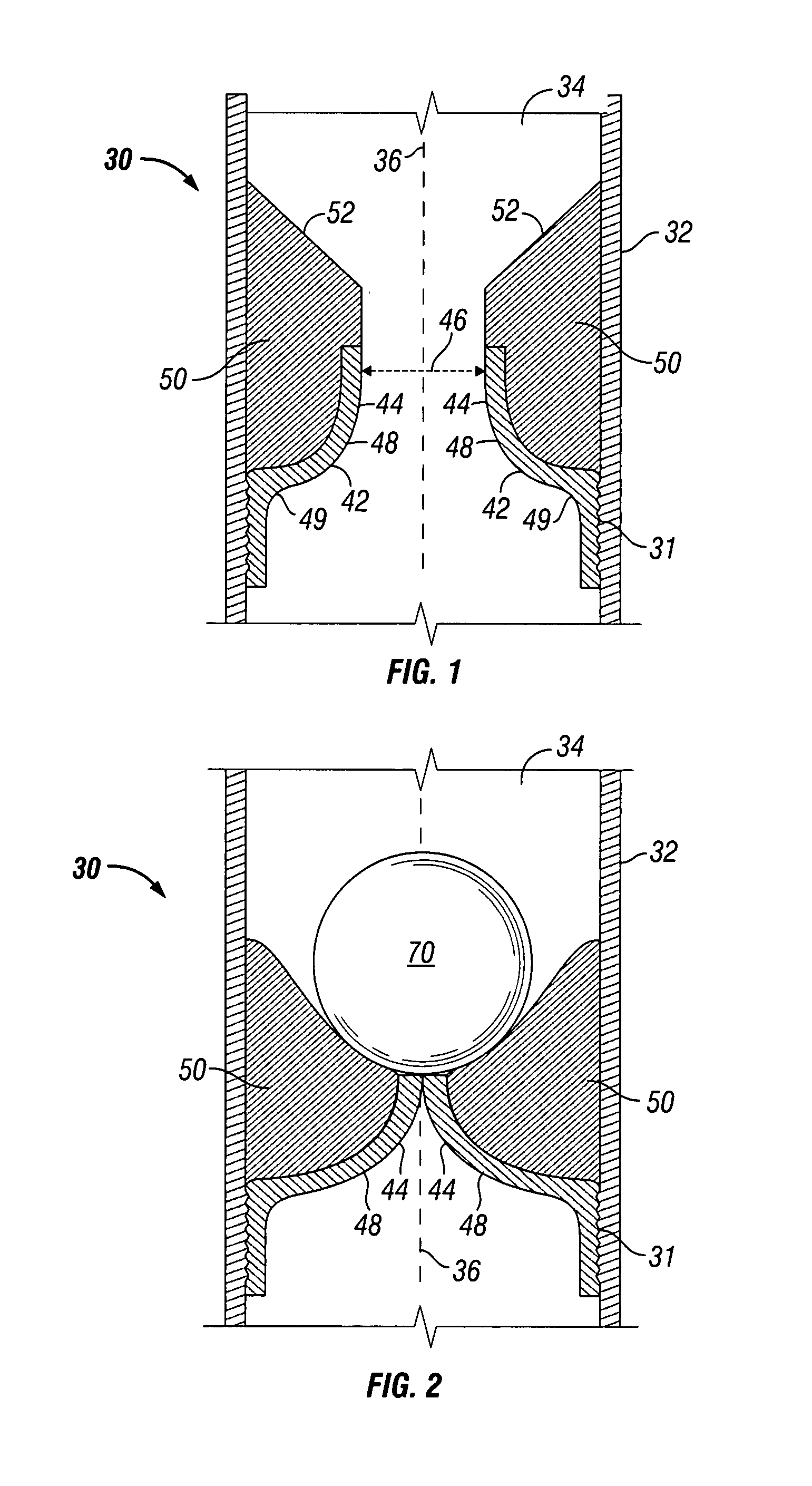

Deformable ball seat

ActiveUS20090044949A1Increase surface areaReduce the possibilityCheck valvesFluid removalEngineeringMechanical engineering

Apparatuses for restricting fluid flow through a well conduit comprise a housing having a longitudinal bore and a collapsible seat disposed within the bore. The seat has a first position defining a first seat inner diameter when the apparatus is in the run-in position and a second position defining a second seat inner diameter when the apparatus is in the set position. The first seat inner diameter is greater than the second seat inner diameter. A plug element is adapted to be disposed into the bore and landed on the seat to move the seat from the first position to the second position. While in the second position, the seat restricts fluid flow through the bore and provides additional support to the plug member landed on the seat.

Owner:BAKER HUGHES INC

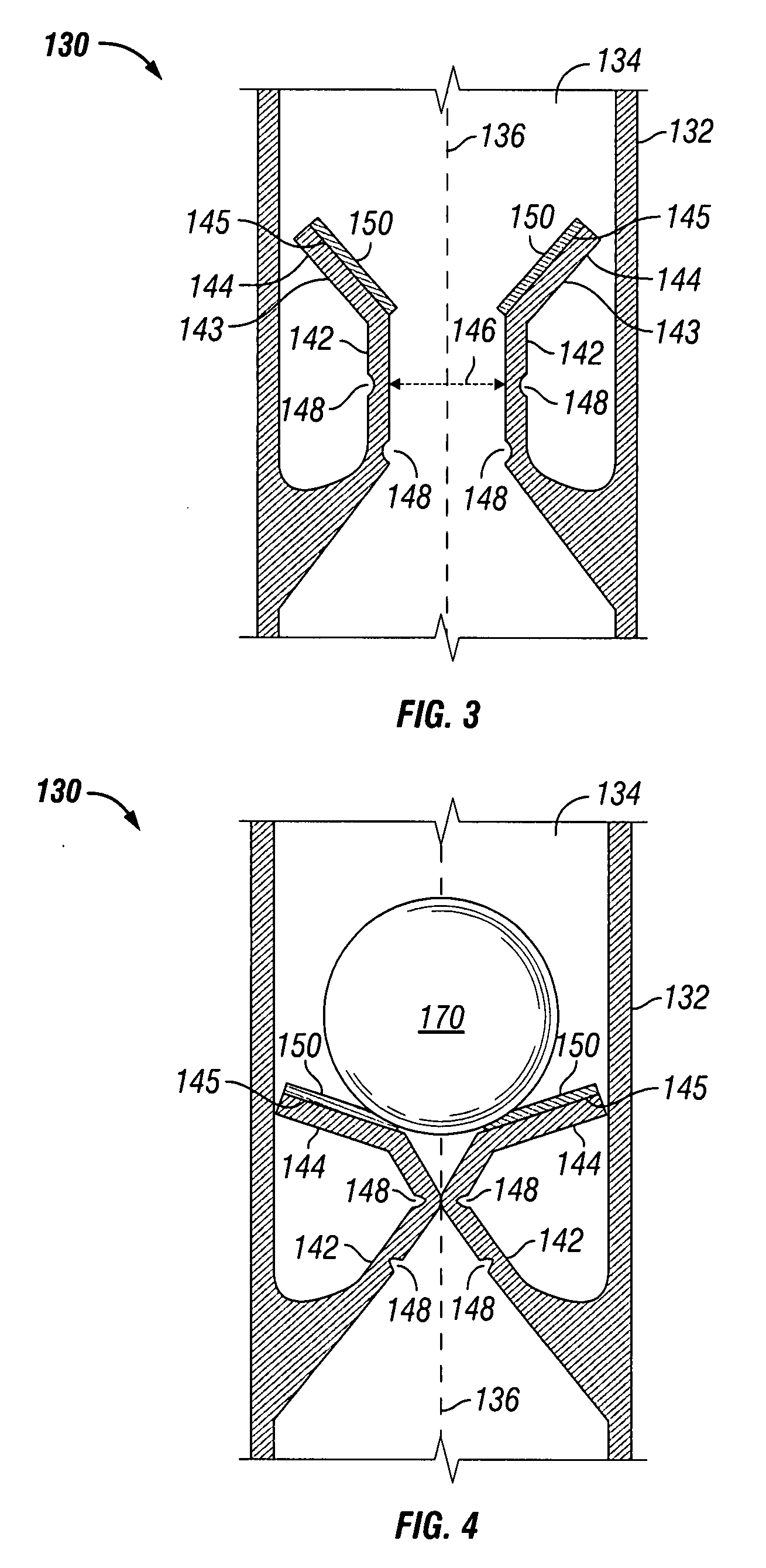

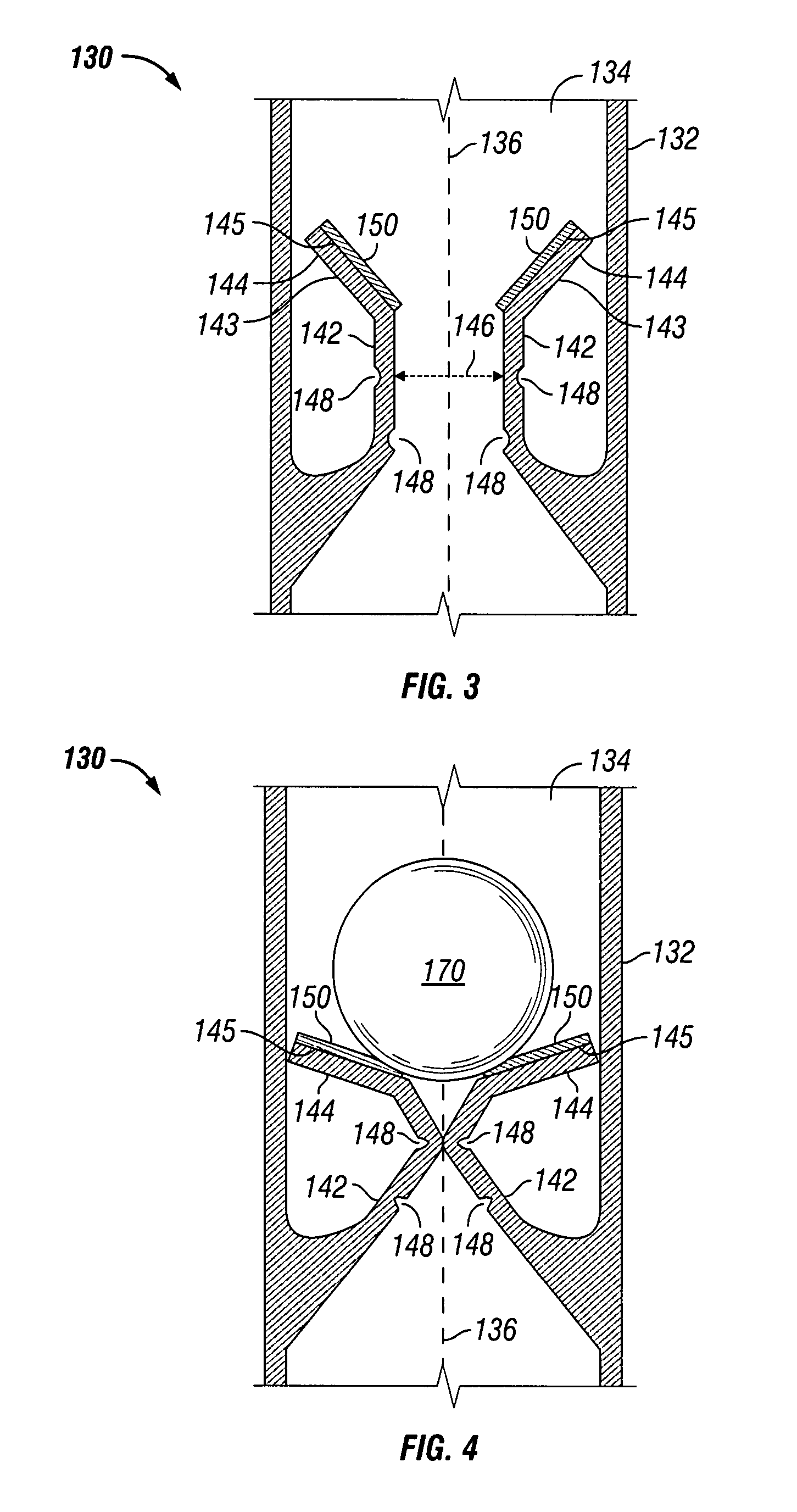

Ball seat having fluid activated ball support

ActiveUS20090044946A1Reduce the possibilityReduce contact forceCheck valvesEqualizing valvesEngineeringPiston

Apparatuses for closing a well conduit comprise a housing having a longitudinal bore and a seat disposed within the bore. A chamber is disposed within the housing and includes a plug element support member, such as ram or piston, operatively associated within the chamber. The plug element support member has a retracted position and an extended position. A passageway is in fluid communication with the bore and the chamber. A plug element such as a ball or drop plug, is adapted to be disposed into the bore and landed on the seat to restrict fluid flow through the bore and the well conduit. Landing the plug element causes and allowing fluid pressure to build causes the plug element support member to move from the retracted position to the extended position to provide support to the plug element landed on the seat.

Owner:BAKER HUGHES INC

Deformable ball seat

ActiveUS7503392B2Increase surface areaReduce the possibilityCheck valvesFluid removalEngineeringMechanical engineering

Apparatuses for restricting fluid flow through a well conduit comprise a housing having a longitudinal bore and a collapsible seat disposed within the bore. The seat has a first position defining a first seat inner diameter when the apparatus is in the run-in position and a second position defining a second seat inner diameter when the apparatus is in the set position. The first seat inner diameter is greater than the second seat inner diameter. A plug element is adapted to be disposed into the bore and landed on the seat to move the seat from the first position to the second position. While in the second position, the seat restricts fluid flow through the bore and provides additional support to the plug member landed on the seat.

Owner:BAKER HUGHES HLDG LLC

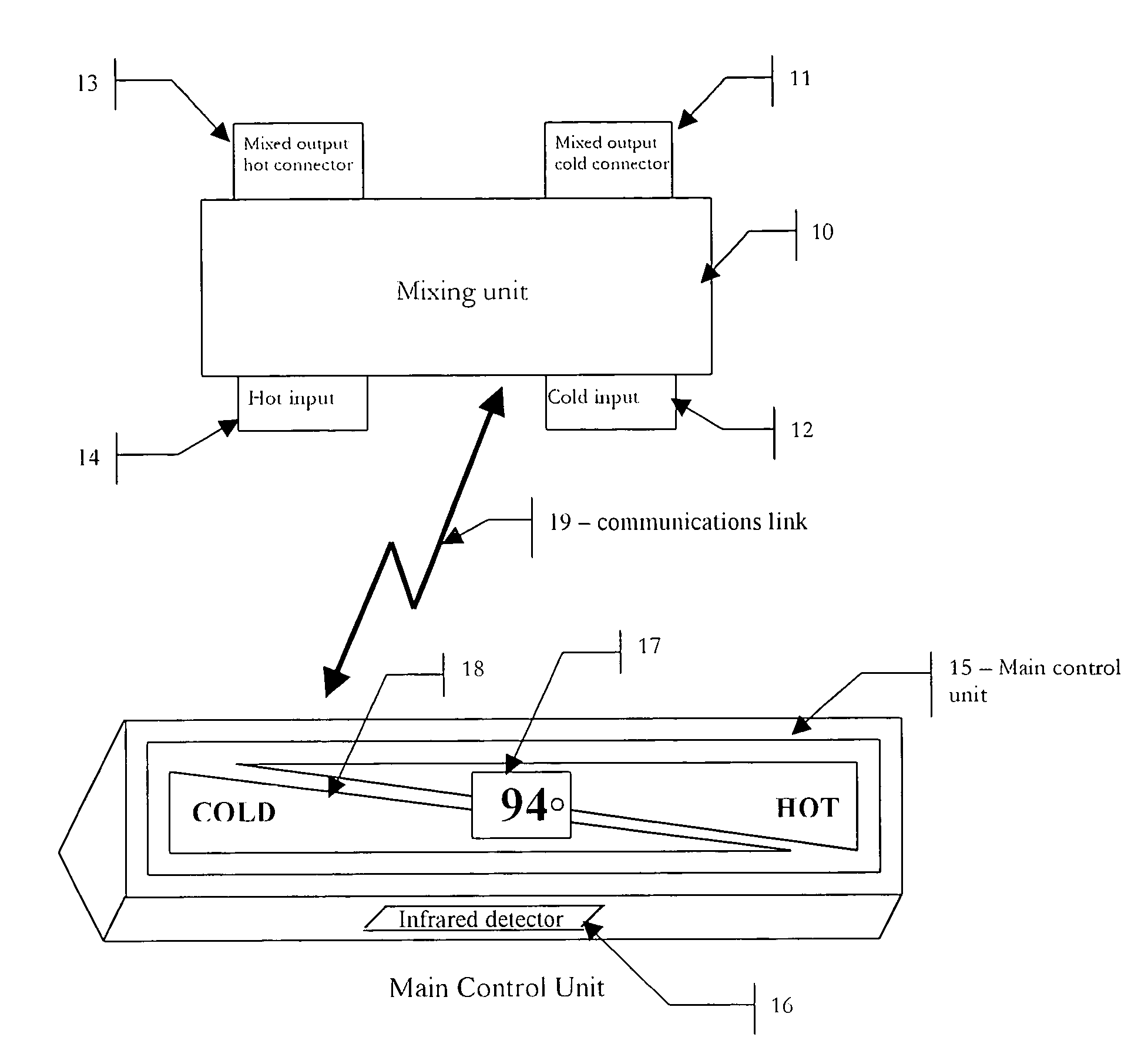

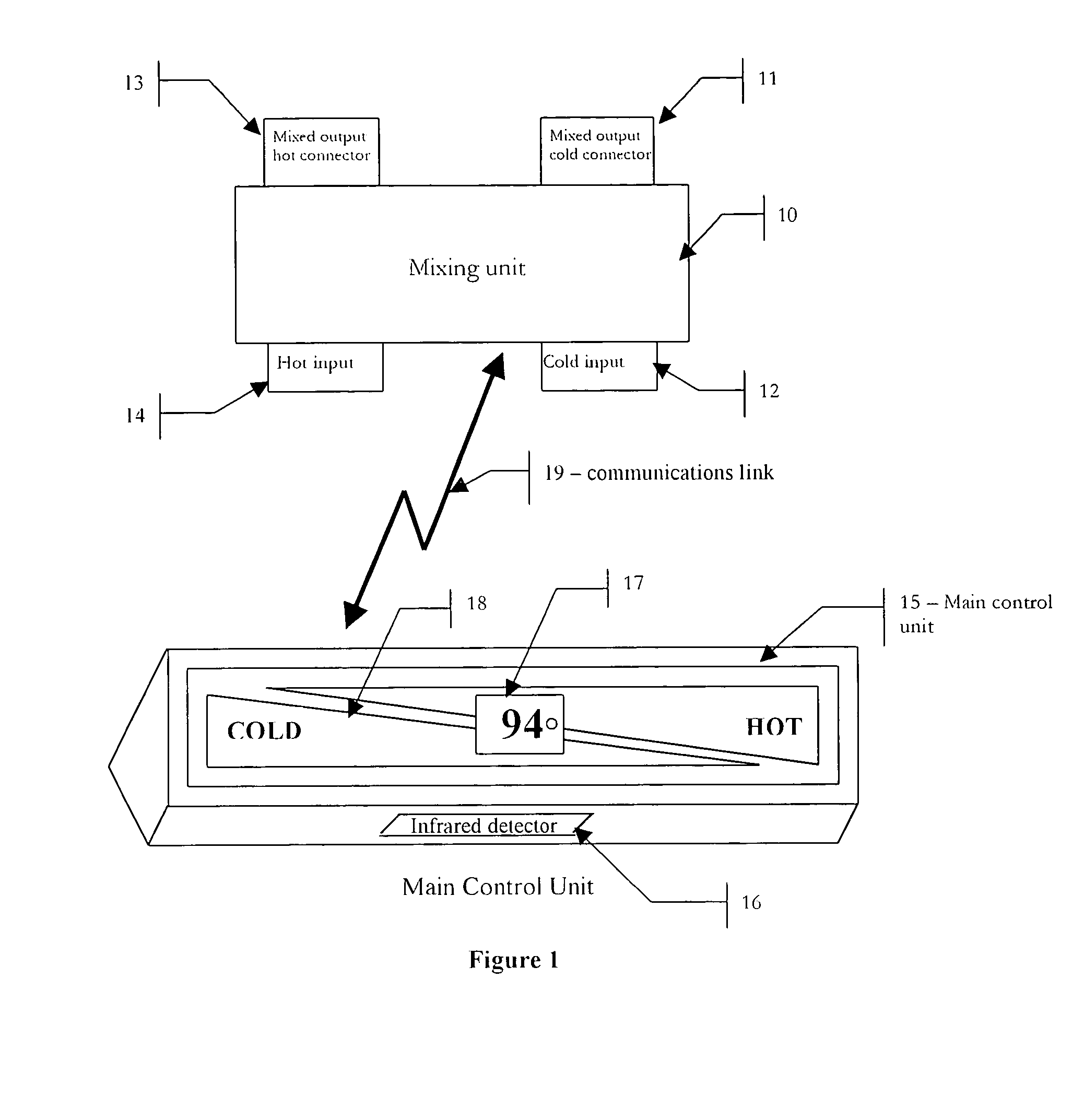

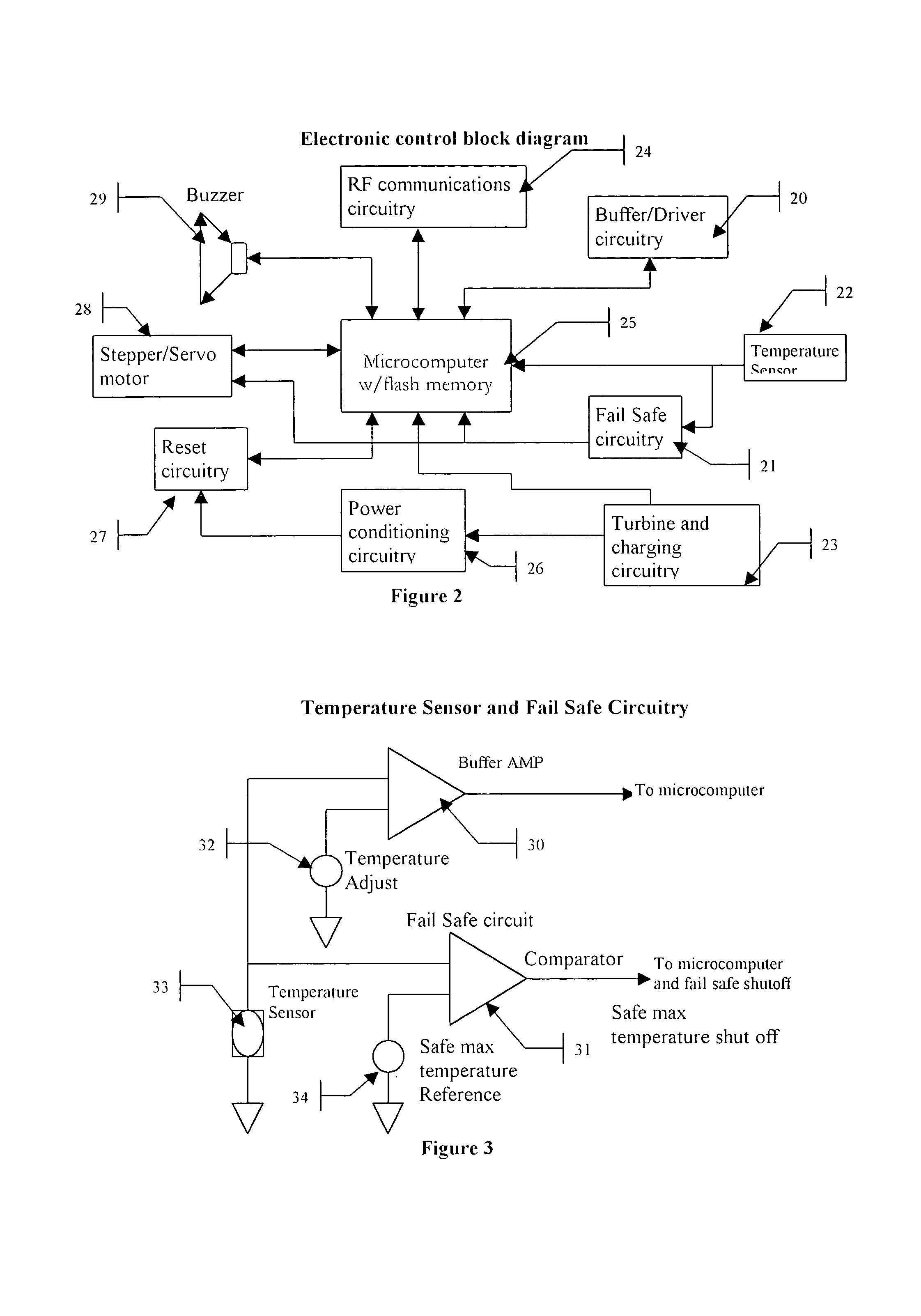

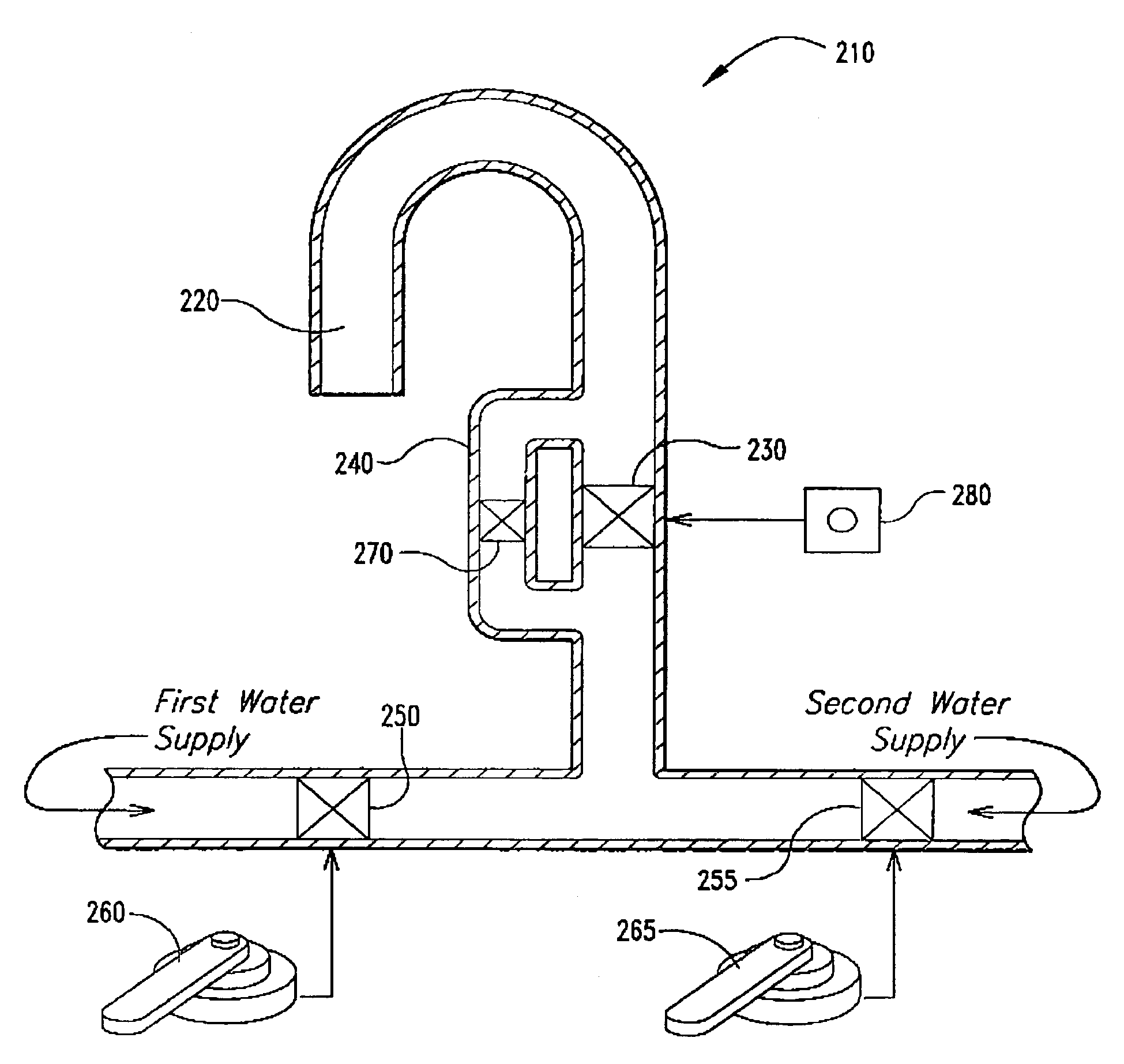

Self powered electronically controlled mixing valve

InactiveUS6913203B2Solve missing installationMinimal capabilityTemperature control without auxillary powerOperating means/releasing devices for valvesControl electronicsRadio frequency

The present invention provides a means to add electronic control of temperature and flow rate for fluids in standard faucets. The device is self powered by means of the fluid flowing through it and generates sufficient power to operate the control electronics. Elimination of an external power source or internal battery, is important for simple retrofit installations as well as maintenance free operation for many years. The invention consists of two components that communicate with each other via either an RF (radio frequency), IR (infra red) or a wired link. The Mixing Unit serves to mix the incoming hot and cold fluids (typically water but any fluid can be mixed) to a desired temperature under control of the Main Control Unit. The Main Control Unit provides a means by which the user can adjust the temperature as well as automatically turn on and off the fluid flow.

Owner:DELANGIS ERIC

One-way valve for medical infusion lines and the like

A check valve for medical infusion lines and the like, includes a diaphragm made of elastic material set between a first tubular connector and a second tubular connector. The diaphragm includes an end wall of a cup-shaped element, having an outer peripheral edge of which is normally pressed in seal contact against an annular valve seat with a conical surface of the first tubular connector under an axial thrust exerted by a side wall of the cup-shaped element. A free edge of the side wall of the cup-shaped element is set resting against a transverse surface of the second tubular connector only in regions corresponding to angular portions of the latter separated by non-resting angular portions.

Owner:IND BORLA

Restricted flow hands-free faucet

ActiveUS6968860B1Operating means/releasing devices for valvesServomotor componentsElectricityWater flow

A faucet comprising a spout, a passageway, an electrically operable valve; a first manual valve; a first manual handle; and a bypass. The passageway conducts water flow through the spout. The electrically operable valve is disposed within the passageway. The first manual valve disposed within the passageway in series with the electrically operable valve. The first manual handle that controls the first manual valve. The bypass has a first end above the electrically operable valve, relative to the water flow, and a second end below the electrically operable valve, such that a portion of the water flow bypasses the electrically operable valve.

Owner:DELTA FAUCET COMPANY

Multi-mode hands free automatic faucet

A hands-free faucet comprises a proximity sensor, a logical control, a handle including a first touch control, a second touch control, and a mode indicator. The logical control has a manual mode (wherein the proximity sensor is inactive, and water flow is toggled on and off by positioning the handle) and a hands-free mode (wherein water flow is toggled on and off in response to the proximity sensor). The first touch control puts the faucet in the hands-free mode when touched by a user. The second touch control toggles the logical control between the hands-free mode and the manual mode when touched by a user. The mode indicator indicates which mode the faucet is presently in. The water flow has a temperature and a flow rate that are determined by the position of the handle.

Owner:DELTA FAUCET COMPANY

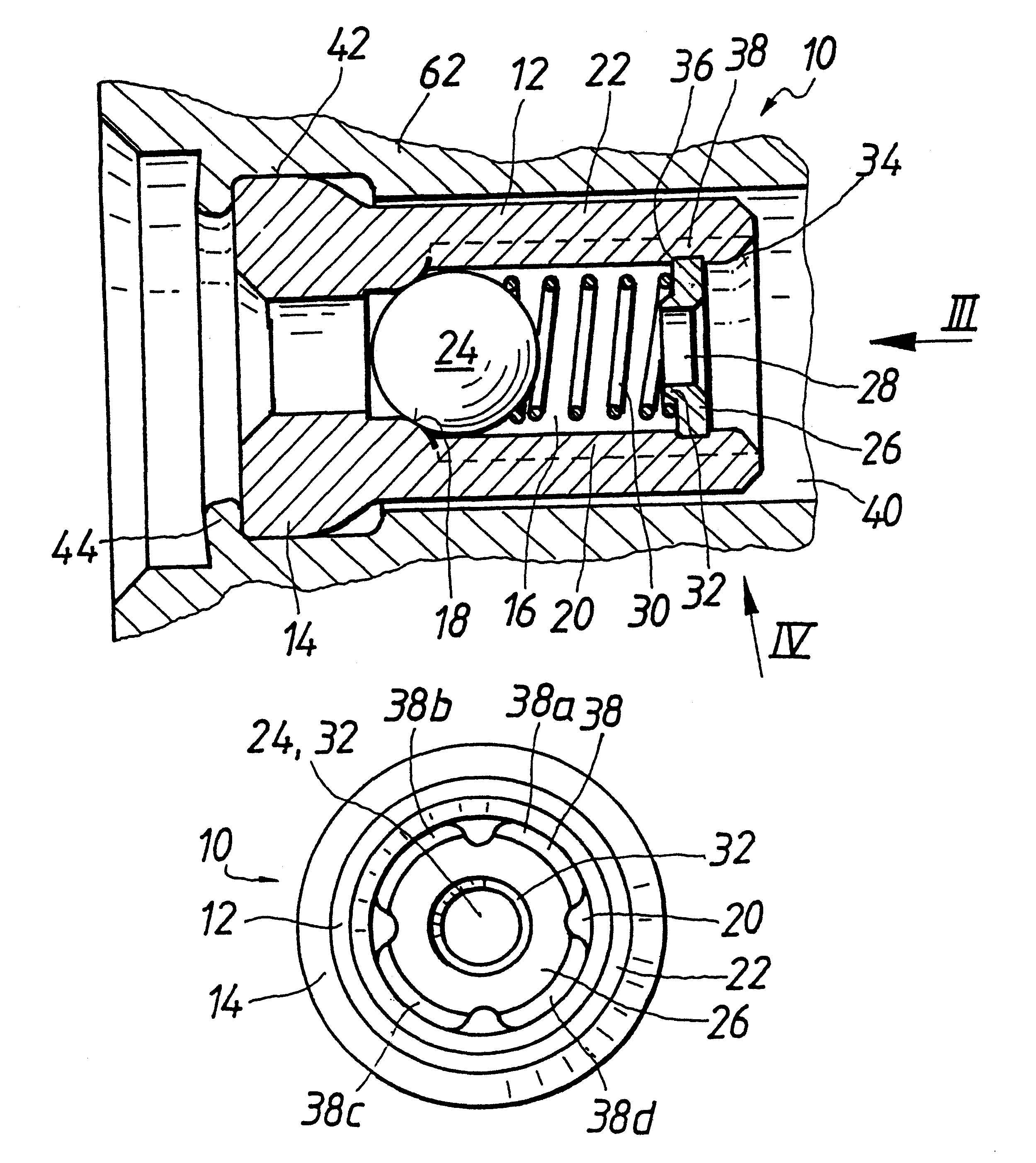

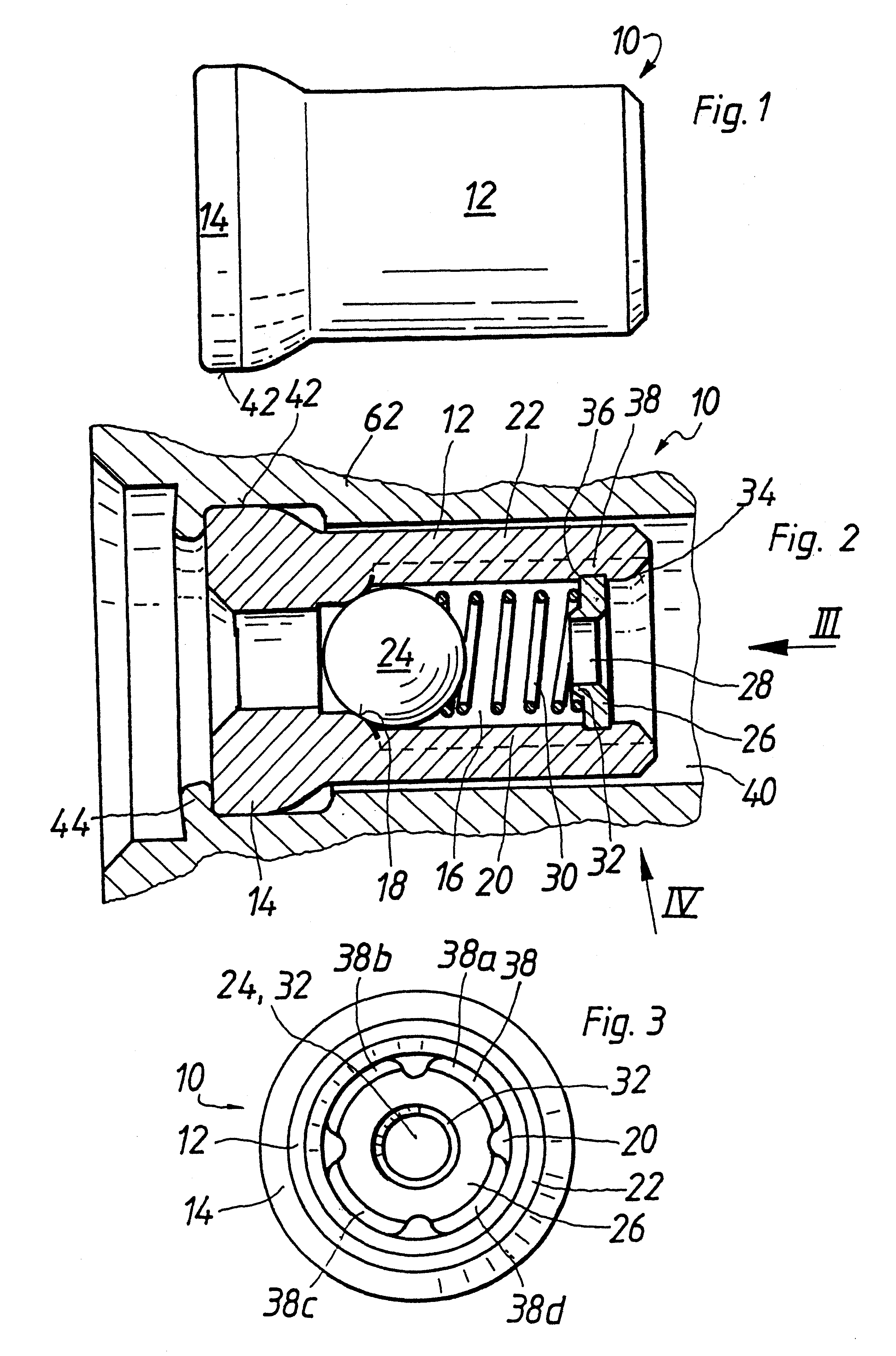

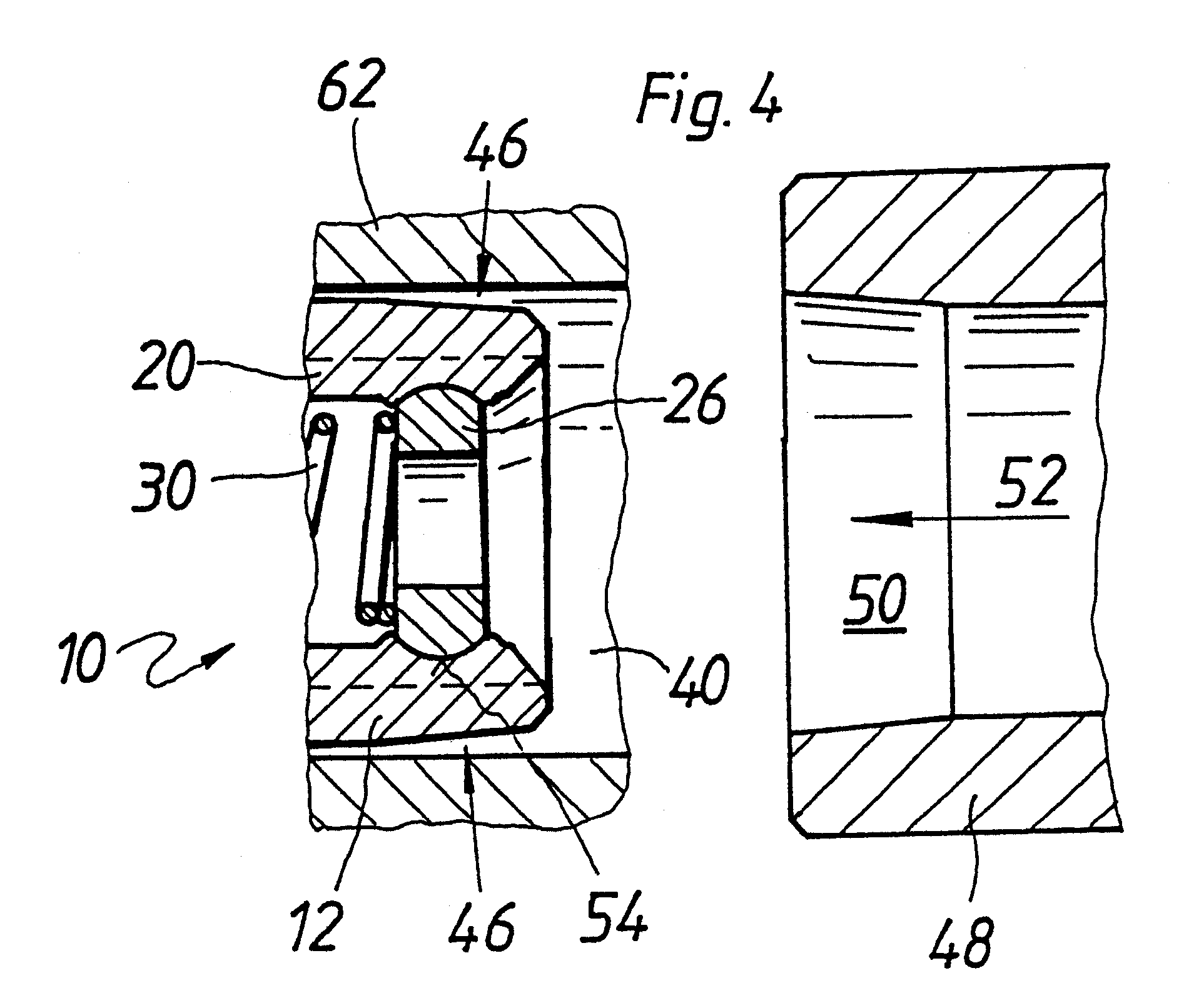

Check valve for a piston pump in a fluid circulation system

The invention relates to a check valve with a tubular valve housing in which a valve ball is received. To make a large flow cross section available and to prevent closure by the valve ball when the check valve is fully open, a perforated disk is press-fitted between longitudinally extending guide ribs of the valve housing and a circumferential wall of the valve housing there is an interstice as an outflow opening, which is not closed even the valve ball contacts the perforated disk. The valve housing is made by stamping, in which the guide ribs and a valve seat are made in one operation and are thereby aligned exactly with one another. In this way, a small radial play of the valve ball can be realized.

Owner:ROBERT BOSCH GMBH

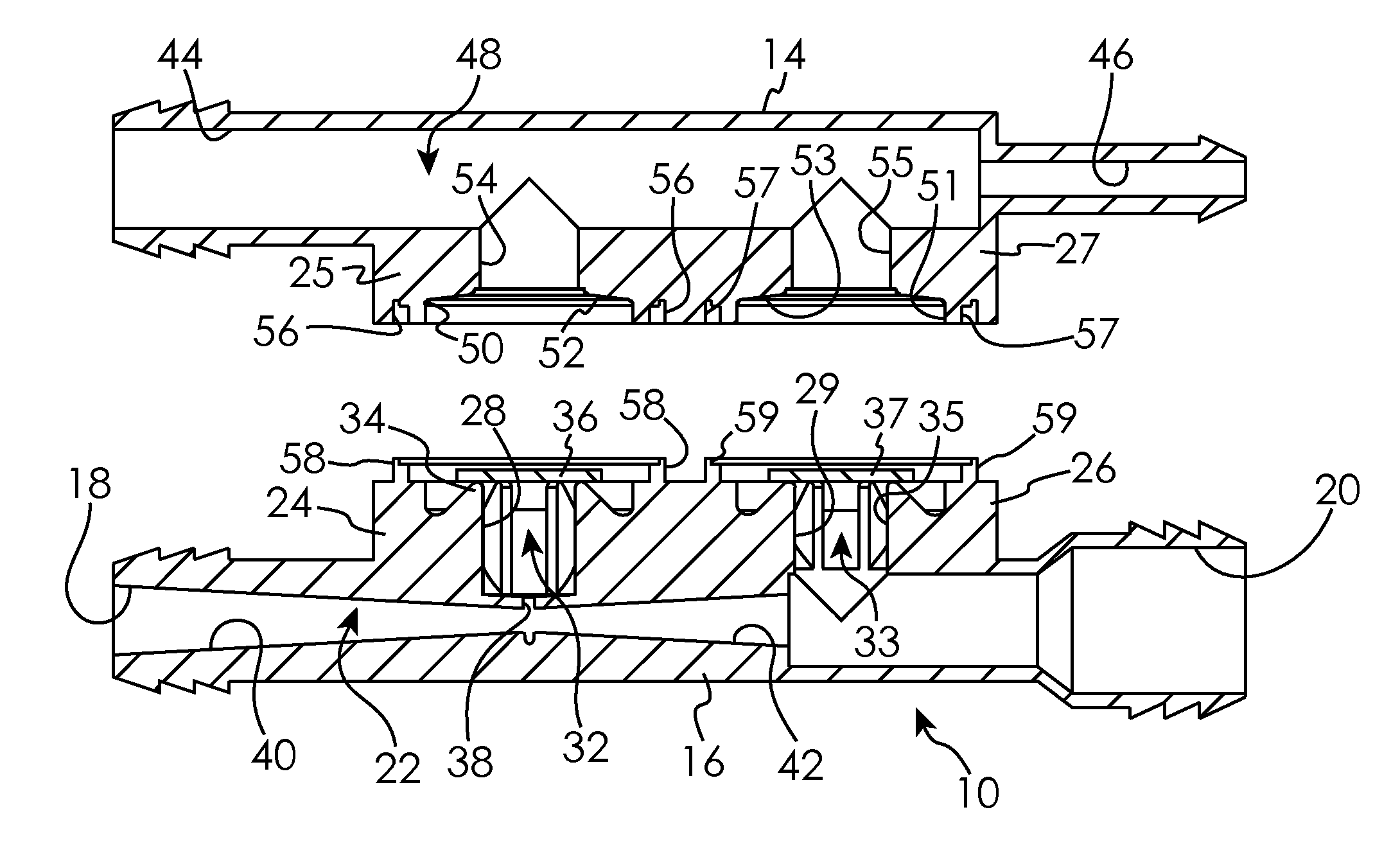

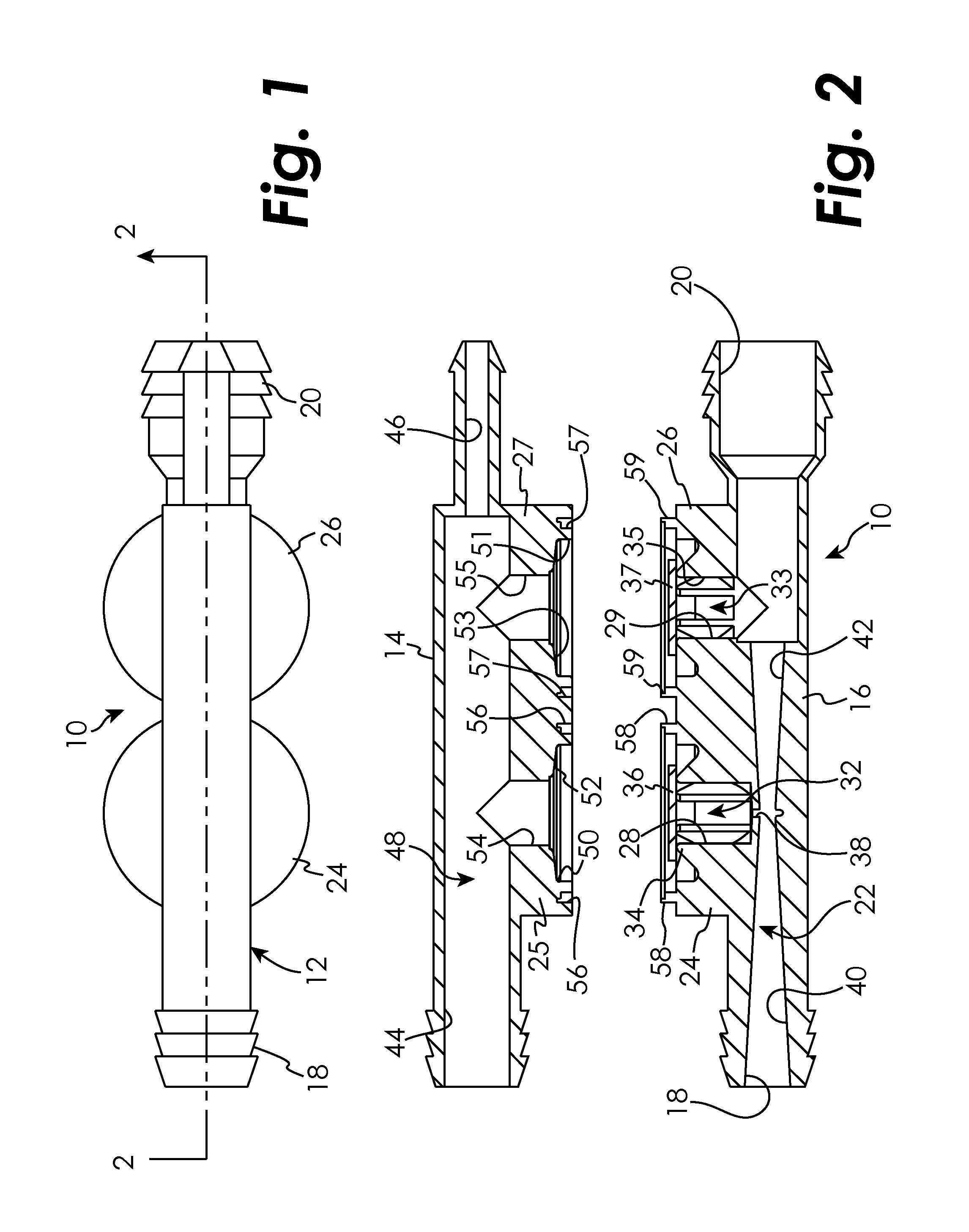

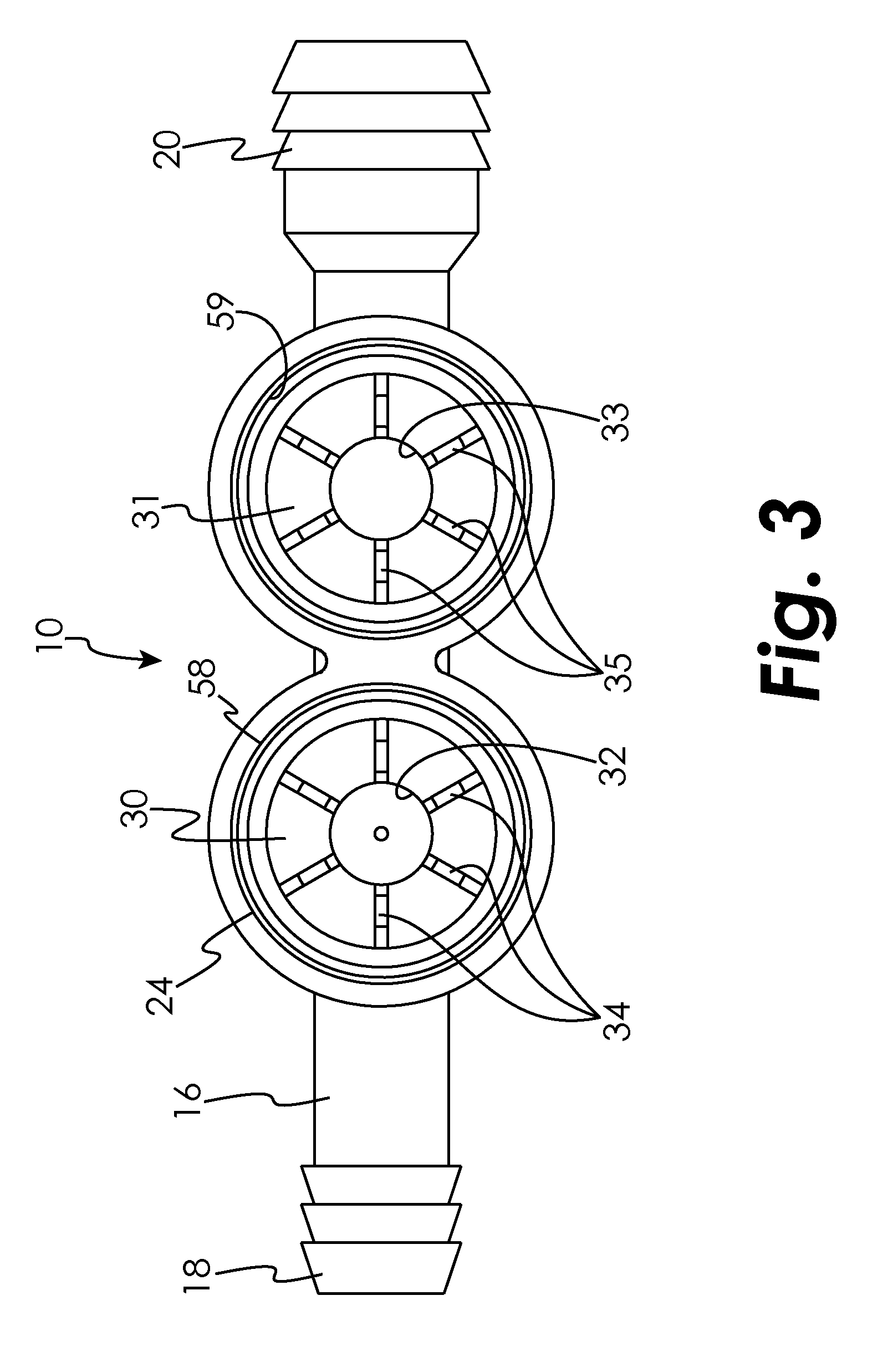

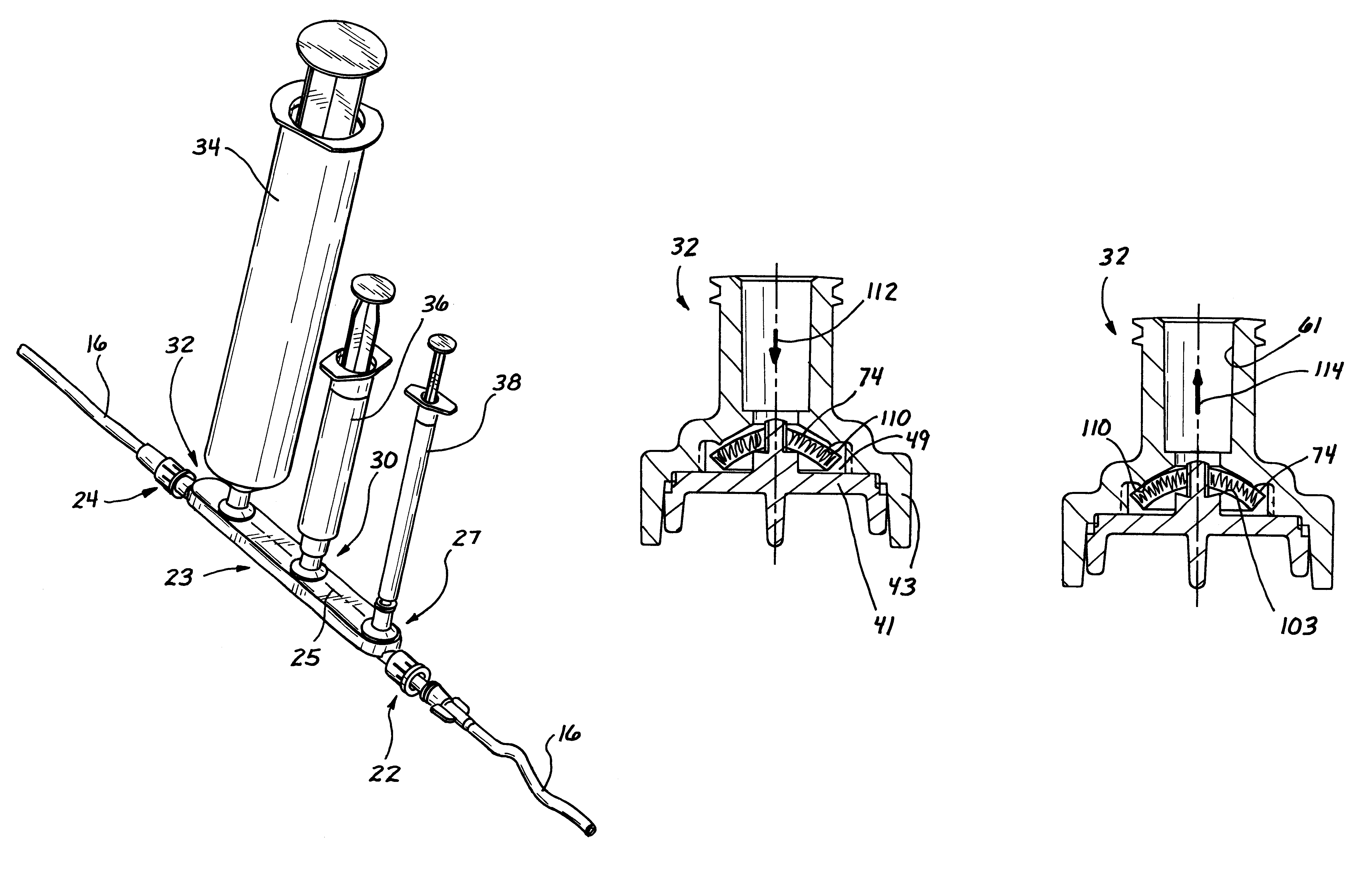

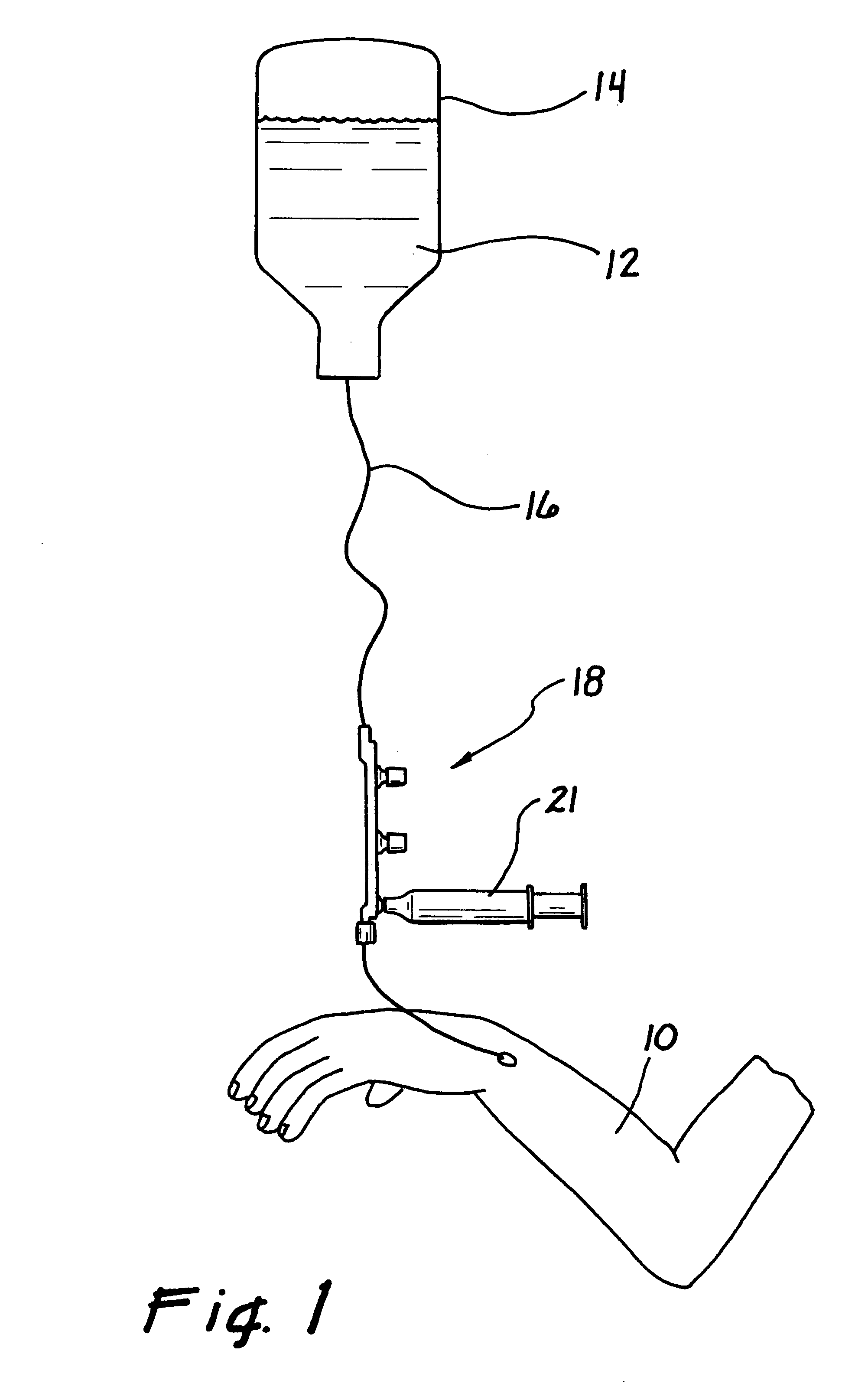

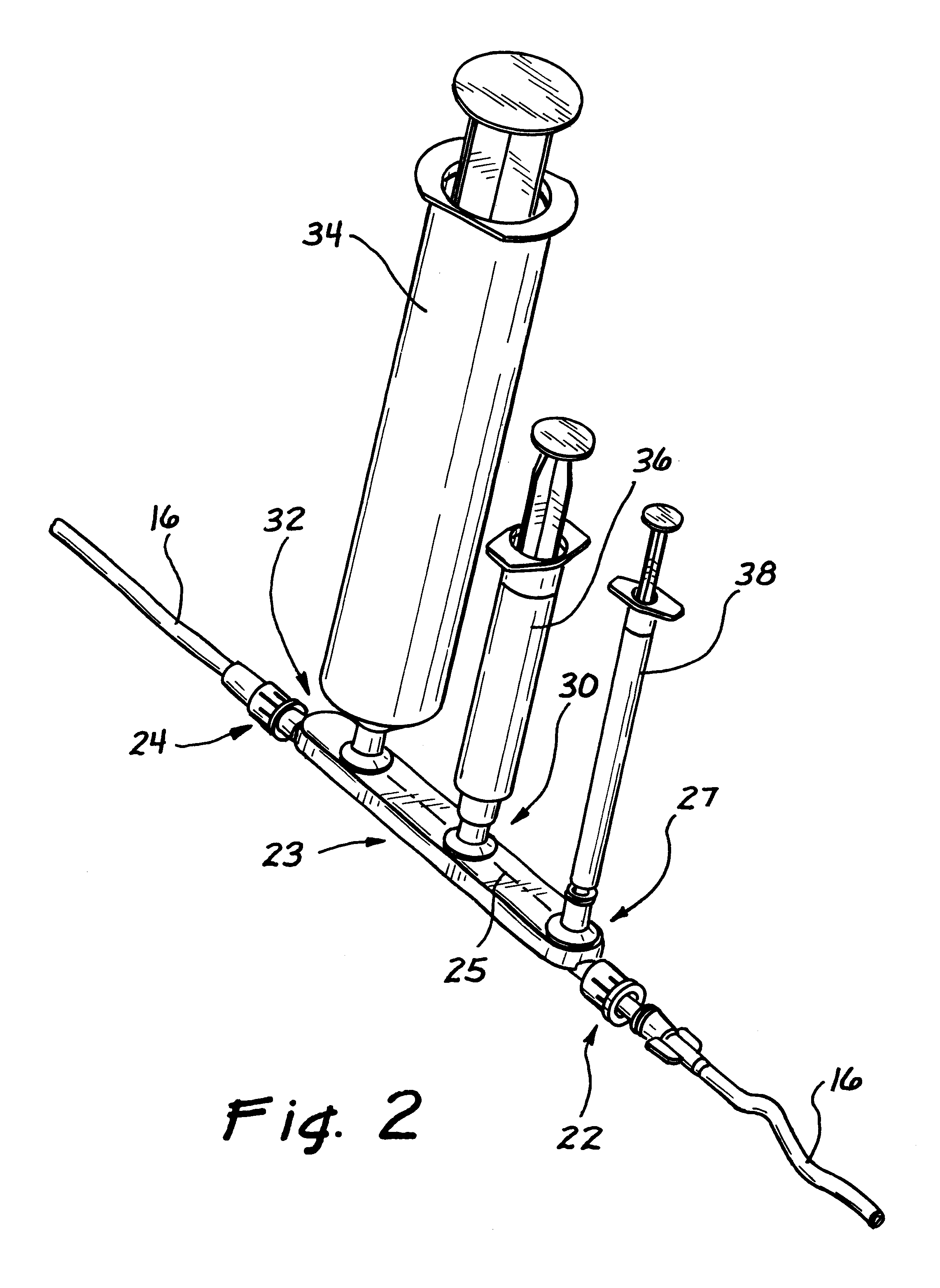

Multi-valve injection/aspiration manifold

An IV manifold includes a plurality of injection / aspiration ports and has an elongate configuration with a width greater than the diameter of the ports. A flow channel is formed between mating members of a housing and provided with a U-shaped configuration. Projections along the flow channel direct fluid flow into valve cavities associated with the ports to clear dead spots around the valve elements. A check valve included in the manifold tends to direct high pressures against the valve elements which respond by forming surface seals thereby avoiding deformation. An aspiration port can be formed with a second seal disposed on the side of the valve element opposite the first seal. Opening this second seal by negative pressure in the lumen of the port provides for the aspiration of fluids in the flow channel. Two-way aspiration can be provided by a valve having a cage with or without compressible characteristics to accommodate low tolerance fittings.

Owner:CAREFUSION 303 INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com