Patents

Literature

232 results about "Reed valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reed valves are a type of check valve which restrict the flow of fluids to a single direction, opening and closing under changing pressure on each face. Modern versions often consist of flexible metal or composite materials (fiberglass or carbon fiber).

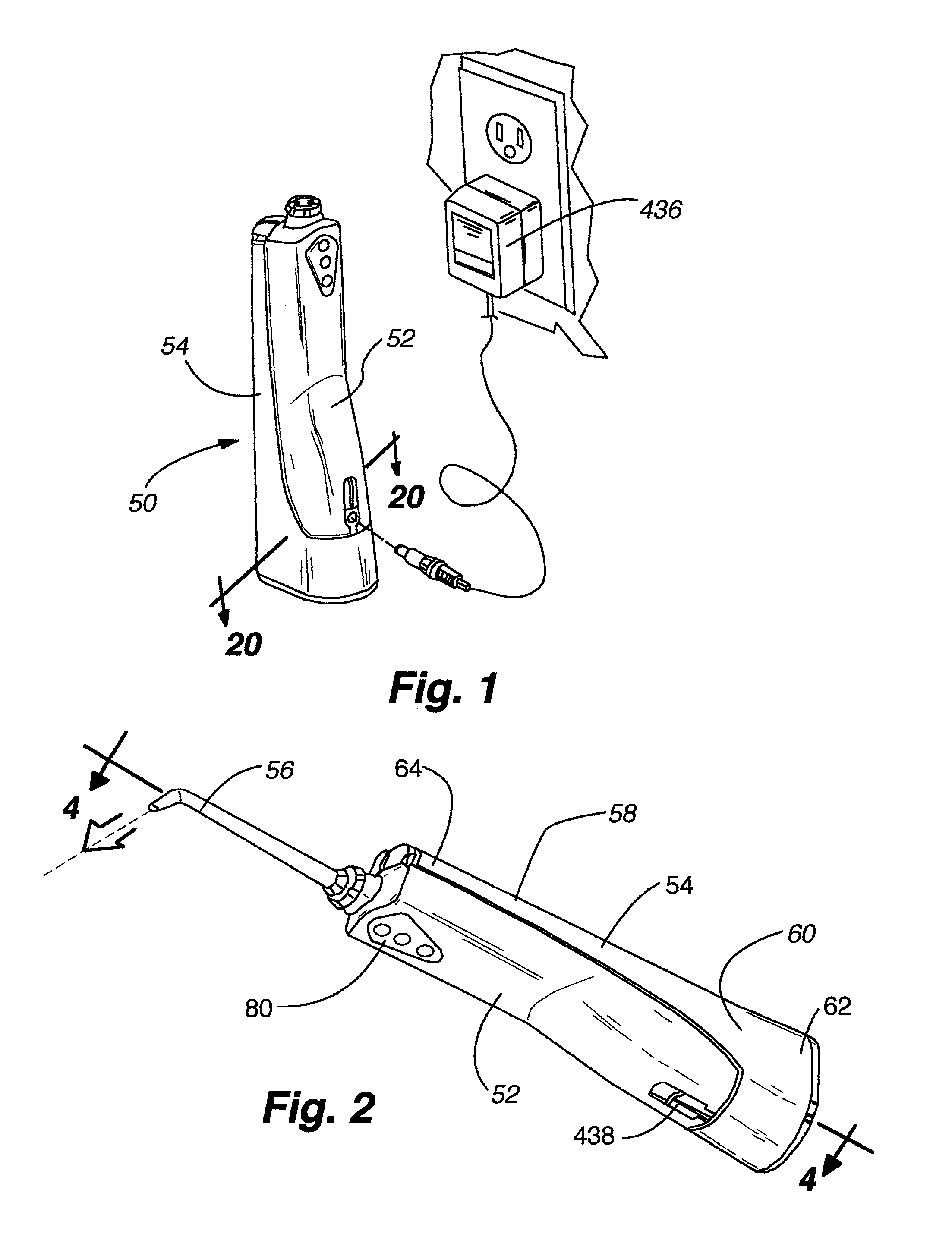

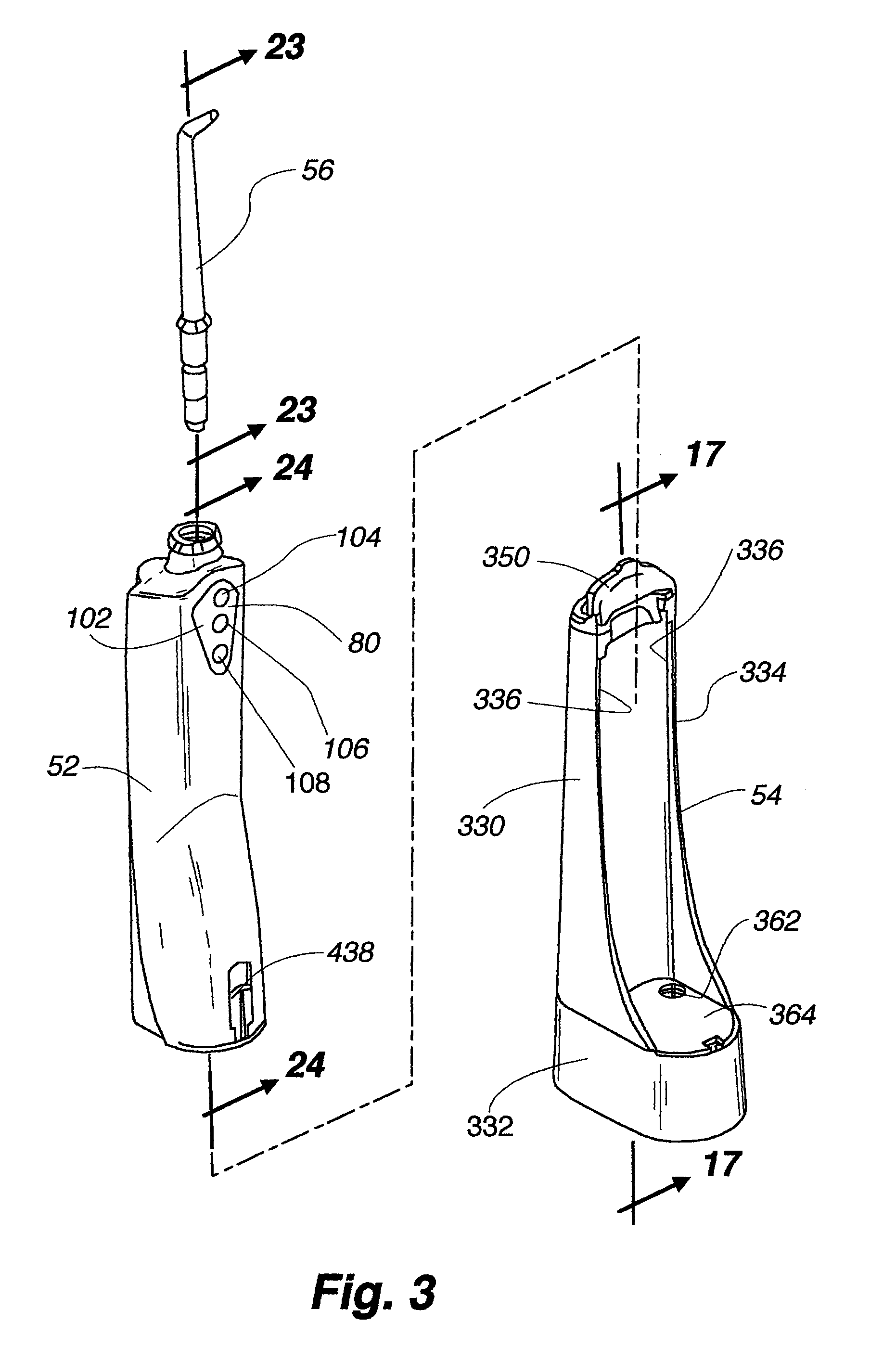

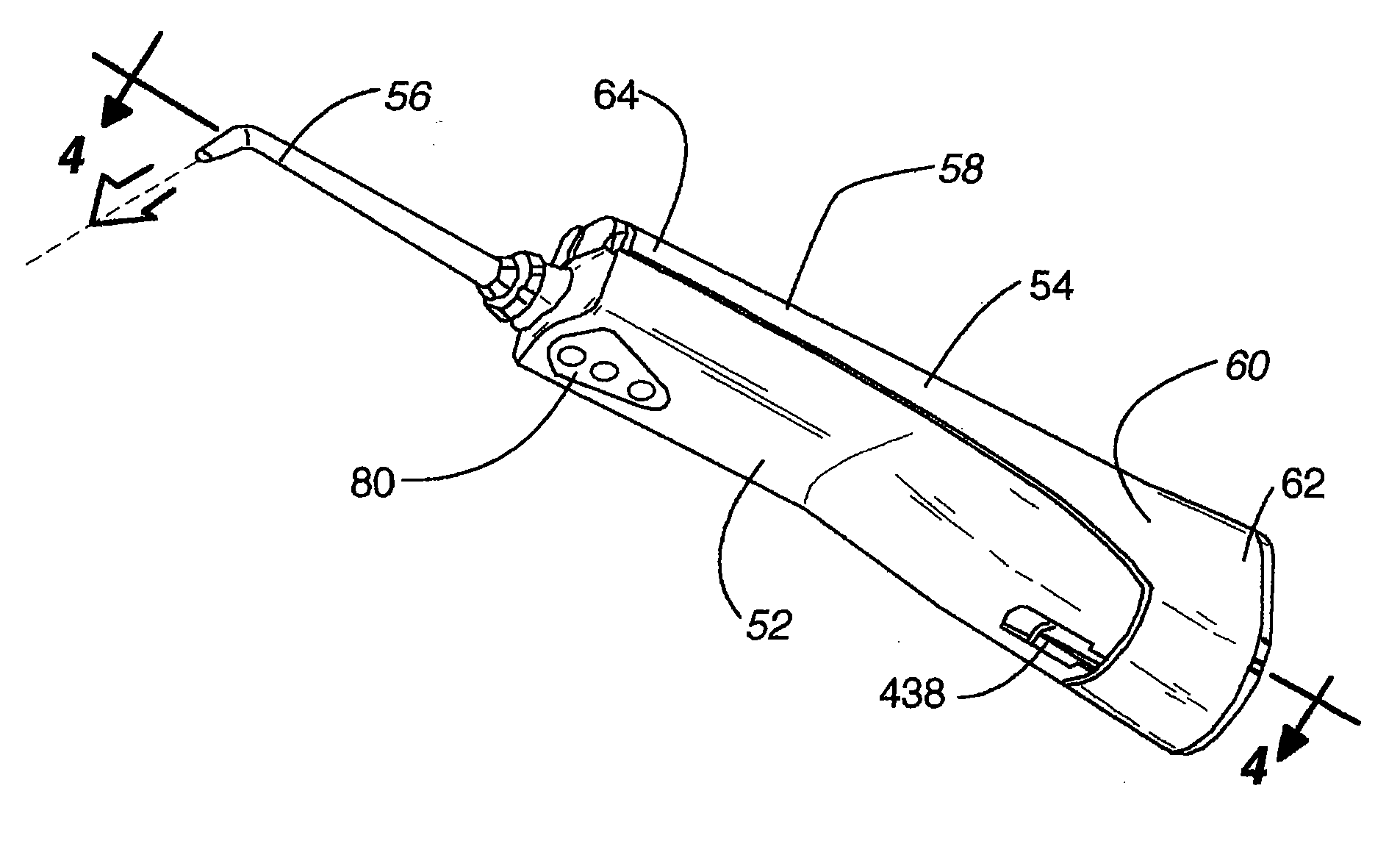

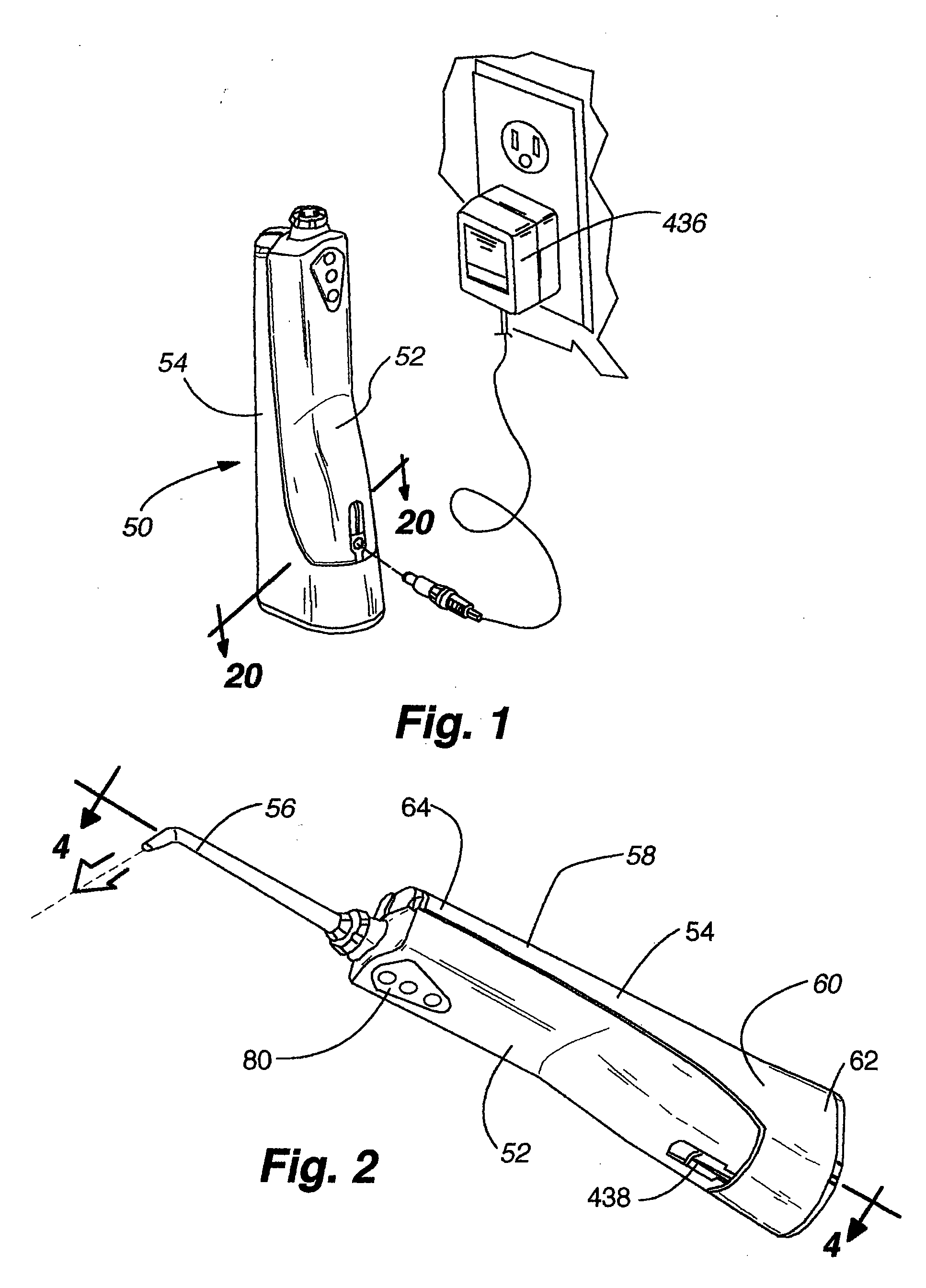

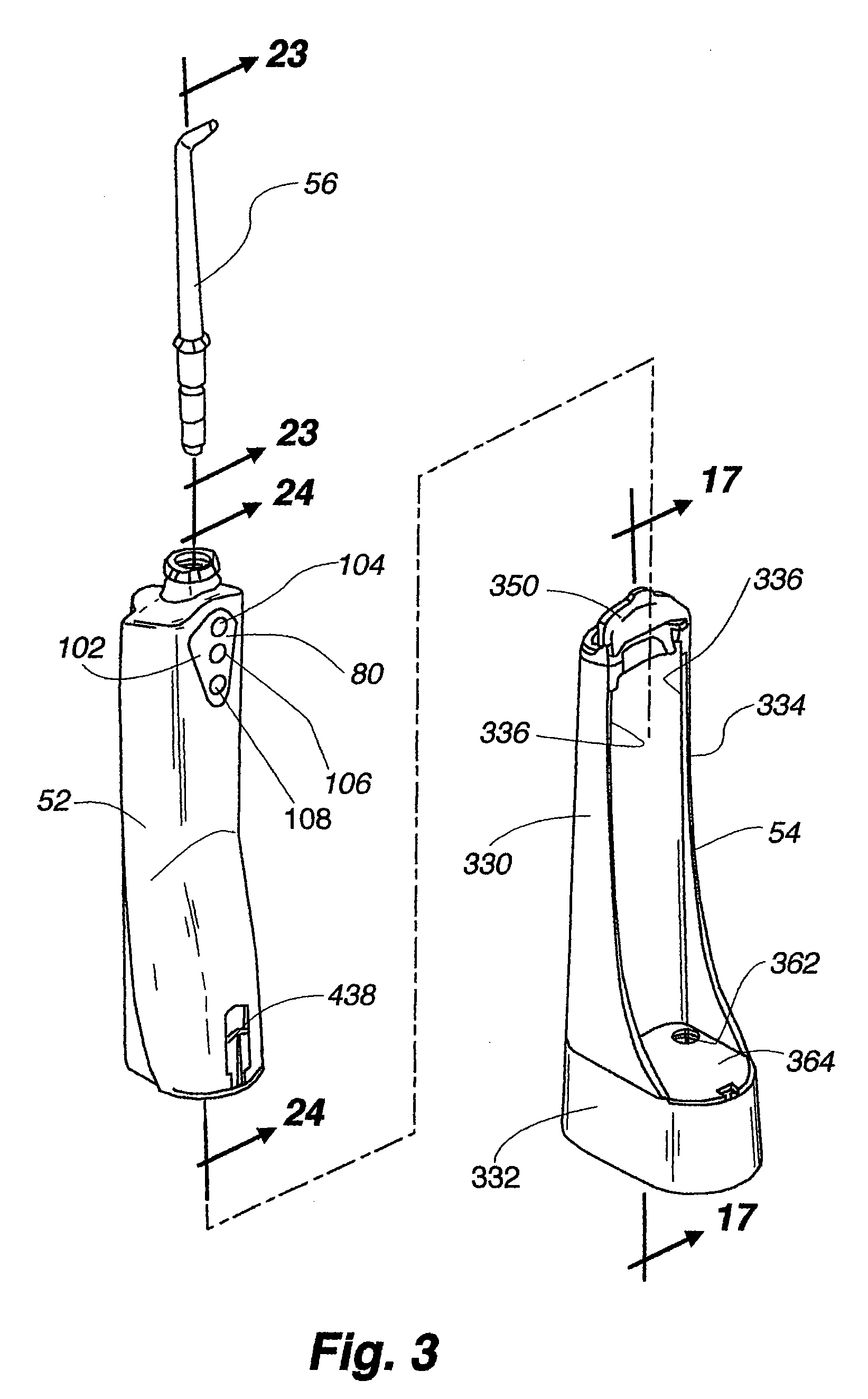

Hand held oral irrigator

According to one broad aspect of one embodiment of the present invention, disclosed herein is a hand held oral irrigation device having a tip for dispensing fluids. In one example, an oral irrigation device includes a body portion, and a reservoir for storing fluids, wherein the body and / or the reservoir define a first major diameter at a lower end of the oral irrigation device, and define a second major diameter at an upper end of the oral irrigation device, the first major diameter being larger than the second major diameter. In this example, by providing such a geometry for the device, a user can grasp the device with one hand about the second major diameter during use. In another example, the body includes a pump for pumping fluids from the reservoir to the tip, wherein the pump includes an inlet valve and an outlet valve, the inlet valve including a reed valve made of flexible fabric material. The outlet valve may also include a reed valve made of flexible fabric material.

Owner:WATER PIK INC

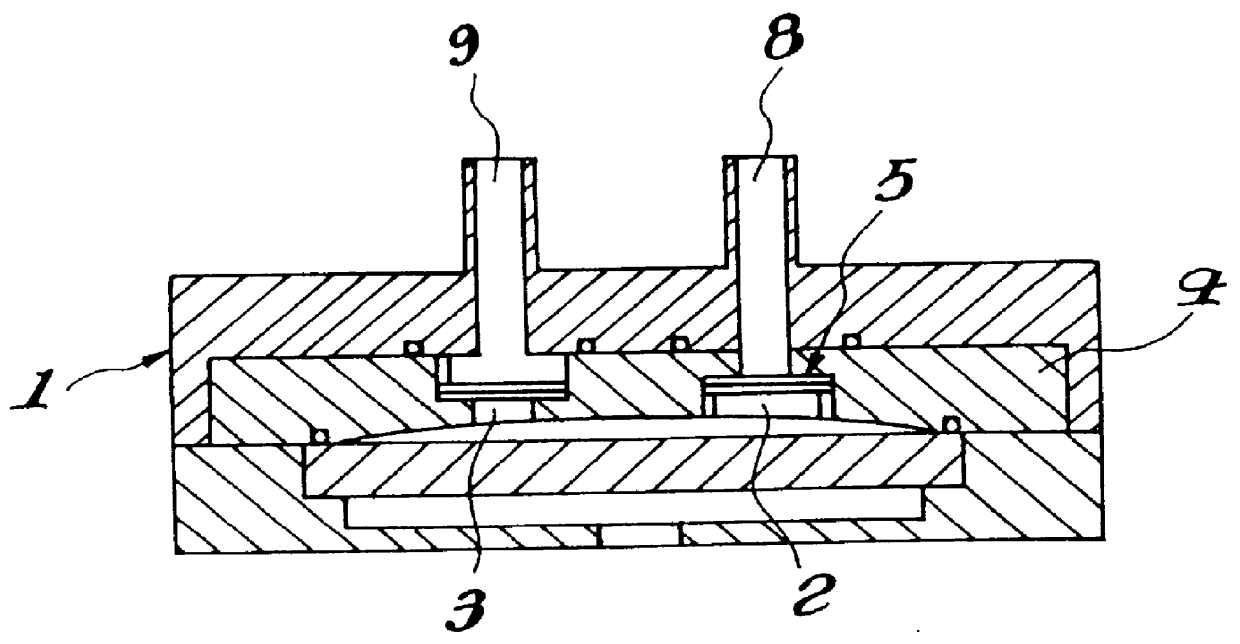

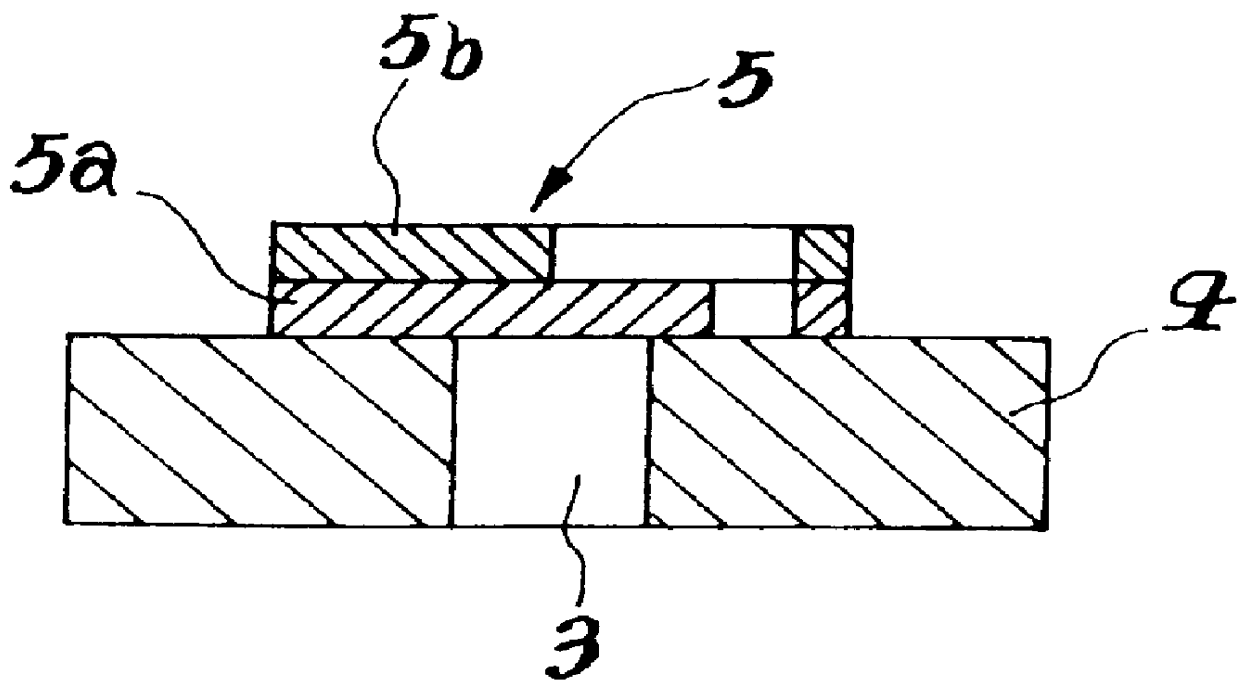

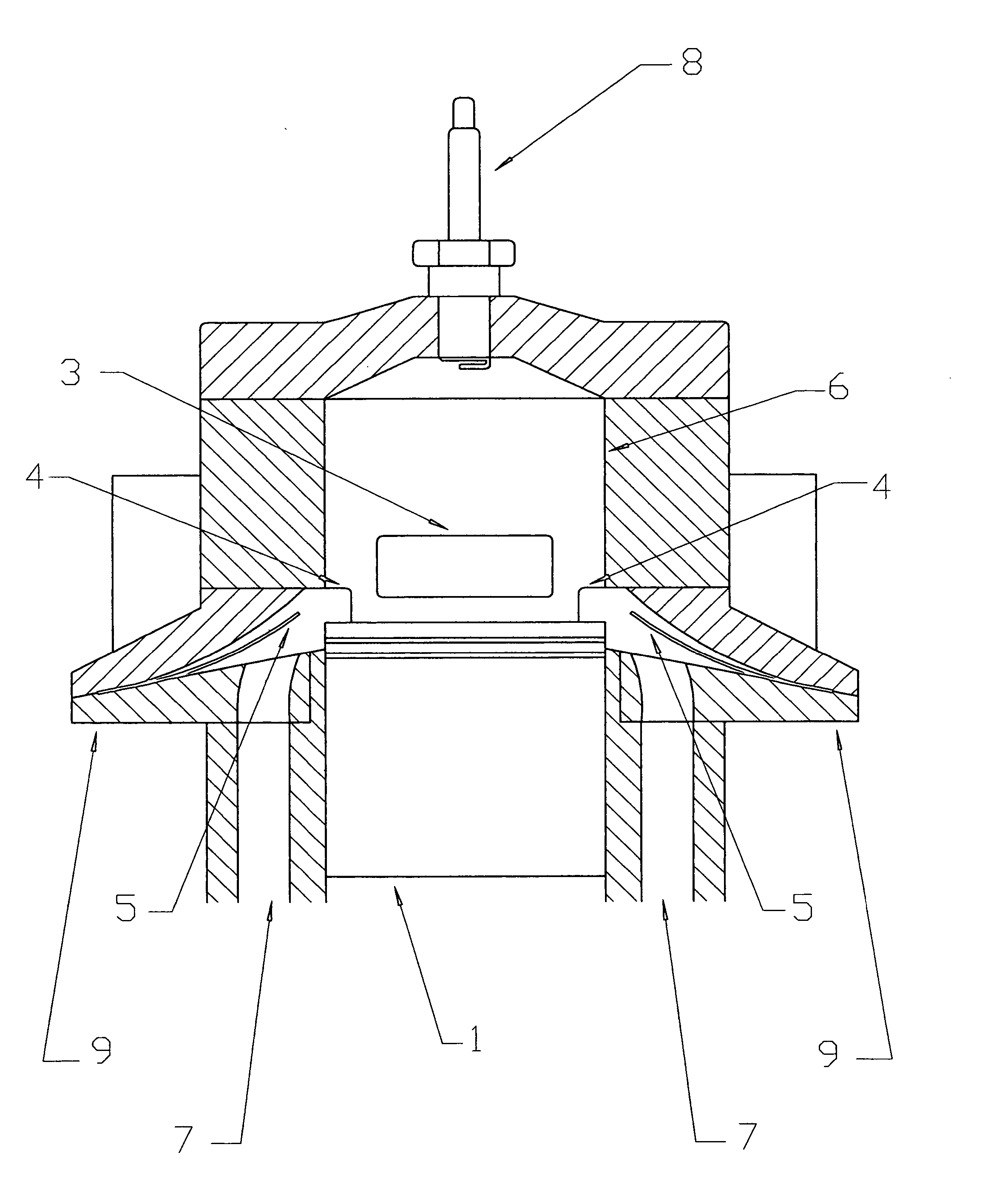

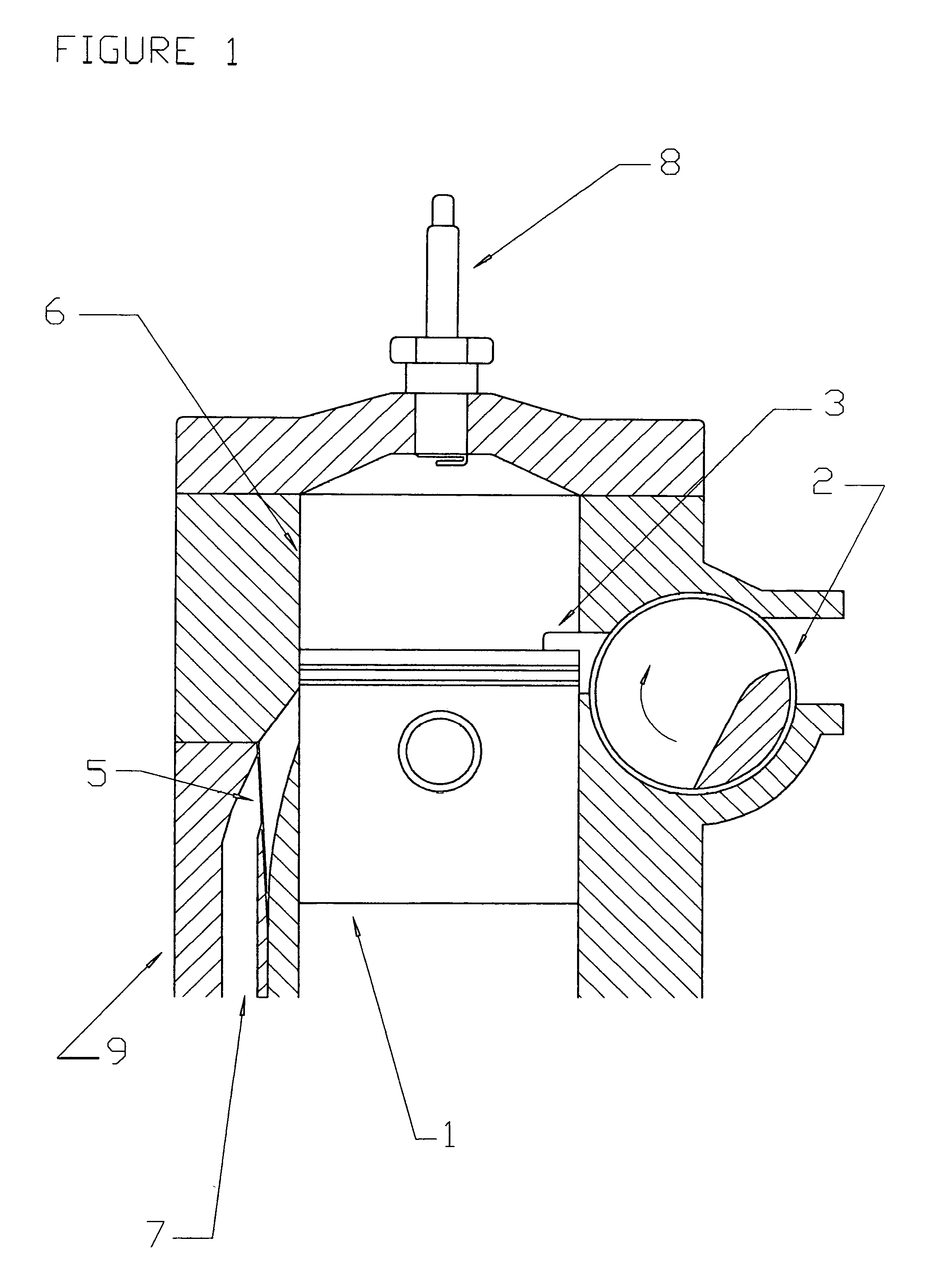

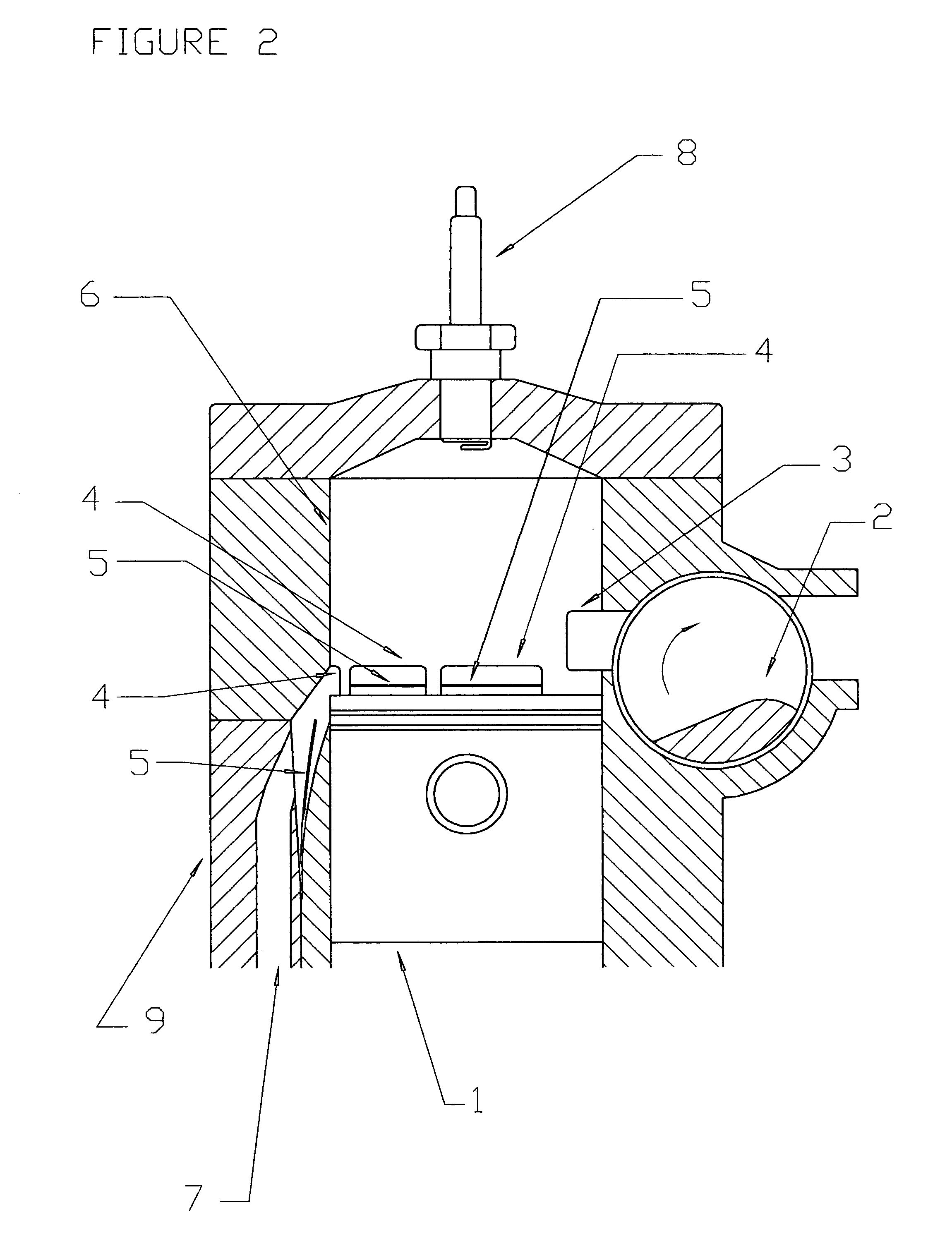

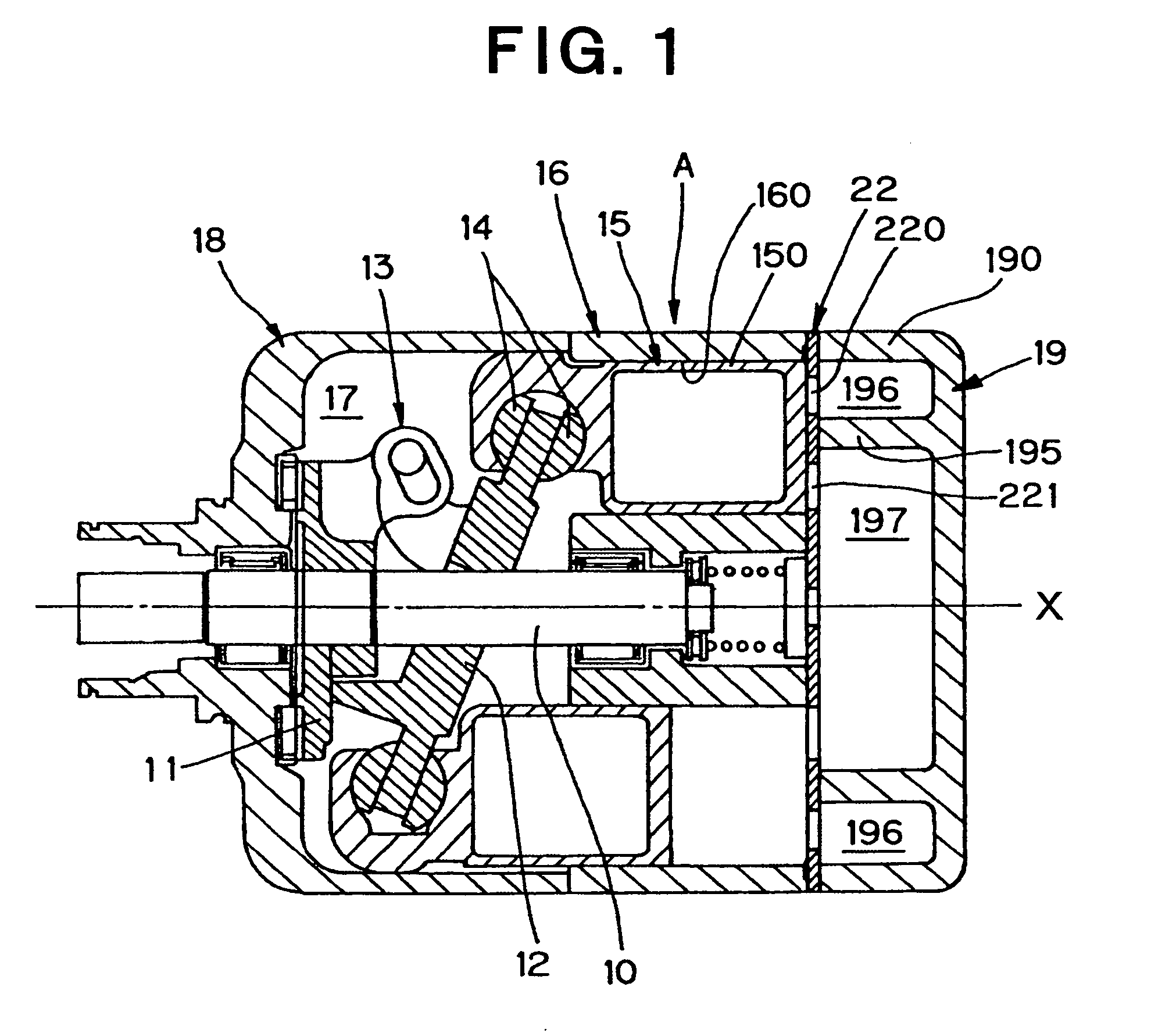

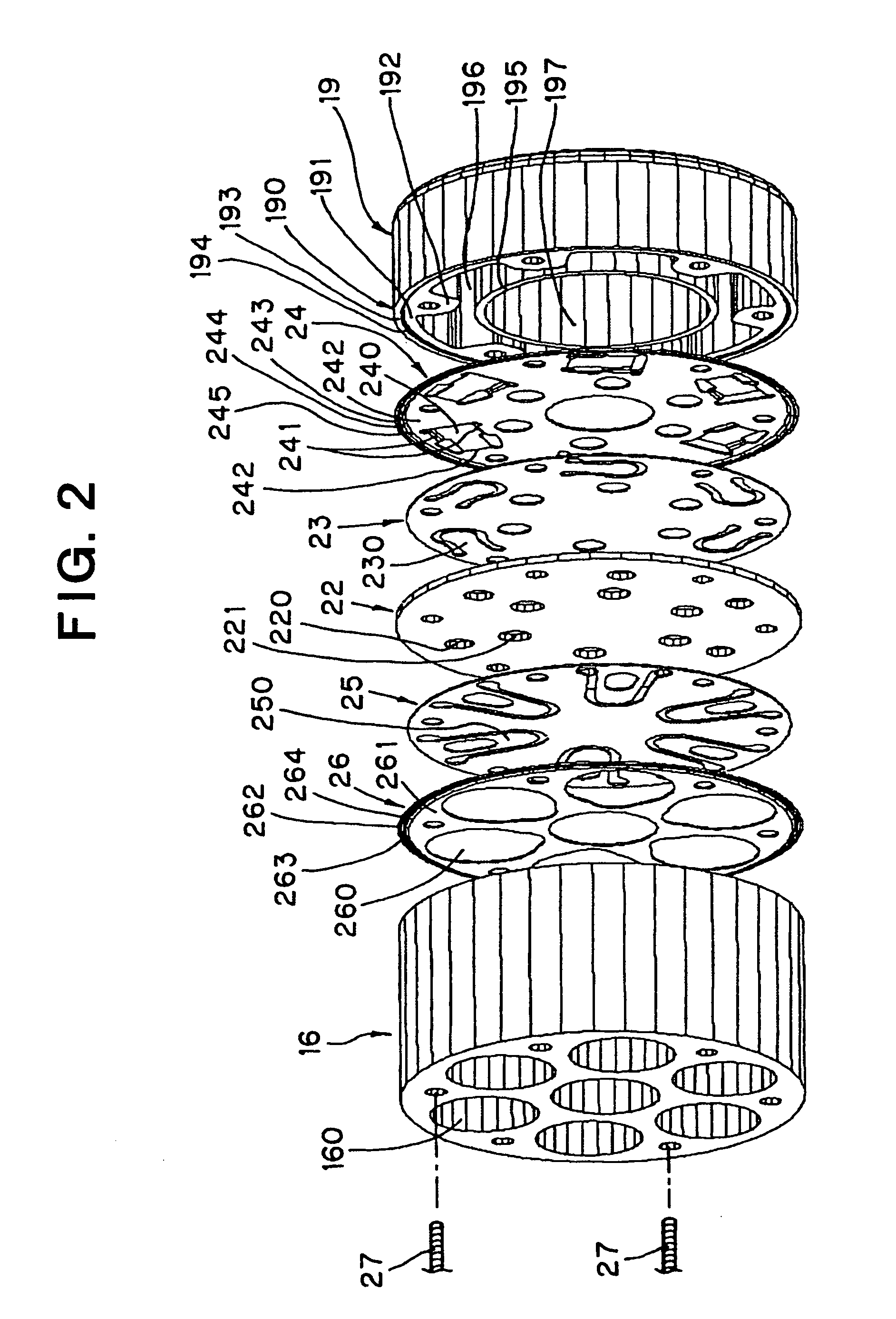

Reed valve for a pump

InactiveUS6116866APrevent backflowImprove sealingPositive displacement pump componentsFlexible member pumpsEngineeringReed valve

A reed valve is disclosed for use with a pump having a casing. A check valve unit is provided within the casing for preventing counterflow of fluids to be carried. A suction port communicates with a suction line into which the fluids to be carried flow, and a discharge port communicates with discharge line from which the fluids to be carried out are discharged. Reed valves are mounted on the suction port and on the discharge port of the check valve, respectively, in such a manner that the reed valves cover the suction port and the discharge port so as to be able to open and close. Each reed valve includes a first reed valve and second reed valve. The first reed valve is made of pliable material, and is formed to have a size capable of covering the entire respective suction port and discharge port. The second reed valve is smaller than first reed valve and is superposed on the first reed valve to engage the first reed valve such that the first reed valve can open and close, while enhancing sealability thereof.

Owner:NITTO KOHKI CO LTD

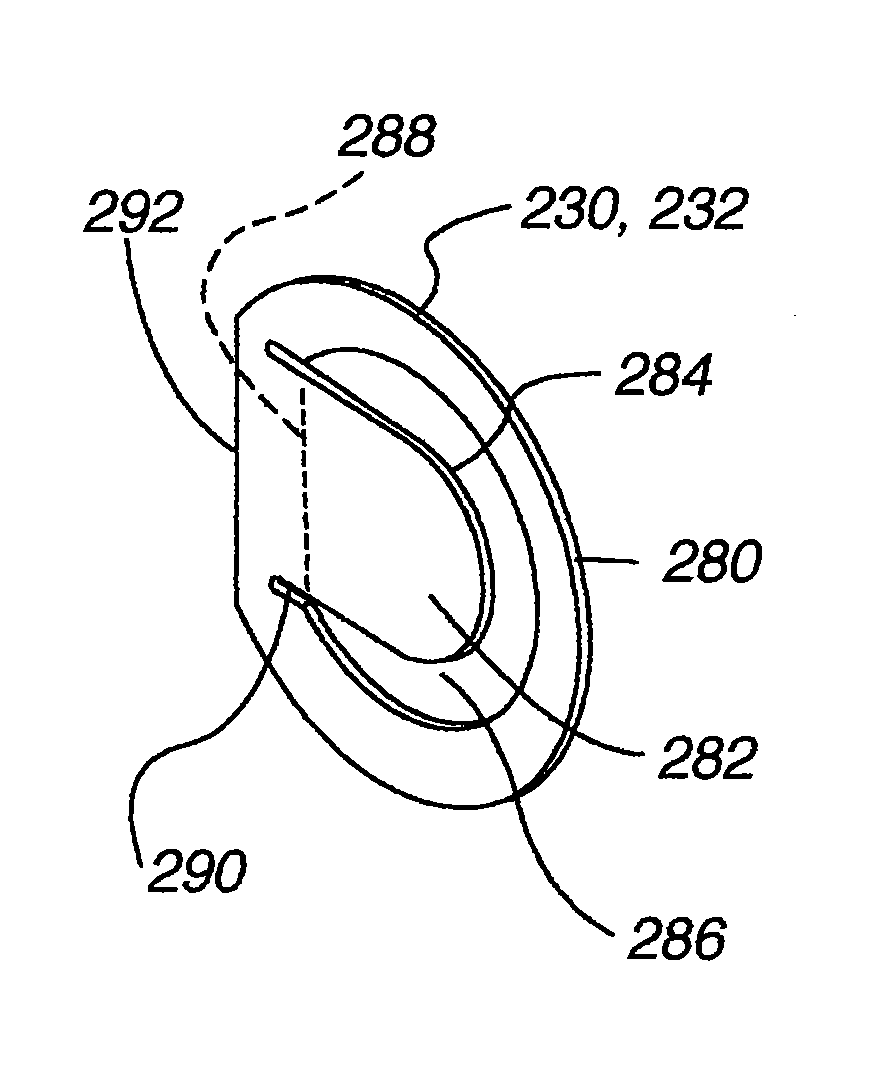

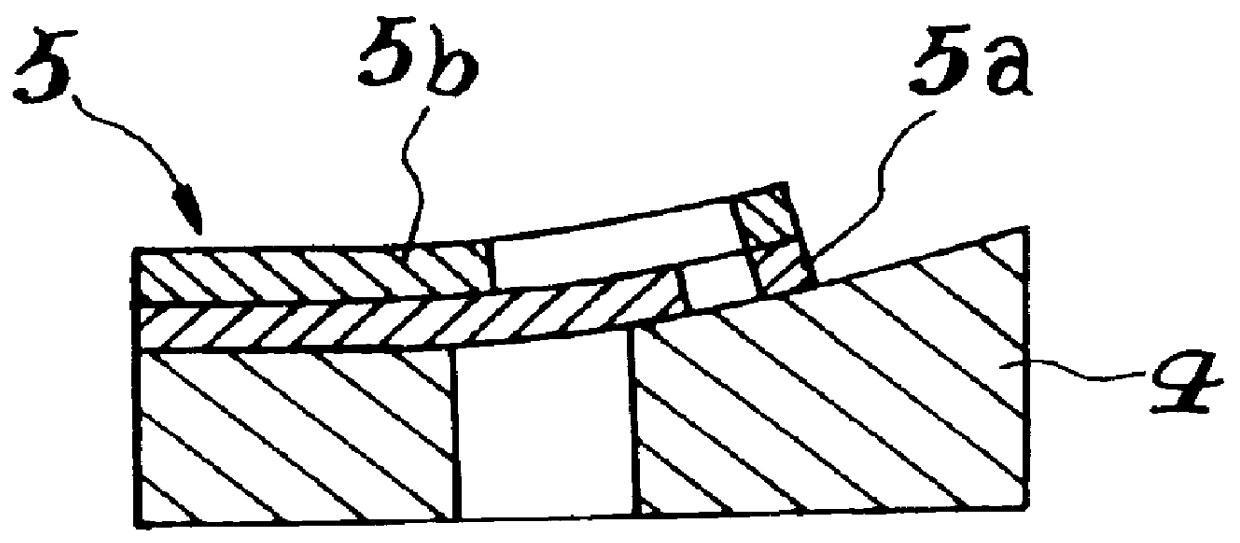

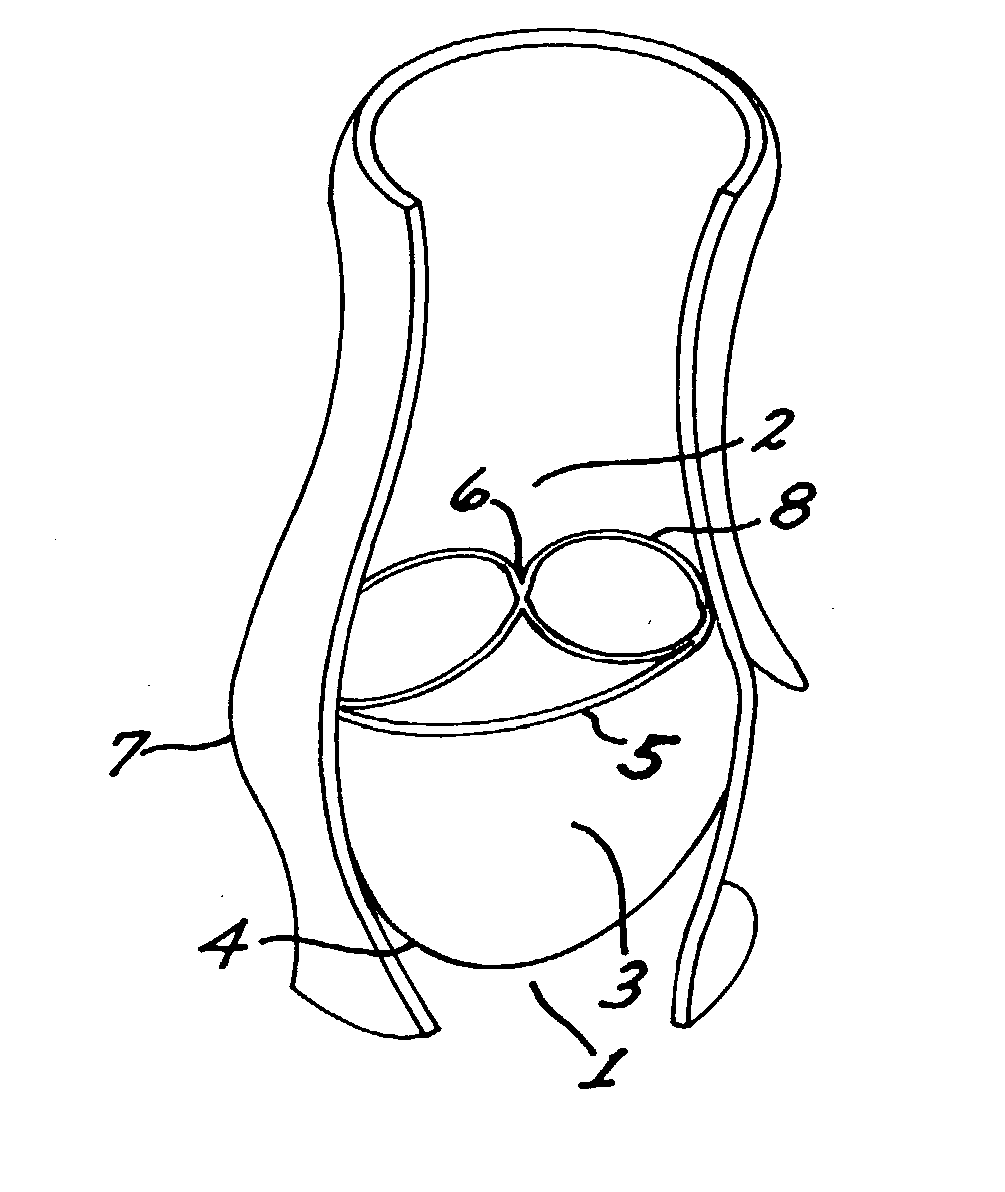

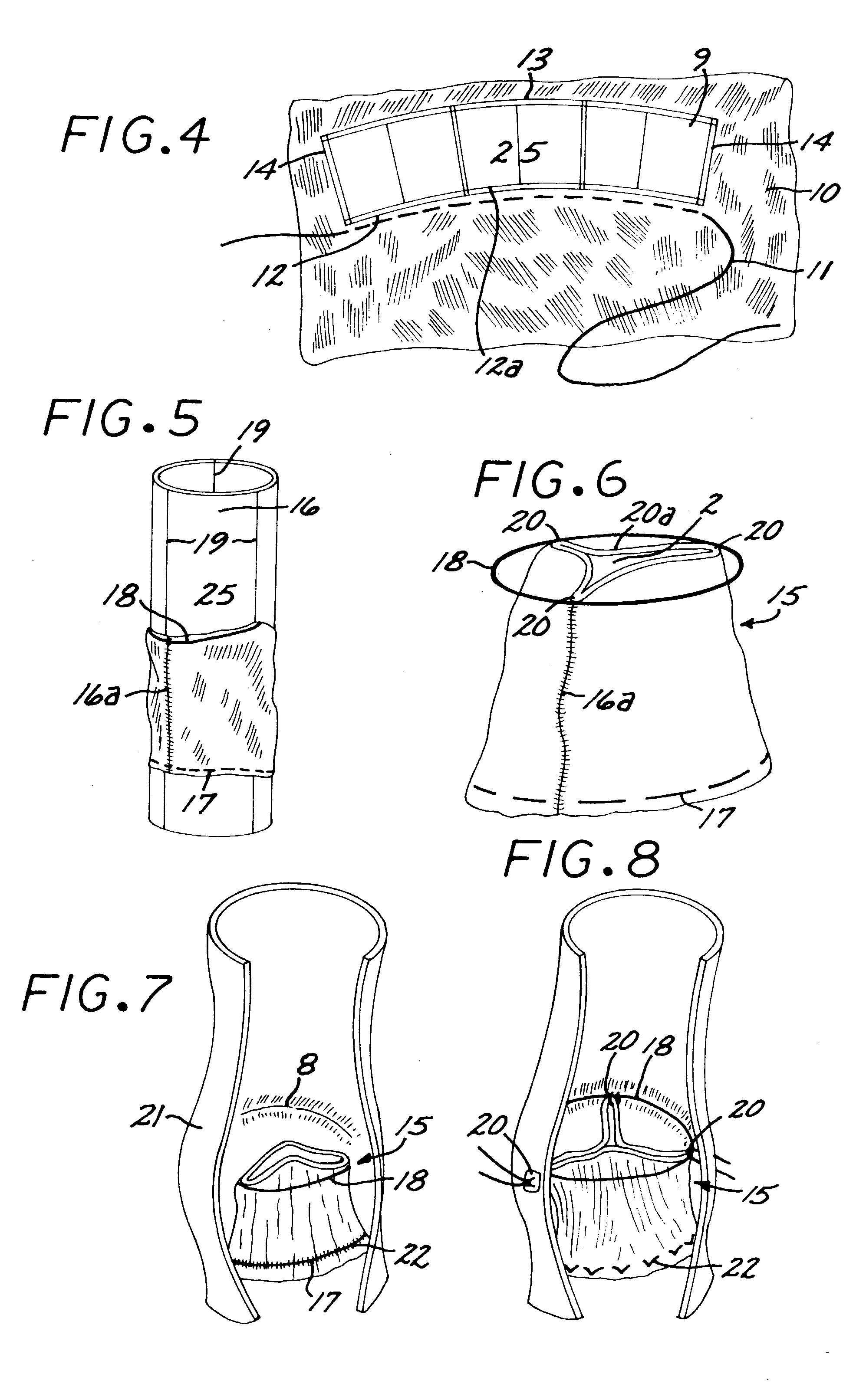

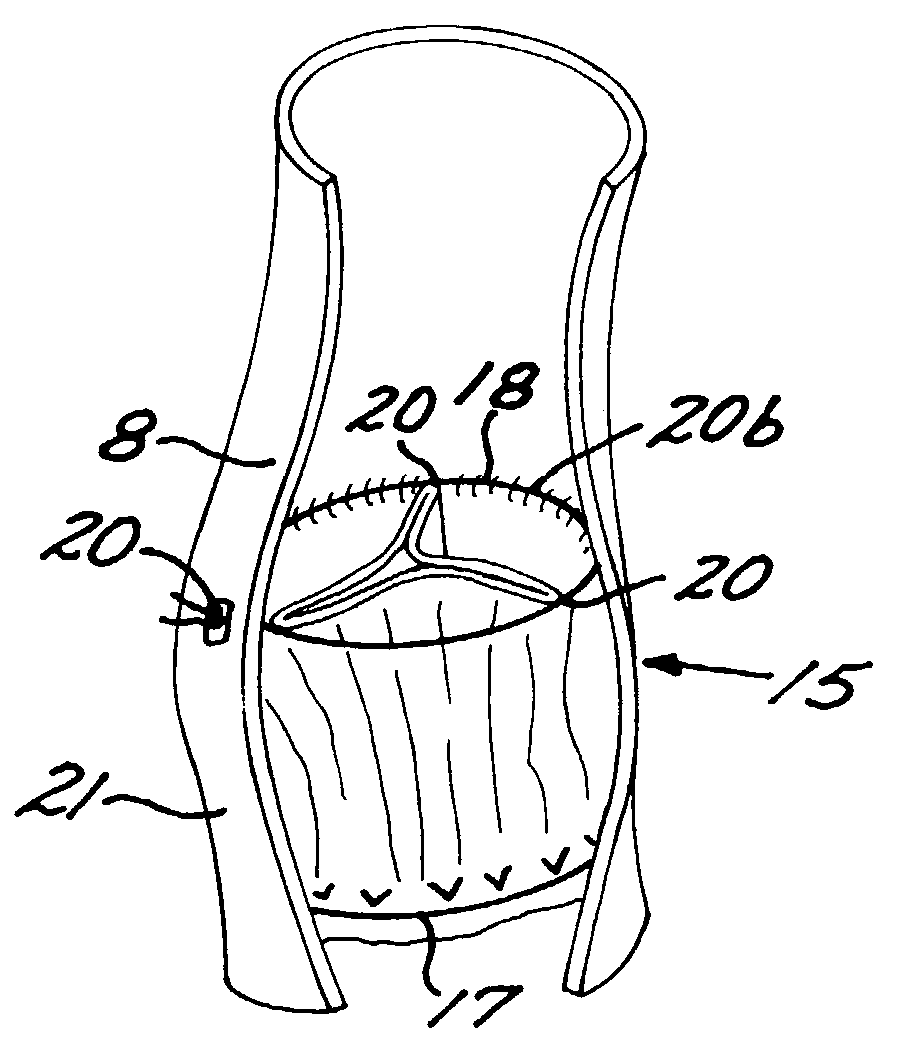

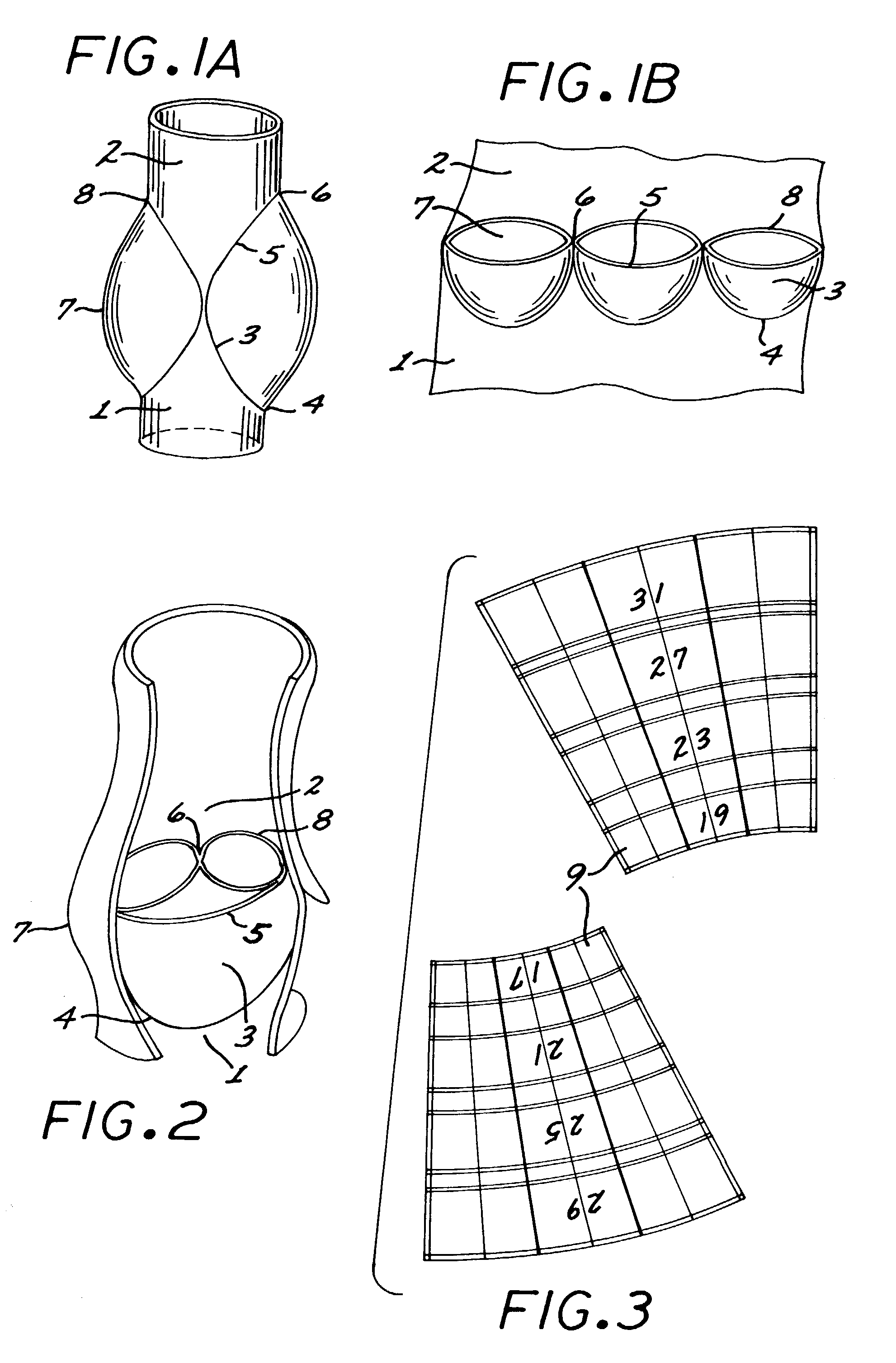

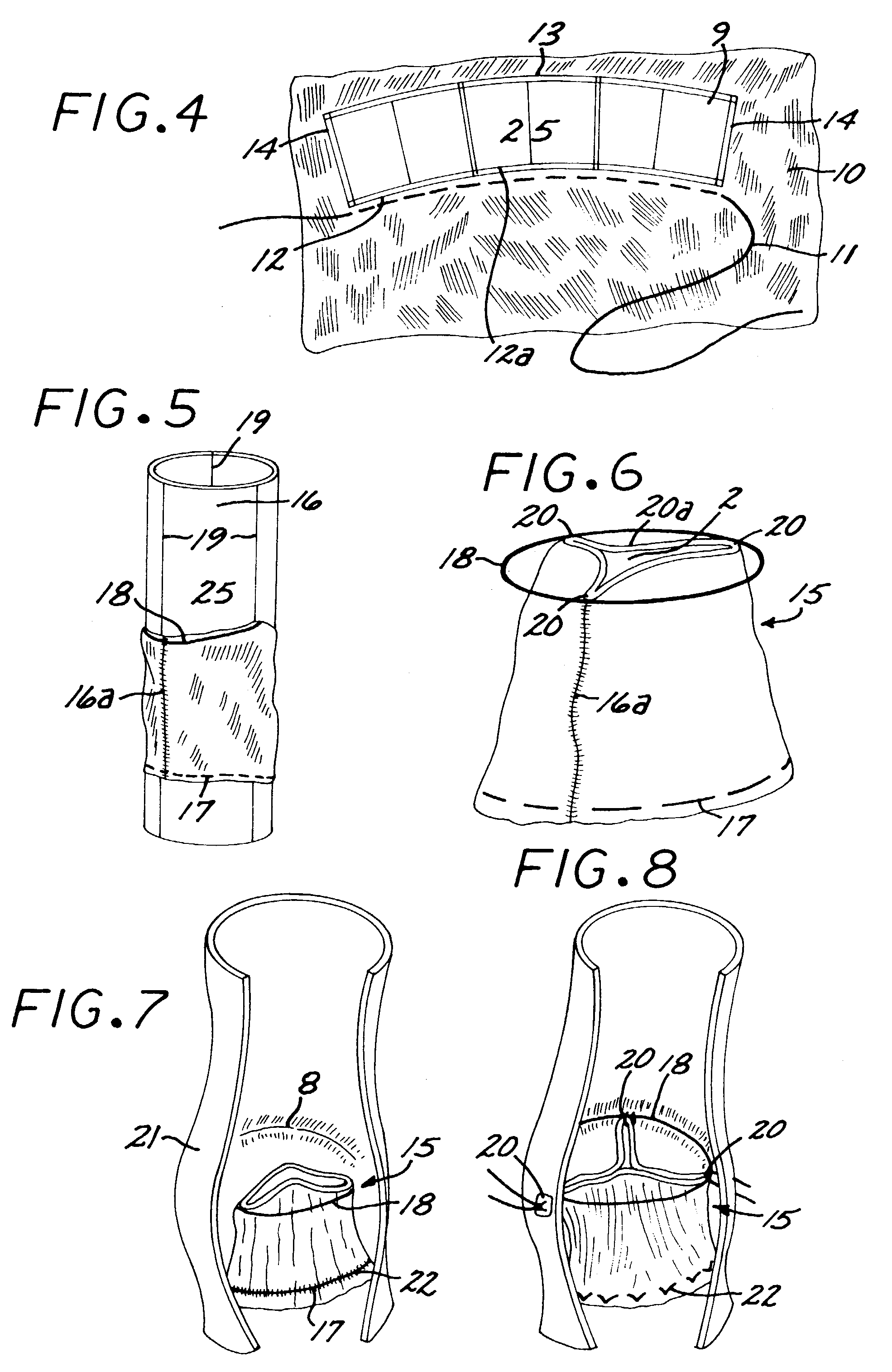

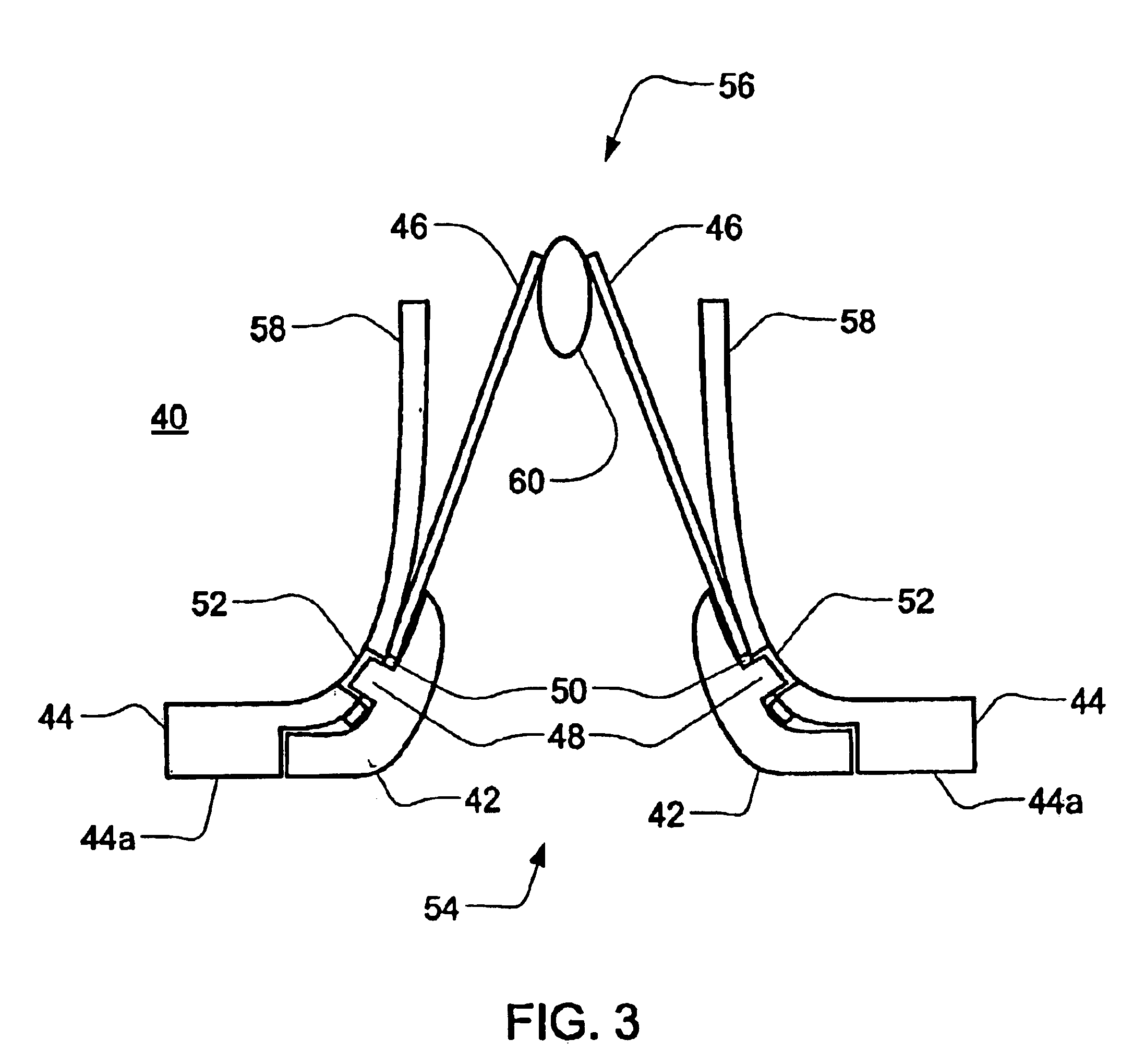

Reed valve for implantation into mammalian blood vessels and heart with optional temporary or permanent support

A multi-leaflet valve adapted to serve as a prosthesis for diseased native valve of a mammal is constructed of biologic membrane or of biocompatible synthetic membrane. The valve has the shape of a truncated cone that has an inflow and an outflow orifice with leaflets forming the outflow orifice and forming a plurality of commissures. A first flexible stent is removably affixed in a substantially circular fashion around the truncated cone in proximity of the inflow orifice, and a second flexible stent is removably affixed at the location of the commissures to form a circle around the truncated cone in proximity of the outflow orifice. The stents maintain the shape of the valve during the surgical implantation procedure. Each stent independently can be left in the valve or can be removed during the implantation procedure based upon the judgement of the cardiac surgeon performing the implantation procedure. A holder designed to maintain the geometry of the valve during implantation to a mammal is also disclosed.

Owner:THE INT HEART INST OF MONTANA FOUND

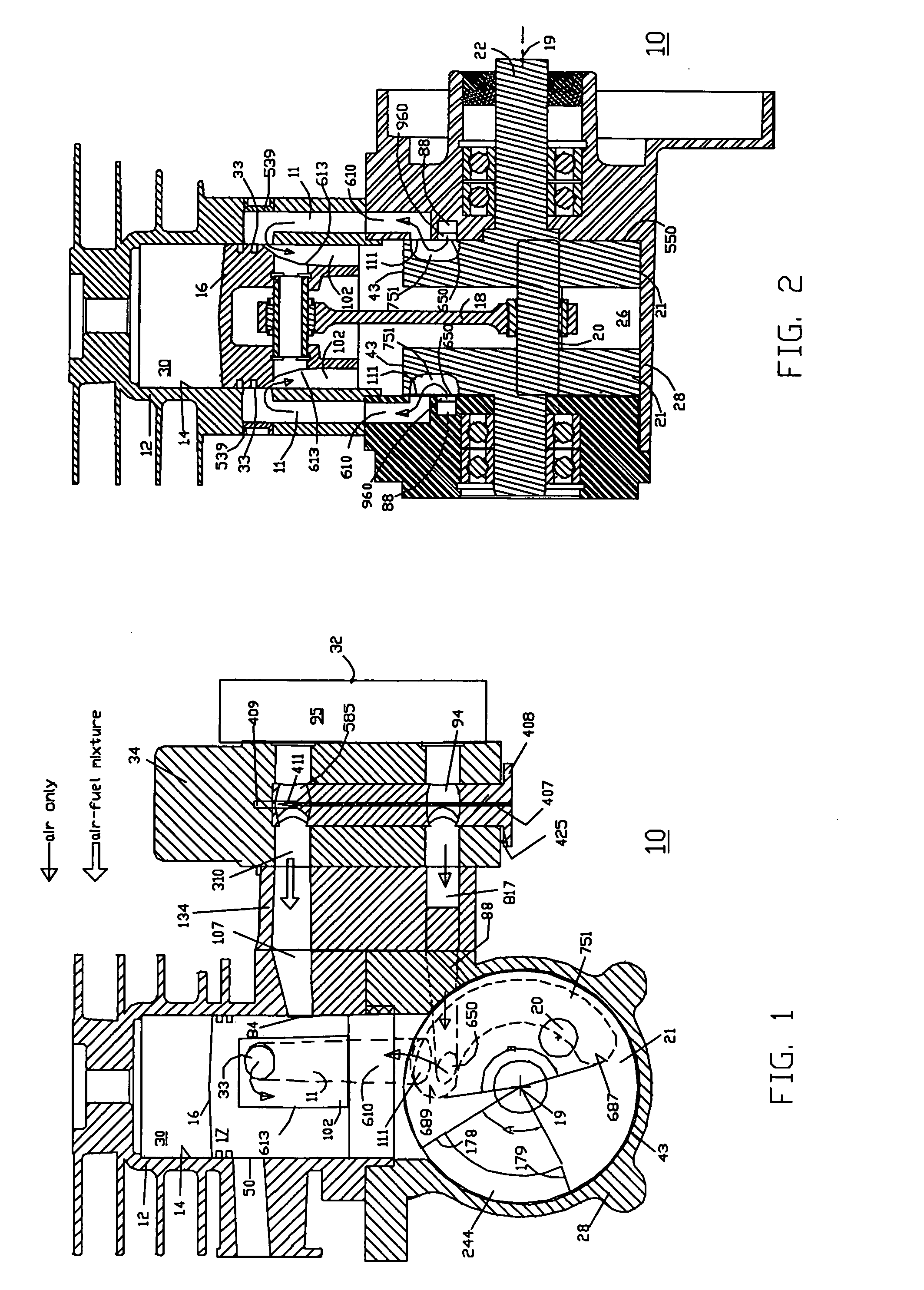

Stratified scavenged two-stroke engine

InactiveUS20050139179A1Increase volumeCombustion enginesEngine controllersCharge injectionFour-stroke engine

A two-stroke internal combustion engine includes at least one gaseous communication charge passage between a crankcase chamber and a combustion chamber of the engine and a piston to open and close the top end of the passage and a rotary valve to open and close the lower end of the transfer passage. The air inlet port to the transfer passage for stratified scavenging is opened and closed by the crank-web that has passages and cutouts. The rotary valve replaces the one-way reed valve used in stratified scavenged and charged two-stroke engines. The air passes from the lower end of transfer passage to the top end and into the crankcase through the piston passage, alternatively air may also pass through the adjacent transfer passage directly or through a passage in the piston into the crankcase. A two-stroke engine also consists of a charge injection system controlled by the crank web eliminating the one-way valve.

Owner:HOMELITE TECH

Reed valve for implantation into mammalian blood vessels and heart with optional temporary or permanent support

A multi-leaflet valve adapted to serve as a prosthesis for diseased native valve of a mammal is constructed of biologic membrane or of biocompatible synthetic membrane. The valve has the shape of a truncated cone that has an inflow and an outflow orifice with leaflets forming the outflow orifice and forming a plurality of commissures. A first flexible stent is removably affixed in a substantially circular fashion around the truncated cone in proximity of the inflow orifice, and a second flexible stent is removably affixed at the location of the commissures to form a circle around the truncated cone in proximity of the outflow orifice. The stents maintain the shape of the valve during the surgical implantation procedure. Each stent independently can be left in the valve or can be removed during the implantation procedure based upon the judgement of the cardiac surgeon performing the implantation procedure. A holder designed to maintain the geometry of the valve during implantation to a mammal is also disclosed.

Owner:THE INT HEART INST OF MONTANA FOUND

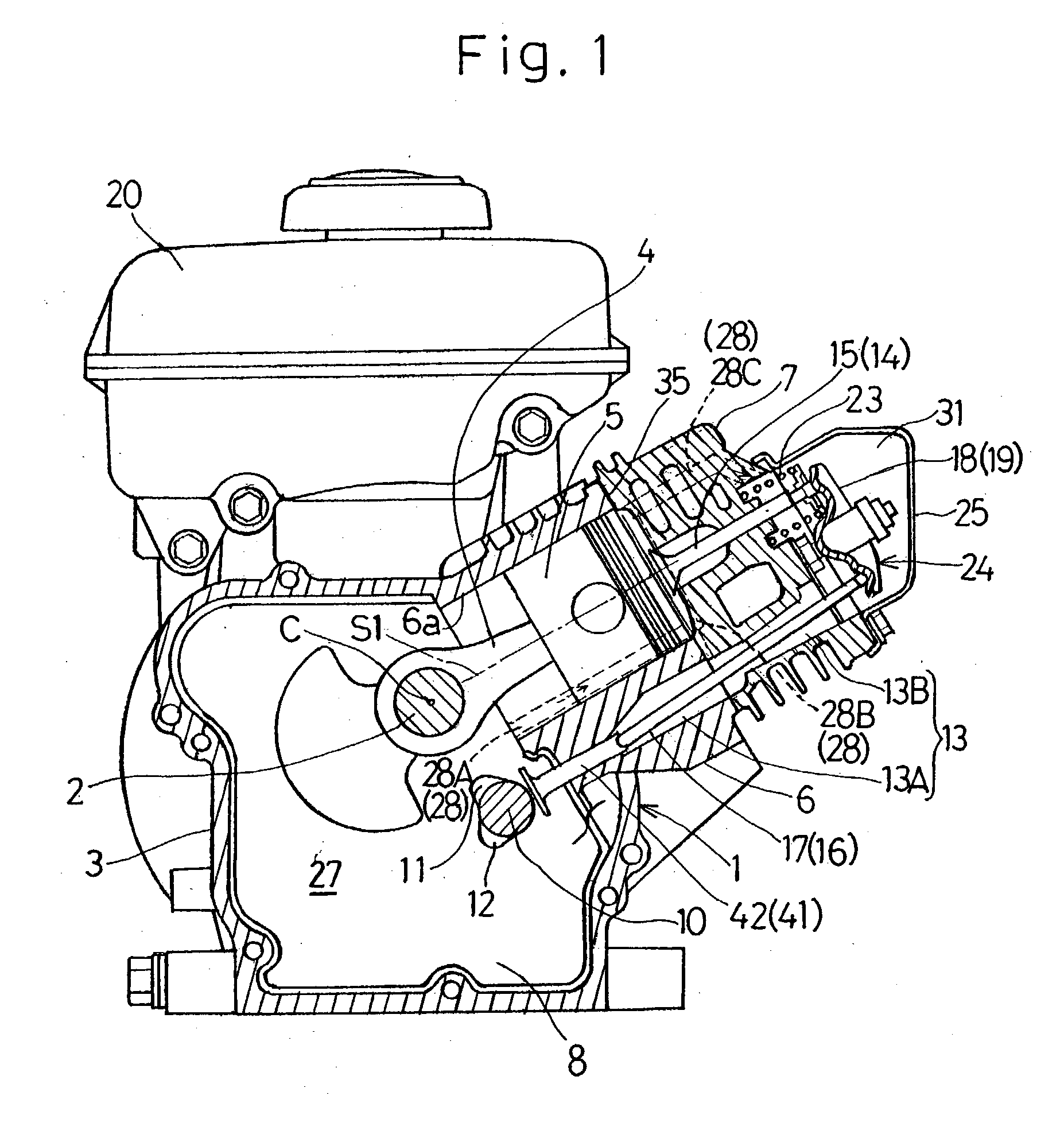

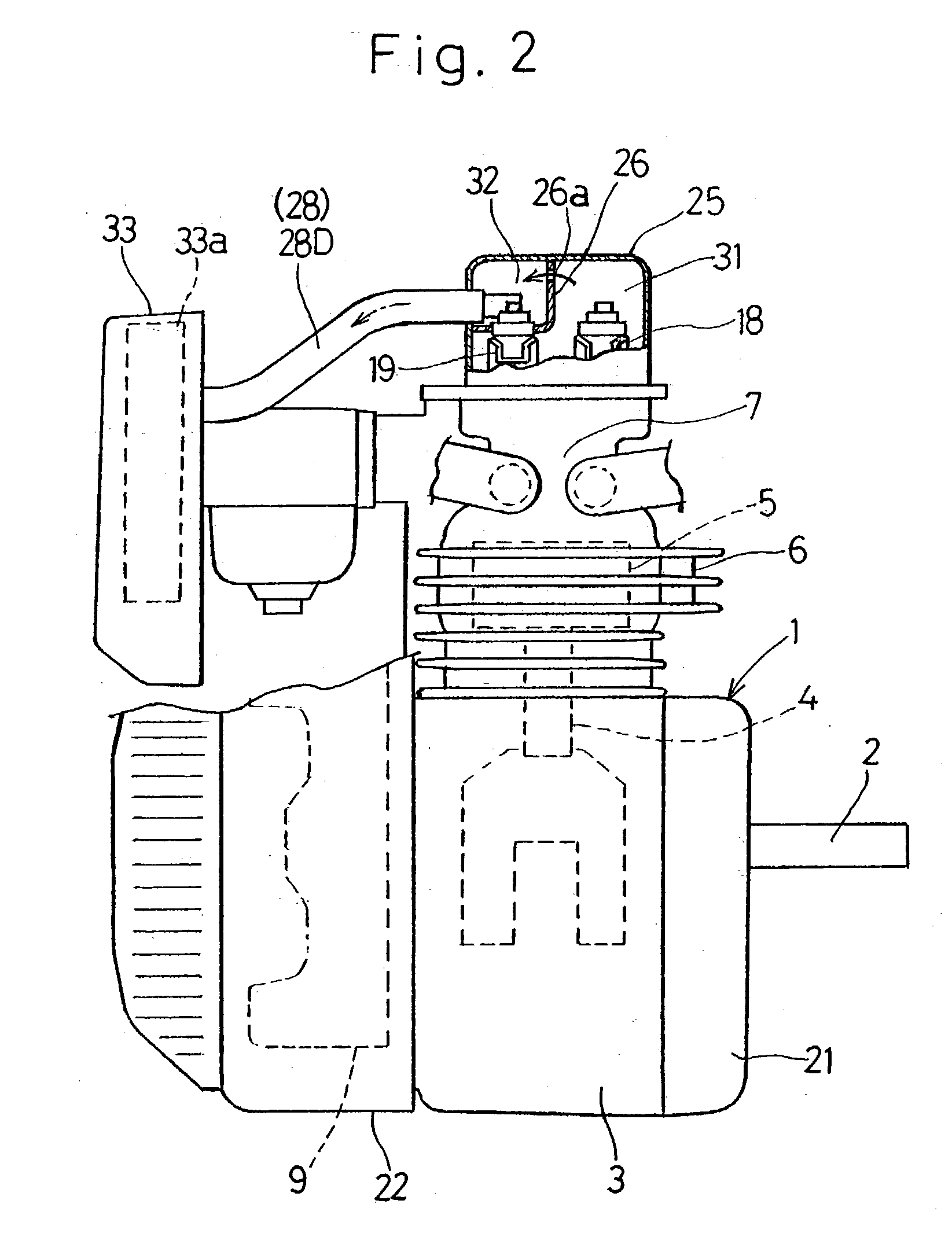

Two-cycle combustion engine with air scavenging system

ActiveUS6978744B2Simple structureReduce the number of partsCombustion enginesCarburettorsCombustion chamberEngineering

Owner:KAWASAKI MOTORS LTD

Hand held oral irrigator

According to one broad aspect of one embodiment of the present invention, disclosed herein is a hand held oral irrigation device having a tip for dispensing fluids. In one example, an oral irrigation device includes a body portion, and a reservoir for storing fluids, wherein the body and / or the reservoir define a first major diameter at a lower end of the oral irrigation device, and define a second major diameter at an upper end of the oral irrigation device, the first major diameter being larger than the second major diameter. In this example, by providing such a geometry for the device, a user can grasp the device with one hand about the second major diameter during use. In another example, the body includes a pump for pumping fluids from the reservoir to the tip, wherein the pump includes an inlet valve and an outlet valve, the inlet valve including a reed valve made of flexible fabric material. The outlet valve may also include a reed valve made of flexible fabric material.

Owner:WATER PIK INC

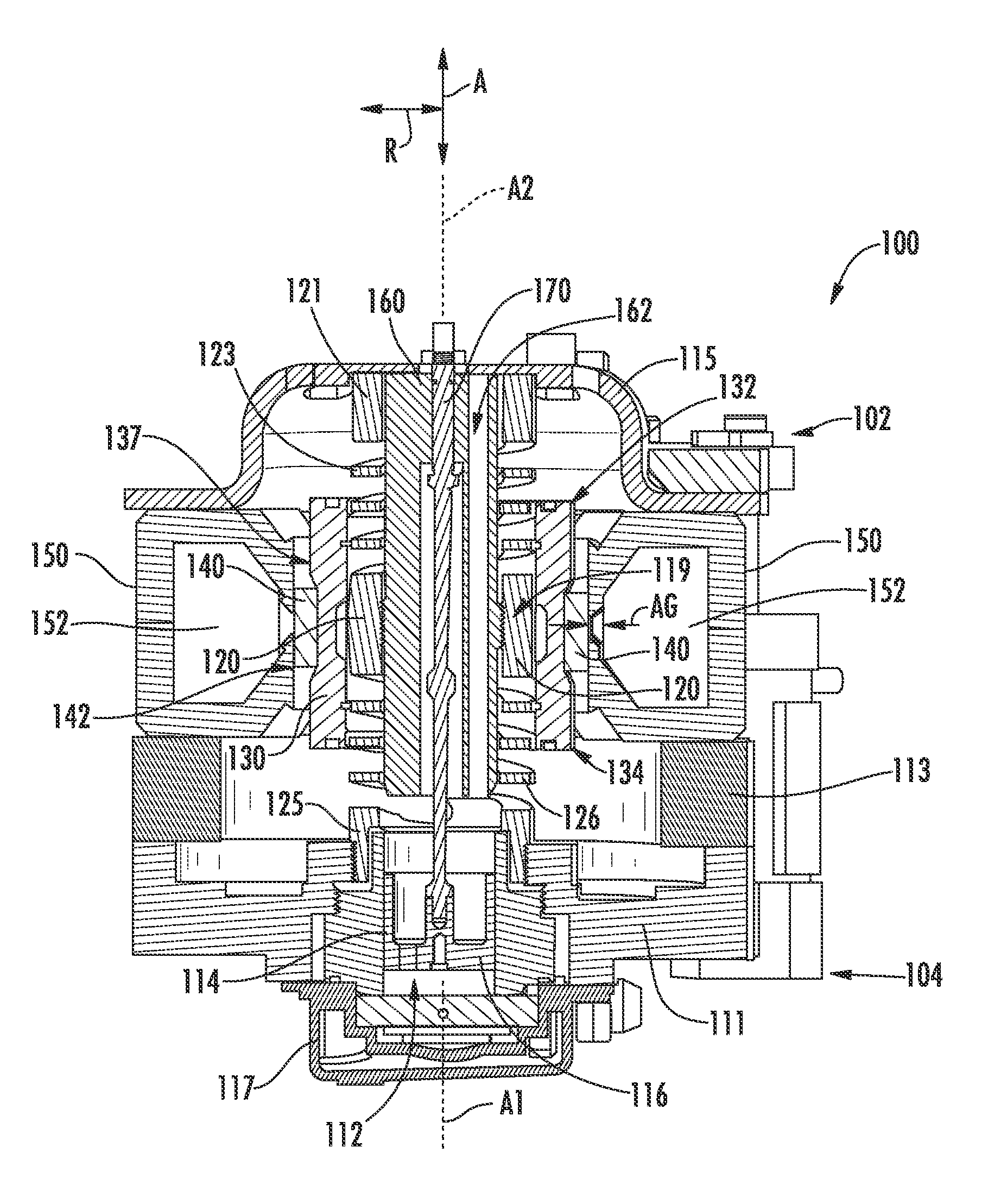

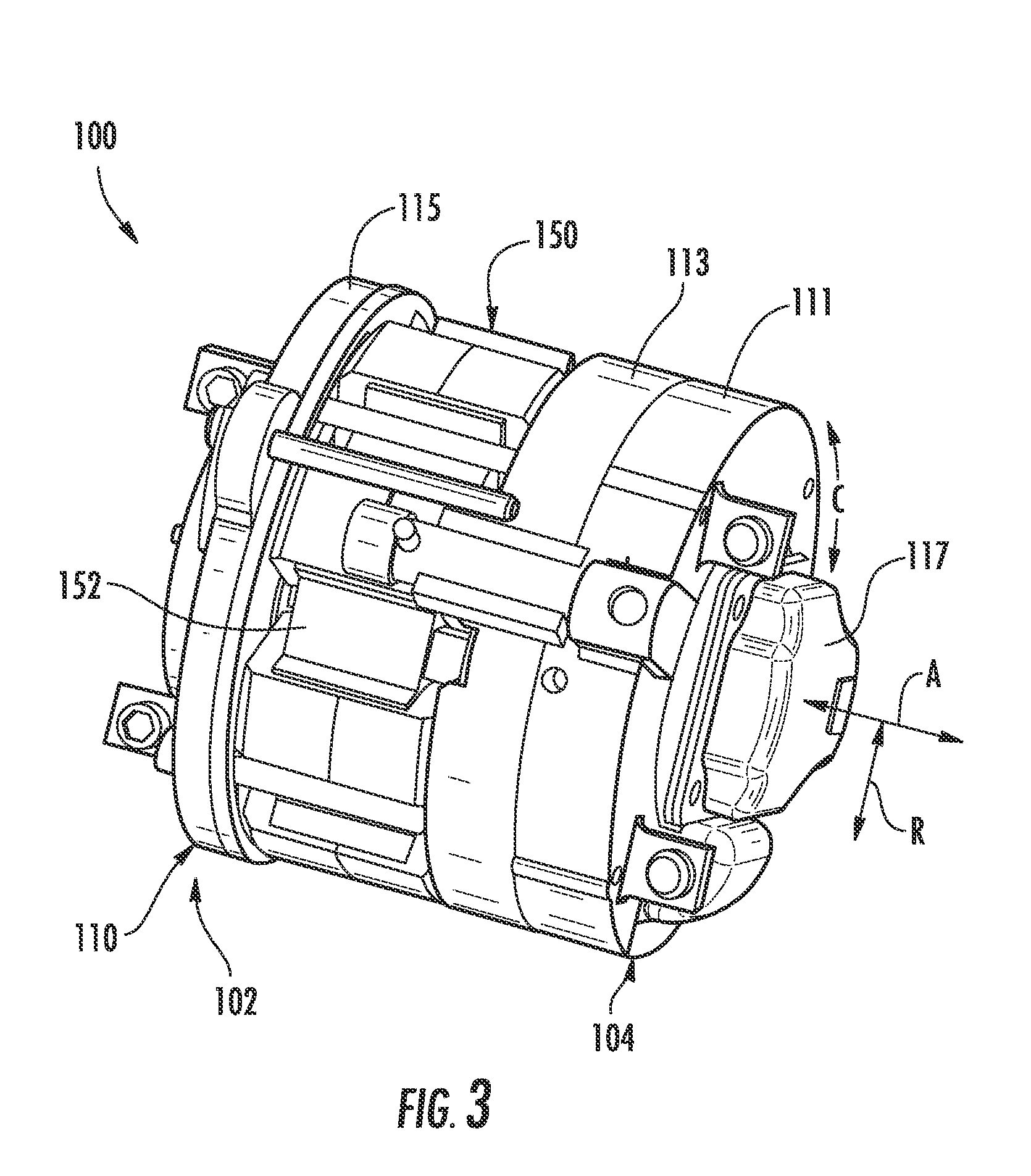

Linear compressor

A linear compressor is provided. The linear compressor includes a piston. The piston includes a piston cylinder having a head plate. The head plate defines a passage that extends through the head plate. A reed valve is mounted to the head plate and positioned over the passage of the head plate. A valve seat is positioned at and extends about the passage of the head plate.

Owner:HAIER US APPLIANCE SOLUTIONS INC

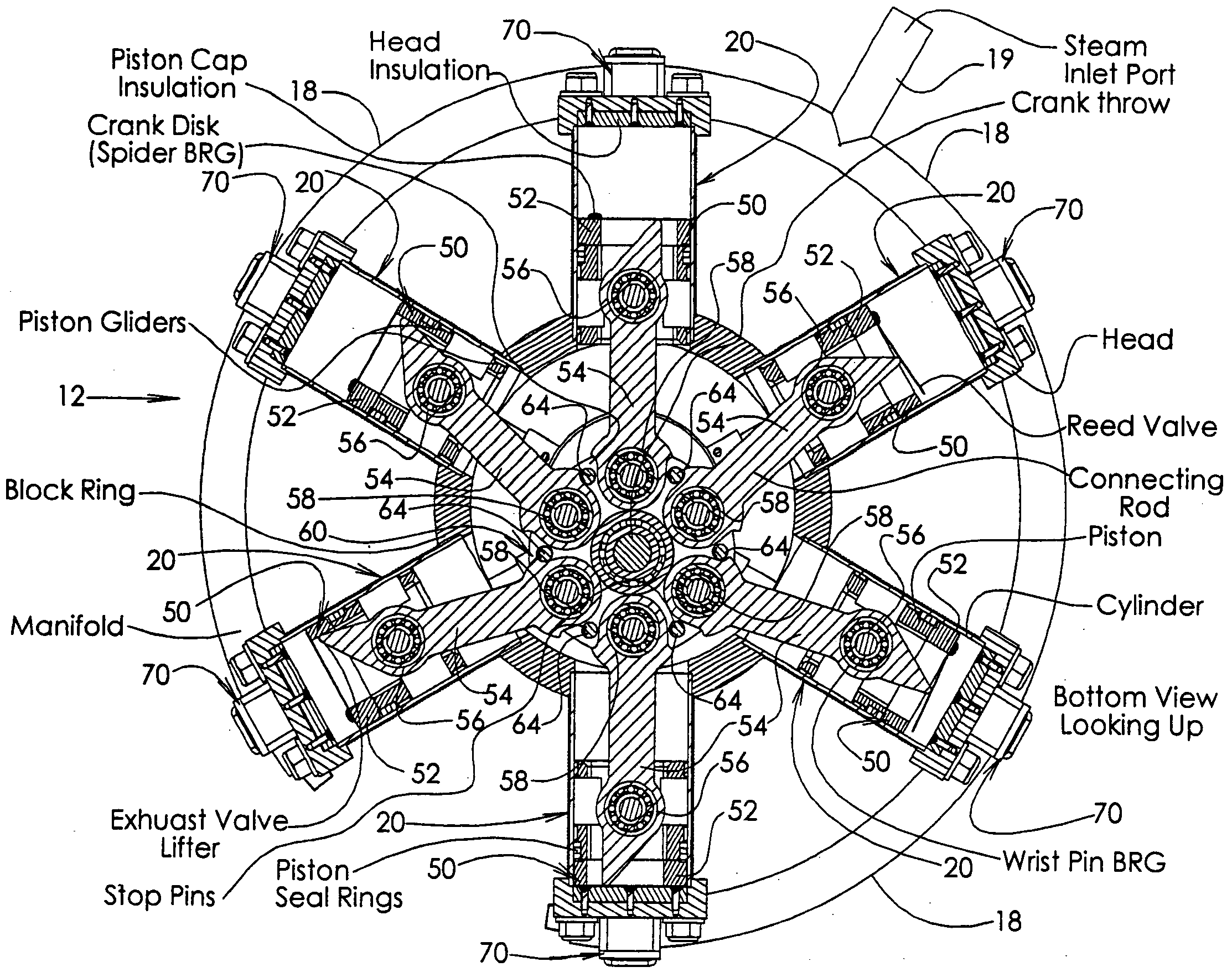

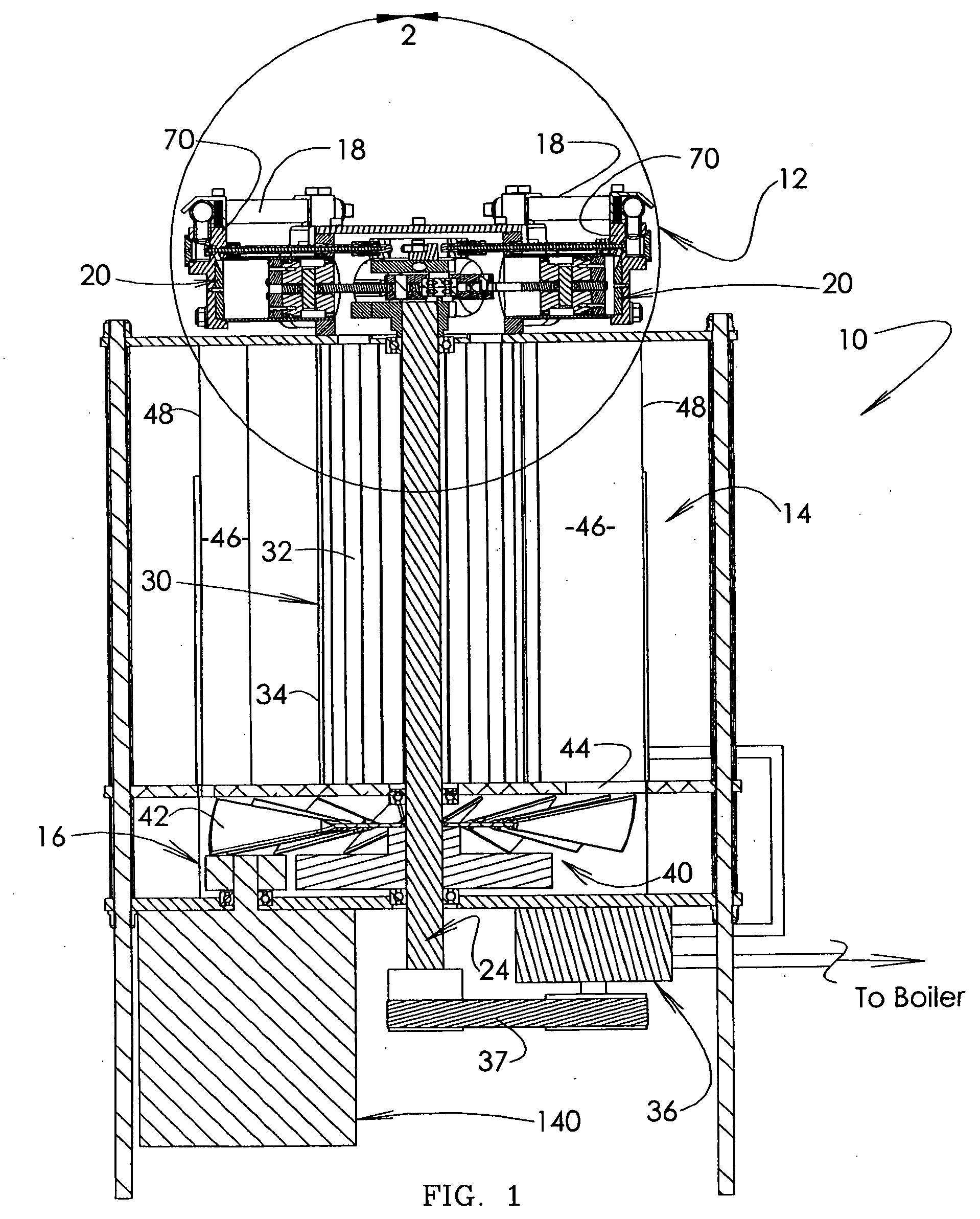

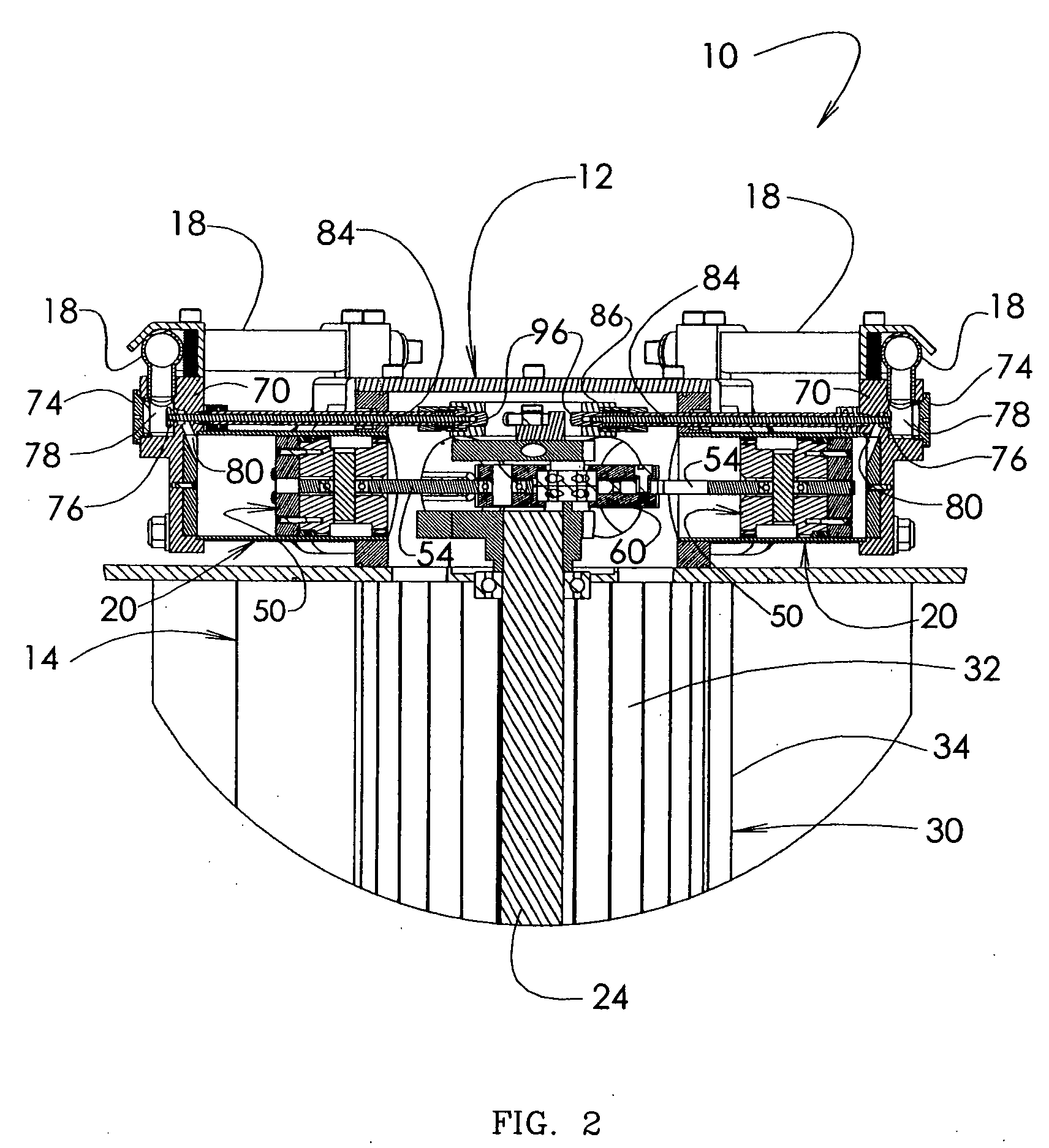

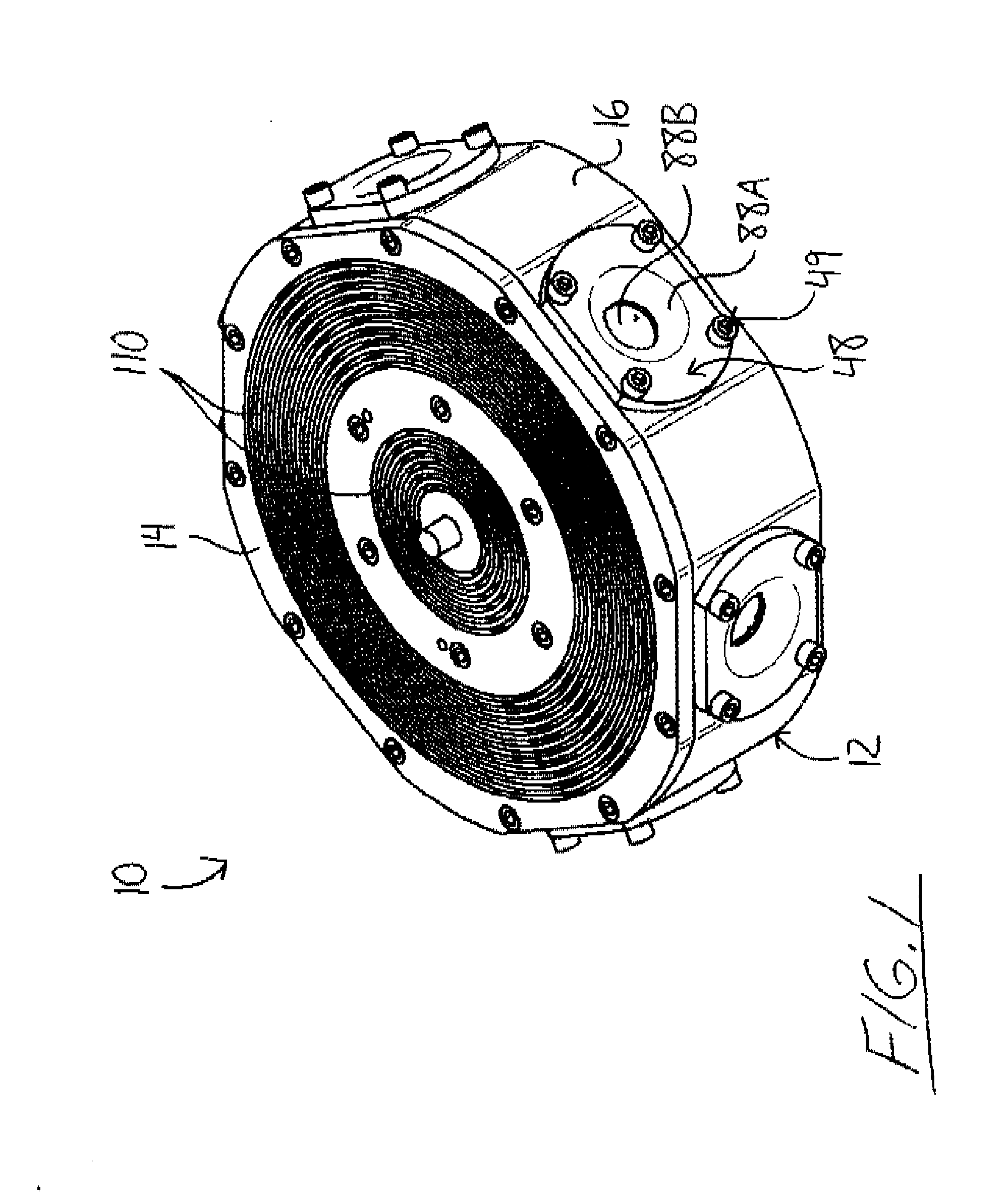

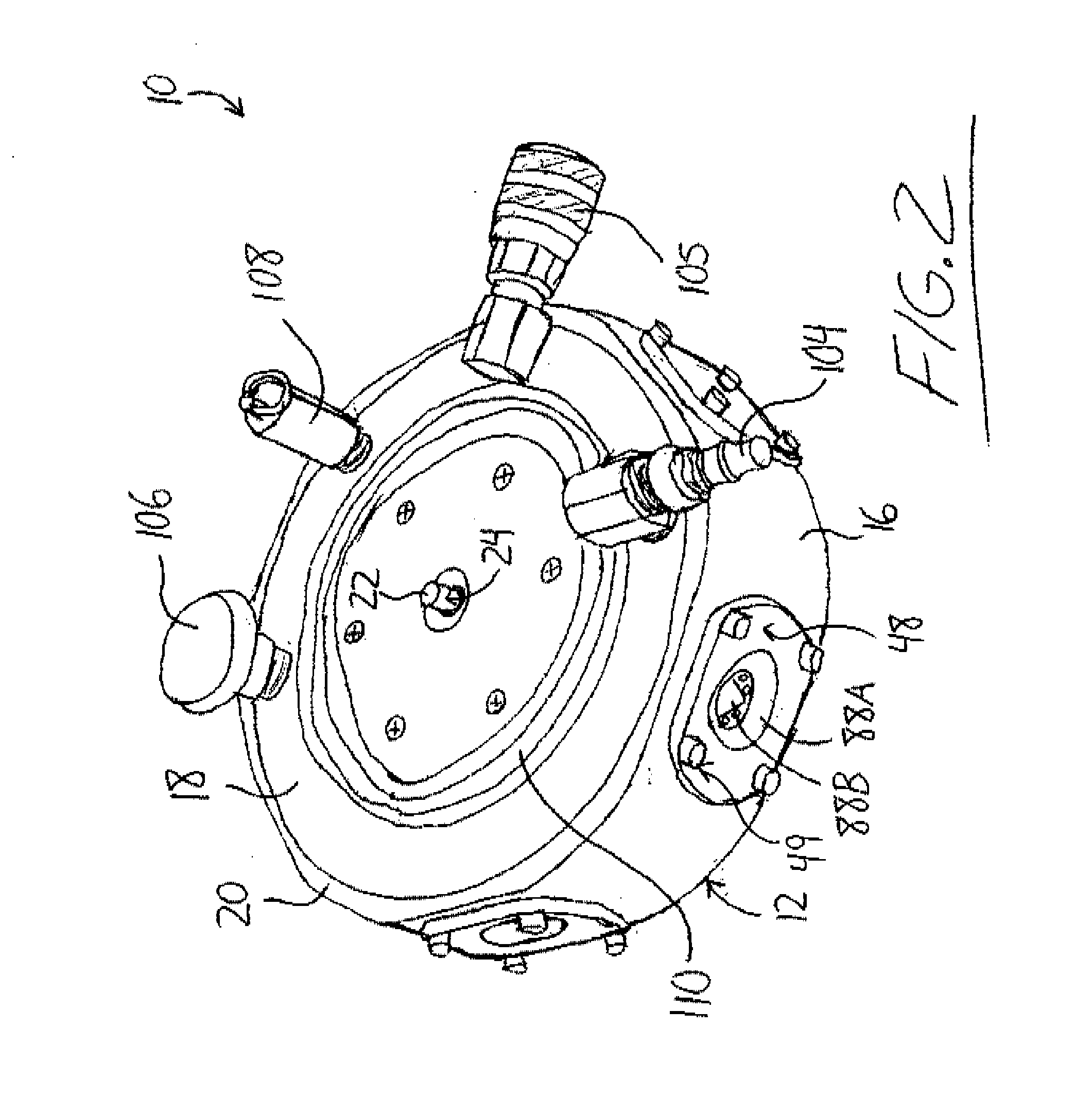

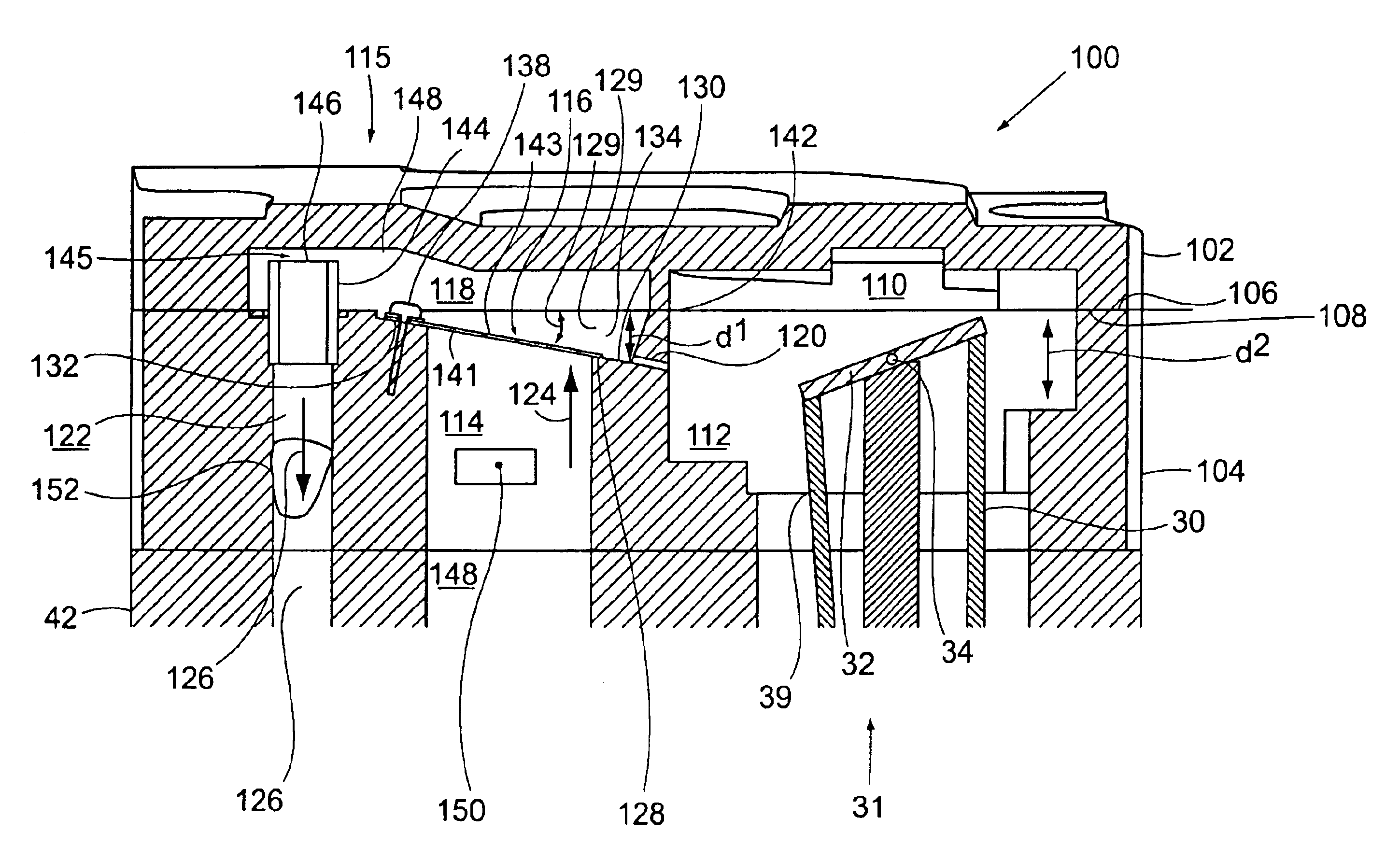

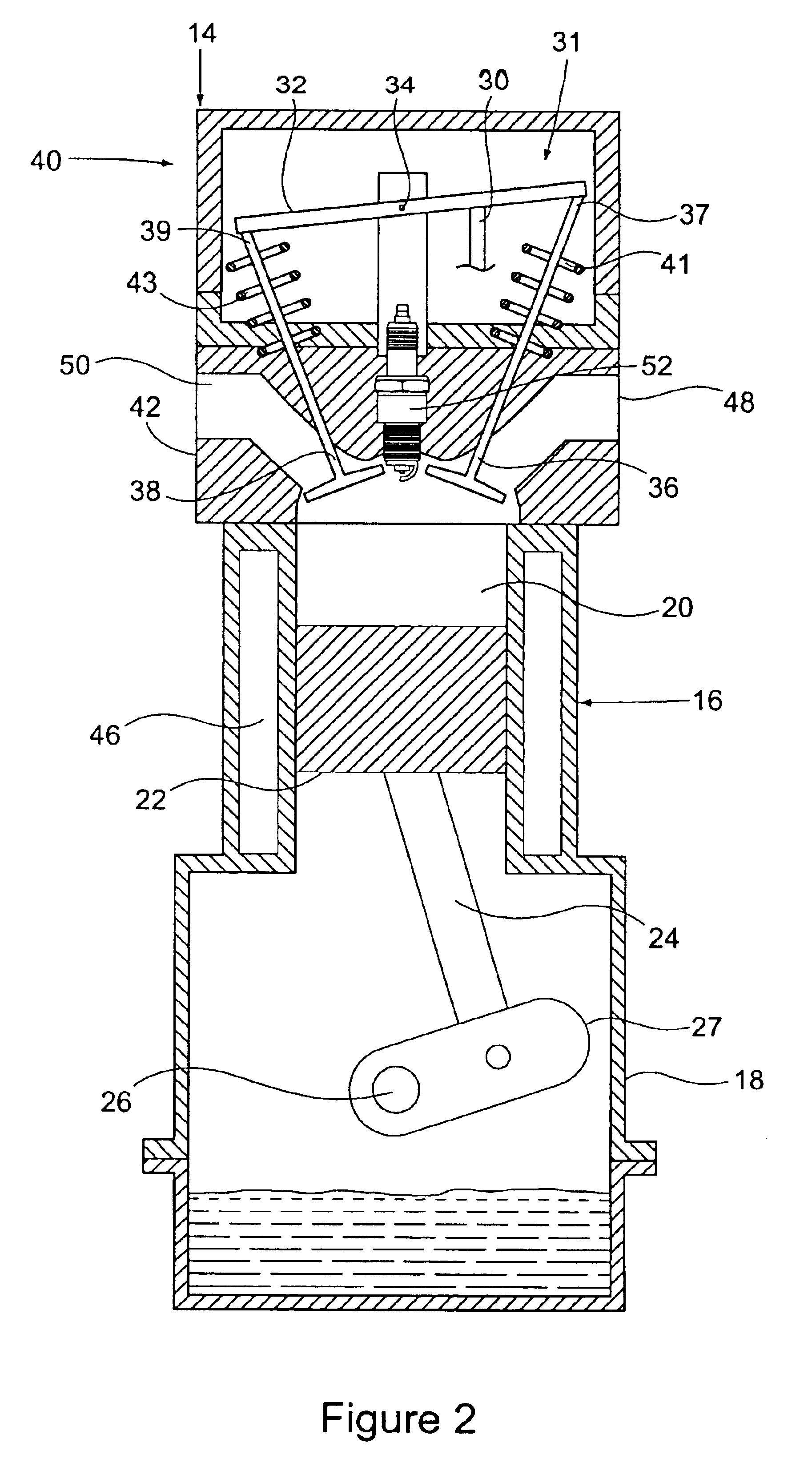

Waste heat engine

InactiveUS20100107637A1Increase and decrease sizeIncrease and decrease and outputSteam engine plantsEngines with rotating cylindersInlet valveReed valve

An engine includes a radial arrangement of cylinders each having a reciprocating piston with a piston head and a connecting rod pivotally linked to the piston head at an upper end. A lower end of each connecting rod is pivotally linked to a crank disk that is rotatably mounted on a crank arm of a crankshaft. Steam intake valves at each cylinder are momentarily opened by a bearing cam roller that is moved in a circular path by rotation of the crank disk to sequentially engage spring urged cam followers on inboard ends of radially extending valve stems. Low pressure steam or gas is injected into the top of each cylinder, as the intake valves of the cylinders are opened in sequence, thereby forcing the piston in each cylinder through a power stroke to move the crank disk and turn the crankshaft. Angular displacement of each connecting rod through the return stroke of the piston urges an exhaust reed valve on the piston head to an open position, thereby releasing exhaust steam to a condenser chamber. The engine is self-starting and operates in a low pressure, low temperature range, using waste heat from an external source, such as exhaust from an internal combustion engine, burning of refuse (e.g. garbage or other solid waste material) or solar heat.

Owner:CYCLONE POWER TECH

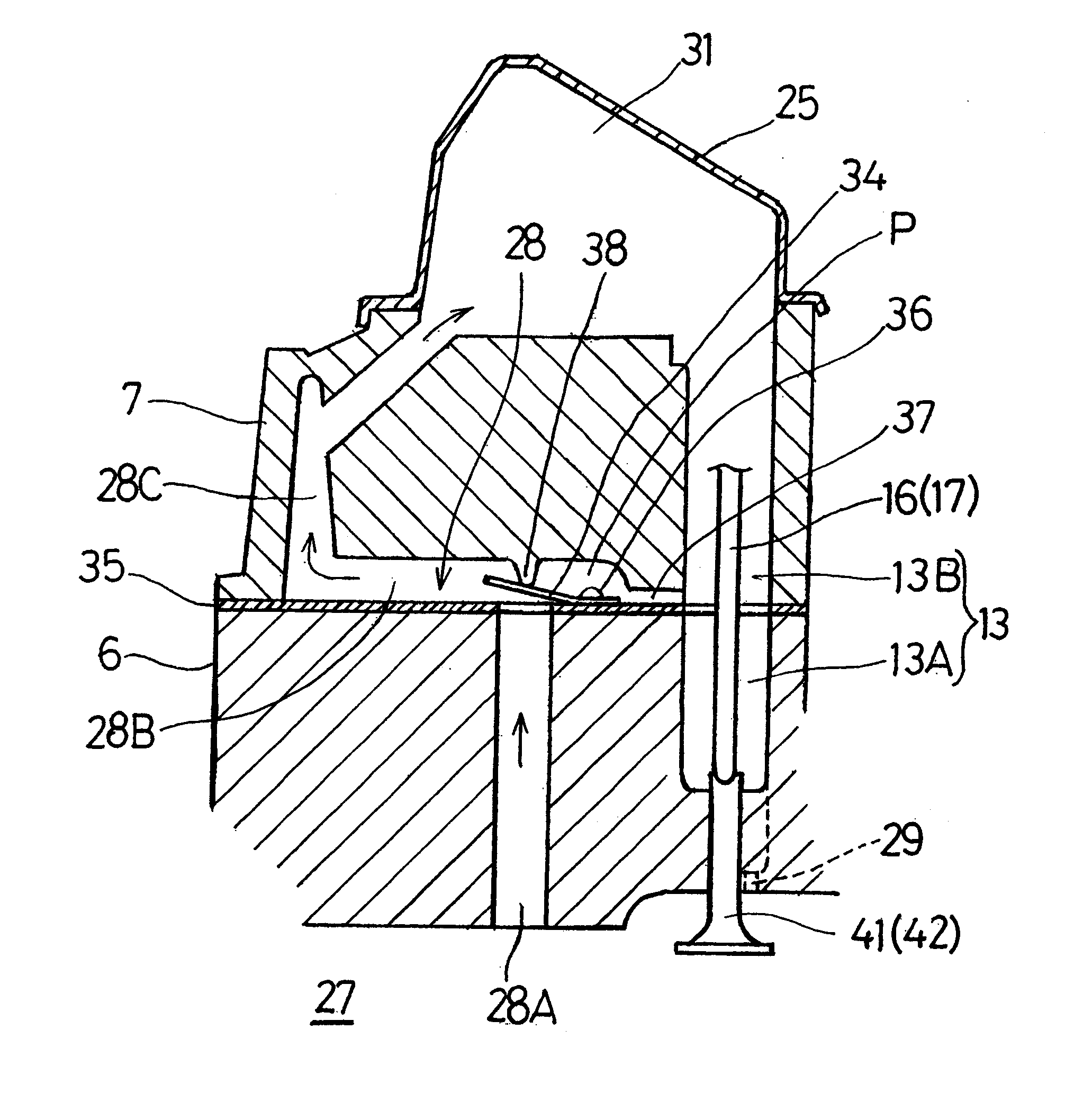

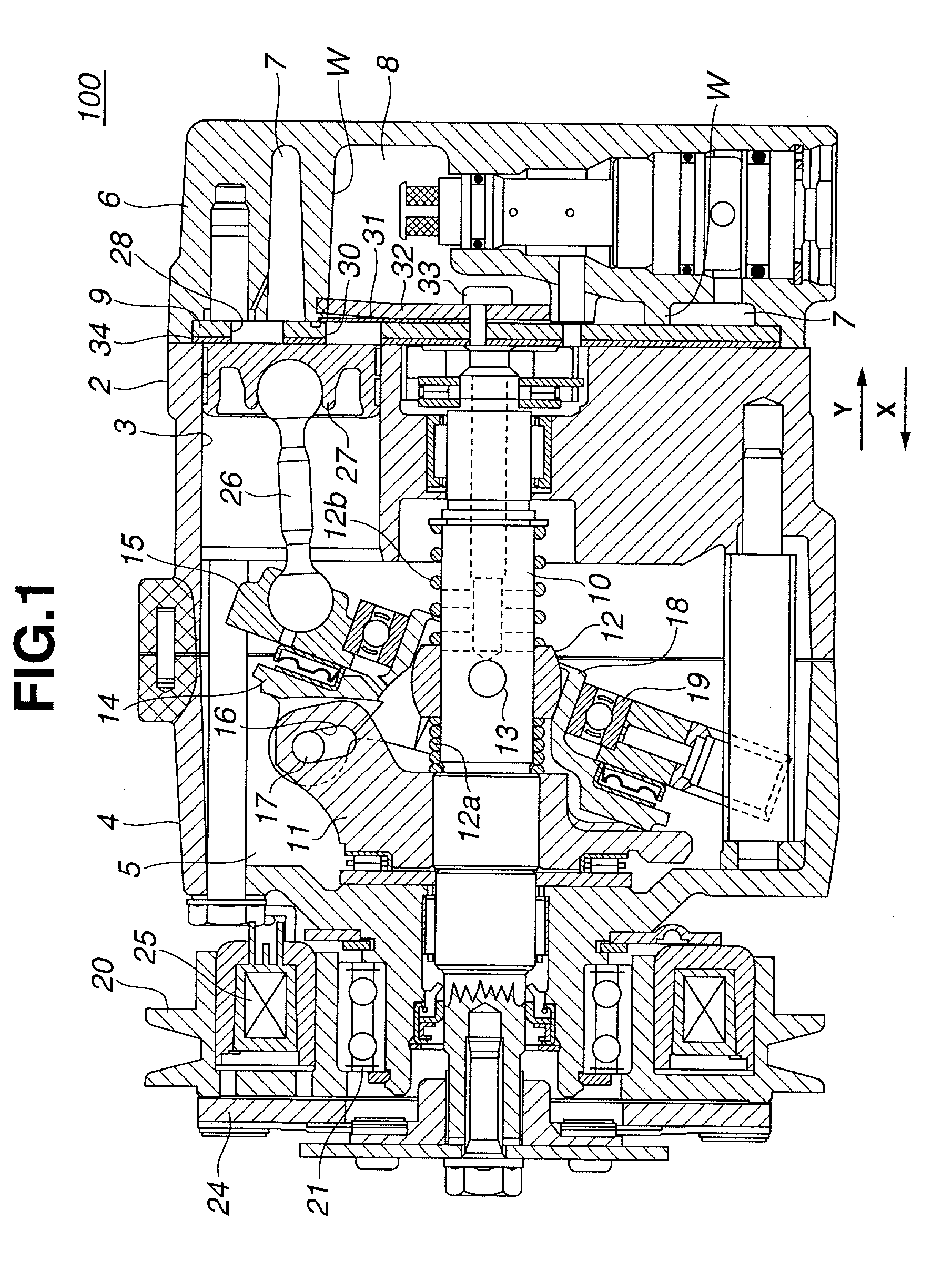

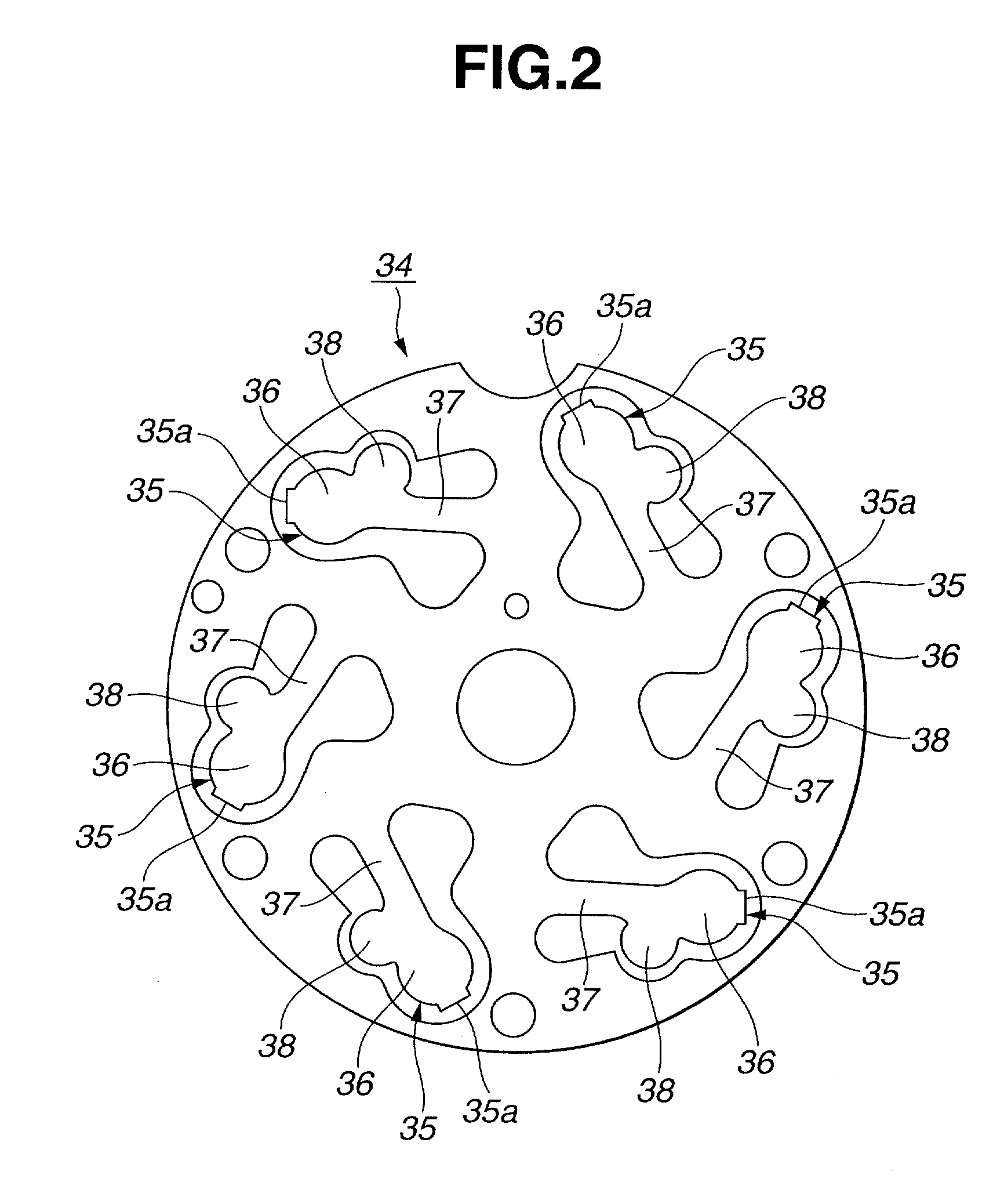

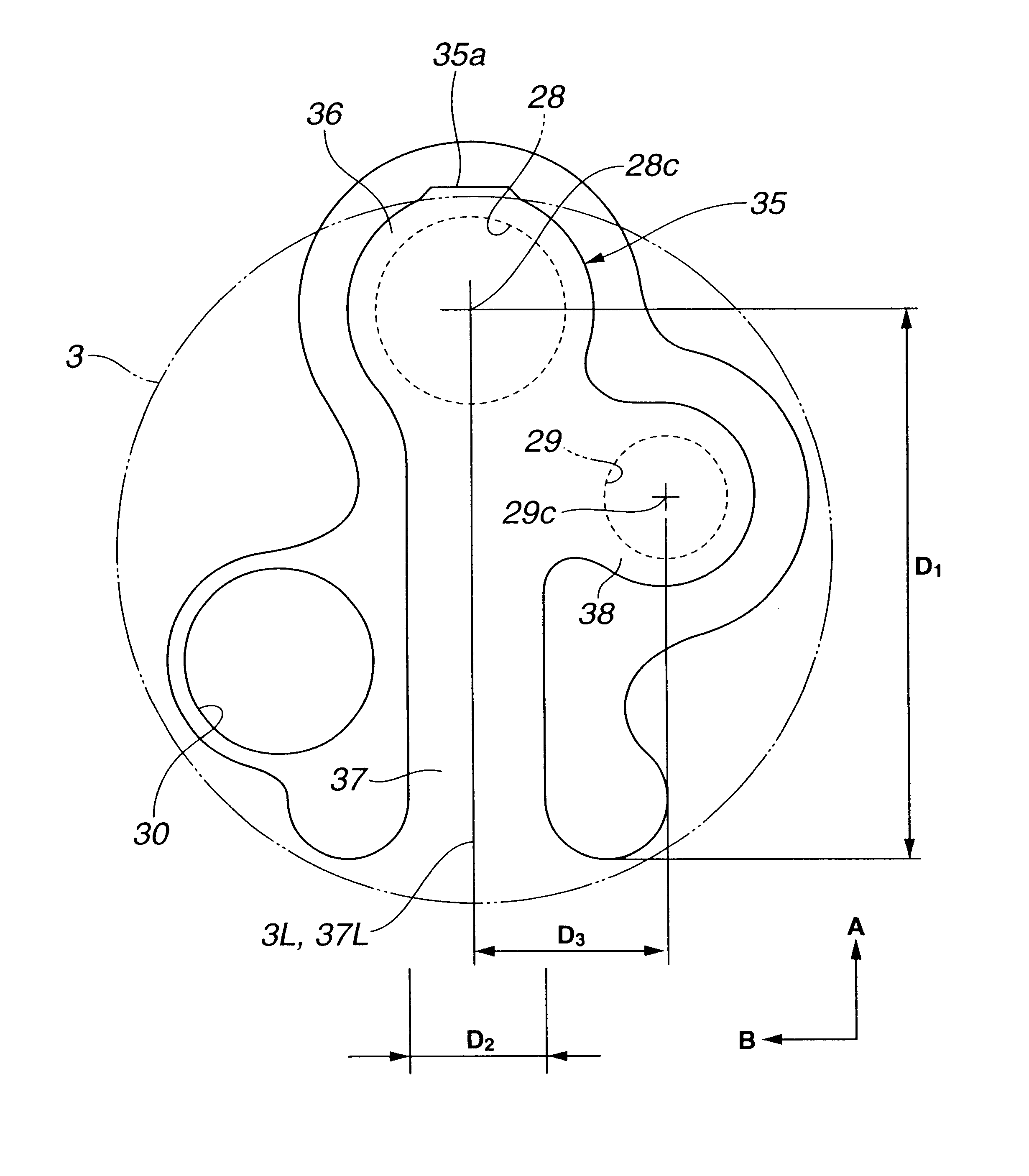

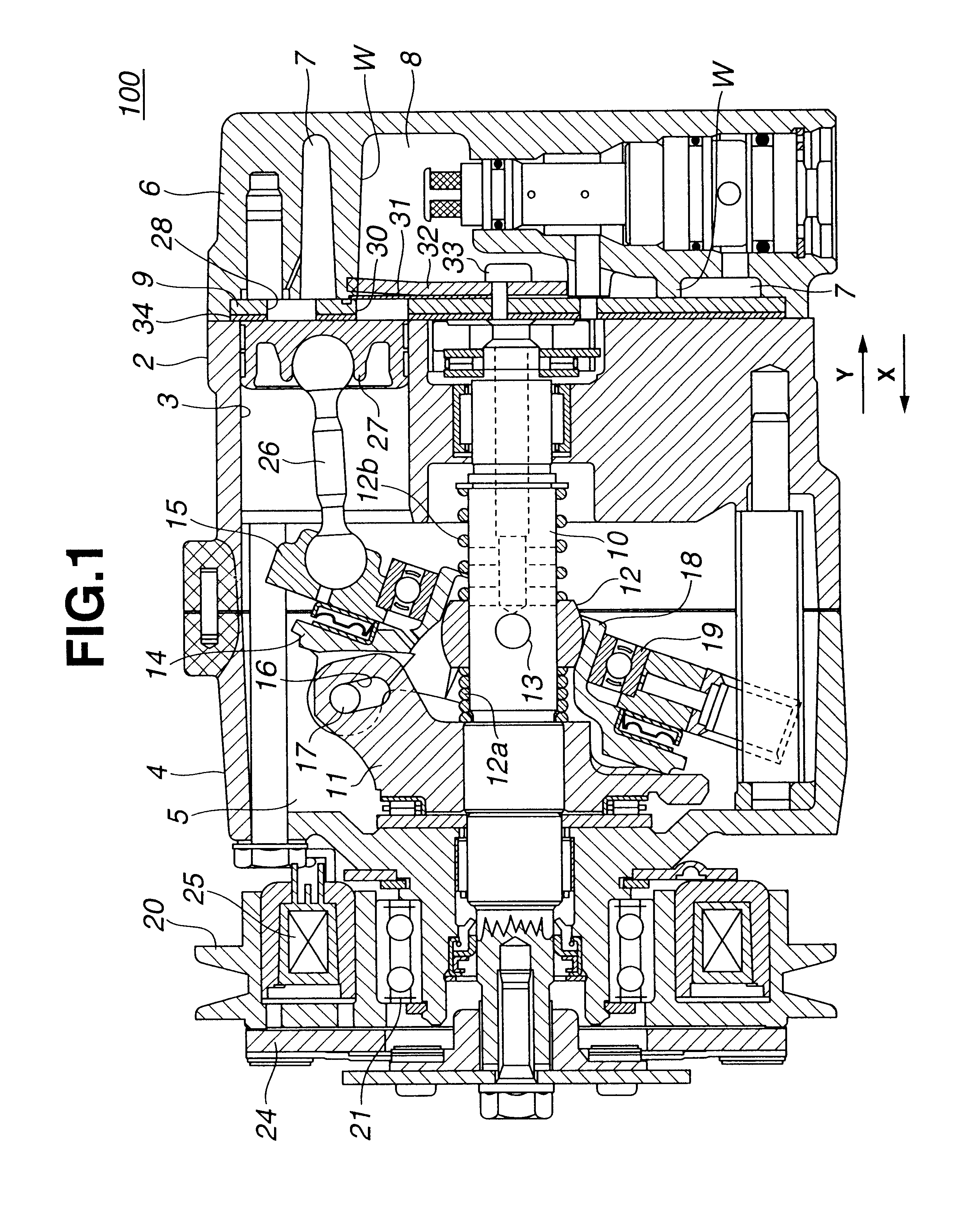

Breathing device for internal combustion engine

InactiveUS20030150437A1Low costSmall sizeEngine sealsInternal combustion piston enginesCombustionEngineering

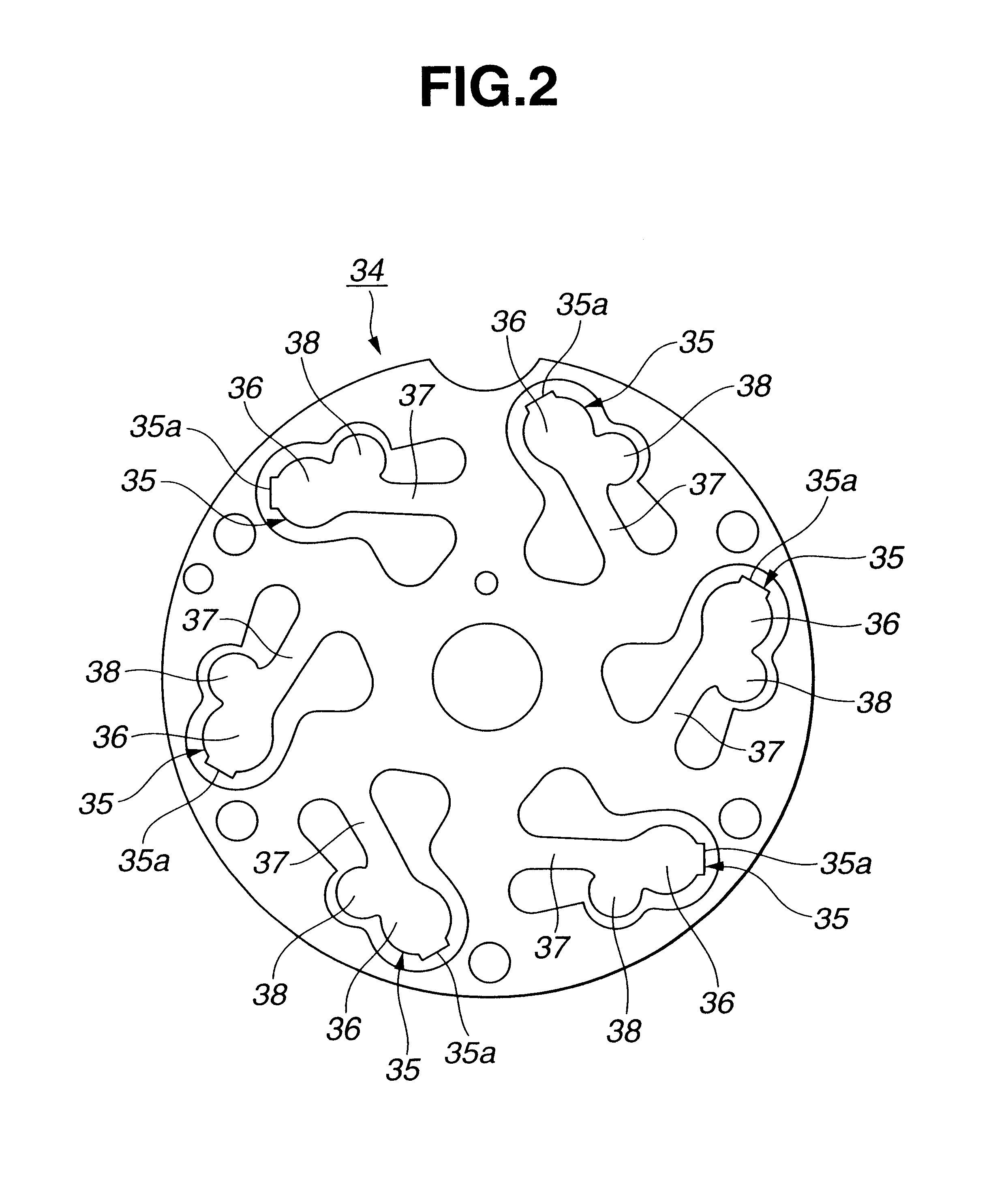

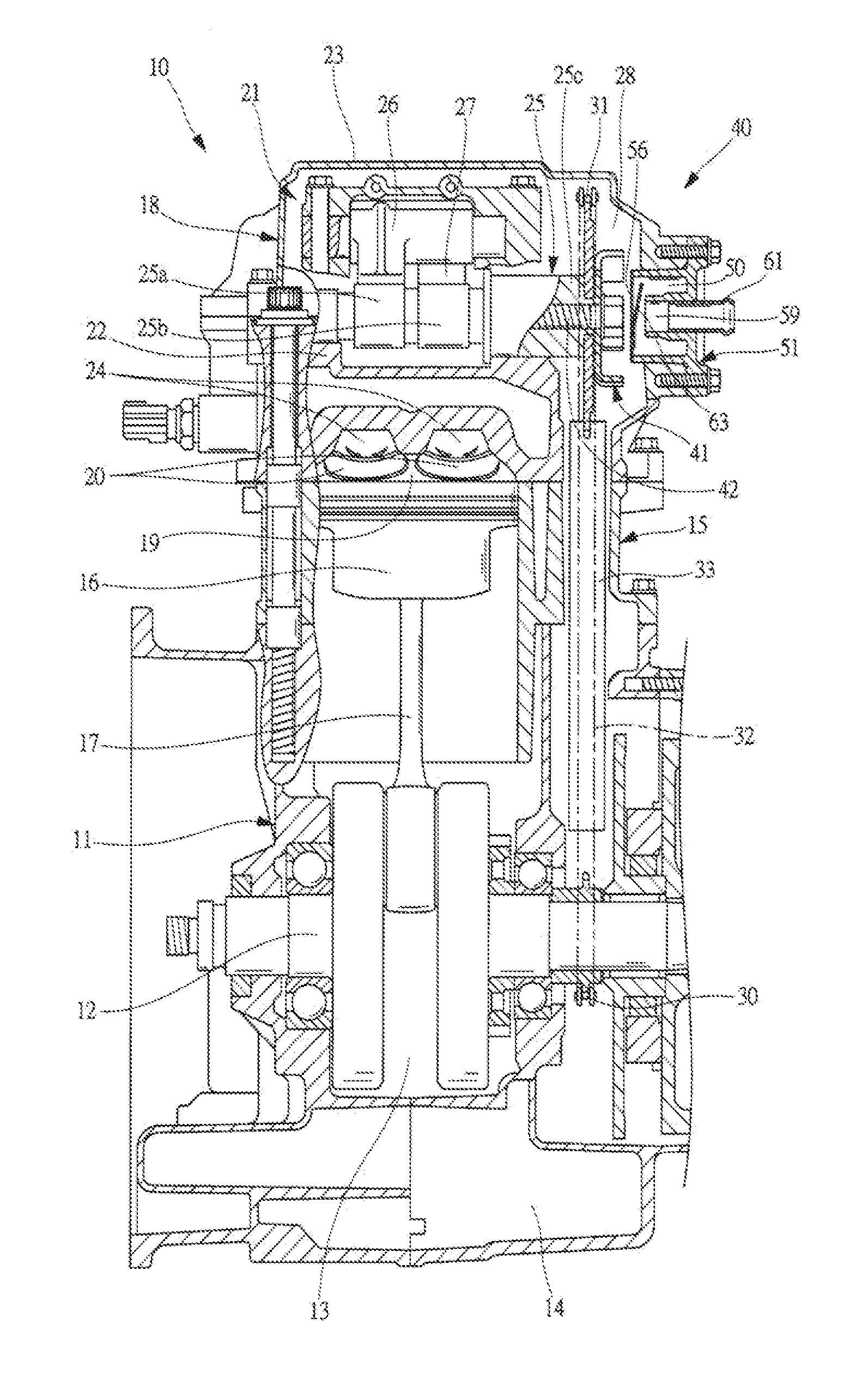

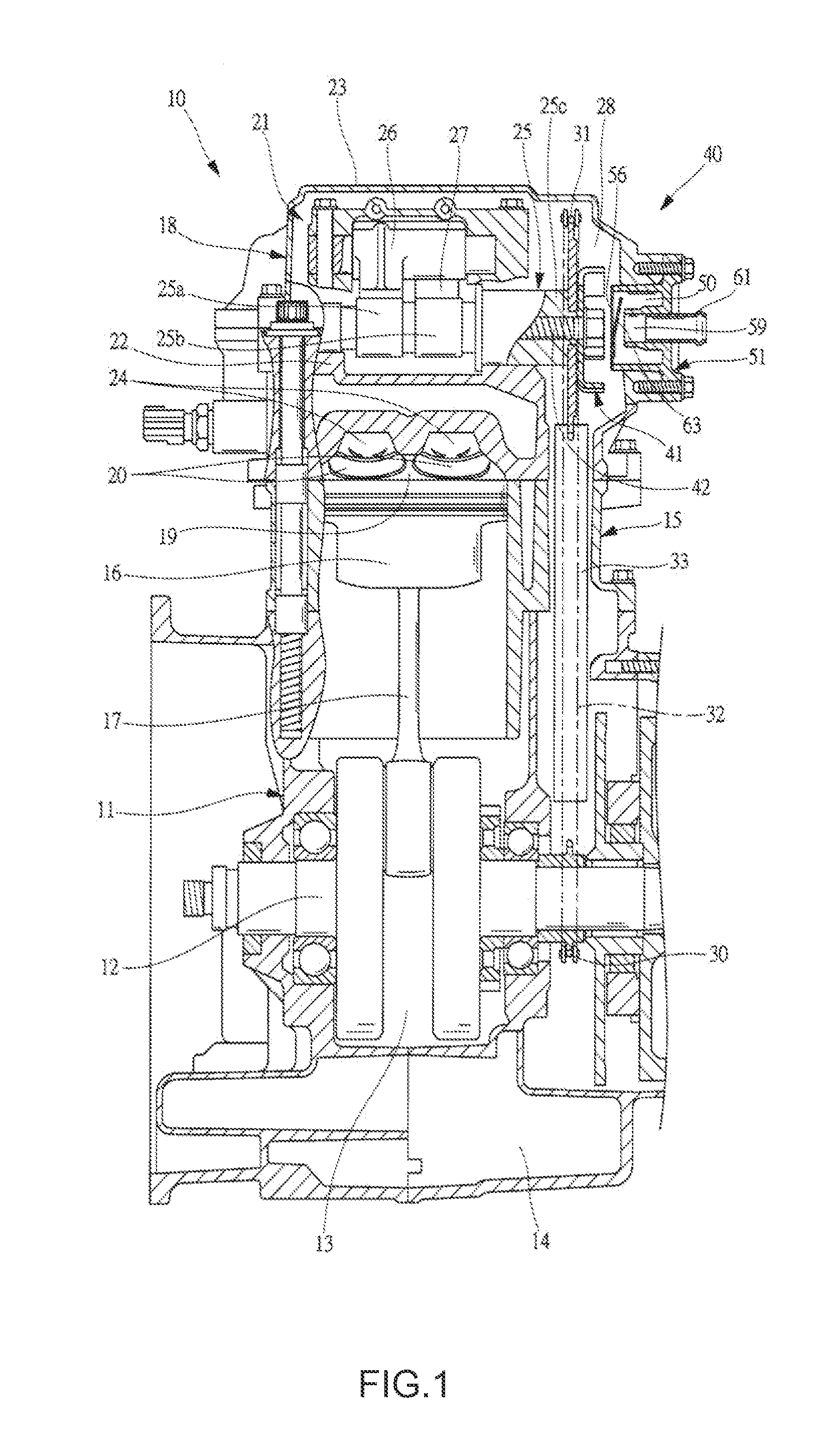

To provide a breathing device for an internal combustion engine, wherein the structure around the check valve is simplified so that the engine as a whole can be manufactured compact, the breathing device includes a check valve (34) for fluid connecting, a crank chamber (27) and a rocker arm chamber (31) in the combustion engine. The check valve (34) is disposed in a head gasket (35) that is interposed between a cylinder block (6) and a cylinder head (7). The check valve (34) is in the form of a reed valve separate from the head gasket (35) and is supported by the head gasket (35) by means of a rivet (36).

Owner:KAWASAKI HEAVY IND LTD

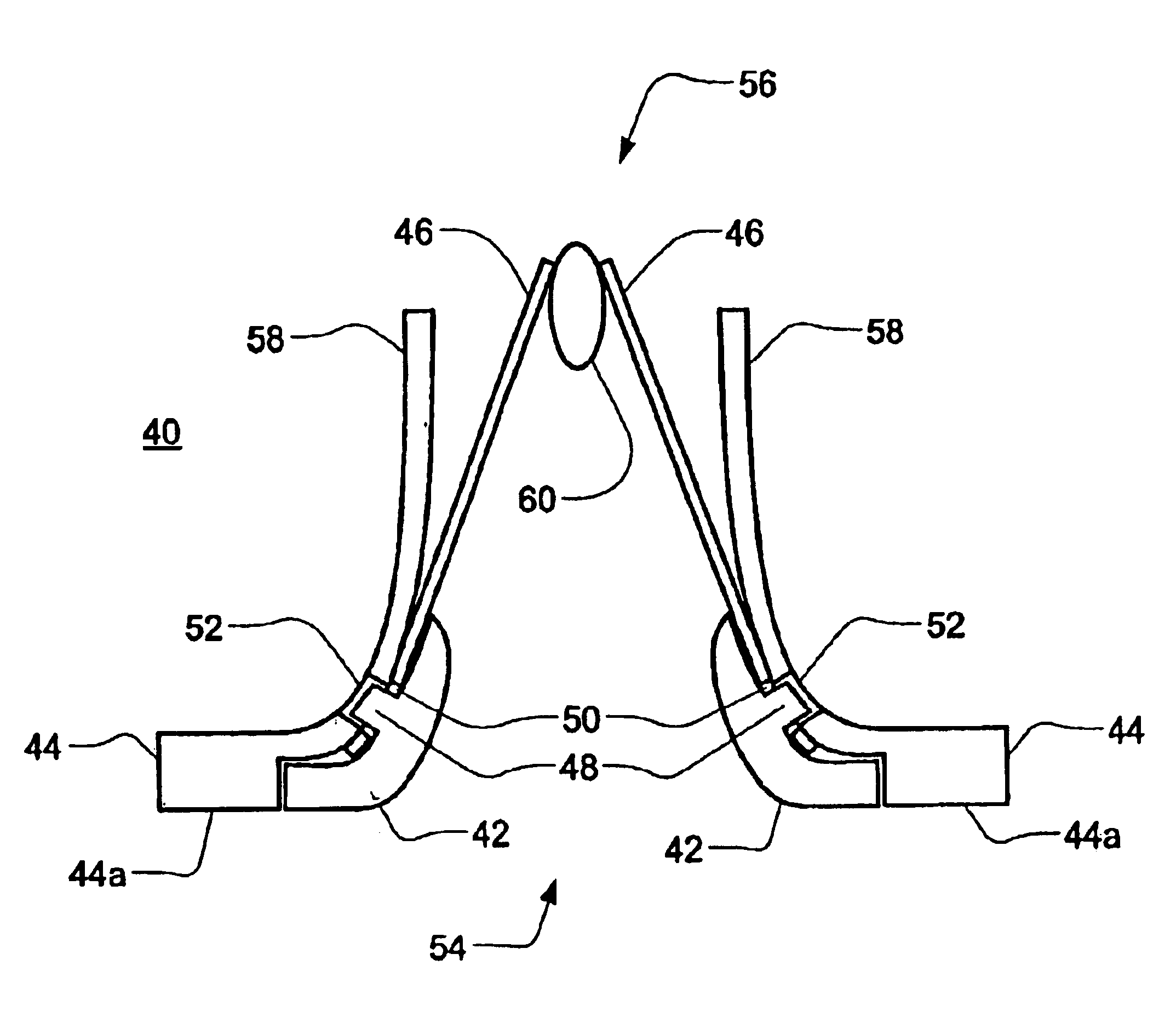

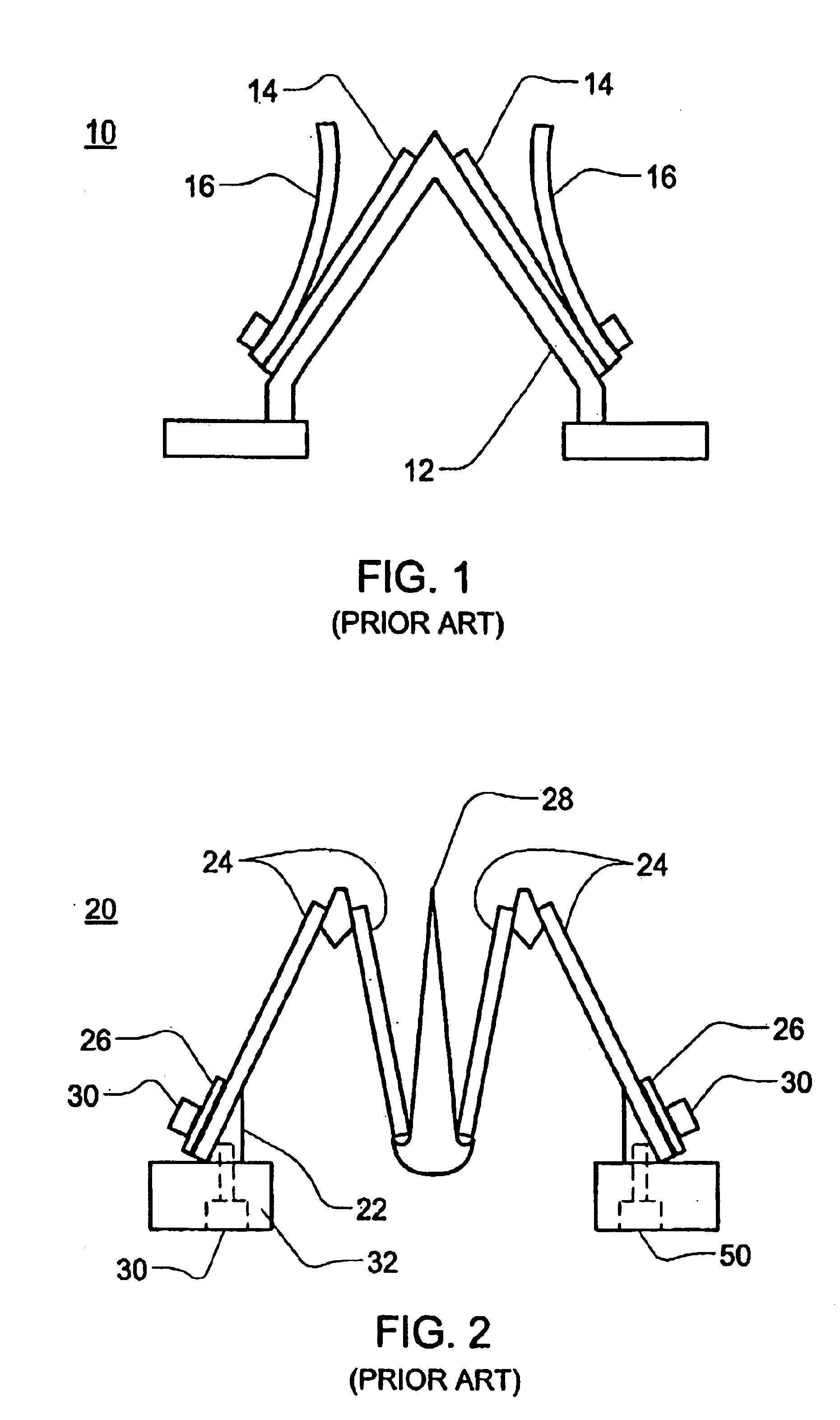

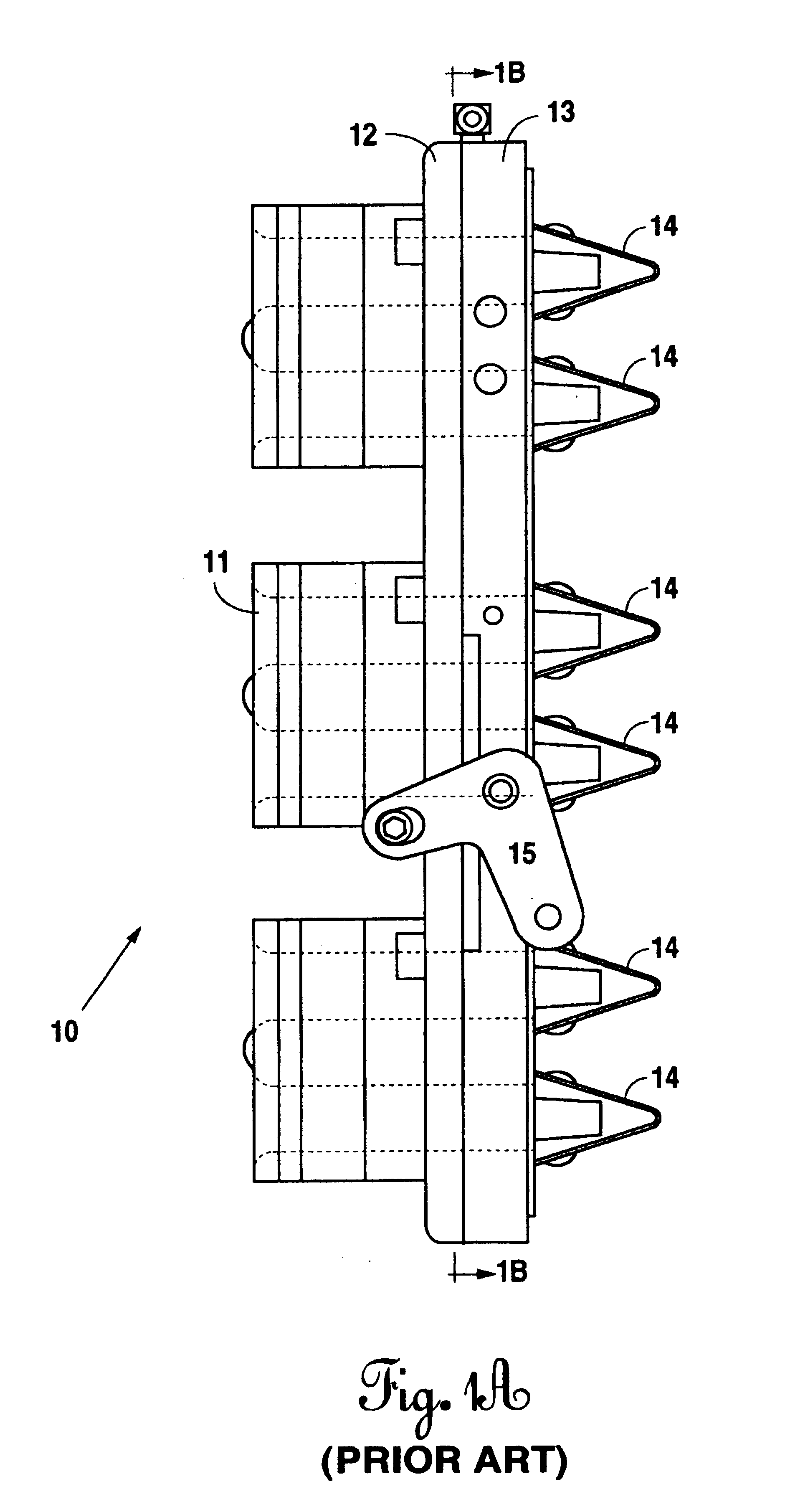

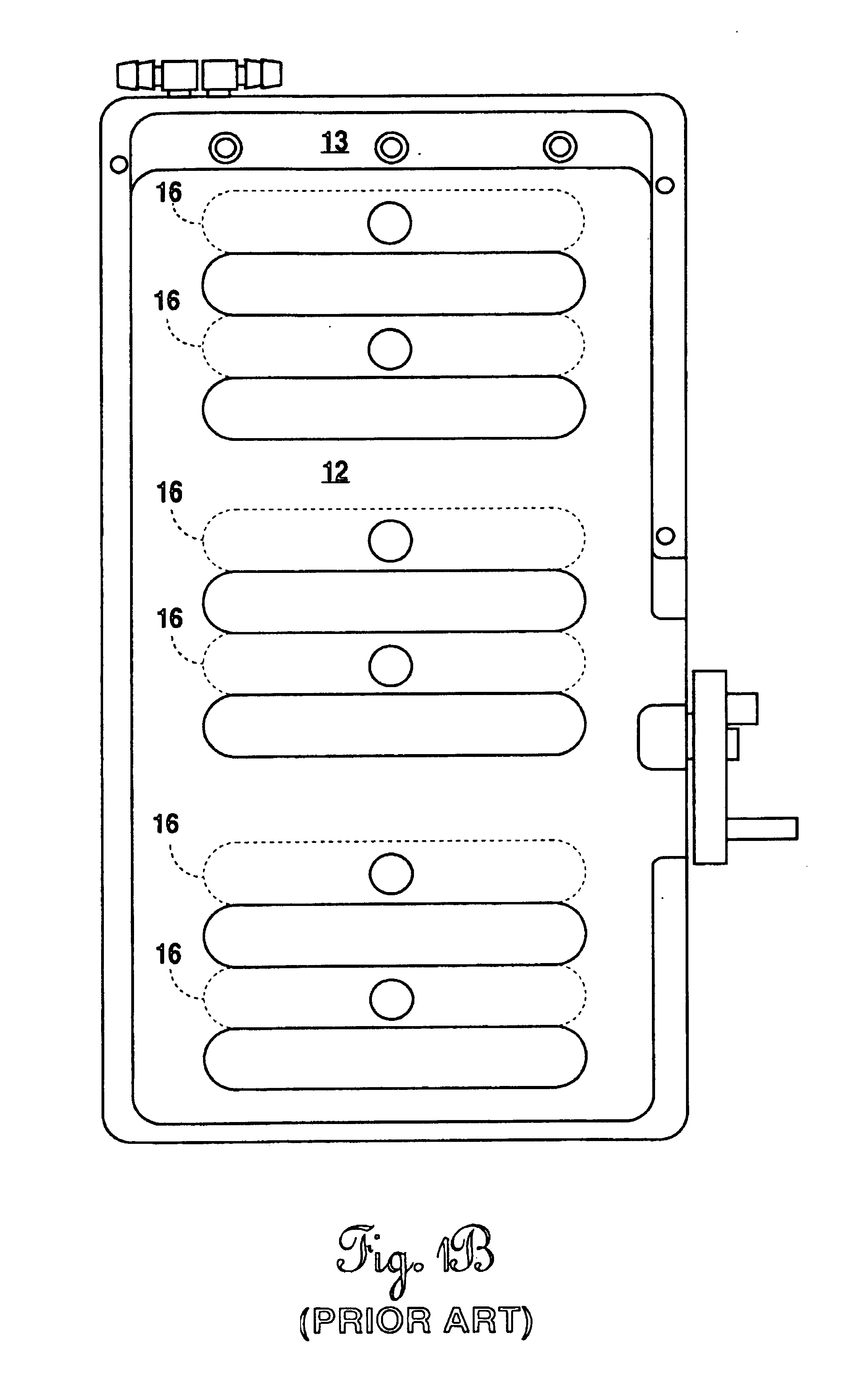

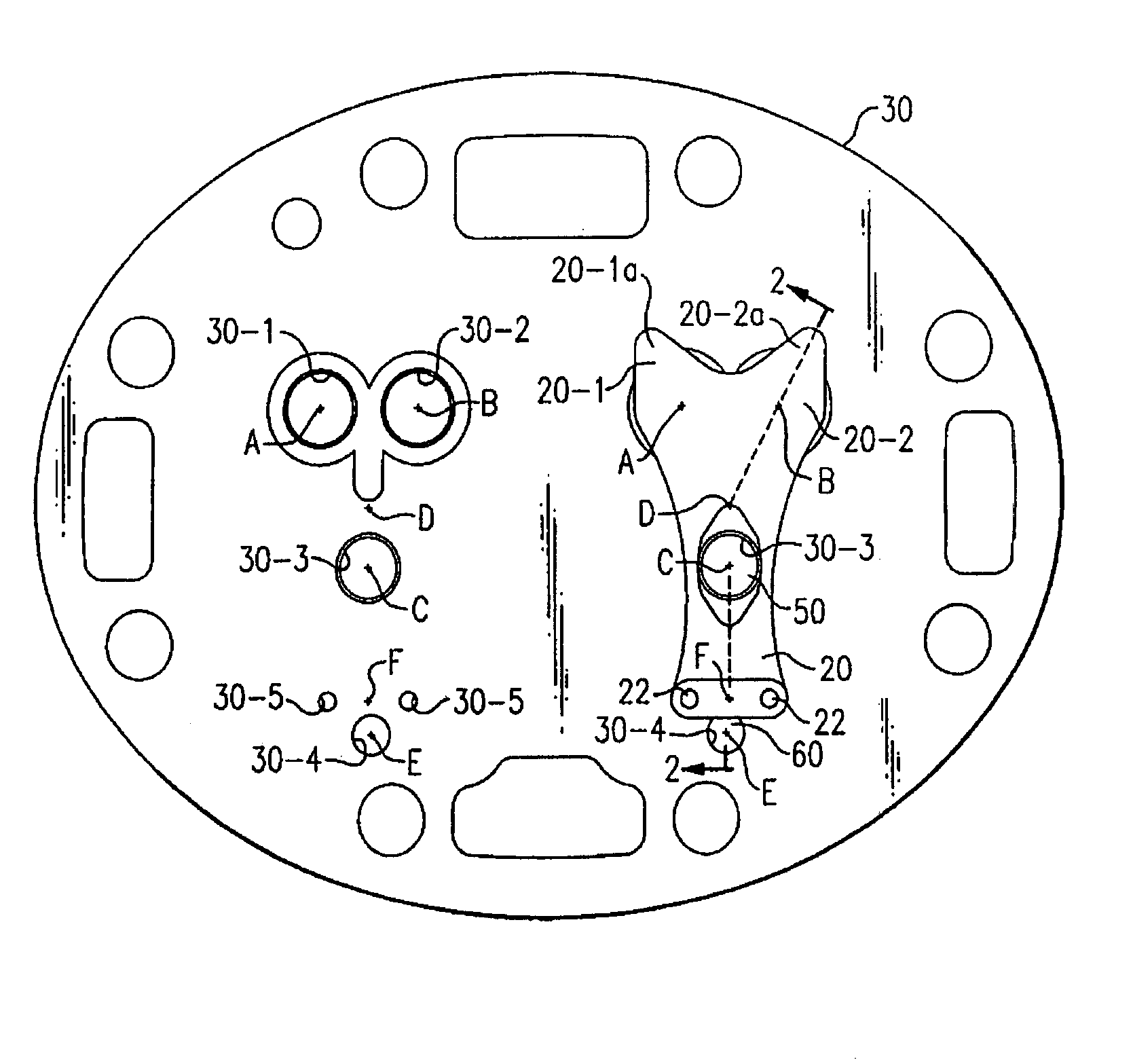

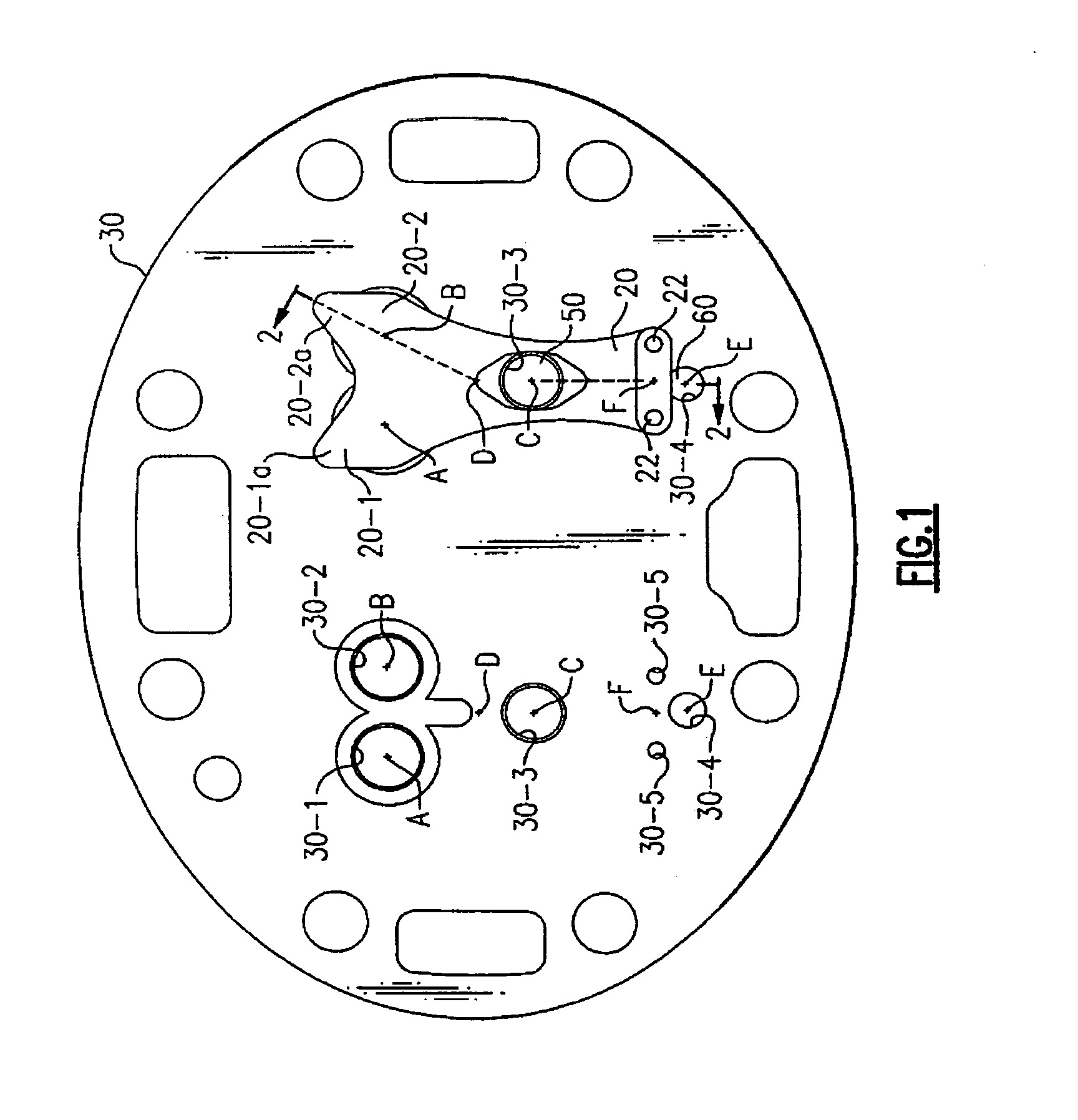

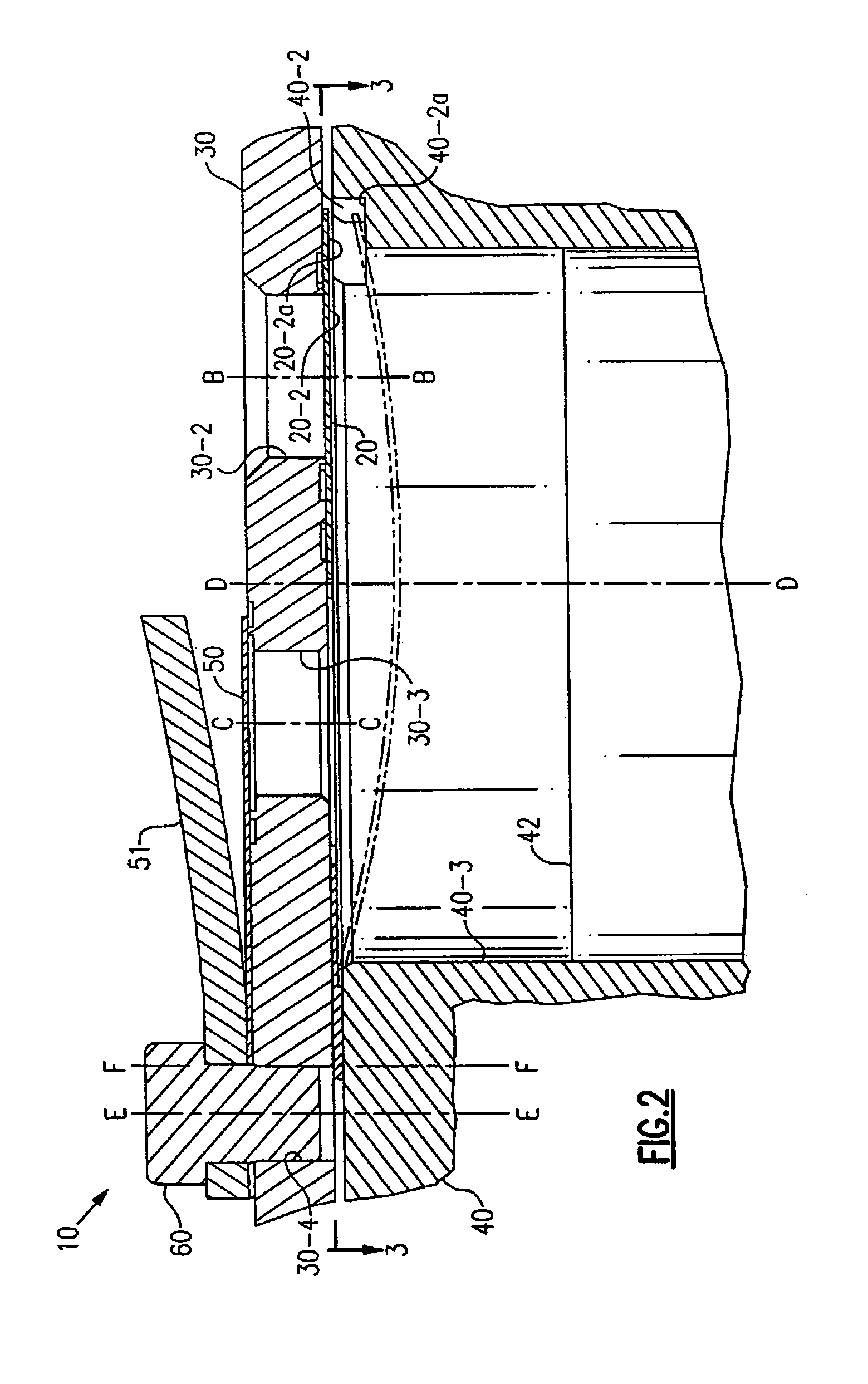

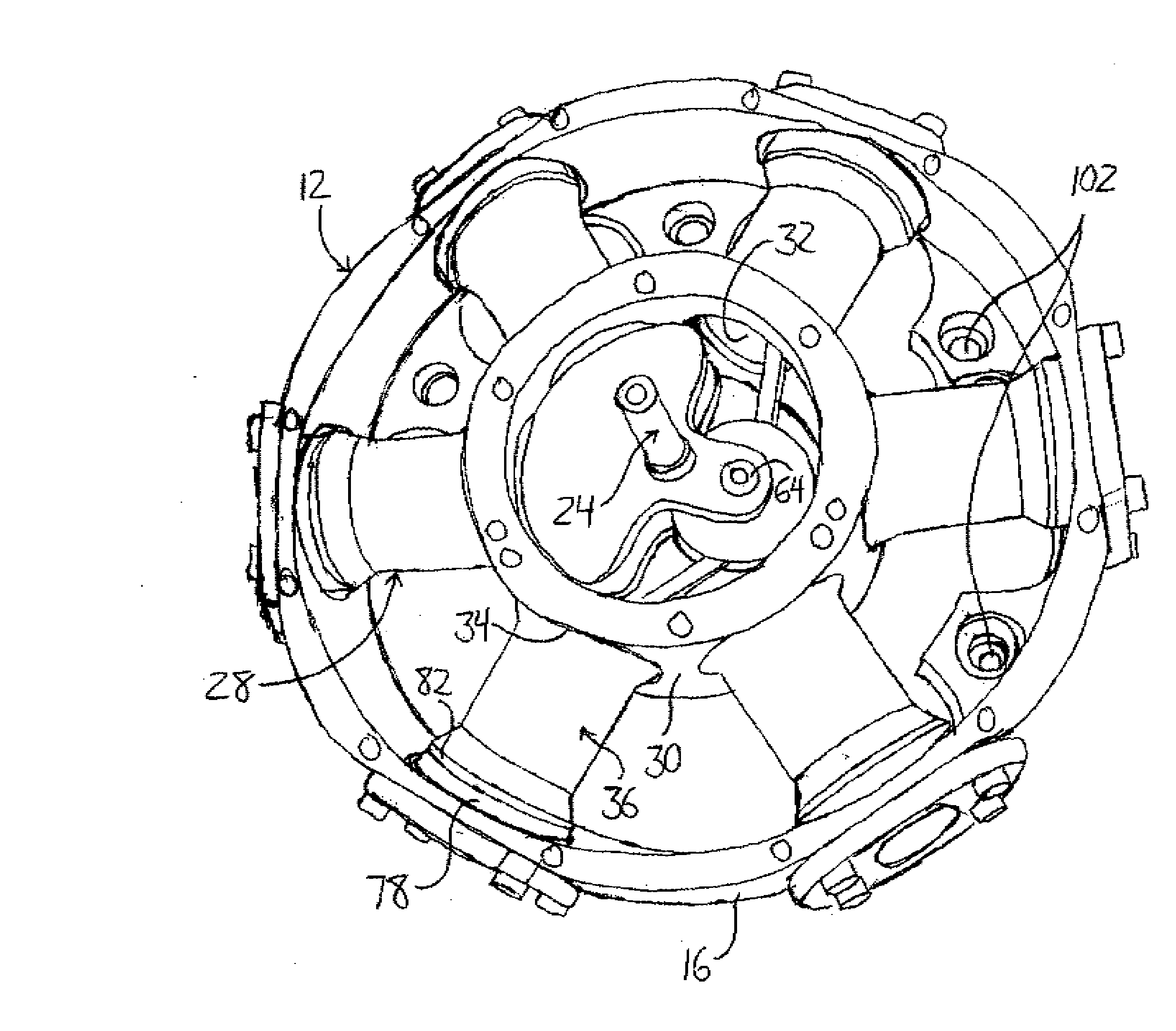

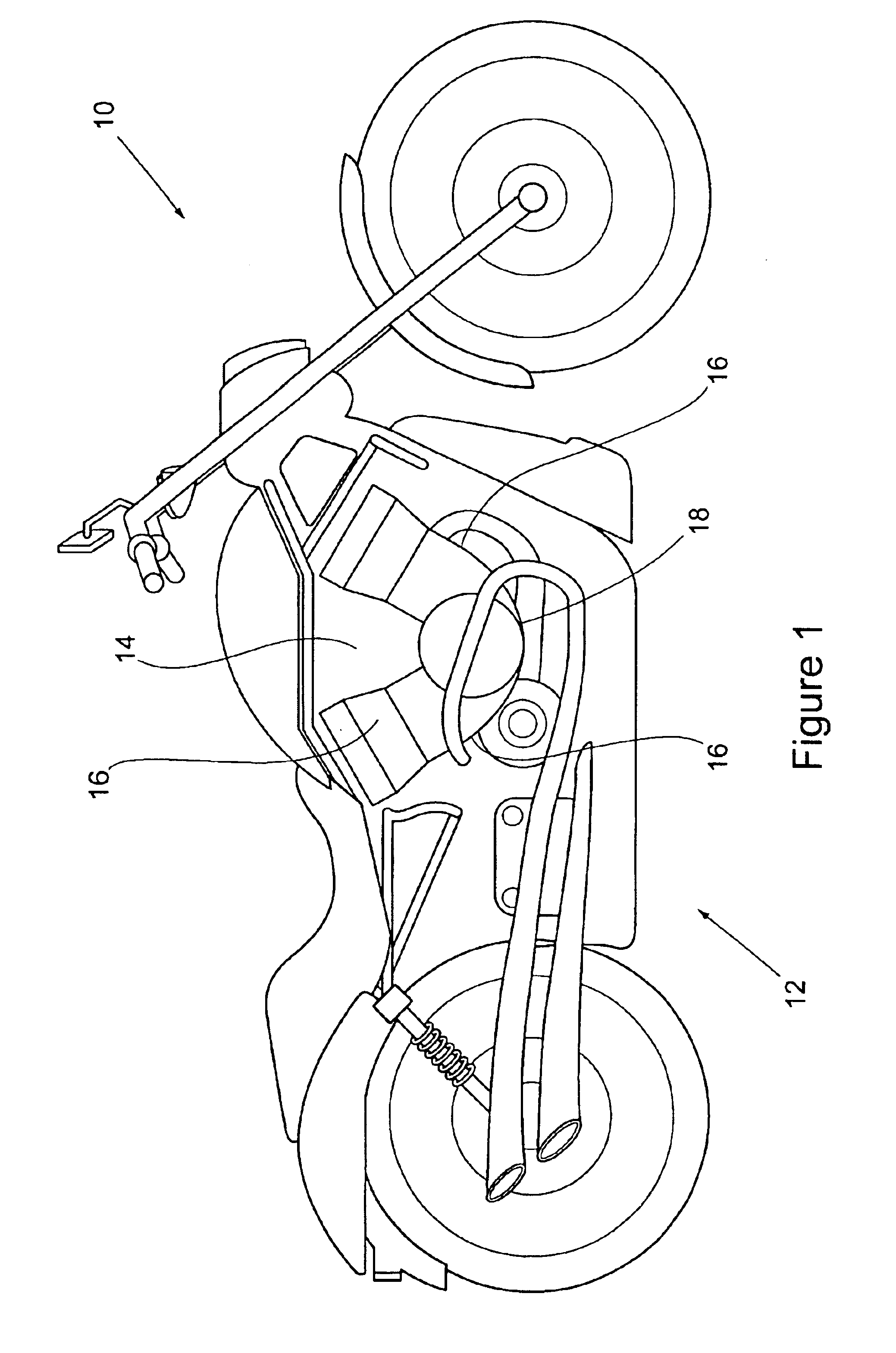

Reed valve assembly

InactiveUS6880577B2Maximize durabilityMaximize desirable airflowCheck valvesCombustion enginesEngineeringReed valve

The reed valve assembly of the present invention includes a reed cage, a retainer, and reed petals. The retainer is independently interlockable with the reed cage. As defined herein, independently interlockable is understood to mean that no additional parts are required to connect the retainer to the reed cage. As implied by the term interlockable, the retainer and reed cage are separable. The reed petals are removably secured to the reed cage. In one embodiment, the reed petals are secured to the reed cage with the retainer.

Owner:MOTO TASSINARI

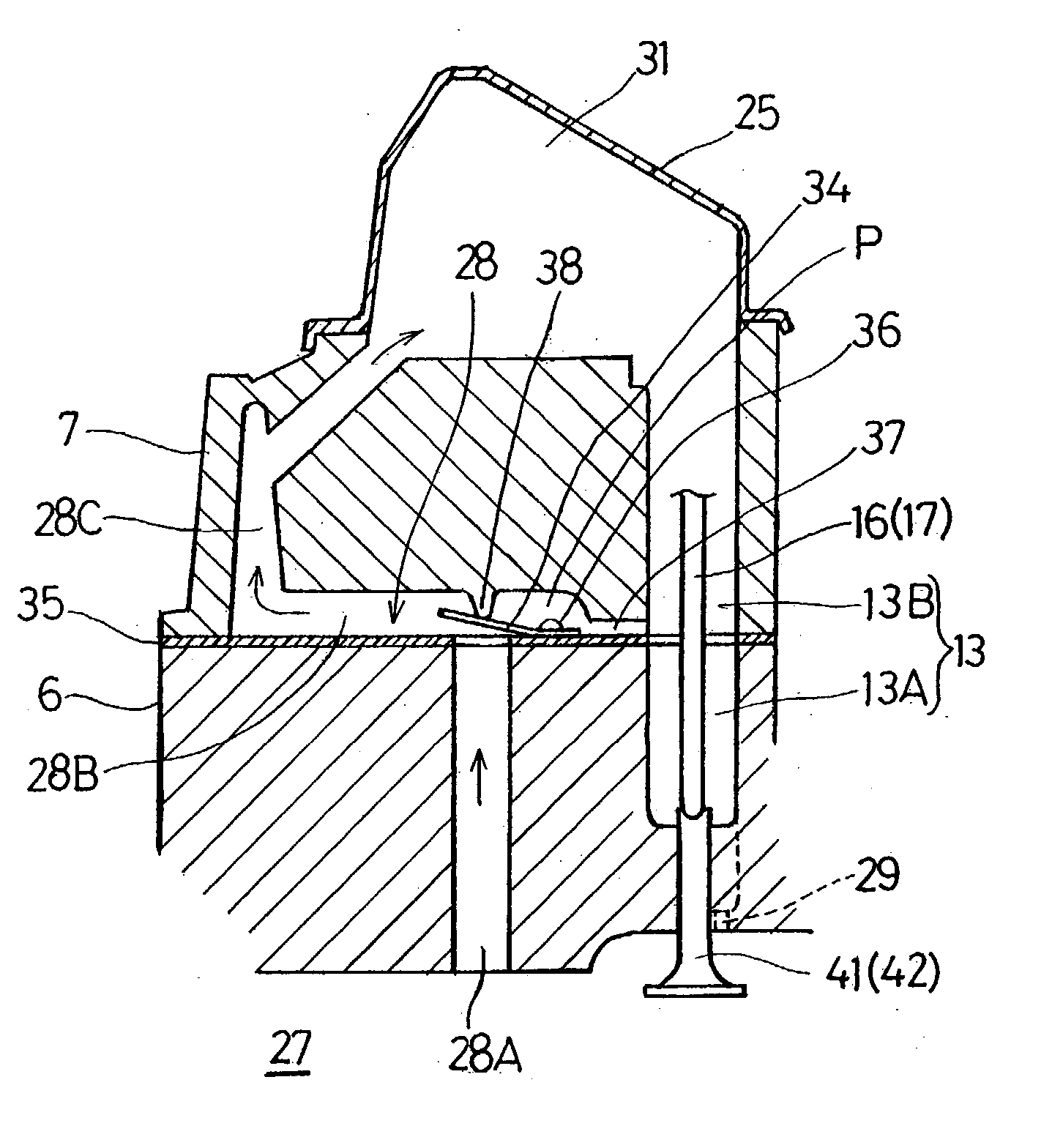

Breathing device for internal combustion engine

InactiveUS6659094B2Low costSmall sizeEngine sealsNon-fuel substance addition to fuelCombustionEngineering

To provide a breathing device for an internal combustion engine, wherein the structure around the check valve is simplified so that the engine as a whole can be manufactured compact, the breathing device includes a check valve (34) for fluid connecting, a crank chamber (27) and a rocker arm chamber (31) in the combustion engine. The check valve (34) is disposed in a head gasket (35) that is interposed between a cylinder block (6) and a cylinder head (7). The check valve (34) is in the form of a reed valve separate from the head gasket (35) and is supported by the head gasket (35) by means of a rivet (36).

Owner:KAWASAKI HEAVY IND LTD

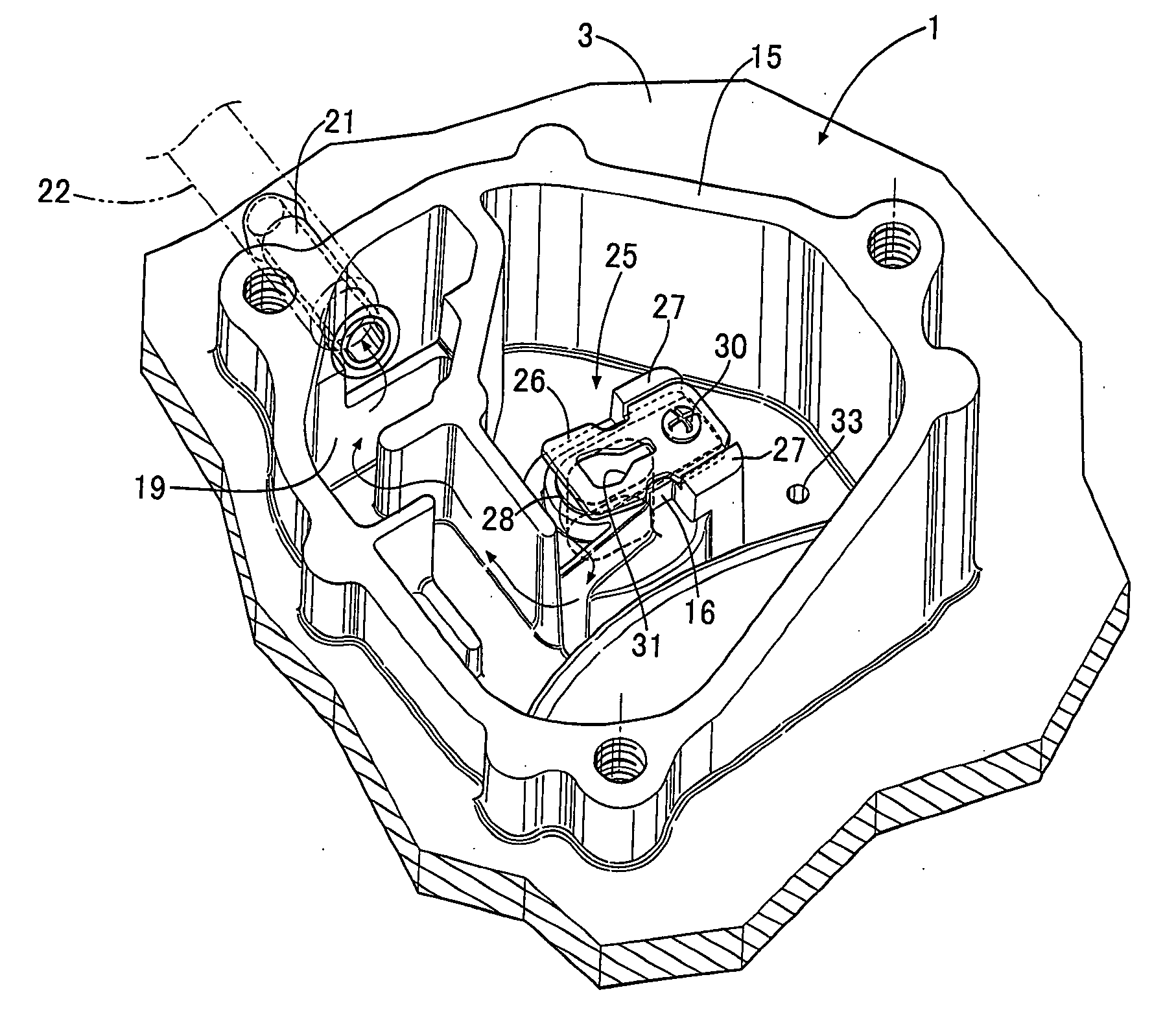

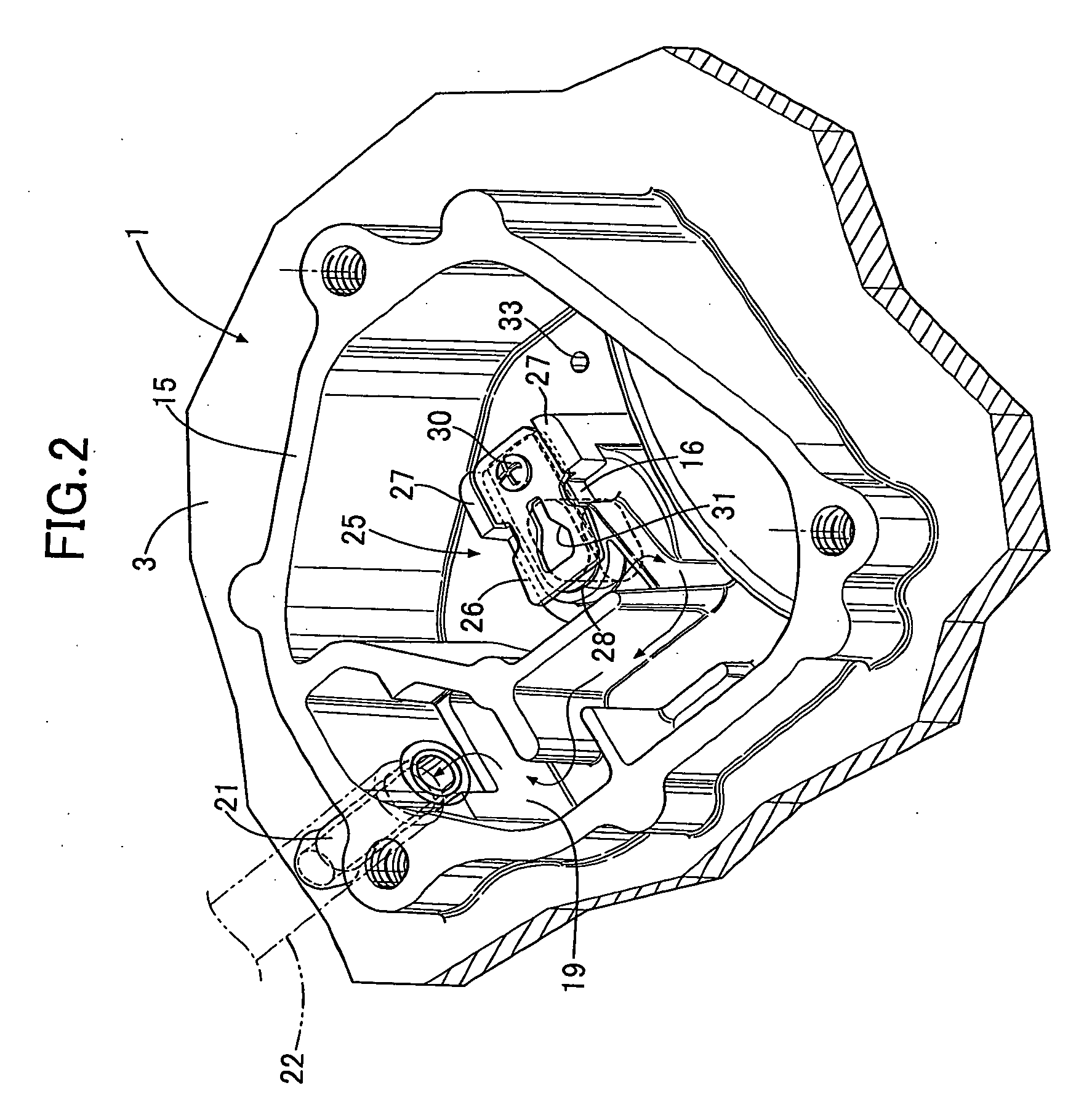

Breather device for engine

ActiveUS20090301449A1Avoid stickingImproved valve-closing responsivenessCombustion enginesPressure lubricationBreatherReed valve

In a breather device for engine, in which an inlet of a breather chamber communicates with a crank chamber through a reed valve, the reed valve being formed of: a fixed stopper plate arranged so as to be opposed to a valve seat formed on an end face of the inlet facing the breather chamber; and an elastic valve plate fixed at one end thereof to the stopper plate and capable of bending elastically to change its position from a closed position in which the elastic valve plate closes the inlet by seating on the valve seat to an opening limit position in which the elastic valve plate opens the inlet and abuts against the stopper plate, the stopper plate is provided at a center part thereof with an oil discharge hole through which oil present between the elastic valve plate and the stopper plate is pushed out when the elastic valve plate is pushed toward the opening limit position in which the elastic valve plate abuts against the stopper plate by pressure in the crank chamber. Accordingly, it is possible to prevent the elastic valve plate from sticking to the stopper plate even if oil mist adheres to the elastic valve plate or the stopper plate of the reed valve.

Owner:HONDA MOTOR CO LTD

Multi-stage sliding air throttle valve assembly and cylinder assembly engine including same

InactiveUS7059299B2Internal combustion piston enginesEngine controllersAir velocityCombustion chamber

A multi-stage air throttle valve assembly is provided for use in a multiple cylinder engine. The valve assembly provides a series of shiftable valve plates to provide full, maximum opening of air ports having passageways therethrough for introduction of air into the combustion cylinders of the engine. By use of two or more such sliding plates, the port size through the assembly may be maximized for enhanced volumetric entry of air into the combustion chambers. A combined reed valve assembly, fuel injectors and / or an air velocity assembly with engine are also disclosed.

Owner:CLARK ARVEL L

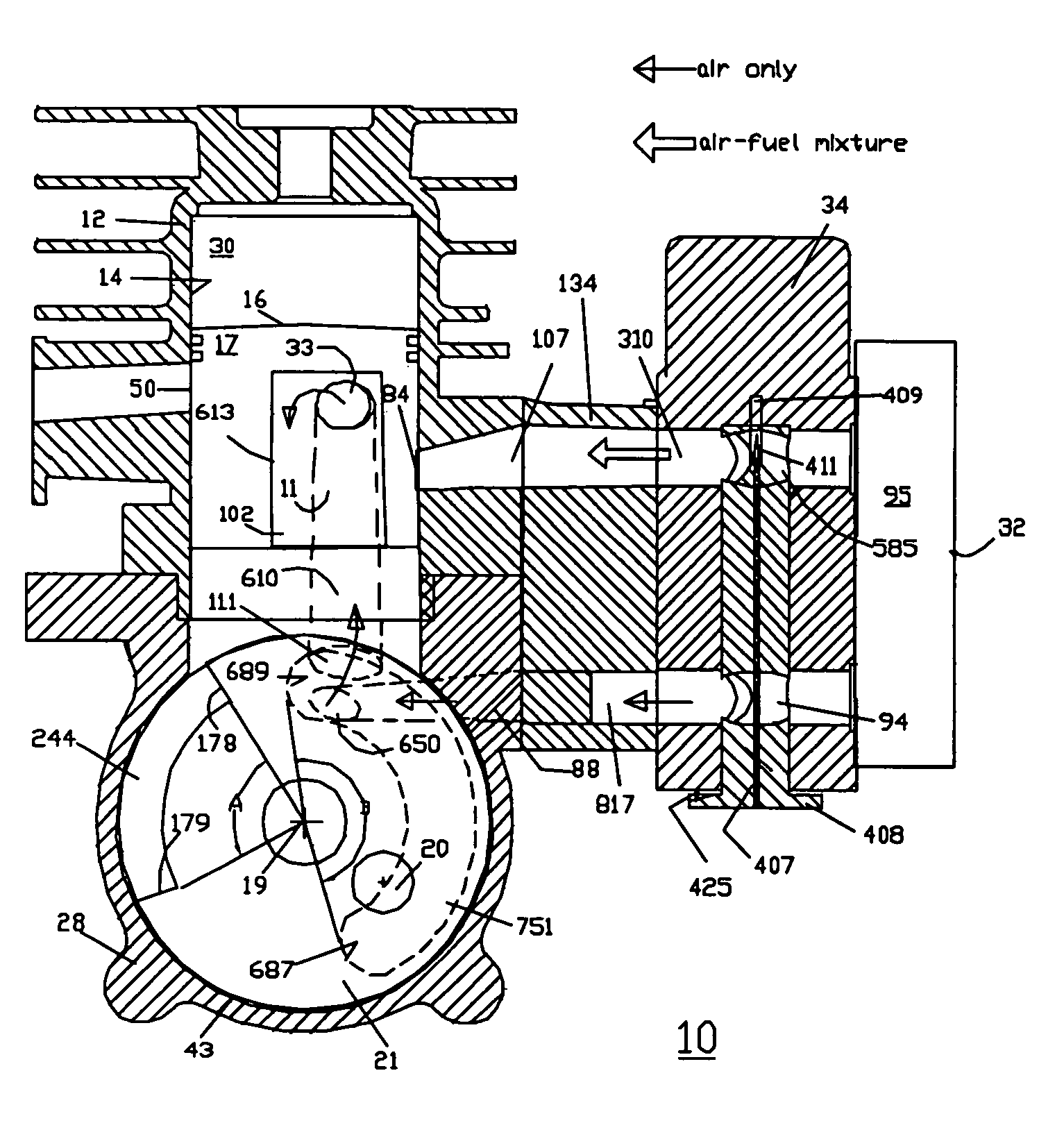

Stratified scavenged two-stroke engine

InactiveUS7093570B2Increase volumeCombustion enginesEngine controllersCharge injectionFour-stroke engine

A two-stroke internal combustion engine includes at least one gaseous communication charge passage between a crankcase chamber and a combustion chamber of the engine and a piston to open and close the top end of the passage and a rotary valve to open and close the lower end of the transfer passage. The air inlet port to the transfer passage for stratified scavenging is opened and closed by the crank-web that has passages and cutouts. The rotary valve replaces the one-way reed valve used in stratified scavenged and charged two-stroke engines. The air passes from the lower end of transfer passage to the top end and into the crankcase through the piston passage, alternatively air may also pass through the adjacent transfer passage directly or through a passage in the piston into the crankcase. A two-stroke engine also consists of a charge injection system controlled by the crank web eliminating the one-way valve.

Owner:HOMELITE TECH

Multi-port suction reed valve with optimized tips

ActiveUS7390176B2Distance minimizationMinimize impactPositive displacement pump componentsCheck valvesReed valveEngineering

A reed valve having a plurality of tips and associated recesses is provided as a compressor suction valve with each valve tip coacting with a suction port. The recesses are located in the housing structure defining the cylinder of the compressor and are spaced a distance on the order of 0.1 inches from the tips when the suction valve is closed. The valve is secured on one side of the cylinder and each tip is located along a line from the center of the cylinder through the center, or axis, of a suction port.

Owner:CARRIER CORP

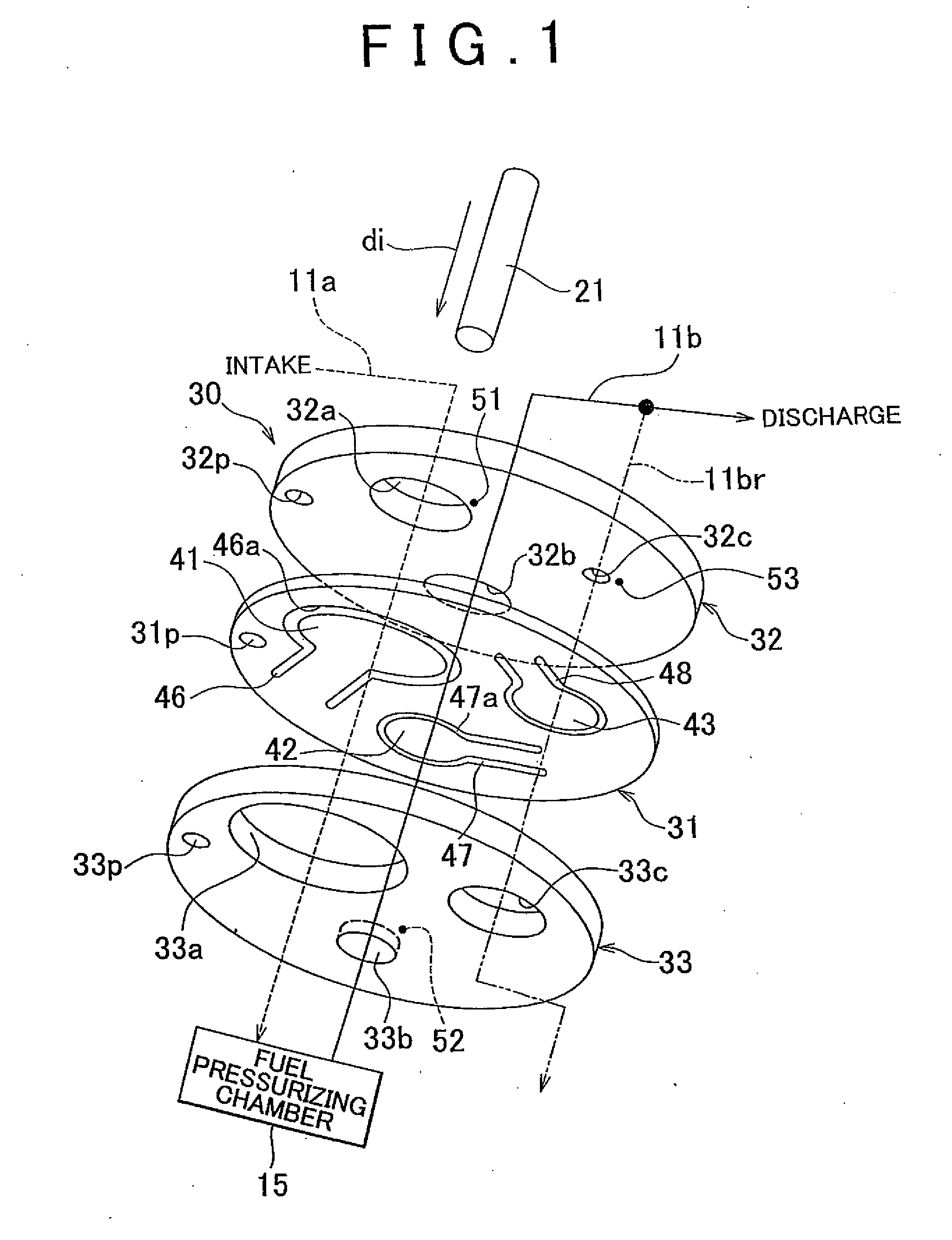

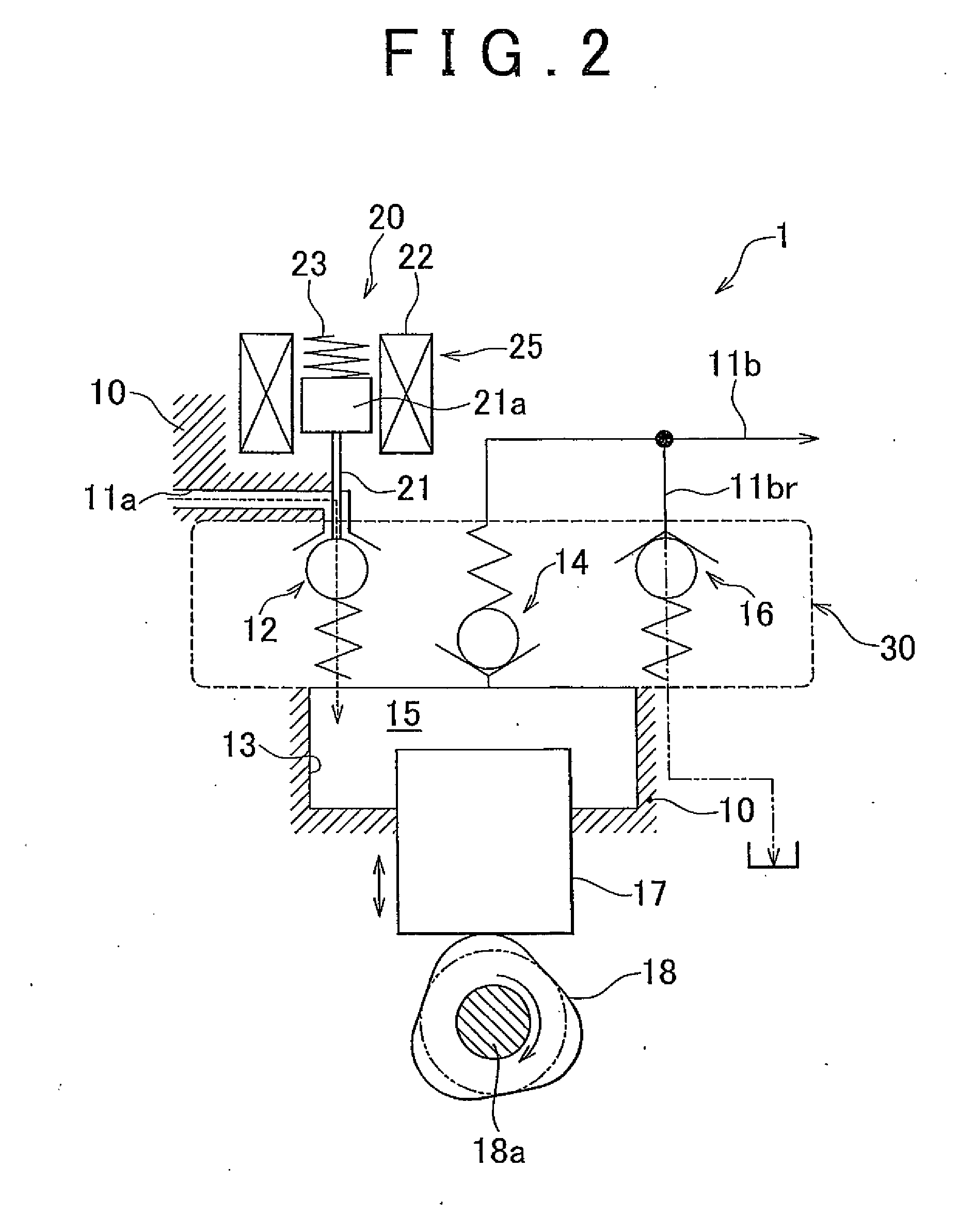

Fuel pump

InactiveUS20120207632A1Low costPositive displacement pump componentsCheck valvesReed valveEngineering

In a fuel pump that includes a pump housing (10) that has fuel passages (11a, 11b), a plunger (17) that is movably housed in the pump housing (10), a fuel pressurizing chamber (15) that is formed in the pump housing (10) and draws in fuel via one of the fuel passages (11a) that is on the intake side of the fuel pressurizing chamber (15), pressurizes the fuel that has been drawn in, and discharges the pressurized fuel via the other fuel passage (11b) that is on the discharge side of the fuel pressure chamber (15), in response to movement of the plunger (17), and valve elements (12, 14, 16) that are arranged in the fuel passages (11a, 11b) near the fuel pressurizing chamber (15), each of the valve elements (12, 14, 16) has a reed valve body (41, 42, 43; 74, 75, 76) arranged in the fuel passage (11a) on the intake side of the fuel pressurizing chamber (15) or the fuel passage (11b) on the discharge side of the fuel pressurizing chamber (15); and an operating member (21) that applies operating force in at least one of a valve opening direction or a valve closing direction to the reed valve body (41, 42, 43; 74, 75, 76) is provided in the pump housing (10).

Owner:TOYOTA JIDOSHA KK

Reciprocating compressor or pump and a portable tool powering system including a reciprocating compressor

A reciprocating compressor or pump features a manifold arranged not only to define a hollow interior for receiving fluid discharged from a plurality of cylinders but also to define a base or frame on which the cylinders are carried. Unique valves formed in part by flexible material reduces the likelihood of fatigue and increases efficiency by retaining less heat relative to conventional reed valves. A compressor or pump mounted at an end of a handle extending parallel to a motor housing likewise extending from the compressor or pump provides an easy to carry portable assembly. A fan mounted between a motor and a compressor pulls air through the compressor inlet to both cool the motor and feed the compressor. A portable tool system powers both pneumatic and electric tools. Connecting rod structures for radial compressors or pumps provide improved strength and easier assembly.

Owner:SCHUETZLE LARRY ALVIN

Rocker box assembly with reed valve

ActiveUS6883505B1Improve performanceExtended service lifeNon-fuel substance addition to fuelInternal combustion piston enginesDiagonalReed valve

A rocker box bottom for an internal combustion engine includes a body that defines an oil / air inlet, an oil outlet, a chamber therebetween and a valve seat between the chamber and the oil / air inlet. The body seals to a rocker box top and defines the inlet and outlets. The seat may accept a valve along a diagonally downward direction with the oil outlet below the seat. In the alternative, the path between the oil / air inlet and the air outlet may turn the air flowing therethrough approximately 180 degrees. In another preferred embodiment, the valve may be a reed valve that, in cooperation with the chamber walls, turns the oil / air mixture flowing therethrough approximately 180 degrees.

Owner:MIDWEST MOTORCYCLE SUPPLY DISTRIBUTORS

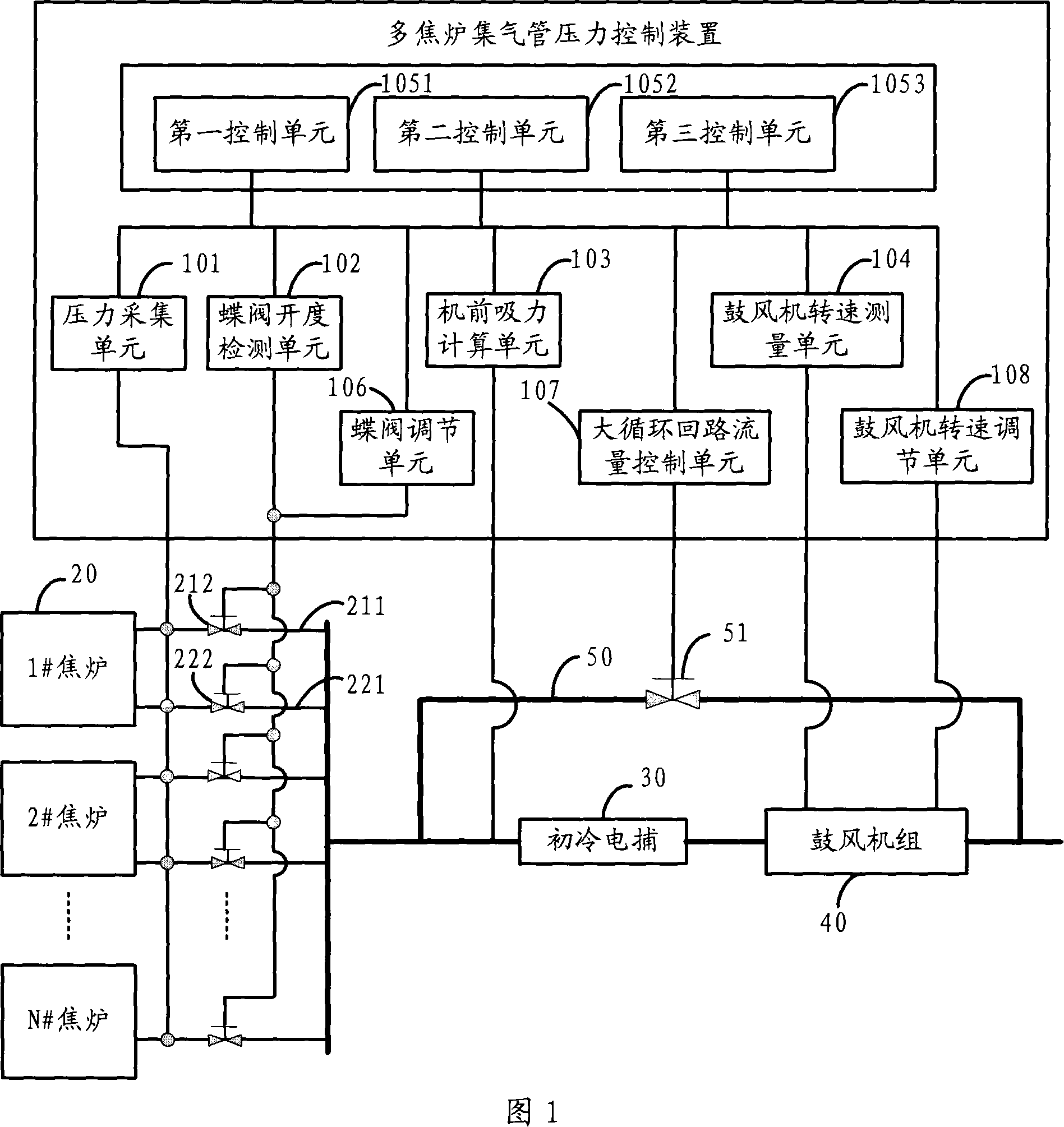

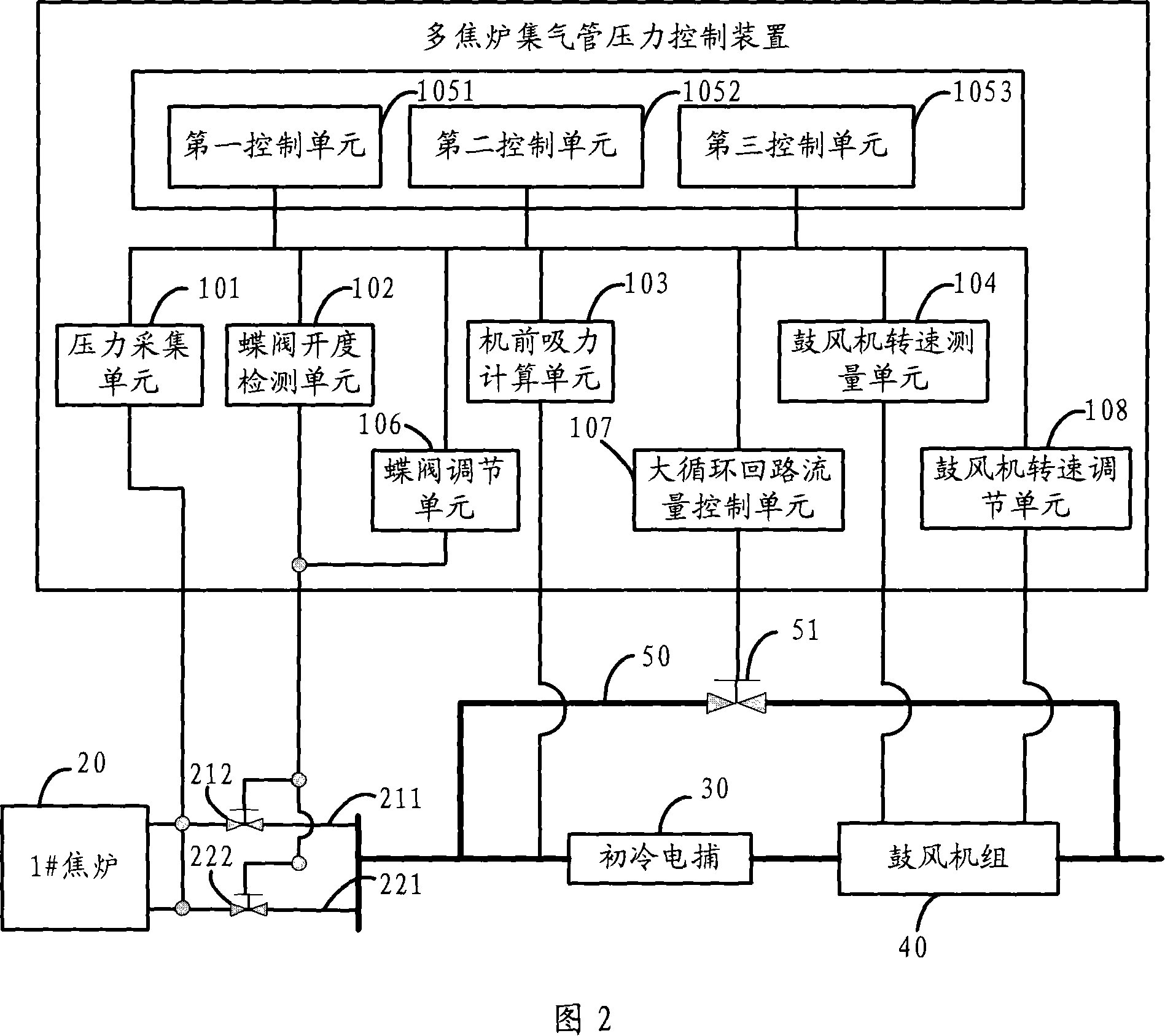

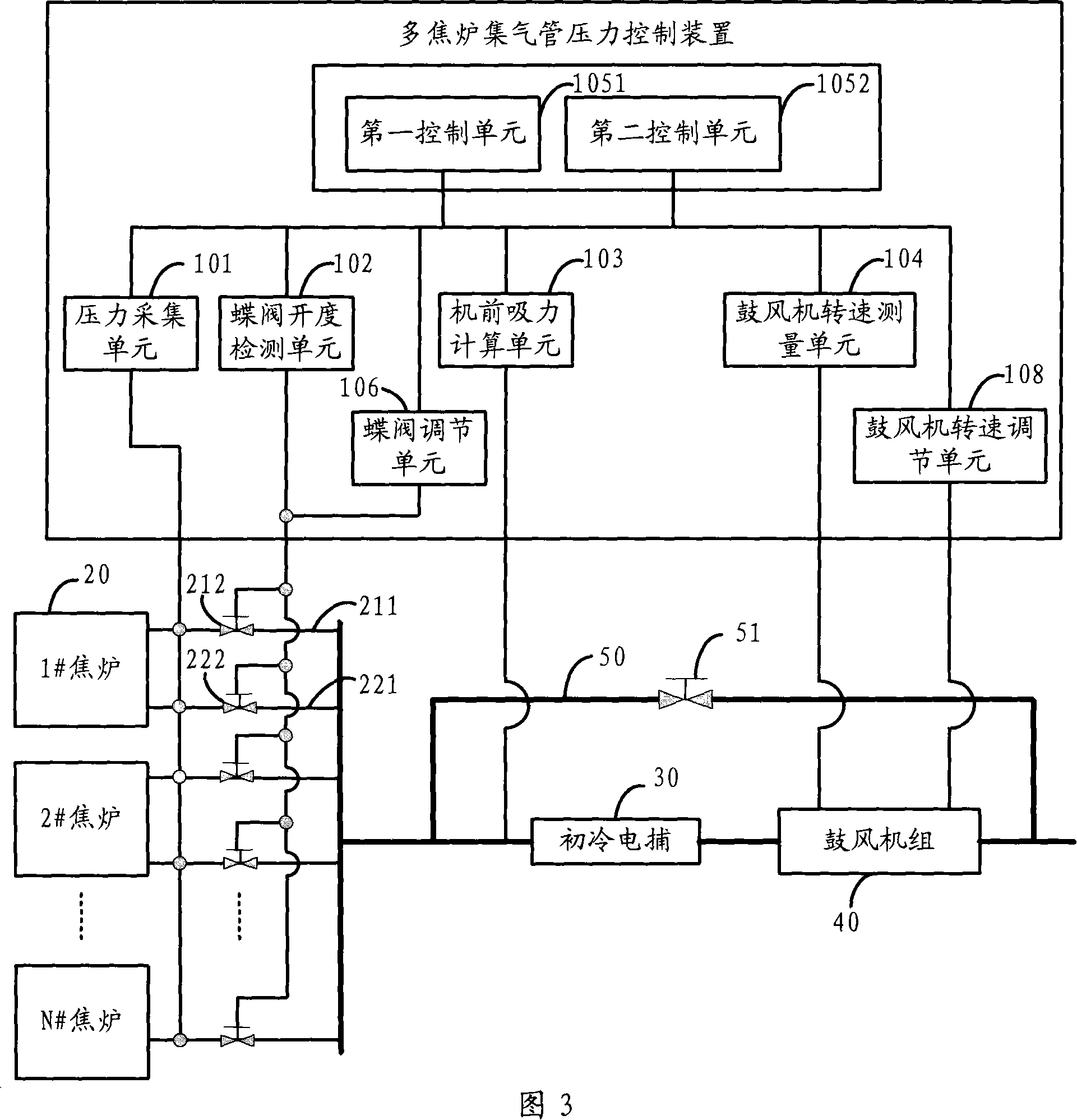

Multi-coke-oven gas-colluection-pipe pressure control apparatus and method

InactiveCN101070477AReduce interactionAddress issues with high impact from stressCoke oven safety devicesOpen adjustmentReed valve

This invention has publicized a more coke oven gathering of gas pipe pressure control device. It comprises the pressure gathering unit which is used to gather various collecting pipes' value of pressure, the reed valve opening detecting element which is used to examine various collecting pipes' reed valve's opening, the reed valve regulating unit which is used to adjust collecting pipe's reed valve's opening, the first control unit which is used to gathering unit gather value of pressure with the controlled variable which establishes in advance determining that the first opening adjustment quantity according to the pressure. This first opening adjustment quantity with the decoupling coefficient product determination which establishes in advance for the second opening adjustment quantity, the union current reed valve's opening, controls states the reed valve regulating unit with to state the second opening adjustment quantity according to this first opening adjustment quantity the superimposition result to make the adjustment to the reed valve. At the same time, this invention has also publicized a coke oven gathering of gas pipe pressure control method. Using this invention may reduce the pressure perturbation between various collecting pipes' effectively.

Owner:SUPCON GRP +1

Controlled auto-ignition two-stroke engine

InactiveUS20060124086A1Limiting instantaneous flowPromotes stress balanceCylinder headsCombustion enginesTop dead centerRotary valve

A controlled auto-ignition or spark ignition two stroke piston engine, fed by homogeneous air-fuel mixture, with crankcase scavenging, in which the amount of air-fuel mixture transferred from the crankcase to the cylinder is not greater than the 50% of the cylinder volume; said engine has reed valves in the transfer ports that connect the crankcase to the cylinder to control the internal dynamics of the air-fuel mixture, limiting the instantaneous maximum flow that is transferred to the cylinder in order to achieve the best stratification level among the air-fuel mixture and the exhaust residual gases, getting this way the thermo chemical activation of part of the fuel contained in the mixture. Said engine also has a rotary valve adjacent to the cylinder exhaust port that rotates in synchronism with the crankshaft, which closes the exhaust port a few degrees after the piston reaches the bottom dead center, thus preventing the leakage of the thermo chemically activated mixture and holding part of the burnt gases inside the cylinder. Then, during the compression stroke, more heat is given to the thermo chemically activated mixture decomposing part of the fuel contained in it into activated radicals which act as igniters when close to the top dead center firing the mixture in a simultaneous and complete way, thus obtaining very low levels of CO, HC and Nox emissions, as well as low fuel and oil consumption.

Owner:FABREGA JUANA ELISABETH

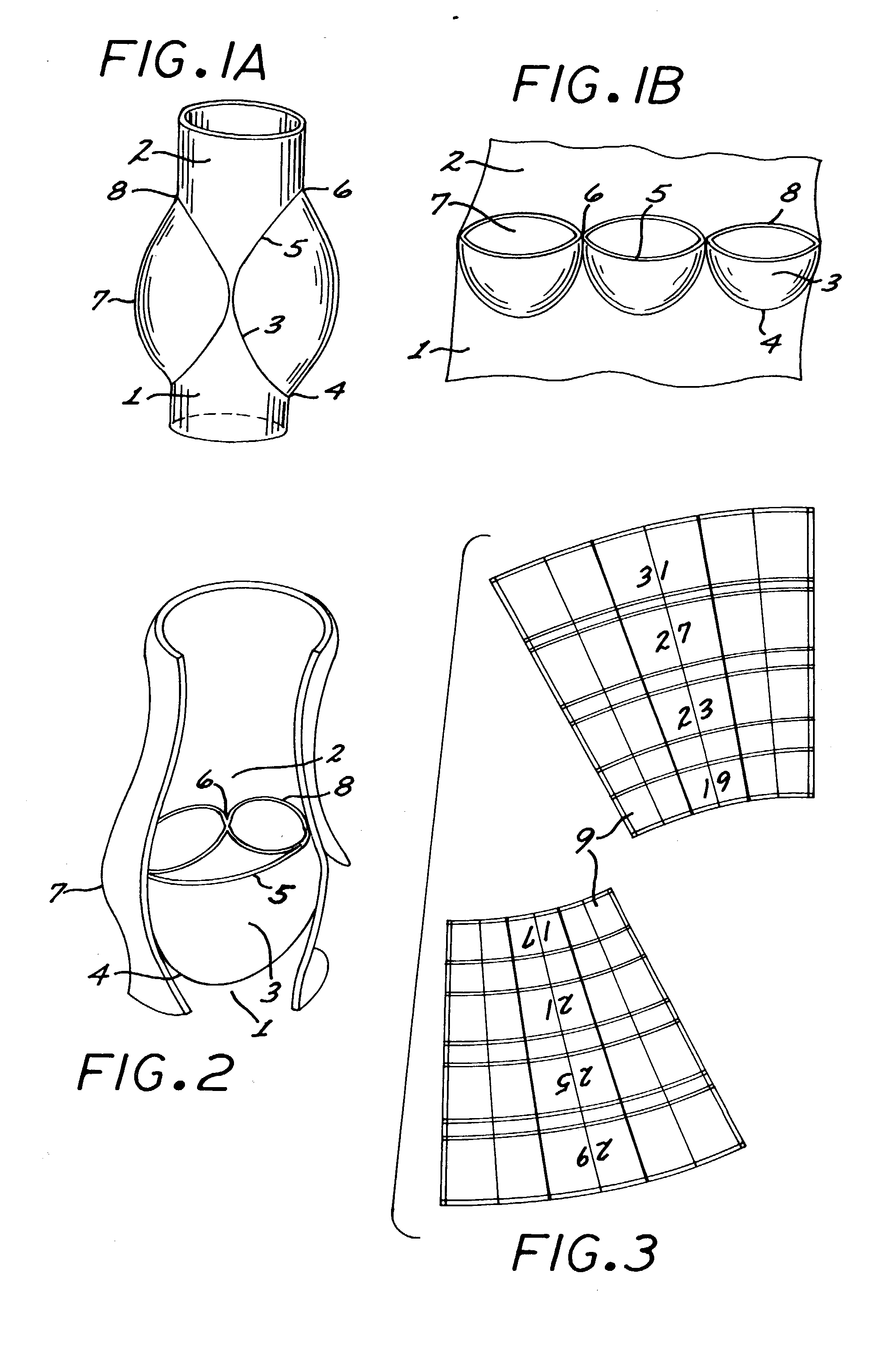

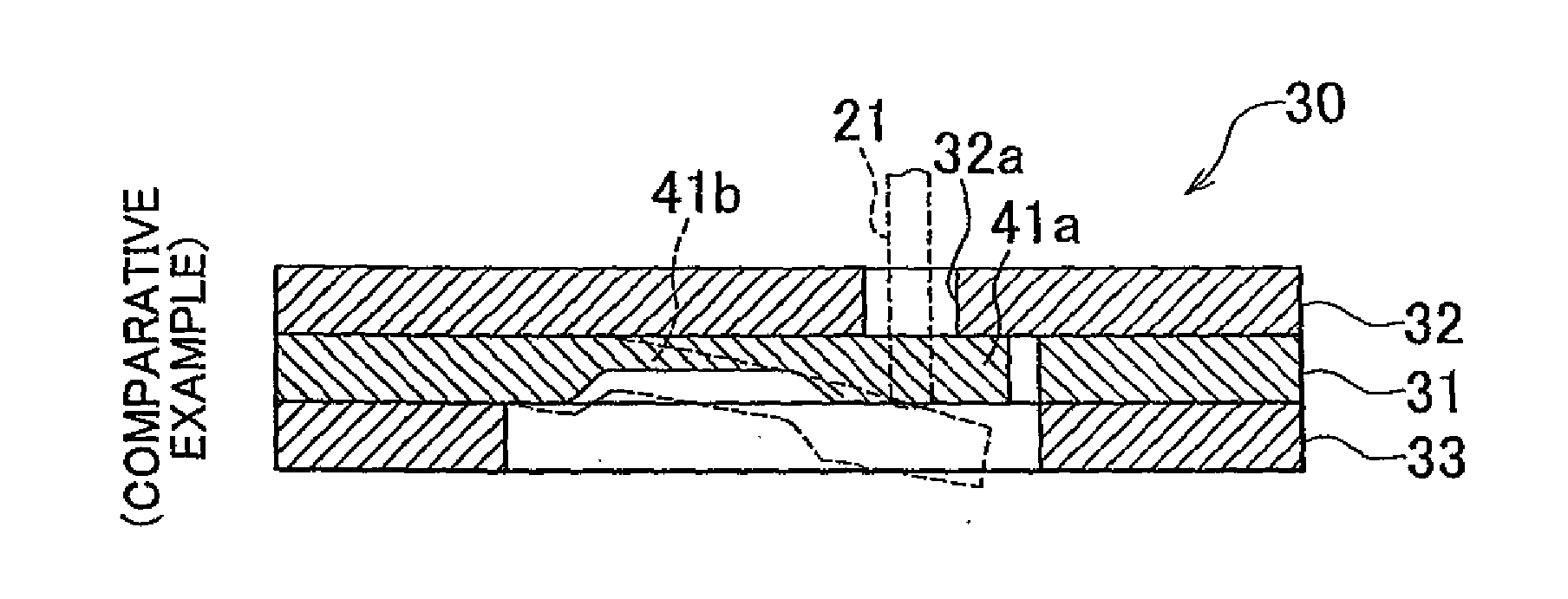

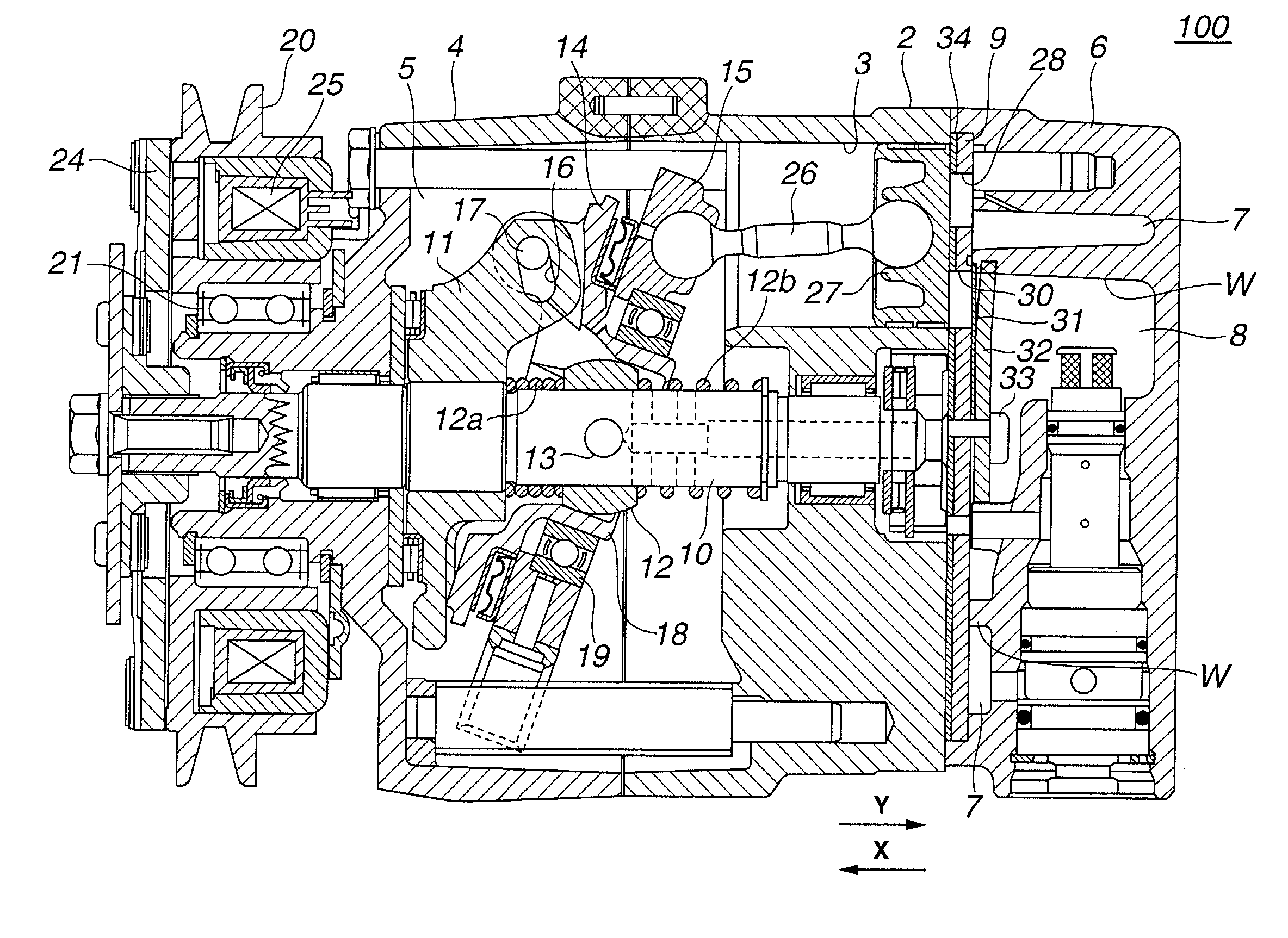

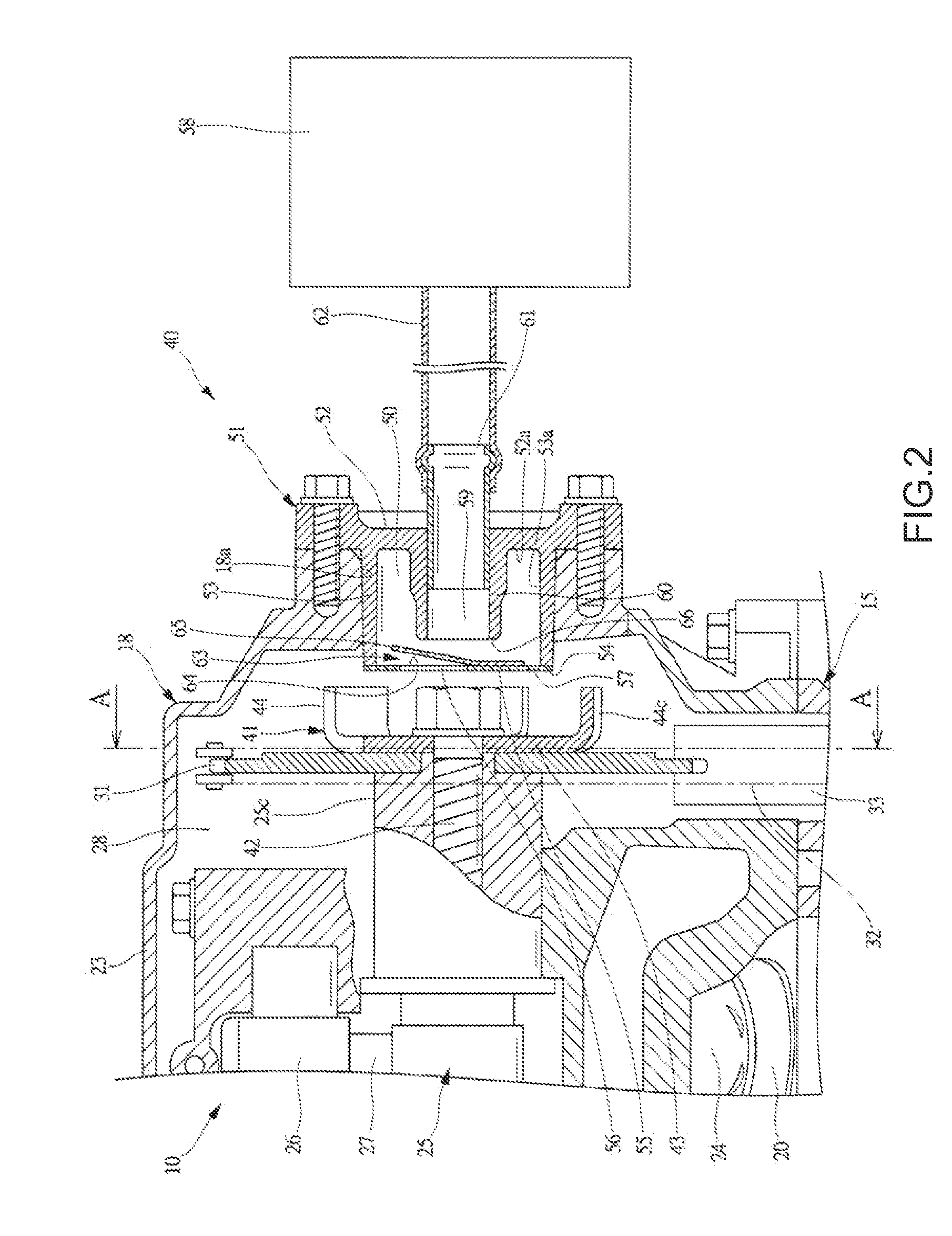

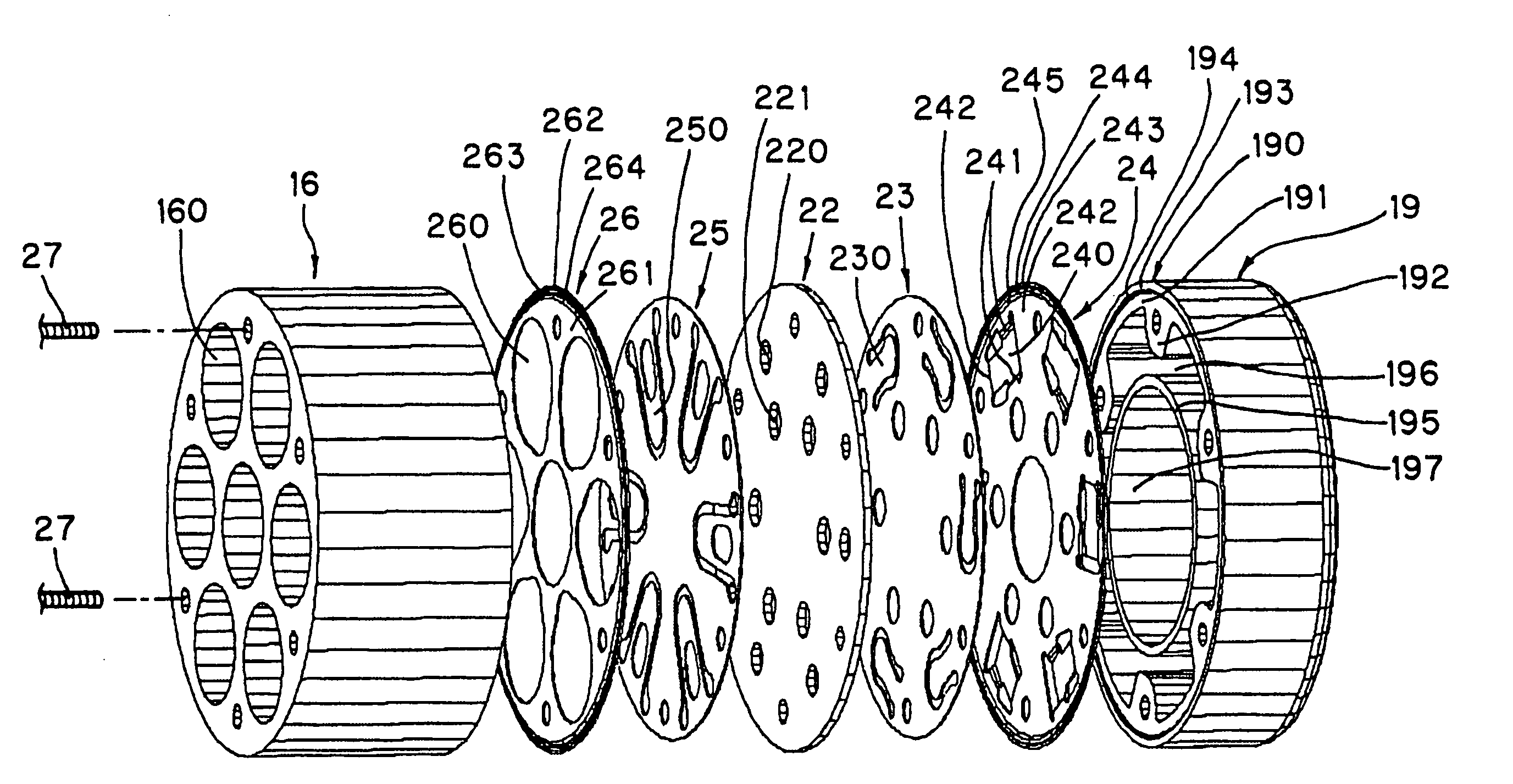

Piston type compressor

Between a cylinder block and a housing, there is disposed a valve base plate. The valve base plate is formed with mutually isolated first and second intake openings for fluidly communicating each of piston chambers in the cylinder block with an intake chamber defined in the housing. A reed valve element is incorporated with each piston chamber. The reed valve element is arranged to open the first and second intake openings with the aid of a fluid when the piston is moved away from the reed valve element and close the first and second intake openings with the aid of the fluid when the piston is moved toward the reed valve element. Due to provision of the two, viz., first and second intake openings, opening movement of the reed valve element is carried out along with a twisting motion of the same.

Owner:CALSONIC KANSEI CORP

Piston type compressor

Between a cylinder block and a housing, there is disposed a valve base plate. The valve base plate is formed with mutually isolated first and second intake openings for fluidly communicating each of piston chambers in the cylinder block with an intake chamber defined in the housing. A reed valve element is incorporated with each piston chamber. The reed valve element is arranged to open the first and second intake openings with the aid of a fluid when the piston is moved away from the reed valve element and close the first and second intake openings with the aid of the fluid when the piston is moved toward the reed valve element. Due to provision of the two, viz., first and second intake openings, opening movement of the reed valve element is carried out along with a twisting motion of the same.

Owner:CALSONIC KANSEI CORP

Breather apparatus for engine

InactiveUS20120080015A1Avoid complex constructionSuppression amountCombustion enginesCrankcase ventillationCylinder headEngineering

This breather apparatus has a rotation separator that is fastened to a camshaft, and that rotation separator has a base plate section and a plurality of protruding plates that extend from the base plate section. Moreover, a separator housing is provided in the cylinder head, and comprises an air intake on one end, and an exhaust outlet on the other end. Furthermore, a reed valve that opens and closes by the change in pressure inside a cam chamber is provided in the air intake. Blowby gas that is guided to the cam chamber hits against the protruding plates when passing in the radial direction of the rotation separator, and oil mist is captured by those protruding plates. Continuing, the blowby gas is guided from the cam chamber into the separator housing via the reed valve. When passing through the reed valve, the flow rate of the blowby gas changes, so oil mist is effectively captured by the inner wall surface of the separator housing.

Owner:SUBARU CORP

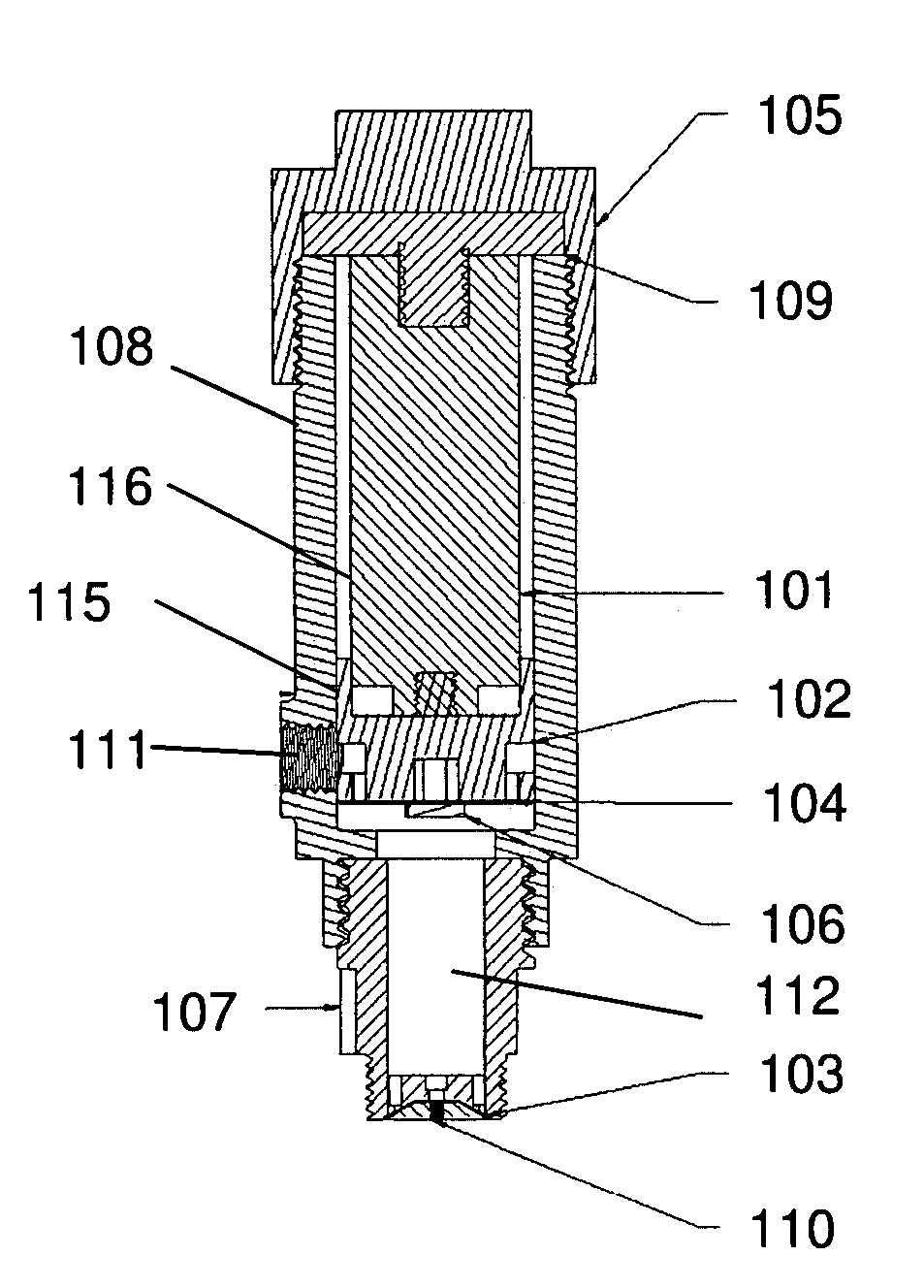

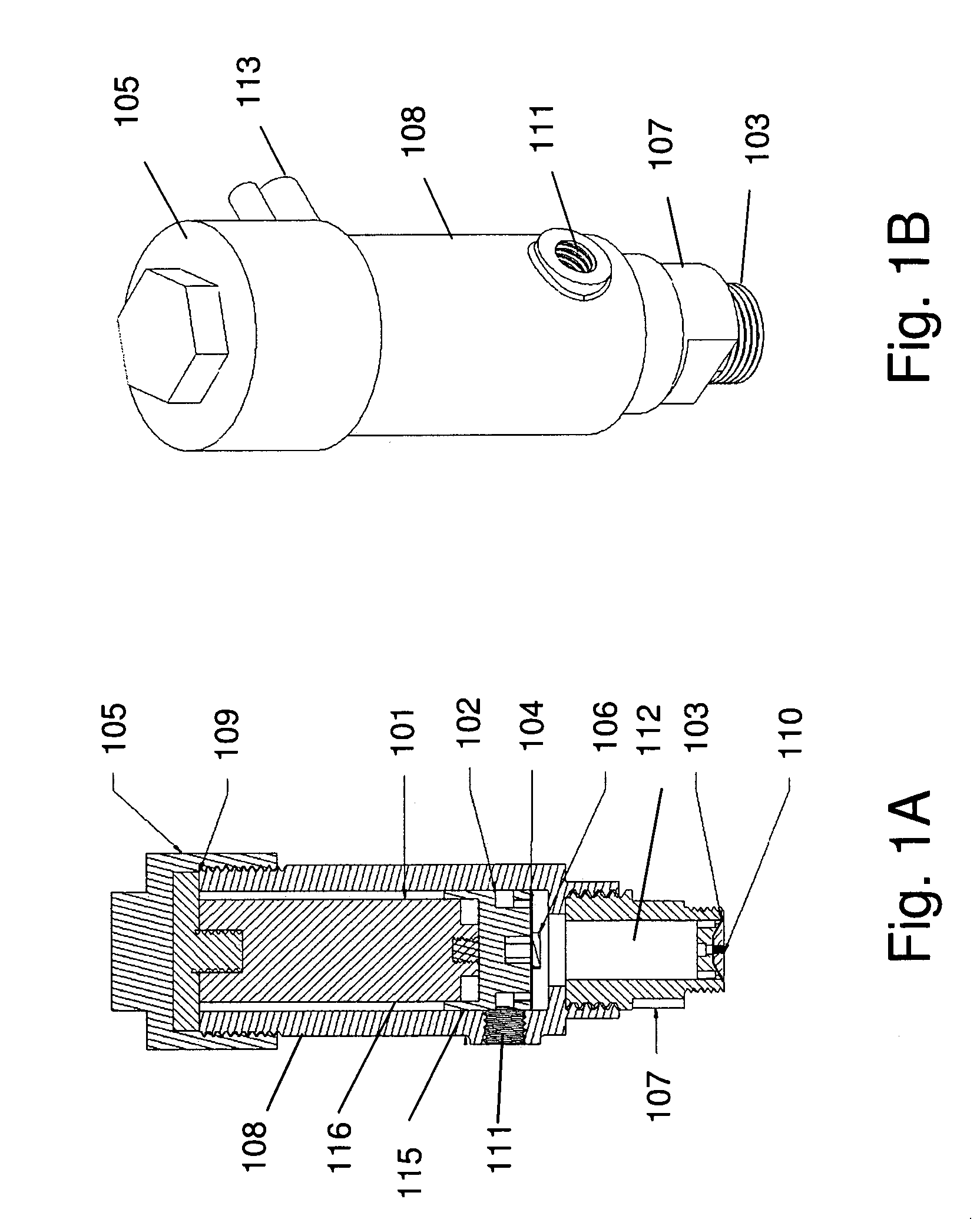

High pressure piezoelectric fuel injector

InactiveUS7721716B1Precise deliveryPrevent protrudingFuel injection with piezoelectric/magnetostrictive elementsMachines/enginesElectricityPiezoelectric actuators

A combined injector and fuel pump suitable for high pressure direct injection of heavy fuels into Diesel engines, in particular small light weight Diesel engines as may be used in small aircraft. The injector utilizes a piezoelectric actuator driving a piston assembly comprising an inlet reed check valve disposed thereon. Fuel enters an inlet port coupled to an inlet chamber on a first side of the piston. Piezoelectric actuator contraction transfers fuel from the inlet chamber through the reed valve to the pressurization chamber on a second side of the piston. Piezoelectric actuator expansion drives the piston to pressurize the fuel in the pressurization chamber, which forces open a conical annular valve and nozzle assembly injecting a finely atomized mist of fuel into the cylinder.

Owner:HARWOOD MICHAEL R

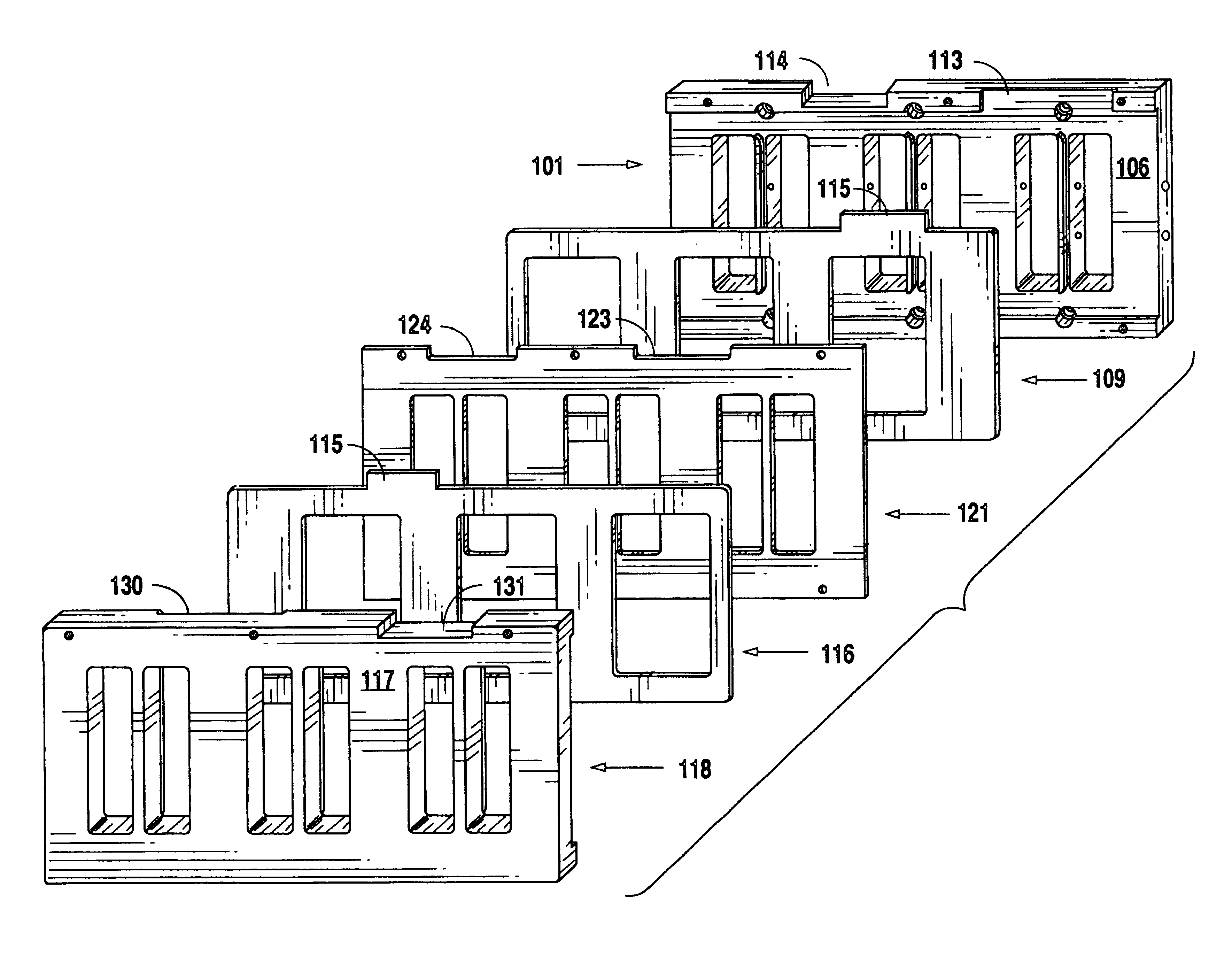

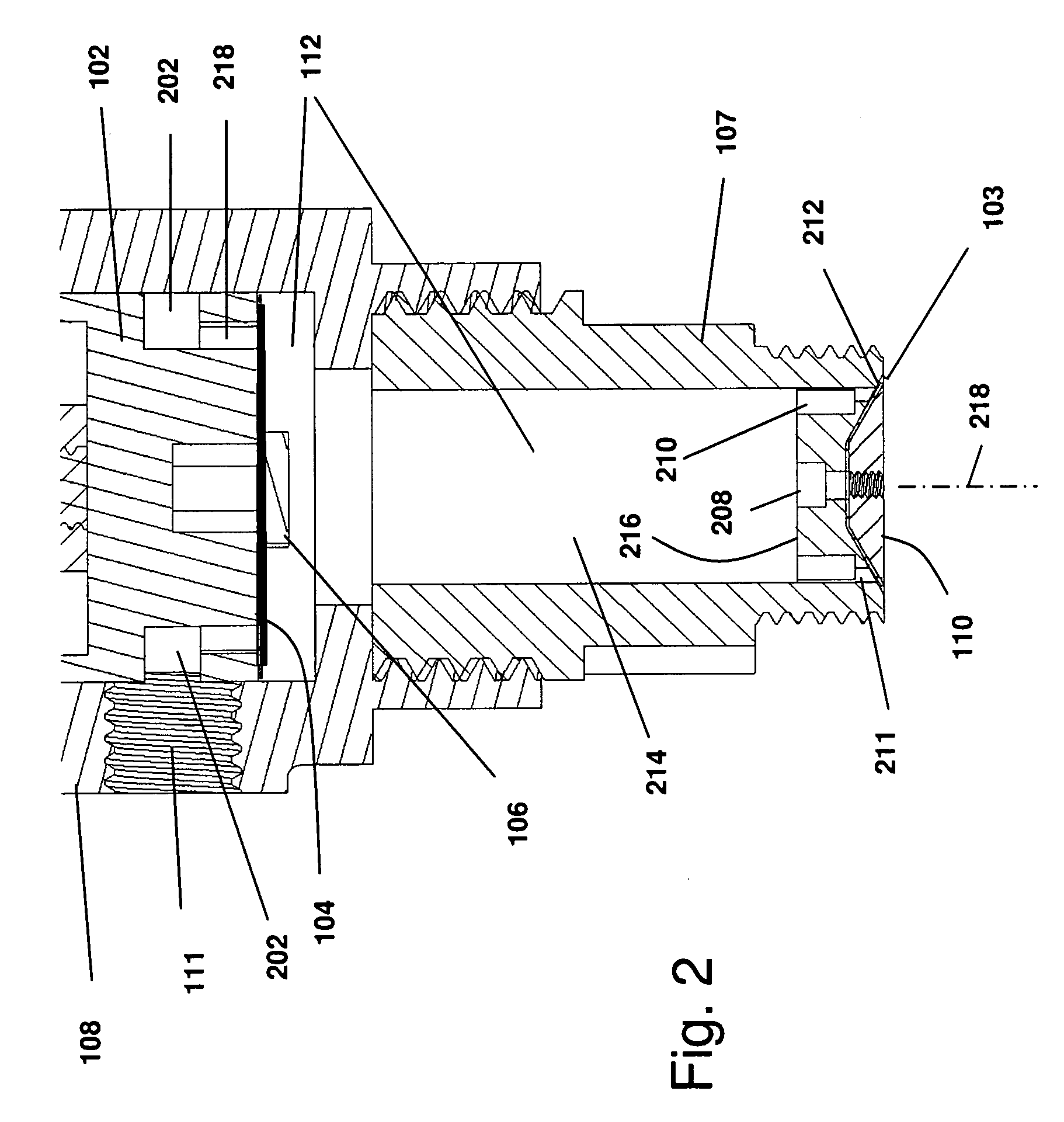

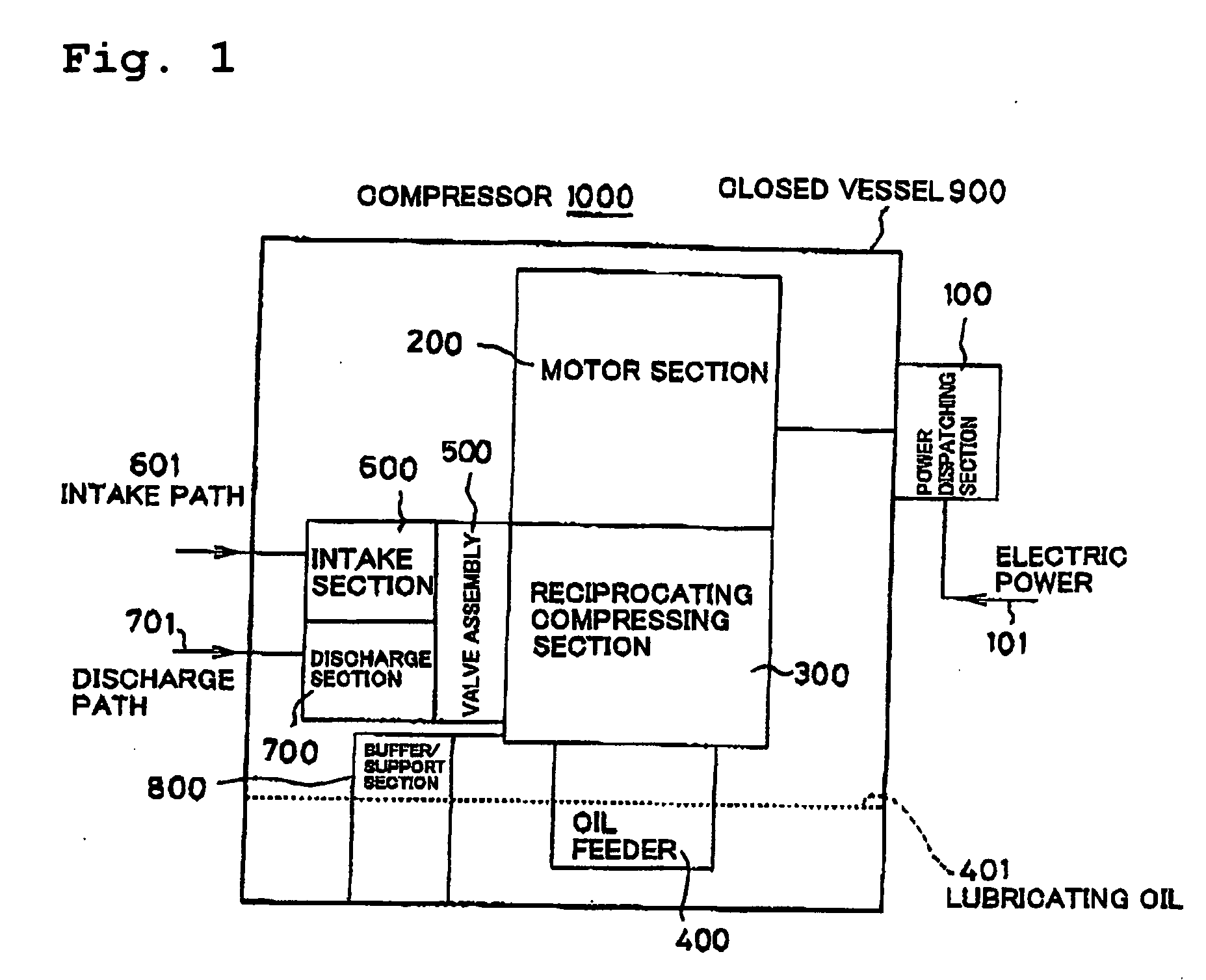

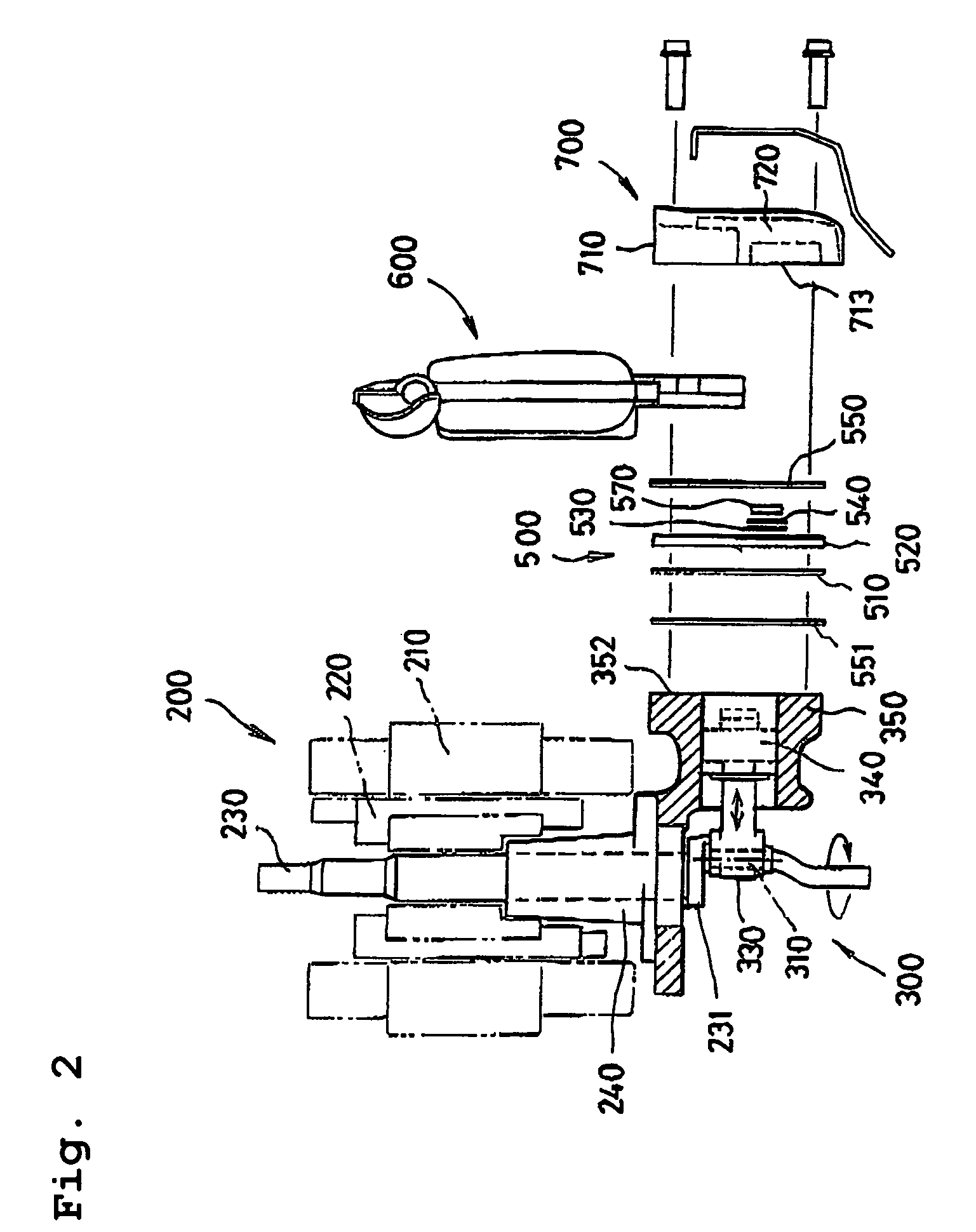

Reciprocating compressor

InactiveUS20070231167A1Reduced discharge resistanceImprove compression efficiencyPositive displacement pump componentsPositive-displacement liquid enginesEngineeringReed valve

A reciprocating compressor is disclosed which has a valve construction using plural discharge ports, plural reed valves and plural valve backers to lower the discharge resistance and improve the compression efficiency. The reciprocating compressor (1000) has within a closed vessel (900) a reciprocating compressing section (300) for compressing a required fluid, the reciprocating compressing section (300) comprising a discharge unit for discharging the fluid and a valve assembly (500) for opening and closing the discharge unit, with a plurality of discharge ports (522A, 522B) being formed in the valve assembly, the valve assembly (500) comprising valve members (560), the valve members (560) comprising reed valves (530A, 530B) disposed correspondingly to the discharge ports (522A, 522B) and valve backers (540A, 540B) disposed respectively on back sides of the reed valves, a valve seat (520) having a recess for receiving the valve members therein, and valve members fixing means for urging end sides of the valve members to fix the valve members elastically to fixing portions (523A, 523B) of the recess.

Owner:SANYO ELECTRIC CO LTD

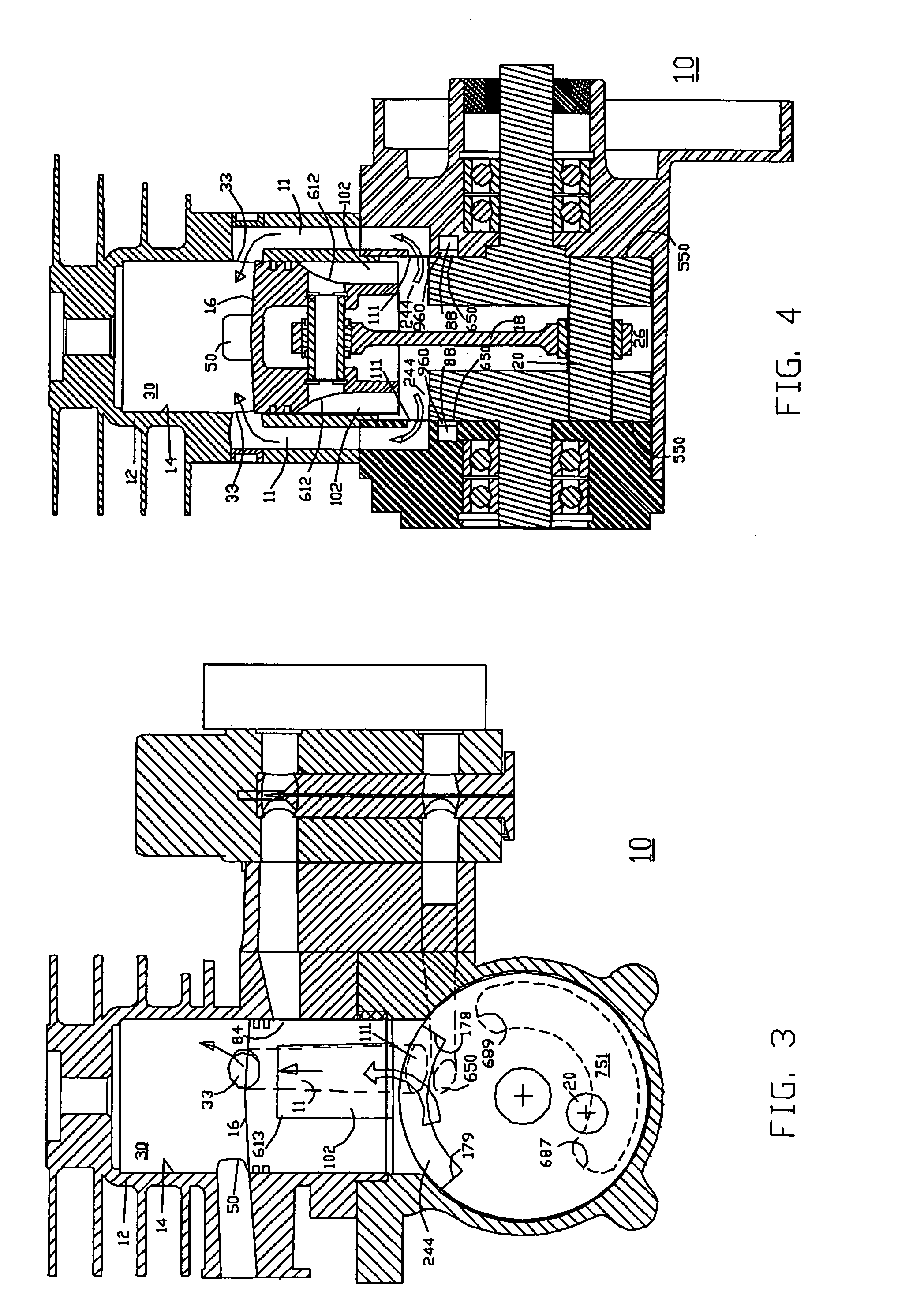

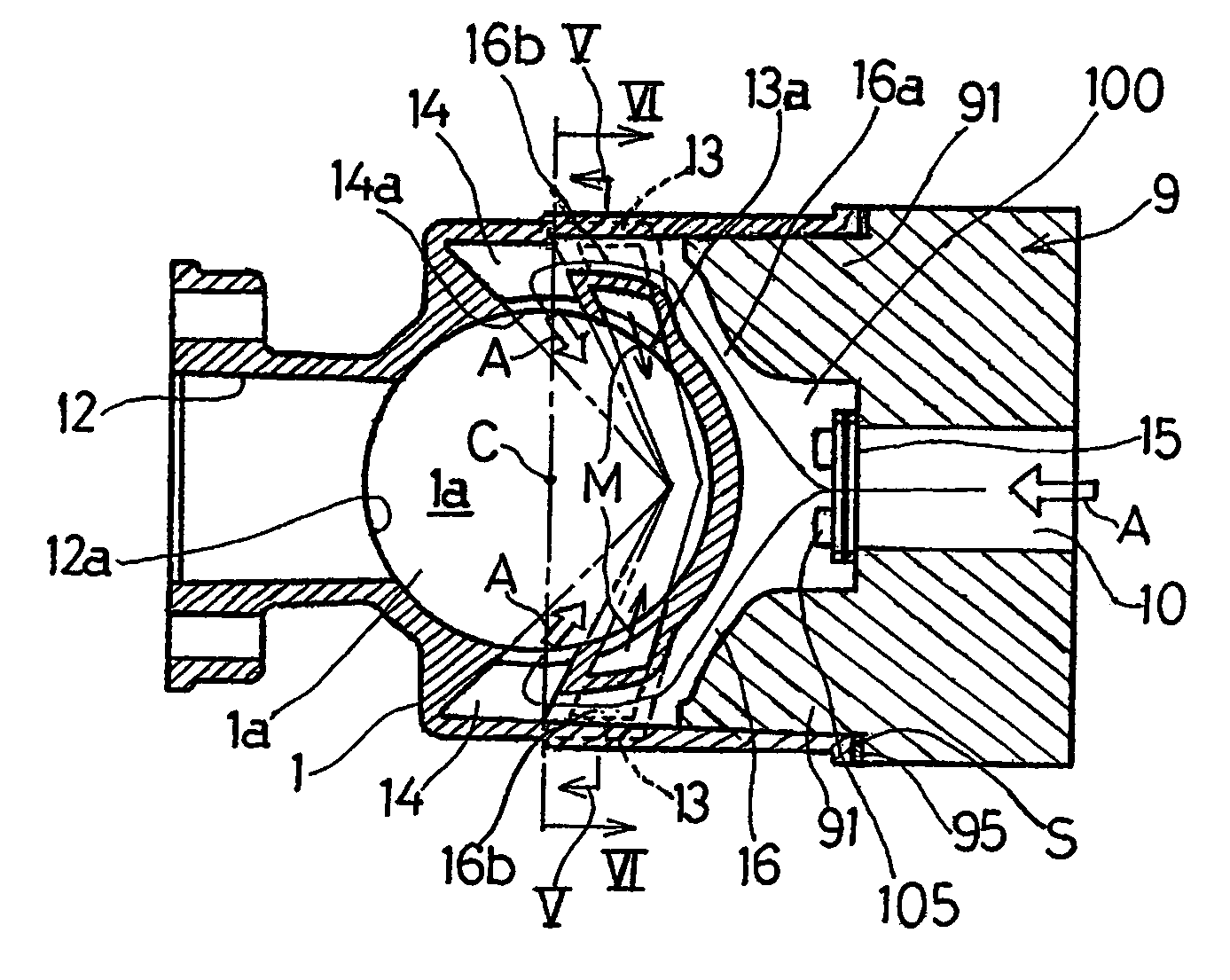

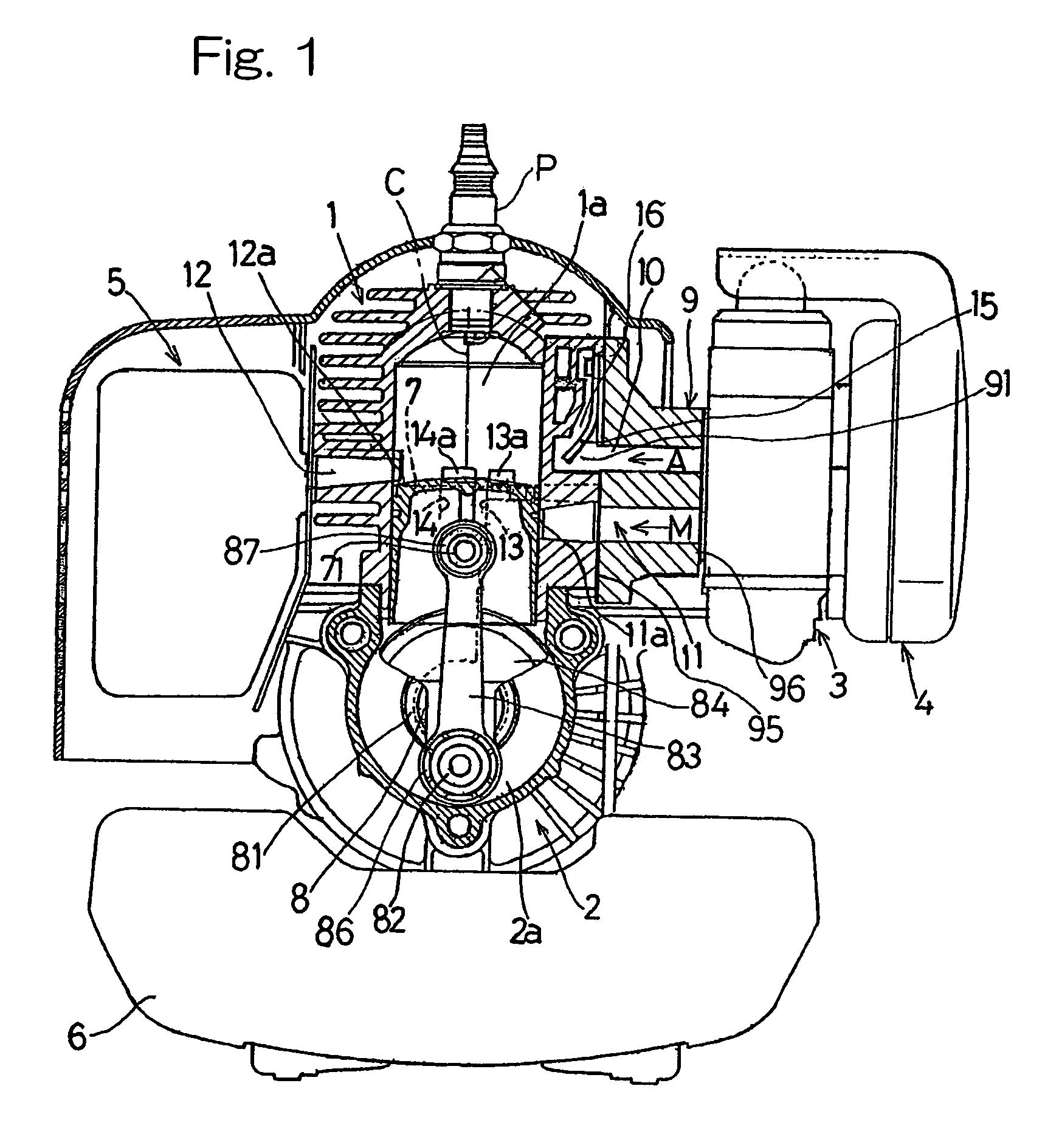

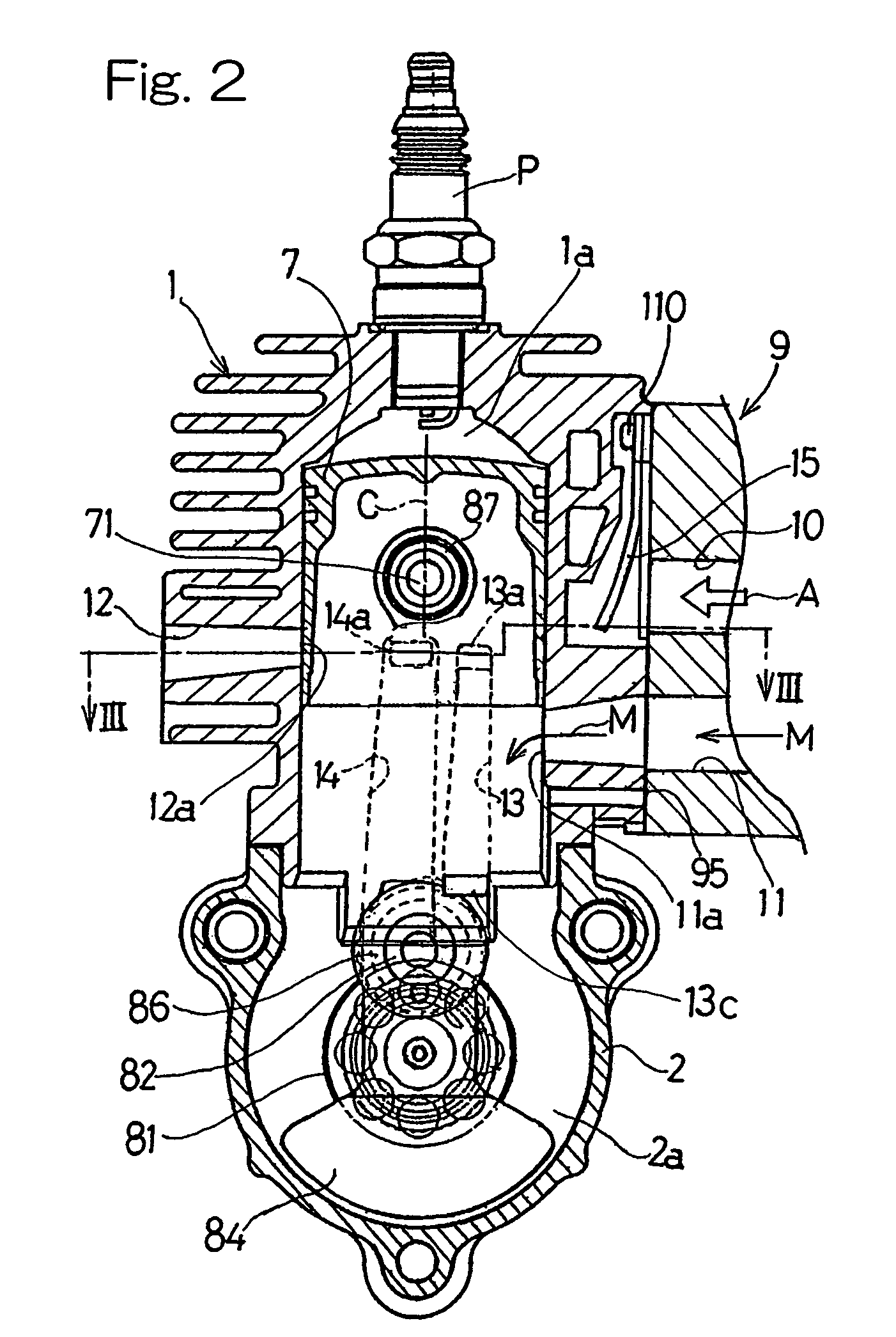

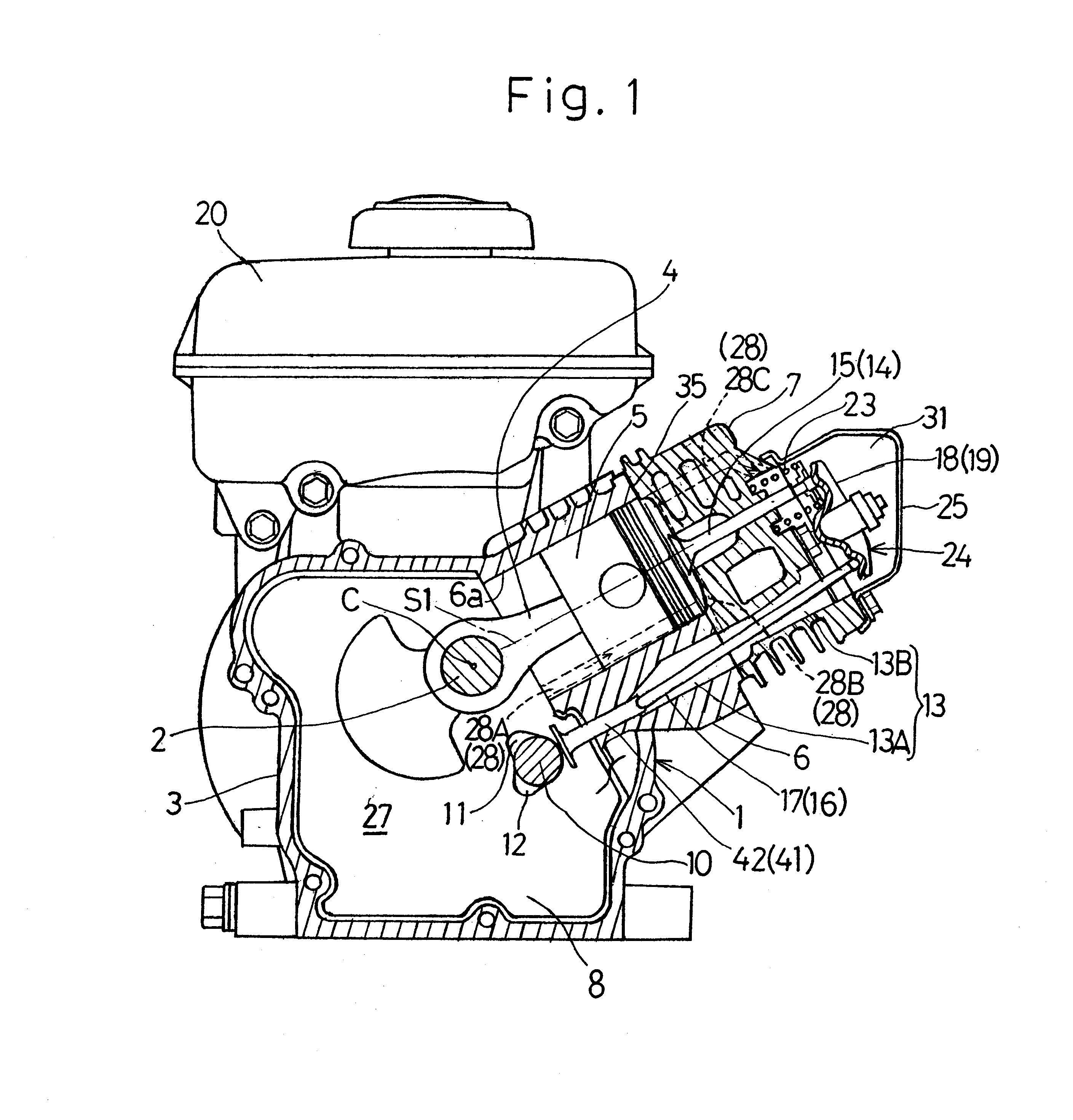

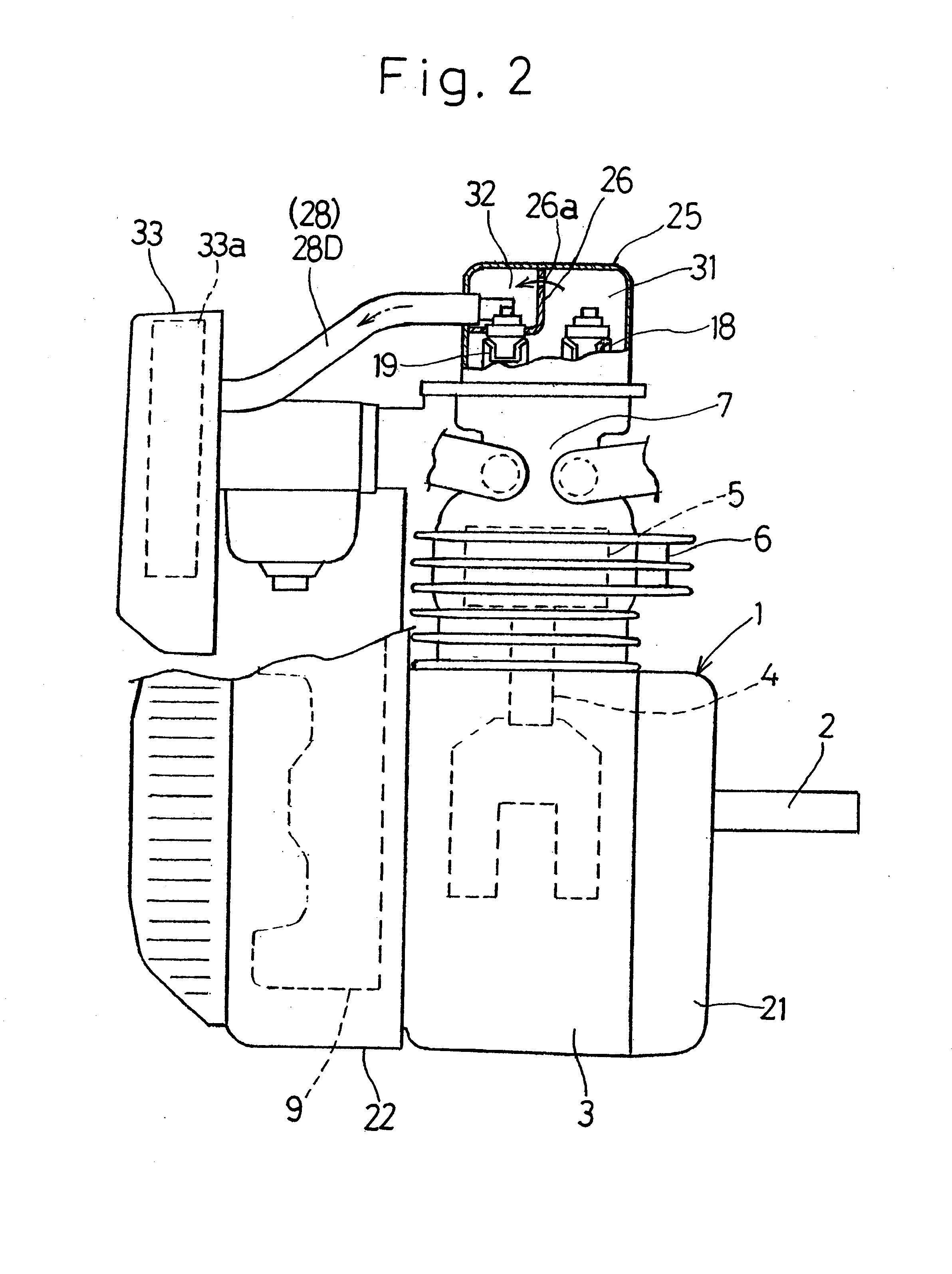

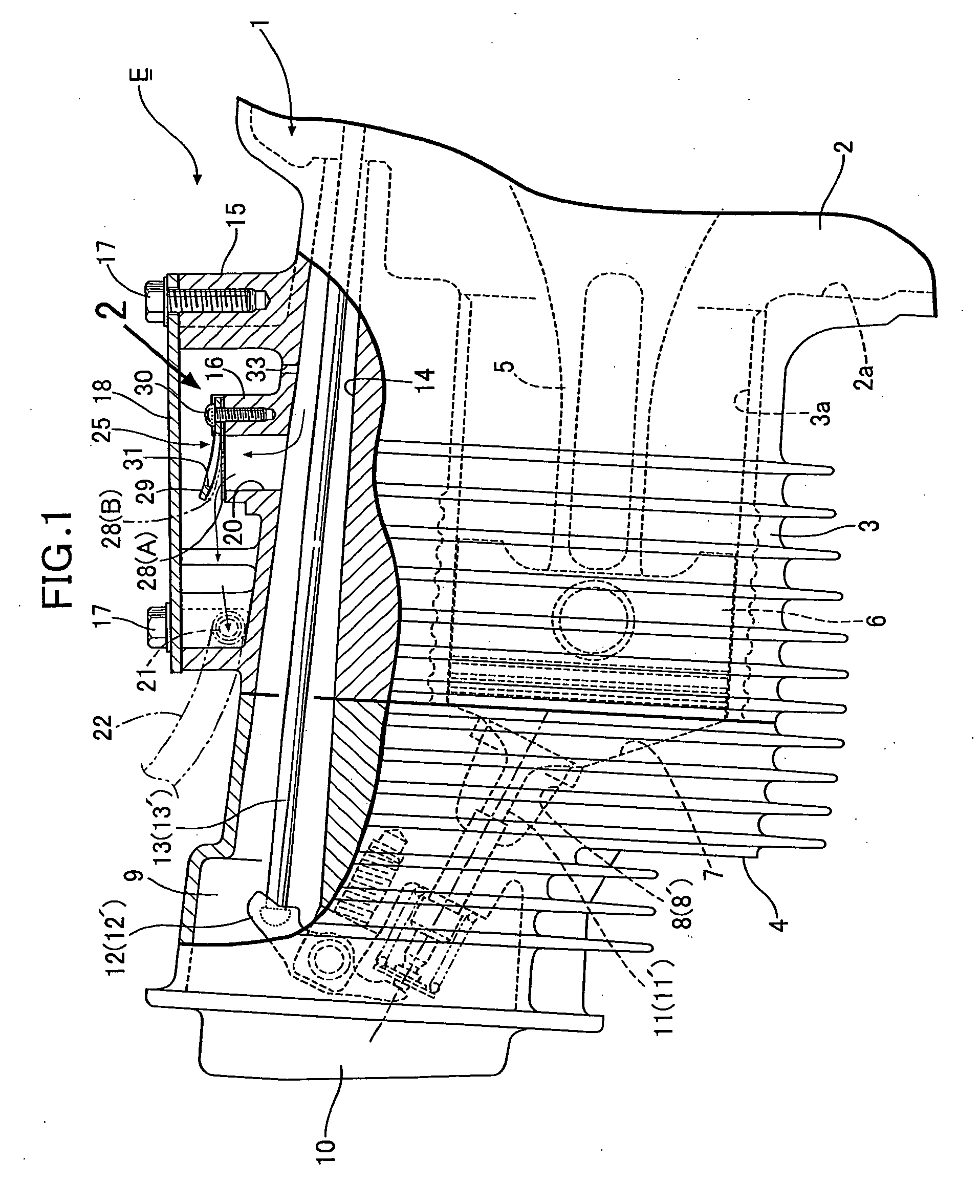

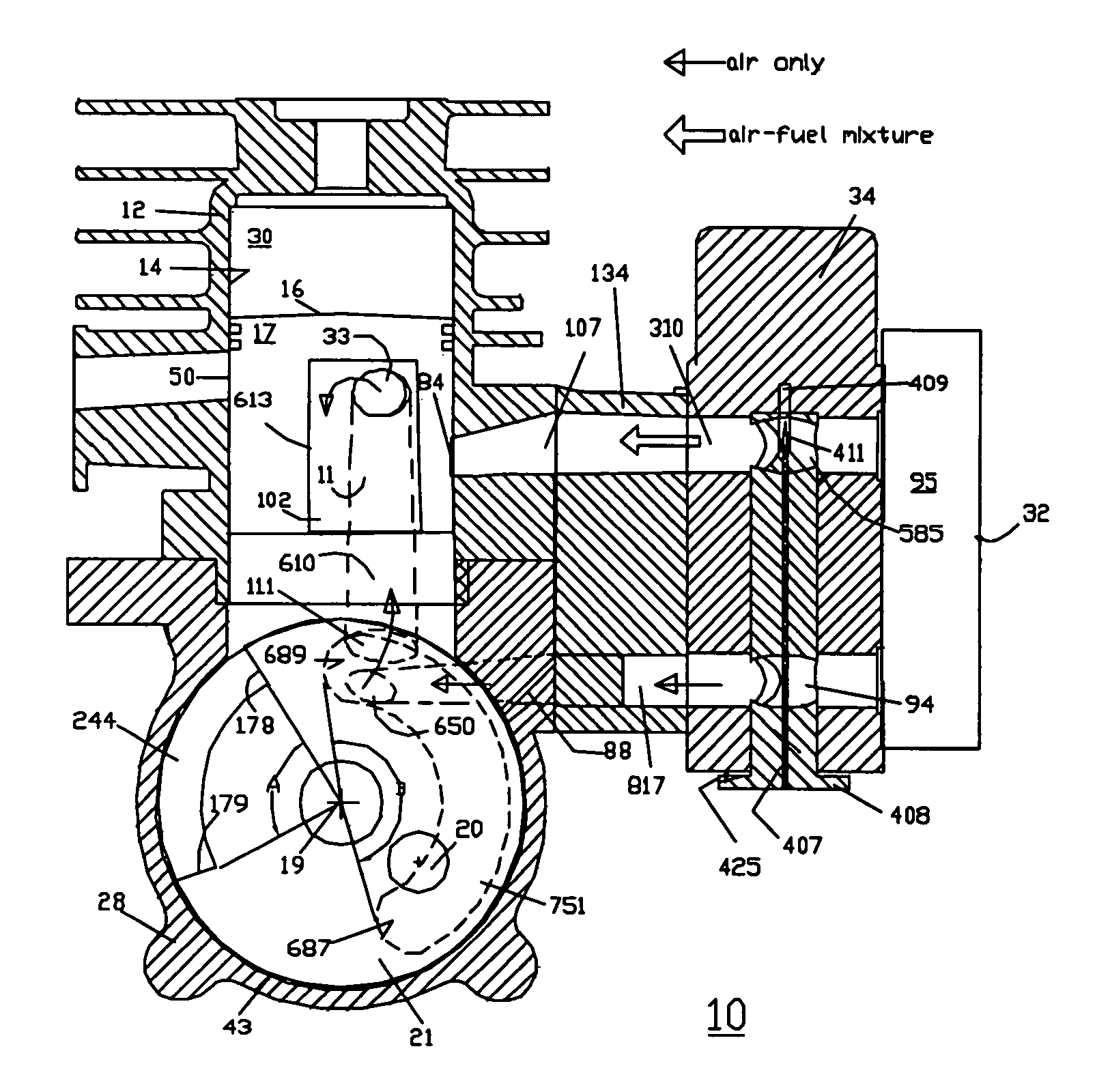

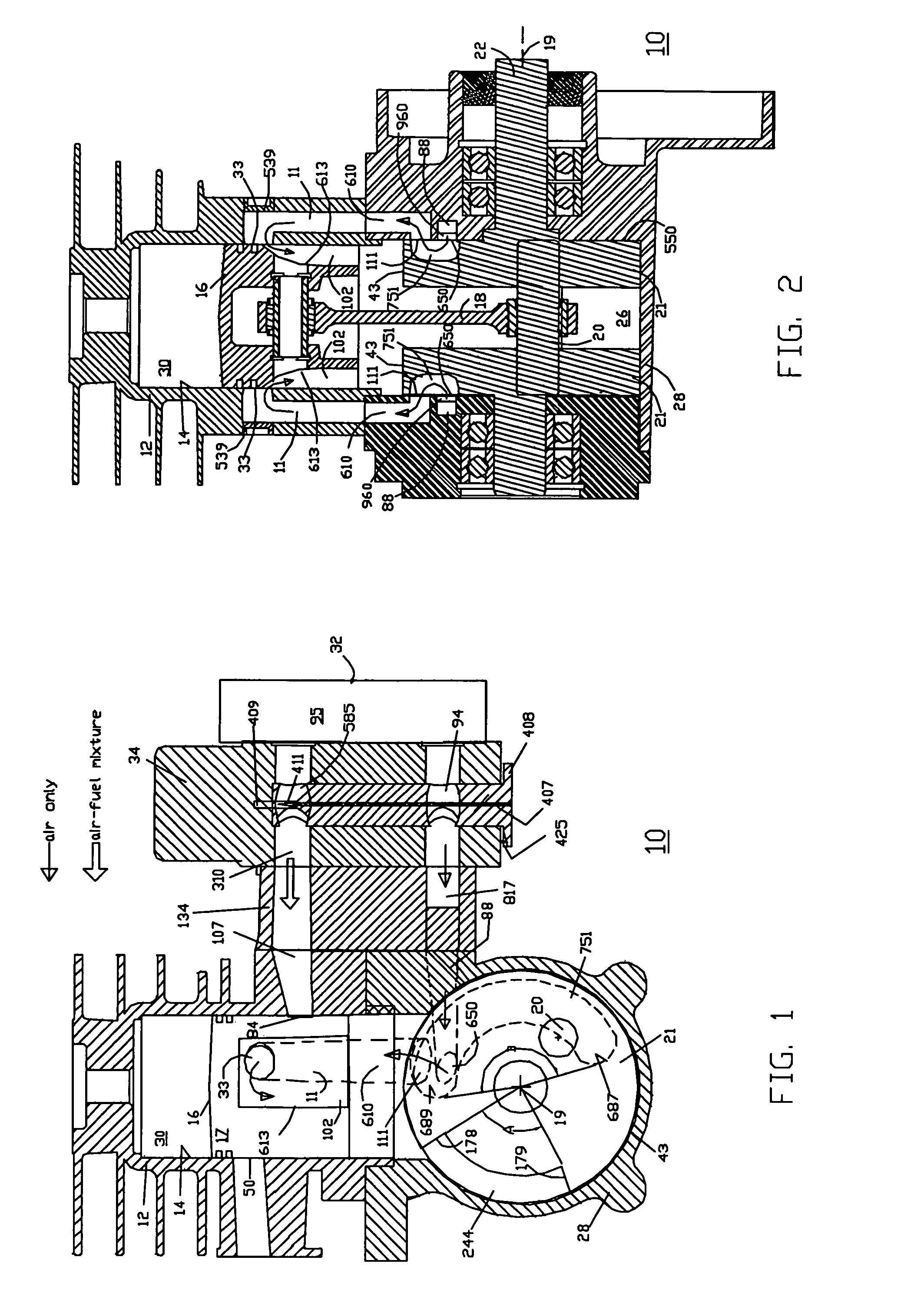

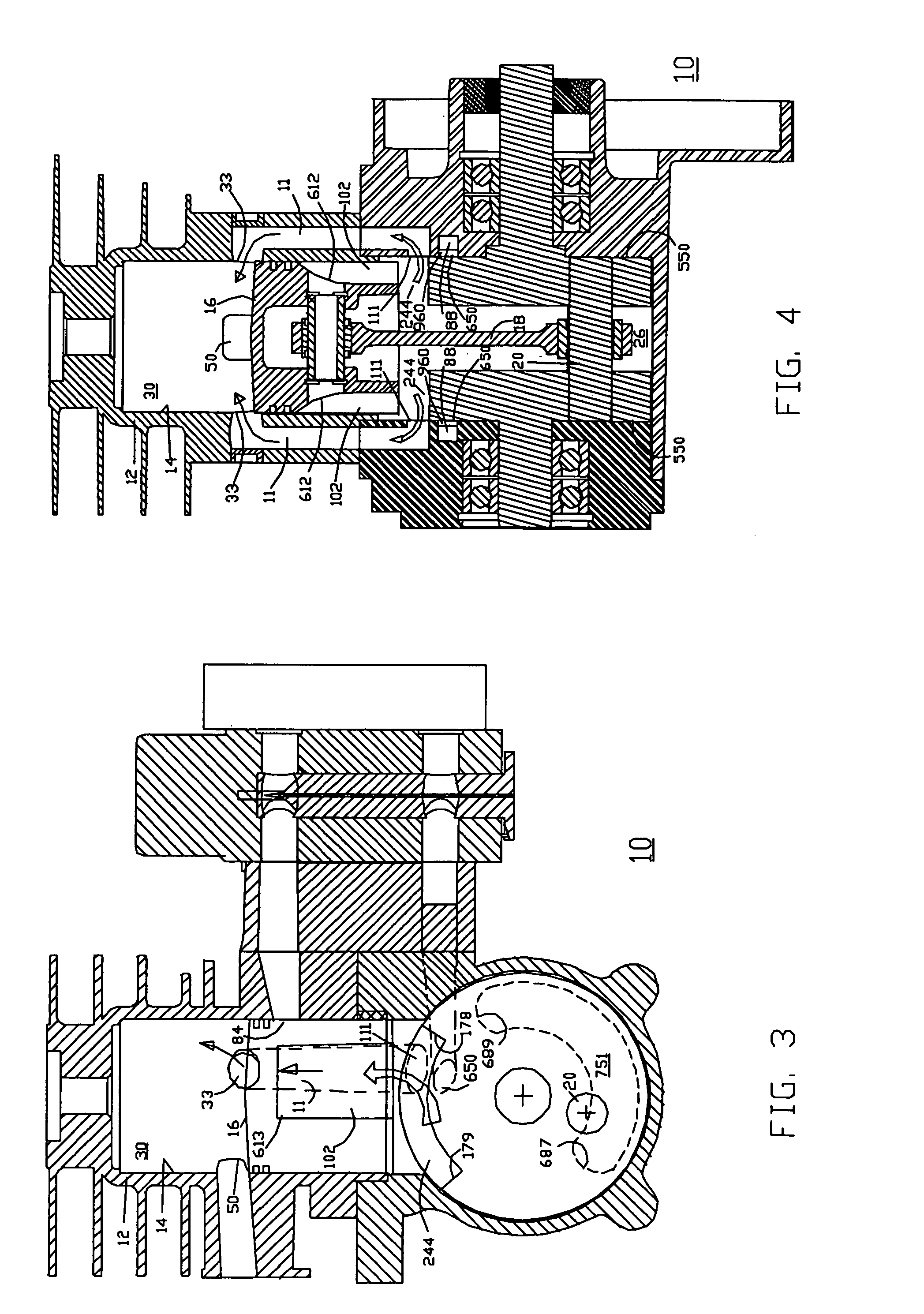

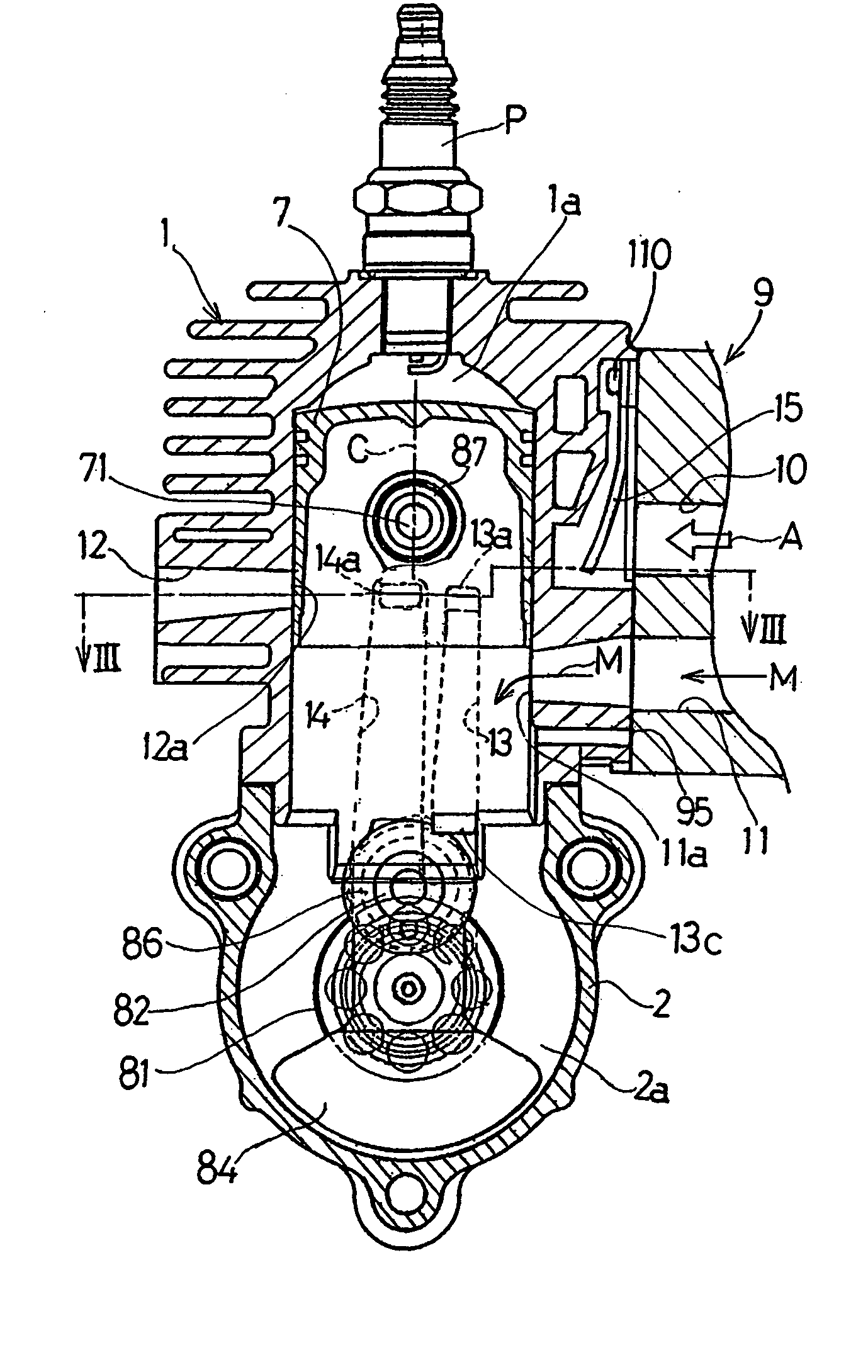

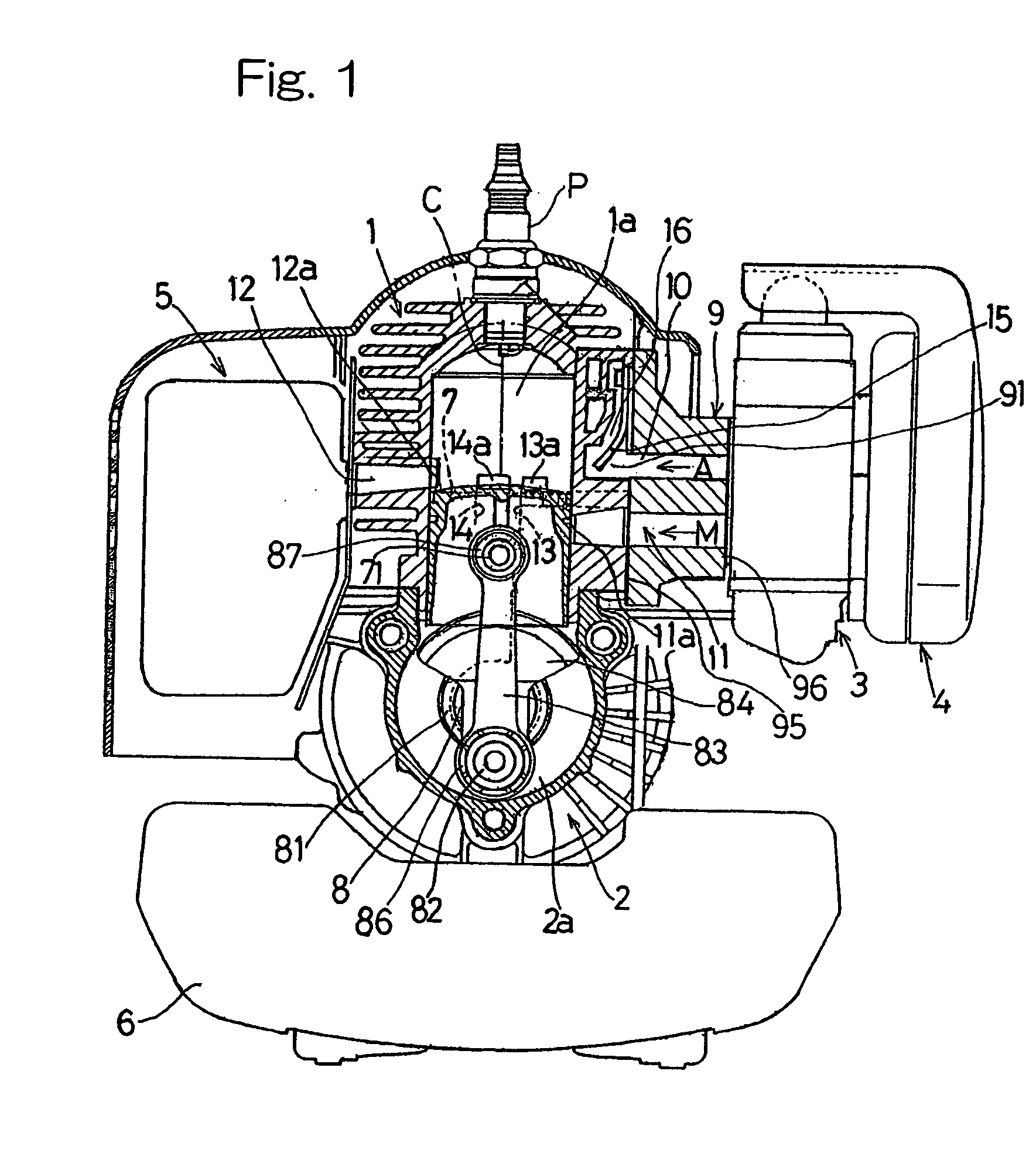

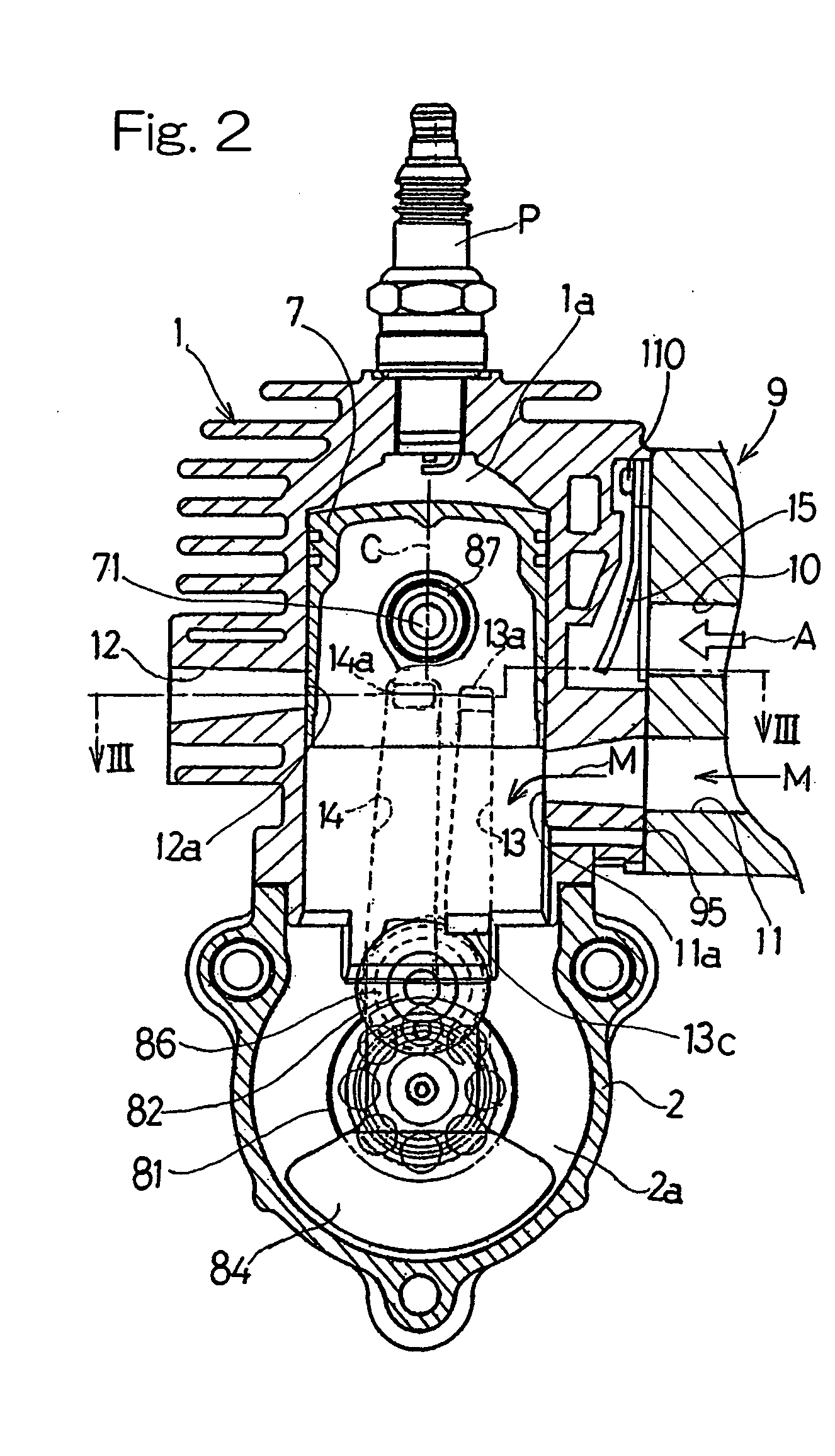

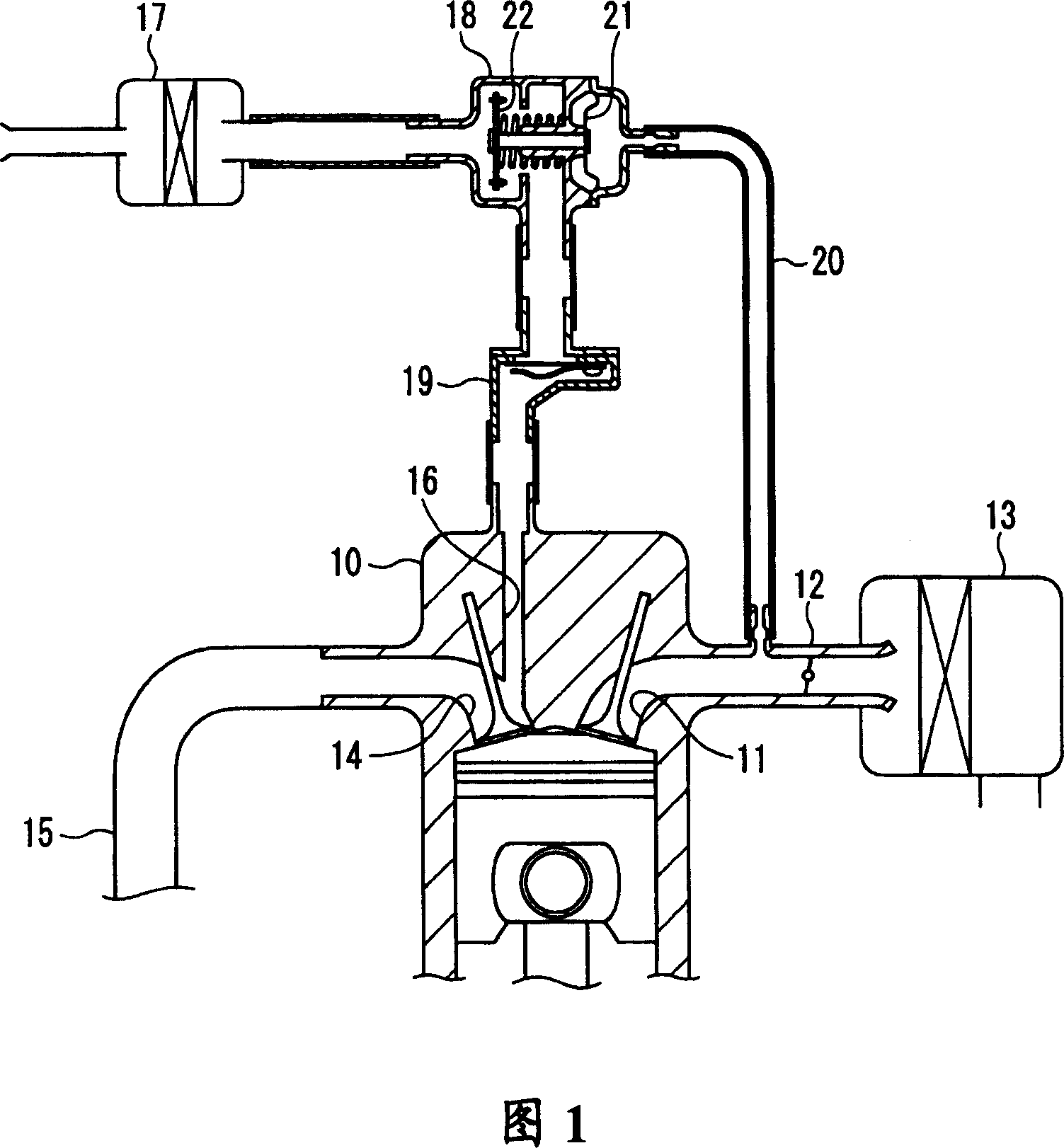

Two-cycle combustion engine with air scavenging system

The two-cycle combustion engine includes a first scavenge passage (12) for communicating directly between a combustion chamber (1a) and a crank chamber (2a), a second scavenge passage (14) for communicating the combustion chamber (1a) and the crank chamber (2a) through a bearing (81) for a crankshaft (8), an air supply passage (10) for introducing air (A) into the second scavenge passage (14), a reed valve (15) provided in the air supply passage (10), and an air-fuel mixture supply passage (11) for introducing an air-fuel mixture (M) into the crank chamber (2a). The second scavenge passage (14) is positioned at a location nearer to an exhaust port (12a) than the first scavenge passage (13). An air introducing passage (16) is formed in an cylinder block (1) so as to communicate the air supply passage (10) with the second scavenge passage (14) by way of a radially outer portion of the first scavenge passage (13).

Owner:KAWASAKI MOTORS LTD

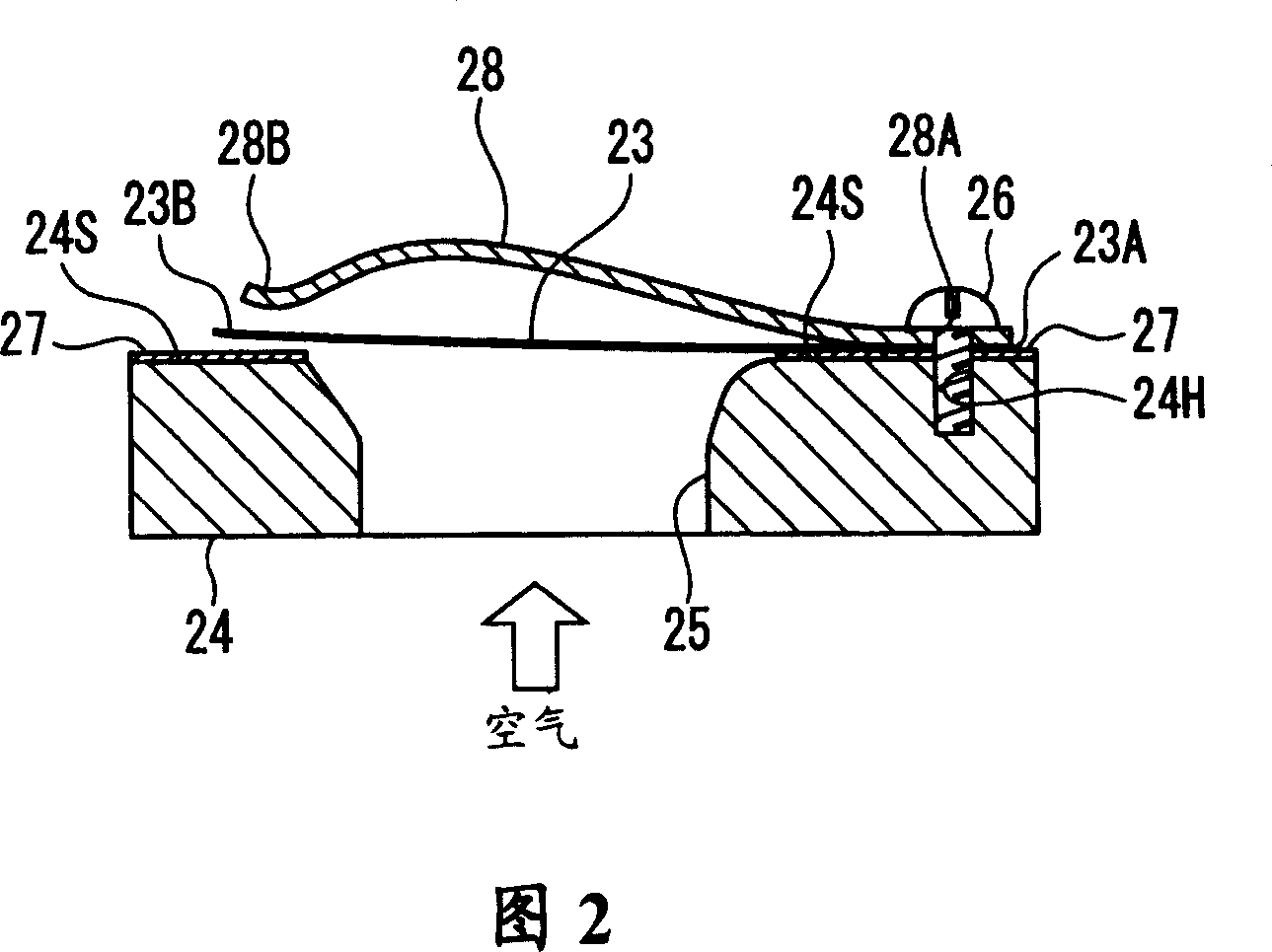

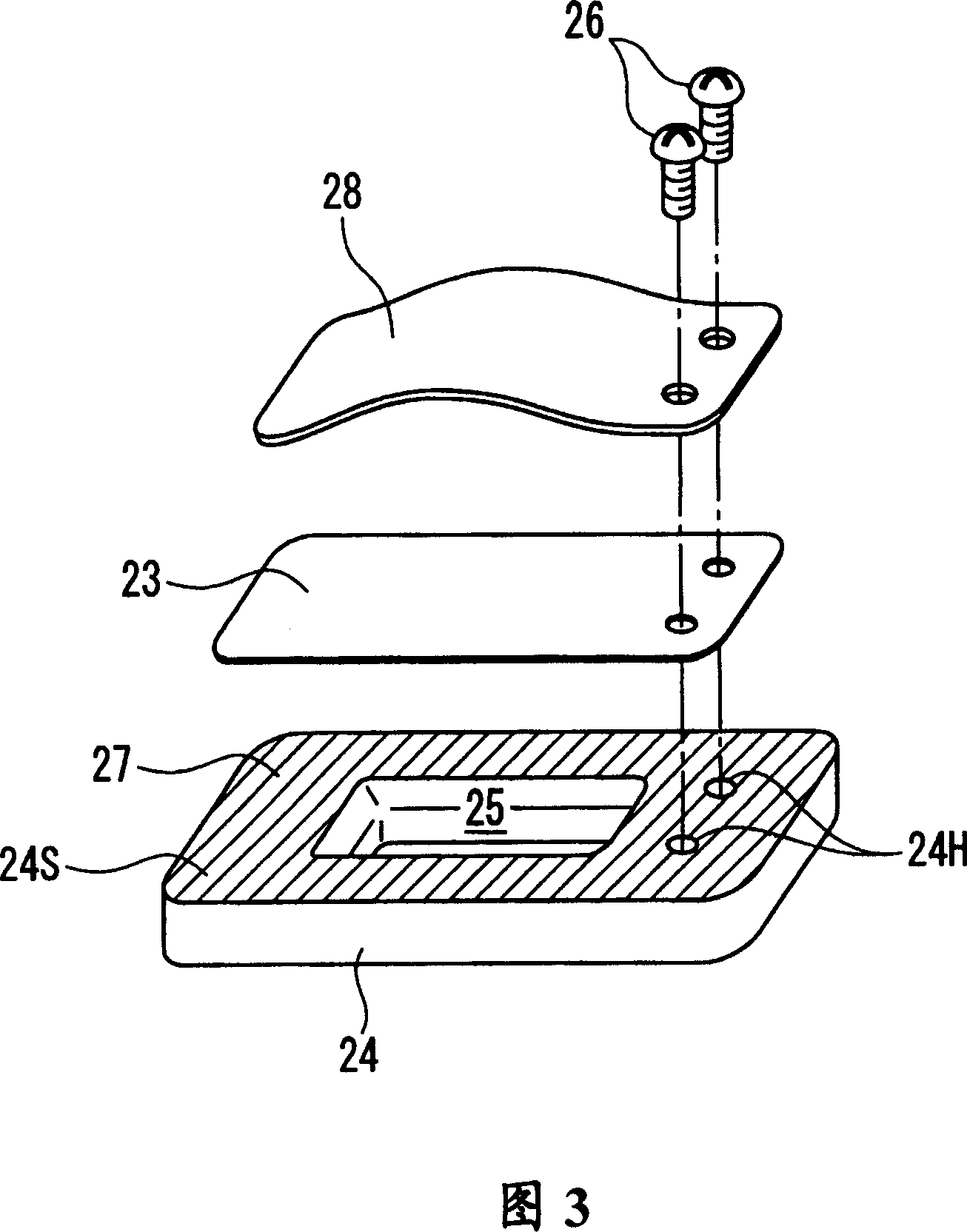

Spring valve

InactiveCN101089436AImprove heat resistanceIncreased durabilityCheck valvesHeat resistanceResin coating

The present invention provides a reed valve and heat resisting property and permanent stability of which are excellent and there is no need to do abrasive machining to the valve sheet installing surface. The structure is provided with the following characters: compressing the valve body (24) provided with a valve port (25) to a whole to form a valve sheet installing surface (24S) provided with a single flat surface; implying the fluoro resin coating to the entire surface of the valve sheet installing surface (24S) to form a fluoro resin membrane (27); fixing one end (23A) of the reed shaped valve sheet (23) to the valve sheet installing surface (24S) by the bolt (26) and making the end block the hole (25); besides, arranging a repelling board (28) which restrains the edge warping of the valve sheet (23) on the valve body (24).

Owner:MIKUNI CORP

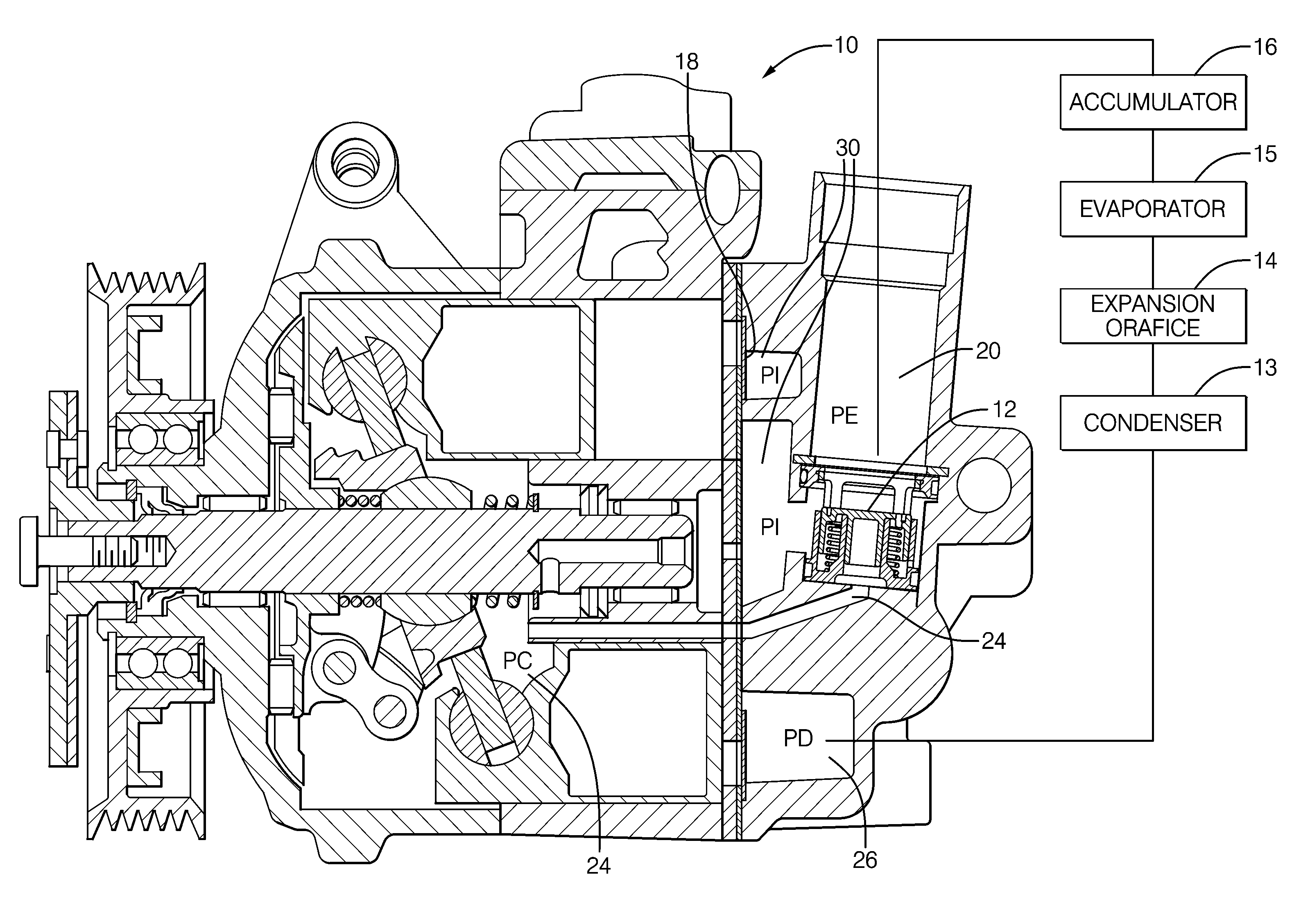

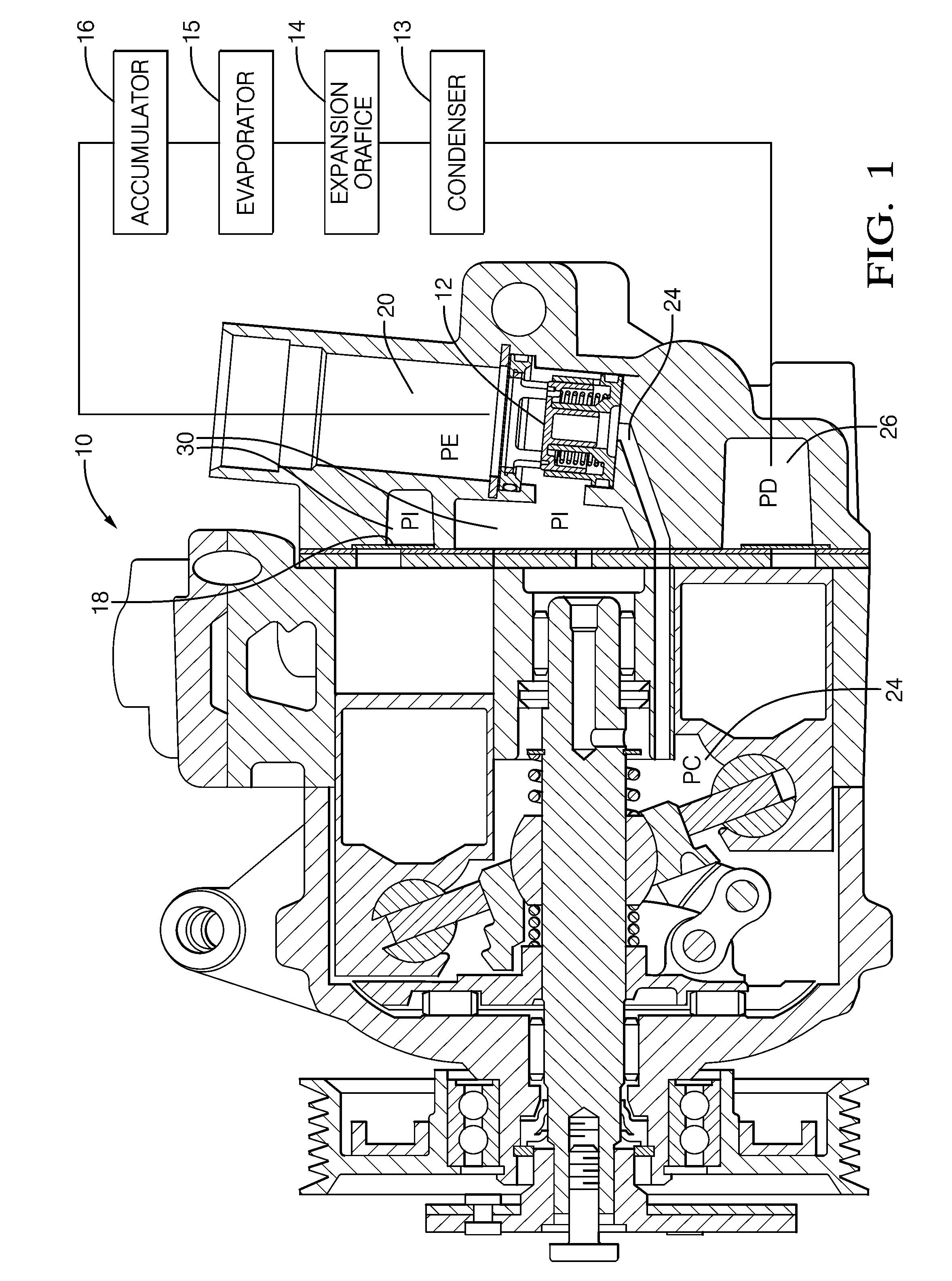

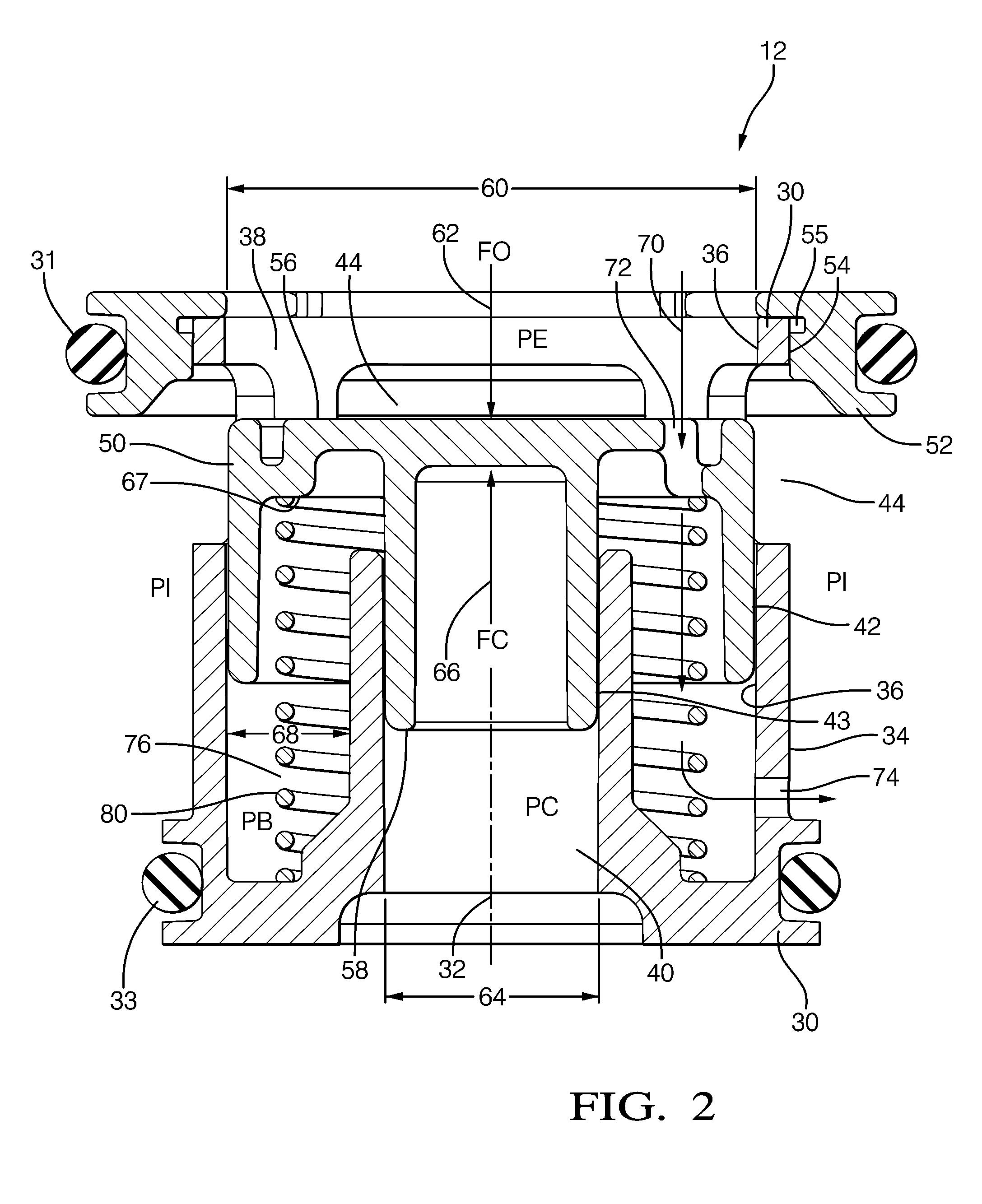

Variable Displacement Compressor With A Compensated Suction Shufoff Valve

ActiveUS20090205347A1Avoid noiseReduce restrictionsCompression machines with non-reversible cyclePump controlInternal pressureCrankcase

A variable displacement compressor with a compensated suction shutoff valve (SSV). The SSV prevents noise generated by a suction reed valve at low refrigerant flow rates in an internal suction region from propagating to an air conditioner evaporator by moving a piston to obstruct an opening and restrict fluid communication. The degree of restriction is decreased by an opening force generated by refrigerant at an external suction pressure acting over a first area, and increased by refrigerant at a crankcase pressure acting over a second area. The second area is smaller than the first area so that at high refrigerant flow rates, the effect of crankcase pressure is reduced so that the restriction is reduced and the compressor operates at greater efficiency. The piston position is also influenced by refrigerant at a pressure intermediate the external suction pressure and the internal suction pressure acting over a third area.

Owner:MAHLE INT GMBH

Inclined plate-type compressors and air conditioning systems including such compressors

ActiveUS20050249608A1Relieve pressureIncrease the lengthSleeve/socket jointsAir-treating devicesCylinder headEngineering

An inclined plate-type compressor includes a cylinder head, a discharge chamber having an annular shape and disposed along an outer circumferential portion of the cylinder head, a suction chamber disposed at a central portion of the cylinder head, a valve plate including discharge ports, and a discharge valve including reed valve-type valve bodies disposed in the discharge chamber. Each valve body opens and closes a corresponding discharge port, and each valve body extends in a circumferential direction of the discharge chamber and is oriented along the annular shape of the discharge chamber. Because each valve body extends in the circumferential direction of the discharge chamber, the length of each valve body may be increased as compared with that in known compressors, wherein the valve body extends in the radial direction over the width of the annular discharge chamber. Consequently, stress, which is generated at a root portion of each valve body when the valve body is opened or closed, may be reduced.

Owner:SANDEN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com