Patents

Literature

238 results about "Head gasket" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

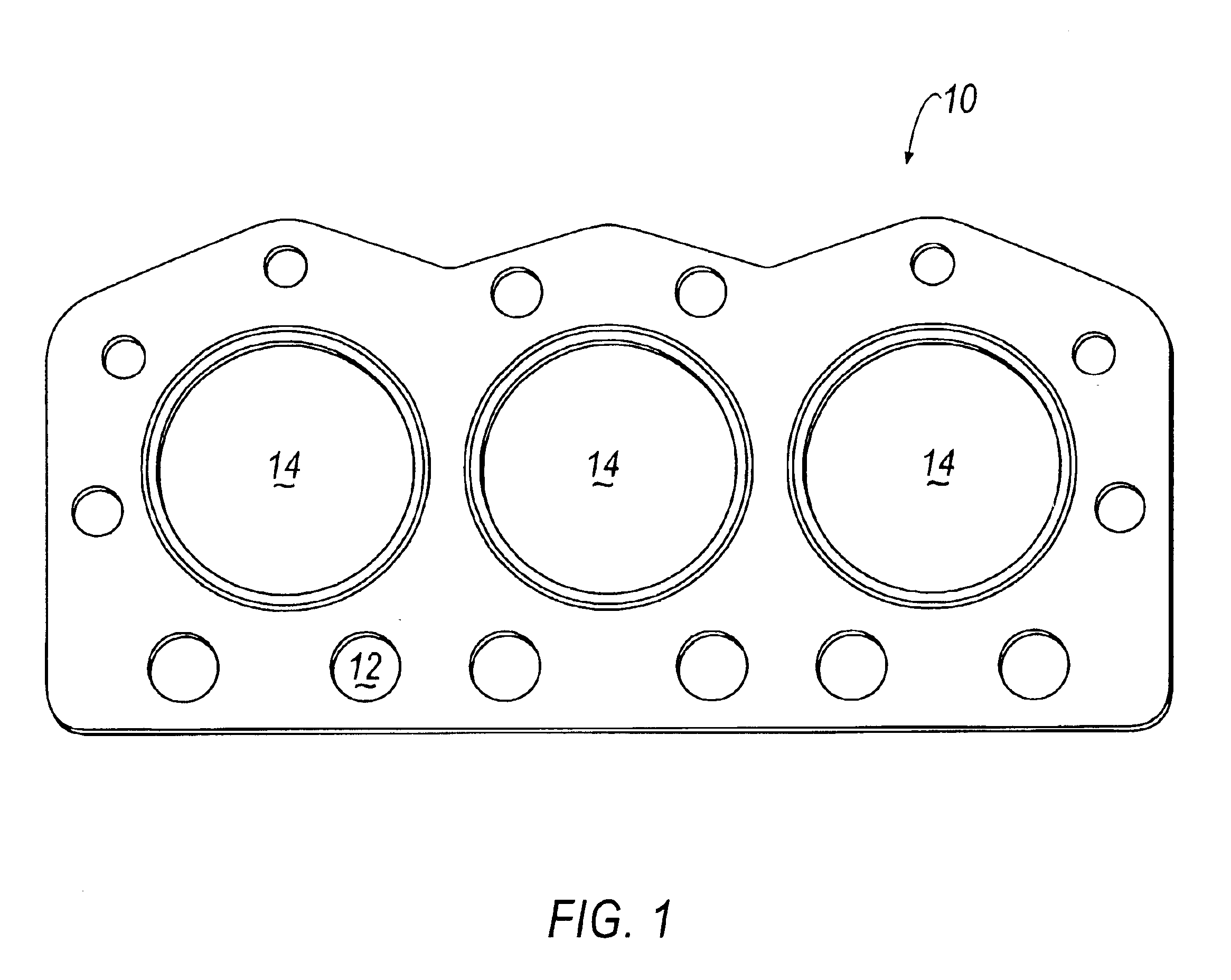

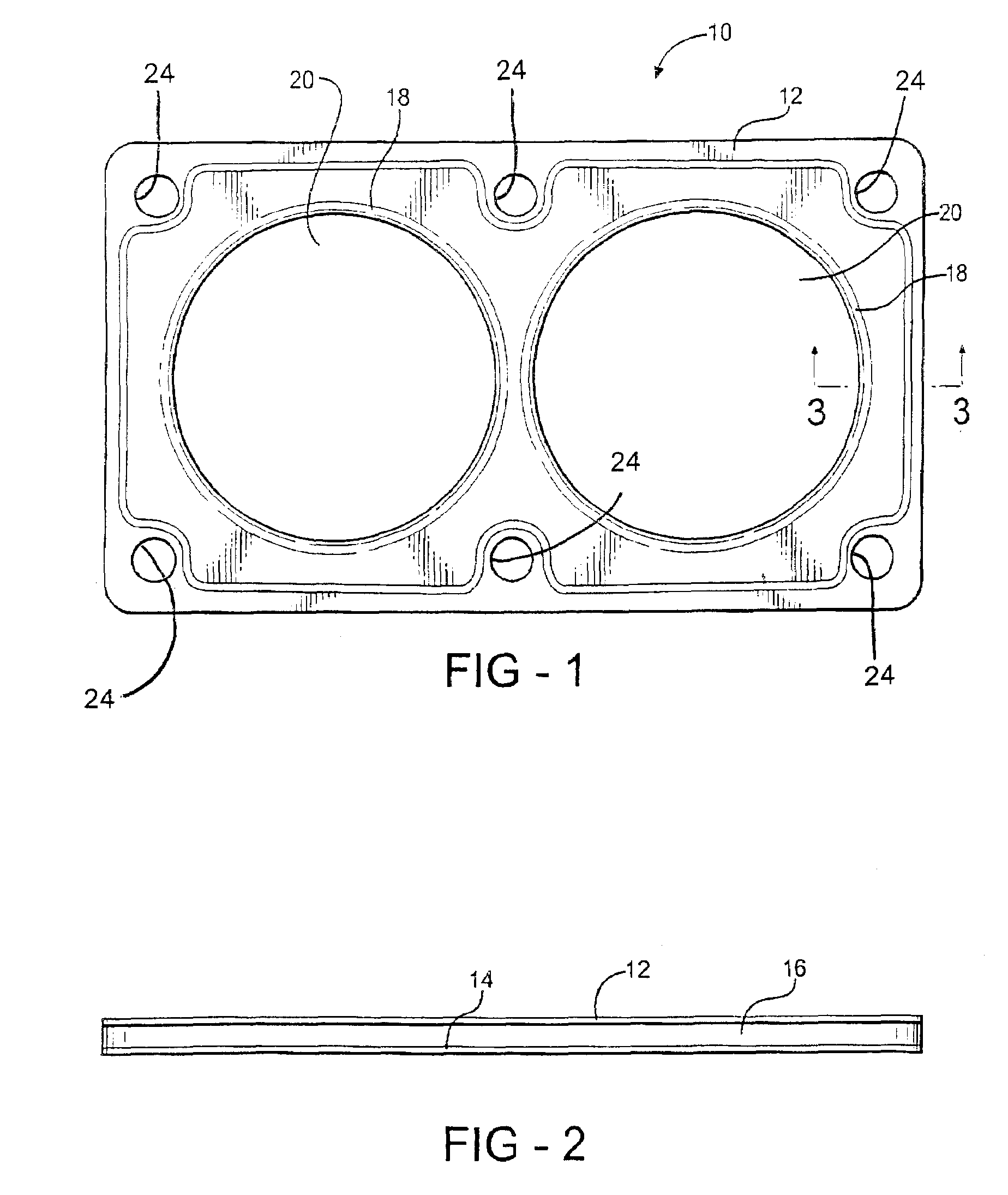

A head gasket is a gasket that sits between the engine block and cylinder head(s) in an internal combustion engine. Its purpose is to seal the cylinders to ensure maximum compression and avoid leakage of coolant or engine oil into the cylinders; as such, it is the most critical sealing application in any engine, and, as part of the combustion chamber, it shares the same strength requirements as other combustion chamber components.

Cylinder head gasket

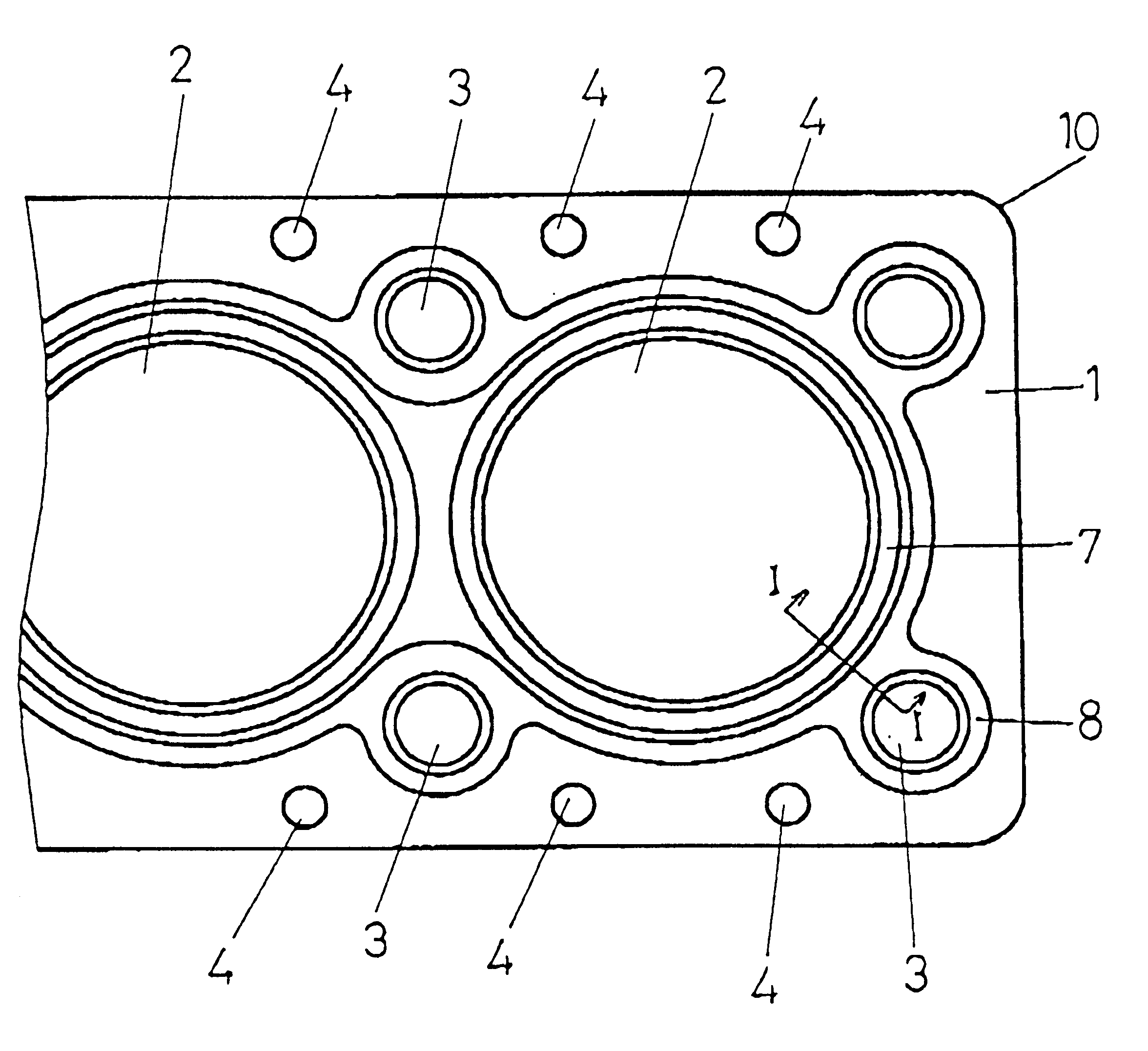

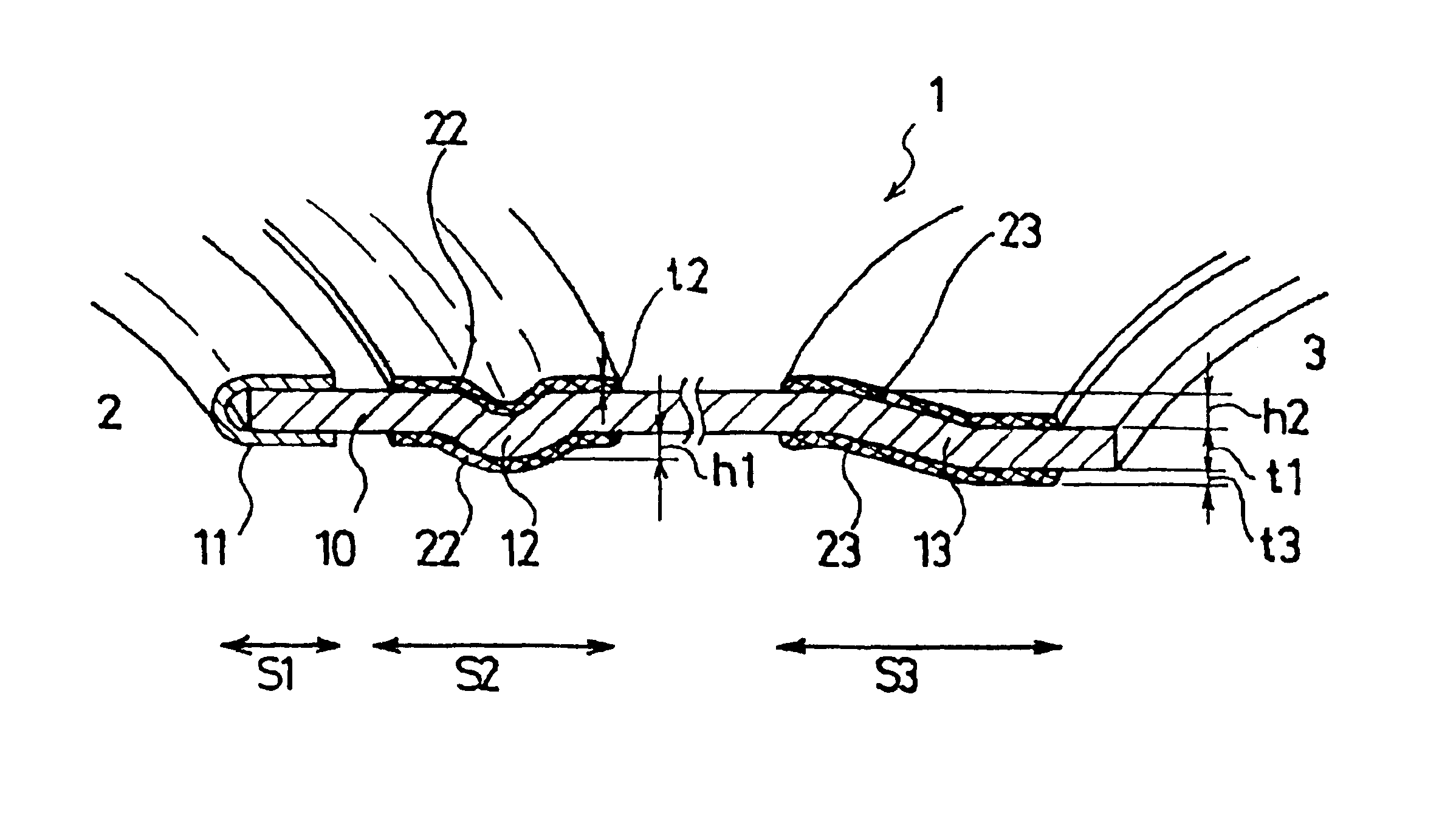

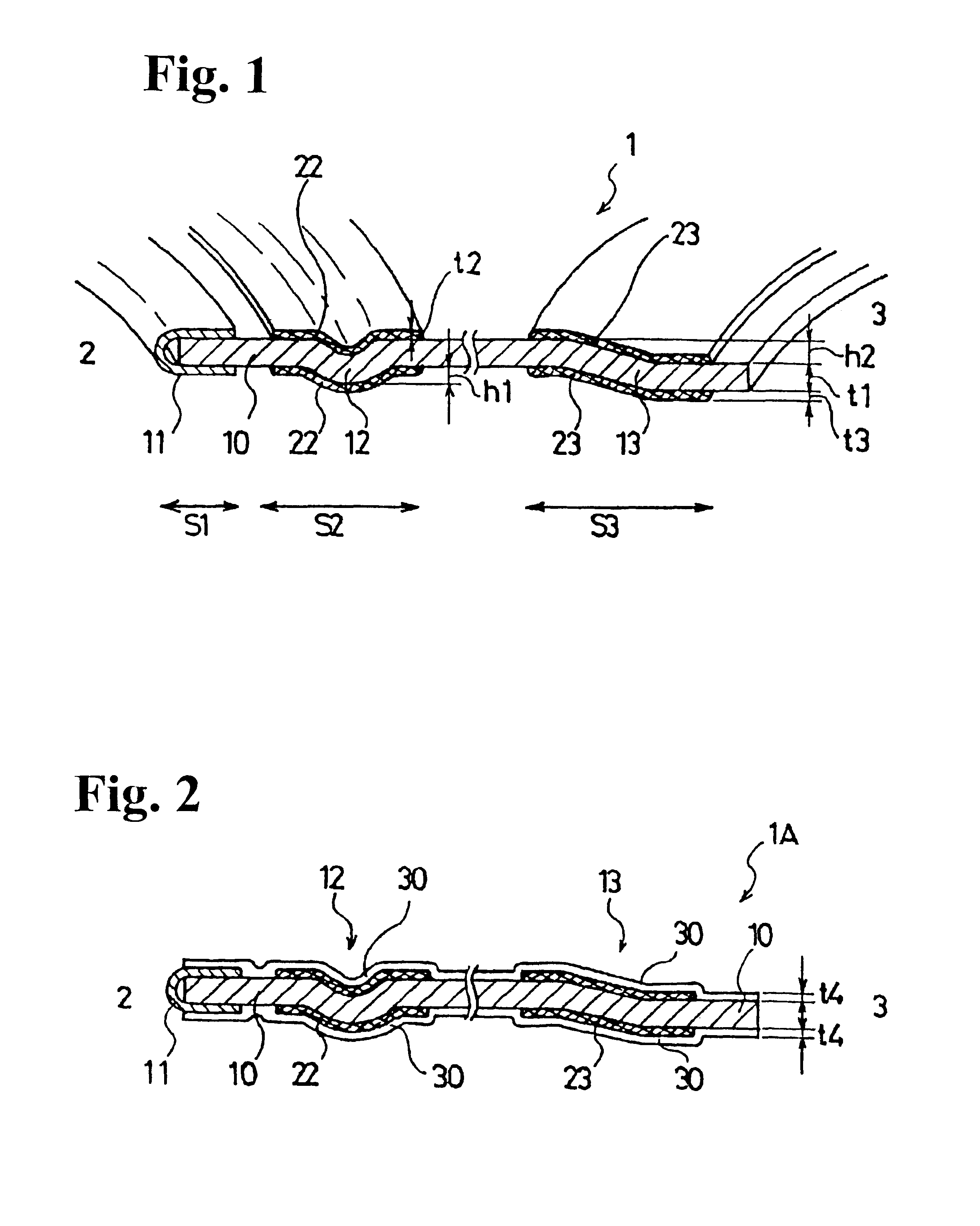

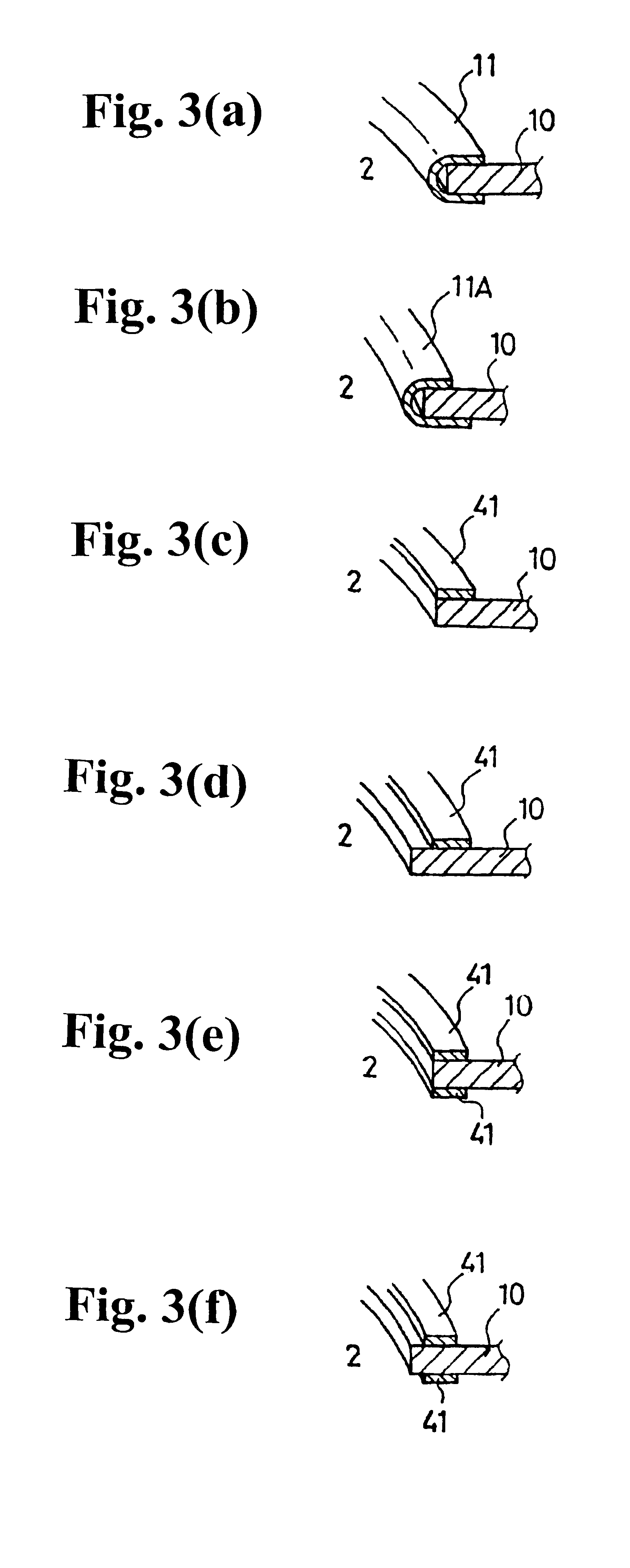

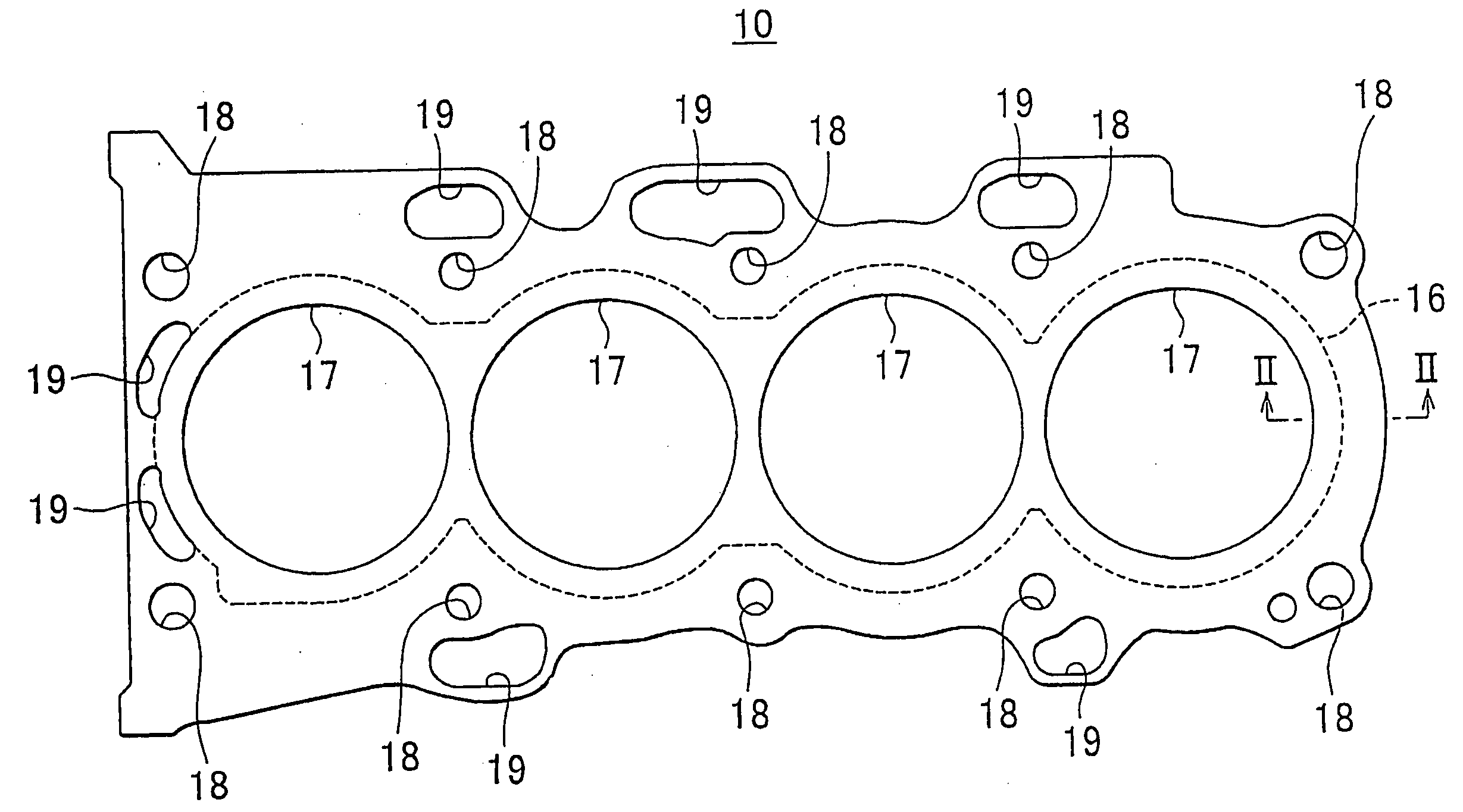

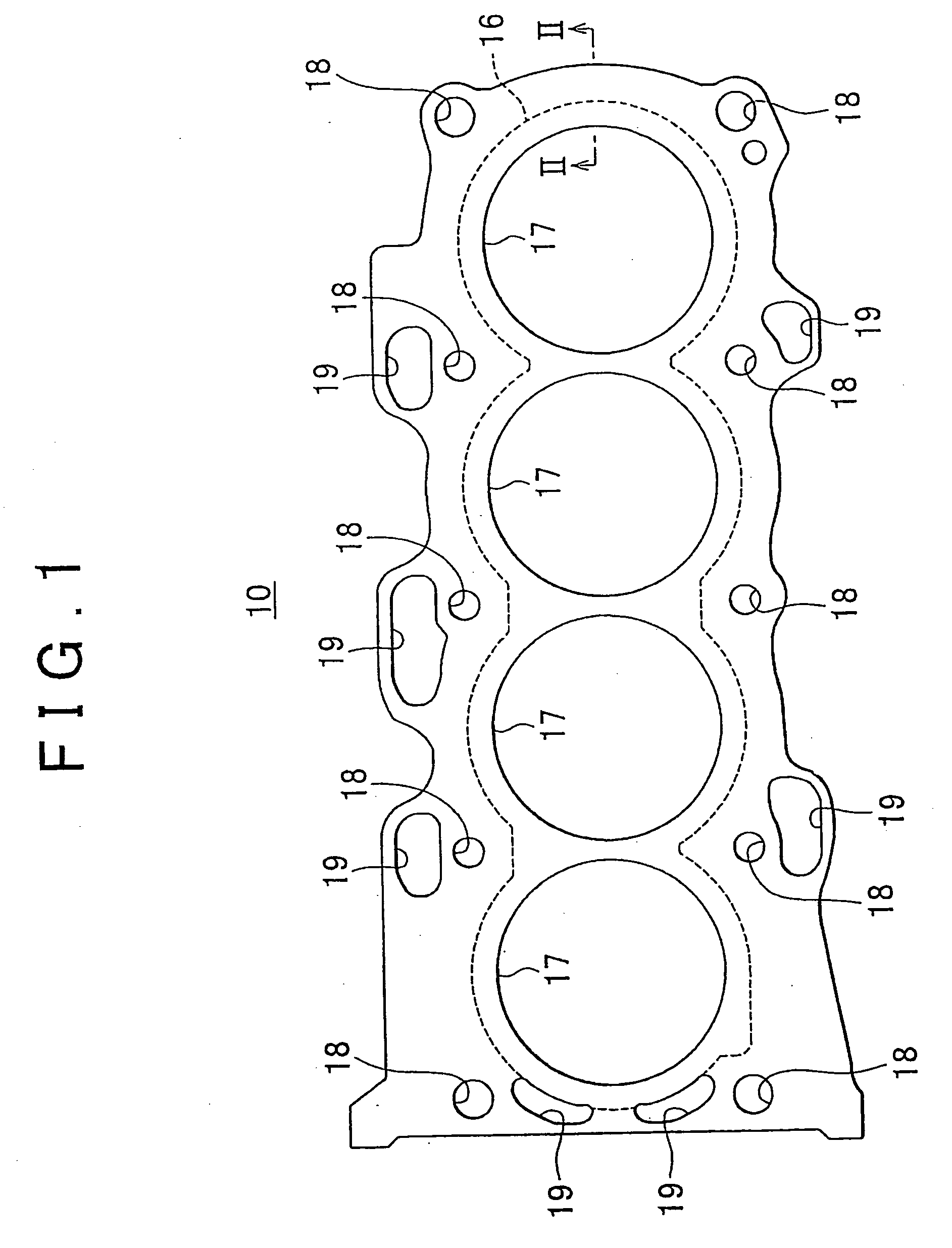

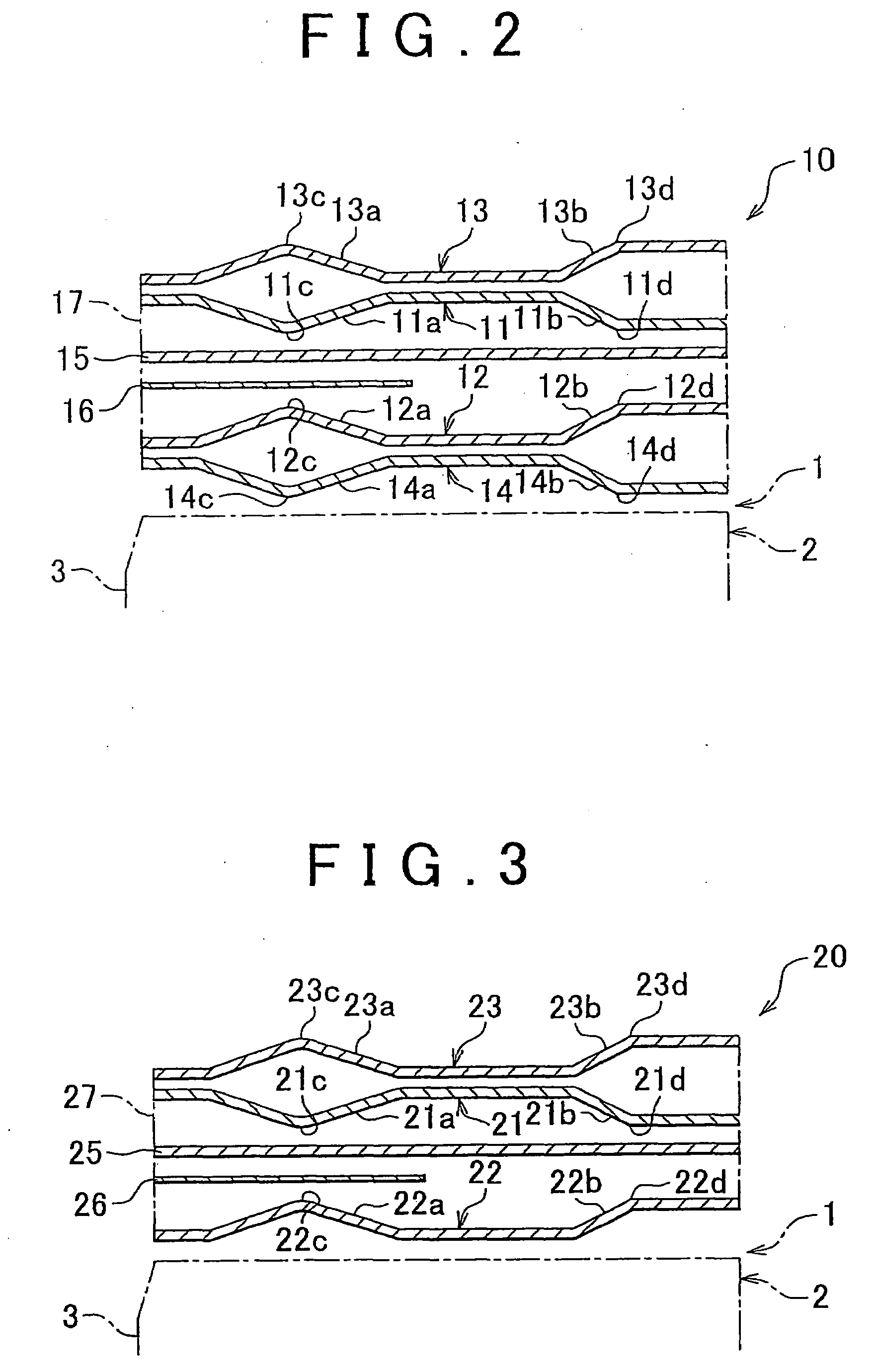

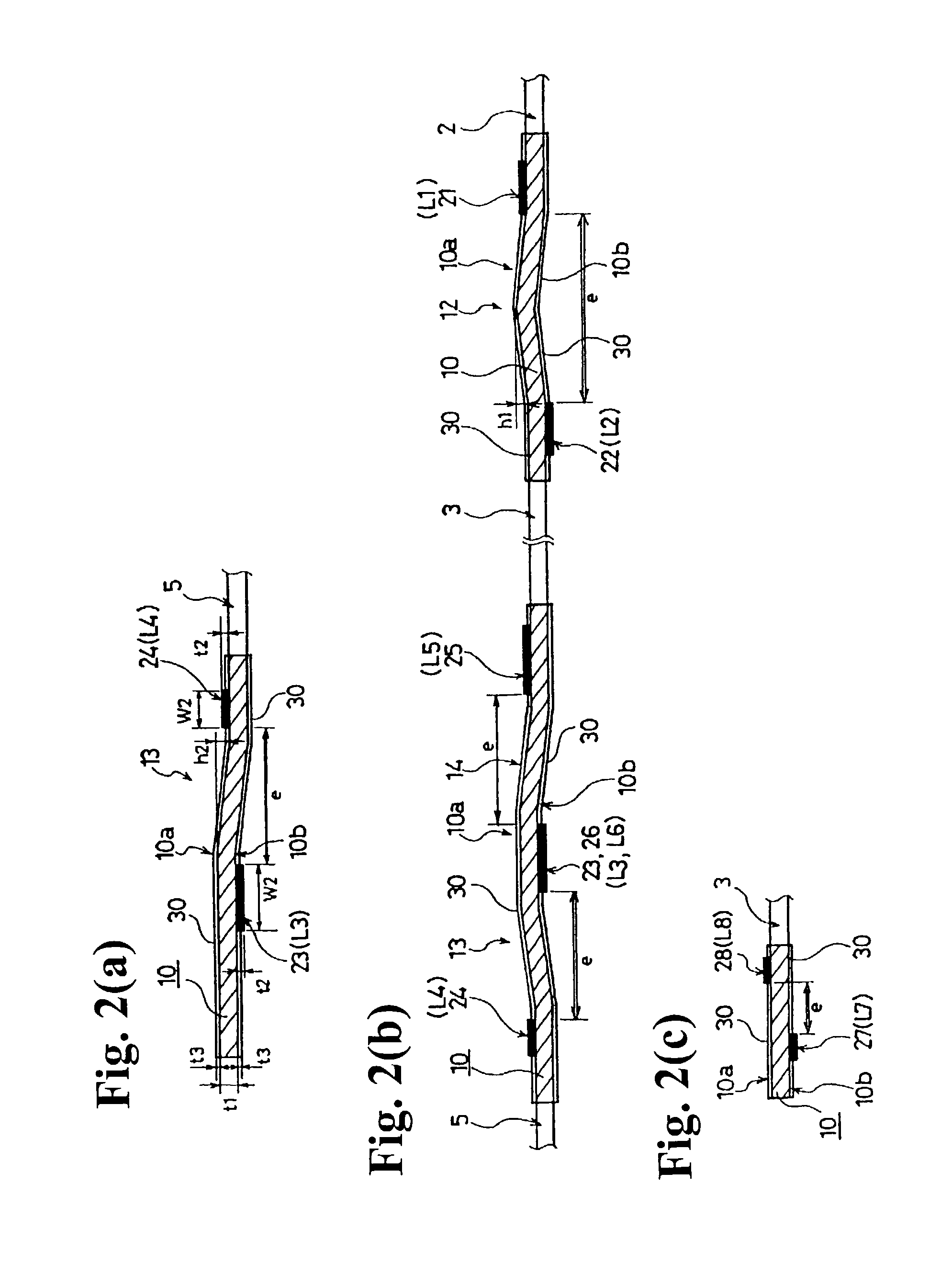

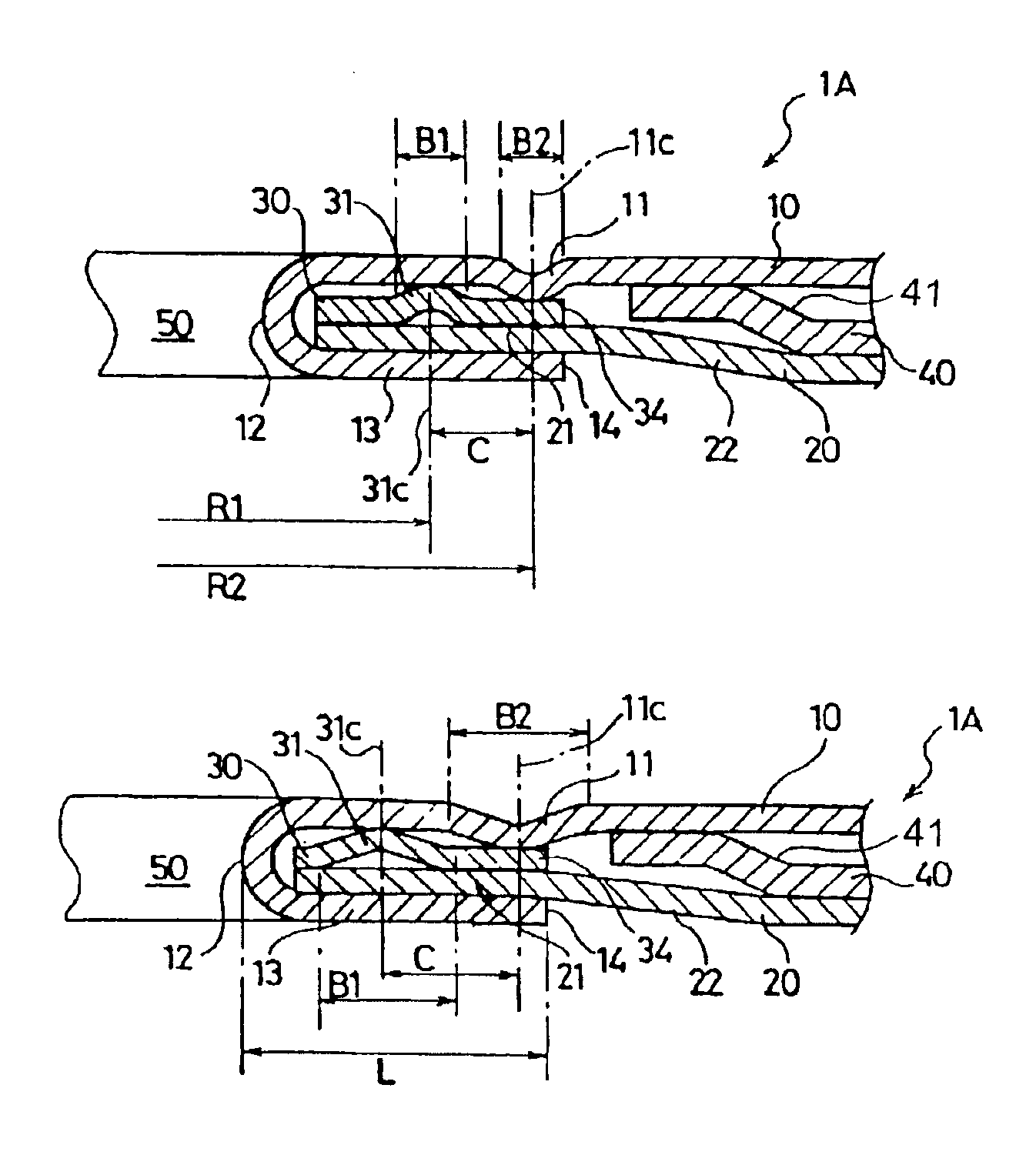

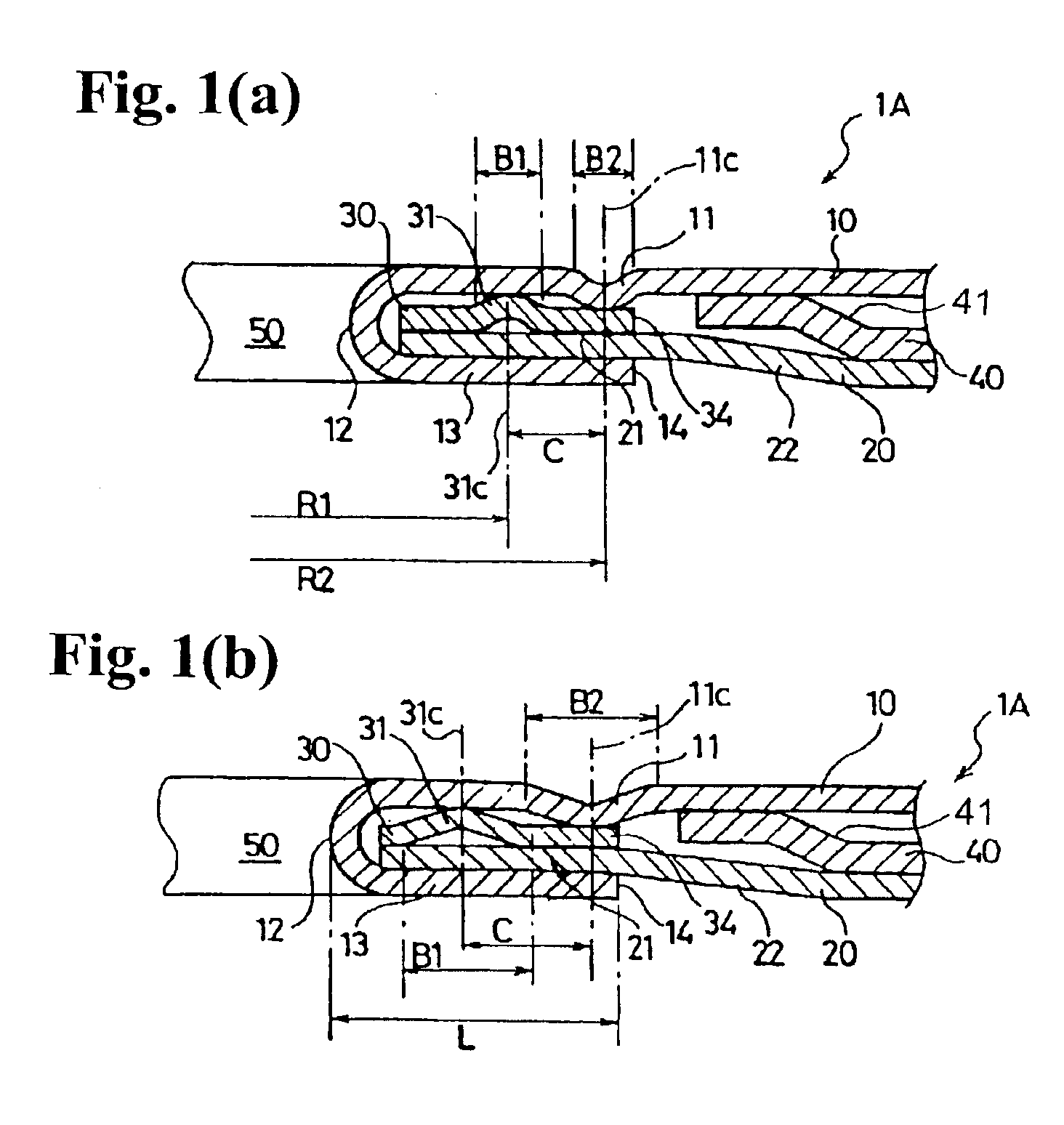

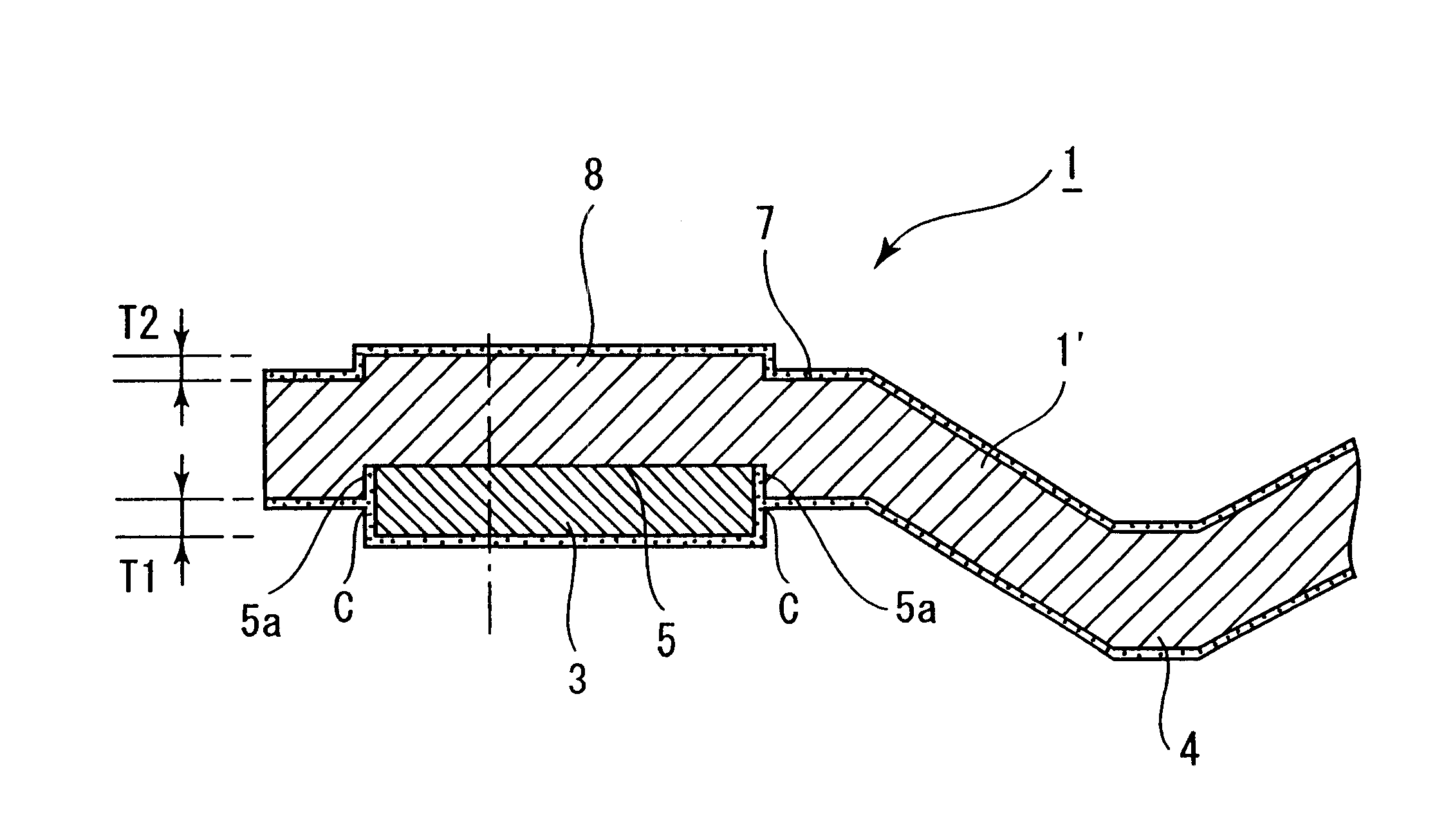

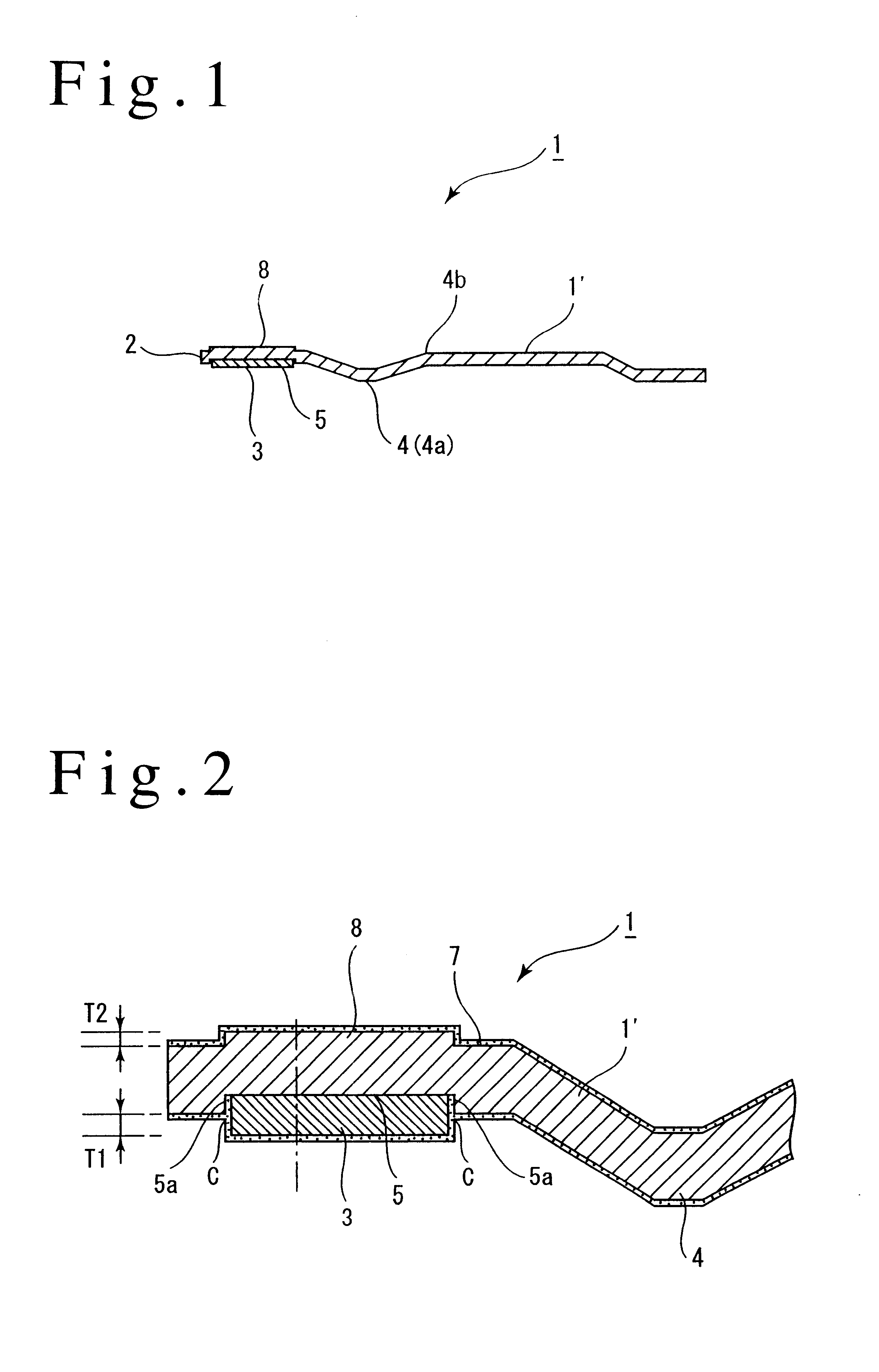

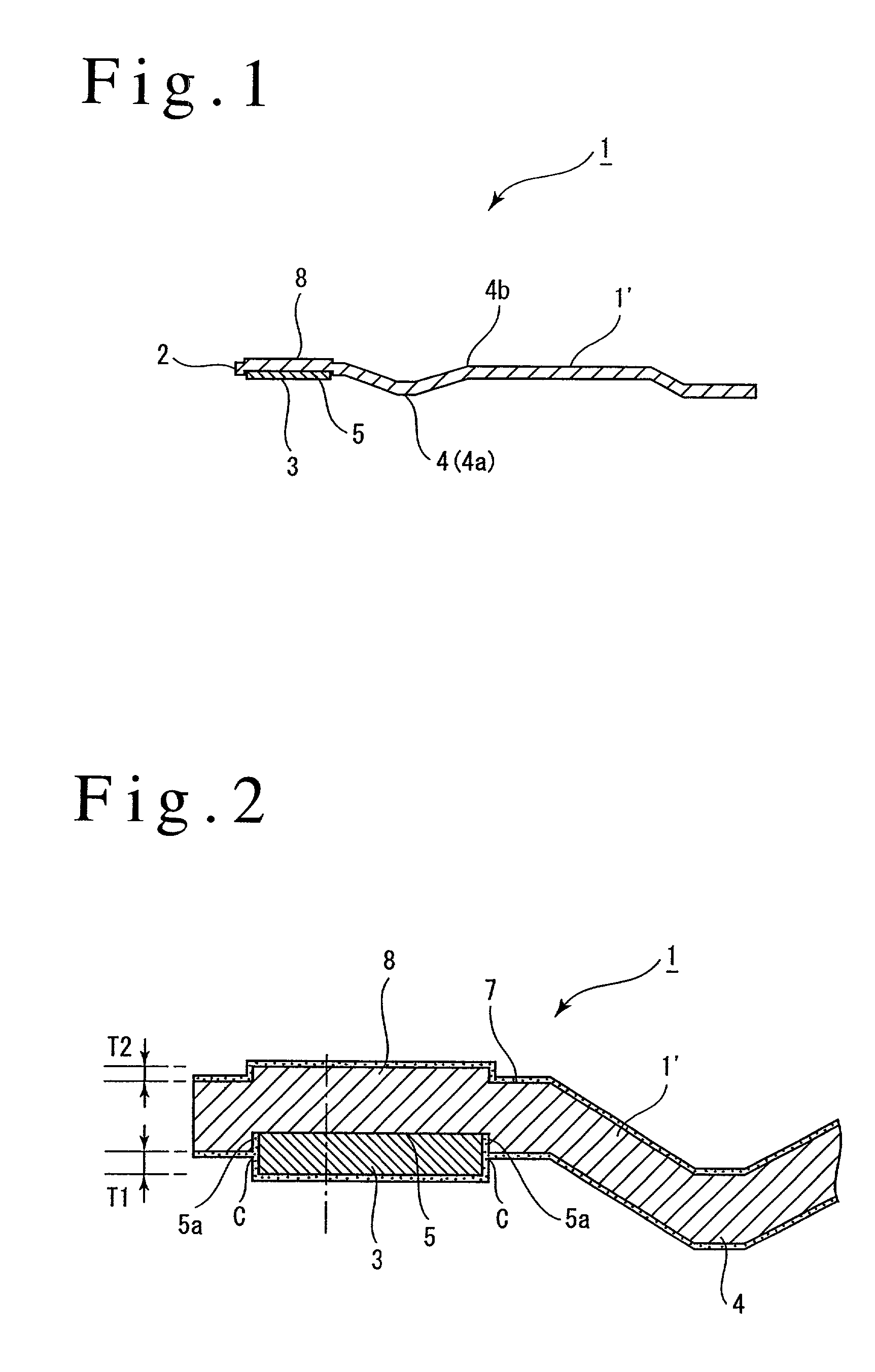

InactiveUS6550782B2Improve heat resistanceIncrease production costEngine sealsSealing arrangements for enginesExternal combustion engineMetal sheet

Owner:UCHIYAMA MFG

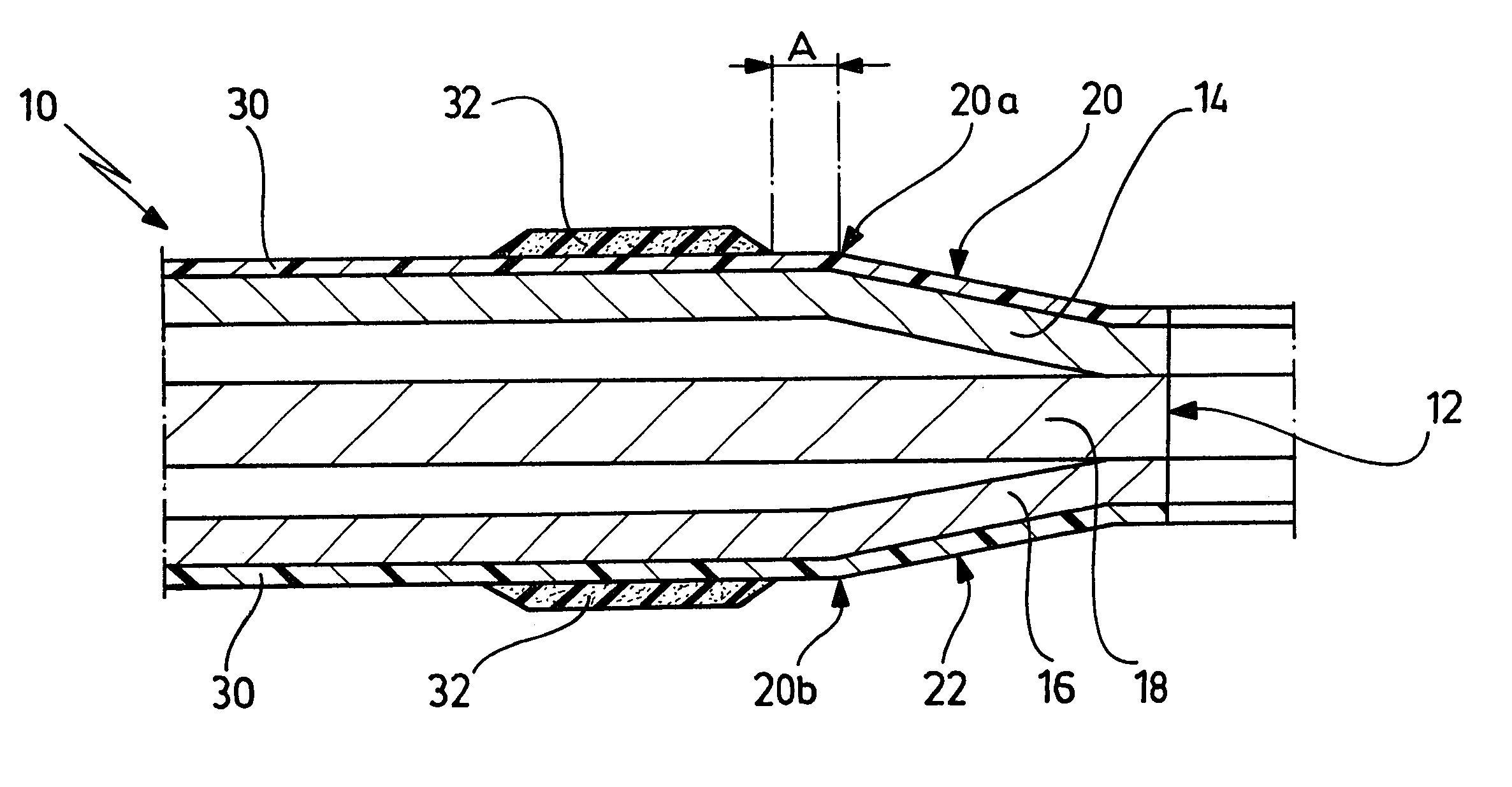

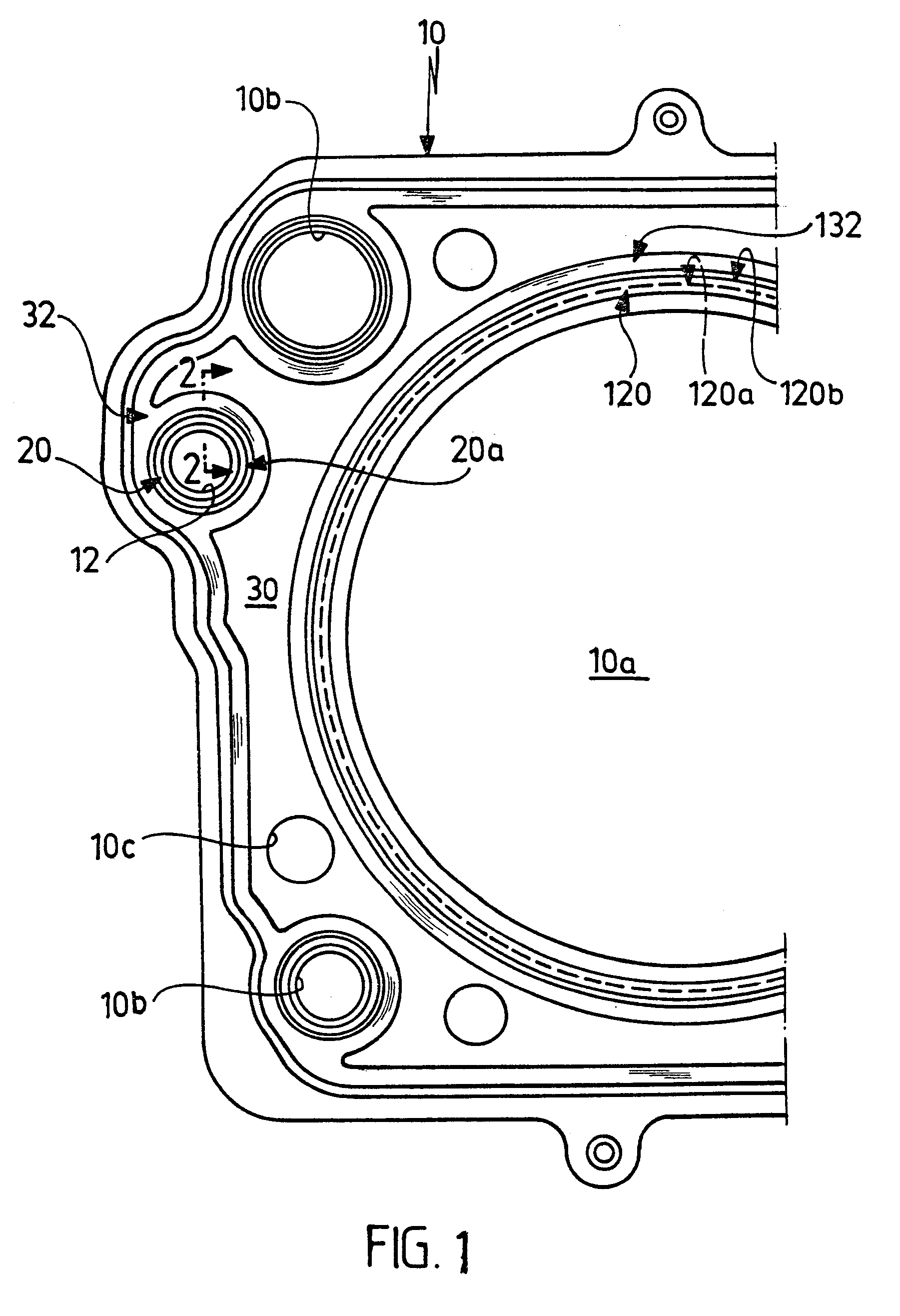

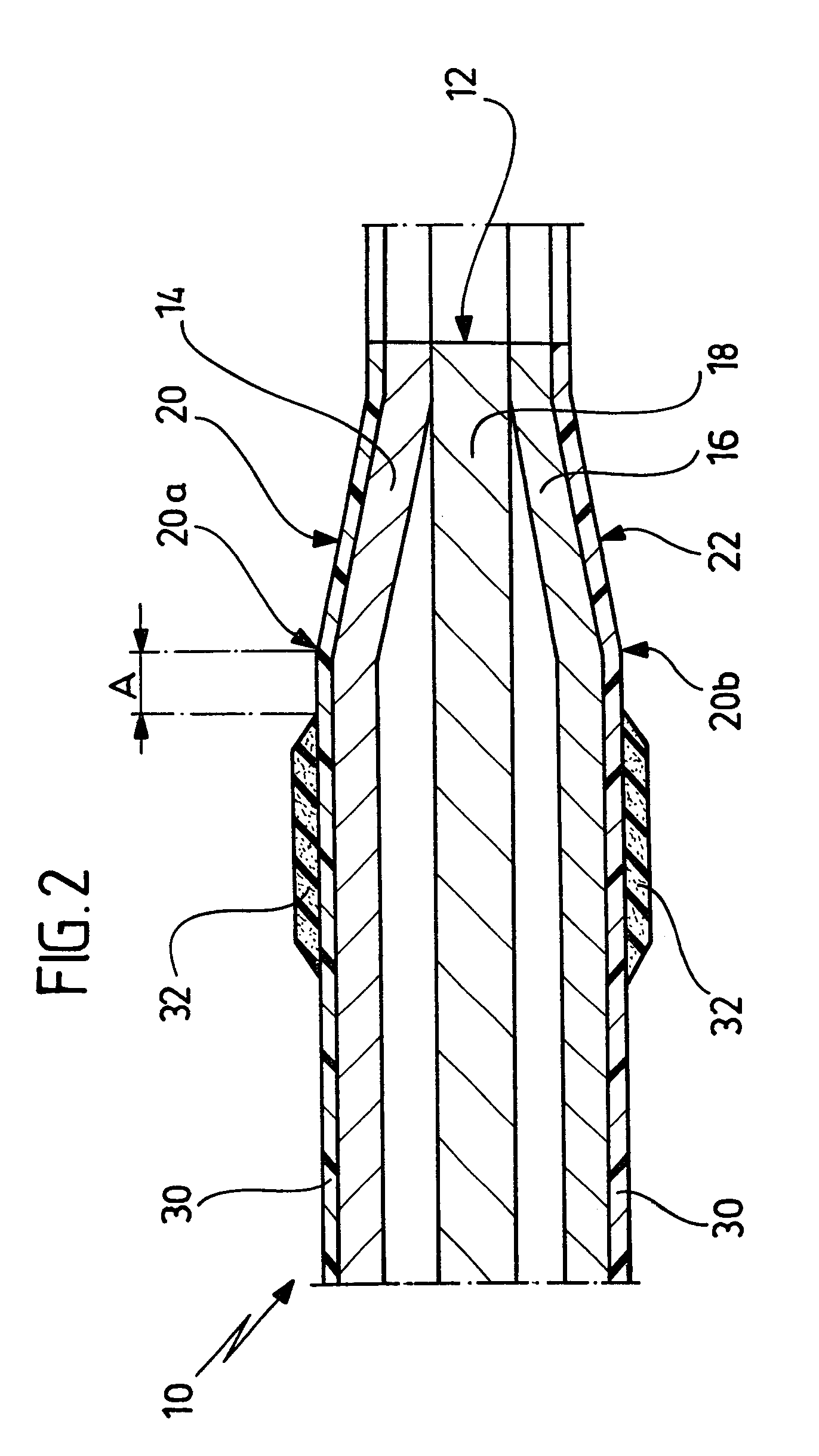

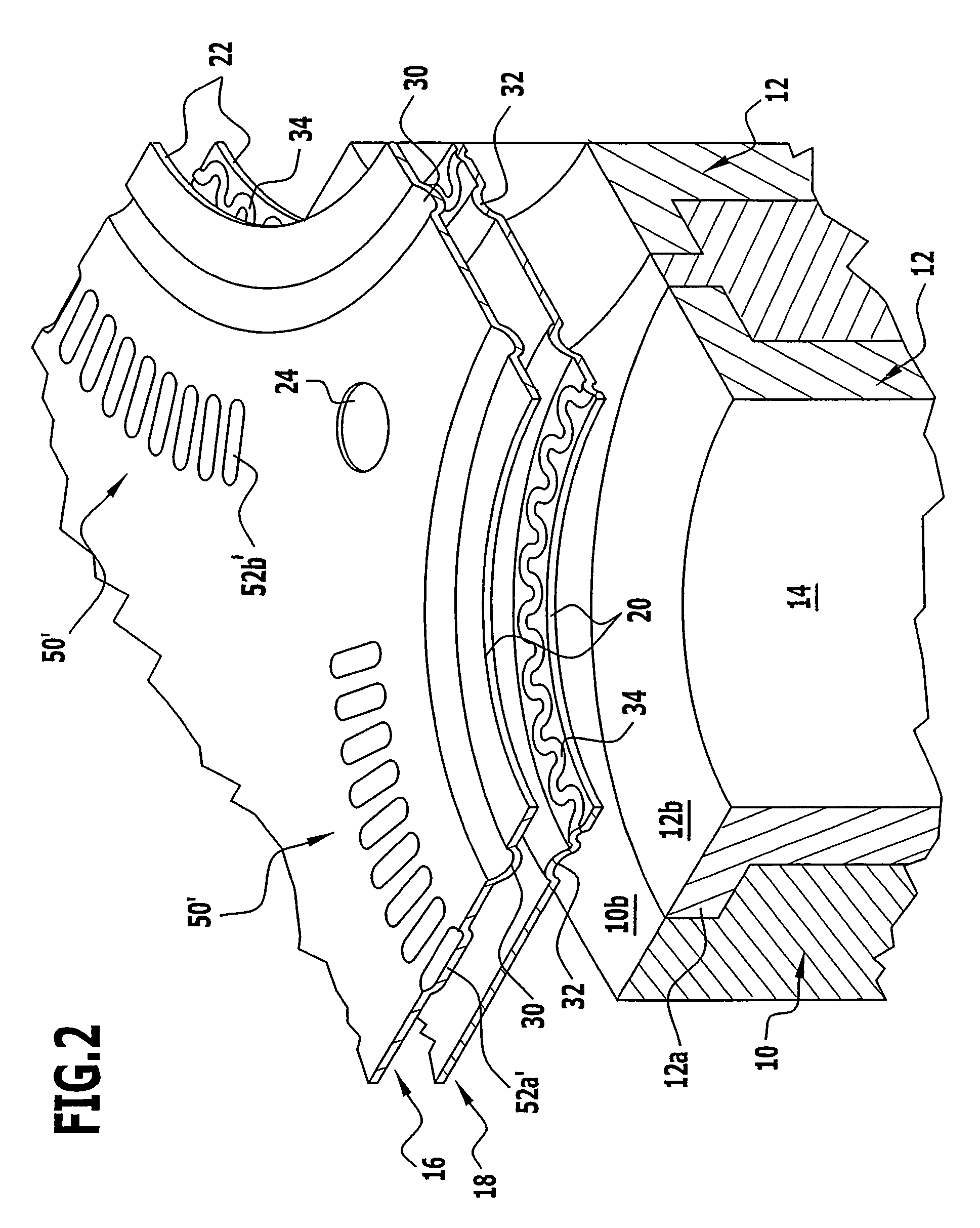

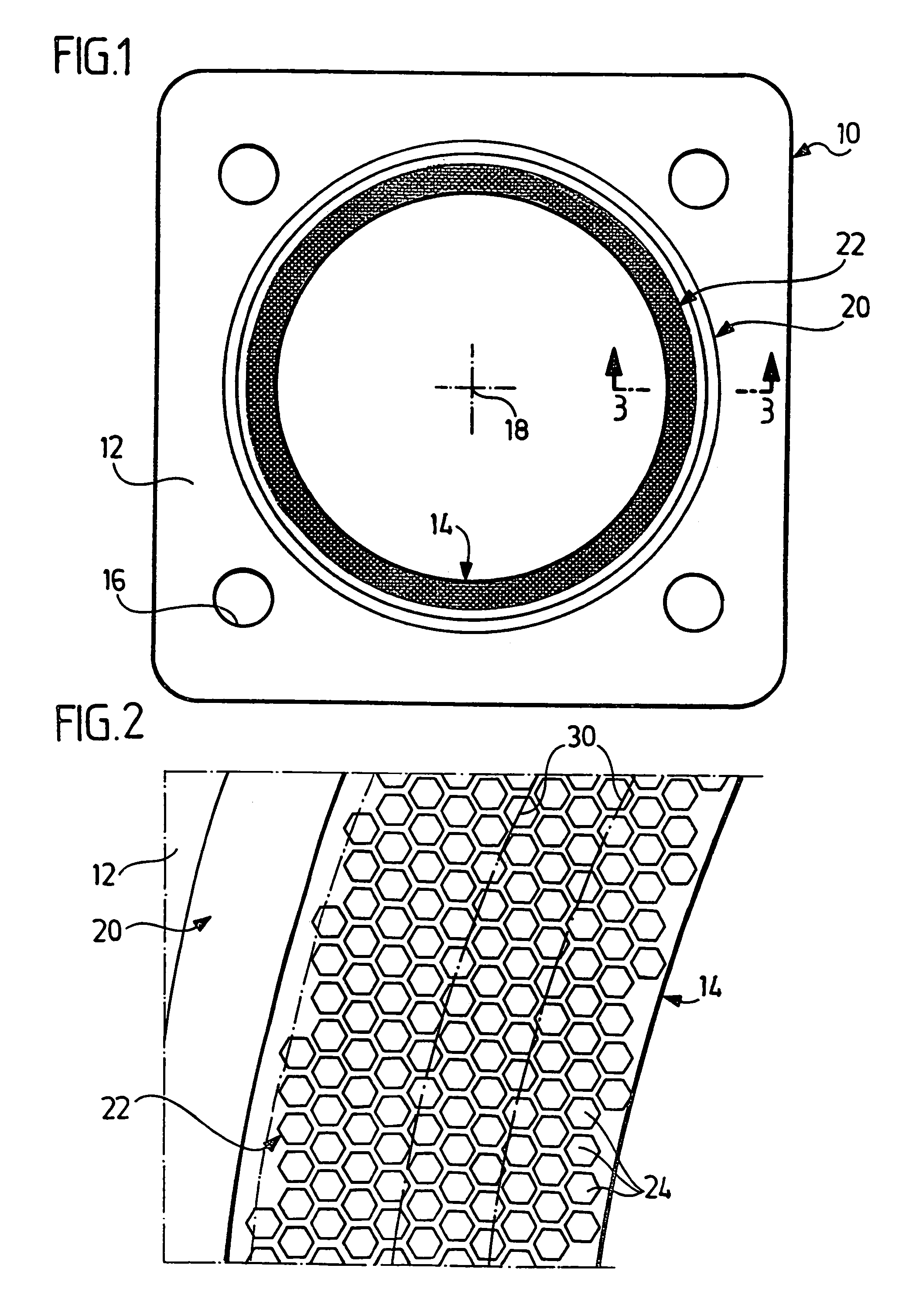

Enhanced multilayer metal gasket

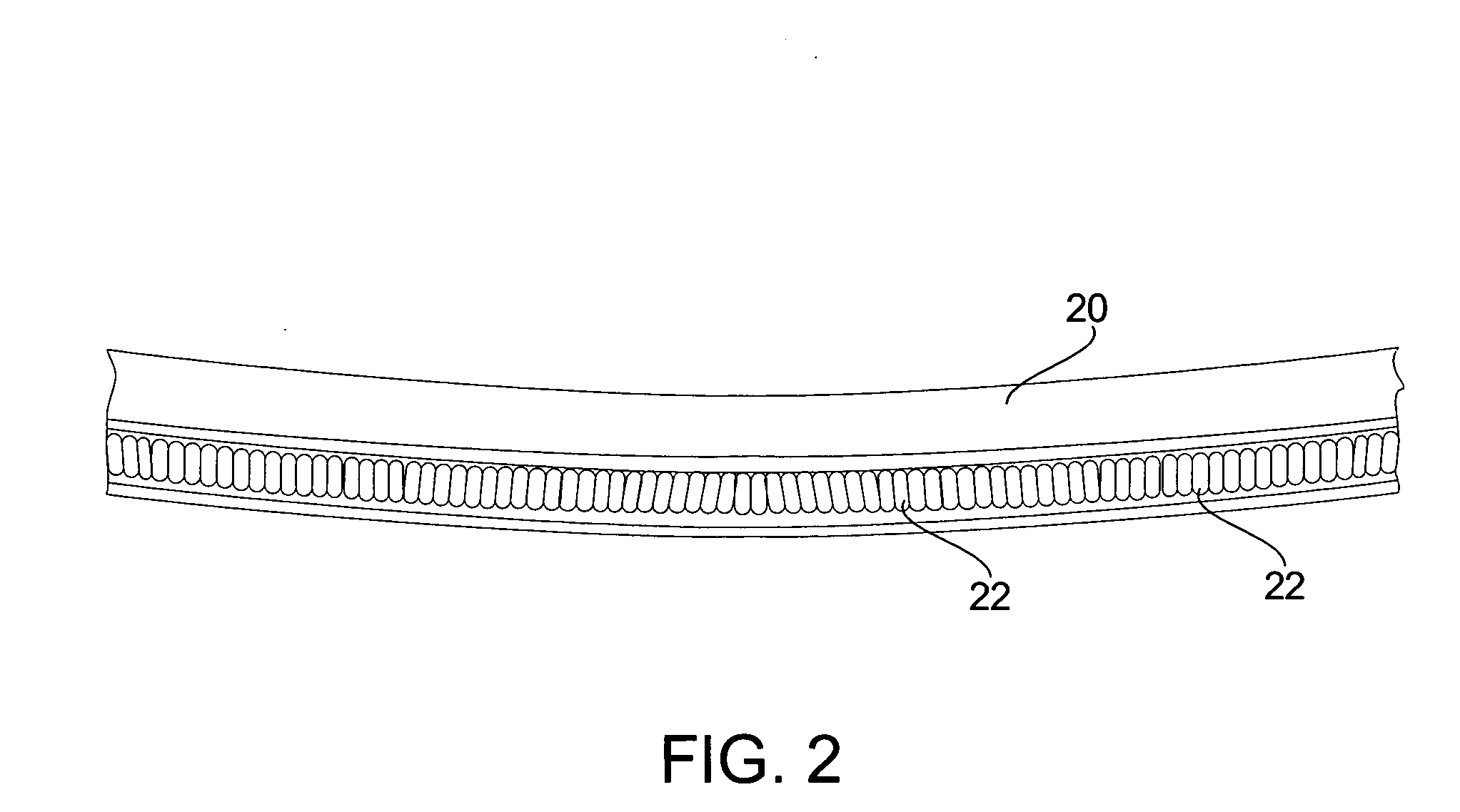

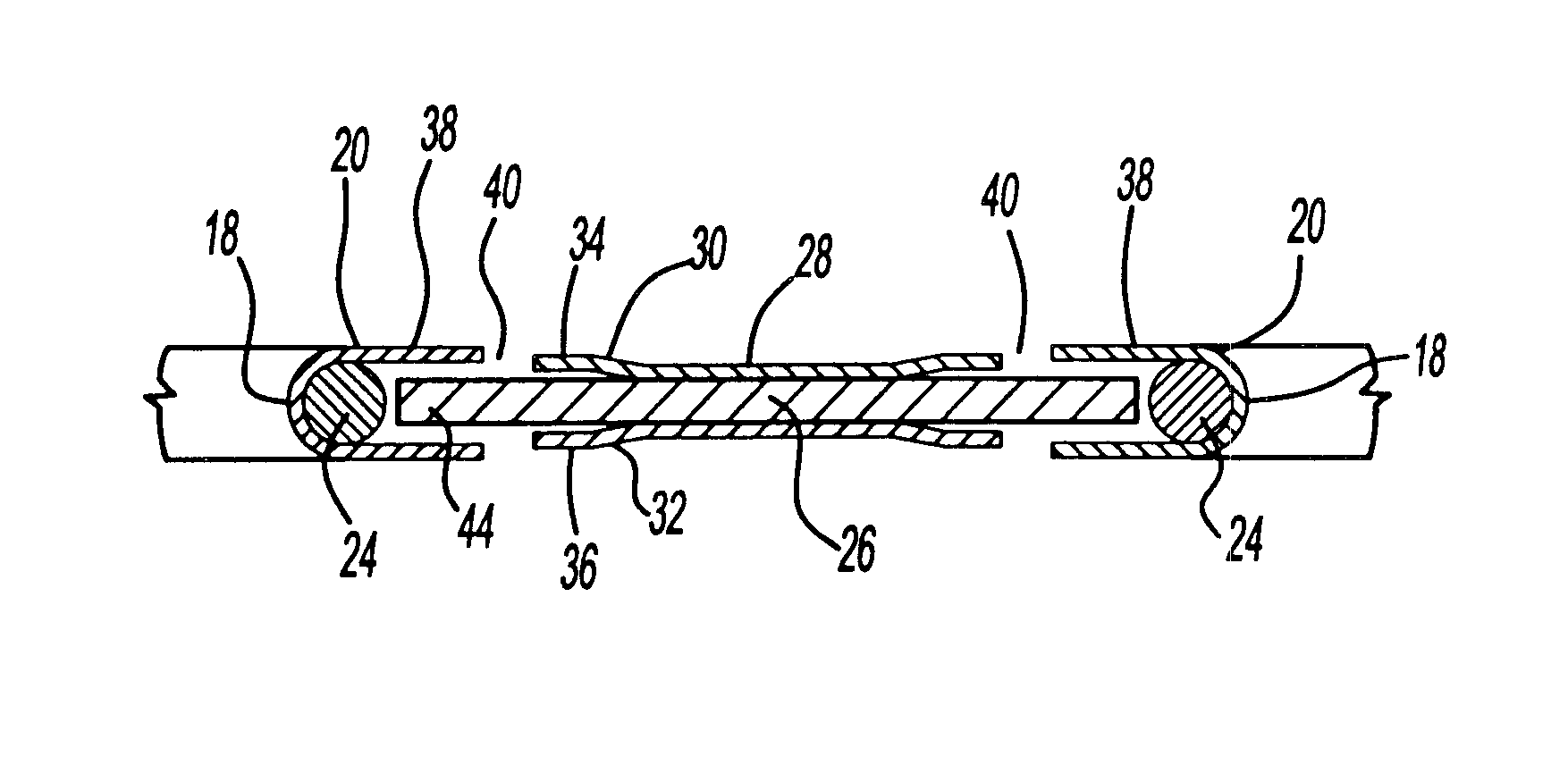

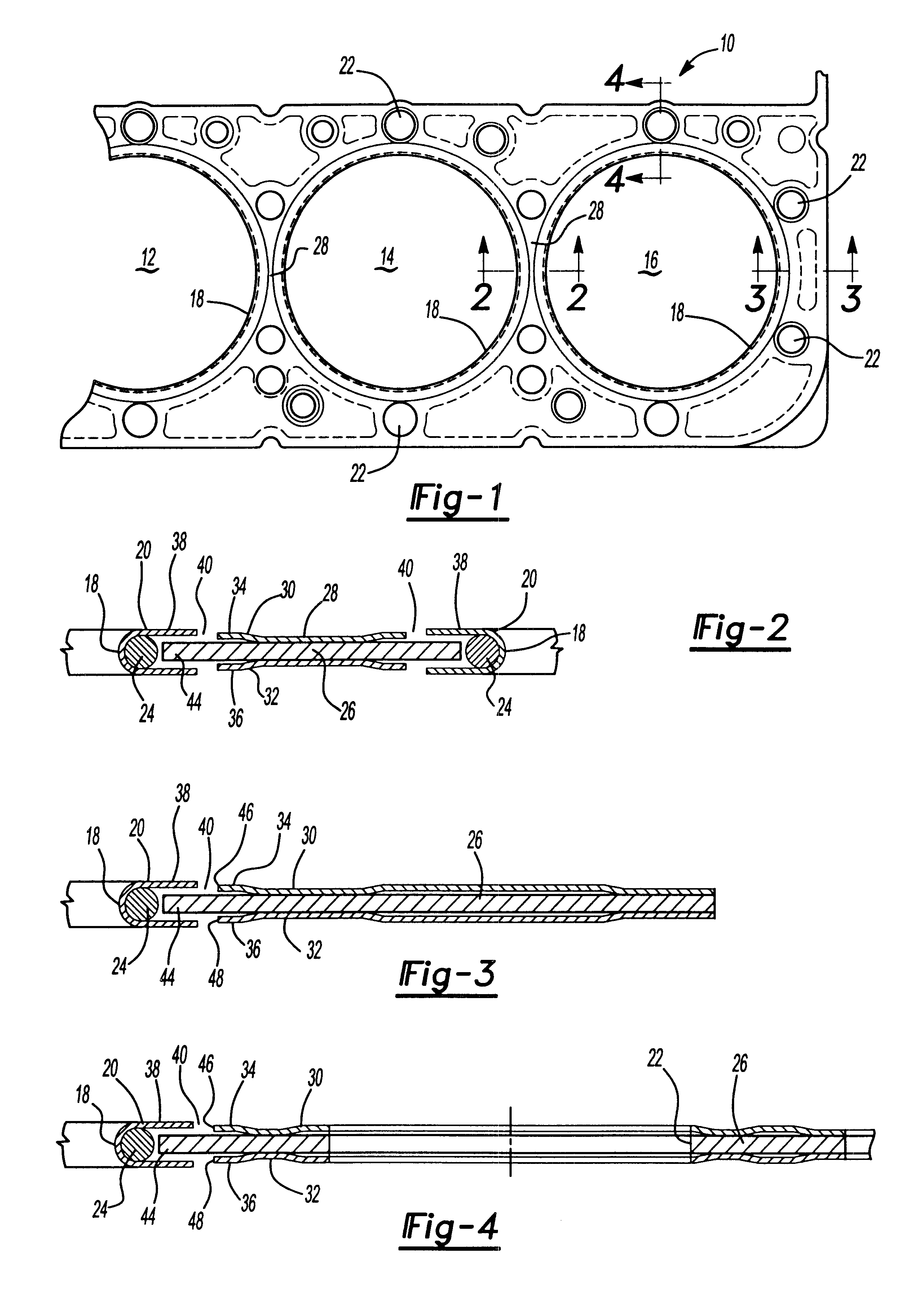

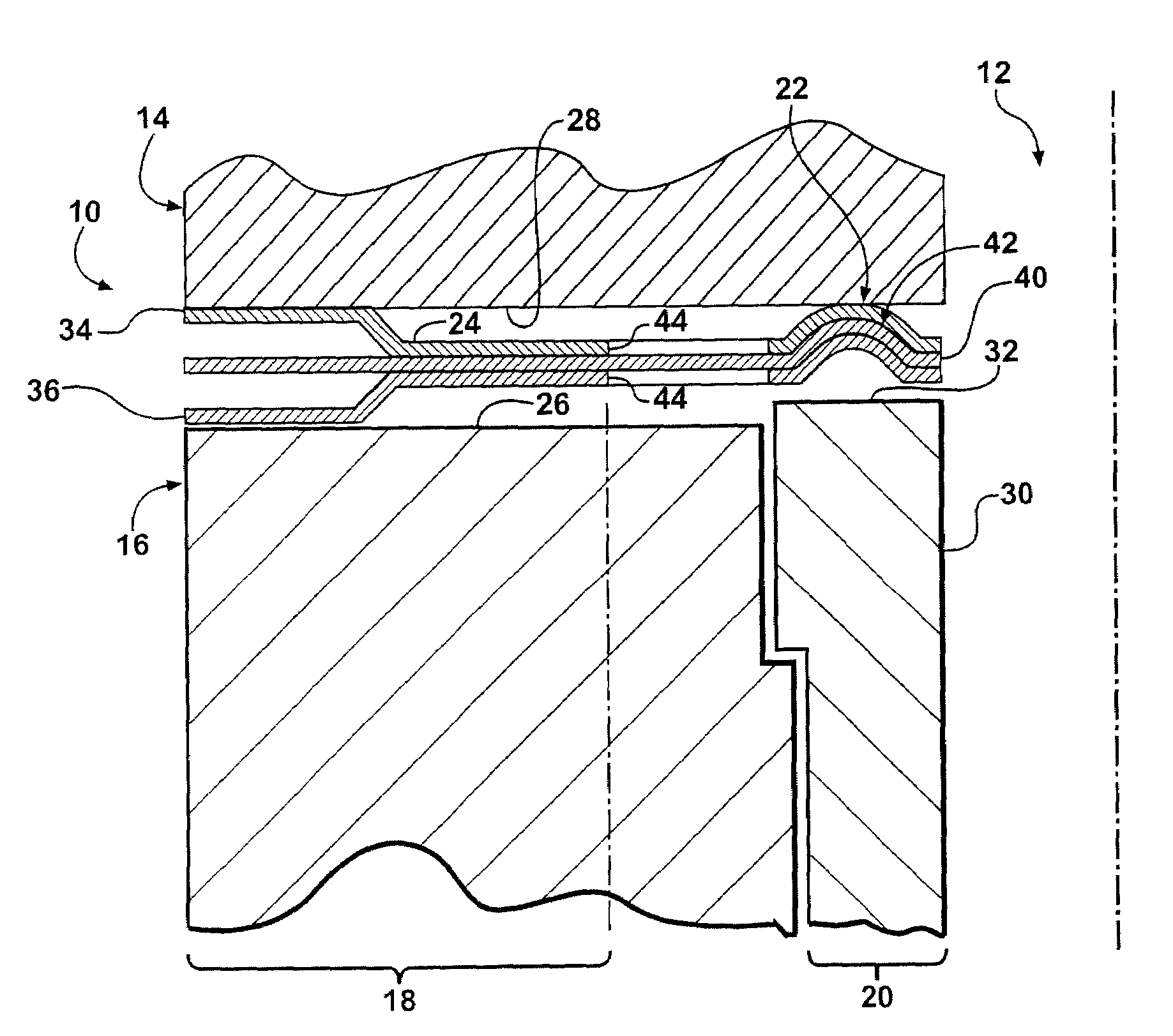

InactiveUS20060119050A1Improve fatigueImproved joint distortion performanceEngine sealsSealing arrangements for enginesVariable thicknessInter layer

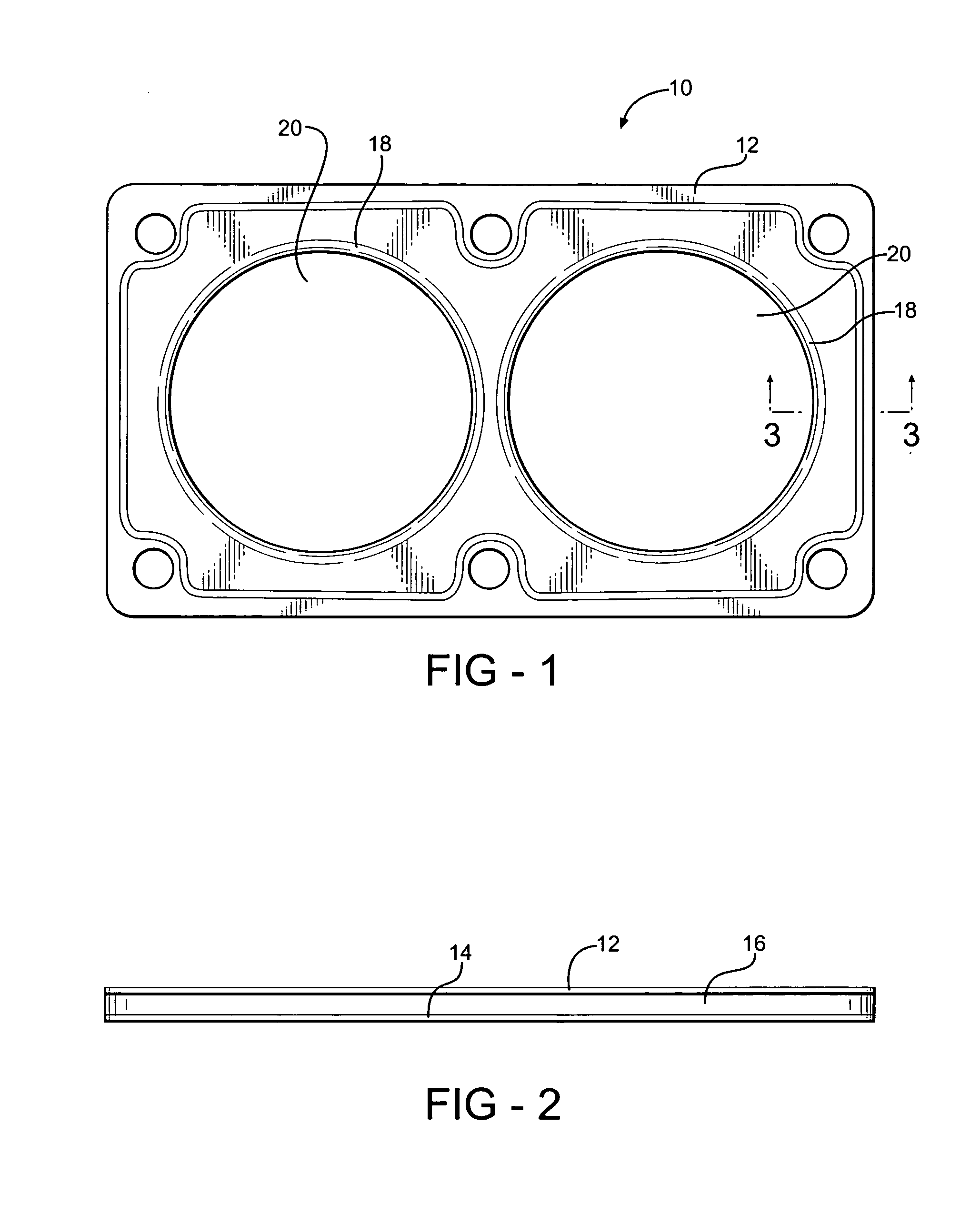

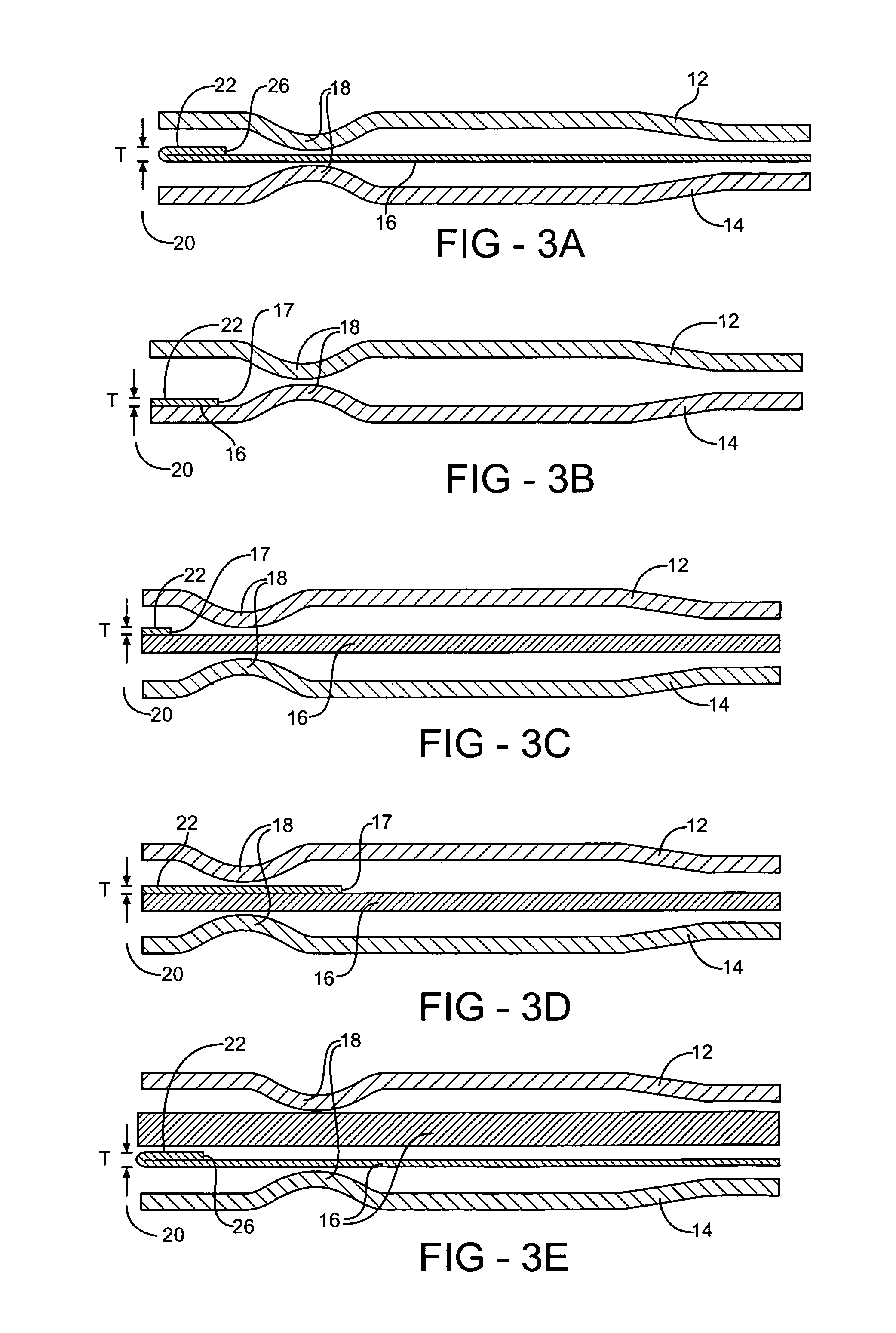

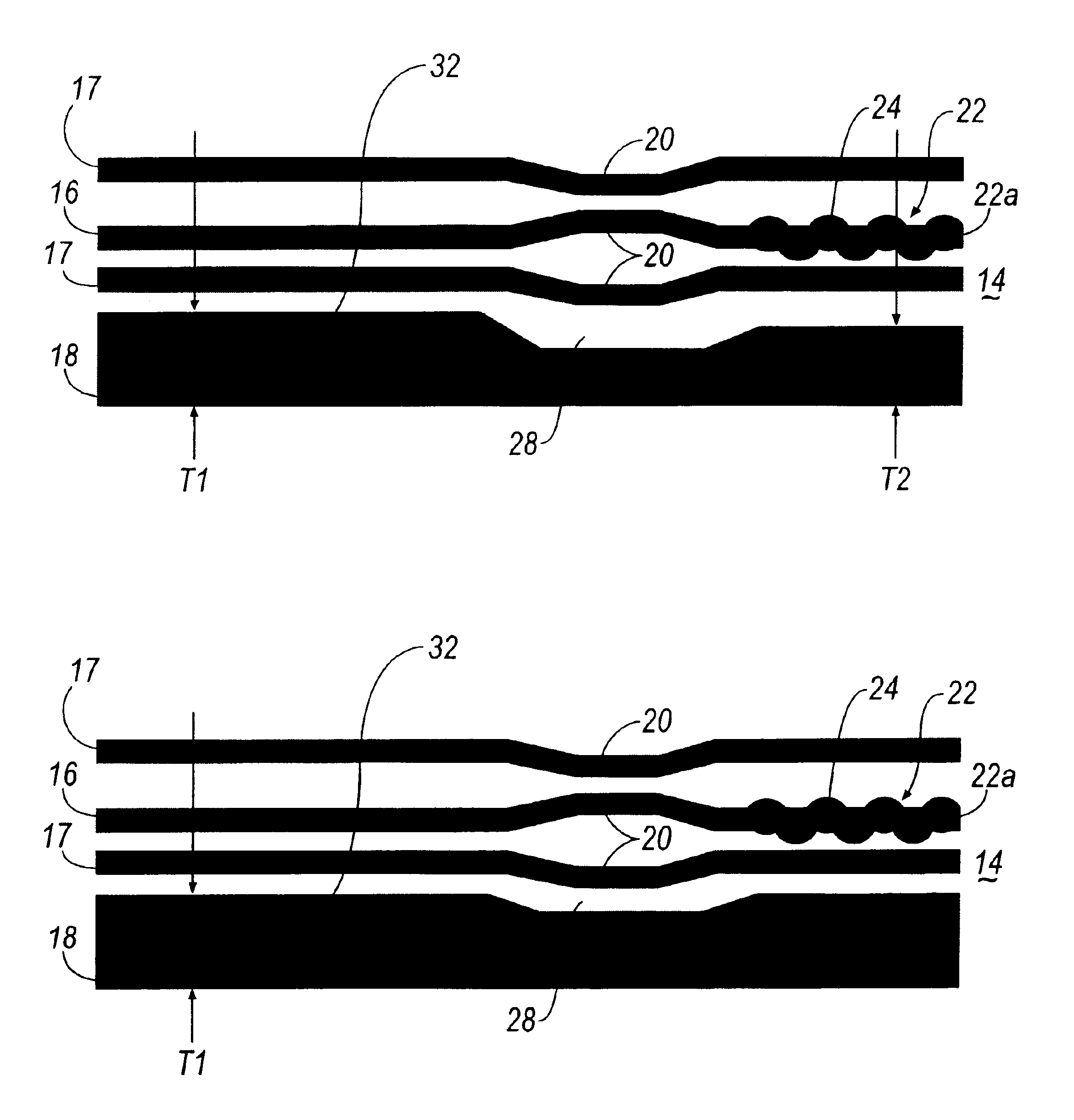

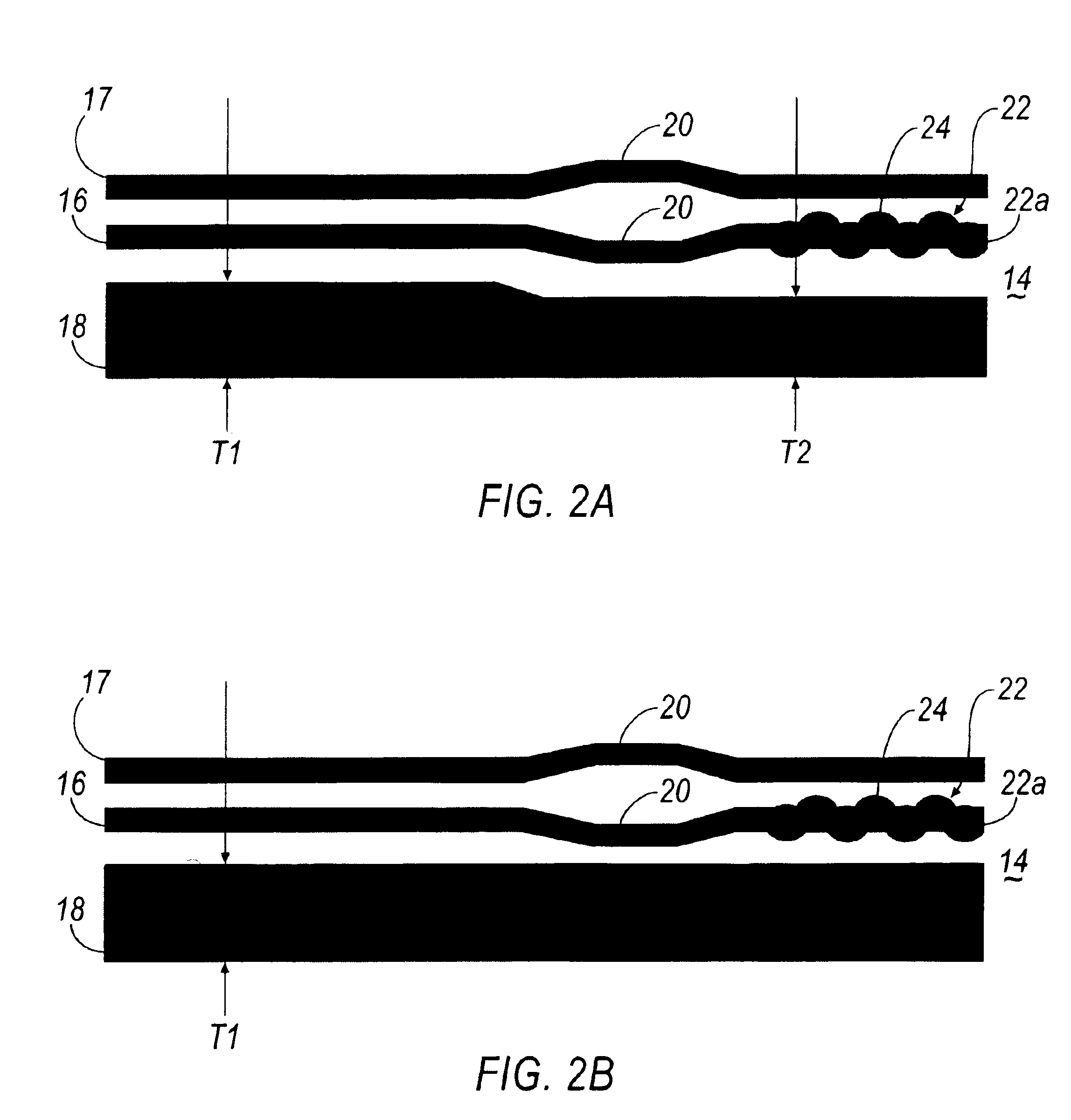

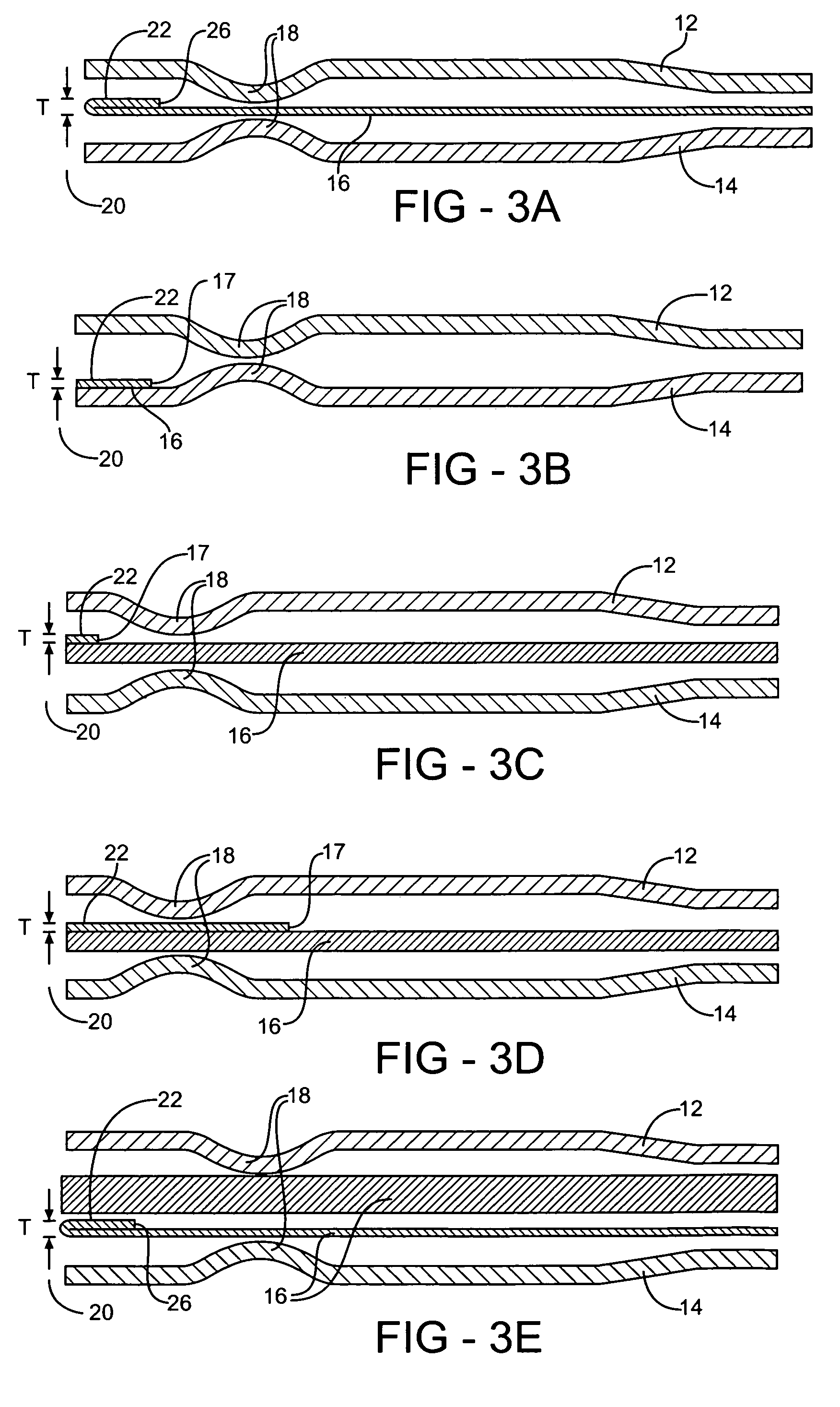

A multilayer metal gasket, such as a multilayer steel head gasket, for an internal combustion engine has upper and lower functional layers and at least one intermediate layer. At least one of these layers has a circumferential compression control feature in the form of a protrusion or groove which varies in thickness or depth, respectively, around its circumference. The variable thickness of the compression control feature enables uniform sealing pressure on the sealing surfaces of the gasket.

Owner:FEDERAL MOGUL WORLD WIDE

Head gasket assembly

InactiveUS20050023768A1Eliminate needEngine sealsSealing arrangements for enginesHead gasketEngineering

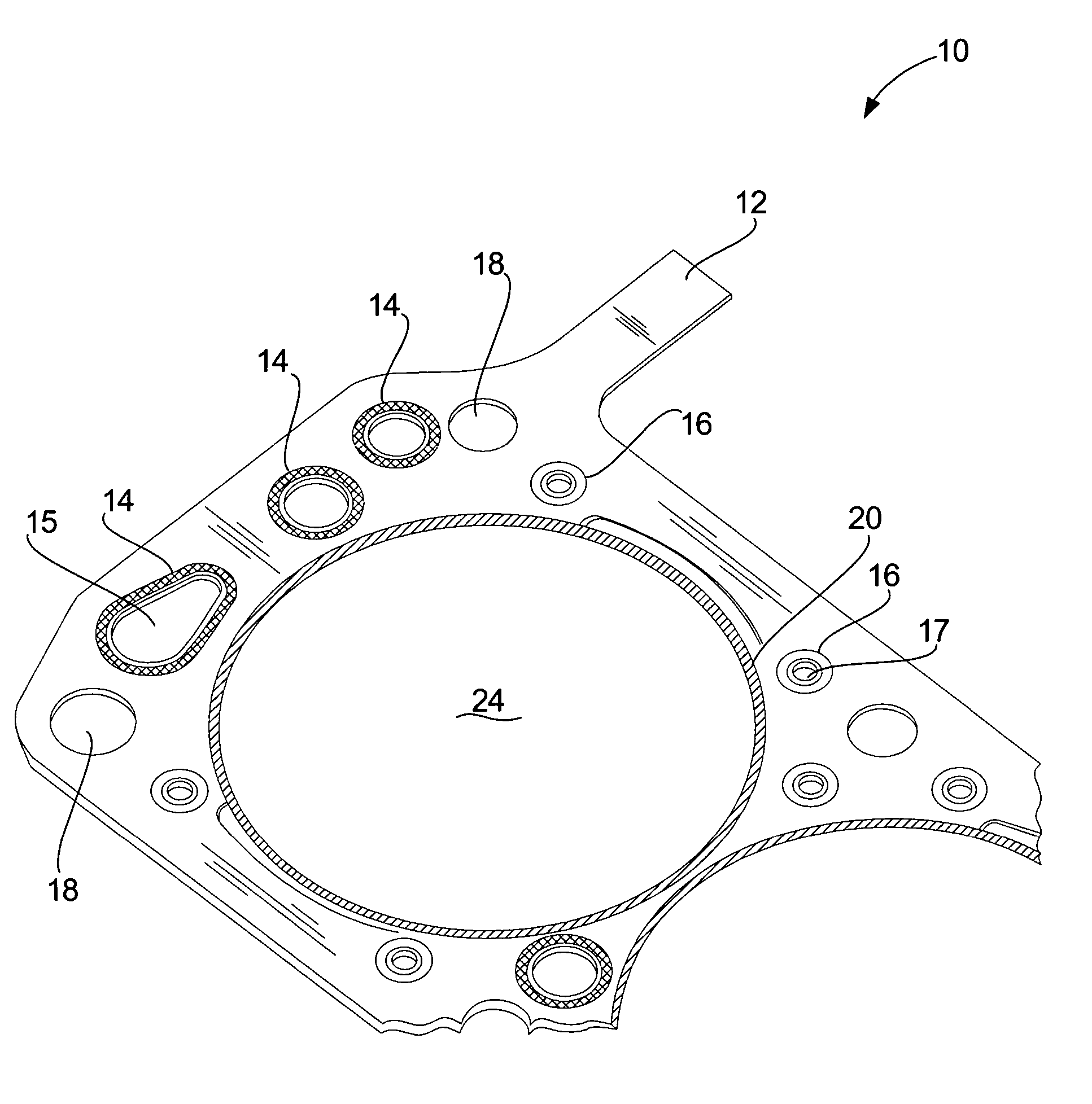

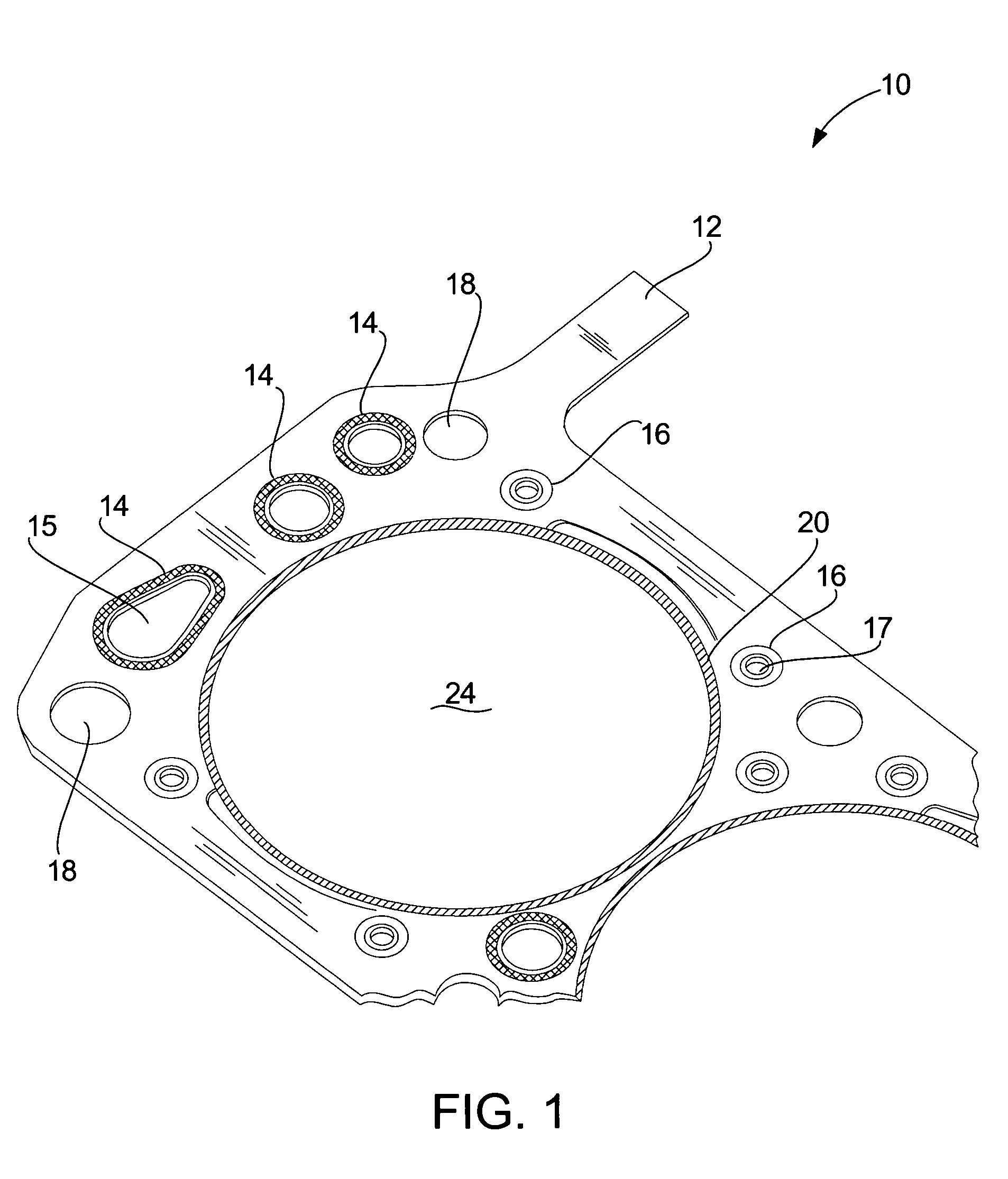

A head gasket assembly is provided comprising a solid non-compressible or rigid gasket body comprising a plurality of apertures for engine coolant, oil and combustion chambers. The gasket body has grooves formed therein for retaining and controlling the compression of elastomeric seals used for sealing engine coolant and oil apertures. The gasket body is then fitted or accompanied by a combustion seal. The combustion seals are specifically designed for the particular engine application, based on temperature, pressure and other operating characteristics. This assembly allows a direct fit with standard engine technology and requires no machining of heads, blocks, or cylinder liners. The result is a gasket body that precisely controls the compression on the seals, which improves engine performance without any machining of the engine while carrying highly elastic compounds to seal coolant and oil.

Owner:COLTEC IND

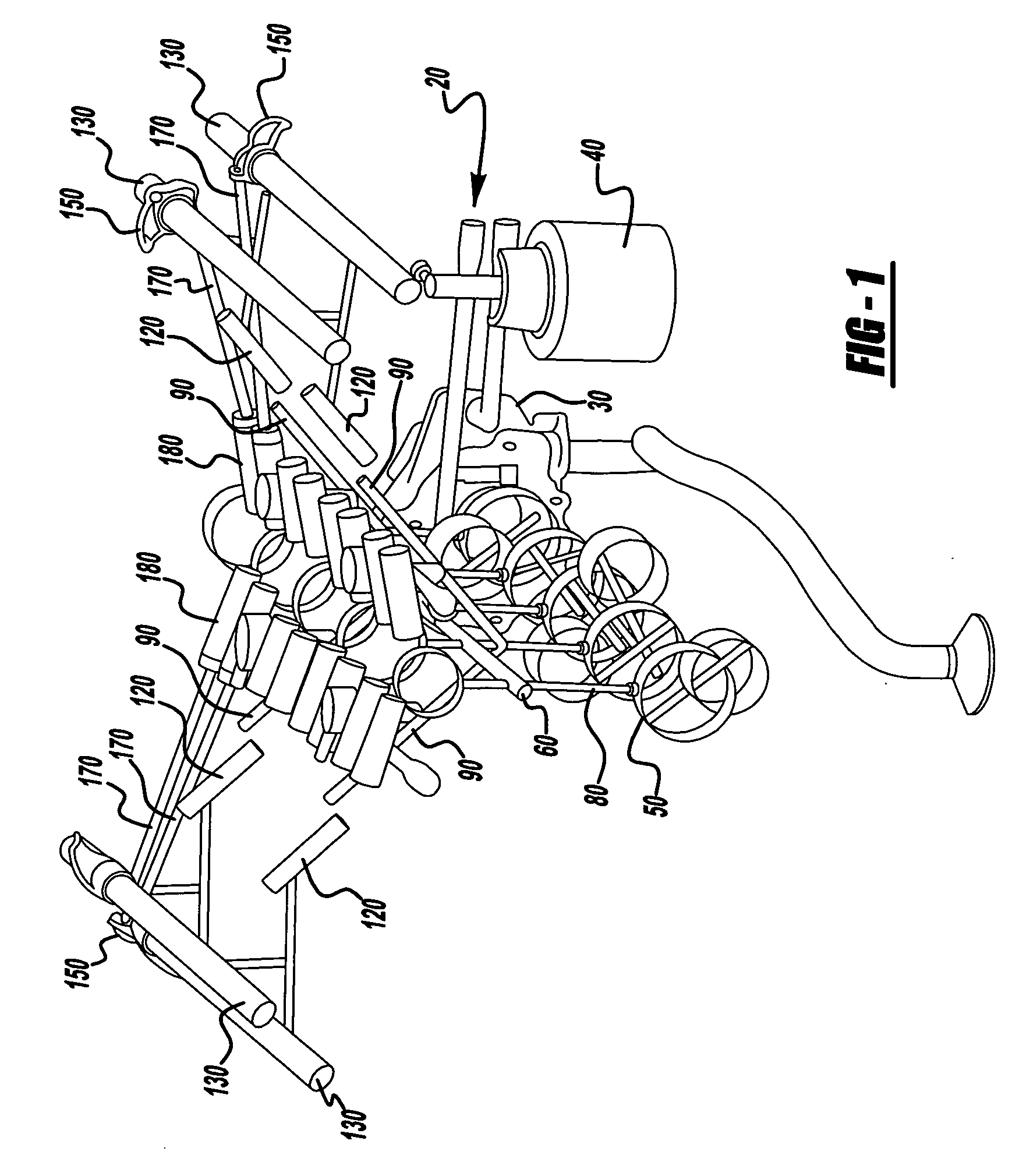

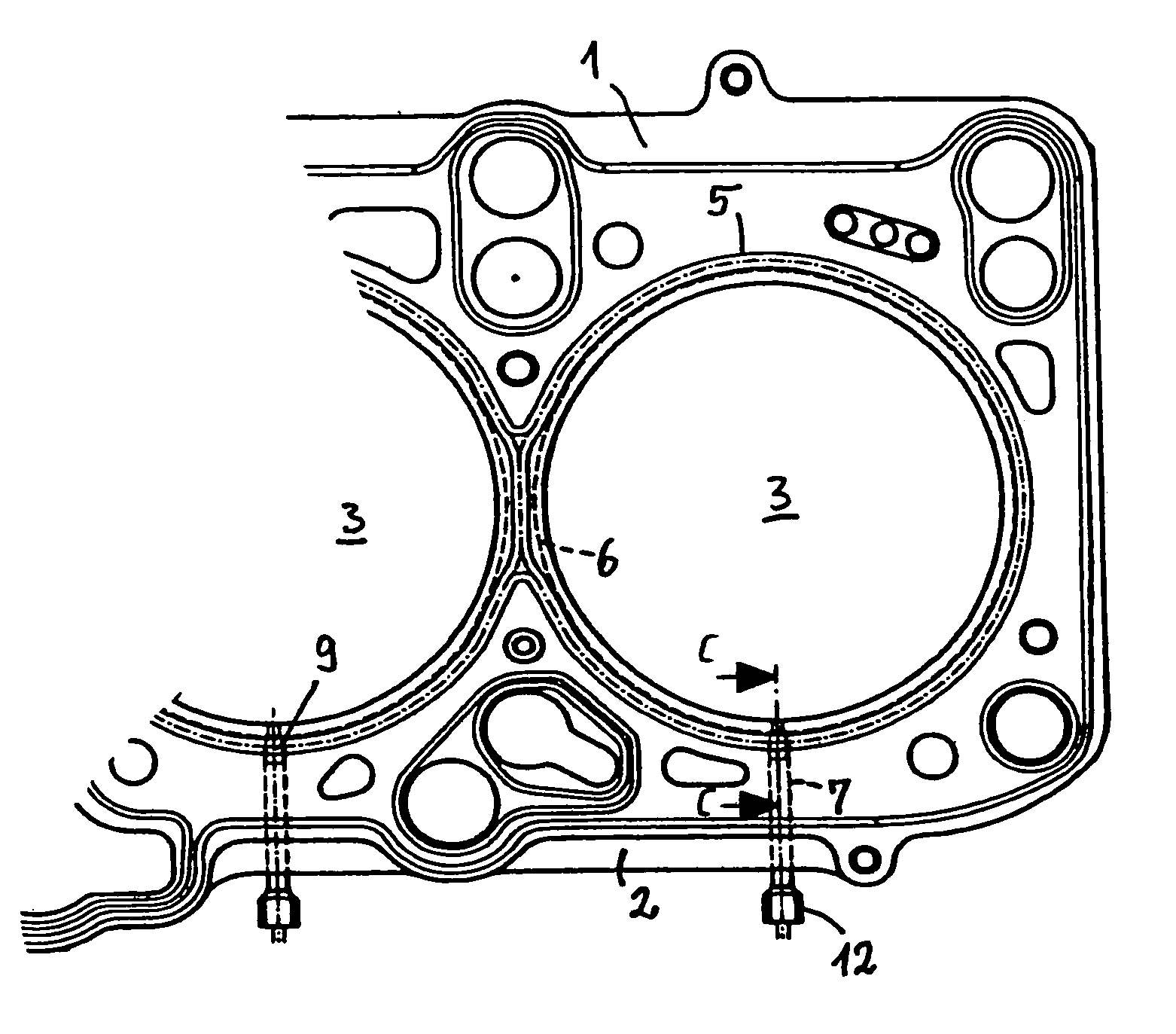

Embedded igniter system for internal combustion engines

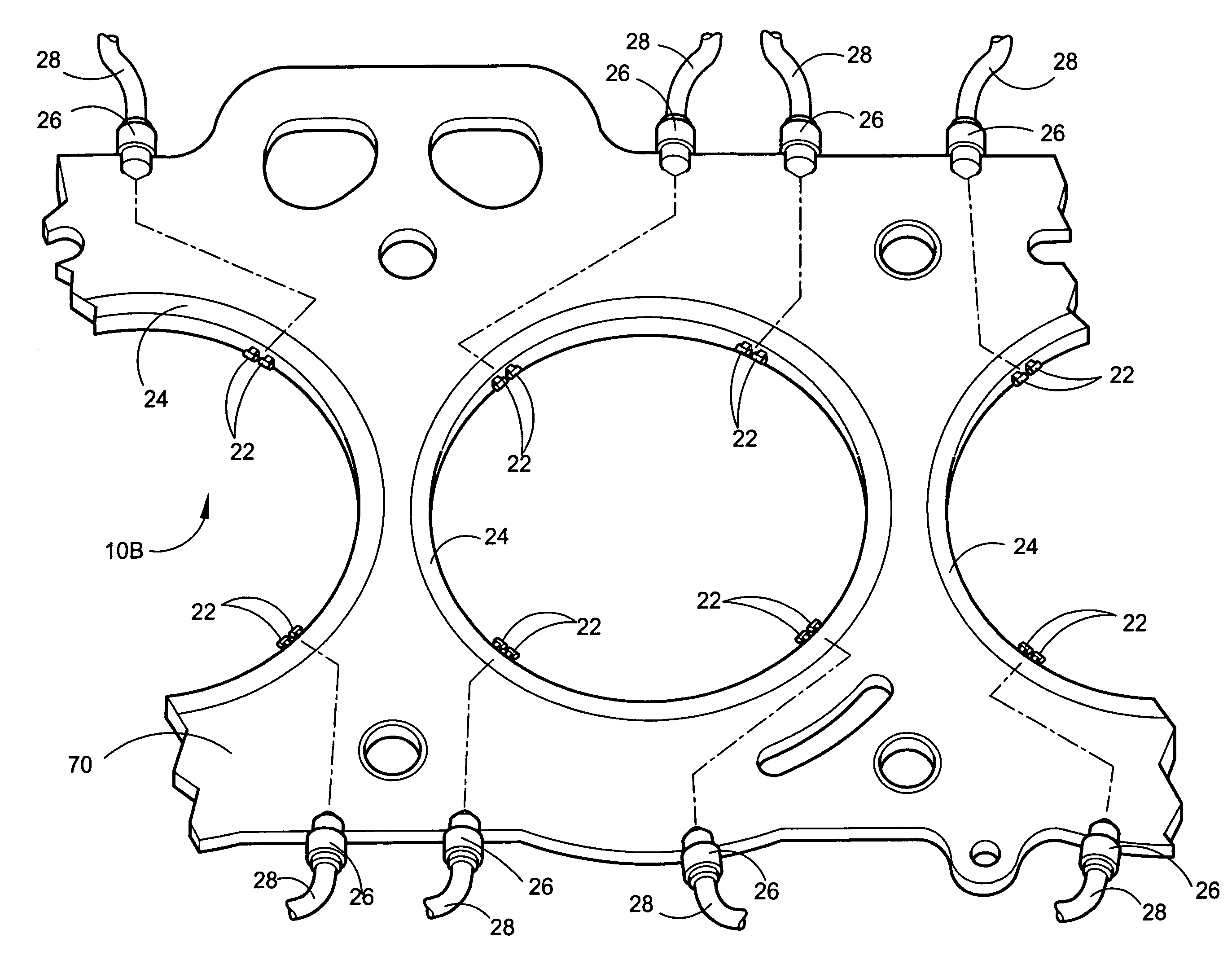

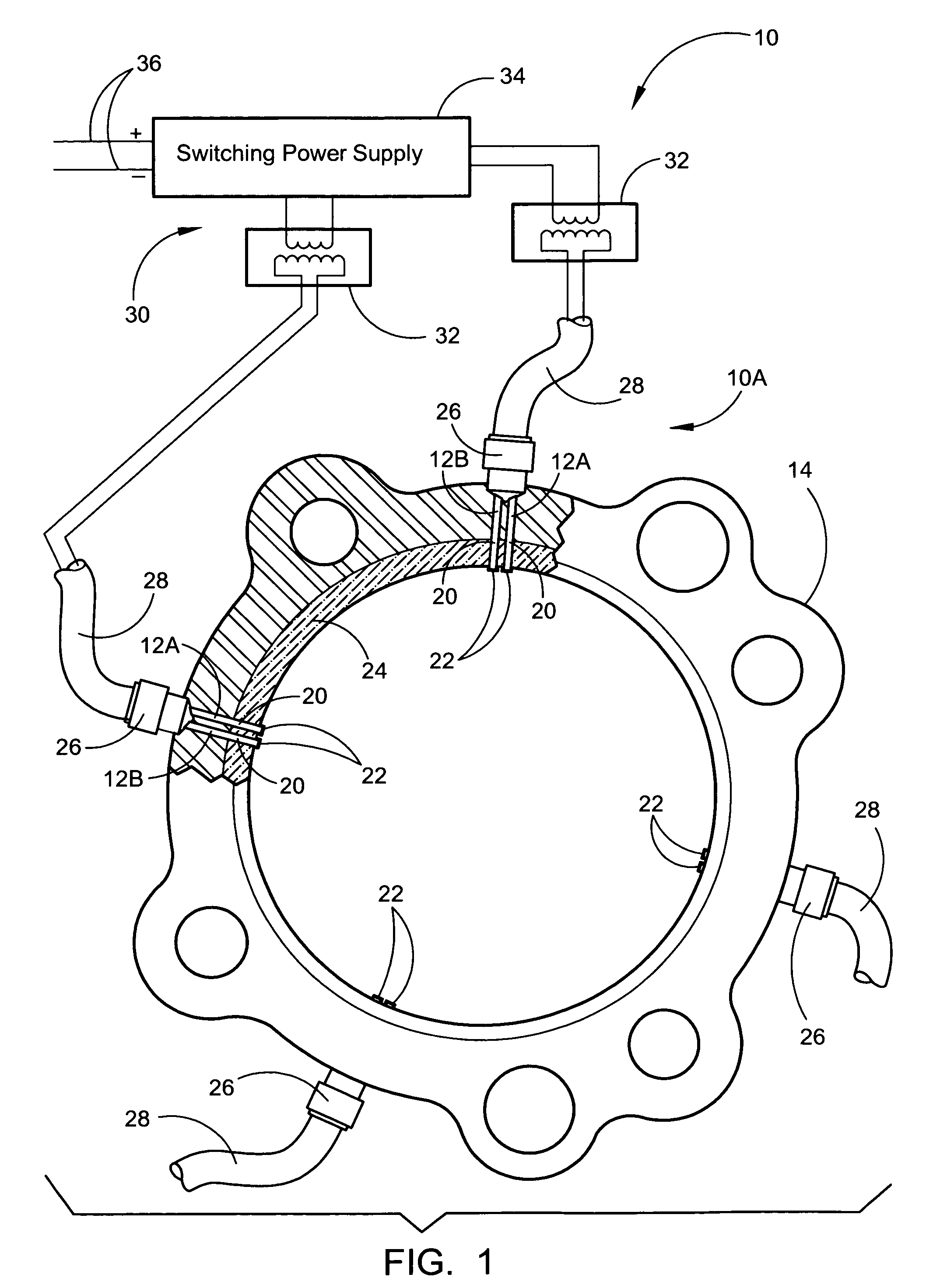

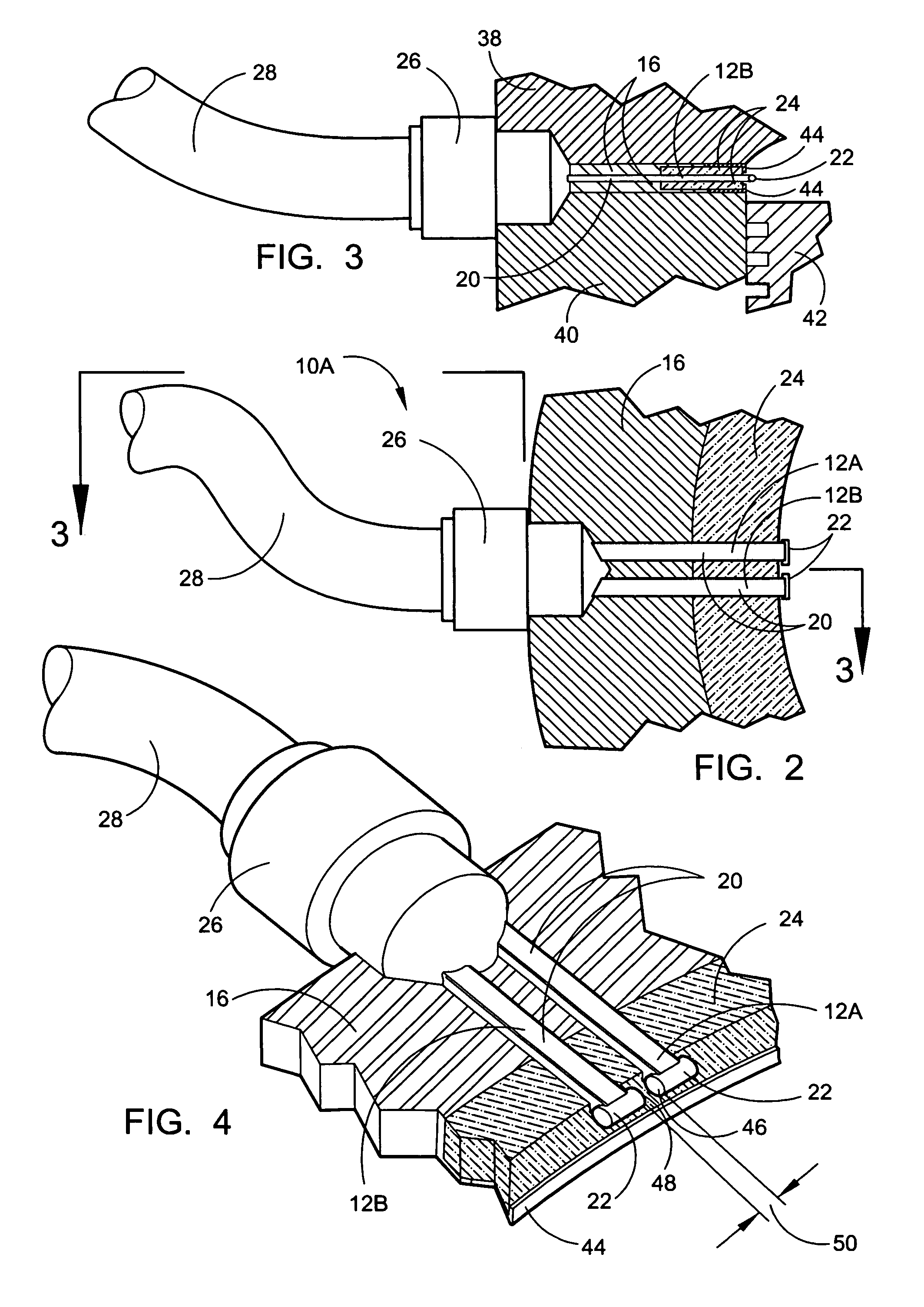

InactiveUS7299785B1Eliminate homogeneityEliminate auto advanceSparking plugsElectric ignition installationFiberElectricity

An embedded igniter for internal combustion engines consisting of a multiple ignition system with separate control for individual pairs of igniters that has been designed to replaces the spark plugs of internal combustion engines. This device allows for a more complete burn of the fuel / air mixture within the combustion chamber. The embedded igniter system will consist of one or more igniter units consisting of a pair of rectangular tantalum bars with iridium electrode pins at the ends. The paired igniter pins are encased in alumina ceramic, a high dielectric / high temperature housing positioned around the combustion chamber holding and insulating the electrodes relative to their position in reference to the combustion chamber. One or more igniter units may be incorporated around each cylinder opening of a head gasket made from a composite of polyamide, carbon fiber and copper or equivalent material or may be incorporated into an internal combustion engine that does not require a head gasket.

Owner:BROWNE BRUCE D +1

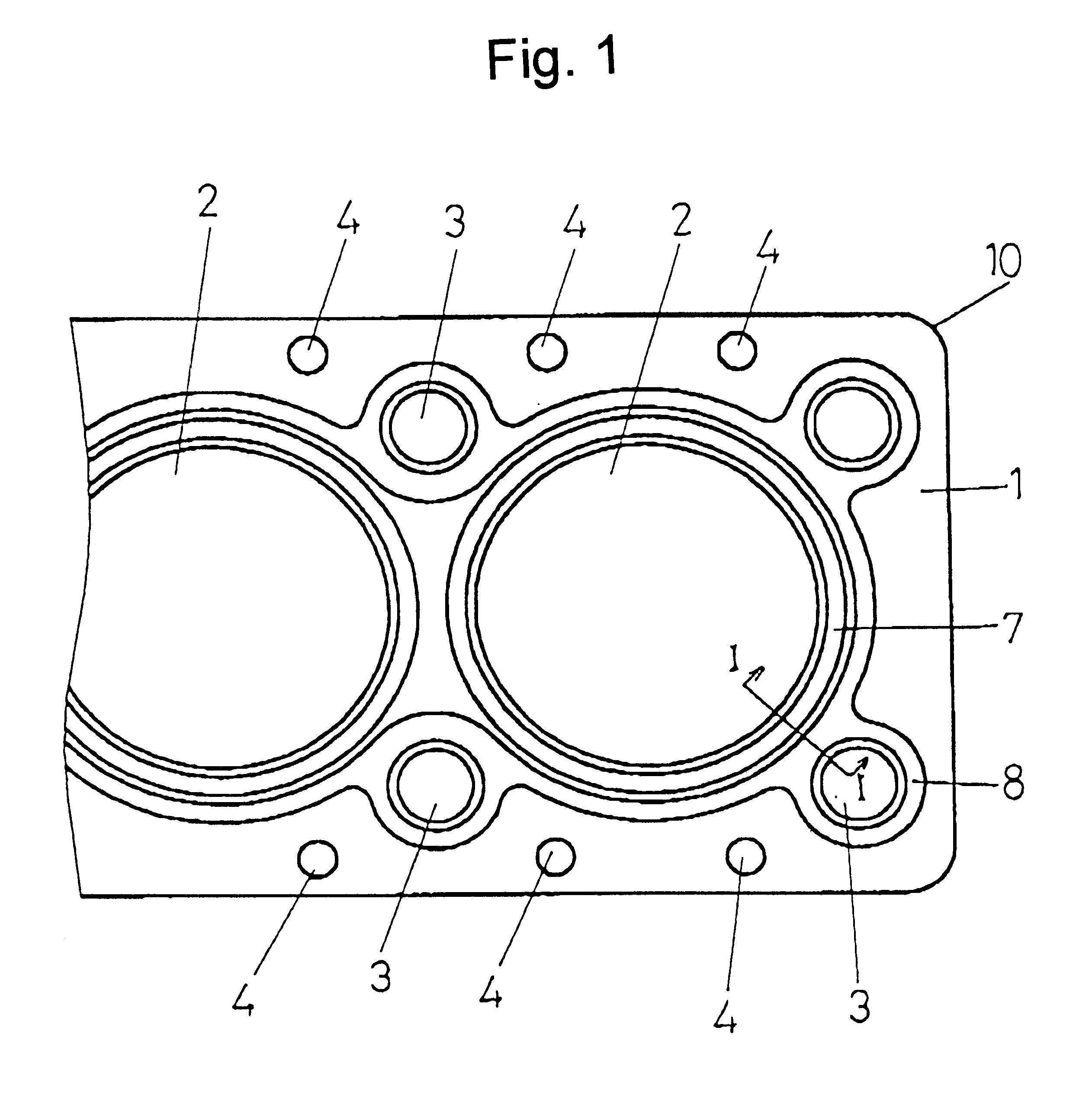

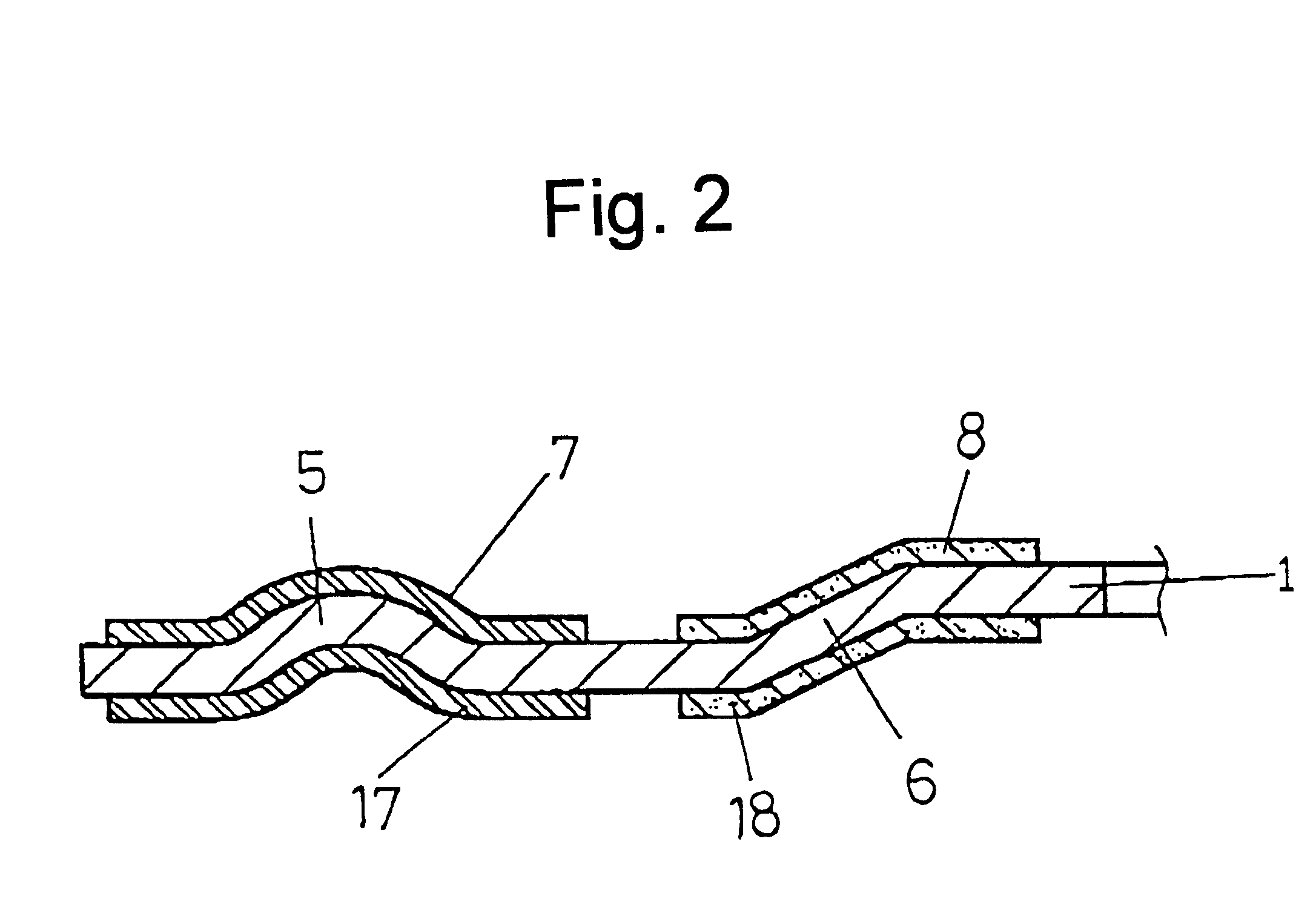

Cylinder head gasket

InactiveUS6349945B1Increase surface pressureImprove plasticityEngine sealsSealing arrangements for enginesPlastic materialsEngineering

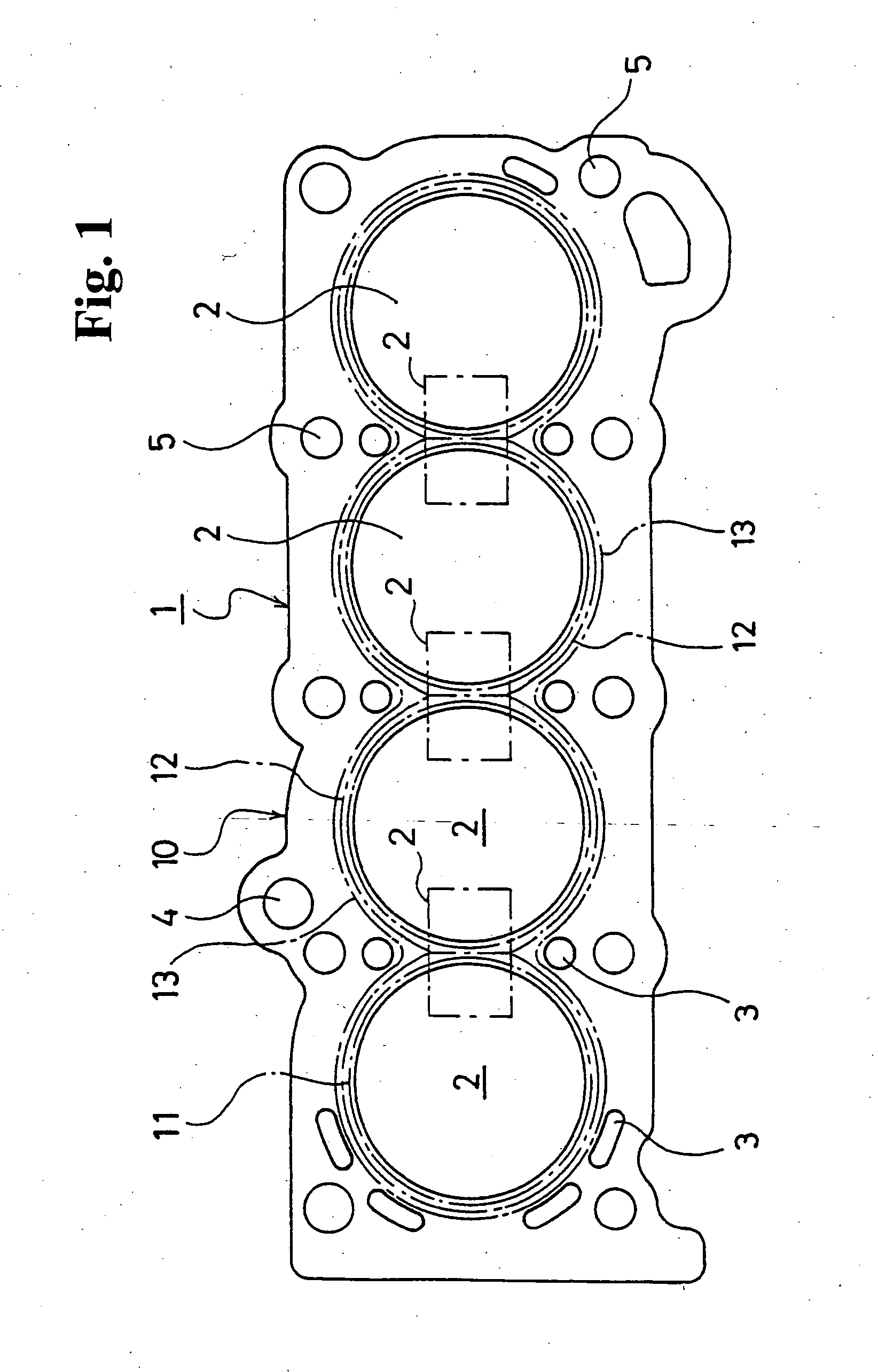

Cylinder head gasket comprising a gasket plate which has at least one metal layer with elastic properties and in which a through opening is formed which is surrounded by a bead-like embossment formed in this metal layer, wherein the bead-like embossment forms an approximately linear, self-contained sealing zone with increased sealing surface pressure when the gasket is fitted and the metal layer is provided with a first coating consisting of a plastic material which has elastic properties on its side forming this sealing zone at least in the area of this sealing zone as well as to both sides of the latter; to improve the sealing capacity of the cylinder head gasket around the said through opening, the metal layer is coated on its side provided with the first coating with a sealing bead closed upon itself, likewise surrounding the through opening and consisting of a plastic material, this bead being arranged on the side of the sealing zone facing away from the through opening as well as at a radial distance from the sealing zone in relation to the through opening, wherein the ridge of the sealing bead is at a greater distance from the metal layer supporting it than the upper side of the first coating.

Owner:ELRINGKLINGER AG

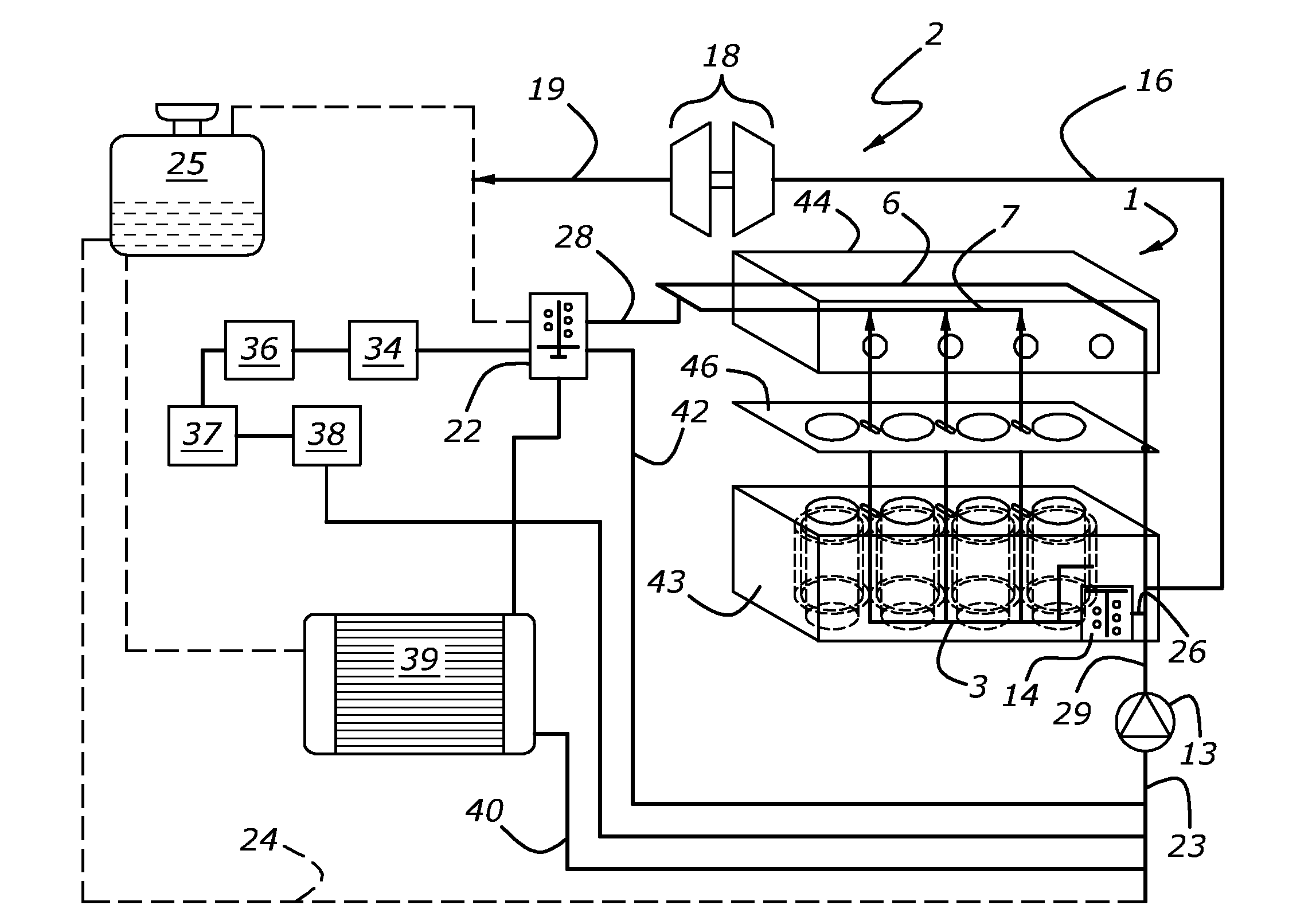

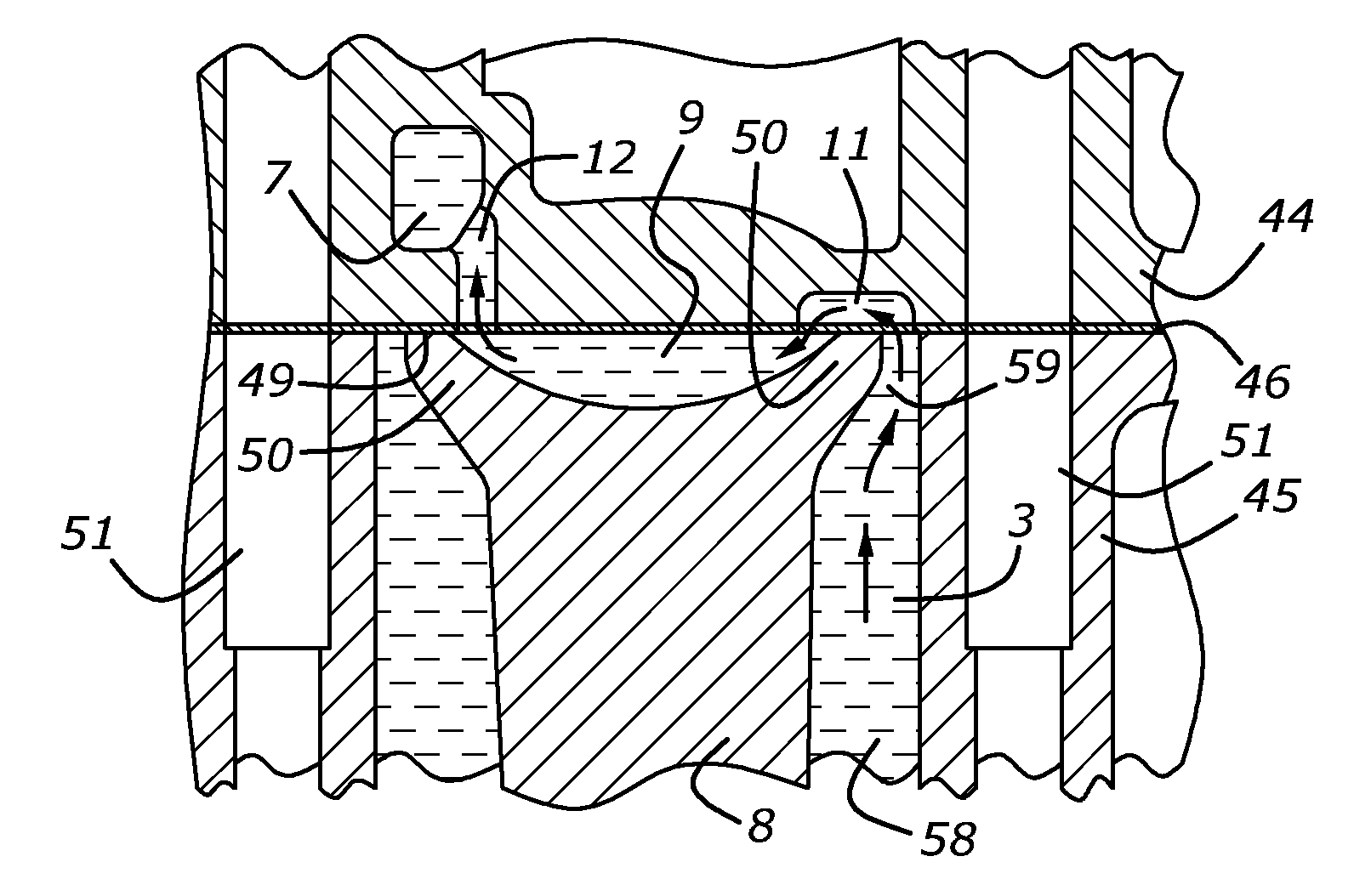

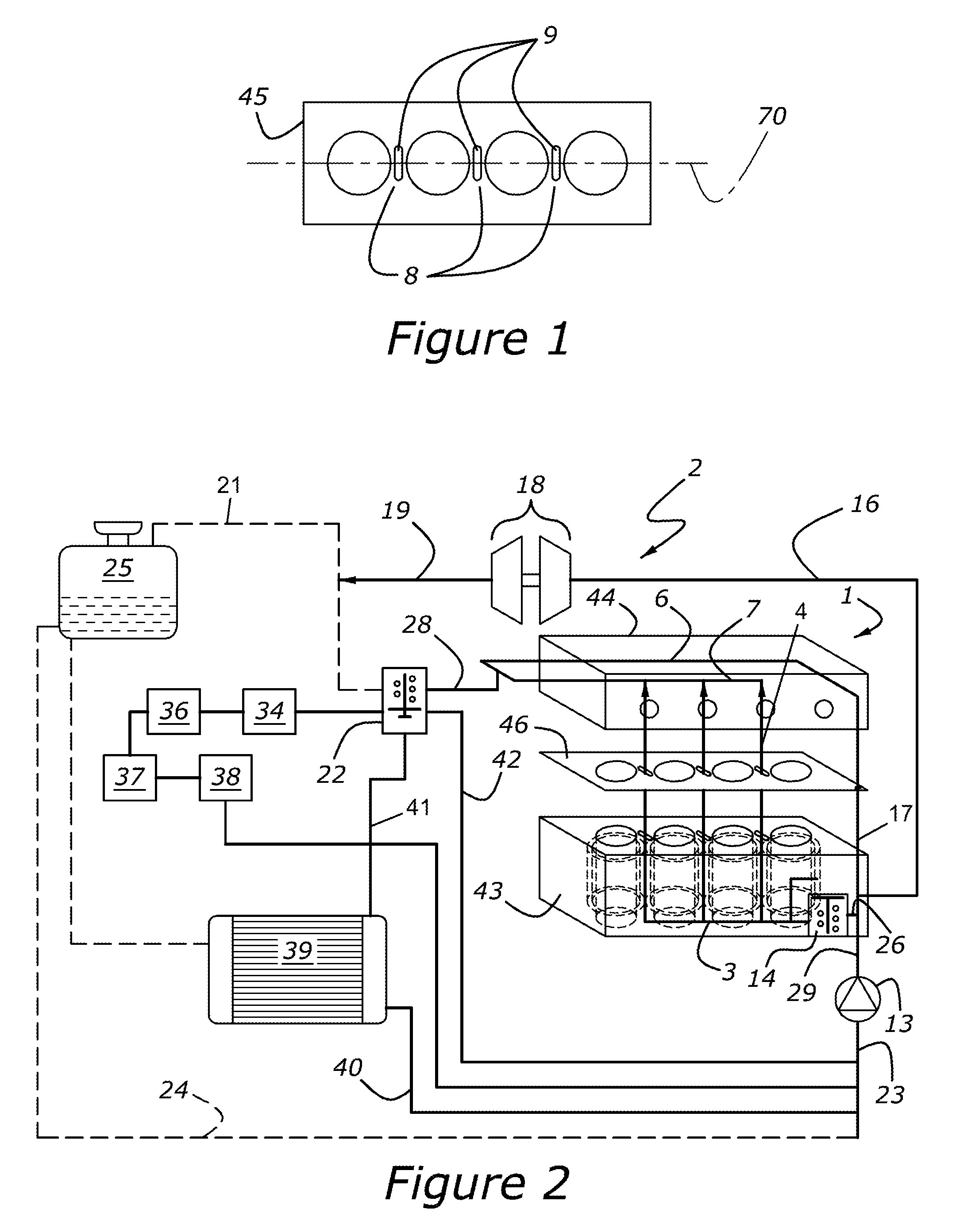

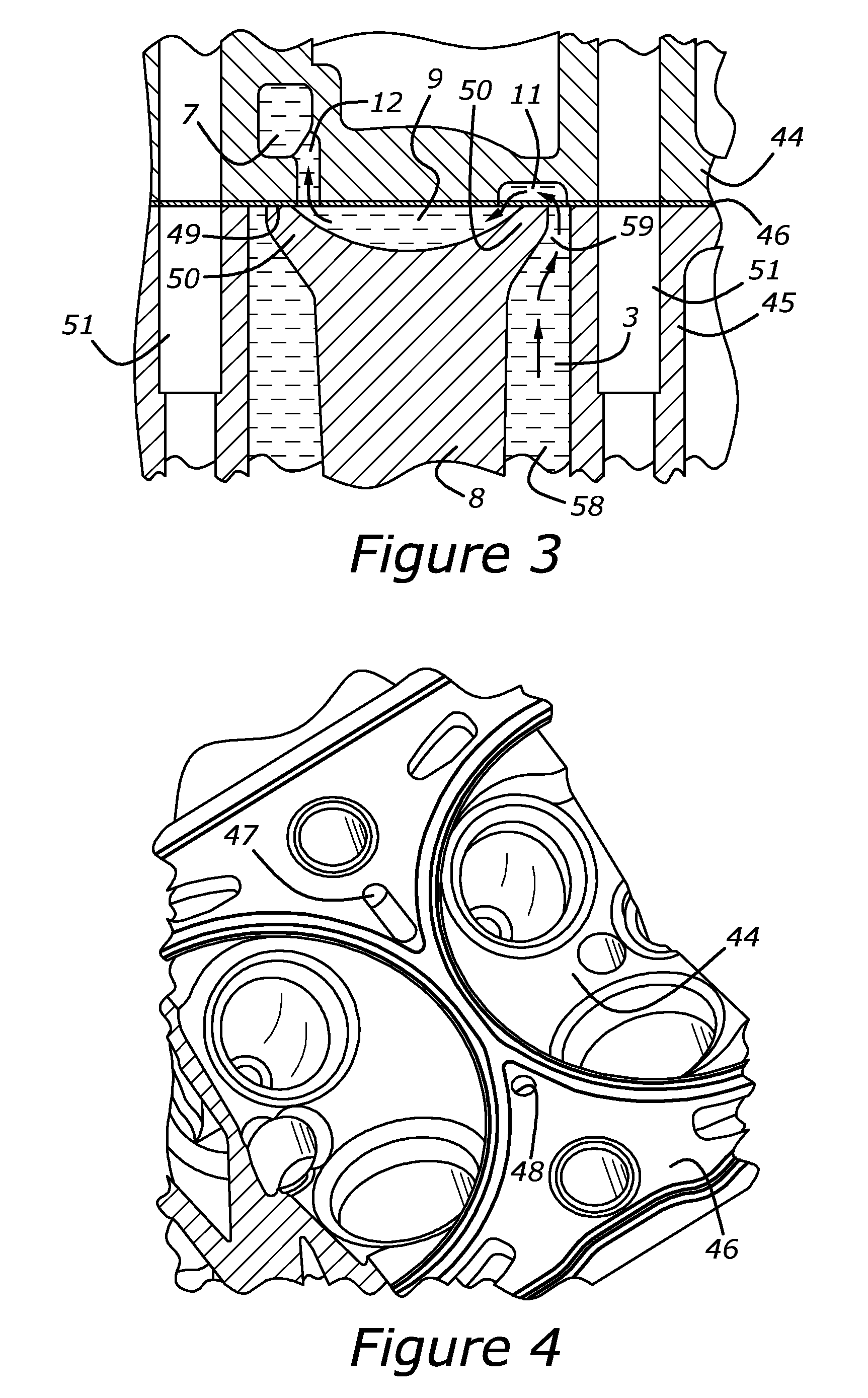

Cooling system

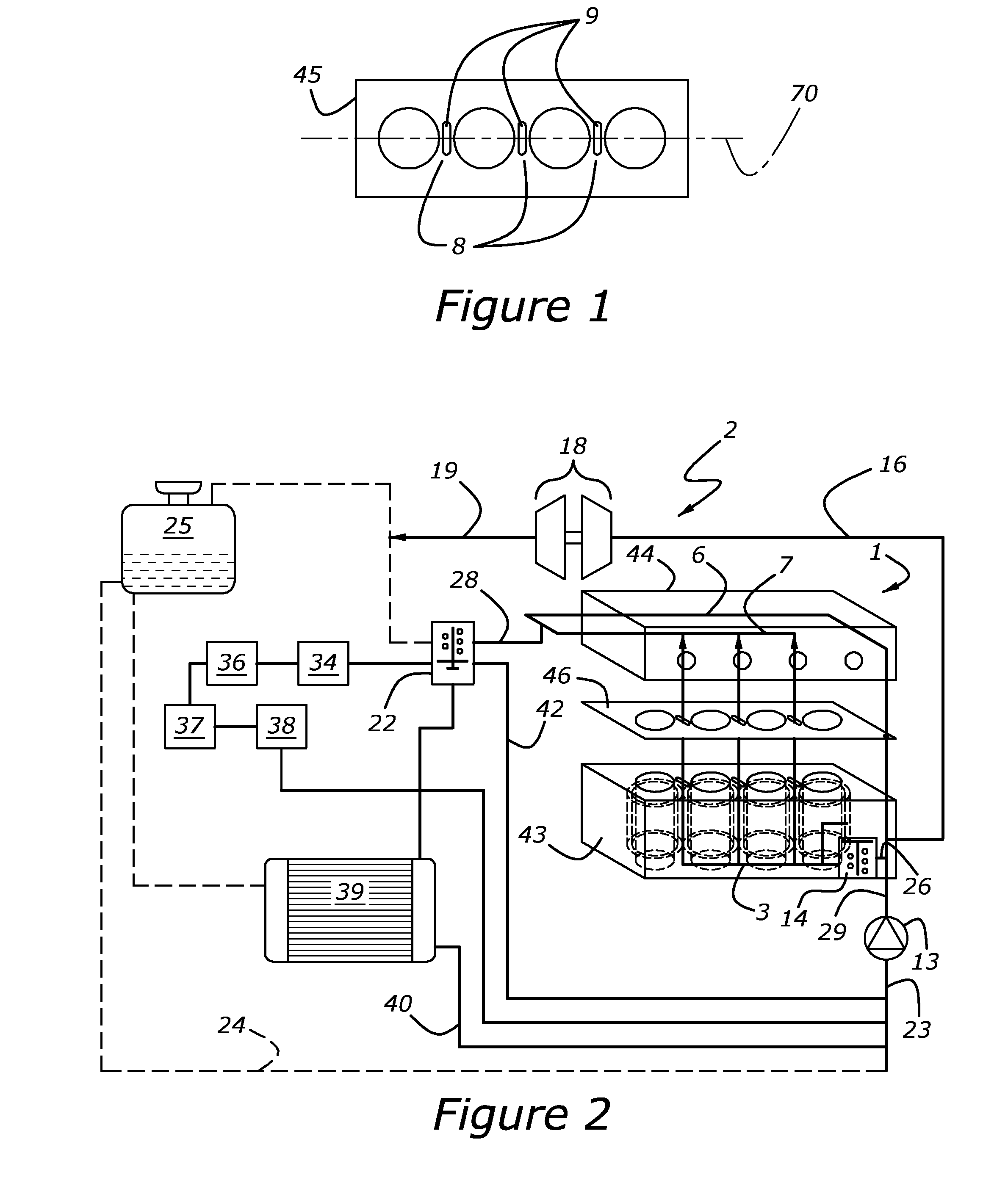

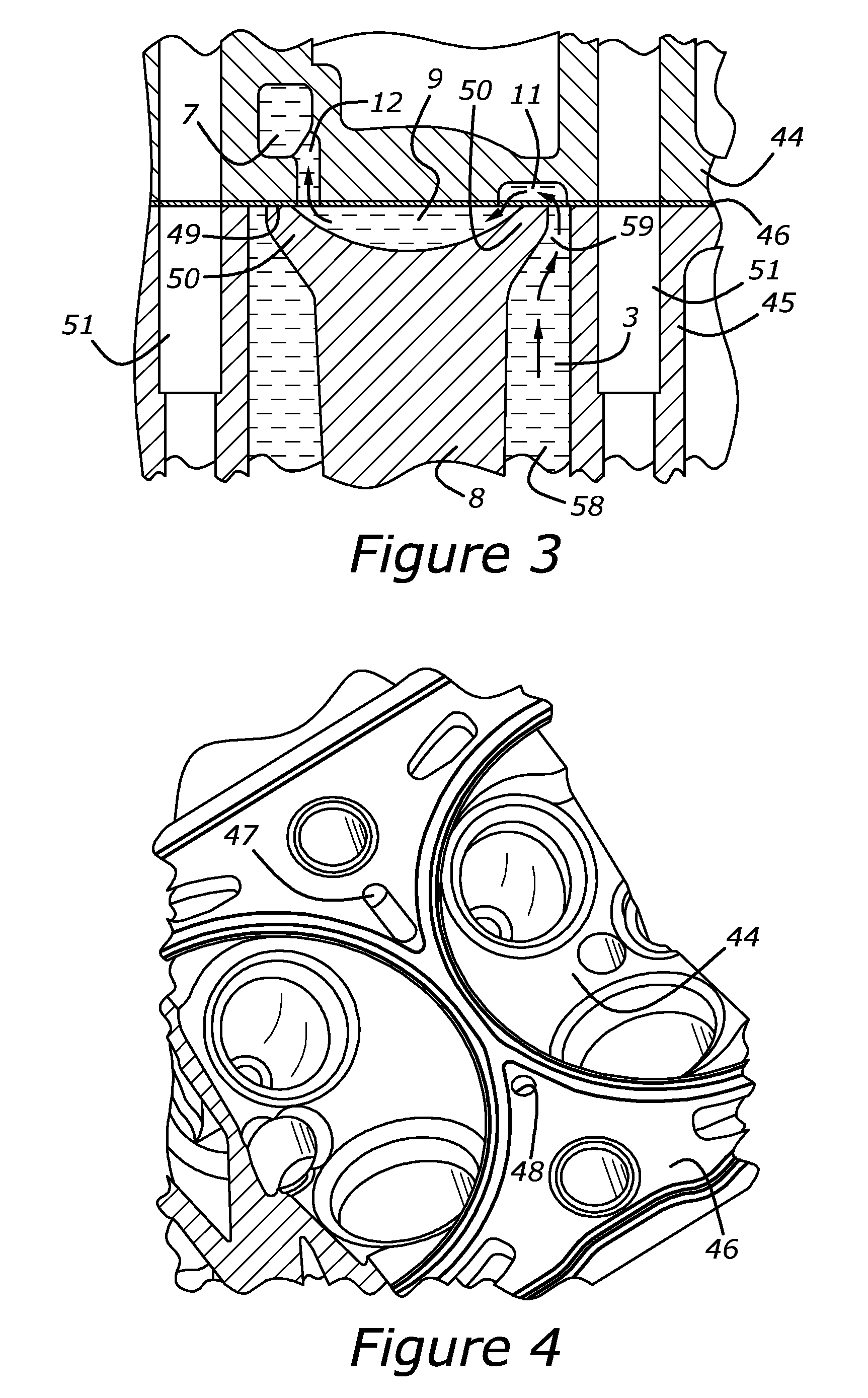

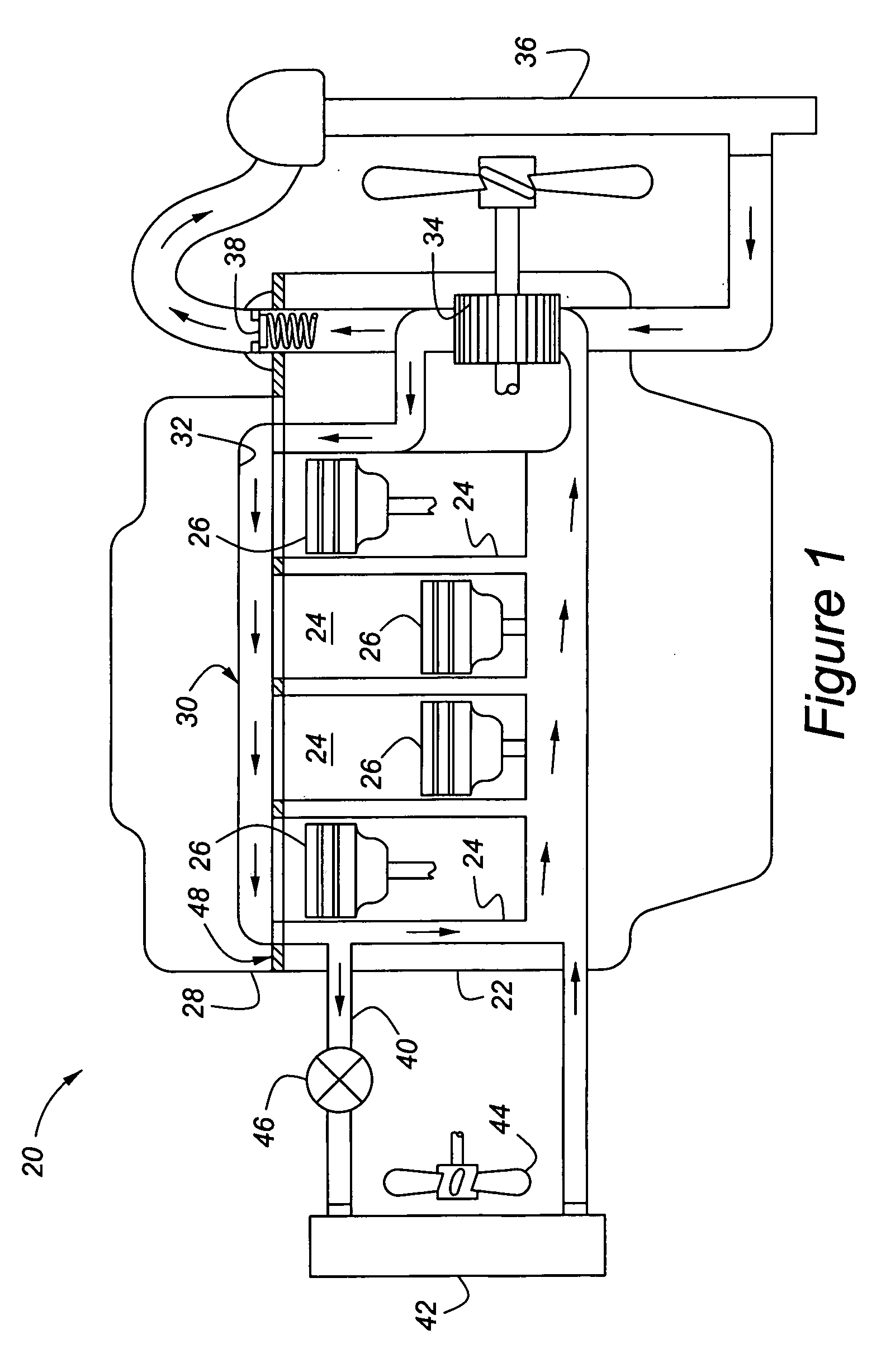

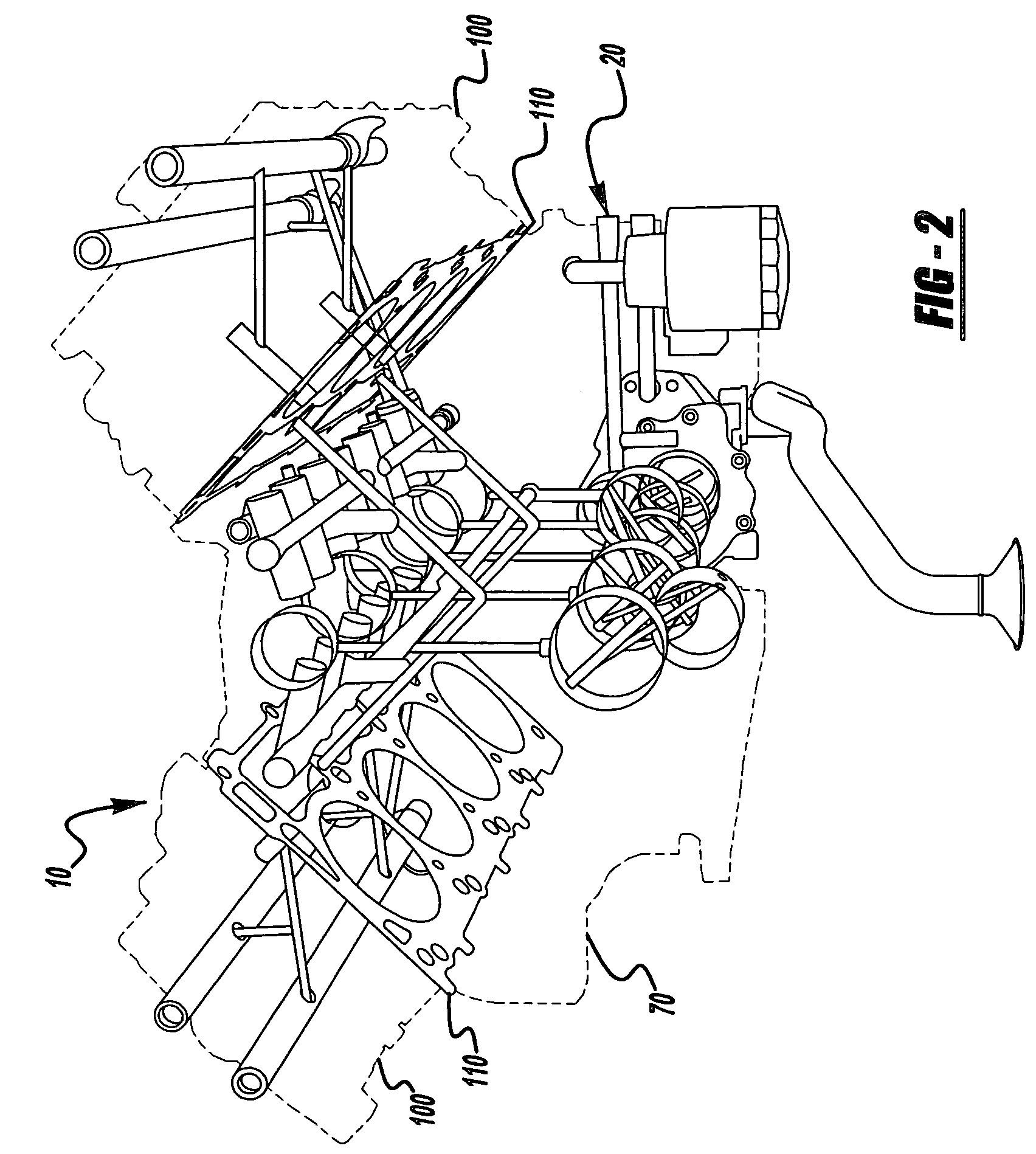

ActiveUS20110023799A1Preserve integrityMaintain structural integrityLiquid coolingCoolant flow controlEngineeringCylinder block

An internal combustion engine is disclosed that has a cylinder block with multiple cylinders, a bridge between adjacent cylinders, a cooling slot in the bridge, and a water jacket portion in the cylinder block. A cylinder head is coupled to the cylinder block which has a first cooling passage fluidly coupling the cooling slot and the water jacket portion in the cylinder block, a water jacket portion in the cylinder head, and a second cooling passage in the cylinder head fluidly coupling the cooling slot with the water jacket portion in the cylinder head. A cylinder head gasket is arranged between the cylinder head and the cylinder block which has a first orifice in the cylinder head gasket cooperating with the first cooling passage a second orifice in the cylinder head gasket cooperating with the second cooling passage.

Owner:FORD GLOBAL TECH LLC

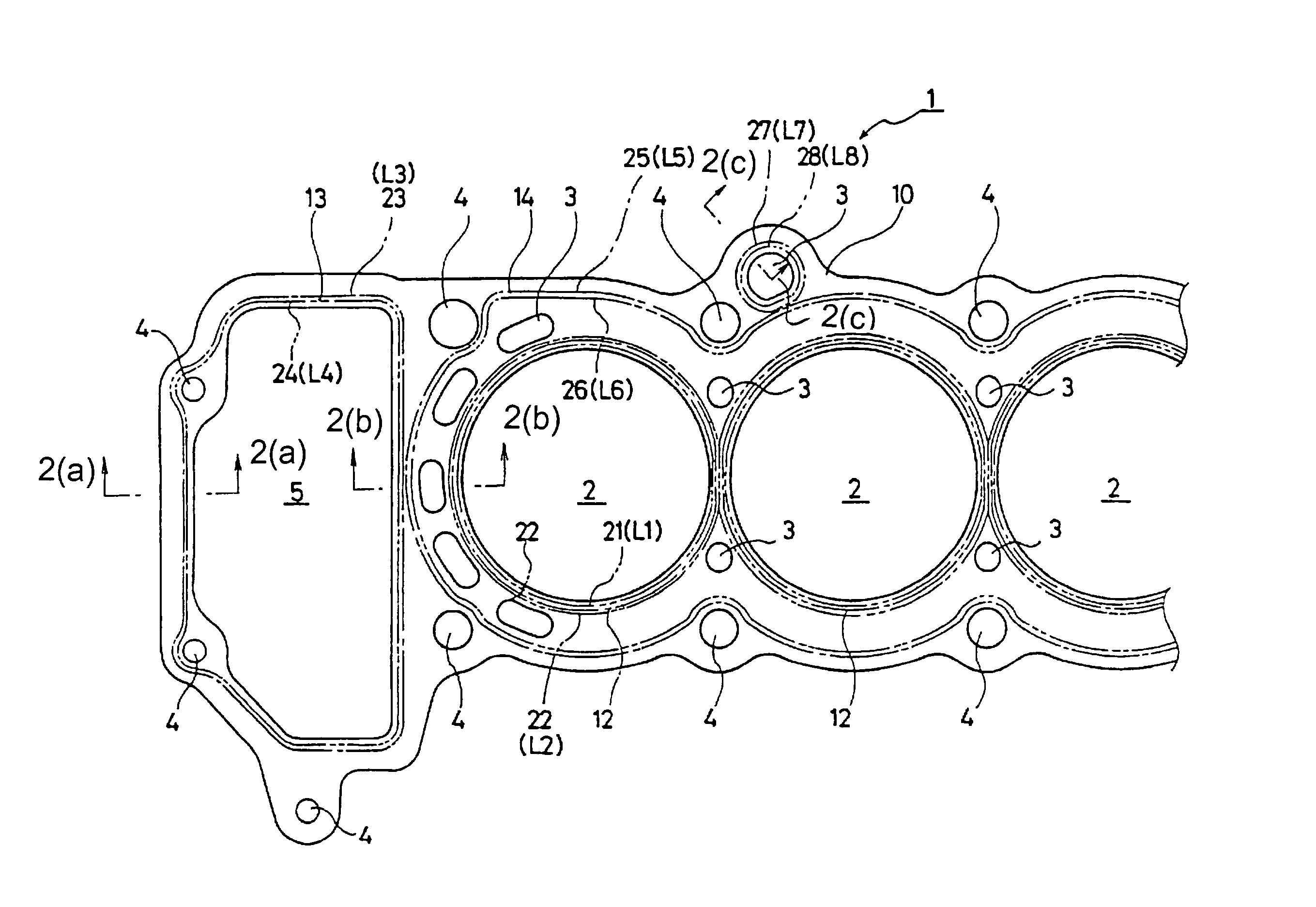

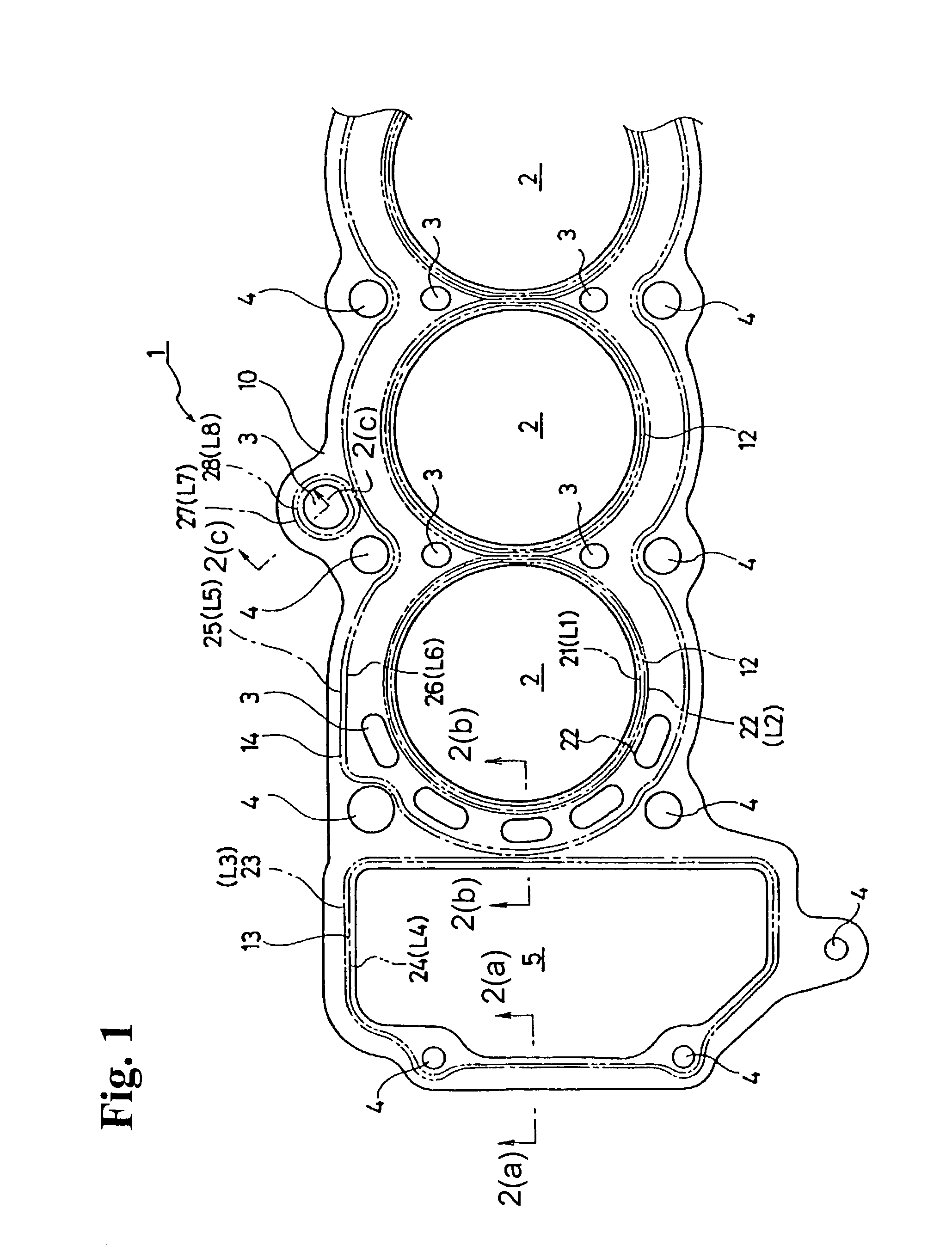

Cylinder head gasket

InactiveUS6682080B2Inhibition of relaxationImprove sealingEngine sealsSealing arrangements for enginesCylinder blockGrommet

A cylinder head gasket is formed of a single metal base plate for sealing between a cylinder head and a cylinder block of an internal combustion engine. The cylinder head gasket has a primary sealing portion including a grommet or shim around a cylinder bore, and a secondary sealing portion outside the primary sealing portion. The secondary sealing portion is formed of a bead and a foamed coating layer coated on one side or both sides of the bead to cover at least a portion of the bead in a belt shape.

Owner:ISHIKAWA GASKET CO LTD

Cylinder head gasket

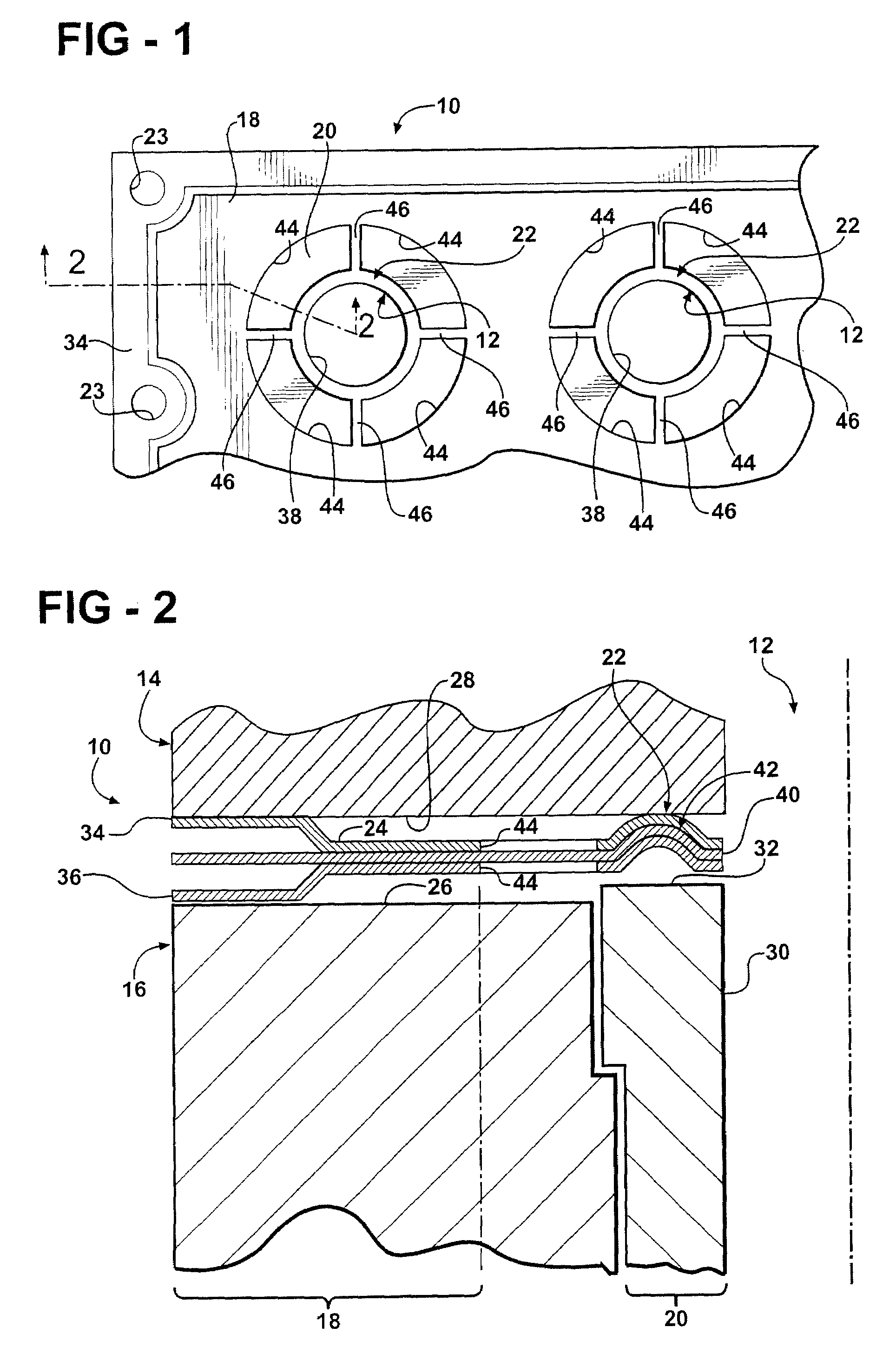

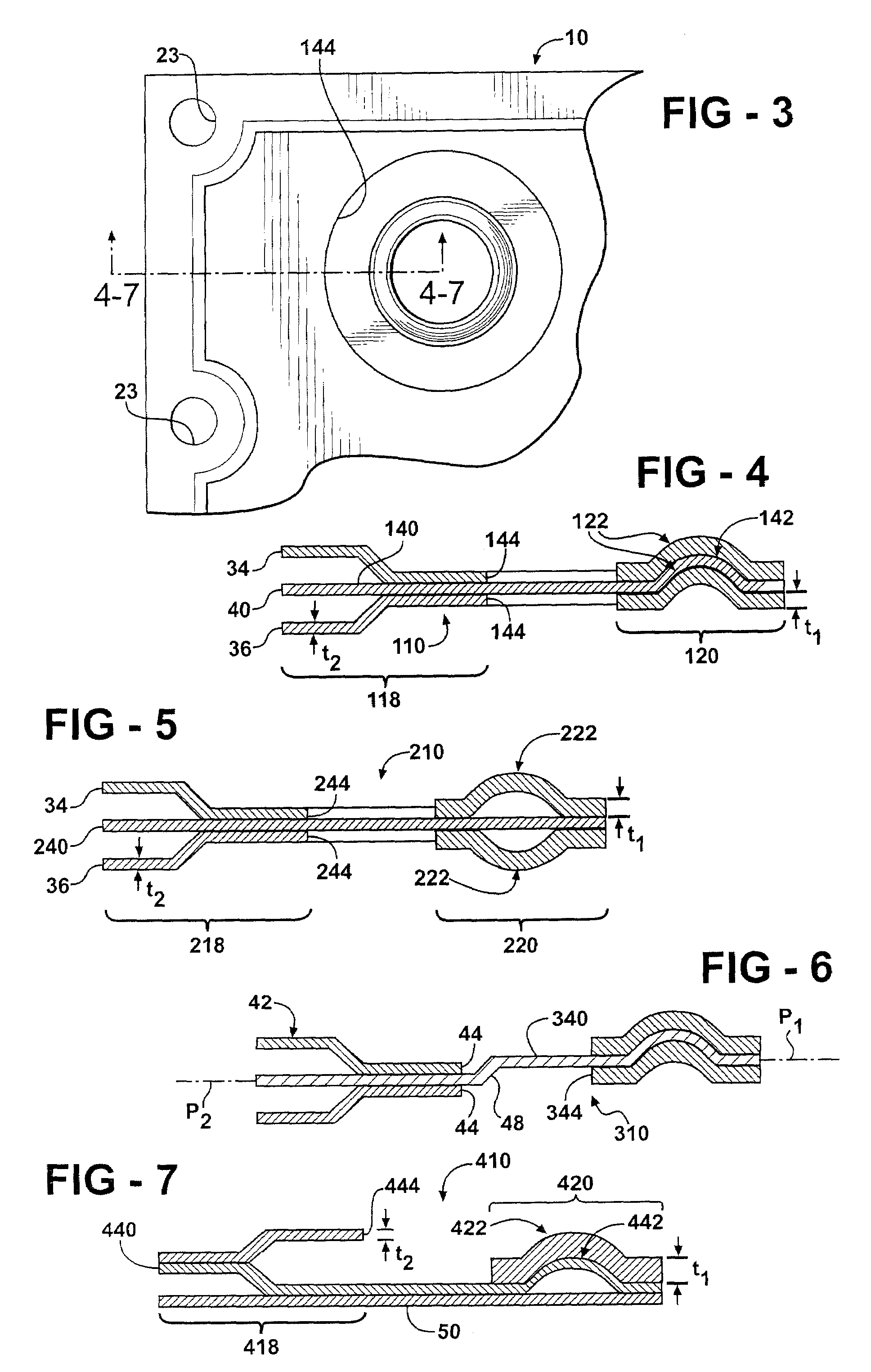

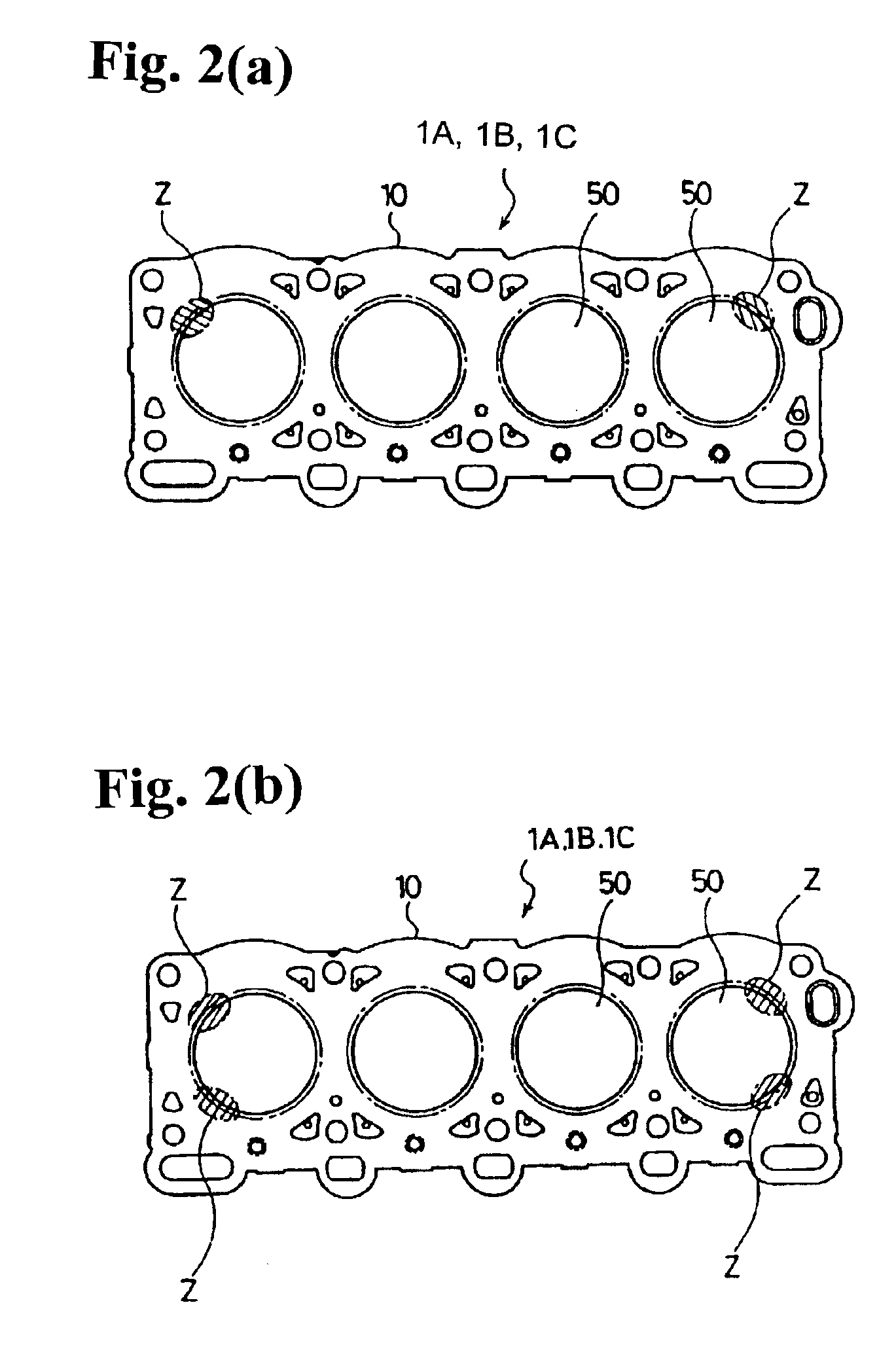

InactiveUS6951338B2Equal sealing stressesUniform thicknessEngine sealsSealing arrangements for enginesVariable thicknessEngineering

A multi-layered cylinder head gasket for positioning between a cylinder head and a cylinder block of an engine includes a spacer layer and a stopper layer. The stopper layer includes either a wave or rigid stopper positioned at a periphery of an aperture of the stopper layer. A sealing bead is positioned adjacent the stopper. Overall, the stopper layer has a generally uniform thickness. The spacer layer, however, has first and second thicknesses with the second thickness being generally less than the first thickness. The second thickness of the spacer layer mates with the stopper and sealing bead when the stopper layer and spacer layer are joined together. A transition area is positioned between the first and second thicknesses. The variable thickness of the spacer layer permits the gasket to provide generally equal sealing stresses while subjected to variable compression forces.

Owner:DANA AUTOMOTIVE SYST GRP LLC

MLS gasket with wire ring stopper

InactiveUS6676134B1Eliminate bead crackingImprove consistencyEngine sealsSealing arrangements for enginesCombustionPre stress

A multi-layer steel cylinder head gasket includes a spacer layer between two beaded mirror image outer layers. A wire ring stopper extends about the boundary of a combustion opening in the stopper layer; the ring is radially spaced from the mirror image beaded outer layer extremities. The ring is covered by a flange folded thereover; the flange extends radially outwardly to overlie the boundary edge of the stopper layer at the combustion opening. The stopper ring pre-stresses the gasket interface at the combustion opening upon securement of a cylinder head to an engine block. Because the stopper ring is spaced from the beaded outer layers, the stresses imposed on the wire ring are decoupled from the beaded outer layers, and lower incidences of bead cracking are realized. In addition, the wire ring diameter is greater than the thickness of the stopper layer, reducing unnecessary compression loads on the stopper layer.

Owner:DANA AUTOMOTIVE SYST GRP LLC

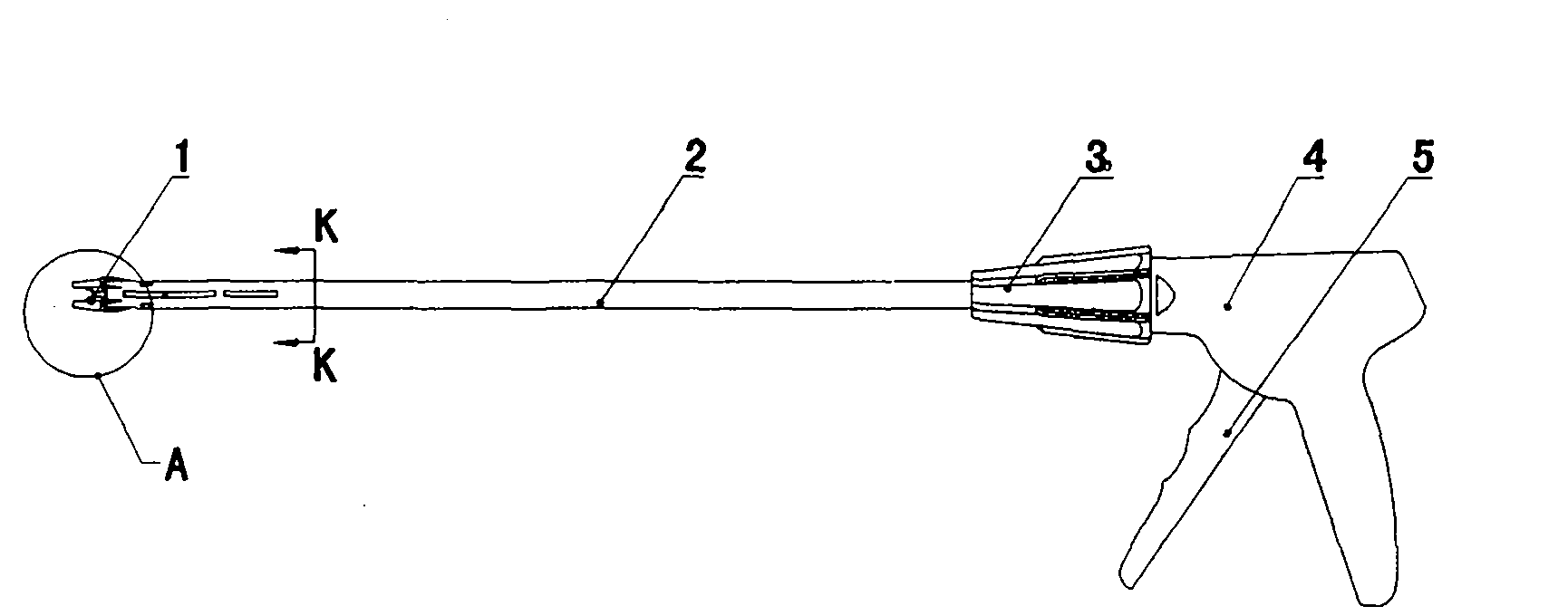

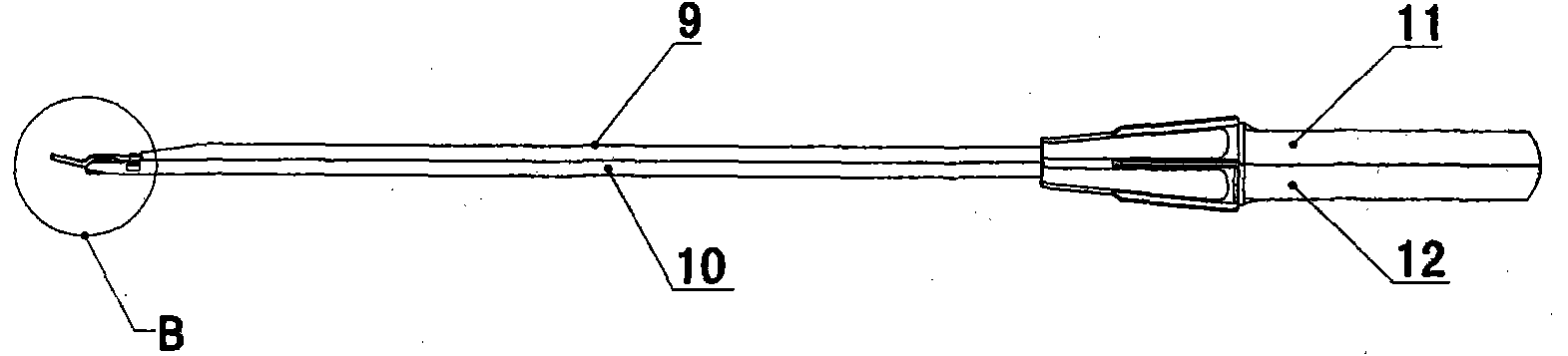

Disposable automatic burst titanium clip

The invention relates to a disposable automatic burst titanium clip which belongs to the field of endoscopic surgical instruments. The disposable automatic burst titanium clip comprises a clip head, a clip lever, a runner, a fixed handle, a movable handle and a titanium clip; and the clip lever comprises a right semi-circular clip lever and a right semi-circular clip lever, and a sending gasket, the titanium clip, a titanium clip mandril, a sending spring, a spring protective plate, a spring seat, a clamping push rod, a sending push rod, the clip head and a clip head gasket 8 are arranged in. The disposable automatic burst titanium clip has the advantages of reasonable structural design, capability of automatic titanium clip filling and bursting, and the integral structure of the titanium clip and the clip body.

Owner:HANGZHOU OPTACLA MEDICAL INSTR

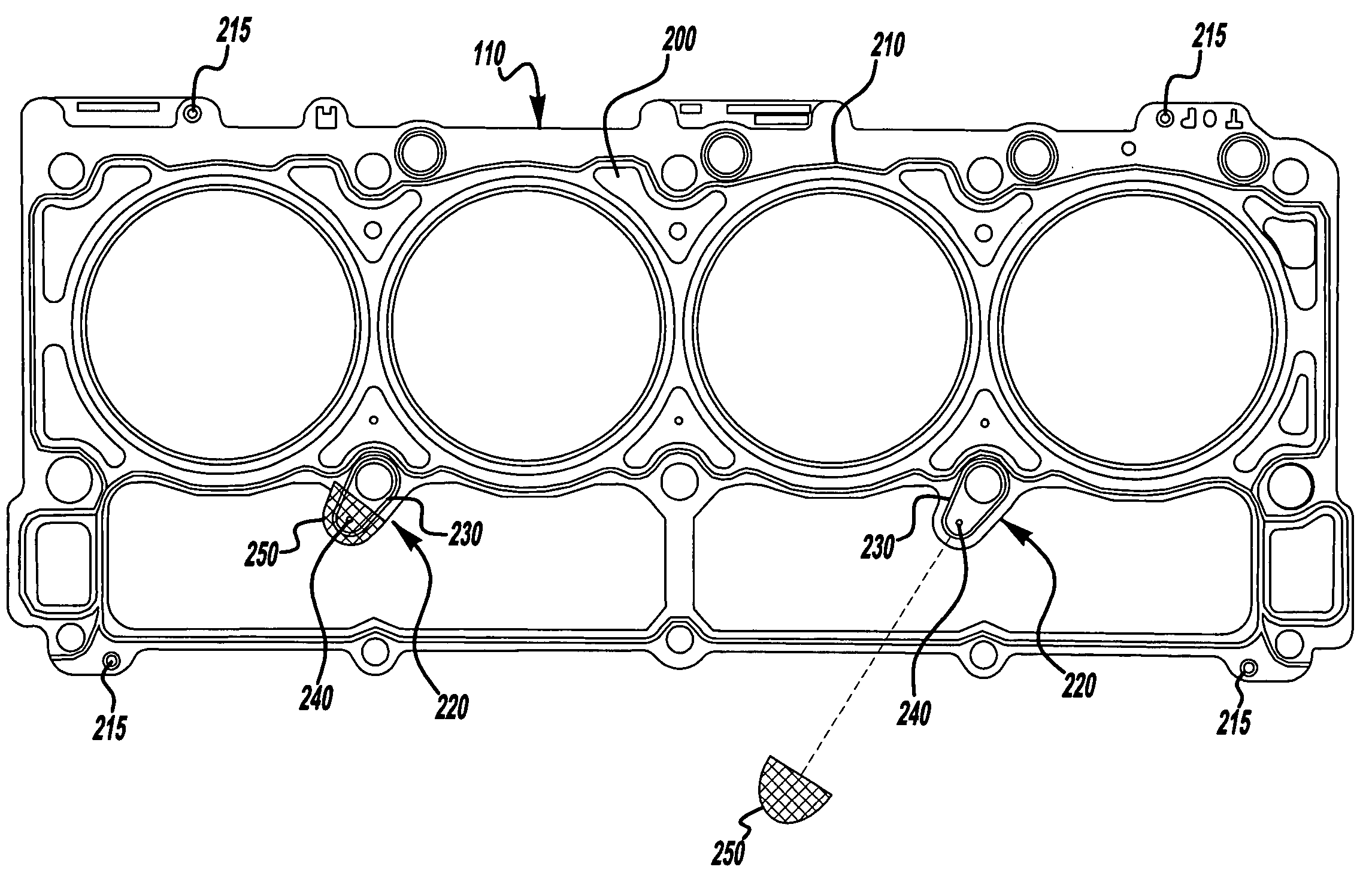

Cooling system defined in a cylinder block of an internal combustion engine

ActiveUS8555825B2Preserve integrityMinimize stress riserLiquid coolingCoolant flow controlExternal combustion engineWater jacket

An internal combustion engine is disclosed that has a cylinder block with multiple cylinders, a bridge between adjacent cylinders, a cooling slot in the bridge, and a water jacket portion in the cylinder block. A cylinder head is coupled to the cylinder block which has a first cooling passage fluidly coupling the cooling slot and the water jacket portion in the cylinder block, a water jacket portion in the cylinder head, and a second cooling passage in the cylinder head fluidly coupling the cooling slot with the water jacket portion in the cylinder head. A cylinder head gasket is arranged between the cylinder head and the cylinder block which has a first orifice in the cylinder head gasket cooperating with the first cooling passage a second orifice in the cylinder head gasket cooperating with the second cooling passage.

Owner:FORD GLOBAL TECH LLC

Cylinder head gasket

ActiveUS20090189359A1Secures stable sealing performanceReduce biasEngine sealsSealing arrangements for enginesCylinder blockPressure increase

A cylinder head gasket includes a first gasket base plate at a cylinder head side, a second gasket base plate at a cylinder block side, a shim that adjusts the gasket thickness, and a pressure increasing plate that increases the surface pressure at the side of periphery portions of the cylinders. In the first and second gasket base plates full beads are swollen at the side of periphery portions of cylinders, and half beads are swollen at a site outward of the full beads. The full beads of the first and second gasket base plates are formed so that top portions of the full beads face each other at positions that are opposite to each other in the up-down direction. The shim and the pressure increasing plate are sandwiched between the top portions.

Owner:TOYOTA JIDOSHA KK +1

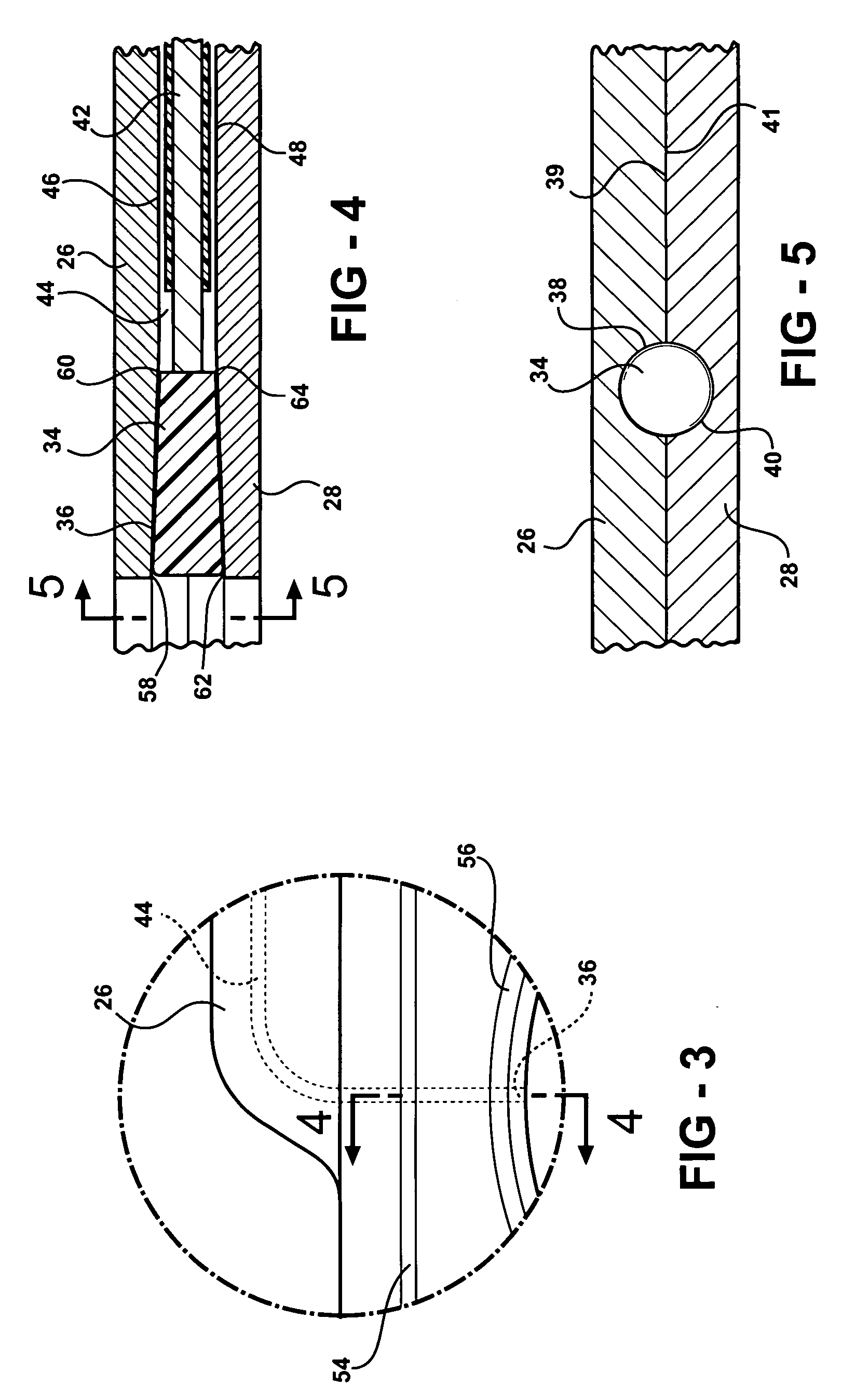

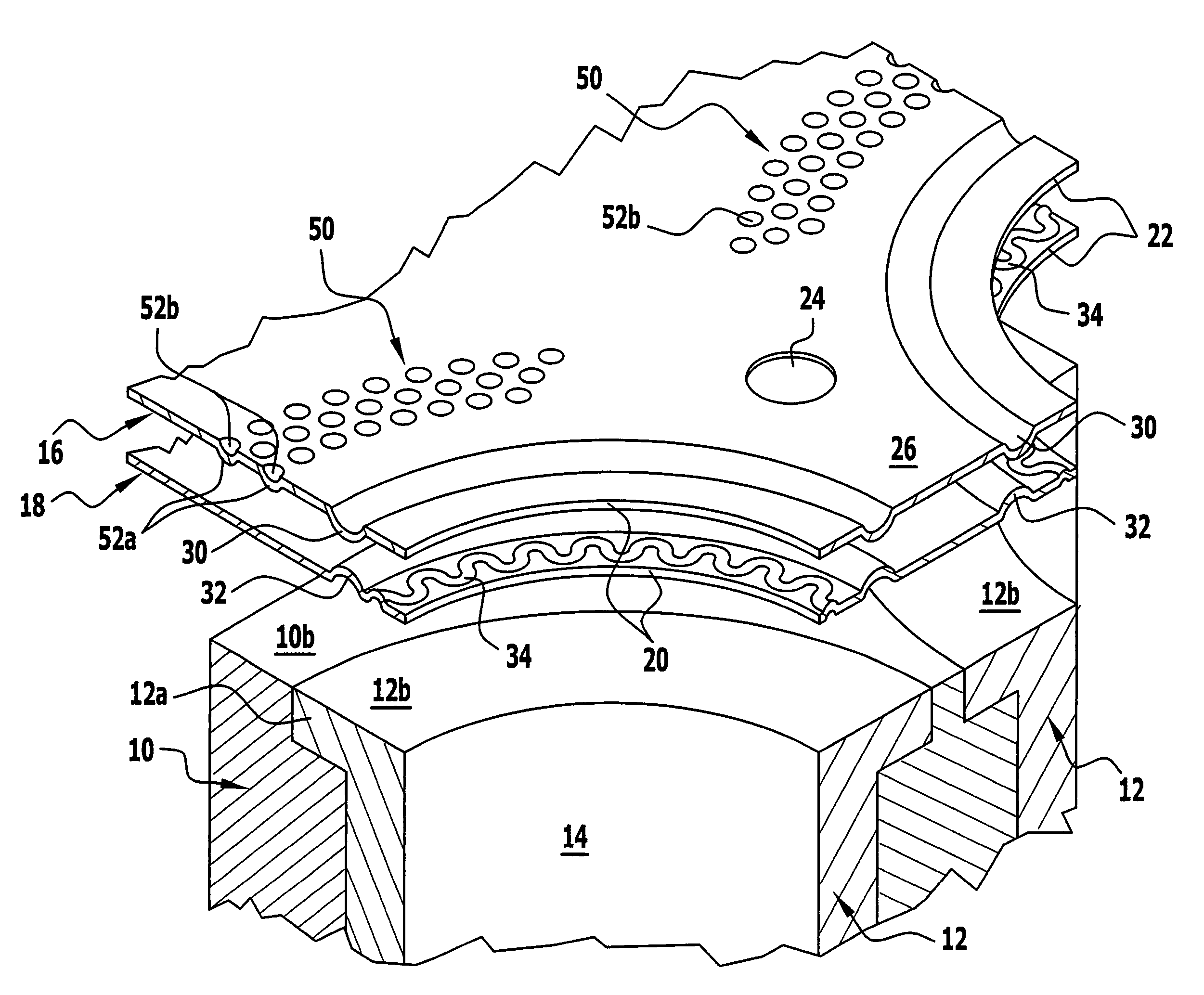

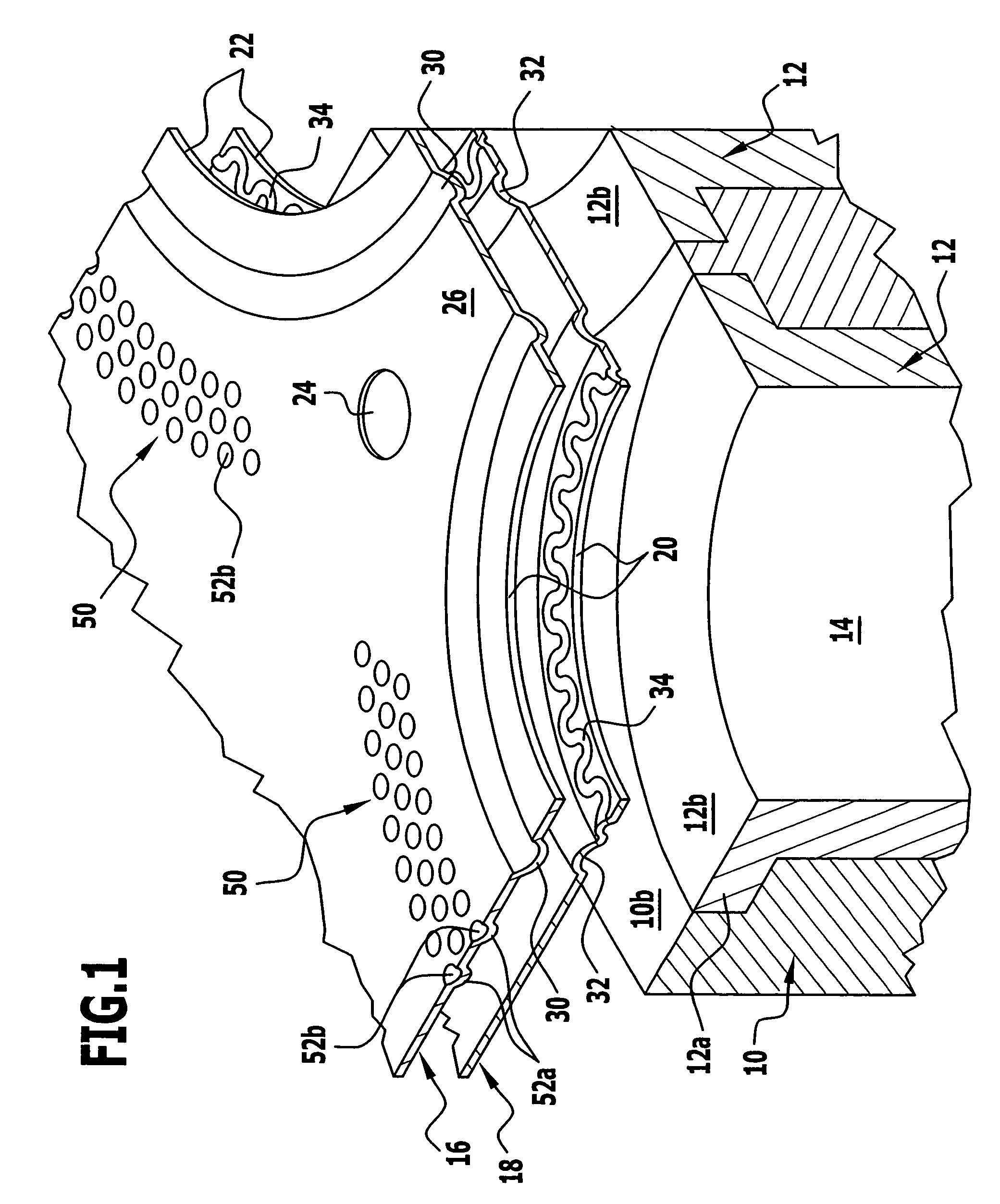

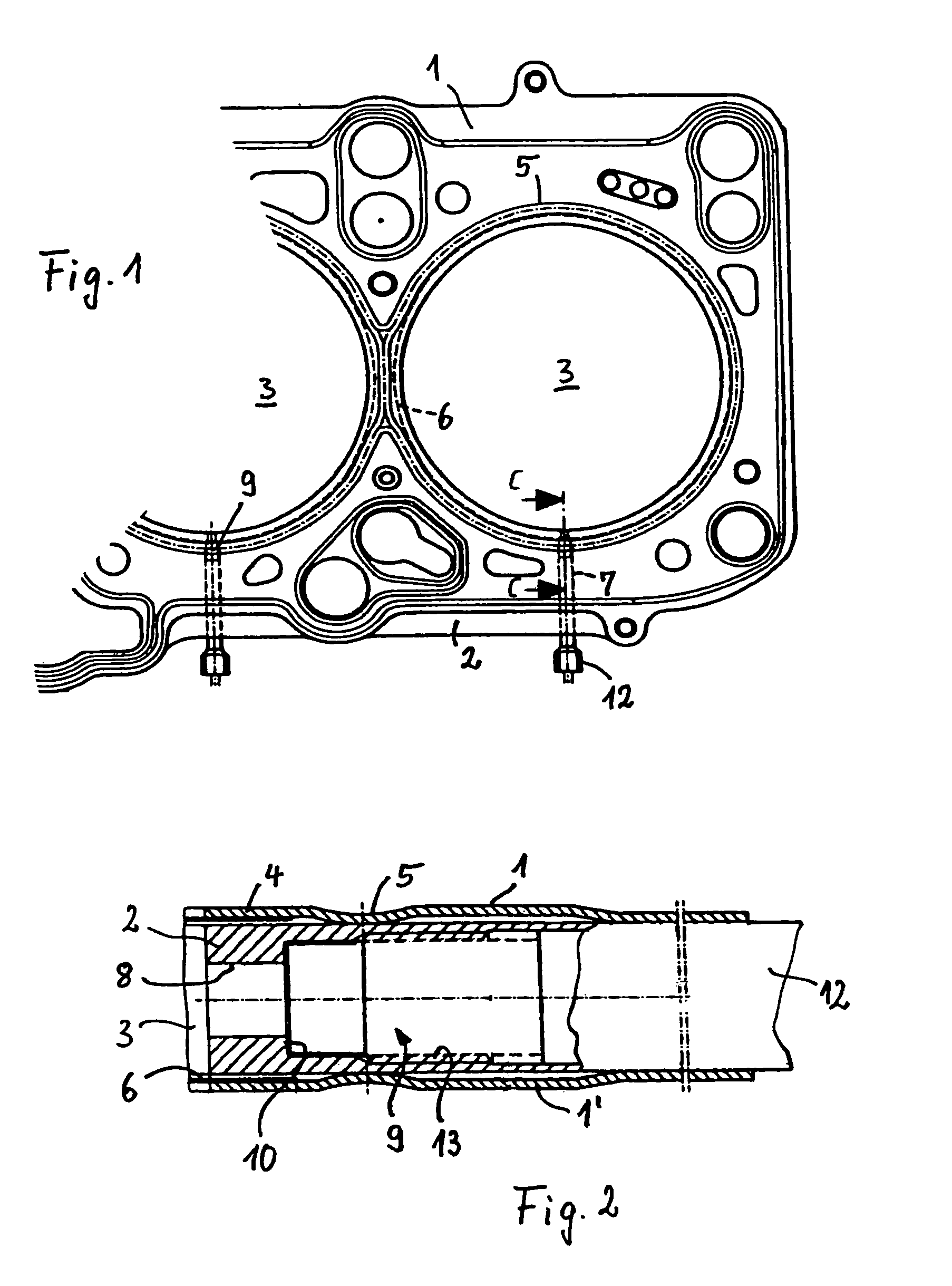

Cylinder head gasket with integrated sensor

InactiveUS20060096362A1Minimal adaptationValve arrangementsEngine sealsCombustionSignal conditioning

A multilayer metal gasket for an internal combustion engine having an integrated sensor or sensors, such as a pressure sensor. The sensor is located within a combustion cylinder opening in the gasket. Preferably, a sensor is located within each combustion cylinder opening of the gasket. The gasket may also include an integrated sensor signal conditioning module. The gasket is made by a method which includes forming the necessary sensor housings and signal line channels within the spacing layers of the gasket.

Owner:FEDERAL MOGUL WORLD WIDE

Cylinder head gasket with seal coatings

InactiveUS20030075873A1Sufficient sealing effectIncrease the number ofEngine sealsSealing arrangements for enginesHead gasketEngineering

A metal gasket seals two engine members of an internal combustion engine. The metal gasket includes a metal gasket member extending substantially throughout an entire area of the engine members and has two surfaces to contact the engine members. At least two seal coatings are coated on the two surfaces of the gasket member to constitute sealing lines on the surfaces of the gasket member. One of the sealing lines on one surface of the metal plate is shifted from the other of the sealing lines on the other surface of the metal plate. Micro coatings are coated on the two surfaces of the gasket member. The thickness of the micro coating is less than that of the seal coating.

Owner:ISHIKAWA GASKET CO LTD

Metallic cylinder head gasket

InactiveUS20090066036A1Improve sealingSolution to short lifeEngine sealsSealing arrangements for enginesEngineeringActive layer

A metal gasket has at least two metal layers having an aligned fluid-conveying opening. One of the metal layers includes a carrier layer and an active layer. The active layer has a raised metal sealing bead circumscribing the opening. The carrier layer and the active layer are at least partially coplanar and are spaced from one another within the plane by at least one cut-out region between the carrier layer and the active layer. The cut-out region allows the active layer to move out of the plane of the carrier layer, and thus, the active layer is able to self-adjust for sealing engagement between opposing surfaces in assembly and during use.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Cylinder head gasket

InactiveUS6851677B2Increase of bead widthReduce in quantityEngine sealsSealing arrangements for enginesSurface pressureHeat load

A cylinder head gasket for an internal combustion engine includes a first metal plate having first holes and first beads formed around the respective first holes, and a second metal plate disposed under the first metal plate and having a second bead extending toward the first metal plate. A distance between the first and second beads or a width of at least one of the first and second beads at a high heat load portion of the cylinder bore is formed to be greater than a distance between the first and second beads or a width of at least one of the first and second beads at a low heat load portion of the cylinder bore to thereby reduce a surface pressure at the high heat load portion.

Owner:ISHIKAWA GASKET CO LTD

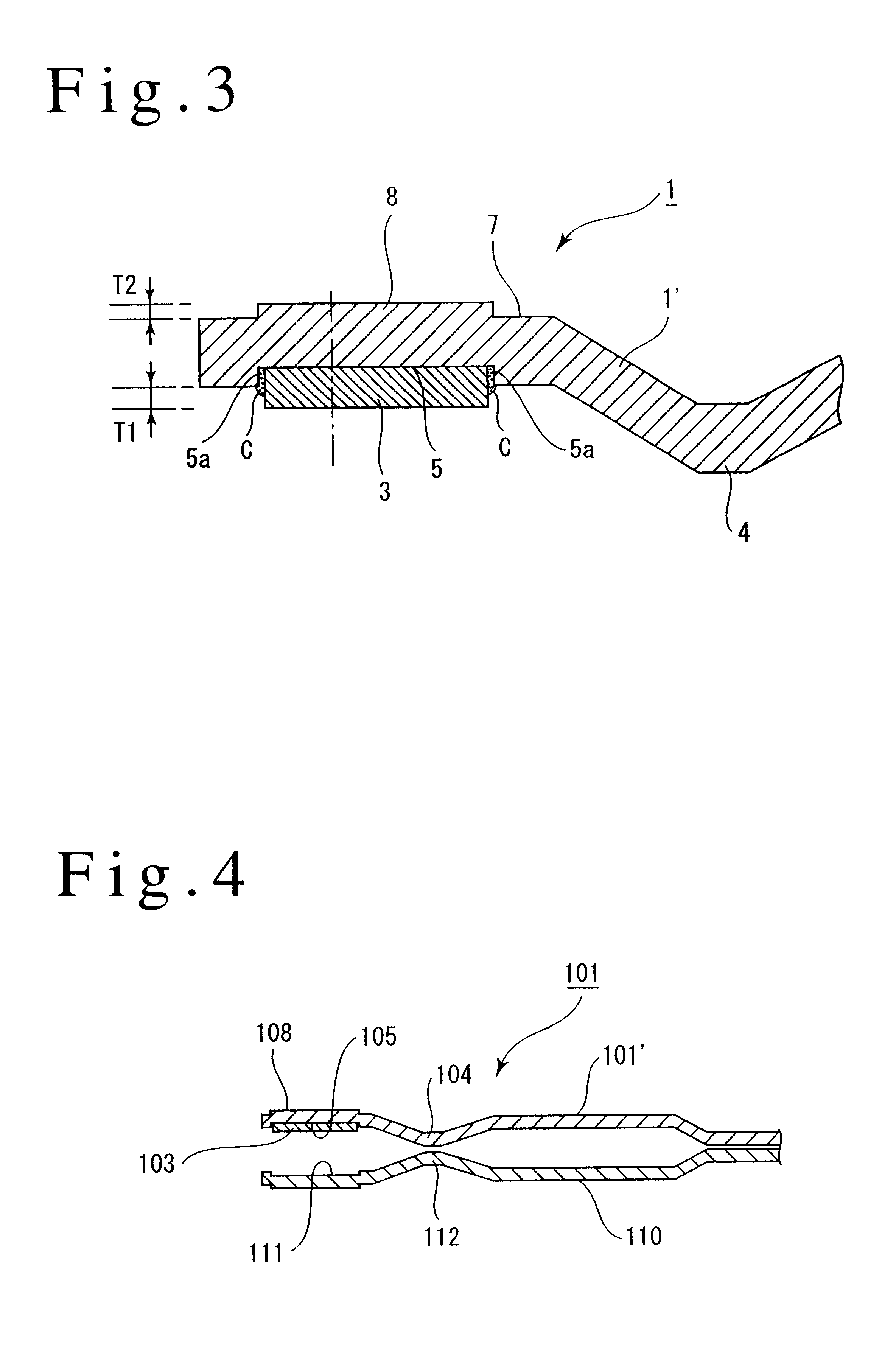

Enhanced multilayer metal gasket

InactiveUS7374177B2Improved fatigue and joint distortion performanceNot promote fatigueEngine sealsSealing arrangements for enginesVariable thicknessInter layer

A multilayer metal gasket, such as a multilayer steel head gasket, for an internal combustion engine has upper and lower functional layers and at least one intermediate layer. At least one of these layers has a circumferential compression control feature in the form of a protrusion or groove which varies in thickness or depth, respectively, around its circumference. The variable thickness of the compression control feature enables uniform sealing pressure on the sealing surfaces of the gasket.

Owner:FEDERAL MOGUL WORLD WIDE

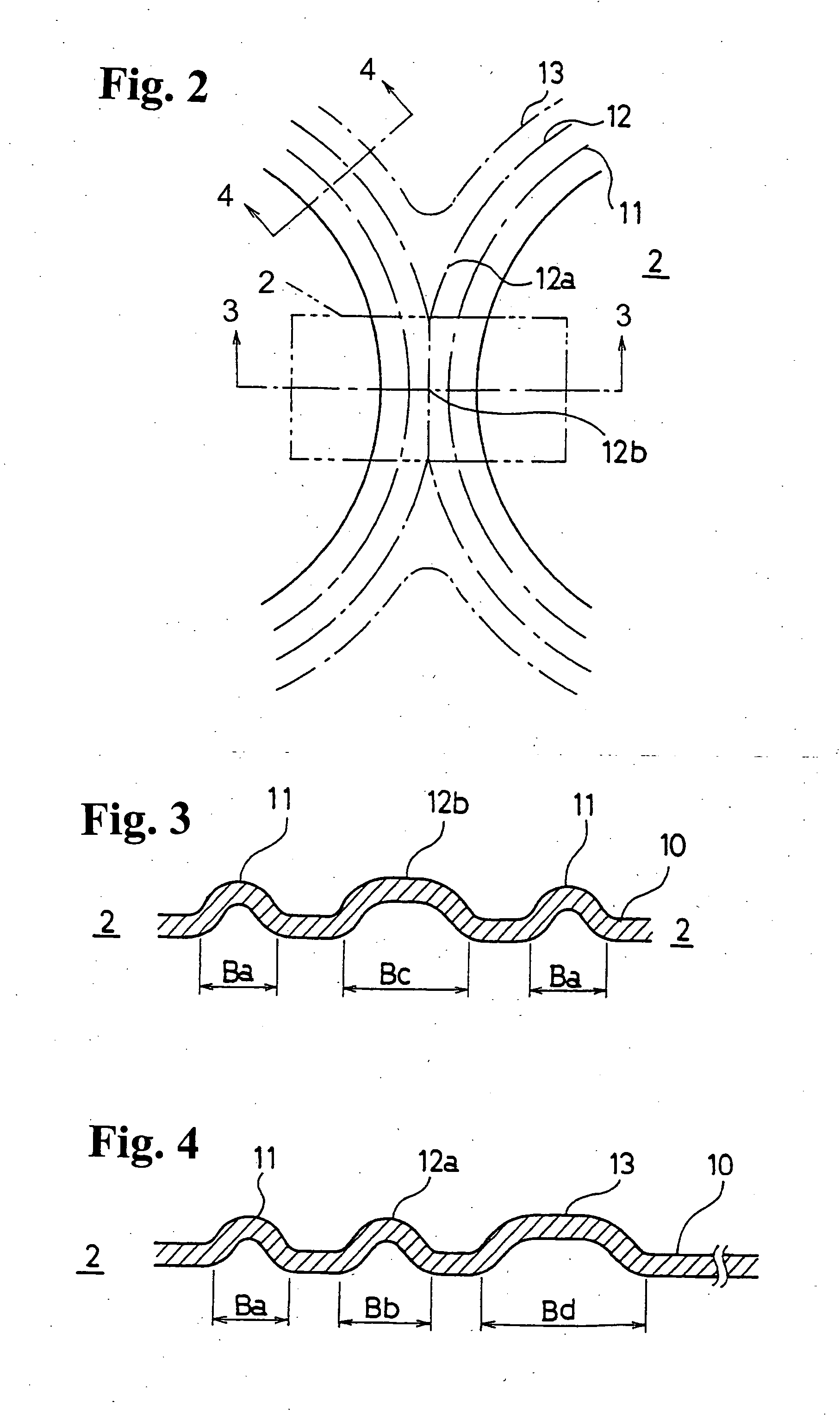

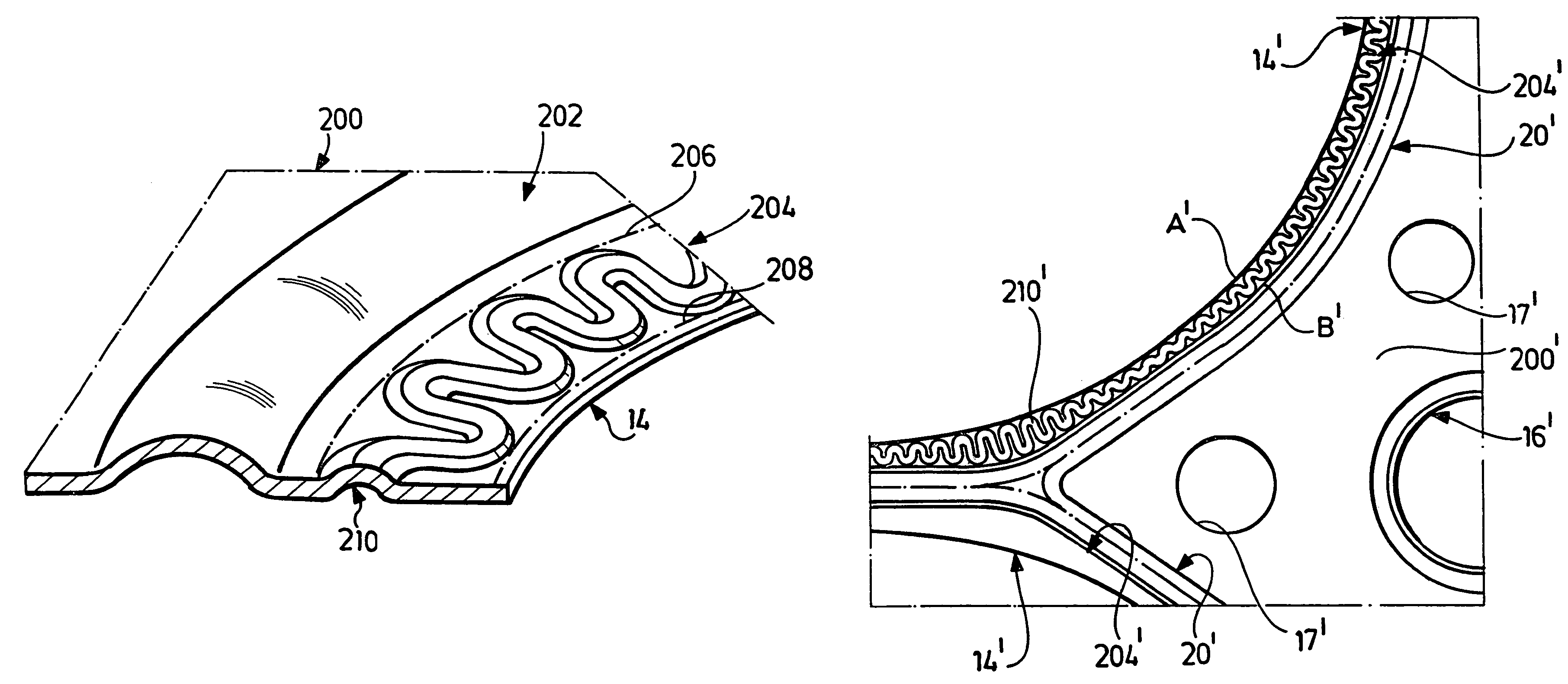

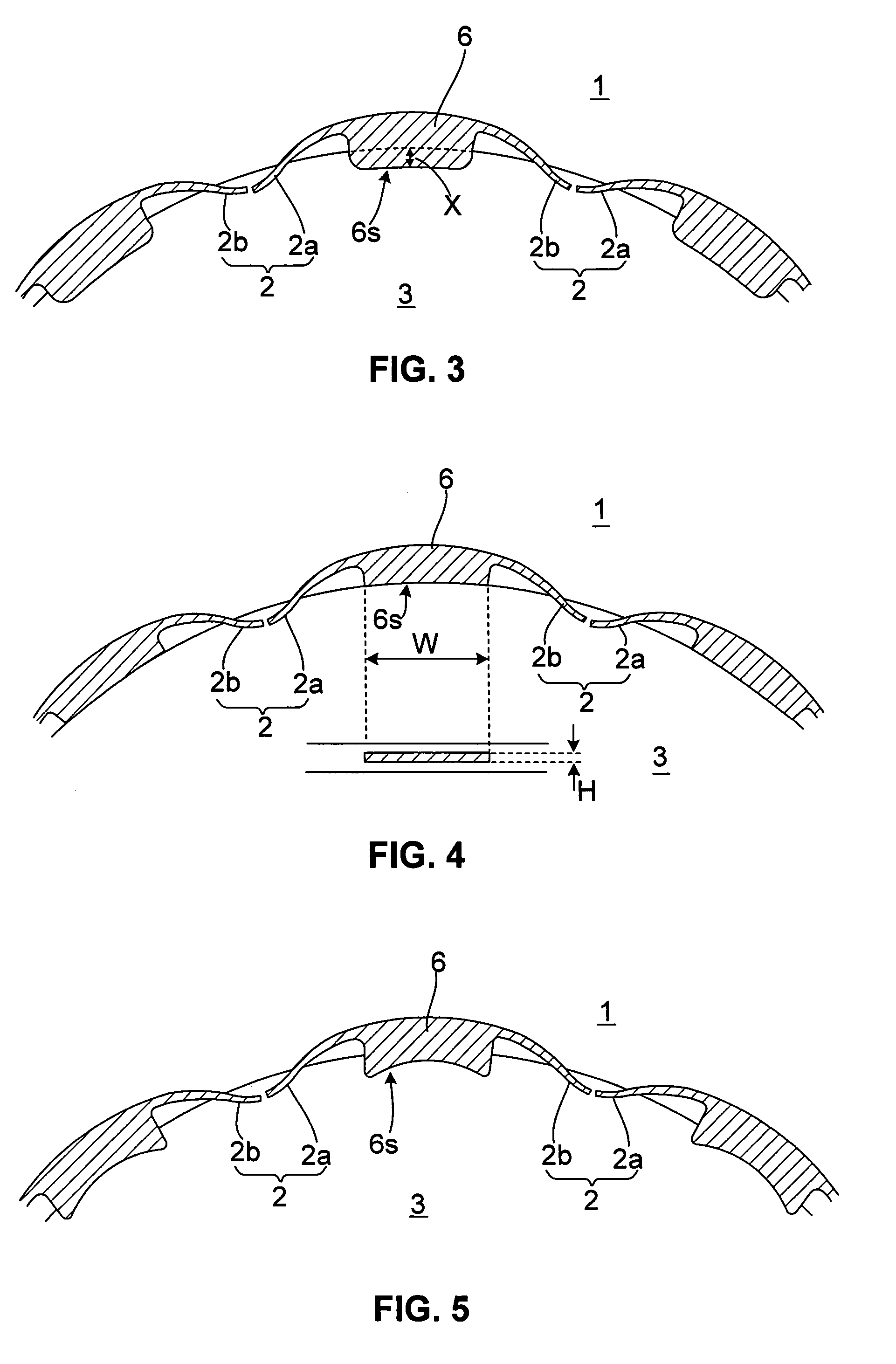

Cylinder head gasket having deformation delimiting devices radially inside and outside sealing bead

InactiveUS7527269B2Improve deformation strengthLess expensiveEngine sealsSealing arrangements for enginesEngineeringHead gasket

Cylinder head gasket is provided having a single-layered or multilayered metallic gasket plate with sealing beads in at least one metal layer, which are elastically deformable in height and surround the combustion chamber through-openings, and deformation delimiting devices which delimit the flattening of the sealing beads. In order to achieve as good a sealing function as possible in the long term and as good a protection as possible of the sealing beads against inadmissibly high deformations during operation of the engine, the deformation delimiting devices, one of which is formed by a meandering bead stamped into a metal layer, and the other by a plurality of elevations stamped out of a metal layer, are provided radially inside and radially outside of the sealing beads.

Owner:ELRINGKLINGER AG

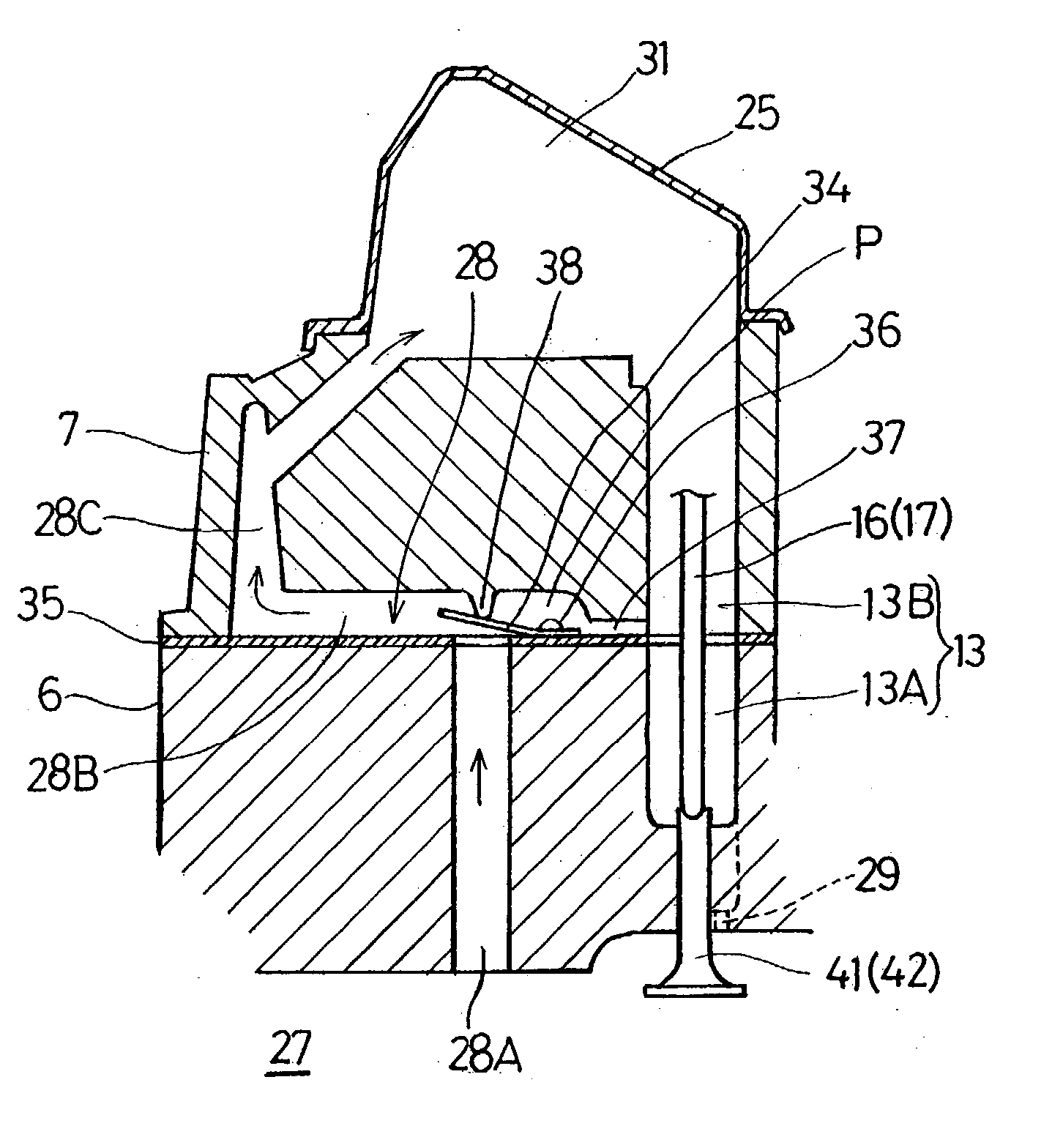

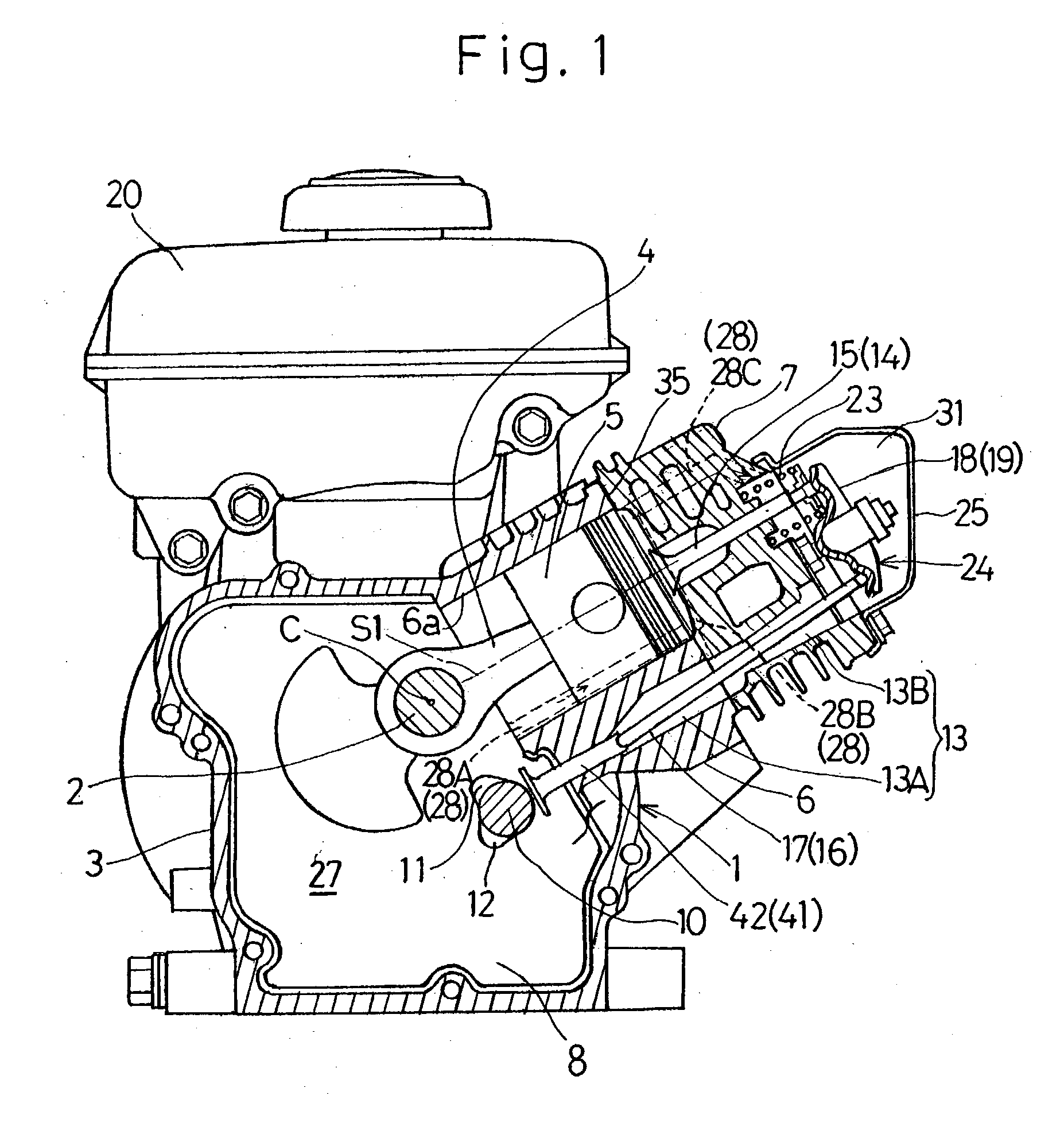

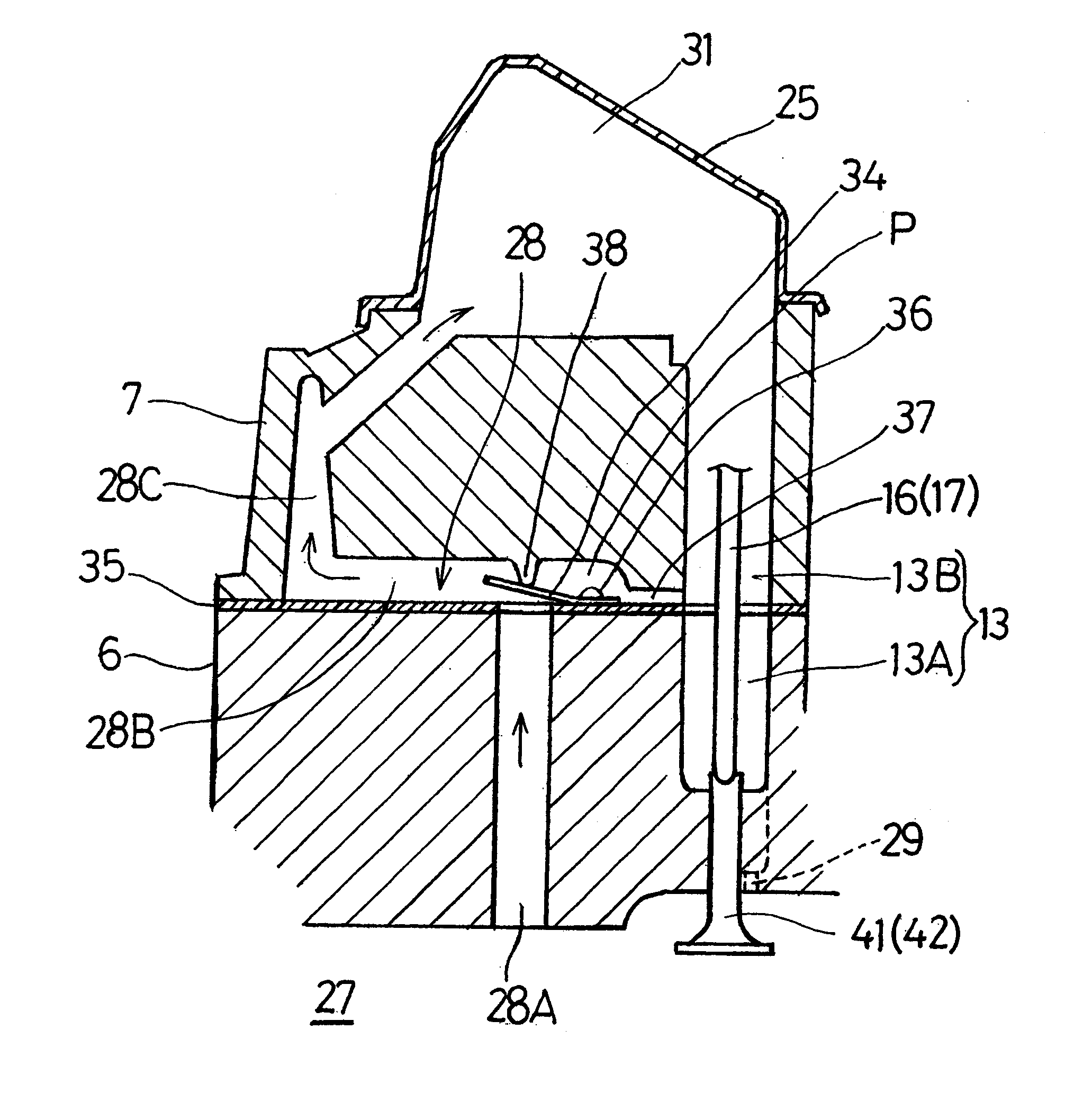

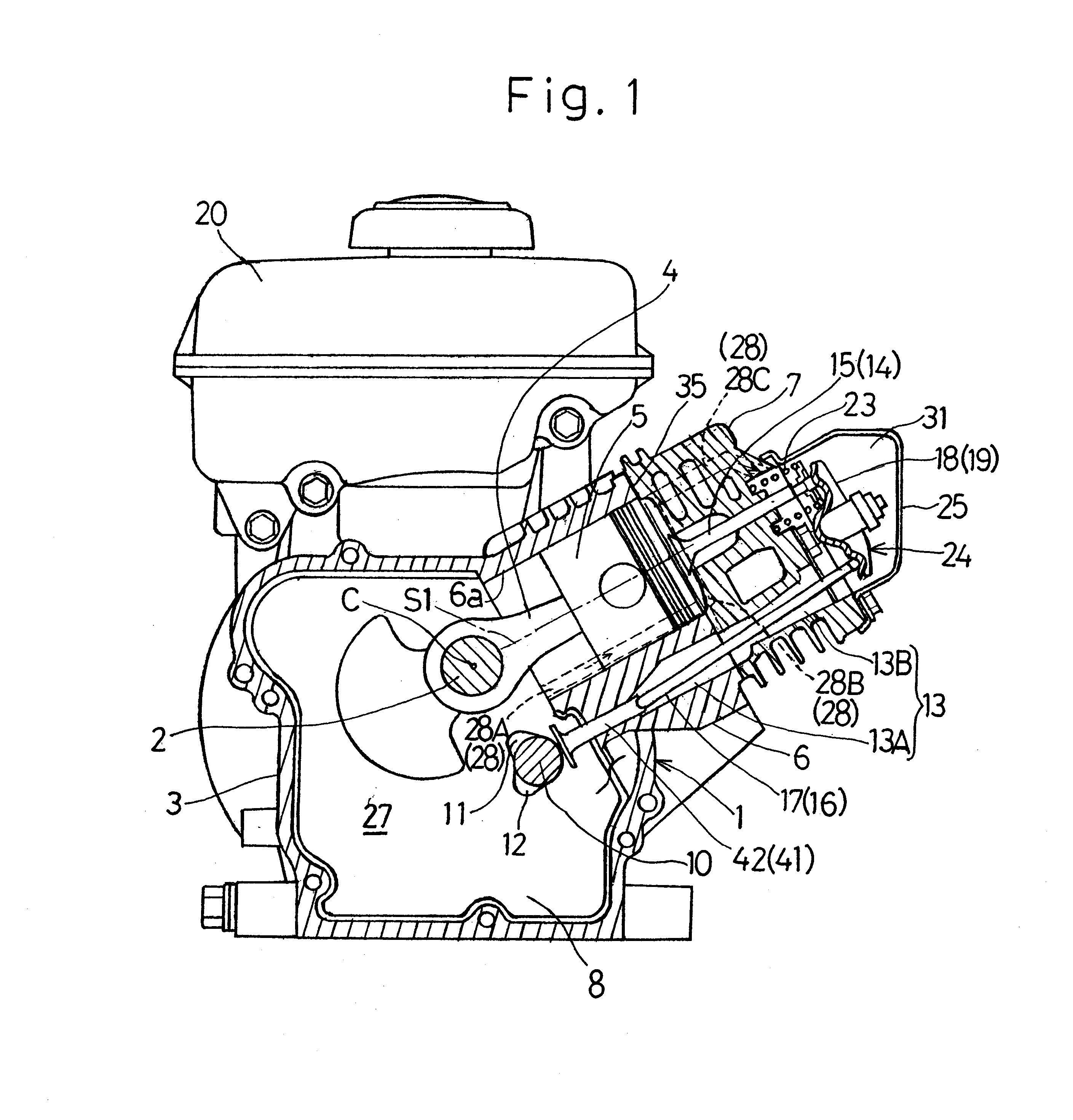

Breathing device for internal combustion engine

InactiveUS20030150437A1Low costSmall sizeEngine sealsInternal combustion piston enginesCombustionEngineering

To provide a breathing device for an internal combustion engine, wherein the structure around the check valve is simplified so that the engine as a whole can be manufactured compact, the breathing device includes a check valve (34) for fluid connecting, a crank chamber (27) and a rocker arm chamber (31) in the combustion engine. The check valve (34) is disposed in a head gasket (35) that is interposed between a cylinder block (6) and a cylinder head (7). The check valve (34) is in the form of a reed valve separate from the head gasket (35) and is supported by the head gasket (35) by means of a rivet (36).

Owner:KAWASAKI HEAVY IND LTD

Cylinder head gasket

InactiveUS6565097B2Engine sealsSealing arrangements for enginesManufacturing cost reductionThermal deformation

A cylinder head gasket comprises a plate, an annular groove formed to surround a combustion chamber opening formed in the plate, a metallic shim fitted into the annular groove, and a full bead located outward of the shim and projecting in the same direction as the shim. The shim is mounted on the plate by an intermittent welding.With this construction, the manufacturing cost can be reduced in comparison to the use of a conventional continuous welding or multi-layer welding. In addition, the thermal deformation of the shim and the plate itself is reduced as compared with when continuous welding or multi-layer welding is used, thus allowing the sealing capability to be improved. In addition, the cylinder head gasket is preferred for use in an engine of a higher combustion temperature than the combustion temperature when the shim is formed of a resinous material.

Owner:TAIHO INDUSTRIES CO LTD +1

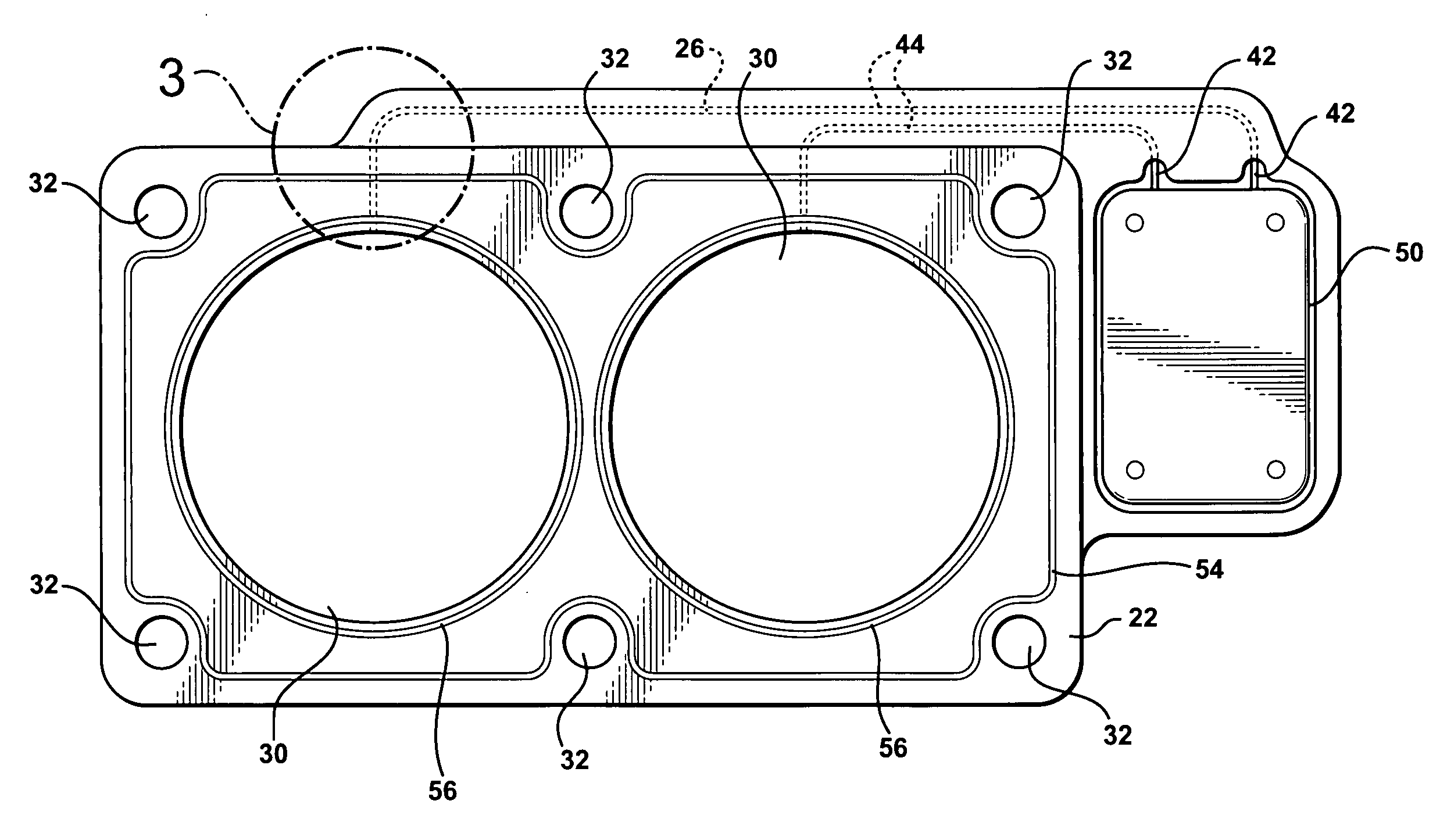

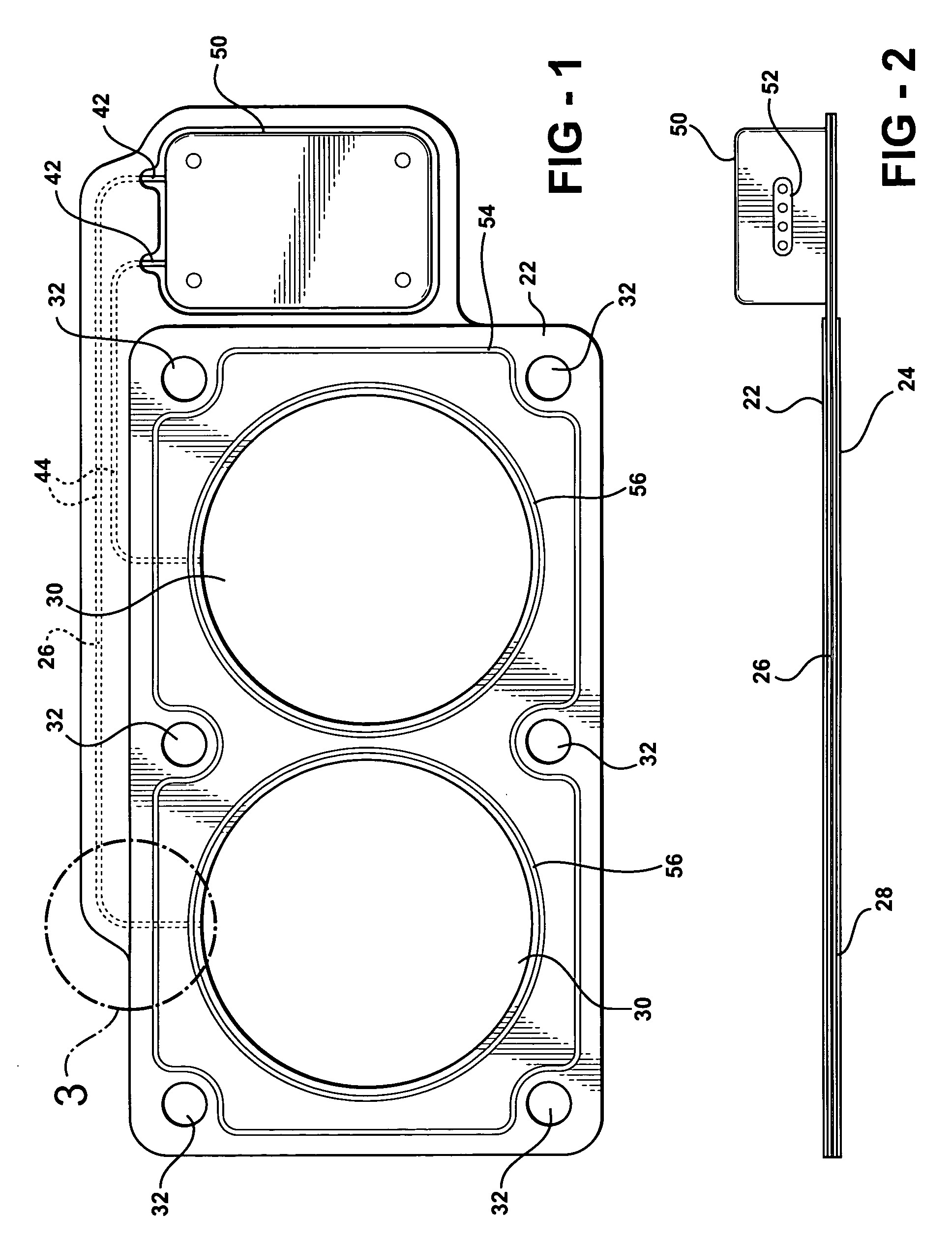

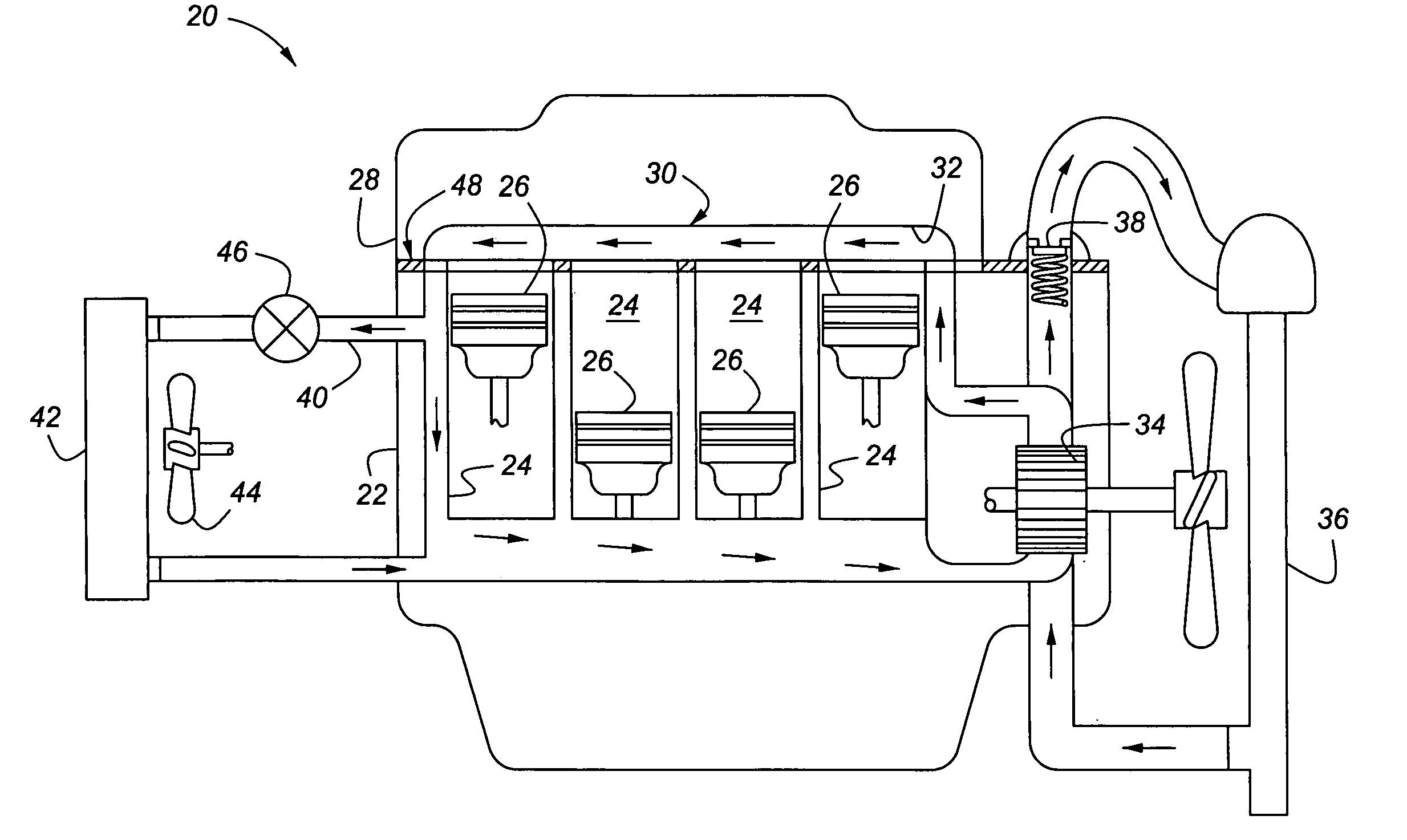

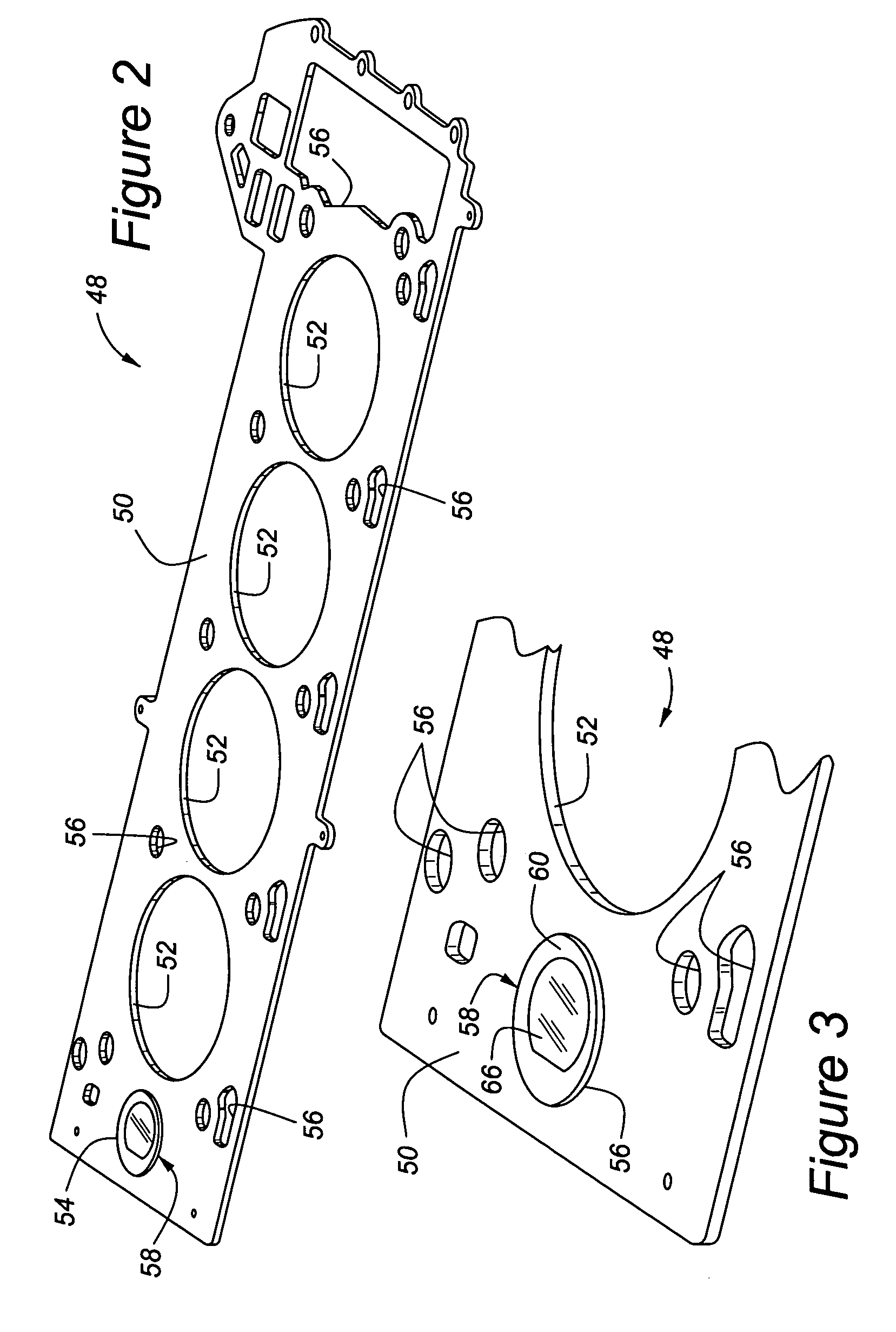

Cylinder head gasket with one-way coolant flow valve

InactiveUS20050279295A1Preventing abnormal coolant flowEngine sealsCoolant flow controlCoolant flowEngineering

A head gasket (48) which acts, when clamped between a cylinder head (28) and a block (22) in a liquid cooled internal combustion engine (20), to form a seal around the combustion chambers (24). A coolant flow path (32) routes through the engine (20) and its directed, in part, through the cylinder head (28) and the block (22), with a corresponding flow opening (54) formed in the head gasket (48) to accommodate flow of liquid coolant in a normal direction. The head gasket (48) includes a one-way valve (58) positioned in the flow opening (54) to allow the flow of coolant in a normal direction but to prevent the flow of liquid coolant through the flow opening (54) in an abnormal, reverse direction. The one-way valve (58) includes movable gate (66) which may be biased against a valve seat (64) in a normally closed condition. The one-way valve (58) can be made as a loose piece article of manufacture which is held in flow opening (54) by self-locking retention clips.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Cylinder head gasket with integral filter element

ActiveUS20050132998A1Easy to optimizeEngine sealsSealing arrangements for enginesEngineeringCylinder block

A cylinder head gasket for an engine is provided. The gasket includes an opening positioned in a gasket substrate and arranged to align with an engine oiling circuit passage to allow oil to flow from a cylinder block through the gasket to a cylinder head. The gasket further includes a filter element attached to the gasket relative to the opening and arranged to provide a barrier to debris in the oiling circuit.

Owner:FCA US

Breathing device for internal combustion engine

InactiveUS6659094B2Low costSmall sizeEngine sealsNon-fuel substance addition to fuelCombustionEngineering

To provide a breathing device for an internal combustion engine, wherein the structure around the check valve is simplified so that the engine as a whole can be manufactured compact, the breathing device includes a check valve (34) for fluid connecting, a crank chamber (27) and a rocker arm chamber (31) in the combustion engine. The check valve (34) is disposed in a head gasket (35) that is interposed between a cylinder block (6) and a cylinder head (7). The check valve (34) is in the form of a reed valve separate from the head gasket (35) and is supported by the head gasket (35) by means of a rivet (36).

Owner:KAWASAKI HEAVY IND LTD

Cylinder head gasket

InactiveUS20010017446A1Engine sealsSealing arrangements for enginesManufacturing cost reductionThermal deformation

A cylinder head gasket comprises a plate, an annular groove formed to surround a combustion chamber opening formed in the plate, a metallic shim fitted into the annular groove, and a full bead located outward of the shim and projecting in the same direction as the shim. The shim is mounted on the plate by an intermittent welding. With this construction, the manufacturing cost can be reduced in comparison to the use of a conventional continuous welding or multi-layer welding. In addition, the thermal deformation of the shim and the plate itself is reduced as compared with when the continuous welding or the multi-layer welding is used, thus allowing the sealing capability to be improved. In addition, the cylinder head gasket is preferred for use in an engine of a higher combustion temperature than a combustion temperature which is allowable with the use of a shim formed of a resin material.

Owner:TAIHO INDUSTRIES CO LTD +1

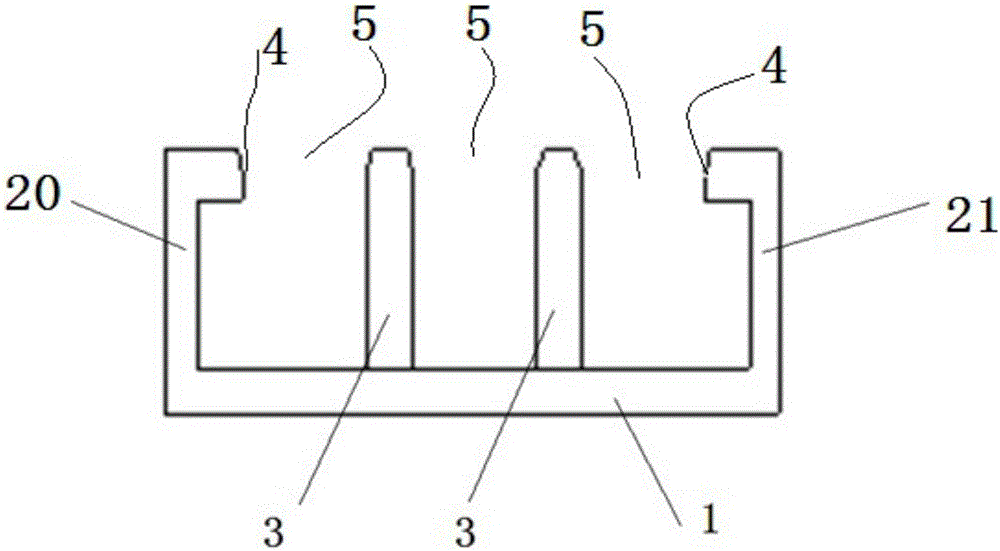

Mould head gasket for extrusion coater, extrusion mould head and extrusion coater

InactiveCN106216171AIncrease profitRealize shuntLiquid surface applicatorsCoatingsPole pieceEngineering

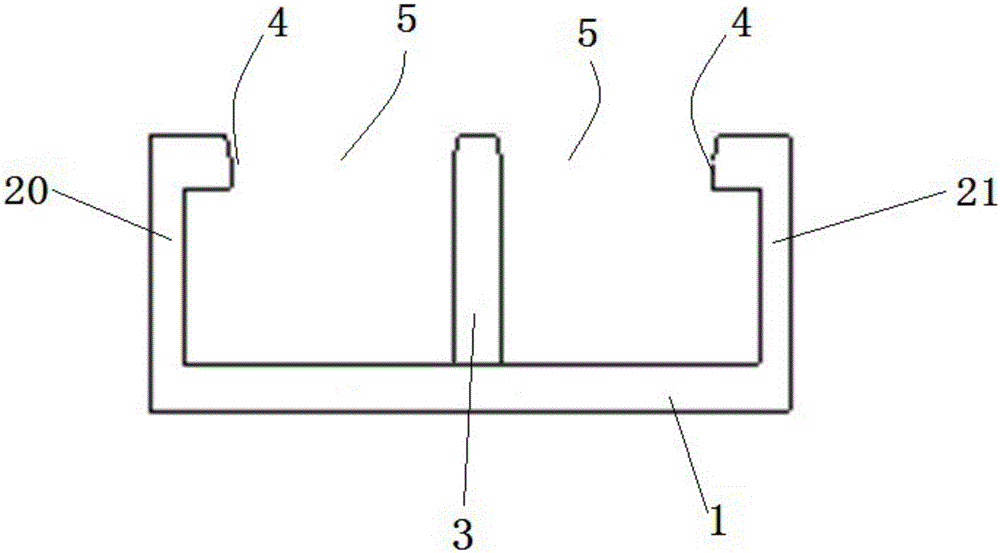

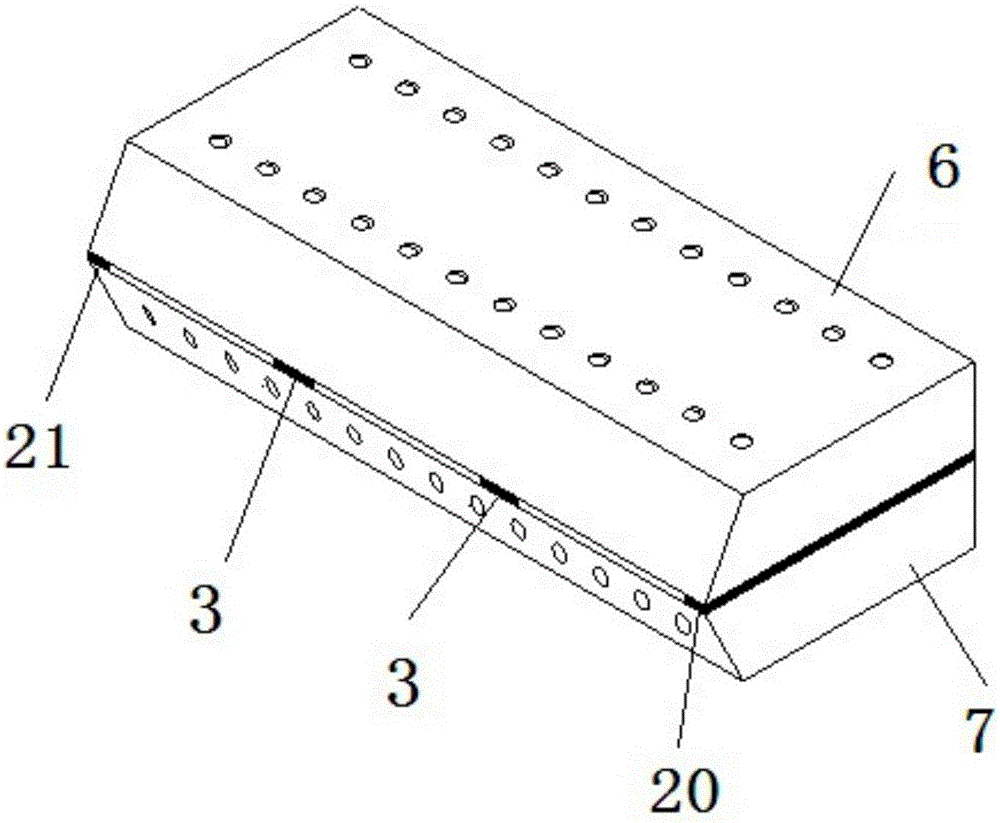

The invention relates to a mould head gasket for an extrusion coater, an extrusion mould head and an extrusion coater. The mould head gasket comprises a left side gasket and a right side gasket, and further comprises a distribution gasket positioned between the left side gasket and the right side gasket, wherein gasket distribution holes are separately formed between two side surfaces of the distribution gasket and the corresponding side surfaces of the corresponding side gaskets; or the mould head gasket further comprises at least two distribution gaskets positioned between the left side gasket and the right side gasket, wherein the gasket distribution holes are separately formed between opposite side surfaces of adjacent distribution gaskets, and between corresponding side surface of the distribution gasket at outer edge and the corresponding side surfaces of the corresponding side gaskets. The mould head gasket for extrusion coater provided by the invention can realize multi-amplitude continuous coating, so that zebra distribution type pole pieces with coating areas and blank areas, which are arranged in a spaced manner in a direction perpendicular to a current collector, are obtained, and the blank areas are automatically reserved for welding lug plates, and therefore, quality and production efficiency of the pole pieces are improved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Cylinder head gasket

InactiveUS20050151327A1Improve stress resistanceImprove compatibilityEngine sealsLighting and heating apparatusReduced sizeEngineering

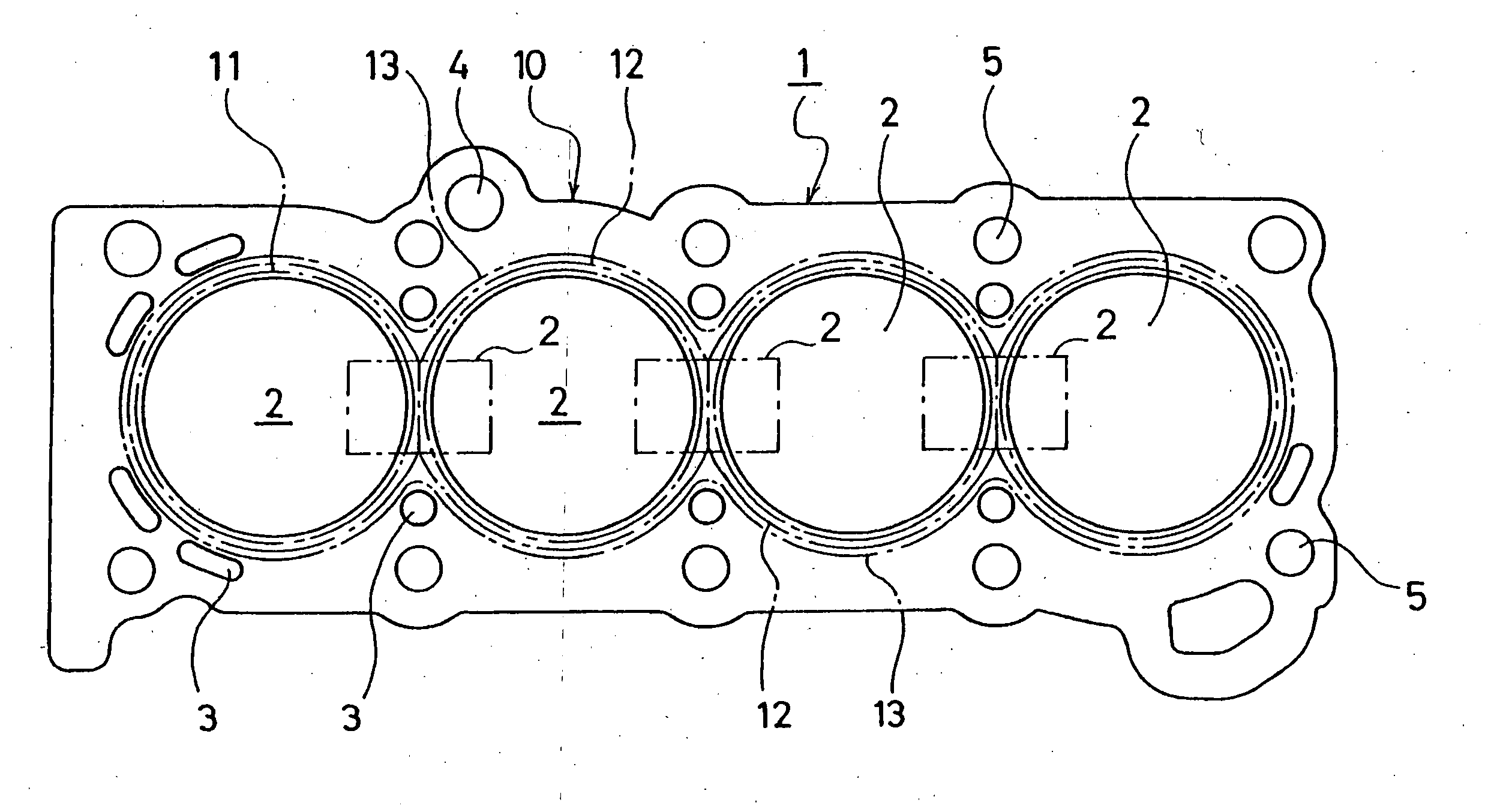

A cylinder head gasket is provided for dealing with gas leak between cylinder bores of an engine with a reduced size and rigidity. A cylinder head gasket is formed of one or more metal plates. One metal plate is provided with a first bead, a second bead, and a third bead arranged from inside in this order around a cylinder bore. The first bead is formed around each of the cylinder bores. The second beads are combined into a single bead having a width greater than a width of other section of the second beads in an area between adjacent cylinder bores. The third bead does not pass through the area between the adjacent cylinder bores and surrounds all of the cylinder bores.

Owner:ISHIKAWA GASKET CO LTD

Cylinder head gasket

A metallic cylinder head gasket for an internal combustion engine having at least one combustion chamber. The gasket includes at least one sheet-metal layer having at least one opening corresponding to the at least one combustion chamber of the internal combustion engine and at least one bore extending from the outer edge to the edge of the opening. A membrane, closing the bore at the combustion-chamber side is exposed to the gas pressure of the combustion chamber. A pressure sensor disposed in the sheet-metal layer is pressurized axially relative to the bore by movement of the membrane by the gas pressure of the combustion chamber.

Owner:ELRINGKLINGER AG +1

At least substantially metallic cylinder head gasket

InactiveUS7490835B2Easy to provideImprove the immunityEngine sealsFlanged jointsEngineeringMetal cylinder

Cylinder head gasket with a metallic gasket plate comprising a combustion chamber opening enclosed by a bead, and a stopper surrounding the opening and delimiting deformation of the bead, the stopper formed by elevations of a gasket sheet metal layer which are obtained by deformation thereof, the stopper is designed such that in sections through the sheet metal layer along circular cylindrical surfaces coaxial with the opening the stopper comprises a row of discrete elevations following one another in a circumferential direction of the opening and corresponding depressions located directly opposite these elevations, and in a plan view of the sheet metal layer in the area of the stopper, the total area occupied by the elevations is at least half of the total area of the stopper, and the shape of the elevations differs from the shape of circular arcs at least partially enclosing the opening.

Owner:ELRINGKLINGER AG

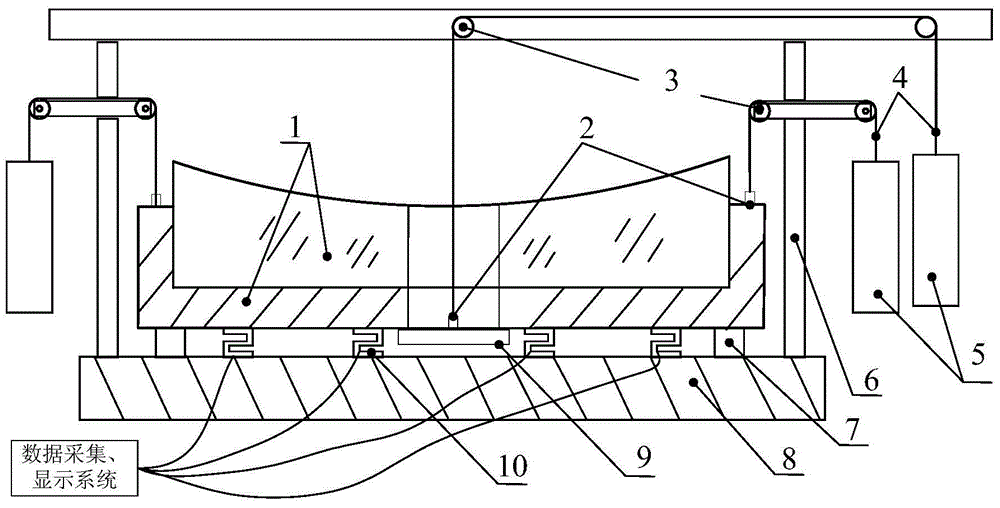

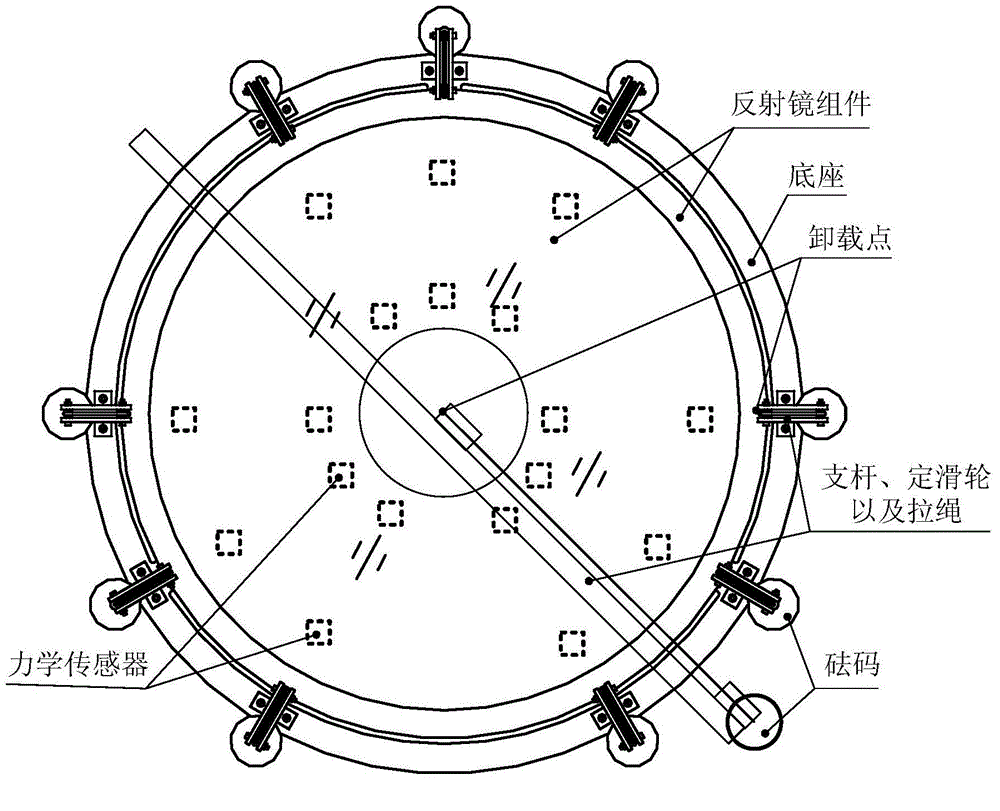

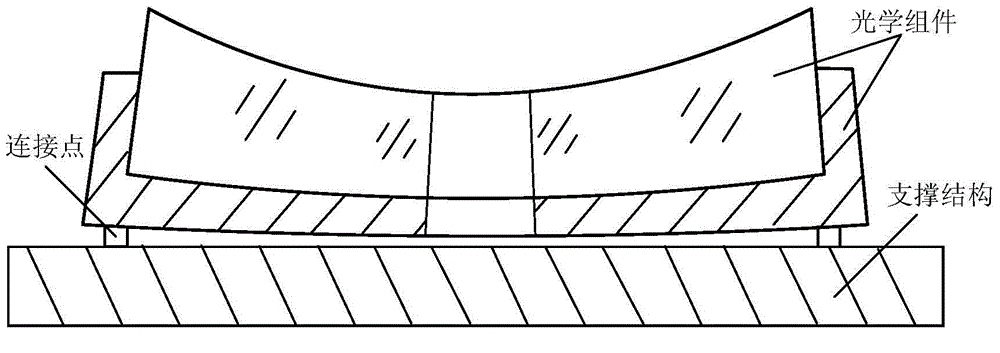

Microstress assembling method for large-caliber reflector assembly

The invention discloses a microstress assembling method for a large-caliber reflector assembly. Related devices comprise sensors, supporting rods, weights, a base, pulling ropes and a tray. Firstly, the mechanical sensors are fixedly installed on the base; secondly, the reflector assembly is placed on the base through three ball head gaskets; thirdly, the supporting rods are installed at the designated positions of the base, one end of each pulling rope is bound to a disassembling point, the pulling ropes wind around two fixed pulleys on the supporting rods, and the weights are bound at the other ends of the pulling ropes. At the moment, whether gravity disassembling is in place or not is judged through reading of the mechanical sensors, and the weight of the weights is adjusted in a fine mode until the reading of the sensors is zero. Finally, after disassembling is completed, a torque wrench is used for screwing screws of the reflector assembly to the preset torque, and disassembling and assembling of the reflector assembly are completed. Thus, microstress assembling of the reflector assembly is achieved, and the reflector surface shape quality and the structural stability of an optical remote sensor are ensured.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

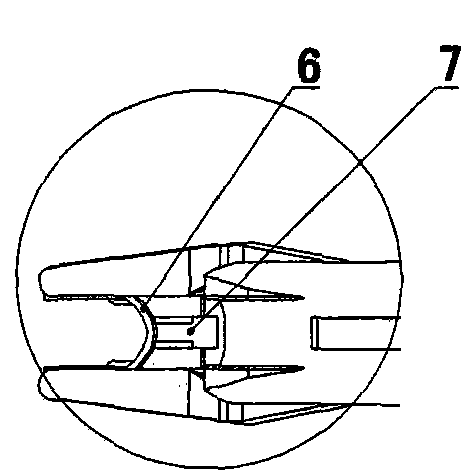

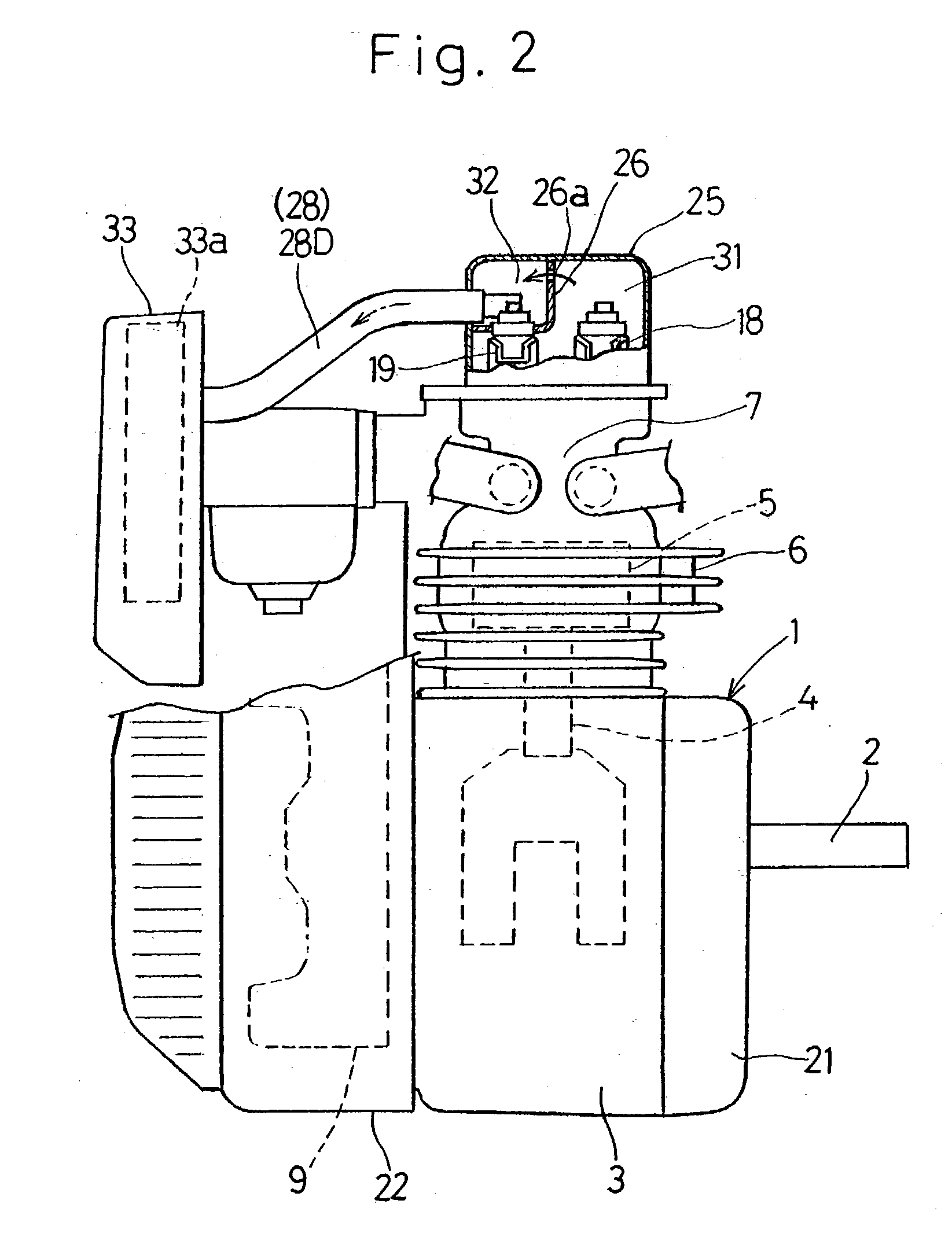

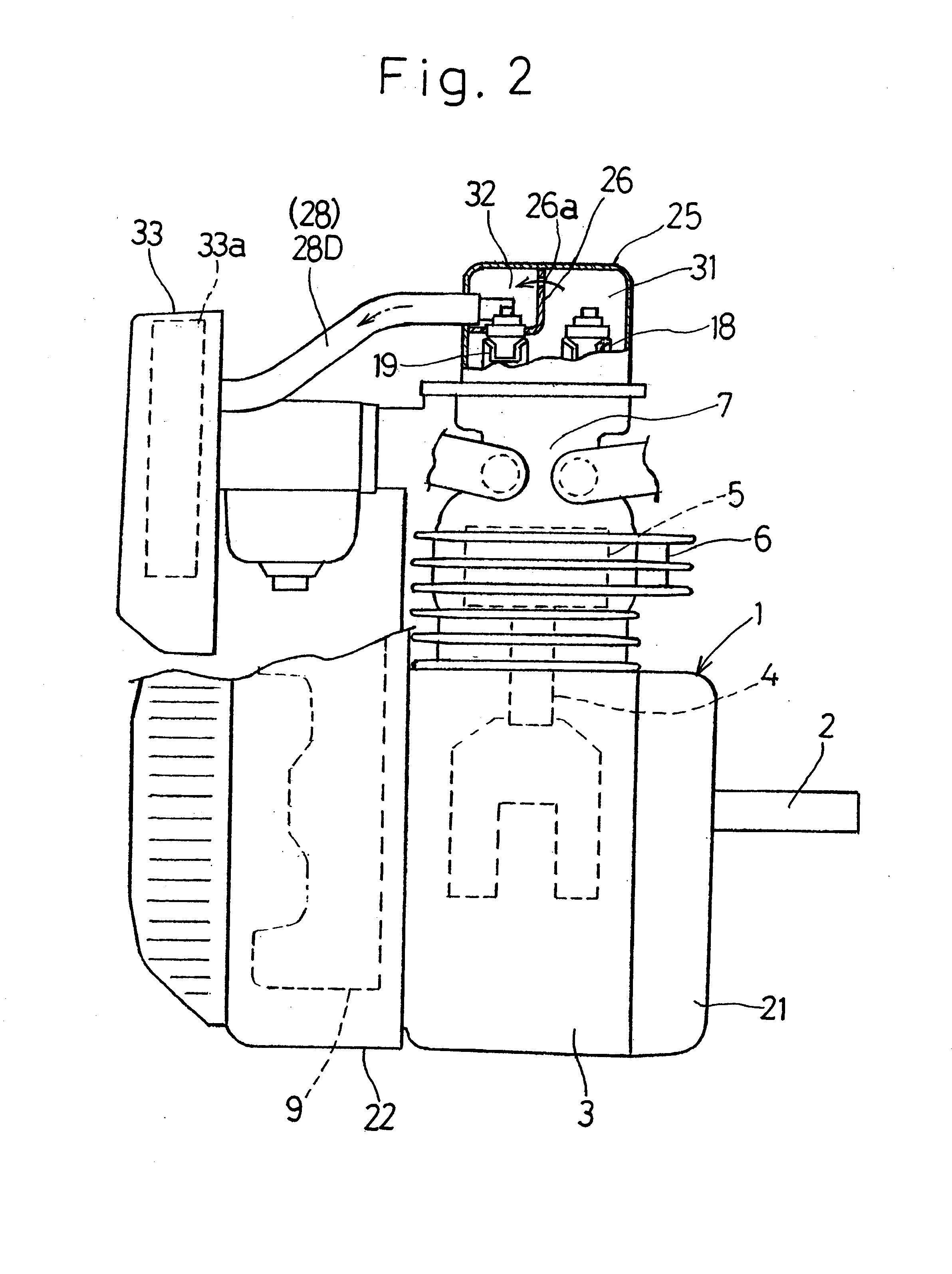

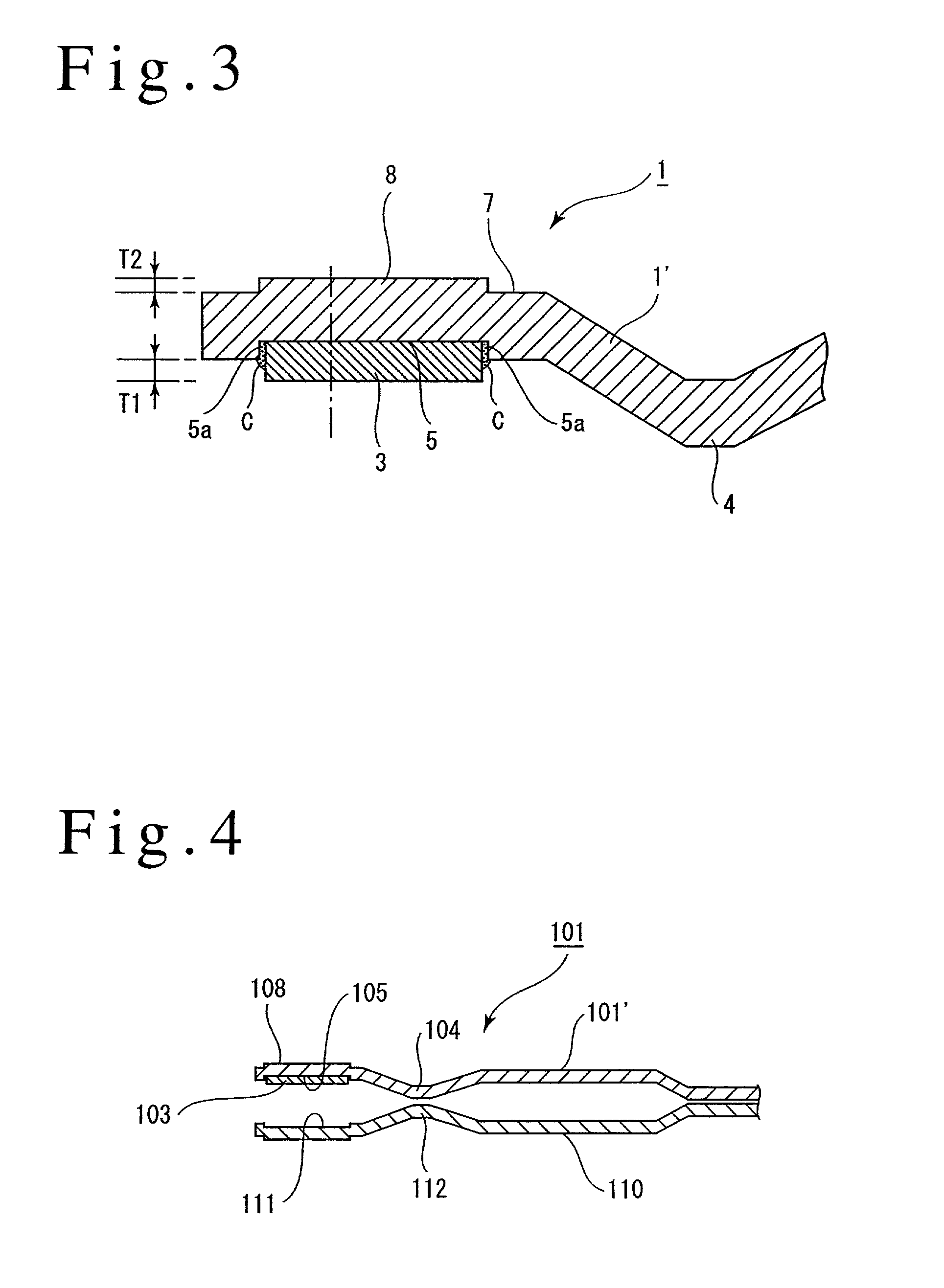

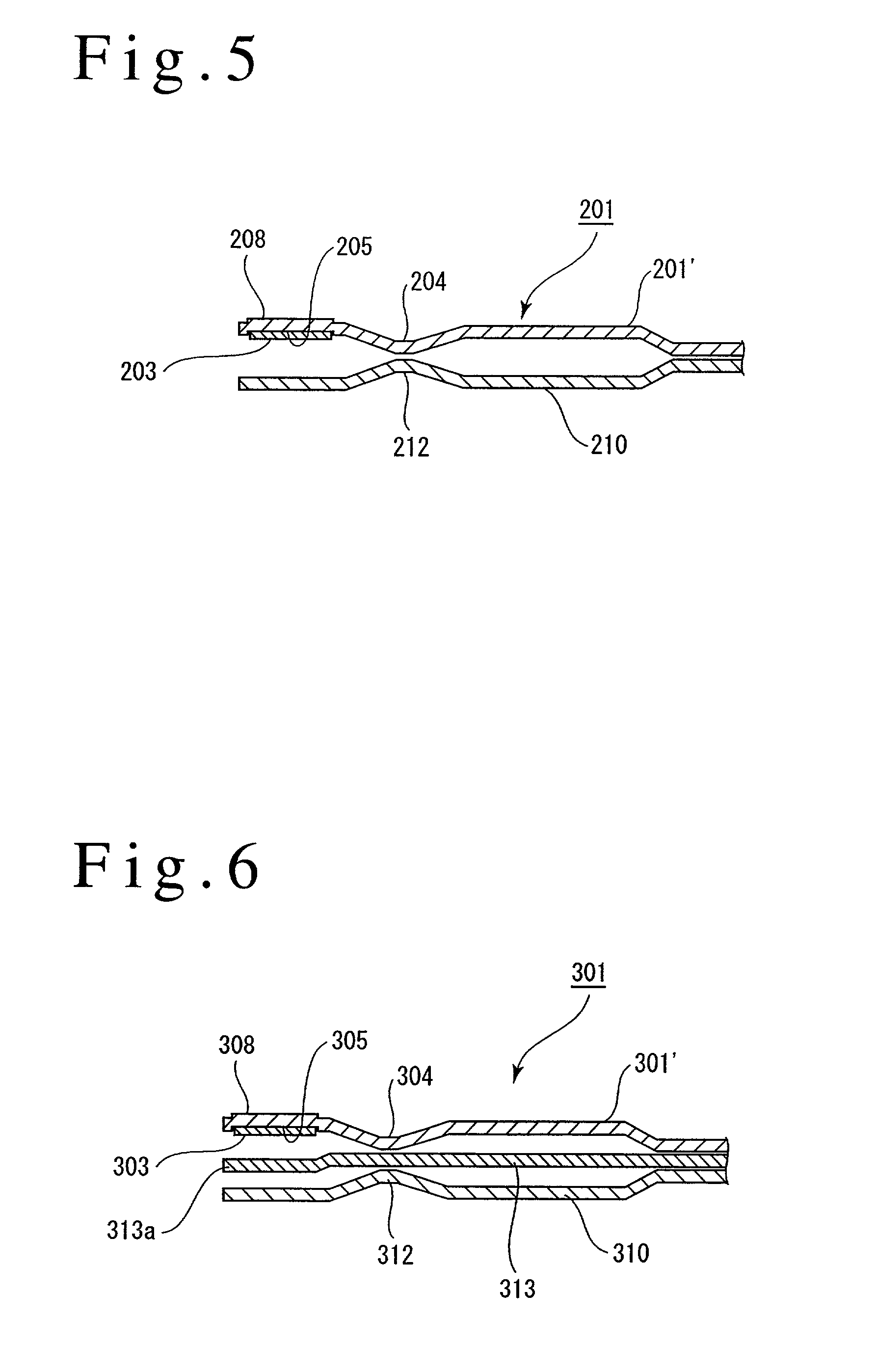

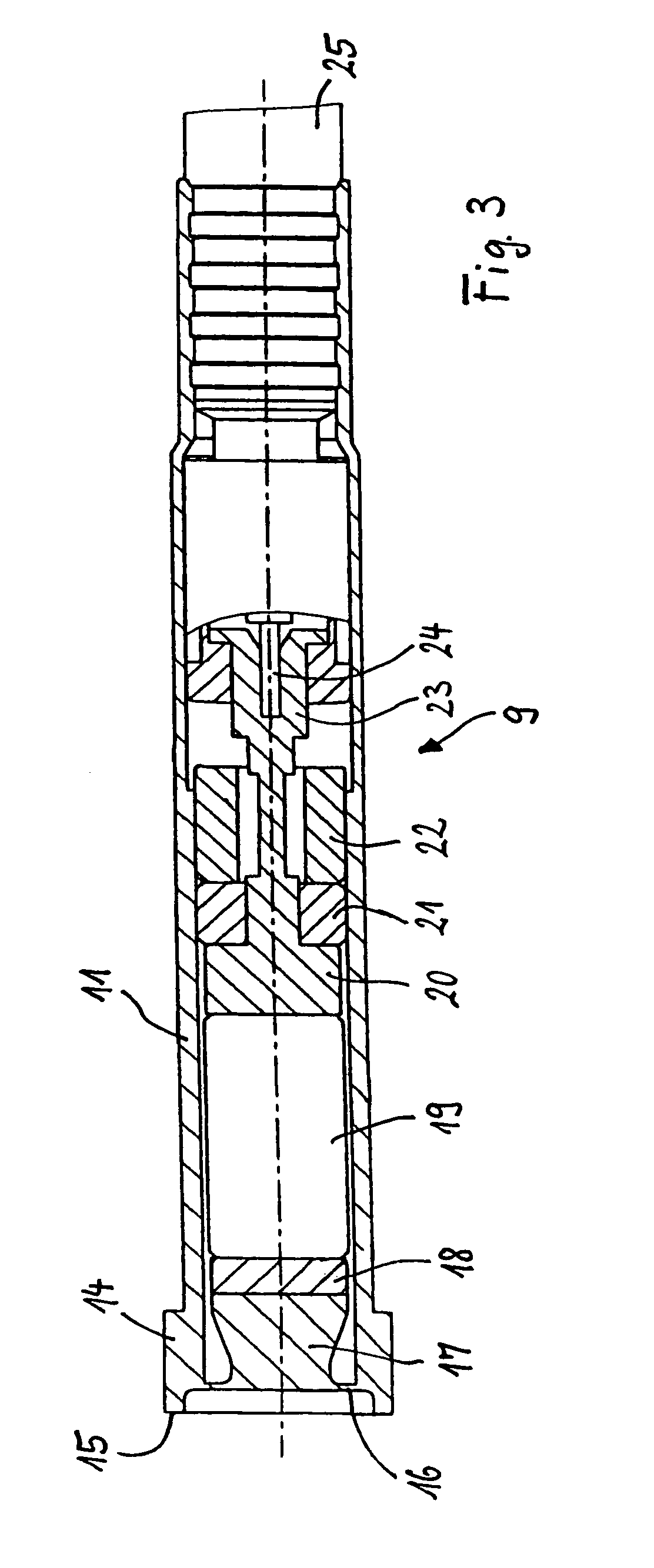

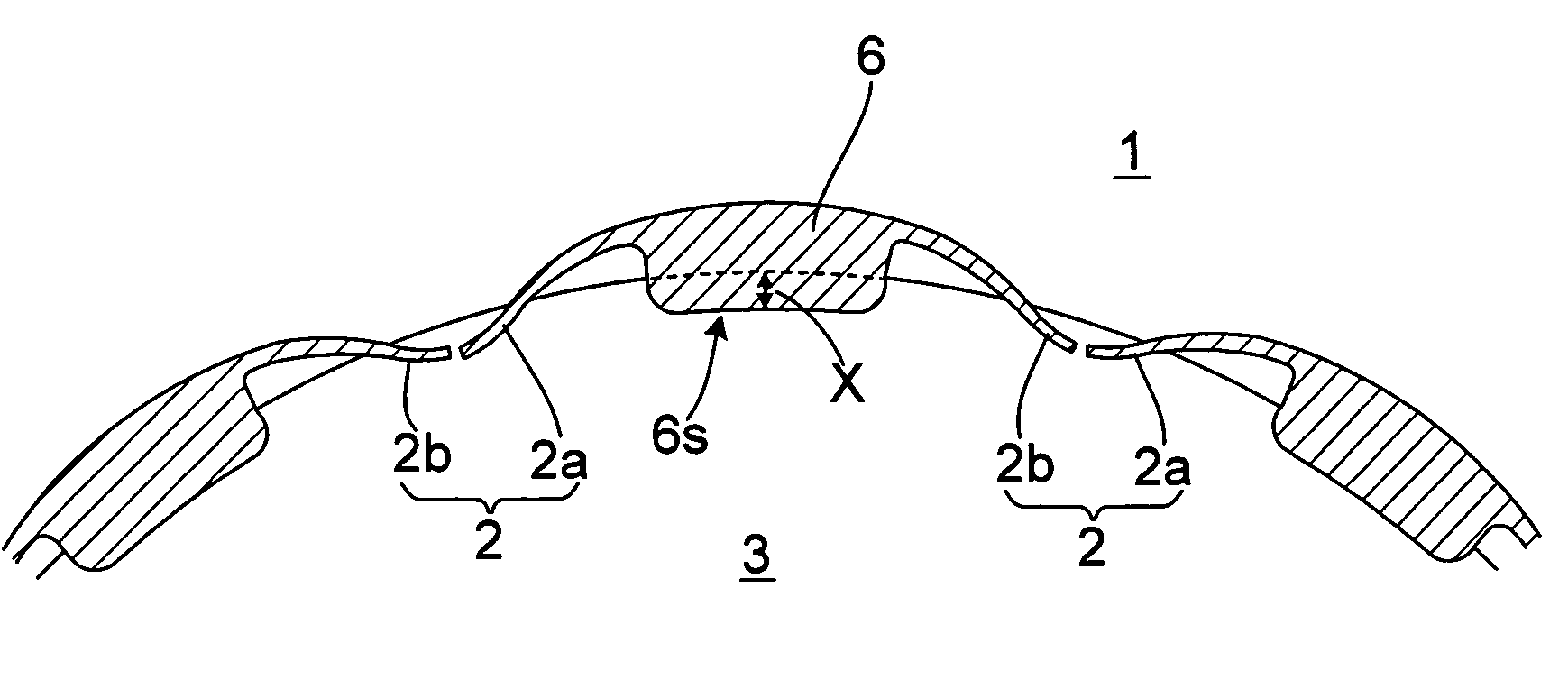

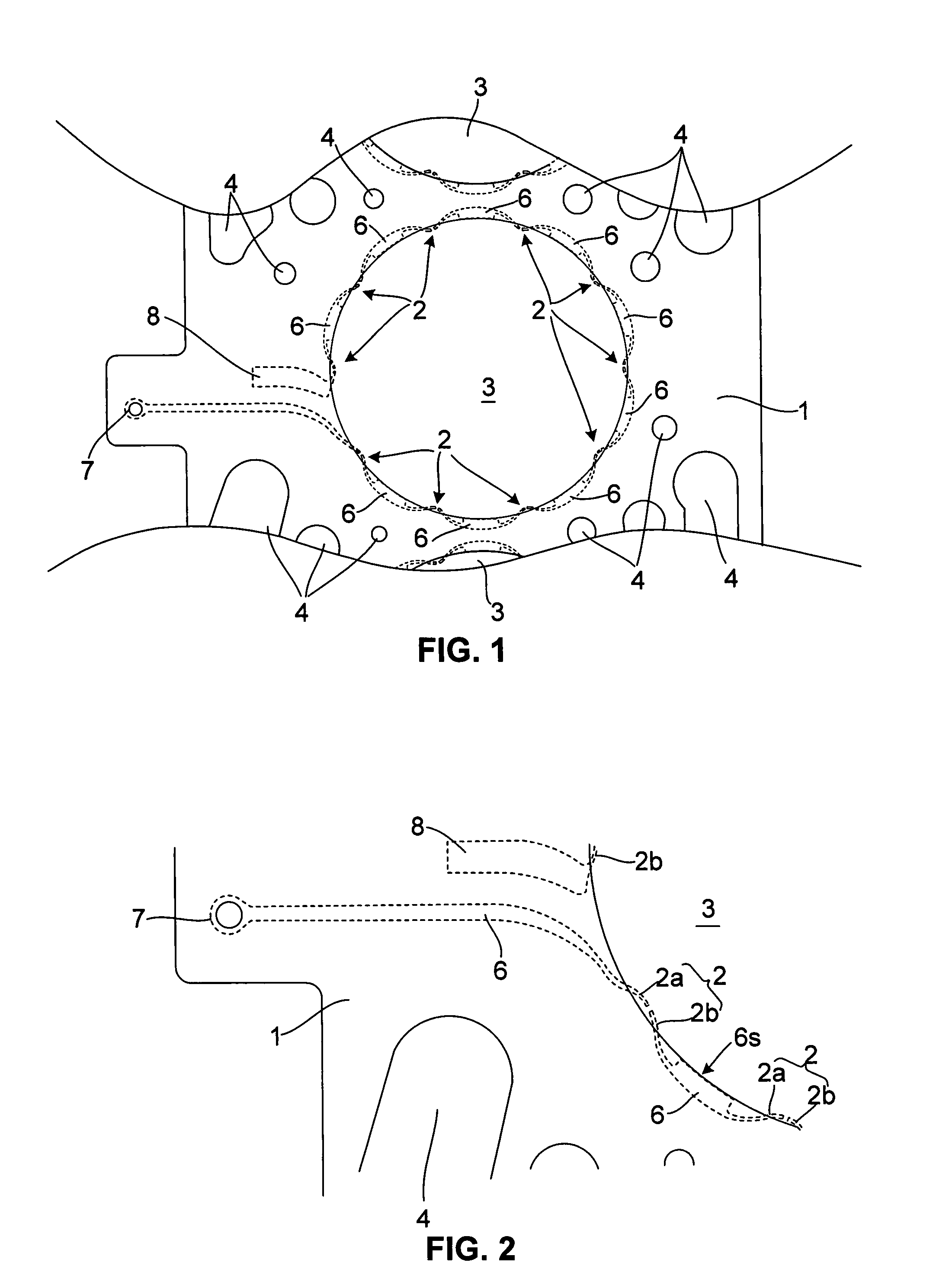

Multipoint ignition device

A multipoint ignition device comprises: a head gasket (1) interposed between a cylinder head and a cylinder block of an engine, having an opening (3) in a position corresponding to a cylinder opening portion; and a plurality of intermediate members (6) connected respectively to a plurality of electrode pairs (2) and held by the head gasket (1). A part of at least one of the plurality of intermediate members (6) is exposed to the opening (3).

Owner:MIYAMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com