Microstress assembling method for large-caliber reflector assembly

A technology for large-diameter mirrors and assembly methods, applied in installation, optical components, optics, etc., can solve problems such as large assembly stress, affecting the surface quality and structural stability of the mirror, and reduce the difficulty of assembly and adjustment Uniform force, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific implementation examples

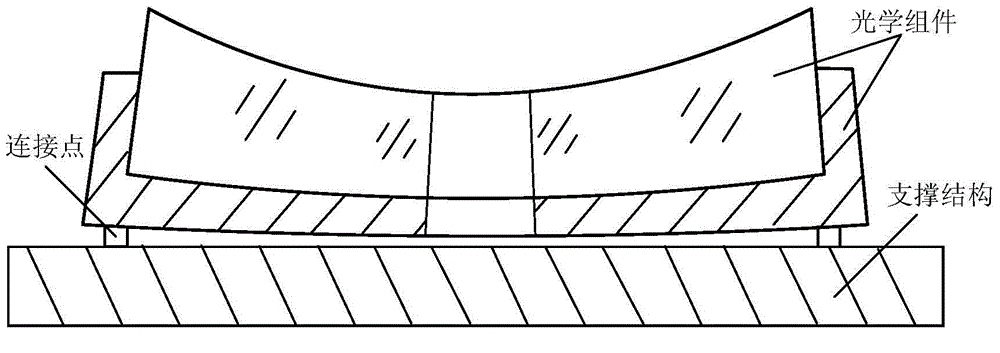

[0026] Such as image 3 As shown, in the assembly process of small and medium-sized optical components in the past, due to the small gravity deformation, it has little effect on the assembly stress of the components, and there is no need to consider the factor of gravity unloading. However, in large-aperture optical components, due to the large span of the three fixed points, the amount of gravitational deformation reaches the micron level. In this case, fixing the connecting screws will lock the gravitational deformation in the component, forming assembly stress. And then affect the surface quality of the mirror.

[0027] After adopting the method, the gravitational deformation of the optical component can be reduced to the minimum. Effectively guarantee the consistency of the sky and the ground, and ensure the optical assembly quality of the remote sensor.

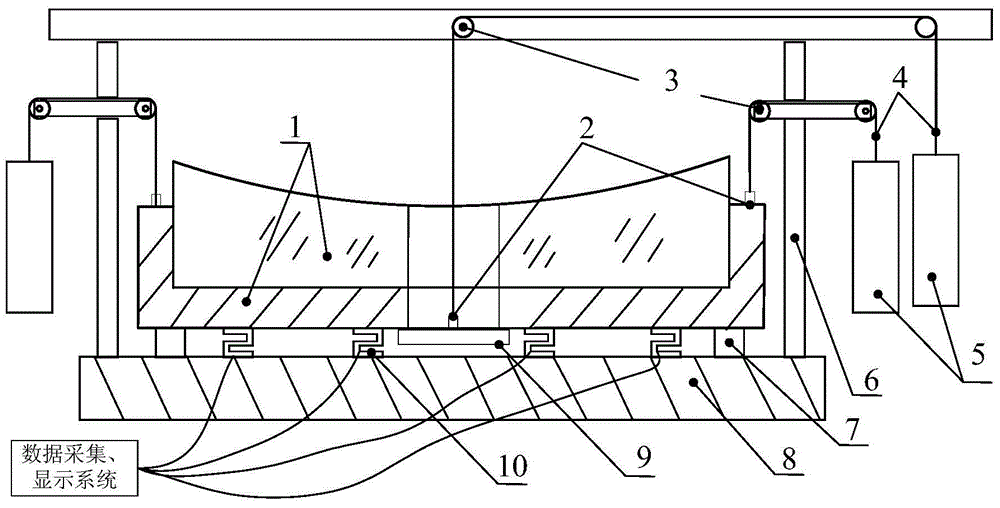

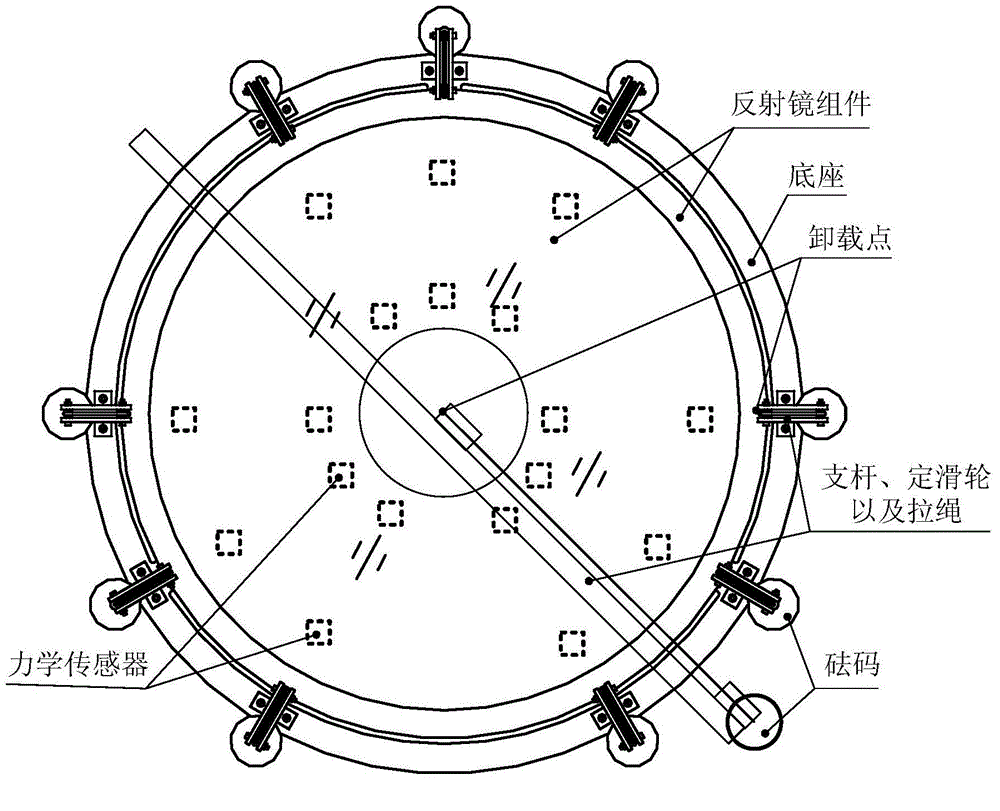

[0028] Such as figure 1 As shown, the principle diagram of the method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com