Plate and band material roll gap adjustable flattening machine

A technology for straightening machines and strips, applied in the field of variable roller pitch leveling machines, which can solve the problems that the straightening capacity of the straightening machine cannot be fully utilized, the thickness and strength of the straightened strips are limited, and the strength is weak, etc., to achieve The effect of the correction plate strip is strong, the thickness range is wide, and it can be replaced quickly

Inactive Publication Date: 2003-04-23

CHINA ERZHONG GRP DEYANG HEAVY IND

View PDF0 Cites 41 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of the constant roller distance straightening machine is that the roller distance cannot change with the thickness and strength of the straightening plate and strip. In this way, either the strength of the roller system and the transmission device is weak, or the thickness and strength of the straightening plate and strip are limited. , the straightening ability of the straightening machine cannot be brought into full play, or two straightening machines are installed to straighten plates and strips with different thickness ranges

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0044] Preface

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

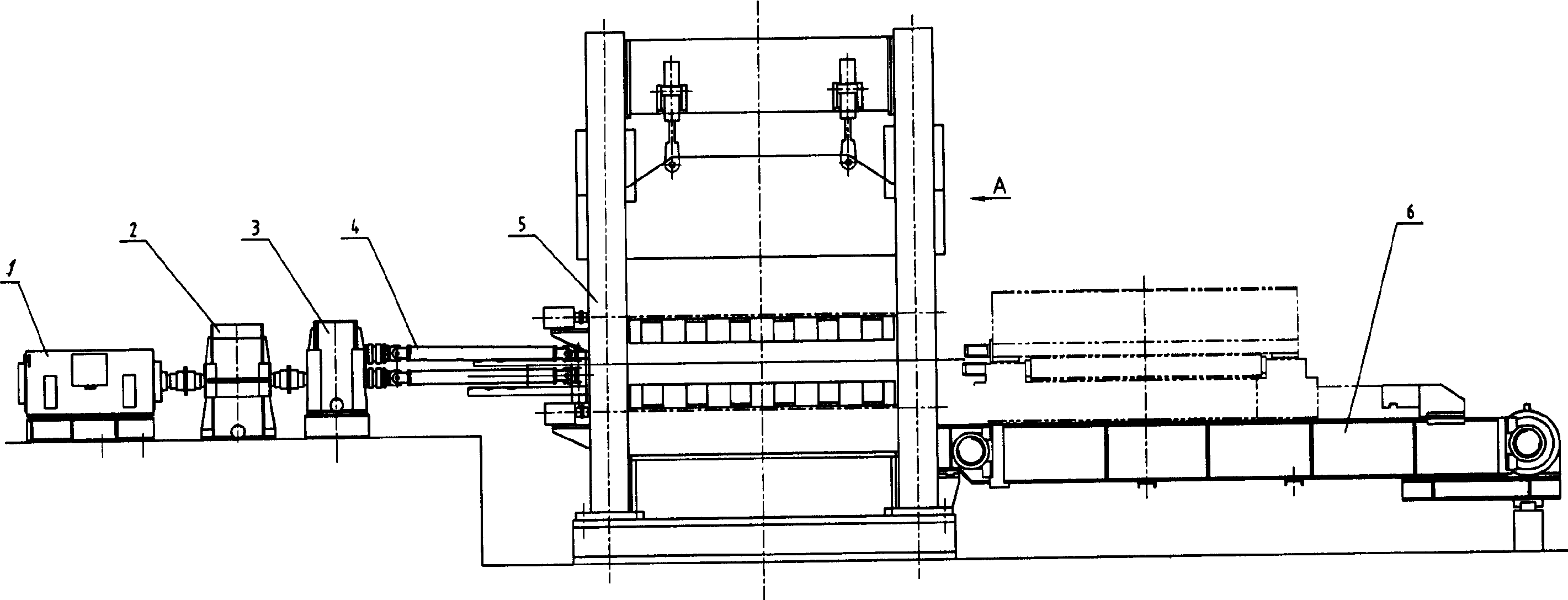

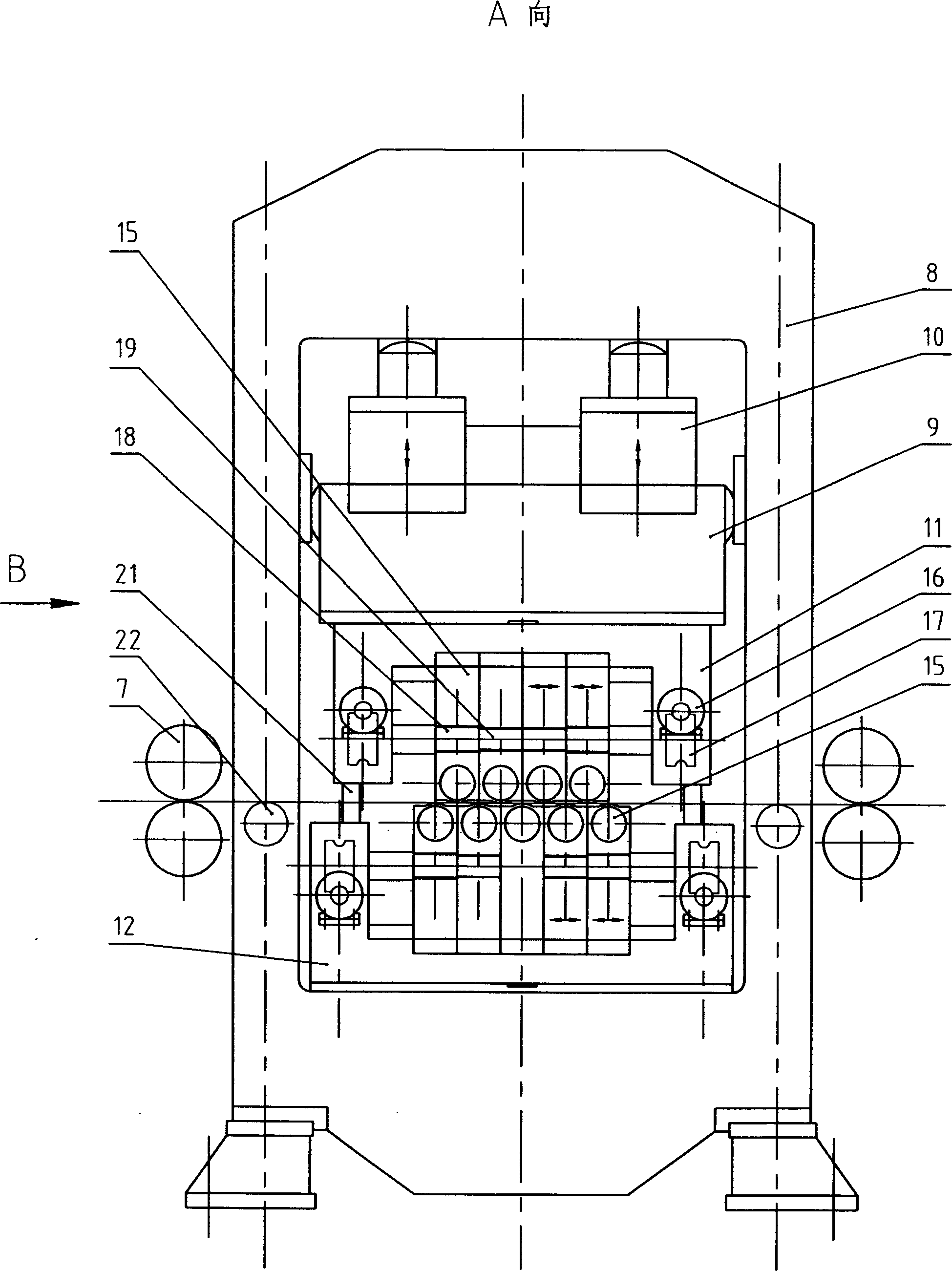

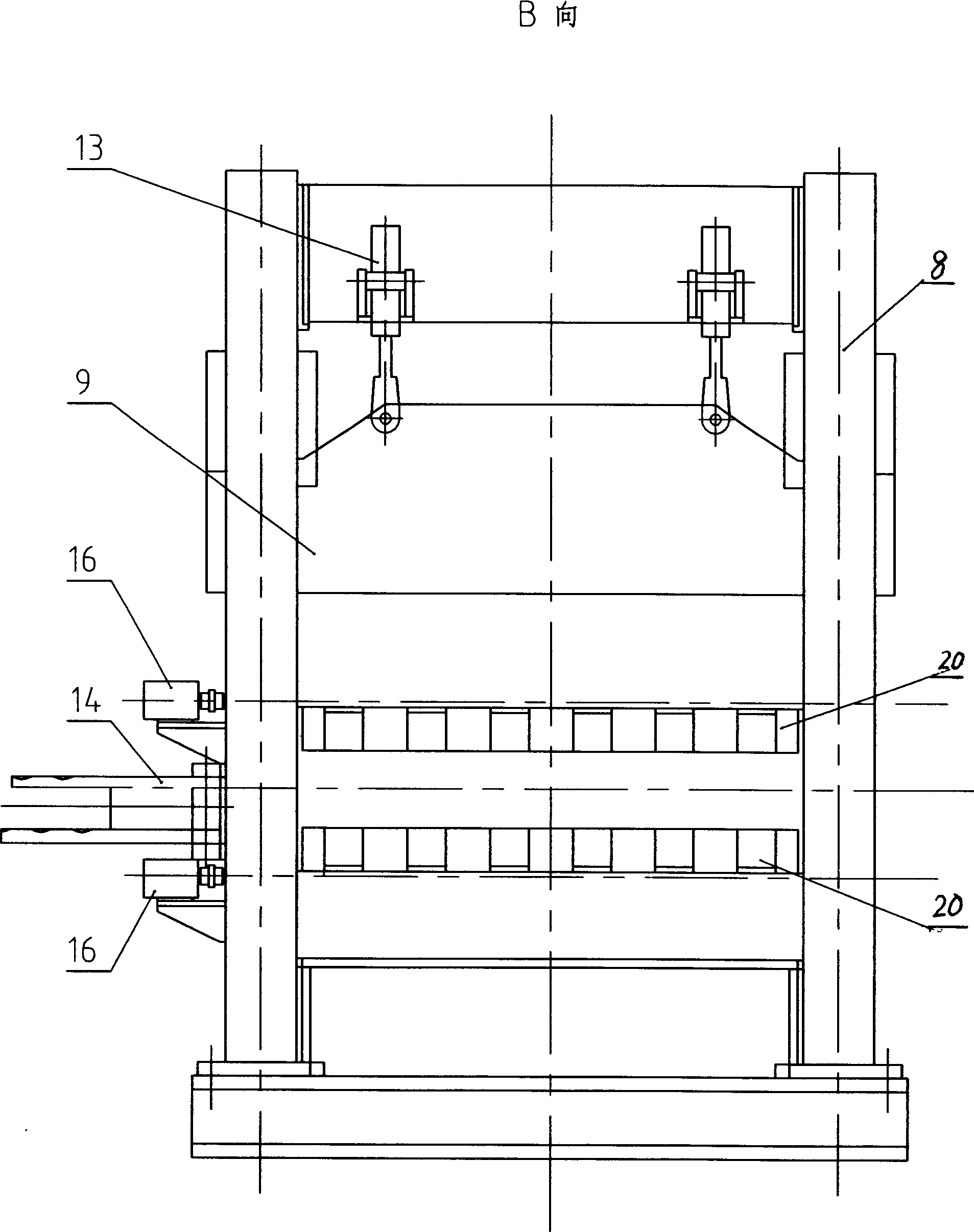

The flattening machine for plate material possesses strong flattening capacity and wide thickness range of plate material is formed from main motor, speed-reducing machine, gear distribution box, cardan shaft, flattening machine self-body, inlet pinch rolls, outlet pinch rolls, roll-changing device, hydraulic lubricating air and water control system and electric transmission and automatic controlsystem. Its upper roll device and lower roll device are respectively equipped with motor, worm speed reducer, screw rod and nut, and the inlet side, outlet side, transmission side and roll-changing side of upper roll device are respectively equipped with downward cylinder, and their pinch rolls are respectively equipped with hydraulic cylinder, motor and speed reducer.

Description

technical field [0001] The invention relates to a variable roller distance straightening machine used for straightening plate and strip in metallurgical machinery or other industries. Background technique [0002] At present, the straightening machines for plate and strip at home and abroad, especially medium and thick steel plates (thickness 4-60mm) are constant roll distance or double constant roll distance straightening machines, and have not found the same principle and structure as the present invention. Or the literature report of the similar sheet and strip material variable roll distance straightening machine. The disadvantage of the constant roller distance straightening machine is that the roller distance cannot change with the thickness and strength of the straightening plate and strip. In this way, either the strength of the roller system and the transmission device is weak, or the thickness and strength of the straightening plate and strip are limited. , The st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D1/02B21D3/02B21D25/00

Inventor 杨固川

Owner CHINA ERZHONG GRP DEYANG HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com