Patents

Literature

2737 results about "Caliber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In guns, particularly firearms, caliber (or calibre in British English) is the specified nominal internal diameter of the gun barrel bore regardless of how or where the bore is measured and whether or not the finished bore matches that specification. It is measured in inches to an accuracy of hundredths or thousandths of an inch or in millimeters. For example, a ".45 caliber" firearm has a barrel diameter of roughly 0.45 inches (11 mm). Barrel diameters can also be expressed using metric dimensions. For example, a "9 mm pistol" has a barrel diameter of about 9 millimeters. Due to the inaccuracy and imprecision of imperial dimensions "converted" to metric units, metric designations are typically far out of specifications published in decimal inches. True "caliber" specifications require imperial measure, and even when cartridge designations (often mistakenly referred to as "caliber") only specify caliber to even tenths or hundredths of an inch, actual barrel/chamber/projectile dimensions are published to at least thousandths of an inch and frequently tolerances extend into ten-thousandths of an inch.

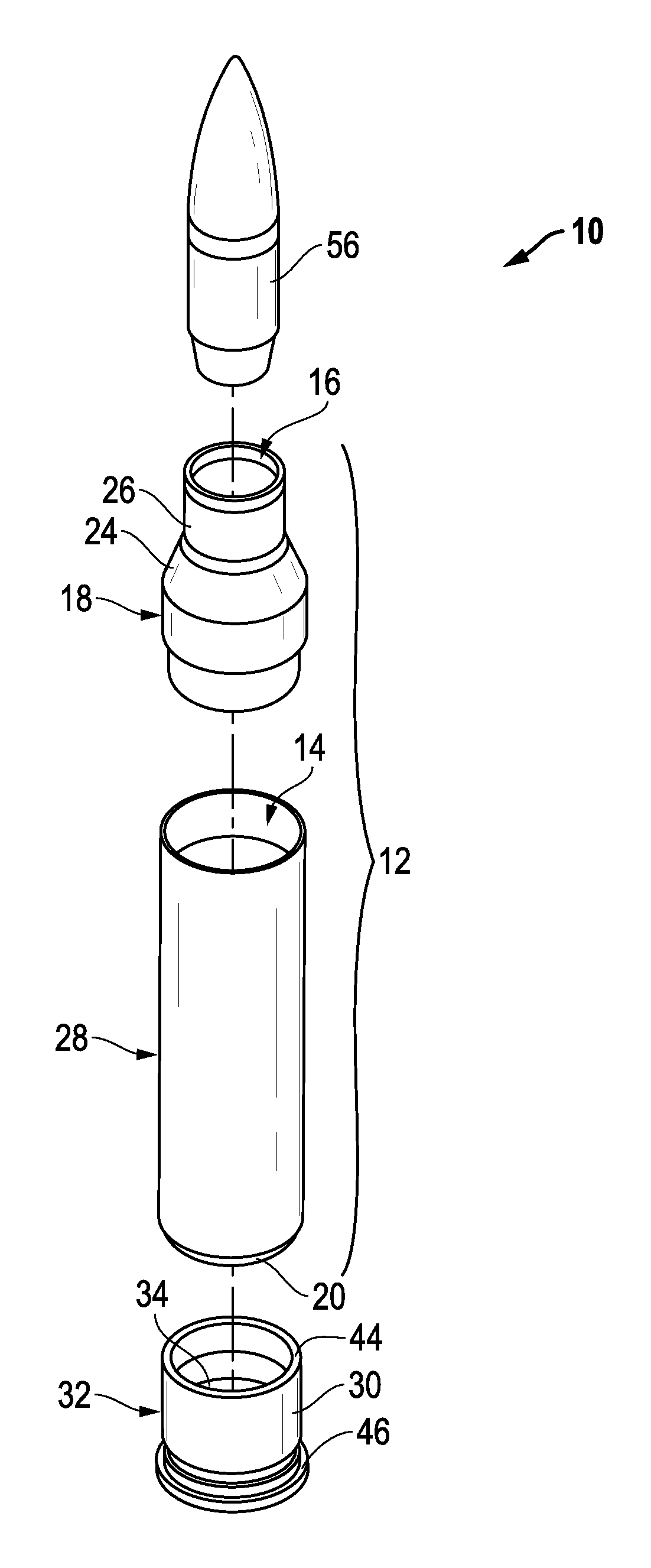

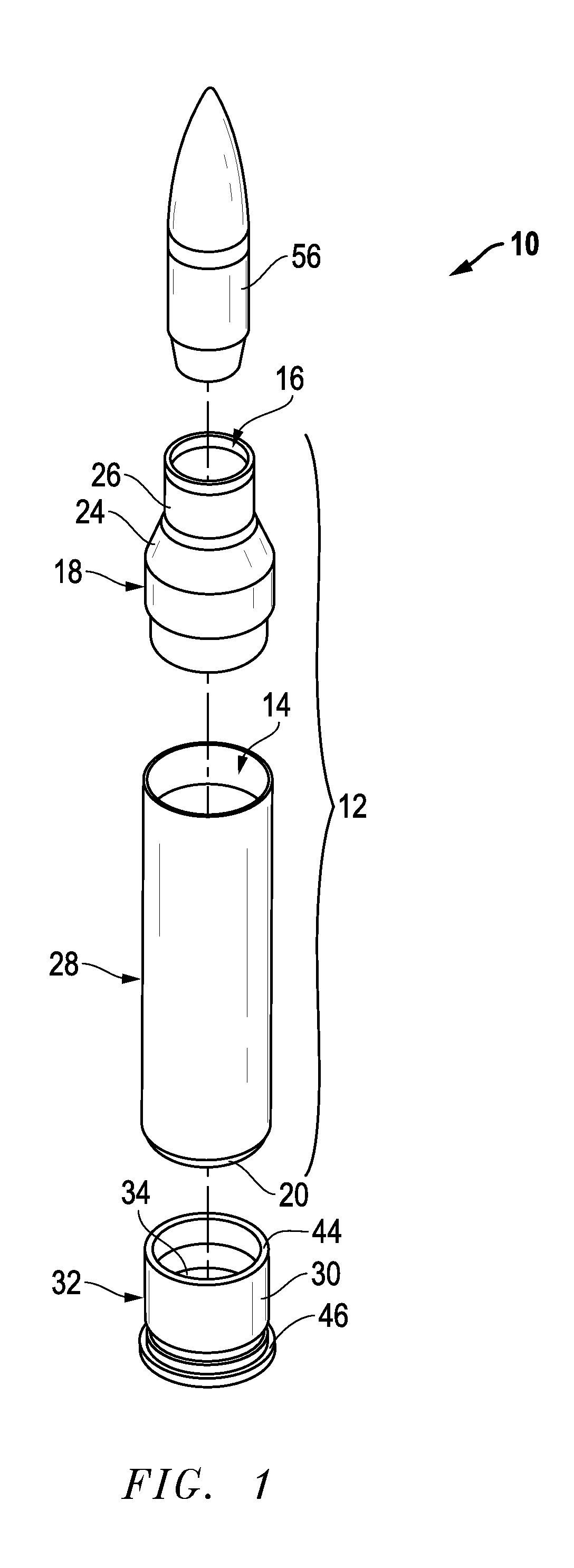

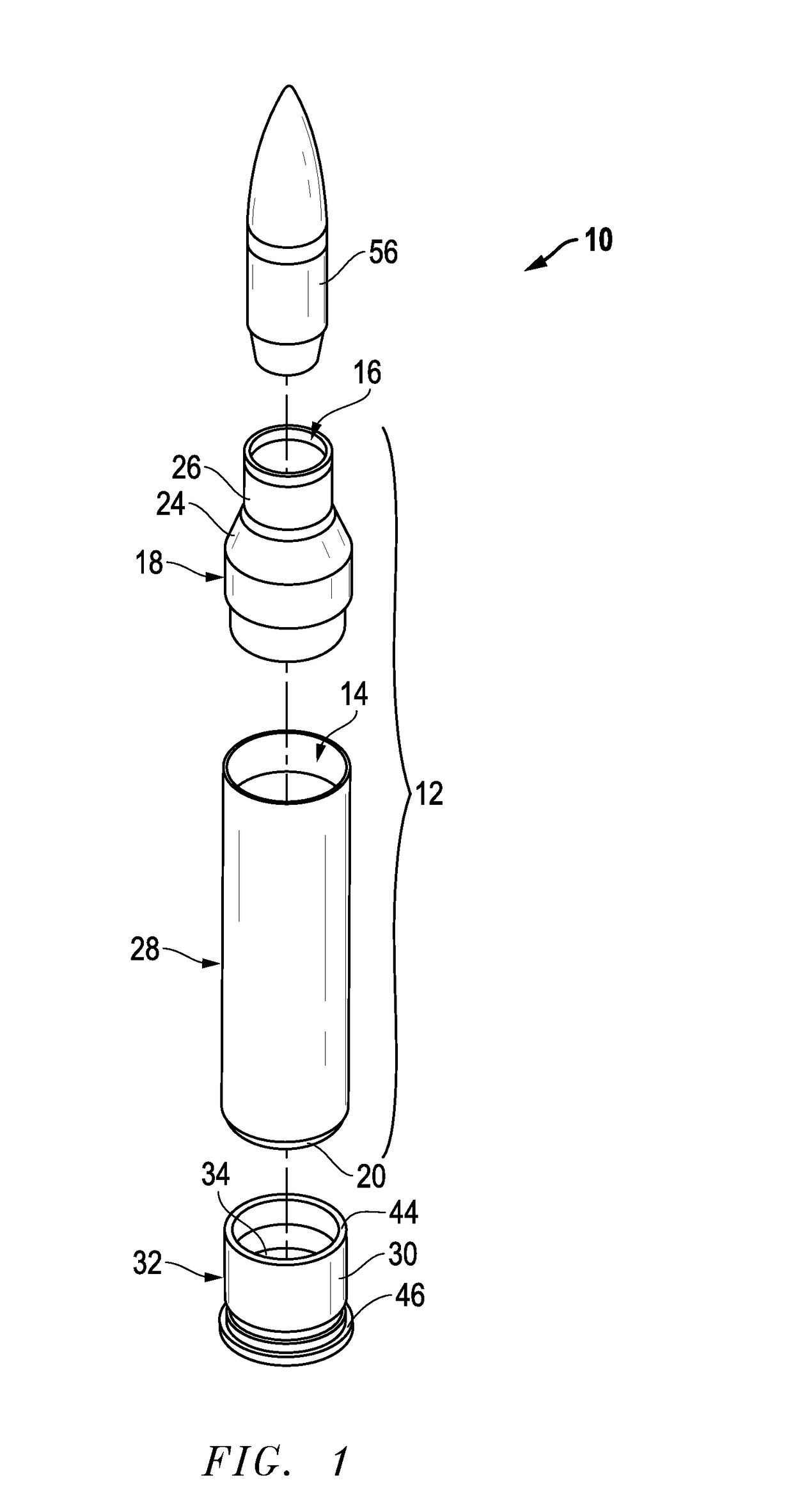

Integrated polymer and metal case ammunition manufacturing system and method

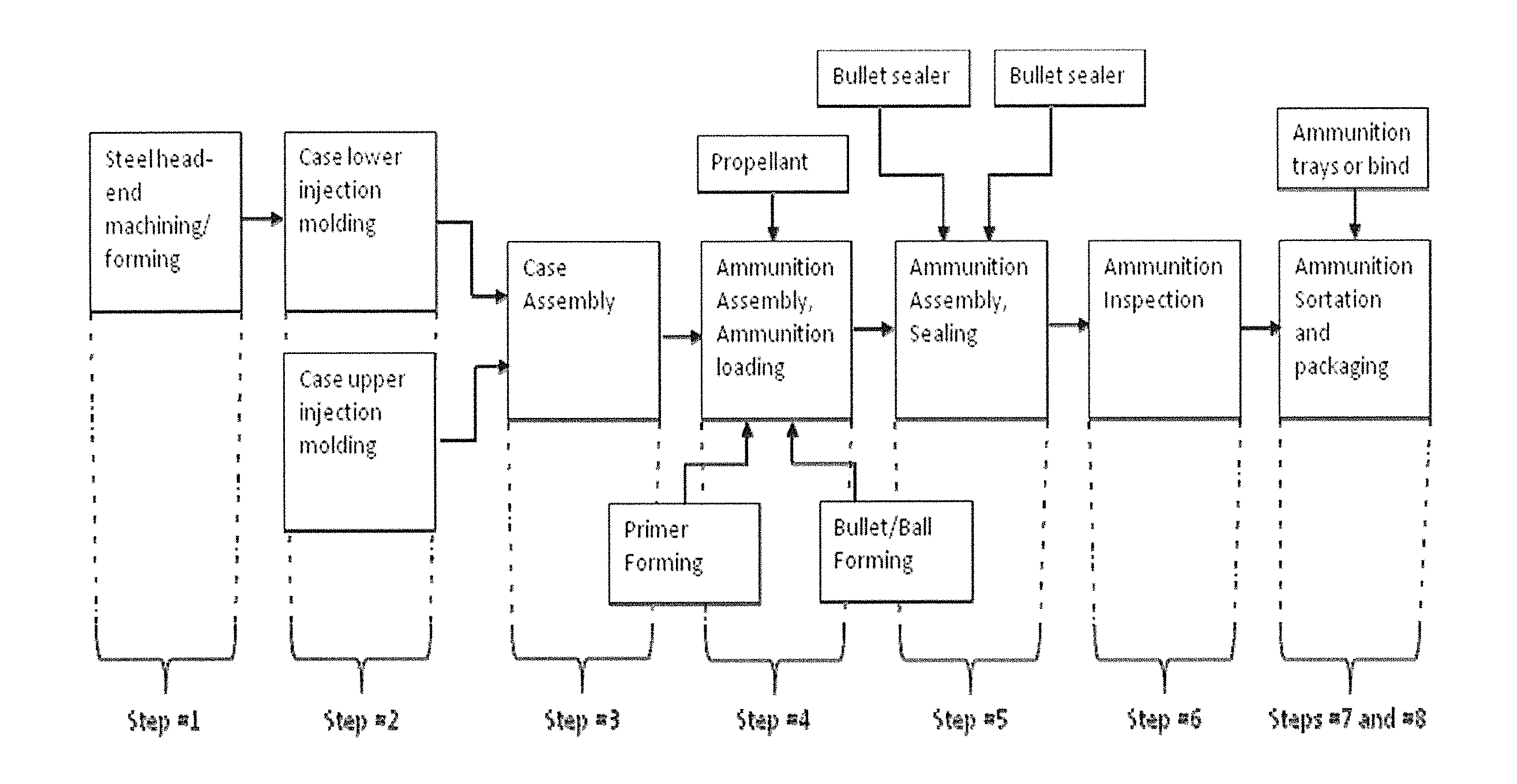

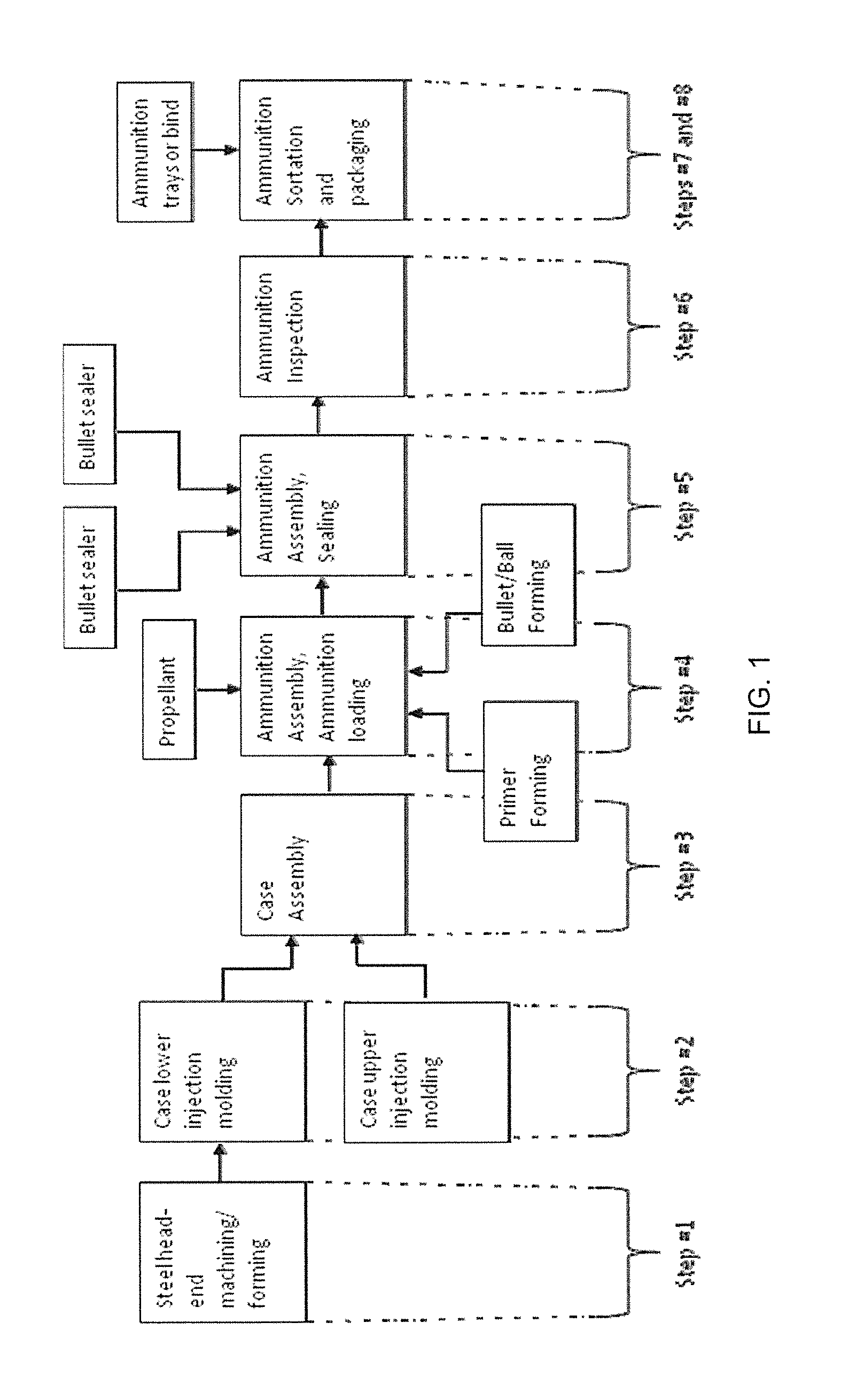

A fully automated, integrated, end-to-end synchronized and compact manufacturing system produces polymer or metal case ammunition. Manufacturing stations support case assembly, sealing (gluing / welding), final product inspection, cartridge packaging or binning, and loading. Station modularity facilitates rapid changeover to accommodate ammunition of differing calibers. Sensors and apparatus may be provided to place a manufacturing cell in a wait state until all components or materials are received in a preferred orientation for proper assembly. The system may join and use multipart cases, each including a lower portion with a head end attached thereto and at least one upper portion having a necked-down transition to the open top end. Elevator feeders, vibratory bowl feeders, and robotic pick-and-place feeders may be used to deliver components for assembly.

Owner:CYBERNET SYST

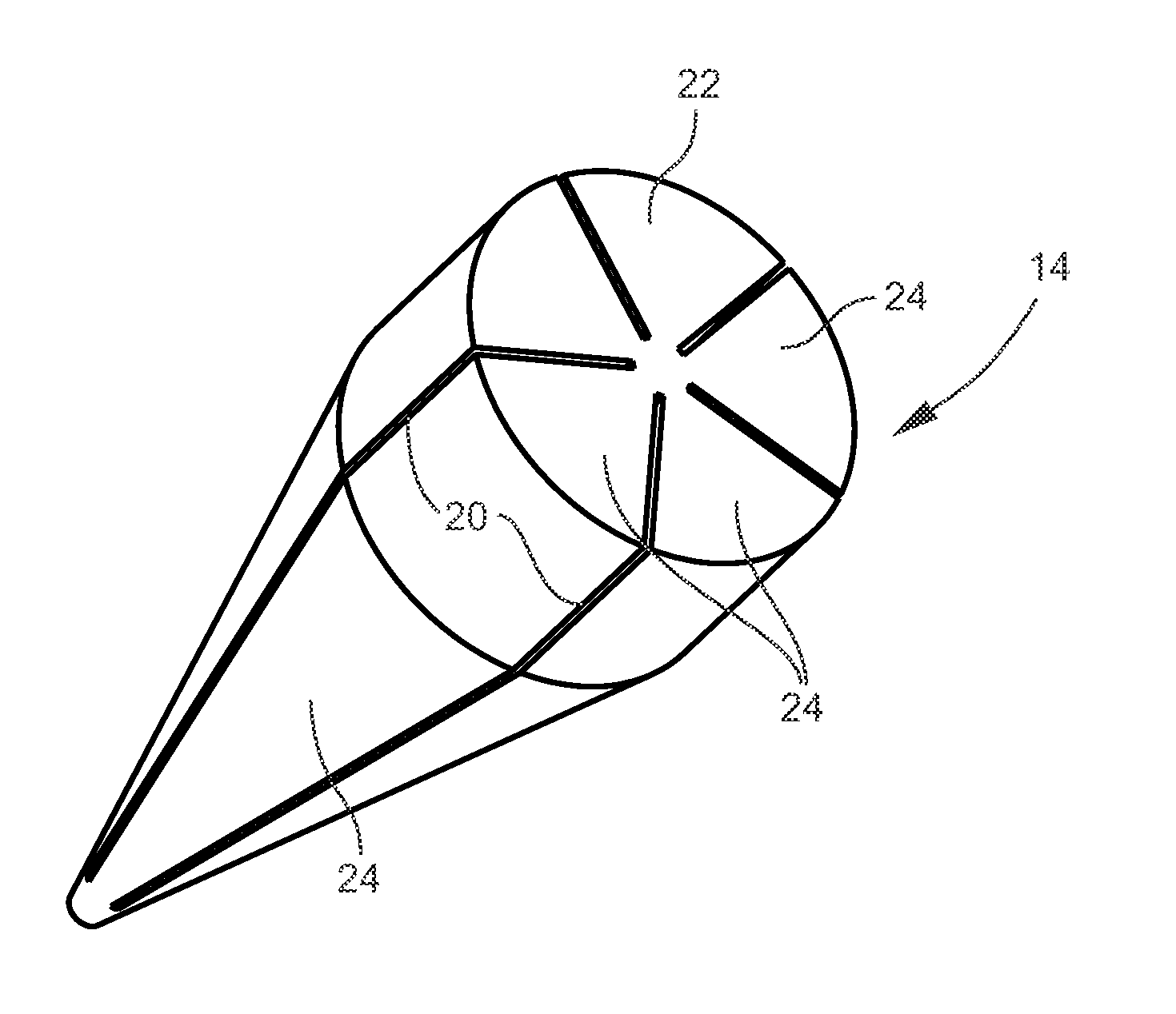

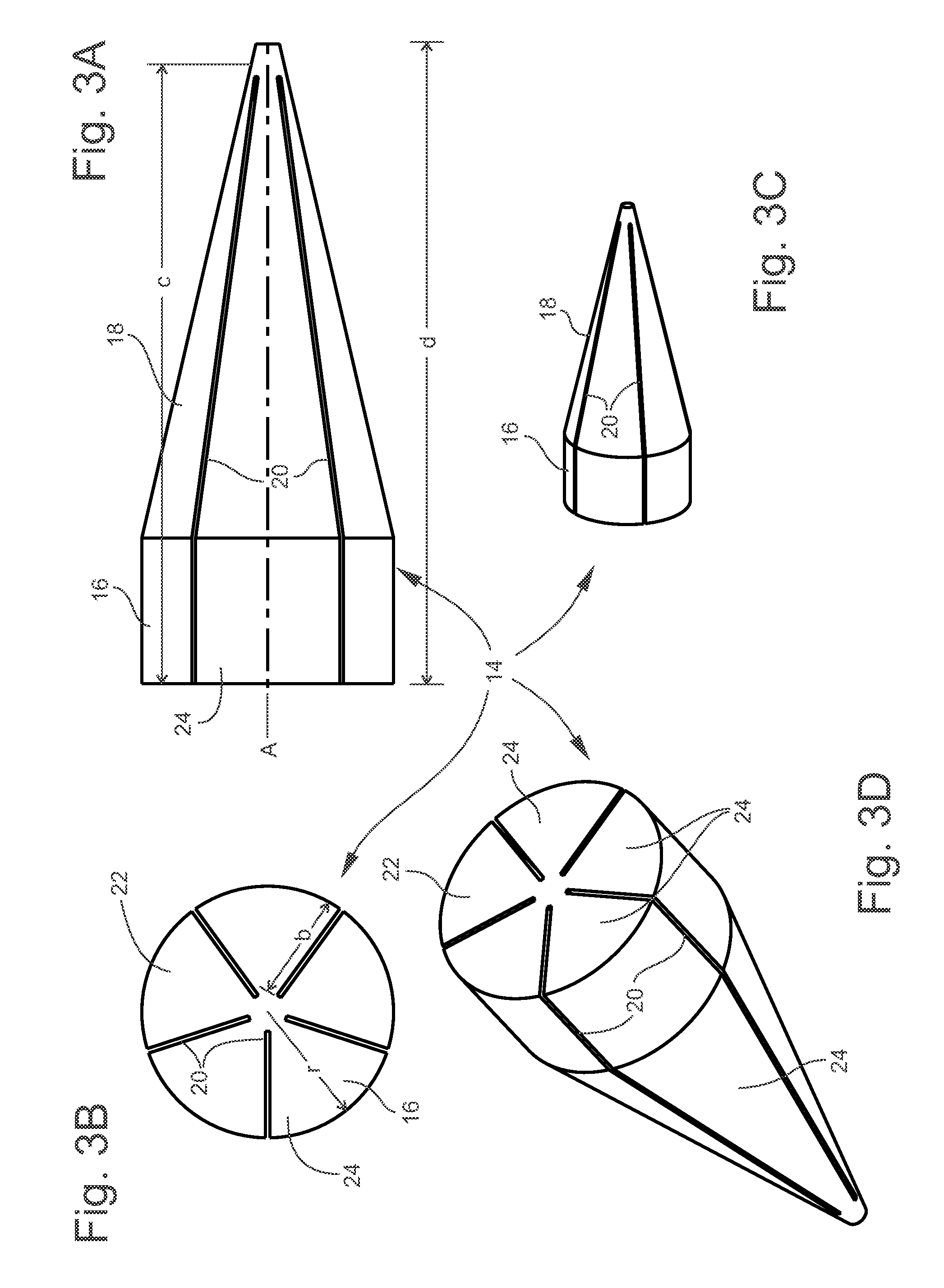

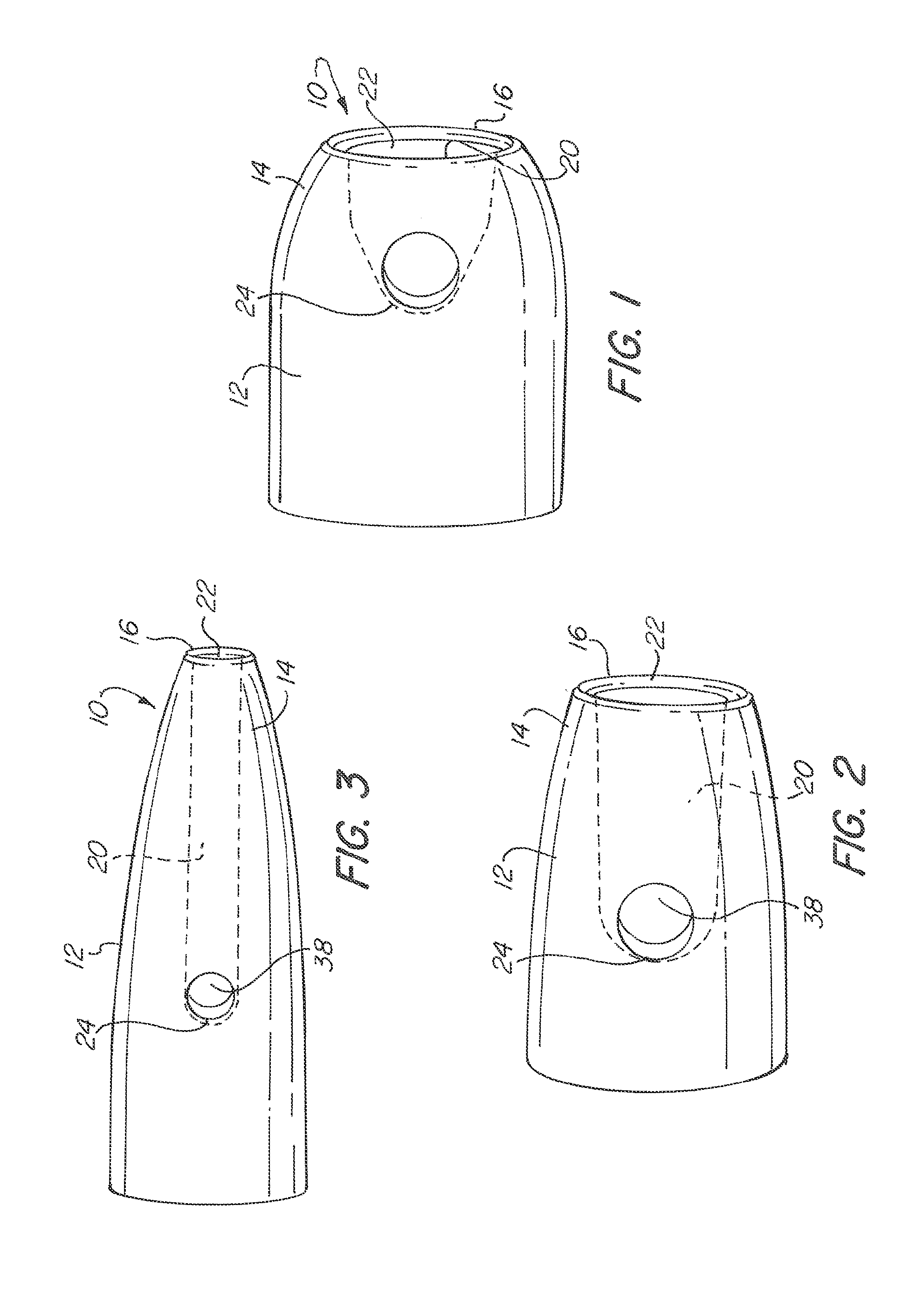

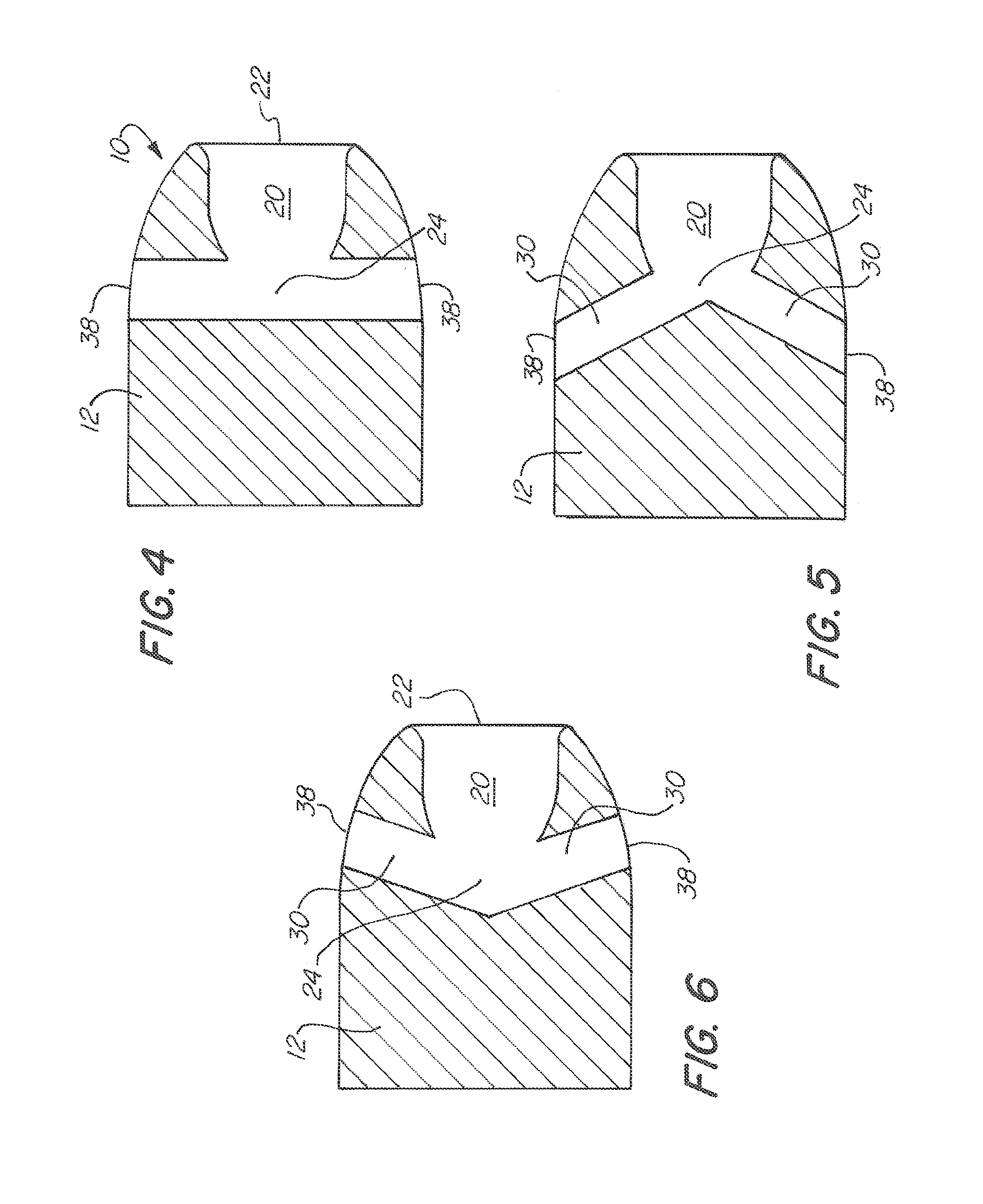

Large caliber frangible projectile

A large caliber, frangible, training projectile imitates, for training purposes, the corresponding tactical projectile. To enable fragmentation of the training projectile at impact, some embodiments of the frangible projectile are partially or entirely made of a material with a lower yield strength than the material used in the counterpart tactical projectile. Some embodiments of the frangible projectile may include portions that are sectioned, welded, or provided with stress risers. Some embodiments of the frangible projectile may include high density particles suspended in a weaker medium. The fragmentation methods may be applied to the overall mass of the projectile, or to a portion of the projectile.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

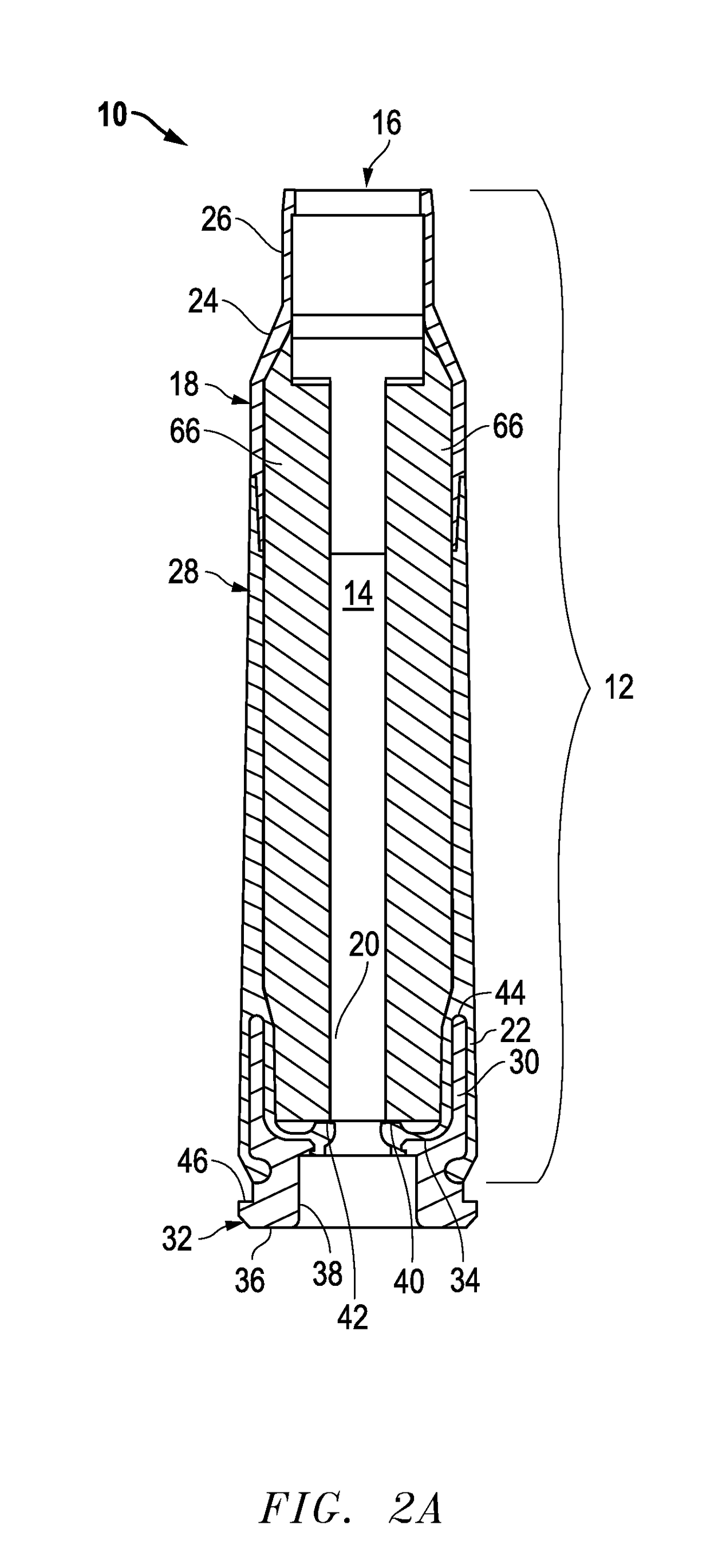

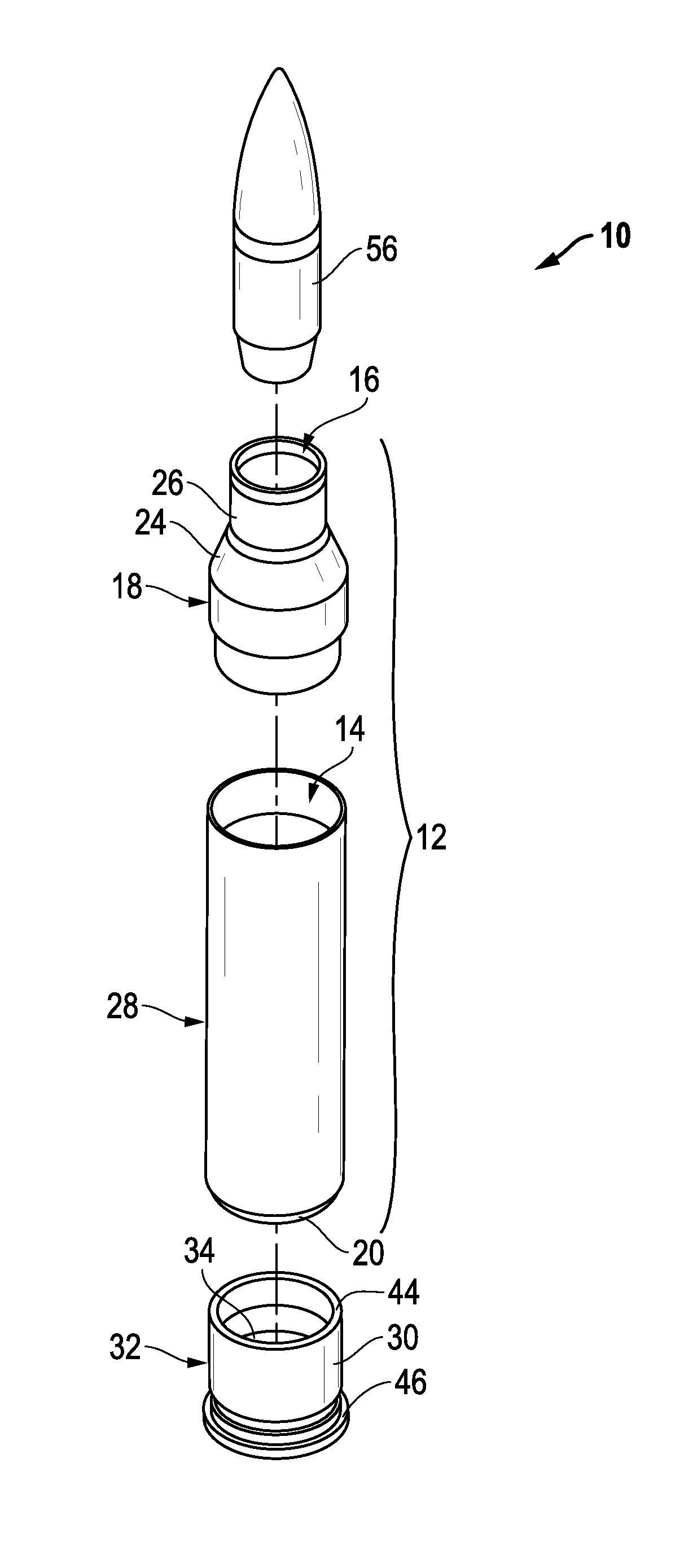

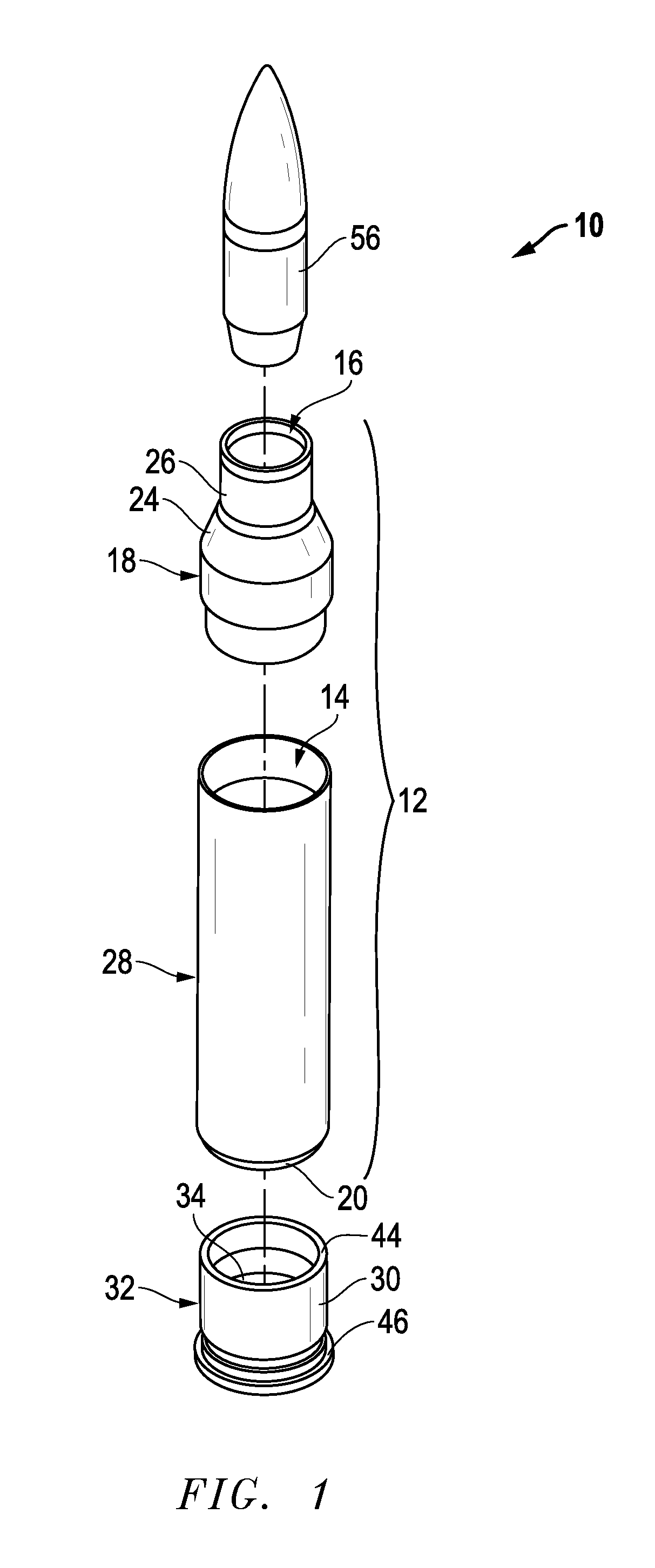

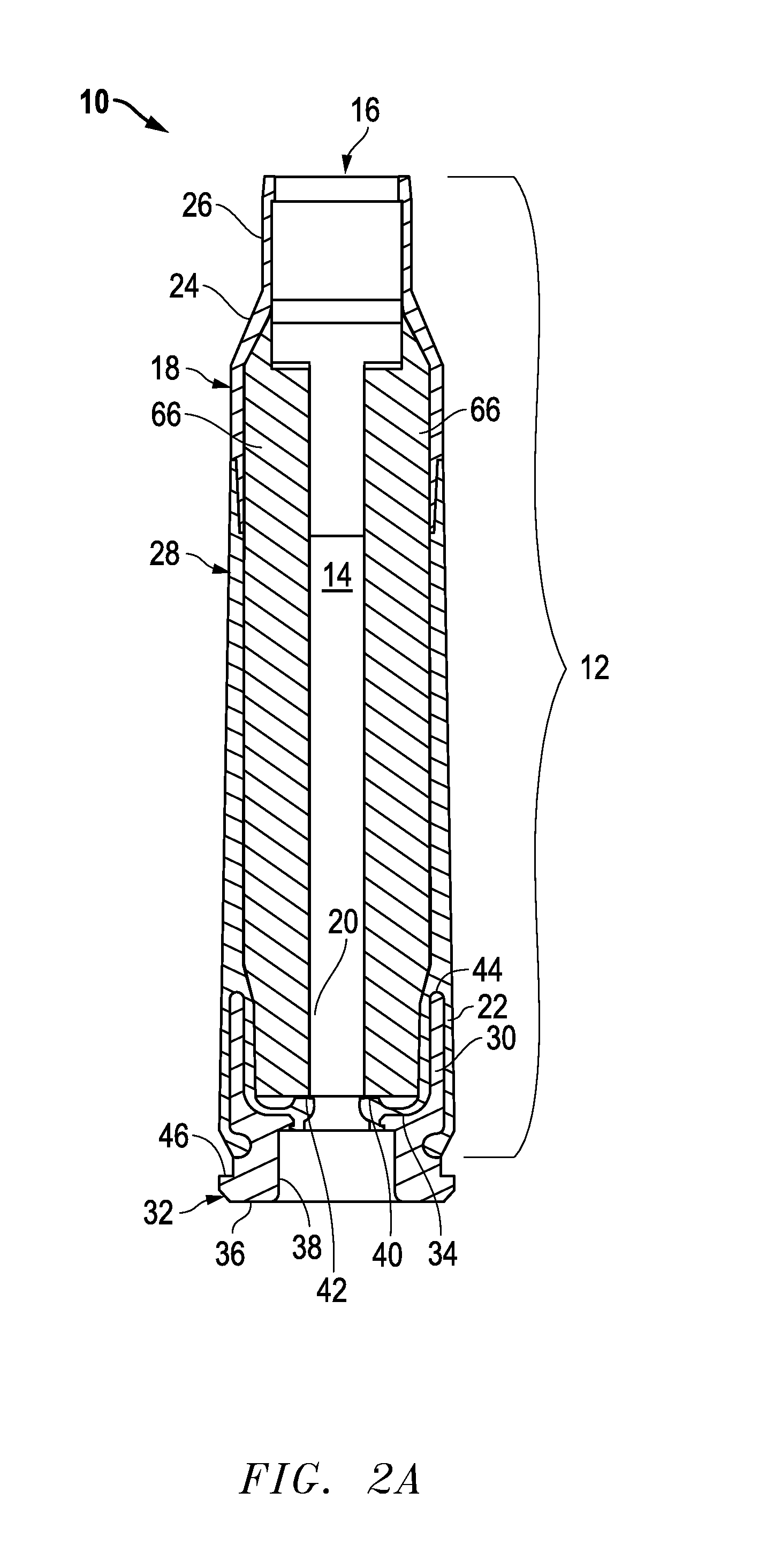

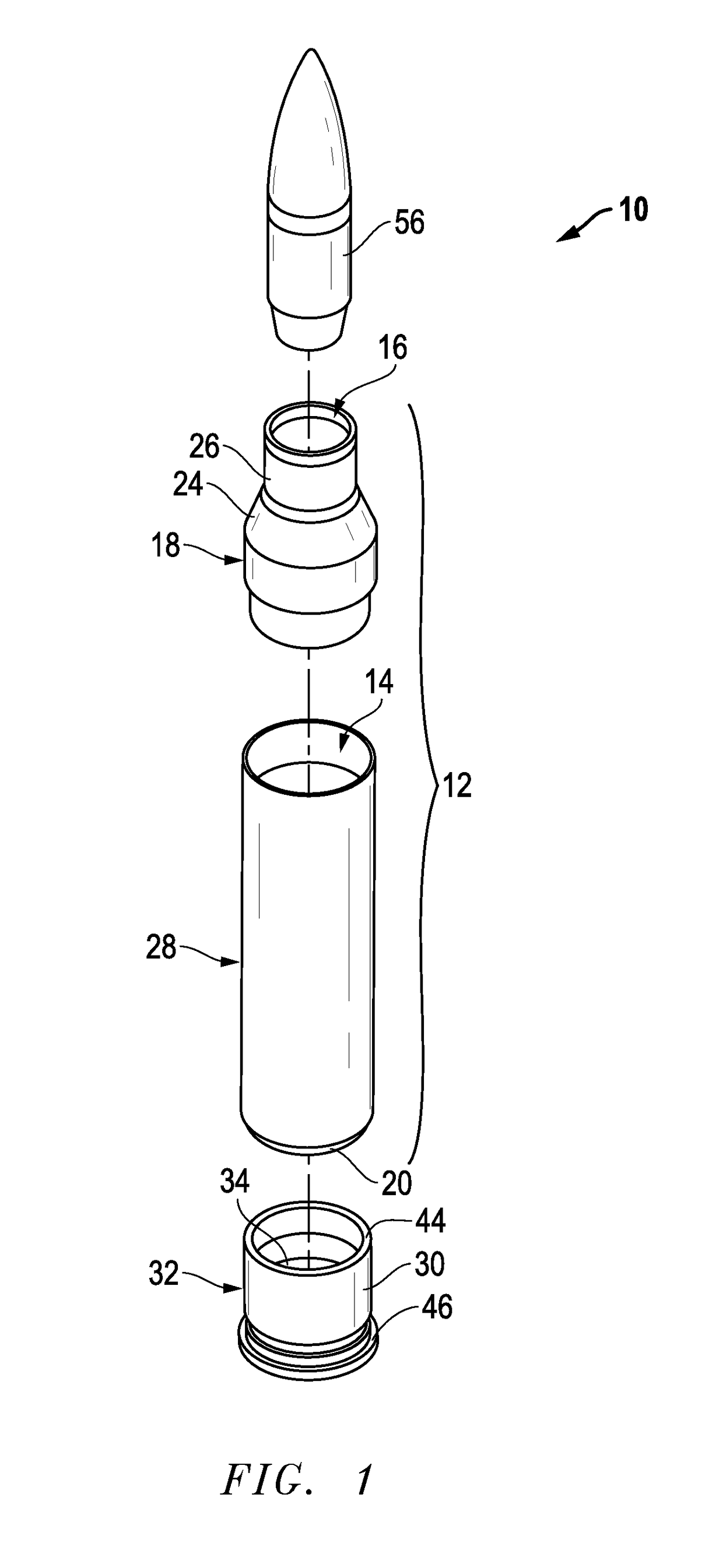

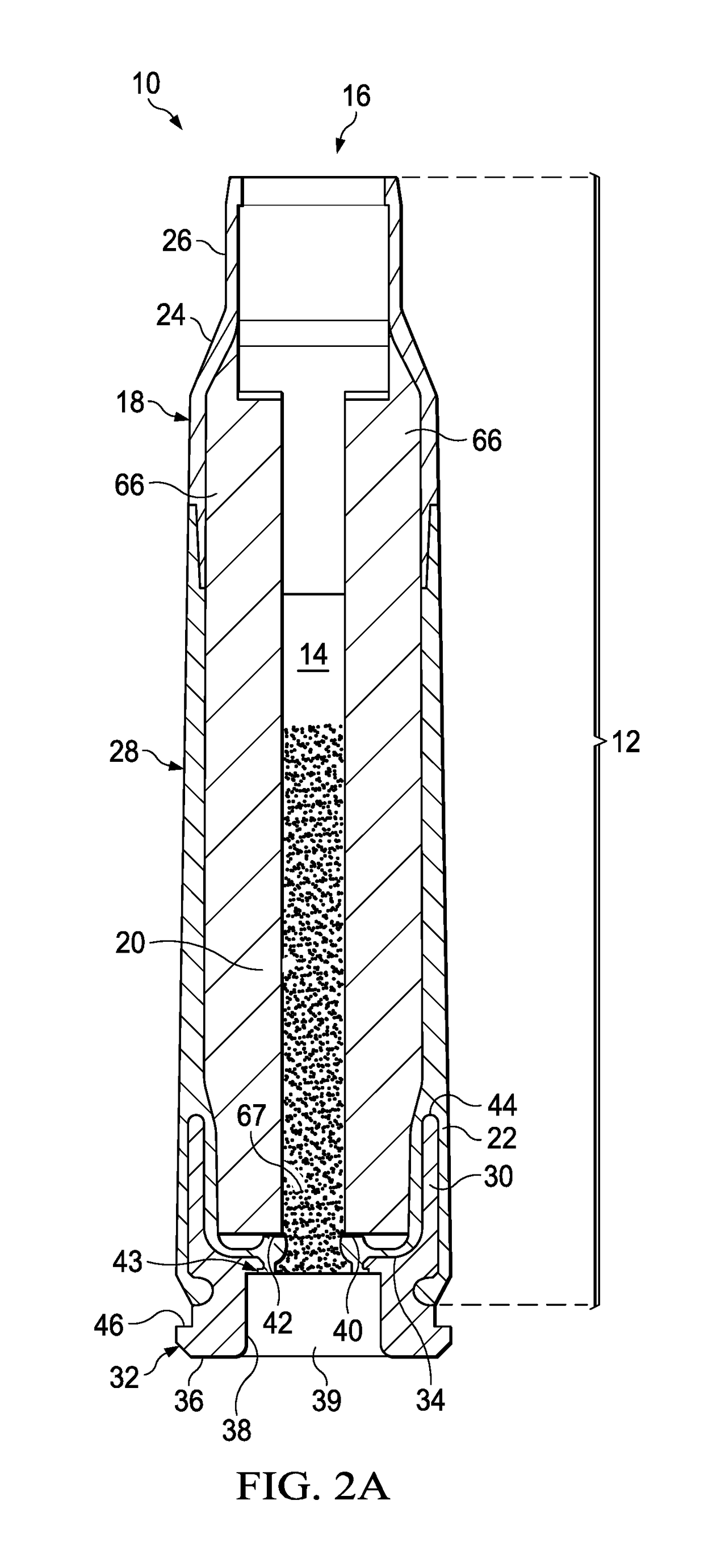

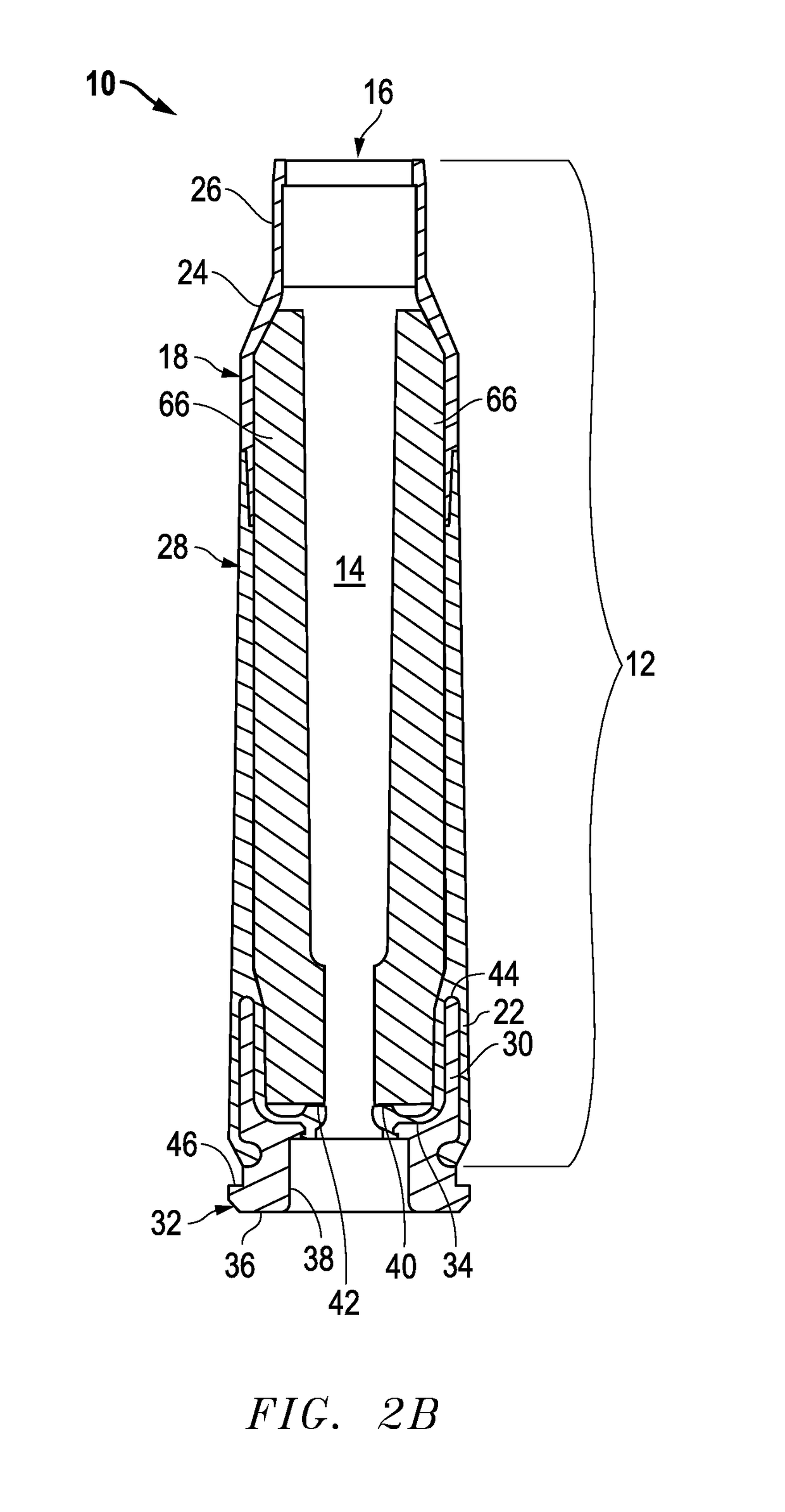

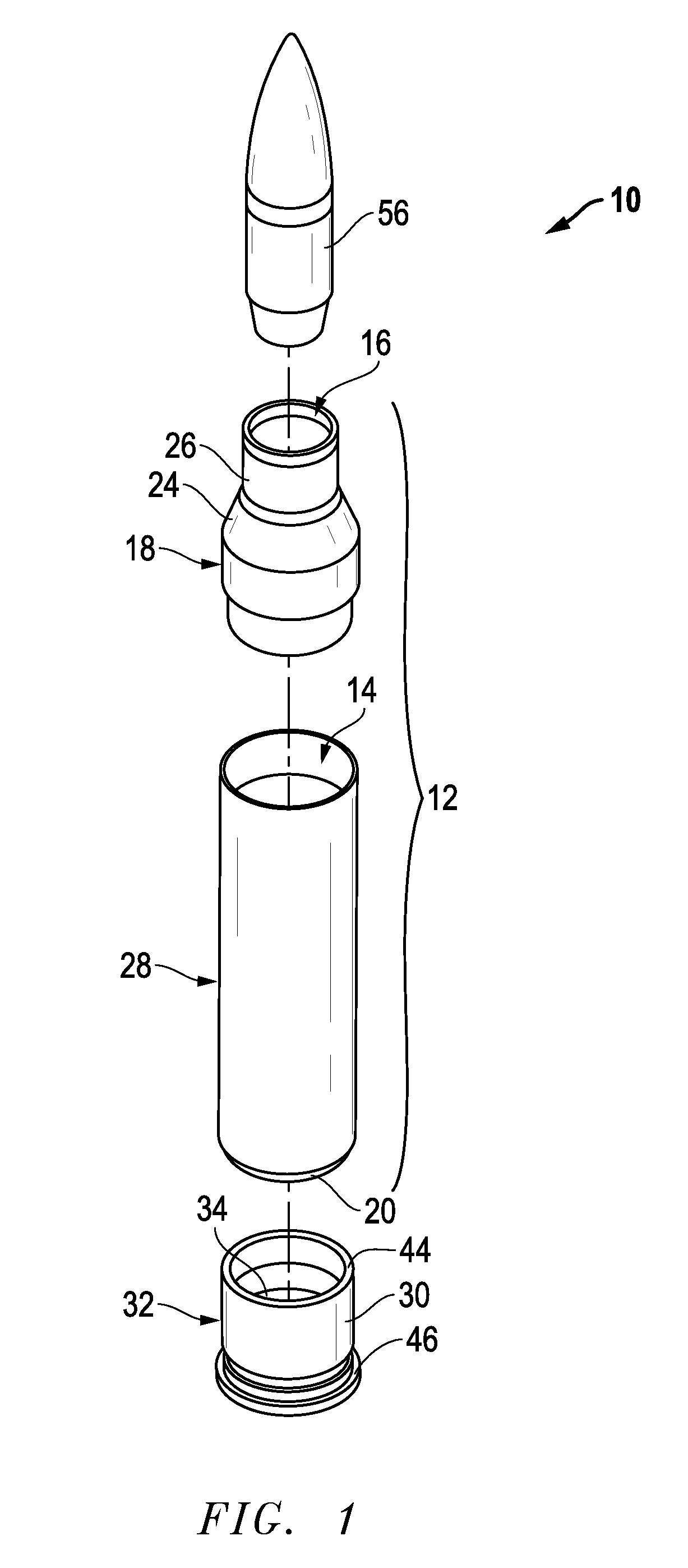

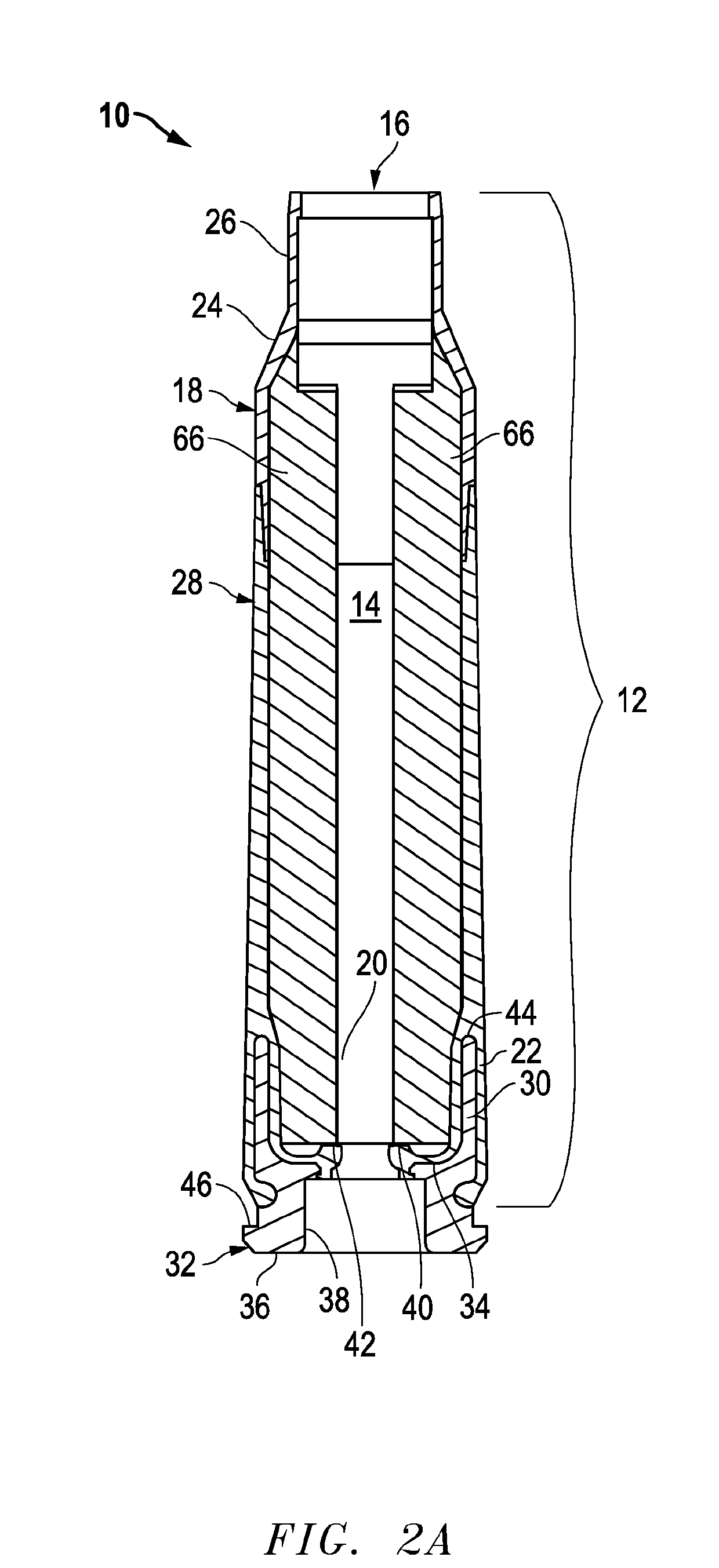

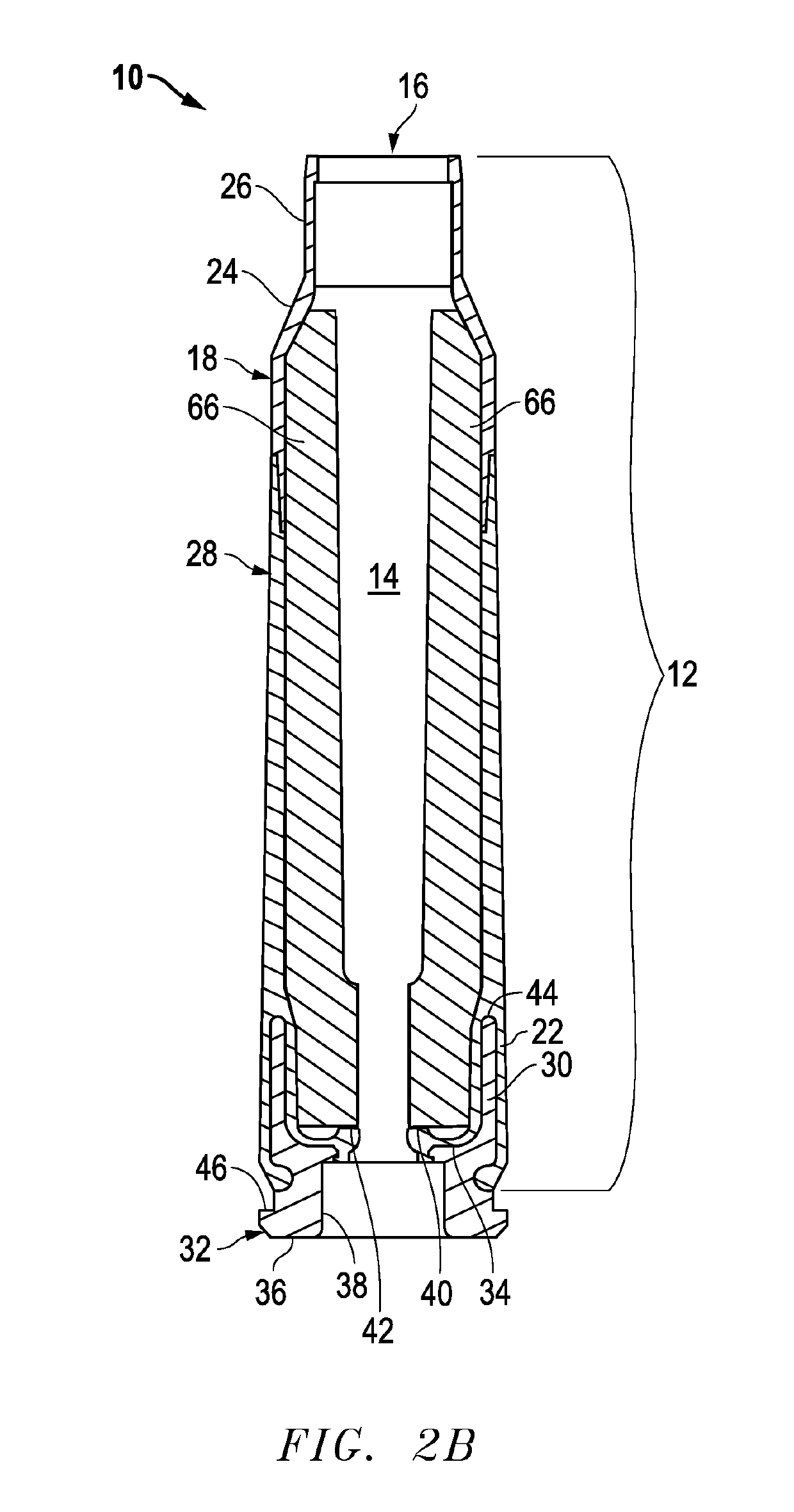

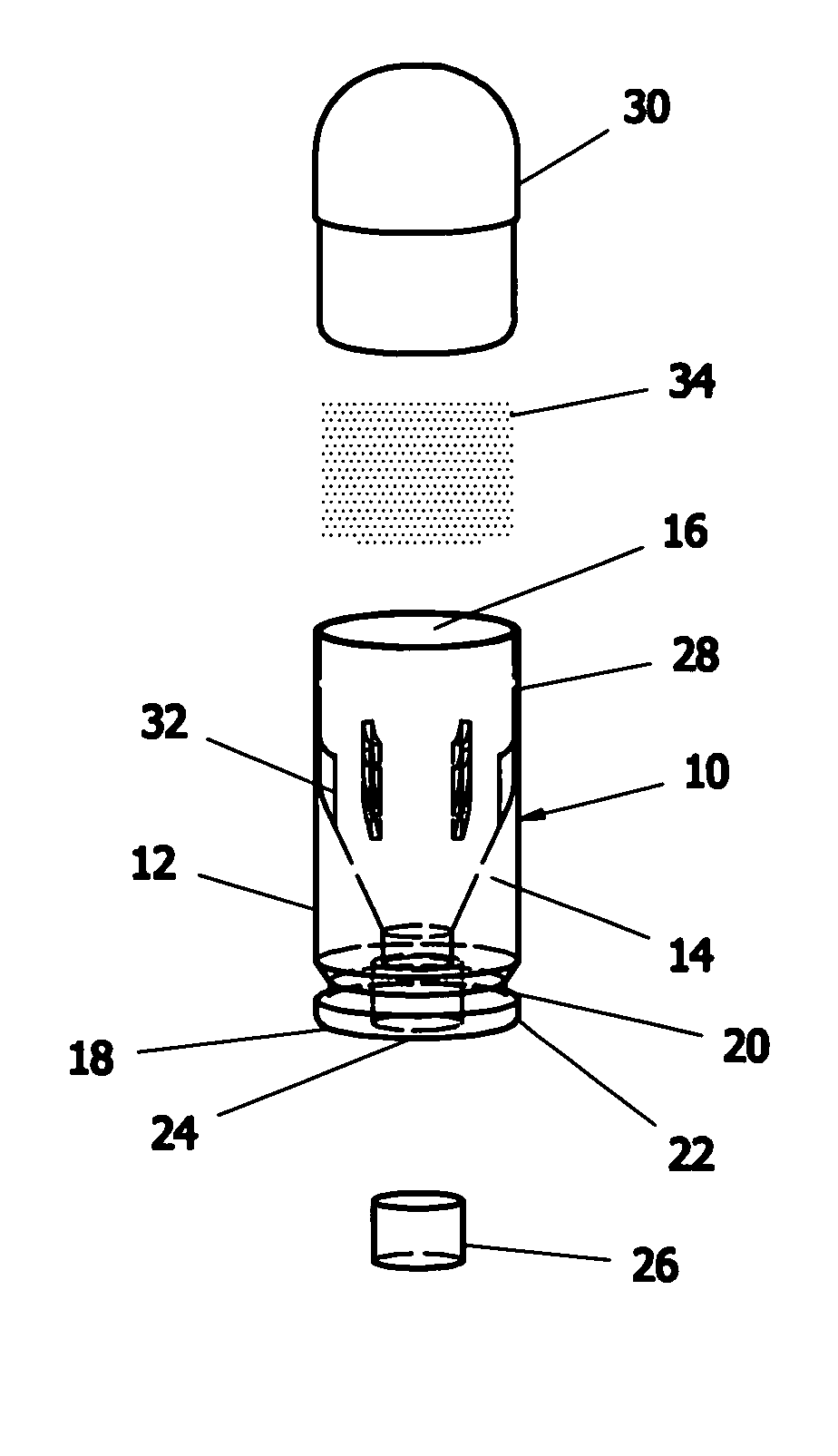

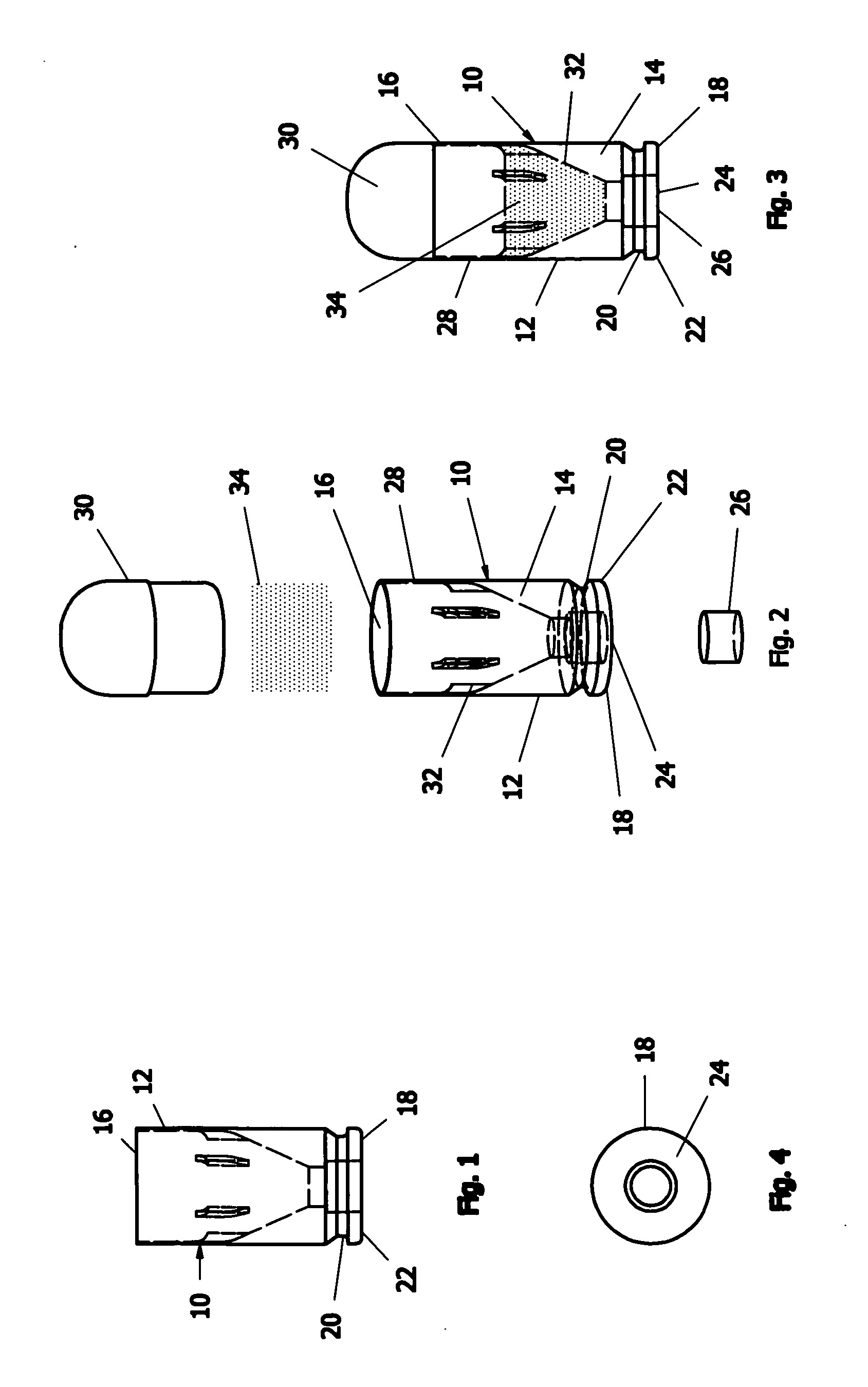

Subsonic polymeric ammunition

The present invention provides a subsonic ammunition including a polymeric casing body comprising a generally cylindrical hollow polymer body having a body base at a first end thereof and a mouth at a second end to define a propellant chamber; a propellant insert positioned in the propellant chamber to reduce the internal volume of the propellant chamber, wherein the propellant chamber has an internal volume that is between 25 and 80% less than the open internal volume of a standard casing of equivalent caliber; a propellant disposed and confined within the propellant chamber; a primer insert positioned at the body base and in communication with the propellant chamber; a primer disposed in the primer insert in combustible communication with the propellant; and a projectile frictionally fitted in the mouth in combustible communication with the propellant.

Owner:TRUE VELOCITY IP HLDG LLC

Method of making polymeric subsonic ammunition

The present invention provides a method of making a subsonic ammunition having a polymeric casing body having a generally cylindrical hollow polymer body having a body base at a first end thereof and a mouth at a second end to define a propellant chamber; a propellant insert positioned in the propellant chamber to reduce the internal volume of the propellant chamber, wherein the propellant chamber has an internal volume that is at least 10% less than the open internal volume of a standard casing of equivalent caliber; and a primer insert positioned in the body base and in communication with the propellant chamber.

Owner:TRUE VELOCITY IP HLDG LLC

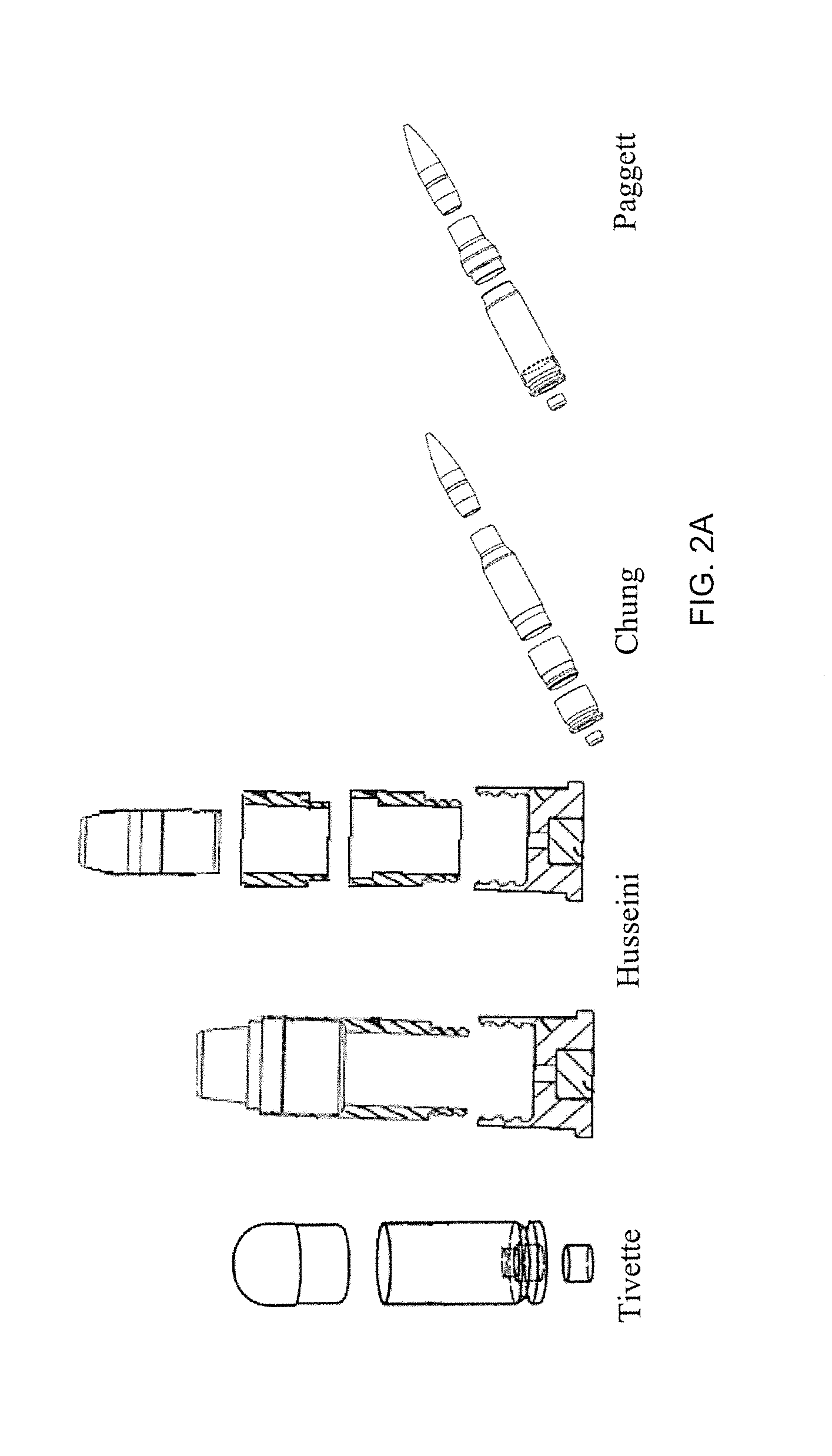

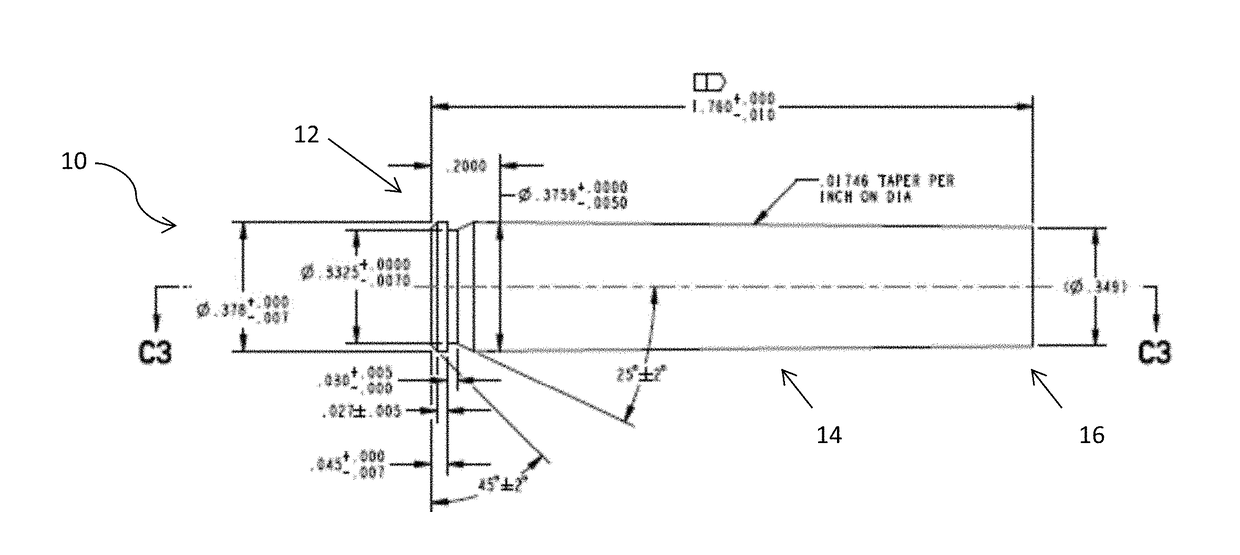

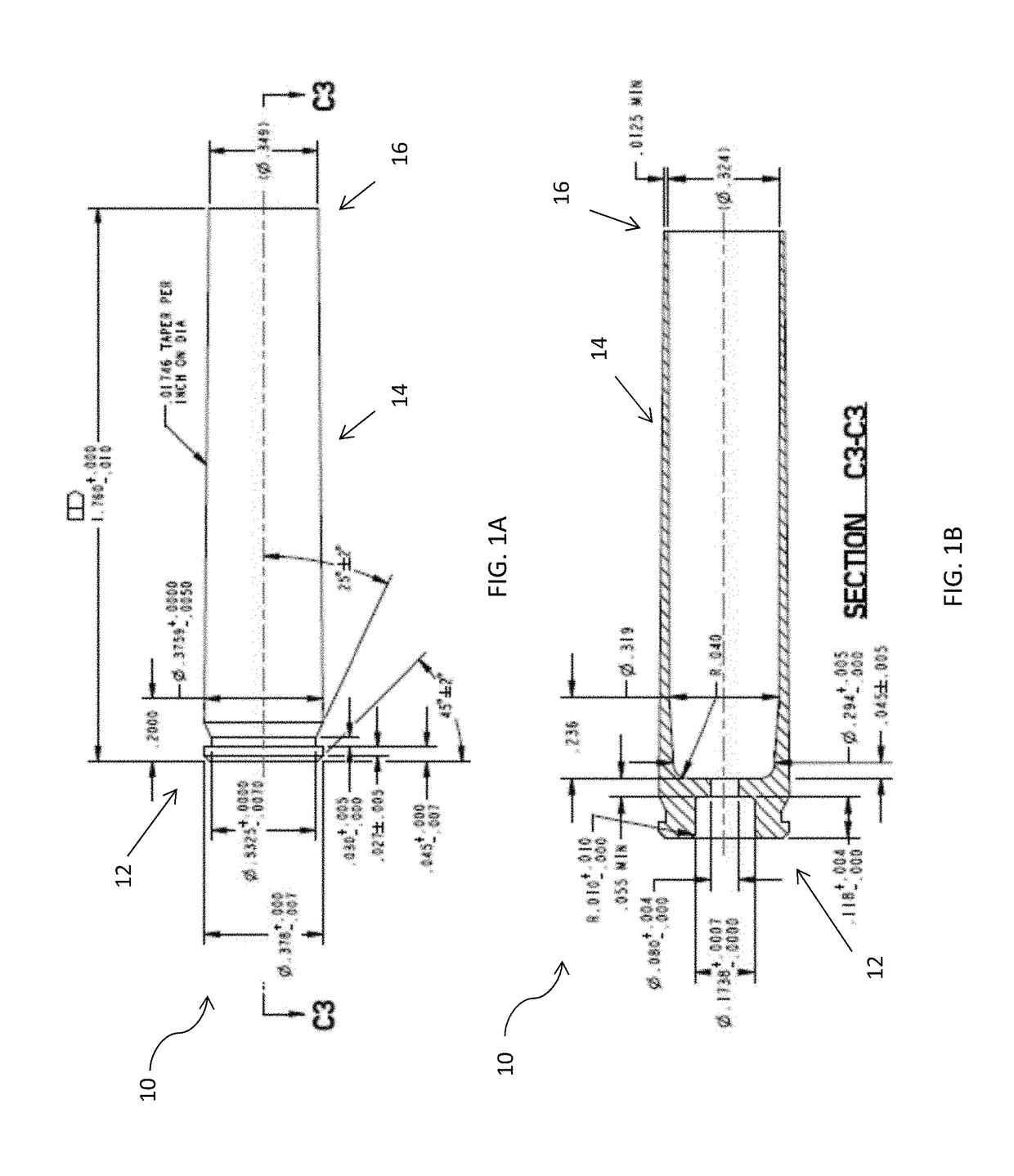

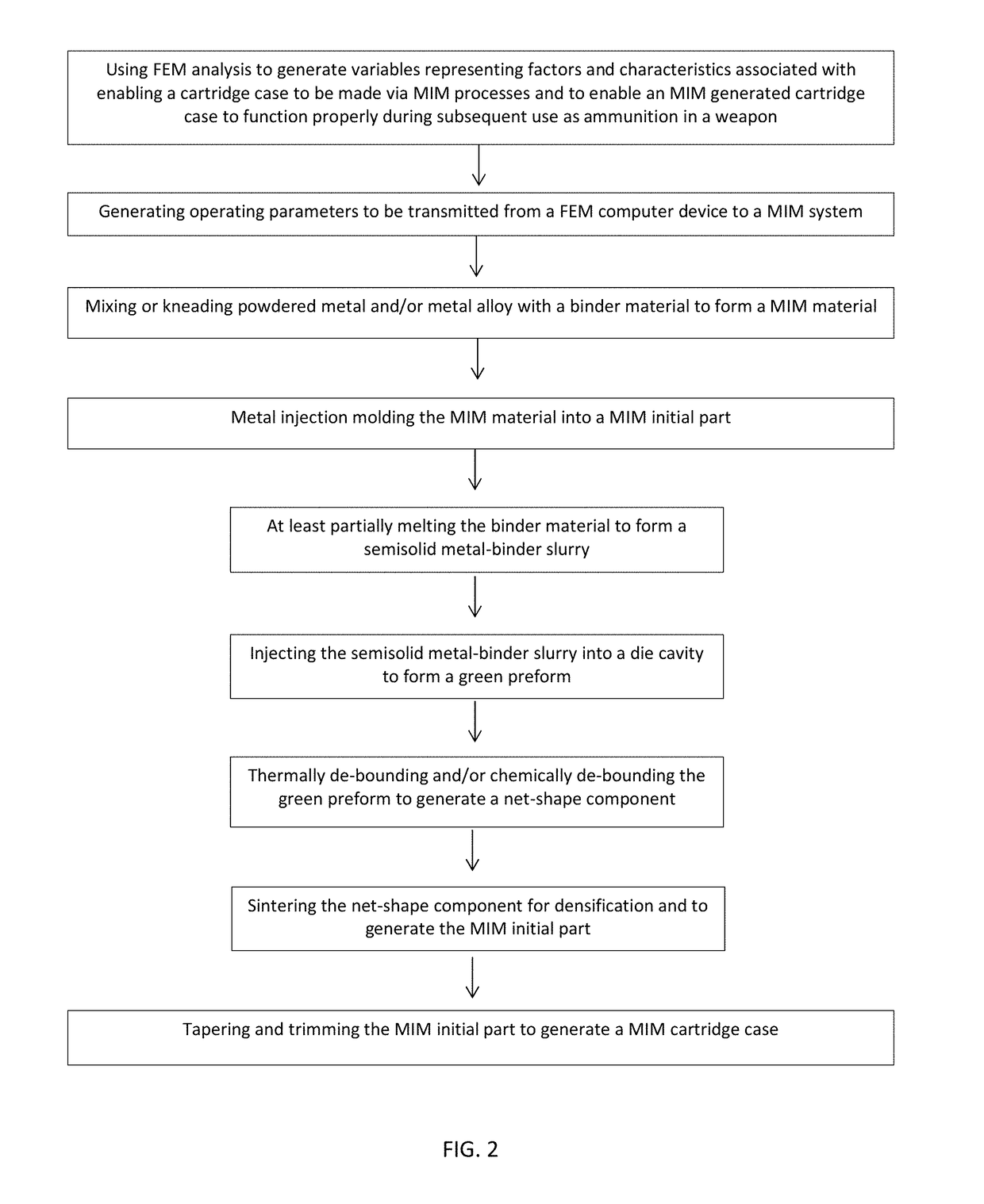

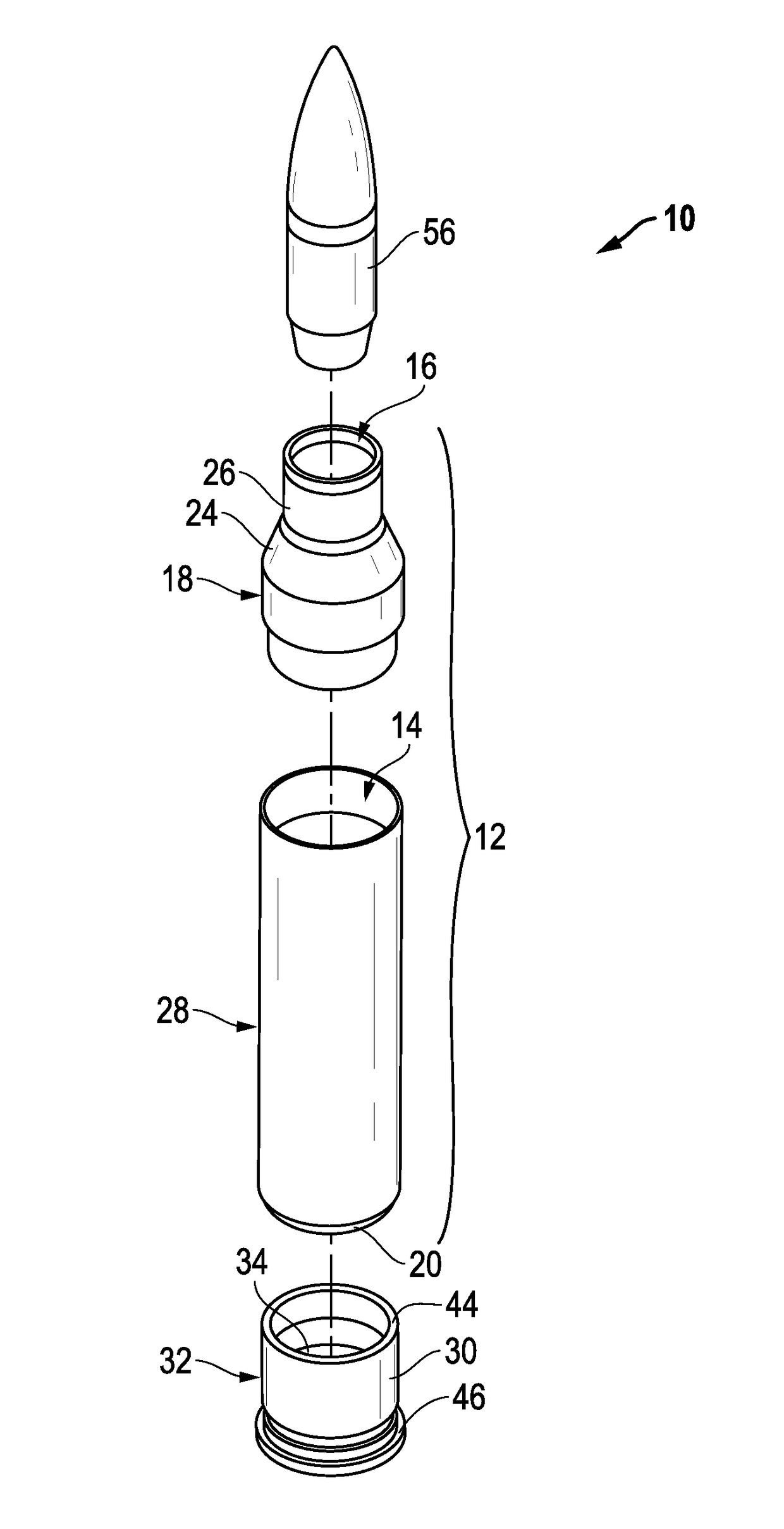

Metal Injection Molded Cased Telescoped Ammunition

ActiveUS20180066925A1Promote generationLight weightTransportation and packagingMetal-working apparatusMetal alloySlug

Disclosed is a cartridge case for various caliber ammunition that can consist essentially of a powdered metal and / or powdered metal alloy(s) that is formed into the cartridge case through an injection mold processing. Also disclosed is a method for forming a cartridge case, which may include use of Metal Injection Molding (“MIM”) processes to produce the cartridge case which retains a primer, propellant, and / or a bullet. Also disclosed are embodiments related to a case telescoped cartridge that may include a cap and a body. The body can consist essentially of or consists entirely of a powdered metal and / or powdered metal alloy(s) that has been formed through MIM. The cap can comprise plastic that has been formed through plastic molding or comprise powdered metal and / or powdered metal alloy(s) that has been formed through MIM.

Owner:CONCURRENT TECH

Method of making a polymeric subsonic ammunition cartridge

The present invention provides a method of making a subsonic ammunition cartridge having a polymeric casing body having a generally cylindrical hollow polymer body having a body base at a first end thereof and a mouth at a second end to define a propellant chamber; a propellant insert positioned in the propellant chamber to reduce the internal volume of the propellant chamber, wherein the propellant chamber has an internal volume that is between 25 and 80% less than the open internal volume of a standard casing of equivalent caliber; and a primer insert positioned in the body base and in communication with the propellant chamber.

Owner:TRUE VELOCITY IP HLDG LLC

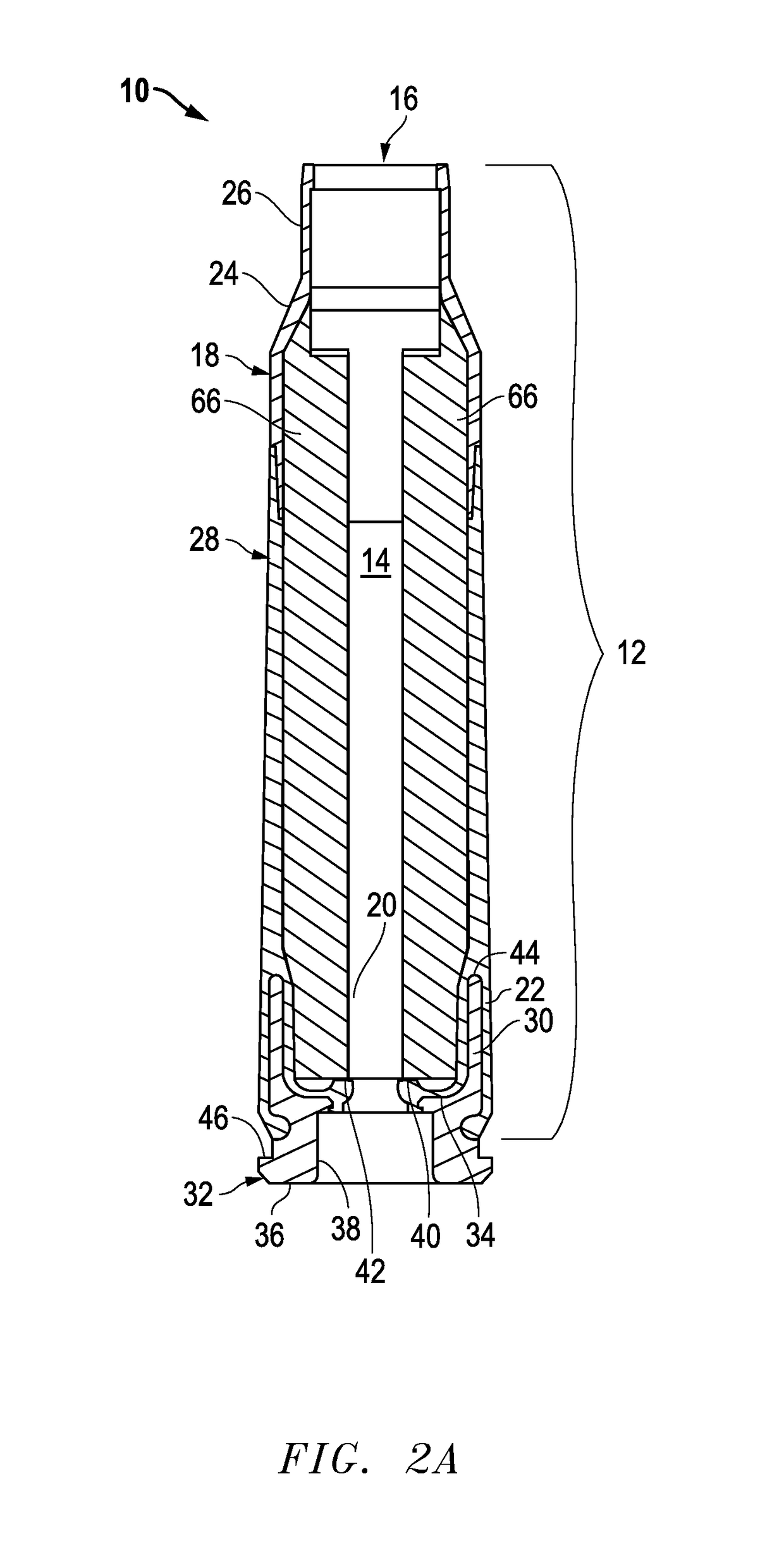

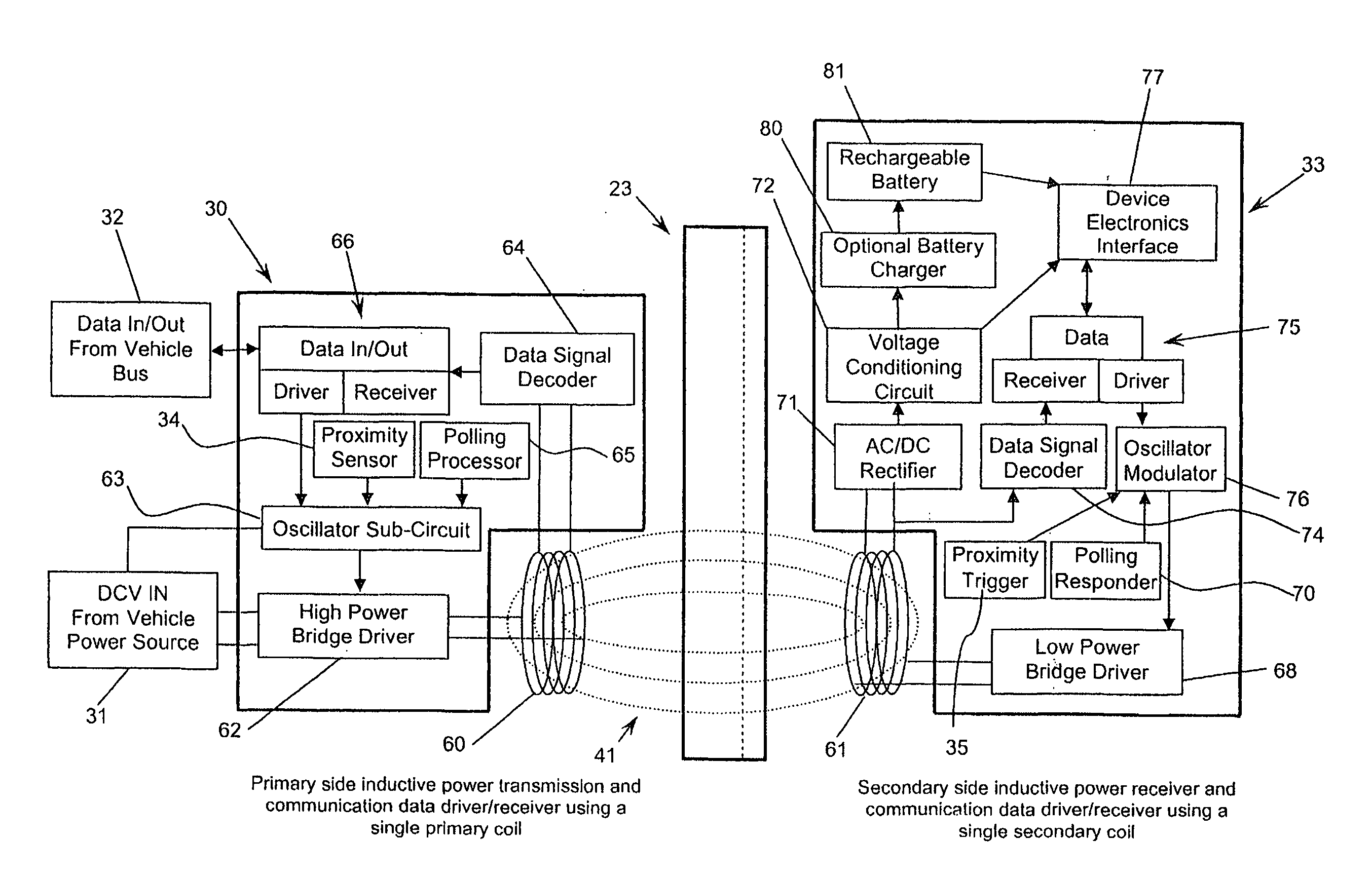

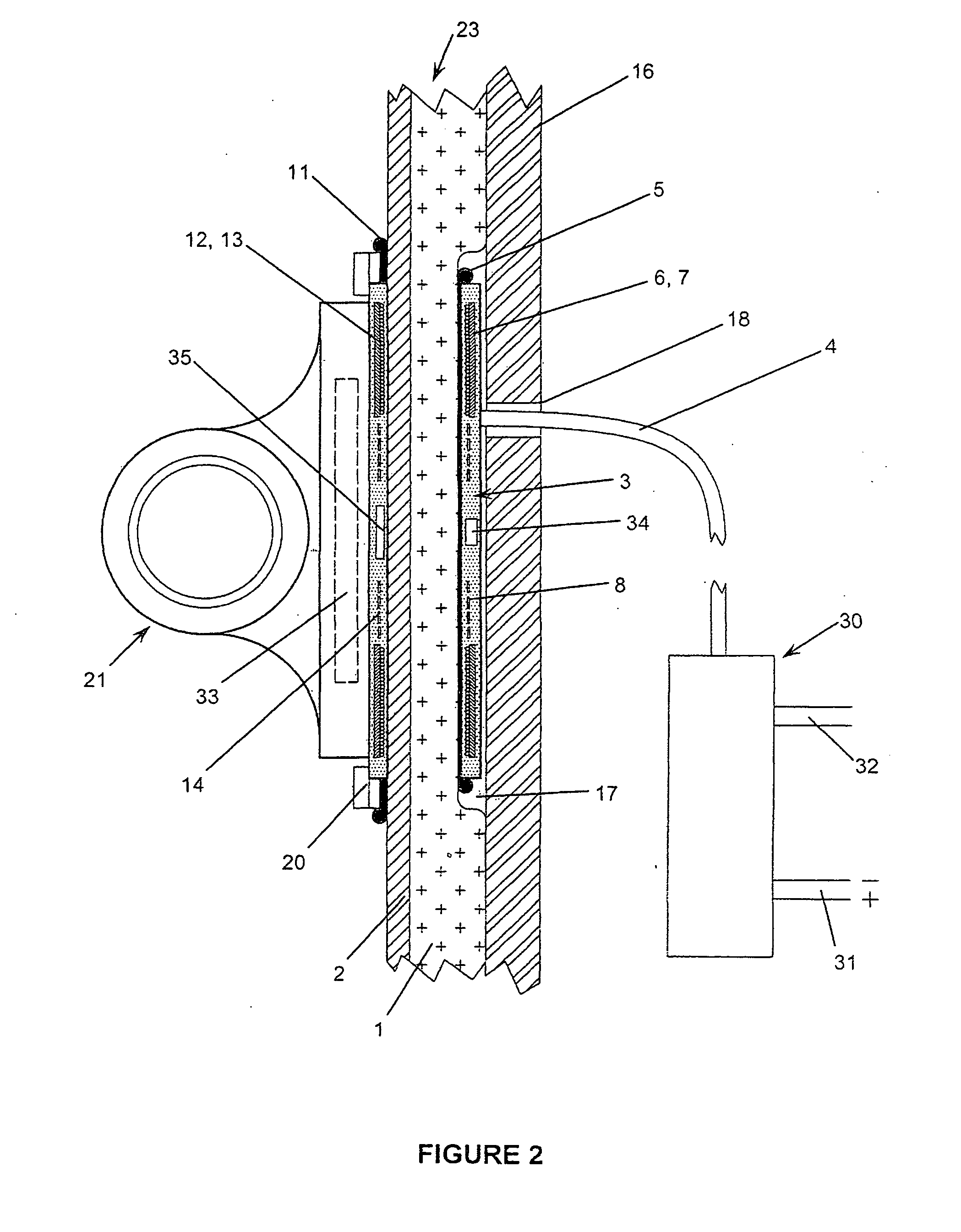

Inductive transmission of power and data through ceramic armor panels

ActiveUS20120032632A1Decreasing its survivabilityCompromising their effectivenessCircuit authenticationElectromagnetic wave systemElectrical devicesData transmission

A system for the inductive transmission of power and data through large caliber ballistic appliqué composite armor panels mountable to military vehicle includes a large caliber ballistic appliqué composite armor panel and a quick-release base mounted to the outer face of the panel and a primary coil mounted to the inner face of the panel so as to be opposite to and aligned with the base; and, a portable electrical device having a secondary coil mounted in its base end, and wherein the armor thickness is no greater than substantially the range of 30 to 50 percent of the diameter of the secondary coil. The base end of the portable electrical device is adapted to releasably mount onto the quick release base for power transfer to the electrical device and for data transfer between the primary coil and the secondary coil by inductive coupling between the primary and secondary coils.

Owner:CYNETIC DESIGNS

Molded semi-universal holster

A receptacle for firearms that comprises a primary receiving cavity for a firearm that is considered to be semi-universal and has multifunctional capabilities. This primary receptacle allows the user to adjust the receiving cavity to fit a plethora of sizes, styles, and calibers within a certain model line. This is accomplished by a series of dual adjustment springs and molded stops that function together to customize tension and squeeze within the receptacle. The compact and ergonomic design allows the receptacle to be easily interchangeable among a variety of carriage or mounting apparatuses.

Owner:OWENS WILLIAM REX

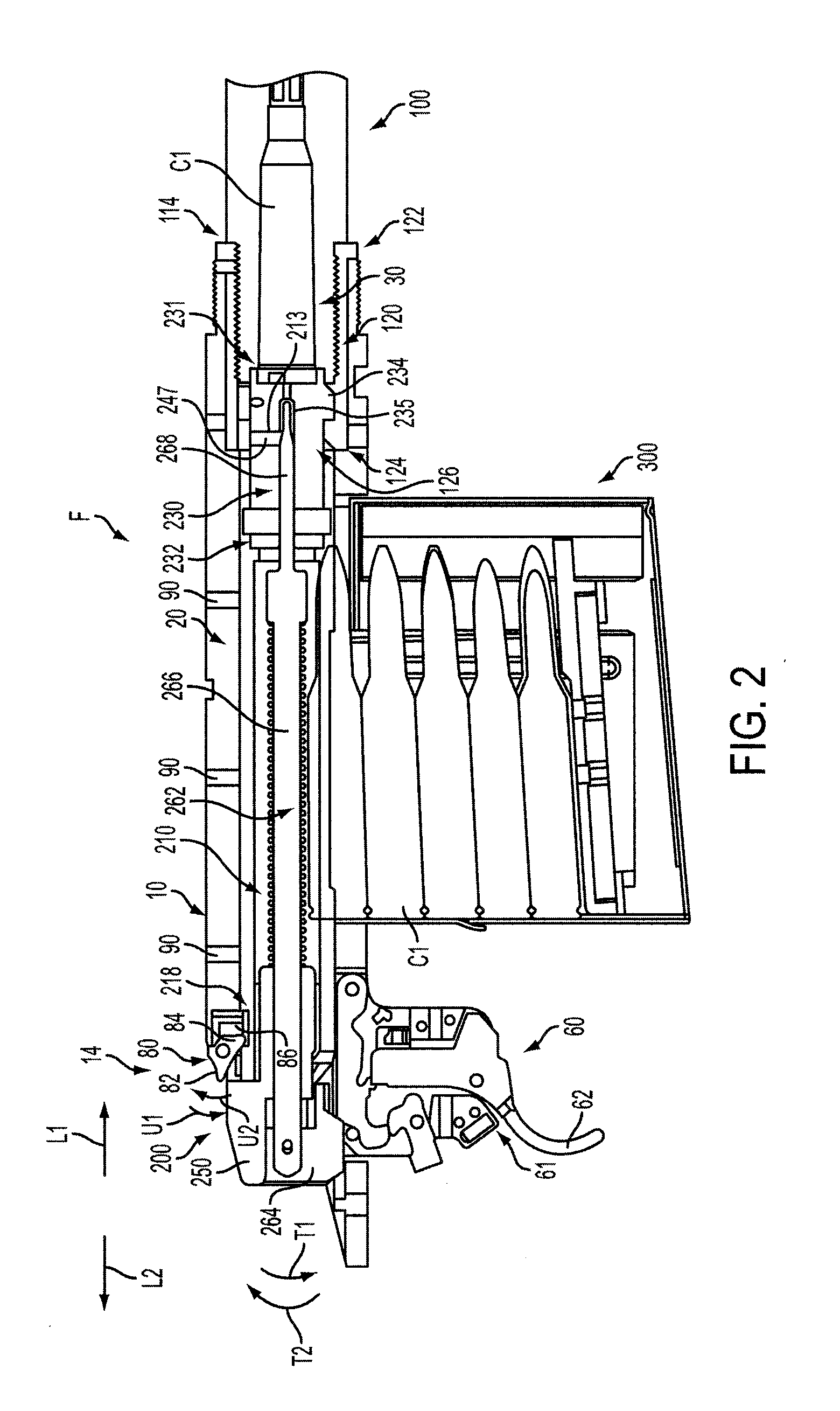

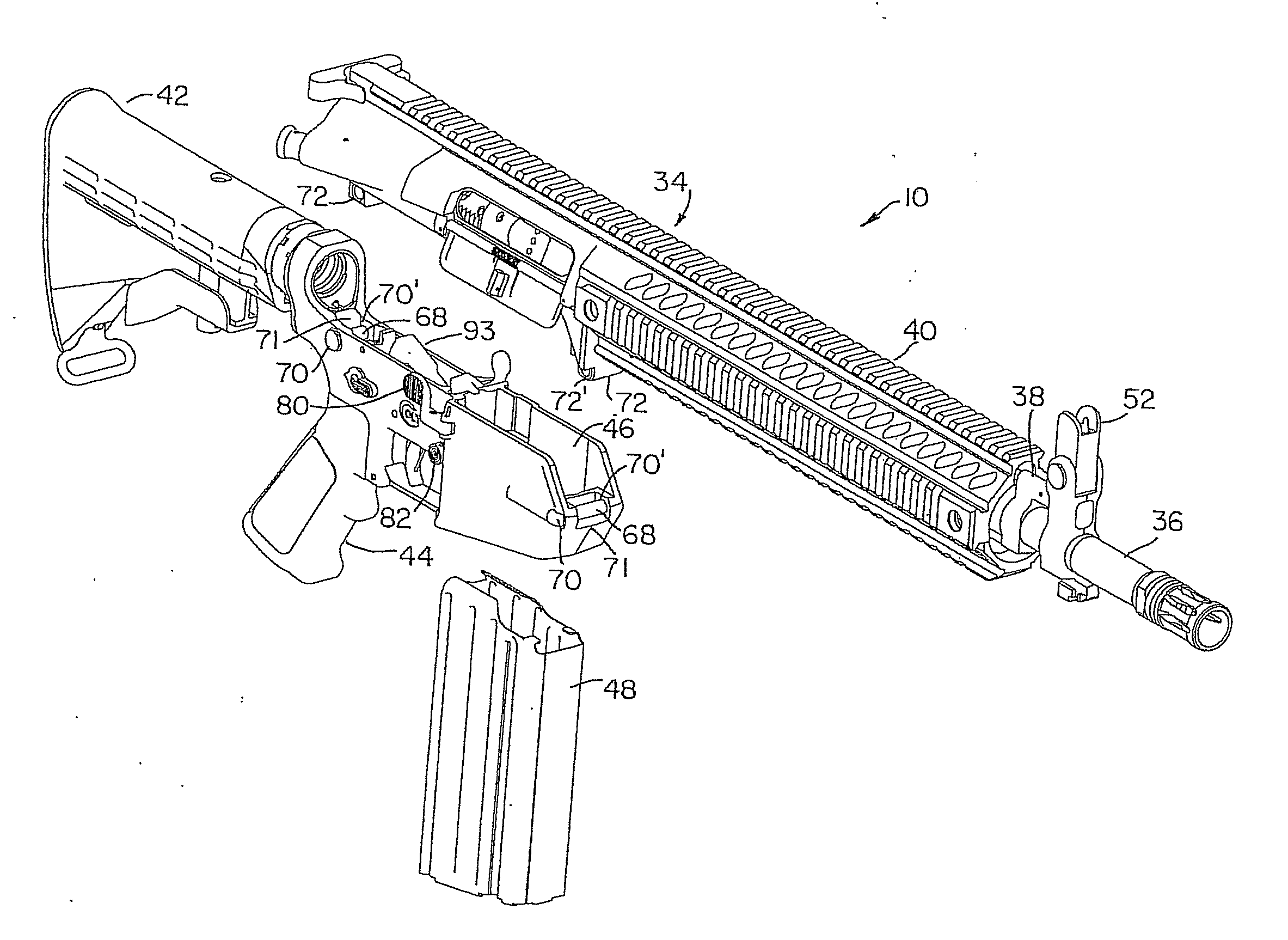

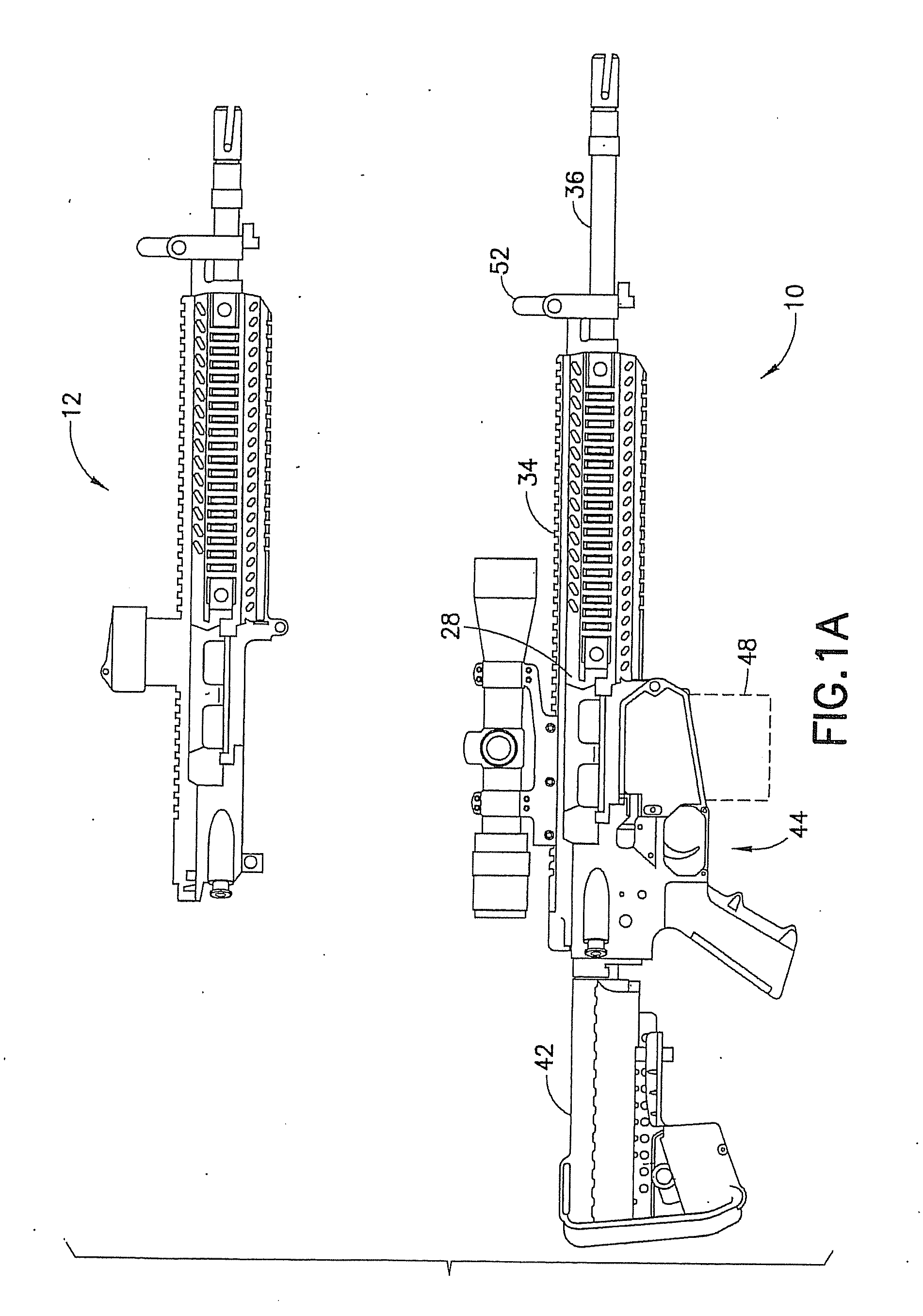

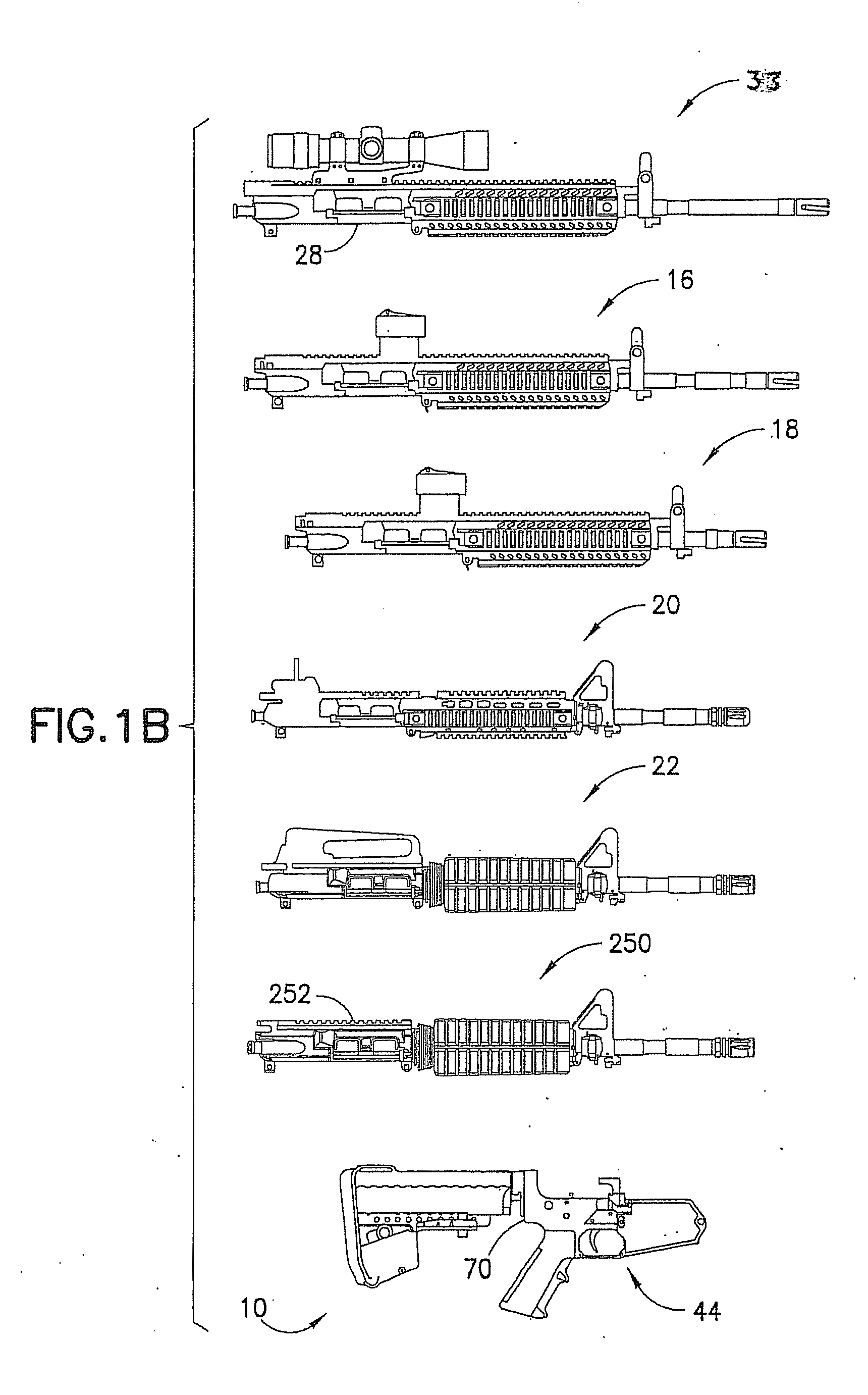

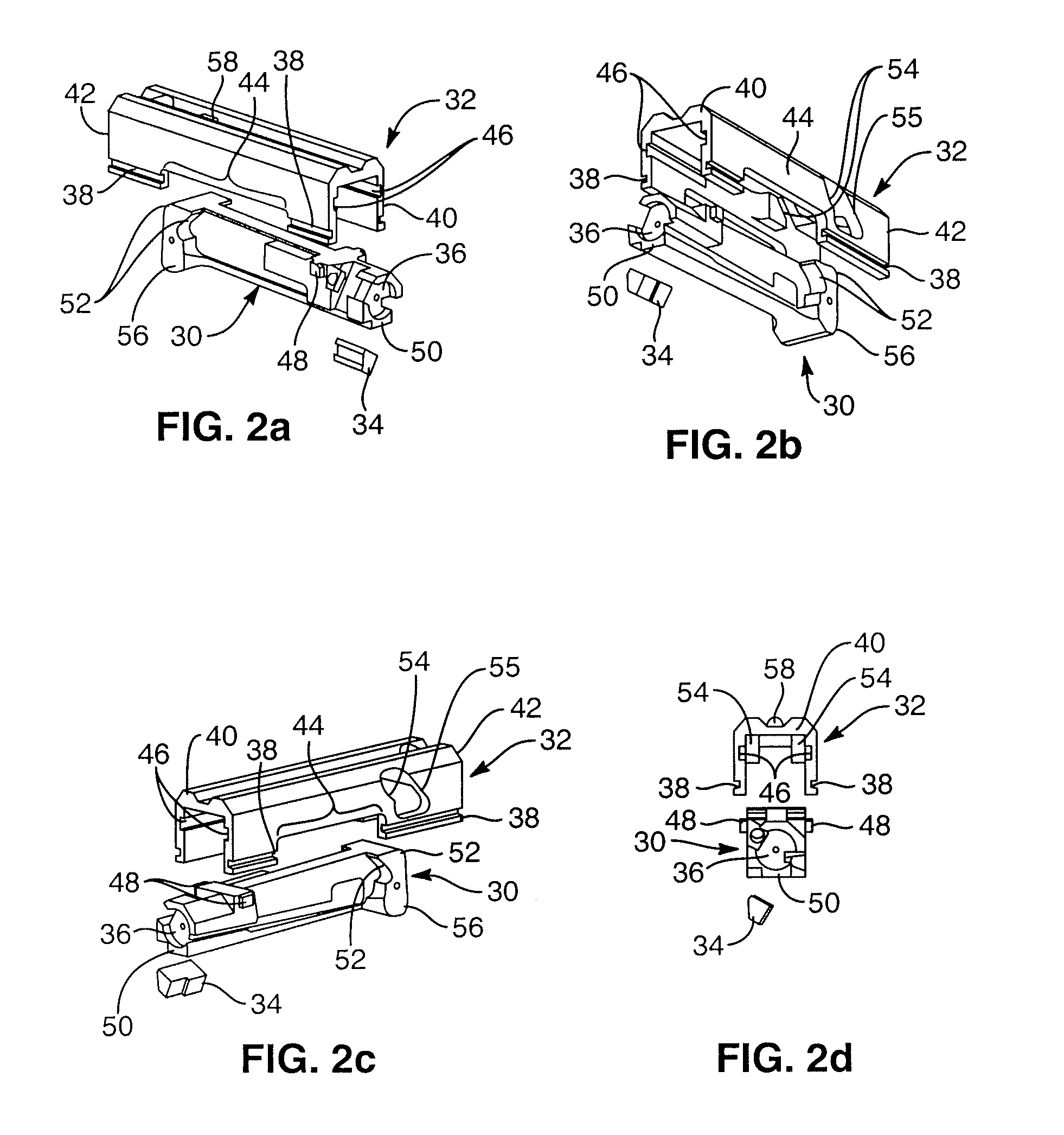

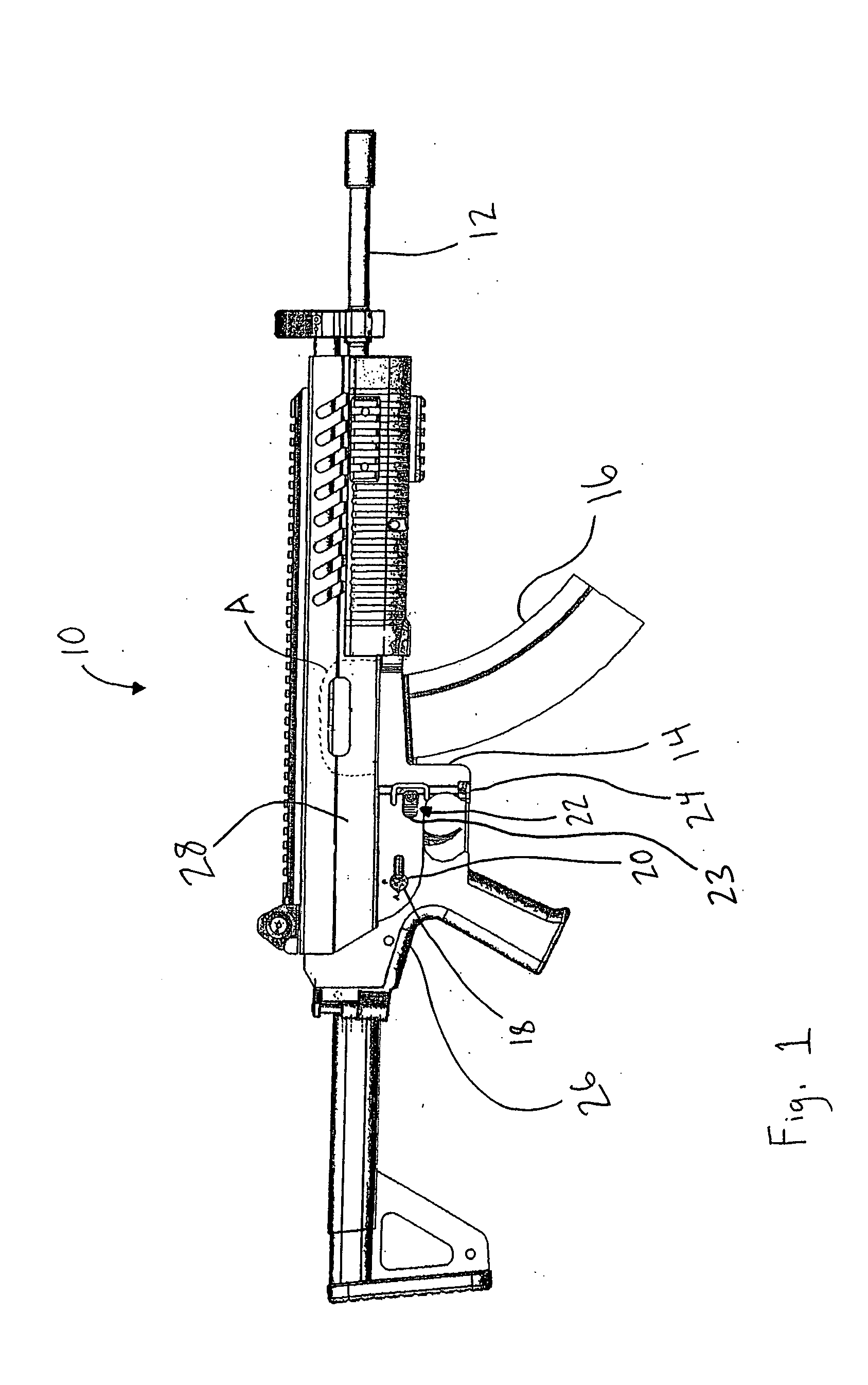

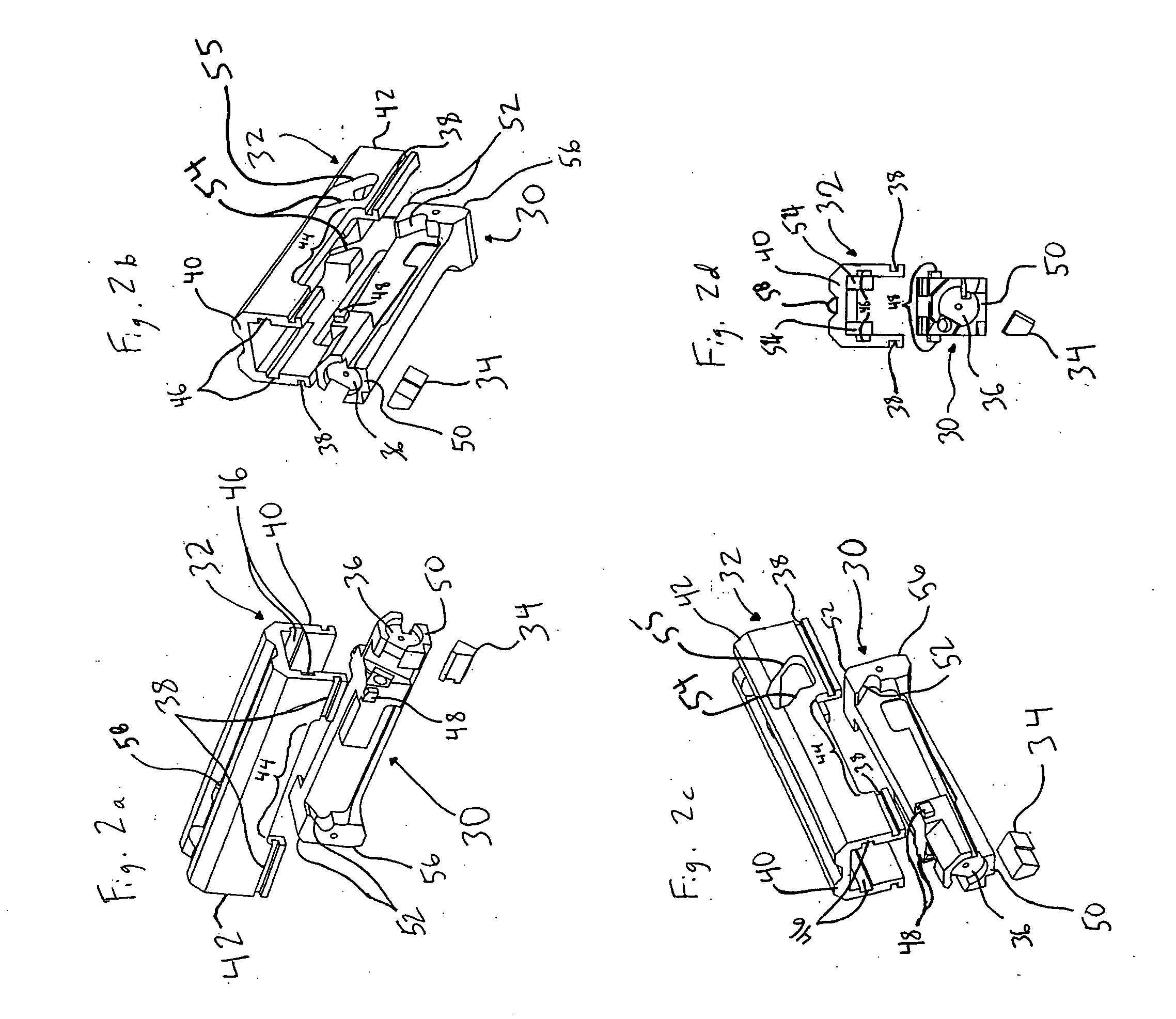

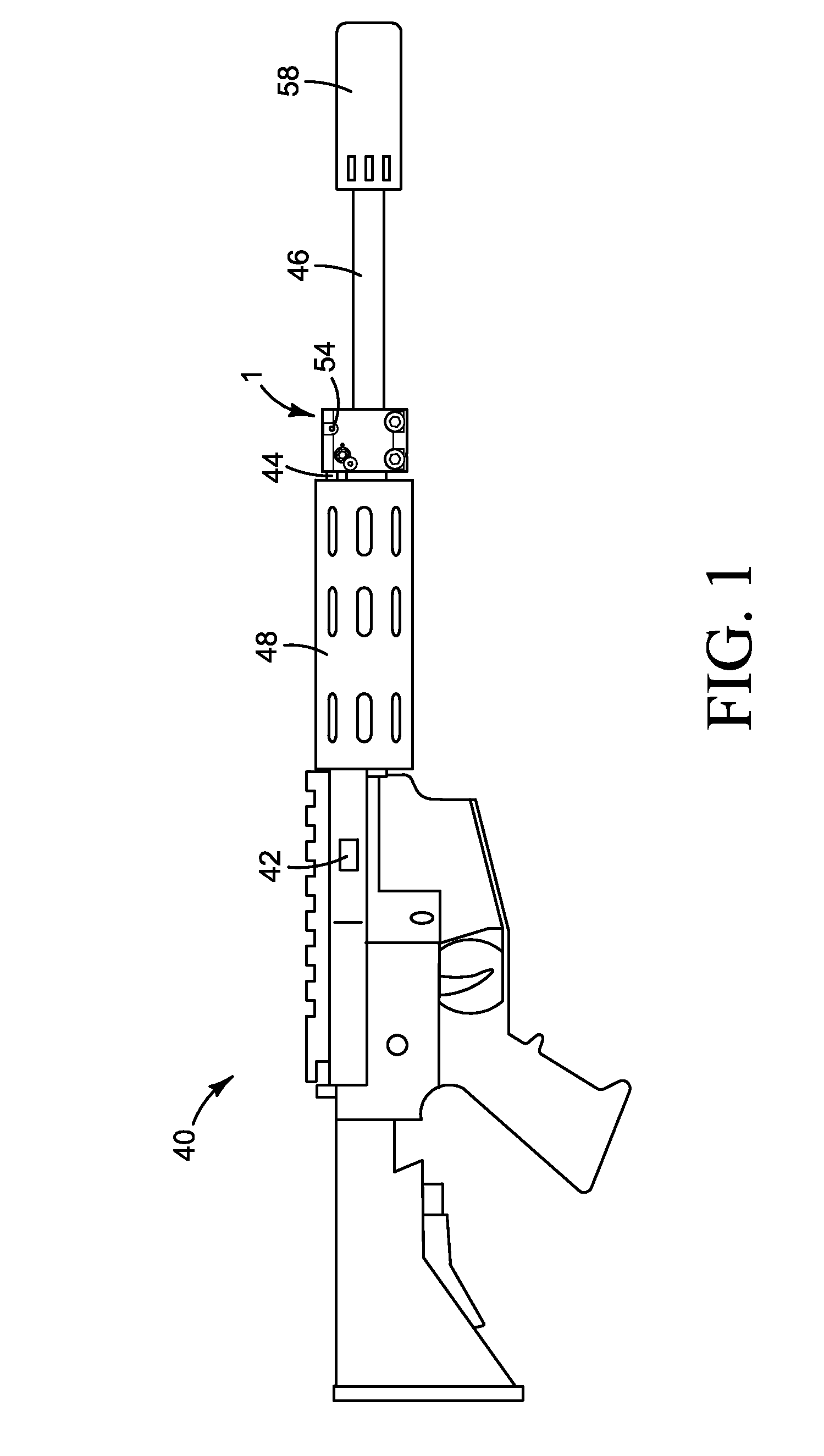

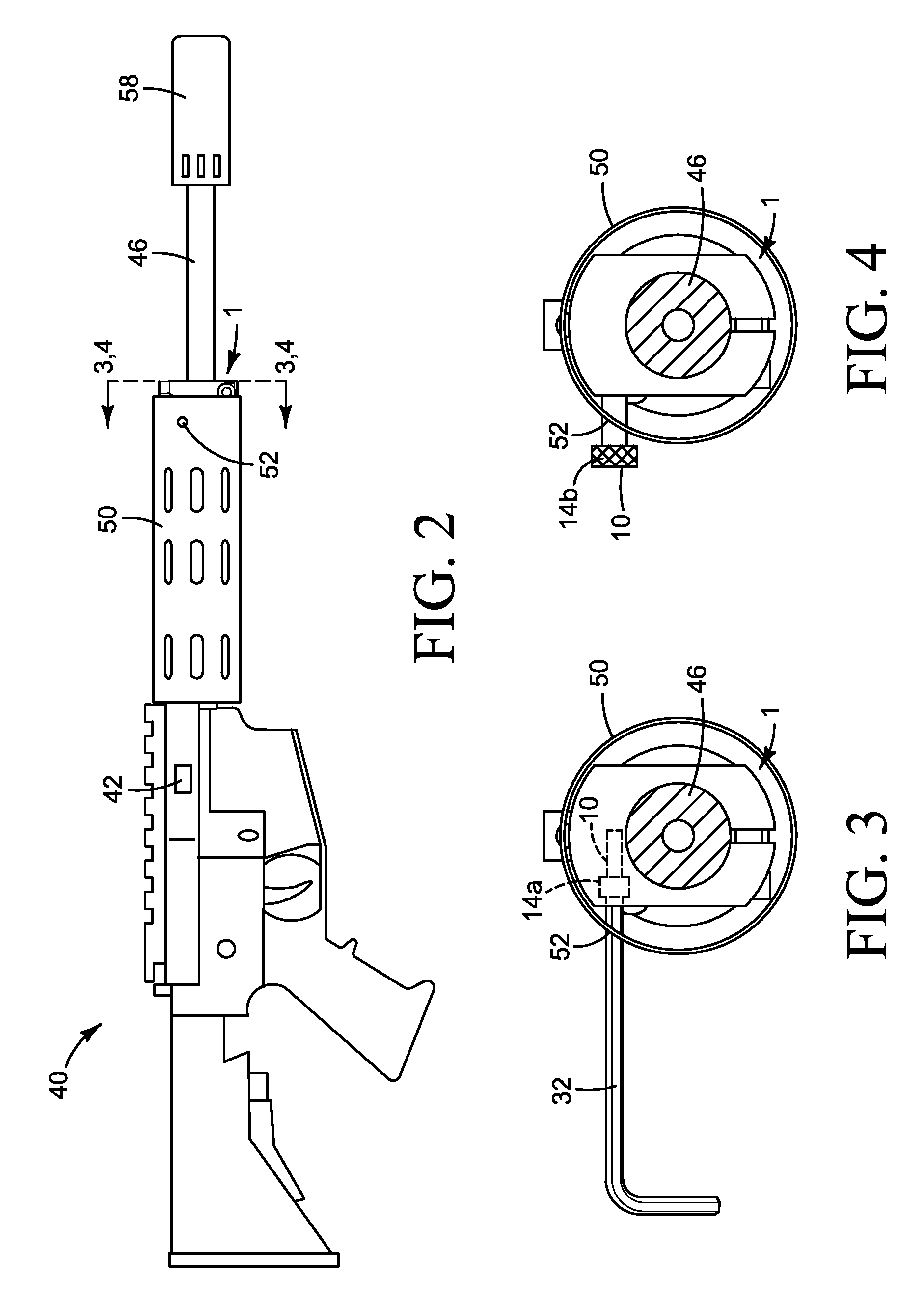

Compact operating system for automatic rifles

InactiveUS6019024AQuick and easy to disassembleQuickly and easily and and reassembledBreech mechanismsSoftware engineeringRifle

An operating system for automatic rifles is described which permits a user to easily remove and replace the bolt and bolt carrier from the rifle, without requiring the user to employ special tools. This invention permits the user to reconfigure the rifle to fire a wide range of different calibers of cartridges, as well as to reconfigure the rifle to feed ammunition from either the top or the bottom of the firearm. This invention further improves the reliability and decreases the manufacturing cost of the operating system by reducing the number of required components. This invention also provides an ergonomic, left hand sided, non-reciprocating cocking handle. The cocking handle assembly is provided with a slot cover which keeps debris from entering the interior of the rifle.

Owner:RMDI

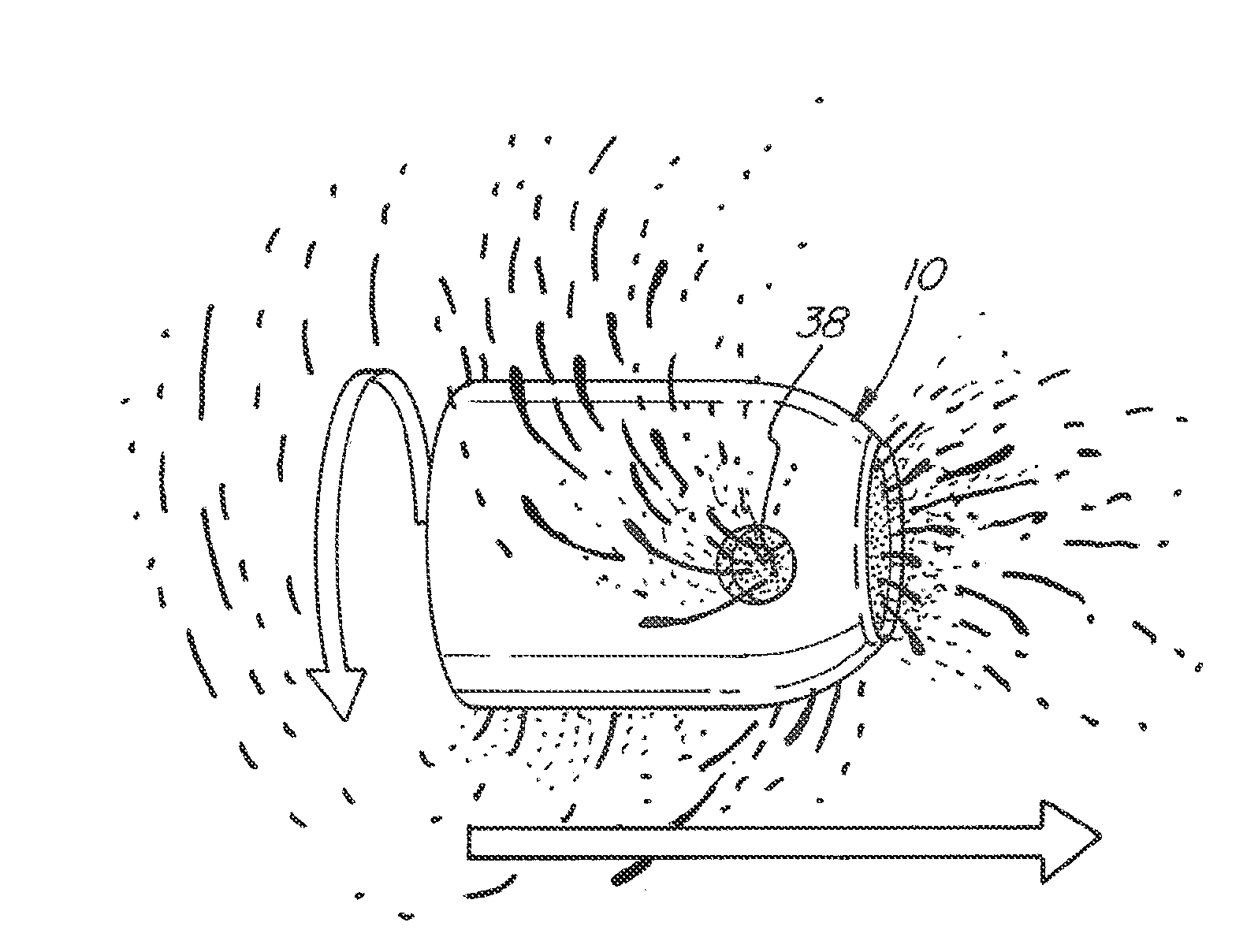

Bullets With Lateral Damage Stopping Power

ActiveUS20140261044A1Raise the possibilityGood stopping effectAmmunition projectilesTraining ammunitionElastomerEngineering

Ammunition which includes a bullet having an effective caliber that is larger than its nominal caliber, comprised of a bullet body with a longitudinal cavity in the forward end, and one or more bores extending from the cavity to bore openings on the exterior of the bullet. In use, target media is gathered in the cavity and ejected under force through the bore openings, increasing the damage done by the bullet. Preferably, the bullet cavity and bores are filled with a polymeric or elastomeric material.

Owner:BRANCA CHRISTOPHER +2

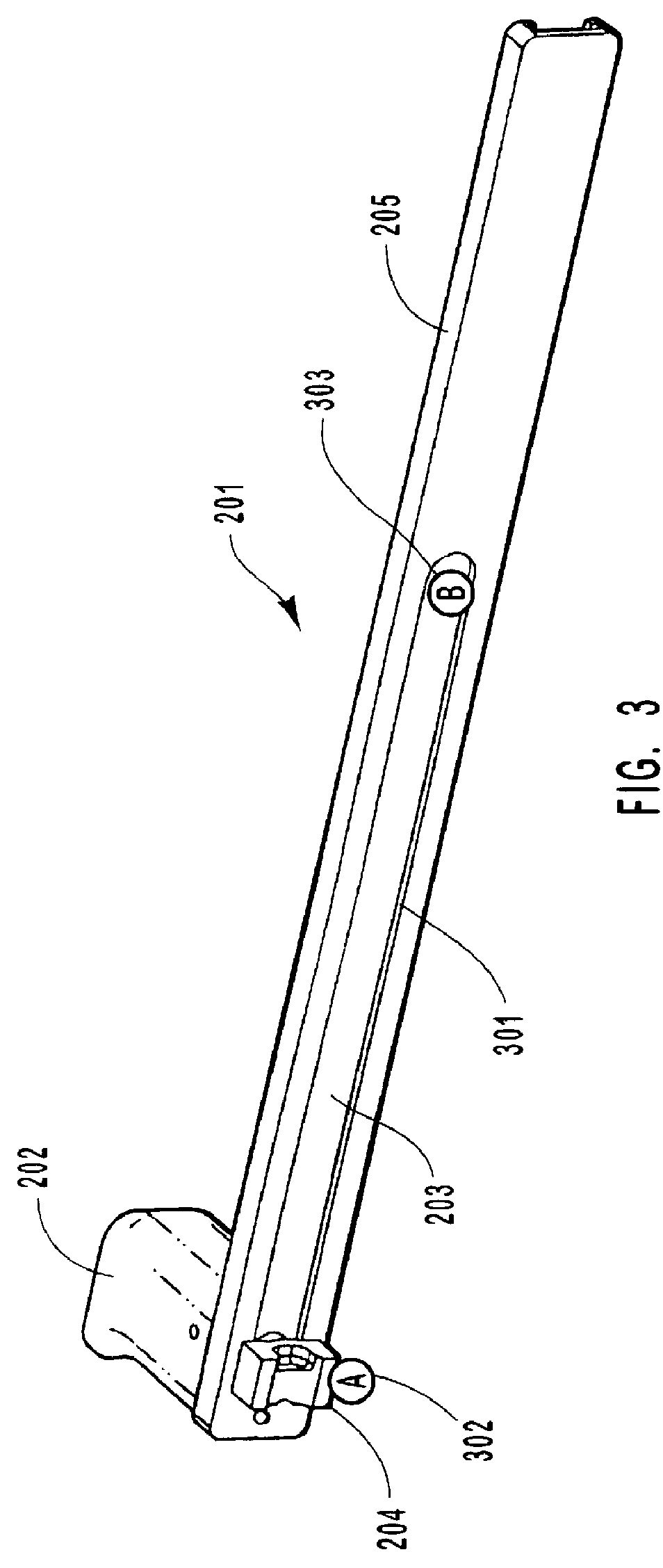

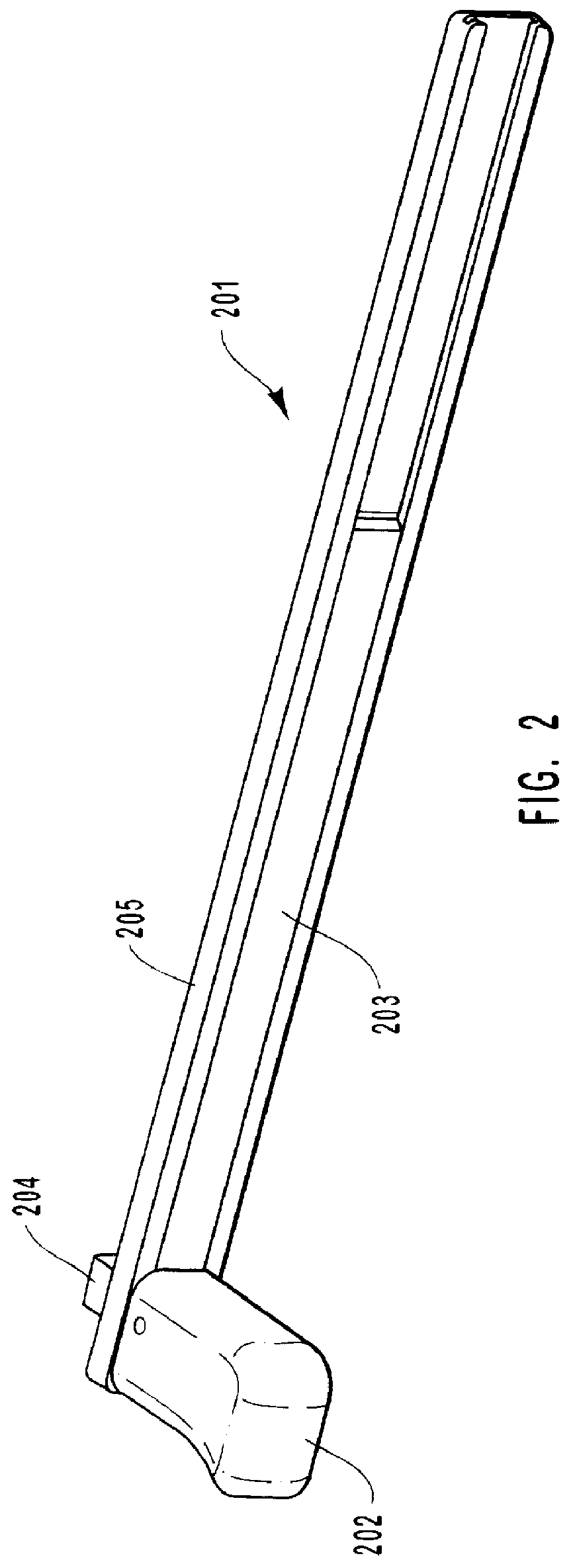

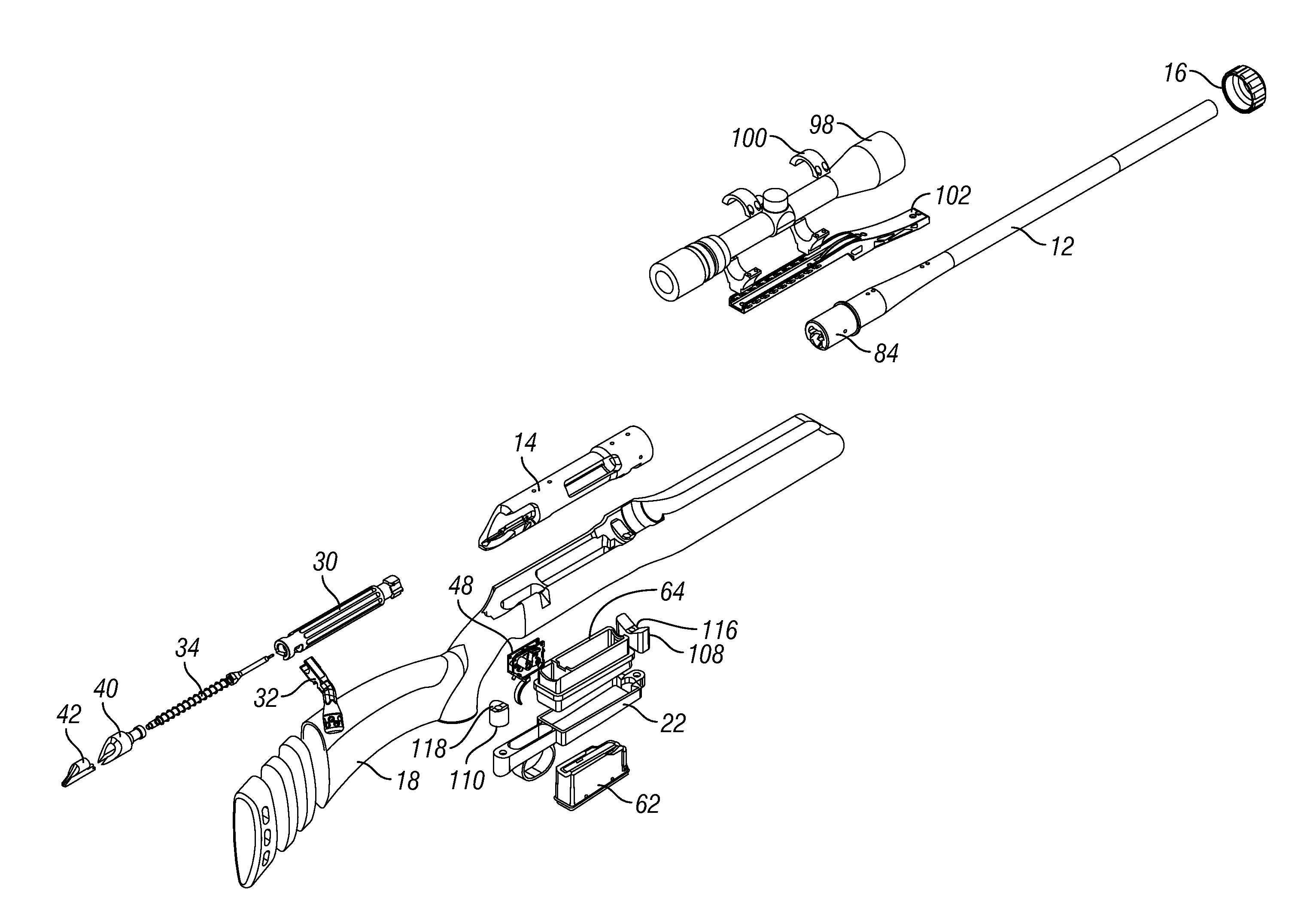

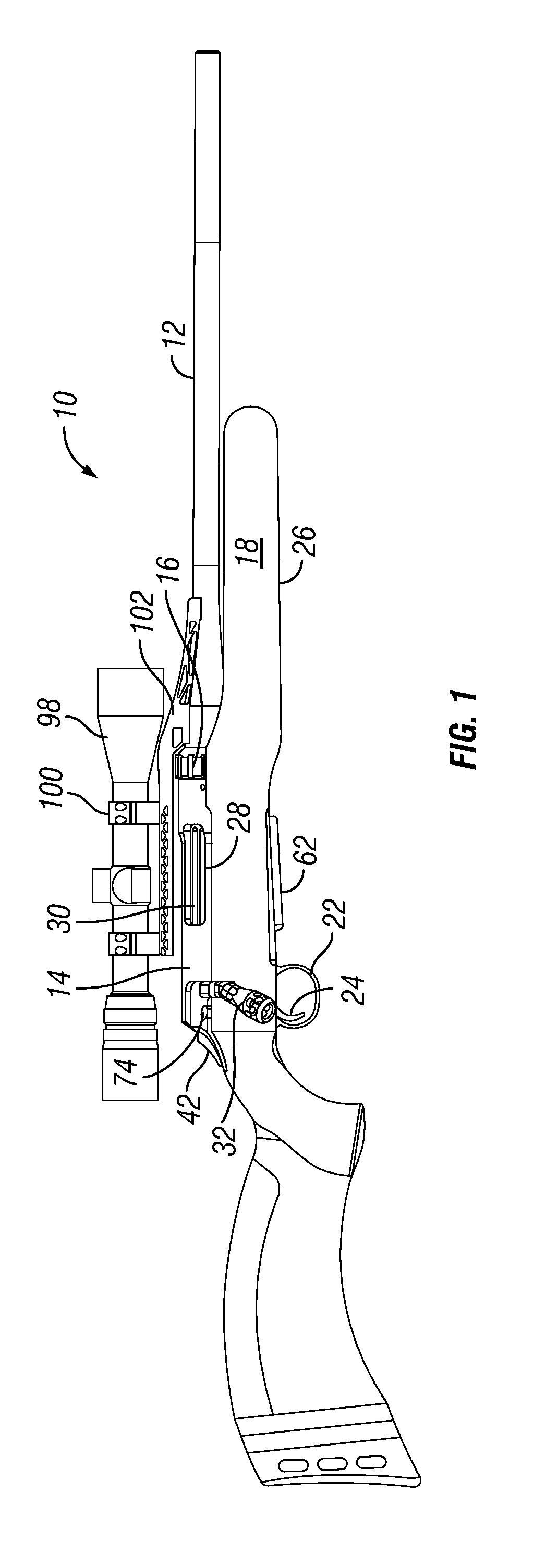

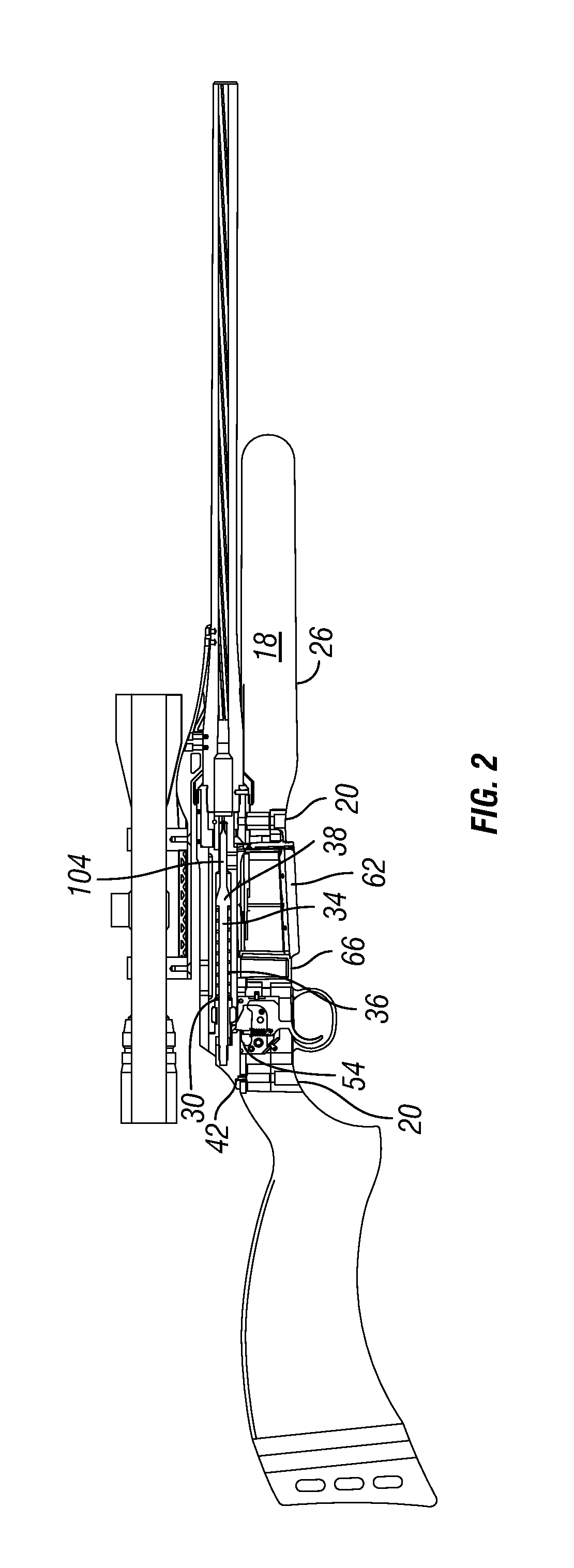

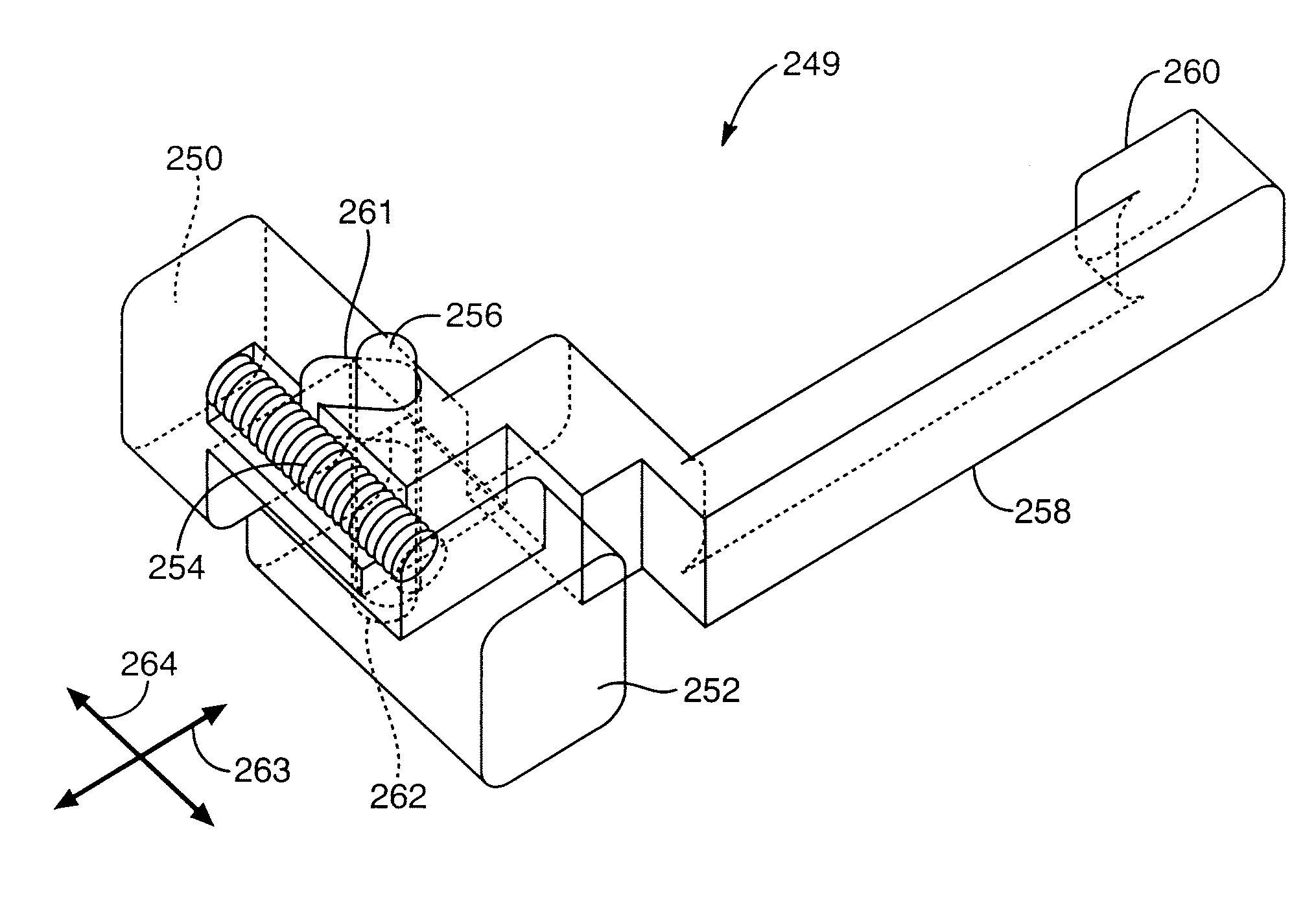

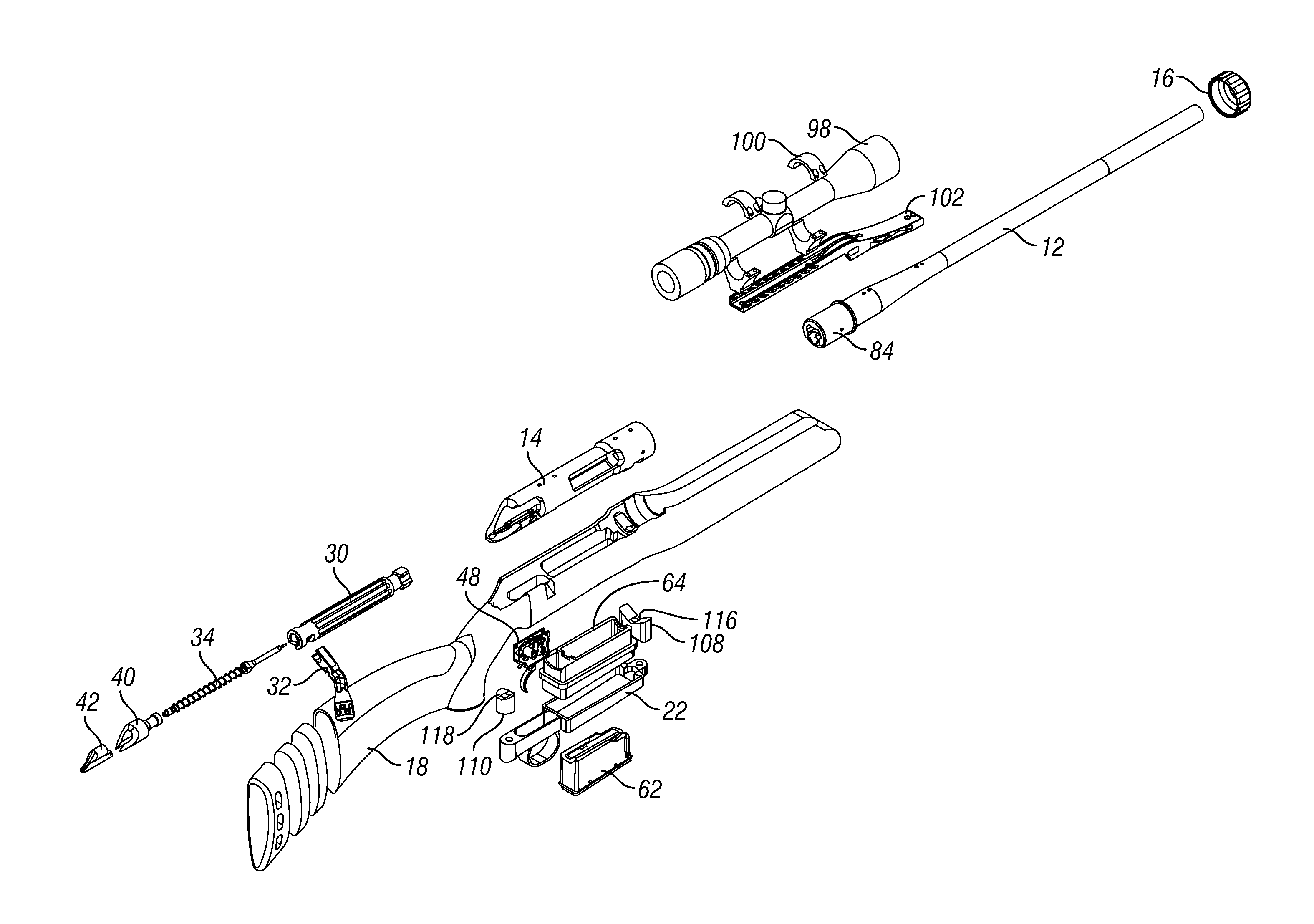

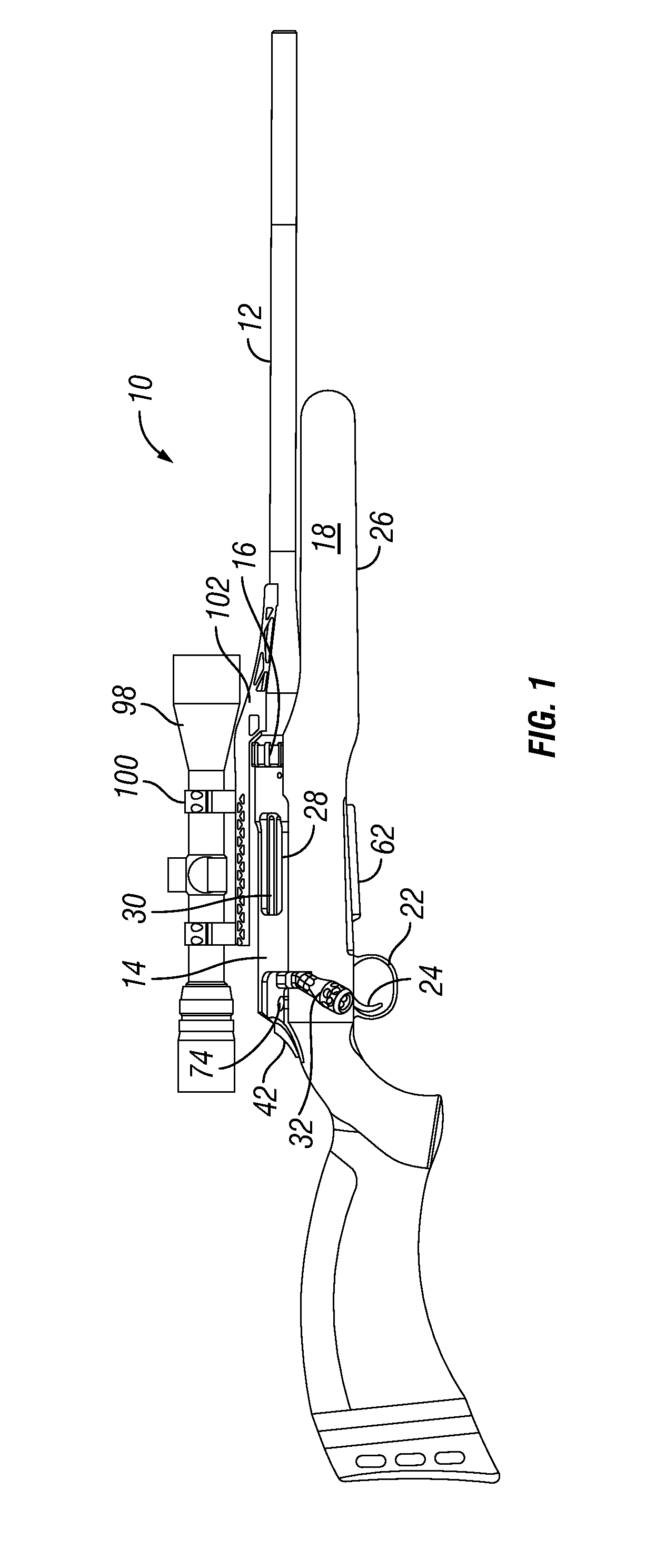

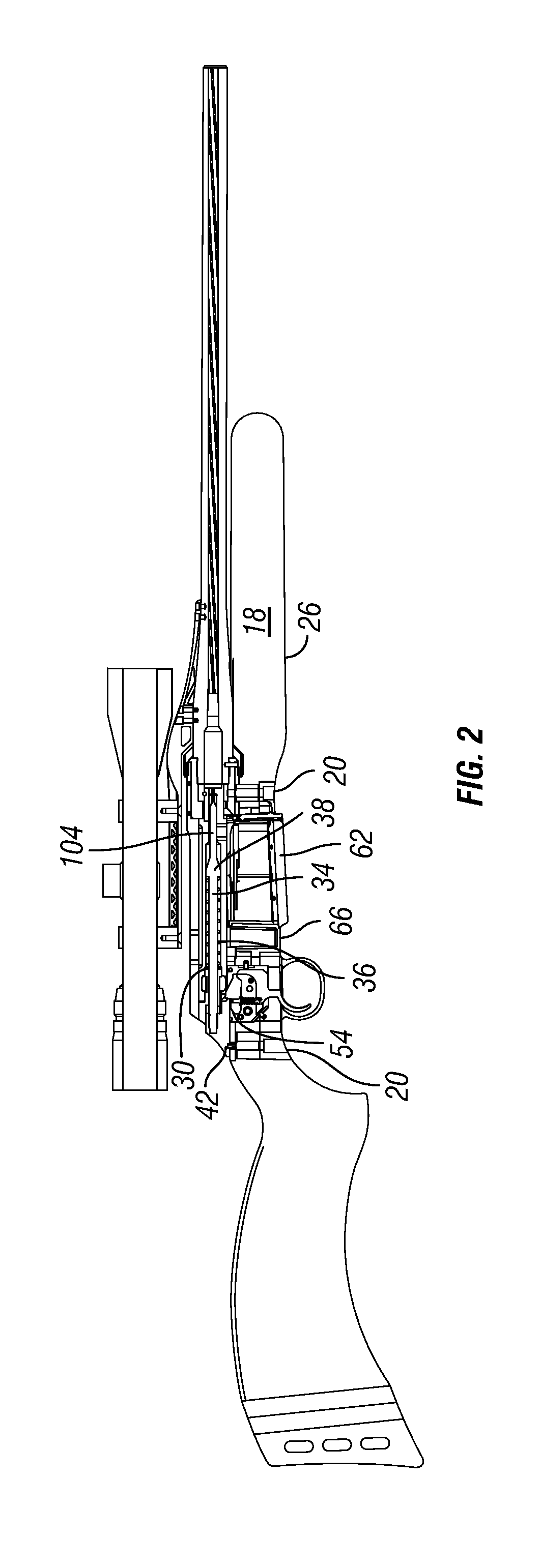

Multi-caliber bolt-action rifle and components

A multi-caliber firearm has a breech sleeve connecting a barrel to a receiver and a stock. The stock includes a forward V-block and a rearward V-block. Each of the V-blocks defines a V-cut along a top portion and a through hole substantially aligned with the cross-sectional center of the V-block. The forward V-block extends through a cutout portion of the receiver and into the breech sleeve. The breech sleeve is fastened to the stock through the through hole in the forward V-block to provide a rigid connection between the stock and the breech sleeve. The receiver is fastened to the stock through the through hole in the rearward V-block to provide a rigid connection between the receiver and the stock.

Owner:SMITH & WESSON

Modular firearm stock system

InactiveUS20100307042A1Ease of actuationEase of engagementCartridge extractorsWeapon assembly/disassemblyModularityEngineering

A modular firearm is disclosed. The firearm that can be configured to operate using ammunition of different calibers via interchangeability of only a few parts. The firearm includes a foldable butt stock assembly for quickly and easily converting the firearm from an extended operating configuration to a compact transport configuration, and vice-versa. Additionally, the firearm includes a modular hand guard assembly having multiple mounting platforms for accommodating a variety of different accessories.

Owner:RA BRANDS

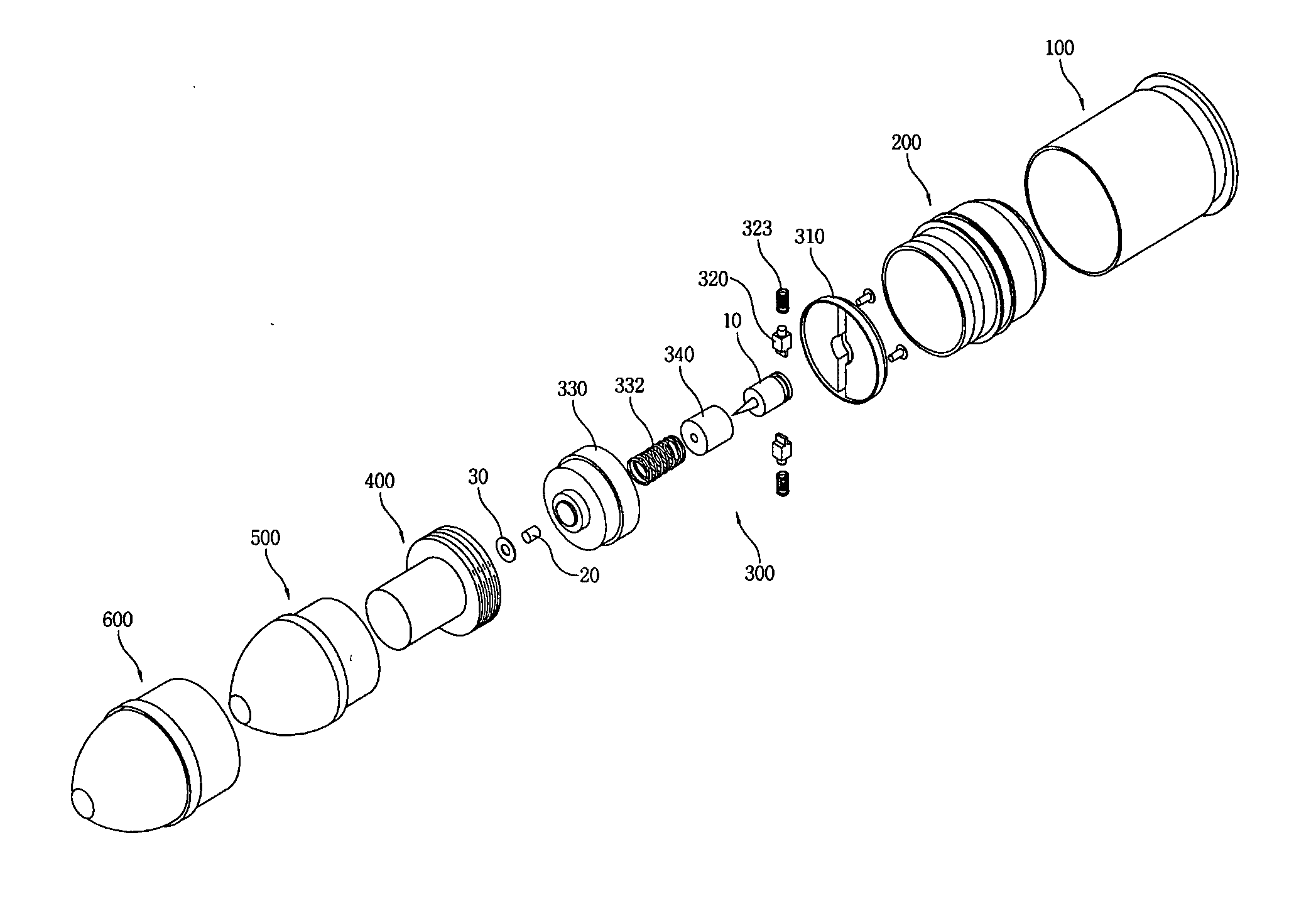

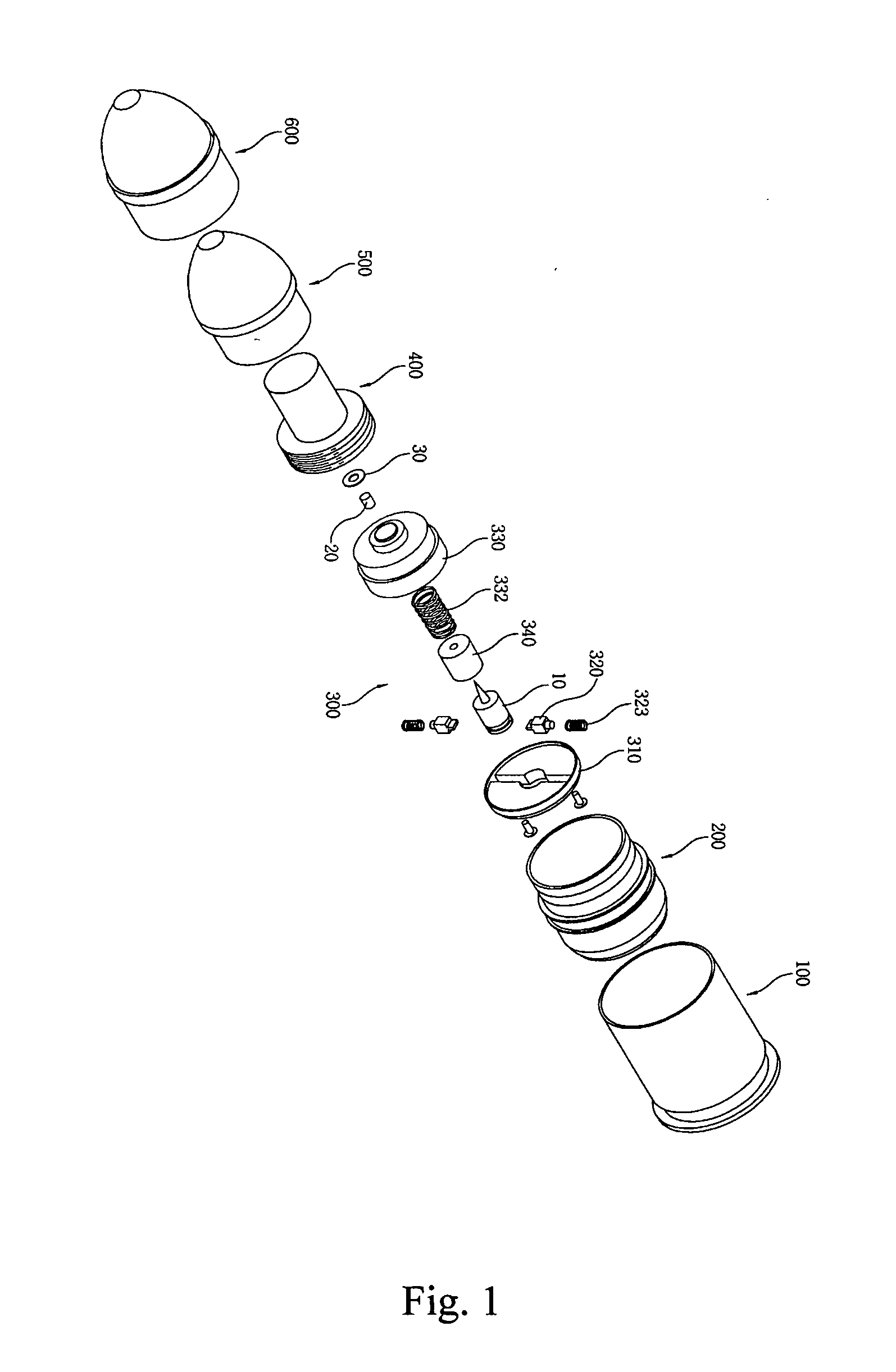

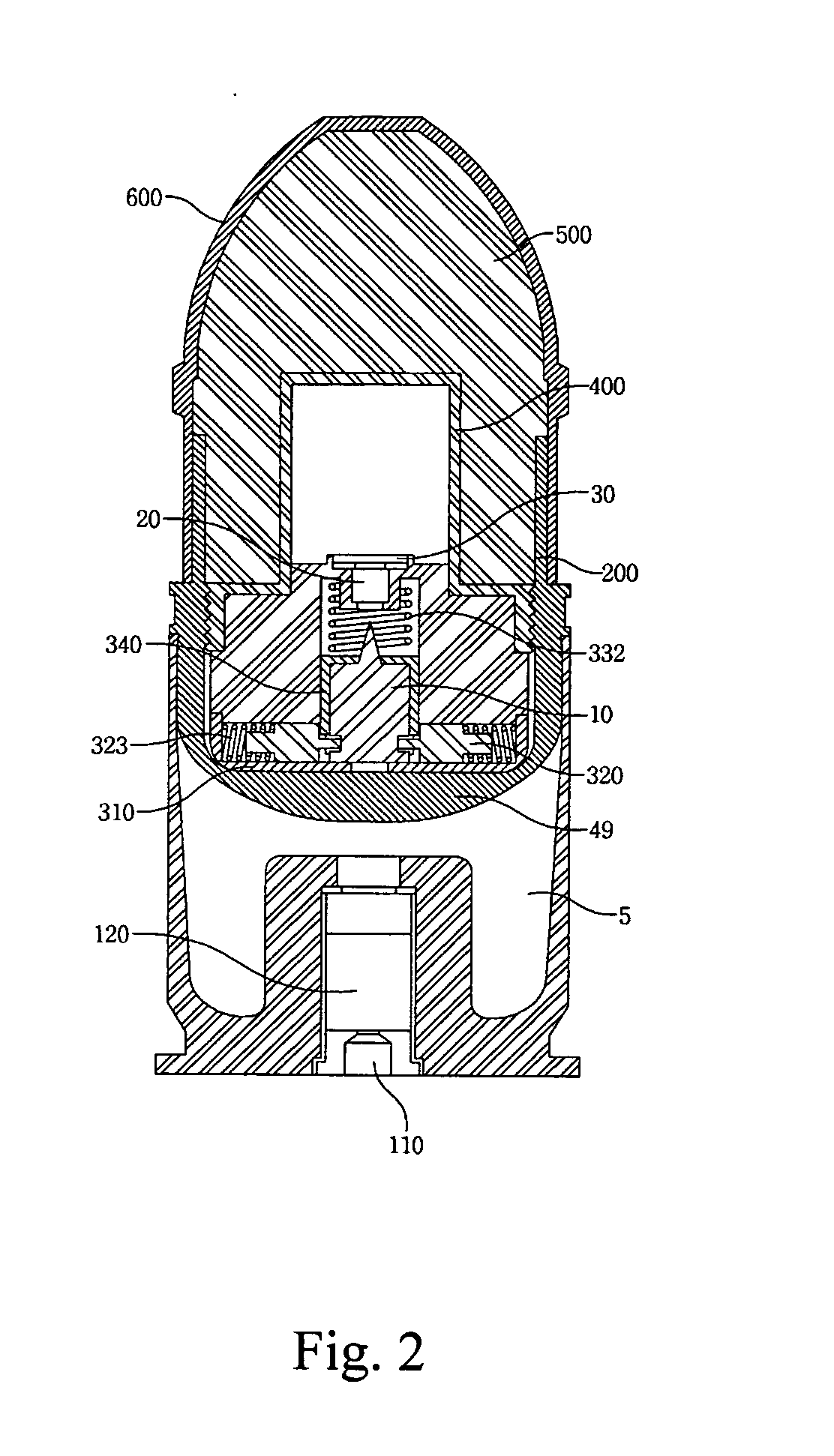

Forty millimeter caliber exercise bullet

ActiveUS20120180685A1Safely securedAvoid failureAmmunition projectilesTraining ammunitionDetonatorCentrifugal force

A forty millimeter caliber exercise bullet has improved for properly exploding on a target, and securely maintaining the unloaded status during ordinary time. The improved exercise bullet comprising that; a skirt (200), a striking pin (10), a safety device assembly (300) consisting a detent cover (310) with a central mounting groove (311) and a pair of mounting grooves (312), a detent (320) for retaining the striking pin (10) by engaging or disengaging into the circumferential groove (11) by springs (323), a detonator cap (330) forming a hollow pocket (331) to insert a detonator trigger (20), a washer (30), and a press-spring (332) for pressing a guiding cap (340), an explosion pipe (400), a smoke shell (500), and an ogive (600). When the bullet is fired, the rotation of bullet generates centrifugal force to slide the retainer outward for disengaging the circumferential groove, then the striking pin moves upward to impact the detonator trigger when it hit on the target.

Owner:C N O TECH KOREA

Method of making polymeric subsonic ammunition

The present invention provides a method of making a subsonic ammunition having a polymeric casing body having a generally cylindrical hollow polymer body having a body base at a first end thereof and a mouth at a second end to define a propellant chamber; a propellant insert positioned in the propellant chamber to reduce the internal volume of the propellant chamber, wherein the propellant chamber has an internal volume that is at least 10% less than the open internal volume of a standard casing of equivalent caliber; and a primer insert positioned in the body base and in communication with the propellant chamber.

Owner:TRUE VELOCITY IP HLDG LLC

Method of making polymeric subsonic ammunition

The present invention provides a method of making a subsonic ammunition having a polymeric casing body having a generally cylindrical hollow polymer body having a body base at a first end thereof and a mouth at a second end to define a propellant chamber; a propellant insert positioned in the propellant chamber to reduce the internal volume of the propellant chamber, wherein the propellant chamber has an internal volume that is at least 10% less than the open internal volume of a standard casing of equivalent caliber; and a primer insert positioned in the body base and in communication with the propellant chamber.

Owner:TRUE VELOCITY IP HLDG LLC

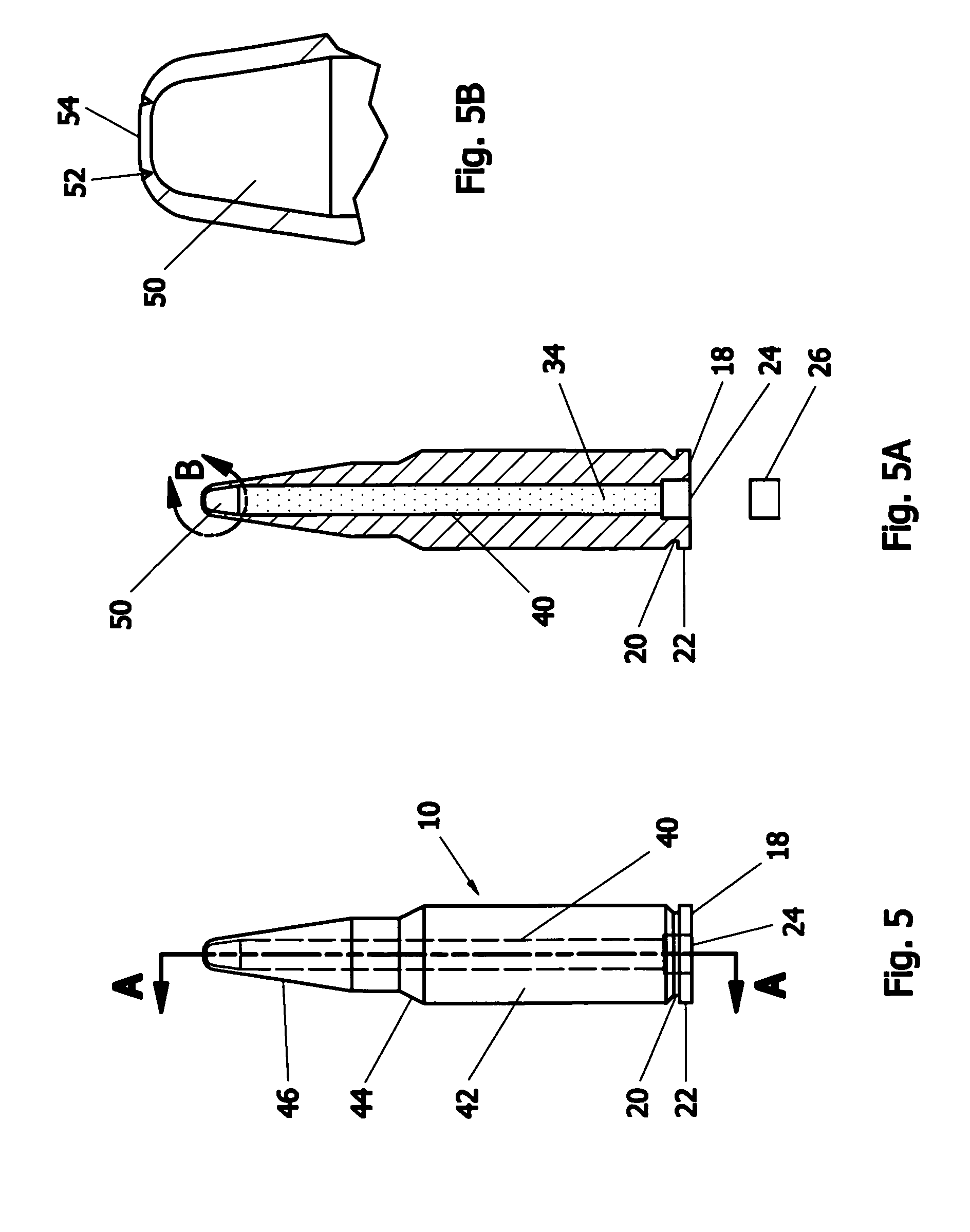

Plastic ammunition casing and method

InactiveUS20100275804A1Ammunition projectilesShotgun ammunitionShotgun pelletInjection molding process

Ammunition having an integrally formed, polymeric casing is provided. Plastic casings for ammunition may be made using injection molding processes for combat ammunition, target ammunition and blanks. The casings, in one embodiment, include a hollow tubular member with an open end and a closed end having an aperture for a primer cap. The base of the casing includes a conical shape within the tube that narrows toward the base. An annular groove and an annular rim are disposed about an outer periphery of the base. Plastic casings may be utilized for ammunition cartridges used in pistols, rifles and shotguns, and are lighter and less expensive to manufacture than traditional brass casings. Further, the polymeric casings may include any desired colorants to distinguish different calibers of ammunition by color, and the spent casings may be recyclable.

Owner:TRIVETTE ROGER BLAINE

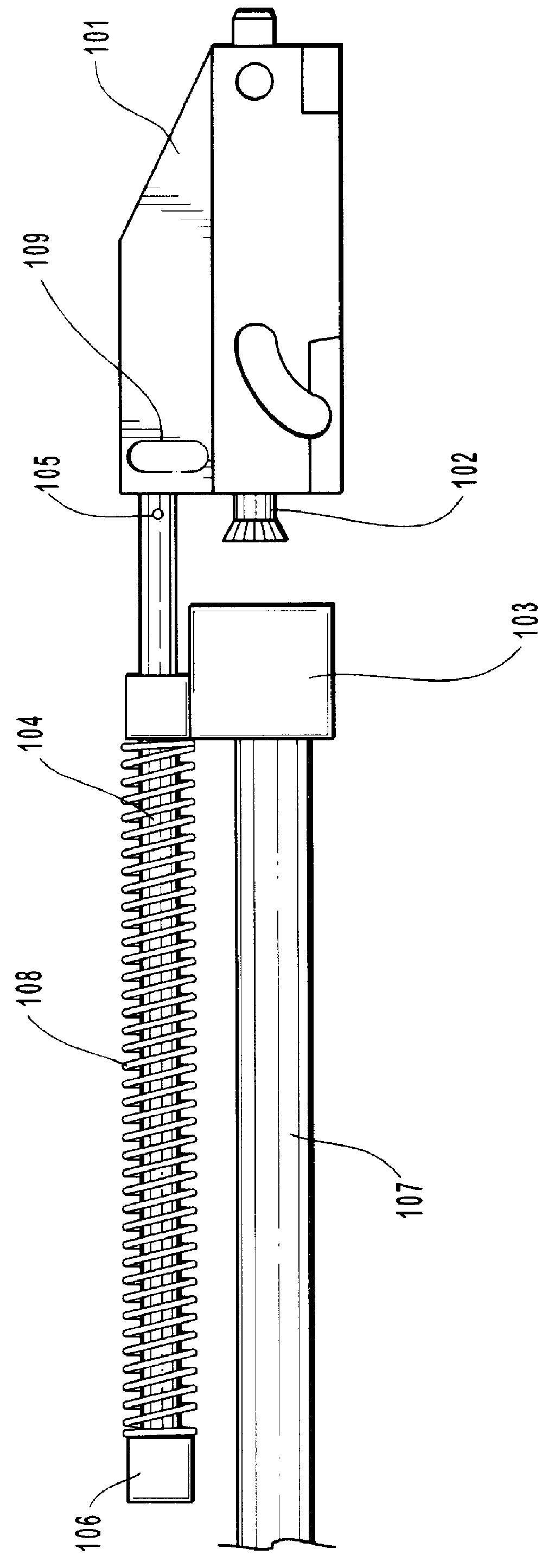

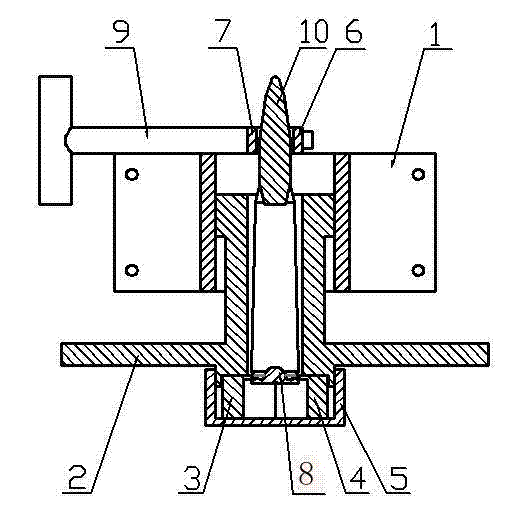

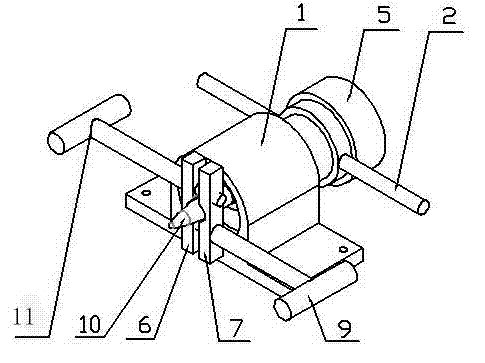

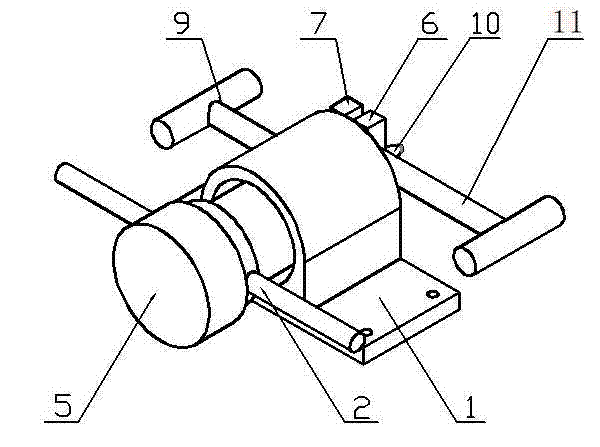

Bullet puller of large-caliber machine gun bullet

InactiveCN102901403ASuitable for small batches of bombsSimple structureCartridge extractorsEngineeringContact position

The invention discloses a bullet puller of a large-caliber machine gun bullet. The bullet puller comprises a base, a bullet pulling screw, snapping clacks, a protection cover, clamping heads and tightening screws; a thread through hole is arranged in the middle of the base, and two rods are welded at the tail of the bullet pulling screw; a left snapping clack and a right snapping clack are two symmetrical semicircle snapping clacks, and a semicircle positioning hole is milled in the middle of each snapping clack; a left clamping head and a right clamping head are cuboid blocks in same structures, semicircle grooves which are matched with the bullet are milled along the height direction of the left clamping head and the right clamping head, a chamfer is arranged at the contact position of the bullet, and the surface of the chamfer is subjected to surface engraving processing; a through hole and a thread hole are milled at positions of two sides in the width direction respectively; and a left tightening screw penetrates through a through hole of the left clamping head and then is screwed into the thread hole of the right clamping head, the right tightening screw penetrates through the through hole of the right clamping head and then is screwed into the thread hole of the left clamping head, the grooves of the left clamping head and the right clamping head oppositely form a closed frame, and the grooves are aligned to a cylindrical portion of the bullet. The bullet puller is simple in structure, safe, convenient and capable of separating a bullet head from a bullet shell of the large-caliber machine gun bullet.

Owner:ZHONGBEI UNIV

Modular Firearm

A firearm having a lower receiver is provided. The receiver is adapted to couple with a plurality of upper receivers having different calibers. The lower receiver comprises a receiver extension having an opening therein. A spring is disposed within the opening. A buffer member is provided having a first portion having an end. The buffer member is coupled to the spring within the opening, wherein the buffer member is movable between a first position where the end is within the opening and a second position wherein the end external to the opening.

Owner:COLTS MFG IP HLDG COMPANY

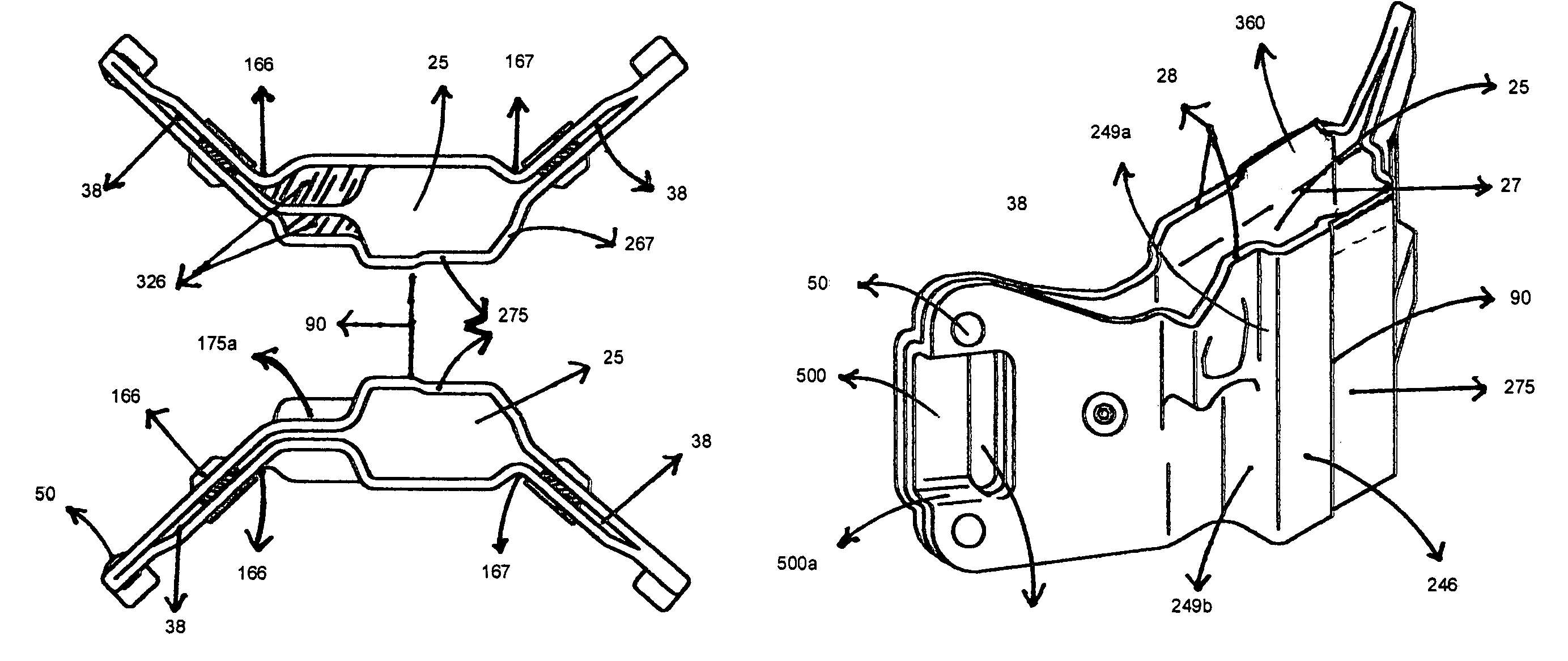

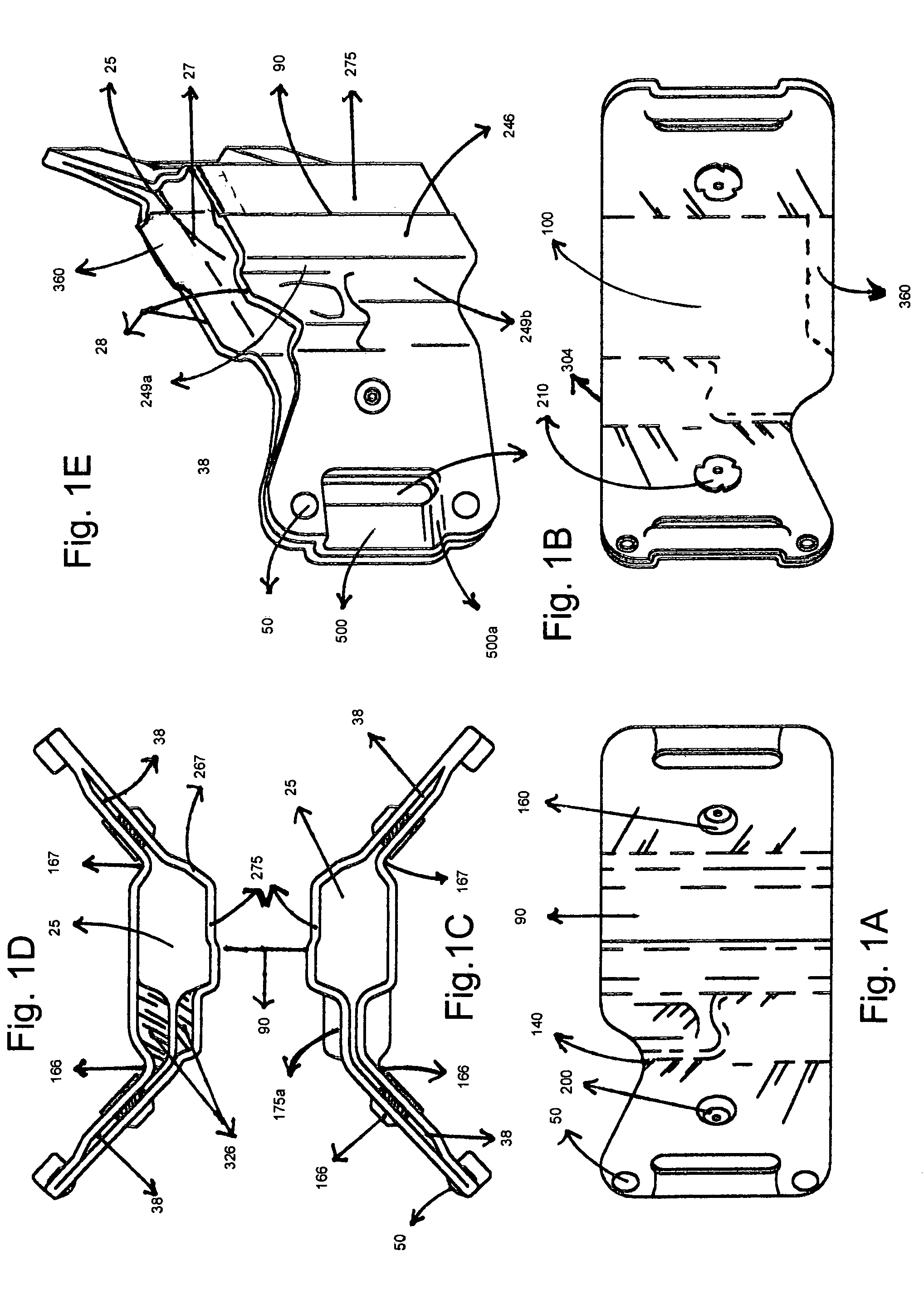

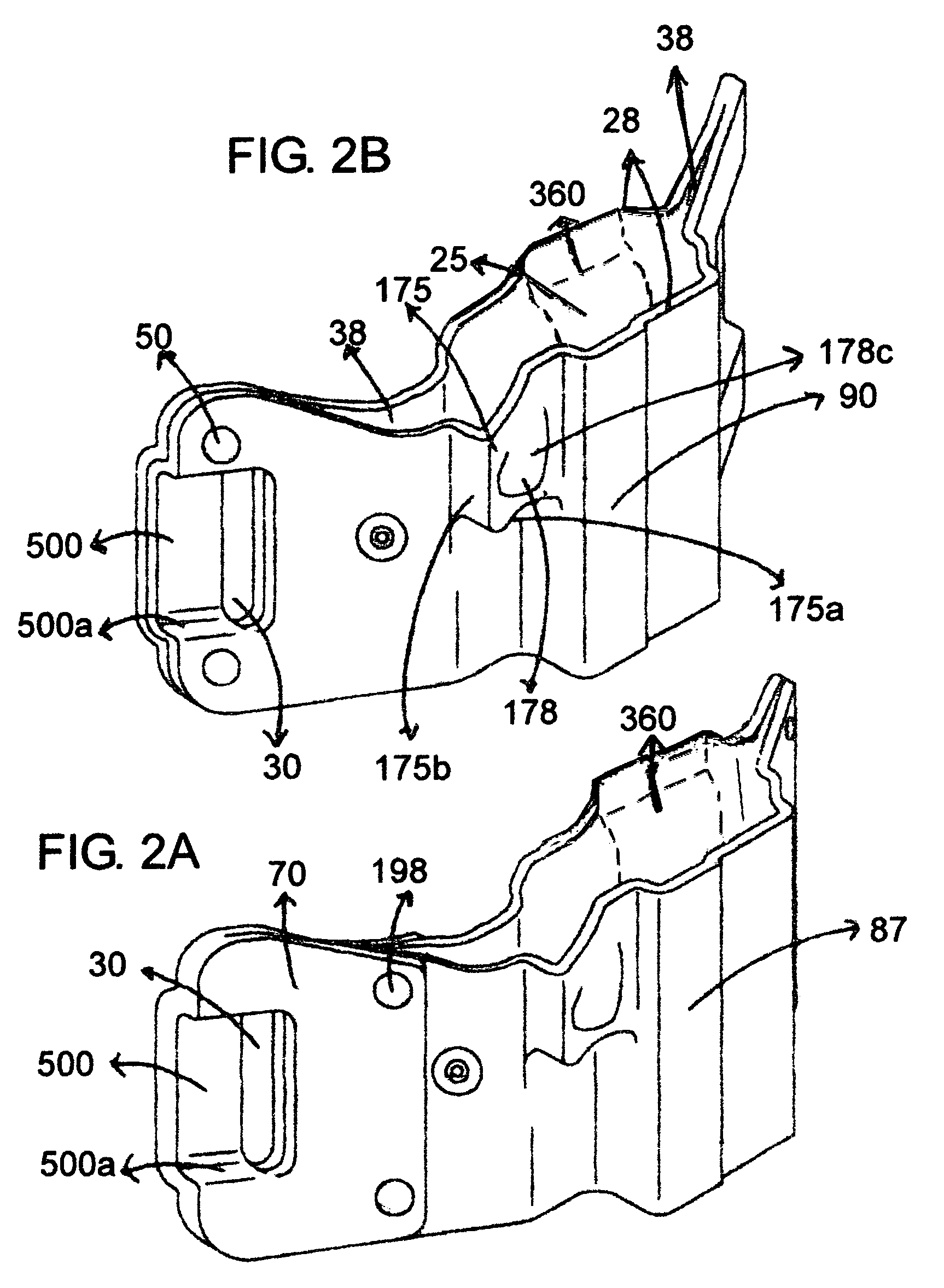

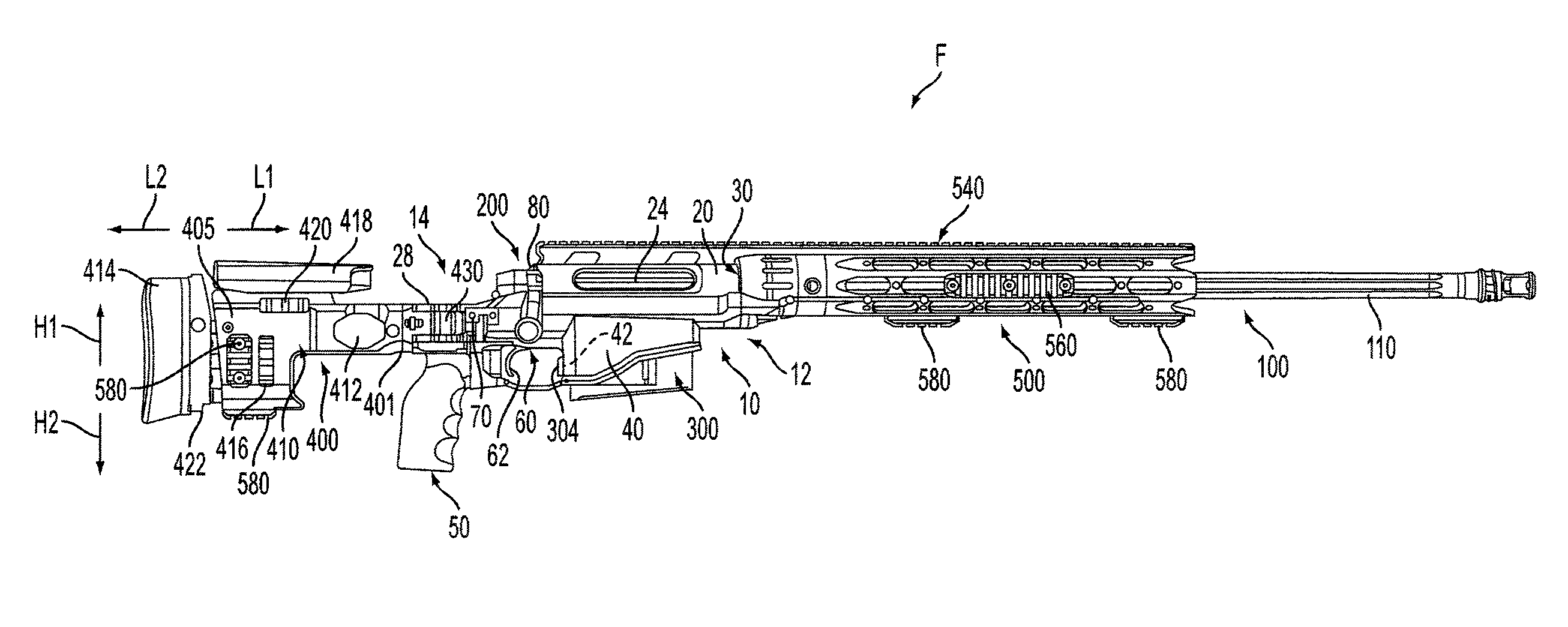

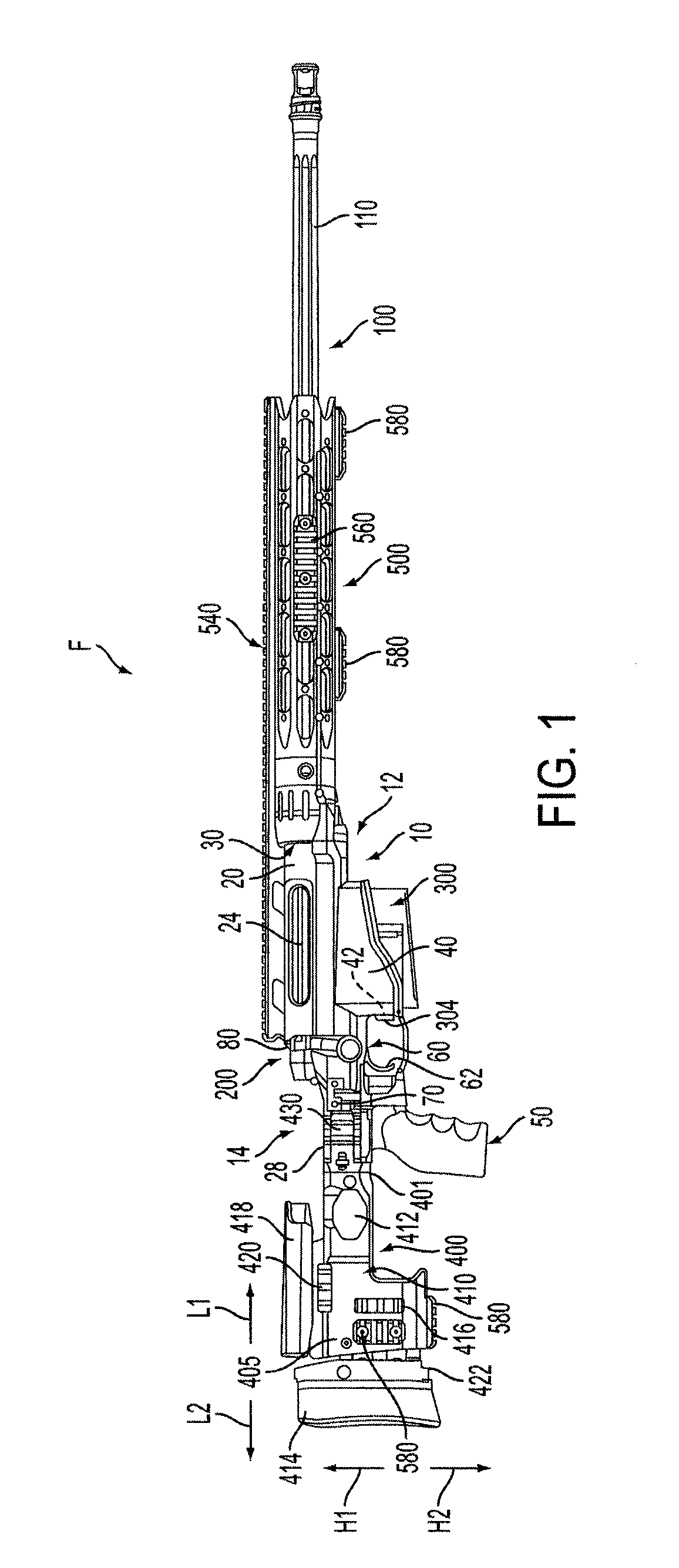

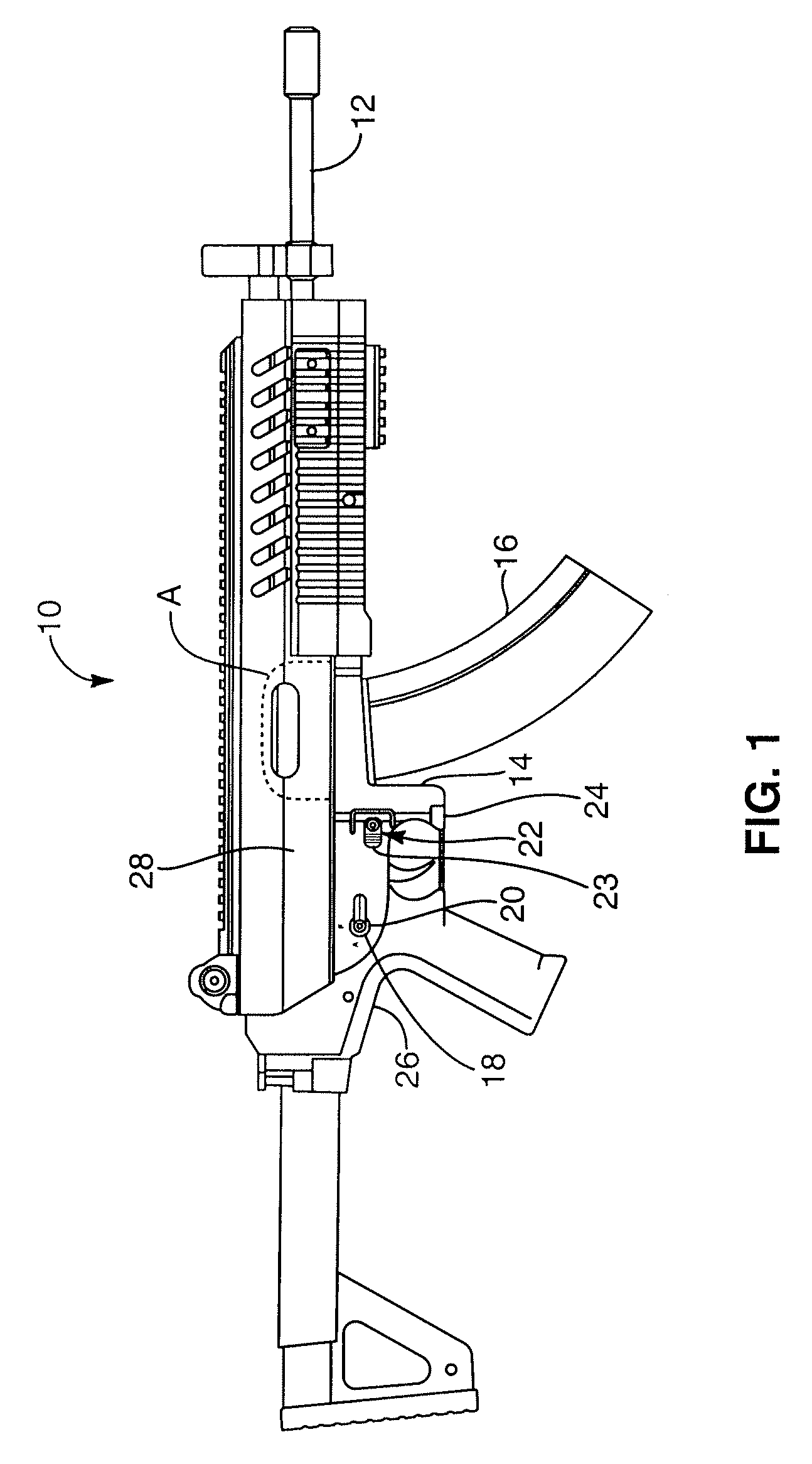

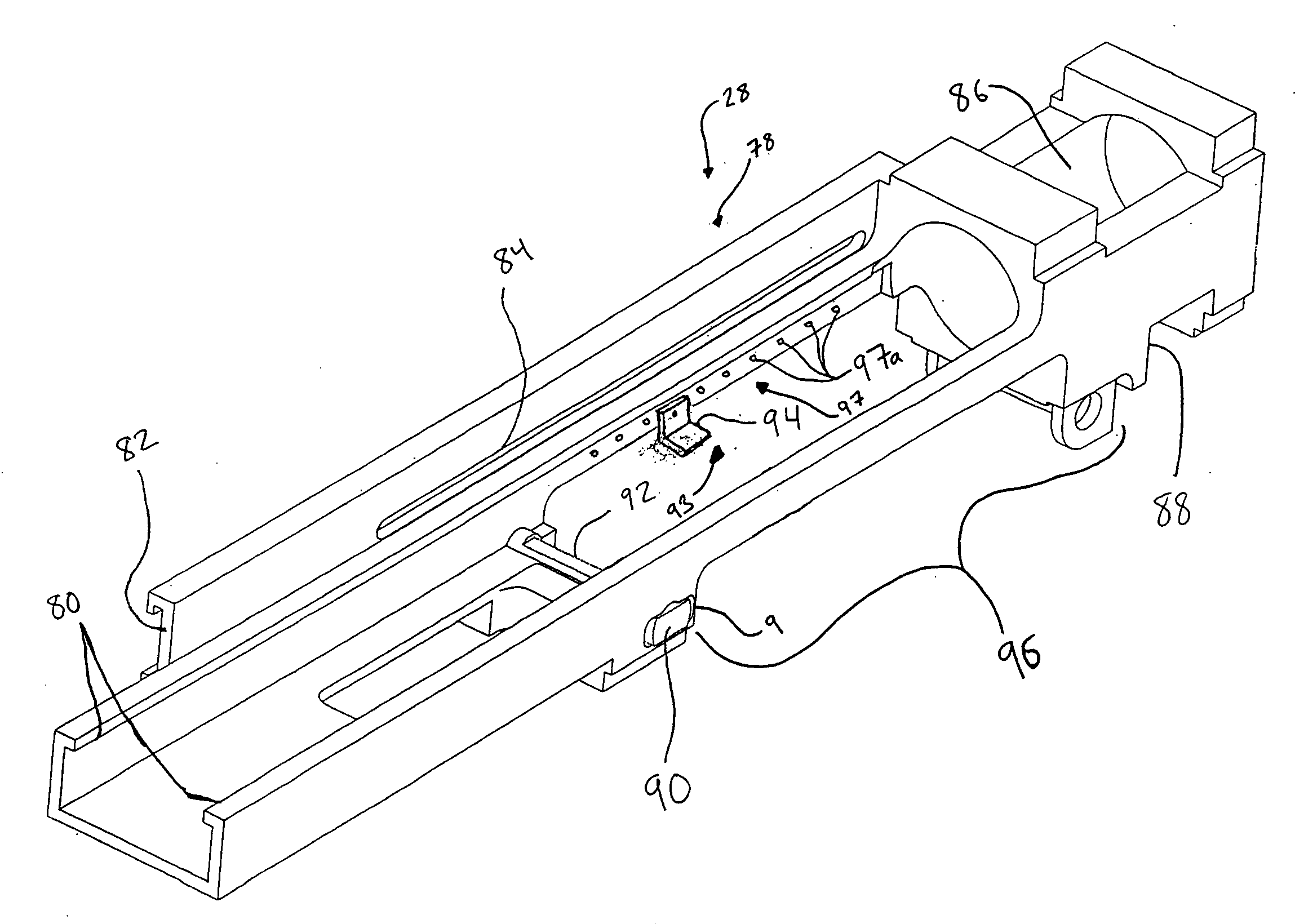

Multi-caliber ambidextrously controllable firearm

InactiveUS20090031605A1Reliable shootingEasy to operateCartridge extractorsBreech mechanismsEngineeringCaliber

A multi-caliber ambidextrously controlled firearm that includes an adjustable ejection system to facilitate the ejection of spent cartridge casings from a firearm. The adjustable ejection system includes an ejection port defined by an aperture in the firearm and a deflector. The deflector is attached to the firearm to adjust the size of the ejection port and may be attached at one of at least two attachment positions of the firearm. The adjustable ejector system includes an ejector selectively attached to the firearm at one of at least two ejector attachment positions. The improved firearm also includes an ambidextrous magazine catch system for selectively retaining a magazine within a firearm. The magazine catch system includes a first button opposite a second button such that either button may be actuated by a user to release the magazine retained with the firearm.

Owner:RMDI

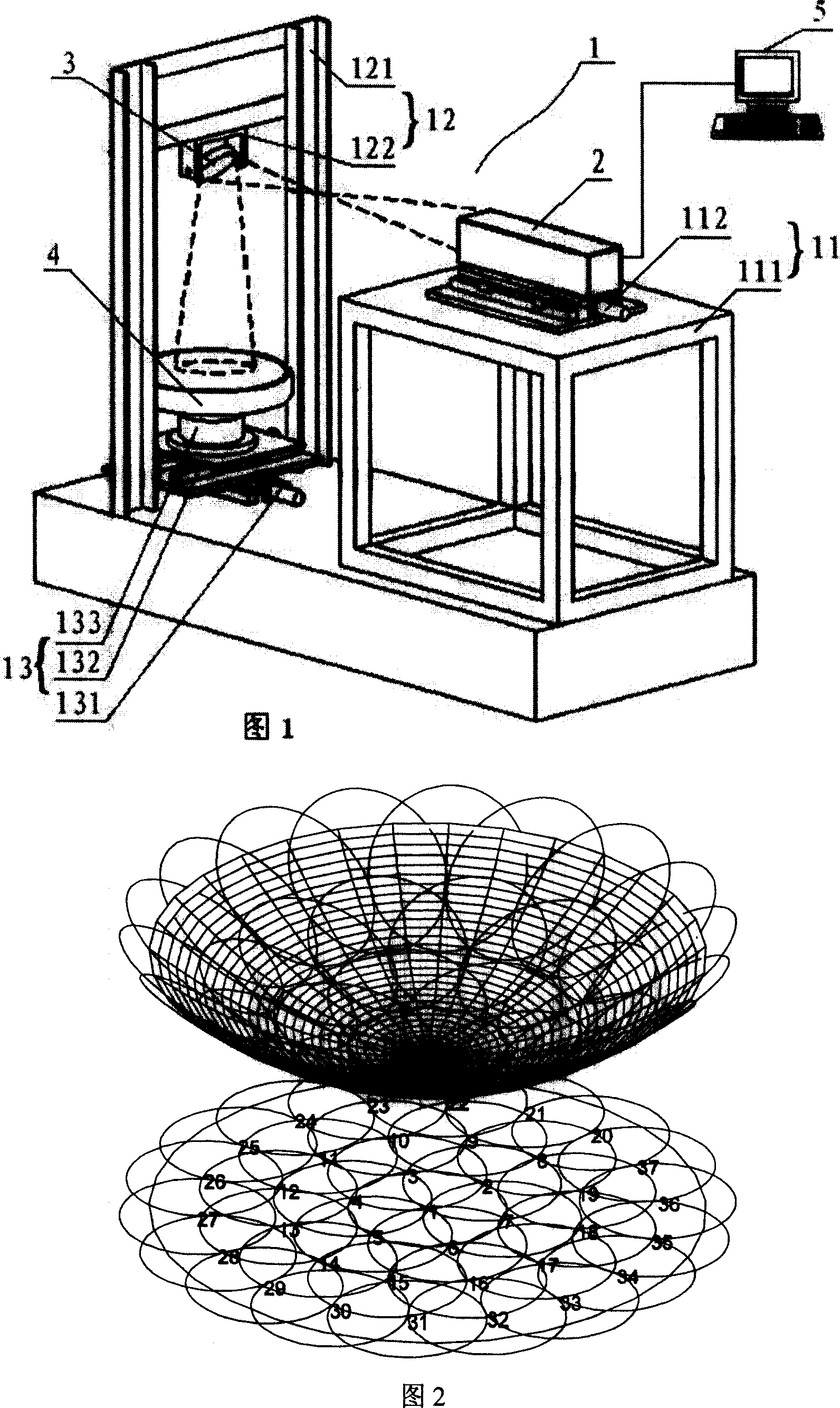

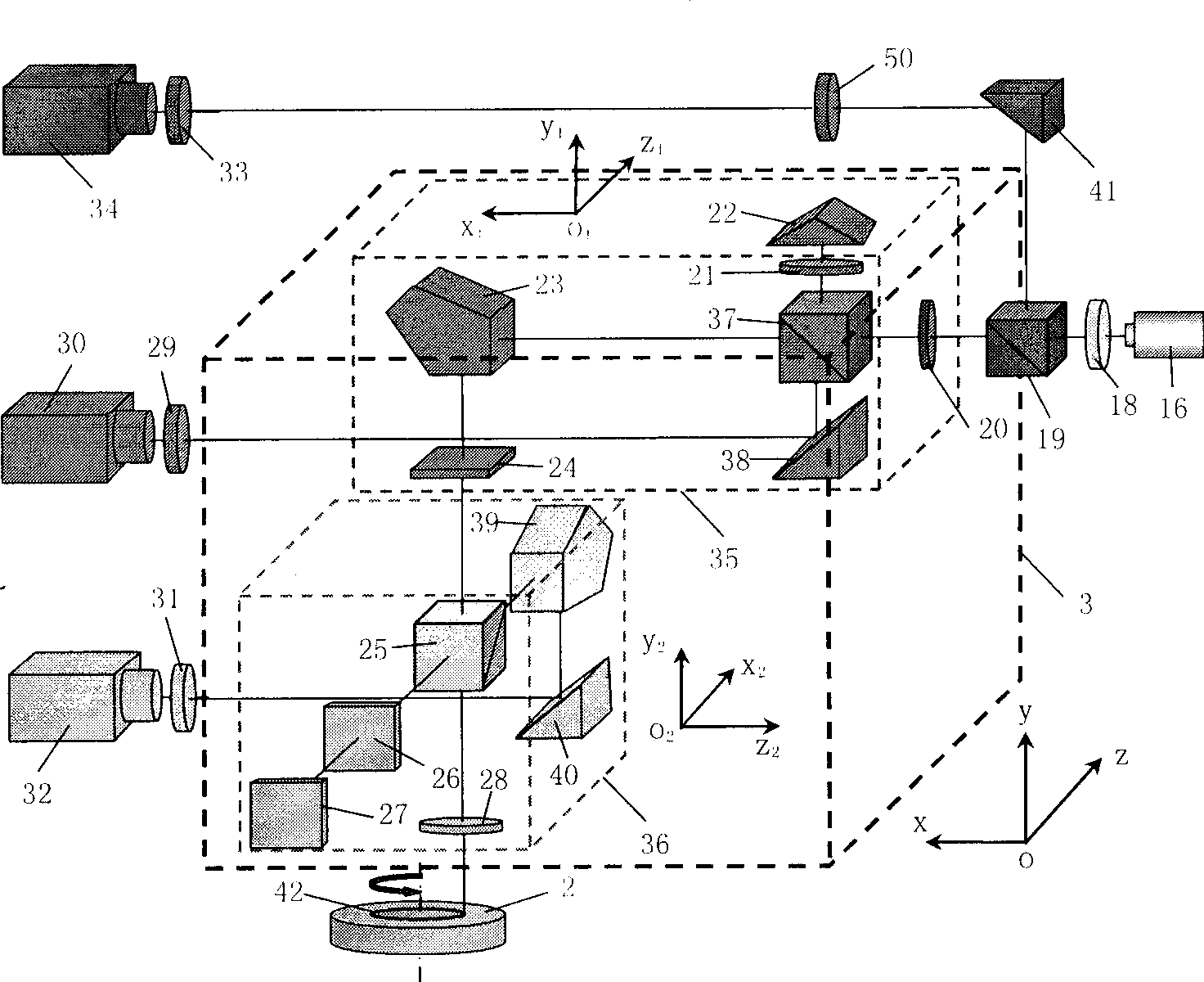

High-frequency error detecting apparatus and method for heavy caliber heavy relative aperture aspherical mirror

InactiveCN101013027AIncrease horizontal resolutionIncrease the vertical measurement rangeUsing optical meansTesting optical propertiesMultiple pointError surface

The invention discloses a high-frequency error detection device and method in the large caliber large relative aperture non-spherical mirror, the device including the five-axis movement adjustment platform with the interferometer focusing platform, the side swing reflecting mirror side swing platform located in front of the interferometer focusing platform, and the measured non-spherical mirror 3D movement adjustment platform located below the side swing reflection mirror side swing platform, and the multiple points supporting machine with the laser wave surface interferometer, the side swing reflection mirrors, and the measured non-spherical mirror installed on the corresponding platforms, and the main control computer with built-in detection data-processing algorithm program connecting with the laser wave surface interferometer. The device uses the main control computer to process the detection data-processing algorithm, which can combine the detected multiple part regions error surface maps into error surface map with medium or high frequency in full caliber, including the initial pose determining method, the overlapping regional data extraction algorithm and the regional data stitching algorithm. The invention is a high-frequency error detection device and method with low-cost, high-precision, high-efficiency in the large caliber large relative aperture non-spherical mirror.

Owner:NAT UNIV OF DEFENSE TECH

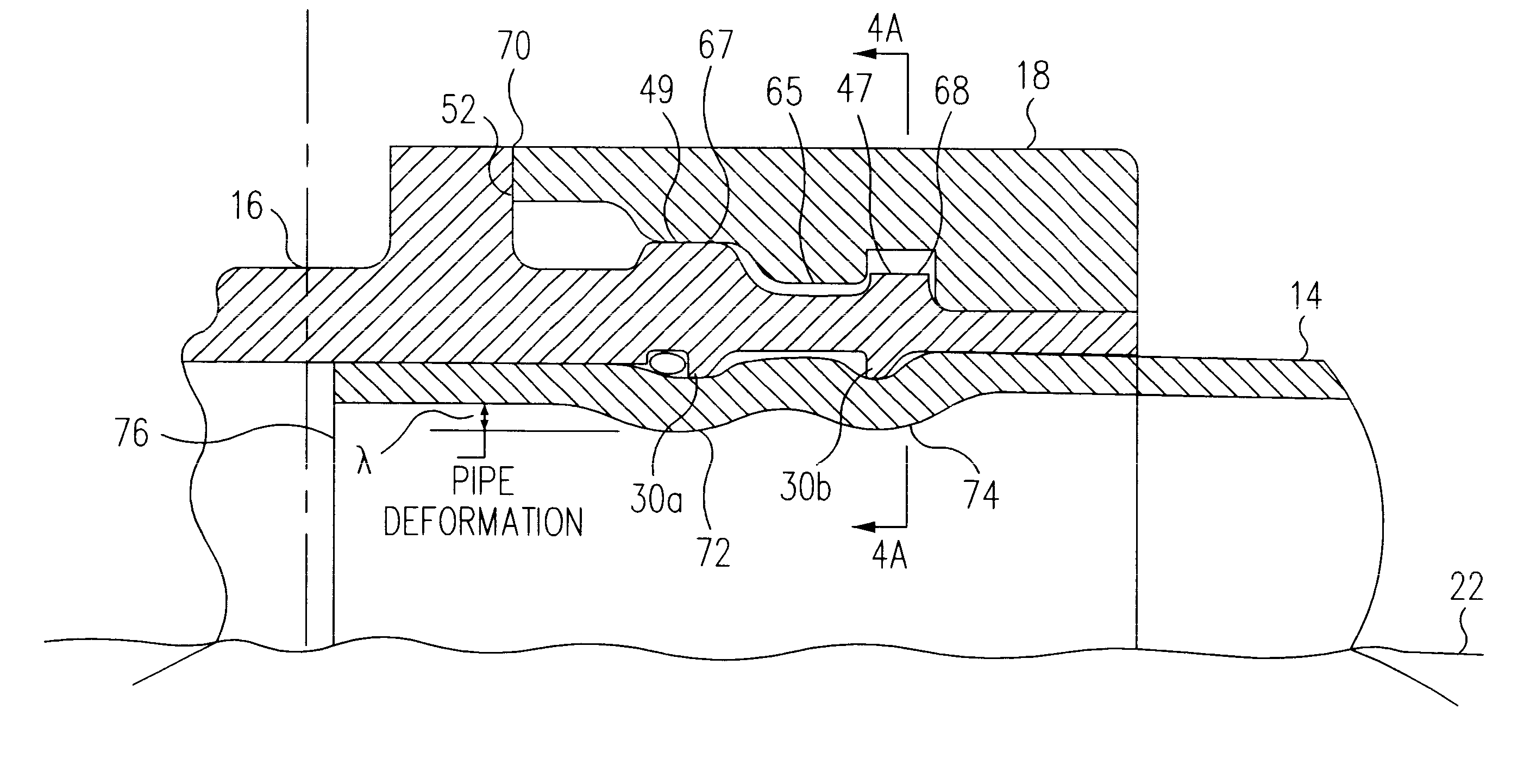

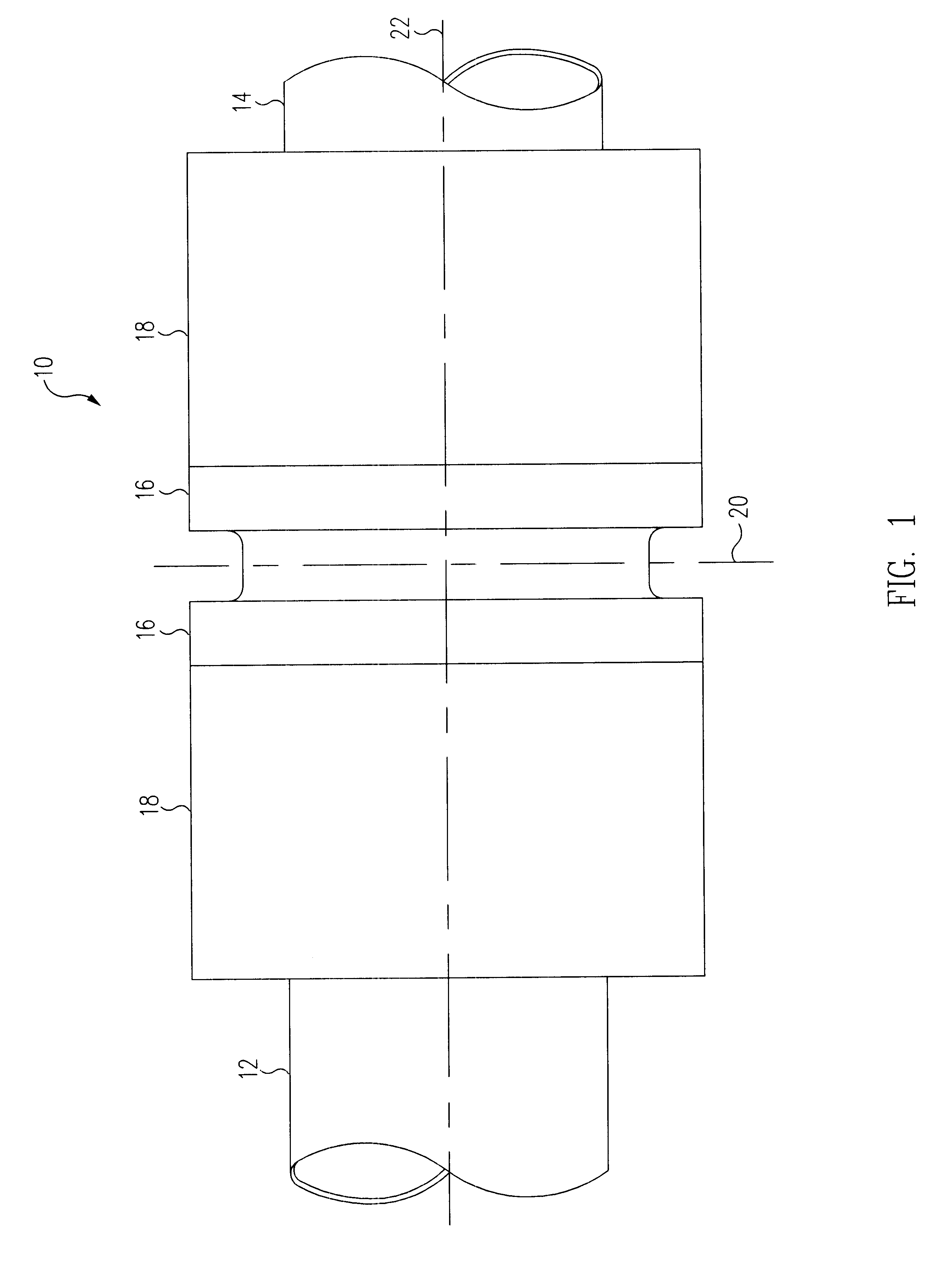

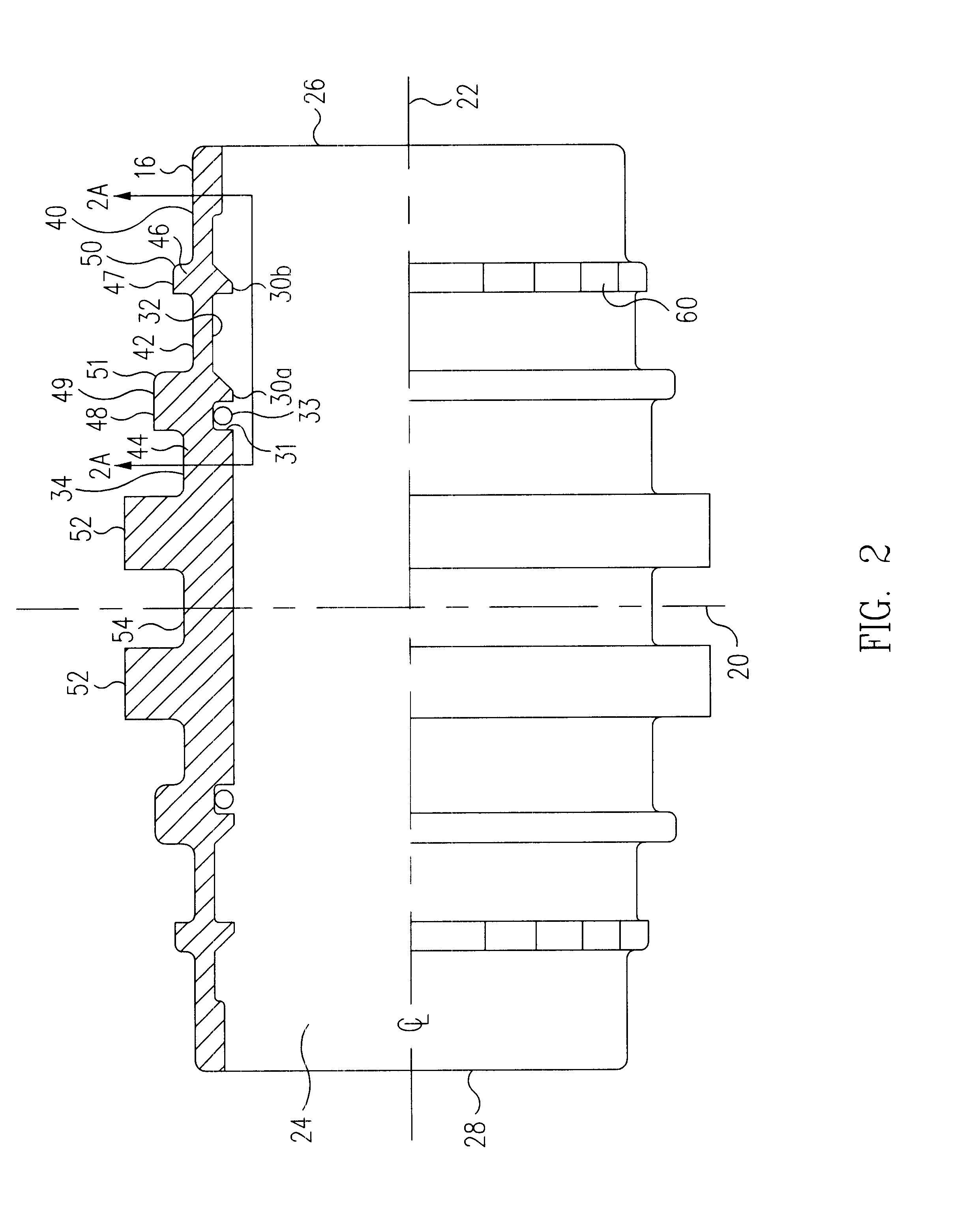

Axial swage fitting for large bore pipes and tubes

InactiveUS6450553B1Enhanced couplingHigh tensile strengthJoints with sealing surfacesMetal working apparatusEngineeringCatheter

A fitting for joining pipes, tubes, or conduits improves coupling capability particularly to a large bore pipe, generally of 2 inches and larger in diameter. The fitting includes a substantially cylindrical sleeve and ring. The sleeve has an inner surface defining a bore, configured to slidably receive the pipe at an open end. The inner sleeve surface also includes protrusions, which deform the outer surface of the pipe upon swaging. The fitting also includes an outer surface having multiple stepped lands of ascending height relative to the open end. The ring has an inner surface configured to engage the multiple ascending steps on the inner sleeve surface. The inner surface of the ring has descending steps that are positioned to interfere with the multiple ascending steps on the outside of the sleeve. Axial motion of the ring causes the ring to slide over the sleeve and apply a radial swaging force directly to the multiple stepped sleeve. The swaging force makes the ring overcome the interference and push down on the multiple ascending steps of the sleeve, which swages the sleeve to the pipe. The multiple ascending steps of the sleeve are positioned relative to the descending steps of the ring, such that only one step at a time is swaged.

Owner:MECH1

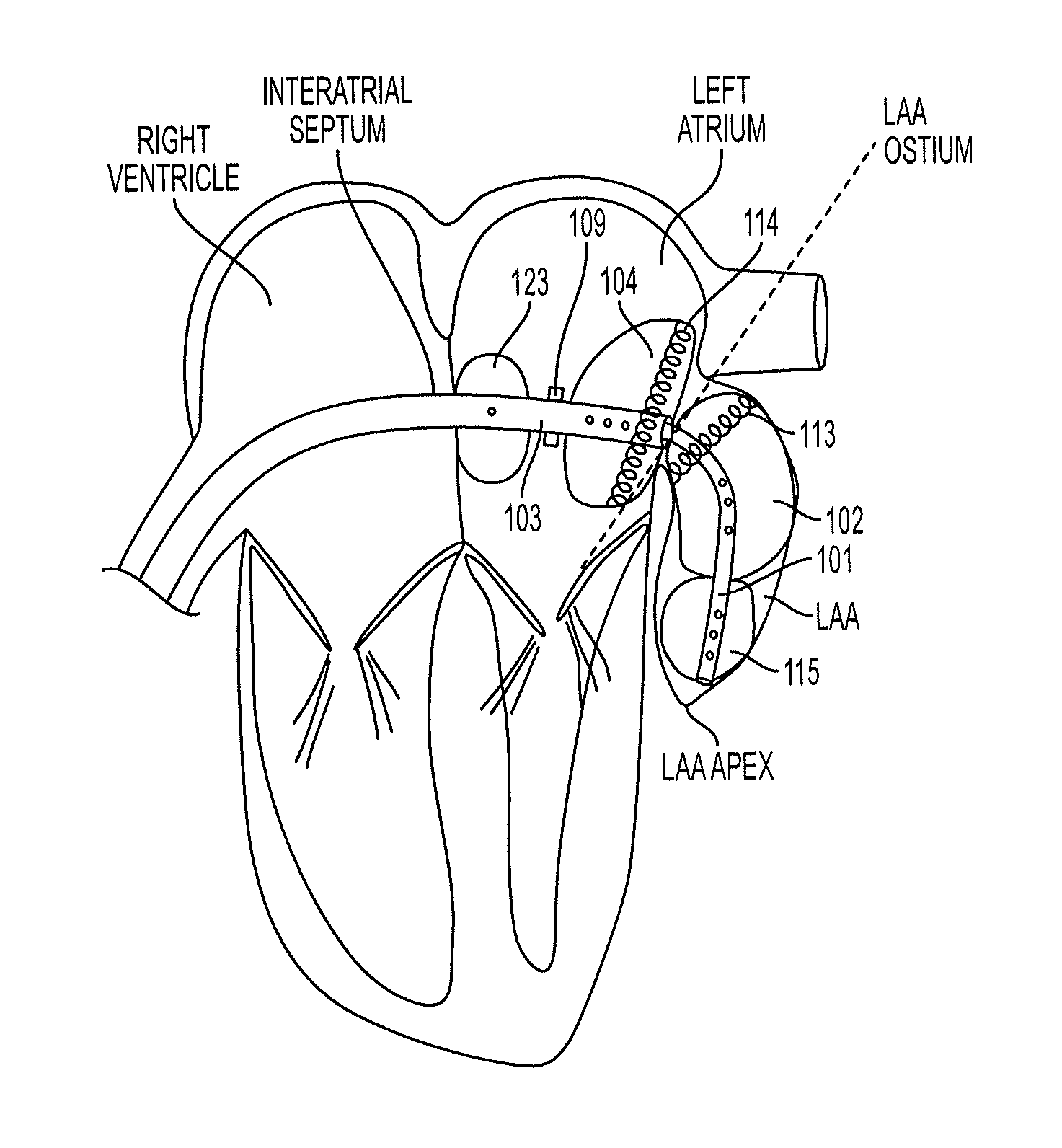

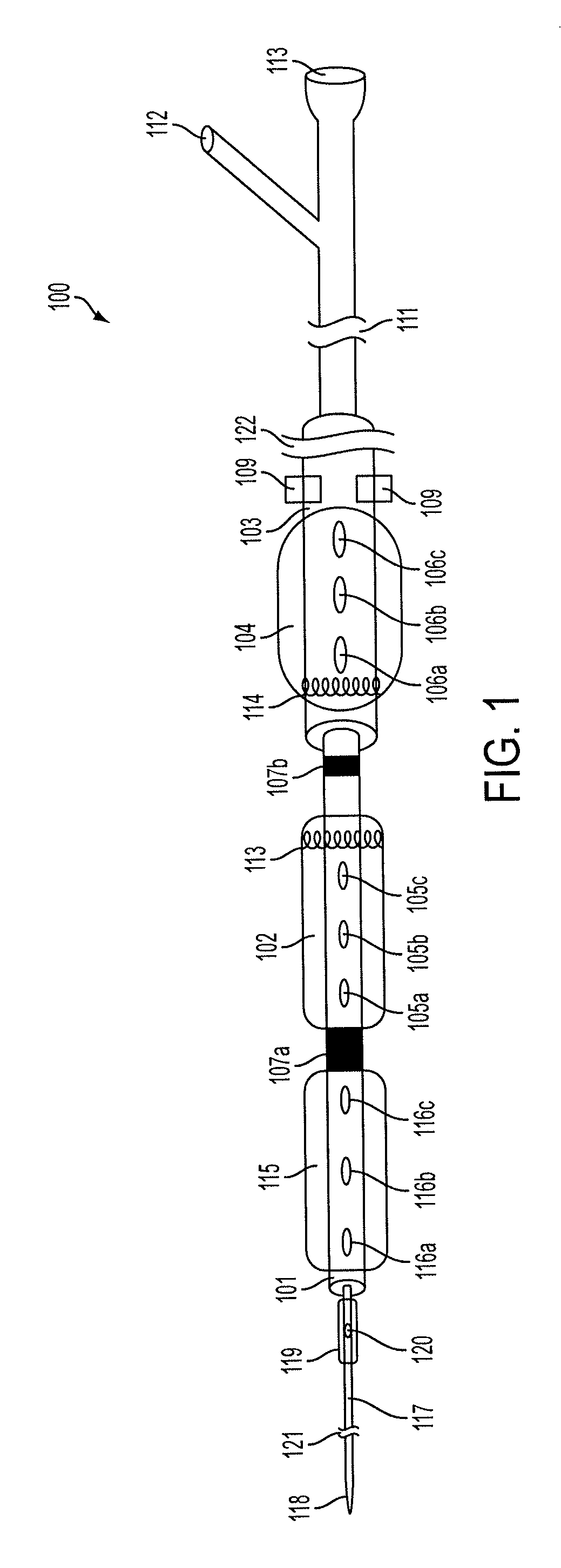

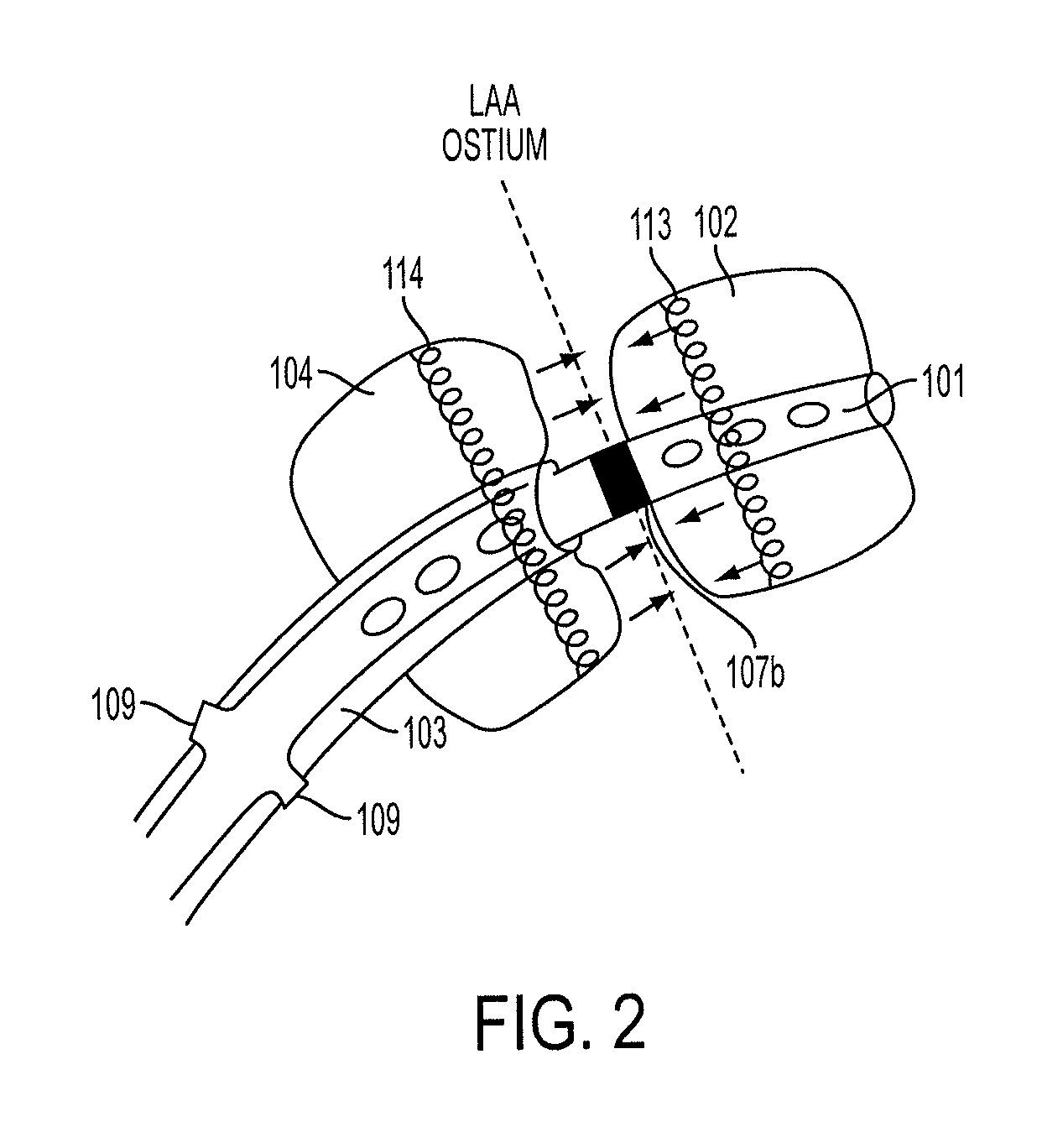

Methods and systems for accessing a pericardial space and preventing strokes arising from the left atrial appendage

The invention presents methods and systems for accessing a pericardial space and preventing strokes arising from a left atrial appendage (“LAA”) by achieving a complete occlusion of the LAA using an epicardial approach without creating a puckering of the LAA ostium. A complete occlusion of the LAA is desired because bleeding arising from the LAA often leads to embolic strokes. Due to the peculiar anatomy of the LAA ostium, traditional LAA ligation techniques using sutures can lead to puckering, thus compromising the occlusion of the LAA. The invention achieves a complete occlusion and a more effective hemostatic seal with the use of inflatable balloons having electromagnetic coils internally, as well as hydrogels, sponges, and caliber tubes attached to the respective balloon's exterior, anchoring balloons, a closure device having a suture looped through two semi-rigid hollow tube that can be coated with hydrogel or silicone, and locking mechanisms.

Owner:KRISHNAN SUBRAMANIAM CHITOOR

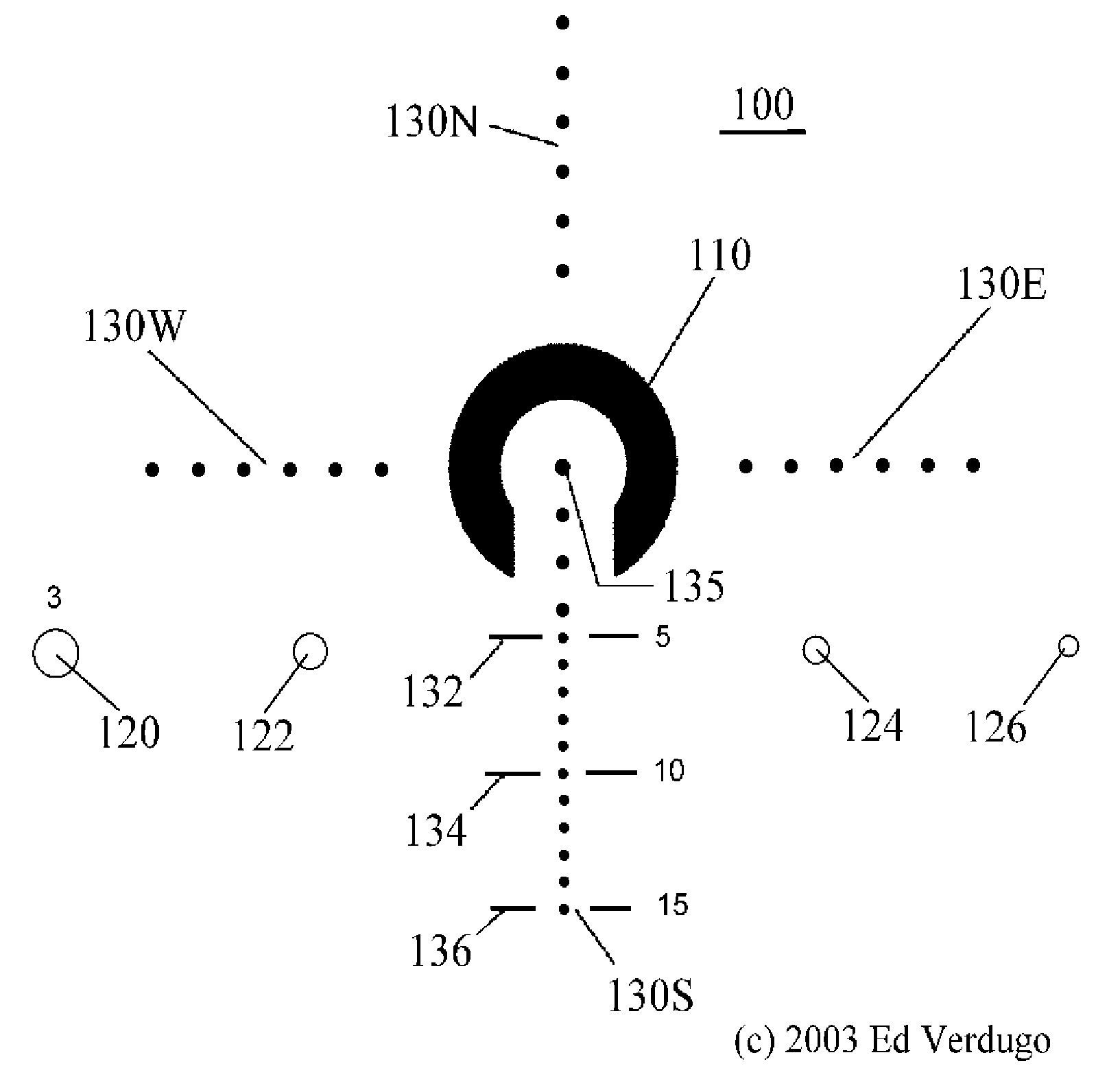

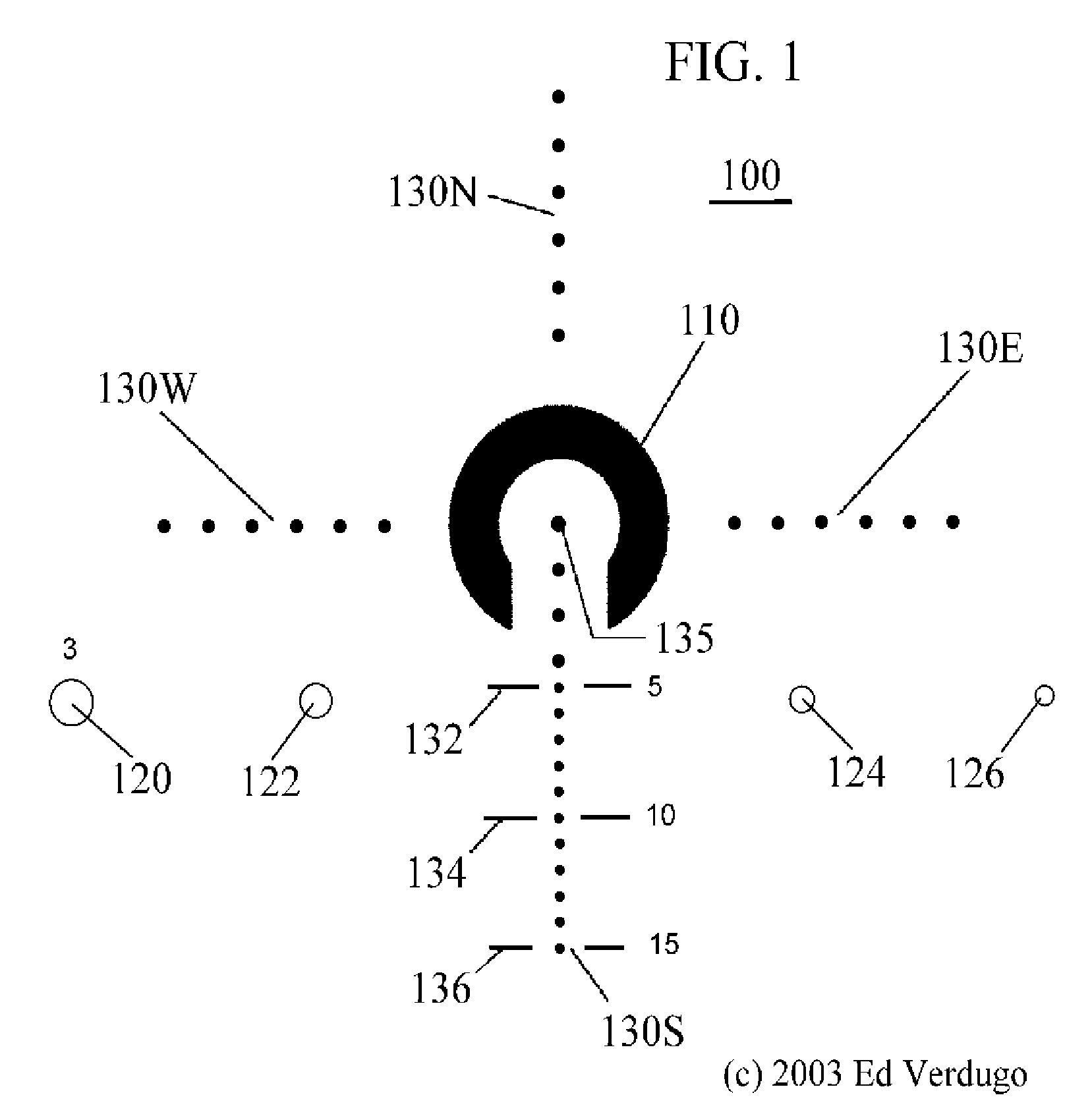

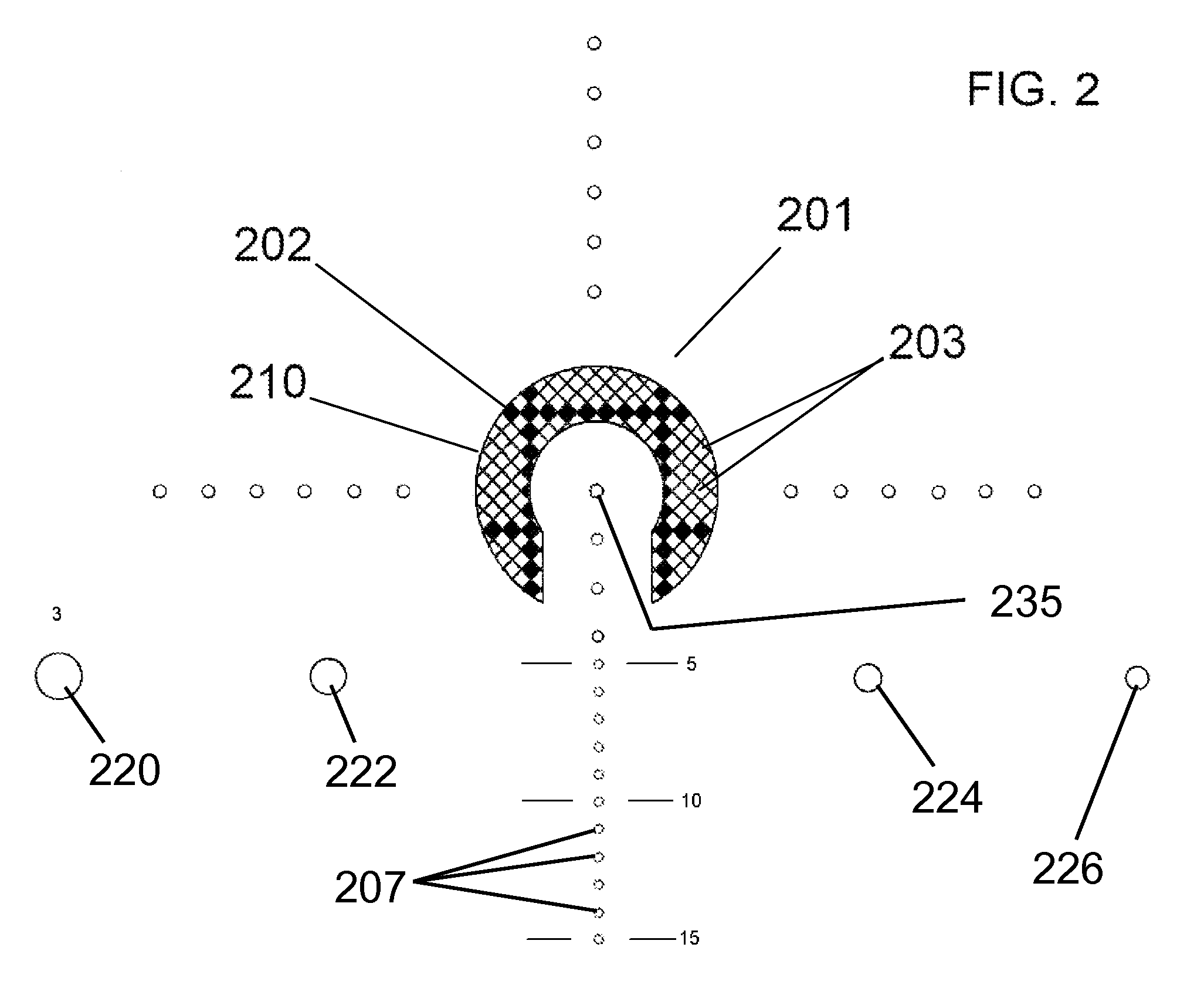

Reticule

ActiveUS20070022651A1Extension of timeImprove accuracySighting devicesTarget acquisitionComputer science

The present invention is a reticule featuring both rapid close-quarters target acquisition and precise distance shooting functionality. The reticule features a broad central aiming ring and four sets of aiming point-indicating dots. The lowest set comprises dots of differing dimensions and distances apart. Ranging rings are also provided. In an alternate embodiment the aiming ring comprises a plurality of varying transparent and opaque cells. The reticule can be illuminated through known or future discovered means for low-light or night shooting. A further alternate embodiment features a caliber specific ranging system.

Owner:VERDUGO EDWARD A

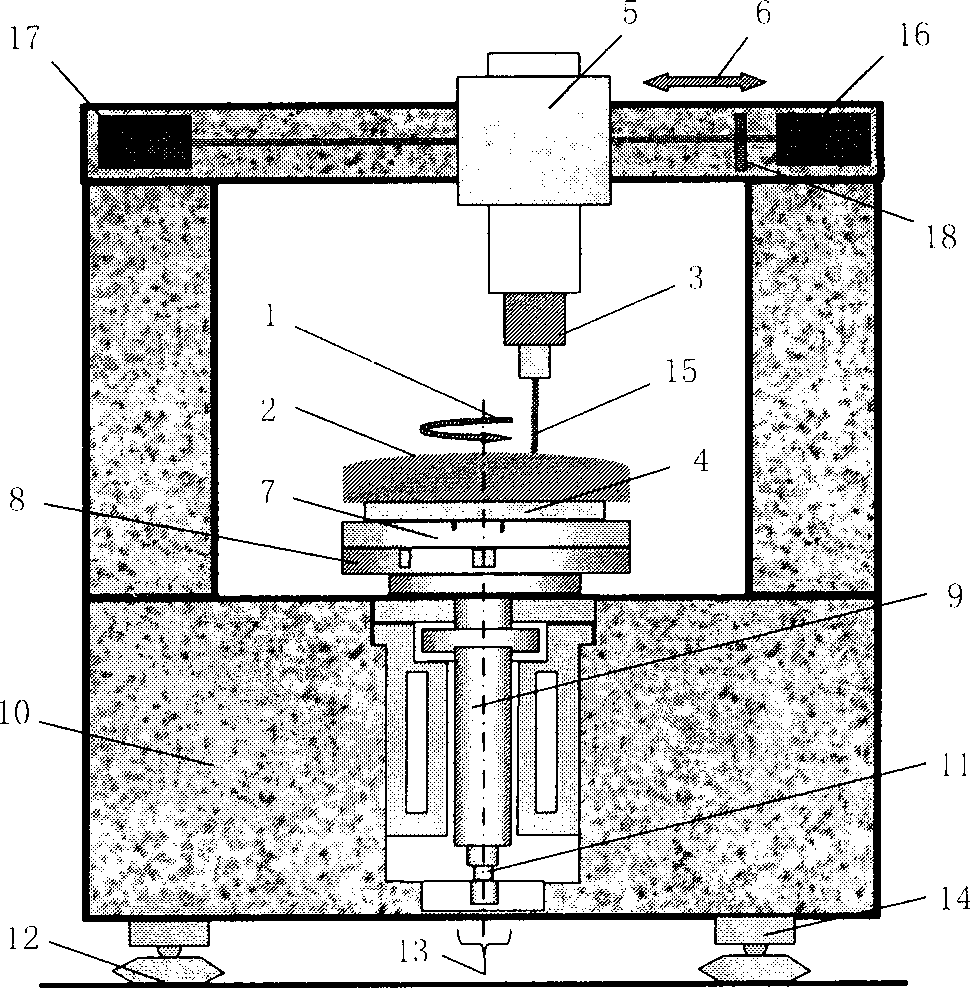

Large caliber aspheric surface measuring apparatus and method based on ultra-precise revolving scanning

InactiveCN101377410AGood effectRealize measurementUsing optical meansMeasurement deviceMacroscopic scale

The invention provides a large diameter aspheric measuring device based on ultra-precision rotary scan and a method, belongs to the macroscopic measuring technology. The device comprises an ultra-precision air flotation turntable, a precision angle and angle measuring system, an ultra-precision linear air flotation guide, a length-measuring device and a gradient measurement system. The gradient measurement system comprises a linear polarization He-Ne laser or a semiconductor laser, a diffraction element, a scanning head and an image receiving unit. The linear polarization He-Ne laser or the semiconductor laser and the image receiving unit are separately fixed on the two sides of the base beam. The scanning head is fixed on the ultra-precision linear air flotation guide. The scanning head comprises a radial gradient measurement sub-scanning head and a tangential gradient measurement sub-scanning head, both of which comprise an error compensation light path. The working platforms of the two sub-scanning heads are orthogonal to each other. The invention discloses a large diameter aspheric measuring method based on ultra-precision rotary scan.

Owner:HARBIN INST OF TECH

Multi-caliber ambidextrously controllable firearm

ActiveUS20060156606A1Reliable shootingEasy to operateSafety arrangementCartridge extractorsEngineeringCaliber

A multi-caliber ambidextrously controlled firearm that includes an adjustable ejection system to facilitate the ejection of spent cartridge casings from a firearm. The adjustable ejection system includes an ejection port defined by an aperture in the firearm and a deflector. The deflector is attached to the firearm to adjust the size of the ejection port and may be attached at one of at least two attachment positions of the firearm. The adjustable ejector system includes an ejector selectively attached to the firearm at one of at least two ejector attachment positions. The improved firearm also includes an ambidextrous magazine catch system for selectively retaining a magazine within a firearm. The magazine catch system includes a first button opposite a second button such that either button may be actuated by a user to release the magazine retained with the firearm.

Owner:RMDI

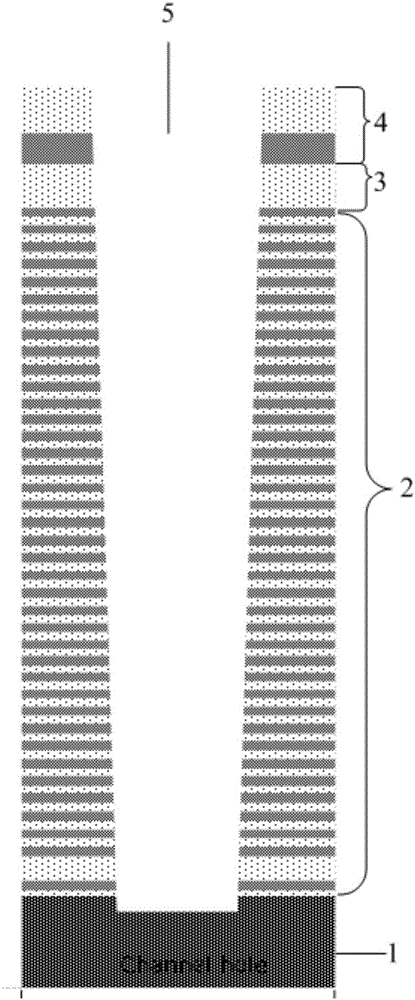

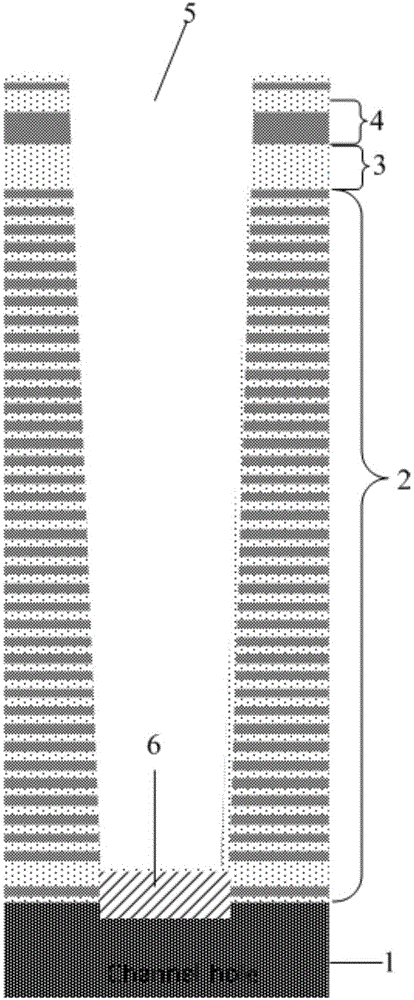

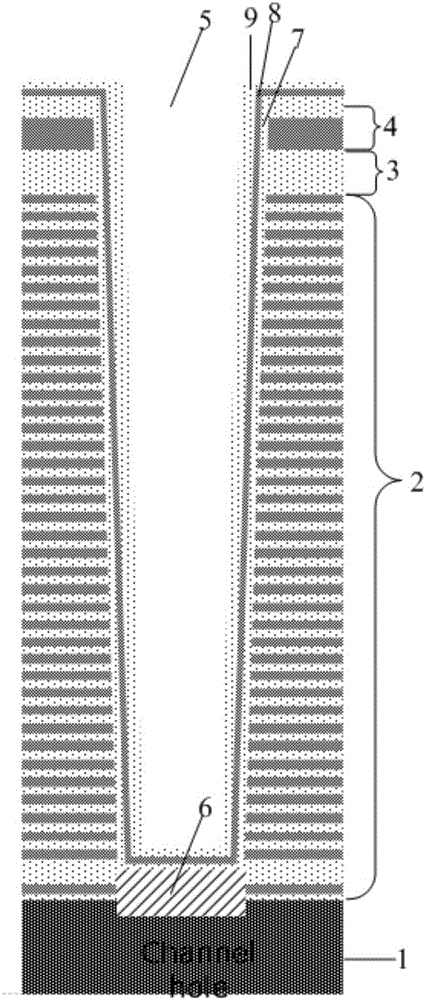

Three-dimensional memory and formation method of channel pore structure thereof

ActiveCN106653684AReduce the difficulty of manufacturing processLow manufacturing process costSemiconductor/solid-state device manufacturingGeomorphologyWidth ratio

The embodiment of the invention discloses a three-dimensional memory and a formation method of a channel pore structure thereof. According to the method, the channel pore structure in the three-dimensional memory is formed through a twice through-hole formation technology of a first through hole and a second through hole, so that the process difficulty and cost of the channel pore structure are greatly reduced, the problems of high process difficulty and high cost caused by ultrahigh through hole depth-to-width ratio under the same caliber are solved, and meanwhile the manufacturing process difficulty and cost of the three-dimensional memory are also reduced.

Owner:YANGTZE MEMORY TECH CO LTD

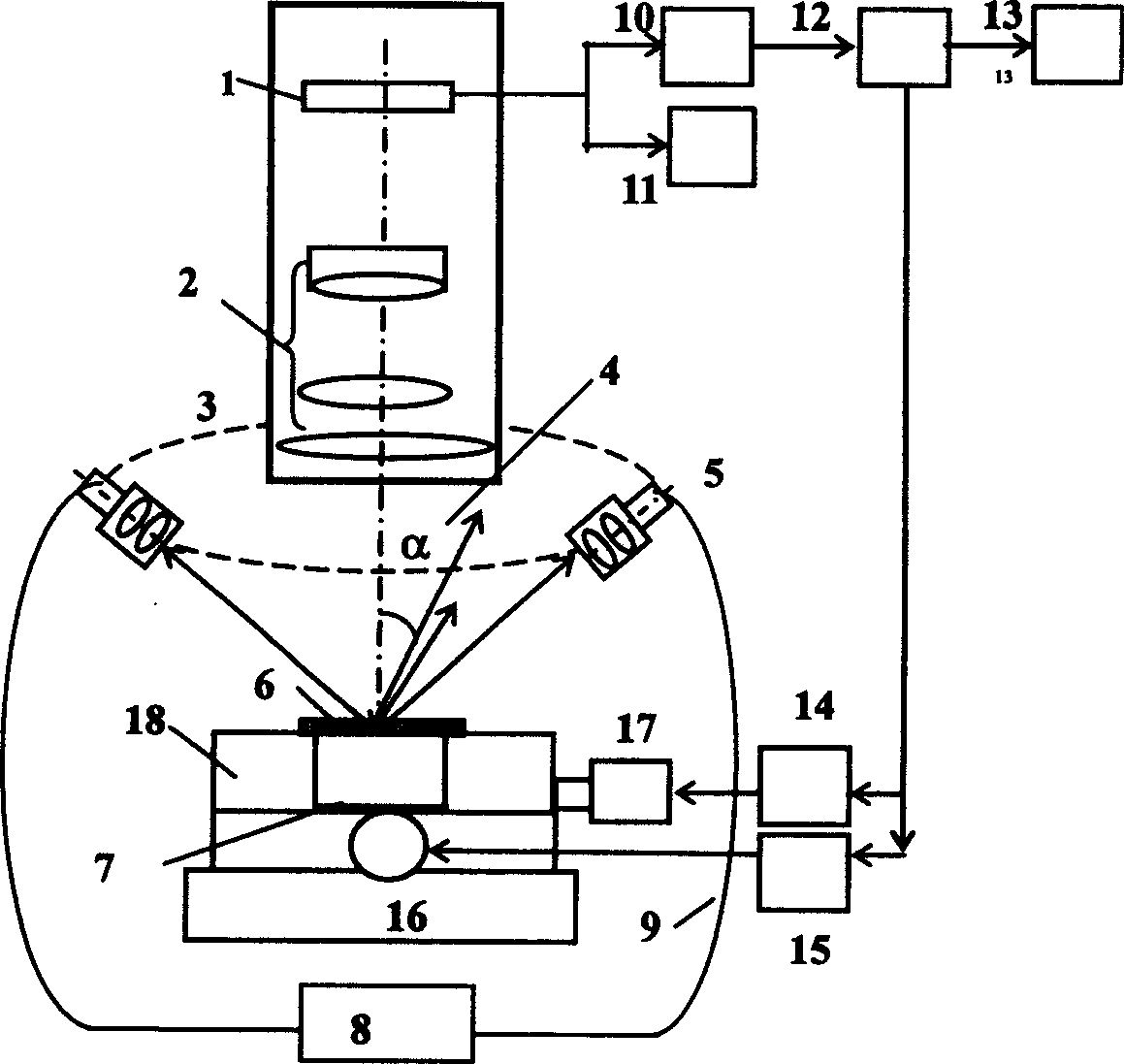

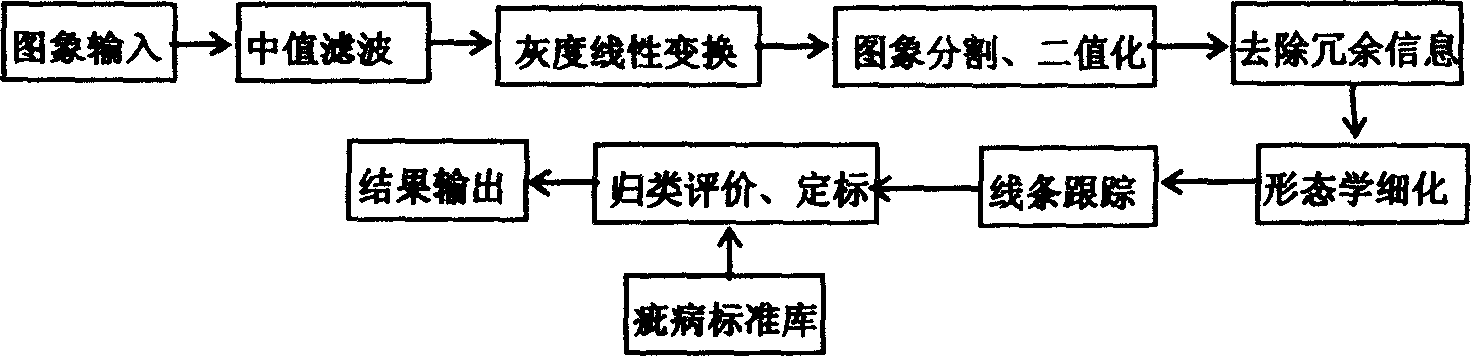

Automatic detection meethod and system for smooth surface flaw

ActiveCN1563957AImprove accuracyQuantitatively accurateMaterial analysis by optical meansMathematical modelComputer-aided

Based on standard of faulty work and light scattering characteristic of faulty work, new type computer aided digitized testing device suitable to large caliber, sub aperture scattering imaging is built. Features of the testing device are as following: Kohler cold light source arranged in multiple optical fiber and multiple azimuth angles; reflecting imaging of scattered light from faulty work on surface to be tested; scattered light collected by micro zooming system and imaged on CCD; Movable operating table in X, Y directions controlled by computer through multiple sub apertures scans surface to be tested in large caliber; building up mathematical model pattern recognition based on mathematical morphology, and software for calibrating size of faulty work. The invention builds objective digital evaluation system, raises working efficiency. The device is suitable for recognizing and evaluating faulty work in size larger than several micros.

Owner:ZHEJIANG UNIV

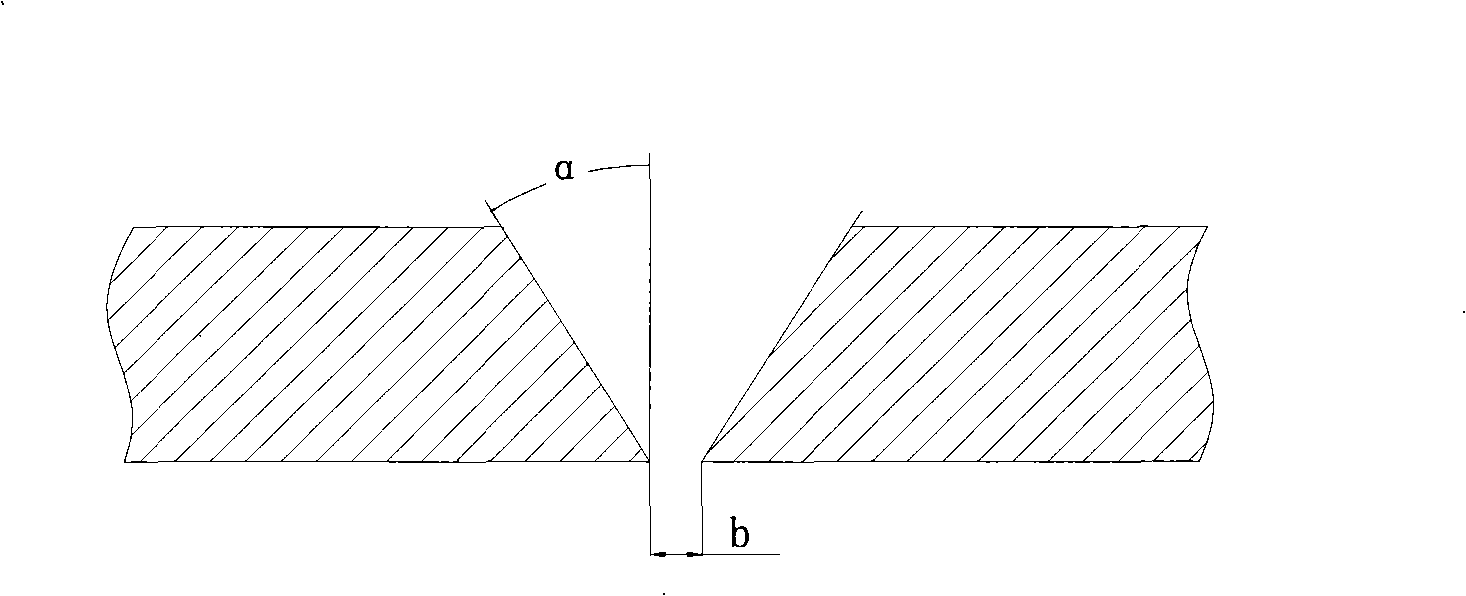

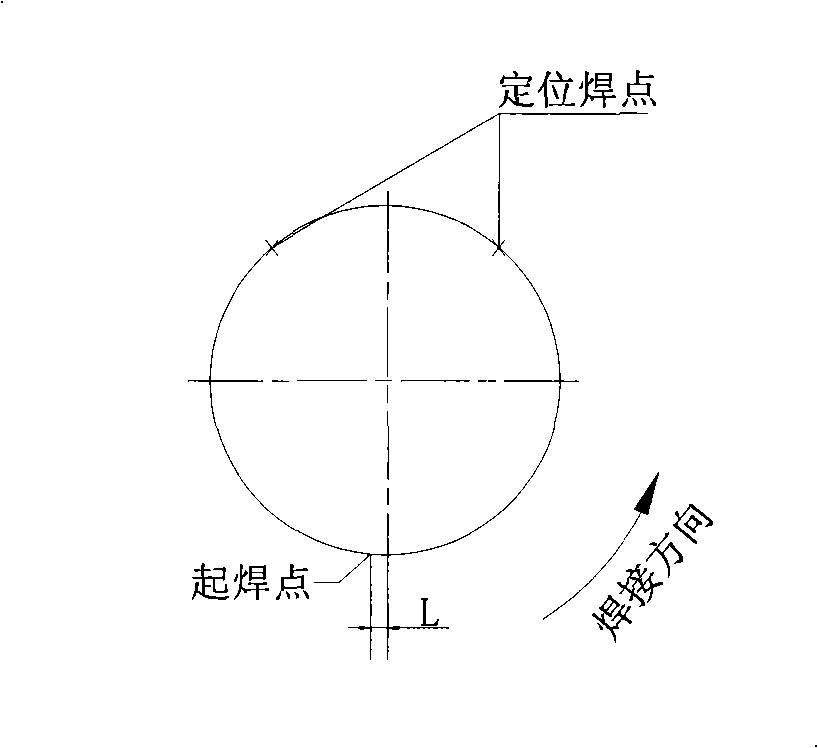

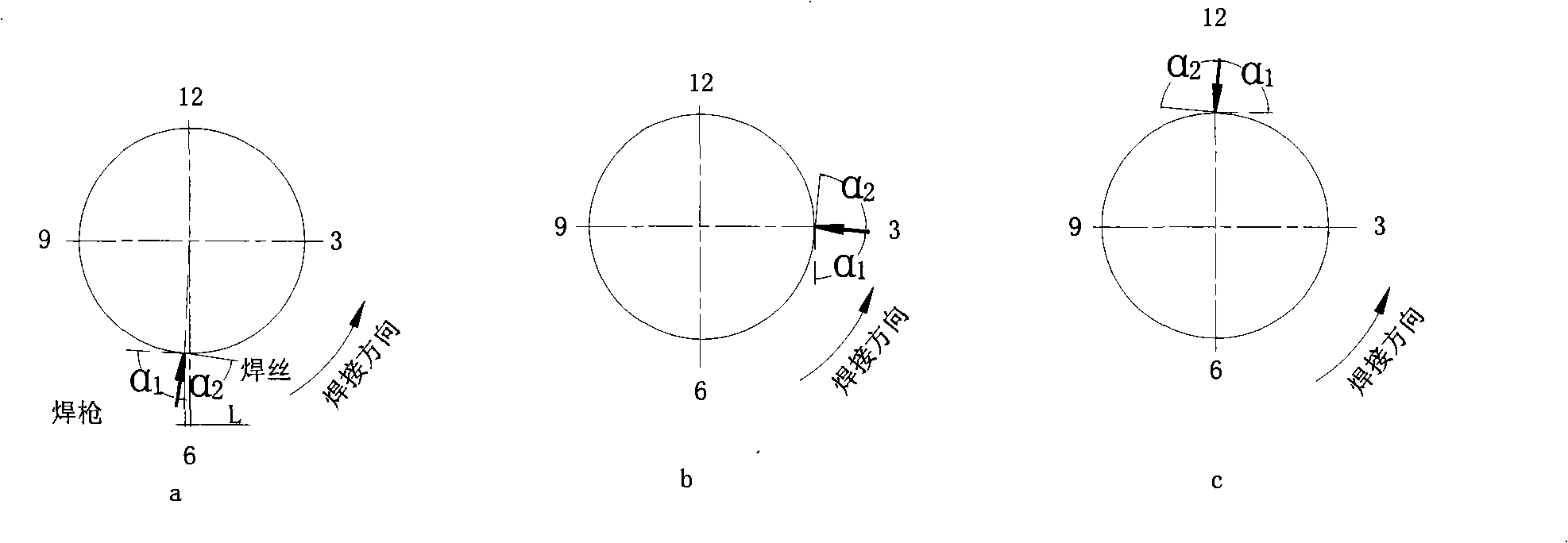

Large caliber aluminium alloy pipeline non-pad tungsten electrode argon arc single face welding and double face shaping method

InactiveCN101301699ABeautiful weldWell formed inside and outArc welding apparatusWelding/soldering/cutting articlesEngineeringWeld seam

The invention discloses a method for large-calibre aluminium-alloy pipeline no-liner tungsten electrode argon arc one-side welding both-side formation, comprising the following steps of: assembling of groove angle and clearance, grinding of tungsten electrode, cleaning before welding, adjusting welding process parameters, tack welding, and welding of a bottom coating, a filling layer and a covering layer. The pipe is horizontally fixed and the position is marked by hour; the welding sequence is left half-ring and right half-ring; each half-ring comprises overhead welding, vertical position welding and downhand welding; the welding is started at a position where L is equal to 5-10mm close to six of the overhead welding; the vertical position welding is then carried out; finally, the front half-ring is ended at 12 of the downhand welding; before the rear half-ring starts welding, the connection is grinded as a slope; the welding seam formed by the connection and the front half-ring welding position is overlapped by 3-5mm; the welding of the rear half-ring is started from 6 of the overhead welding and ended at 12 of the downhand welding through the vertical position welding; the welding is carried out by a continuous feeding method. The surface of the welding seam of the method has no pores or cracks, is completely welded and beautiful, and has good internal and external forming; by the non-destructive testing, the first-time qualification rate achieves 100%, the welding seam achieves the class-1 quality, the construction procedures are reduced, and the construction cost is reduced.

Owner:ANGANG CONSTR CONSORTIUM

Multi-caliber bolt-action rifle and components

A multi-caliber firearm has a breech sleeve connecting a barrel to a receiver and a stock. The stock includes a forward V-block and a rearward V-block. Each of the V-blocks defines a V-cut along a top portion and a through hole substantially aligned with the cross-sectional center of the V-block. The forward V-block extends through a cutout portion of the receiver and into the breech sleeve. The breech sleeve is fastened to the stock through the through hole in the forward V-block to provide a rigid connection between the stock and the breech sleeve. The receiver is fastened to the stock through the through hole in the rearward V-block to provide a rigid connection between the receiver and the stock.

Owner:SMITH & WESSON

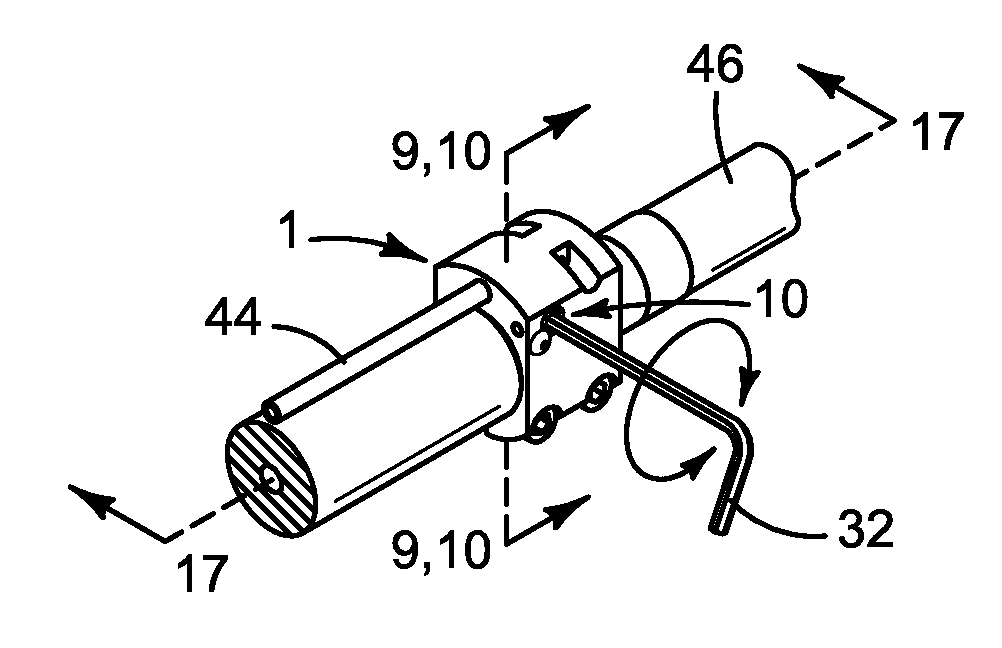

Adjustable Gas Block

InactiveUS20130098235A1Limited rangeEffective regulationSighting devicesDetentAtmospheric temperature

An adjustable gas block designed to interface with the gas-operating system of an auto-loading firearm. This design provides continuously adjustable gas flow, from fully closed to fully open, in small, discrete, uniform, and fully-repeatable increments.The design works by means of a click adjustment valve screw which has a number of grooves that are engaged by a spring-loaded detent. As the screw is turned in or out, either by a tool or by an integrated finger-adjustable knob or handle, the clicks of the detent provide both audible and tactile feedback to the user. This allows a user to optimize the operation of a firearm by responding to variations in ammunition loading, bullet weight, atmospheric temperature, cartridge caliber, and for the installation / removal of a silencer, each of which changes the volume and pressure characteristics of the gas-operating system.

Owner:REINKEN RALPH J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com