Patents

Literature

613 results about "Slug" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slug, or land slug, is a common name for any apparently shell-less terrestrial gastropod mollusc. The word slug is also often used as part of the common name of any gastropod mollusc that has no shell, a very reduced shell, or only a small internal shell, particularly sea slugs and semislugs (this is in contrast to the common name snail, which applies to gastropods that have a coiled shell large enough that the animal can fully retract its soft parts into the shell).

Apparatus of antenna with heat slug and its fabricating process

ActiveUS20060071308A1Simple structureEasy to makeAntenna supports/mountingsSemiconductor/solid-state device detailsEngineeringDual band antenna

An apparatus of antenna with heat slug and its fabricating process are provided, in which the antenna with heat slug can be realized with a single sheet or double sheets of metal. A dual-band antenna module with a mask cover is taken as an example to realize the apparatus. Each single sheet of metal can be achieved by simply cutting and bending a metal plate. Thereby, it is a simple and low-cost fabricating process. In the known fabricating process of integrated circuit, the heat slug and the antenna can be combined in a module at the same step. Therefore, integrating the antenna with heat slug in a fabricating process needs not to develop a new process.

Owner:IND TECH RES INST

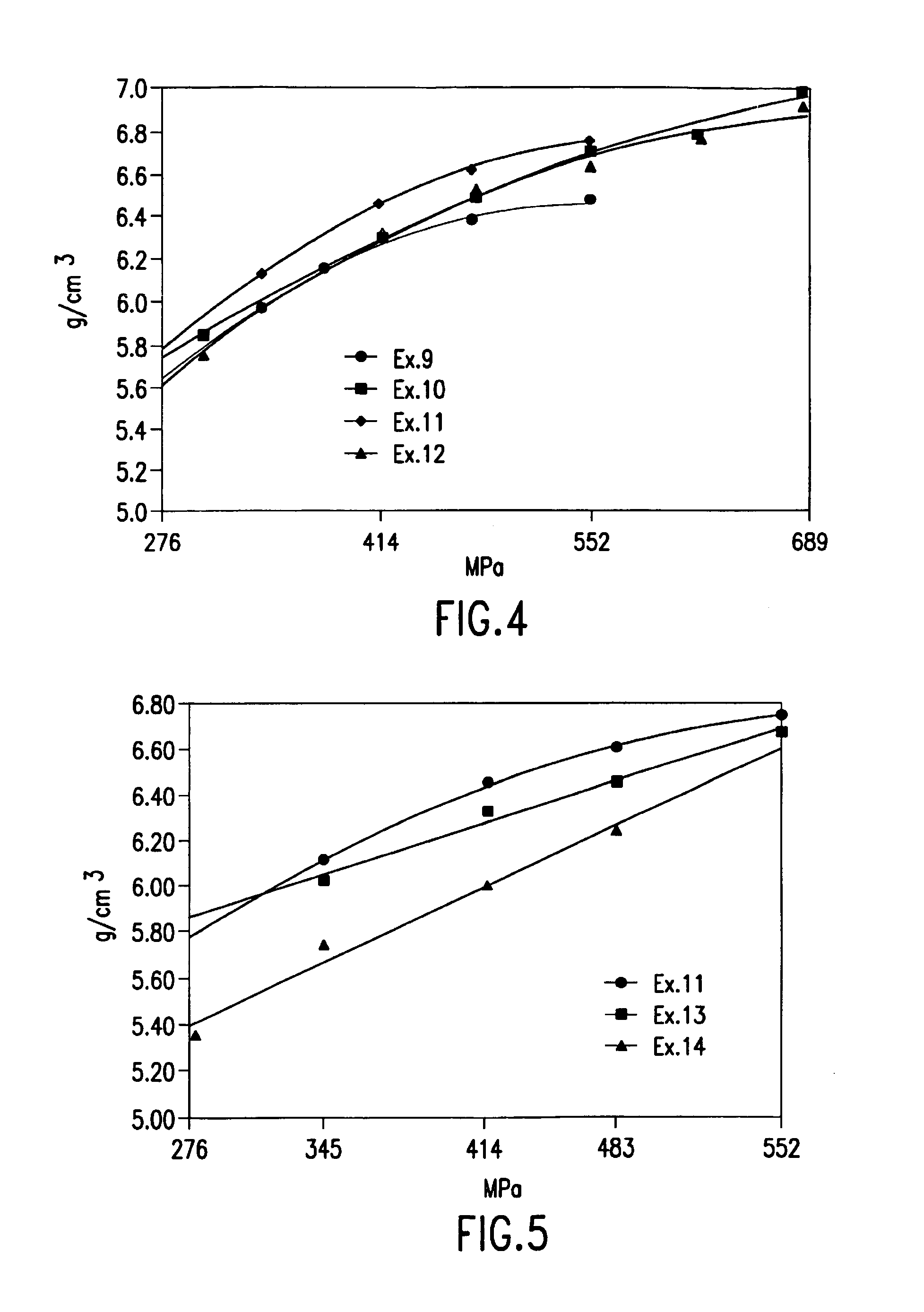

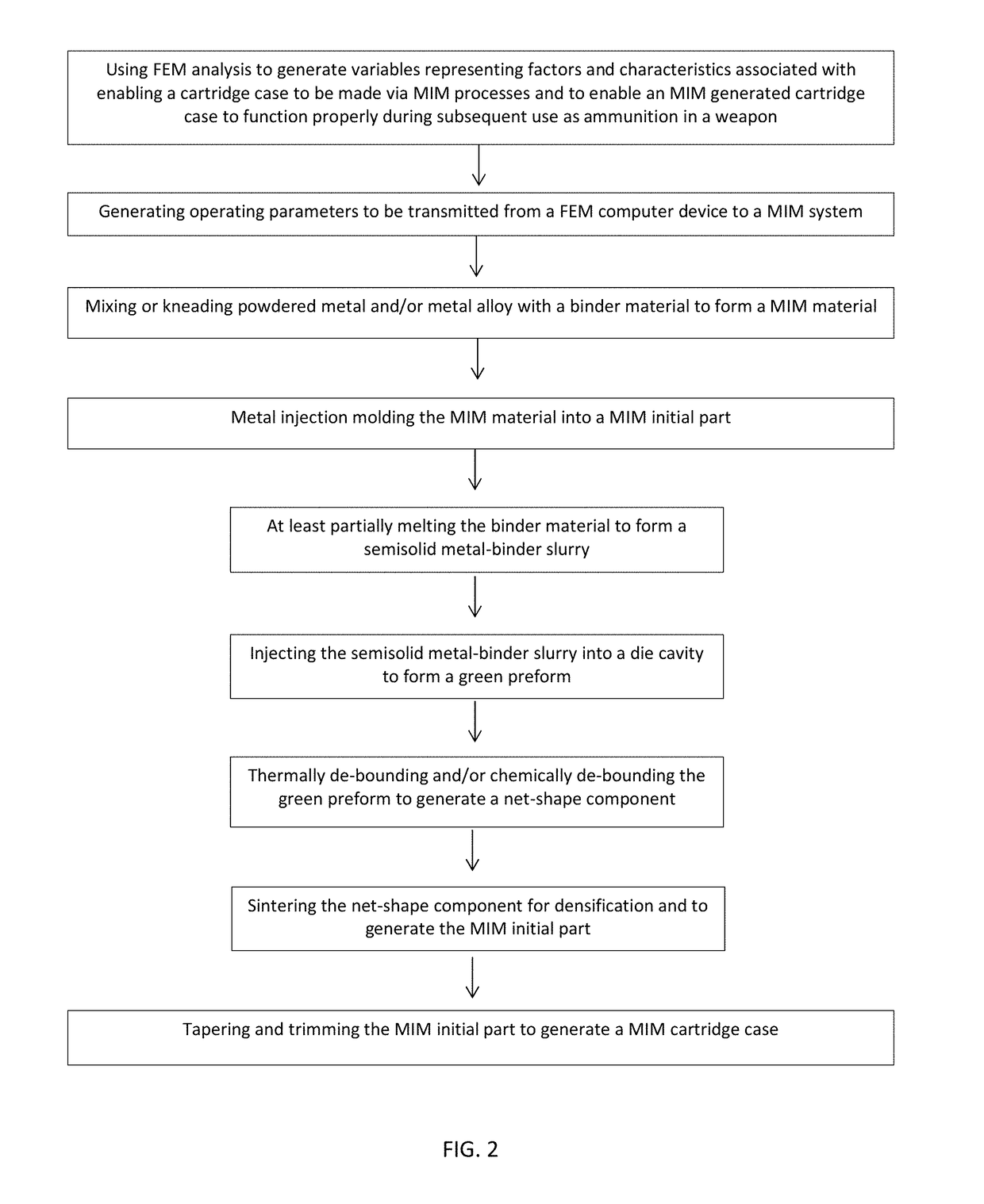

Metal Injection Molded Cased Telescoped Ammunition

ActiveUS20180066925A1Promote generationLight weightTransportation and packagingMetal-working apparatusMetal alloySlug

Disclosed is a cartridge case for various caliber ammunition that can consist essentially of a powdered metal and / or powdered metal alloy(s) that is formed into the cartridge case through an injection mold processing. Also disclosed is a method for forming a cartridge case, which may include use of Metal Injection Molding (“MIM”) processes to produce the cartridge case which retains a primer, propellant, and / or a bullet. Also disclosed are embodiments related to a case telescoped cartridge that may include a cap and a body. The body can consist essentially of or consists entirely of a powdered metal and / or powdered metal alloy(s) that has been formed through MIM. The cap can comprise plastic that has been formed through plastic molding or comprise powdered metal and / or powdered metal alloy(s) that has been formed through MIM.

Owner:CONCURRENT TECH

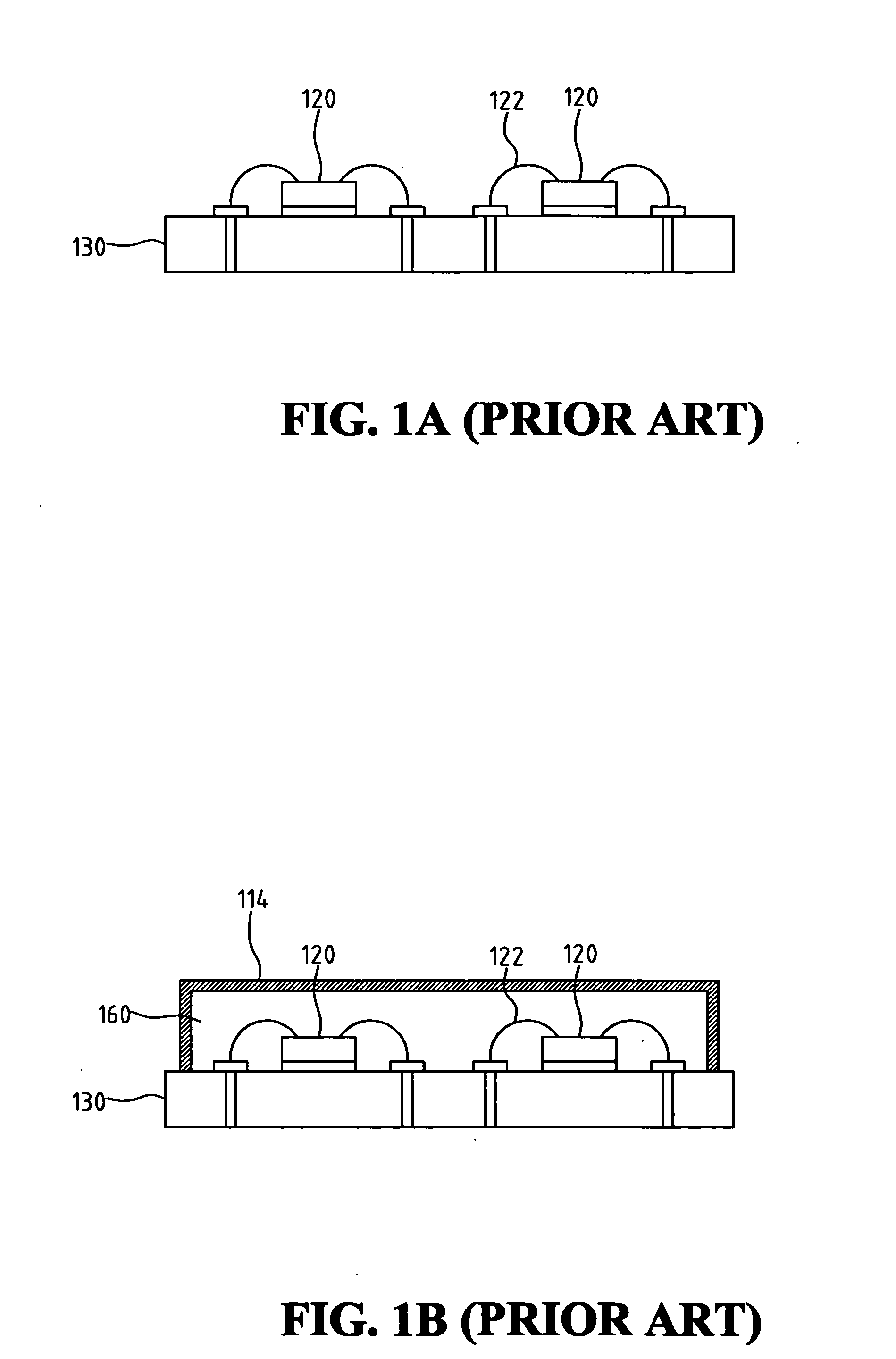

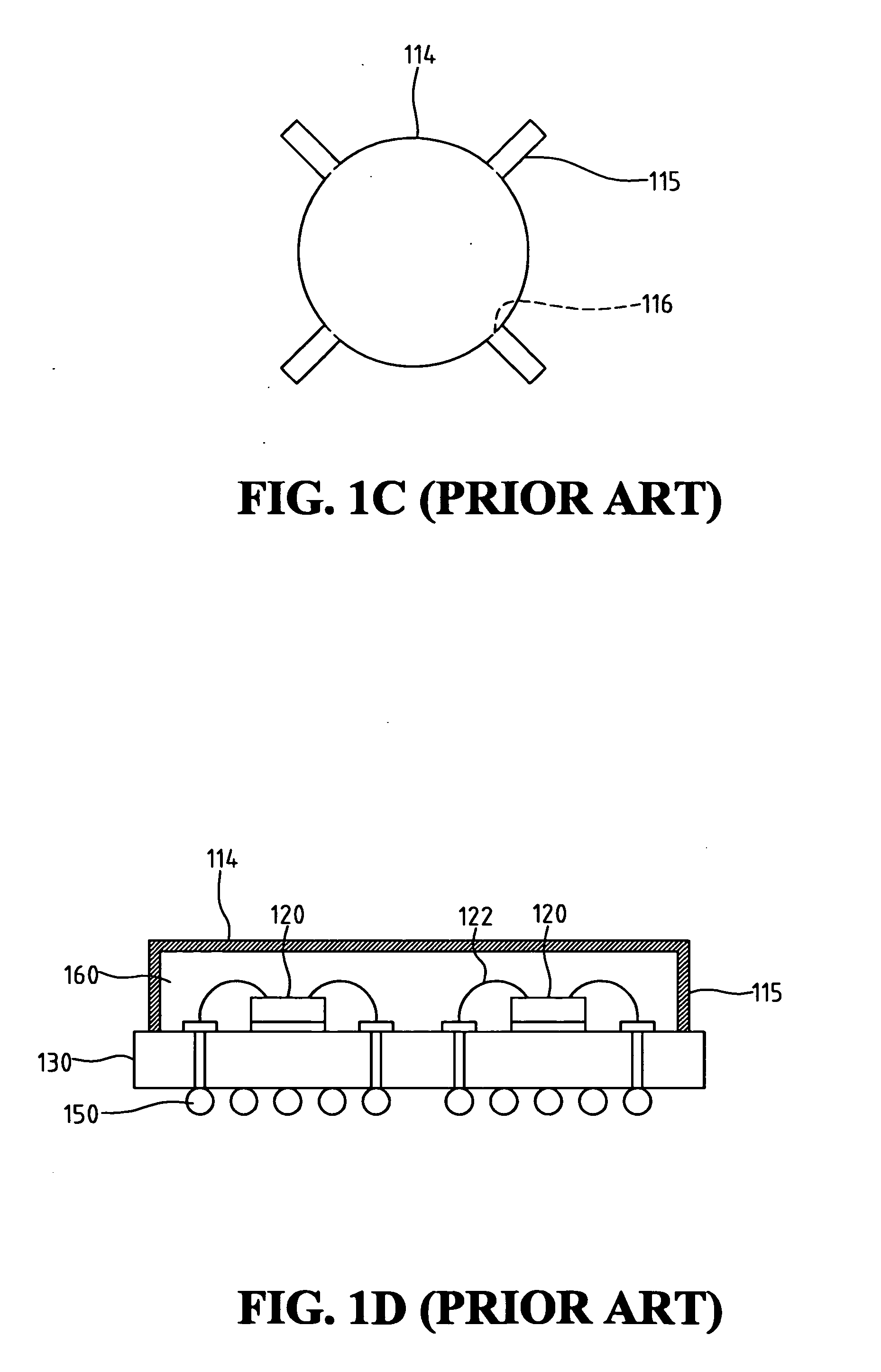

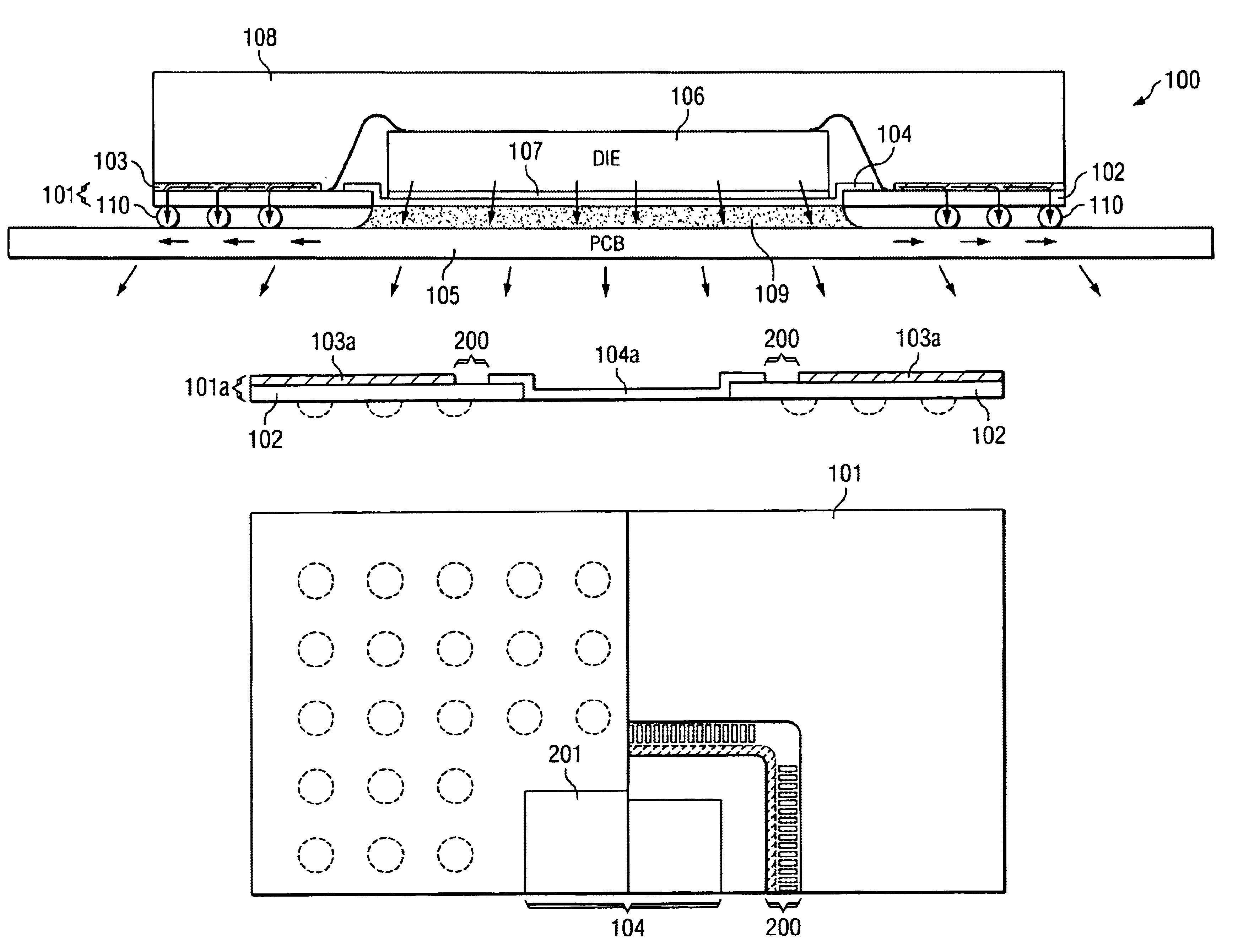

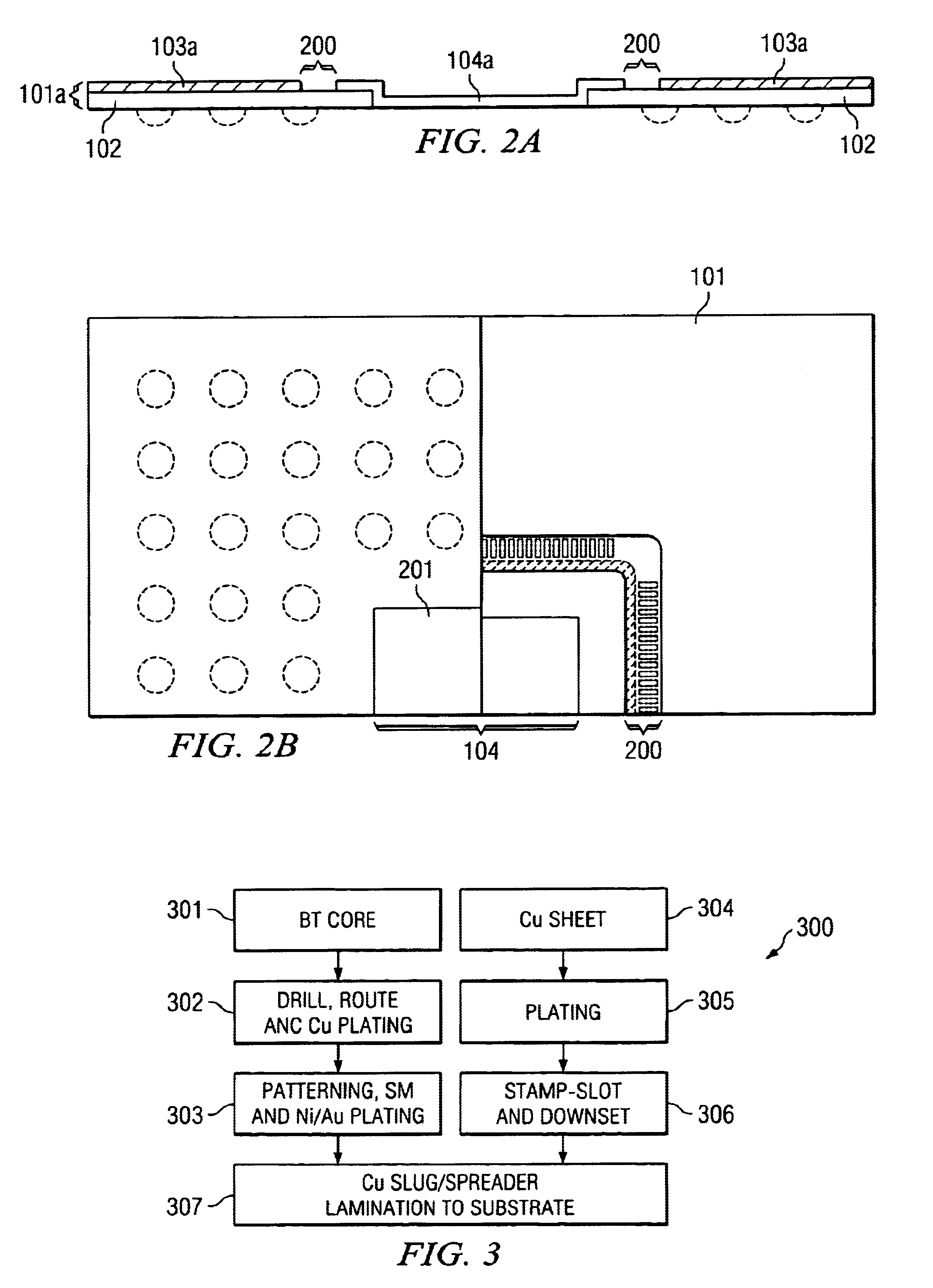

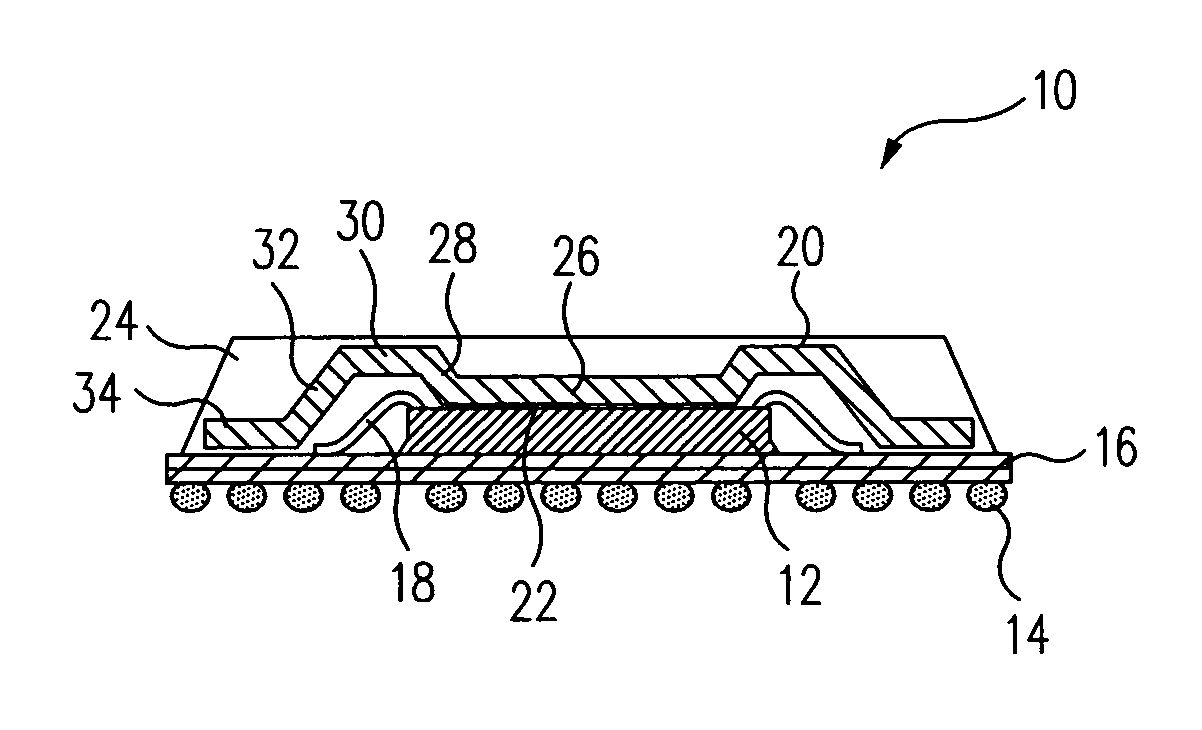

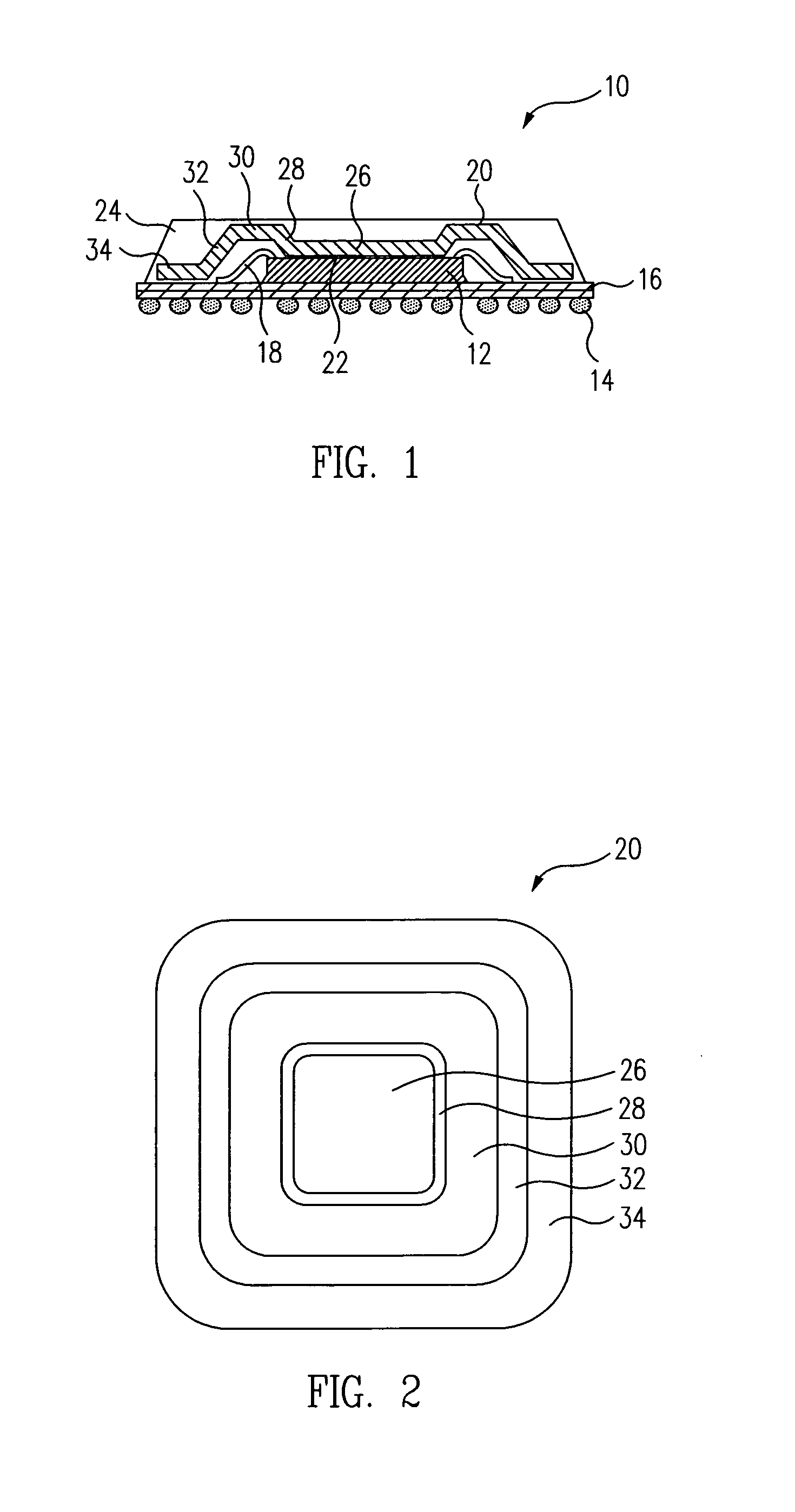

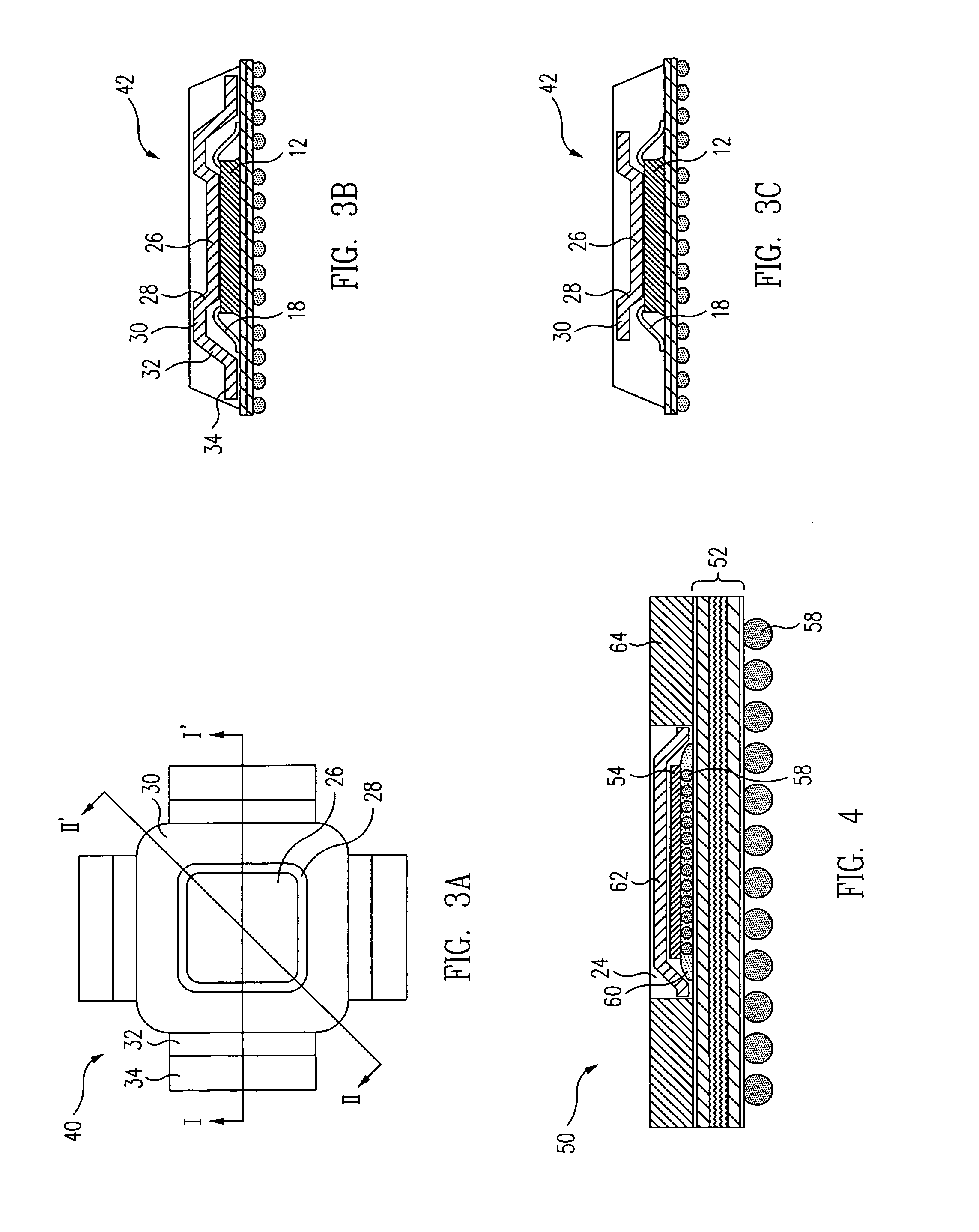

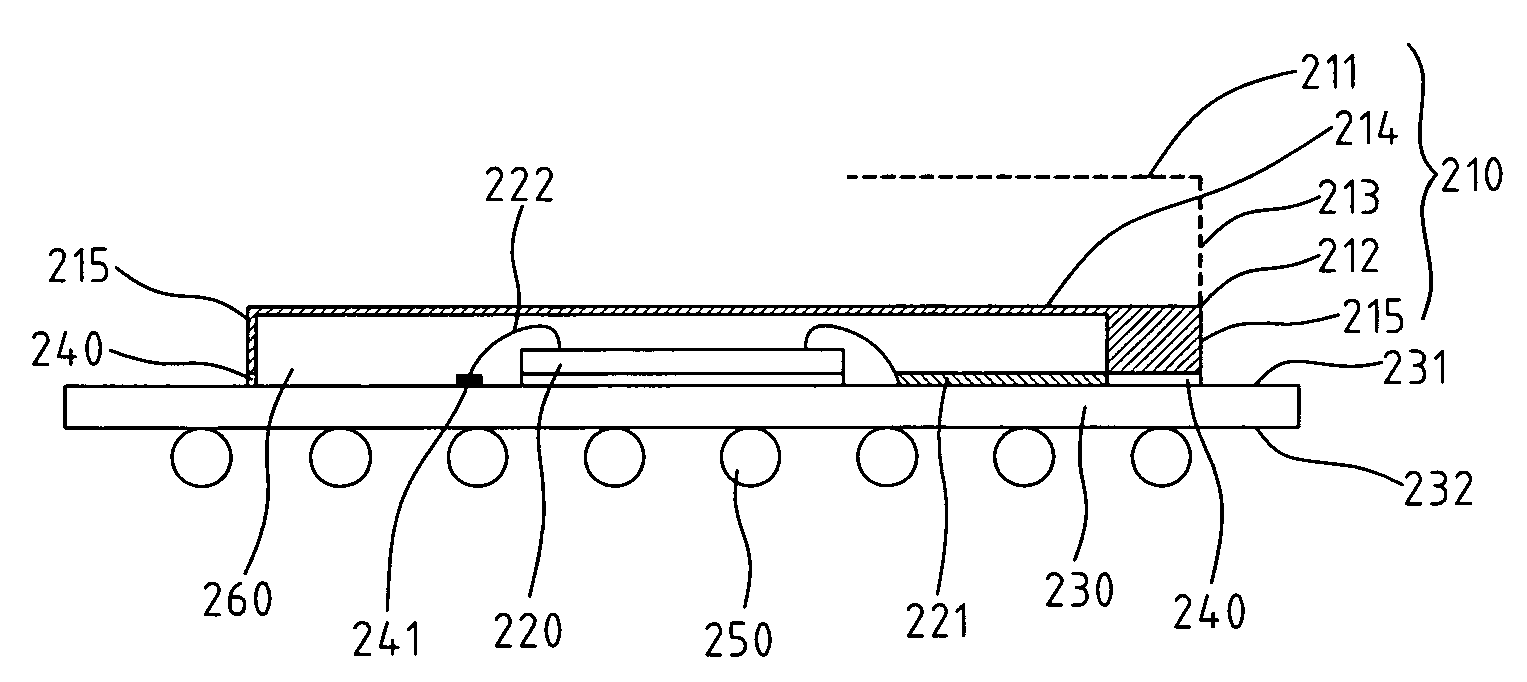

BGA/LGA with built in heat slug/spreader

A ball or land grid array plastic substrate portion is formed with a hole therethrough in the region on which the integrated circuit die is to be formed, with a copper heat slug inserted within the opening having a bottom surface substantially aligned with the bottom surface of the plastic portion to allow molding tooling for conventional ball or land grid array packages to be employed. The integrated circuit die is mounted on the heat slug, which has a solderable bottom surface and is directly soldered to the PCB. An additional copper heat spreader region is formed on an upper surface of the plastic portion.

Owner:STMICROELECTRONICS SRL

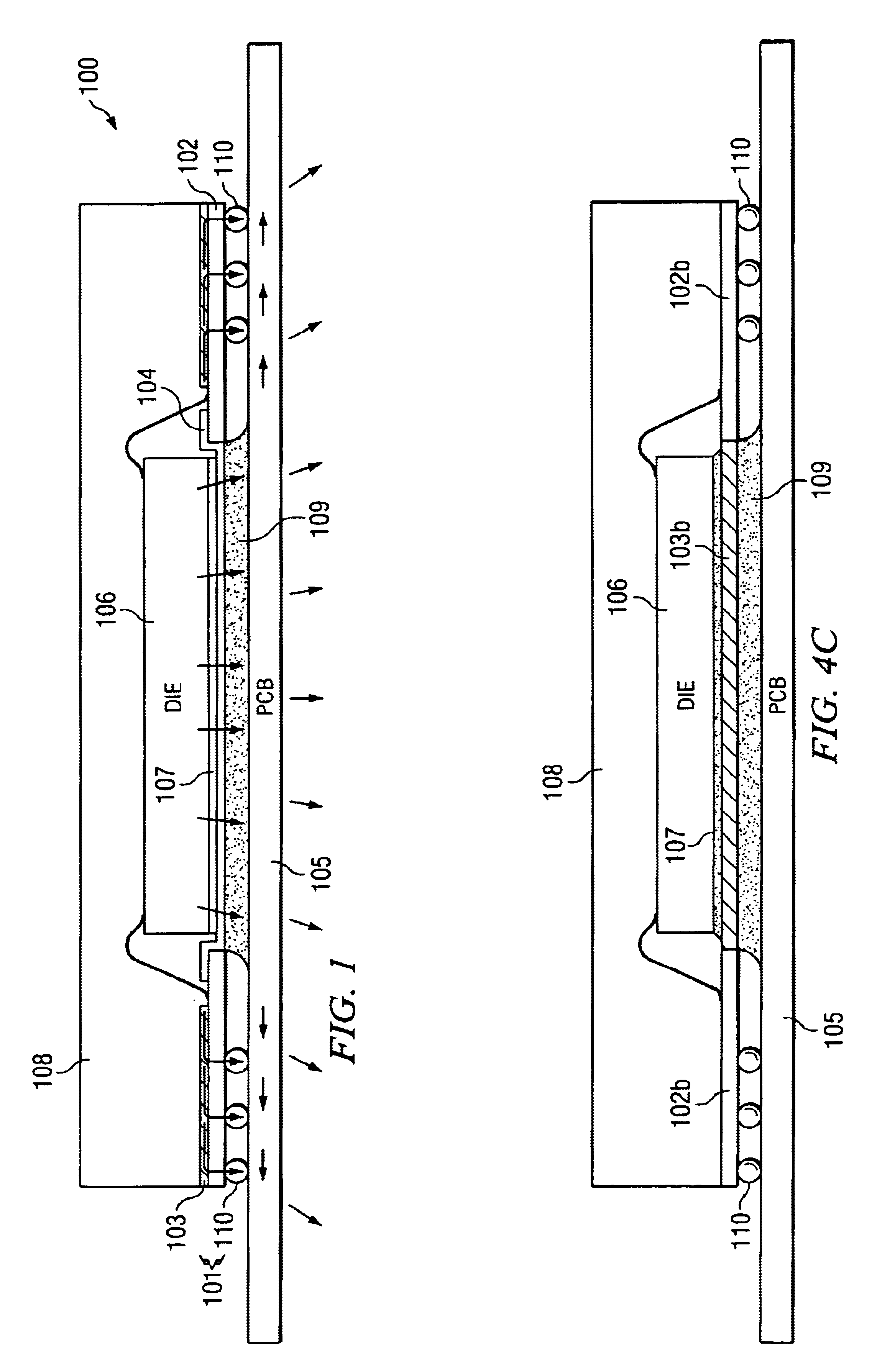

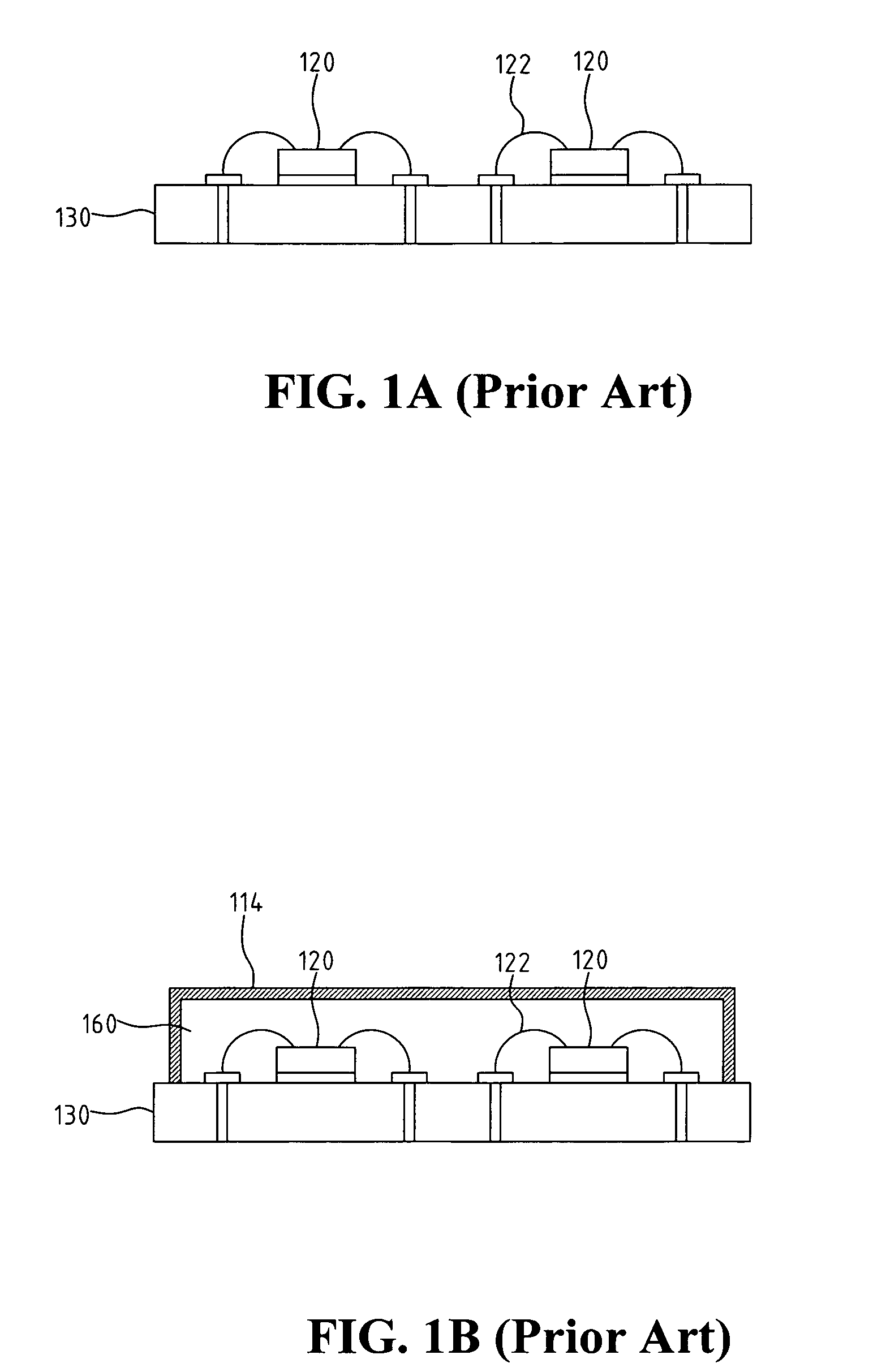

Embedded heat spreader ball grid array

InactiveUS7126218B1Reduce thermal resistanceSacrificing thermal performanceSemiconductor/solid-state device detailsSolid-state devicesInterconnectionBall grid array

A heat slug or spreader is attached directly to a surface of the die in a ball grid array (BGA) package. The heat spreader roughly conforms to the topological profile of the die, underlying substrate, and electrical interconnections between the die and the substrate, such as bond wires. The outer portion of the heat spreader substantially cover the outer portion of the substrate, or alternatively, cover only those portions extending in laterally from the sides of the chip and not the corners. An encapsulant completely covers the heat spreader and die.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Methods and systems for performing multiple reactions by interfacial mixing

Methods and systems of performing multiple reactions in a high throughput format by utilizing interfacial mixing of adjacently positioned reagent slugs in a fluid conduit. Preferred applications of the methods and systems are in performing biochemical analyses, including genotyping experiments for multiple different loci on multiple different patient samples. Microfluidic systems are provided that increase throughput, automation and integration of the overall reactions to be carried out.

Owner:CAPLIPER LIFE SCI INC

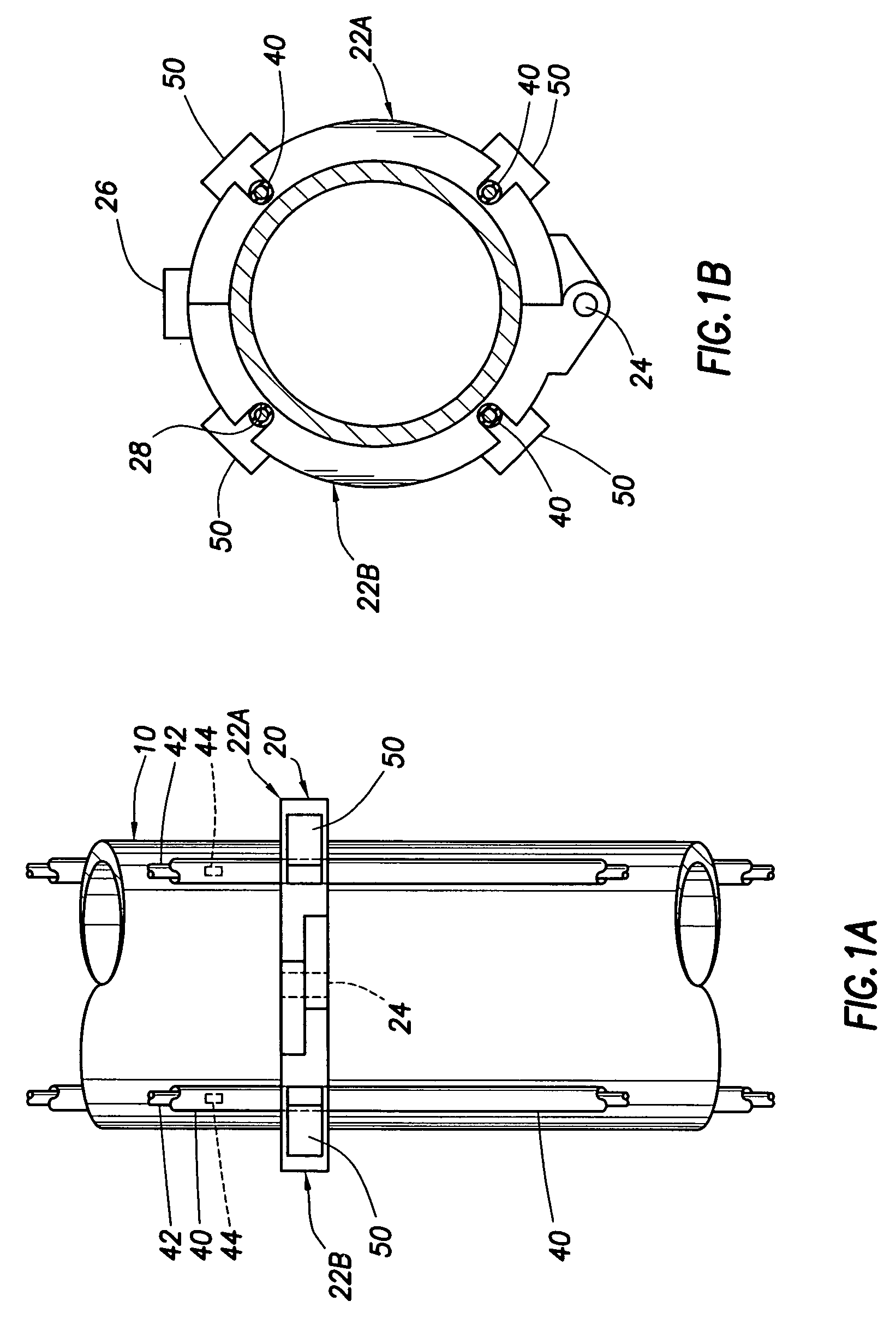

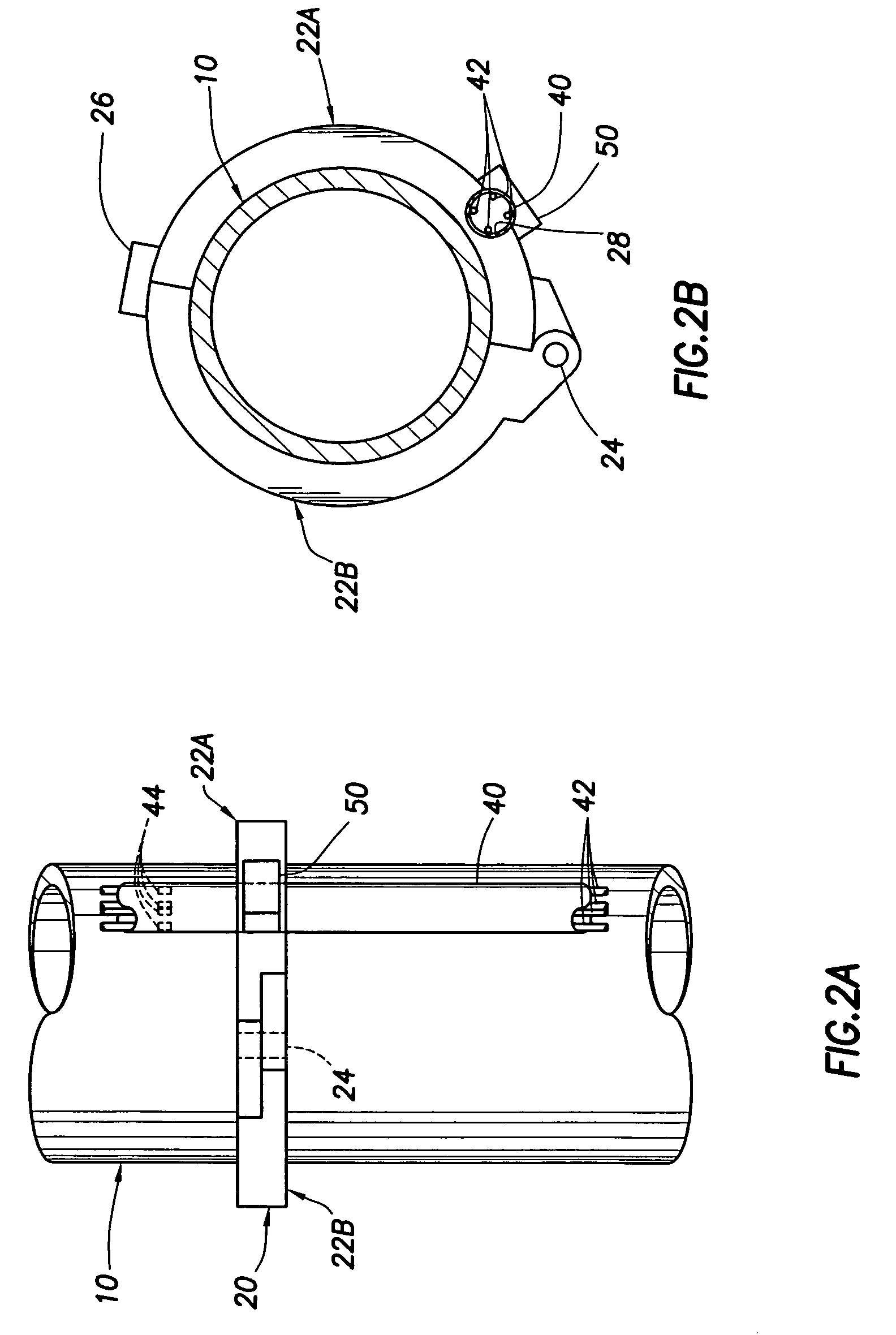

Apparatus and method for retroactively installing sensors on marine elements

Sensors, including fiber optic sensors and their umbilicals, are mounted on support structures designed to be retro-fitted to in-place structures, including subsea structures. The sensor support structures are designed to monitor structure conditions, including strain, temperature, and in the instance of pipelines, the existence of production slugs. Moreover the support structures are designed for installation in harsh environments, such as deep water conditions using remotely operated vehicles.

Owner:SHELL OIL CO

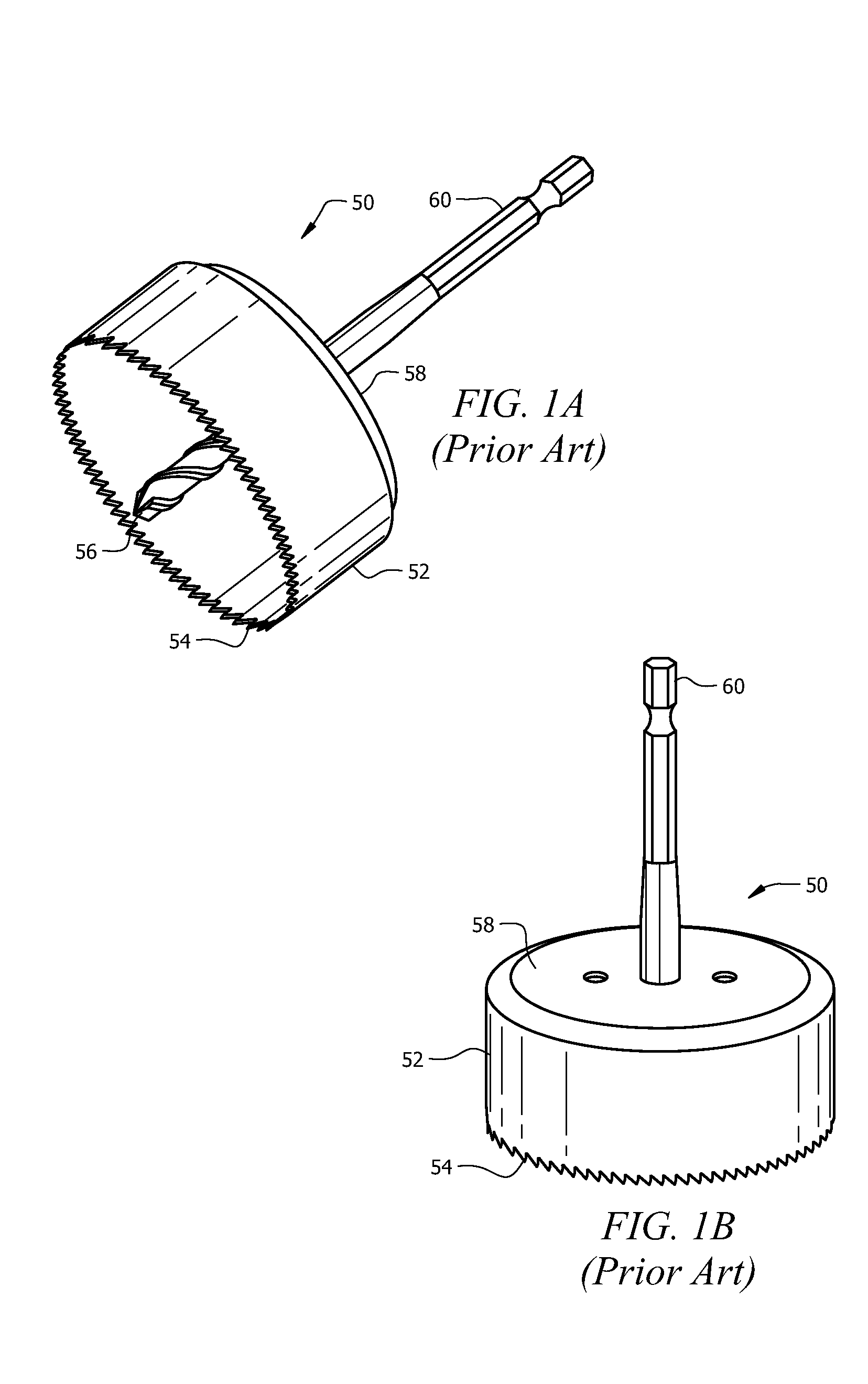

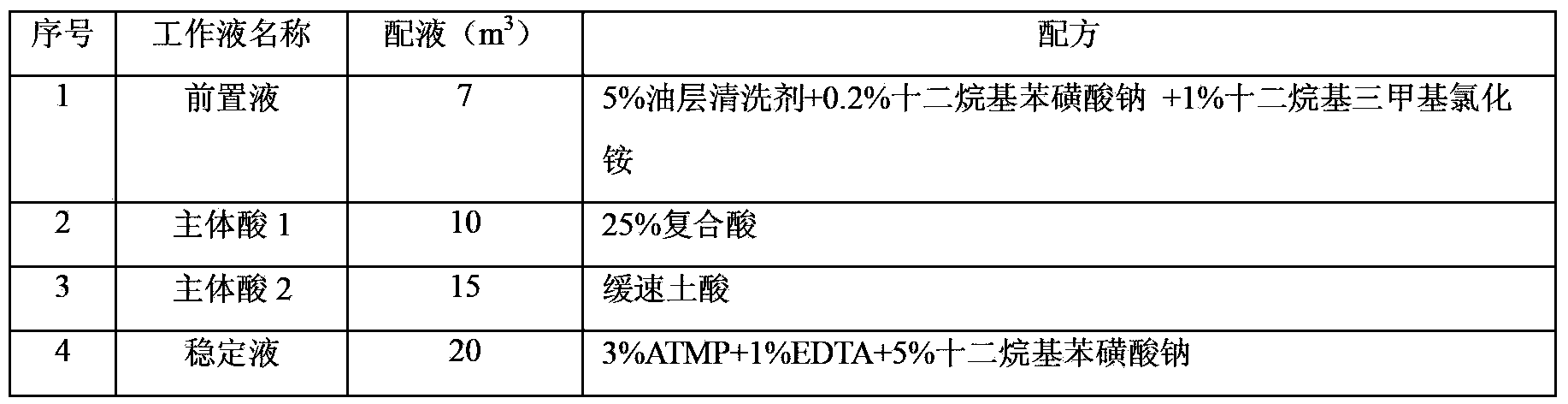

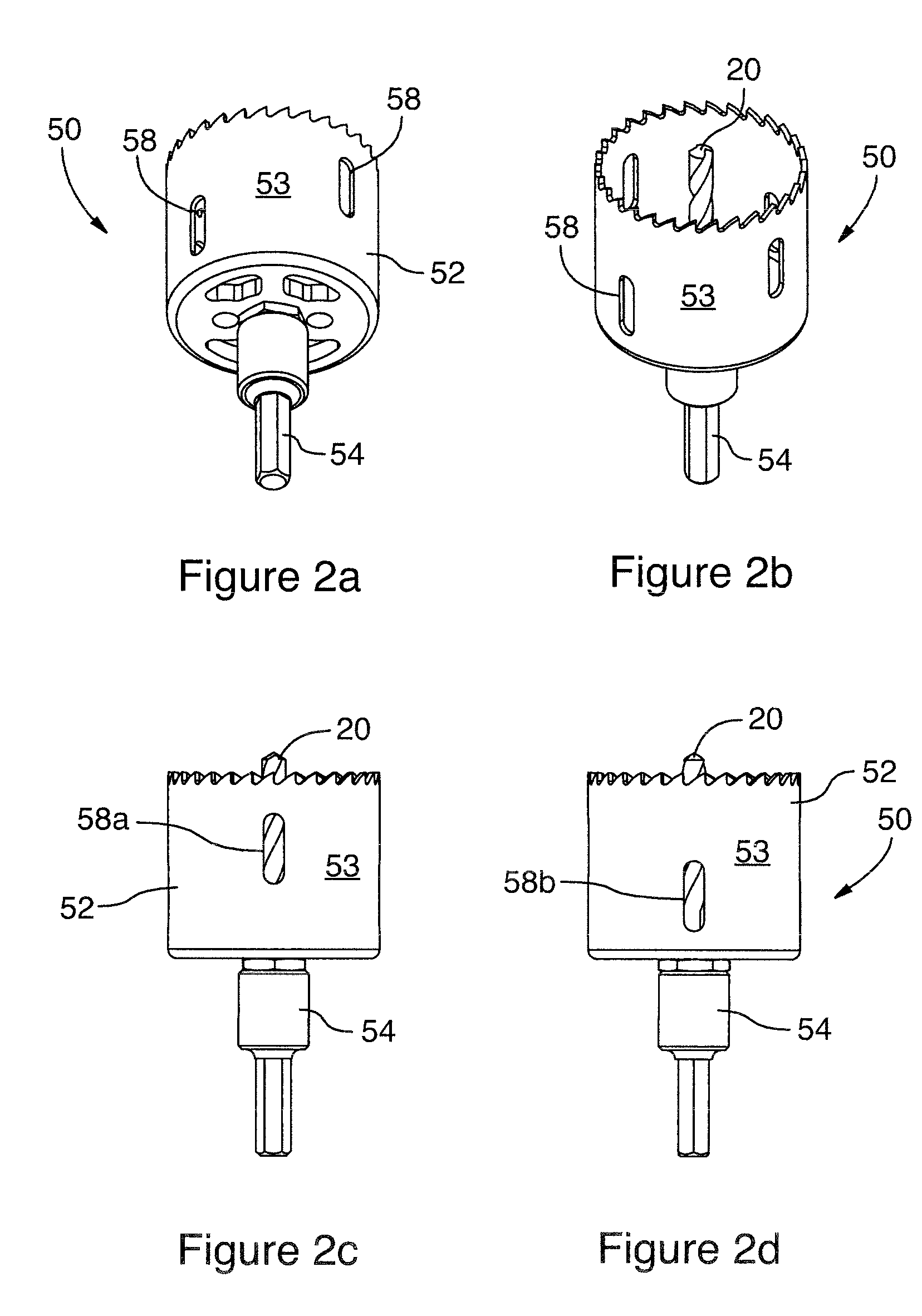

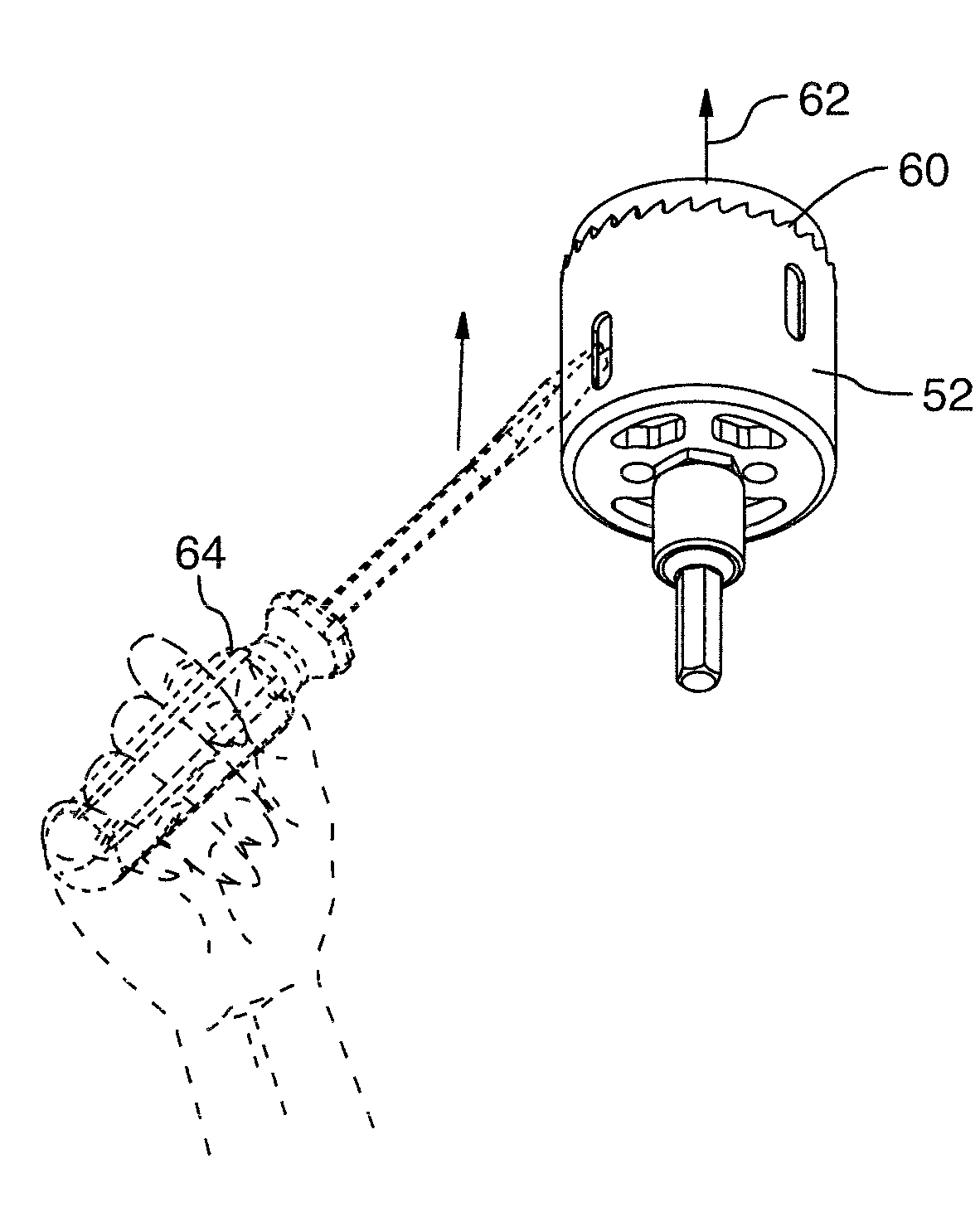

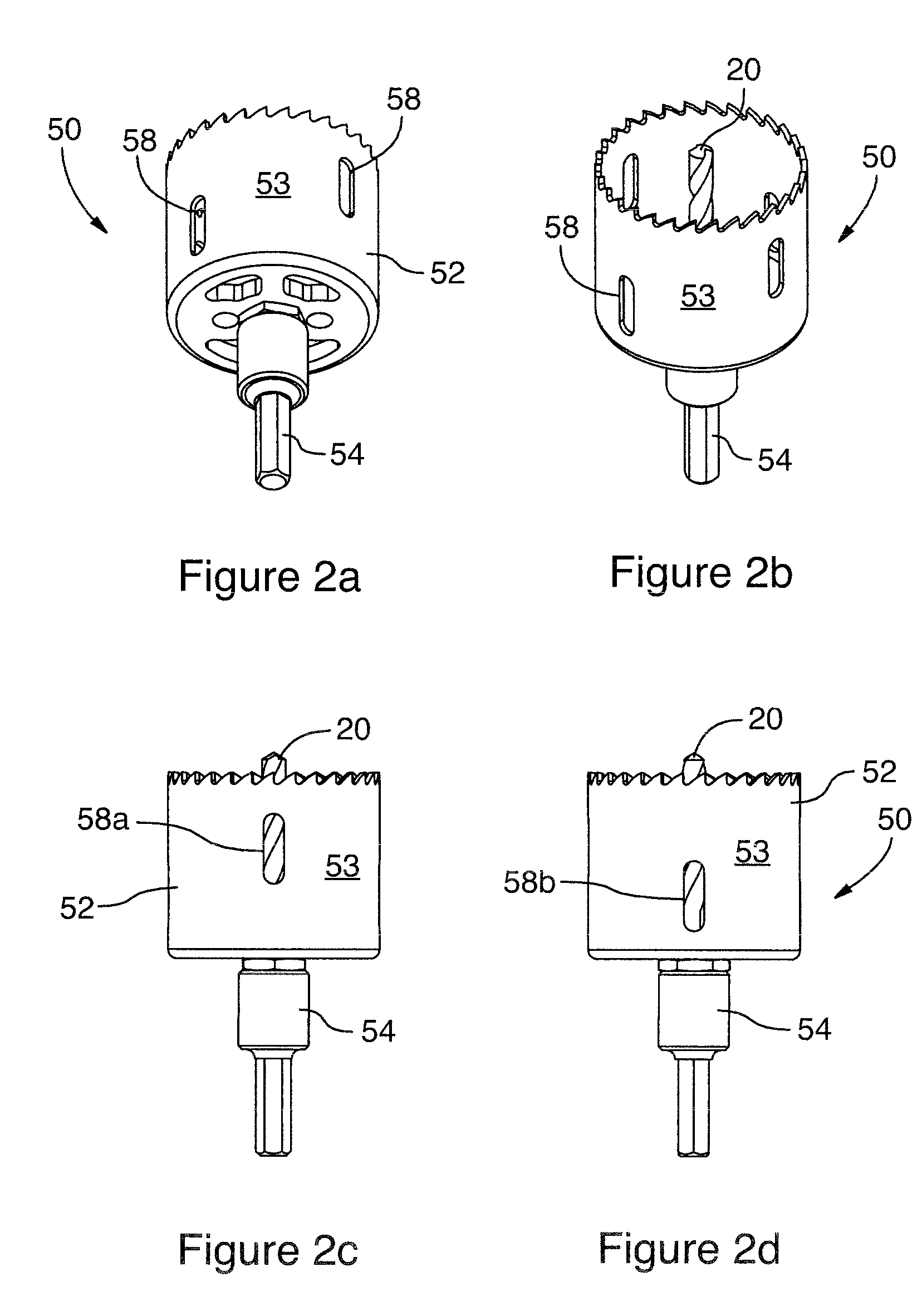

Hole saw system with improved slug removability

InactiveUS20090035082A1Reduce weightEasy to disassembleTransportation and packagingPliersHole sawEngineering

There is provided a hole saw system comprising a hole saw including a bottom portion and a body portion; a mandrel, including apparatus for receiving the hole saw; wherein the hole saw includes a plurality of slot pairs, the slot pairs being offset from each other on the body portion allowing a tool to be inserted into one of the slot pairs for removal of a slug.

Owner:TEAM FAIR HLDG

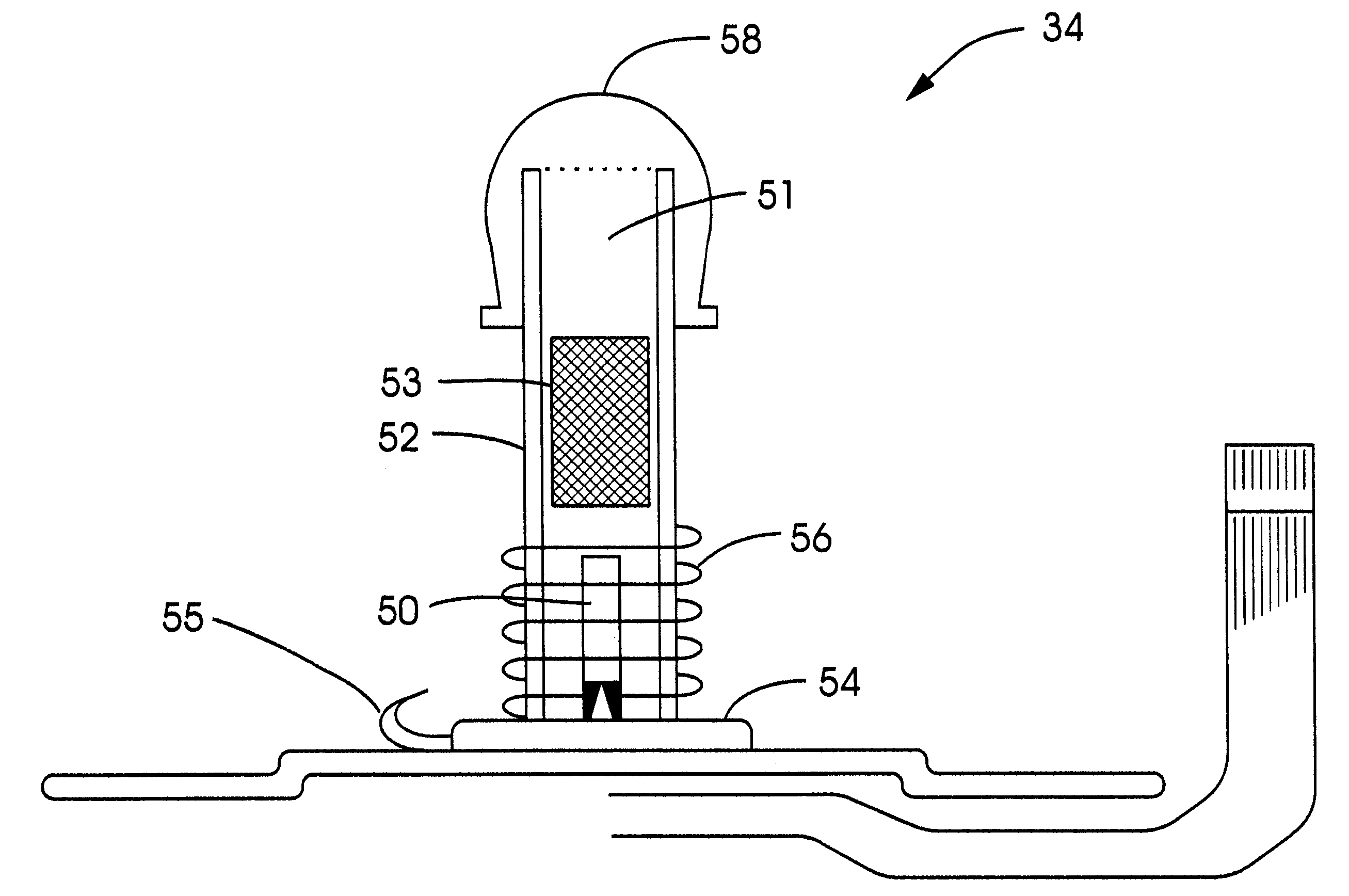

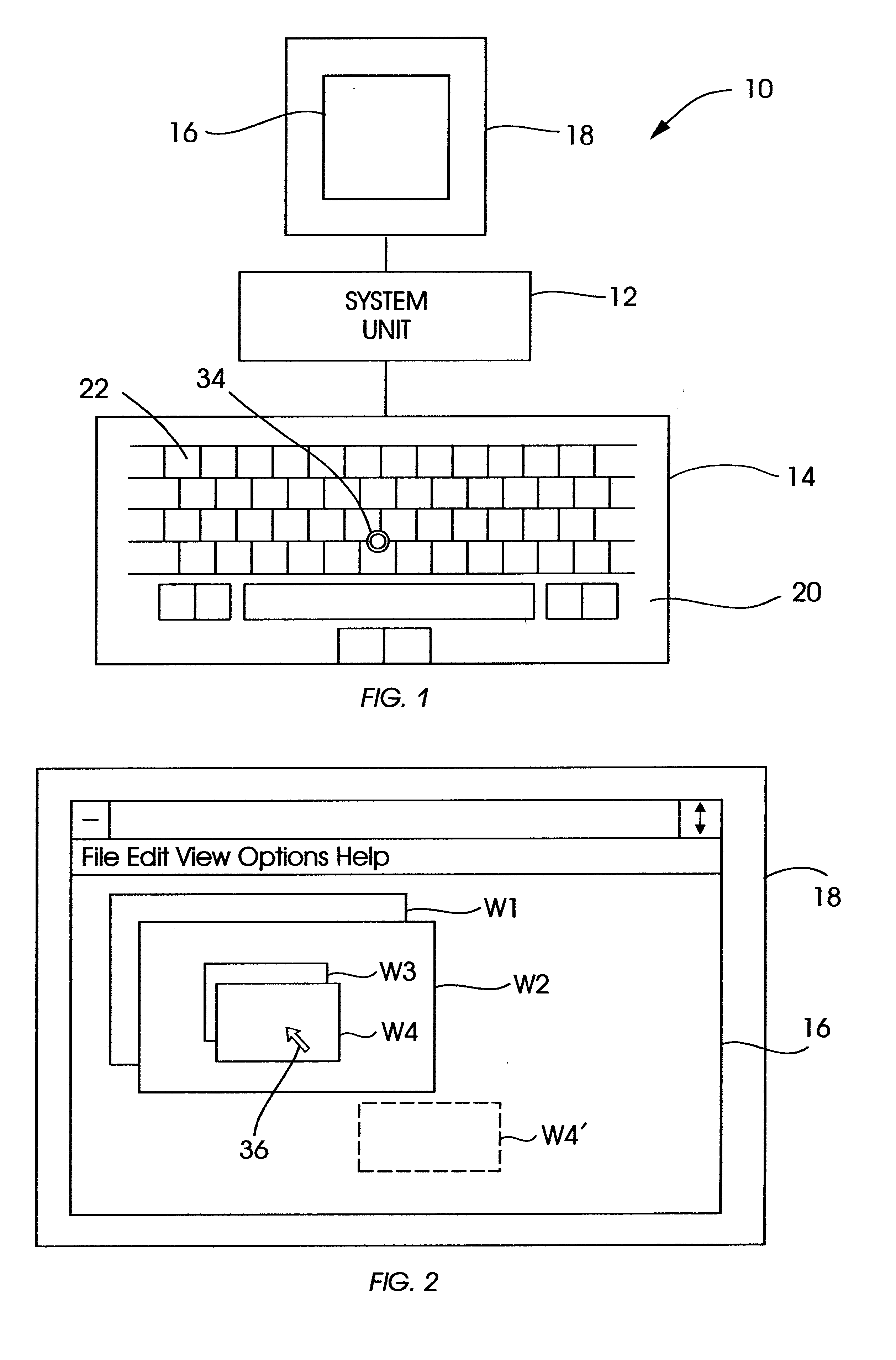

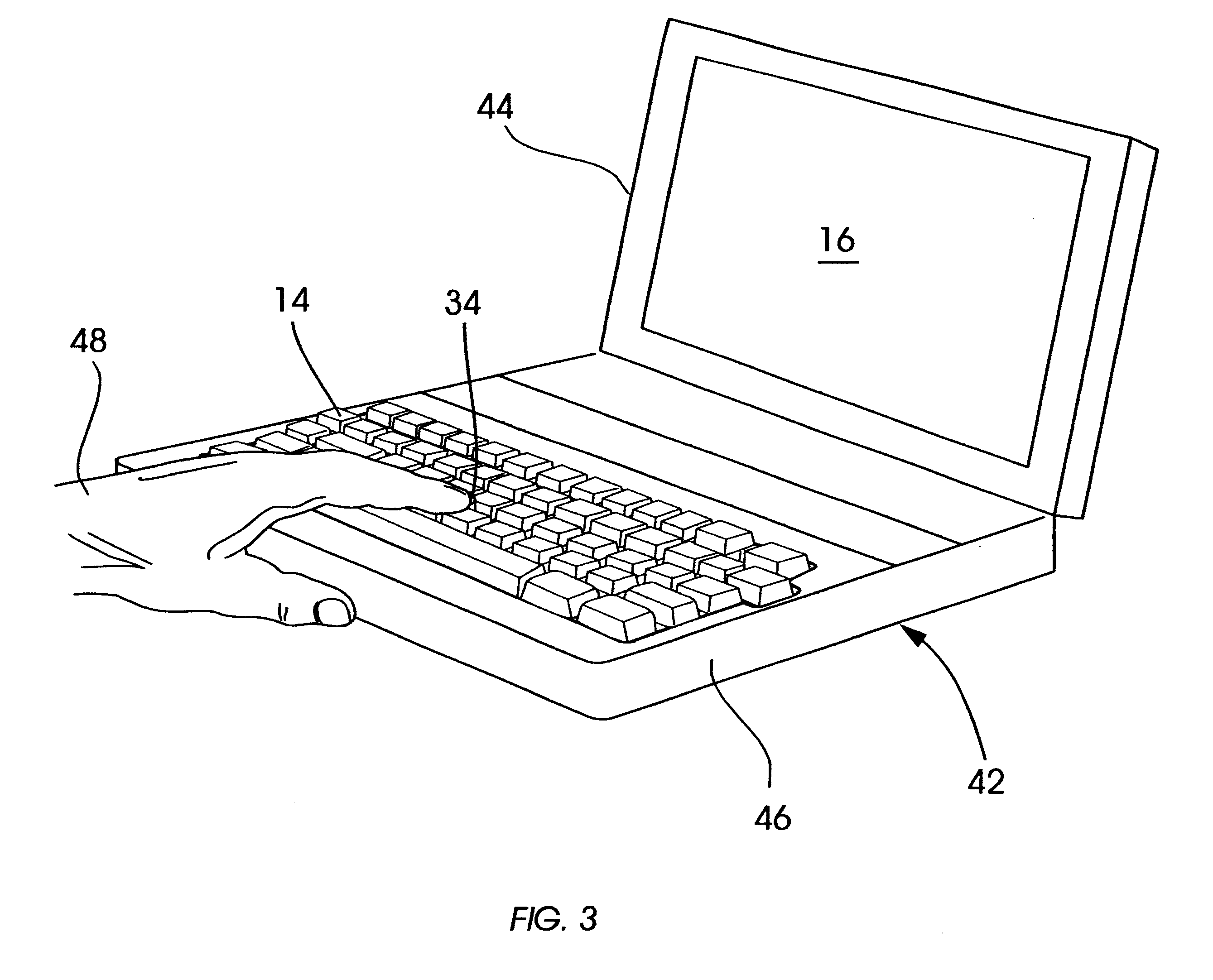

Integrated pointing device having tactile feedback

InactiveUS6271834B1Easy to operateInput/output for user-computer interactionElectronic switchingGraphicsGraphical user interface

An integrated manual control input device is provided for use in a computer system having a graphical user interface. The device comprises a pointing actuator mounted to a computer keyboard between preselected ones of the keys for engagement by a user's index finger. The pointing actuator includes a coil in the form of a cylinder that, when carrying a current, produces a magnetic field to drive a ferromagnetic slug to provide tactile feedback to a user of the control input device.

Owner:LENOVO (SINGAPORE) PTE LTD

Powder compaction and enrobing

InactiveUS20050147710A1RobustQuicker release characteristicLayered productsConfectioneryMetallurgyMethyl cellulose

An apparatus and method is disclosed for forming a compacted powder slug coated with a film. The powder, e.g. of a medicament, is compacted and enrobed to produce compacted powder slugs by preferably mechanically compacting a powder and forming a film of a material, preferably hydroxy propyl methyl cellulose, by vacuum or pressure differential, about the surface of the powder thus compacted.

Owner:BIOPROGRESS TECH

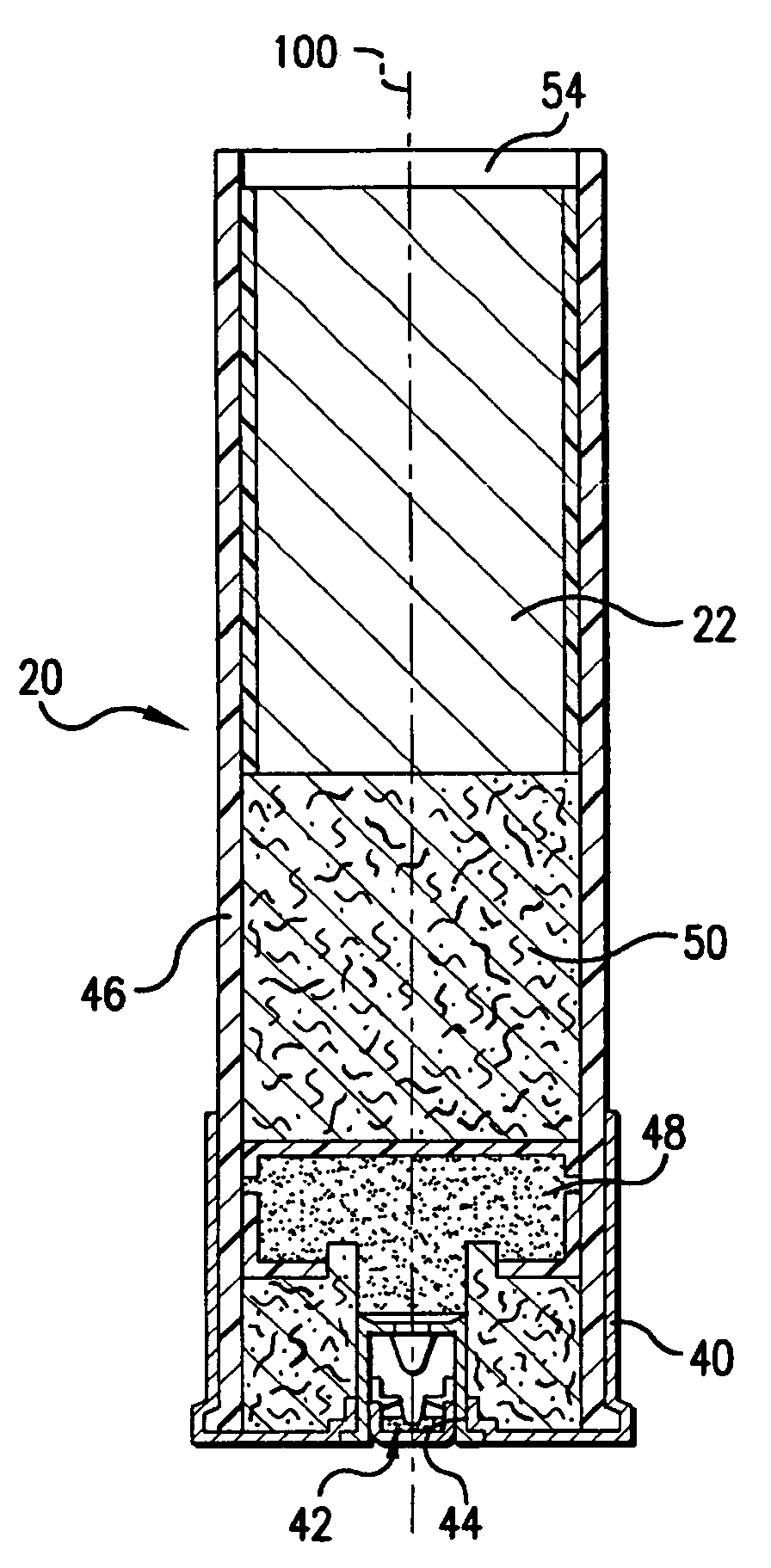

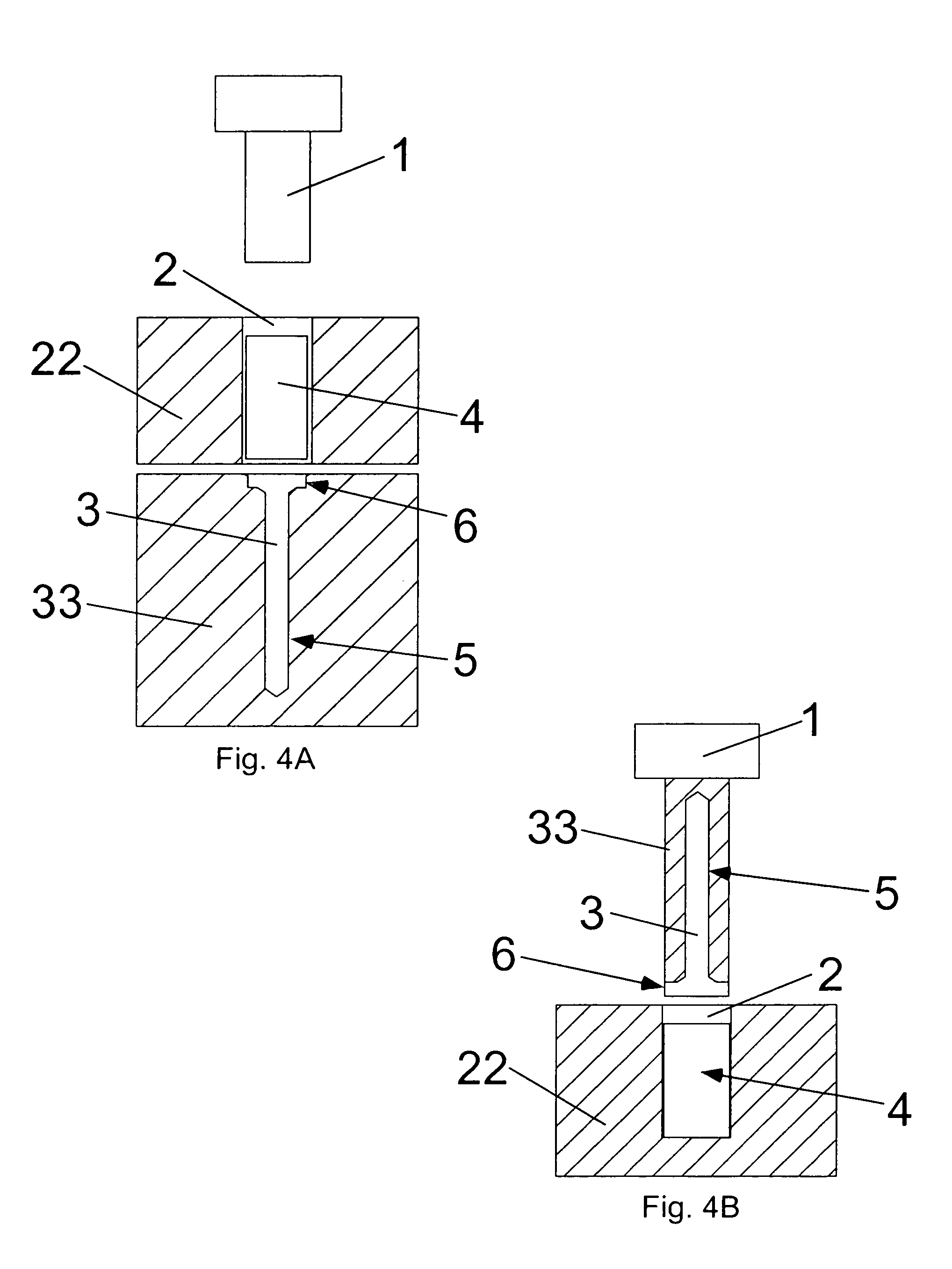

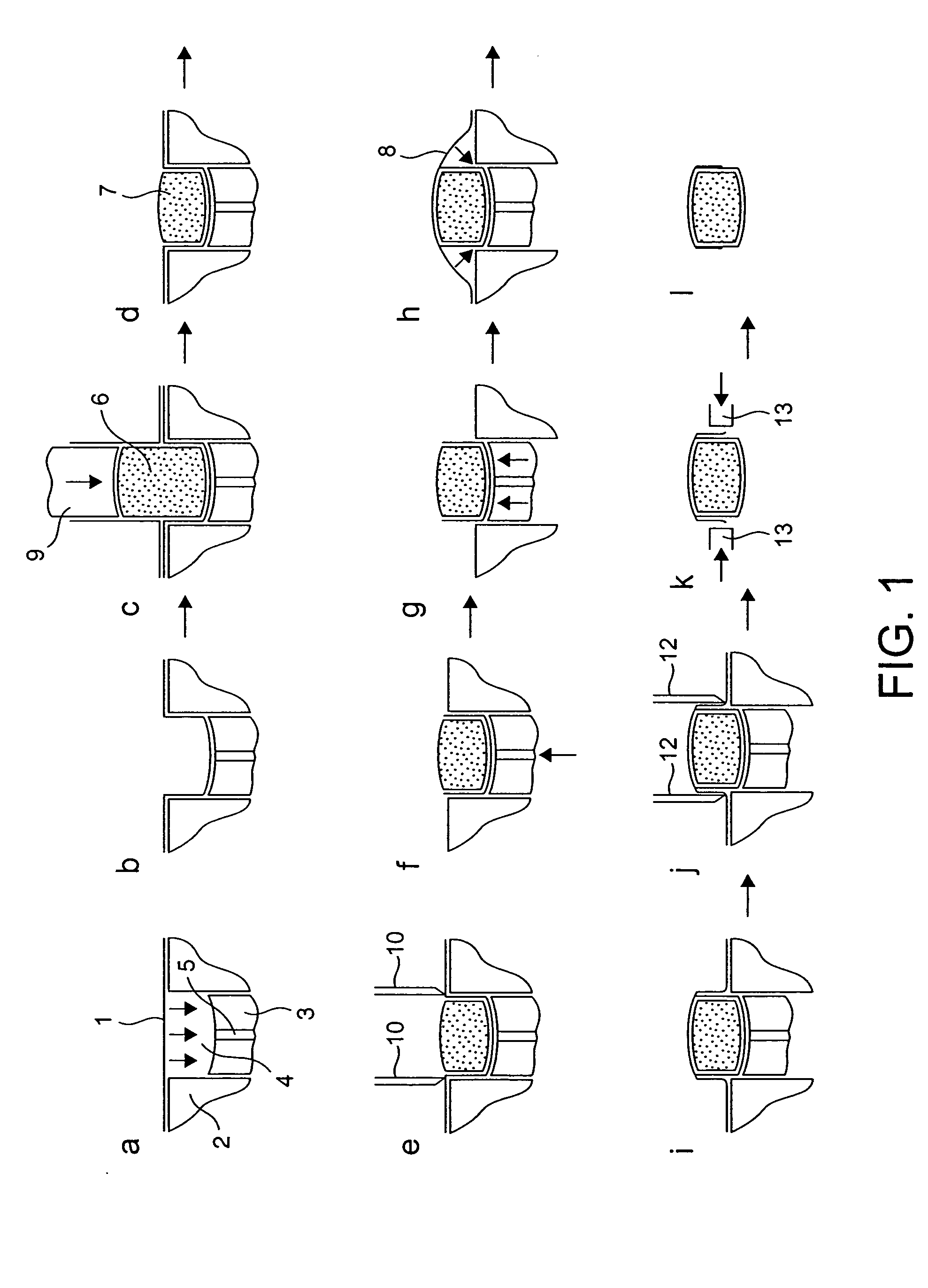

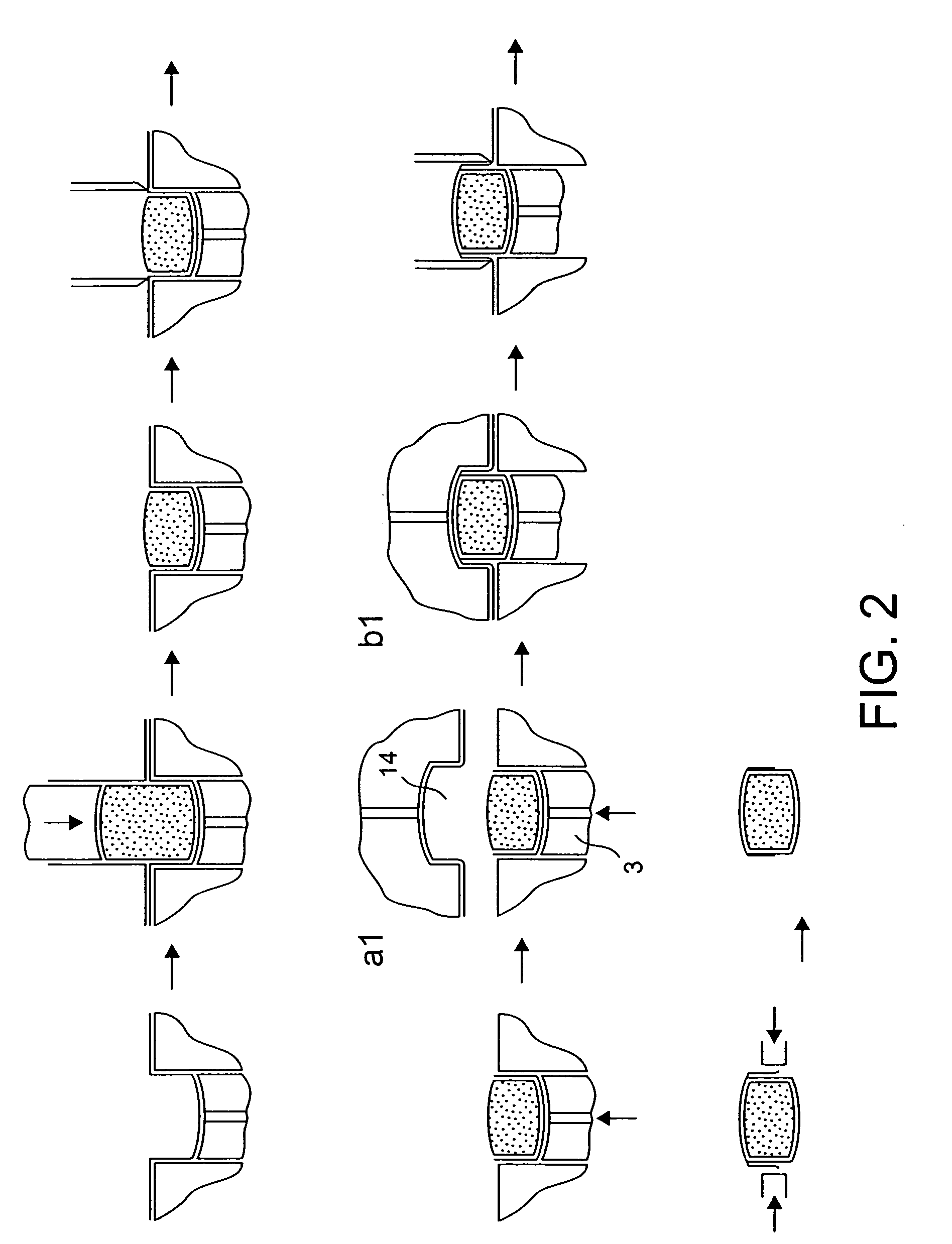

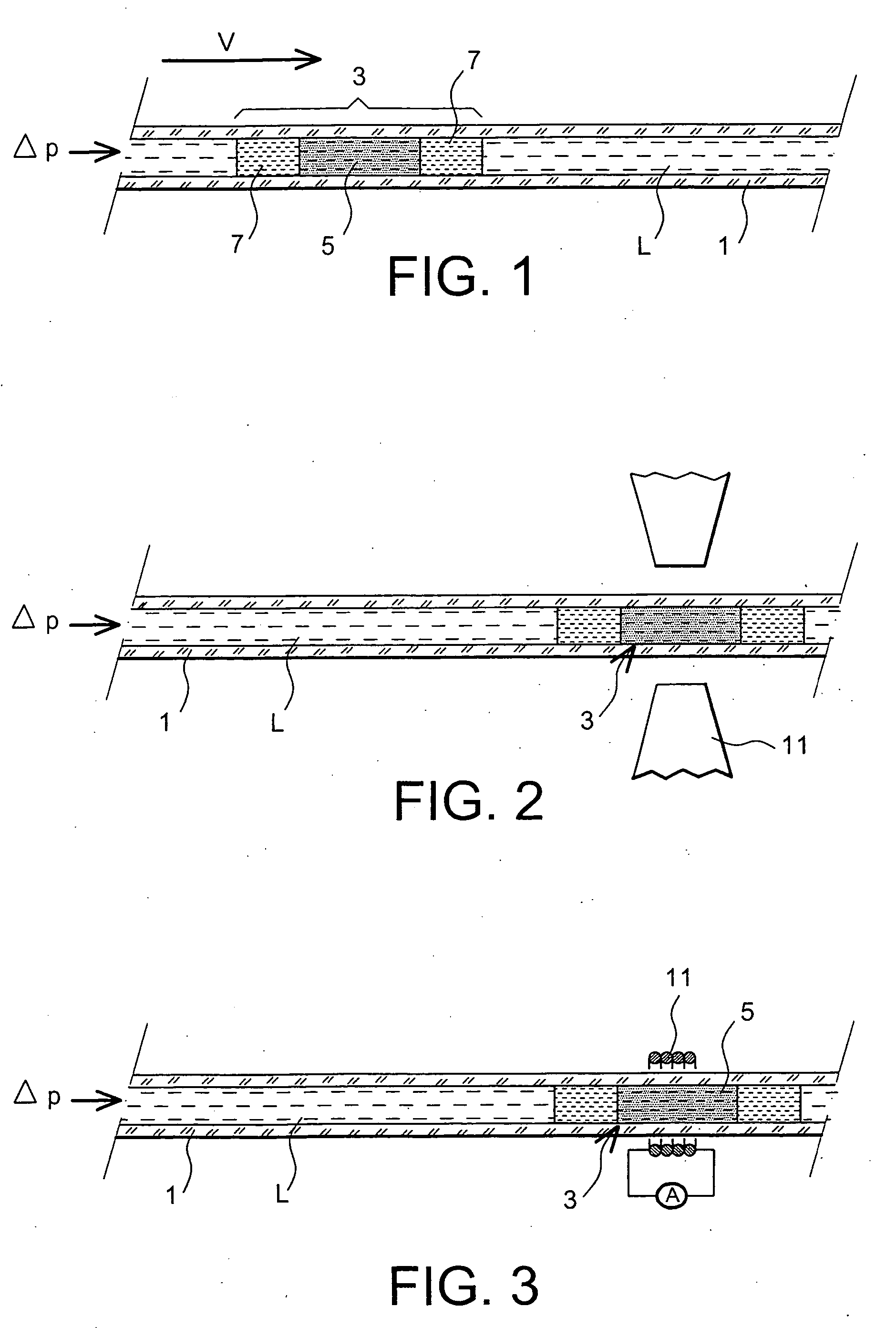

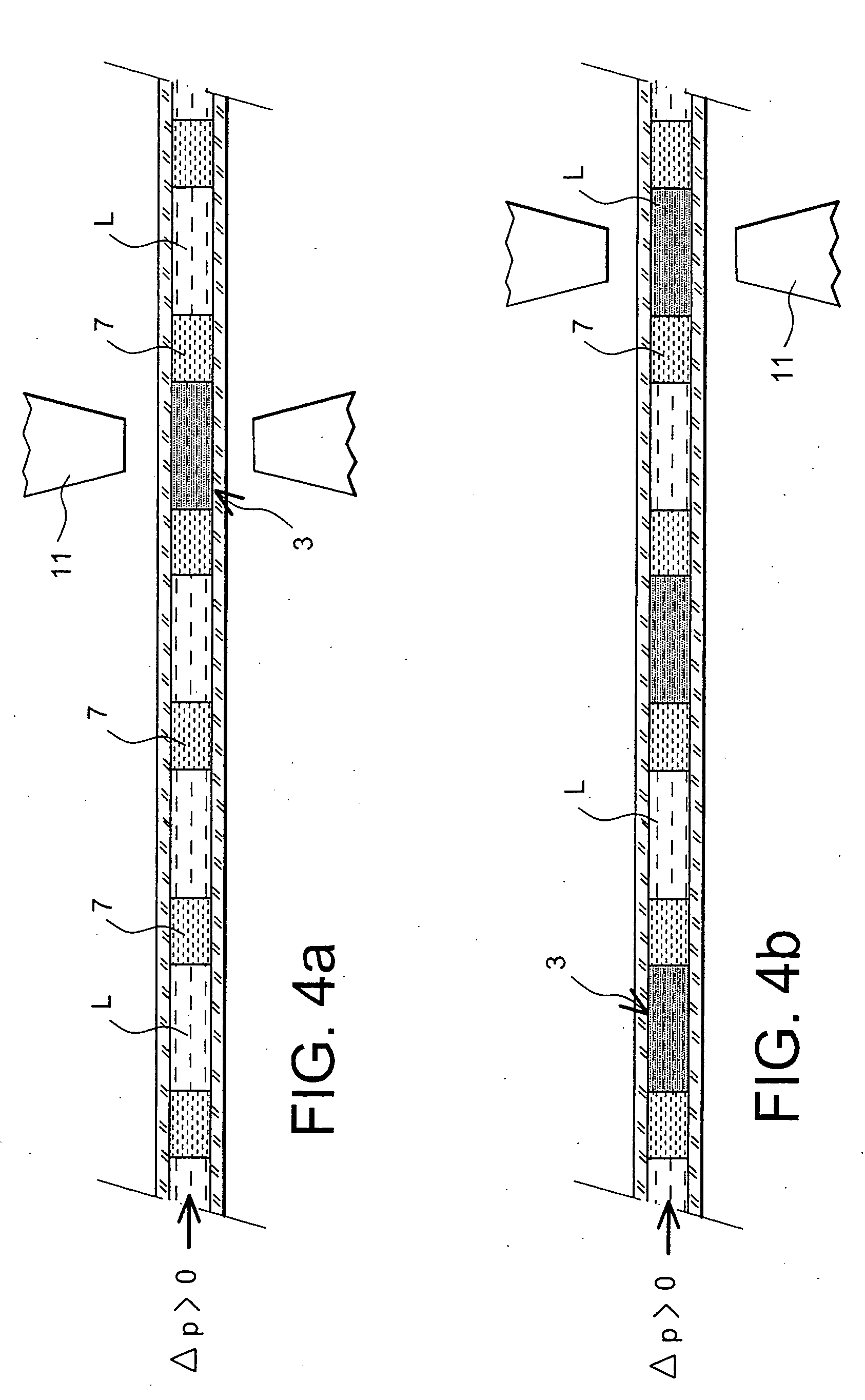

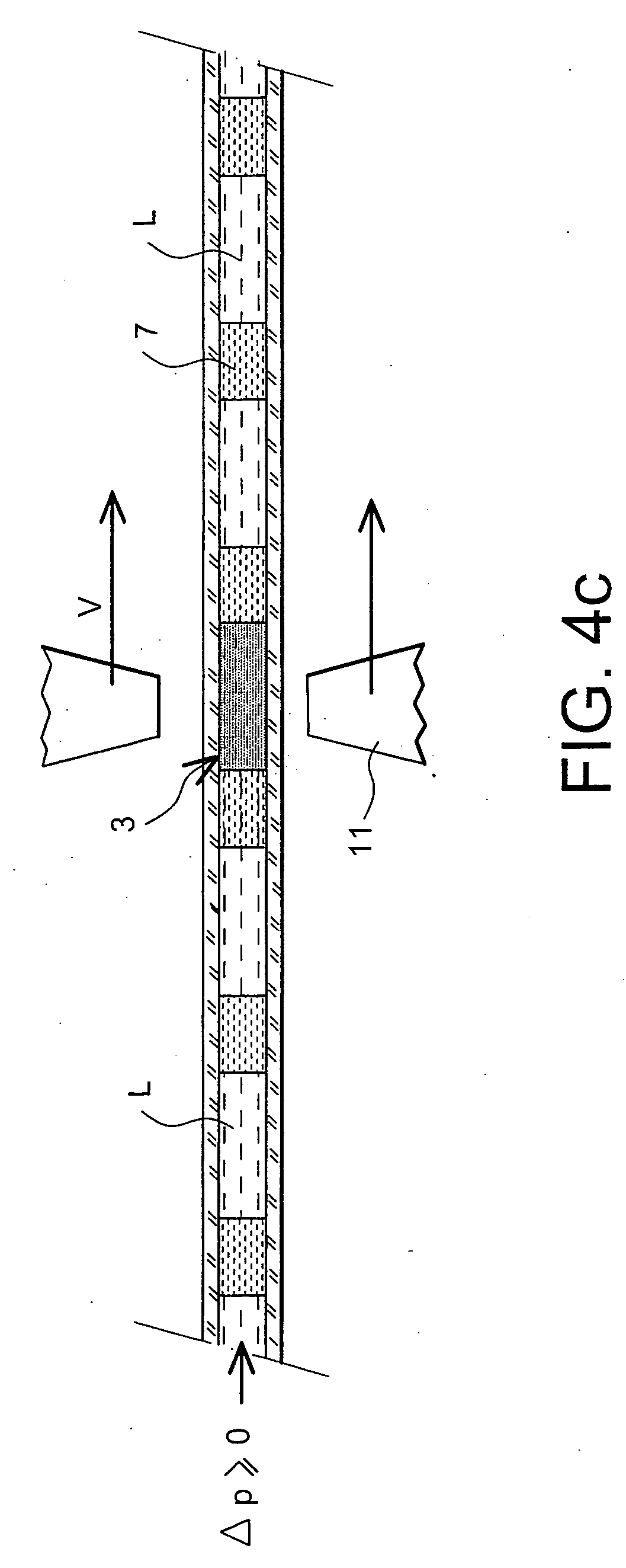

Method for moving a fluid of interest in a capillary tube and fluidic microsystem

InactiveUS20040241693A1Low viscosityGood physical and chemical stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteCapillary channel

The present invention relates to a method for the displacement of an analyte fluid within a capillary microchannel and to a microfluidic system. In particular, it relates to the field of microfluidics, and especially to microfluidic systems. The method comprises steps which consist in introducing at least one ferrofluid train (3) into the said capillary channel (1), the said ferrofluid train (3) comprising a slug of ferrofluid (5) and, placed against at least one of the two ends of the slug of ferrofluid and in contact with it, a slug of liquid (7) immiscible with both the ferrofluid and the analyte fluid; in introducing the said analyte fluid (9) into the said capillary channel, in proximity to the ferrofluid train and on the side having the slug of liquid (7) immiscible with both the ferrofluid and the analyte fluid; and in controlling the analyte fluid displacement within the said capillary channel by the action of a magnetic field on the ferrofluid train, which field is generated by a magnet system placed on the outside of the said capillary channel.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

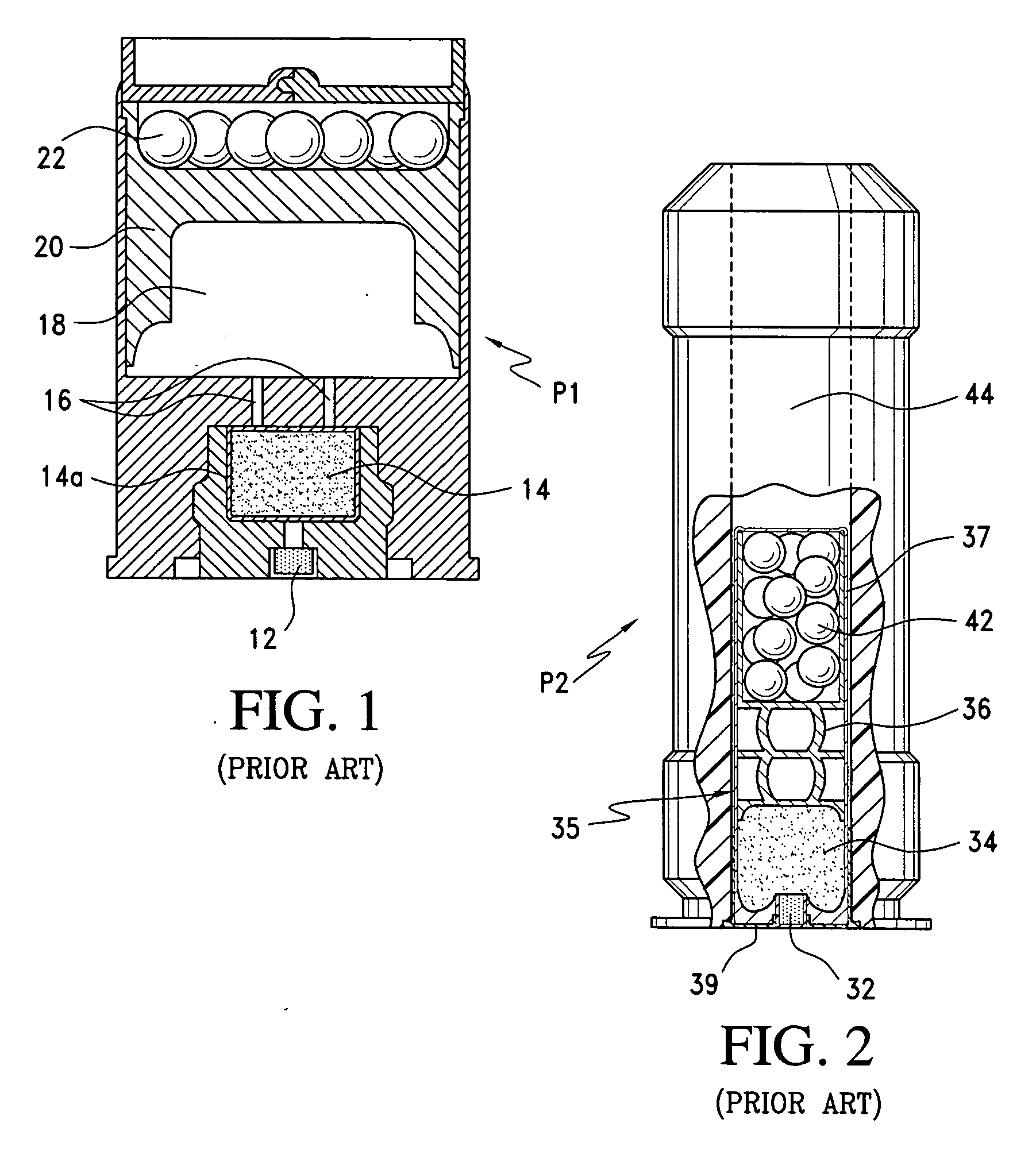

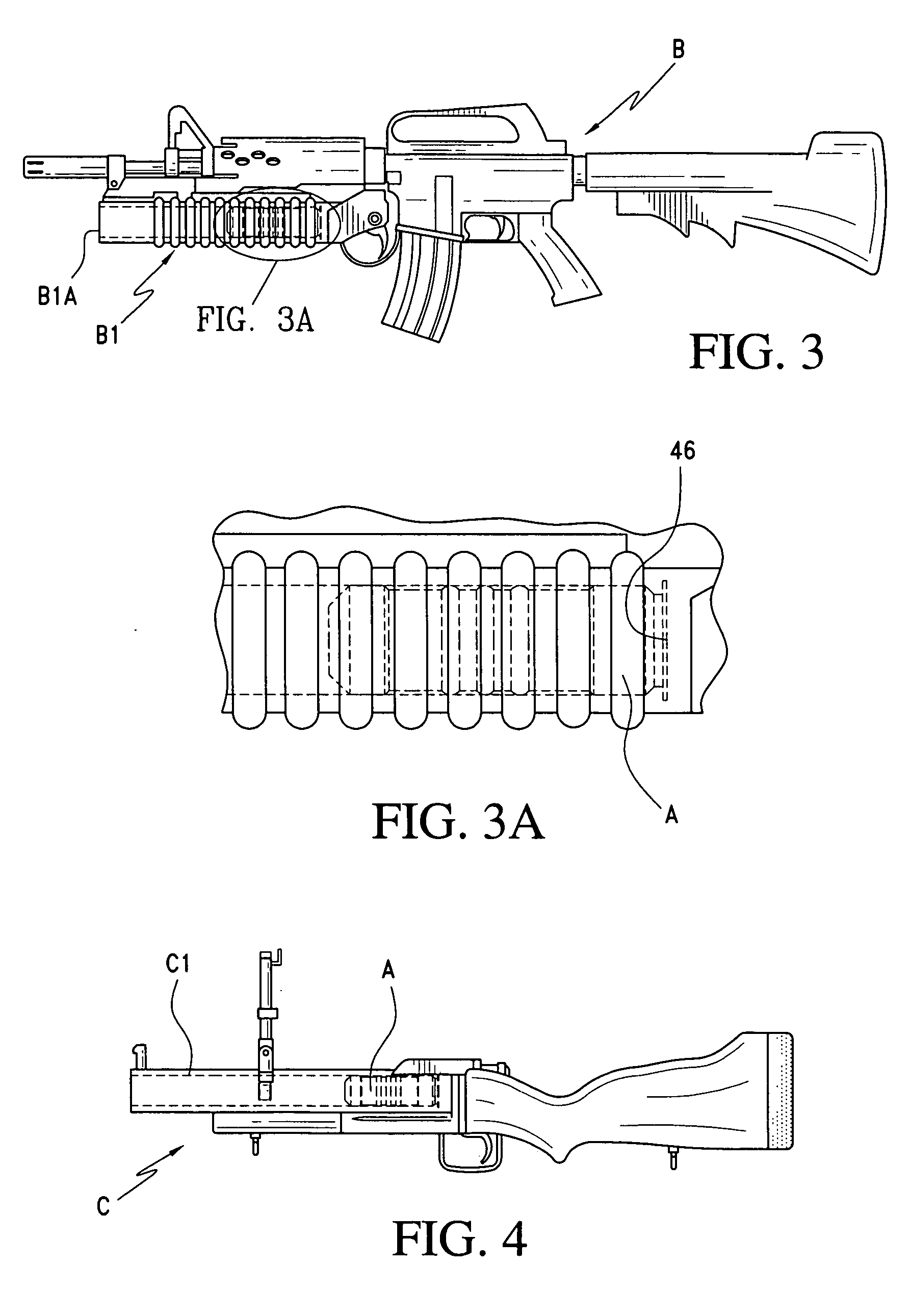

High-pressure fixed munition for low-pressure launching system

InactiveUS20060260500A1Improved muzzle velocityIncrease rangeShotgun ammunitionTraining ammunitionHigh pressureSlug

A high-pressure fixed munition for a low-pressure launching system having a cylindrical body with a centrally located bore is provided. The bore of the munition has a reduced diameter on the charge end in which a primer charge is positioned. The bore is filled above the primer charge with a propellant and above the propellant with a payload. The payload may include multiple buckshot pellets, frangible buckshot pellets, tear gas, multiple slugs, frangible slugs, paint balls, rubber pellets, bean bags, or the like. The munition may also include a pressure disk between the propellant and the payload, and tactile ridges or on the outside surface of the munition body or be of a specific color for purposes of identification of the payload.

Owner:ENGEL BALLISTIC RES

System and method for spot check analysis or spot sampling of a multiphase mixture flowing in a pipeline

This disclosure relates in general to systems and methods for spot checking flow properties of a multiphase mixture containing one or more hydrocarbons flowing through a pipeline or the like. More specifically, but not by way of limitation, embodiments of the present invention provide systems and methods for creating slug-type flows of isokinetically obtained samples of the multiphase mixture flow. By spot checking the slug-type flow of an isokinetically obtained sample of the multiphase flow, embodiments of the present invention may provide for determining flow properties of gas, oil / condensate and / or water components of the multiphase flow. In certain aspects of the present invention, an active sampling device may be used to enrich one of the phases of the slug-type flow of the sampled multiphase mixture and / or take a representative sample of one of the phases of the slug-type flow of the sampled multiphase mixture.

Owner:SCHLUMBERGER TECH CORP

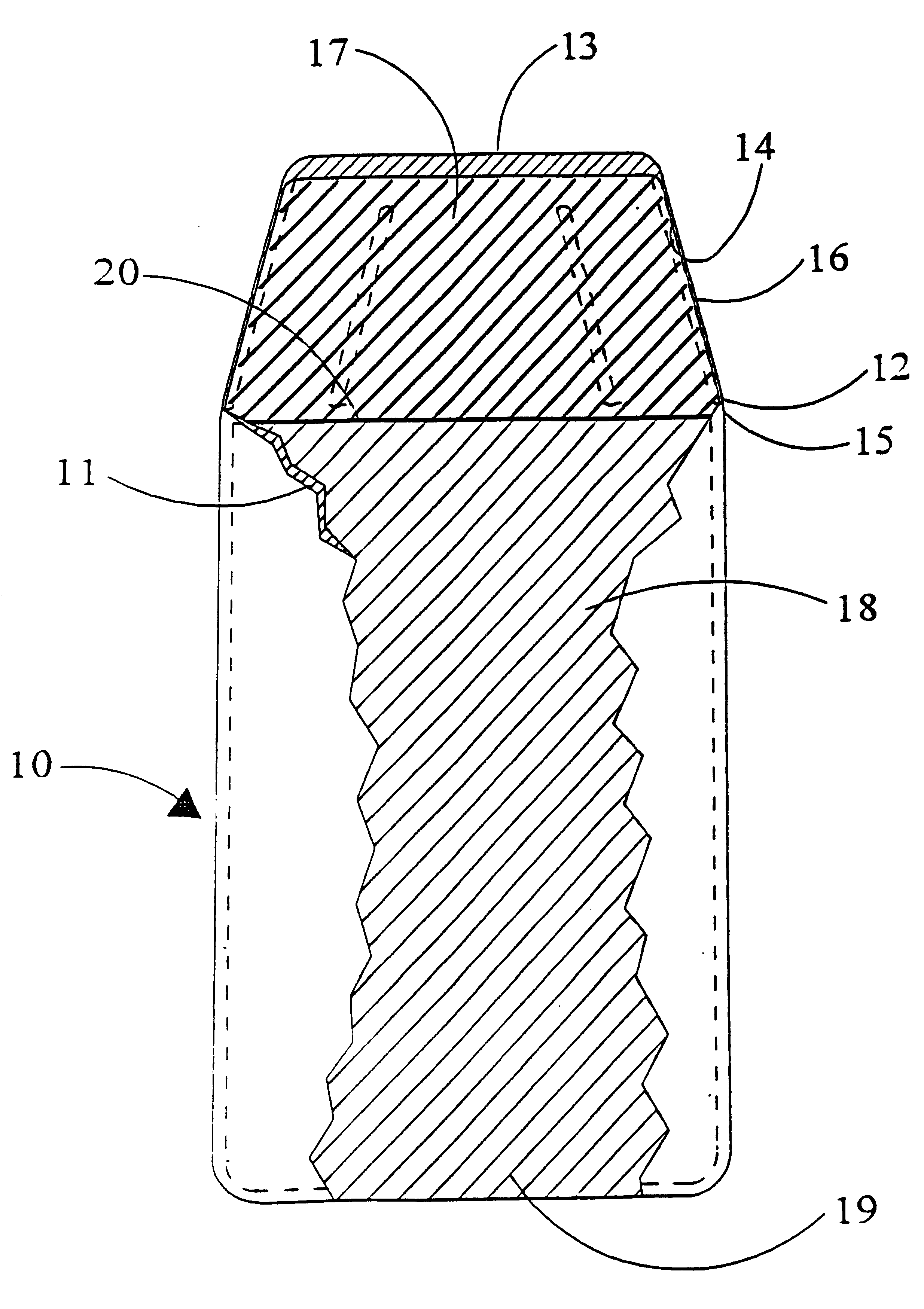

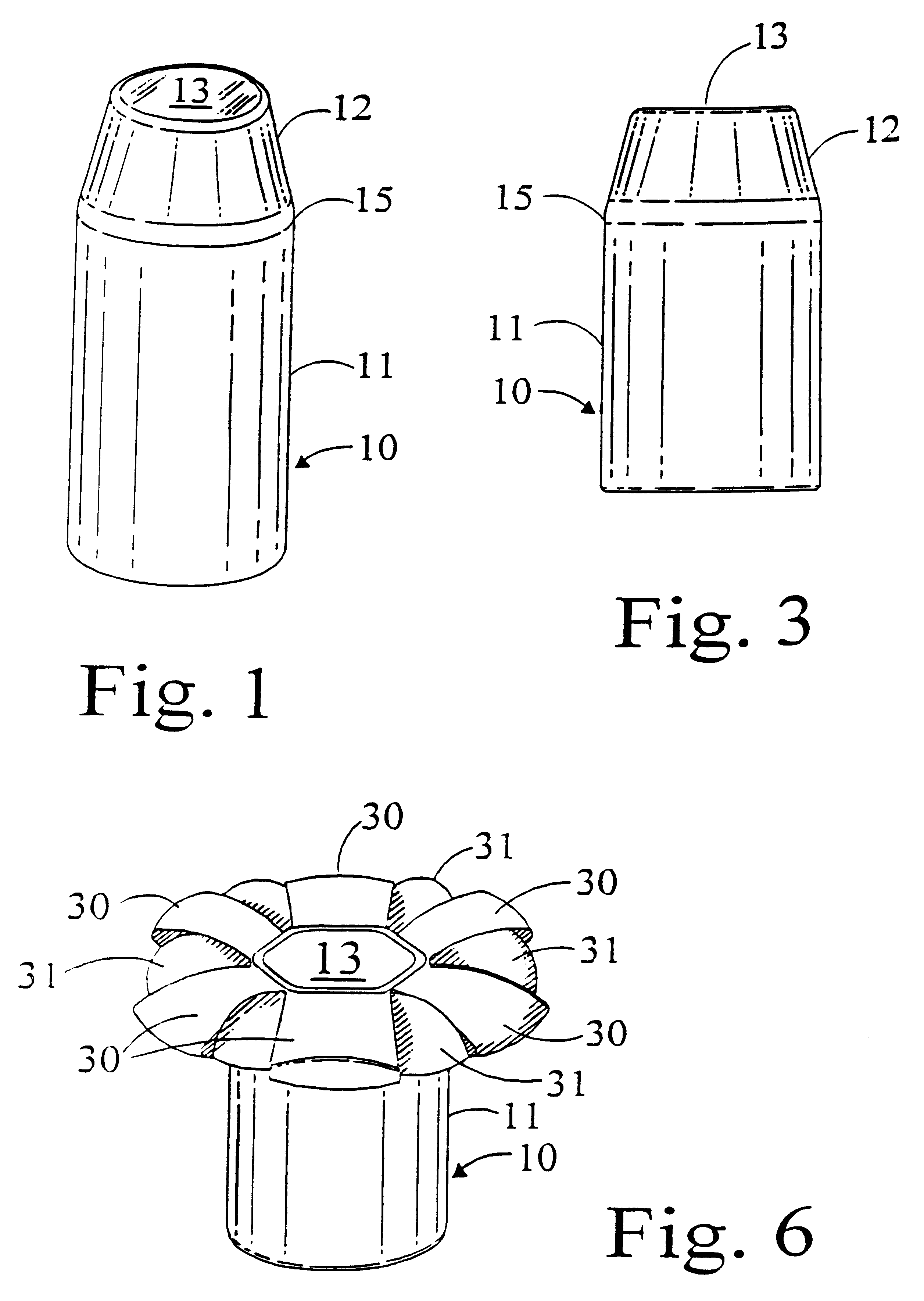

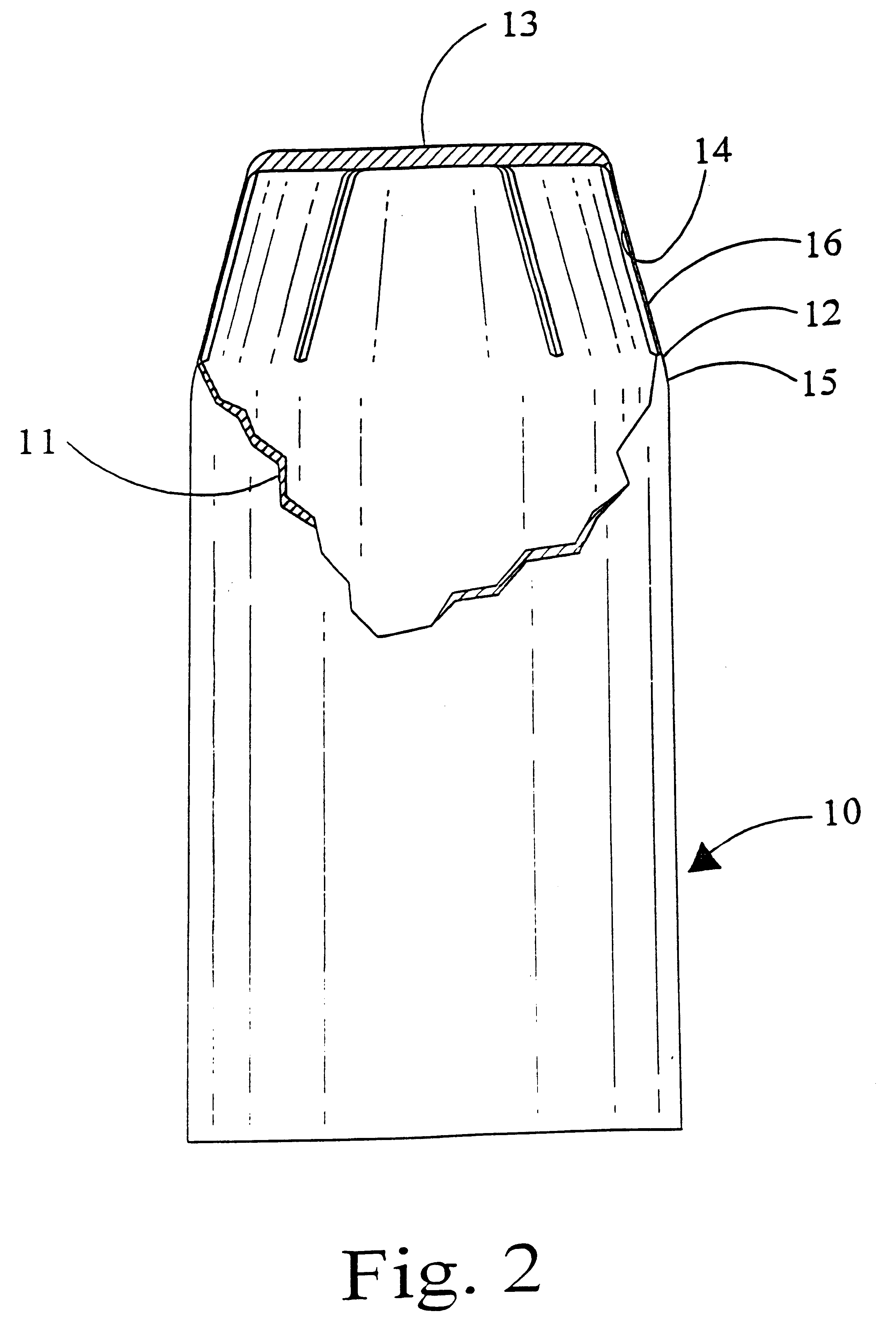

Captive soft-point bullet

A bullet comprised of a jacket of malleable metal having a closed nose portion and a rear end portion defined by a cylindrical wall, the closed nose portion having wall-weakening areas encapsulating a forward core made of a deformable material which promptly deforms, collapses axially, and expands radially to a substantial extent along with the weakened wall areas, when the bullet strikes a target. The wall weakened areas of the nose portion are ruptured by the core material to produce a collapsing and readily expanding action. These weakened wall areas are in the form of longitudinally extending, deep, internal or external, circumferentially spaced grooves with underlying web areas which are ruptured by the core material, to produce the collapsing and expanding action. This core is preferably made mainly of rubber, urethane, silicone, or one of a substantial number of plastics, such as fluorocarbons, polycarbonates, polypropylenes, polystyrenes, polyethylenes, PVC.TM., silicone rubber, Nylon.TM., and vinyl acetate, each of which has a hardness within a range of Shore A-20 to Rockwell R-122. A second core, made mainly of metal such as tungsten, lead, zinc, copper, tin, iron or alloys thereof or hard plastic, is seated, under pressure, behind the nose core and within the rear end portion of the jacket. The advantages of the bullet result from the fact that it collapses axially and expands widely and quickly, upon striking a target, and yet penetrates an adequate distance, without losing an appreciable amount of weight, and without passing through the entire body of the target, to thereby provide an adequate penetration, optimum expansion bullet.

Owner:FEDERAL CARTRIDGE

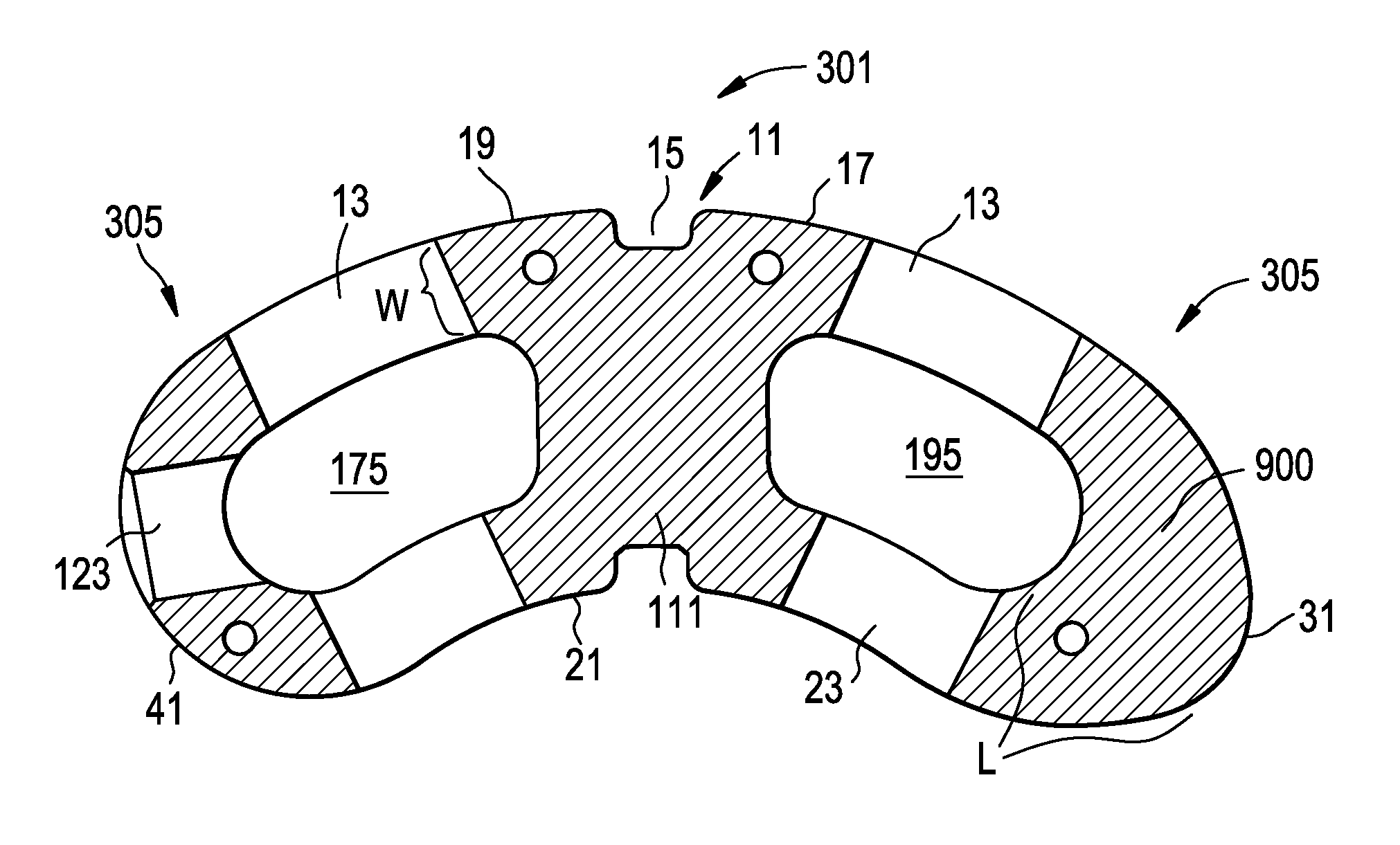

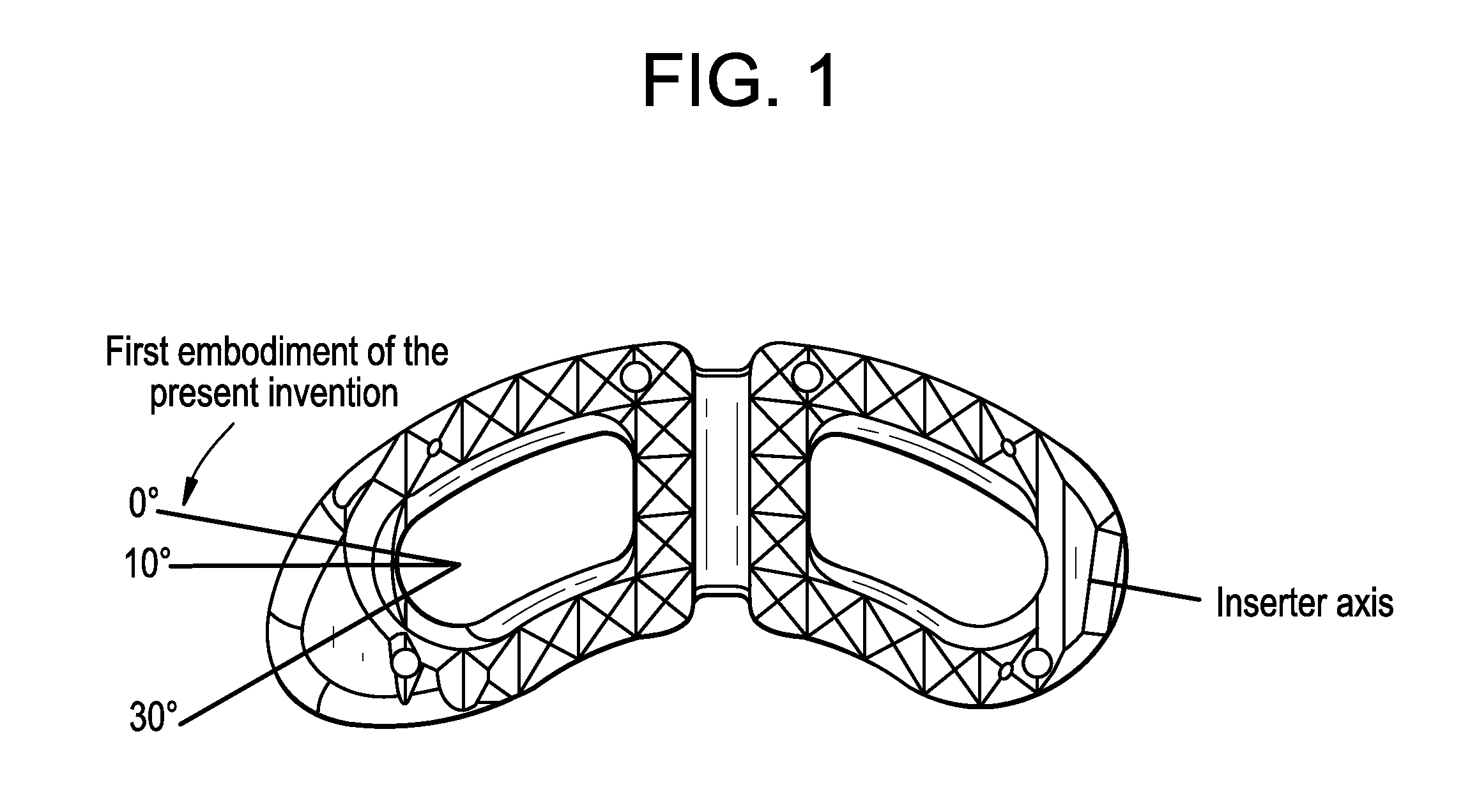

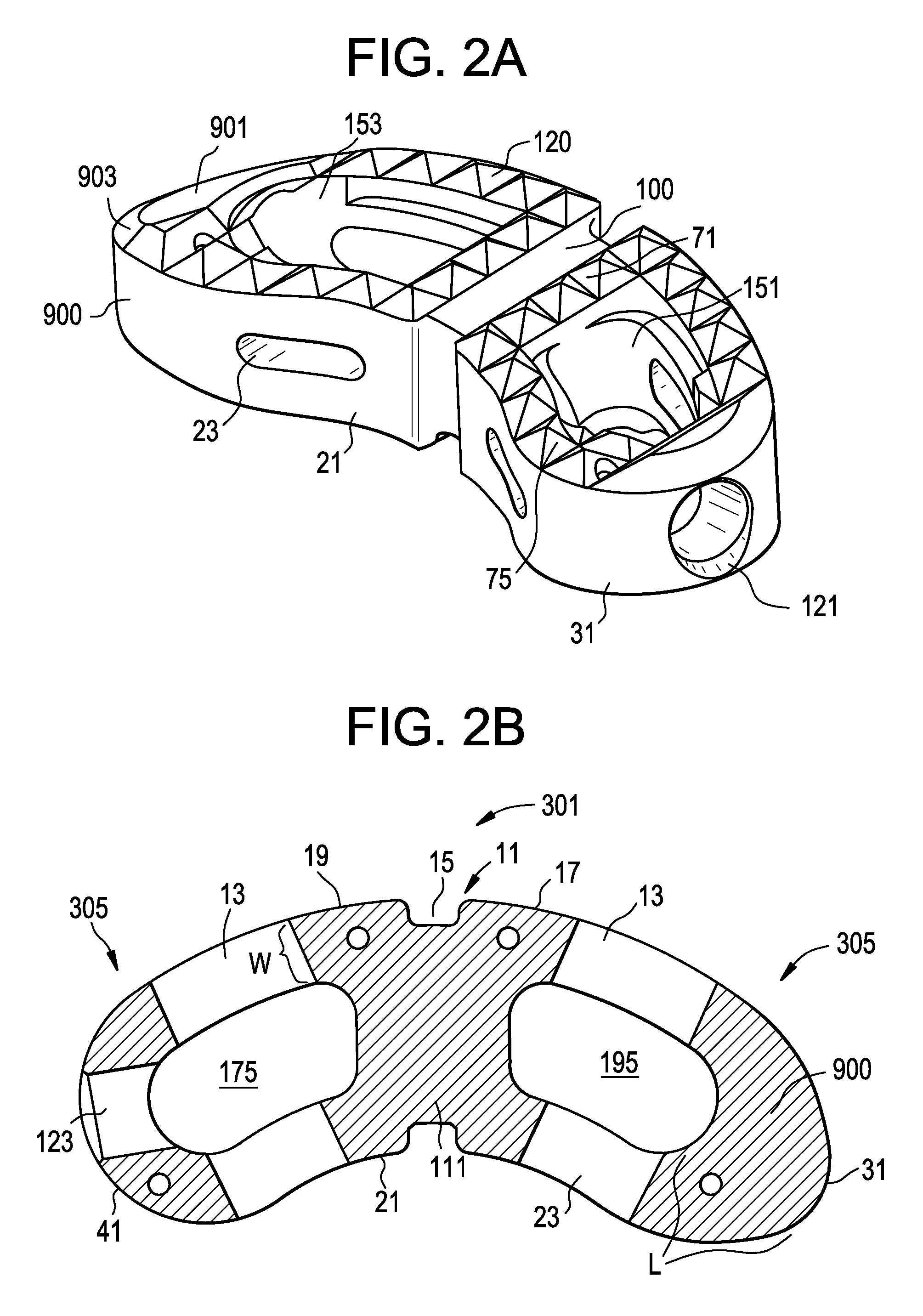

Angled Bullet-Nose Banana Cage

A banana-shaped cage adapted for use as an intervertebral fusion cage, wherein the leading direction of the nose of the banana cage is substantially in-line with the angle of the inserter shaft that inserts the cage into the disc space. It has been found that insertion of this cage requires lower insertion forces than the conventional cage whose leading direction substantially follows the arc of the banana curve.

Owner:DEPUY SYNTHES PROD INC

Apparatus of antenna with heat slug and its fabricating process

ActiveUS7042398B2Simple structureEasy to makeSimultaneous aerial operationsSemiconductor/solid-state device detailsEngineeringHeat sink

An apparatus of antenna with heat slug and its fabricating process are provided, in which the antenna with heat slug can be realized with a single sheet or double sheets of metal. Each single sheet of metal can be achieved by simply cutting and bending a metal plate. Thereby, it is a simple and low-cost fabricating process. In the known fabricating process of integrated circuit, the heat slug and the antenna can be combined in a module at the same step. Therefore, integrating the antenna with heat slug in a fabricating process needs not to develop a new process.

Owner:IND TECH RES INST

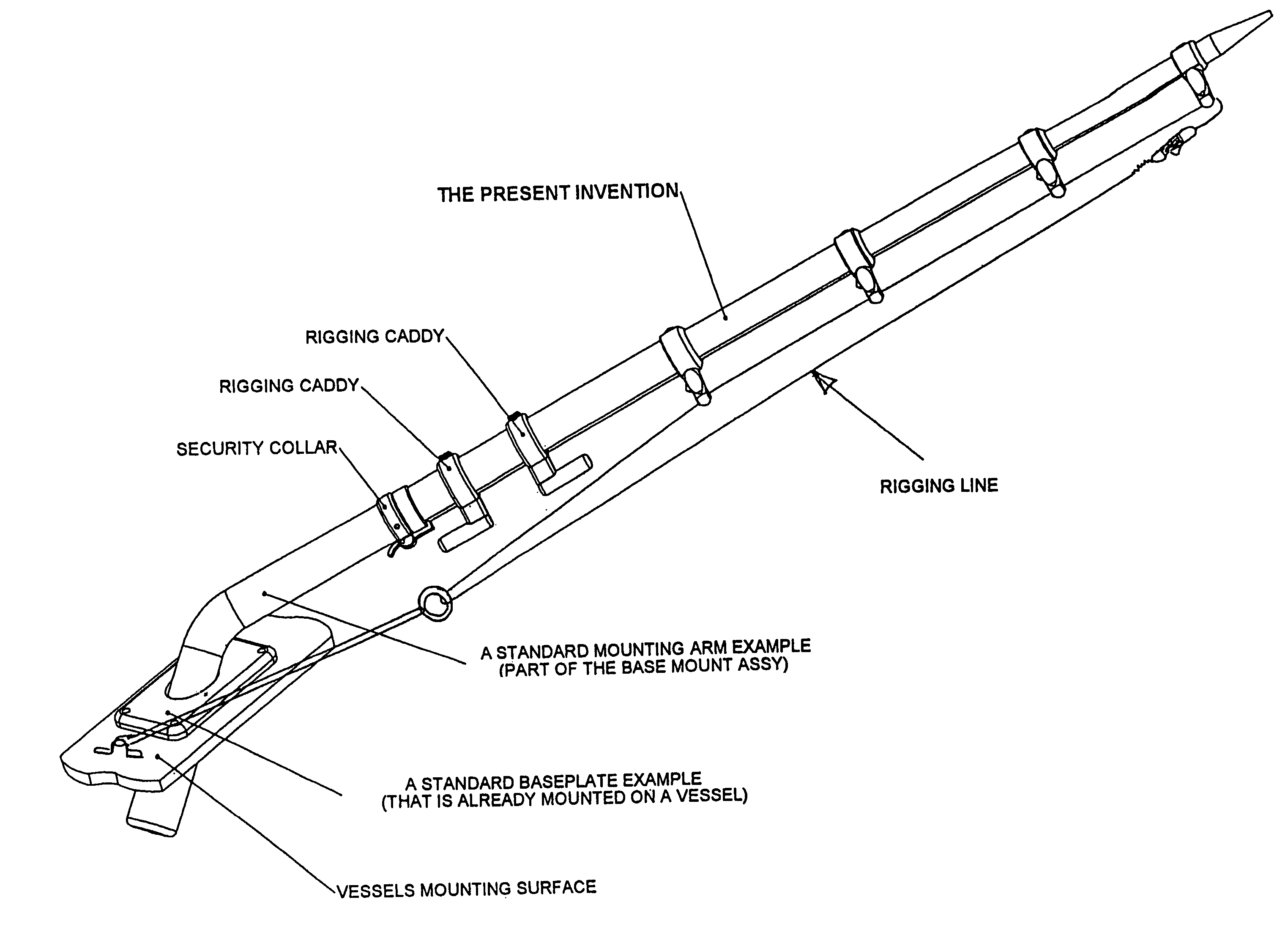

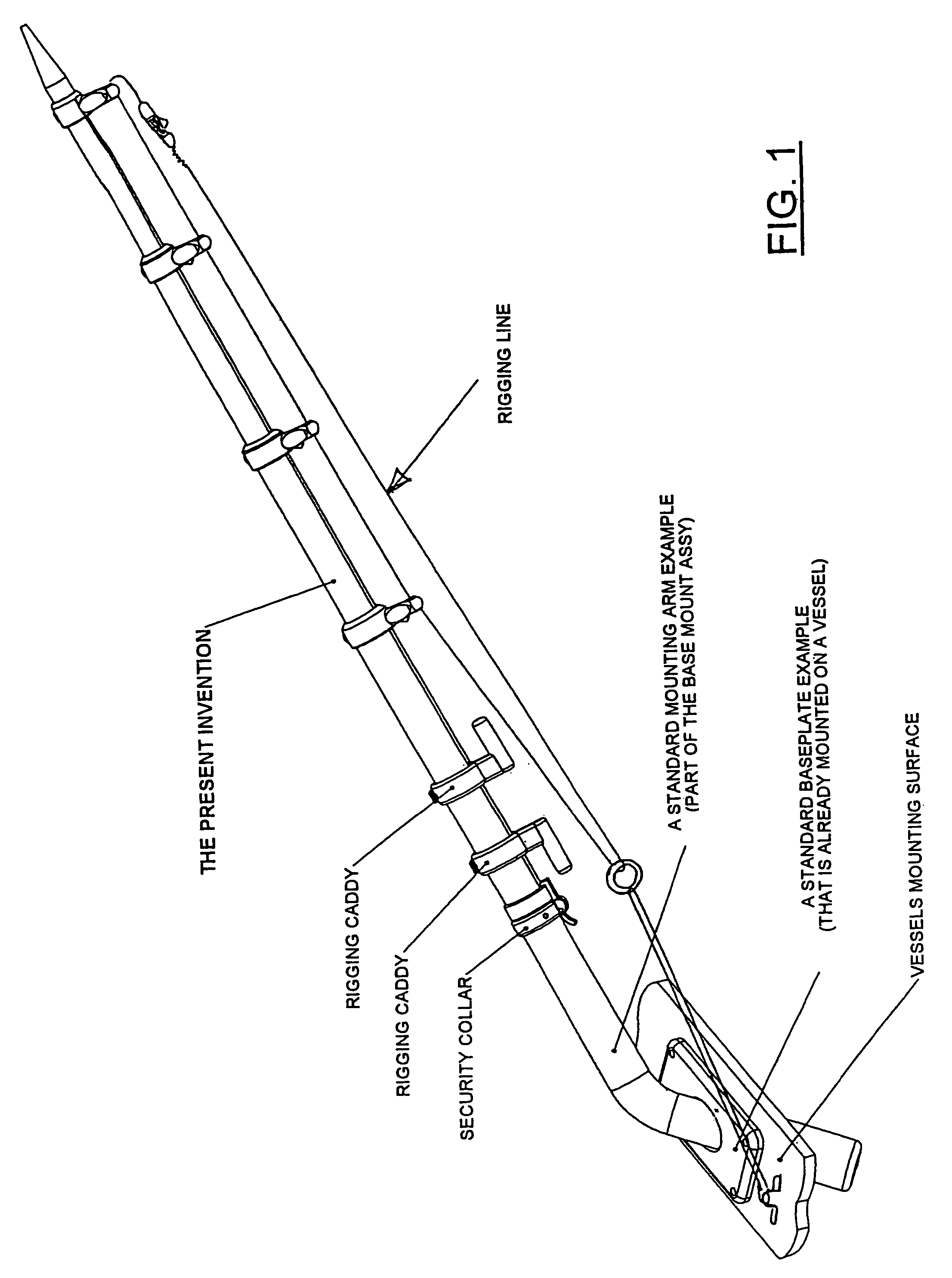

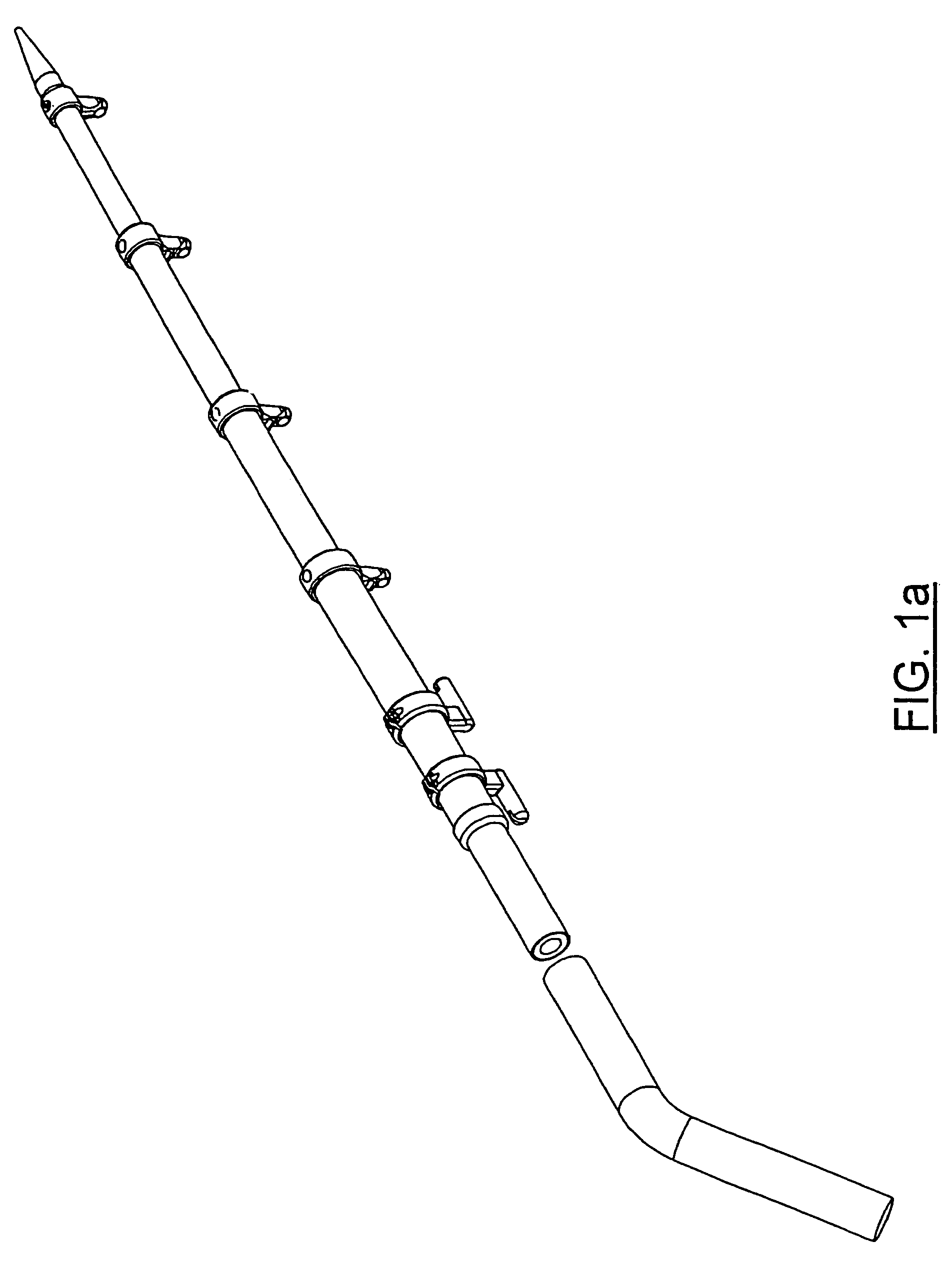

Telescoping outrigger boom with tube locking mechanisms

An outrigger assembly for a fishing vessel to extend fishing lines away from the vessel, including a telescopic boom having a plurality of aligned ‘D’ tubes of consecutively smaller diameters that can be individually locked in place when extended and having the smaller tubes telescopically mounted inside larger tubes for storage, first embodiment provides a manually operable locking mechanism using an external shift bullet to lock the tubes in place, and second embodiment combines the locking means of the first embodiment with a cam lever operated eyelet locking system, the eyelets provide support for a fishing rigging, both embodiments protect the locking mechanism from elements found in the environment.

Owner:TACO METALS

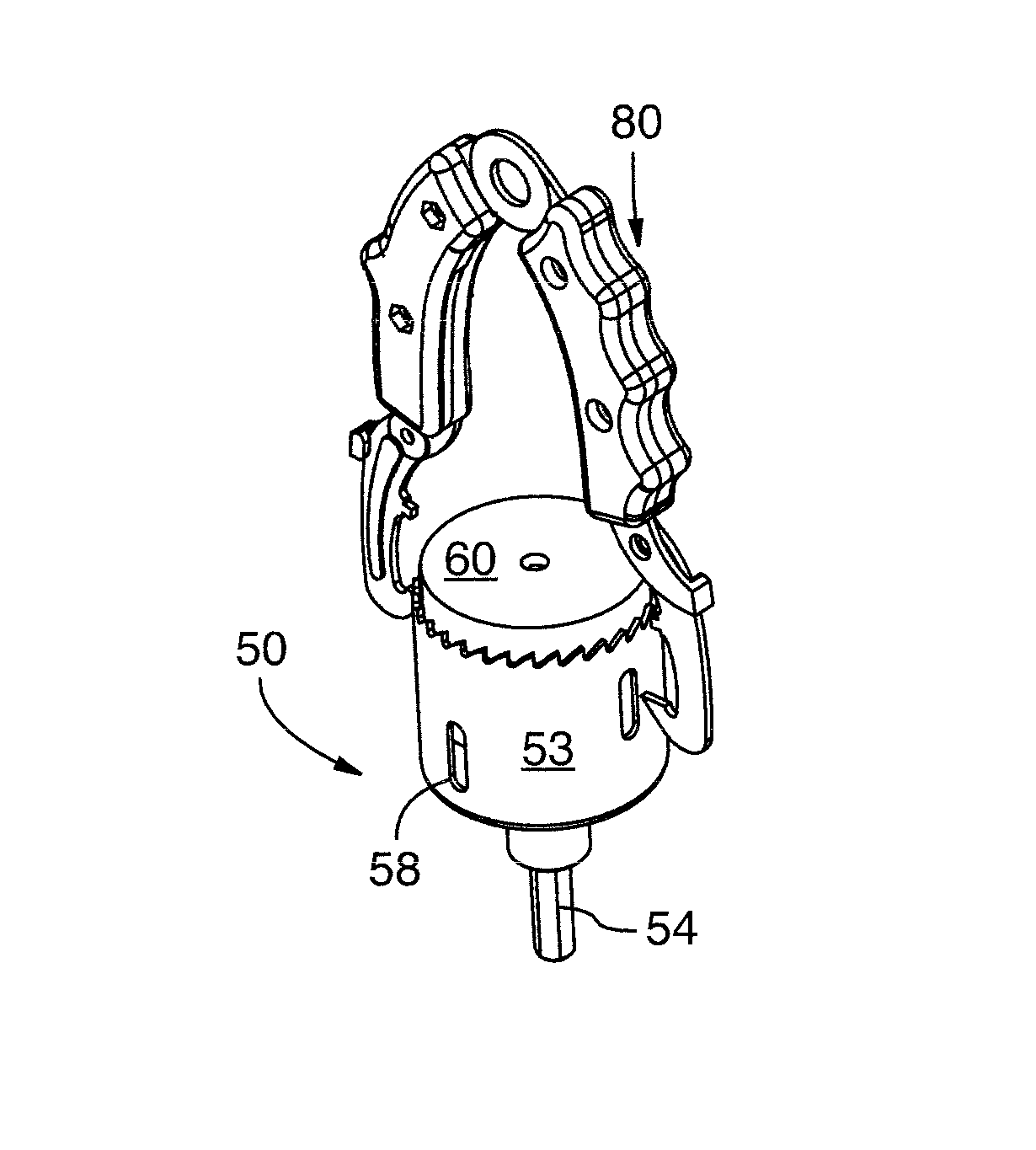

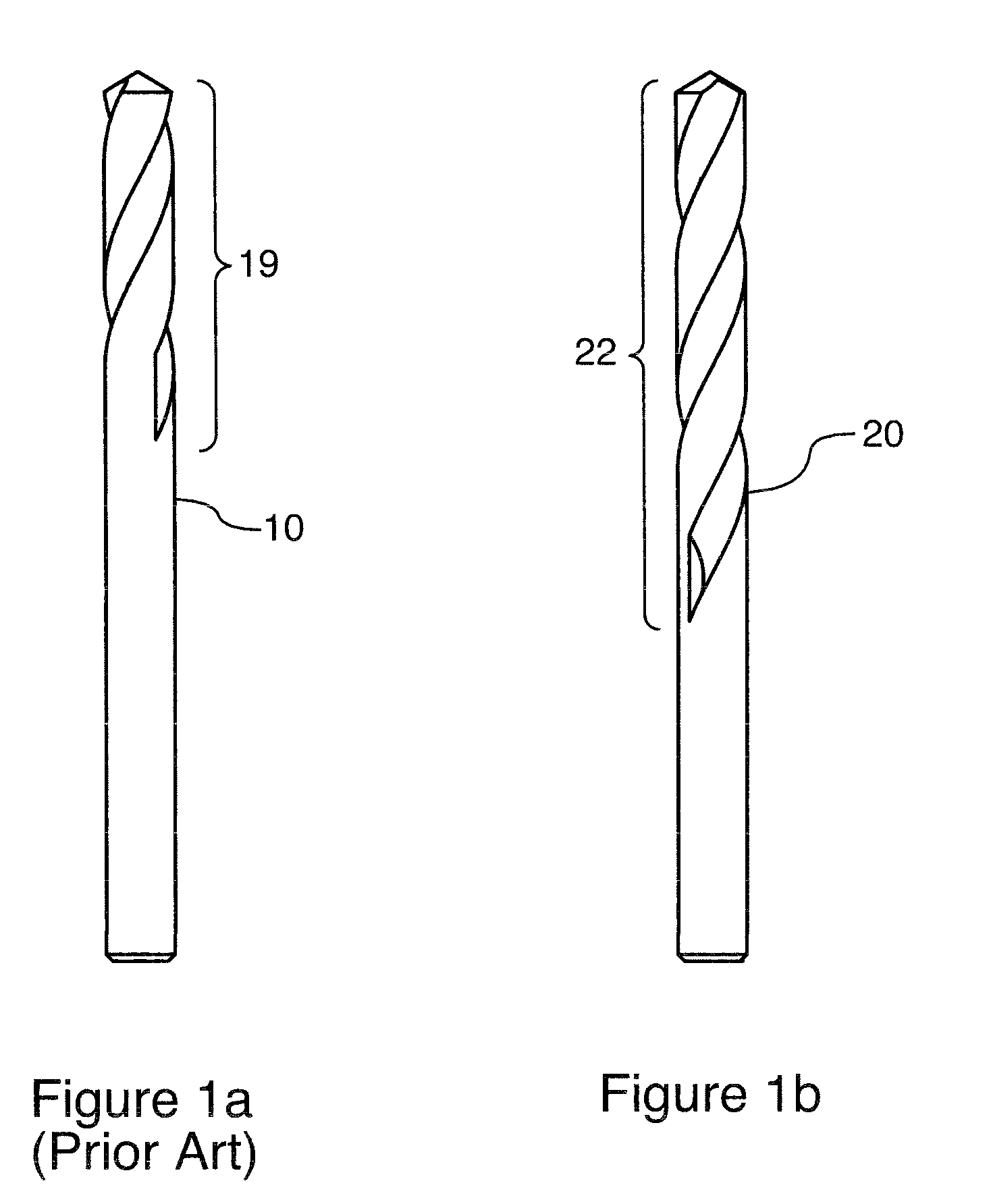

Hole saw having efficient slug removal

InactiveUS7658576B1Reduce frictional contactUniform forceThread cutting feeding devicesTransportation and packagingHole sawEngineering

A hole saw having efficient slug removal preferably includes a saw cup, a shank portion and a pilot cutting device. A cutting surface is formed on an open end of the saw cup. An inside surface of the saw cup is given a low friction treatment and preferably an outside surface thereof. The shank portion is retained on a closed end of the saw cup. The pilot cutting device is preferably a drill, but other cutting devices may also be used. A second embodiment of a hole saw having efficient slug removal preferably includes a saw cup, a shank portion and a pilot cutting device. The saw cup includes a prior art saw cup, at least two side openings and a cutting surface. The at least two side openings are formed through the prior art saw cup to remove a substantial portion of a side wall.

Owner:CAPPYS CONCEPTS

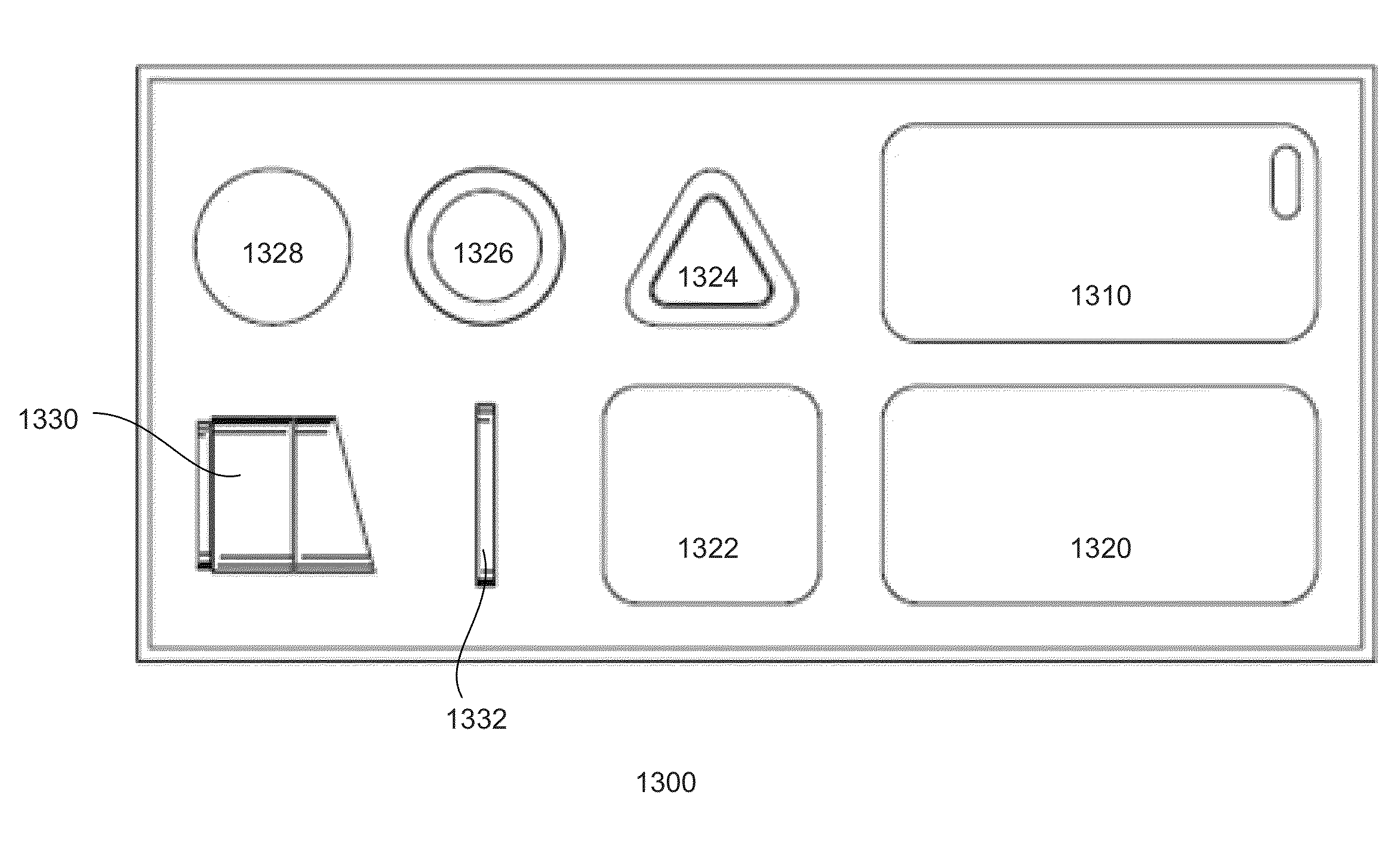

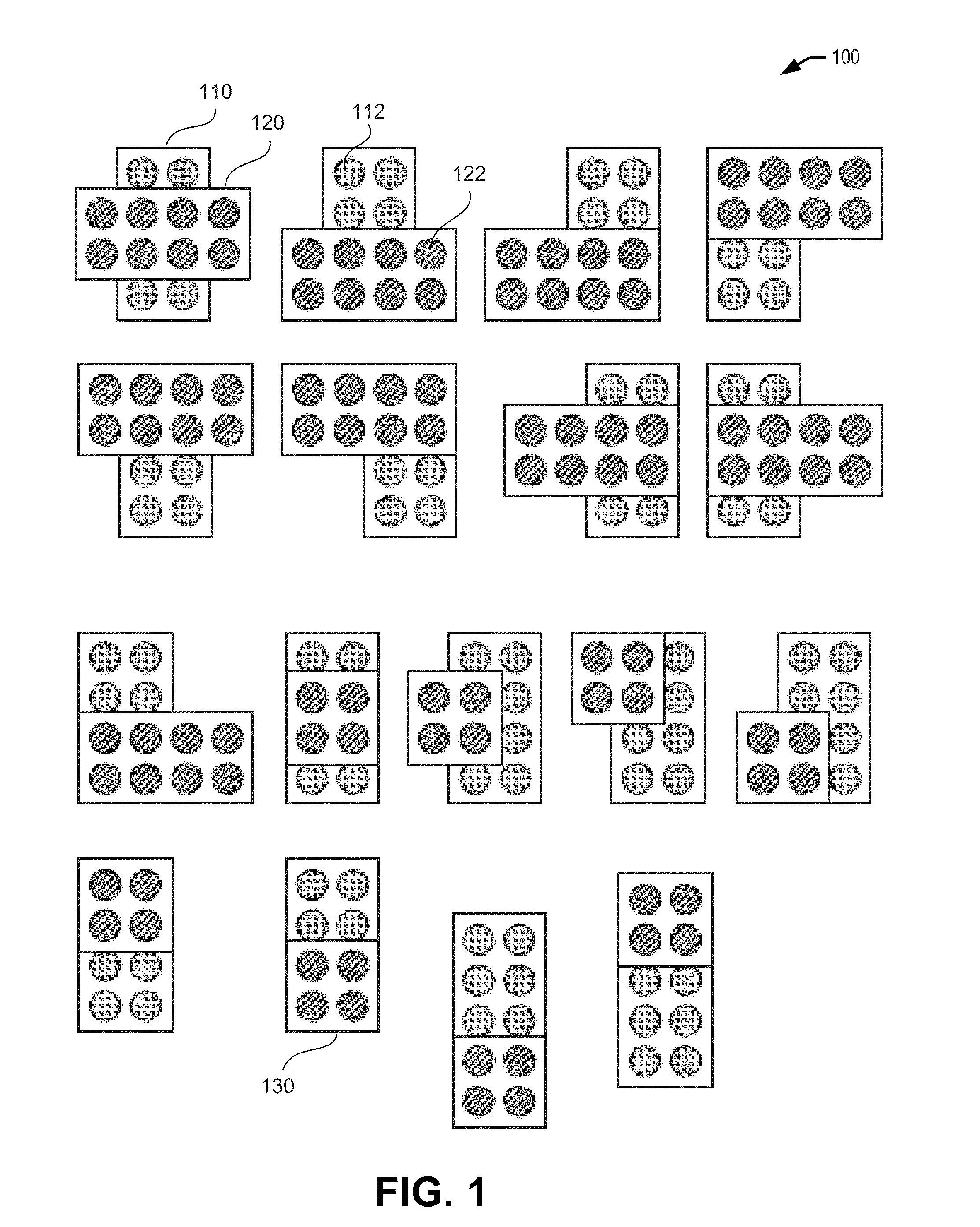

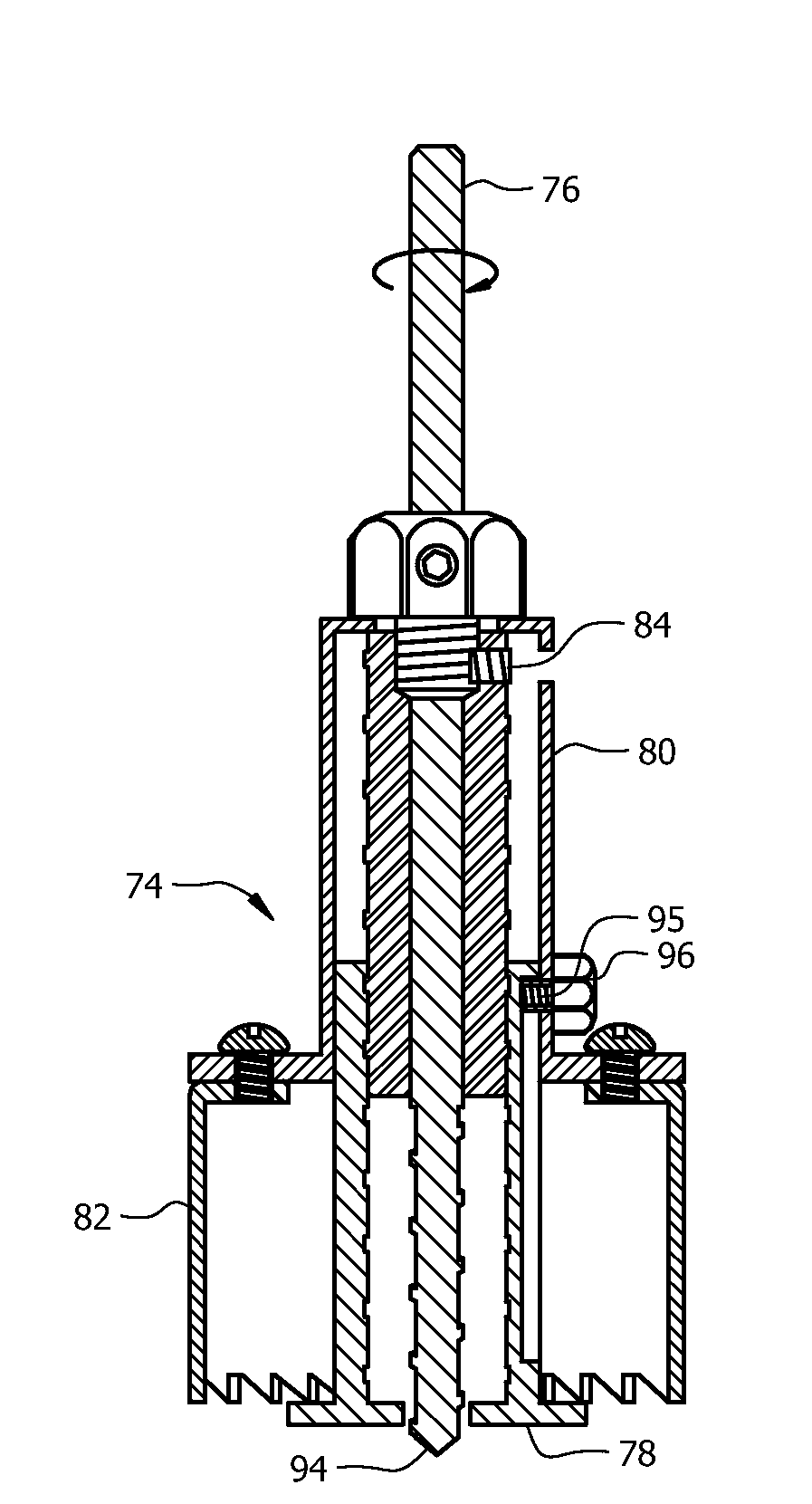

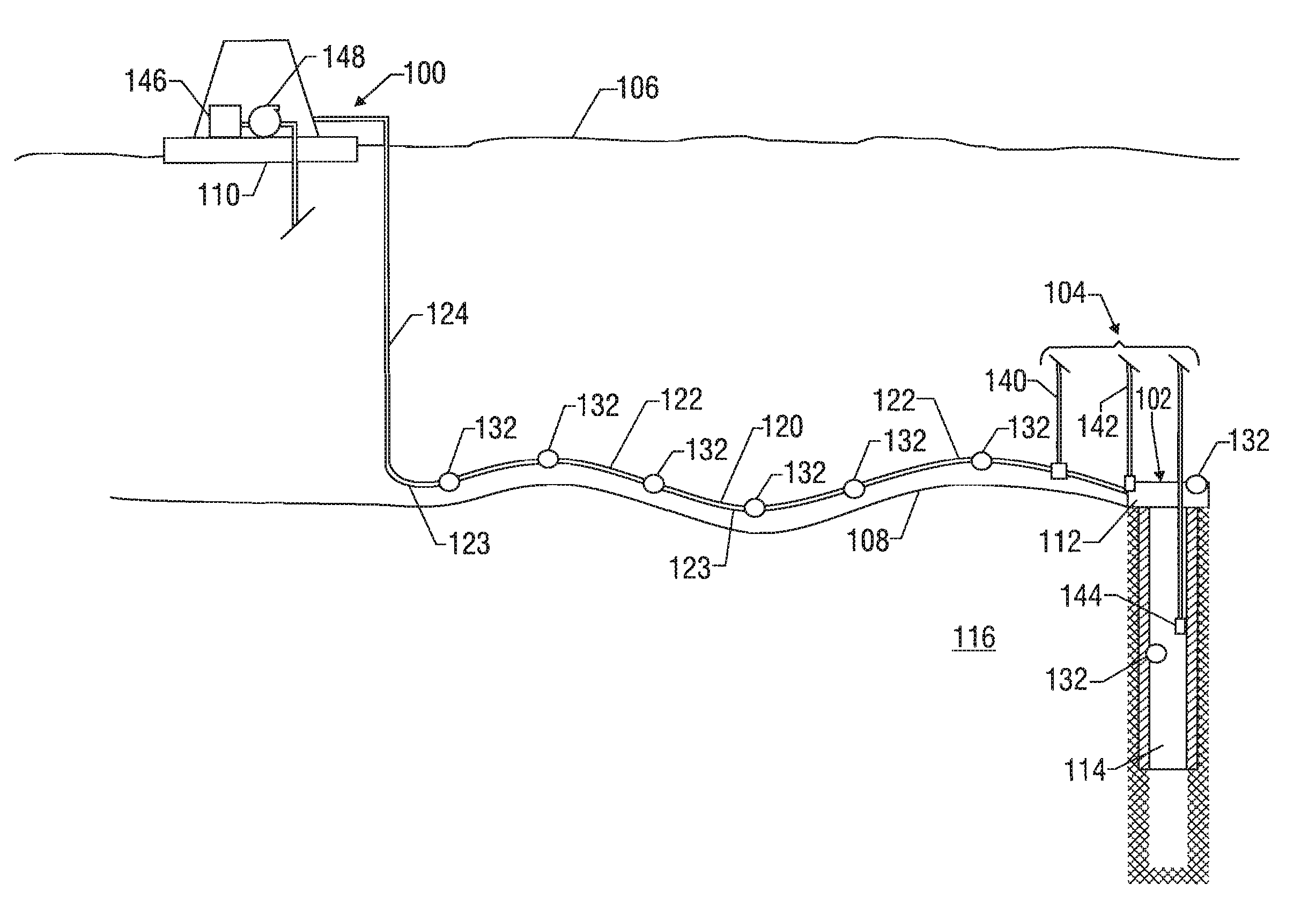

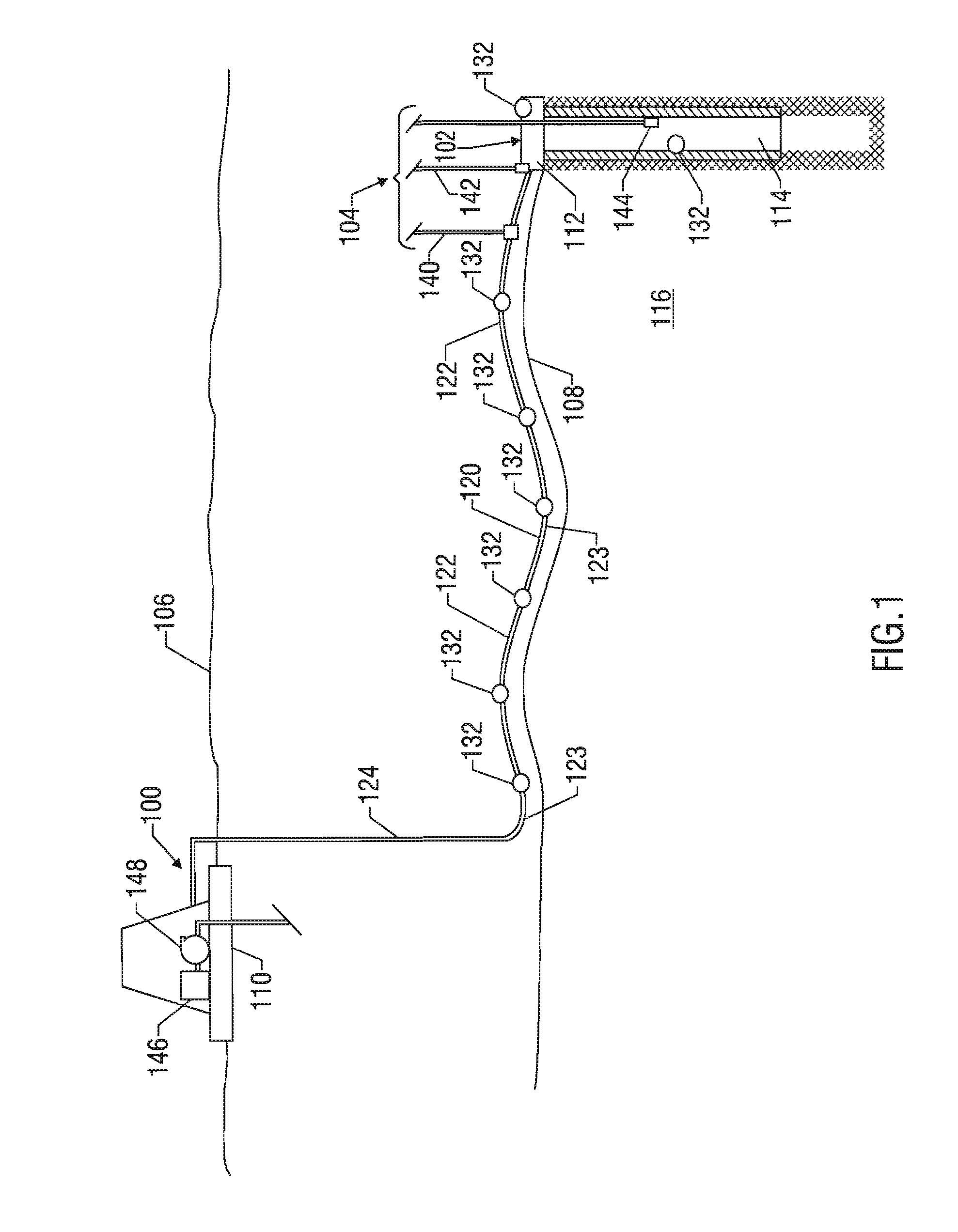

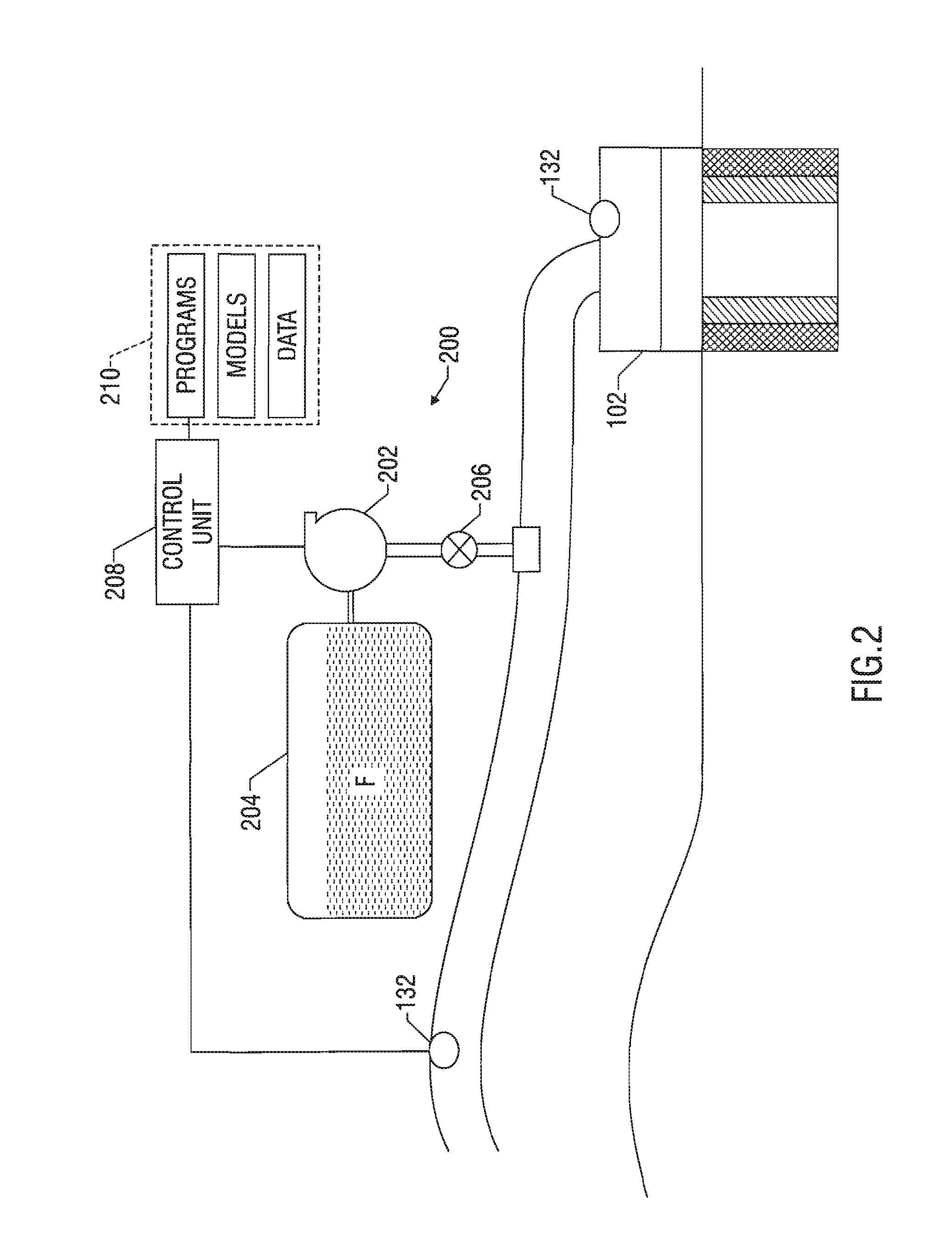

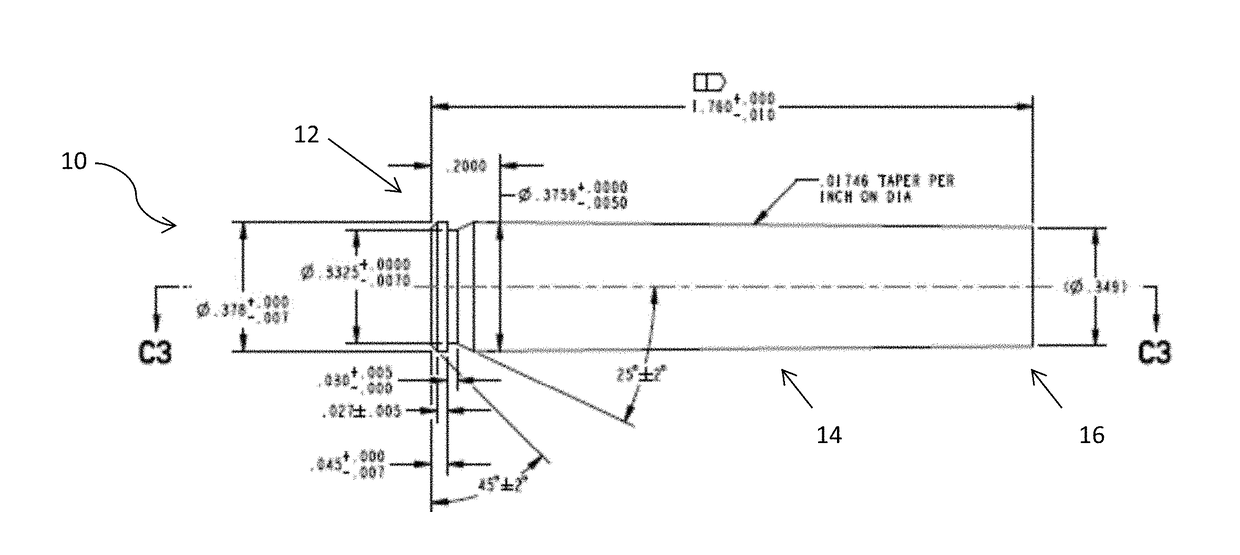

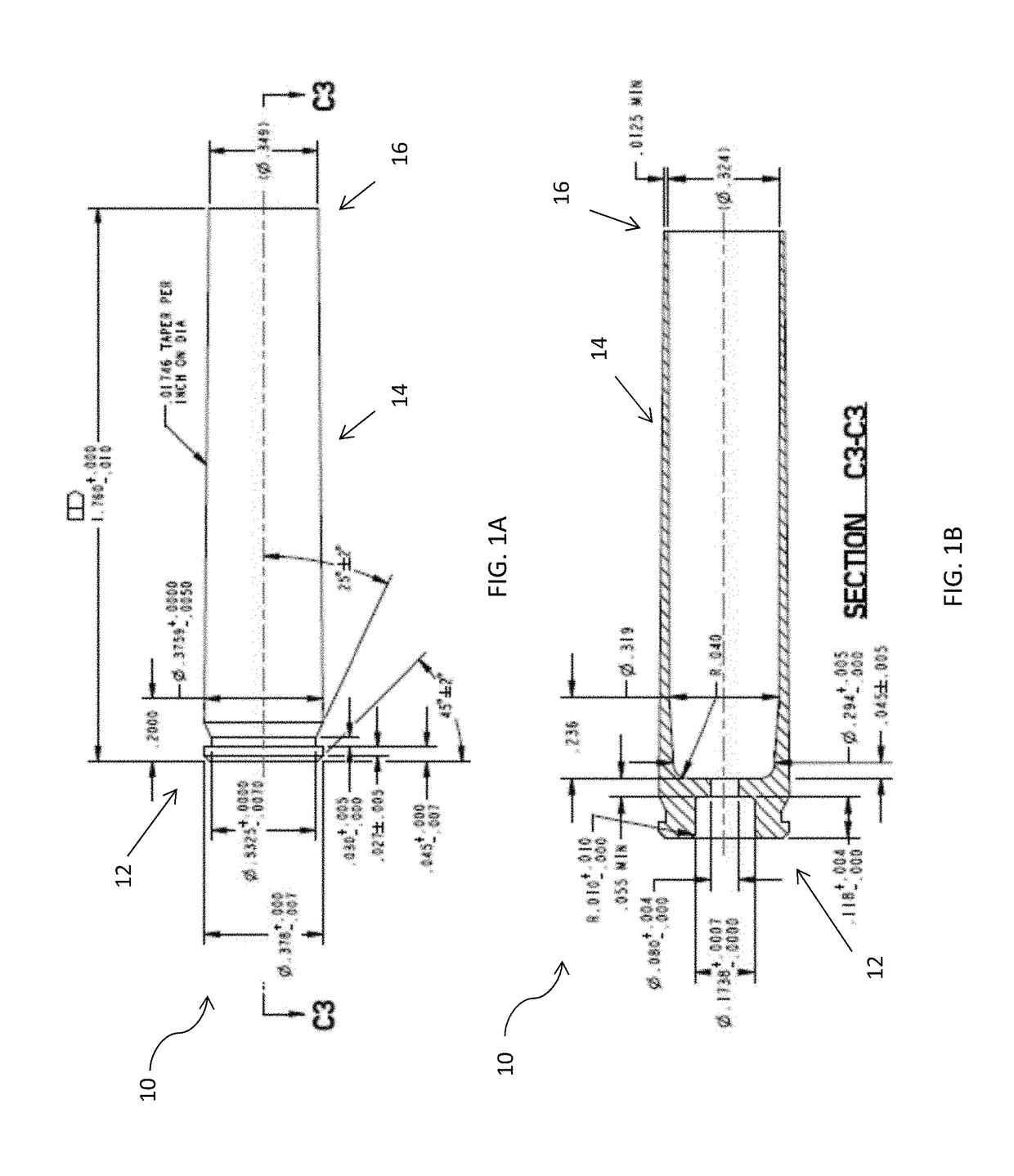

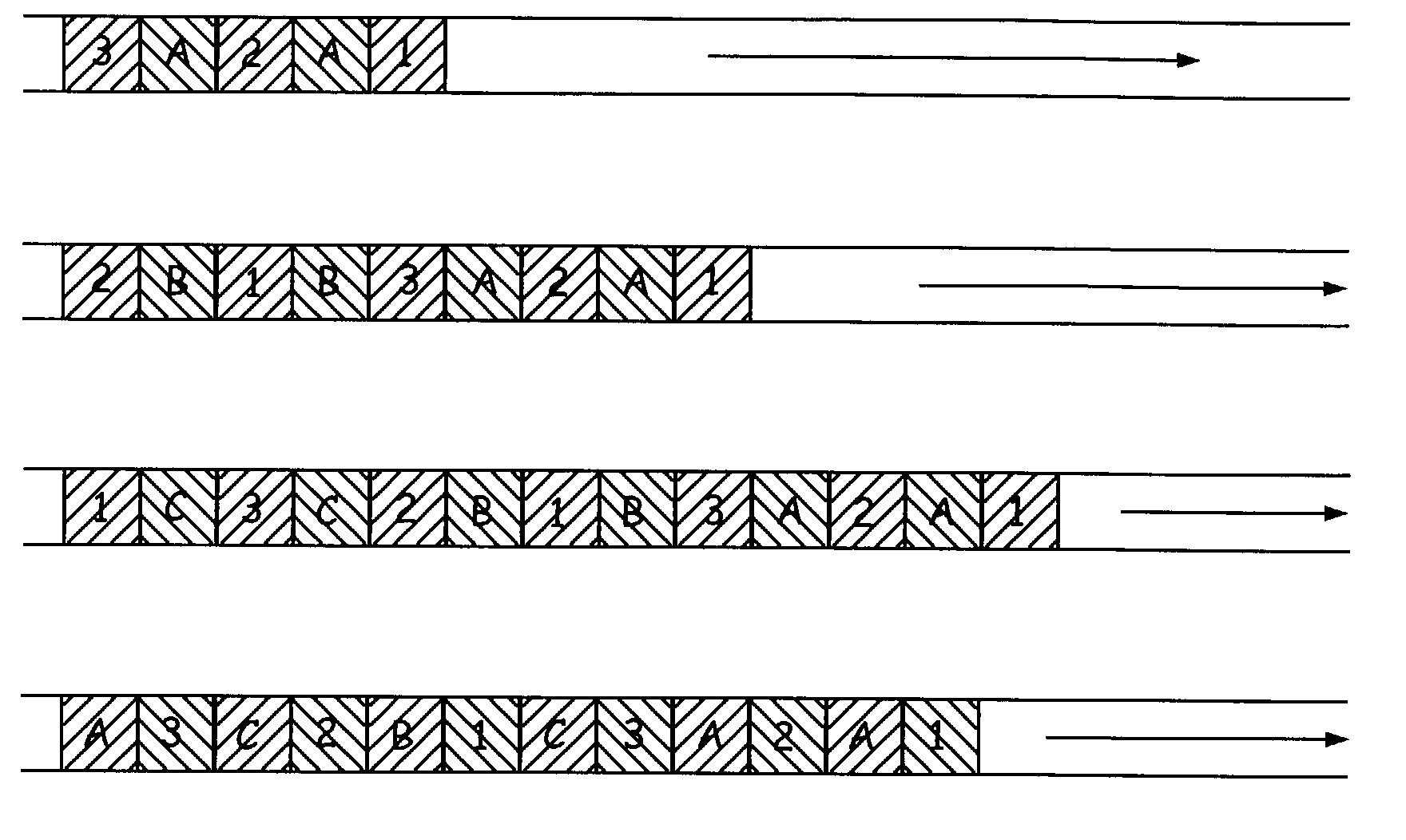

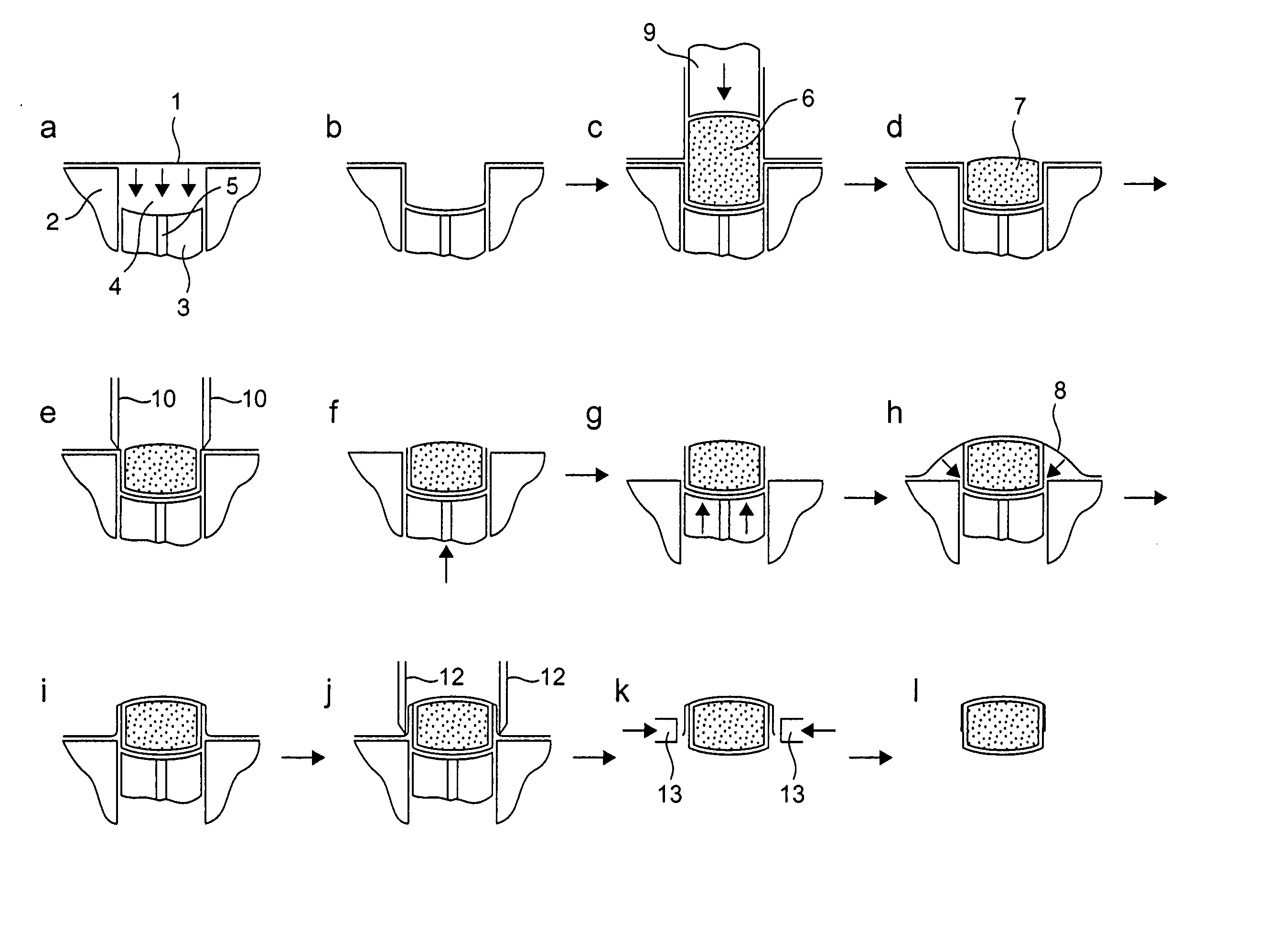

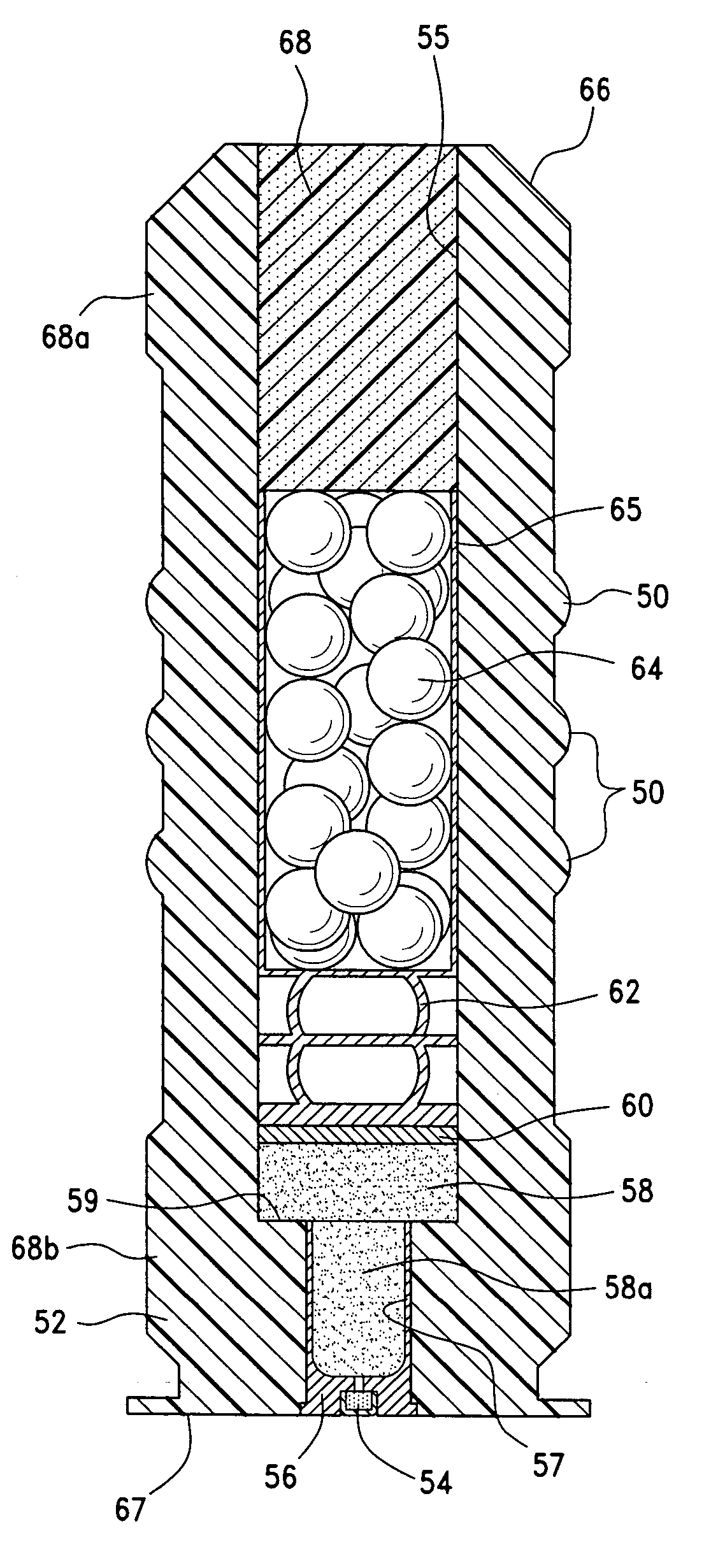

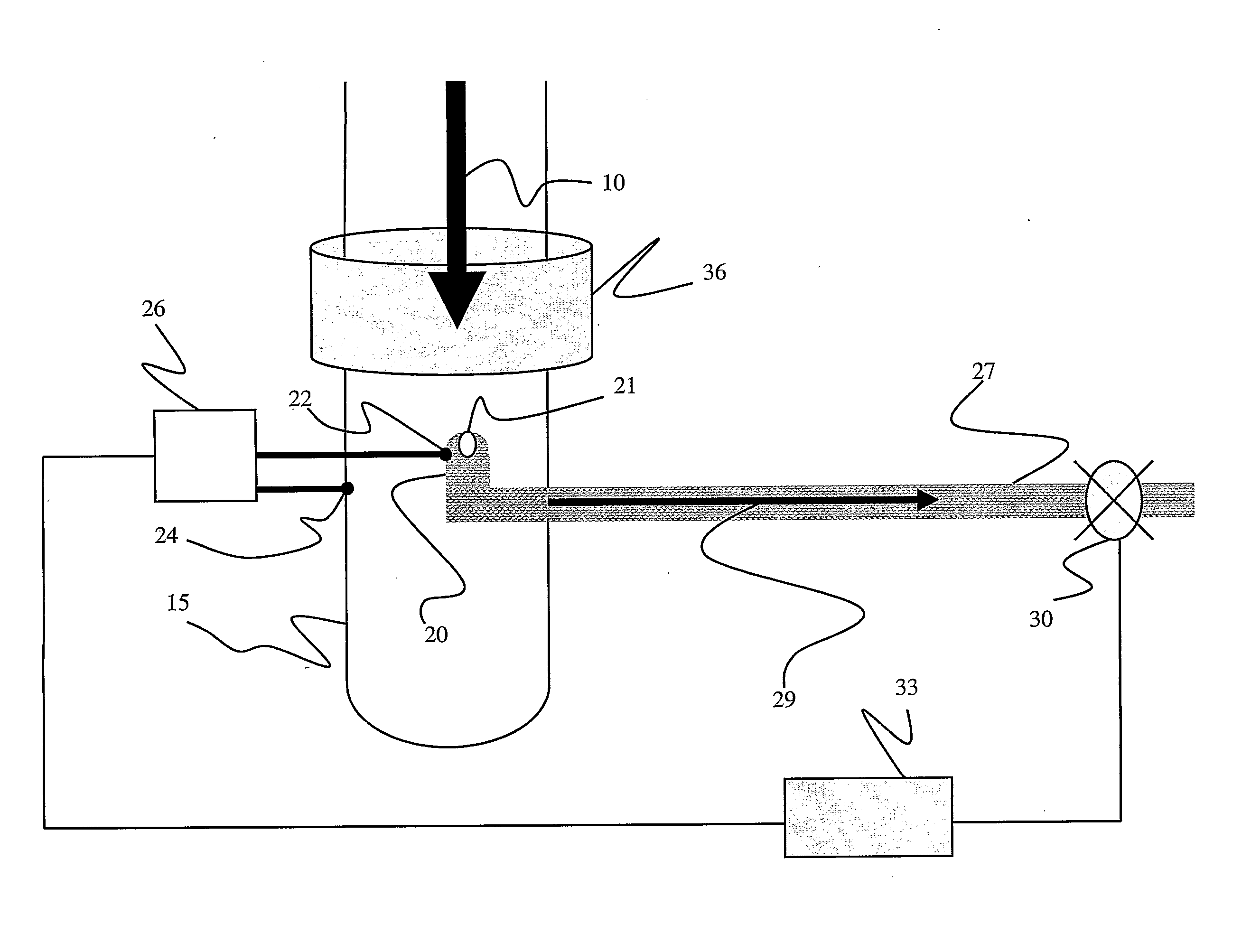

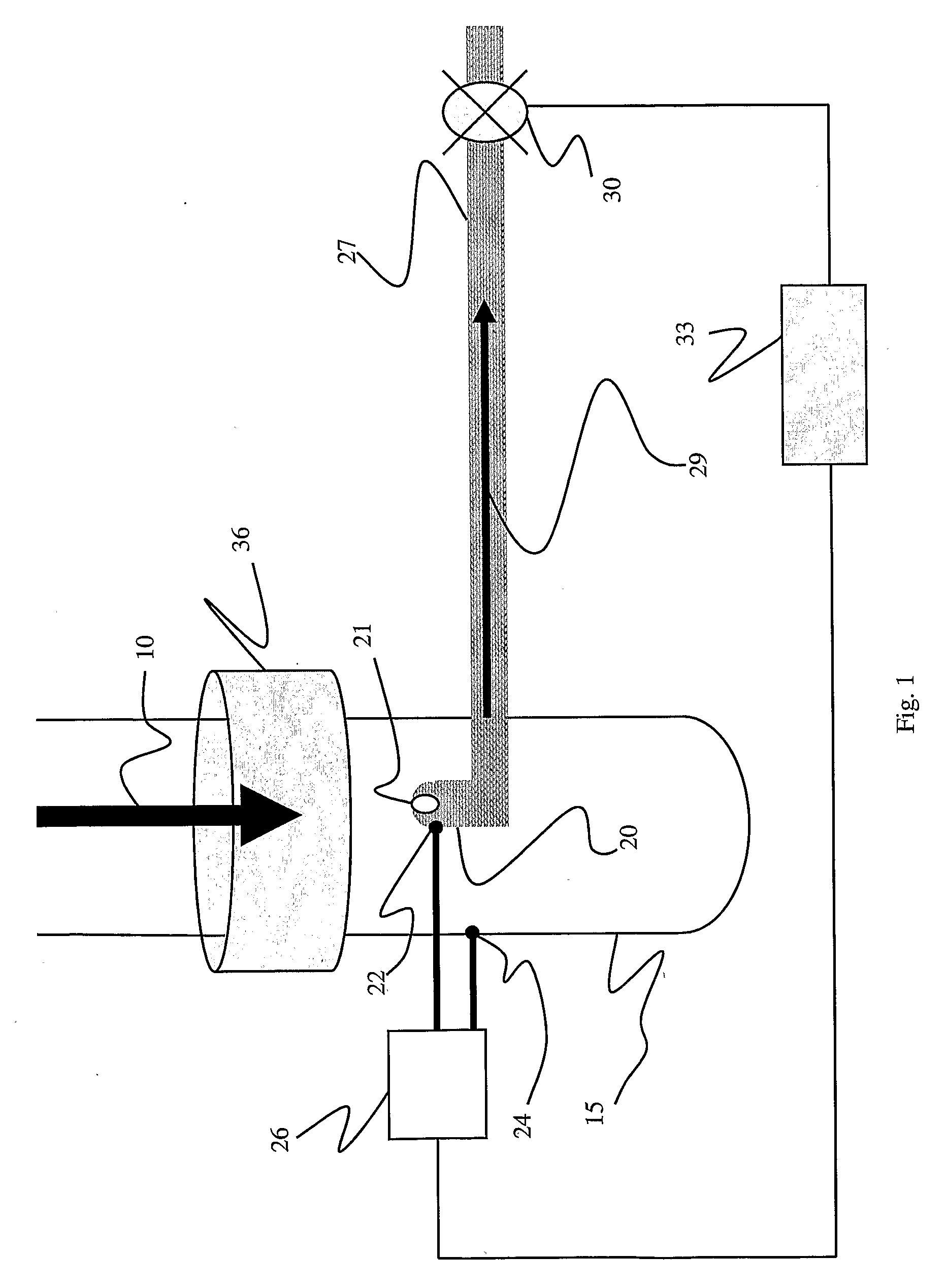

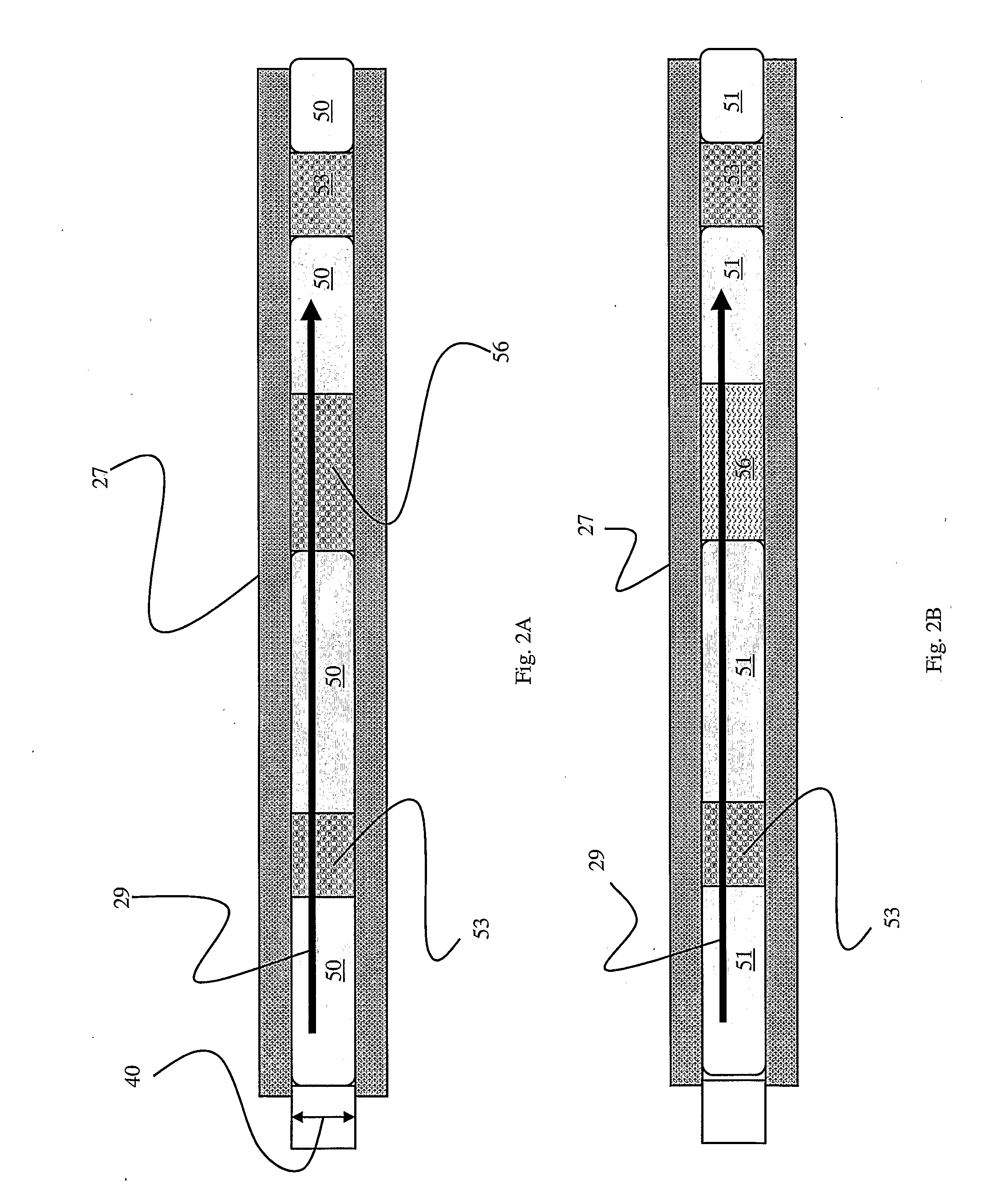

[real-time monitoring and control of reservoir fluid sample capture]

InactiveUS20050150287A1Withdrawing sample devicesBorehole/well accessoriesLine tubingMonitoring and control

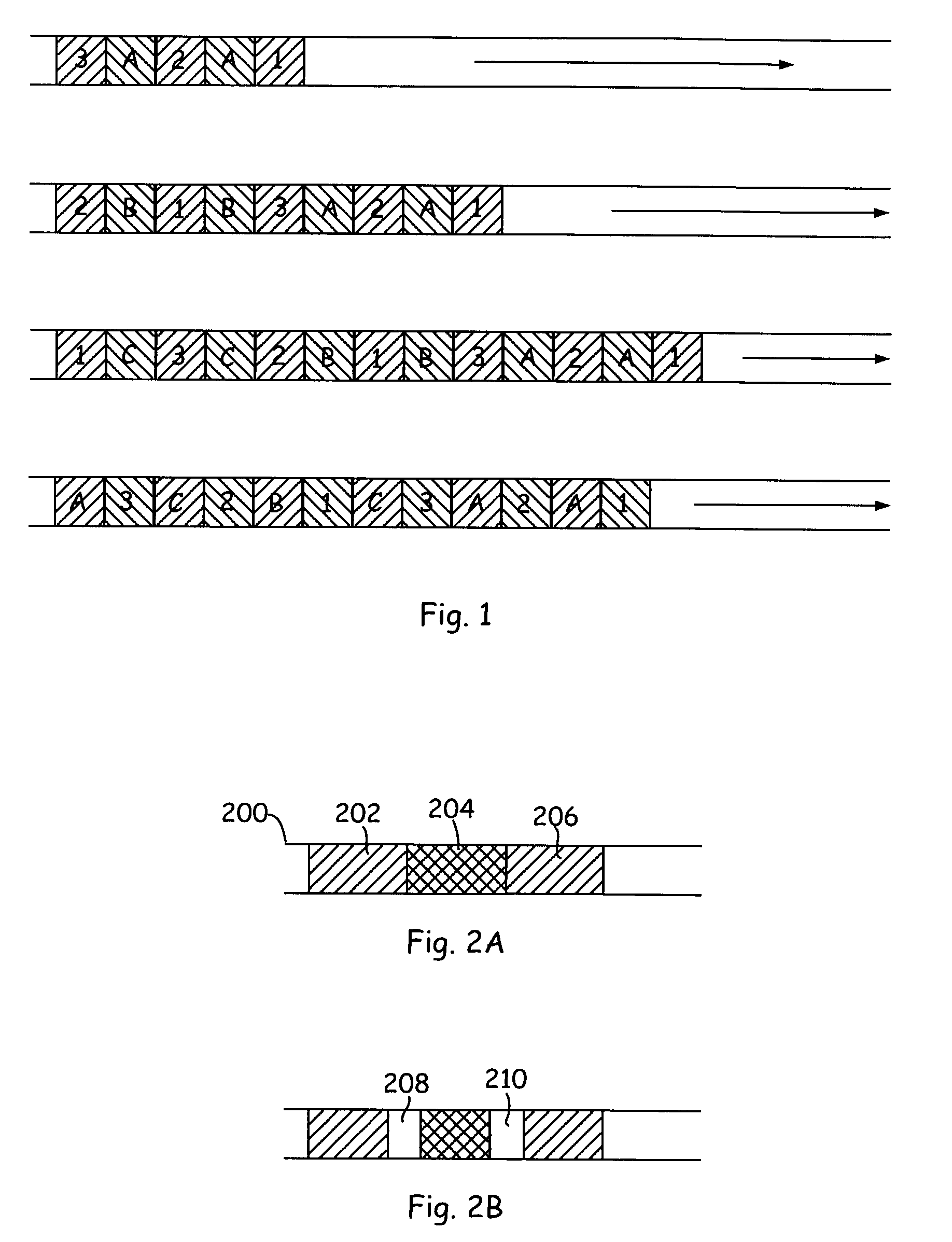

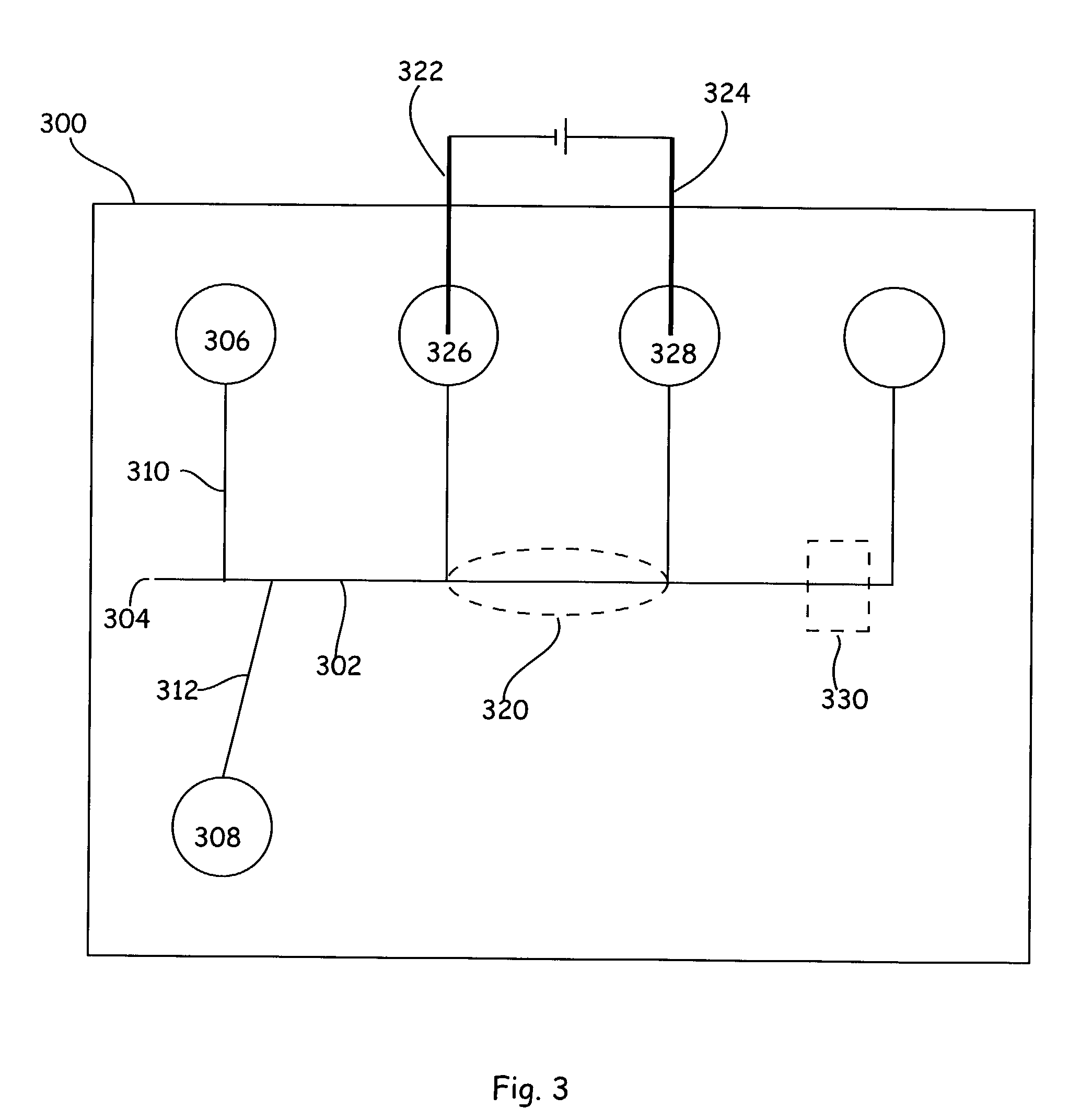

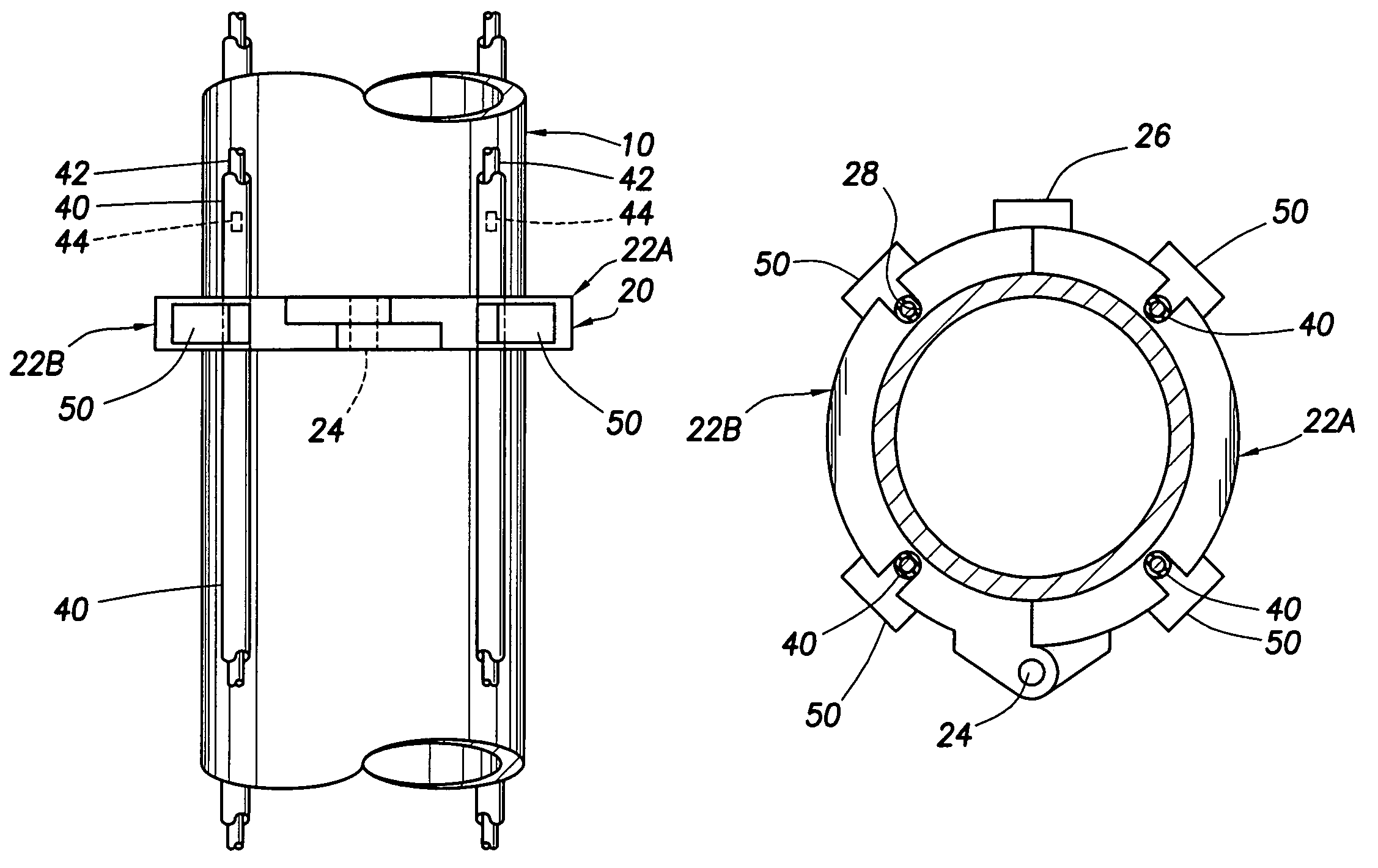

A method of sampling reservoir fluid includes establishing communication between a reservoir and an entry port of a flow line disposed in a borehole penetrating the reservoir. The method includes separating fluid received in the entry port into individual fluid components and sequentially flowing slugs of each individual fluid component along the flow line, observing the slugs as they move along the flow line in order to determine the composition of the slugs, estimating when a desired slug containing a desired fluid component would be in the vicinity of a sample chamber in the flow line, and opening the sample chamber to capture the desired slug when the desired slug is in the vicinity of the sample chamber. The method also includes checking that the sample chambers open and close successfully. Finally, the method further includes creating an accurate record of events, which can then be used to audit the sampling process.

Owner:SCHLUMBERGER TECH CORP

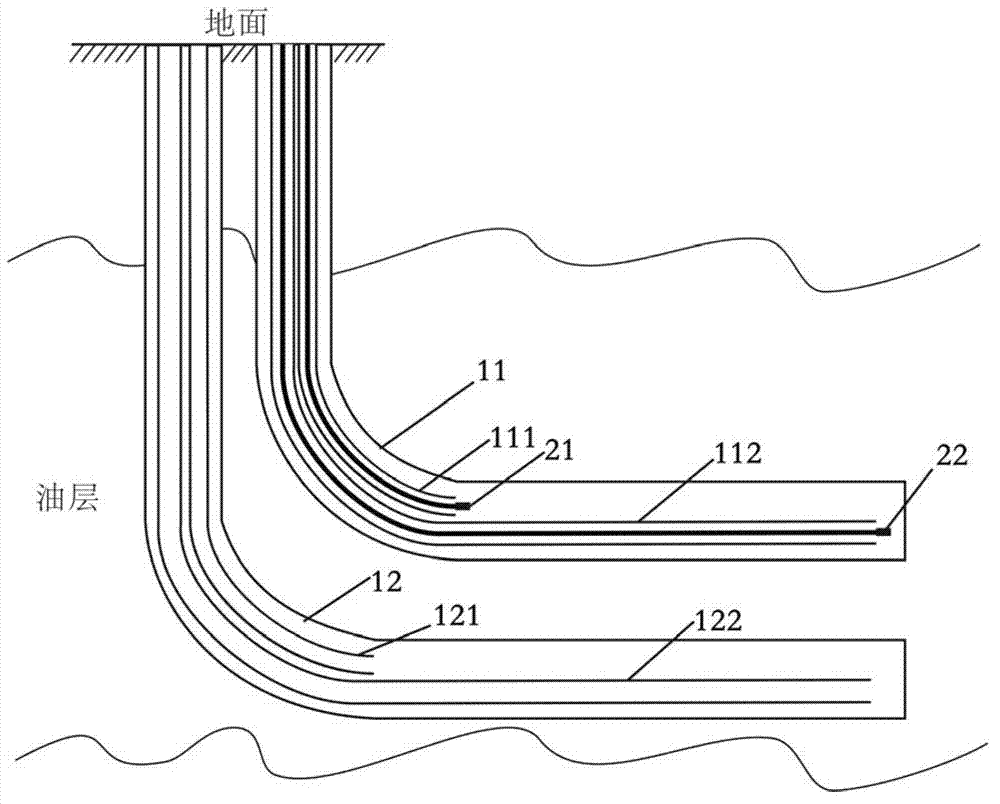

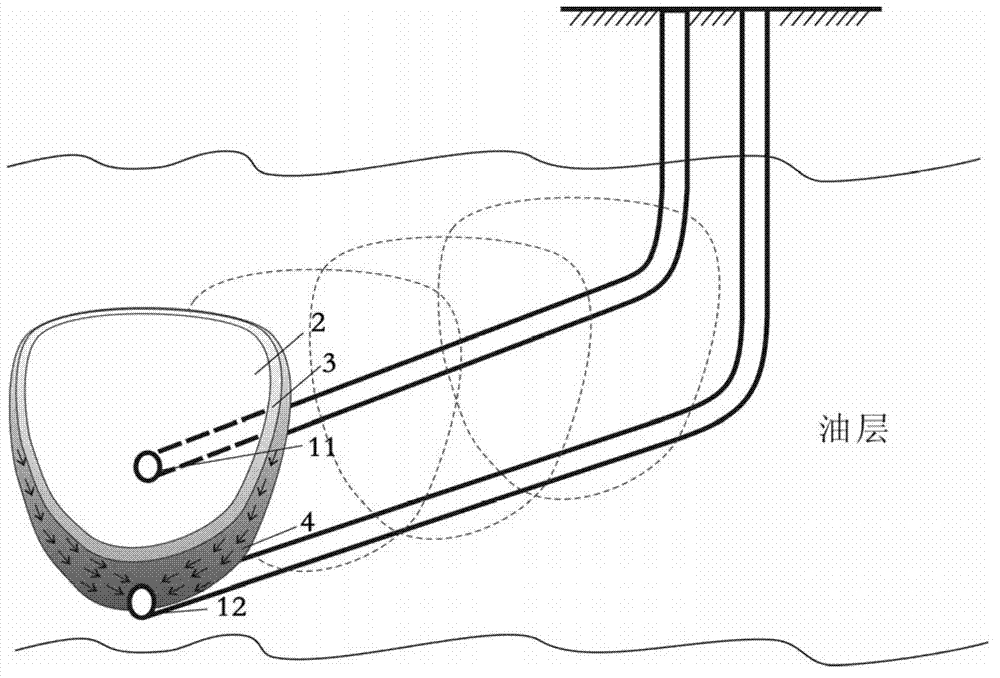

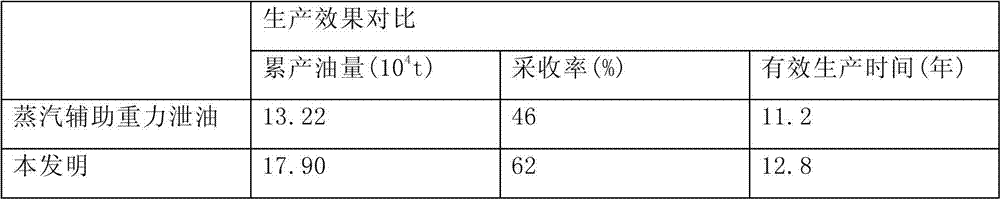

Method for mining deep and ultra-deep thick oil pools by using double horizontal well fire flooding drainage

The invention discloses a method for mining deep and ultra-deep thick oil pools by using double horizontal well fire flooding drainage. A horizontal flooding well network is arranged in a thick oil pool mining region, an injection well and a production well are arranged in an oil layer at the same vertical plane to form a horizontal flooding well pair, the horizontal section of the production well is located on the lower portion of the horizontal section of the injection well and is parallel with the horizontal section of the injection well, the injection well and the production well conduct steam injection cycling preheating at the same time, when the temperature of the oil layer between the horizontal sections of the injection well and the production well is raised to the preset temperature, the injection well and the production well stop the cycling preheating at the same time, a slug of oxygen enriched air is injected by the injection well continuously, the oil layer of the horizontal sections is lighted, the air is injected by the injection well after lighting, and the production well conducts continuous mining production. Compared with normal steam flooding mining methods such as a steam assistant gravity oil drainage technology, the method has the advantages that the recovery ratio is increased by more than 10-20%, the ultimate recovery ratio can reach more than 60% and the economic benefits are better than other methods.

Owner:PETROCHINA CO LTD

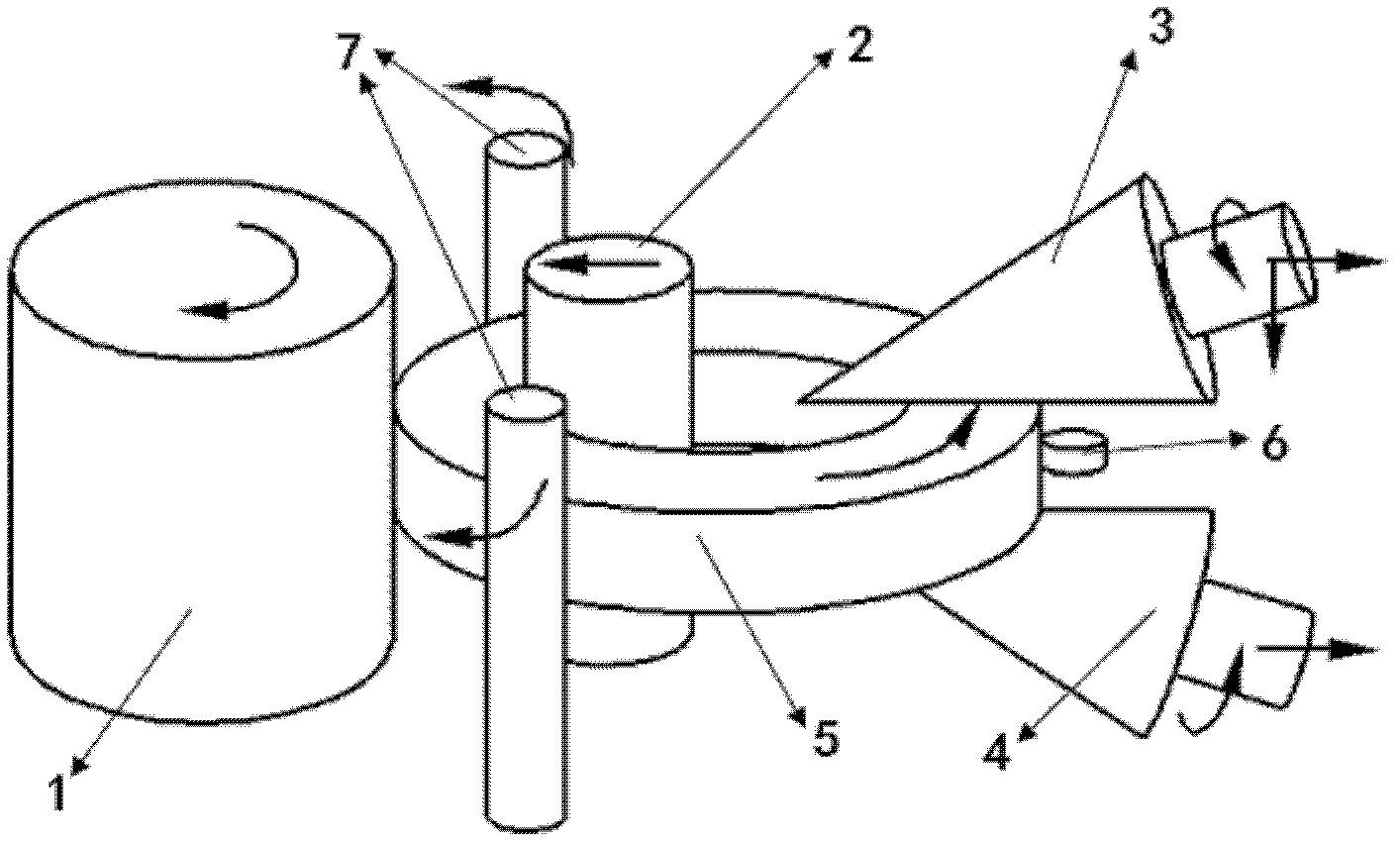

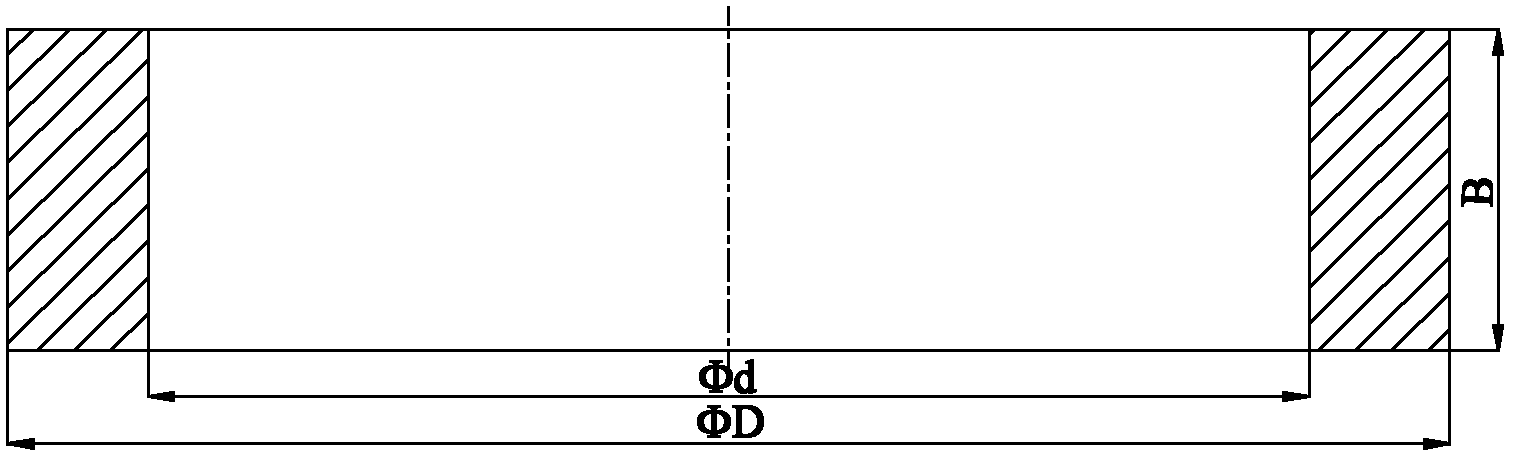

Fine-grain roll-forming method for large annular piece made of high alloy steel

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS +1

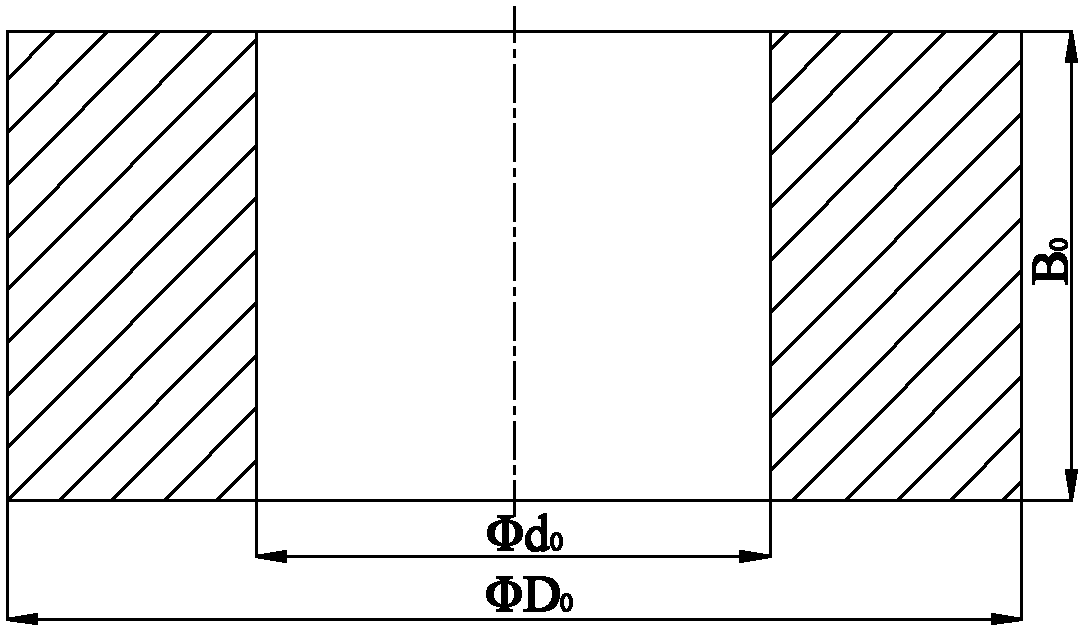

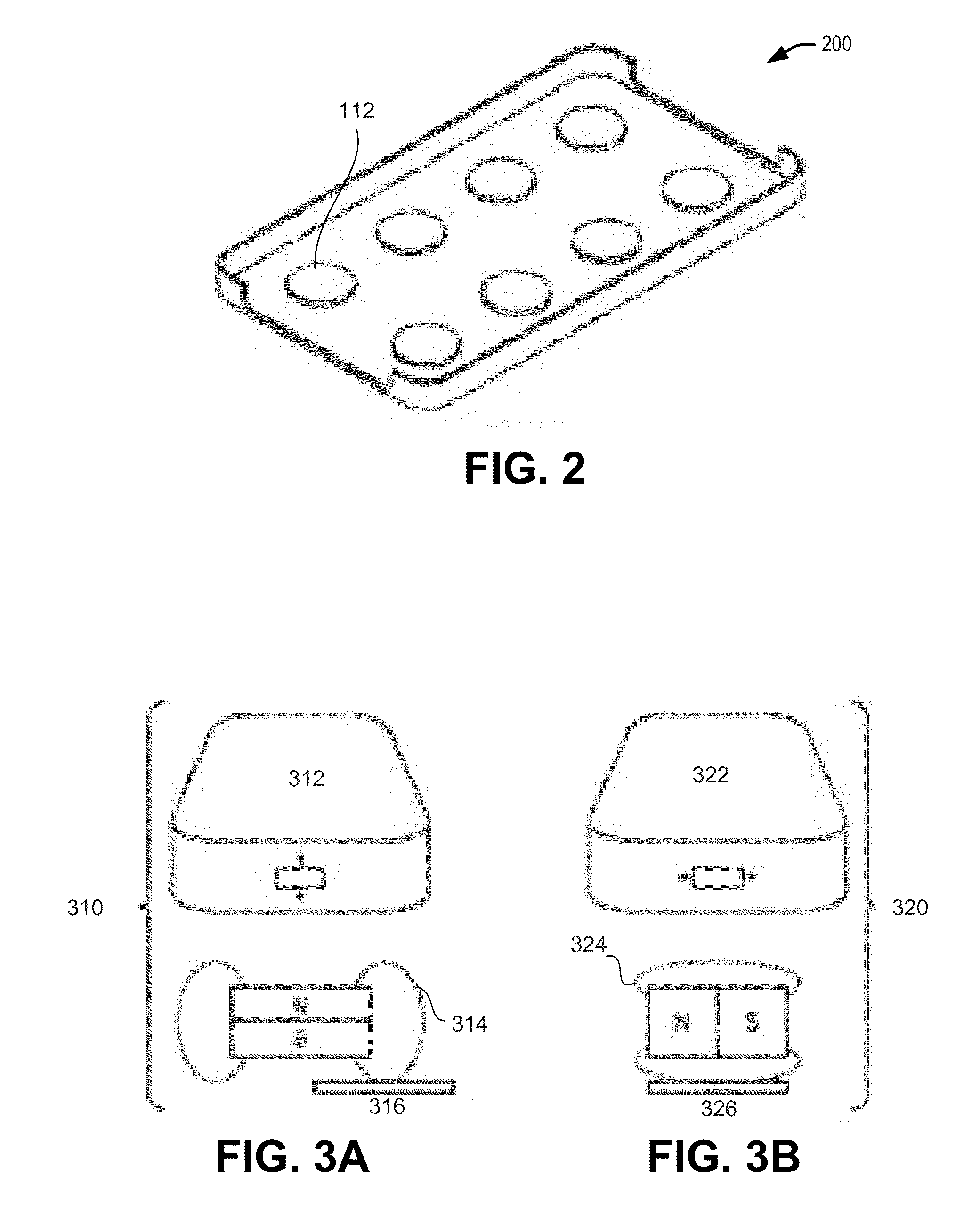

Portable device case and accessories

Owner:LOGITECH EURO SA

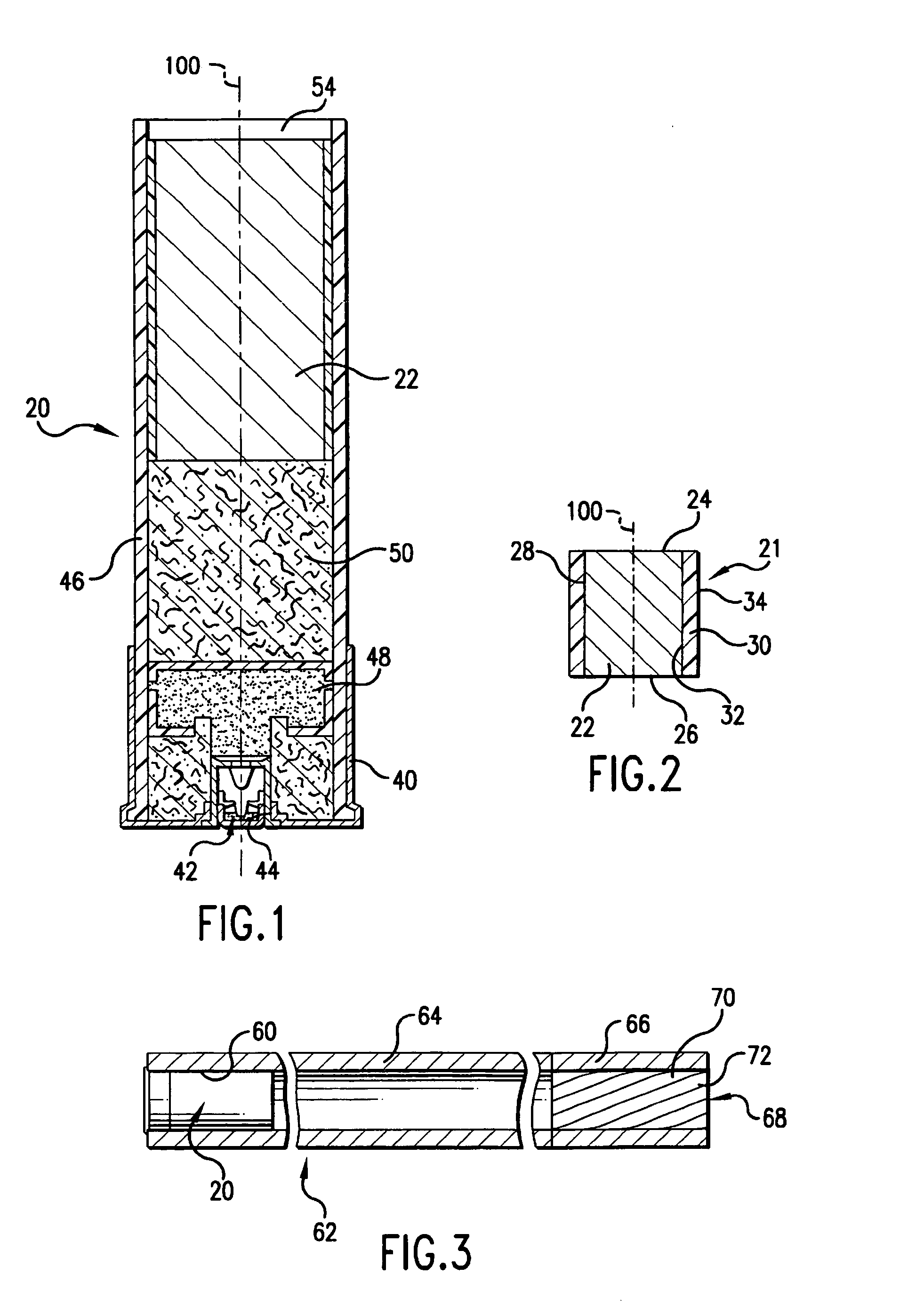

Slug for industrial ballistic tool

InactiveUS7159519B2Reduces and eliminates introductionTo offer comfortAmmunition projectilesShotgun ammunitionParticulatesImpurity

A frangible projectile for expelling from an industrial ballistic tool may be formed by a powder metallurgy process. A preferred embodiment of slug consists essentially of compacted and optionally sintered material and comprises up to 35% ferrotungsten in particulate form, up to 3% lubricant, and the balance iron in particulate form with inevitable impurities.

Owner:OLIN CORP

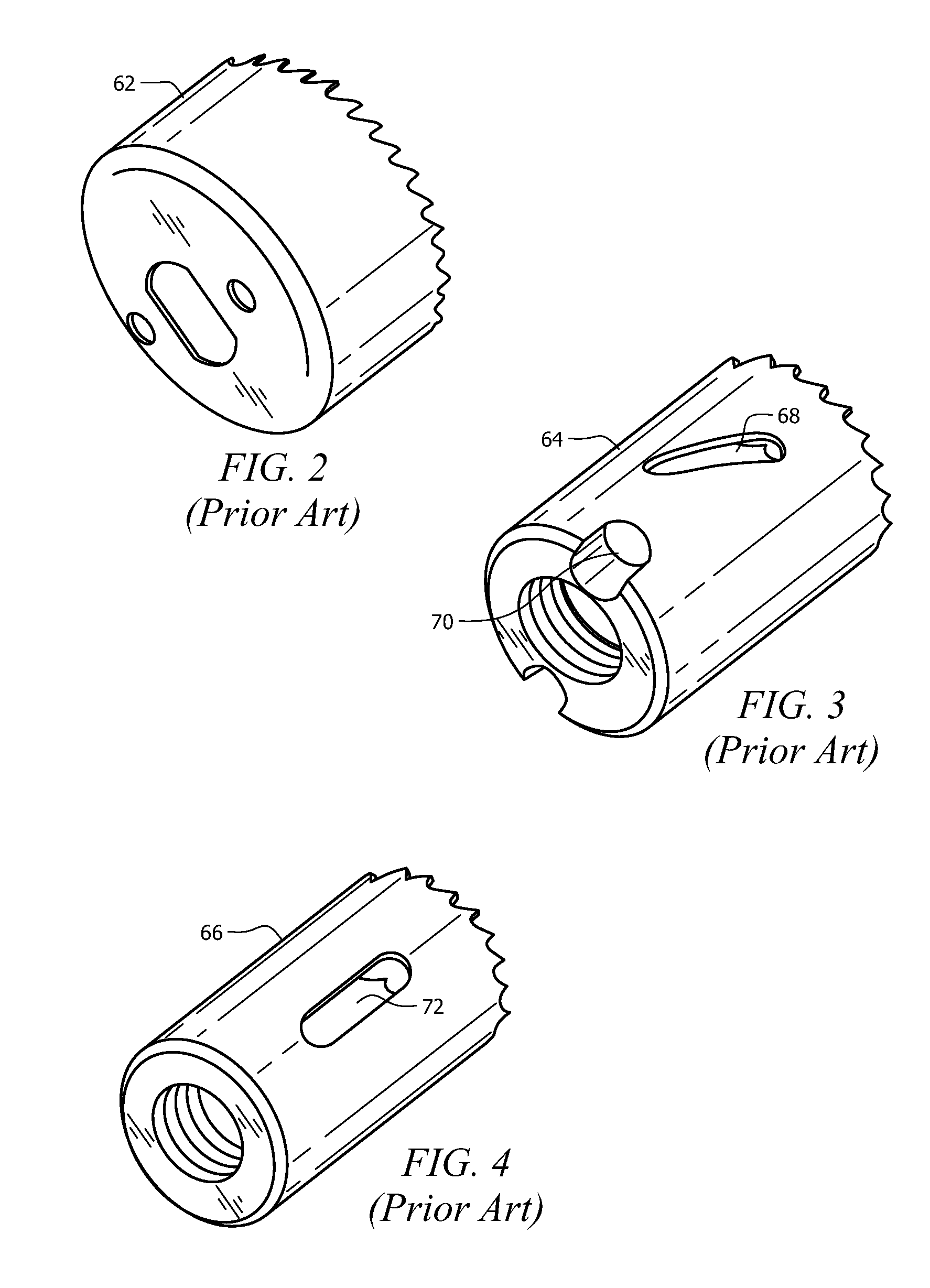

Hole saw slug removal device

InactiveUS7160064B2Simple designMinimal expenseThread cutting feeding devicesTransportation and packagingCircular discHole saw

The hole saw slug removal device is a device constructed to fit within a hole saw that provides for automatic ejection of waste slugs from within the hole saw. The hole saw slug removal device generally consists of two discs affixed on either end of a compression spring. The device is then inserted into the hole saw, and one disc retains the compression spring within the hole saw by locking onto the drill bit or against the inner surface of the hole saw. Upon operation of the hole saw, the spring compresses and the other disc is pushed down by the force of the sawing. After the sawing is completed, the spring decompresses, and the disc is pushed forward, automatically ejecting the waste slug that has become trapped within the hole saw. The slug removal device may lack one disc and instead be permanently affixed to a hole saw.

Owner:JASSO ABELARDO

Pesticidal compositions and methods of use thereof

ActiveUS20100227010A1Enhances insecticidal/pesticidal activityImprove insect repellent effectBiocideOrganic active ingredientsVegetable oilGnat

A pest-combating composition including sodium lauryl sulfate and one or more of C6-12 fatty acids, preferably lauric and / or capric and / or caprylic acid, soy methyl ester, and 2-undecanone, and methods of combating pests utilizing same, are disclosed. The compositions can include a carrier oil such as silicon oil, soy methyl ester, or a vegetable oil, and can be in the form of an emulsion. The composition may be constituted as a spray composition, an aerosol, a lotion, a paste, or another compositional form. Pests that may be usefully combated with such composition include flying insects, including flies, mosquitoes, and wasps, ants, including arthropods such as fire ants, ticks, fleas, cockroaches, silver fish, thrips, gnats, aphids, Japanese beetles, and agricultural and horticultural arthropods and insects including beetles (potato and bean), flea beetles, fleahoppers, squash bugs, slugs, leaf hoppers, harlequin bugs, milk weed bugs, spiders, mites, lice, rodents, and deer.

Owner:HOMS

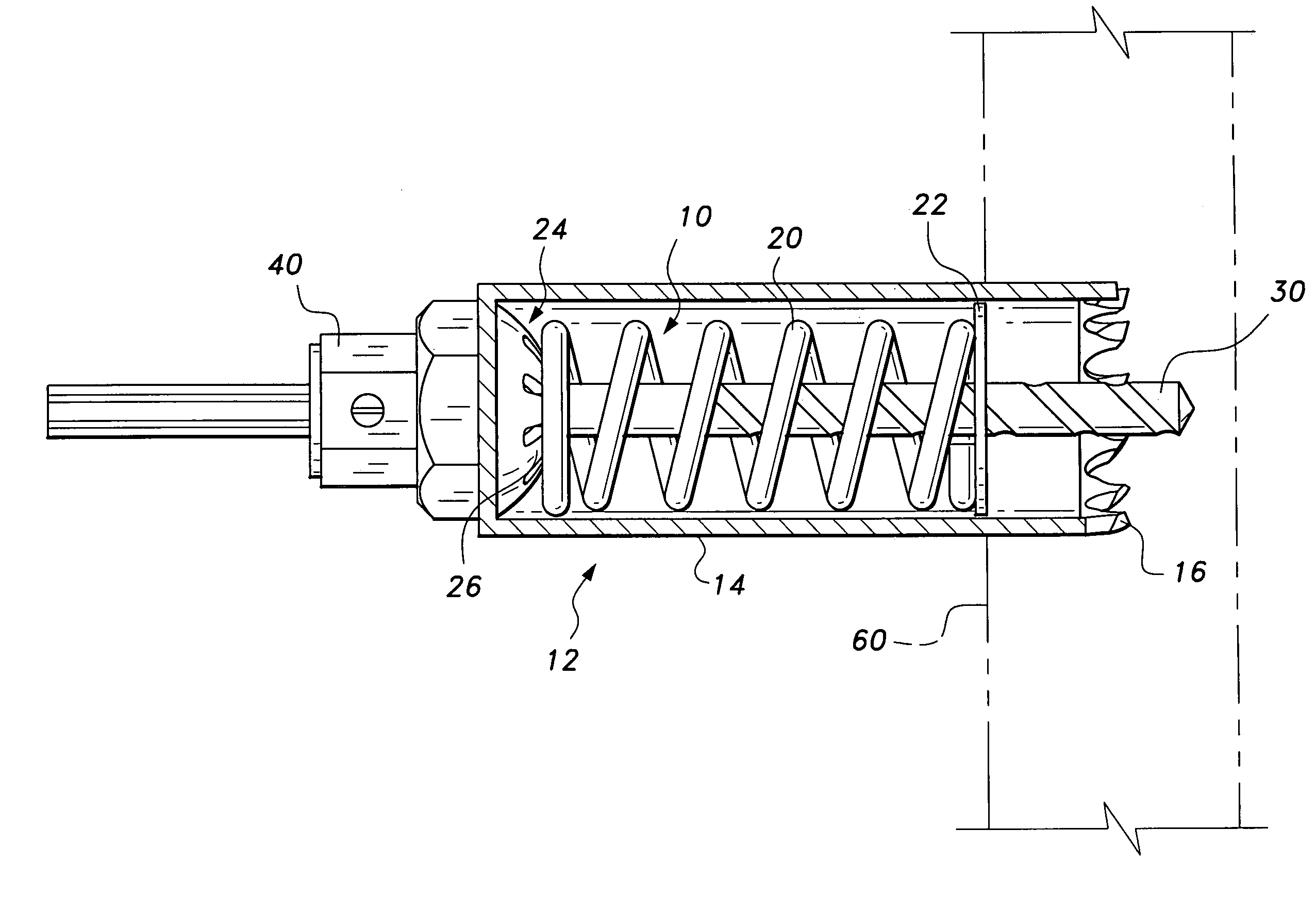

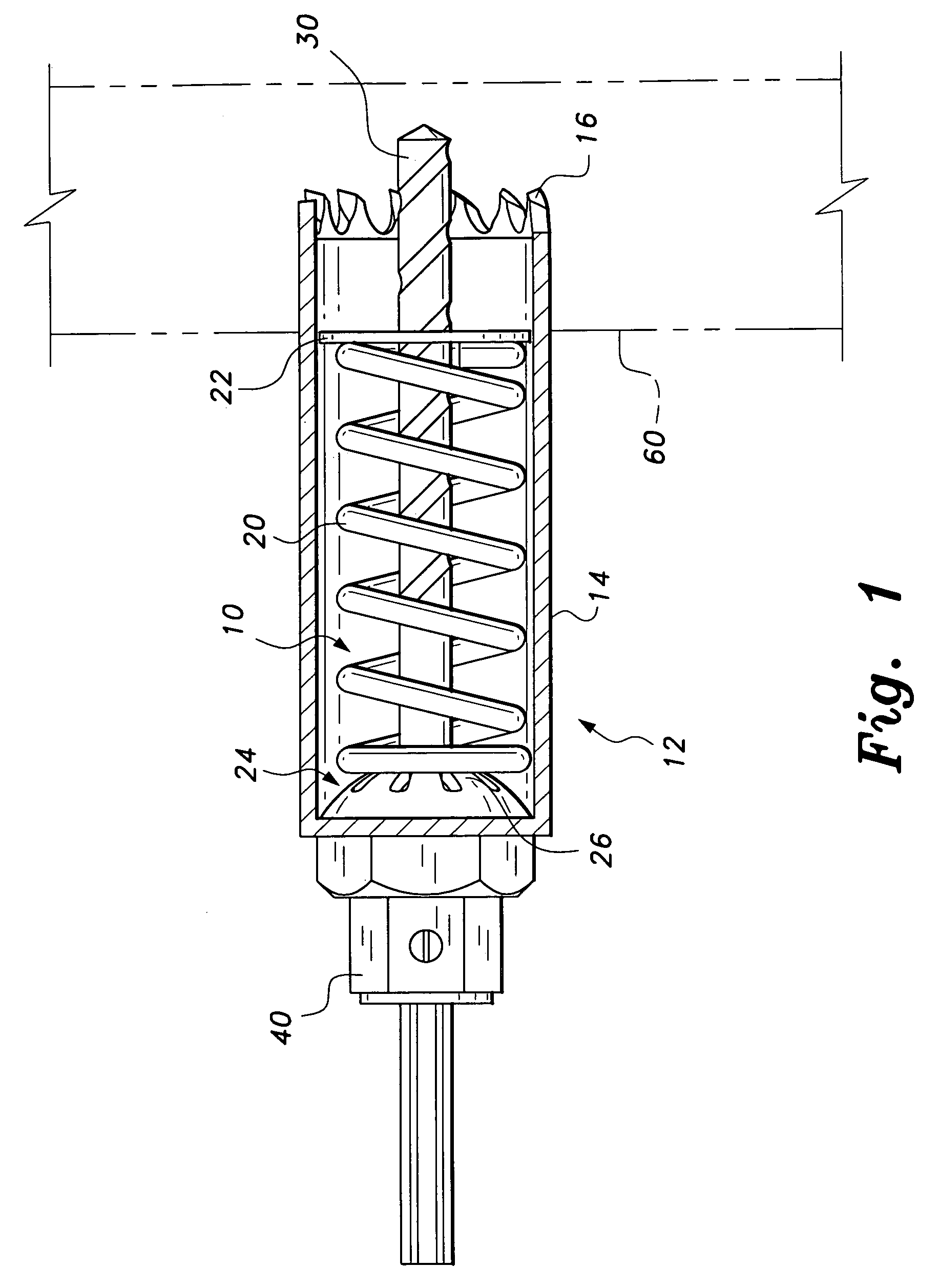

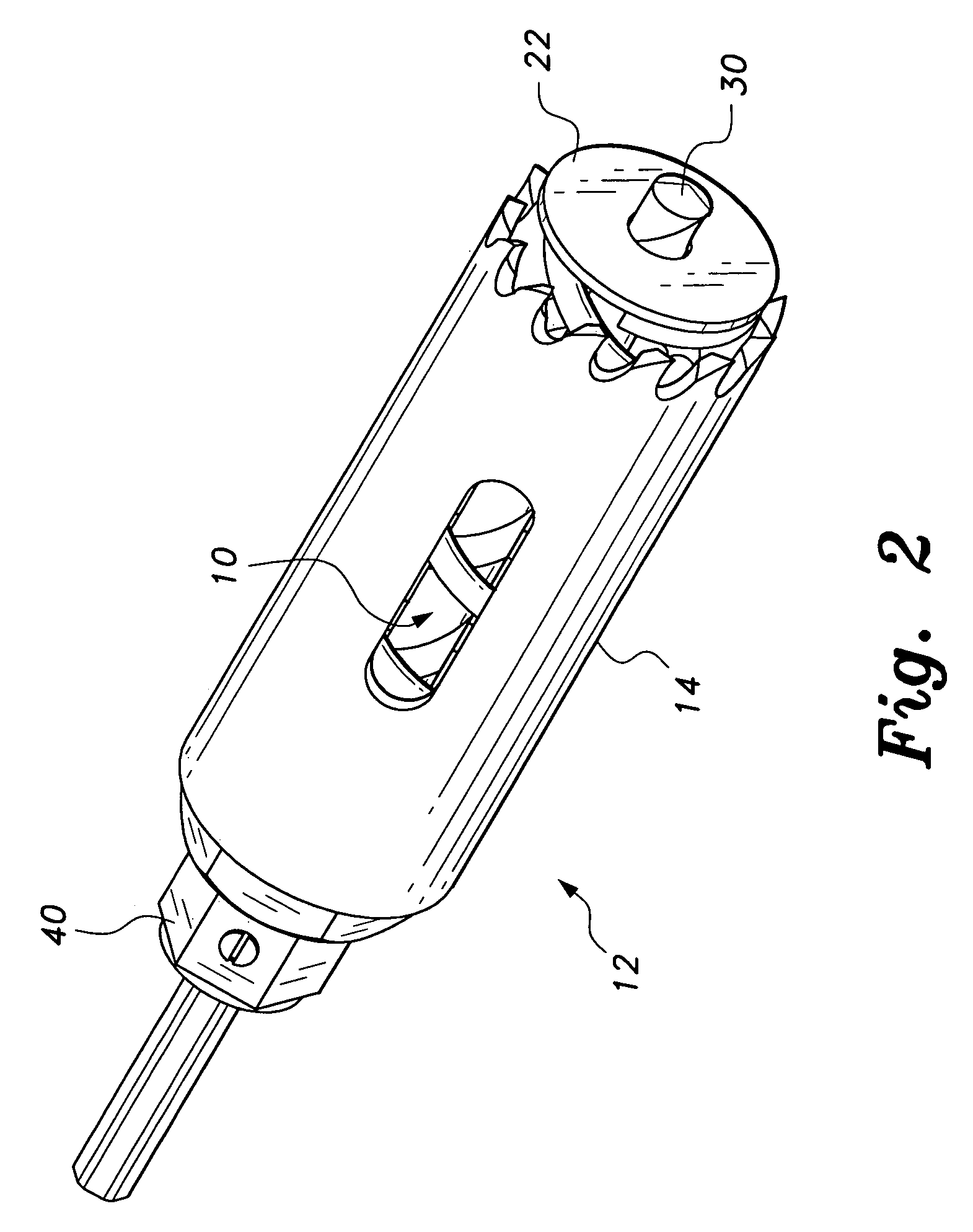

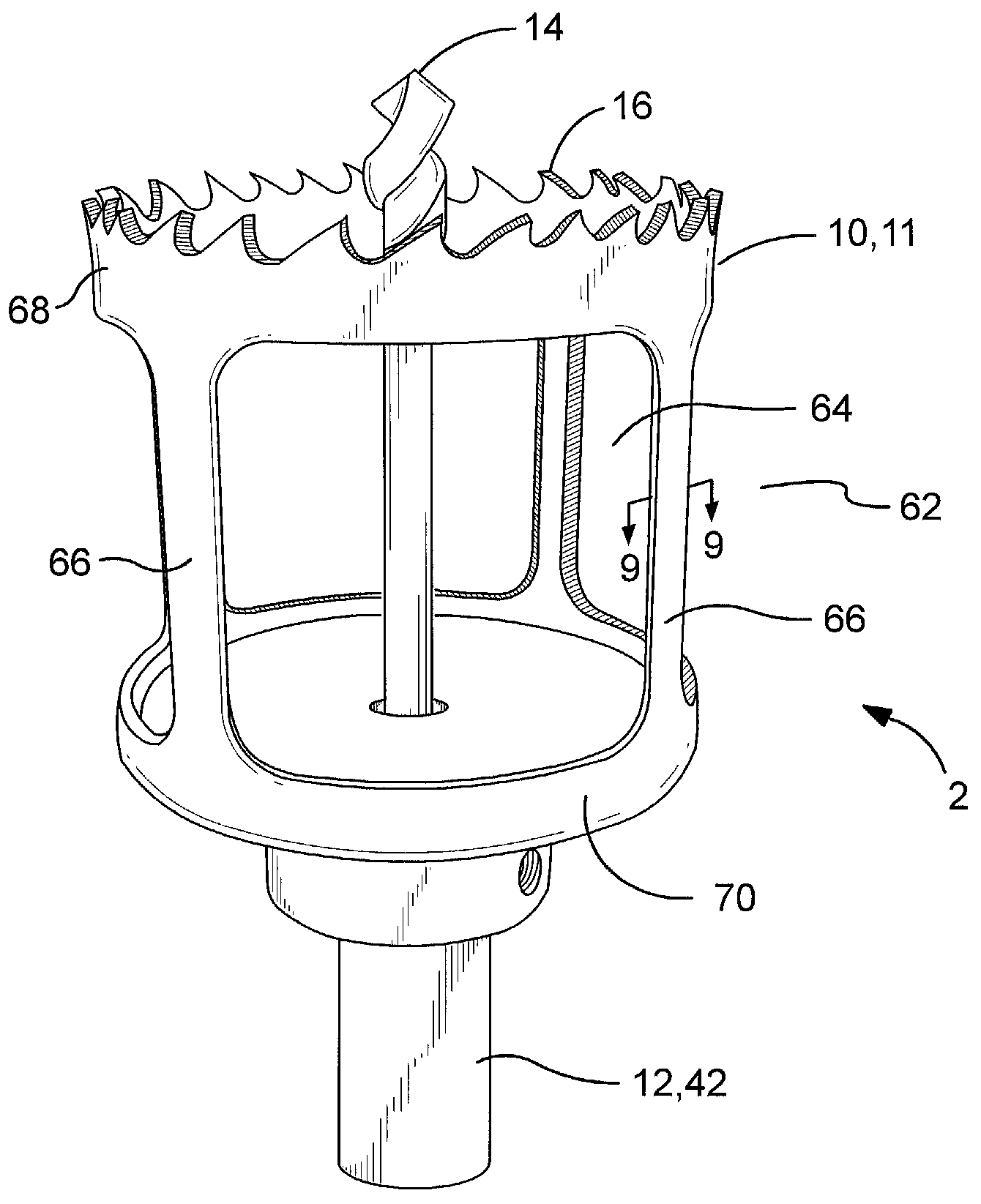

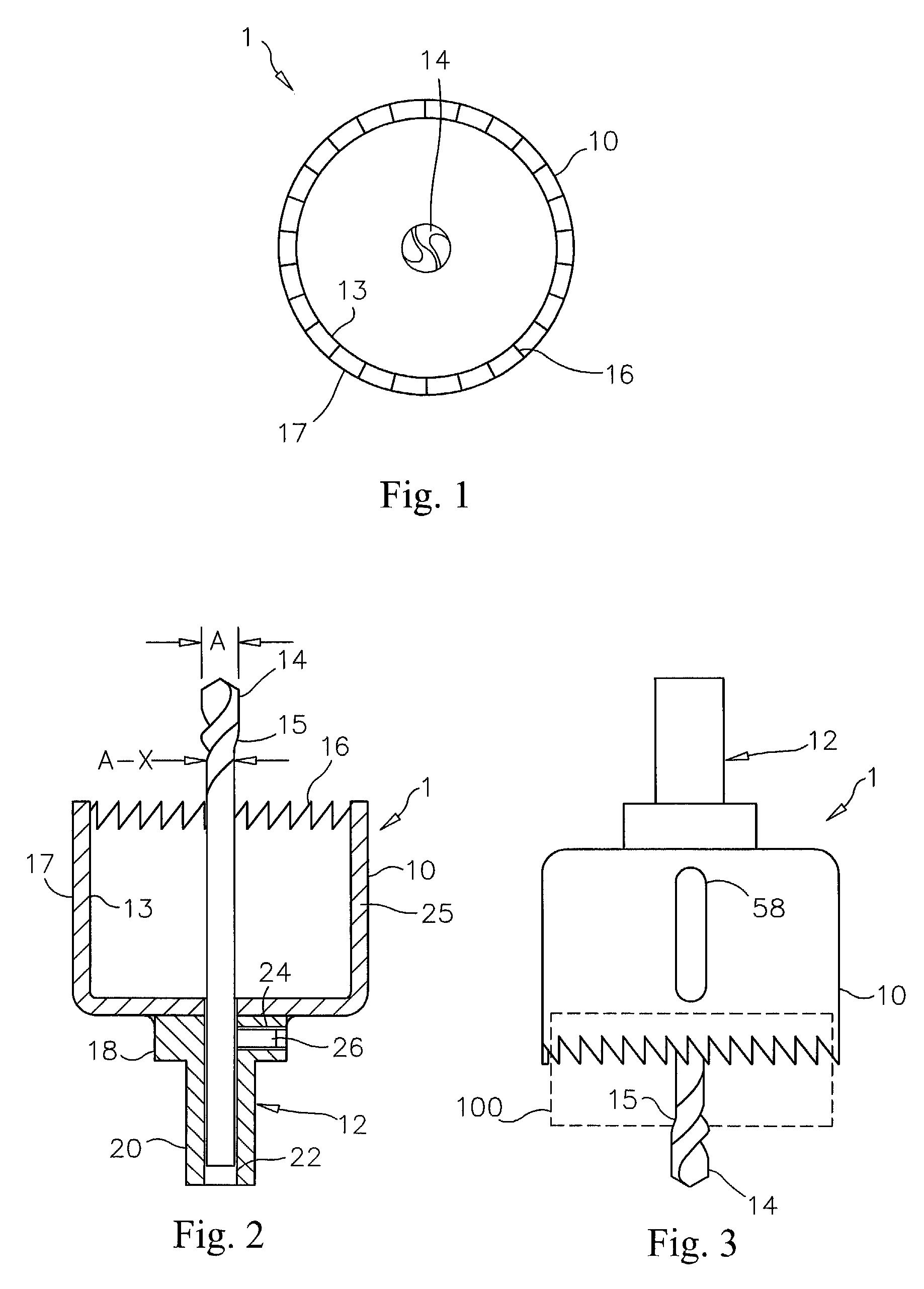

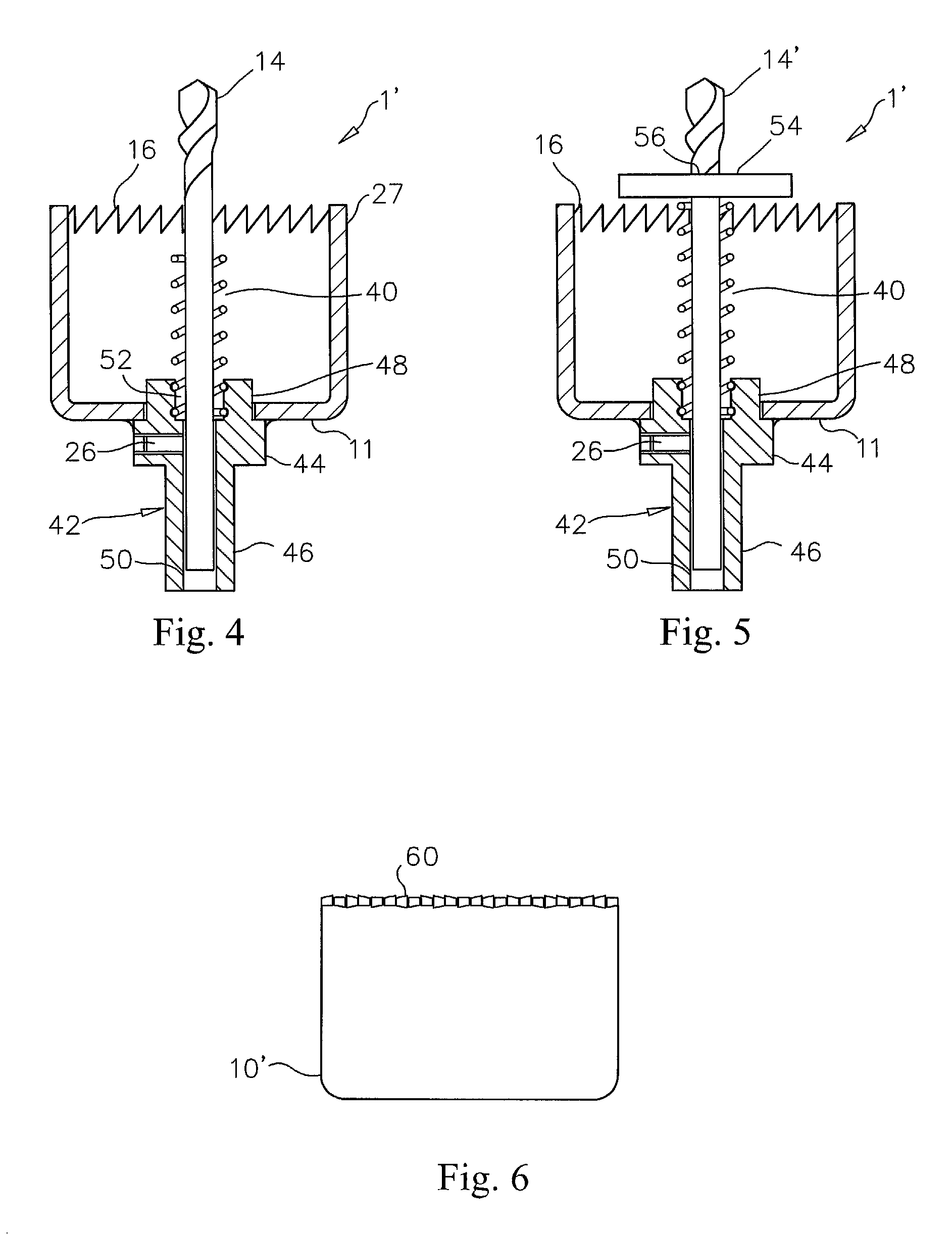

Hole saw and slug remover

ActiveUS20100086372A1Readily apparentThread cutting feeding devicesTransportation and packagingHole sawEngineering

A hole saw with slug remover including a top cylindrical housing; a bottom cylindrical housing attached to the top cylindrical housing, the bottom cylindrical housing having teeth for cutting; a pilot drill extending through the top cylindrical housing and bottom cylindrical housing; a drive screw rotatably affixed to the top cylindrical housing, the drive screw having a threaded exterior; and an ejection plunger engaging the threaded exterior of the drive screw wherein the ejection plunger is forced downward to eject a slug when the drive screw rotates counter-clockwise and is forced upward when the drive screw rotates clockwise.

Owner:WERNER TRAVIS E

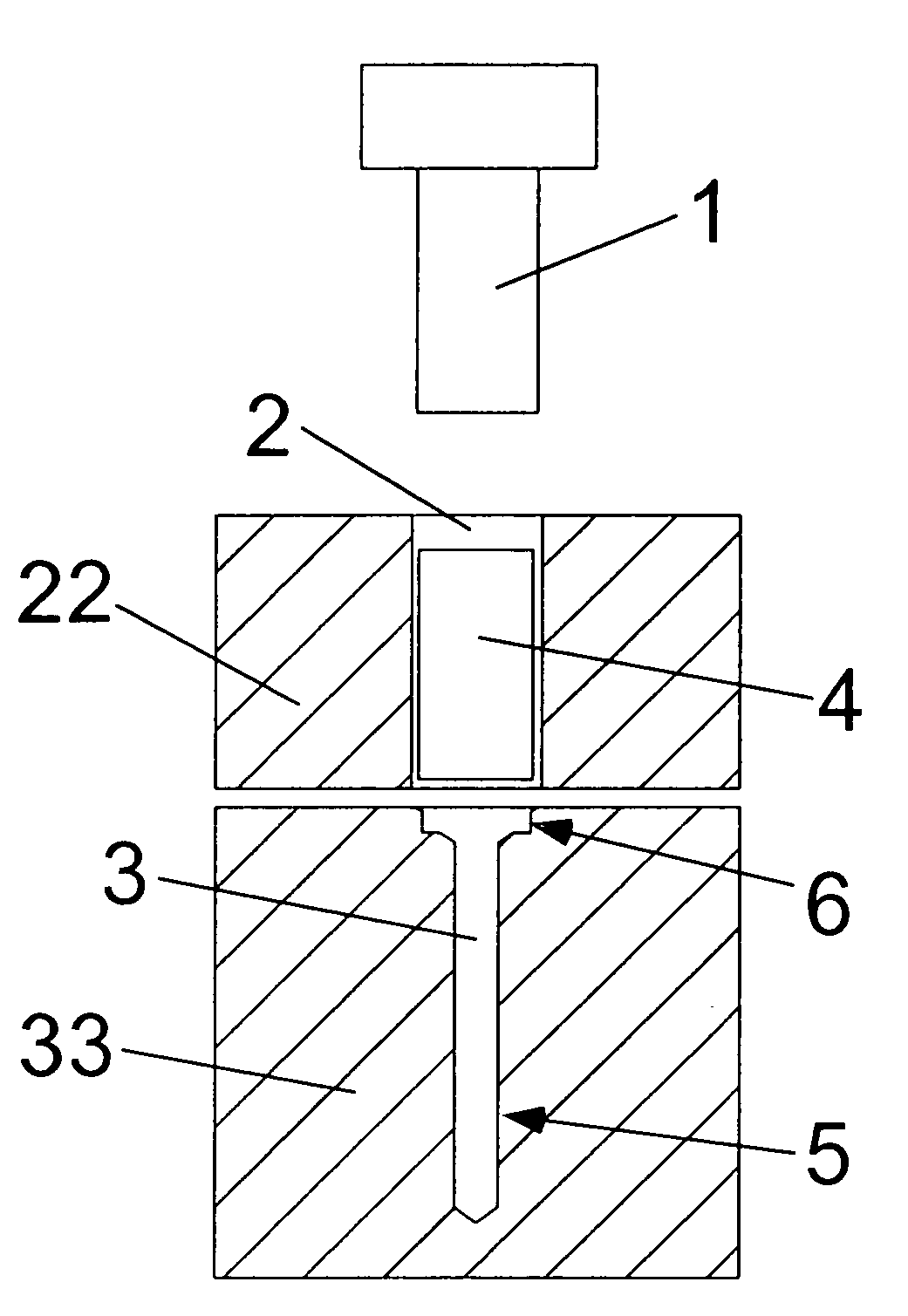

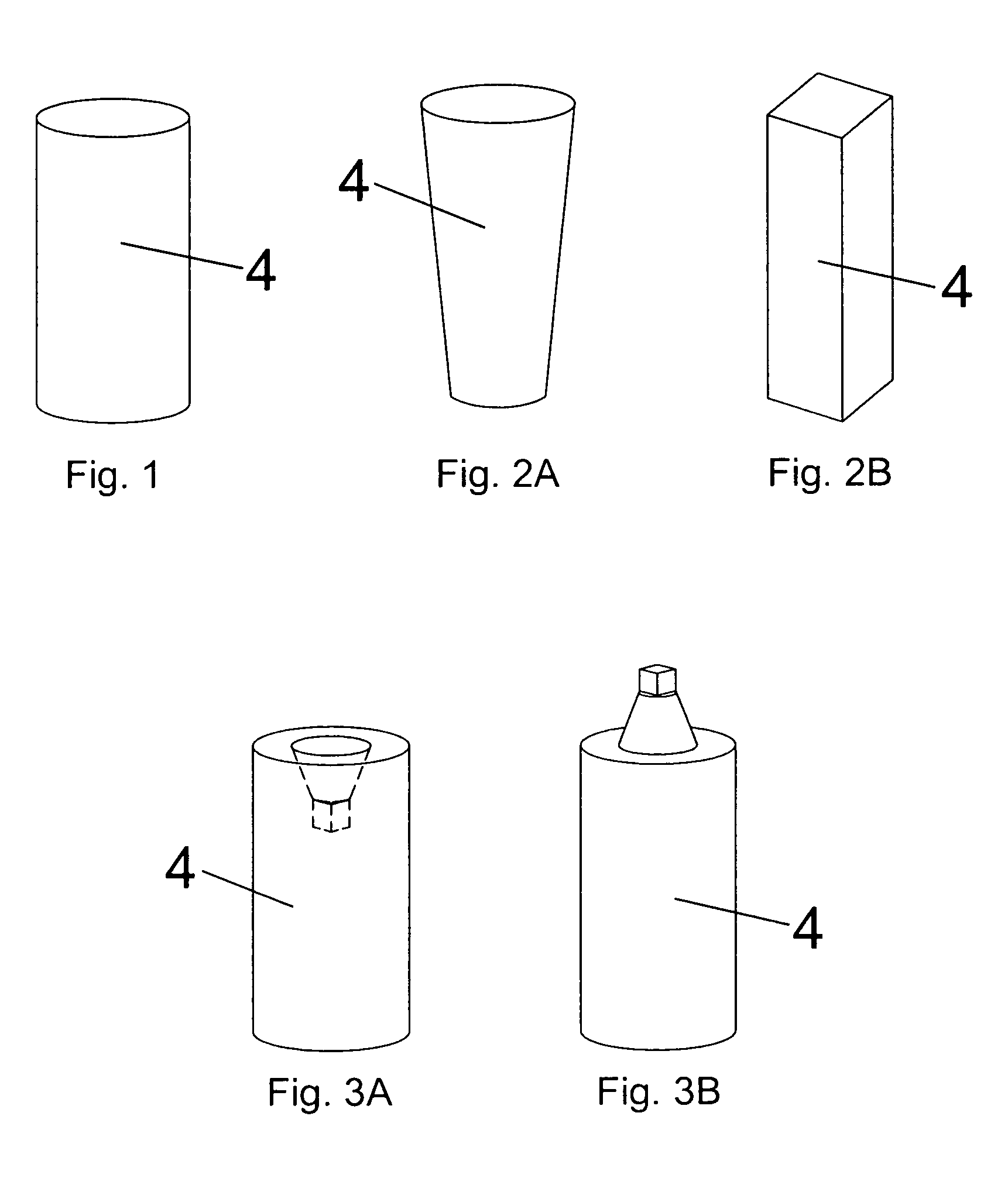

Oriented polymer implantable device and process for making same

ActiveUS7378144B2High strengthHigh degreeSuture equipmentsInternal osteosythesisPolymer scienceUltimate tensile strength

A device is formed by the process into a bone screw or fastener, wherein the head has a degree of polymer alignment and strength, and wherein the shank has a higher degree of polymer alignment and strength. In practice of the present invention, the polymer slug is pressed into the die cavity by the actuation of ram press, causing the slug to conform to the die cavity. Through this process, the polymer molecular orientation is aligned to different degrees, in different zones of the device.

Owner:DSM IP ASSETS BV

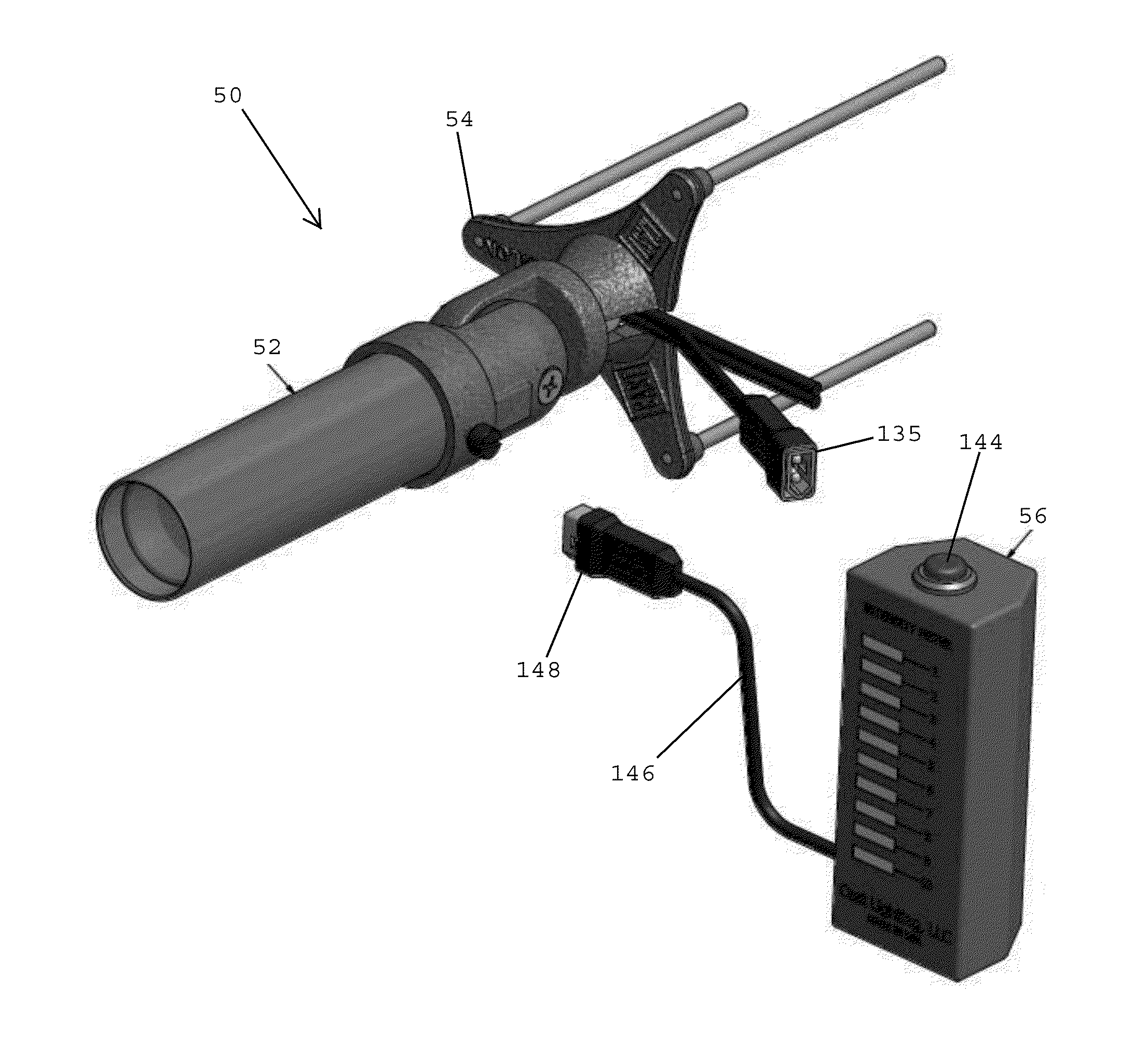

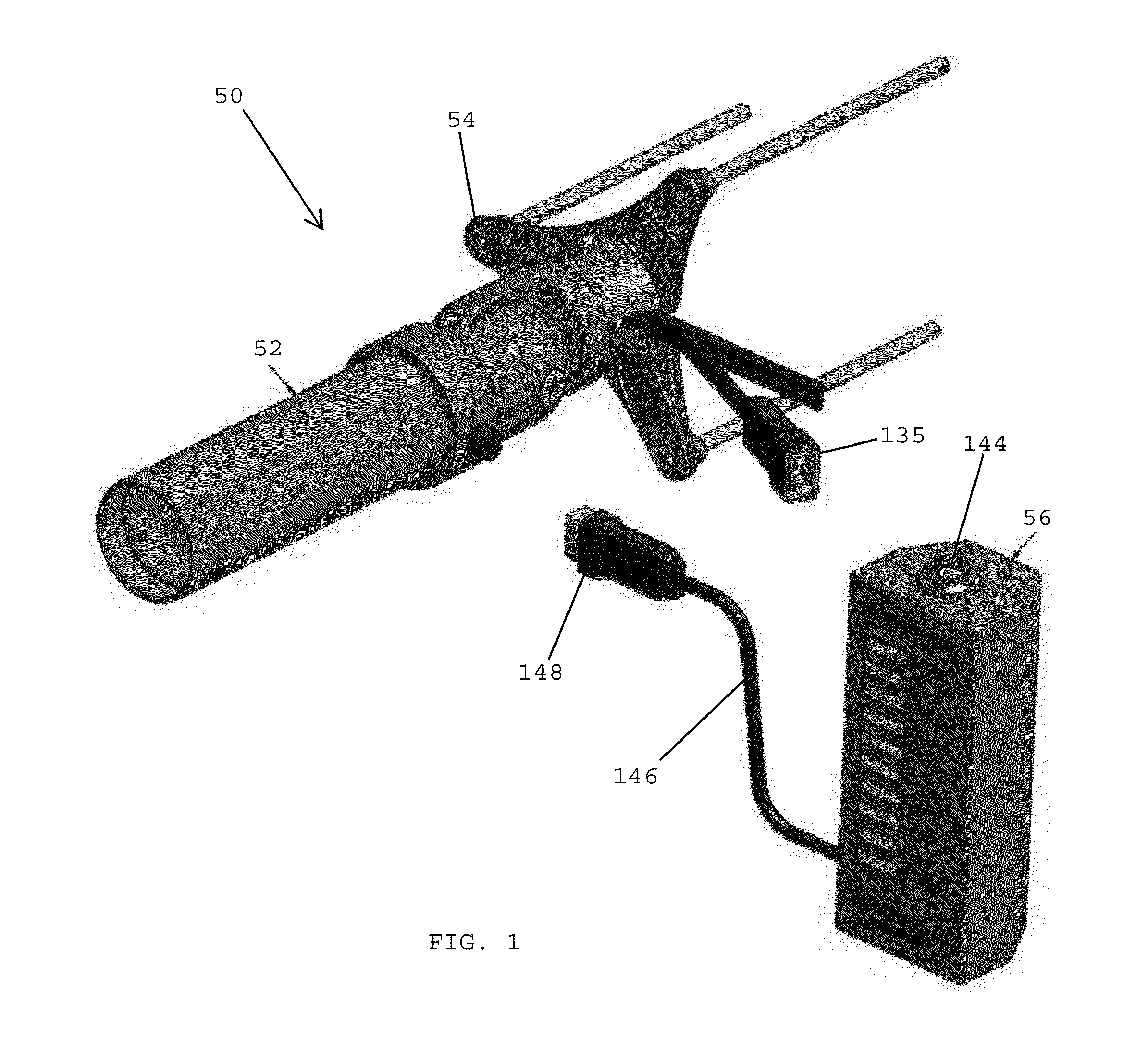

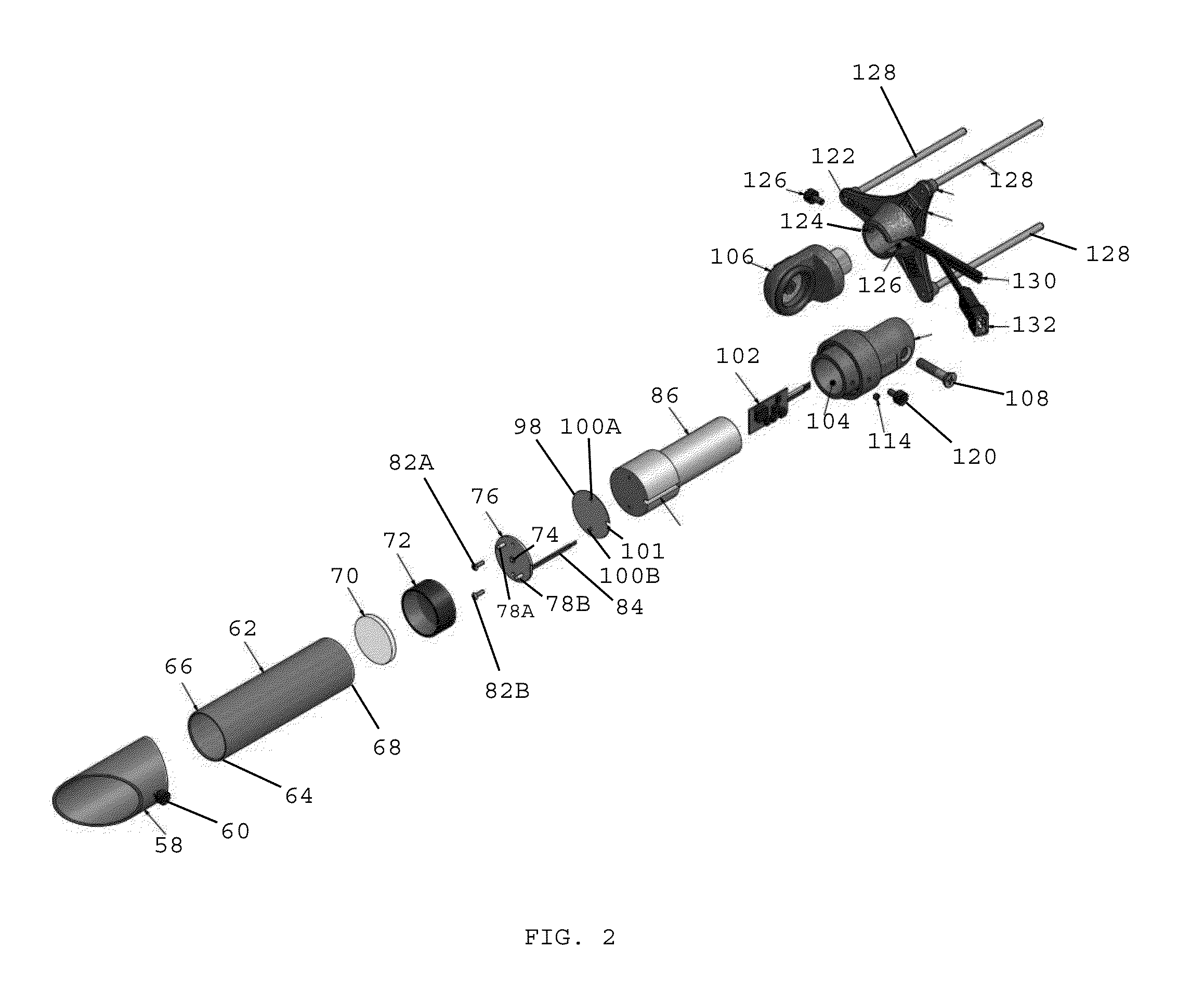

LED directional lighting system with light intensity controller

ActiveUS20140119022A1Provide flexibilityNot to damageMechanical apparatusPoint-like light sourceElectricityEngineering

A landscape lighting system includes a light engine slug, an LED secured to a leading end of the light engine slug, an LED driver for controlling operation of the LED, wherein the LED driver is spaced from the LED, and conductive wires electrically interconnecting the LED driver and the LED. The lighting system includes a plurality of interchangeable light diverting elements adapted to be secured over the LED. Each of the light diverting elements has a unique light diversion angle associated therewith, whereby only one of the light diverting elements is secured over the LED at any one time. The landscape lighting system includes a light intensity controller in communication with the LED driver. The light intensity controller includes a control element that enables an operator to selectively increase and decrease the intensity of the light generated by the LED.

Owner:MIND HEAD

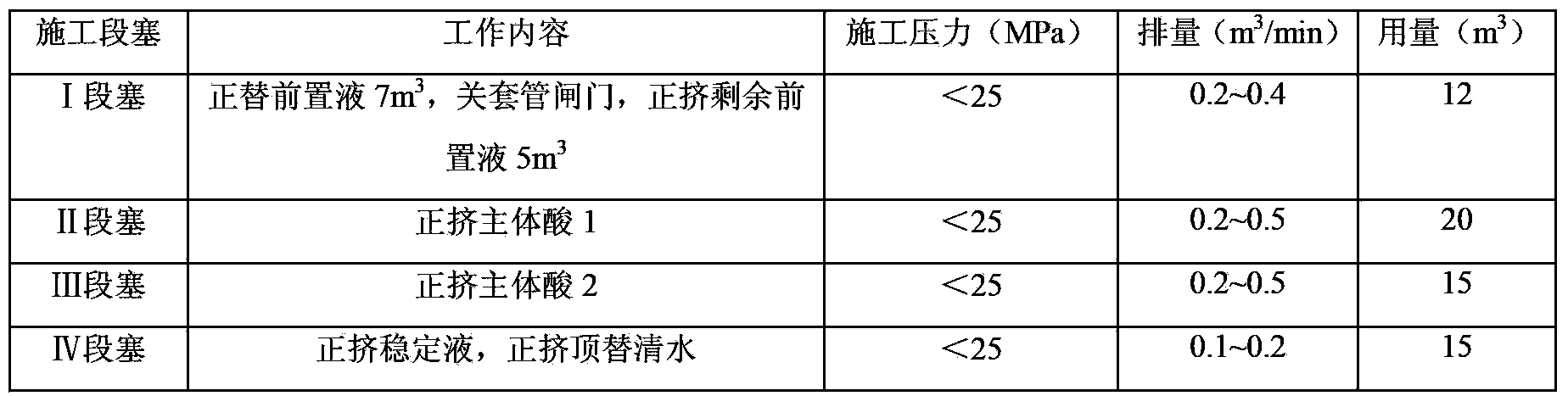

Deep blockage removal and injection increase method for water injection well of medium-and-high-permeability sandstone reservoir

InactiveCN104295275AImprove injection effectIncrease validity period of boosterCleaning apparatusFluid removalEffective dateSewage

The invention provides a deep blockage removal and injection increase method for a water injection well of a medium-and-high-permeability sandstone reservoir. The method mainly solves the problems of oil pollution, deep blockage removal of a ground layer and the like of a sewage injection well, which can not be solved in the existing conventional acidification method. In the method, the slug type injection technology of "washing-clearing-blockage removing-stabilizing" is adopted; and the injection increase effect can be improved and the injection increase effective date can be prolonged. The method comprises the following steps: during construction, firstly, the well is backwashed at high displacement, and impurities near a well bore and a bore hole are washed; secondly, organic blockages near an oil layer are washed; then, organic and inorganic blockages in the areas near the well and the deep part of the oil layer are removed in the mode of multistage injection and multiple acid liquid systems, so that the seepage capability is improved; and finally, stabilizing treatment is adopted for prolonging the injection increase effective date. Through the adoption of the slug type injection technology, blockage damage is removed in batches, and substrate treatment, scale prevention treatment and scale inhibition treatment are performed so that the injection increase effect is improved, the injection increase effective date is prolonged and a better blockage removal effect is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hole saw system with improved slug removability

InactiveUS8052356B2Reduce weightEasy to disassembleThread cutting feeding devicesThread cutting machinesHole sawMechanical engineering

There is provided a hole saw system comprising a hole saw including a bottom portion and a body portion; a mandrel, including apparatus for receiving the hole saw; wherein the hole saw includes a plurality of slot pairs, the slot pairs being offset from each other on the body portion allowing a tool to be inserted into one of the slot pairs for removal of a slug.

Owner:TEAM FAIR HLDG

Method and apparatus for preventing slug flow in pipelines

InactiveUS7395864B2Risk minimizationPrevent reduce buildFluid removalUnderwater drillingEngineeringSlug

Disclosed is a method and system for controlling the formation of liquid or gas slugs along a pipeline. In embodiments, an injection unit injects a liquid surface tension reducing agent, such as a foamant, into the pipeline upstream of the high point. A control unit can be used to control the injection unit. In certain arrangements, the control unit adjusts the injection of the agent based on measured parameters of interest. In embodiments where the control unit utilizes temperature measurements, one or more temperature sensors are positioned along the pipeline. The control unit utilizes the temperature measurements to determine whether a predetermined condition exists or a liquid or gas slug is present.

Owner:BAKER HUGHES HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[real-time monitoring and control of reservoir fluid sample capture] [real-time monitoring and control of reservoir fluid sample capture]](https://images-eureka.patsnap.com/patent_img/8c758555-6731-4fc4-9b44-e969453d0ecb/US20050150287A1-20050714-D00000.png)

![[real-time monitoring and control of reservoir fluid sample capture] [real-time monitoring and control of reservoir fluid sample capture]](https://images-eureka.patsnap.com/patent_img/8c758555-6731-4fc4-9b44-e969453d0ecb/US20050150287A1-20050714-D00001.png)

![[real-time monitoring and control of reservoir fluid sample capture] [real-time monitoring and control of reservoir fluid sample capture]](https://images-eureka.patsnap.com/patent_img/8c758555-6731-4fc4-9b44-e969453d0ecb/US20050150287A1-20050714-D00002.png)