Patents

Literature

263results about How to "Improve injection effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

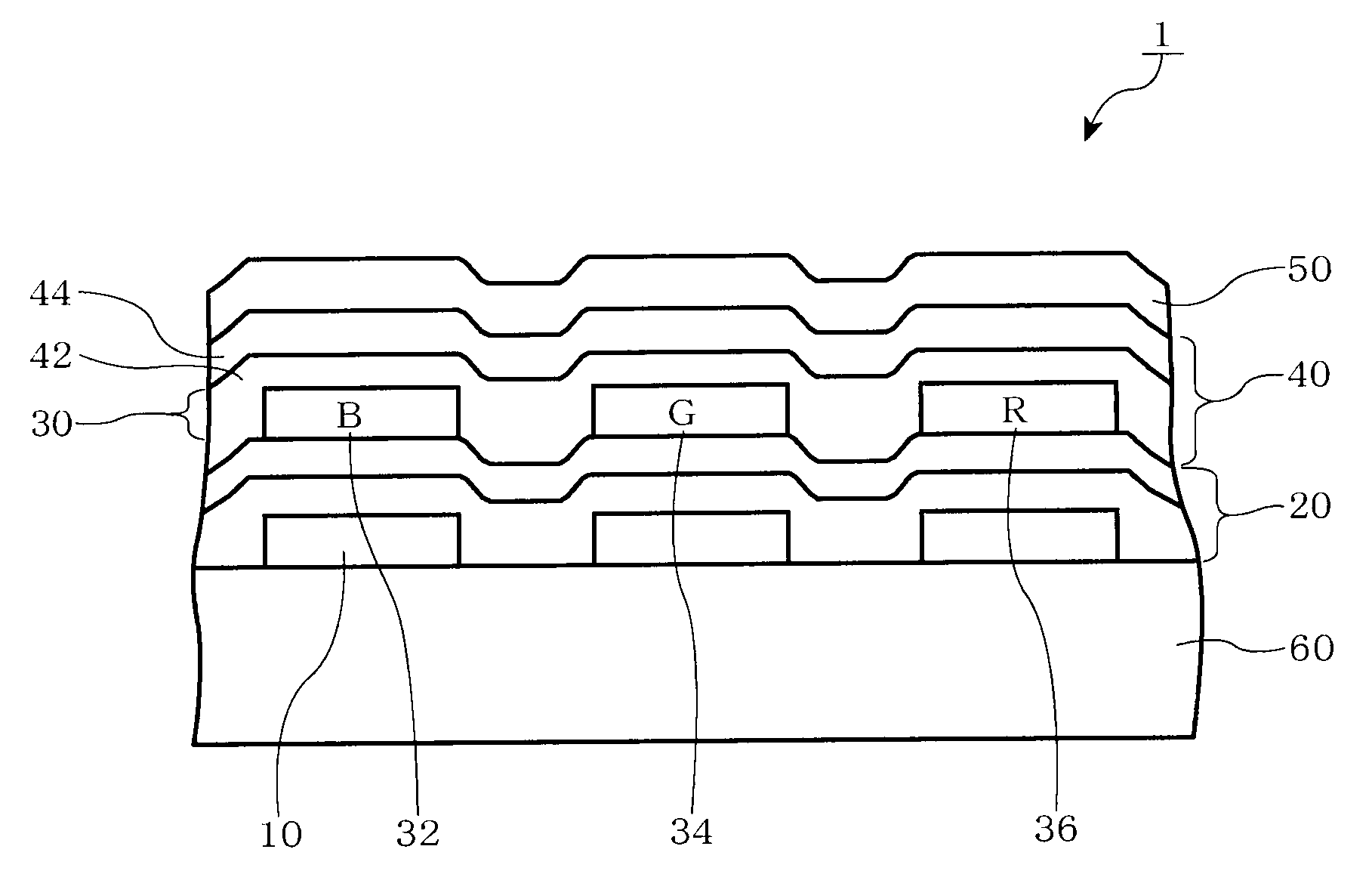

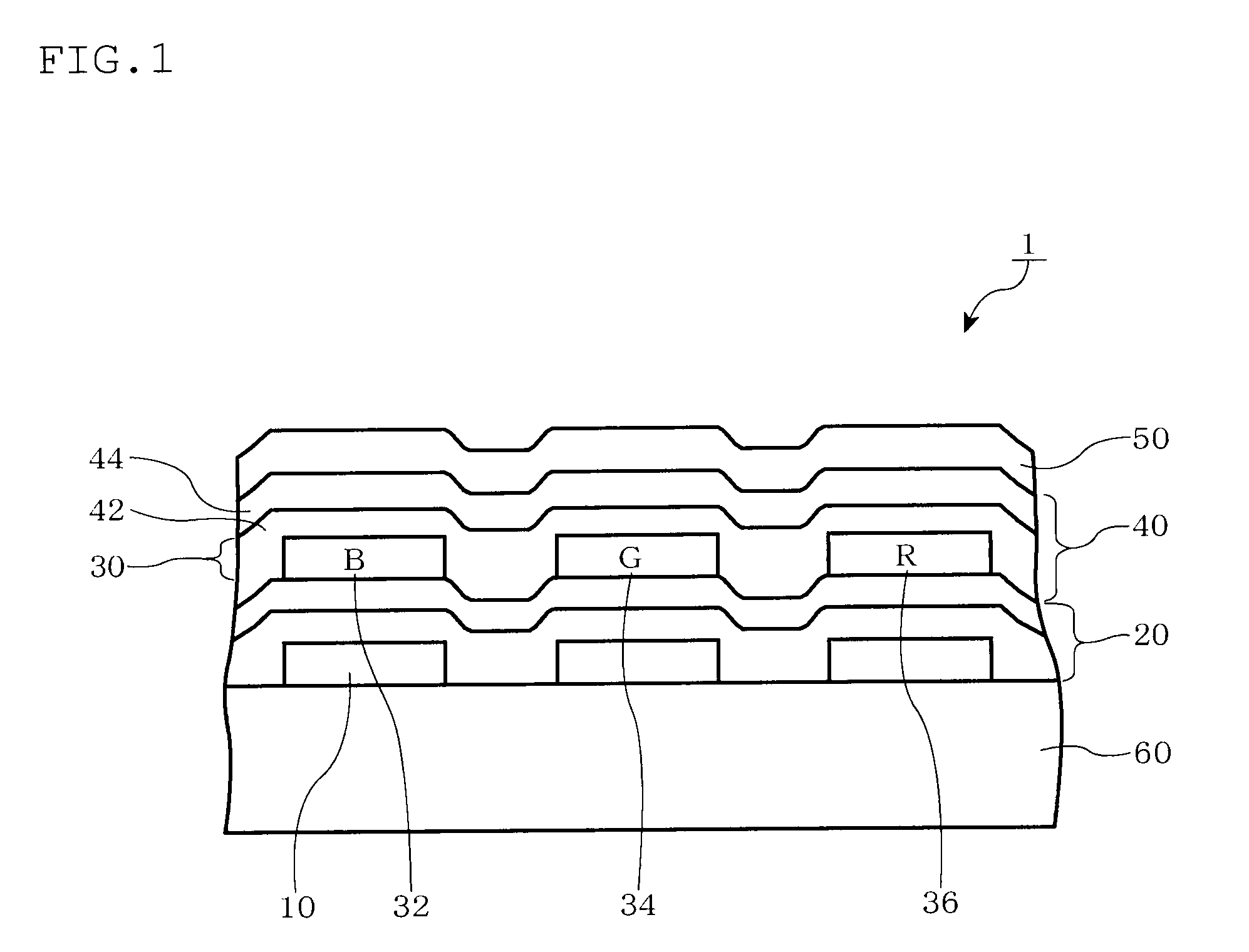

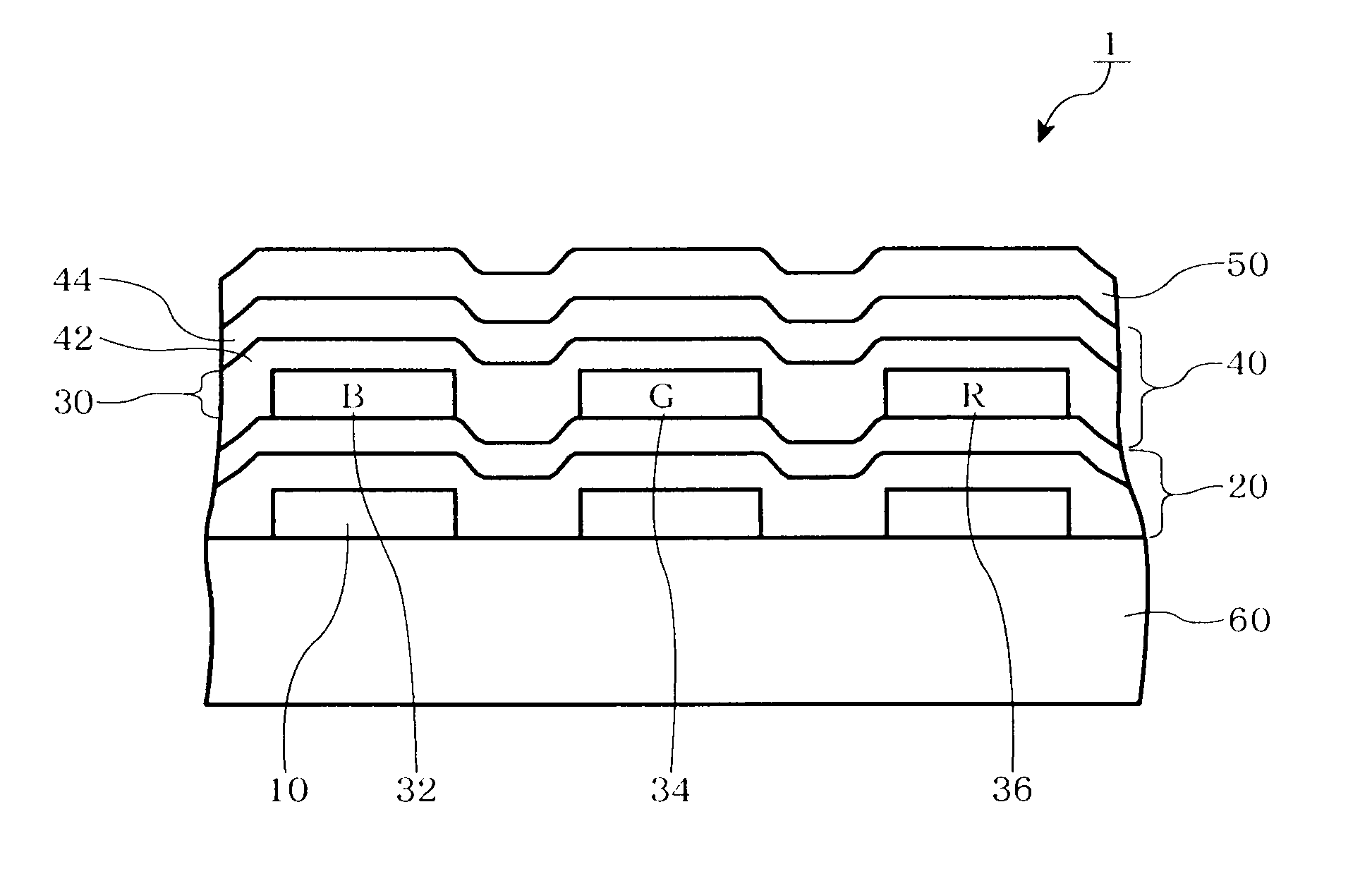

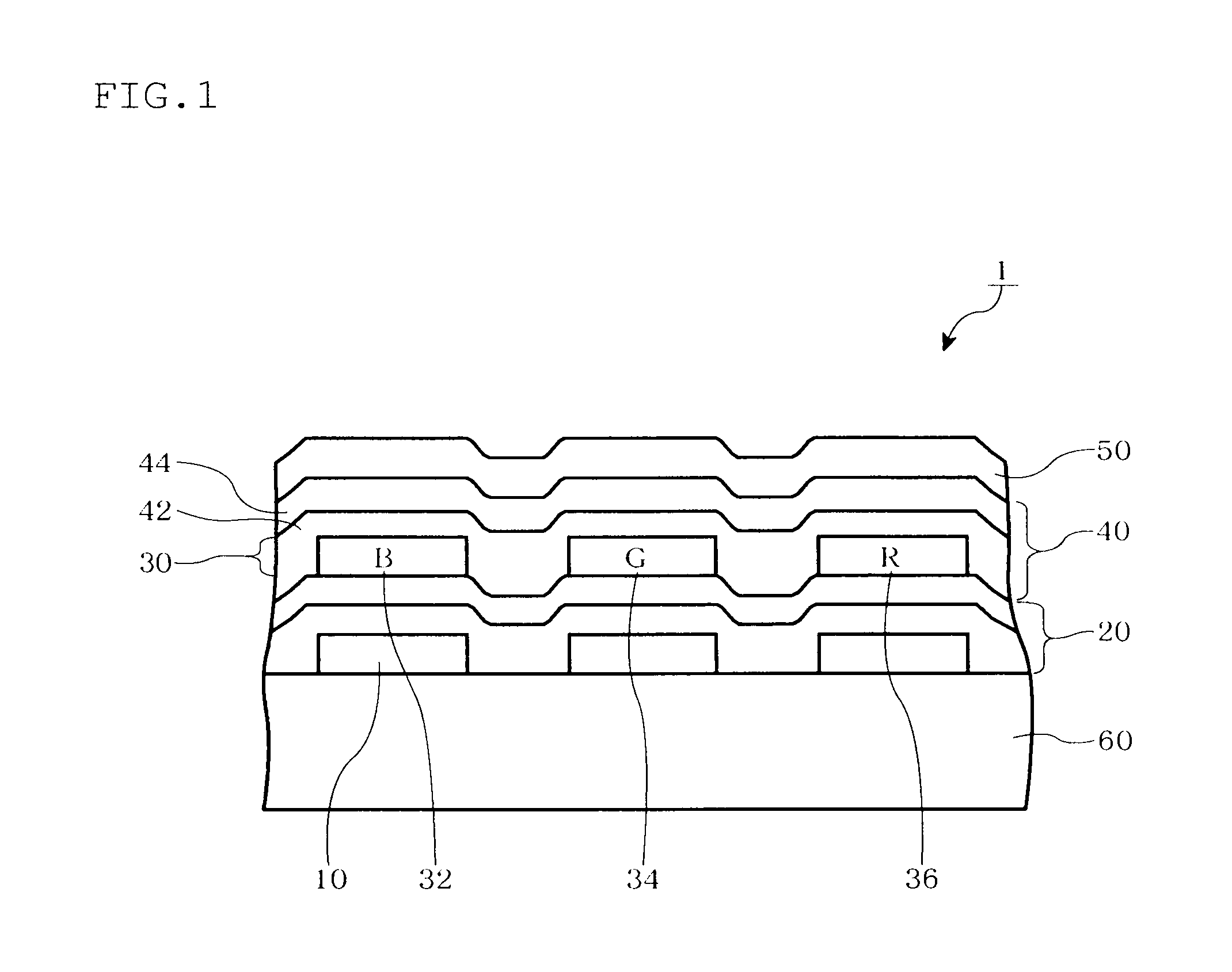

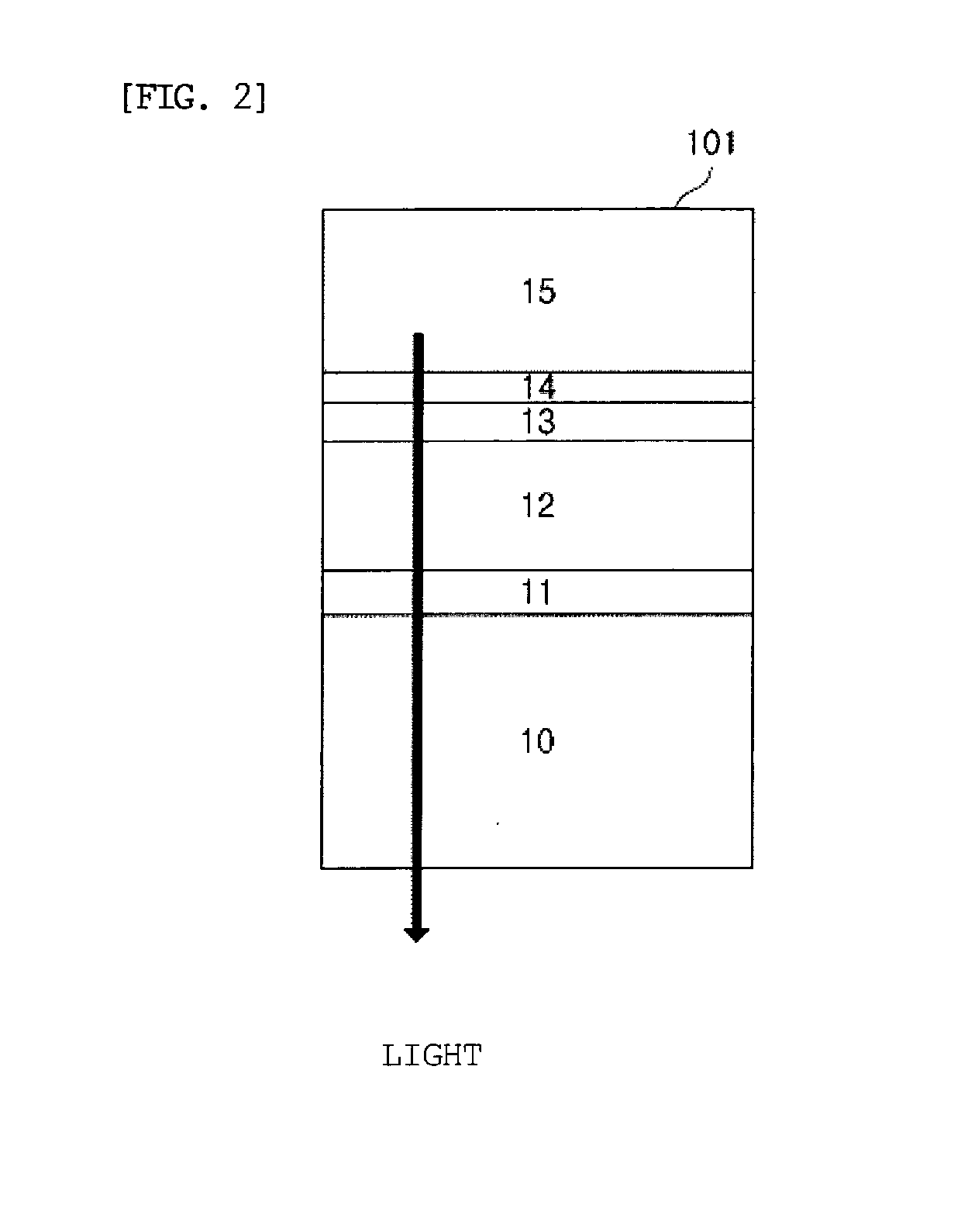

Organic electroluminescent device

InactiveUS20100314644A1Reduced luminous efficiencyImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingDopantElectronic transmission

An organic electroluminescence device including opposite anode and cathode, and a hole-transporting region, an emitting layer and an electron-transporting region in sequential order from the anode between the anode and the cathode, wherein the emitting layer is formed of a red emitting layer, a green emitting layer, and blue emitting layer; the blue emitting layer contains a host BH and a fluorescent dopant FBD; the triplet energy ETfbd of the fluorescent dopant FBD is larger than the triplet energy ETbh of the host BH; the green emitting layer contains a host GH and a phosphorescent dopant PGD; a common electron-transporting layer is provided adjacent to the red emitting layer, the green emitting layer and the blue emitting layer within the electron-transporting region; the triplet energy ETel of a material constituting the electron-transporting layer is larger than ETbh; and the difference between the affinity of the host GH and the affinity of the material constituting the electron-transporting layer is 0.4 eV or less.

Owner:IDEMITSU KOSAN CO LTD

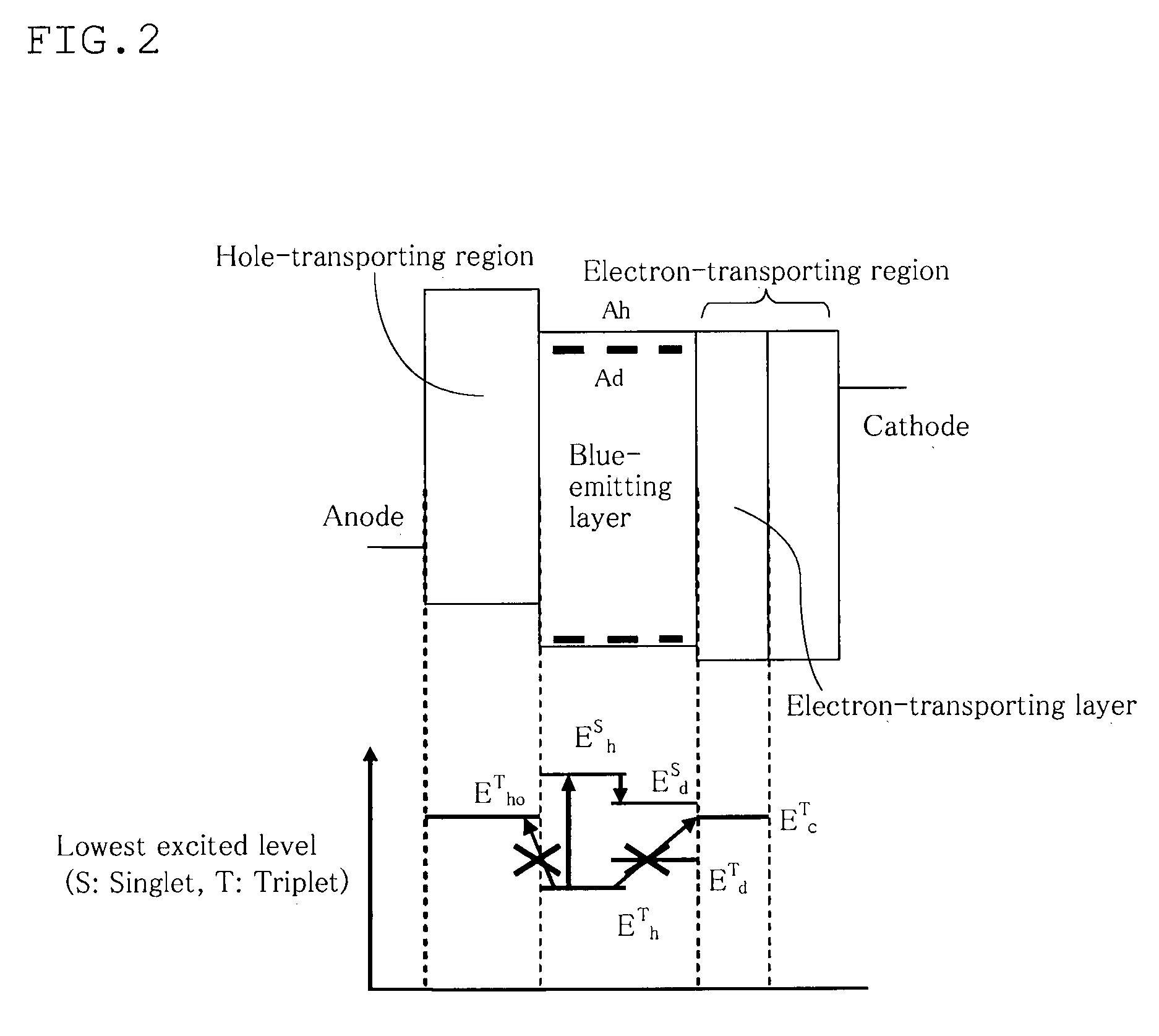

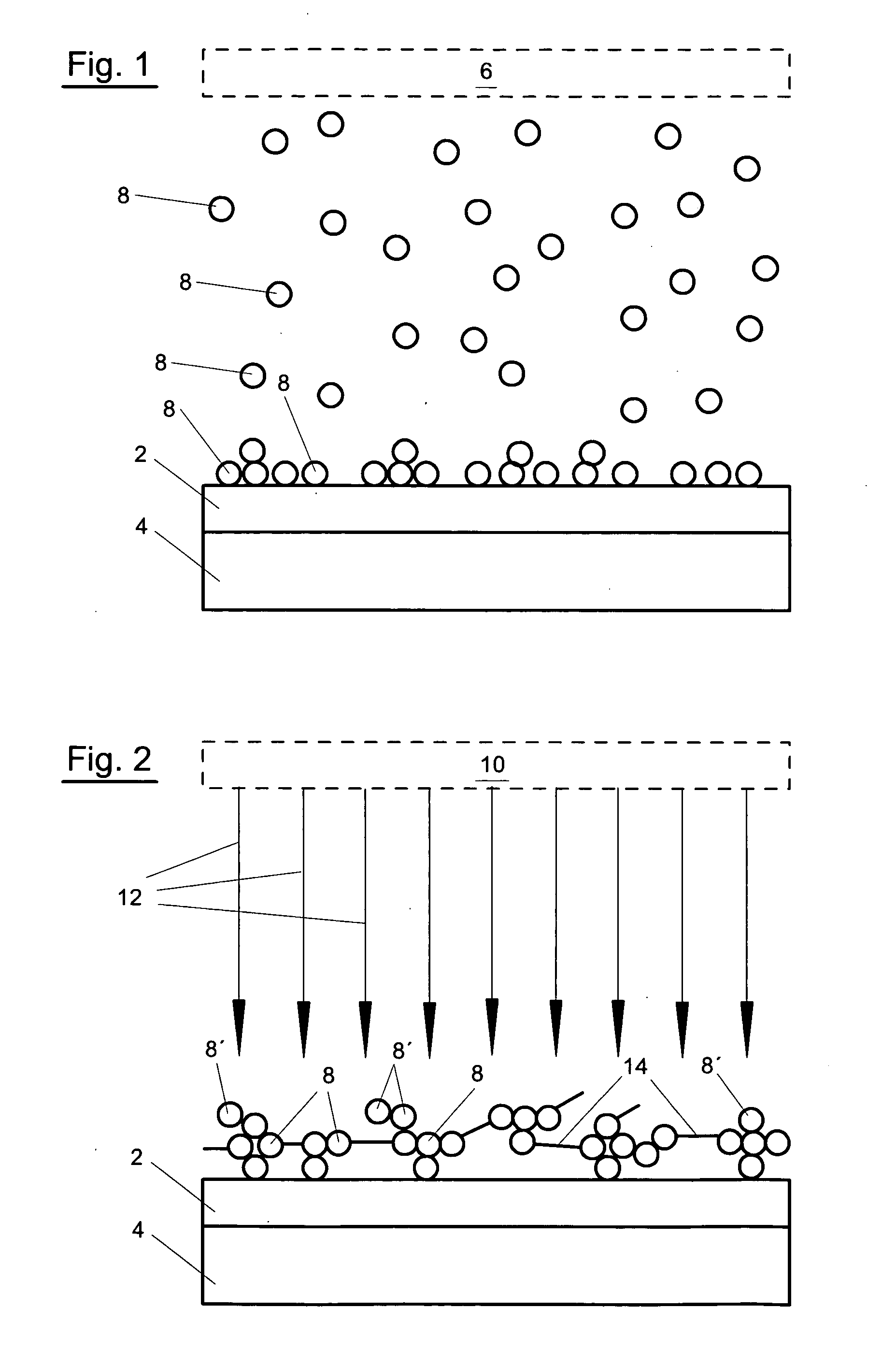

Electronic device having an electrode with enhanced injection properties

InactiveUS20060038170A1Low operating voltageHigh light emissionSolid-state devicesPretreated surfacesOLEDMolecular charge

The present invention relates to methods and apparatus for producing an electronic device, such as an organic light-emitting diode (OLED), having an electrode with enhanced injection properties. An example method according to the invention comprises the steps of providing an electrode, depositing a first layer of molecular charge transfer material on the electrode, and cross-linking the molecular charge transfer material. With the method according to the invention, an OLED with higher light efficiency, lower operating voltage, and longer lifetime can be produced. The present invention further relates to an electronic device having an electrode with enhanced injection properties.

Owner:IBM CORP

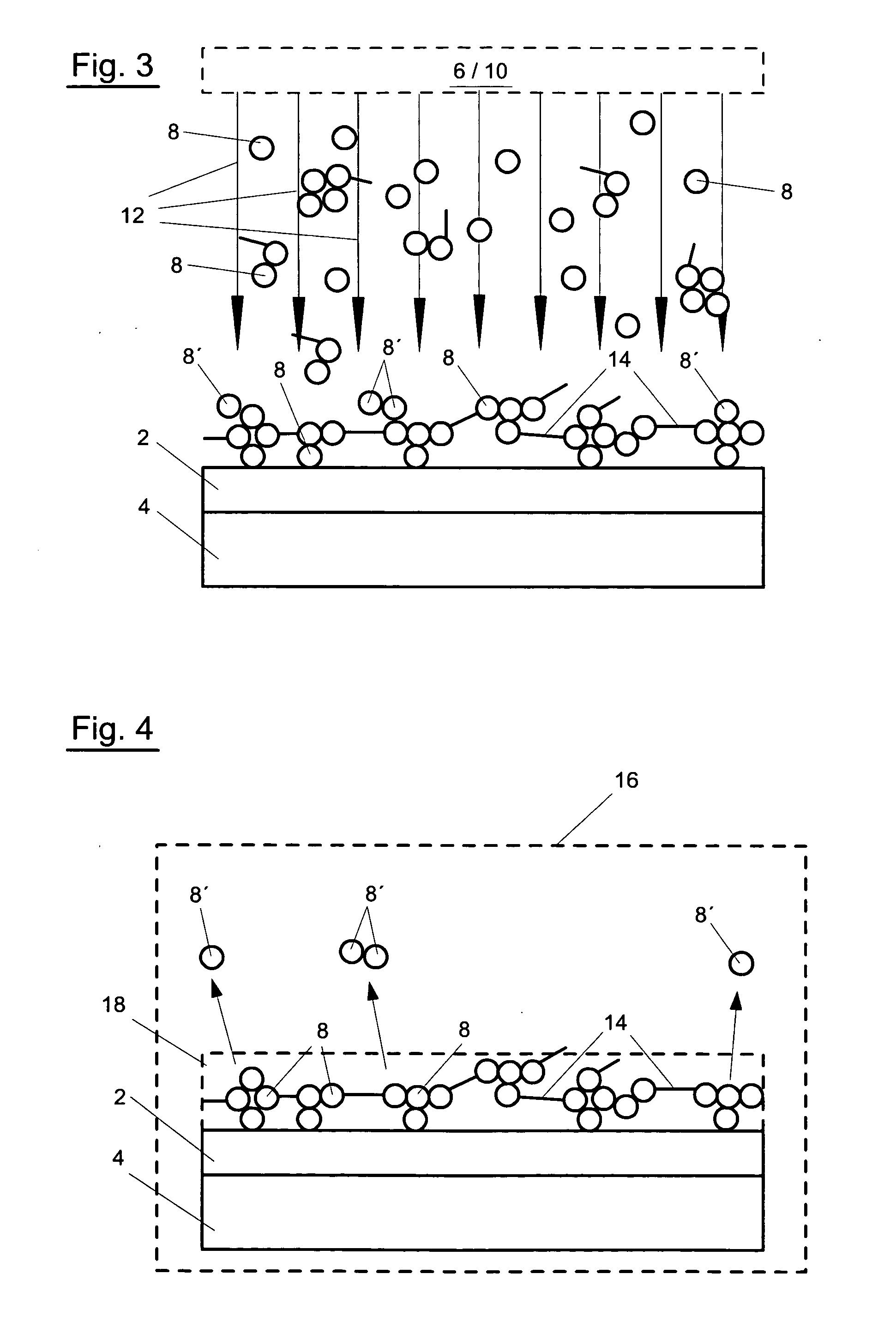

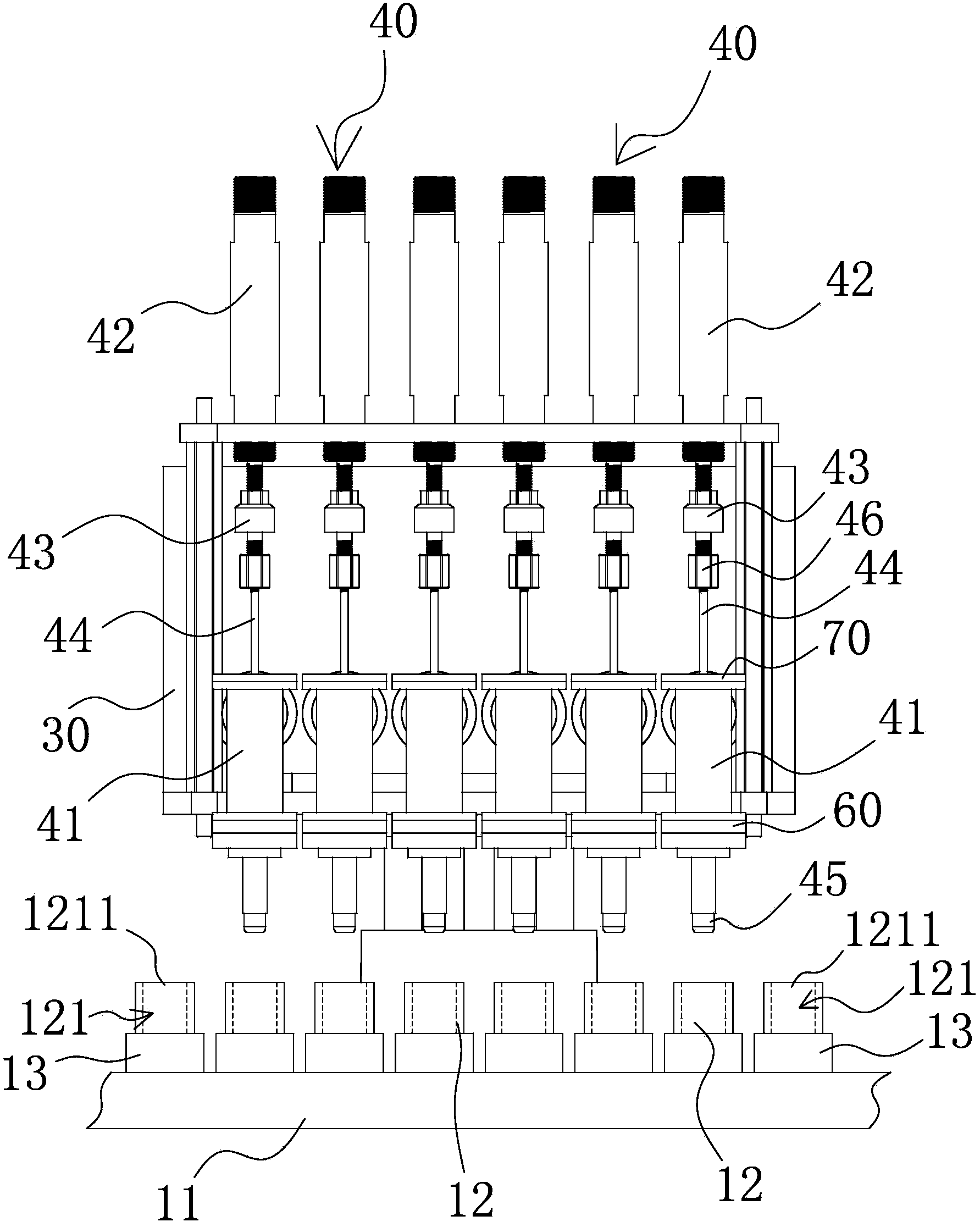

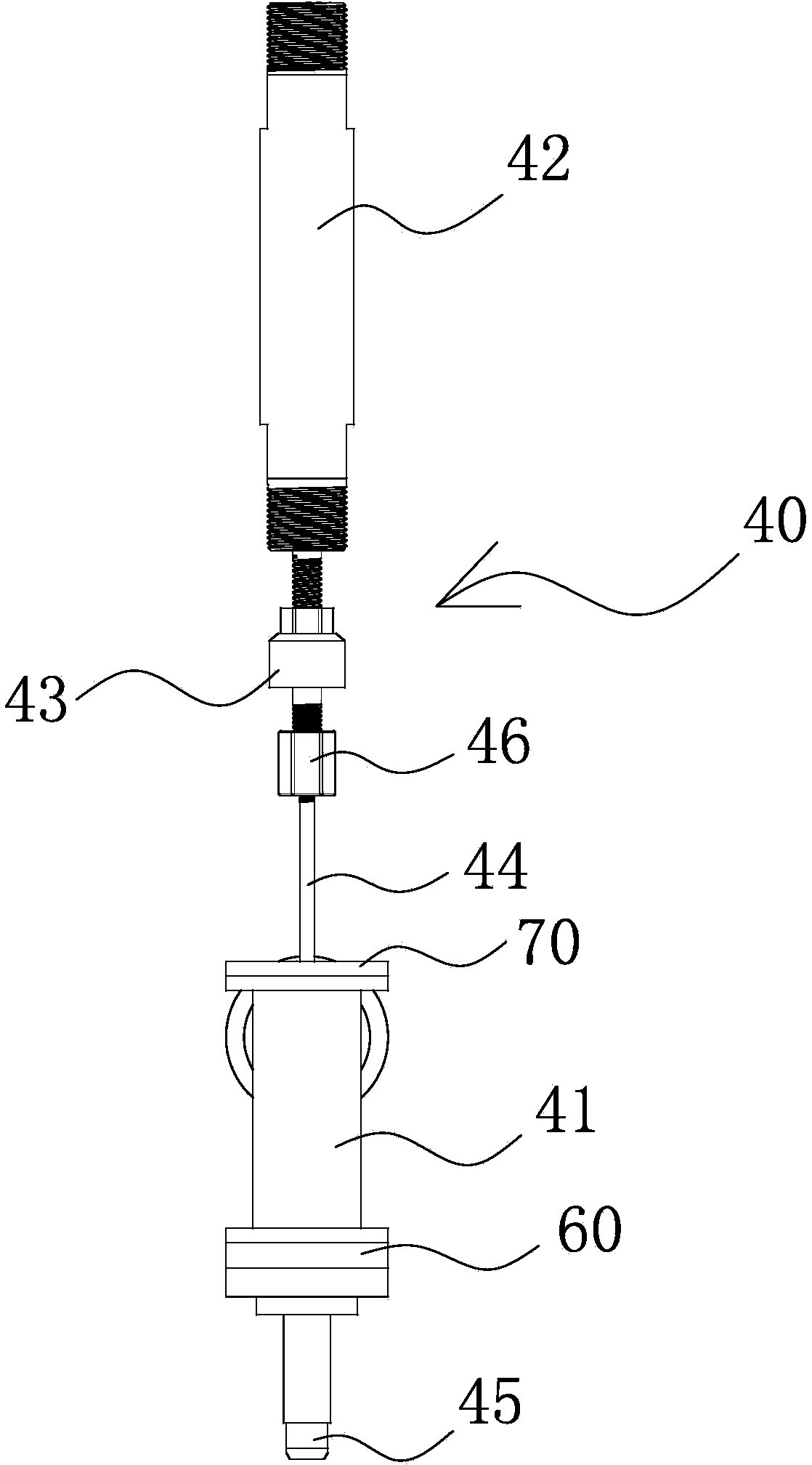

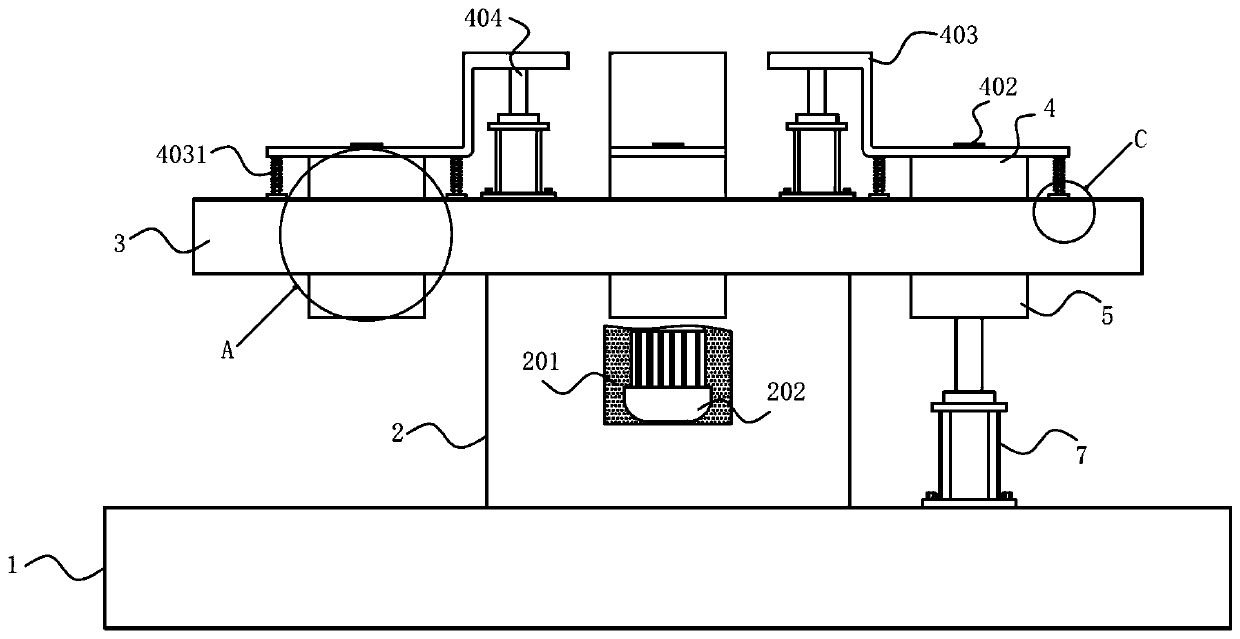

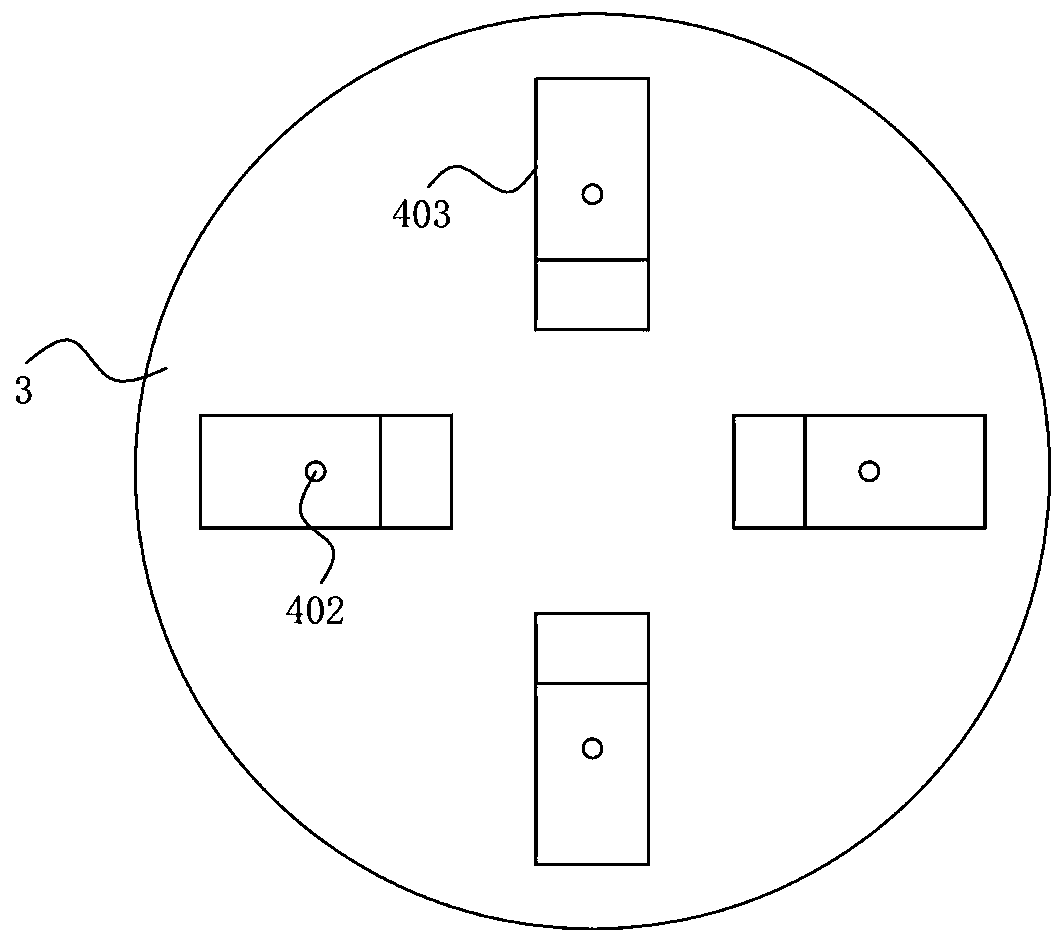

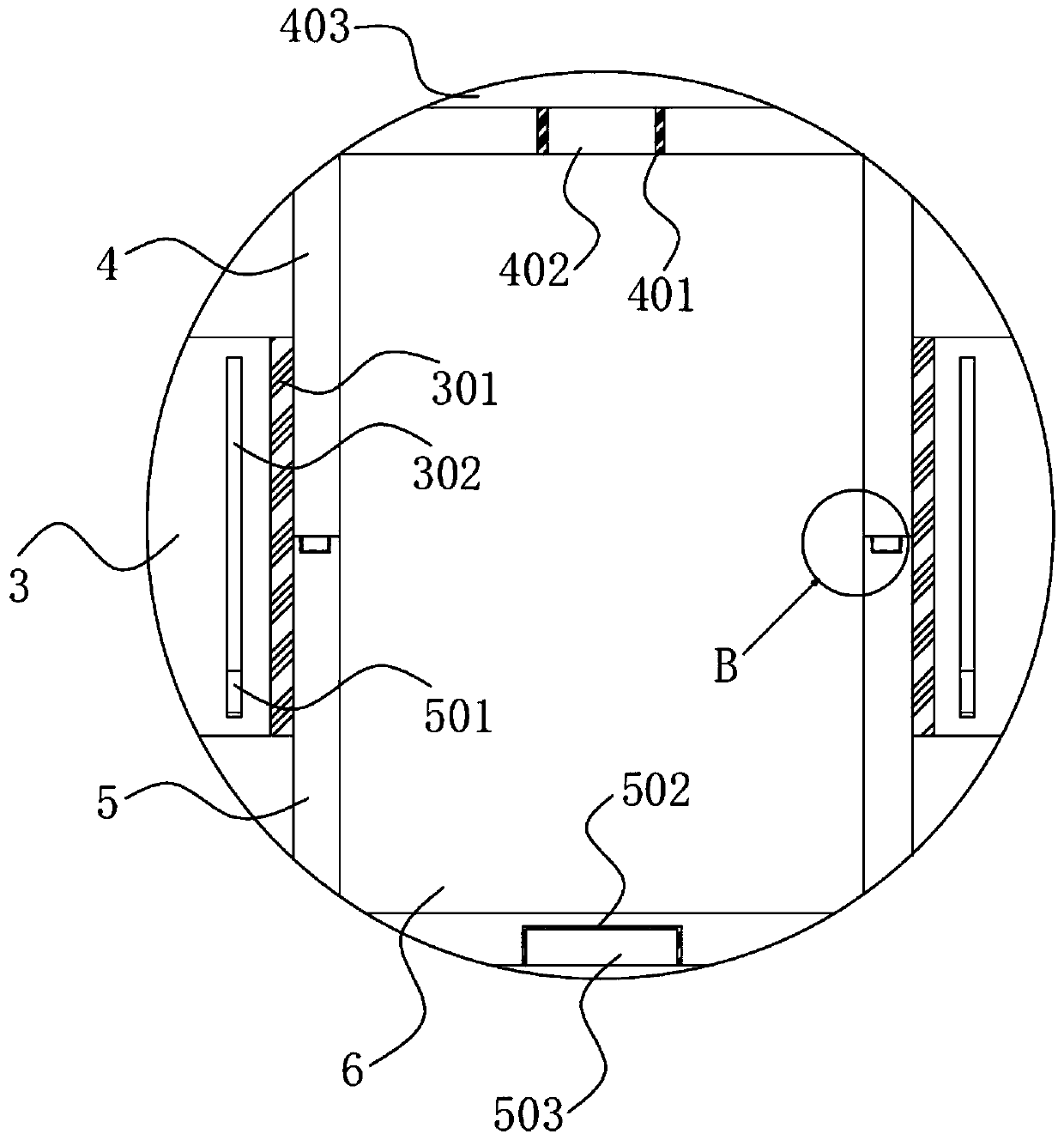

Improved cell glue injection device

ActiveCN104241710ASimple structural designIngenious structural designFinal product manufactureCell sealing materialsEngineeringInjection device

The invention provides an improved cell glue injection device and belongs to the technical field of cell production. The improved cell glue injection device comprises a bearing platform, a material tank for storing glue and multiple glue injection assemblies, wherein the material tank is fixedly arranged on the bearing platform; a stainless steel layer, a thermal insulating layer and a shell layer are arranged in sequence from inside to outside; each glue injection assembly comprises a glue injection pipe fixedly arranged on the bearing platform and a power element arranged corresponding to the glue injection pipe; a vertically arranged glue injection channel and a glue injection outlet communicated with the glue injection channel are formed in the middle part of the glue injection pipe; the material tank is communicated with each glue injection pipe and the glue can be conveyed to the corresponding glue injection channel; the tail end of the power element is connected with a glue injection pin rod through a floating joint; the glue injection pin rod and the glue injection channel are coaxially arranged; the power element is movably connected on the bearing platform, drives the glue injection pin rod to stretch into the glue injection channel and discharges the glue in the glue injection channel from the glue injection outlet. The improved cell glue injection device has the advantages of reasonable structure, economical efficiency and applicability and good glue injection effect.

Owner:NINGBO BEITERUI ENERGY TECH

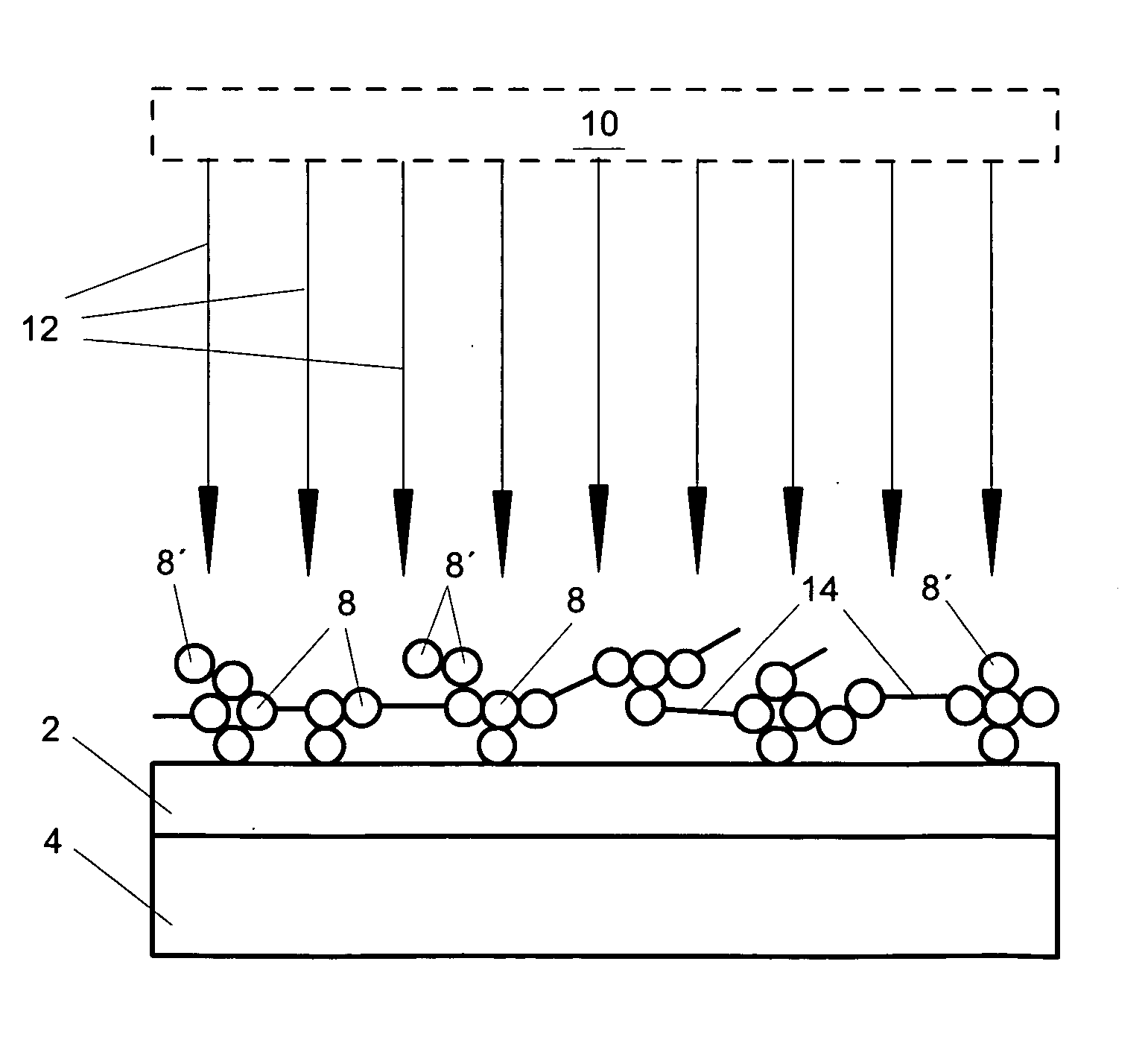

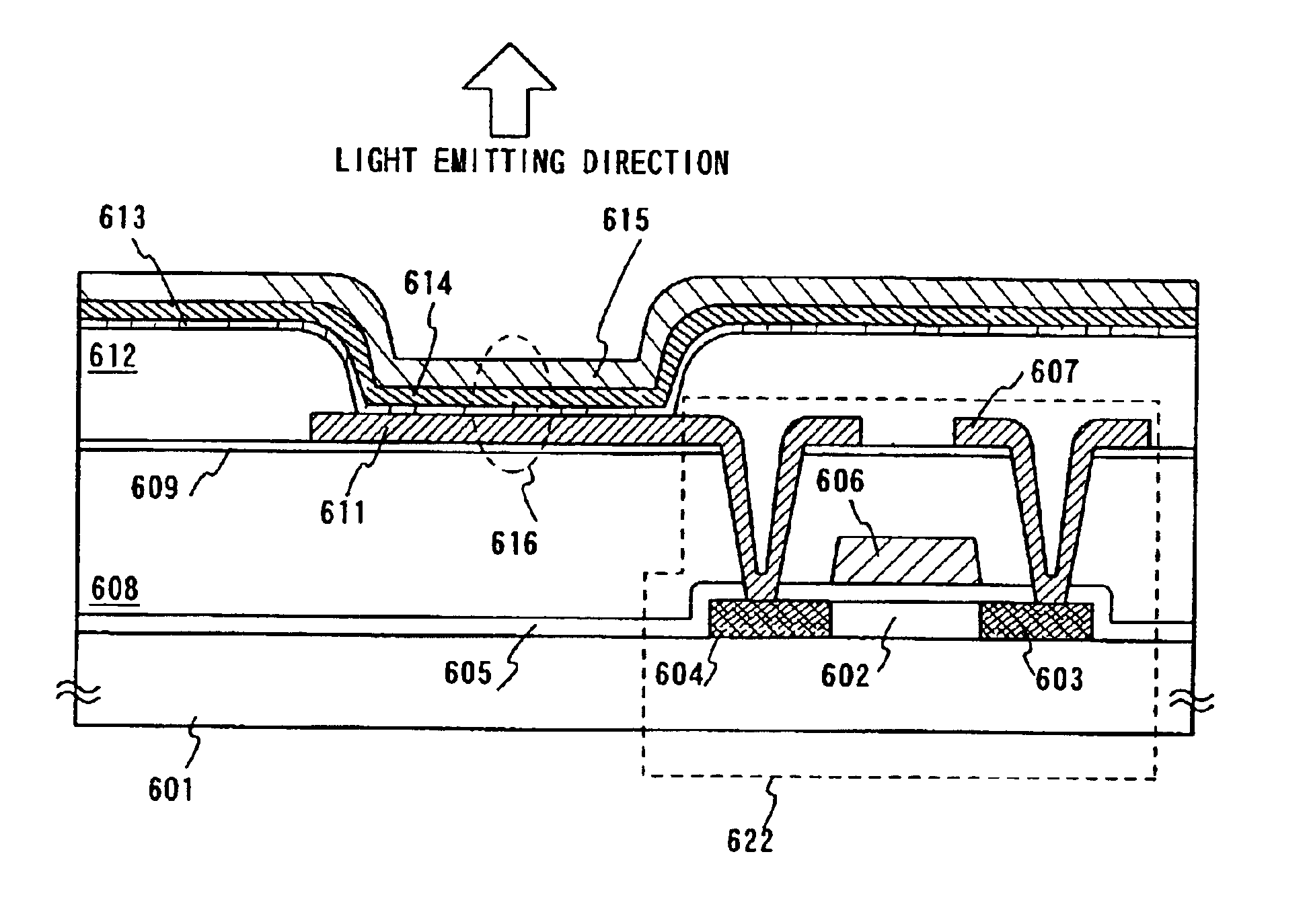

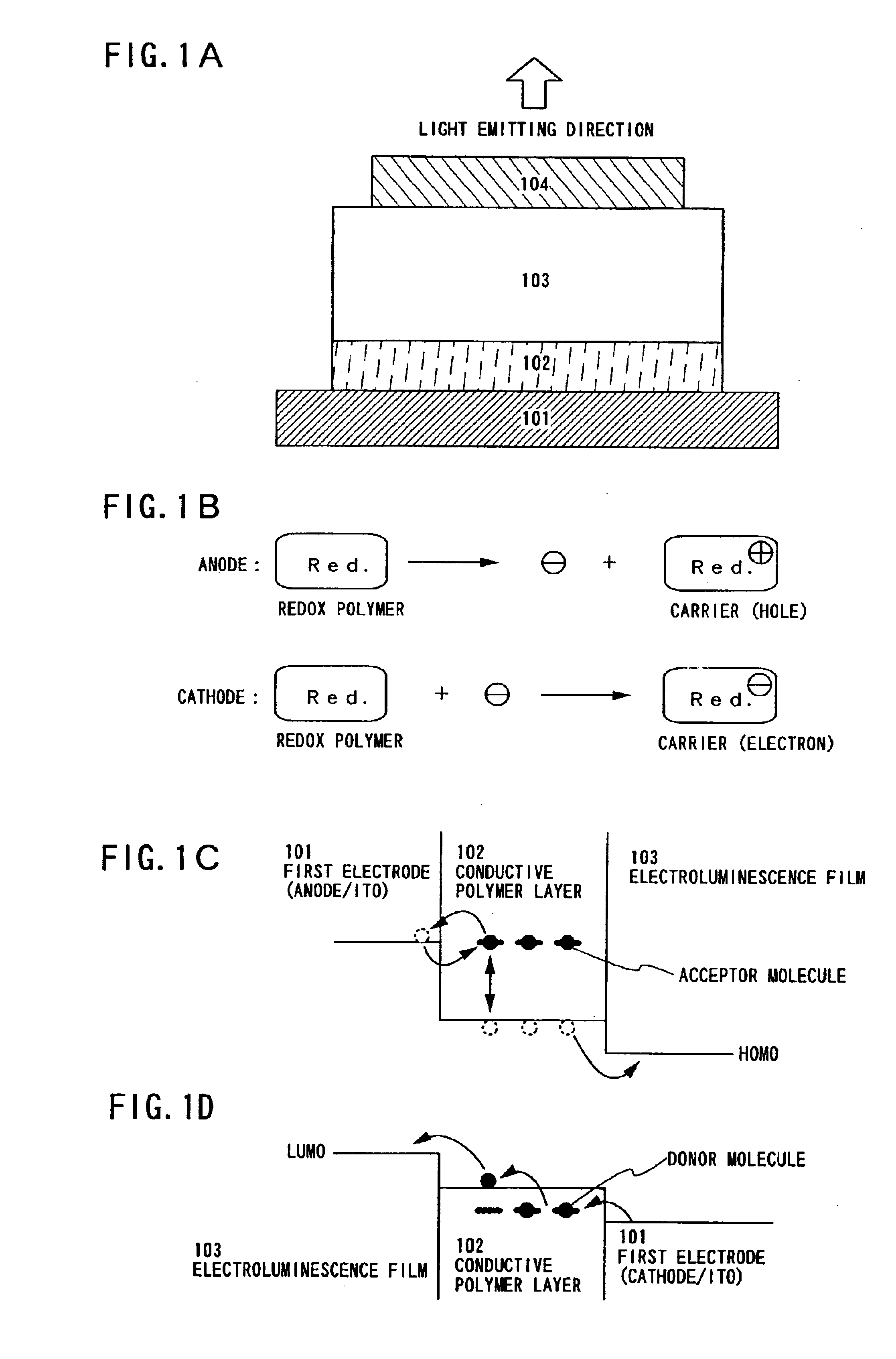

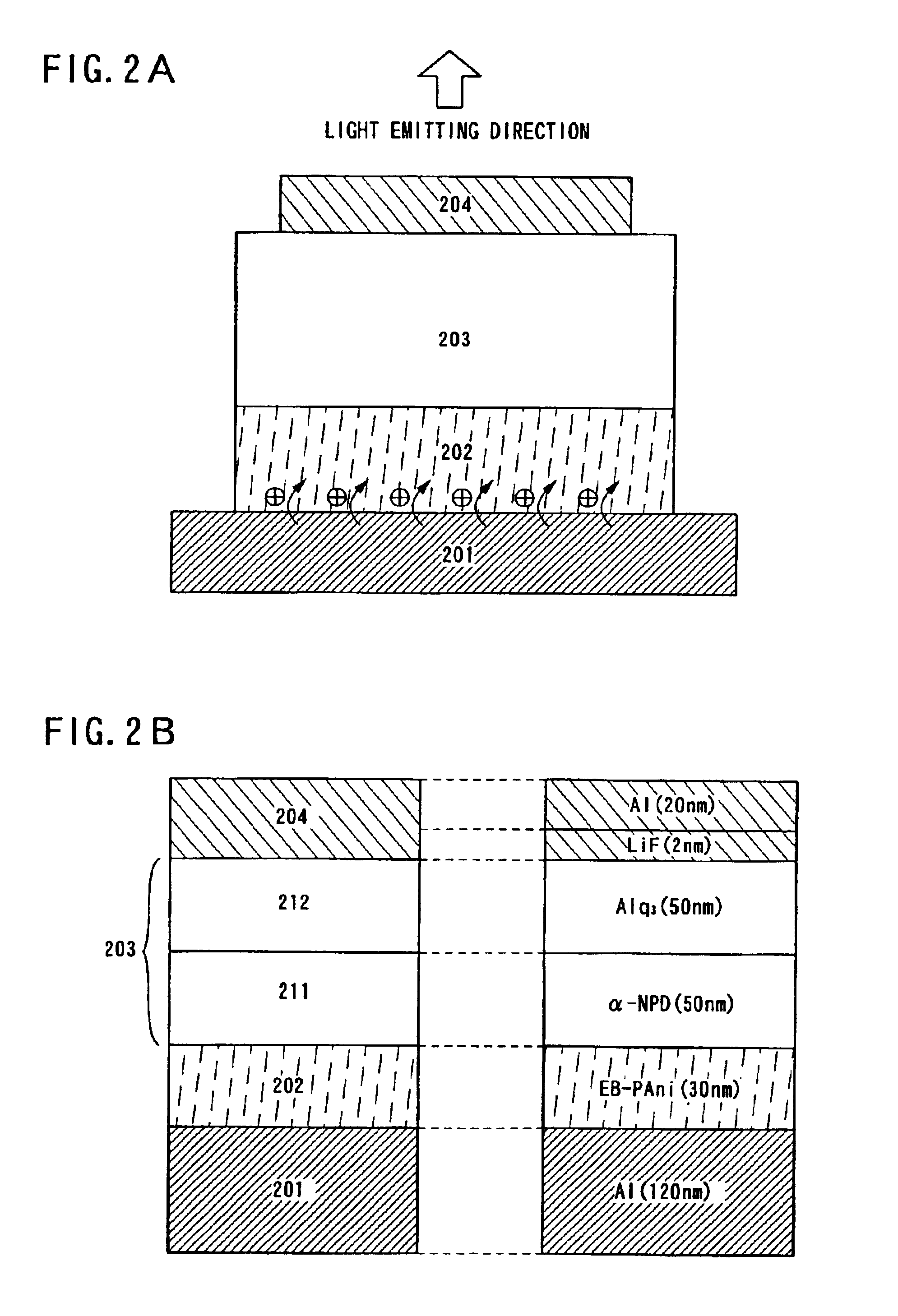

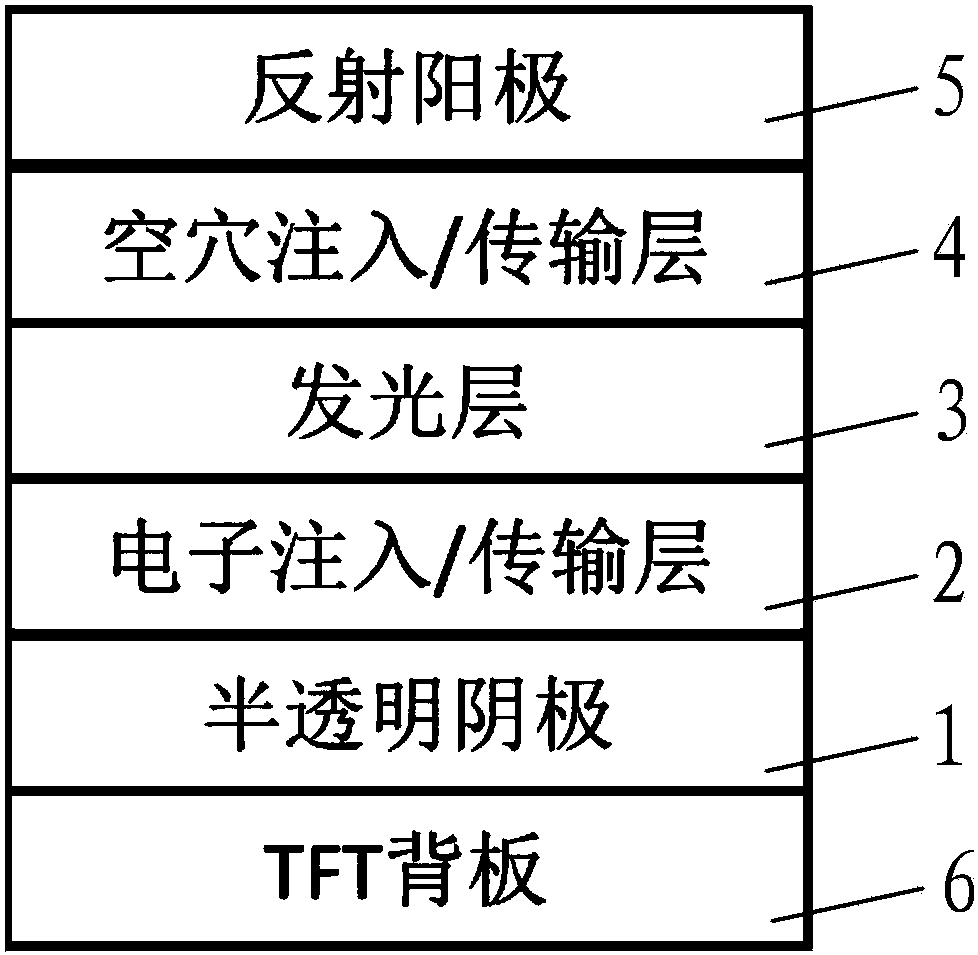

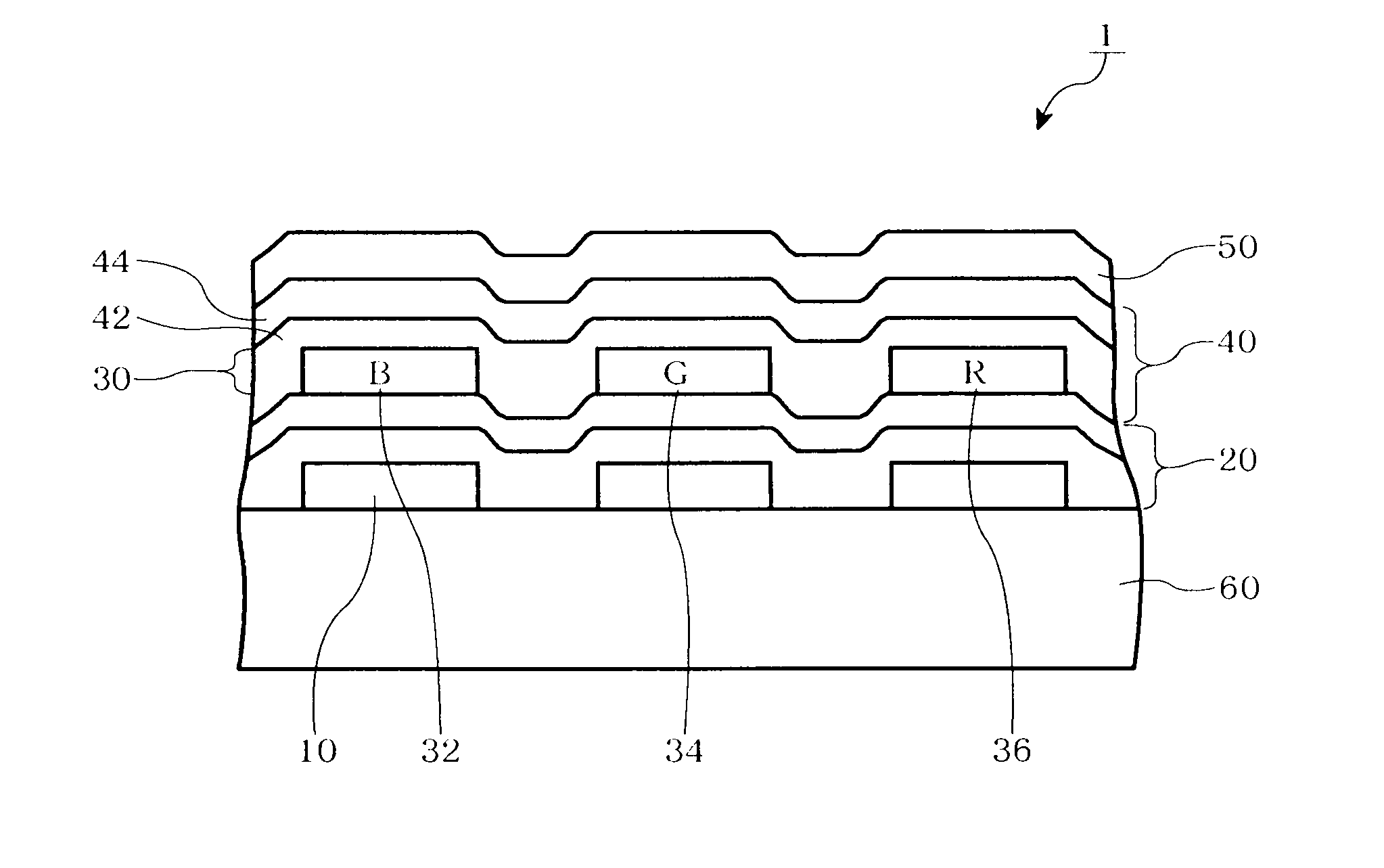

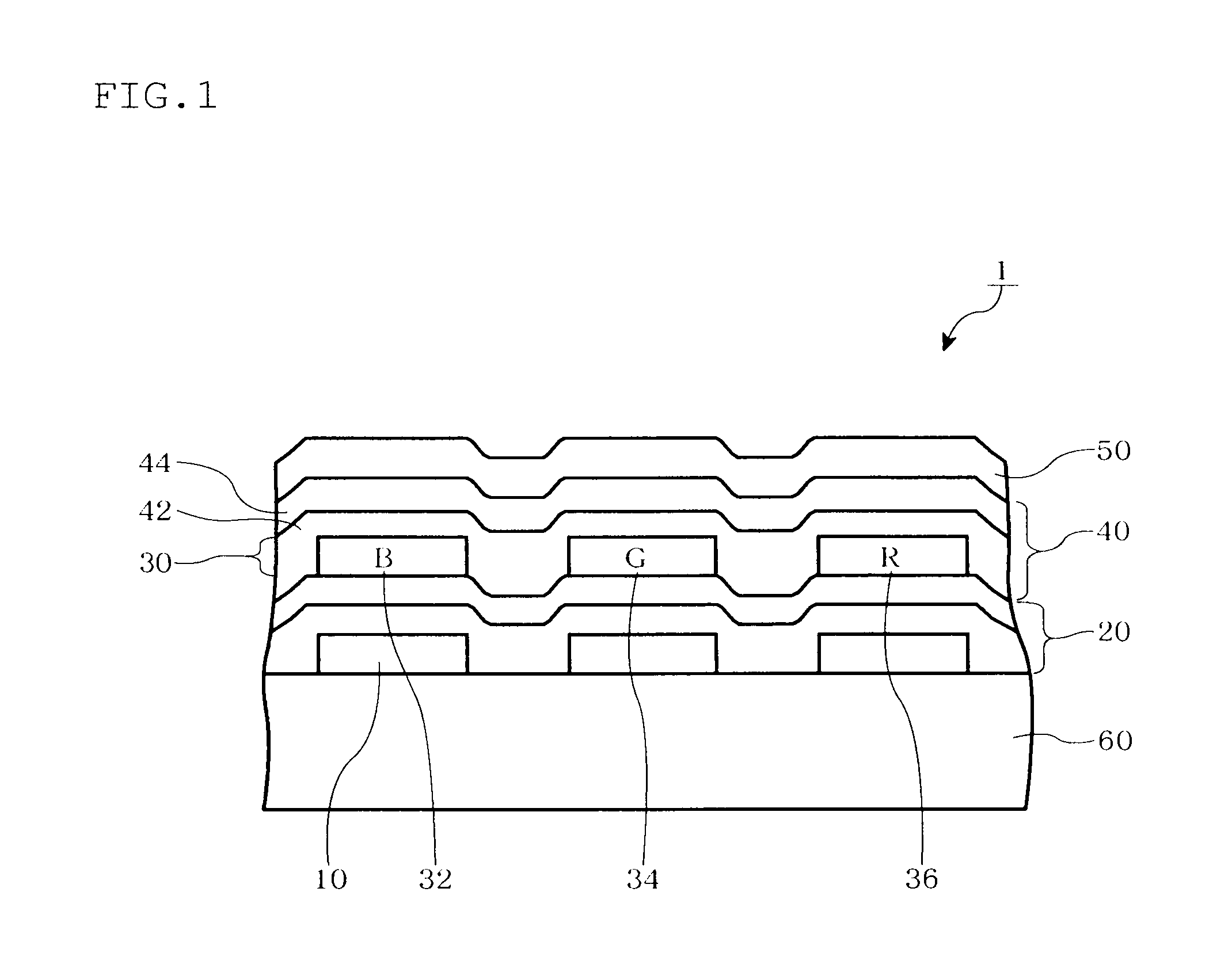

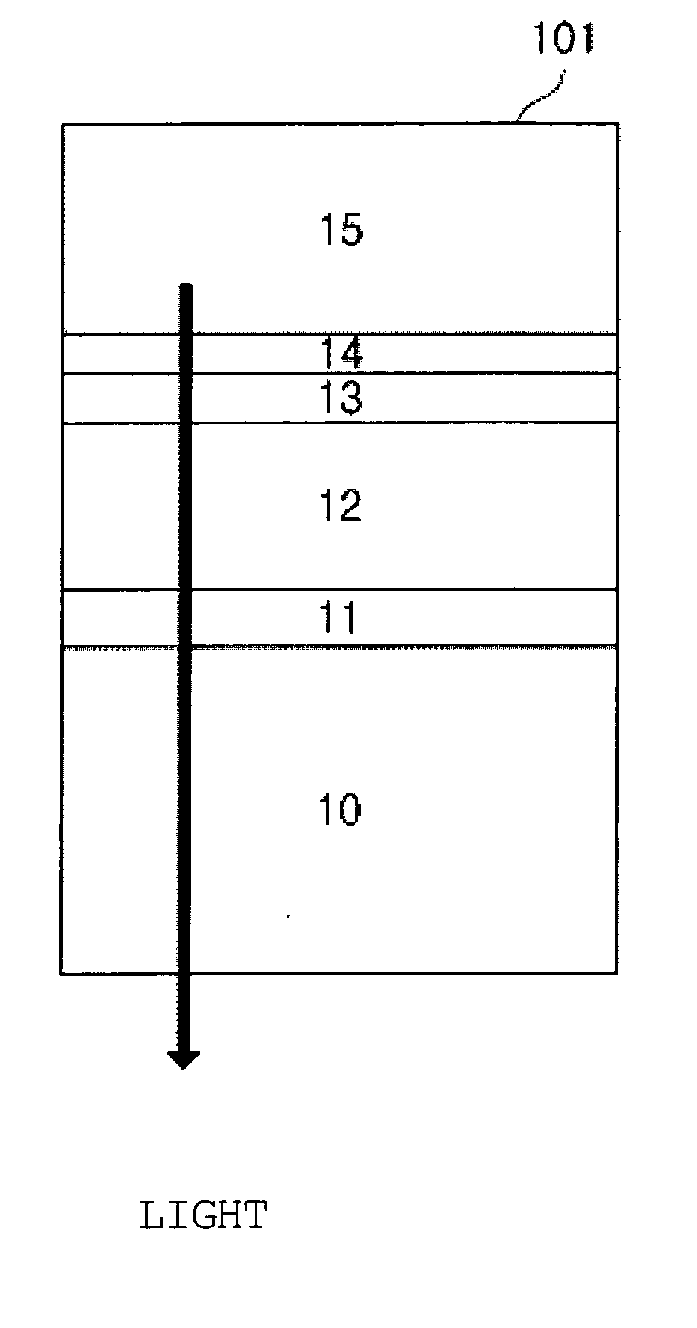

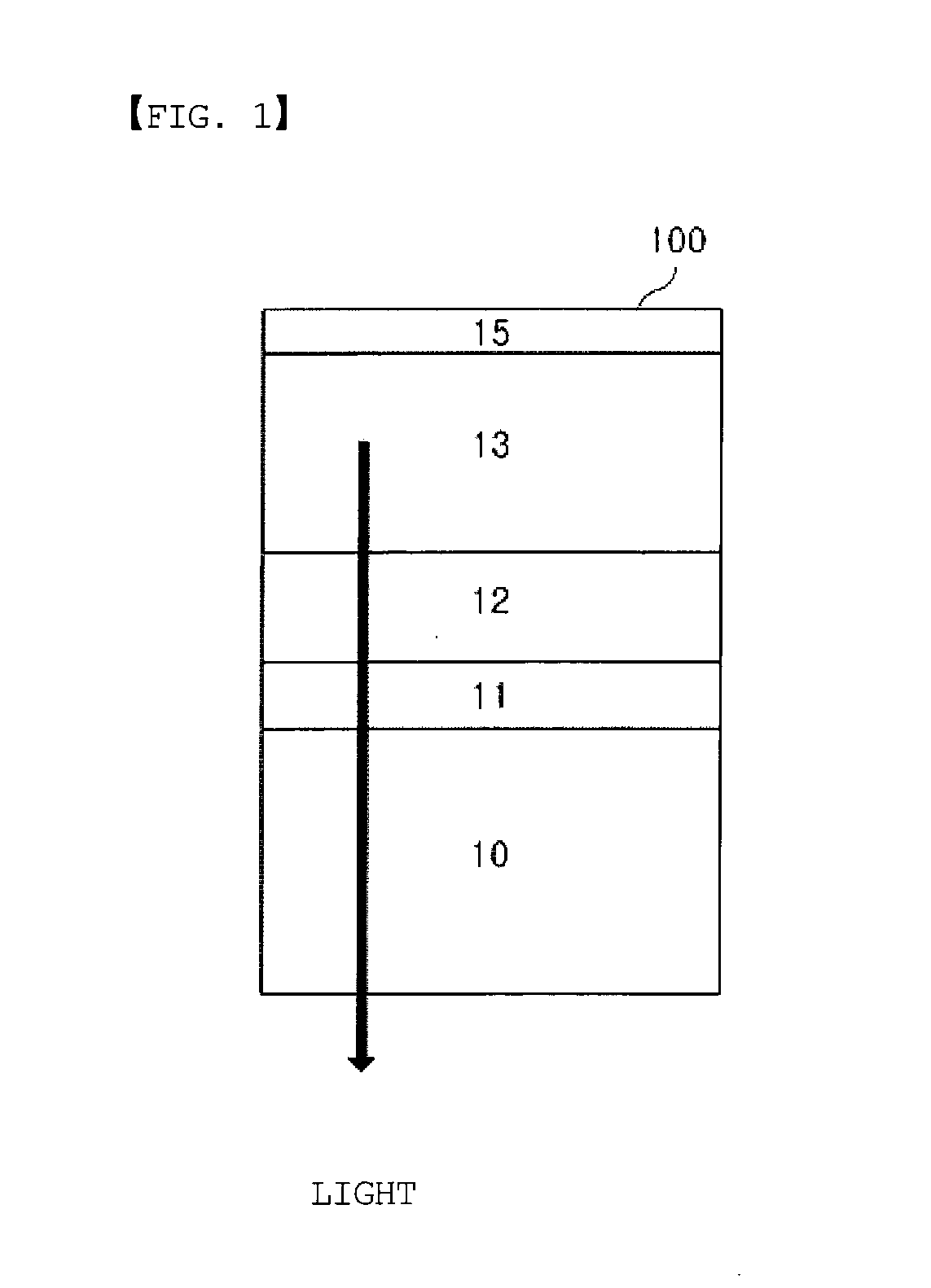

Light emitting device and manufacturing method therefor

InactiveUS6838836B2Low costIncrease productionDischarge tube luminescnet screensStatic indicating devicesGeneral purposeConductive polymer

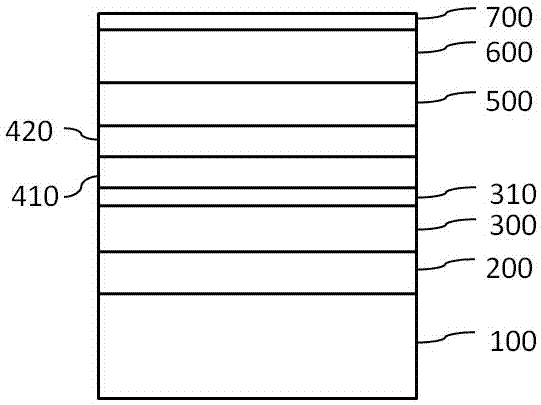

To provide a light emitting element having a top emission structure, which can be easily manufactured without considering an ionization potential of an electrode (particularly an electrode in contact with a substrate) and a manufacturing method therefor. A light emitting device having the top emission structure according to the present invention includes: a first electrode (101) formed of general-purpose metal (specifically, a wiring material such as Ti or Al) having a light-shielding property or reflectivity; a conductive polymer layer (102) formed by applying a conductive polymer material onto the first electrode (101); an electroluminescence film (103) formed in contact with the conductive polymer layer (102); and a light-transmissive second electrode (104) formed on the electroluminescence film 103, in which the conductive polymer layer (102) is formed of materials including a redox polymer etc., while being free of problems regarding work function (as shown in FIG. 1A).

Owner:SEMICON ENERGY LAB CO LTD

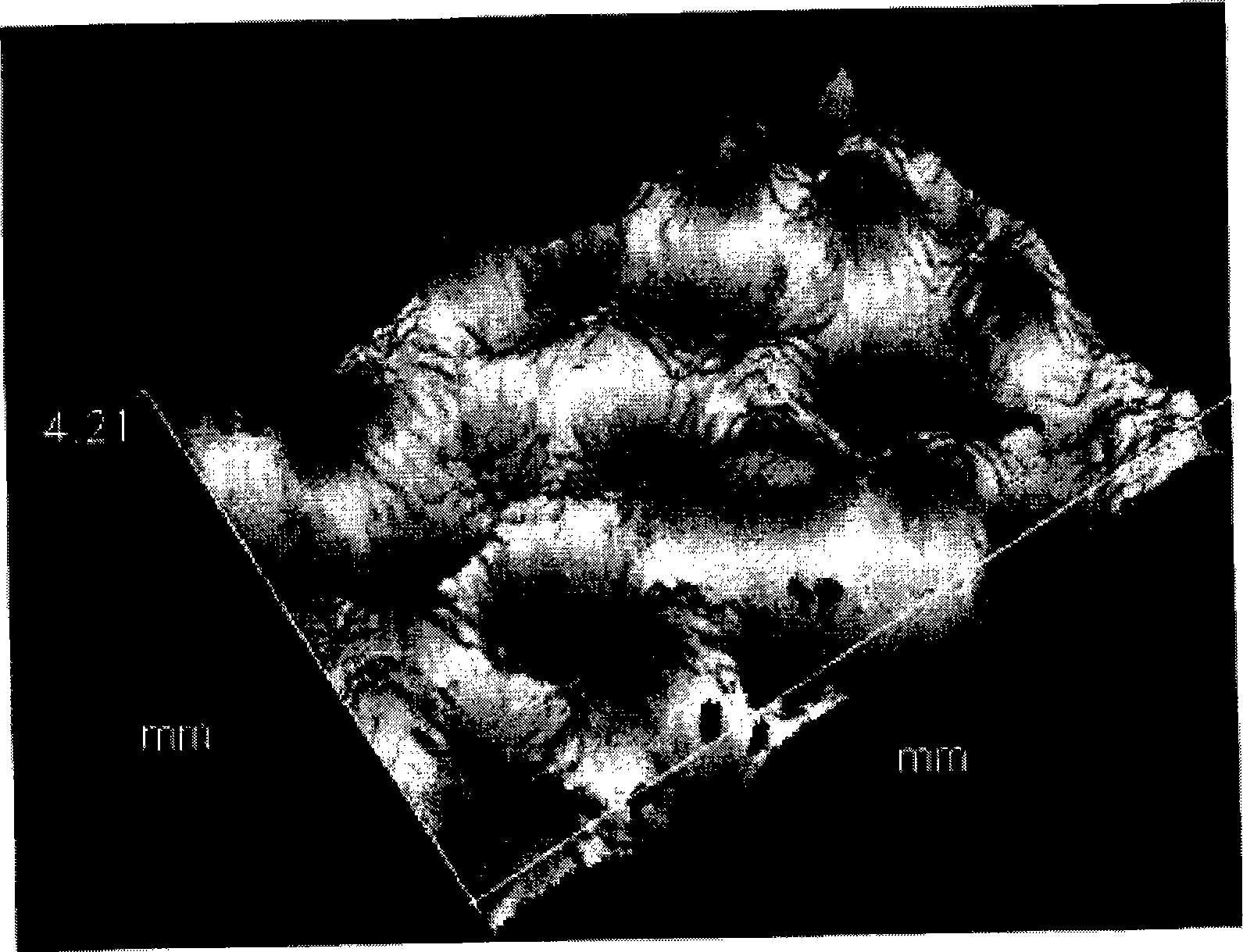

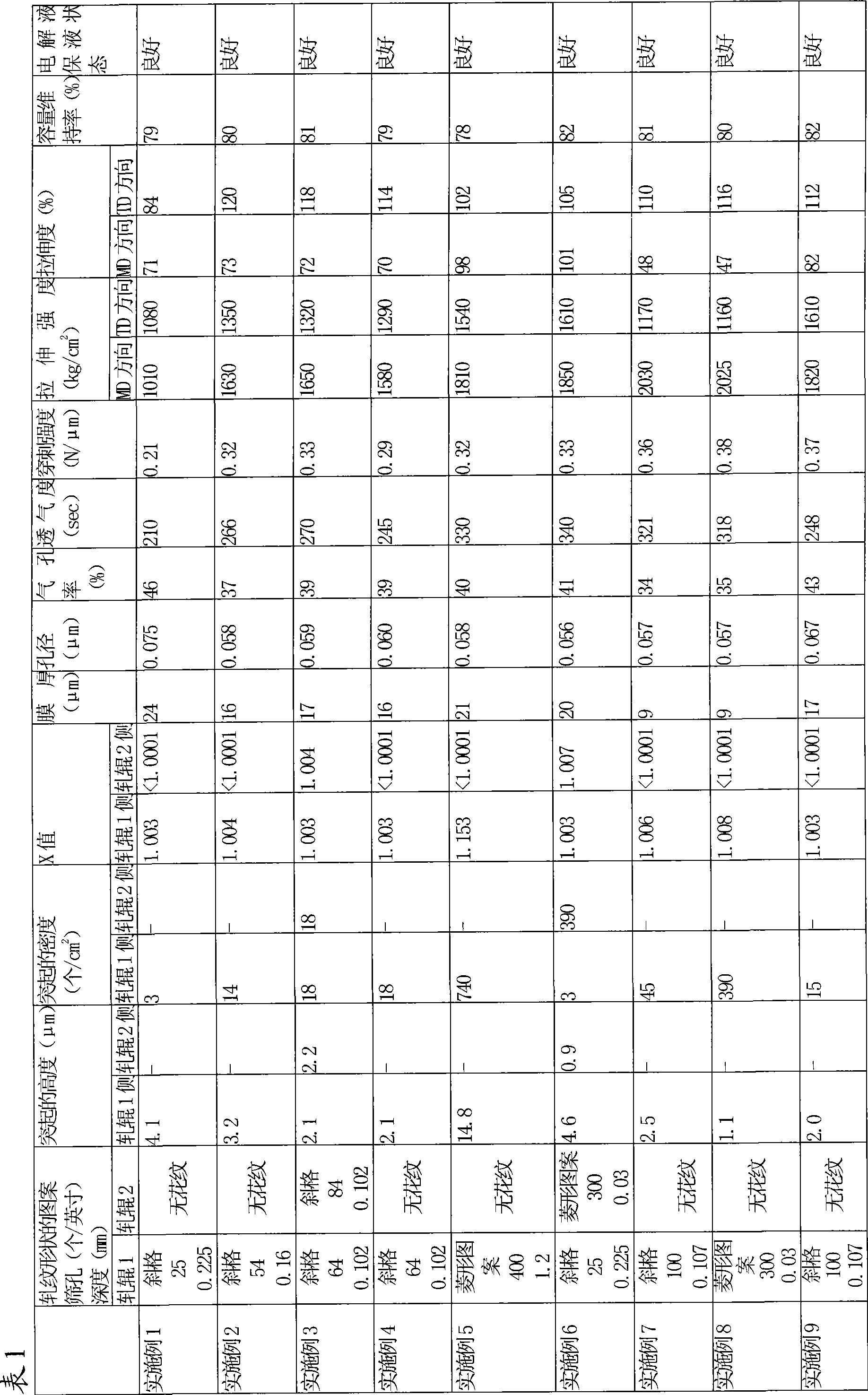

Polyolefin microporous membrane

ActiveCN101535386AAvoid compressionAvoid destructionSolid electrolytesCell seperators/membranes/diaphragms/spacersPolyolefinPolymer science

A polyolefin microporous membrane, which has a thickness of 1-100[mu]m, a pore diameter of 0.01-1[mu]m and a protrusion having a height of 0.5-30[mu]m arranged by embossing at least on one surface, is provided. A method for manufacturing the membrane and a battery separator made of the membrane are also provided.

Owner:ASAHI KASEI KK

Filler composition comprising beta-glucans

InactiveUS20130196944A1Significant positive effectPositive influenceOrganic active ingredientsCosmetic preparationsCross-linkMedicine

The present invention pertains to a filler composition comprising β-glucan moieties and optionally a cosmetically and / or pharmaceutically acceptable carrier. It further relates to a filler composition, wherein the β-glucan moieties are cross-linked. in one embodiment of the instant invention the filler composition is a dermal filler. In one further embodiment of the present invention the filler composition is for the treatment of wrinkles and / or folds. In another embodiment of the instant invention the filler composition is for use in the treatment of a medical condition. The filler composition provided in the present invention may further comprise one or more active pharmaceutical ingredients. Further, the present invention pertains to a process for preparing the filler composition as claimed herein.

Owner:MERZ PHARMA GMBH & CO KGAA

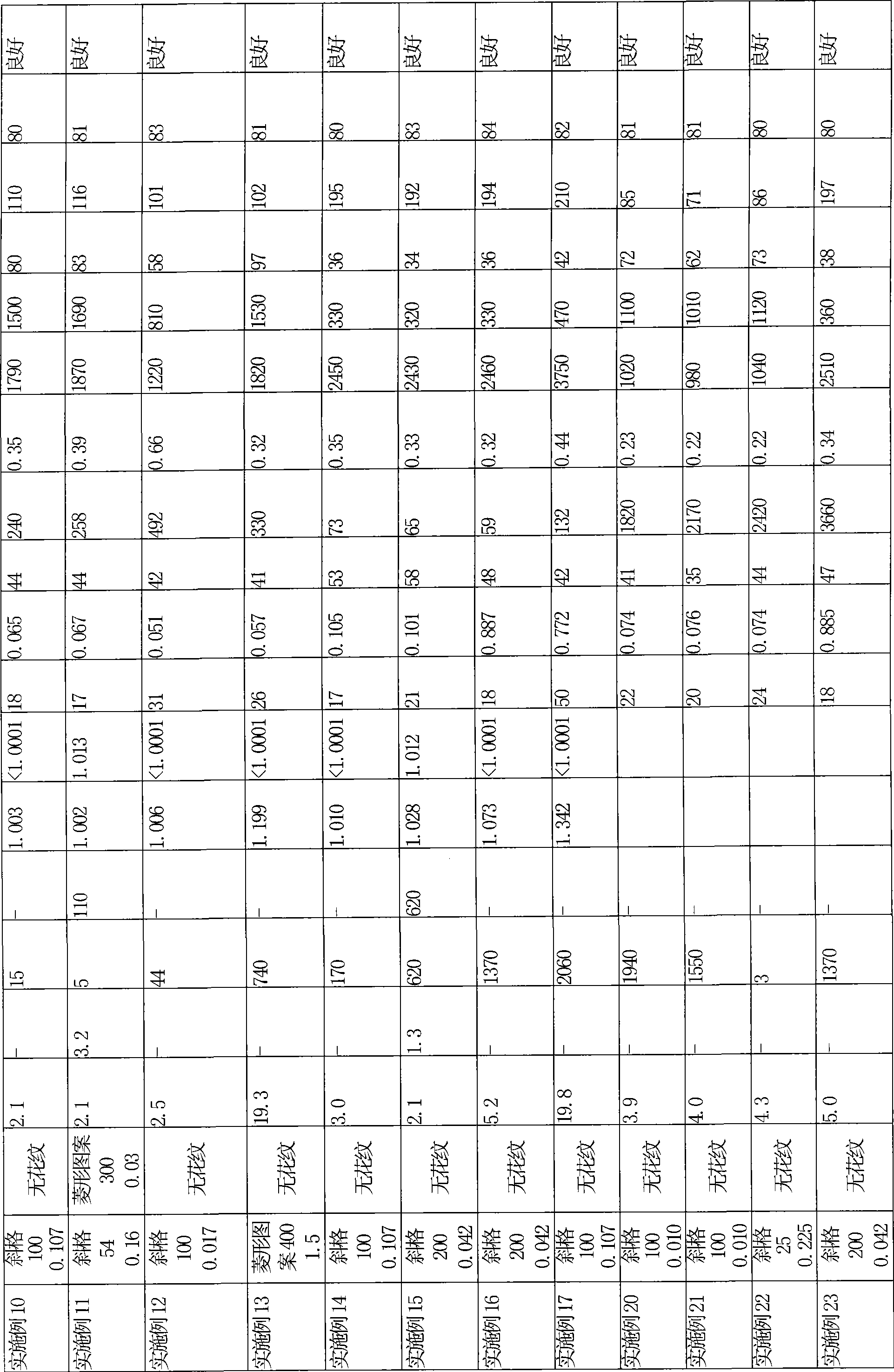

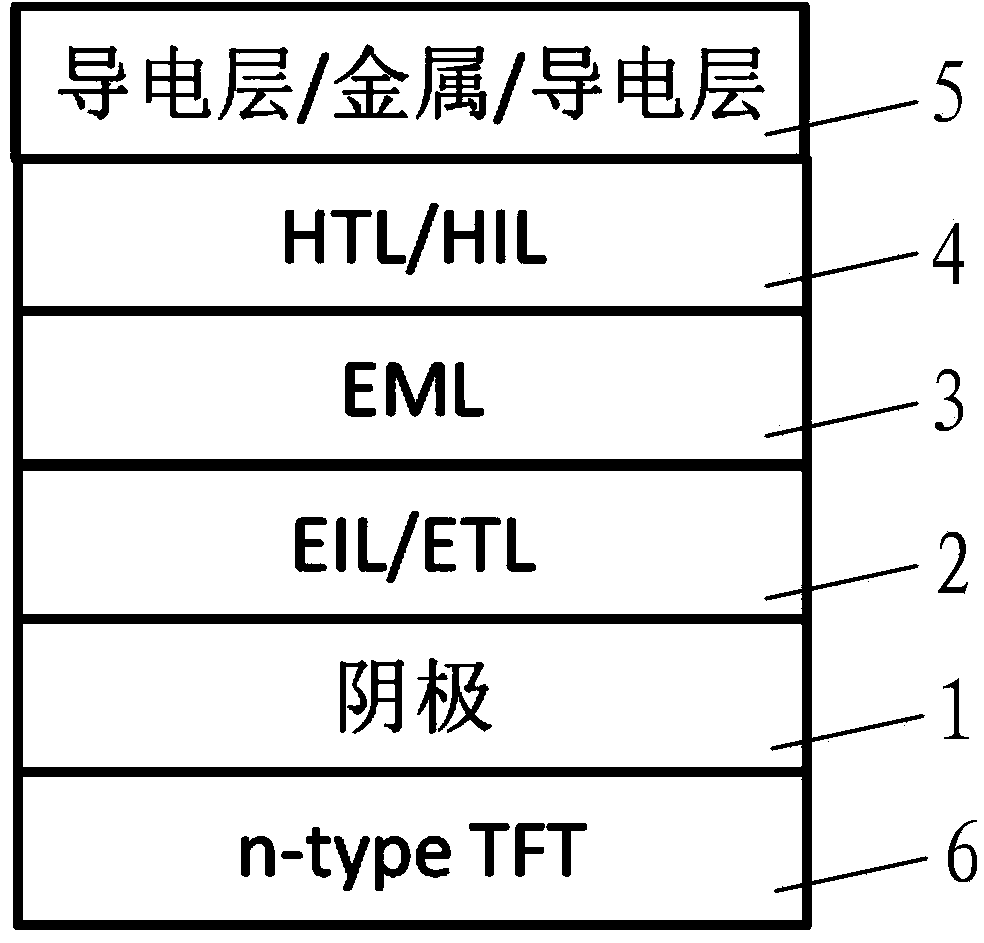

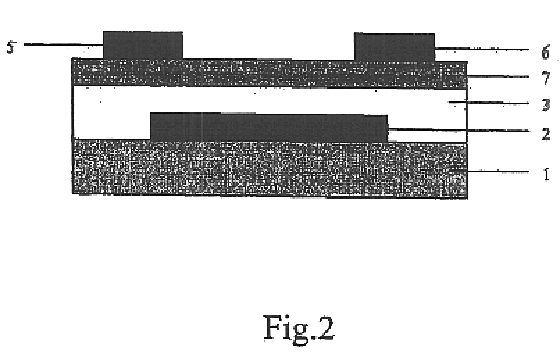

Inverted type organic electroluminescence structure

InactiveCN104201290ALower injection barrierImprove injection abilitySolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionAlloy

The invention provides an inverted type organic electroluminescence structure. The inverted type organic electroluminescence structure comprises a substrate, and a cathode layer, an electron injection layer, an electron transport layer, a luminous layer, a hole injection layer, a hole transport layer and an anode layer, which are sequentially arranged on the substrate from bottom to top, wherein the anode layer comprises a first conducting layer, a metal layer and a second conducting layer, and the cathode layer contains chemical compositions of magnesium, aluminum, silver, ytterbium and samarium and alloy of the above compositions, or the magnesium, the aluminum, the silver, the ytterbium and the samarium mixed with zinc oxide. The inverted type organic electroluminescence structure reduces the electron injection potential barrier, and improves hole injection capacity.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Root canal filling paste capable of being stored and injected

InactiveCN1857190AImprove the development effectStay hydratedImpression capsDentistry preparationsInjectorSyringe

The present invention provides a kind of root canal filling paste with calcium phosphate bone cement as main material and capable of being stored at certain conditions without change in property and capable of being injected. The root canal filling paste consists of solid powder and curing liquid, the solid powder includes calcium phosphate powder and developing agent, and the curing liquid contains humectant, thickener, coagulant and water. The root canal filling paste compounded with the solid powder and the curing liquid is stored in an injector, and when it is used, the injector with root canal filling paste is set in the air for minutes for the paste to raise its temperature before being injected to root canal. The injected paste will solidify fast to convert into high strength hydroxyapatite. The present invention has less operation steps, shortened surgical operation period and raised root canal treating quality.

Owner:XIAMEN UNIV

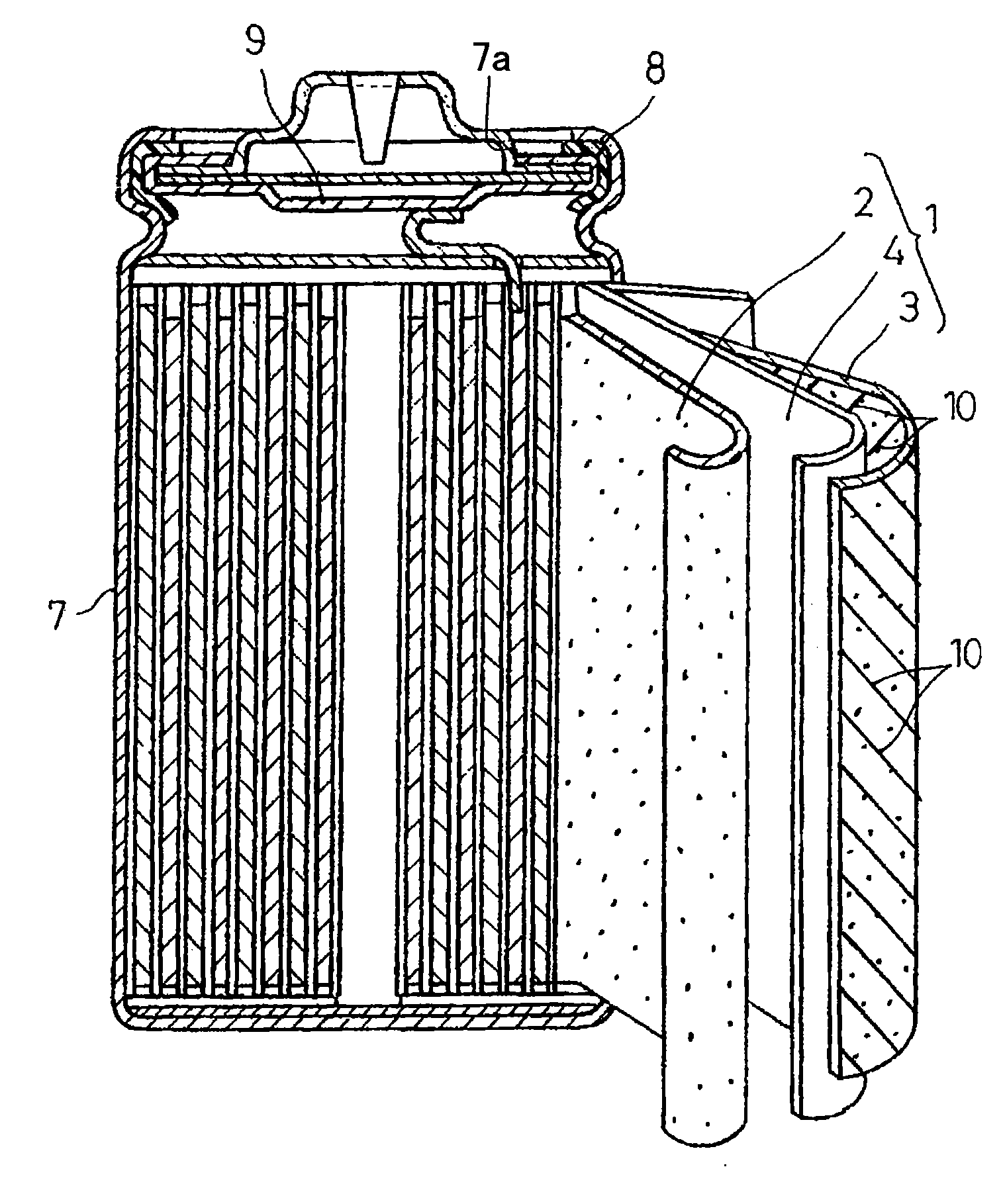

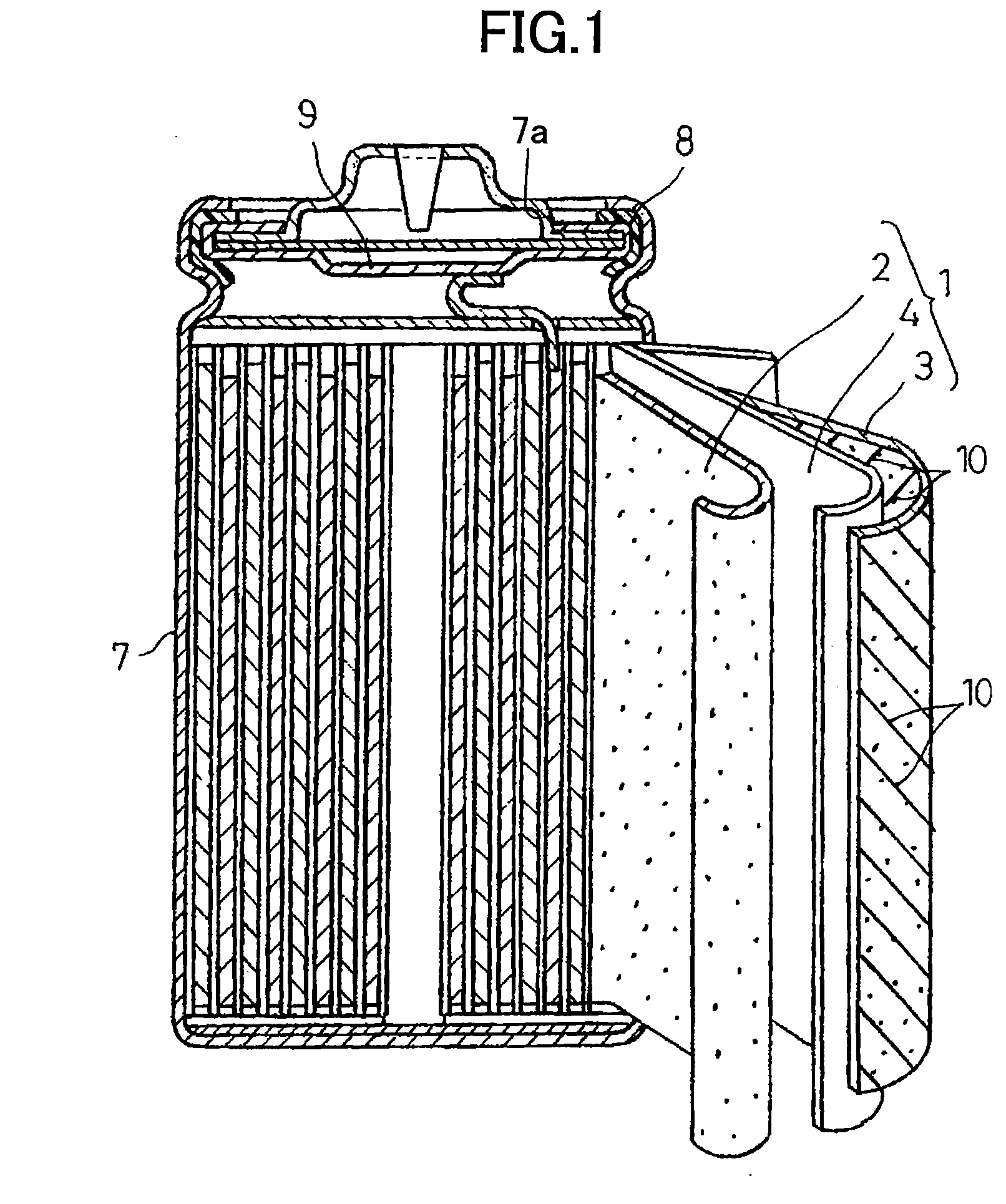

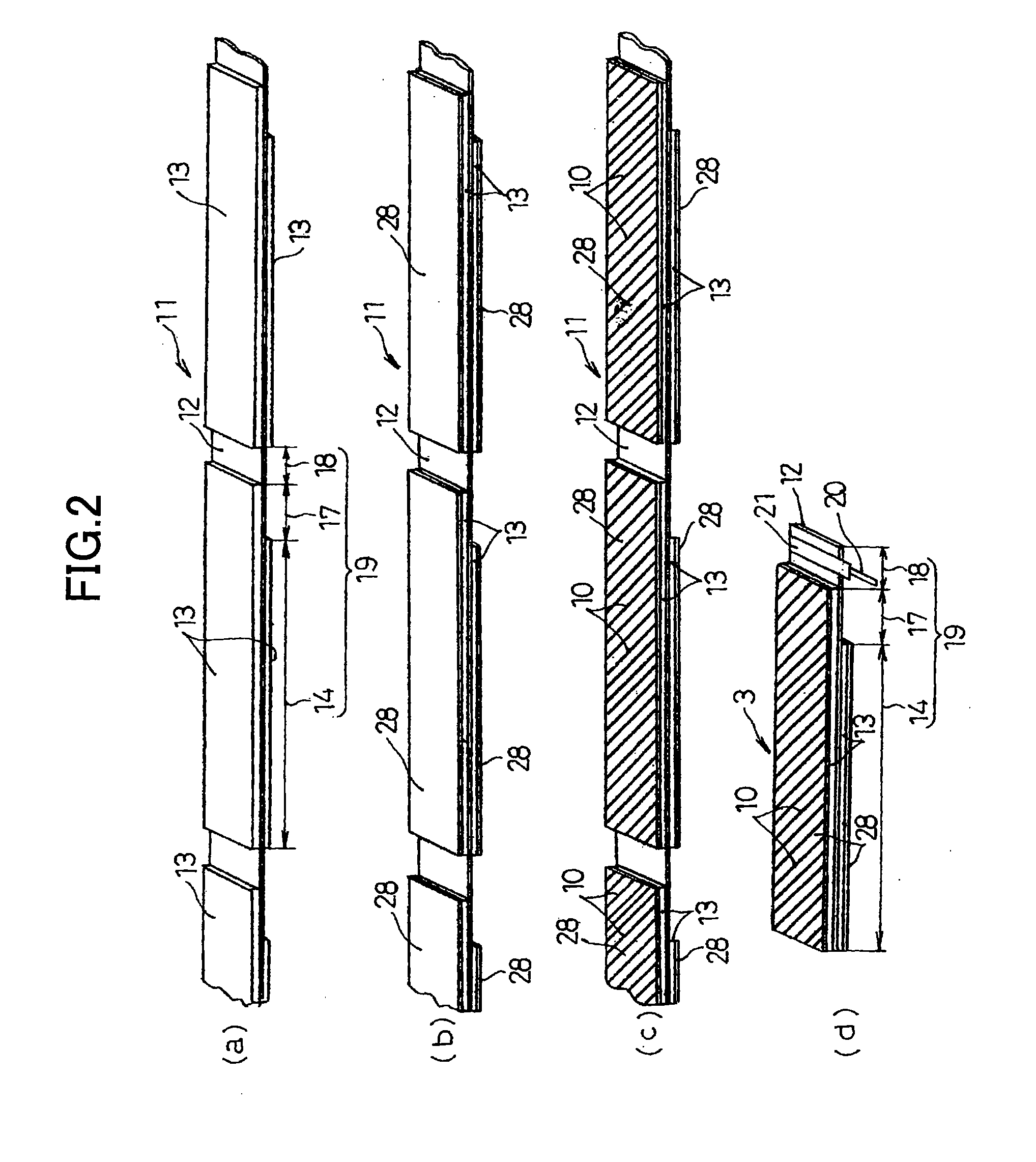

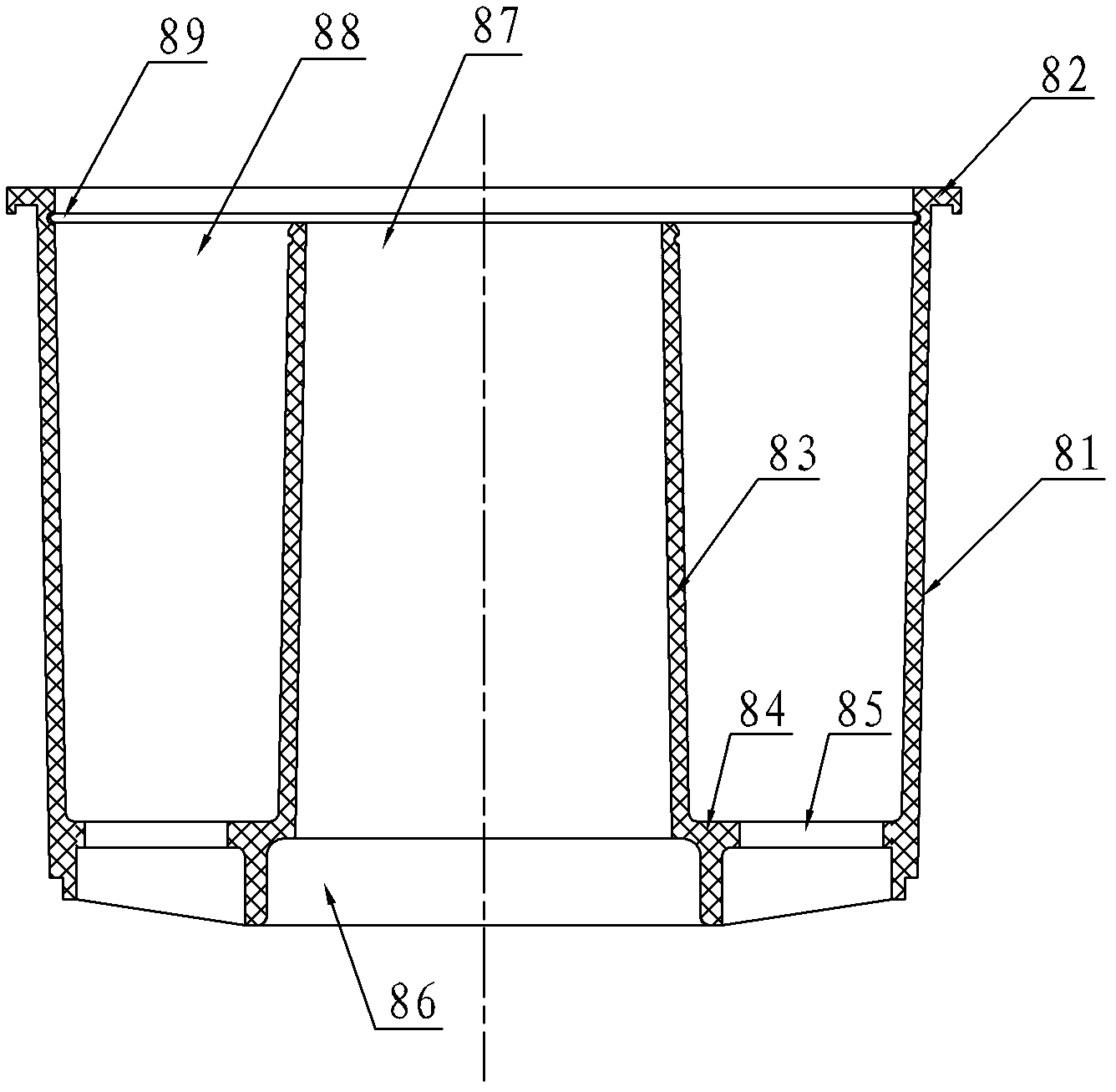

Secondary battery and method for producing the same

InactiveUS20100136394A1High yield productionAvoid it happening againFinal product manufactureElectrode carriers/collectorsEngineeringElectrolyte

A secondary battery includes an electrode plate group (1) in which a positive electrode plate (2) and a negative electrode plate (3) are wound or stacked with a separator (4) interposed therebetween and a battery case (7) in which the electrode plate group (1) and an electrolyte are contained. At least one of the positive electrode plate (2) and the negative electrode plate (3) includes a porous protective film (28) formed on a surface of an active material layer. In a surface of the at least one of the electrode plates on which the porous protective film (28) is provided, a plurality of grooves (10) are formed, and the grooves (10) are also formed in the surface of the active material so that each of the grooves (10) extends from the surface of the porous protective film (28) to the surface of the active material layer.

Owner:PANASONIC CORP

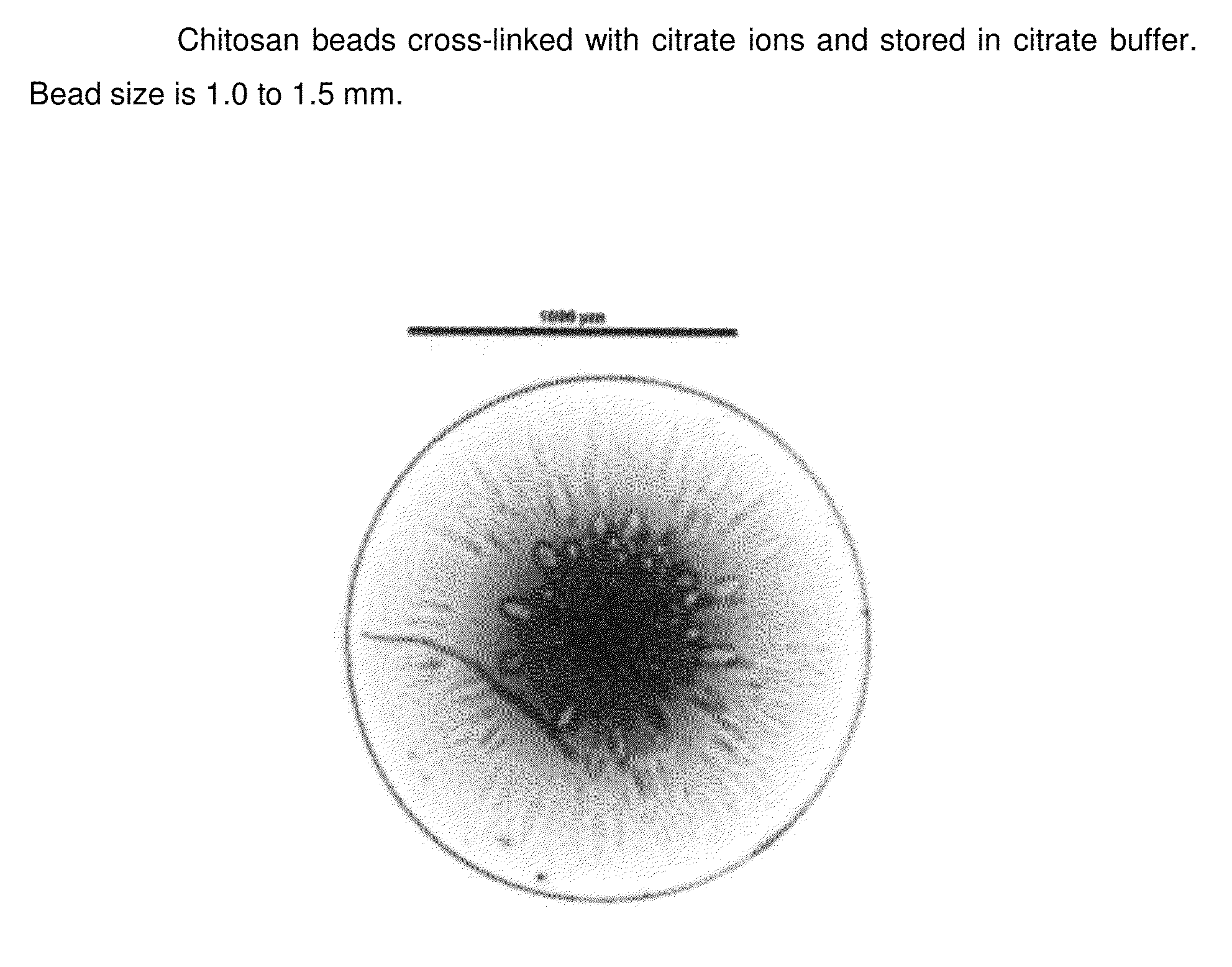

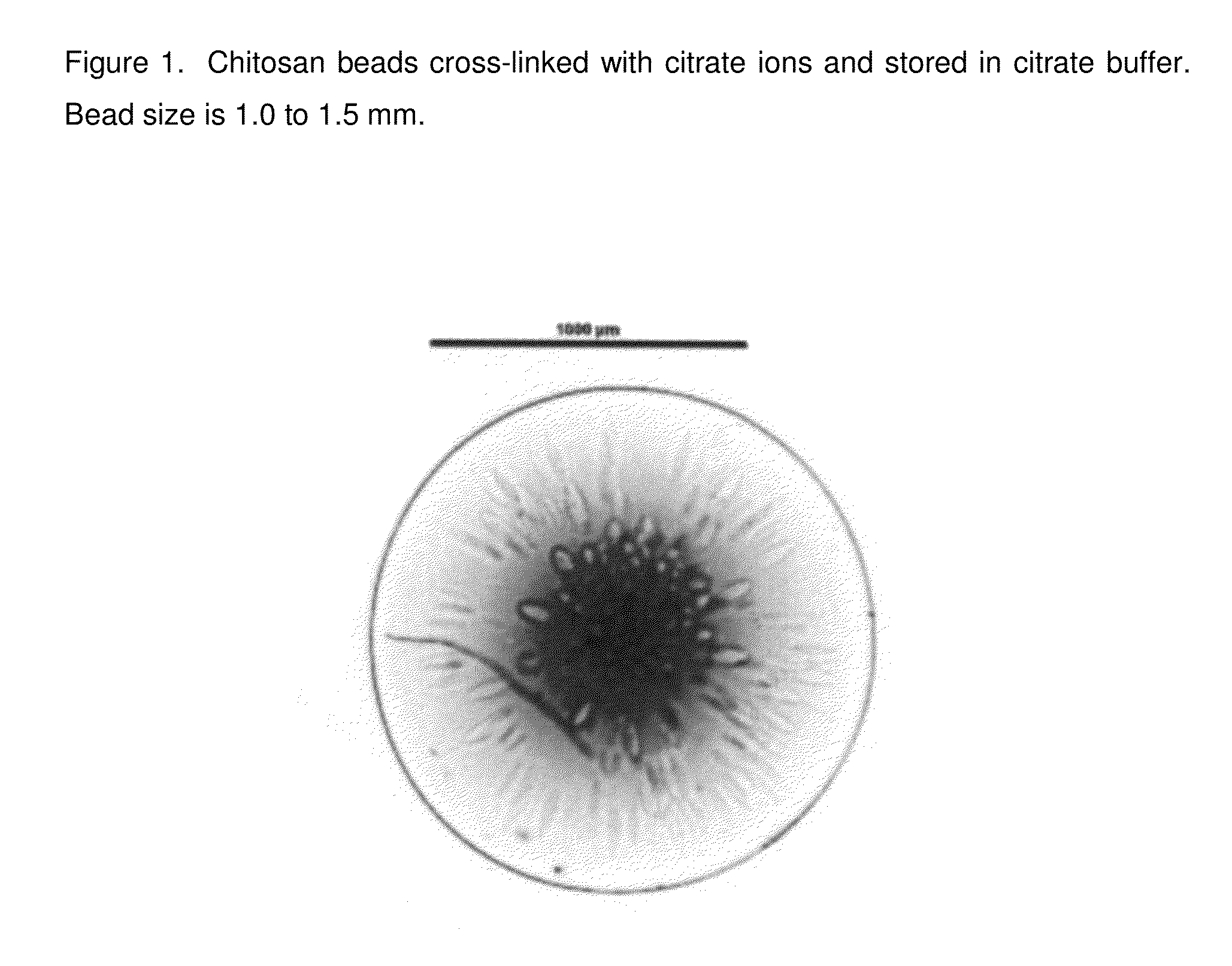

Chitosan beads and filler comprising such beads

InactiveUS20140377368A1Lasting effectRapidly volumeBiocideCosmetic preparationsCross-linkCITRATE ESTER

The present invention pertains to chitosan beads consisting of chitosan cross-linked with citrate ions. The present invention furthermore pertains to a filler comprising such chitosan-citrate beads. In one embodiment of the instant invention the filler is a dermal filler. In one further embodiment of the present invention the dermal filler is for the treatment of wrinkles and / or folds. In another embodiment of the instant invention the filler is for use in the treatment of a medical condition. The filler provided in the present invention may further comprise one or more active pharmaceutical ingredients. Further, the present invention pertains to a process for preparing the filler as claimed herein.

Owner:MERZ PHARMA GMBH & CO KGAA

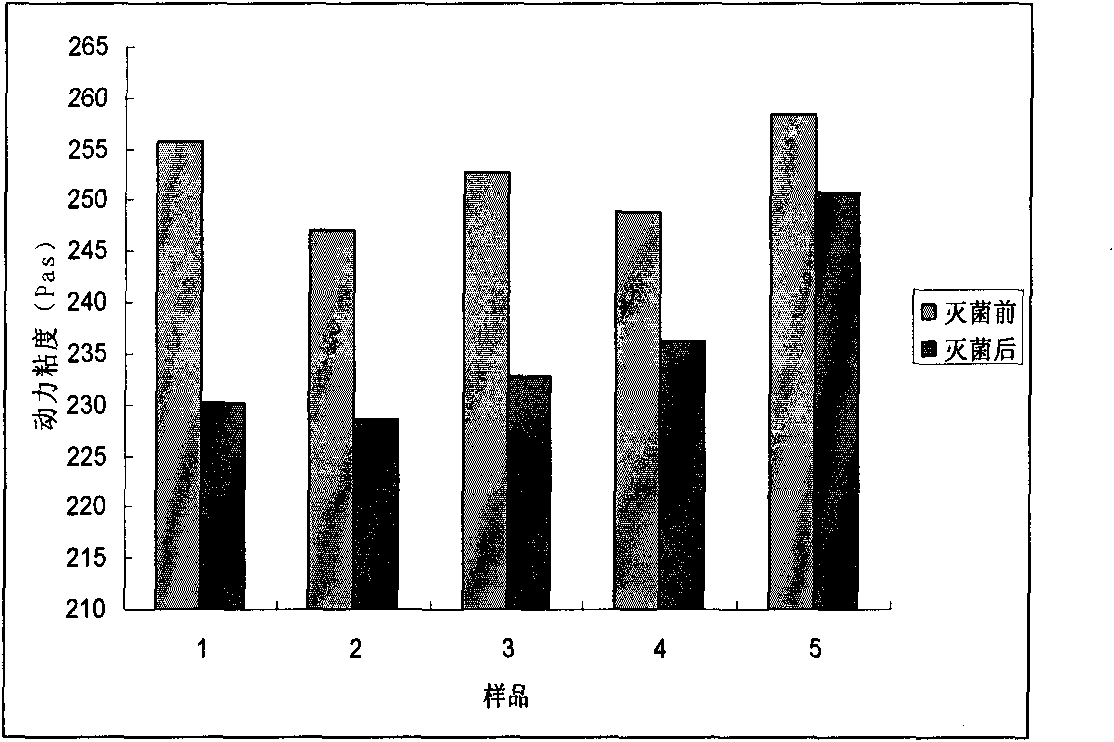

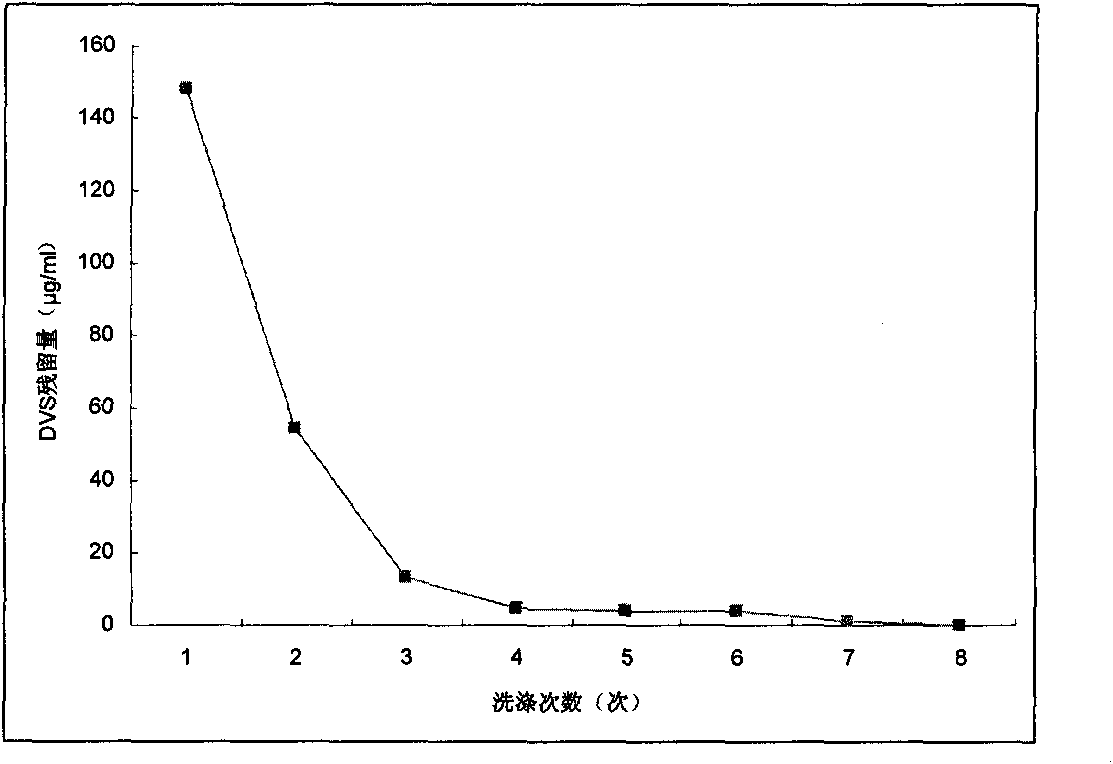

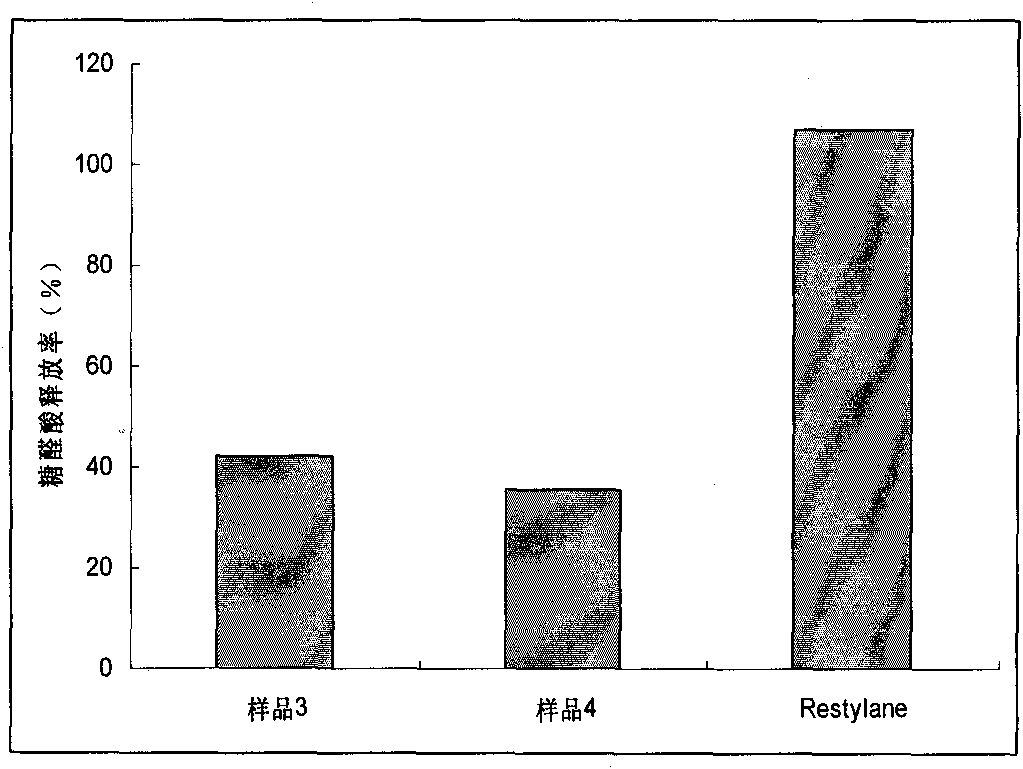

Preparation method for agranular crosslinking sodium hyaluronate with high-temperature-resistant and enzymatic-hydrolysis-resistant characteristics

InactiveCN102757572AGood gelLong retention time in the bodyProsthesisOrganic solventEnzymatic hydrolysis

The invention relates to a novel preparation method for agranular crosslinking sodium hyaluronate. Crosslinking reaction is performed in the low-concentration linear molecule state, and accordingly excess exposure of enzymatic-hydrolysis sites caused by crushing or extrusion of mechanical external forces of crosslinking sodium hyaluronate in traditional processes can be avoided. Redundant crosslinker can be eliminated effectively by white-powdered crosslinking sodium hyaluronate particles obtained by physical precipitation by using organic solvent, and accordingly accurate distribution of different concentrations of products can be guaranteed. The crosslinking sodium hyaluronate has the characteristics of high-temperature resistance, enzymatic-hydrolysis resistance and agranulation, and excellent injectability can be improved evidently. Kinetic viscosity of the agranular crosslinking sodium hyaluronate is reduced by 3-10% after sterilizing at 121 DEG C for 30 minutes, enzymatic hydrolysis is performed to 1000 U of sodium hyaluronate for 48 hours, and releasing amount of uronic acid is smaller than 40%.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

Aliphatic polyester

ActiveUS9234073B2Improve injection effectImprove mechanical propertiesCoatingsPolyesterPolymer science

A method of producing a molded article involving preparing a copolymer obtained by condensation of (i) 90 to 99.5 mol %, based on components i) to ii), of succinic acid; (ii) 0.5 to 10 mol %, based on components i) to ii), of 4 to 10 mol % sebacic acid; (iii) 98 to 102 mol %, based on components i) to ii), of 1,3-propanediol or 1,4-butanediol; (iv) 0.05 to 0.5% by weight, based on the total weight of components i) to iii), of a crosslinker; and (v) 0.35 to 2% by weight, based on the total weight of components i) to iii), of 1,6-hexamethylene diisocyanate. The copolymer is injection molded or blow molded to form a molded article having a wall thickness above 200 μm.

Owner:BASF SE

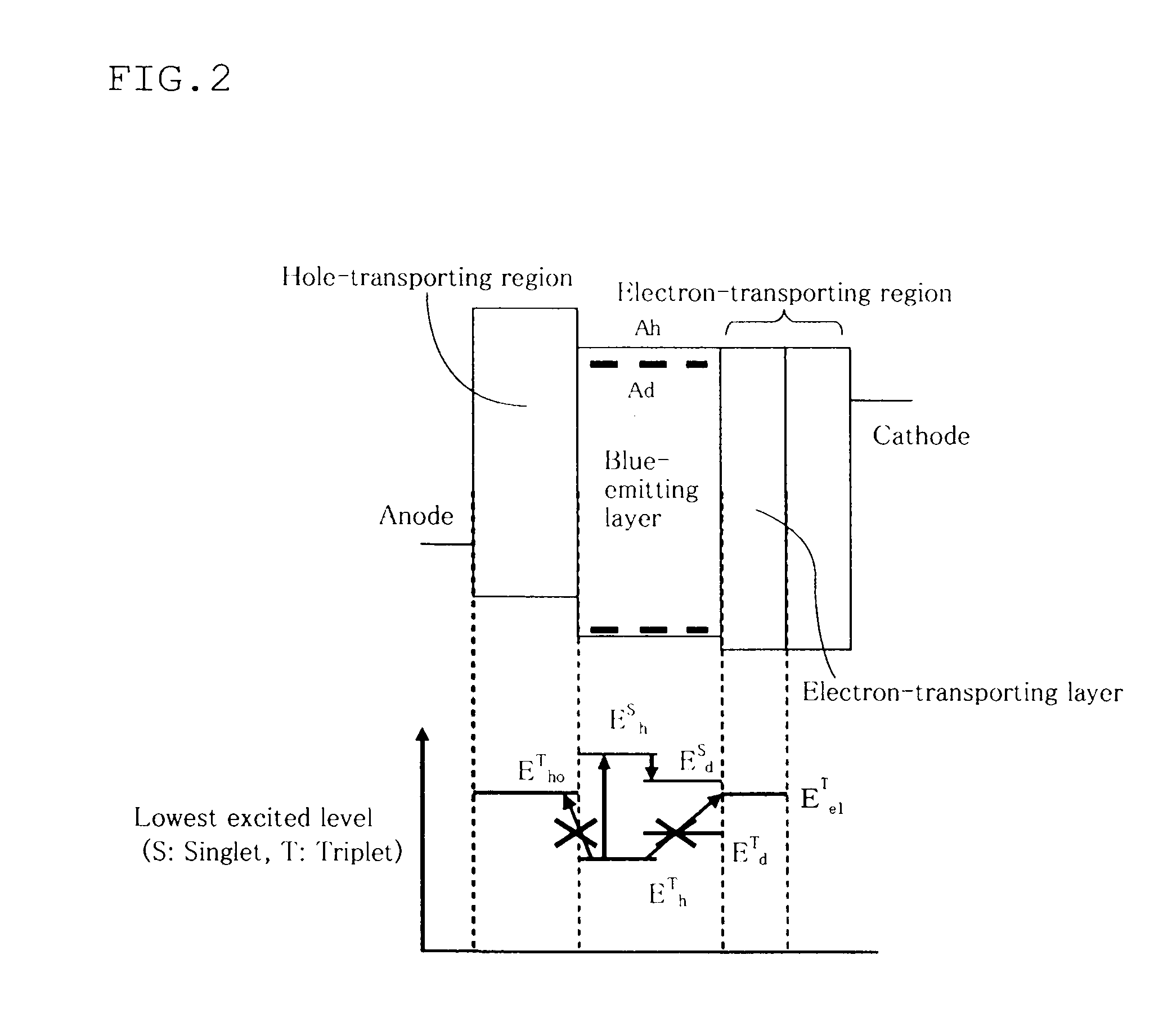

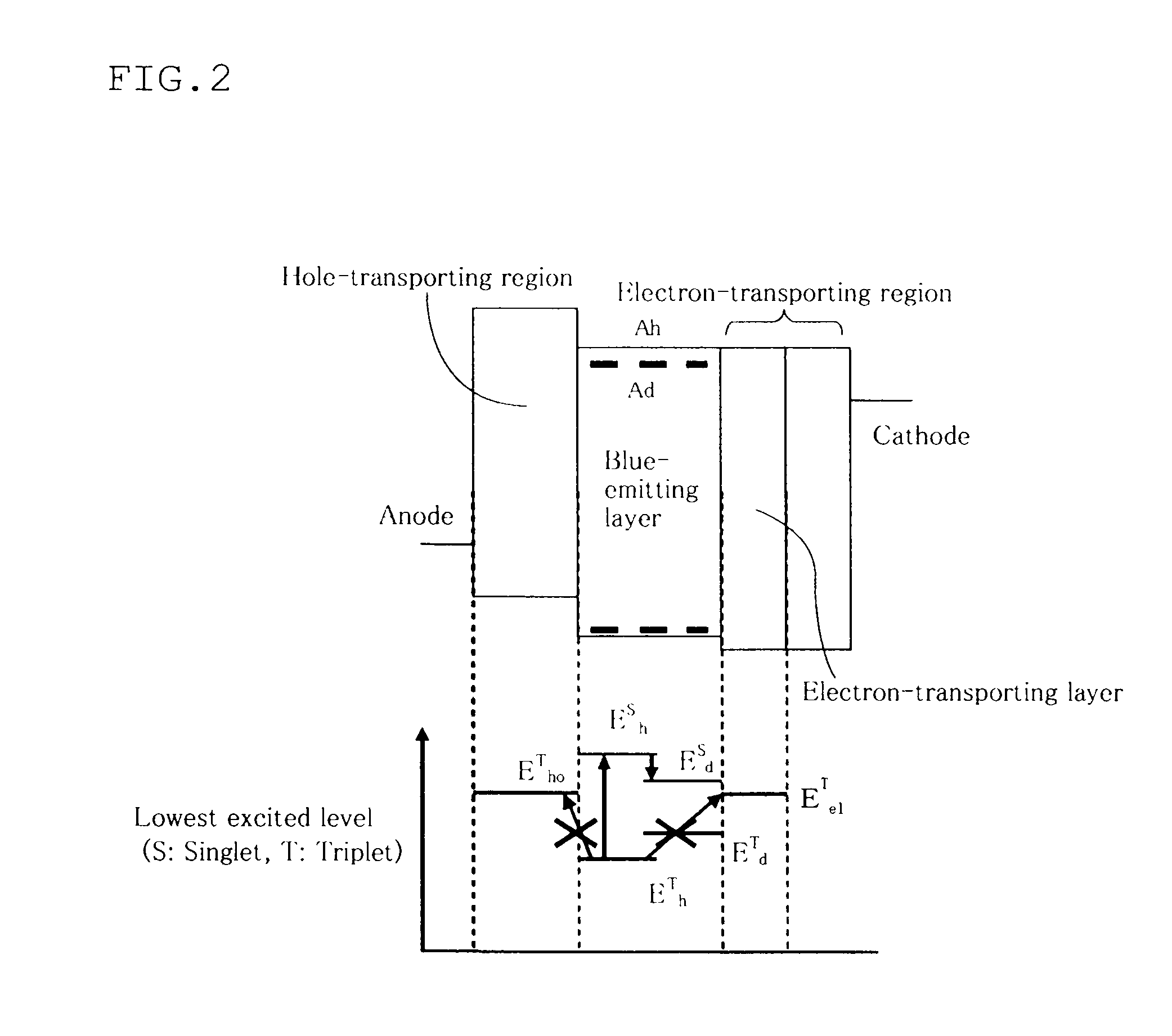

Organic electroluminescence device

ActiveUS20110049483A1Reduced luminous efficiencyImprove luminous efficiencySolid-state devicesAzo dyesDopantElectron transporting layer

An organic electroluminescence device including opposite anode and cathode, and a hole-transporting region, an emitting layer and an electron-transporting region in sequential order from the anode between the anode and the cathode, wherein the emitting layer includes a red emitting portion, a green emitting portion, and a blue emitting portion; the blue emitting portion includes a host BH and a fluorescent dopant FBD; the triplet energy ETfbd of the fluorescent dopant FBD is larger than the triplet energy ETbh of the host BH; the green emitting portion includes a host GH and a phosphorescent dopant PGD; the electron-transporting region includes a common electron-transporting layer adjacent to the red emitting portion, the green emitting portion and the blue emitting portion; the common electron-transporting layer includes a material having a triplet energy ETel larger than ETbh; and the difference between the affinity of the host GH and the affinity of the material constituting the common electron-transporting layer is 0.4 eV or less.

Owner:IDEMITSU KOSAN CO LTD

Organic electroluminescence device

ActiveUS8461574B2Improve efficiencyExcellent phosphorescent deviceSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionDopant

Owner:IDEMITSU KOSAN CO LTD

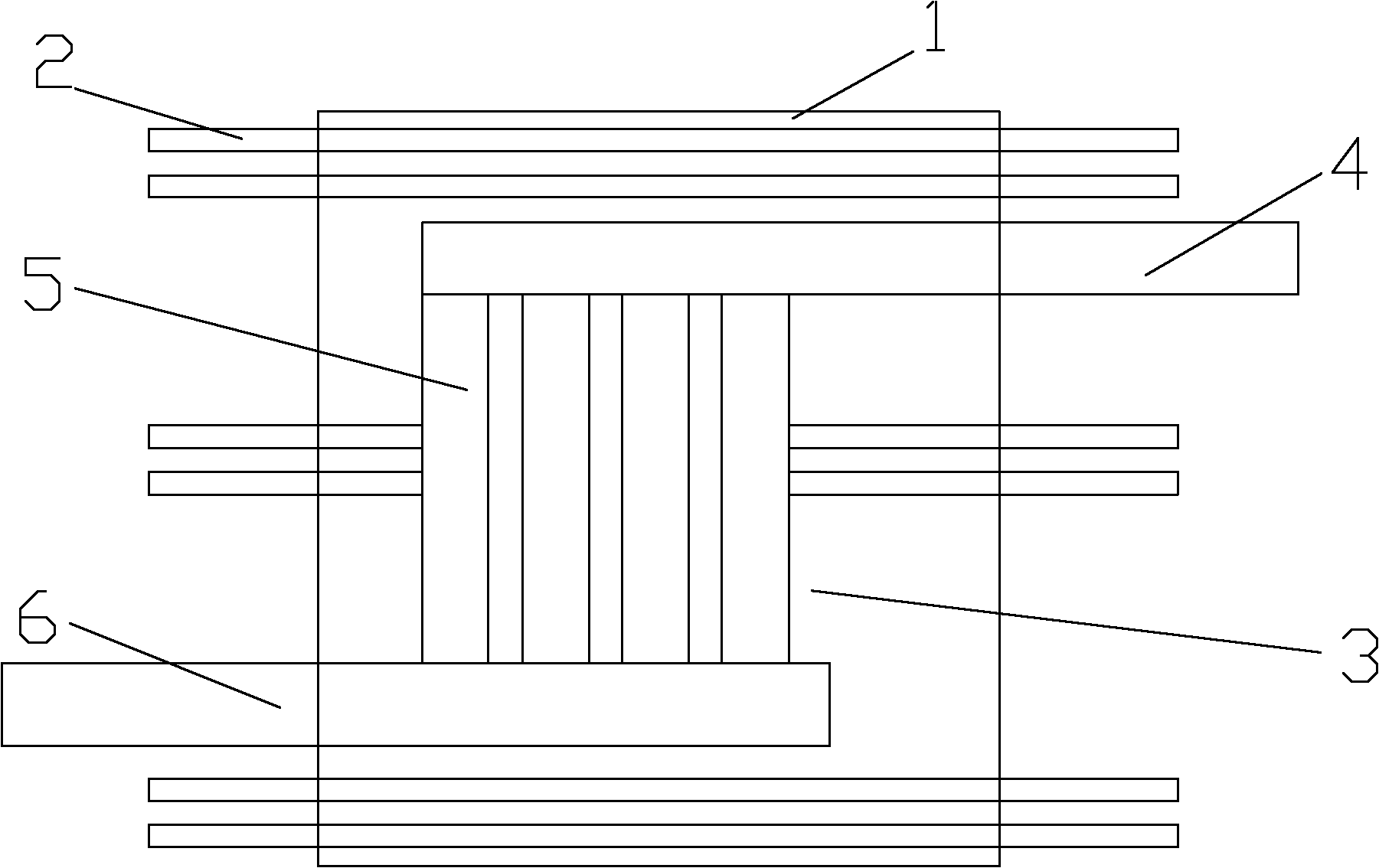

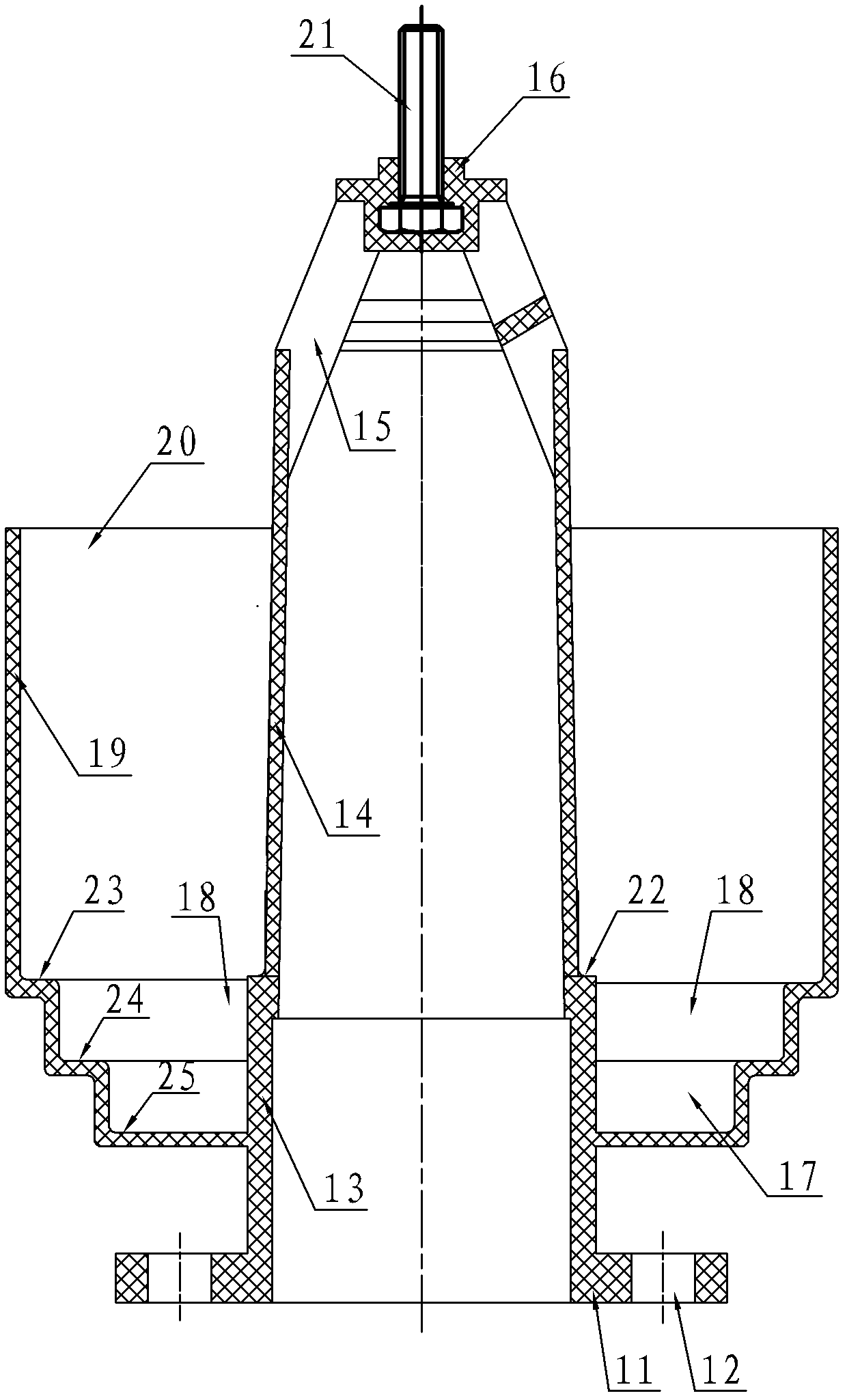

Sharp cooling and sharp heating highlight forming die

The invention discloses a sharp cooling and sharp heating highlight forming die, belonging to the technical field of injection moulding. The invention comprises a cavity insert and is characterized in that the inside of the cavity insert is provided with a plurality of cooling water channels transversely and a steam line; the steam line contains a main gas inlet pipe, shunts and a main gas outletpipe; the main gas inlet pipe extends in the upper right of the cavity insert and extends to the middle part of the cavity insert; four shunts are connected on the main gas inlet pipe side by side and extend downwards; the tail parts of the four shunts are connected with the main gas outlet pipe; and the main gas outlet pipe is arranged transversely and extends out of the lower left of the cavityinsert. The invention solves the problem of the prior art that the injection moulding equipment can not realize the fast heating and fast cooling of the mould, thus the product has the appearance quality defects such as weld marks and flow marks, and provides the sharp cooling and sharp heating highlight forming die which has simple structure and can realize fast heating and fast cooling and achieve better injection moulding effect.

Owner:KUNSHAN ESON PRECISION ENGINEERING CO LTD

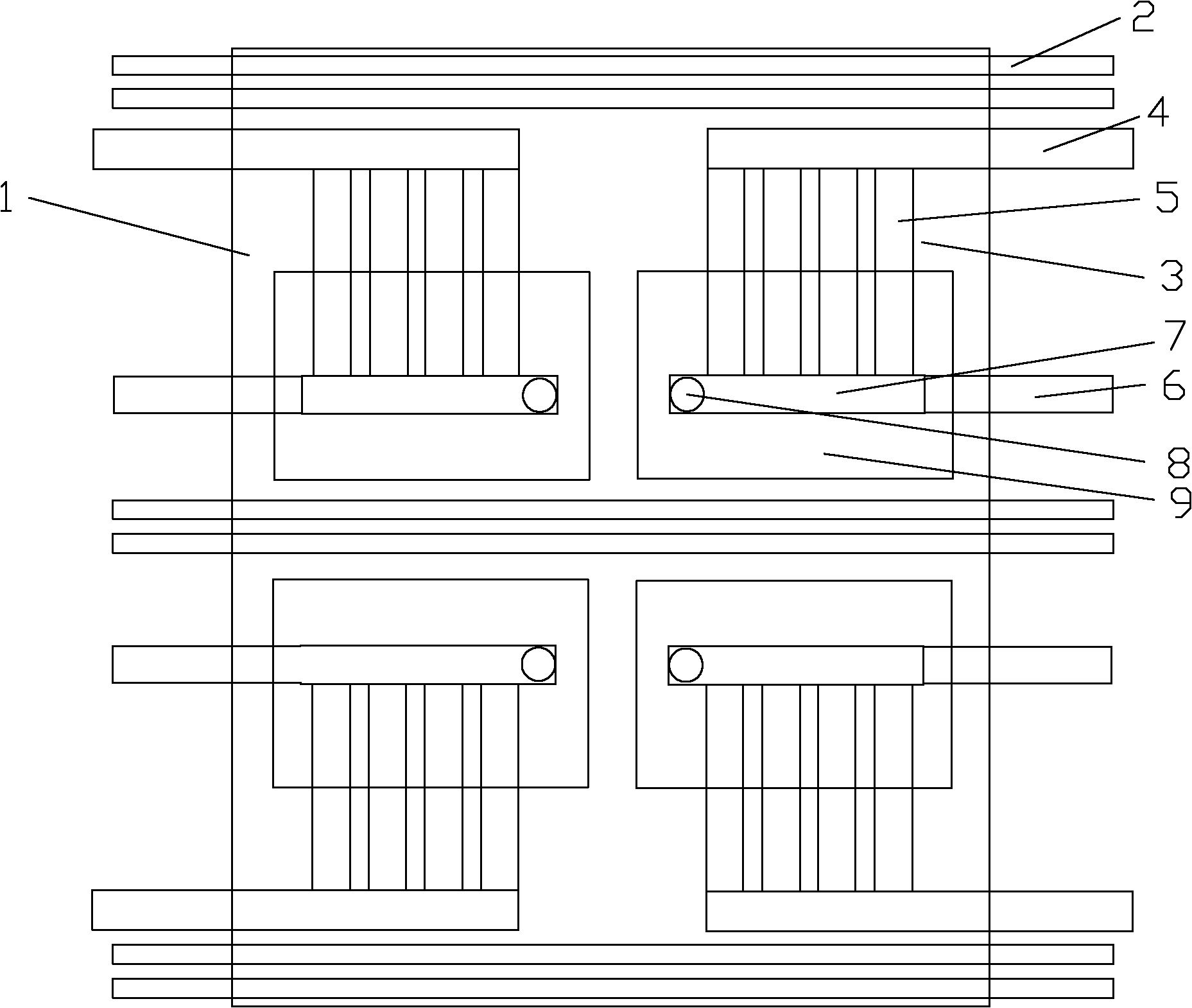

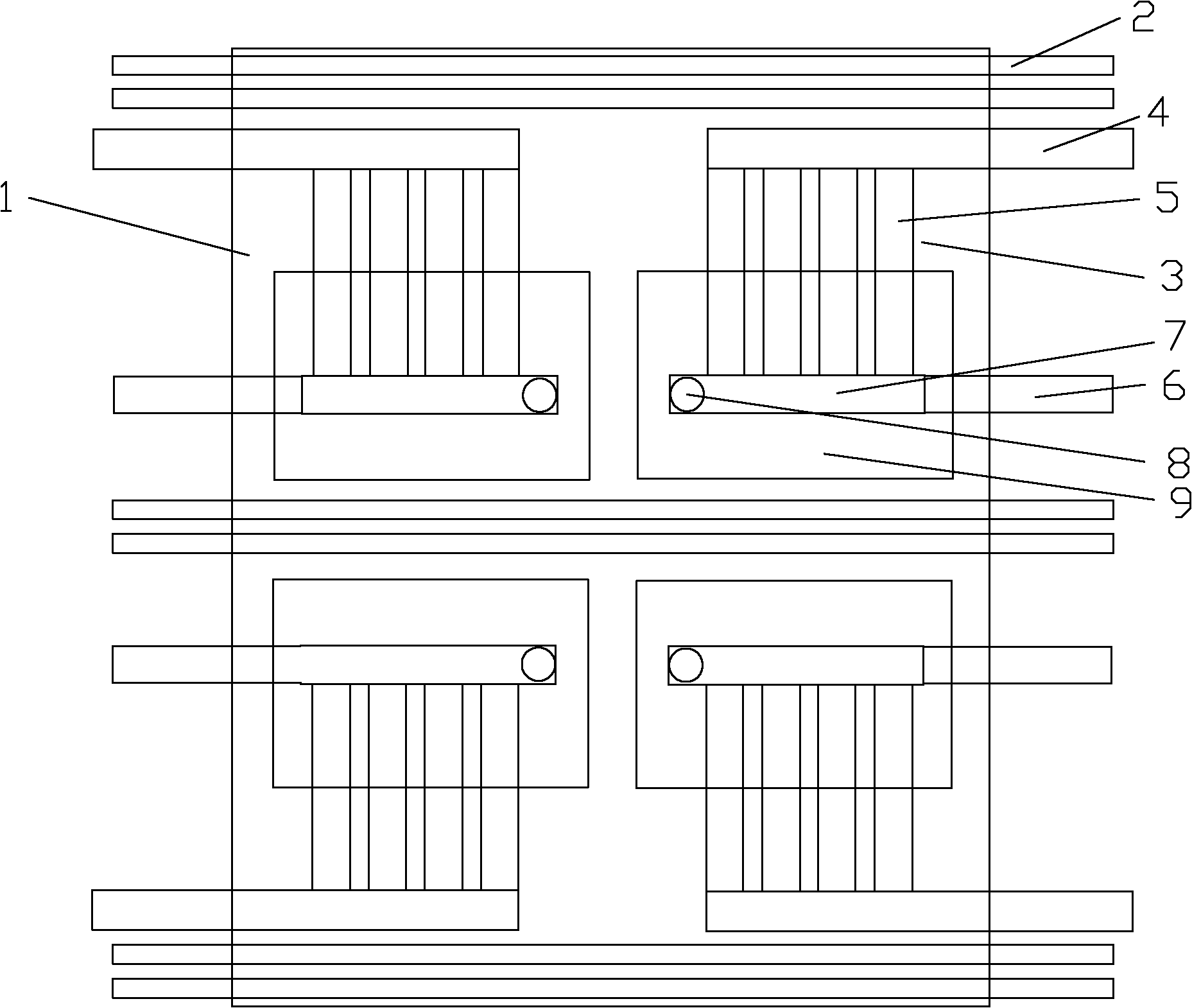

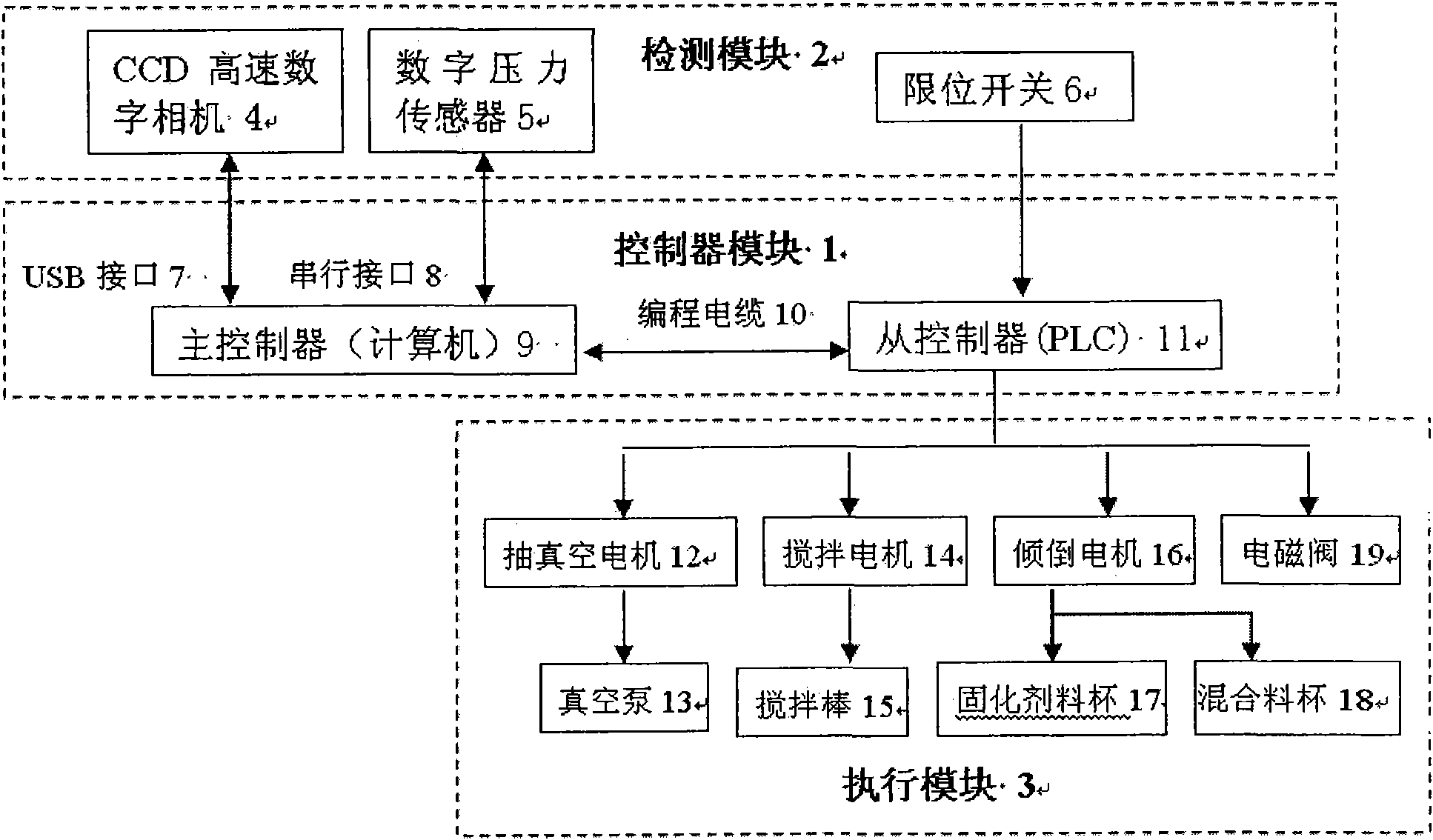

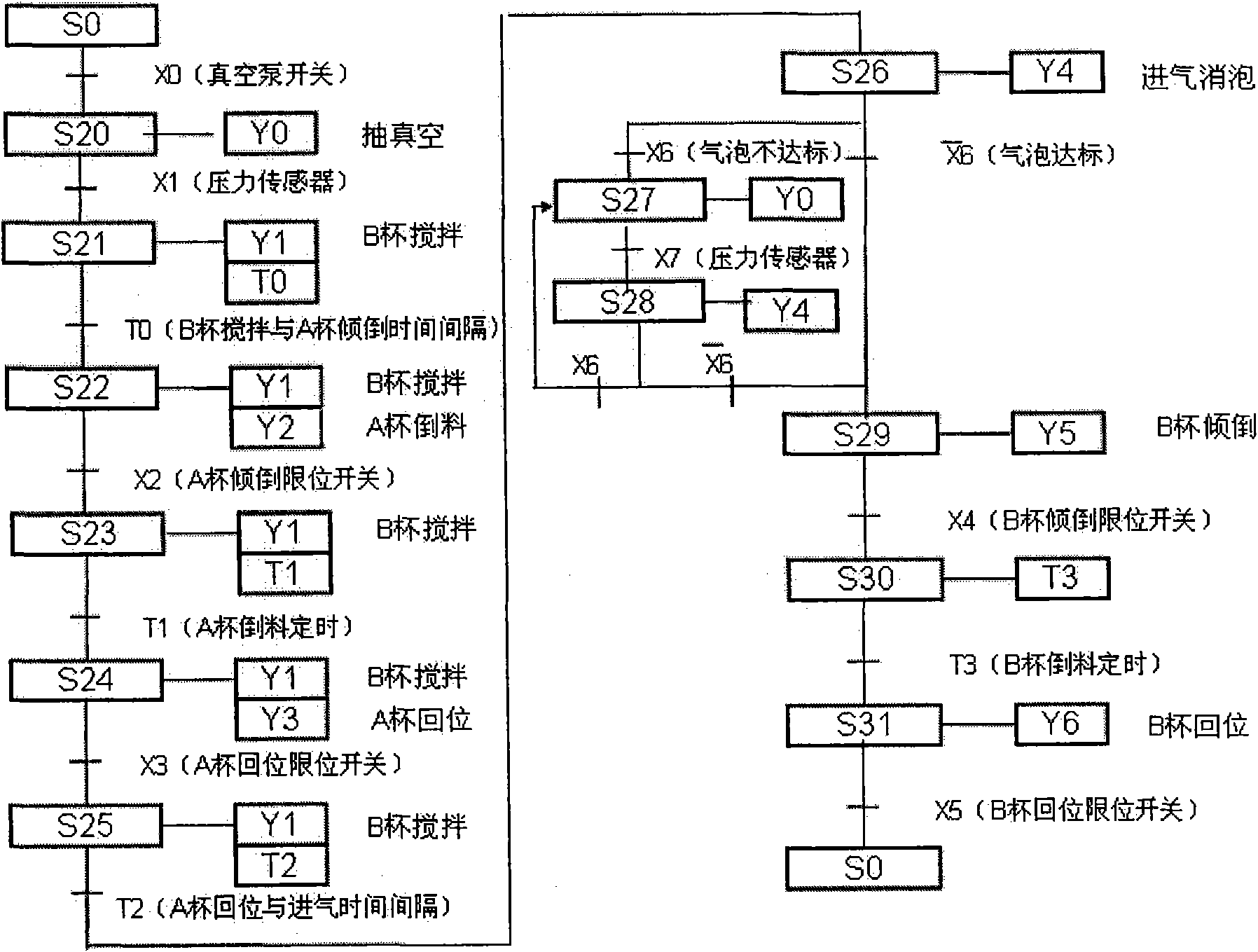

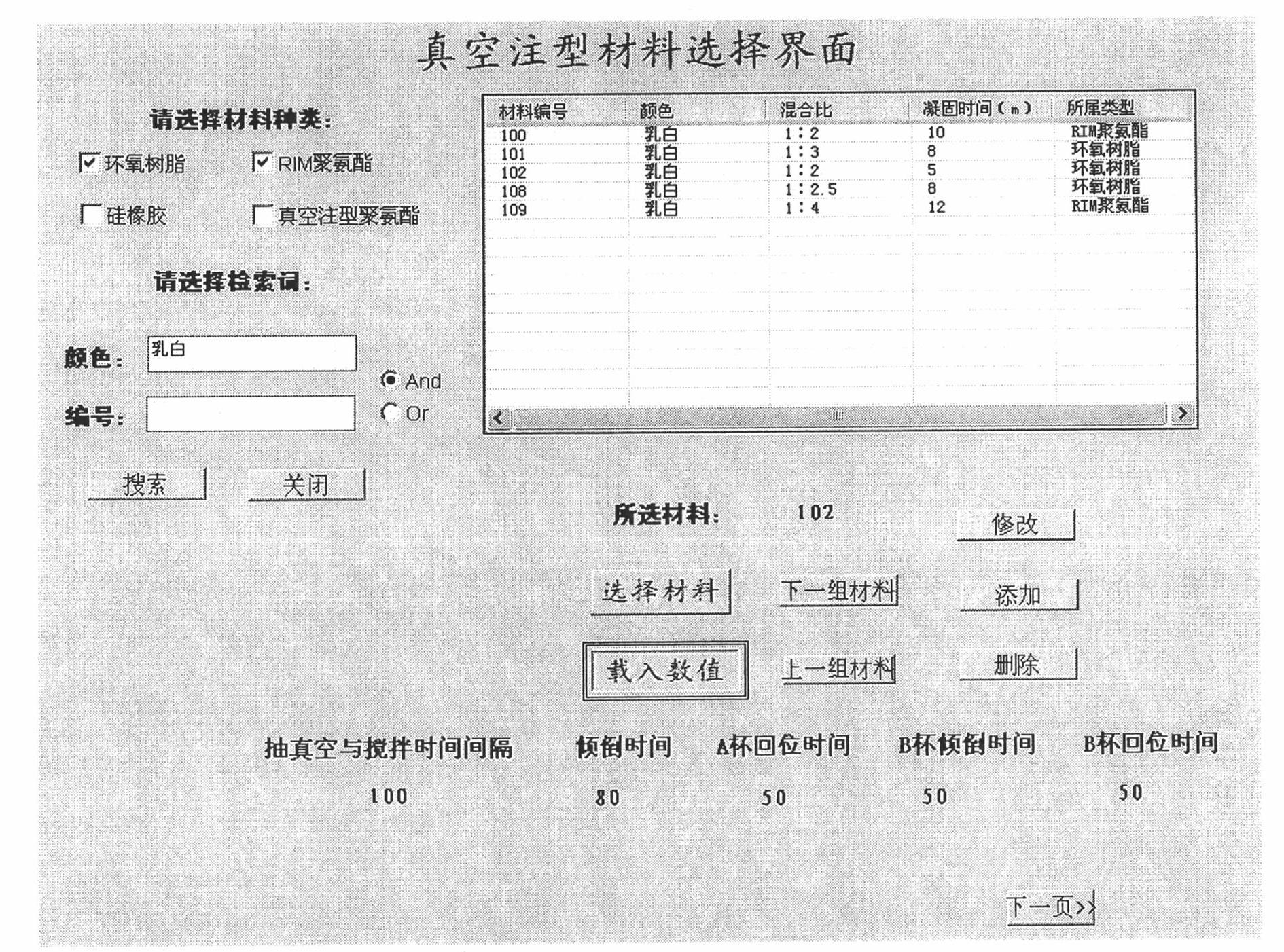

Full-automatic vacuum molding control system and method

The invention relates to a full-automatic vacuum molding control system and a method. The system comprises a detection module, a control module and an execution module, wherein the control module comprises a computer as a main controller and a programmable logic controller as a secondary controller, the detection module comprises a CCD (Charge-Coupled Device) high-speed digital camera, a digital pressure sensor and a limit switch, the execution module comprises a vacuum pump connected with a vacuumizing motor, a stirring rod connected with a stirring motor, and a firming agent material cup and a mixed material cup connected with a tilted motor as well as an electromagnetic valve for air intake. The control method realizes visual, automatic and intelligent control of the vacuum molding process. The invention can greatly save the labor resource cost and improve the molding working efficiency and the product quality.

Owner:SHANGHAI UNIV

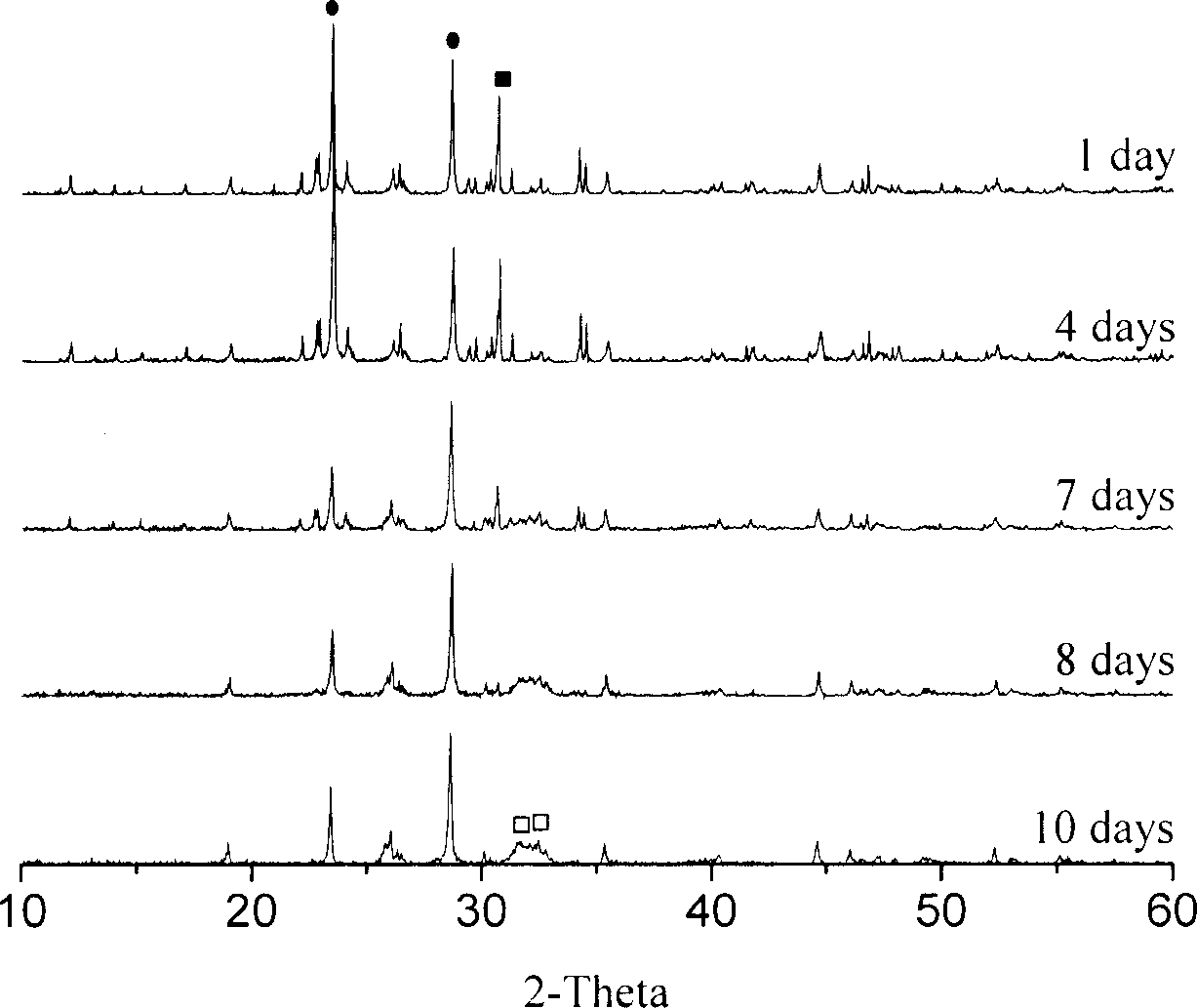

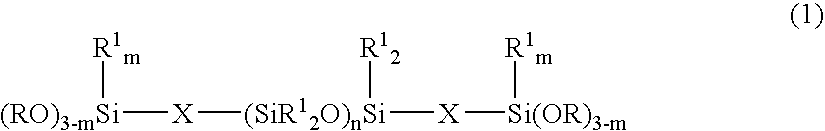

Room temperature-curable organopolysiloxane composition

A room temperature-curable organopolysiloxane composition is provided. The composition comprises(A) 100 parts by weight of a organopolysiloxane represented by the following general formula (1):wherein R is a monovalent hydrocarbon group containing 1 to 5 carbon atoms, R1 is independently a substituted or unsubstituted monovalent hydrocarbon group containing 1 to 10 carbon atoms; n is an integer of at least 10; X is oxygen atom or an alkylene group containing 2 to 5 carbon atoms, and m is independently an integer of 0 or 1; or a mixture of such organopolysiloxane;(B) 50 to 150 parts by weight of a colloidal calcium carbonate having a specific surface area measured by BET method of at least 10 m2 / g;(C) 100 to 200 parts by weight of a heavy calcium carbonate having a specific surface area measured by BET method of up to 8 m2 / g;(D) 1 to 25 parts by weight of an organosilicon compound having at least 3 hydrolyzable groups bonded to silicon atom in one molecule represented byR2aSi(OR3)4-a wherein R2 is a monovalent hydrocarbon group containing 1 to 12 carbon atoms, R3 is a monovalent hydrocarbon group containing 1 to 5 carbon atoms, and a is 0 or 1; or its partial hydrolysate; and(E) 0.01 to 10 parts by weight of a curing catalyst. The mass ratio of the component (B) to the component (C) is less than 1.

Owner:SHIN ETSU CHEM IND CO LTD

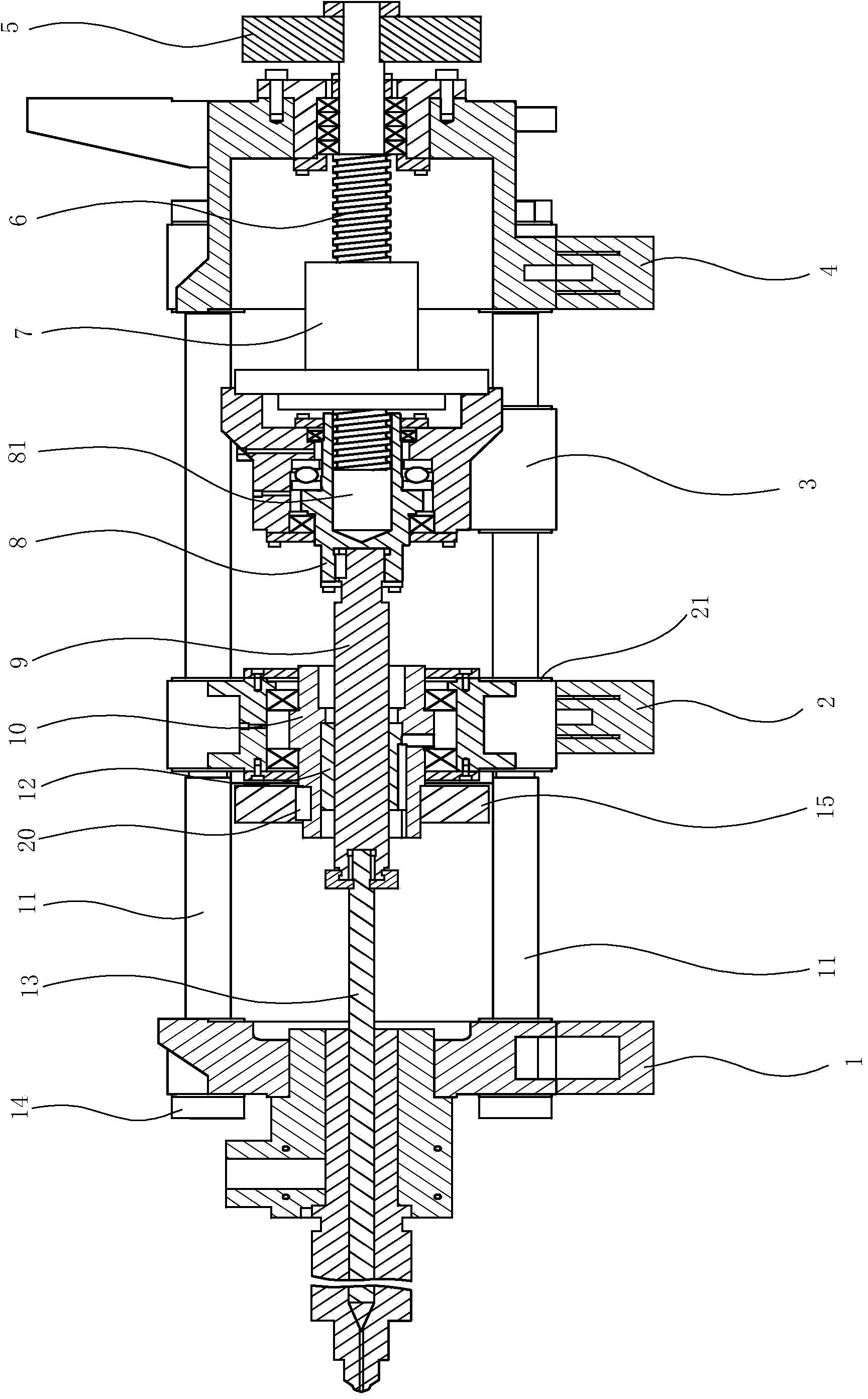

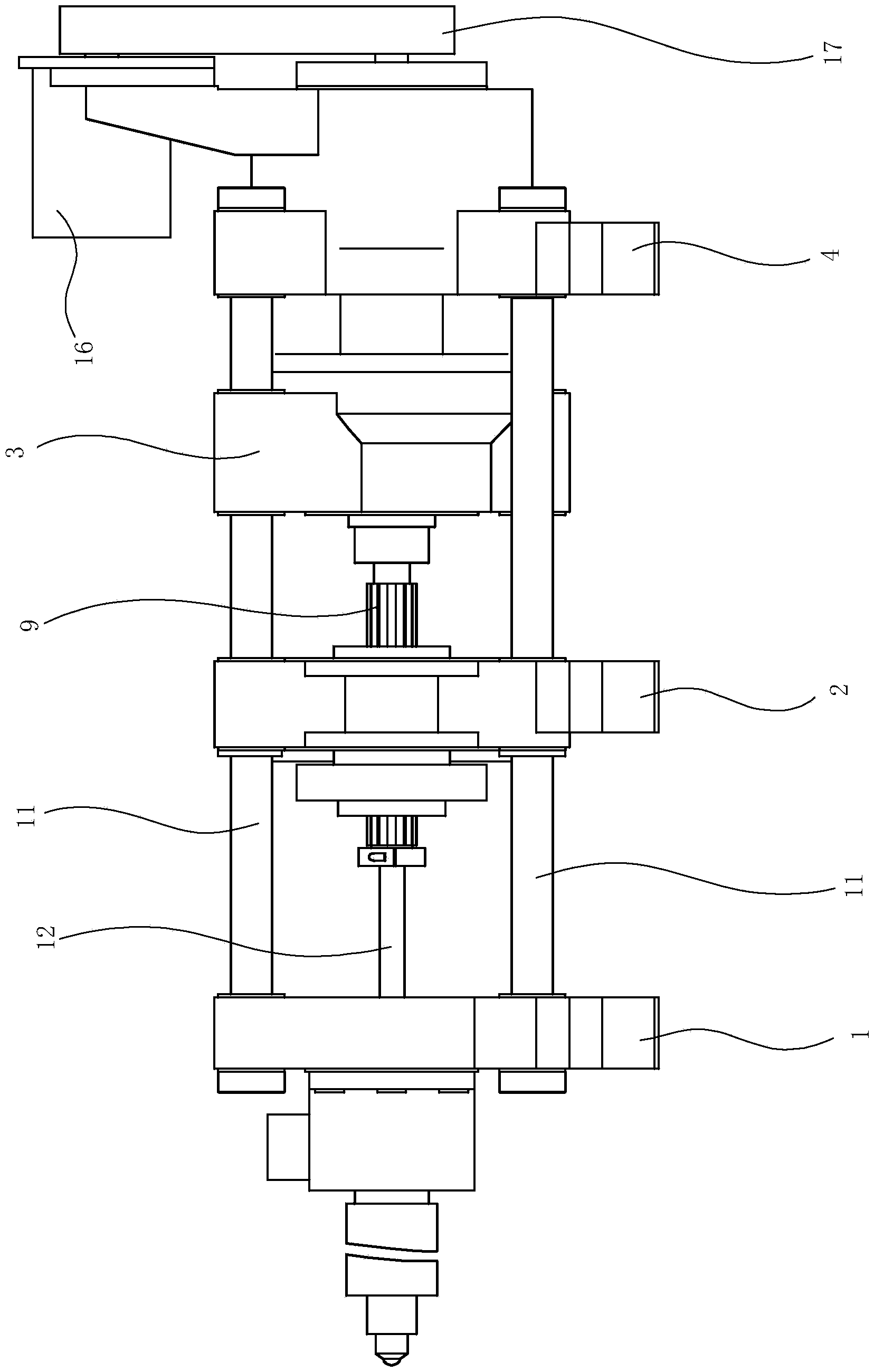

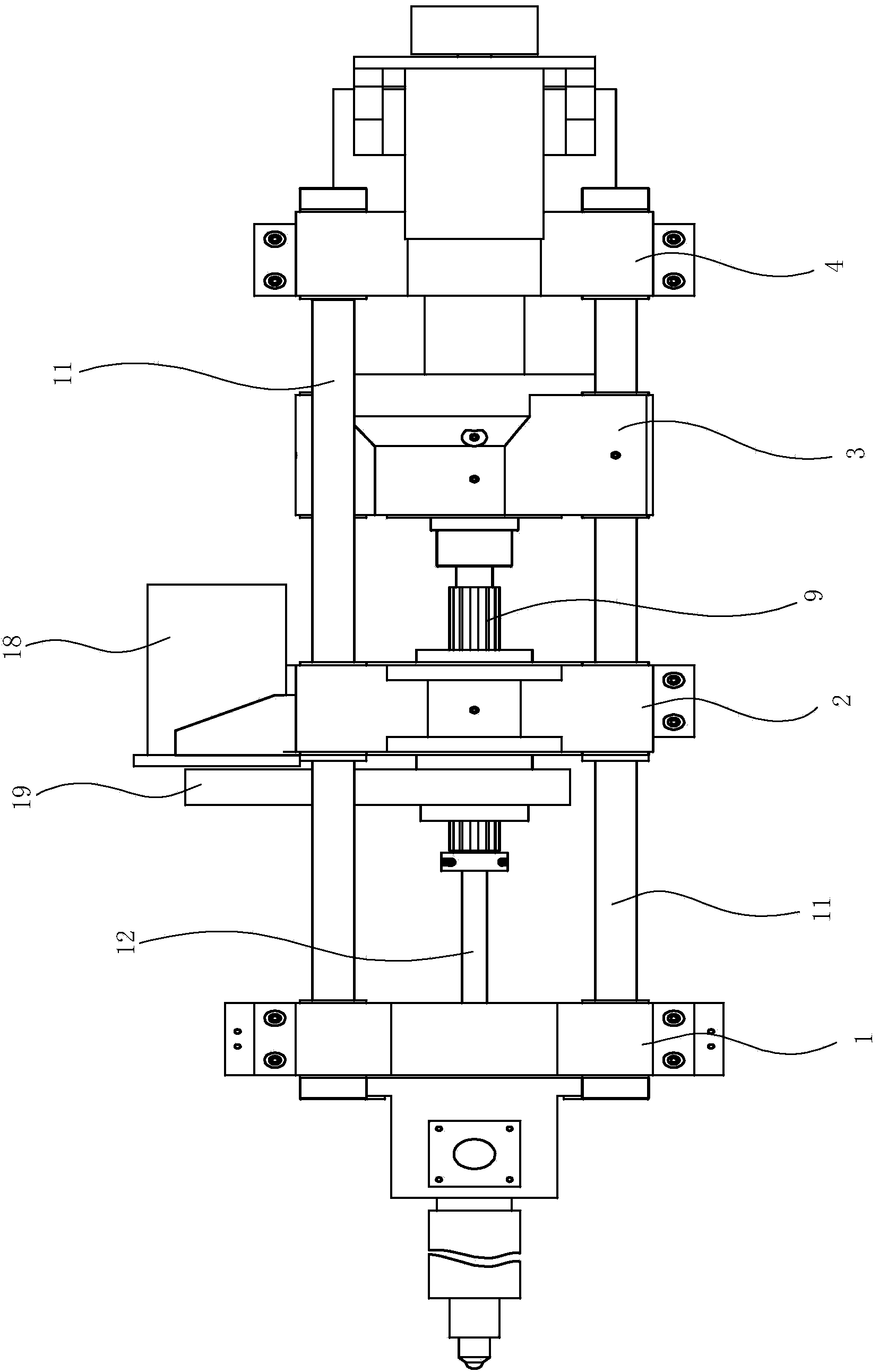

Electric injection device for injection molding machine

The invention discloses an electric injection device for an injection molding machine. The electric injection device comprises a screw rod which is arranged in an injection front plate in a penetrating manner and a pin roller screw rod pair, wherein the pin roller screw rod pair comprises a nut and a pin roller screw rod arranged in an injection tail plate in the penetrating manner. The electric injection device is characterized in that the tail of an injection movable plate is fixedly connected with the nut; the injection movable plate is internally and rotatably provided with a pressure transmission shaft; the front end of the pressure transmission shaft is connected with a spline shaft; the other end of the spline shaft is connected with the screw rod; an injection middle plate is internally and rotatably provided with a transmission shaft; the transmission shaft is internally sleeved with a spline sleeve; a spline pair is composed of the spline sleeve and the spline shaft. With the adoption of the spline pair, the weight of a movement part in the injection process is lightened and the injection performance of the injection molding machine is improved.

Owner:宁波海雄塑料机械有限公司

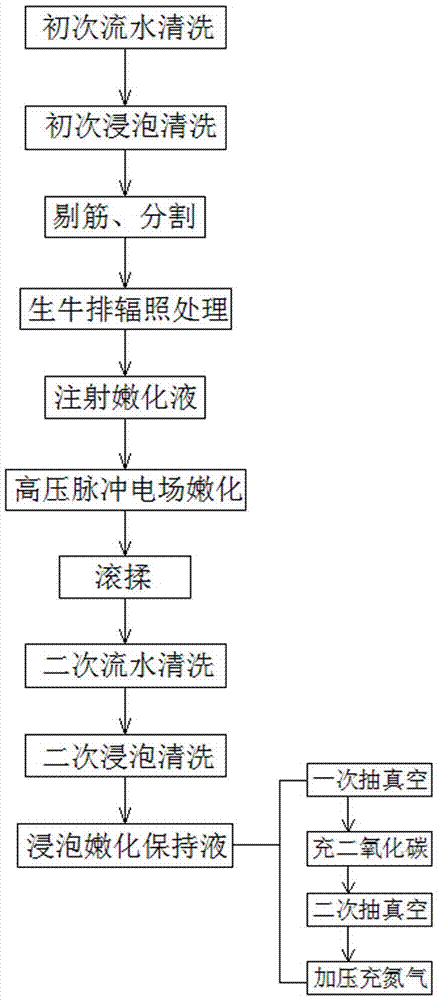

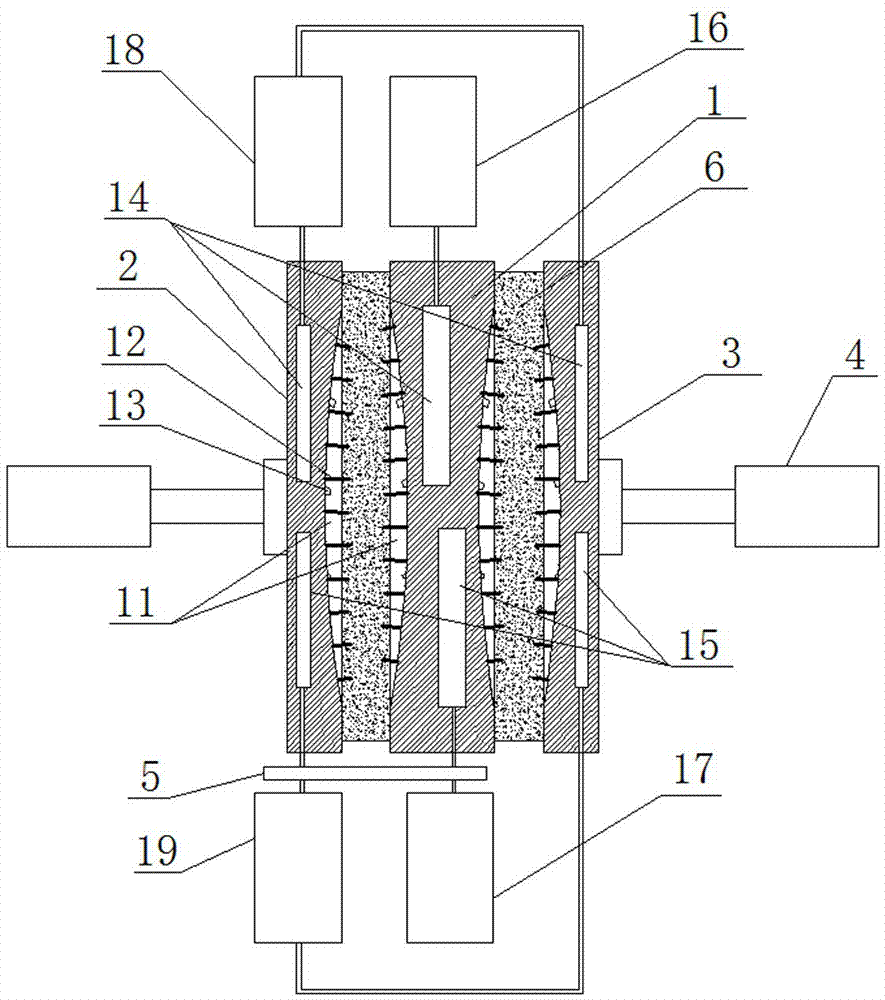

Method for tenderizing beef steak

Owner:福建佳客来食品股份有限公司

Organic thin film transistor (OTFT)

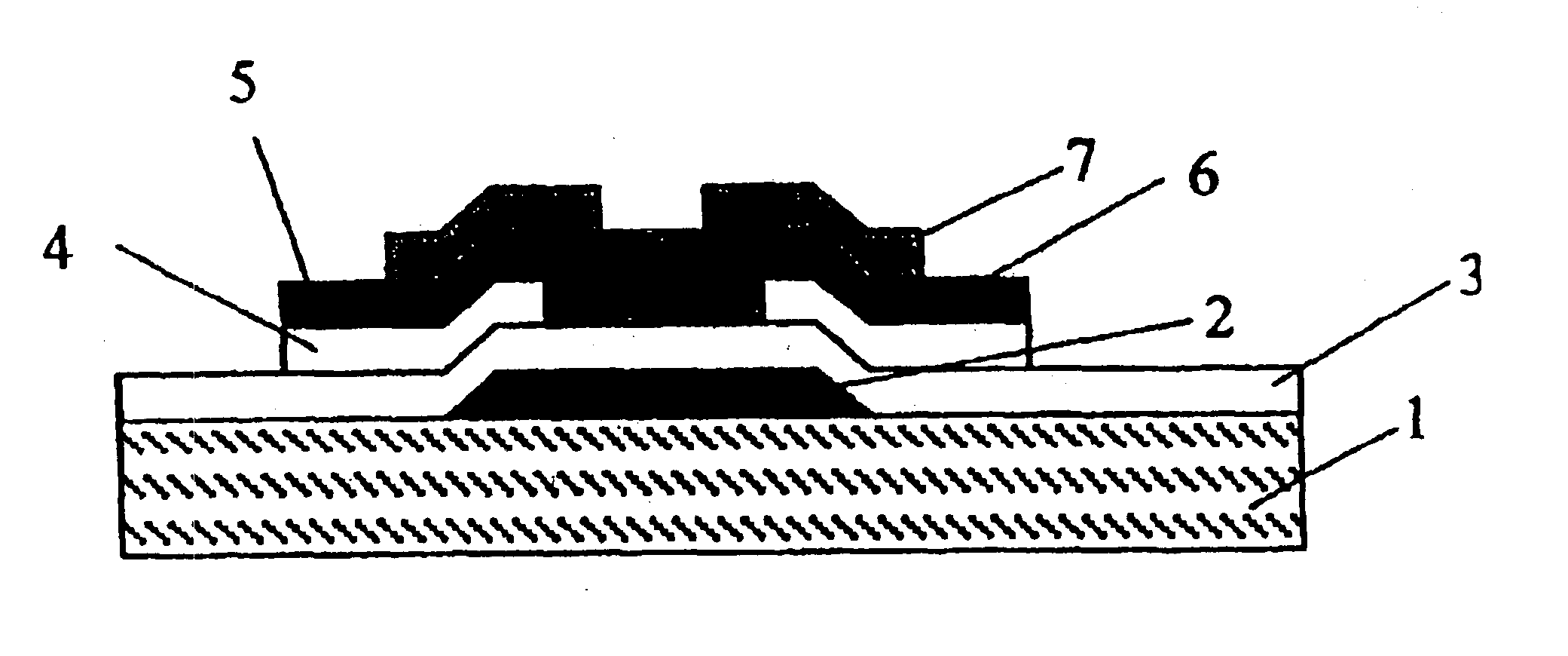

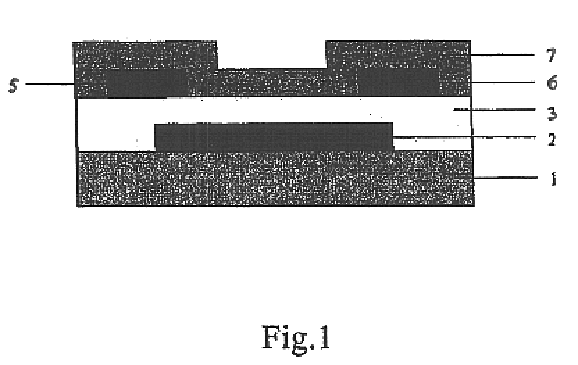

InactiveUS6847048B2Reduce leakage currentImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerGas phase

The present invention relates to an organic thin film transistor (OTFT) comprising: a substrate (1), a gate electrode (2) formed on the substrate (1), a gate insulation layer formed on the gate electrode, a source electrode (5) and a drain electrode (6) formed on the gate insulation layer including a first insulation layer (3) and a second insulation layer (4) with different dielectric constants, and an active layer (7) which overlays the source electrode (5) and the drain electrode (6). Without adding the conventional complicated processes like photolithography but adding two simple processes of spin coating or vaporously coating the second insulation film and self-aligned dry RIE, the present invention not only can improve the carrier's injection property so as to improve the OTFT device's properties, but also can block the leakage current of the gate insulation layer and reduce the device's parasitic capacitance. Therefore, the material with high dielectric constant can be used as the insulation layer to increase the channel capacitance so as to reduce threshold voltage of the device and reduce the adverse effect of the leakage between the source and gate electrodes, the gate and drain electrodes.

Owner:CHANGCHUN FULEBO DISPLAY TECH

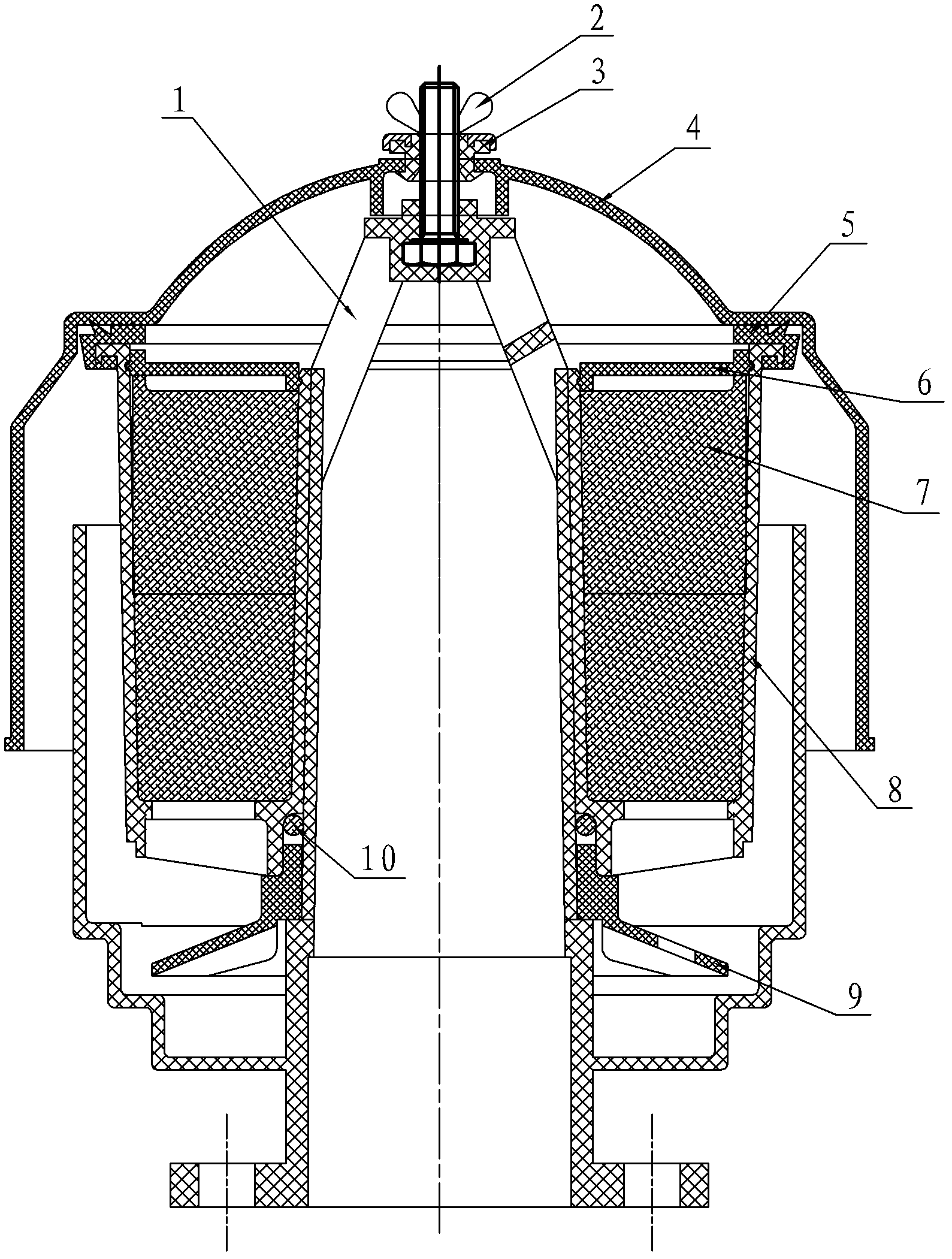

Oil bath air filter

InactiveCN102322374AEasy to pressComply with lightweight design requirementsCombustion-air/fuel-air treatmentMachines/enginesCombustionAir filter

The invention relates to an oil bath air filter, which comprises an air inlet pipe seat, a butterfly nut, an anti-vibration sealing ring, a shell, an upper port sealing ring, a ventilated filter element cover, an oily filter element, a filter element accommodating body and an oil baffle disc. In the oil path dust cross structure, dust absorption oil is stored in an oil storage cavity, air contacts the dust absorption oil and then enters a capillary tube of the oily filter element after being sucked, dust and solid particles in the air are subjected to secondary oil adsorption, and fine dust in the air can be adsorbed and removed; the oily filter element is a polyurethane foam sponge, has high filtering efficiency and long service life, and is convenient to clean; the shell and the air inlet pipe seat are formed by pressing modified engineering plastic which has high injection forming performance, a cavity which meets the design requirement can be conveniently formed by pressing, and air inlet resistance and anti-vibration sound absorption performance are high; and steel is replaced by the plastic, so that production efficiency is high, quality is stable, weight is light, the air inlet quality of a diesel engine is ensured and the sufficient combustion of diesel oil is better facilitated due to a dual seal structure, and the output power of the diesel engine is improved.

Owner:江苏鑫田柴油机有限公司

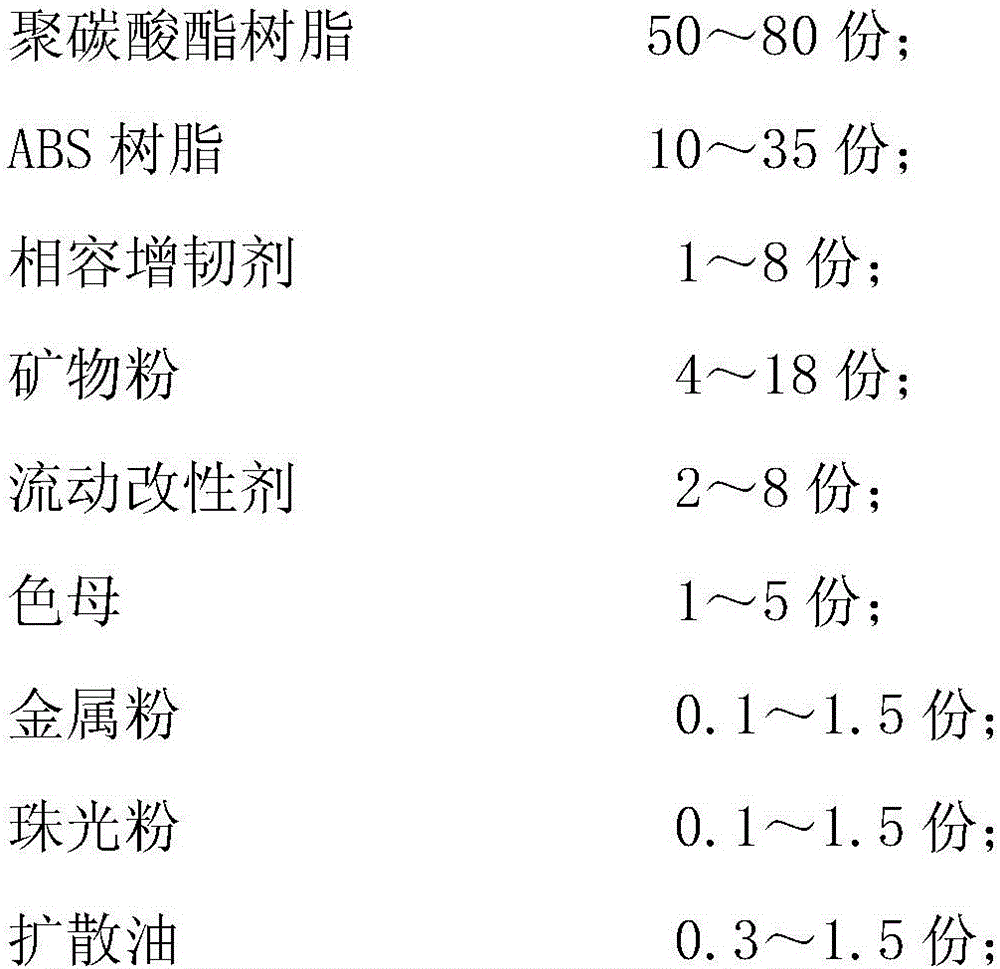

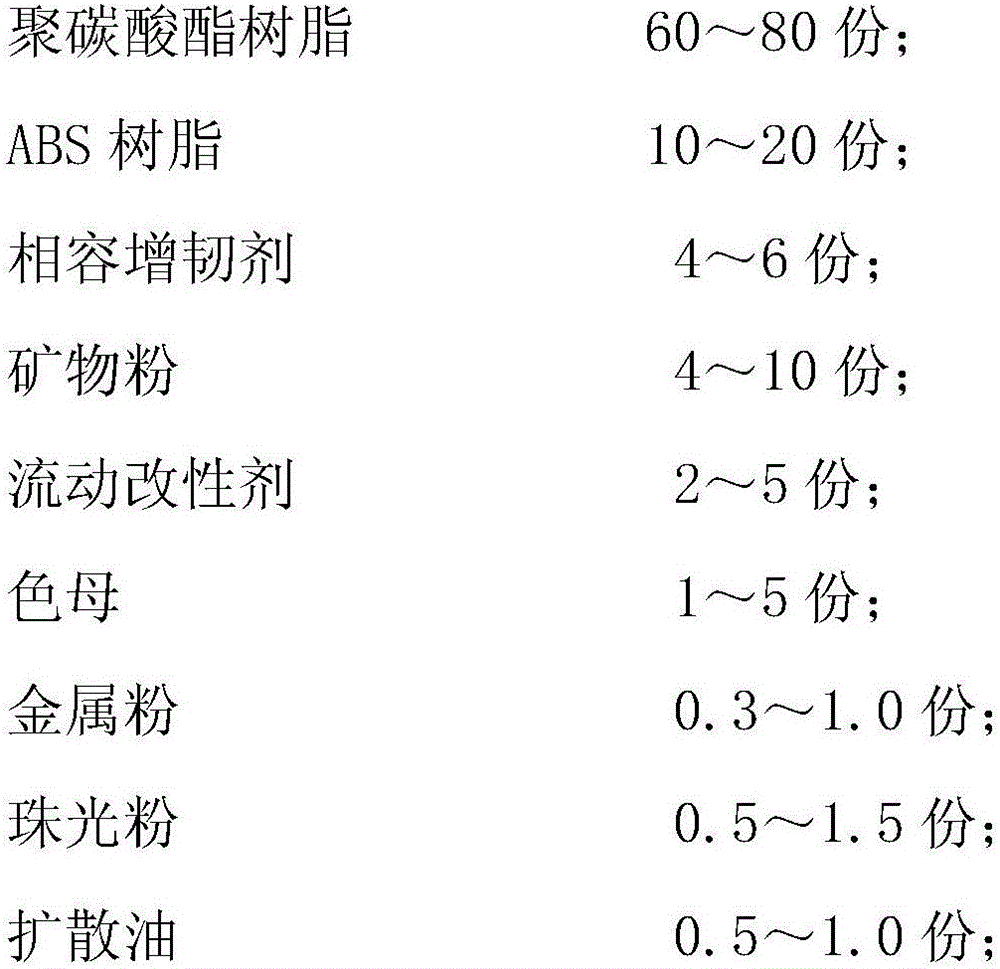

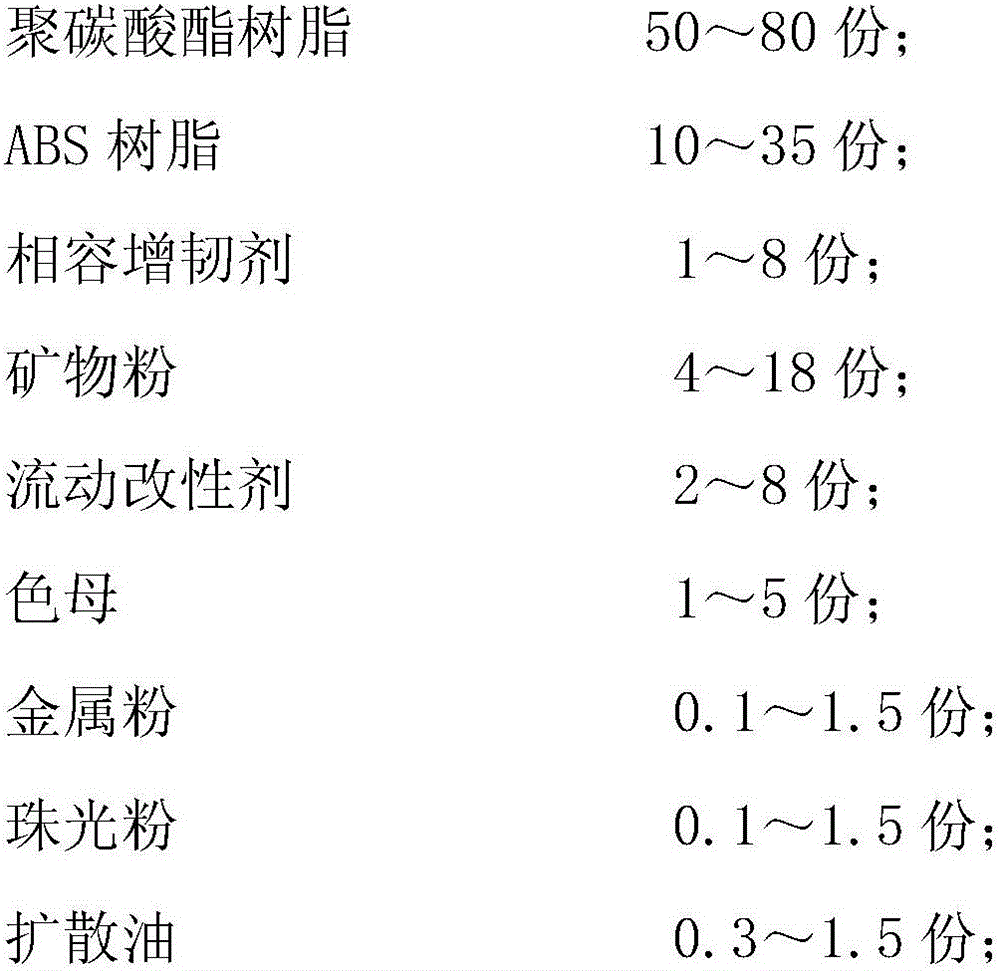

Composite material and preparation method thereof

The invention discloses a composite material and a preparation method thereof. The composite material is prepared from 50 to 80 parts by mass of polycarbonate resin, 10 to 35 parts by mass of ABS resin, 1 to 8 parts by mass of a compatible flexibilizer, 4 to 18 parts by mass of mineral powder, 2 to 8 parts by mass of a flow modifier, 1 to 5 parts by mass of color masterbatch, 0.1 to 1.5 parts by mass of metal powder, 0.1 to 1.5 parts by mass of pearl powder and 0.3 to 1.5 parts by mass of diffusion oil. The composite material is produced by blending raw materials according to a mass part ratio and carrying out melting granulation. Through use of the metal powder and pearl powder, alloy material colorful metal effects satisfy household electrical appliance product appearance and use requirements and the composite material has the advantages of scratch resistance, high hardness and environmental friendliness. The flow modifier can provide material flowability and improve the material injection molding performances. The micro / nano-silicate particles can improve the mechanical properties and gloss of the composite material and improve wear resistance of the composite material so that the composite material meets spray-free and high gloss appearance requirements.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

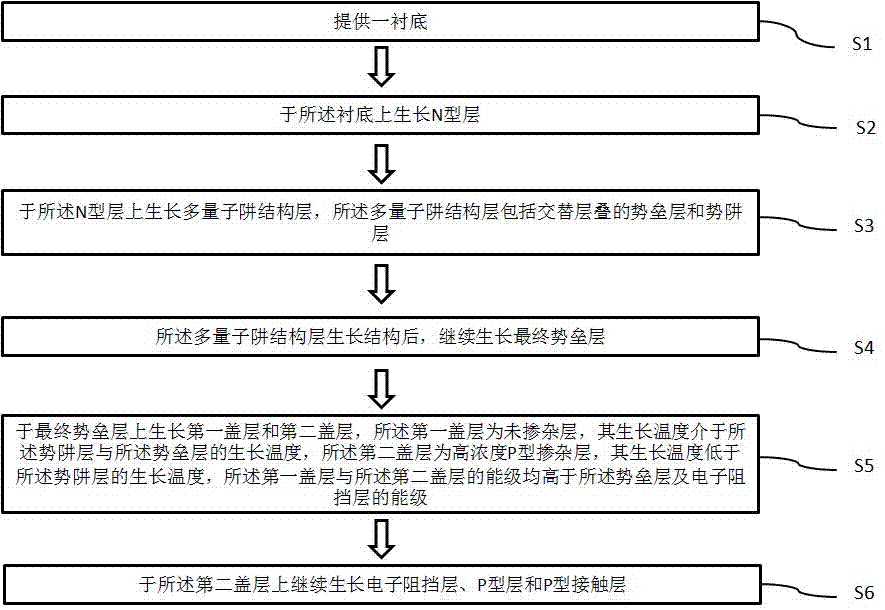

Semiconductor light-emitting element and preparation method thereof

ActiveCN107394019AReduced luminous efficiencyReduce overflowSemiconductor devicesHigh concentrationHole injection layer

The present invention belongs to the semiconductor technology field, in particular to a semiconductor light-emitting element and a preparation method thereof. According to the present invention, a first cover layer and a second cover layer of high energy levels grow at a low temperature between a final barrier layer and an electron barrier layer, the first cover layer is an un-doped layer growing relatively at the low temperature and is used to reduce the situation that the P-type impurities diffuse to a multi-quantum well structural layer, so that the luminescence efficiency reduces, and the second cover layer is a hole injection layer, is doped with the P-type impurities of high concentration to improve a hole injection effect. Meanwhile, by utilizing the higher energy levels of the first cover layer and the second cover layer, the electron overflow is reduced effectively, and the luminescence efficiency of the semiconductor element is improved.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

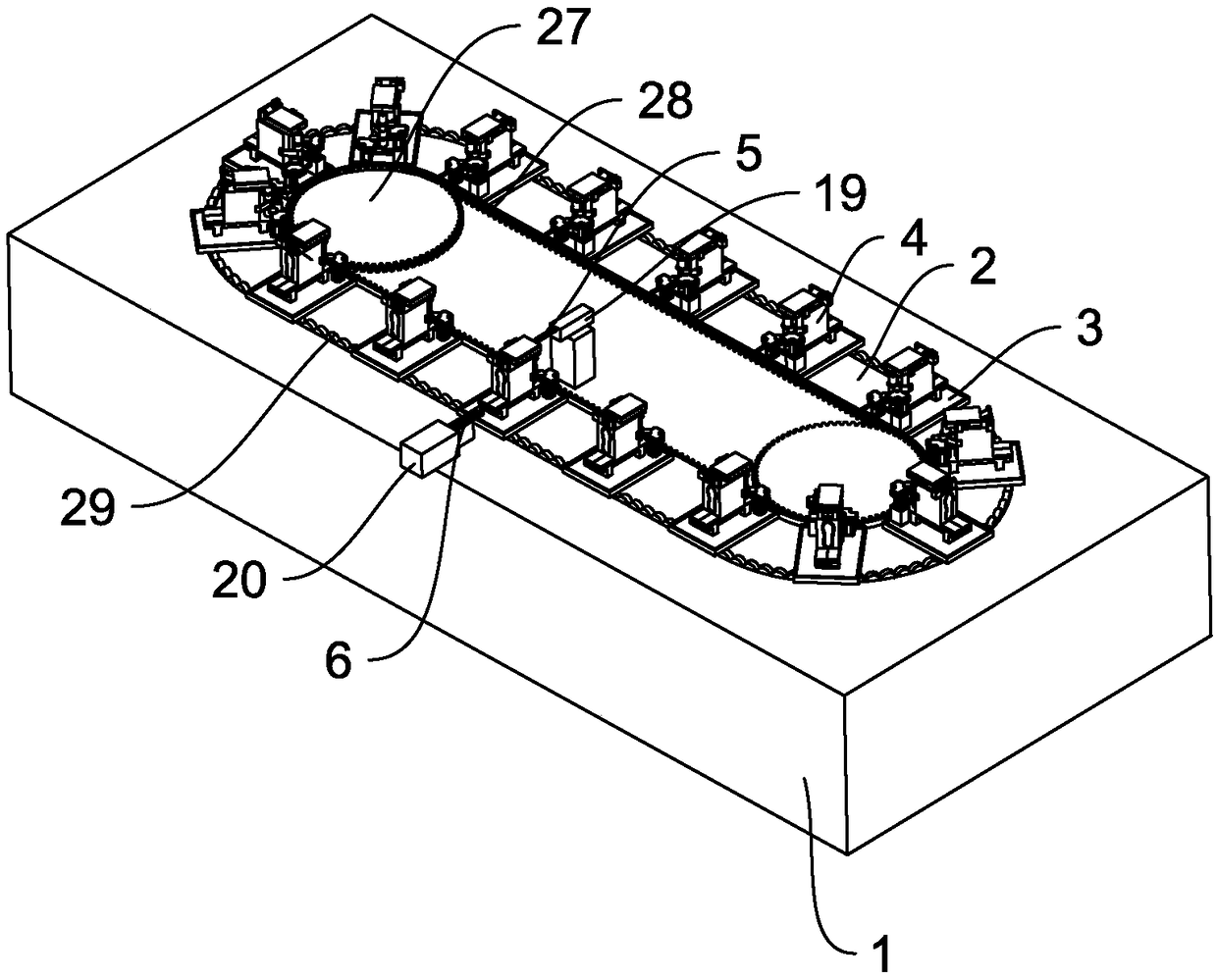

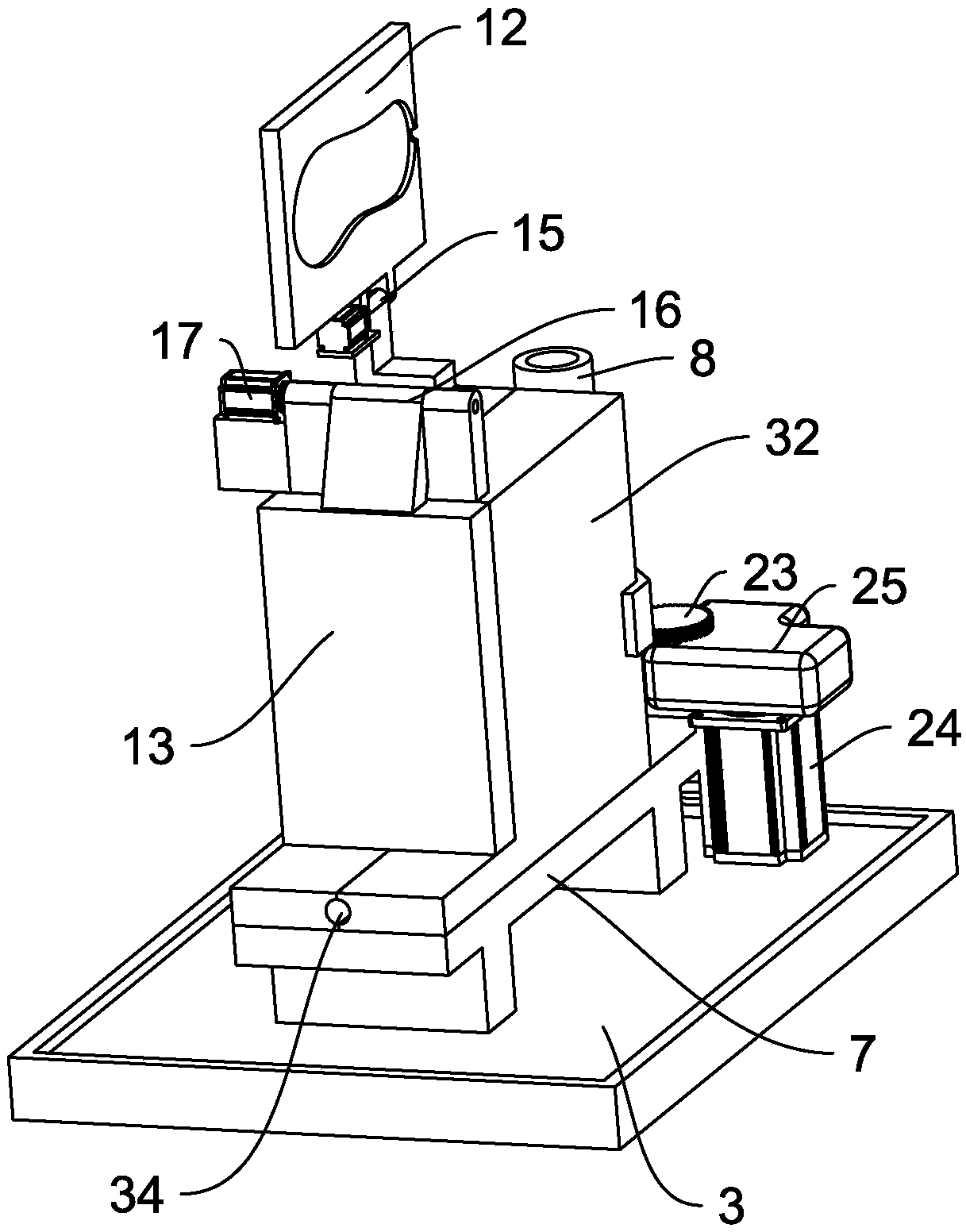

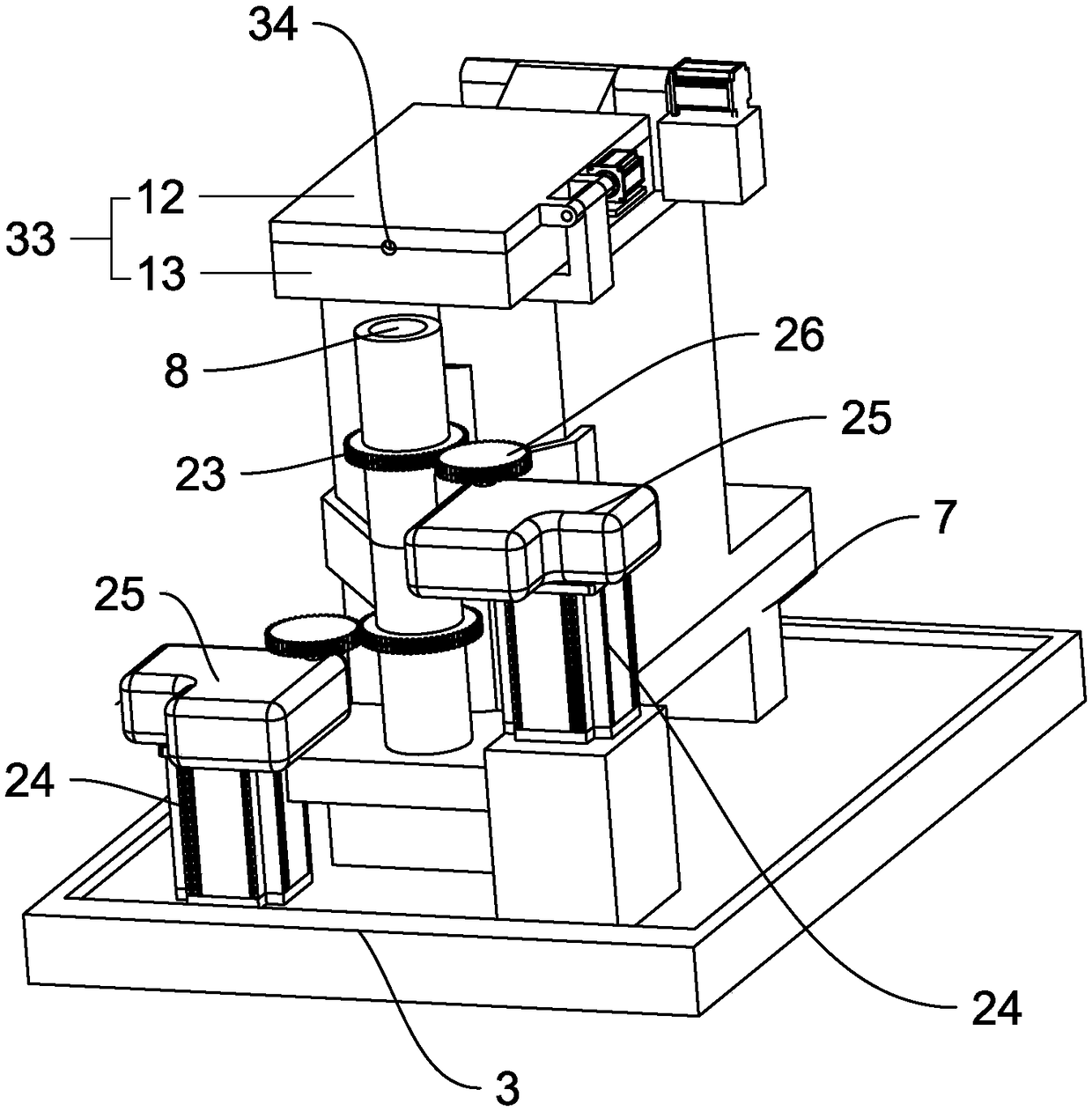

Rain shoe injection molding device

ActiveCN108749060AImprove injection effectImprove product qualityDomestic footwearNumerical control systemBatch production

The invention belongs to the technical field of molds, and discloses a rain shoe injection molding device. The device comprises a machine frame, wherein a circle of sliding grooves are formed in the upper surface of the machine frame; and a plurality of station platforms are arranged in the sliding grooves at intervals along the circumferential direction, each station platform is internally provided with a shoe mold which is composed of an upper mold and a shoe sole mold, and the mold opening and closing of the shoe molds are controlled by a numerical control system. The rain shoe injection molding device has the advantages that the multiple station simultaneous injection molding is adopted, so that the overall production efficiency is greatly improved, and the large-batch production is met.

Owner:台州三发鞋业有限公司

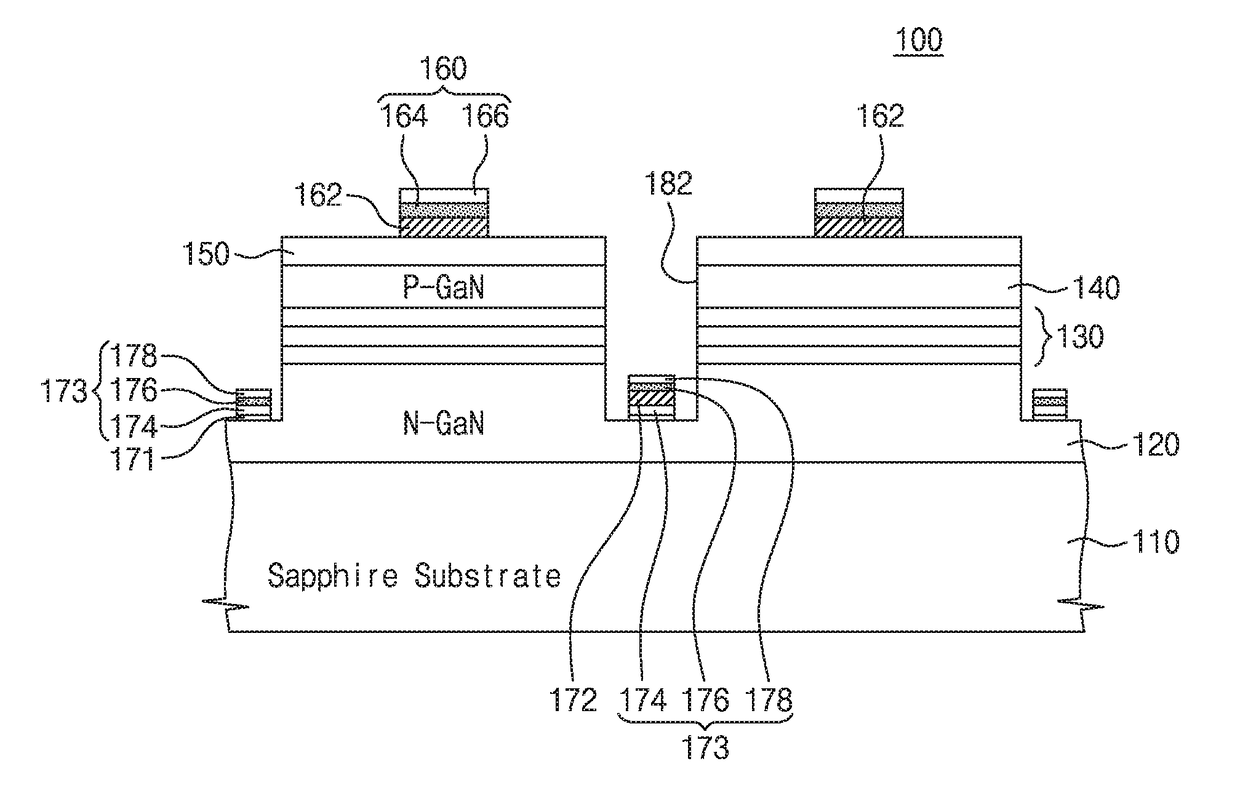

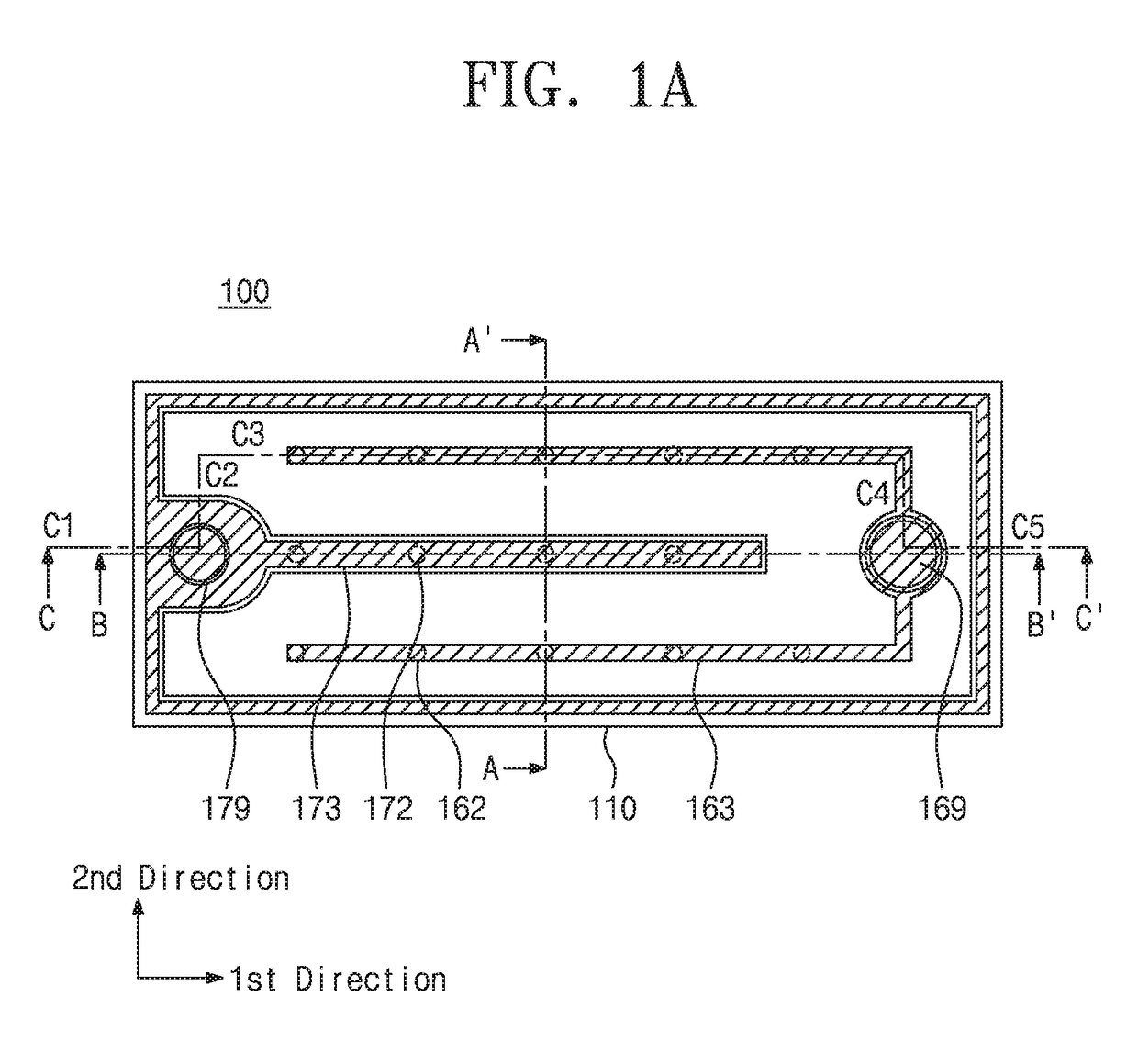

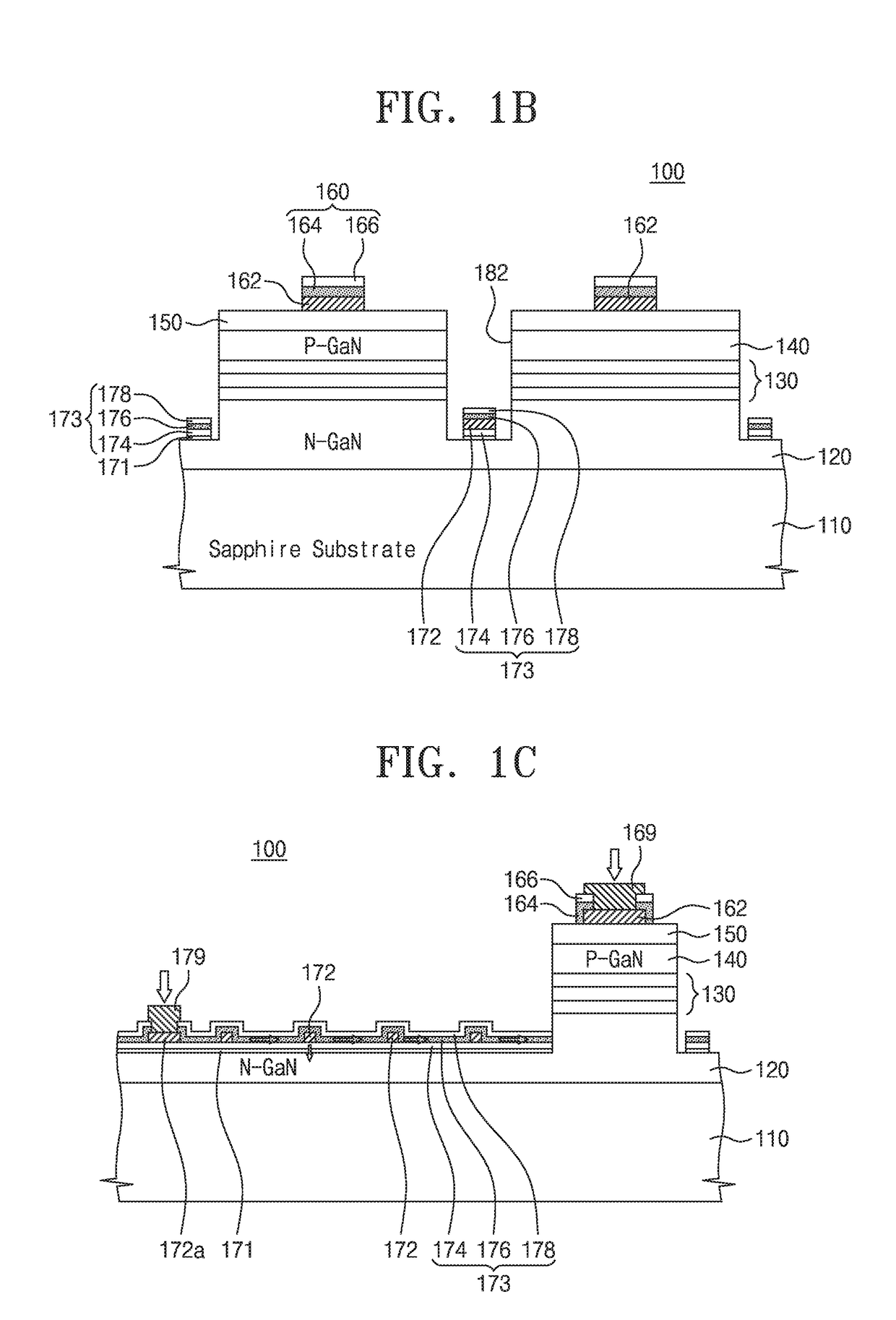

Light-emitting diode device for enhancing light extraction efficiency and current injection efficiency

ActiveUS20170358714A1Improve light extraction efficiencyImprove extraction efficiencySolid-state devicesSemiconductor devicesElectricityThin layer

Provided is a GaN light-emitting diode (LED) device. The LED device may include a substrate, an n-type GaN layer on the substrate, an active layer on the n-type GaN layer, a p-type GaN layer on the active layer, a current spreading layer including a transparent conductive metal oxide material on the p-type GaN layer, a plurality of upper current injection electrodes provided on the current spreading layer to be spaced apart from each other, an upper electrode pattern extending to cover the upper current injection electrodes, and an upper electrode pad electrically connected to the upper electrode pattern. The upper electrode pattern may include first and second upper electrode patterns, which are sequentially stacked and are a silver or silver alloy thin layer and a transparent conductive metal oxide thin layer, respectively.

Owner:KOREA UNIV RES & BUSINESS FOUND

Rotary plastic handicraft injection mold and injection molding method thereof

InactiveCN110435072AImprove continuityFacilitate continuous injection moldingEngineeringInjection molding machine

The invention discloses a rotary plastic handicraft injection mold and an injection molding method thereof. The rotary plastic handicraft injection mold comprises a base; the top of the base is fixedly connected with a support through bolts; the upper end of the support is connected with a workbench through a bearing; the lower end of the middle of the workbench is fixedly connected with the output end of a stepping motor; one end of the base is fixedly provided with a second telescopic air cylinder through bolts; and the output end of the second telescopic air cylinder is inserted into the lower end of one lower mould base According to the rotary plastic handicraft injection mold and the injection molding method thereof, through the cooperation of the stepping motor, the workbench, fixedgrooves, limiting blocks, limiting grooves, adjusting support plates and first telescopic air cylinders, the continuous injection molding of the injection mold is facilitated, the mold closing efficiency is high, the sealing performance is good, the injection molding effect is good, through the cooperation of guiding grooves, rubber pads, the limiting grooves, the limiting blocks and the second telescopic air cylinder, the continuous ejection blanking of the lower mold base is convenient, the blanking rate is effectively improved, therefore, the continuity of injection molding work is effectively improved, and the working efficiency is greatly improved.

Owner:义乌市拓一斯玩具有限公司

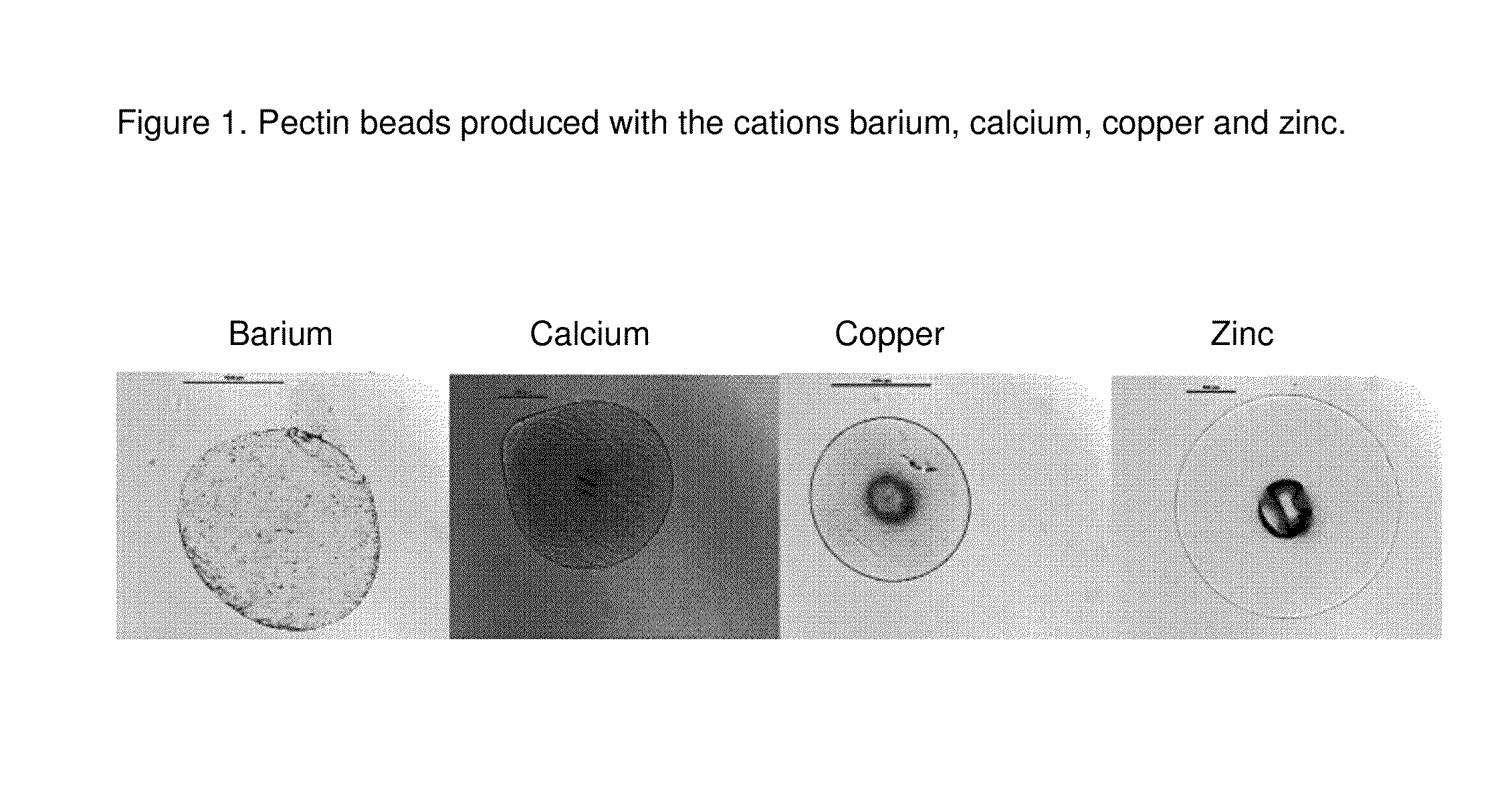

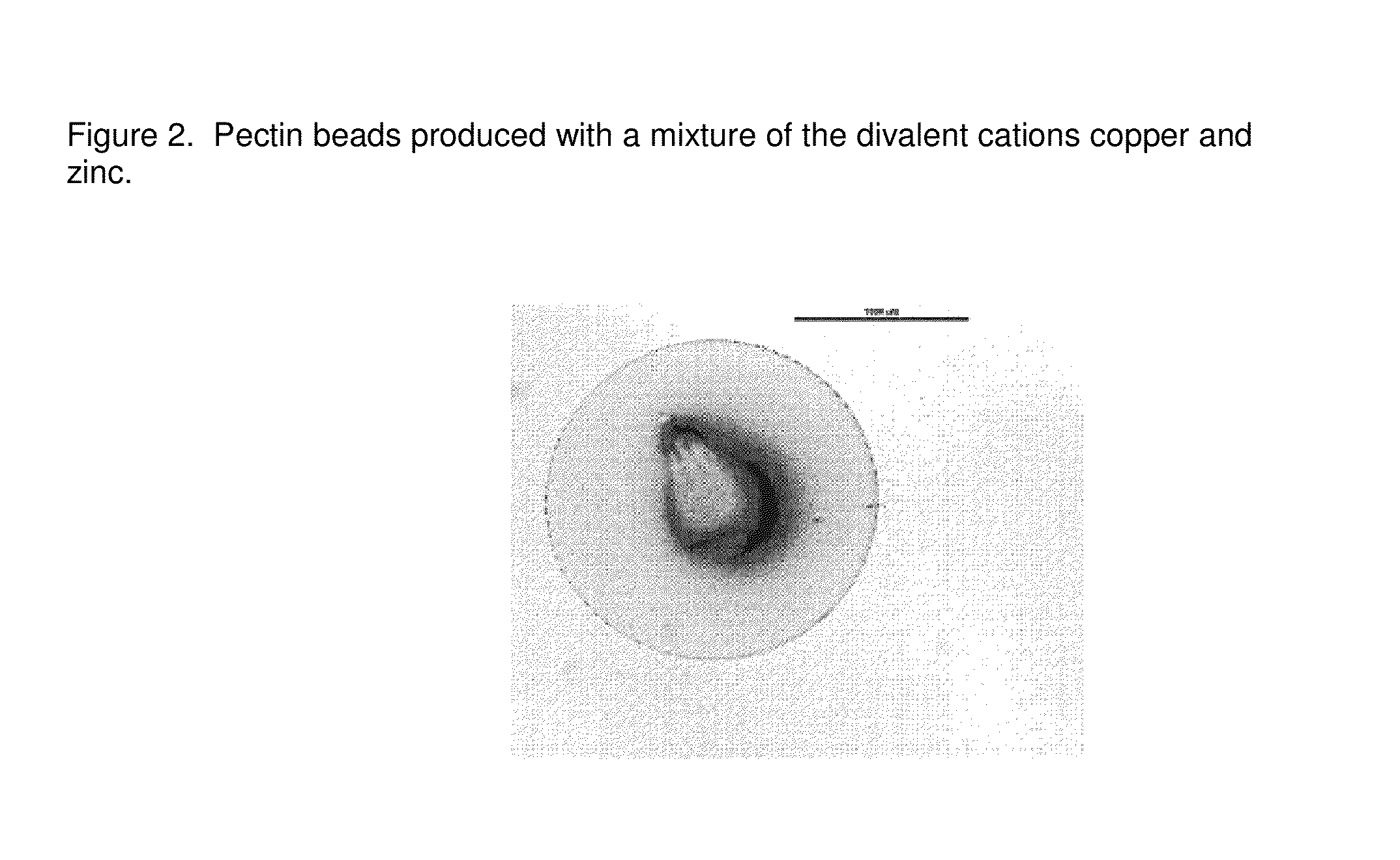

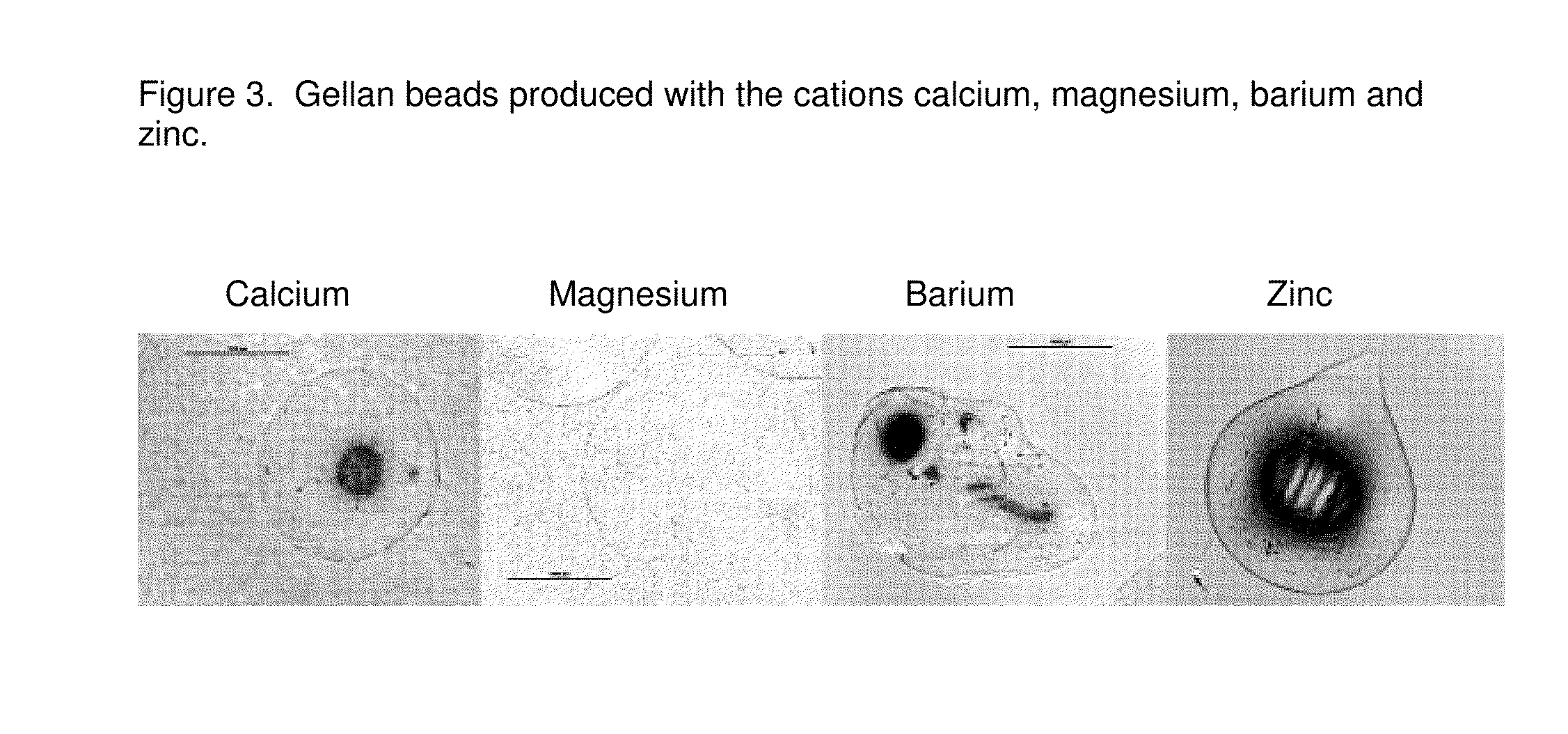

Filler comprising beads

InactiveUS20150010603A1Lasting effectRapidly volumeBiocideCosmetic preparationsBiopolymerInjection device

The present invention pertains to a filler comprising beads wherein the beads comprise a polyanionic biopolymer and divalent cations and wherein the polyanionic biopolymer is not alginate. Further, the present invention pertains to a process for manufacturing the claimed filler, and to an injection device comprising the filler.

Owner:MERZ PHARMA GMBH & CO KGAA

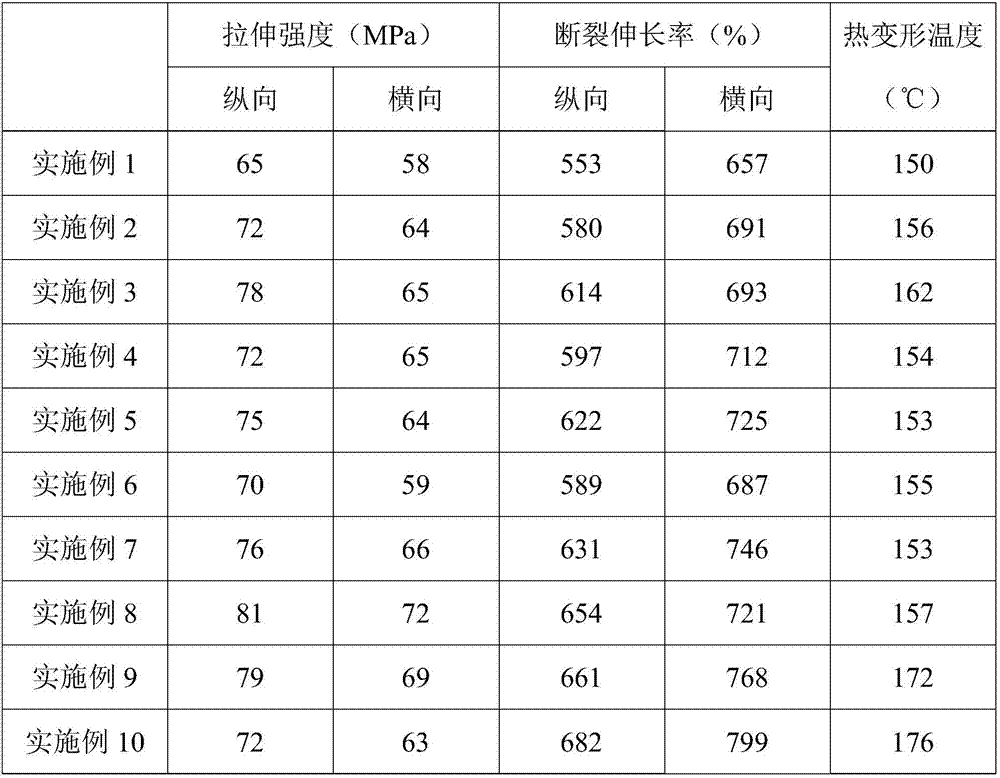

High-temperature-resistant film and preparation method thereof

InactiveCN106945368AHigh tensile strengthRelatively high hardnessSynthetic resin layered productsHeat deflection temperatureTear resistance

The invention provides a high-temperature-resistant film and a preparation method thereof, and belongs to the technical field of films. The high-temperature-resistant film comprises an outer layer, a middle layer and an inner layer, wherein the outer layer is 10%-30% of total weight of the film, the middle layer is 50%-70% of total weight of the film, and the inner layer is 10%-30% of total weight of the film; the outer layer and the inner layer are prepared from PP M800E; the middle layer is prepared from the following components in percentage by weight: 60%-80% of MDPE 5400 and 20%-40% of LDPE TN00. The high-temperature-resistant film provided by the invention is simple in structure and has good impact resistance and tear resistance, the performance of the high-temperature-resistant film is not changed in a high-temperature environment, substances harmful to a human body are not released, and the thermal distortion temperature can reach 150 DEG C or above.

Owner:KUNSHAN JINMENG PLASTIC FILM

Organic light emitting diode device

InactiveUS20110198636A1Increase currentImprove color qualityMaterial nanotechnologySolid-state devicesMetal clustersLight-emitting diode

Disclosed herein is an organic light emitting diode device, including: an organic EL element layer; an electrode layer supplying power to the organic EL element layer; and a metal nanocluster layer which is formed by covering a plurality of metal clusters with media and which is located between the organic EL element layer and the electrode layer to induce a luminescence enhancement effect. The organic light emitting diode device is advantageous in that carriers can be easily injected, so that light output efficacy is improved, thereby enhancing fluorescent emission output.

Owner:KOREA ADVANCED INST OF SCI & TECH

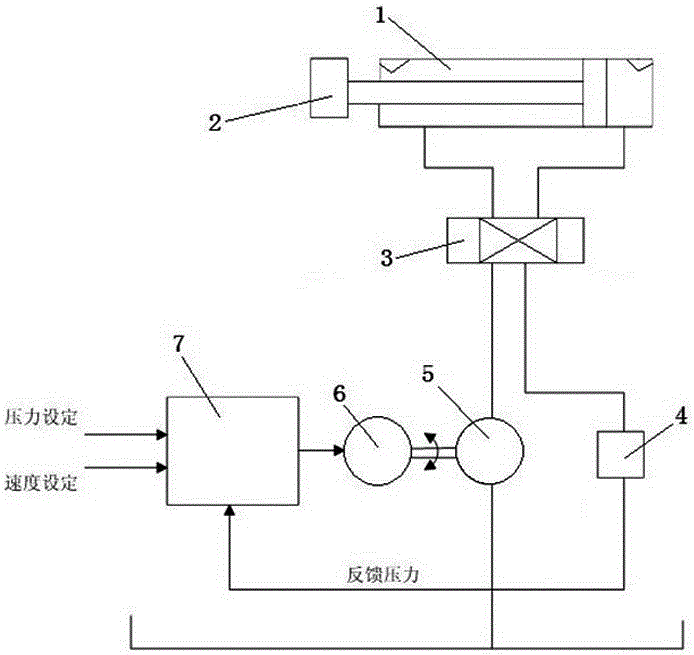

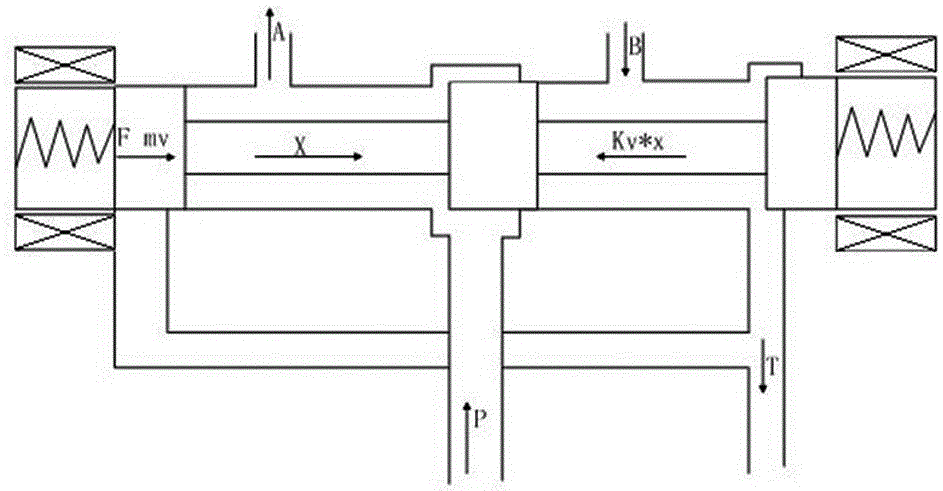

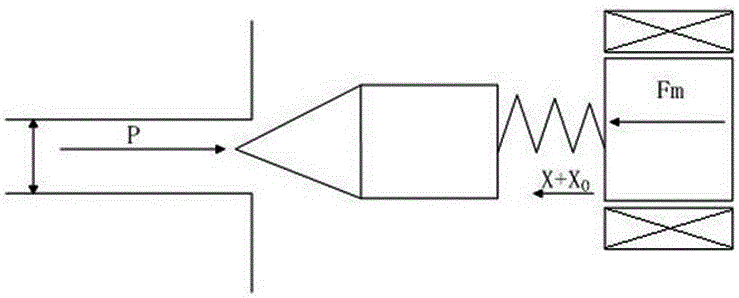

Electro-hydraulic proportional control system of injection molding machine and design method thereof

The invention discloses an electro-hydraulic proportional control system of an injection molding machine. The electro-hydraulic proportional control system comprises a servo motor, a metering pump, a pressure sensor, an electro-hydraulic proportional valve, a hydraulic oil cylinder and an injection mold. The electro-hydraulic proportional valve is installed on the hydraulic oil cylinder and connected with the metering pump and the pressure sensor. The servo motor is connected with the metering pump. A controller is in communication connection with the servo motor and the pressure sensor. The electro-hydraulic proportional control system of the injection molding machine can improve the control performance of the system in a high-speed state substantially, and a good injection effect is achieved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com